Patents

Literature

404 results about "Liquid density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The knowledge of liquid density is very important as it gives an idea which are the objects that can float on the liquid and also the objects which will sink in the liquid. The liquid density of water at 4 o C is almost 1 gm/cc and for all practical purposes, the density of water is taken as 1 gm/cc.

Method and device for measuring density of a liquid

InactiveUS20080223130A1Improve accuracyMinimal roughnessMaterial analysis by observing immersed bodiesSpecific gravity using centrifugal effectsLiquid densityEngineering

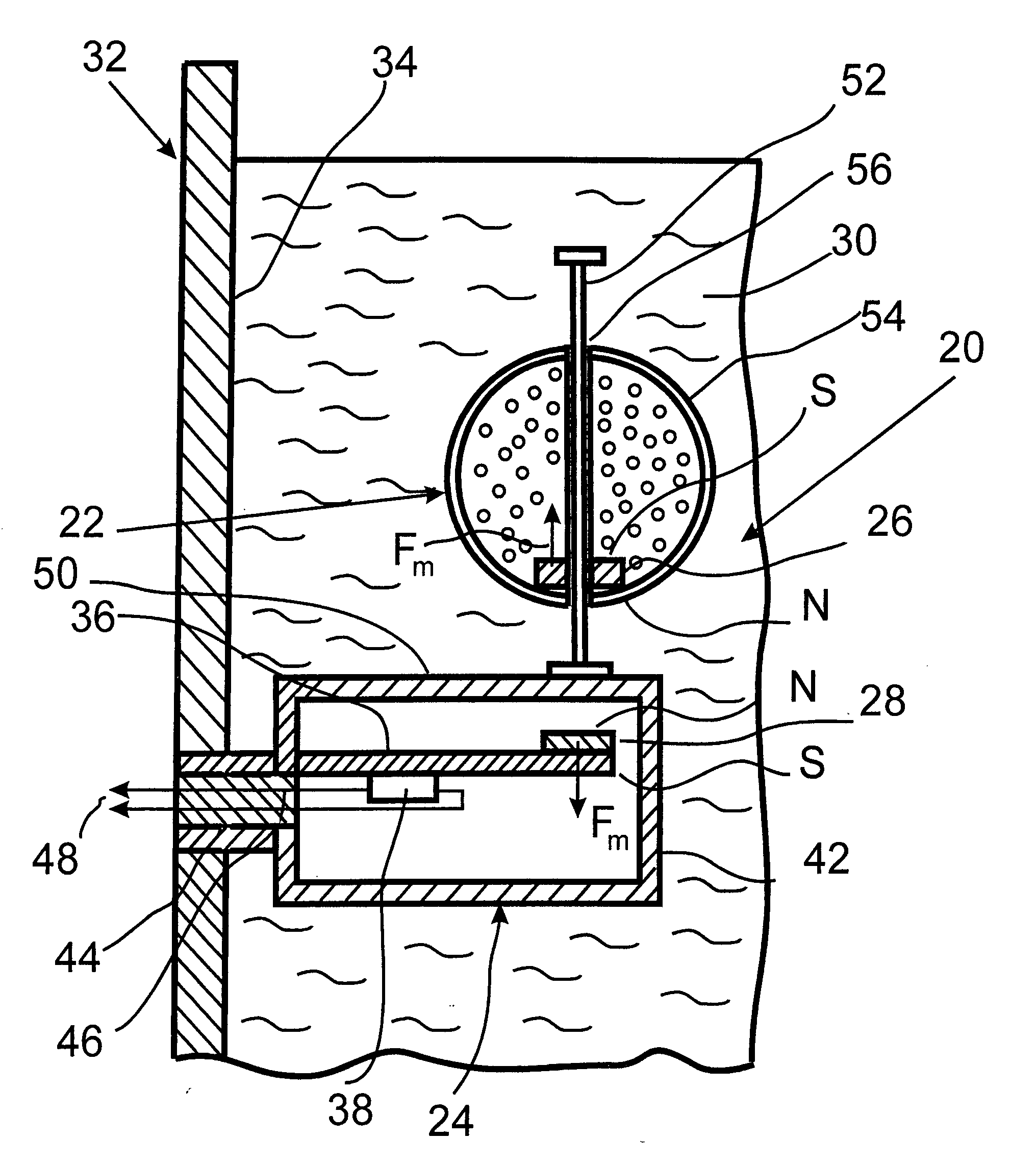

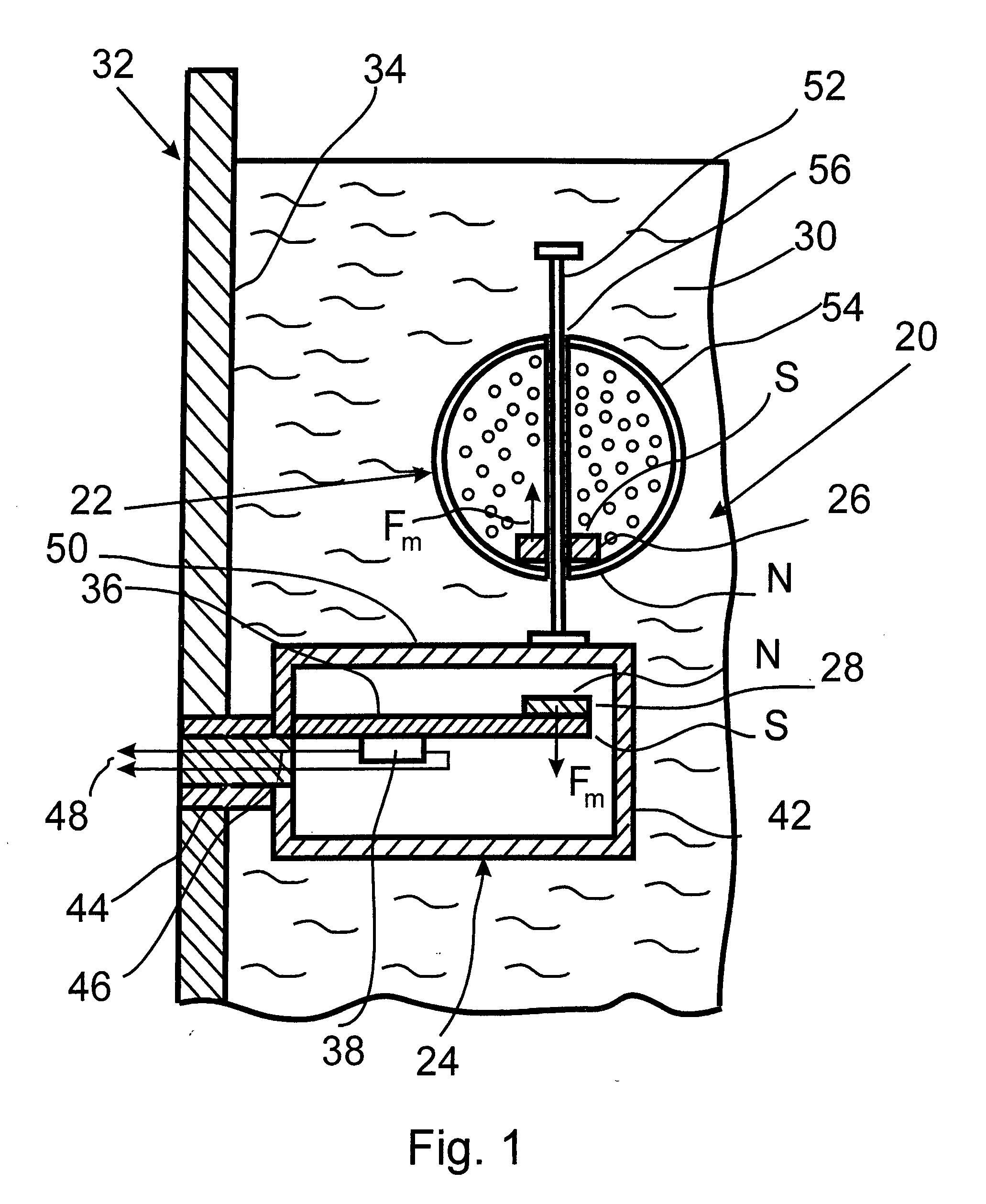

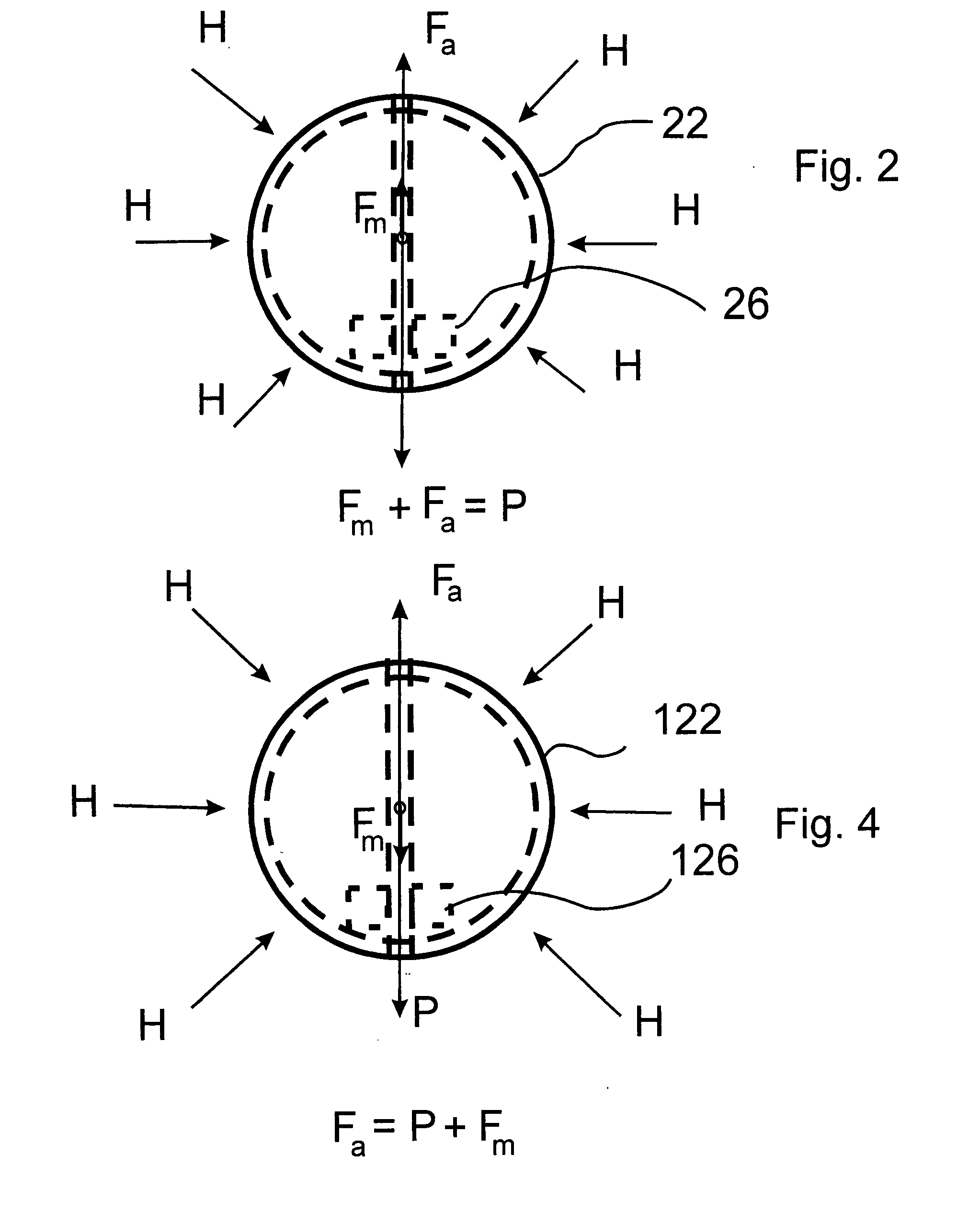

A sensor for measuring density of a liquid that comprises a float unit having a sealed hollow casing that contains a first magnet and a strain-gauge unit having a sealed hollow casing that contains a strain gauge and a second magnet arranged coaxially to the first magnet. Coaxiality of the magnets is provided by means of a guide rod installed on the casing of the strain-gauge unit and used to guide the float unit by inserting the guide rod into the central opening of the float unit casing. A characteristic feature of the sensor is that changes in the density of the liquid that cause displacement of the float cause detectable deformations of the strain gauge via forces of magnetic interaction between the first and second magnets without physical contact between the magnets. Since the elements of the sensor are located in sealed casings, they are not subject to damage and do not require maintenance.

Owner:PROVINA

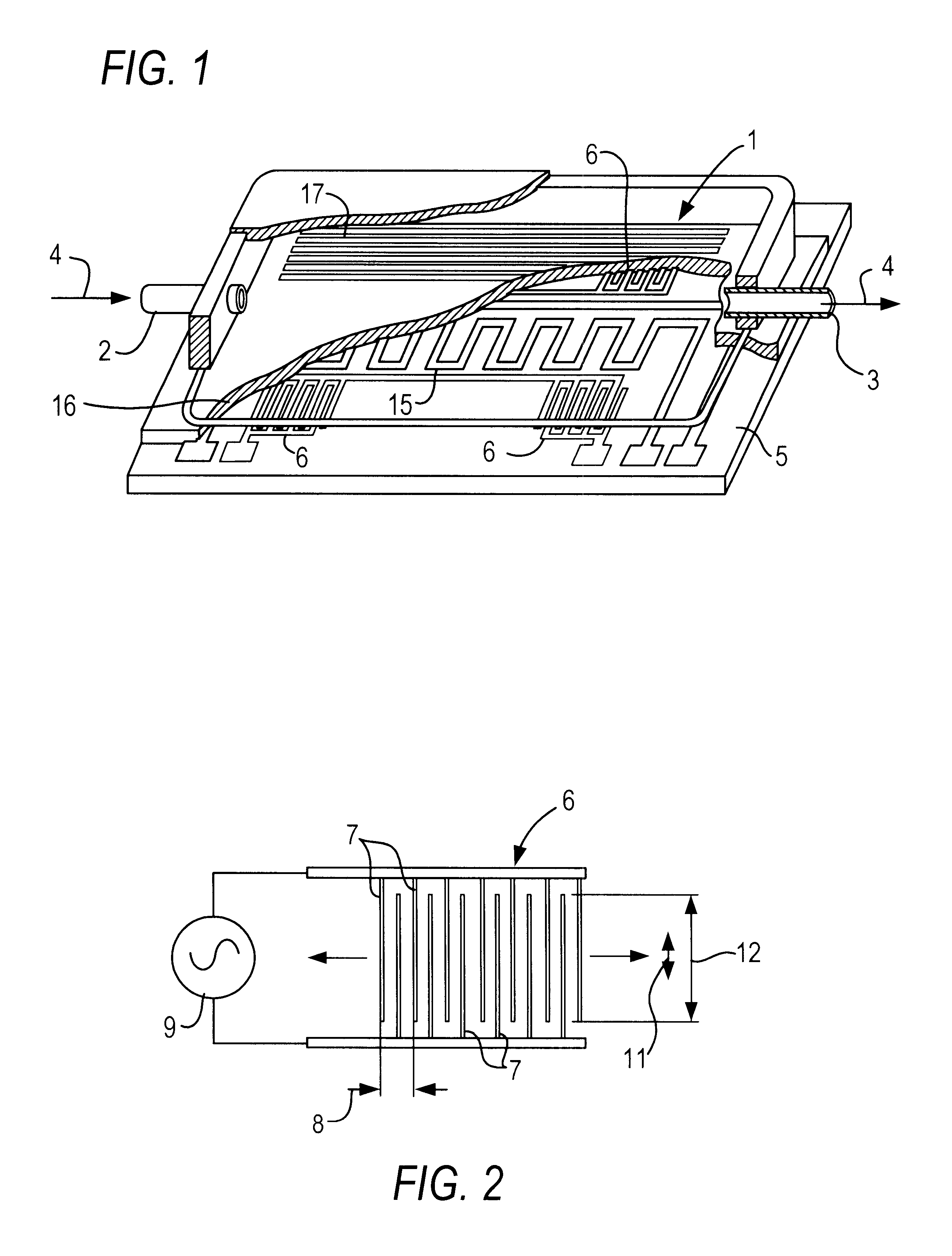

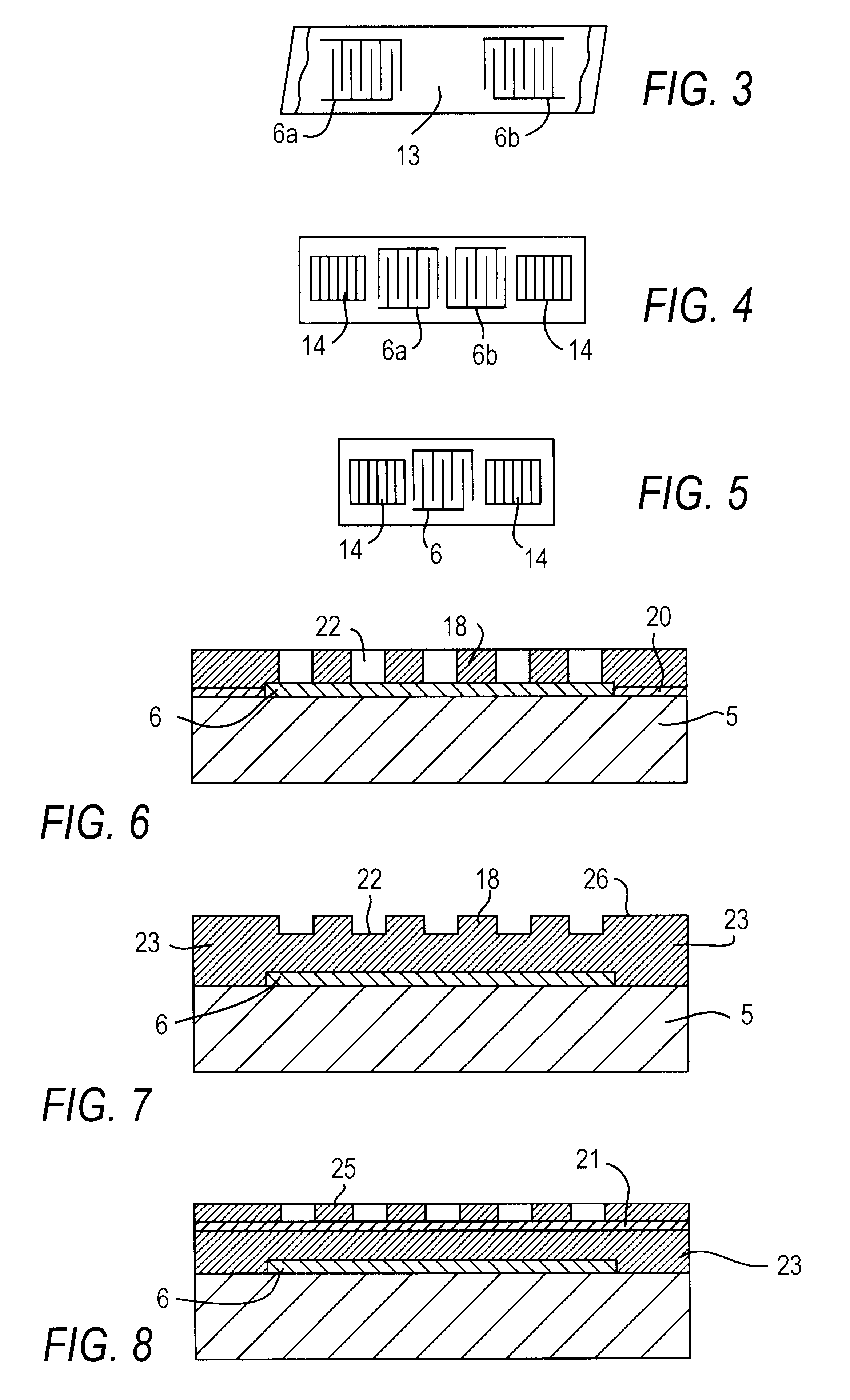

Sensor array and method for determining the density and viscosity of a liquid

InactiveUS6543274B1Analysing fluids using sonic/ultrasonic/infrasonic wavesFlow propertiesSensor arrayLiquid density

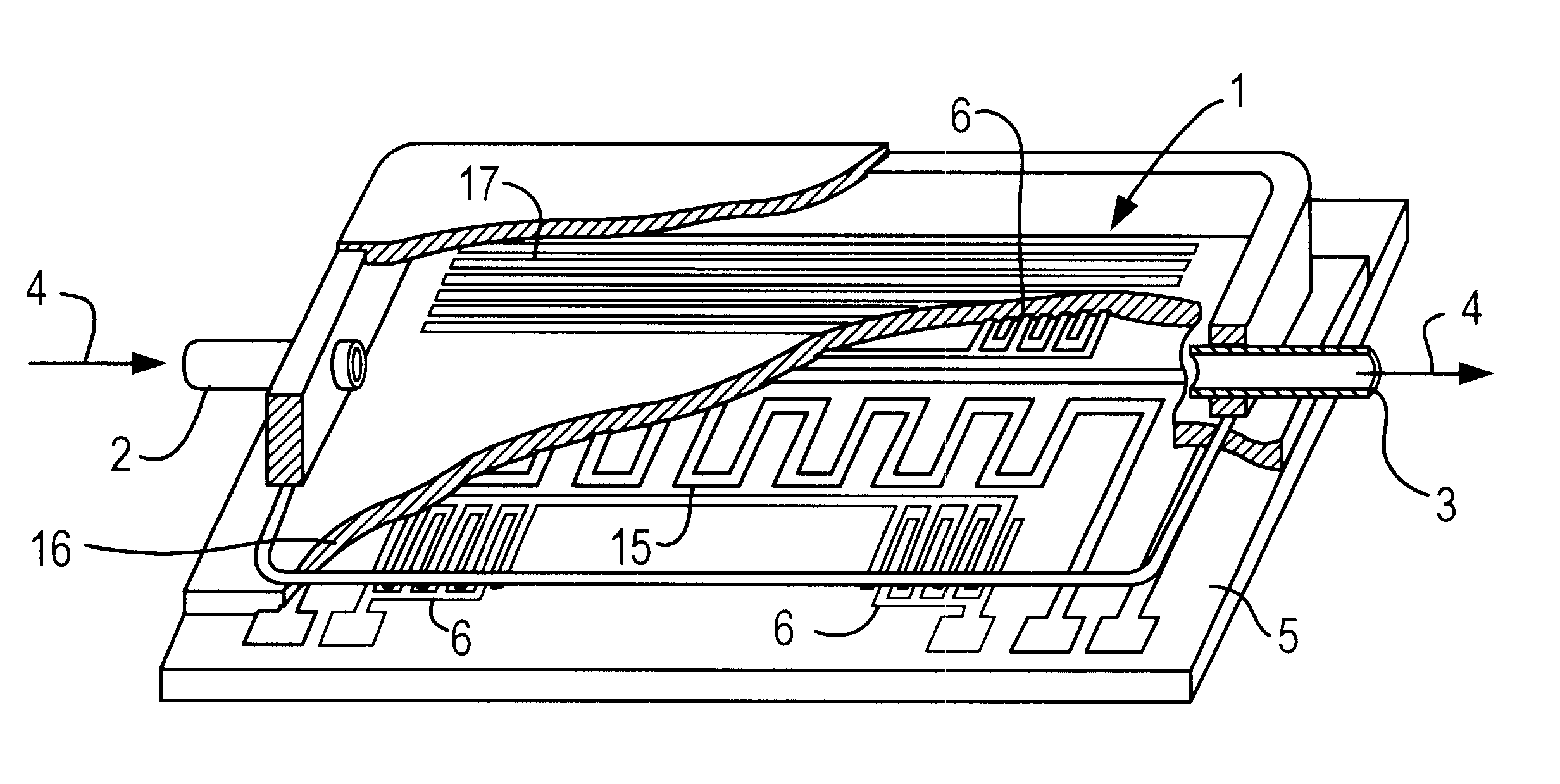

A sensor arrangement for ascertaining the density and the viscosity of a liquid is proposed, having an arrangement comprising at least two basic sensor elements, at least one of which can be wetted with the liquid, and having electro-acoustical transducers (6) in the basic sensor elements for generating and detecting surface acoustic waves with predetermined wave modes, from whose propagation behavior along a measurement path a measure for the density and the viscosity of the liquid can be ascertained. Liquid traps (17) for the liquid, which extend in the applicable measurement path, are disposed in the region of at least one of the basic sensor elements, parallel to the direction of propagation of the surface acoustic wave.

