Biological filling permeable reactive barrier and construction method thereof

A construction method and reaction wall technology, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of no monitoring facilities, failure, poor coverage of circulation pipelines, etc. Achieve the effects of shortening the construction period, strengthening the gas export function, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] like Figure 8 Shown is a bio-filled permeable reaction wall provided in this embodiment, including: a holding tank 1 , an active filler 2 disposed in the holding tank 1 , a circulation air duct 3 and an isolation cover 5 .

[0044] The holding tank 1 is filled with active filler 2 . The circulation air guide pipe 3 is embedded in the active filler 2 , and multiple groups of the circulation air guide pipe 3 are arranged at intervals along the length direction of the storage tank 1 . The isolation cover 5 is arranged on the upper side of the active filler 2 , and the circulation air duct 3 is arranged through the isolation cover 5 .

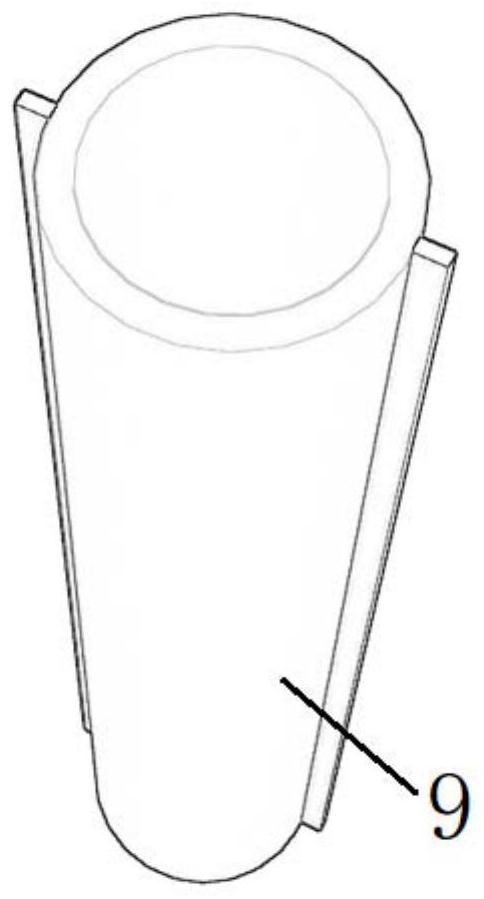

[0045] The circulating air guiding pipe 3 is provided with a plurality of circulating air guiding branch pipes 4 at intervals along the axial direction. . The circulation air guiding branch pipe is arranged with an inclination downward. A one-way ventilation pipe 6 is also provided through the isolation cover 5 , and the one-way ventila...

Embodiment 2

[0049] like Figure 1 to Figure 8 Shown is a construction method of a bio-filled permeable reaction wall provided in this embodiment, which is used to construct the bio-filled permeable reaction wall described in Example 1, and the bio-filled permeable reaction wall is constructed in sections, each section 5 -8m, the construction method of the reaction wall includes the following steps:

