Patents

Literature

253 results about "Air leak" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Air leak syndrome. A condition characterised by alveolar or airway rupture into the pulmonary interstitium, typically accompanied by escape of air into regional tissues, including the pleura, mediastinum, subcutaneous tissues or abdominal cavity; it is more common in children. Aetiology.

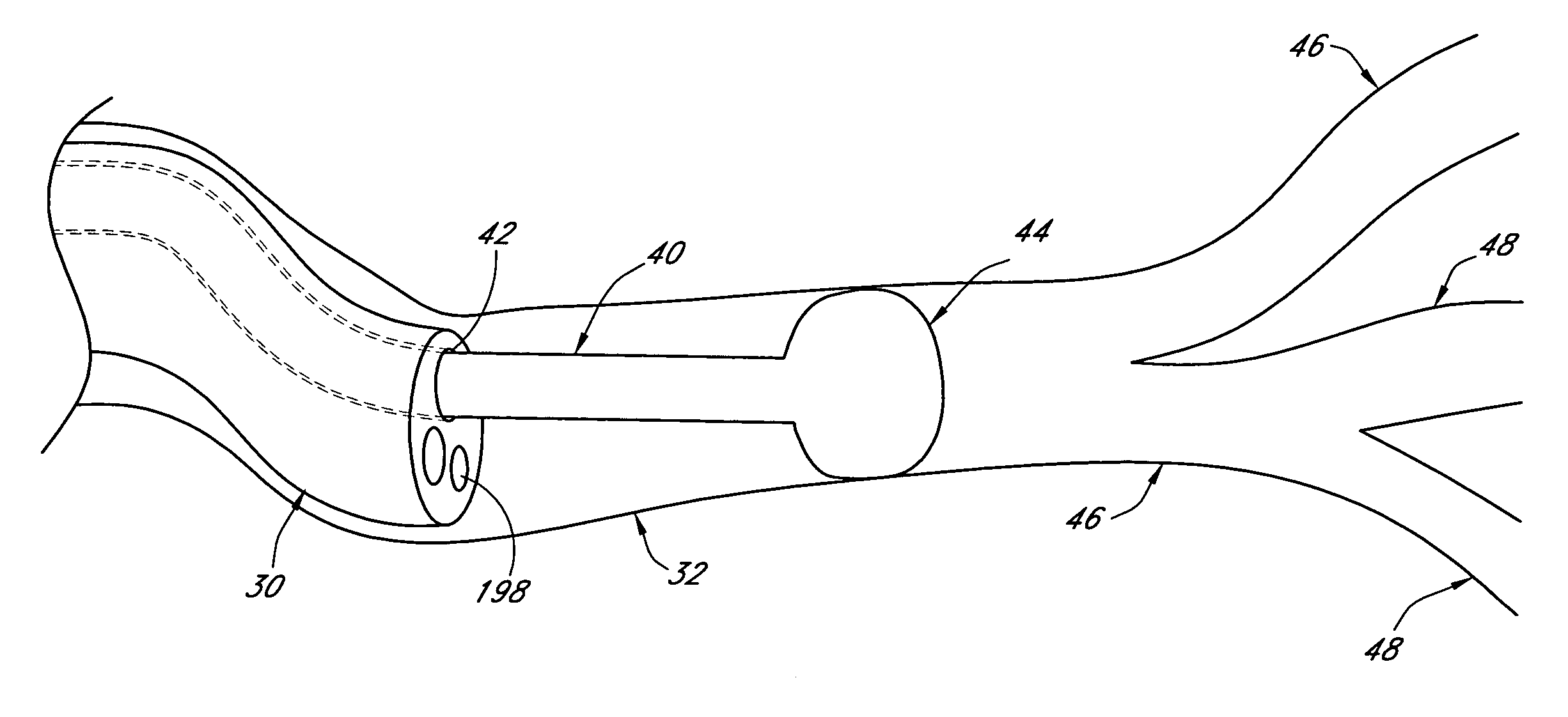

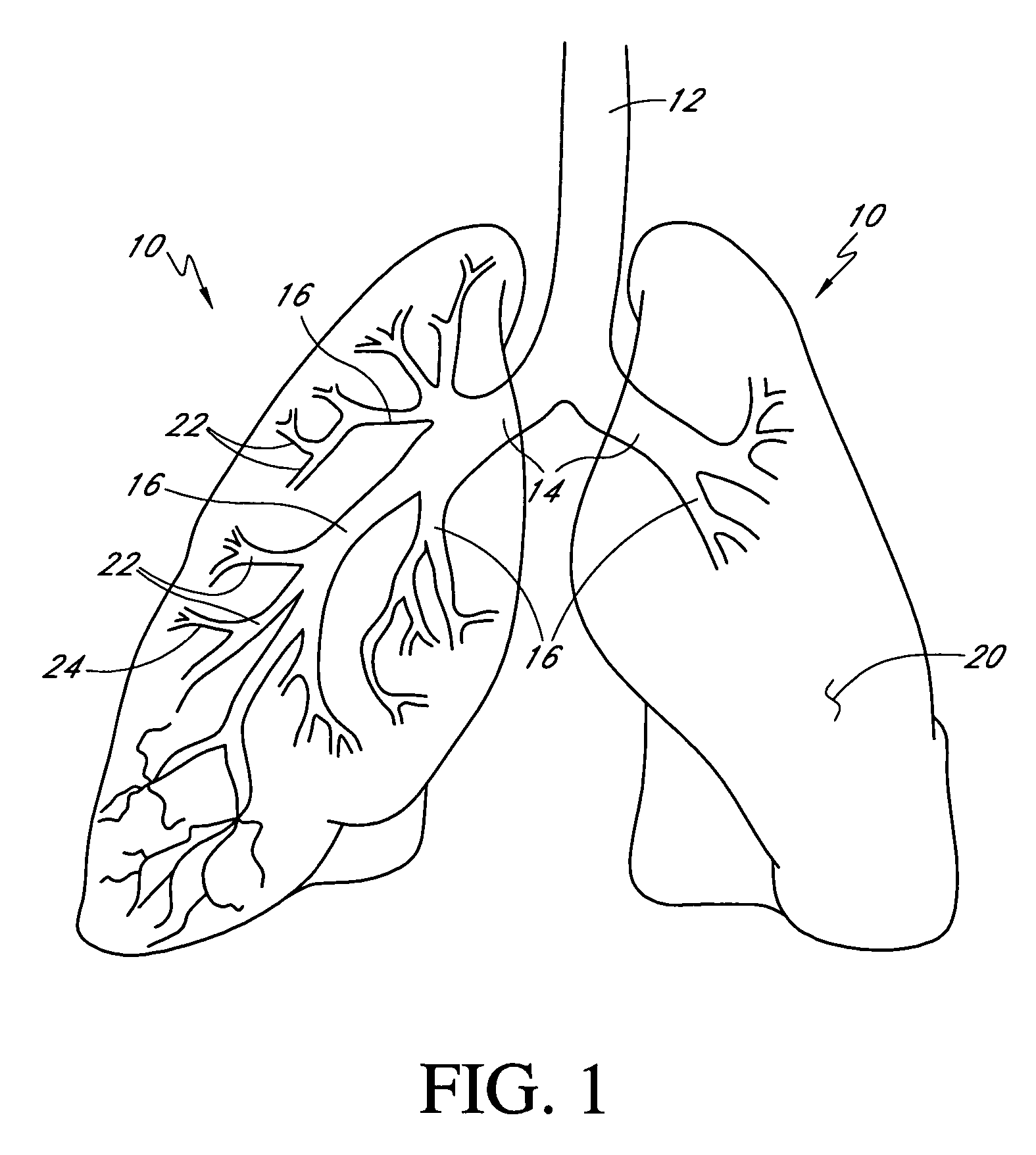

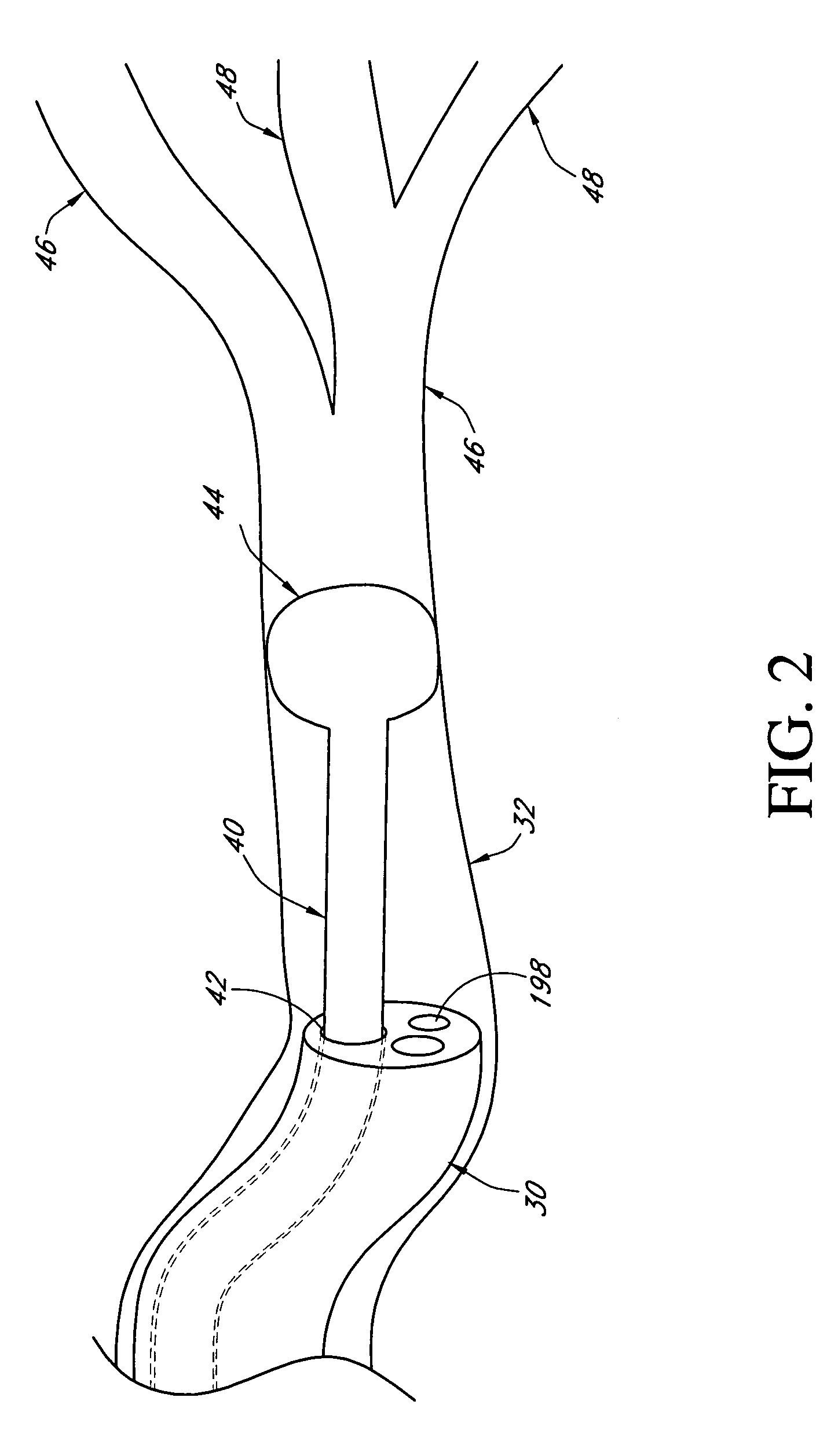

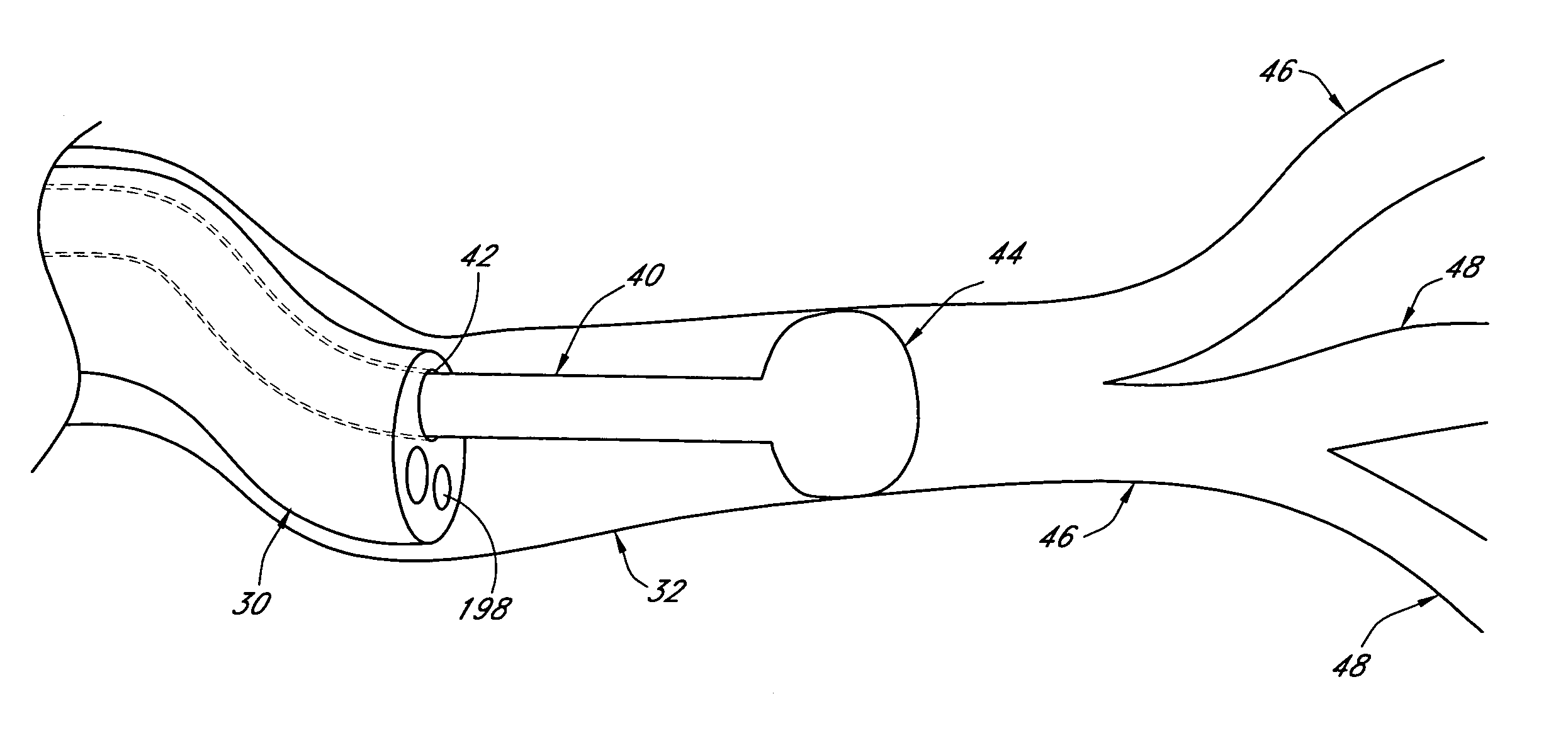

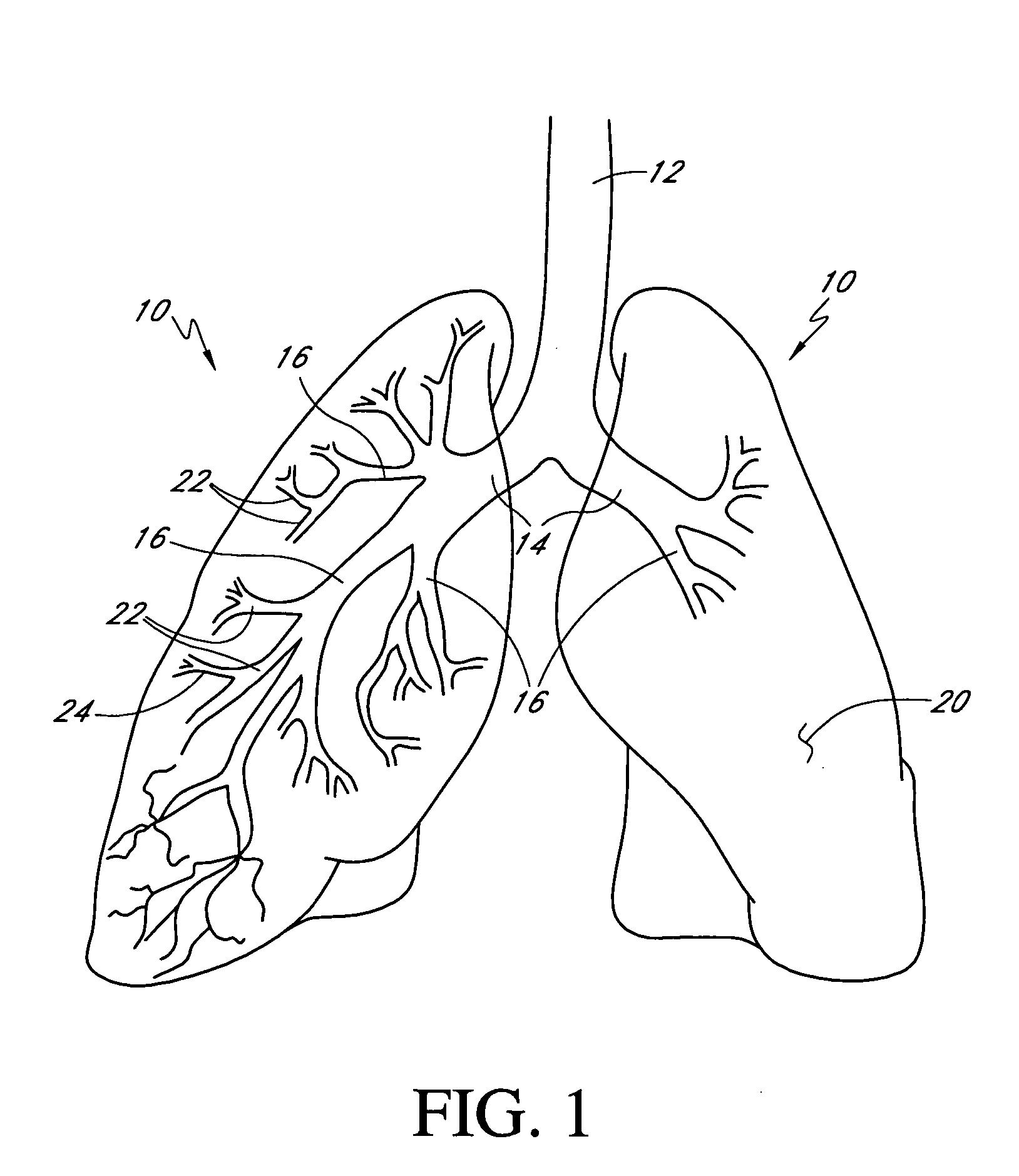

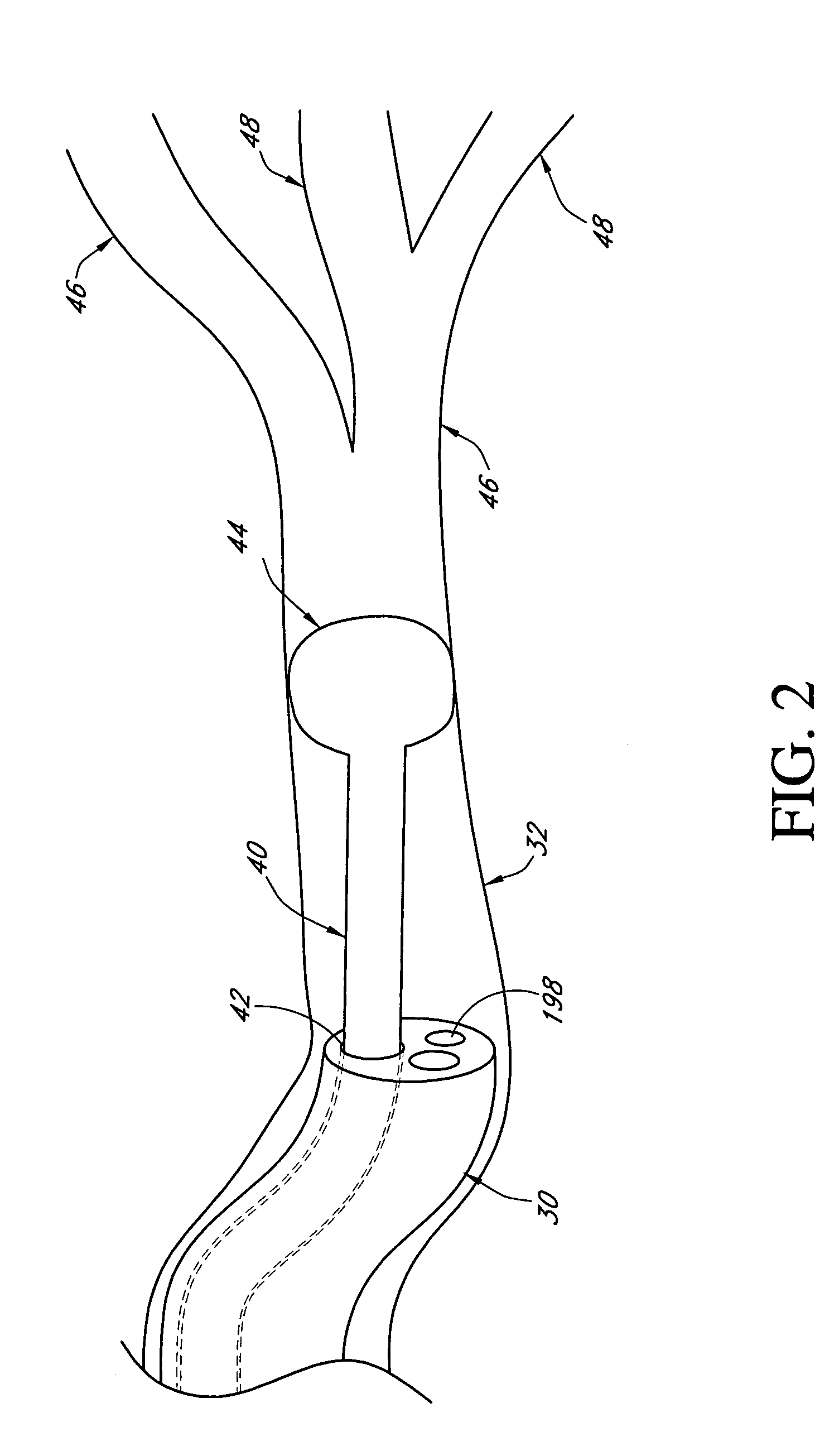

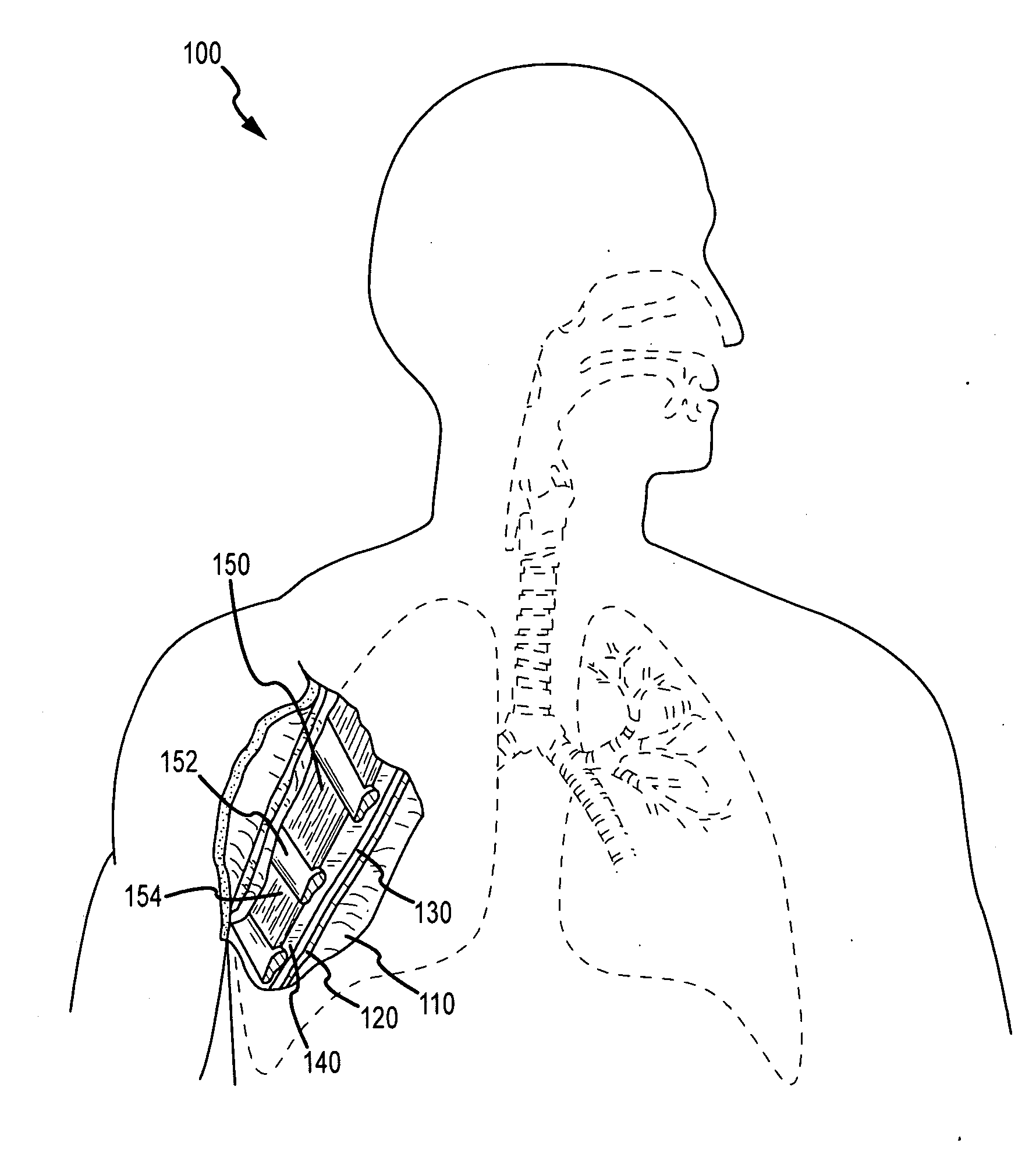

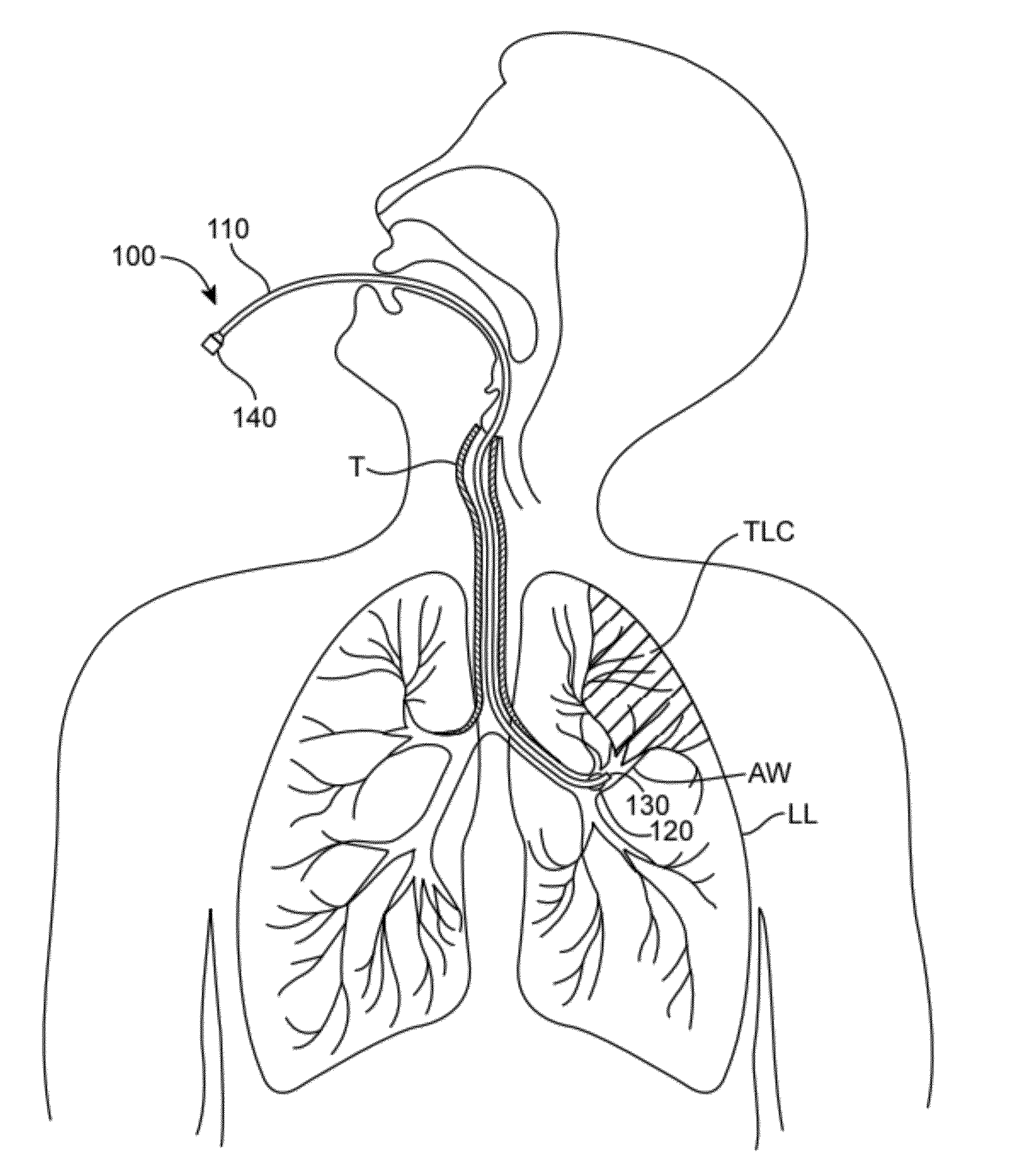

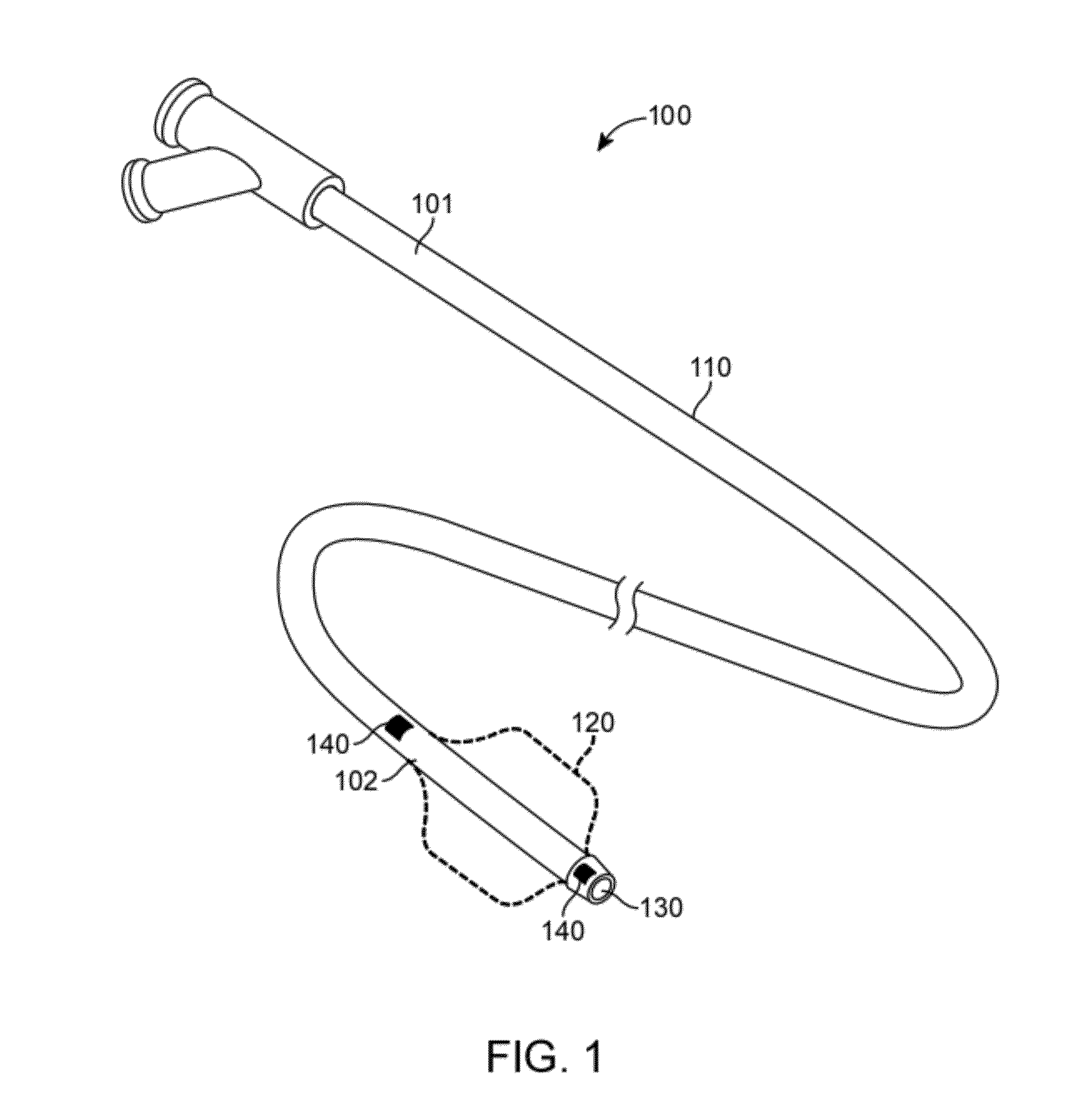

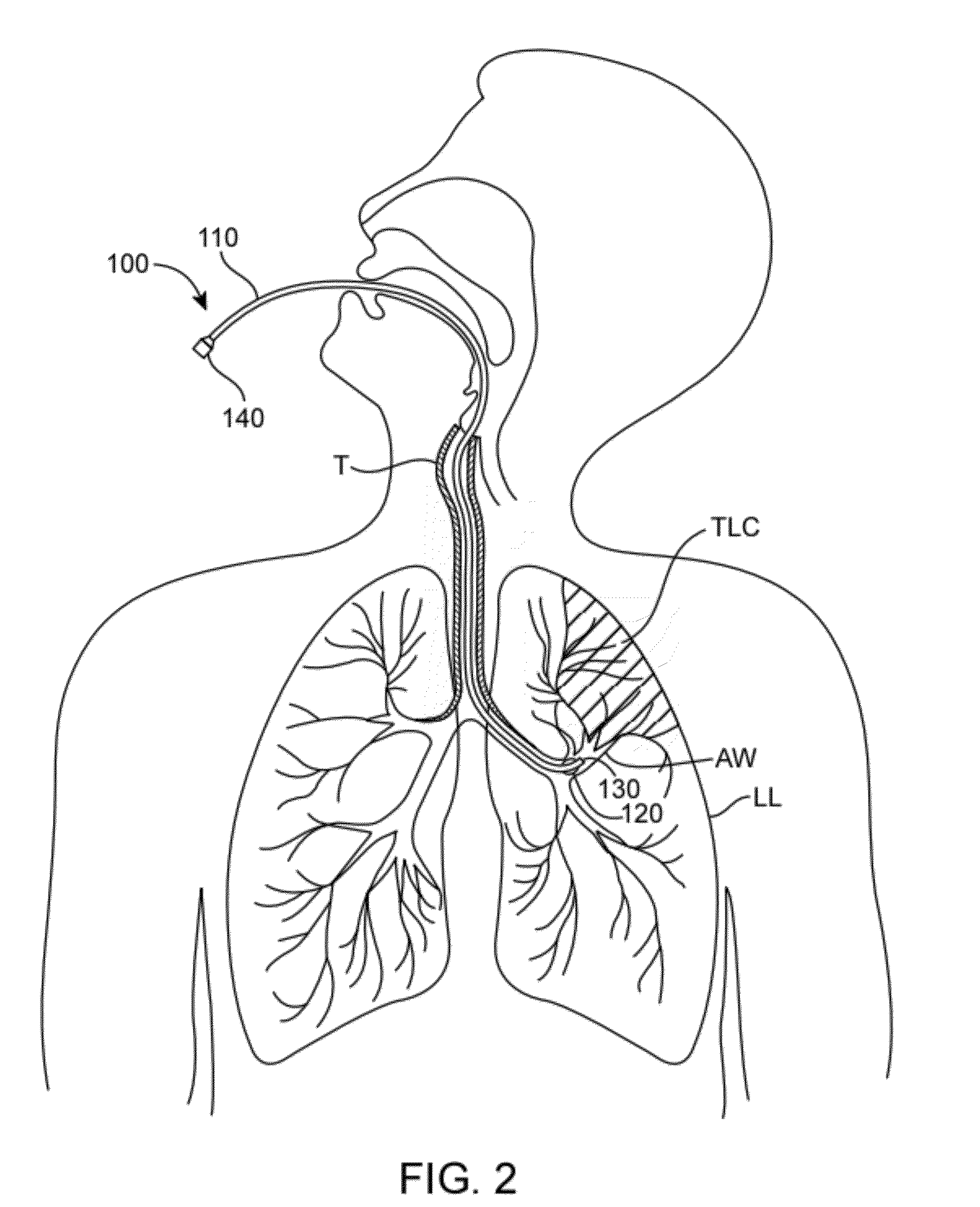

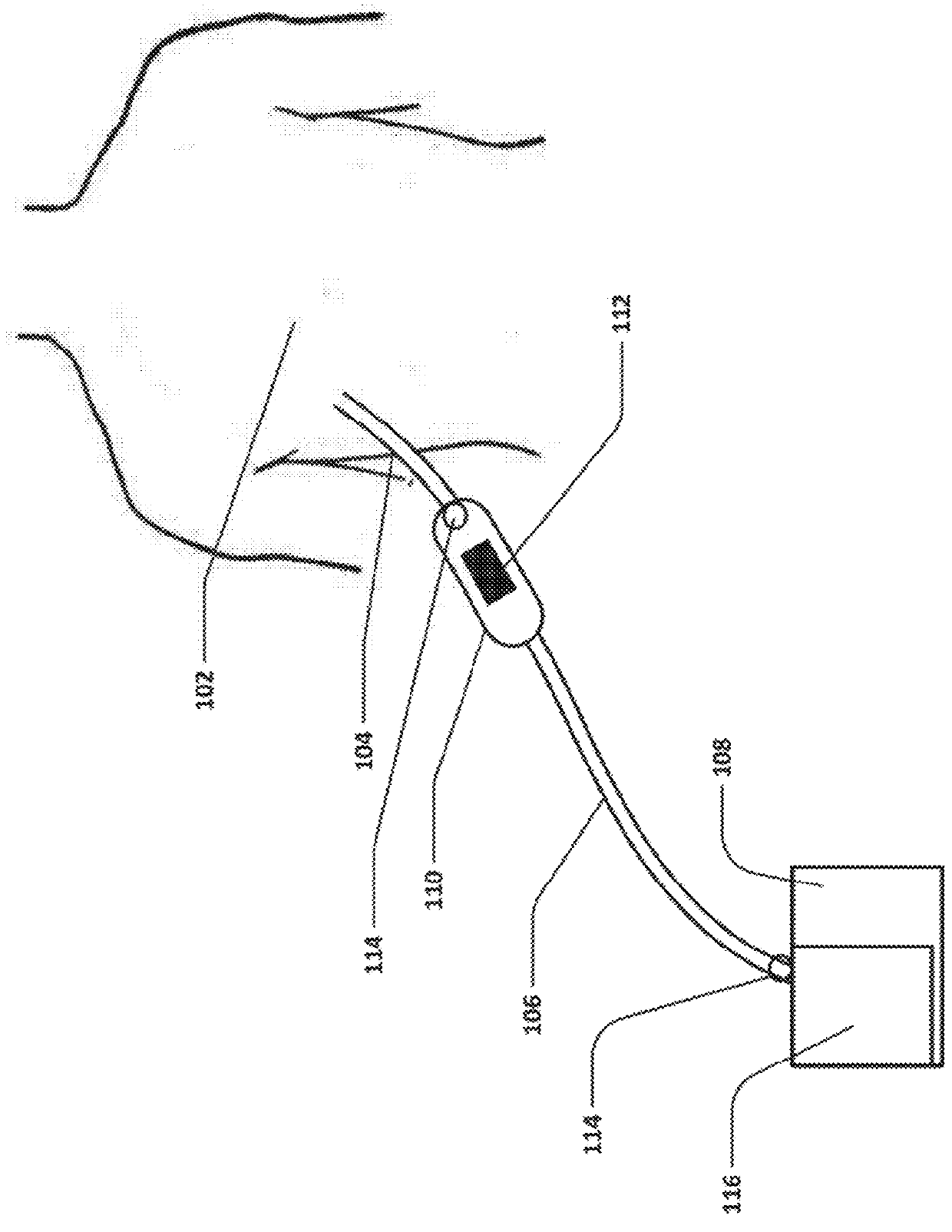

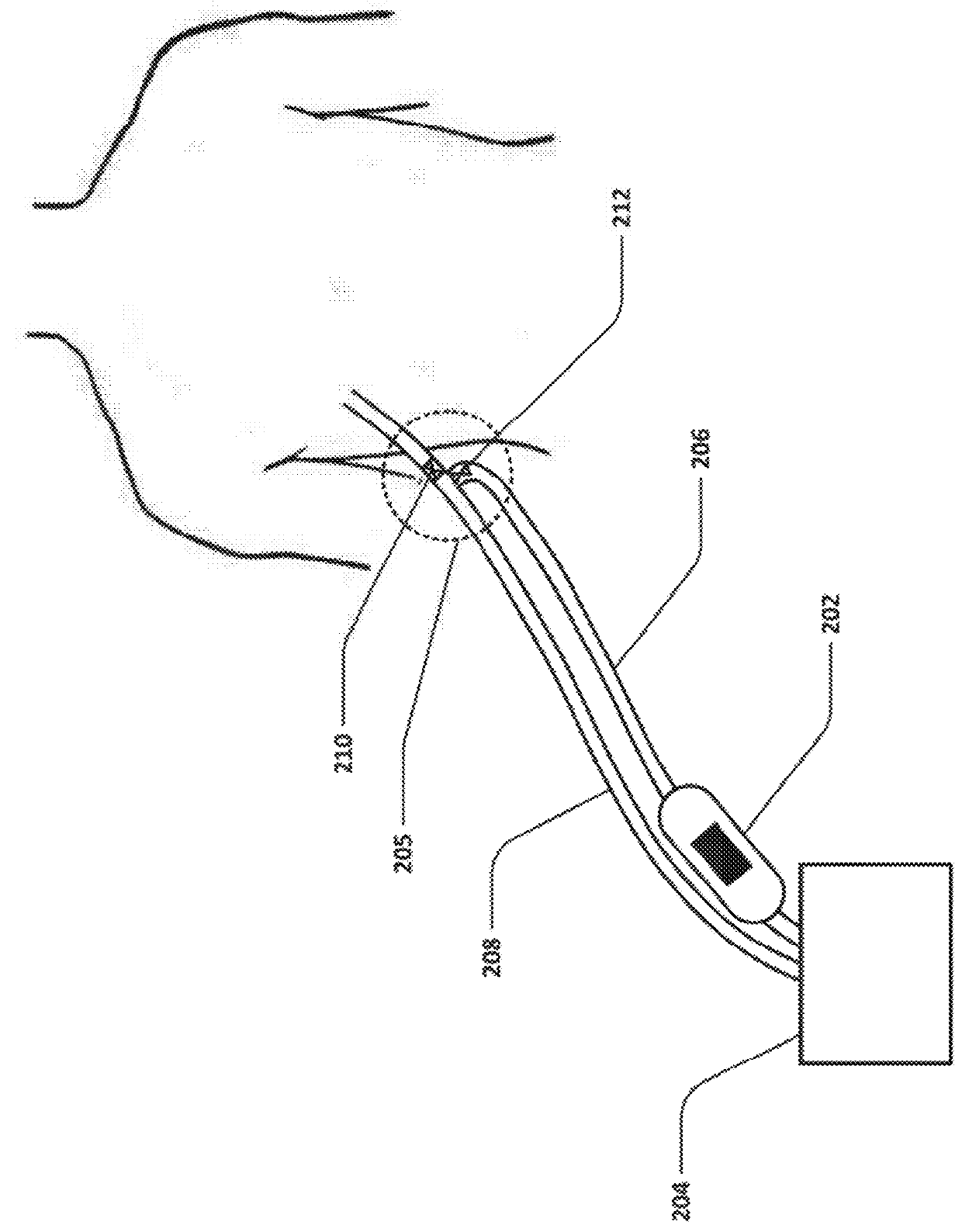

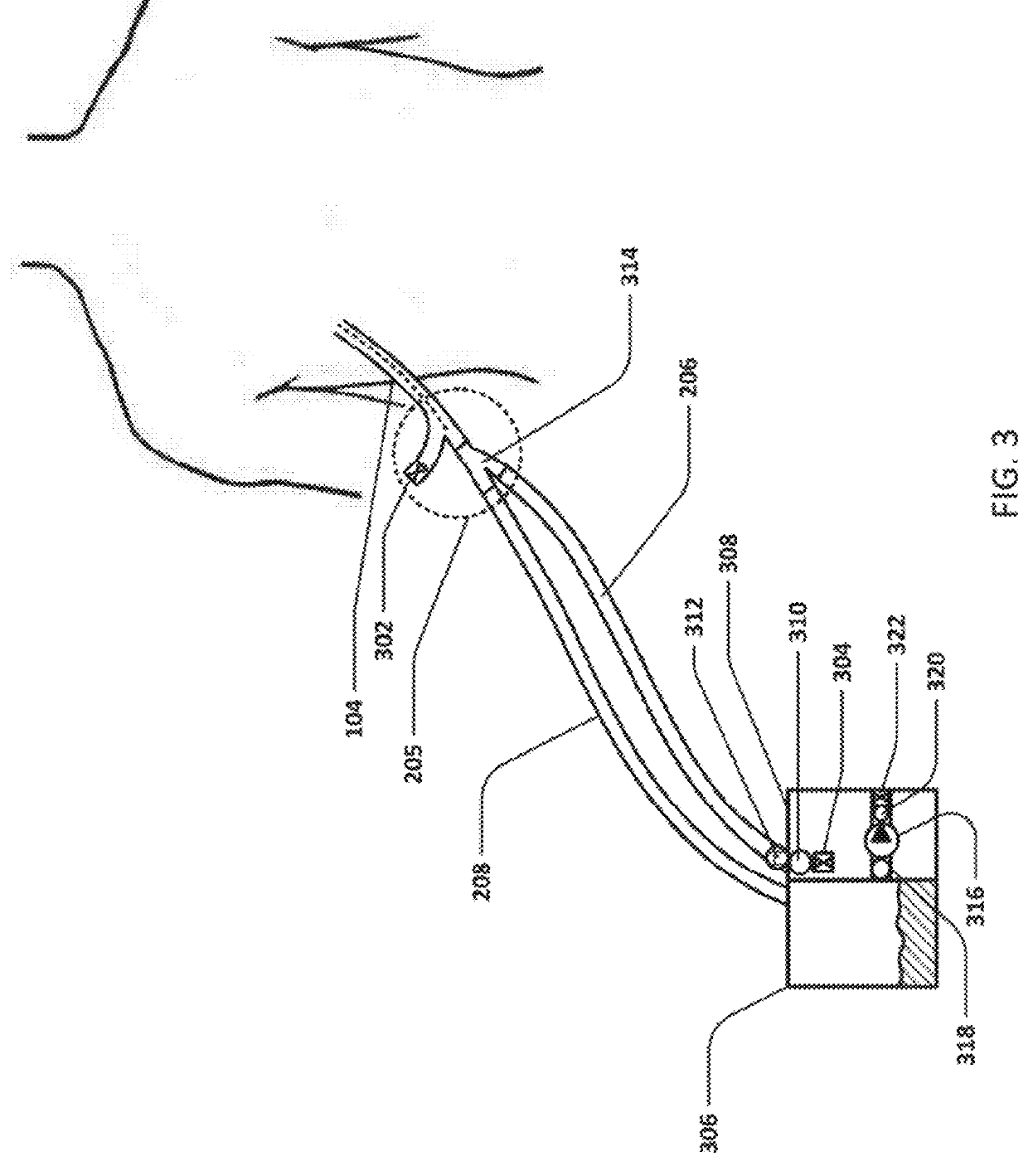