Owner:ROBERT BOSCH GMBH

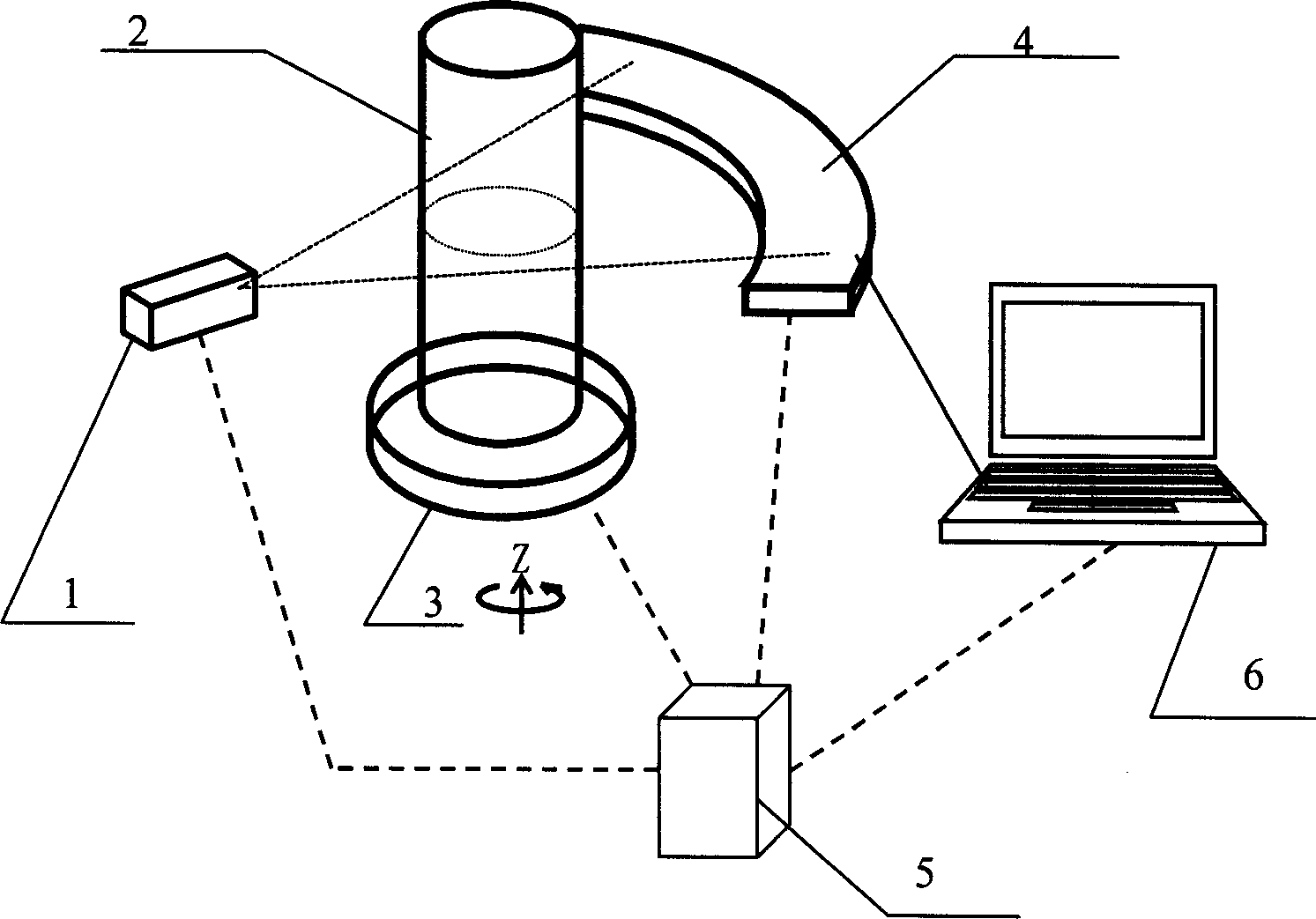

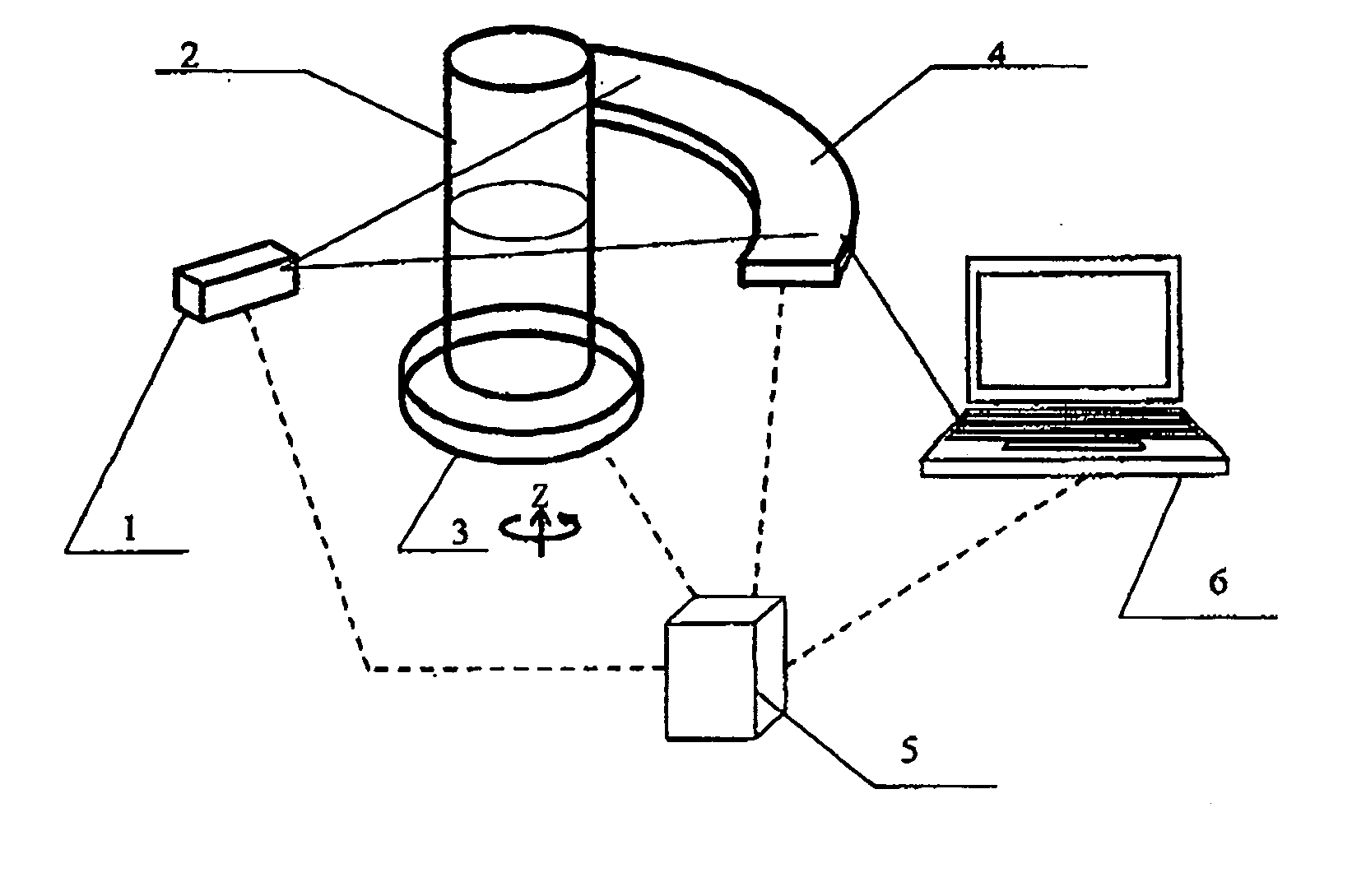

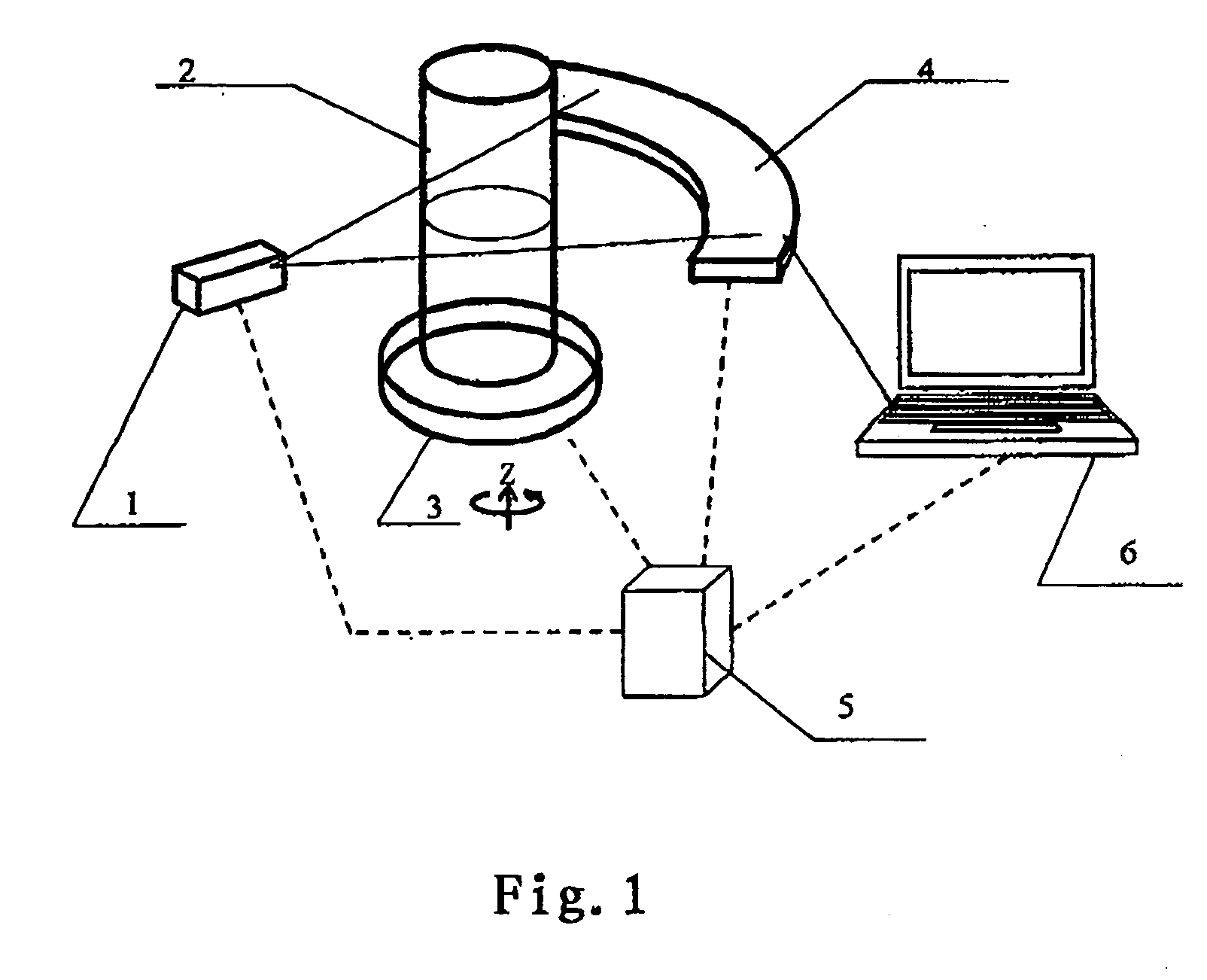

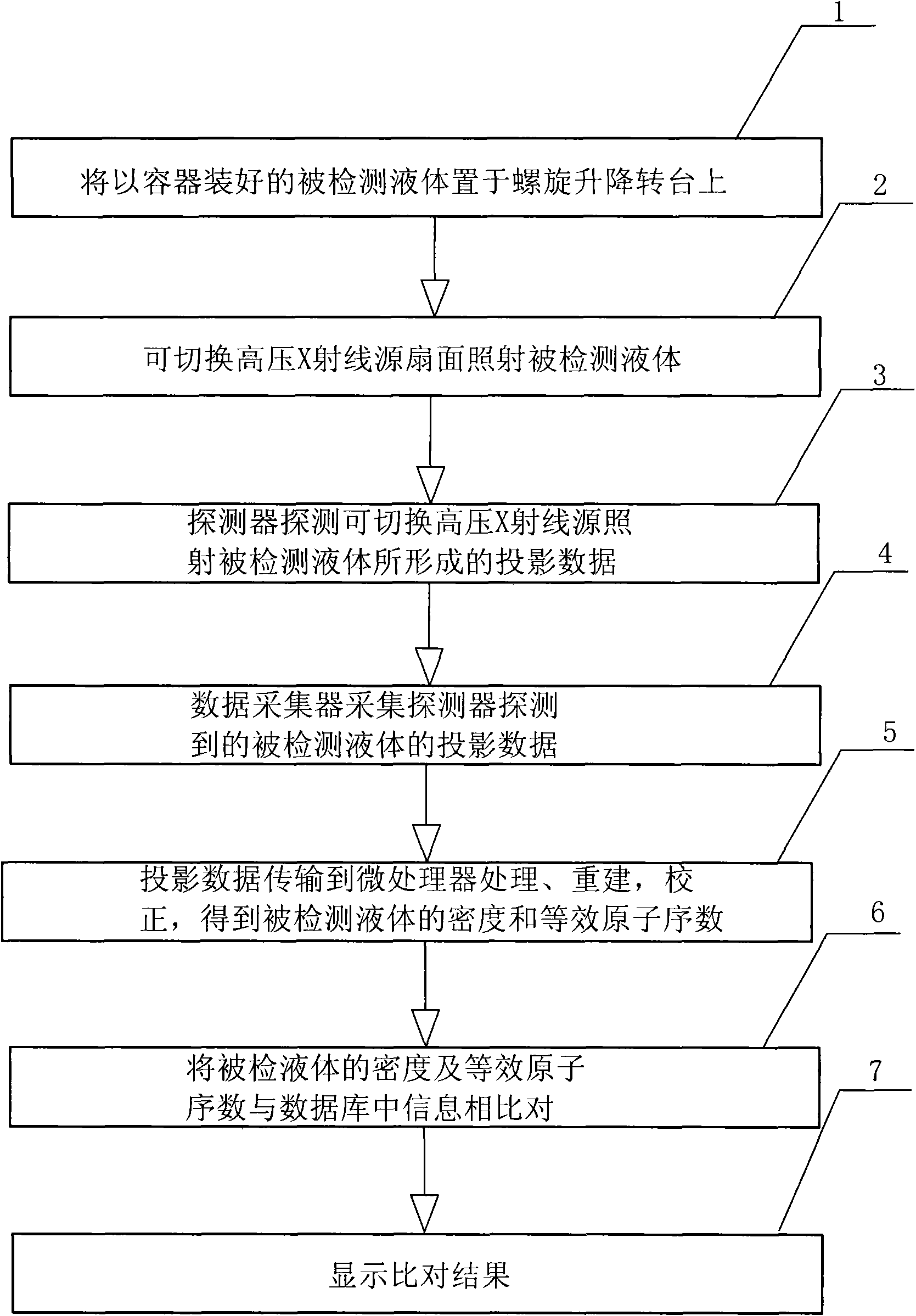

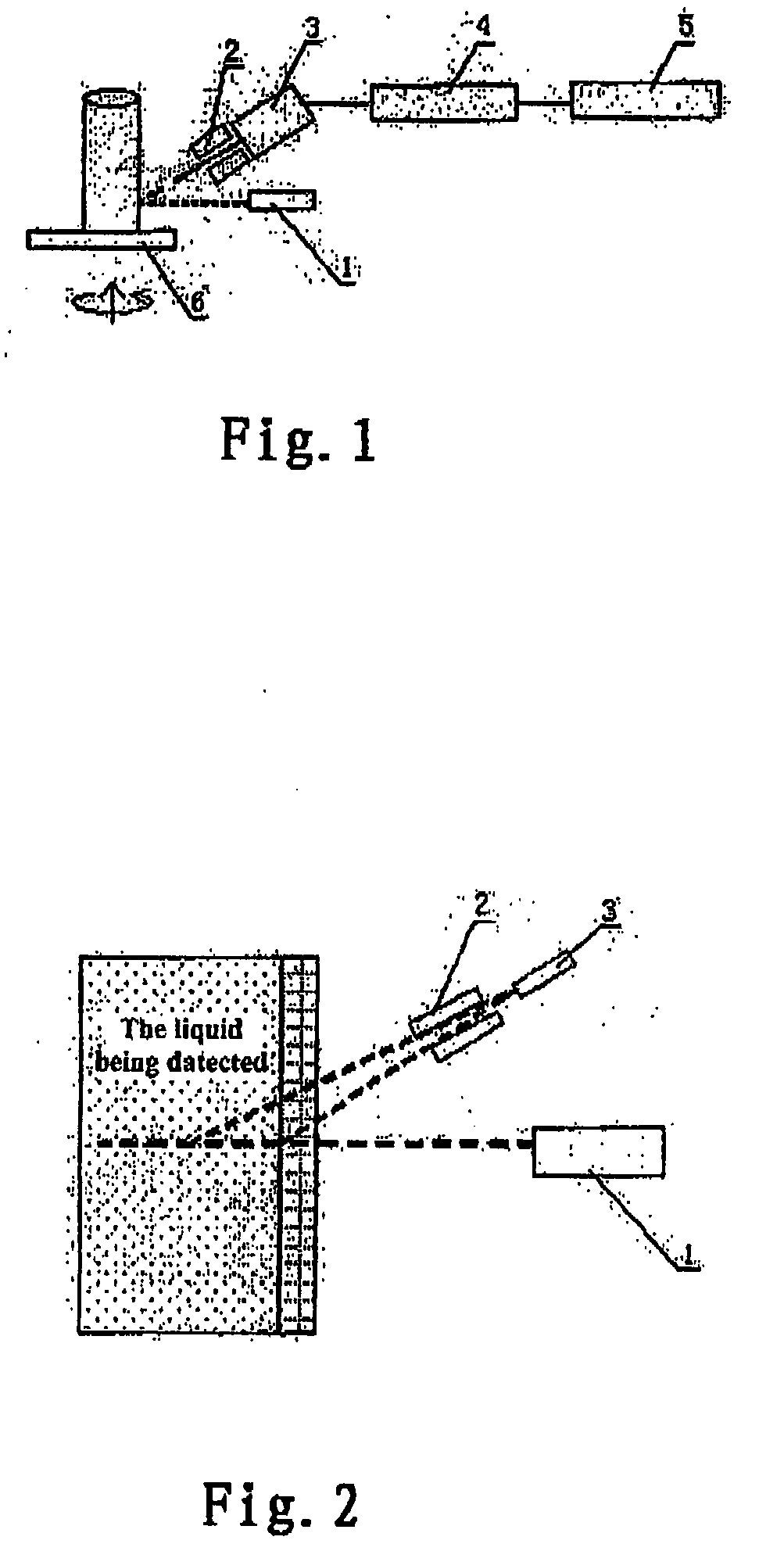

Safety CT inspection and inspector for liquid by ray resource

ActiveCN1779444AReduce volumeImprove anti-interference abilityMaterial analysis by transmitting radiationLiquid densityLight beam

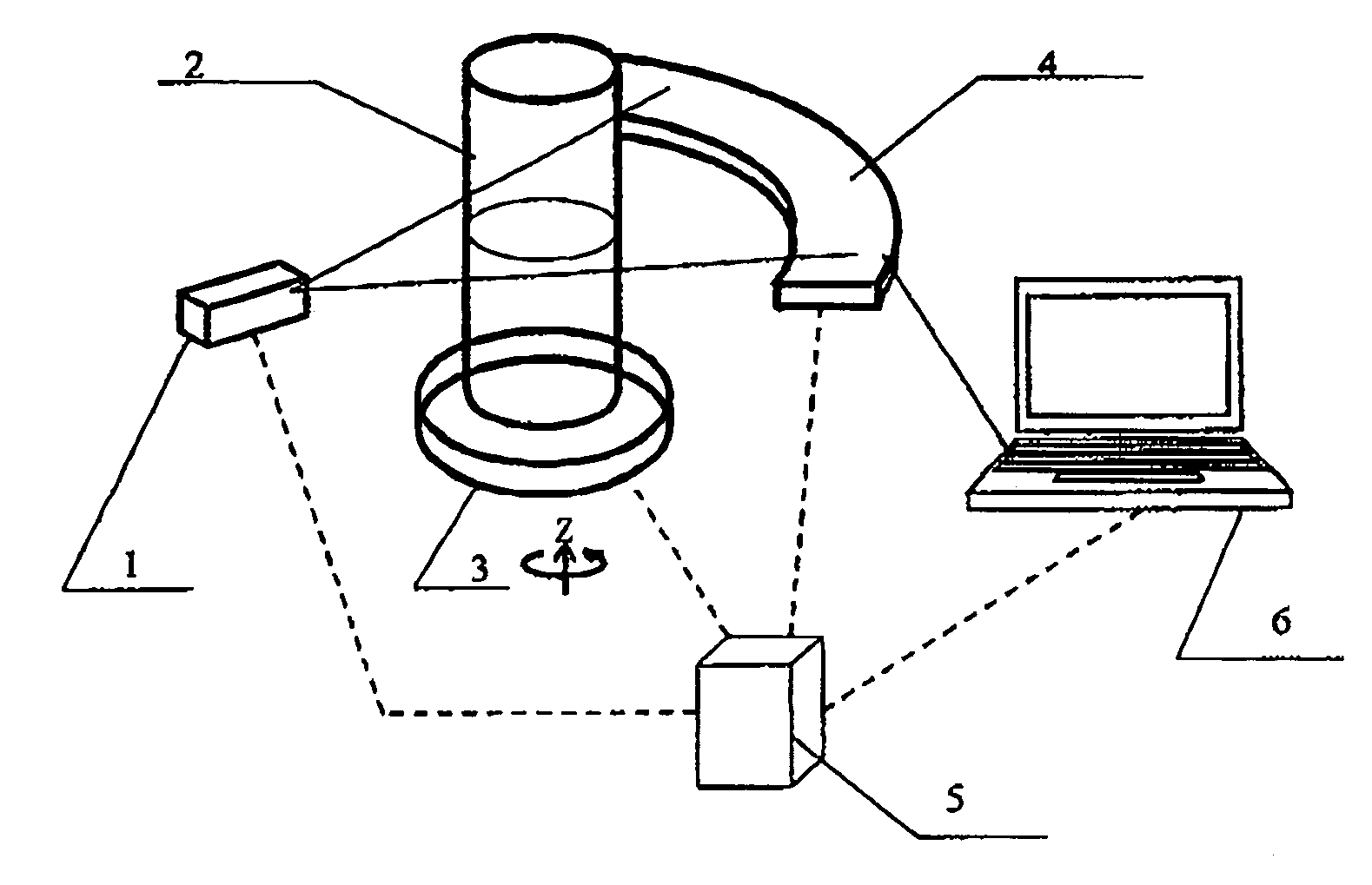

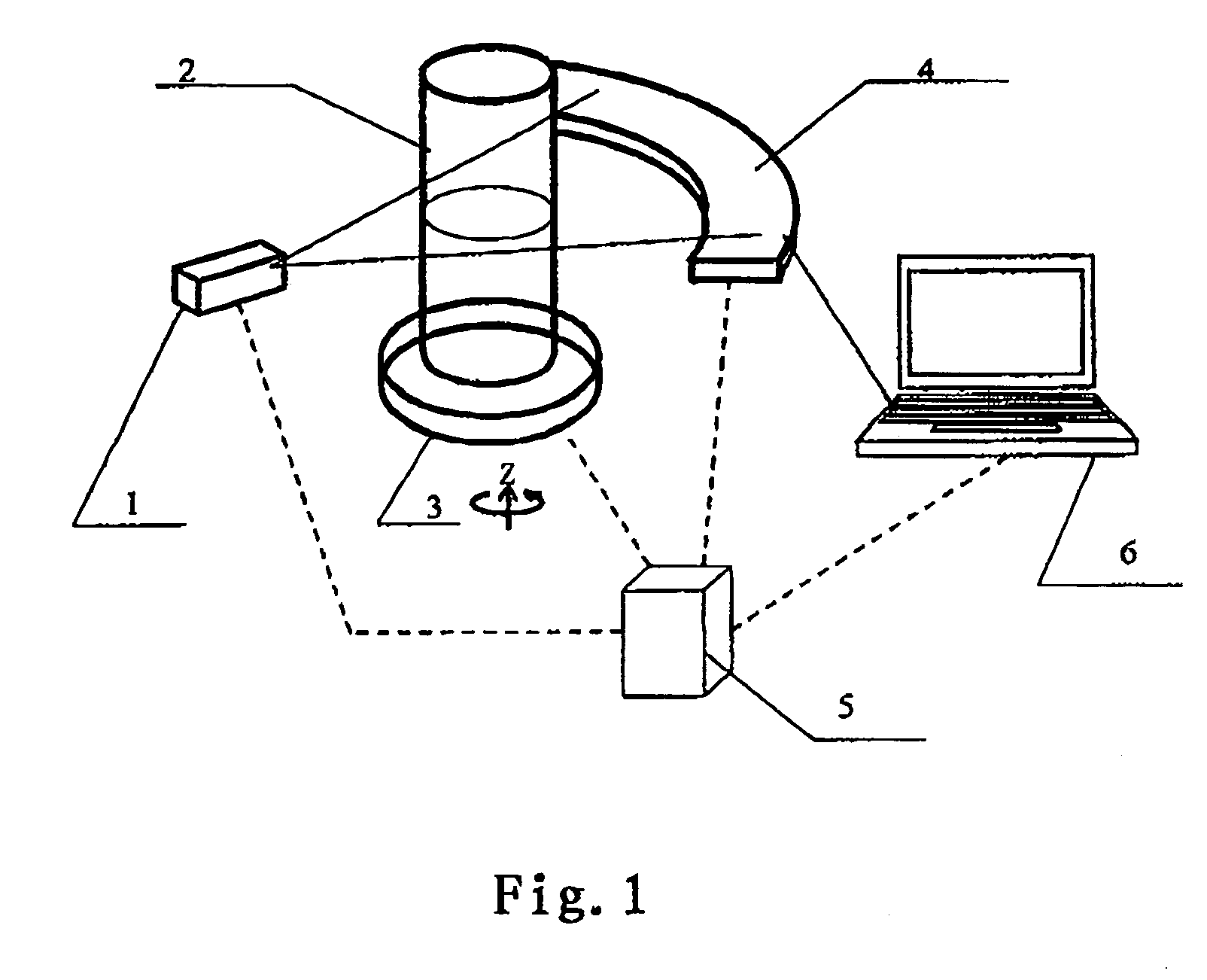

A method for carrying out CT safety detection on liquid by radioactive source includes setting detected liquid article on rotary platform, emitting ray on liquid article by radioactive source and passing ray through said article to be received by detector and data collector just facing ray beam and to be formed as projective data, transmitting projective data to computer data processor for obtaining liquid density of detected liquid article, comparing obtained density to density of dangerous article stored in databank and displaying detection result of detected liquid article in direct ¿C viewing way.

Owner:TSINGHUA UNIV +1

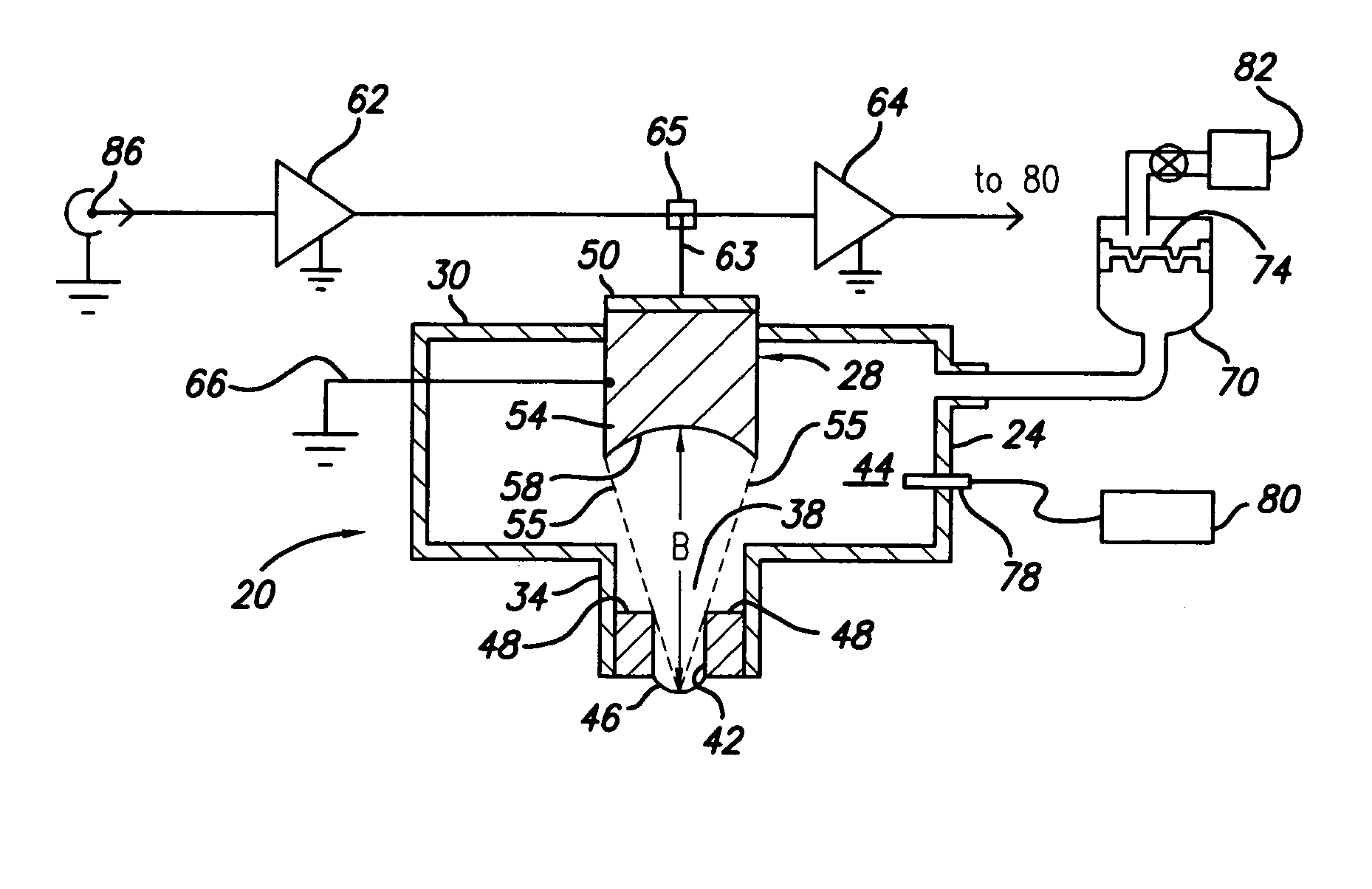

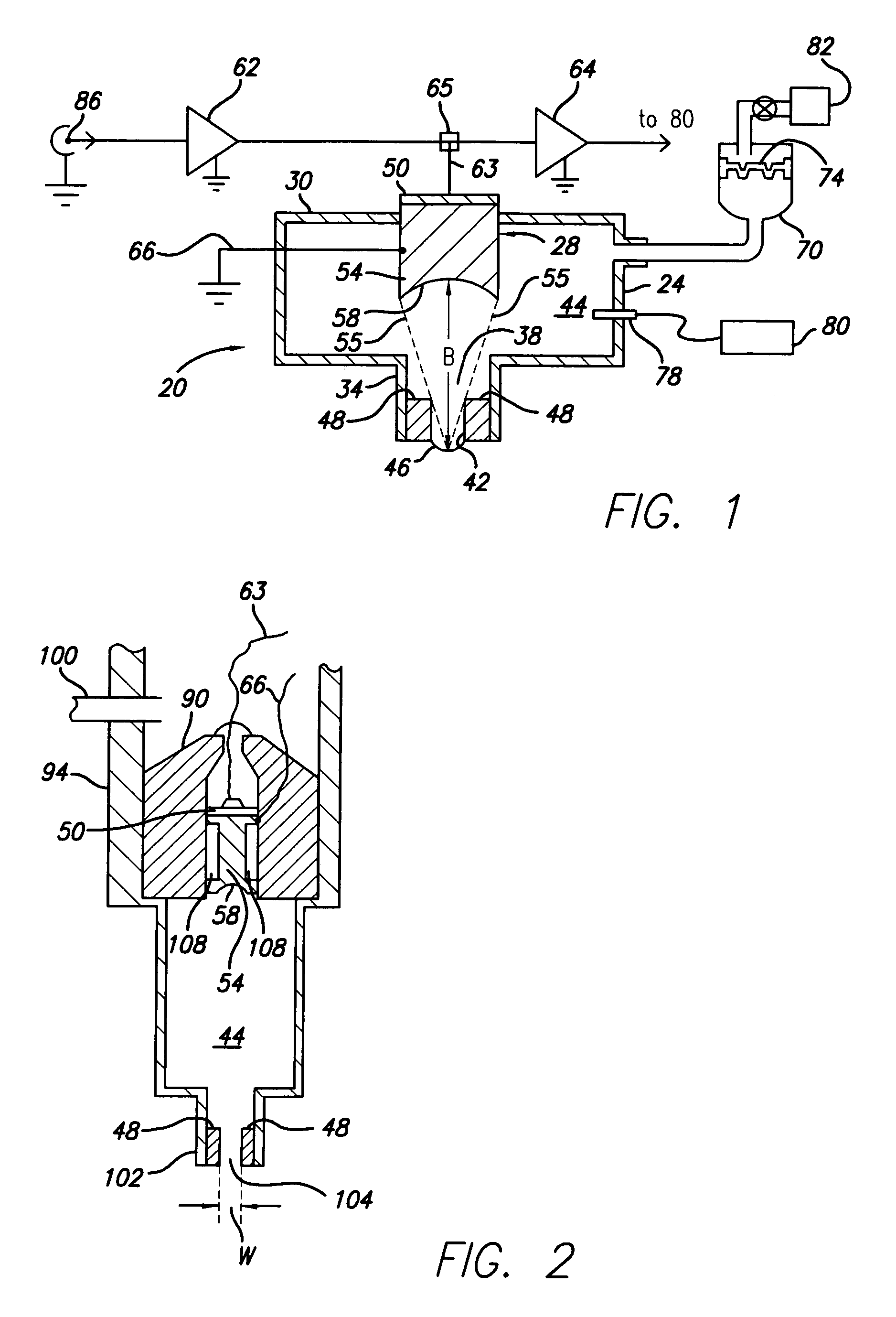

CT method and apparatus for liquid safety-detection with a radiation source

ActiveUS20060239402A1Small volumeImprove anti-interference abilityWithdrawing sample devicesUsing wave/particle radiation meansLiquid densityRadiation imaging

A CT method and an apparatus for liquid safety-detection with a radiation source relate to a radiation imaging detecting technology field. The invention comprises using a radiation source, a detector and data collector, a computer data processor; and the main steps are: 1) a liquid article to be detected being placed onto a rotary platform which is rotatable; 2) the ray emitted from the radiation source passing through the liquid article, and being received and formed into projection data by the detector and data collector; and 3) the projection data being transmitted to the computer data processor, which processes it to obtain the liquid density of the detected article, compares the result with the densities of dangerous articles in a current database, and then visually displays the detected information of the detected liquid article. Comparing to the prior art, the invention has a small volume, a strong anti-interference, a high accuracy of detection, an easy shielding, and a high use safety and reliability.

Owner:TSINGHUA UNIV +1

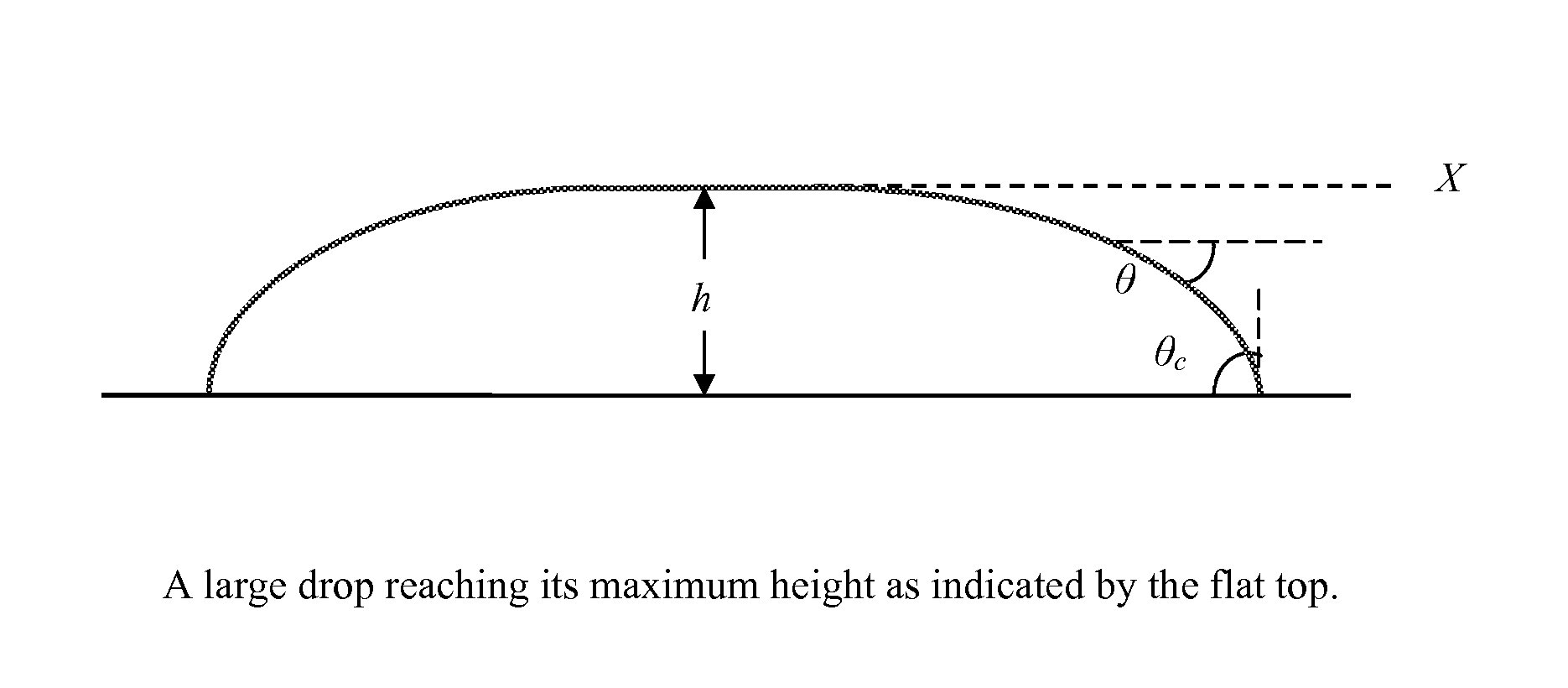

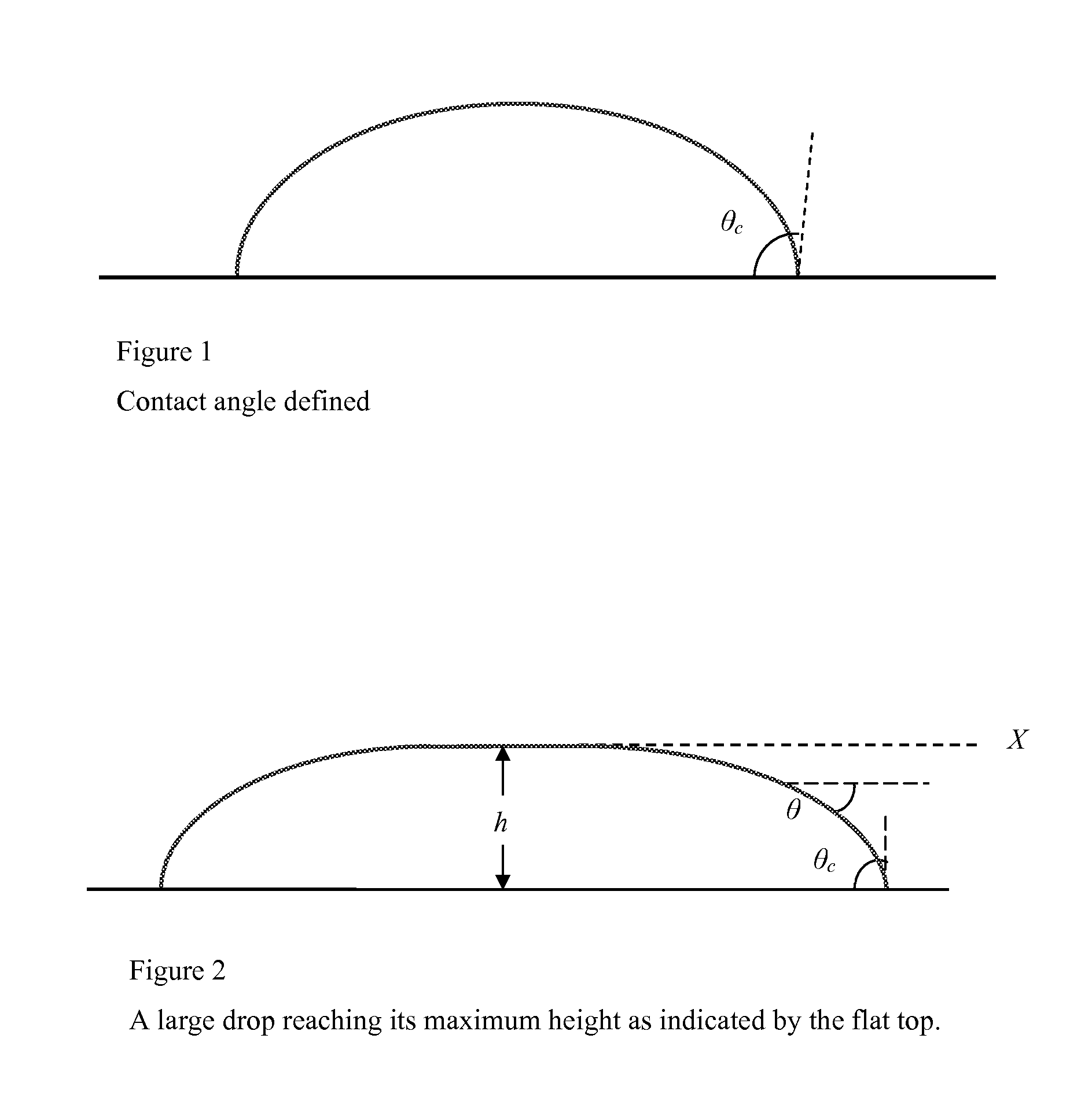

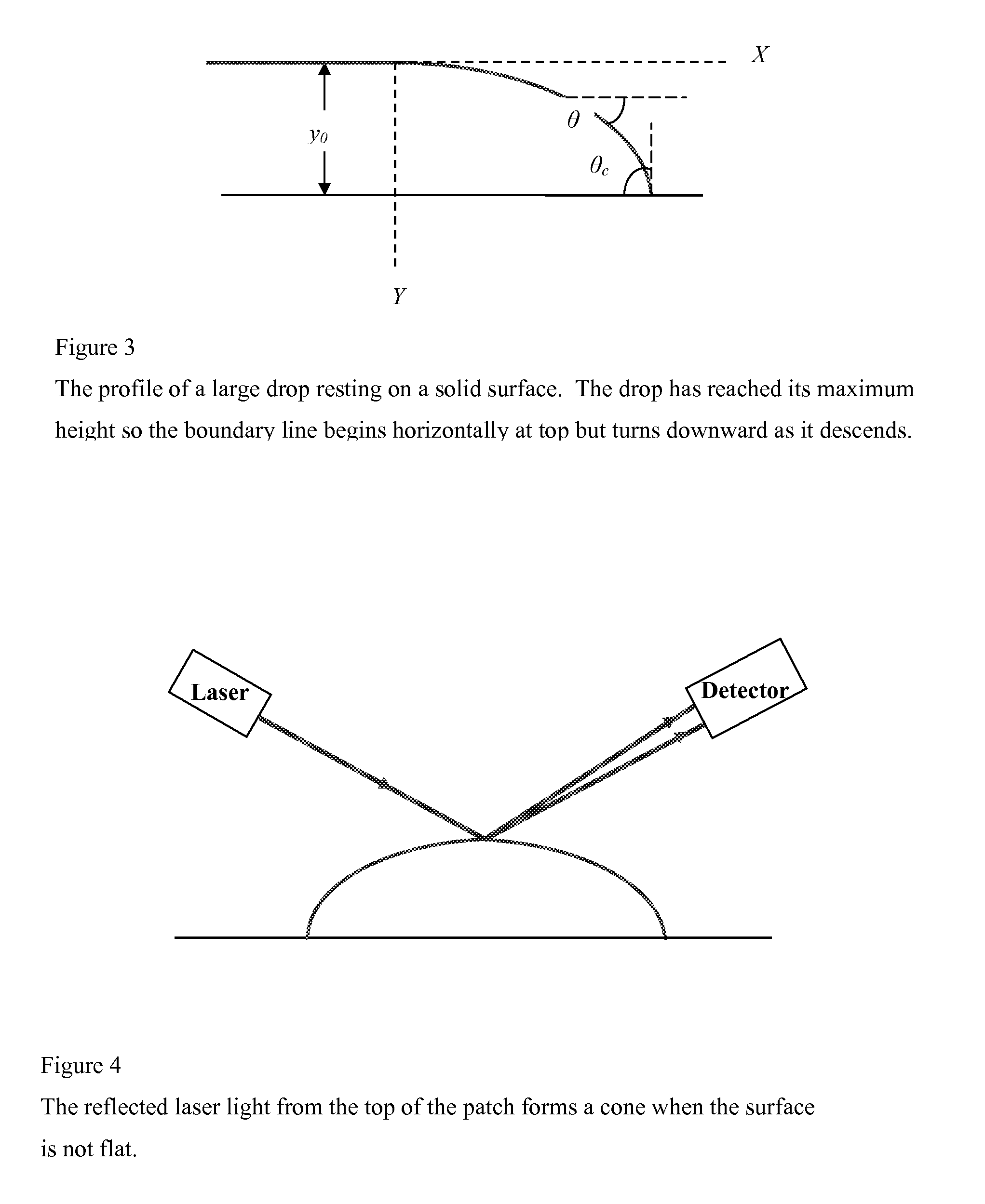

Method and apparatus for measurement of fluid properties

A method and apparatus for determining the contact angle and / or surface tension of a liquid on a solid surface is described. The method involves placing a fluid drop on a solid surface, and gradually increasing its volume by adding more fluid, while continuing to determine the corresponding increase in fluid height, until the drop attains maximum height beyond which additional fluid only increases the drop footprint and not height, and determining the equilibrium height and in turn the contact angle by means of an equation that correlates contact angle with depth below the fluid surface, together with the fluid surface tension and liquid density. The method may in turn be used to determine the fluid surface tension from the equilibrium height when the contact angle and density of the fluid are known.

