Patents

Literature

1871results about "Molten metal conveying equipments" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

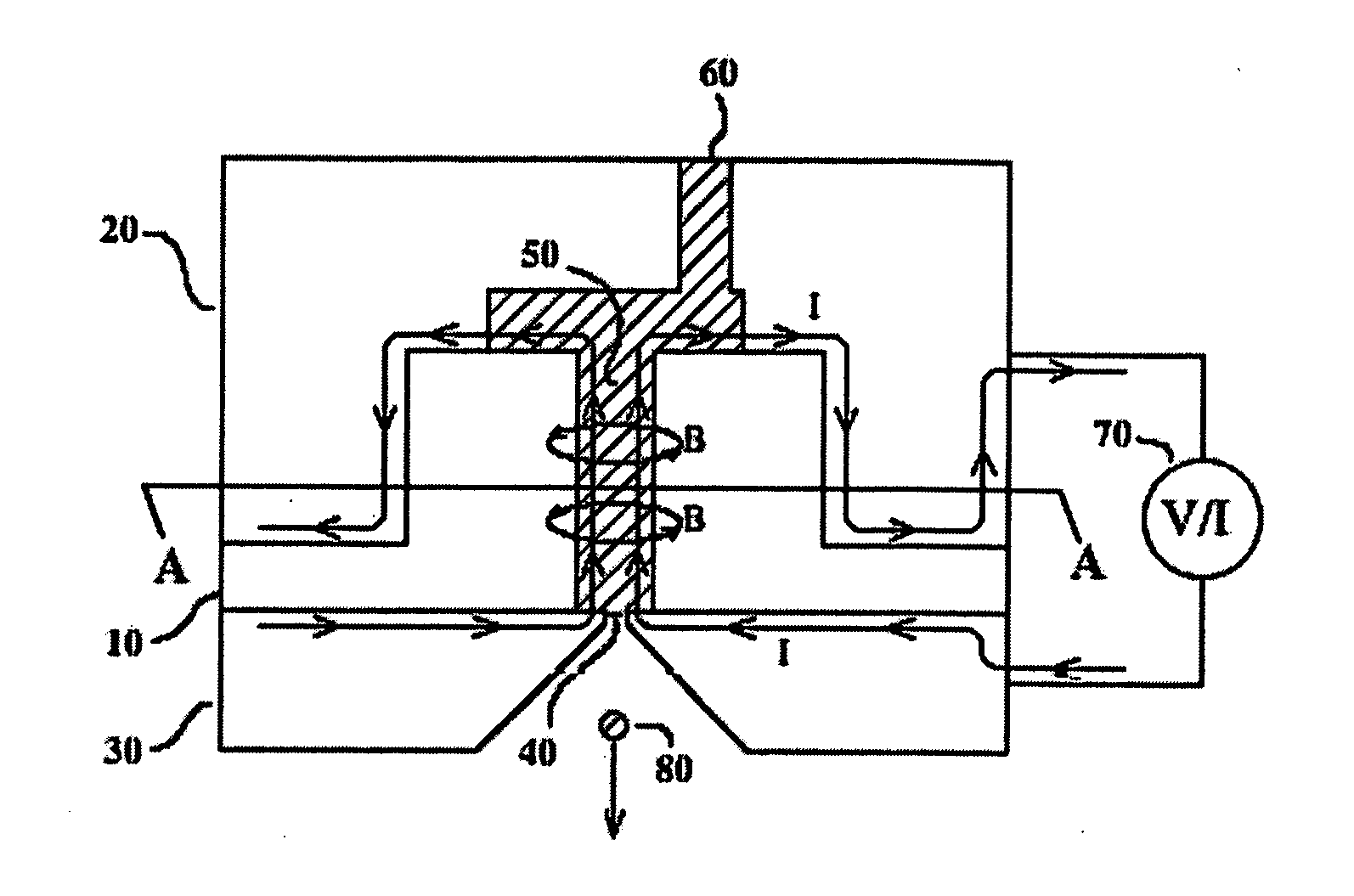

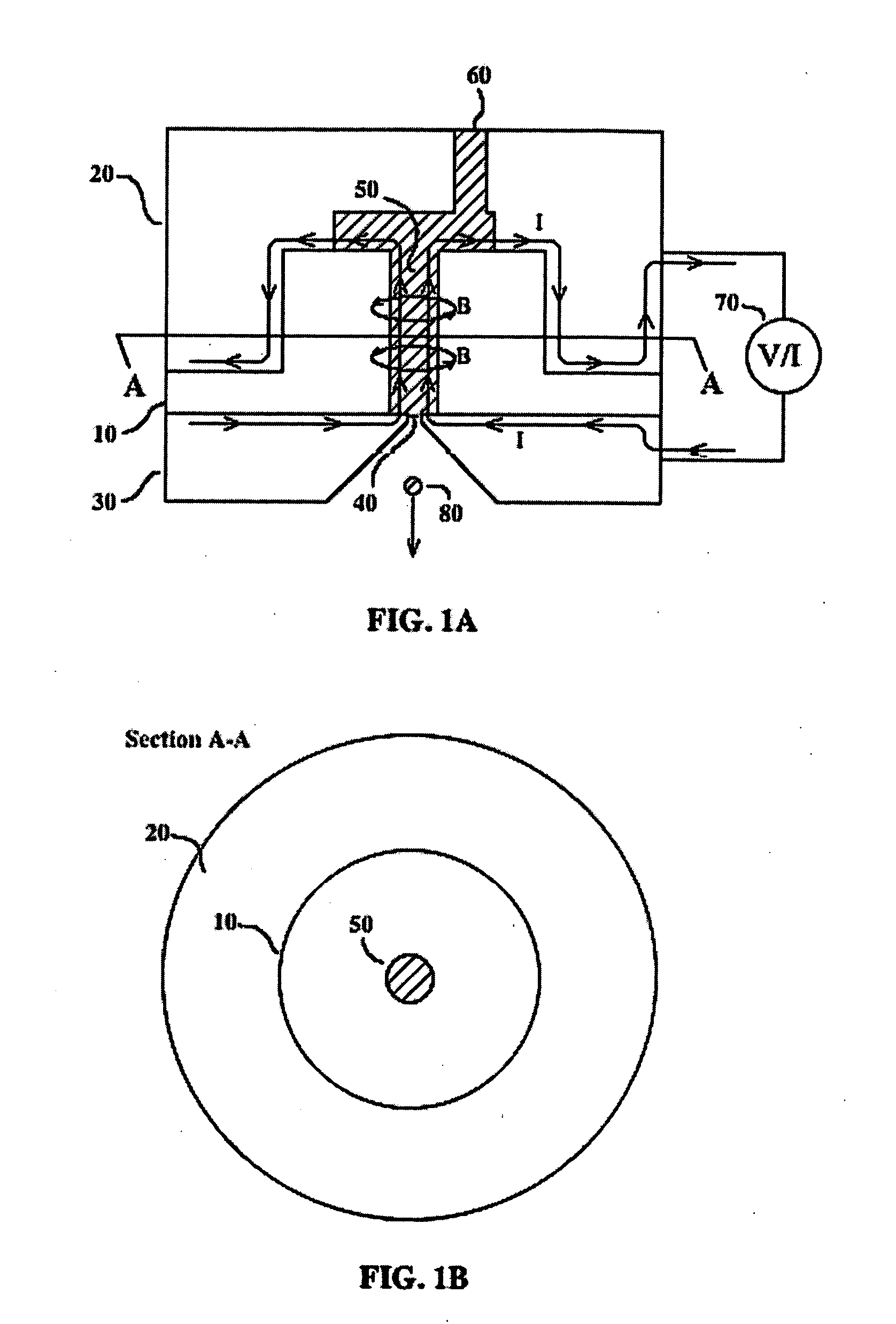

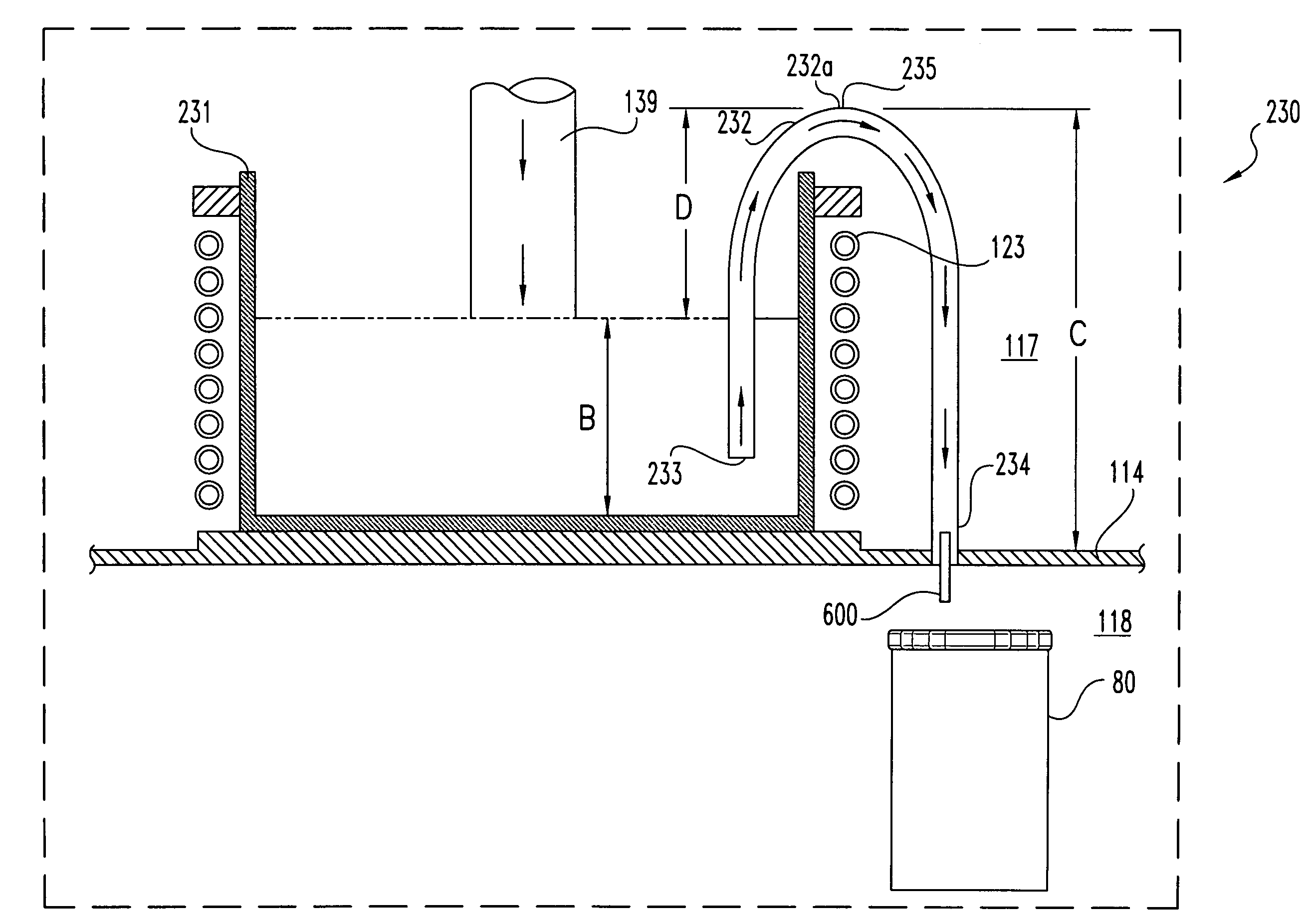

Transferring molten metal from one structure to another

ActiveUS20080314548A1Formation of dross in the ladle or launder are greatly reduced or eliminatedEliminate useMolten metal pouring equipmentsMolten metal supplying equipmentsDie castingMolten metal