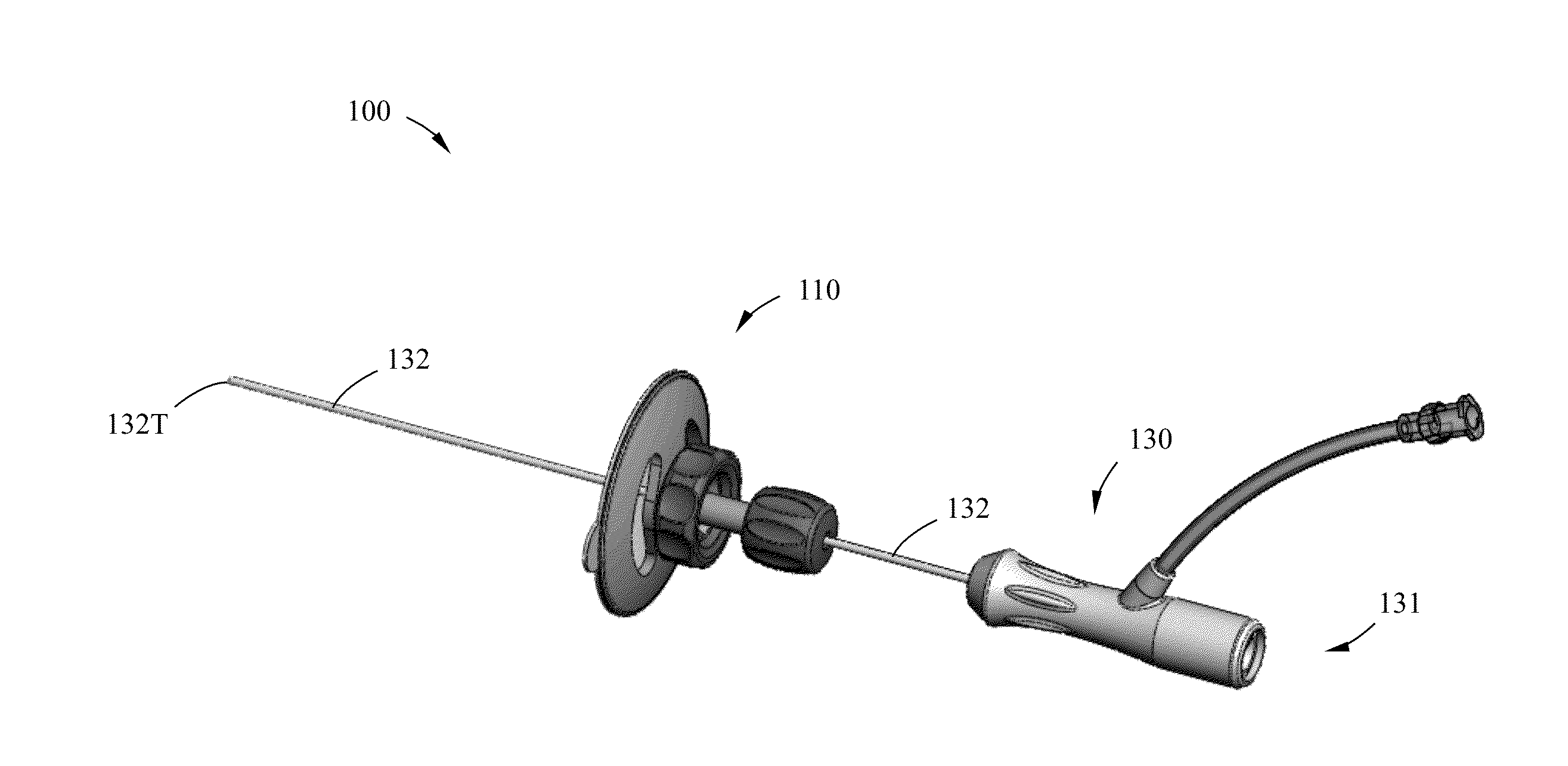

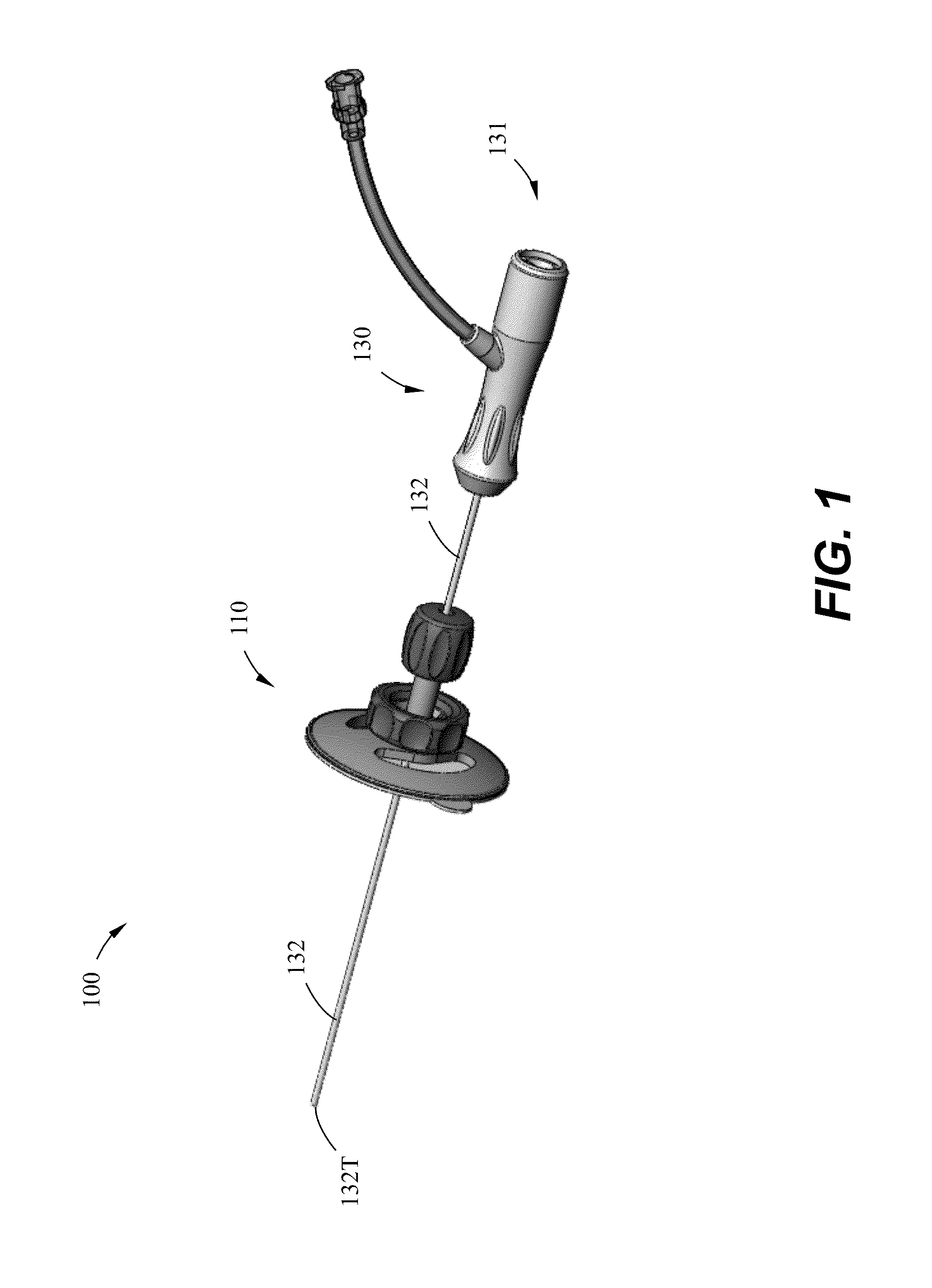

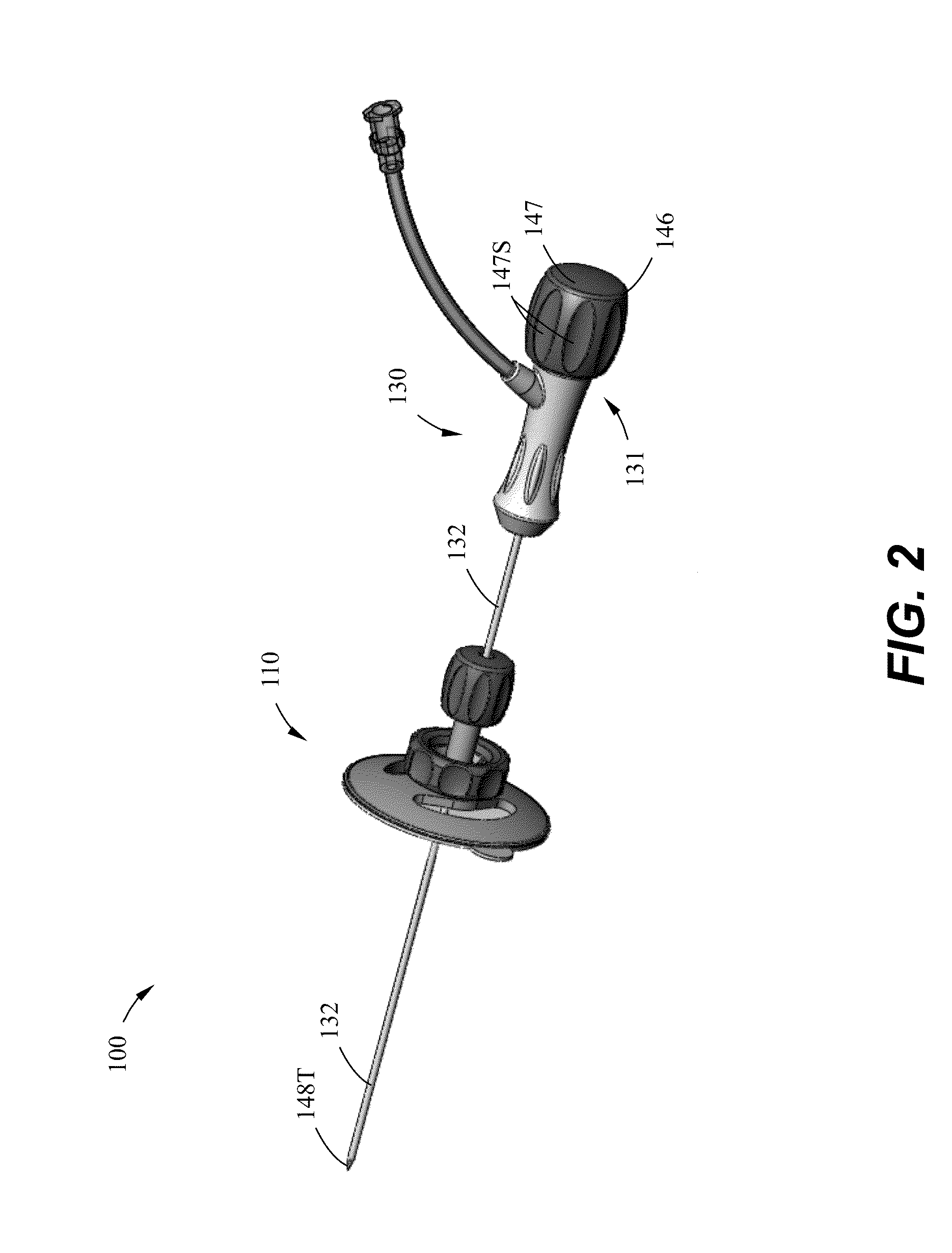

Bronchoscopic repair of air leaks in a lung

ActiveUS7533671B2Minimizes dislodgingSmall sizeRespiratorsBronchiAirway occlusionIntensive care medicine

Methods and systems for minimally invasively treating an air leak in a lung comprise the steps of detecting an air leak in a lung; locating an airway in fluid communication with the air leak, introducing a bronchoscope into a patient's airway to a position adjacent the target section and occluding an airway upstream of the air leak for a period of time. The airway occlusion is preferably removed after the air leak has substantially permanently healed. The method can also include the injection of a substance into the airway on a distal side of the occlusion.

Owner:GYRUS ACMI INC (D B A OLYMPUS SURGICAL TECH AMERICA)

