Patents

Literature

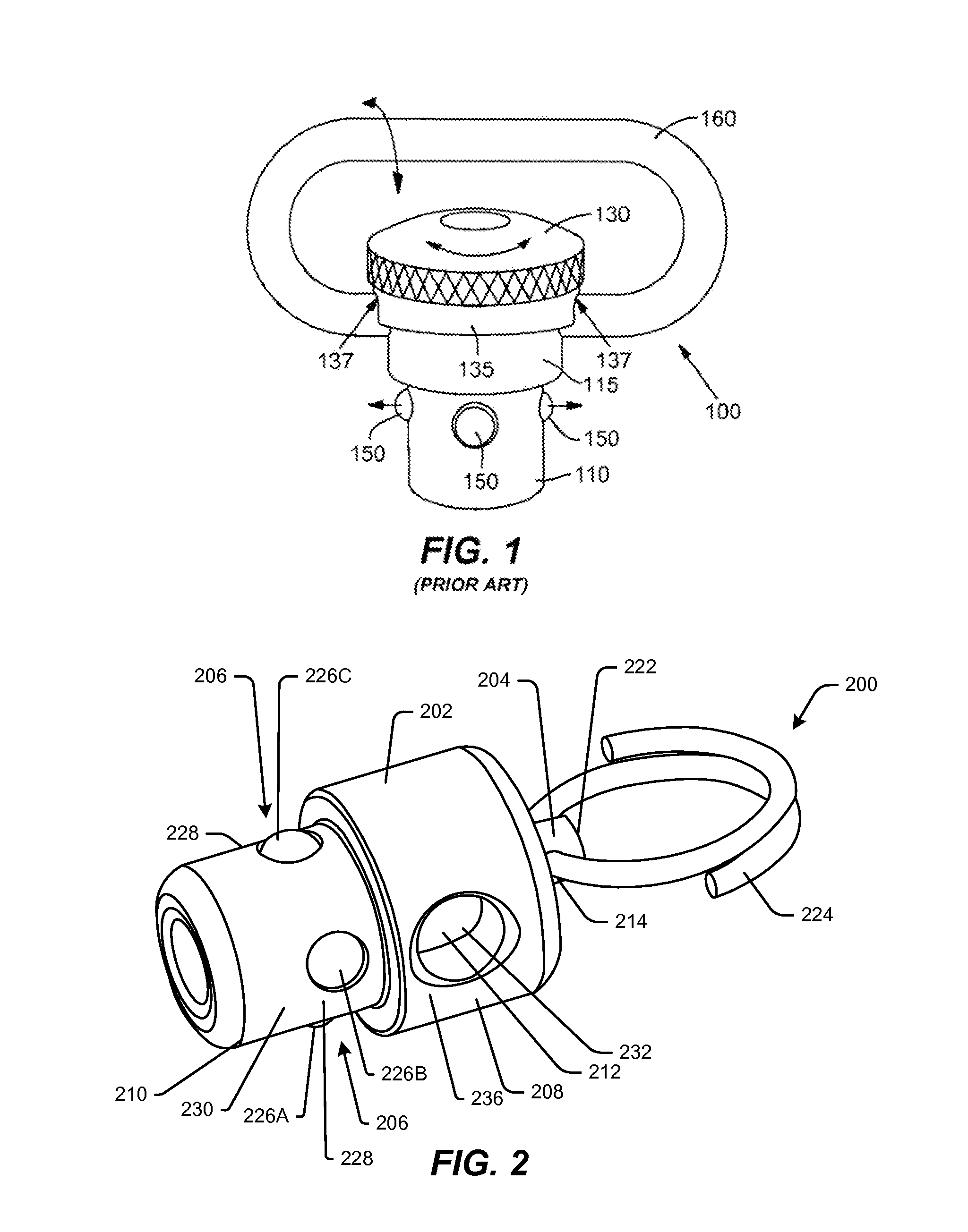

1788 results about "Rotational joint" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

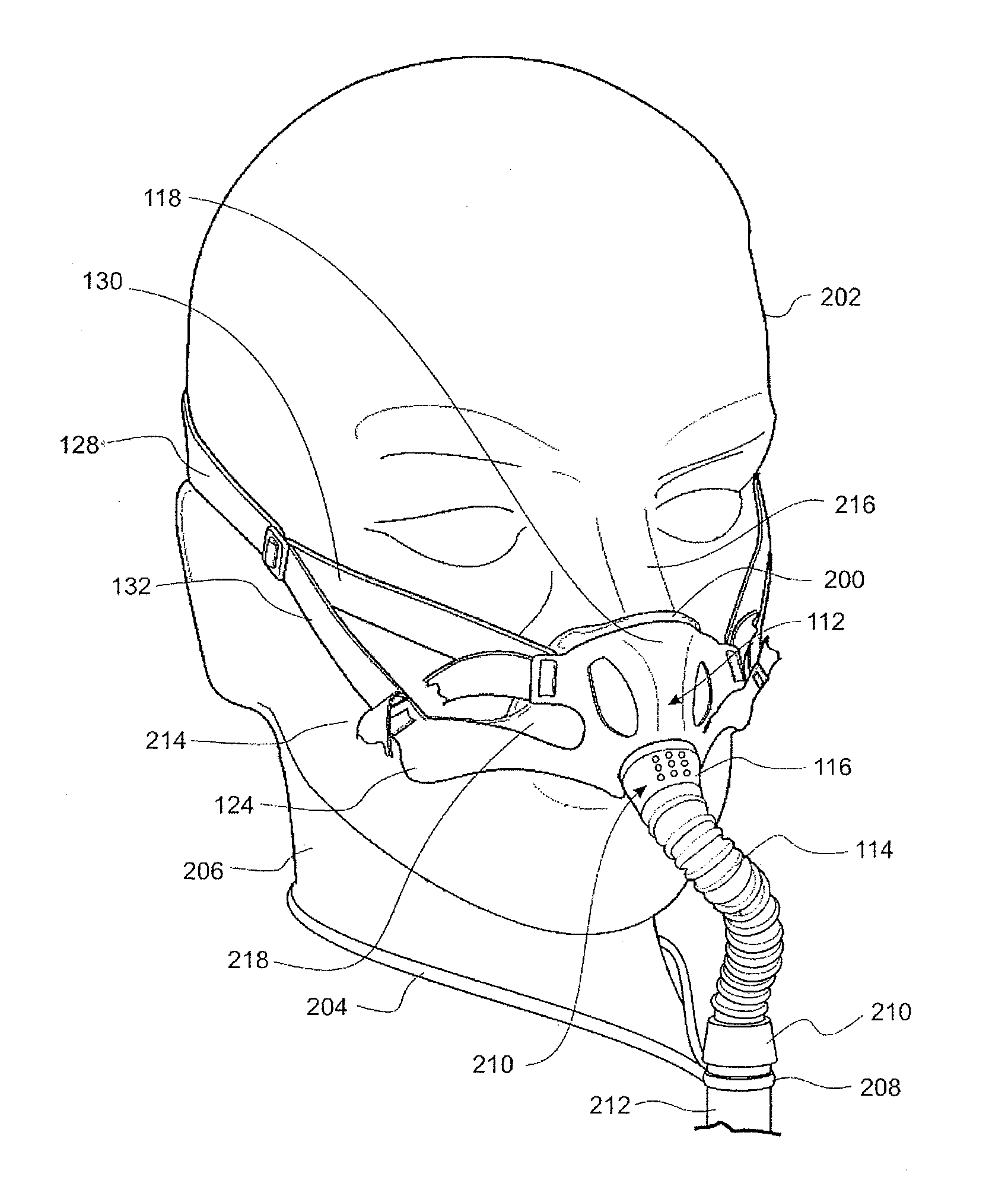

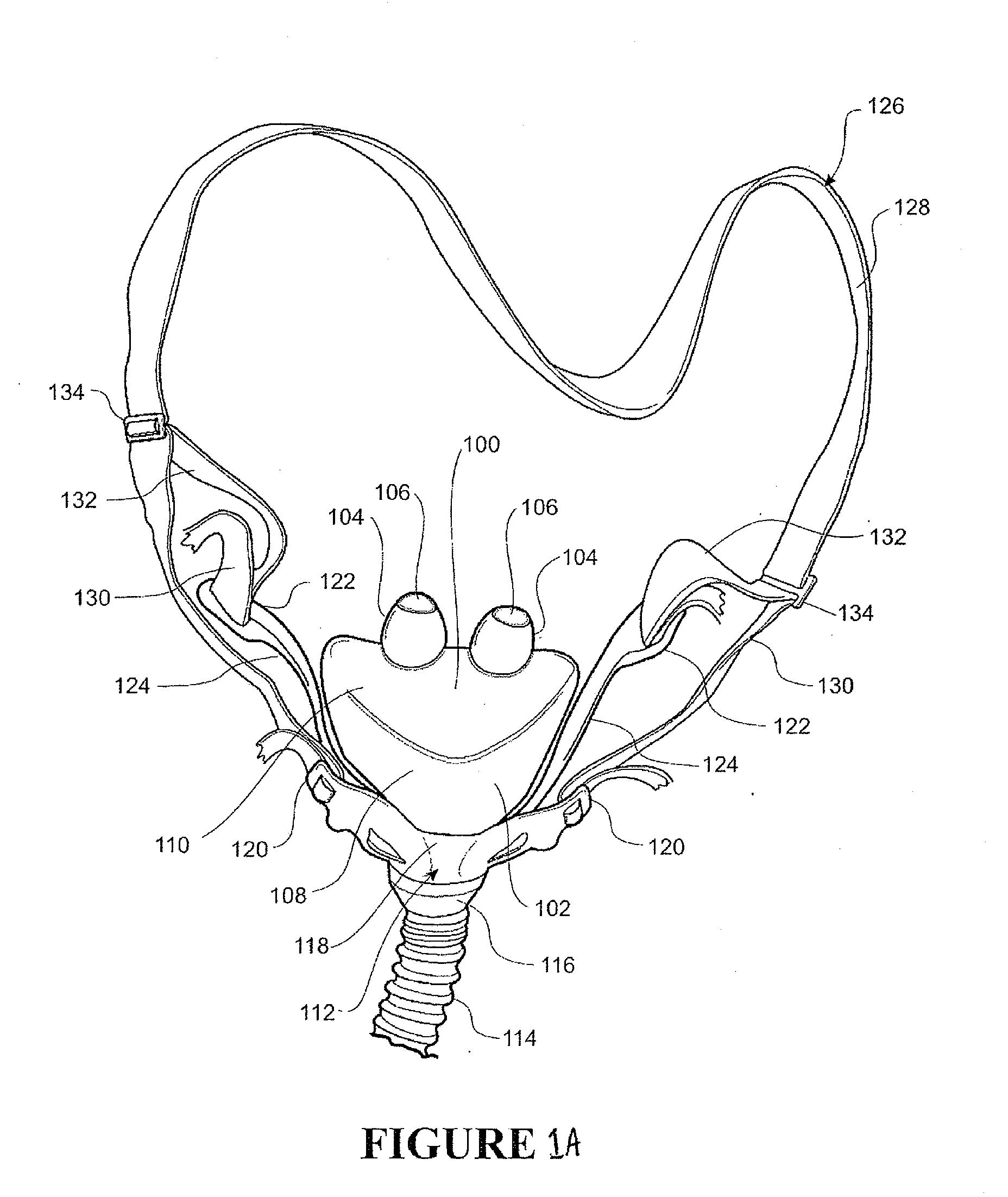

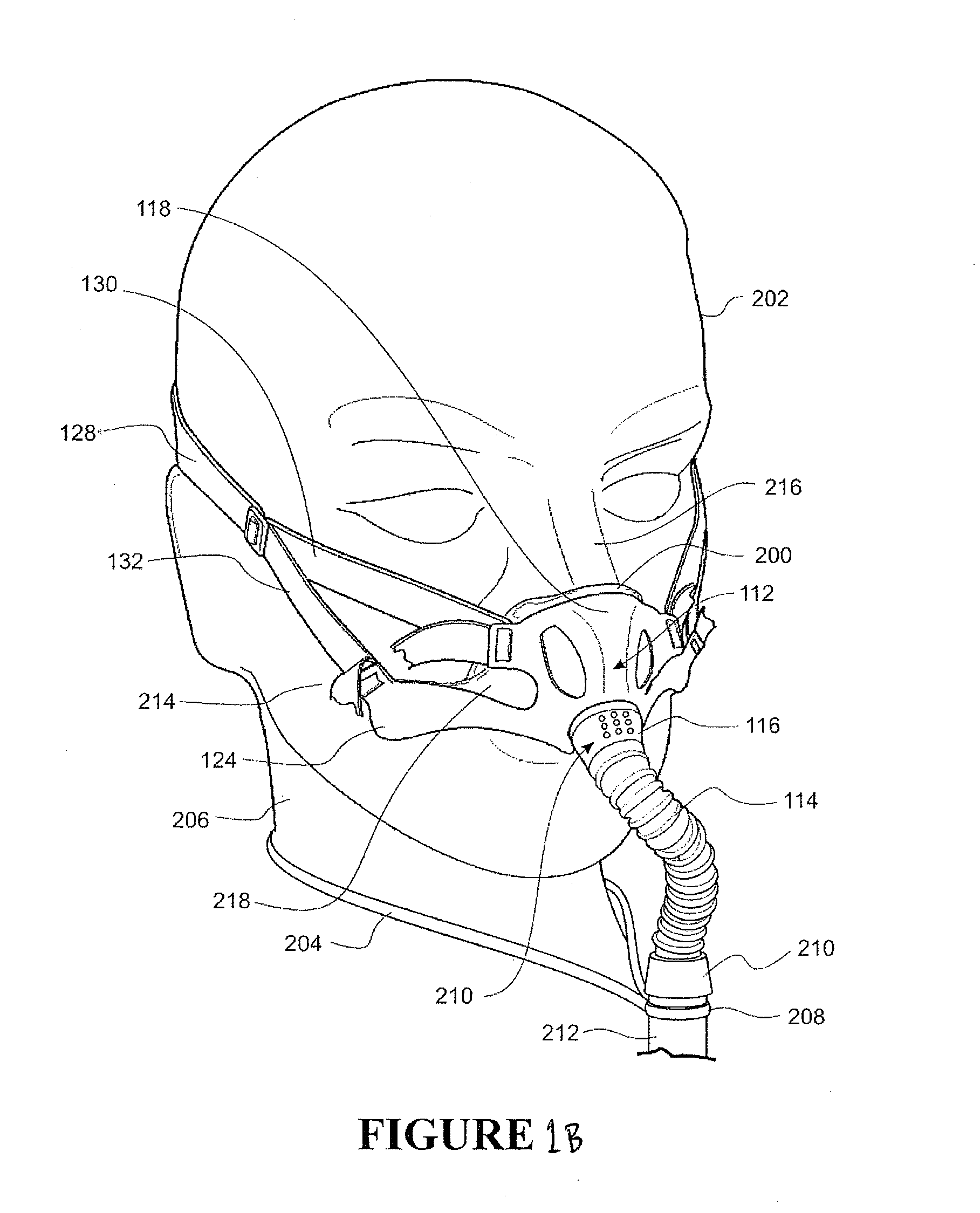

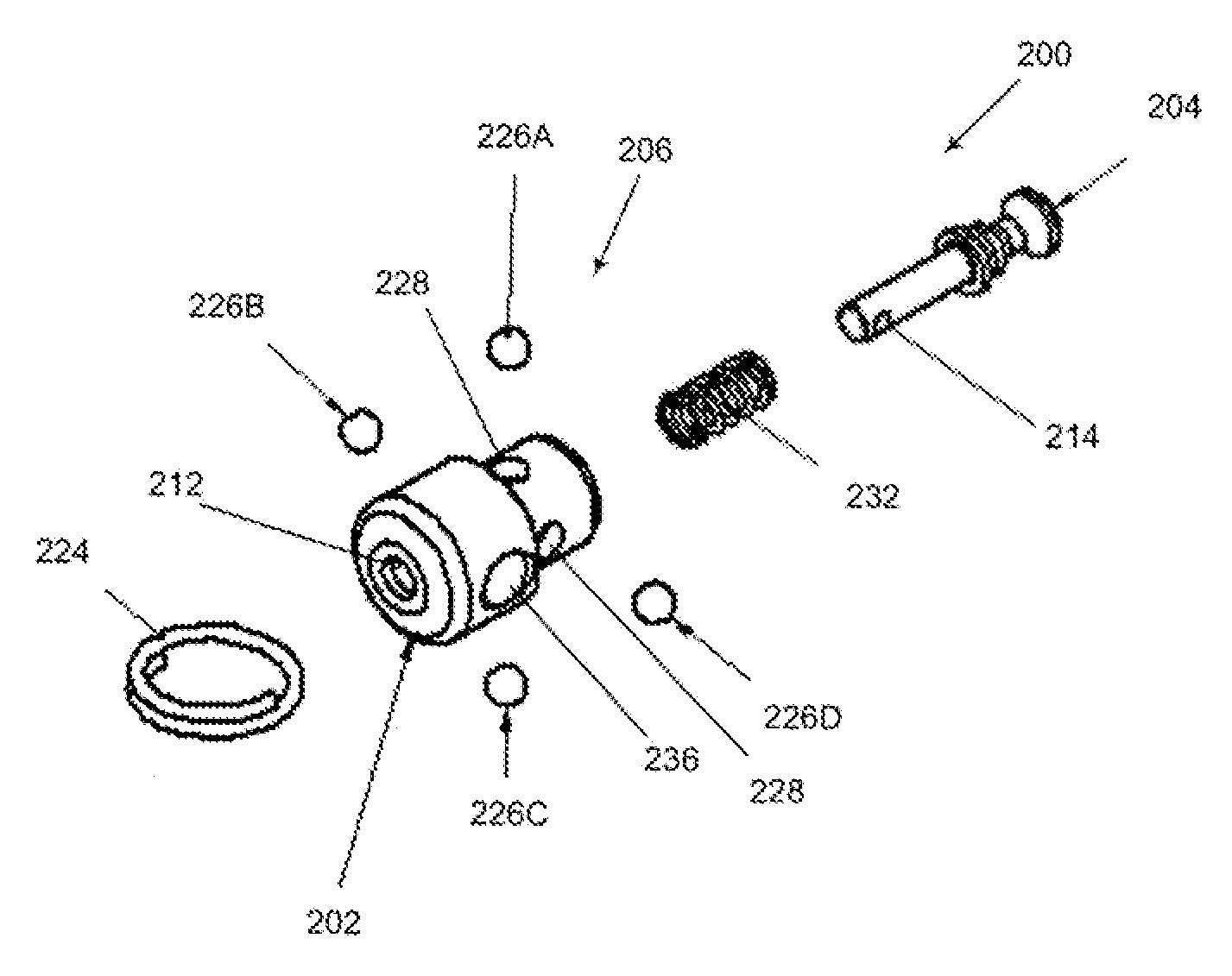

Patient interface and aspects thereof

A patient interface has a single loop headstrap and a mask for covering at least the nostrils of the user. The single loop headstrap extends from the mask at either end. A short length of supple conduit is coupled to the mask by a swivel or ball joint to allow rotation of the conduit relative to the mask through different angles and orientations.

Owner:FISHER & PAYKEL HEALTHCARE

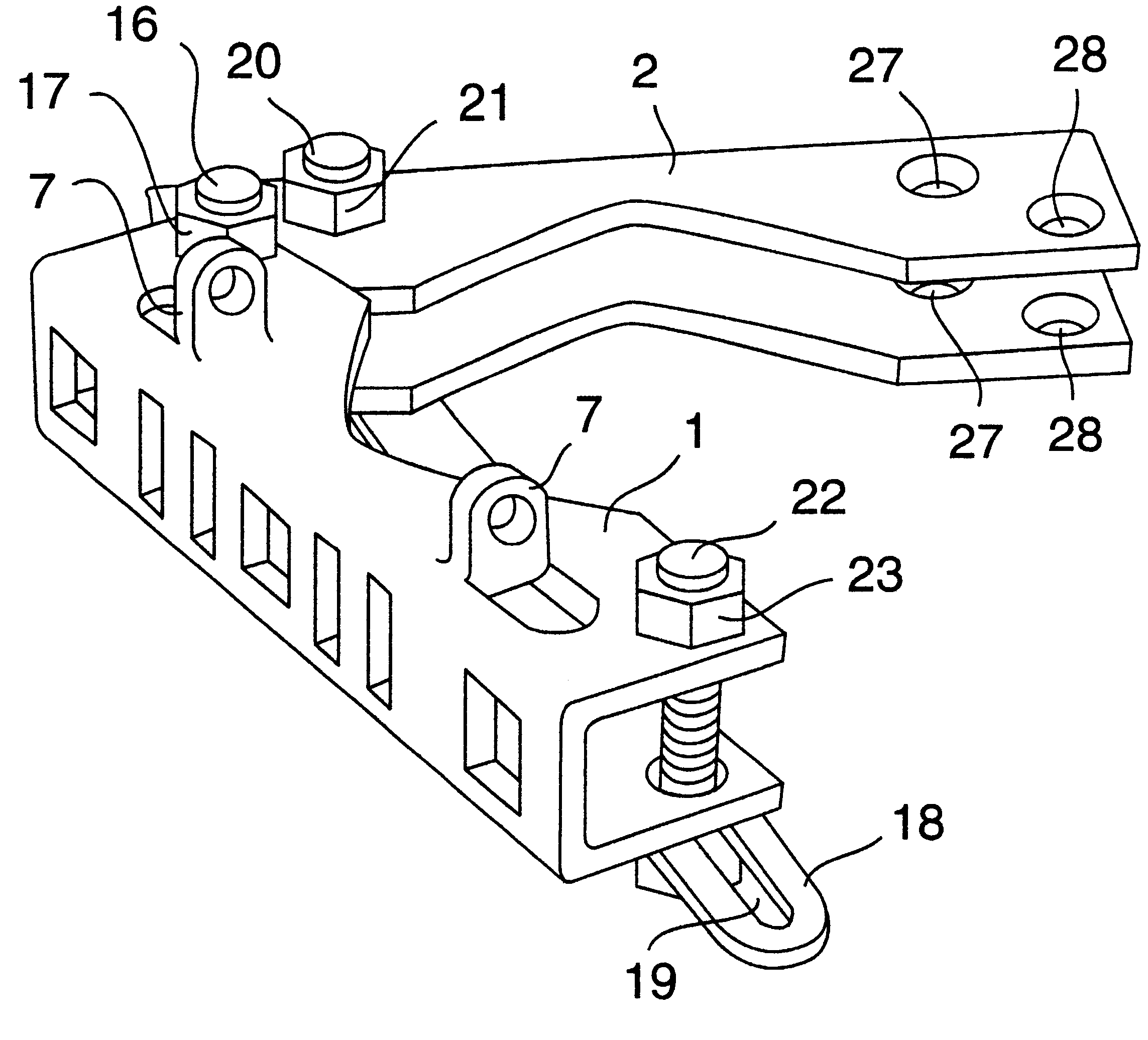

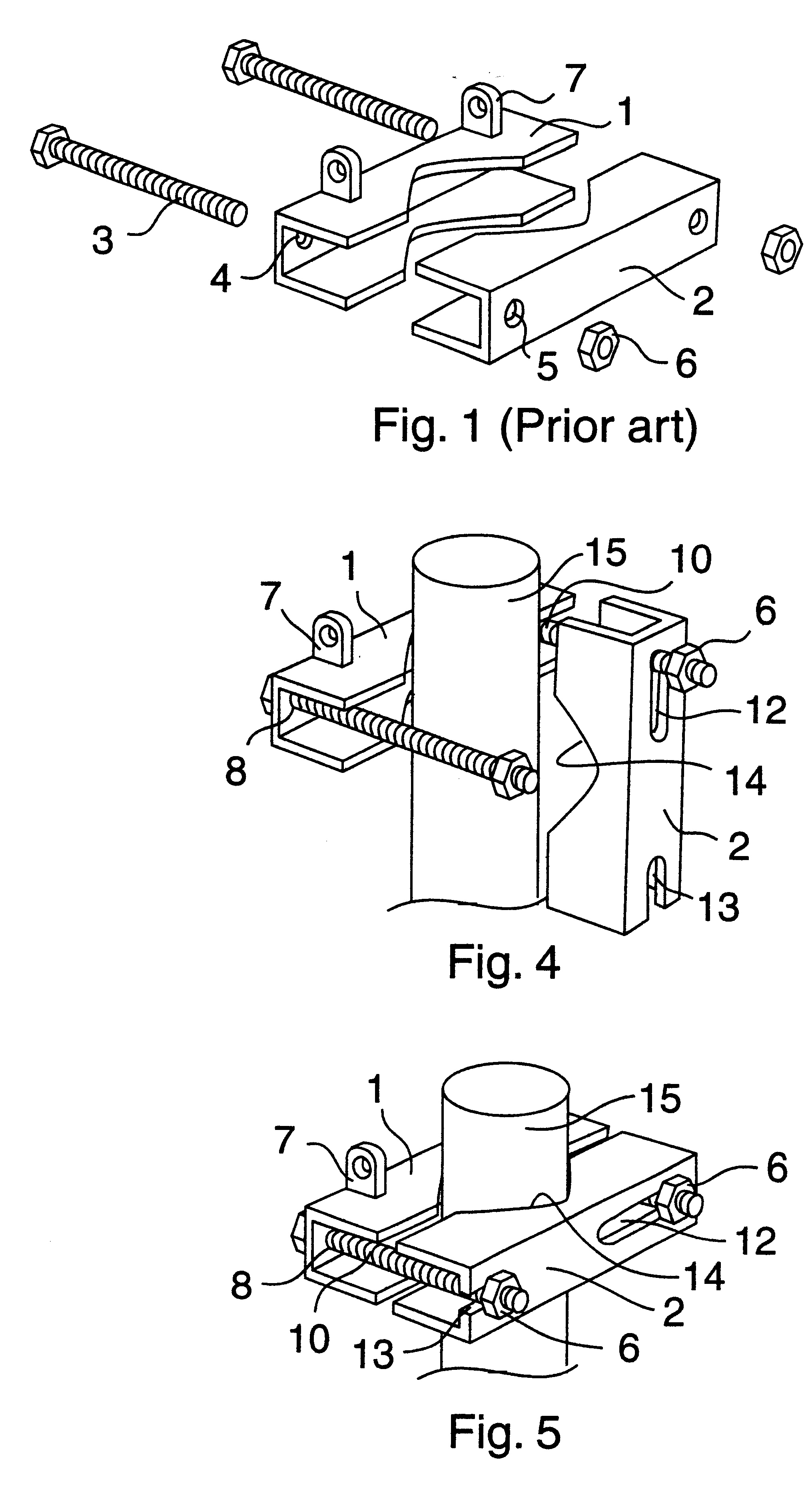

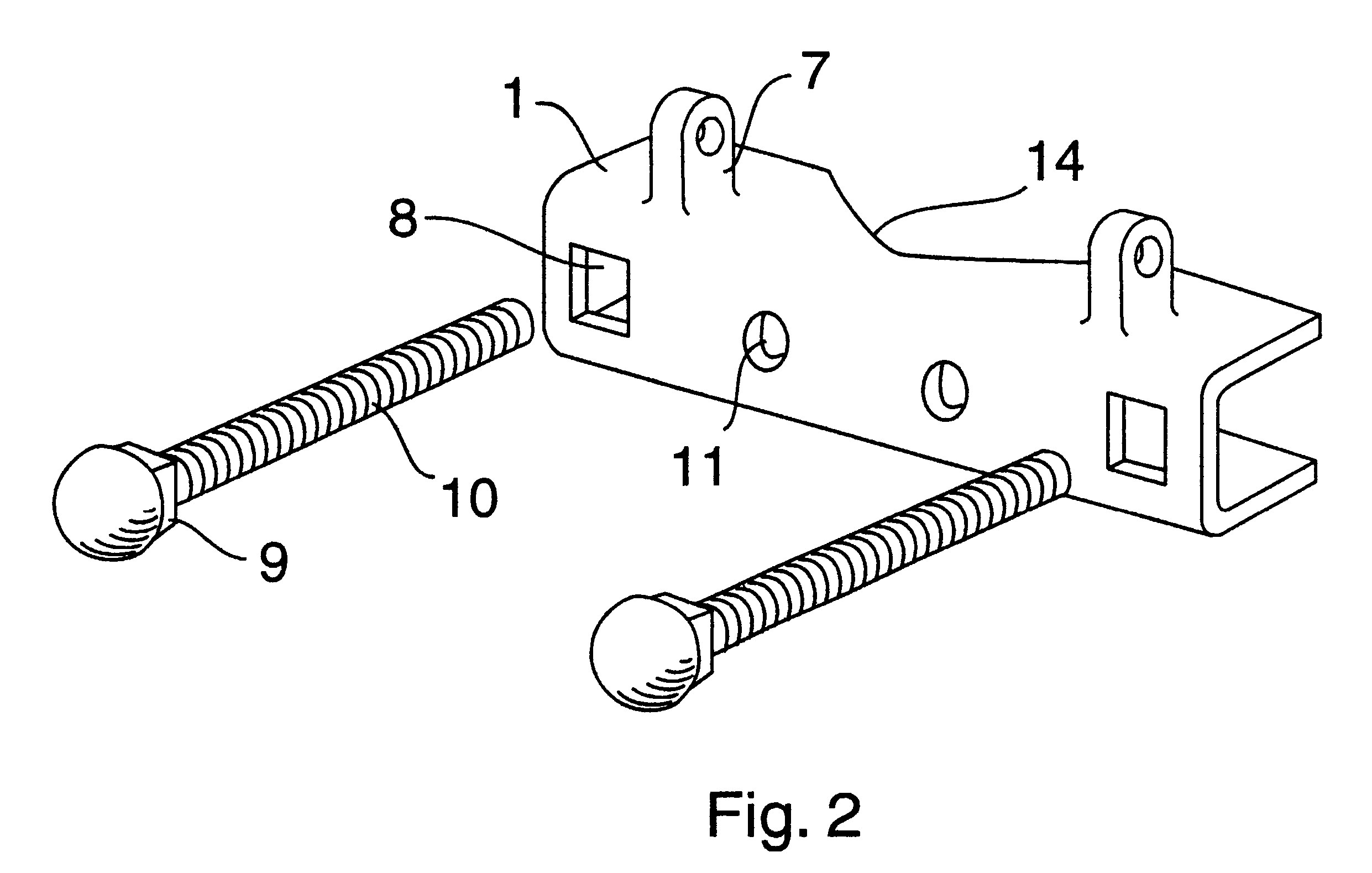

Mounting bracket

A mounting bracket useful for securing a base, such as an antenna to a pole, a tube or a post, or a similar anchor support, and including a first clamp part, being a base clamp, to be secured to the base (the antenna) adapted to be locked against the pole, and a second clamp part, being tightening clamp, adapted to partly embrace the pole and to be tightened to the base clamp with the pole clamped therebetween, preferably by a screw-nut connection on each side of the pole. The tightening clamp, is formed with two elongated slots extending in the longitudinal direction of the clamp, a first slot of which may be closed and the second slot of which is open at the end of the clamp. The slots having a width matching the diameter of the clamp screws, a length which is at least twice the diameter of the clamp screws and arranged such that the open slot of the tightening clamp can be rotated freely past the corresponding bolt thereby engaging the corresponding clamp screw through the open end of the slot after the pole has been placed in contact with the base clamp. A tightening clamp and a base clamp can be joined in a rotational joint. Thereby an object, which is mounted, e.g. an antenna, can be panned.

Owner:INTEL CORP

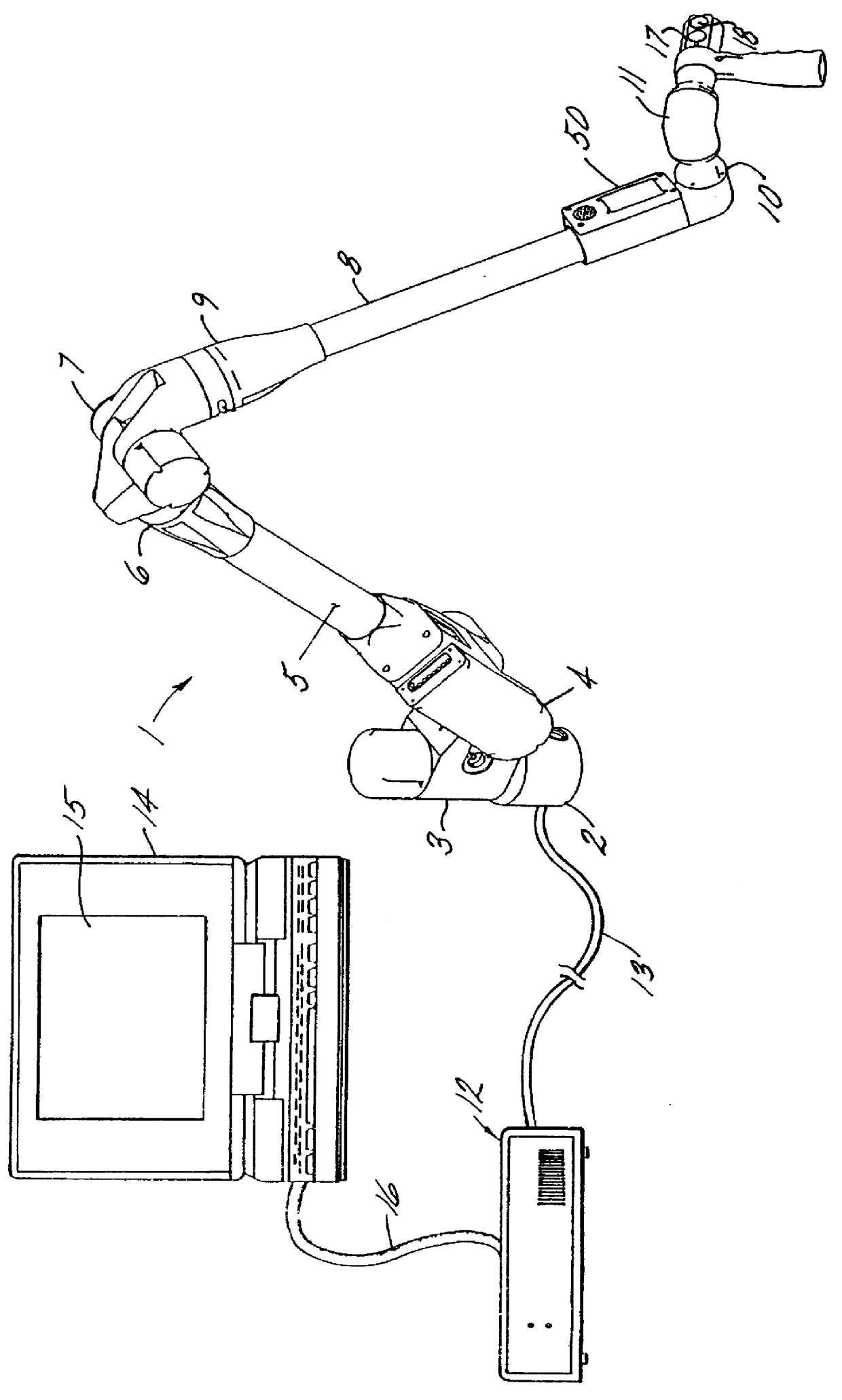

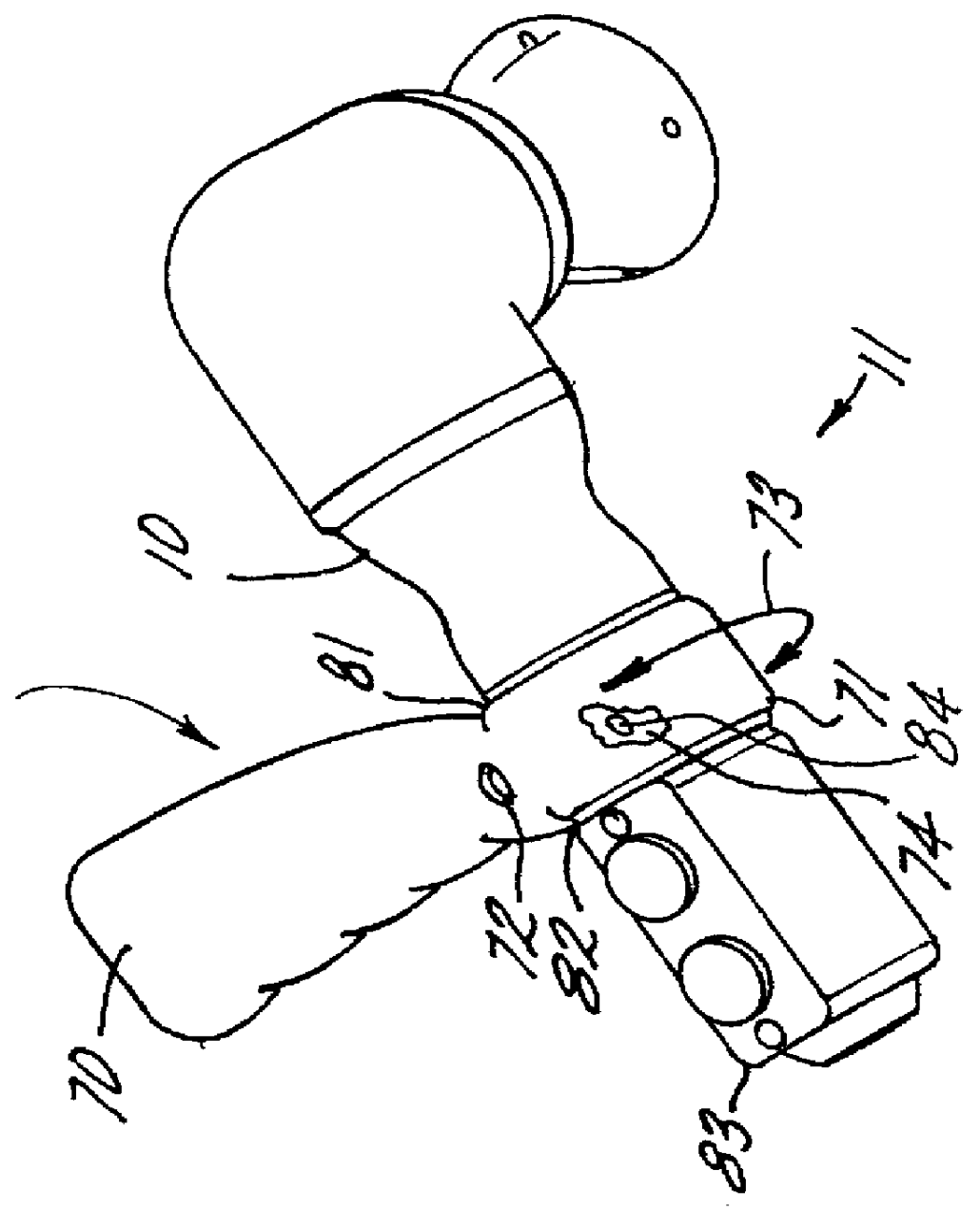

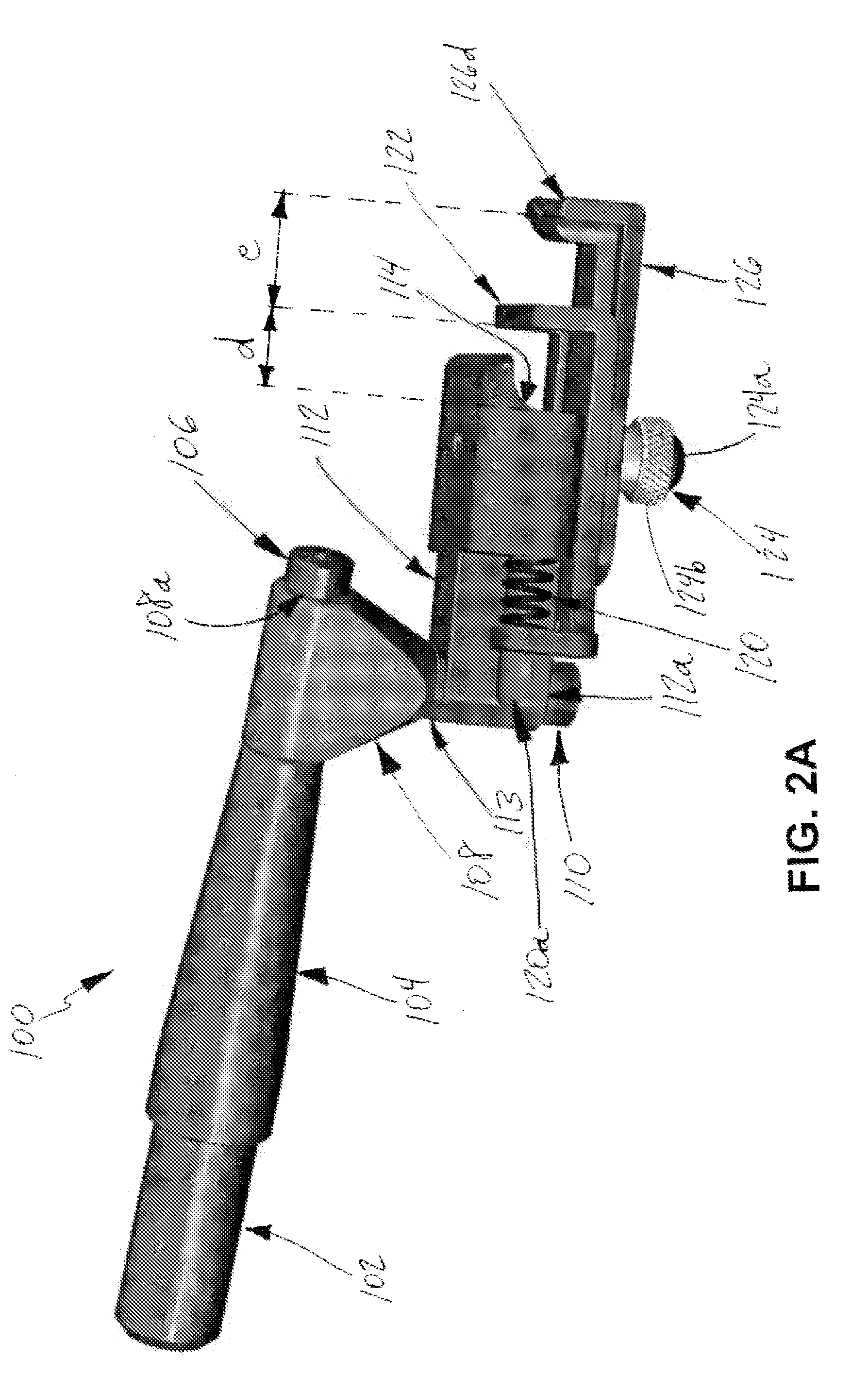

Adjustable handgrip for a coordinate measurement machine

InactiveUS6151789AEasy to holdDispensing apparatusMechanical measuring arrangementsDetentEngineering

A novel adjustable hand grip device for use with a three dimensional coordinate measurement system provides an ergnomically formed pistol grip rotatably positioned on a manually manipulated multijointed measuring arm allowing a plurality of angular positions convenient to an operator. The adjustable hand grip includes a clamp for releasably securing the device n a preselected position. An embodiment of the present invention includes a ball and detent device for releasably positioning the hand grip in a plurality of preselected positions. In yet another embodiment the hand grip device includes a swivel joint allowing rotation of the pistol grip relative to the clamp.

