Patents

Literature

11219results about "Connections" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

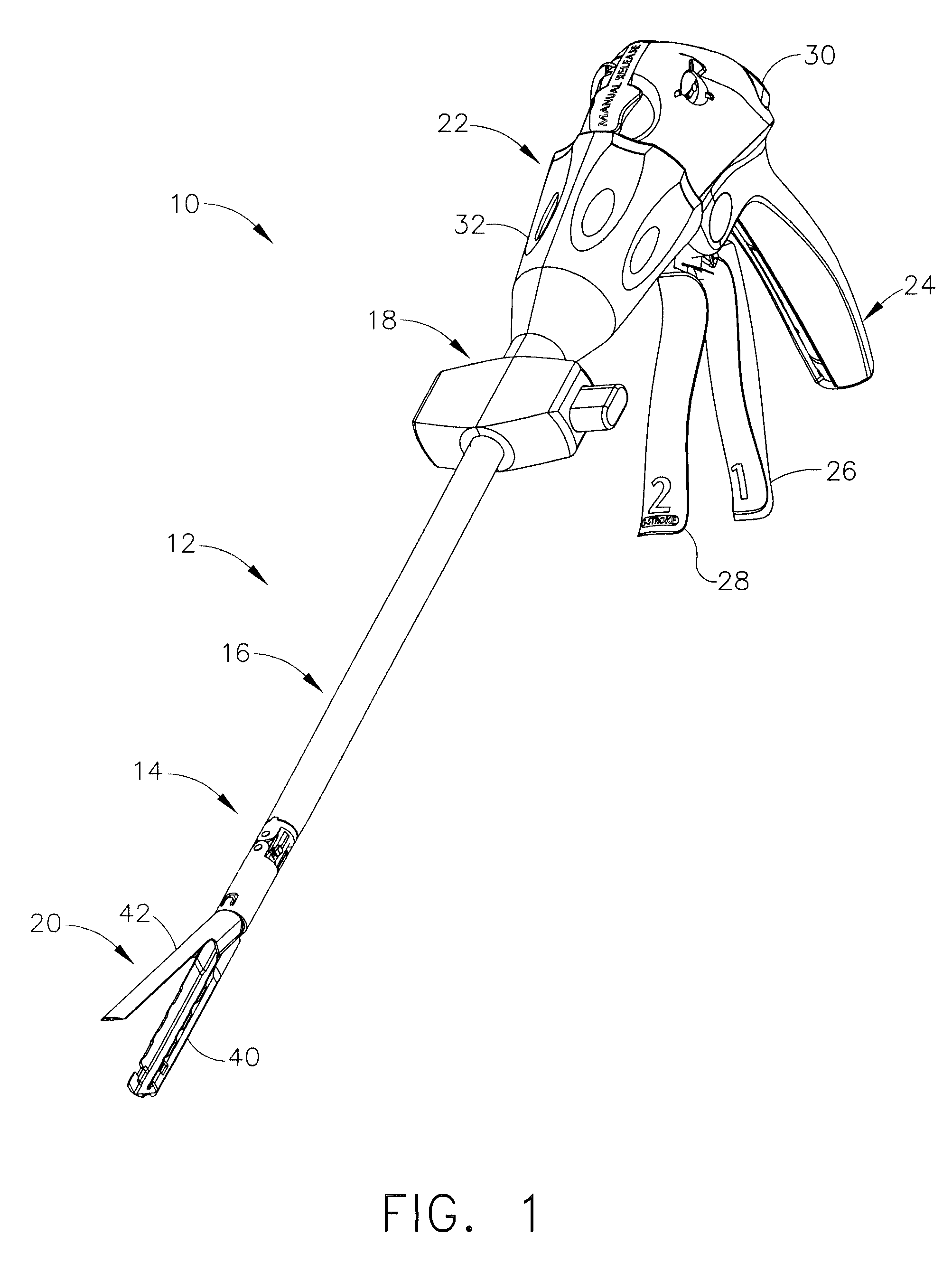

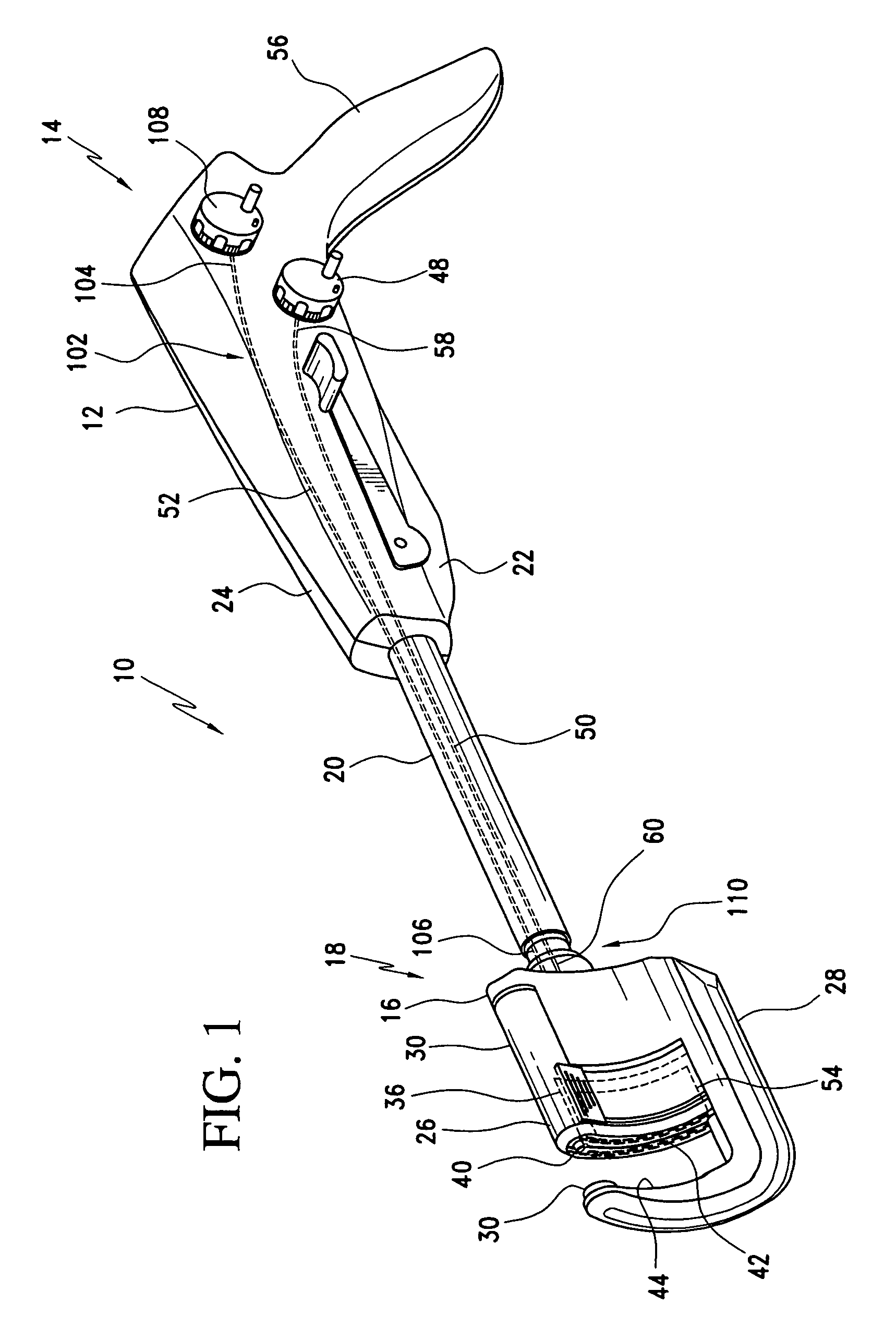

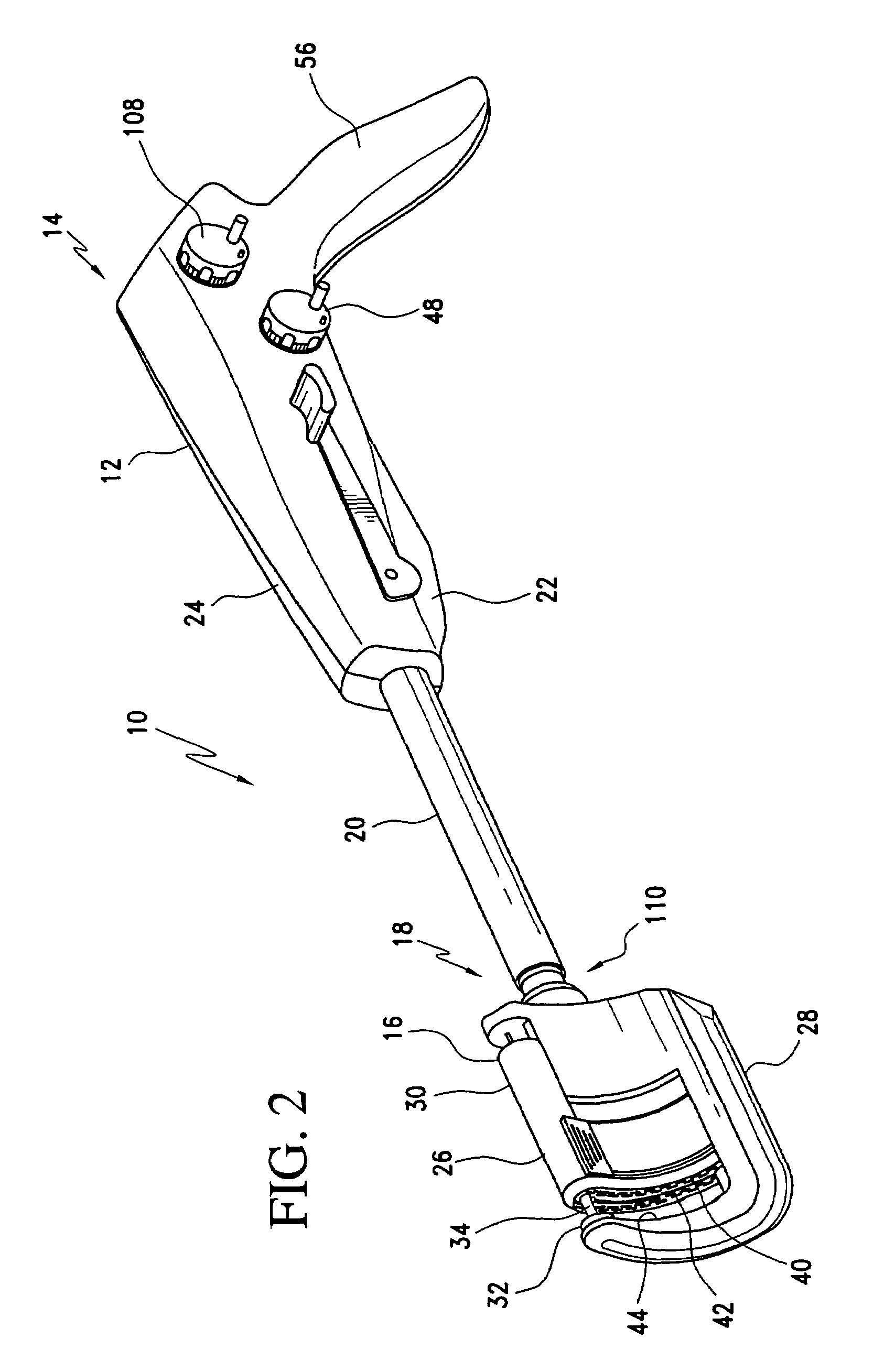

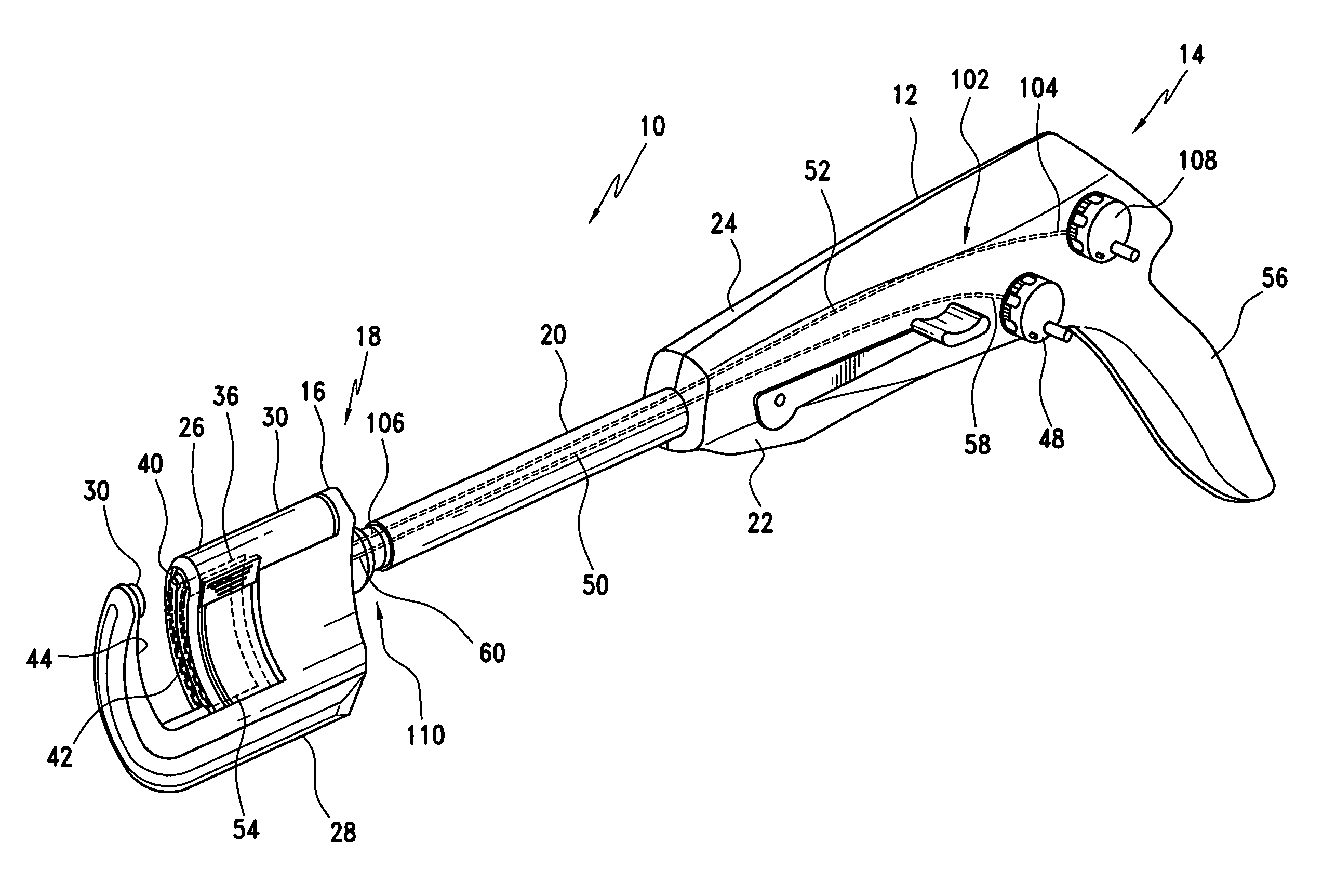

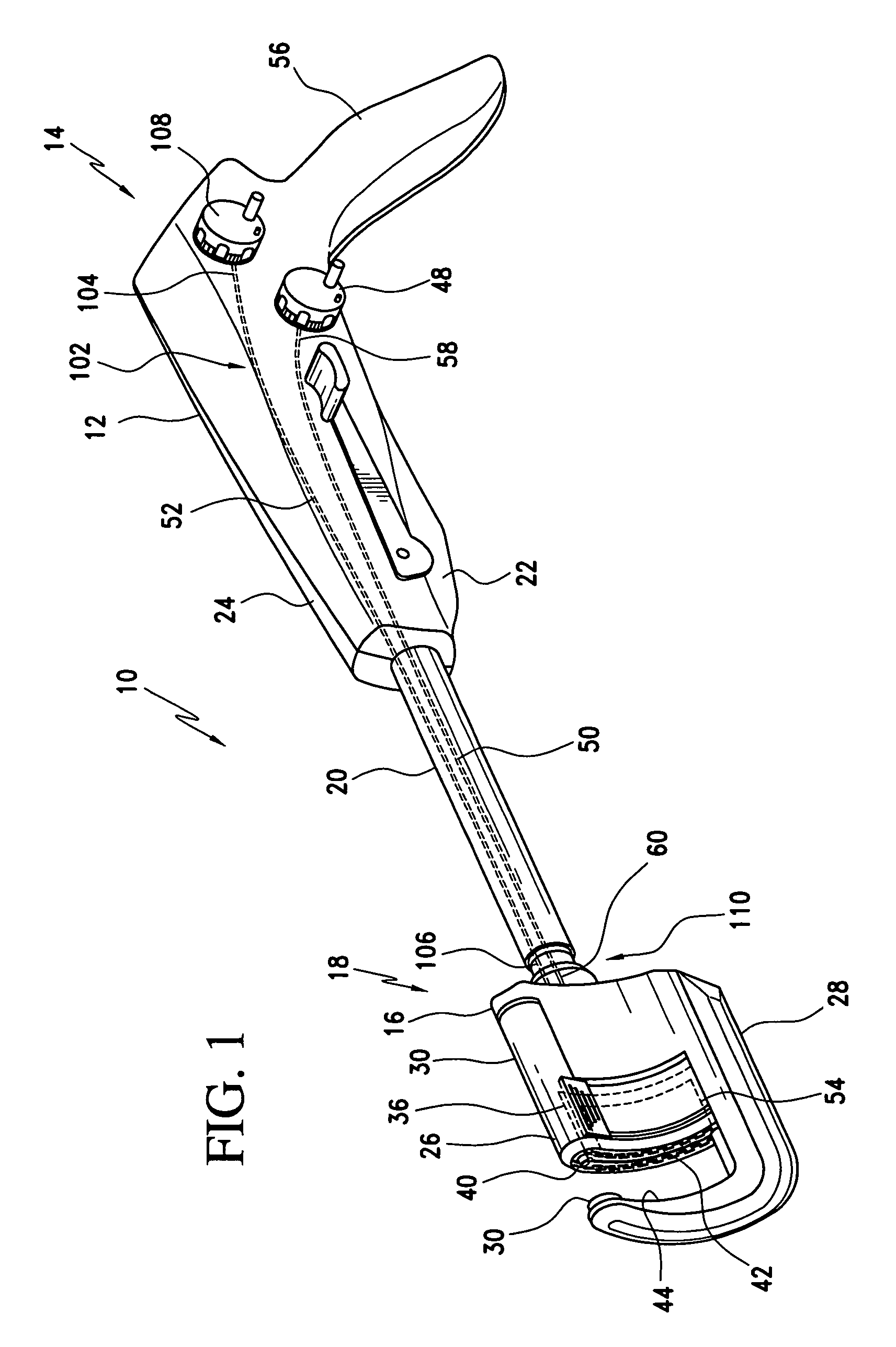

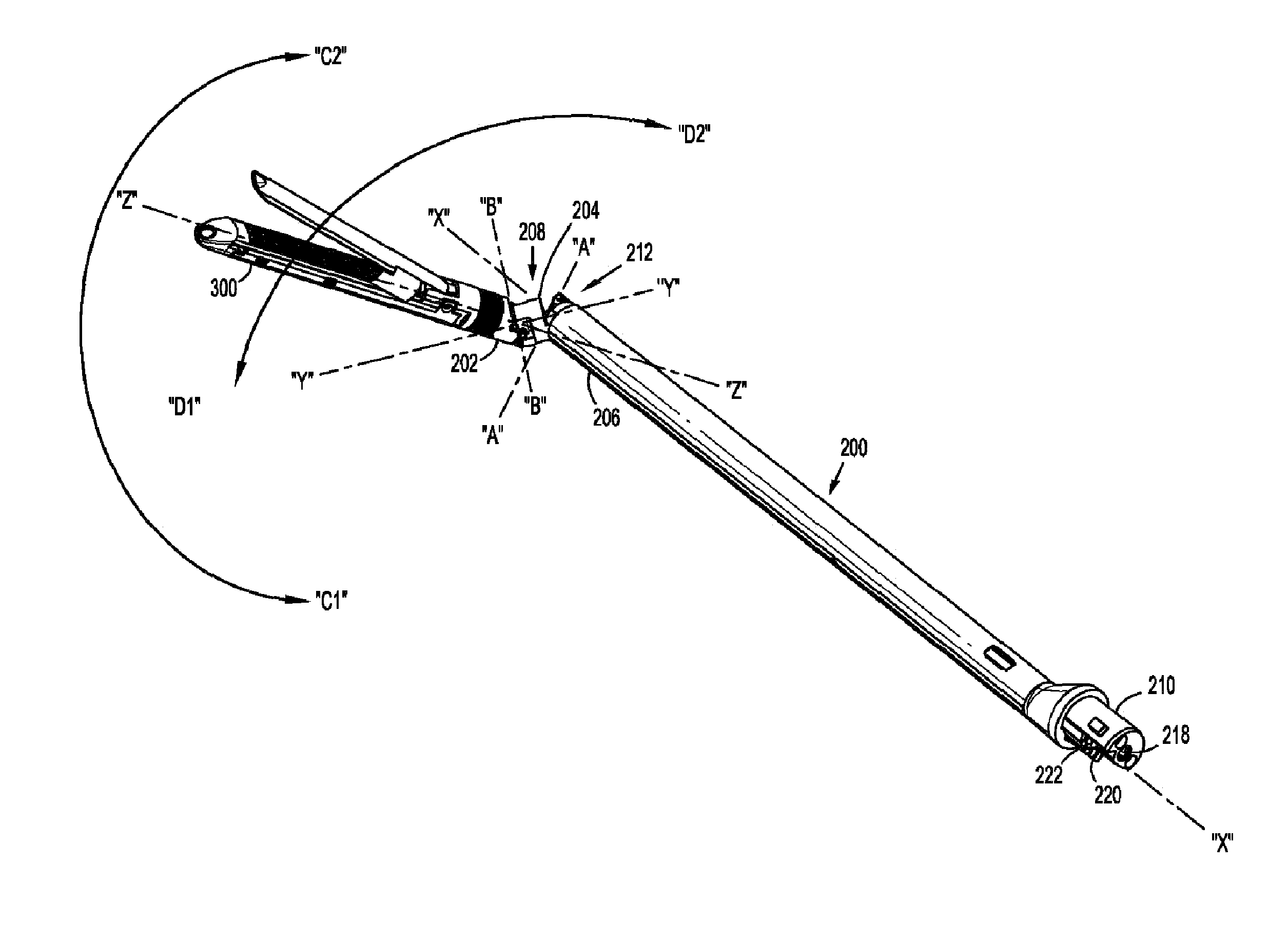

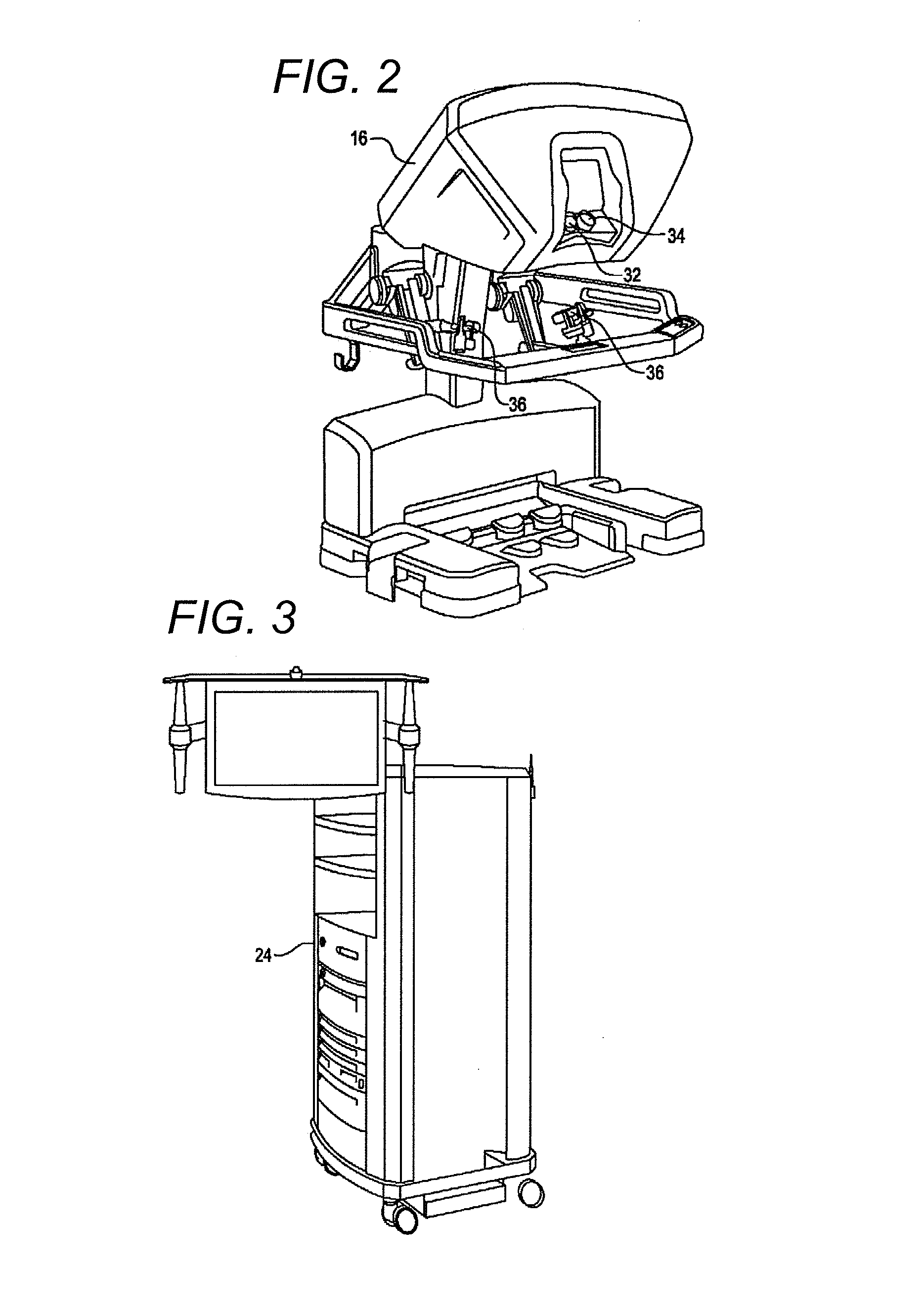

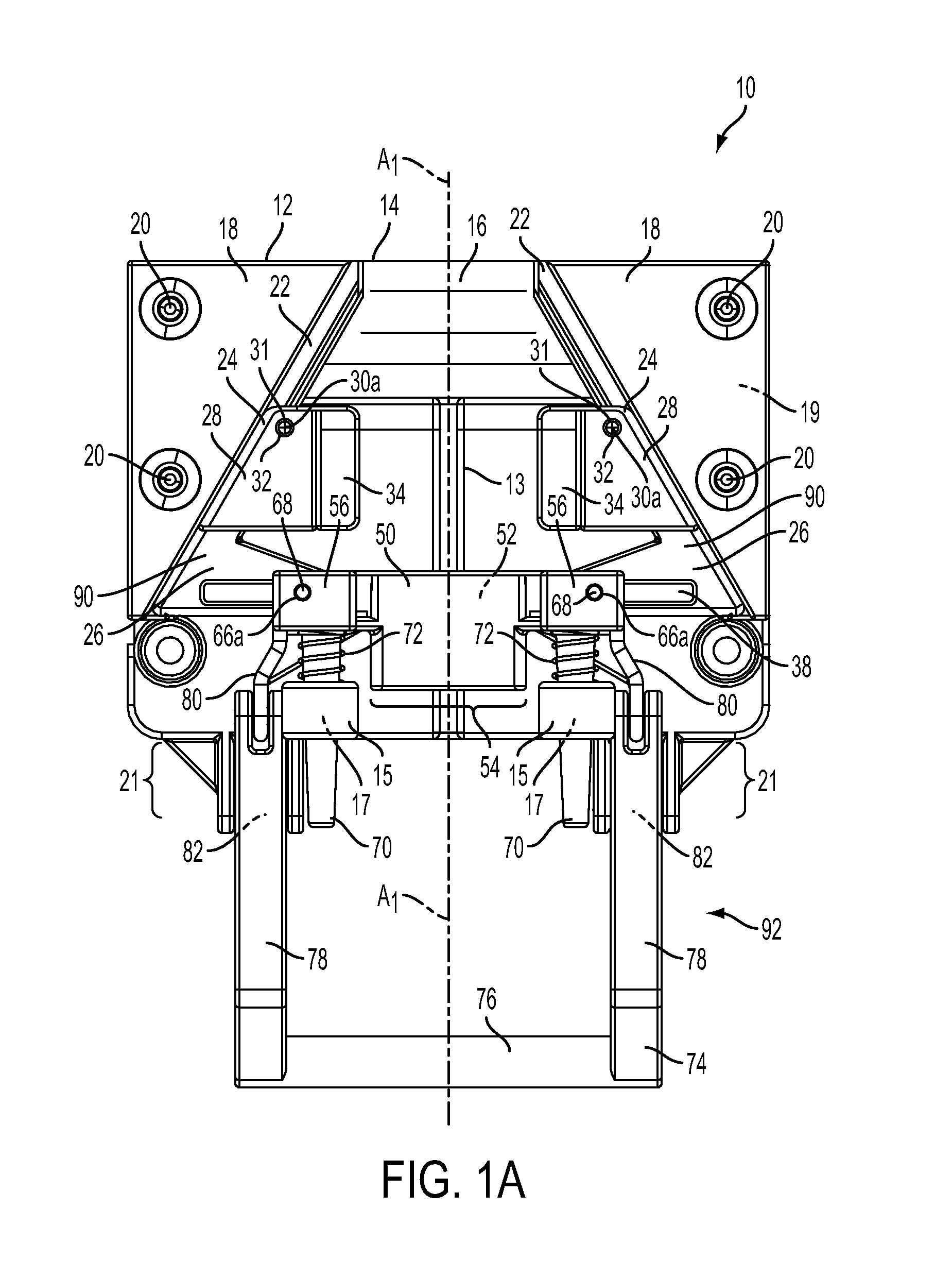

Surgical instrument with articulating shaft with single pivot closure and double pivot frame ground

ActiveUS7784662B2Give flexibilityIncrease flexibilitySuture equipmentsStapling toolsSurgical siteEngineering

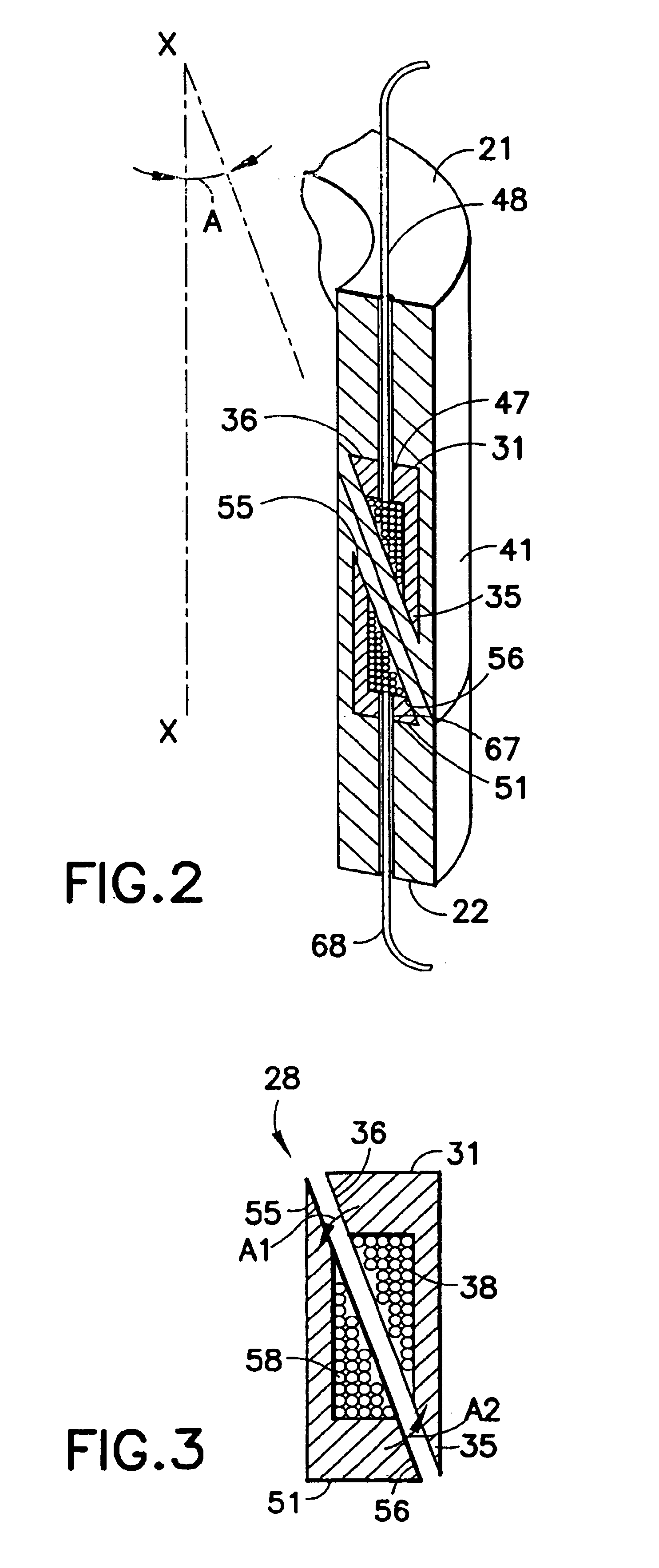

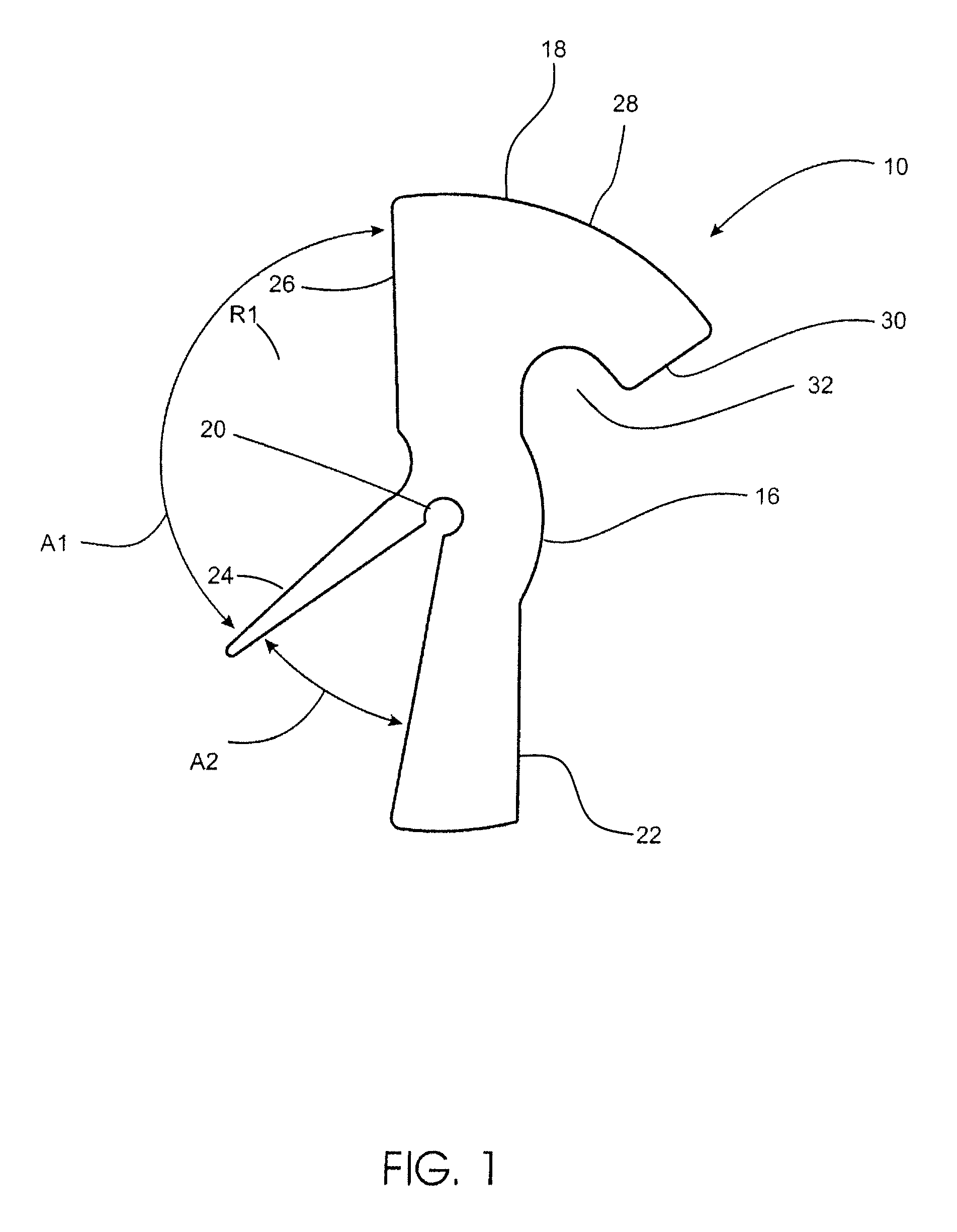

A surgical stapling and severing instrument particularly suited to endoscopic use includes a proximal portion that is manipulated external to a patient to position an attached elongate shaft and end effector to a desired surgical site inside of the patient. An articulation joint pivotally attaches the end effector to the elongate shaft to give further clinical flexibility in reaching tissue at a desired angle. A closure tube assembly includes a single pivoting portion that overrides the articulation joint in order to distally translate to the end effector to close, yet pass over an articulated shaft by having a multiple pivot frame ground encompassed therein to accommodate the longitudinal change in closure sleeve pivot. Thereby, additional clinical flexibility in positioning the end effector is achieved without losing the ability for separate closure and firing motions transferred by the shaft.

Owner:ETHICON ENDO SURGERY INC

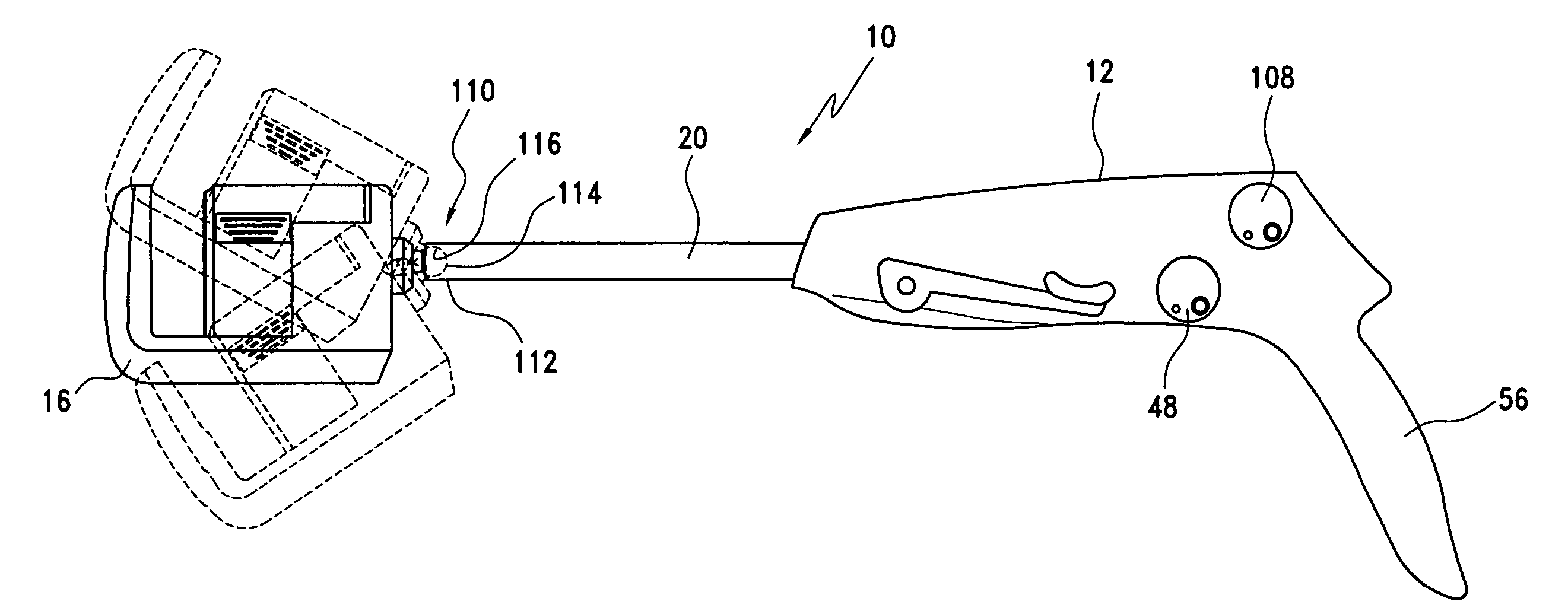

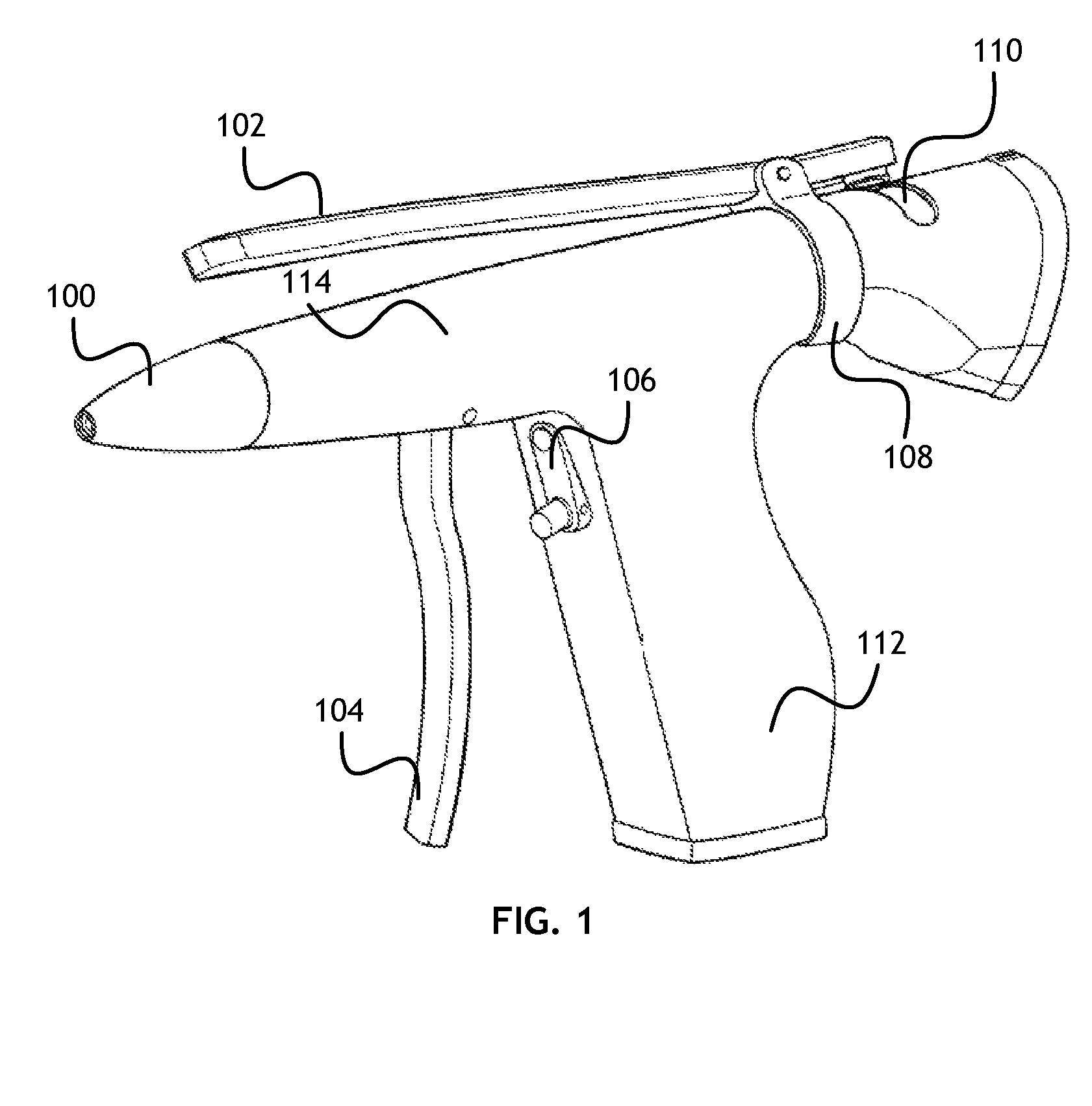

Rotating curved cutter stapler

ActiveUS7549563B2Expand accessReduce usageSuture equipmentsStapling toolsRobot end effectorEngineering

A rotating surgical stapler having a proximal end and a distal end includes a handle at the proximal end and an end effector at the distal end for selective rotation to improve access to tissue requiring treatment and ease of use of the present linear surgical stapler. A support shaft connects the handle to the end effector and includes a longitudinal axis. The end effector is coupled to the support shaft for rotation about a longitudinal axis of the stapler.