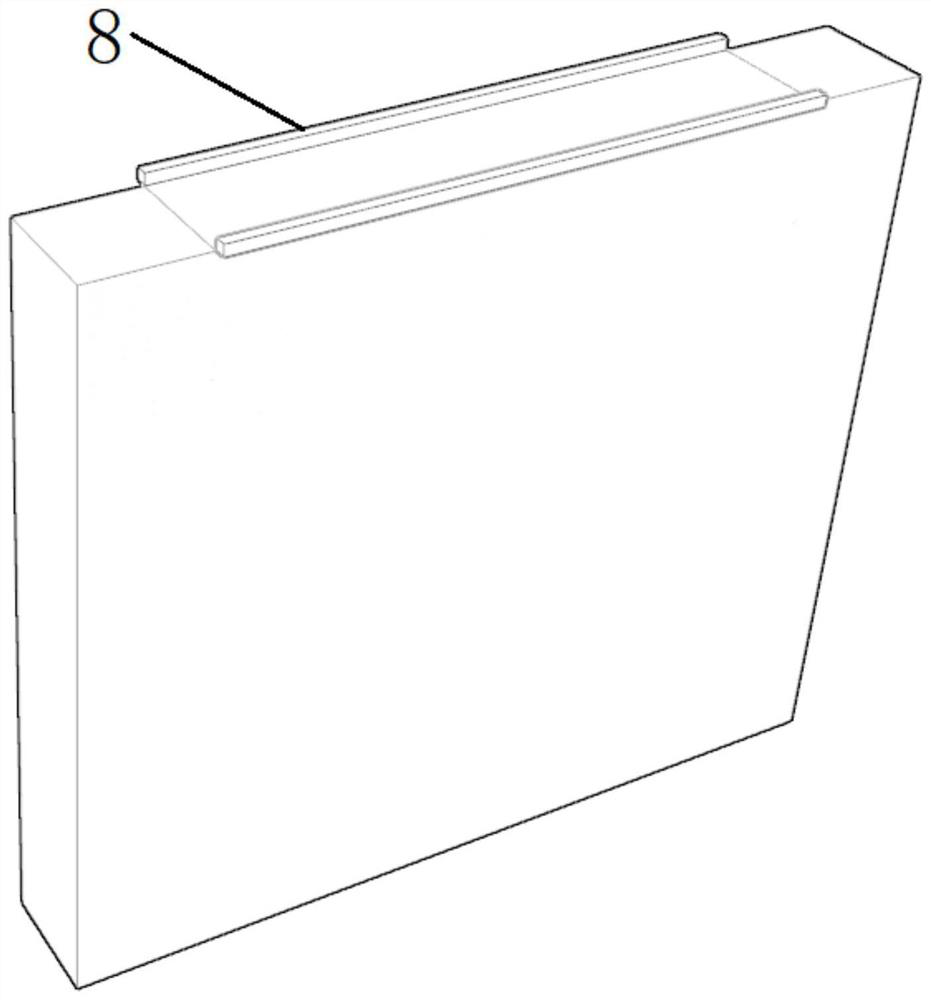

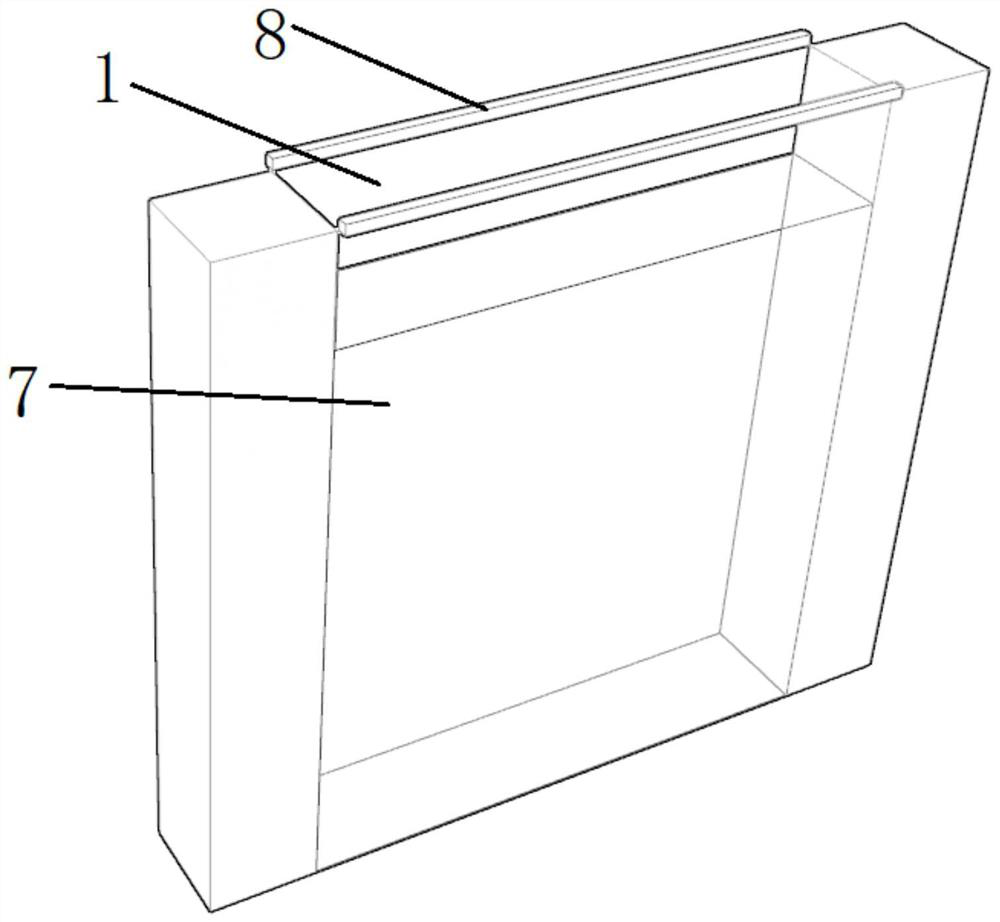

[0050] Before construction, first determine the interval range and construction location of each section of the reaction wall. In order to improve the verticality of the storage pool 1, the tilting of the storage pool 1 after excavation is avoided. like figure 2 As shown, before excavating the storage pool 1, a guide groove 8 is installed at the position where the wall is built. like image 3 As shown, the ground where the wall is built is excavated to form a holding pool 1, and biopolymer mud 7 is continuously injected into the holding pool 1 during the excavation process. To support t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com