Owner:UNIV OF NORTHERN IOWA RES FOUND

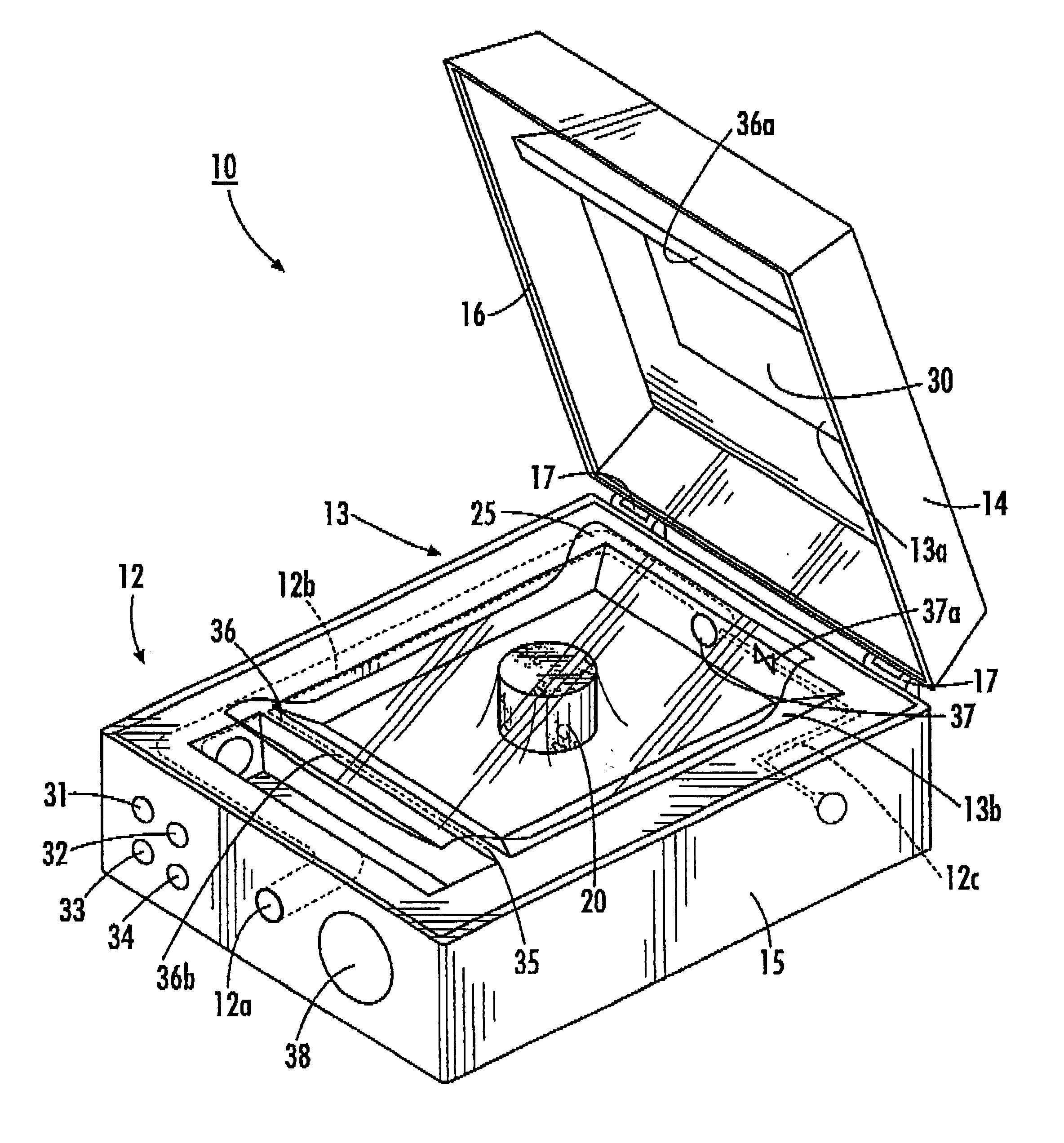

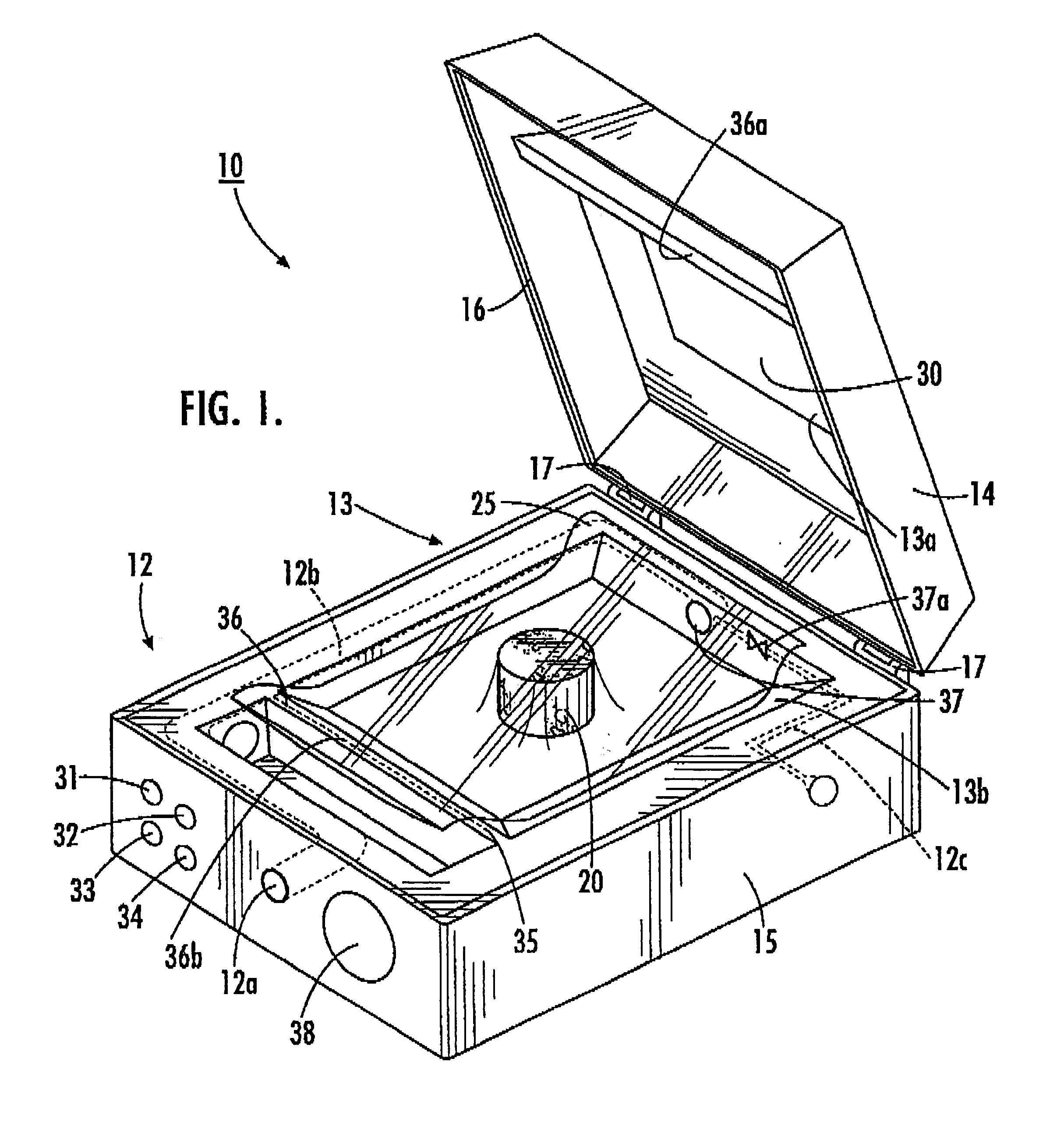

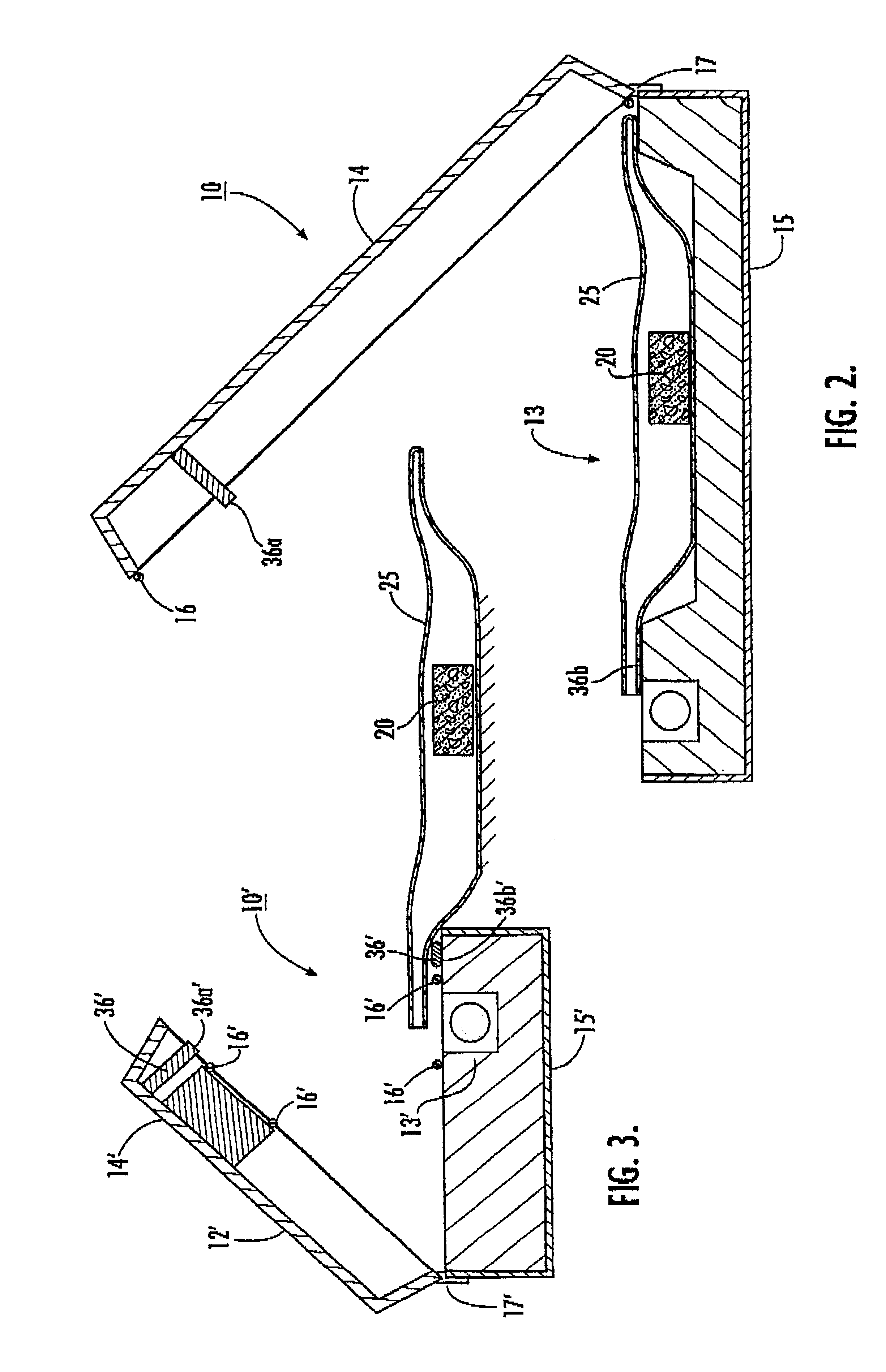

Methods and apparatus for sealing a porous material sample for density determination using water displacement methods and associated surface conformal resilient compressible bags

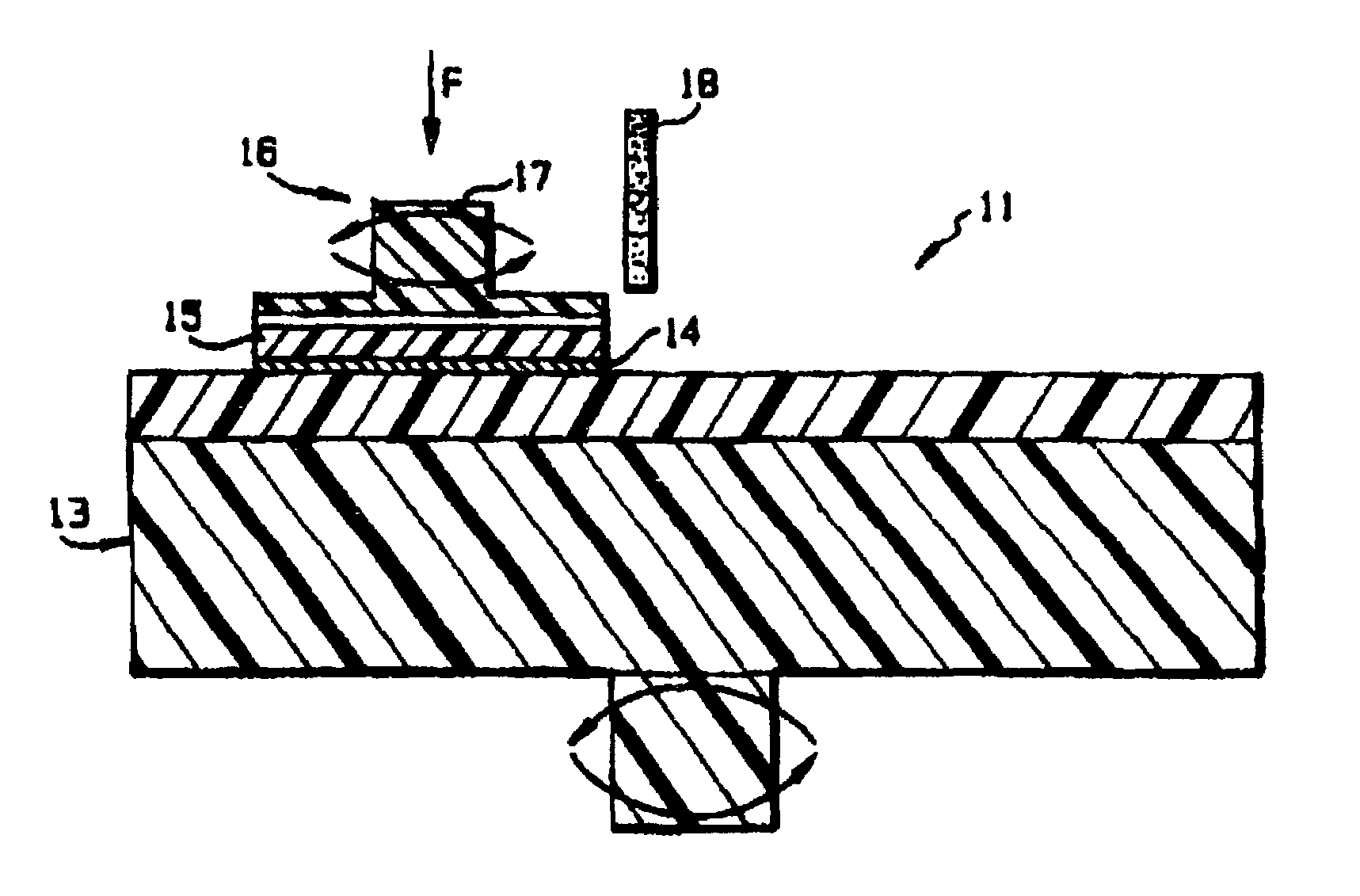

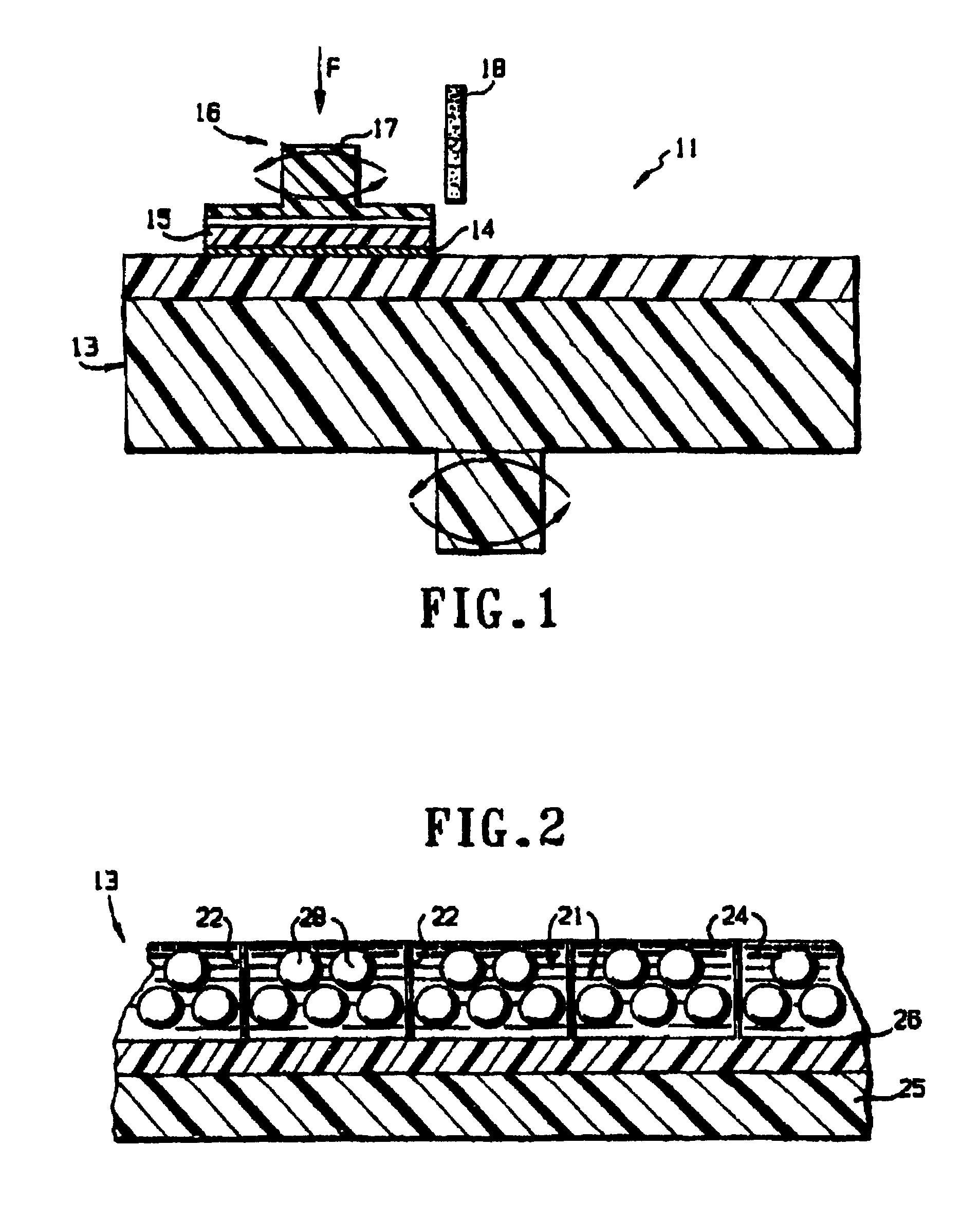

InactiveUS6321589B1Easy to useReduce operator-induced variation on sealed configurationMaterial analysis by measuring buoyant forcesMaterial analysis by observing immersed bodiesPorosityVacuum pressure

Water-resistant preformed resilient bags are applied to a porous material specimen having a coarse external surface to provide for more consistent measurement results in water displacement tests. The preformed bag is configured to collapse and substantially conform to the material specimen's external surface and to provide planar collapsed portions extending away from the specimen. The preformed bags are precision manufactured and each applied to a respective specimen in a manner in which the bag consistently displaces the same volume of water when used in water displacement tests over many specimens. The volume of the bag can be accounted for when obtaining the volume of the specimen. The method of sealing the specimen includes inserting the specimen into a preformed bag and collapsing and sealing the bag such that is conformal to the external surface of the specimen. The method can provide a preferred operating vacuum pressure corresponding to the specimen type (such as porosity or coarseness) which can automatically direct the operational parameters of the bag sealing operation. The system includes a preformed bag configured to receive a material specimen therein, a vacuum apparatus for removing the air from the bag, and a sealing means for sealing the bag. In one embodiment the vacuum apparatus includes an integrated scale for measuring various weights associated with the specimen for liquid density determinations.

Owner:INSTROTEK

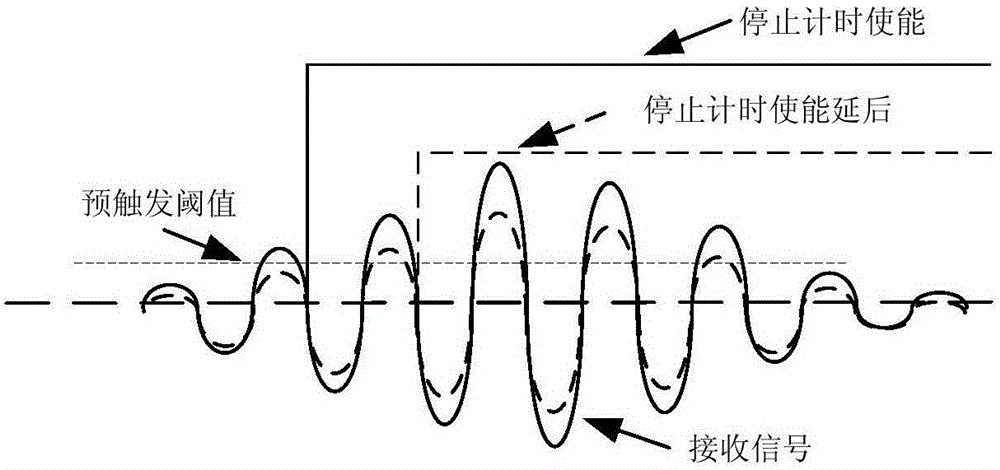

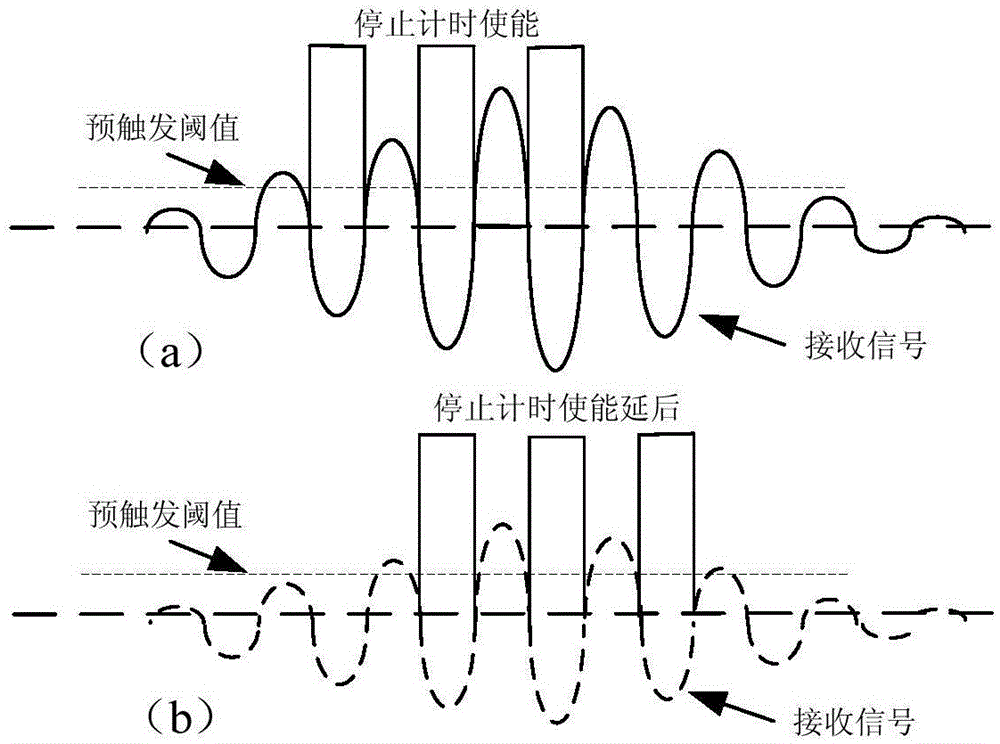

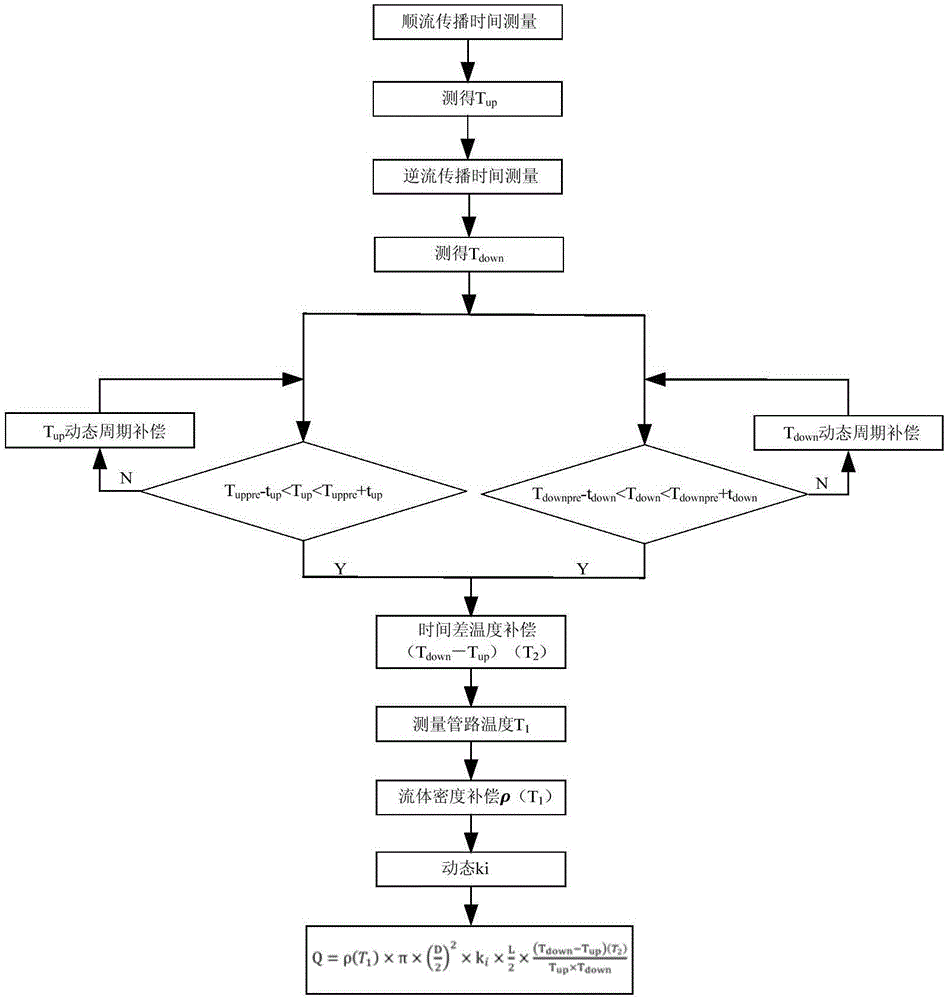

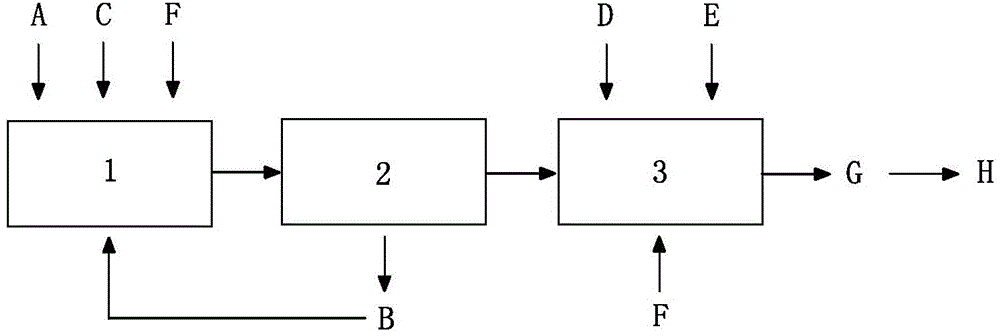

Dynamic compensation method for ultrasonic flow meter

ActiveCN105091970AEliminate calculation biasImprove calculation accuracyTesting/calibration apparatusVolume/mass flow measurementLiquid densityLookup table

The invention discloses a dynamic compensation method for an ultrasonic flow meter. The dynamic compensation method comprises the step of measuring time dynamic period compensation and further comprises the step of conducting fluid density compensation, the step of conducting time difference temperature compensation of ultrasonic countercurrent spreading time and ultrasonic fair current spreading time, the step of looking up a calibration coefficient dynamically according to a calibration coefficient lookup table established in advance and the step of calculating the flow of multistage dynamic compensation, and therefore measuring time dynamic period compensation is conducted on the problem that ultrasonic spreading time measurement has deviation due to the water attack effect brought by instant opening and closing of a valve or residual bubbles in a pipeline; furthermore, compensation is conducted on the liquid density change caused by the temperature; temperature compensation is conducted on the time difference benchmark treating the influences of the temperature change of an element in a circuit box, the lookup table is established on the calibration coefficient without a constant value, and dynamic looking-up is conducted during flow calculation.

Owner:BEIJING INST OF CONTROL ENG

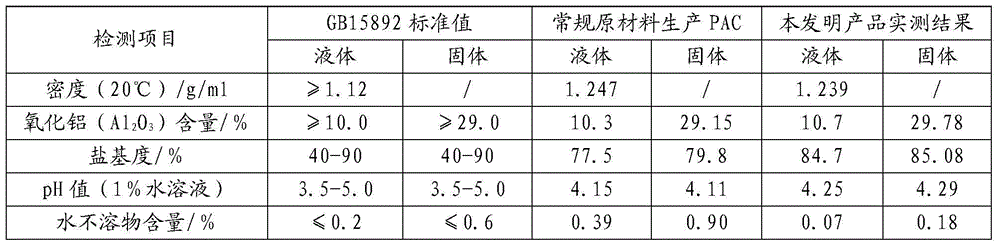

Recycling process of polyaluminium chloride filter residue

ActiveCN104402031AReduce manufacturing costReduce the dosing ratioAluminium chloridesLiquid densityProcess equipment

The invention discloses a recycling process of polyaluminium chloride filter residue; the process is as follows: adding water and hydrochloric acid into a first reaction kettle to prepare a 22-28% hydrochloric acid solution, adding the filter residue, stirring until the filter residue is dissolved; heating to 55 to 85 DEG C, adding aluminium-containing waste slag, after the addition, controlling the material liquid system temperature to be 92 to 118 DEG C for reacting for 2.5-5h; controlling the basicity of the material liquid after the reaction to be 27% + / -11% by adjustment of weight parts of the hydrochloric acid and the filter residue; separating the residue from the material liquid after the reaction, taking mother liquor, adding calcium aluminate powder; adjusting the material liquid density to be greater than or equal to 1.20g / ml, adding a synergist solution, reacting at 85-125 DEG C for 2.5-5h to obtain liquid polyaluminium chloride; and collecting and recycling the produced filter residue for reusing in production system to continue participating into the reaction. The recycling process achieves reuse of the filter residue in the polyaluminium chloride production system without addition of process equipment and other materials, greatly reduces the polyaluminium chloride production cost, reduces filter residue emissions, and conforms to environmental protection concepts of circular economy, energy saving and emission reduction.