Owner:ETHICON ENDO SURGERY INC

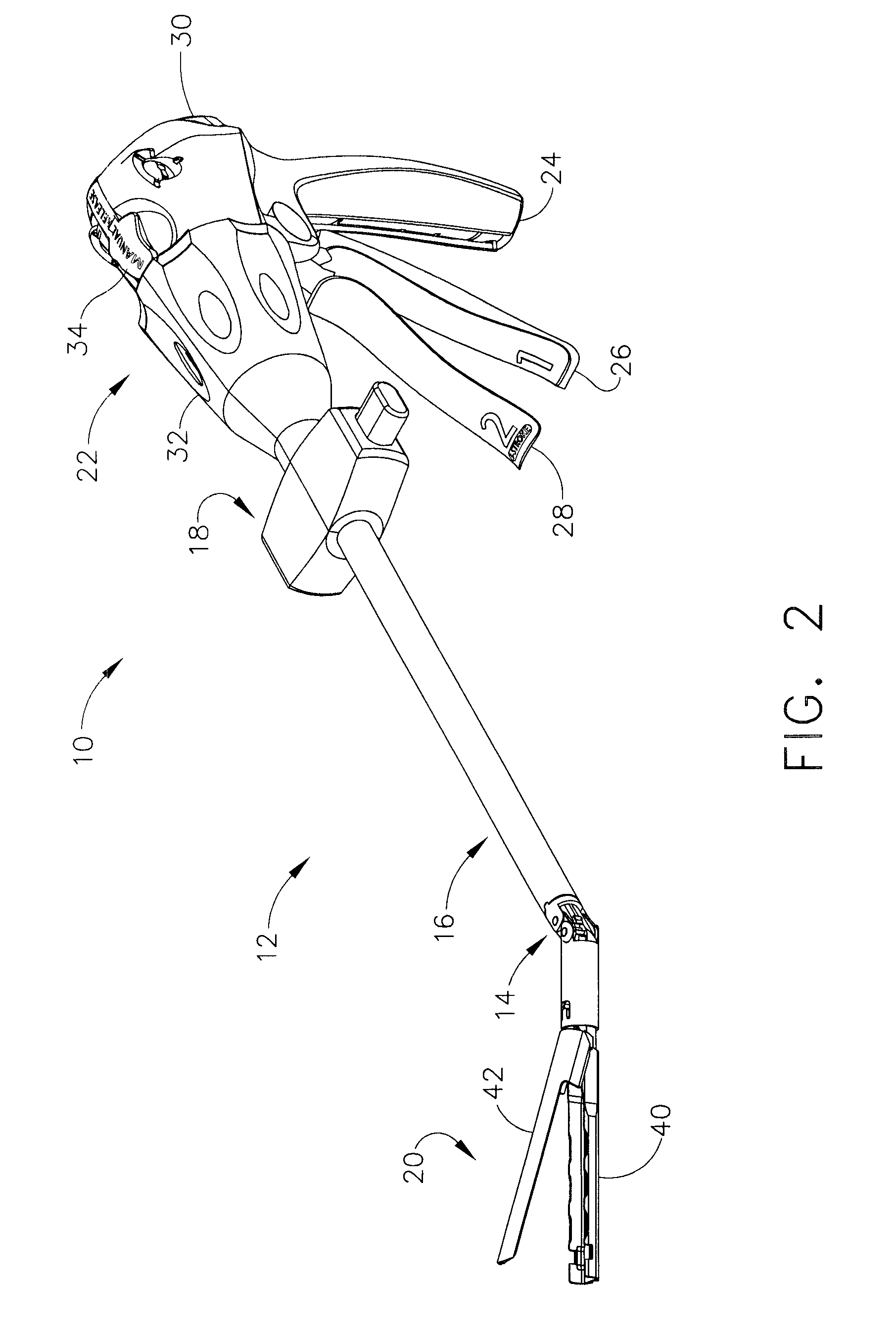

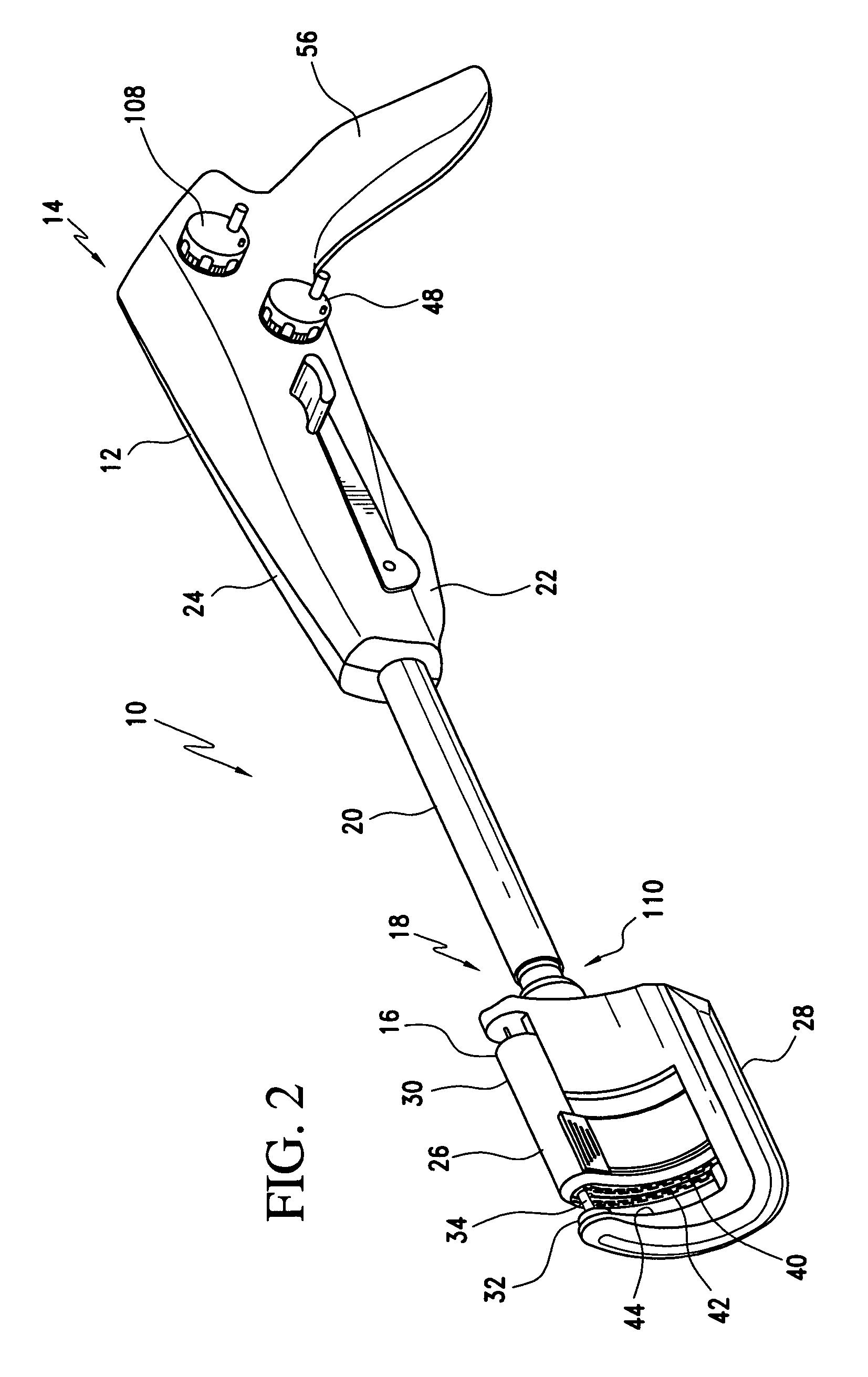

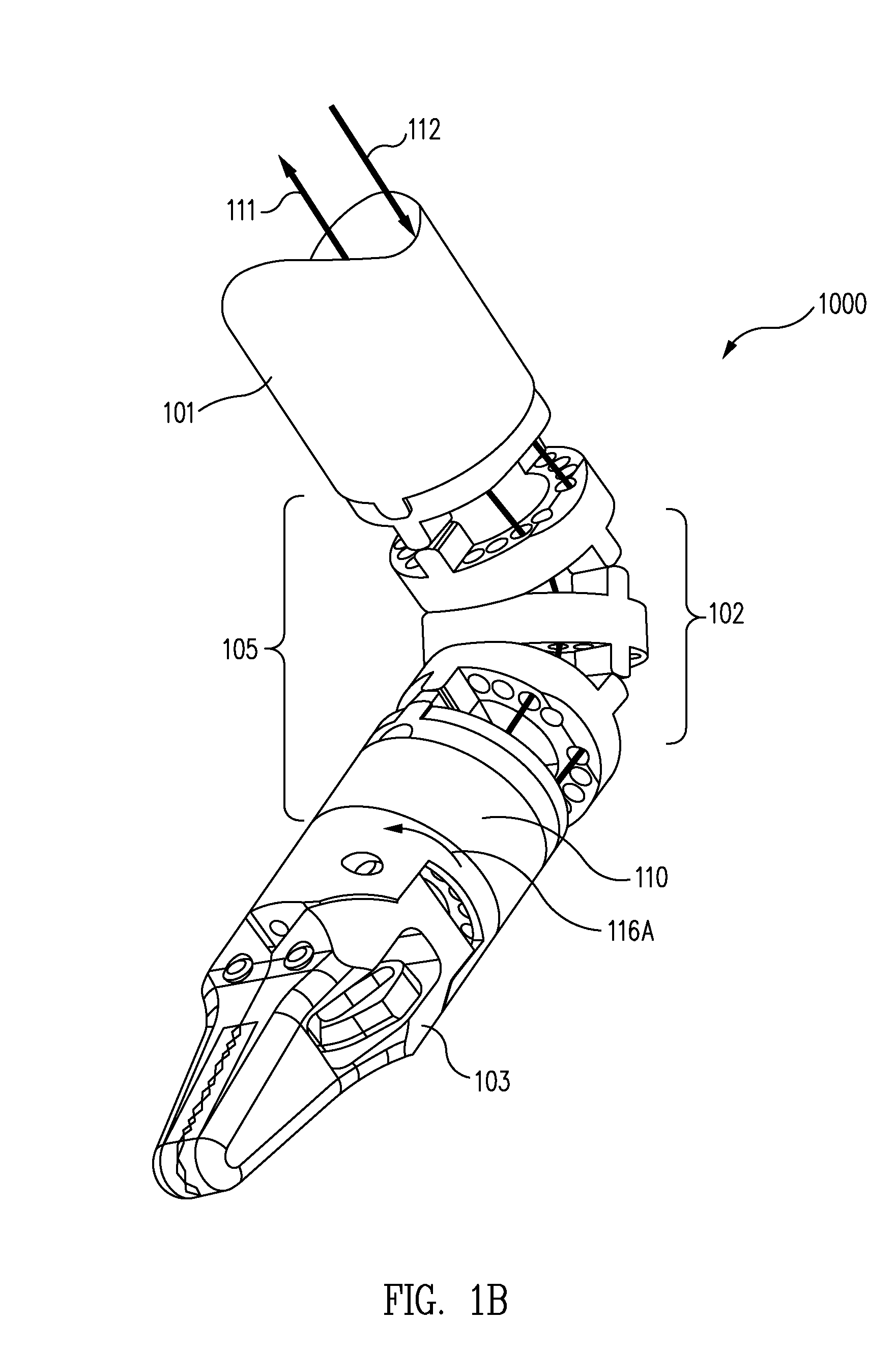

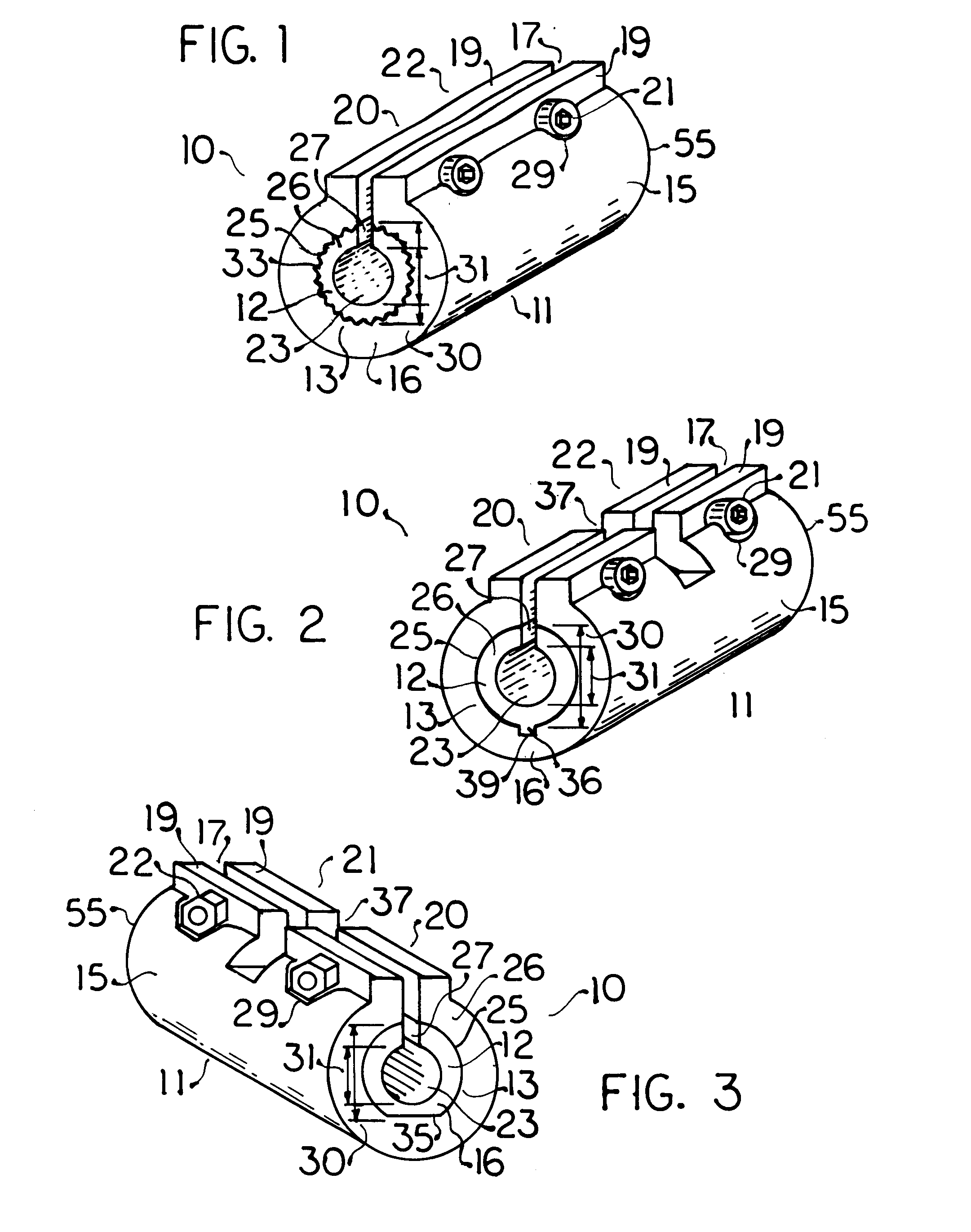

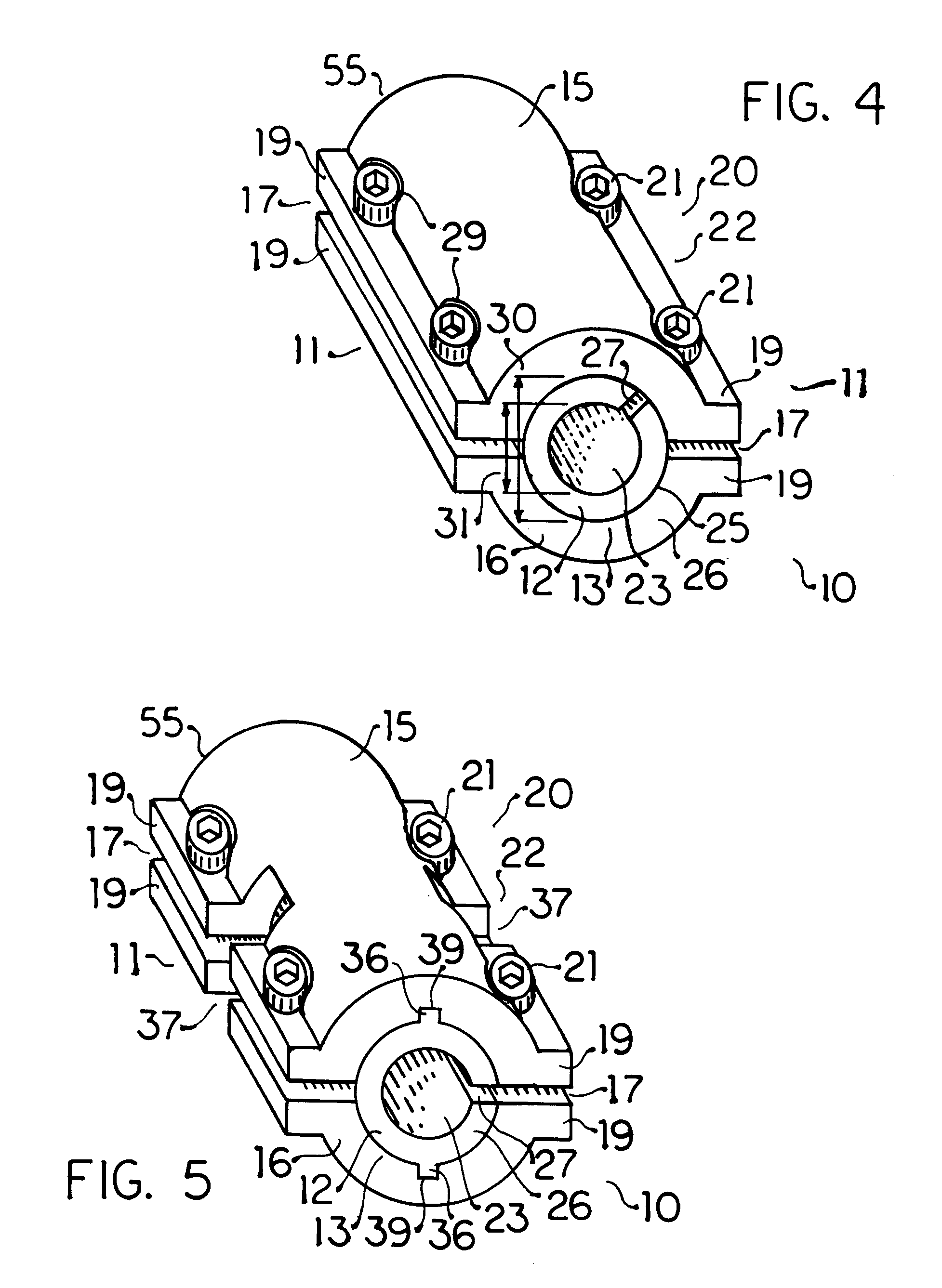

Articulating curved cutter stapler

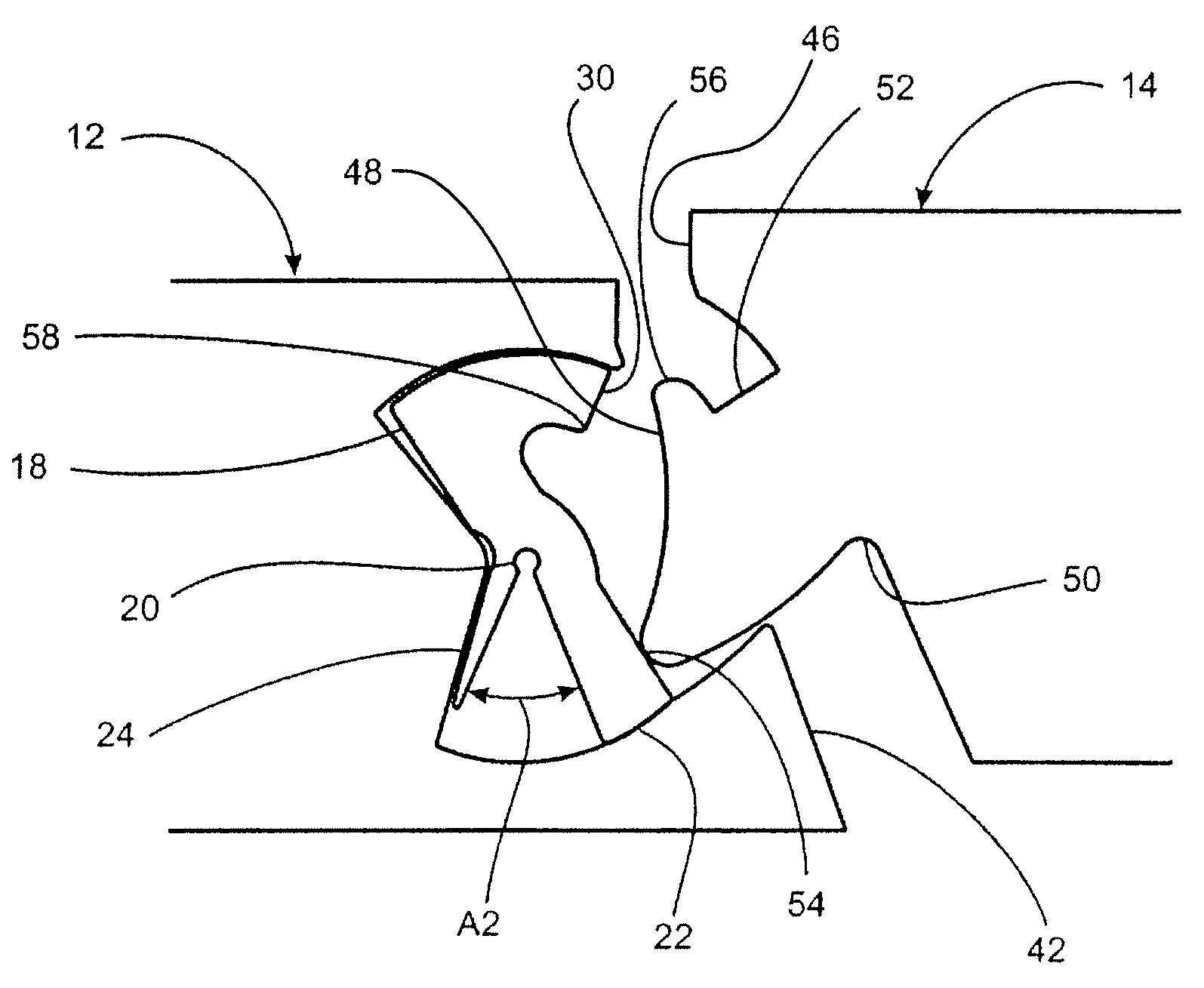

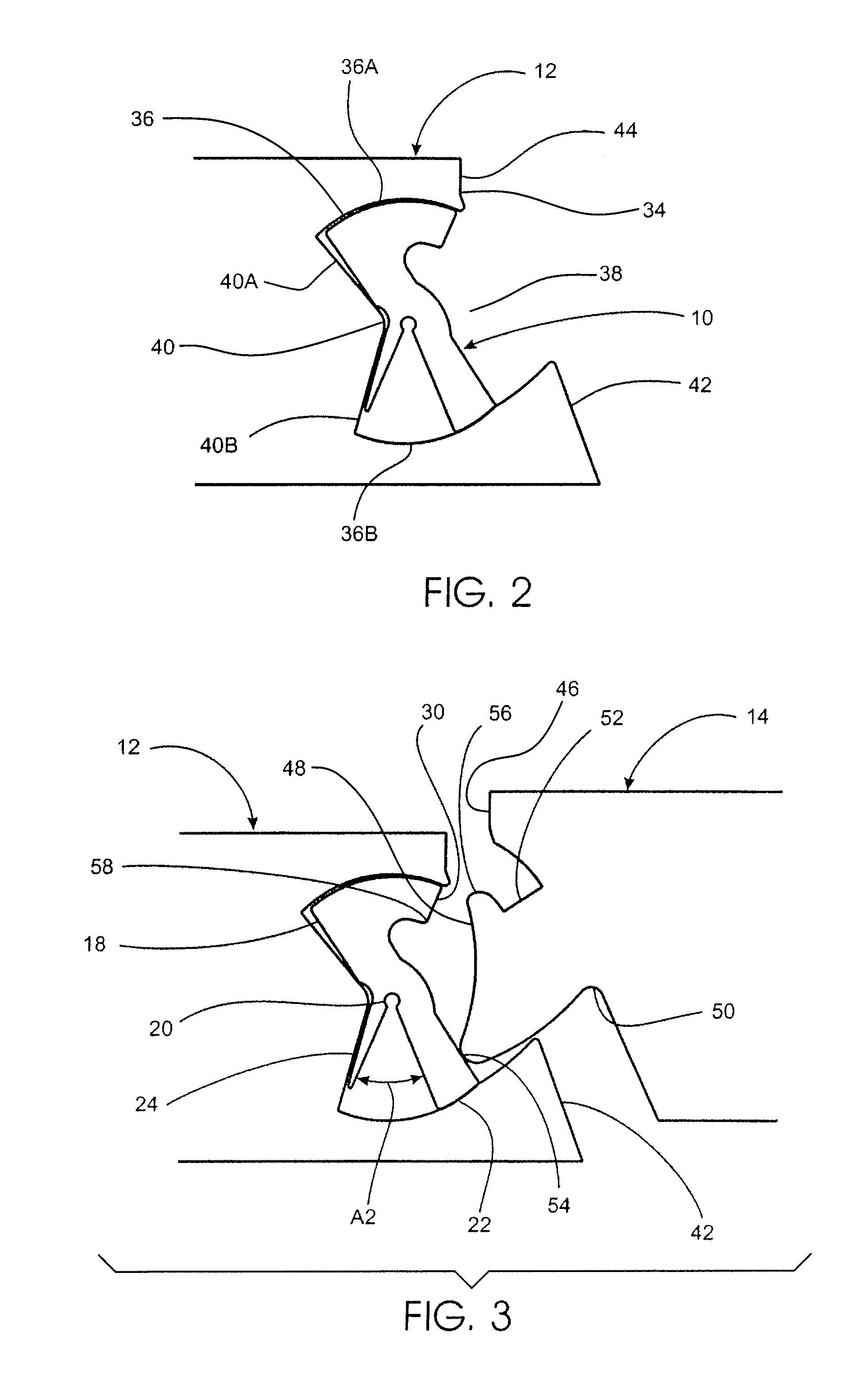

ActiveUS7766207B2Expand accessReduce usageSuture equipmentsStapling toolsEngineeringRobot end effector

An articulating surgical stapler having a proximal end and a distal end includes a handle at the proximal end and an end effector at the distal end for selective articulation to improve access to tissue requiring treatment and ease of use of the present linear surgical stapler. A support shaft connects the handle to the end effector. An articulation mechanism is positioned between the support shaft and the end effector permitting selective movement of the end effector relative to the support shaft.

Owner:ETHICON ENDO SURGERY INC

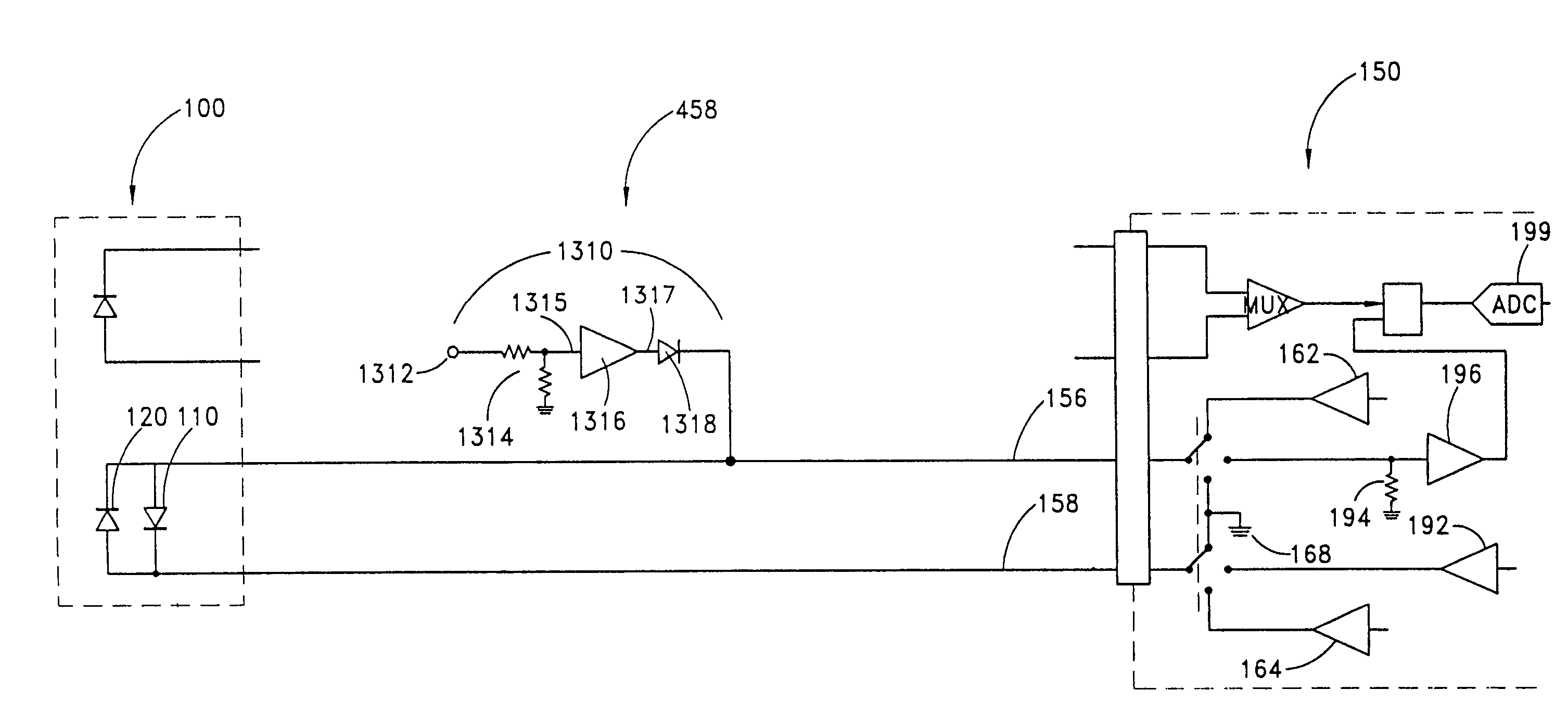

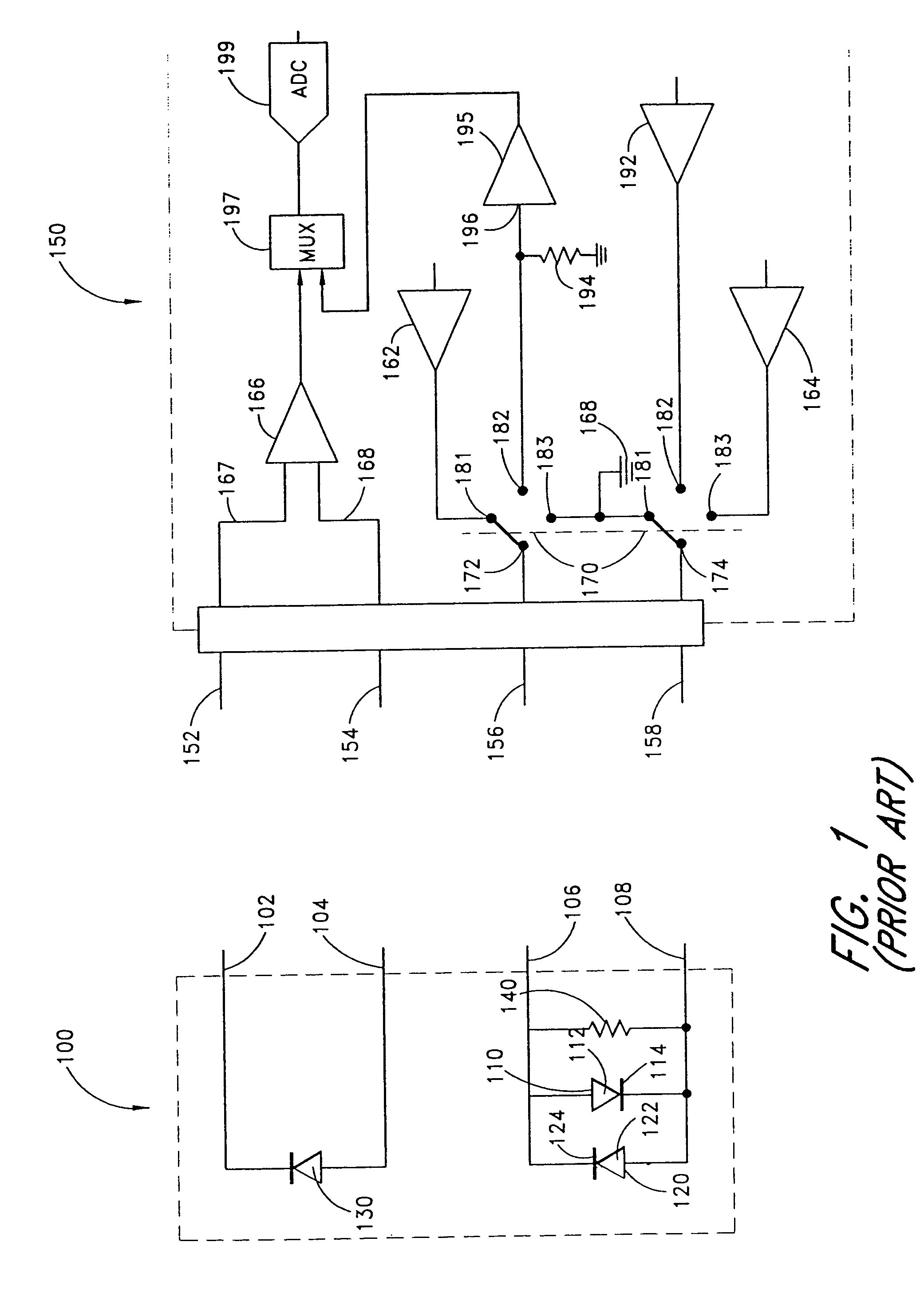

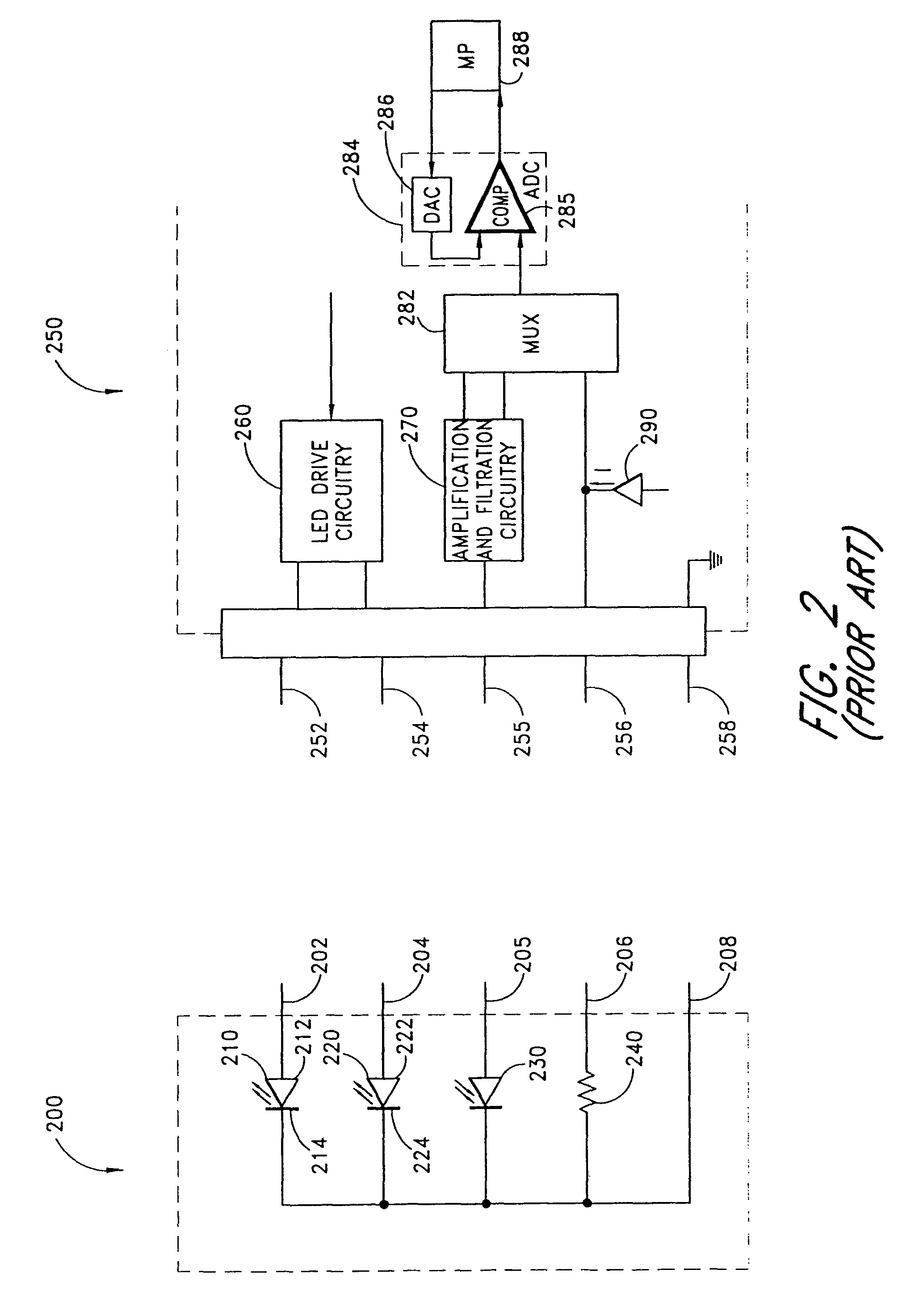

Pulse oximetry sensor adaptor

InactiveUS6993371B2Avoid complex processCost of very criticalDiagnostic recording/measuringSensorsAudio power amplifierPulse oximetry

An adapter allows the interconnection of a sensor originating from one manufacturer to be coupled with conventionally incompatible monitors originating from other manufacturers to form a properly functioning pulse oximetry system. The adapter matches a sensor driver in a monitor to the current requirements and light source configuration of a sensor. The adapter also matches a sensor's light detector signal level to the dynamic range requirements of a monitor preamplifier. Further, the adapter provides compatible sensor calibration, sensor type and security information to a monitor. The adapter may have a self-contained power source or it may derive power from the monitor, allowing both passive and active adapter components. The adapter is particular suited as an adapter cable, replacing a conventional patient cable or sensor cable as the interconnection between a sensor to a monitor in a pulse oximetry system.