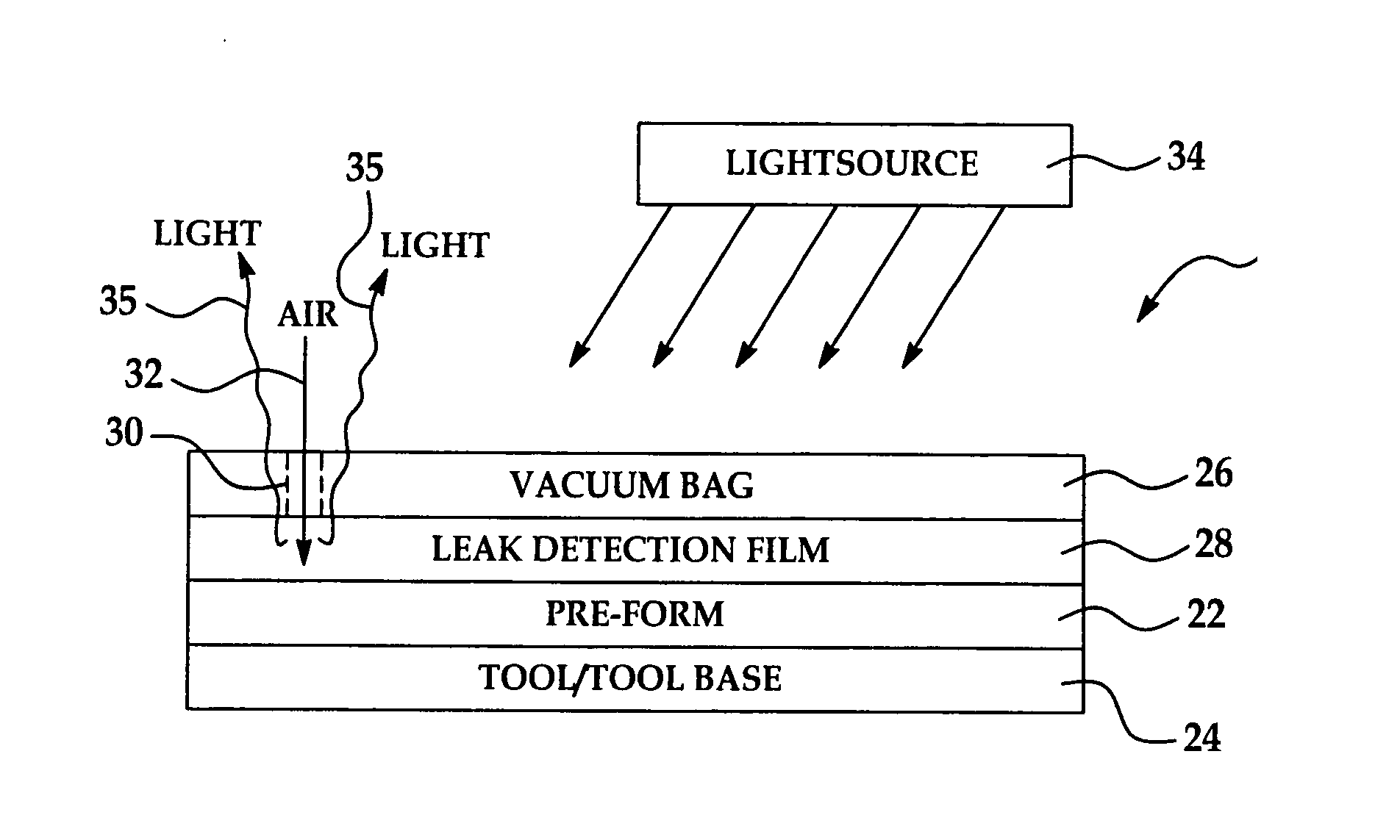

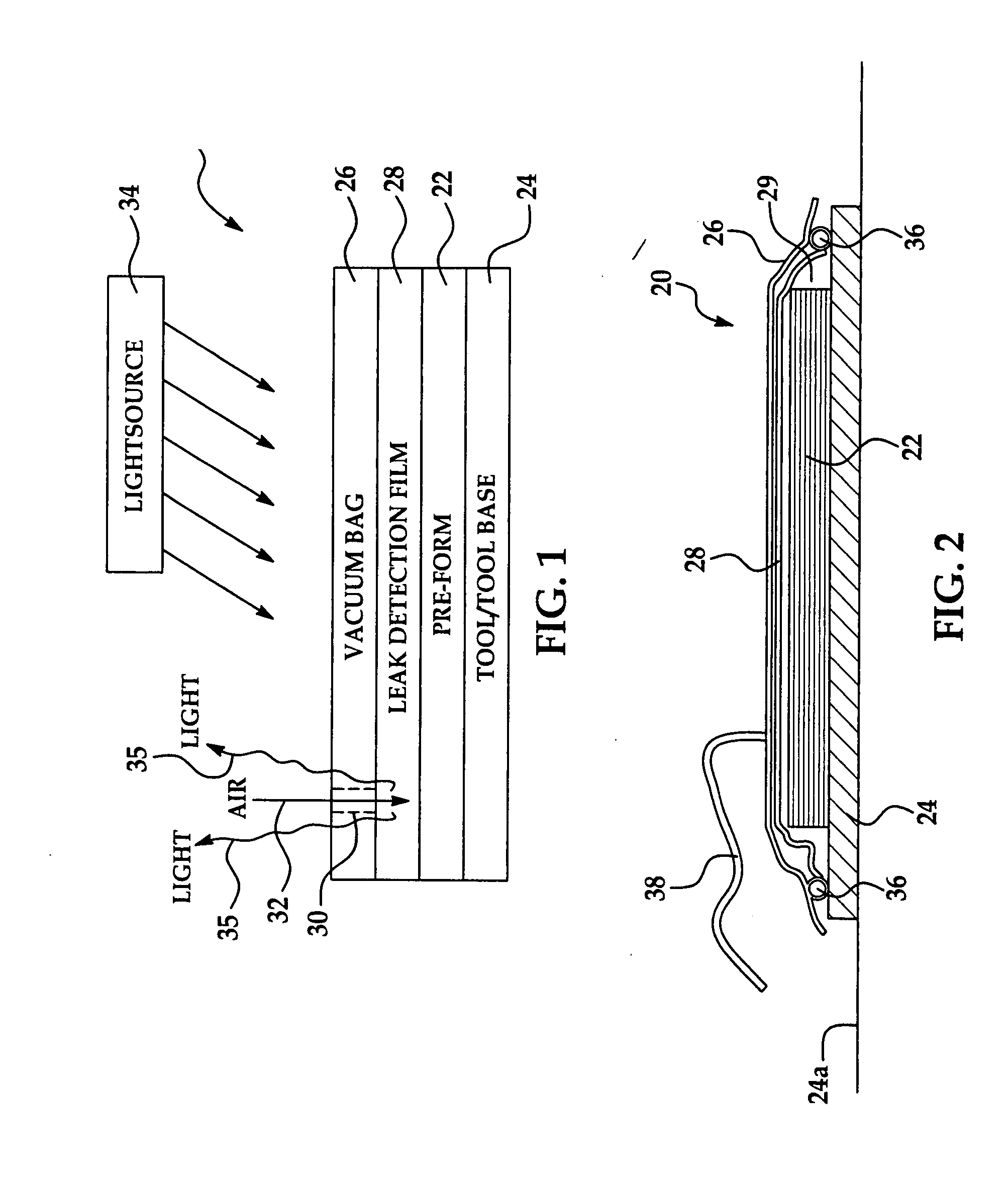

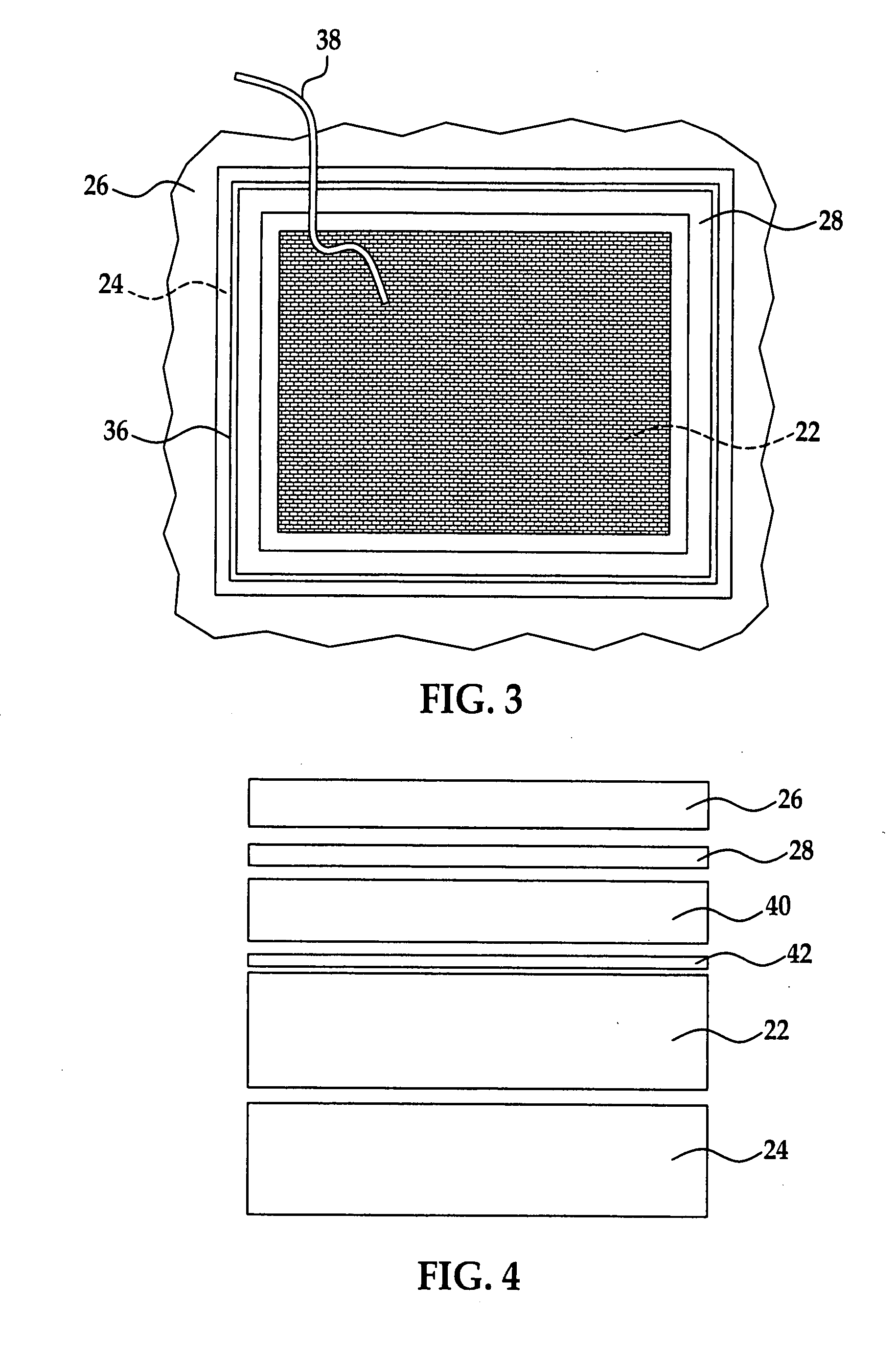

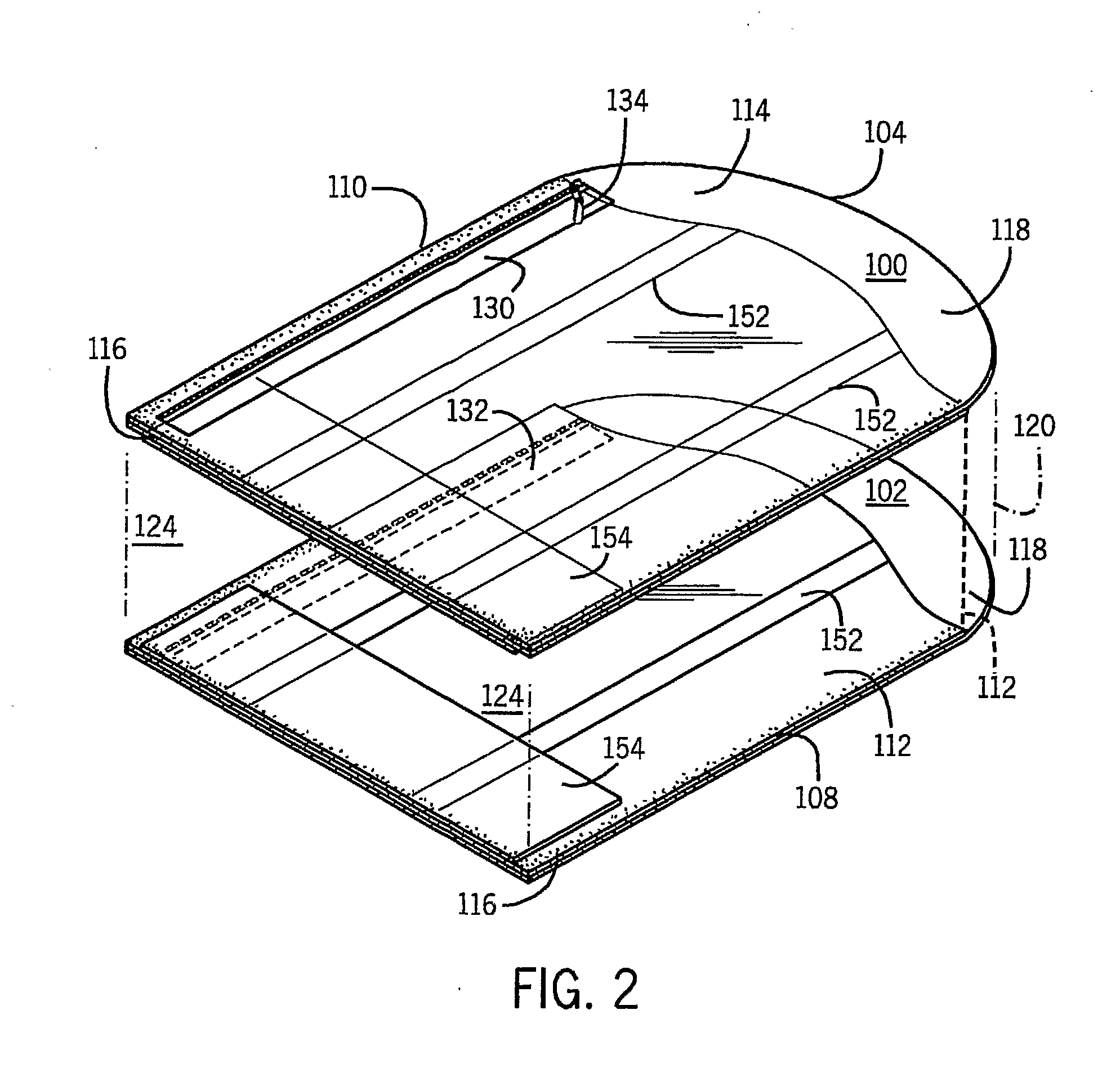

Leak Detection in Vacuum Bags

ActiveUS20080148817A1Keep the pressureDetection of fluid at leakage pointMeasurement of fluid loss/gain rateEngineeringLength wave

Air leaks in a vacuum bag are detected using a leak detection film covering the inside face of the bag. The film includes a gas permeable binder carrying oxygen sensitive material that changes in physical appearance at the location of an air leak. The film may be adhered to the inside face of the bag or may form a separate membrane that is placed over a layup being molded in the bag. The film may be illuminated with light having a wavelength selected to cause the film to luminesce.

Owner:THE BOEING CO

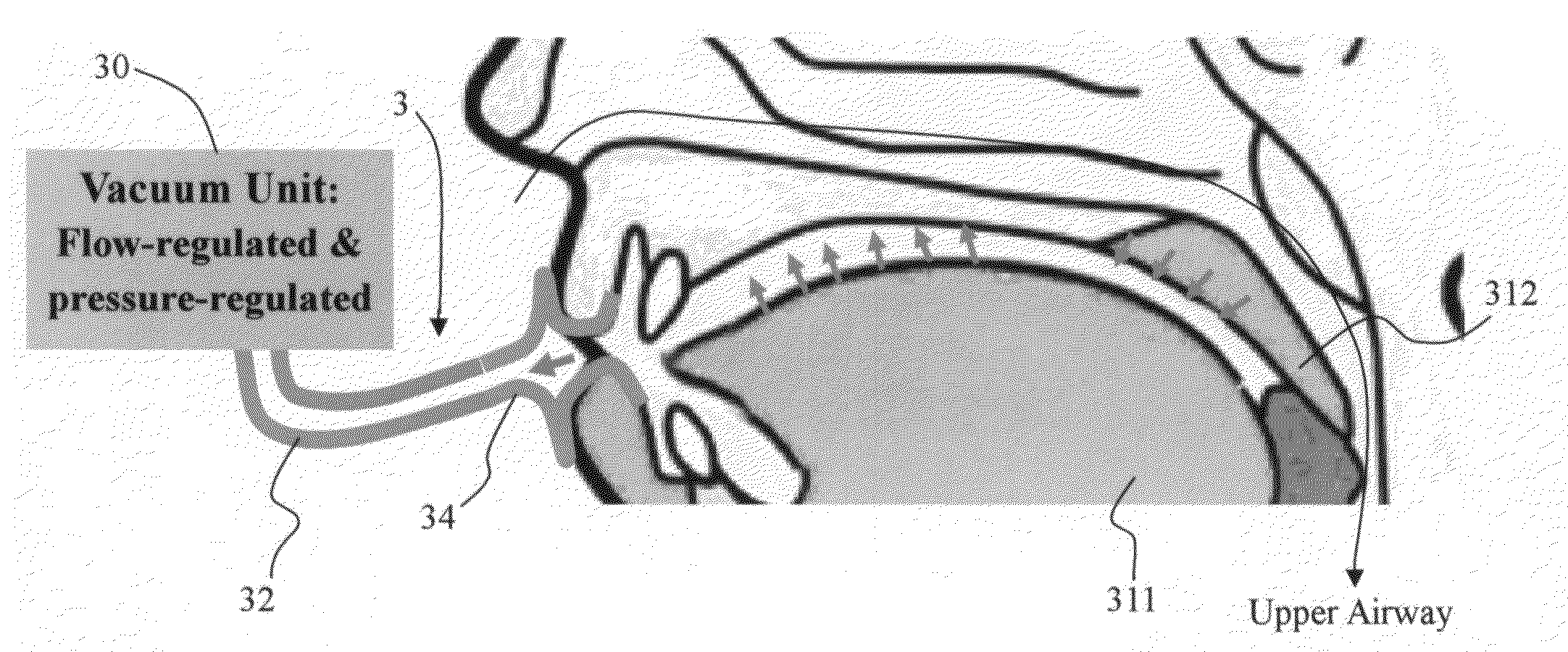

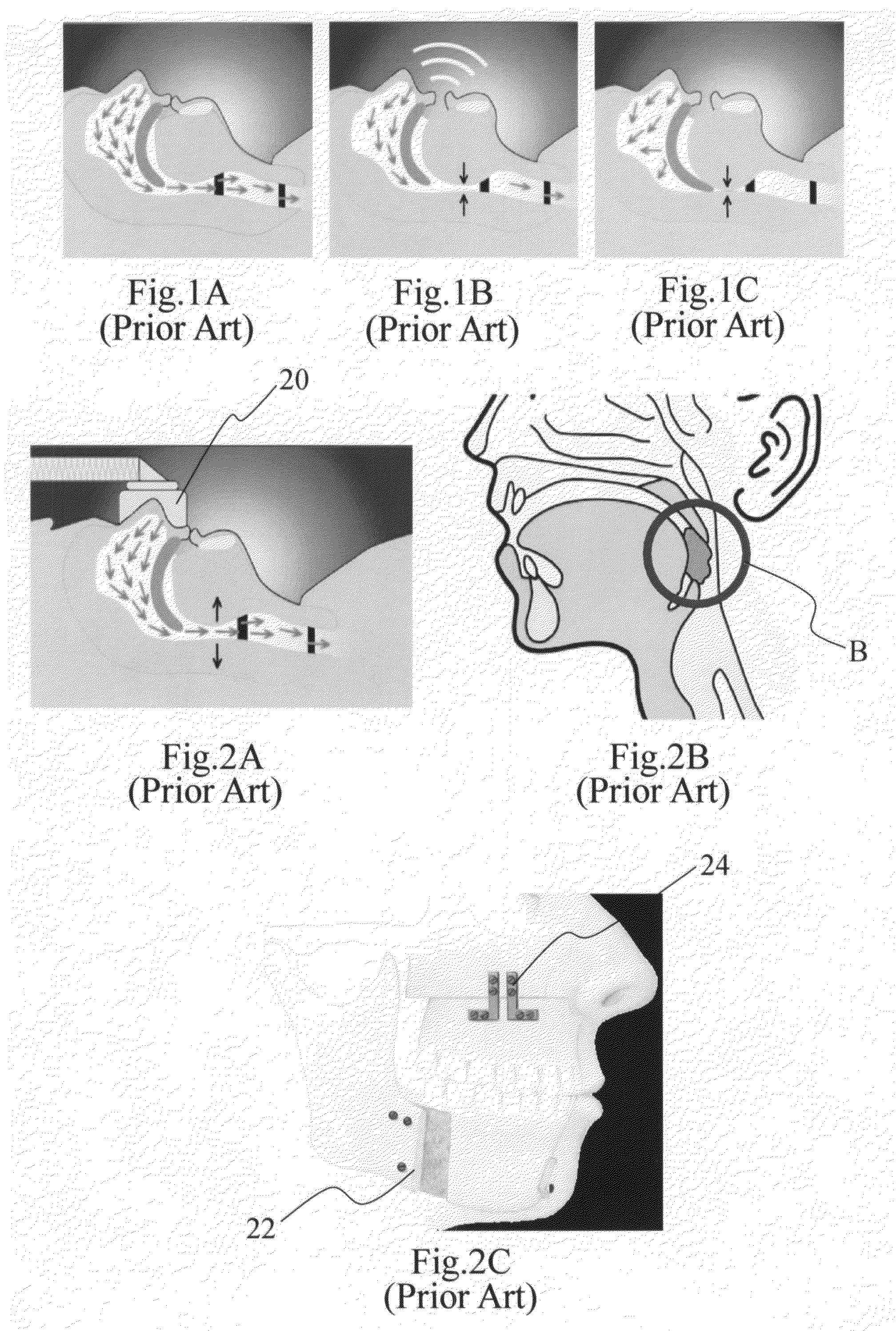

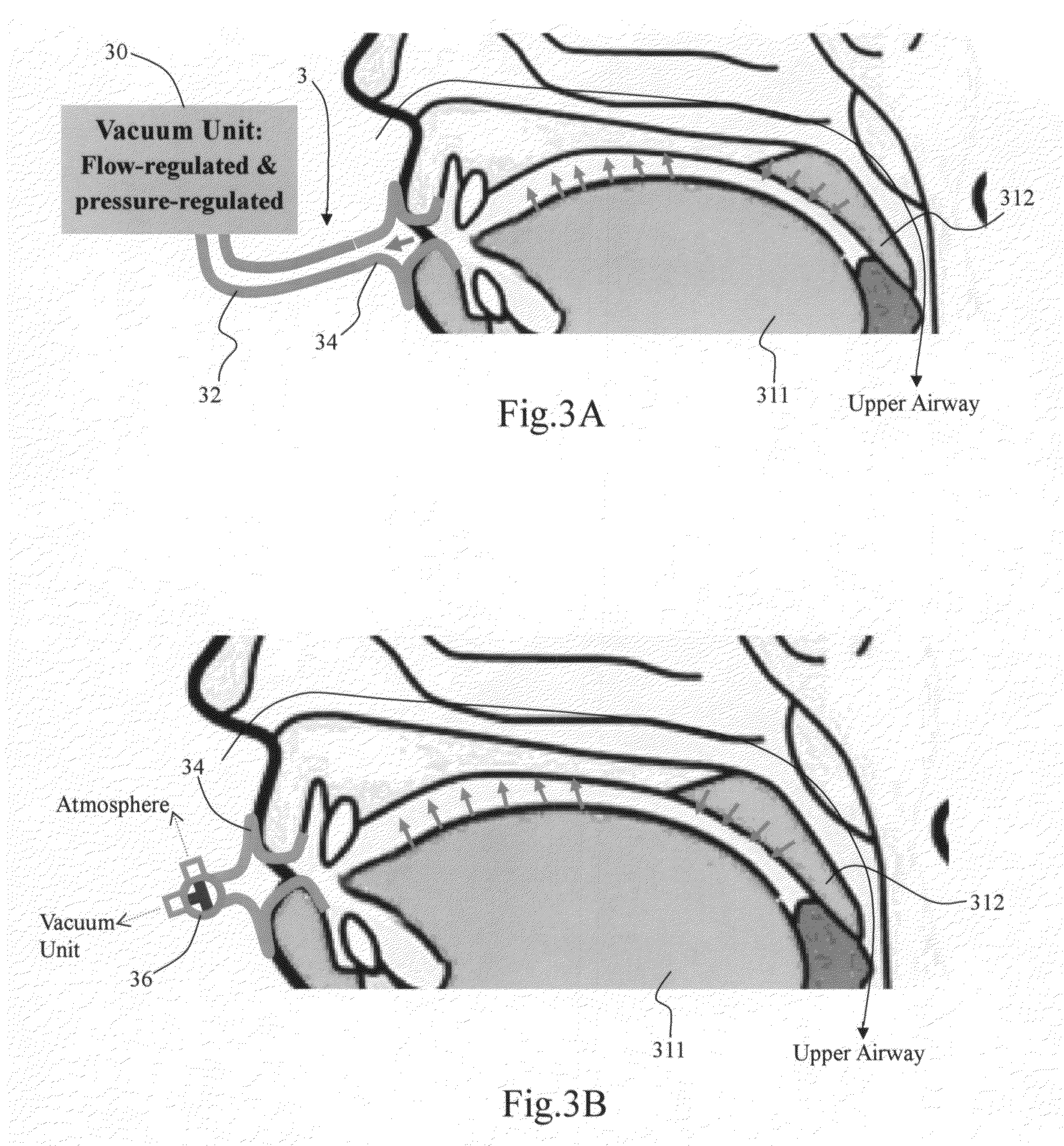

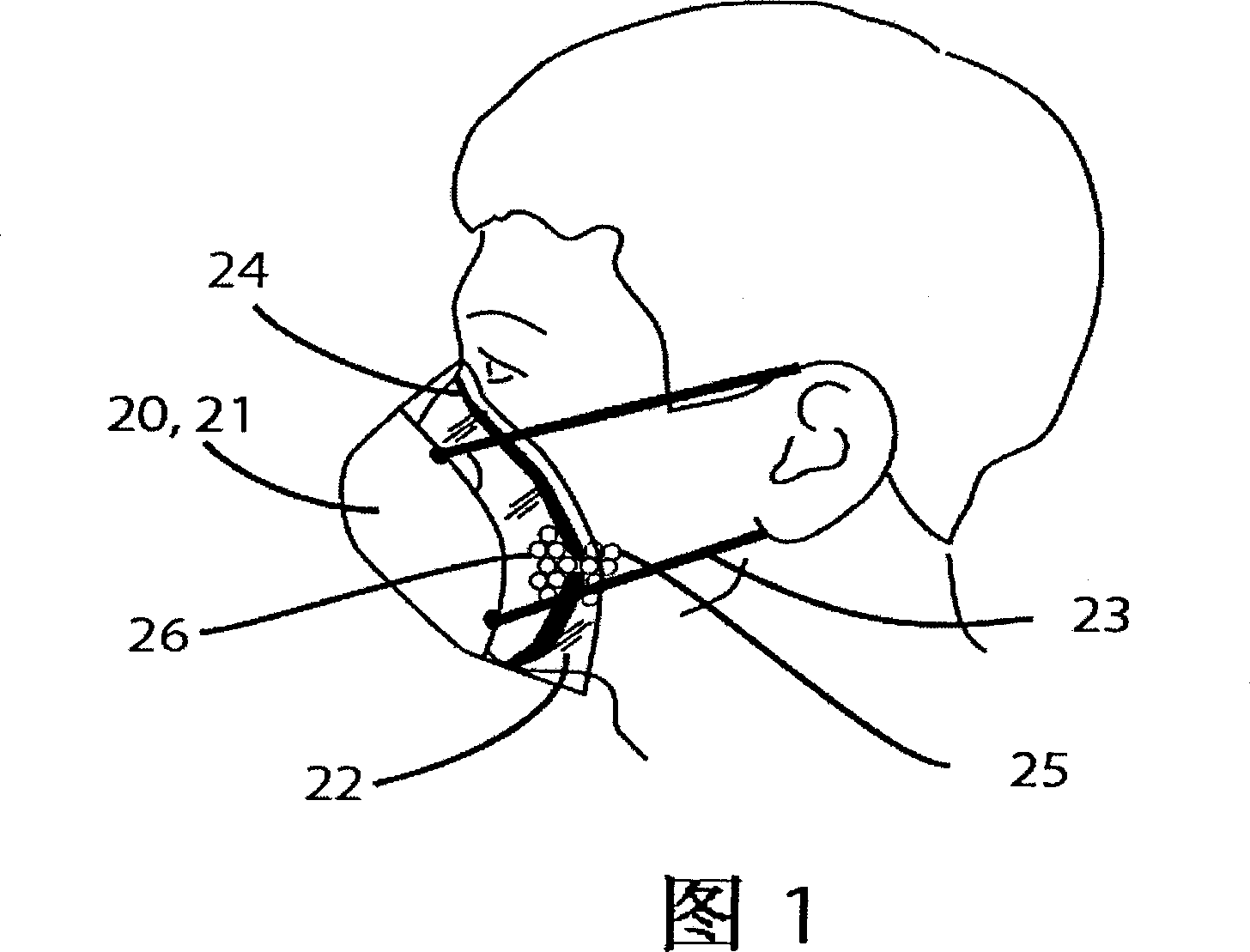

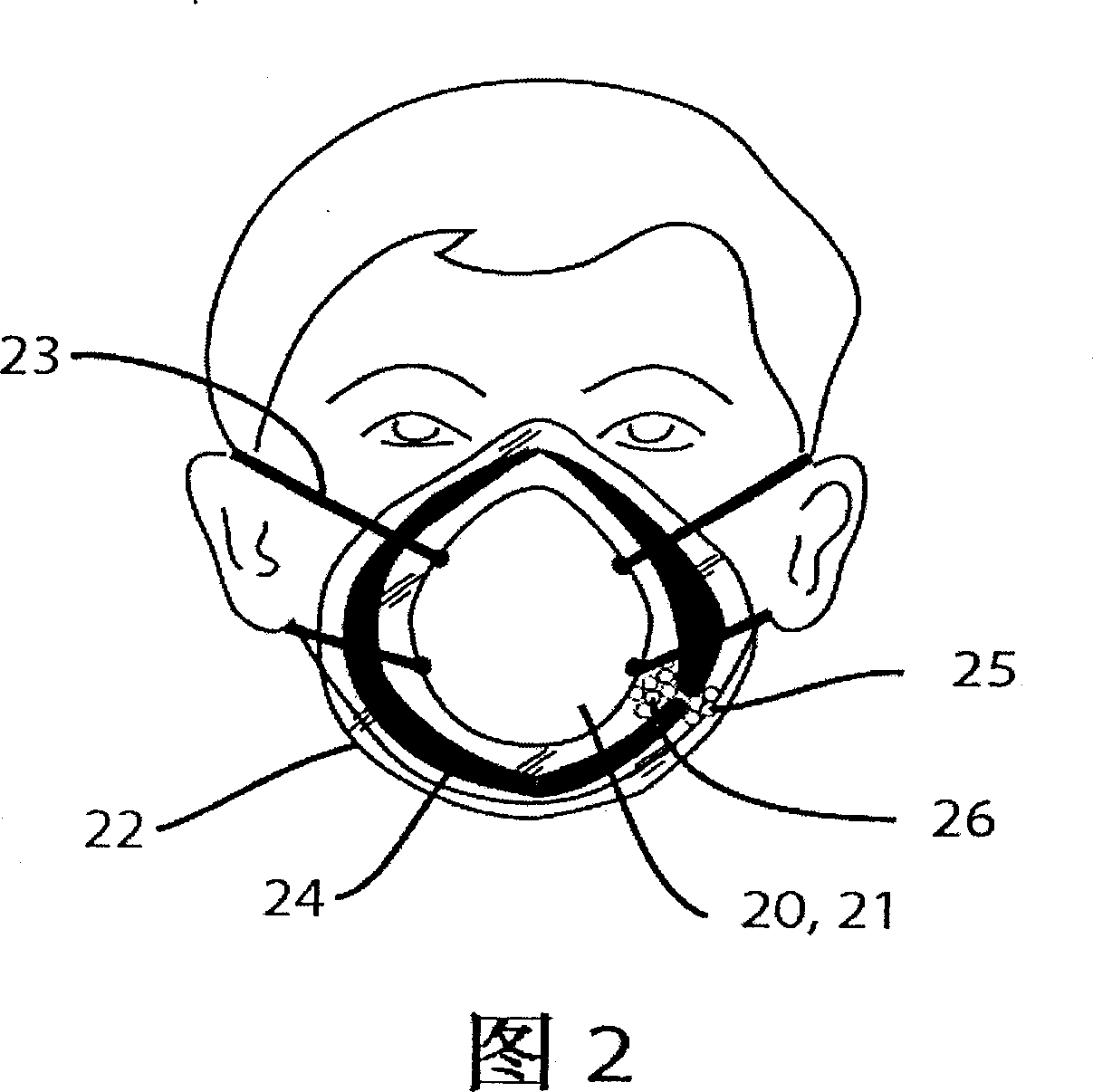

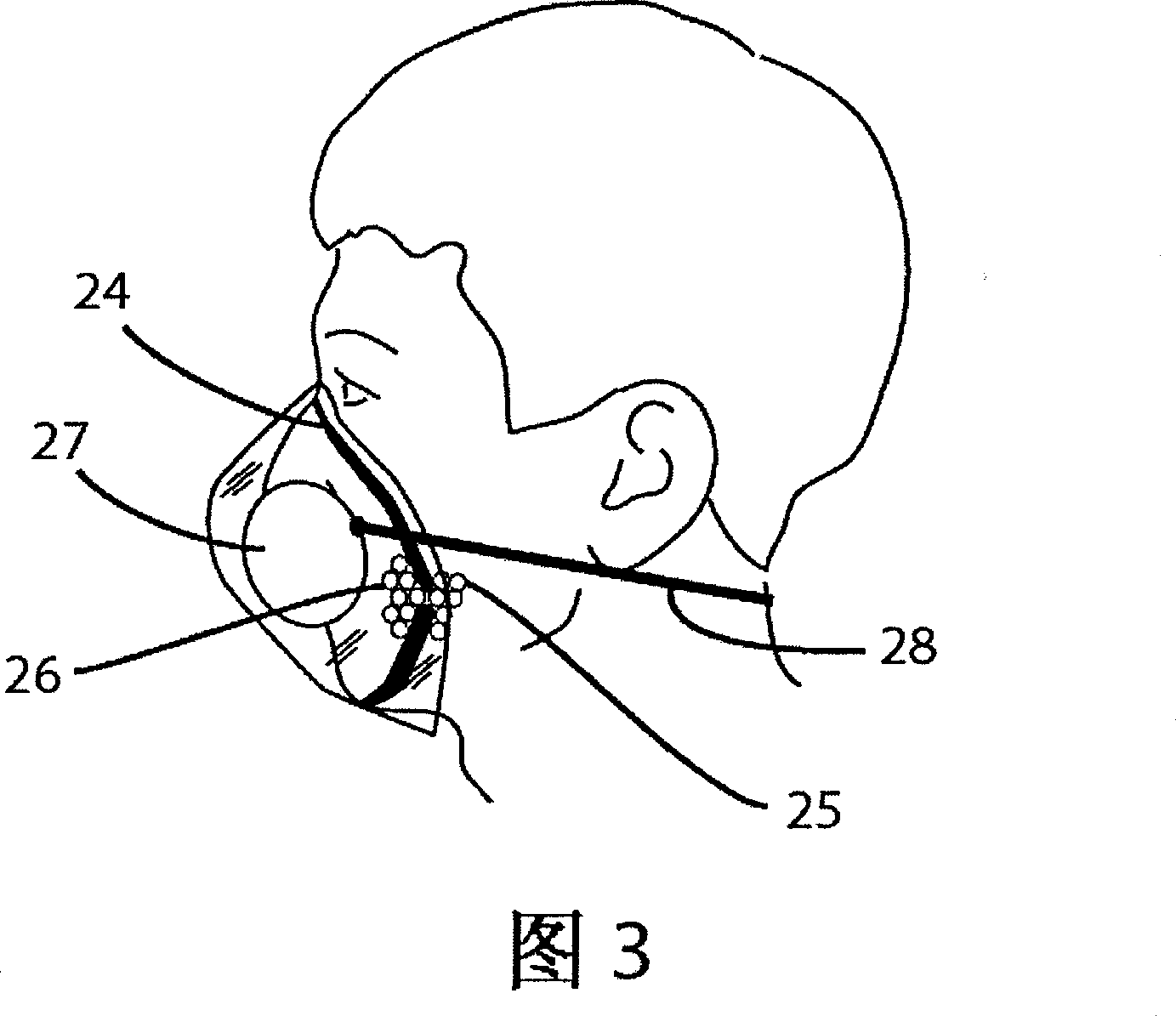

Method and apparatus for treating obstructive sleep apnea by using negative oral pressure to a patient

ActiveUS20070277818A1Improve efficacyImprove complianceRespiratorsBreathing masksNasal cavitySoft palate

The present invention provides a method and apparatus for treating obstructive sleep apnea by using negative oral pressure to a patient. The present apparatus includes a vacuum unit for controlling and maintaining negative pressure of an oral cavity of the patient, a tube with one end thereof connecting to the vacuum unit to suck out air in the oral cavity to generate the negative pressure therein, and a mouthpiece connecting to the other end of the tube and fitting into and sealing the patient's mouth to prevent the oral cavity from air leakage. By using negative pressure in the oral cavity, the patient's soft palate is pulled toward the oral cavity and the patient's tongue is pulled toward an upper palate so as to maintain the patient's nasal air passageway open.