Owner:FARO TECH INC

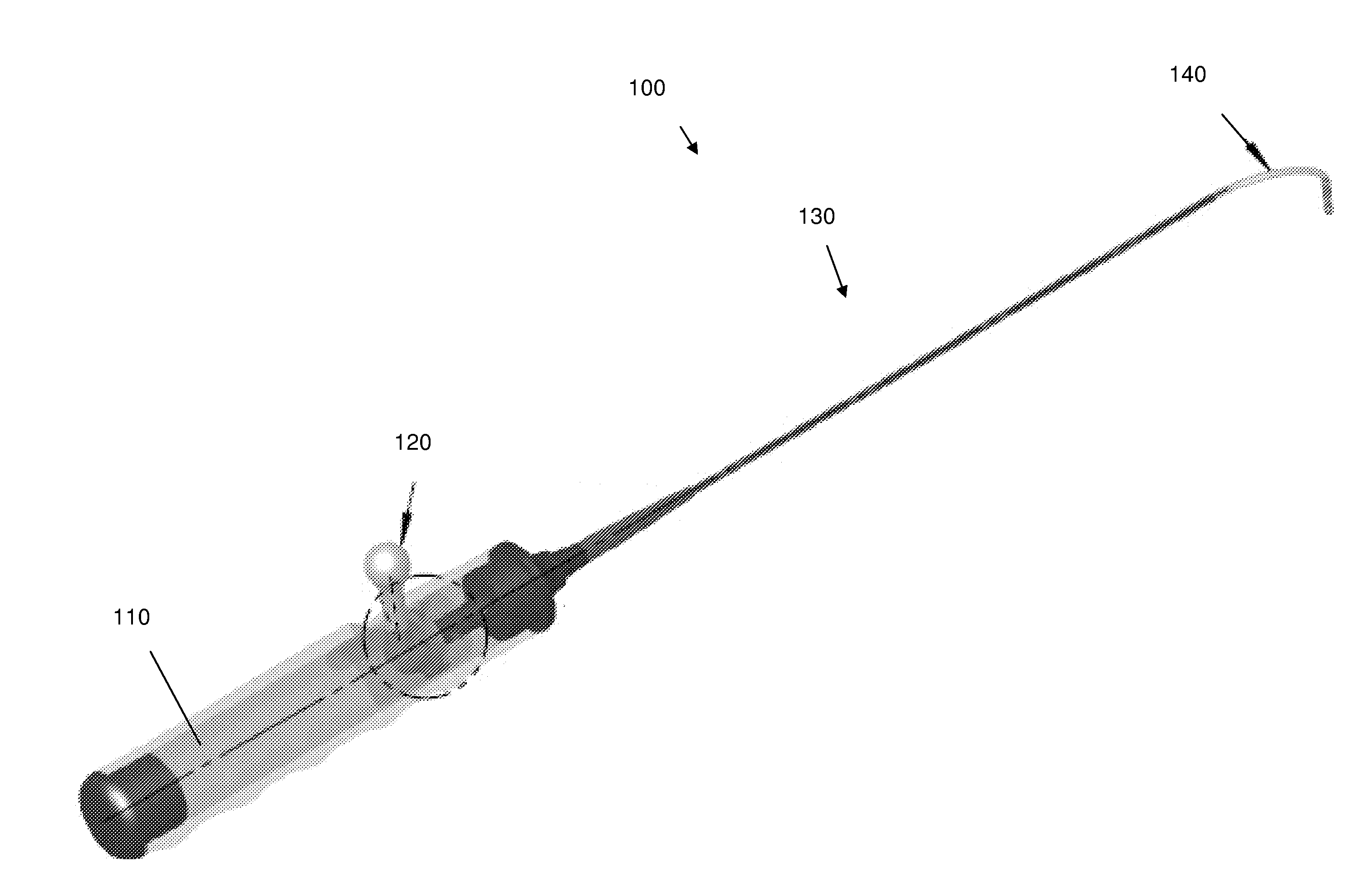

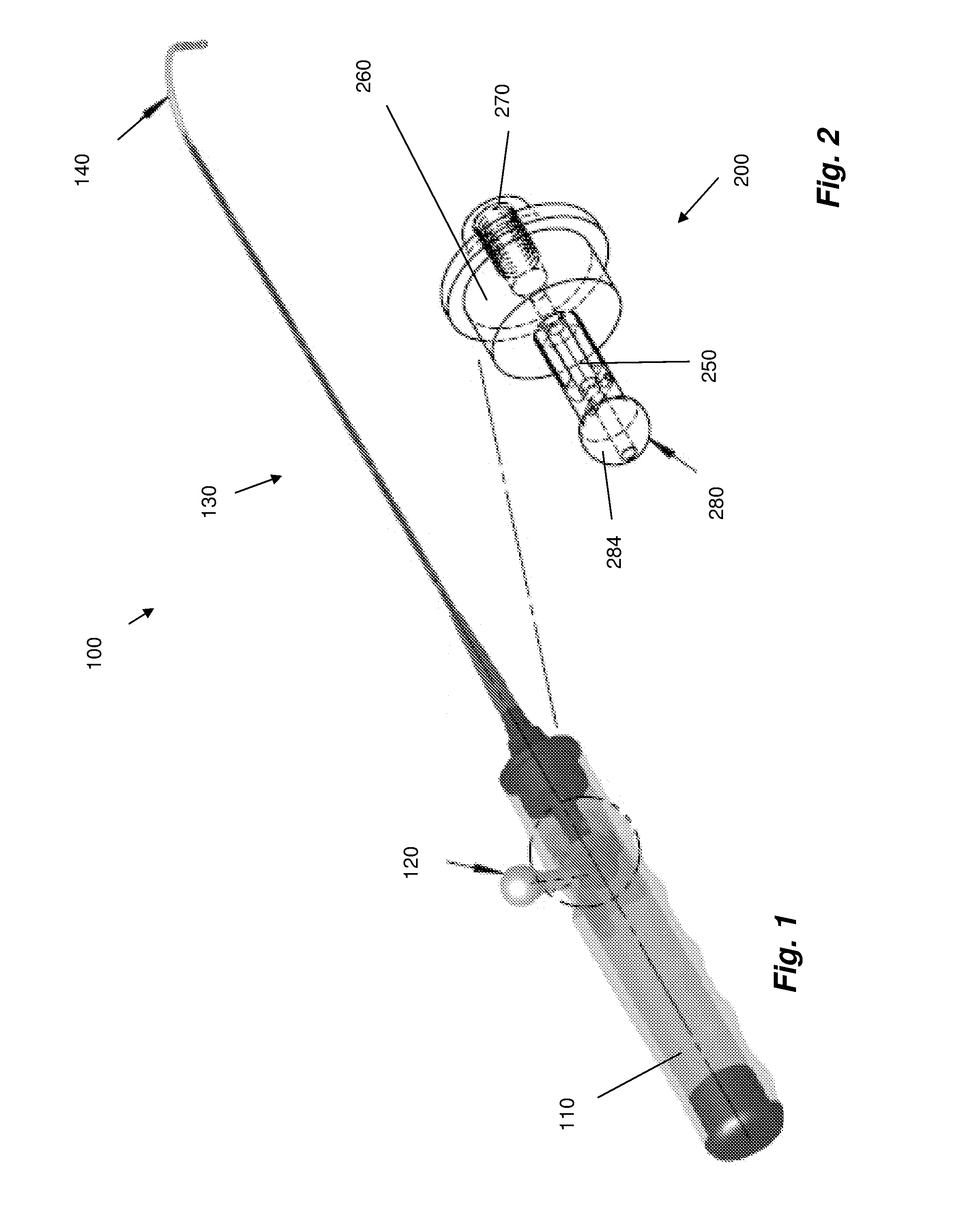

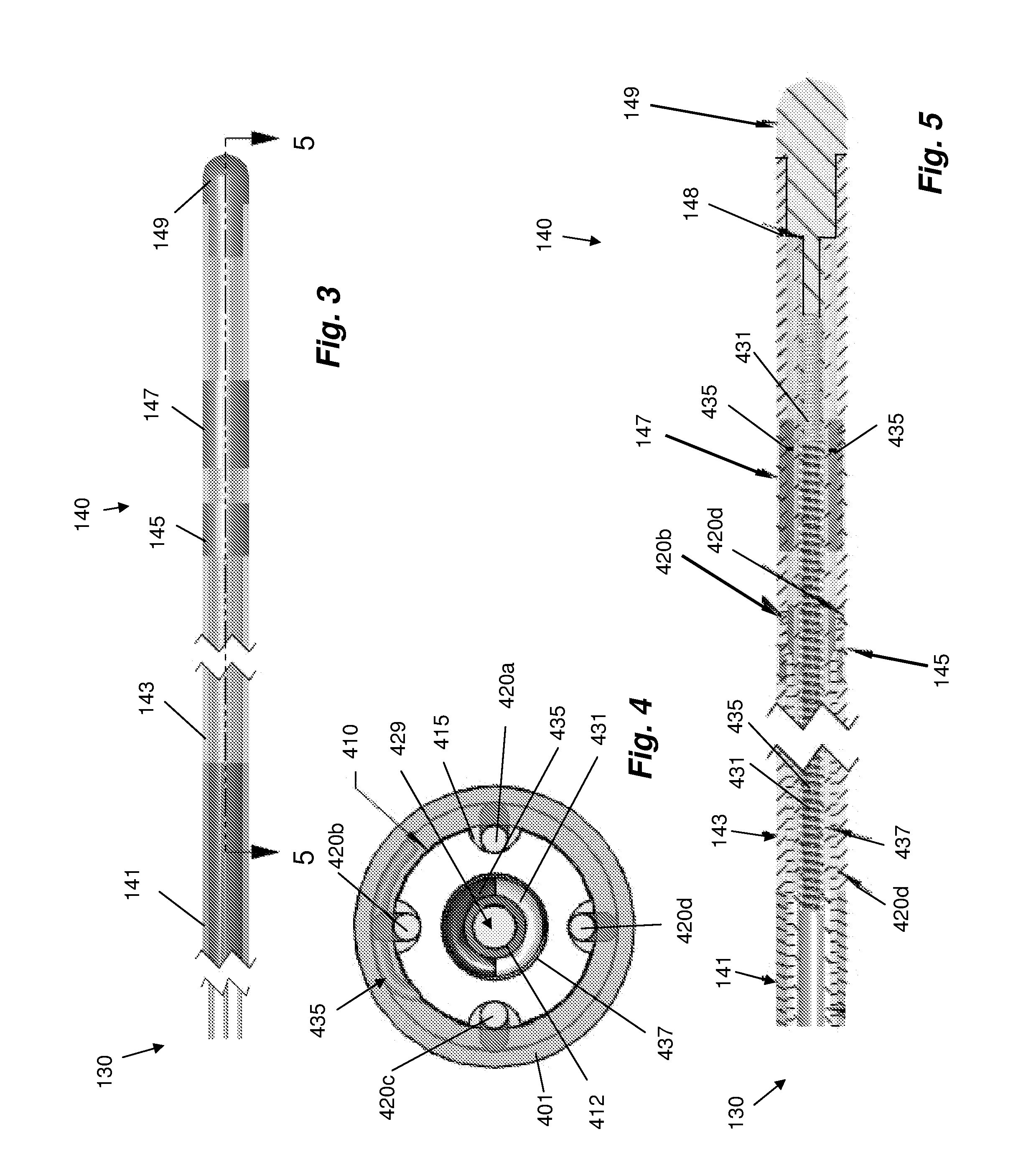

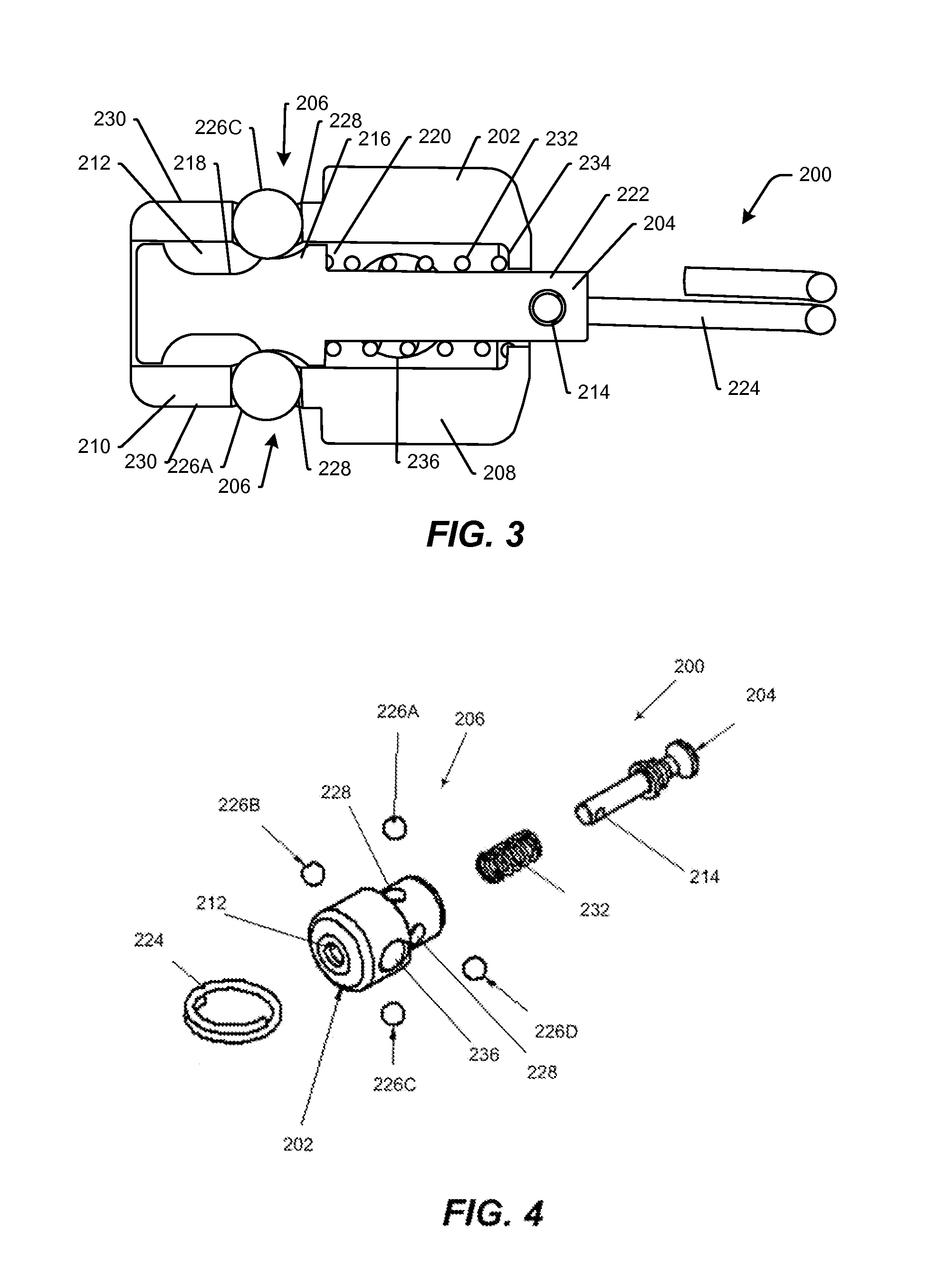

Catheter Control Mechanism and Steerable Catheter

ActiveUS20100106141A1Flexible operationInexpensive and durableElectrocardiographyCatheterSteering wheelEngineering

A steerable multi-polar lead shaft assembly includes a core member extending longitudinally through the shaft assembly, a plurality electrically conductive elements disposed within the core member, a plurality of steering wires circumferentially distributed about the core member. A control mechanism for a steerable catheter, such as the steerable multi-polar lead assembly, includes a mounting portion adapted to engage a steerable shaft, a stem extending from the mounting portion, a swivel joint arranged at a proximal end of the stem, a control yoke rotatably mounted on the swivel joint, adapted to engage a plurality of steering wires of the steerable catheter, and a handle connected with the yoke, adapted for direct manipulation by a user.

Owner:OSCOR

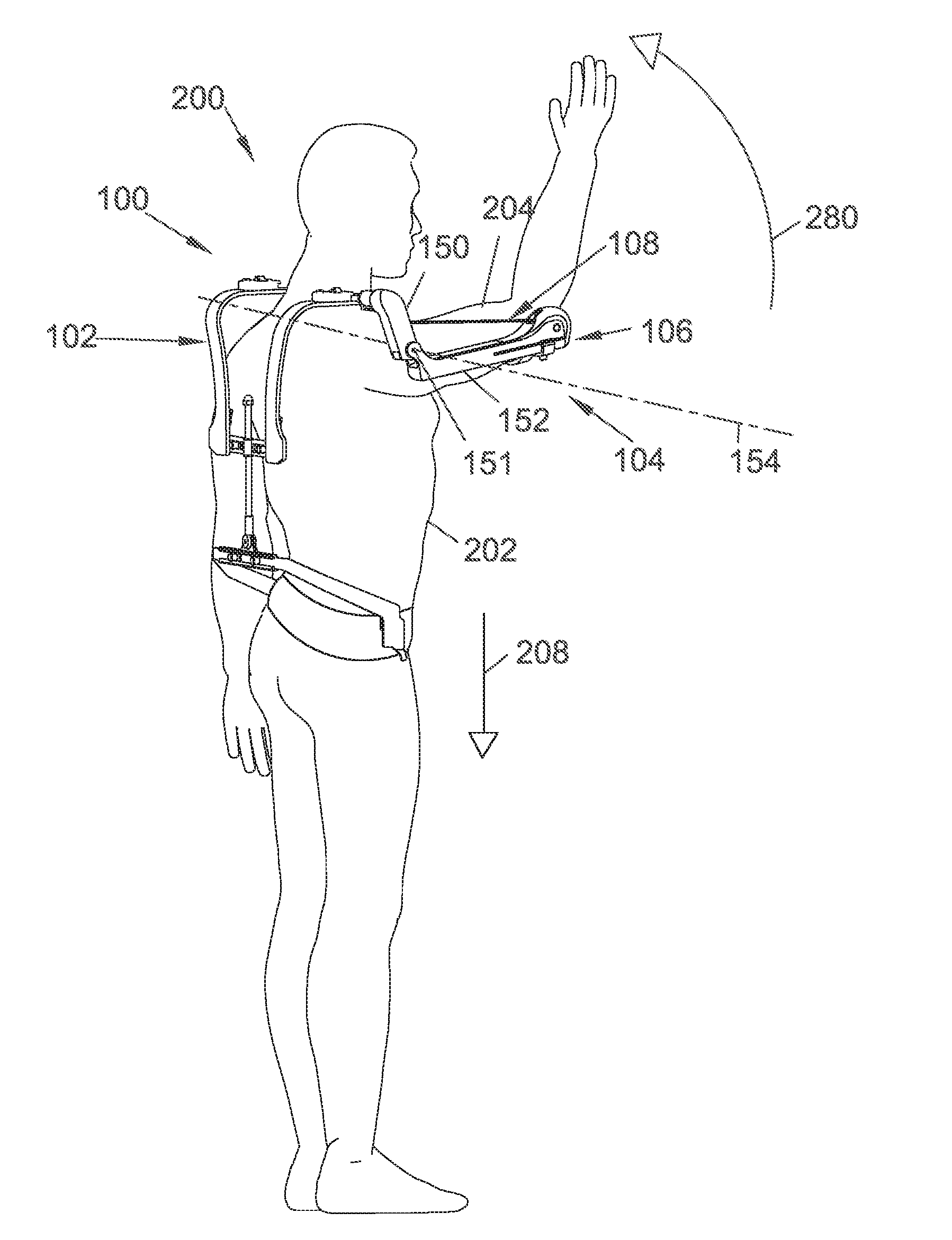

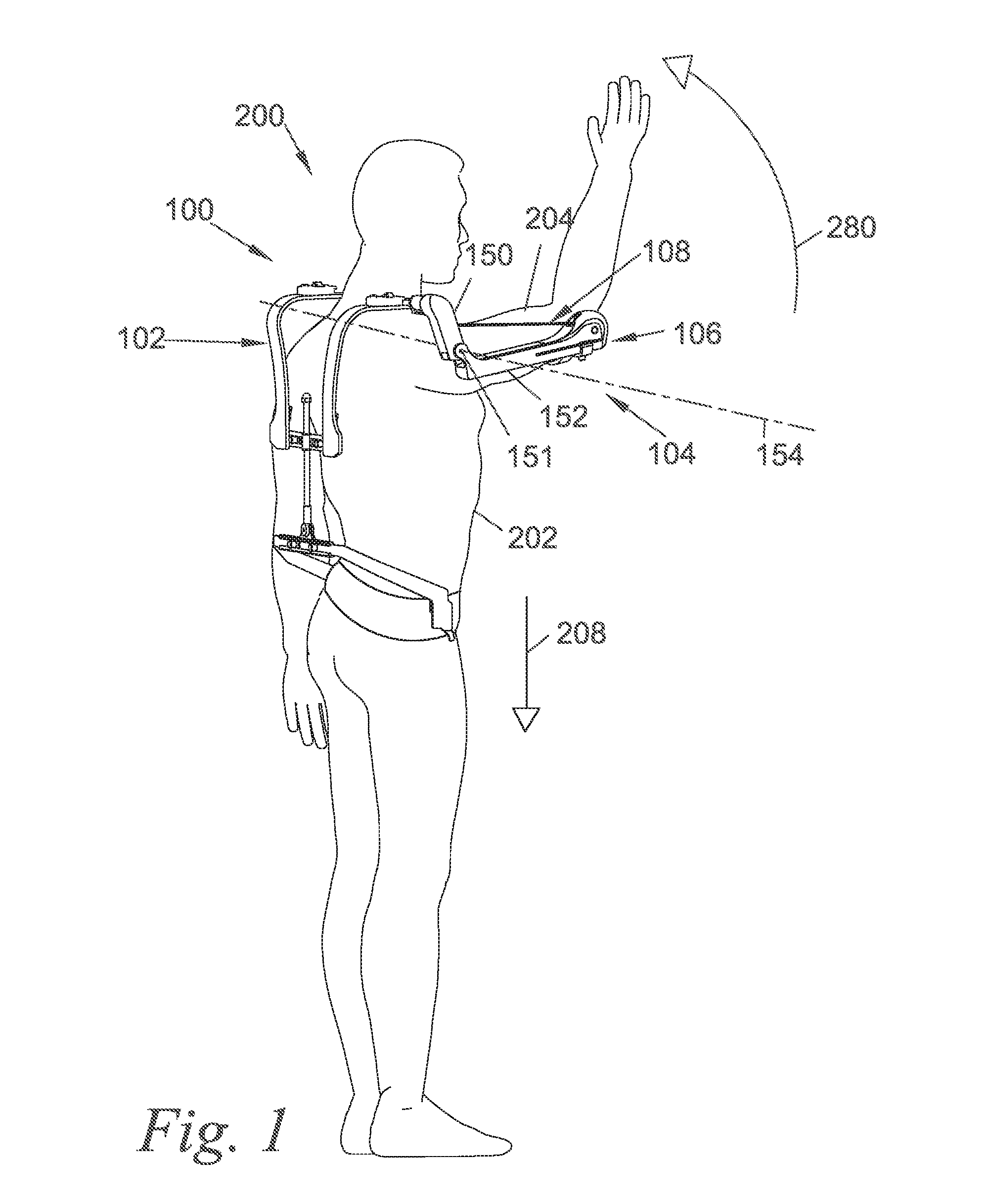

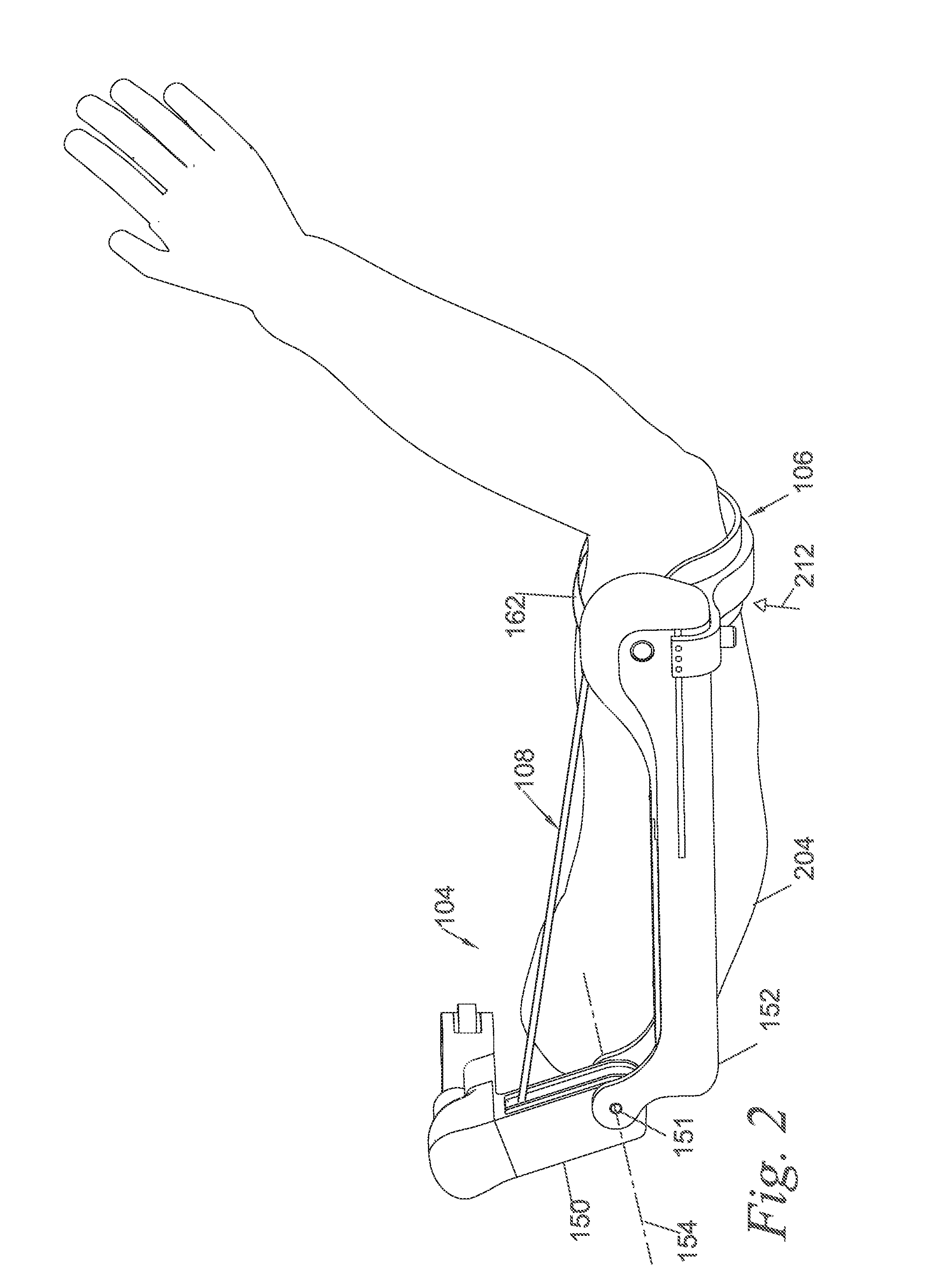

Method and apparatus for human arm supporting exoskeleton

ActiveUS20160339583A1Reducing human shoulder forceReduce torqueProgramme-controlled manipulatorMachine supportsHuman bodyEngineering

An arm supporting exoskeleton comprises a shoulder base coupled to an arm link mechanism. The arm link mechanism comprises a proximal link and a distal link configured to rotate relative to each other about a rotating joint; at least one arm-coupler adapted to couple a user's arm to the distal link; a tensile force generator coupled to the proximal link and the distal link, and providing a torque to flex the distal link relative to the proximal link; and a protrusion located substantially at the rotating joint. When the distal link extends past a toggle angle, the protrusion constrains the tensile force generator, and the torque provided by the tensile force generator remains substantially small. When the protrusion does not constrain the tensile force generator, the torque tends to flex the distal link relative to the proximal link, thereby reducing human shoulder forces and torques required to raise the user's arm.

Owner:RGT UNIV OF CALIFORNIA

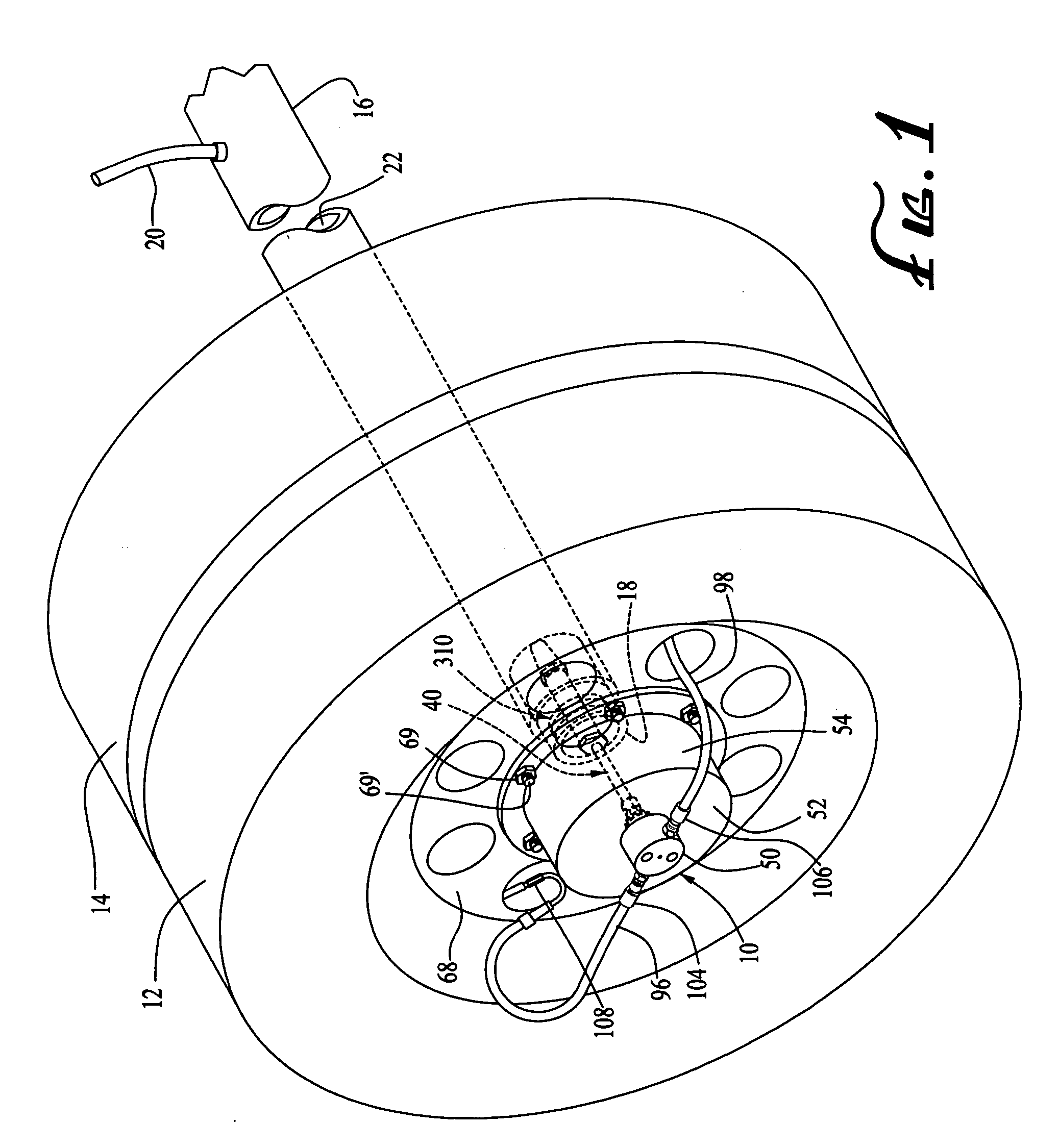

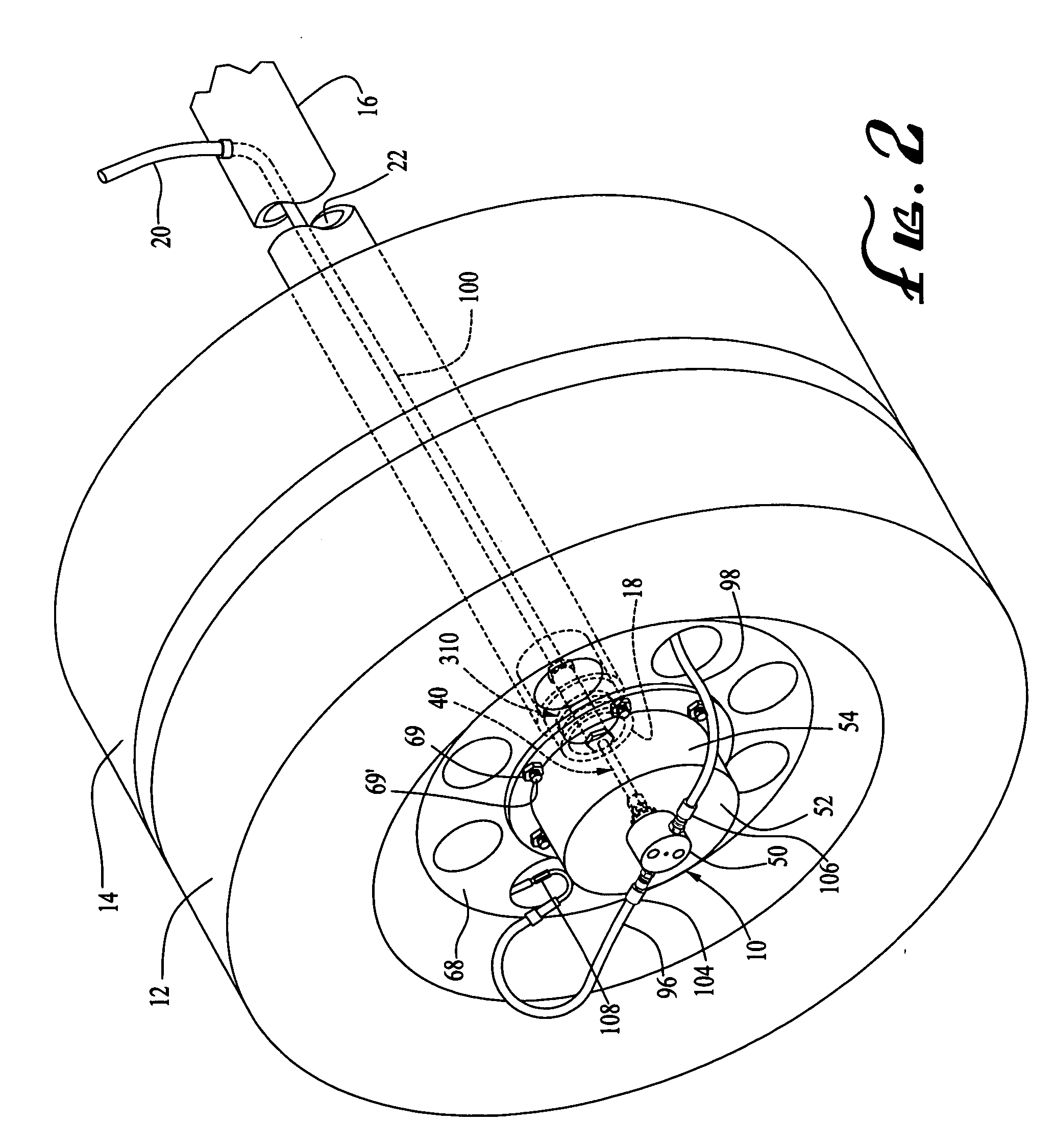

Integrated rotary union and hub cap

ActiveUS20090283190A1Easy to installReduce misalignmentTyre measurementsTyre-inflating valvesEngineeringHeavy duty

A rotary union is integrated into the interior of a heavy-duty vehicle hub cap. The hub cap includes a cylindrical sidewall, and an outboard wall that is integrally formed with an outboard end of the sidewall, and which extends generally perpendicular to the sidewall. The hub cap also includes a radially-extending flange that is formed on an inboard end of the sidewall, which receives fasteners to mount the hub cap on a wheel hub. The sidewall and the outboard wall form an interior compartment in the hub cap, and a rotary union is mounted to the hub cap in the interior compartment. The rotary union is mounted on the inboard surface of the outboard wall of the hub cap and is in general axial alignment with an axial centerline of a wheel end assembly, providing fluid communication from a tire inflation system to the tires of the vehicle.

Owner:HENDRICKSON USA L L C

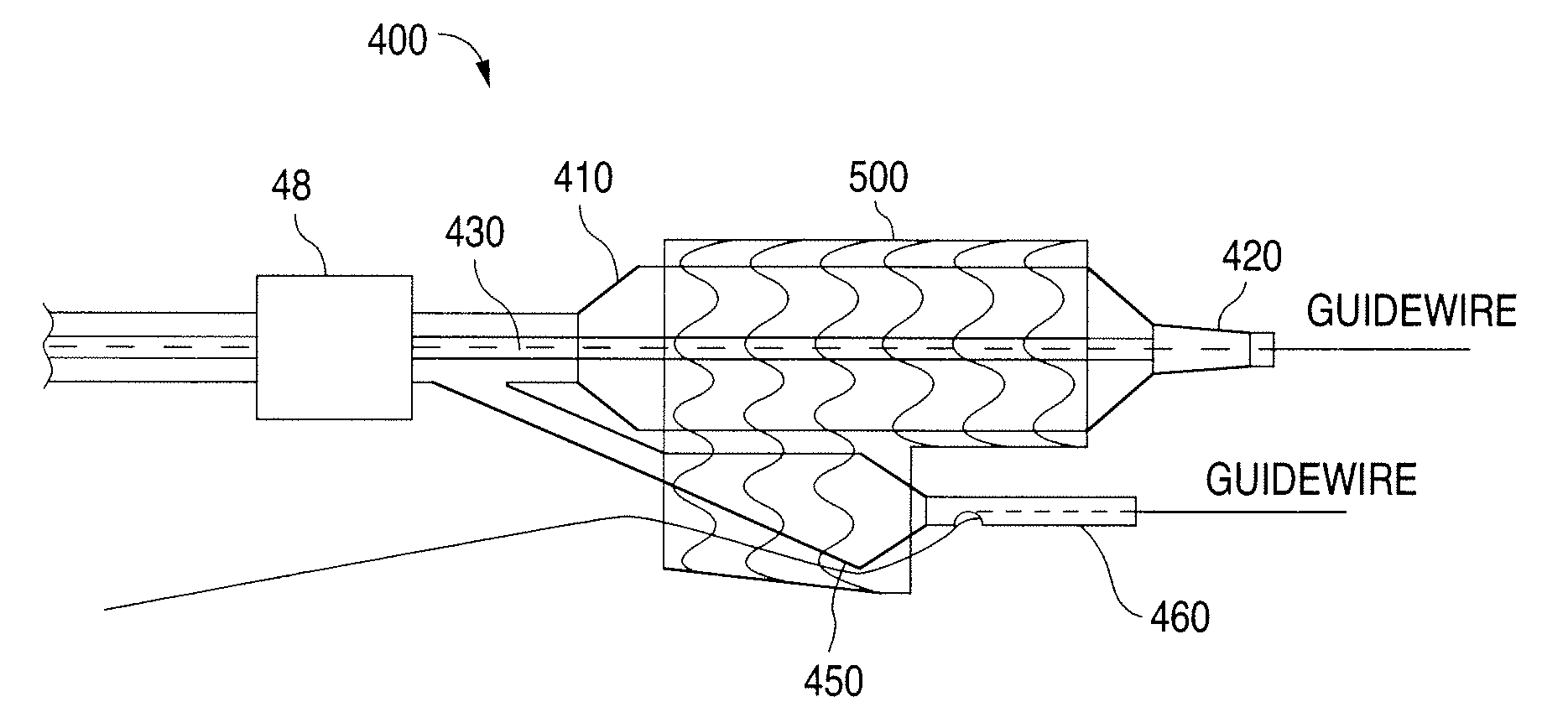

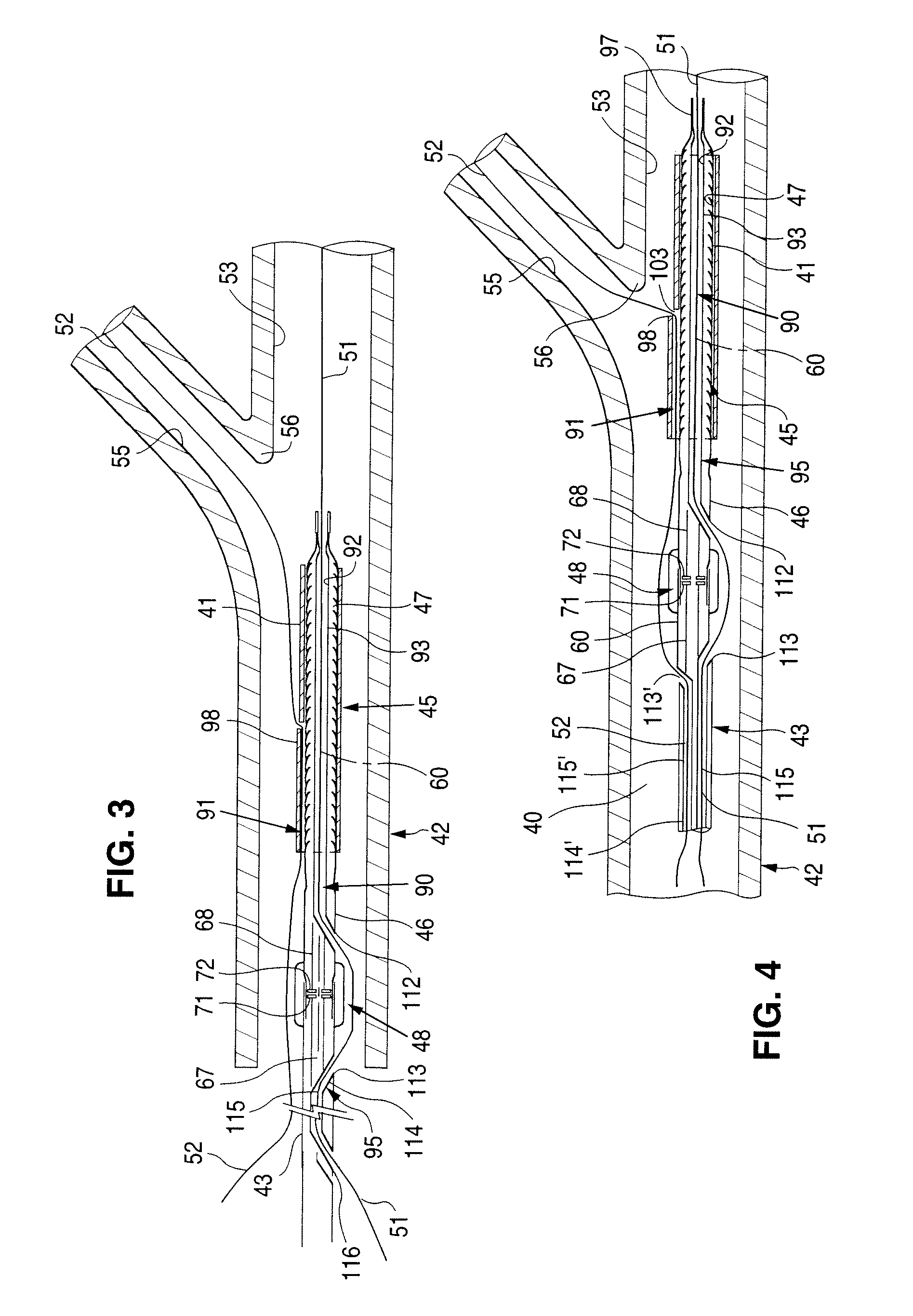

Bifurcation stent delivery catheter and method

A bifurcation stent delivery catheter includes a first branch balloon, a second branch balloon adjacent the first branch. A centering balloon is optionally disposed distal of the second branch balloon. The balloons are coupled by a coupling device to a main shaft of a catheter. The coupling device allows axial forces to be transmitted from the main shaft to the balloons while allowing the balloons to rotate axially relative to the main shaft with ease. The coupling device functions as an axial rotational joint. The coupling device can have a flexible tubular member that connects the balloons to the main shaft, the tubular member having a torsional flexibility greater than that of the main shaft. The coupling device can have a tubular wall having a cut extending circumferentially around the tubular wall and protective boot covering the cut. The coupling device can have a wound member that allows the axial rotation.

