Patents

Literature

27433results about "Building constructions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

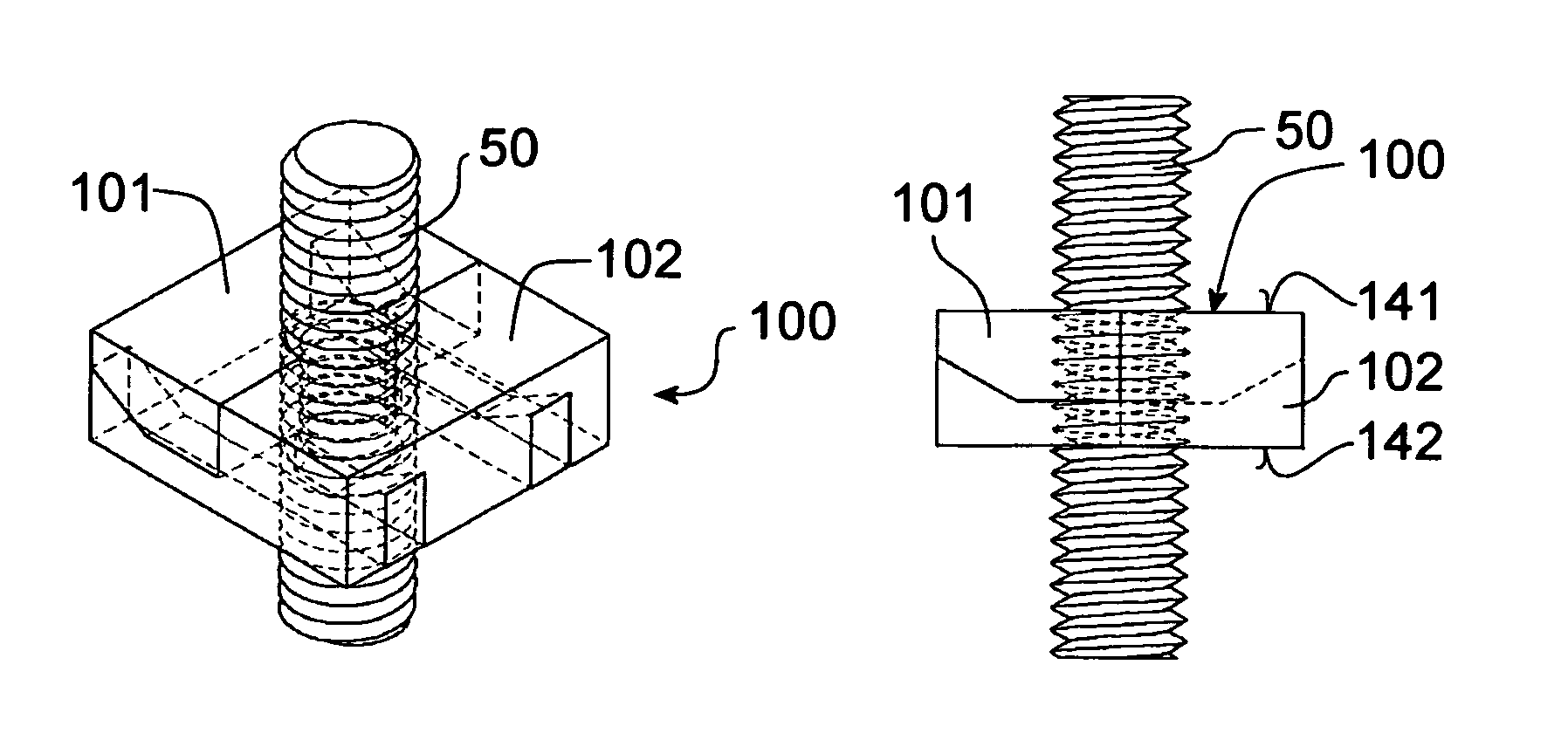

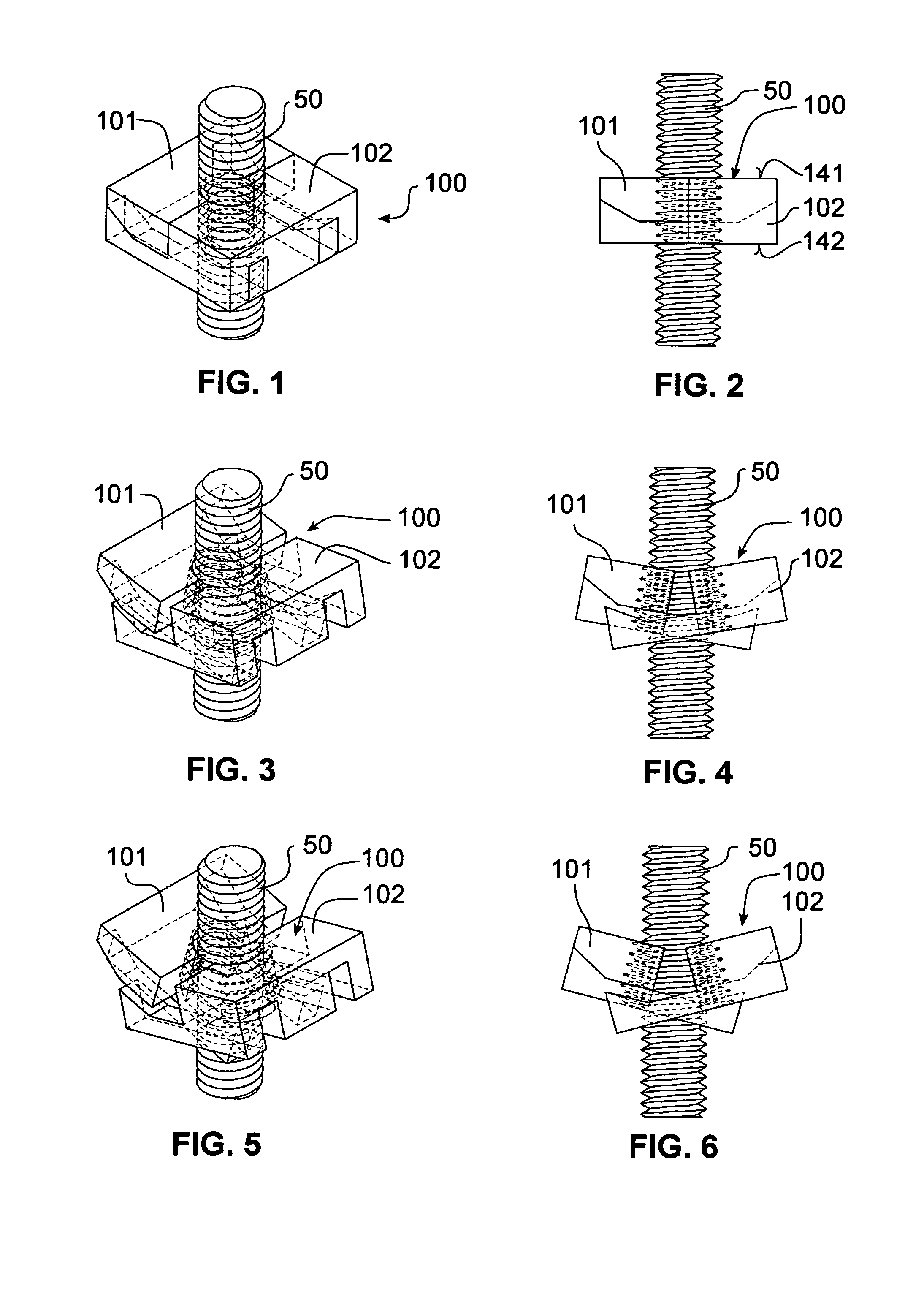

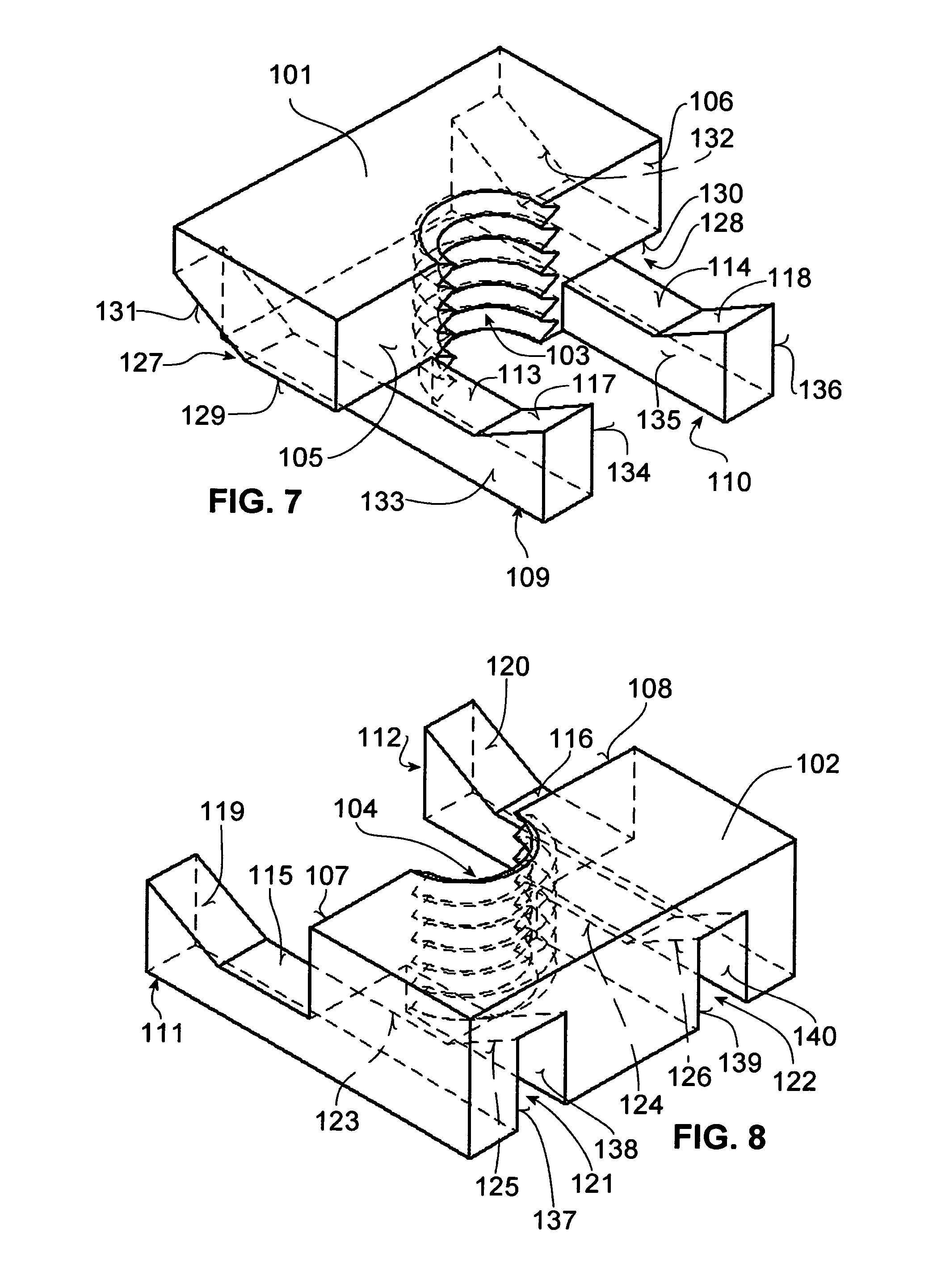

Nut having at least two parts

ActiveUS7934896B2Avoid cloggingIncrease the number ofDrilling rodsNutsRelative displacementEngineering

A nut includes an internal thread and at least two parts, each of the parts having a section of the internal thread which can be pushed onto an external thread in the radial direction. The parts may have connecting elements which interact and permit a relative displacement of the parts in a direction running radially to the axis of the internal thread into a position of use. The connecting elements may have guide surfaces which are inclined at an angle to the plane running radially to the axis of the internal thread and guide the parts in a rotational movement about an axis of rotation running transversely to the axis. A part may have a locking arm with a guide surface only on one side which produces the rotational movement during the displacement of the parts and bears against a complementary guide surface of the other part.