Owner:SOMNICS INC

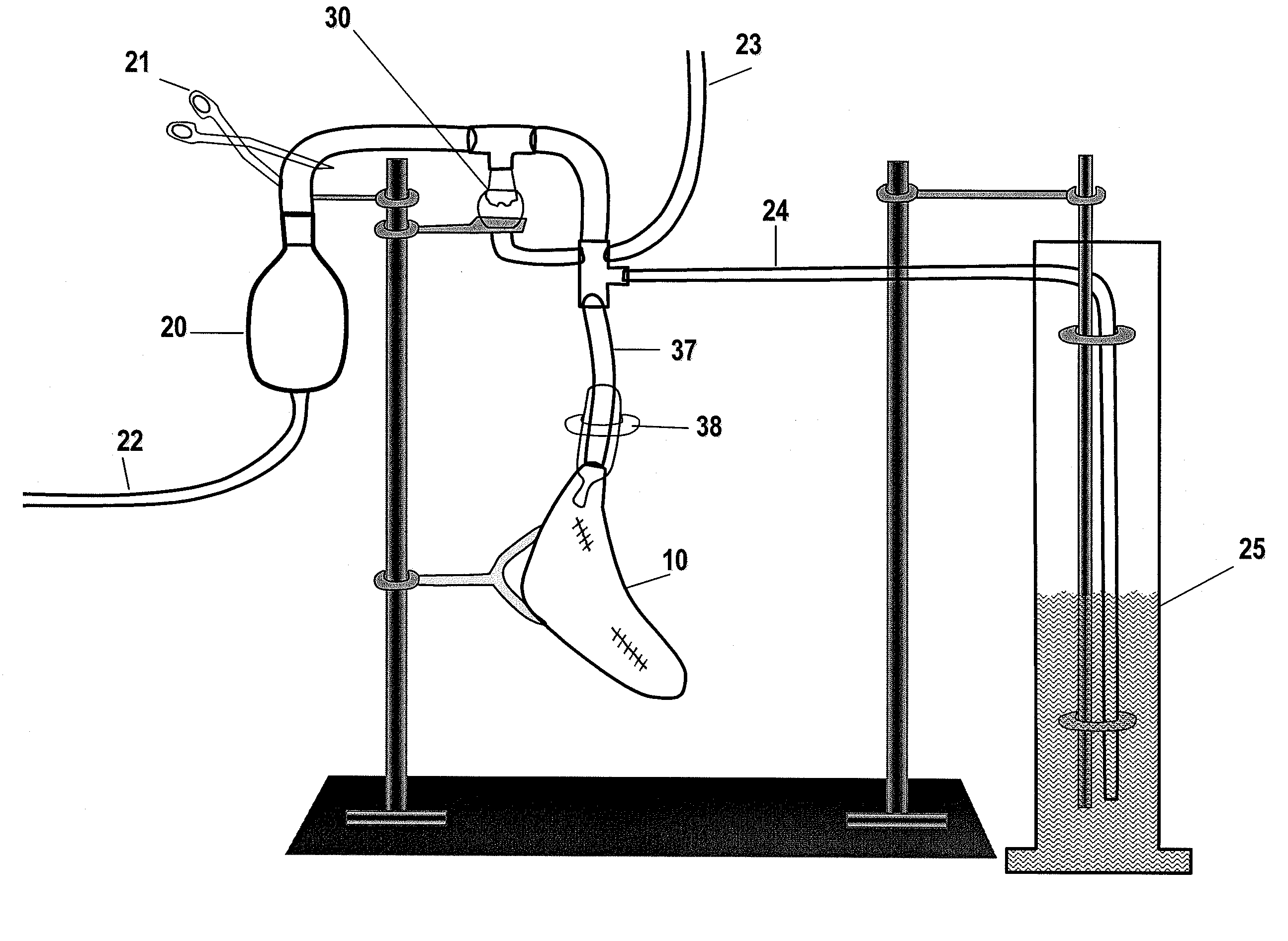

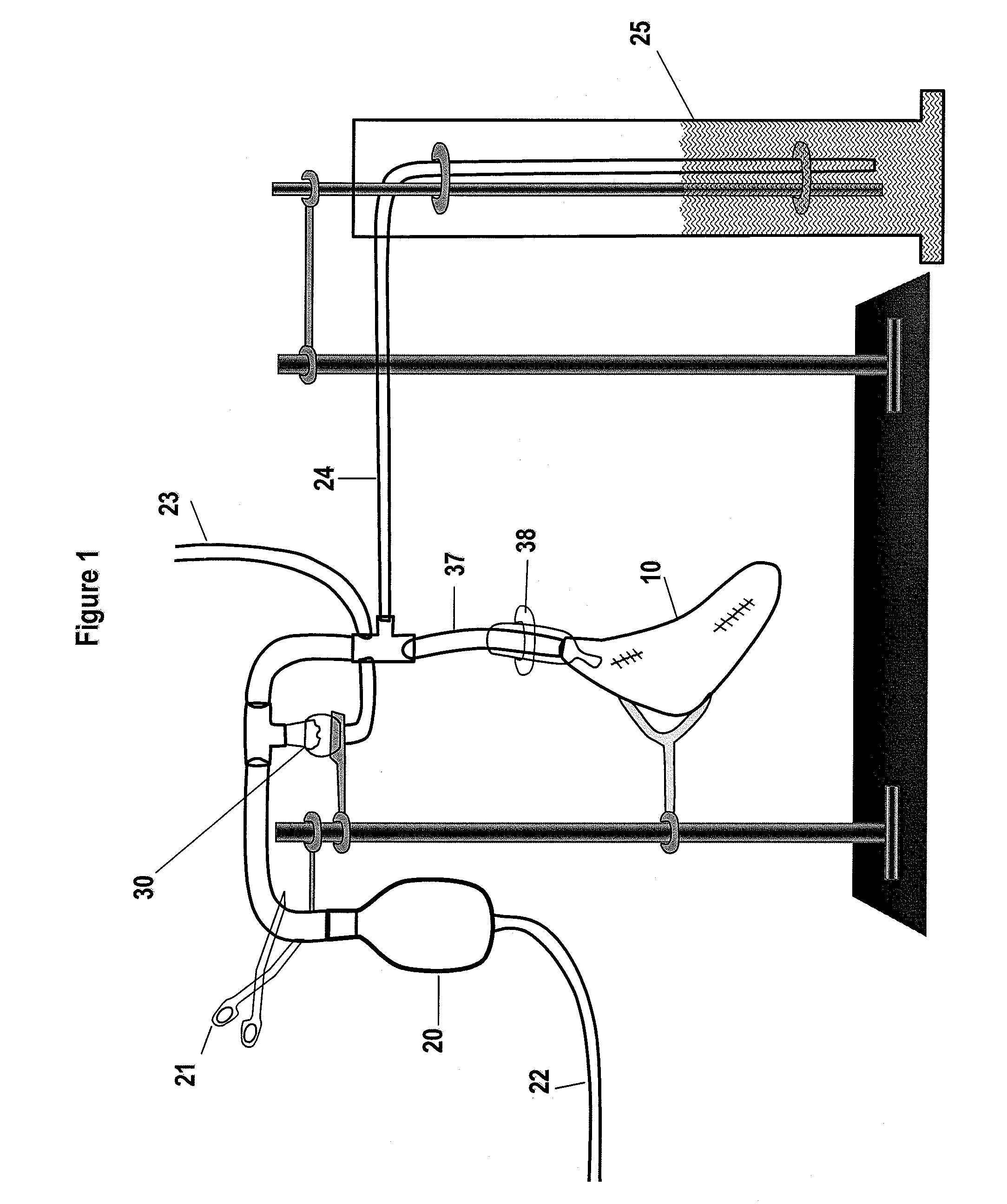

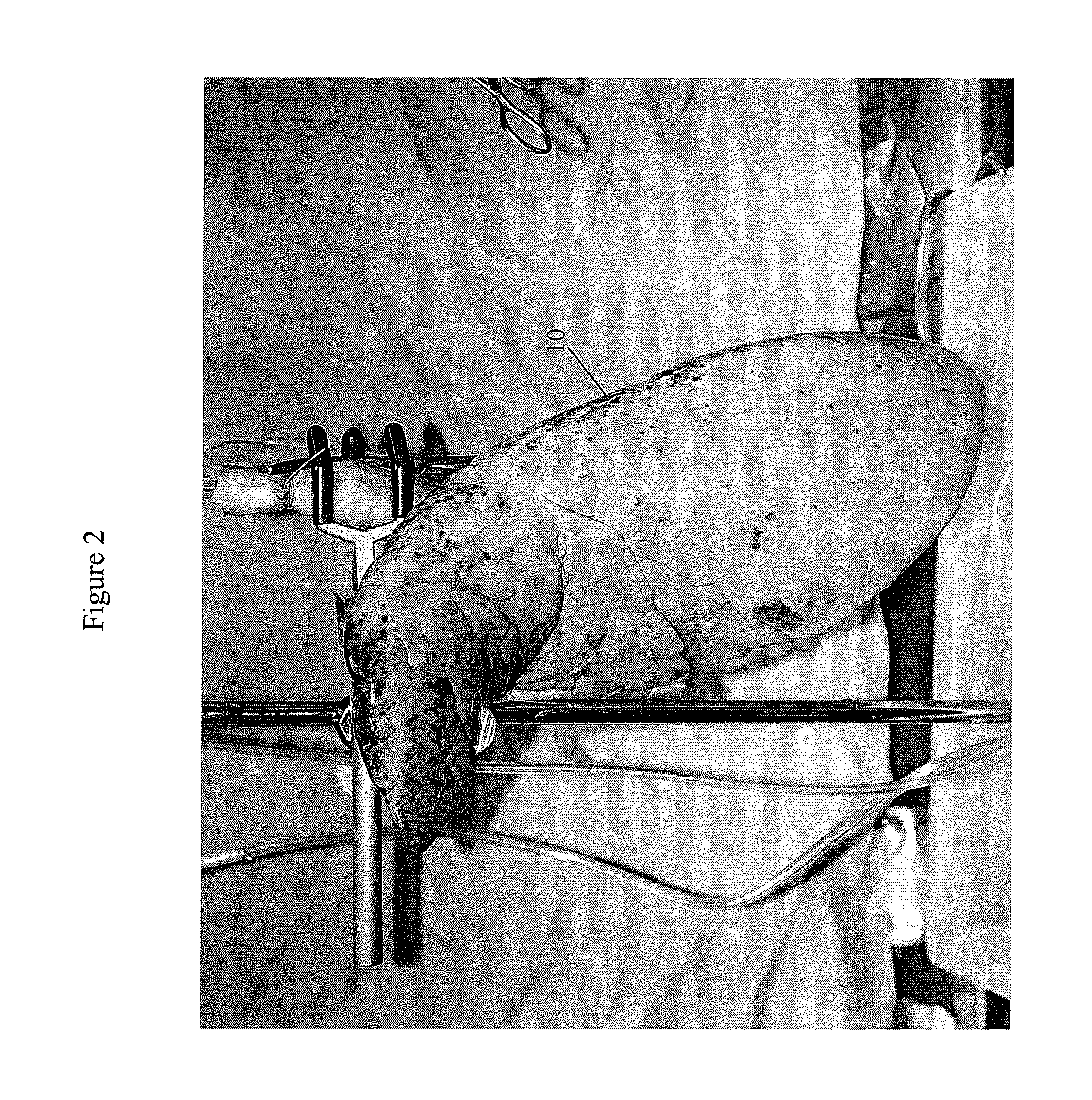

Bronchoscopic repair of air leaks in a lung

ActiveUS20050137714A1Minimizes dislodgingSmall sizeBronchiOcculdersAirway occlusionIntensive care medicine

Methods and systems for minimally invasively treating an air leak in a lung comprise the steps of detecting an air leak in a lung; locating an airway in fluid communication with the air leak, introducing a bronchoscope into a patient's airway to a position adjacent the target section and occluding an airway upstream of the air leak for a period of time. The airway occlusion is preferably removed after the air leak has substantially permanently healed. The method can also include the injection of a substance into the airway on a distal side of the occlusion.

Owner:GYRUS ACMI INC (D B A OLYMPUS SURGICAL TECH AMERICA)

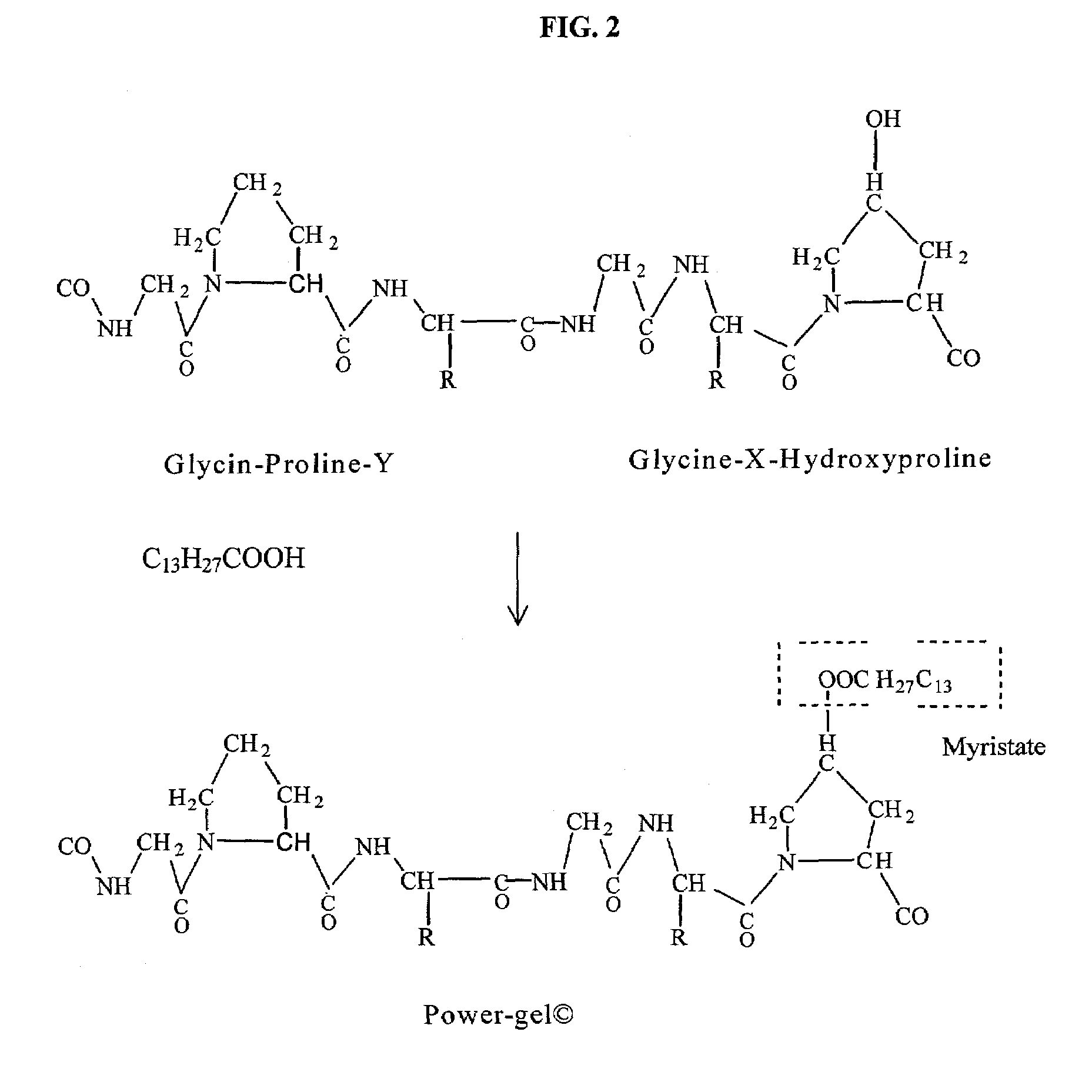

Use of a regenerative biofunctional collagen biomatrix for treating visceral or parietal defects

ActiveUS20090142396A1Avoiding and inhibiting persistent tissue leakImprove lung functionPowder deliveryPeptide/protein ingredientsSurgical treatmentTissue defect

Techniques for treating visceral or parietal membrane and tissue defects include the application of a collagen biomatrix to the defect to repair and regenerate a visceral or parietal membrane, for example in patients suffering tissue defects or undergoing visceral or parietal surgical treatment. Such approaches avoid persistent tissue leaks and their consequences such as fluid leaks and air leaks. The use of collagen biomatrix, optionally in conjunction with a fibrin sealant, an anti-adhesive, or both, can minimize tissue leaks or fluid leaks in injured patients suffering tissue defects or subjects undergoing surgery such as visceral or parietal resections and other operations.

Owner:BAXTER INT INC +1

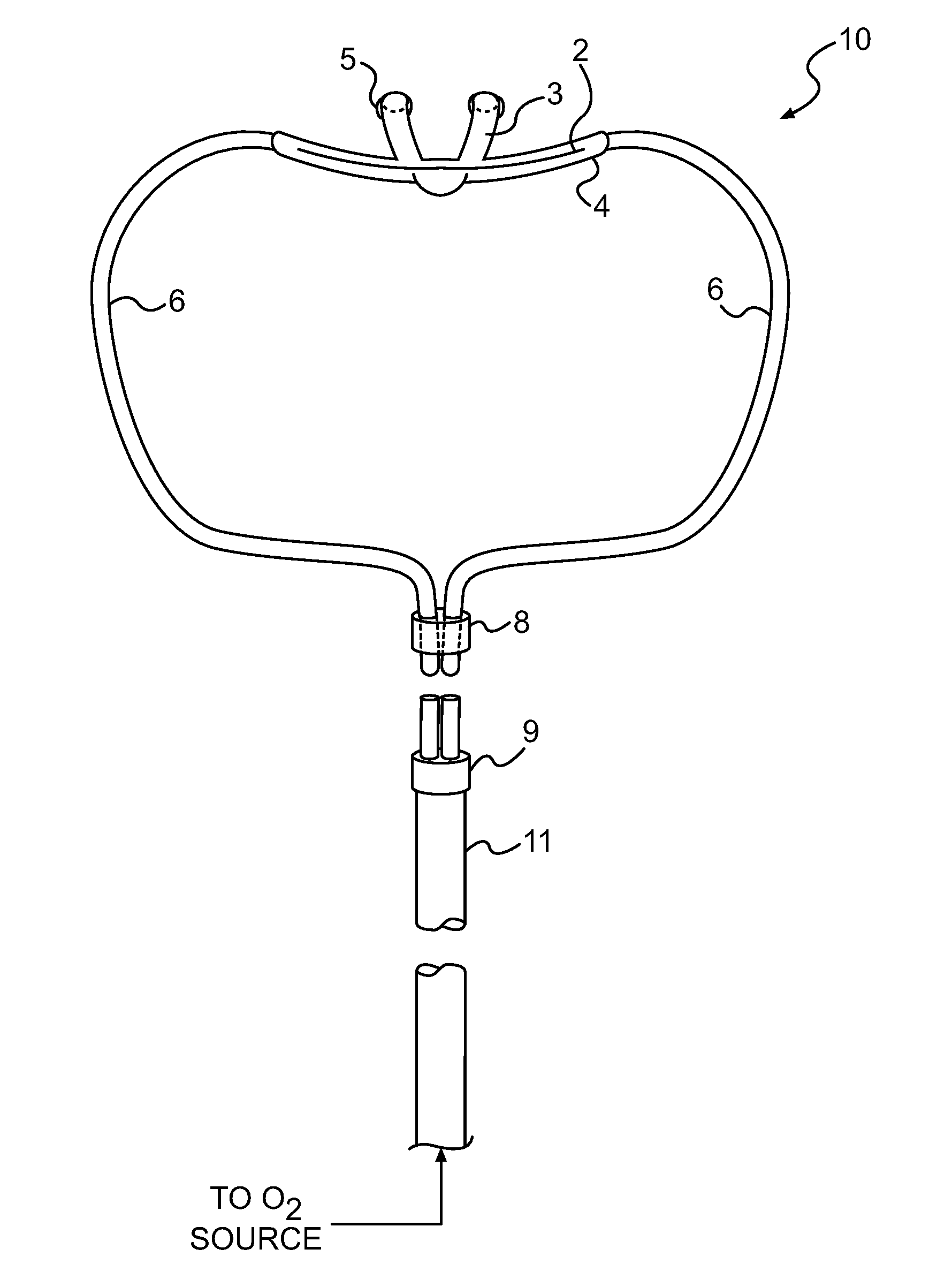

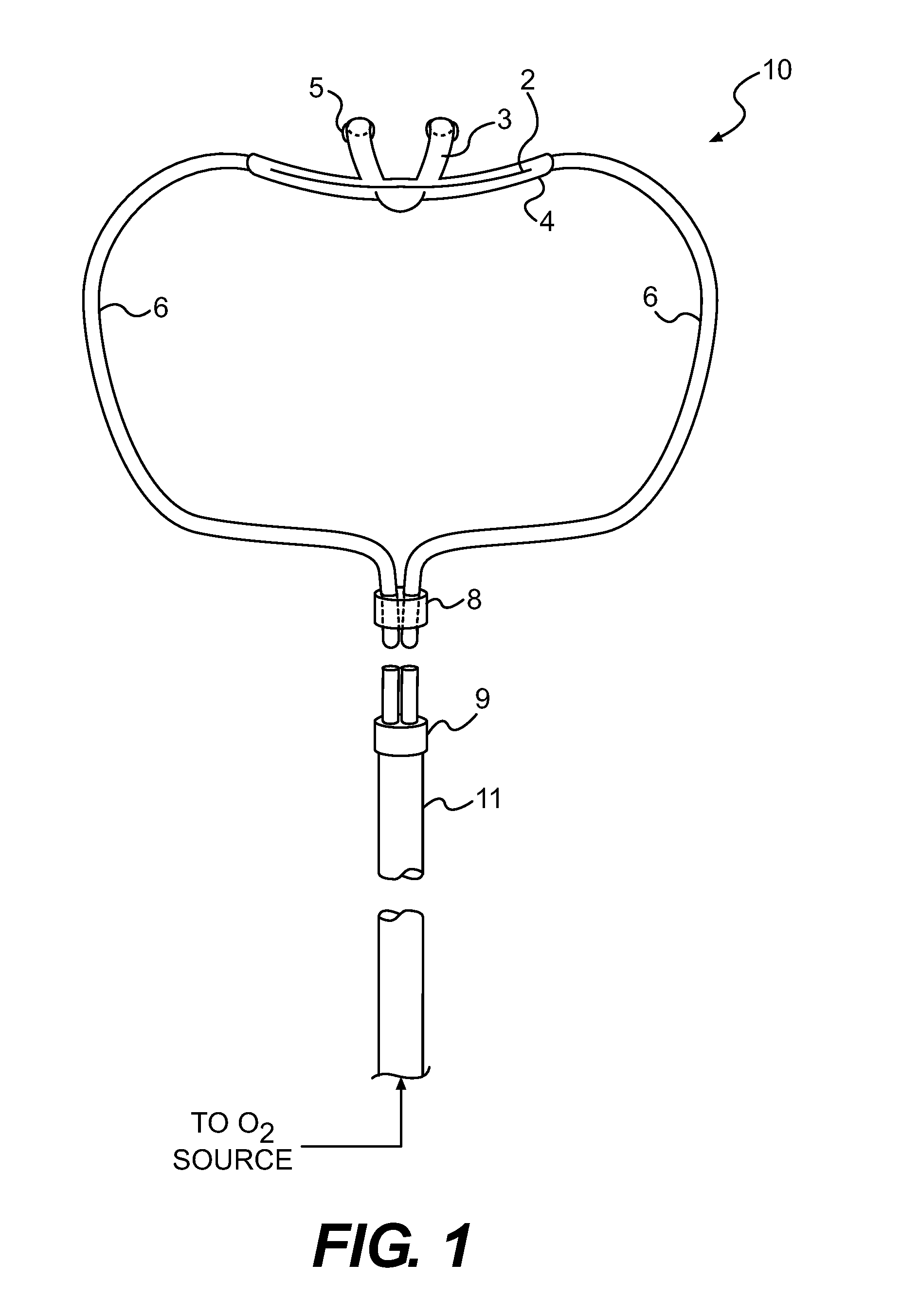

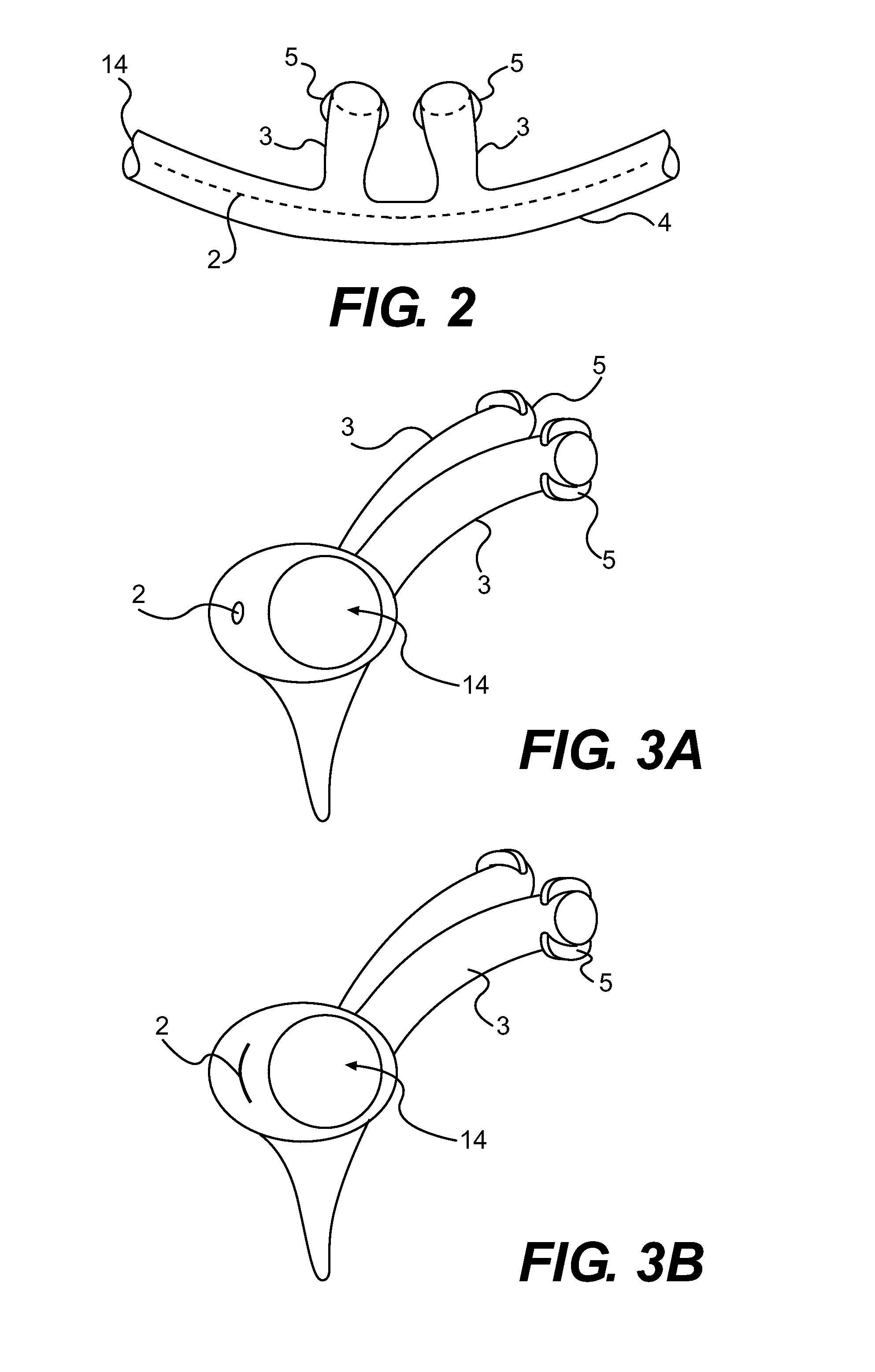

Nasal Cannula Assembly

An embodiment of the present invention is a nasal cannula for delivering continuous positive airway pressure (“CPAP”) to a patient's nares during operative procedures or in critical care areas. A malleable metal or plastic is encased in the bridge of the cannula to allow it to be shaped to the patient's face. As a result of contouring the cannula to the face, air leaks are minimized allowing a seal to be provided when an op site is applied to cover the upper lip, nasal cannula and nose. The cannula's nasal inserts can end in nontapered or slightly tapered non-sealing beads, which may be slightly angled out to accommodate various facial anatomies. When approximately several liters per minute of oxygen are flowed through the cannula, CPAP is obtained.

Owner:JEMI AIRWAY MANAGEMENT

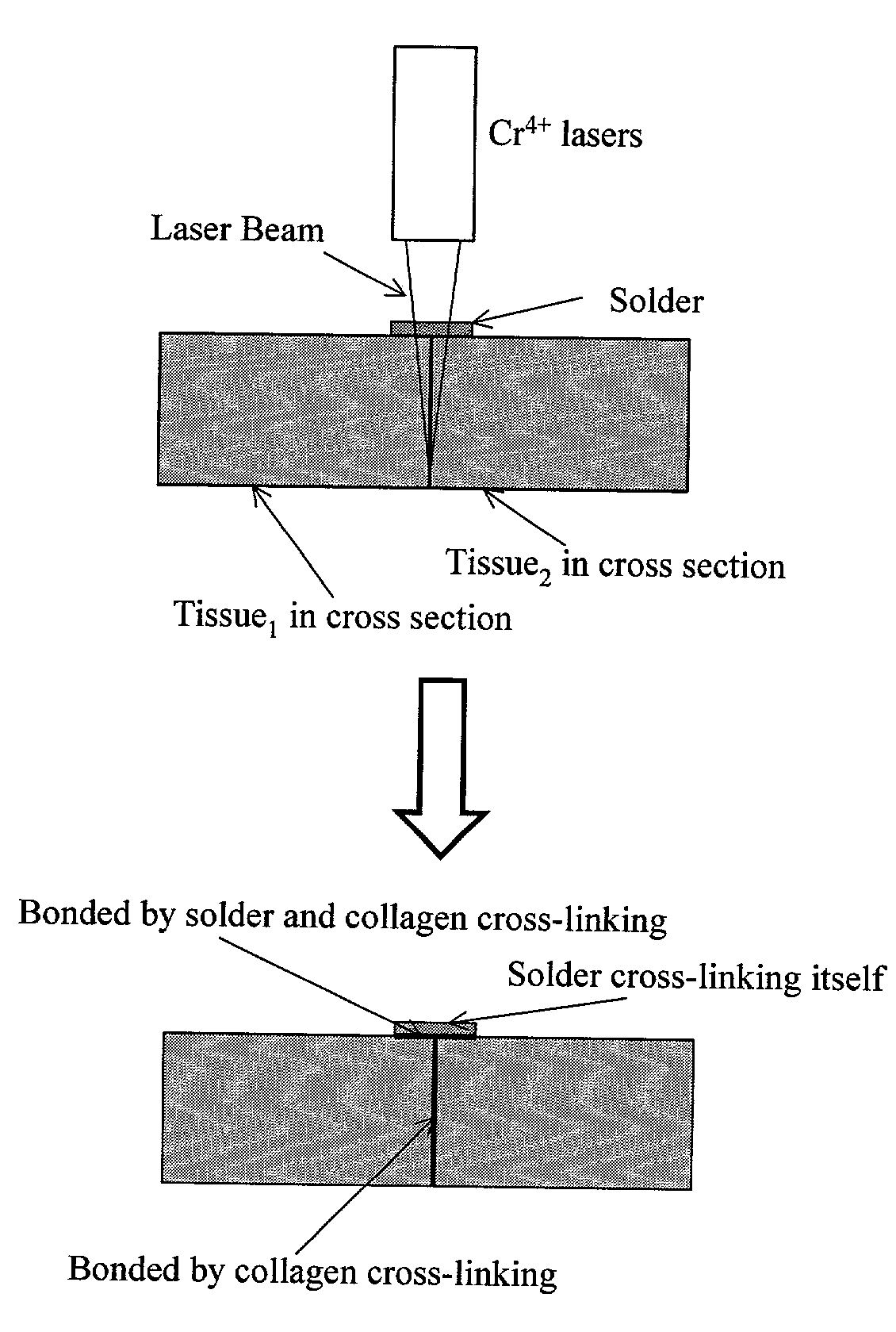

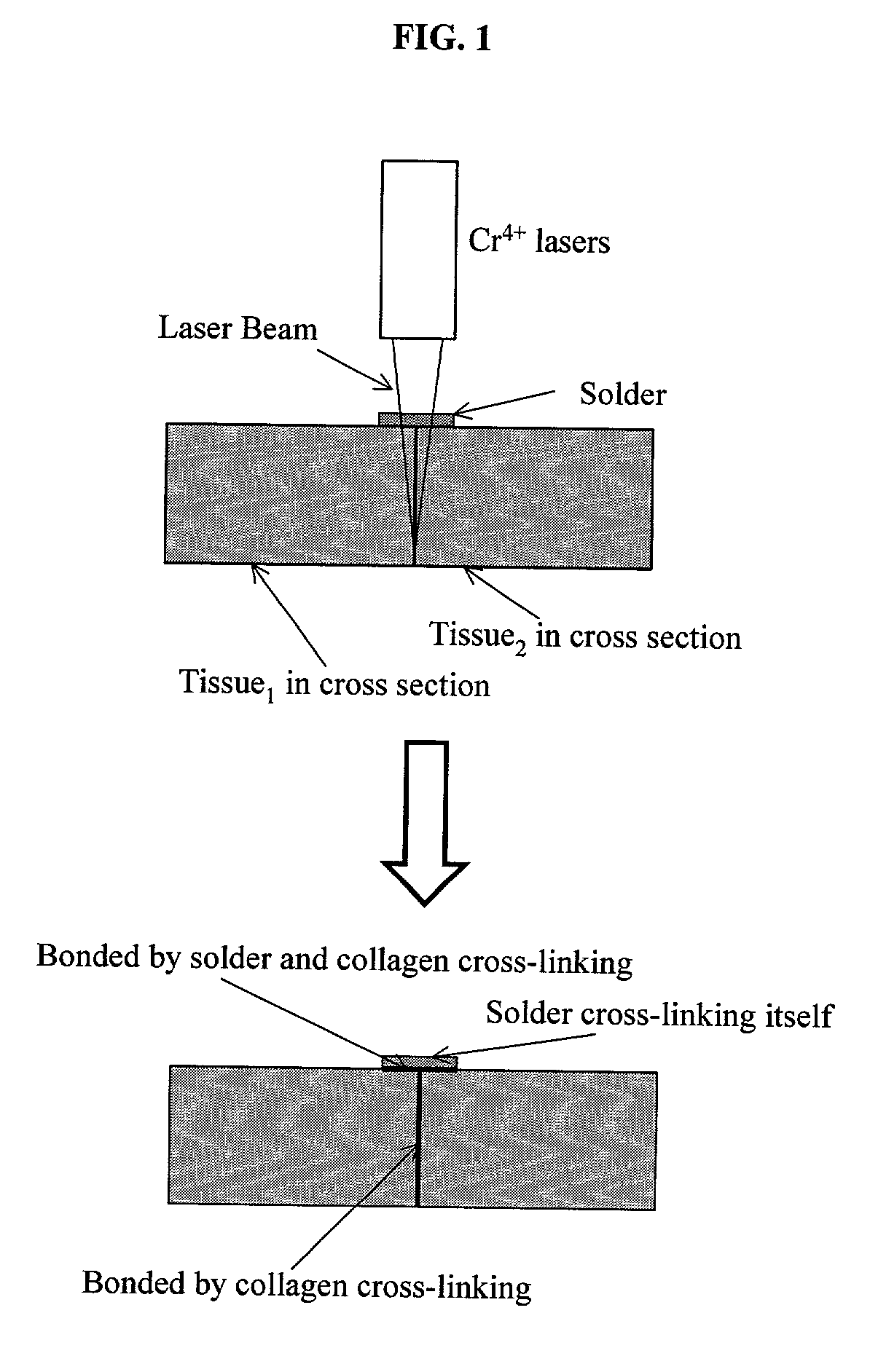

Gelatin based on Power-gel(TM) as solders for Cr4+laser tissue welding and sealing of lung air leak and fistulas in organs

InactiveUS7033348B2Enhancement in post-procedure effectivenessImprove welding strengthDiagnosticsSurgical instrument detailsEngineeringWeld strength

Laser tissue welding can be achieved using tunable Cr4+ lasers, semiconductor lasers and fiber lasers, where the weld strength follows the absorption spectrum of water. The use of gelatin and esterified gelatin as solders in conjunction with laser inducted tissue welding impart much stronger tensile and torque strengths than albumin solders. Selected NIR wavelength from the above lasers can improve welding and avoid thermal injury to tissue when used alone or with gelatin and esterified gelatin solders. These discoveries can be used to enhance laser tissue welding of tissues such as skin, mucous, bone, blood vessel, nerve, brain, liver, pancreas, spleen, kidney, lung, bronchus, respiratory track, urinary tract, gastrointestinal tract, or gynecologic tract and as a sealant for pulmonary air leaks and fistulas such as intestinal, rectal and urinary fistulas.

