Patents

Literature

1018 results about "Liquid level measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

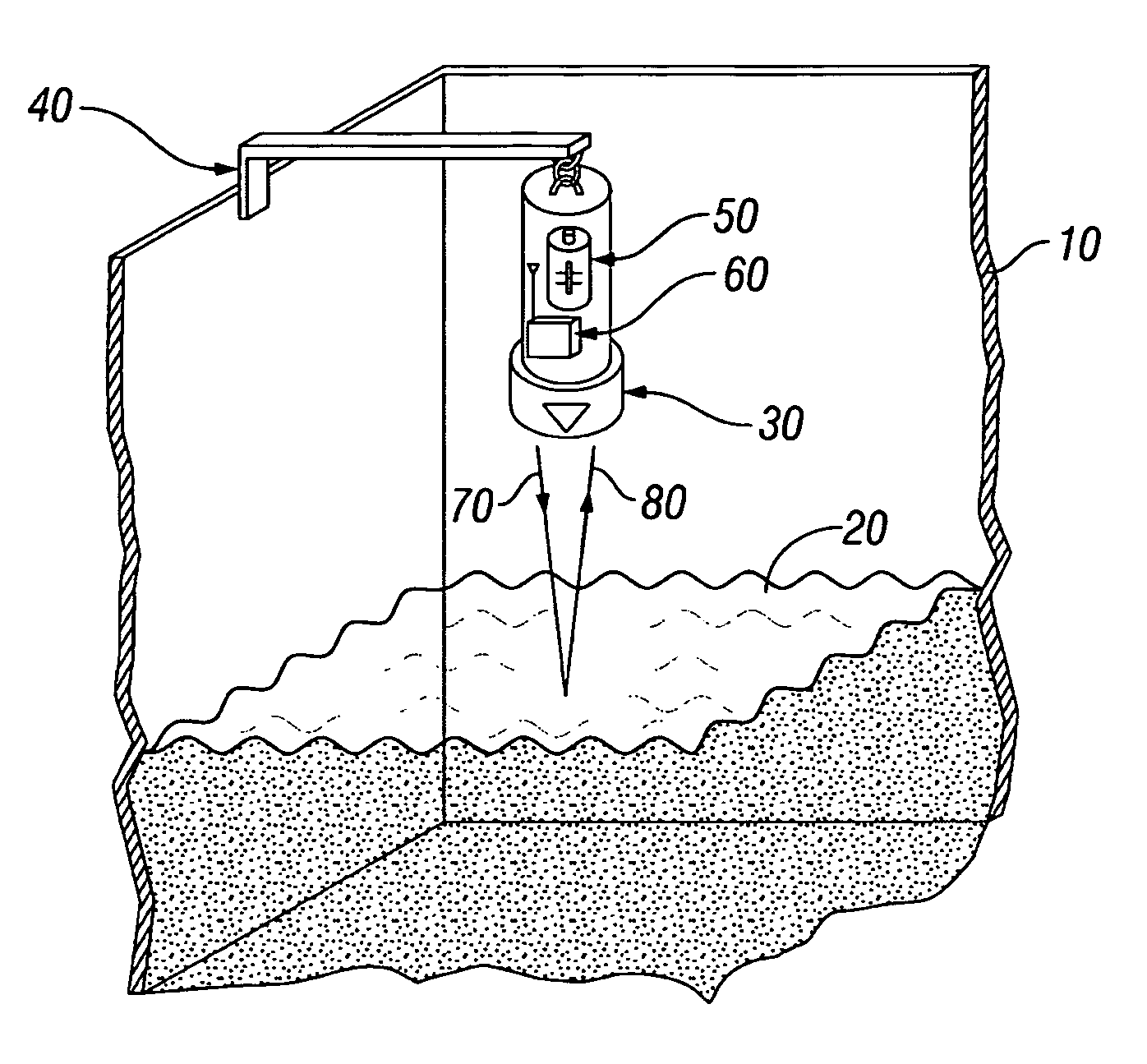

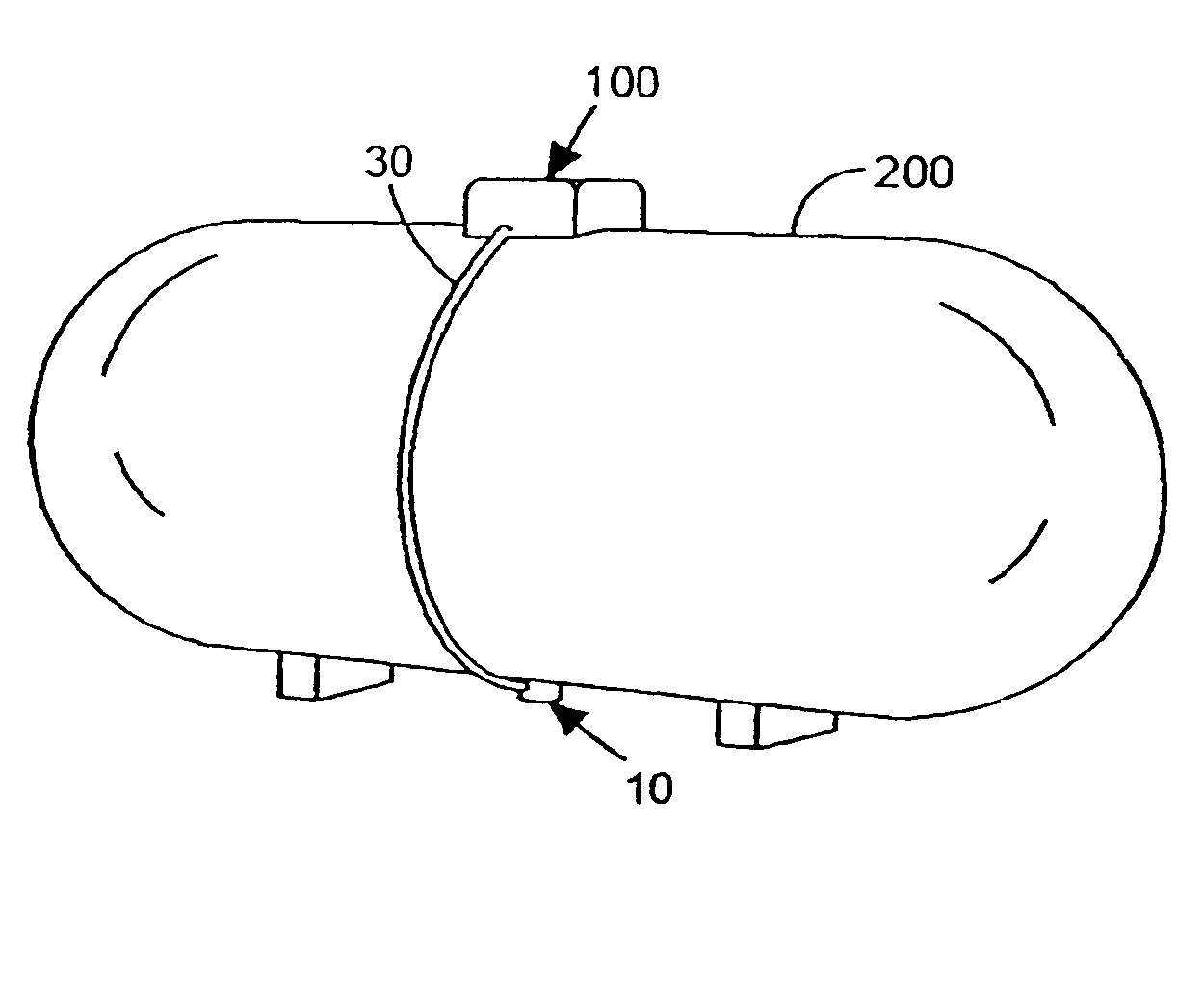

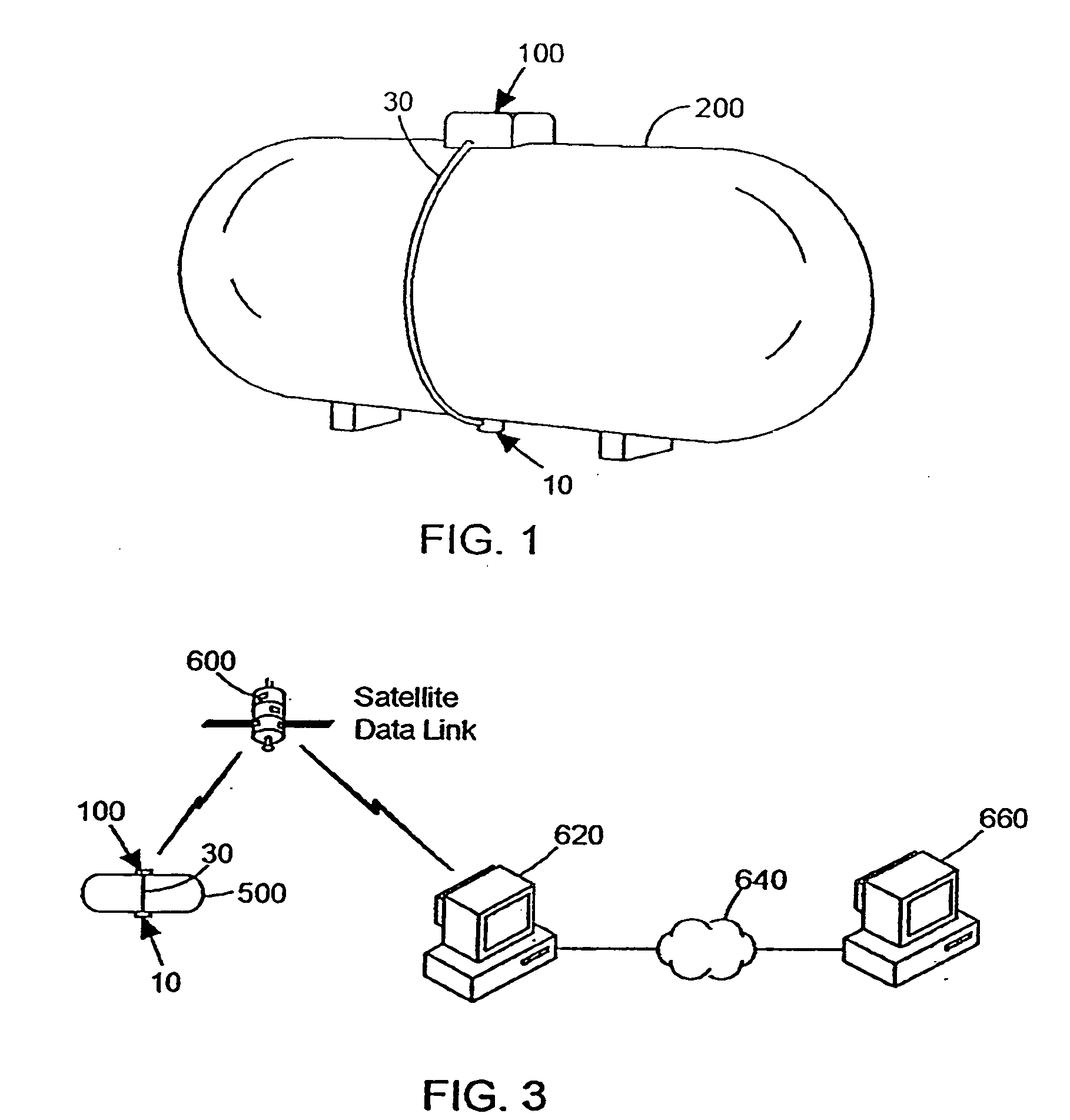

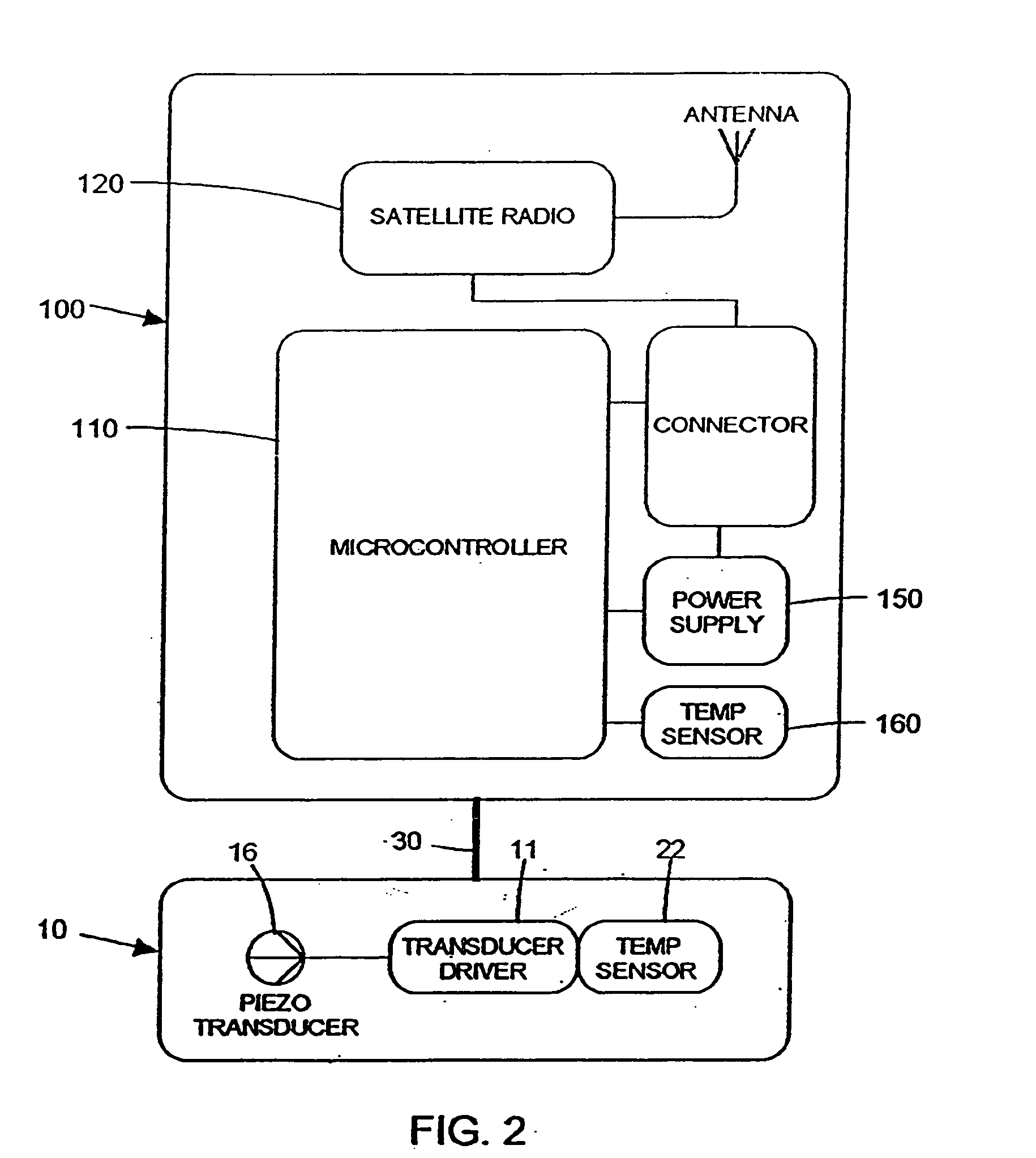

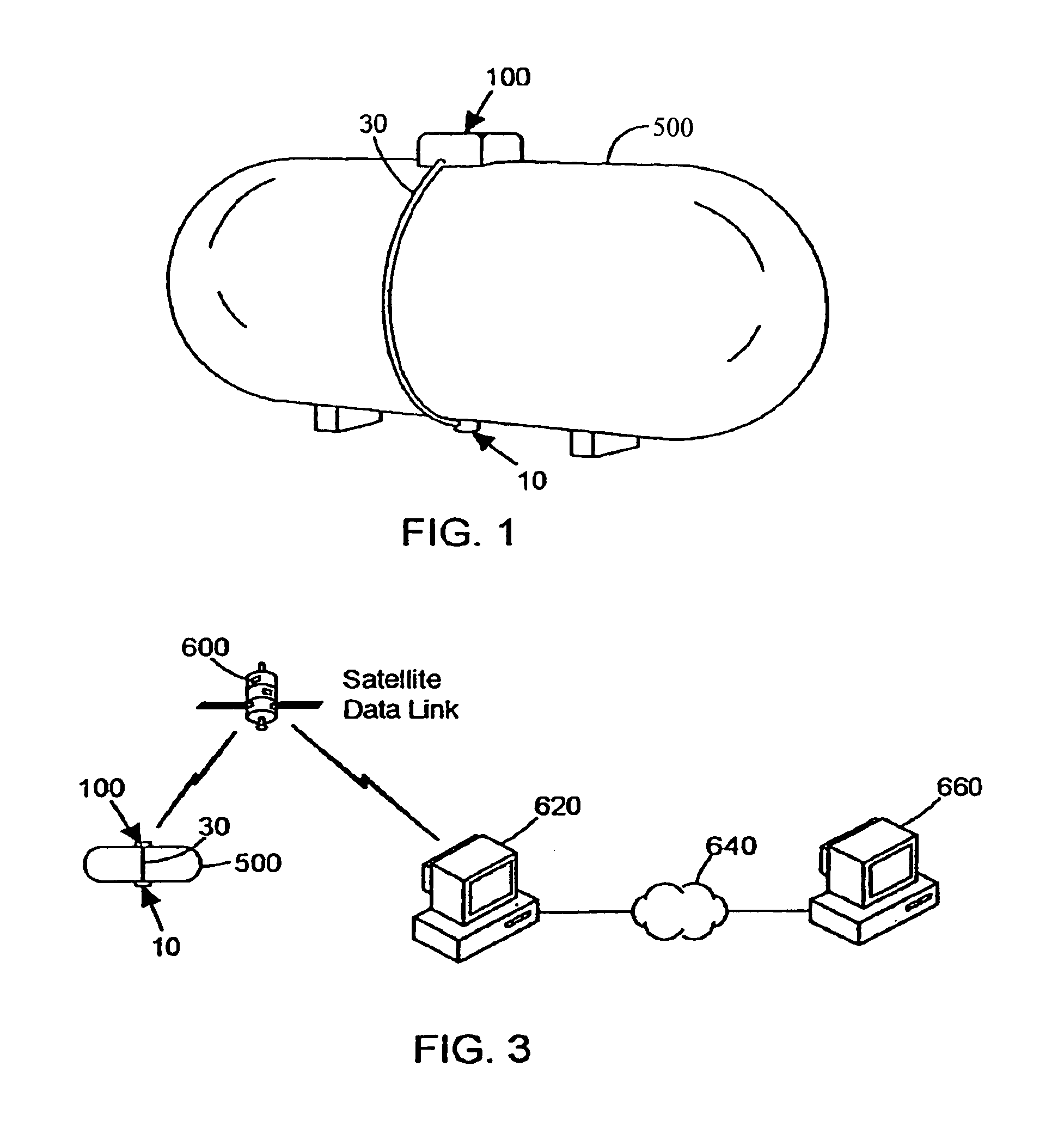

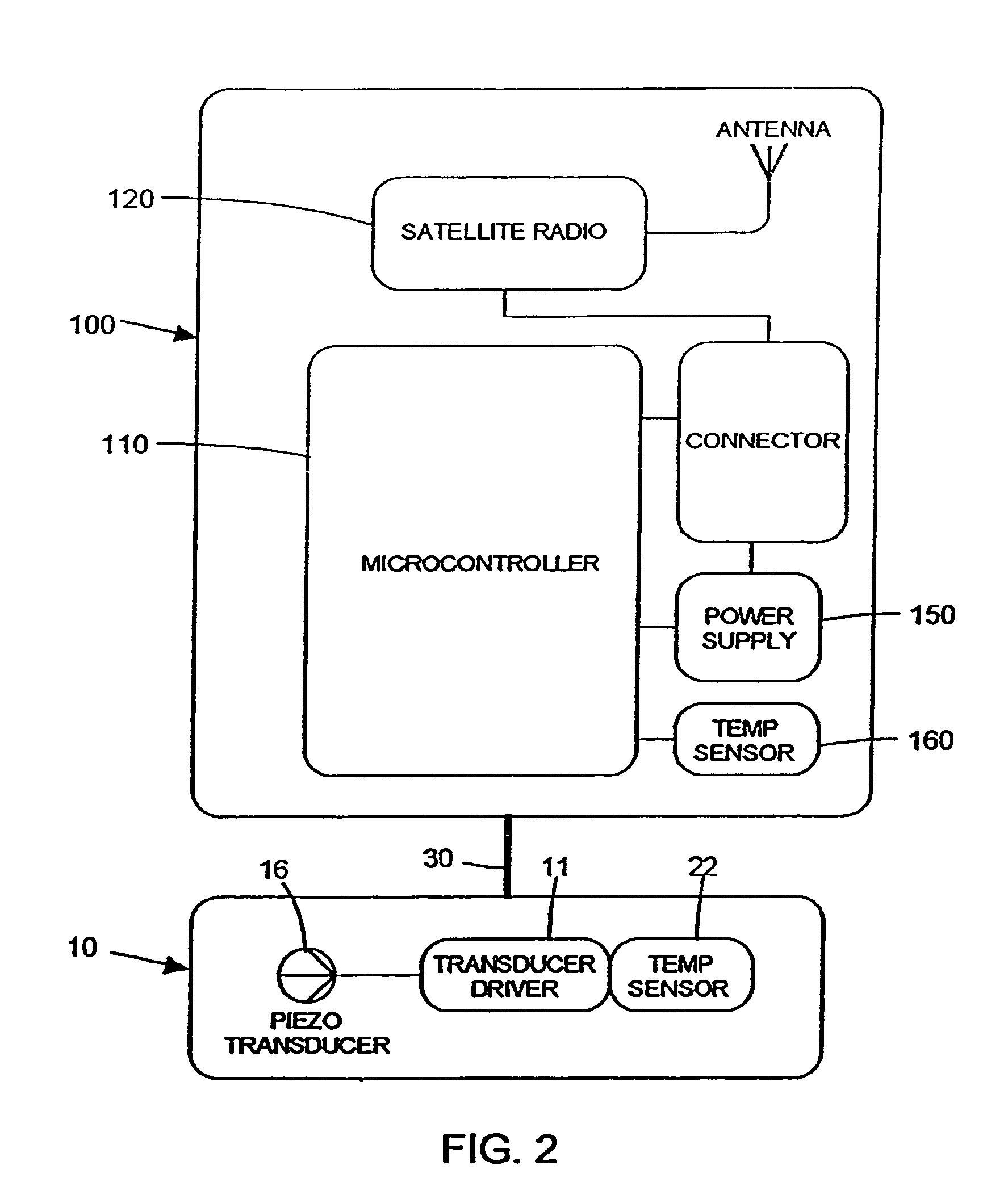

Safety tank level gauging system

InactiveUS20070084283A1Save energyExtend battery lifeTelemetry/telecontrol selection arrangementsVolume/mass flow measurementLiquid level measurementUltrasonic sensor

An apparatus and method is disclosed to automate the measurement of the fluid levels of individual tanks used at the work site of an oil well. An ultrasonic transducer may be removably attached to each tank at the site. The fluid level of each tank may be determined from the time elapsed from the transmission of an ultrasonic signal from the transducer and when a signal reflected from the fluid is received at the transducer. The transducer may wirelessly transmit a signal representative of the fluid level to a receiving unit. The receiving unit may be able to instantaneously determine the overall fluid flow rate from the tanks based on the fluid levels when compared to previous fluid levels. The transducers may take fluid level measurements at regular intervals or may make measurements only when directed by the receiving unit.

Owner:BJ SERVICES CO

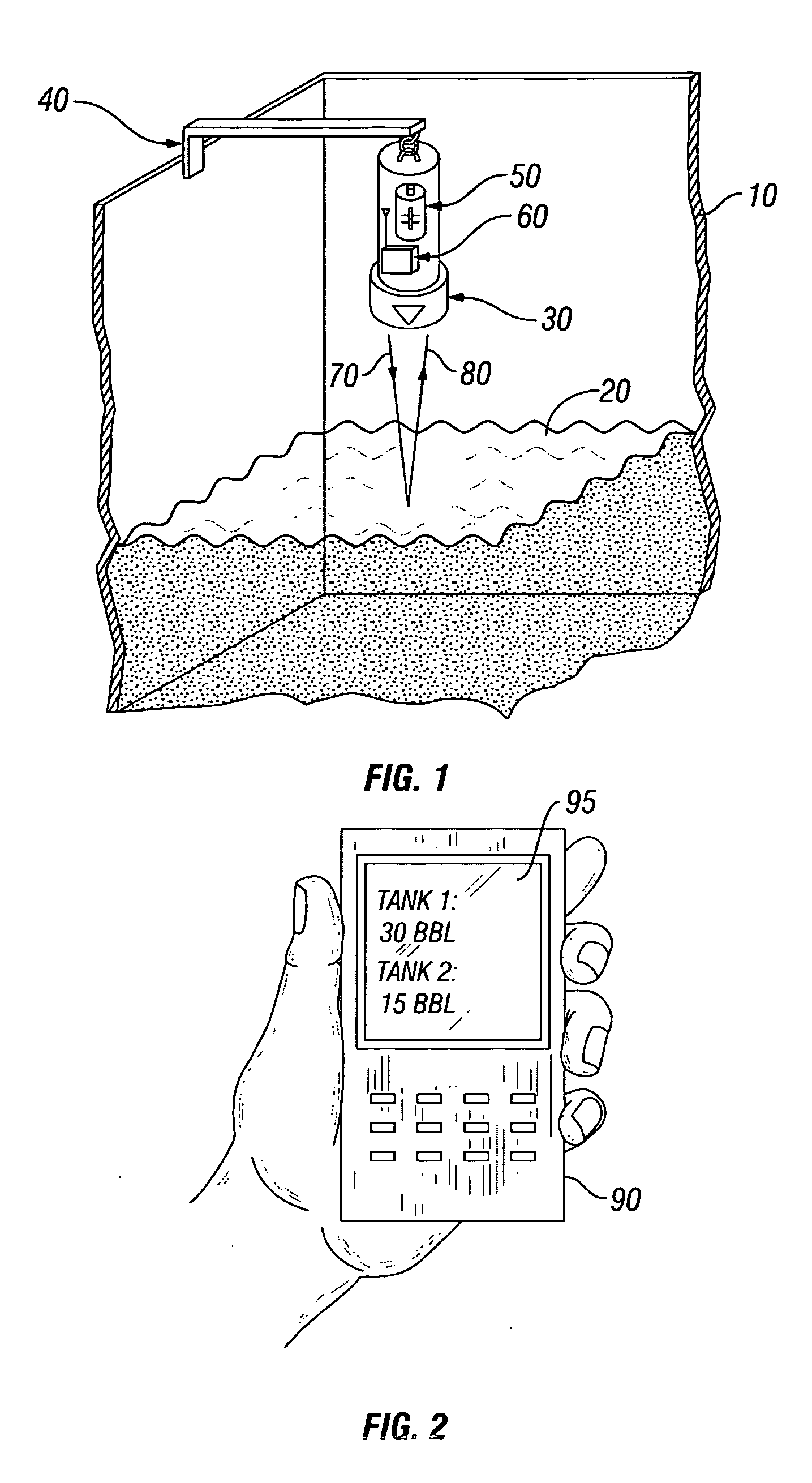

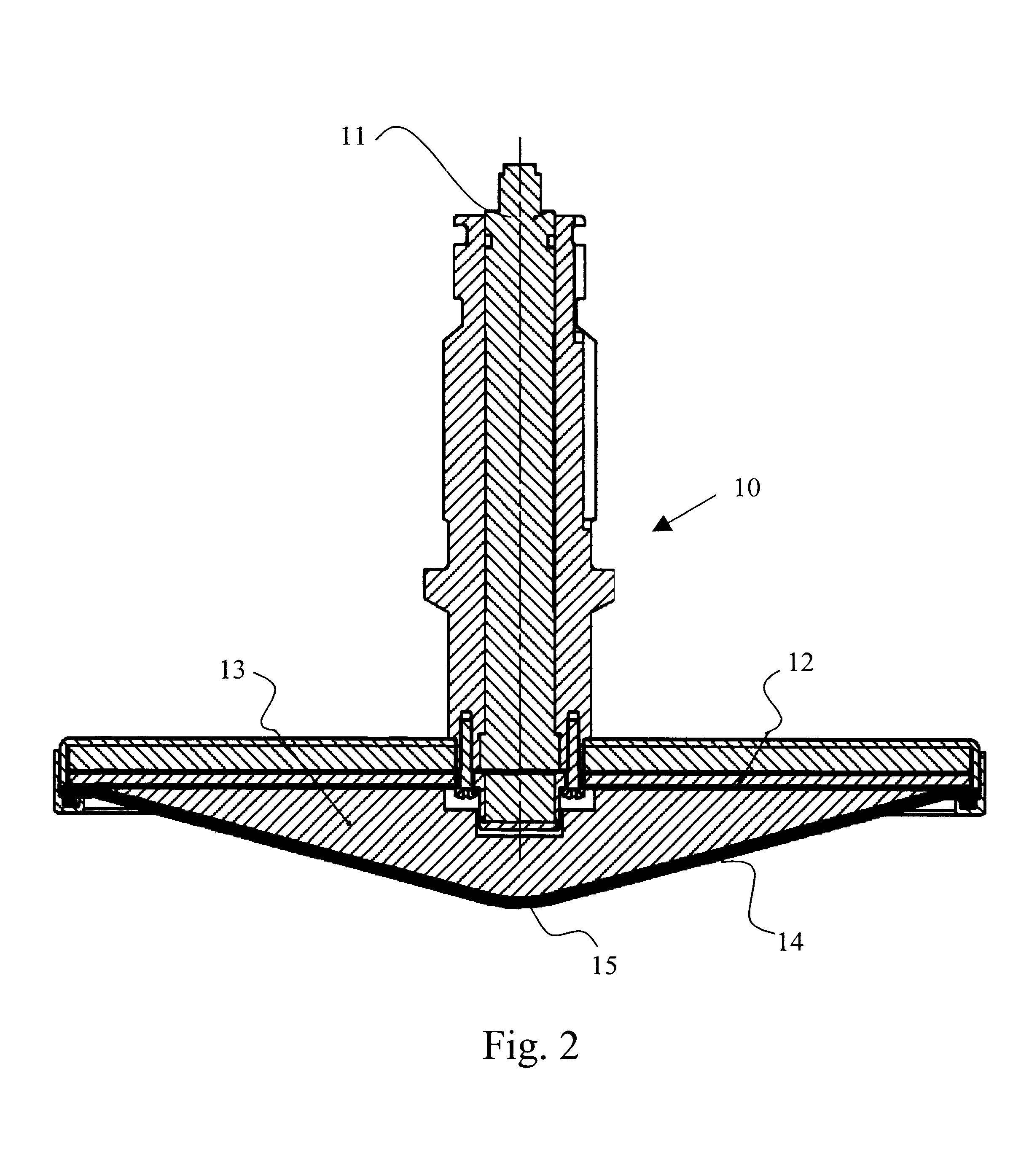

Device in a level gauging system

InactiveUS6629458B1Antenna supports/mountingsProtective material radiating elementsRadarLevel measurement

The present invention relates to a device in a level gauging system comprising an antenna using radar waves to gauge a level of a surface of a fluid kept in a container. The antenna is arranged above the fluid surface and comprises a plane surface facing the fluid surface and being substantially parallel with the fluid surface. The plane surface has means for transmitting radar waves towards the fluid surface and means for receiving reflected radar waves from the fluid surface in order to gauge the fluid level. The antenna comprises a radome which at least partially covers the plane surface and is shaped such that condensed fluid is directed away from the antenna by force of gravity. A thermally insulating filling material is provided between the radome and the plane surface.