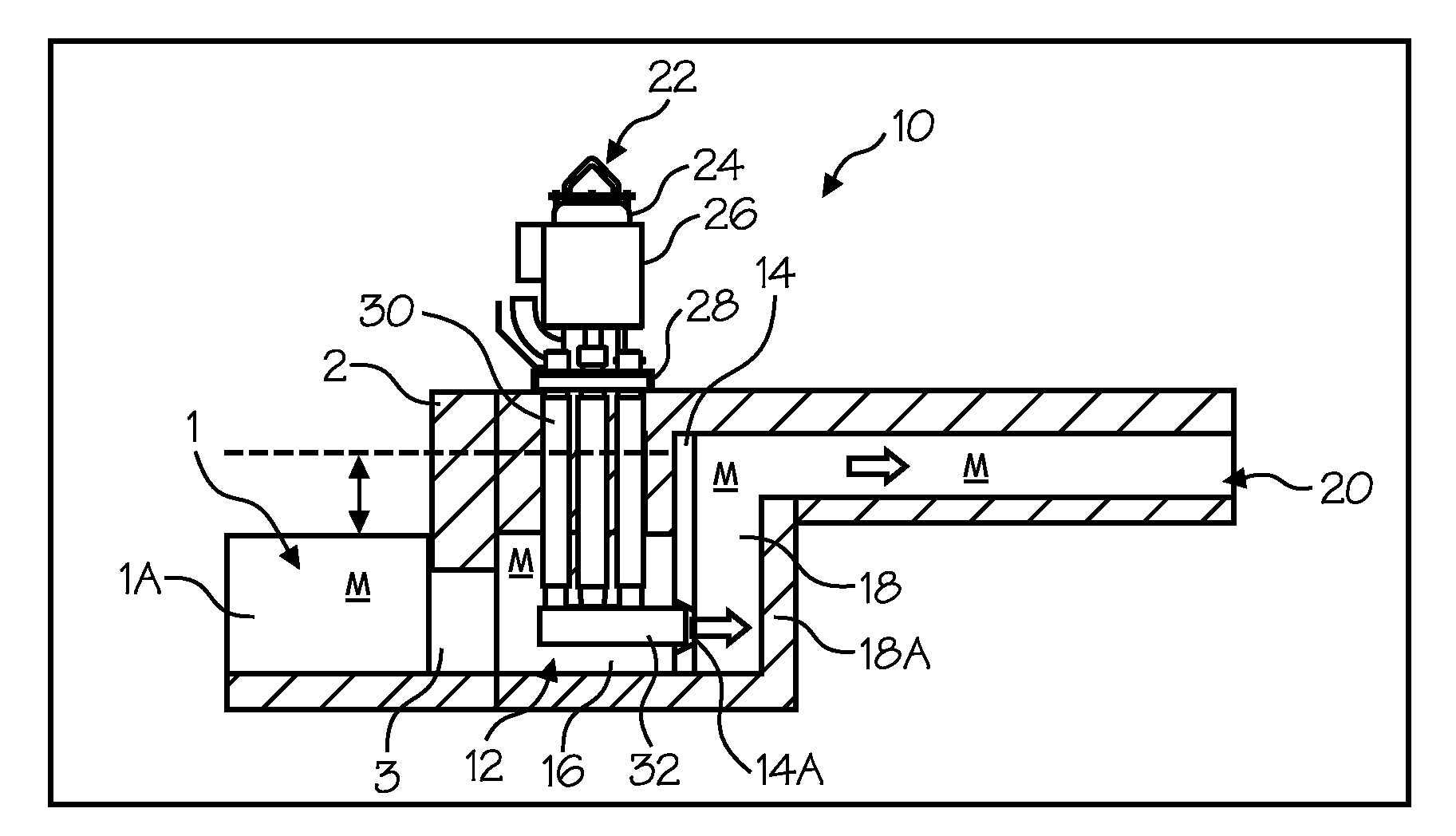

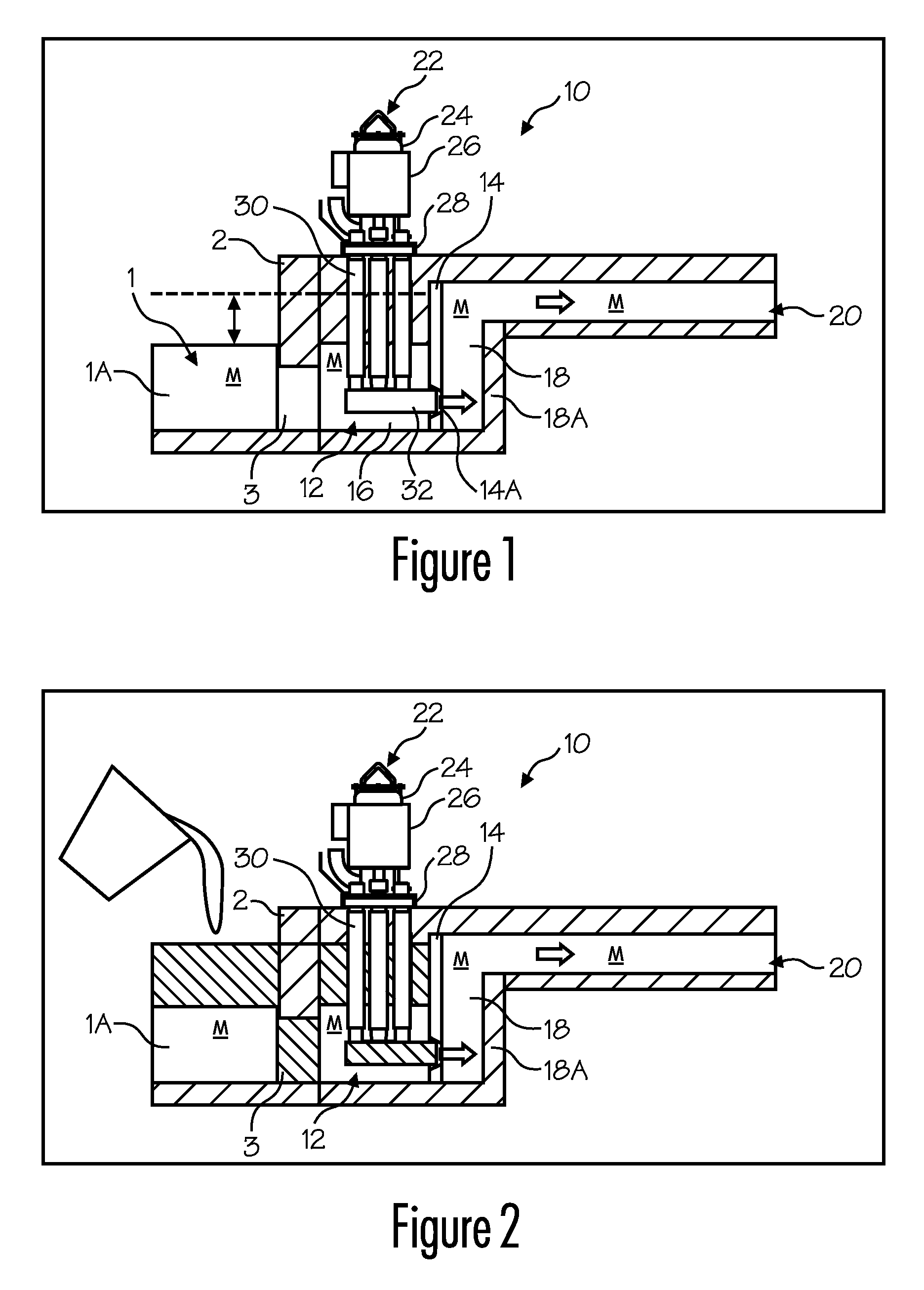

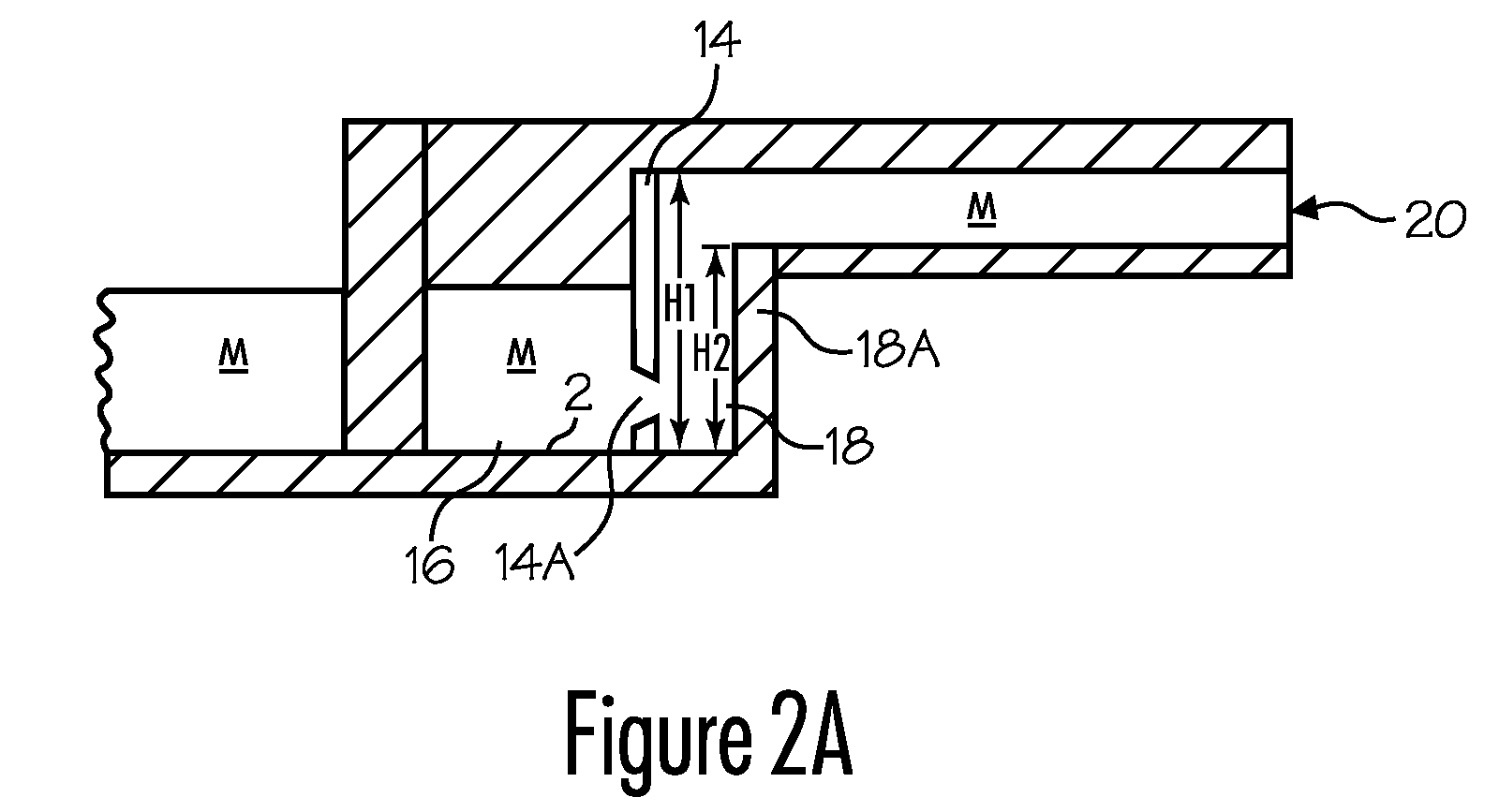