Owner:RES FOUND OF THE CITY UNIV OF NY THE

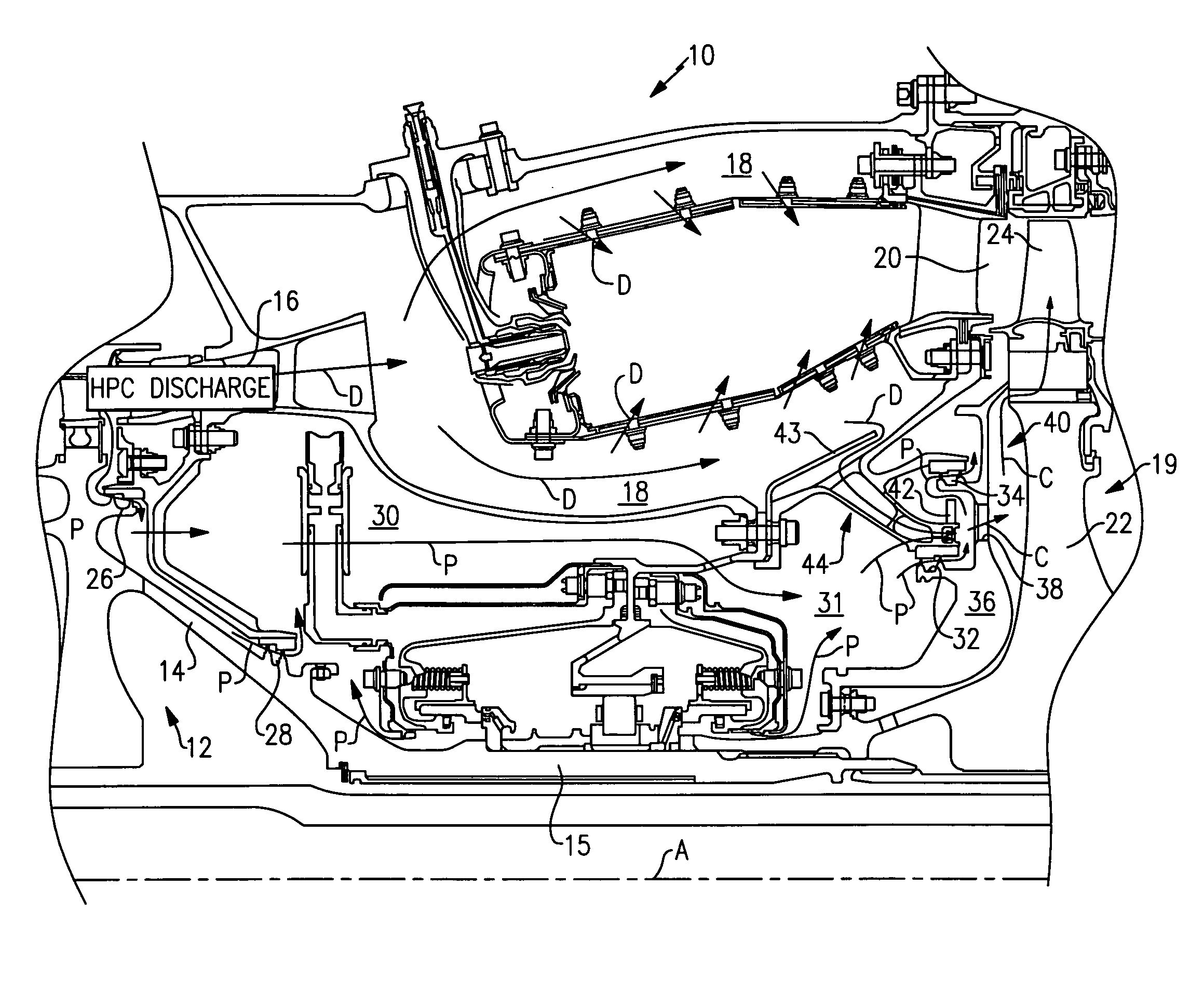

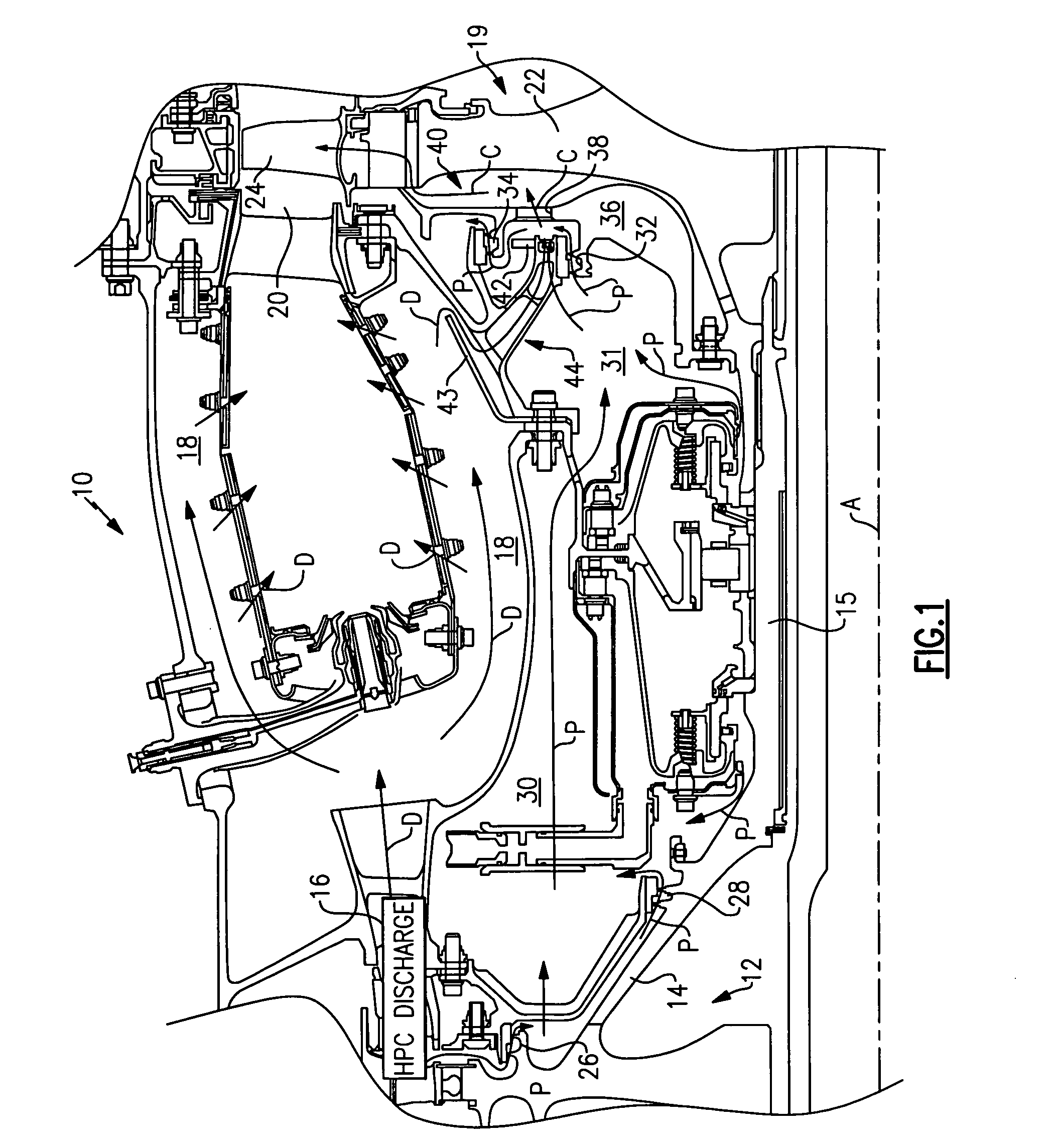

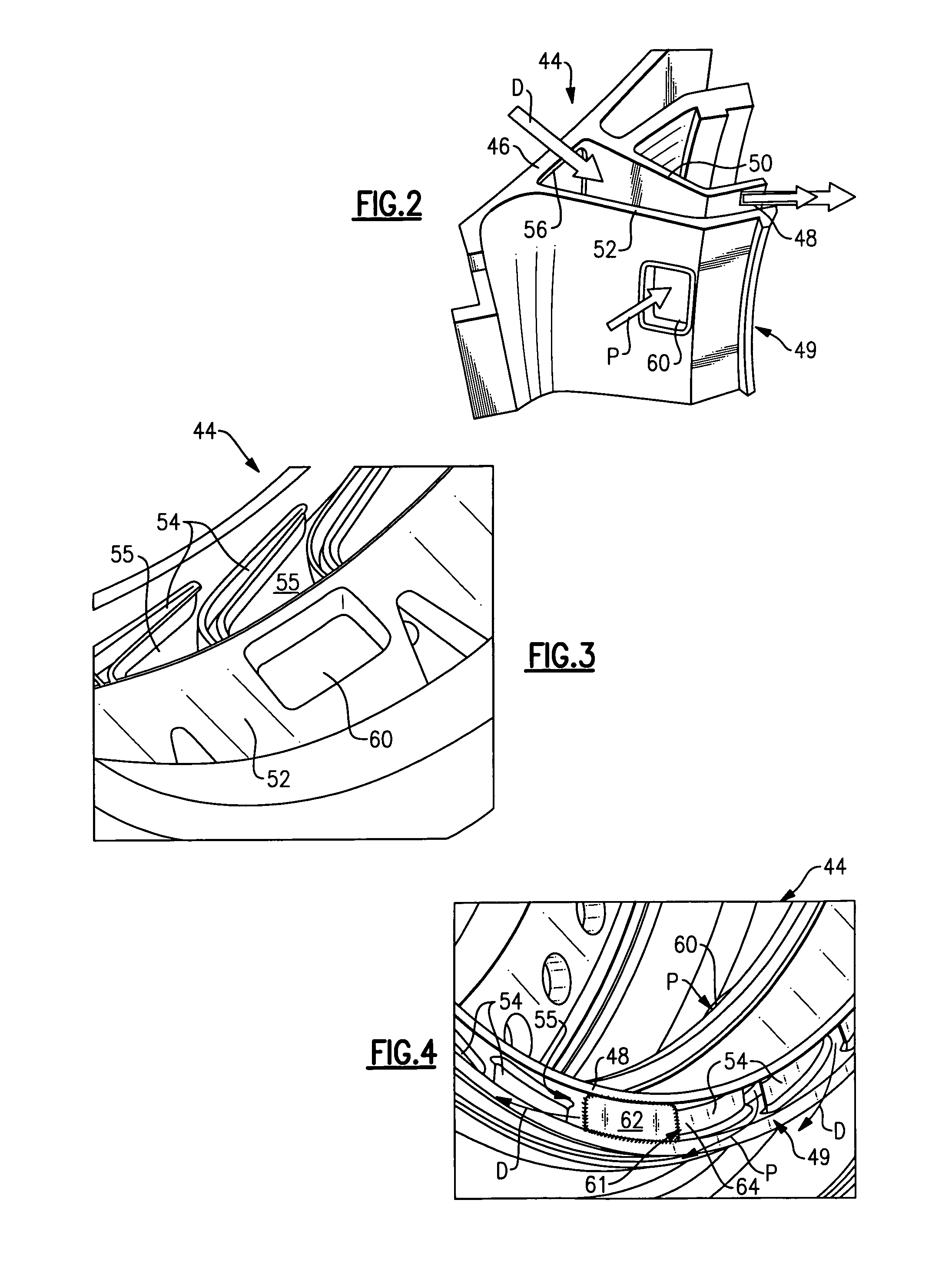

Preswirl pollution air handling with tangential on-board injector for turbine rotor cooling

InactiveUS20080041064A1Reduce the impactMinimizes decrease in velocityEngine fuctionsBlade accessoriesOn boardPollution

A gas turbine engine includes a turbine rotor and a compressor, which provides discharge air. A nozzle, typically referred to a tangential on-board injector (TOBI), is arranged near the rotor to deliver the discharge air near the turbine rotor for cooling it. The TOBI receives pollution air leaking past seals within the gas turbine engine. The TOBI swirls the discharge air and the pollution air before it reaches the turbine rotor. The TOBI provides multiple passages separated by vanes. At least some of the passages include discharge inlets and outlets for carrying the discharge air from the compressor to the turbine rotor. Typically, several of the passages are unused and blocked. However, the example arrangement provides a pollution inlet and outlet in at least one of the normally unused, blocked passages. The pollution air flowing through its passage in the TOBI is swirled so that the pollution air that intermingles with the swirled discharge air, while minimizing the reduction in velocity of the discharge air that is used to cool the turbine rotor.