Owner:JPMORGAN CHASE BANK NA

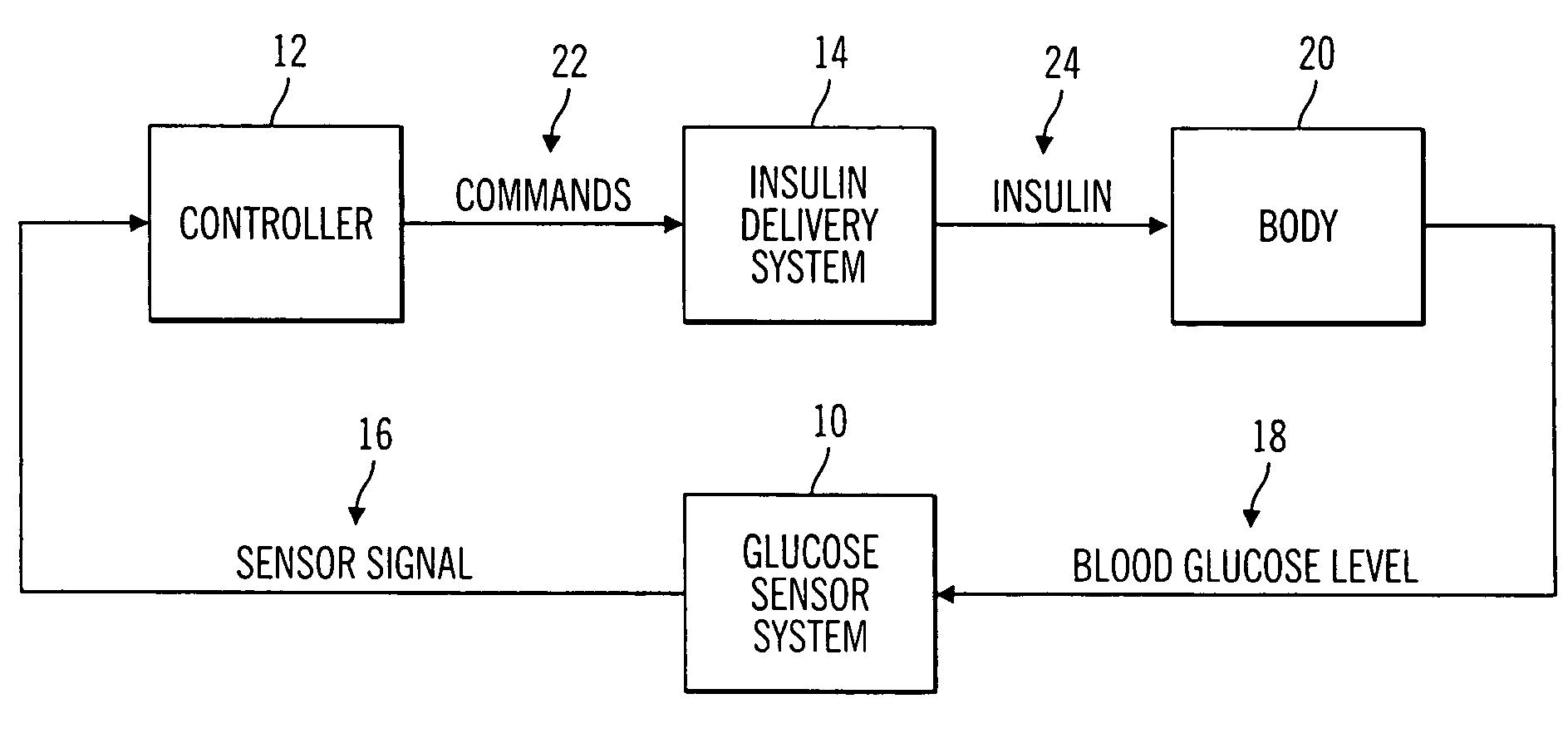

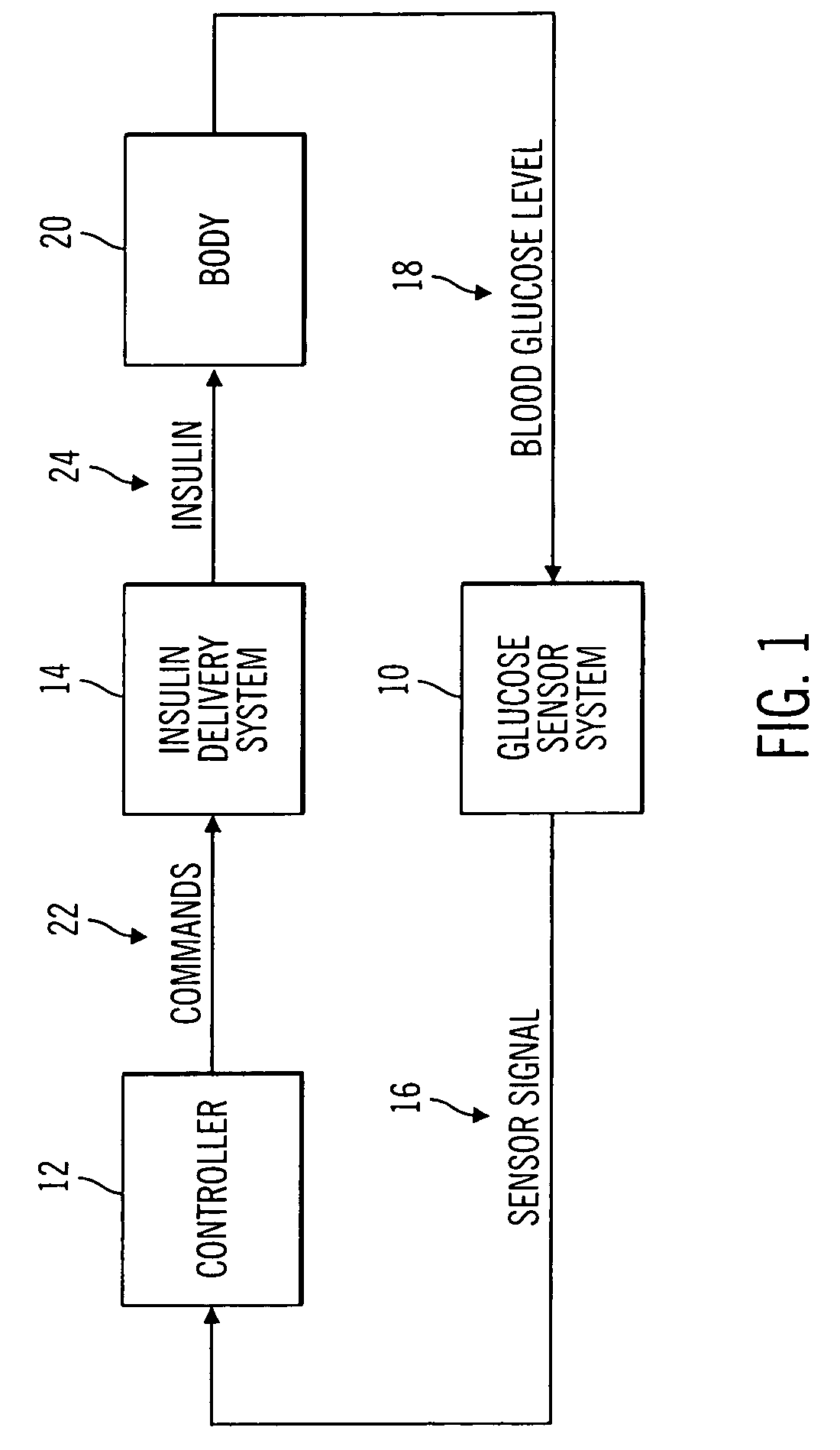

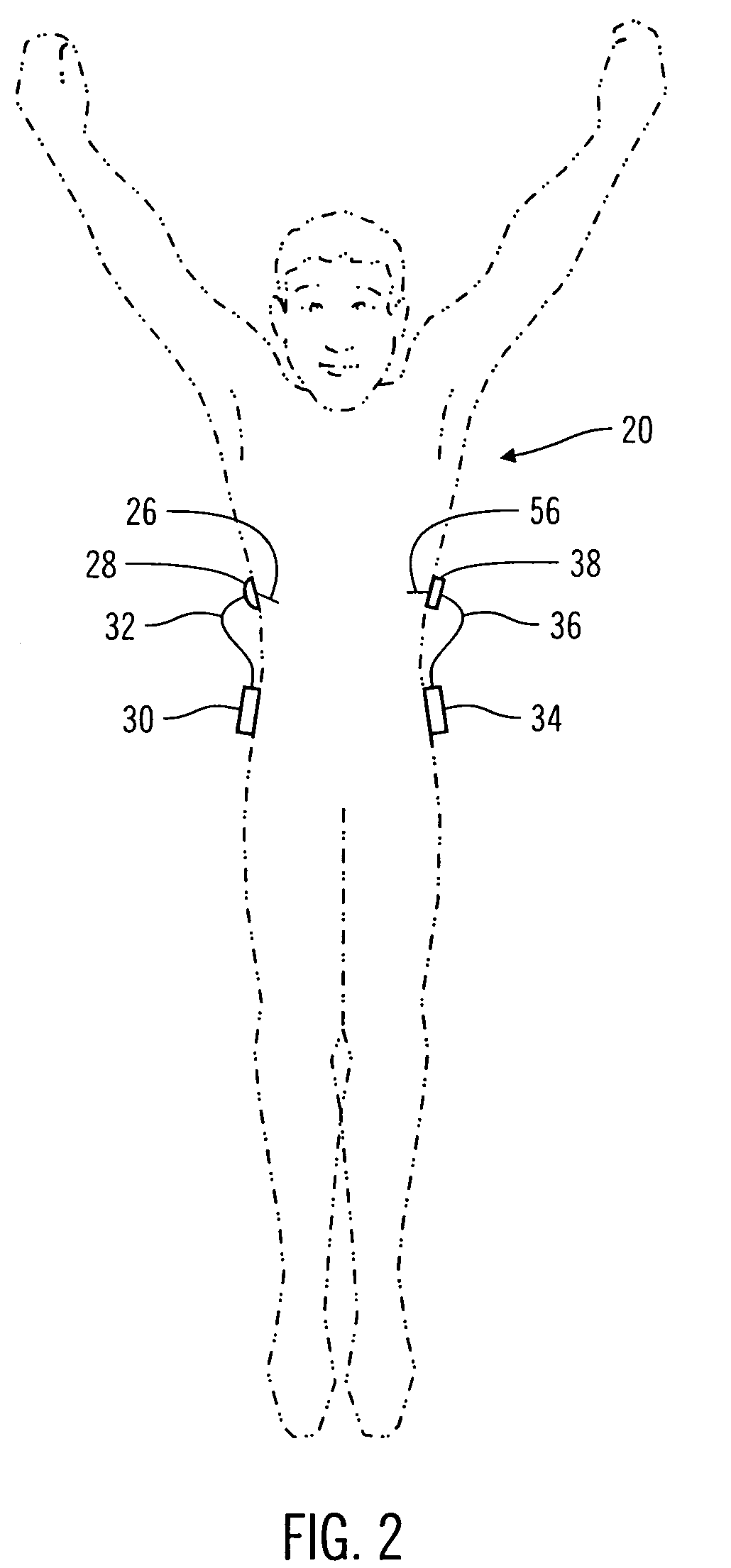

Closed-loop method for controlling insulin infusion

A closed loop infusion system controls the rate that fluid is infused into the body of a user. The closed loop infusion system includes a sensor system, a controller, and a delivery system. The sensor system includes a sensor for monitoring a condition of the user. The sensor produces a sensor signal, which is representative of the condition of the user. The sensor signal is used to generate a controller input. The controller uses the controller input to generate commands to operate the delivery system. The delivery system infuses a liquid into the user at a rate dictated by the commands from the controller. Preferably, the sensor system monitors the glucose concentration in the body of the user, and the liquid infused by the delivery system into the body of the user includes insulin.

Owner:MEDTRONIC MIMIMED INC

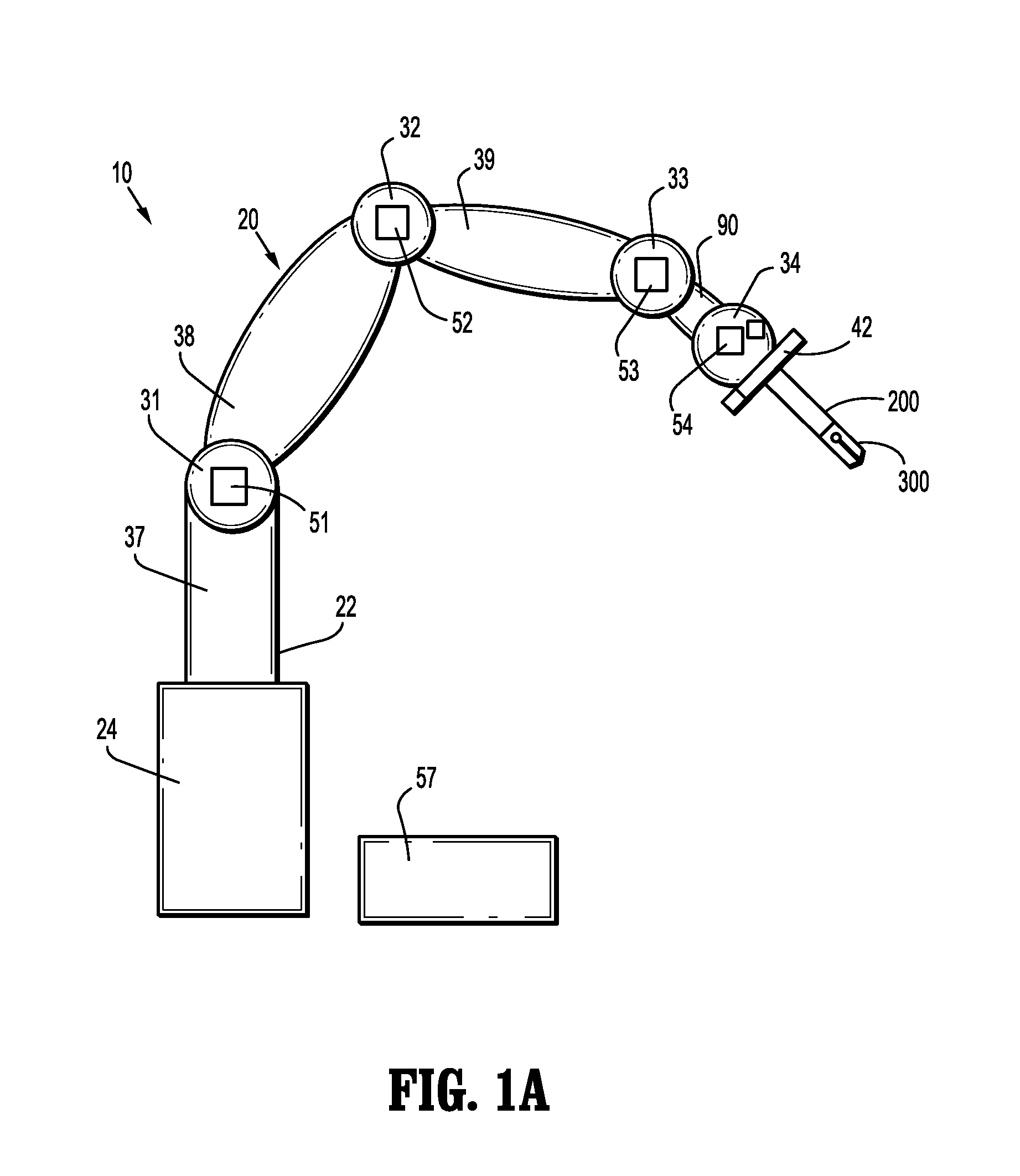

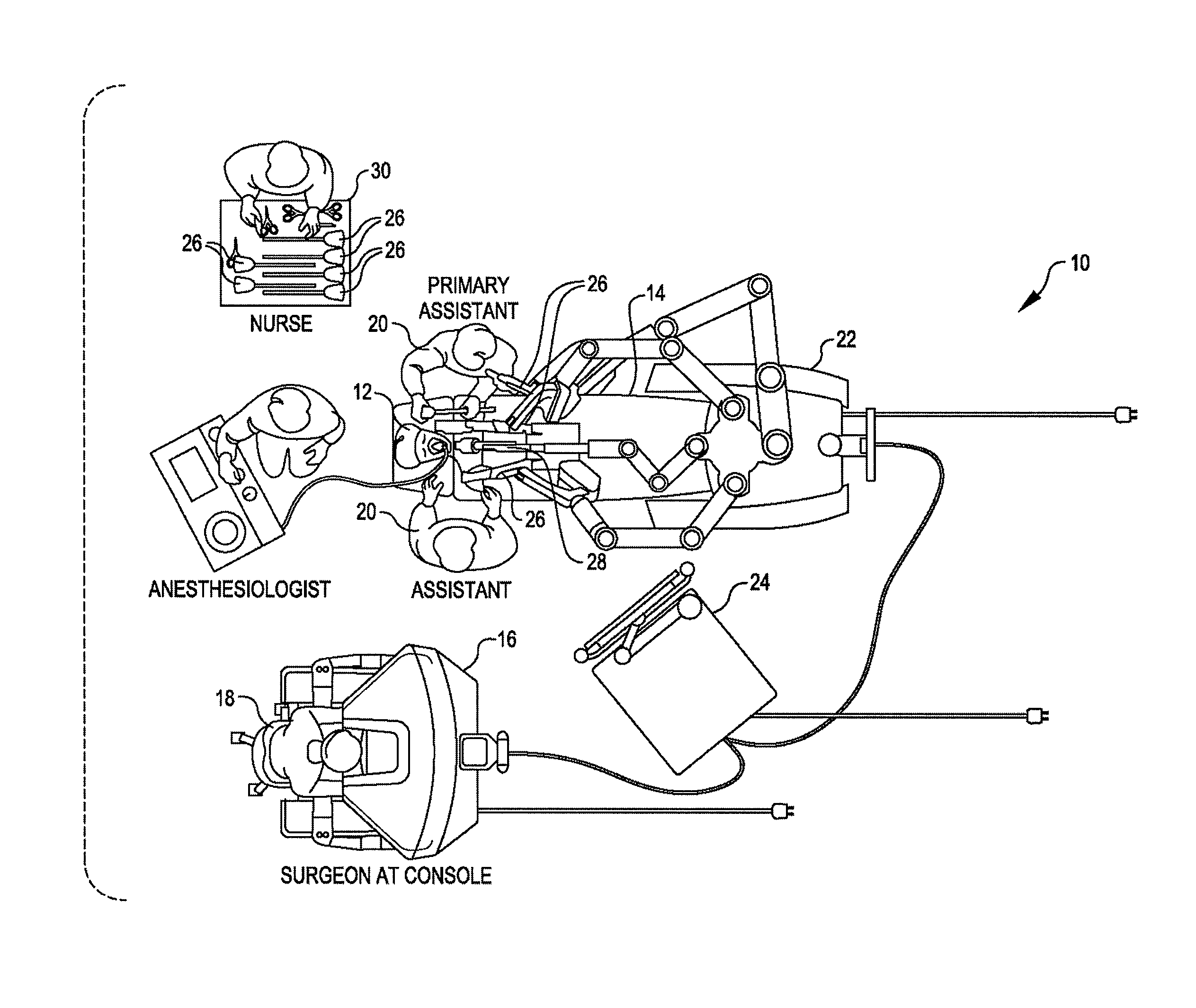

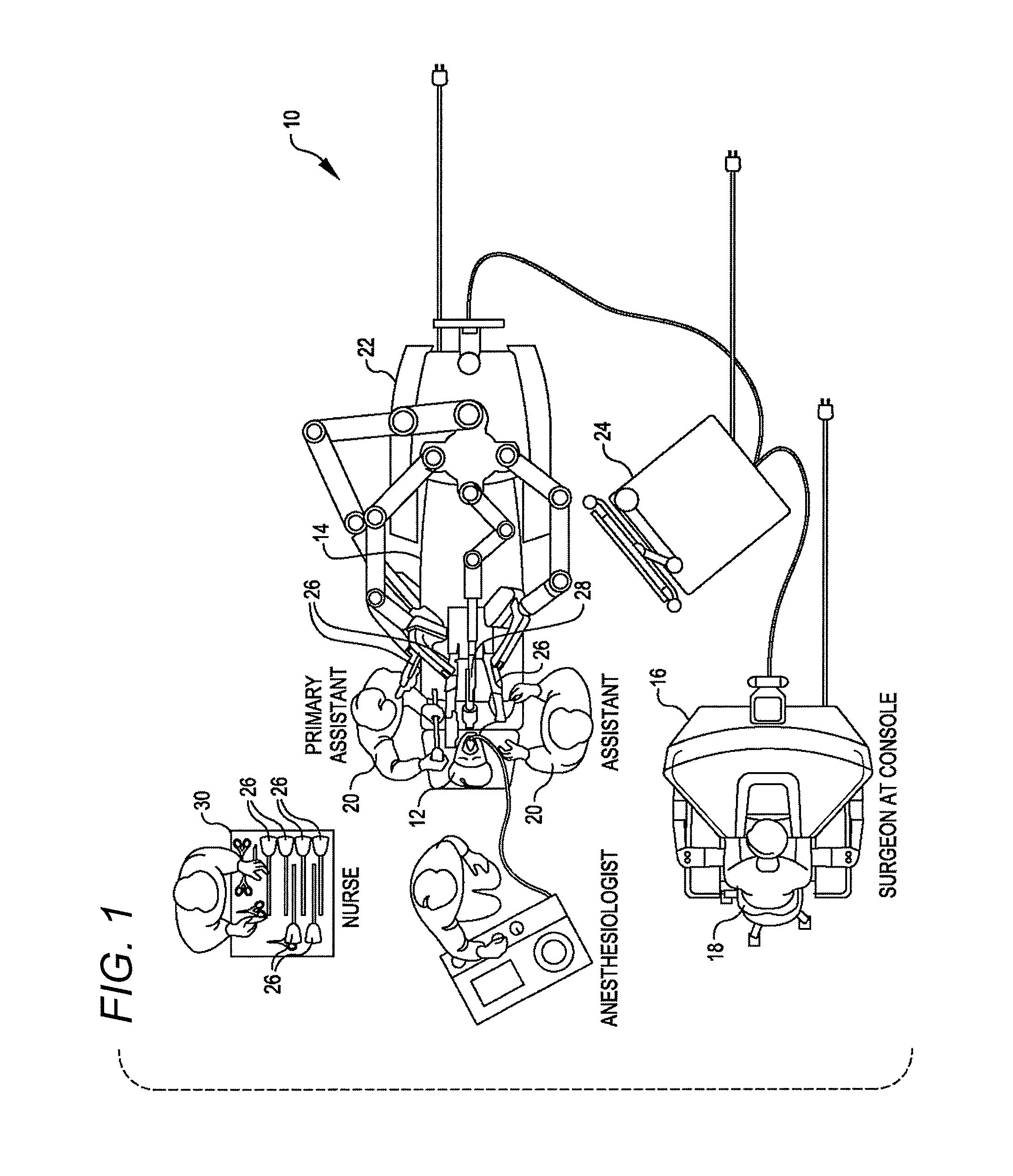

Roll joint and method for a surgical apparatus

A roll joint utilizes at least one tendon guide surface to guide actuator tendons for distal roll off and on their respective drums on a central shaft of the roll joint. The tendon guide surface turns the actuator tendon in an axial direction in a more compact space than might be required for a pair of pulleys, while using fewer parts with larger features more easily formed on a small scale.

Owner:INTUITIVE SURGICAL OPERATIONS INC

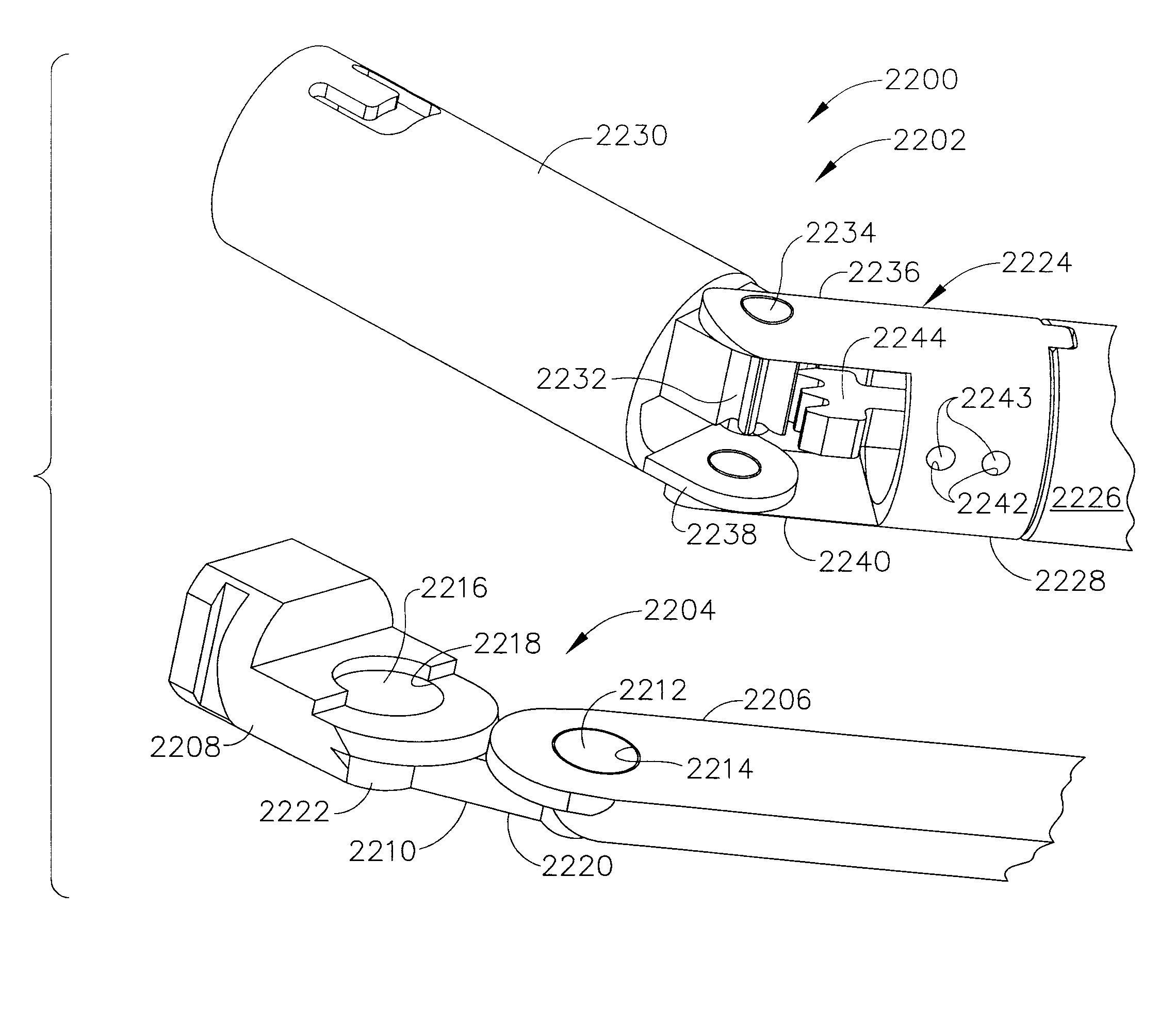

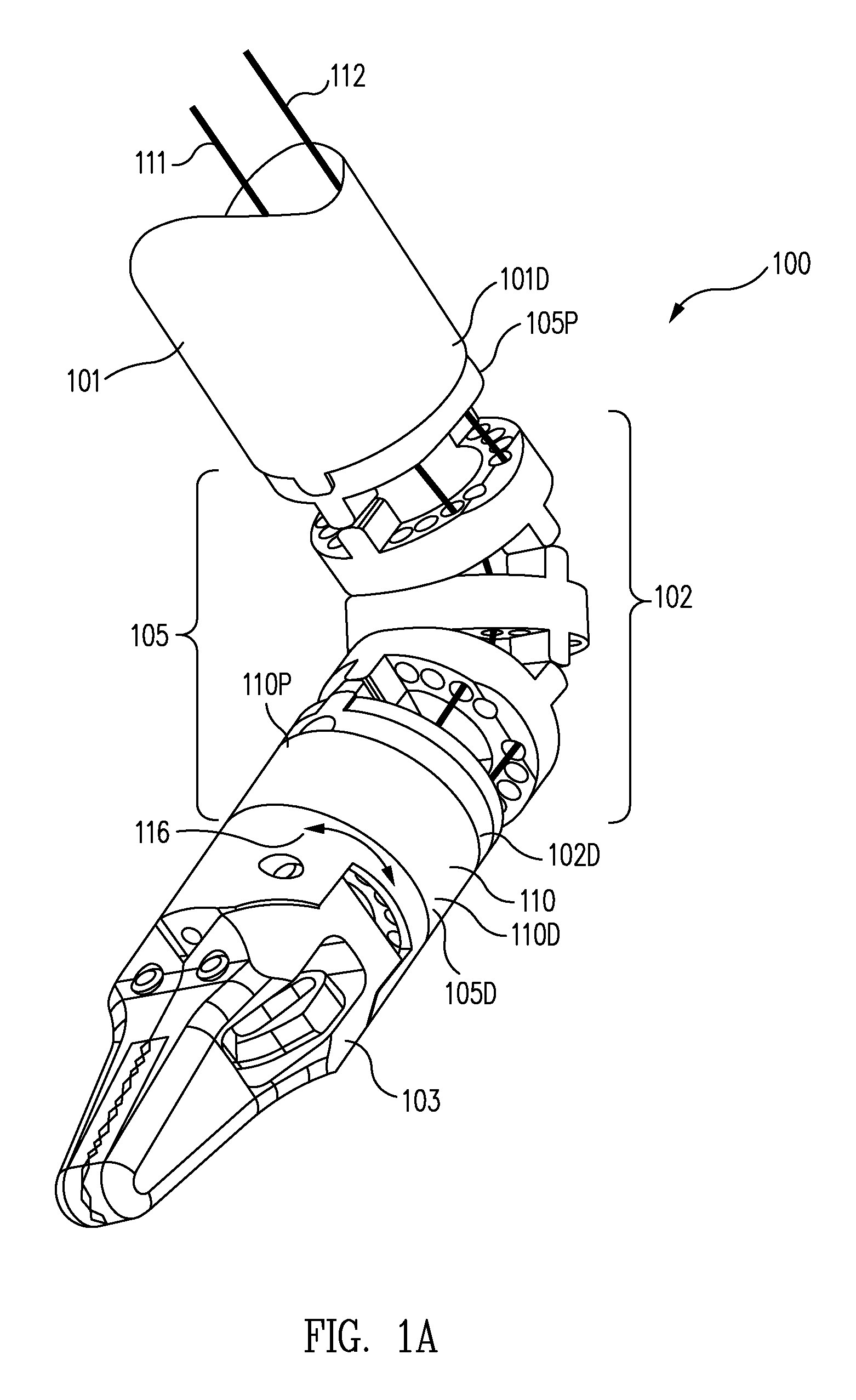

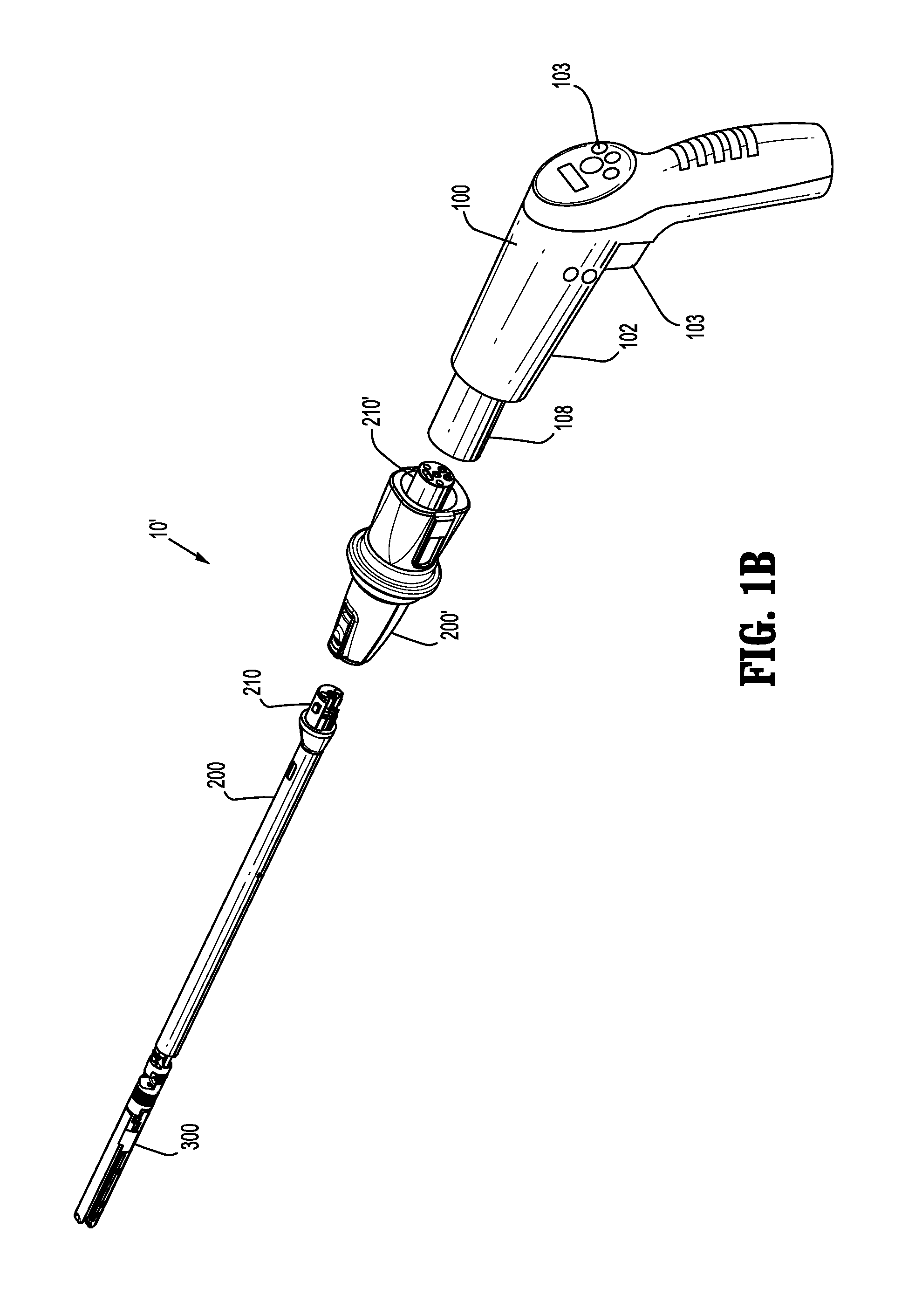

Medical device adapter with wrist mechanism

A surgical device adapter for coupling an end effector to a surgical device includes: a proximal joint housing that is couplable to the surgical device; a middle joint housing that is pivotally coupled to the distal end of the proximal joint housing; and a distal joint housing that is pivotally coupled to the distal end of the middle joint housing. The middle joint housing is pivotable about a first pivot axis defined between the proximal joint housing and the middle joint housing. The distal joint housing is couplable to the end effector and pivotable about a second pivot axis defined between the middle joint housing and the distal joint housing, the second pivot axis being transverse to the first pivot axis.

Owner:TYCO HEALTHCARE GRP LP

Method and device for ergonomically and ambidextrously operable surgical device

A handheld surgical device includes a multi-position throttle, rotatably attached to the body of the device, to allow for ambidextrous positioning of a motor speed control lever. The motor speed control lever may interact with a speed control sensor in the body of the device capable of detecting the actuation level of the motor speed control lever in any one of two or more positions.

Owner:MICROAIRE SURGICAL INSTR

Surgical instrument motor pack latch

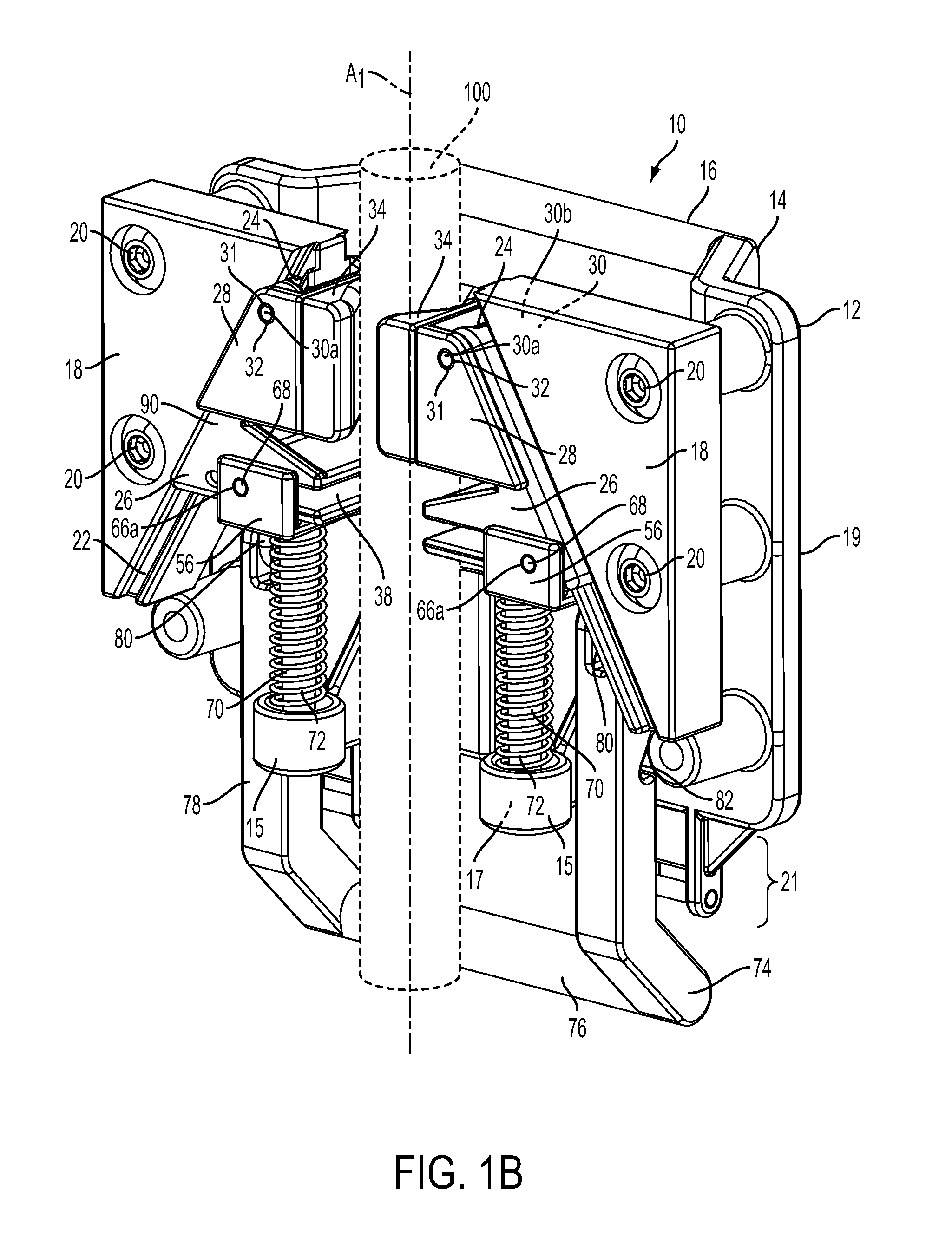

ActiveUS8912746B2Avoid separationProgramme-controlled manipulatorComputer controlEngineeringTorsion spring

A latch mechanism selectively retains a first assembly to a second assembly. The first and second assemblies are configured for sliding engagement along an engagement axis. The latch mechanism includes a latch shaft mounted to the first assembly to rotate about a latch shaft axis, a torsion spring to bias the latch shaft relative to the first assembly, and a transverse latch member coupled with the second assembly. The latch mechanism is configured to automatically latch in response to the first assembly being pushed toward the second assembly. The transverse latch member interacts with the latch shaft to rotate the latch shaft in a first direction in response to movement of the first assembly toward the second assembly. Further motion of the first assembly toward the second assembly results in rotation of the latch shaft opposite to the first direction into a retention configuration that retains the transverse latch member.