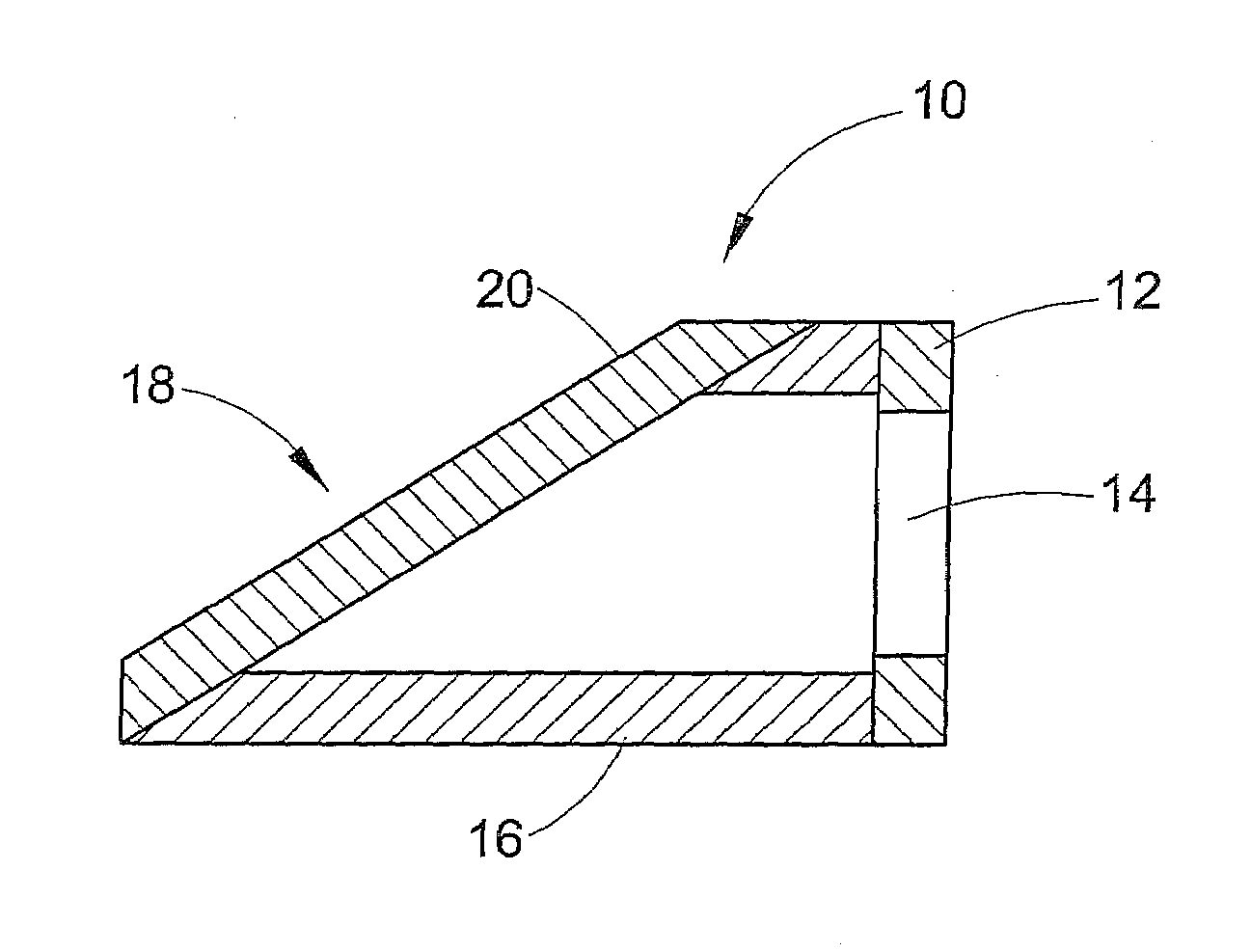

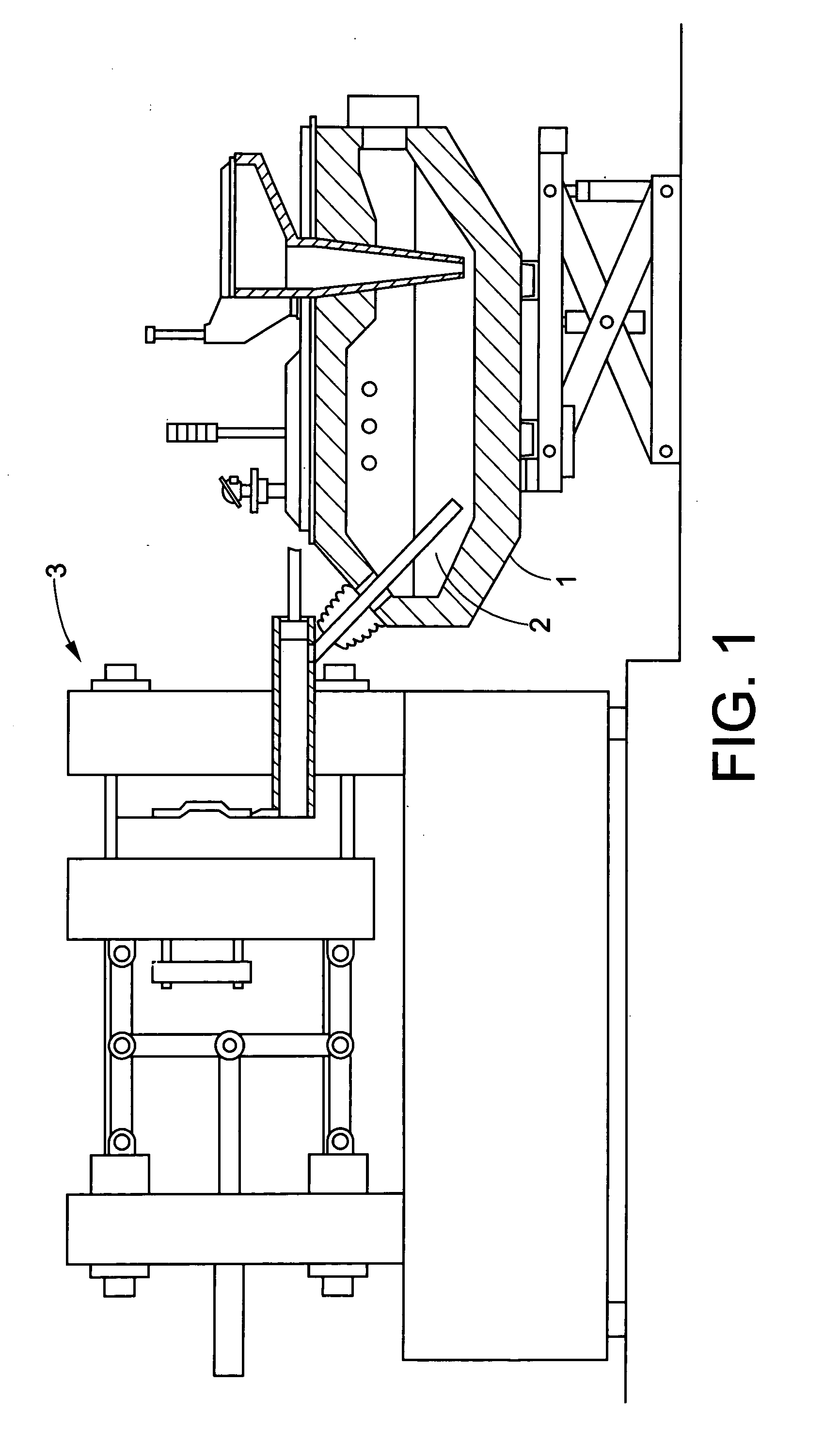