Owner:SCHNIER DIETMAR

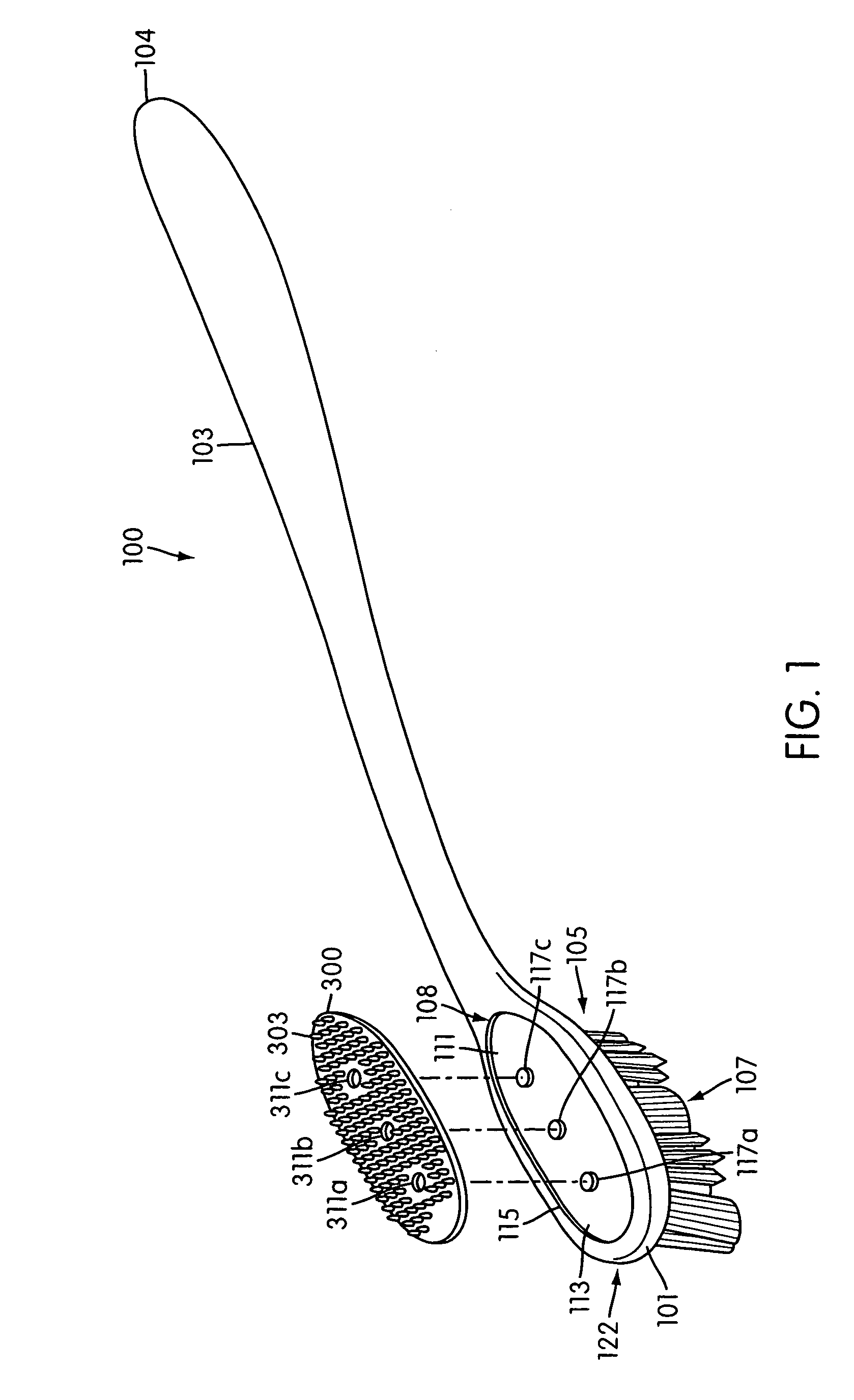

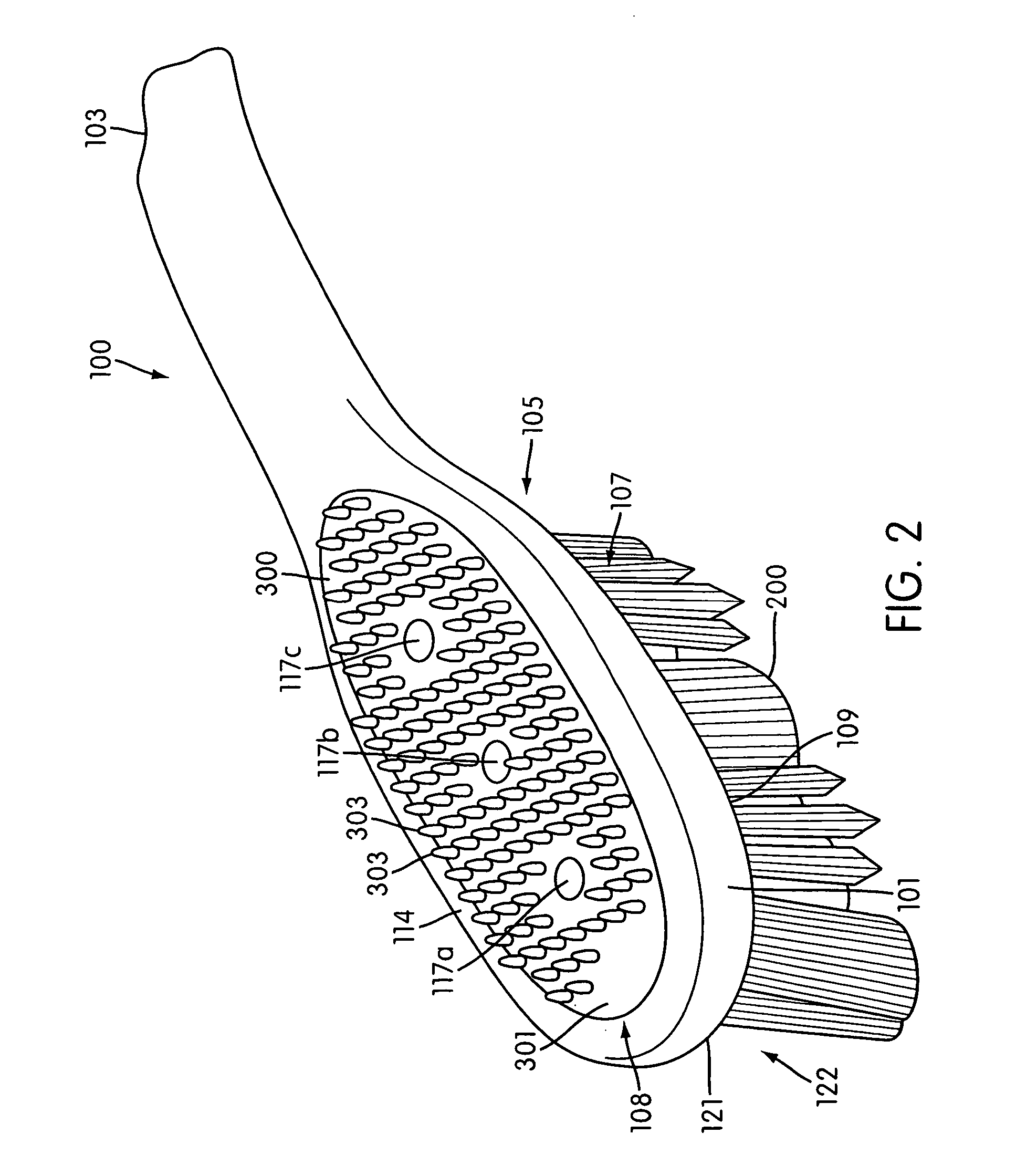

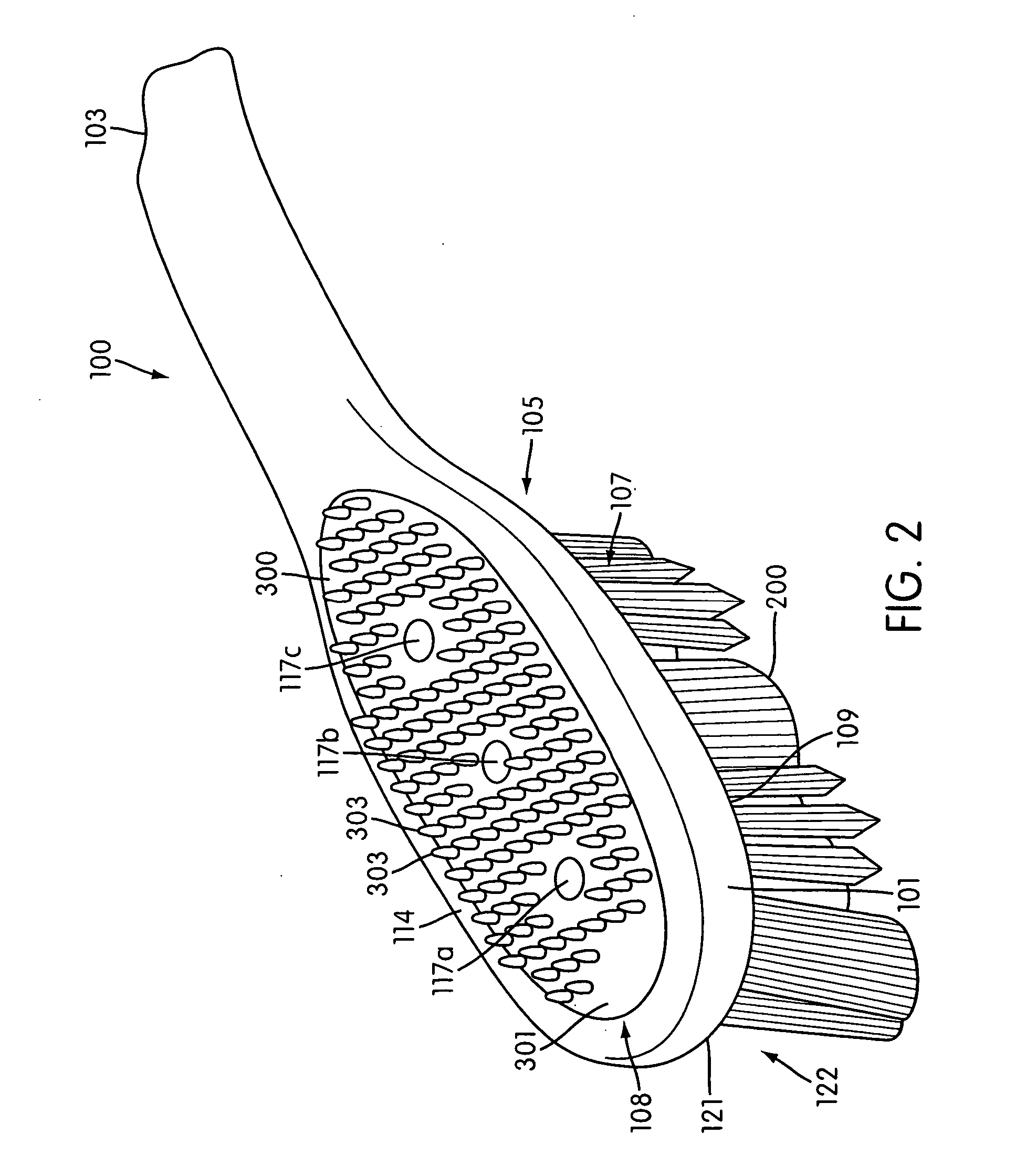

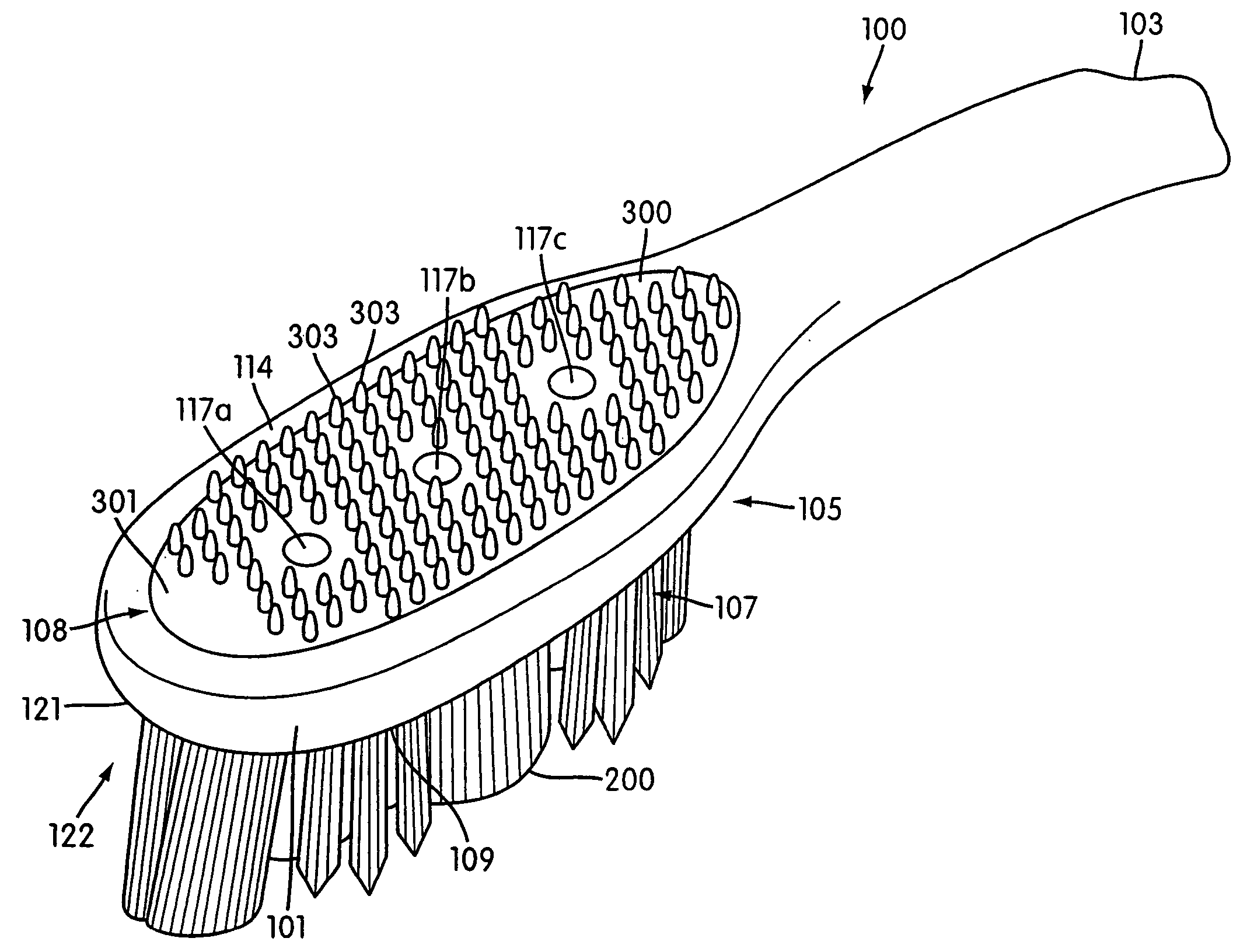

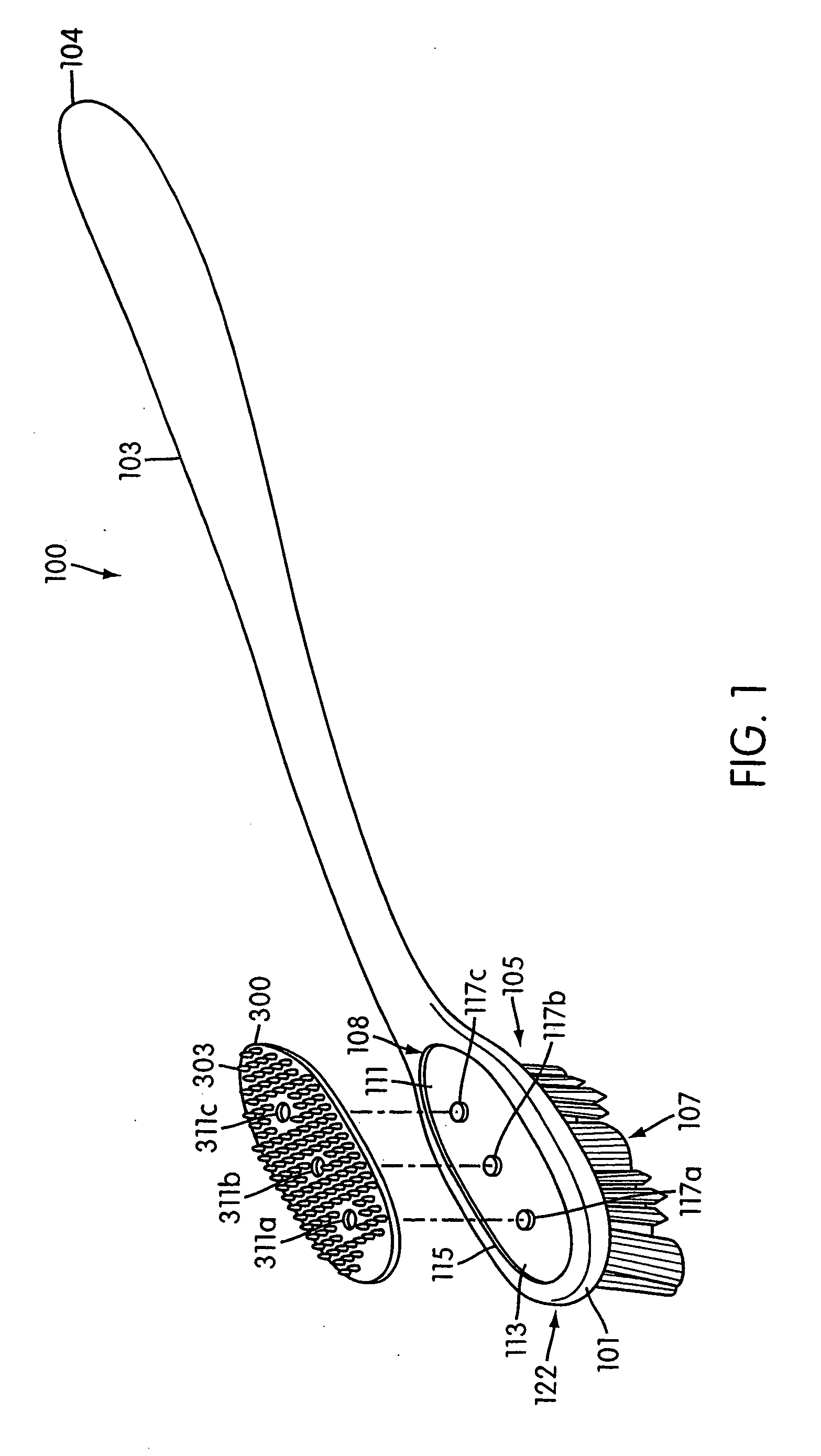

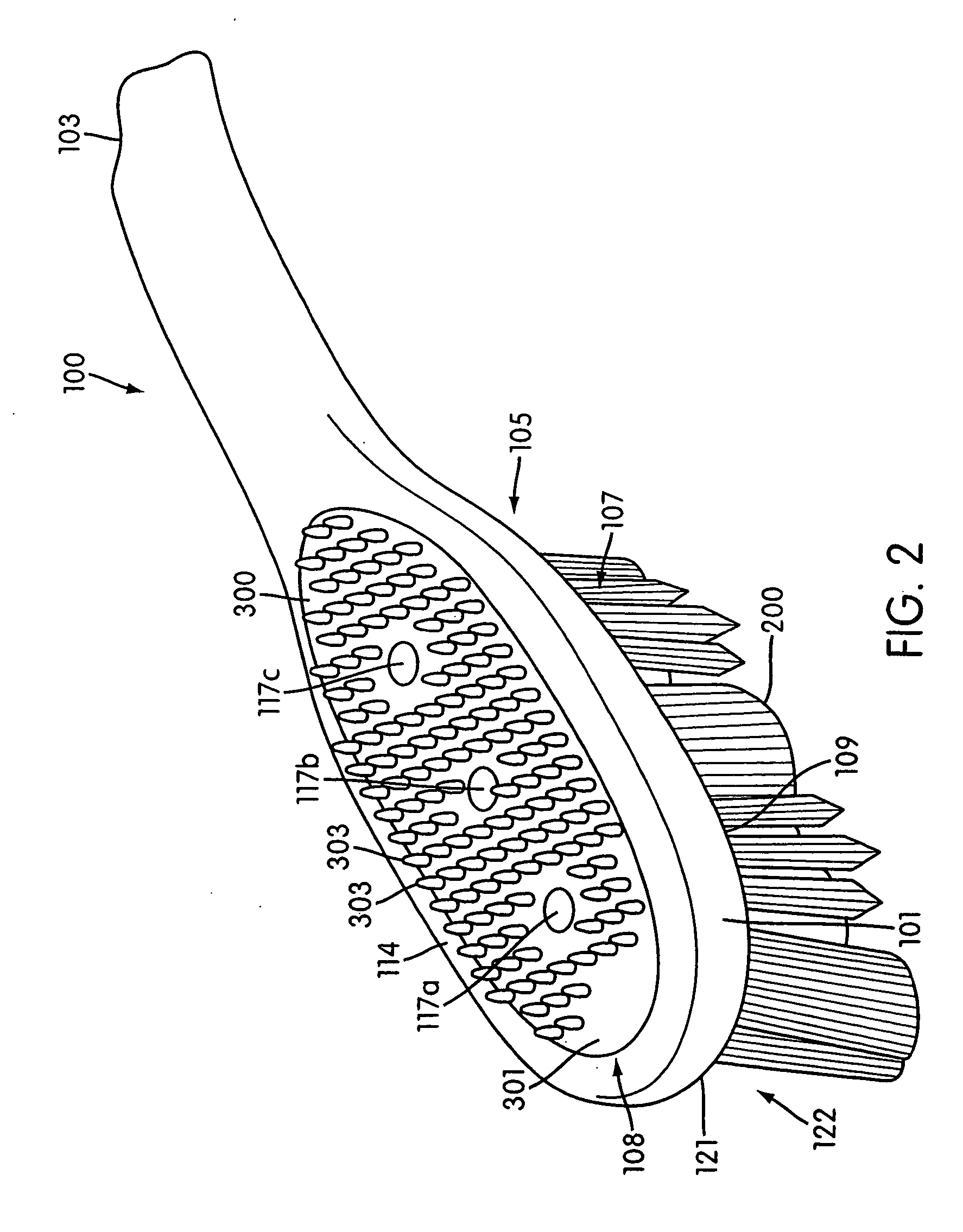

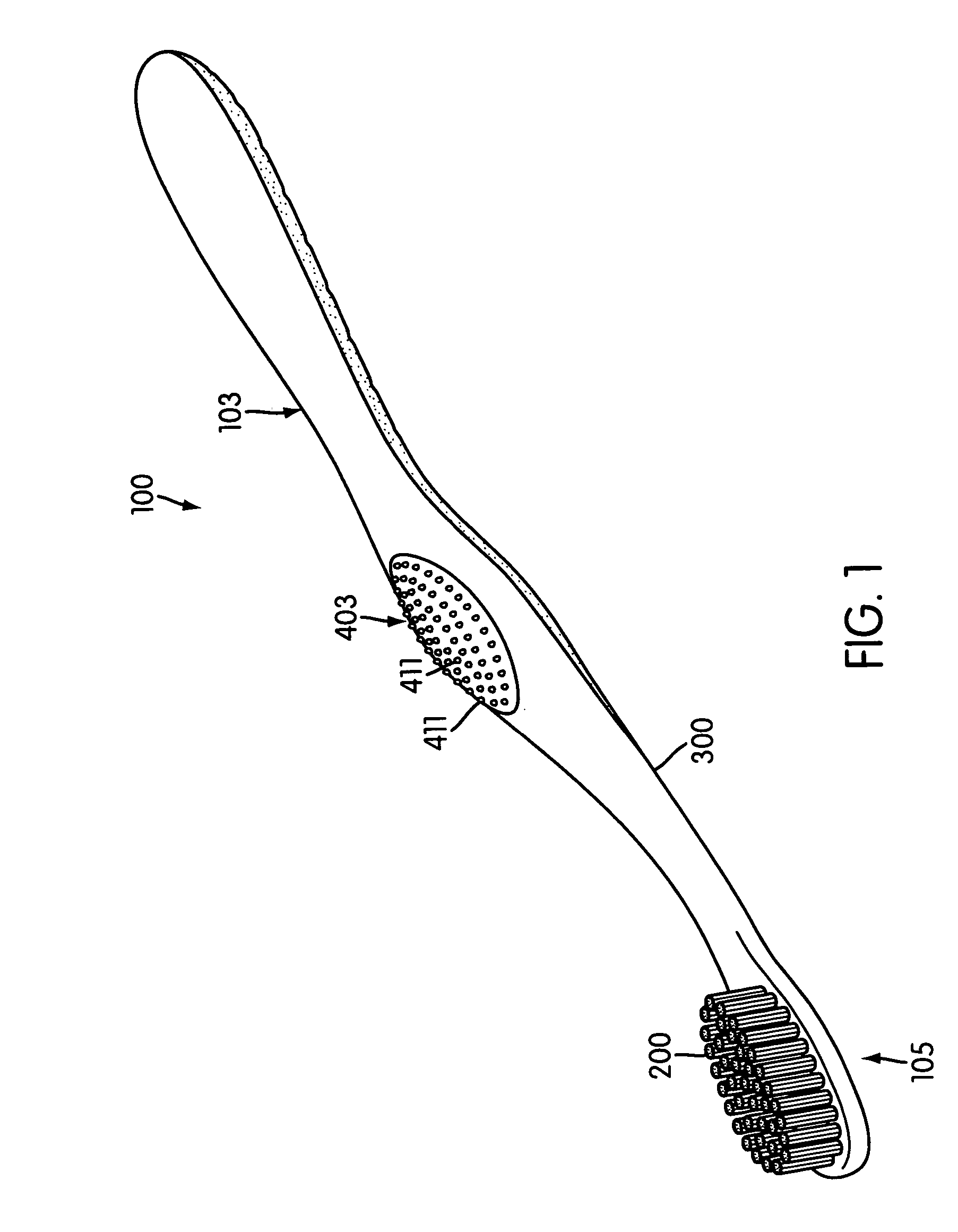

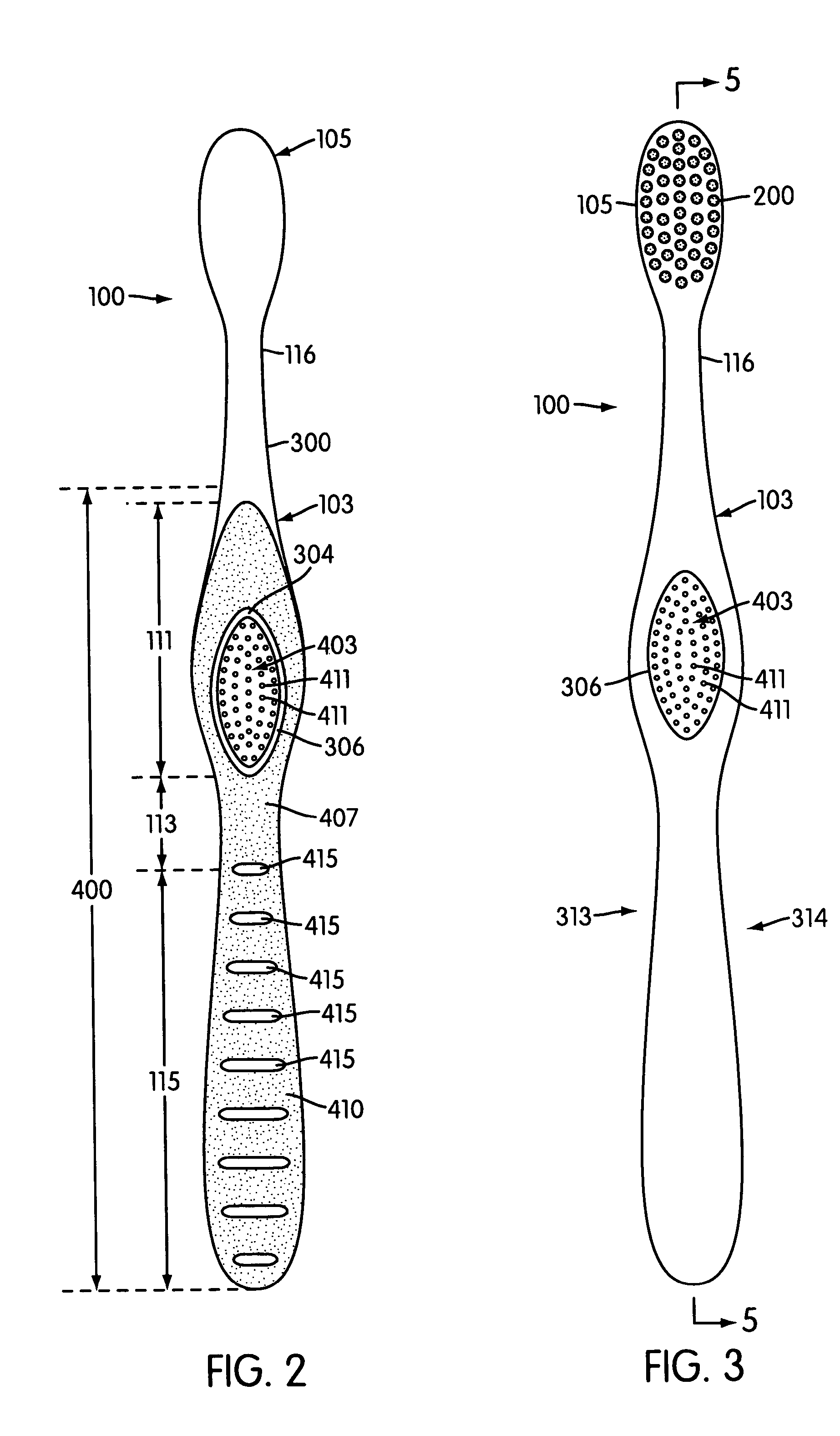

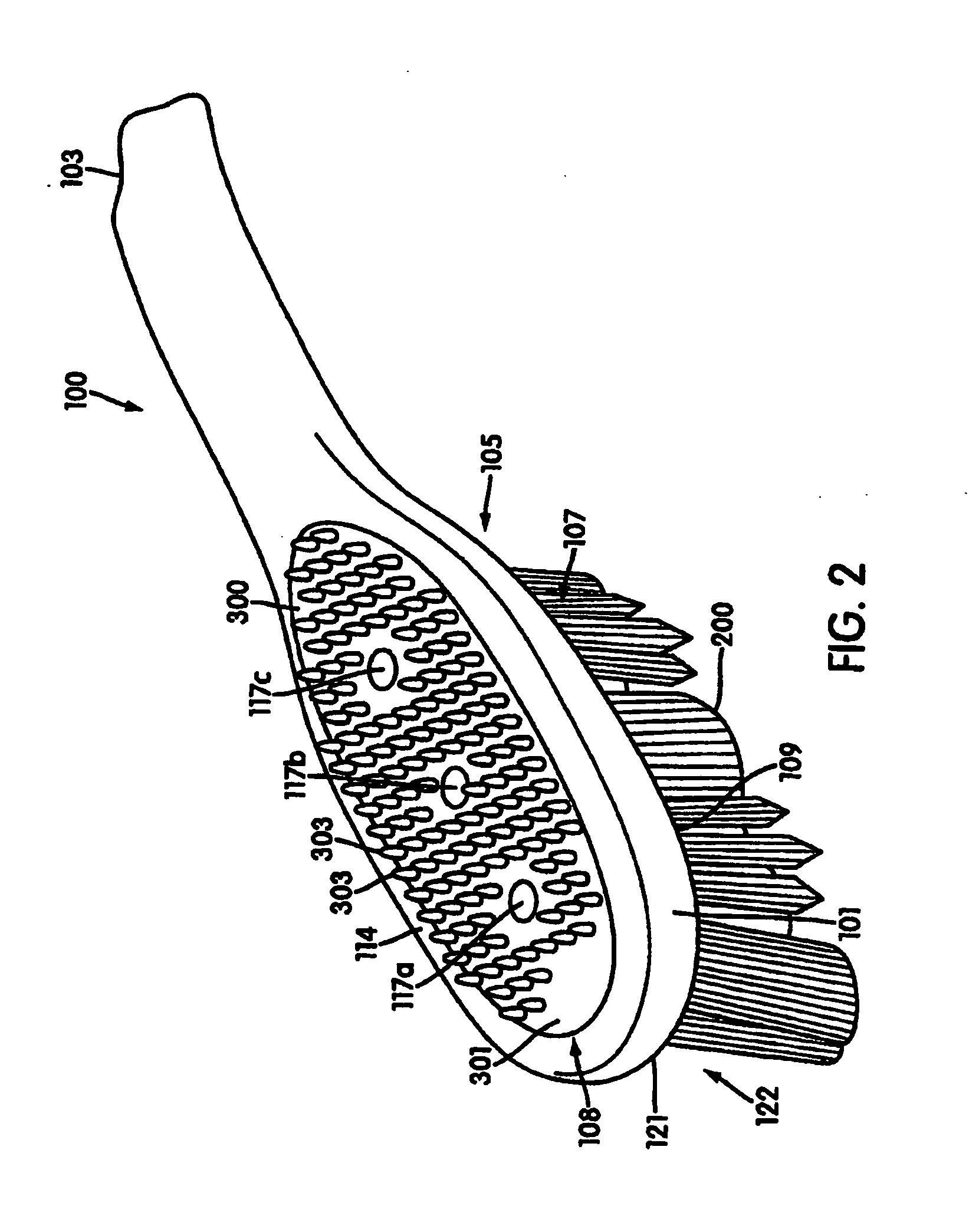

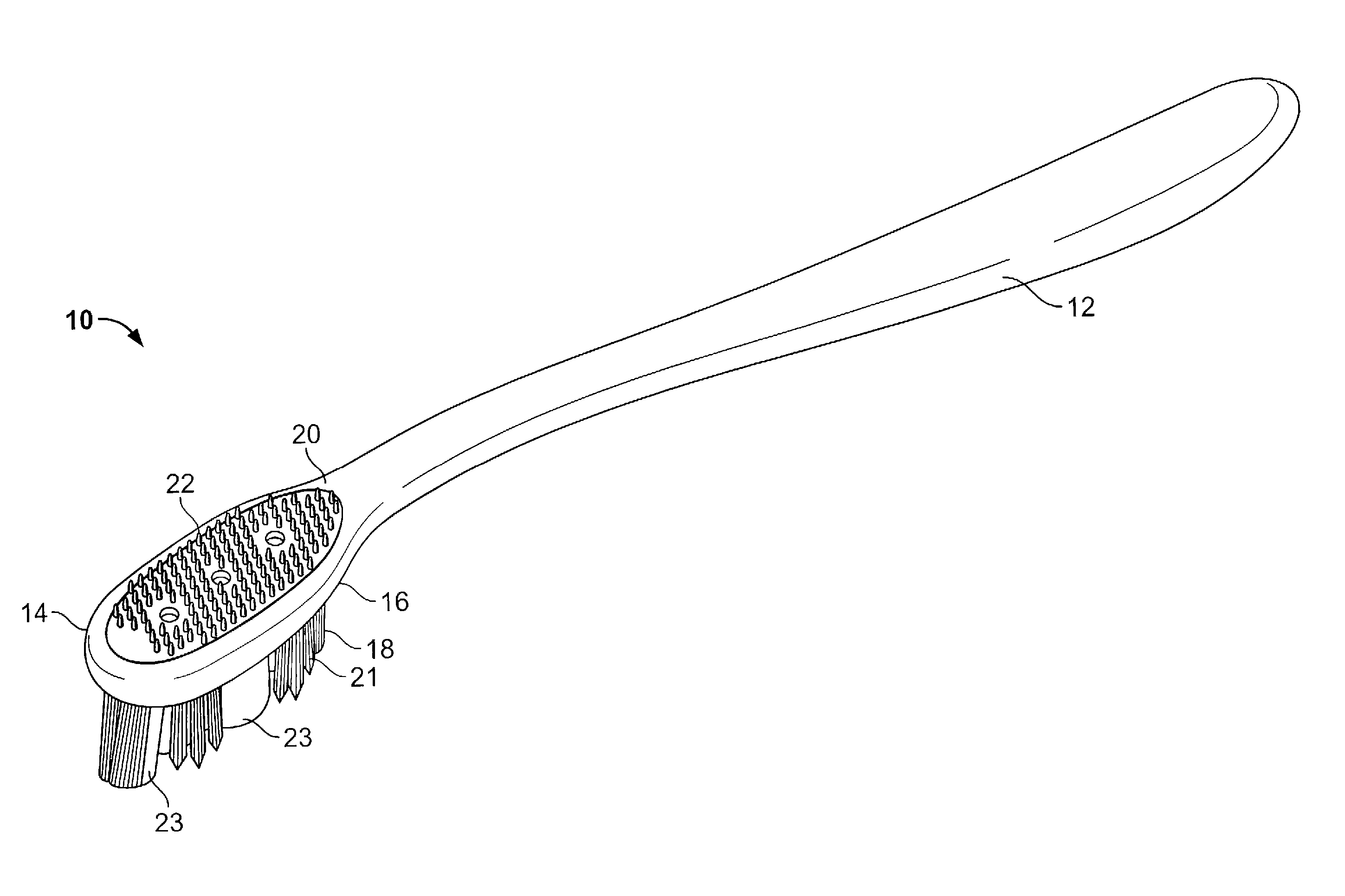

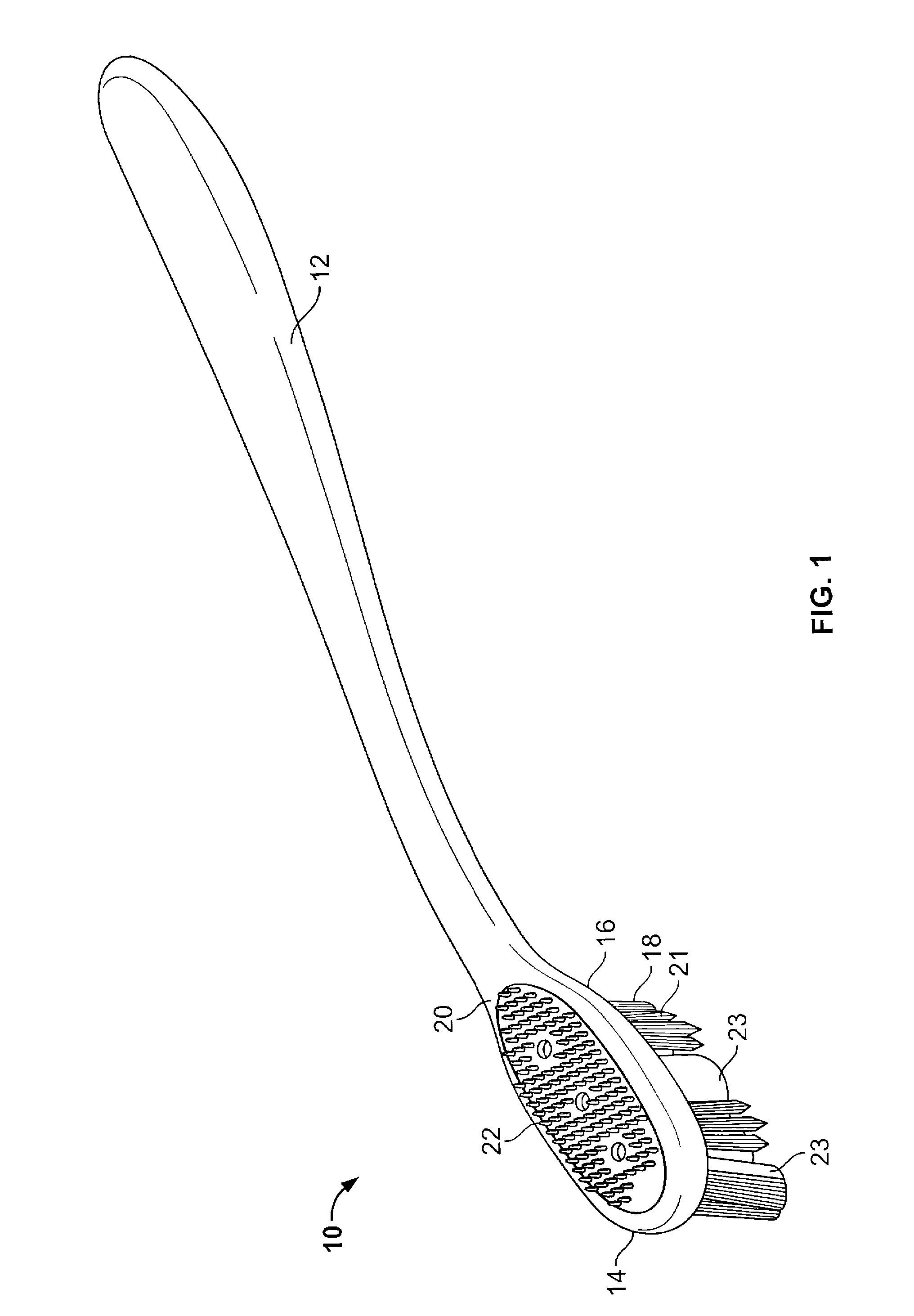

Oral care implement

An oral care implement with a handle includes a head with a tissue cleanser. The tissue cleanser may be a pad composed of an elastomeric material. The pad is disposed on the head on a surface opposite the tooth cleaning elements. The tissue cleanser may include a plurality of nubs extending for cleaning between the papillae of the tongue. The tissue cleanser may include a plurality of conically shaped nubs. A tissue cleanser can be used to reduce oral malodor problems and remove oral epithelial cells.