Owner:ROSEMOUNT TANK RADAR

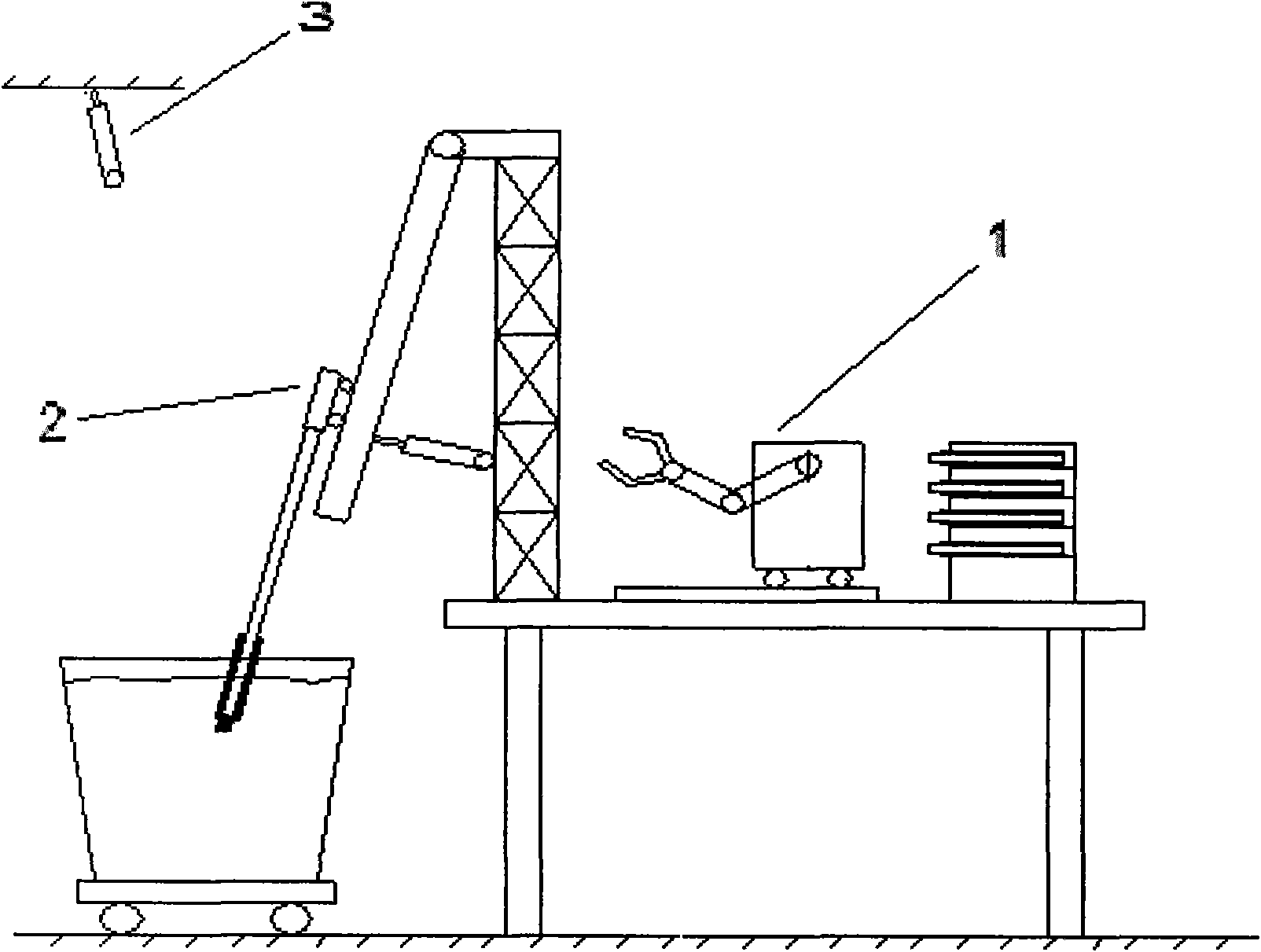

Exactly temperature-measuring and sampling system of molten steel and method thereof

ActiveCN101975679AEasy to controlHigh precisionWithdrawing sample devicesMachines/enginesLiquid statePosition control

The invention discloses an exactly temperature-measuring and sampling system of molten steel and a method thereof, belonging to the technical field of liquid metal treatment process in the metallurgy field, and comprising an intelligent robot system, an automatic temperature measuring and sampling gun system, a liquid level height detector and an industrial control computer. The whole system is integrally controlled by the industrial control computer. The liquid level height detector is used for measuring the depth of the liquid level of the molten steel firstly, and then the intelligent robot is responsible for of installing probes, finally the automatic temperature measuring and sampling gun system is used for realizing the automatic temperature measurement and sampling. The invention has the advantages of realizing the exact position of temperature measurement and sampling of each gun on the basis of the infrared molten steel liquid level measurement and the servo position control, completely eliminating the system accidental error of measuring results caused by a manual measuring manner and providing reliable guarantee for improvements on the quality control and the precision of the molten steel.

Owner:BEIJING SHOUGANG CO LTD

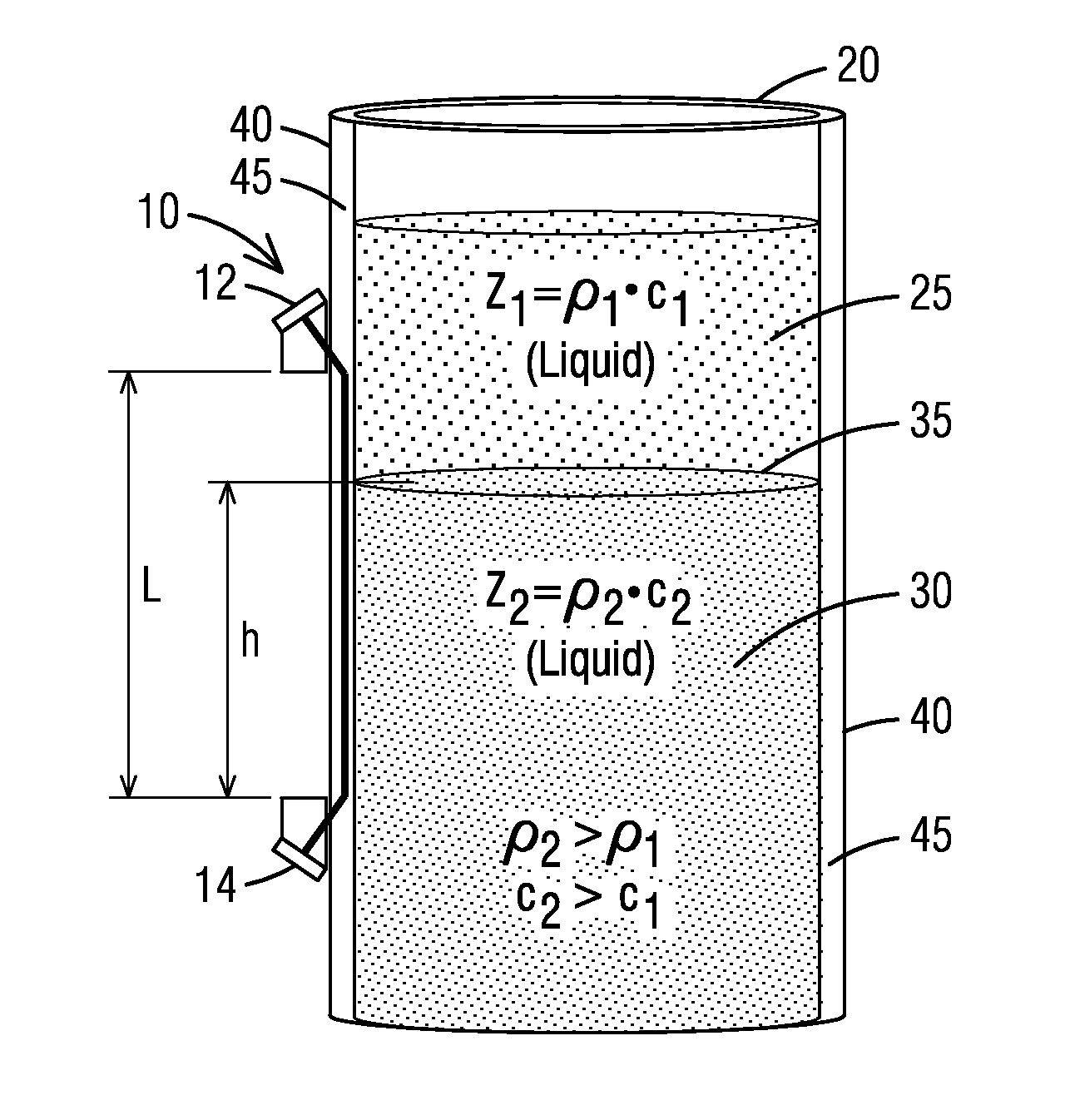

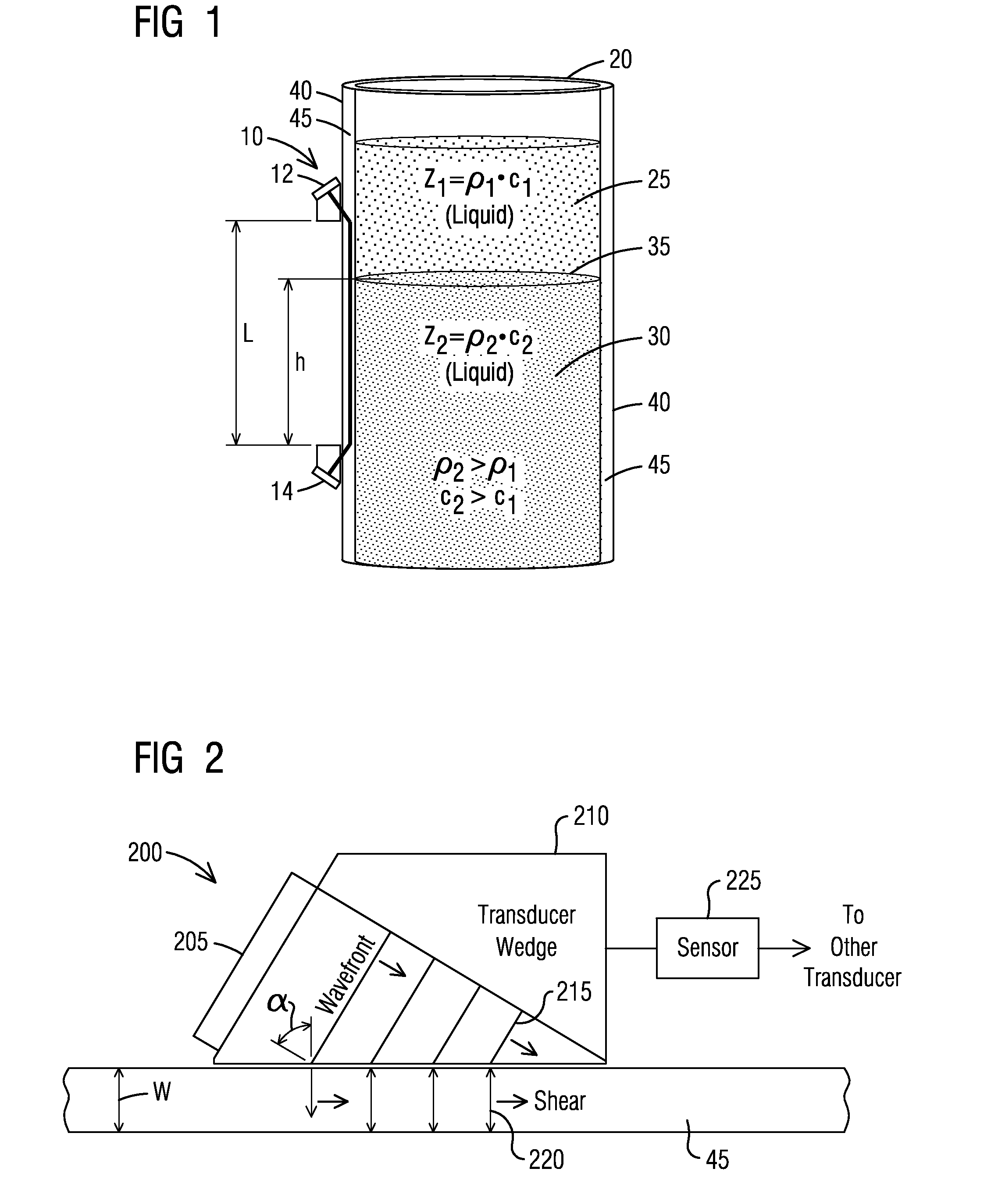

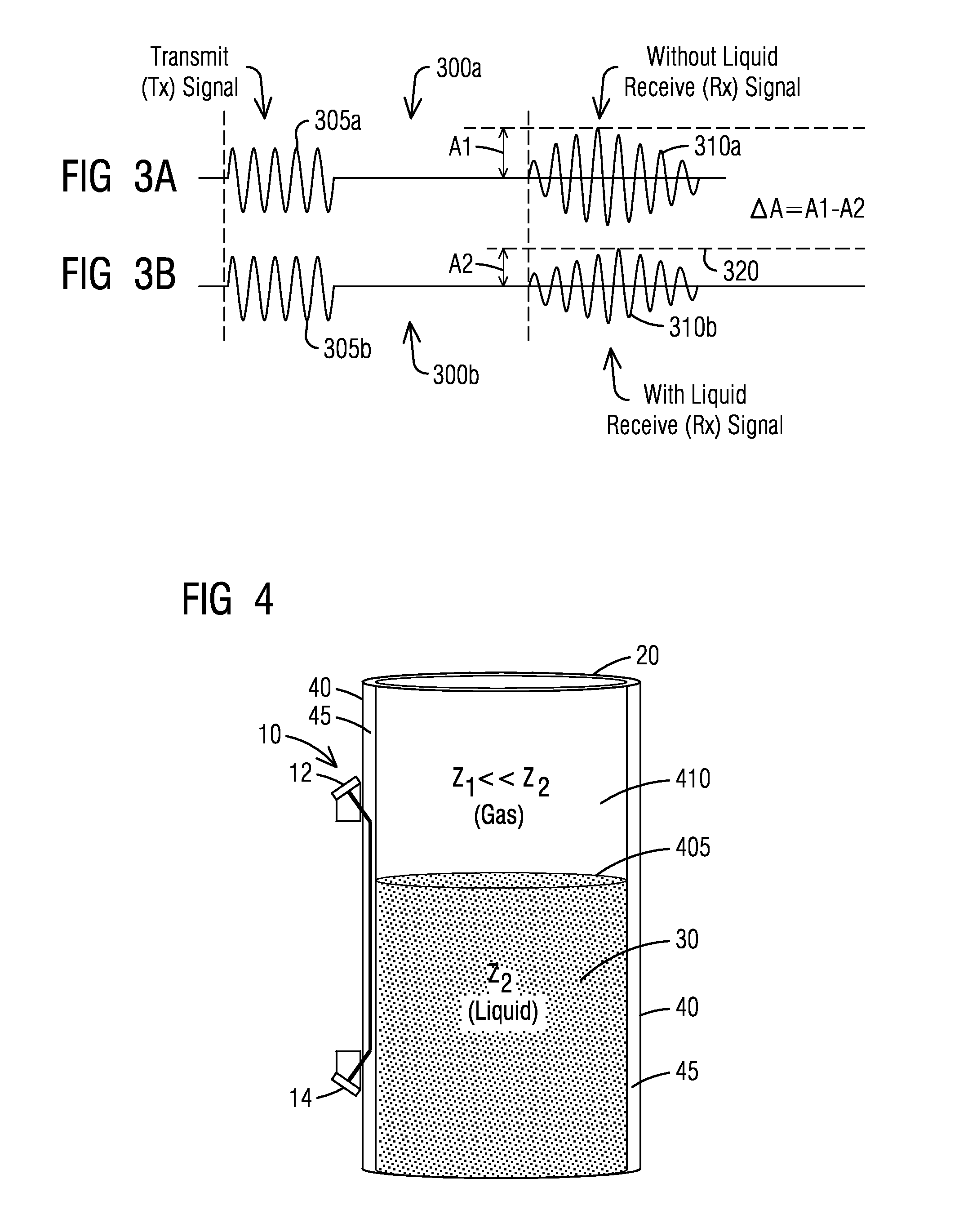

Determining height of a liquid level interface in a container from acoustic signal or echo time measurement

An ultrasonic liquid level detector includes clamp-on transducers for a liquid level measurement by the clamp-on transducers instead of insertion type transducers. The ultrasonic liquid level detector measures a height of a liquid-liquid interface or a gas-liquid interface based on an acoustic attenuation of an acoustic pulse or a transit-time of the acoustic pulse using a pulse echo technique or a combination thereof.

Owner:SIEMENS AG +1

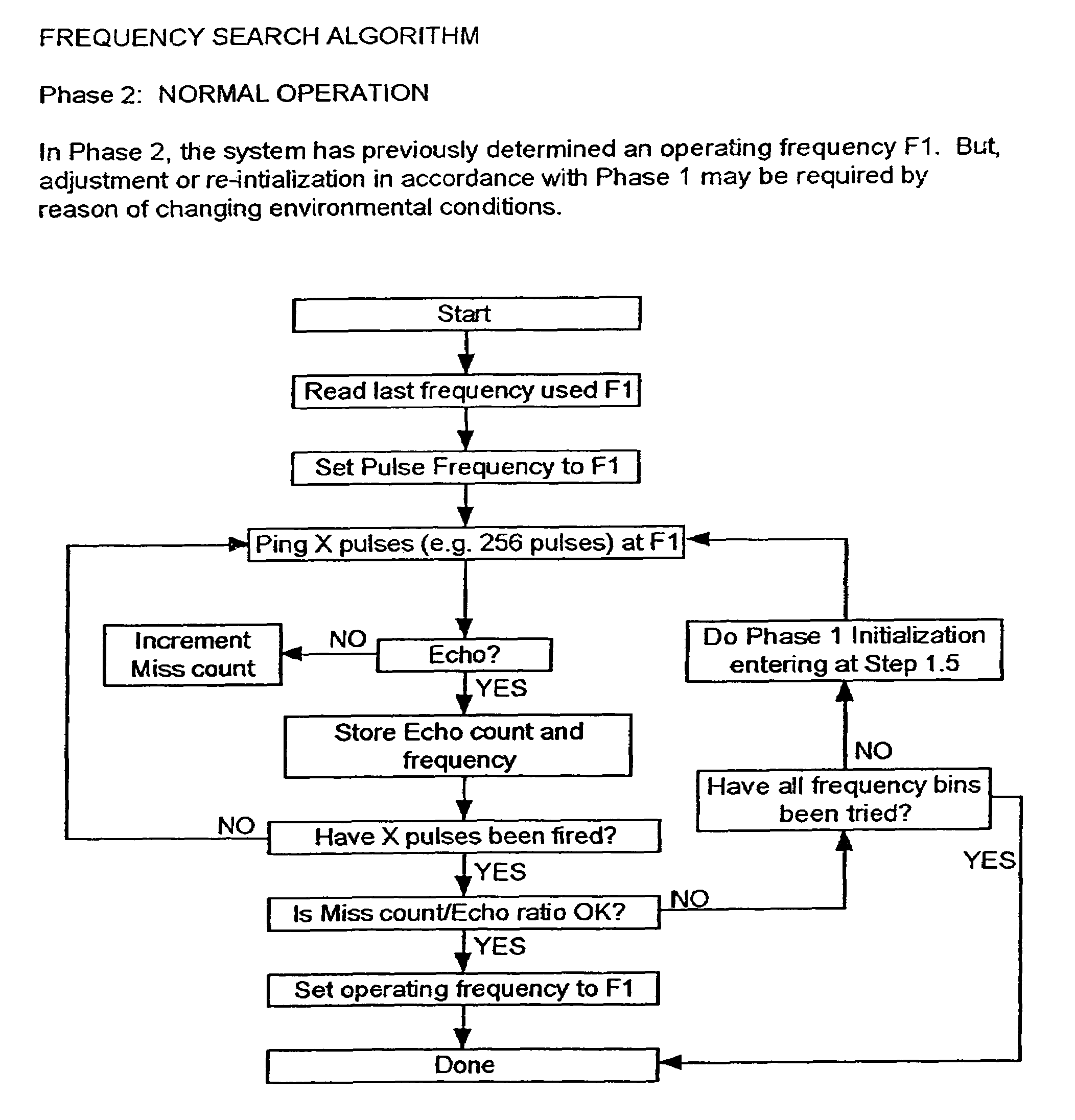

Ultrasonic fuel level monitoring device

InactiveUS20050284218A1Machines/enginesLubrication indication devicesLiquid level measurementFuel tank

The invention describes a method of altering the transmitted frequency used in an ultrasonic ranging system for liquid level measurement in a fuel tank. The frequency agility of the system is an important component of performing liquid level measurement in an enclosed vessel.

Owner:SCHMITT MEASUREMENT SYST

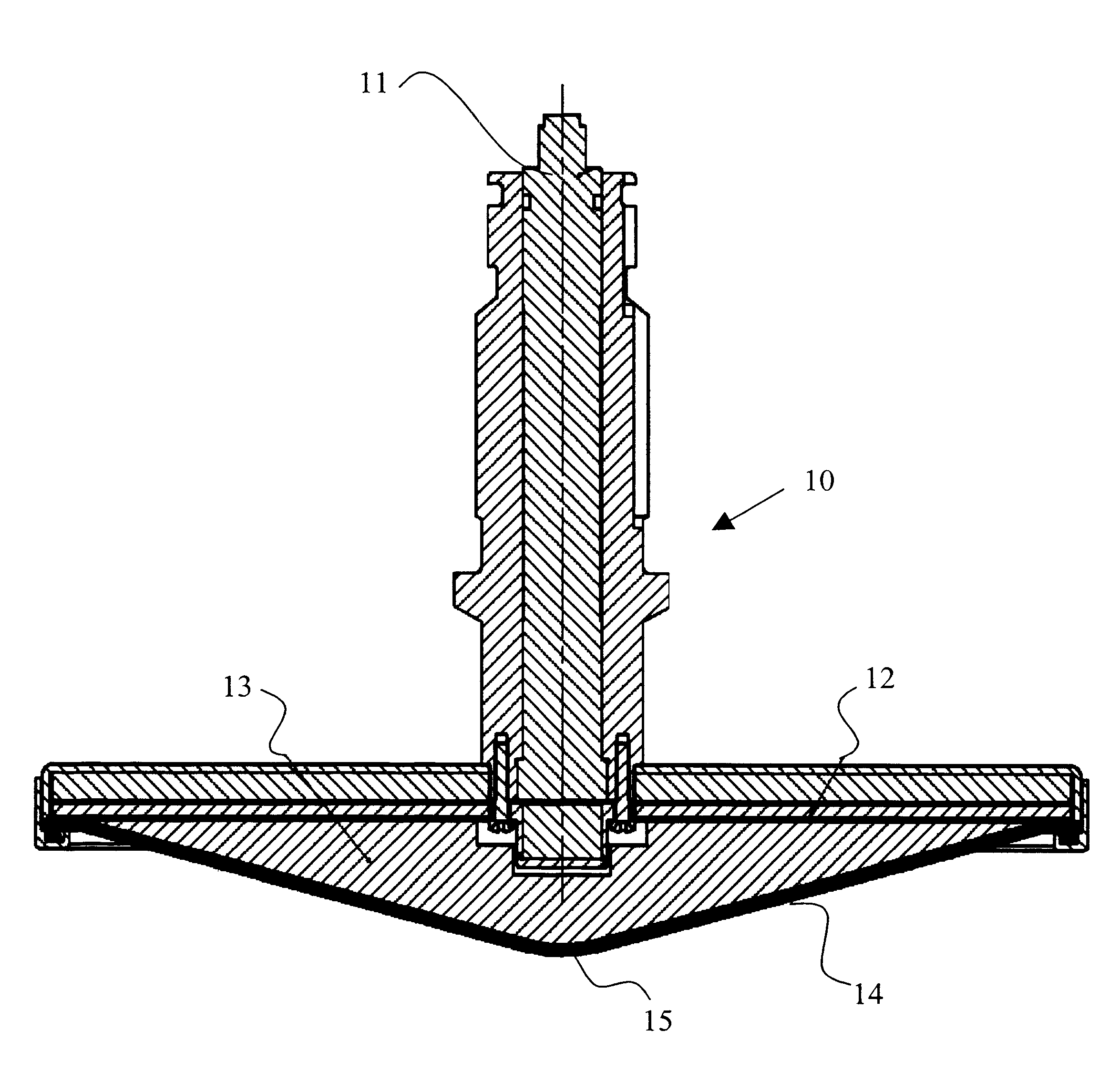

Systems and methods for remotely measuring a liquid level using time-domain reflectometry (TDR)

ActiveUS20140159743A1Maintaining impedance characteristicImprove sealingCapacitance measurementsMachines/enginesCoaxial cableLiquid level measurement

A remote pulse TDR liquid level measurement system and method may include inserting a probe into a body of water. The probe has a probe / air interface, and the body of water includes an air / water interface. A narrow pulse is remotely transmitted to the probe via a coaxial cable. A first impedance mismatch is received from the probe / air interface in a form of a positive reflected pulse, and a second impedance mismatch is received from the air / water interface in a form of a negative reflected pulse. A time between the positive reflected pulse and the negative reflected pulse is calculated, and the time is converted to a distance, the distance being indicative of the water level.

Owner:GE HITACHI NUCLEAR ENERGY AMERICAS

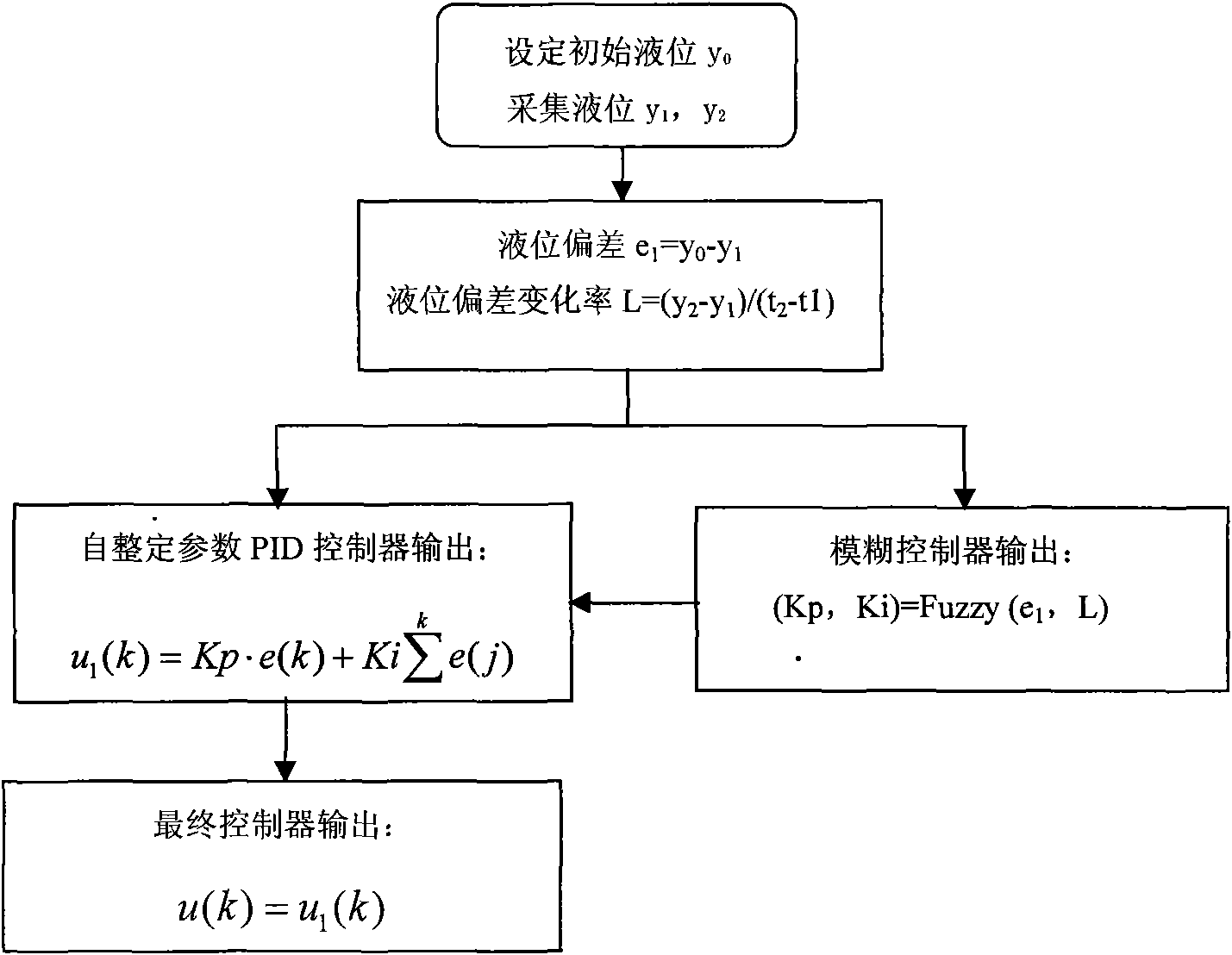

Liquid level control method of continuous casting crystallizer based on Fuzzy-PID

The invention relates to a liquid level control method of a continuous casting crystallizer based on Fuzzy-PID and belongs to the technical field of continuous casting production. The liquid level control method makes use of fuzzy control to carry out online correction of parameters in self-adjusting parameter PID control. Under the control of a computer and a PLC, the control method makes use of self-setting parameter PID control and fuzzy control to realize mixed control of the liquid level of the crystallizer, and also adopts a flow rate deviation compensating module, and the like. The control process of the control method comprises the following steps: setting an initial liquid level y0 and acquiring liquid levels y1 and y2 through a liquid level sensor and a liquid level measuring device; inputting the acquired data y1 and y2 in a PLC; adopting the self-setting parameter PID control and the fuzzy control to realize mixed control of a processing signal; and carrying out compensation through the compensating module; moreover, the output of the PLC, u(k) is equal to u1(k), and the PLC controls the position of a stopper through a stopper controller so as to control the liquid level of the crystallizer.

Owner:NORTHEASTERN UNIV LIAONING

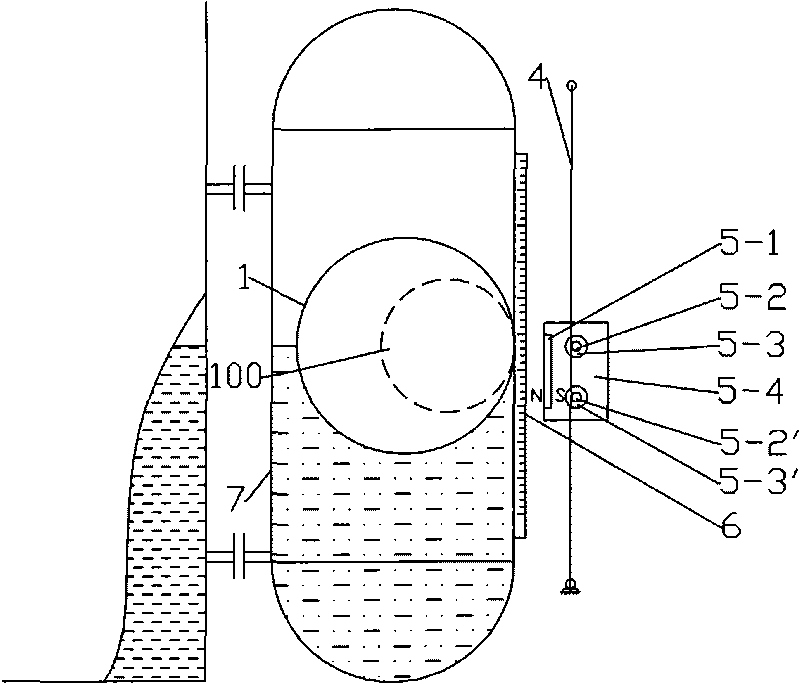

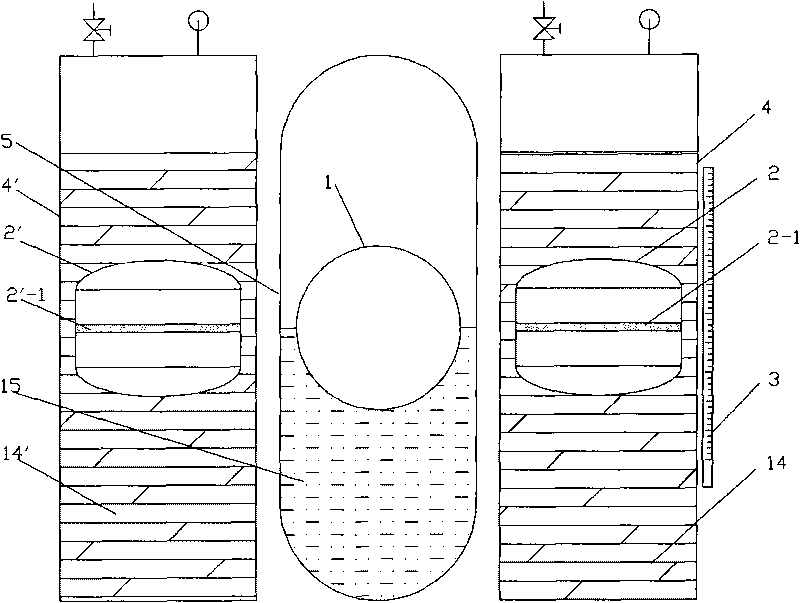

Float type level gauge for high-temperature high-pressure or high-temperature low-density medium

InactiveCN101726344ASolve high temperature and high pressureSolve densityLevel indicators by floatsMagnetic tension forceSpherical shaped

The invention relates to a float type level gauge for high-temperature high-pressure or high-temperature low-density medium, comprising a float chamber, a float and a graduated scale; the float type level gauge is characterized in that: the float is a hollow spherical shape; the float type level gauge further comprises a guide rail and a magnetic connector, a magnetic steel or a disc-shaped magnetic steel is arranged in the magnetic connector and forms magnetic attraction with a magnetic ball body in the float made of the nonferrous magnetic material or the disc-shaped magnetic steel the float made of the nonferrous magnetic material, a metal shaft laterally spanned at two side walls of the magnetic connector is exposed to two side walls and is attached to the guide rail by magnetic force, and the metal shaft can move up and down along the guide rail under the driving of the magnetic force; in addition, resistance wires are wound on the guide rail to measure the change of the resistance value of a return circuit, so as to realize continuous remote transmission of a signal. The float type level gauge for high-temperature high-pressure or high-temperature low-density medium solves the difficult problem of liquid level measurement in the high-temperature high-pressure or high-temperature low-density medium and has high measuring precision; in addition, the structure is simple, the usage is convenient, the manufacturing and maintaining cost is low and the application is wide.