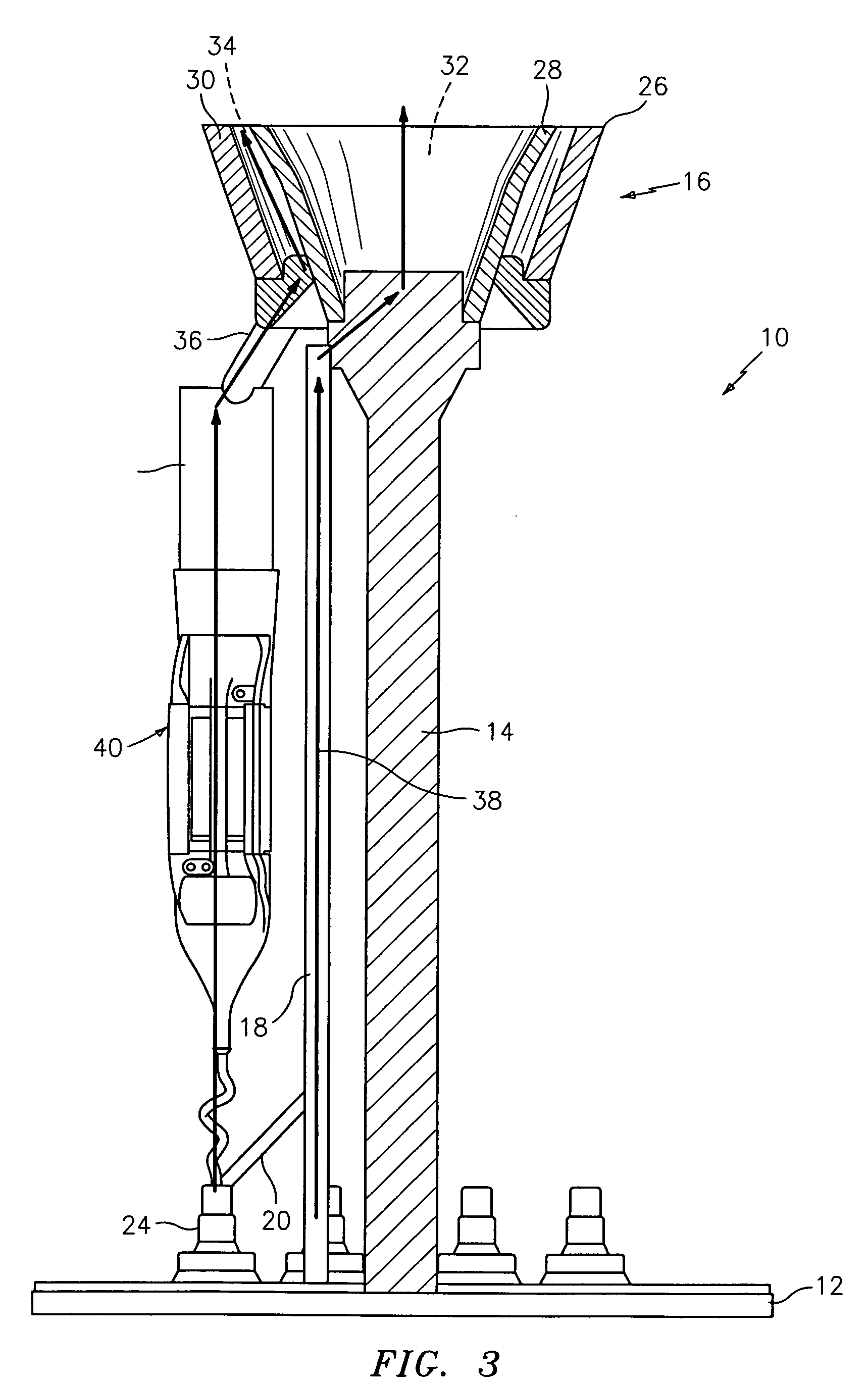

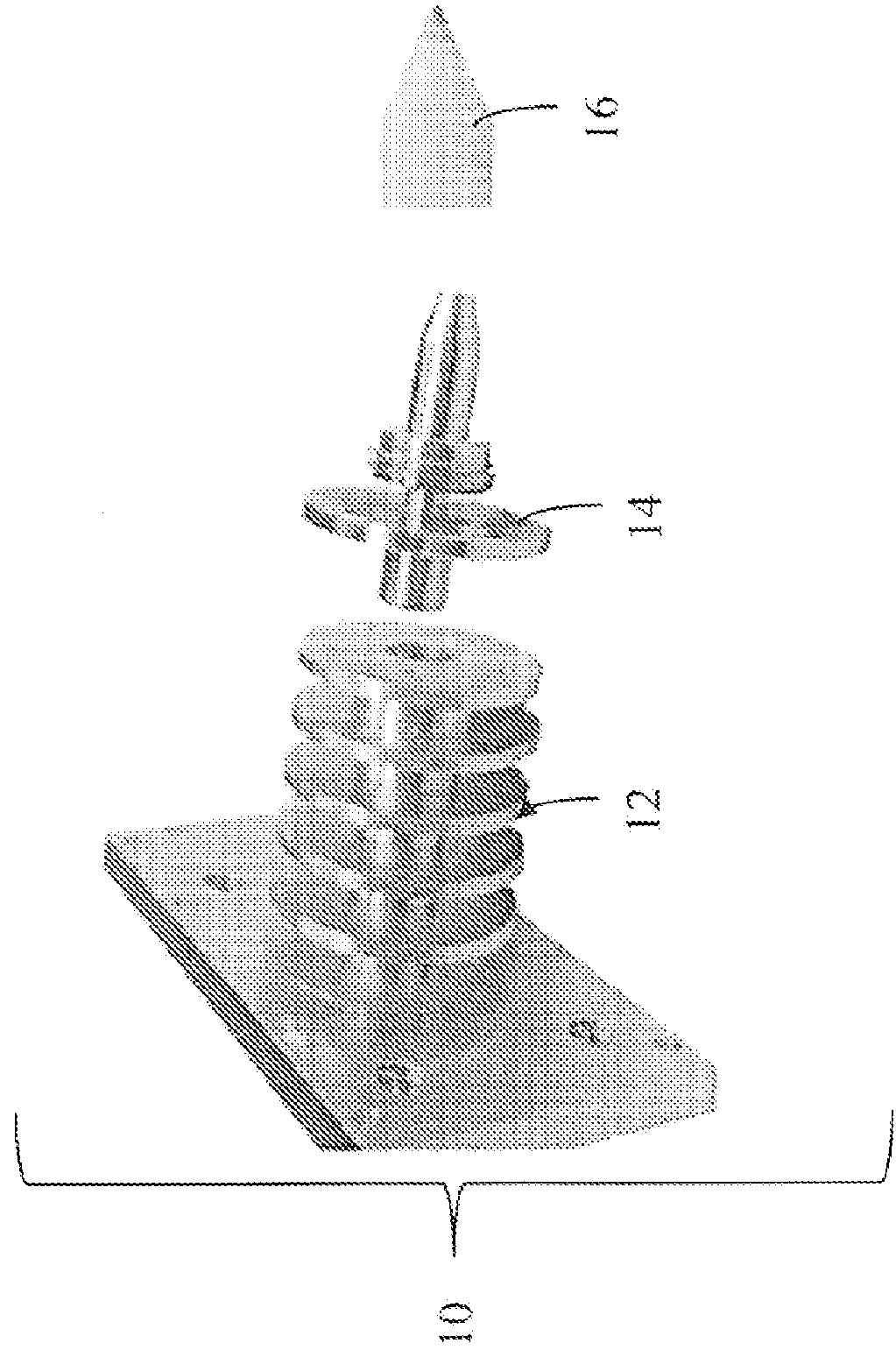

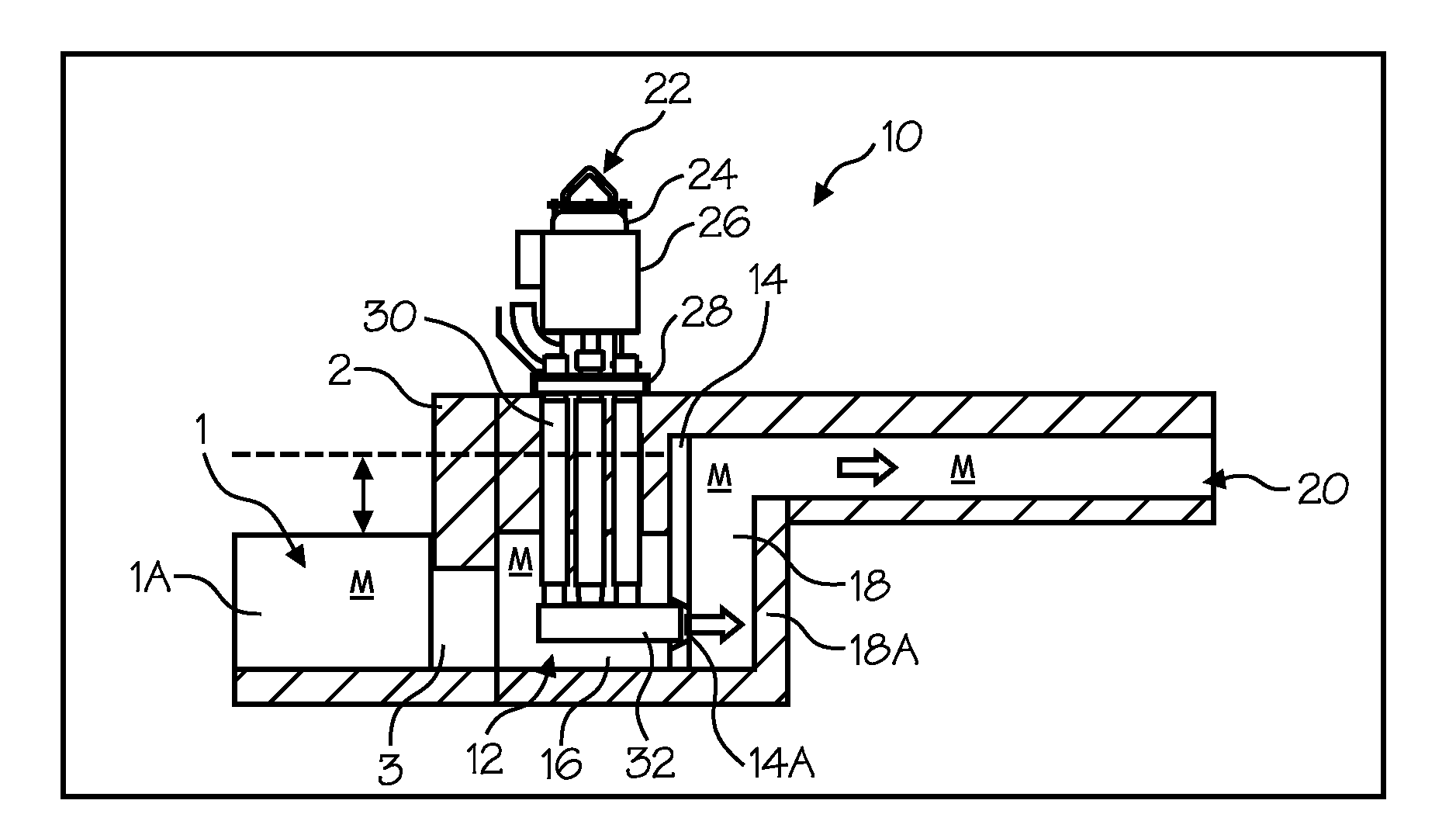