Owner:COLGATE PALMOLIVE CO

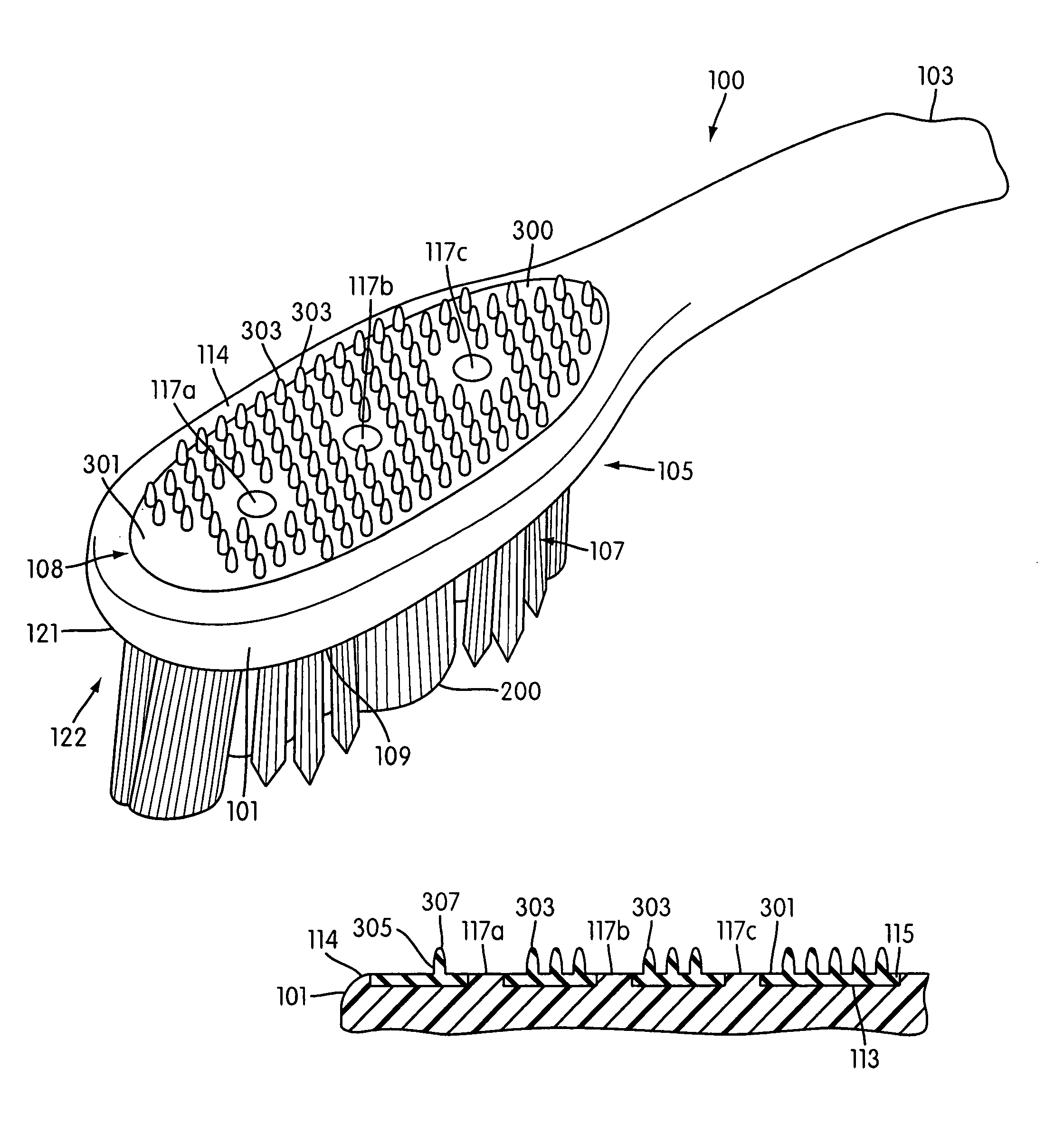

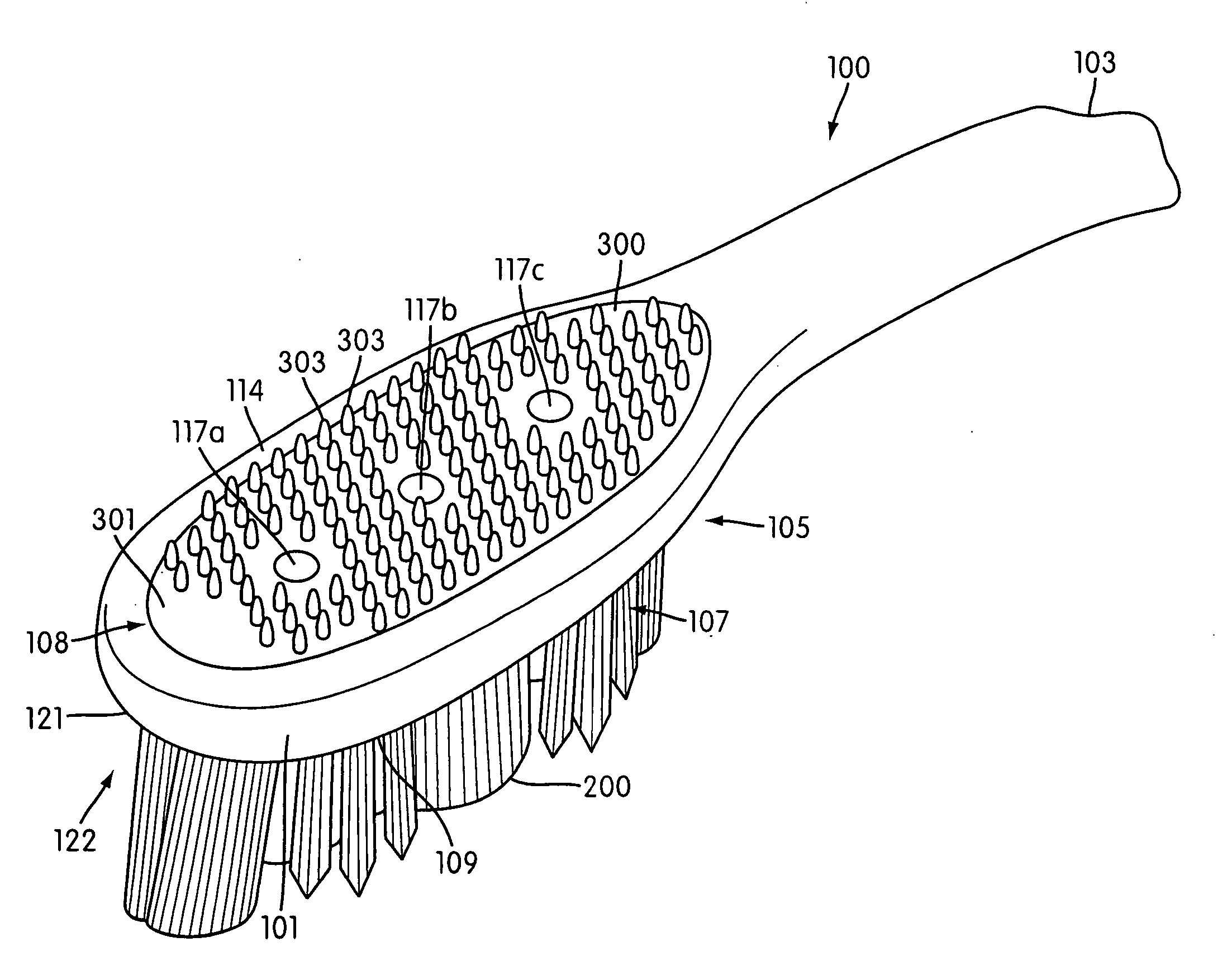

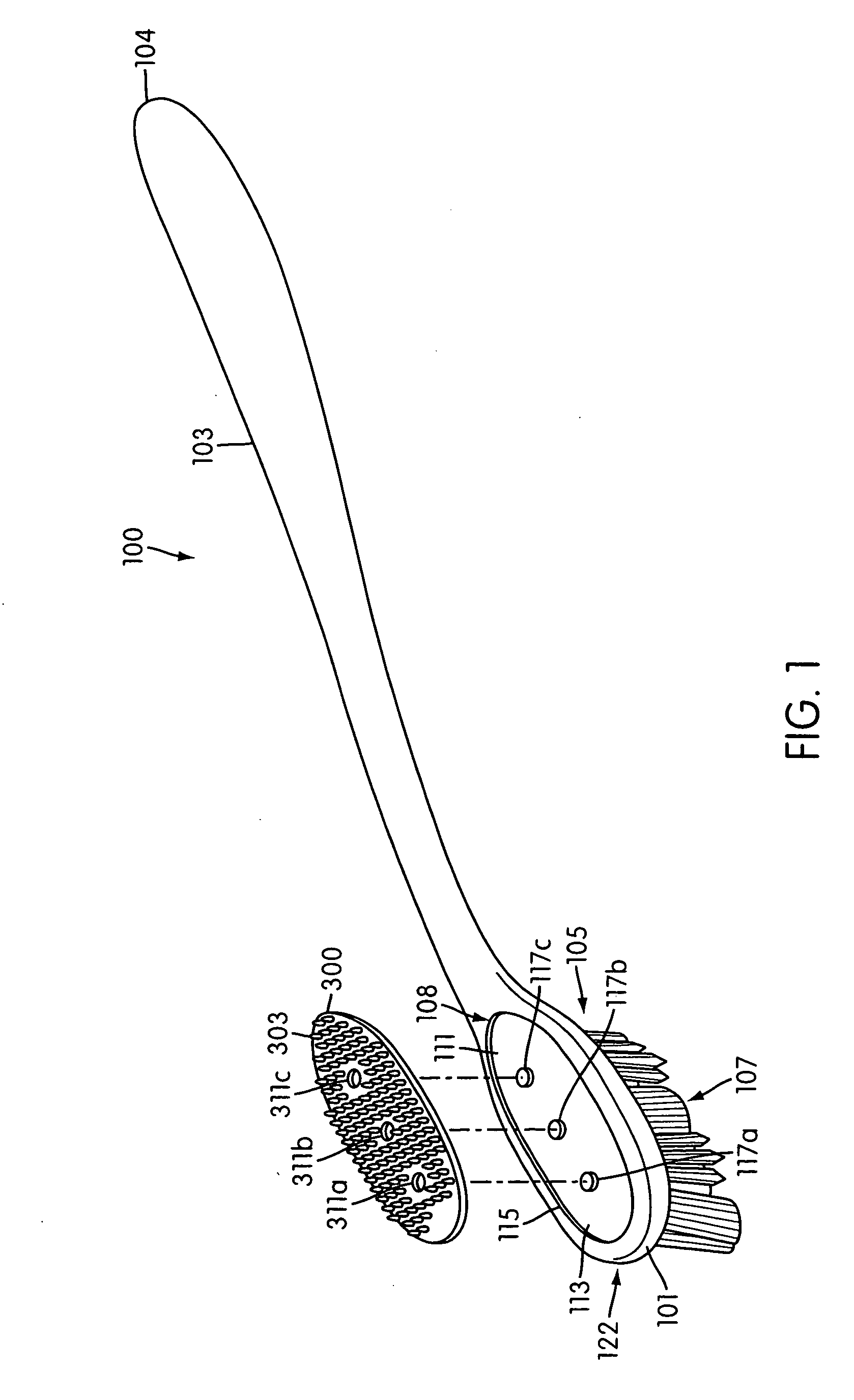

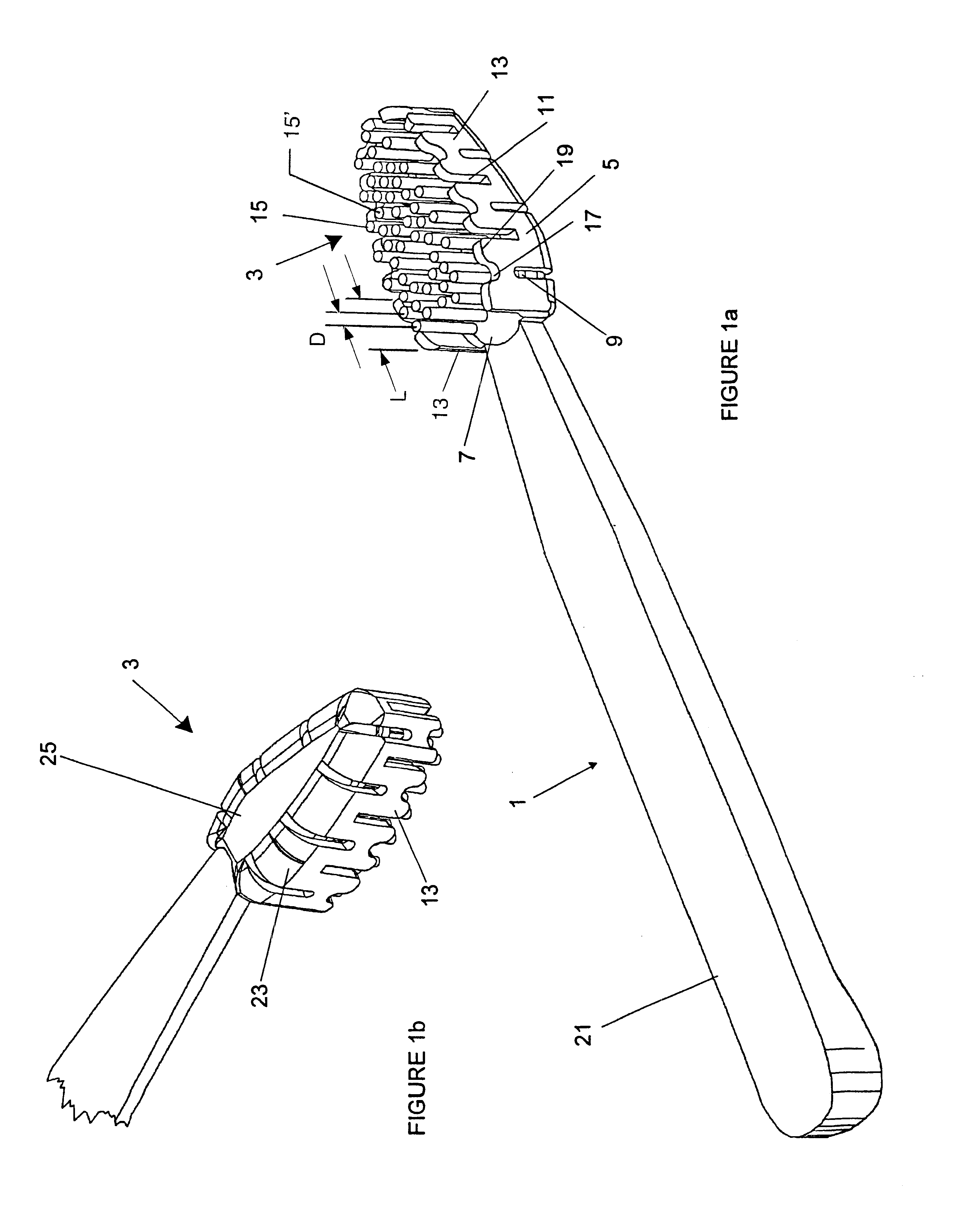

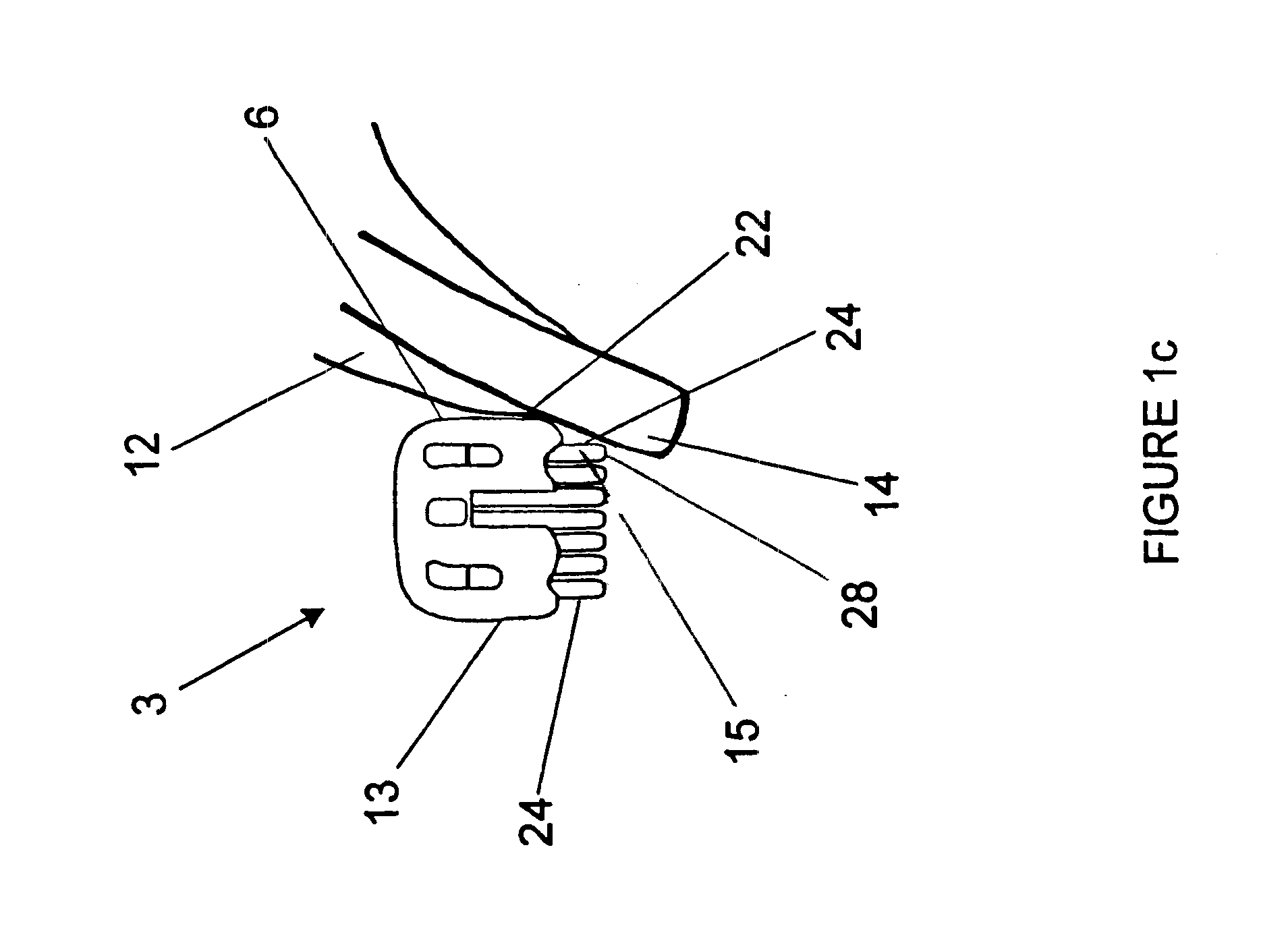

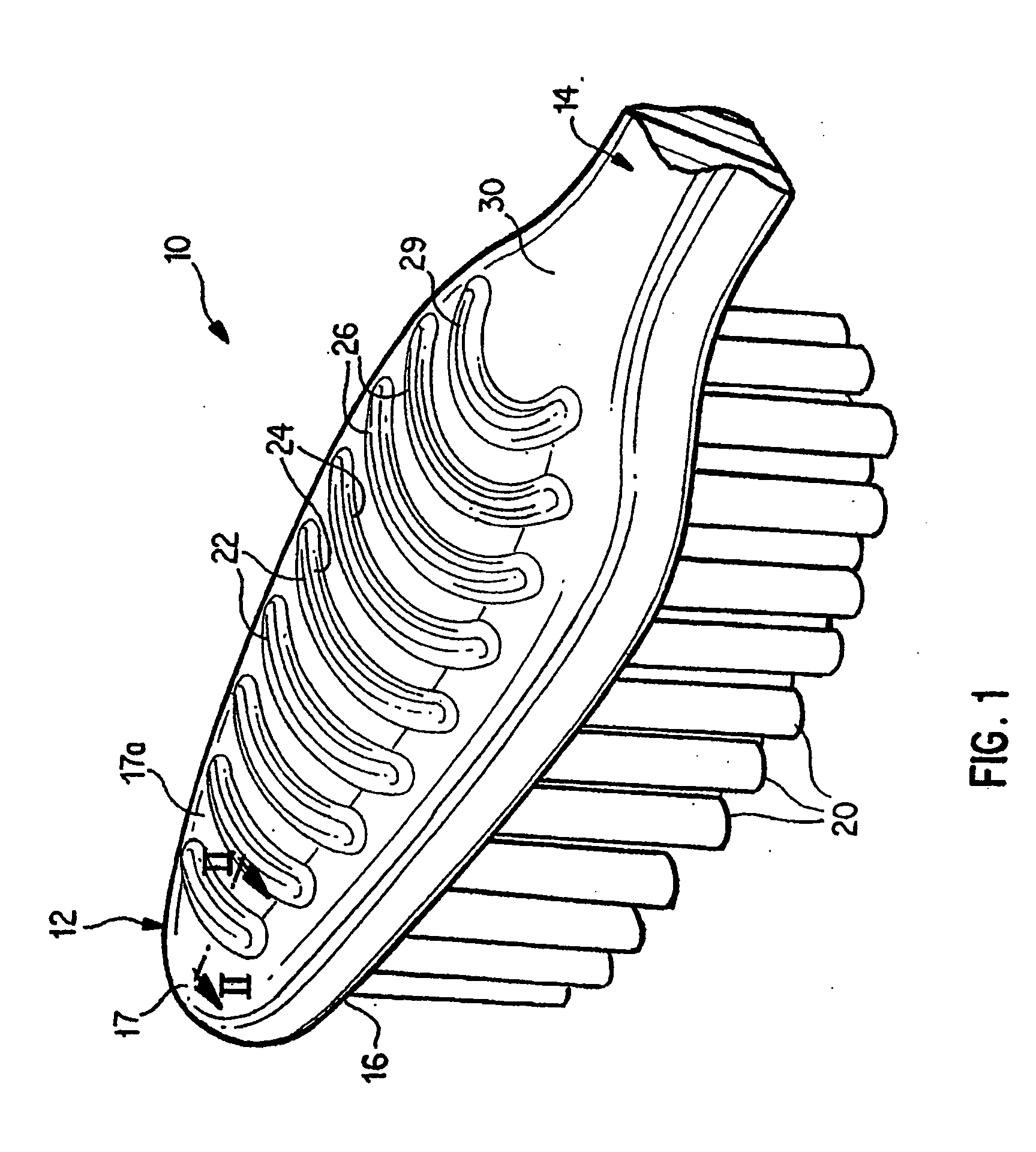

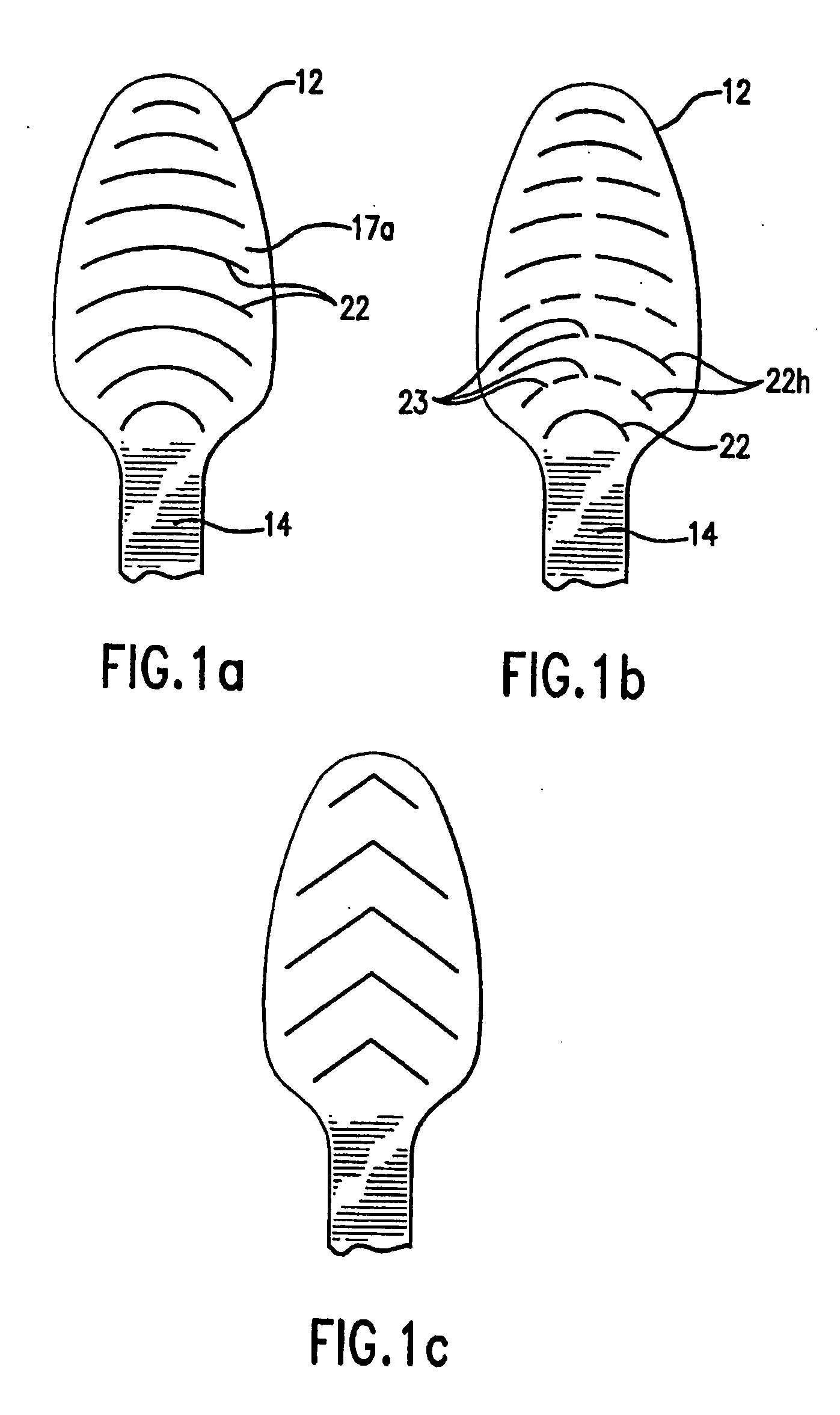

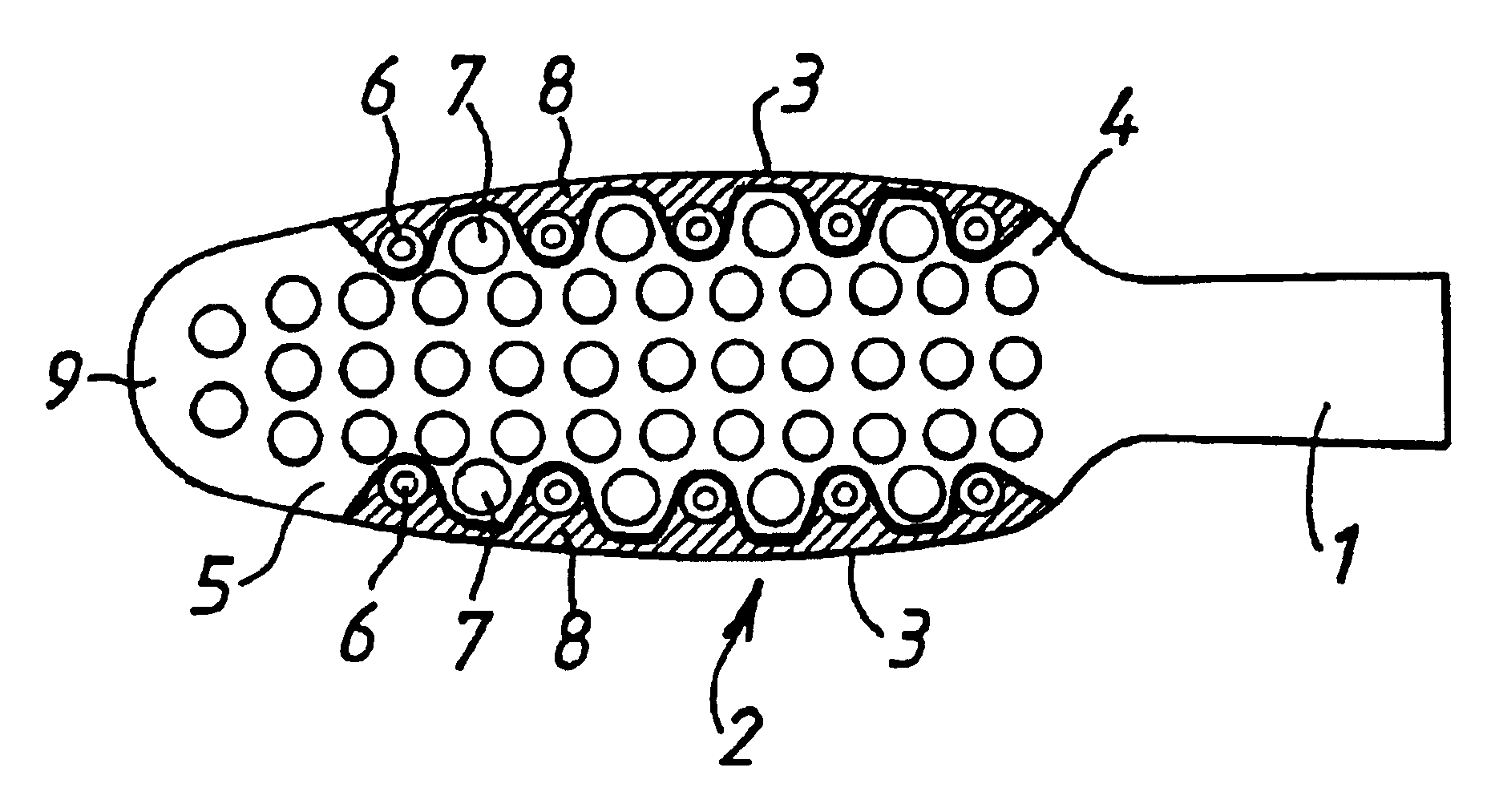

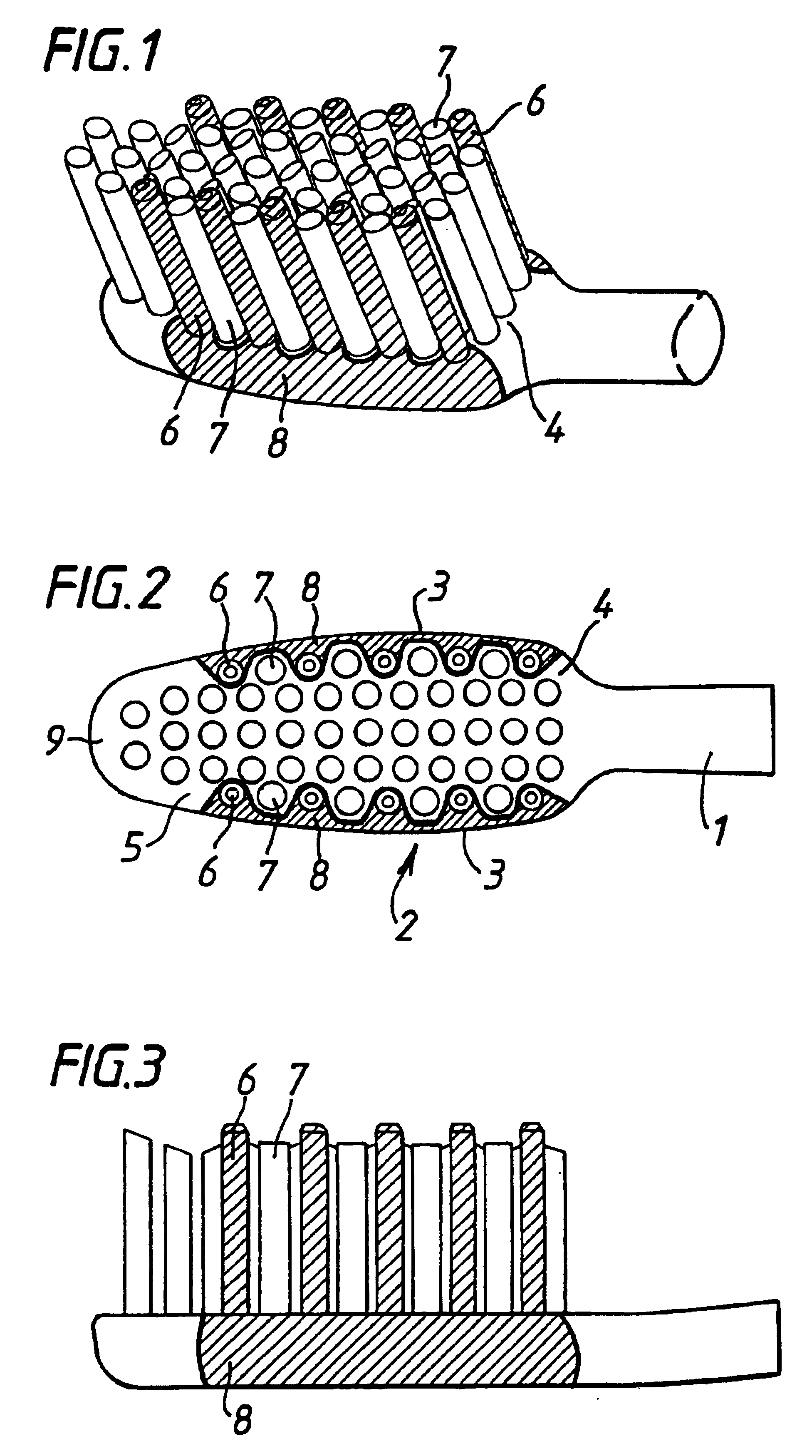

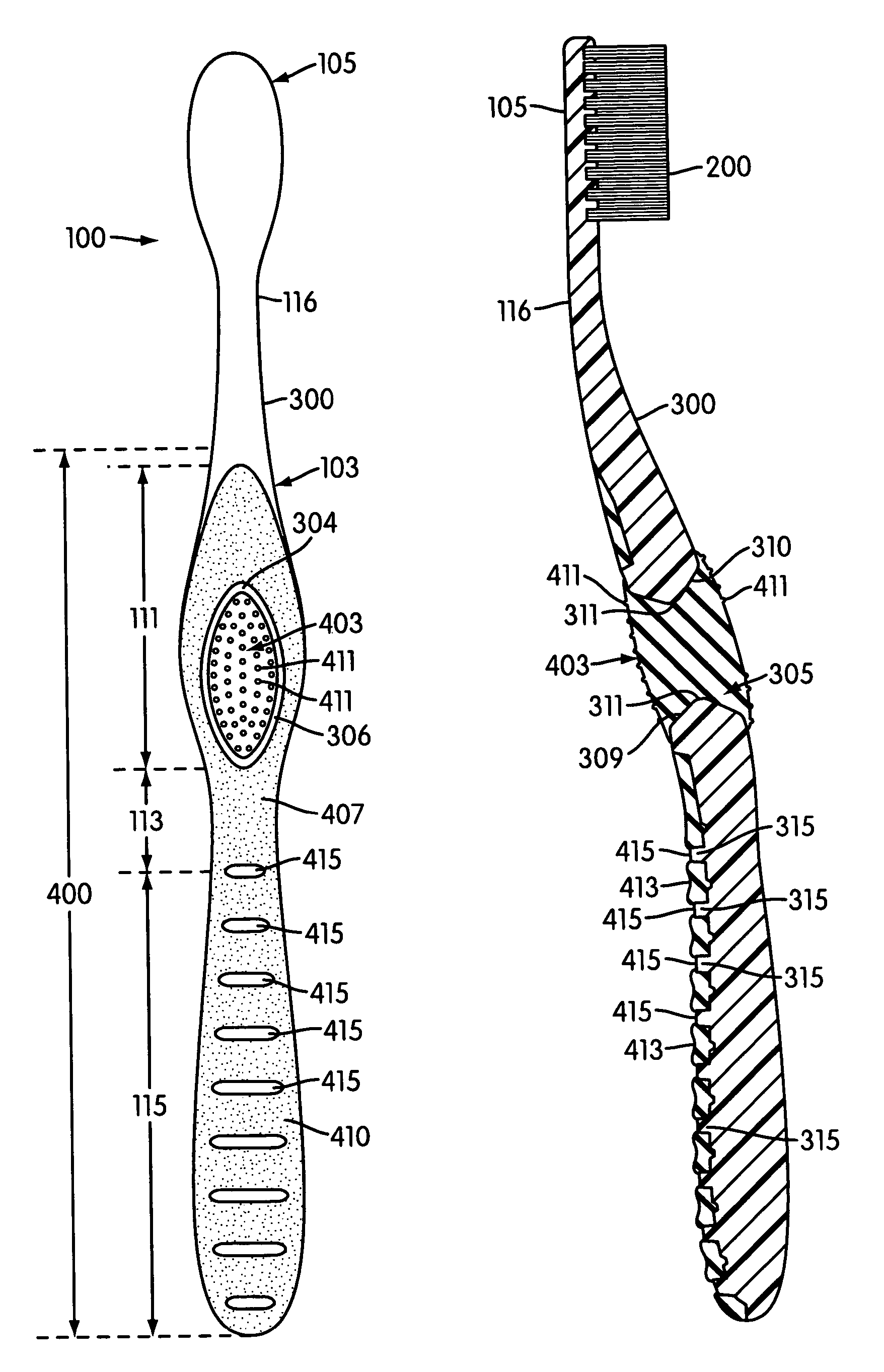

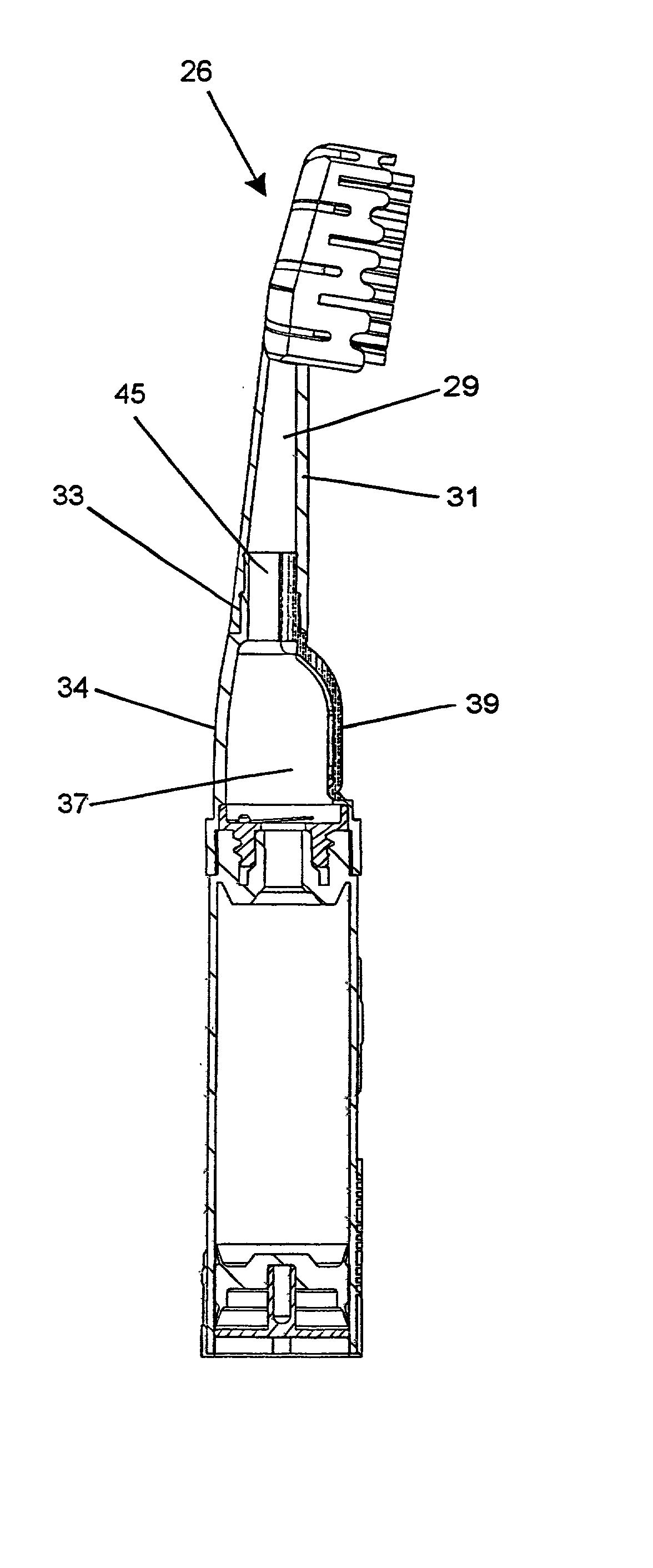

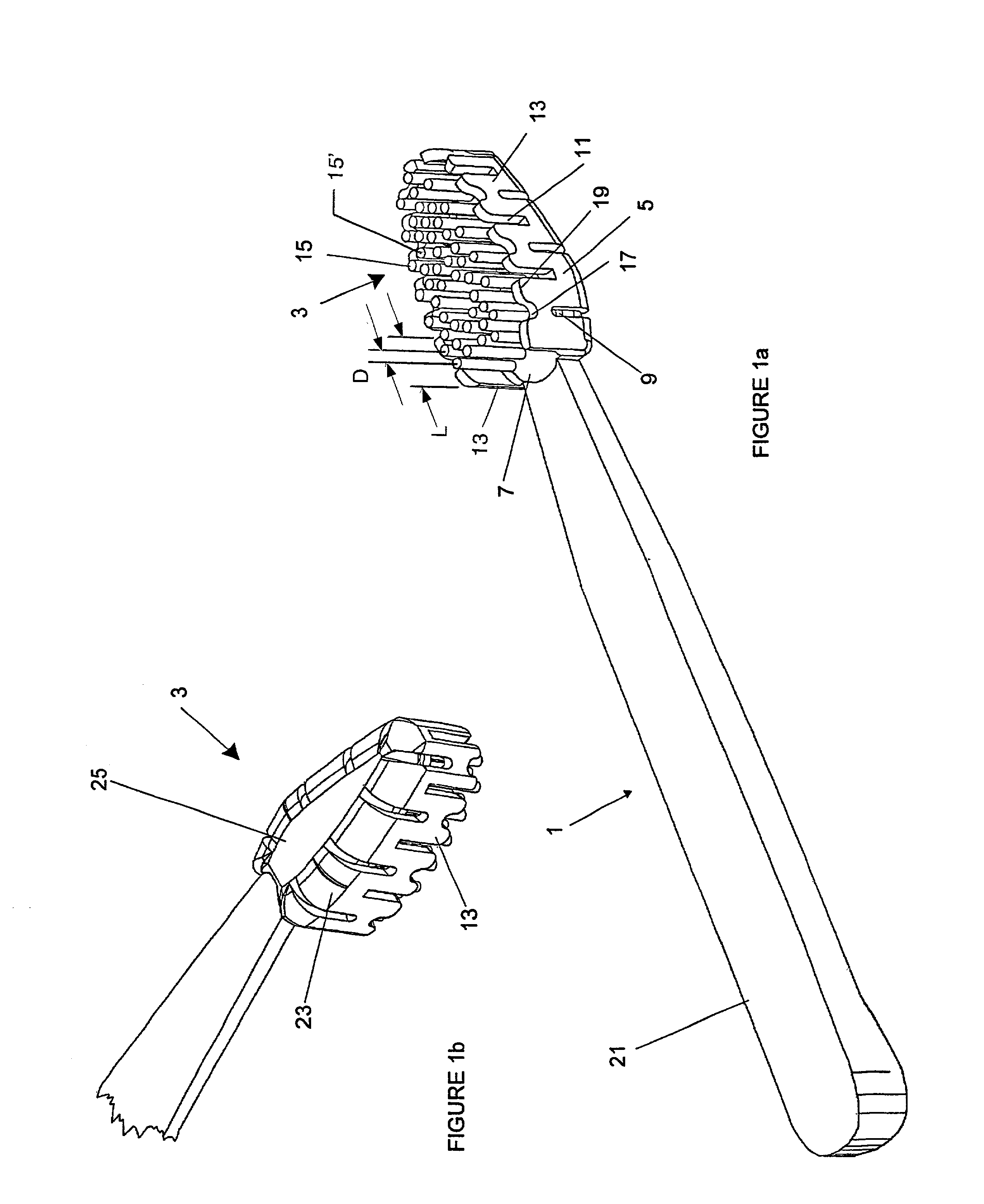

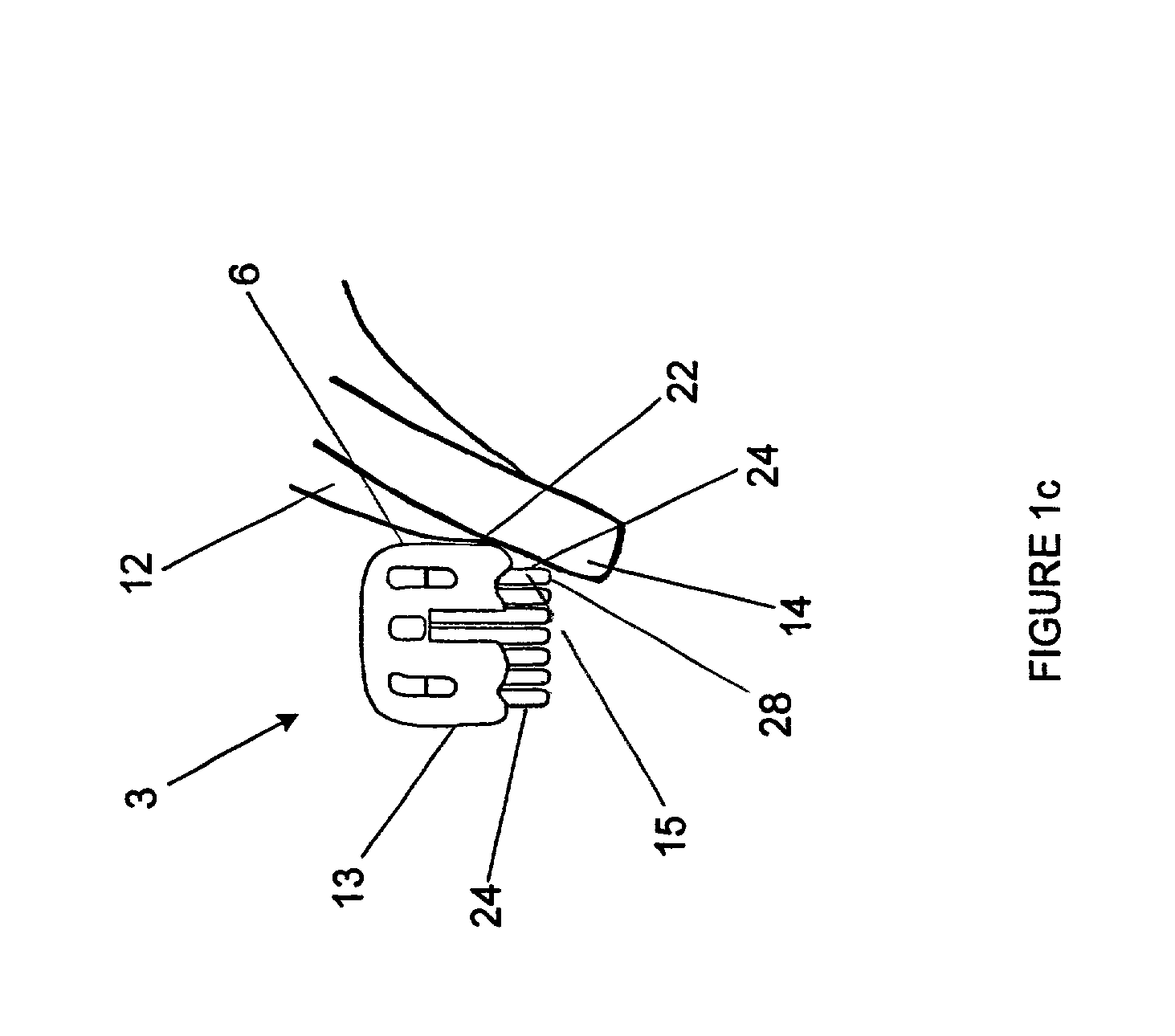

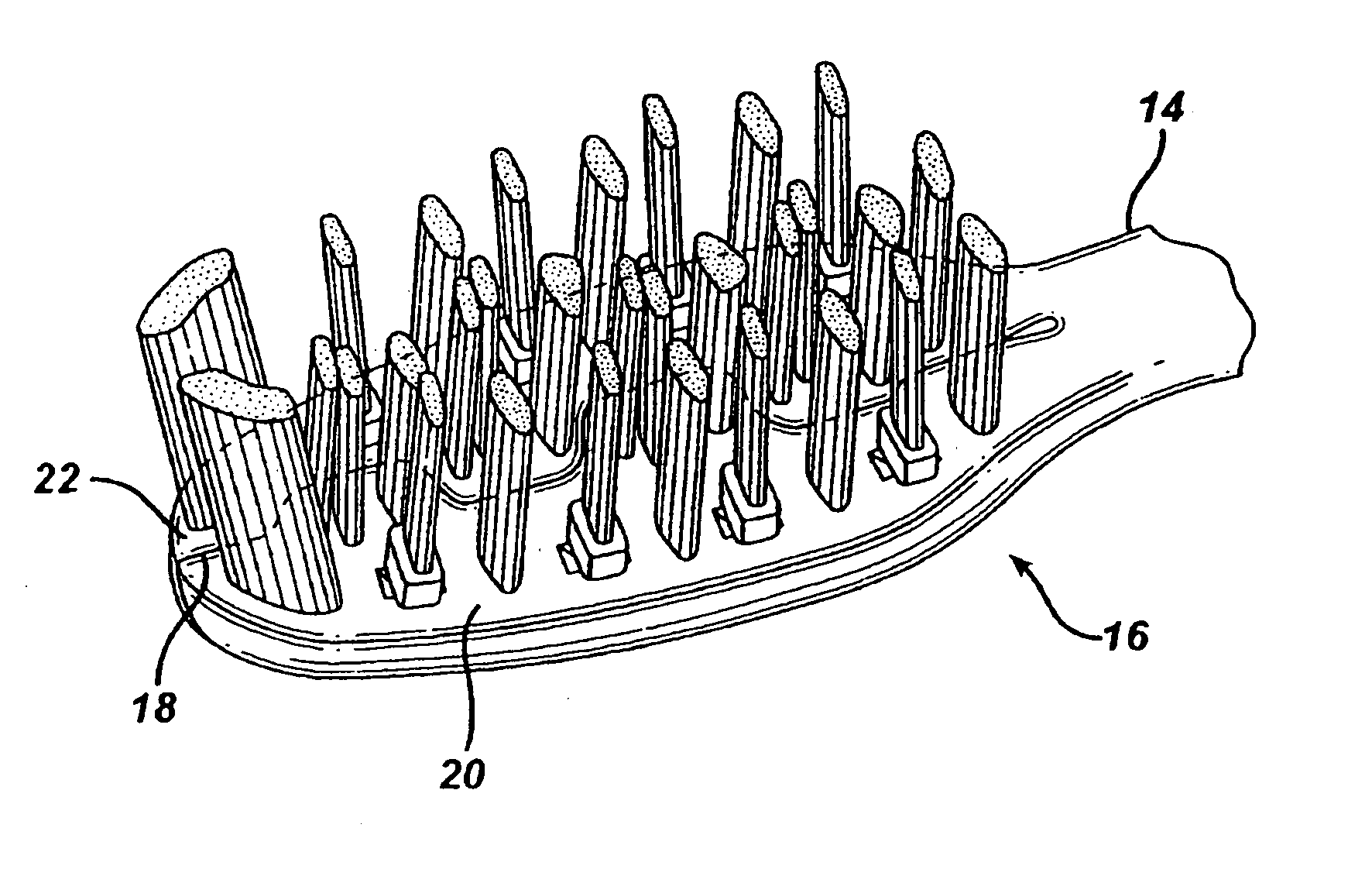

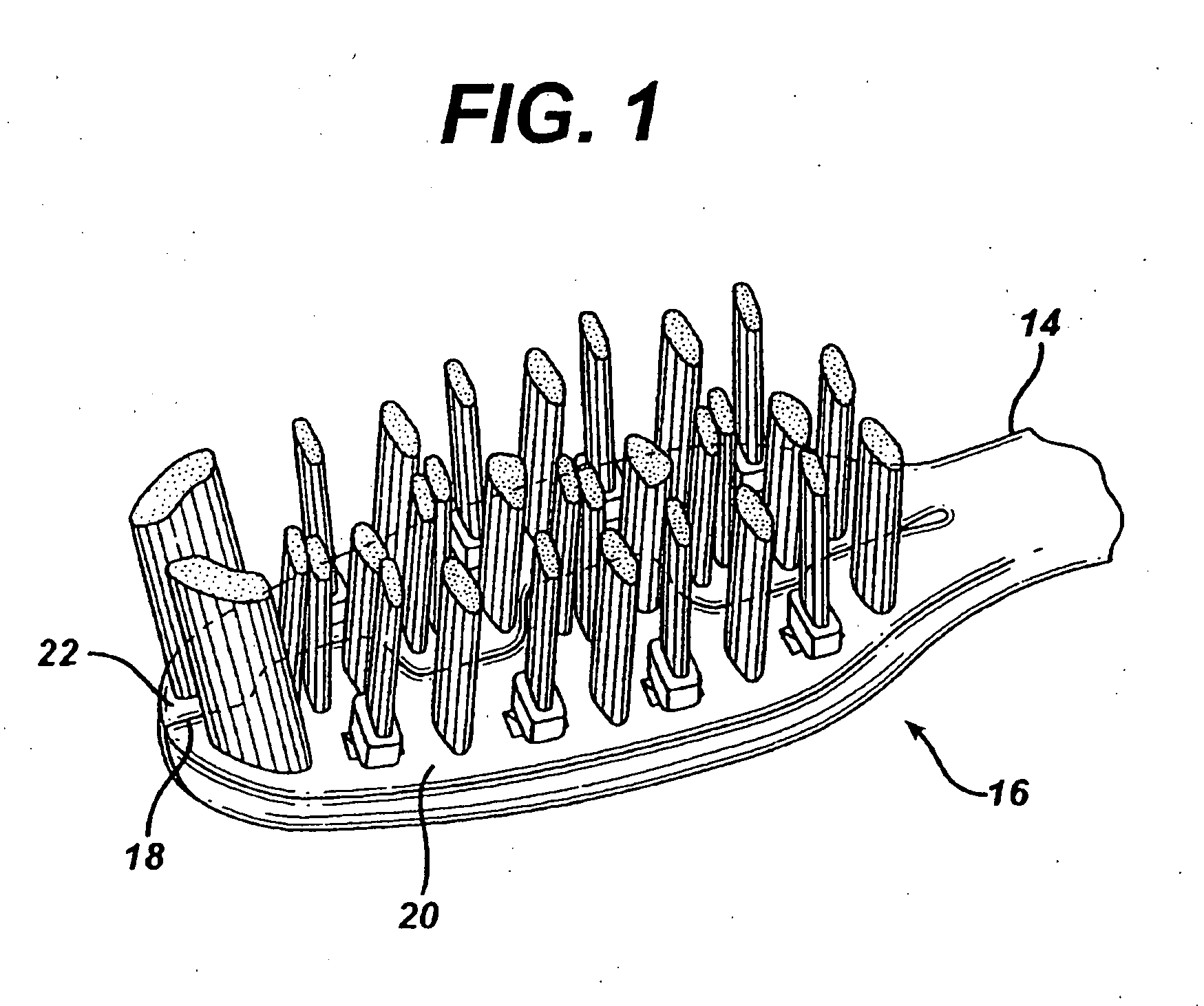

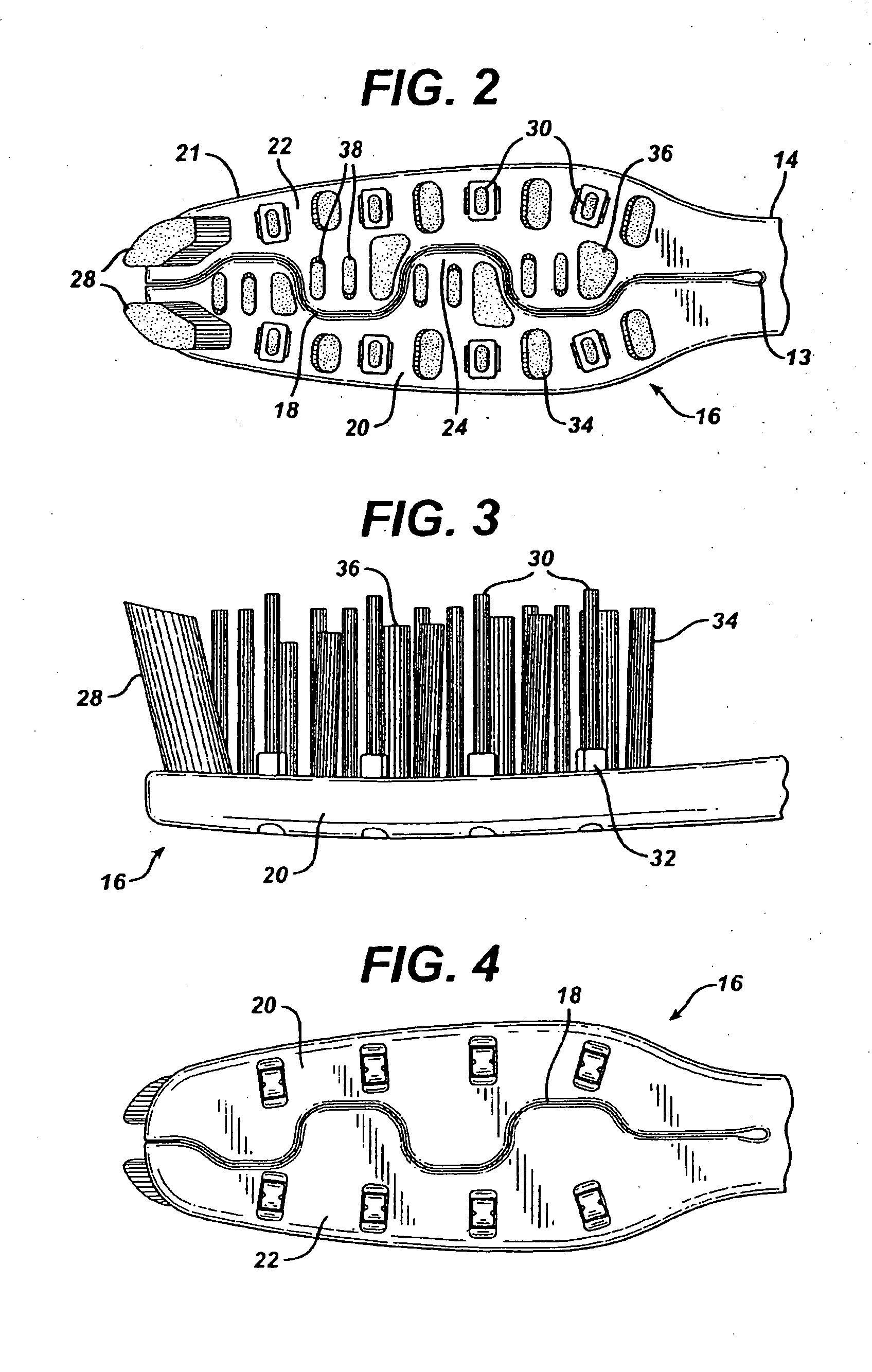

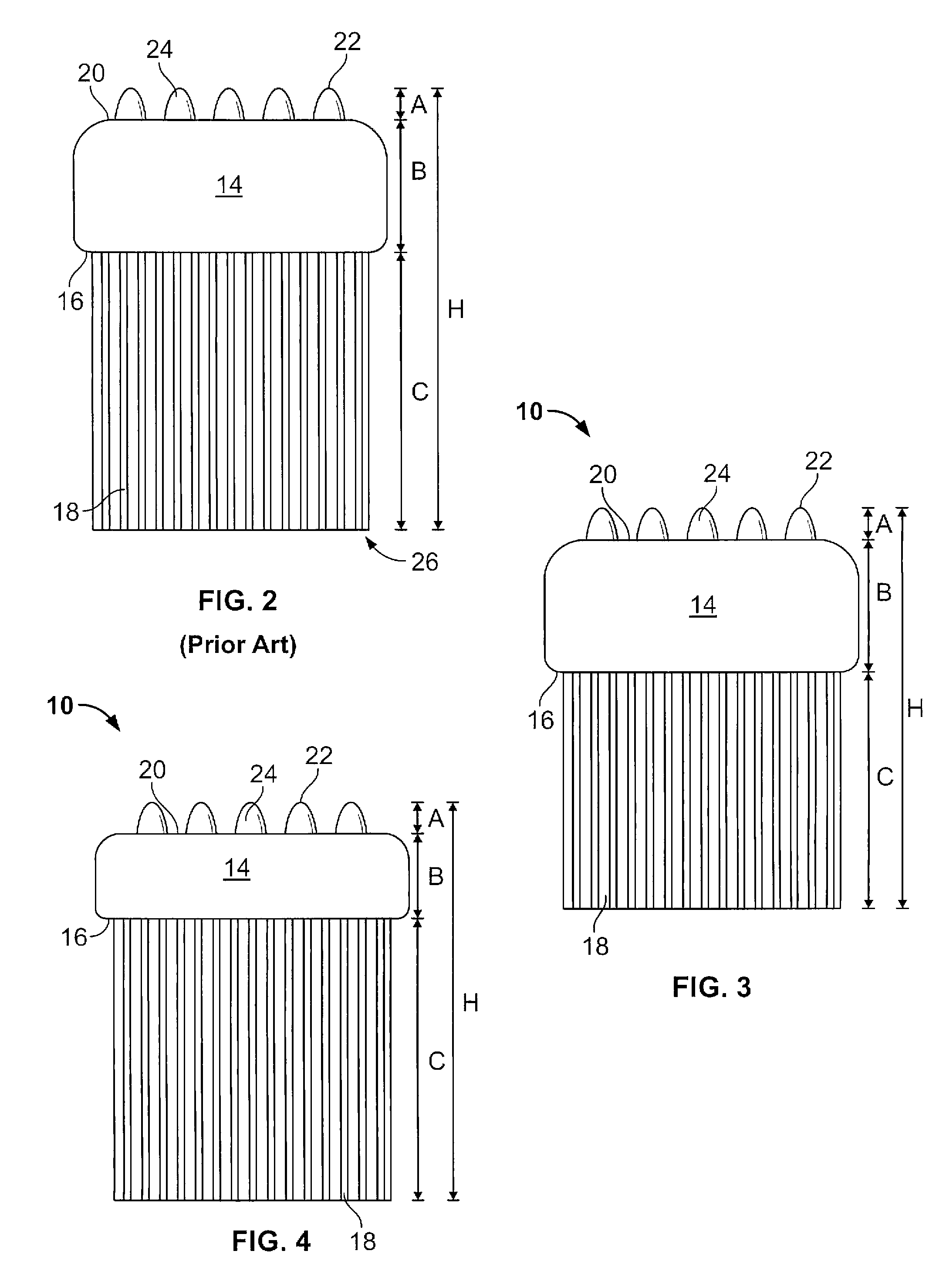

Toothbrush with tongue cleaning member

InactiveUS20040255416A1Large penetrationMinimal heightEar treatmentCarpet cleanersTongue cleaningEngineering

A toothbrush having a handle portion formed with a neck at one end thereof and extending along a first longitudinal axis. A head section is coupled to the neck. The head section includes a plurality of first cleaning members provided on a first head side thereof which extends outwardly from the first head side generally perpendicular to the first longitudinal axis. The head section further includes a second cleaning member provided on a second head side thereof opposite to the first head side. In order to reliably clean the tongue surface, the second cleaning member includes a plurality of flat-tipped conical-shaped cleaning elements which extend outwardly from the second head side of the head section generally perpendicular to the first longitudinal axis. Alternately, the second cleaning member can include a plurality of grated cleaning elements which extend outwardly from the second head side of the head section generally perpendicular to the first longitudinal axis.

Owner:COLGATE PALMOLIVE CO

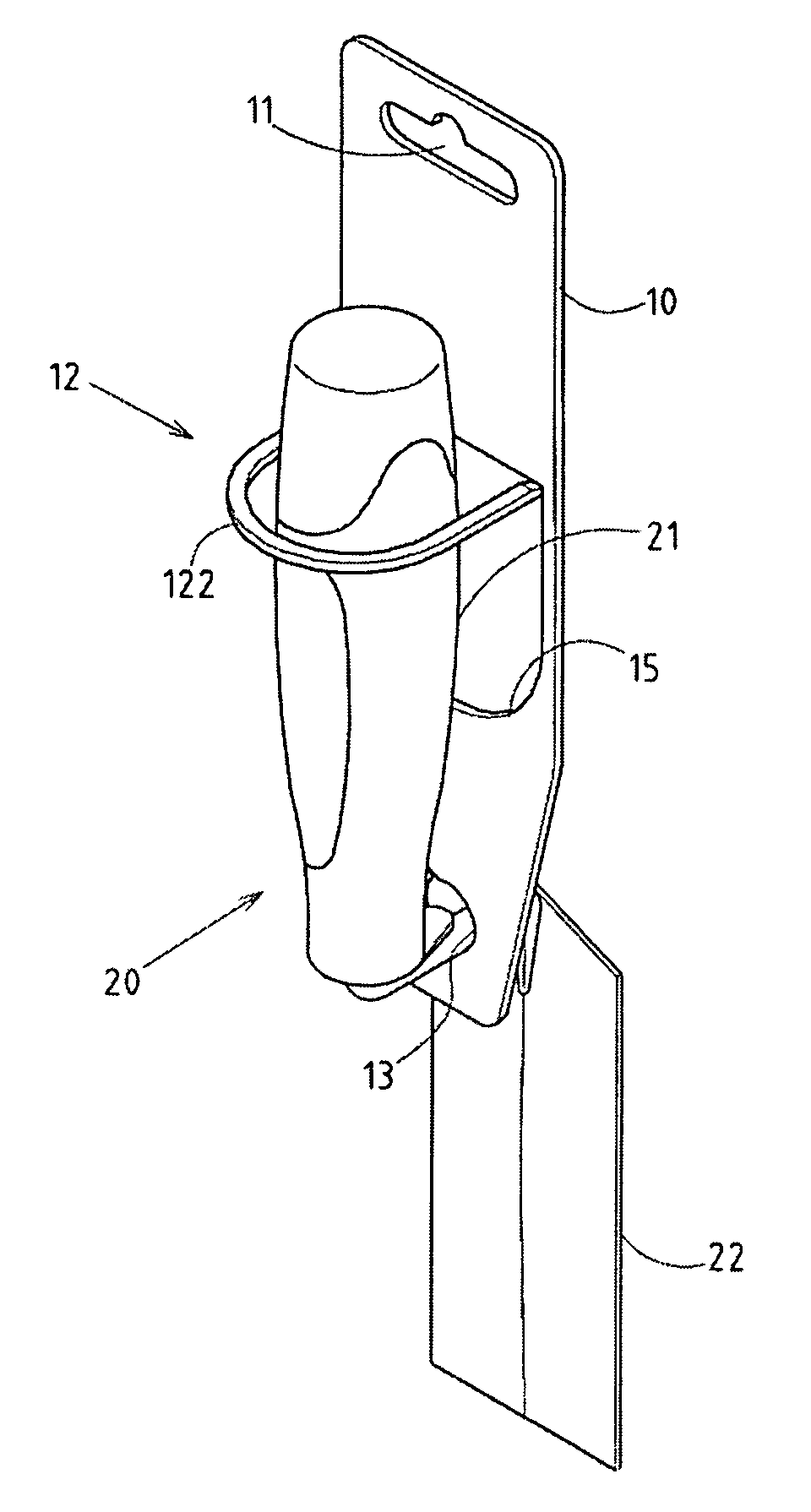

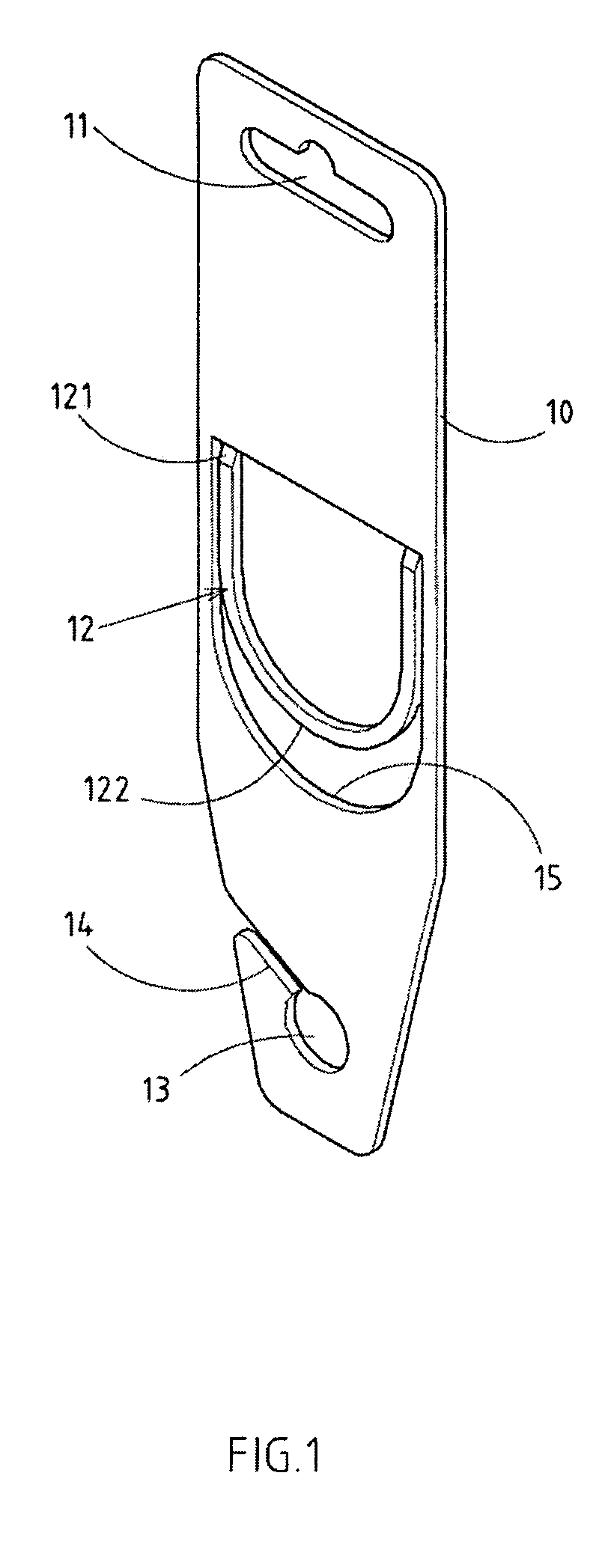

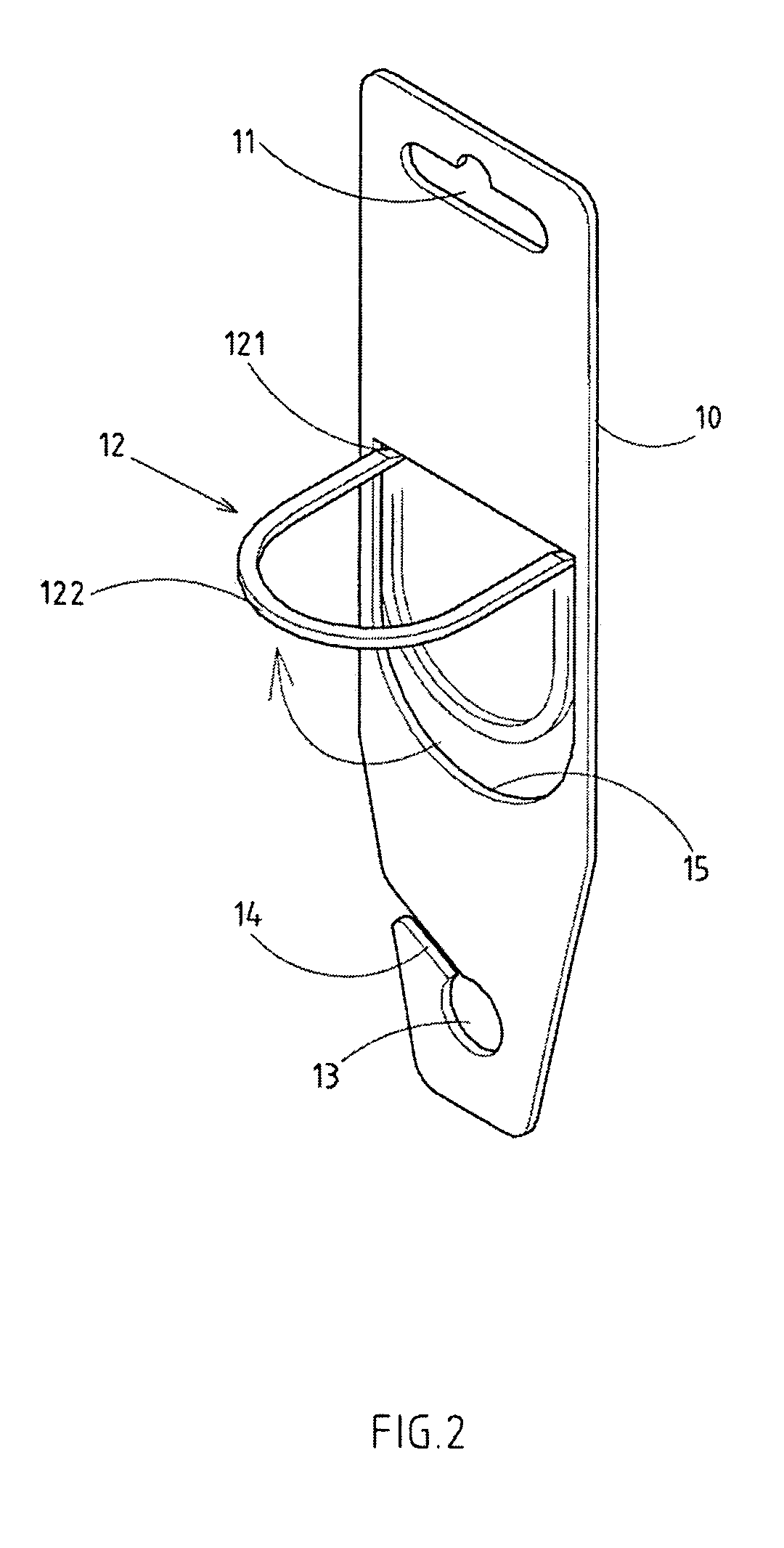

Hangtag for plaster trowel

InactiveUS7296772B2Stands/trestlesContainer/bottle contructionHorizontal and verticalMechanical engineering