Owner:ABBOTT CARDIOVASCULAR

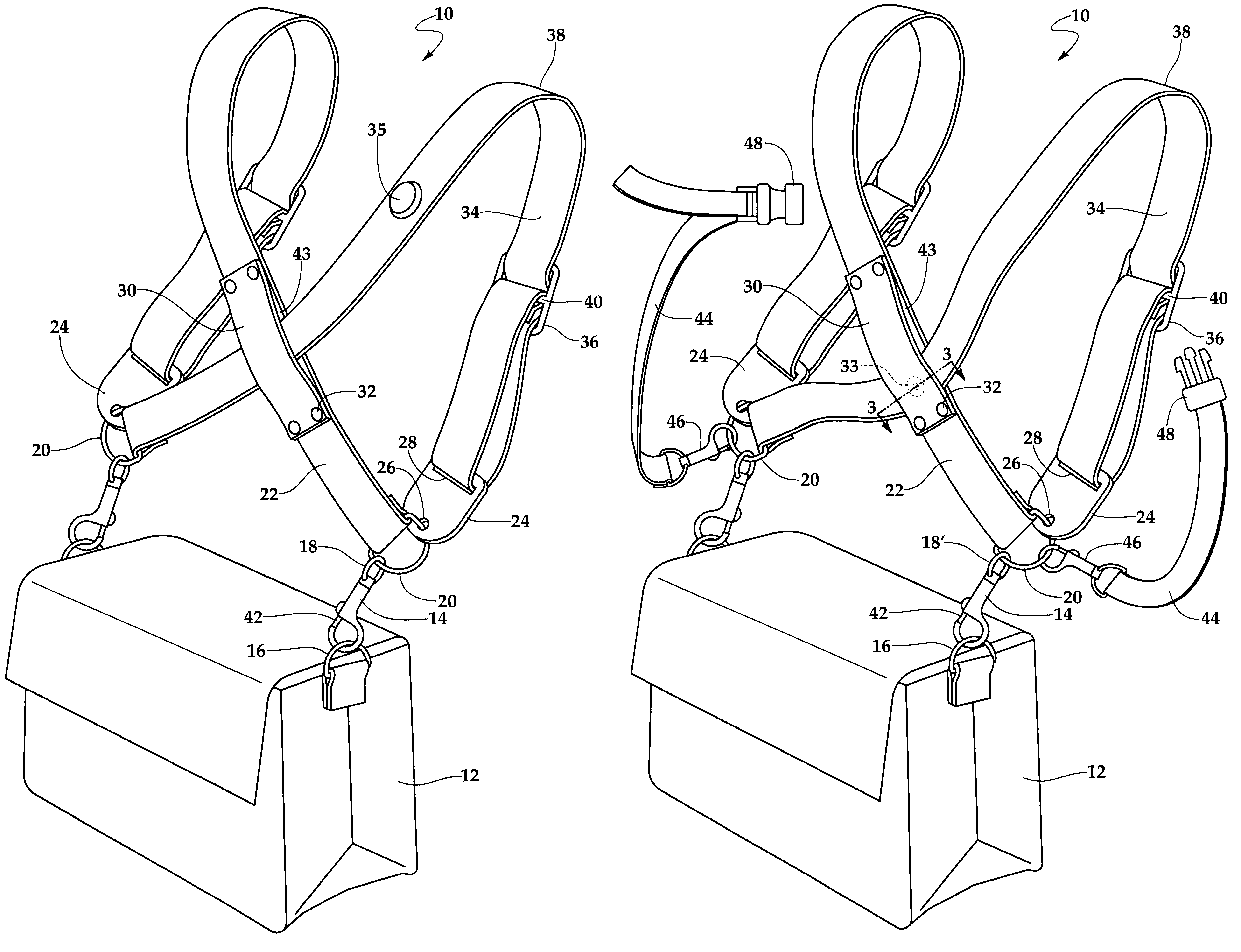

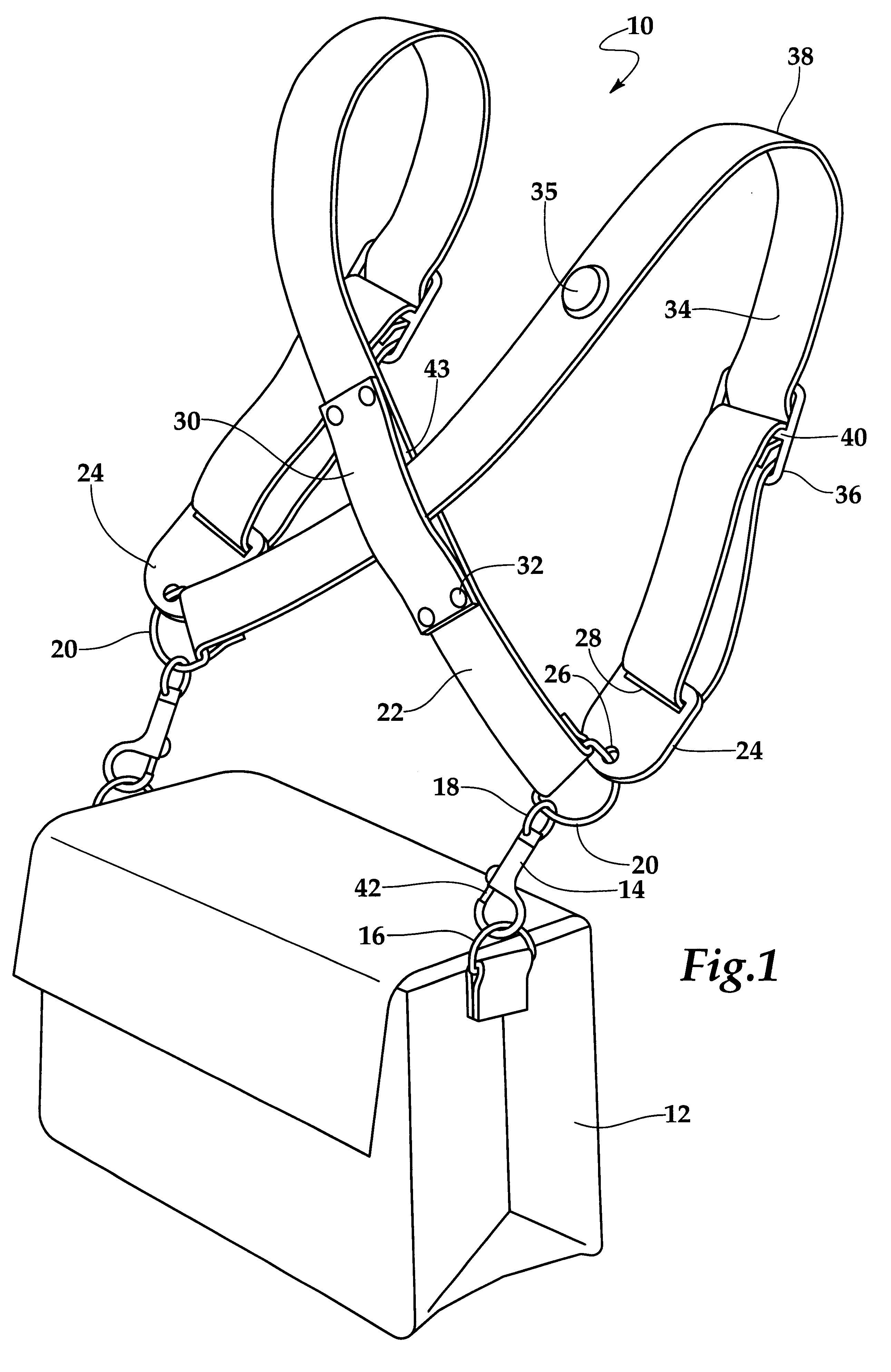

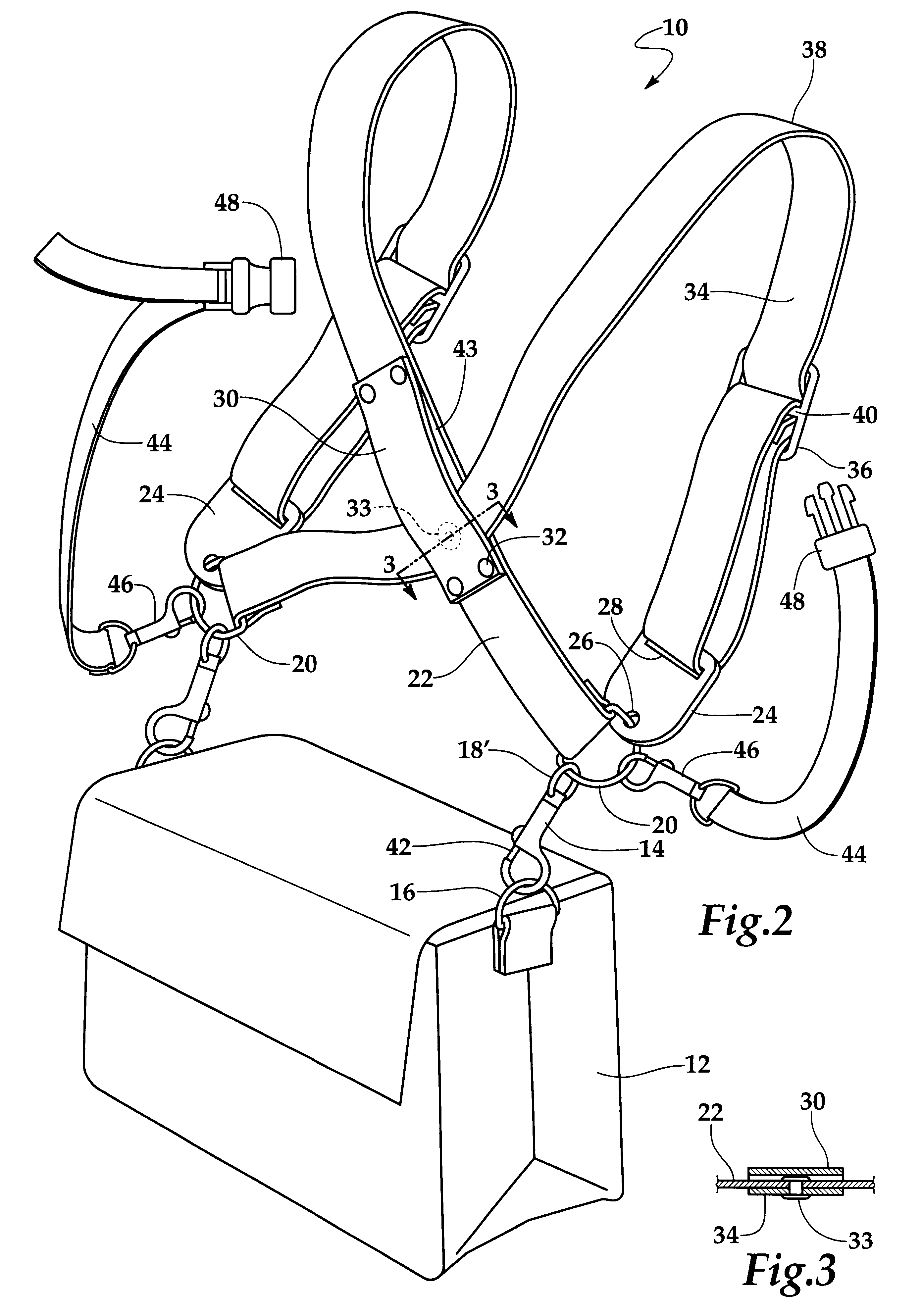

Dual strap system for conversion of bags to backpacks

The present invention discloses a dual strap system used for connection to a utility bag, such as a computer bag, by which the bag can be converted into a backpack, In a first embodiment, the dual straps of the system cross each other by means of a rigid member disposed at the crossing point to provide a twist resistant arrangement and properly center the present invention on the back of the user. One strap has a stop located thereon which helps position the straps with respect to the rigid member when the strap is off the bag and maintain the integrity of the device during the time the device is not installed on the bag. An attachment clip system is also provided which automatically positions the straps properly for use when the right hand grab technique is used to shoulder the device. Further, the clip system is designed to keep the straps from tangling when the device is off the bag. In a second embodiment, a swivel is provided for connection of the two straps which allows the rigid member to act as a cantilever-like member which helps provide a proper opening in the straps for shouldering the present invention.

Owner:JOHNSON JUSTIN

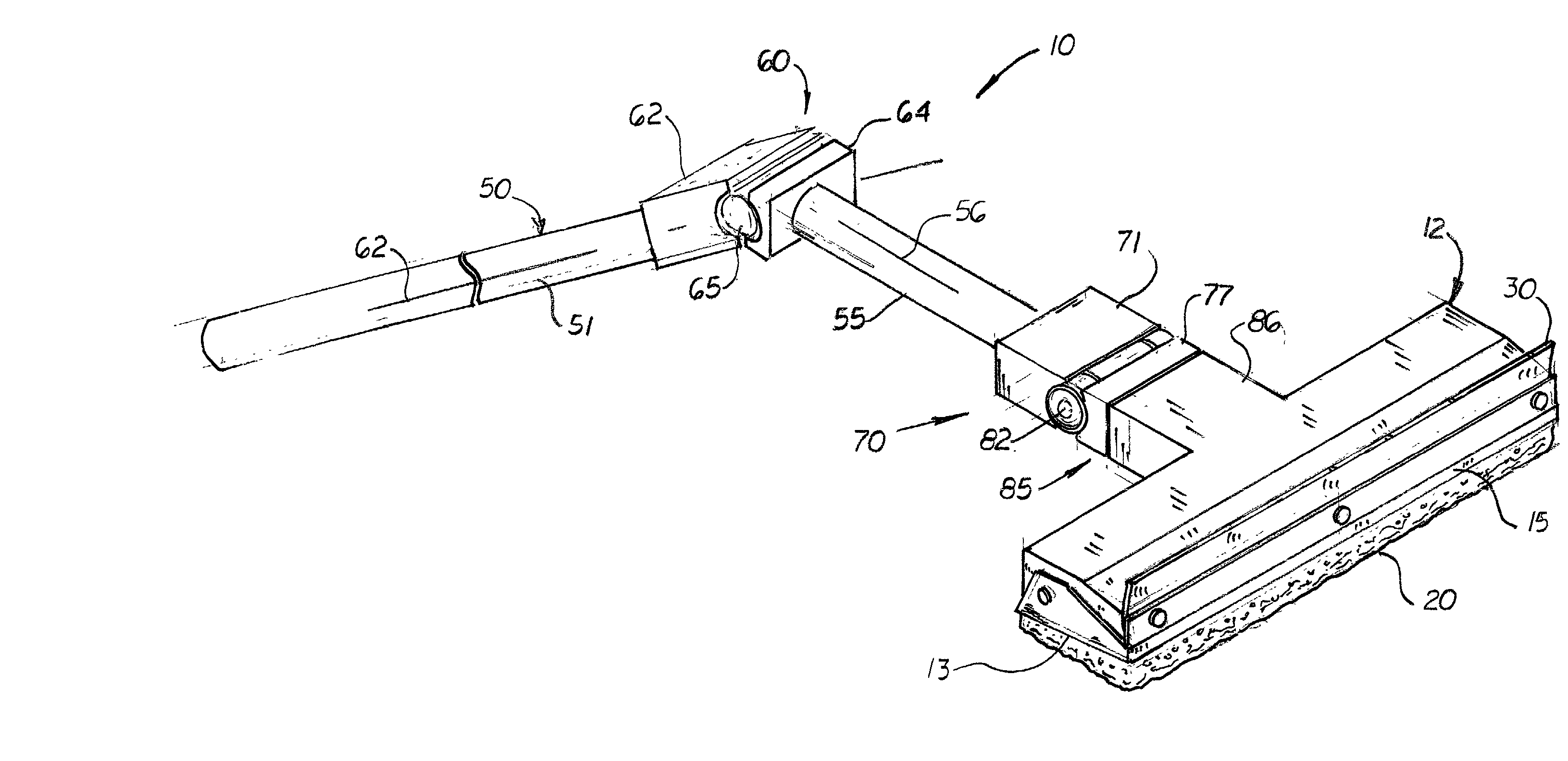

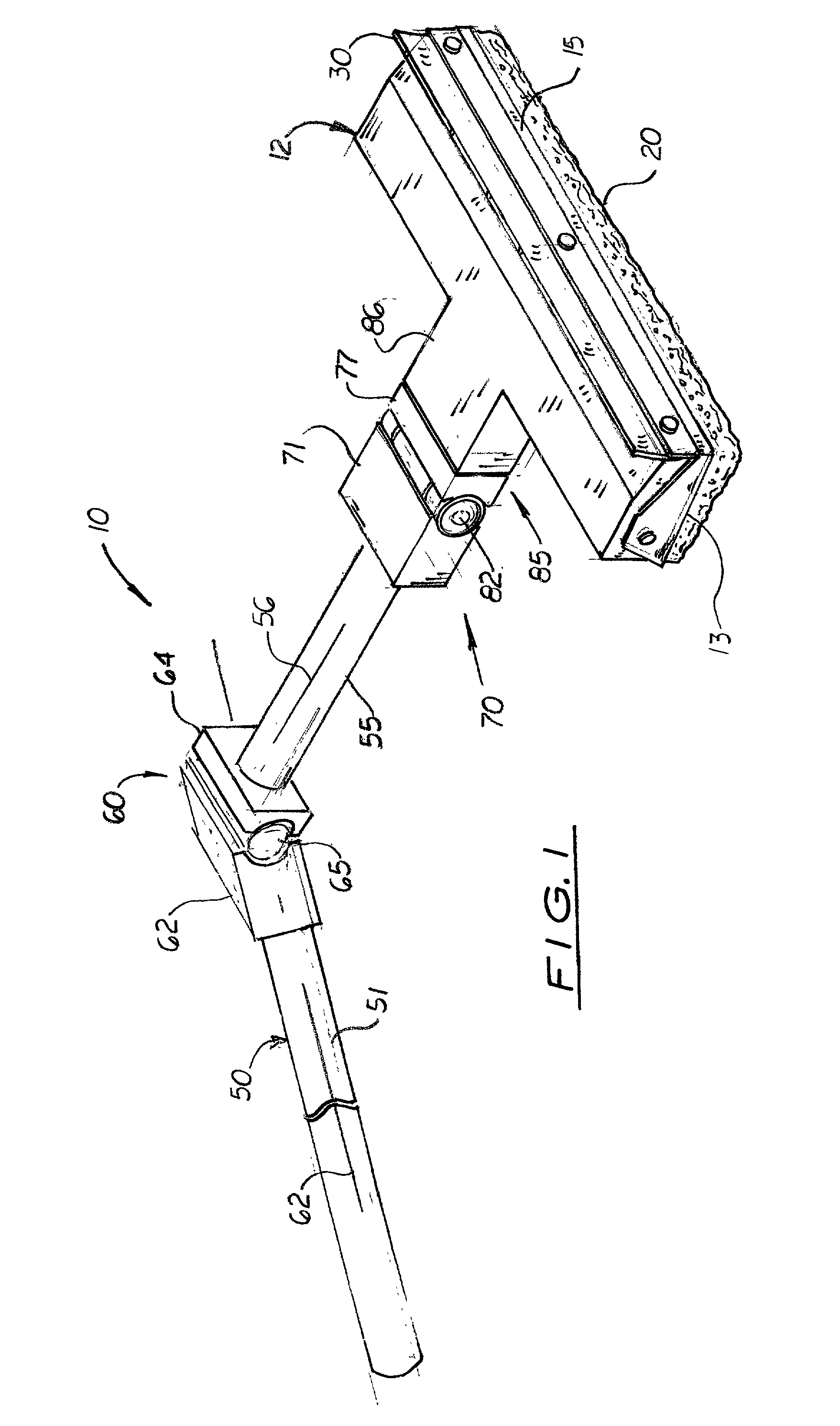

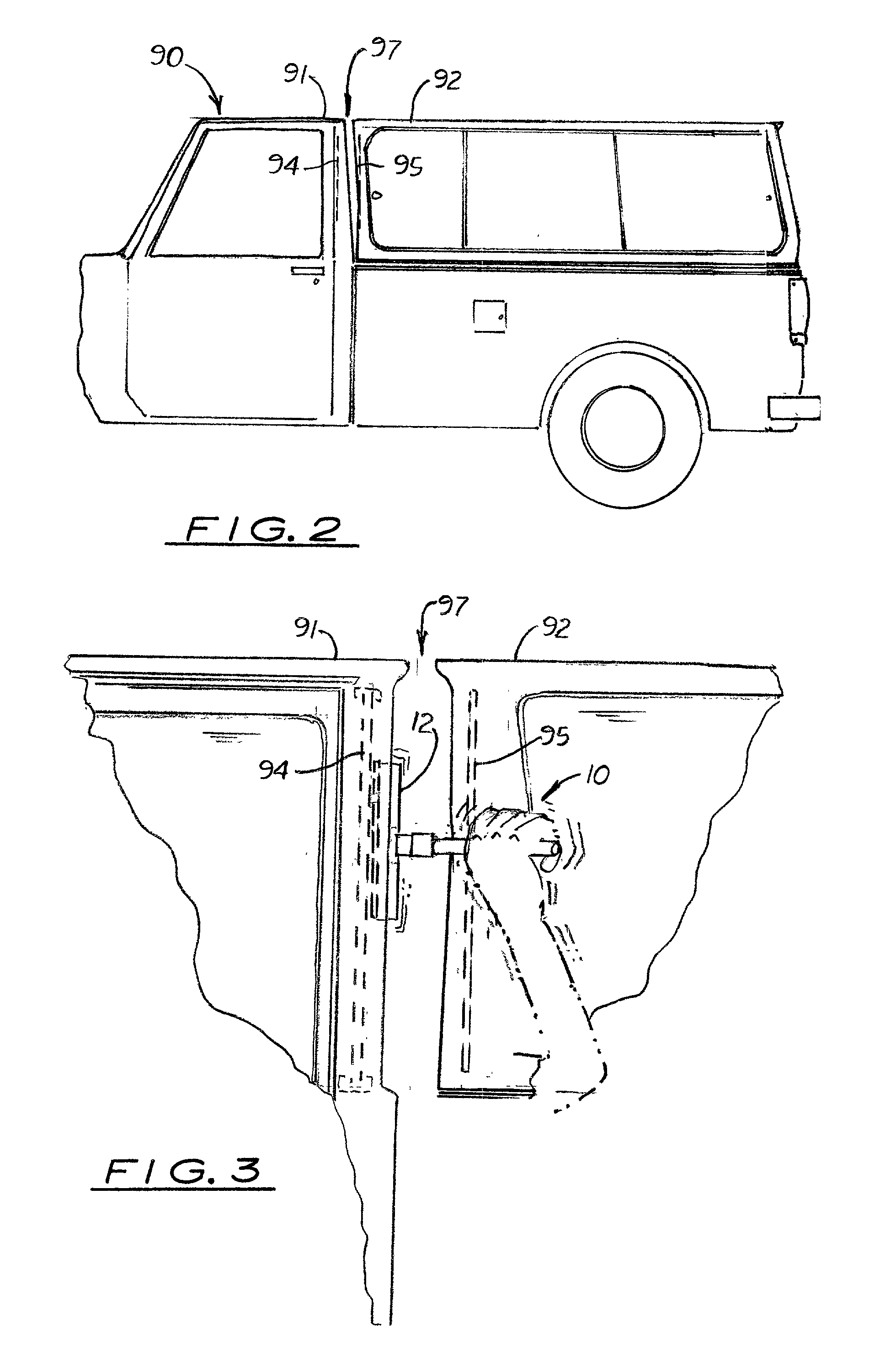

Low profile combination scrubbing and squeegee device

InactiveUS20020078519A1Easy to adjustBoard cleaning devicesCarpet cleanersEngineeringMotorized vehicle

A low profile combination brush and scrubbing device used to clean tight fitting, narrow, hard to reach windows on a motor vehicle. The device comprises a low profile body with a cleaning surface, such as a sponge or cleaning pad attached on its top surface, and a rubber blade attached along its front surface that extends downward in a direction opposite the cleaning surface. Connected to the body is an articulating elongated pole. Disposed between the body and the elongated pole is a rotating joint that enables the user to rotate the body 180 degrees around the central axis of the elongated pole. Disposed between the body and the elongated pole are first and second pivoting joints that allow the user to selectively adjust the angular position of the pole and body so that the body may be placed against the surface of both windows. The three joints work together to allow the user to easily adjust the position of the elongated pole on the body so that the device may be used on tight fitting, hard to reach surfaces of a vehicle.

Owner:BOOTHBY MICHAEL

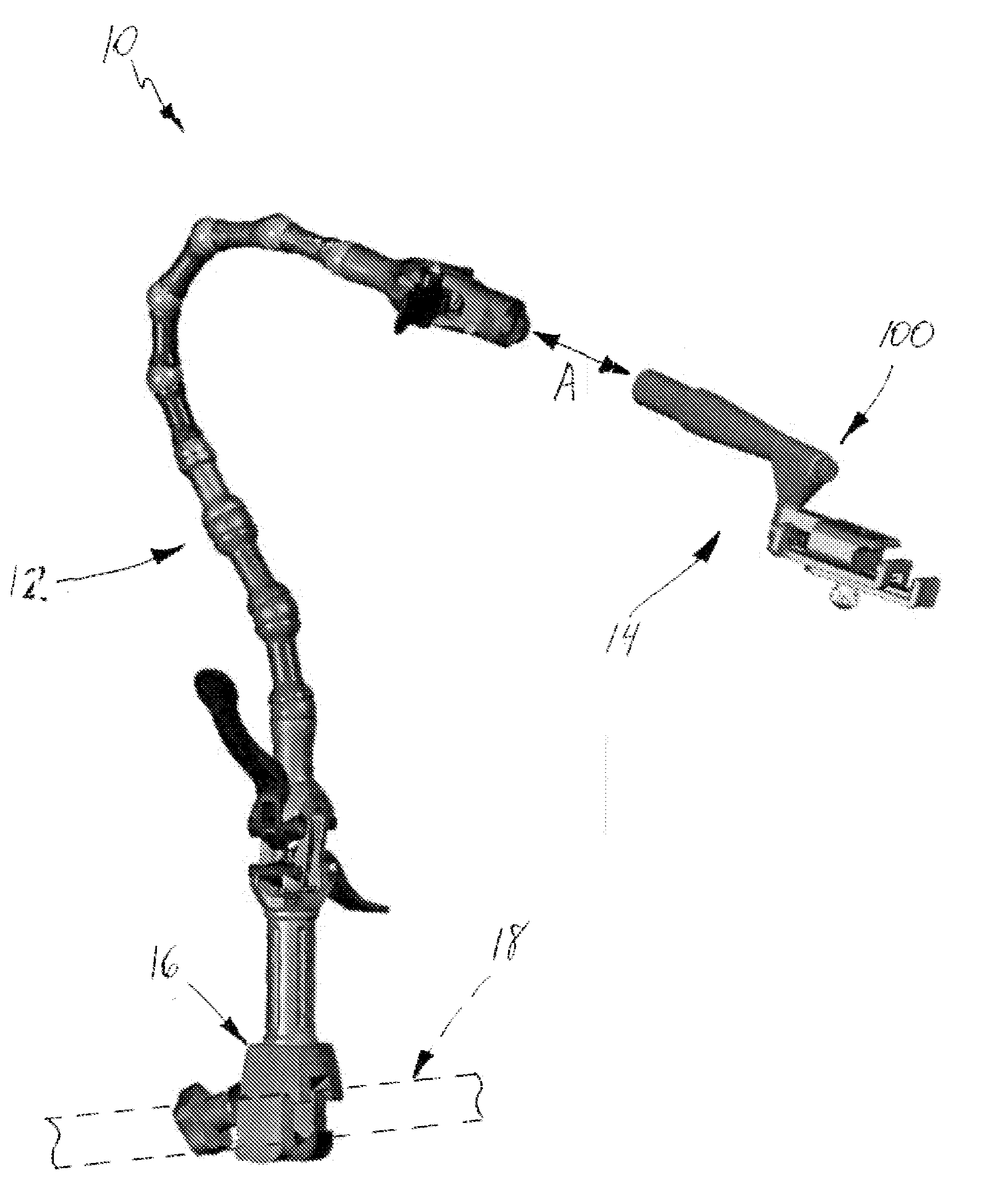

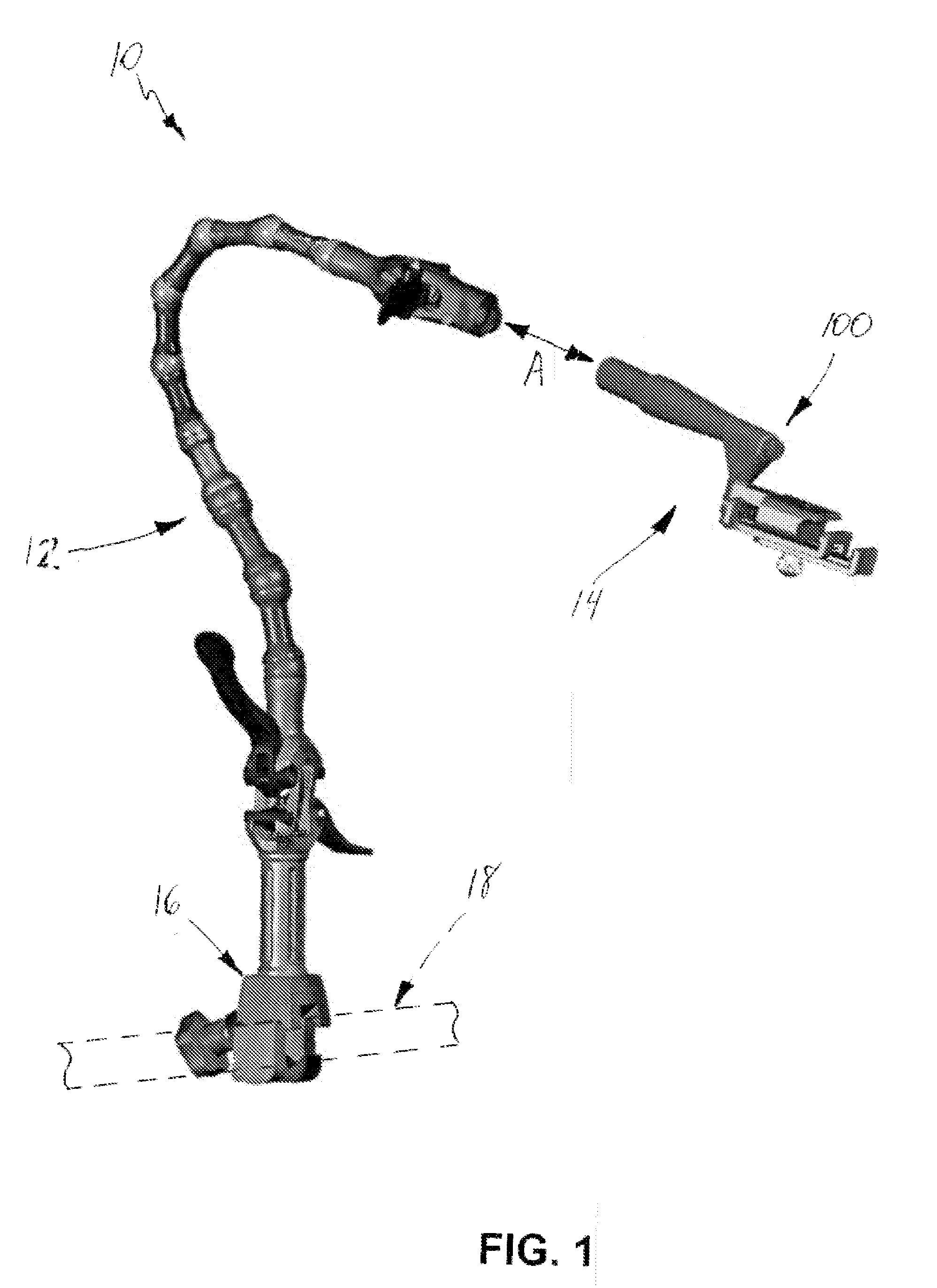

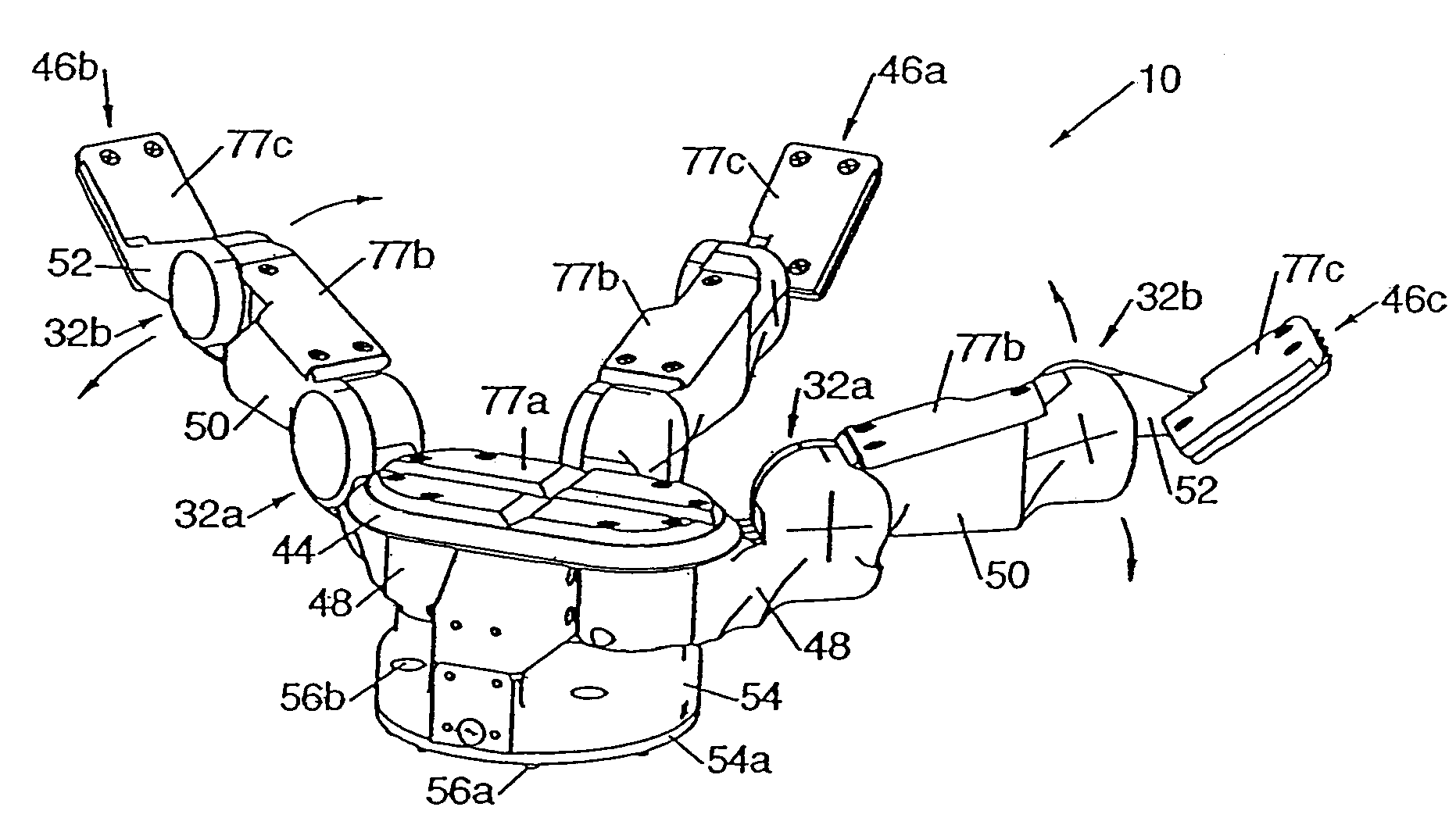

System and method for positioning a laparoscopic device

A laparoscopic instrument holder for positioning a laparoscopic device includes a central portion having a first member operatively associated with a second member, the members selectively movable with respect to one another along a central axis, with the central portion having a proximal end defined by the first member and a distal end defined by the second member. The holder also includes at least three proximal rotational joints coupled to the first member proximate the proximal end, at least two distal rotational joints coupled to the second member proximate the distal end, a first ball and socket joint coupled to a distal rotational joint, and a second ball and socket joint coupled to the first ball and socket joint. In addition, the holder includes a clamp configured and dimensioned for retaining a laparoscopic device, with the clamp coupled to the second ball and socket joint, and a coupling portion proximate a first of the proximal rotational joints.