Owner:UNITED TECH CORP

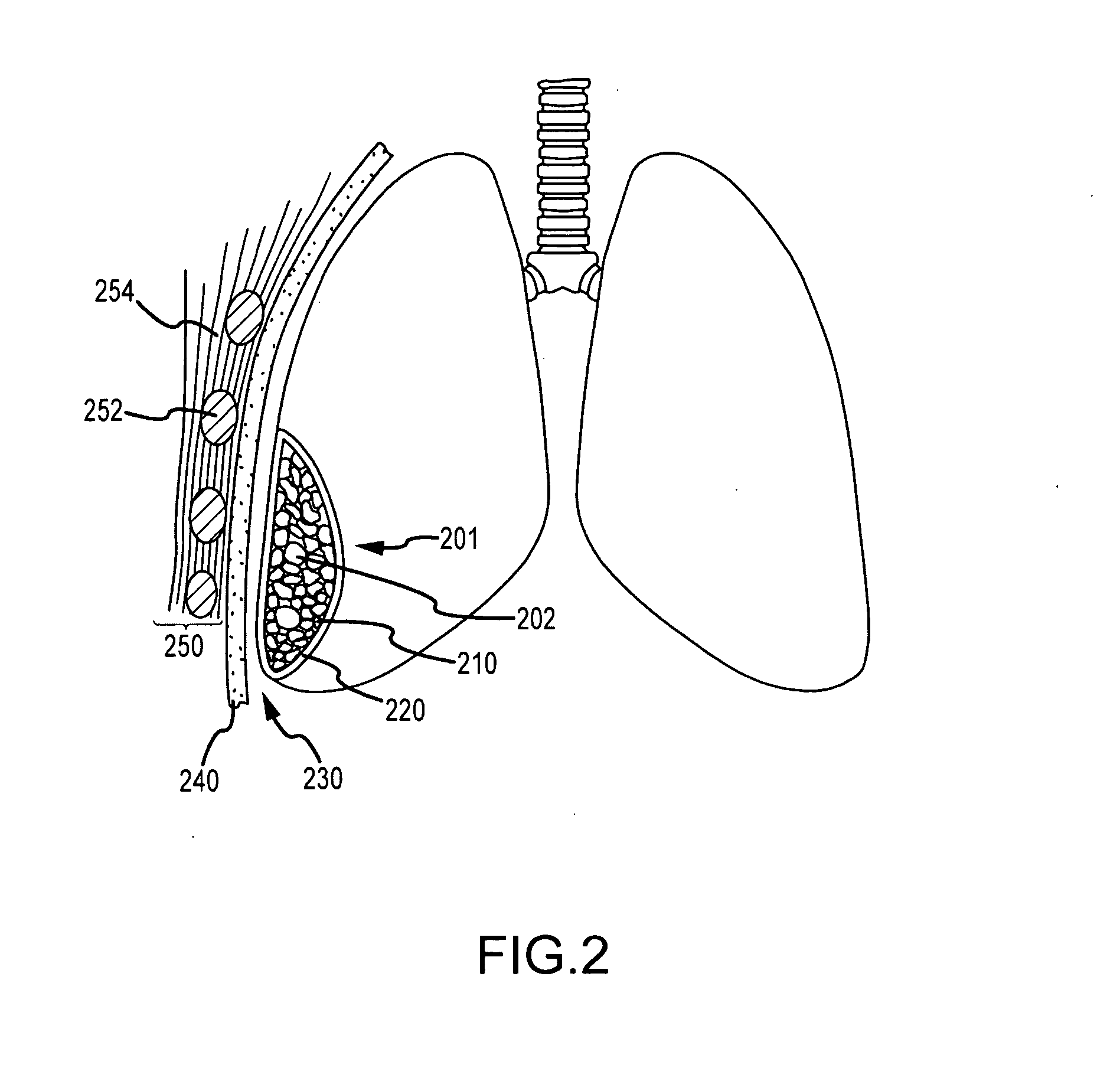

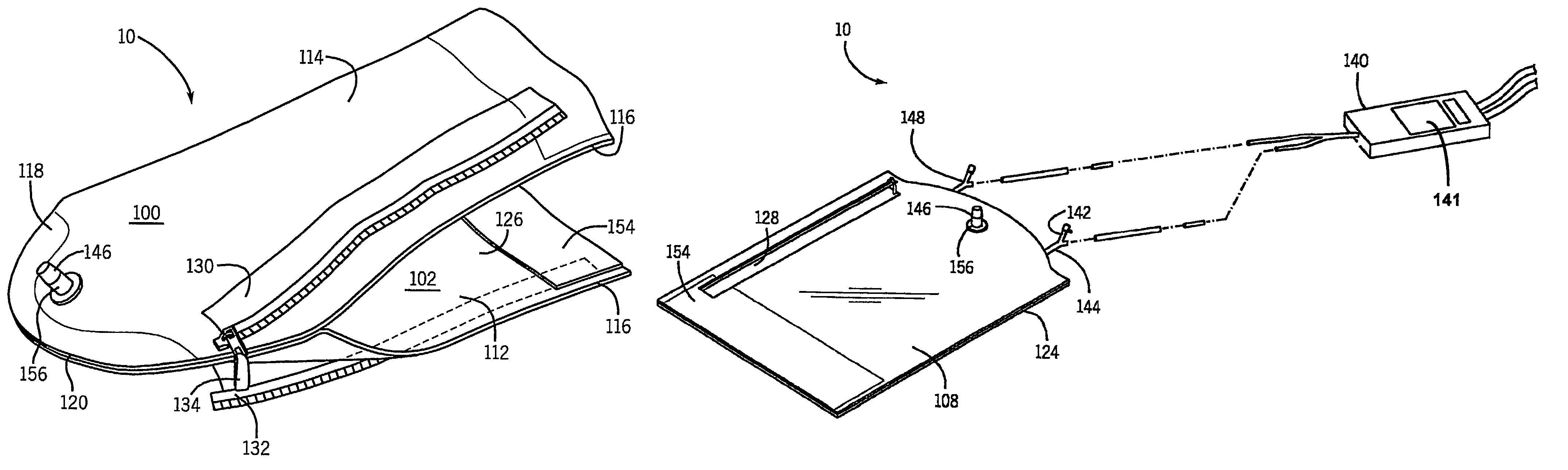

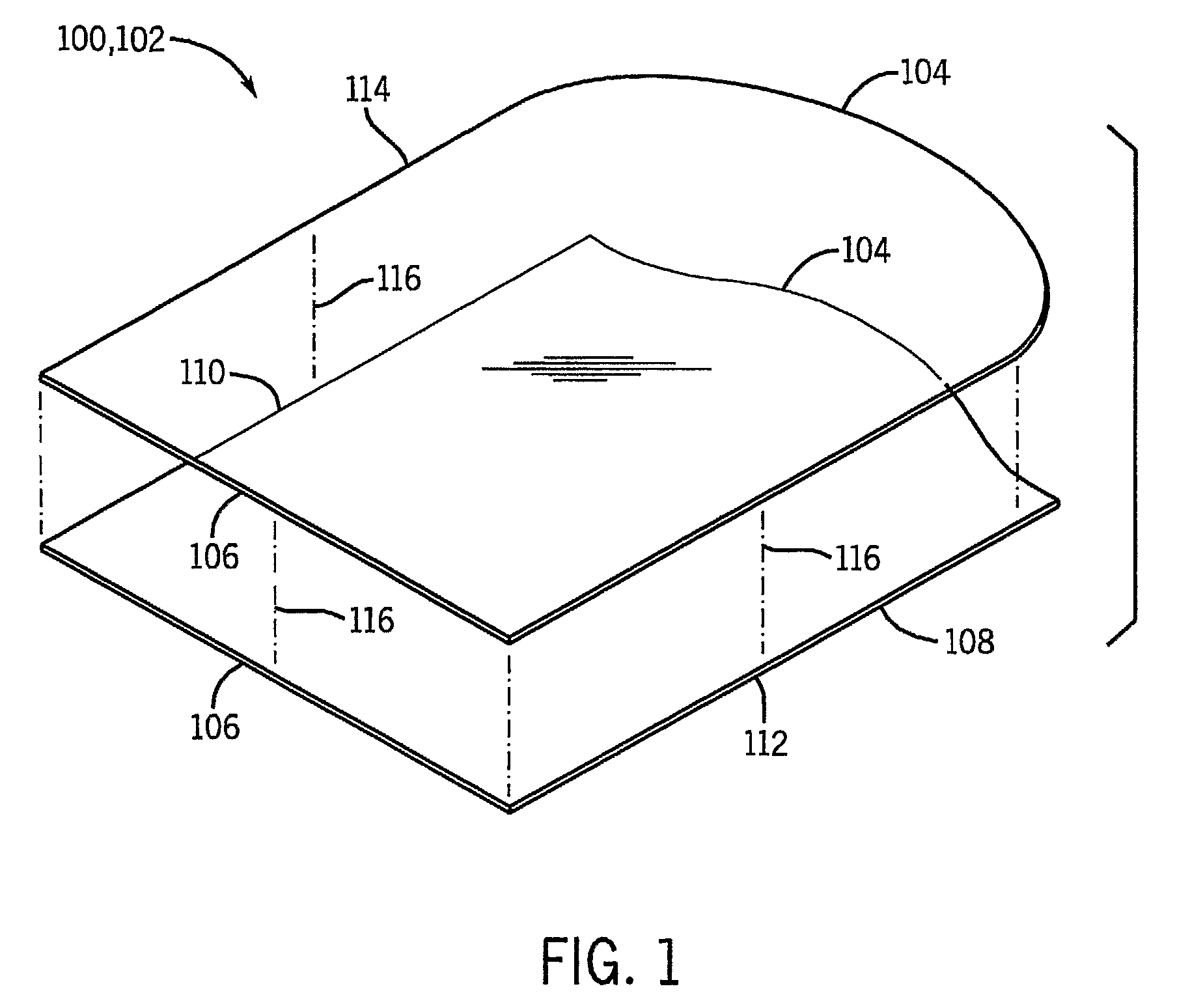

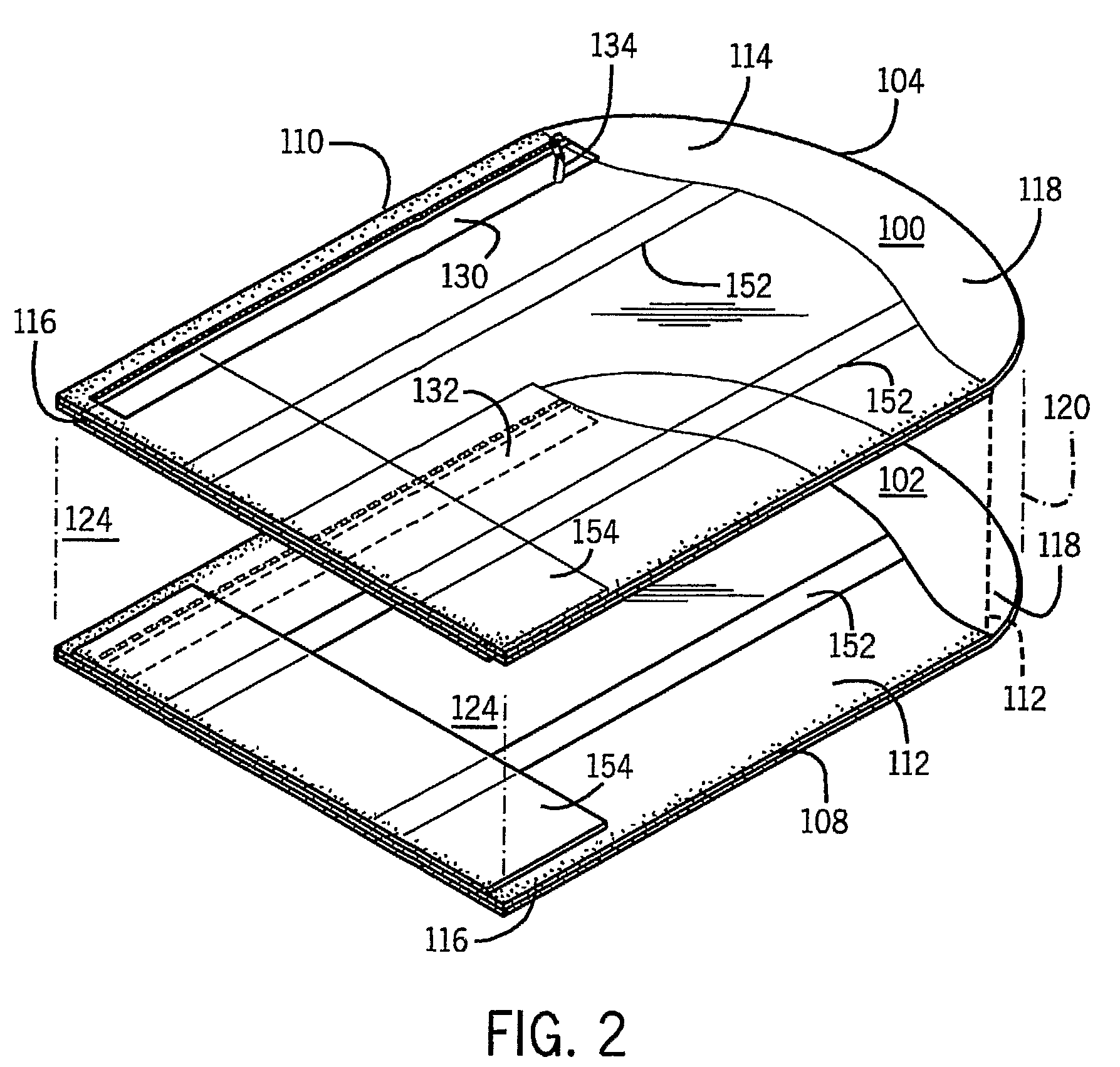

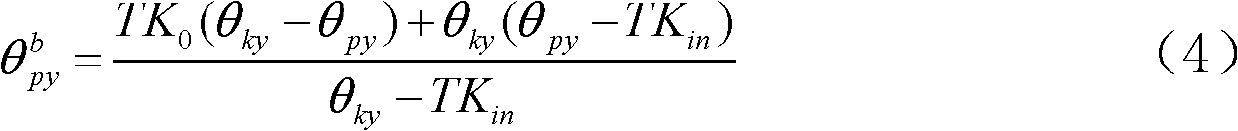

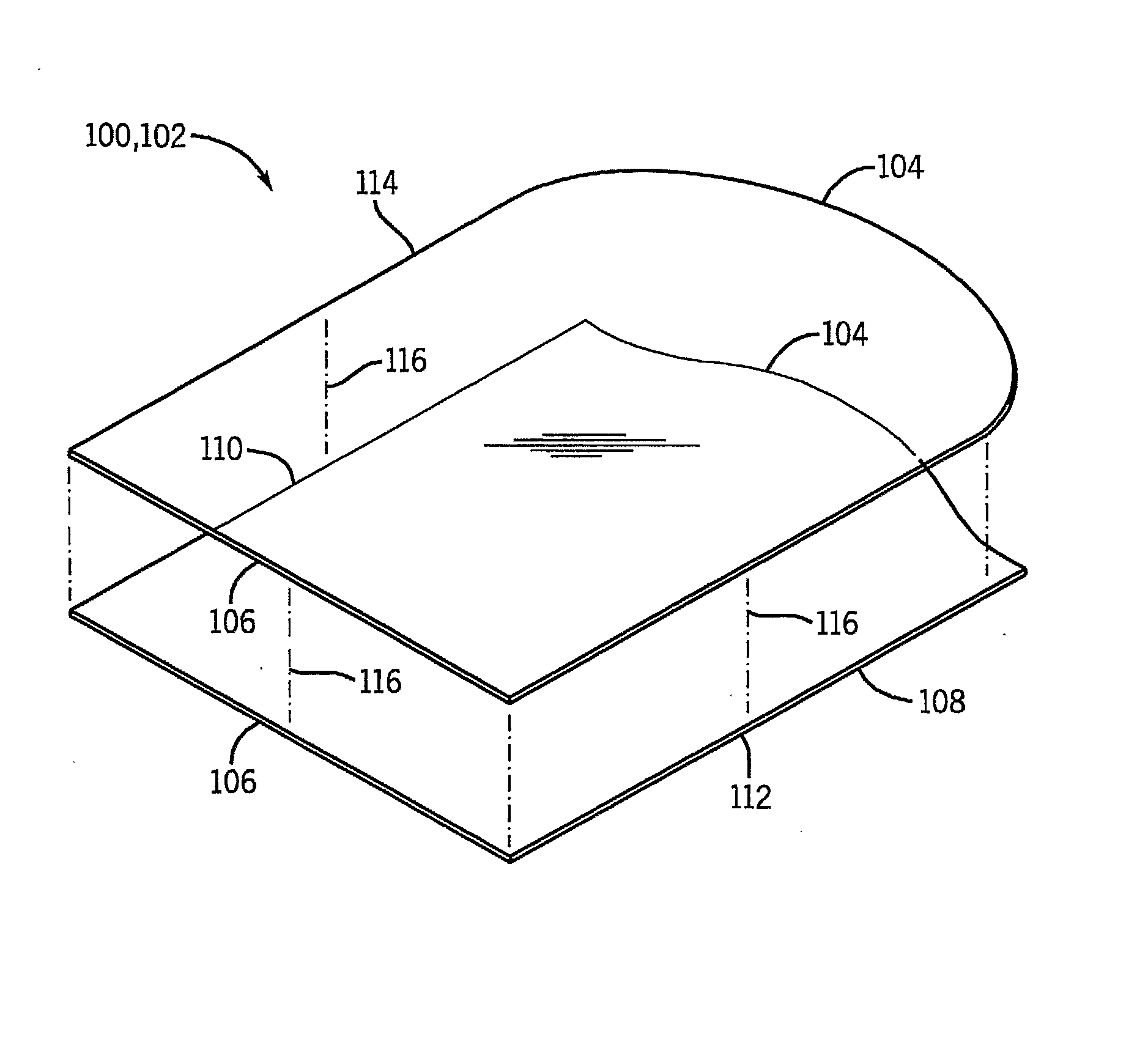

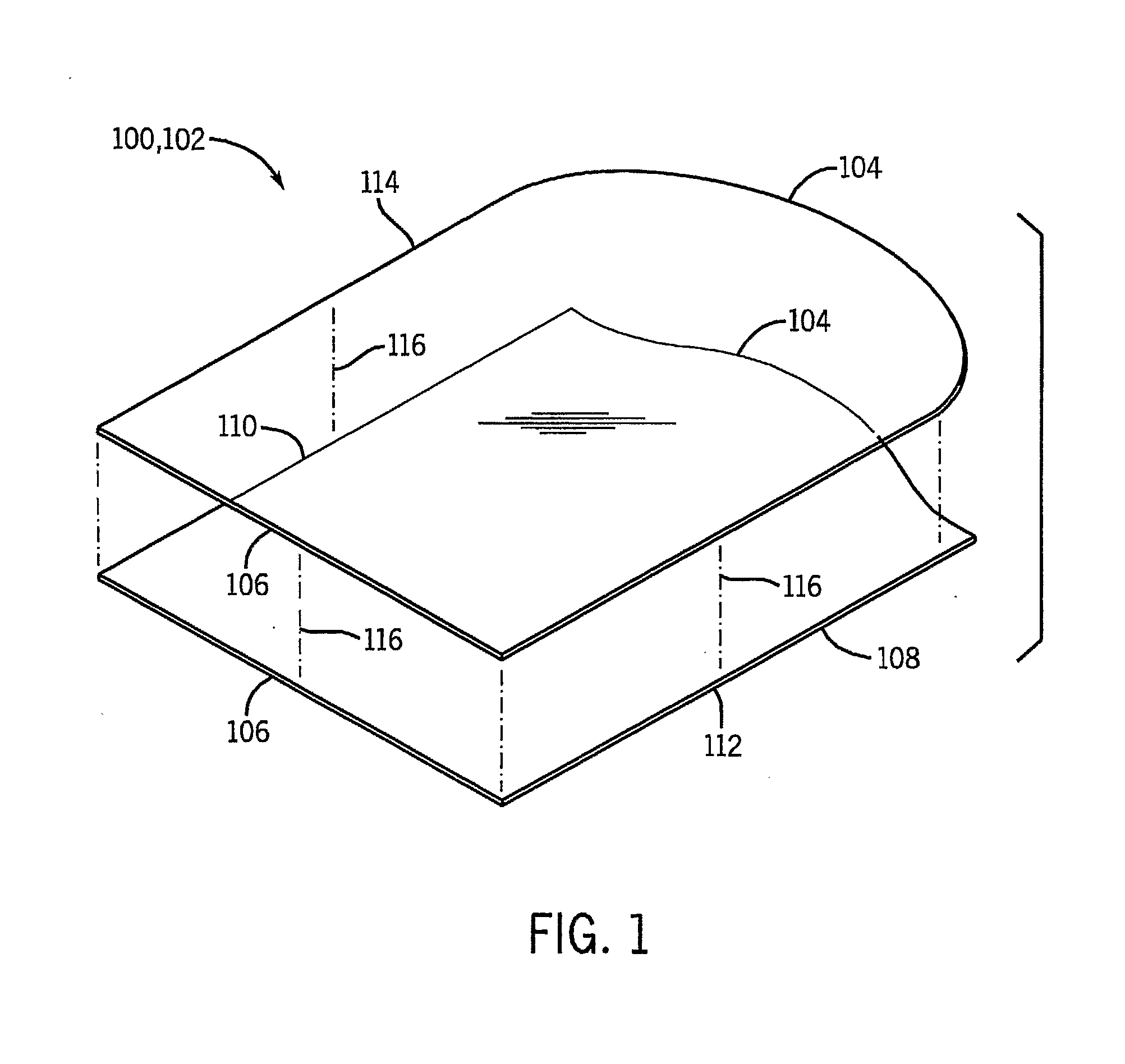

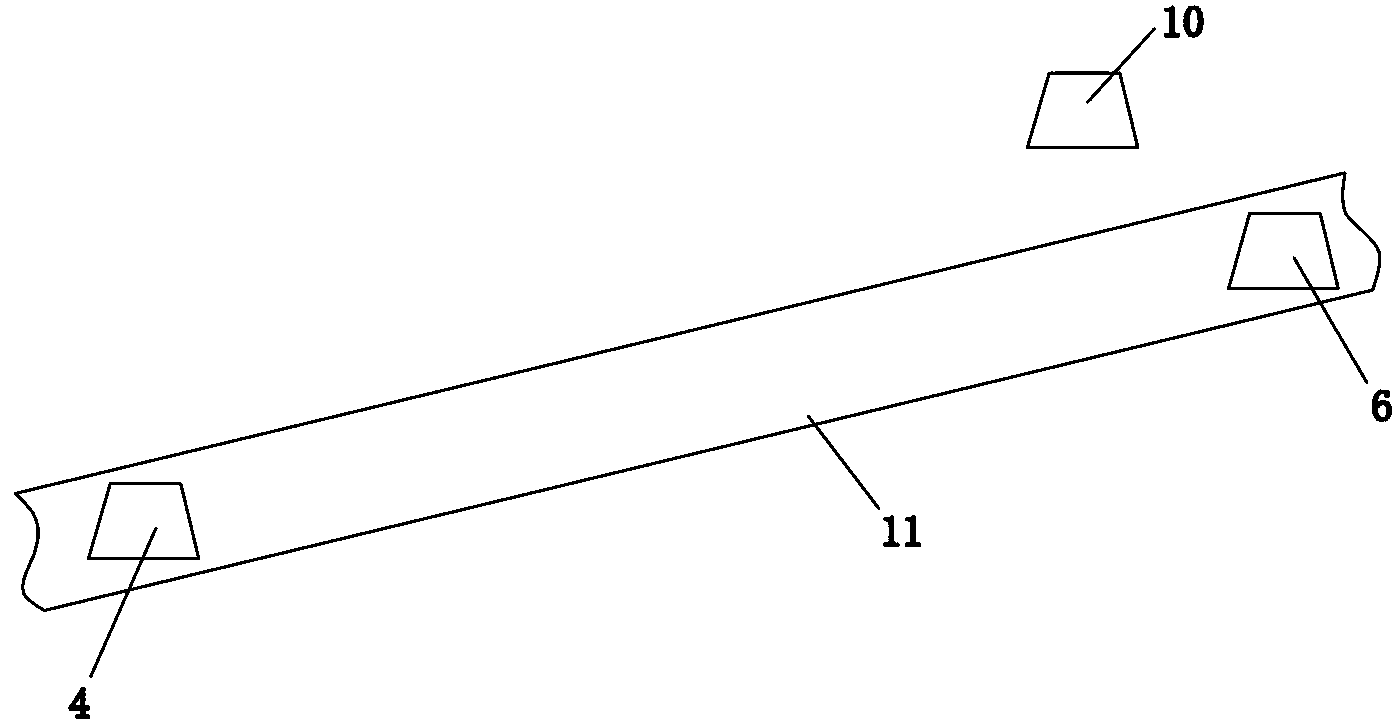

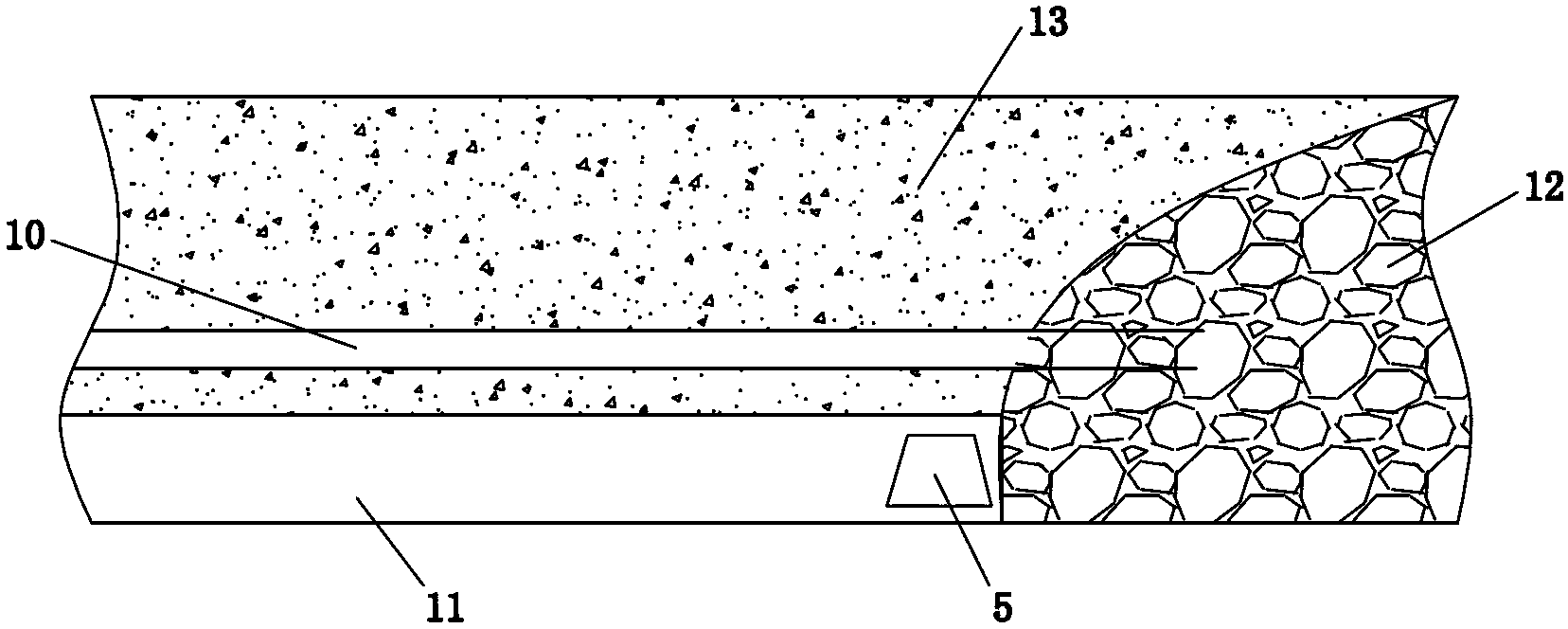

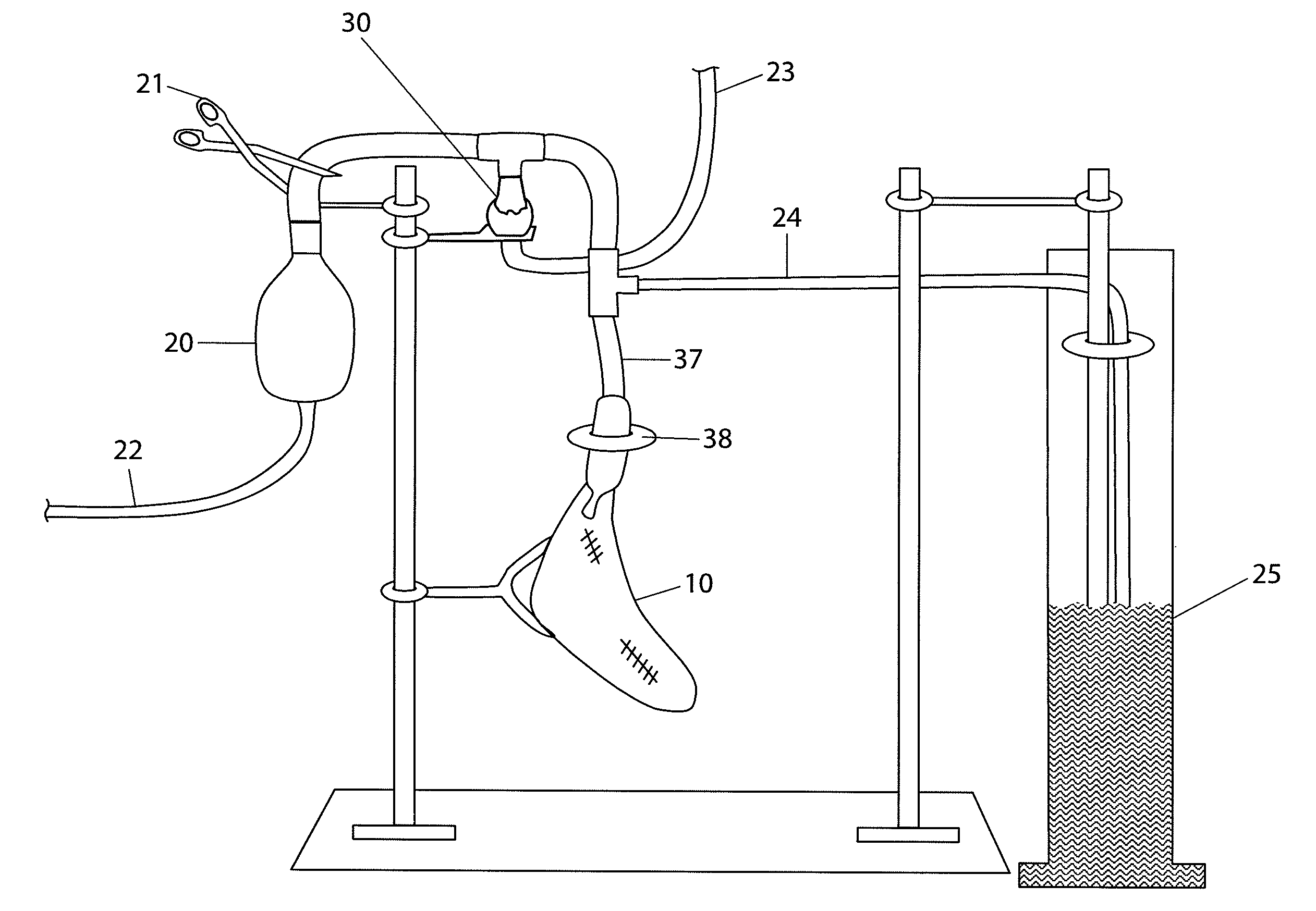

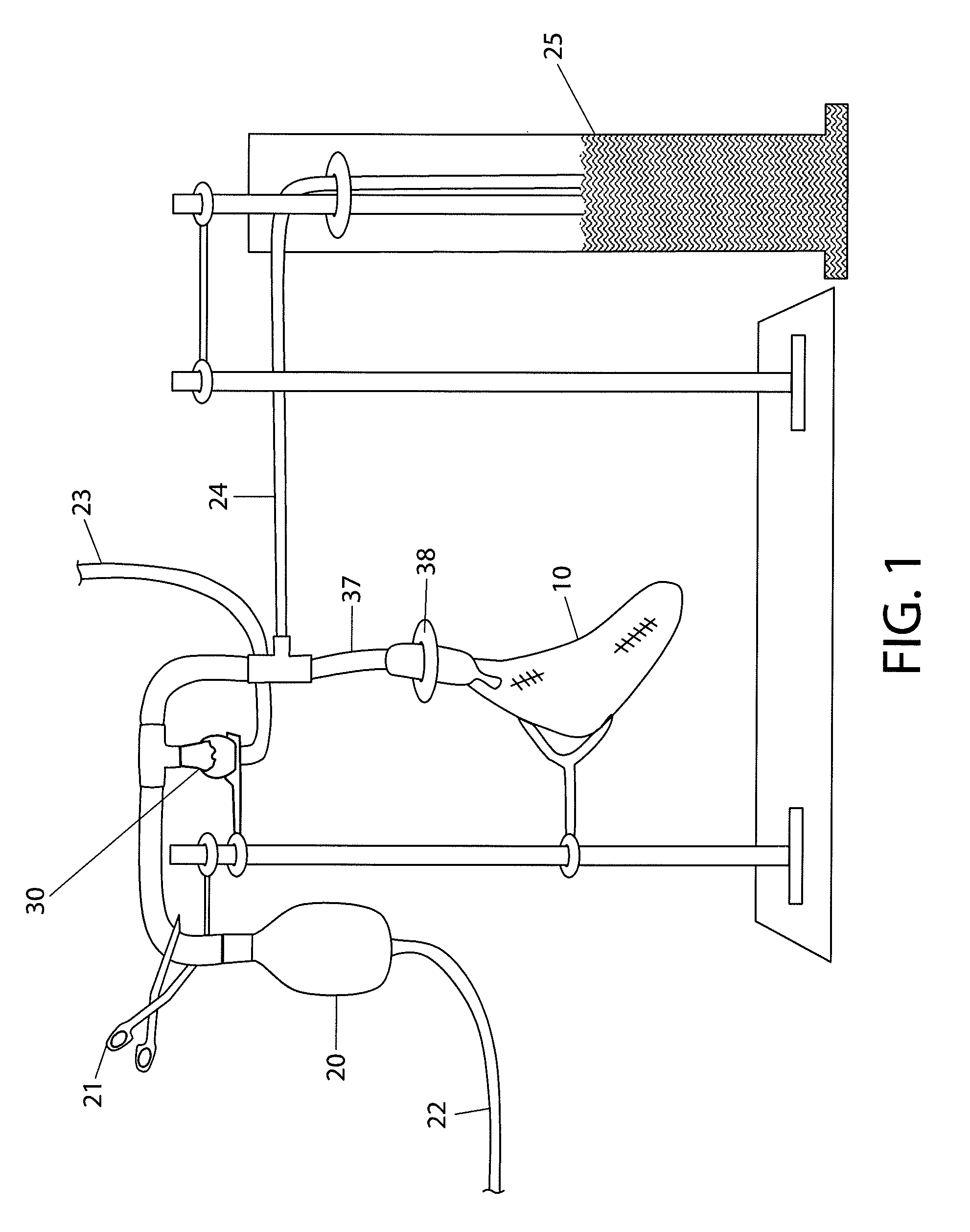

Inflatable compression dressing

InactiveUS7935066B2Promote healingReduce swellingSurgical needlesPlastersVisual inspectionAtmospheric pressure

An improved inflatable compression dressing (10) for use in controlling swelling and promoting healing to wounds subsequent to surgery while allowing visual inspection of the wound during healing is provided. The dressing comprises a bladder (138) formed by an outer wall (114) secured to an inner wall (112) to define an elongated, cup-shaped cavity for receiving an appendage (136); an air supply delivering air to the bladder; and a sensor monitoring air pressure within the bladder and indicating said air pressure to an air pressure control (140). The air pressure control provides air to the bladder at a rate which substantially matches air leaked from the bladder. Thus, the air supply inflates the bladder so as to provide uniform air pressure to the appendage, wherein the appendage is an arm or a leg.

Owner:MAYO FOUND FOR MEDICAL EDUCATION & RES

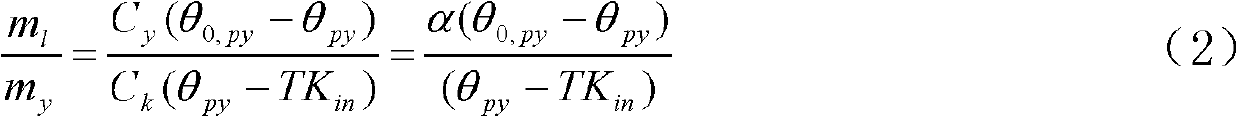

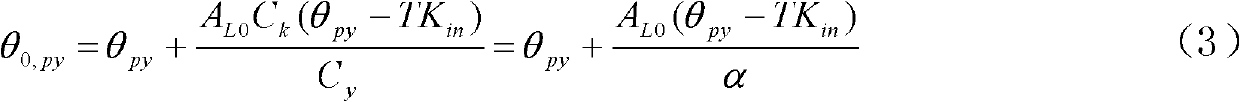

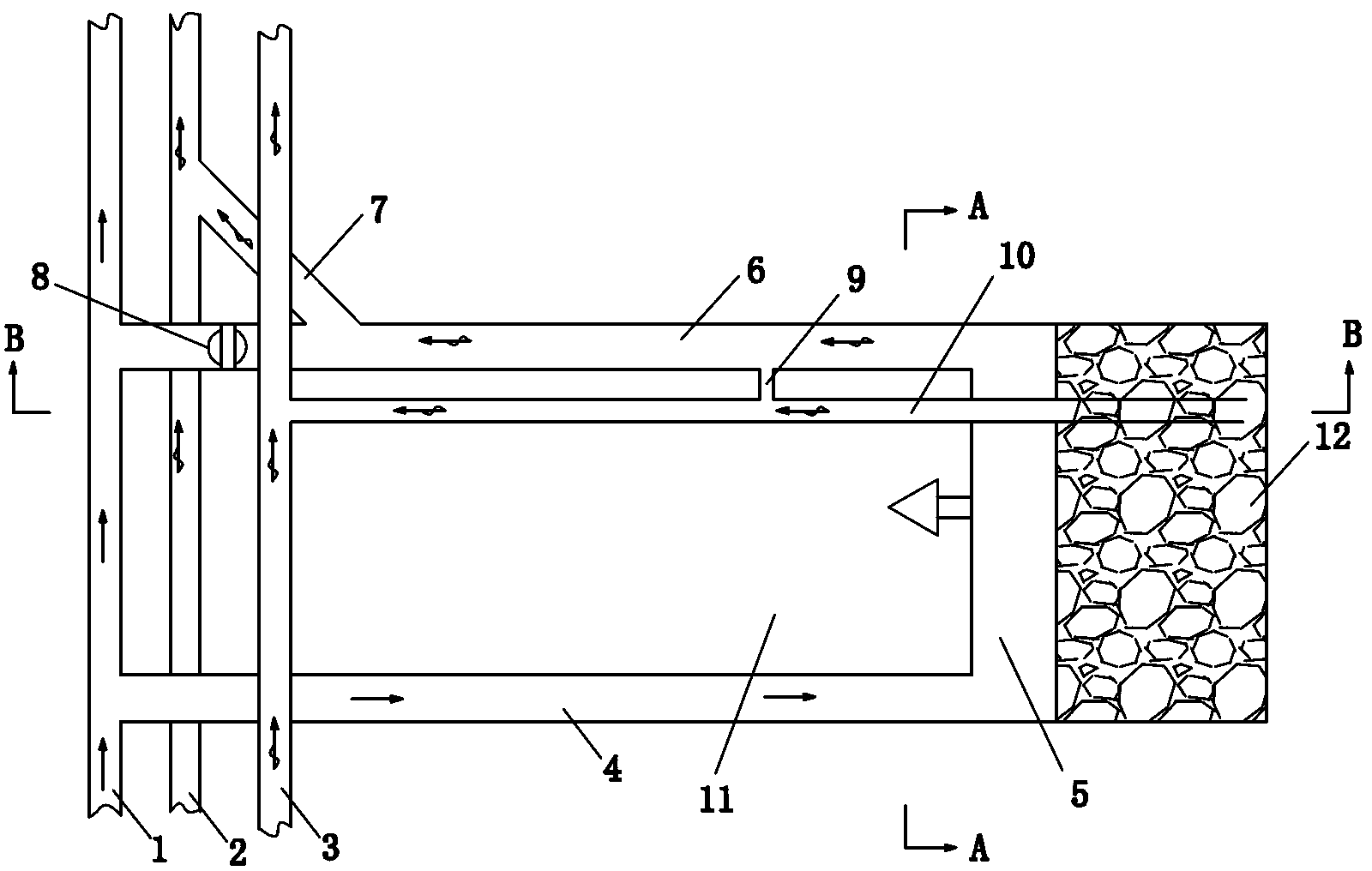

Method for testing air leak rate of air preheater

ActiveCN102213708AConvenient operation monitoringEasy to implementMaterial analysisAir preheaterEngineering

The invention relates to a method for testing the air leak rate of an air preheater, which is easy to implement, accurate and reliable and is suitable for analyzing and testing the air preheater. The accuracy of temperature measurement can reach 0.1 DEG C, the smoke venting temperature is within the range of between 100 and 200 DEG C approximately, and when a boiler runs stably, the smoke venting temperature is constant basically, so the relative accuracy of the temperature measurement is higher than the analytic accuracy of the oxygen content of smoke. Therefore the air leak rate, which is calculated according to the change of the smoke venting temperature, of the air preheater has the higher test accuracy. The method comprises the following steps of: 1) measuring the smoke venting temperature theta py of the air preheater and the temperature TKin of air entering the air preheater; and 2) utilizing a formula, namely when the change of the air leak rate is needed to be monitored due to the change of the air leak rate with the change of the running condition or equipment condition of the air preheater, measuring the air temperature TKin and the smoke venting temperature thetapy in the running state, which corresponds to the temperature thetapy, of the boiler, and calculating the air leak rate AL by the formula.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

Inflatable Compression Dressing

InactiveUS20080234616A1Control swellingReduce swellingSurgical needlesPlastersVisual inspectionAtmospheric pressure

The present invention provides an improved inflatable compression dressing (10) for use in controlling swelling and promoting healing to wounds subsequent to surgery while allowing visual inspection of the wound during healing. The dressing comprises a bladder (138) formed by an outer wall (114) secured to an inner wall (112) to define an elongated, cup-shaped cavity for receiving an appendage (136); an air supply delivering air to the bladder; and a sensor monitoring air pressure within the bladder and indicating said air pressure to an air pressure control (140). The air pressure control provides air to the bladder at a rate which substantially matches air leaked from the bladder. Thus, the air supply inflates the bladder so as to provide uniform air pressure to the appendage, wherein the appendage is an arm or a leg.

Owner:MAYO FOUND FOR MEDICAL EDUCATION & RES

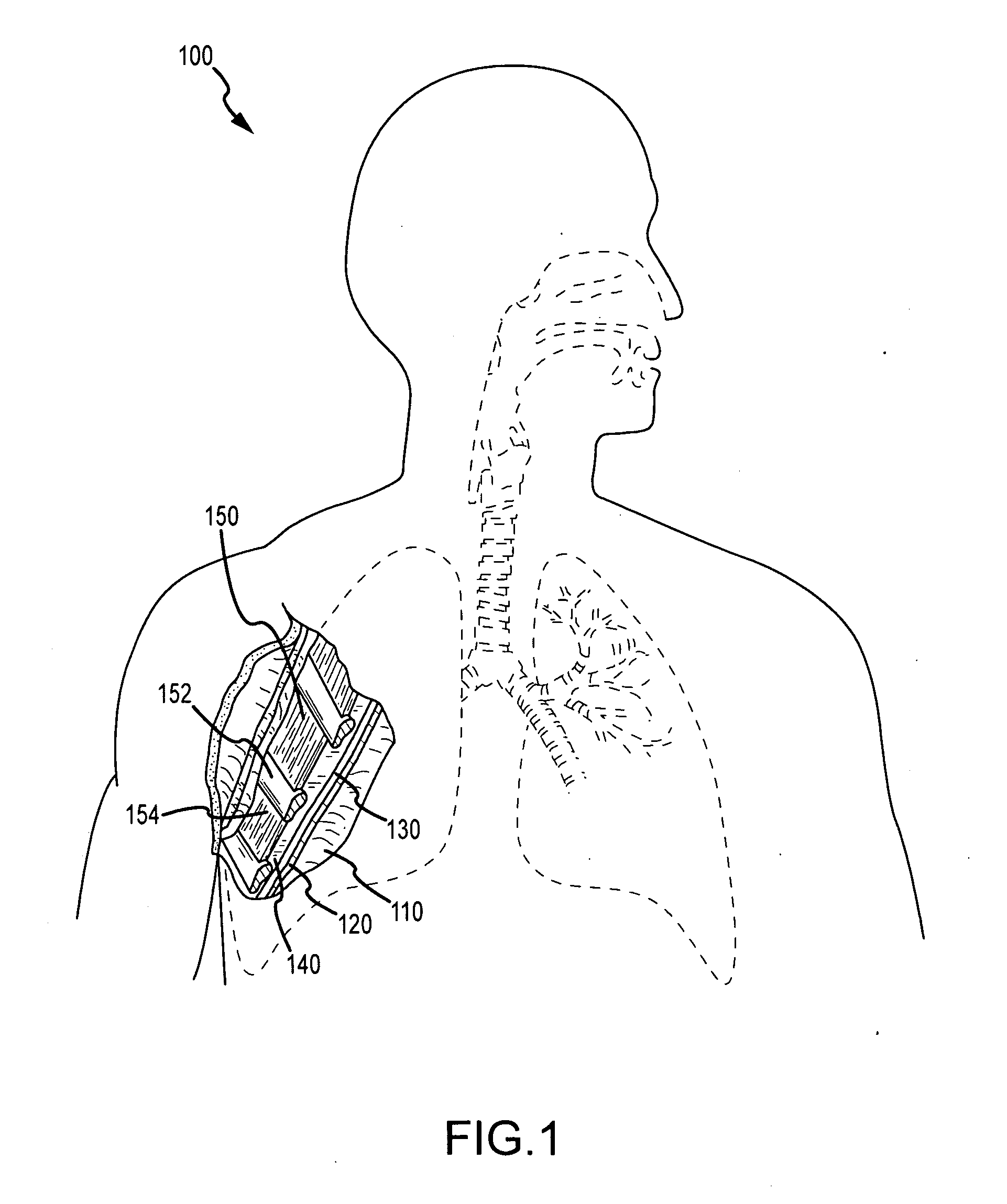

System and method for detection and repair of pulmonary air leaks

A method for repairing pulmonary air leaks in a lung residing in a chest cavity and having an intake air stream and an outer surface is disclosed. An exemplary method comprises: introducing a first component of a biphasic sealant component as a liquid into the intake air stream of the damaged lung; ensuring that there is a pressure differential between the intake air stream and the outer surface of the lung; and introducing a second component of a biphasic sealant component into the chest cavity. The first sealant component collects at the air leak site and forms a sealant in combination with the second sealant component.

Owner:FRIEDBERG JOSEPH S

Face mask and air leak real-time detection method

InactiveCN1919376AAvoid harmReal-time display of air leakageRespiratory device testingBreathing masksEngineeringInstrumentation

The invention discloses a face mask and leakage detecting method of face mask, which contains lid, wherein the mask possesses head coil or ear coil, which contains at least one fixed or replaced filtering device, the mask is composed of inner mask and transparent periphery around the inner mask, the filtering device is placed on the inner mask, the transparent periphery attaches the user face, which forms sealing edge with entire mask, the fine frosted pit is formed on the inner side of transparent peripheral back with external side as smooth surface or the back possesses real-time variation displayed covering layer. The invention can display connecting degree between mask and face, which monitors leakage condition effectively.

Owner:朱桦

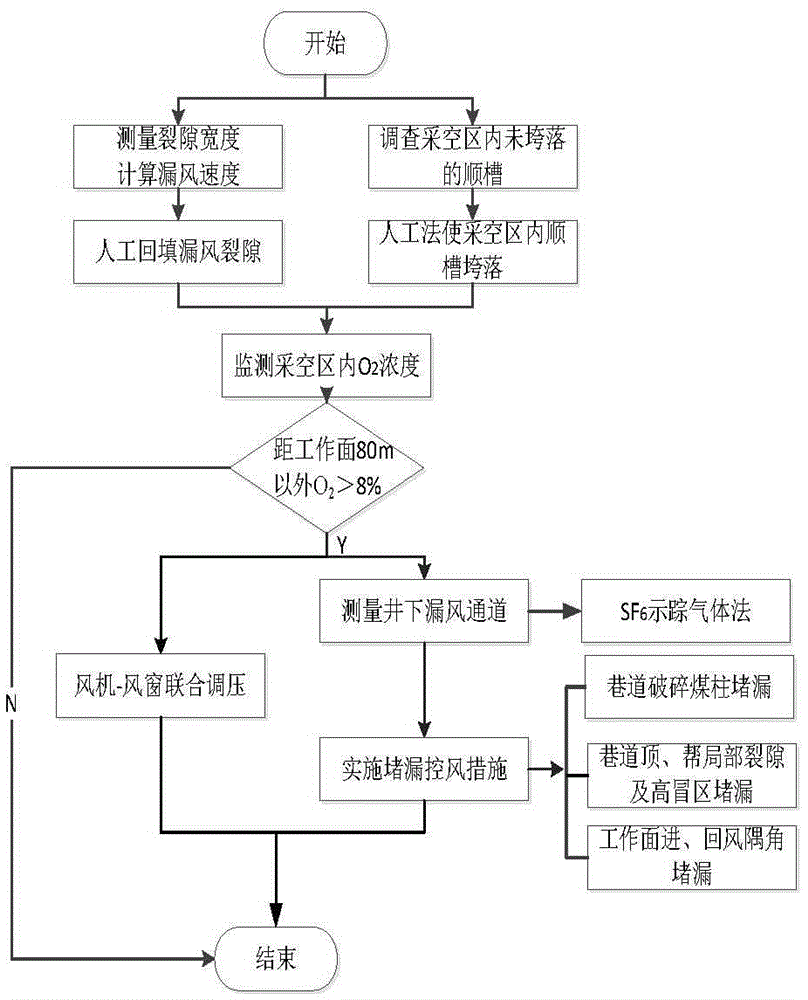

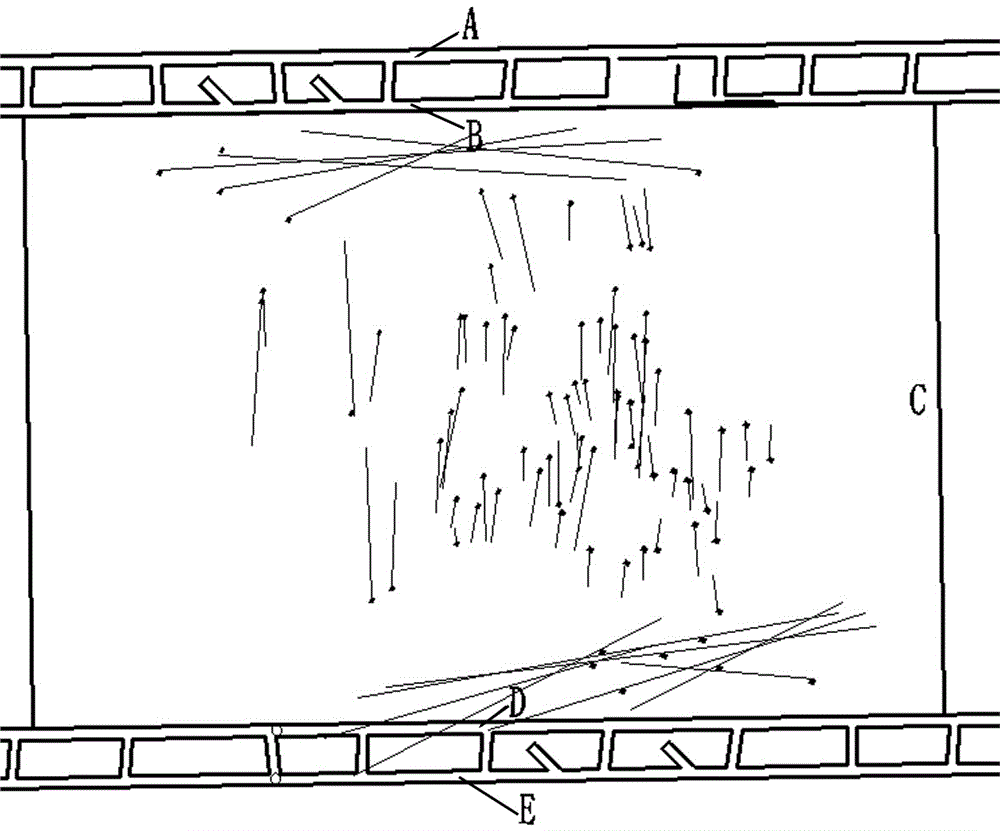

Method for controlling goaf air leakage in exploitation process of shallow buried close-range coal seam

InactiveCN106593523ASafe and Efficient MiningImprove reliabilityDetection of fluid at leakage pointFluid pressure control with auxillary non-electric powerCoal spontaneous combustionMonitoring system

The invention provides a method for controlling goaf air leakage in the exploitation process of a shallow buried close-range coal seam. The method mainly comprises technologies such as plugging of earth surface air leaking fractures and detecting and plugging of downhole air leaking channel, namely, first, the widths of earth surface mining-induced fractures are measured and the speed of fracture air leaking is calculated; the fractures with the widths and the air leaking air speeds being out of gauge are plugged, an air inlet roadway and an air outlet roadway which are difficult to cave by a roof in a goaf is caved by a manual way, and air leaking toward the goaf is reduced; next, a beam tube monitoring system is used for monitoring the concentration of O2 in the goaf, and whether air leaking exists or not in the goaf is judged according to the concentration of O2; then, a tracer gas method is used for detecting air leaking channels of downhole coal pillars, the air inlet roadway, the air outlet roadway and the like, and corresponding plugging measures are adopted; and at the time of plugging, a fan-air-window combined pressure regulating method is used for balancing air pressure of the goaf and a working face, goaf air leaking is reduced, and coal spontaneous combustion in the goaf is avoided.