Owner:蓝保(厦门)水处理科技有限公司

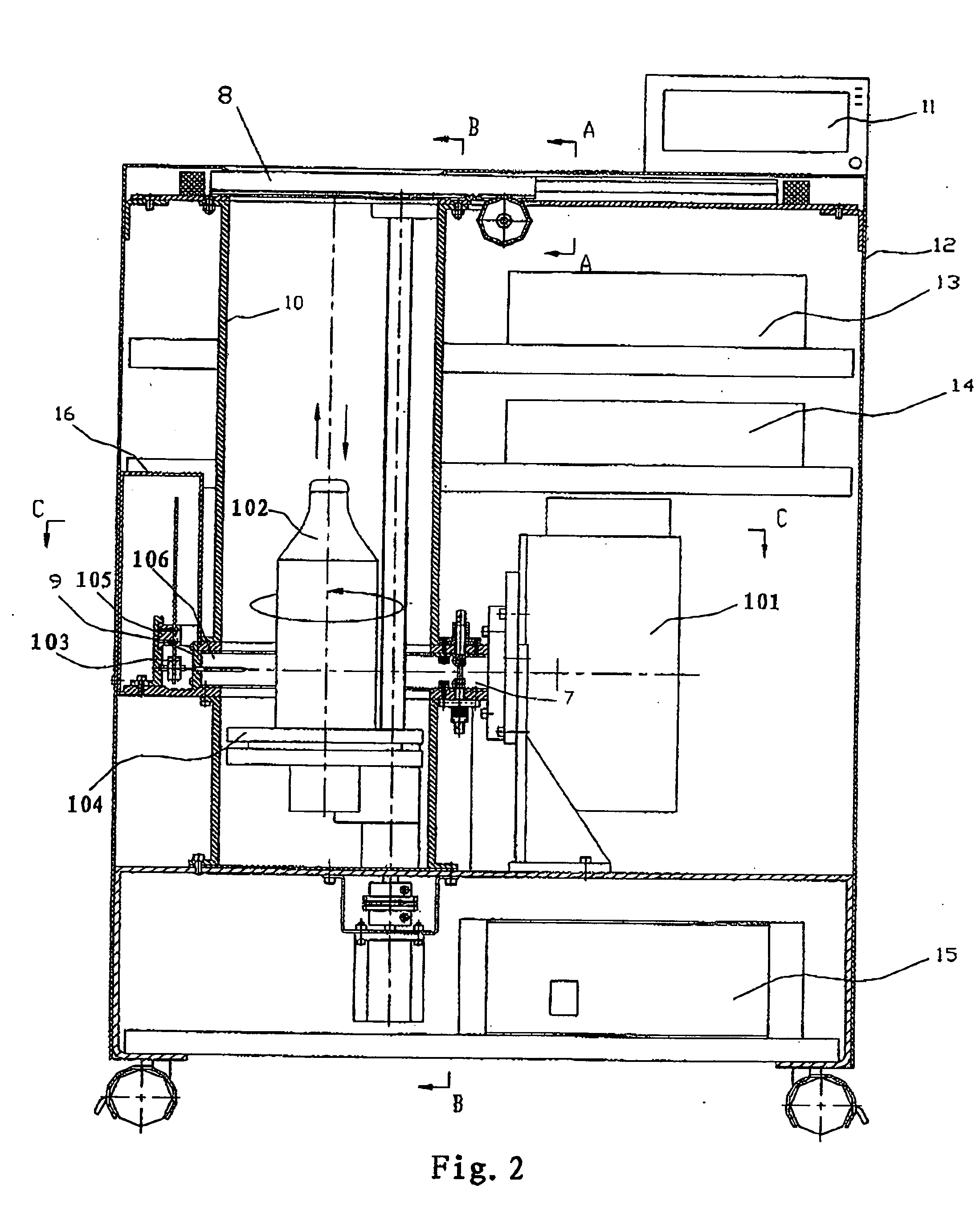

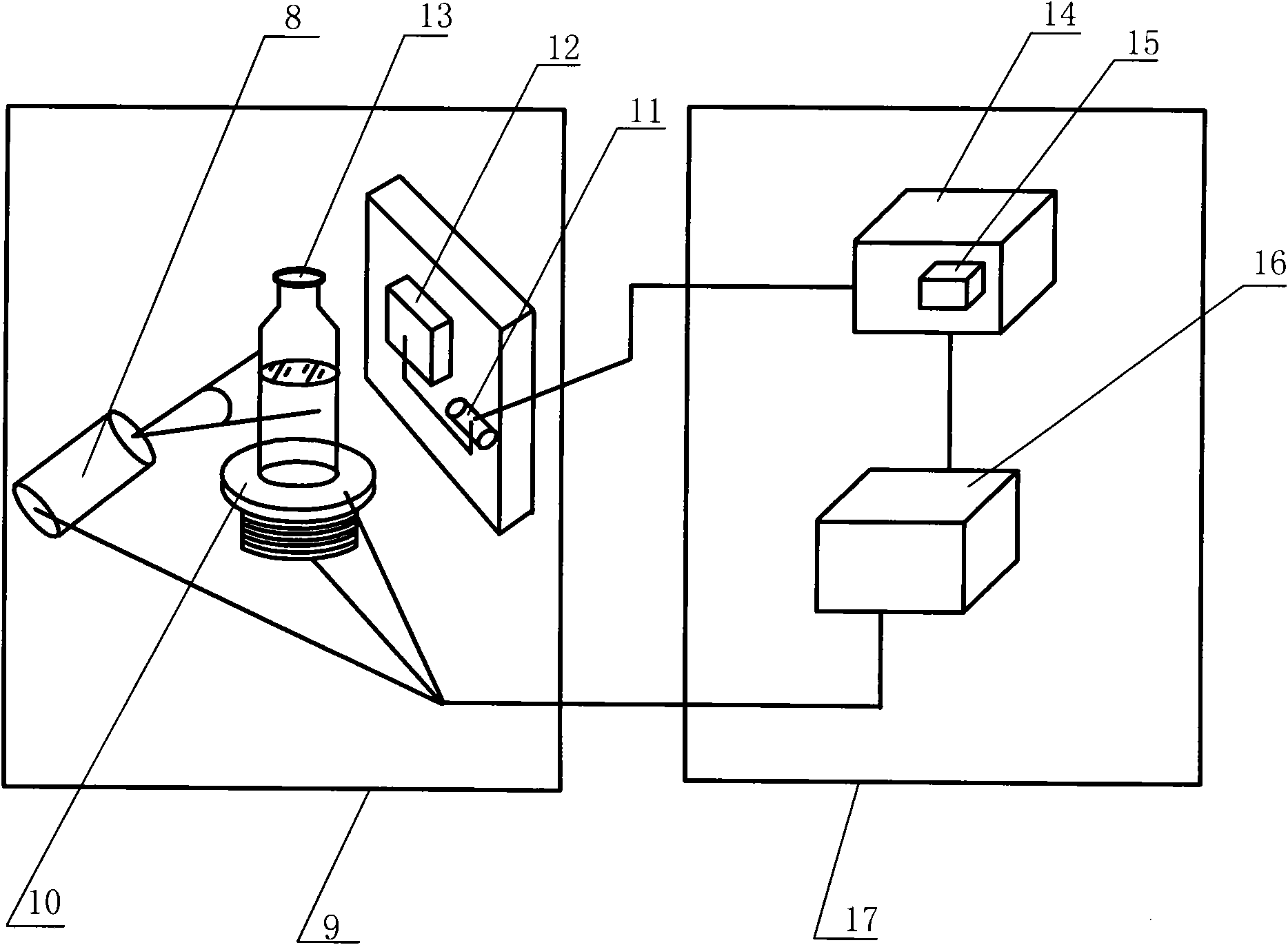

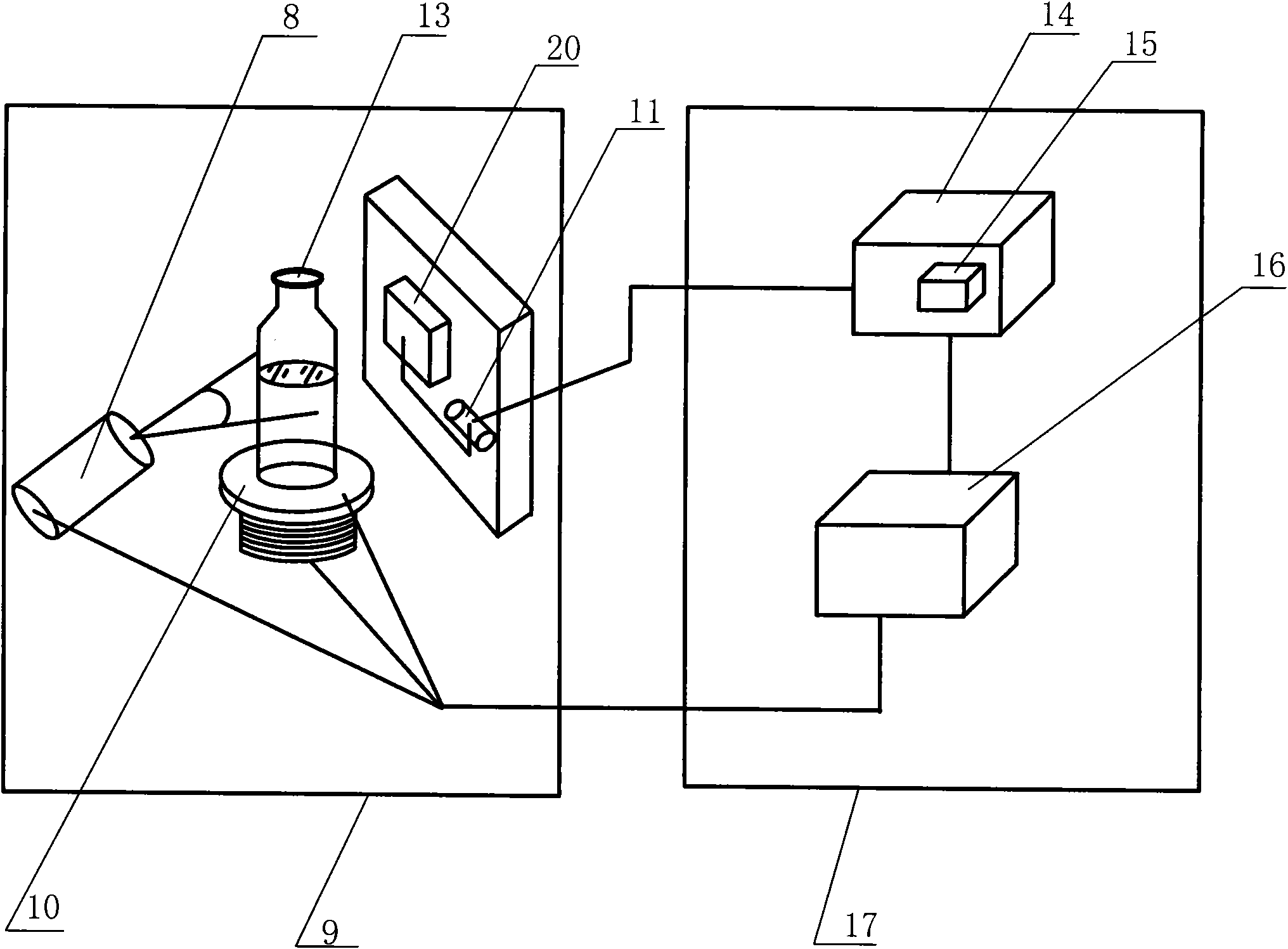

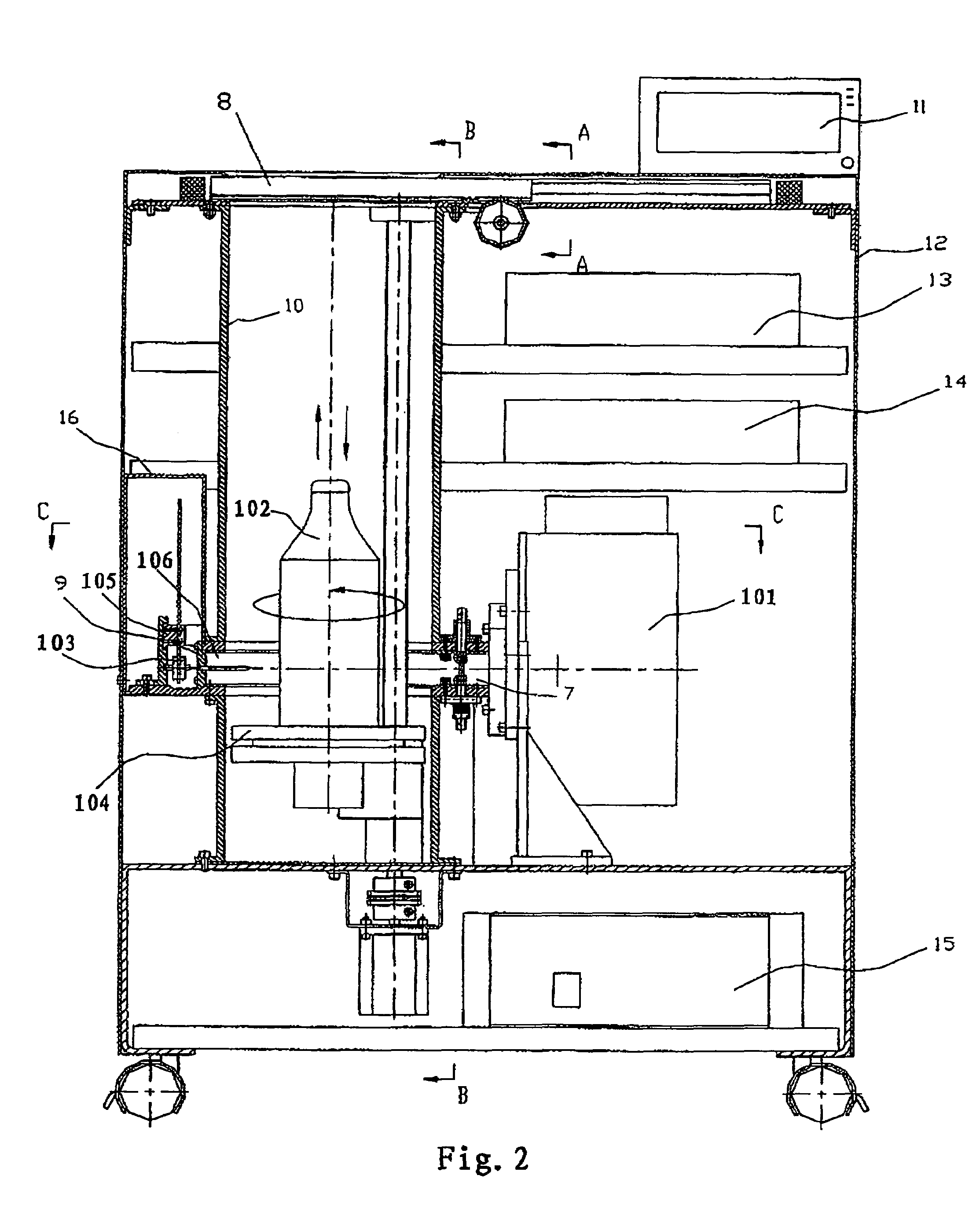

Double-energy X-ray spiral CT device for detecting liquid safety, and detection method thereof

ActiveCN101629916AStrong resolutionPrevent bringing inMaterial analysis by transmitting radiationSpecific gravity measurementLiquid densityData acquisition

The invention relates to a double-energy X-ray spiral CT system for detecting liquid safety, which comprises a detecting device consisting of an X-ray source, a rotary table, a detector or an interlayer detector and a data acquisition unit, and a control part consisting of a microprocessor and a controller, wherein the front end of the detecting device is provided with the X-ray source; the X-raysource is the switchable high-voltage X-ray source or the fixed high-voltage X-ray source; the middle part of the detecting device is provided with the spiral lifting rotary table used for placing a detected liquid; the rear side of the spiral lifting rotary table is provided with the detector or the interlayer detector; the data acquisition unit is connected with the detector or the interlayer detector; the control part comprises the microprocessor and the controller connected with the microprocessor; the controller is connected with the X-ray source and the spiral lifting rotary table; and the microprocessor is connected with the data acquisition unit. The method comprises irradiation, detection, acquisition, comparison, and obtaining a detection result. The system can detect liquid density and equivalent atomic number and ensures to accurately judge liquid property.

Owner:THE FIRST RES INST OF MIN OF PUBLIC SECURITY +1

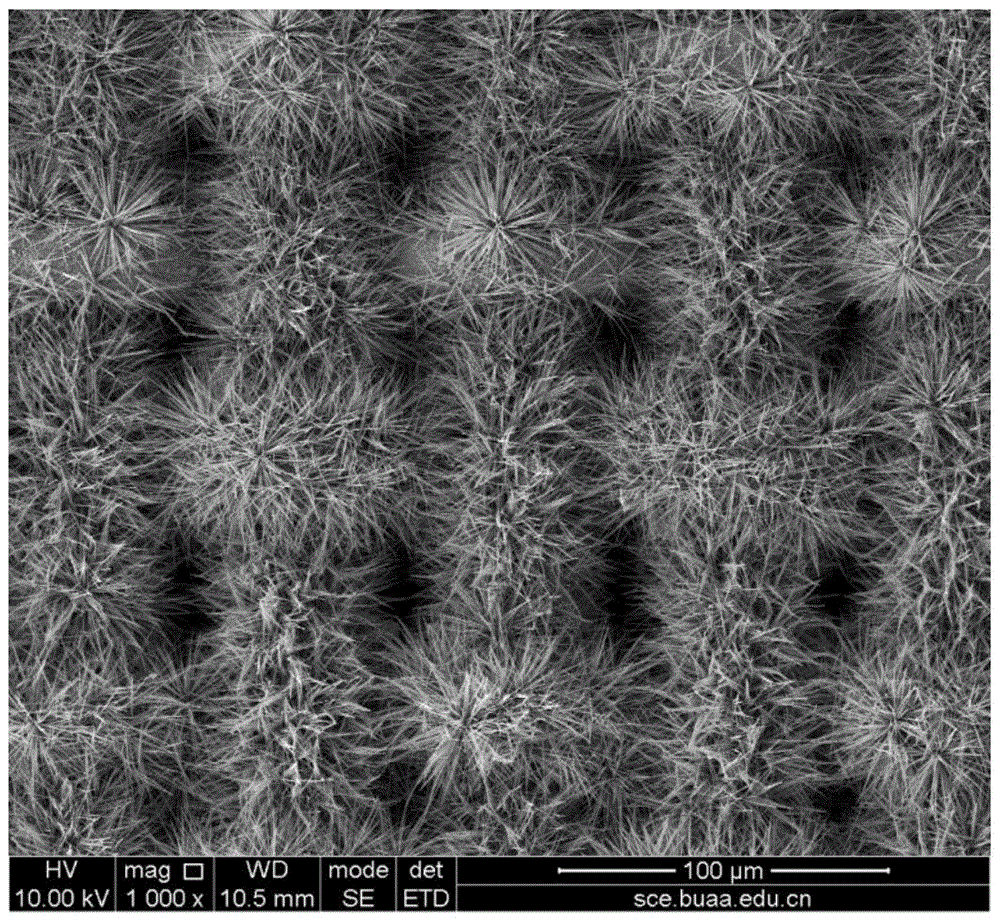

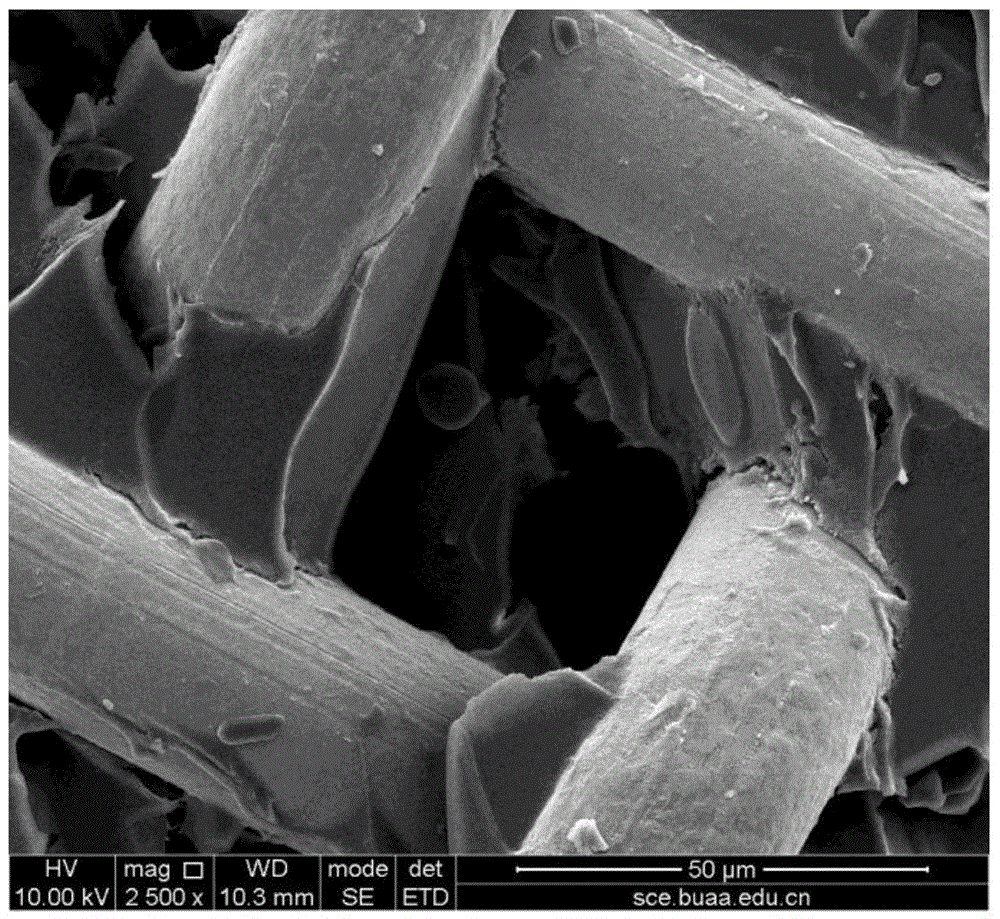

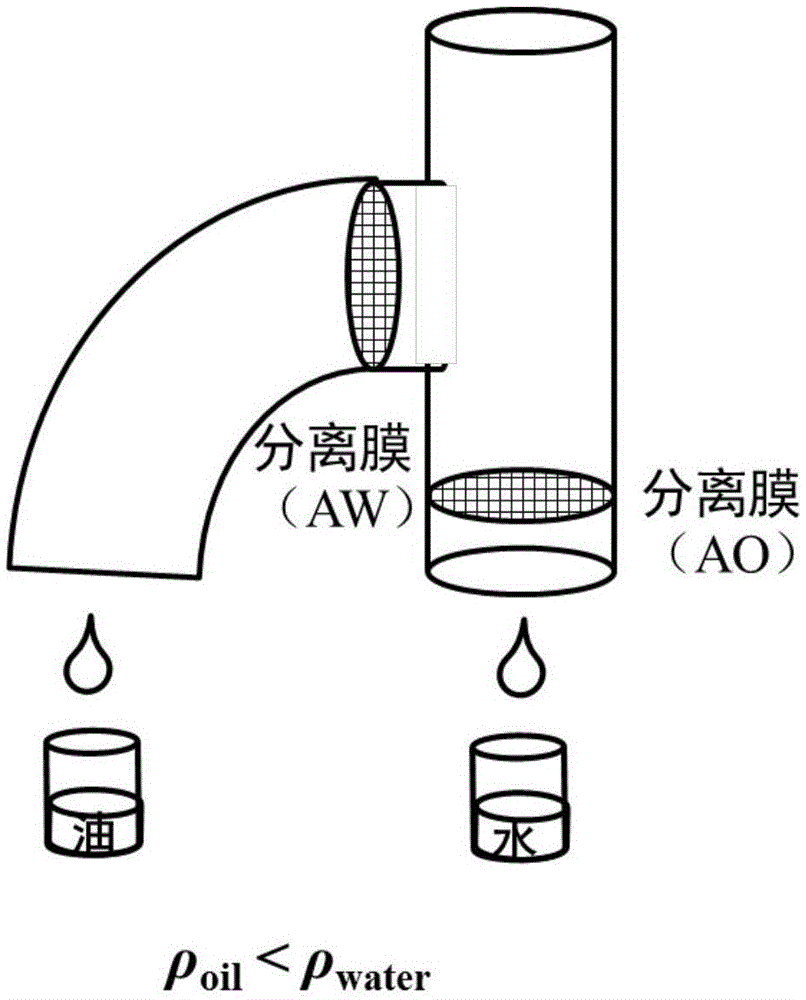

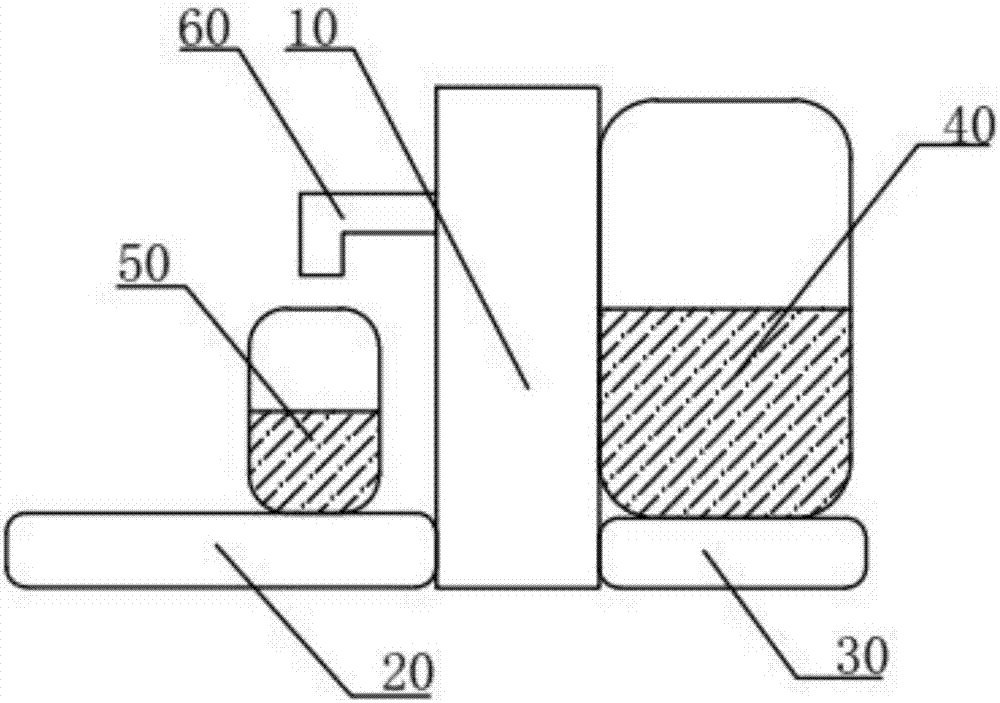

T-type oil-water separation equipment integrating two special wettable materials

ActiveCN105582693AImprove throughputHigh-throughput oil-water separation processNon-miscible liquid separationVolumetric Mass DensityDensity difference

The invention discloses T-type oil-water separation equipment integrating two special wettable materials, and belongs to the technical field of wastewater treatment. The T-type oil-water separation equipment is of a three-channel structure and is arranged into a lateral T shape or an inverted T shape according to an oil-water separation system. In the three-channel structure, a vertically-upward channel serves as an oil-water mixing system inlet channel, and the other two channels serve as separation channels. A super-hydrophobic and super-oleophilic separation membrane AW and a super-hydrophilic and underwater super-oleophobic separation membrane AO are arranged in the two separation channels respectively. Compared with an existing oil-water separation mode adopting a single membrane, the problem that a liquid barrier layer is formed due to the large liquid density difference is solved, and continuous oil-water separation is achieved; meanwhile, hydrostatic pressure borne by the separation membranes is reduced in the double-channel separation mode, and the requirement for the mechanical strength of the separation membranes is reduced; continuous oil-water separation without the consideration of the oil-water density difference can be achieved.

Owner:BEIHANG UNIV

Method and apparatus for liquid safety-detection by backscatter with a radiation source

ActiveUS20060133566A1High-precision detectionSmall volumeUsing wave/particle radiation meansMaterial analysis by transmitting radiationLiquid densityData acquisition

A method and an apparatus for liquid safety-detection by backscatter with a radiation source relate to a radiation detecting technology field. The invention comprises using a radiation source, a collimator, a detector, a data collector and a computer data processor, and has the main steps of: 1) a liquid article to be detected being placed onto a rotatable platform; 2) the ray emitted from the radiation source causing Compton scattering at the surface of the liquid after passing through the package layer of the liquid article; 3) the scattering photons being received by the detector after passing the collimator; 4) the detector transmitting the received data to the data collector; and 5) the data collector transmitting the amplified and shaped data to the computer data processor, which processes the data to obtain the liquid density of the detected article, then compares the result with the densities of dangerous articles in a current database, and gives warning if finding that the density of the detected article is consistent with that of a dangerous article. Comparing to the prior art, the invention has a convenient use, a rapid and accurate detection, a strong anti-interference, a high use safety and reliability, and an easy protection.

Owner:LI YULAN +12

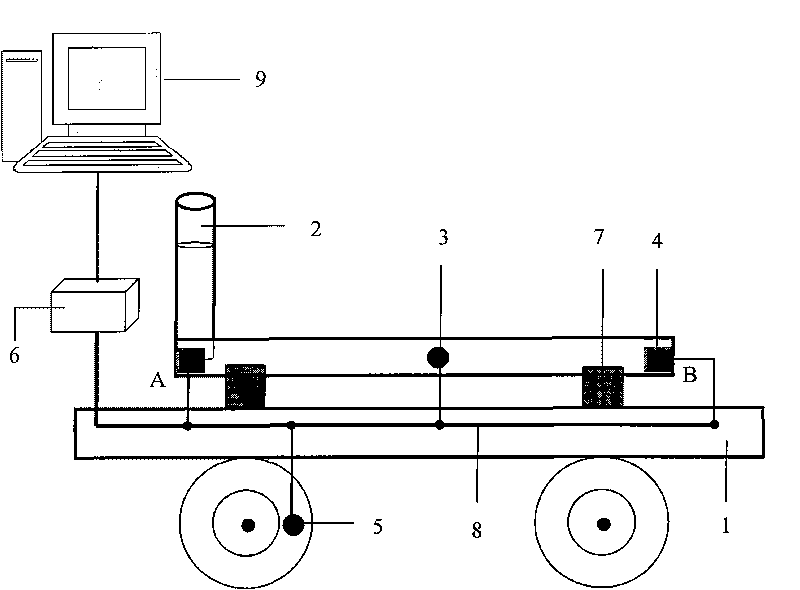

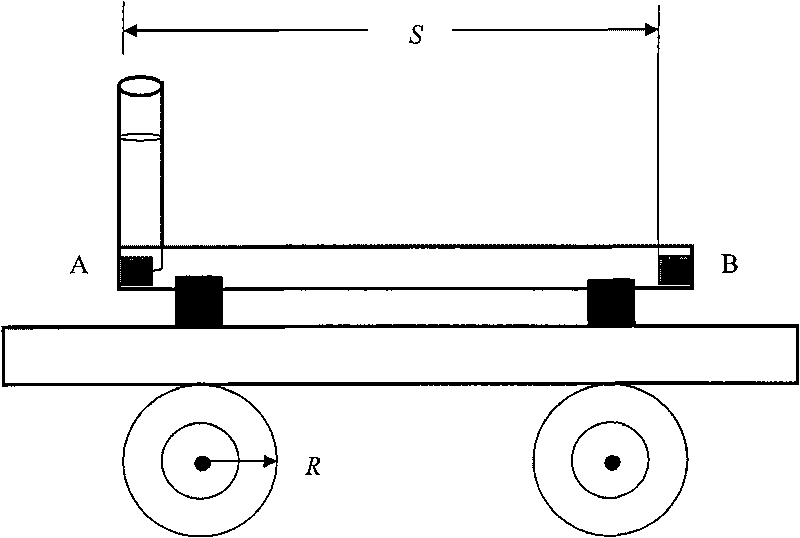

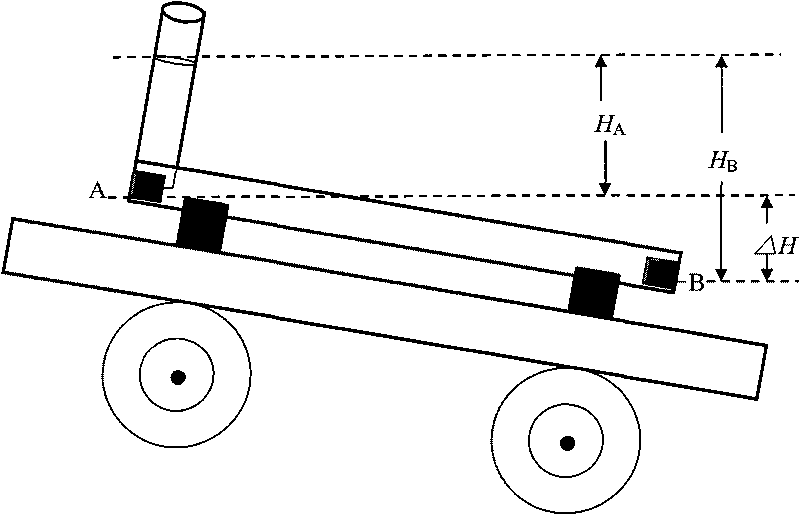

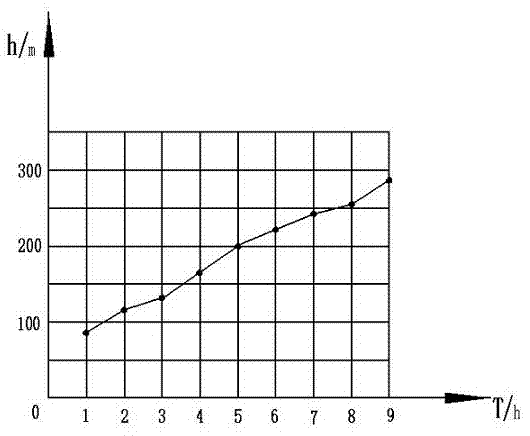

Device for measuring deflection/ displacement line shape by pressure difference and method thereof

InactiveCN101718543AWide measurement rangeFast measurementHydrostatic levellingElasticity measurementLiquid densityControl system

The invention provides a device for measuring deflection / displacement line shape by pressure difference and a method thereof. The device comprises a trolley and an L-shaped pipeline filled with liquid, wherein the horizontal section of the L-shaped pipeline is arranged on the trolley along the length direction of the trolley; the two ends of the horizontal section of the L-shaped pipeline are respectively provided with pressure sensors A and B, and the bottom is provided with a temperature sensor; a wheel of the trolley is provided with a displacement transducer; the temperature sensor, the pressure sensors A and B and the displacement transducer are connected with a control system provided with an interface and a memorizer by a data bus; and the displacement transducer is used for controlling the measurement to start for once after the trolley rotates for N rounds. The two pressure sensors are used for measuring the pressure difference at the two ends of the pipeline, and calculating by the liquid density at the different temperatures, thus measuring the vertical altitude difference between two points. The invention has the advantages of wide measuring plane, high accuracy, no influence by light interference, high degree of automation, low measuring cost, etc.