Owner:CIVCO MEDICAL INSTR CO

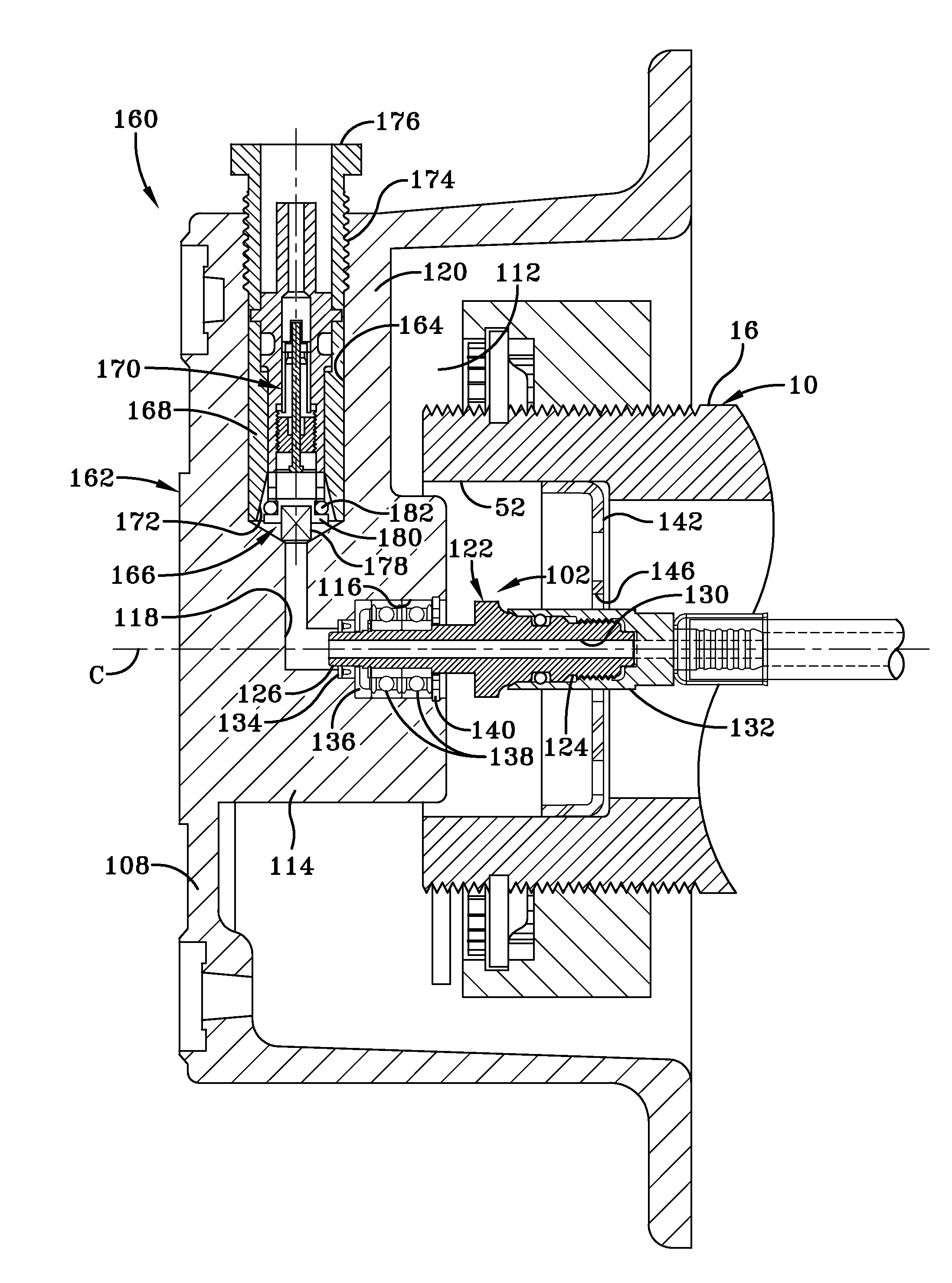

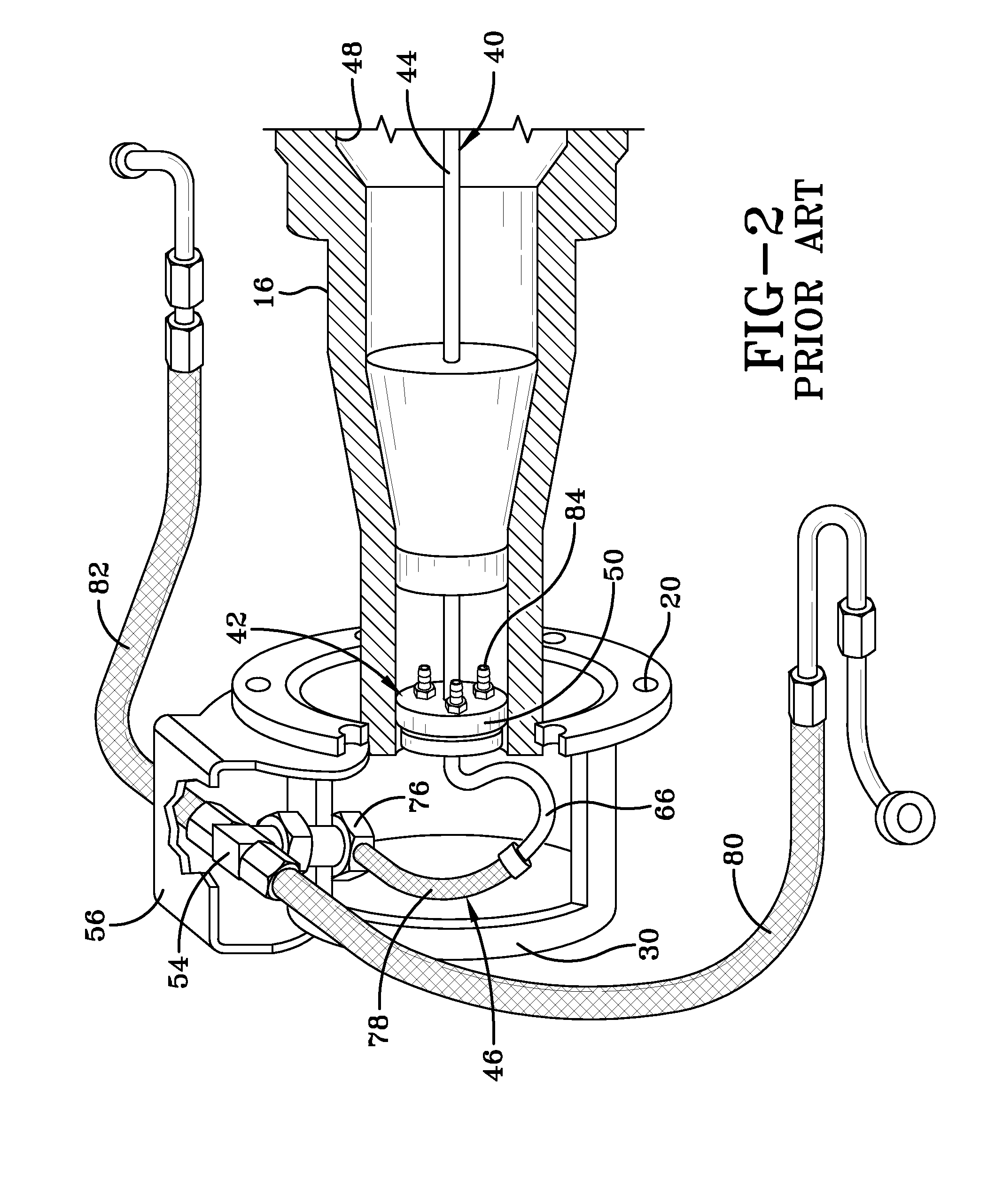

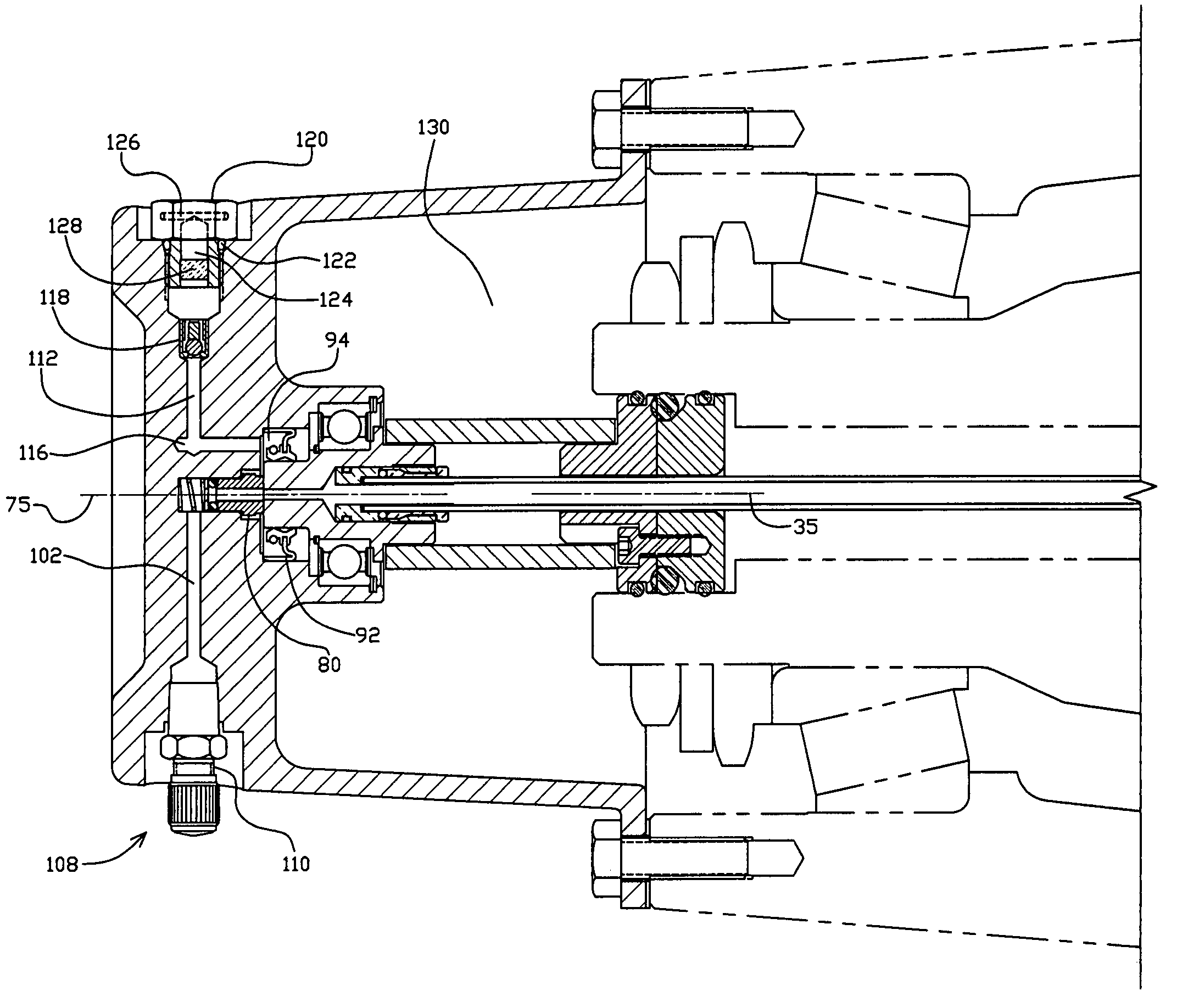

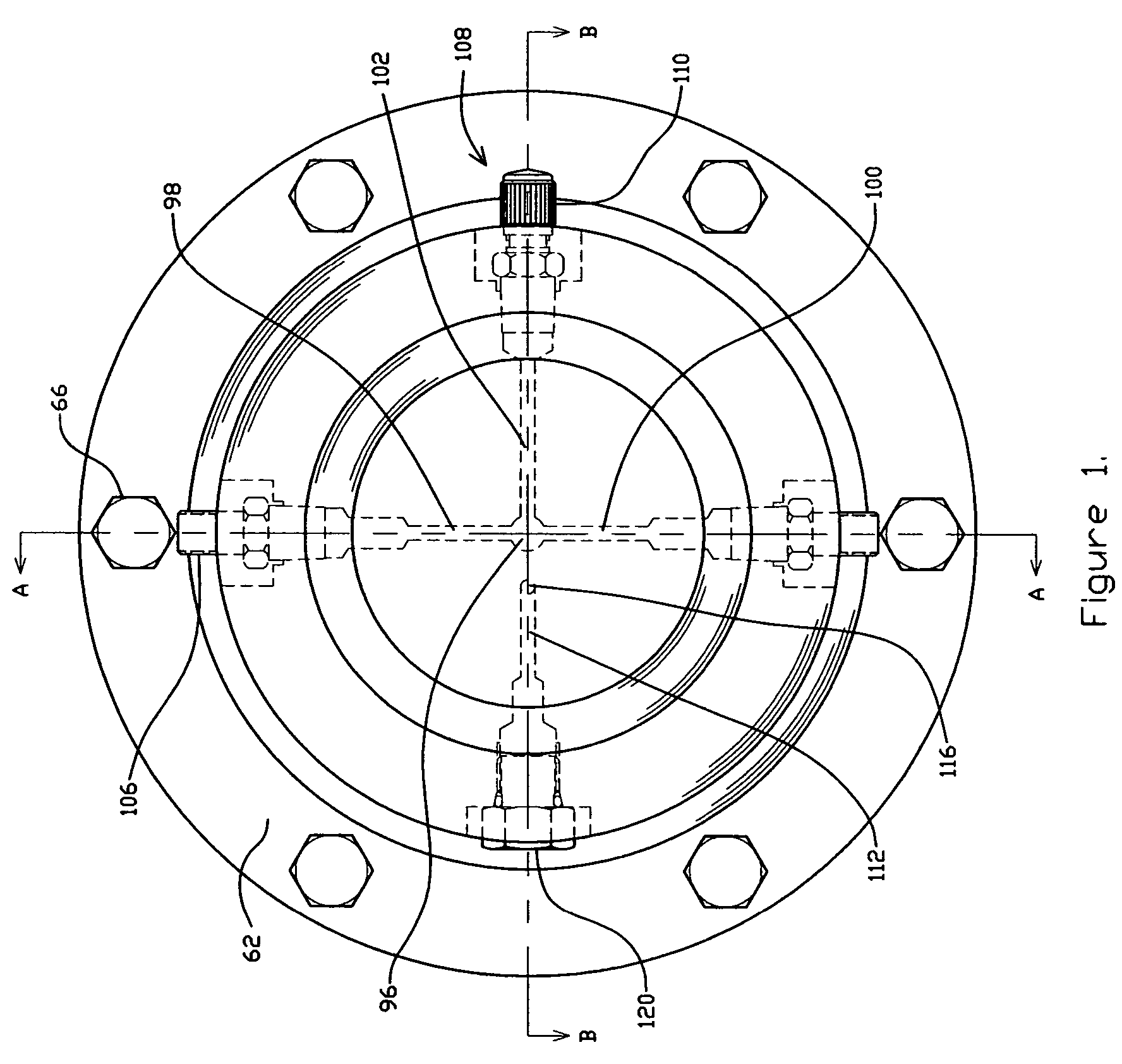

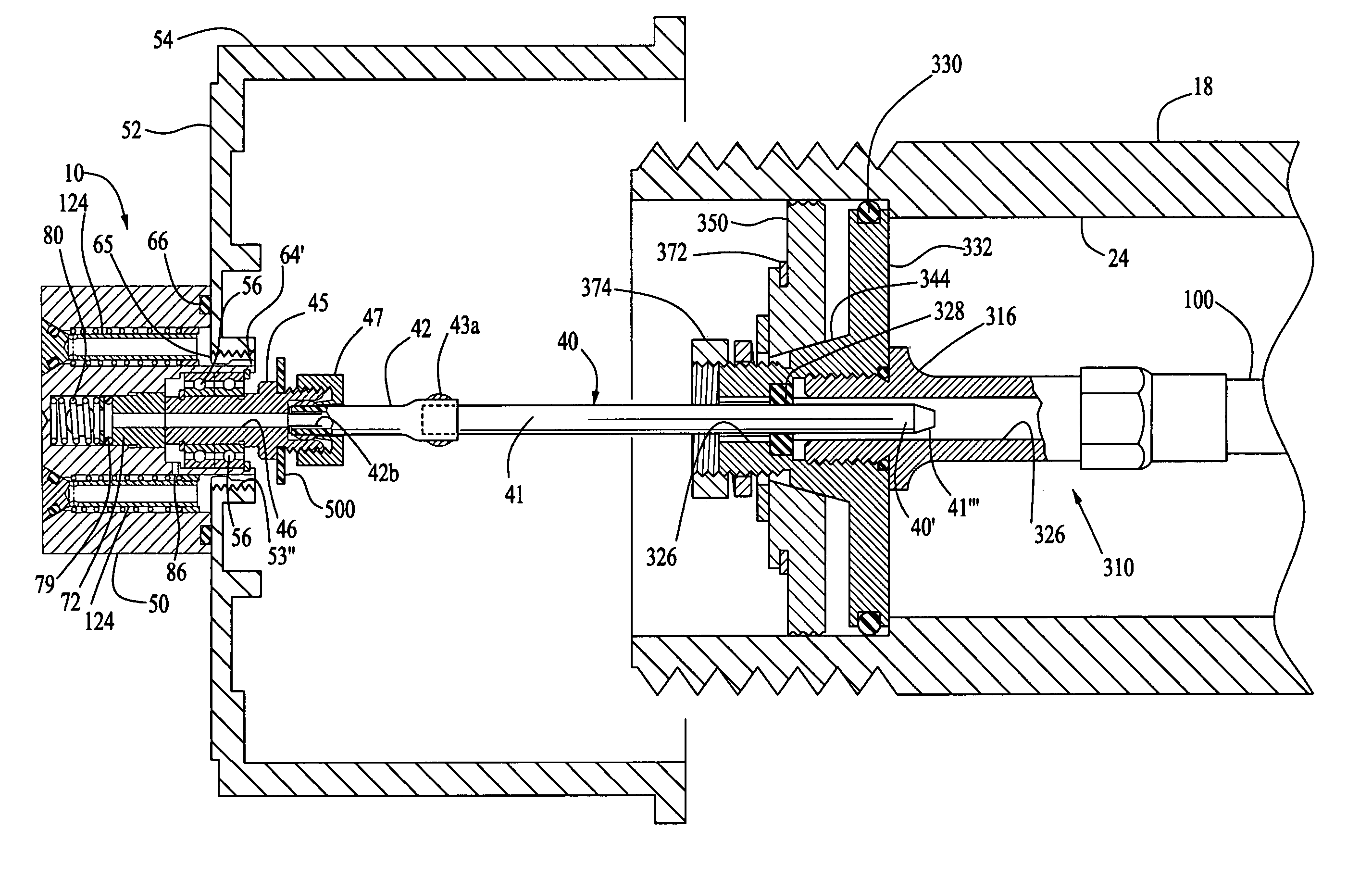

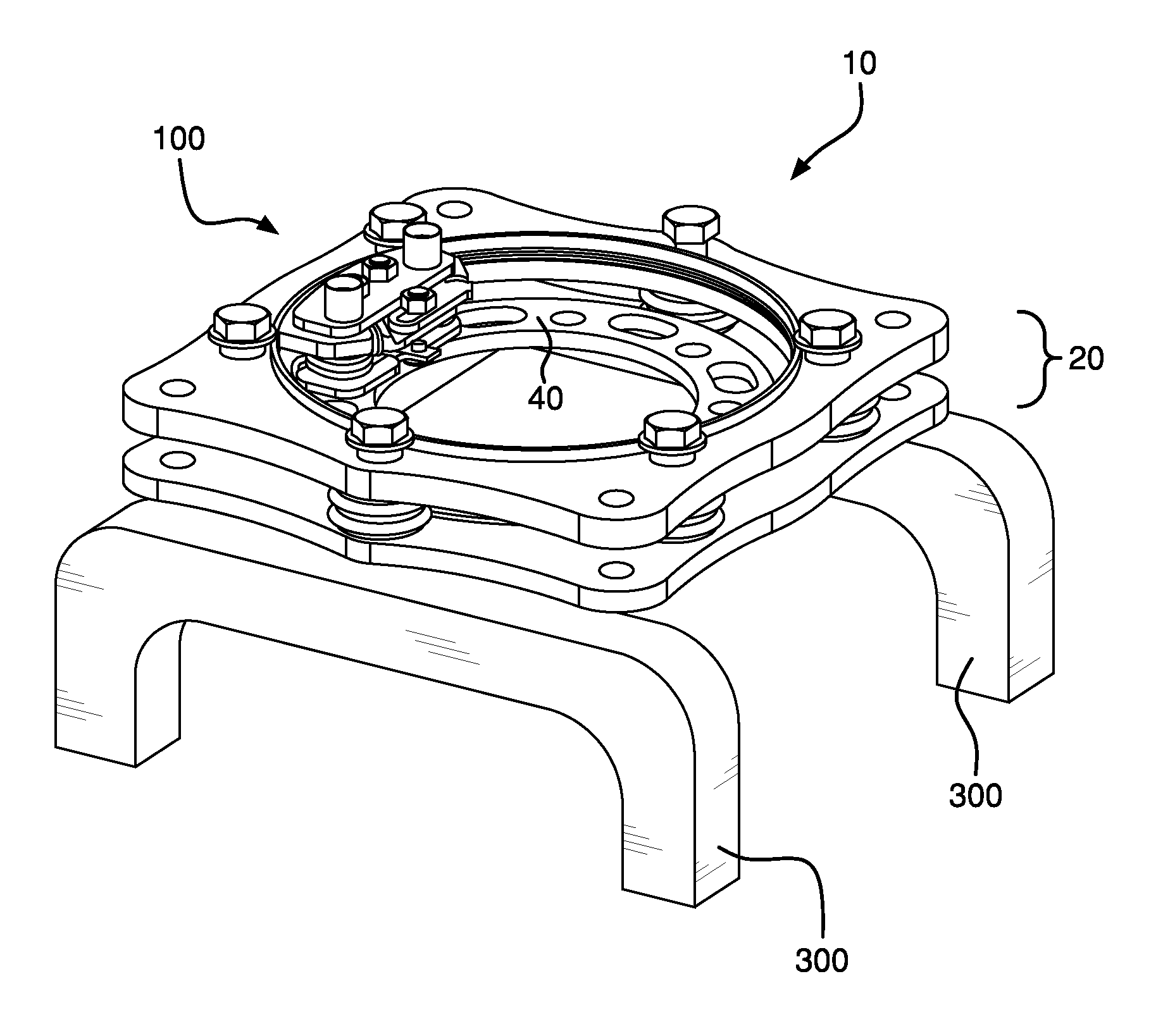

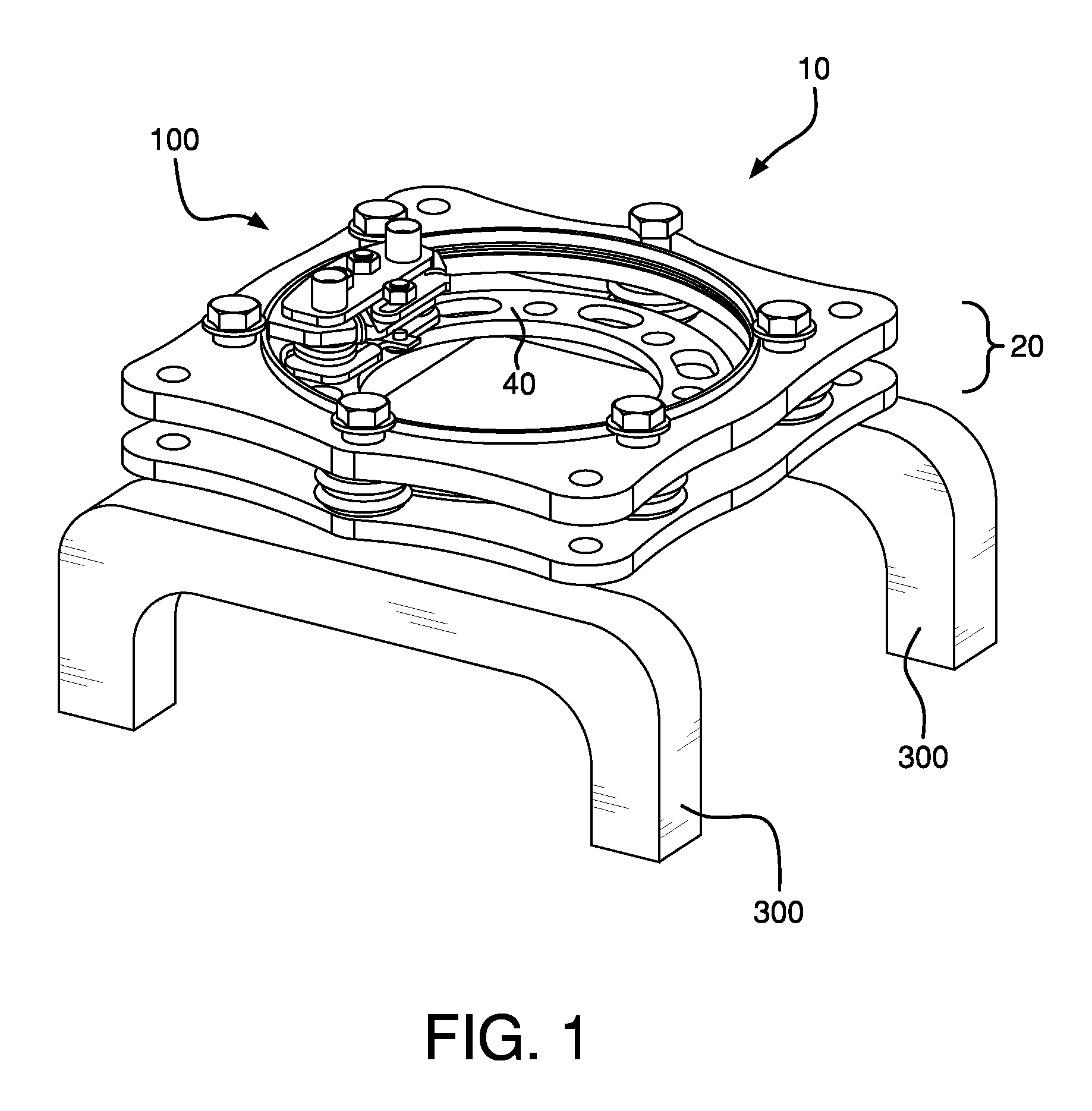

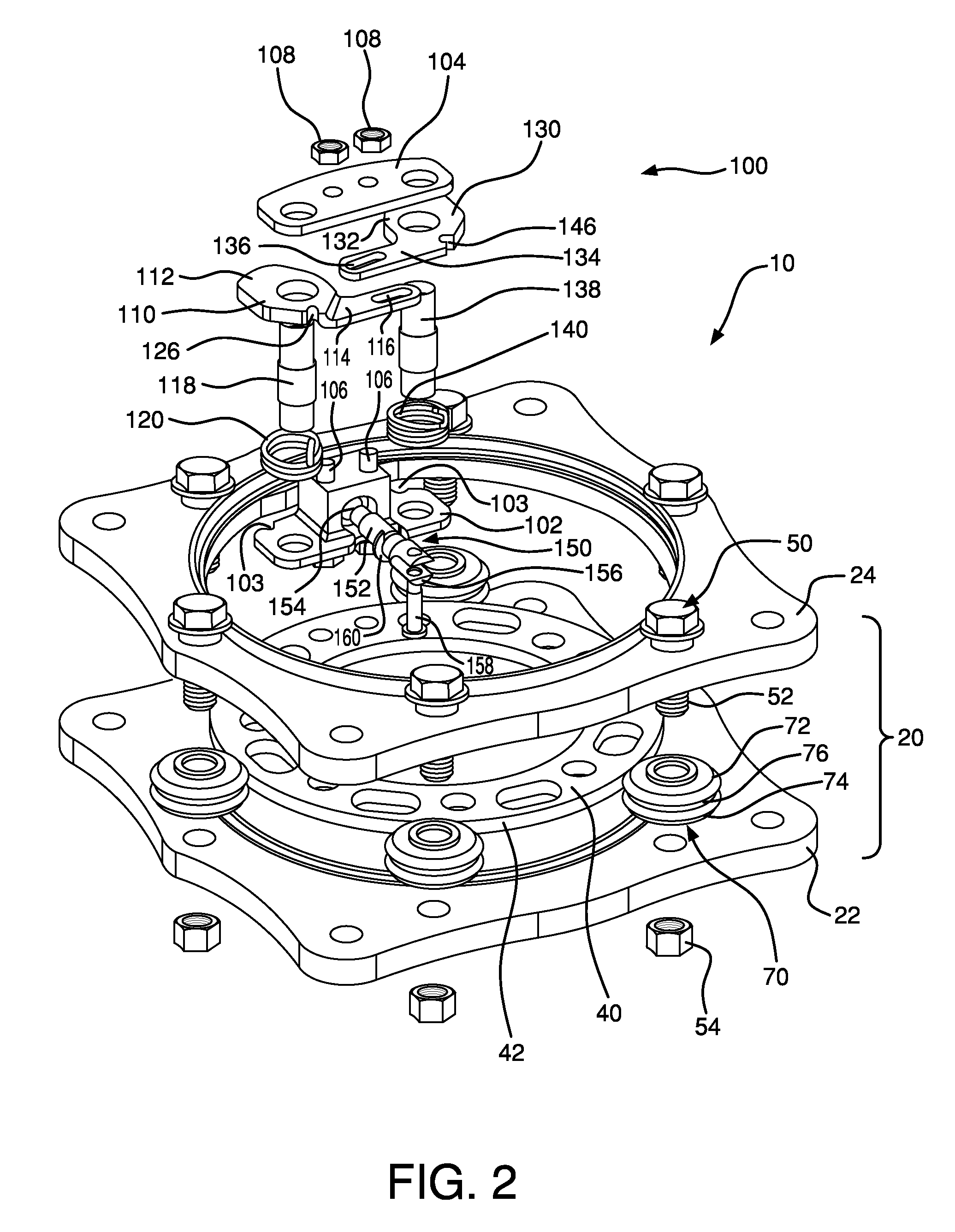

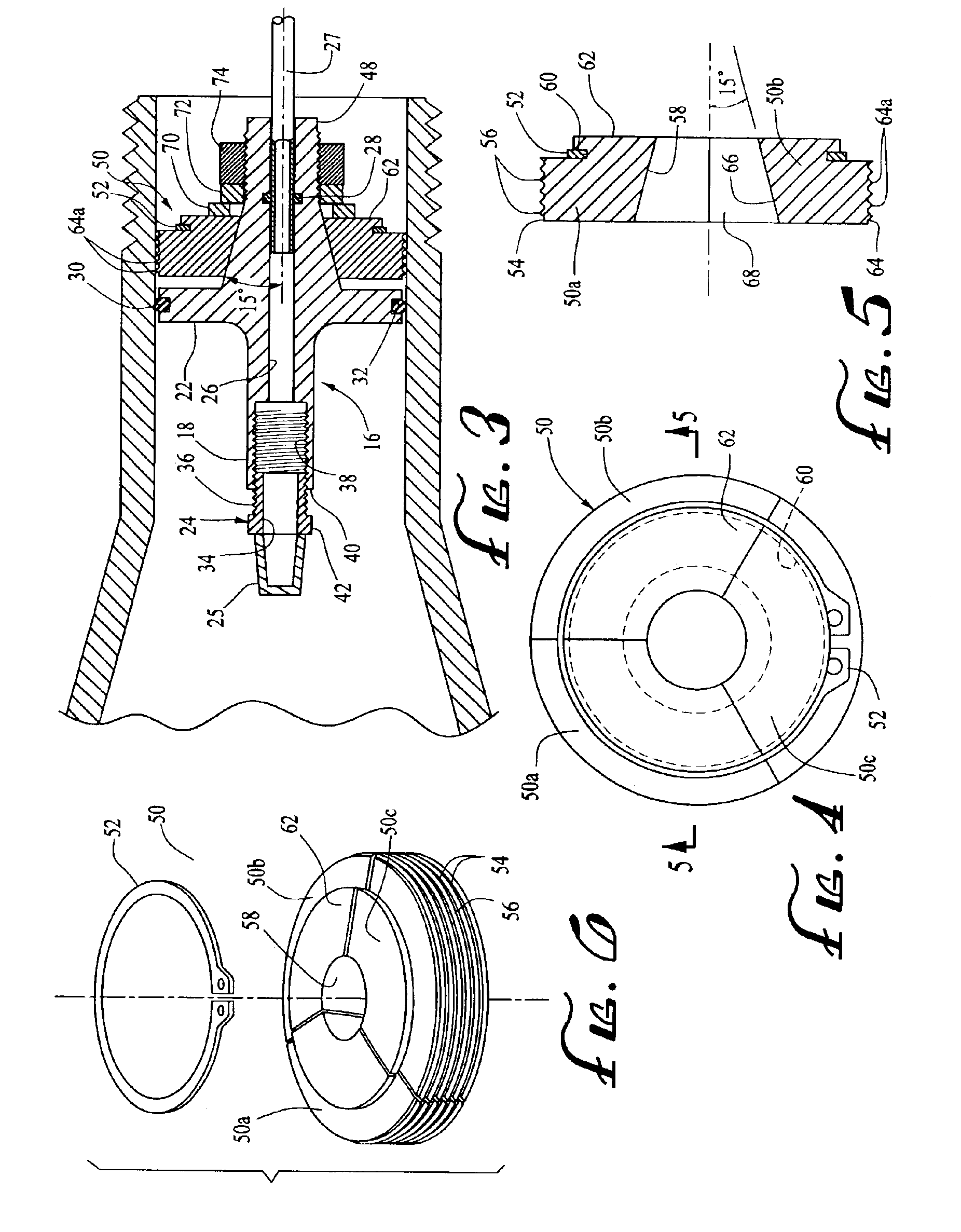

Central tire inflation system rotary air union

ActiveUS7207365B2Tyre measurementsTyre-inflating valvesCentral tire inflation systemAtmospheric pressure

A central tire inflation system for maintaining tire inflation on a vehicle having a torque transfer sleeve connected between an axle plug assembly and a stationary shaft on the rotary union assembly. A flexible conduit extends through the axle plug to the rotary union assembly and is used to provide air pressure to tires connected to the rotary union assembly. The torque transfer sleeve limits rotational torque on the flexible conduit. Primary and secondary seals are provided on the rotary union assembly as well. A vent chamber between the primary and secondary seals allows the release of air which exits the primary seal, which prevents pressure from entering the lubrication area of the rotary union assembly.

Owner:PRESSURE SYST INT LLC

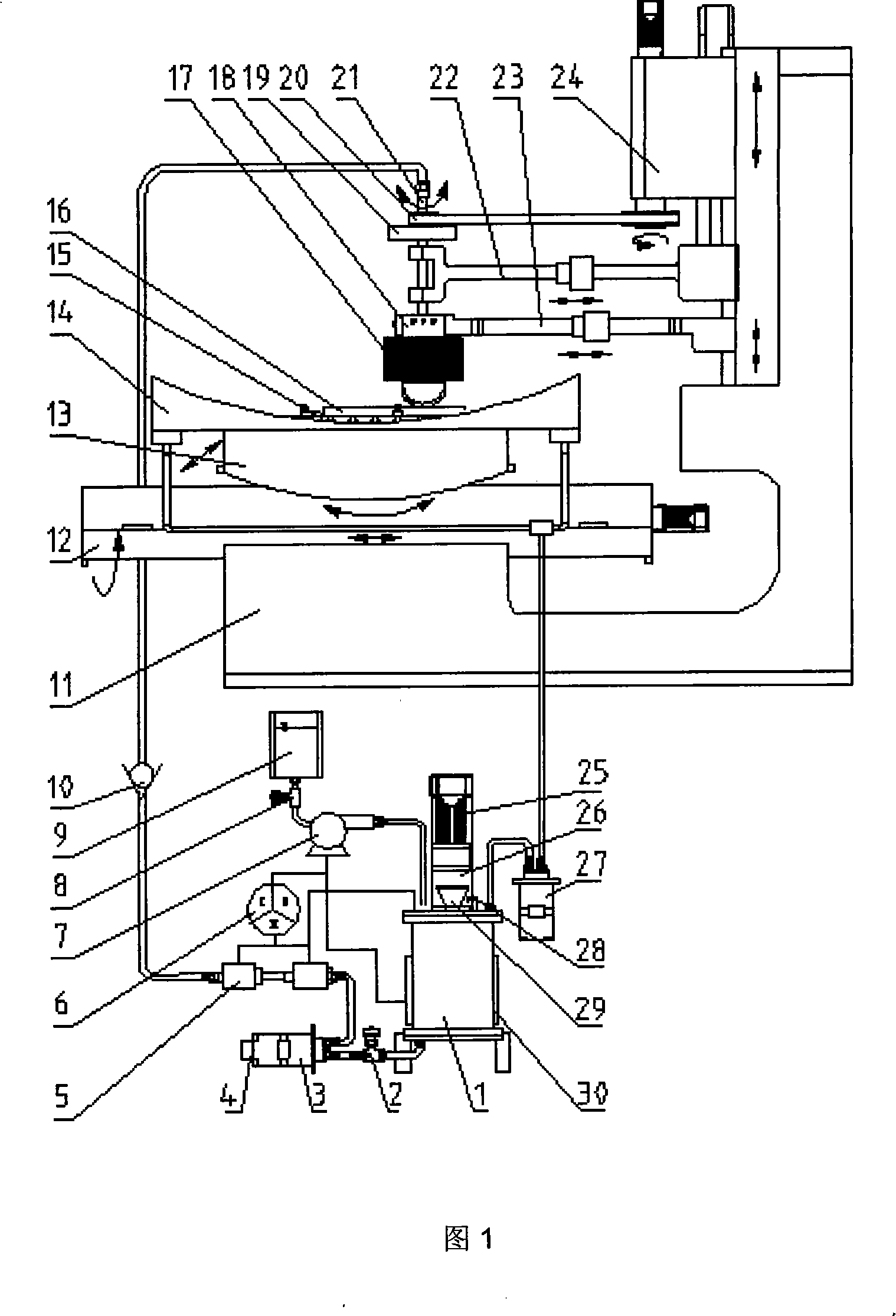

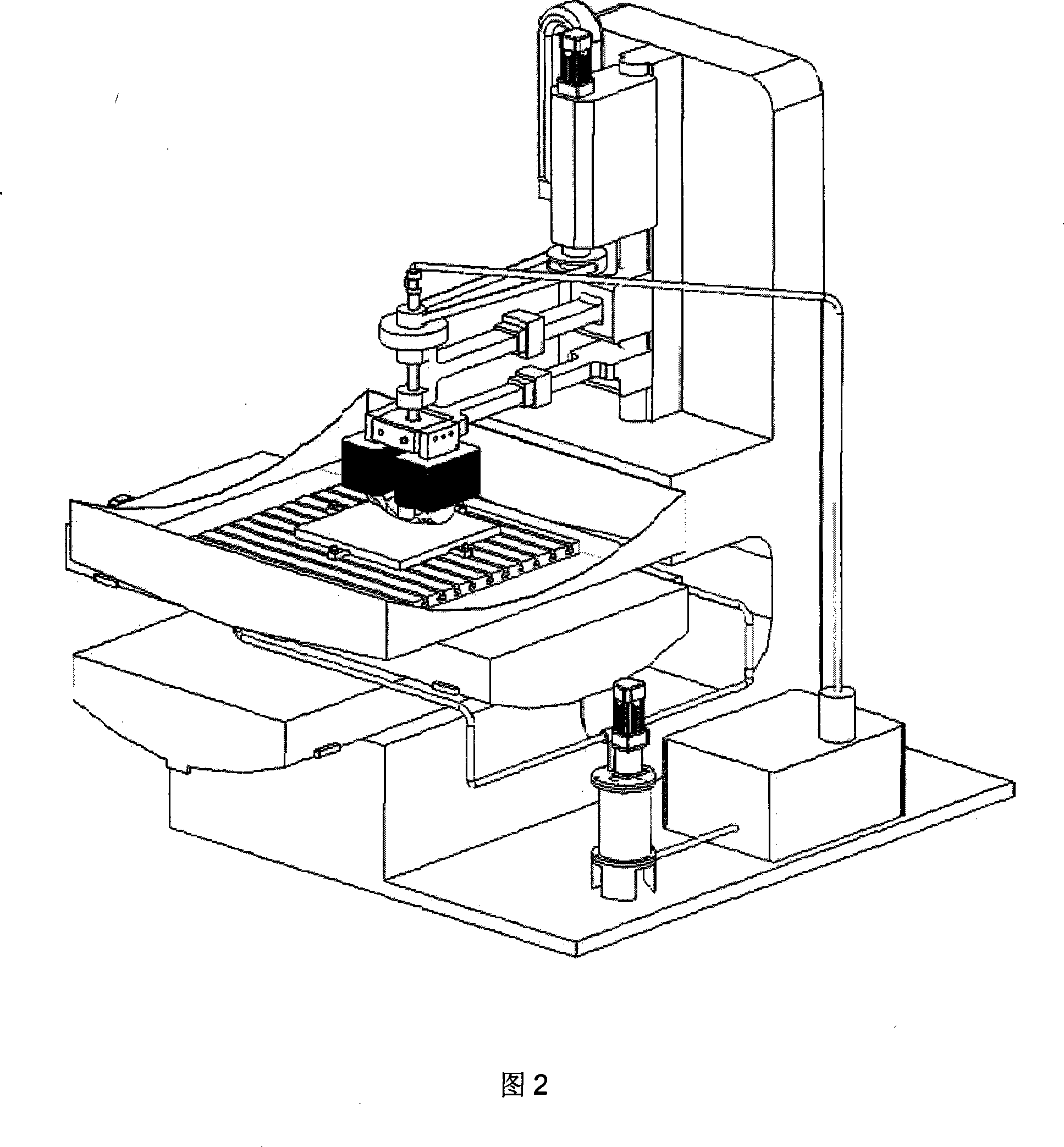

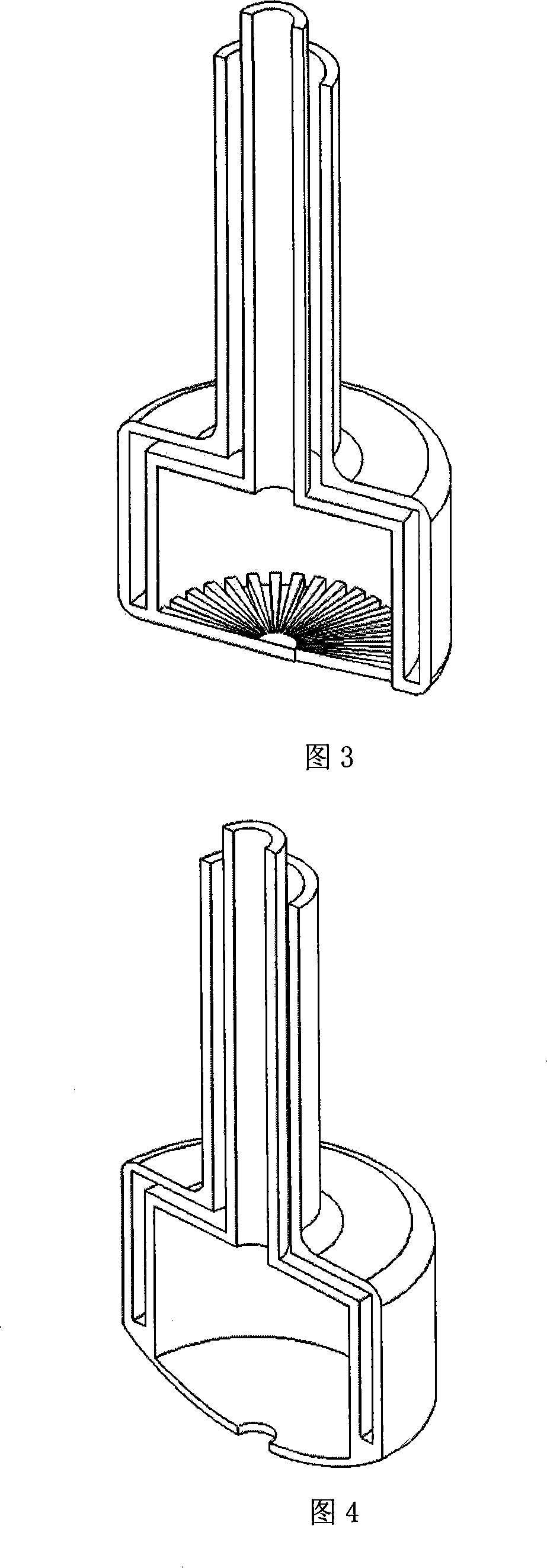

Precise magnetic flowage polishing system for optics parts and method thereof

InactiveCN101224556AImprove processing efficiencyEasy clampingOptical surface grinding machinesPeristaltic pumpTemperature control

The invention relates to an optical part magnetic rheologic precise polishing system and a method; magnetic rheologic liquid which flows out of a liquid storage cylinder is pressurized by a peristaltic pump and then enters a polishing head through a rotating connector and a guide pipe; the clearance between a workpiece and the polishing head is fully filled by the magnetic rheologic liquid; under the action of electromagnetic field, the magnetic rheologic liquid is transformed from the liquid state to the half-solid state so as to form a flexible grinding head used for polishing. The polishing head of the invention is not directly contacted with the workpiece; the polishing heads with different shapes and specifications can be replaced according to the processed workpiece; a computer automatic control device can realize the viscousity control and the temperature control of the magnetic rheologic liquid, and different polishing efficiency and precisions can be obtained by changing the factors such as magnetic field and rotation speed, etc.; the method of the invention can process the curved workpieces and plane workpieces with different shapes, more particularly the ultra-precise polishing of the large plane optical parts; the system has the advantages of high processing efficiency, wide applicable range, high processing precision and convenient operation.

Owner:DONGHUA UNIV

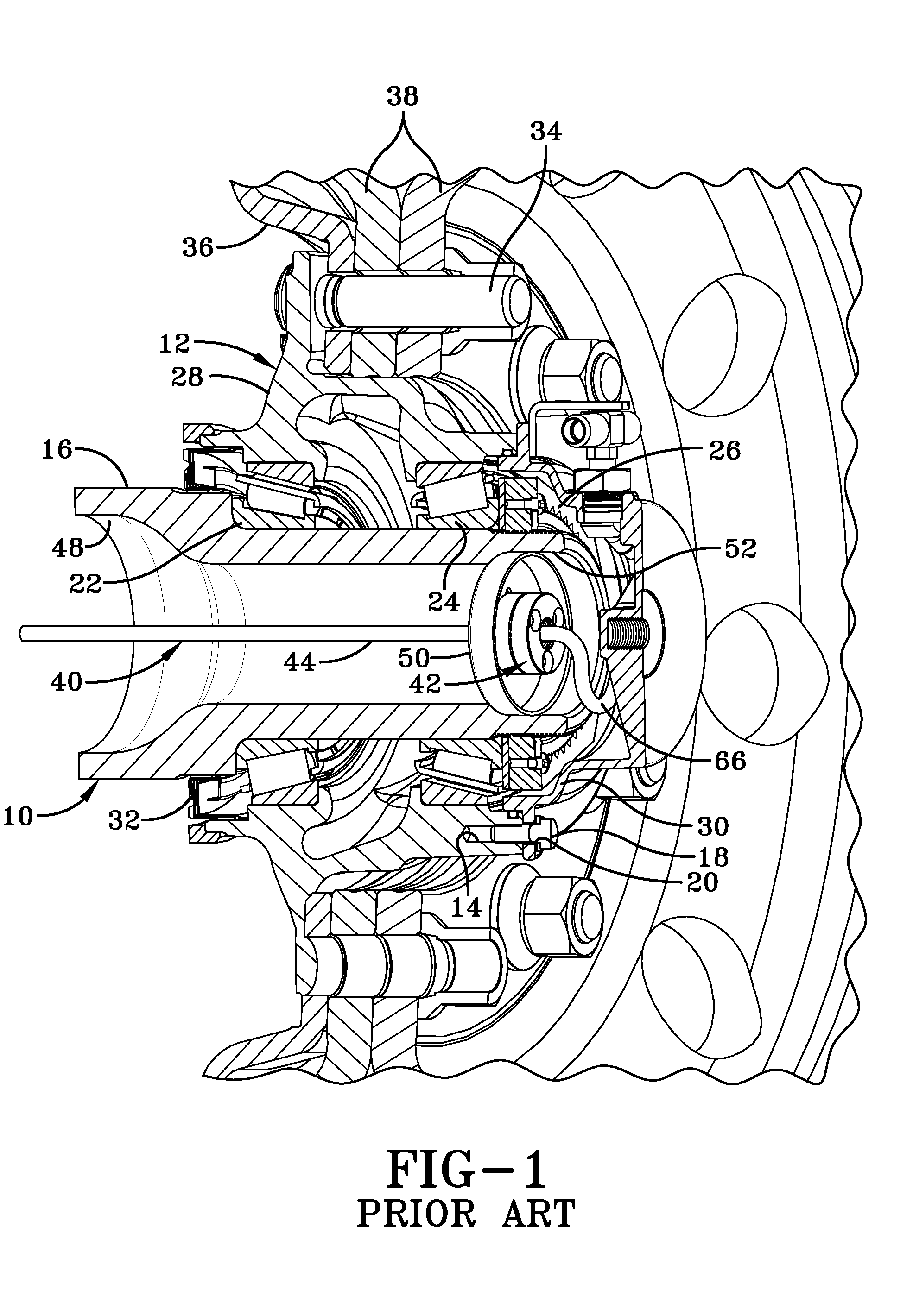

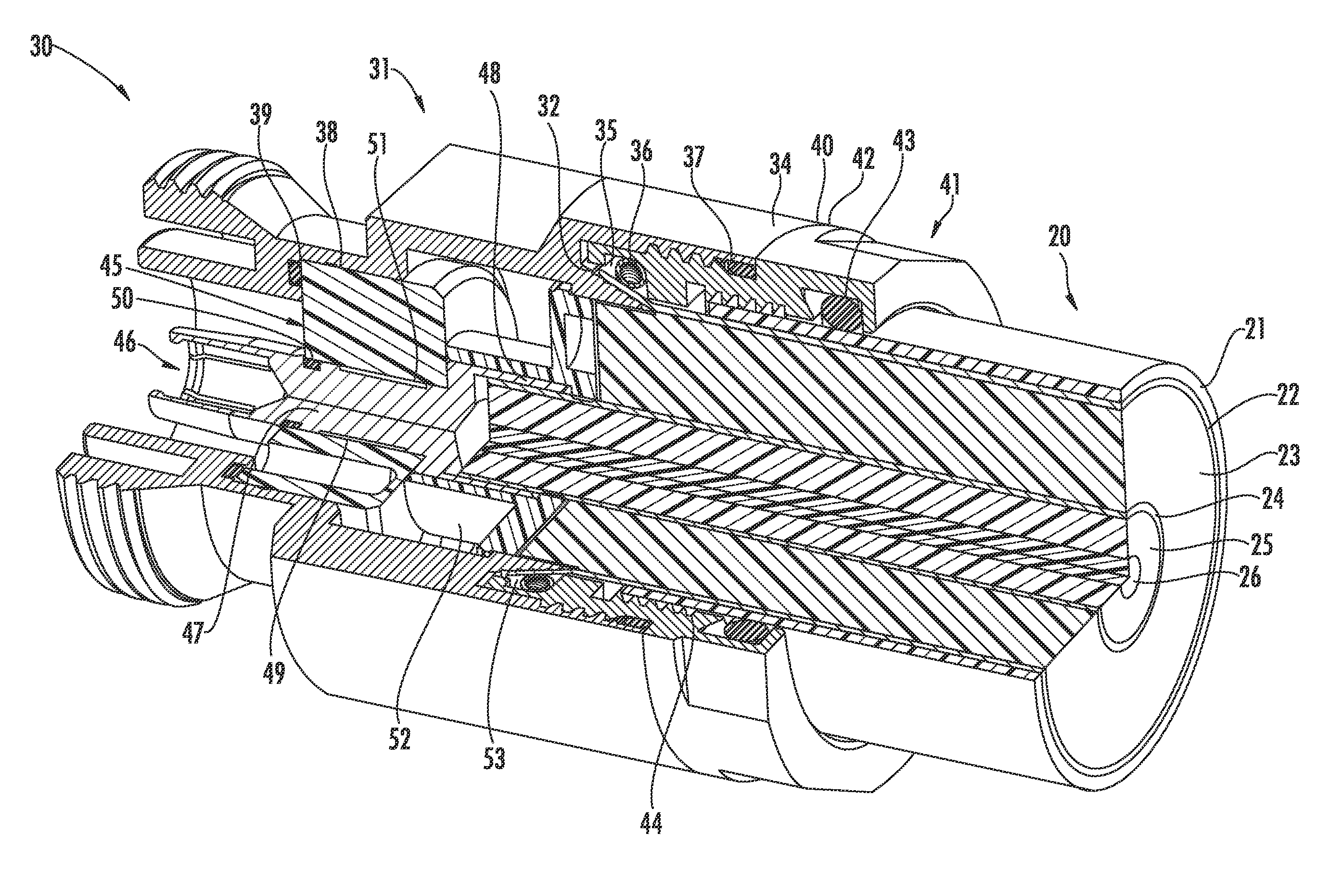

Rotary union assembly for use in air pressure inflation systems for tractor trailer tires

InactiveUS20050133134A1Prevent pressure buildupAvoid distortionTyre measurementsTyre-inflating valvesAtmospheric pressureGuide tube

A rotary union assembly for an automatic tire inflation system for maintaining the pressure in the tires on a tractor trailer or other vehicle having a source of pressurized air for communication with the tires. The assembly communicates the tires with the air source through the axle interior using a conduit having a rigid portion and a flexible portion that extends between a support in the axle spindle and a rotary union housing secured against the outside end surface of the hub cap so as to be outside the wheel lubrication compartment and rotatable with the hub cap. The two-component conduit allows for a durable seal with the support in the axle spindle and accommodates misalignment of the rotary union housing with the conduit support. Relief valves in the housing prevent excessive pressure buildups in the housing and in the hub cap in the event of an air leak.