Owner:DALIAN CONSERVATION SCI & TECH CO LTD

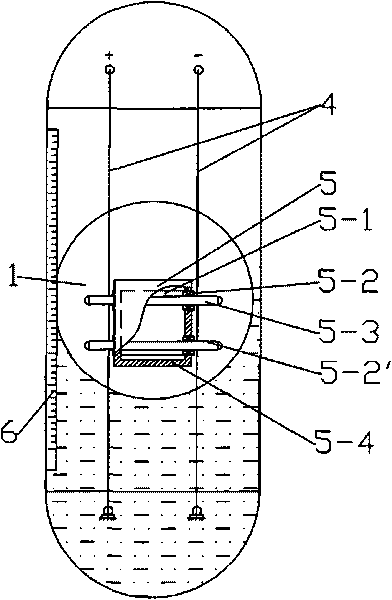

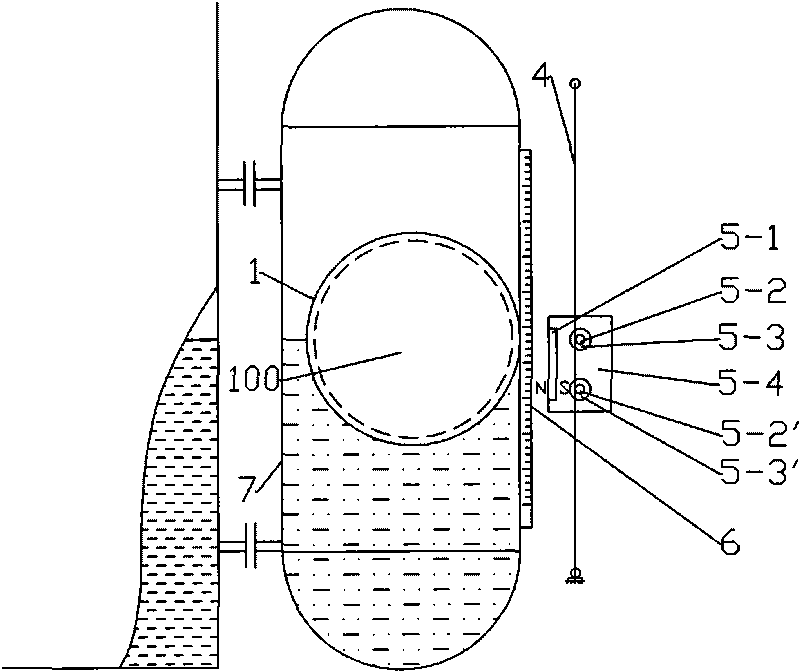

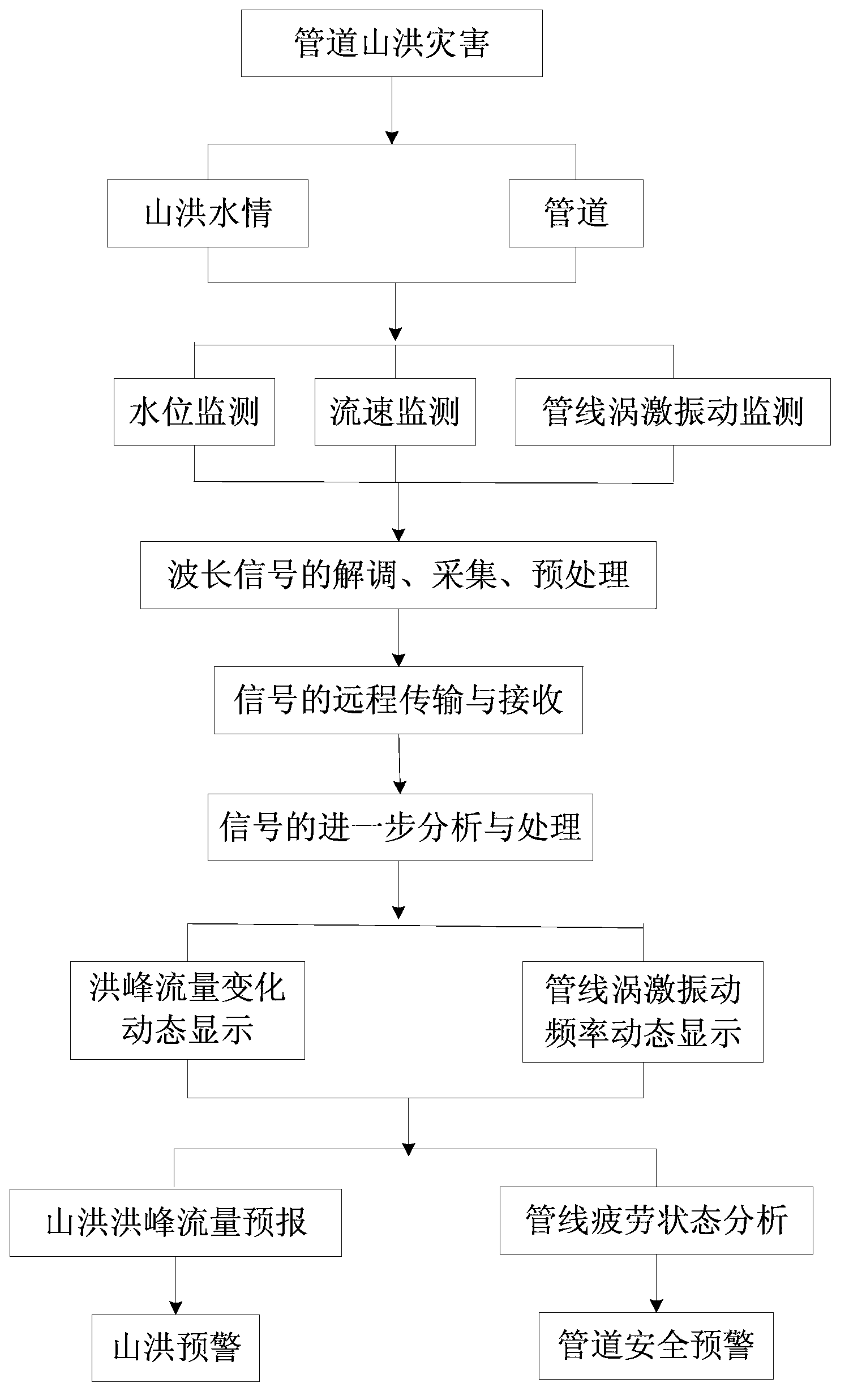

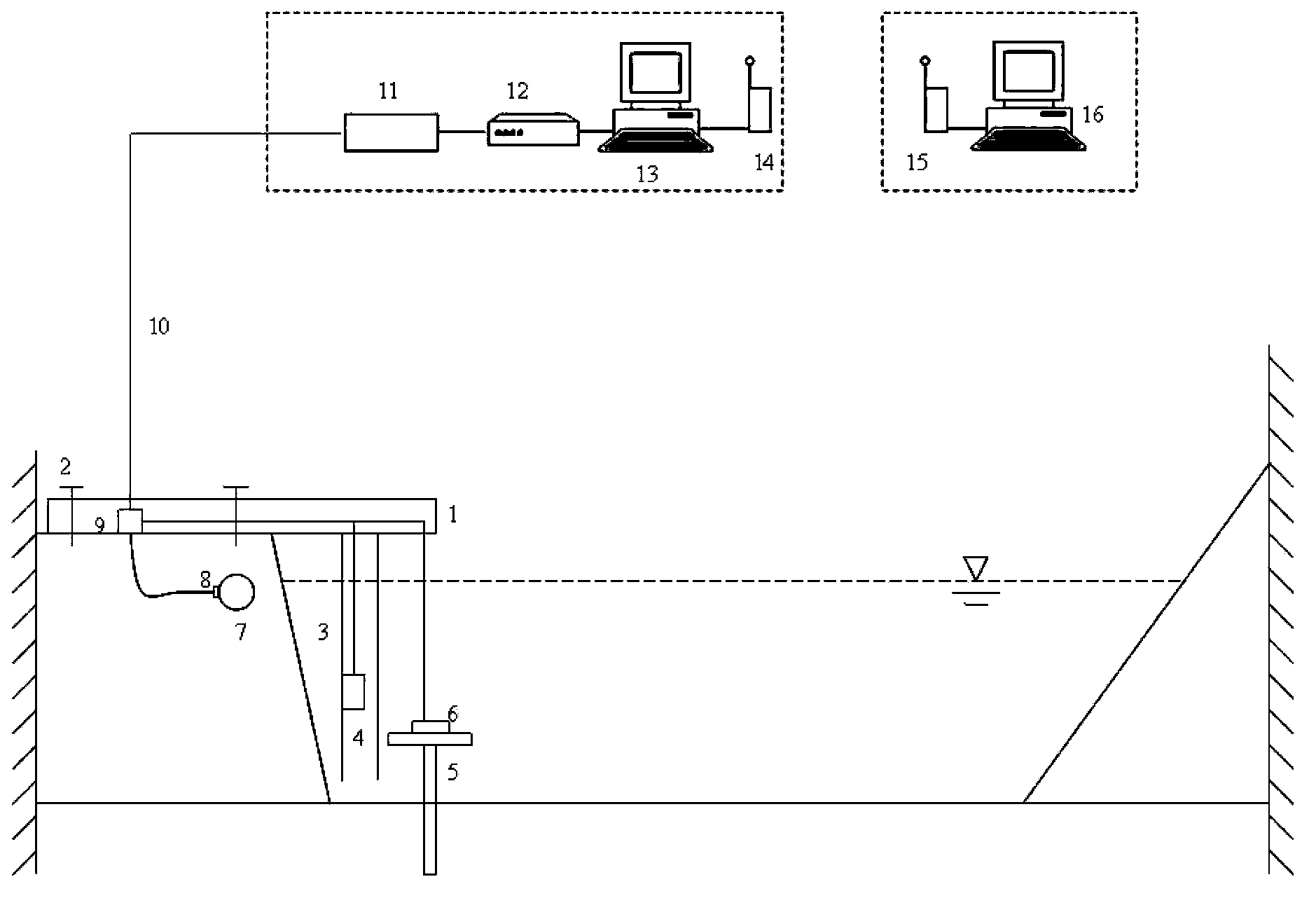

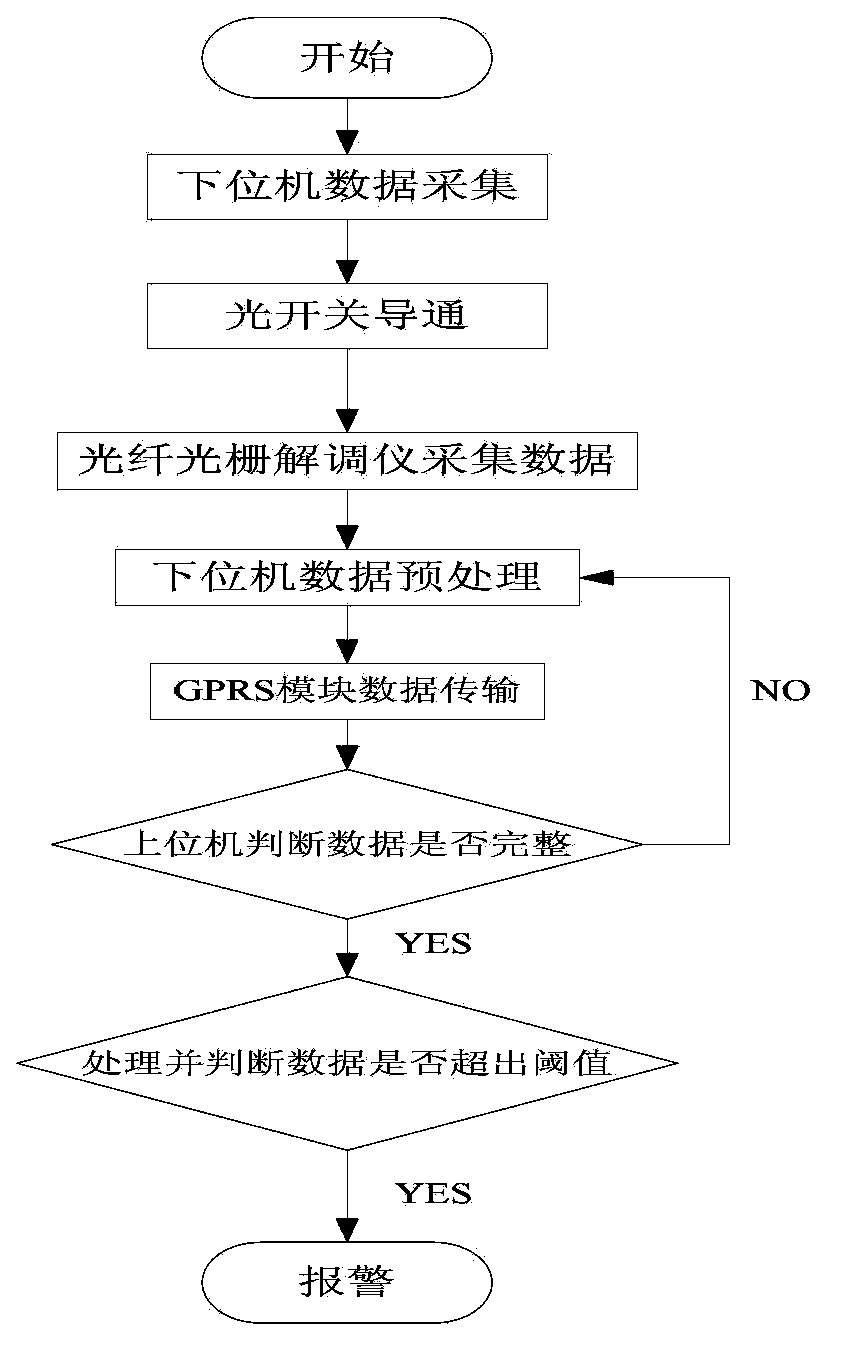

Oil-gas pipeline torrential flood disaster monitoring method

ActiveCN103700221ASimple networkingEasy to realize automatic real-time online monitoringHuman health protectionAlarmsGratingDisaster monitoring

The invention discloses an oil-gas pipeline torrential flood disaster monitoring method based on an optical fiber grating sensing technology, and relates to the technical field of linear velocity measurement, liquid level measurement, mechanical vibration measurement, common safety devices, and pipeline systems. The method comprises the following processes: performing water level monitoring, flow speed monitoring and pipeline vortex-induced vibration monitoring on torrential flood water and a pipeline; demodulating, acquiring and preprocessing wavelength signals; remotely transmitting and receiving signals; further analyzing and processing the signals; dynamically displaying flood peak flow change and dynamically displaying pipeline vortex-induced vibration frequency; predicting torrential flood peak flow and analyzing the pipeline fatigue state; performing torrential flood forecasting and pipeline safety pre-warning. The method is high is spatial resolution, low in cost, safe and effective.

Owner:PIPECHINA SOUTH CHINA CO

Ultrasonic fuel level monitoring device

Owner:SCHMITT MEASUREMENT SYST

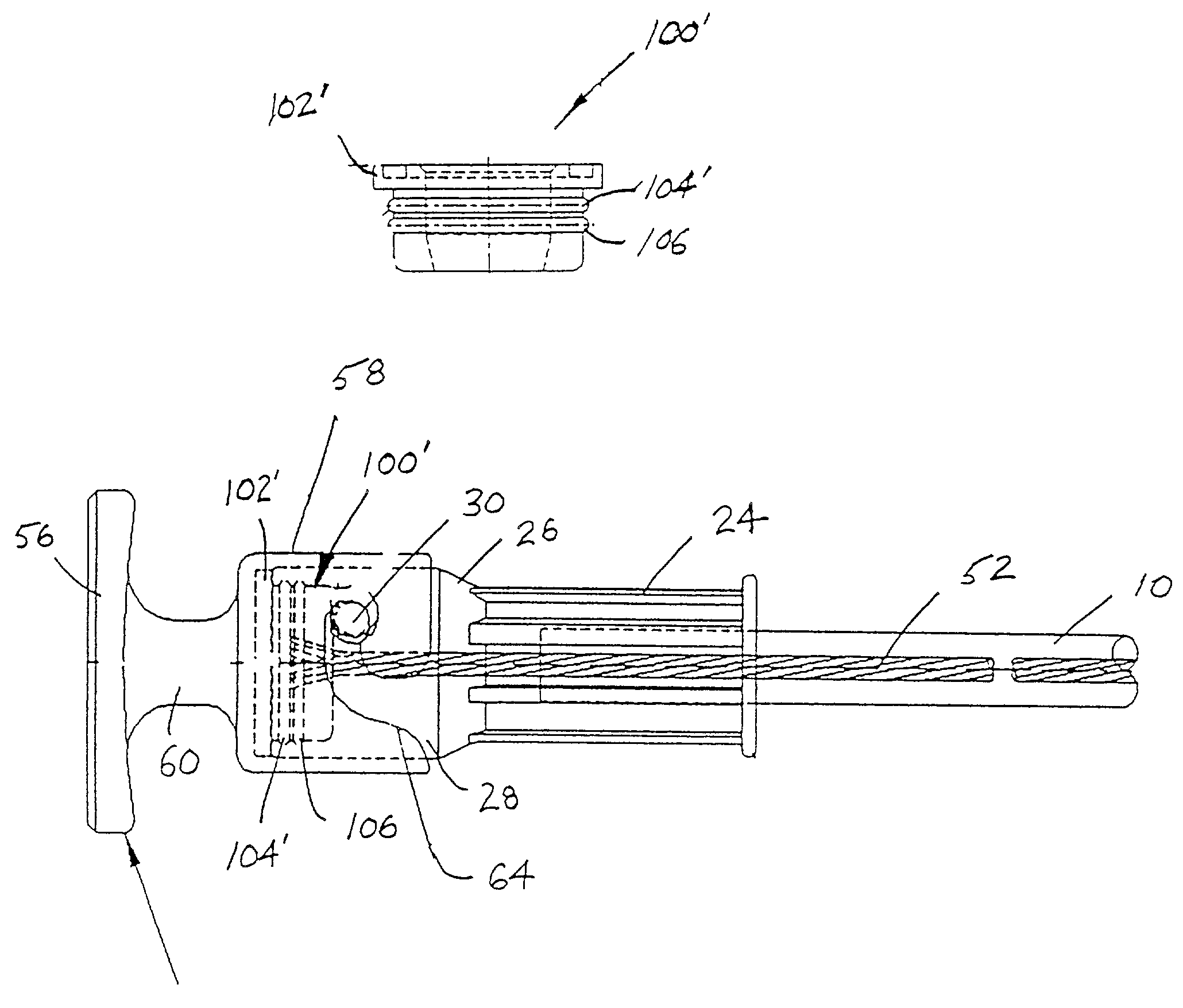

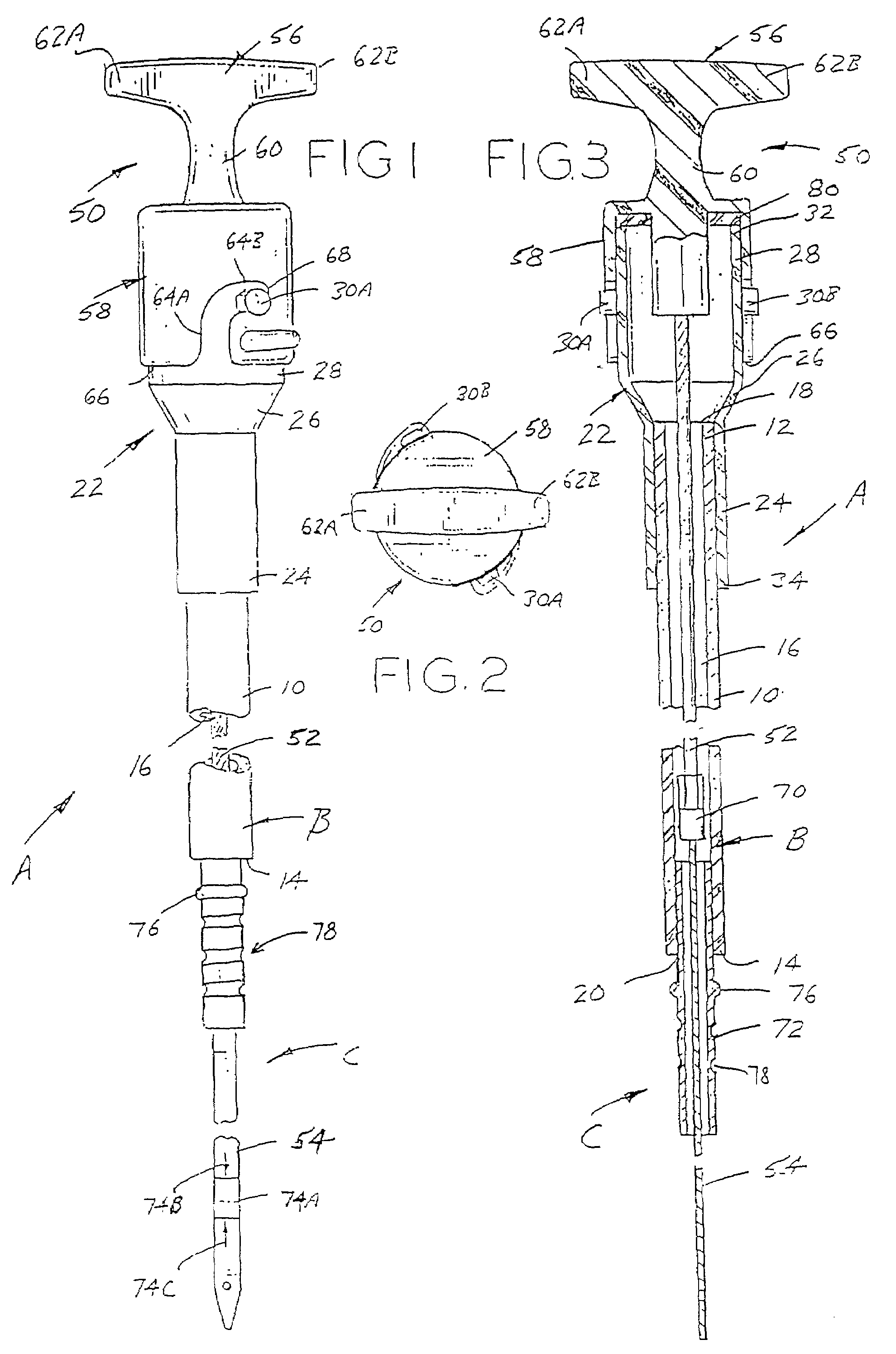

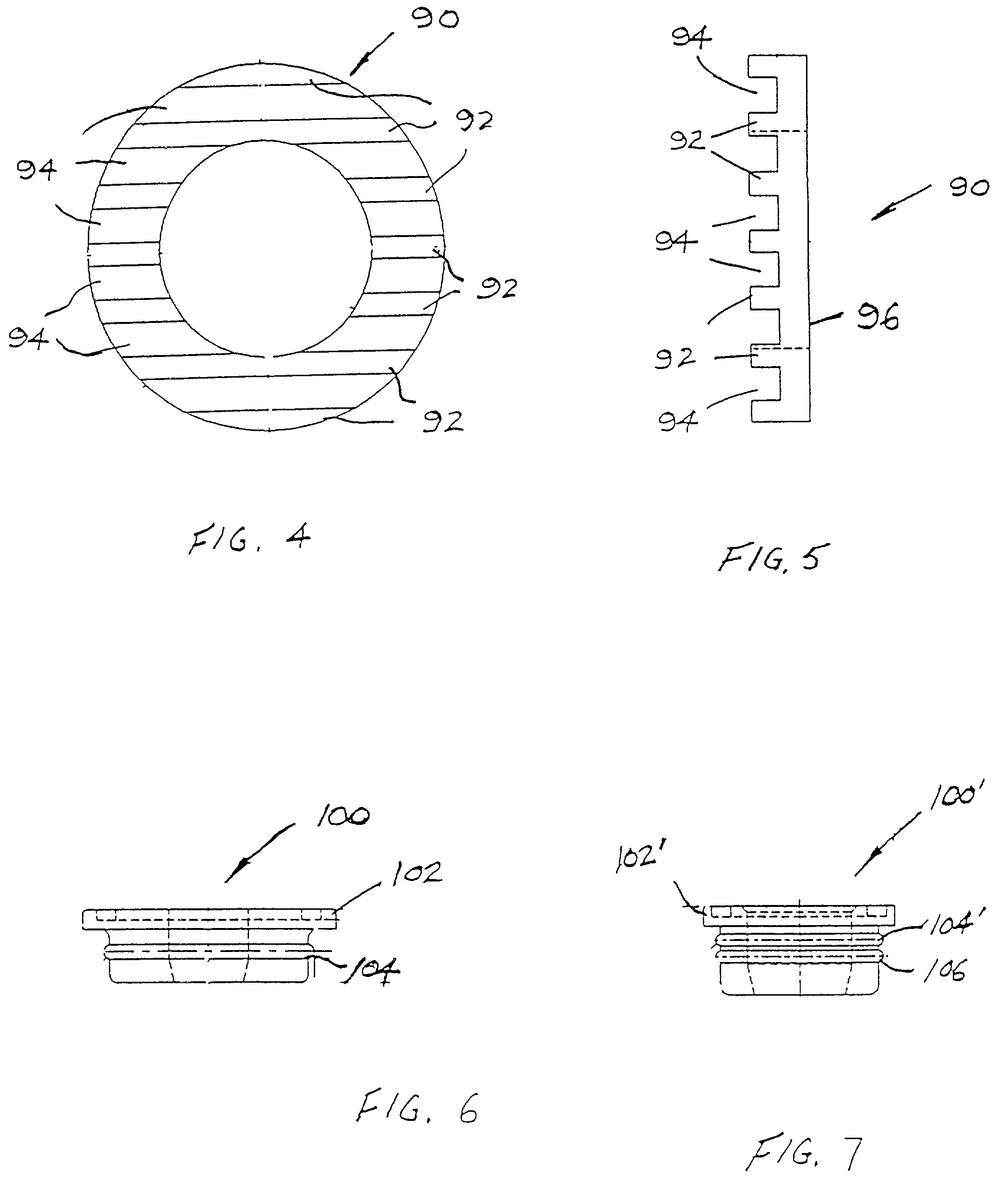

Fluid level measuring device

InactiveUS7055384B2Improve sealingPositive lock featureLevel indicators by dip membersUsing mechanical meansLocking mechanismLevel measurement

A fluid level measuring device, also referred to as a dipstick, for measuring the fluid level in a fluid reservoir or tank, such as an oil pan or transmission reservoir in an internal combustion engine. The fluid level measuring device includes a stationary tube assembly in which a dipstick assembly is disposed. The dipstick assembly includes a fluid level indicator measuring blade attached to an elongated shaft which is directly molded into a plastic handle assembly. The plastic handle assembly includes a bayonet type locking mechanism for locking the handle to the stationary tube assembly. A compressible seal forms a pressurized seal between the stationary tube assembly and the handle.

Owner:FURON

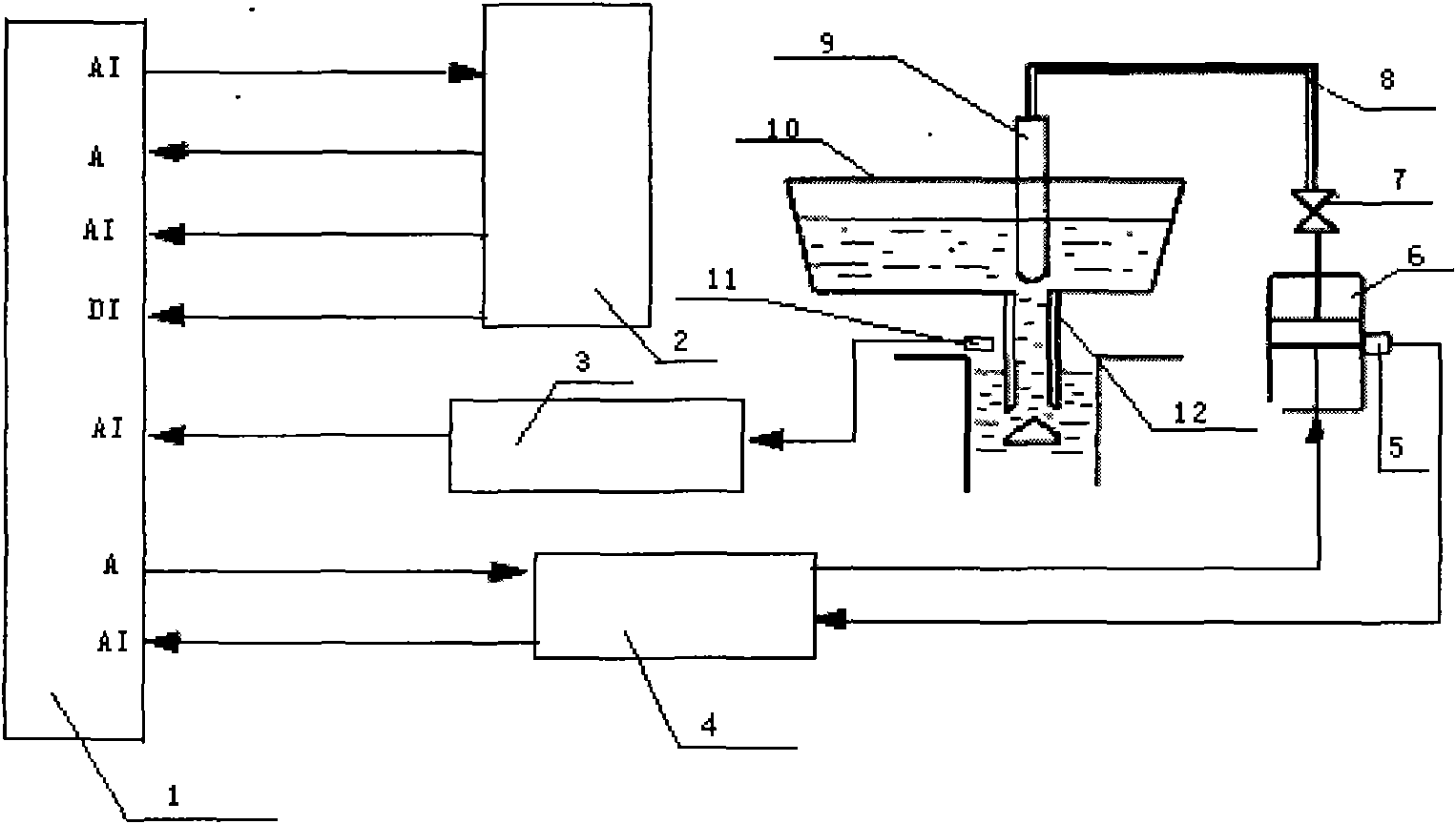

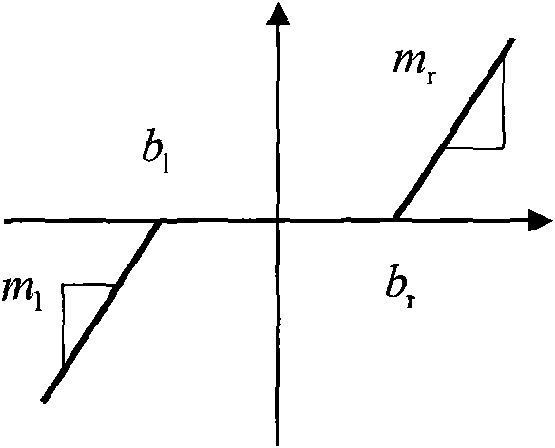

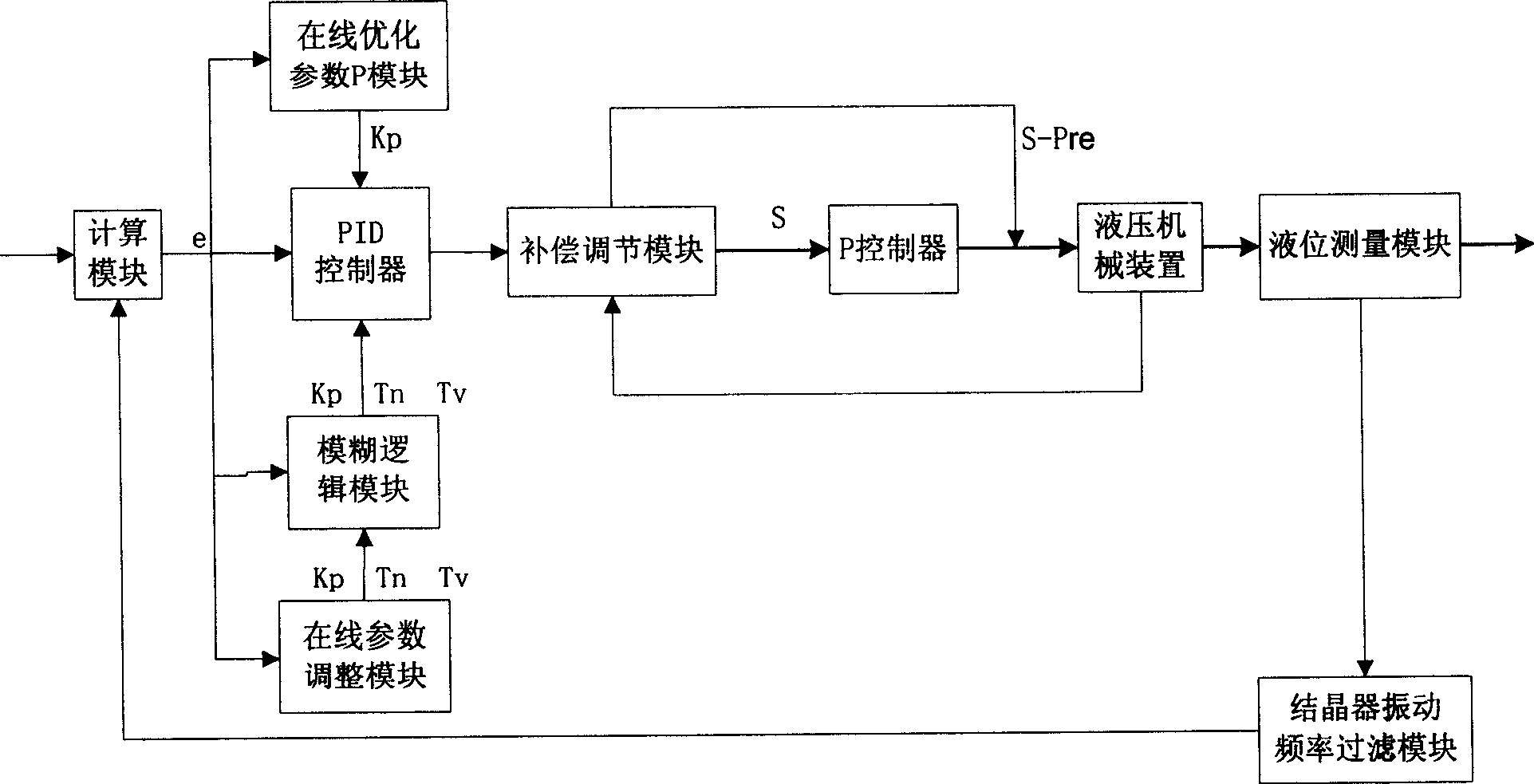

Liquid level on-line control system and method for self-adapting and fuzzy logic PID crystallizer

ActiveCN101364114ASolve liquid level fluctuationsImprove stabilityLevel controlControllers with particular characteristicsLiquid level measurementControl system

The invention relates to a self-adapting fussy-logic PID crystallizer liquor-level on-line control system and a control method. The system comprises a calculation module for receiving an input crystallizer liquid-level preset value and an actual value measured by a liquid-level measurement module and calculating the difference (e) of the two values; an on-line parameter regulation module; a fuzzy logic module which is connected with the on-line parameter regulation module, receives the difference (e), determines the conditions of abnormal fluctuation, nozzle wearing, slagging and slag sloughing according to the difference (e), receives Kp, Tn and Tv input from the on-line parameter regulation module and outputs the regulated Kp, Tn and Tv to a PID controller; a PID controller; a P controller; a hydraulic mechanical device; and a liquid-level measurement module. The control system and the control method can improve the system control accuracy and control the system stability under the complex casting conditions, organically integrate the fuzzy control and the PID techniques, enhance the strong point and avoid the weaknesses, combine the advantages of both flexibility and strong applicability of the fuzzy control and high control accuracy of the PID, and effectively solve the problem of liquid-level fluctuation of the crystallizer during the production.