Owner:CHONGQING JIAOTONG UNIVERSITY +1

CT method and apparatus for liquid safety-detection with a radiation source

ActiveUS7508908B2Small volumeImprove accuracyWithdrawing sample devicesUsing wave/particle radiation meansLiquid densityData acquisition

A CT method and an apparatus for liquid safety-detection with a radiation source relate to a radiation imaging detecting technology field. The invention comprises using a radiation source, a detector and data collector, a computer data processor; and the main steps are: 1) a liquid article to be detected being placed onto a rotary platform which is rotatable; 2) the ray emitted from the radiation source passing through the liquid article, and being received and formed into projection data by the detector and data collector; and 3) the projection data being transmitted to the computer data processor, which processes it to obtain the liquid density of the detected article, compares the result with the densities of dangerous articles in a current database, and then visually displays the detected information of the detected liquid article. Comparing to the prior art, the invention has a small volume, a strong anti-interference, a high accuracy of detection, an easy shielding, and a high use safety and reliability.

Owner:TSINGHUA UNIV +1

Separation device

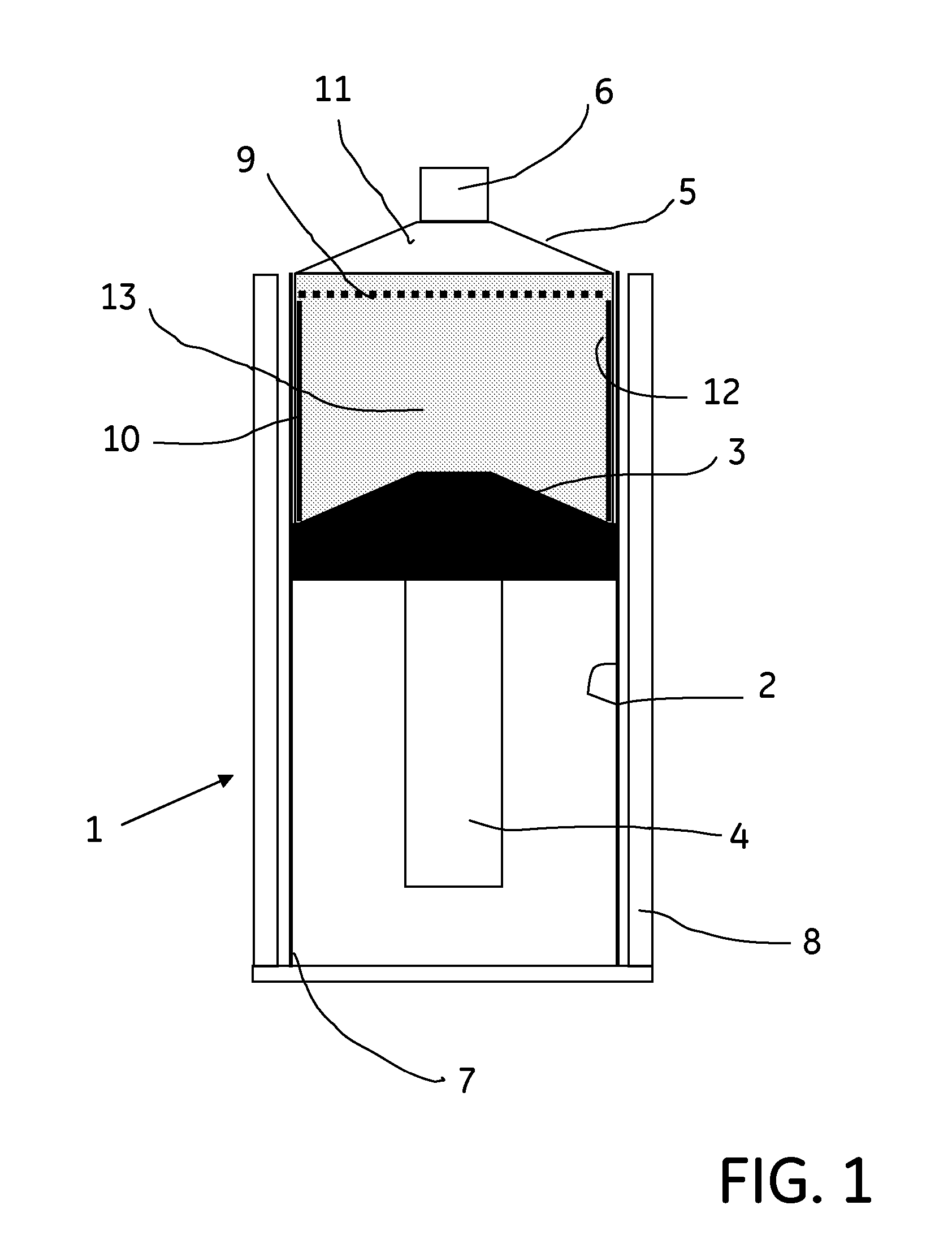

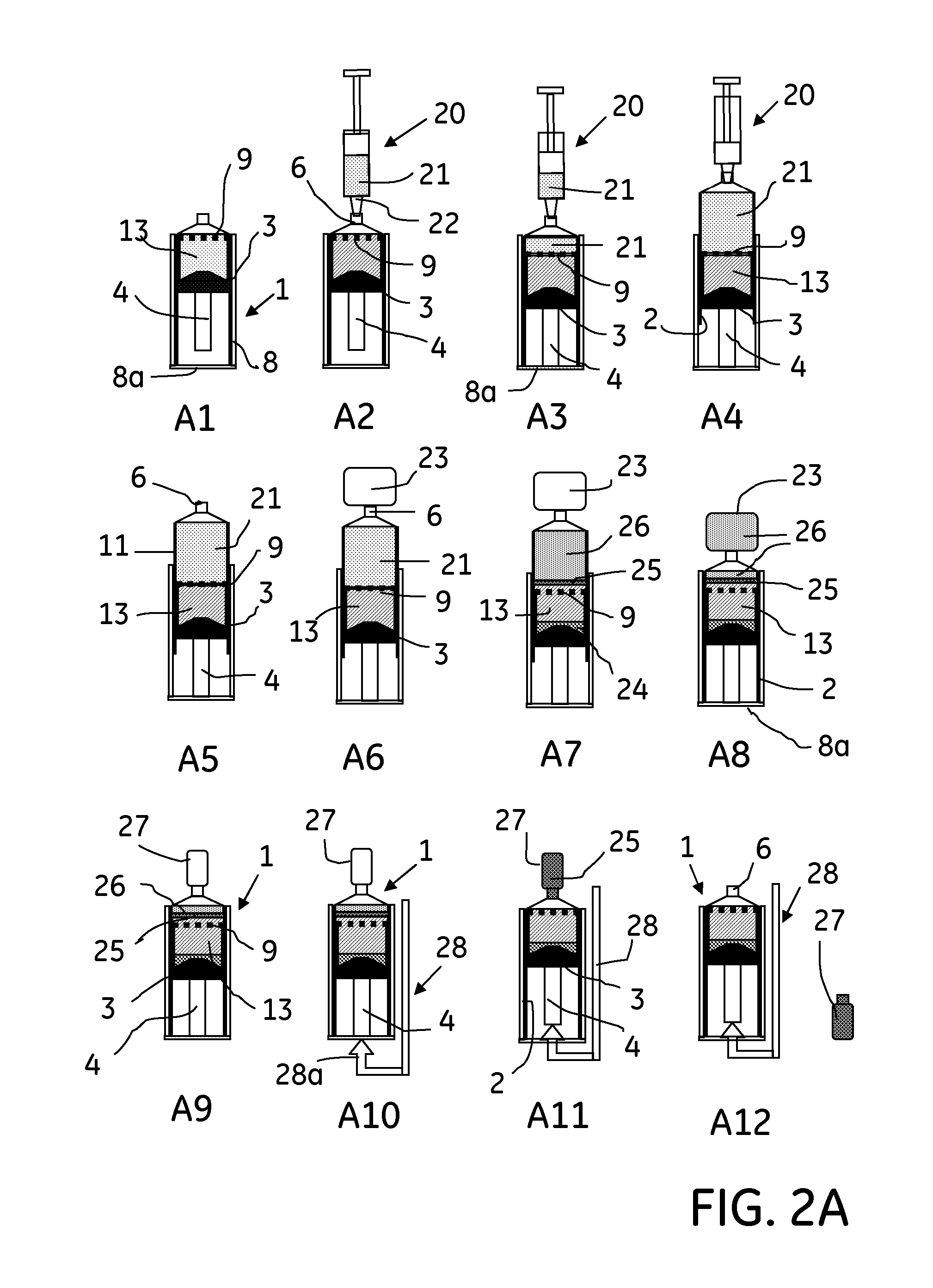

InactiveUS20110124106A1Easy to useEasy withdrawalArtificial cell constructsLaboratory glasswaresLiquid densityEngineering

A separation device for separating a wanted end product from a liquid sample comprises a container (2) having a first end (5) and a second end (7), the first end having a central orifice (6), a plunger (3) slideably disposed in the container (2) to define a variable liquid receiving chamber between the plunger (3) and the orifice (6), and a permeable partition member (9) mounted to the plunger (3) in a spaced relationship thereto to define a compartment (12) between the partition member (9) and the plunger (3) for receiving liquid density gradient medium (13), wherein liquid may be drawn into the container (2) and expelled therefrom, respectively, through the orifice (6) by movement of the plunger (3) relative to the container (2). A method for separating a wanted end product from a liquid sample is also disclosed.

Owner:GE HEALTHCARE BIO SCI CORP

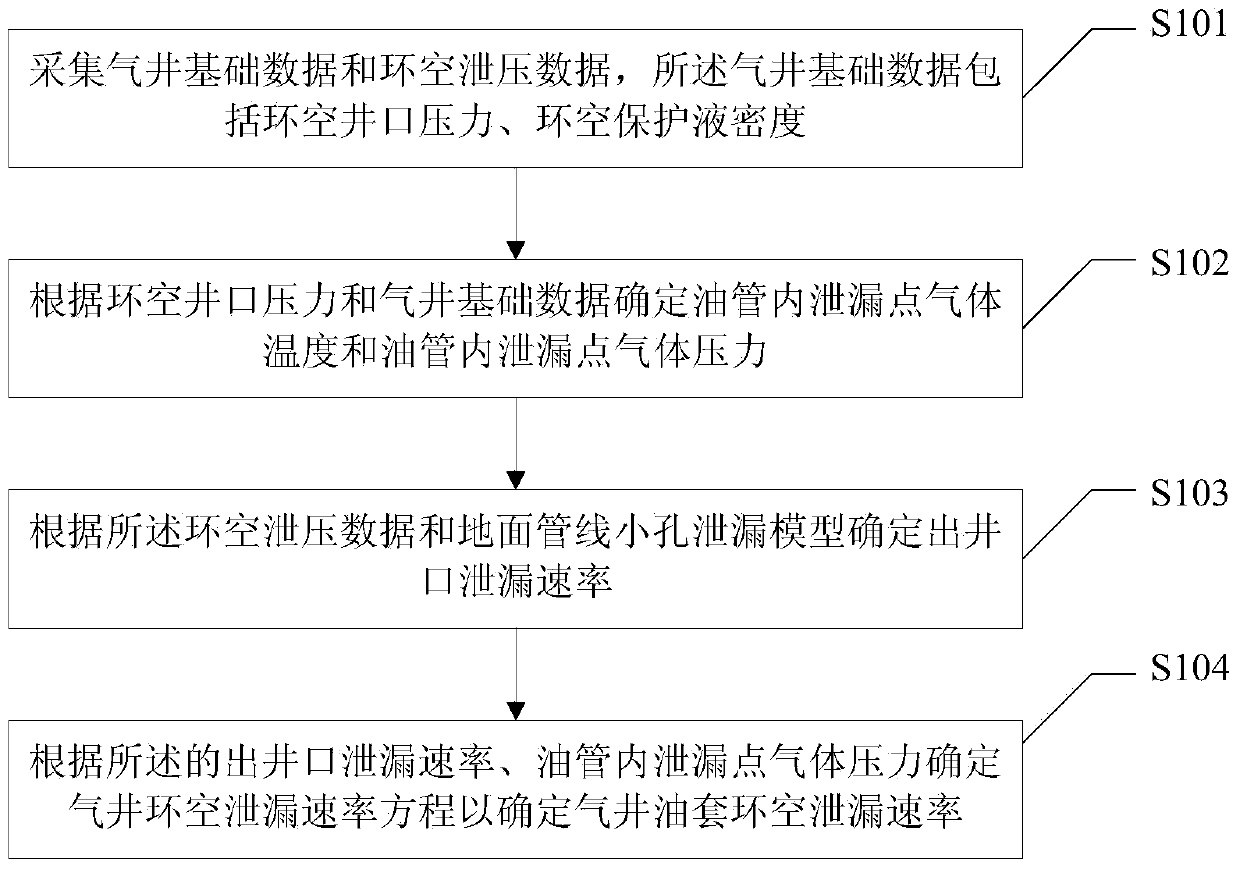

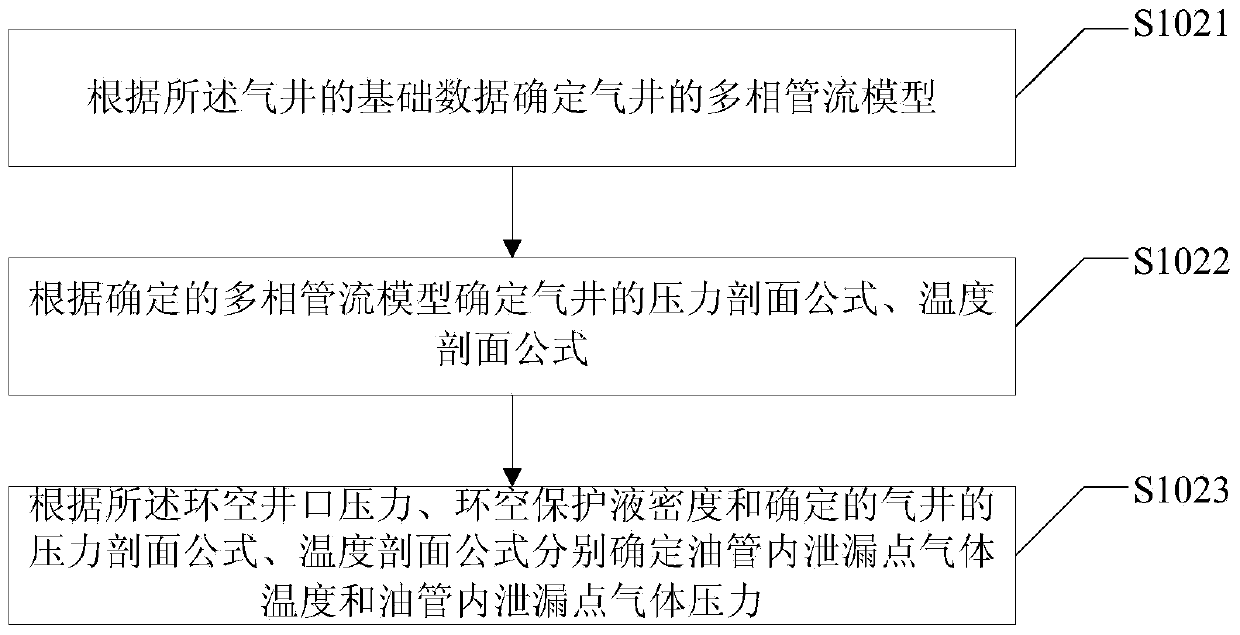

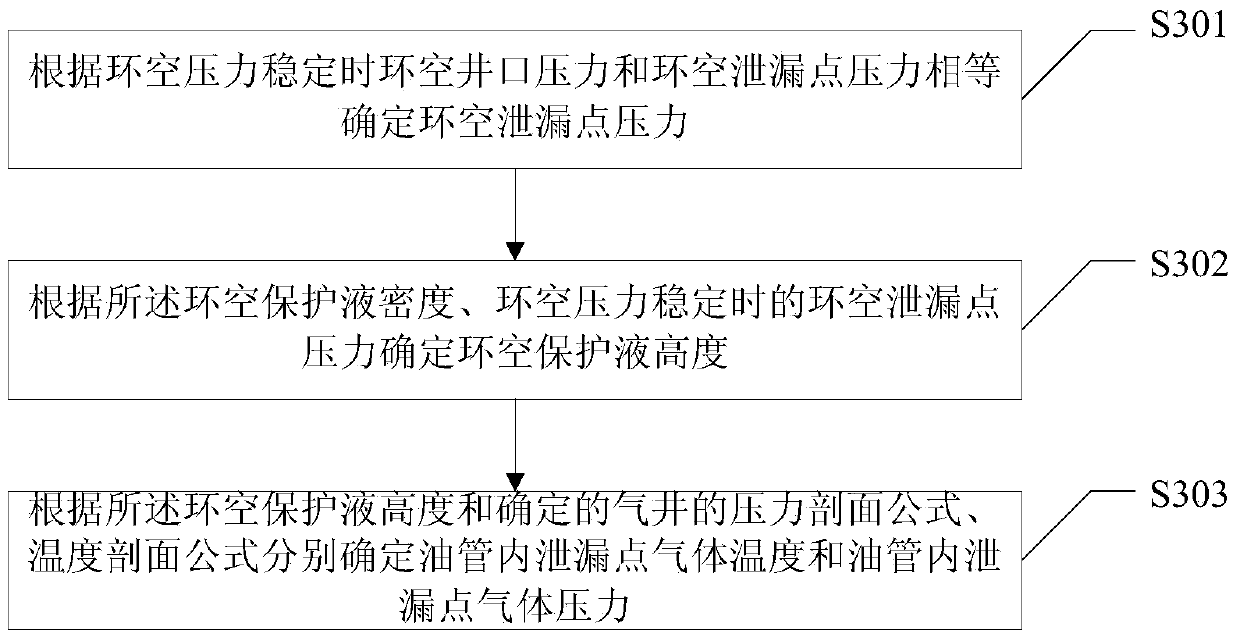

Method and device for determining leakage rate of oil casing annulus of gas well

ActiveCN103745103AMake up for incalculable deficienciesSpecial data processing applicationsLiquid densityLeakage rate

The invention provides a method and a device for determining a leakage rate of an oil casing annulus of a gas well. The method comprises the steps of: acquiring basic data and annulus pressure relief data of the gas well, wherein the basic data of the gas well comprise an annulus wellhead pressure and an annulus protection liquid density; determining a gas temperature of a leakage point in an oil pipe and a gas pressure of the leakage point in the oil pipe based on the annulus wellhead pressure and the basic data of the gas well; determining a wellhead leakage rate based on the annulus pressure relief data and a surface pipeline hole leakage model; determining a gas well annulus leakage rate equation based on the wellhead leakage rate and the gas pressure of the leakage point in the oil pipe so as to determine the leakage rate of the oil casing annulus of the gas well. According to the method and the device for determining the leakage rate of the oil casing annulus of the gas well, the leakage rate of the oil casing annulus can be calculated by utilizing the daily production data of the gas well and the pressure relief parameters of the oil casing annulus, and the shortage that the leakage rate of the oil casing annulus of the gas well cannot be calculated currently is covered.

Owner:PETROCHINA CO LTD

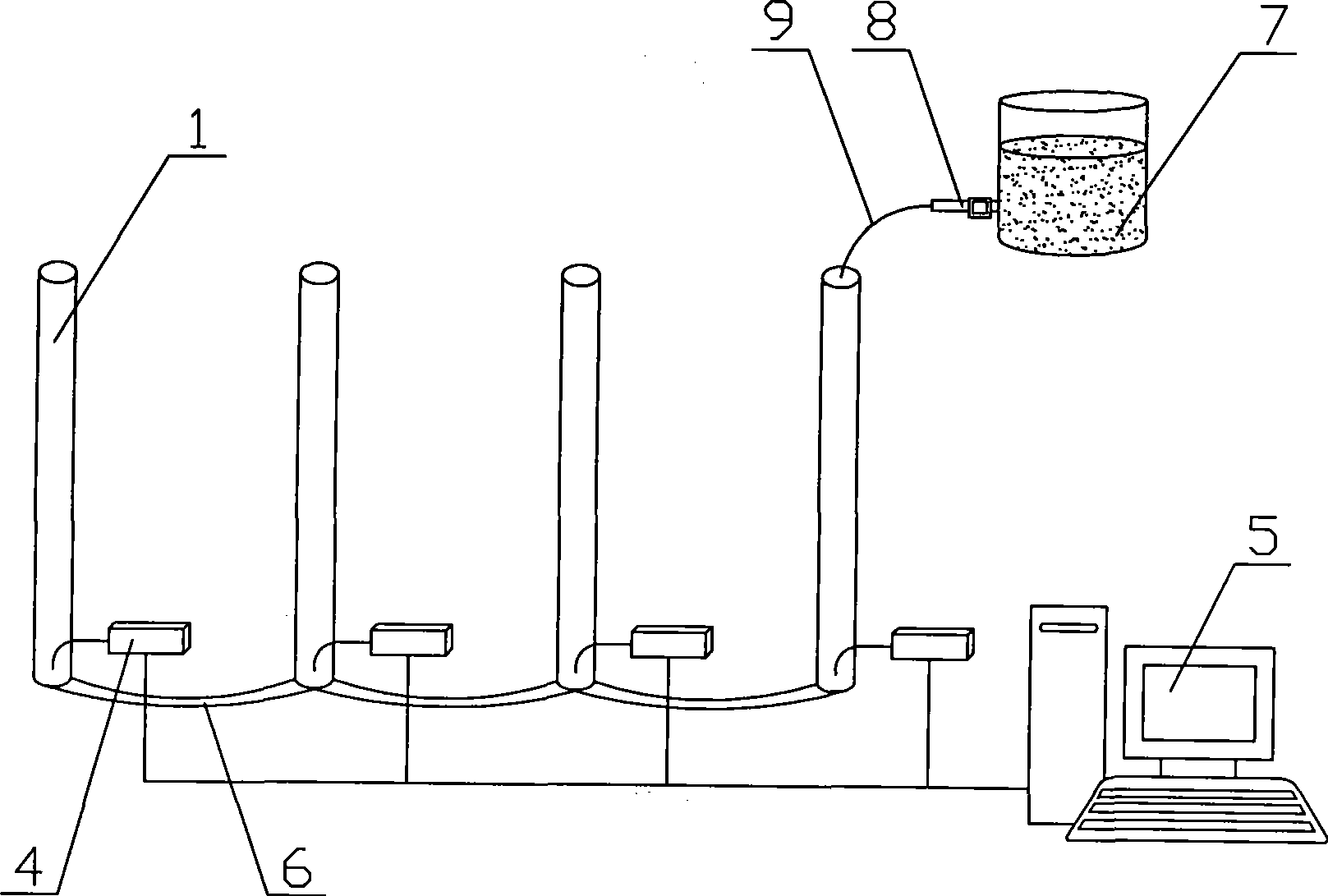

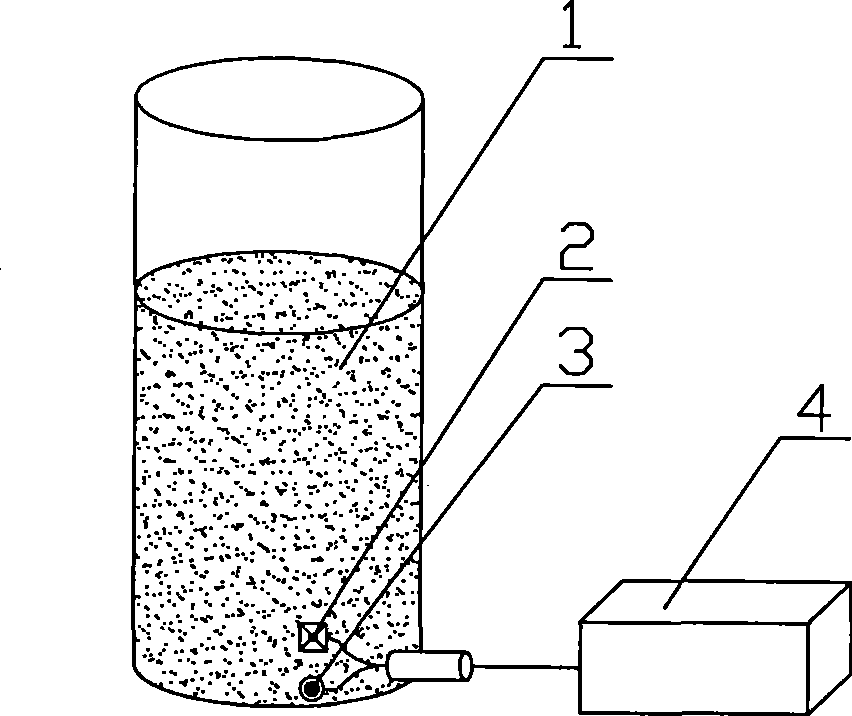

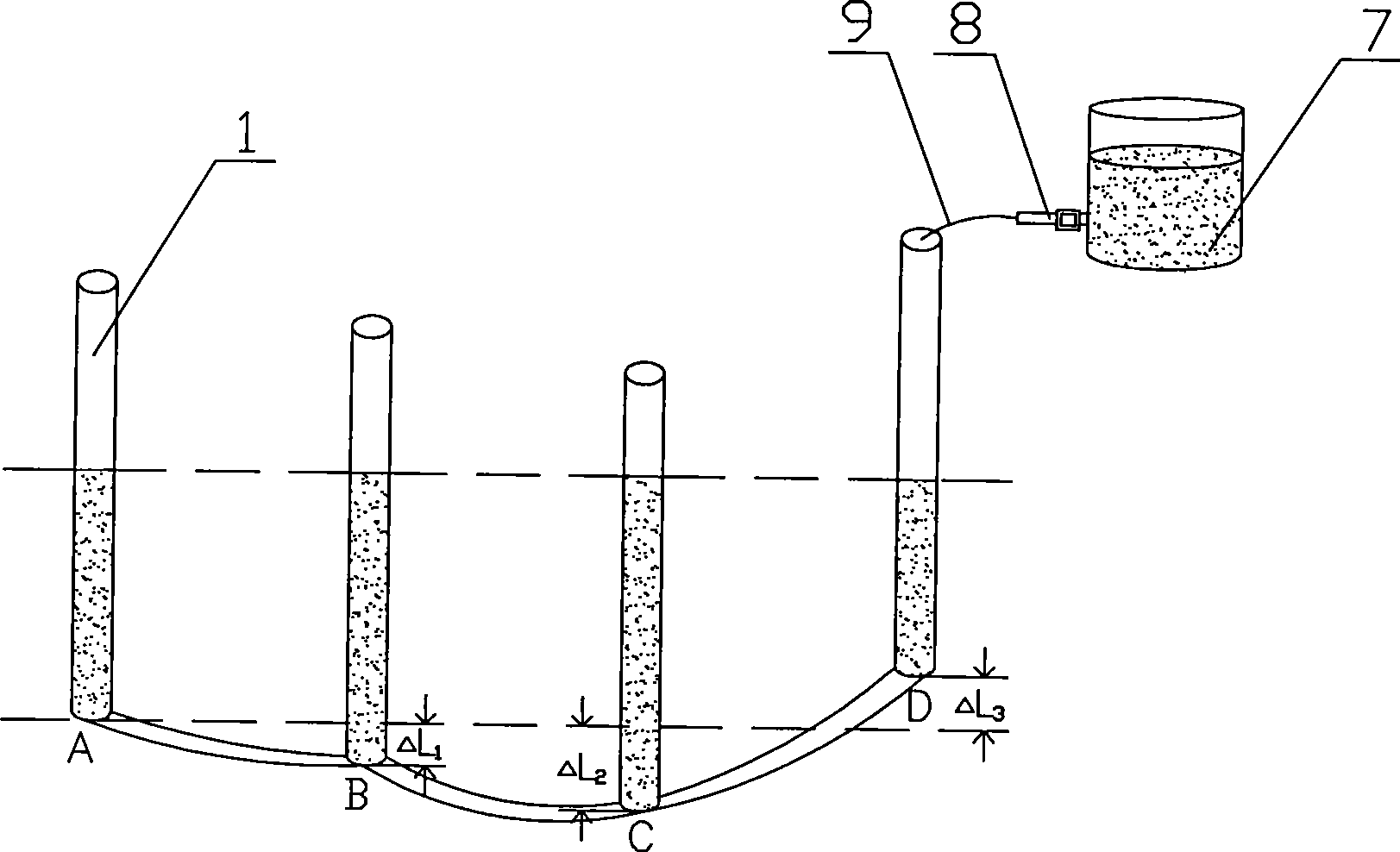

Method for measuring vertical displacement by hydraulic pressure and temperature and device thereof

InactiveCN101446486ANot affected by interferenceHigh measurement accuracyUsing fluid meansElasticity measurementLiquid densityComputerized system

The invention provides a method for measuring vertical displacement by utilizing hydraulic pressure and temperature and a device thereof. The invention is characterized in that pressure sensors and temperature sensors are respectively arranged at the bottom parts inside n same liquid containing tubes; the pressure sensors and the temperature sensors are connected with a computer system through a circuit; the lower parts or the bottoms of the n liquid containing tubes are communicated with each other through hoses, wherein, a liquid containing tube is vertically arranged at the datum point, and the rest liquid containing tubes are arranged vertically at a plurality of points to be measured; and the change in vertical displacement of the points to be measured can be obtained through comparison between all the points to be measured and the datum point liquid surface elevation difference Delta Ln and the analysis by the computer. The method provided by the invention takes into account the effects of environmental temperature on the measurement accuracy; the change in the hydraulic column is measured by the pressure sensors; the liquid density is subjected to conversion at different temperatures; and the invention has the characteristic of high measuring accuracy. Meanwhile, the method is not affected by disturbance by beams. The invention has the characteristics of simple structure, convenient installation and debugging, good reliability, and low cost.

Owner:CHONGQING JIAOTONG UNIVERSITY

Chemical mechanical polishing slurry

InactiveUS6976904B2Minimize damageDamaging contacts of the solid abrasive particles with one another are minimizedPolishing machinesRevolution surface grinding machinesLiquid densitySolid density

A liquid suspension for planarizing an outer surface of a material comprises a liquid suspension medium of a specific liquid density; and a plurality of solid, contact-sensitive abrasive particles of a constant solid density and suspended in the liquid suspension medium. The liquid and solid densities are approximately the same so that the abrasive particles freely and stably suspend in the liquid suspension medium, without gravitational separation by settling down or floating up. In this way, damaging contacts of the solid abrasive particles with one another are minimized.