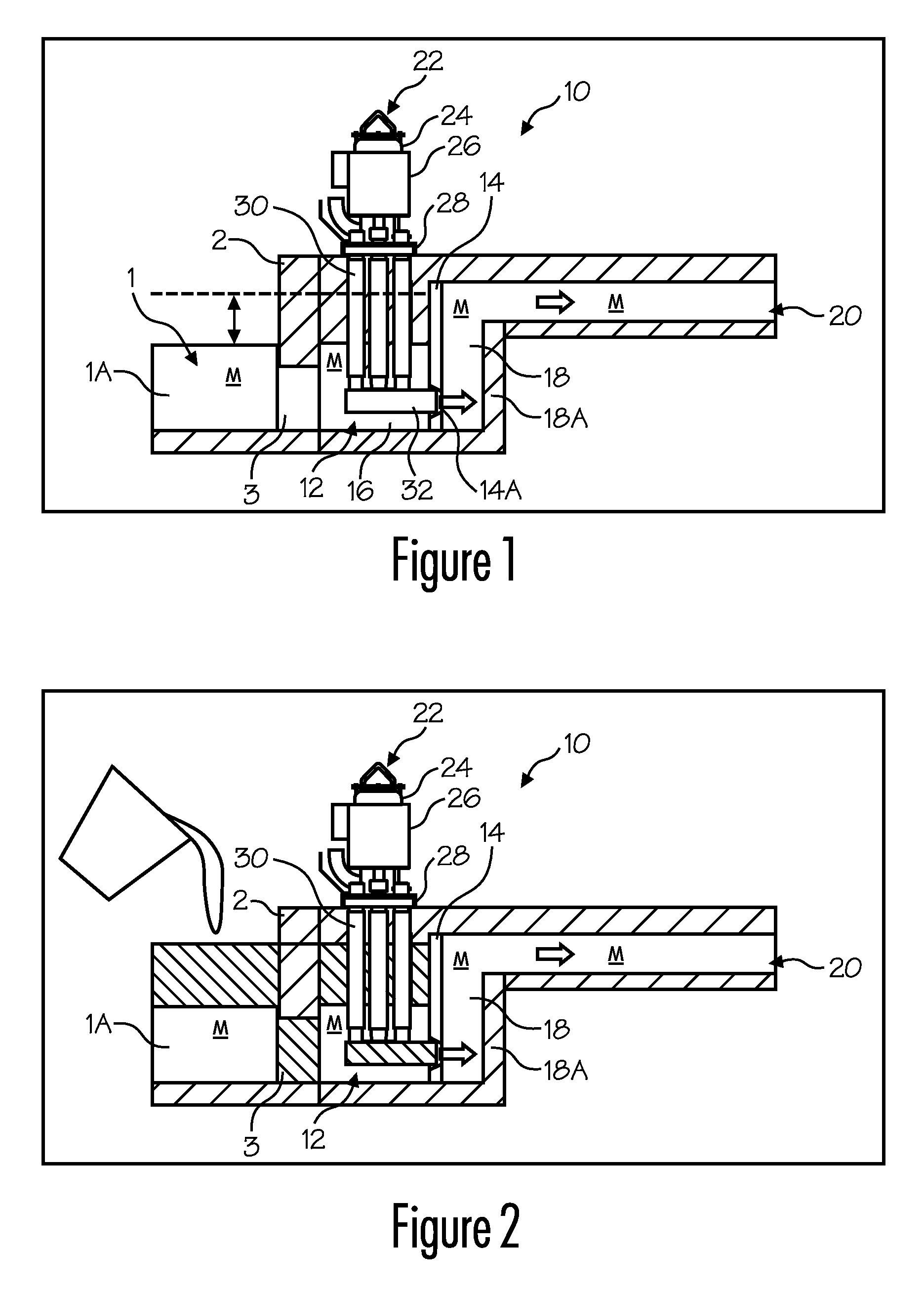

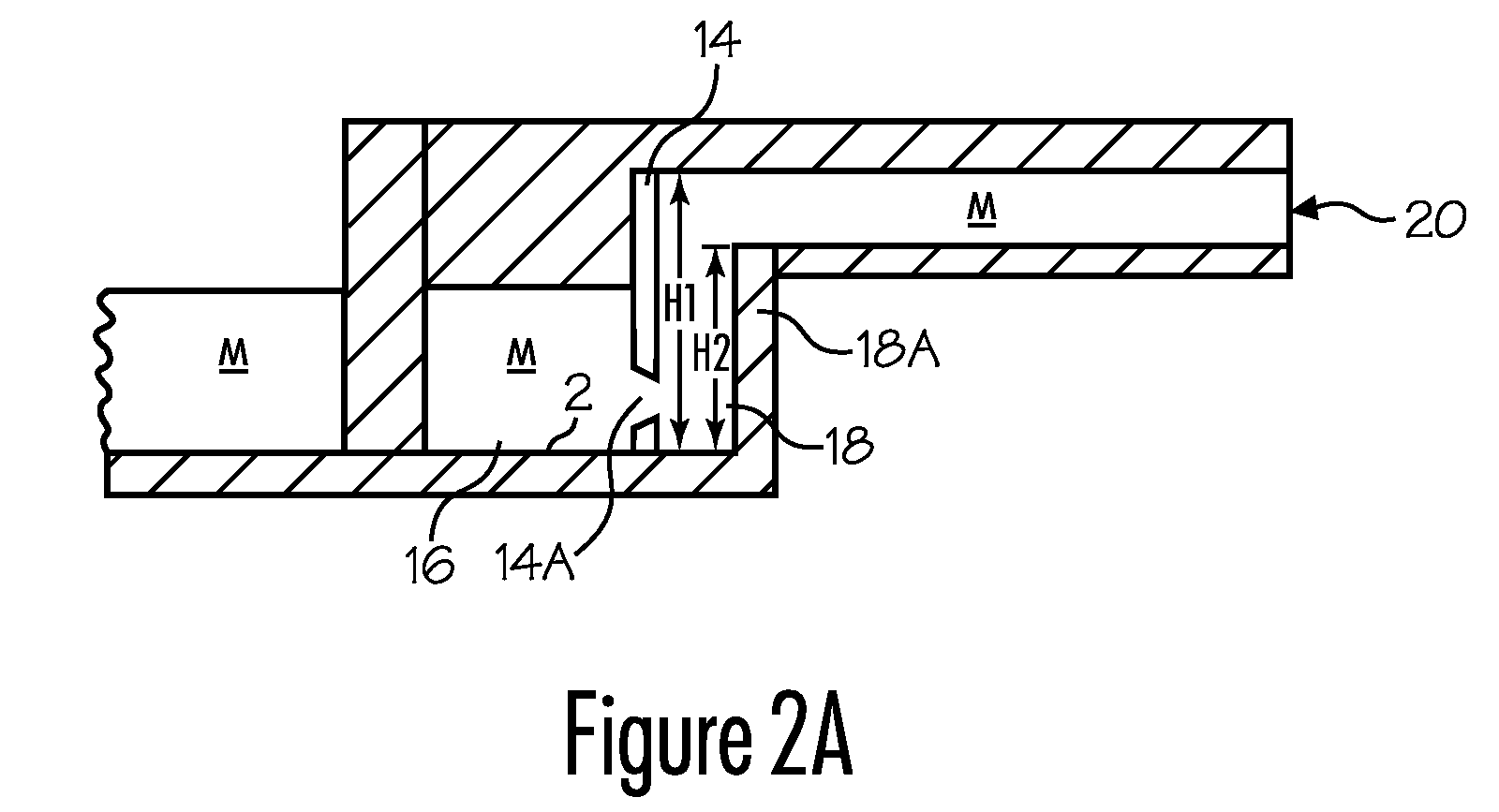

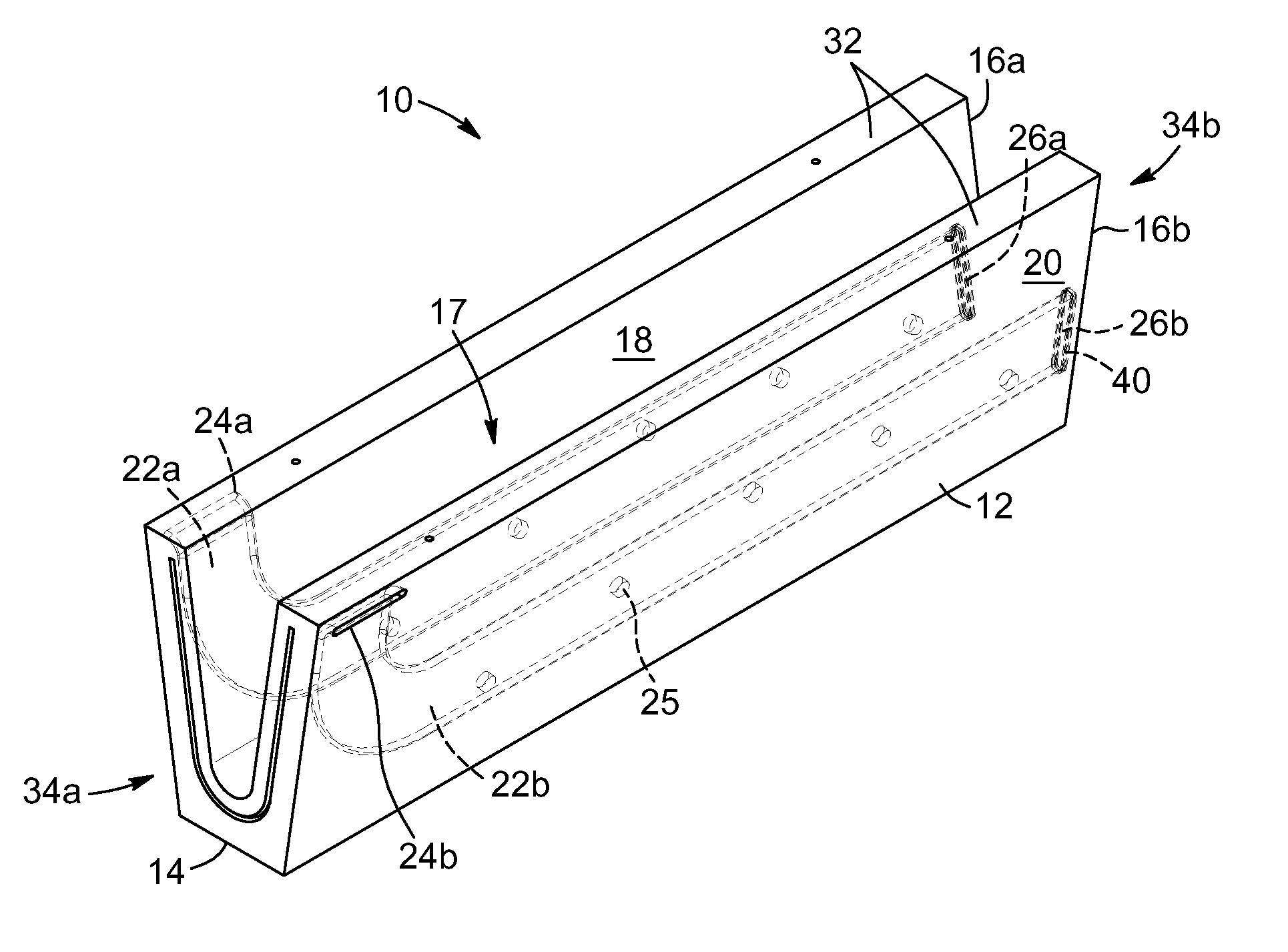