Owner:AIRGO IP

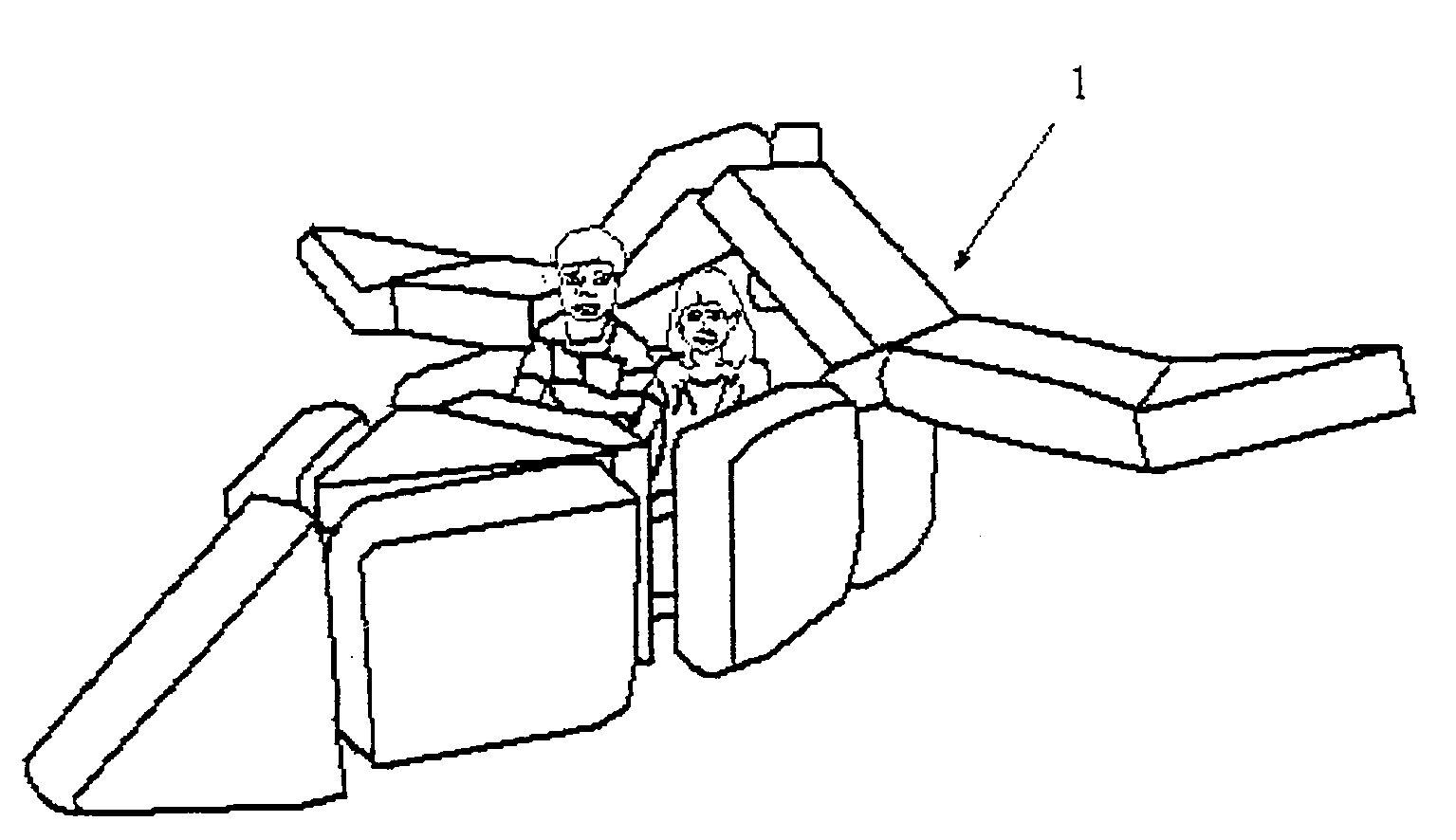

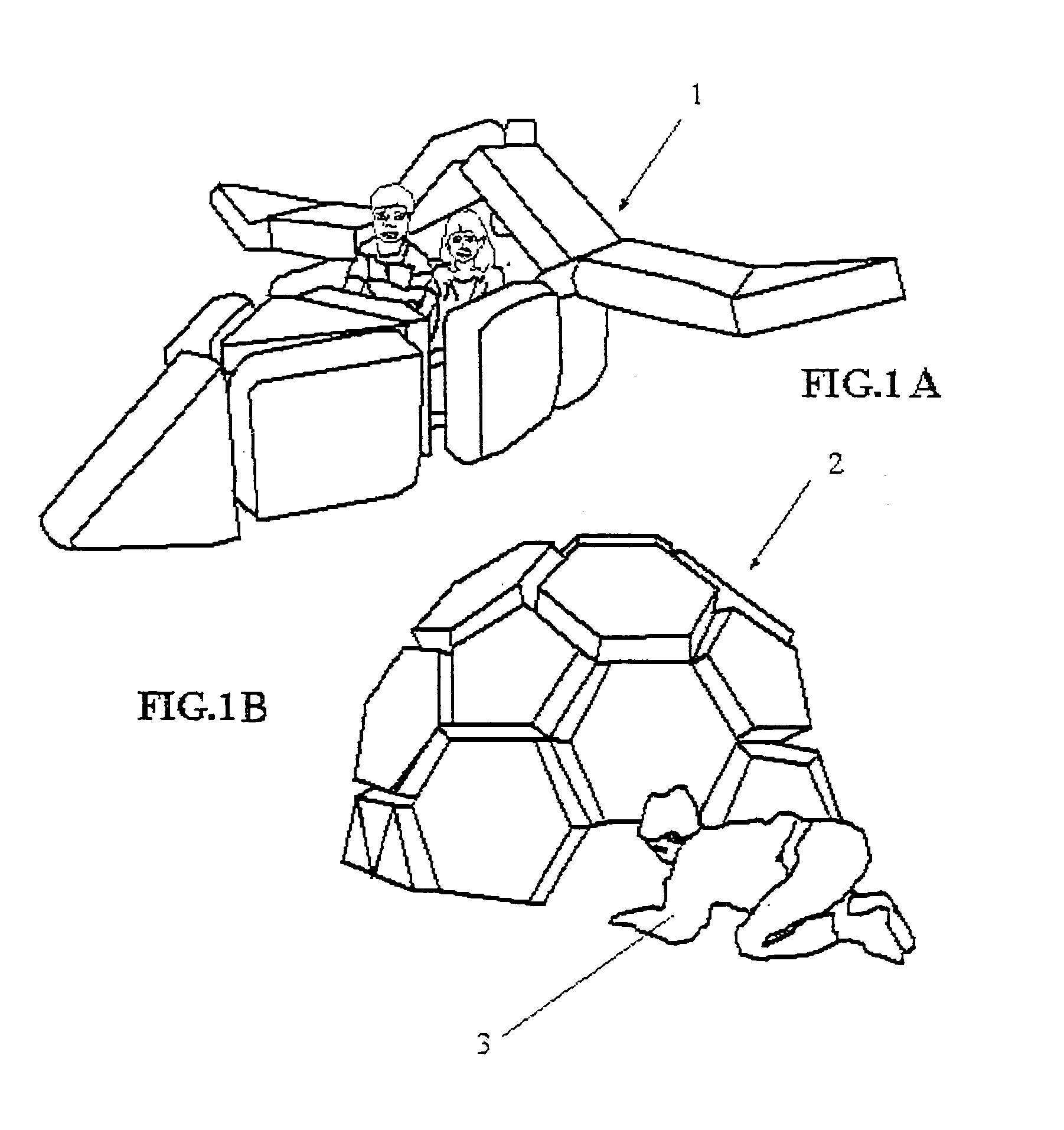

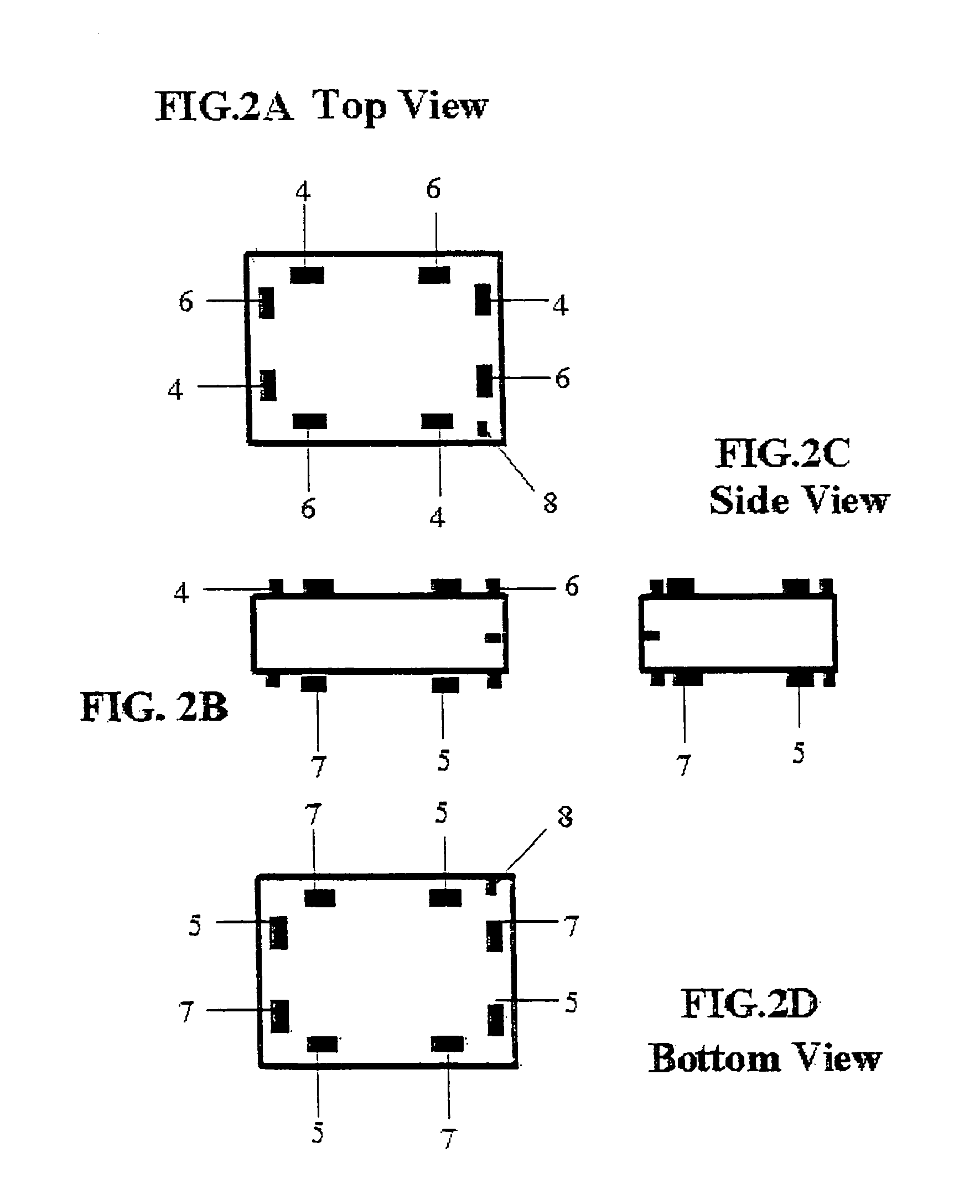

Blocks and building system for the construction of lifesize inflatable play structures

A system for the construction of life size play structures includes a multiplicity of inflatable building blocks, each being a member of a finite set of different multi-sided block types. Each such type is a cylinder having the cross section of a regular polyhedron, and the length of each side of each polyhedron is identical. The blocks are attached to each other by means of a rotating joint which aligns each contiguous side of each block with the contiguous side of the adjoining block, but which does not allow each such to translate relative to the adjoining block. The joints are constructed at fixed locations along the sides according to specific dimensional ratios. Stiffening means are used to maintain the dimensional integrity of each block, and to maintain the uniformity of the system from block to block.

Owner:LIOU DICK

Process for anodizing a robotic device

A robotic device has a base and at least one finger having at least two links that are connected in series on rotary joints with at least two degrees of freedom. A brushless motor and an associated controller are located at each joint to produce a rotational movement of a link. Wires for electrical power and communication serially connect the controllers in a distributed control network. A network operating controller coordinates the operation of the network, including power distribution. At least one, but more typically two to five, wires interconnect all the controllers through one or more joints. Motor sensors and external world sensors monitor operating parameters of the robotic hand. The electrical signal output of the sensors can be input anywhere on the distributed control network. V-grooves on the robotic hand locate objects precisely and assist in gripping. The hand is sealed, immersible and has electrical connections through the rotary joints for anodizing in a single dunk without masking. In various forms, this intelligent, self-contained, dexterous hand, or combinations of such hands, can perform a wide variety of object gripping and manipulating tasks, as well as locomotion and combinations of locomotion and gripping.

Owner:BARRETT TECH LLC

Seat swivel with brake for infinite rotational position adjustment

A seat swivel for providing angular adjustment of a seat to an infinite number of rotational positions with respect to a seat base. The seat swivel includes a swivel assembly having a swivel plate rotatably supported between a pair of fixed plates, the swivel plate being adapted to be affixed to the seat and the fixed plates being adapted to be affixed to a seat base. The seat swivel further includes a brake assembly having a mechanism for releasably retaining the seat in any one of the infinite number of positions when the seat is subjected to a first dynamic impact loading, the mechanism being either mechanically or electrically actuated, the mechanism being adapted to withstand a dynamic impact loading of up to about 16 g in at least one rotational position of the seat.

Owner:BE AEROSPACE INCORPORATED

Multi-diameter tube coupling

A multi-diameter tube coupling is provided for interconnecting flexible plastic tubing of the type used in drip irrigation systems and the like, wherein the tube coupling is adapted for use with a range of different tubing sizes. The tube coupling includes a central body defining an internal flow path, with a retainer collet mounted thereon at each open end of the flow path to capture a seal member having a compliant, pressure-activated seal lip. The retainer collet includes an annular array of lock fingers for unidirectional slide-fit locked reception of one end of a length of tubing within a range of different sizes, with the seal lip engaging the tubing to provide a substantially leak-proof connection. Alternatively, the collet lock fingers accommodate slide-fit locked reception of a barbed swivel adapter, with the seal lip engaging the adapter to provide a substantially leak-proof connection.

Owner:RAIN BIRD CORP

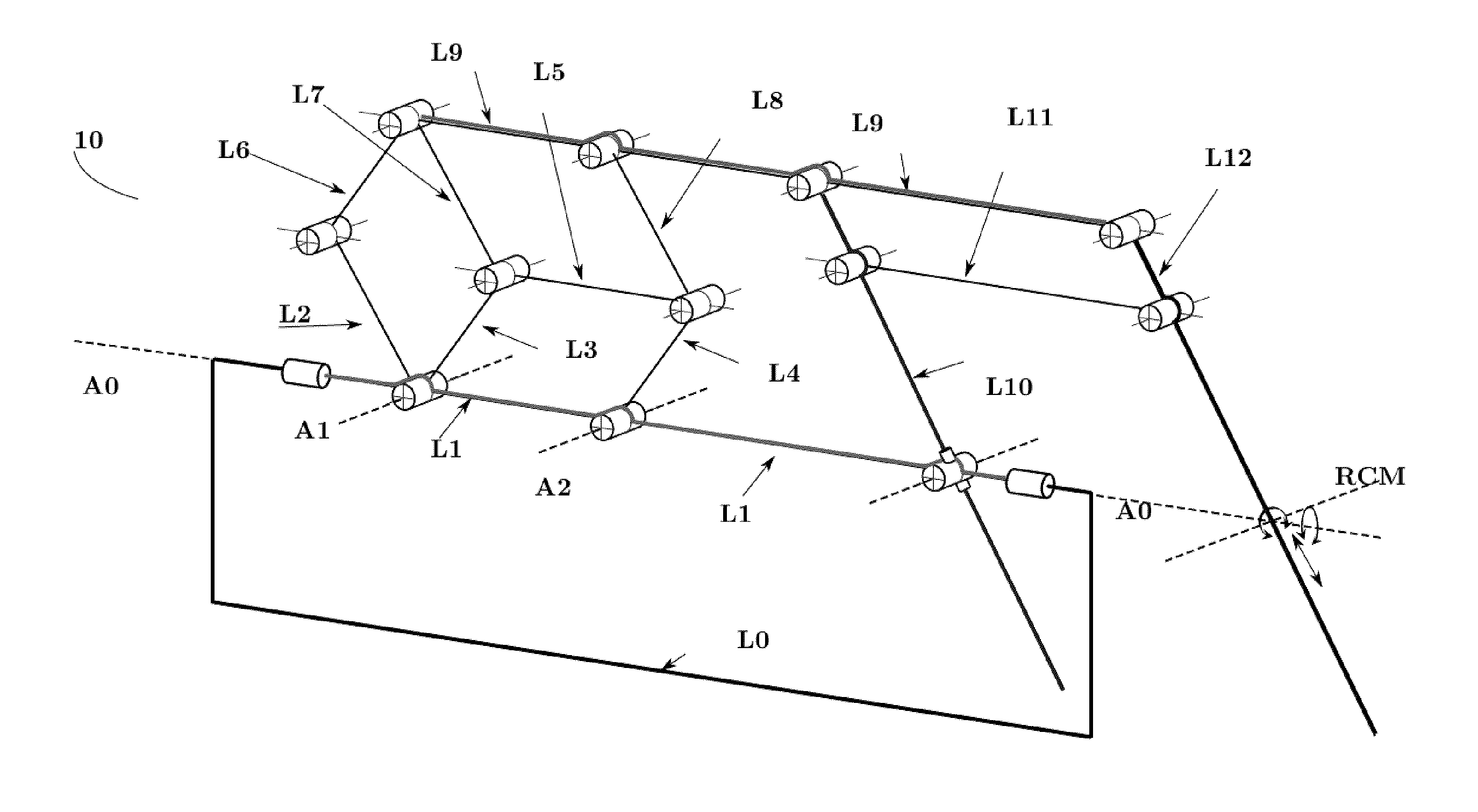

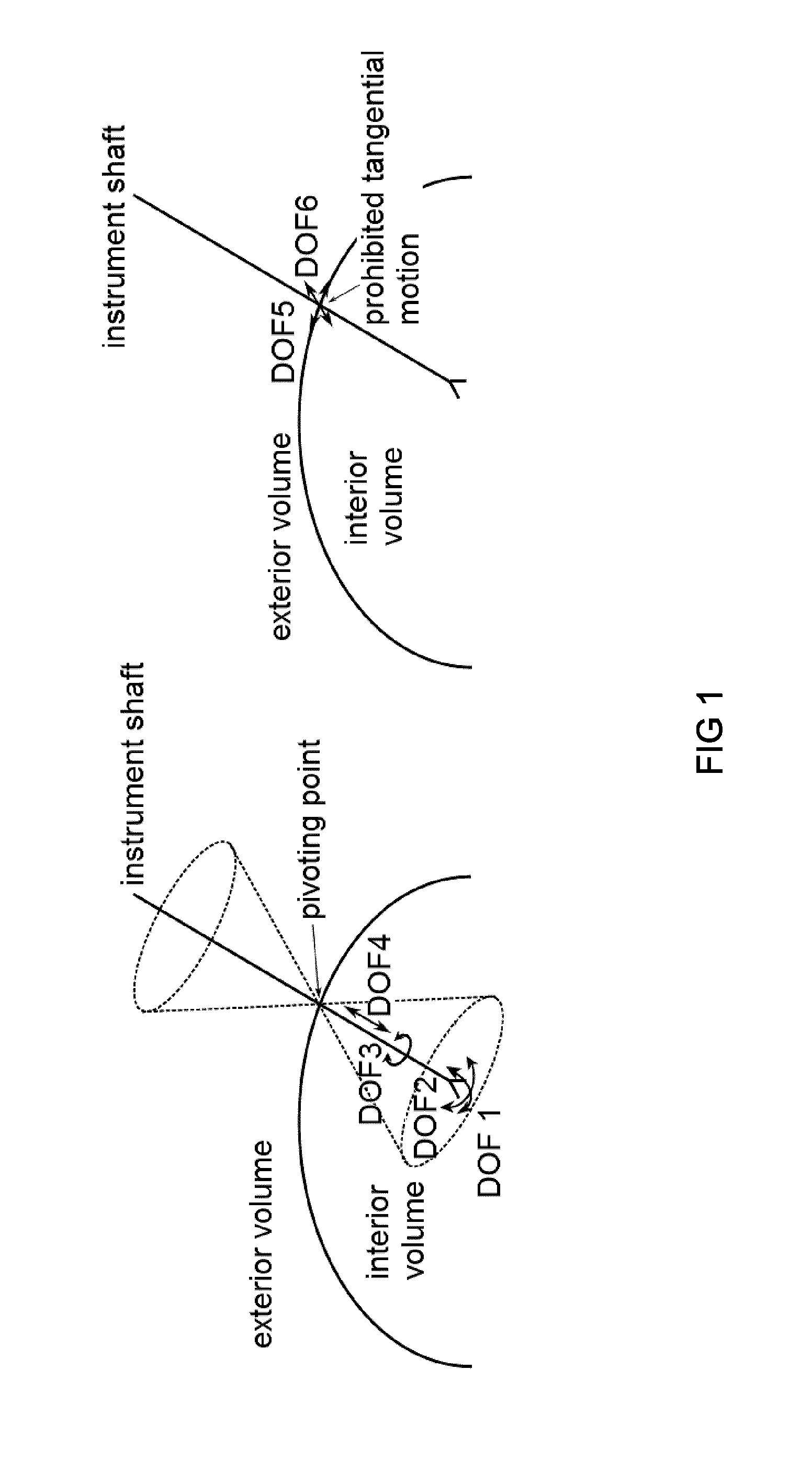

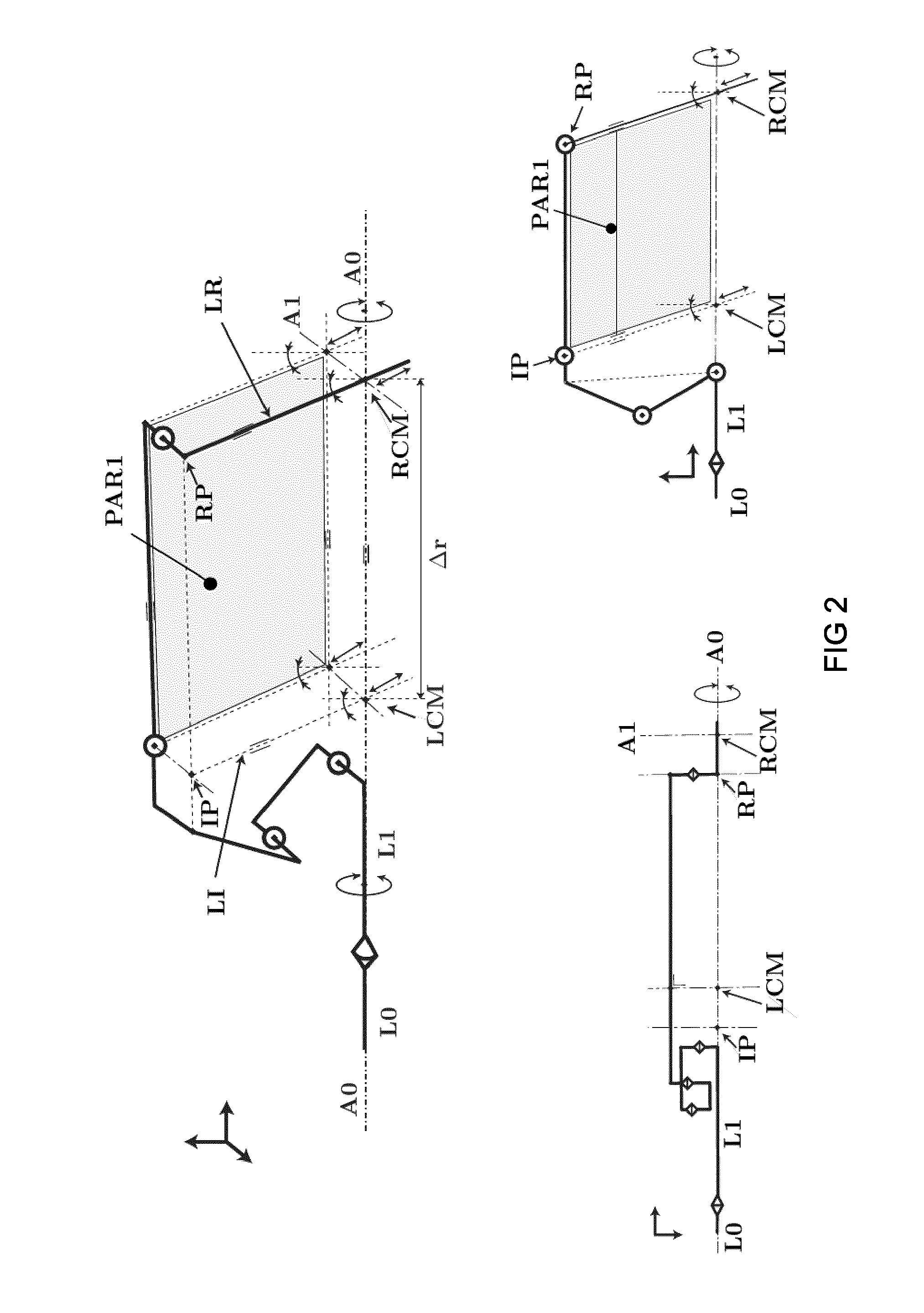

An apparatus for generating motion around a remote centre of motion

ActiveUS20150351857A1Easy to controlEasy to manufactureProgramme-controlled manipulatorDiagnosticsEngineeringTarsal Joint

Apparatus (10) for generating motion around a remote center of motion (RCM), comprising a distal link (L12, LR) arranged to revolve about the remote center of motion and to translate through the remote center of motion, a proximal link (L10, LI) arranged to revolve about a proximal center of motion (LCM), coupled to a base link, through a rotational joint (150) and a sliding joint (181), a first mechanism comprising a first link (L9, BE) pivotally coupled to the proximal link (L10) and to the distal link (L12) and operable to transfer motion of the proximal link relative to the proximal center of motion to a motion of the distal link relative to the remote center of motion by maintaining a parallelogram (PAR1), and a second mechanism operable to move the first link with two degrees of freedom in a plane parallel to the plane of motion of the proximal link, characterised in that the second mechanism comprises one link or a serial connection of links (L4, L8, L3, L7, L2, L6) connecting the base link to the first link, configured to have an orientation of instant motion which is different from an orientation of instant motion of the proximal link (L10), relative to the base link.

Owner:KATHOLIEKE UNIV LEUVEN

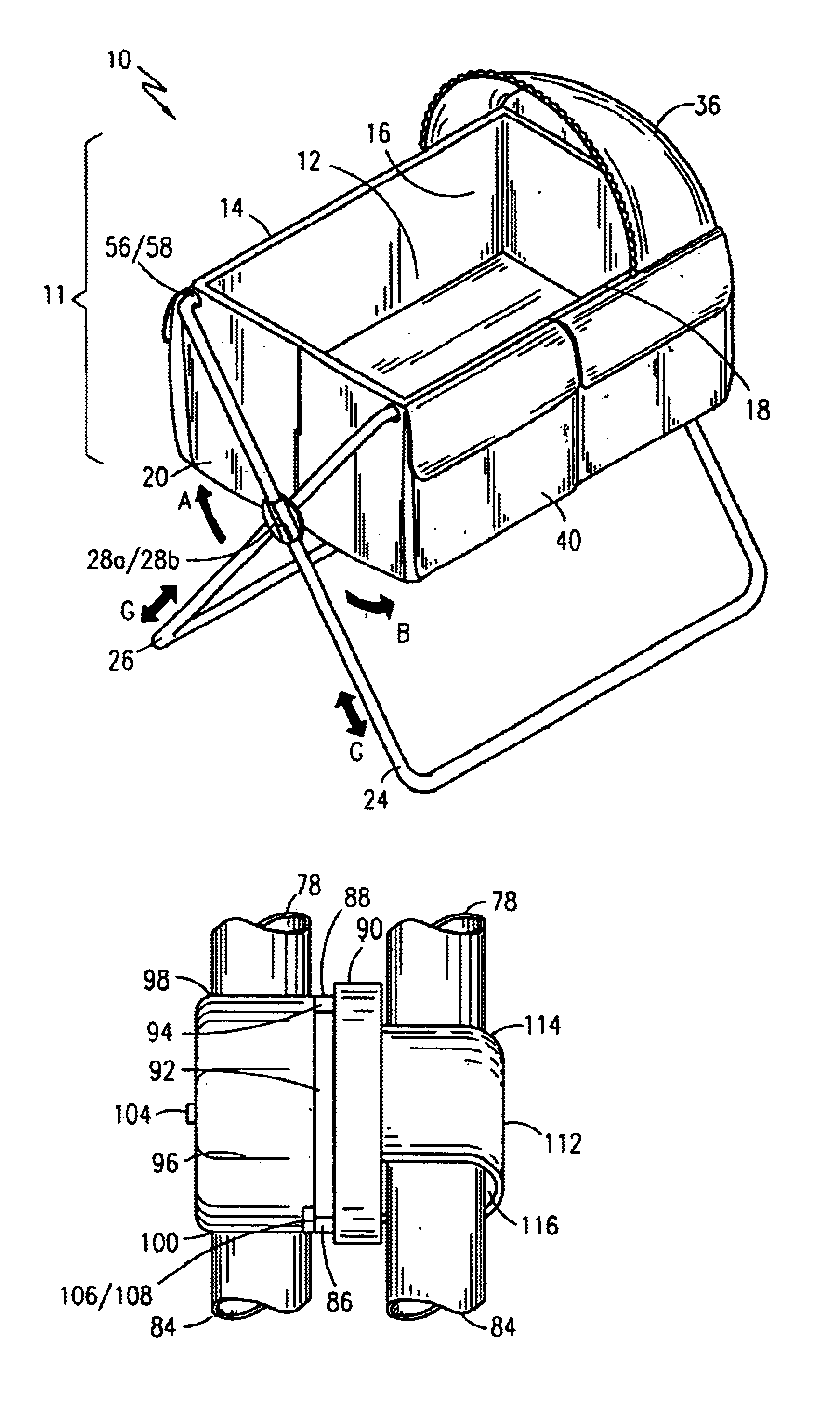

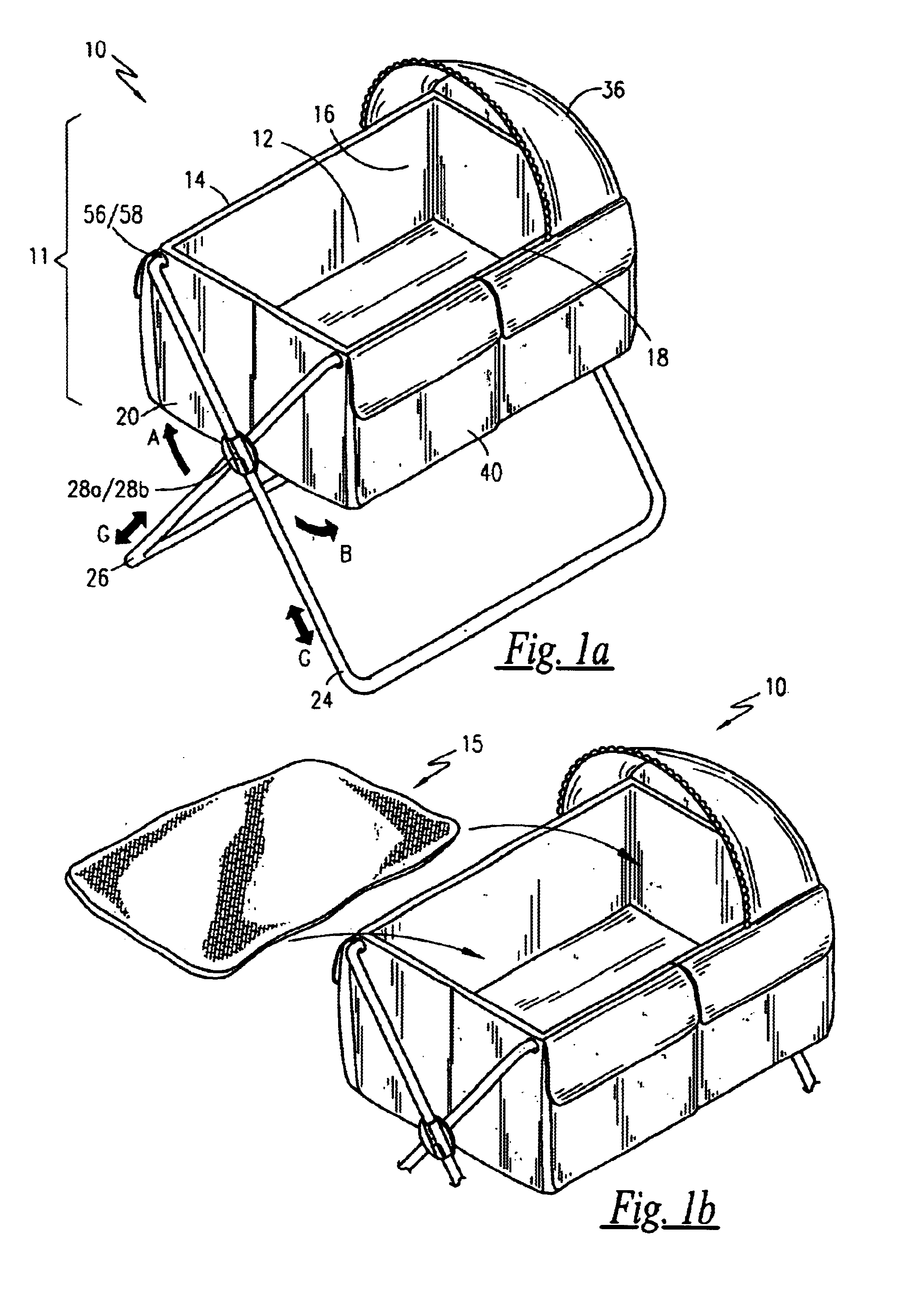

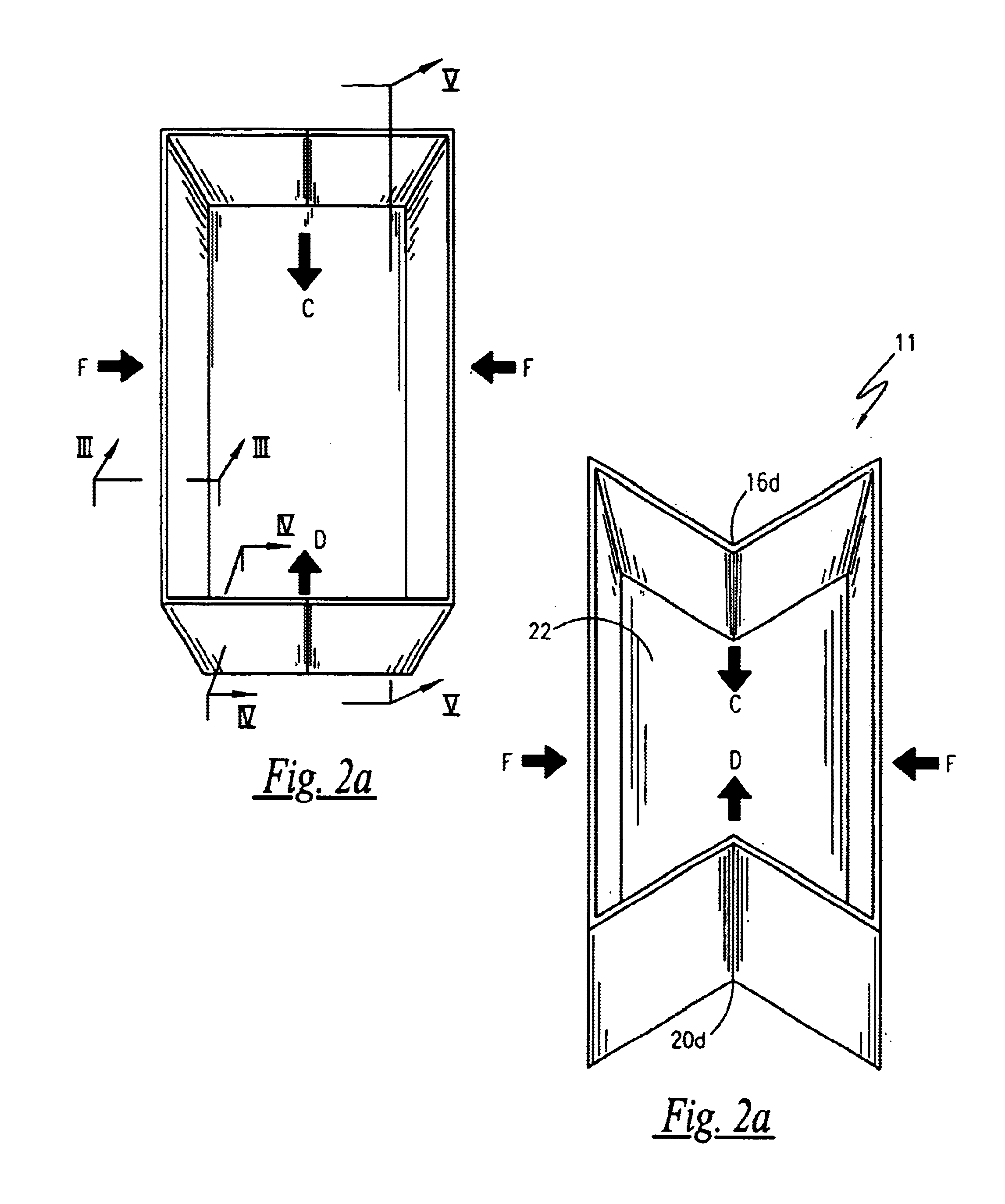

Portable child's bed

InactiveUS6687928B1Suitable for useEasy to useRopes and cables for vehicles/pulleyKids bedsInfant CareEngineering

A portable child's bed is a bassinet hangably suspended from a pair of frame members. The bassinet includes a pair of opposing sidewalls that have a seam which allows for the sidewalls to inwardly pivot and then fold so as to allow for the compaction of the bassinet unit. The bassinet also includes a plurality of storage pockets capable of holding such infant-care related items such as diapers, powder, ointments, small blankets, towelettes, formula, feeding bottles and many other related items. The bassinet may also include a canopy for shielding the infant's head while resting or sleeping. The frame members include a telescoping strut which extendably expands or contracts within a strut housing. The telescoping strut and strut housing are in fluid communication and connected by a rotatable joint having an anterior and posterior sleeve to accommodate the pair of frames. The anterior sleeve is rotatable through 180°, thereby providing the pair of frames the ability to fully expand and position the telescoping struts in such a way so as to provide support to the bassinet. The anterior sleeve also allows for the frames to be compacted so as to reconfigure the portable child's bed into a lightweight and convenient travel bag.