Owner:LI FAMILY HLDG

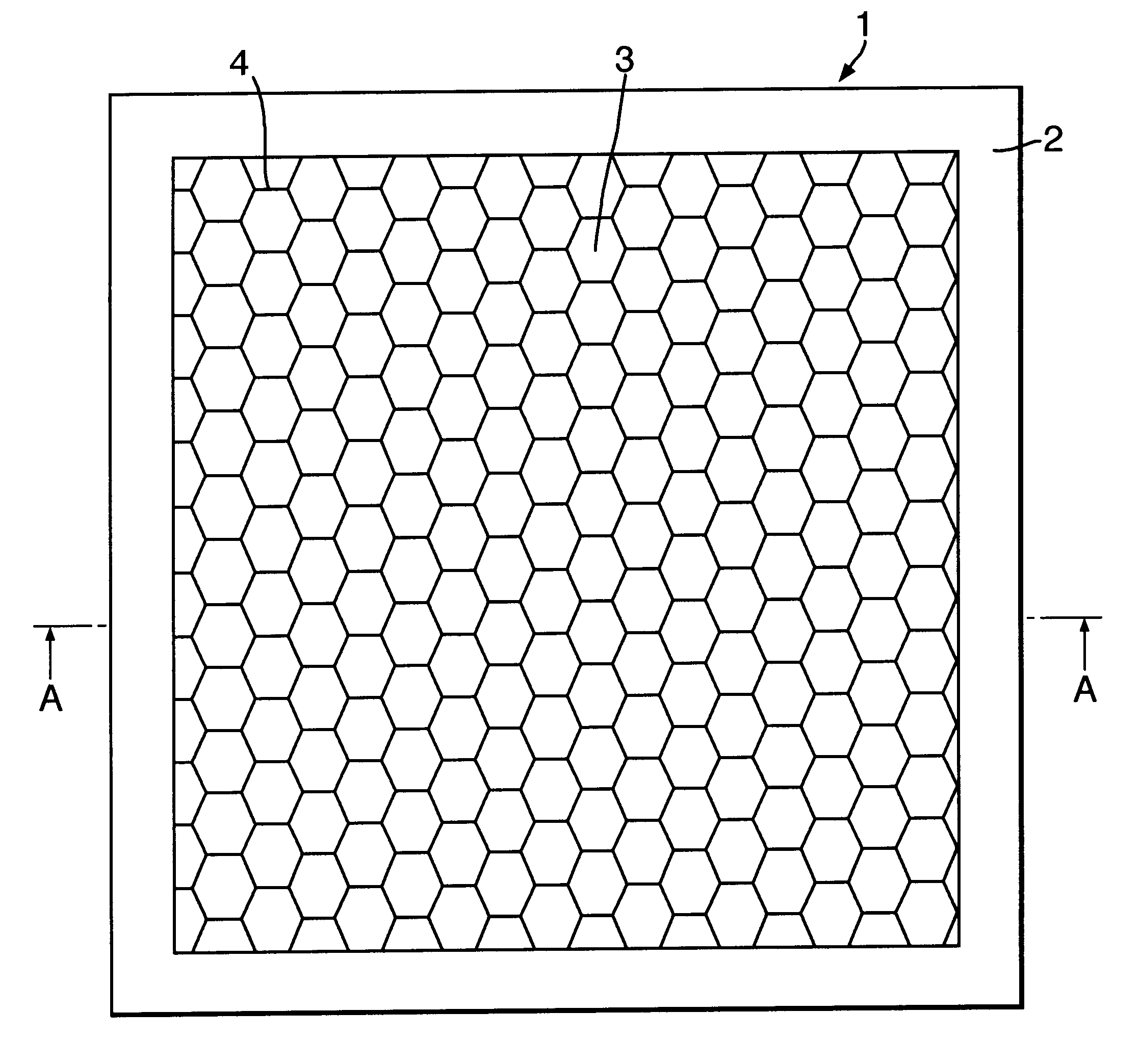

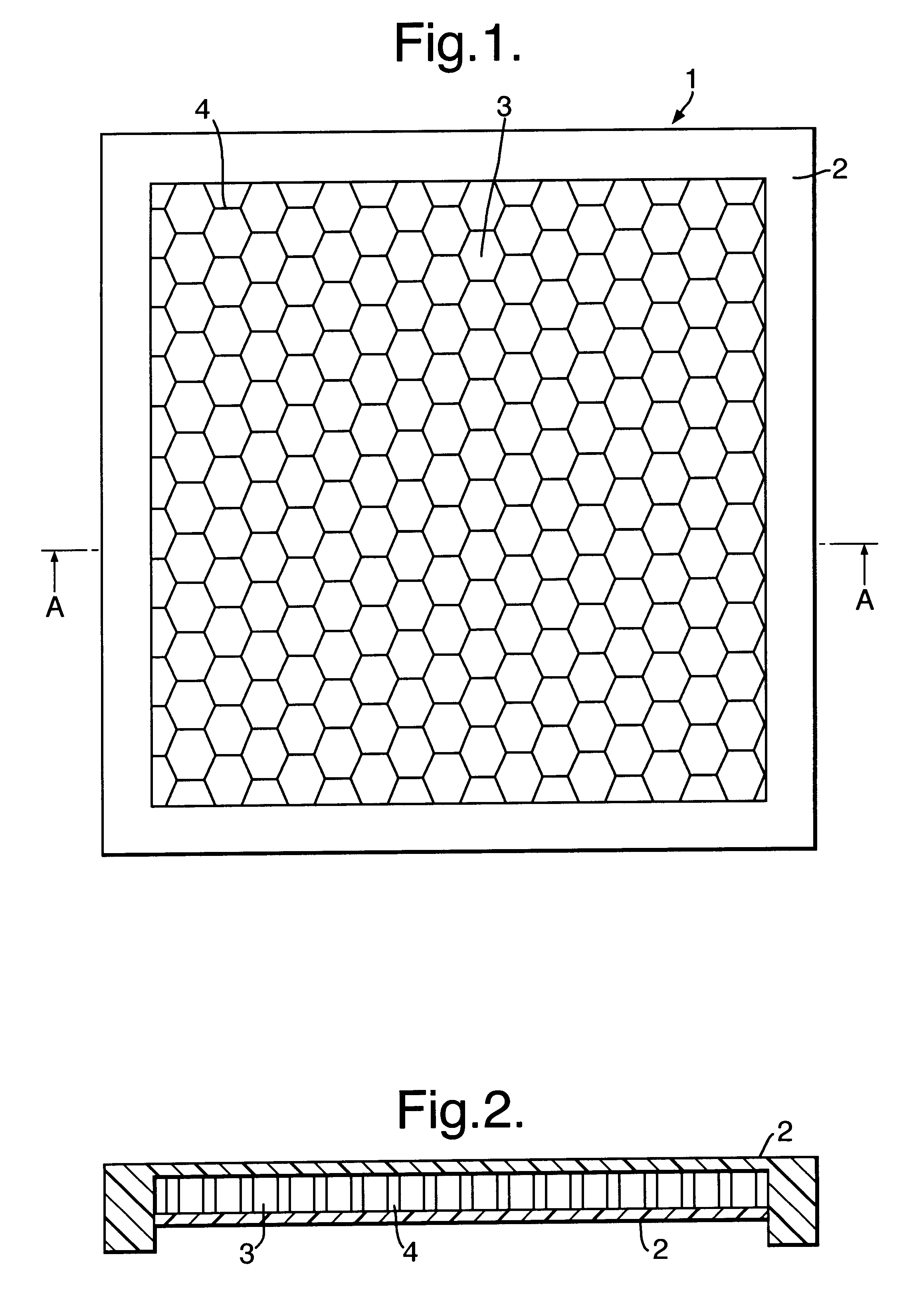

Baffle for a liquid tank

A baffle (1) for reducing hydraulic ram pressure in a liquid in a tank (5,9) in which it is located resulting from impact of a projectile on an external surface (6,10) of the tank, includes at least two outer walls (2) spaced apart to define therebetween at least one cavity (3) and a compressible gas or gaseous mixture at reduced, atmospheric or enhanced pressure contained in the cavity (3). The baffle outer walls (2) are sufficiently strong to withstand the pressure of the gas or gaseous material contained in the cavity (3) are sufficiently strong to resist the hydrostatic pressure of liquid in a tank (5,9), when the baffle (1) is located in the liquid in the tank (5,9), and are spaced apart by an amount sufficient to provide the cavity with a volume sufficient to allow a shock wave or waves in the liquid resulting from compression of the liquid by impact of a projectile on the tank external surface (6) to be reduced by expansion of the compressed liquid into the cavity volume. The gas or gaseous mixture has a density sufficiently different from the density of the liquid to provide substantially total reflection within the baffle (1) of the shock wave or waves impinging on the baffle.

Owner:BAE SYSTEMS PLC

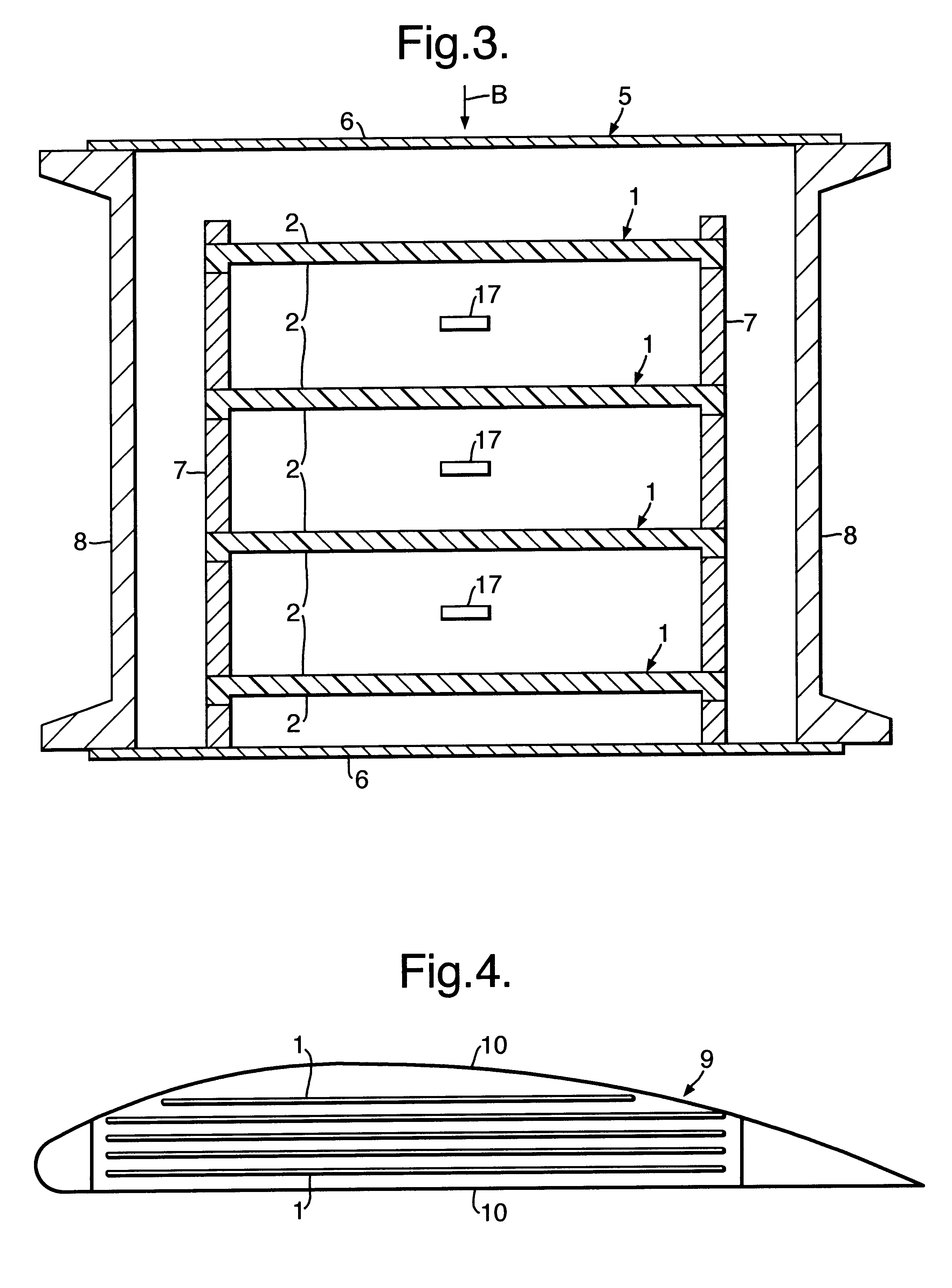

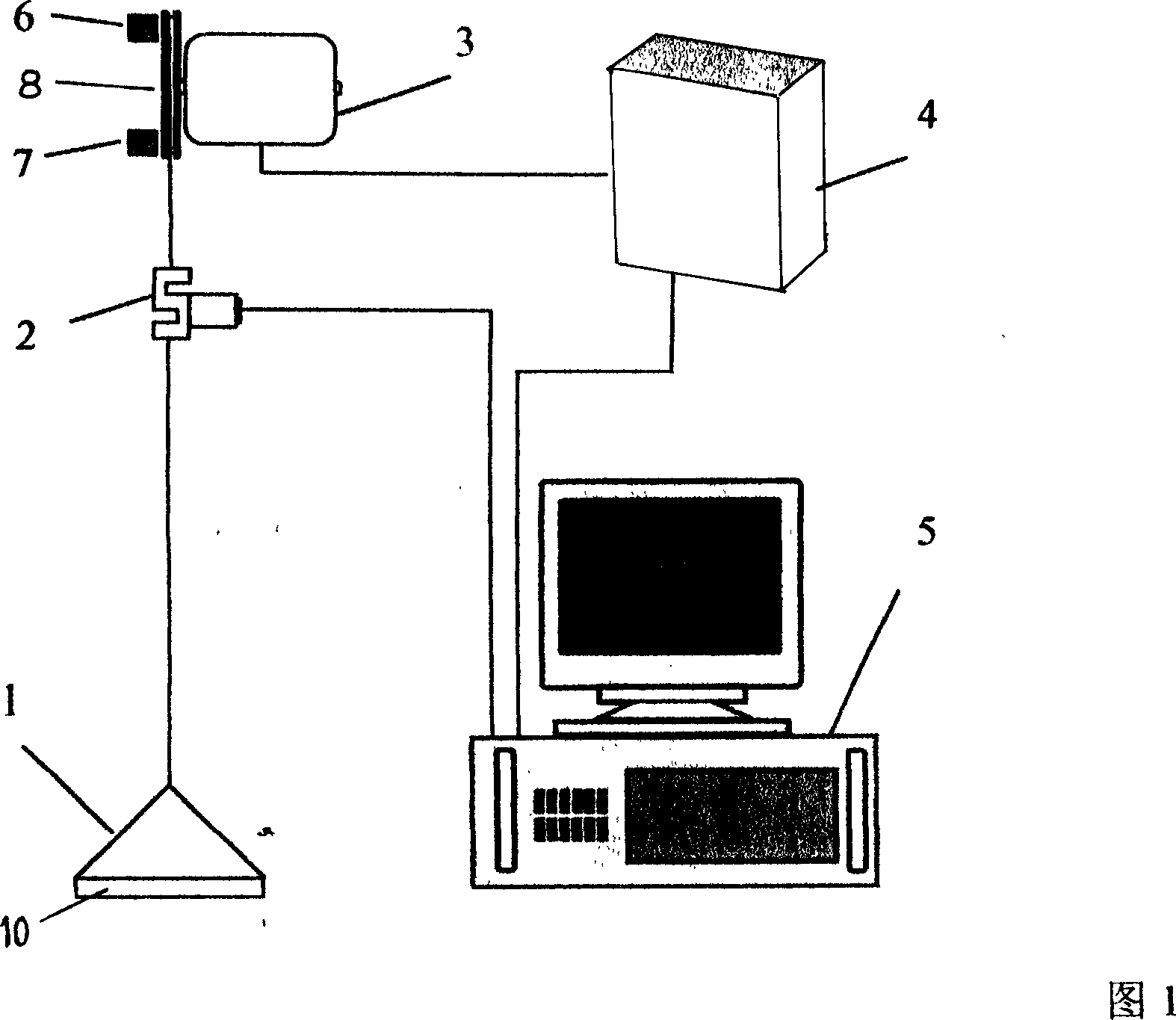

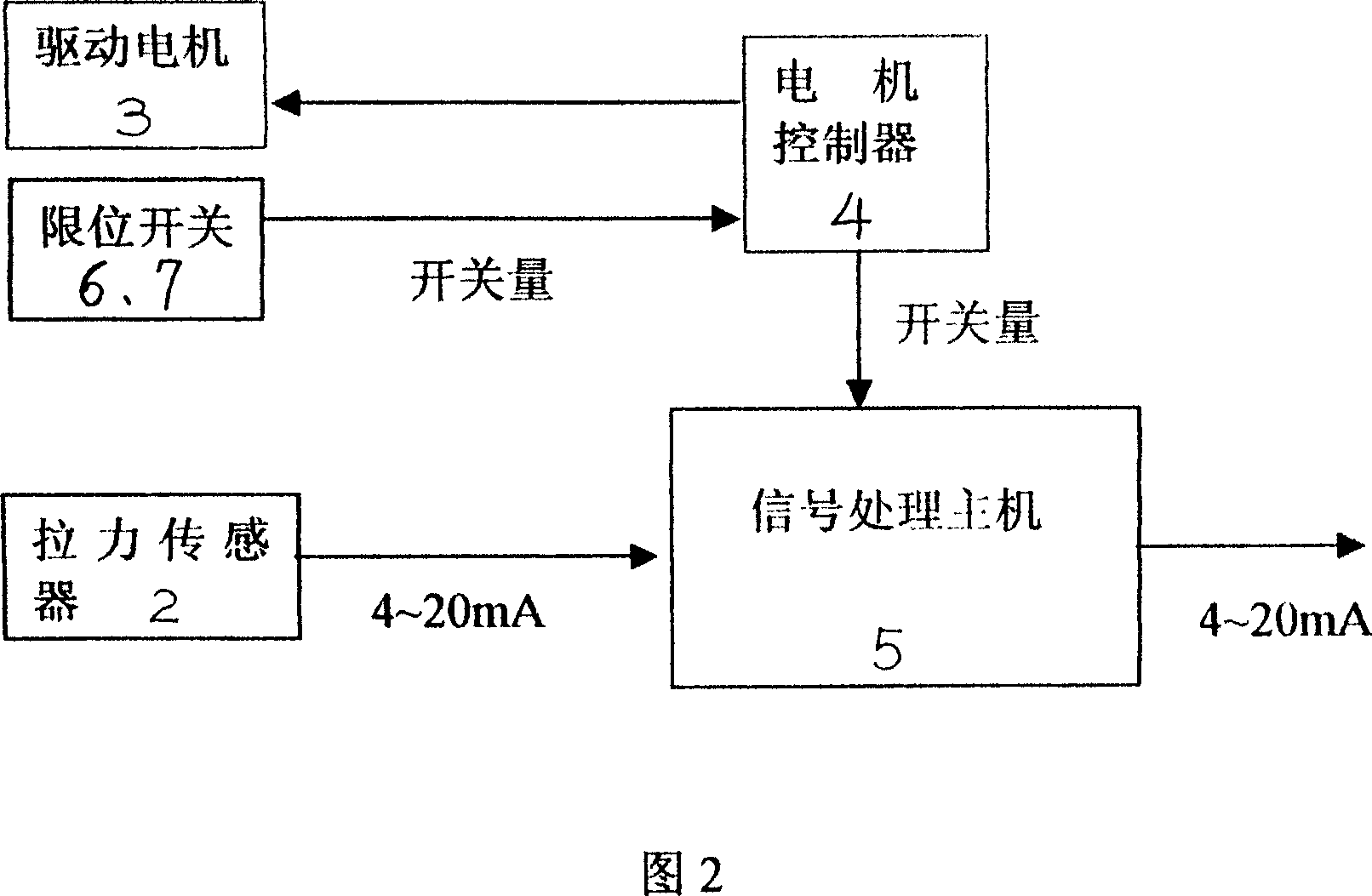

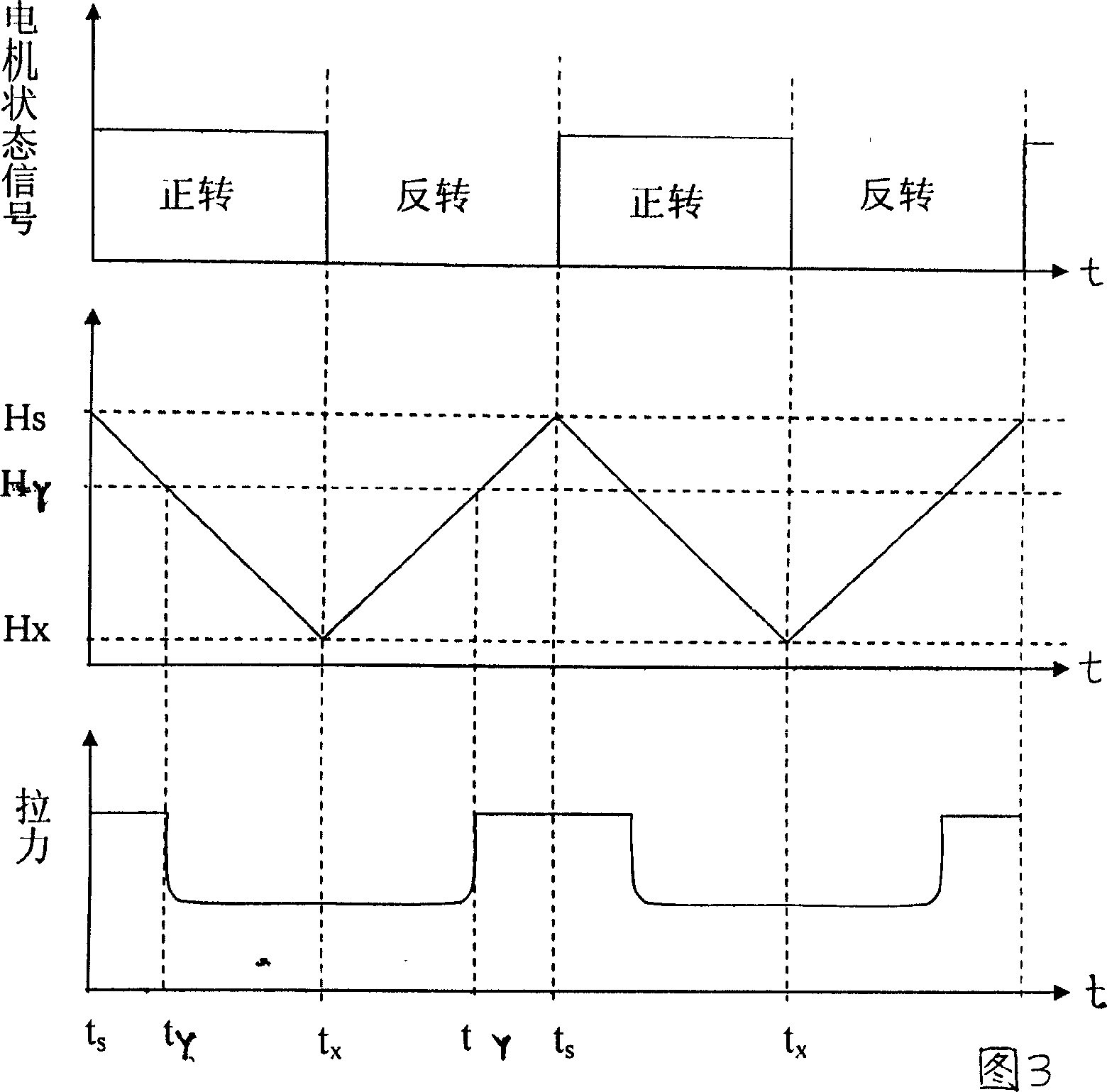

Buoyancy scanning type polyphase liquid-level interface detection method and detector therefor

InactiveCN1967174AAccurate measurementRealize automatic metering managementMachines/enginesLubrication indication devicesLiquid densityPull force

The invention discloses a buoyancy scanning multiphase liquid location surface detection method, and it is: vertical reciprocating the uniform speed pulling floater, and when it touching liquid location or surface, it produces pulling force mutation, and scanning to detect the mutation moment, and multiplying the floater running speed and time, then amending with the initiation location, so as to come up with the accurate liquid location or surface height value. The detecting device to implement the said detecting method includes the signal processing host, the floater, the driven motor and the pulling sensor, and the floater, whose overall average density greater than the density of measured liquid, has the flat bottom, the pulling sensor connecting on the floater traction line in series, the pulling sensor signals sending into the signal processing host through data transmission channel, the switch signals of the driven motor electrical controller connecting to the signal processing host. The technology scheme can detect the liquid location or surface under the changing conditions of the measured liquid density, and also detect the multi-media crossing surface or liquid location of different densities, each un-mixed multiple liquids and liquid-solid-coexistence, and it has the technical features of simple technical compose, accurate detection, broad application.

Owner:DANDONG DONGFANG MEASUREMENT&CONTROL TECHCO

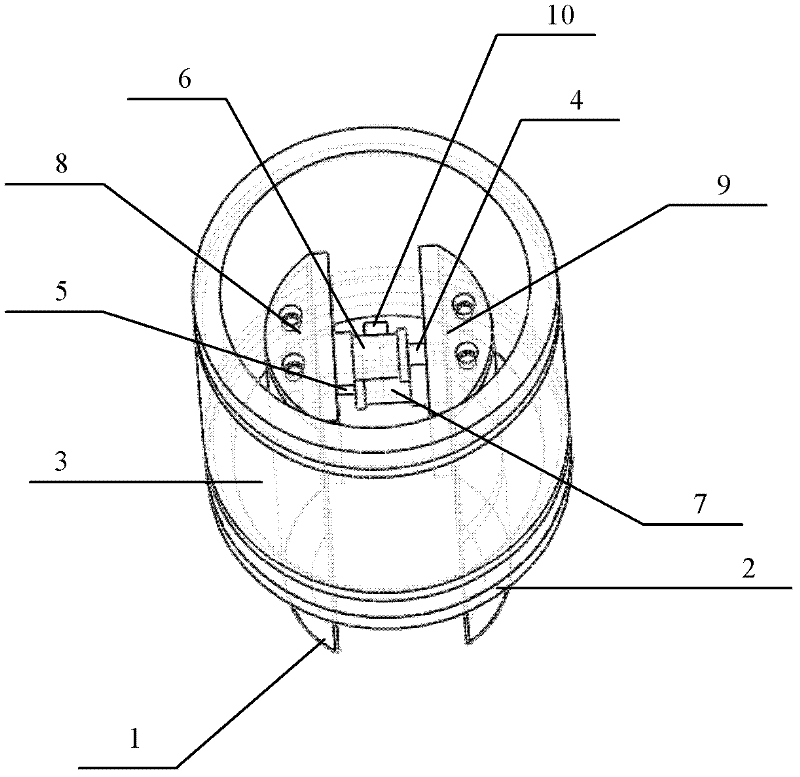

Resonant tuning fork liquid density sensor with piezoelectric actuation and piezoelectric detection

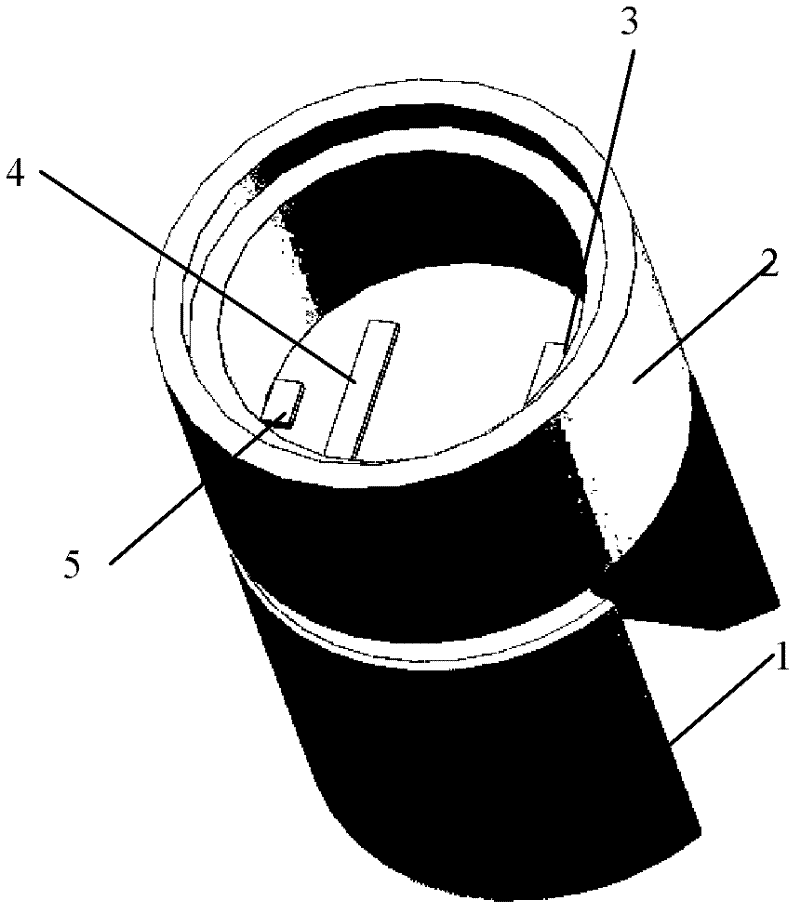

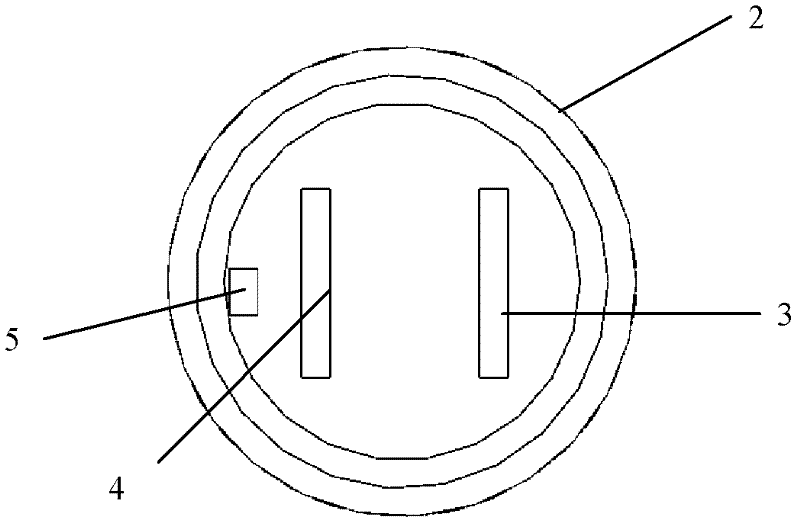

ActiveCN102353612AReal-time online measurementReal-time detectionSpecific gravity measurementLiquid densityPiezoelectric actuators

The invention discloses a resonant tuning fork liquid density sensor with piezoelectric actuation and piezoelectric detection, comprising a tuning fork body, a clamped body, a piezoelectric actuator, a piezoelectric vibration pickup, and a temperature sensor, wherein, the piezoelectric actuator and the piezoelectric vibration pickup are arranged on the clamped body, the generated alternating force is transmitted to the tuning fork body by the piezoelectric actuator to let the tuning fork body produce simple harmonic vibration with intrinsic frequency itself; when immersing the tuning fork body in a liquid under test, the additional mass of the tuning fork body changes so as to let the vibration frequency of the tuning fork body change; by picking up the vibration signal with the piezoelectric vibration pickup, the detection of the vibration frequency of the tuning fork body is realized; because the vibration frequency of the tuning fork body is a monotone function of the liquid density, thus the real-time on-line detection of the liquid density is realized; and the temperature sensor is arranged on the clamped body for real-time detection of the temperature of the liquid under test, and is used for compensating the variation of the elastic modulus of the tuning fork body. According to the invention, the high precision on-line detection of densities of various liquids at different temperature can be realized.

Owner:BEIHANG UNIV

Method for determining whether liquid accumulation exists in gas well or not and determining liquid accumulation degree

ActiveCN104504611ASimple methodThe method is simple and feasibleData processing applicationsLiquid densityLiquid height

The invention relates to the determination of the liquid level height difference of a well casing of a gas well in the field of gas field development, provides a method for determining the liquid level height difference of the well casing of a liquid accumulation gas well by utilizing the communicating vessel principle, and particularly relates to a method for determining whether liquid accumulation exists in a gas well or not and determining the liquid accumulation degree. According to the method, firstly, the oil pressure, the casing pressure, the gas density and the liquid density of the gas well during well closing are obtained; secondly, the accumulation liquid height difference of the well casing of the gas well is obtained through the calculation of the oil pressure, the casing pressure, the gas density and the liquid density, and the liquid accumulation and the liquid accumulation degree are judged through the accumulation liquid height difference. The accumulation liquid height difference of the well casing of the gas well can be determined through inputting and obtaining oil pressure and casing pressure data of the gas well after the well closing, only well closing oil pressure and casing pressure data needs to be specified, and a well testing instrument does not need to be placed into the well bottom. Compared with the prior art, the method has the advantages that the method is simple and convenient, and the cost is lower.

Owner:PETROCHINA CO LTD

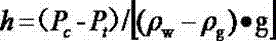

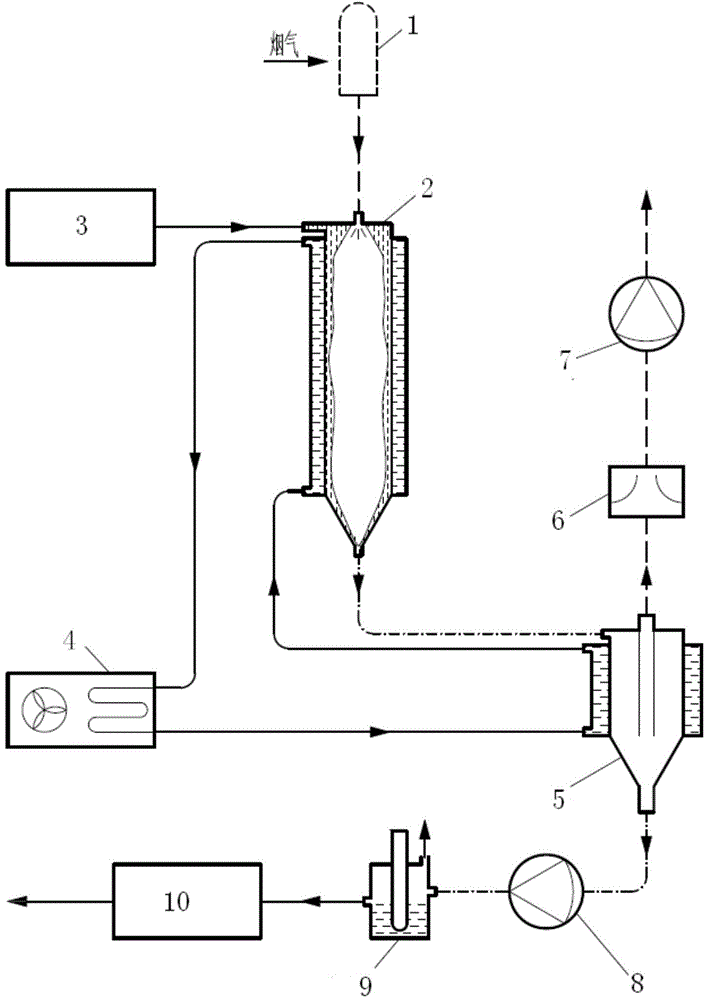

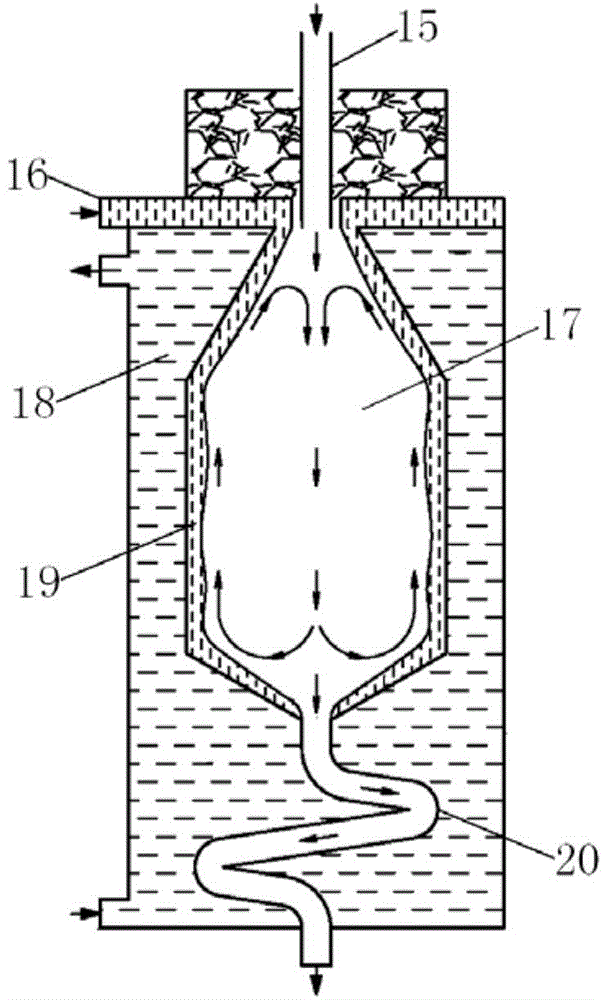

On-line detection device and method for gas-liquid transfer method escaping ammonia

The invention discloses an on-line detection device and method for gas-liquid transfer method escaping ammonia. The online detection device comprises a fluid flowmeter, an absorption liquid supply system, a smoke dust filter, a liquid membrane heat absorption tube, a gas-liquid first-stage separator, a flow-through tank, a measurement control system, a water quality ammonia nitrogen sensor used for detecting the concentration of NH4<+> contained in absorption liquid in the flow-through tank, and a liquid density sensor used for detecting density of liquid in the flow-through tank. The on-line detection device and method can accurately detect the concentration of escaping ammonia online.