Owner:SHANGHAI BAOSIGHT SOFTWARE CO LTD

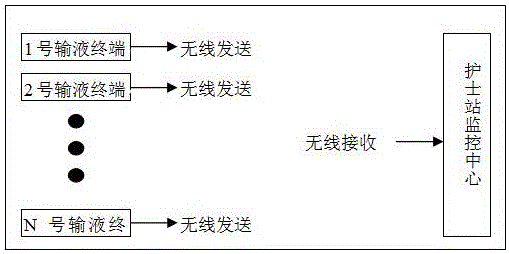

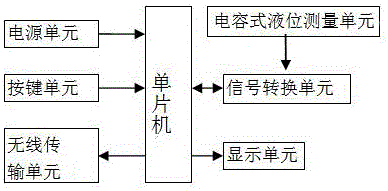

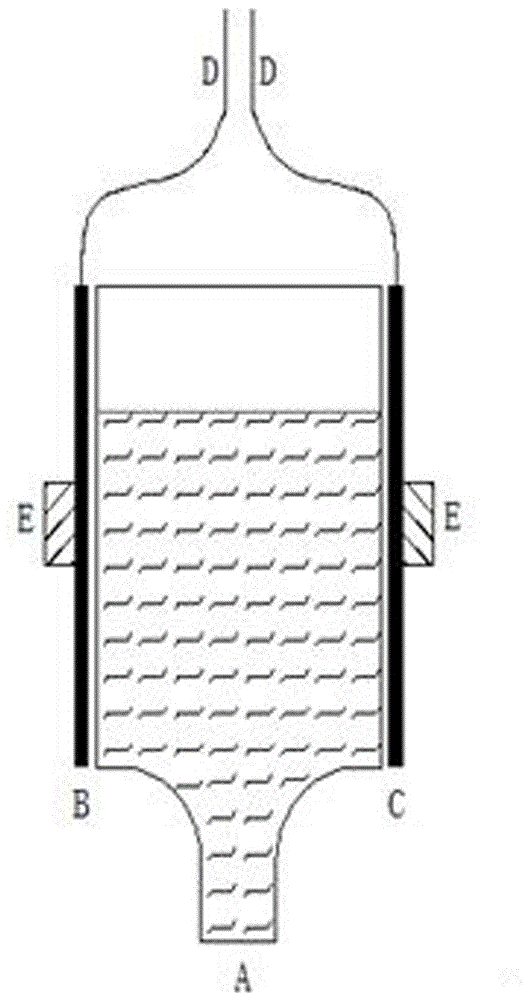

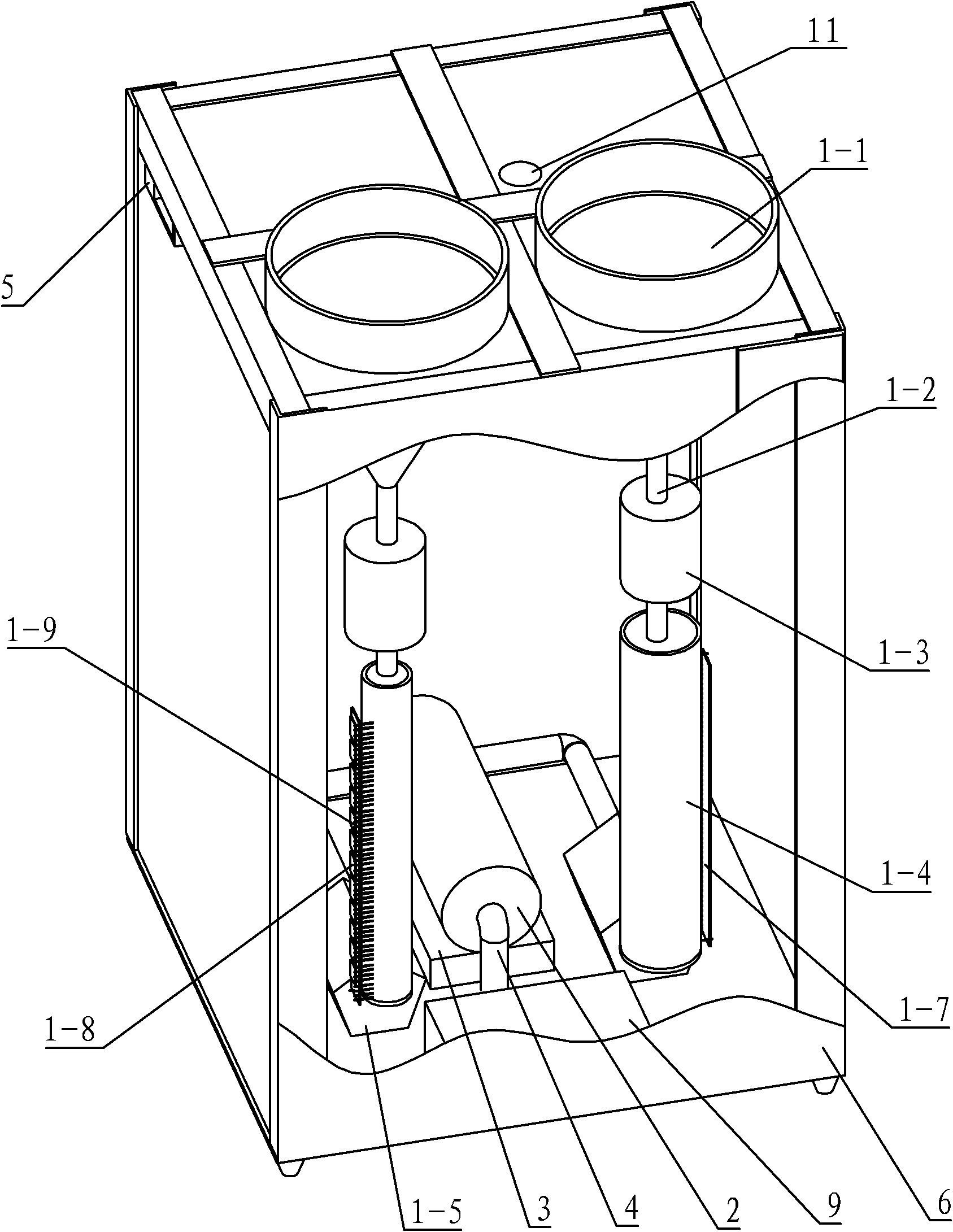

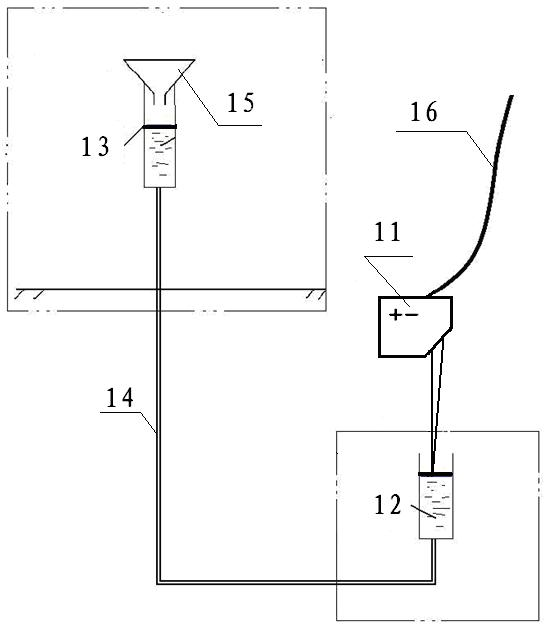

Medical transfusion liquid level real-time monitoring system and method based on wireless transmission

InactiveCN105709299AEasy to handleImprove work efficiencyMedical devicesFlow monitorsMicrocontrollerBottle

The invention discloses a medical transfusion liquid level real-time monitoring system and method based on wireless transmission. The medical transfusion liquid level real-time monitoring system comprises a nurse station monitoring center and multiple transfusion terminals, wherein each transfusion terminal comprises a power supply unit, a push-button unit, a wireless transmission unit, a singlechip, a display unit, a capacitive liquid level measuring unit and a signal converting unit; the nurse station monitoring center comprises a wireless transmission module, a power supply module, a microprocessor and a display terminal; the power supply unit, the push-button unit, the wireless transmission unit, the display unit and the signal converting unit are respectively connected with the singlechip; the capacitive liquid level measuring unit is composed of two metal sheets, and the metal sheets are opposite, clung and fixed outside a transfusion bottle to form a capacitor; and the transfusion terminals and the nurse station monitoring center are connected in a wireless communication manner, and the nurse station monitoring center is used for carrying out compiles processing on data and displaying and realizing monitoring of the nurse station monitoring center on the whole transfusion area. The medical transfusion liquid level real-time monitoring system and method can carry out concentrated and real-time monitoring on the transfusion condition of the whole inpatient area.

Owner:GUANGXI COLLEGE OF WATER RESOURCES & ELECTRIC POWER

Rainfall information acquiring and metering method and unit, and rainfall meter

ActiveCN102323628ASimple stepsEasy to detectRainfall/precipitation gaugesLevel measurementEngineering

The invention discloses a rainfall information acquiring and metering method and unit, and a rainfall meter. The rainfall meter comprises a box body, an acquiring and metering unit, a drainage pump, a drainage pipe, an input device, a display and a controller, wherein the acquiring and metering unit comprises a rainfall collector, a water inlet connection pipe, a rainfall collector and a water pumping connection pipe; a metering circuit board is arranged on the outer wall of the rainfall collector, a shift register is arranged on the metering circuit board, metering pins of the shift registerare arranged on the metering circuit board at equal intervals and extend into the rainfall collector, and signaling pins of the shift register extend into the rainfall collector and are positioned onthe bottom surface of the rainfall collector. According to the method disclosed by the invention, the signaling pins output modulation pulse electric signals, and rainfall (water) quantity and rainfall (water) rate are metered by adopting a liquid level measuring method and utilizing the characteristic of a conductive liquid through detecting electric signals received by the metering pins.

Owner:XIDIAN UNIV

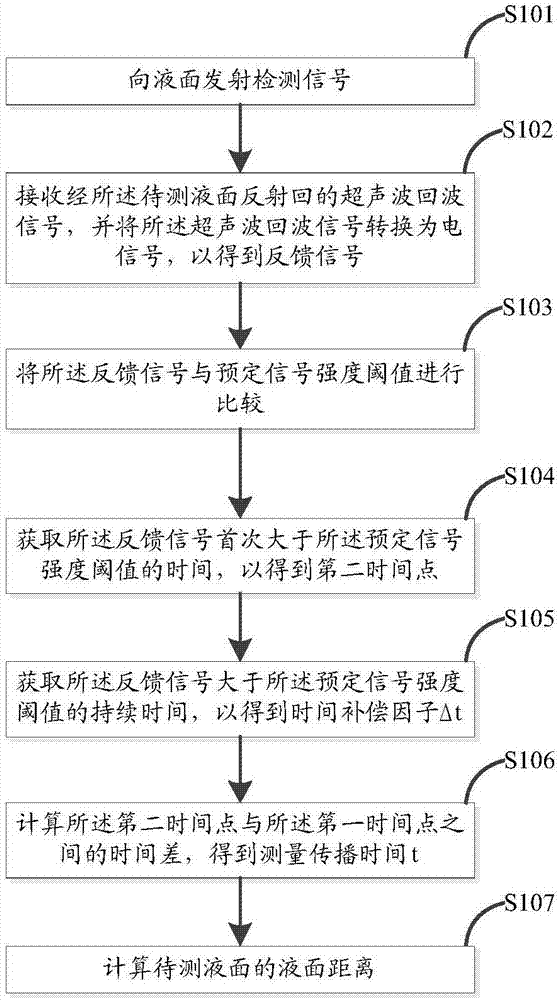

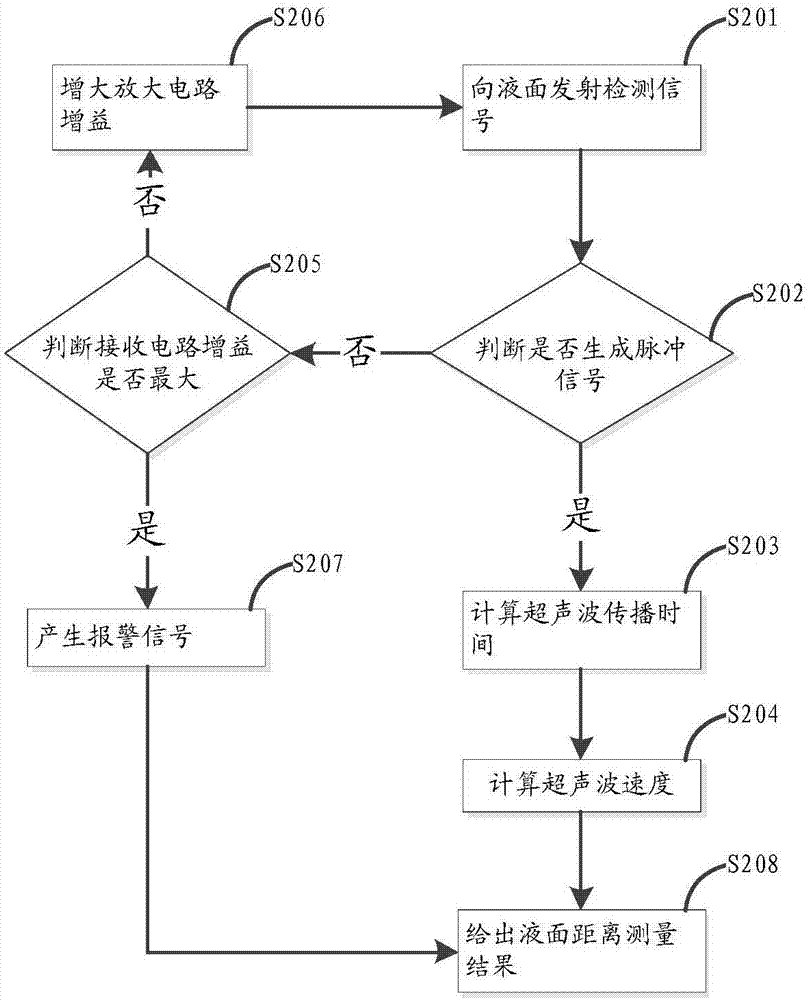

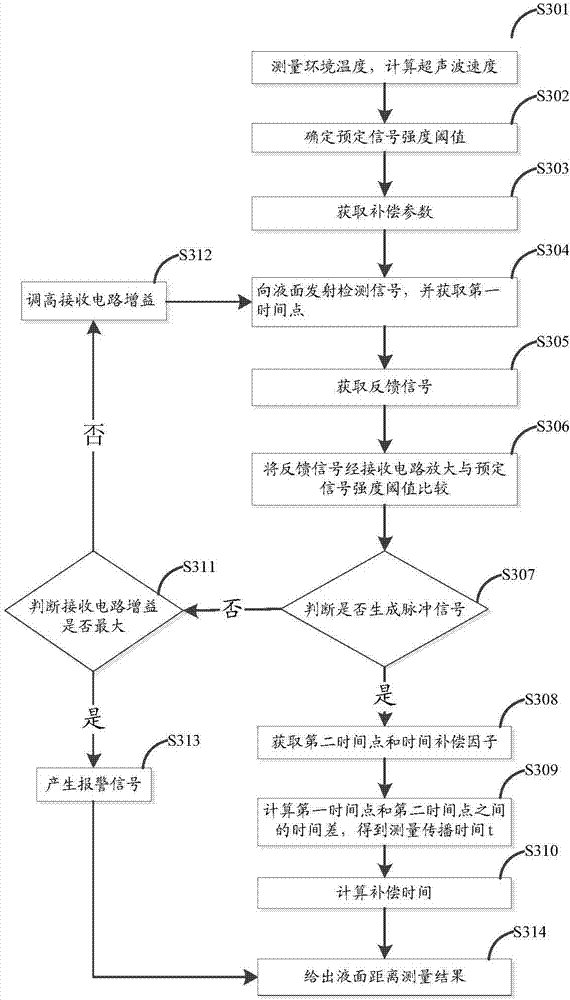

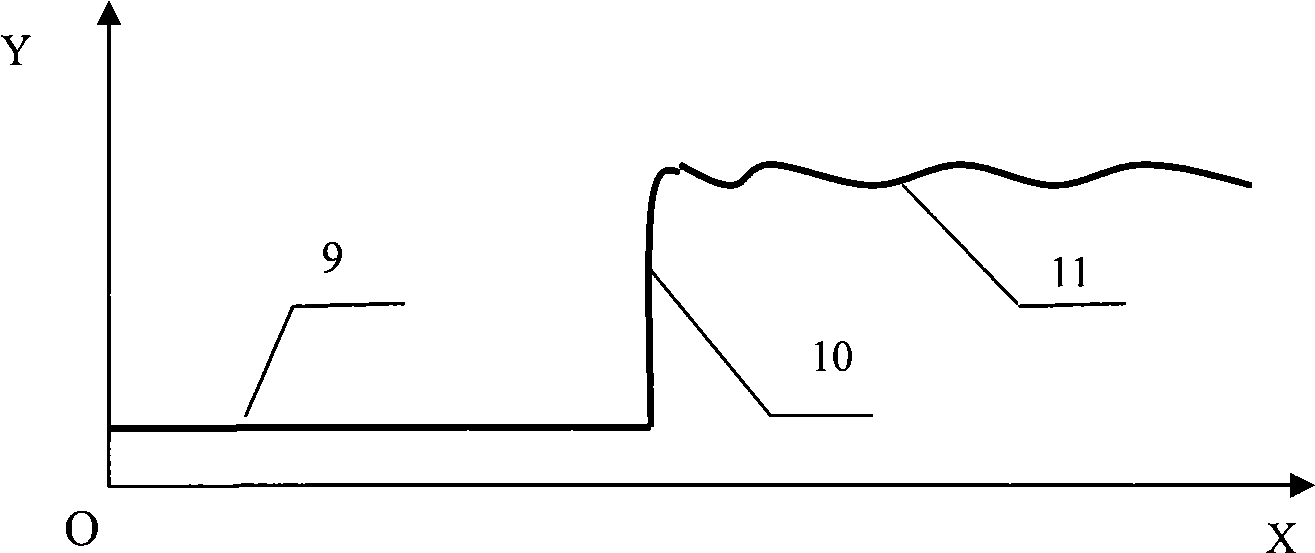

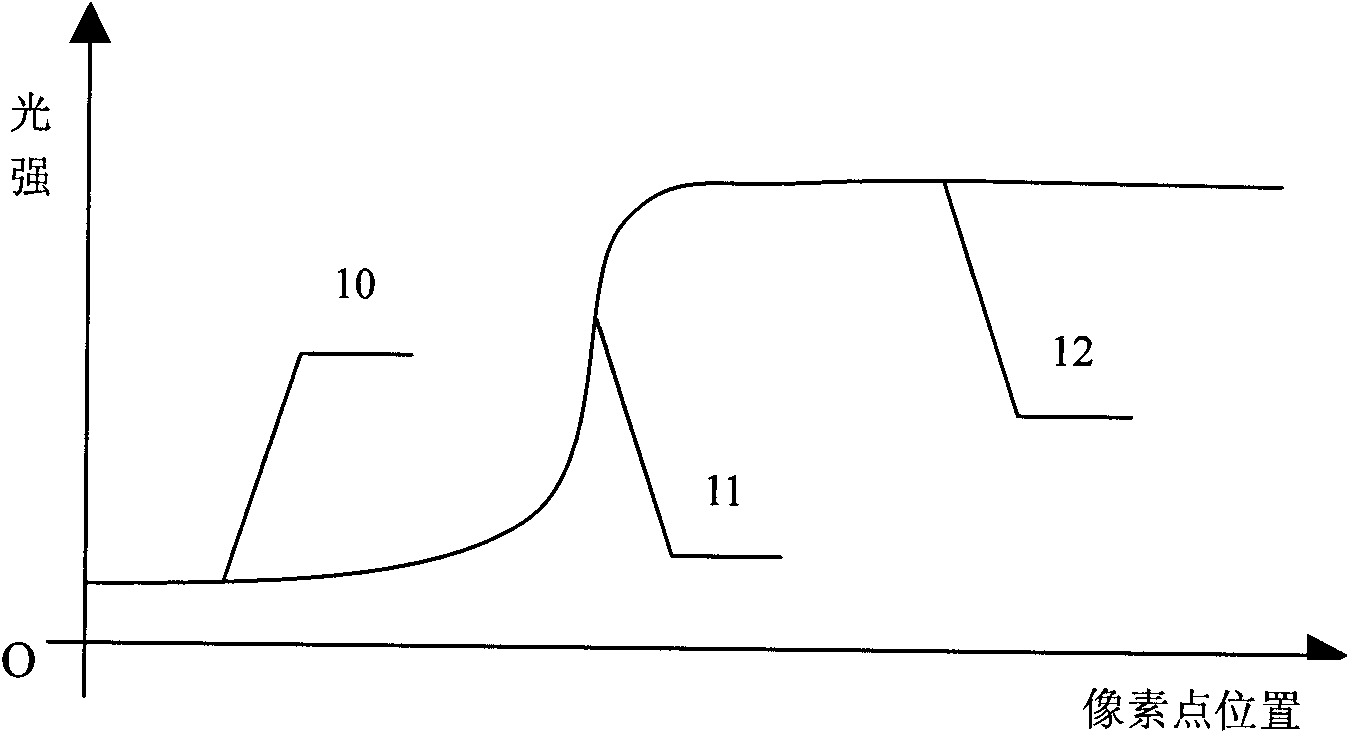

Ultrasonic liquid level measuring method and ultrasonic liquid level measuring device

ActiveCN107576371AReduce mistakesHigh precisionMachines/enginesLevel indicatorsLiquid level measurementMeasurement device

The invention discloses an ultrasonic liquid level measuring method and an ultrasonic liquid level measuring device. The method comprises the steps that an ultrasonic signal is sent to a to-be-measured liquid level to serve as a detection signal, an ultrasonic echo signal which is reflected back through the to-be-measured liquid level is received, the ultrasonic echo signal is converted to be an electric signal, a feedback signal is obtained, the feedback signal is compared with a preset signal strength threshold value, the time compensation factor delta t is obtained, the measurement propagation time is calculated, the compensation time is calculated by means of the time compensation factor delta t, the measurement propagation time is compensated, and then the precise liquid level distance is obtained through calculation. According to the ultrasonic liquid level measuring method and the ultrasonic liquid level measuring device based on the method, on the condition that the manufacturing cost is not increased, by using the simple and easy-to-implement device, the stability and accuracy of ultrasonic liquid level measurement are improved.