Owner:CHINA UNIV OF MINING & TECH

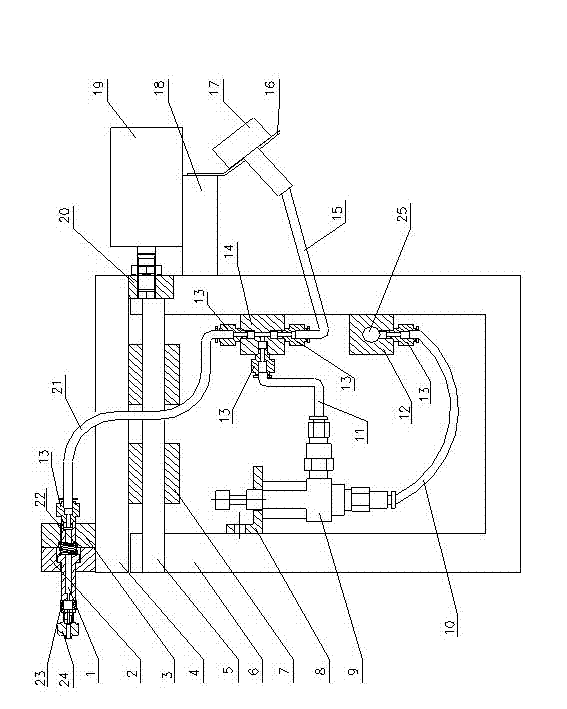

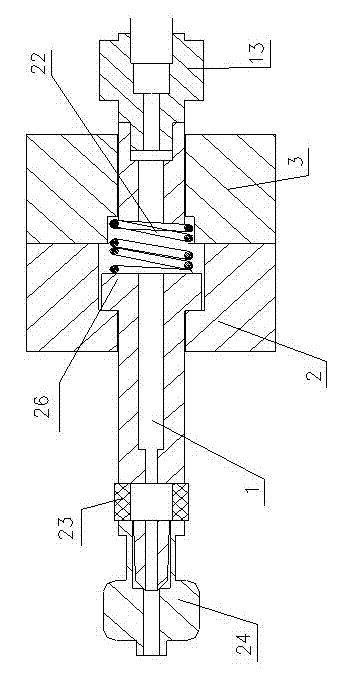

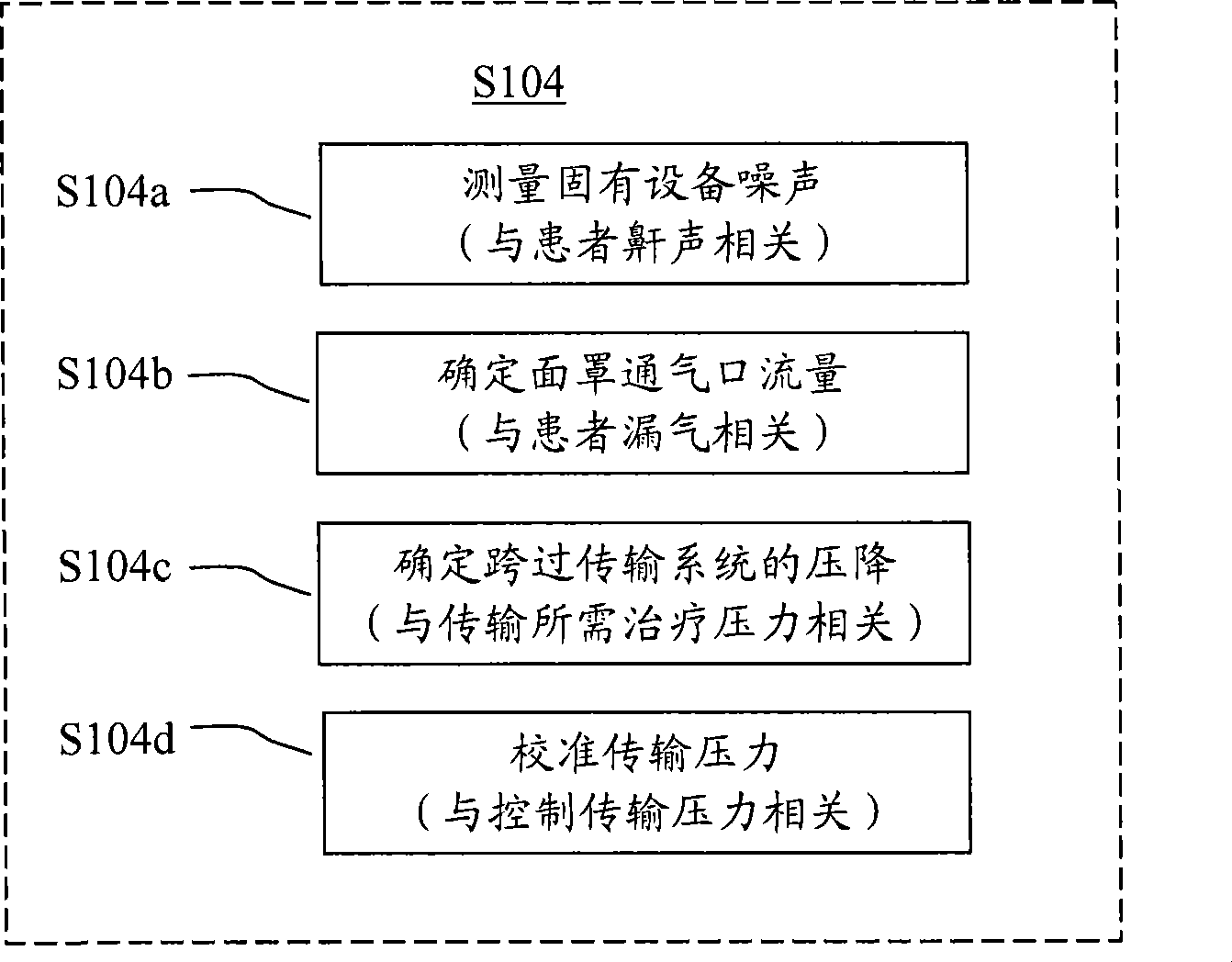

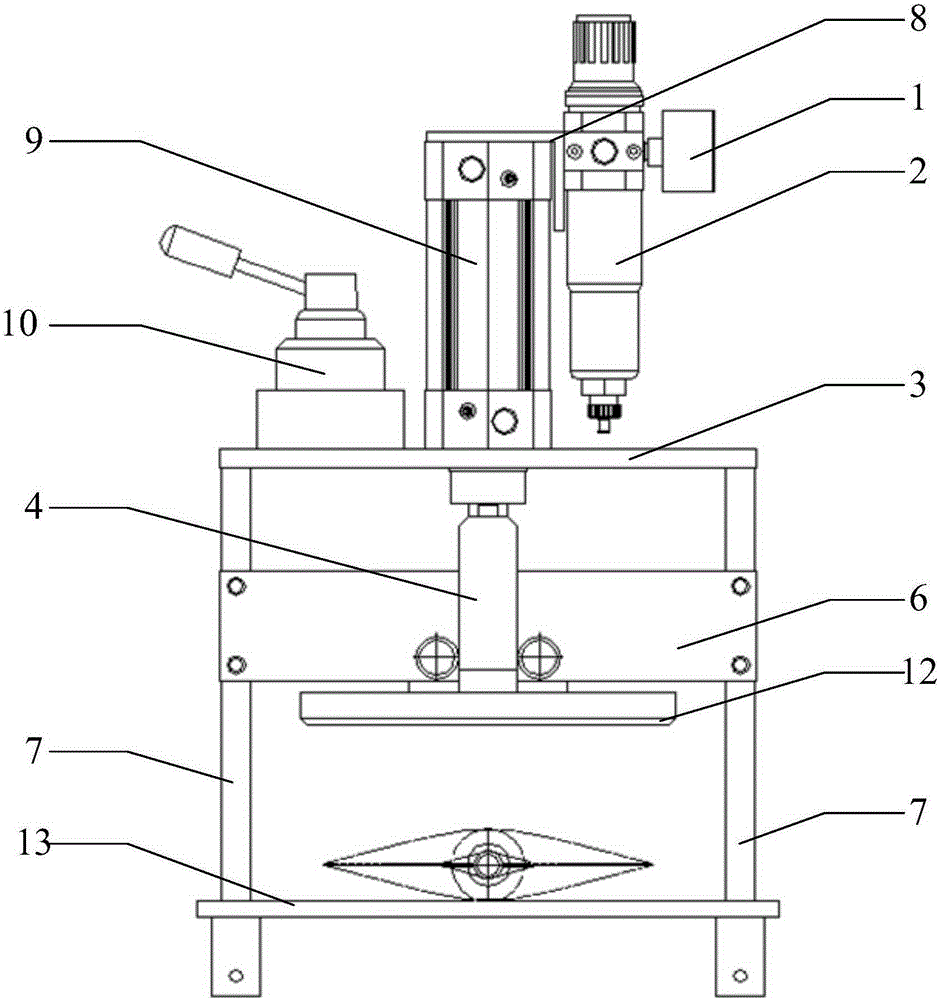

Device for detecting air leakage between needle seat and infusion tube of infusion set

ActiveCN102829929AImprove detection efficiencyImprove cleanlinessMeasurement of fluid loss/gain rateInfusion setIntensive care medicine

The invention relates to a device for detecting air leakage between a needle seat and an infusion tube of an infusion set. The device is characterized by comprising a bracket, wherein a travel mechanism used for splicing a gas testing assembly and the needle seat in a sealed way is arranged on the bracket, a gas transmission mechanism used for providing compressed air for the gas testing assembly is further arranged on the bracket, and the gas transmission mechanism is connected with an air leakage judgment mechanism. According to the device for detecting air leakage between the needle seat and the infusion tube of the infusion set, provided by the invention, the automation of the air leakage detection of the needle seat and the infusion tube is achieved; after the automatic detection substitutes for manual operation, the detection efficiency is greatly improved, and the infusion set is protected from being polluted by germs, so that the cleanliness of the infusion set is ensured; and with no need for huge energy consumption and large production spaces, the detection cost is greatly lowered.

Owner:梁启明

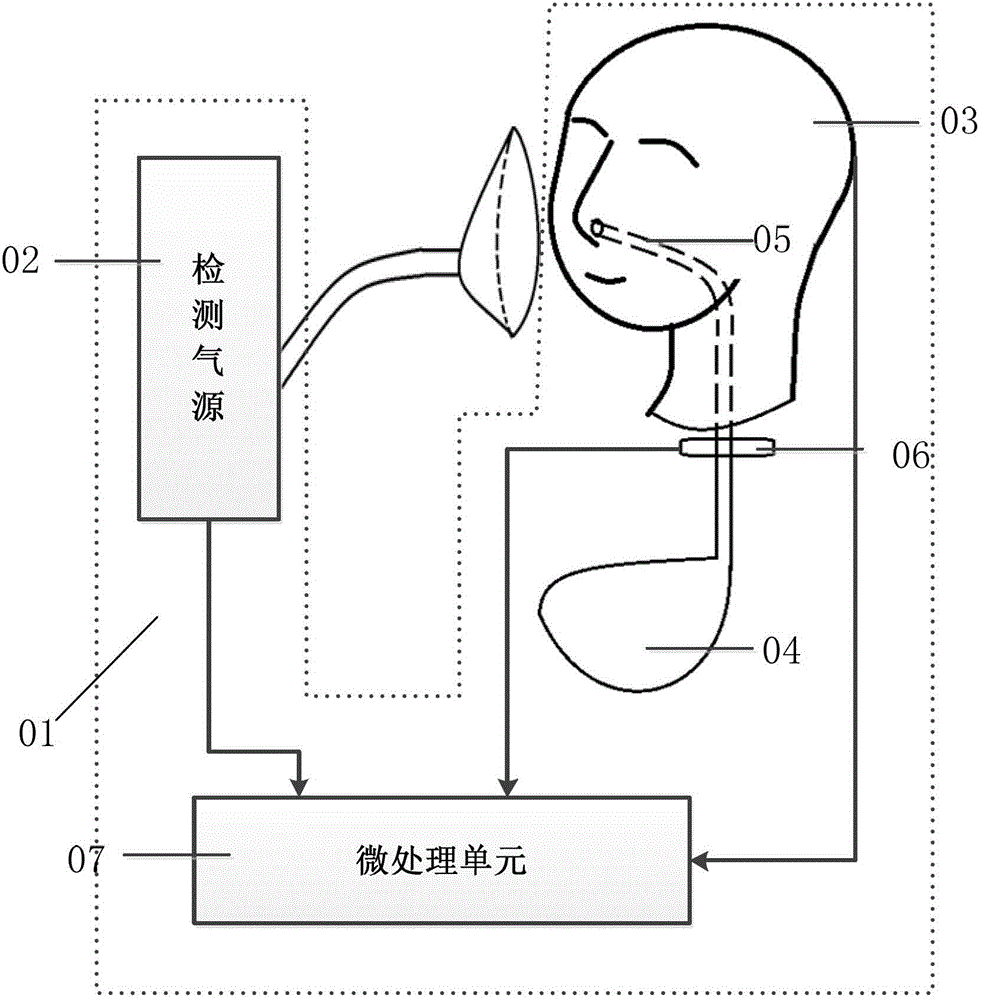

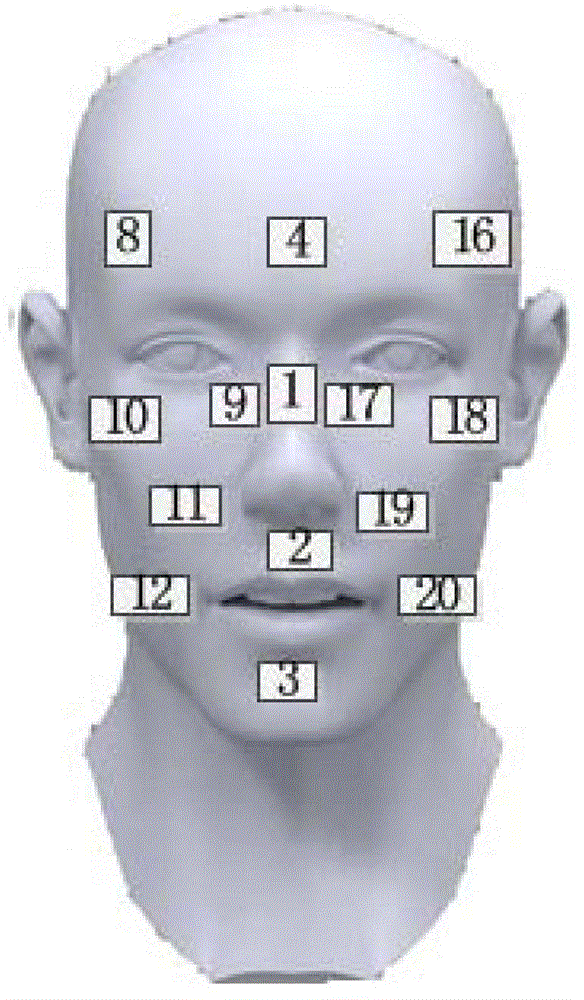

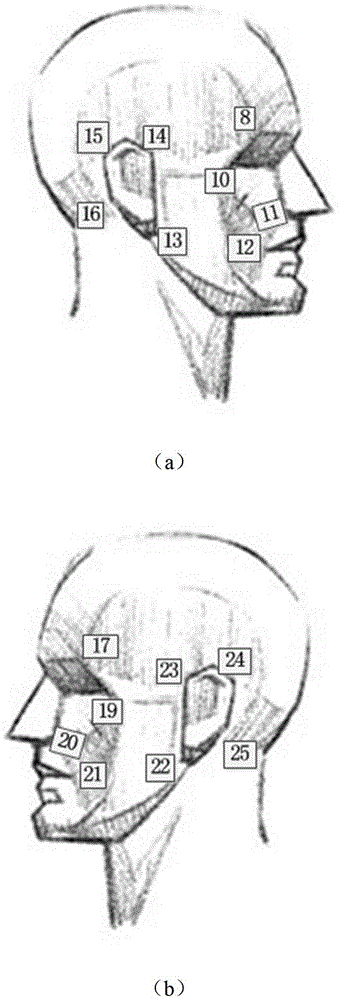

Detection system for noninvasive ventilation interface

InactiveCN102944371AMeasurement of fluid loss/gain rateEducational modelsSurface stressNoninvasive ventilation

The invention belongs to a detection system (01) for a noninvasive ventilation interface and particularly relates to a detection system for evaluating the air leakage and the comfortableness of interfaces such as a nasal mask, a mouth-nose mask and a full-face mask (08) for noninvasive ventilation by combining three-dimensional structure characteristics of human heads. The detection system comprises a detection air source (02), a human head three-dimensional model (03), a simulation trachea (05), a lung model (04) and a micro processing unit (07), wherein the detection air source (02) can be used for generating a designated ventilation waveform; the human head three-dimensional model (03) can be used for detecting the surface stress; the simulation trachea (05) and the lung model (04) are connected with the human head three-dimensional model and allow sensors (06) to be placed; and the micro processing unit (07) can be used for evaluating the air leakage and the comfortableness of the head and the face. The air leakage is detected by comparing the preset ventilation waveform of the air source with the actually-detected waveform of the trachea model, and the stresses of the mask worn at different positions of the head are measured by a plurality of pressure sensors arranged on the head model and are compared with a human tolerance threshold, and thus the comfortableness of the mask is judged.

Owner:BEIHANG UNIV

Methods and systems for endobronchial diagnosis

A method of diagnosing an air leak in a lung compartment of a patient may include: advancing a diagnostic catheter into an airway leading to the lung compartment; inflating an occluding member on the catheter to form a seal with a wall of the airway and thus isolate the lung compartment; measuring air pressure within the lung compartment during multiple breaths, using the diagnostic catheter; displaying the measured air pressure as an air pressure value on a console coupled with the diagnostic catheter; and determining whether an air leak is present in the lung compartment based on the displayed air pressure value during the multiple breaths.

Owner:PULMONX

Method for measuring air-leaking rate of sinter machine body

InactiveCN1661311AEffective monitoring of air leakage changesReduce air leakage rateMuffle furnacesRetort furnacesEngineeringHeat losses

A method for measuring air leakage rate includes setting thermocouples separately at branch tube straight section of sintering air box and under grate of sintering machine to measure temperature t0 under the grate before air leakage and temperature tm at the straight section after air leakage, utilizing obtained t0 and tm to calculate out air leakage rate K by using formula of K=Co[(1-lambda)t0-tm] / Co[(1-lambda)t0-tm]+CA(tm-ta) where lambda-heat loss, Co-constant value, Ca- air specific heat and tA-temperature of air leaked in.

Owner:BAOSHAN IRON & STEEL CO LTD

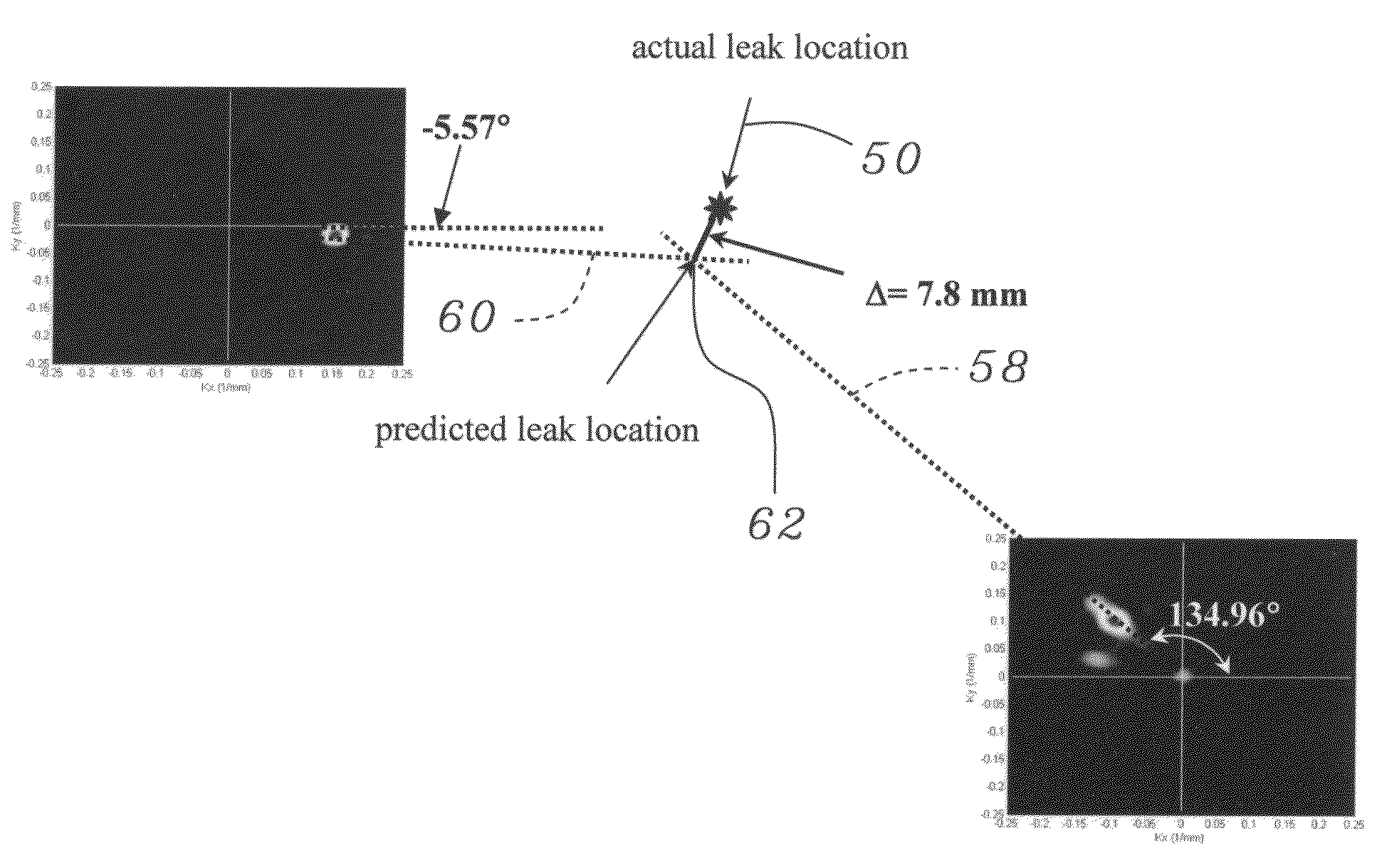

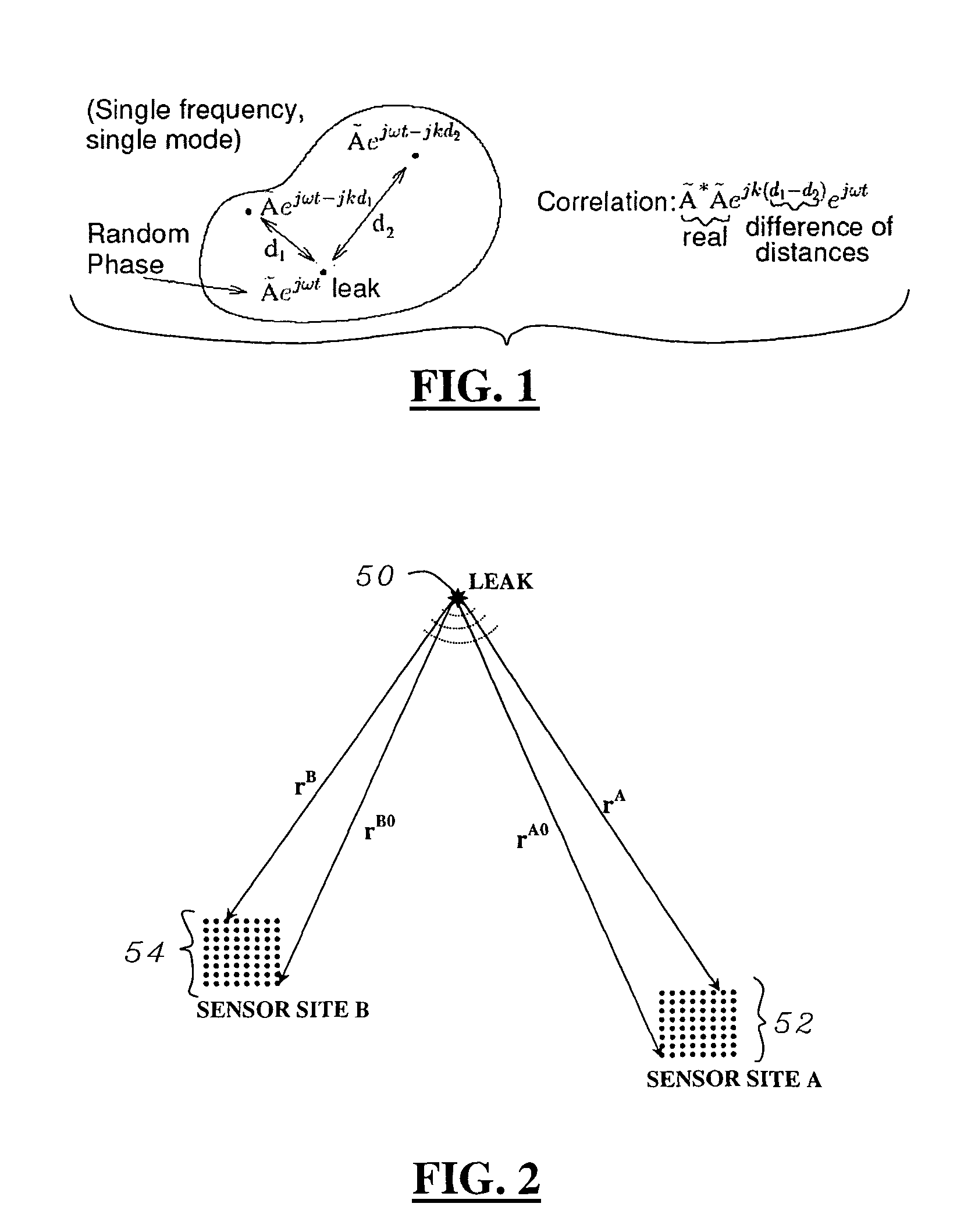

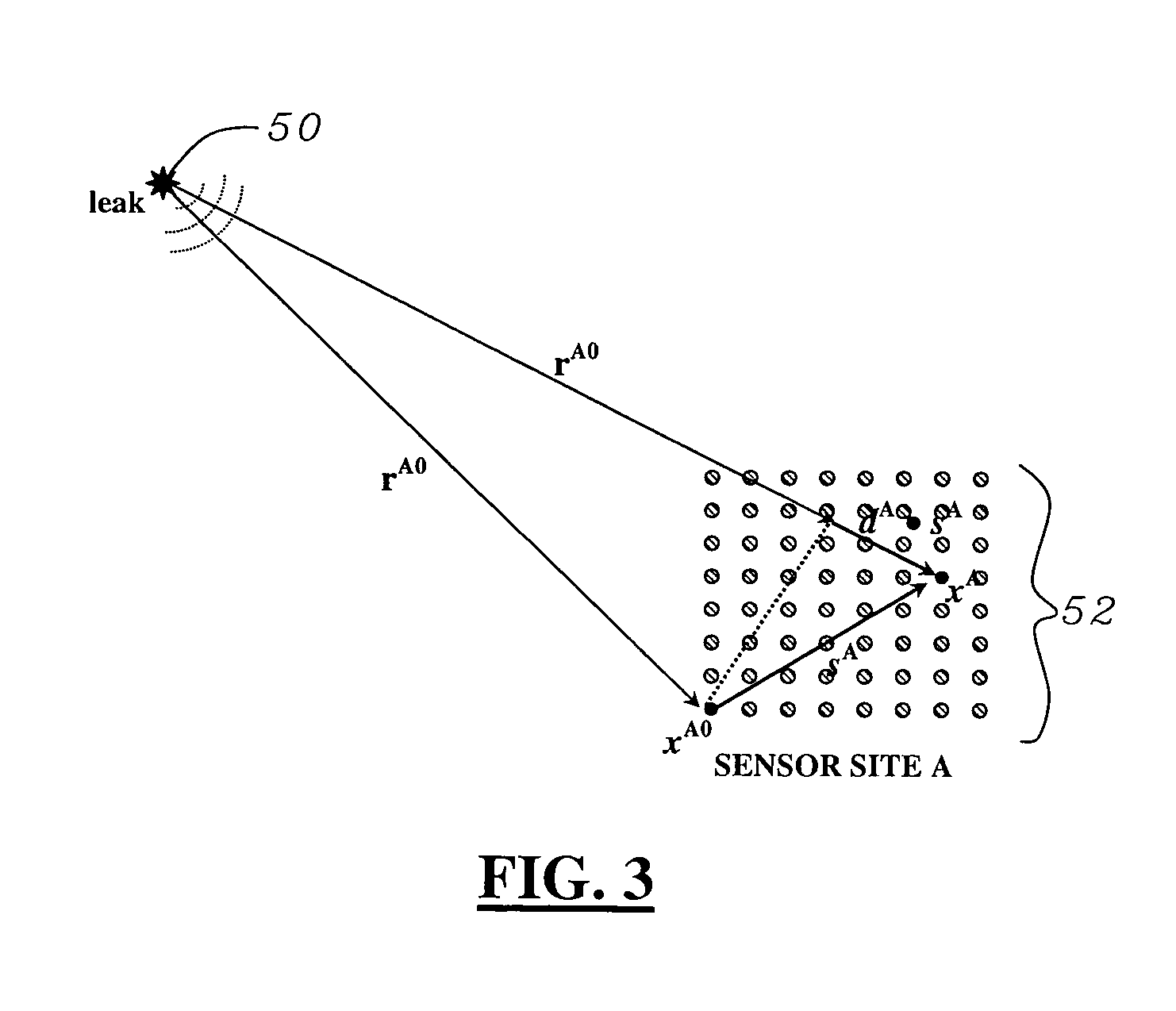

Leak detection using structure-borne noise

InactiveUS7739899B1Quick checkDetection of fluid at leakage pointMeasurement of fluid loss/gain rateEngineeringLeak detection

A method for detection and location of air leaks in a pressure vessel, such as a spacecraft, includes sensing structure-borne ultrasound waveforms associated with turbulence caused by a leak from a plurality of sensors and cross correlating the waveforms to determine existence and location of the leak. Different configurations of sensors and corresponding methods can be used. An apparatus for performing the methods is also provided.

Owner:IOWA STATE UNIV RES FOUND

Devices and methods for managing chest drainage

ActiveUS20180104391A1Reduces and eliminates poolingObjective and accurate measureMedical devicesIntravenous devicesDrainage tubesThoracic cavity

Disclosed is a chest drainage system which reduces or eliminates pooling of blood / liquid and / or clogging / clotting in the drainage tube and / or chest tube, and provides objective and accurate measures of drained fluid volume and chest air leak. The chest drainage system continuously monitors chest tube and drainage tube status and clears pooled liquid in the drainage tube, and / or a clogged chest tube when necessary to restore negative pressure to the chest.

Owner:ESCULON LLC

High-position inclined E-type ventilation system of coal face

InactiveCN103075173AIncrease the leakage sinkReduce air leakageTunnel/mines ventillationGas removalPressure functionAir volume

The invention relates to a ventilation system, of which the gas of an upper corner and a ventilation roadway is ultra-limit on a coal face, in particular to a high-position inclined E-type ventilation system of the coal face, and belongs to the technical field of coal mine safety equipment. A gas discharging high-position tunnel is formed between the ventilation roadway and an intake airway closed to a coal seam upper rock layer of the ventilation roadway, so as to form the high-position inclined E-type ventilation system with one intake airway and two ventilation roadways; the gas of a goaf can be restrained from pouring out to the upper corner and the ventilation roadway through adjusting the air quantity and air pressure of the ventilation roadway and the gas discharging high-position tunnel; and the gas of the goaf can be introduced to migrate to a gas special tunnel. The system uses a high-position tail tunnel, so that air leak congruence of the goaf is increased, and the gas accumulation of a U-type ventilation system is changed; and under the negative pressure of the ventilation system and / or the auxiliary extraction negative pressure functions, a high-position inclined E-type work face air power system is formed, so that the gas accumulation problem of the upper corner on the work face can be effectively solved.

Owner:JIANGSU VOCATIONAL INST OF ARCHITECTURAL TECH

System and method for detection and repair of pulmonary air leaks

A method for repairing pulmonary air leaks in a lung residing in a chest cavity and having an intake air stream and an outer surface is disclosed. An exemplary method comprises: introducing a first component of a biphasic sealant component as a liquid into the intake air stream of the damaged lung; ensuring that there is a pressure differential between the intake air stream and the outer surface of the lung; and introducing a second component of a biphasic sealant component into the chest cavity. The first sealant component collects at the air leak site and forms a sealant in combination with the second sealant component.

Owner:FRIEDBERG JOSEPH S

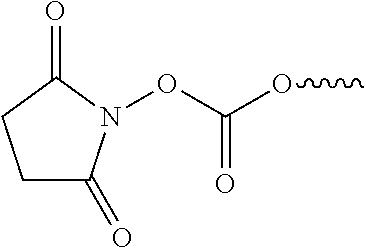

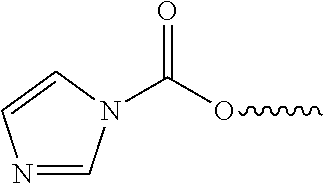

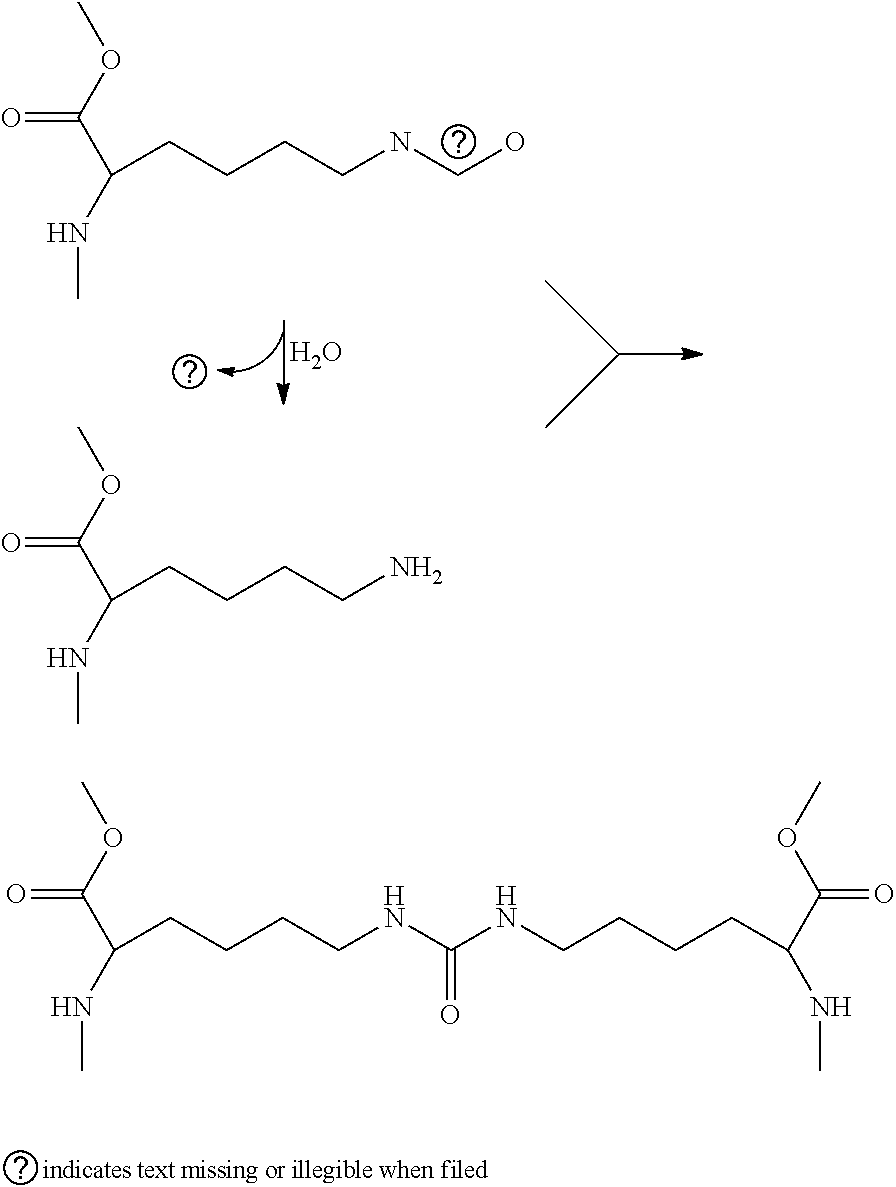

Amphiphilic Peptides for Thoracic Air Leakage Occlusion

Provided are compounds and methods useful for sealing air leaks in the thoracic cavity. Compounds and compositions of the invention comprise certain amphiphilic peptides, 8-200 amino acid residues long, that self-assemble spontaneously to form a gel in the presence of physiological pH and / or in the presence of a cation. In one embodiment, the peptide comprises a repeated sequence arginine-alanine-aspartic acid-alanine (RADA). Methods of the invention include a method of occluding a pulmonary air leak in a subject, comprising applying a compound of the invention to the site of a pulmonary air leak. The compounds and methods of the invention can be combined with other agents useful to treat cancer, inflammation, or infection.

Owner:3 D MATRIX

In-Situ Forming Foam for Endoscopic Lung Volume Reduction

InactiveUS20140271531A1The result is validReducing lung volumeOrganic active ingredientsMedicineCatheter

Systems and methods related to polymer foams are generally described. Some embodiments relate to compositions and methods for the preparation of polymer foams, and methods for using the polymer foams. The polymer foams can be applied to a lung at or near an alveolar duct targeted for reduction, occluding the airway and leading to tissue necrosis because the foam prevents oxygenation of the tissue surrounding the duct. In some embodiments, the polymer foams can be formed within a body cavity (i.e., in-situ foam formation). In addition, the foam may form a seal, eliminating the source of air leaks.

