Pressure relief gas directional drilling and blocking extraction method for mining adjacent layers in close-range coal seam group

A technology of directional drilling and coal seam group, which is applied in the direction of gas discharge, mining equipment, earthwork drilling, etc., and can solve the problem of high extraction cost, easy overrun of gas, and difficult management of roof-through-bed drilling and floor-through-bed drilling and other problems, to achieve the effect of reducing the amount of construction and the number of drilling construction, short treatment period, and high drainage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

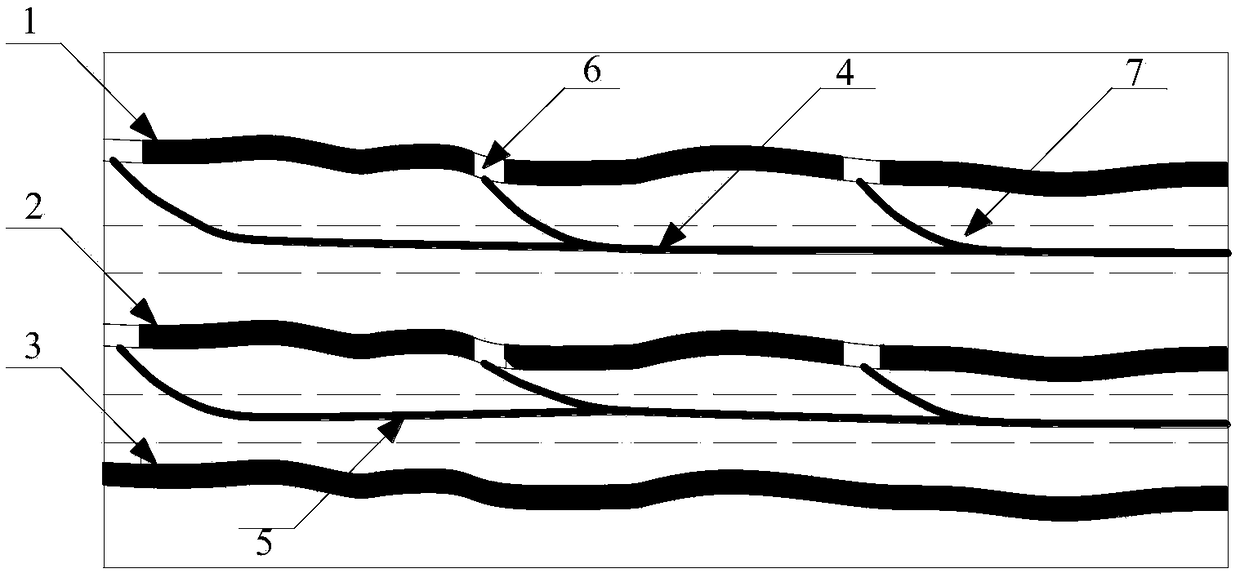

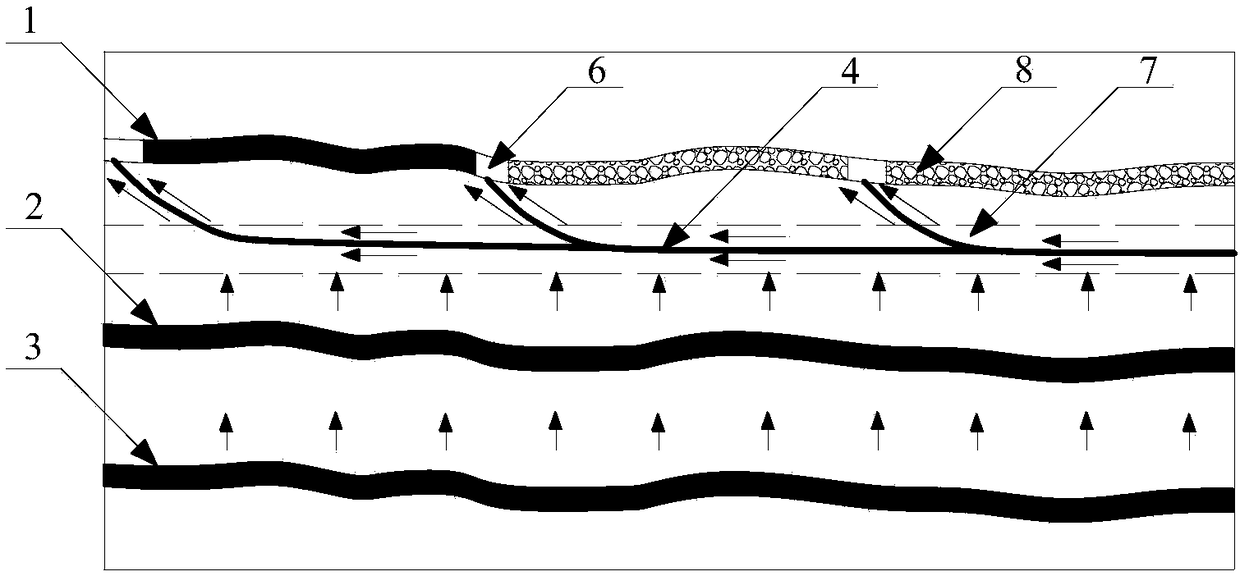

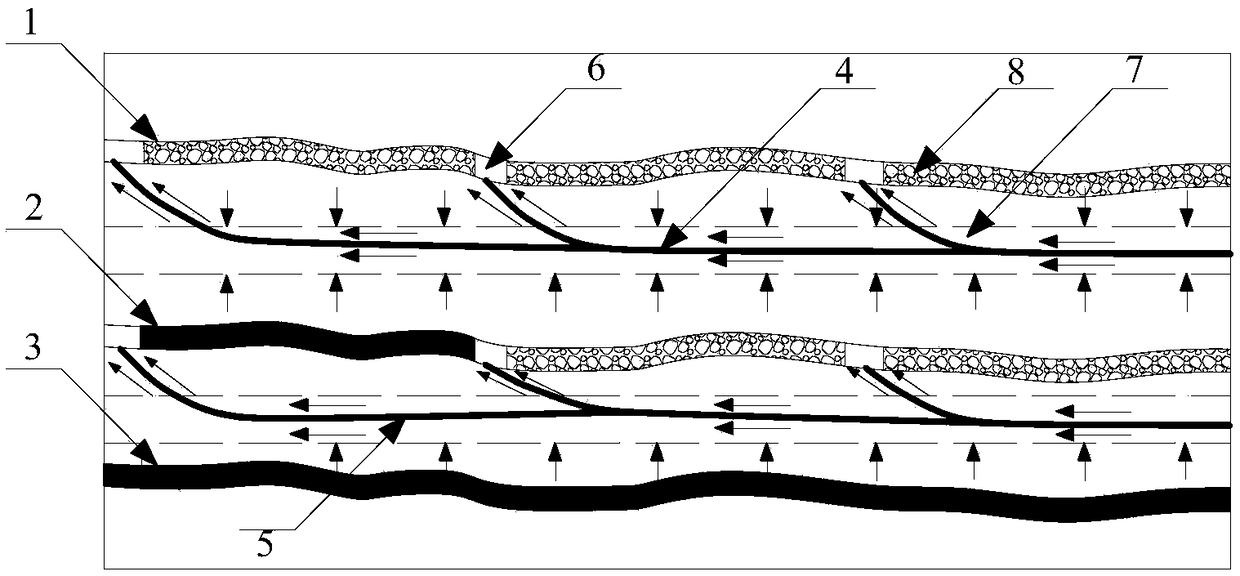

[0031] see figure 1 The invention relates to a method for directional drilling interception and extraction of pressure relief gas in adjacent layers of coal seam group mining, comprising the following steps:

[0032] Step 1: Construction of directional drilling 4 on the upper floor. The upper coal seam 1 is selected as the first mining layer, and a plurality of drilling sites 6 are set on the side of the air return roadway 8 of the working face 9, and multiple groups of upper floor directional drilling 4 are pre-constructed on the bottom plate of the upper coal seam 1 in the drilling sites 6 .

[0033] Step 2: The upper coal seam 1 is mined to release pressure and gas to block and drain. The upper coal seam 1 is mined, the middle coal seam 2 and the floor of the upper coal seam 1 are moved and damaged, causing the middle coal seam 2 to relieve pressure and expand, and a large amount of adsorbed gas is desorbed and then migrates and diffuses to the mining face 9 of the upper c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com