Owner:WANG SEE TUH

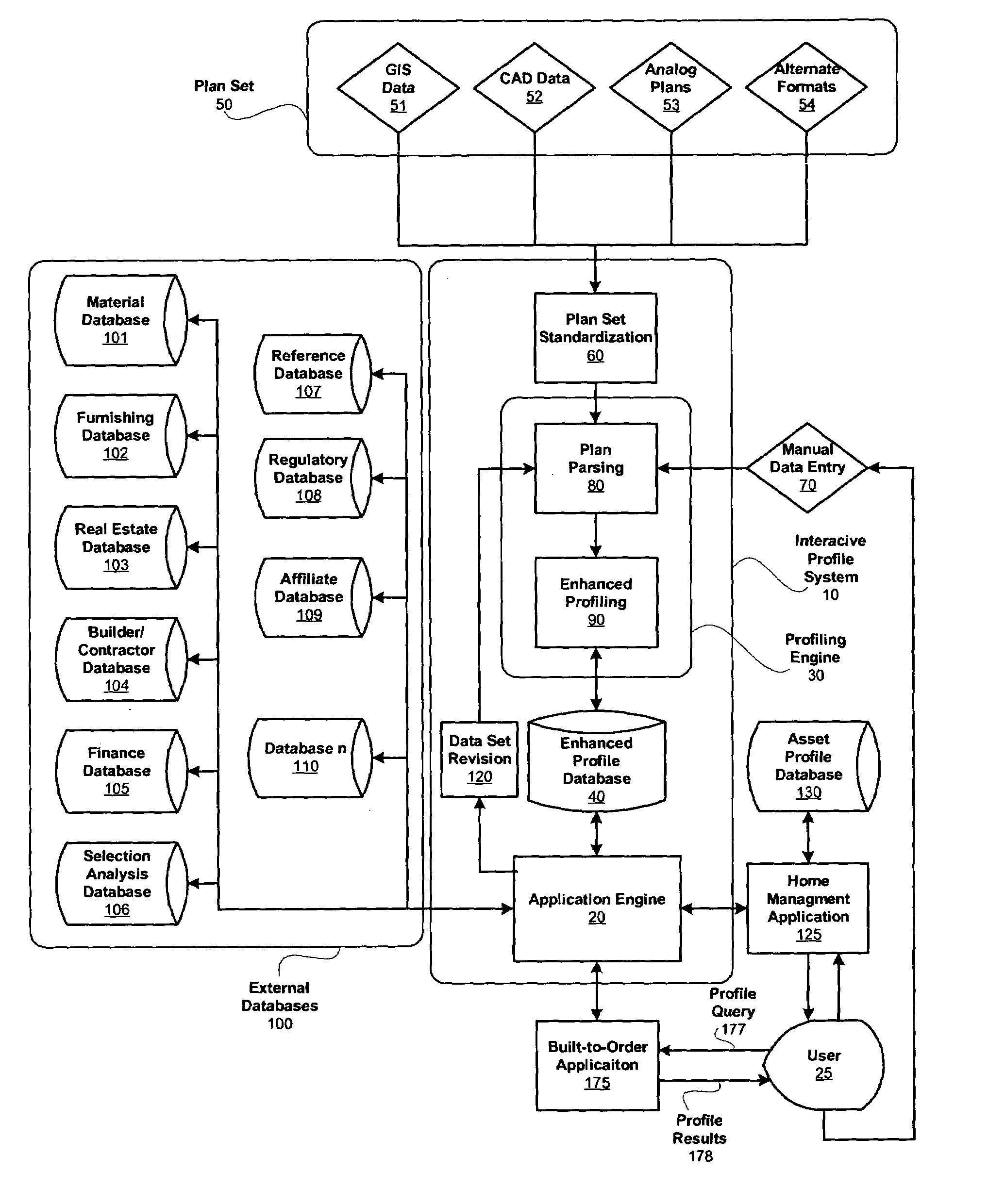

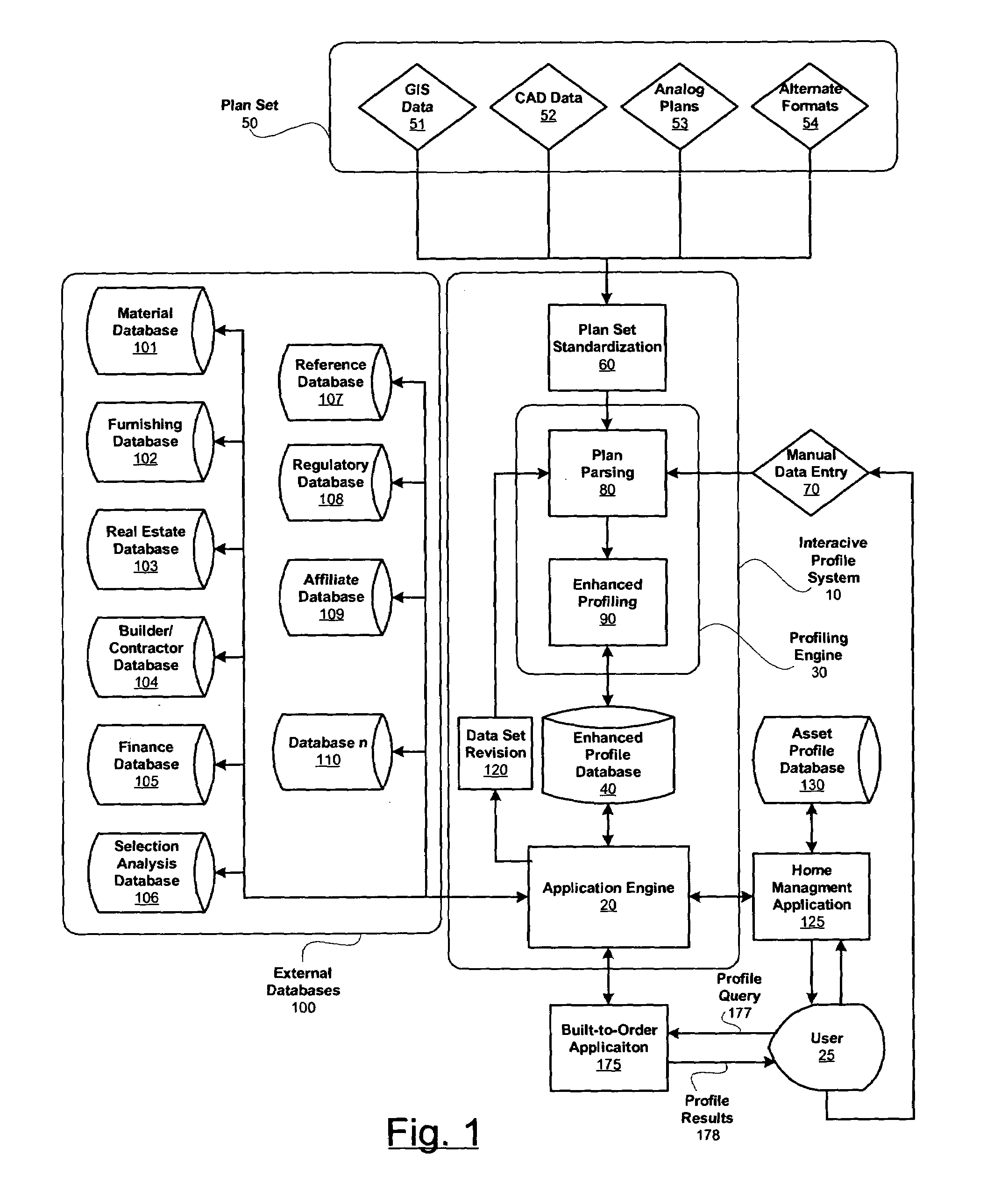

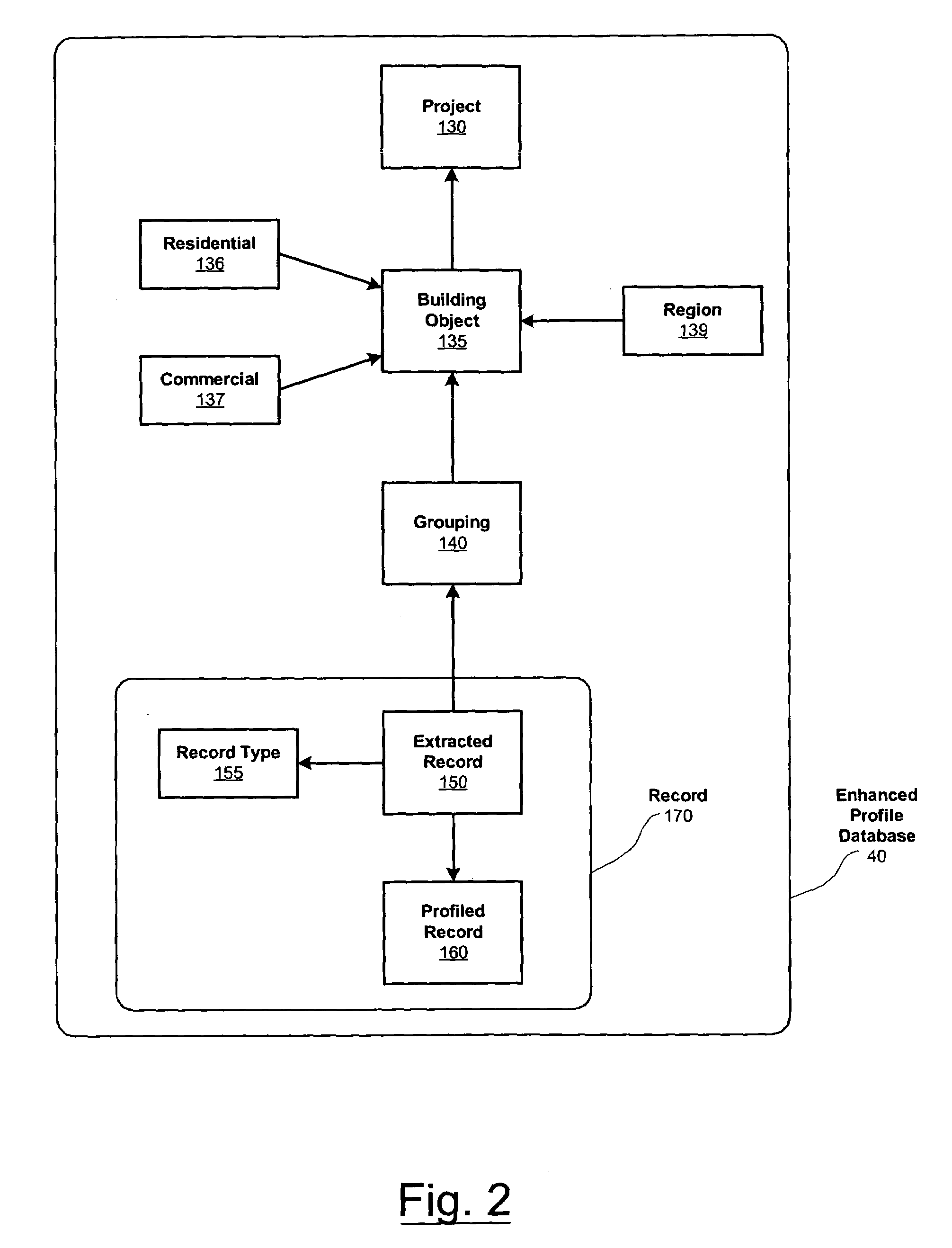

Generating cad independent interactive physical description remodeling, building construction plan database profile

InactiveUS6922701B1Enhanced interactionReduces lengthy communicationGeometric CADData processing applicationsExecution planData set

A method for generating an interactive profile of a structure, such as a building, employing an interactive profile system that preferably utilizes an Internet web browser to interface with a user. The interactive profile system includes an application engine embodied in a computer program that is preferably based within a server. A plan set, usually in a CAD format, is received into the interactive profile system, typically submitted by the user or client. The building can be any structure, such as a home, office or warehouse, and can also include the property that the structure occupies. The plan set is converted to a profile data set by the profiling engine. In compliance with an enhanced data protocol, which is a specific format for organizing the profile data set in a standardized array. The profiling engine parses, or extracts, the profile data set to develop and link a plurality of potentially interrelated building. The profiling engine performs a systematic enhancement of the plan set, building upon the elemental physical descriptions of the plan set. Each element of the physical description is functionally analyzed for relational attributes and then expanded and tagged. The user directs a profile query to the application engine of the interactive profile system. The profile query is relatable to the enhanced profile and more specifically relatable to at least one of the plurality of interrelated elements of the building. Typical profile requests can include proposed or actual changes to the building, requests for material listings, and project assessments.

Owner:HAVENOMICS LLC

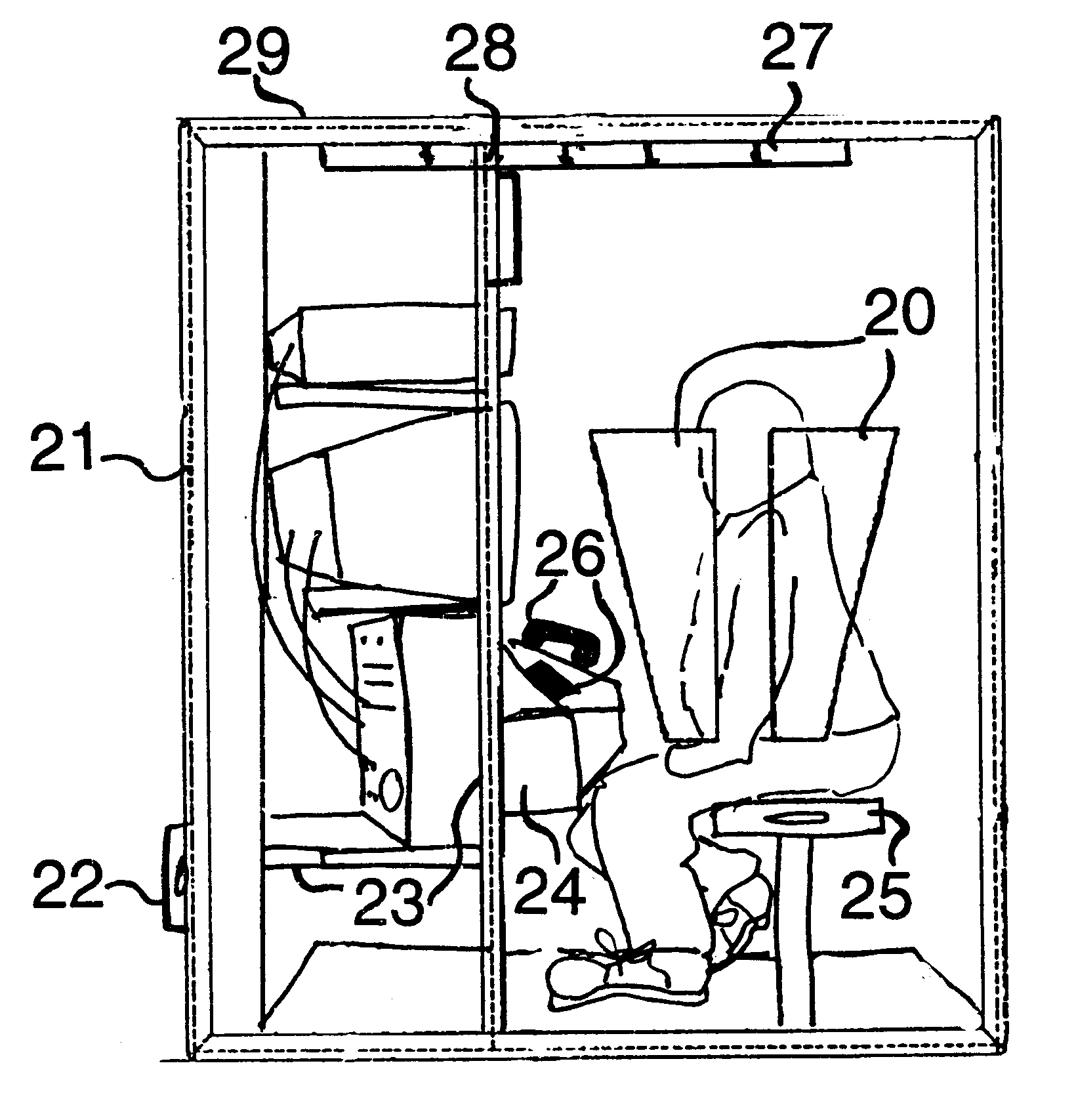

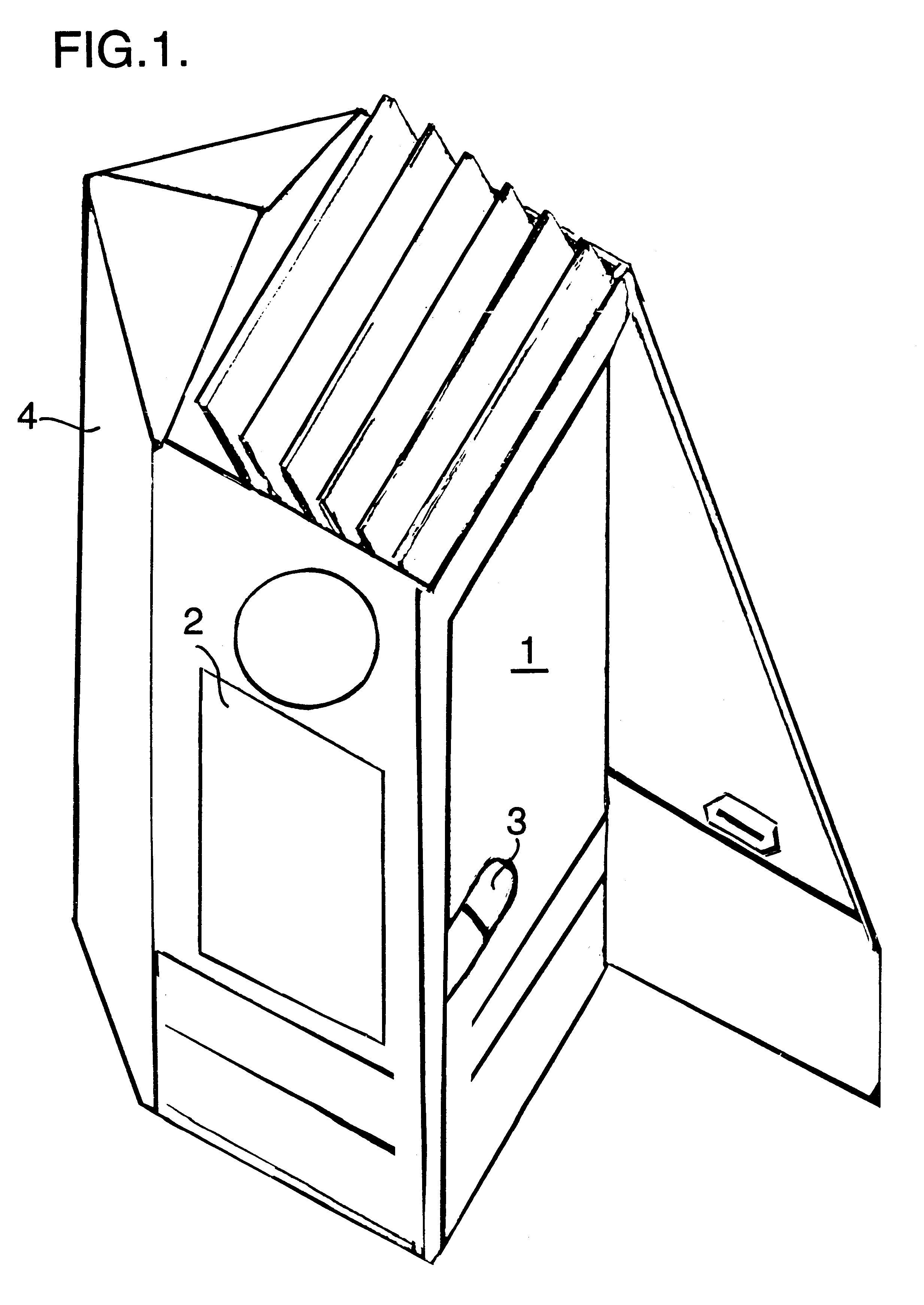

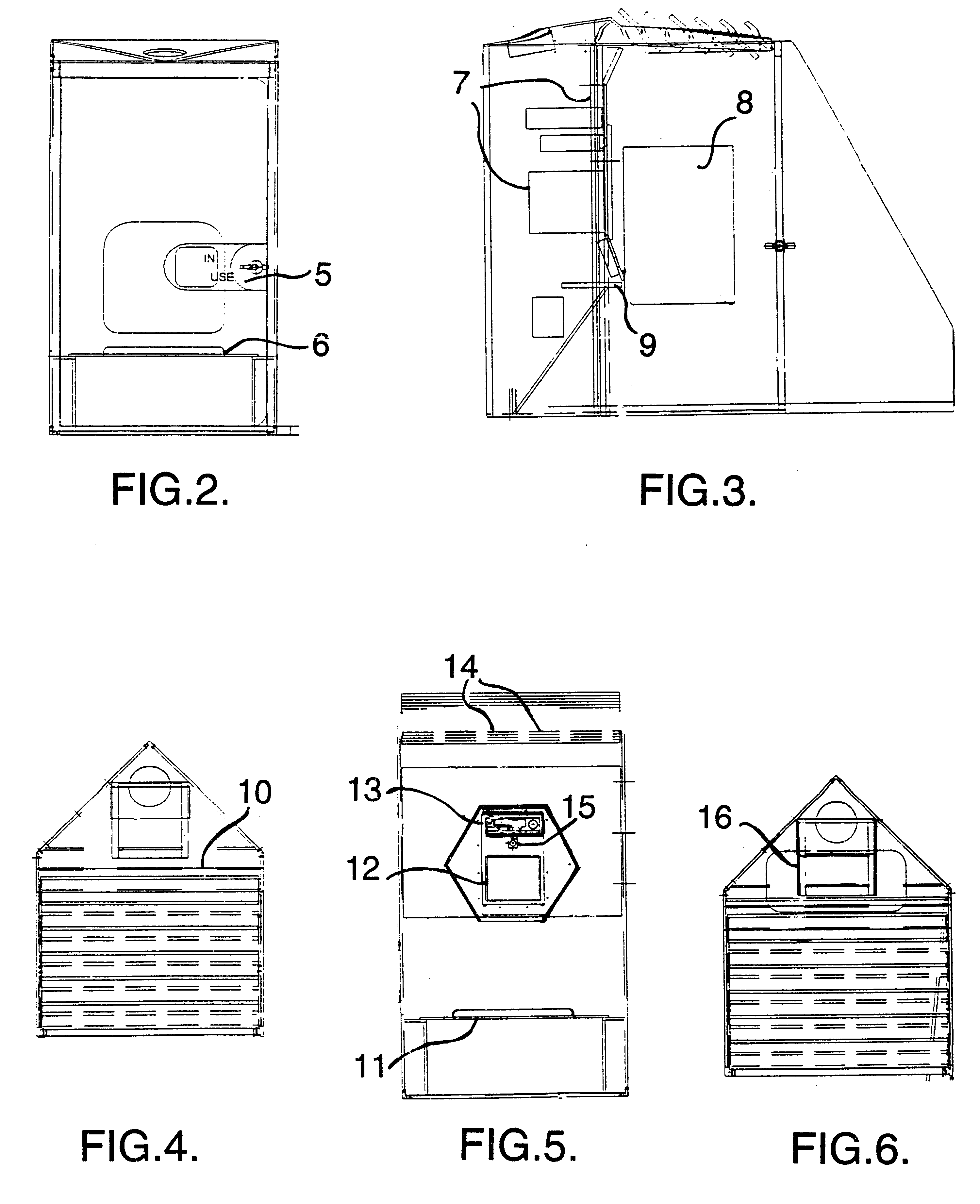

Modular video conference enclosure

InactiveUS6205716B1Easily broken down into transportable pieceTelevision system detailsTelevision conference systemsModularityDistance collaboration

A secure, modular and movable interactive two-way telecollaborative video conferencing and imaging enclosure for conducting business or privileged medical, legal, or other confidential matters in private, being particularly equipped for remote monitoring of physiological attributes of one or more users by medical specialists and remote interaction between users and medical specialists.

Owner:PELTZ DIANE P

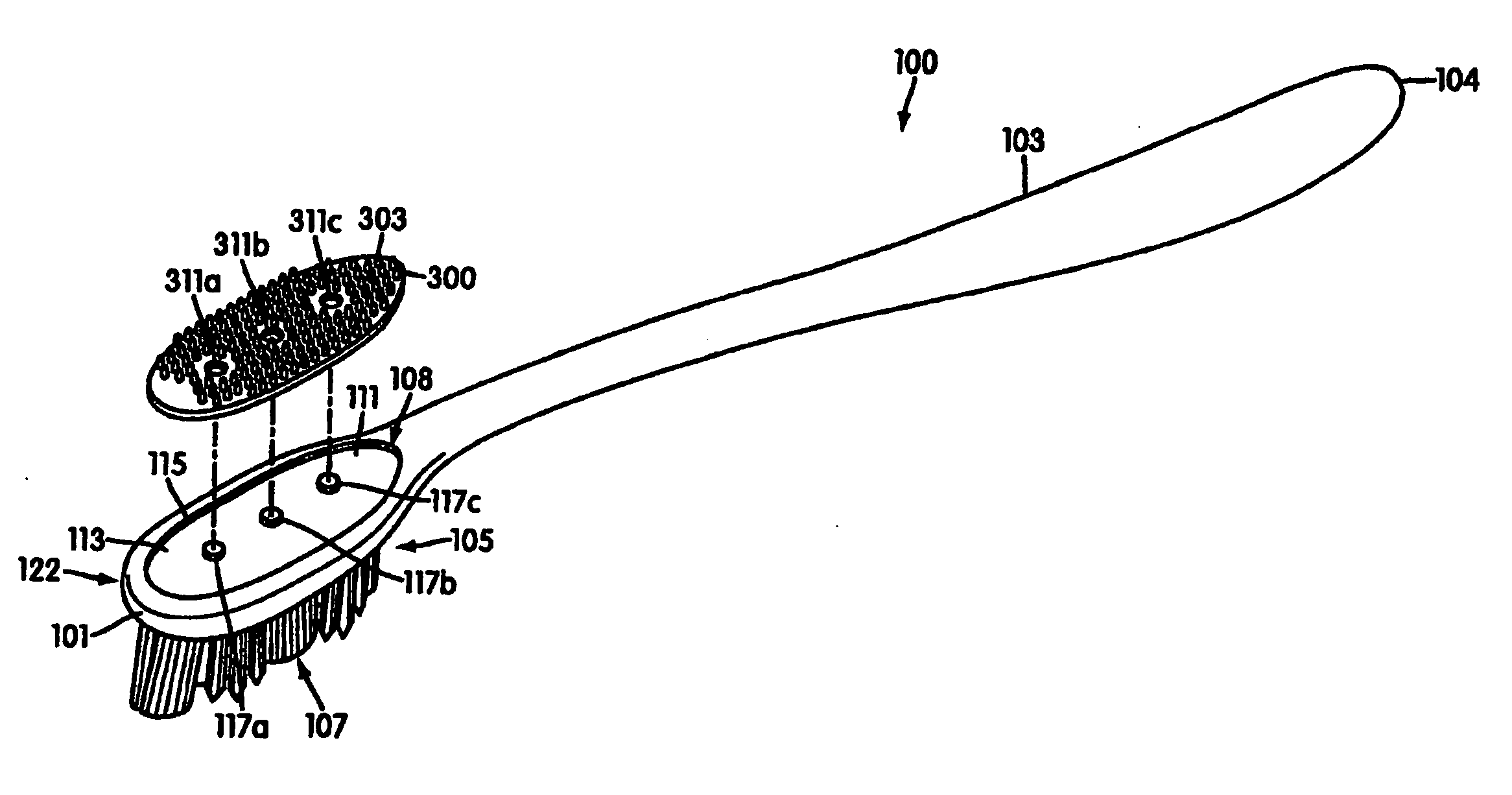

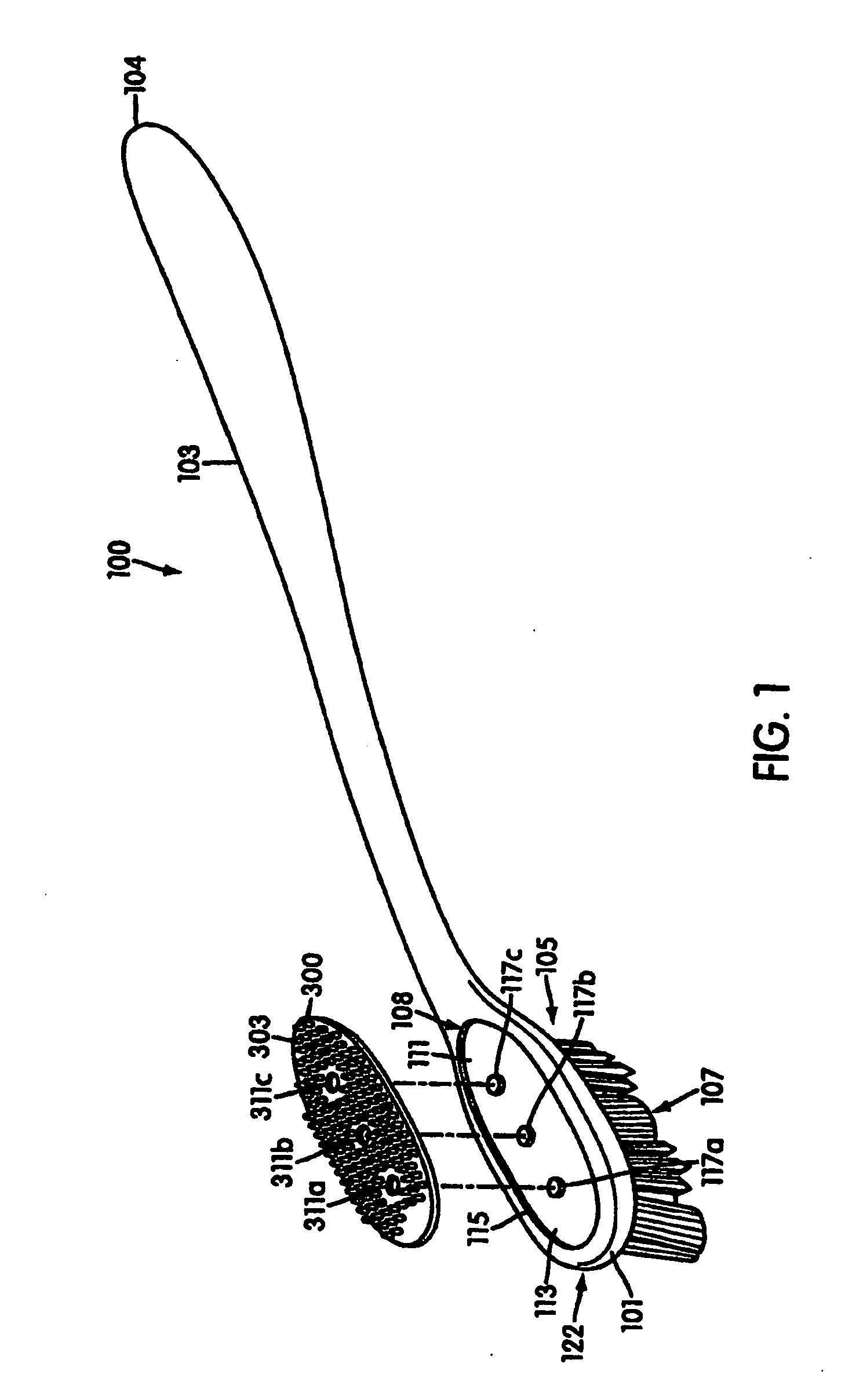

Oral care implement

InactiveUS20050000049A1Easy to cleanEfficient removalGum massageEar treatmentCleansers skinMouth care

An oral care implement with a handle includes a head with a tissue cleanser. The tissue cleanser may be a pad composed of an elastomeric material. The pad is disposed on the head on a surface opposite the tooth cleaning elements. The tissue cleanser may include a plurality of nubs extending for cleaning between the papillae of the tongue. The tissue cleanser may include a plurality of conically shaped nubs. A tissue cleanser can be used to reduce oral malodor problems and remove oral epithelial cells.