Owner:INTUITIVE SURGICAL OPERATIONS INC

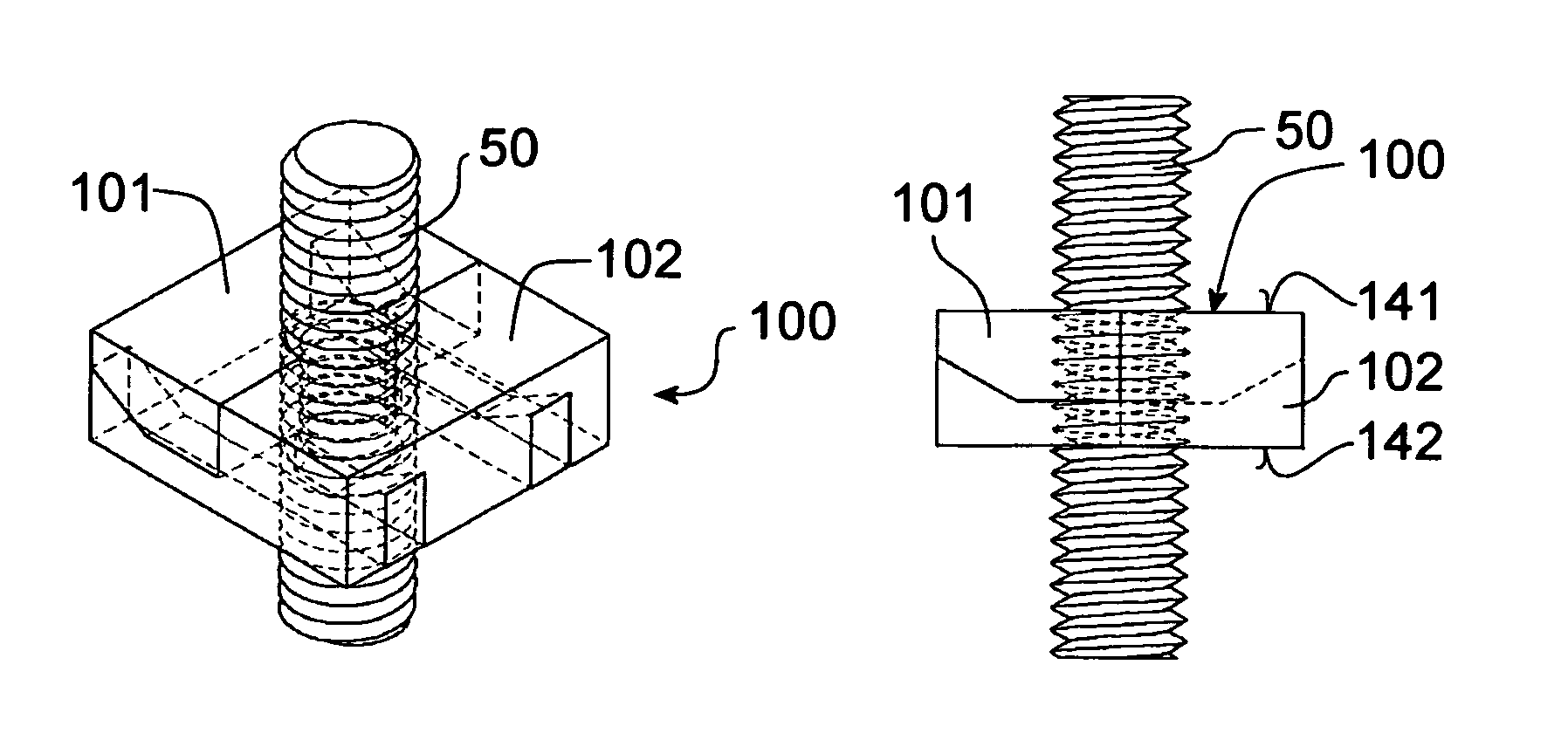

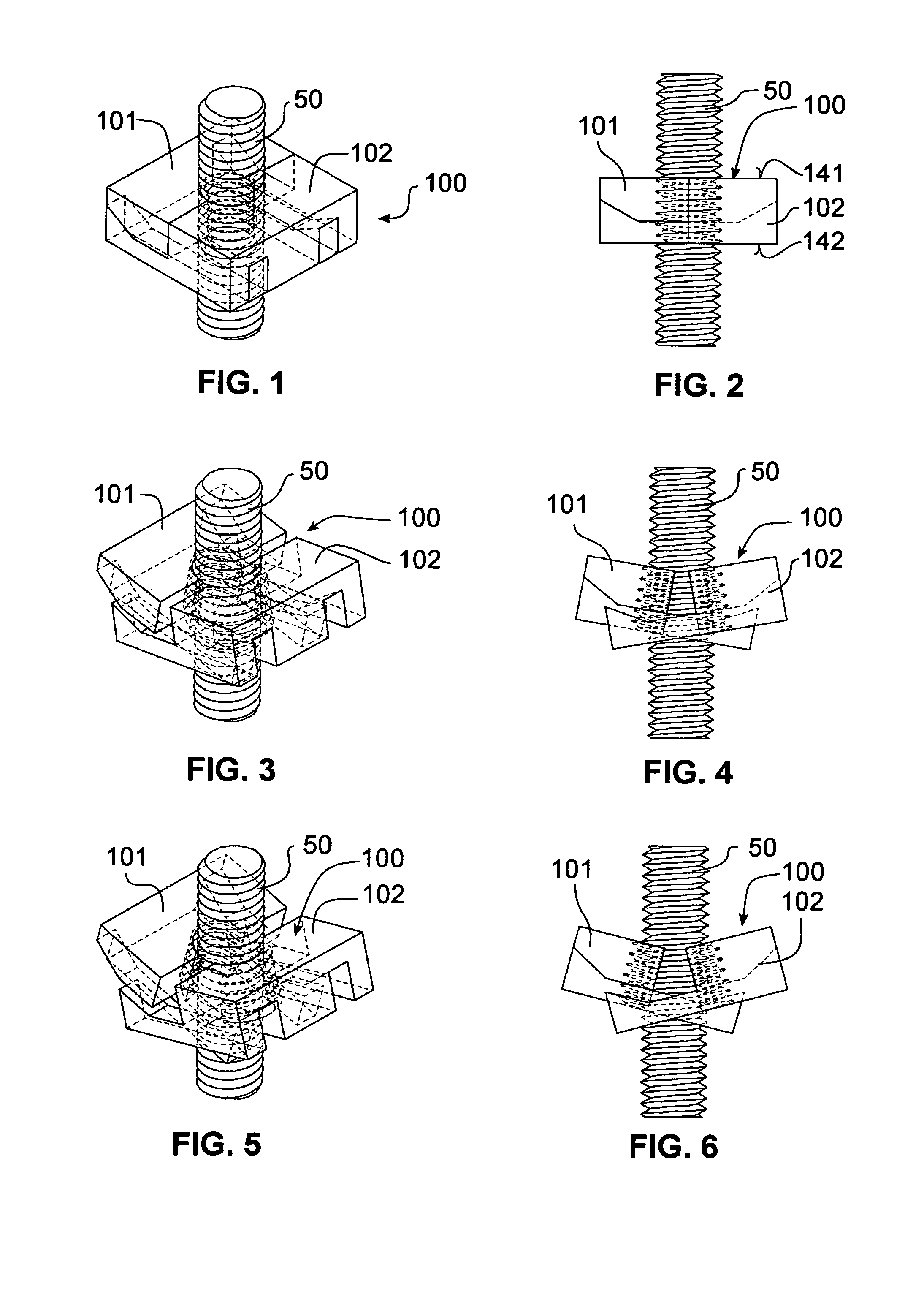

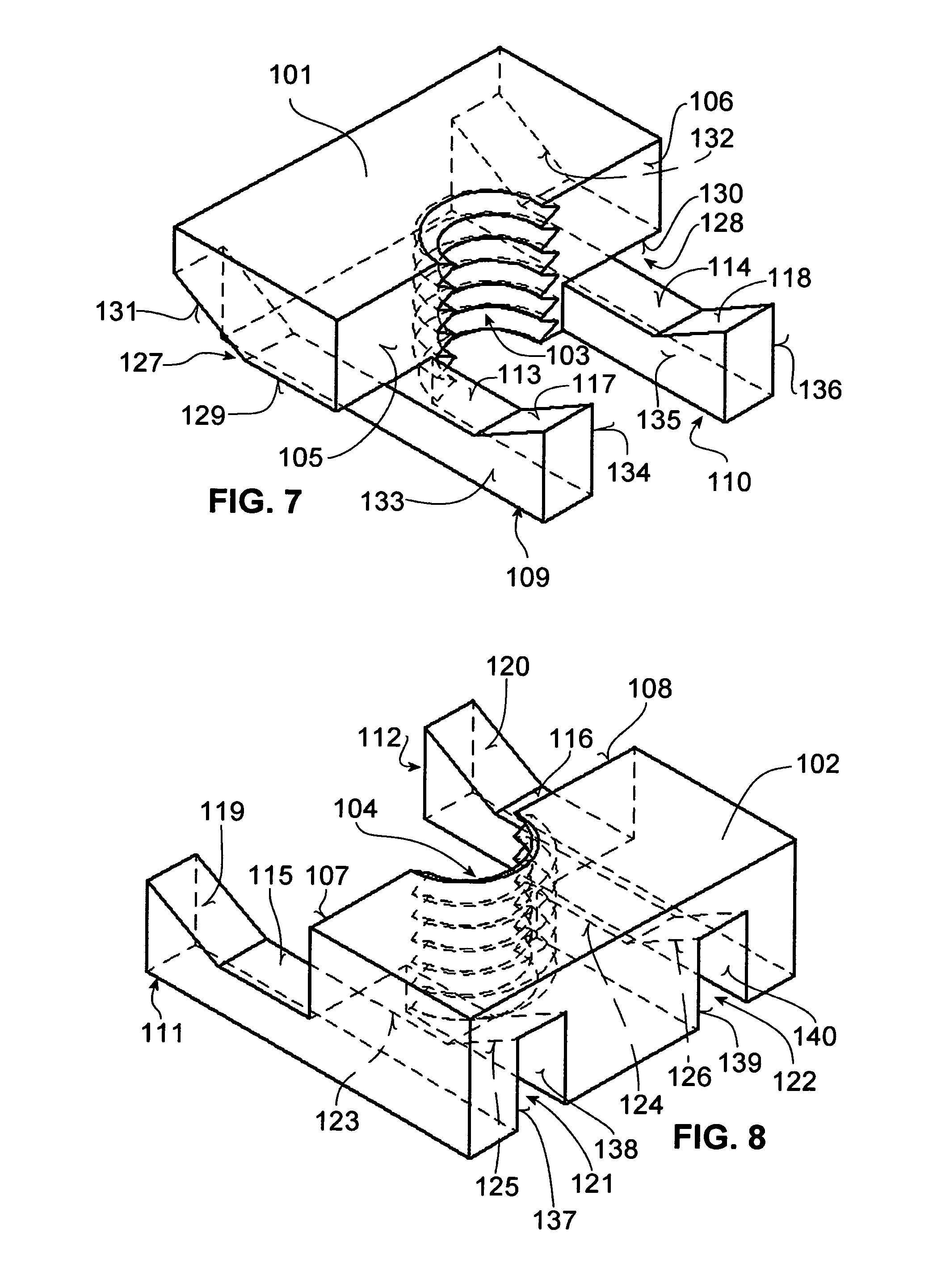

Nut having at least two parts

ActiveUS7934896B2Avoid cloggingIncrease the number ofDrilling rodsNutsRelative displacementEngineering

A nut includes an internal thread and at least two parts, each of the parts having a section of the internal thread which can be pushed onto an external thread in the radial direction. The parts may have connecting elements which interact and permit a relative displacement of the parts in a direction running radially to the axis of the internal thread into a position of use. The connecting elements may have guide surfaces which are inclined at an angle to the plane running radially to the axis of the internal thread and guide the parts in a rotational movement about an axis of rotation running transversely to the axis. A part may have a locking arm with a guide surface only on one side which produces the rotational movement during the displacement of the parts and bears against a complementary guide surface of the other part.

Owner:SCHNIER DIETMAR

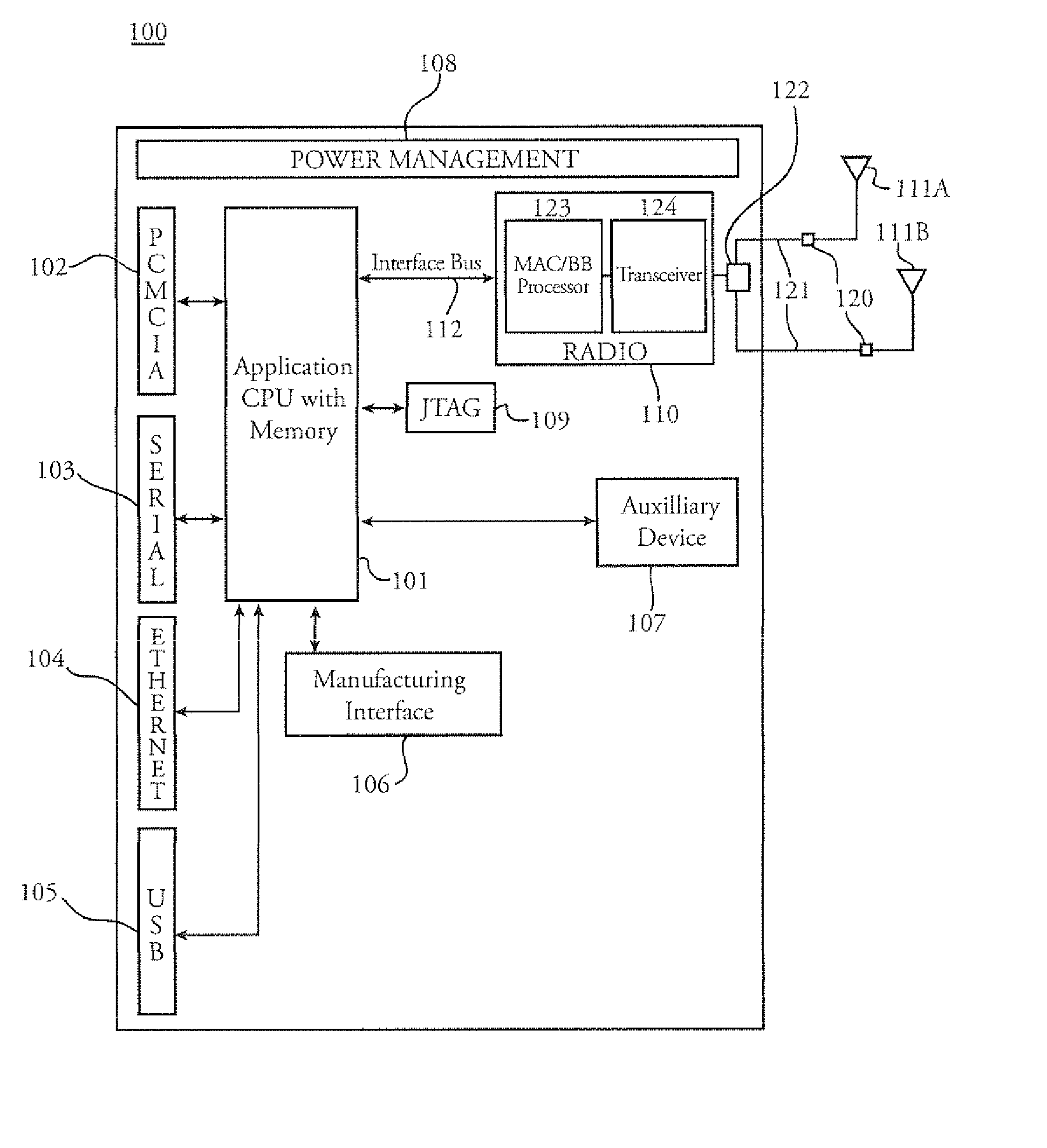

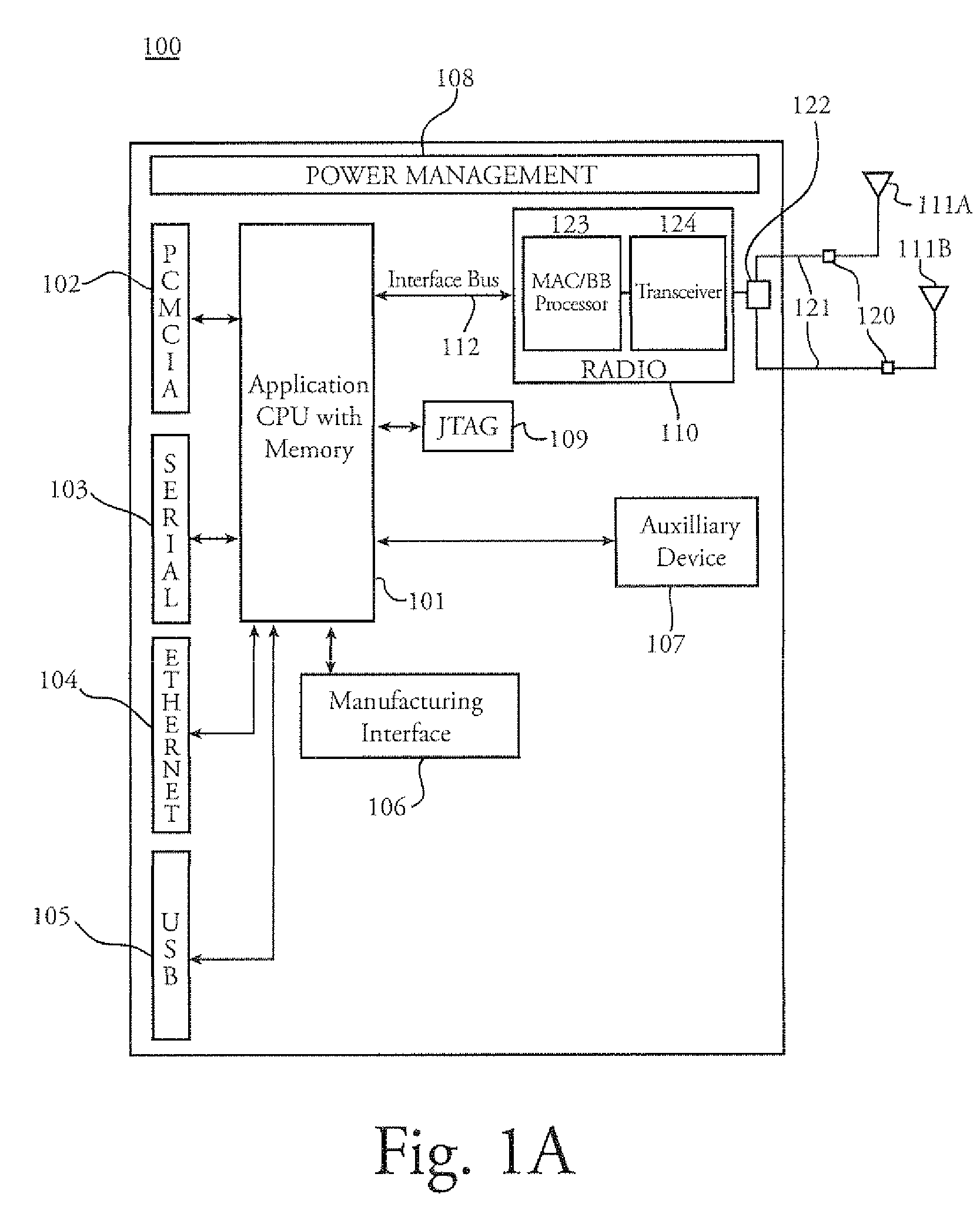

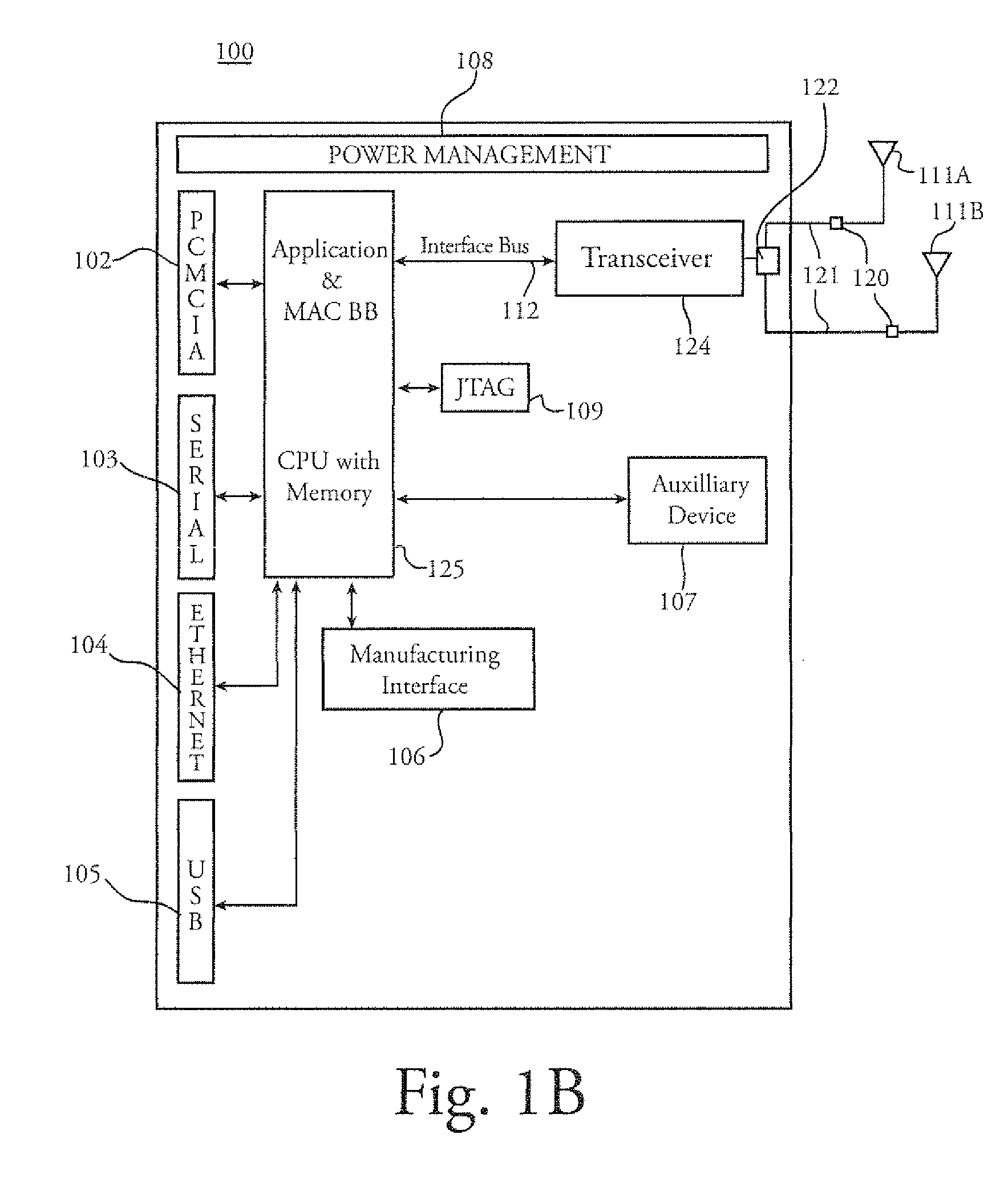

Medical device wireless adapter

The invention relates generally to a medical device wireless adapter, and more particularly, to a module that adapts an existing legacy or newly designed medical device to a healthcare provider's wireless infrastructure.

Owner:WELCH ALLYN INC

Implants formed of shape memory polymeric material for spinal fixation

ActiveUS20050033295A1Absorb energySuture equipmentsInternal osteosythesisJoint arthrodesisImplanted device

This invention relates to a orthopedic implant that comprises a shape memory polymeric material. The orthopedic implant can be fabricated or molded in a desired configuration selected to provide support or tension to bony structures. Examples of implantable devices include spinal rods, bone plates, and bone fixation cords. The orthopedic implant can be deformed to a second configuration different from the first configuration either prior to implantation or after implantation. When desired, the shape memory polymeric material can be induced to revert to it original molded configuration. This can compress the attached bony structure and / or promote arthrodesis.