Owner:TAIHUA WISDOM IND GRP CO LTD

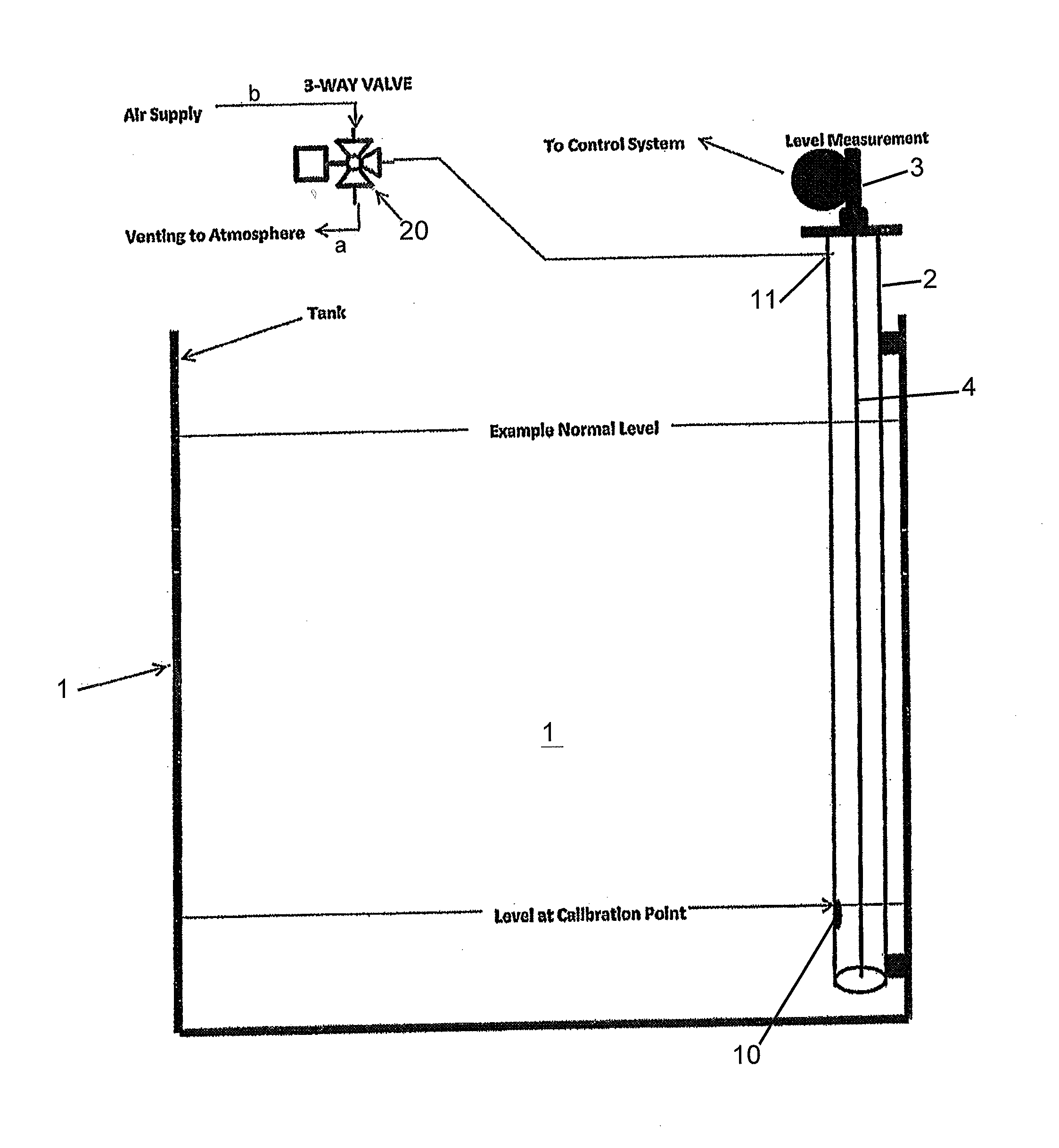

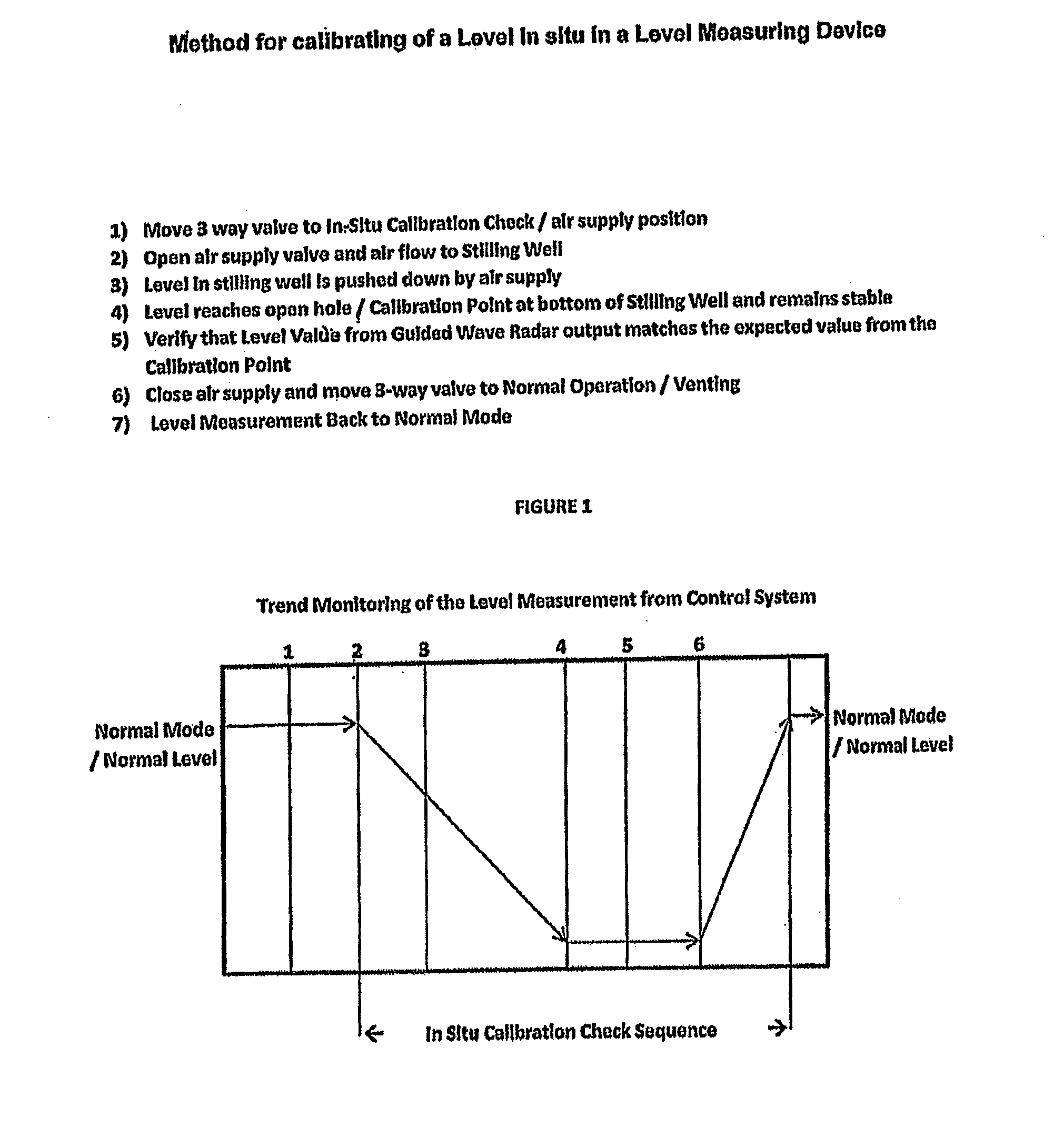

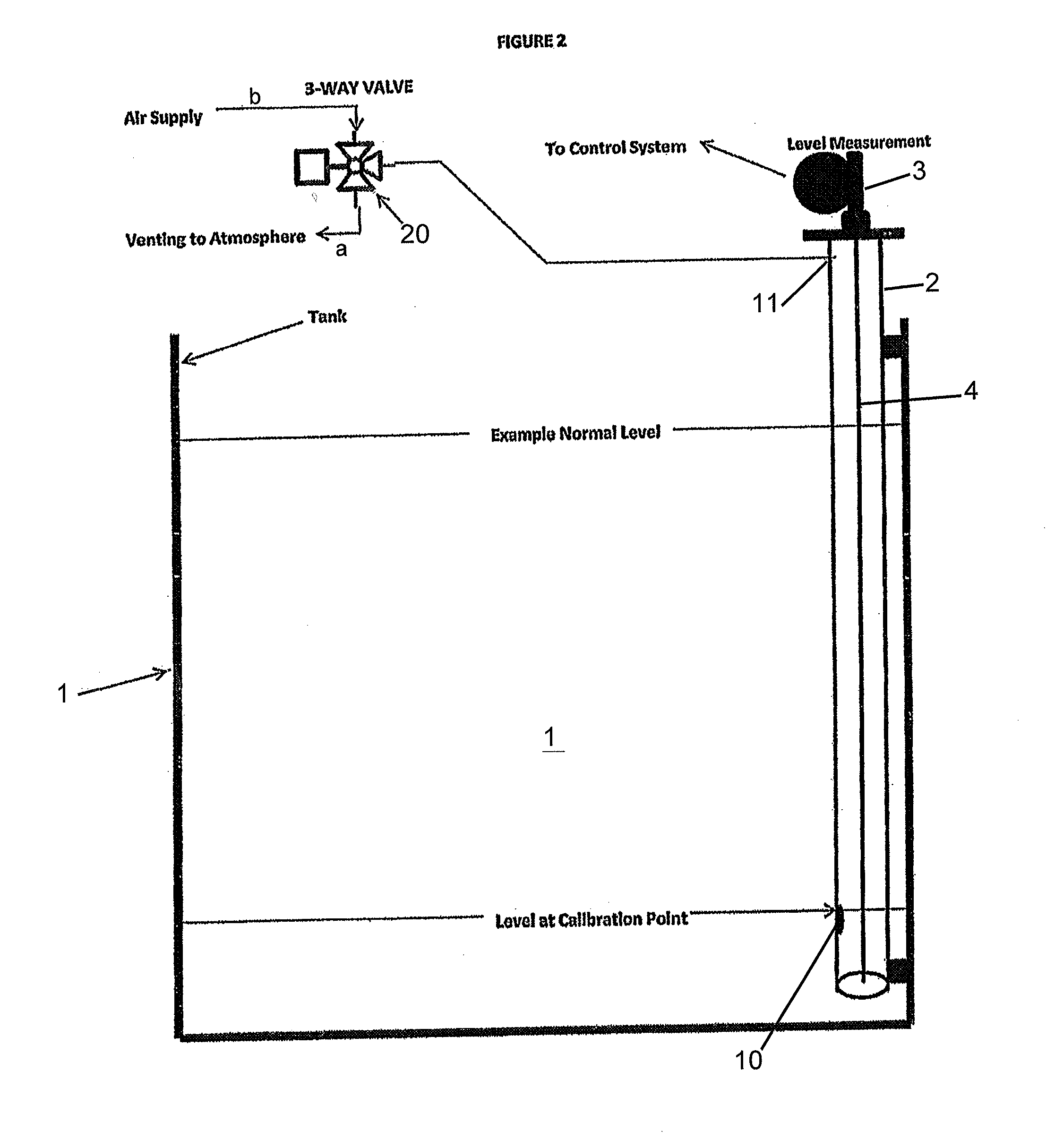

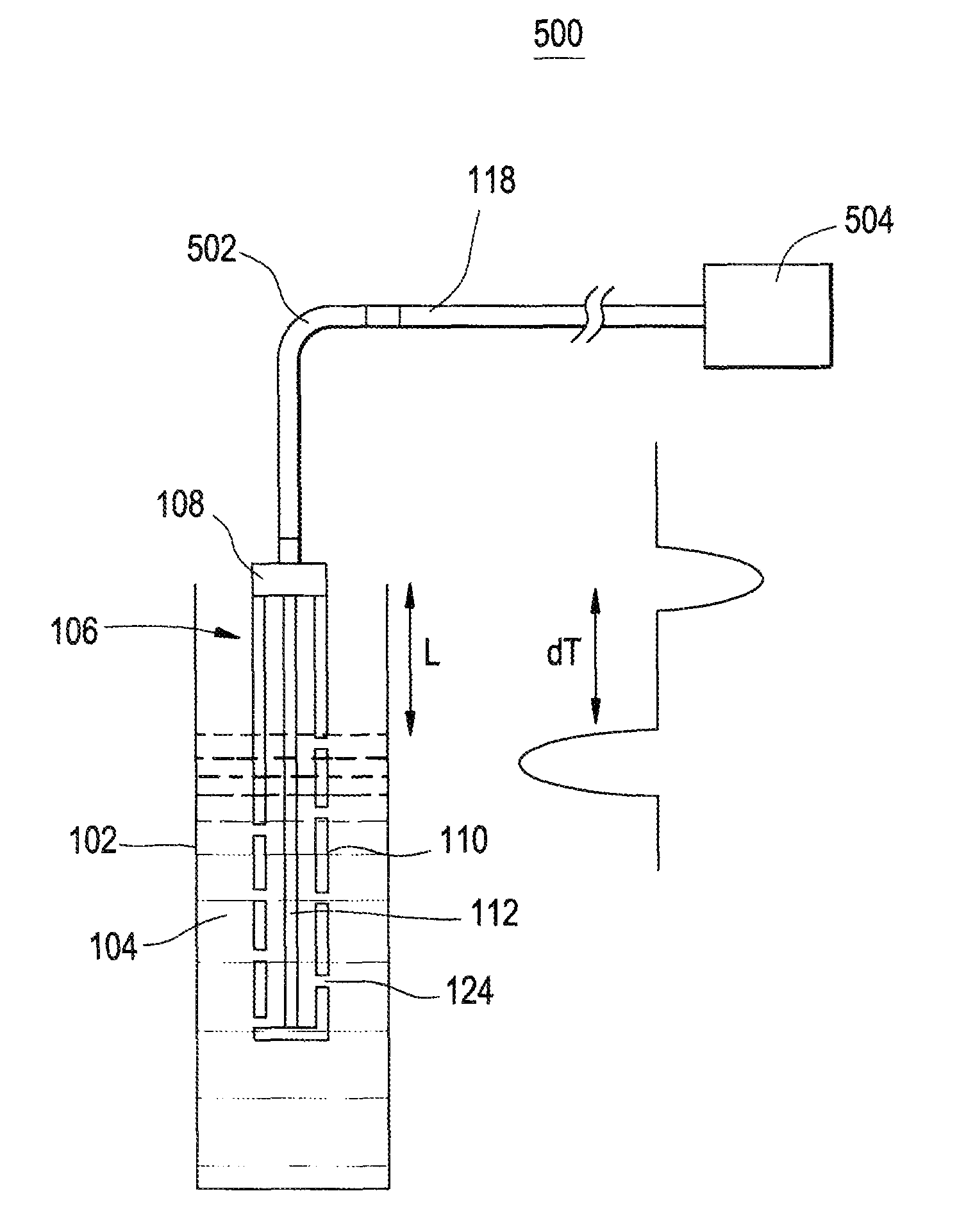

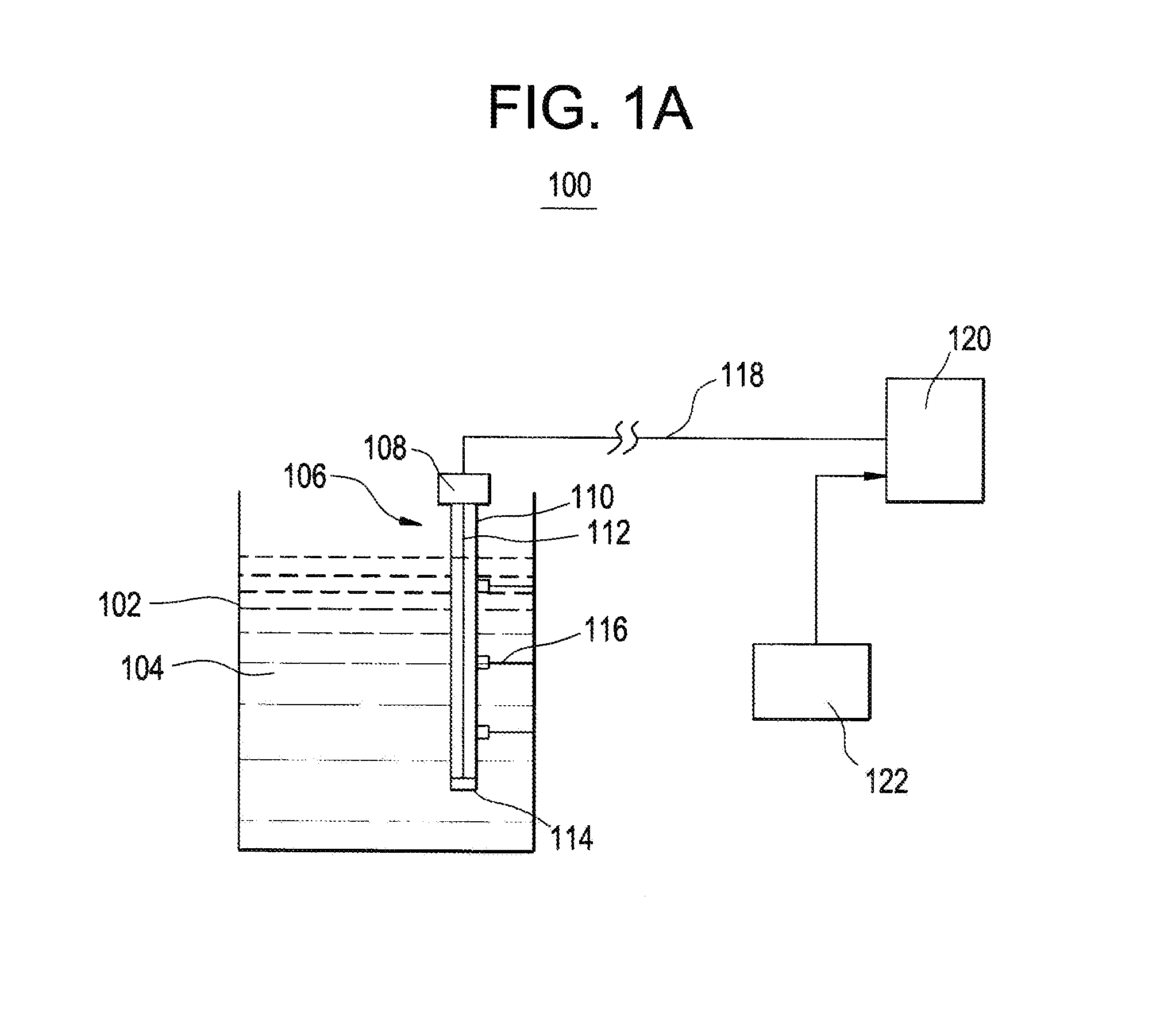

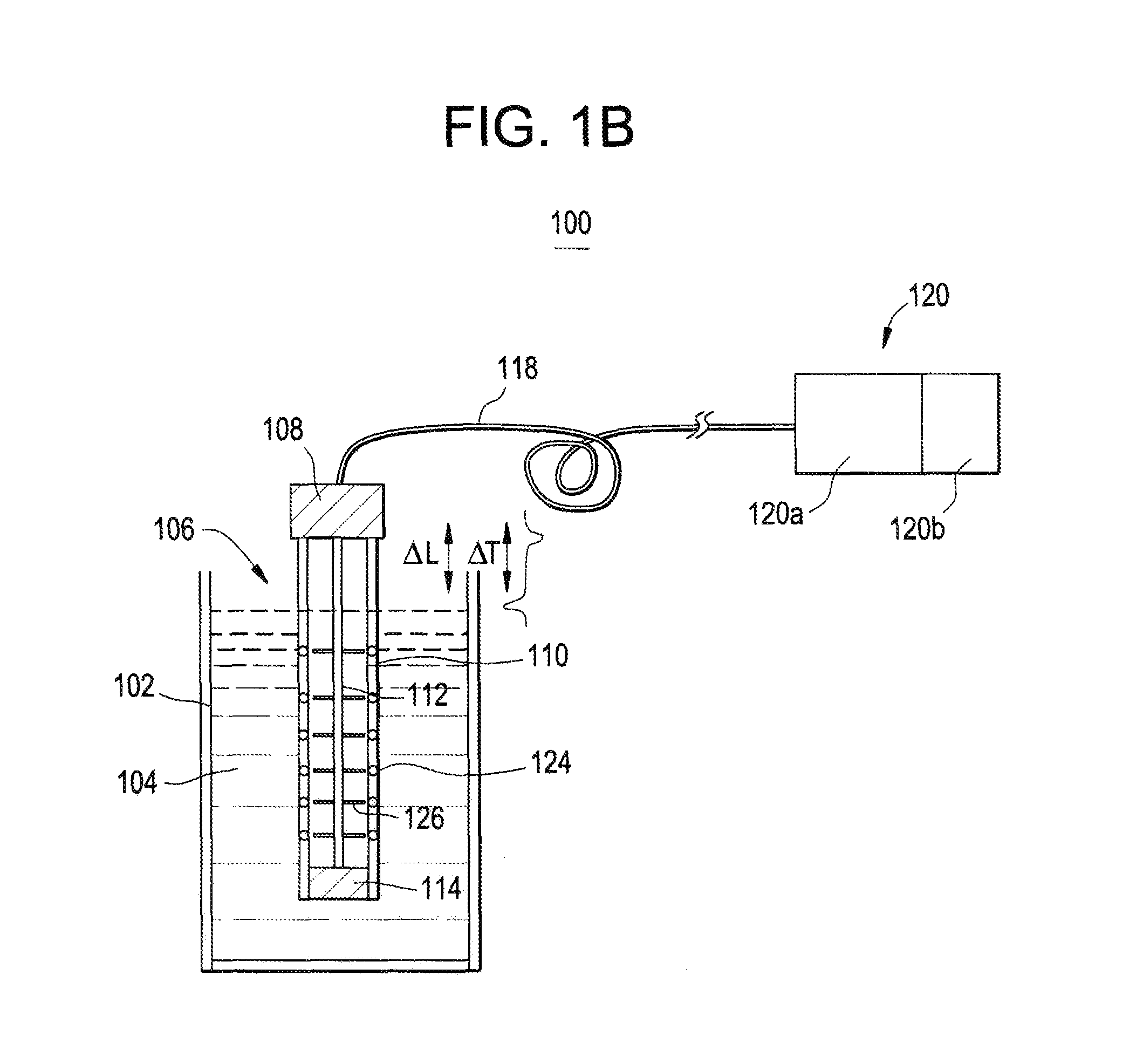

In Situ Calibration of a Level Measuring Device

InactiveUS20140326038A1Testing/calibration apparatusLevel indicatorsIn situ calibrationLevel measurement

A calibration system for a level meter comprising a tank having a sidewall and a bottom defining a tank interior, and a stilling well coupled to said tank, said stilling well having a sidewall, proximal and distal ends and a stilling well interior, and the distal end in fluid communication with the tank interior near the tank bottom, said proximal end of said stilling well being sealingly coupled to said level meter, said stilling well having a calibration fluid path allowing fluids to flow out of said stilling well interior; said stilling well having a vent opening that is sealingly closable near said proximal end; and a source of pressurized gas connectable to said stilling well interior, said stilling well having a measurement configuration where said vent opening is opened allowing said proximal end to vent gases in said stilling well interior, and a calibration configuration, where said pressurized air source is connected to said stilling well and flowing into said stilling well interior, where said pressurized gas may exit said stilling well interior only at said calibration flow path.

Owner:ABB INC

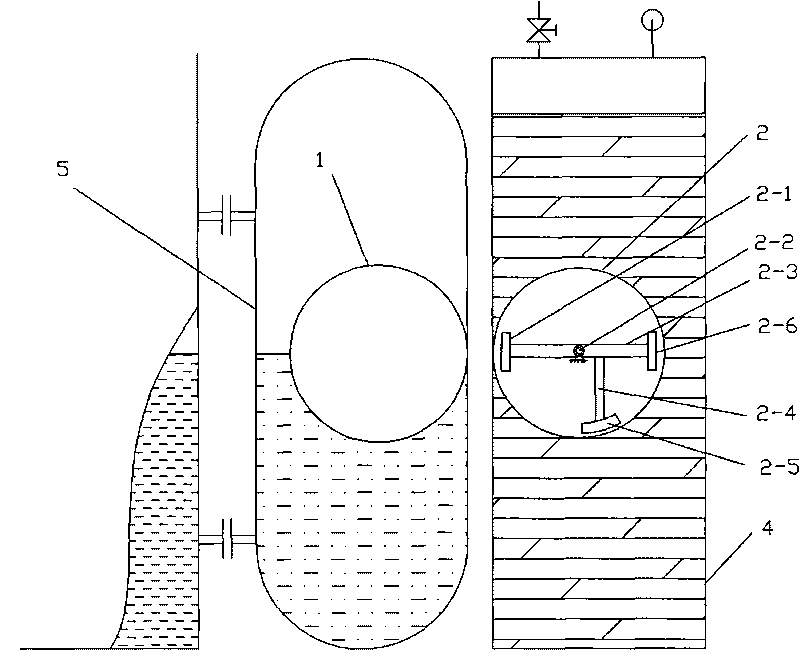

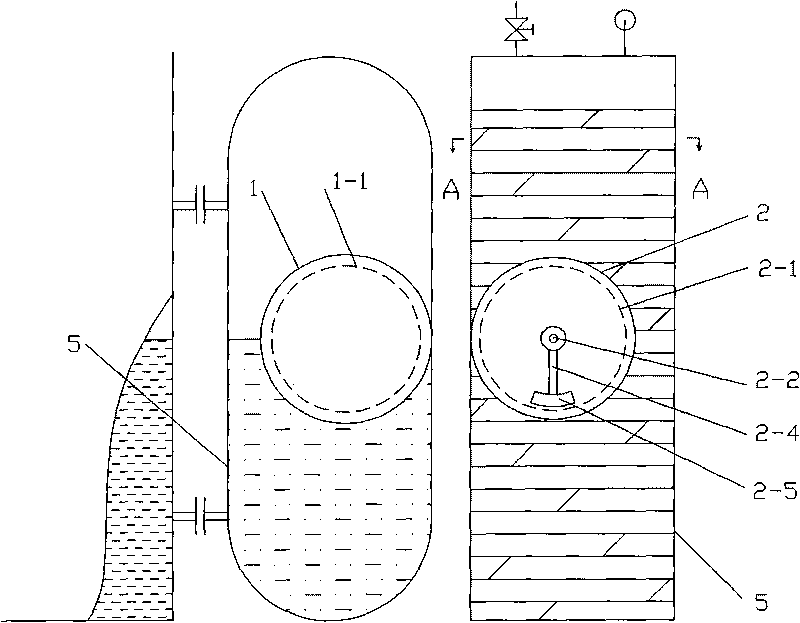

Float-type liquidometer with buoy for high-temperature high-pressure medium or high-pressure low-density medium

InactiveCN101699230ASolve high temperature and high pressureSolve densityLevel indicators by floatsMagnetic tension forceRolling resistance

The invention relates to a float-type liquidometer with buoy for high-temperature high-pressure medium or high-pressure low-density medium, comprising a float chamber, a float, a buoy chamber and a buoy. Upward lifting power is provided for the float by buoyancy to the buoy via magnetic force attraction between the float and the buoy. A force balance mechanism for lifting the float has simple structure, saves complex mechanical transmission mechanisms and has convenient transportation and installation; friction among other designed magnetic coupling components is in rolling friction structure, thus reducing lag and improving precision. The invention solves the problem of liquid level measurement in high-temperature high-pressure medium or high-pressure low-density medium and has high measurement precision, simple structure, convenient use, low maintenance and production cost and wide applicable range.

Owner:DALIAN CONSERVATION SCI & TECH CO LTD

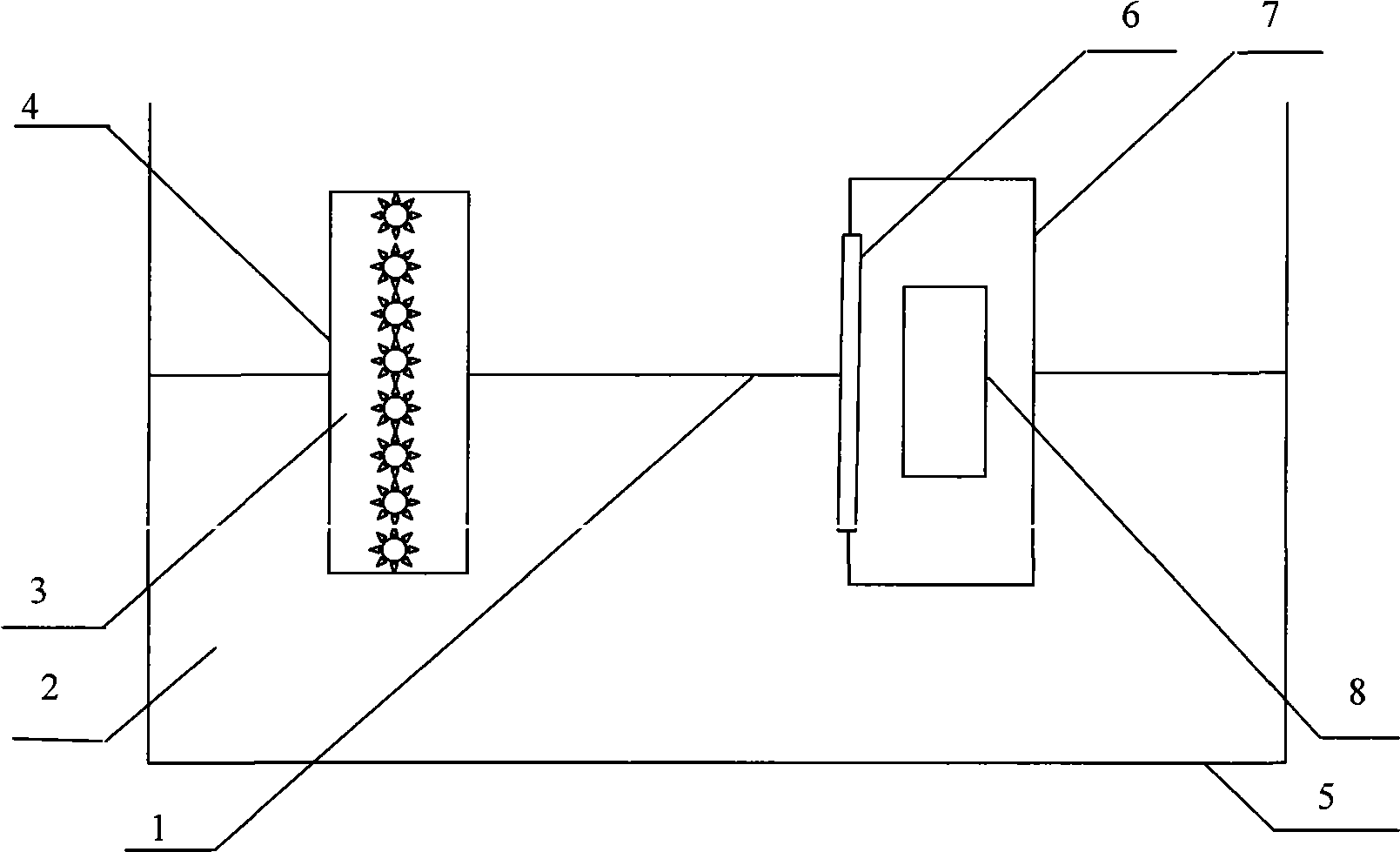

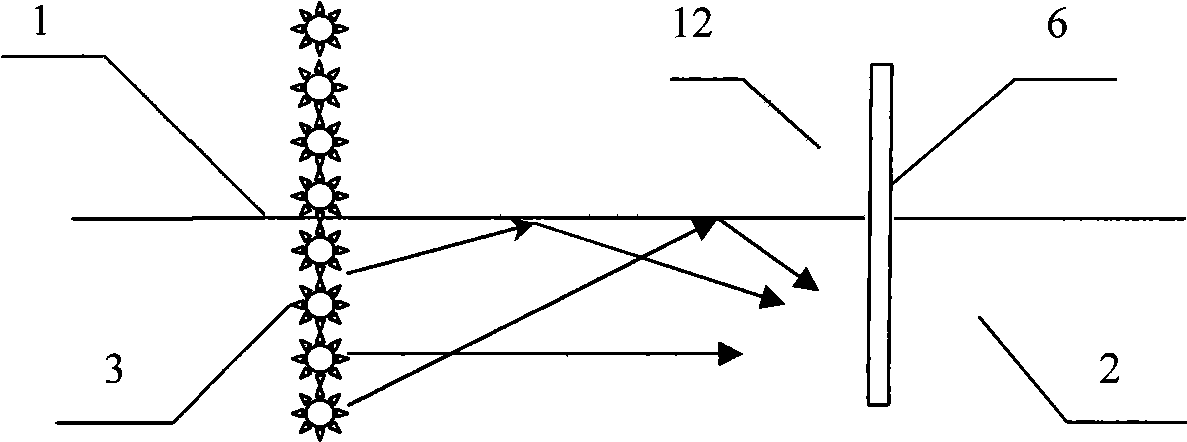

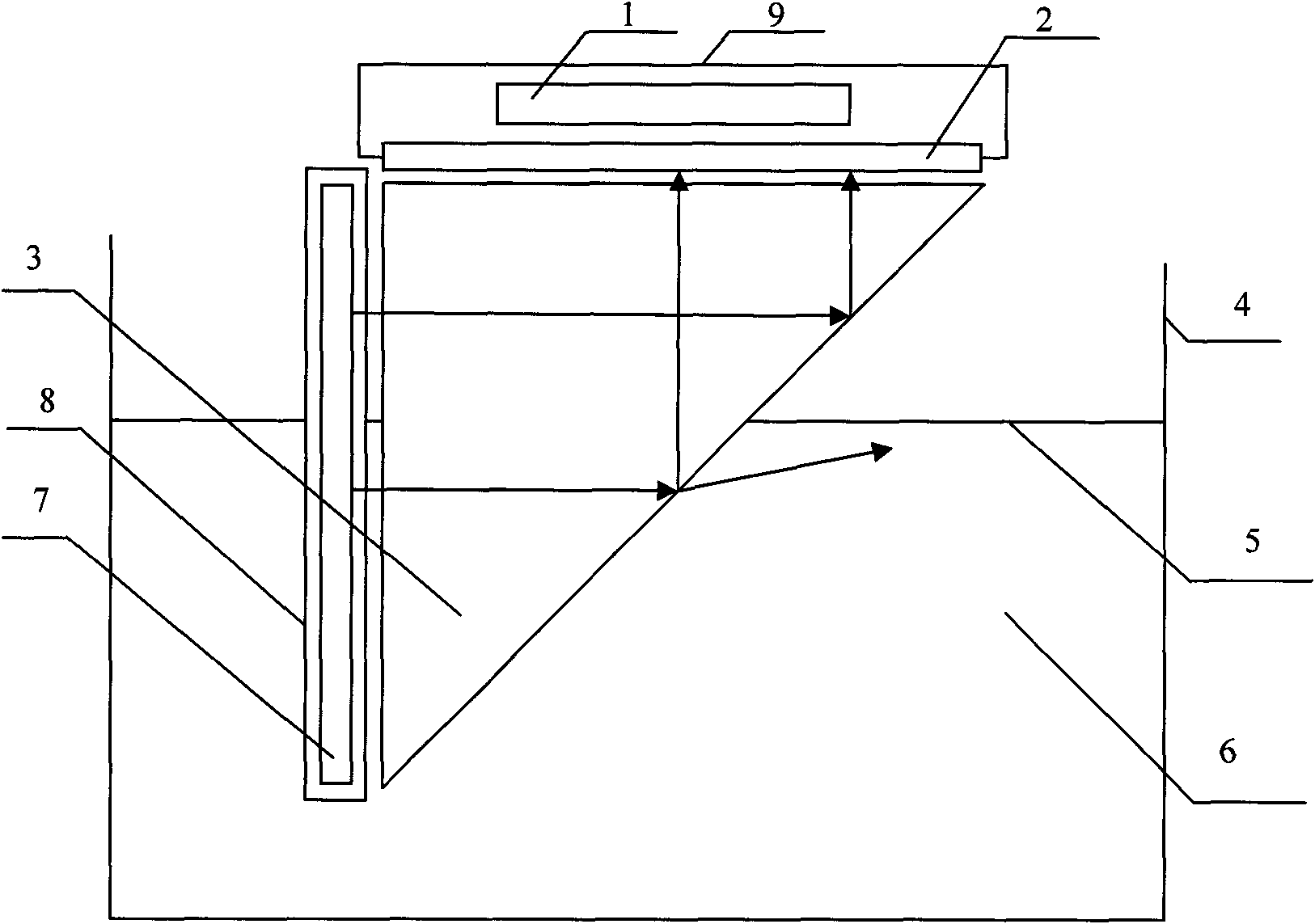

Intelligent light source linear array CCD liquid level measuring method and device

InactiveCN101509801AHigh strengthReduce intensityMachines/enginesLevel indicatorsLiquid temperatureLiquid level measurement

The invention discloses an intellectualized light source linear array CCD liquid level measurement method and a measurement device. By using a feedback measurement structure, the method can obtain a result of comparably high precision through measurement of twice or a plurality of times and the intellectualized regulation of the light source. The device mainly consists of a point-to-point switch controllable linear array light source, a linear array CCD, a control circuit, etc. During the measurement of liquid level, all the luminous points on the linear array light source intelligently complete primary measurement scanning and determine the basic position of liquid level; the partial luminous points on the linear array light source are closed so as to complete the accurate measurement of liquid level. The intellectualized light source linear array CCD liquid level measurement method is a liquid level measurement method with higher precision and also an optical liquid level measurement method needing no optical imaging lenses, and has the advantages of little effect on the precision by the temperature change and concentration change of liquid, relatively simple structure, easiness for arrangement and the capability of working under corrosiveness and other vile industrial environments, etc. If a receiving device is arranged outside a transparent container, non-contact measurement can be realized.

Owner:如皋市生产力促进中心

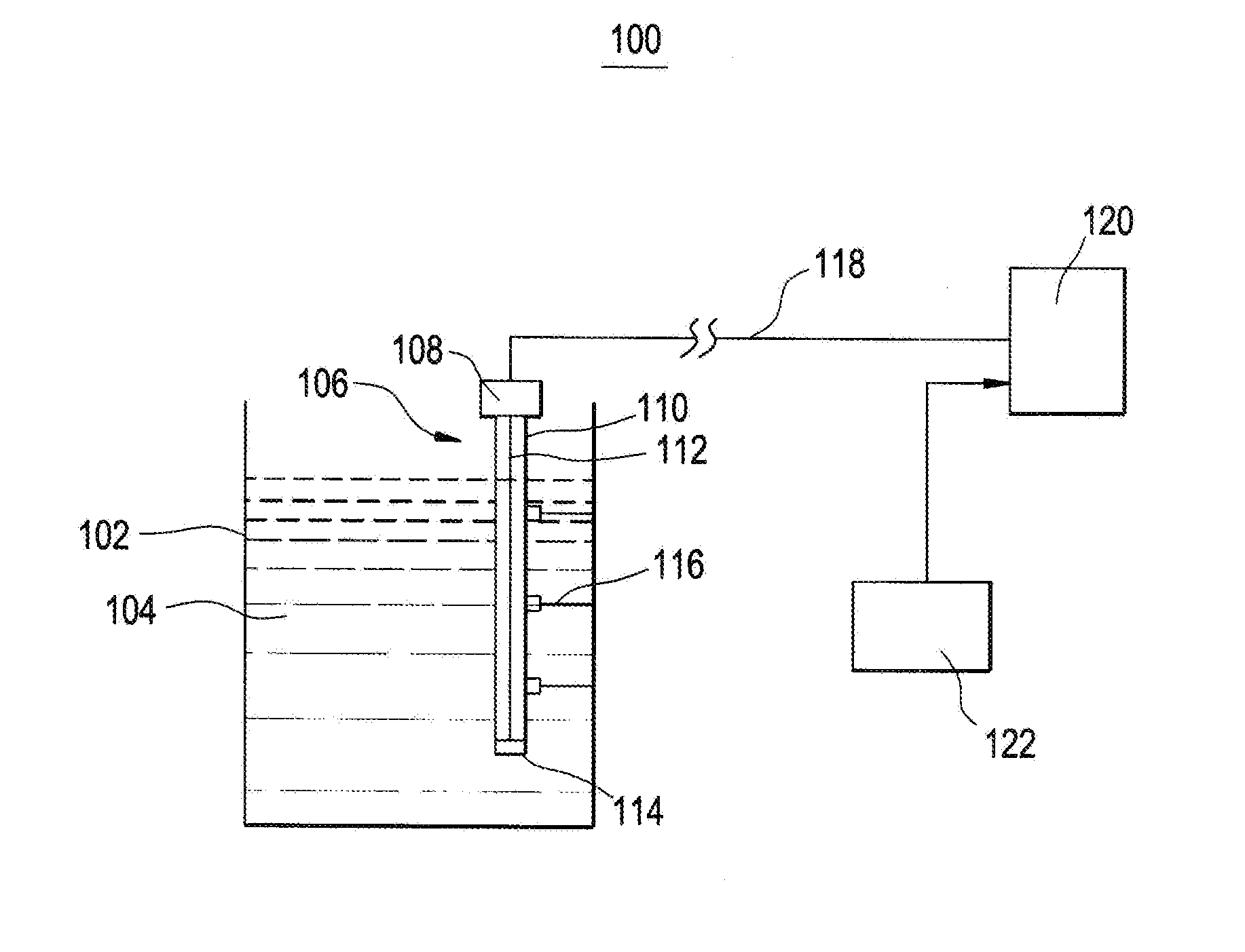

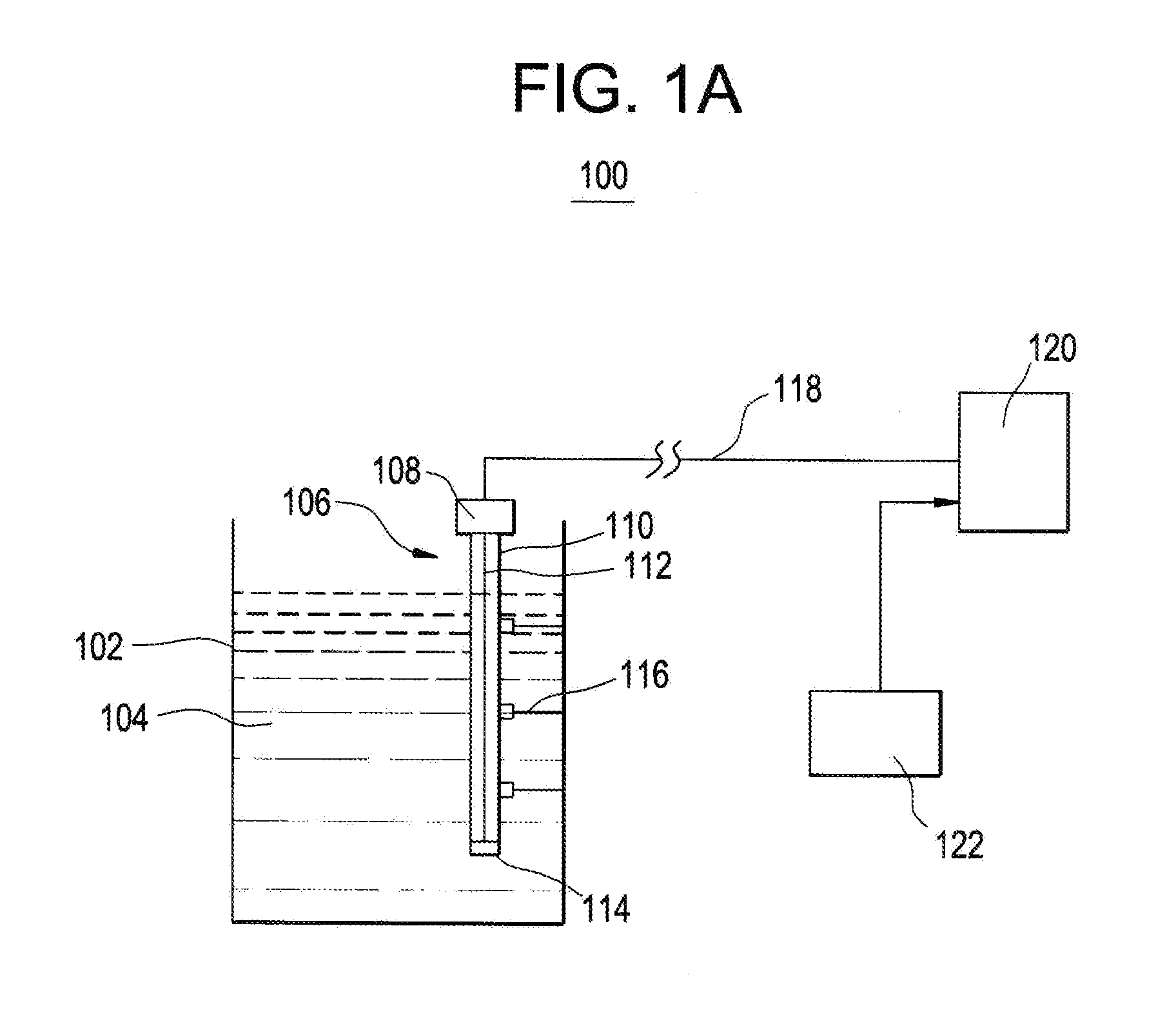

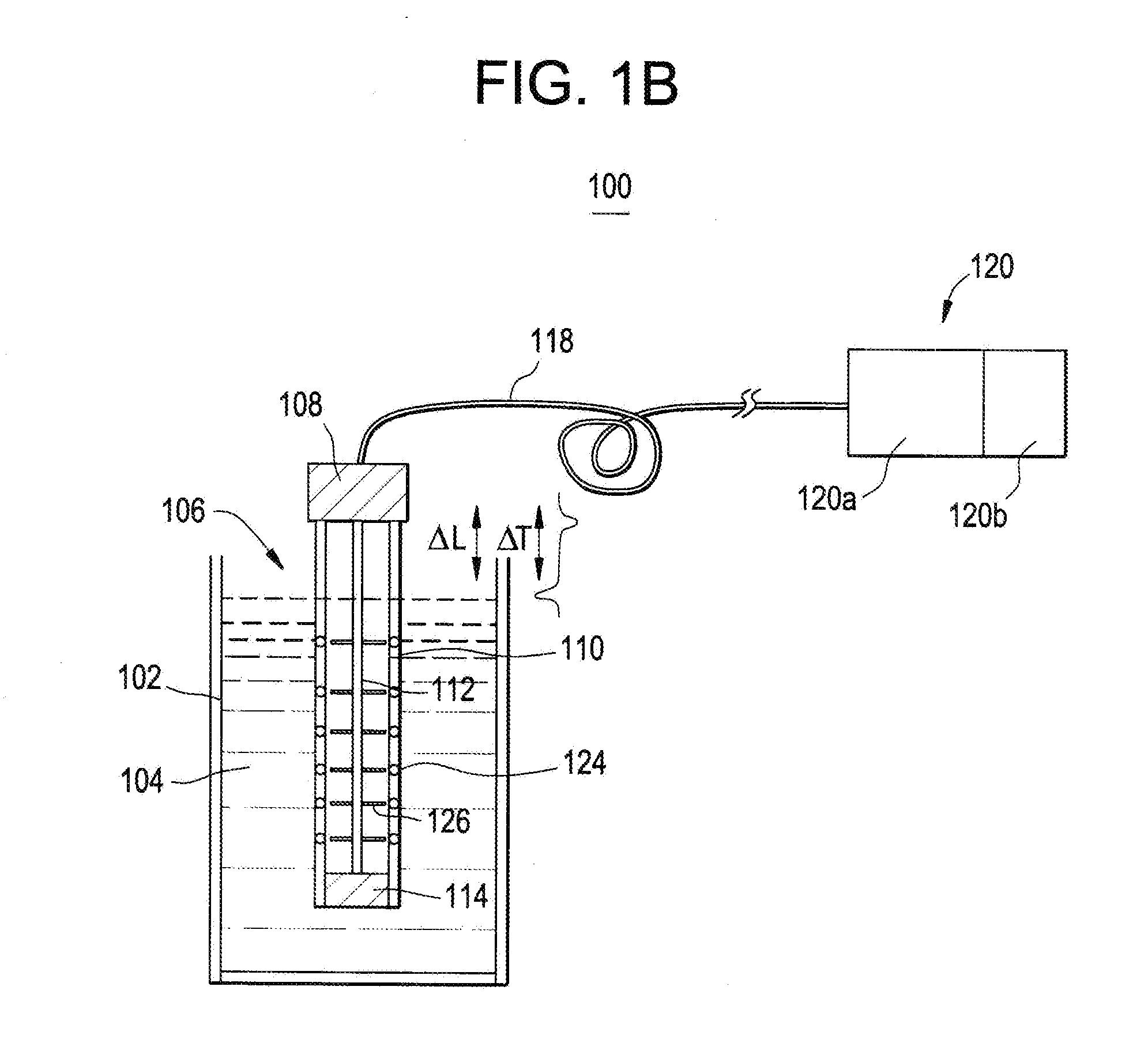

Systems and methods for remotely measuring a liquid level using time-domain reflectometry (TDR)