Owner:COLGATE PALMOLIVE CO

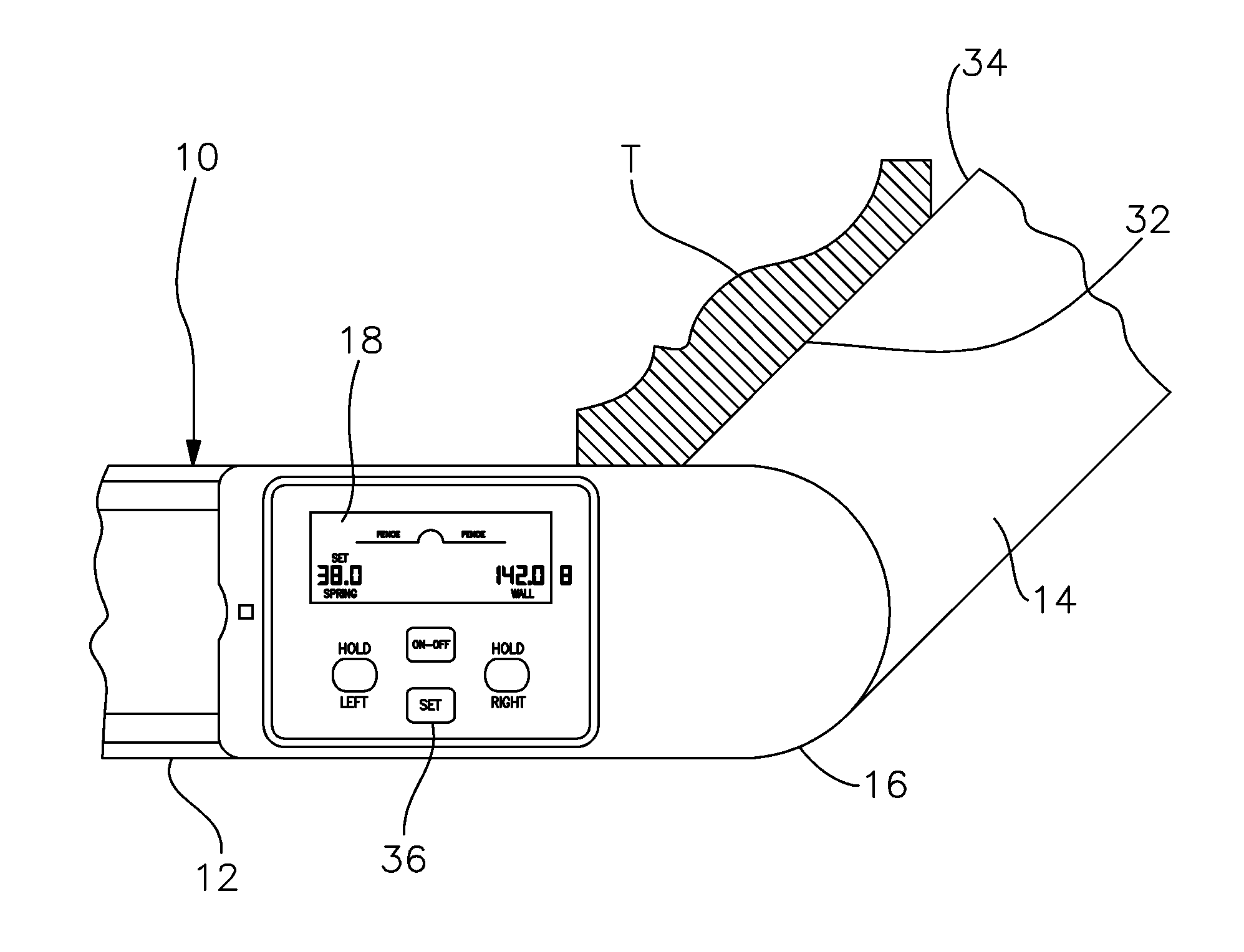

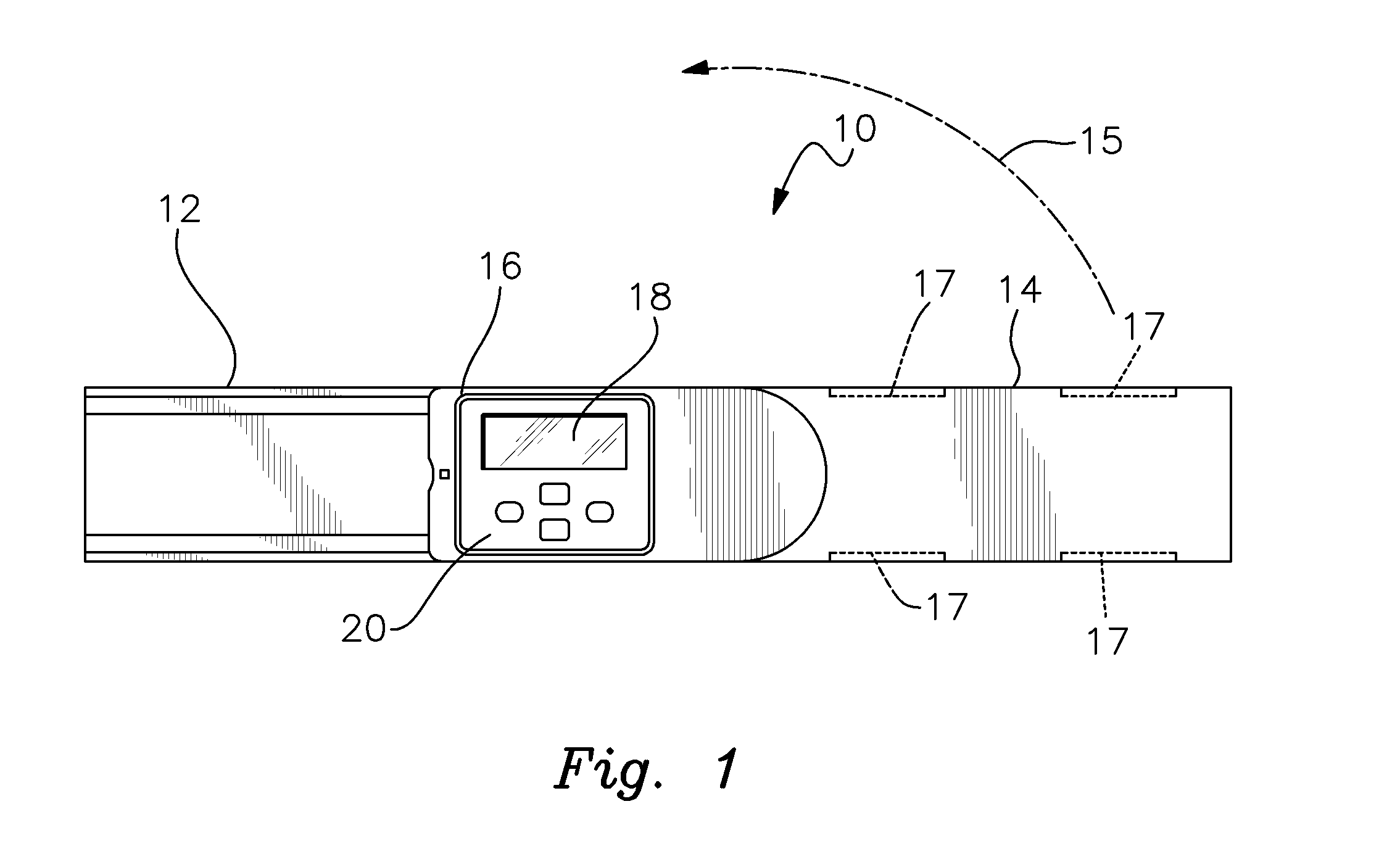

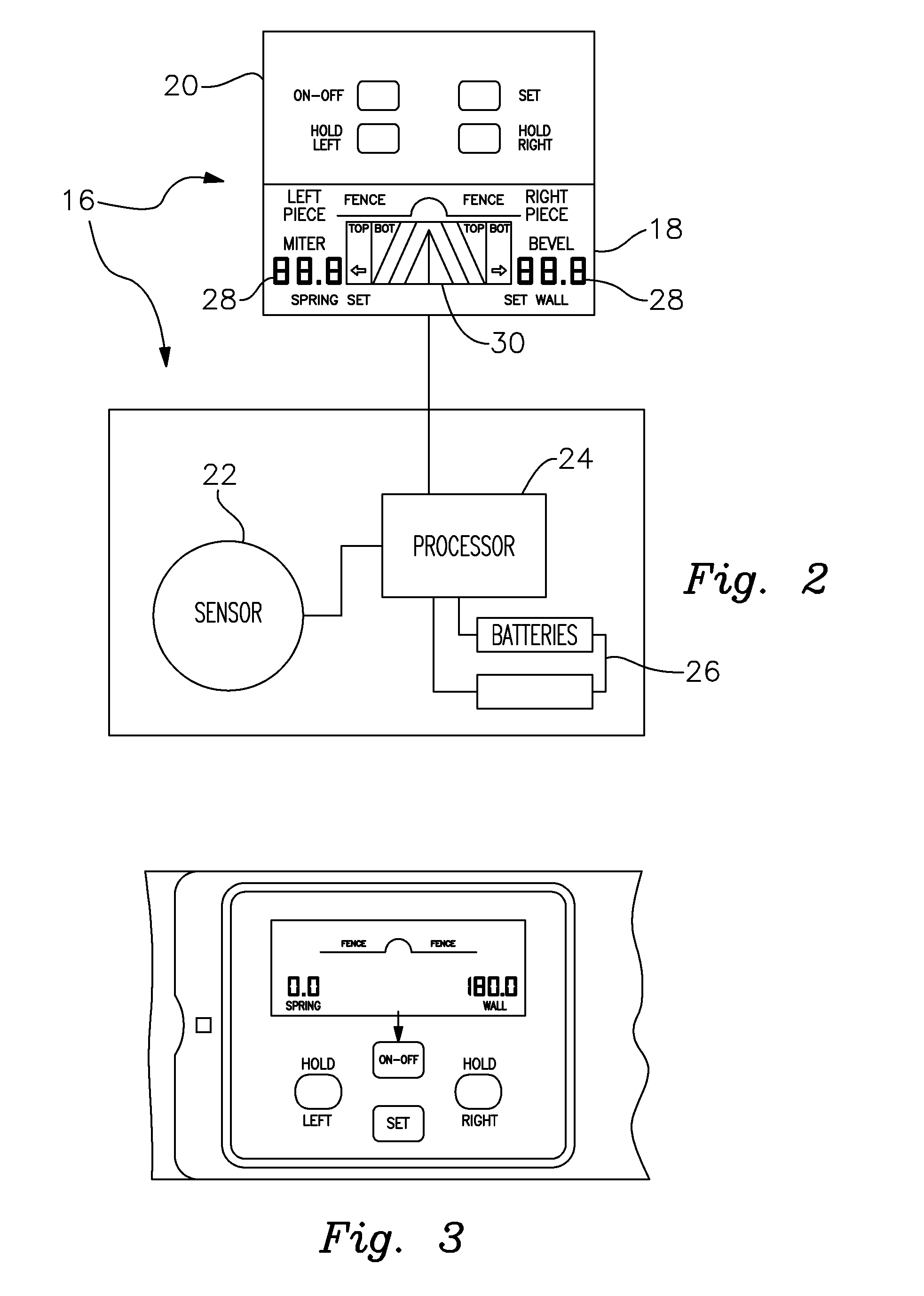

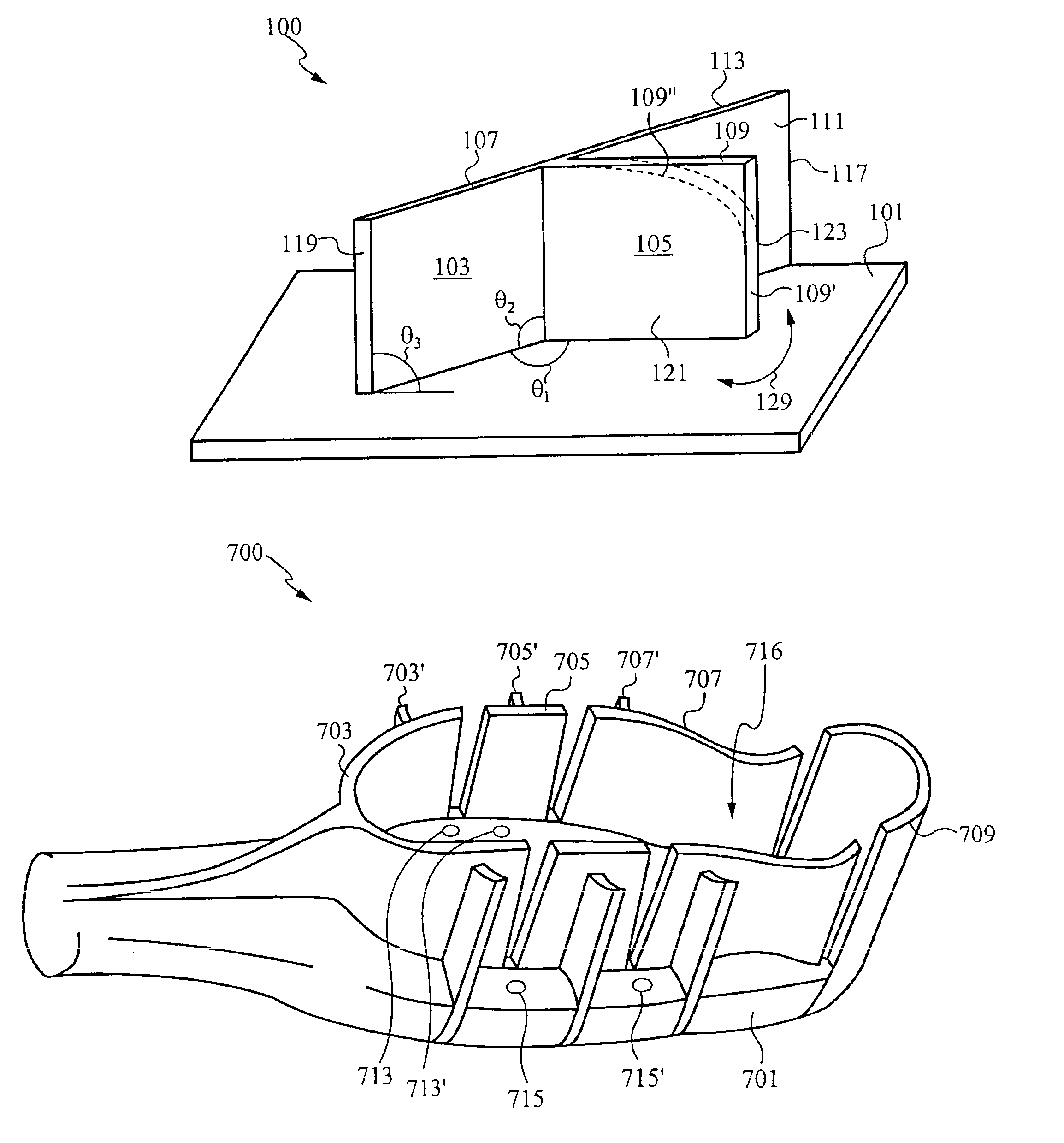

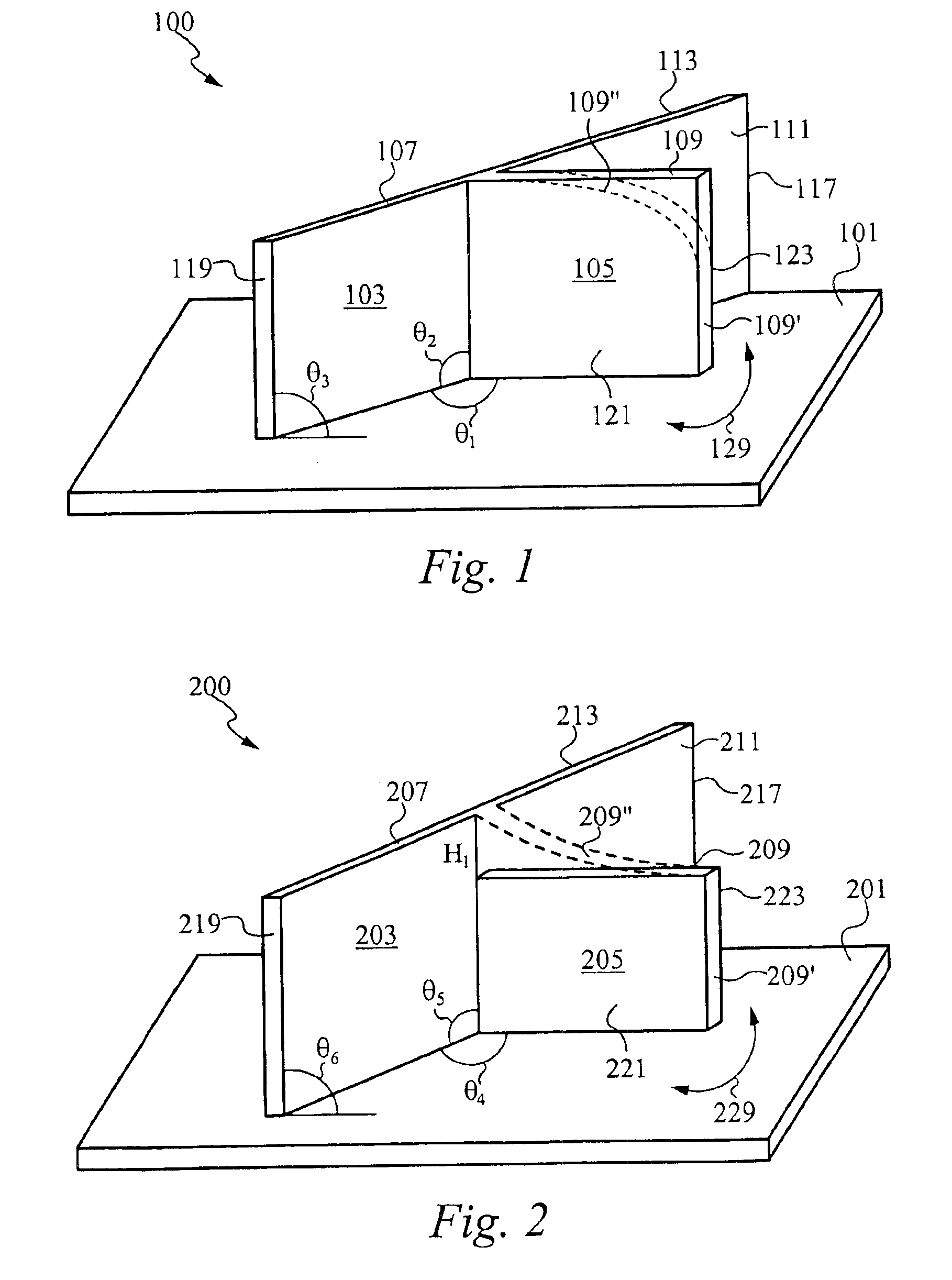

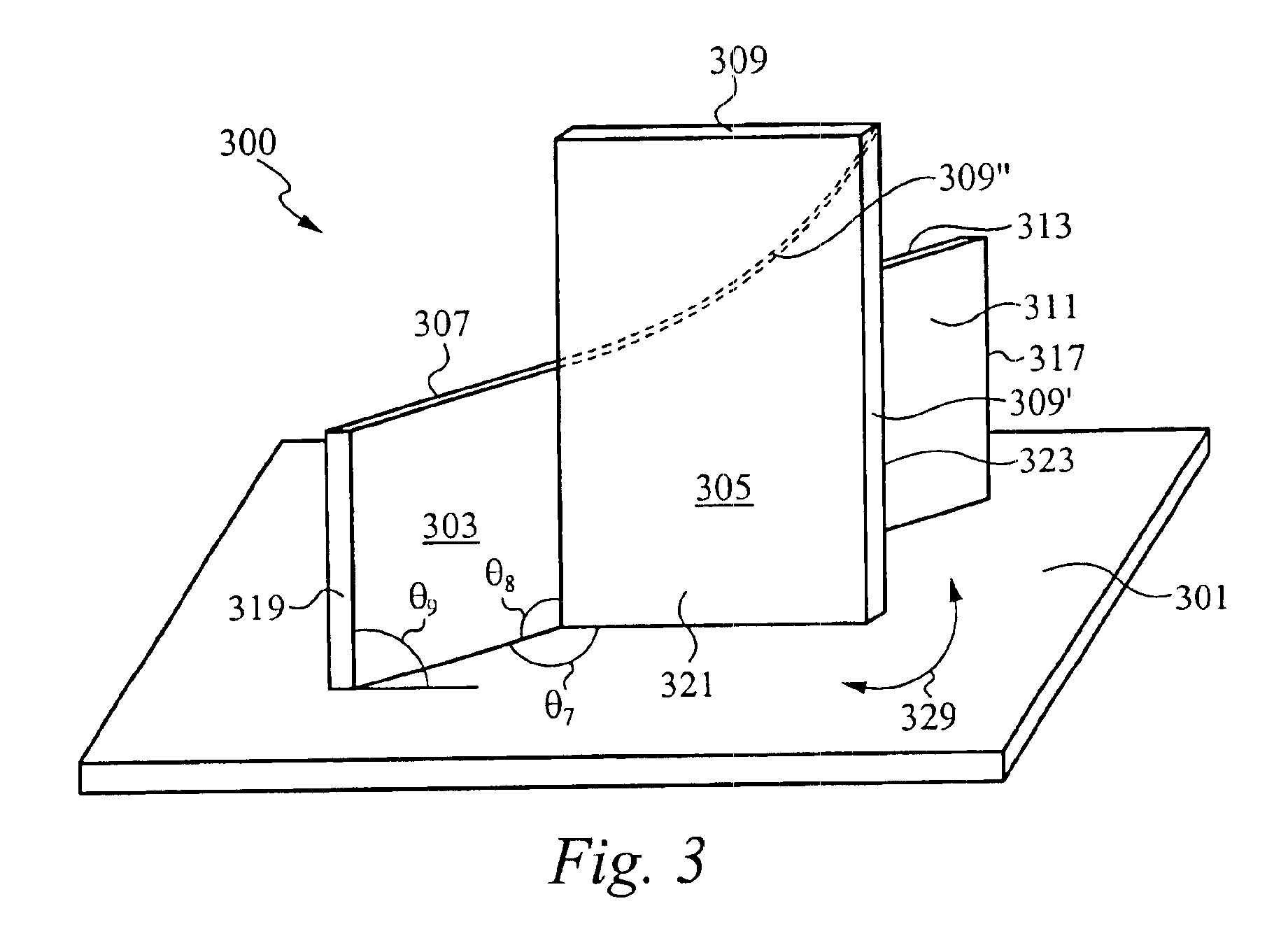

Crown Molding Protractor

InactiveUS20160238365A1Calculated quickly and accuratelyFacilitates and guides adjustmentBuilding constructionsAngles/tapers measurement gaugesProtractorCrown molding

A digital protractor is provided for measuring spring and wall angles and determining and effecting bevel and miter angle adjustments of a miter saw to adjoining pieces of trim in accordance with the measured spring and wall angles. The protractor includes a pair of pivotally interconnected arms. At least one sensor is attached to one of the arms and a digital readout is secured to the other arm. The readout includes means for determining the bevel and miter angles such that the protractor can be set to those angles to properly adjust the miter saw in accordance with the calculated angles.

Owner:WIXEY BARRY DOUGLAS +2

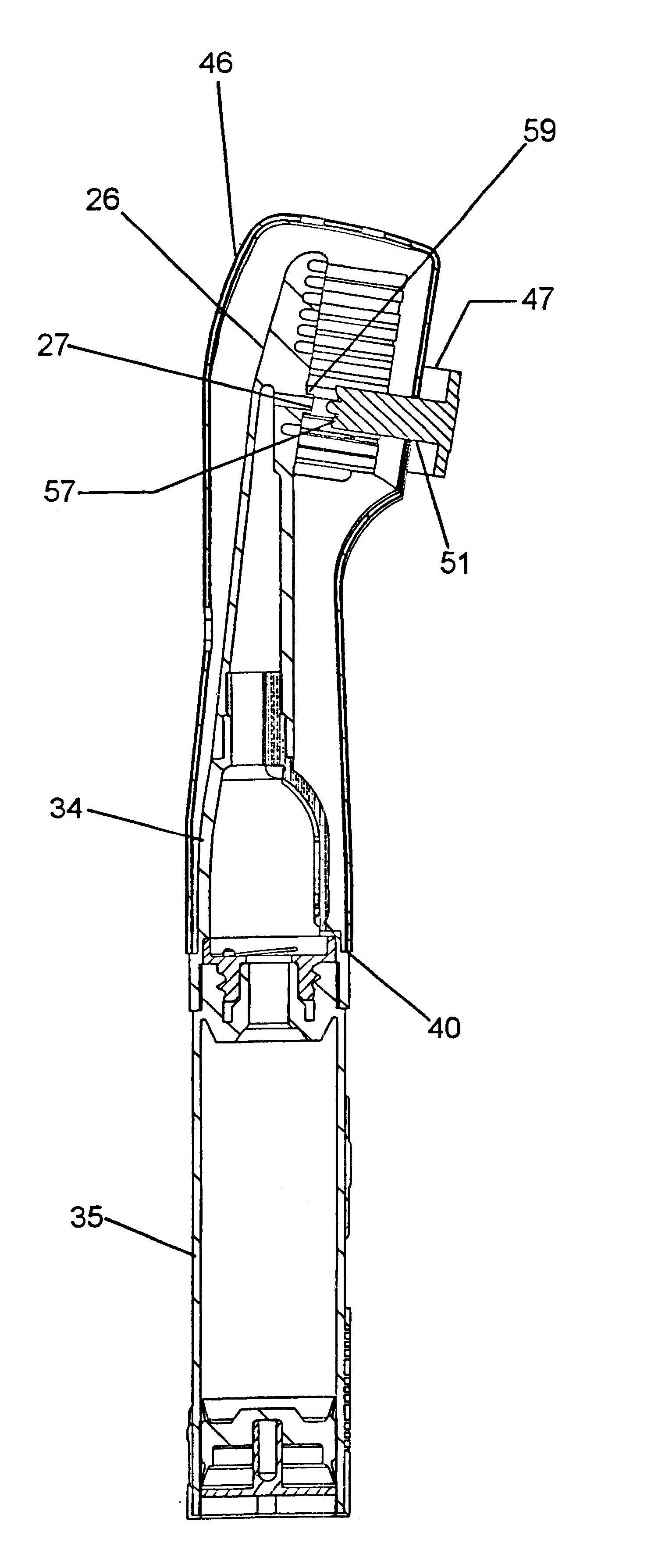

Toothbrush for massaging and protecting gums

InactiveUS6599048B2Control deflectionControl pressureCarpet cleanersFloor cleanersBristleMechanical engineering

A toothbrush that utilizes a replaceable brush head having rubber gum guard on its top surface and a triangular shaped rubber pad on its bottom surface. The rubber gum guard is shorter than the height of the bristles and is positioned on the peripheral edge of a brush head for functioning as a sensor for providing feedback to prevent brushing at excessive pressures and improper angles as well as for massaging the gumlines without the risk of gum damages. The triangular shaped rubber pad is for conforming to and massaging gumlines at the back of teeth. The replaceable brush head having the rubber gum guard and massaging pad features is economically used in conjunction with a permanent handle that dispenses dentifrice material to the top of bristles. The handle has a resilient contractible connector for secure mounting of the replaceable brush head.

Owner:KUO YOUTI

Oral care implement

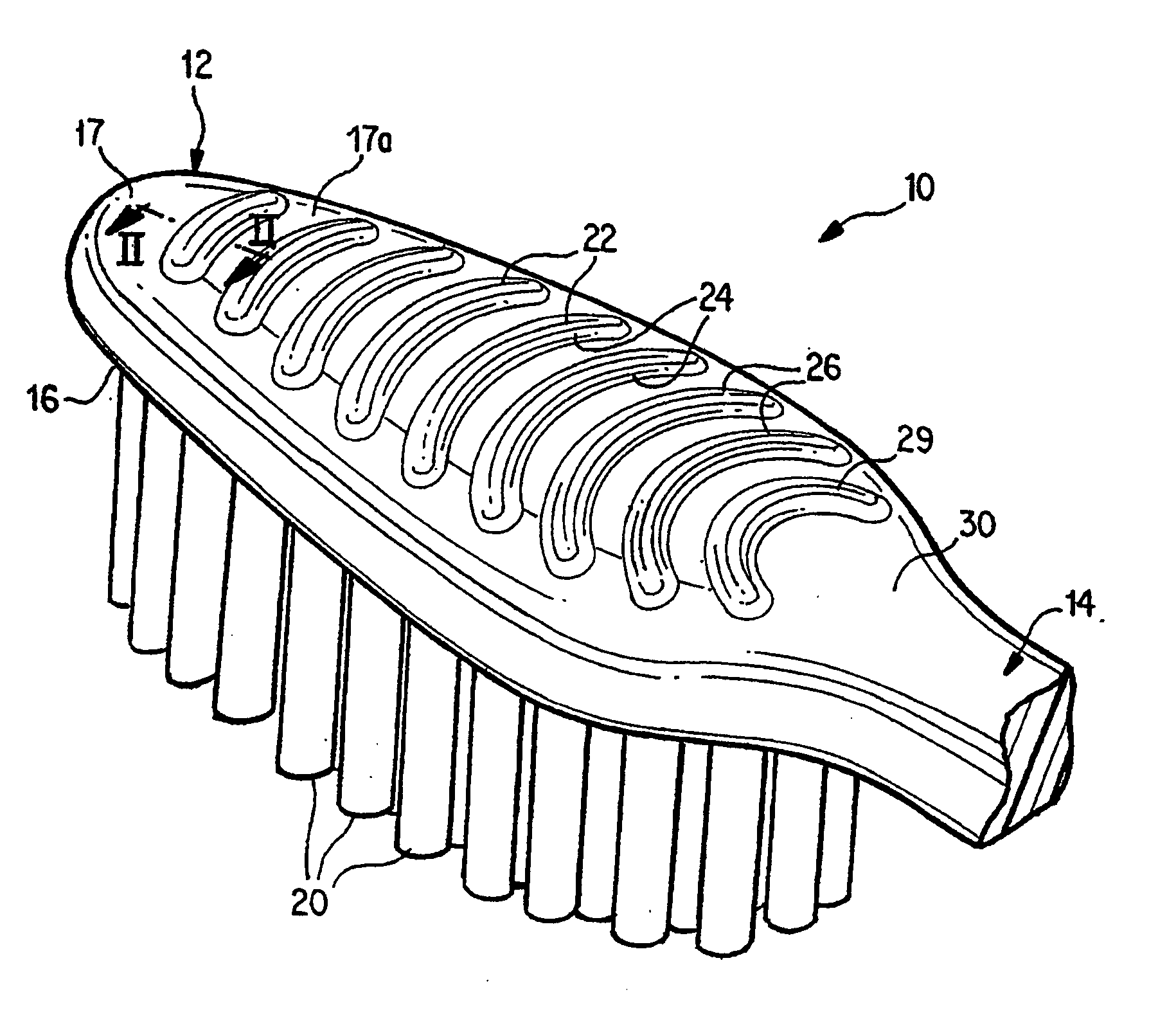

ActiveUS20060010628A1Easy to cleanEfficient removalEar treatmentCarpet cleanersCleansers skinMouth care

An oral care implement including a handle and a head with a tongue cleanser. The tongue cleanser has at least one ridge which is at least as wide as it is high. In one preferred construction, the ridges are shaped so as to define a concave surface facing generally toward the handle. The ridges also preferably include aligned segments from front to back that are oriented at different angular positions.

Owner:COLGATE PALMOLIVE CO

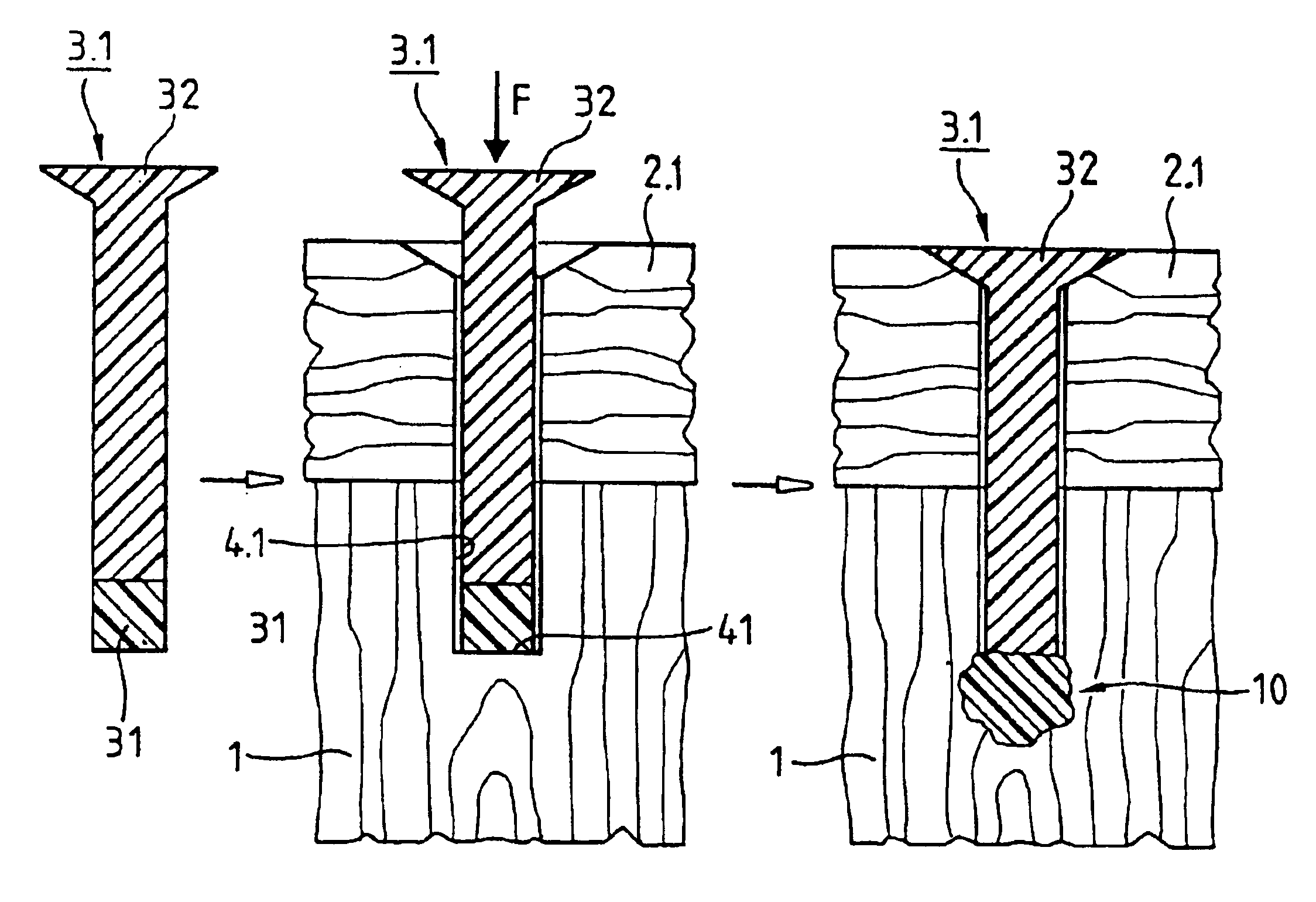

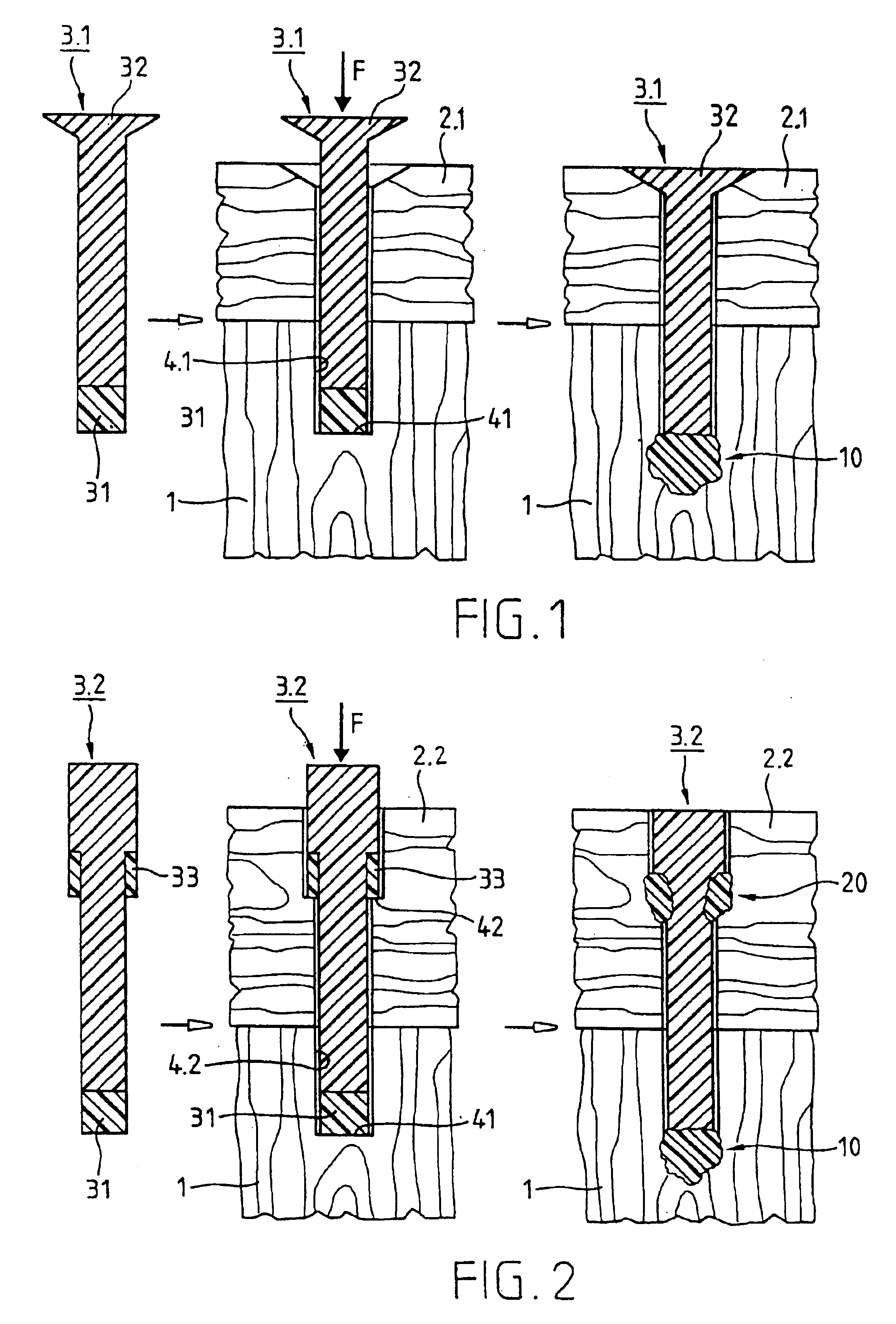

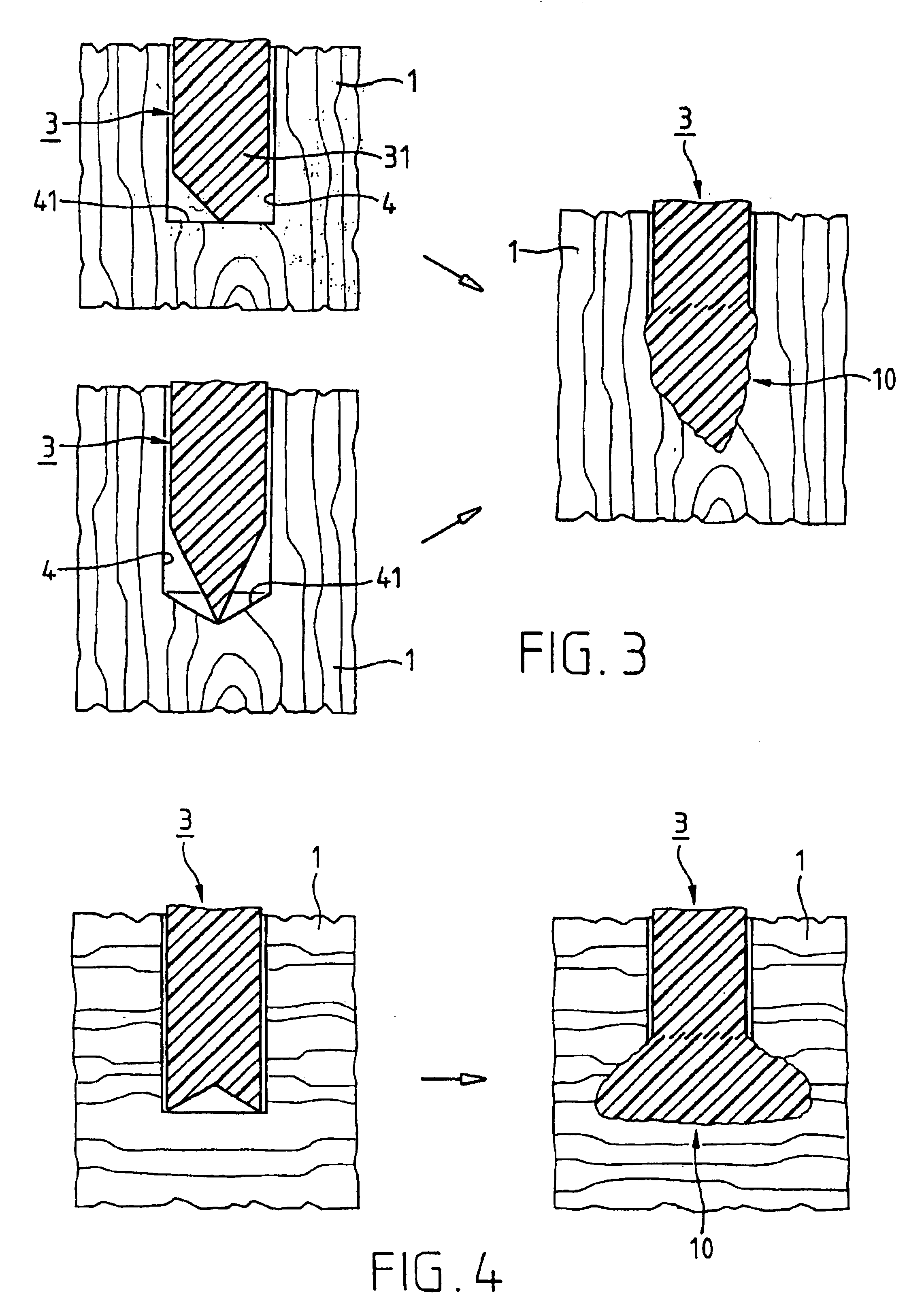

Process for anchoring connecting elements in a material with pores or cavities and connecting elements therefor

InactiveUS6913666B1Easy to reachReduce disadvantagesRivetsCylinder headsEngineeringUltrasonic vibration

A joining pin (3.2) with which two parts (1 and 2) made from a porous material, particularly wood or a wood-like material, are to be joined together, is anchored in the porous material at predetermined anchoring points (31, 33). For this purpose, a bore (4.2) with a closed inner end (41) is made in the parts (1 and 2). The shape of this bore (4.2) is so matched to the joining pin (3.2) that it can be introduced substantially without force expenditure into the bore and is positionable in a first position. At least one predetermined anchoring point (31, 33) between the joining pin (3.2) and the wall of the bore (4.2) is formed when pressure is built up by pressing the joining pin (3.2) with a pressing force (F) more deeply into the bore to a second position. Energy is supplied in a planned manner to the joining pin (3.2) so that at the predetermined anchoring points (31, 33) the thermoplastic material of the joining pin (3.2) is plasticized. The locally plasticized plastic material is pressed by the local pressure into the porous material of the parts and forms local, macroscopic anchors (10, 20). The joining pin (3.2) is, e.g., made entirely from a thermoplastic material and the energy for plasticizing is supplied thereto by ultrasonic vibration.

Owner:WOODWELDING

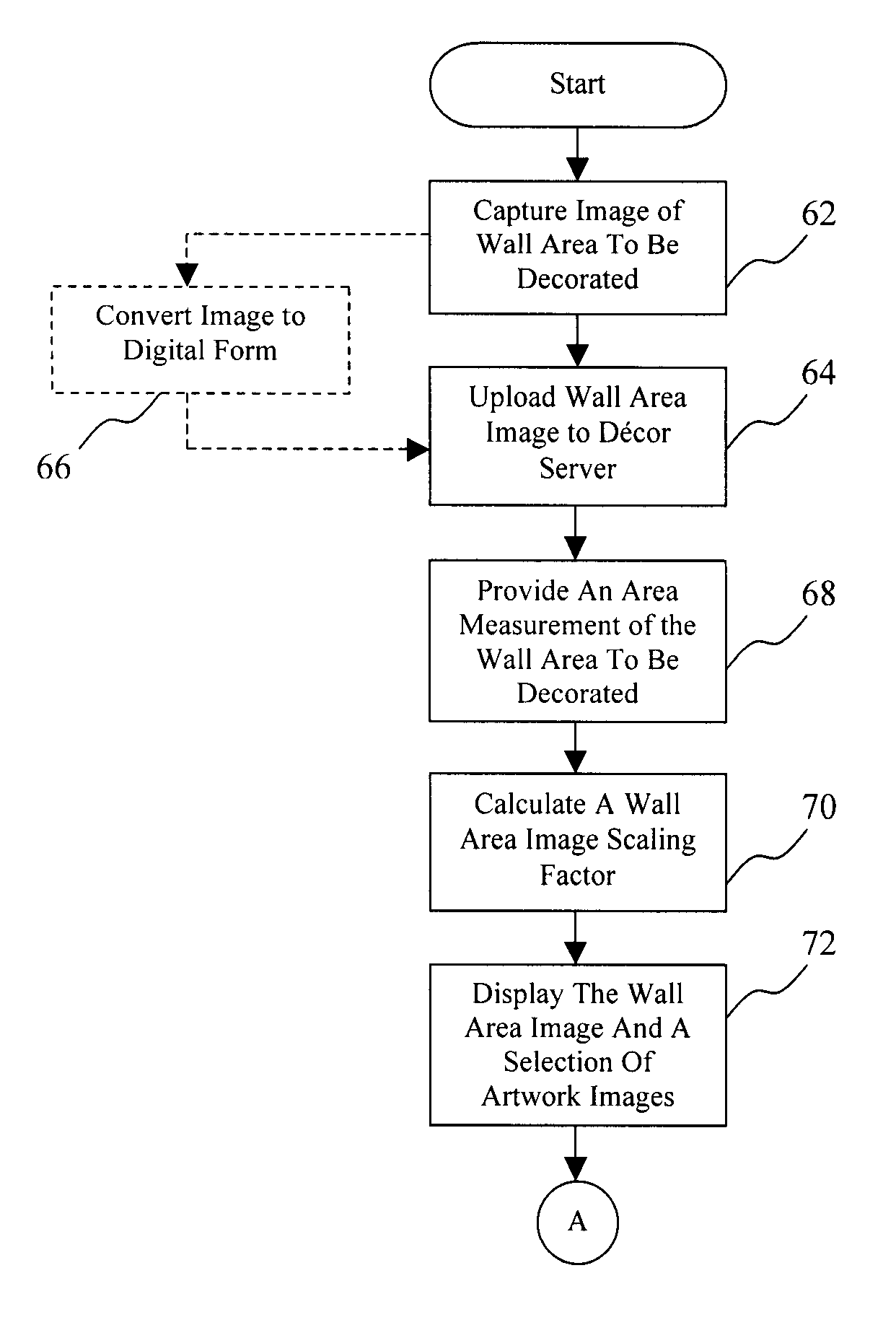

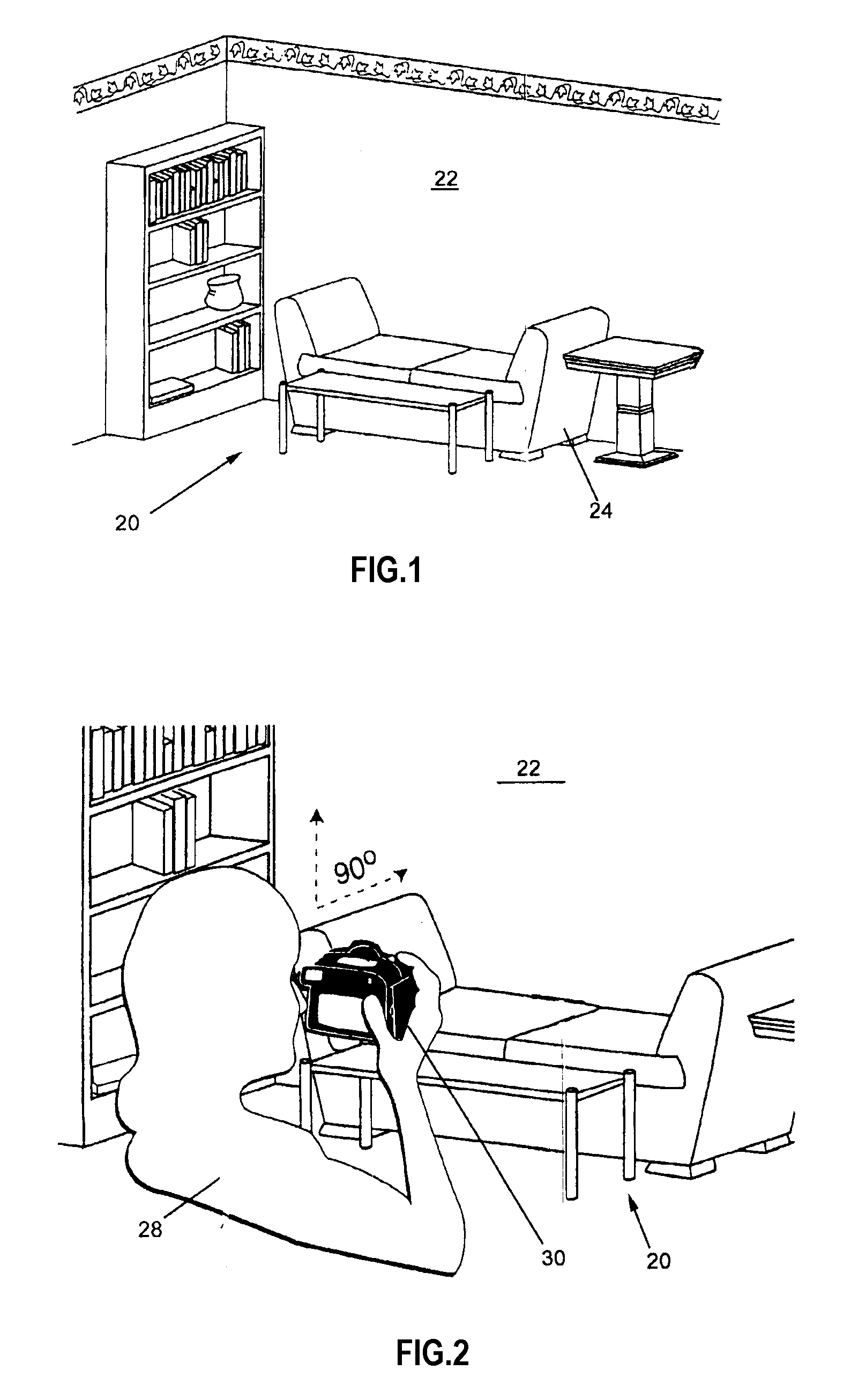

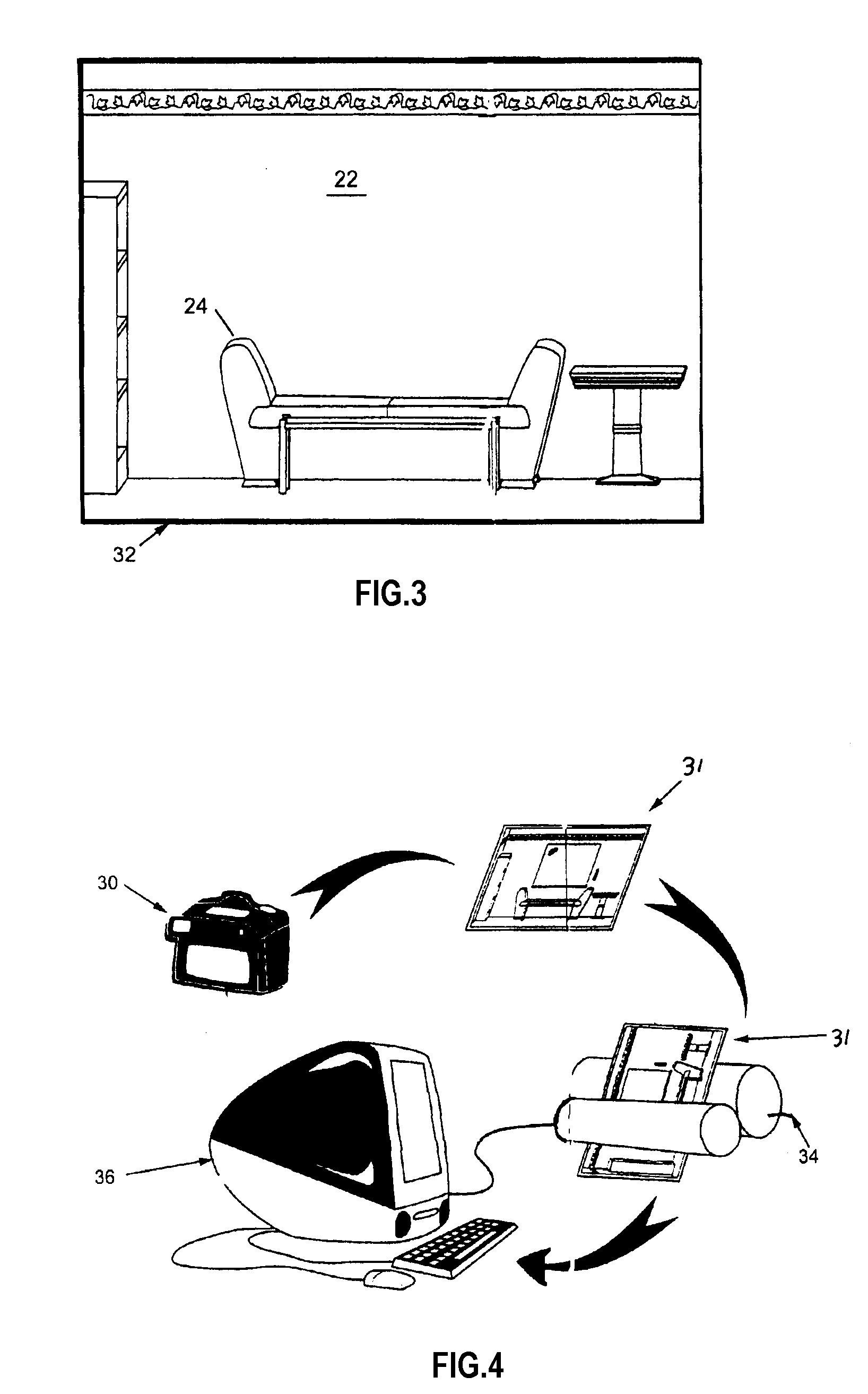

Method and System for Virtual Decoration

InactiveUS20070143082A1Simulation is accuratePublic buildingsService system furnitureComputer graphics (images)

Systems and methods for facilitating the decoration of an area, and particularly a surface such as a wall in a room, are provided. A user may view a virtual impression of the placement of selected artwork on a particular wall. The user provides an image of the area to be decorated, along with a reference scale associated with the area, to a server. The user views and selects an image of an artwork object from an available selection of artwork images, the artwork image having a corresponding size of the artwork object. The image of the artwork is scaled such that the ratio of the size of the artwork object and the size of the artwork image substantially corresponds to the ratio of the size of the area to be decorated and the size of the area image. The scaled artwork image is then overlayed on the area image and may be viewed by the user to provide a simulated image of the area and artwork.