Owner:WARSAW ORTHOPEDIC INC

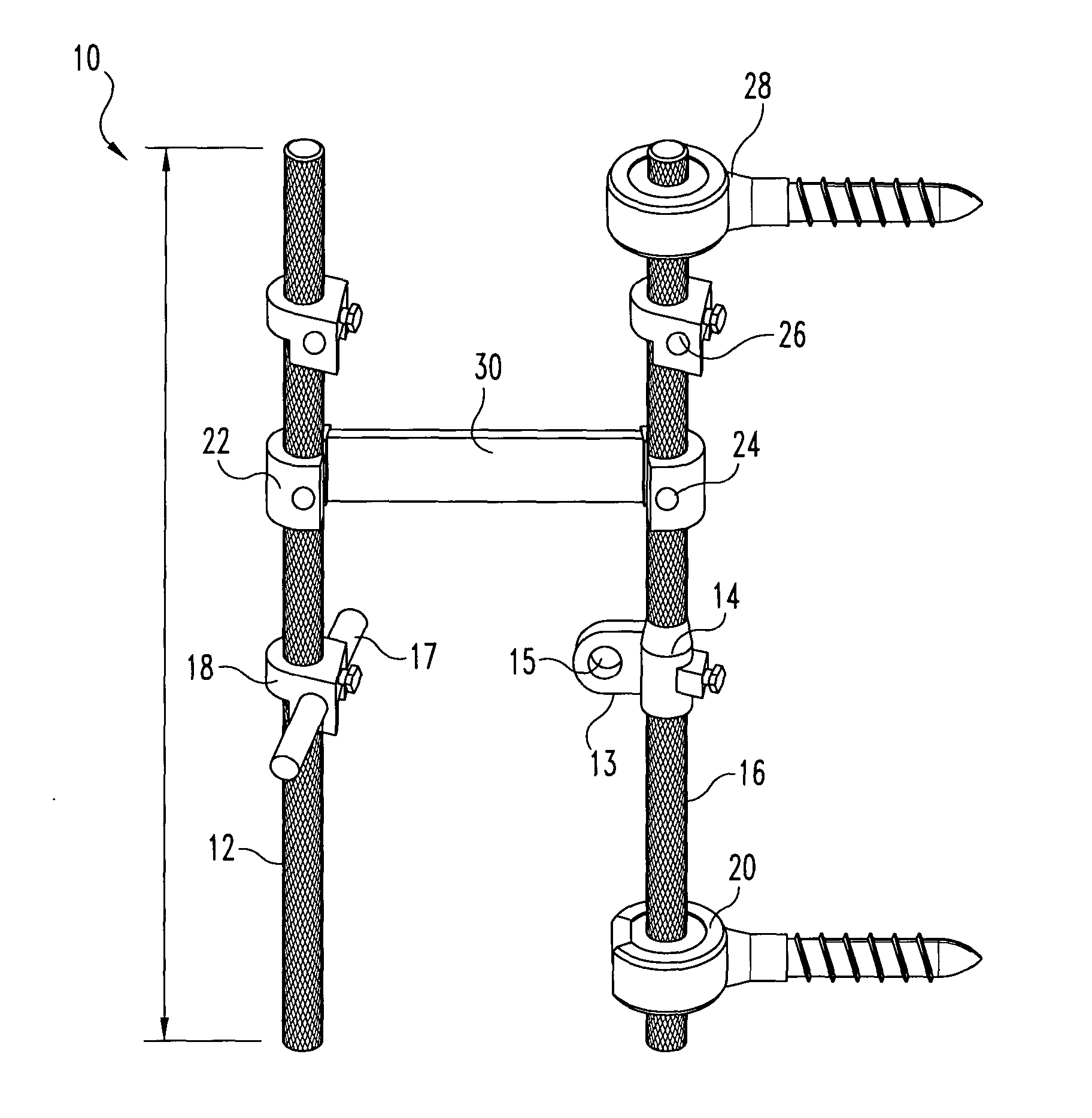

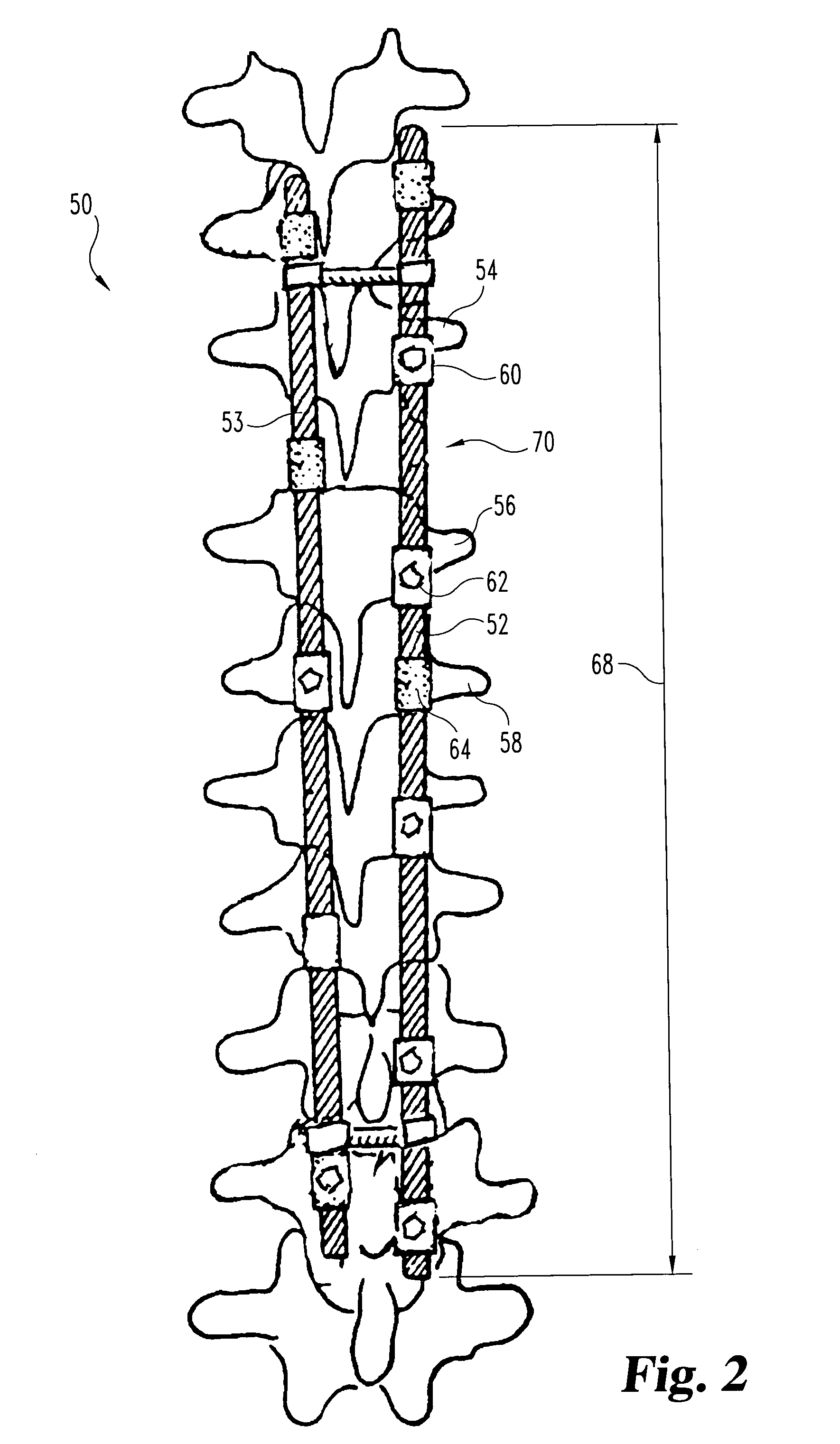

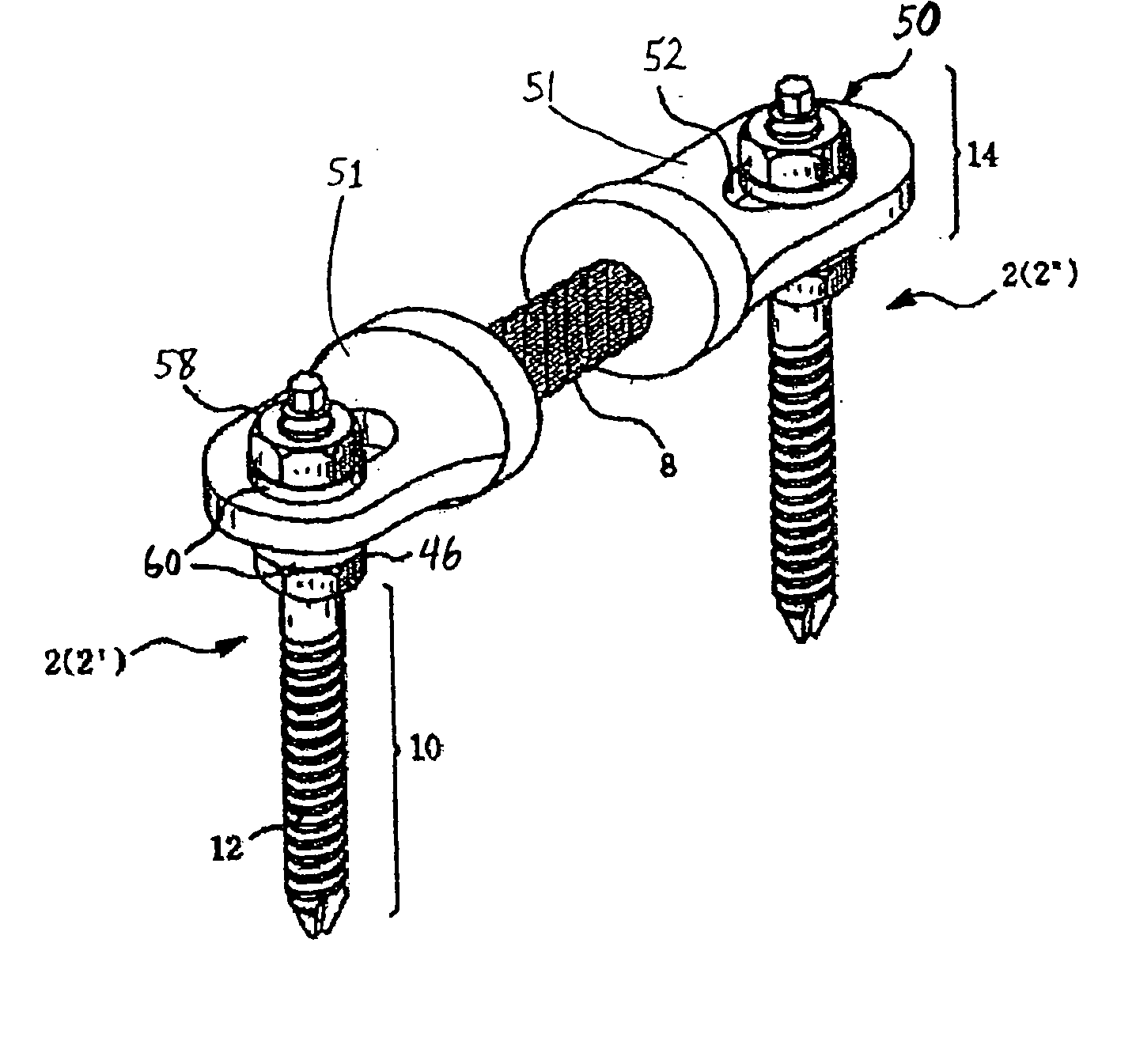

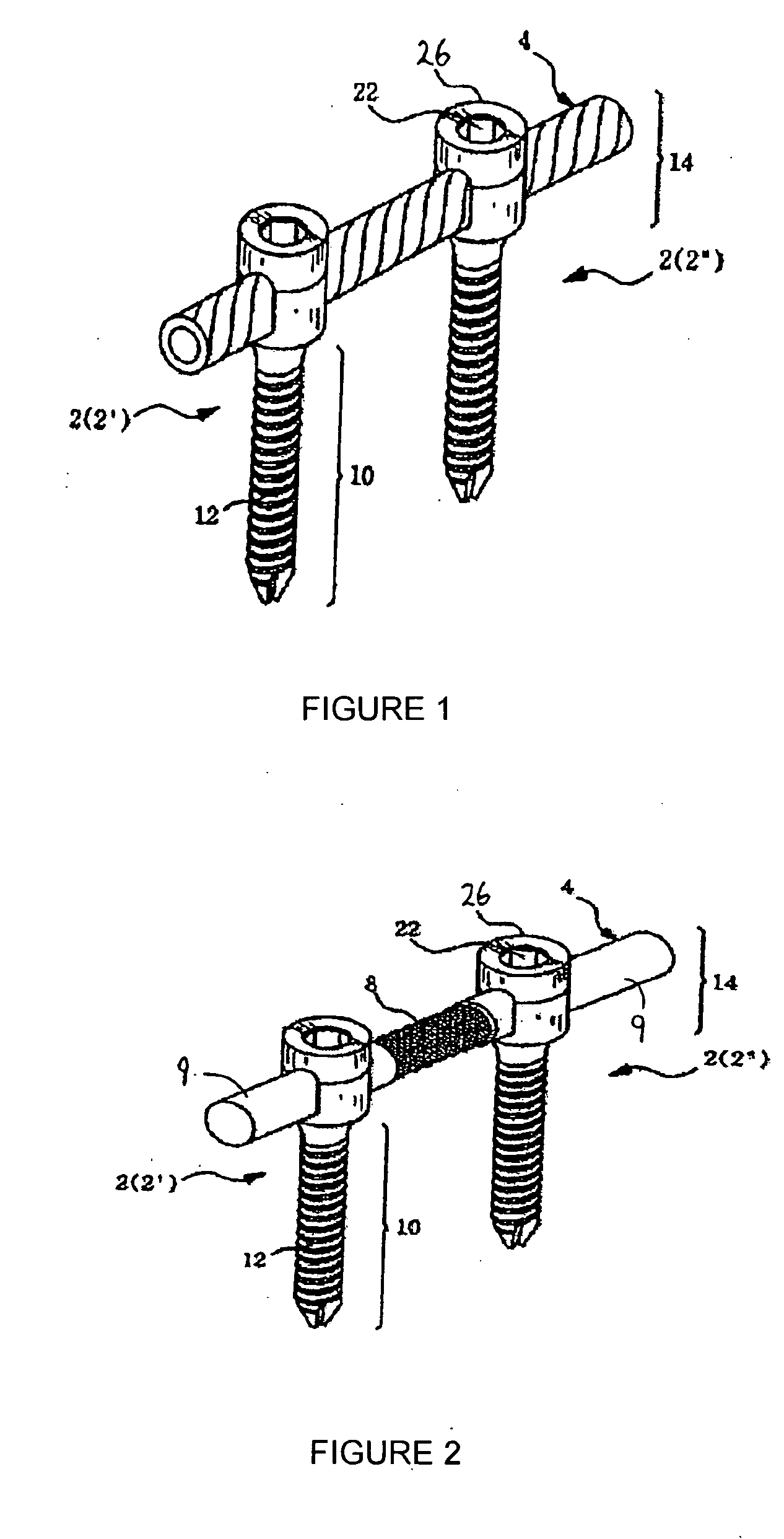

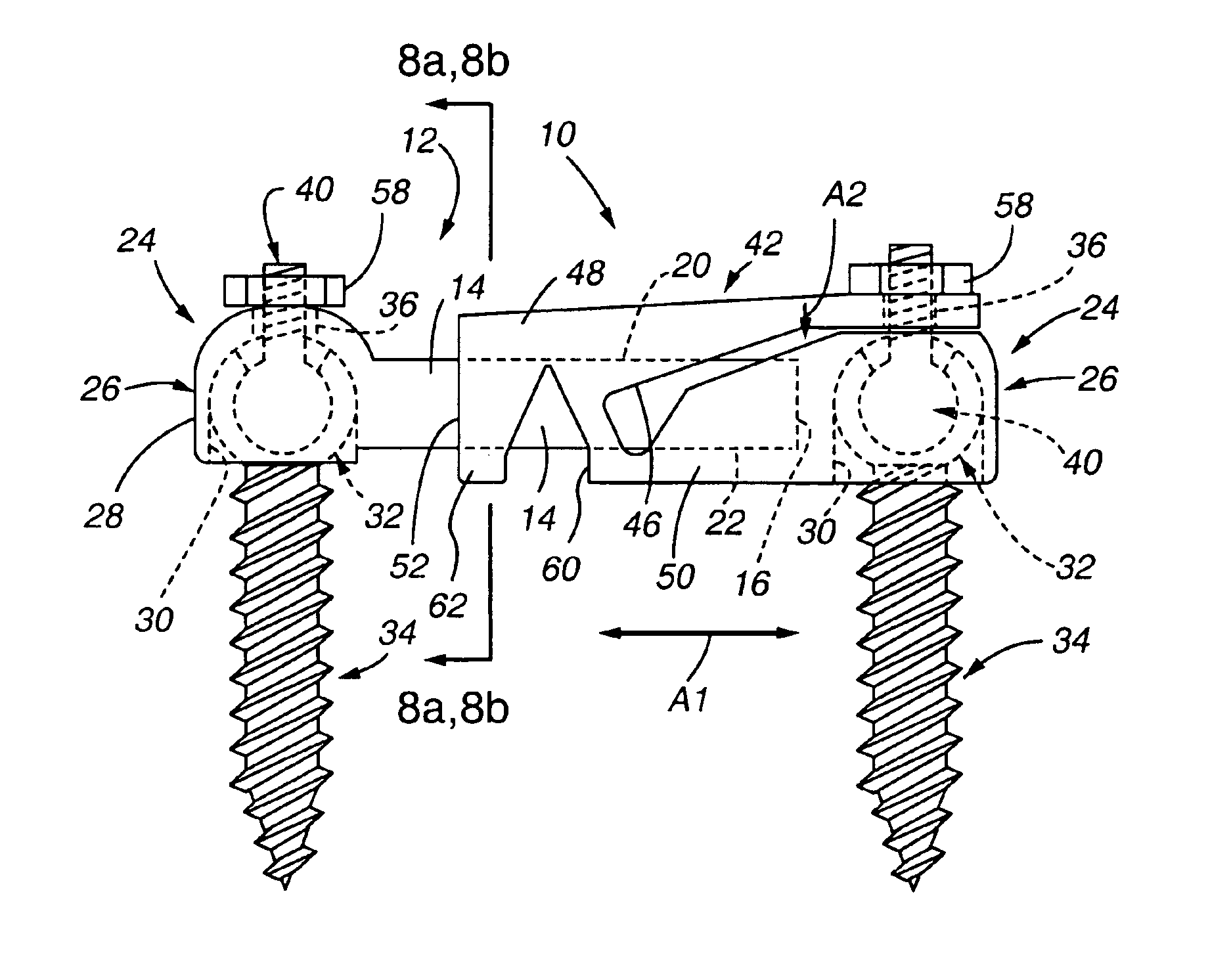

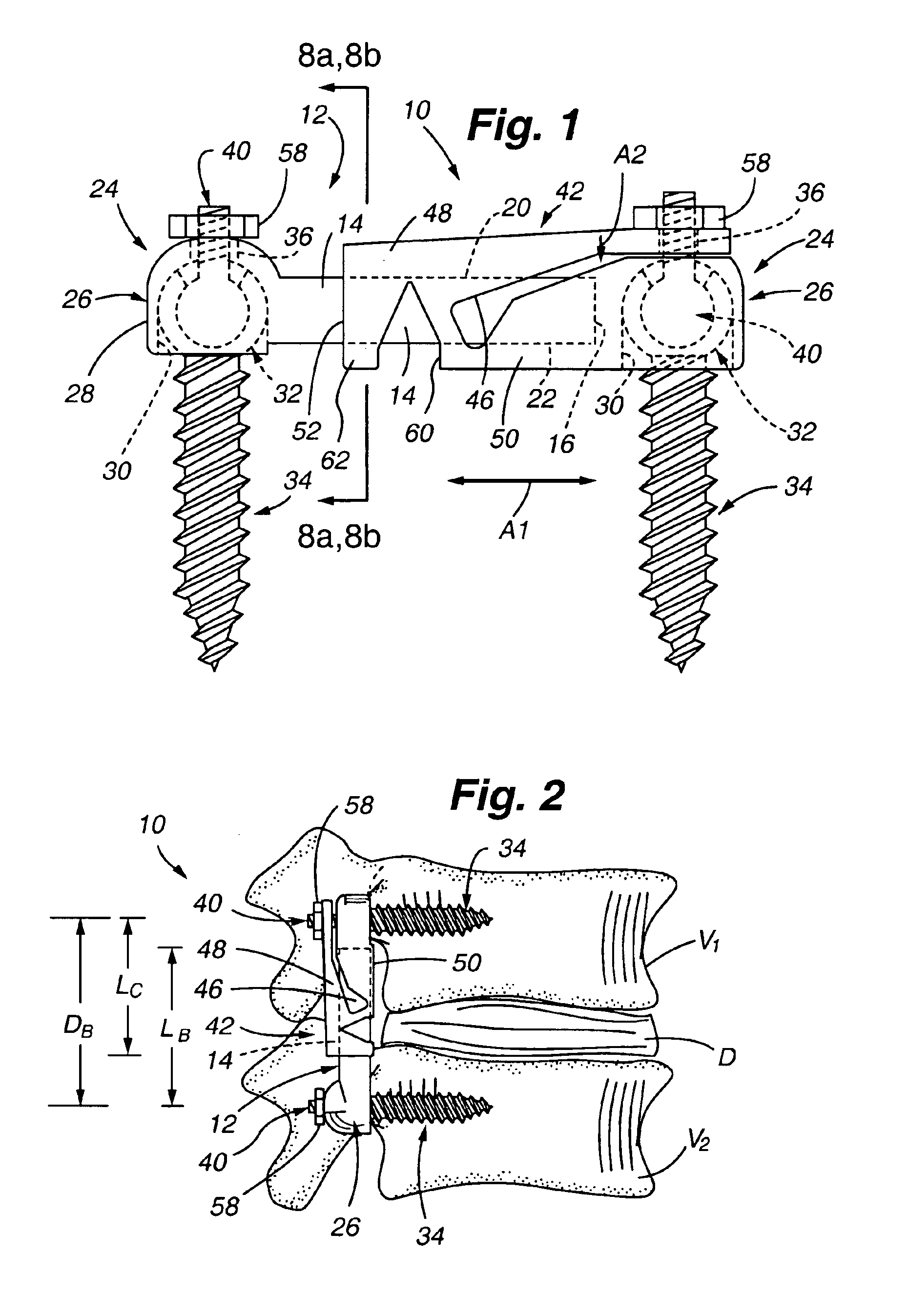

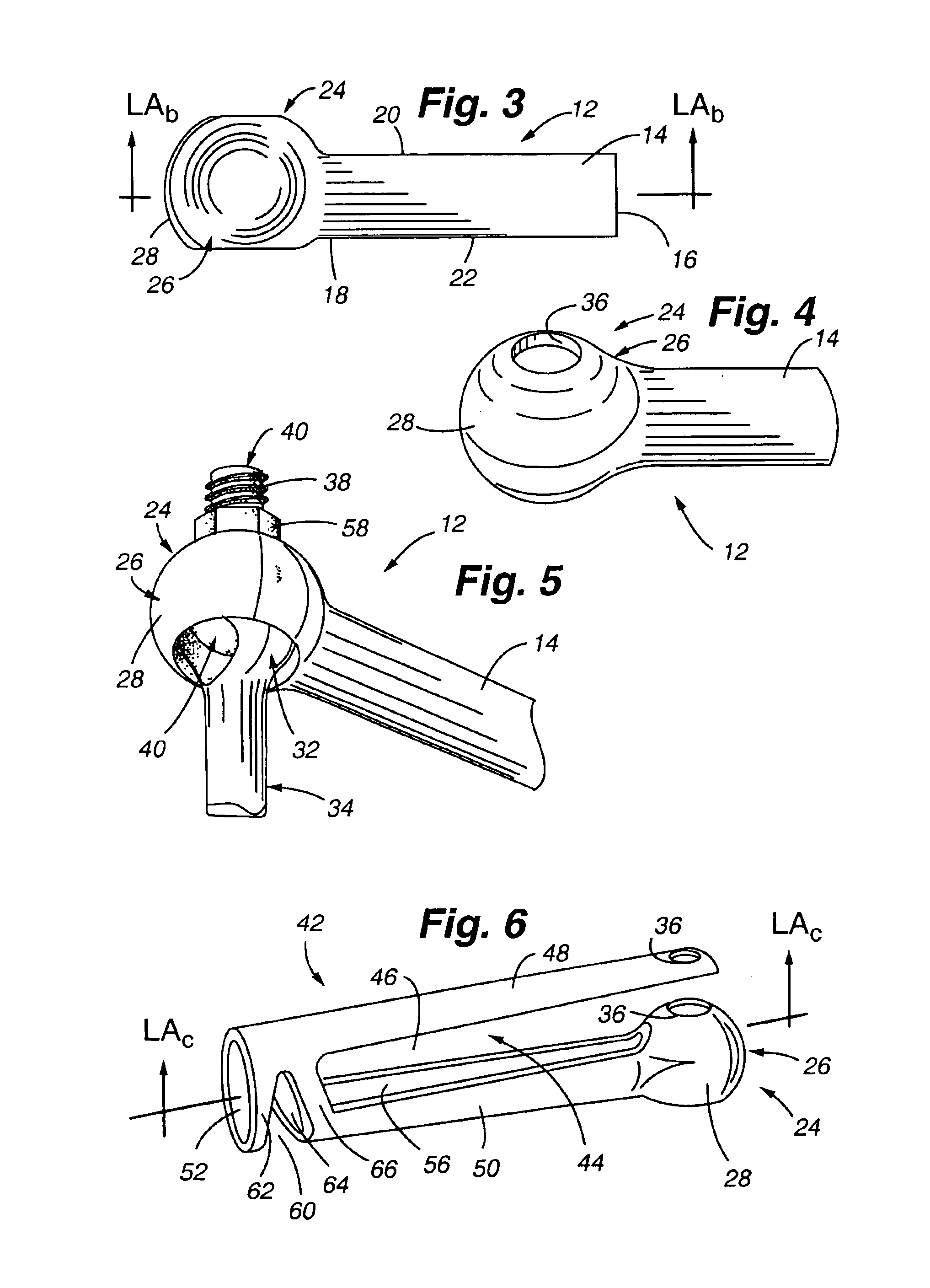

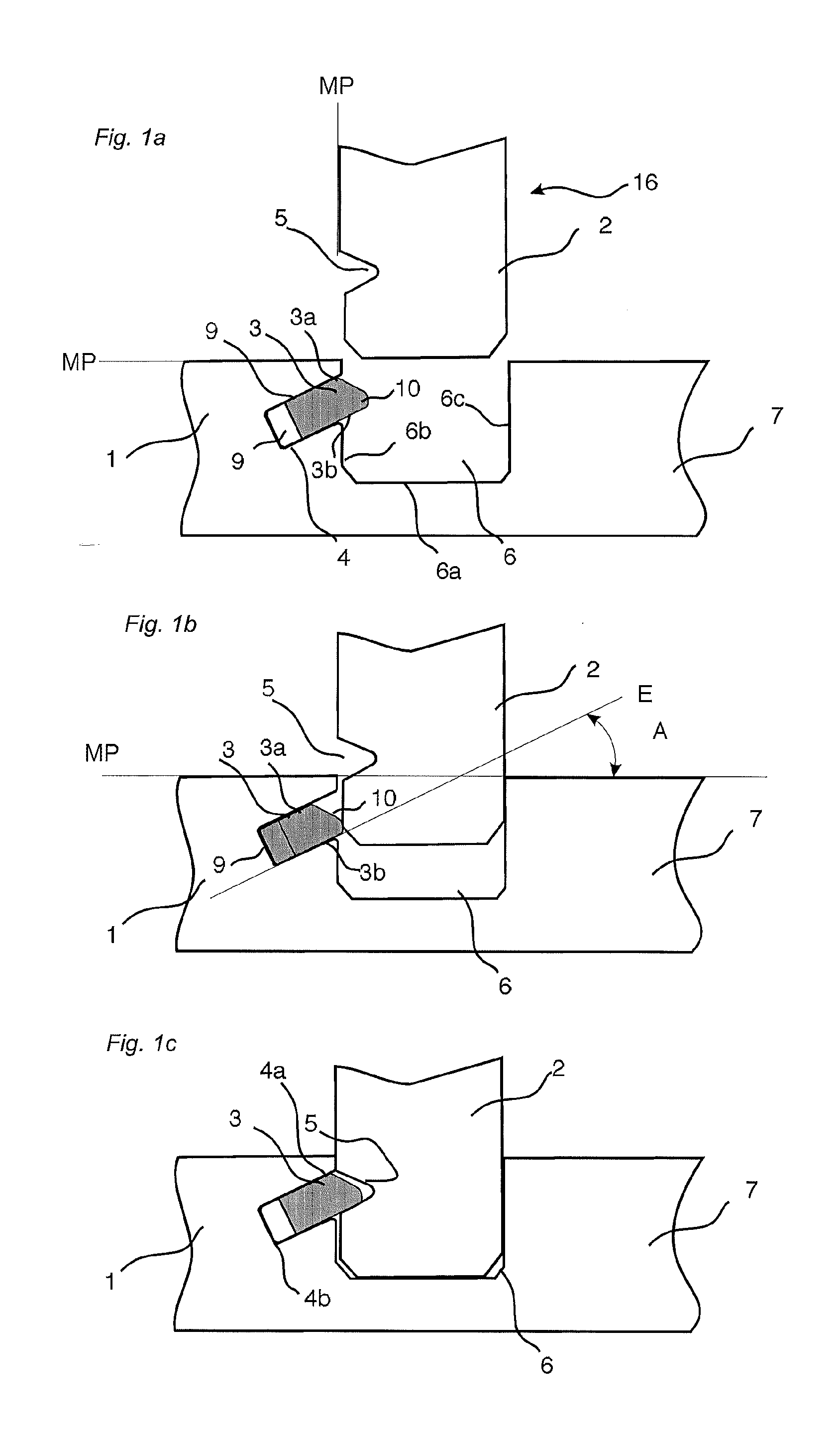

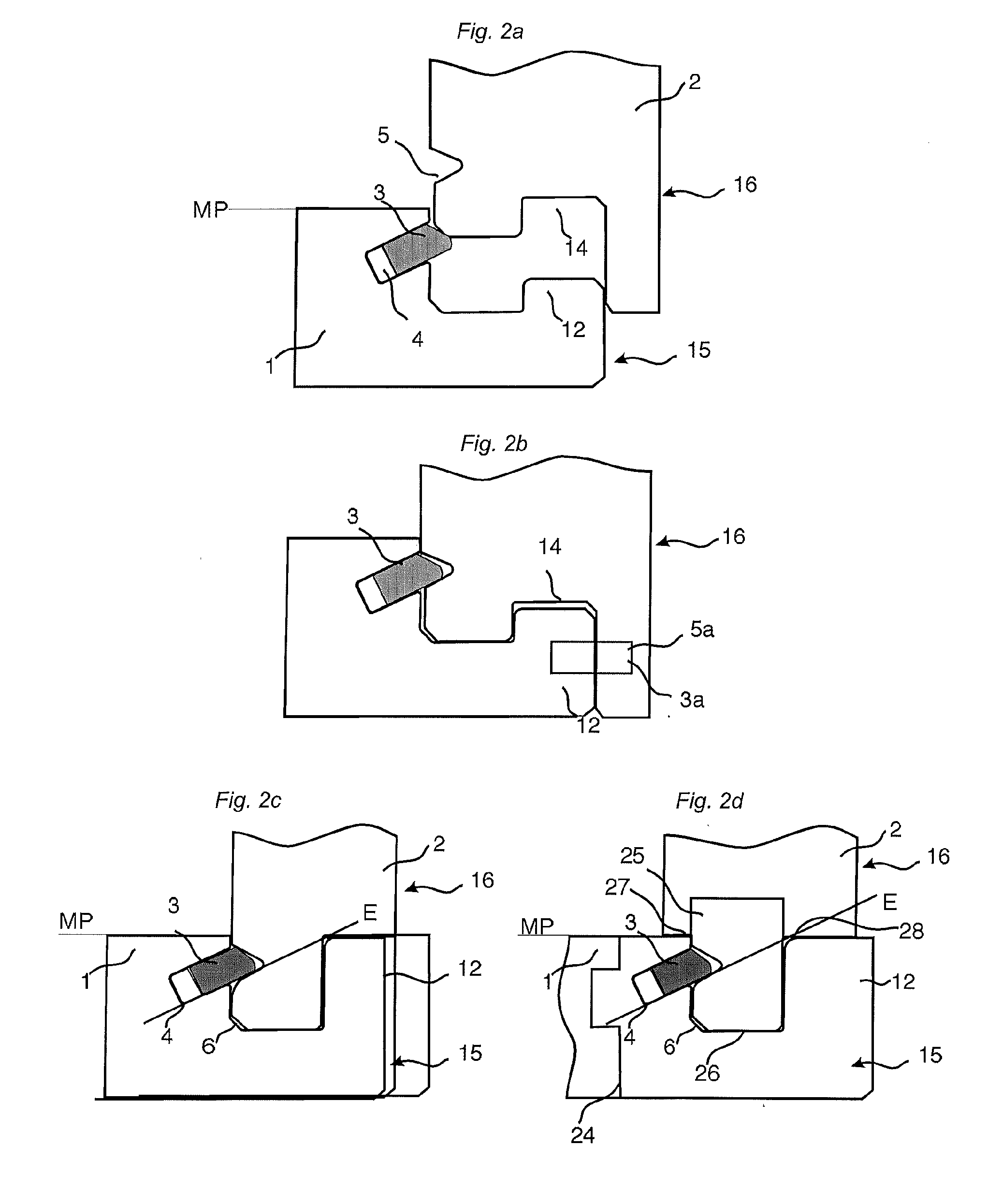

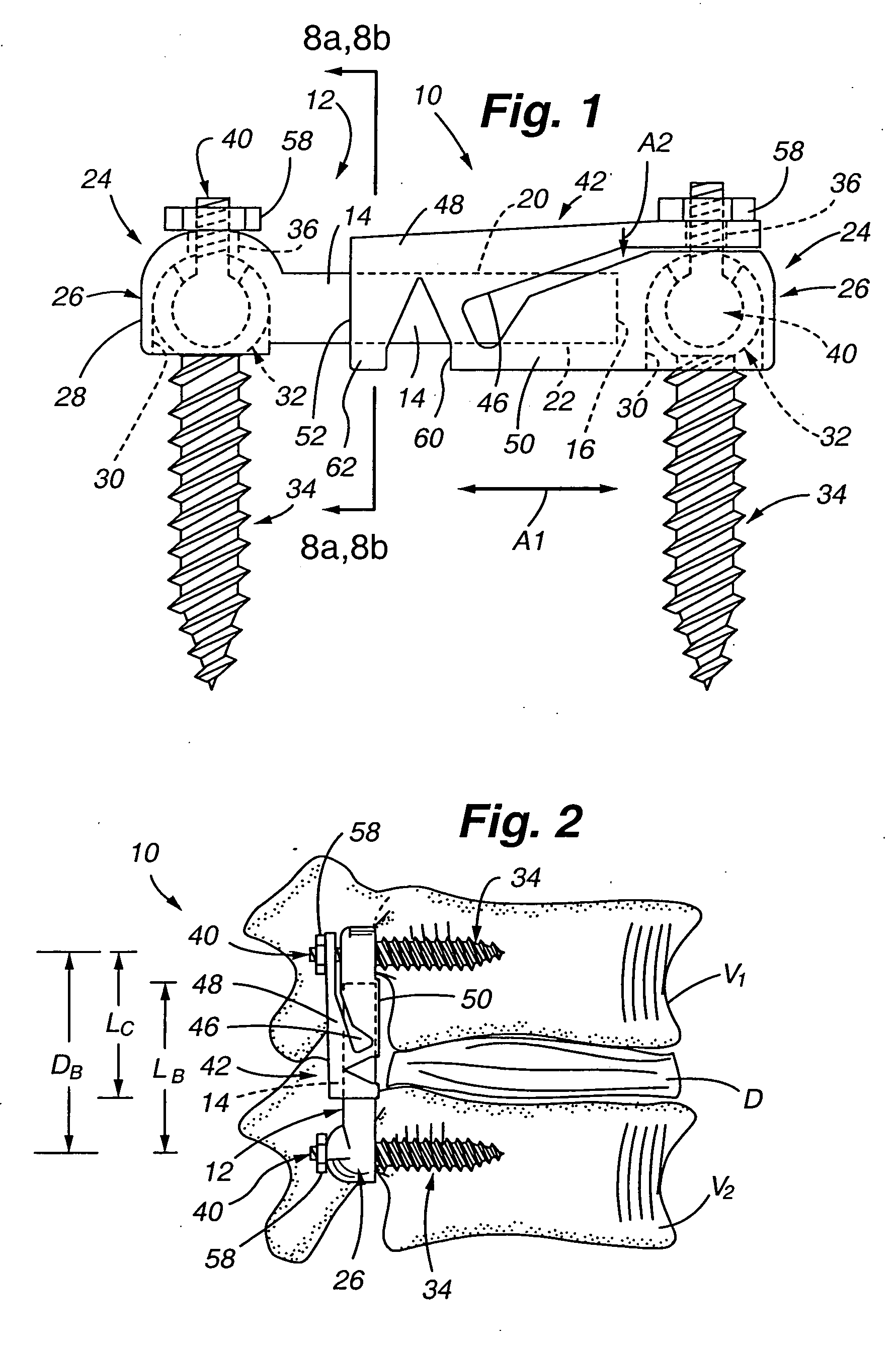

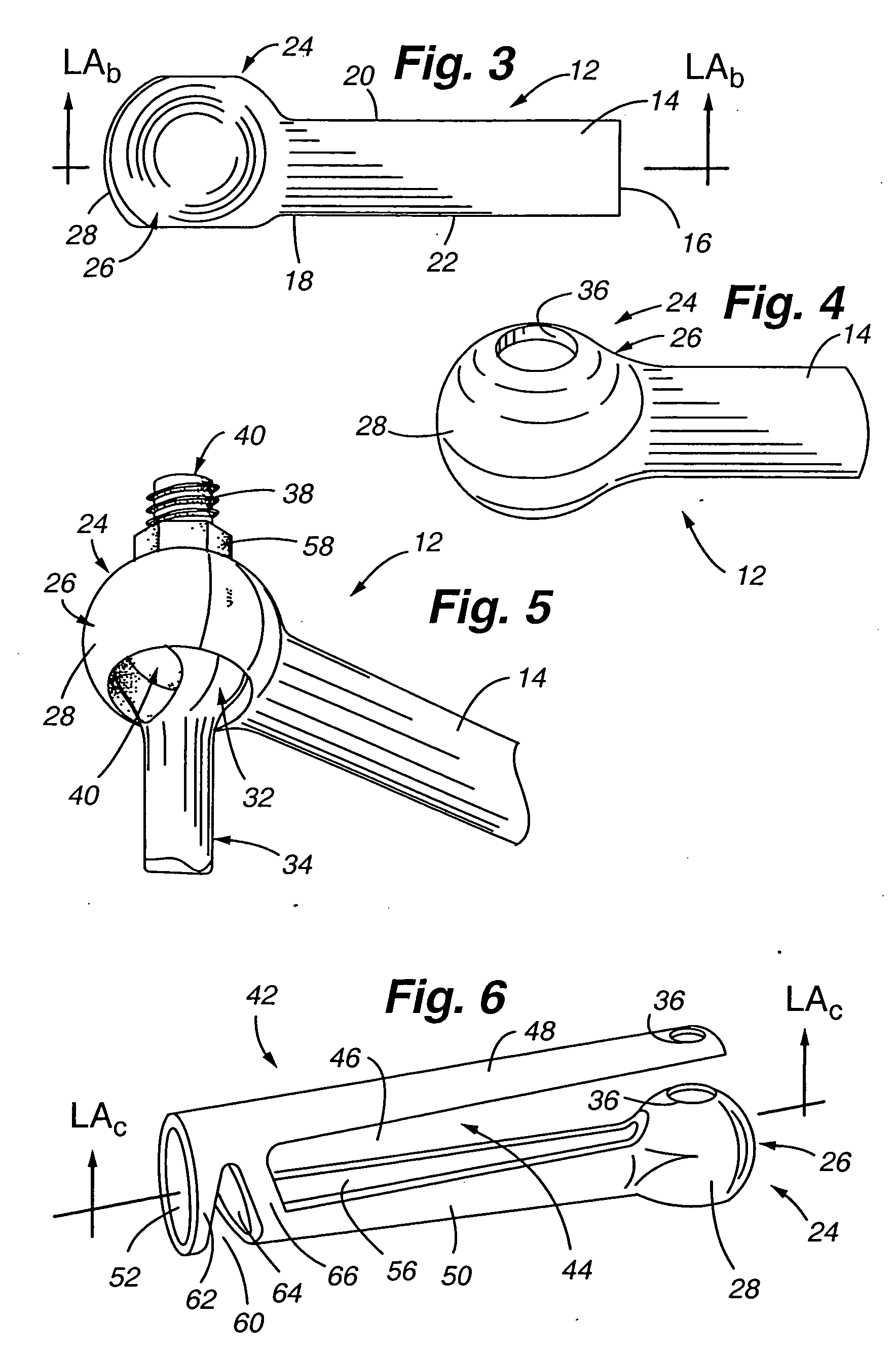

Method and apparatus for flexible fixation of a spine

ActiveUS20050124991A1Easy constructionSimple designInternal osteosythesisCannulasSpinal columnCoupling

A flexible spinal fixation device having a flexible metallic connection unit for non-rigid stabilization of the spinal column. In one embodiment, the fixation device includes at least two securing members configured to be inserted into respective adjacent spinal pedicles, each securing member each including a coupling assembly. The fixation device further includes a flexible metal connection unit configured to be received and secured within the coupling assemblies of each securing member so as to flexibly stabilize the affected area of the spine.

Owner:N SPINE INC

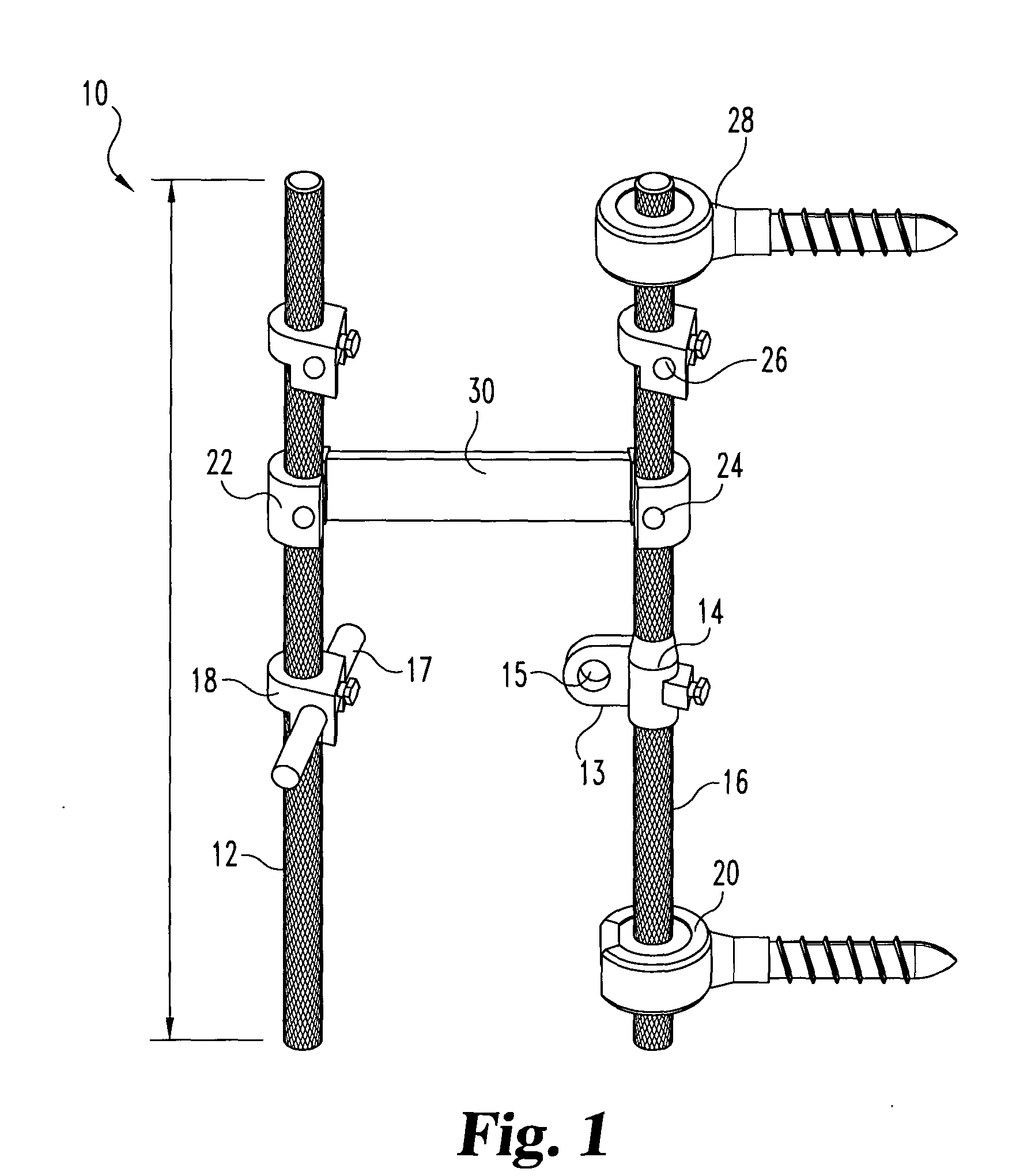

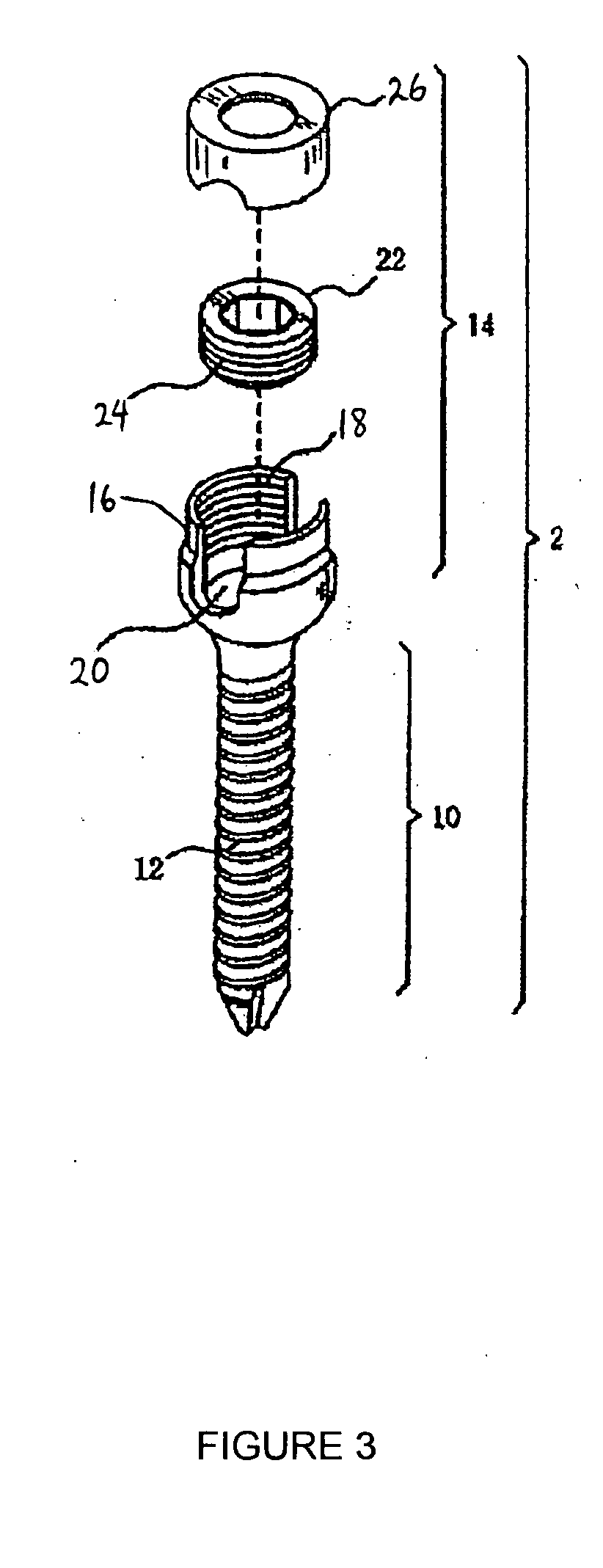

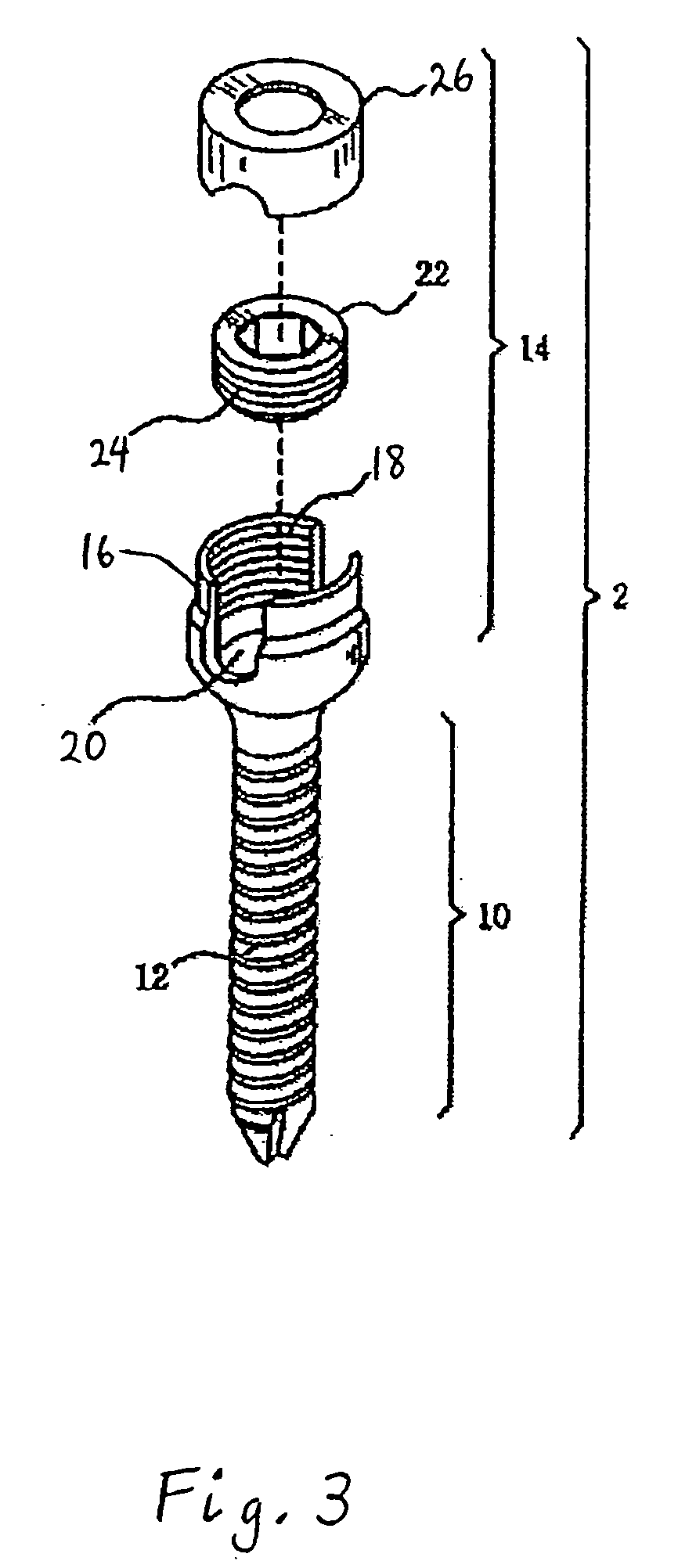

Adjustable rod and connector device and method of use

InactiveUS6991632B2Minimal displacementEasy to useInternal osteosythesisJoint implantsImplanted deviceIliac screw