Owner:FREYMAN TOBY +2

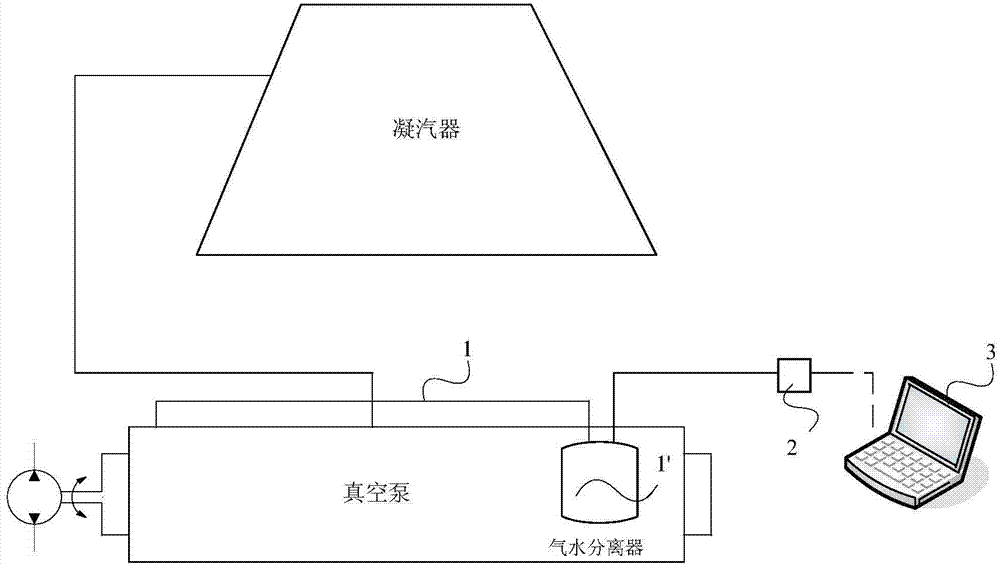

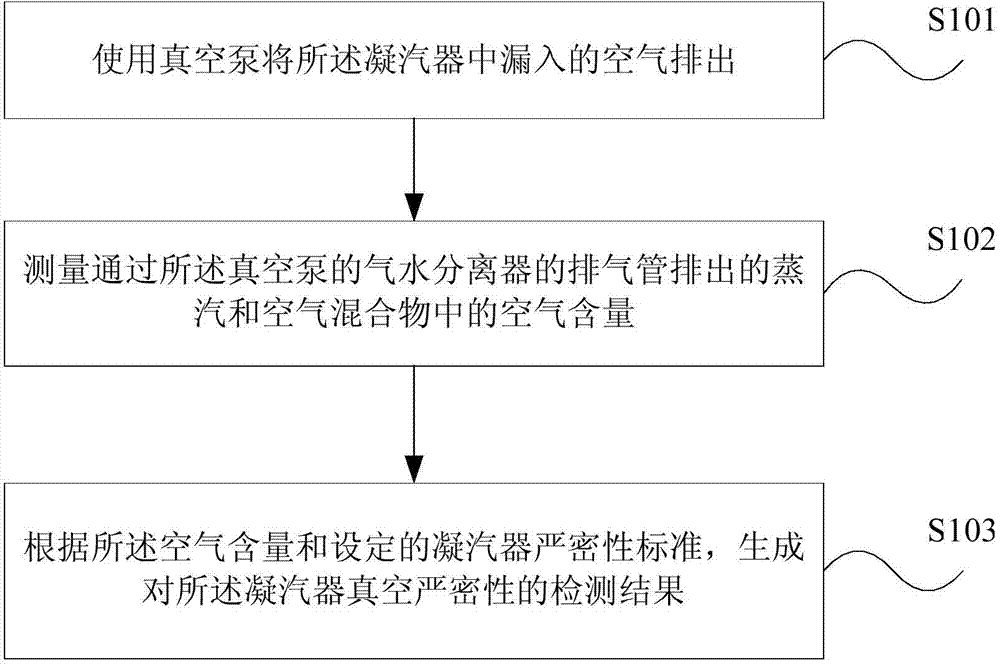

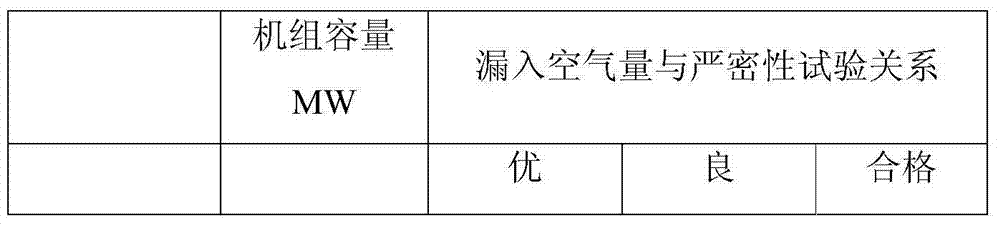

Condenser vacuum leakproofness detecting system and method

InactiveCN103487218AWill not affect normal operationDoes not affect stable operationMeasurement of fluid loss/gain rateMaintenance strategyPower grid

The invention provides a condenser vacuum leakproofness detecting system and method. The detecting system comprises a vacuum pump, an air outlet measuring device and a computing device. The vacuum pump is connected with a condenser, the air outlet measuring device is installed on an air outlet pipe of an air-water separator of the vacuum pump, and the computing device is connected with the air outlet measuring device. The vacuum pump is used for discharging air leaking into the condenser and part of steam in the condenser, the air outlet measuring device is used for measuring the air content in a steam-air mixture discharged out of the air outlet pipe of the air-water separator of the vacuum pump, and the computing device generates a detection result about the vacuum leakproofness of the condenser according to the air content and a set condenser leakproofness standard. According to the condenser vacuum leakproofness detecting system and method, the vacuum leakproofness of the condenser can be accurately judged, and therefore a basis is provided for operation and maintenance strategy formulation of a unit. In addition, due to the fact that measurement is conducted at the air outlet position, normal operation of the unit will not be affected, and the situation that test accuracy is ensured at the cost of influencing stable operation of a power grid is avoided.

Owner:STATE GRID CORP OF CHINA +1

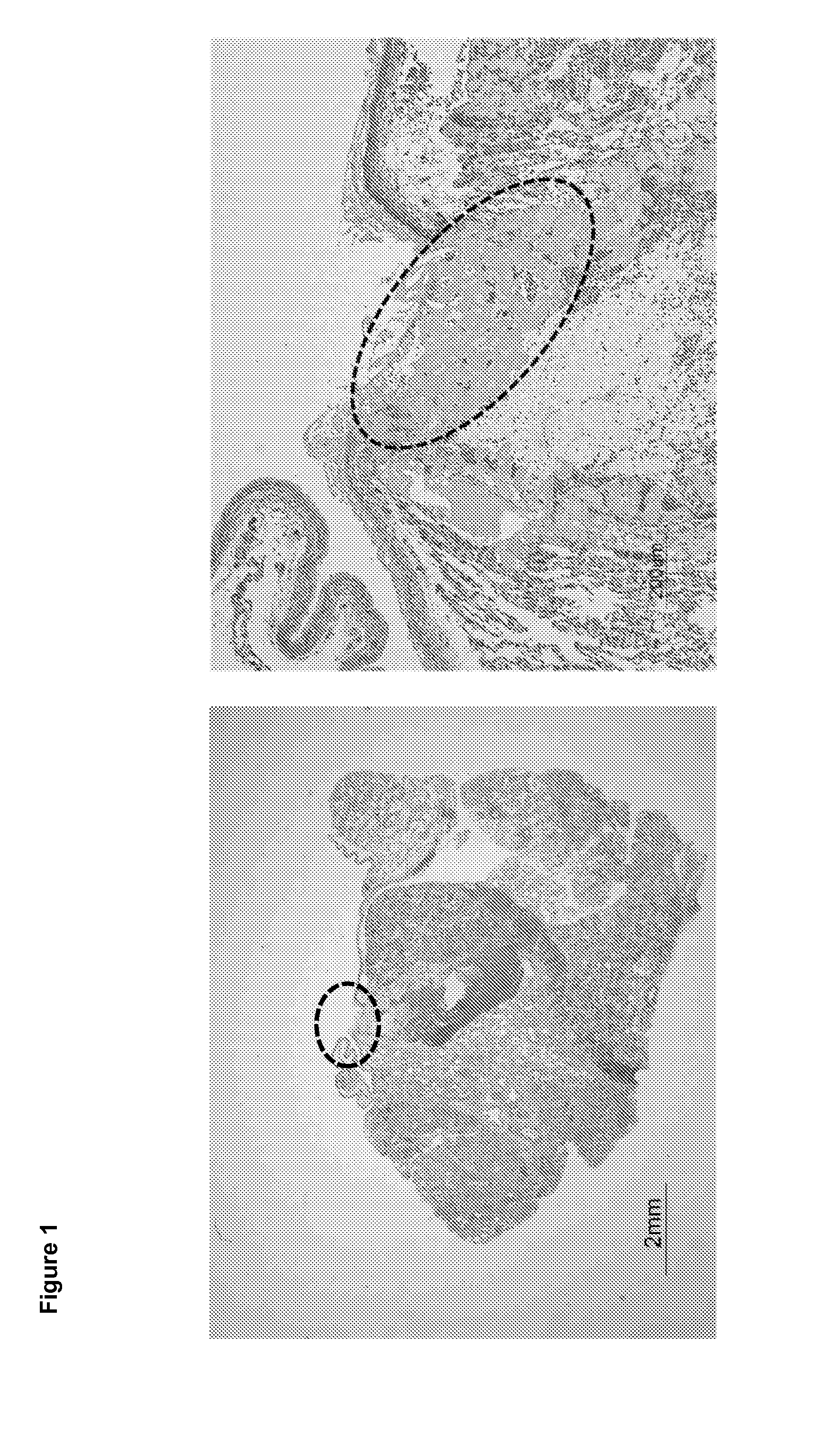

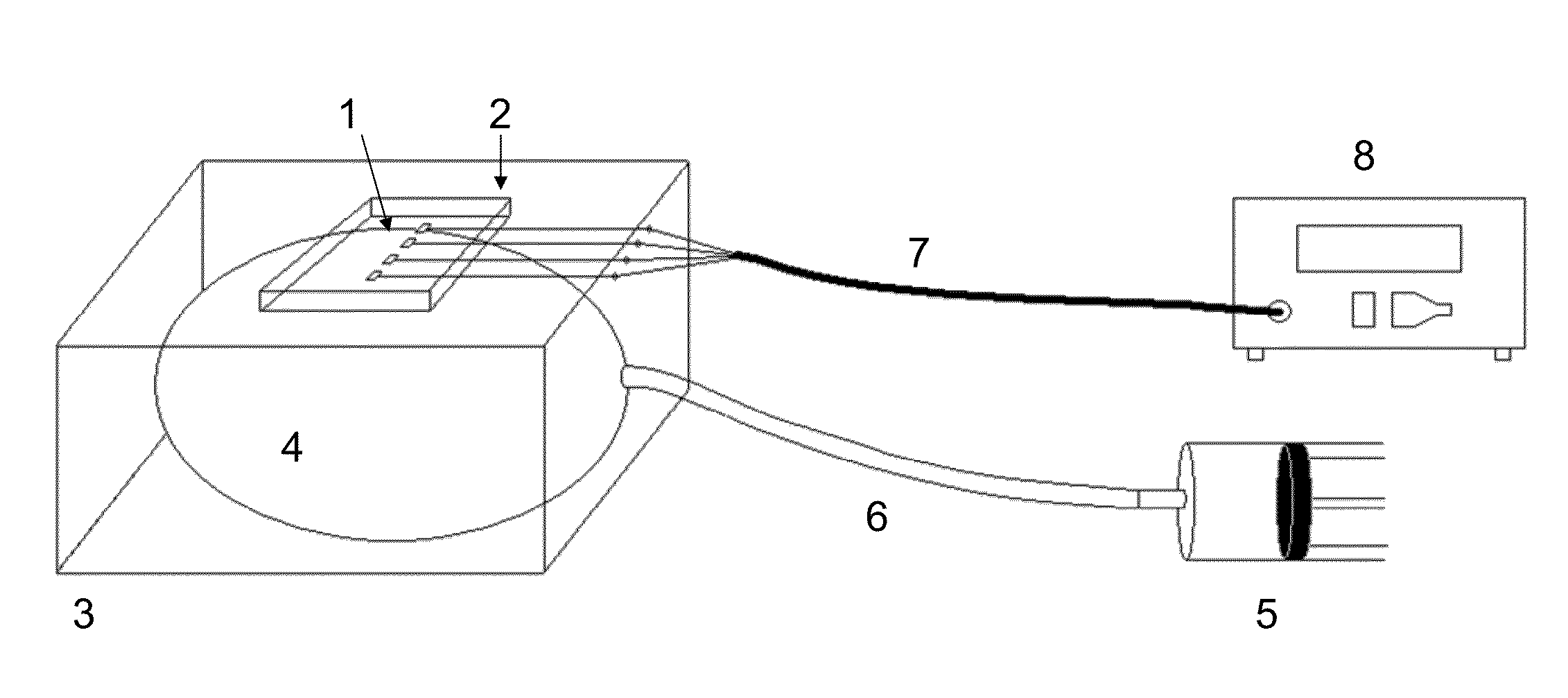

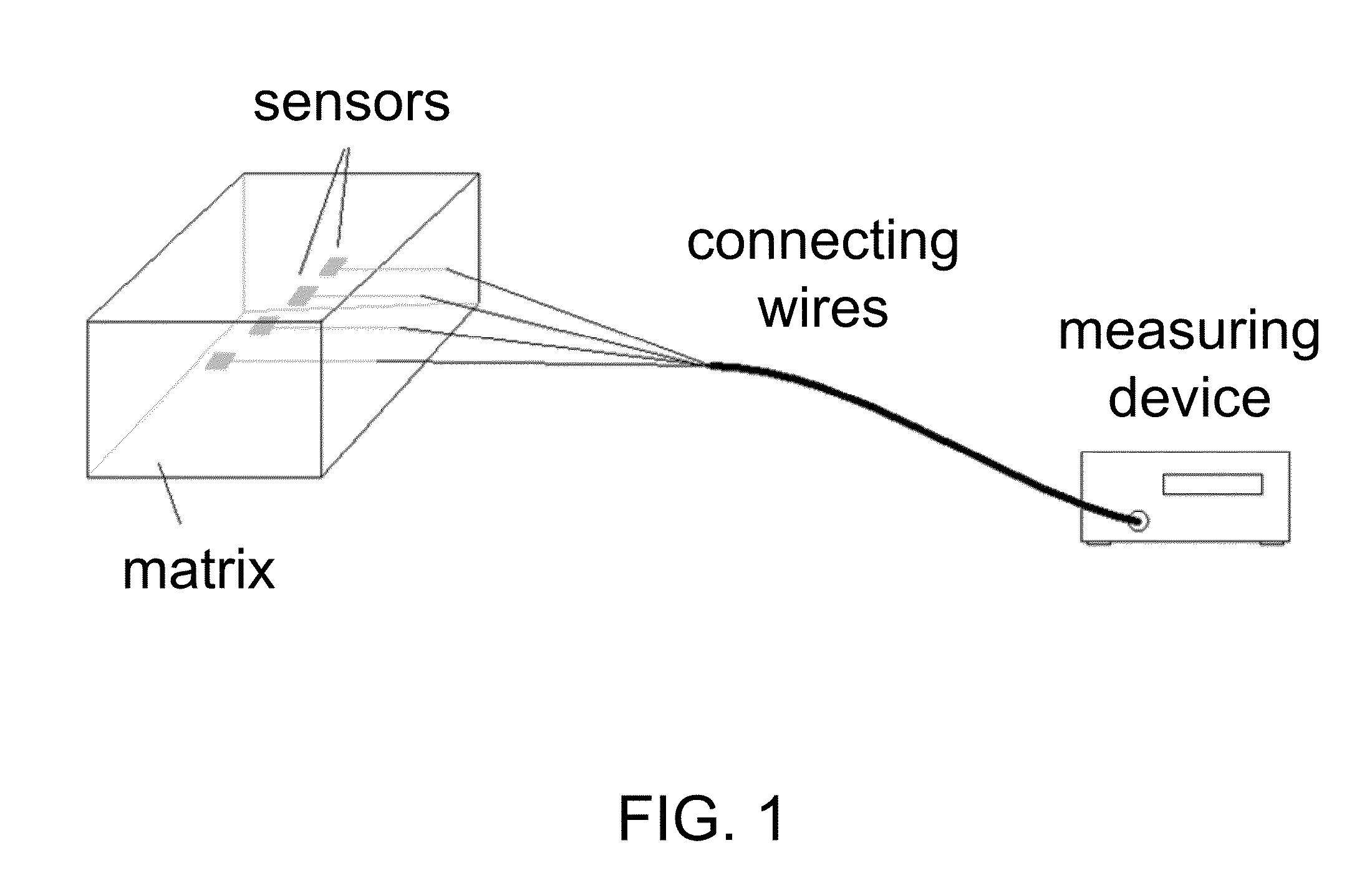

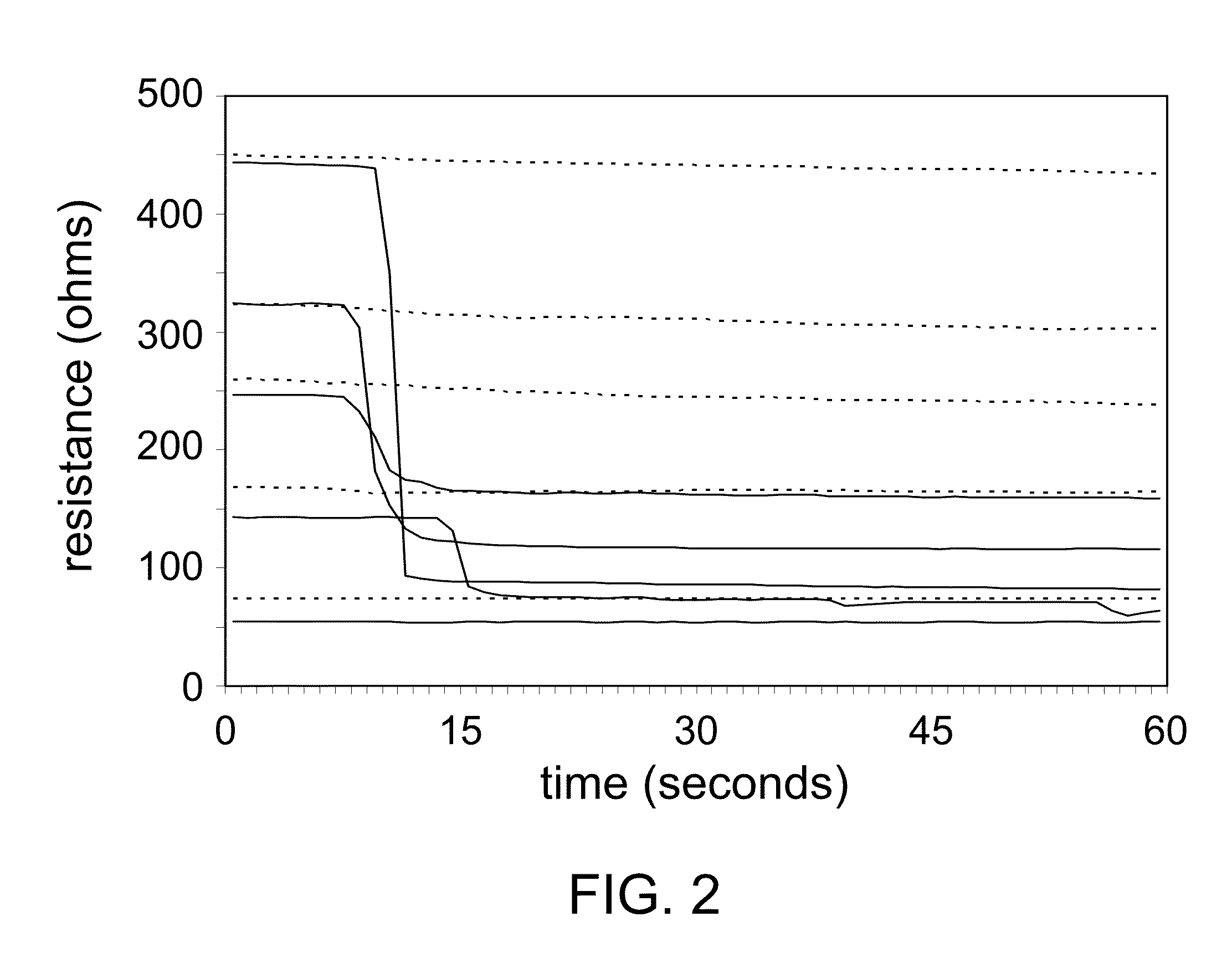

Protective matrix for intracorporeal biosensors that improves gastrointestinal leak detection, detects air leaks after lung surgery, and measures cardiac output after heart surgery

ActiveUS20140018696A1Avoid lostDiagnostic recording/measuringSensorsMeasurement devicePulmonary compliance

The system and method may measure and monitor physiological changes in a body. In some embodiments, the system and method may measure the impedance at a site in the body. In some embodiments, the system and method identify, quantify, and localize leaks from a site following surgery, measure cardiac contractility, or lung compliance. In an embodiment, the system includes a measuring device with one or more sensors embedded in a porous matrix. Changes in the electrical properties of one or more sensors may be used to determine the presence of leaks from a site following surgery, measure cardiac contractility, or lung compliance, depending on the position of the device.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

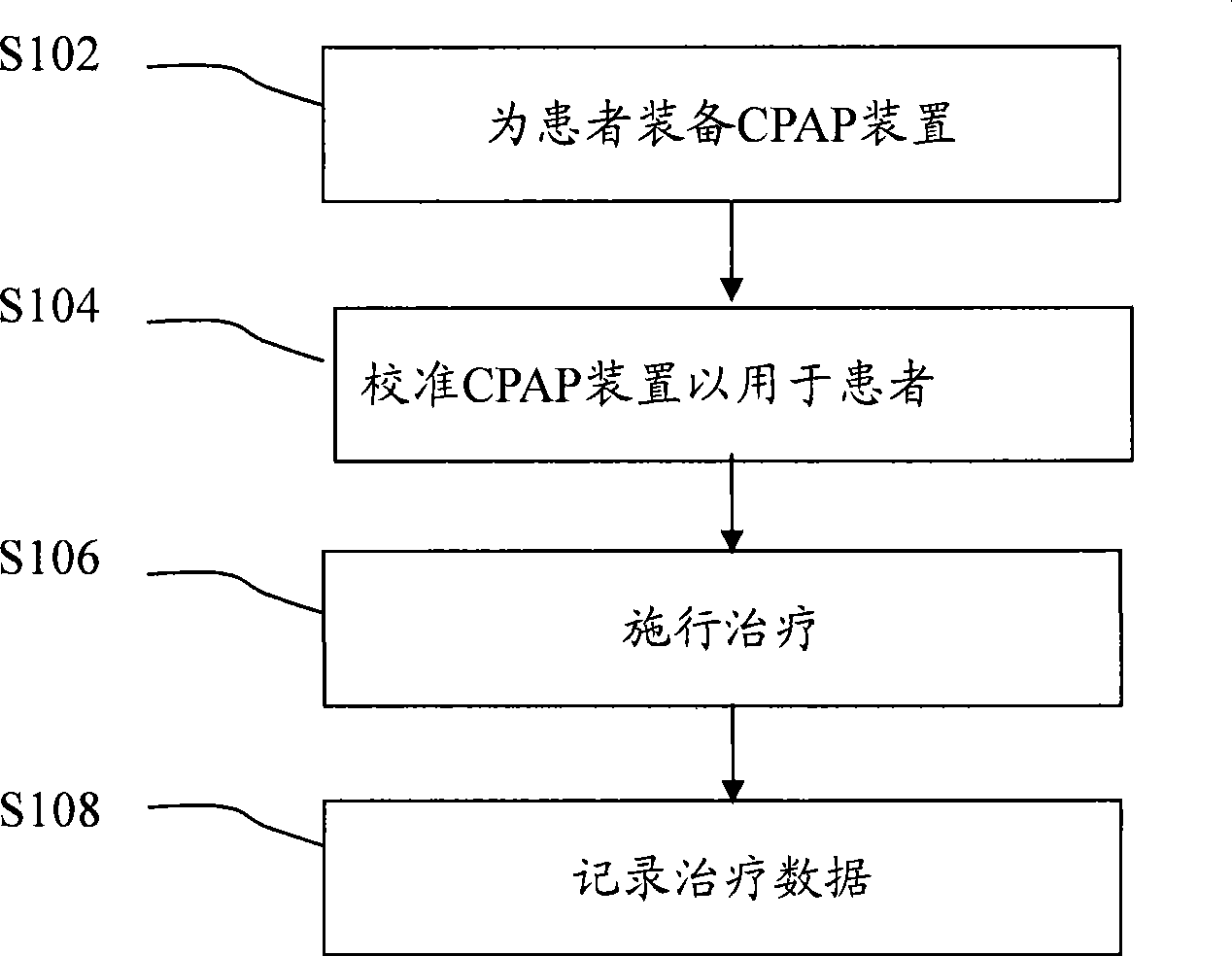

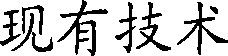

Systems and/or methods for calibration-less devices or less expensive calibration devices for treating sleep-disordered breathing

ActiveCN101460212ARespiratory masksMedical devicesPhysical medicine and rehabilitationTreatment sleep

Systems and / or methods for treating sleep-disordered breathing (SDB) are provided. In particular, systems and / or methods are provided that include software systems for use with auto-titrating devices (e.g. APAP devices) that reduce and / or eliminate the need to calibrate the auto-titrating devices. The software system also may reduce and / or eliminate the need for certain sensors used in such calibrations. Certain example embodiments compute snore based on noises measured during expiration and inspiration, and certain example embodiments set patient leak utilizing the vent flow level. Certain example embodiments change treatment pressure thresholds after measuring patient improvement by monitoring a variable correlated with actual delivery pressure in accordance with an example embodiment, and certain example embodiments provide pressure according to motor speed in accordance with an example embodiment.

Owner:RESMED LTD

Leak detection equipment

InactiveCN105203278AIndicates air leaksPrevent missed detectionMeasurement of fluid loss/gain rateConstant stressDirect observation

The invention discloses leak detection equipment for a flexible packaging product. The leak detection equipment comprises a rack and pressurization equipment. The pressurization equipment is an air cylinder piston assembly capable of applying pressure on the flexible packaging product continuously, and the fixed end of the air cylinder piston assembly is fixedly connected with the rack. A detection platform where the flexible packaging product to be detected is placed is further fixedly arranged on the rack. The air cylinder piston assembly is connected with a pressure gage used for detecting pressure of an air cylinder. The air cylinder piston assembly adopted for pressurization can output pressure continuously with the pressure maintenance characteristic, and whether the packaging product leaks air can be detected more thoroughly through pressure detection, with a certain time length, on the packaging bag; besides, pressure changes of the air cylinder are detected through the connected pressure gage, pressure changes in the packaging product pressurized by the air cylinder are displayed accordingly, and therefore the sealing air leak condition of the flexible packaging product can be correctly reflected; manual direct leak observation is replaced with reading of the pressure gage, and therefore the leak detection equipment is more reliable and saves labor.

Owner:长沙汇一制药机械有限公司

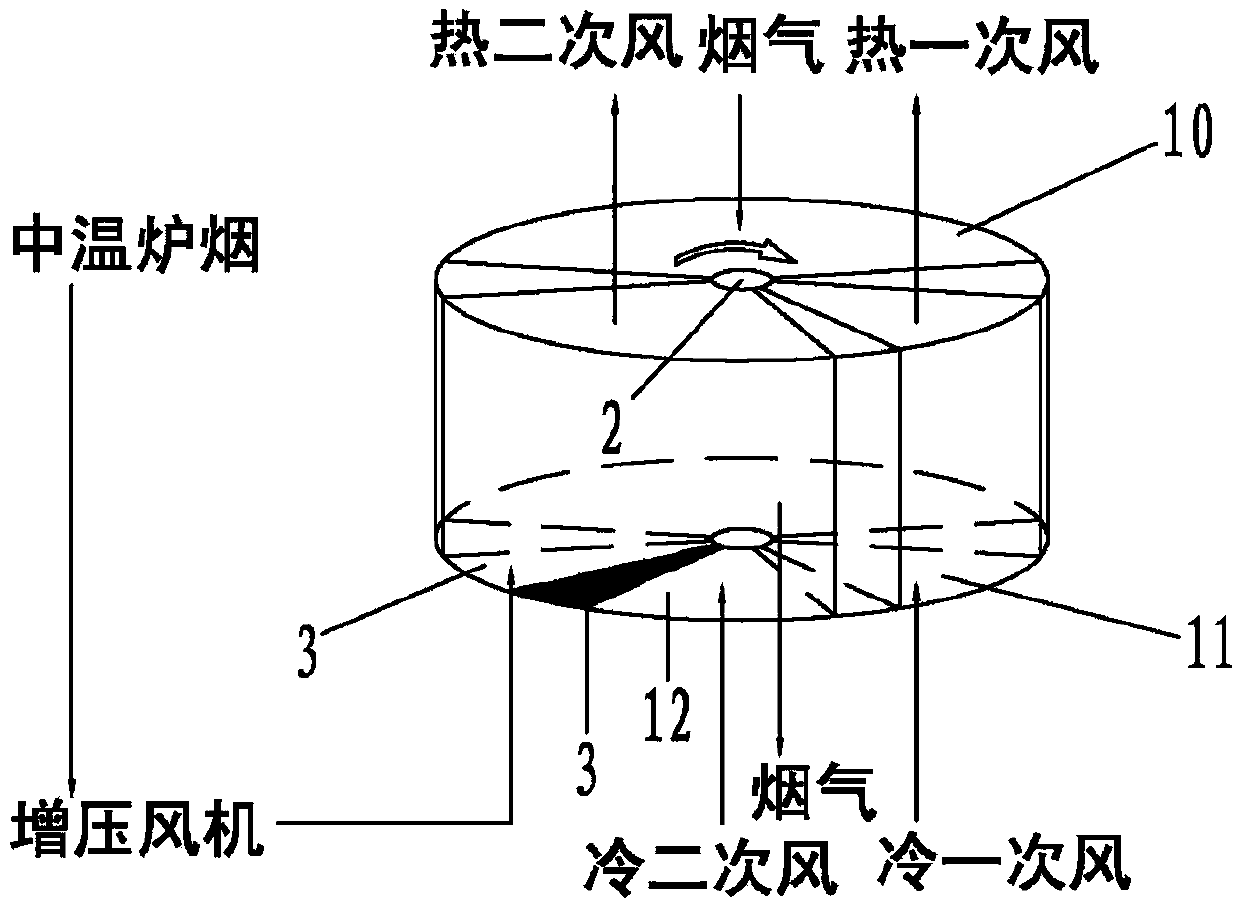

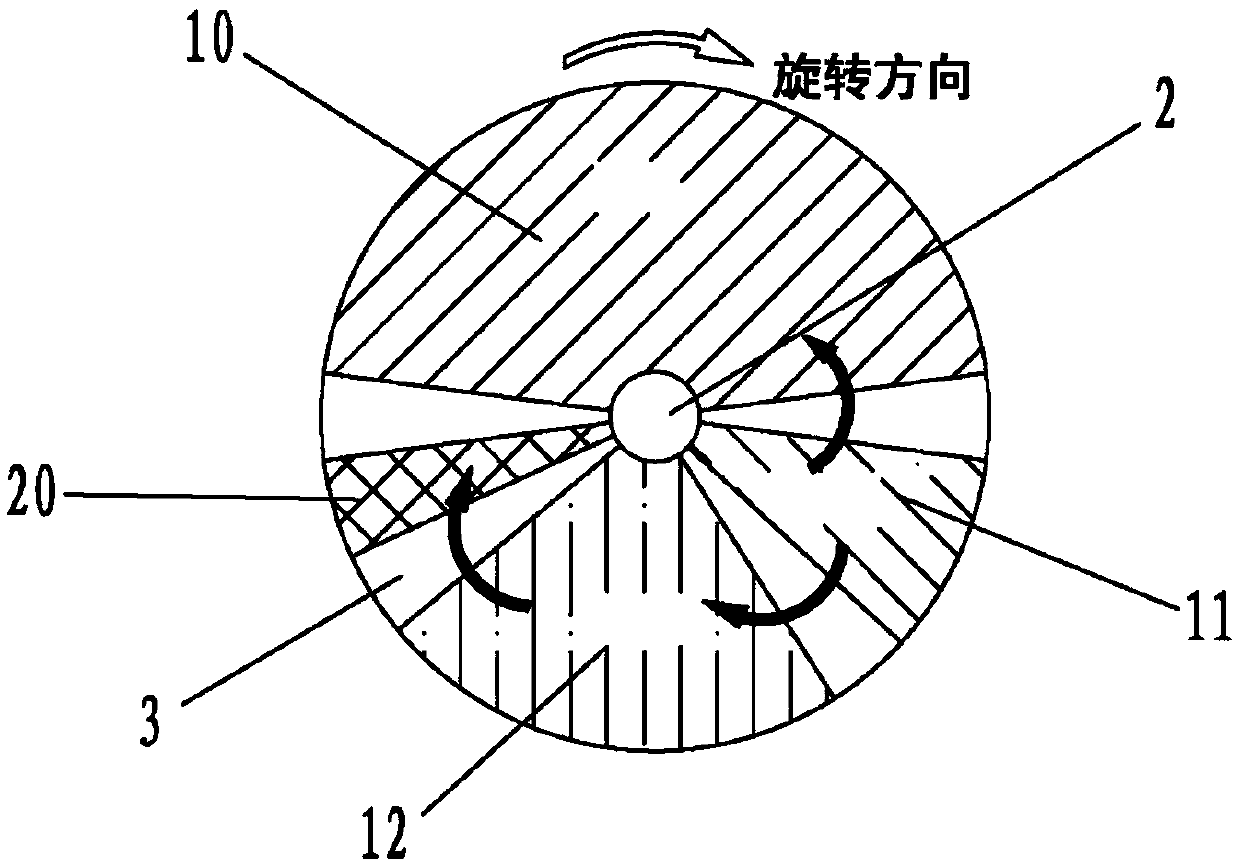

Rotary type air pre-heater and secondary air side air-leaking-reducing and plugging-preventing method thereof

PendingCN107655027ASolve the cloggingReduce air leakageIndirect carbon-dioxide mitigationHeat exchange apparatusAir preheaterCombustion

Owner:DATANG DONGBEI ELECTRIC POWER TESTING & RES INST +2

Devices and methods for obtaining tissue samples

InactiveUS20150057570A1Encourage captureMinimizing undesirable collateral damageSurgical needlesVaccination/ovulation diagnosticsTissue sampleMedical device

Medical devices and systems, and methods of their use, are disclosed having configurations suitable for obtaining biological tissue samples suitable for analysis, such as biopsy, while minimizing undesirable collateral damage to surrounding tissue or minimizing air leaks. Certain disclosed medical systems provide for obtaining biological tissue samples, while preserving organ functionality.

Owner:SPINE VIEW INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com