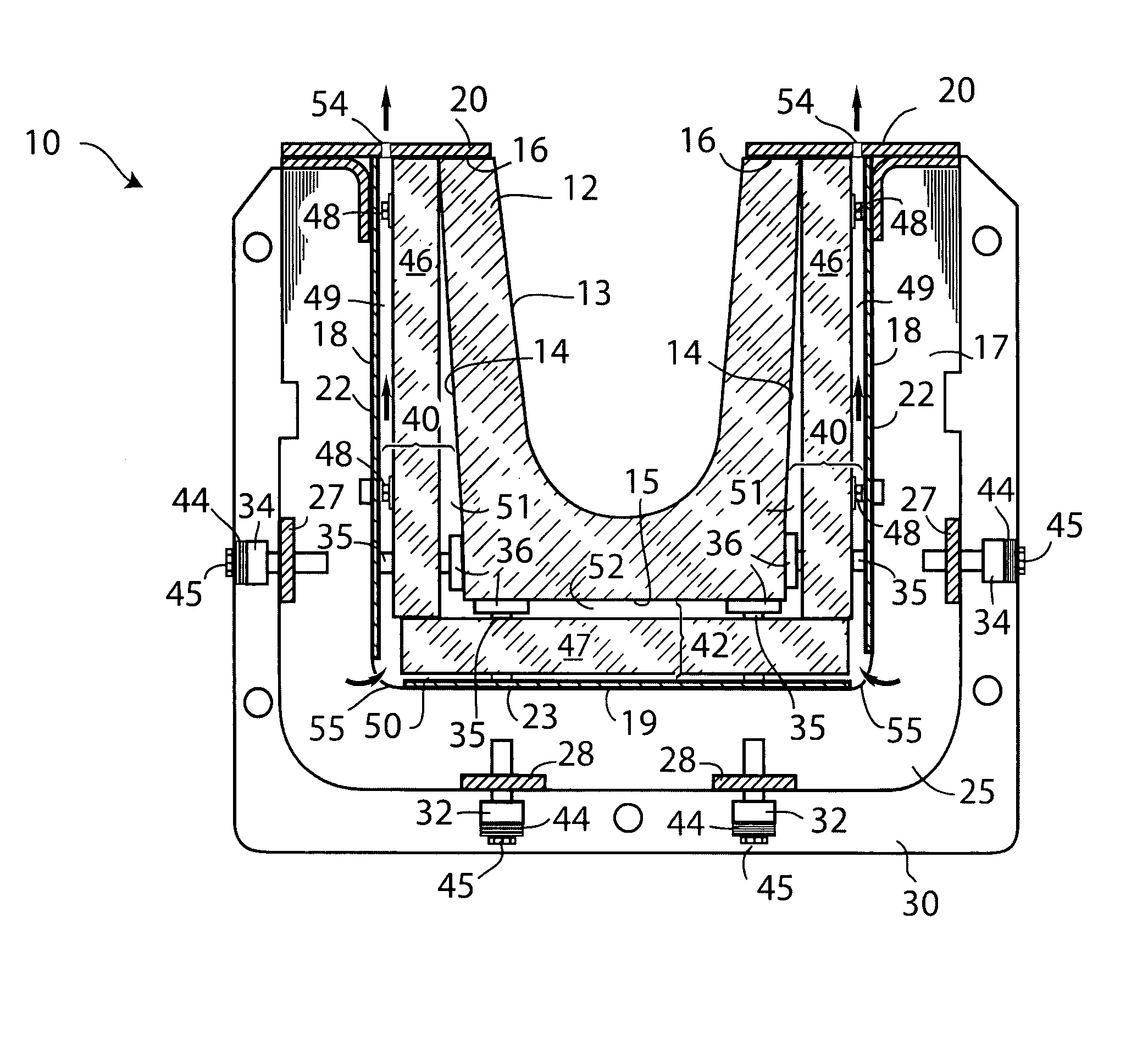

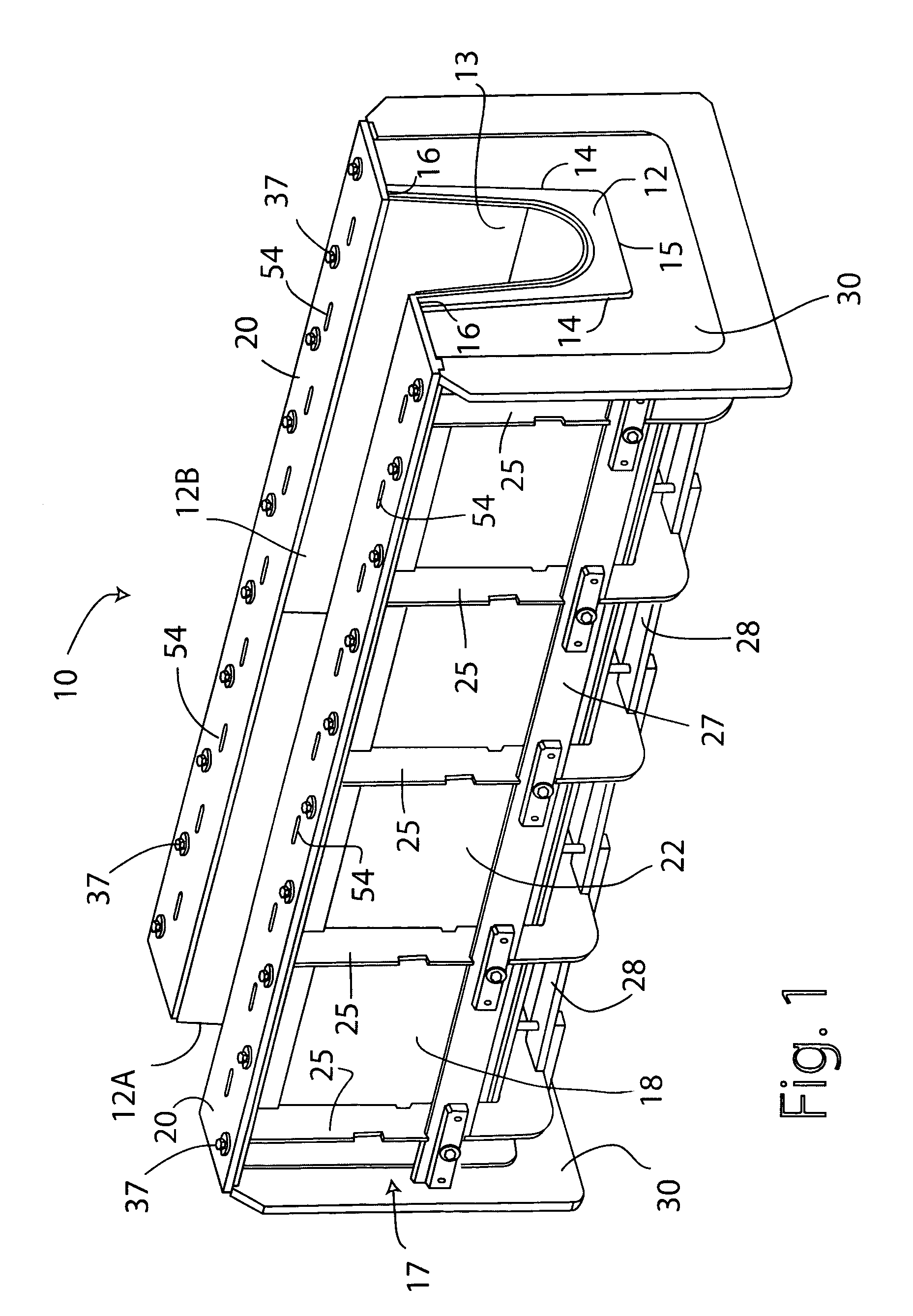

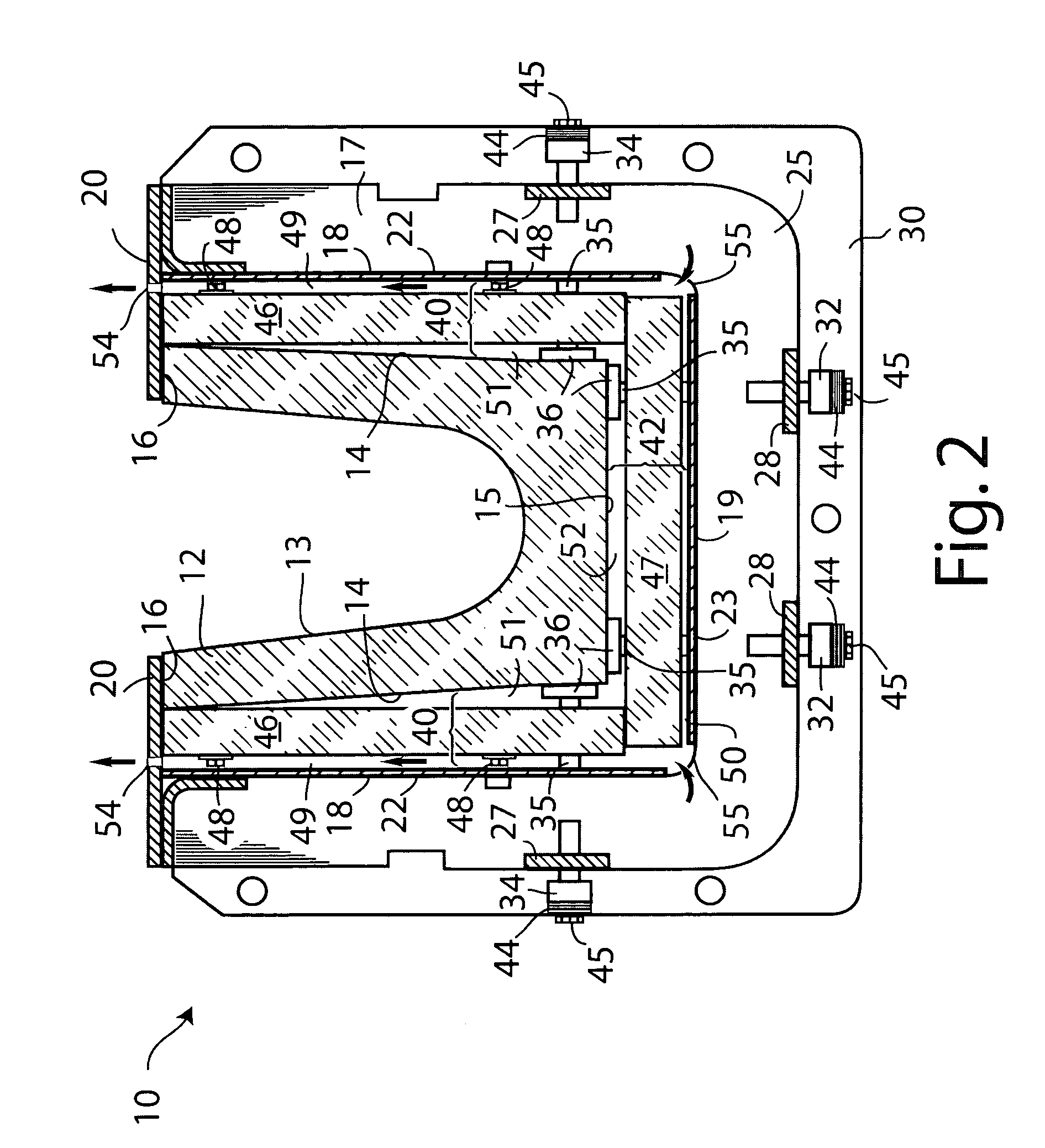