Owner:DEGNAN DONALD A

Toothbrush

InactiveUS6886207B1Use minimizedEqual bending momentsCarpet cleanersFloor cleanersBristleMechanical engineering

The toothbrush of the present invention comprises an elongated handle having a head attached to one end. The head has a bristle-bearing face having longitudinal perimeter portions adjacent longitudinal edges and at least two perimetric, elastomeric massaging elements alternately arranged with groups of bristle tufts along each of the longitudinal perimeter portions. The brush can comprise further massaging elements which are not located along the longitudinal perimeter portions though the use of such additional elements is preferably minimised. The perimetric massaging elements have rotational symmetry through an angle of 120° or less, preferably being circular. The cross-sectional area proportion of elastomeric massaging elements to bristles on the brush head is less than 25%. Alternately there are four or fewer elastomeric massaging elements which are not perimetric massaging elements. A brush with both bristles and gum massaging elements arranged as set out above provides both cleaning and gum massaging benefits without creating an undesirable aesthetic impression derived from the use of rubber-like materials in the part of the brush head traditionally comprising only bristles.

Owner:THE PROCTER & GAMBLE COMPANY

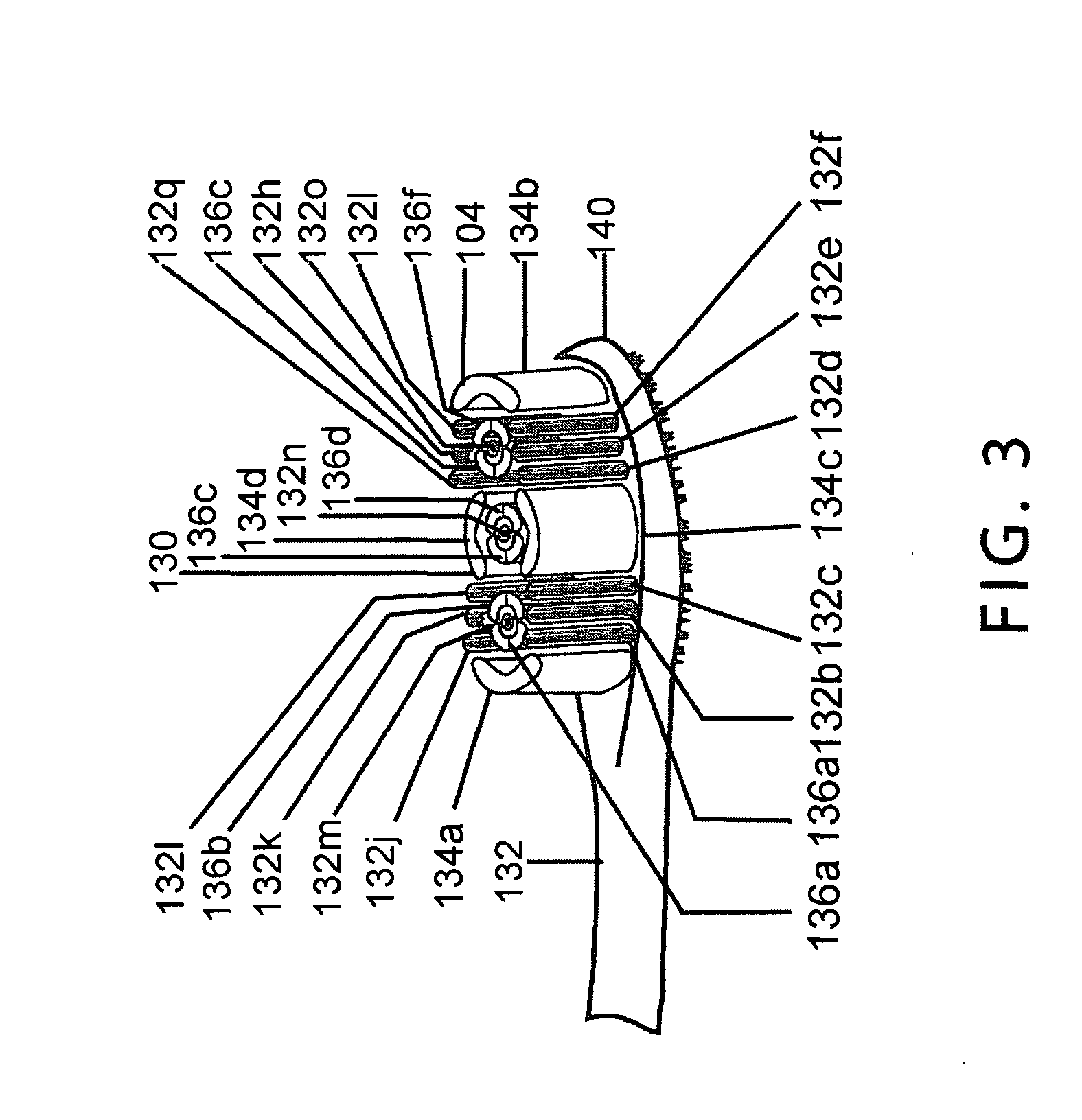

Multi-directional wiping elements and device using the same

InactiveUS6859969B2Easy to moveLiquid processingReconditioning/cleaning record carriersBristleEngineering

Multi-directional wiping elements are disclosed. The wiping elements comprise intersecting squeegee segments that provide top wiping squeegee edges and side wiping squeegee edges. Devices utilizing the multi-directional wiping elements of the present invention can include bristles that are configured to simultaneously wipe a working surface with the wiping elements. In accordance with the embodiments of the invention, the multi-directional wiping elements are utilized in a toothbrush cleaning head that is configured to be operated manually or, alternatively, is motorized and is configured to rotate, oscillate, vibrate and / or move according to a combination thereof.

Owner:EEGEE

Oral care implement

ActiveUS20050210612A1Easy to cleanEfficient removalEar treatmentCarpet cleanersCleansers skinMouth care

An oral care implement with a handle includes a head with a tissue cleanser. The tissue cleanser may be a pad composed of an elastomeric material. The pad is disposed on the head on a surface opposite the tooth cleaning elements. The tissue cleanser may include a plurality of nubs extending for cleaning between the papillae of the tongue. The tissue cleanser may include a plurality of conically shaped nubs. A tissue cleanser can be used to reduce oral malodor problems and remove oral epithelial cells.

Owner:COLGATE PALMOLIVE CO

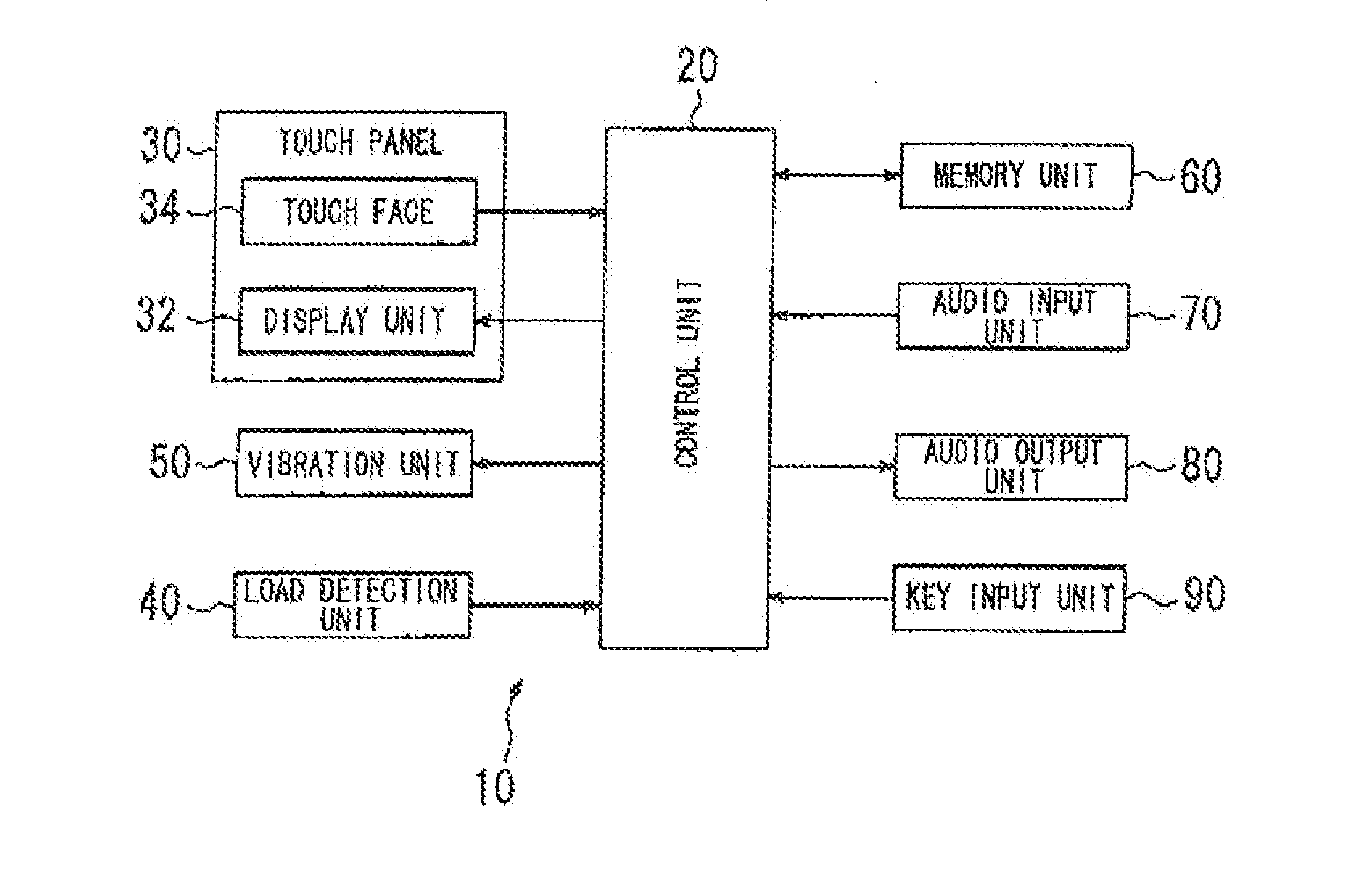

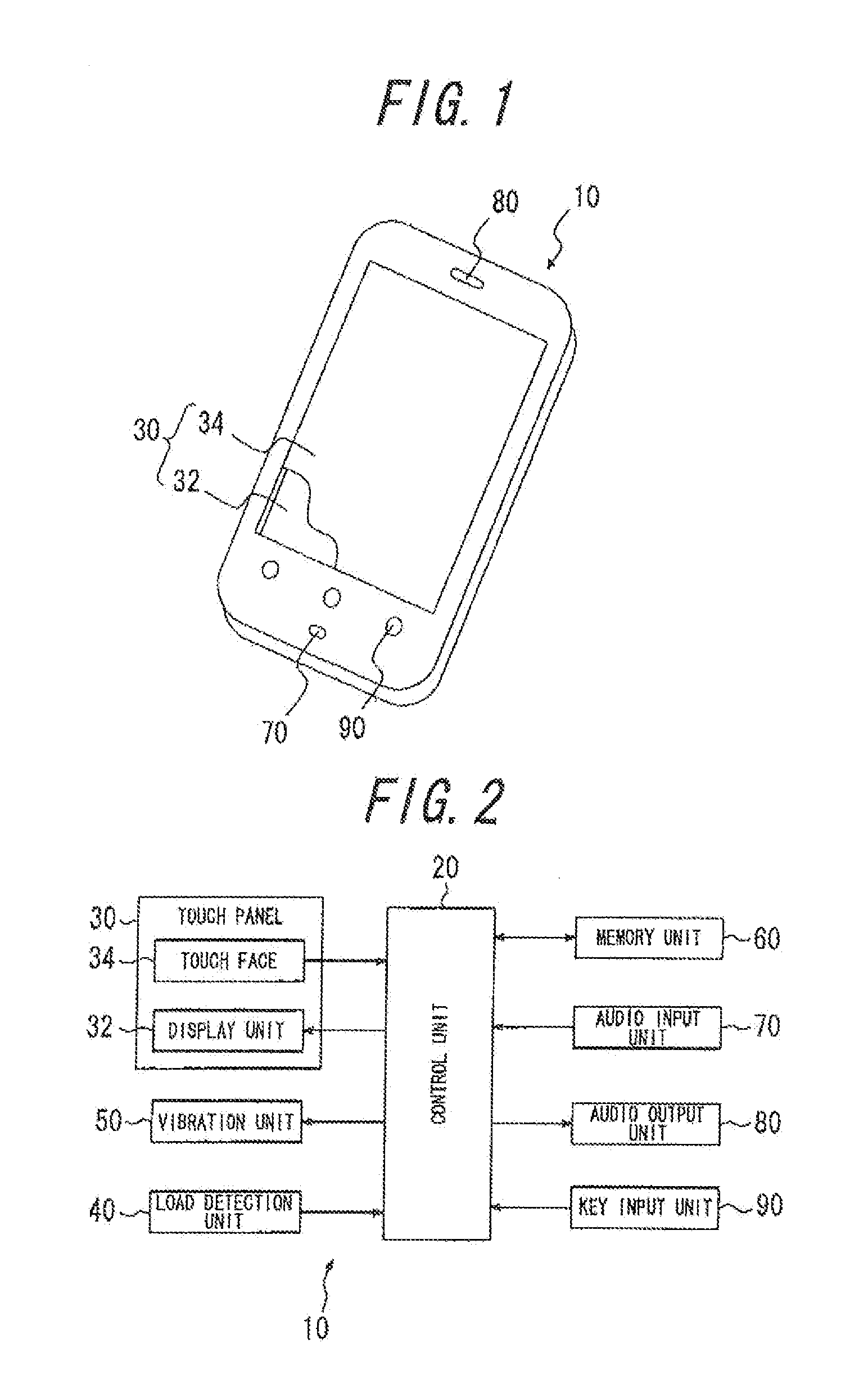

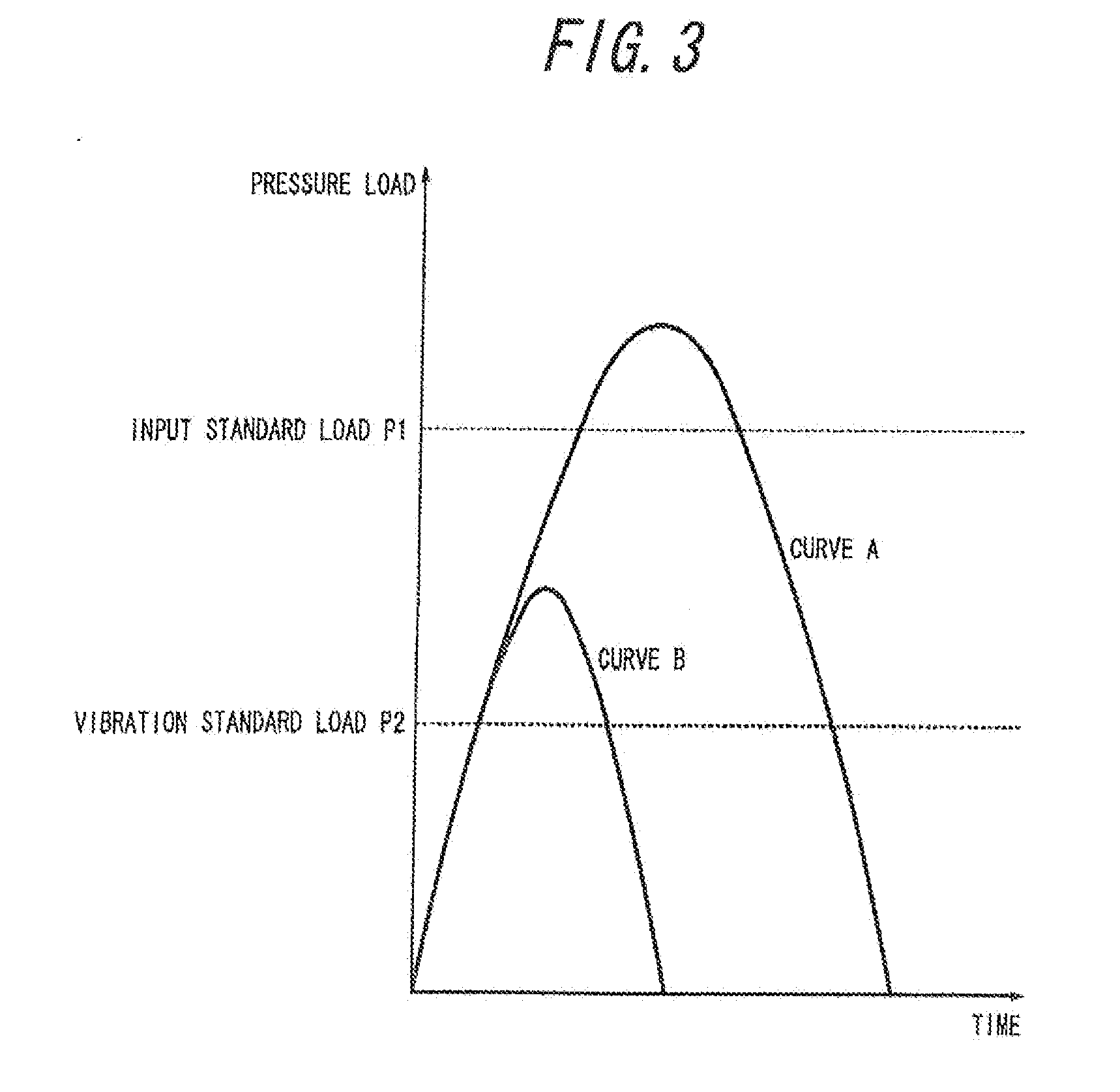

Input apparatus

ActiveUS20120126962A1Inhibit inputElectronic switchingRepeater circuitsExecution controlHuman–computer interaction

An input apparatus capable of preventing a user's unintentional input by notifying the user of a change in a pressure load is provided.The input apparatus has a touch face configured to receive a touch operation, a load detection unit configured to detect a pressure load of the touch operation to the touch panel, a vibration unit configured to vibrate the touch face, and a control unit, when the load detection unit detects a pressure load satisfying a standard load to receive an input, configured to perform a control to receive the input by the touch operation. When the load detection unit detects a pressure load satisfying a standard load, lower than the standard load to receive an input, the control unit controls the vibration unit to vibrate.

Owner:KYOCERA CORP

Oral care implement

InactiveUS7047591B2Easy to handleImprove comfortTravelling carriersHoldersMechanical engineeringOral cavity

Owner:COLGATE PALMOLIVE CO

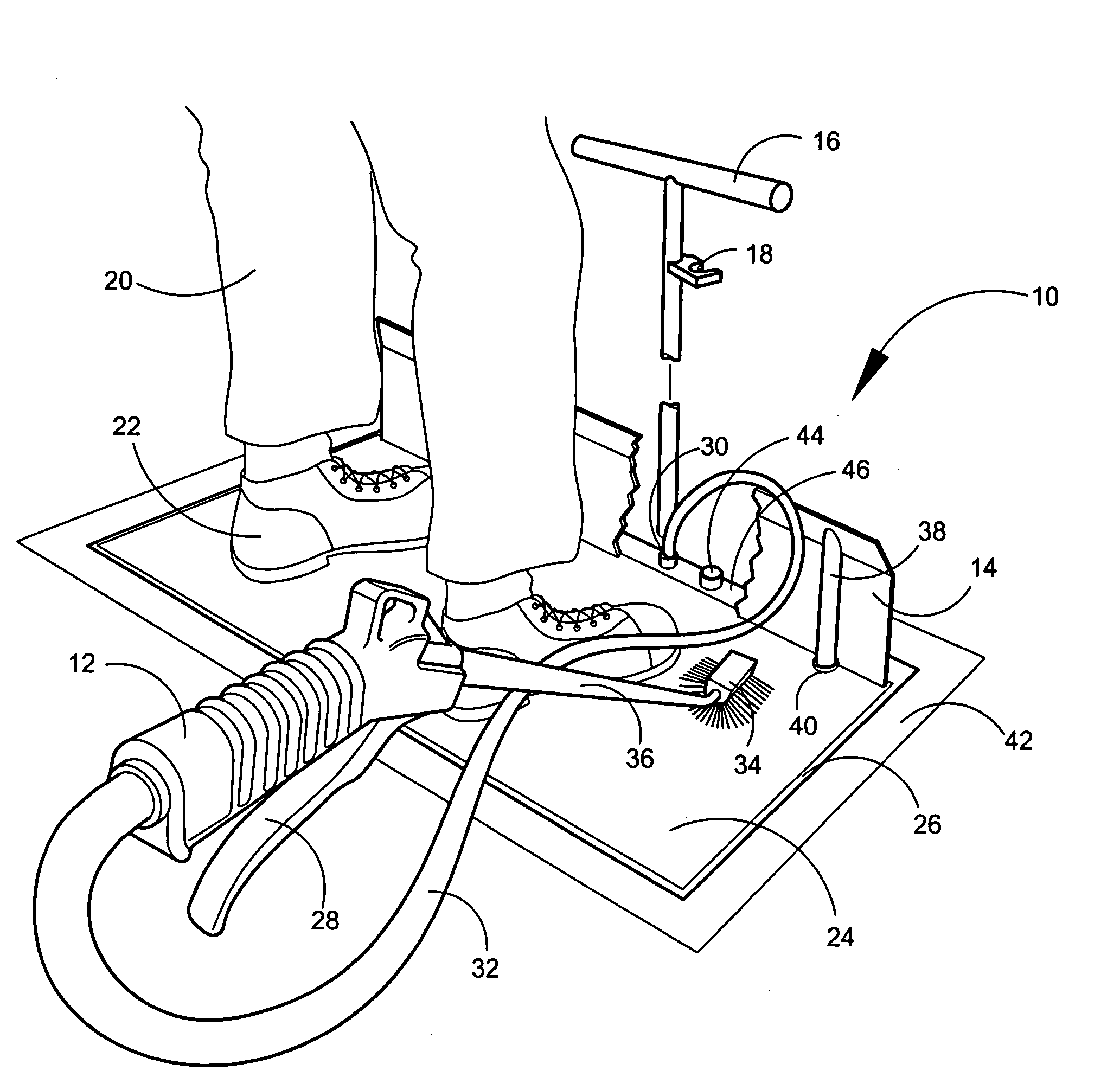

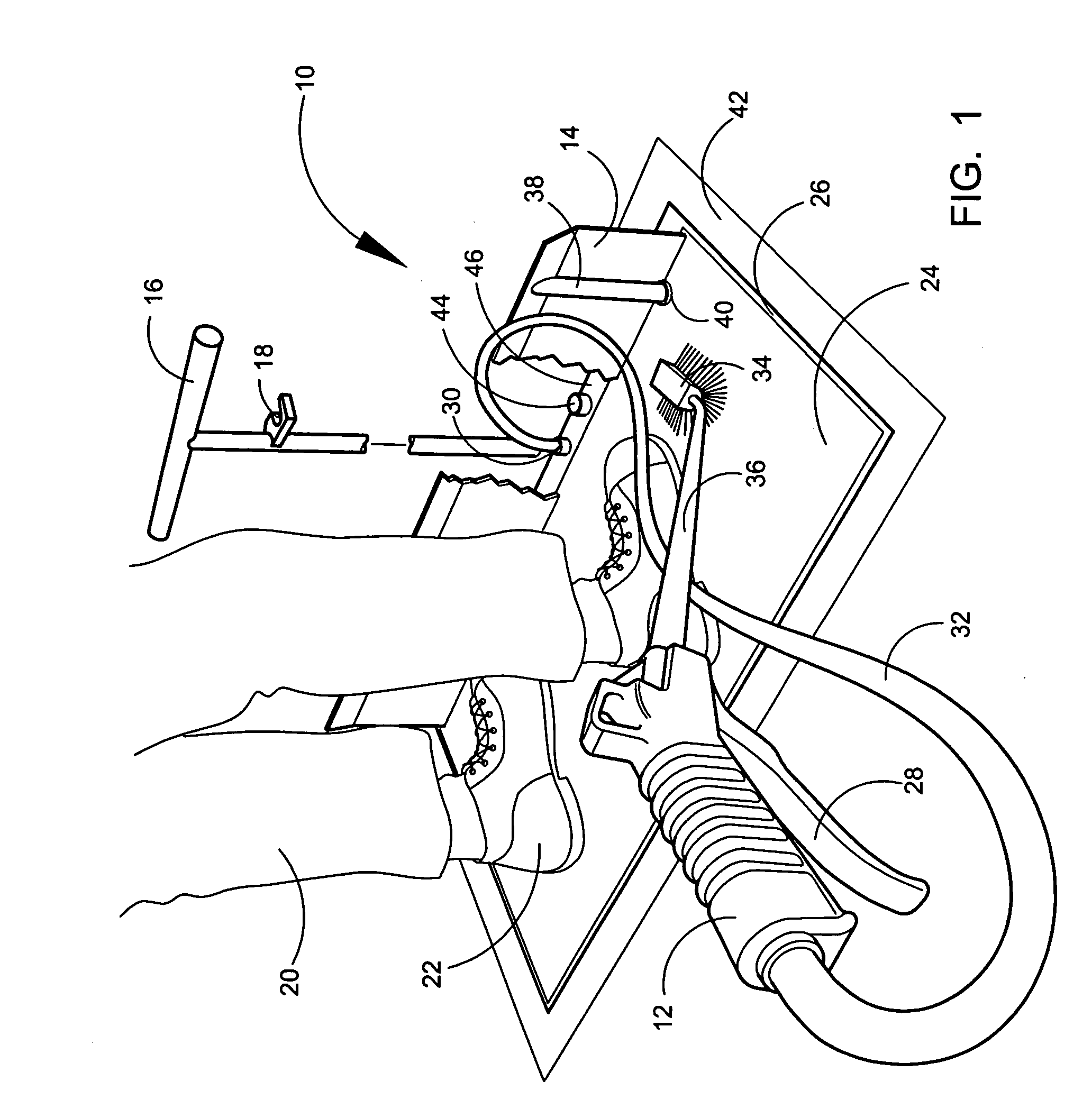

Shoe and foot cleaning and disinfecting system

InactiveUS20080104782A1Reduce health hazardsImprove overall utilizationBowling gamesCarpet cleanersEngineeringThermal water

A cleaning and disinfecting system for the cleaning and disinfecting of footwear or feet. The system provides for cleaning and disinfecting the bottom of the feet or footwear. An optional brush on a wand provides cleaning to upper foot areas as required. The system is automatically activated only when a person stands on the device, thereby minimizing the volume of fluid required to perform the process. Optionally, a venturi component allows the addition of a cleaning or disinfecting fluid with the cleaning solution or water. When the system is attached to a hot water line and fitted with heating elements, it can be used to remove snow from shoes and boots.

Owner:HUGHES RANDALL L

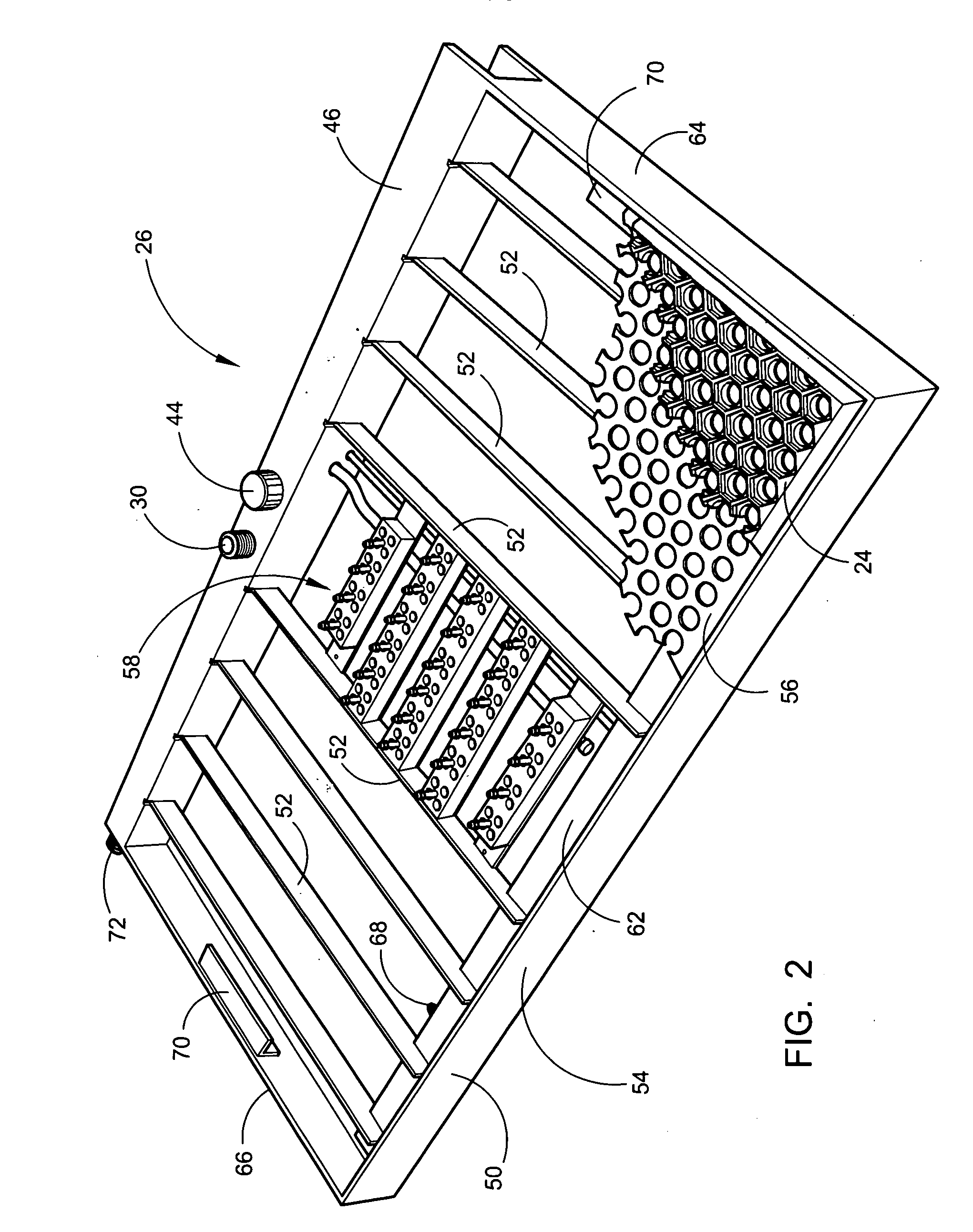

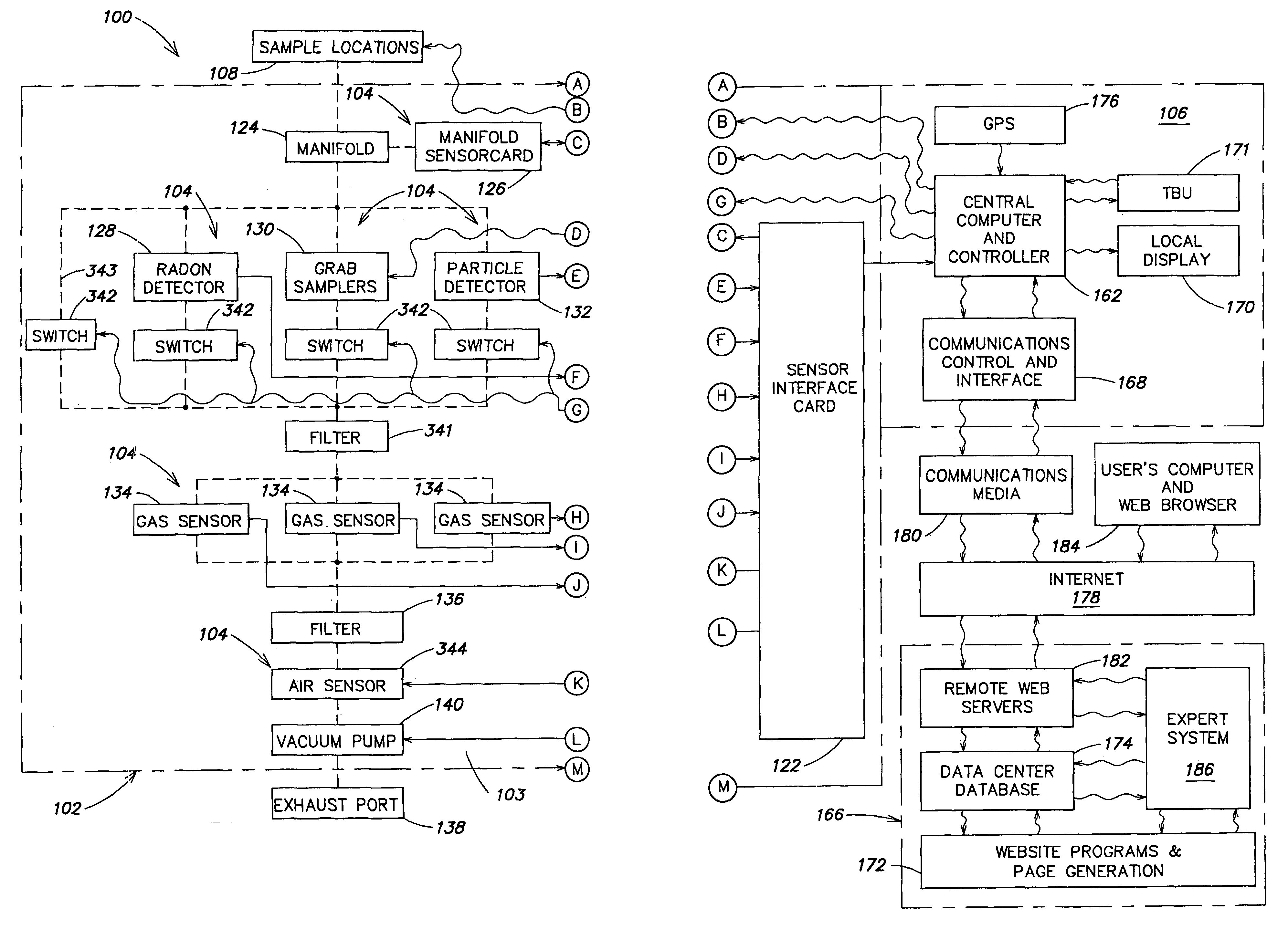

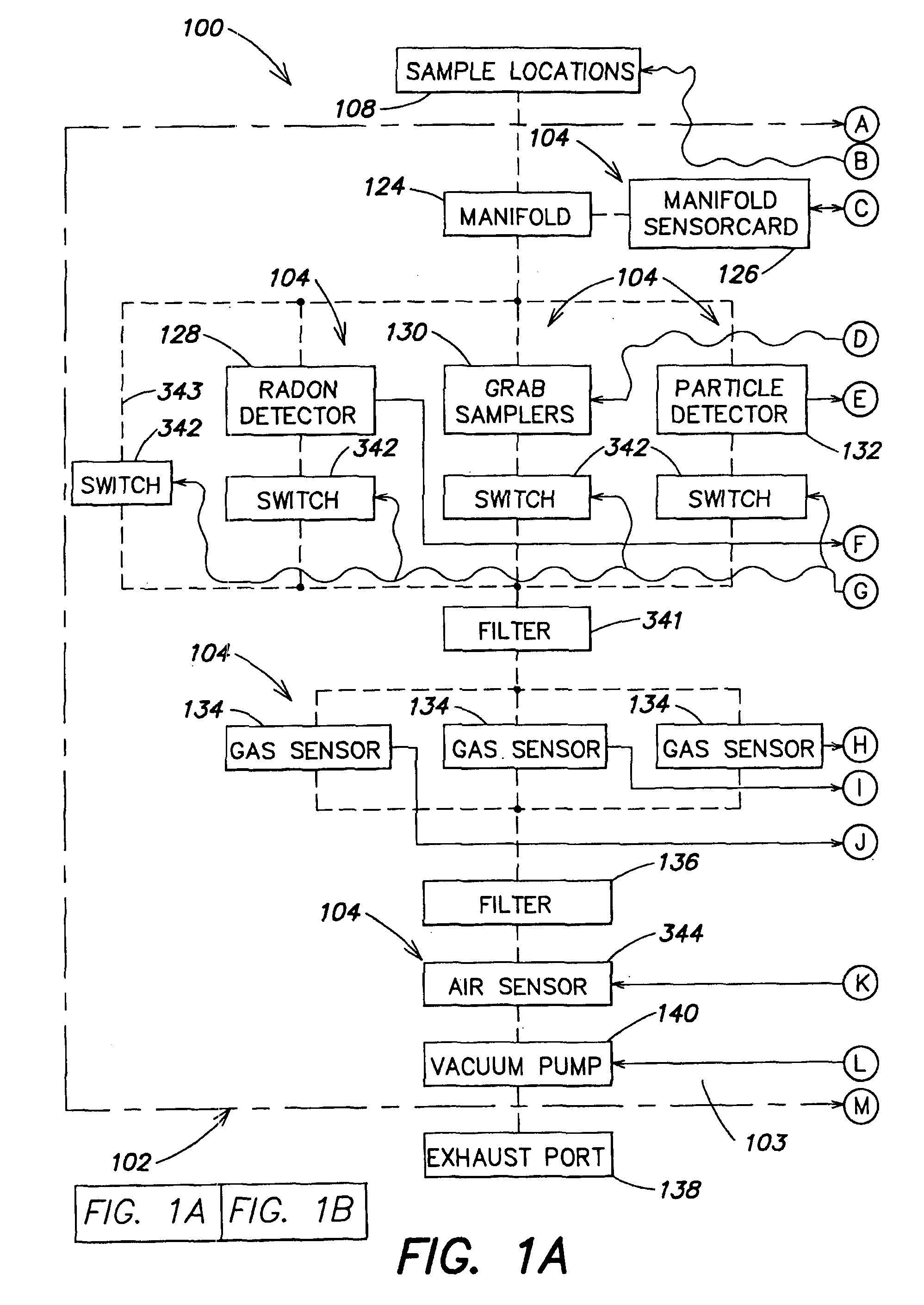

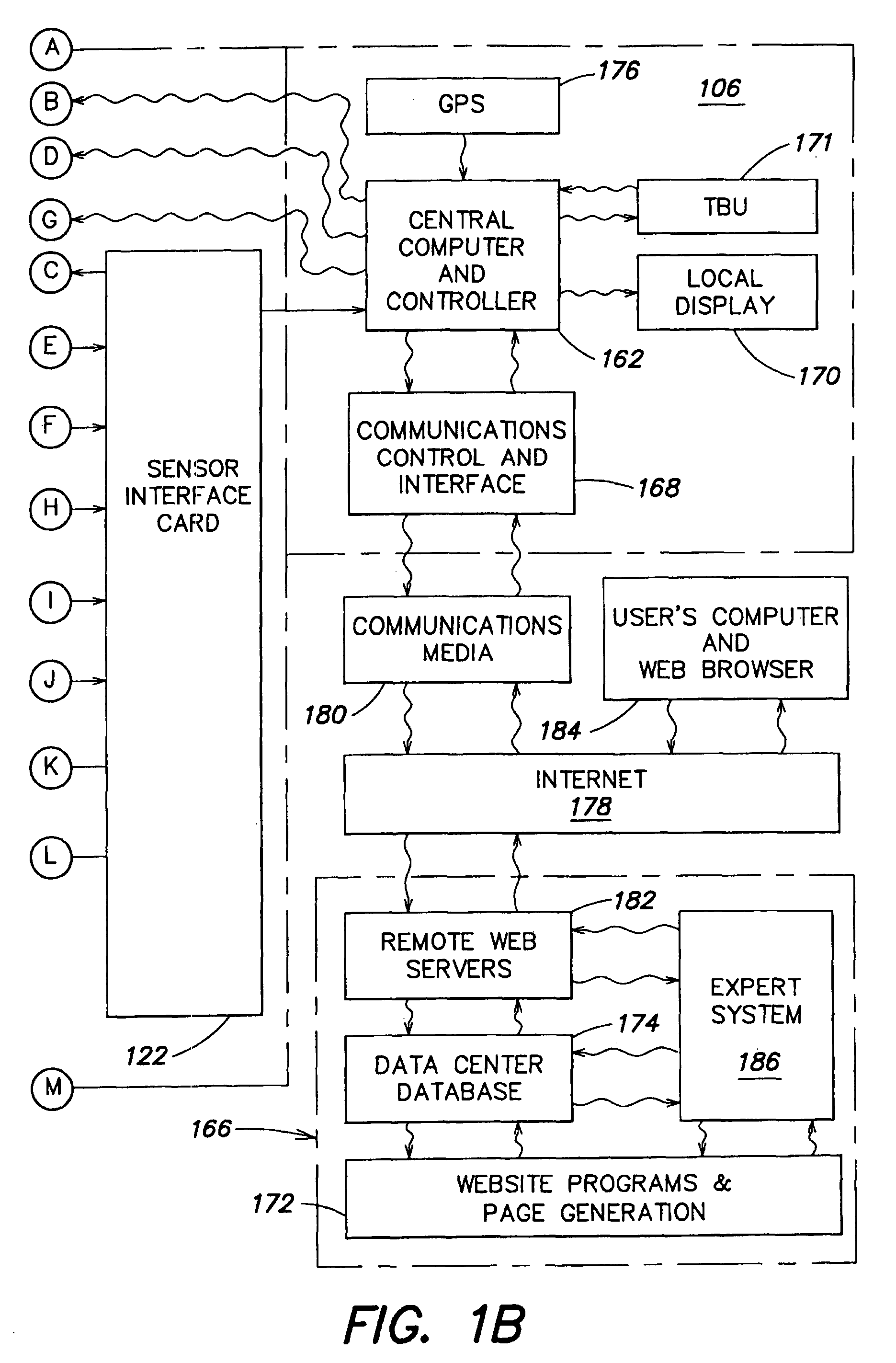

Air quality monitoring systems and methods

InactiveUS7302313B2Accurate locationRoom for correctingLighting and heating apparatusTemperatue controlAir monitoringData center

An air monitoring system is disclosed having an air monitoring unit with at least one sensor for measuring data of an air quality parameter and a computer for storing the air quality parameter data received from the sensor. The air monitoring unit may use an installed or a portable system, or a combination of both, for measuring the air quality parameters of interest. A remote data center may be provided, and the data may be uploaded to the data center from the unit by a communications media such as the Internet. Information or instructions may also be downloaded from the data center to the unit via the communications media for controlling or modifying the function of the unit. An expert system may be provided with the air monitoring system for controlling the unit. The information or instructions downloaded to the unit may be generated by the expert system.