Owner:WILSON MICHELLE

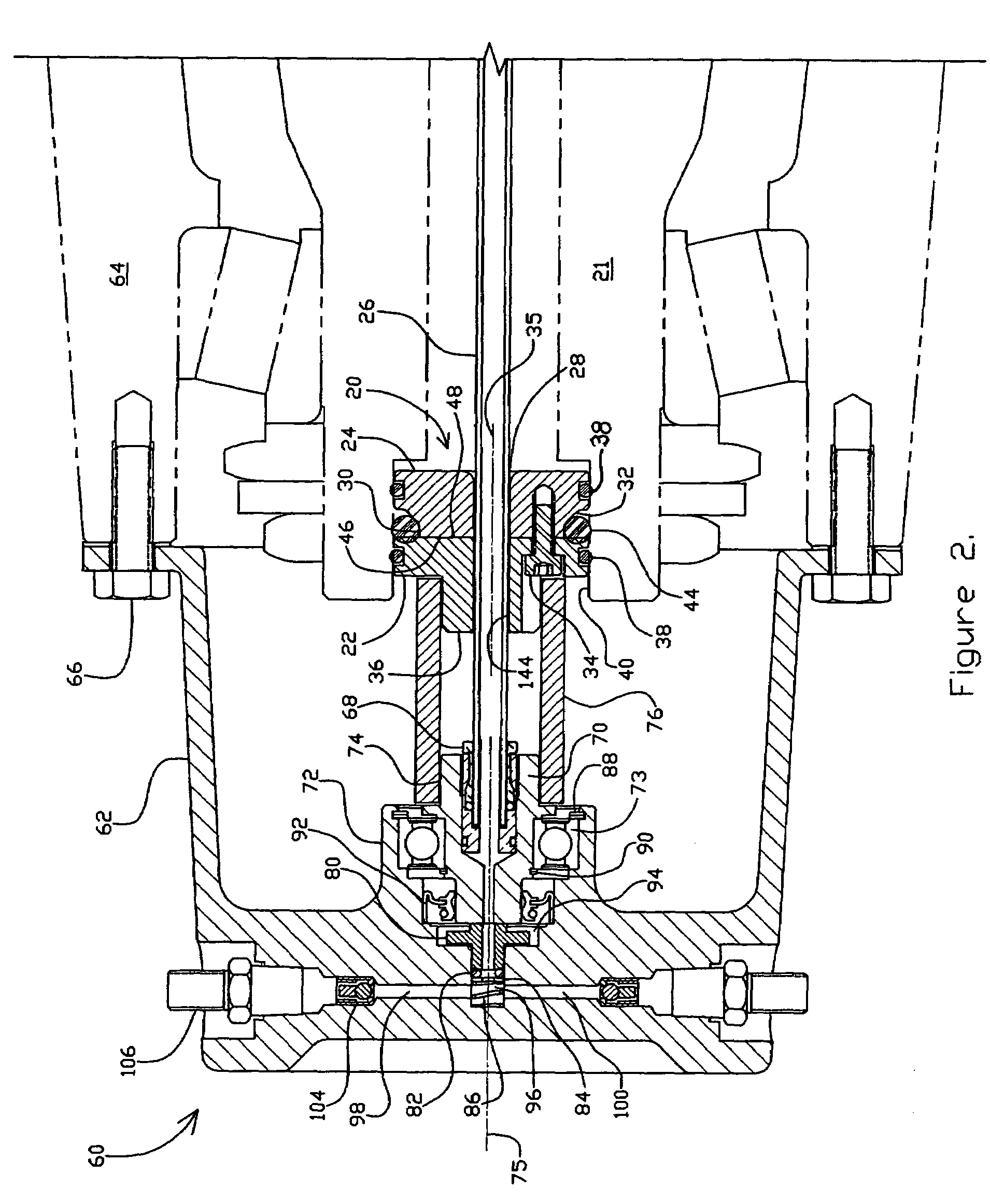

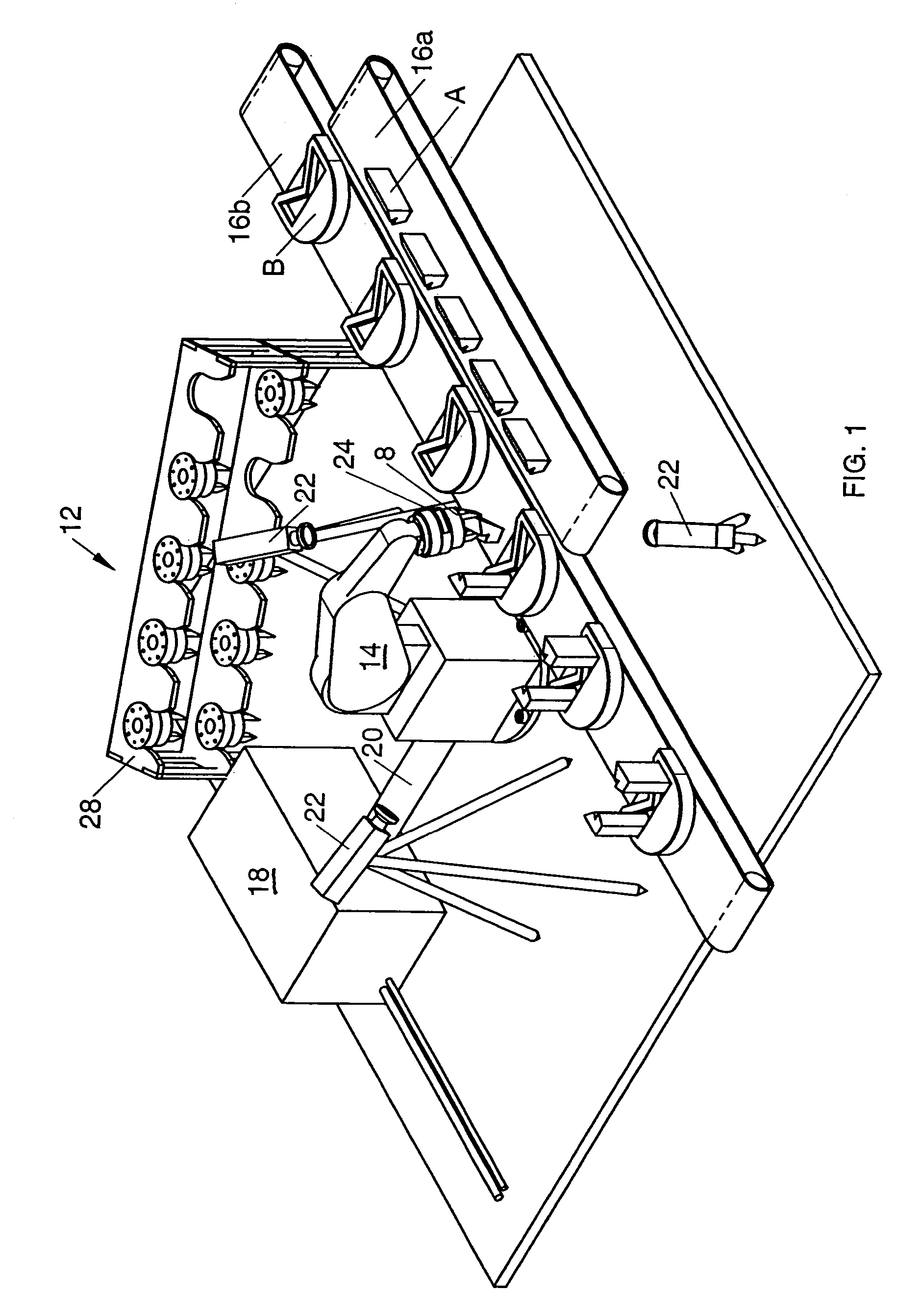

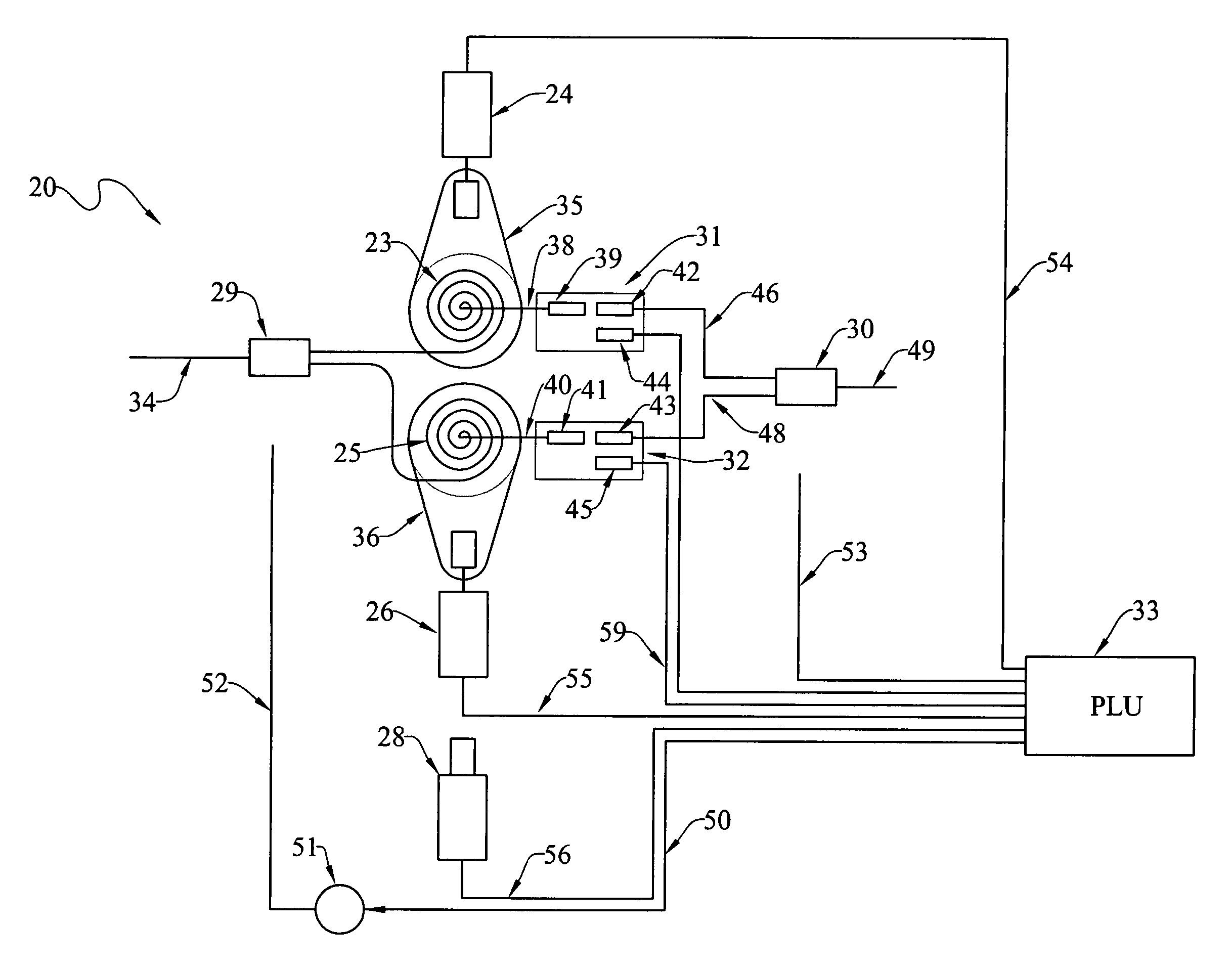

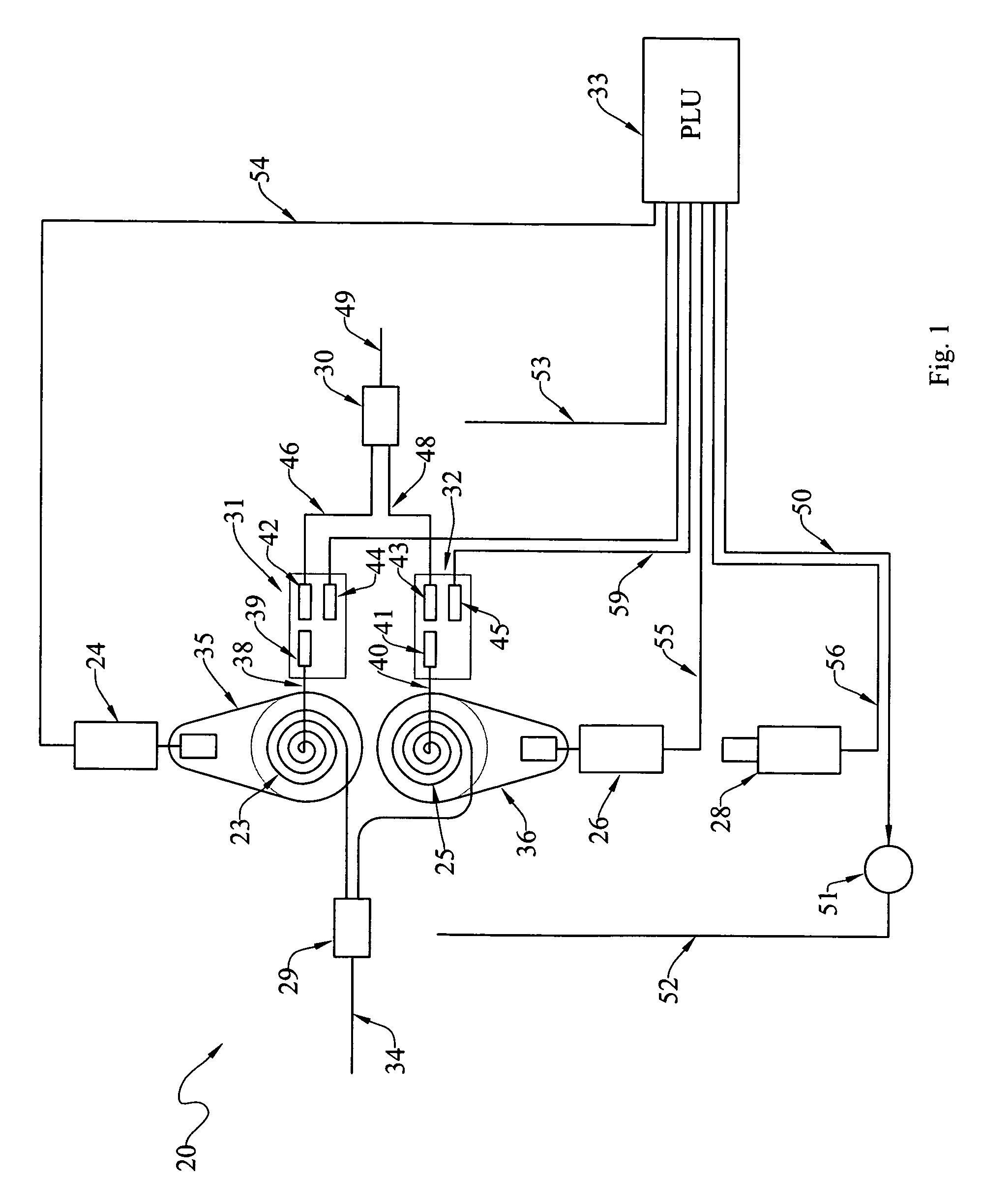

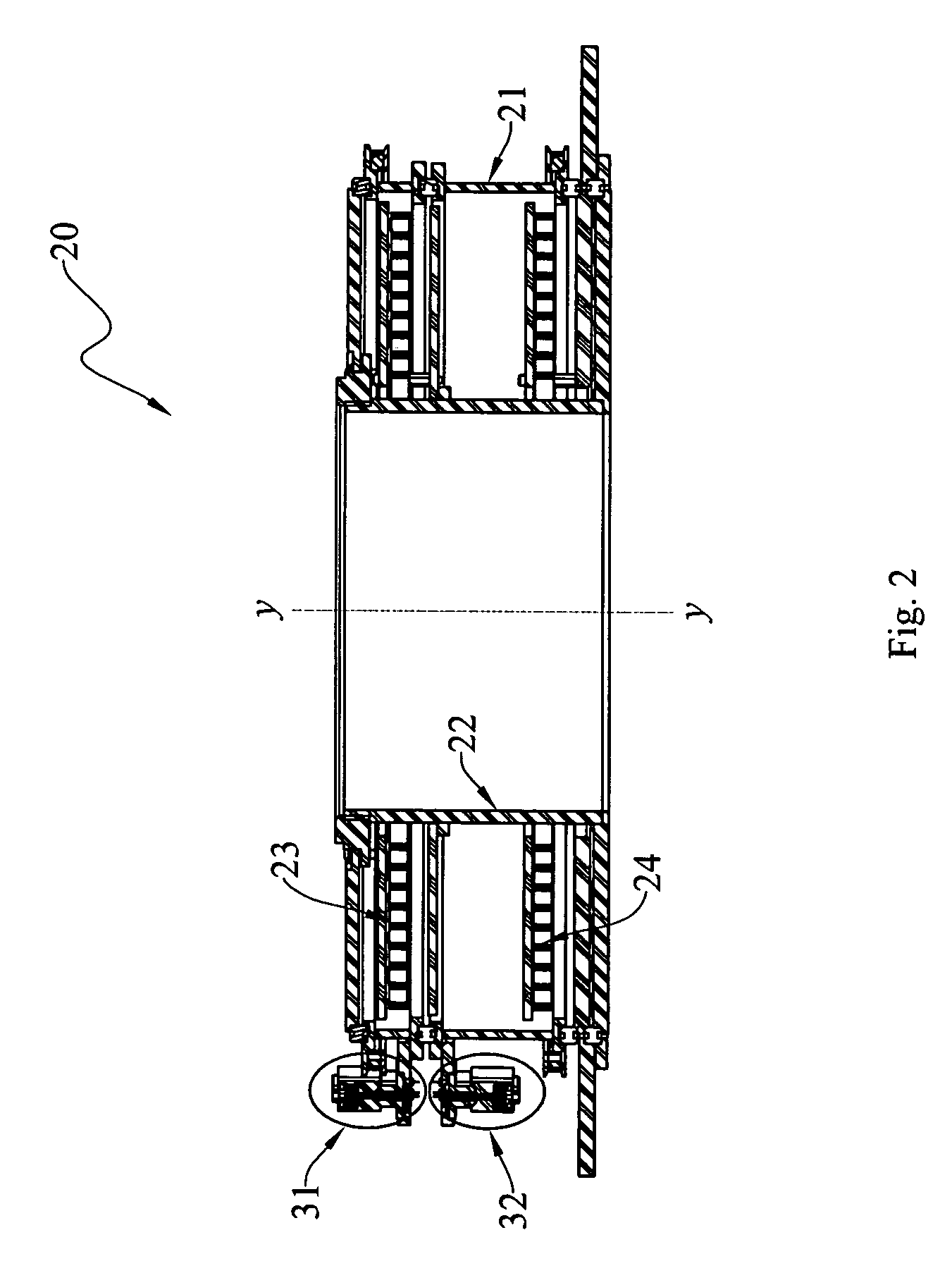

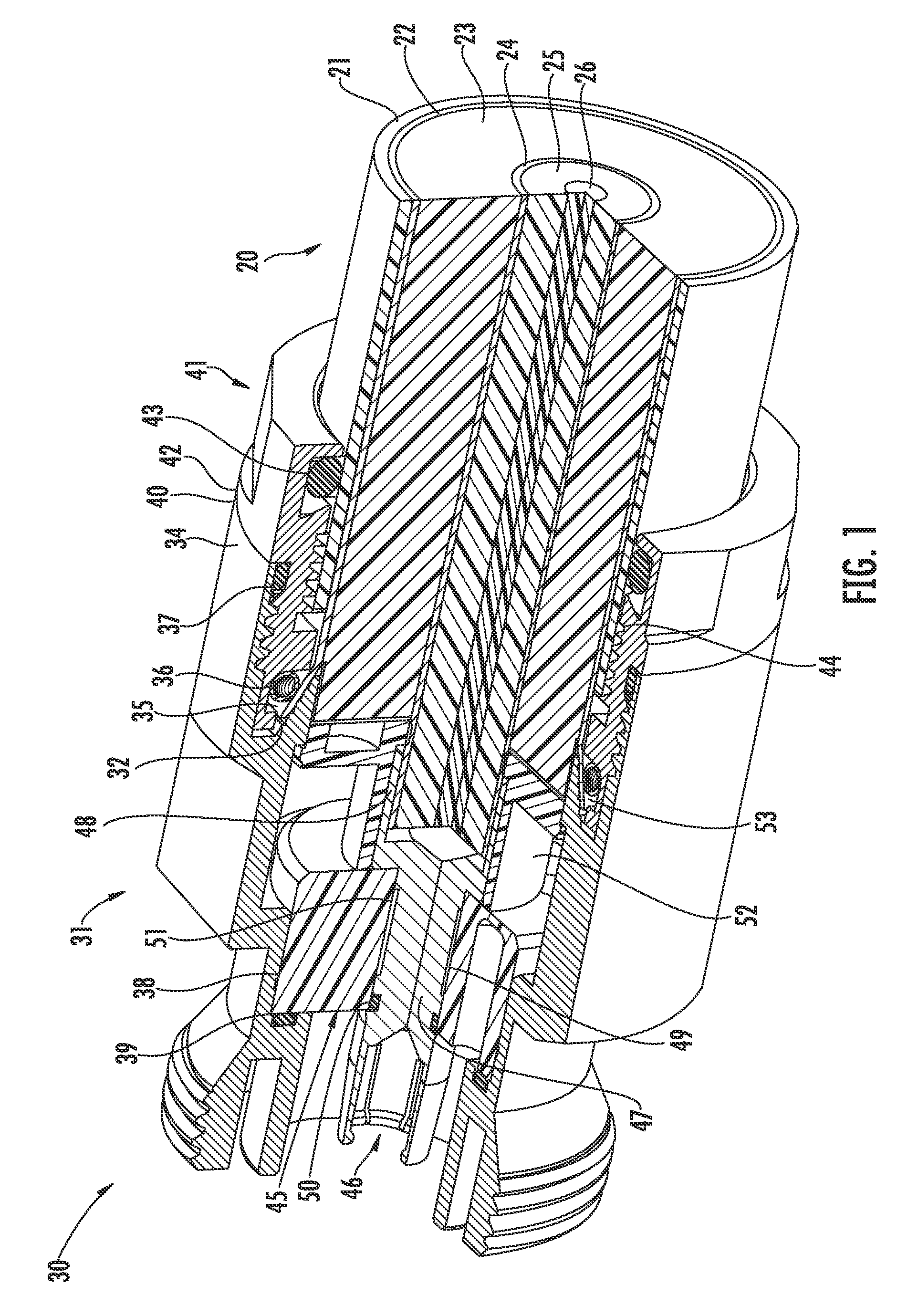

Off-axis rotary joint

An off-axis rotary joint (20) for selectively enabling communication of a signal (i.e., electrical and / or optical) between a housing (21) mounted for rotation about an axis (y-y) relative to a hollow shaft assembly (22) at all permissible relative angular displacements (e.g., 0°, 180°, 360°, 540°, 720°, etc.) between the housing and shaft assembly, broadly includes: a first conductor (23) having an first end mounted on the second member and having a second end mounted on the first member, the first conductor being adapted to convey a signal between its ends; a first motor (24) operatively arranged to selectively rotate the first conductor first end through a desired angular displacement relative to the second member; a second conductor (25) having an first end mounted on the second member and having a second end mounted on the first member, the second conductor being adapted to convey a signal between its ends; a second motor (26) operatively arranged to selectively rotate the second conductor second end through a desired angular displacement relative to the first second member; an encoder (28) for monitoring the angular displacement of the first member relative to the second member; a first divider / combiner (29) communicating with the second end of each of the conductors; a second divider / combiner (30); a first connector (31) mounted on the first member for selectively communicating the first and second divider / combiners through the first conductor; a second connector (32) mounted on the first member for selectively communicating the first and second divider / combiners through the second conductor; and a controller (33) for selectively operating the first and second motors and the first and second connectors; whereby a signal may be conveyed though the joint at all permissible angular displacements of the housing relative to the shaft assembly.

Owner:FOCAL TECH

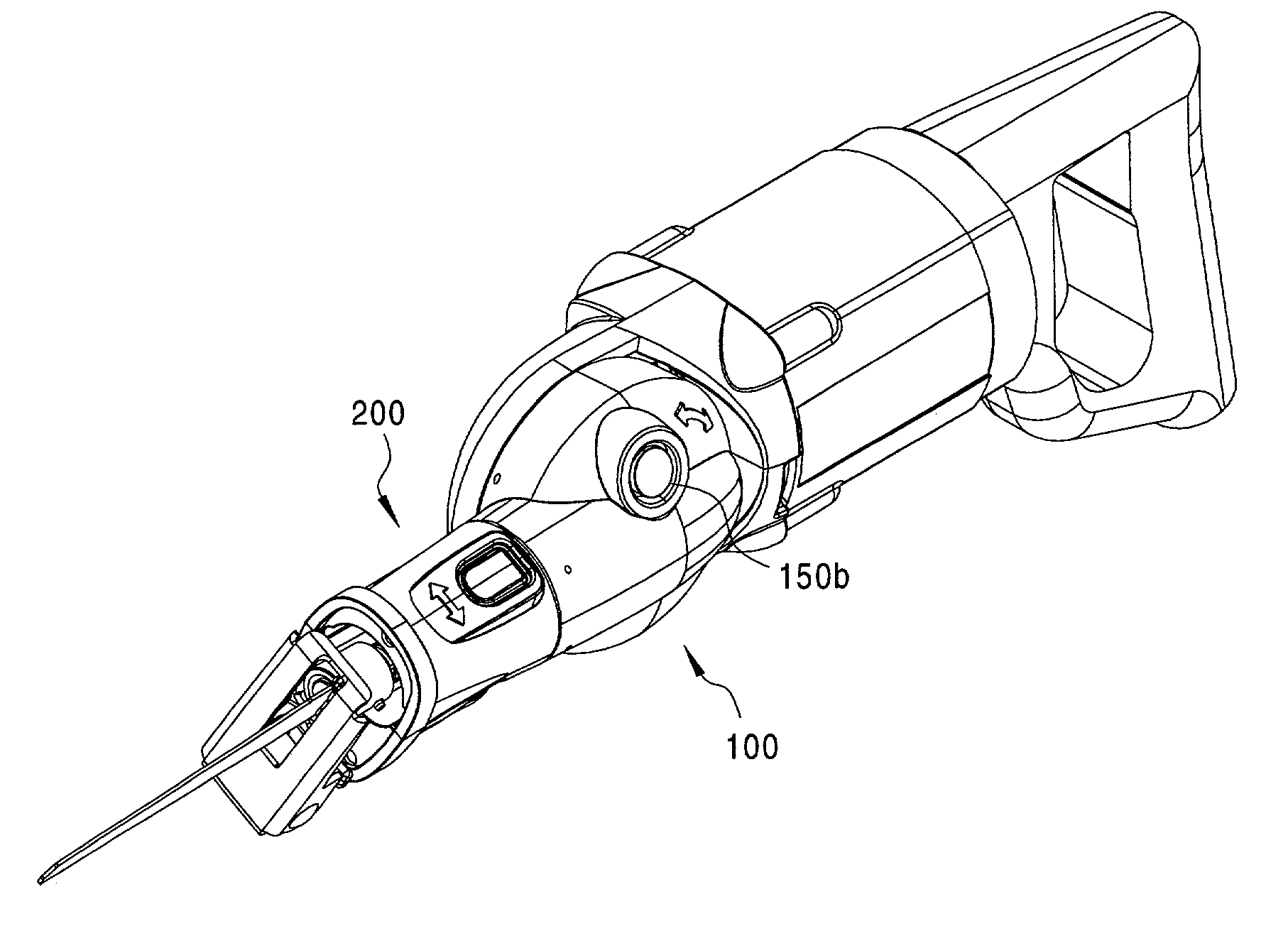

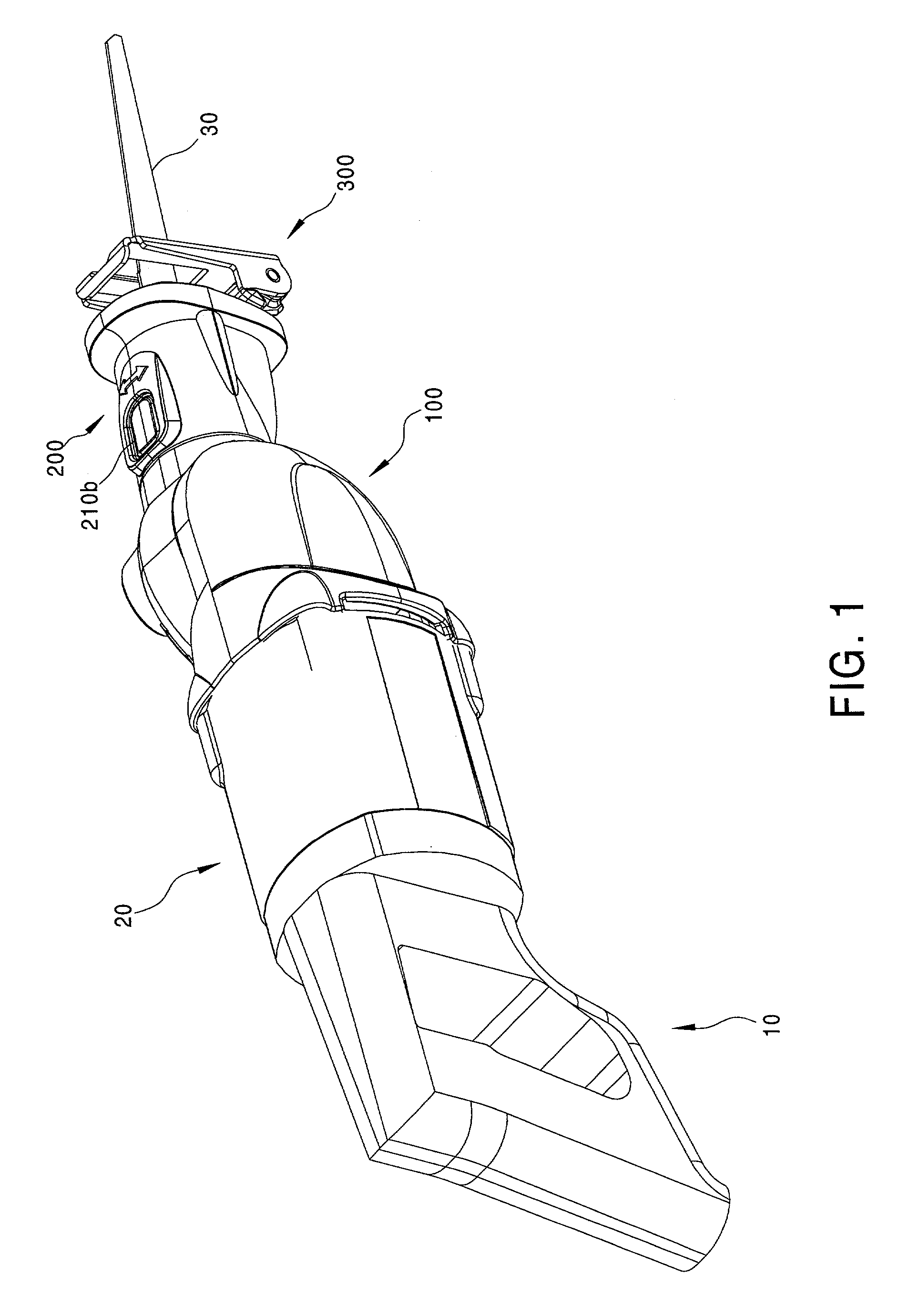

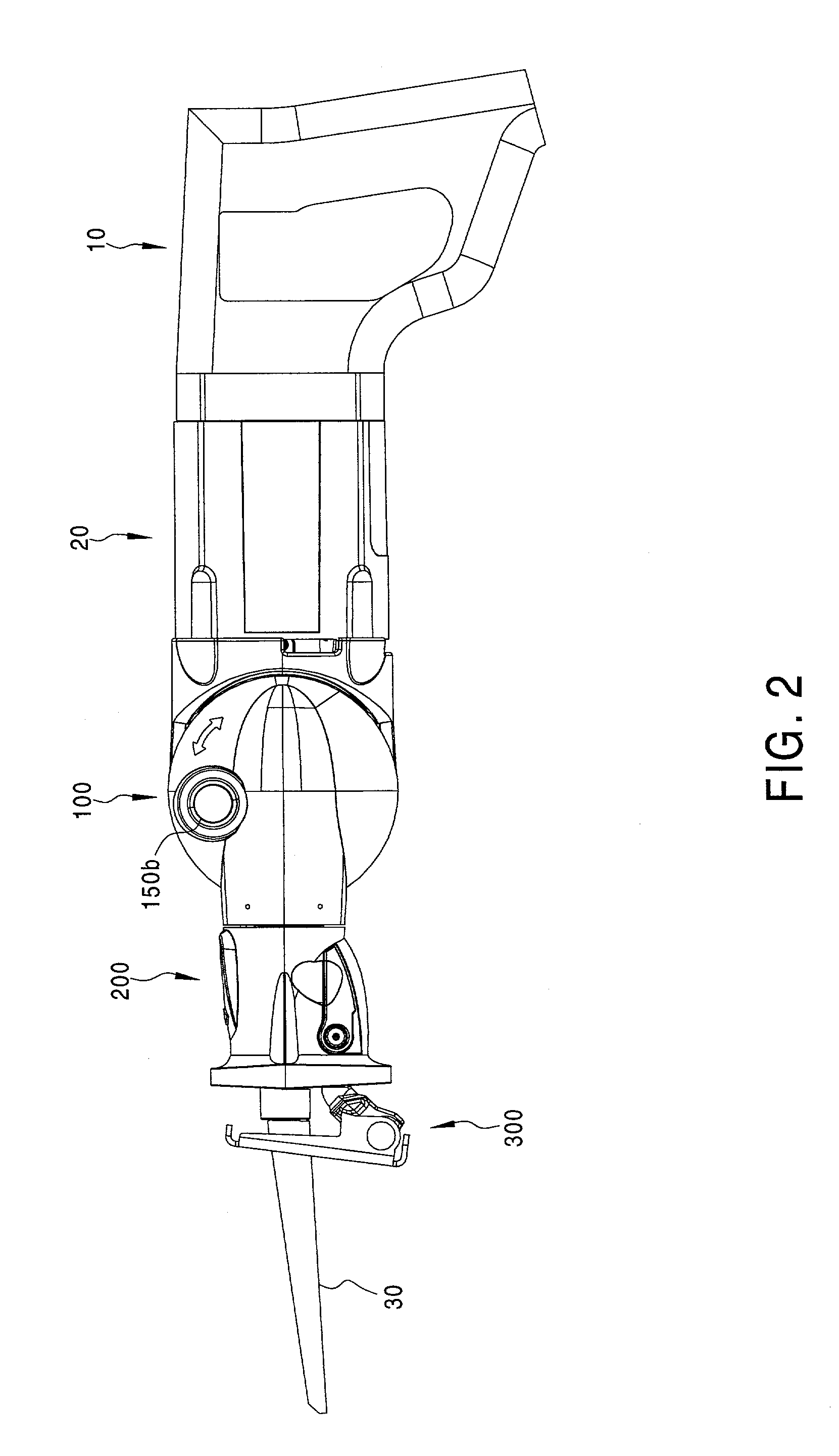

Adjustable reciprocating saw

InactiveUS7204026B2Improve versatilityIncrease the number ofMetal sawing devicesPortable power-driven toolsTransverse axisReciprocating motion

An adjustable reciprocating saw has the ability to adjust the orientation of the saw blade in relation to the rest of the tool. The saw blade can pivot about two transverse axes, one parallel with and one perpendicular to the reciprocating motion axis of the saw blade. The portions of the saw's housing which rotate relative to one another are attached with a rotating joint comprising a pin and groove design. Rotation locks selectively prevent rotation of the saw blade about each axis. The rotation locks can be released through simply depressing buttons on the saw. A rear internal bearing increases the durability and decreases the size of the saw. A keyless adjustable shoe is mounted to the saw.

Owner:PORTER CABLEDELTA +1

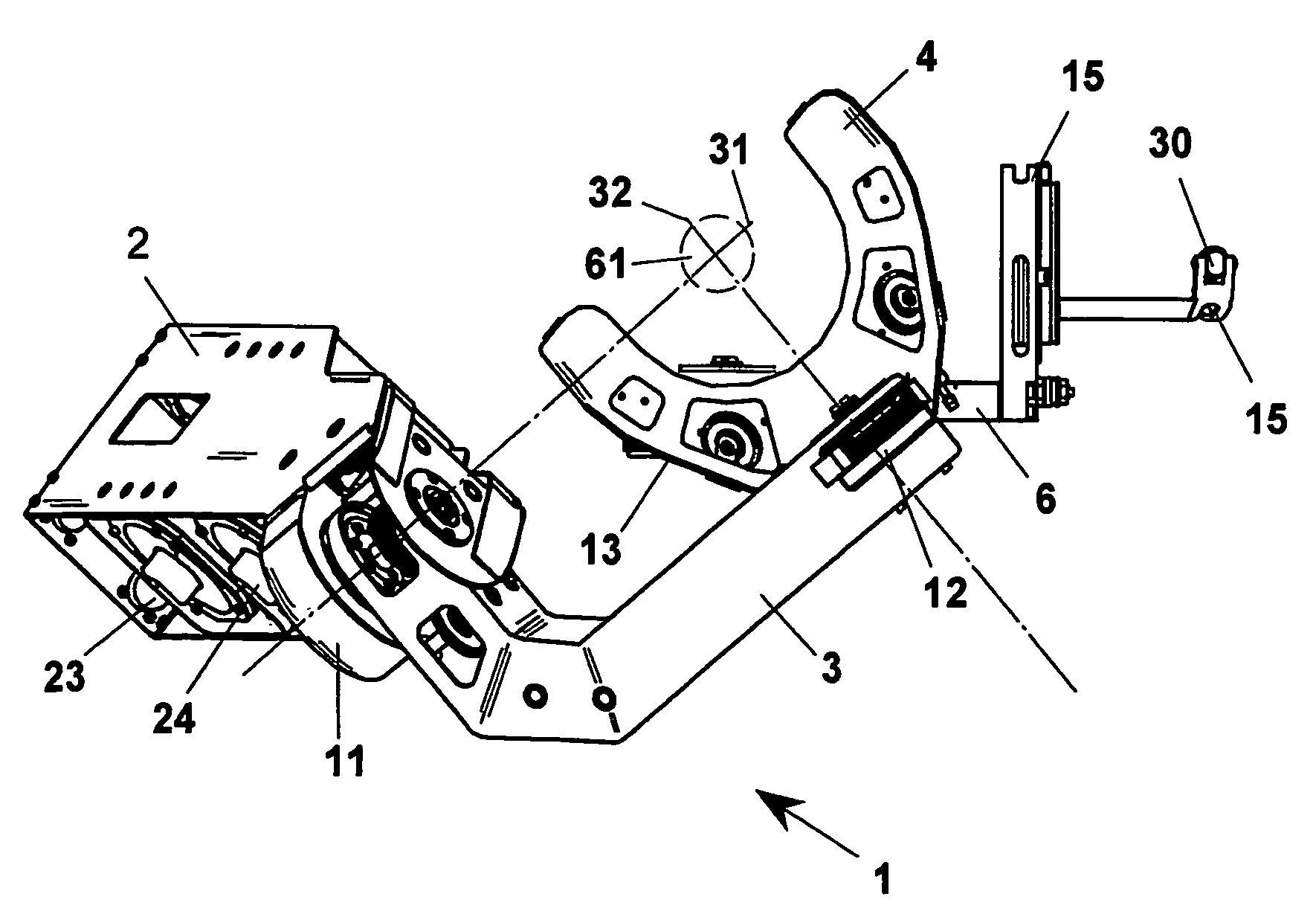

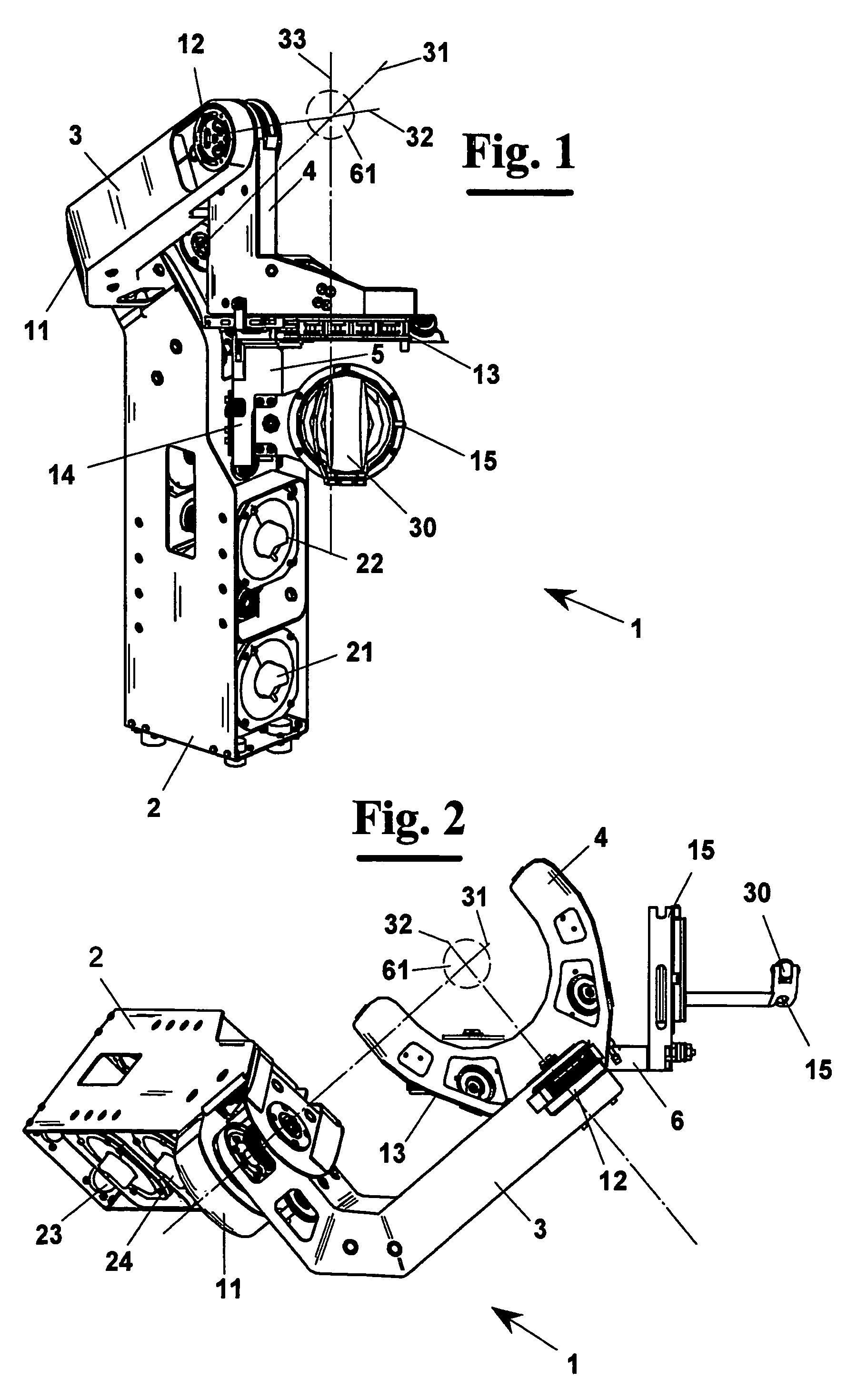

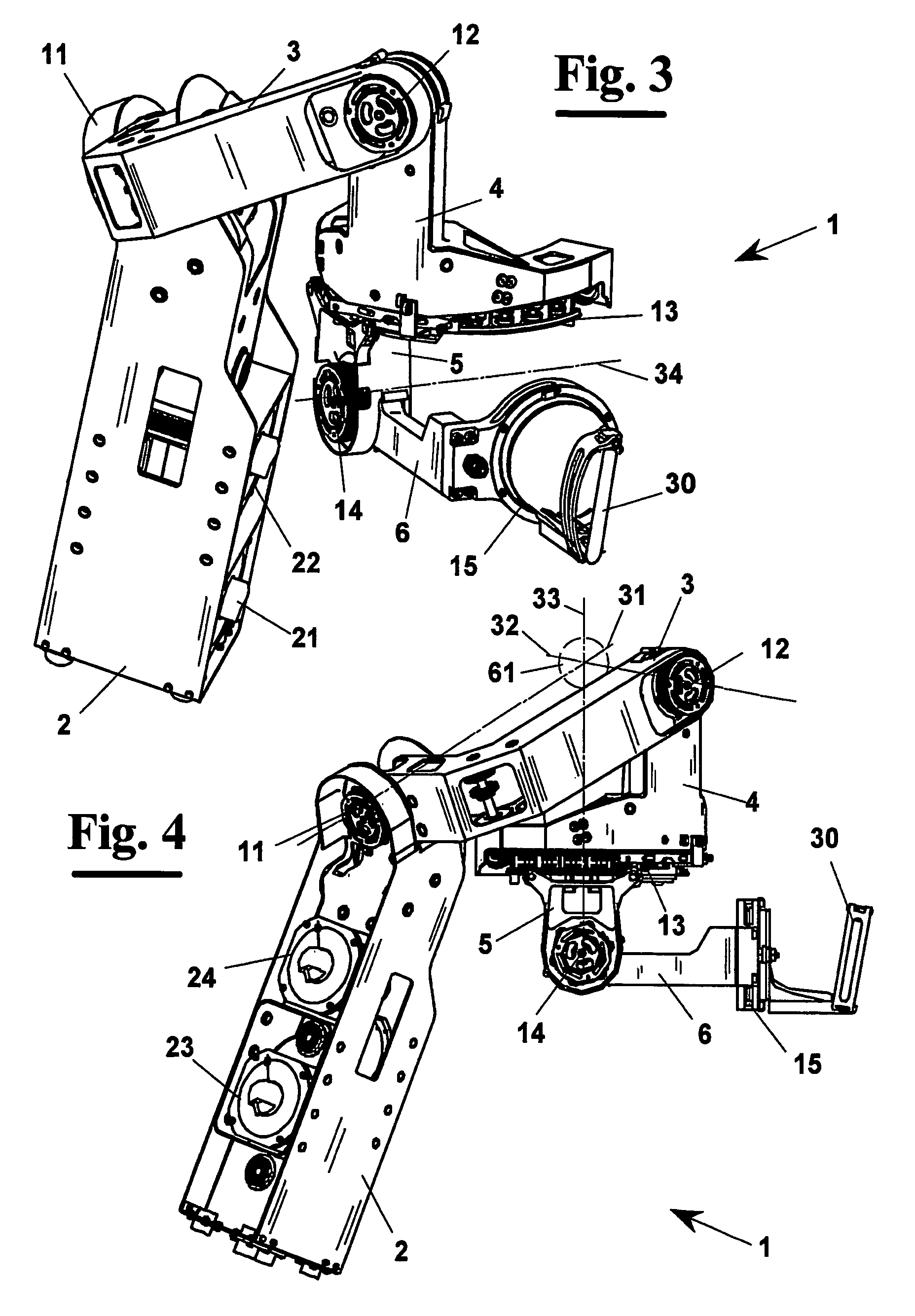

Exoskeleton interface apparatus

InactiveUS7409882B2Force is limitedIncrease workspaceInput/output for user-computer interactionProgramme-controlled manipulatorRotational axisExoskeleton

An exoskeleton interface apparatus includes five rigid links (2-6) arranged in series, capable of rotating reciprocally at the respective ends for monitoring angular movements of the arm, of the forearm and the wrist of an user (60) and having at the tip an handgrip (30) for engaging with the user (60) by reflecting a force feedback. The rigid links (2-6) can rotate at their ends about rotational joints (11-14) having rotational axes (31-34) incident in the intersection point of the physiological axes of the shoulder. The rotational joints (11-14) are brought into rotation about the respective rotational axes (31-34) by means of respective motors (21-24), for example servo-motor such as torque motors. All the motors (21-24) are mounted on the fixed base link (2) in order to minimize the mass of the parts in movement and the inertia reflected on the user (60). A plurality of idle pulleys (50) is provided, spatially arranged for orienting the tendons (41-44), which brake the free movement of the relative rotational joint, responsive to signals corresponding to constraints on the slave in case of teleoperation or to constraints created by virtual reality systems.

