Liquid level on-line control system and method for self-adapting and fuzzy logic PID crystallizer

A fuzzy logic and control system technology, applied in the direction of adaptive control, liquid level control, general control system, etc., can solve the problems of PID control overshoot, stabilization time, and control error that cannot meet the real-time control requirements of the system, so as to solve the liquid The effect of bit fluctuation problem, high precision of PID control and flexible applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

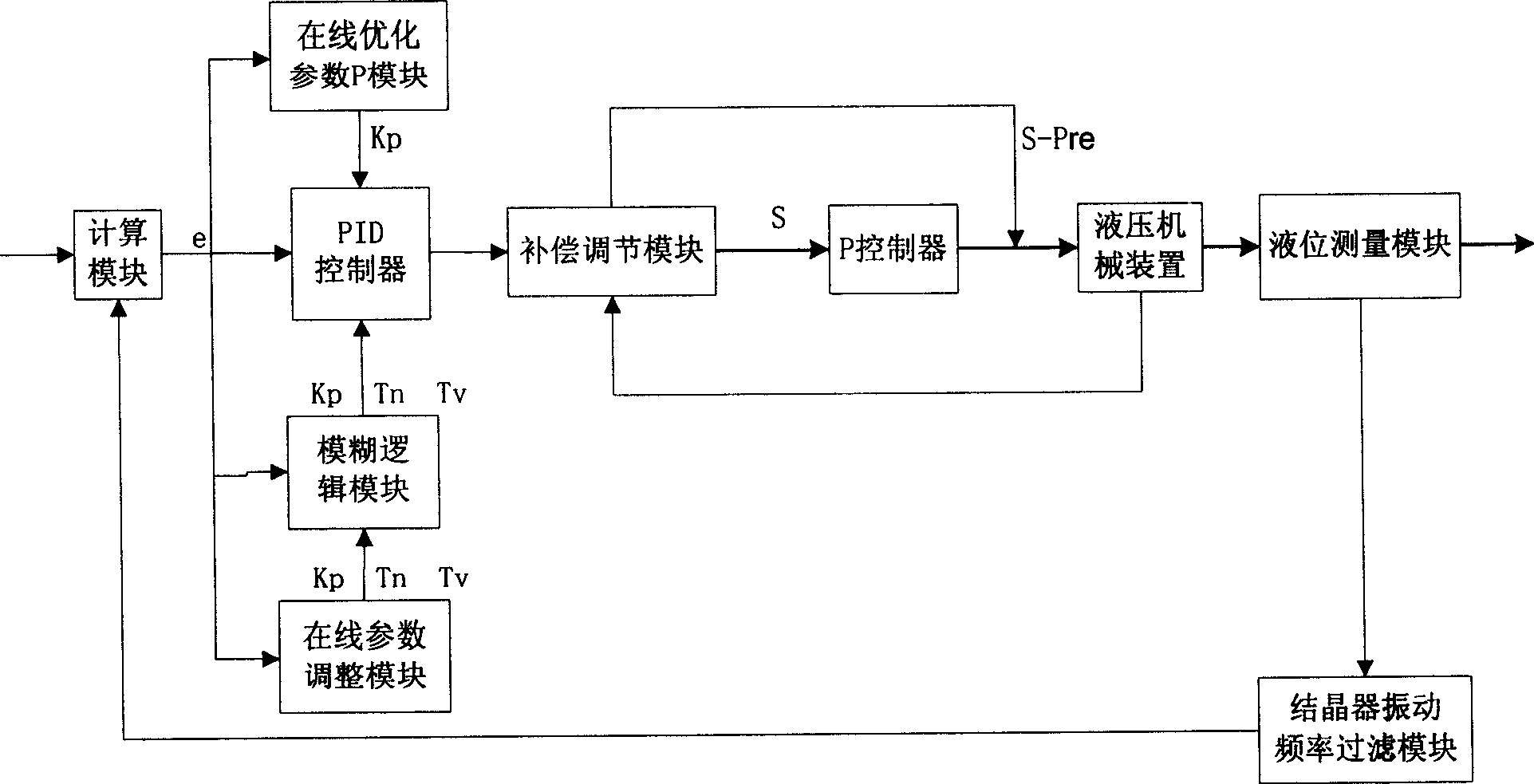

[0052] Such as figure 1 As shown, an adaptive and fuzzy logic PID crystallizer liquid level online control system, including:

[0053] The difference calculation module receives the input crystallizer liquid level set value and the actual value measured by the liquid level measurement module, and calculates the deviation e between the two values;

[0054] The online parameter adjustment module receives e according to different steel grades, different slab specifications, and different pouring parameters, such as pouring steel grades, pouring slab sections, crystallizer sizes, etc., and online adjusts the parameters that should be used by the PID controller Parameter K p (PID proportional coefficient), T n (PID integral coefficient) and T v (PID differential coefficient) and output;

[0055] The fuzzy logic module is connected with the online parameter adjustment module, receives e, judges nozzle wear, slagging and slagging off according to e, and receives input parameters ...

Embodiment 2

[0070] An adaptive and fuzzy logic PID crystallizer liquid level online control method, using the system described in Embodiment 1, includes the following steps:

[0071] Calculation step, receiving the input crystallizer liquid level setting value and the actual value measured by the liquid level measurement module, and calculating the deviation e of the two values;

[0072] Online parameter adjustment step, receiving e, online adjustment of the parameter K that should be used in the PID control step p , T n and T v and output;

[0073] The fuzzy logic step, receiving e, judging nozzle wear, slagging and slagging off according to e, receiving the pull speed adjustment input parameter, receiving the K inputted by the online parameter adjustment module p , T n and T v , the output adjusted K p , T n and T v ;

[0074] PID control step, receiving e, the K outputted by the fuzzy logic step p , T n and T v , to perform PID control and output PID control signal;

[007...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com