Owner:RITLAND STEPHEN

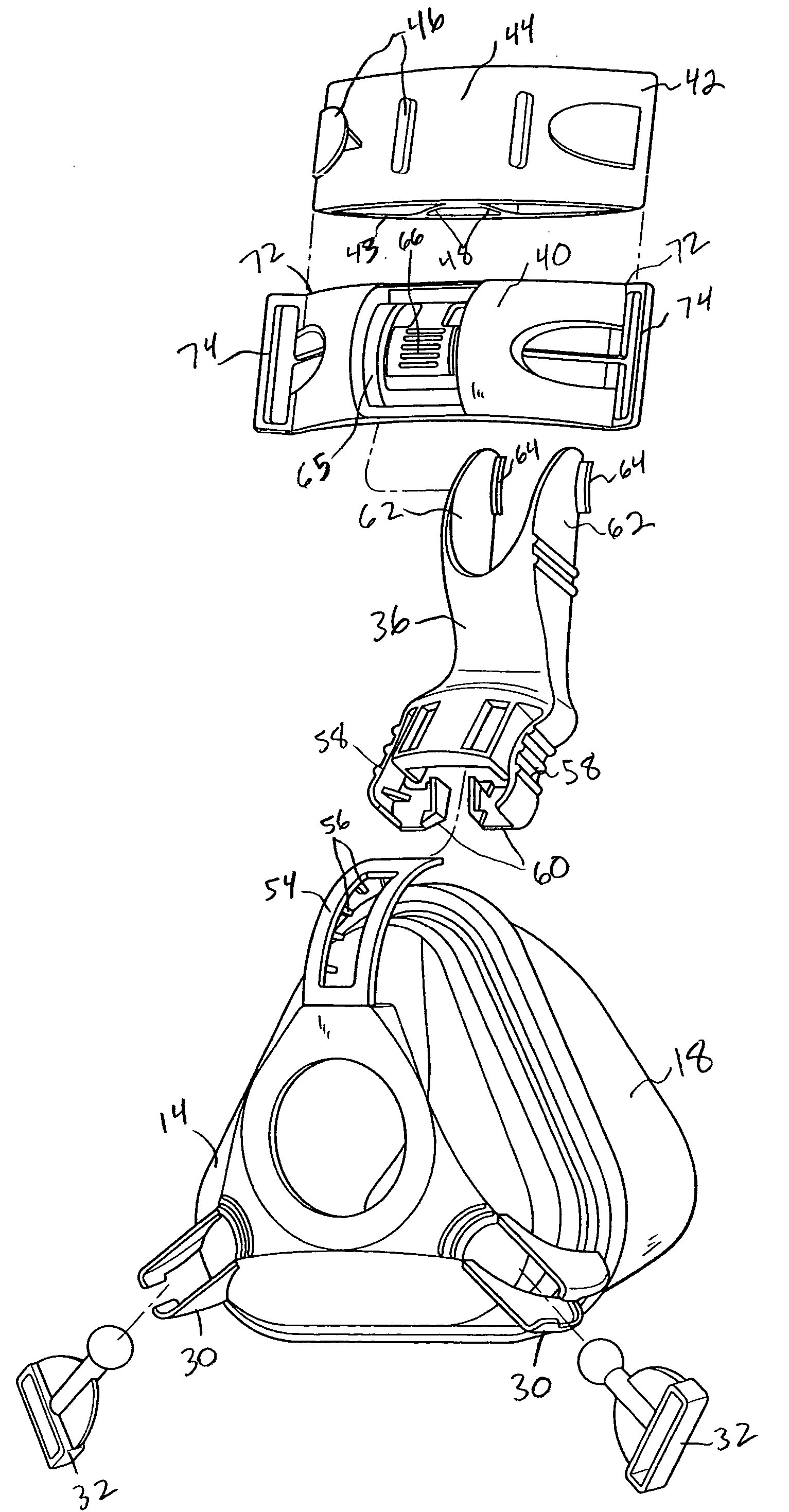

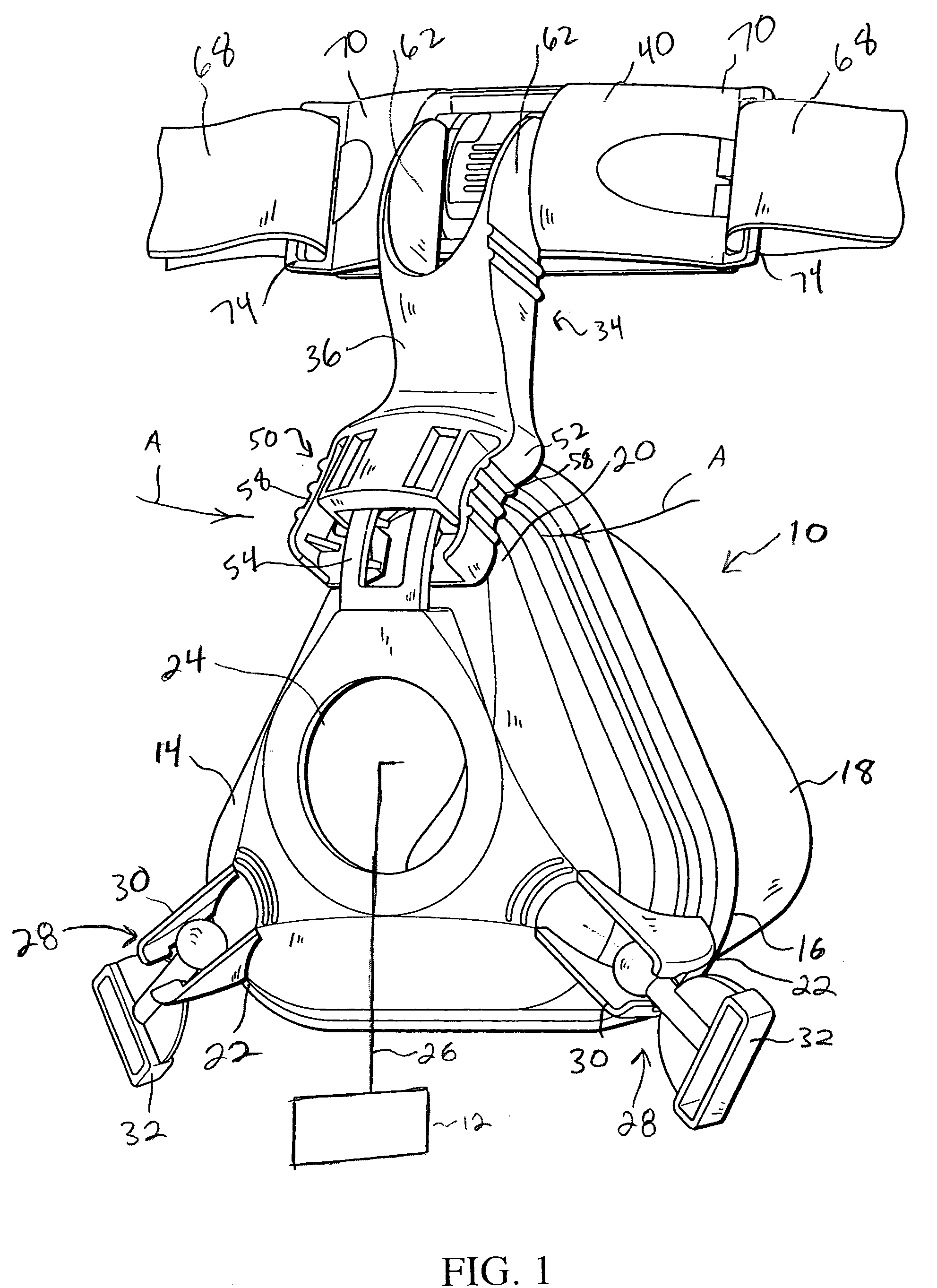

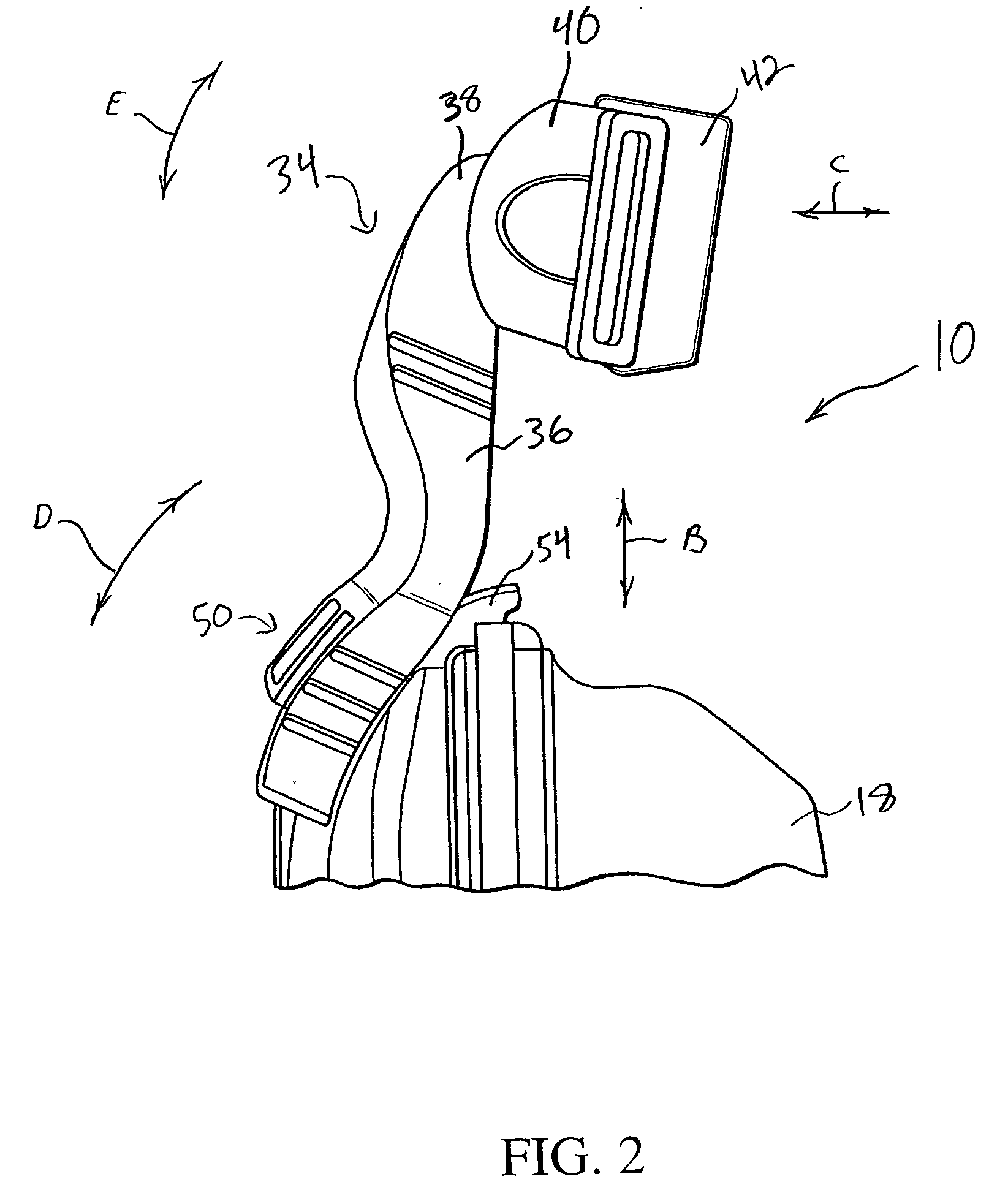

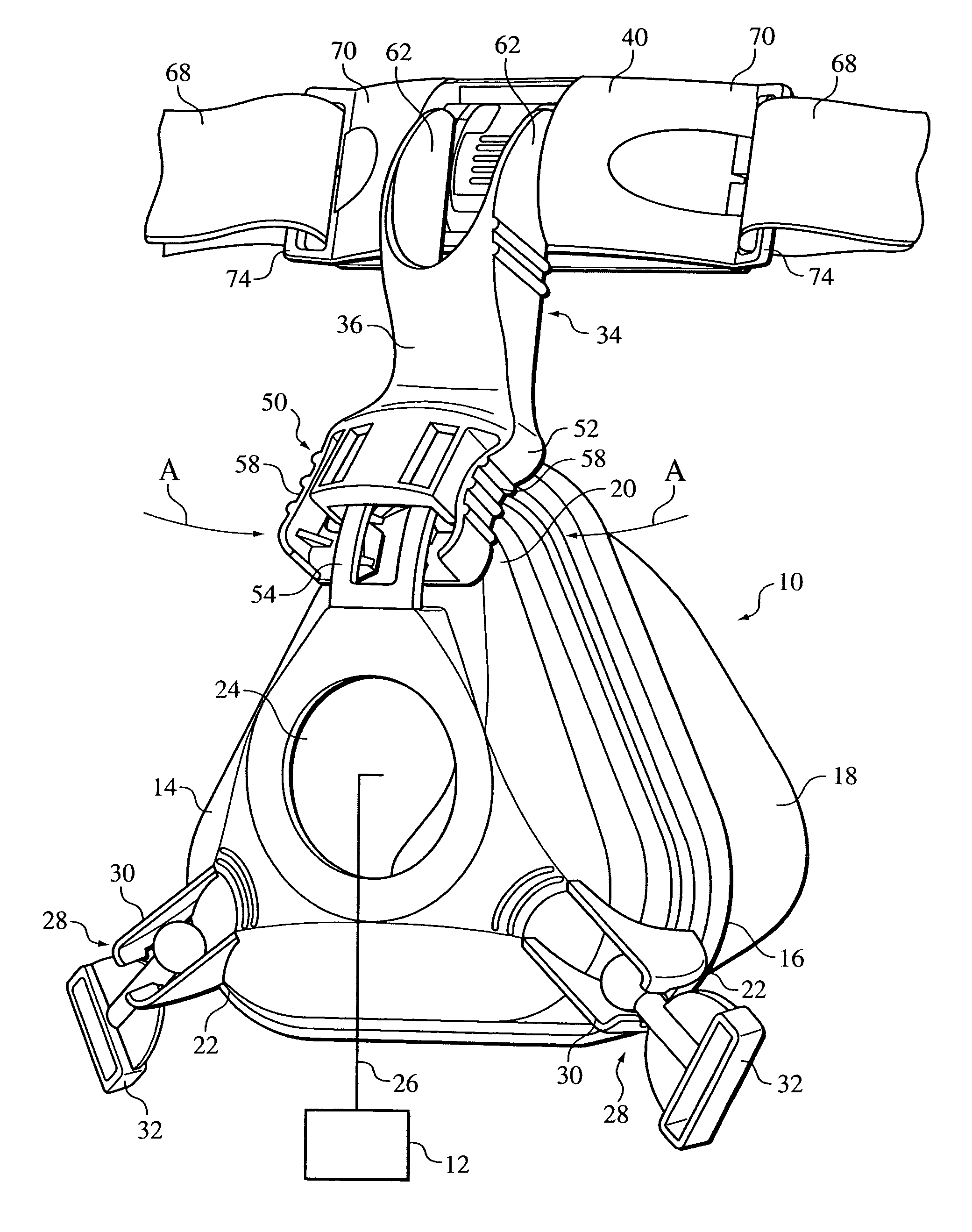

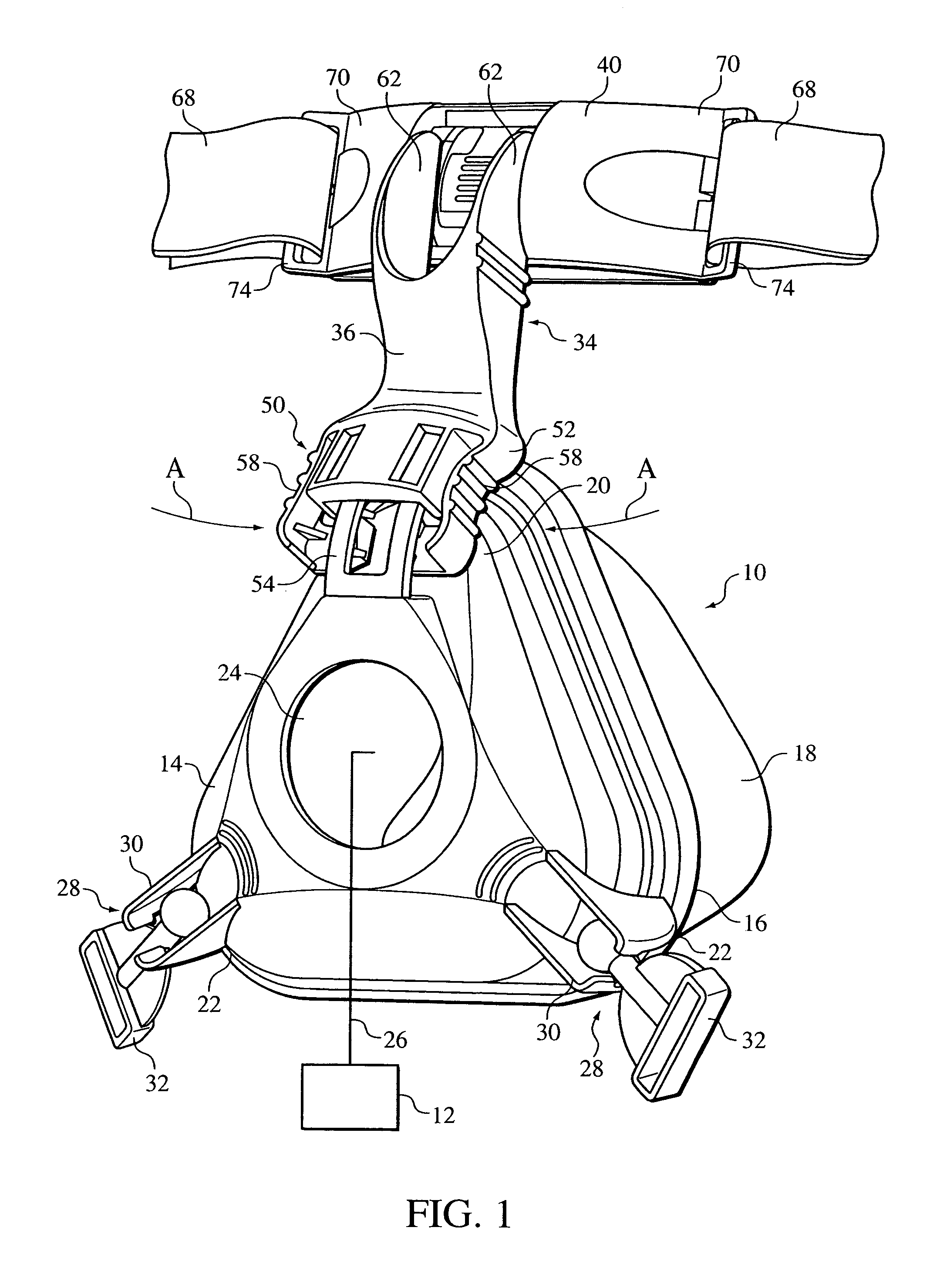

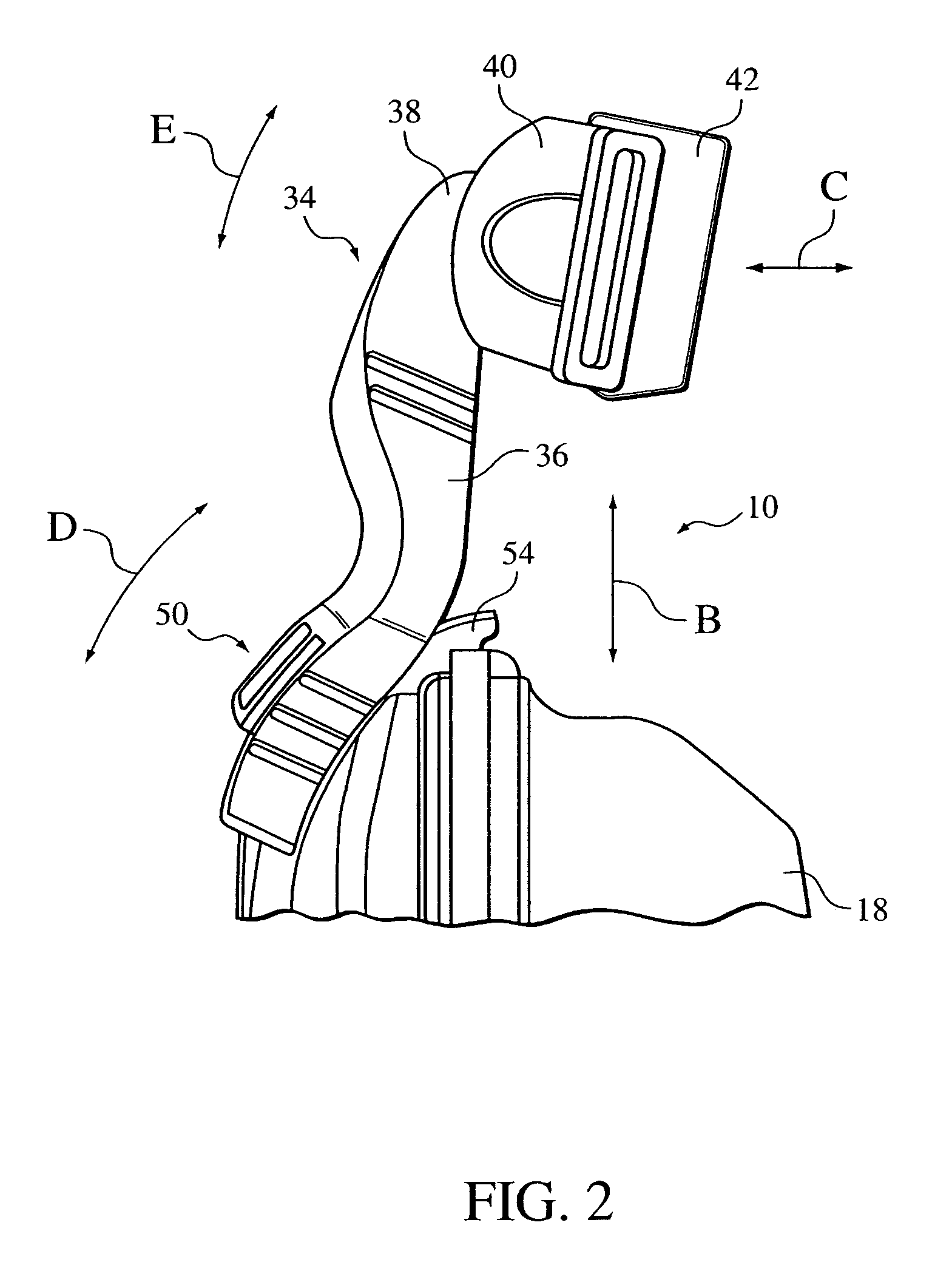

Patient interface with forehead support system

ActiveUS20040045551A1Easy to disassembleImprove stabilityPhysical therapyBreathing masksSupporting systemForehead

A patient interface having a forehead support adjustably. The forehead support assembly includes a support arm that is adjustably mounted to the mask shell, thereby allowing the adjustment of the distance between the forehead support bracket and the mask shell in order to adjust for patient's of different sizes. A forehead support bracket is pivotally connected to the support arm. The pivoting forehead support bracket is self-aligning to allow the forehead pad to remain parallel to the patient's forehead at all times, thus enhancing comfort and stability. The forehead support bracket is removable from the support arm, allowing the headgear (with support bracket attached) to be donned separately from the mask and support arm. The forehead support bracket in one embodiment has a forehead pad formed from the headgear itself.

Owner:RIC INVESTMENTS LLC

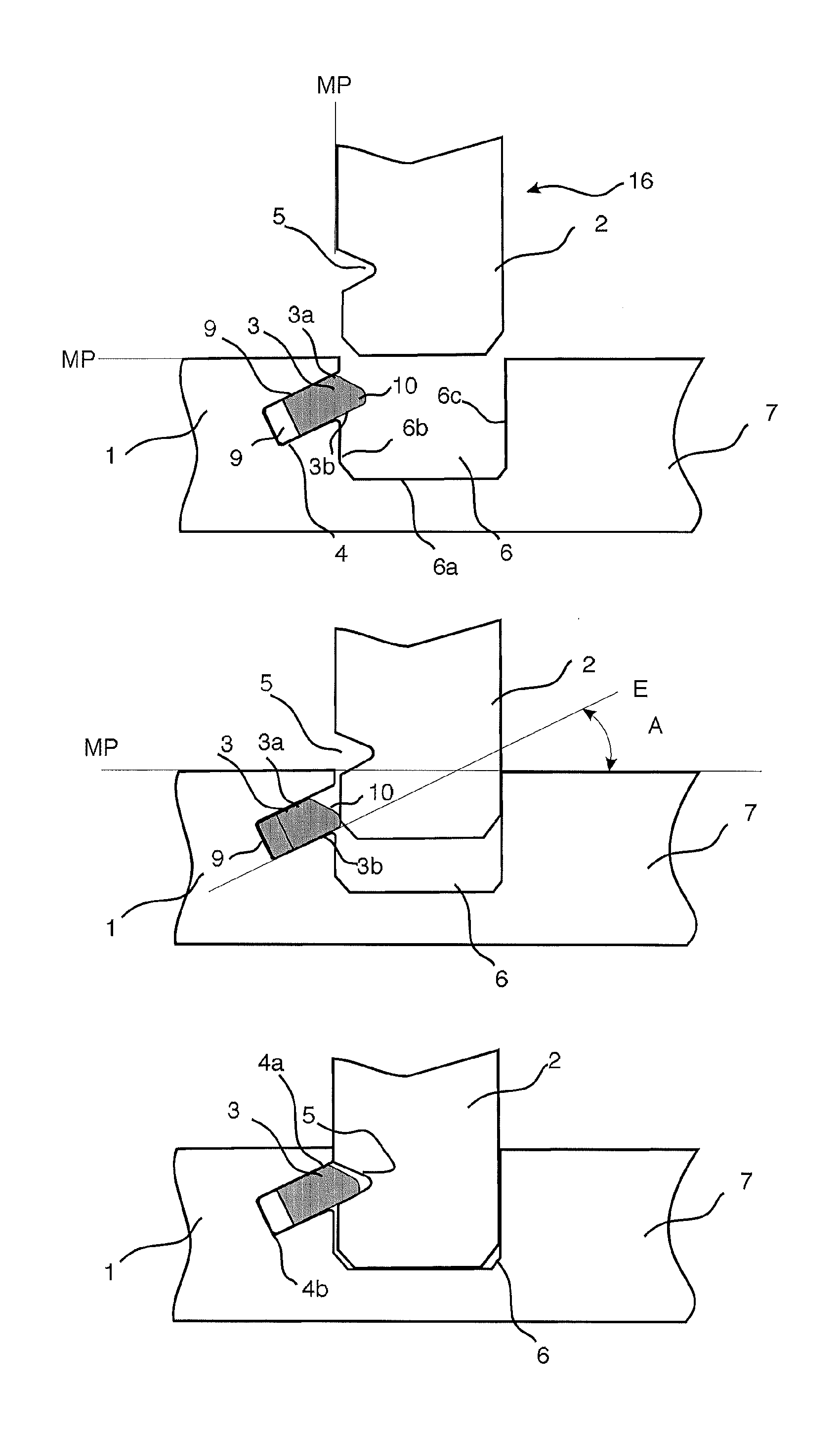

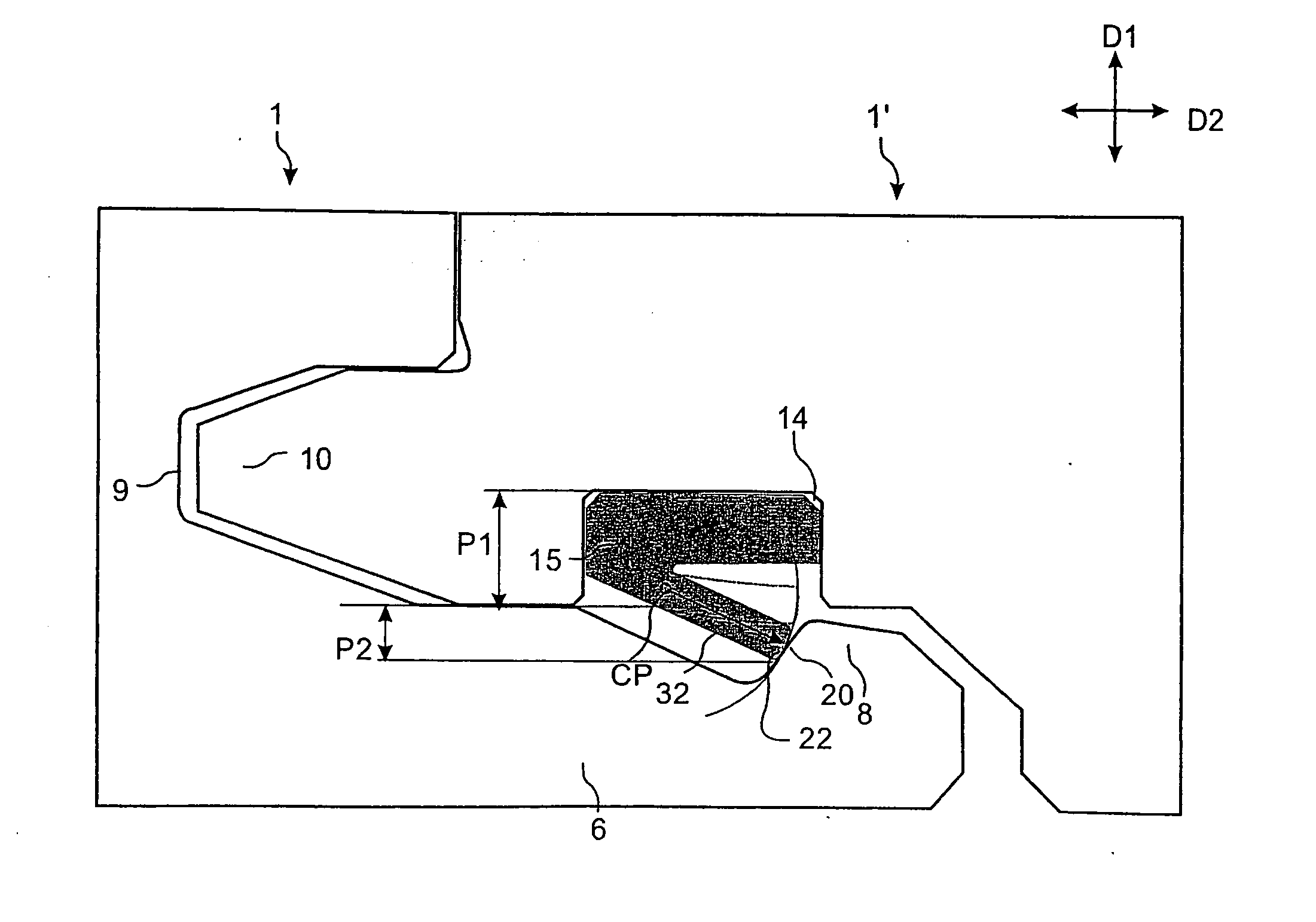

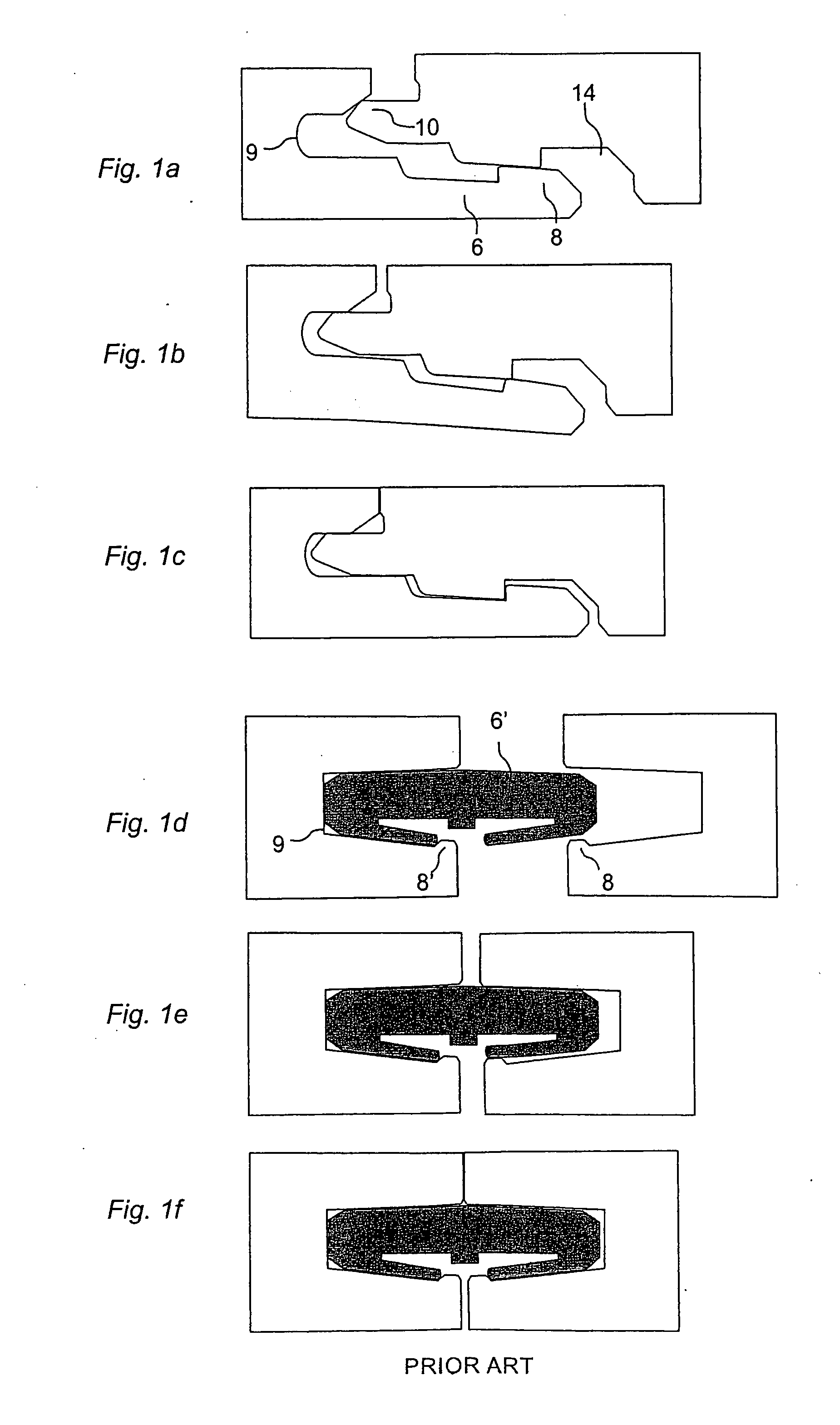

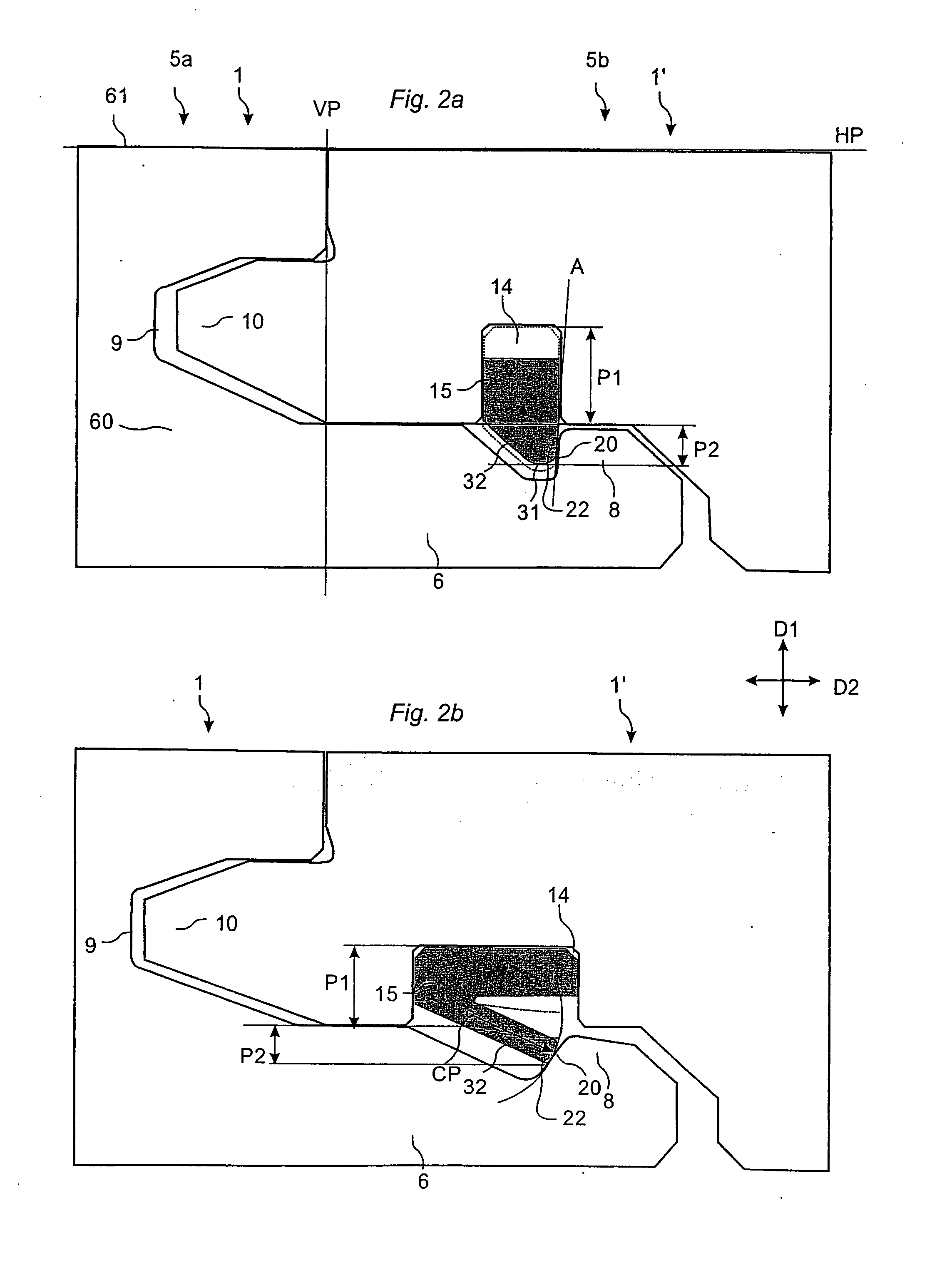

Mechanical locking system for building panels

ActiveUS20120279161A1Simple wayProduced cost-effectivelySheet joiningBuilding componentsElectrical and Electronics engineering

Panels are shown which are provided with a mechanical locking system allowing perpendicular connection with a snap action.

Owner:VÄLINGE INNOVATION AB

Method and apparatus for flexible fixation of a spine

InactiveUS20050149020A1Improved construction and designMinimize injuryInternal osteosythesisCannulasSpinal columnCoupling

A flexible spinal fixation device having a flexible connection unit for non-rigid stabilization of the spinal column. In one embodiment, the fixation device includes at least two securing members configured to be inserted into respective adjacent spinal pedicles, each securing member each including a coupling assembly. The fixation device further includes a flexible connection unit configured to be received and secured within the coupling assemblies of each securing member so as to flexibly stabilize the affected area of the spine.

Owner:DEPUY SYNTHES PROD INC

Mechanical locking system for panels and method of installing same

ActiveUS20080034708A1Simple horizontal displacementReduces snapping resistanceCovering/liningsWallsMechanical engineeringEngineering

Floor panels ( 1, 1 ') are provided with a mechanical locking system including a flexible locking element 15 in a locking groove 14 which during a horizontal motion is displaced vertically.

Owner:VÄLINGE INNOVATION AB

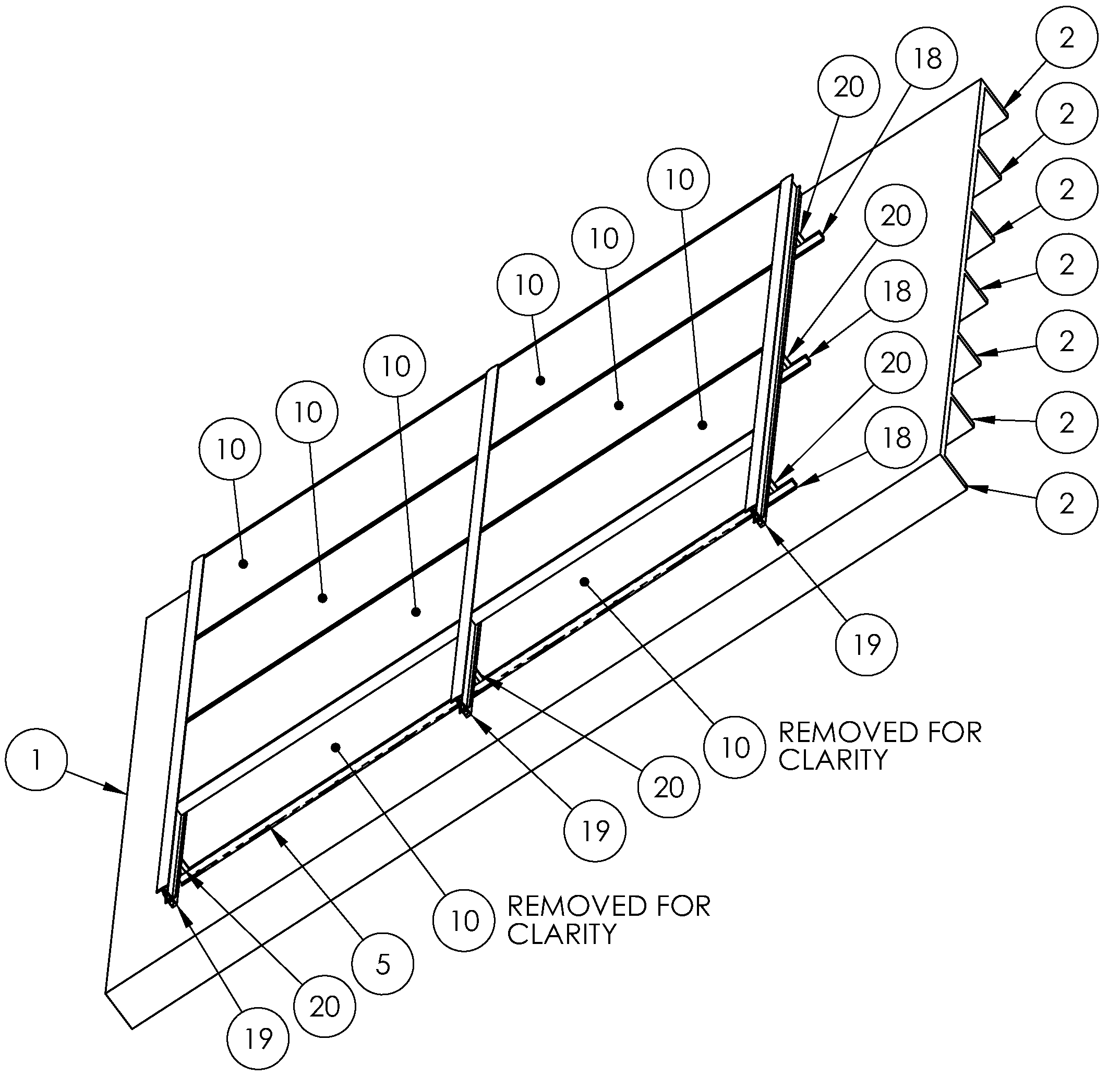

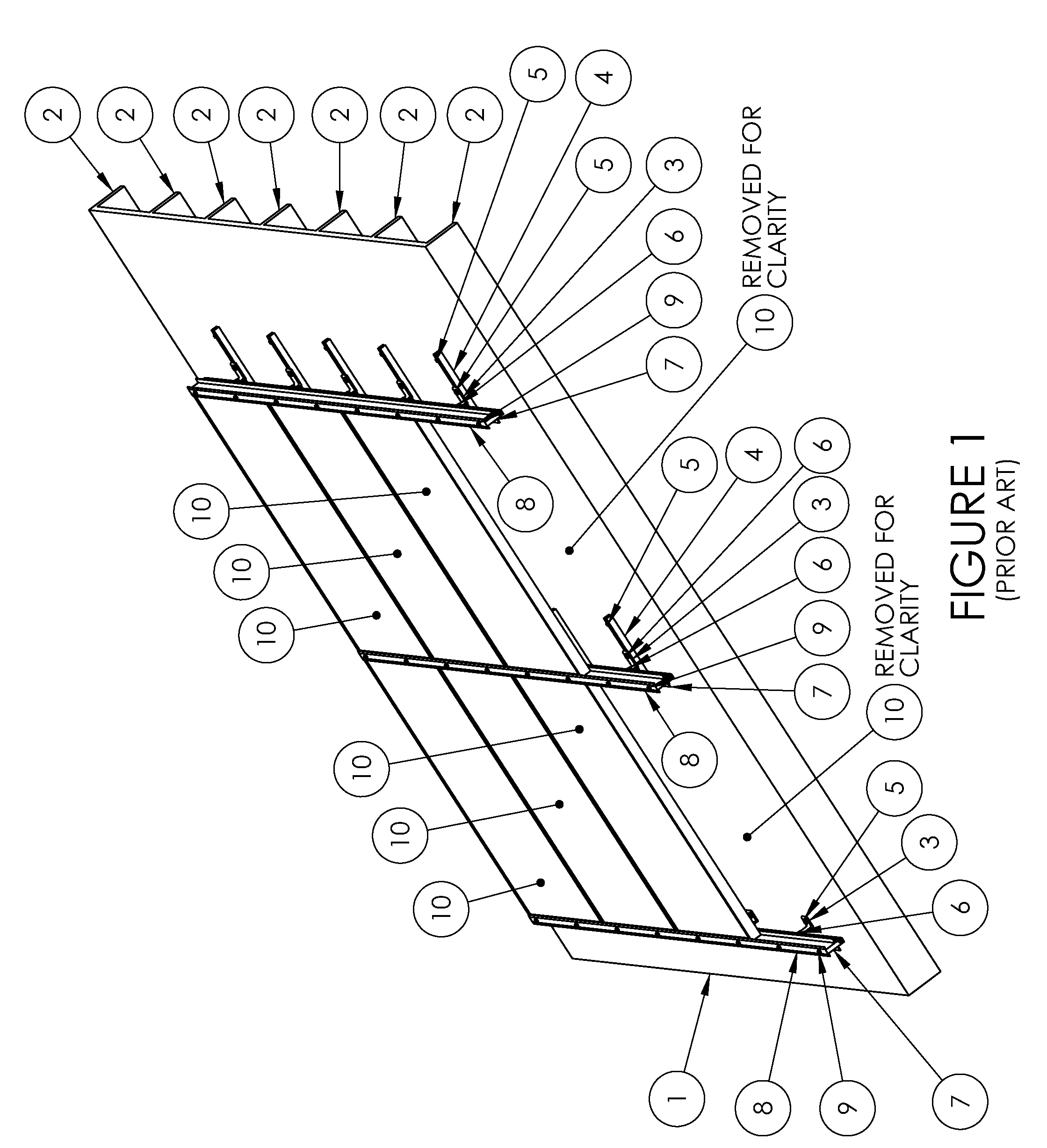

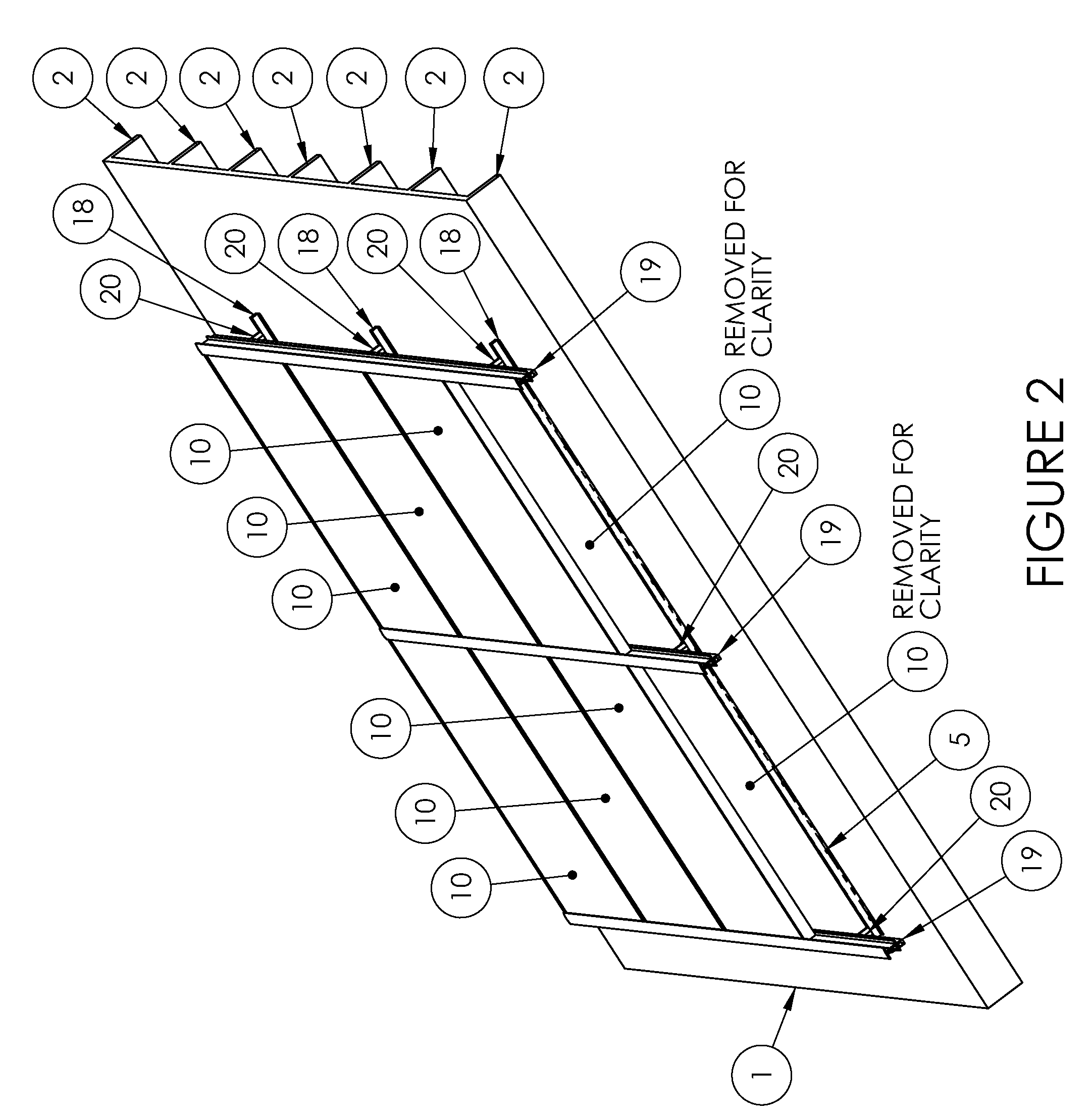

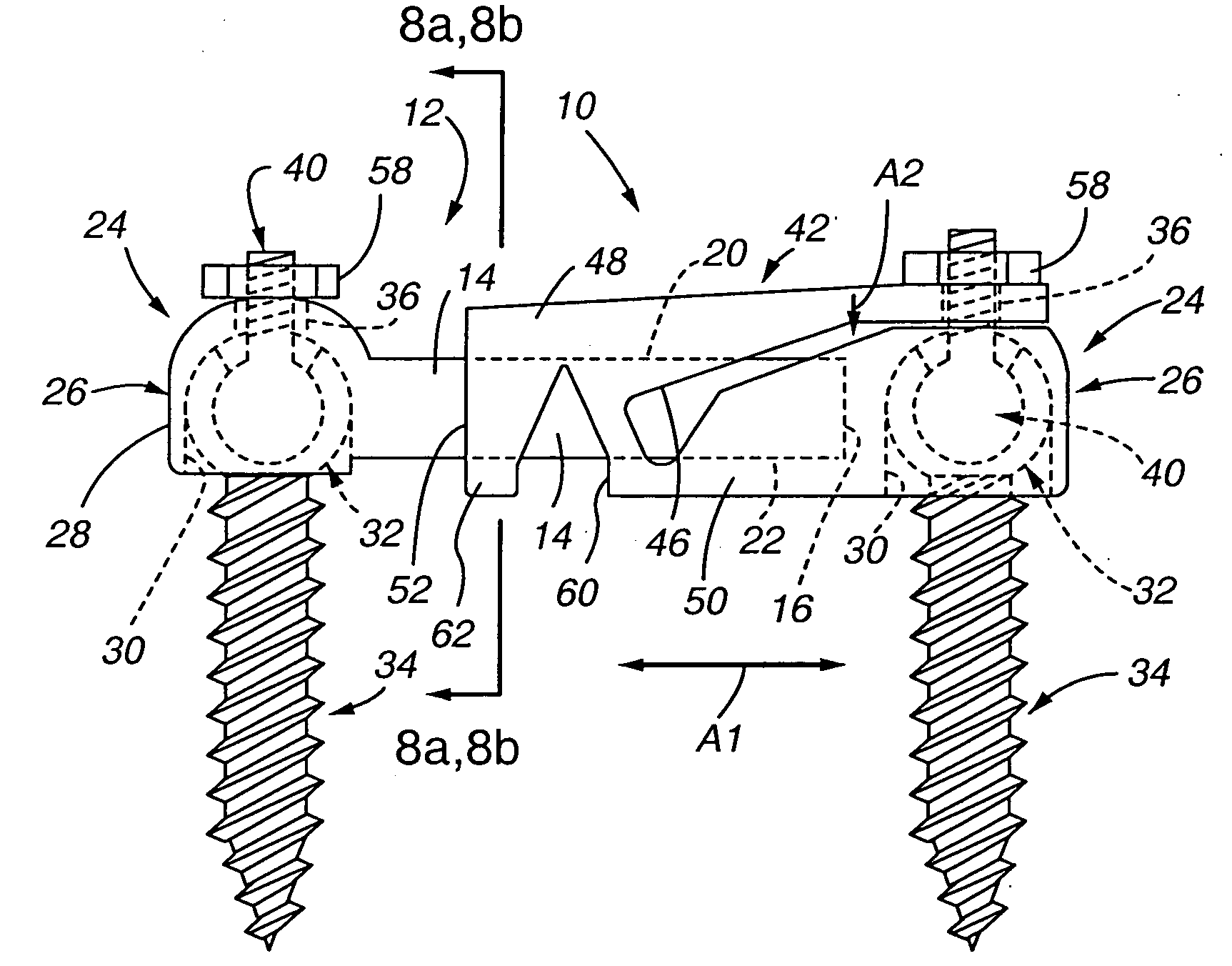

Photovoltaic mounting system with locking connectors, adjustable rail height and hinge lock

InactiveUS20090282755A1Cost-effectiveTurn easilyPhotovoltaic supportsSolar heating energyElectricityPhotovoltaic mounting system

A cam-actuated connection device joins rail mounting members of a photovoltaic panel array. The connection device slides within channels of mounting members until the members are in a properly positioned grid. When in position, the connection device is rotated to lock the mounting members in a rigid grid network. The connecting device can be subsequently loosened, repositioned and locked into position. The rail-mounting members create a grid for installation of multiple PV panels. The mounting rail allows the unit to remain relatively compact in nature but still covers a wide range of PV panel thicknesses. The rail system has a hinged connection with the mounting rail that allows an installer to assemble the module in a near perpendicular fashion to the mounting rail, make the required electrical connections and then lower the PV module into its working position. The unit is then locked into its working position.