ActiveUS9074922B2Increase distanceAccurate water levelCapacitance measurementsMachines/enginesTime domainCoaxial cable

A remote pulse TDR liquid level measurement system and method may include inserting a probe into a body of water. The probe has a probe / air interface, and the body of water includes an air / water interface. A narrow pulse is remotely transmitted to the probe via a coaxial cable. A first impedance mismatch is received from the probe / air interface in a form of a positive reflected pulse, and a second impedance mismatch is received from the air / water interface in a form of a negative reflected pulse. A time between the positive reflected pulse and the negative reflected pulse is calculated, and the time is converted to a distance, the distance being indicative of the water level.

Owner:GE HITACHI NUCLEAR ENERGY AMERICAS

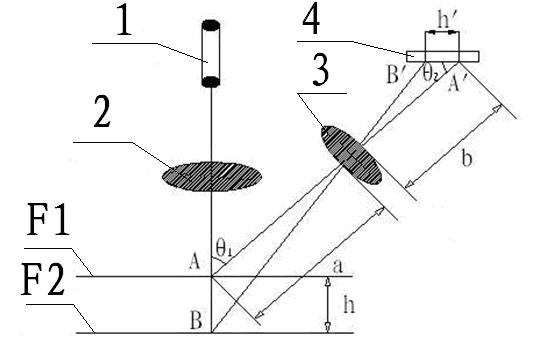

High-precision real-time laser triangulation method and triangulation device for liquid level

InactiveCN102419198AHigh sensitivityHigh precisionMachines/enginesLevel indicatorsSpectral responseMechanical engineering

The invention discloses a high-precision real-time laser triangulation method and a high-precision real-time laser triangulation device for a liquid level. The triangulation device comprises a laser triangulation displacement sensor, wherein the laser triangulation displacement sensor comprises a laser, a converging lens, a receiving objective and a charge coupled device (CCD); a laser beam emitted from the laser passes through the converging lens; the laser beam is refracted by a liquid surface; the laser beam is imaged on the CCD after passing through the receiving objective; the triangulation device also comprises an indoor liquid taking hopper, an indoor liquid taking test tube, an outdoor liquid taking test tube, a U-shaped tube and a signal line, wherein the indoor liquid taking hopper and the outdoor liquid taking test tube are fixedly arranged on a test worktable; the indoor liquid taking test tube is connected with the outdoor liquid taking test tube through the U-shaped tube; the laser triangulation displacement sensor is arranged above the outdoor liquid taking test tube; and the laser triangulation displacement sensor is electrically connected with an industrial personal computer through the signal line. The triangulation device has the advantages that: non-contact real-time liquid level measurement can be realized; and the sensitivity is high, the spectral response is wide, the dynamic range is wide, the linearity is high, the precision is high and the measurement range is wide.

Owner:CHANGCHUN UNIV OF SCI & TECH

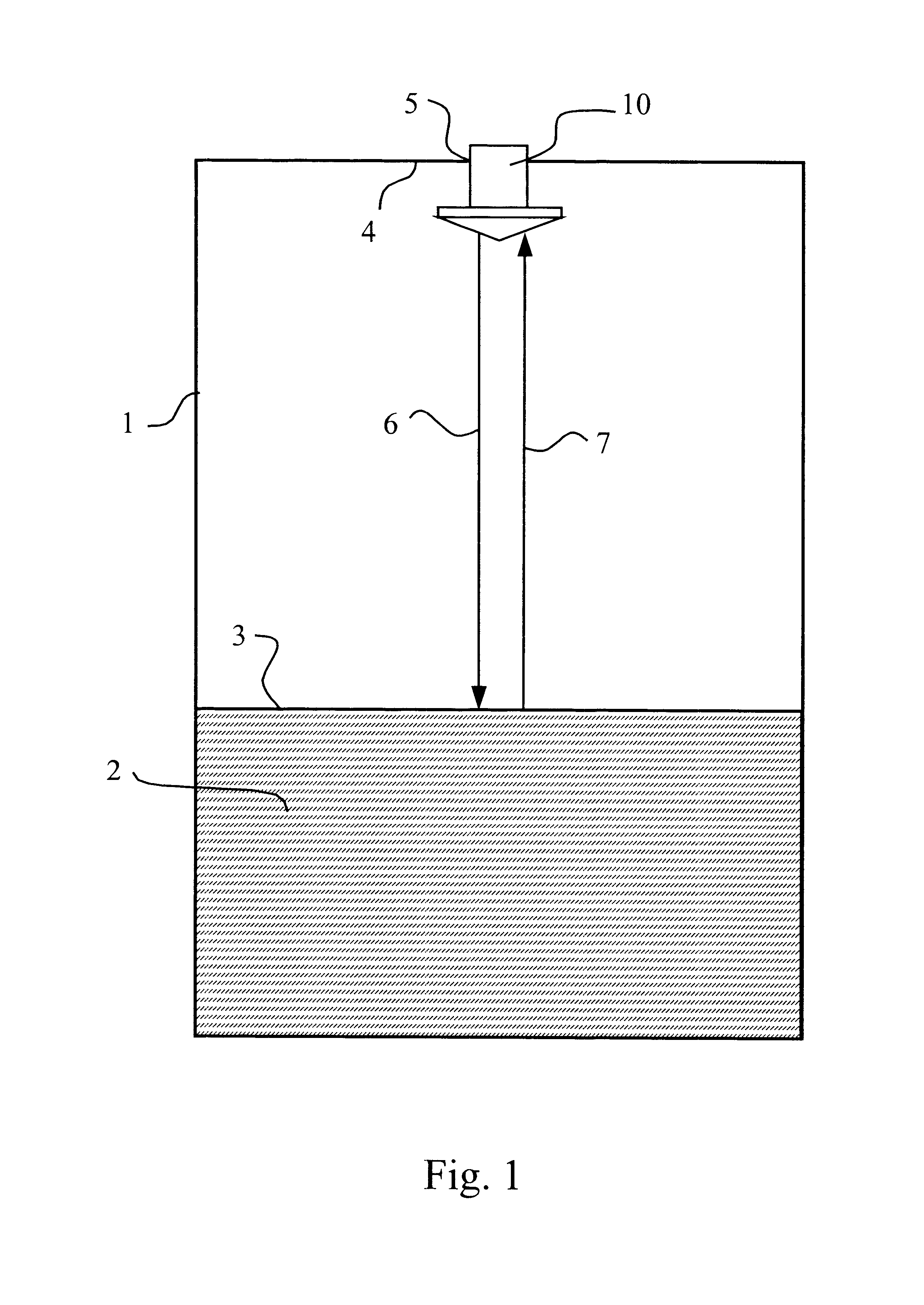

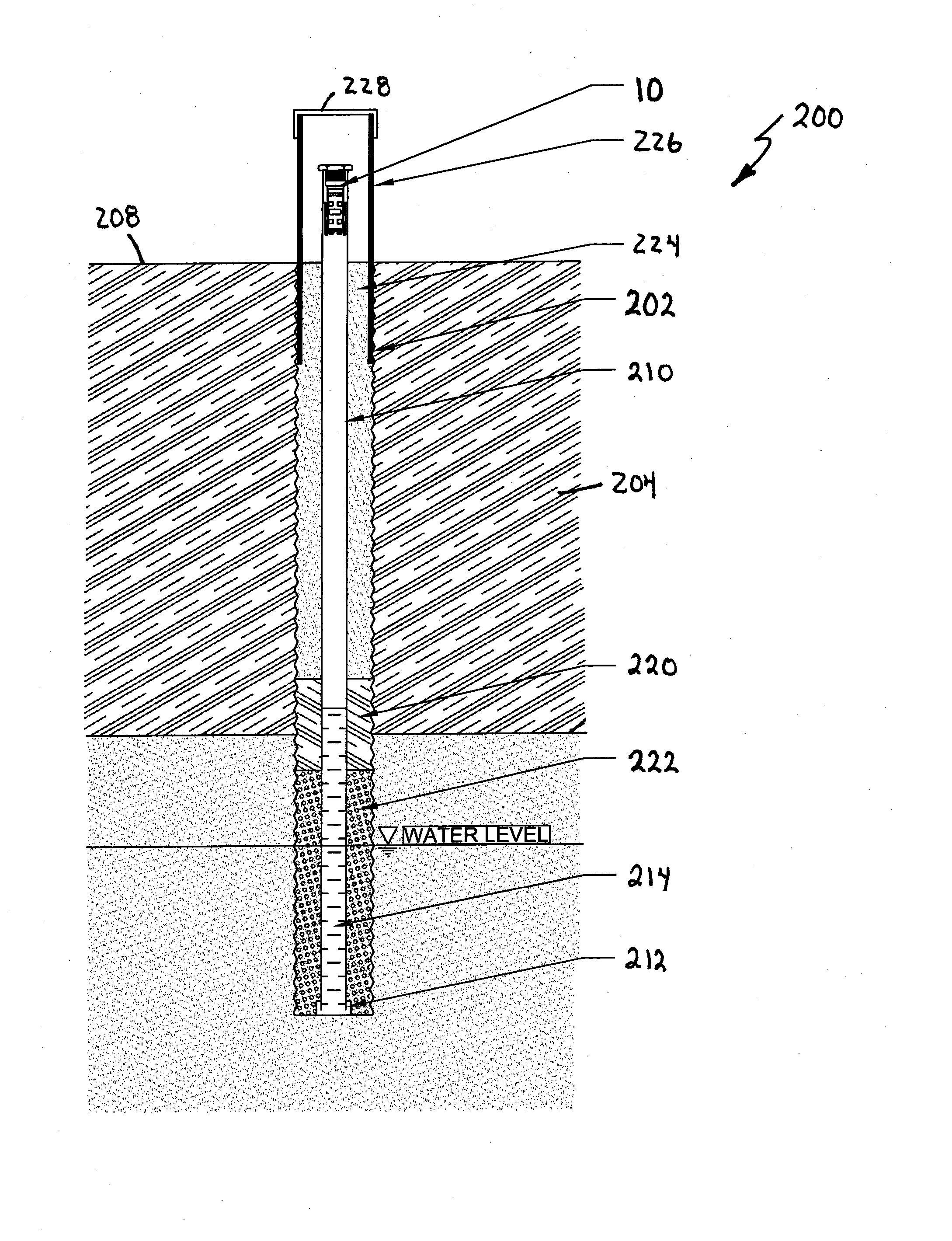

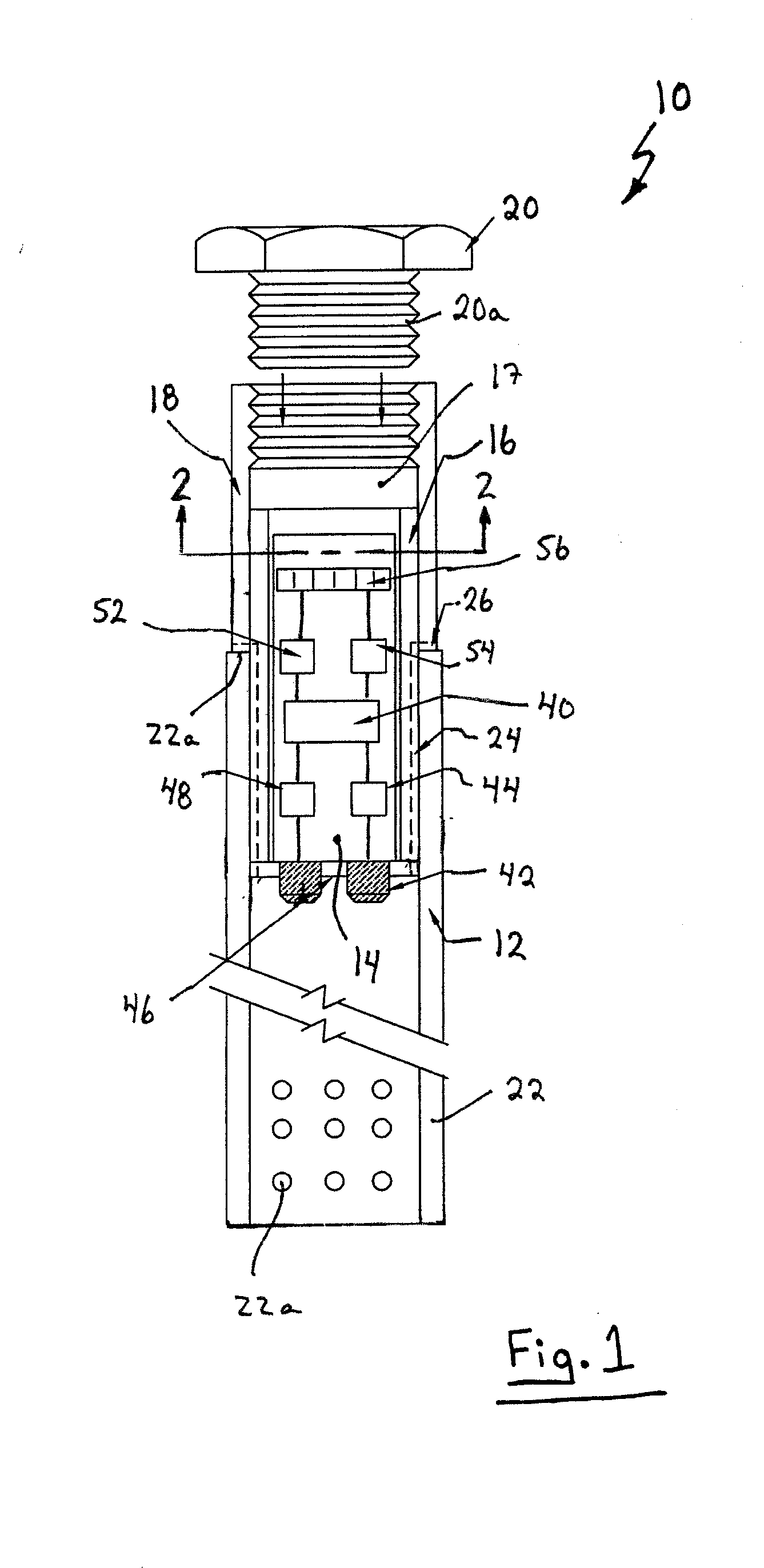

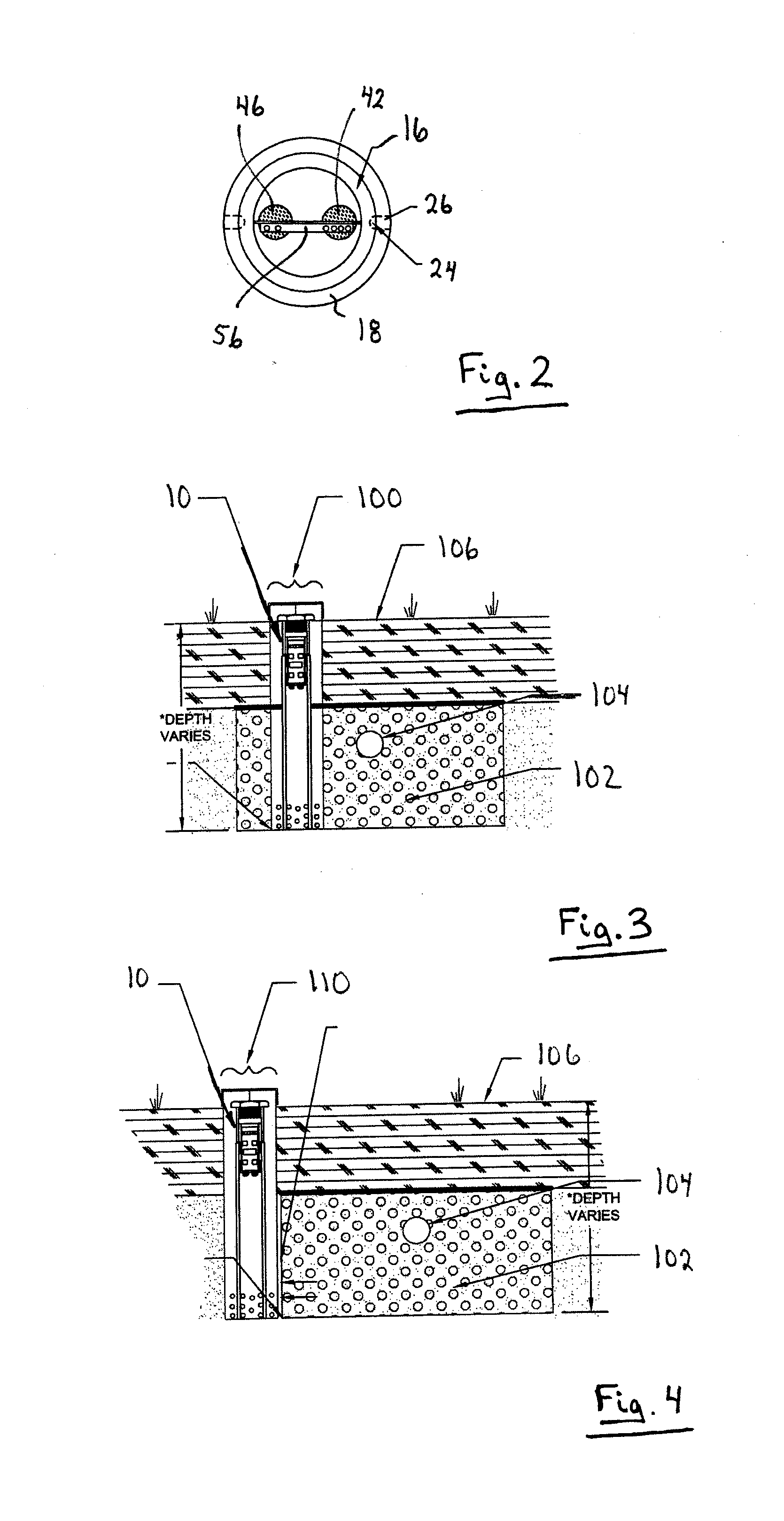

Liquid level measurement device and installation incorporating the same

ActiveUS20080060430A1Avoid interferenceMonitored quickly and easilyWater treatment parameter controlMachines/enginesLiquid level measurementEngineering

A liquid level measurement device comprises a generally seamless pipe for insertion into an installation in which liquid level is to be monitored and a non-contact sensor assembly disposed within the pipe at a location spaced above the liquid. The sensor assembly senses the level of the liquid and generates output representative of the liquid level.

Owner:ENG TECH CANADA

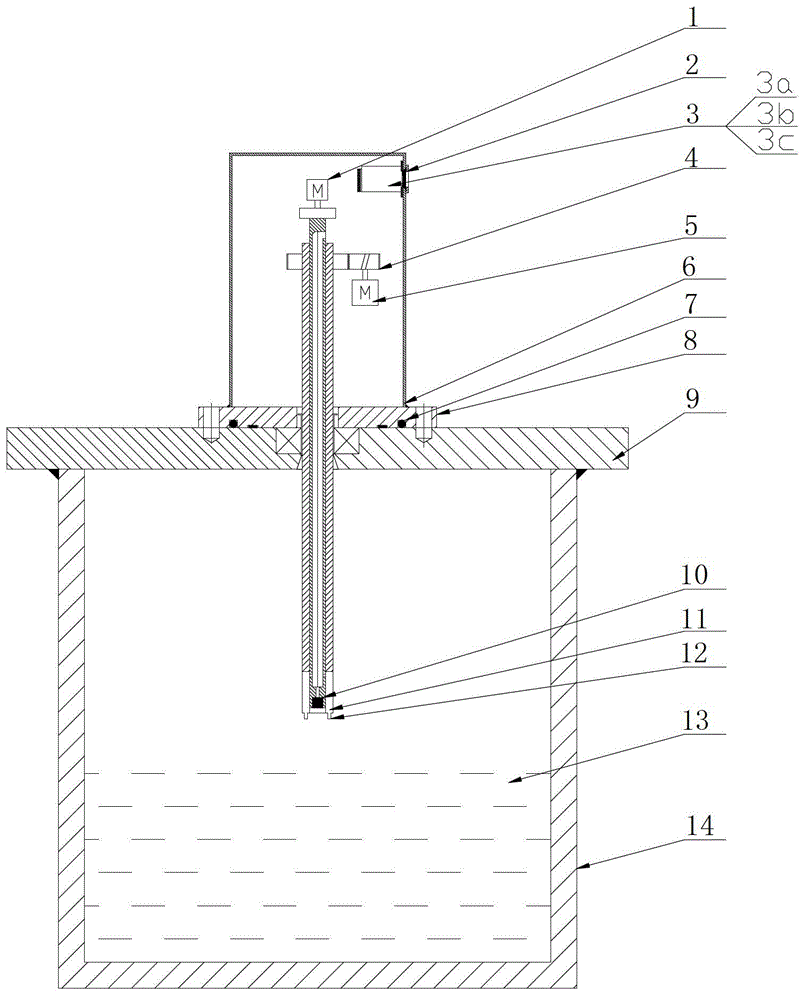

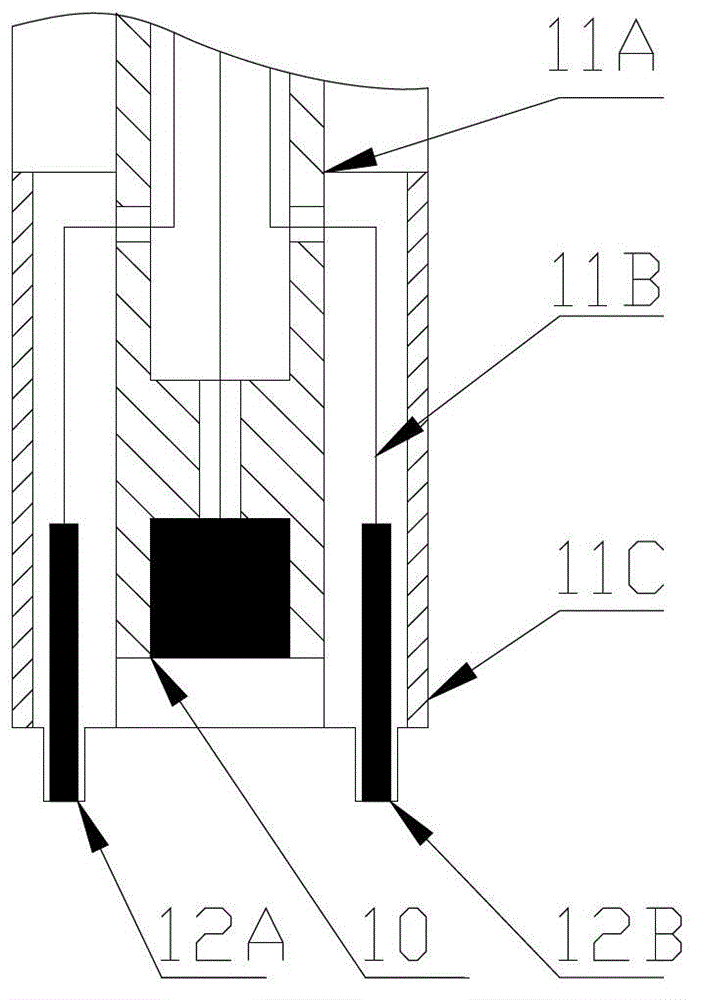

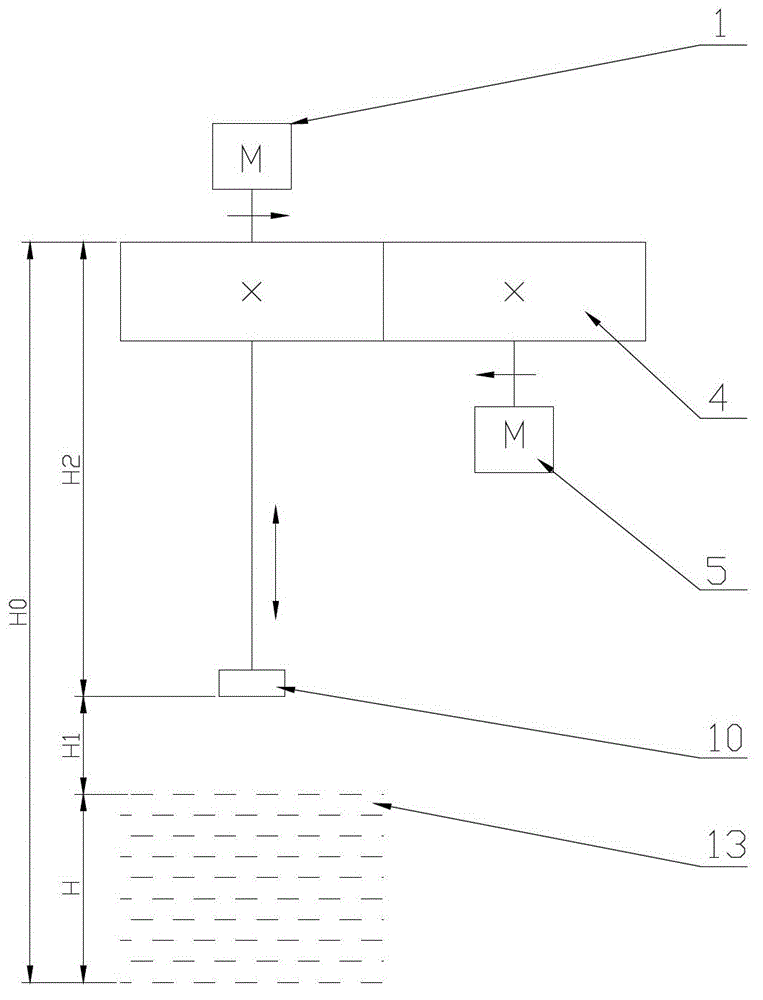

Non-contact type single-point liquid metal liquid level measurement device

InactiveCN102914343AHigh measurement accuracyExpand the scope of useTesting/calibration apparatusMachines/enginesMeasurement deviceLiquid metal

The invention discloses a non-contact type single-point liquid metal liquid level measurement device, which consists of a sensing probe, a lifting casing pipe, a liquid level probe, a direct-current stepping motor, an upper flange plate, a lower flange plate, a sealing shell, a meshing gear, a sealing element, a signal processing system, a motor driving system and a wireless transmission system, wherein the sensing probe detects the free liquid level of detected liquid metal; and the stepping motor is controlled by a corresponding control algorithm to drive the lifting casing pipe to lift, thereby keeping the sensing probe always in non-contact with the liquid level of detected liquid metal to realize non-contact measurement; the maximum detection distance between the sensing probe and the liquid level of detected liquid metal can be automatically calibrated by the liquid level probe, and the liquid level can be prevented from contacting with the sensing probe; and the sealing element can ensure the tightness of a measured container and is suitable for measuring the metal liquid level of the pressure container. The liquid level device can measure the liquid level of the liquid metal of which the temperature is up to 600DEG C, can be used for a long time, and has the advantages of high reliability and good sensitivity and accuracy, and is suitable for the accurate non-contact measurement of the high-temperature liquid metal liquid level.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