Owner:HUANENG POWER INT INC +2

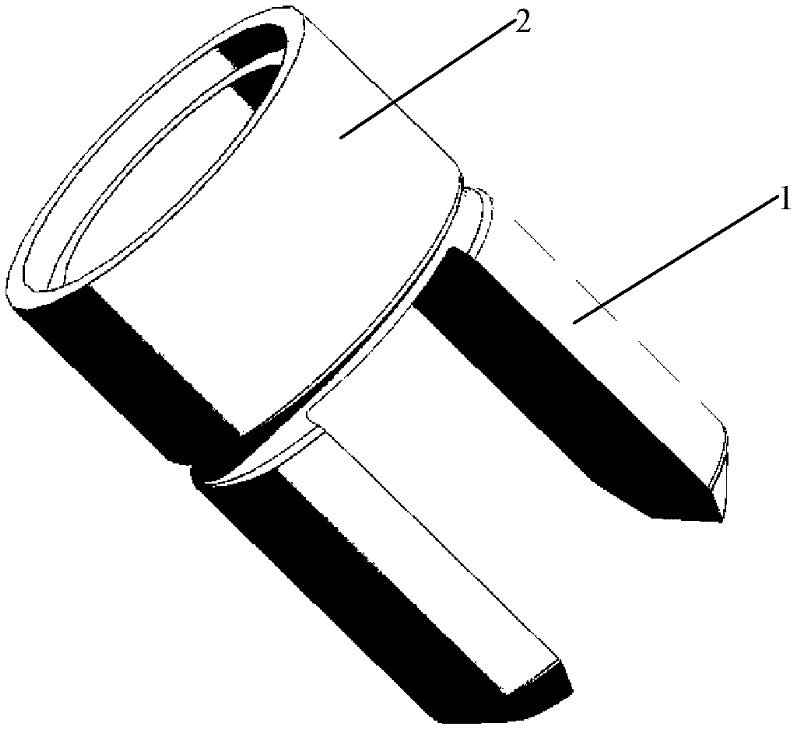

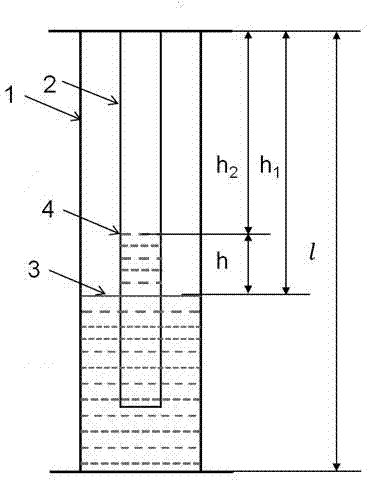

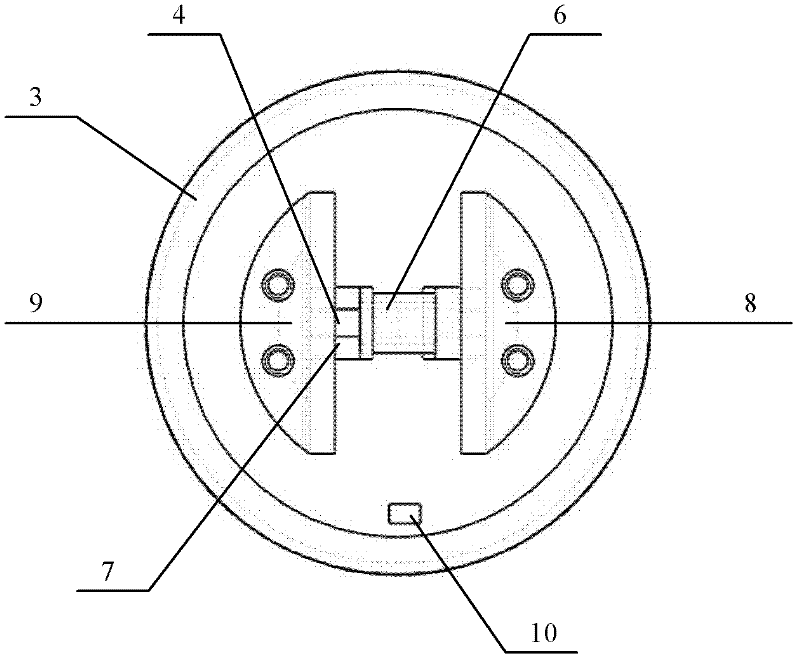

Electromagnetic excitation detection-based resonant tuning fork liquid density sensor

ActiveCN102507369AHigh measurement accuracyImprove reliabilitySpecific gravity measurementTuning forkLiquid density

An electromagnetic excitation detection-based resonant tuning fork liquid density sensor comprises a tuning fork, a fixed support body, a protection tube, two magnetic cylinders, two coils, two fixing members, and a temperature sensor. The protection tube is welded on the fixed support body. The magnetic cylinders and the coils are mounted on the fixed support body via the fixing members, for cooperative use, to constitute an exciter and a detector respectively. The exciter transfers the generated alternating force to the tuning fork via the fixed support body, so that the tuning fork generates simple harmonic vibration according to the natural frequency of the tuning fork, and the vibration signal is acquired by the detector to realize detection of the tuning fork vibration frequency. The vibration frequency of the tuning fork and liquid density are in monotonic function relationship, thus real-time online measurement of the liquid density can be realized. The temperature sensor is attached to the fixed support body to real-time detect the temperature of the measured liquid, so as to compensate change in the modulus of elasticity of the tuning fork. The sensor of the invention can realize high-precision online measurement of various liquid densities at different temperatures.

Owner:锦州天辰博锐仪表有限公司

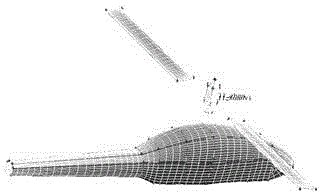

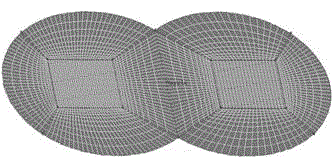

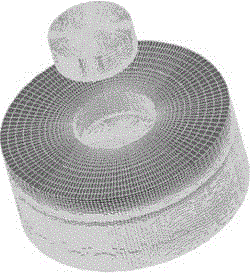

Prediction method for aerial spray drift of helicopter based on model

ActiveCN102915395ADrift PredictionAccurately predict drift rangeSpecial data processing applicationsAviationLiquid density

The invention relates to a prediction method for aerial spray drift of a helicopter based on a model, belonging to the technical field of agricultural aerial sprays. According to the method, atomization surfaces of an agricultural helicopter and a nozzle are simulated, a to-be-predicted domain and boundary conditions of the to-be-predicteddomain are determined, the Fluent is run so as to obtain a wind field formed on the atomization surfaces after the air flow generated by the movement and a rotor wing of a spraying helicopter is blocked by the main body of the helicopter, and variations of pesticide liquid concentration and pesticide liquid density in each of grids of the to-be-predicted domain in the boundary conditions can be simulated through iterative operation so as to obtain the deposition distribution of the pesticide liquid droplet and predict the aerial spray drift of the helicopter. According to the invention, the CFD (computational fluid dynamics) thoughts are applied to the technical field of the agricultural aerial sprays, and the deposition distribution, the drift range and the like of the pesticide liquid to be aerially sprayed can be quickly and effectively simulated, thereby creating conditions for accurately, safely, conveniently and quickly evaluating the agricultural aerial spray operation.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

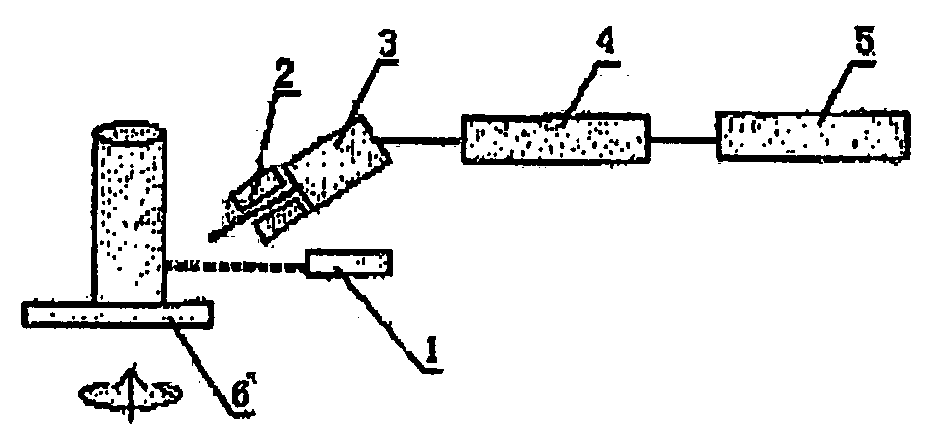

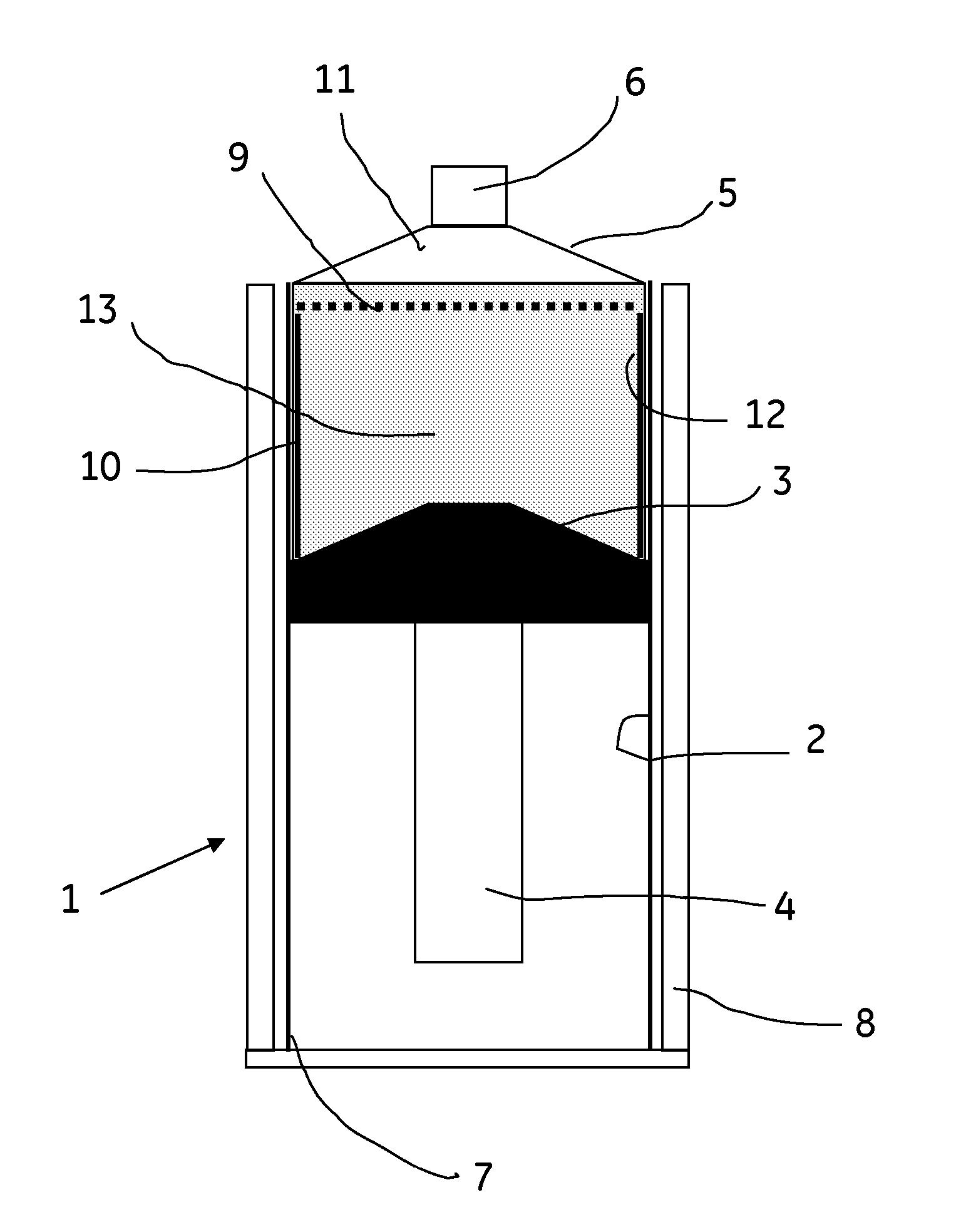

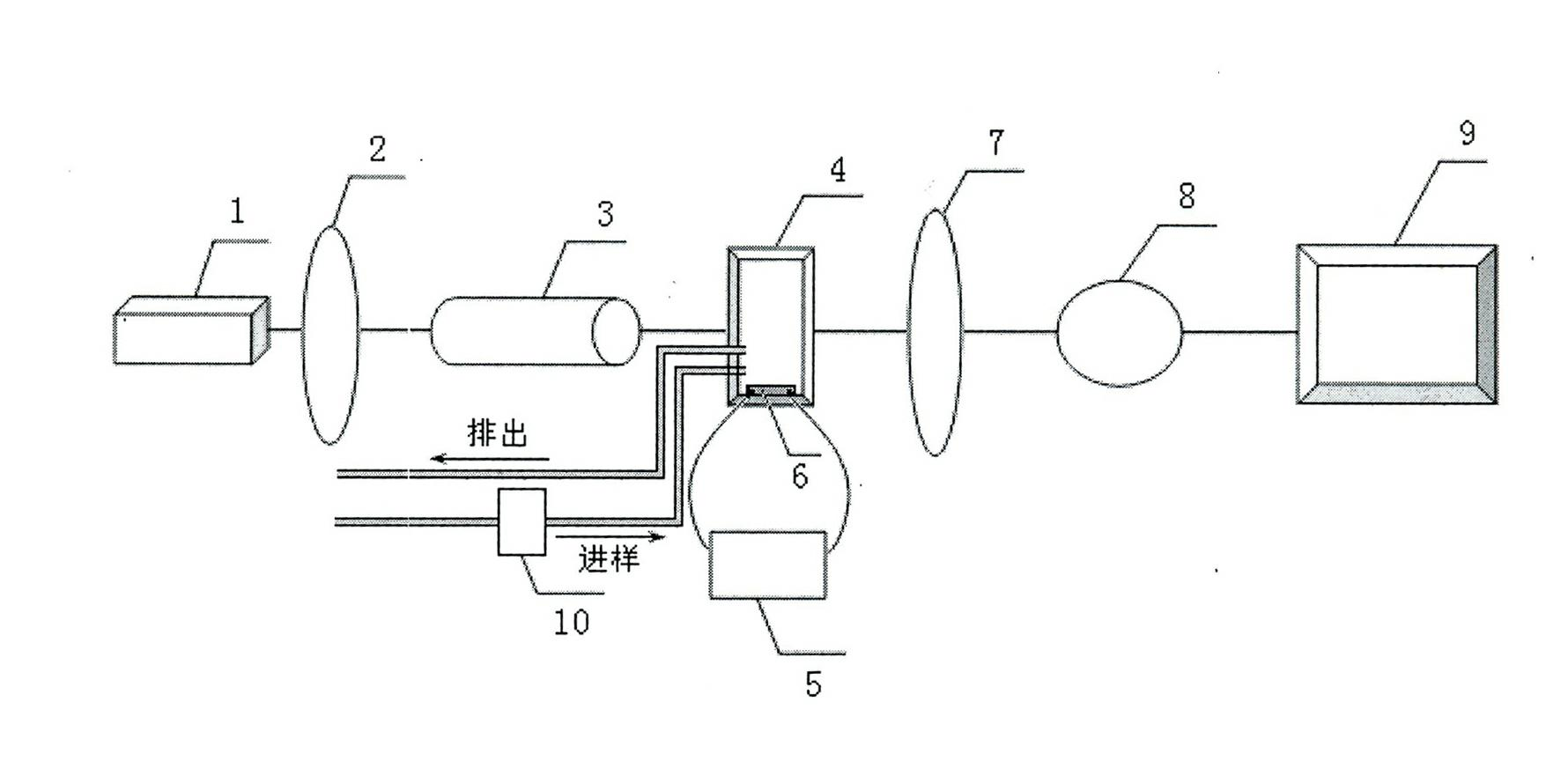

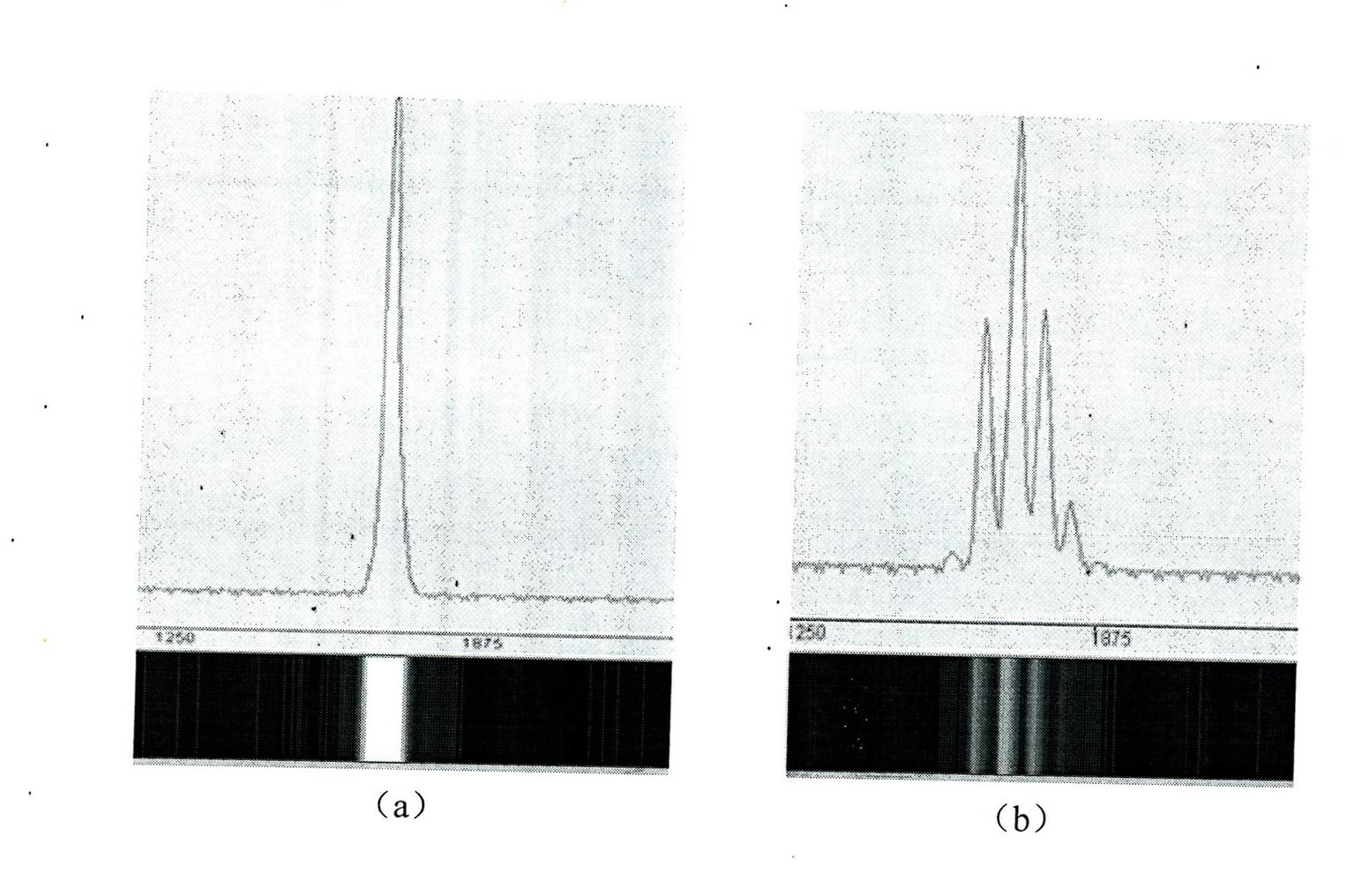

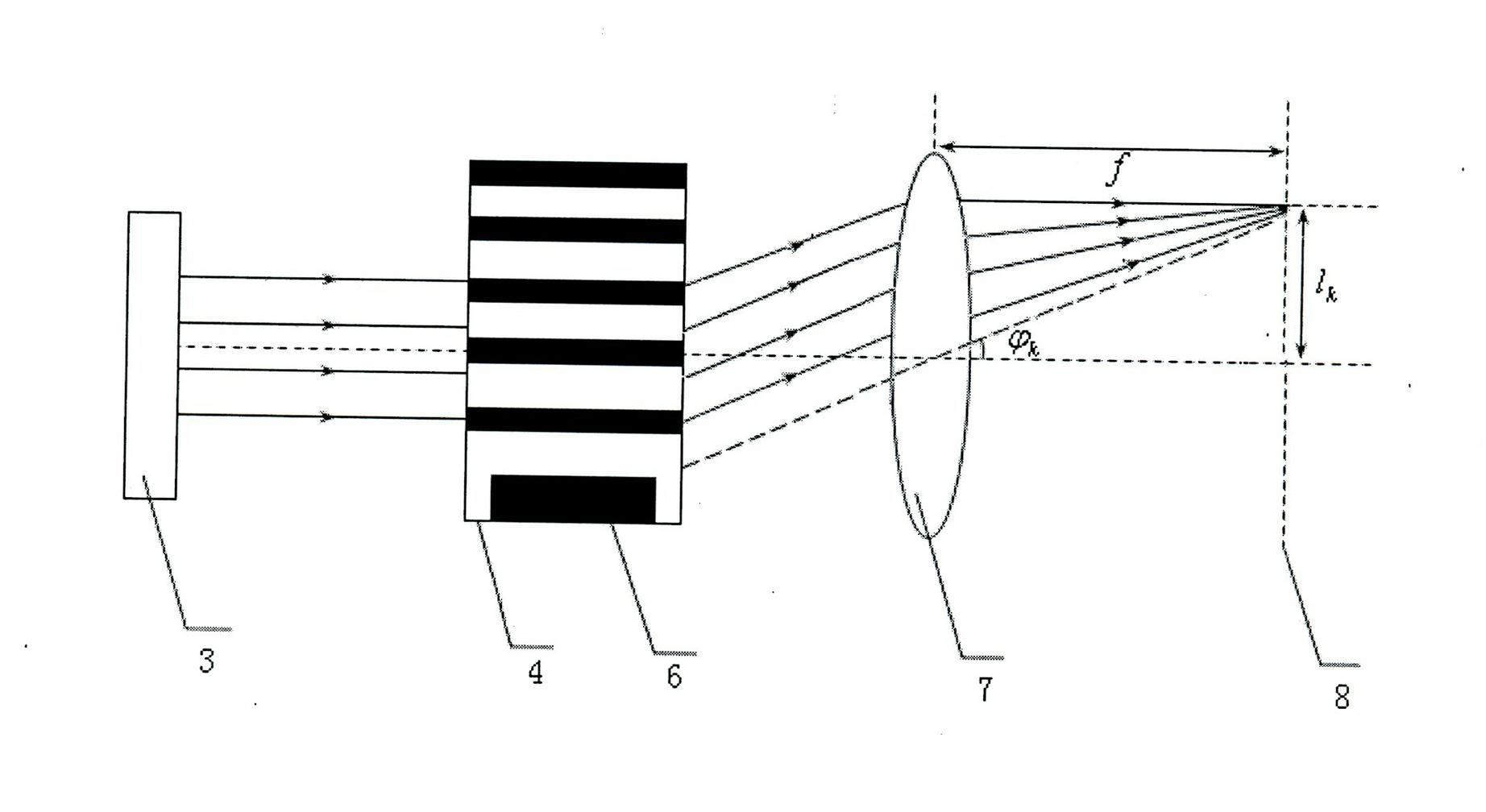

Liquid density on-line monitoring system based on ultrasonic diffraction grating

InactiveCN102564895ADisadvantages to avoidAvoid the downsideSpecific gravity measurementPeristaltic pumpGrating

The invention provides a liquid density on-line monitoring system based on ultrasonic diffraction grating, which comprises a laser, a beam expander, a collimator, a piezoelectric ceramic plane ultra radiation wave generator, a direct digital synthesizer (DDS) ultrasonic signal source, an ultrasonic pool, a peristaltic pump sample introduction system and a charge coupled device (CCD) monitoring system. A high-quality monochromatic line light source can be obtained after laser beams output by the laser pass through the beam expander and the collimator, and high frequency sine and cosine signalsgenerated by the DDS ultrasonic signal source stimulate the piezoelectric ceramic plane ultra radiation wave generator to form 'the ultrasonic grating' in the ultrasonic pool. Emergent laser beams ofthe line light source become a row of extremely fine monochromatic diffraction stripes through the diffraction of 'the ultrasonic grating', a converging lens converges emergent rays of same-directiondiffraction angles on the photosensitive surface of the CCD monitoring system. Diffraction strips are collected by the CCD monitoring system into computers, and the space between strips and the density of liquid samples are calculated. The liquid density on-line monitoring system has the advantages of being high in precision, easy to measure in real time, simple and compact in structure, high in operability, free of complicated optical systems, low in cost and the like.