Owner:POWERMOUNT SYST +1

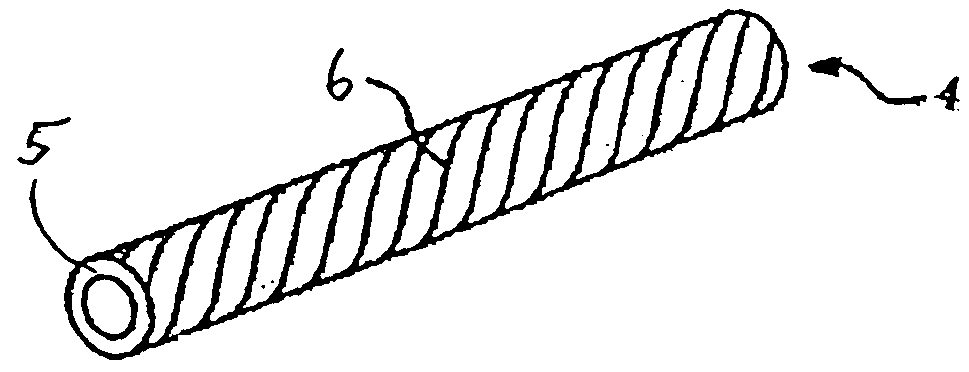

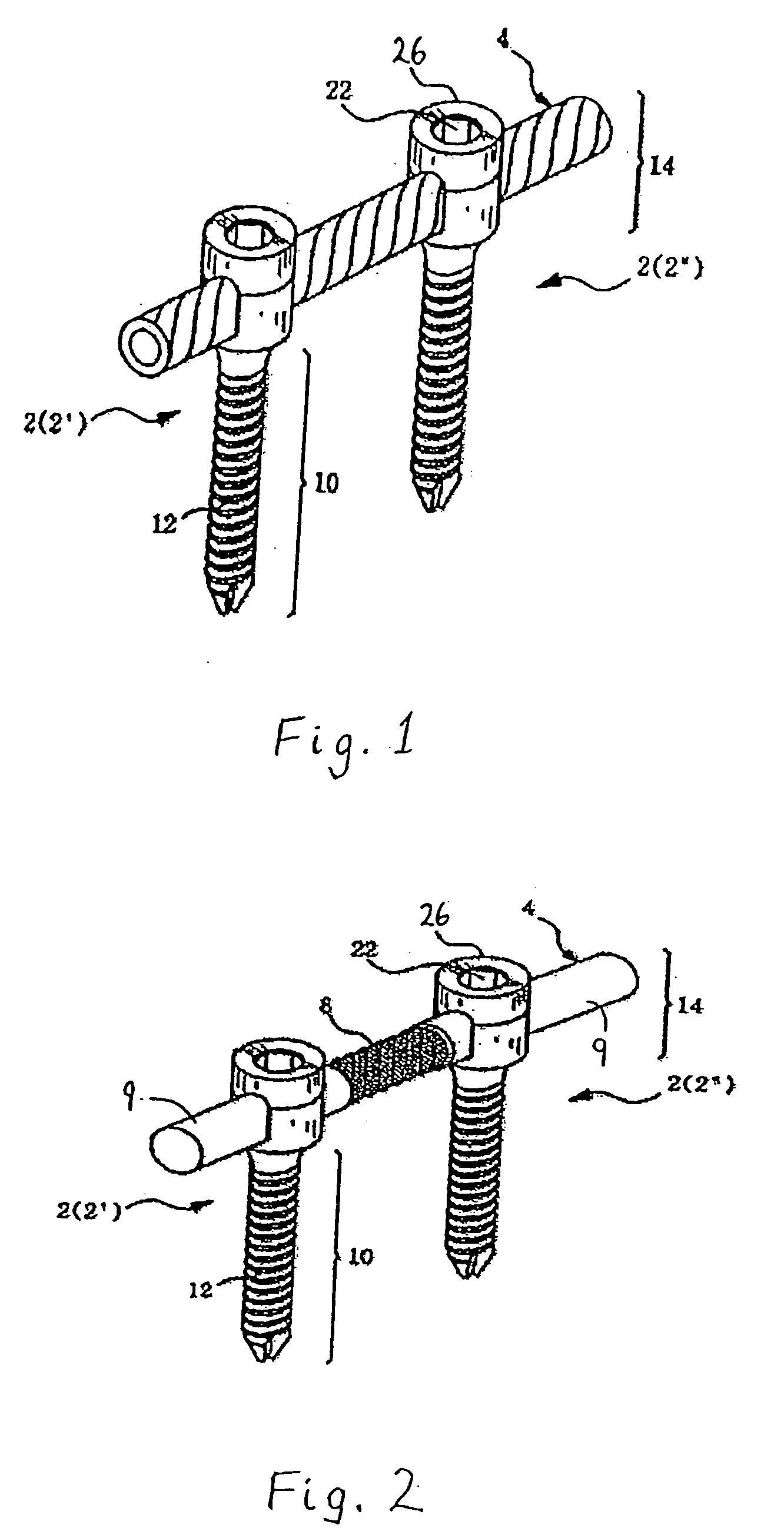

Adjustable rod and connector device and method of use

InactiveUS20050149023A1Minimal displacementLow-profileSuture equipmentsInternal osteosythesisImplanted deviceIliac screw

A low-profile surgical rod implant device is provided that allows the length of a rod spanning two bone screws to be adjusted at the time of implantation. In a separate aspect of the invention, the rod implant device can be secured by tightening and securing an end of the rod implant device at one of the bone screws. Embodiments are provided for use with polyaxial pedicle screws and substantially straight shank pedicle screws in spinal applications. In a separate aspect of the invention, a bone screw connector having an interference type fit is also provided. A method for implanting the device is also provided.

Owner:RITLAND STEPHEN

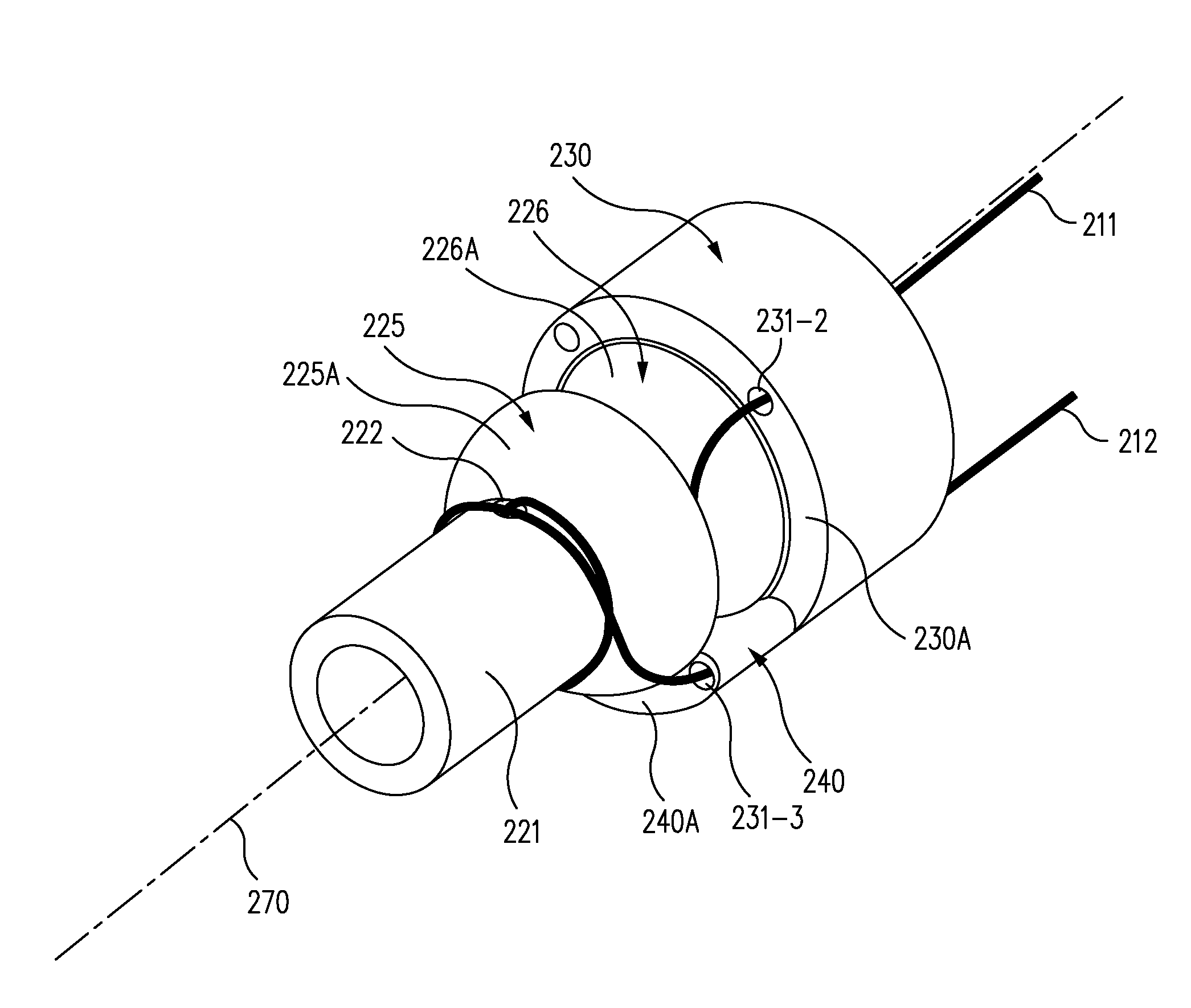

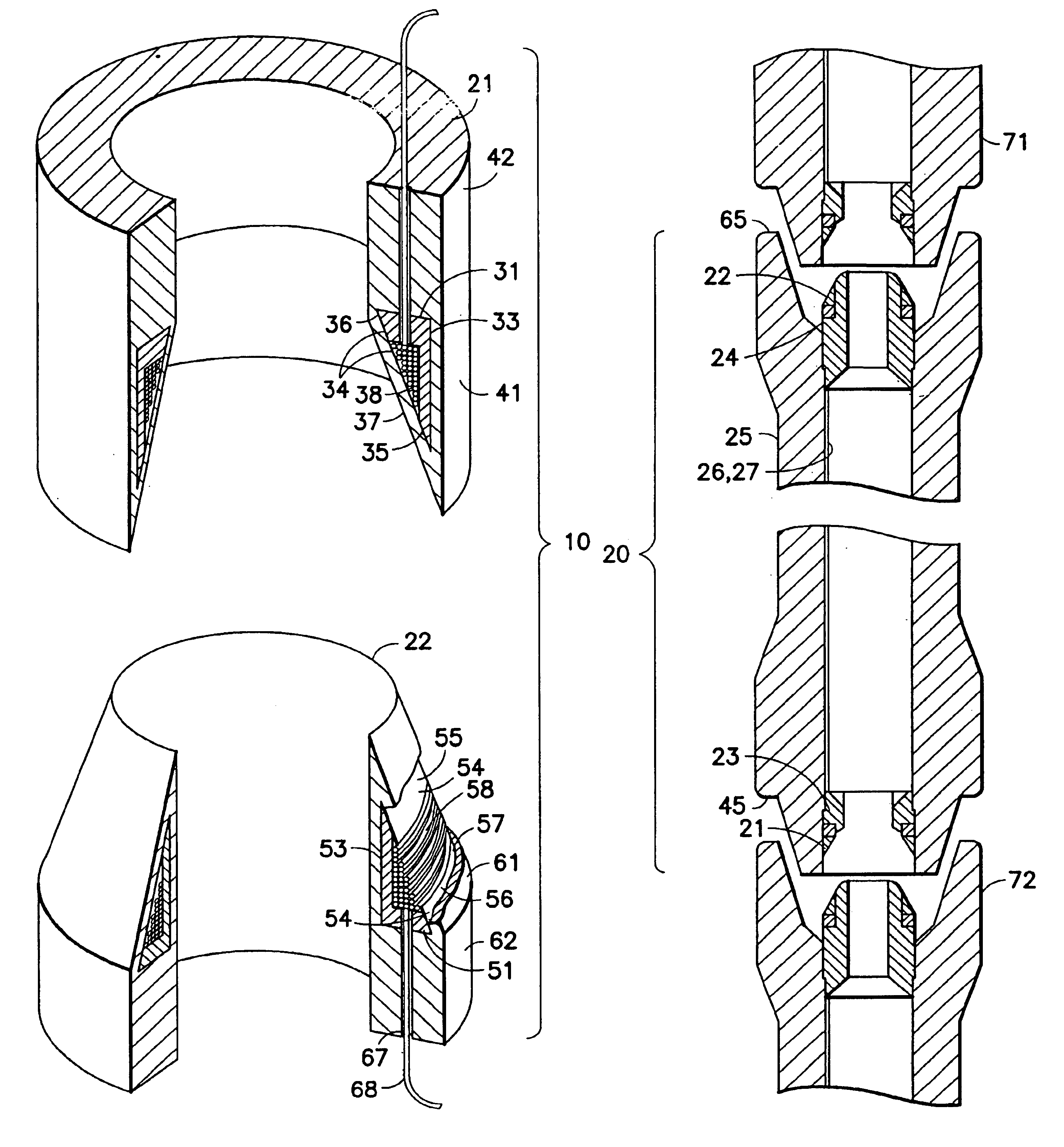

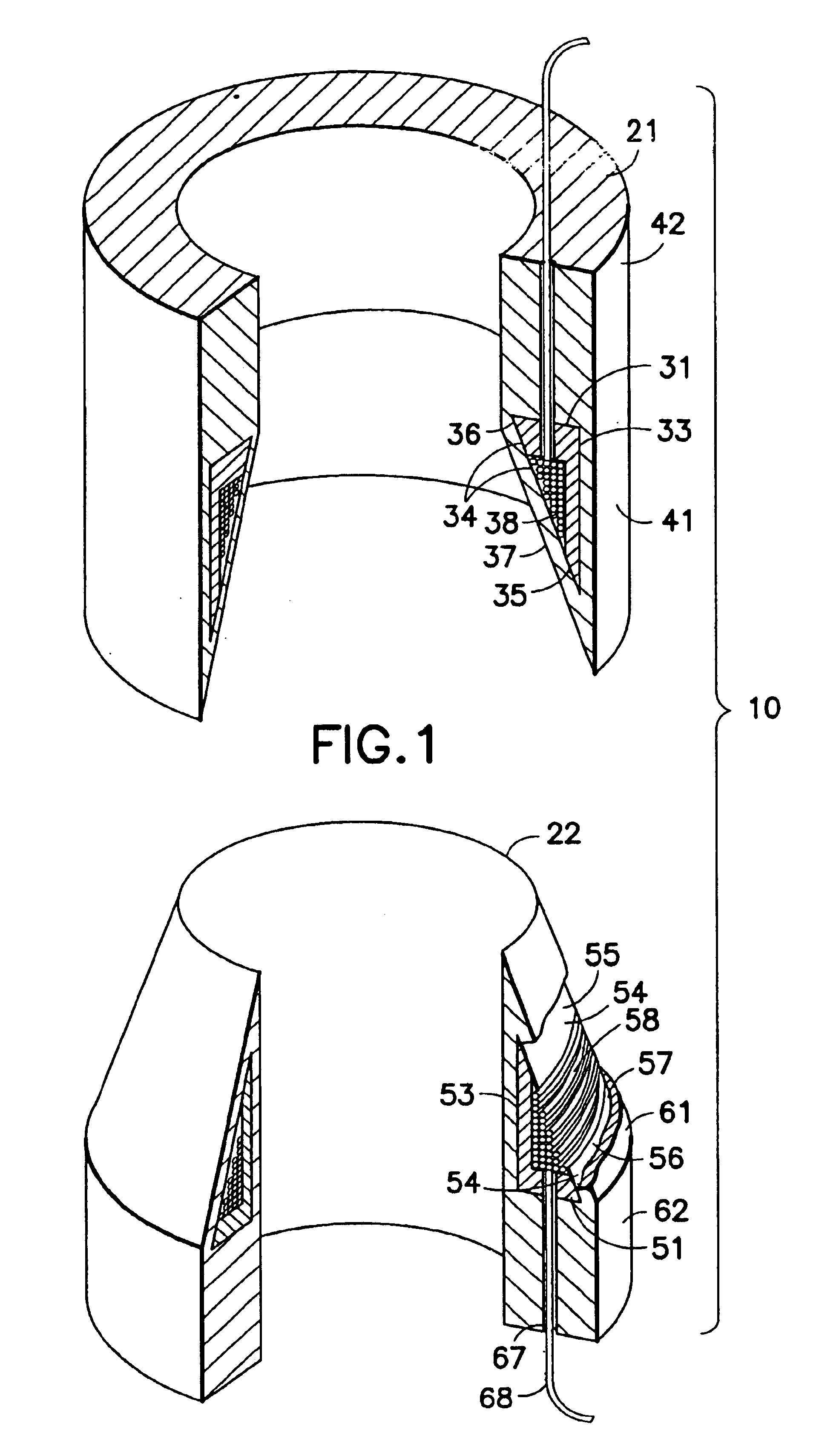

Low-loss inductive couplers for use in wired pipe strings

A first flux-loop inductive coupler element electrically couples with a second flux-loop inductive coupler element. The first flux-loop inductive coupler element comprises a first ring-like core having high magnetic permeability and a conical-section annular first face transverse to the plane of the first core. The first face has a first annular groove separating a first conical-section larger-diameter face and a first conical-section smaller-diameter face. A first coil is wound within the annular groove. The first and second cores form a low-reluctance closed magnetic path around the first coil and a second coil of the second flux-loop inductive coupler element.A first current-loop inductive coupler element electrically couples with a second current-loop inductive coupler element. The first current-loop inductive coupler element has a first high-conductivity, low-permeability shaped belt of a first end of a first pipe joint, a first ring-like core located at the first end, and a first electrically conductive coil wound about the first ring-like core. The first high-conductivity, low-permeability shaped belt partially encloses the first coil. It is shaped to cooperate with the second high-conductivity, low-permeability shaped belt of an adjacent second pipe joint having a second electrically conductive coil and a second high-conductivity, low-permeability shaped belt to create a closed toroidal electrical conducting path. The closed toroidal electrical conducting path encloses the first coil and the second coil when the first and second pipe joints are mated.

Owner:SCHLUMBERGER TECH CORP

Threaded hoist ring screw retainer

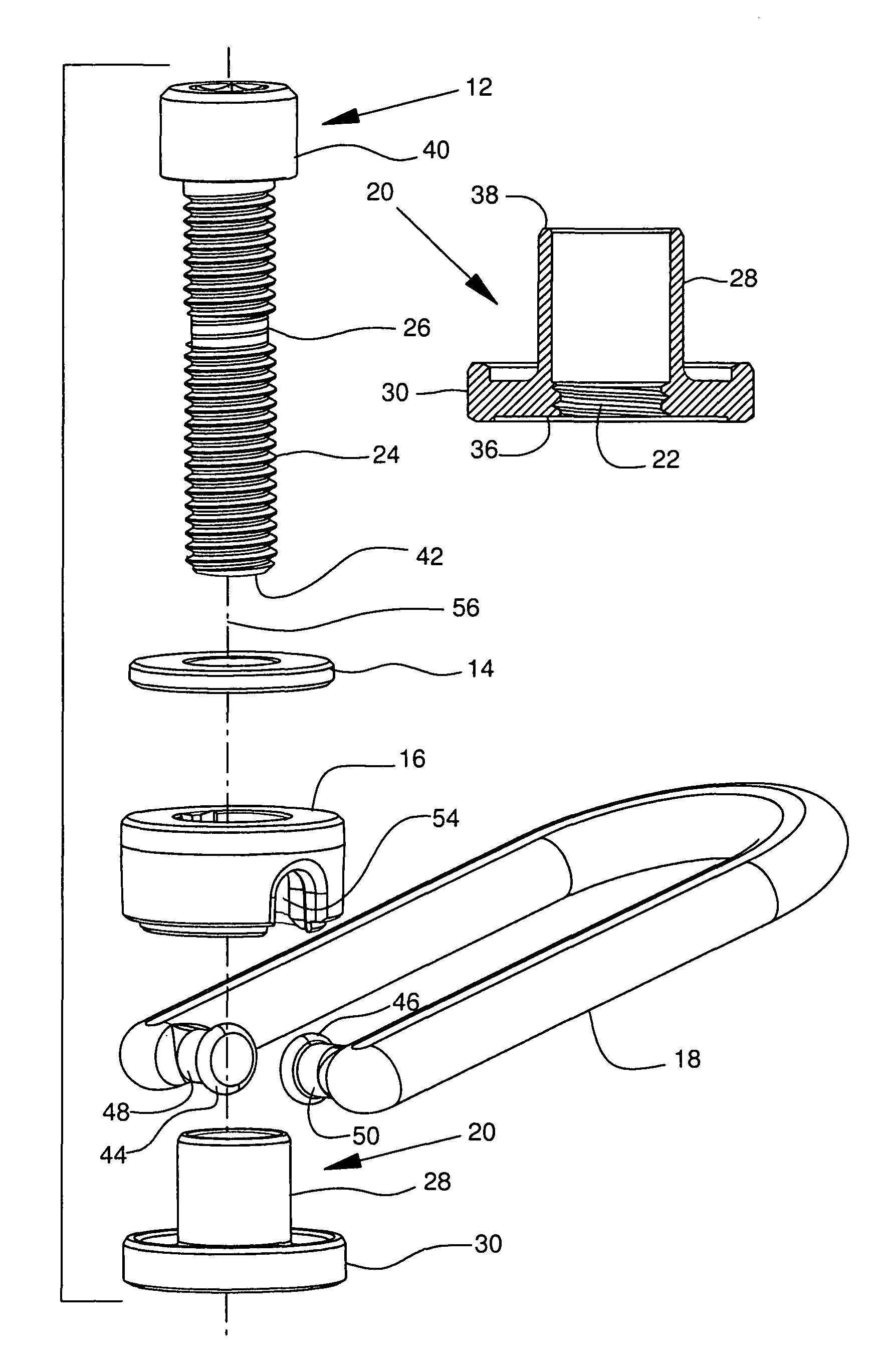

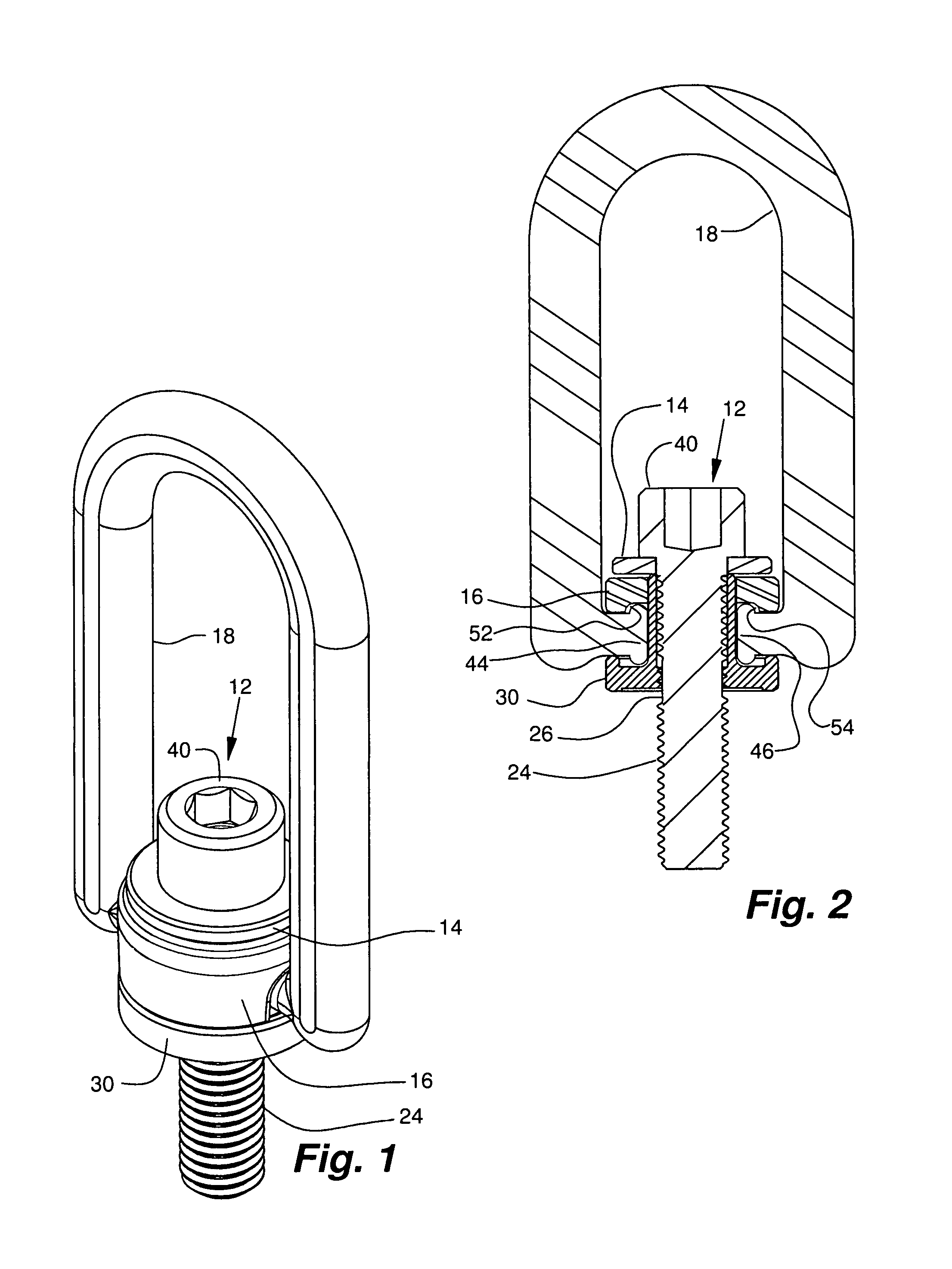

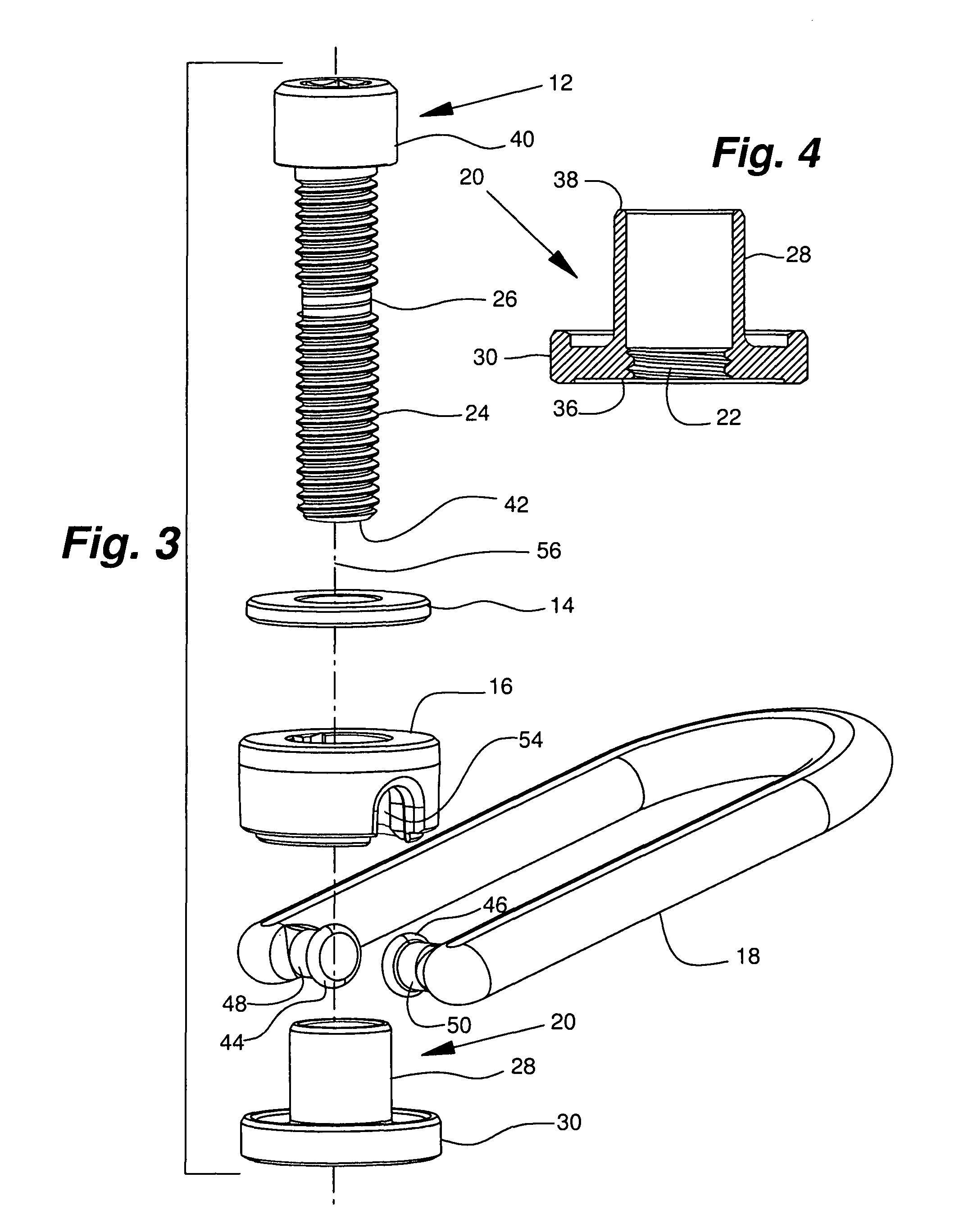

An omni-positional hoist ring assembly including a bushing element that includes a sleeve with an axial length, a proximal end and a distal end. A load bearing flange is radially disposed about the proximal end of the sleeve. The sleeve has an internal thread extending at least part way of the axial length of the sleeve. A mounting screw element has a major axis, a head, and a shank disposed generally co-axially around the major axis. The shank includes a threaded shank portion and a bearing portion. The bearing portion is a generally cylindrical axially extending portion of the shank that has a diameter approximately equal to the minor diameter of the thread in the threaded shank portion. A thrust washer element is provided between the head and the distal end of the sleeve. A body element receives the in-turned opposed ends of the legs of a lifting loop element in sockets. The lifting loop is free to pivot. The body element is free to rotate about the sleeve, so the lifting loop will self align with a load that is applied to it from any direction within a hemisphere centered on the major axis of the mounting screw element. The elements of the hoist rig assembly are assembled by aligning them and inserting the mounting screw element into the sleeve and threadably advancing it until the bearing is aligned with the internal thread so further rotation of the mounting screw element does not threadably advance the mounting screw element relative to the sleeve.

Owner:MJT HLDG

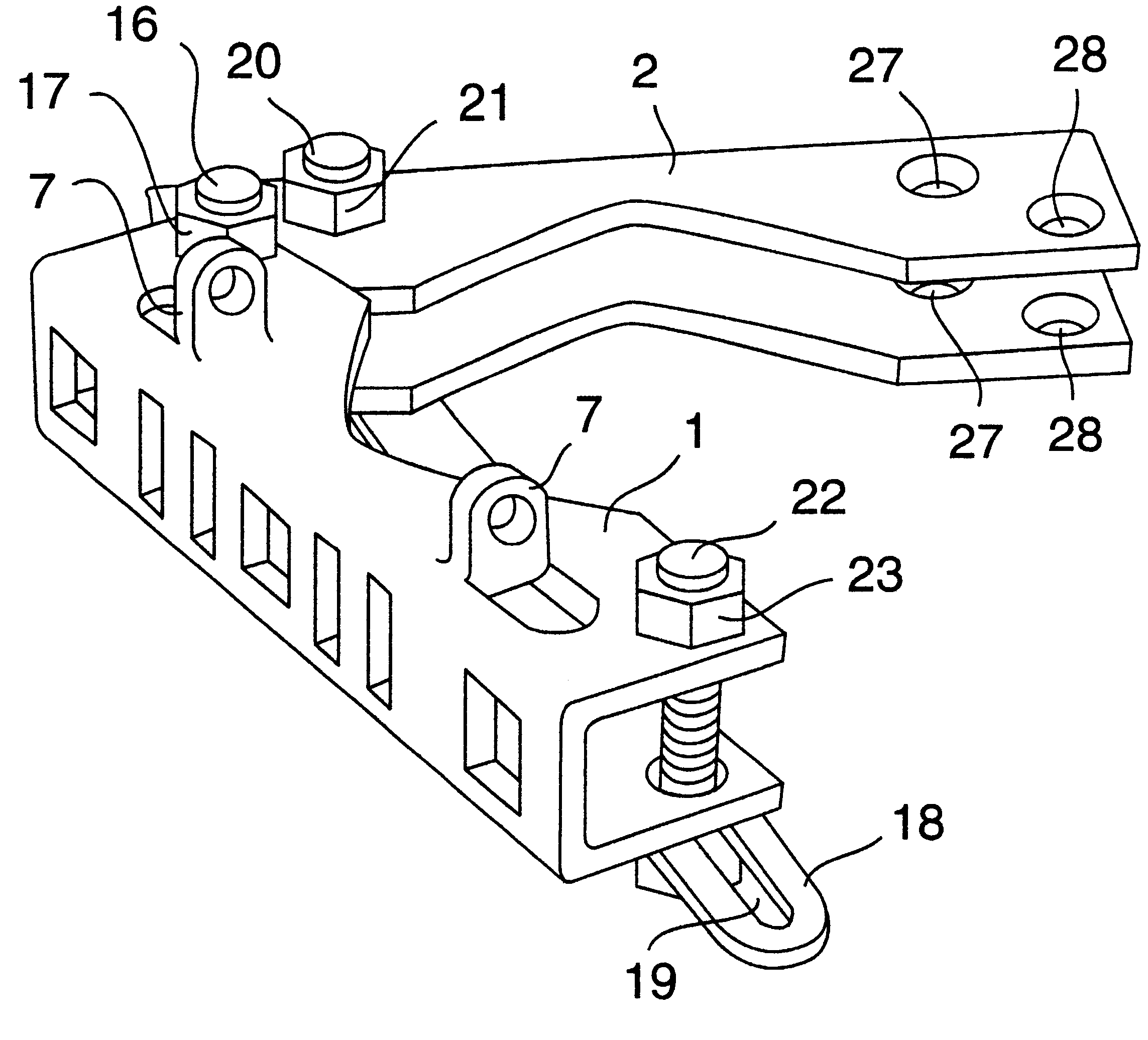

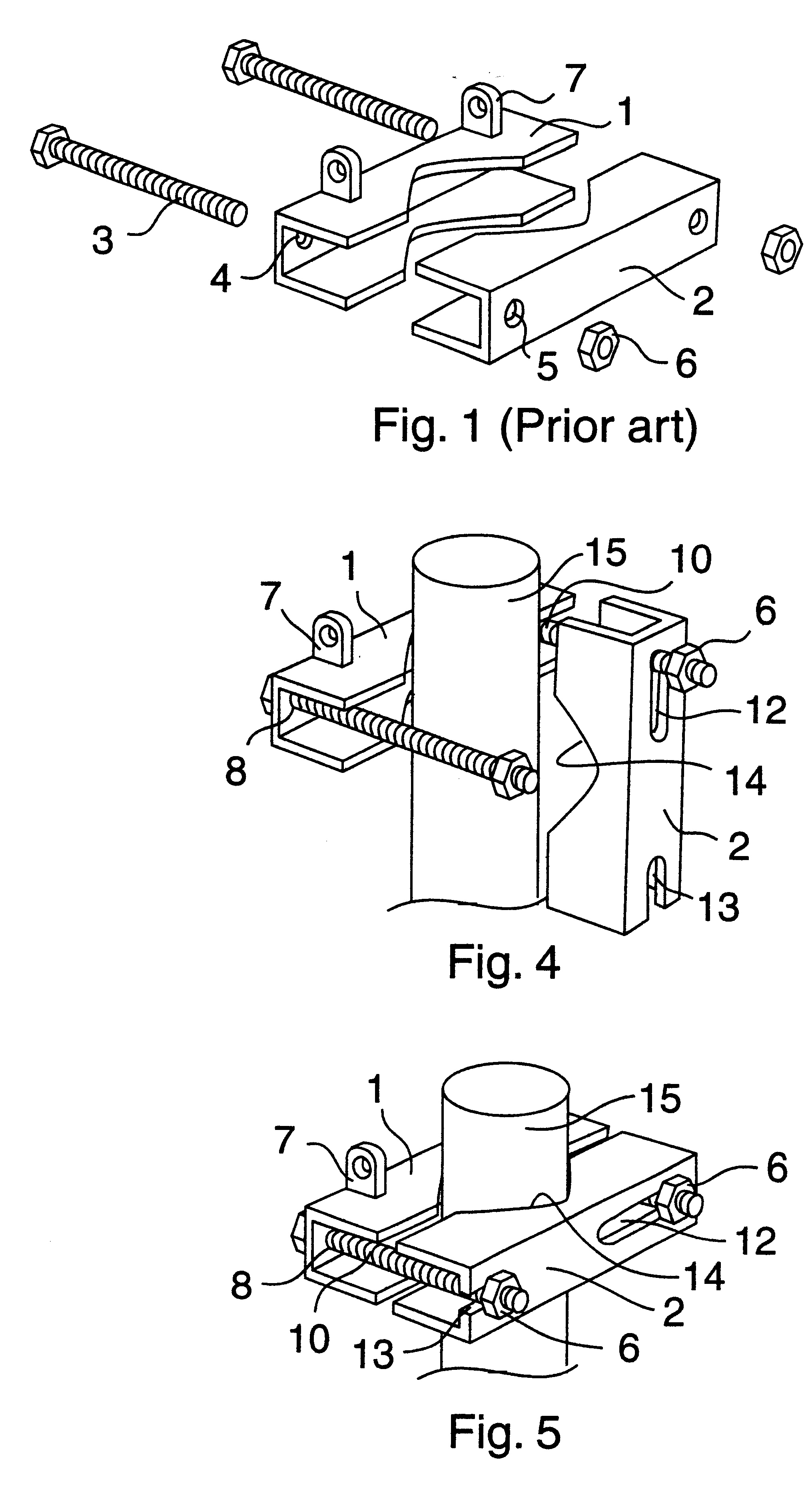

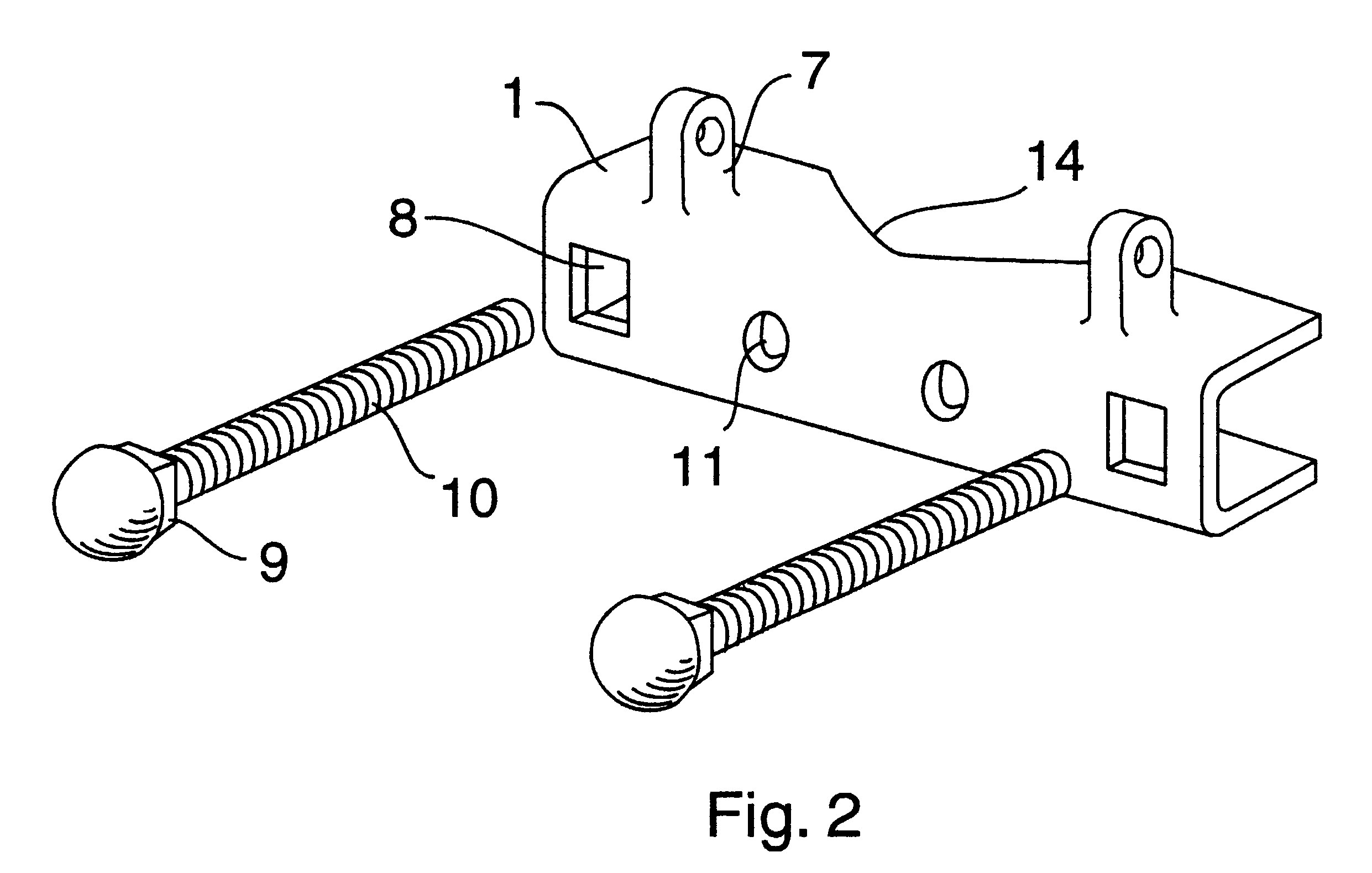

Mounting bracket

A mounting bracket useful for securing a base, such as an antenna to a pole, a tube or a post, or a similar anchor support, and including a first clamp part, being a base clamp, to be secured to the base (the antenna) adapted to be locked against the pole, and a second clamp part, being tightening clamp, adapted to partly embrace the pole and to be tightened to the base clamp with the pole clamped therebetween, preferably by a screw-nut connection on each side of the pole. The tightening clamp, is formed with two elongated slots extending in the longitudinal direction of the clamp, a first slot of which may be closed and the second slot of which is open at the end of the clamp. The slots having a width matching the diameter of the clamp screws, a length which is at least twice the diameter of the clamp screws and arranged such that the open slot of the tightening clamp can be rotated freely past the corresponding bolt thereby engaging the corresponding clamp screw through the open end of the slot after the pole has been placed in contact with the base clamp. A tightening clamp and a base clamp can be joined in a rotational joint. Thereby an object, which is mounted, e.g. an antenna, can be panned.