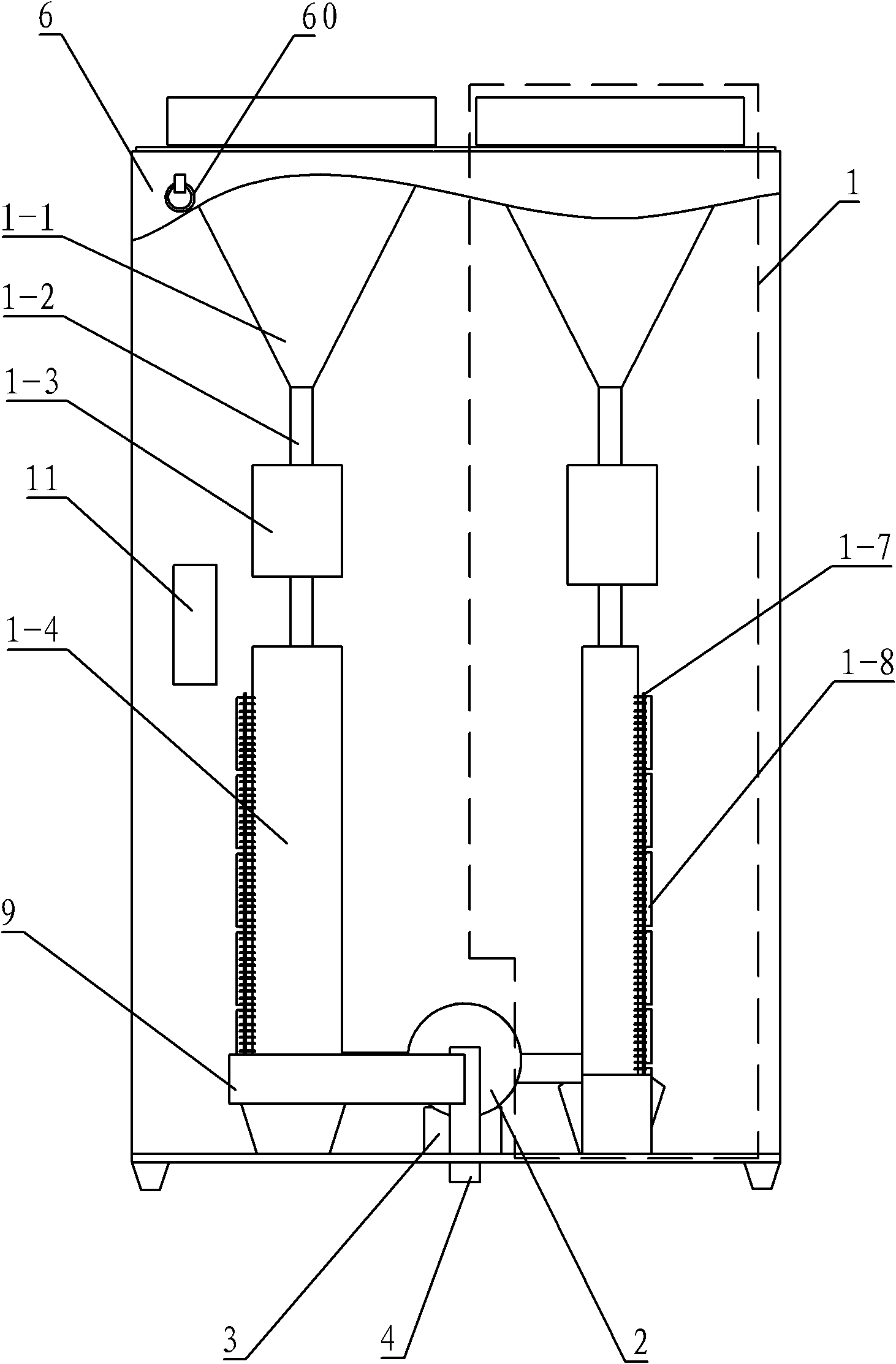

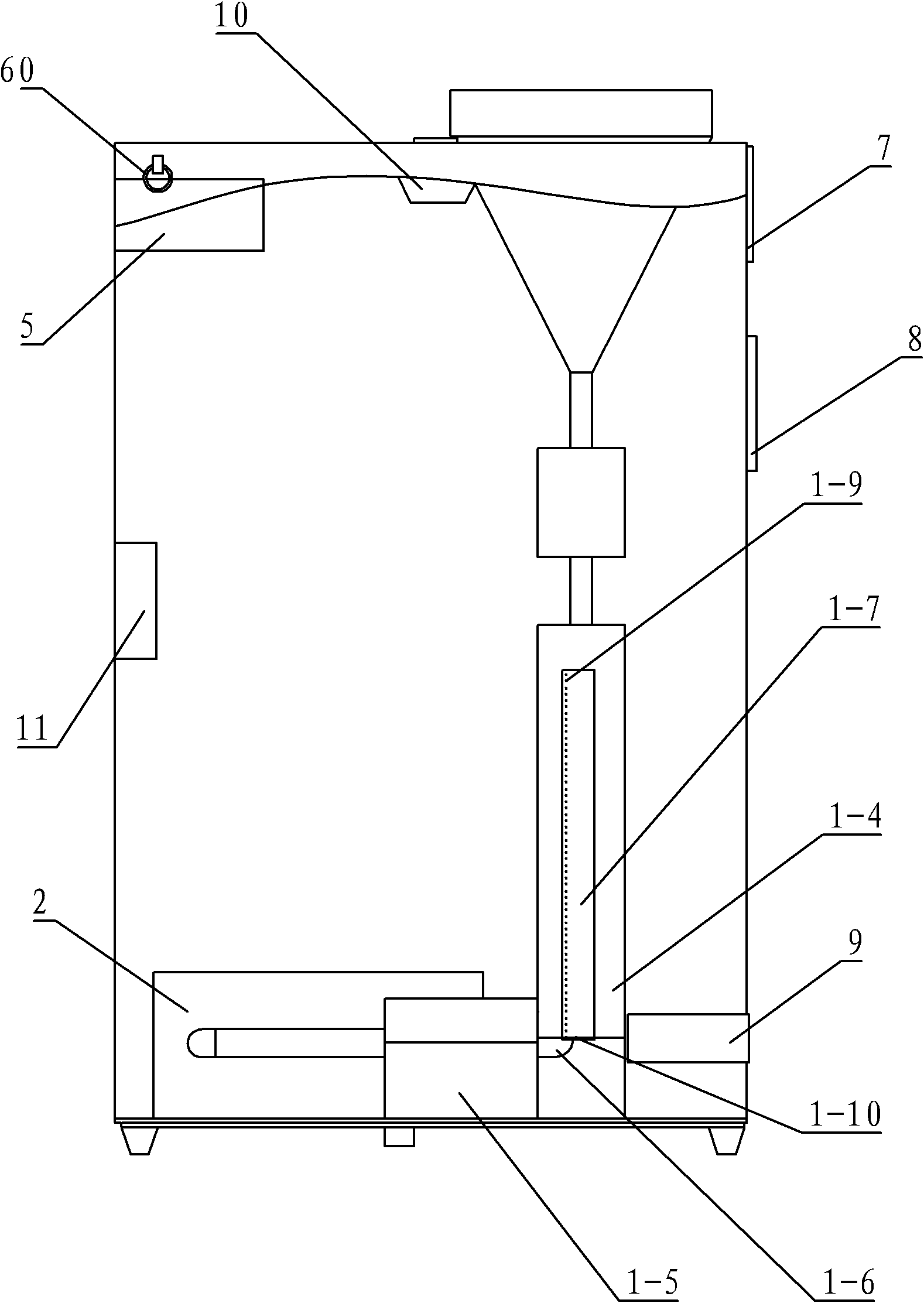

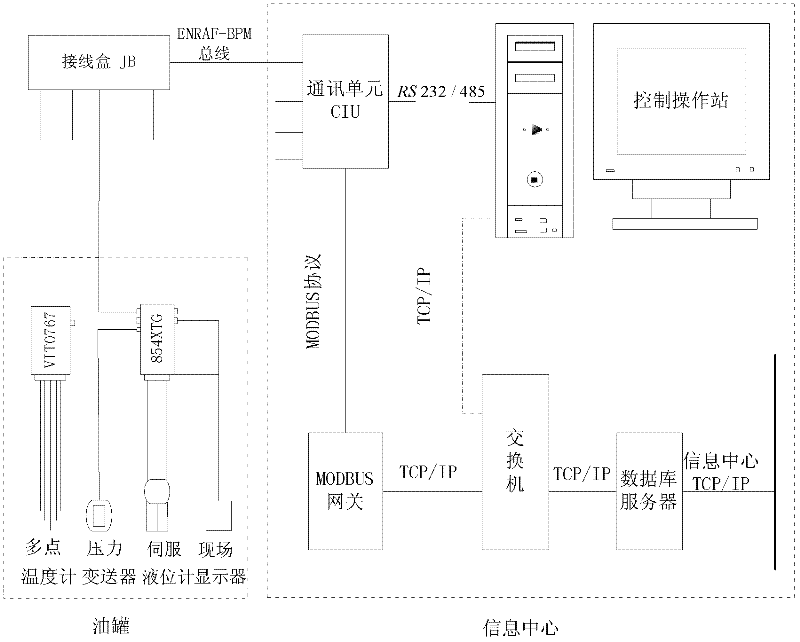

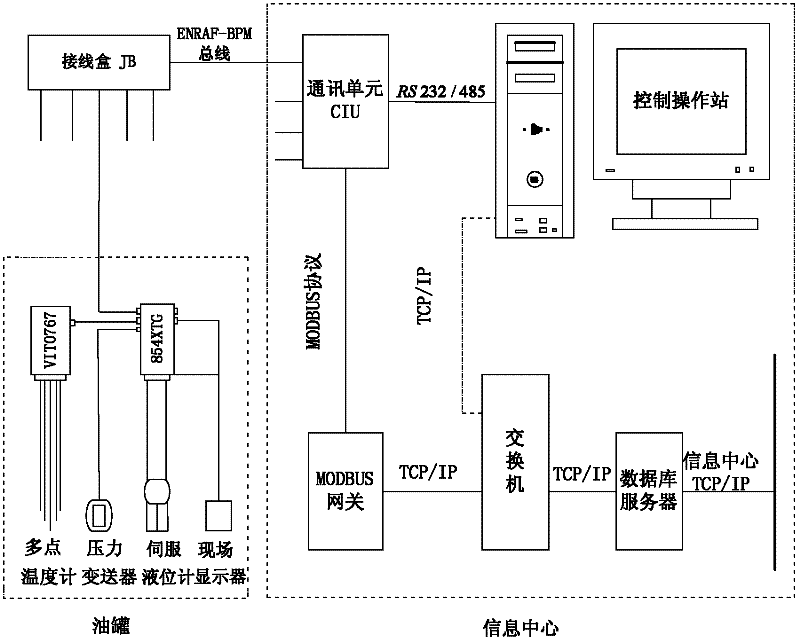

Large-scale multiple oil-tank liquid level automation measurement integration system

InactiveCN102393721AMeet construction requirementsAchieve integrationMachines/enginesLevel indicatorsModbusCommunication unit

The invention discloses a large-scale multiple oil-tank liquid level automation measurement integration system. The system comprises: an oil tank measurement sensor group, an on-site junction box, a communication unit CIU, a MODBUS gateway, a switch, a control operation station and a database server. The oil tank measurement sensor group is connected with a communication unit CIU bus through the on-site junction box. The communication unit CIU is connected with the liquid level measurement control operation station. The communication unit CIU is directly connected with the switch through the MODBUS gateway. In the invention, all functions of original liquid level measurement can be maintained; oil tank information integration can be realized; a information construction requirement of multiple oil tank concentration measurement can be satisfied. The oil tank measurement information is divided into two parts to display and store, which raises redundancy of the system.

Owner:JIANGSU UNIV OF SCI & TECH

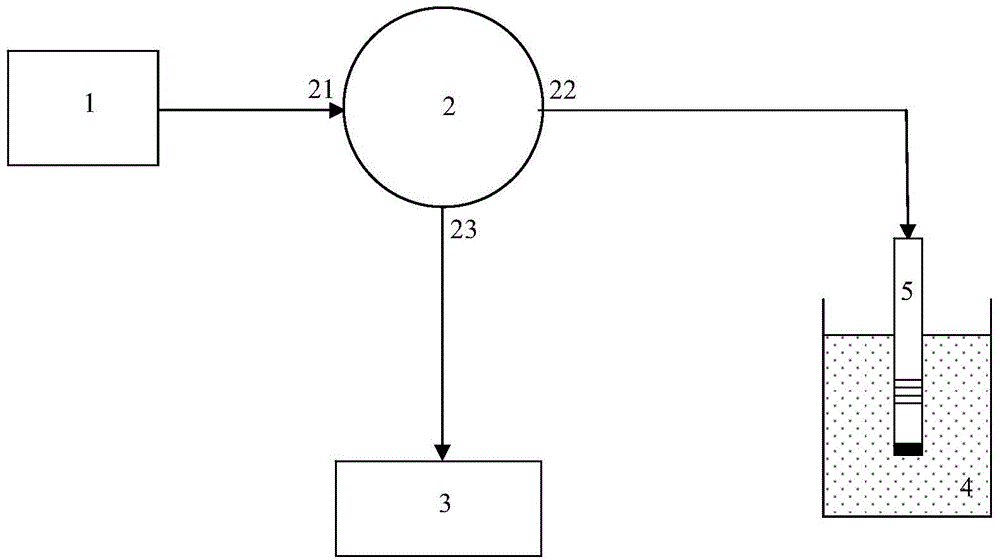

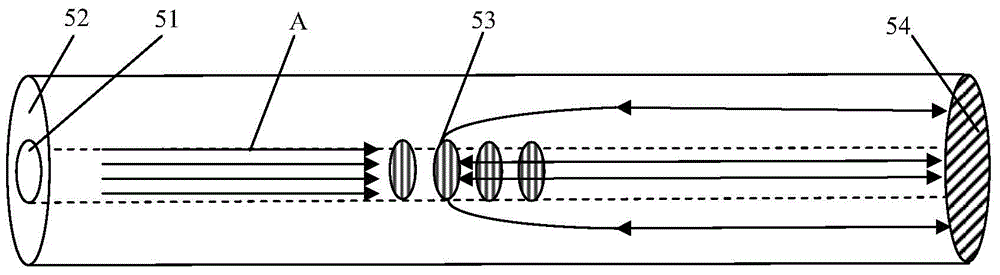

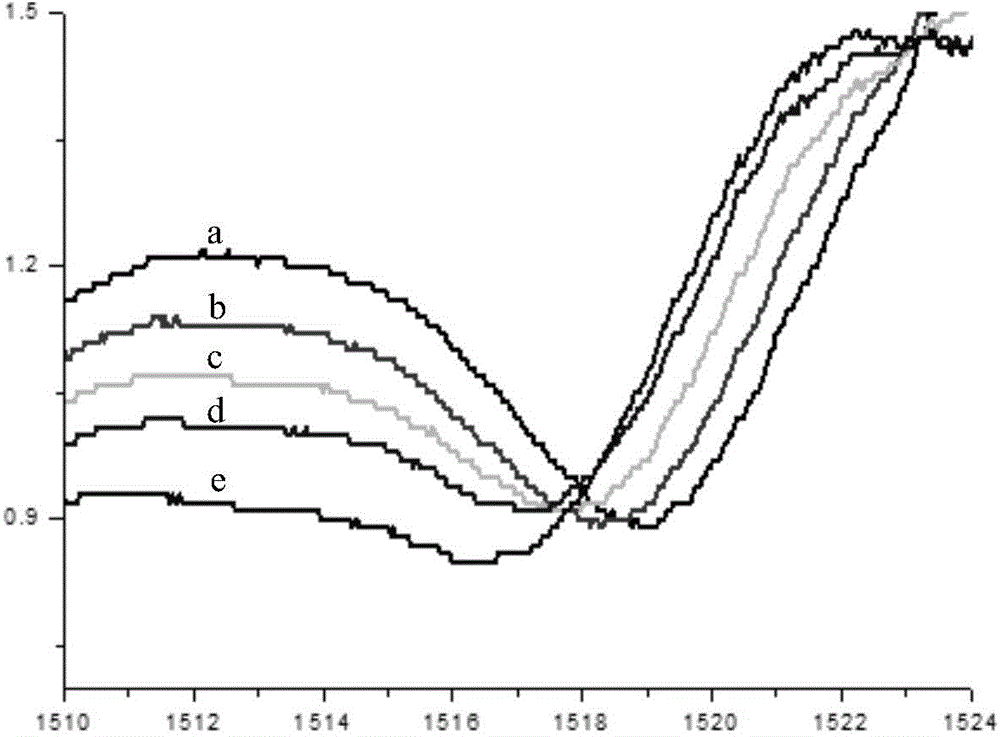

Liquid level measurement device and method

InactiveCN104089682ARealize continuous measurementHigh measurement accuracyMachines/enginesLevel indicatorsContinuous measurementGrating

The invention discloses a liquid level measurement device and method and relates to liquid level measurement. The device is provided with a light source, a three-port circulator, a spectrograph, a liquid container to be measured and a liquid level sensor. The sensor is inserted into the liquid container to be measured, the other end of the sensor is connected with a first output port of the circulator, the light source is connected with the input end of the circulator, and a second output port of the circulator is connected with the spectrograph; signal light enters the circulator and then is output through the first output port of the circulator; after the signal light reaches the sensor, interference occurs at the position of a fiber bragg grating through reflection of a silver film; reflected light re-enters the circulator through the first output port of the circulator and then is output to the spectrograph through the second output port of the circulator, and the spectrum of the output light can be obtained by measuring the spectrum of the reflected light; the relation between the height of the outside liquid level and the wavelength of interference fringes can be obtained by measuring the drifting of the wavelength of the interference fringes through the spectrograph, and liquid level height can be measured through spectrum analysis. By the adoption of the liquid level measurement device and method, continuous liquid level measurement is realized, measurement accuracy is high, and safety performance is high.

Owner:XIAMEN UNIV

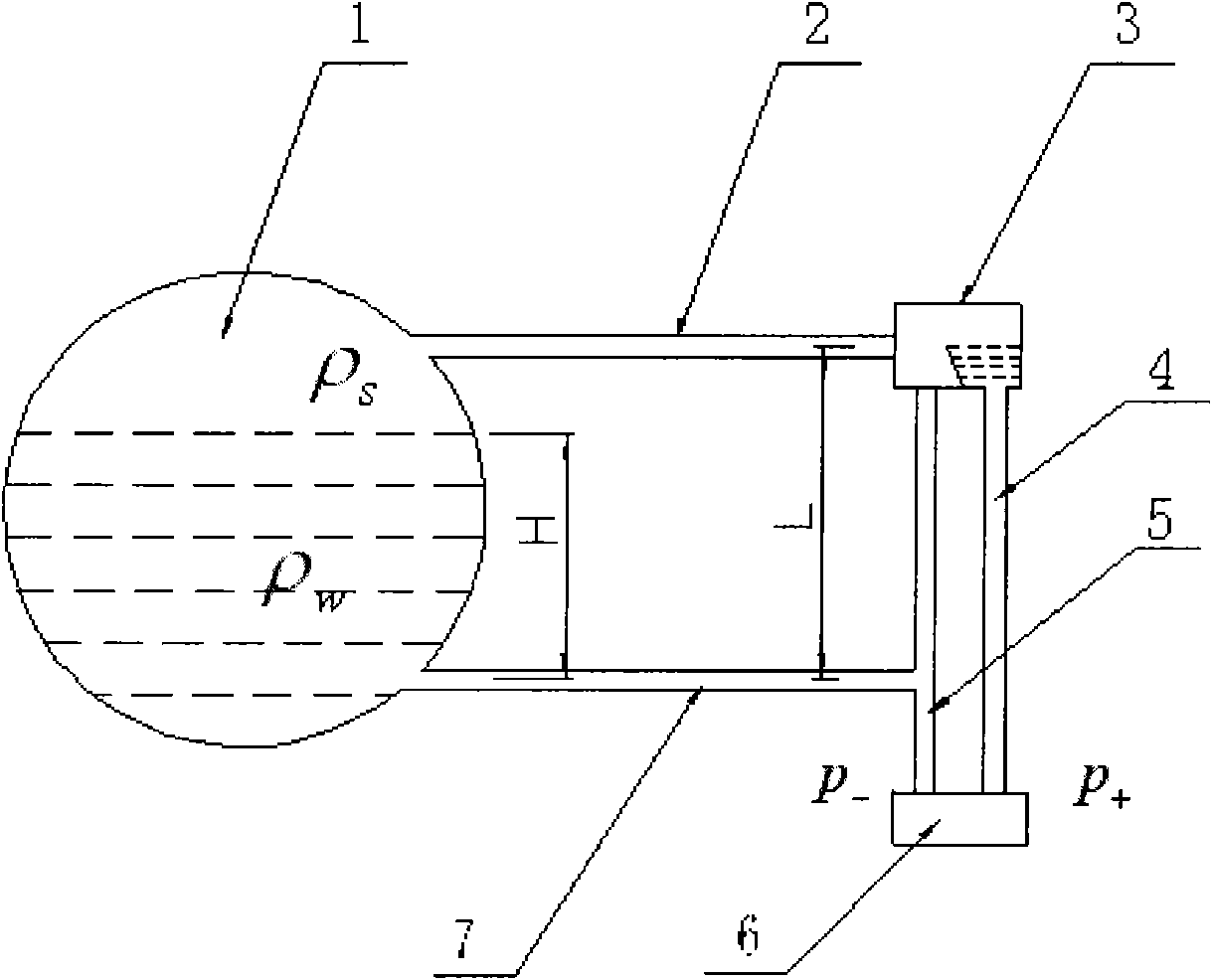

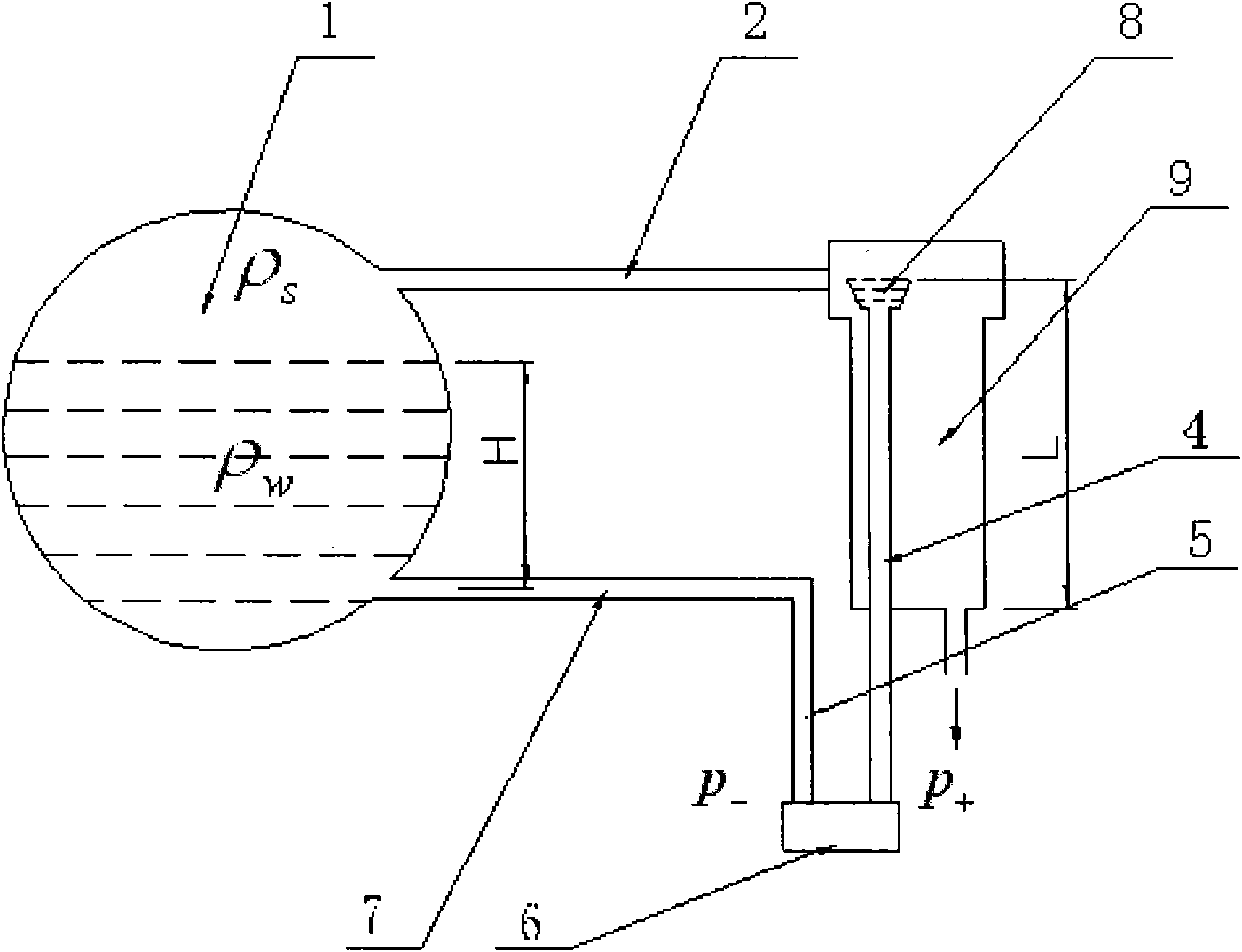

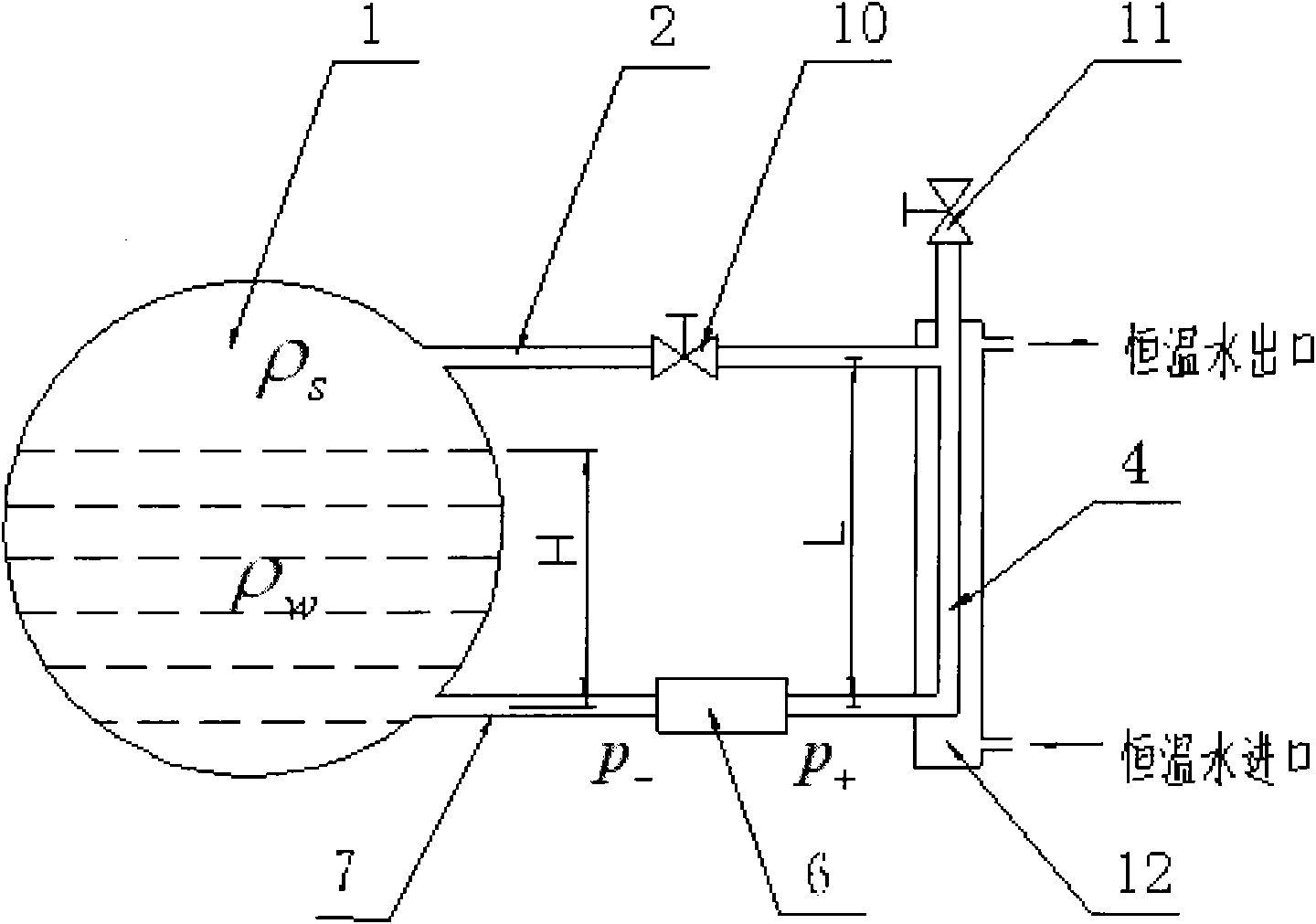

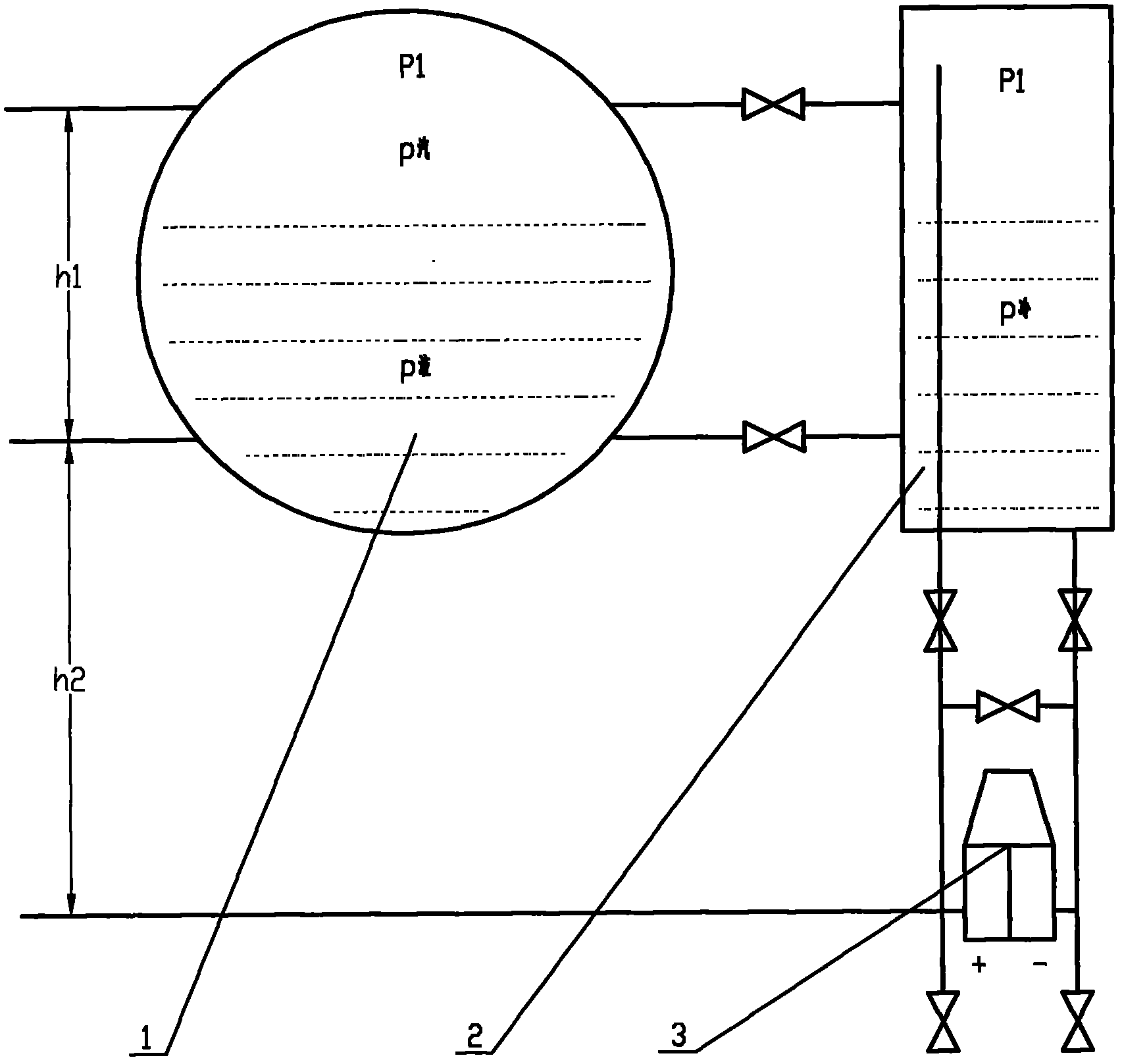

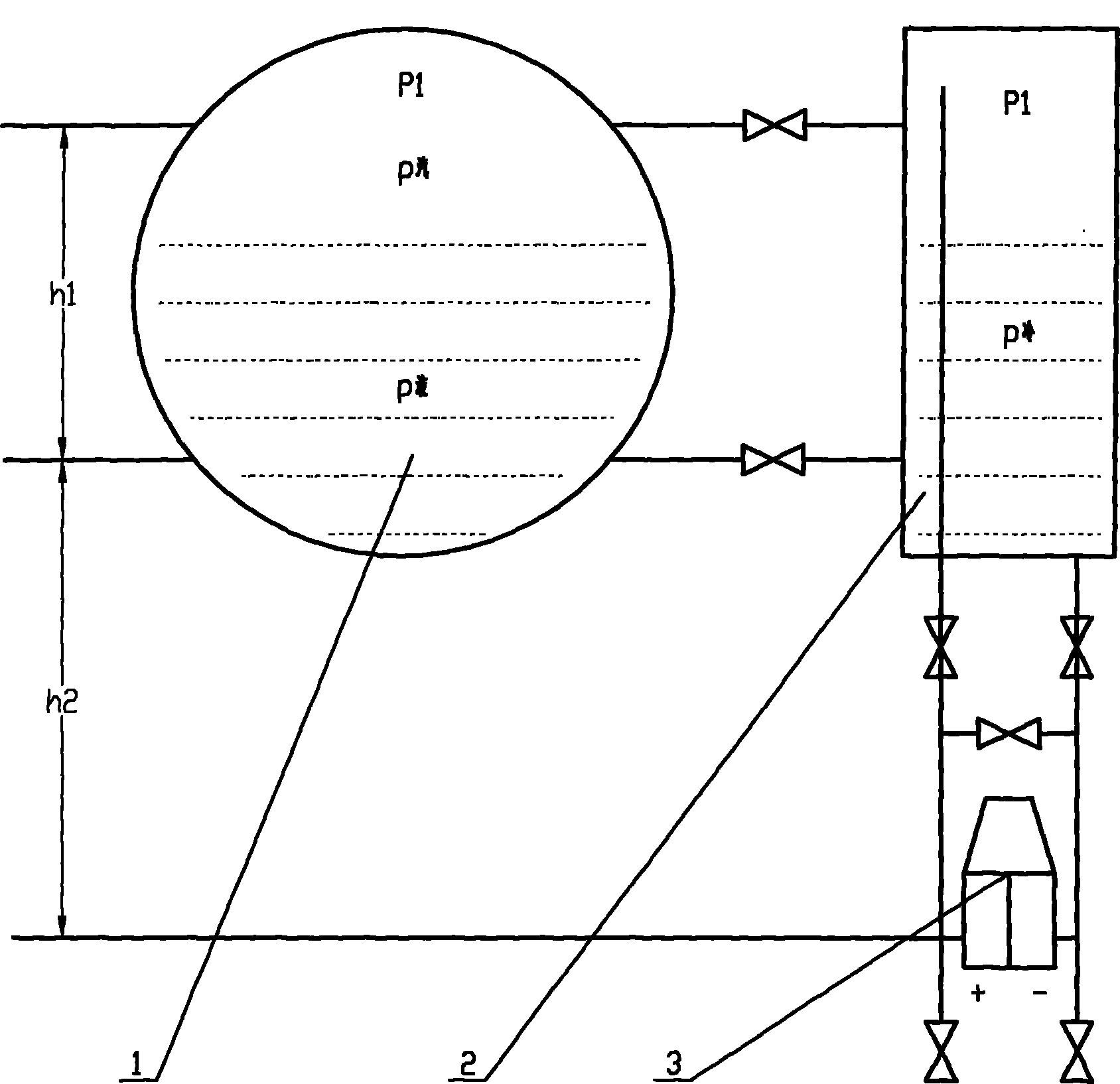

Differential pressure type liquid level measurement device for pressure container

InactiveCN101986108AEasy to fillGuaranteed liquid levelLevel indicators by pressure measurementLiquid level measurementIsolation valve

The invention discloses a differential pressure type liquid level measurement device for a pressure container, and relates to liquid level measurement technology of the pressure container. The device comprises a steam lead-out pipe, a saturated water lead-out pipe, a positive pressure pipe and a differential pressure transmitter, wherein the steam lead-out pipe is directly connected with the positive pressure pipe and an isolating valve is arranged on the steam lead-out pipe; the positive pressure pipe is arranged in an outer constant-temperature sleeve in which constant-temperature fluid is held; the top end of the positive pressure pipe is provided with a water injection valve; the saturated water lead-out pipe and a negative pressure pipe are combined into a whole and horizontally arranged at a zero position at the horizontal level of a high-pressure container; and the differential pressure transmitter is arranged on the saturated water lead-out pipe which is connected with the positive pressure pipe through the differential pressure transmitter. The device effectively overcomes the disadvantages of indefinite density and liquid level caused by bubbling, vaporizing and the like of water in the positive pressure pipe and measurement error caused by the mounting position of the differential pressure transmitter in a single-chamber balance container method and a double-chamber balance container method, and has obvious characteristics of high measurement accuracy, convenience of use and low manufacturing cost.