Owner:MASSIMO BERGAMASCO +5

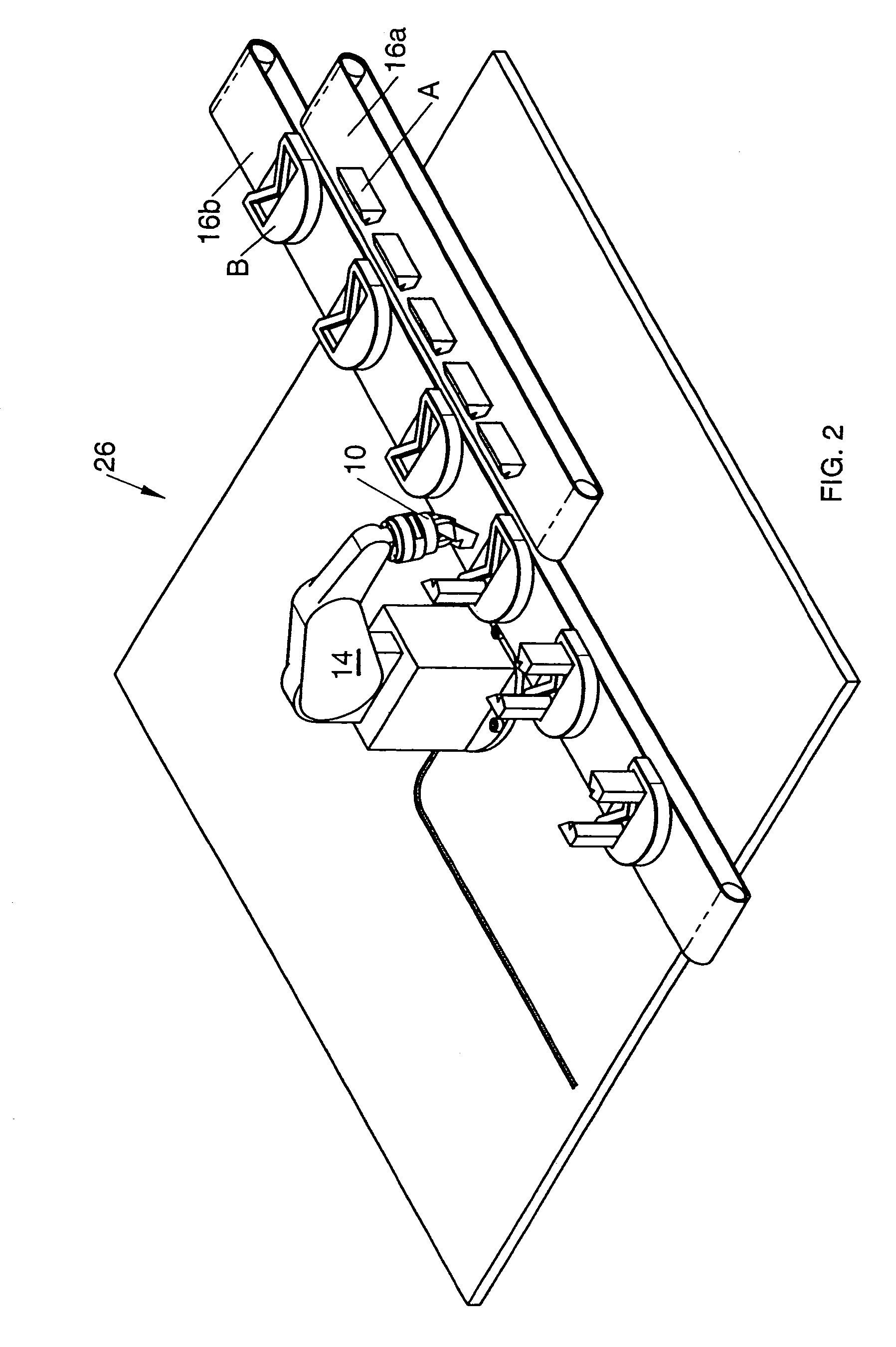

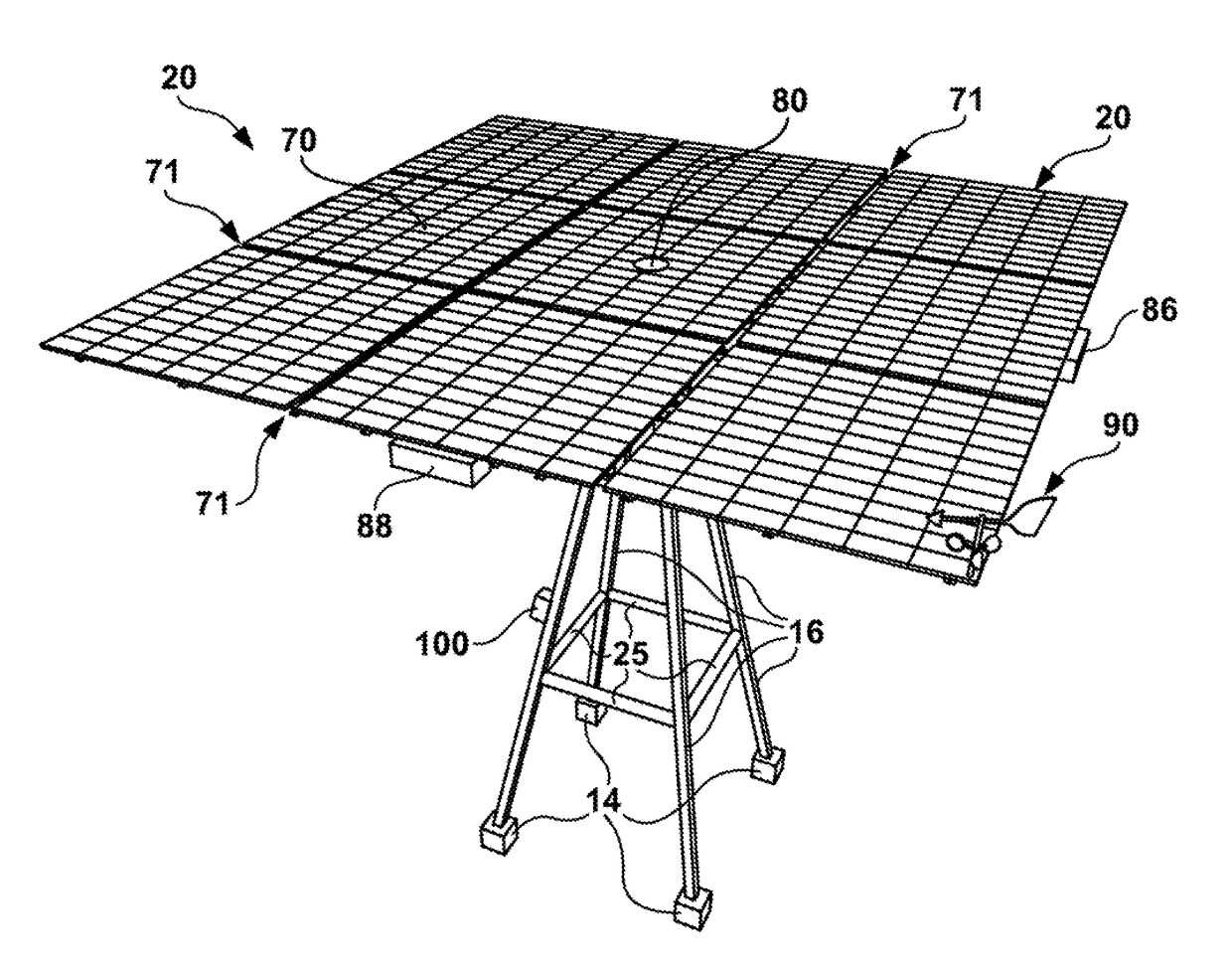

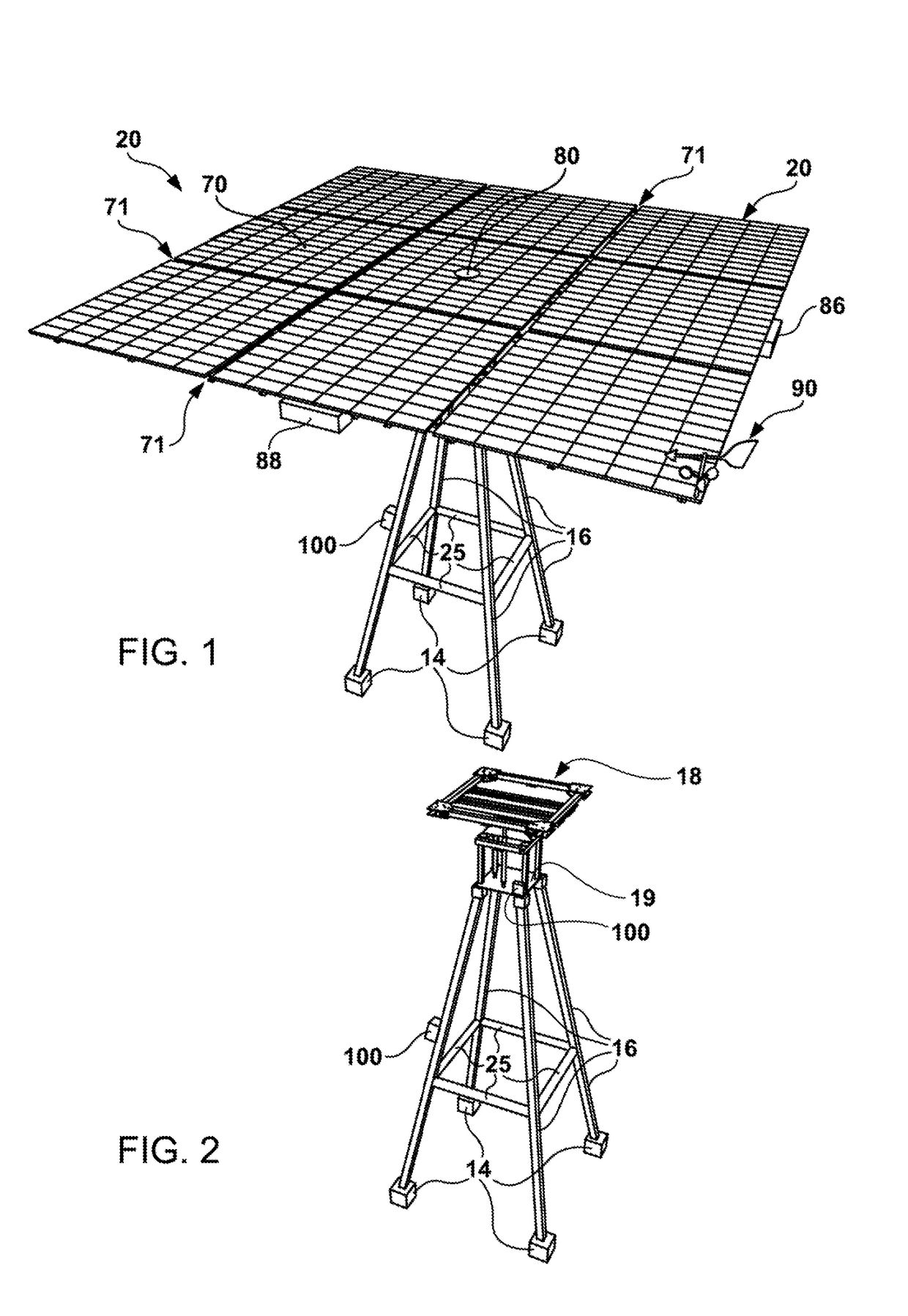

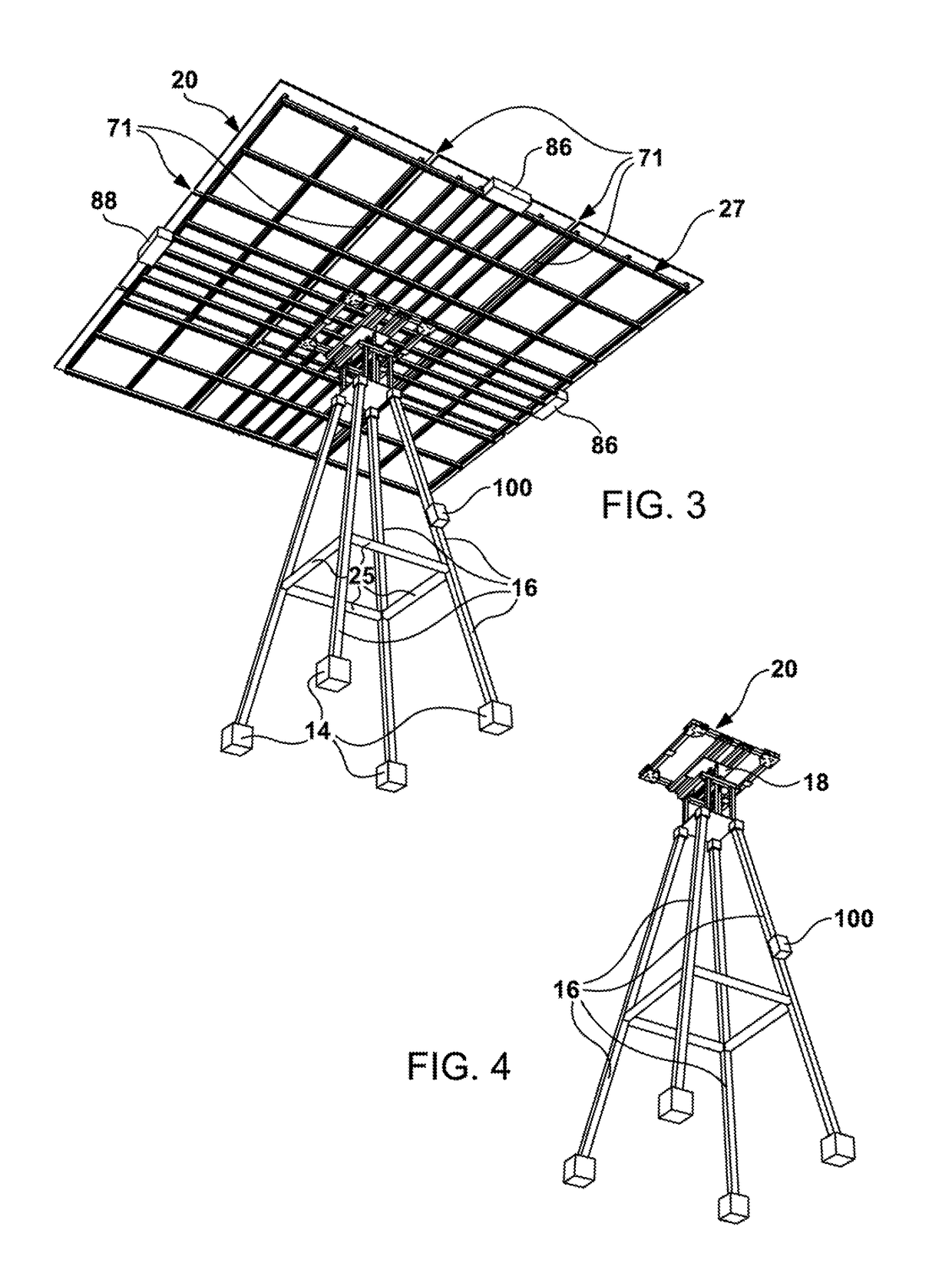

Solar Tracker System for Large Utility Scale Solar Capacity

The present invention solar tracker system is directed to a solar tracker that includes a main platform capable of supporting a plurality of solar panels, a sub-platform, one or more support poles supporting the sub-platform and a linking mechanism that connects the sub-frame to the apex of the one or more supporting poles, wherein the linking mechanism rotates in a first axis, a second linking mechanism rotates in a second axis. The mail planar platform hosting the solar panels is encompassed with edge disrupters and spacing channels for adverse wind condition management. The system includes a solar tracker system includes a radiation sensor for determining the best tracking position for maximizing capture of solar energy. The large scale solar tracker system also includes at least two linear hydraulic actuators, each linear hydraulic actuator containing a distal end and proximal end, a rotational joint that connects the distal end of the linear actuators to the sub-platform and the proximal end to the support beam. The second embodiment of the present invention is a plurality of solar tracker apparatus specifically arranged into a large utility scale field system.

Owner:LOKEY ROGER F

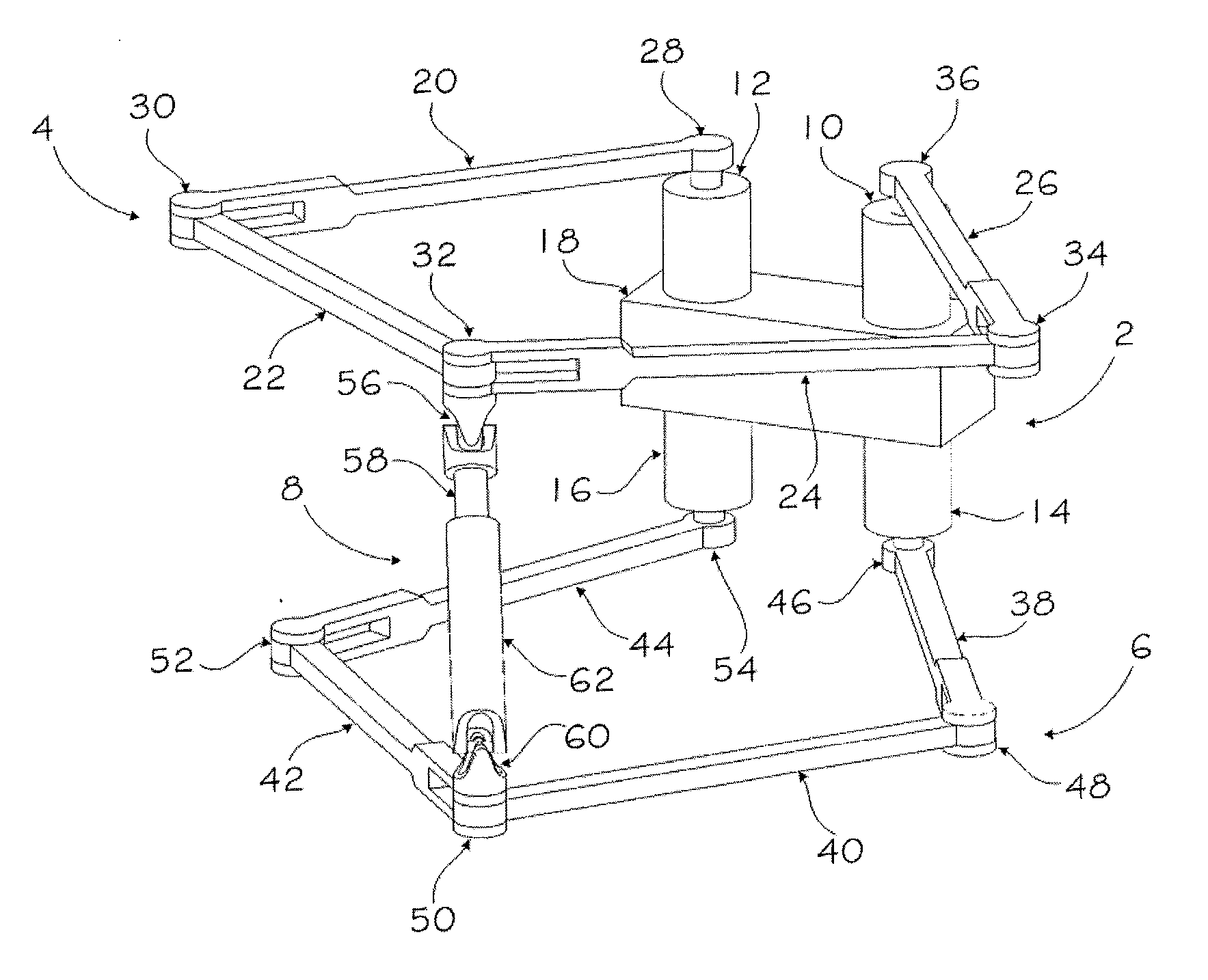

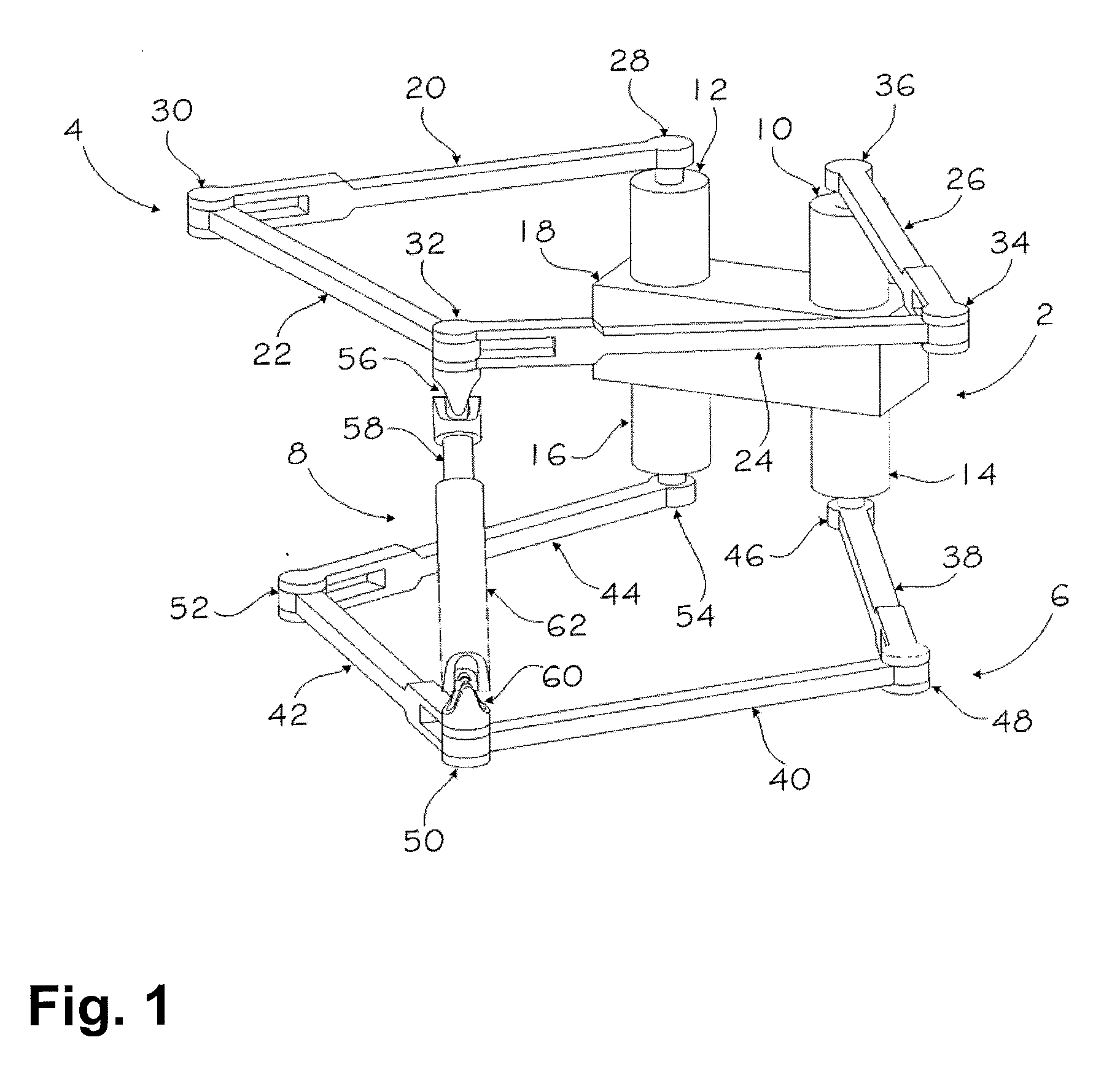

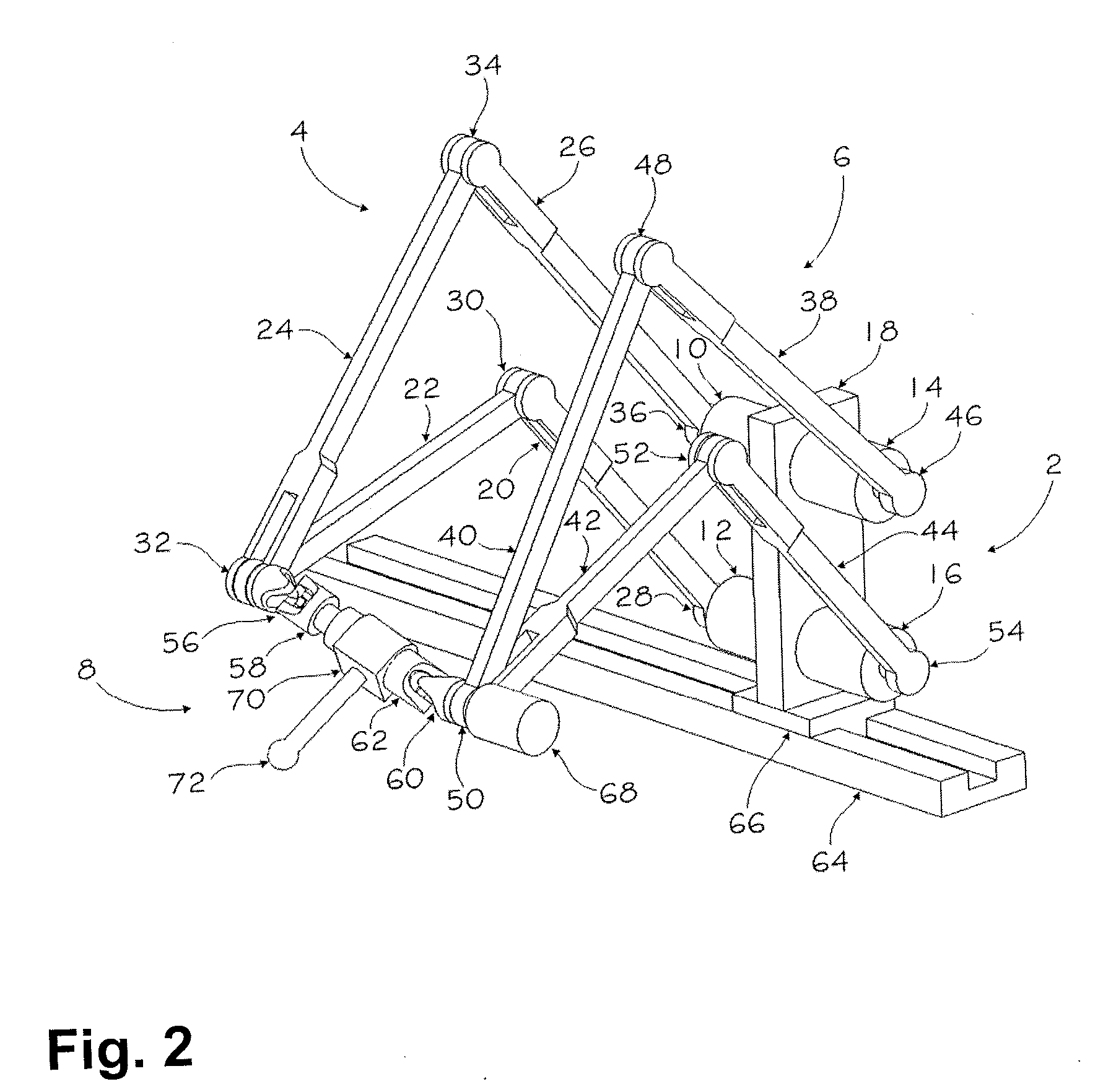

Parallel manipulator

InactiveUS20080295637A1Constrain movementMechanical apparatusJointsDegrees of freedomRotational degrees of freedom

A manipulator for supporting and displacing an object comprises a base. A moving portion supports the object. Two articulated mechanisms each having five rotational joints between links, with each articulated mechanism being connected to the base by two of the rotational joints. The moving portion is connected to both the articulated mechanisms by moving-portion joints. The articulated mechanisms and moving-portion joints are arranged with respect to each other between the base and the moving portion so as to constrain movement of the moving portion to displacements in two translational degrees of freedom and two rotational degrees of freedom with respect to the base. Four actuators are each operatively connected to a different one of the rotational joints between the base and the articulated mechanisms so as to selectively control the displacements of the moving portion in any one of the four degrees of freedom of the moving portion.

Owner:POLYVALOR S E C

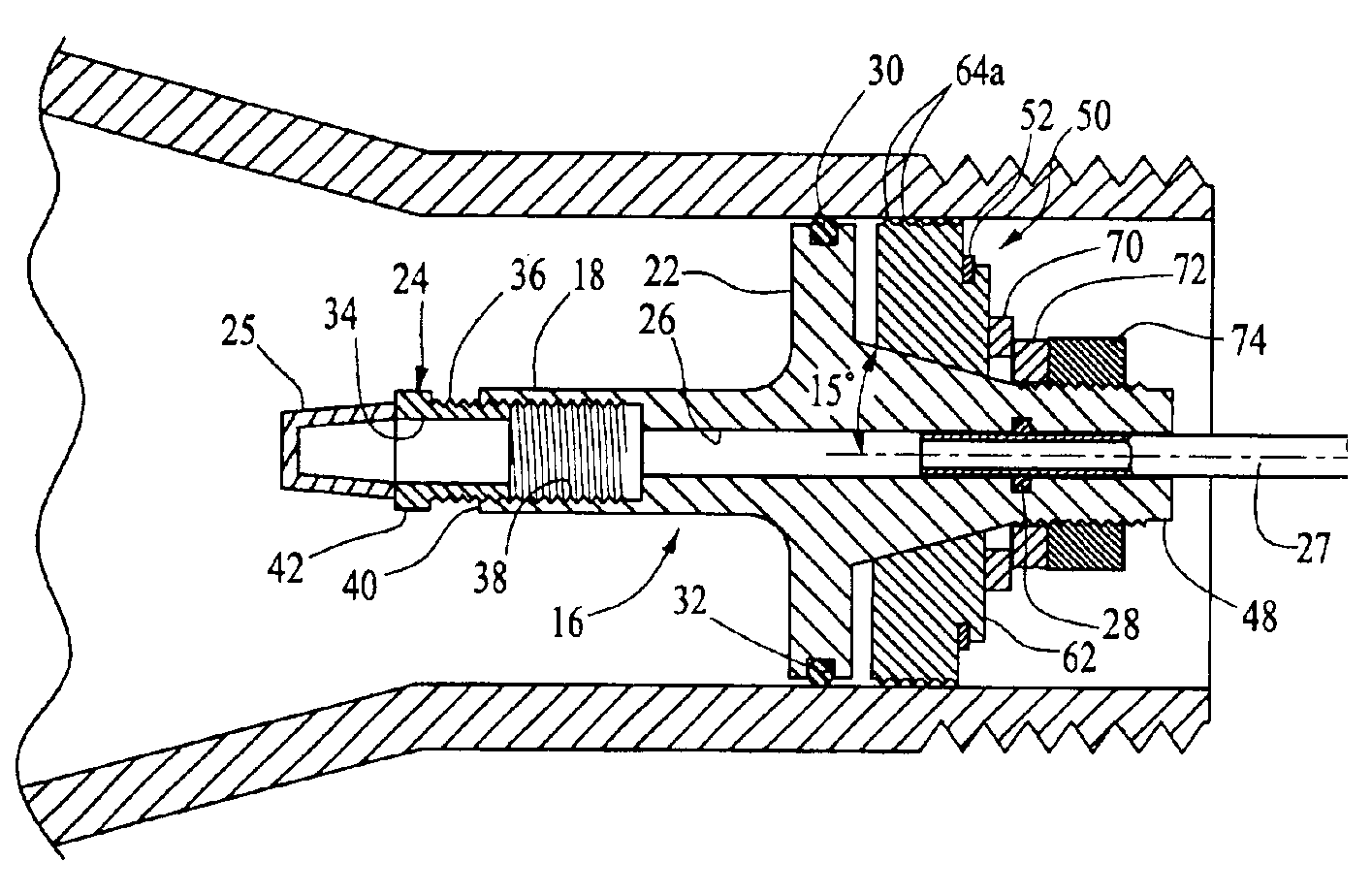

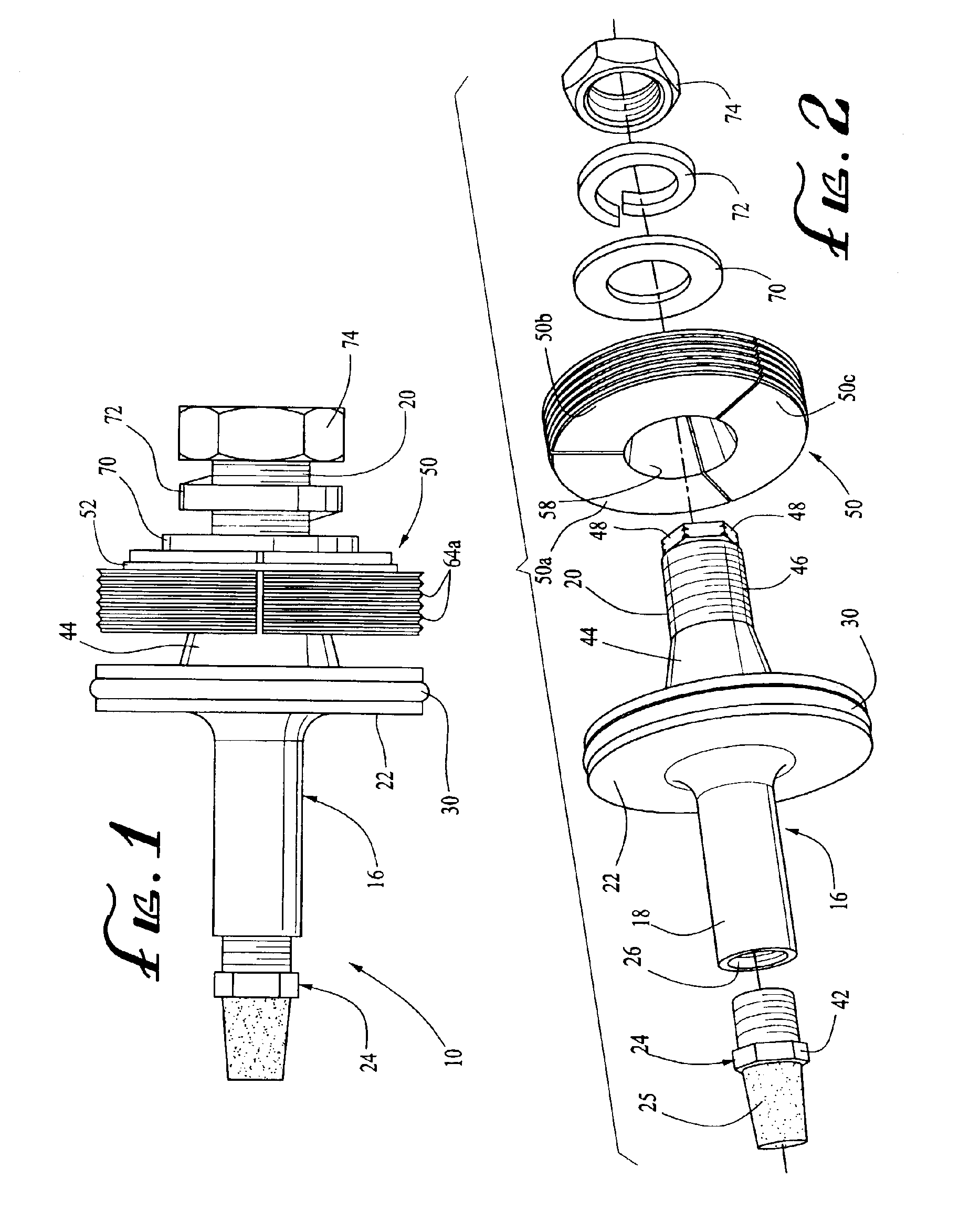

Expandable spindle plug assembly for use with automatic tire inflation systems

An assembly to be mounted in an axle spindle for communicating pressurized air from the axle to a rotary union in a tire inflation system. The assembly includes an arbor having an air flow channel extending therethrough, a flange intermediary of the arbor ends and an axially inclined portion proximate the flange. A sealing member is carried by the flange for forming an airtight seal with the axle spindle. A split ring locking assembly is disposed about the inclined portion of the arbor that is comprised of a plurality of segments held by an expansible retention spring. The segments move radially outwardly upon the locking assembly being moved along the inclined arbor portion and engage the axle spindle, securing the plug assembly within the spindle, A fastening member threadably engages the arbor for urging the locking assembly along the inclined arbor portion to effect securement of the plug assembly within the axle spindle.

Owner:AIRGO IP

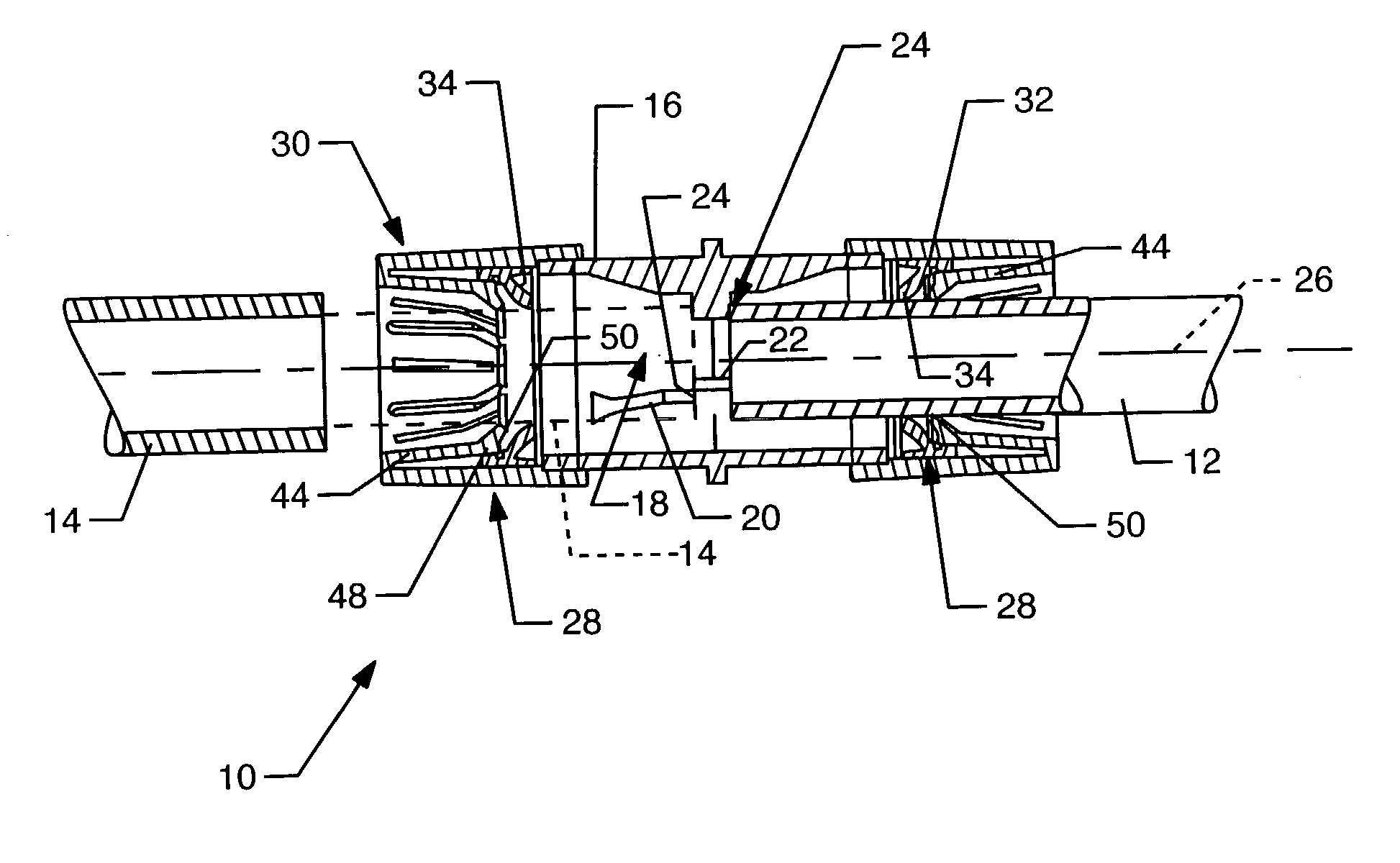

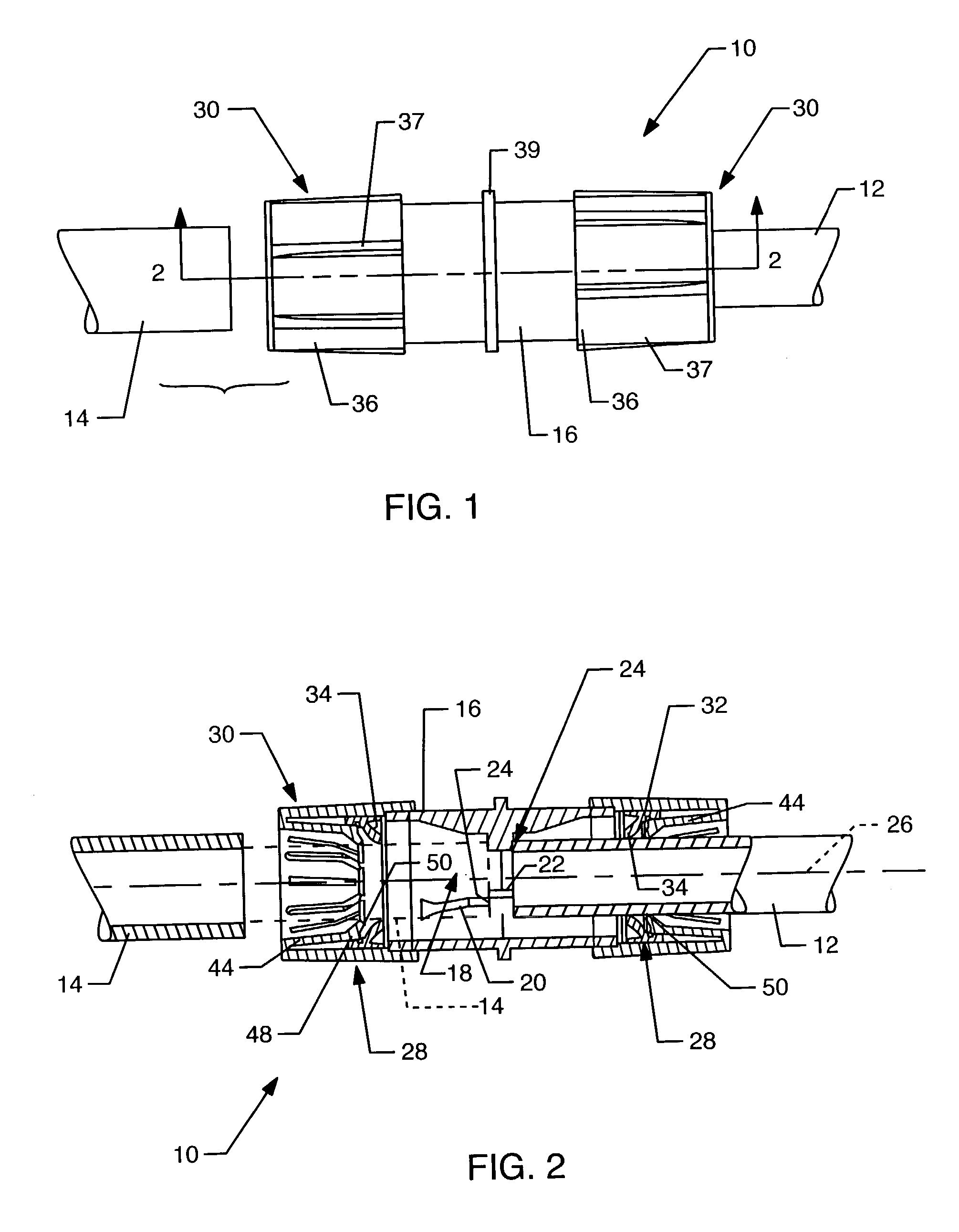

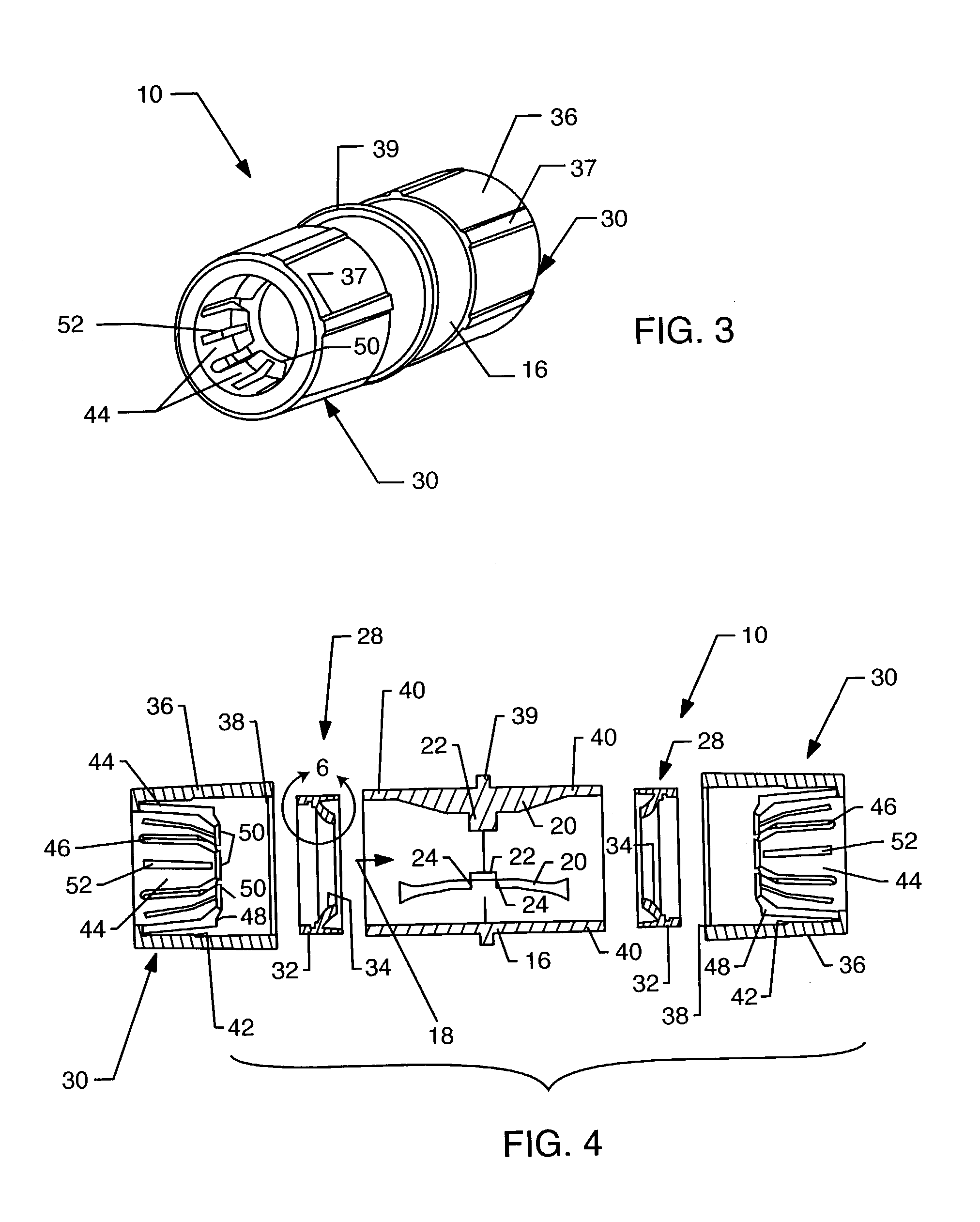

Connector for coaxial cable having rotational joint between insulator member and connector housing and associated methods

ActiveUS8206176B2Reduce and eliminate rotationReduce harmTwo pole connectionsContact member assembly/disassemblyElectrical conductorCoaxial cable

Owner:COMMSCOPE TECH LLC

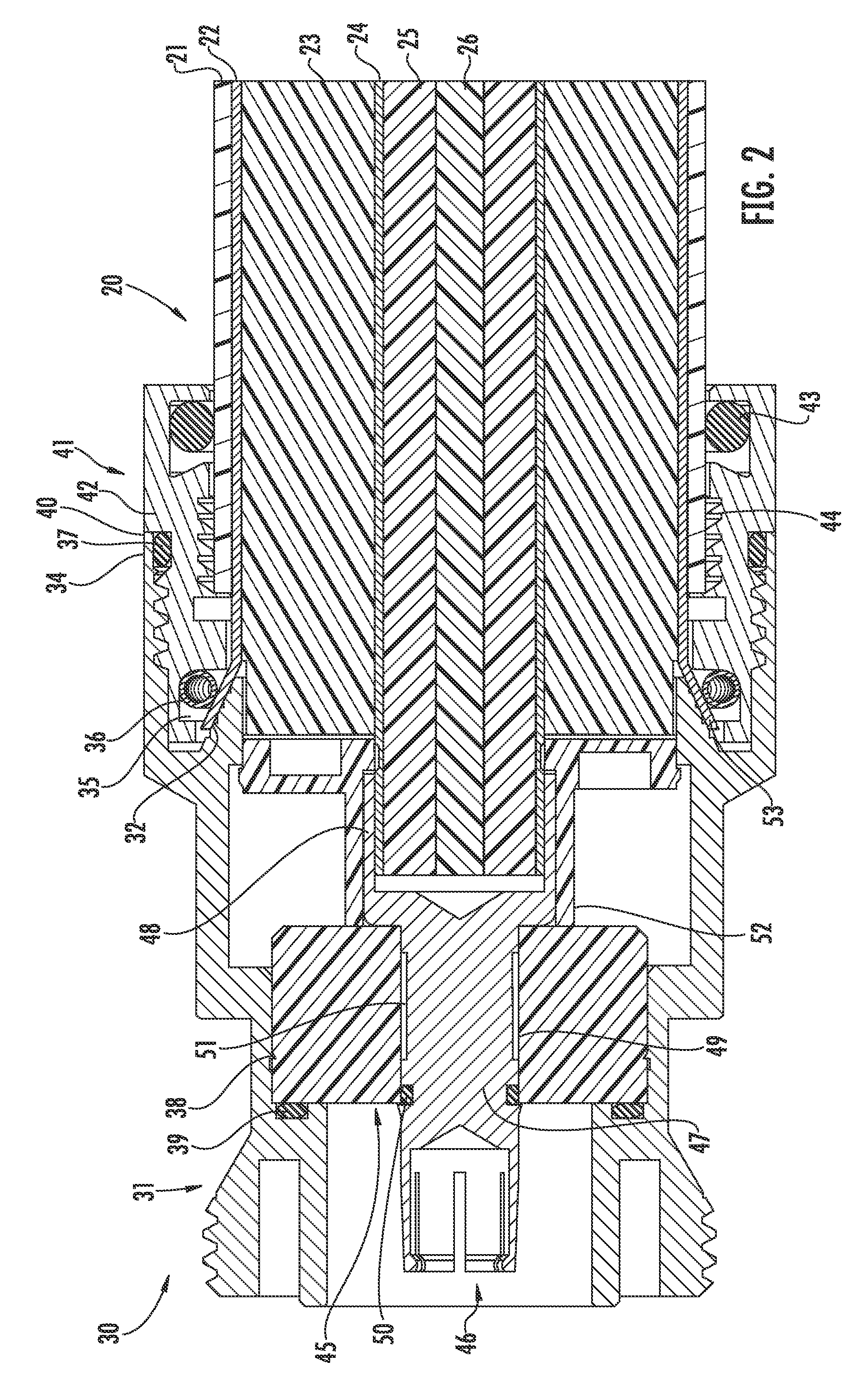

Detachable swivel and associated mount

Embodiments of the invention relate to a detachable swivel and associated mount. In one embodiment, a detachable swivel can be provided. The detachable swivel can include a housing with an axial cavity; at least one retention device; and an internal body operable to mount within the axial cavity, the internal body operable to contact the at least one retention device, wherein the internal body axially translates within the axial cavity between a first position and a second position; wherein an axial force applied to a portion of the internal body and away from the housing causes the internal body to translate between the first and second position.