Owner:INTEL CORP

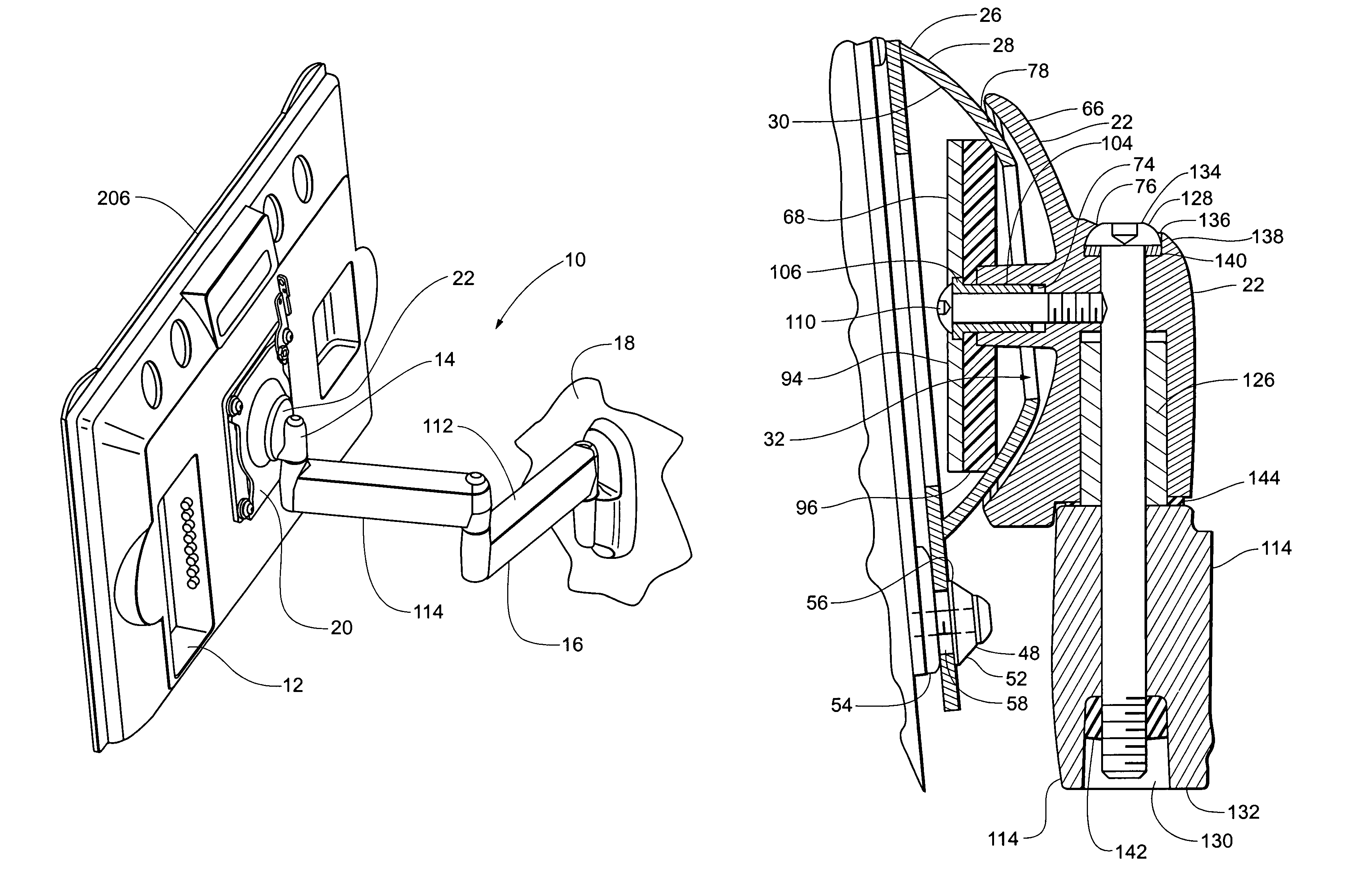

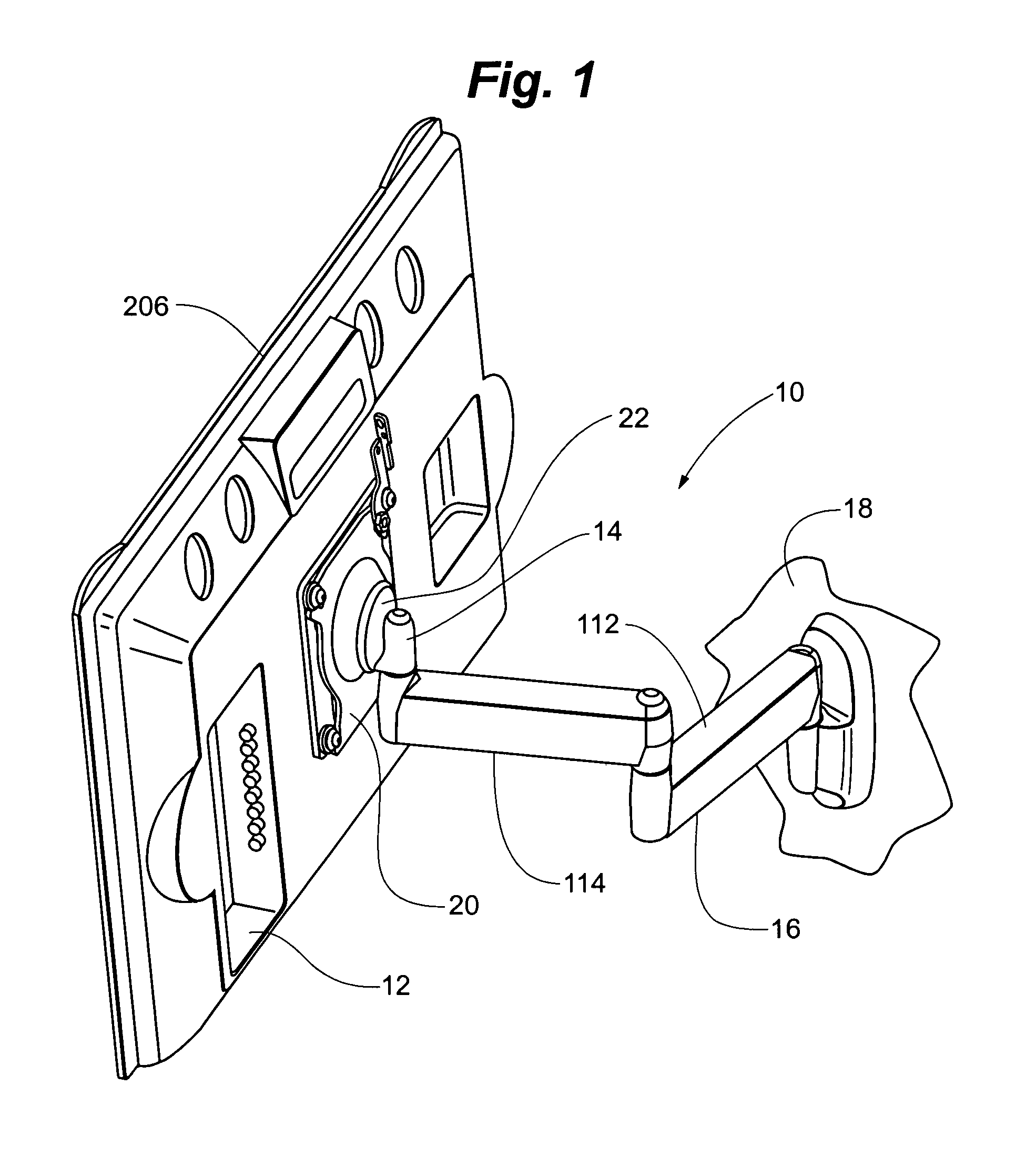

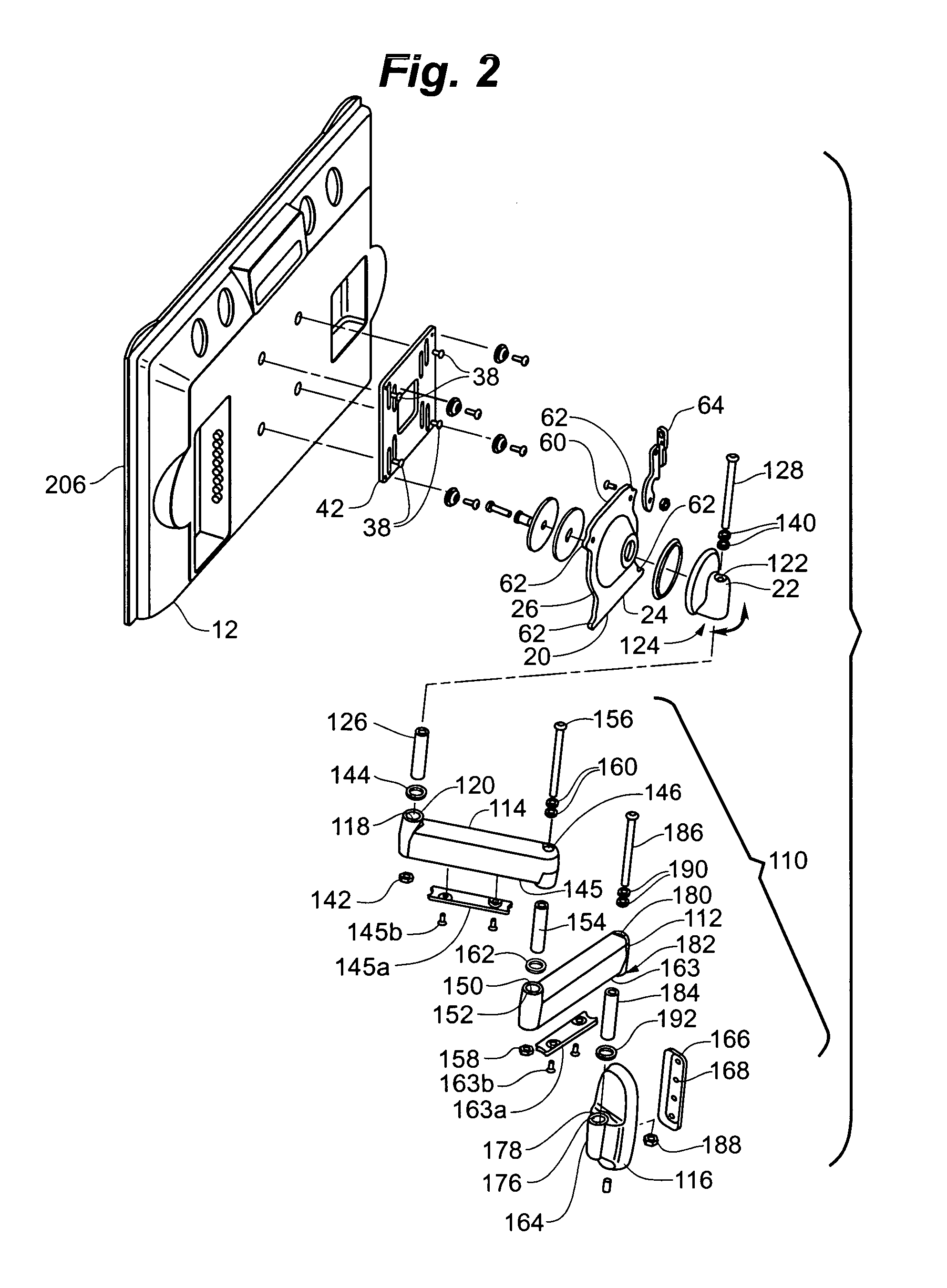

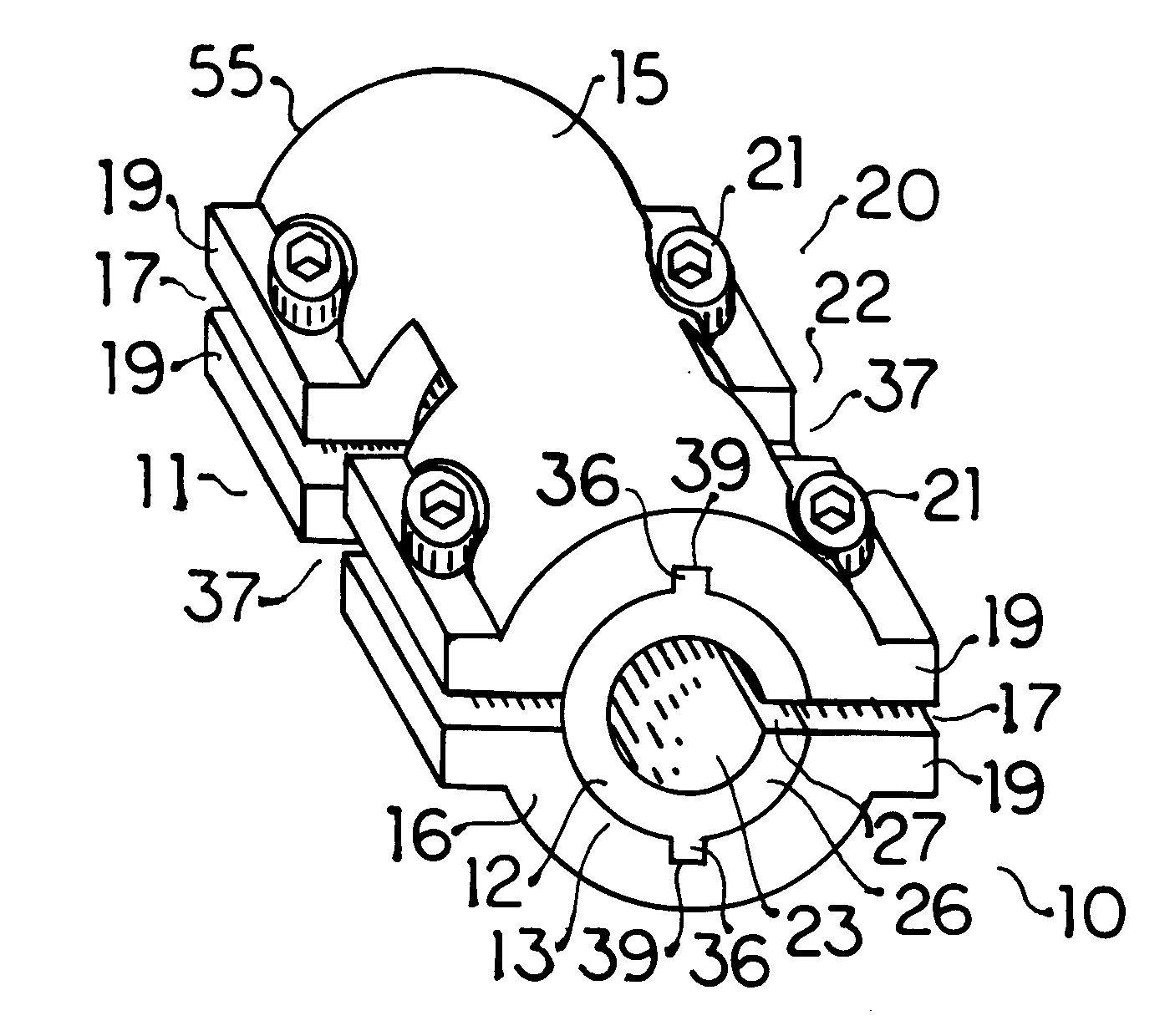

Self-balancing adjustable flat panel mounting system

A self-balanced adjustable mounting system for a flat panel display. A display interface having a hollow, semi-spherical shell portion is attached to the flat panel display. The semi-spherical shell is formed with a generally constant radius of curvature. The center of the radius of curvature is disposed proximate the center of gravity of the flat panel display with the display interface attached. The display interface is received in a guide structure that has a bearing portion engaging the outer surface of the semi-spherical shell, and a second bearing portion engaging the inner surface of the semi-spherical shell through an aperture formed in the semi-spherical shell. The semi-spherical shell is guided between the first and second bearing portions so that the flat panel display and device interface are generally rotatable about the center of the radius of curvature of the semi-spherical shell. The display is self balancing in virtually any position in the range of travel of the device due to the location of the center of rotation proximate the center of gravity.

Owner:LEGRAND AV INC

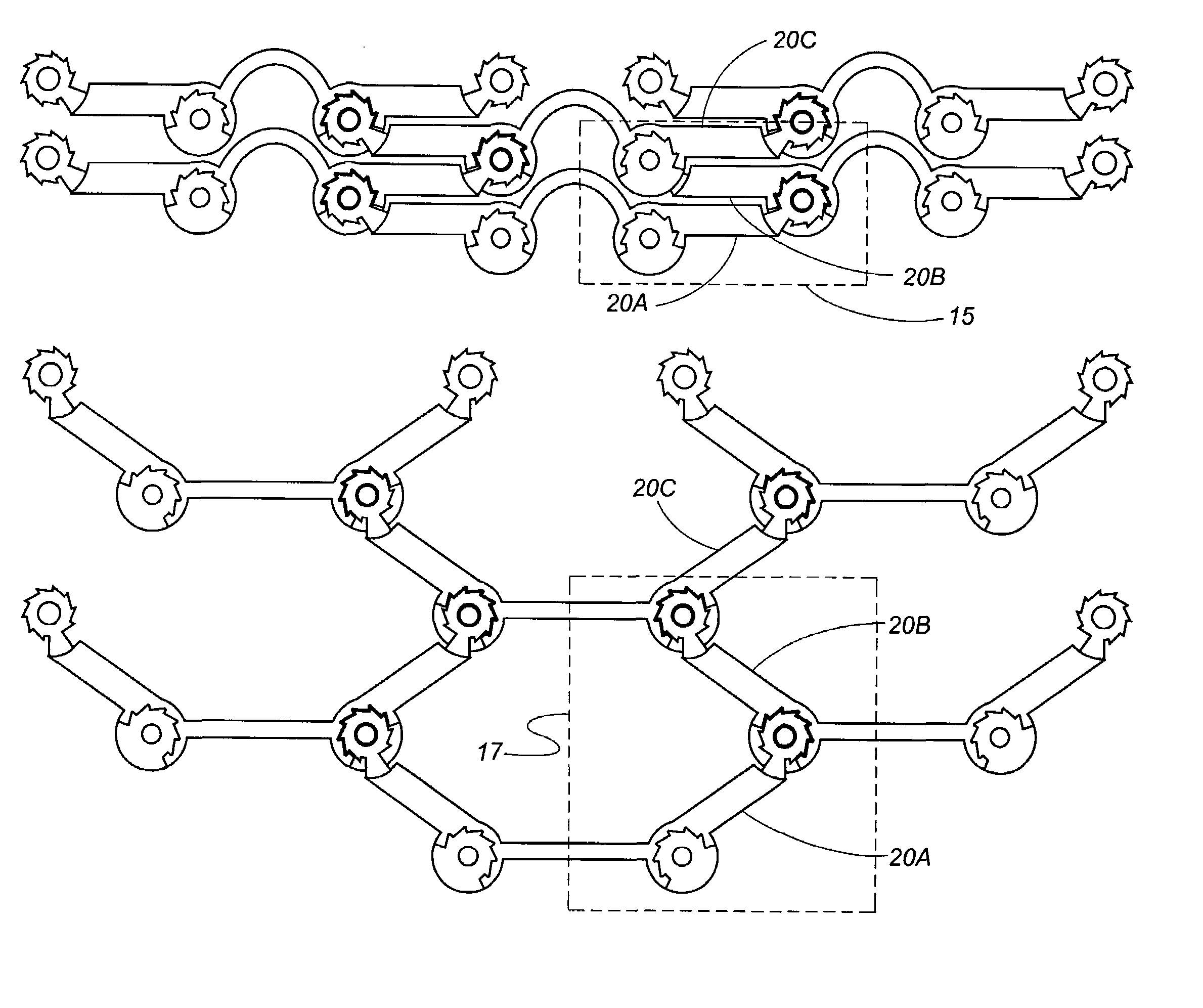

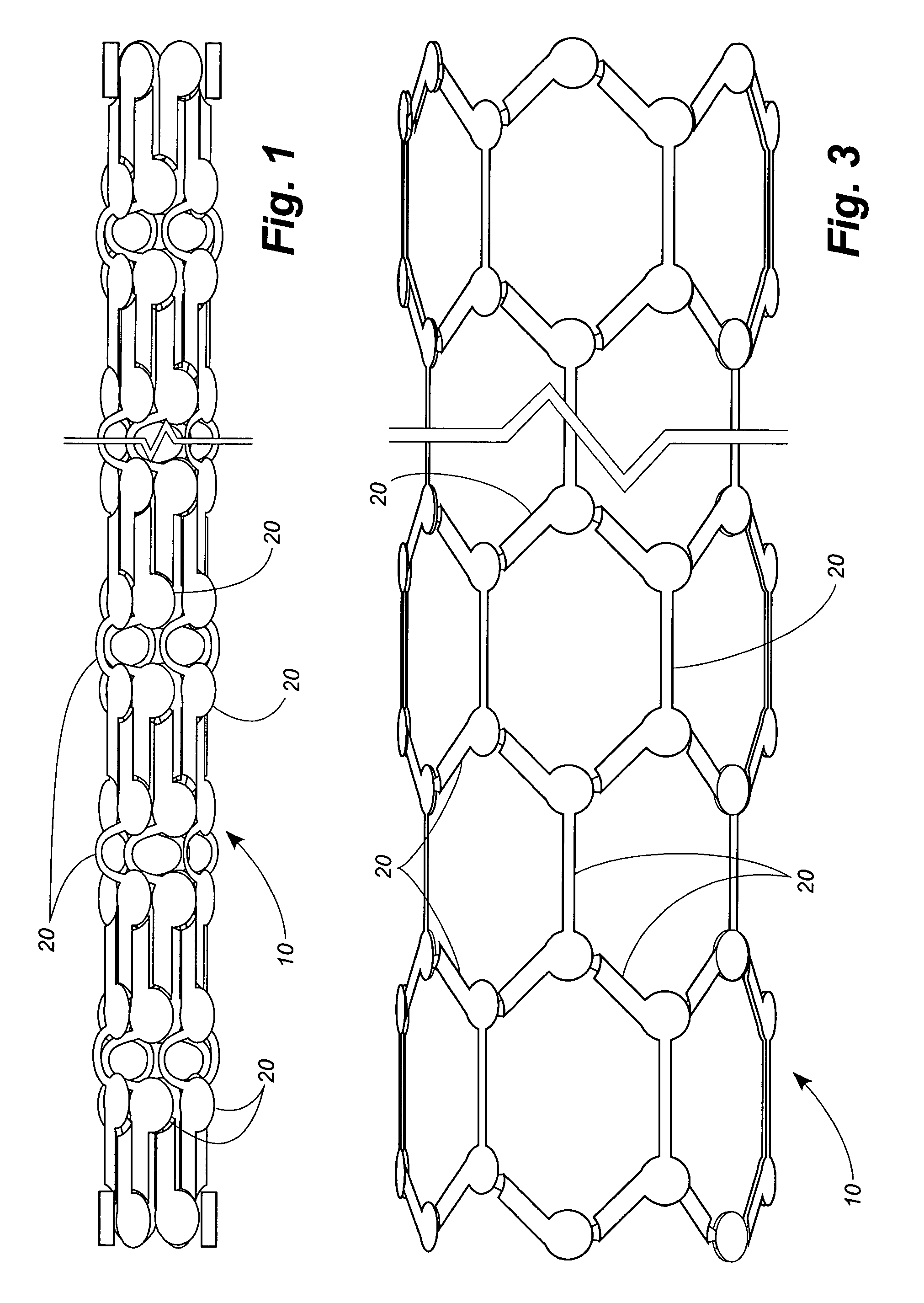

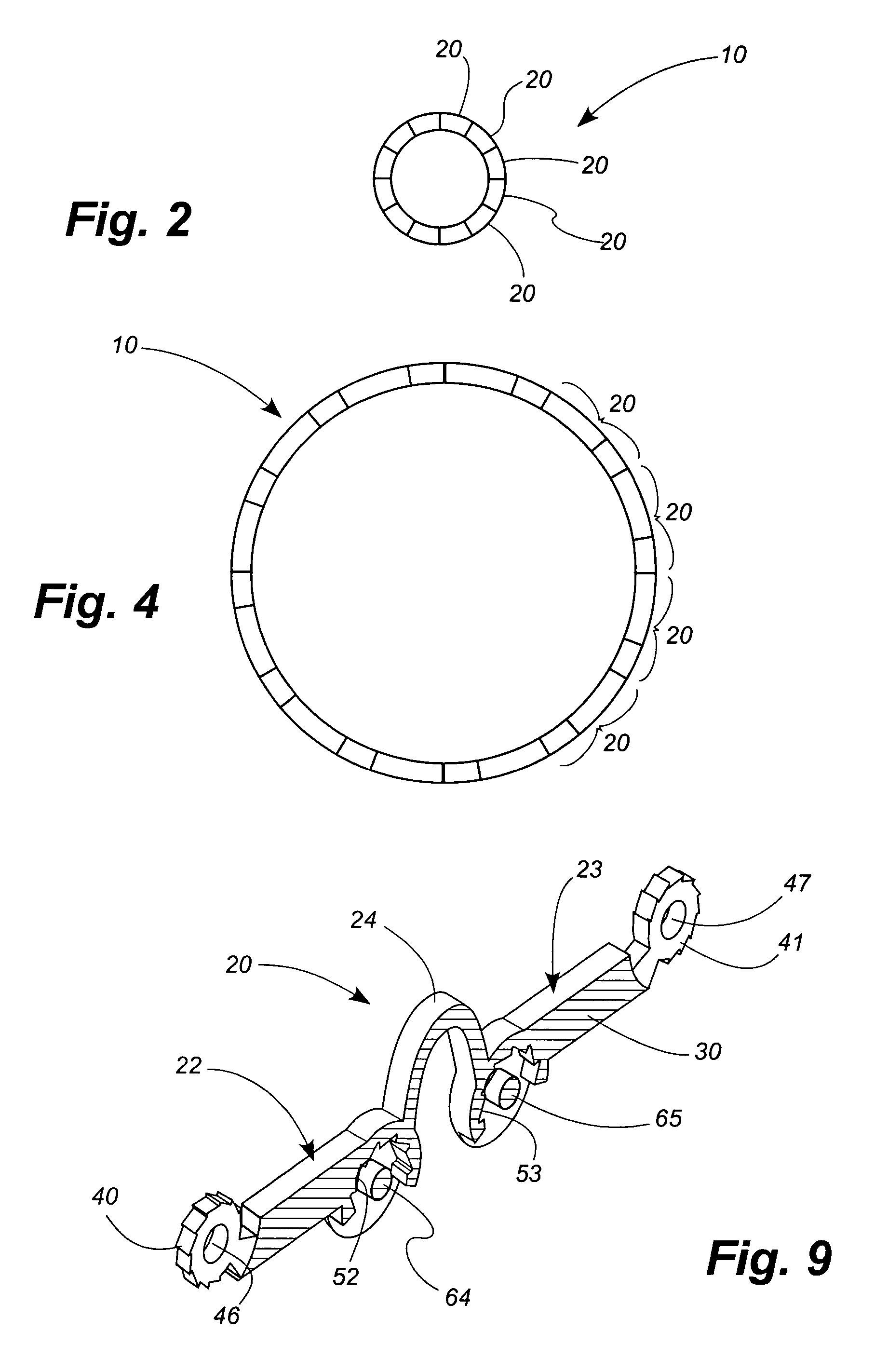

Stent with micro-latching hinge joints

A stent is constructed using interconnected links having micro-mechanical latching mechanisms. The micro-mechanical latching elements allow relative rotational movement of interconnected links in one rotational direction but restrict relative rotational movement of the two links in the opposite direction. The micro-mechanical latch surface features are formed using microelectronic mechanical systems (MEMS) manufacturing methods. The male surface of the latching components contains an array of ridges or protrusions, and the receiving surface contains a matching array of recesses. The array of ridges or protrusions and the corresponding recesses have uniformly dissimilar slopes that result in a substantially greater frictional force in one direction than in the opposite direction. The separation distance between the two surfaces is such that the male latch surface is engaged with the receiving surface recesses in the low stress “locked” state, preventing motion in the undesired direction. Each male ridge or protrusion can be underlined by a void that promotes elastic deflection when sliding in the desired direction and recovery into the ‘locked’ state when aligned with the recesses.

Owner:MIRUS LLC

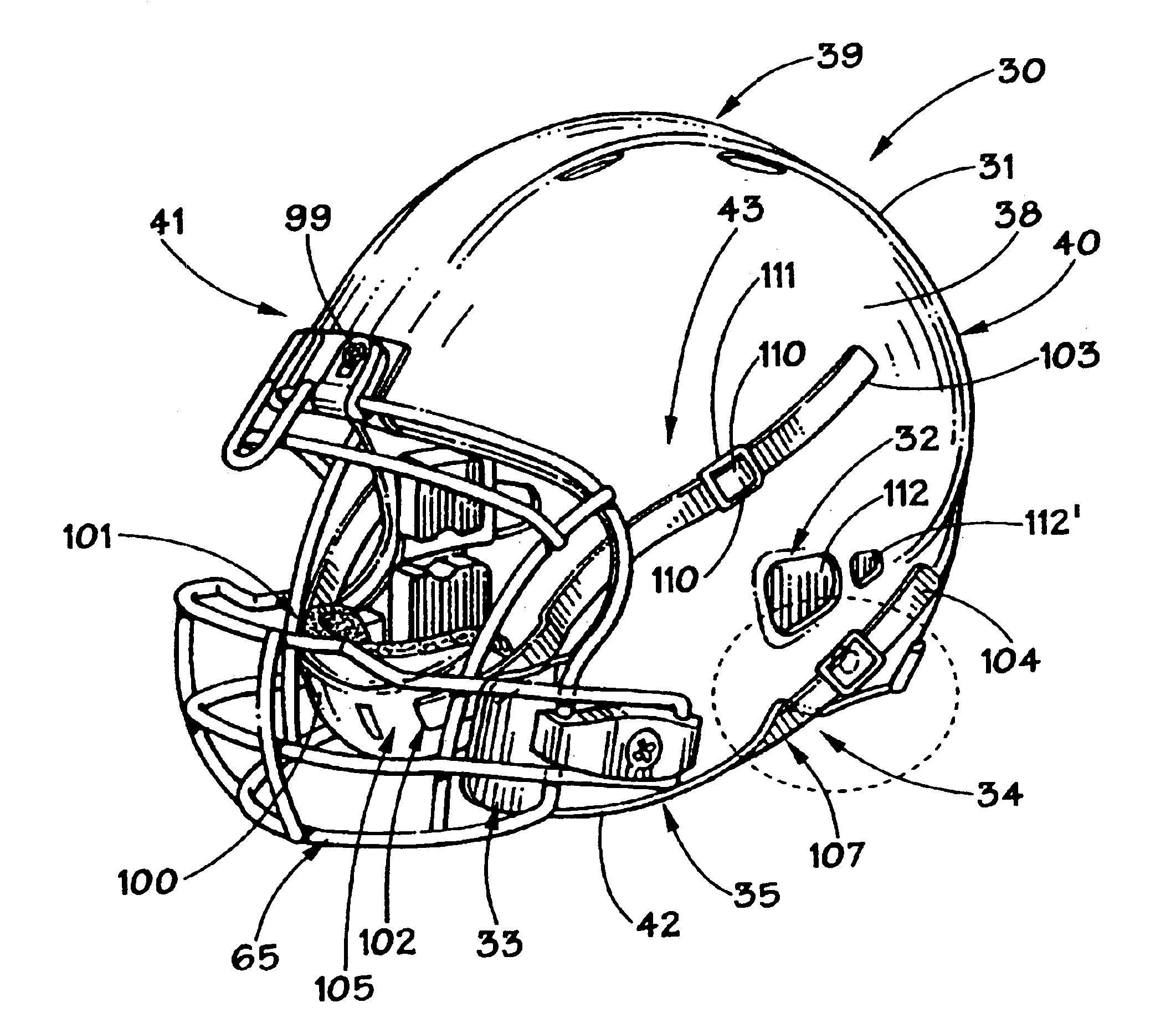

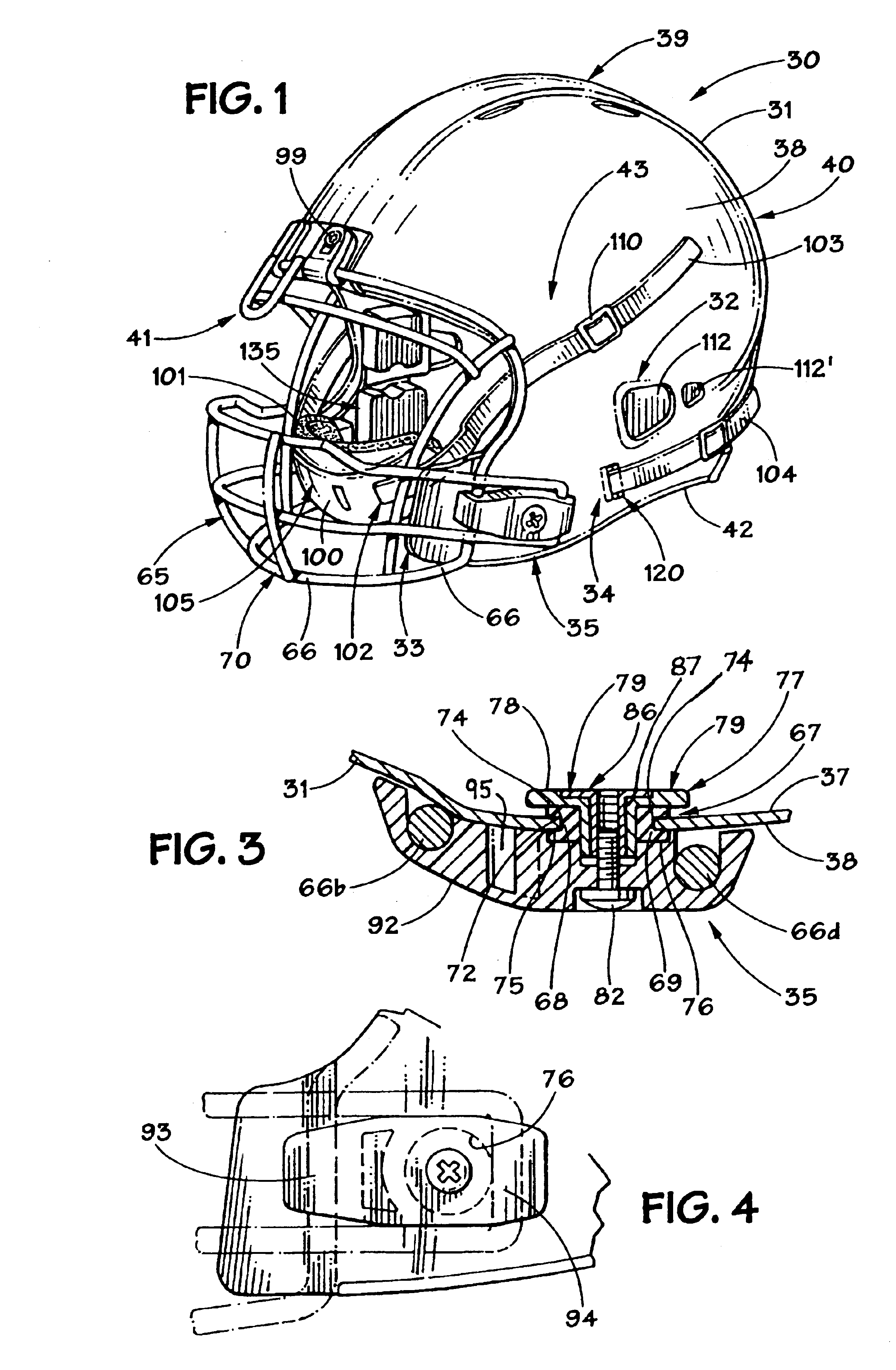

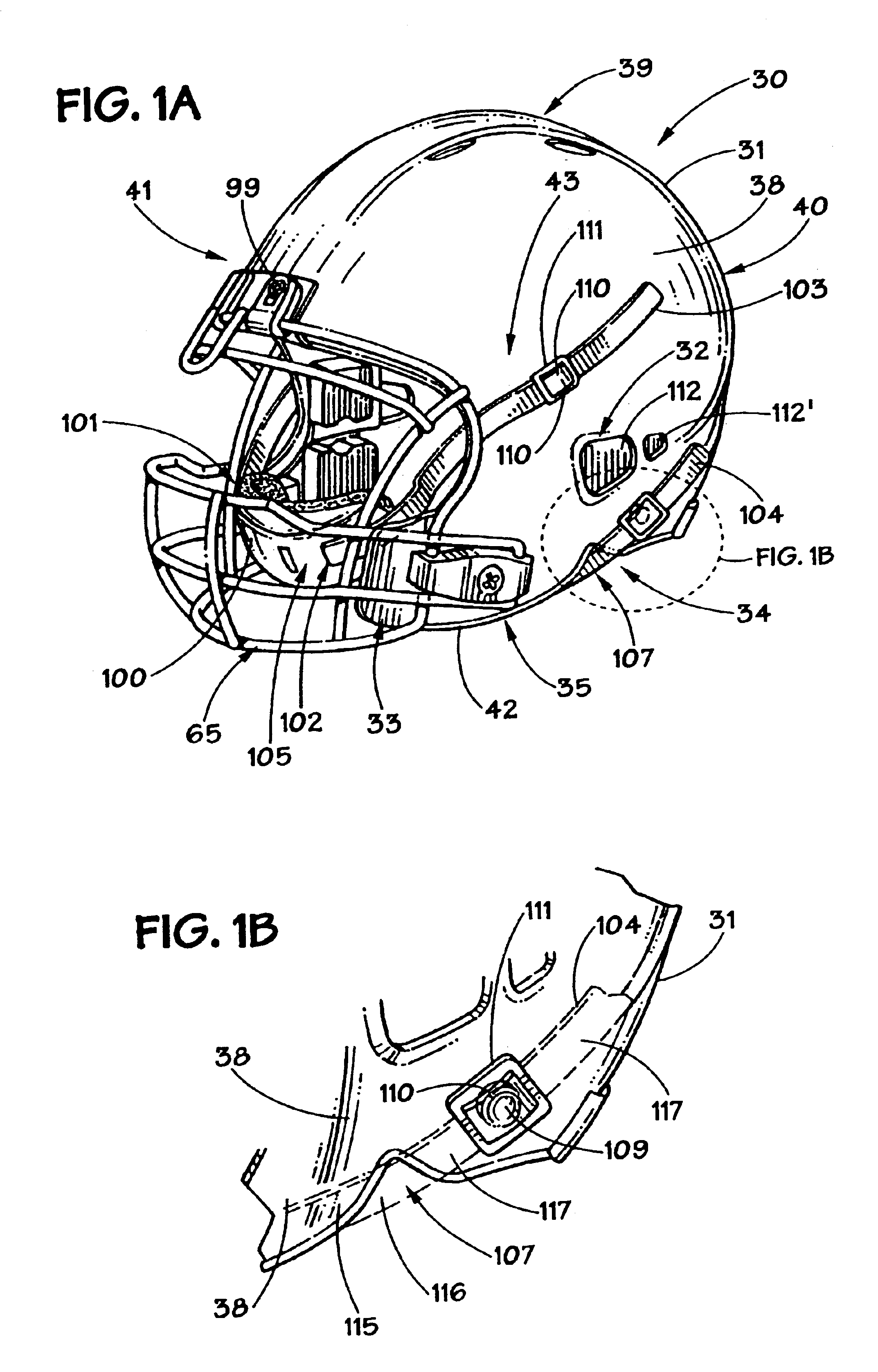

Football helmet

Owner:RIDDELL

Patient interface with forehead support system

ActiveUS7069932B2Minimize leakage and pressureEasy to disassemblePhysical therapyRespiratory masksSupporting systemForehead

Owner:RIC INVESTMENTS LLC

Multiple shaft diameter flexible coupling system

Compression exerted by a clamp collar integral to a molded plastic flexible shaft coupling accommodating angular shaft misalignment upon the circumferential outward surface of a radially compressible molded sleeve insert located in a shaft bore of the flexible coupling facilitates engagement of a reduced diameter shaft located within the sleeve insert. Use of a sleeve insert having a different internal diameter similarly accommodates flexible coupling to another diameter shaft. Utilization of sleeve inserts selected from a plurality of different reduced internal diameters and exterior diameters sized to fit either shaft bore enables flexible coupling of both multiple matched shaft diameters and an exponential number of differing opposed shaft diameter combinations within a range limited by the flexible coupling shaft bores. Radial compressibility of the sleeve insert is facilitated by the utilization of resilient material, interruption of the circumferential extension by a longitudinal slot, or both. Utilization of congruent longitudinally uniform, radially non-uniform, flexible coupling shaft bore and insert sleeve outward surfaces provides additional torque transmission capacity.

Owner:SHINOZUKA KINZOU

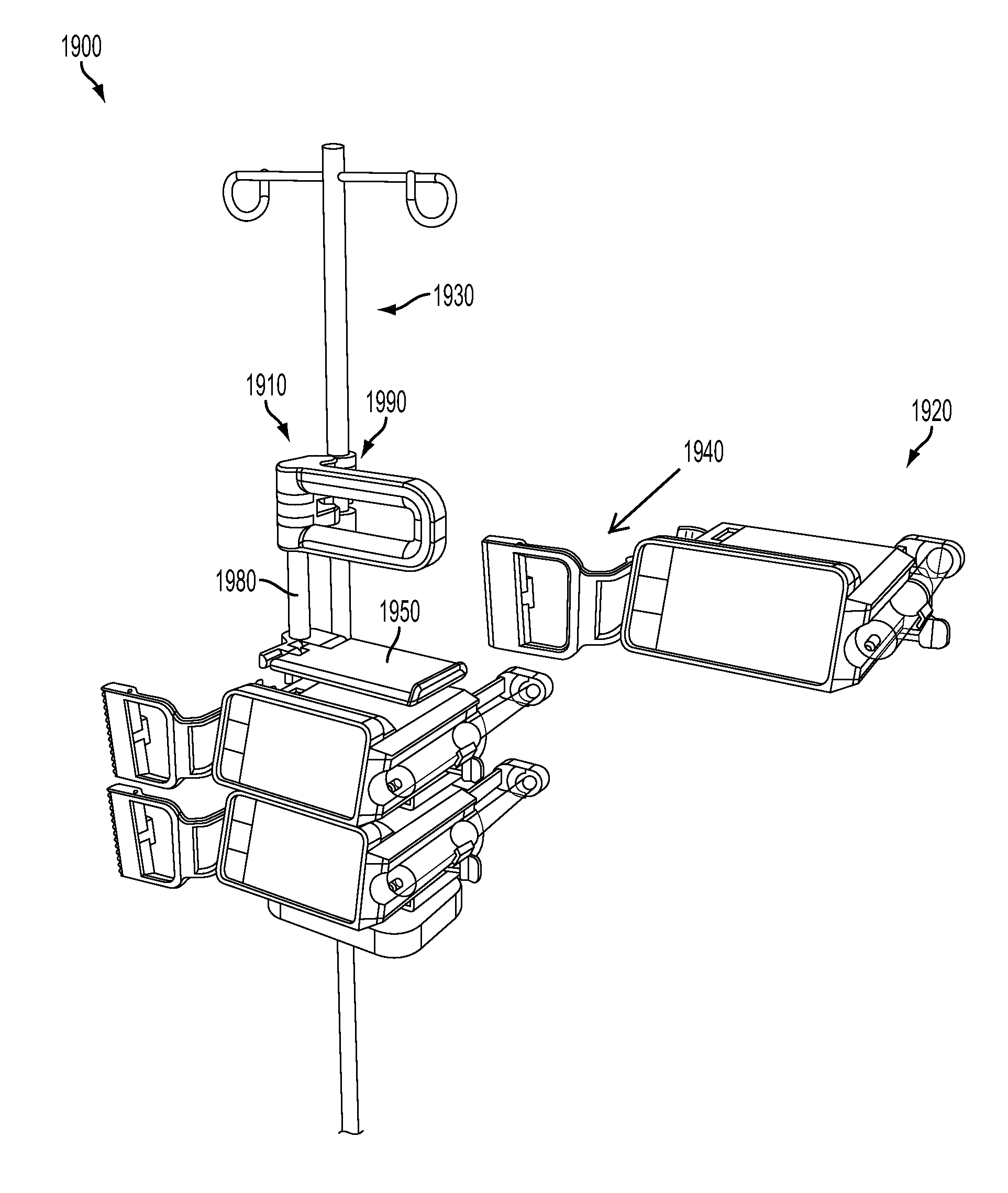

System, Method, and Apparatus for Clamping

ActiveUS20130272773A1Ropes and cables for vehicles/pulleyIntravenous devicesEngineeringMechanical engineering

A protective mechanism for use when gripping a medical device to a rack is provided. A related system and method are also provided. The protective mechanism includes a guide member, a connector, an actuation member configured to have a first end portion and a second end portion. The first end portion of the actuation member is pivotally coupled to the guide member. The cover member is pivotally coupled to the guide member and is configured to interact with the actuation member so as to pivot to uncover the connector when the actuation member pivots in a first direction and to pivot to cover the connector when the actuation member pivots in a second direction.

Owner:DEKA PROD LLP

Flooring system

A joint for connecting two adjacent flooring panels together in a substantially vertical manner includes a rotatable locking member made of plastic, metal or another resilient material. The rotatable locking member is located within a groove or opening of one flooring panel and the second flooring panel has a tongue shaped to mate with the rotatable locking member. Upon installation, the rotatable member rotates and locks around the back of the tongue via a groove above the tongue. The rotatable locking member includes a resilient arm which is bent away from its initial rest position upon installation, so that when the rotatable locking member locks onto the tongue, the resilient arm is bent providing a biasing force which holds the panel securely in position.

Owner:MUEHLEBACH MORITZ ANDRE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com