Method for controlling goaf air leakage in exploitation process of shallow buried close-range coal seam

A technology of mining process and control method, which is applied in auxiliary non-electrical fluid pressure control, by detecting the appearance of fluid at the leakage point, mining equipment, etc., can solve problems such as shortage, unsatisfactory, and spontaneous combustion of leftover coal in goafs. Achieve the effects of strong practicability, high reliability, safe and efficient mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] specific implementation plan

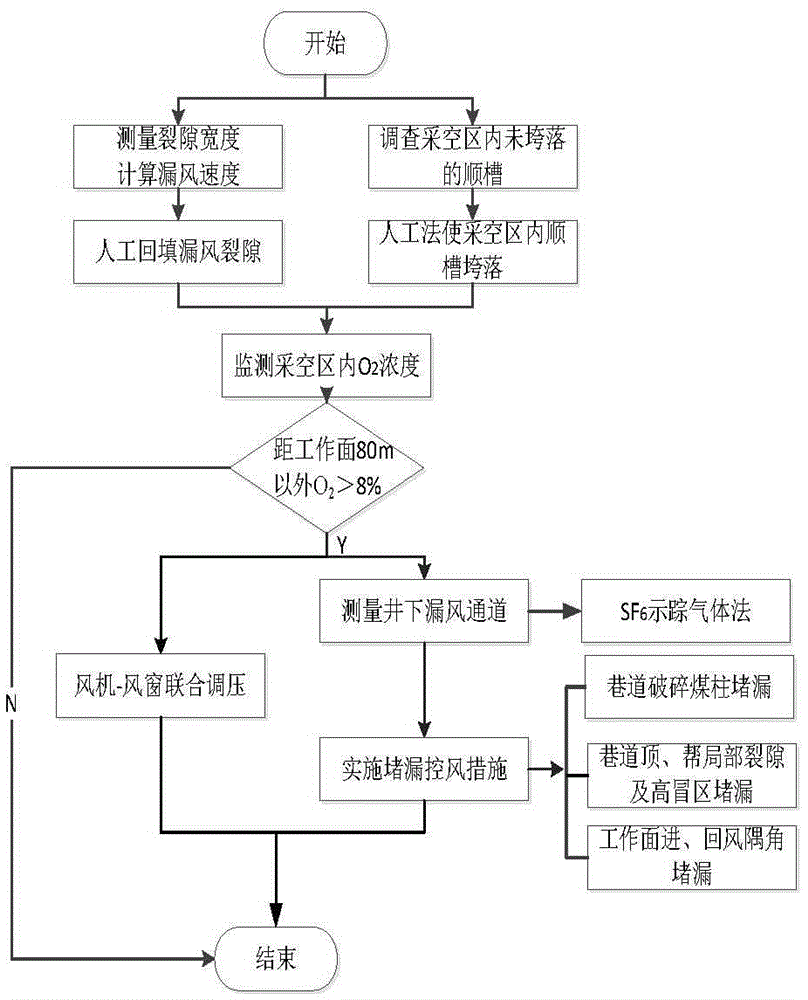

[0023] figure 1 Shown is a flow chart of the present invention for implementing a method for comprehensive air leakage control in gobs during shallow-buried and close-distance coal seam mining. The present invention will be further described below in conjunction with examples.

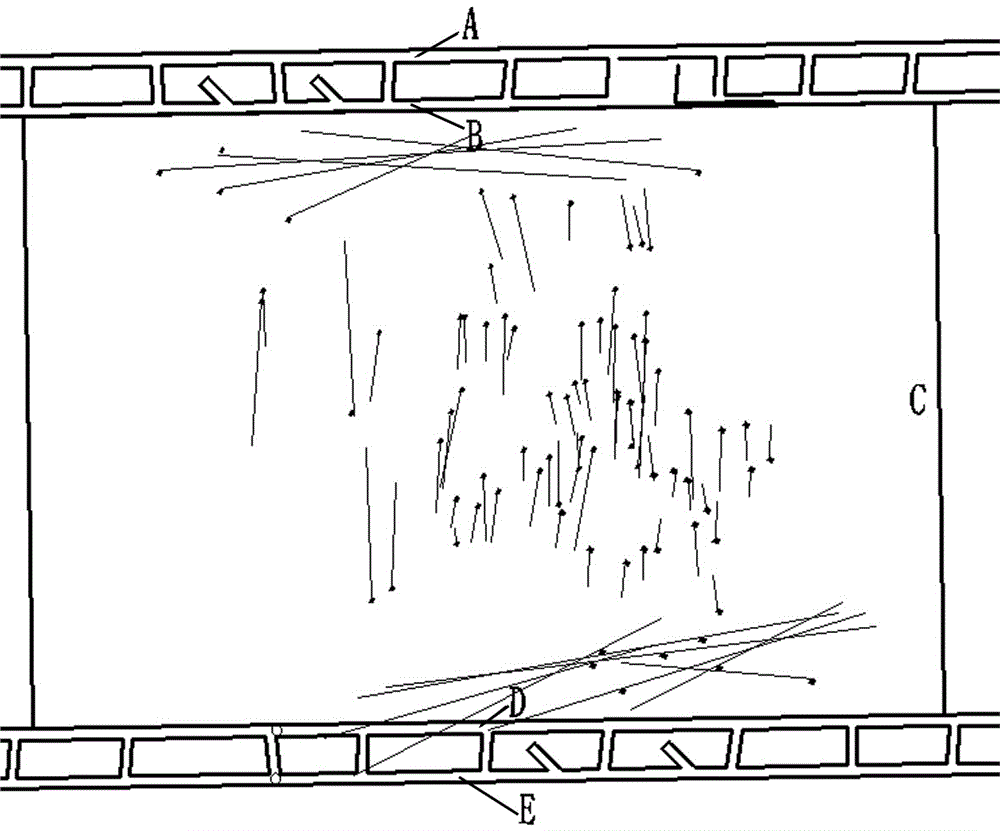

[0024] Implementation background: The burial depth of the 12-coal coal seam in the third panel area of a mine is 96-233m, the minimum thickness of the coal seam is 1.95m, the maximum is 8.03m, and the average is 5.4m. The No. 12 coal in the three panel area began to be mined in 1999, and the mining was completed in 2007. A total of 6 fully mechanized mining working faces were arranged in the panel area, with a cutting height of 3.6m and a thickness of 2.9m for the remaining top coal. The supporting 5m supports were used for mining along the coal seam floor , the average recovery height is 4.6m, and the distance between the 12th coal seam and the 22nd coal seam i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com