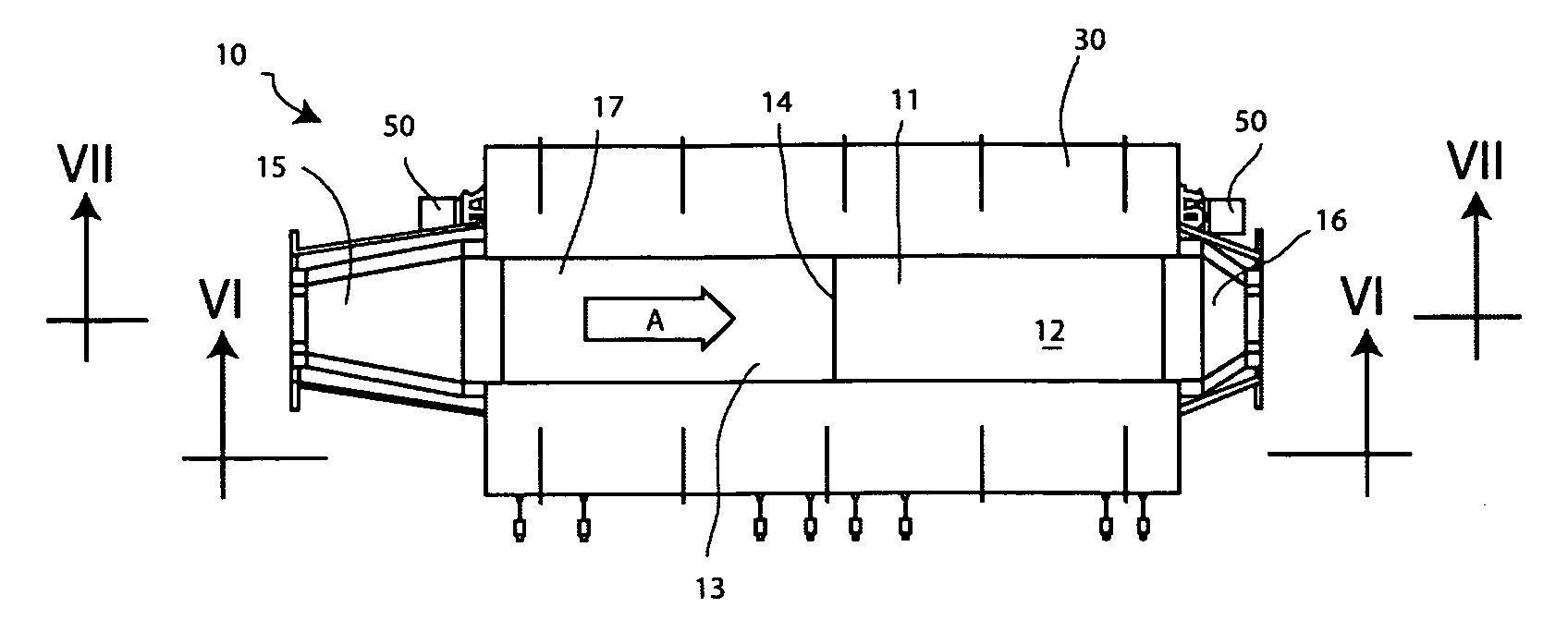

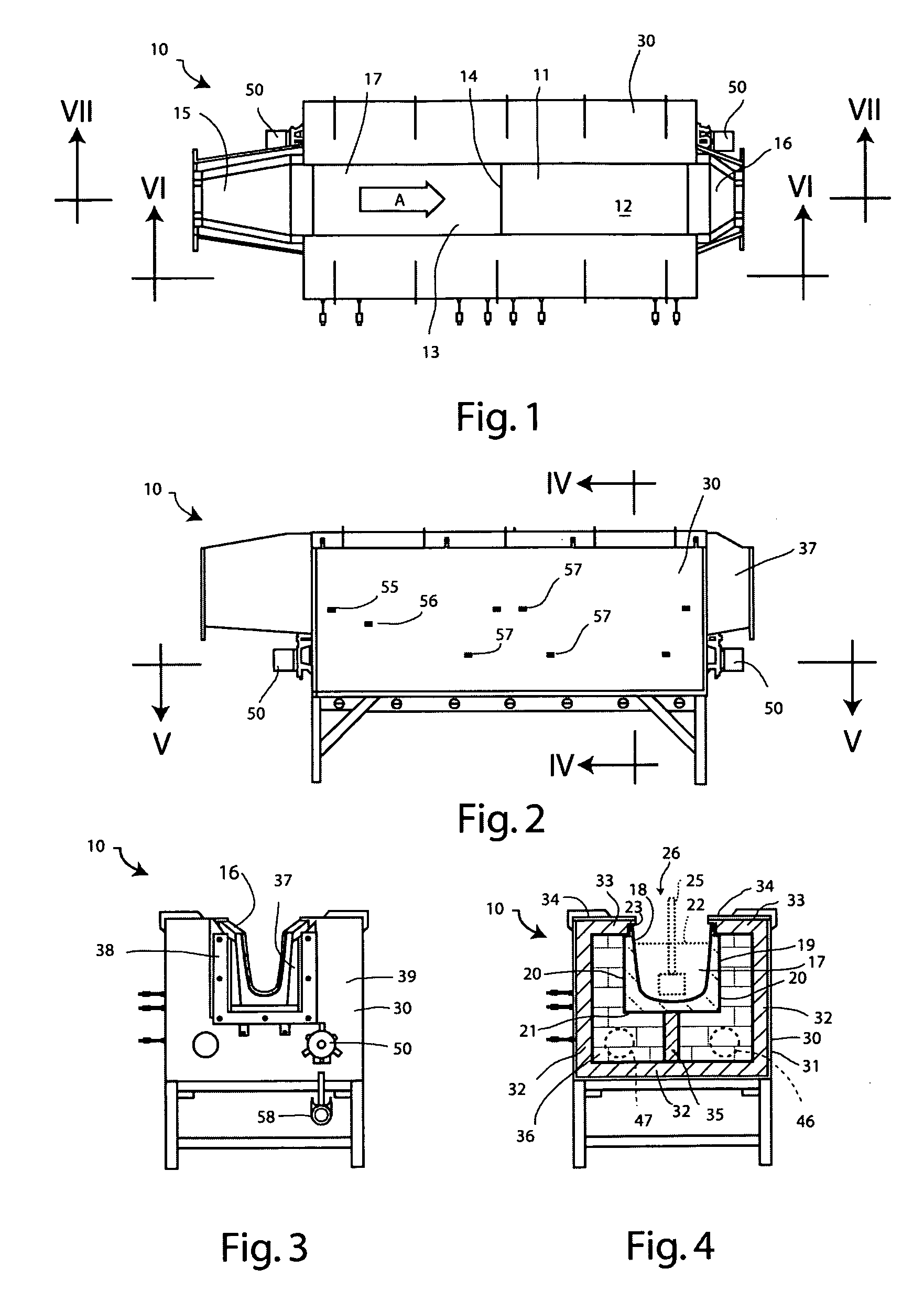