Owner:AIRCUITY

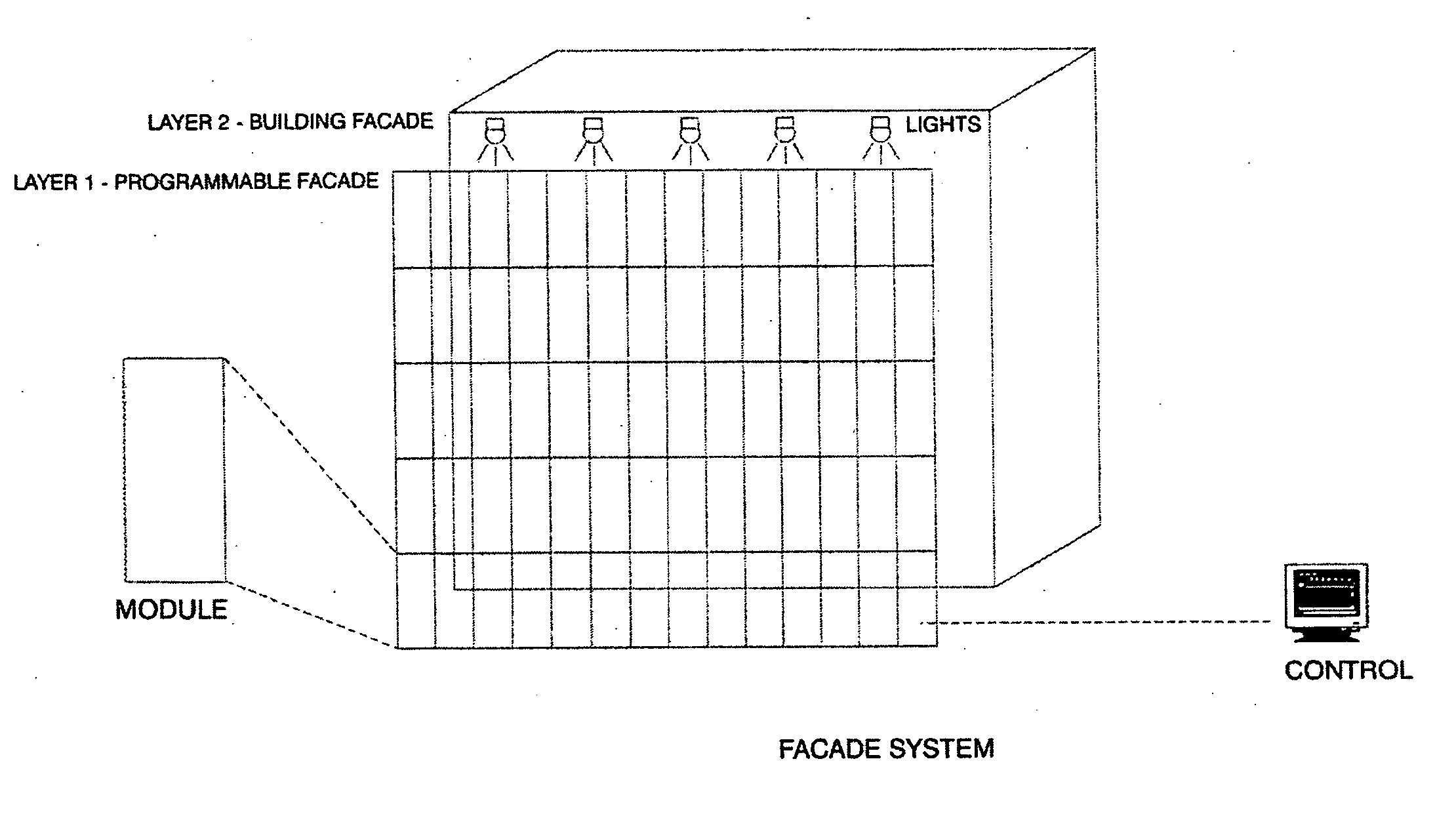

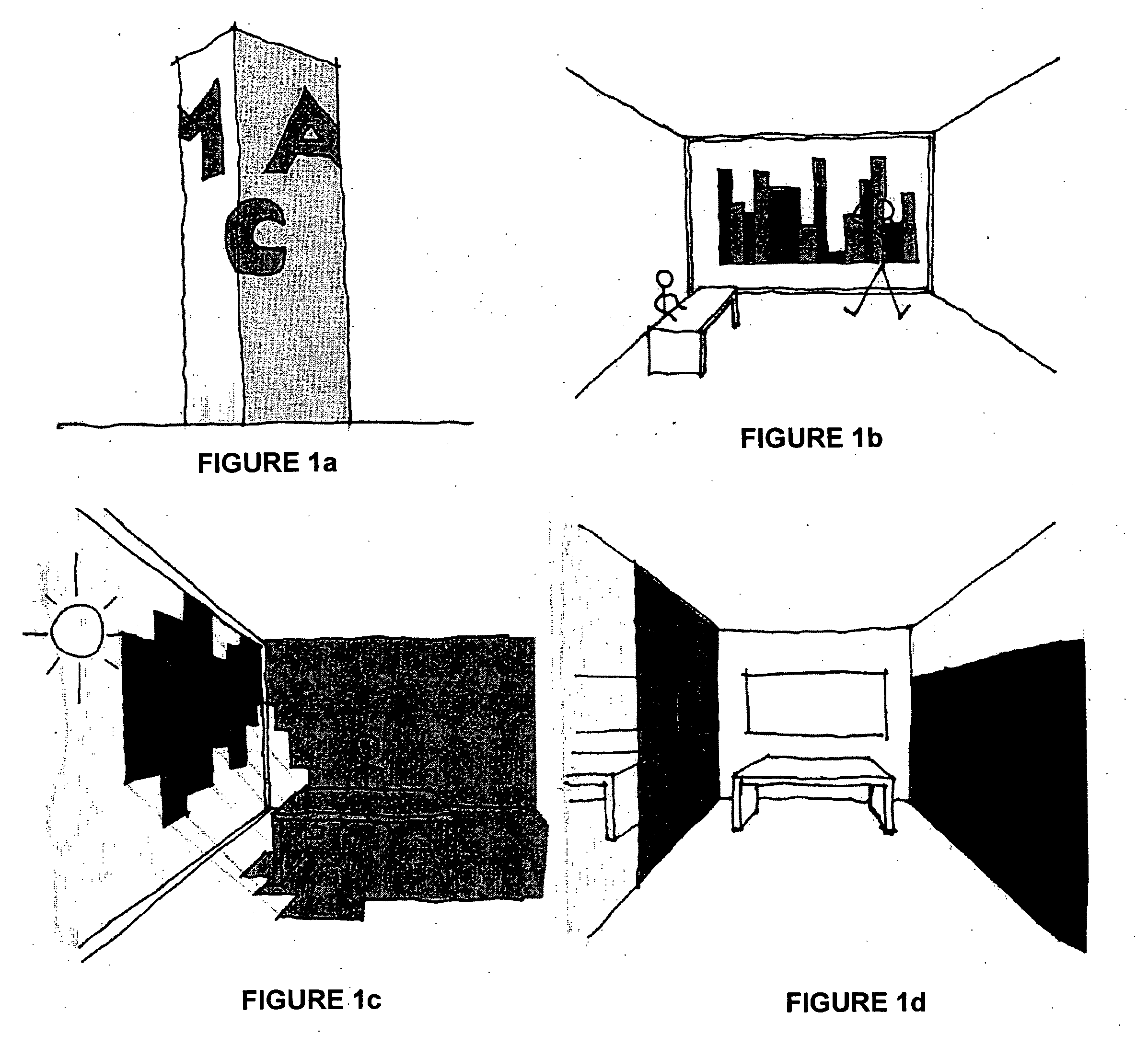

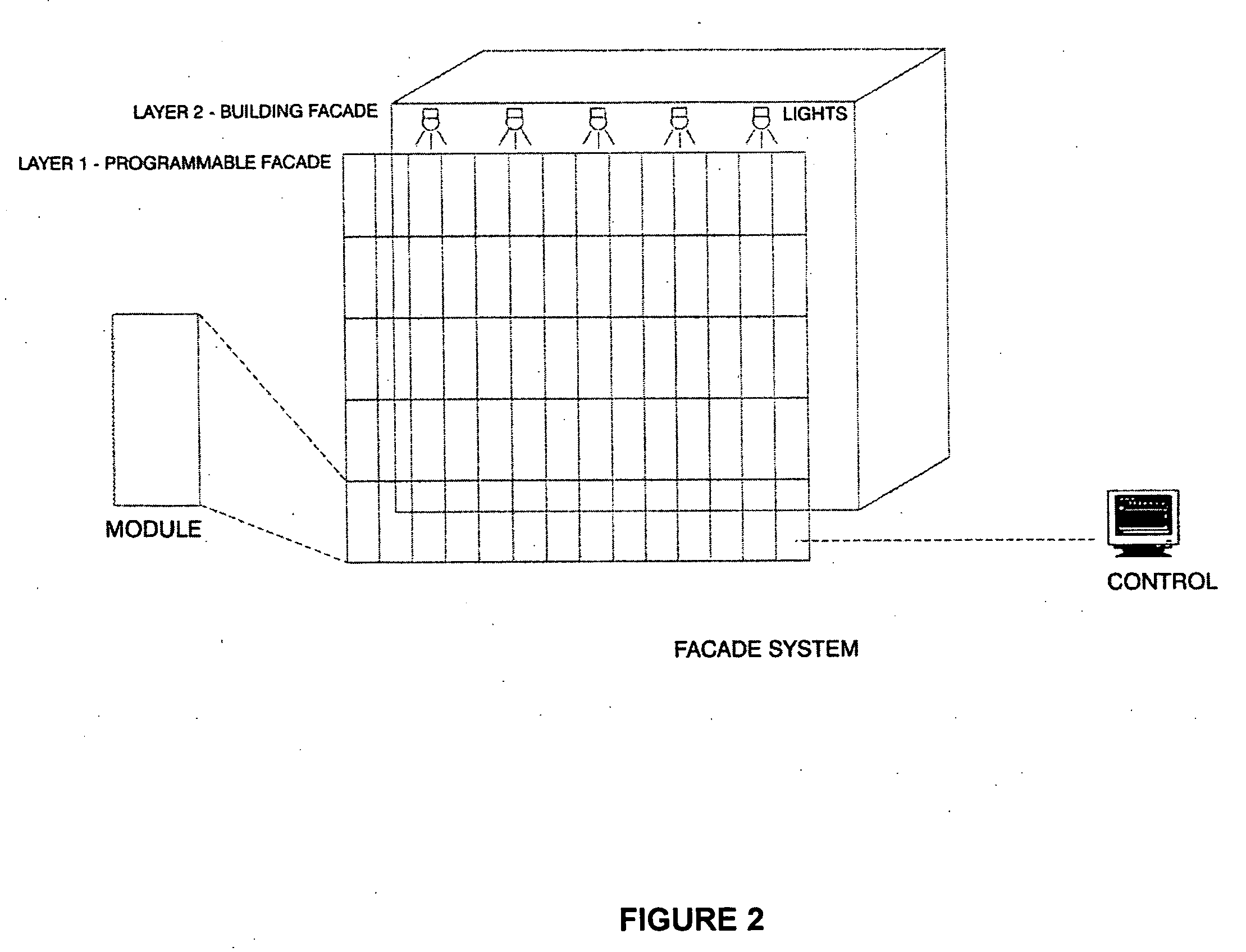

Programmable window: a device for controlling the opacity of small-scale areas within a large scale transparent membrane

ActiveUS20060107616A1Accurately and selectively controlLittle controlStatic indicating devicesPolarising elementsEffect lightMembrane configuration

Natural lighting profiles are affected in a building facade and internal transparent membrane using a transparent sheet having one or more pixel elements, wherein each of the pixel elements is capable of being driven to control opacity (by shading). A programmable controller is used to send control commands to control opacity of the pixel elements, wherein the percentage of light transmitted through the display panel forming part of the facade is controlled via the controller.

Owner:MASSACHUSETTS INST OF TECH

Toothbrush for massaging and protecting gums

InactiveUS20030077107A1Control deflectionControl pressureCarpet cleanersFloor cleanersBristleEngineering

This invention relates to a toothbrush that utilizes a replaceable brush head having rubber gum guard on its top surface and a triangular shaped rubber pad on its bottom surface. The rubber gum guard is shorter than the height of the bristles and is positioned on the peripheral edge of a brush head for functioning as a sensor for providing feedback to prevent brushing at excessive pressures and improper angles as well as for massaging the gumlines without the risk of gum damages. The triangular shaped rubber pad is for conforming to and massaging gumlines at the back of teeth. The replaceable brush head having the rubber gum guard and massaging pad features is economically used in conjunction with a permanent handle that dispenses dentifrice material to the top of bristles. The handle has a resilient contractible connector for secure mounting of the replaceable brush head.

Owner:KUO YOUTI

Oral care implement

InactiveUS20050166344A1Easy to cleanEfficient removalEar treatmentCarpet cleanersCleansers skinMouth care

An oral care implement with a handle includes a head with a tissue cleanser. The tissue cleanser may be a pad composed of an elastomeric material. The pad is disposed on the head on a surface opposite the tooth cleaning elements. The tissue cleanser may include a plurality of nubs extending for cleaning between the papillae of the tongue. The tissue cleanser may include a plurality of conically shaped nubs. A tissue cleanser can be used to reduce oral malodor problems and remove oral epithelial cells.

Owner:COLGATE PALMOLIVE CO

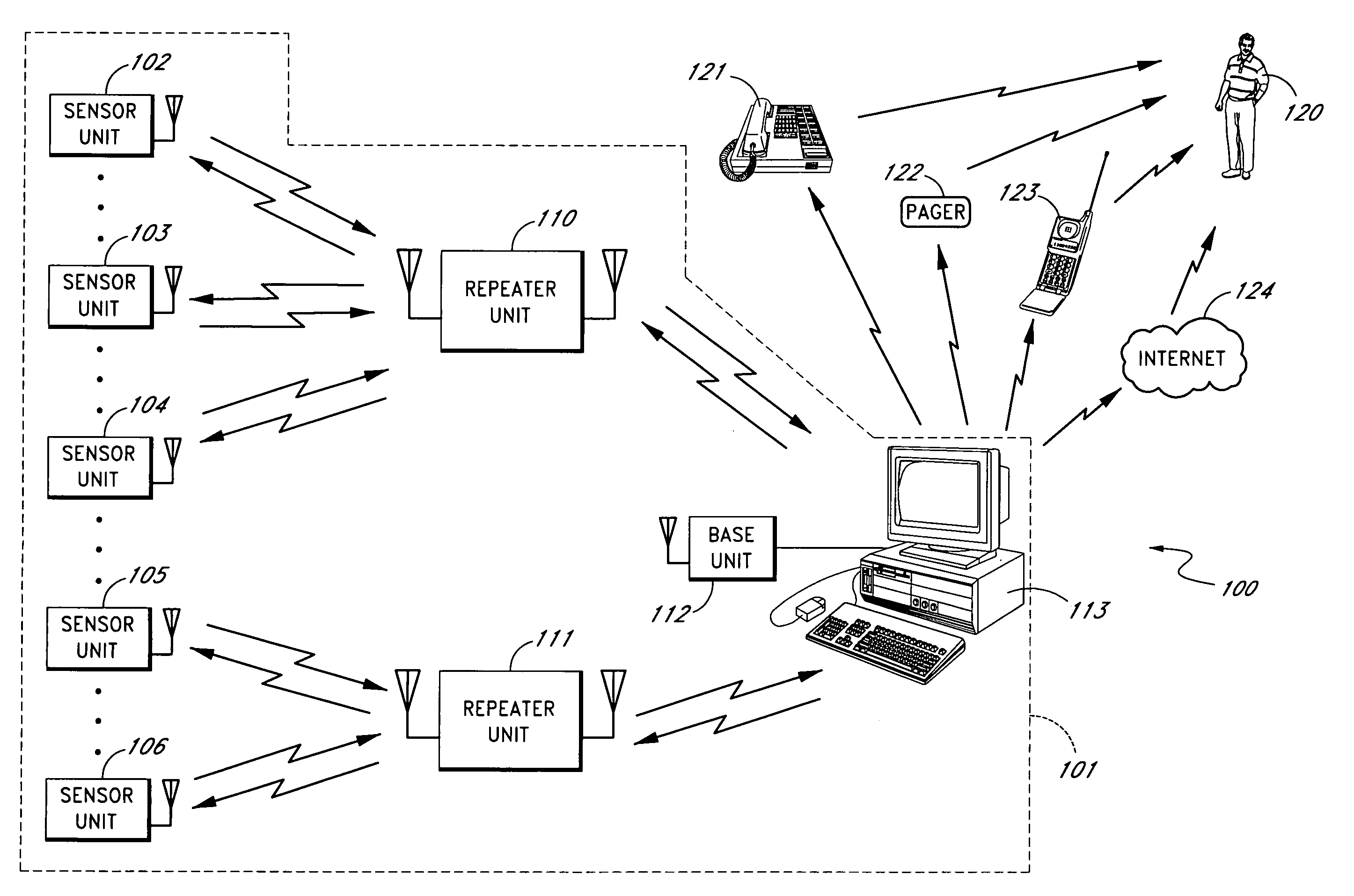

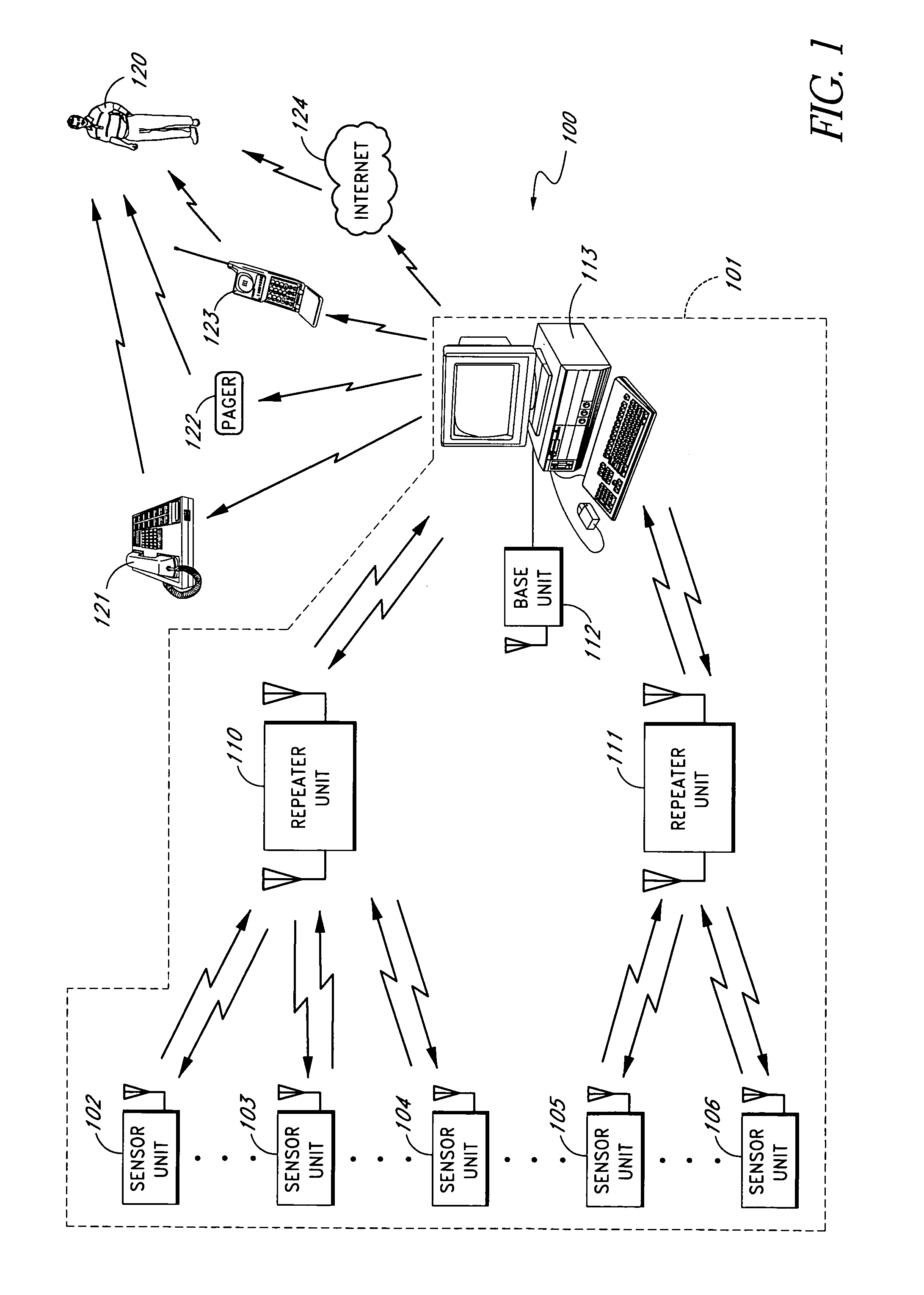

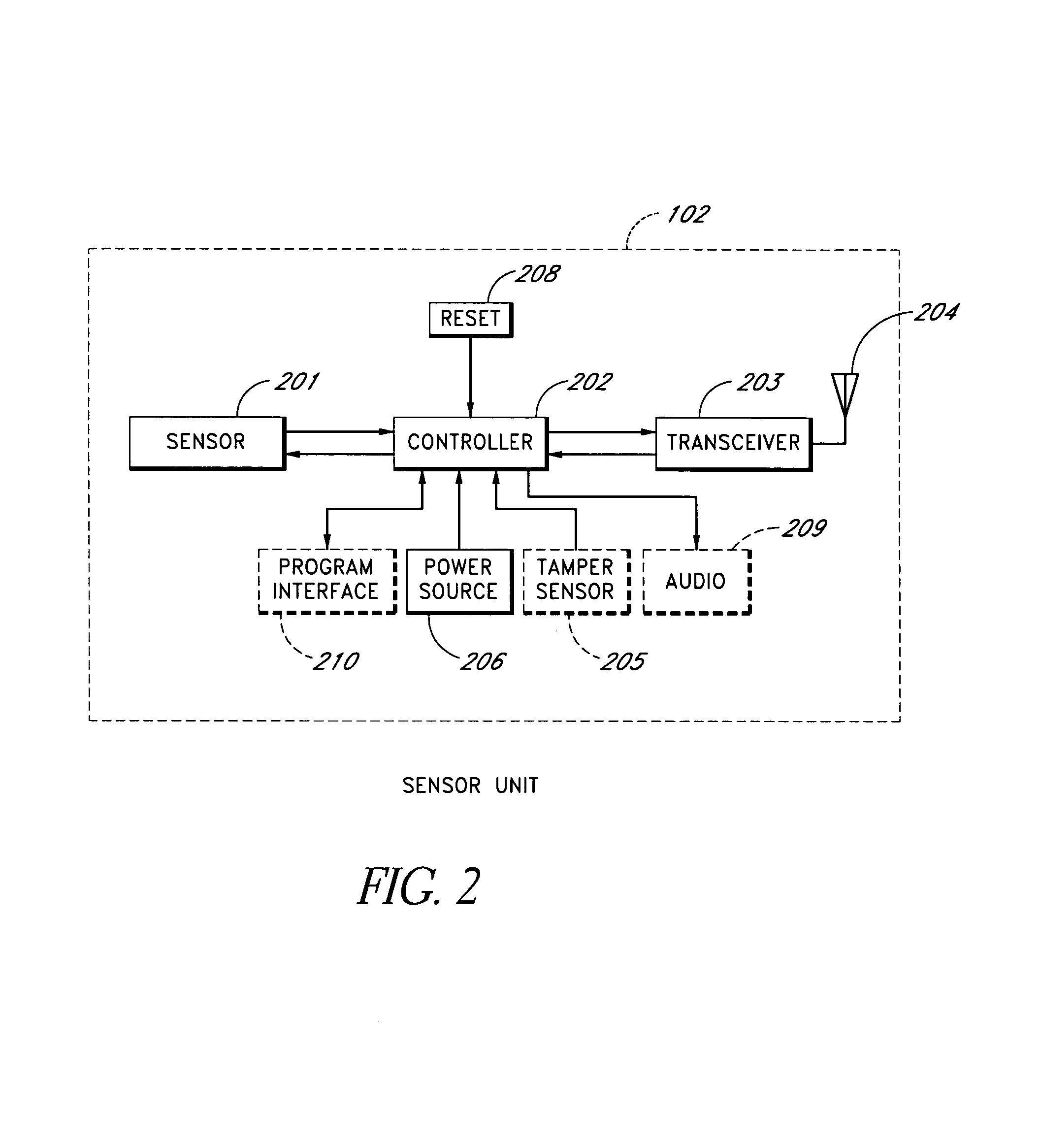

Method and apparatus for detecting moisture in building materials

ActiveUS7142123B1Low costIncrease rangeElectric signal transmission systemsBuilding constructionsPagerThe Internet

A moisture sensor system is described. In one embodiment, the system provides an adjustable threshold level for the sensed moisture level. The adjustable threshold allows the moisture sensor to adjust to ambient conditions, aging of components, and other operational variations while still providing a relatively sensitive detection capability. In one embodiment, the adjustable threshold moisture sensor is used in an intelligent sensor system that includes one or more intelligent sensor units and a base unit that can communicate with the moisture sensor units. When one or more of the moisture sensor units detects a excess moisture the moisture sensor unit communicates with the base unit and provides data regarding the moisture condition. The base unit can contact a supervisor or other responsible person by a plurality of techniques, such as, telephone, pager, cellular telephone, Internet (and / or local area network), etc. In one embodiment, one or more wireless repeaters are used between the moisture sensor units and the base unit to extend the range of the system and to allow the base unit to communicate with a larger number of sensors.

Owner:GOOGLE LLC

Toothbrush head

A toothbrush has a handle and a head part, on which bristle filaments and at least one flexible cleaning element are arranged. The at least one flexible cleaning element is arranged on a carrier element which consists of a hard material and is connected to the head part. A process for producing such a toothbrush is also disclosed.

Owner:THE GILLETTE CO

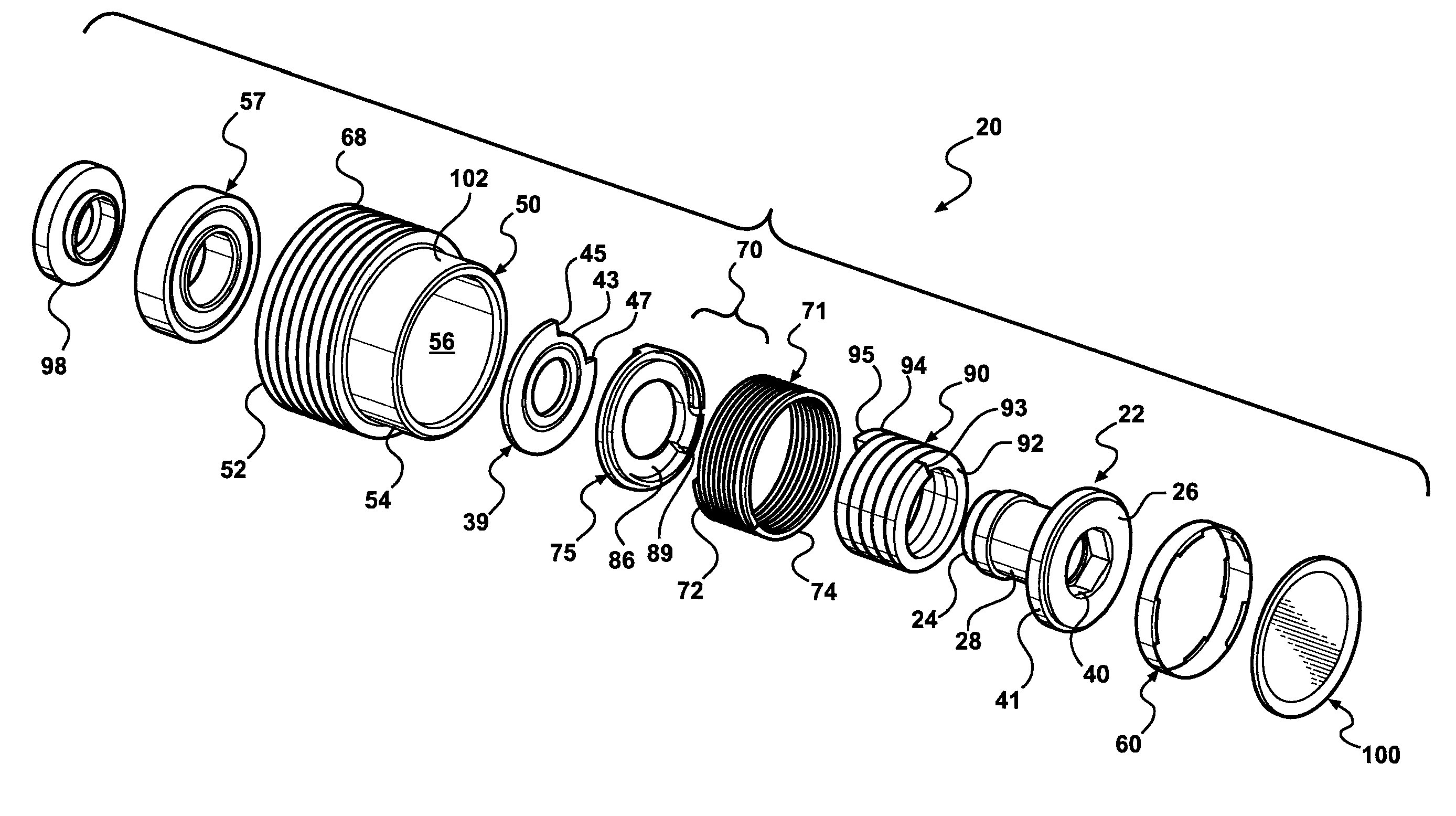

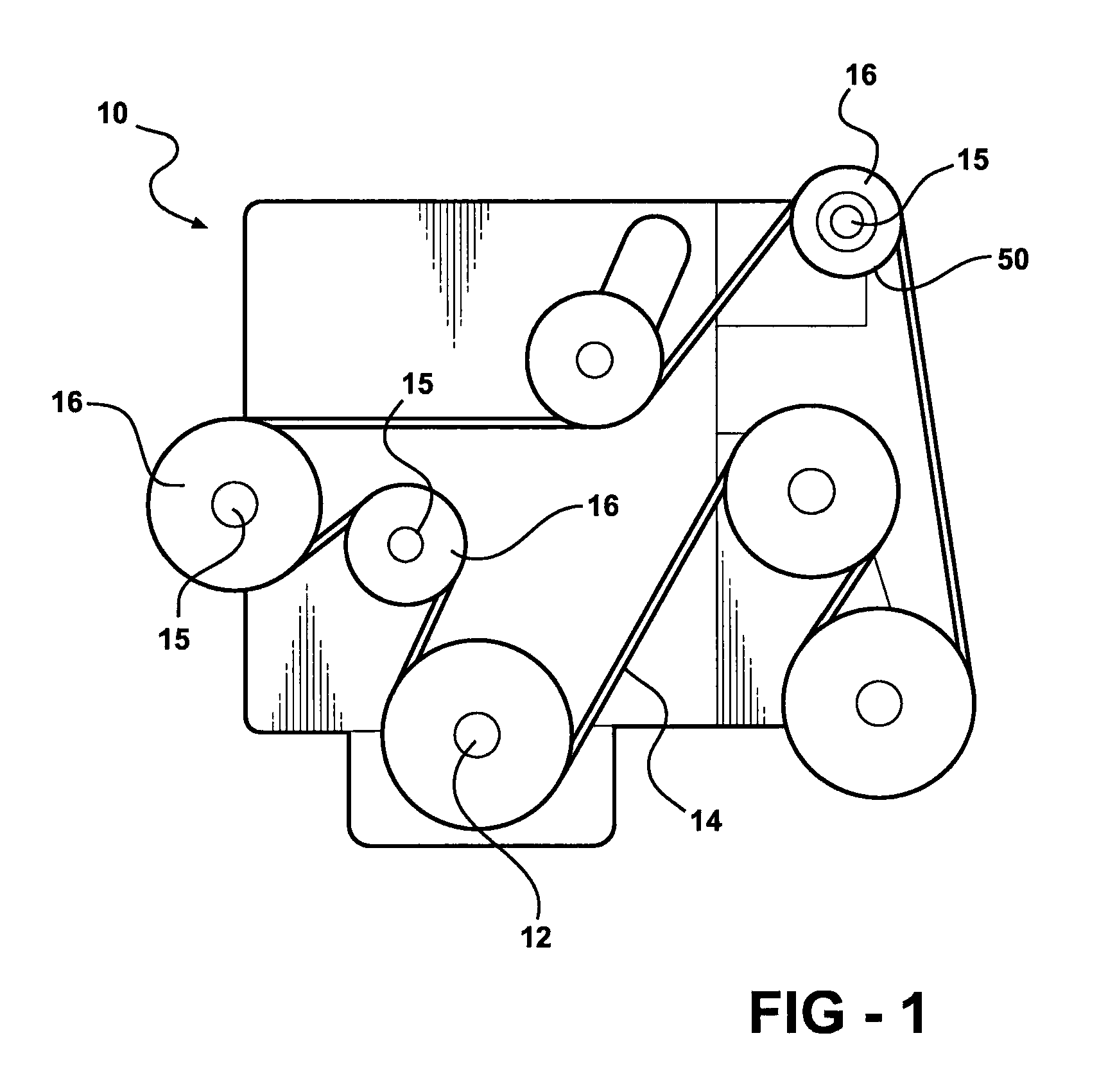

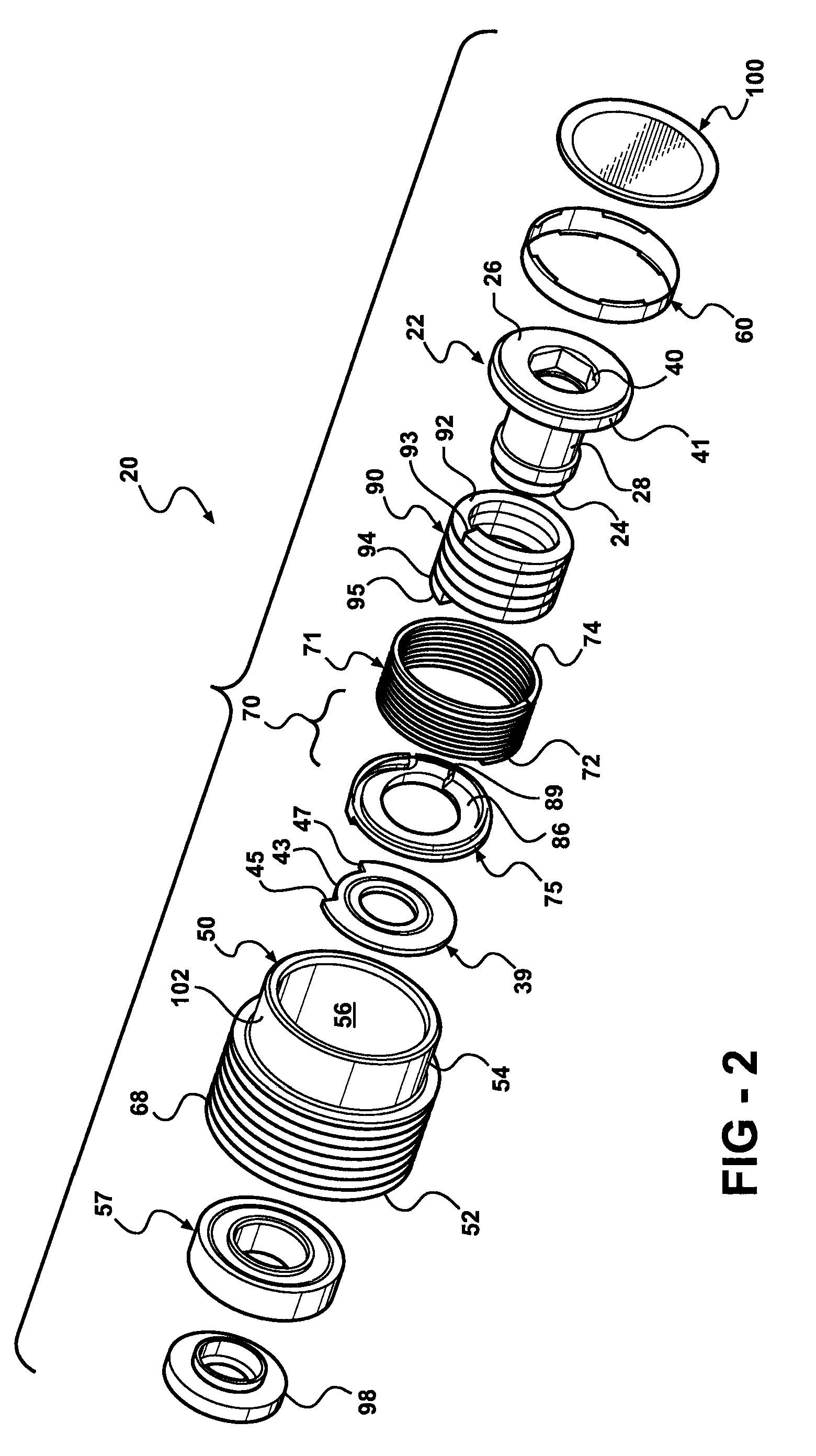

Spring travel limiter for overrunning alternator decoupler

ActiveUS7712592B2Prevent movementPrevent rotationYielding couplingSlip couplingSerpentine beltAlternator

A decoupler assembly for transferring rotary movement between an engine driven shaft and a serpentine belt. The decoupler includes a hub configured to be assembled to the shaft. The hub has a helical first slot formed therein. A pulley is rotatably coupled to the hub. A carrier is mounted on the hub and includes a helical second slot formed therein, as well as an anti-ramp up boss formed thereon. A thrust plate is fixed to the hub and has a slot formed therein. A torsion spring is compressed between a hub end retained in the helical first slot and a carrier end retained in the helical second slot for transferring torque between the hub and carrier. The anti-ramp up boss travels within the slot formed in the thrust plate for limiting rotation between the carrier and thrust plate and preventing rotation of the torsion spring relative to the hub and carrier.

Owner:LITENS AUTOMOTIVE INC

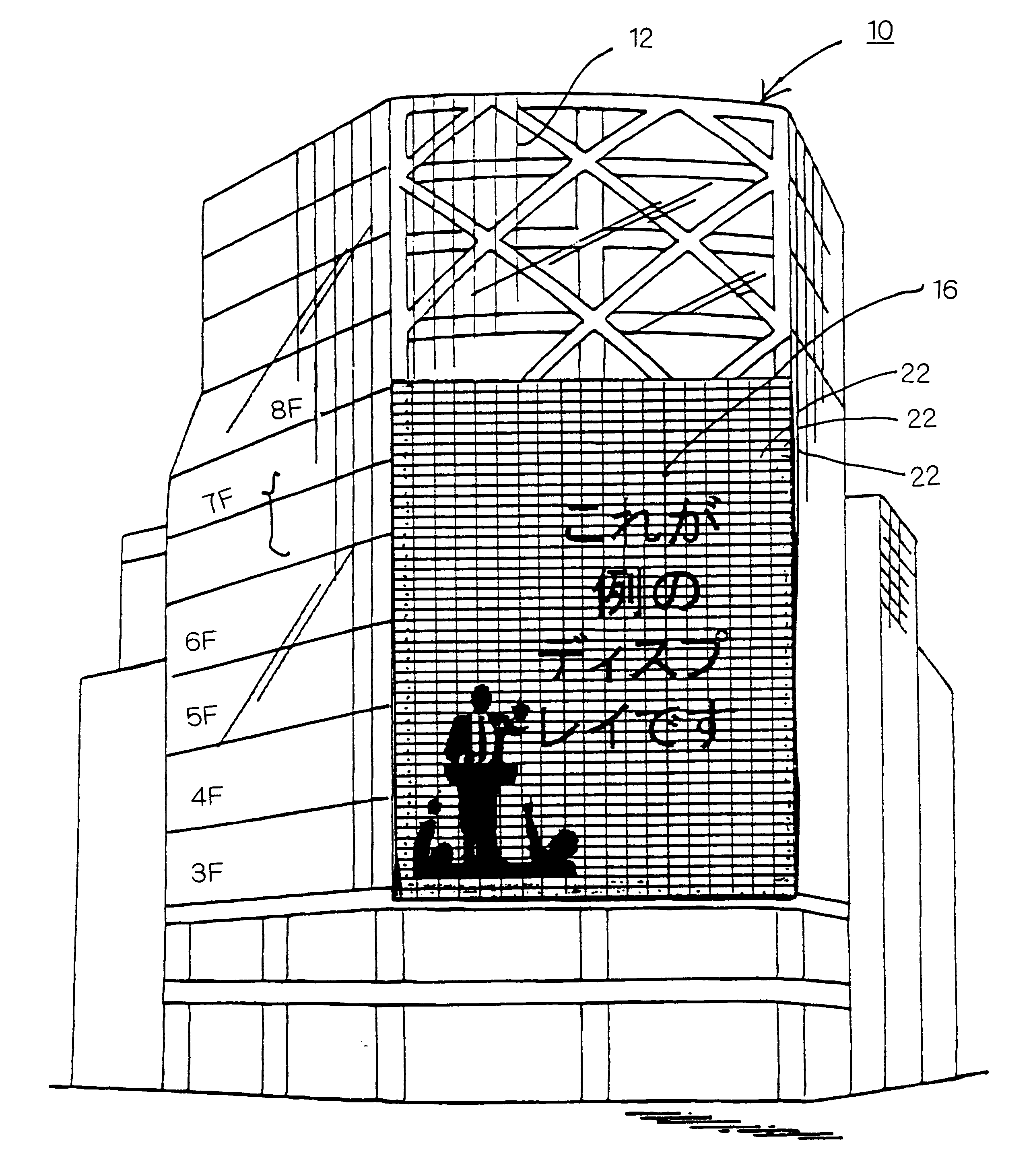

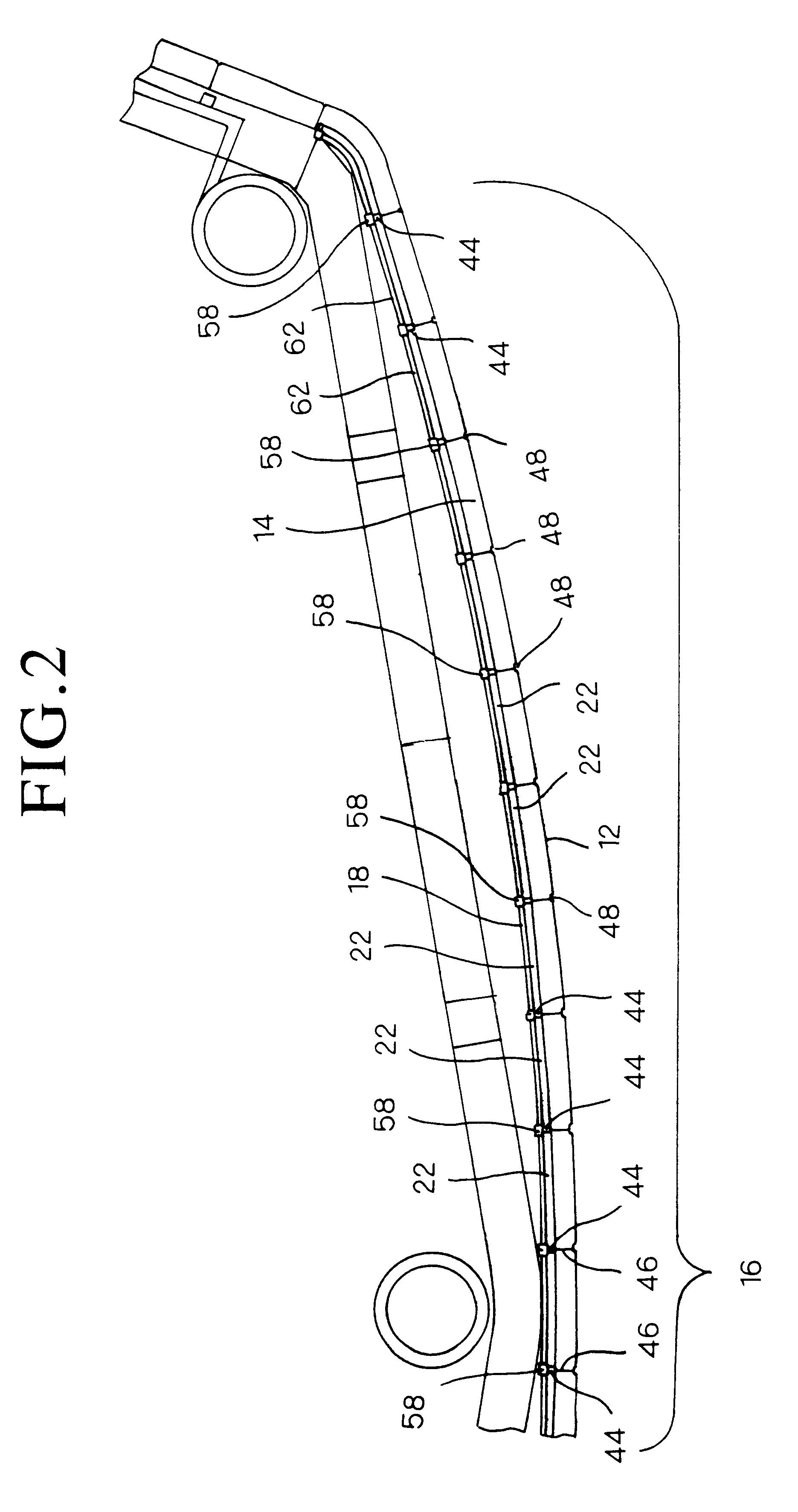

High-rise building with large scale display device inside transparent glass exterior

InactiveUS6237290B1Easy to carryImprove device performanceStampsPublic buildingsFloor slabWindow shutter

A high-rise building with a large scale dot-matrix display device is disclosed. The glass panels arranged in rows and columns form a curtain wall structured transparent outer wall 12 extending over an exterior of a building 10. Each panel is installed apart from end portions of floor slabs to form a void space therebetween. A plurality of louver structured modules 22 are arranged within the void space in rows and columns to form a large scale display area. Each module 22 has a louver-like structure formed of a plurality of posts 24 arranged in substantially parallel relationship and a plurality of parallel, uniformly spaced beams 26 connecting said adjacent posts 24. A plurality of LED combination lamps 28 are mounted on each beam 26 at uniform pitches as those between the adjacent beams 26. The LEDs are driven by drive circuits disposed in each beam 26. The vertical guide members 44 are fixed to the end portions of the floor slabs 20. The guide members 44 are arranged substantially in parallel relationship so that the modules 22 are supported between the adjacent guides 44 at the both lateral sides thereof. A plurality of vertical mullion members 48 fixed to the vertical guide members 44 as spaced apart from each of the vertical guides 44, so that the glass panels 12 are supported therebetween.