Owner:BLUE FORCE GEAR

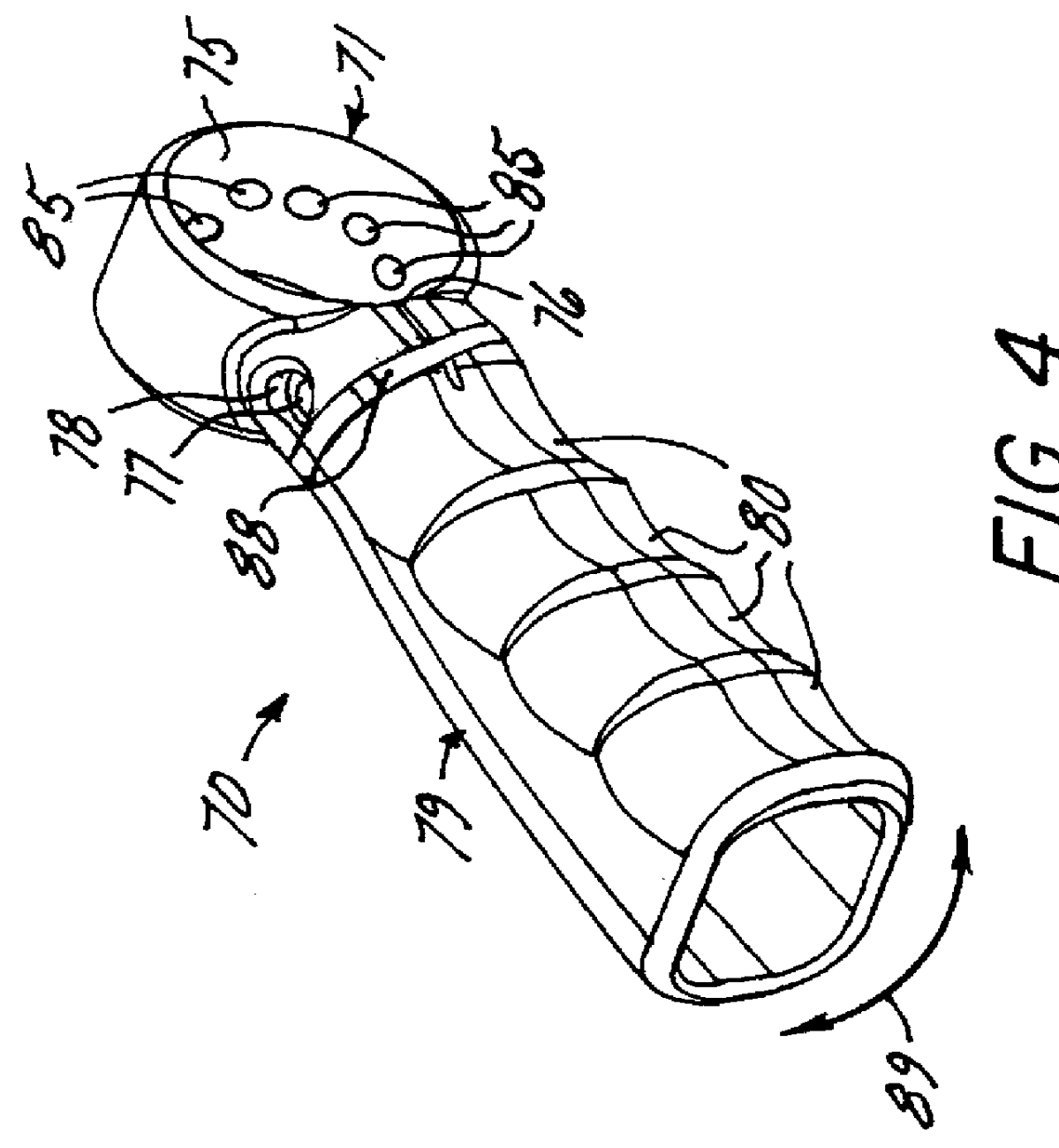

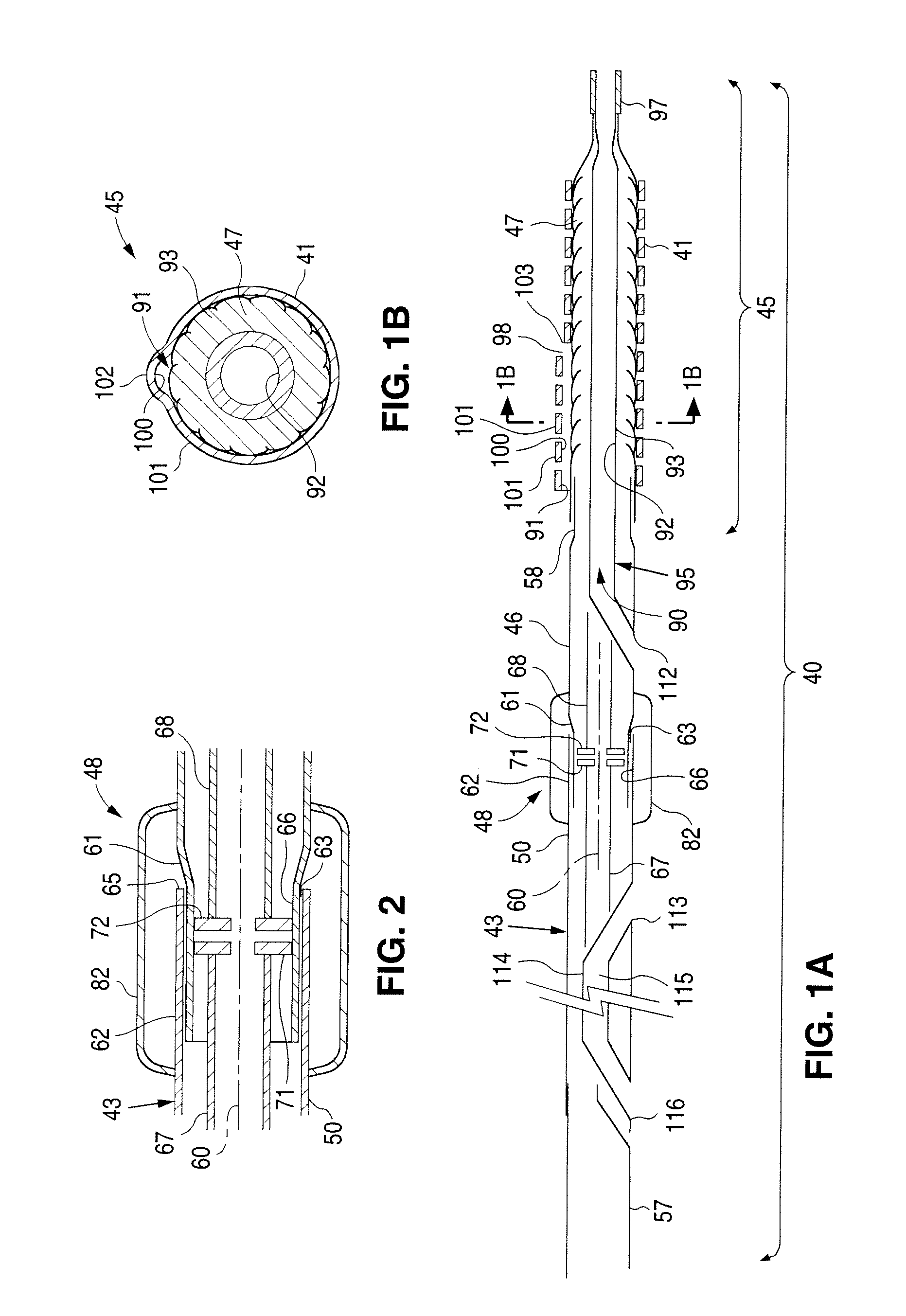

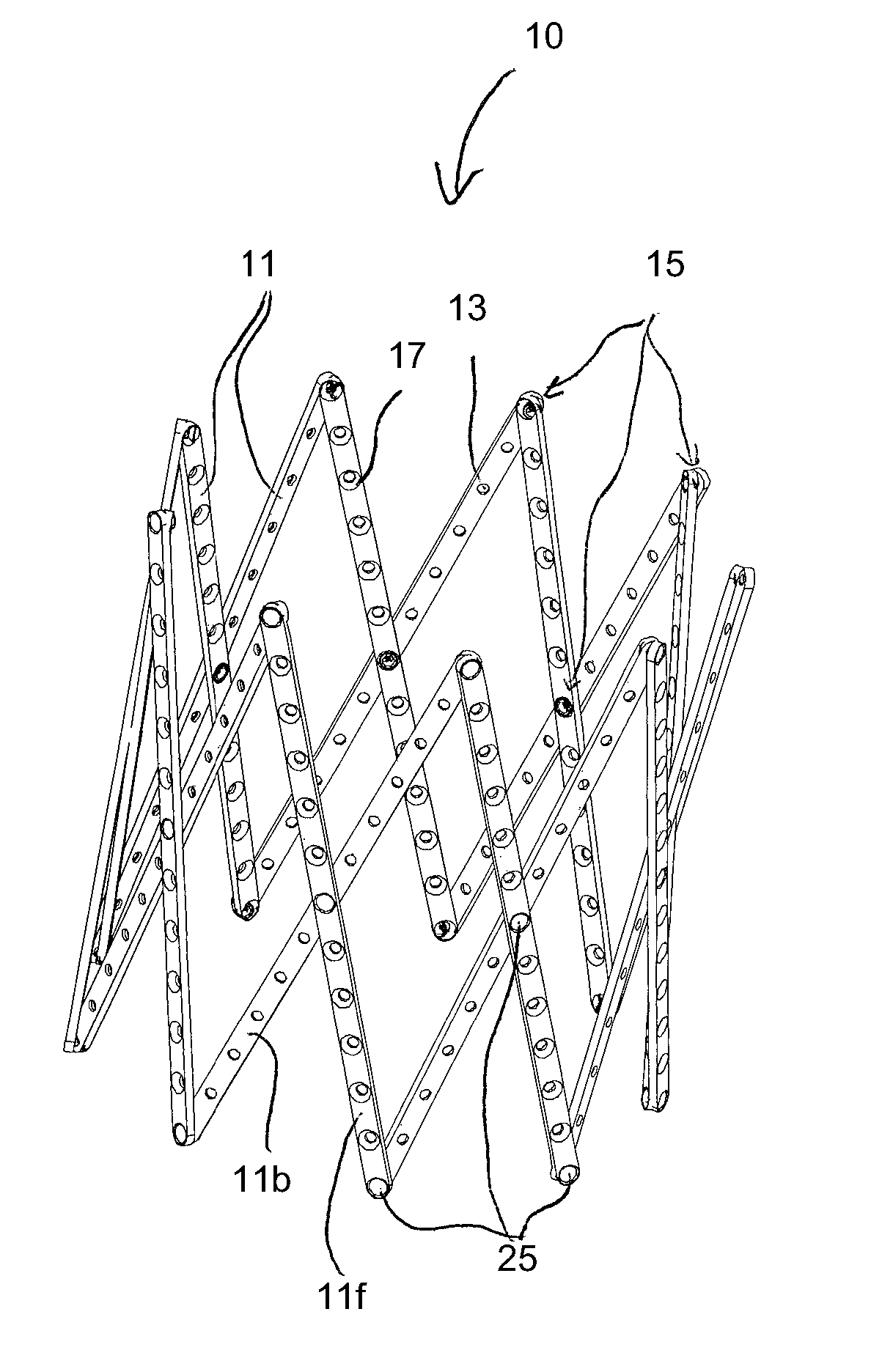

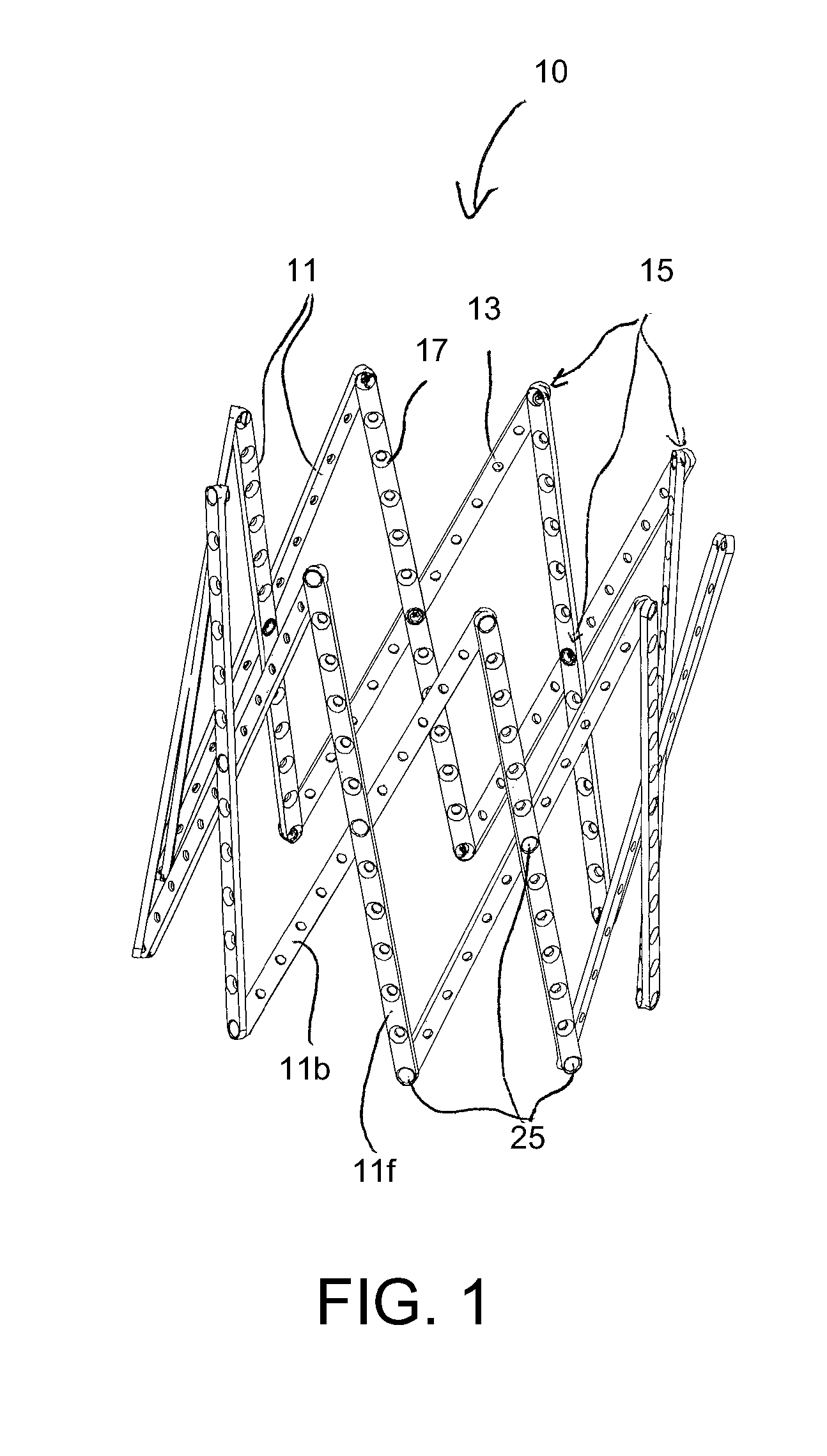

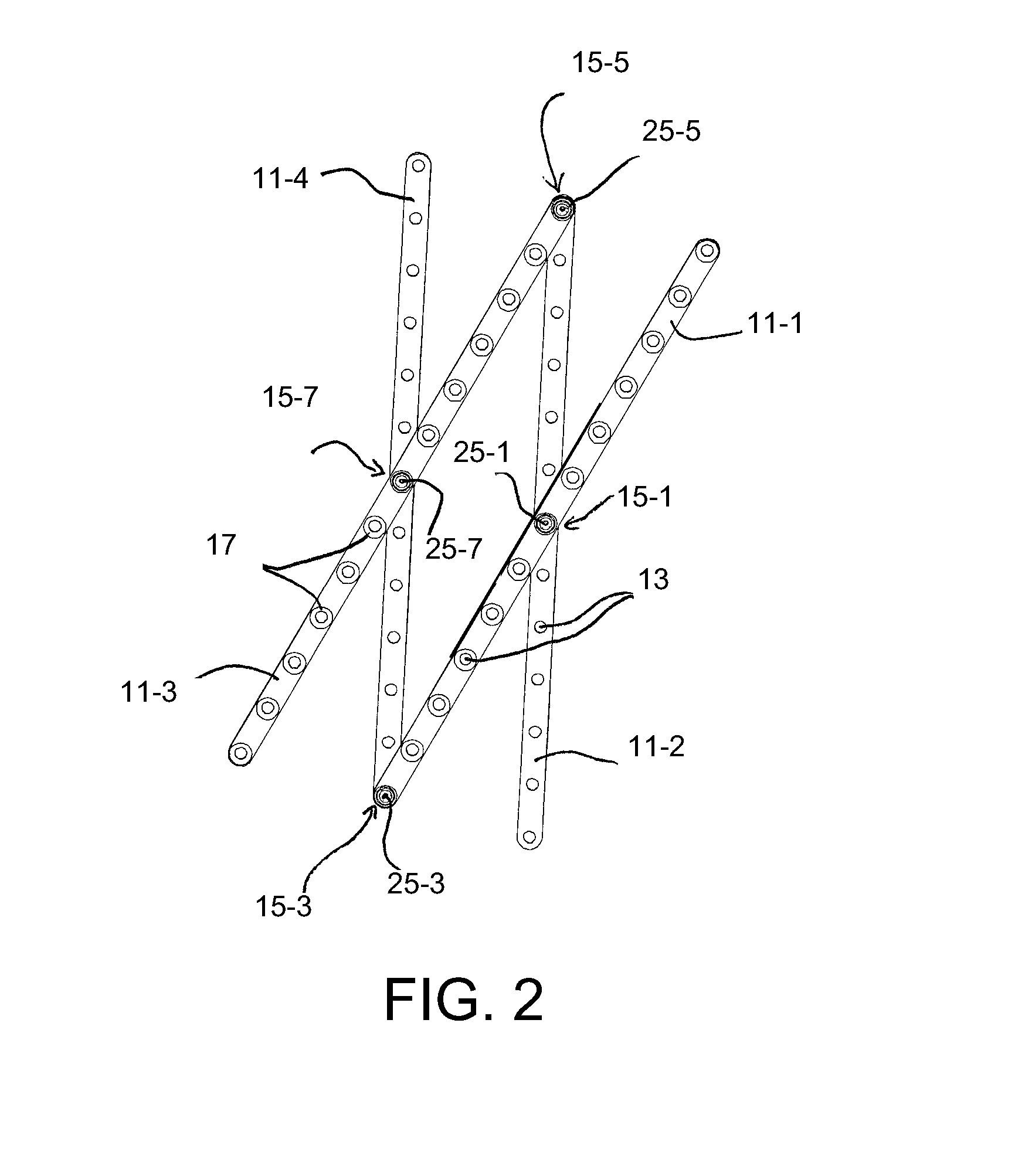

Repositionable endoluminal support structure and its applications

ActiveUS20110219603A1Readily retrieved and repositionedReadily re-deployedStentsHeart valvesProsthetic valveRange of motion

An endoluminal support structure includes strut members interconnected by swivel joints to form a series of linked scissor mechanisms. The structure can be remotely actuated to compress or expand its shape by adjusting the scissor joints within a range of motion. In particular, the support structure can be repositioned within the body lumen or retrieved from the lumen. The support structure can be employed to introduce and support a prosthetic valve within a body lumen.

Owner:EDWARDS LIFESCI CARDIAQ

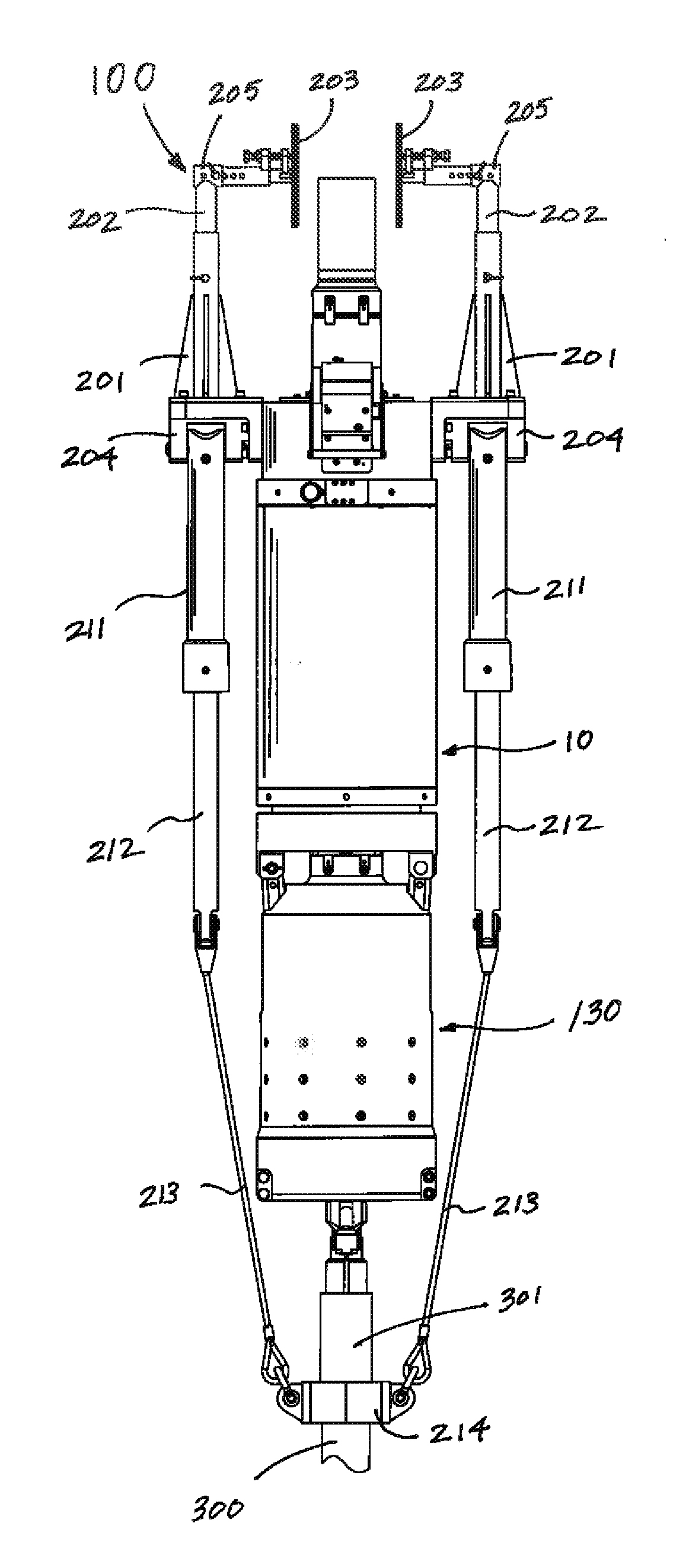

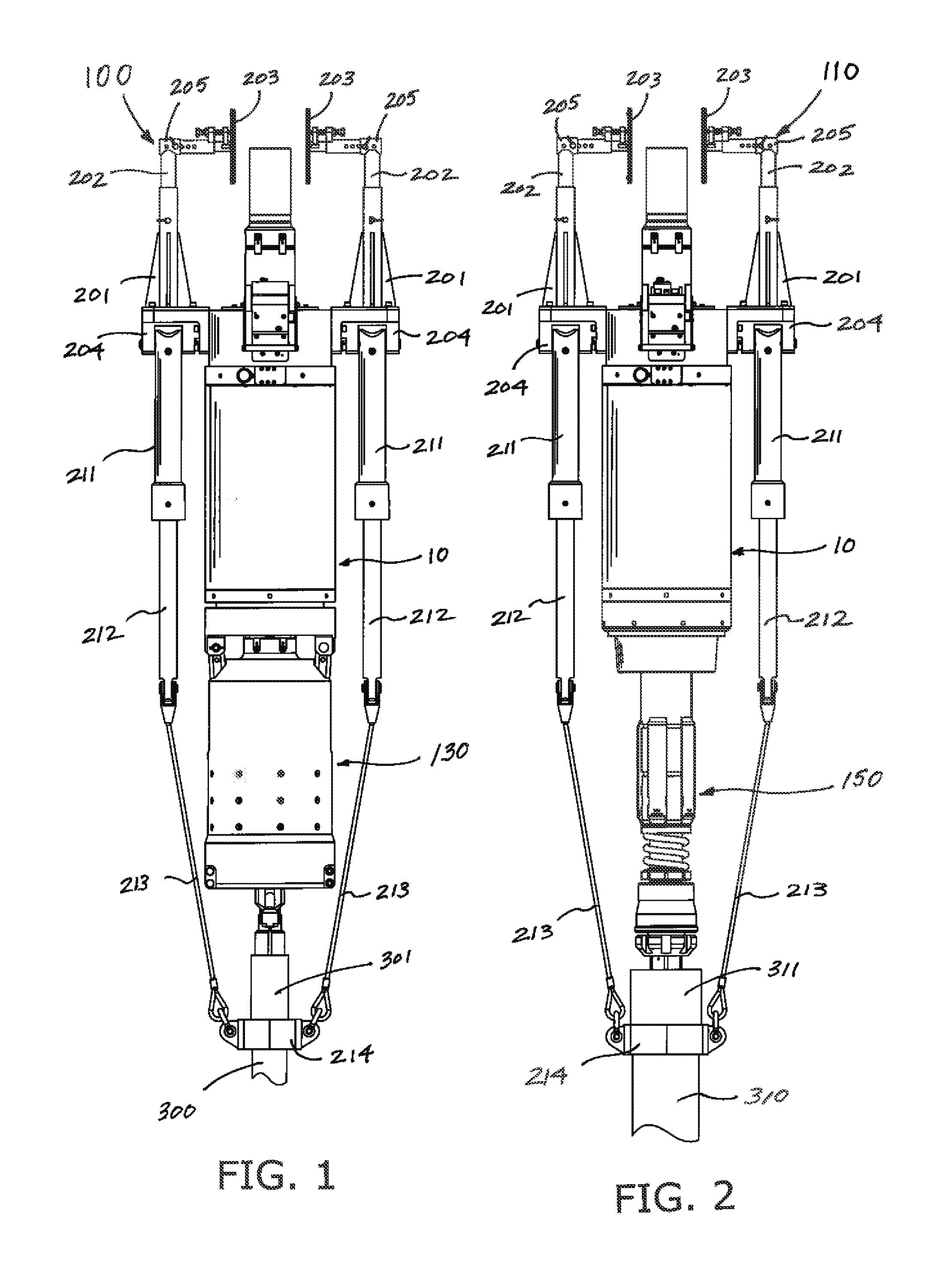

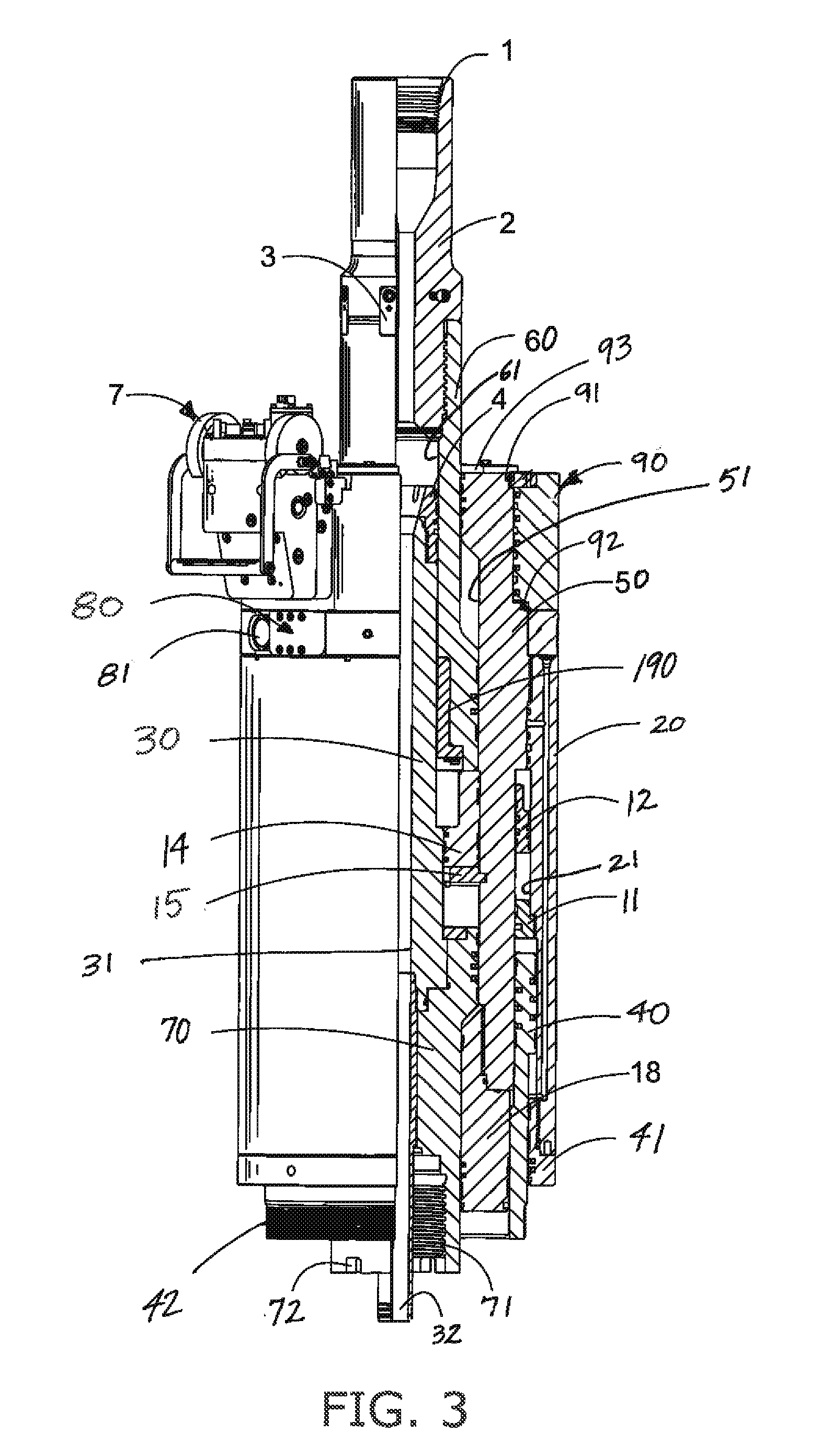

Modular Apparatus for Assembling Tubular Goods

InactiveUS20130075077A1Quickly and efficiently and safely assemble and installQuick modificationDrilling rodsConstructionsEngineeringActuator

A modular pipe gripping assembly has a universal actuator assembly having a control fluid swivel. An external pipe gripping assembly can be attached to the actuator assembly for gripping the external surface of a section of pipe. Alternatively, the external pipe gripping assembly can be quickly and easily removed and replaced with an internal pipe gripping assembly for gripping the internal surface of a section of pipe. Control fluid pressure is trapped within the actuator assembly, but relieved from a fluid swivel, permitting high speed rotation of the modular pipe gripping assembly and preserving swivel seal life.

Owner:HENDERSON KRIS +2

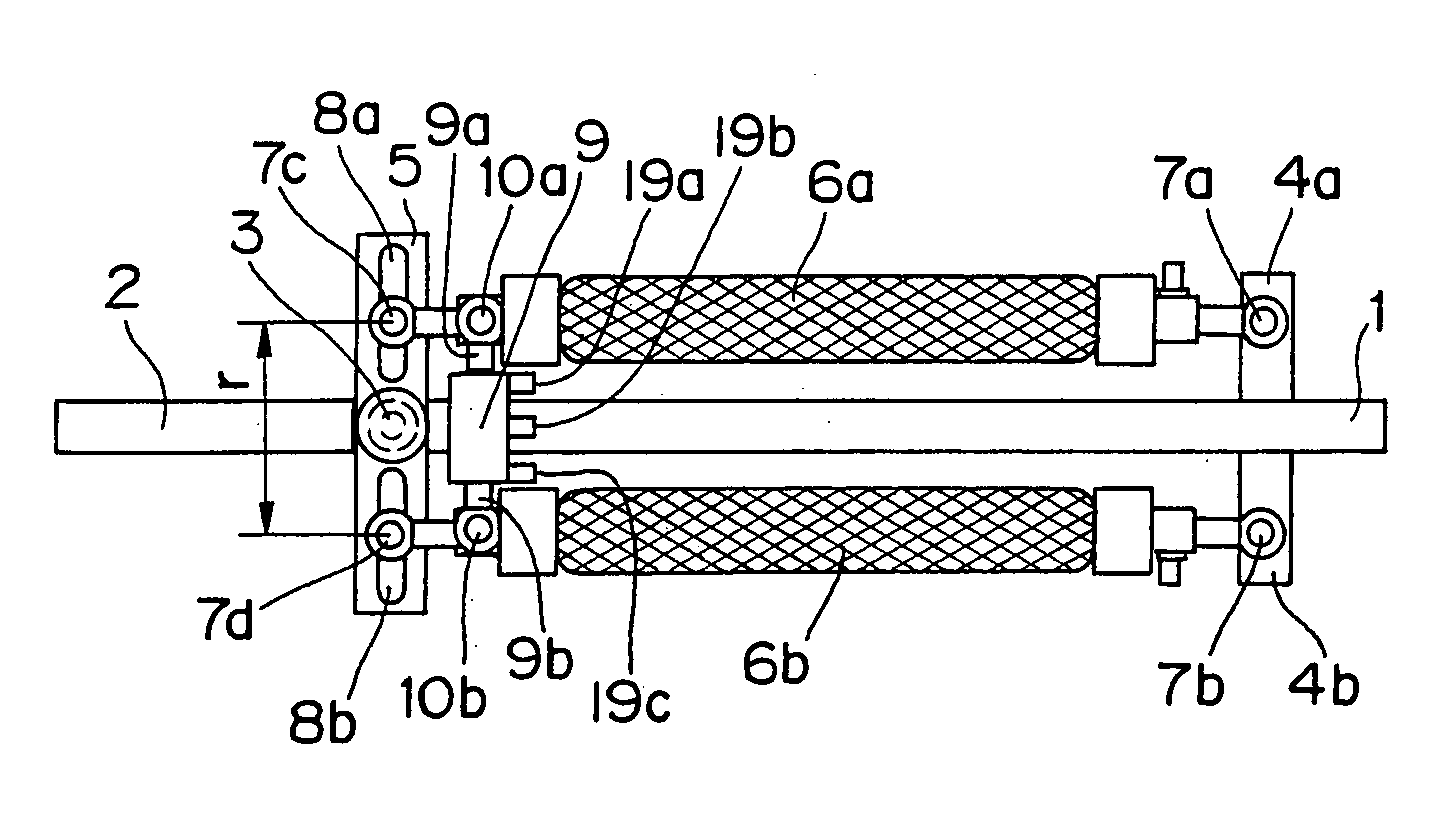

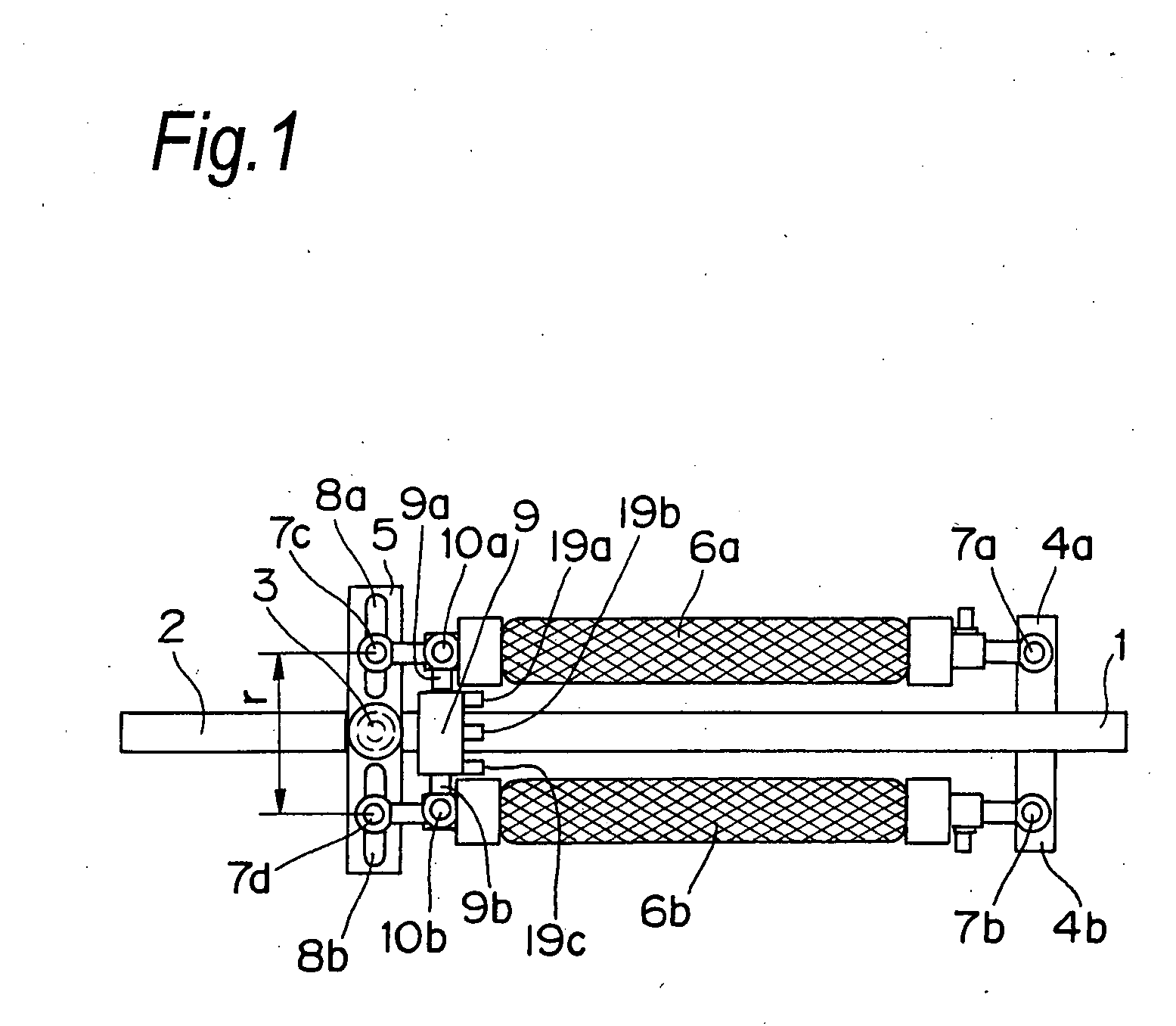

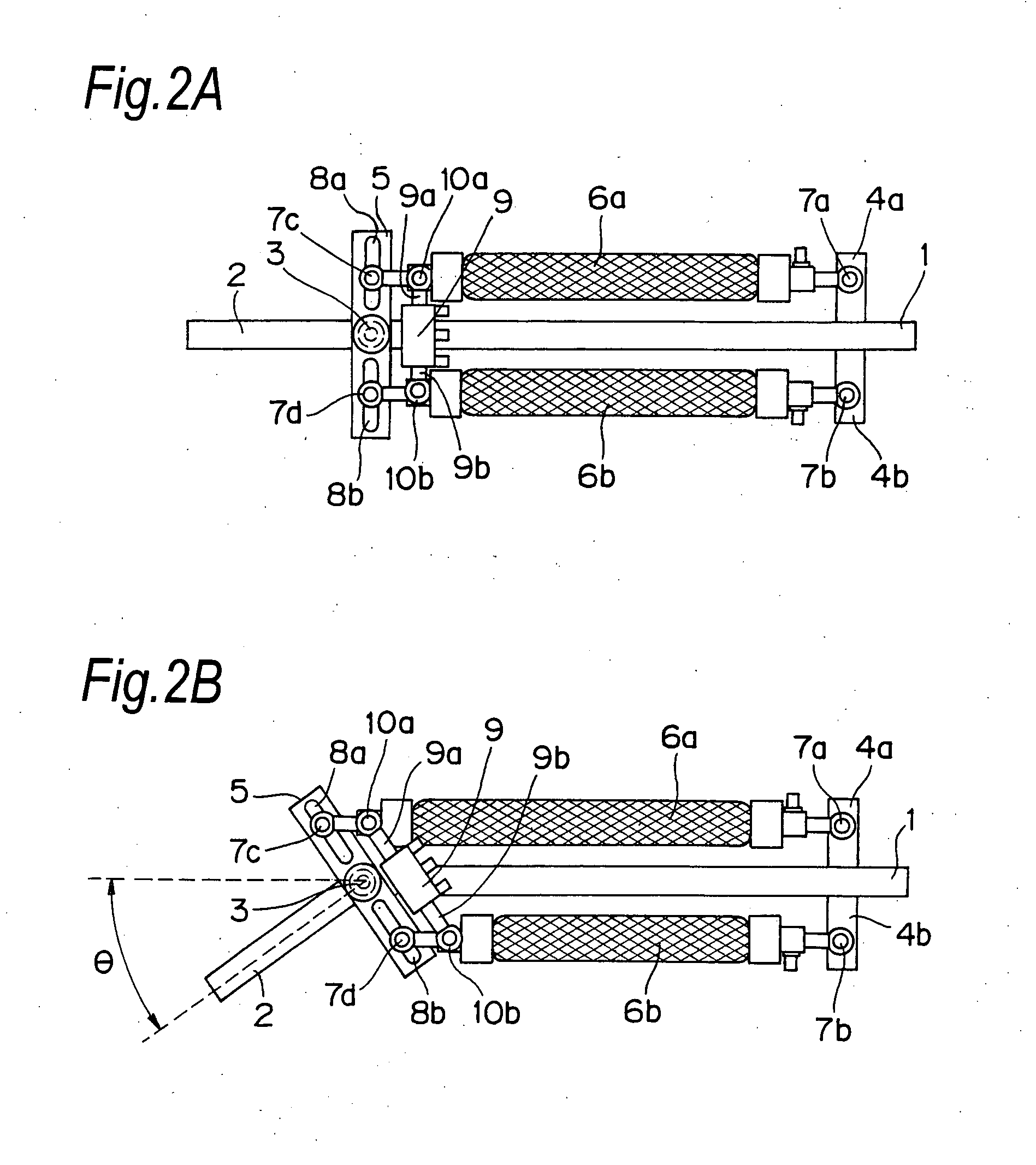

Joint driving device

ActiveUS20070144299A1Improve reliabilityGreater torque for gripingProgramme-controlled manipulatorFluid-pressure actuatorsActuatorControl theory

A first elastic body actuator and a second elastic body actuator are used for driving a first configuration member and a second configuration member to swing them with respect to each other, wherein one end portion of the first elastic body actuator is secured to the first configuration member and the other end portion of the first elastic body actuator is secured to the second configuration member, and one end portion of the second elastic body actuator is secured to the first configuration member and the other end portion of the second elastic body actuator is secured to the second configuration member, such that the position at which the other end portion of the second elastic body actuator is secured to the second configuration member and the position at which the one end portion of the first elastic body actuator is secured to the second configuration member are substantially symmetric about a rotational joint. The interval between the portion of the first elastic body actuator which is secured to the second configuration member and the portion of the second elastic body actuator which is secured to the second configuration member is moved by a securing-position variable mechanism.

Owner:PANASONIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com