Owner:YANSHAN UNIV

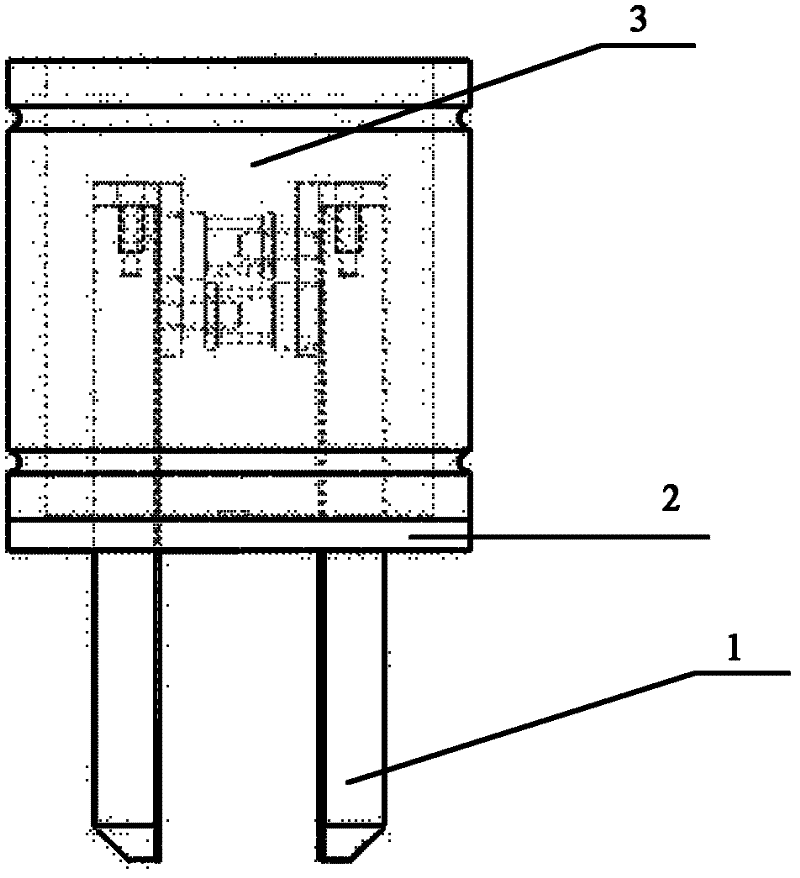

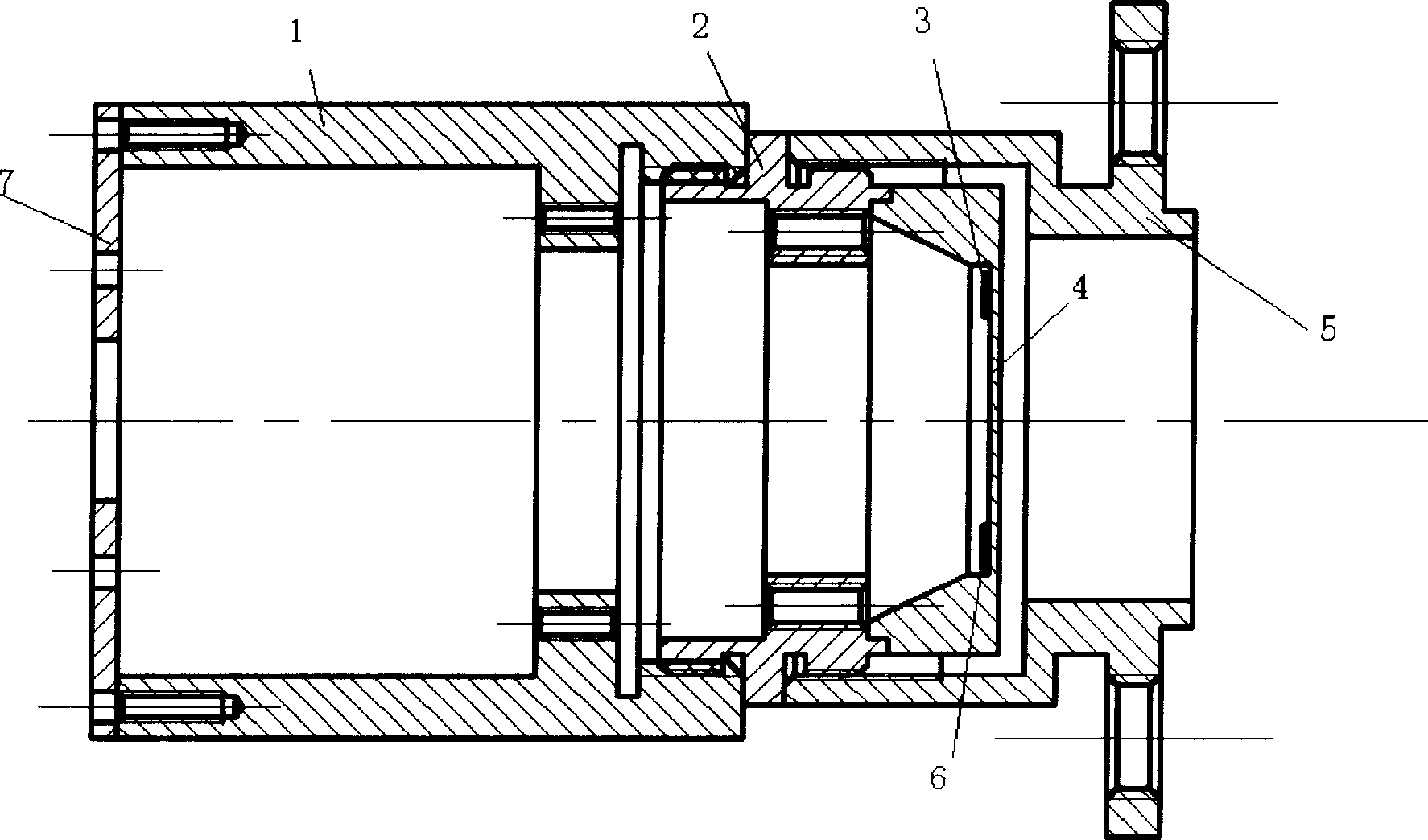

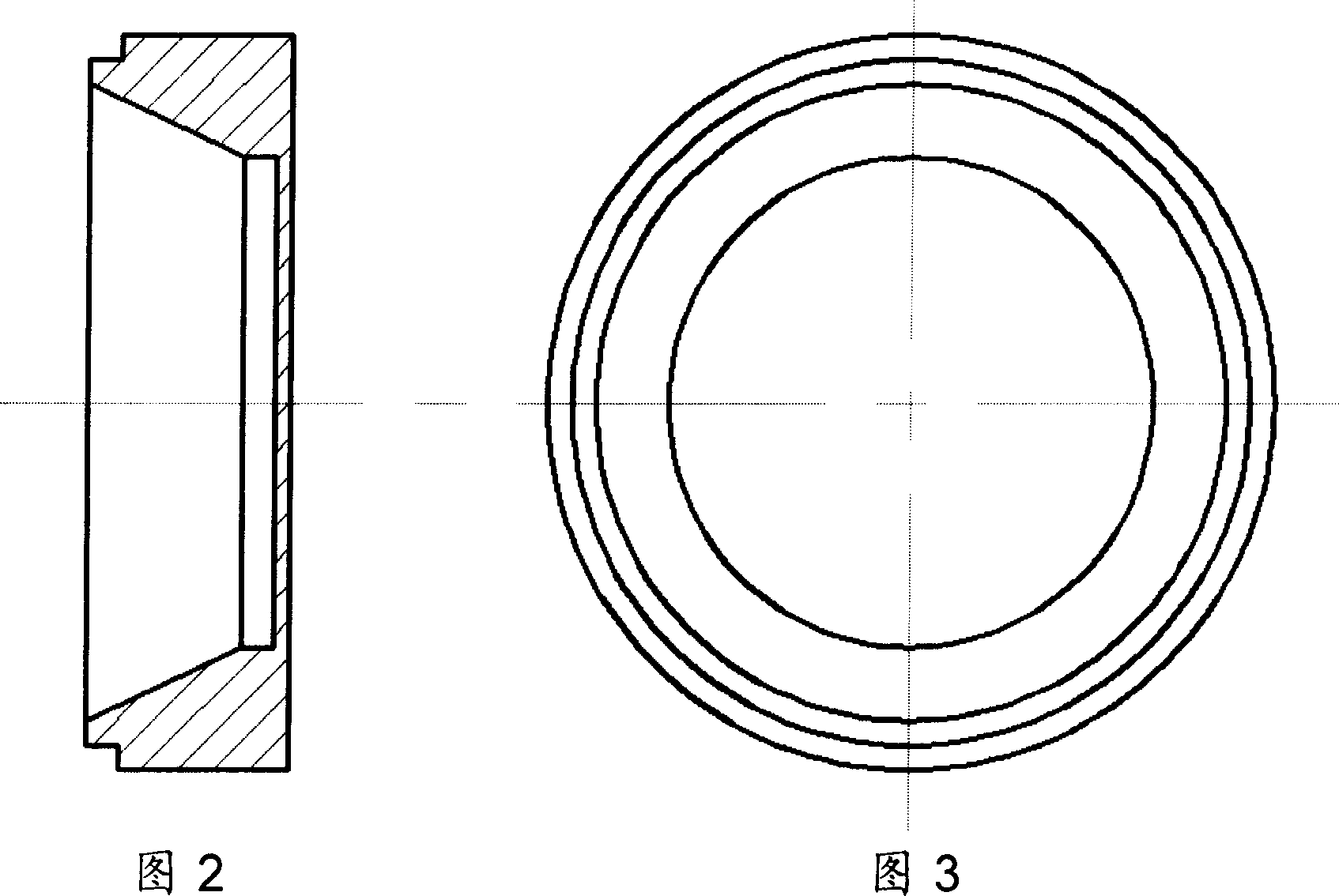

Besonance sensor for measuring liquid density

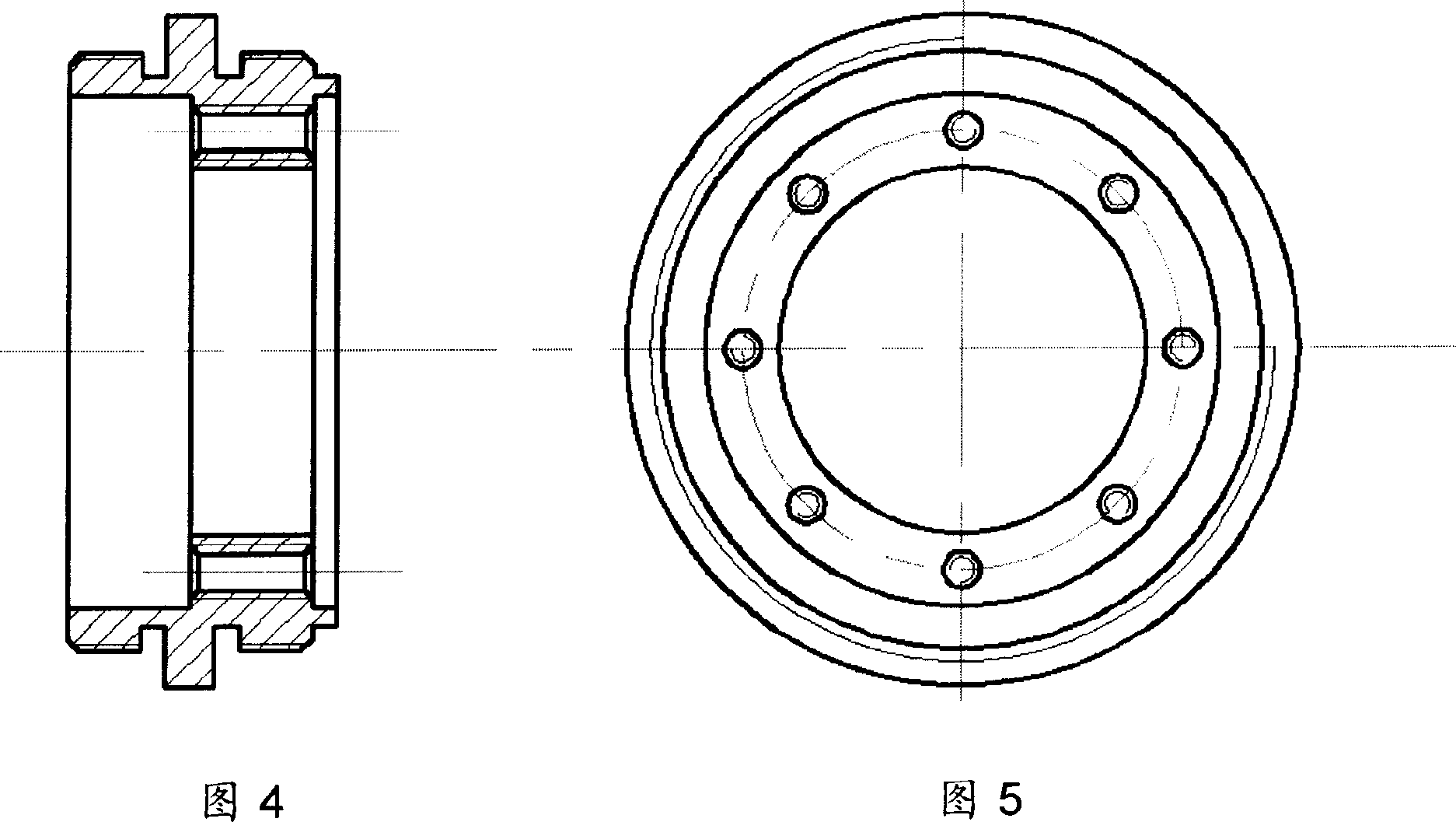

InactiveCN1834615AMode shape is simpleNot easy to change the mode shapeSpecific gravity measurementLiquid densityChaff

This invention relates to resonant-type measuring liquor density sensor. It includes chaff, chaff base seat, r, piezo-electric vibration pick-up, chaff circuit box, chaff box flange structure and end shield. Chaff processing must ensure planeness and parallelism of the two surfaces in sensor structure. The chaff and the base seat is welded as a integer by vacuum digital bundle welding, the flange structure is connected to the base seat through screw thread, the piezo-electric vibration pick-up and piezo-electric vibrator are separately pasted to same side of the chaff. Then chaff circuit is connected to the seat though screw thread. There is no need of insulation in this system; measuring precision is high, stable and reliable.

Owner:BEIHANG UNIV

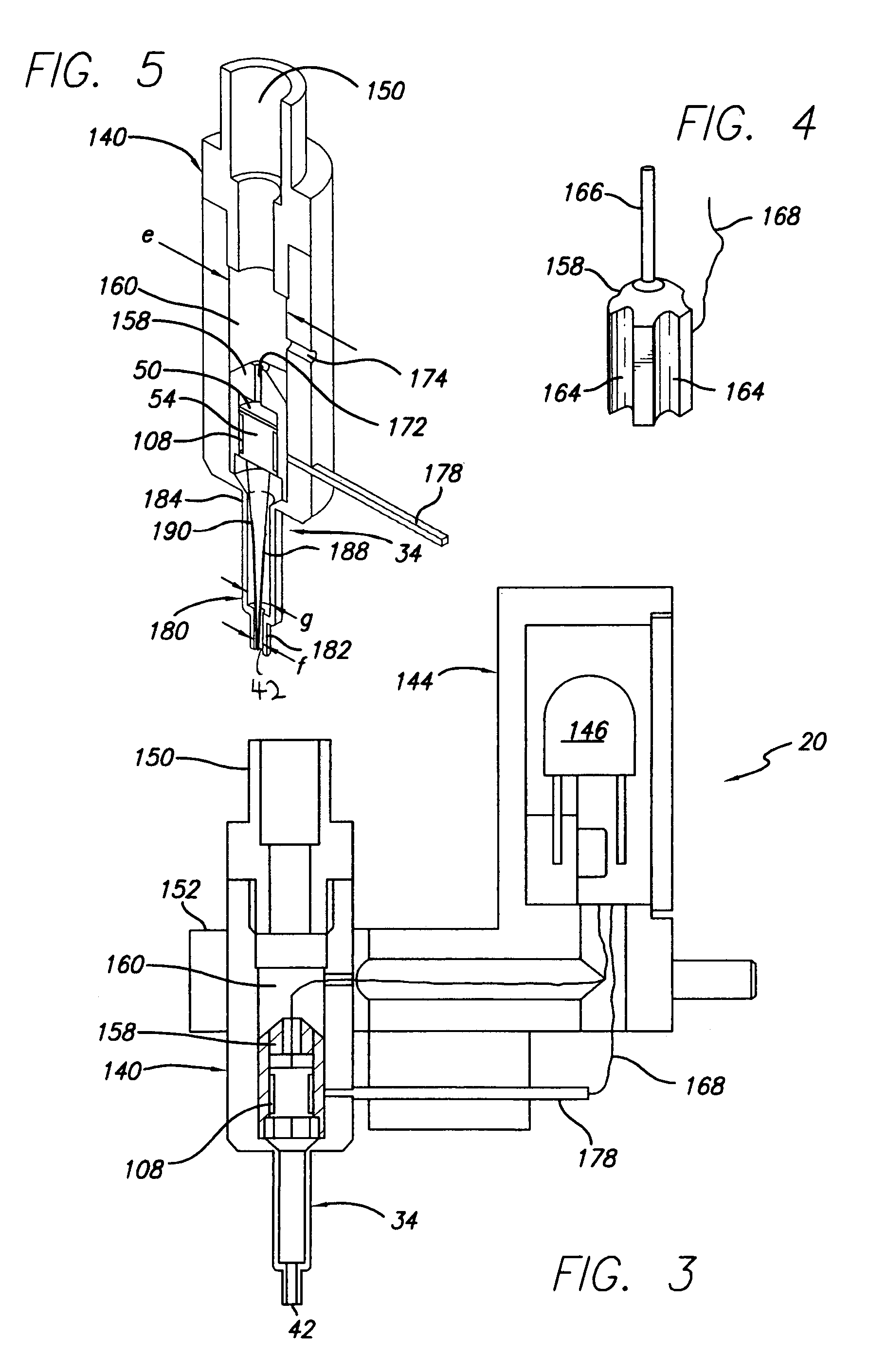

Acoustic liquid dispensing apparatus

ActiveUS7426866B2Accurately knowAnalysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesLiquid liquid partitionLiquid density

A liquid dispensing apparatus for dispensing droplets of a liquid, and methods for measuring various fluid parameters of the liquid are described. The liquid dispensing apparatus comprises a container having a chamber for holding a liquid. An orifice is positioned at an end of the chamber for dispensing droplets of the liquid, the orifice being configured to retain the liquid in the container if the container is positioned with the orifice facing in a downward direction. An acoustic transducer means is at least partially positioned in the chamber for periodically propagating a focused acoustic beam toward the orifice and through at least some of the liquid while the liquid is contained in the chamber, with the focused acoustic beam being capable of causing a droplet of the liquid to be ejected from the orifice when a free surface of the liquid is within the depth of field of the acoustic transducer means. Fluid parameters that can be measured include the sound velocity in the liquid, liquid level and liquid concentration, liquid acoustic impedance, liquid density and ultrasonic viscosity.

Owner:LABCYTE

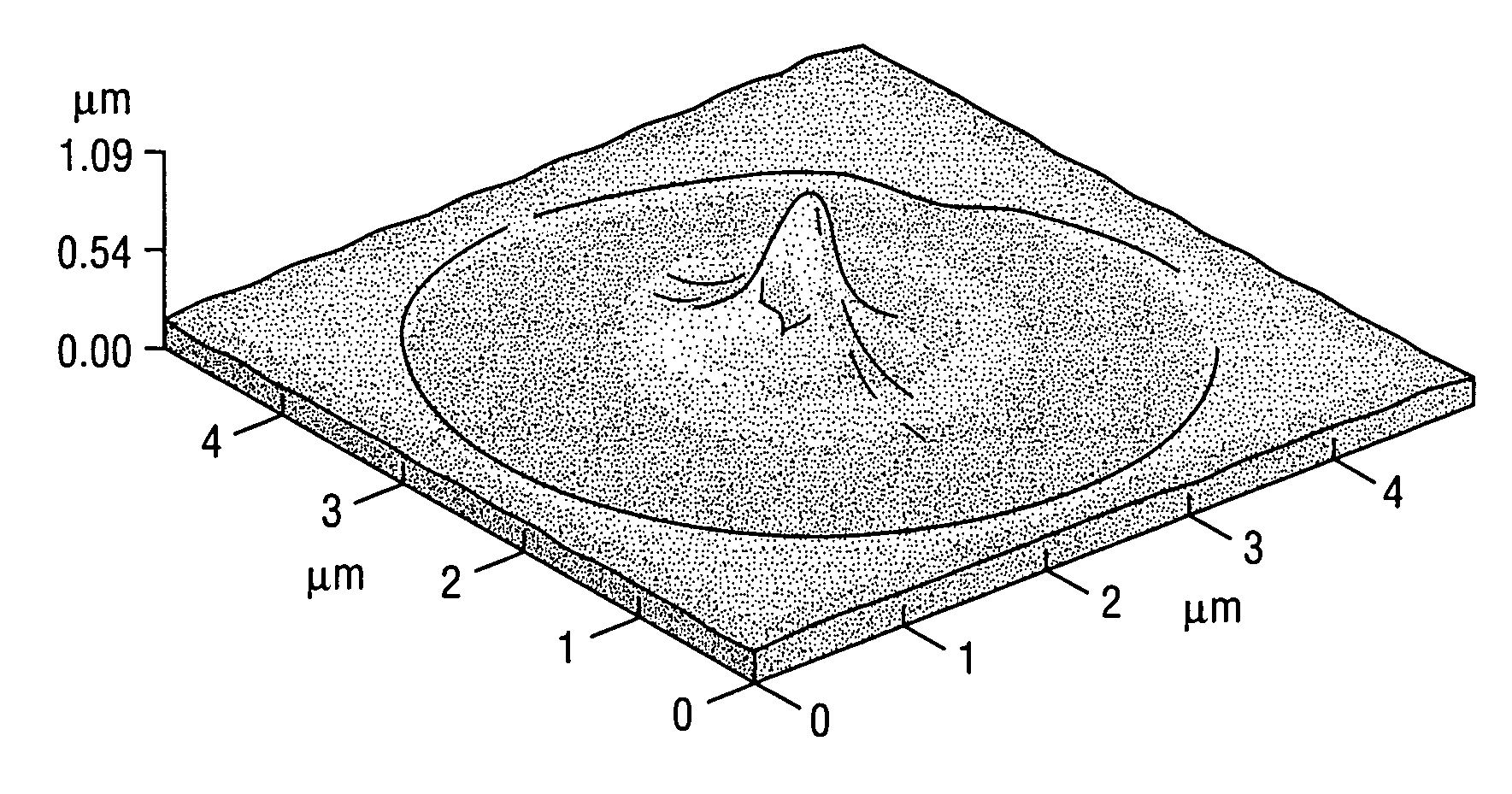

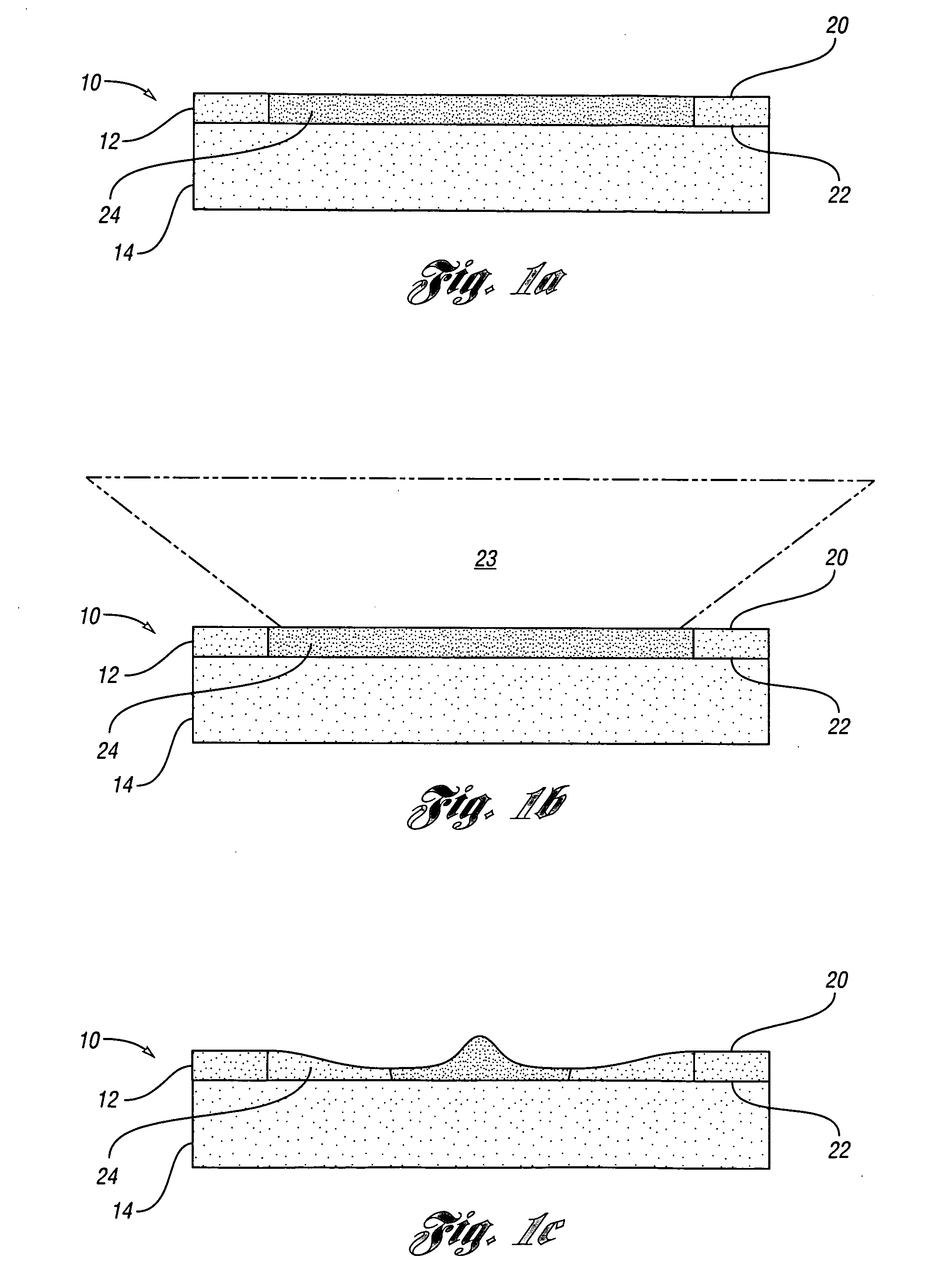

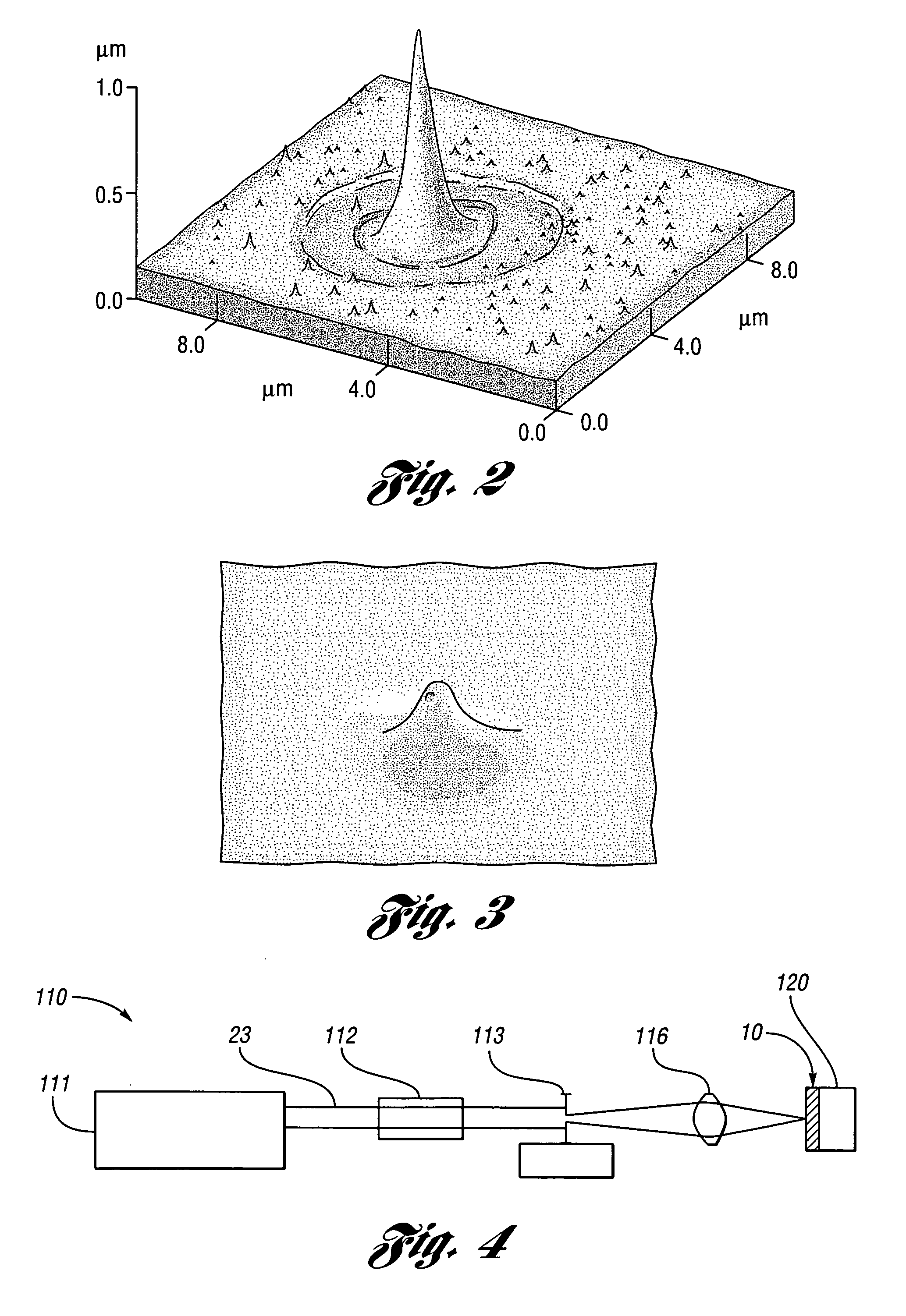

Method of forming micro-structures and nano-structures

InactiveUS20060258133A1Efficient manufacturingNanotechSemiconductor/solid-state device manufacturingMicro structureLiquid density

Methods of forming a nano-structure for electron extraction are disclosed. One method of forming a nano-structure comprises irradiating an area on a first surface of a thermal conductive film to melt the area across the film. The film is insulated on a second surface to provide two-dimensional heat transfer across the film. The liquid density of the film is greater than the solid density thereof. The method further comprises cooling the area inwardly from the periphery thereof to form a nano-structure having an apical nano-tip for electron extraction.

Owner:WAYNE STATE UNIV

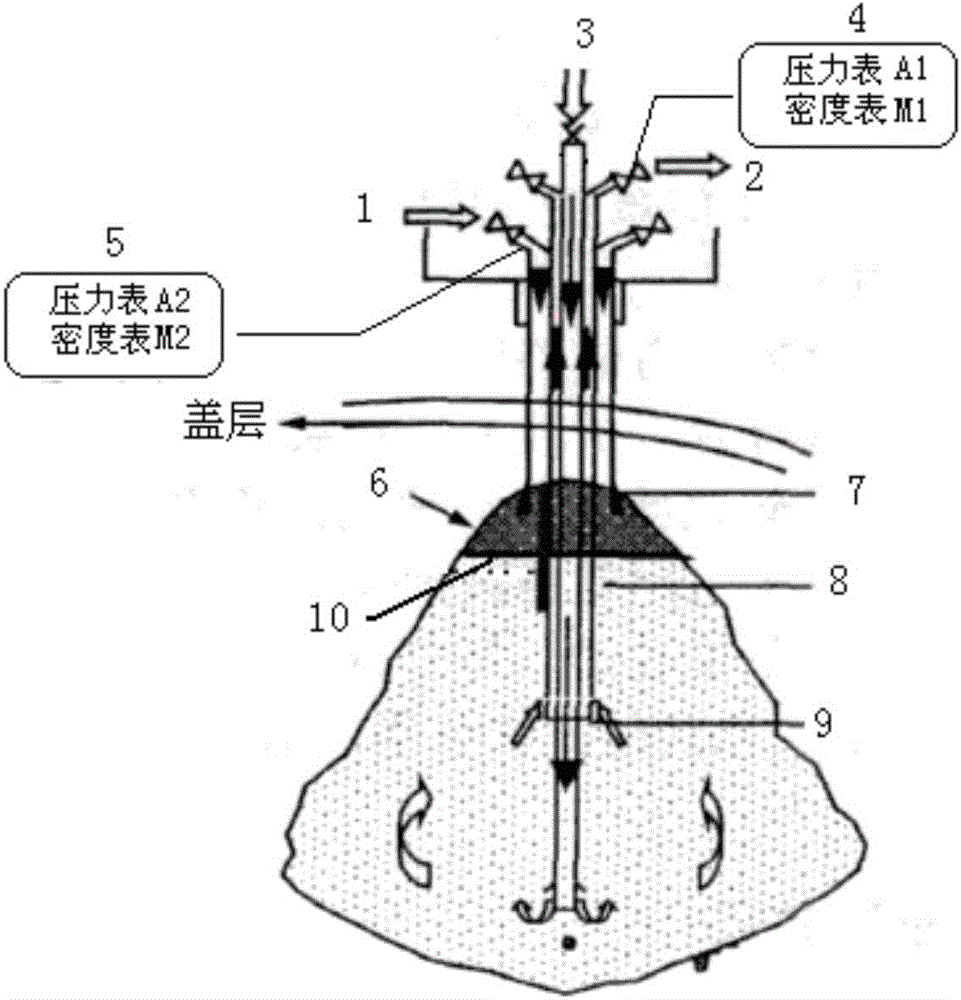

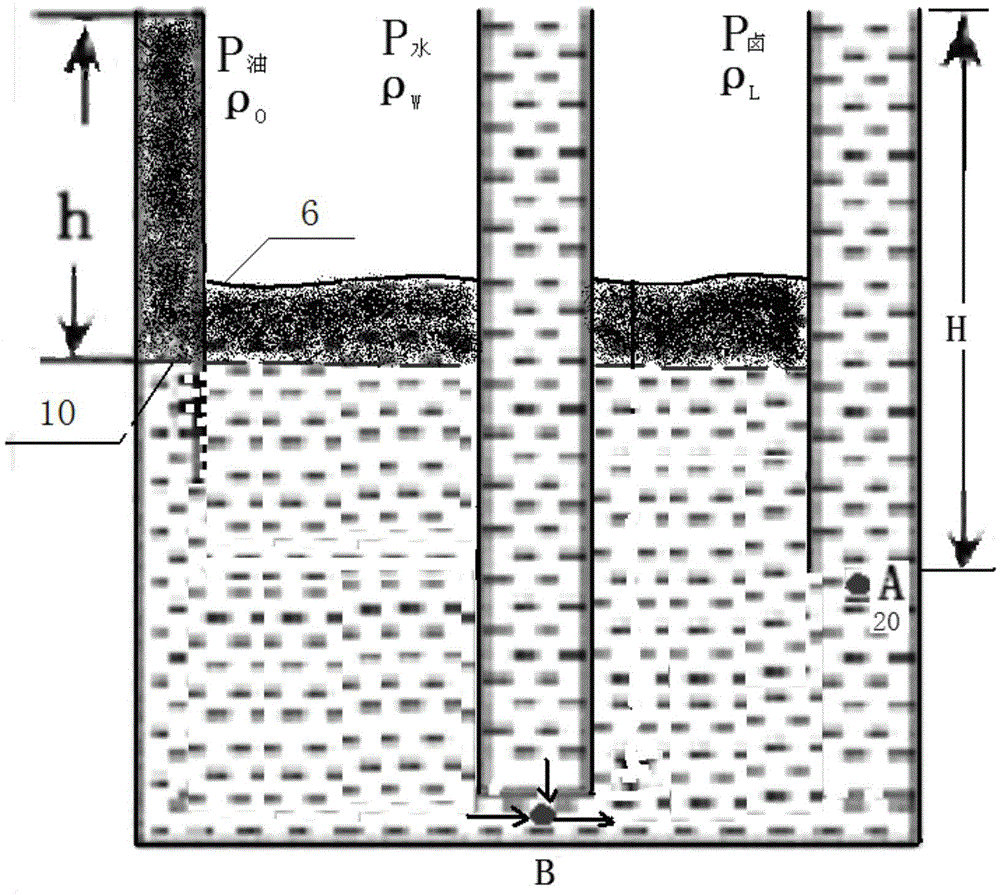

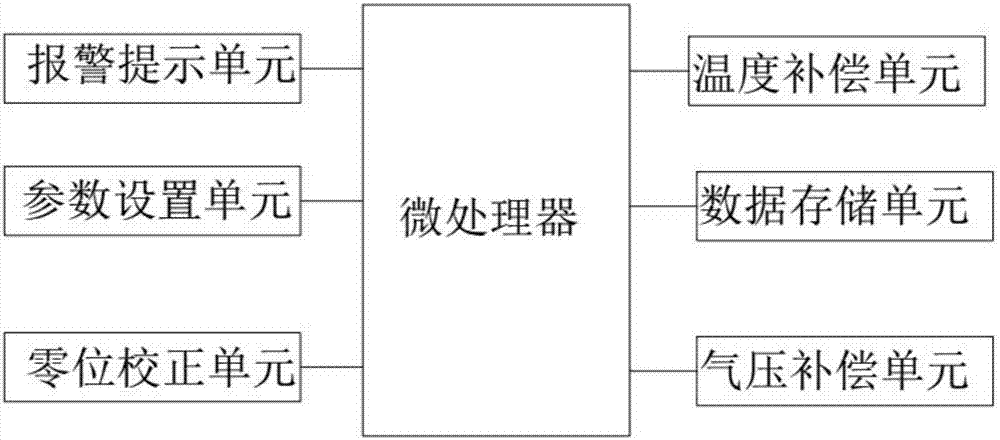

Salt cavern type gas storage cavity construction process oil-water interface detection method

ActiveCN104568052AAvoid construction risksAvoid cumbersome processLevel indicators by pressure measurementLiquid densityOil water

The invention discloses a salt cavern type gas storage cavity construction process oil-water interface detection method which includes the steps: mounting a high-precision pressure meter and a density meter on a wellhead; respectively measuring the wellhead pressure and the liquid density of a brine mining pipe and an oil filling pipe; substituting measured data into a calculation formula derived according to equivalent 'U'-shaped pipe model construction, and performing oil-water interface calculation to obtain the real depth of an oil-water interface. By the detection method, a downhole tripped detection instrument is omitted, construction risks caused by cable damage or instrument damage in the tripping process are avoided, measure process is simplified, and the complicated technological process of tripping a string again in change of the design depth of the oil-water interface is avoided.

Owner:CHINA PETROLEUM & CHEM CORP +1

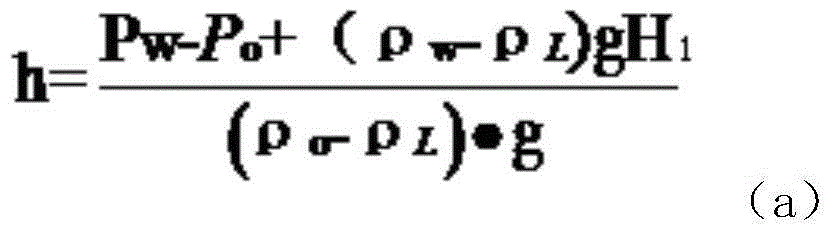

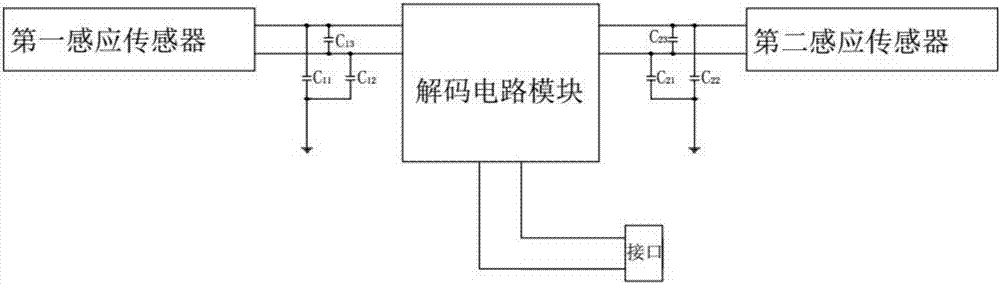

Passive liquid-level measuring device

PendingCN107063386AEasy to installLevel indicators by pressure measurementLevel indicators by weight measurementLiquid level measurementLiquid density

The invention discloses a passive liquid-level measuring device. The device comprises at least one inductive sensor and a decoding circuit module, wherein the inductive sensor is a pressure sensor or a gravity sensor and is disposed at a liquid container and used for acquiring gravity or pressure change parameters in the liquid container in real time. The pressure or gravity change parameters are transferred to the decoding circuit module, and the decoding circuit module acquires liquid-level change parameters in the liquid container according to the prestored cross section and liquid density of the liquid container, and is connected with an external host computer through a data interface. The passive liquid-level measuring device can be installed in a household electrical appliance, and acquire the liquid-level change parameters in a container dynamically in real time.

Owner:SHENZHEN NENGDIAN TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com