Owner:AVIX

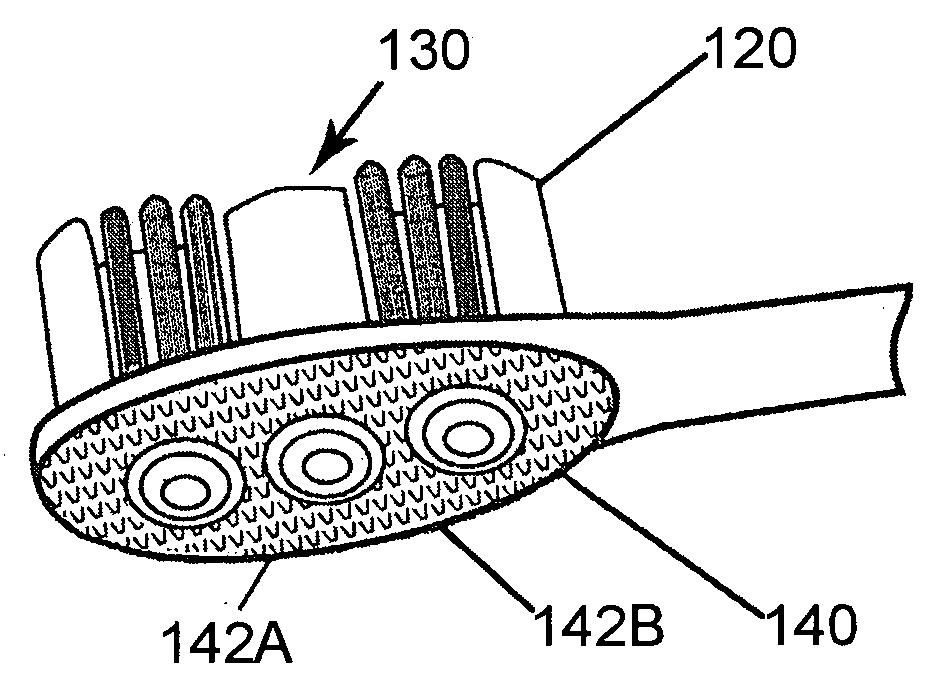

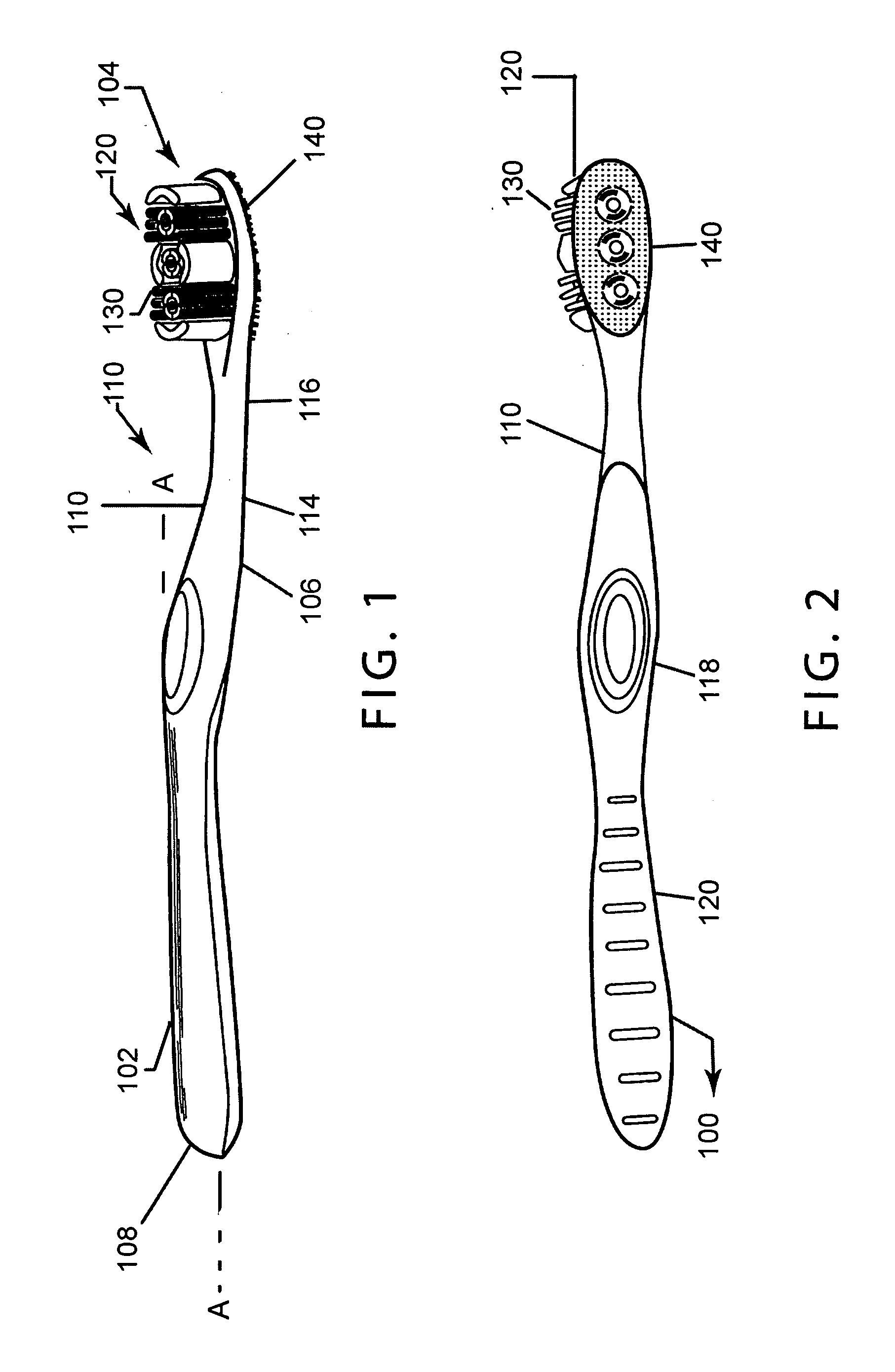

Toothbrush with Low Profile Head

ActiveUS20080189888A1Low profileExpand accessCarpet cleanersBrush bodiesDental cleaningBiomedical engineering

A toothbrush includes a handle, and a head at an end of the handle having a thickness, a first surface, and an opposed second surface. Tooth cleaning elements extend outwardly from the first surface and have a length. A tissue cleanser is positioned on the second surface and has a plurality of tissue engaging elements and a height. A head height includes the thickness of the head, the length of the tooth cleaning elements, and the height of the tissue cleanser, and is less than 17.7 mm.

Owner:COLGATE PALMOLIVE CO

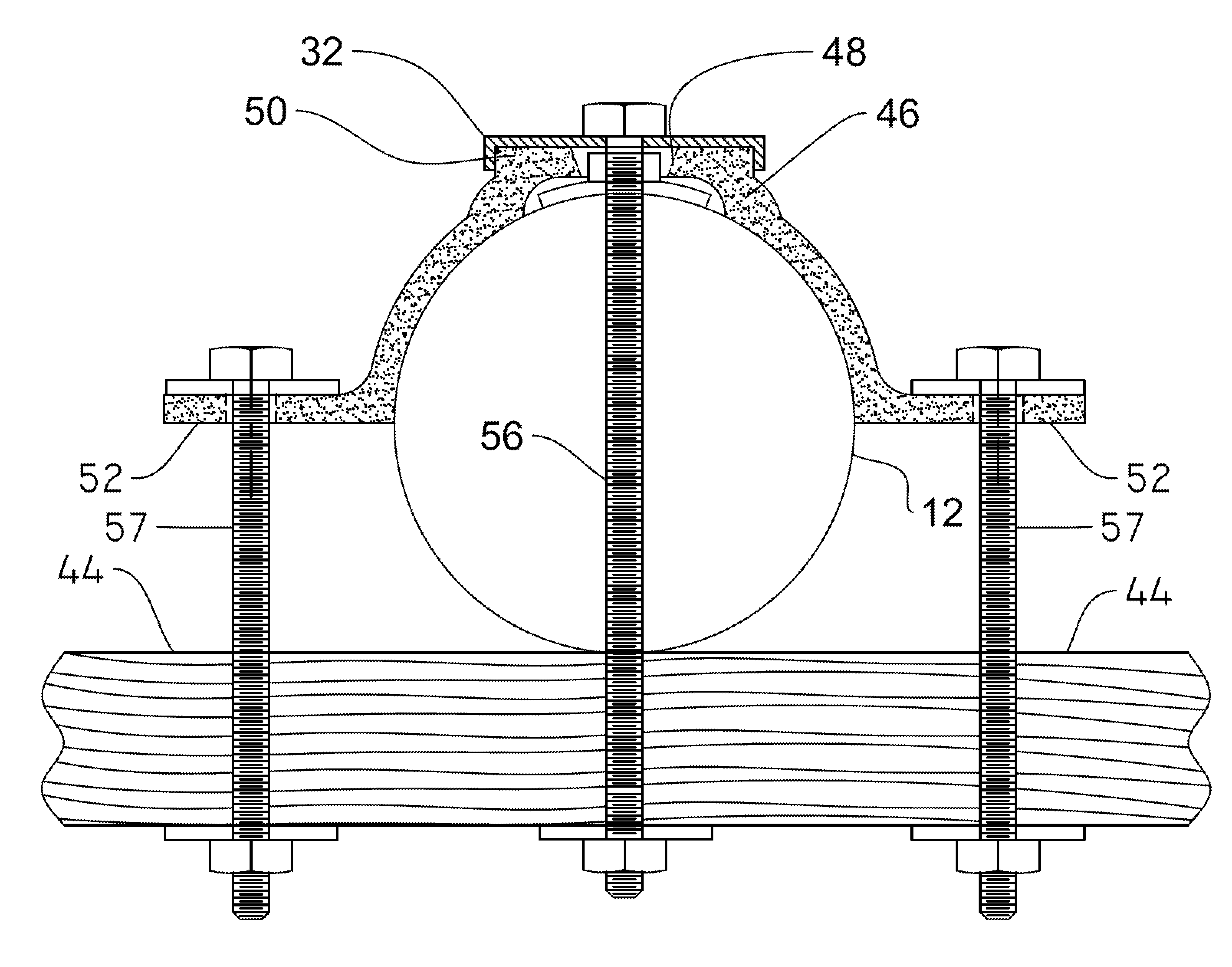

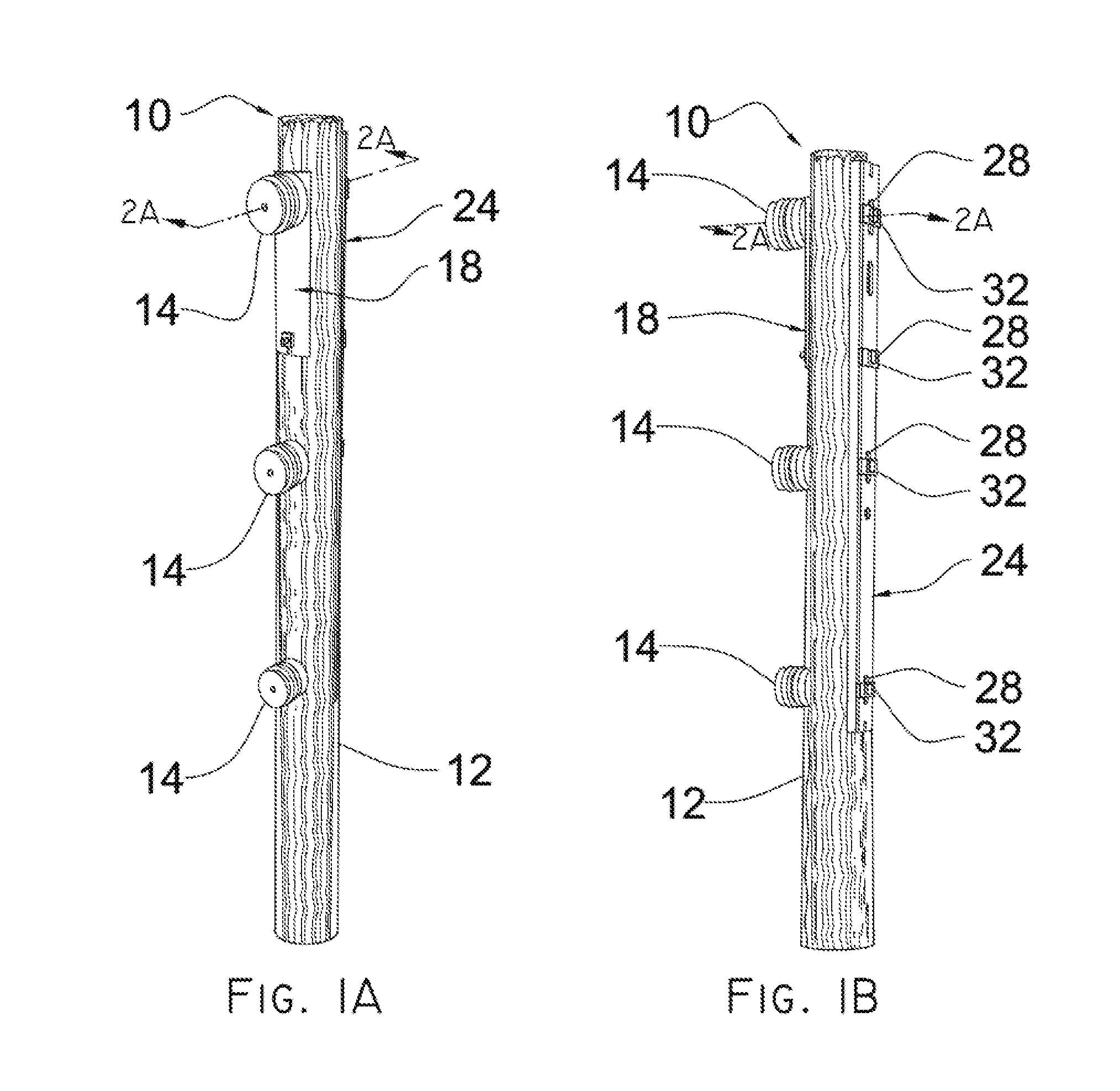

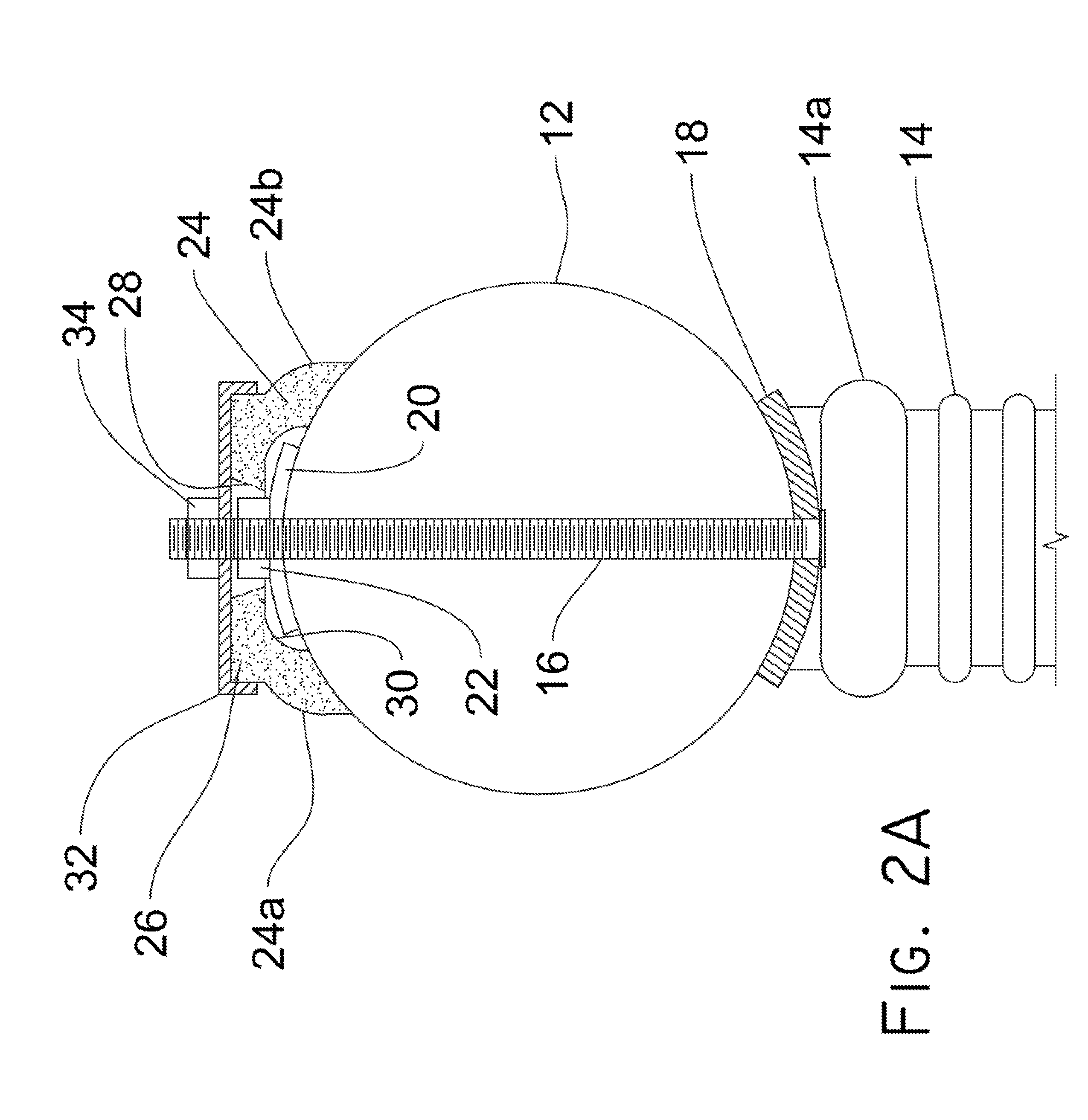

Utility or meter pole top reinforcement method and apparatus

ActiveUS9394716B2Provide stabilityProvide strengthTowersBuilding constructionsEngineeringMechanical engineering

An apparatus for reinforcing an upstanding utility / meter pole having a worn top includes an elongate brace adapted to bear against the pole near a top end of the pole. A washer plate is disposed in overlying relation to the elongate brace. A front support is secured to an opposite side of the pole by an elongate bolt that extends diametrically through the pole and is engaged by a nut to secure the brace and front support in sandwiching relation to the pole. A second embodiment reinforces a cross arm of a pole and a third embodiment ensleeves a pole at its uppermost end in a cylindrical body that serves as a prosthesis for a disintegrating pole top.

Owner:PLS TECH

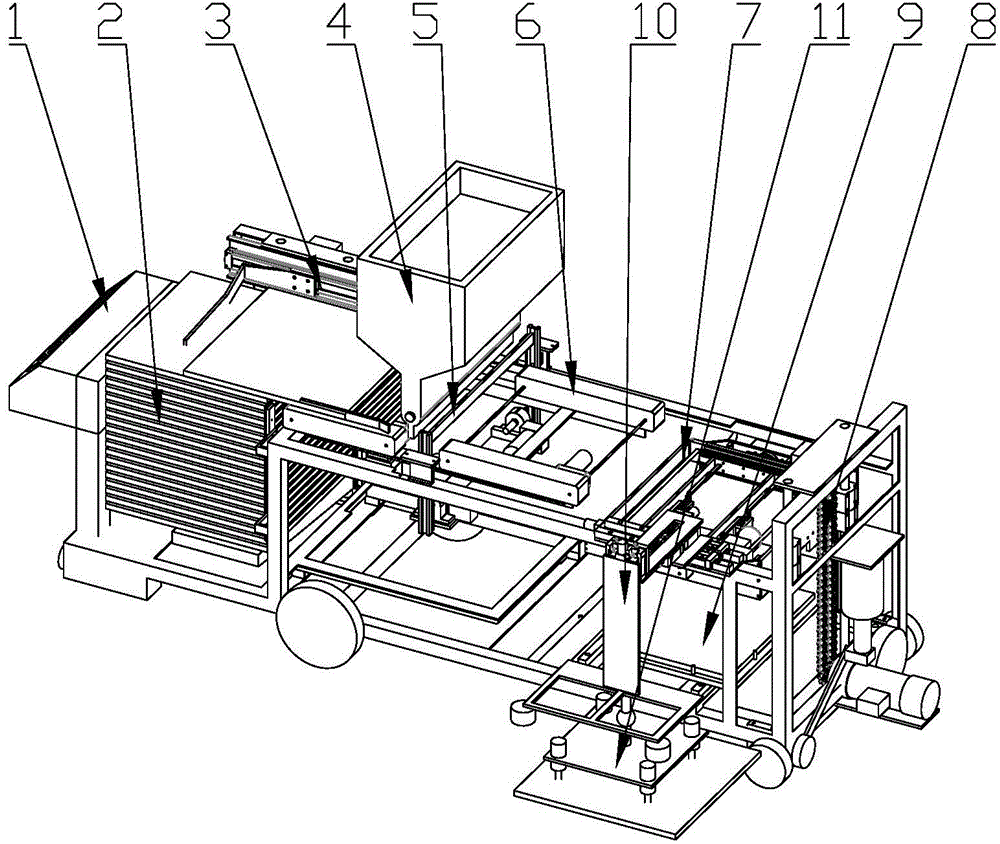

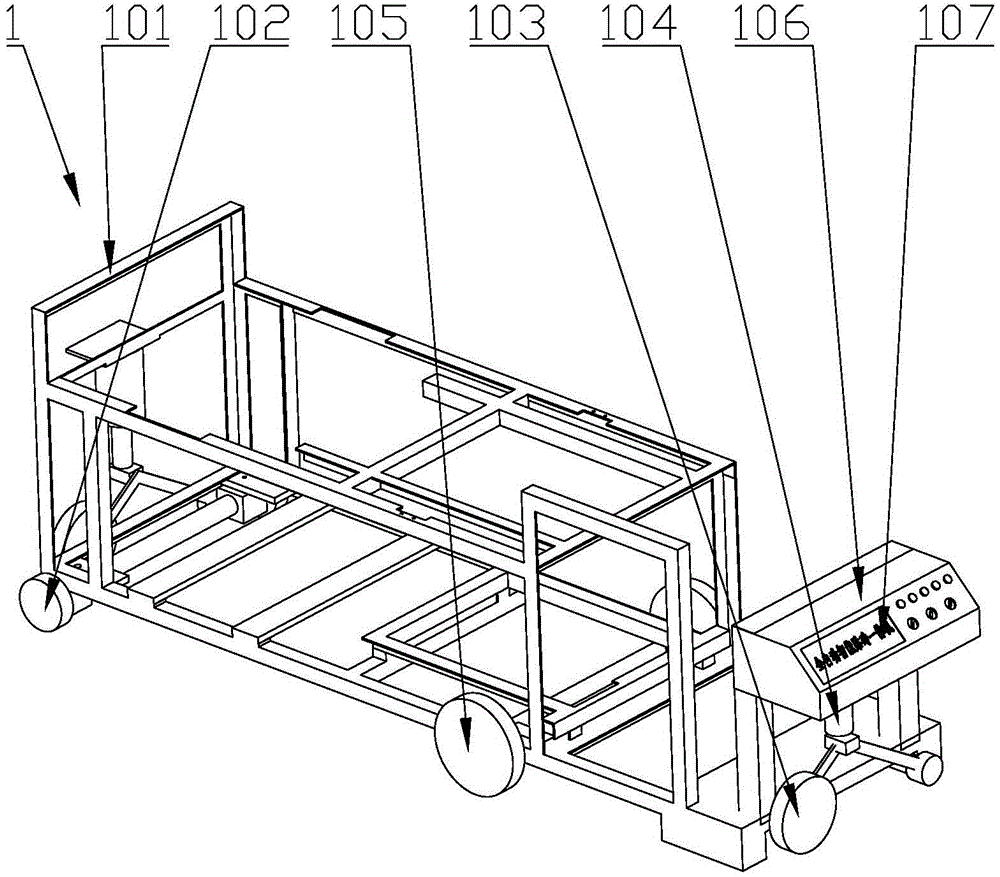

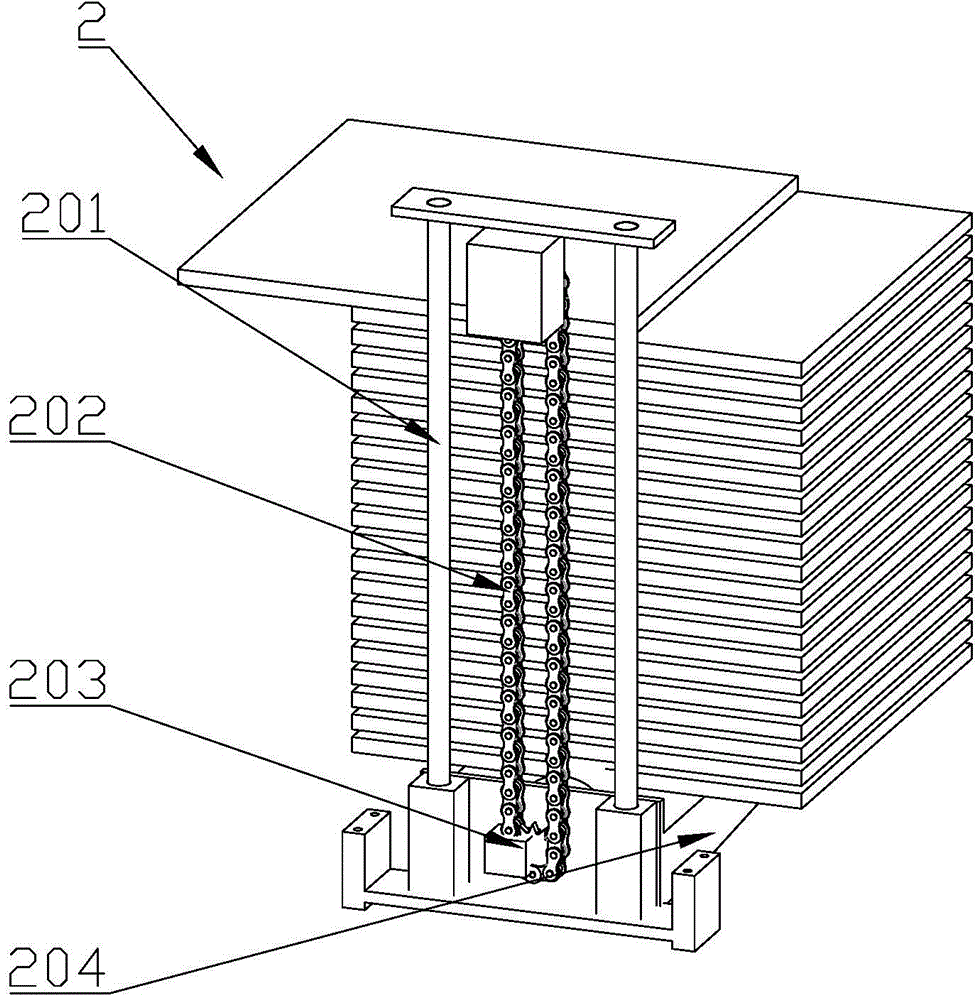

Full-automatic intelligent tiling machine

InactiveCN104060808ARealize fully automatic mechanized operationImprove work efficiencyBuilding constructionsEngineeringPositioning system

The invention discloses a full-automatic intelligent tiling machine, which comprises a rack, a feeding lifting system, an automatic pulling system, an automatic plastering hopper, an automatic mortar scraping mechanism, a material transportation mechanism, a feeding automatic turnover mechanism, a feeding automatic lifting platform, a second-time positioning system, a four-axis positioning system for floor tile tiling, and a measurement and vibration tiling mechanism. The tiling machine is also provided with a wall tiling system and a ground and wall tiling pouring system. The full-automatic intelligent tiling machine has the advantages that due to the adoption of the tiling machine which enables that ground tiles and wall tiles can be tiled simultaneously, manpower can be replaced completely and a full-automatic machinery operation in tiling is realized, so that working efficiency is greatly improved and labor intensity is reduced; besides, the wall tiles and the ground tiles tiled by the intelligent tiling machine are superior in quality in consideration of good tidiness, sound smoothness and aesthetic appearances, so that the intelligent tiling machine is particularly suitable for large-area ground or wall tiling; the craft of plastering first and then tile paving, and that of tile paving first and then mortar pouring can be adopted by the intelligent tiling machine simultaneously, and a suitable tiling craft can be chosen according to the smoothness degree of ground surfaces and wall surfaces, so that tiling efficiency is better improved.

Owner:王越

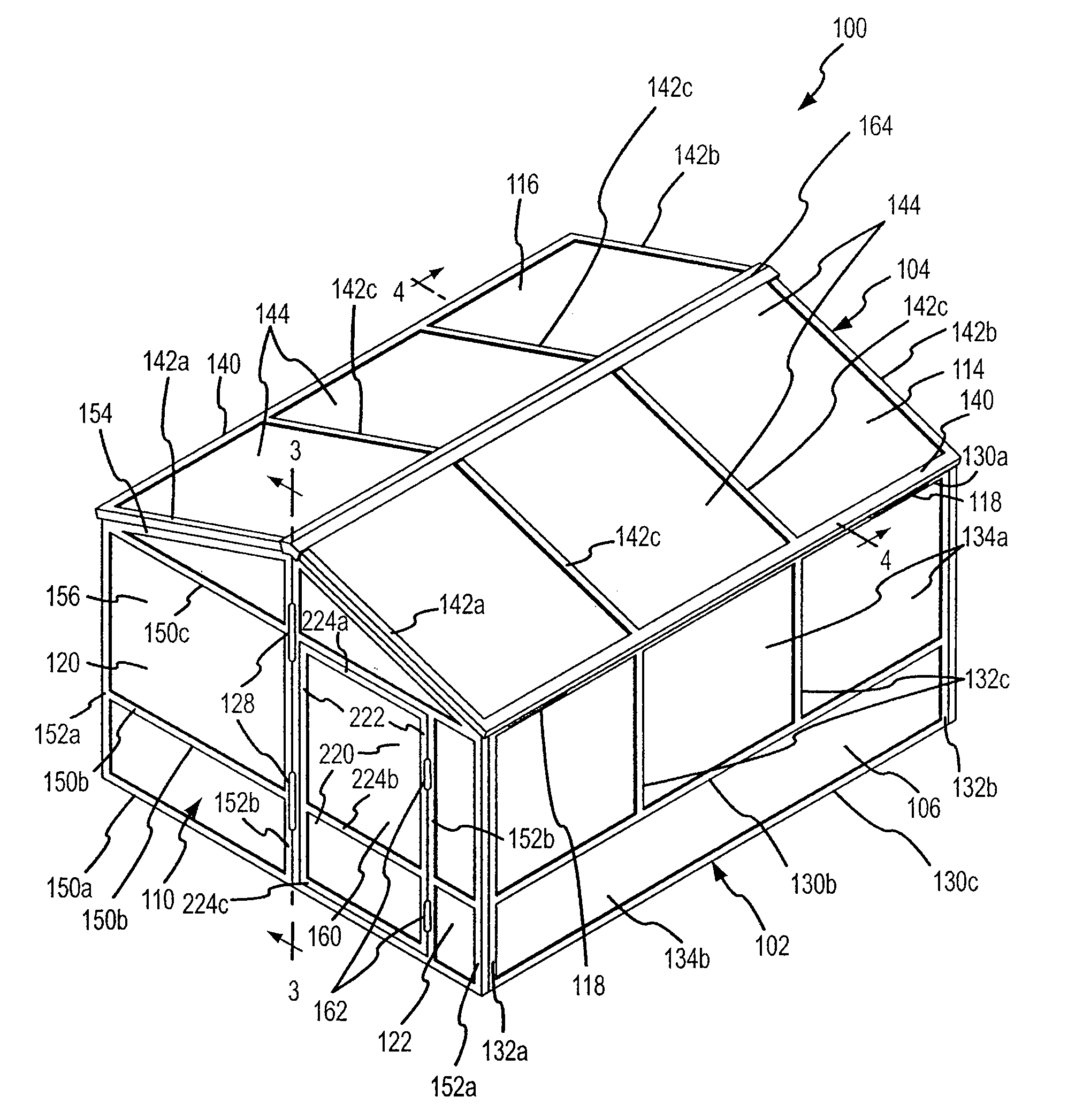

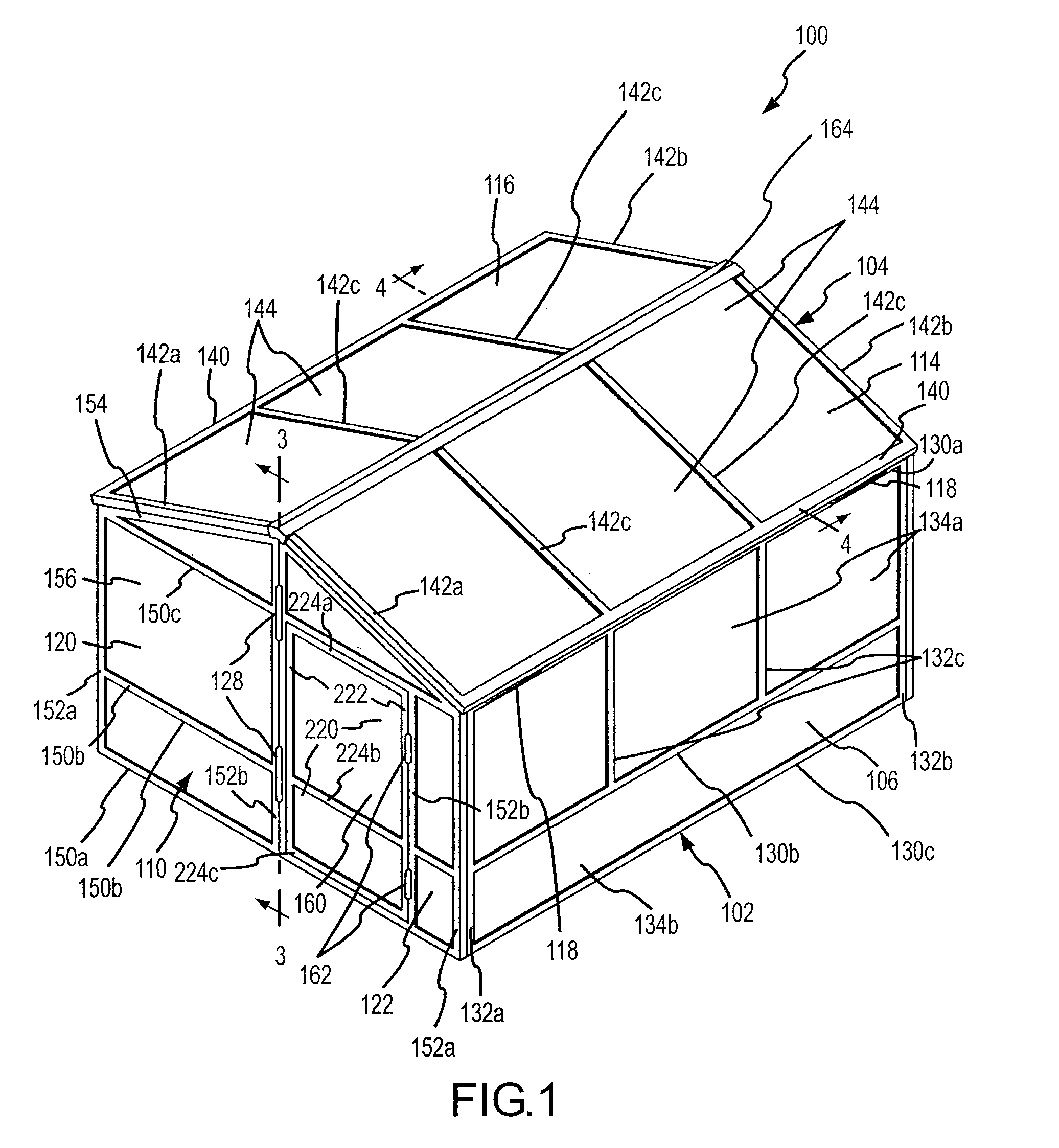

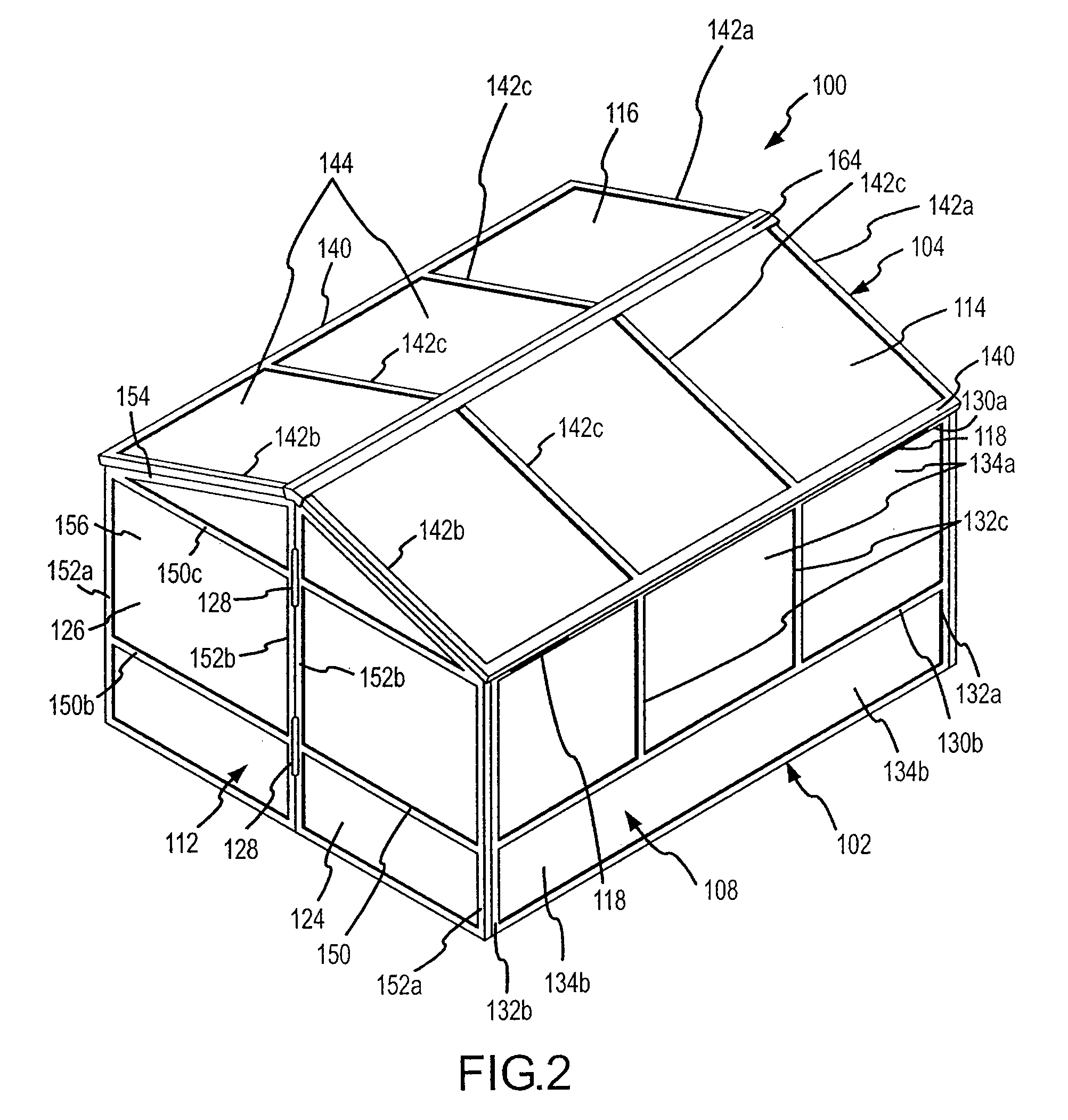

Folding shed

Owner:ULTRAFOLD BUILDINGS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com