Owner:SHENYANG INST OF ENG +1

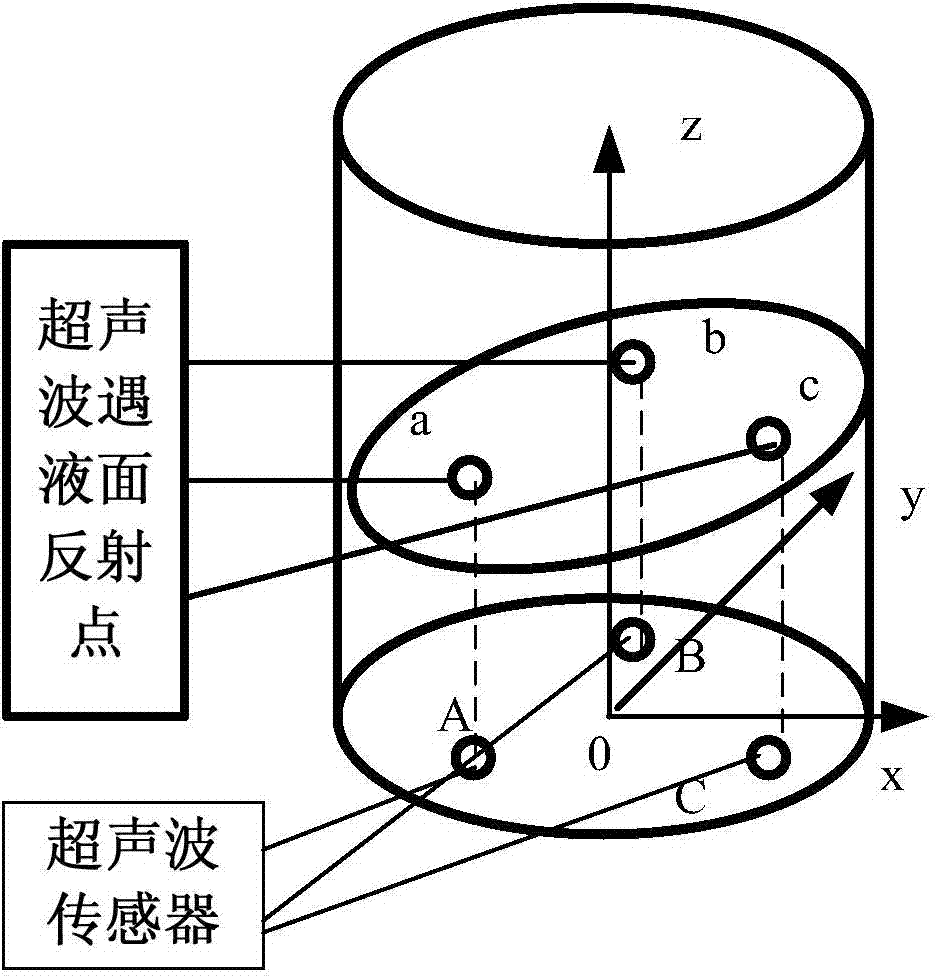

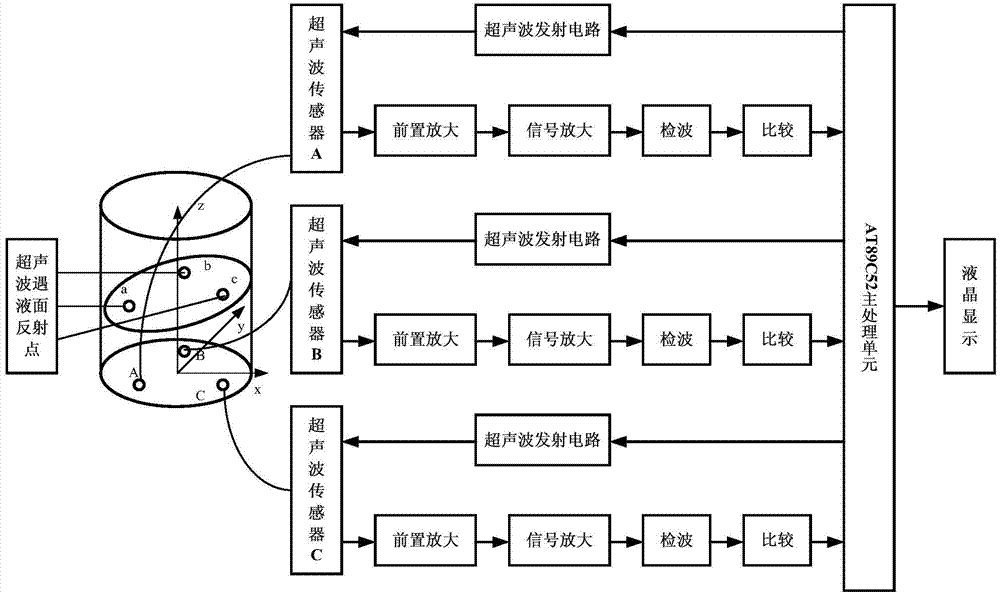

Method and system for ultrasonic dynamic liquid level measurement based on neural network

InactiveCN103499374ARealization of dynamic liquid levelMachines/enginesLevel indicatorsMicrocontrollerControl signal

The invention discloses a method for ultrasonic dynamic liquid level measurement based on a neural network. The method comprises the steps that a single-chip microcomputer transmits control signals to three ultrasonic sensors, a timer is started to begin timing simultaneously, and a pulse ultrasonic wave is generated simultaneously; the ultrasonic sensors convert echo signals into voltage signals and transmit the voltage signals to a front pre-amplification circuit, the voltage signals are transmitted to an ultrasonic wave receiving and detecting circuit after being amplified through the pre-amplification circuit, and envelope detection of the high-frequency input signals is achieved; a receiving and comparing circuit compares the voltage signals generated after detection conducted by an envelope detection circuit with the reference voltage set by a system, and digital signals are output according to the comparison result; after an external interrupt control interface receives an effective falling edge, the single-chip microcomputer generates interruption, the value, existing at present, of the timer is recorded, a mean value and the shaking gradient are used as input parameters needed by the neural network, the two parameters are transmitted to a neural network mathematic module which is well trained, and the output values of the neural network are obtained.

Owner:JIANGSU UNIV

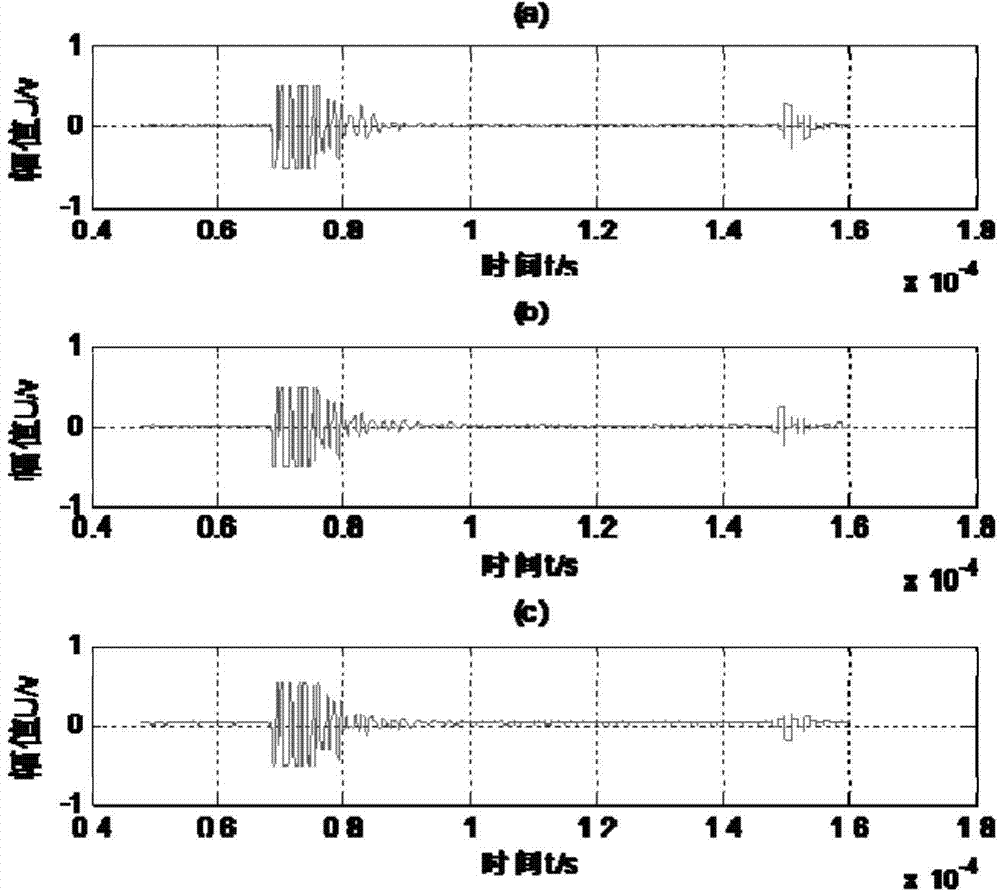

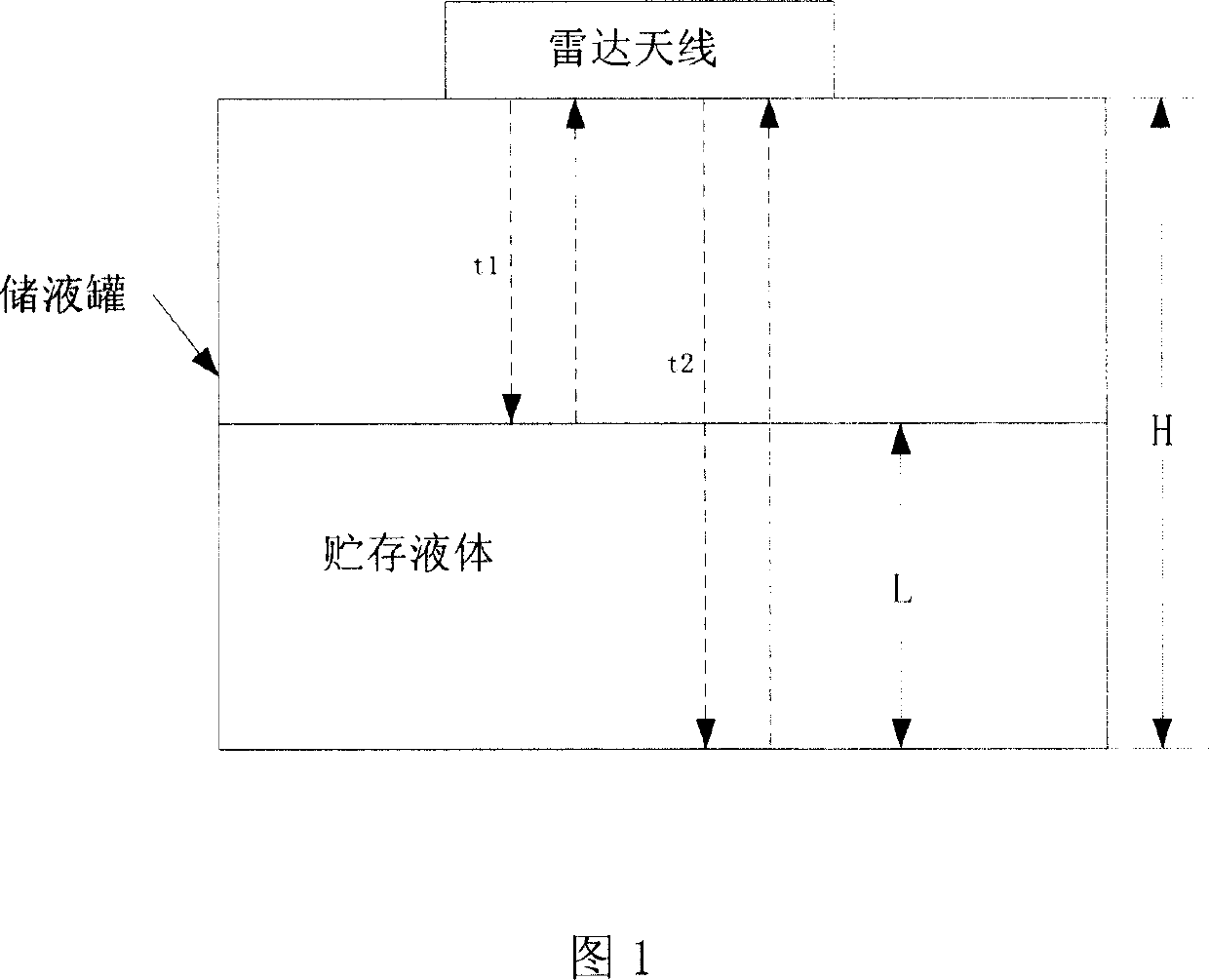

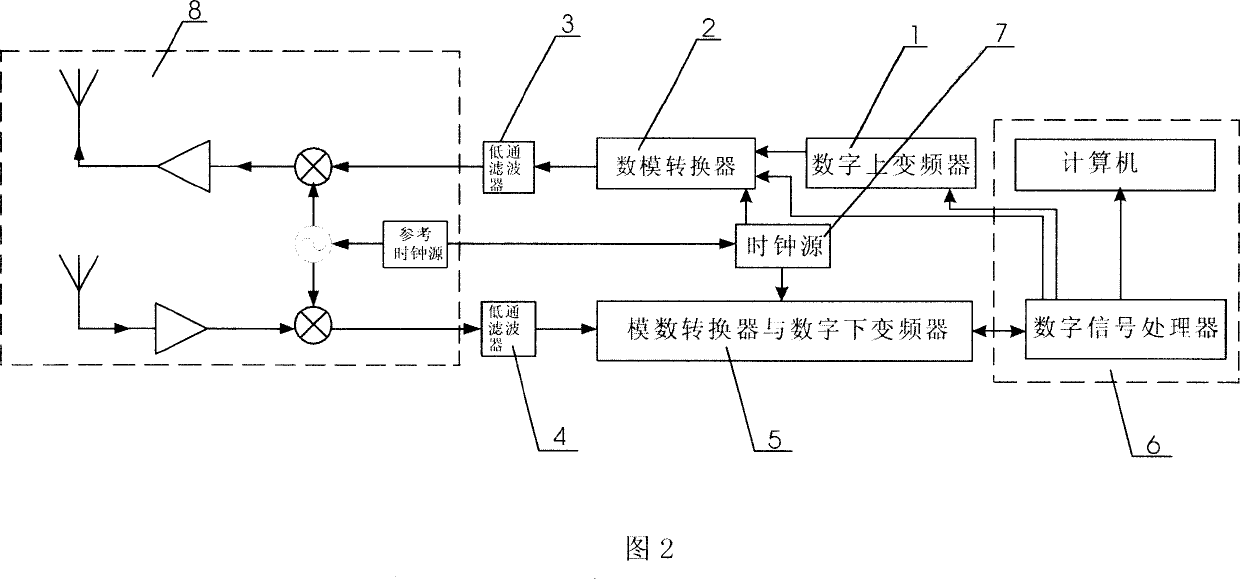

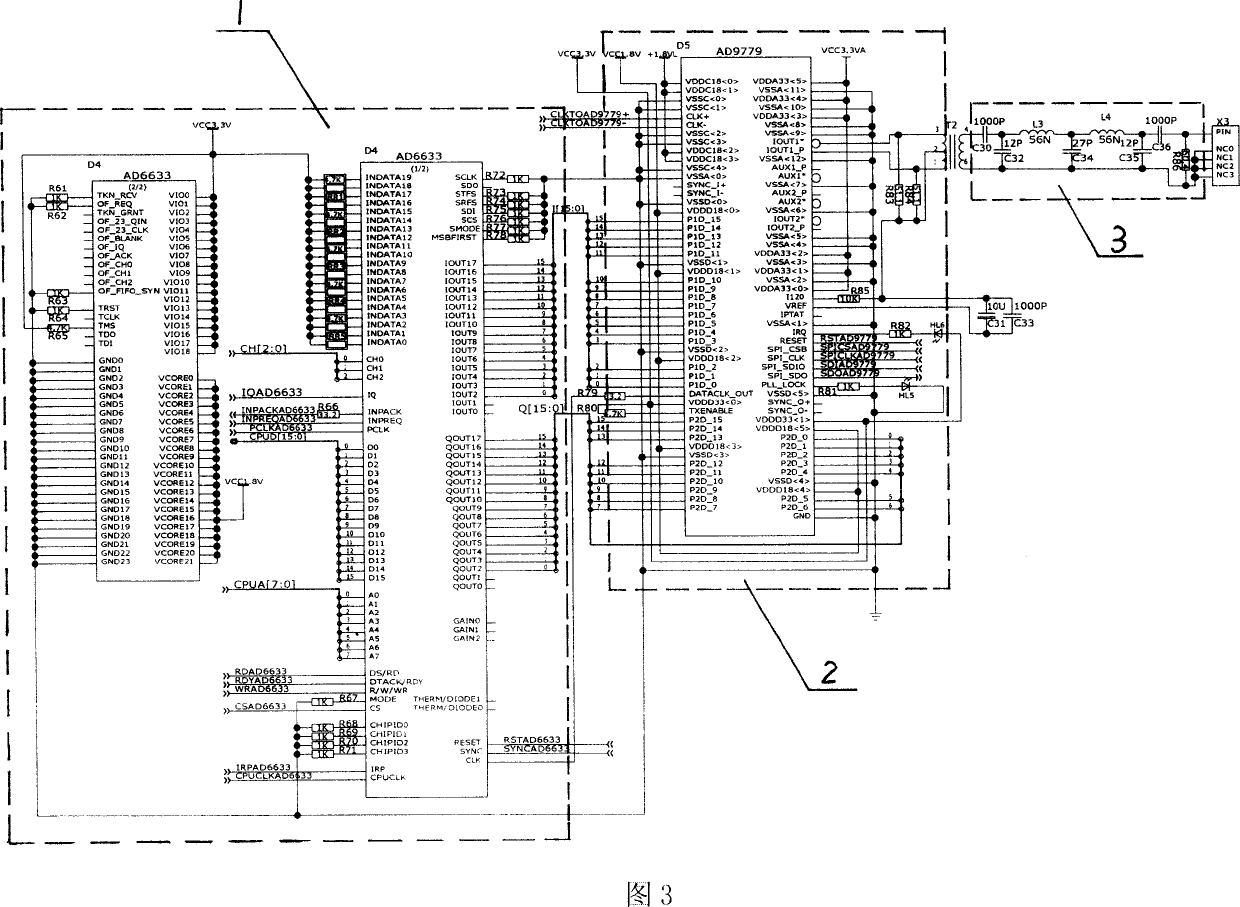

Method for measuring liquid level by using radar and radar level gauge using same

InactiveCN1971221AHigh signal to noise power ratioHigh measurement accuracyMachines/enginesLevel indicatorsDigital down conversionLiquid level measurement

The invention relates to the field of liquid level measurement device, specifically a method of liquid level measurement with radar and radar liquid level instrument with this method. To solve the current problems of low accuracy of measurement result and high cost, the invention employs the technical project: a method of liquid level measurement with radar, the liquid level to be measured can be obtained based on the formula L=H-c1(Deltphi11 / 4 piDeltf1); a radar liquid level instrument with this method includes radio-frequency unit, transmitting element, receiving element and processing unit, radio-frequency unit includes reference clock source and clock source, reference clock source is connected with the clock source in radio-frequency unit; said transmitting element comprises digit up converter, D / A converter and low-pass filter, said receiving element includes low-pass filter and digit down converter and D / A converter.

Owner:戴奉周 +1

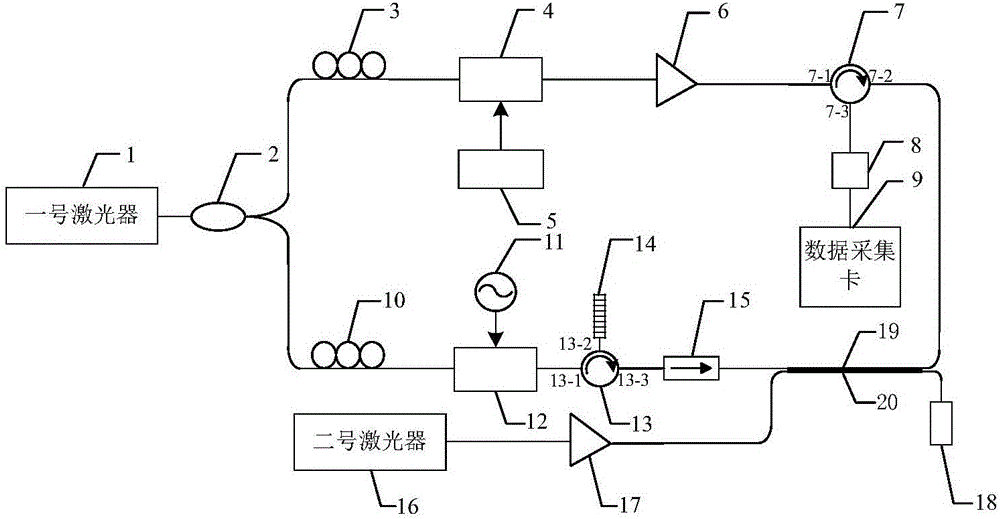

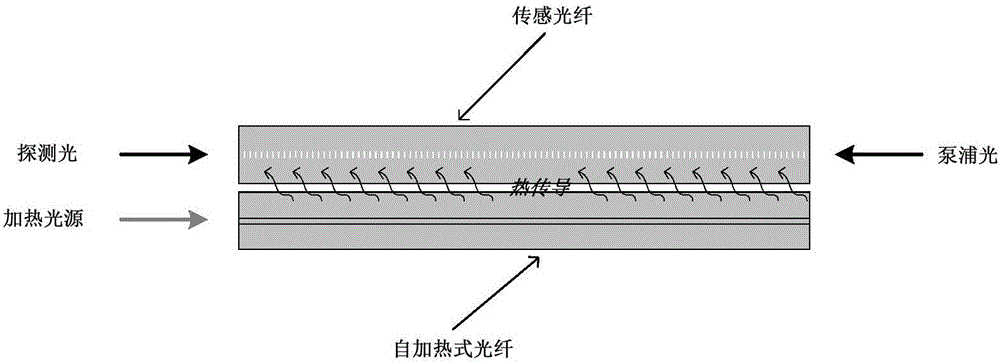

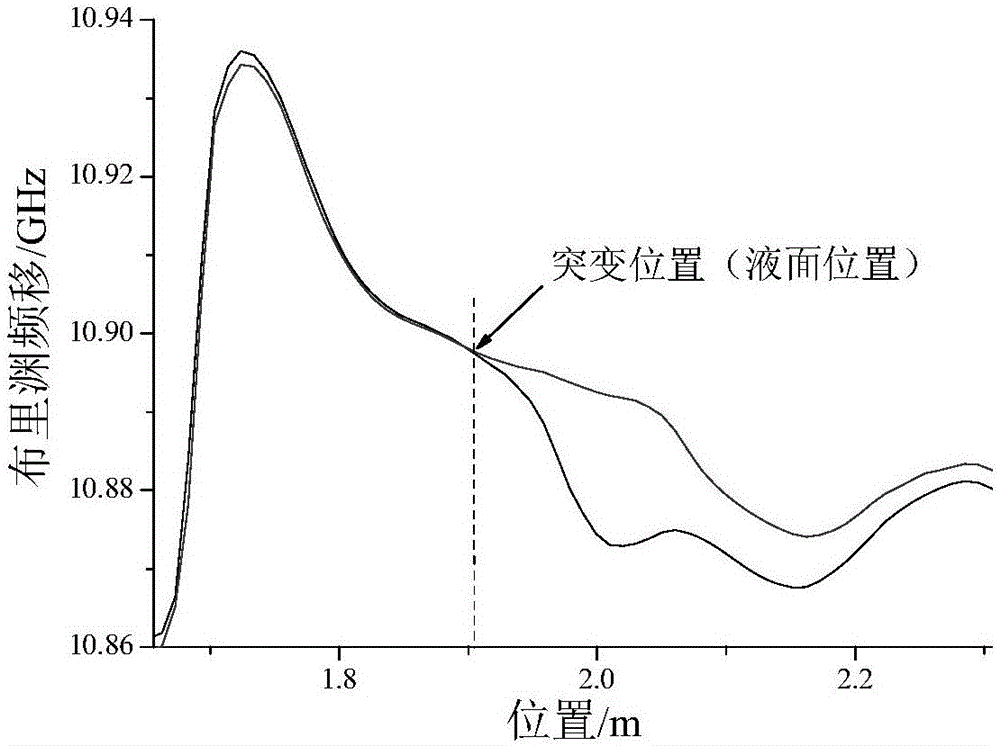

Optical fiber liquid level measurement device and method

InactiveCN106404121AEasy to makeStable structureMachines/enginesLevel indicatorsGratingErbium doping

The invention relates to an optical fiber liquid level measurement device and an optical fiber liquid level measurement method and belongs to the technical field of optics. The invention aims at solving the problems that an existing optical liquid level sensor is complex in manufacturing process, low in measurement accuracy, small in measurement range and unstable in device structure. The optical fiber liquid level measurement device comprises a laser, an optical fiber coupler, a polarization controller, an electrooptical modulator, an erbium-doped optical fiber amplifier, a microwave source, an arbitrary-function generator, a circulator, an optical fiber Bragg grating, an optical isolator, a sensing optical fiber, a self-heating type optical fiber, a photoelectric detector, a data acquisition card and a power meter. The optical fiber liquid level measurement method comprises the following steps: combining a Brillouin optical-time domain analysis technology with the self-heating type optical fiber, wherein the self-heating type optical fiber converts optical energy into heat energy and is pasted with the sensing optical fiber together to realize thermal transmission; and immersing a sensing part into liquid, judging the position where the liquid level is located by virtue of a temperature abrupt change point, thereby realizing centimeter magnitude resolution, meanwhile, measurement range is tens of centimeters, so that high-resolution and high-accuracy liquid level measurement is realized.

Owner:HARBIN UNIV OF SCI & TECH

Correction method for multi-point measurement of steam drum liquid level of high pressure boiler

InactiveCN102116660ASolve problems that are difficult to be accurate and consistentEliminate systematic errorsMachines/enginesLevel indicatorsThermal stateDifferential pressure

The invention discloses a correction method for multi-point measurement of a steam drum liquid level of a high pressure boiler. The method comprises the following steps of: calculating a range and migration of a differential pressure transmitter according to height between a liquid level measurement device and two connecting ports of a steam drum, height from the liquid level measurement device and the lower connecting port of the steam drum to the differential pressure transmitter, saturated water density and saturated steam density in the steam drum and condensate density in the liquid level measurement device; inputting the range and the migration to the differential pressure transmitter to serve as an original zero point and an original range; actually measuring a thermal-state zero value PA and a thermal-state range value PR of the differential pressure transmitter; calculating effective measuring ranges in PA and PR; establishing polygonal function relation; corresponding an effective thermal-state zero value Pr and an effective thermal-state range value Pr to a zero value La and a range value Lr of liquid level indication respectively; displaying according to linear relation; and performing temperature and pressure compensation calculation on La, Lr, steam drum temperature Tsteam and steam drum pressure Psteam to acquire a corrected value of the steam drum liquid level Ldelta so as to play a role in three-impulse adjustment and interlocking control of the steam drum liquid level.

Owner:TIANJI COAL CHEM IND GROUP

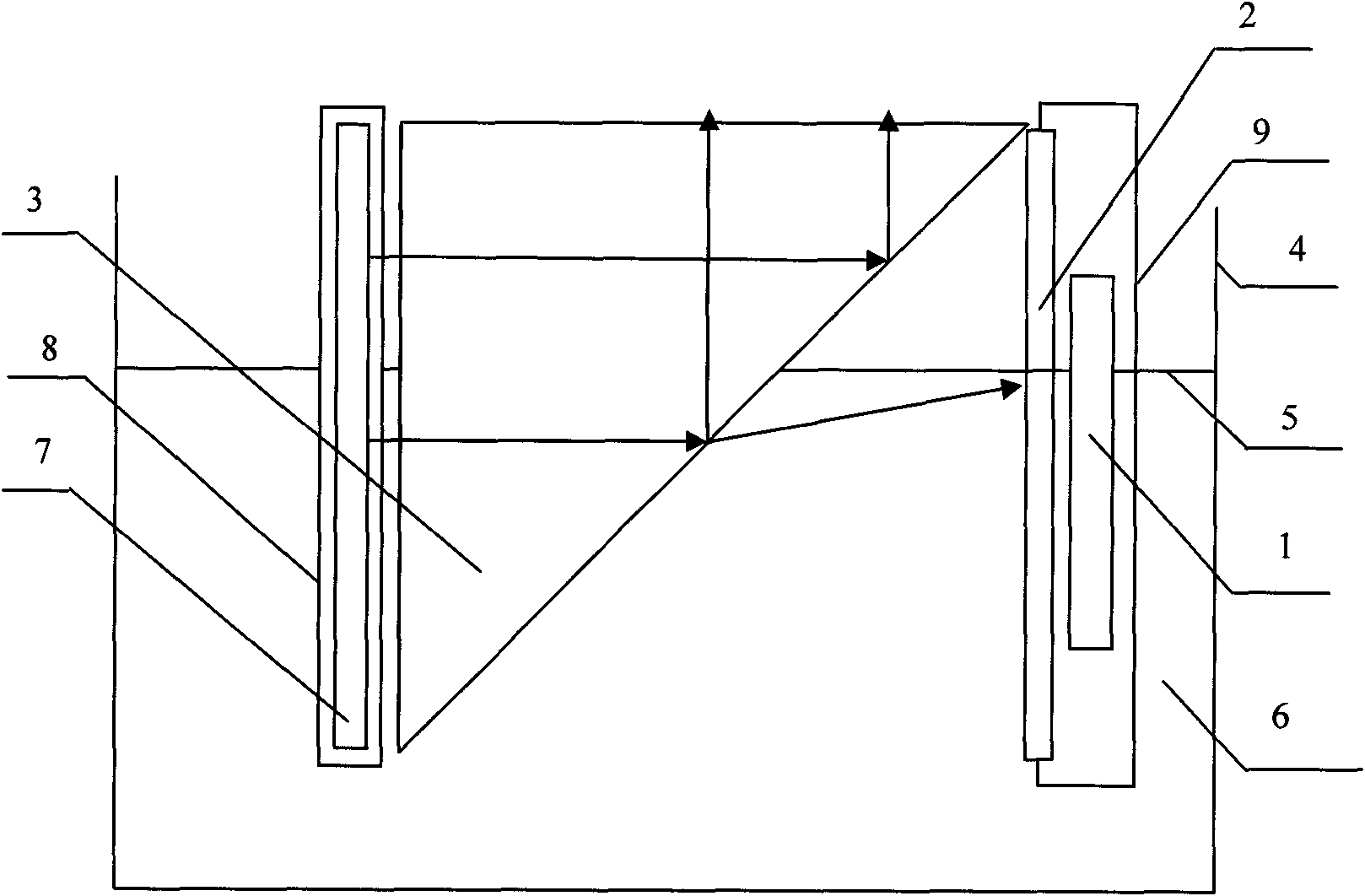

Liquid level measuring method and device based on isosceles right triangular prism

InactiveCN101782419AAccuracy is less affected by changes in liquid concentrationSimple structureMachines/enginesLevel indicatorsMeasurement devicePrism

The invention discloses liquid level measuring method and device based on an isosceles right triangular prism. Liquid level measurement is realized by utilizing the principles of refraction, reflection, total reflection, and the like of a light beam in an isosceles right triangular prism and extracting the liquid level characteristic information in linear array CCD image data. The measuring device mainly comprises a line light source, the isosceles right triangular prism, a linear array CCD, a control circuit, and the like, wherein the isosceles right triangular prism is placed into a container; the parallel light emitted by the line light source is projected into the triangular prism perpendicular to the side surface that a right-angle side of a cross section of the triangular prism is located, and is intersected with the side surface that the inclined side is located. The method is an optical liquid level measuring method without an optical imaging lens and has the advantages of less influence on precision by change of liquid concentration, relatively simple structure, operation in corrosive hostile industrial environments, and the like.

Owner:HARBIN ENG UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com