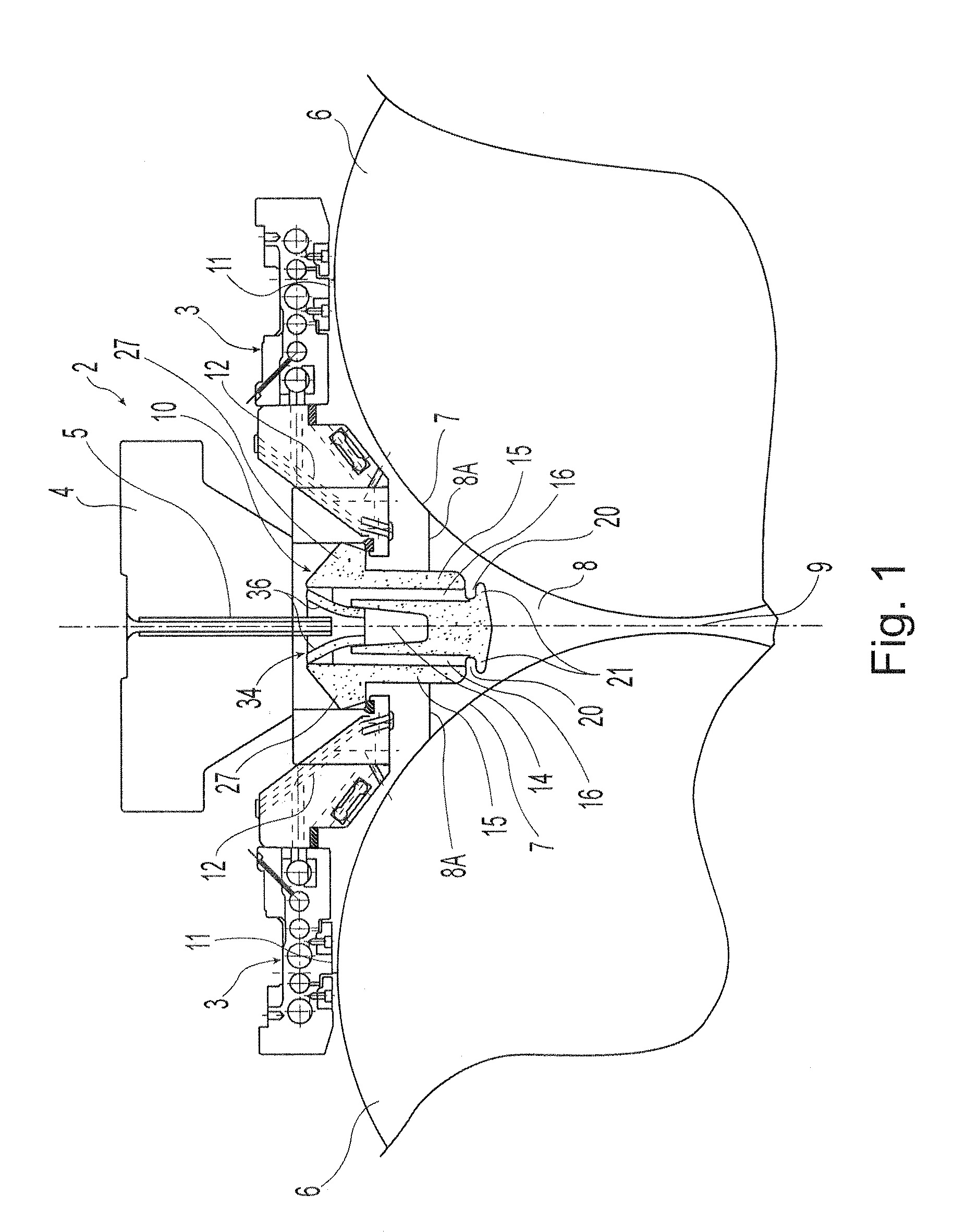

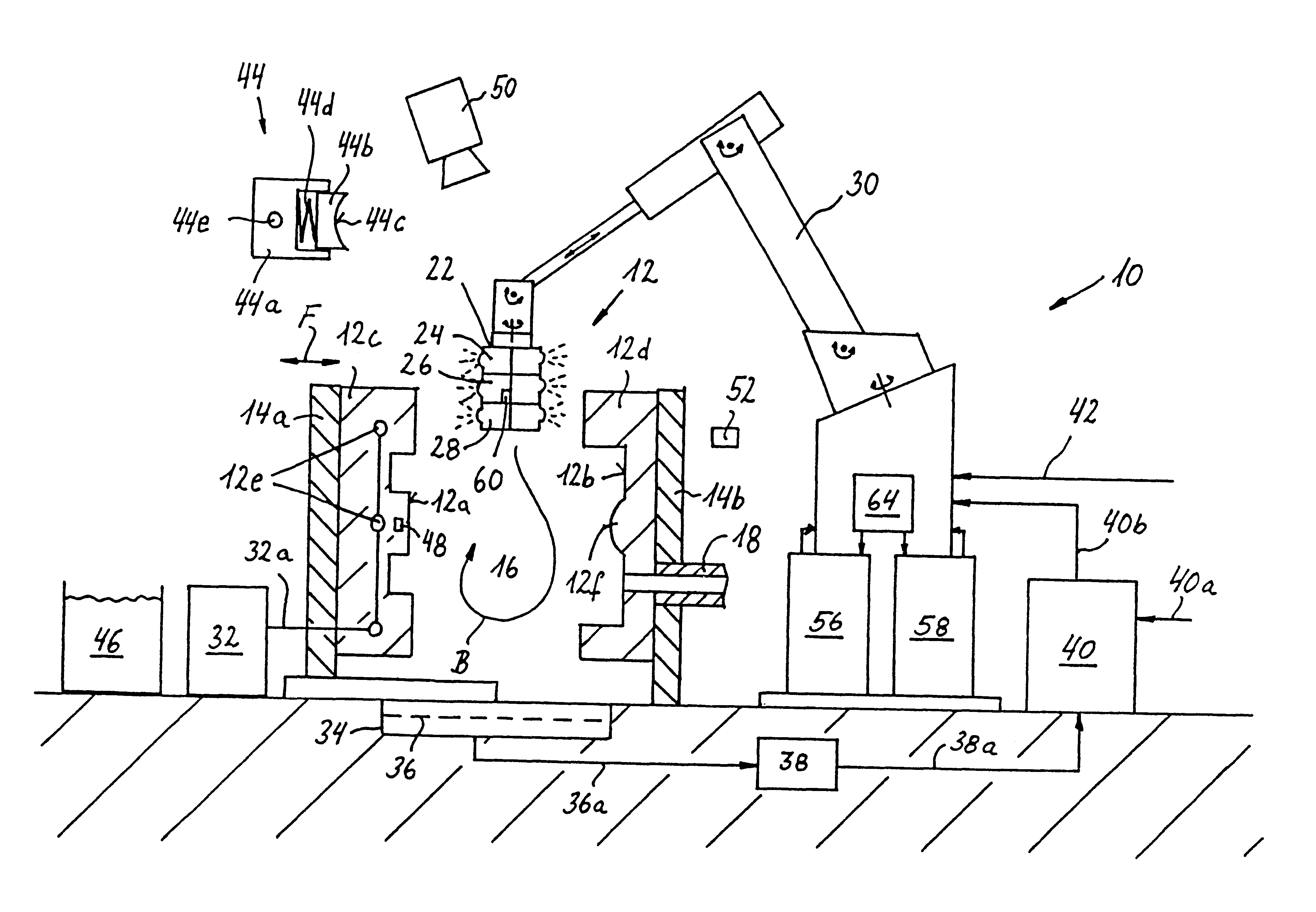

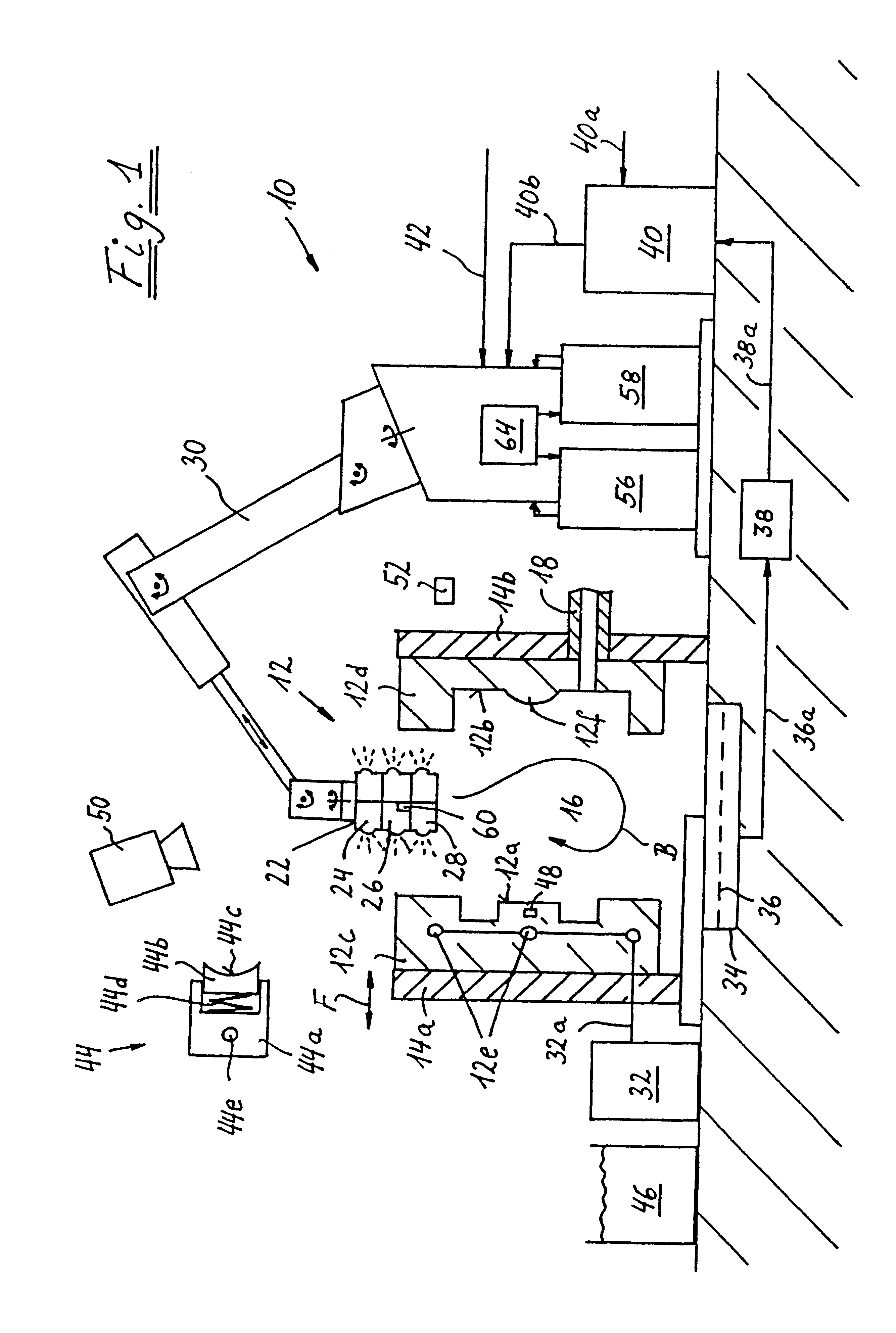

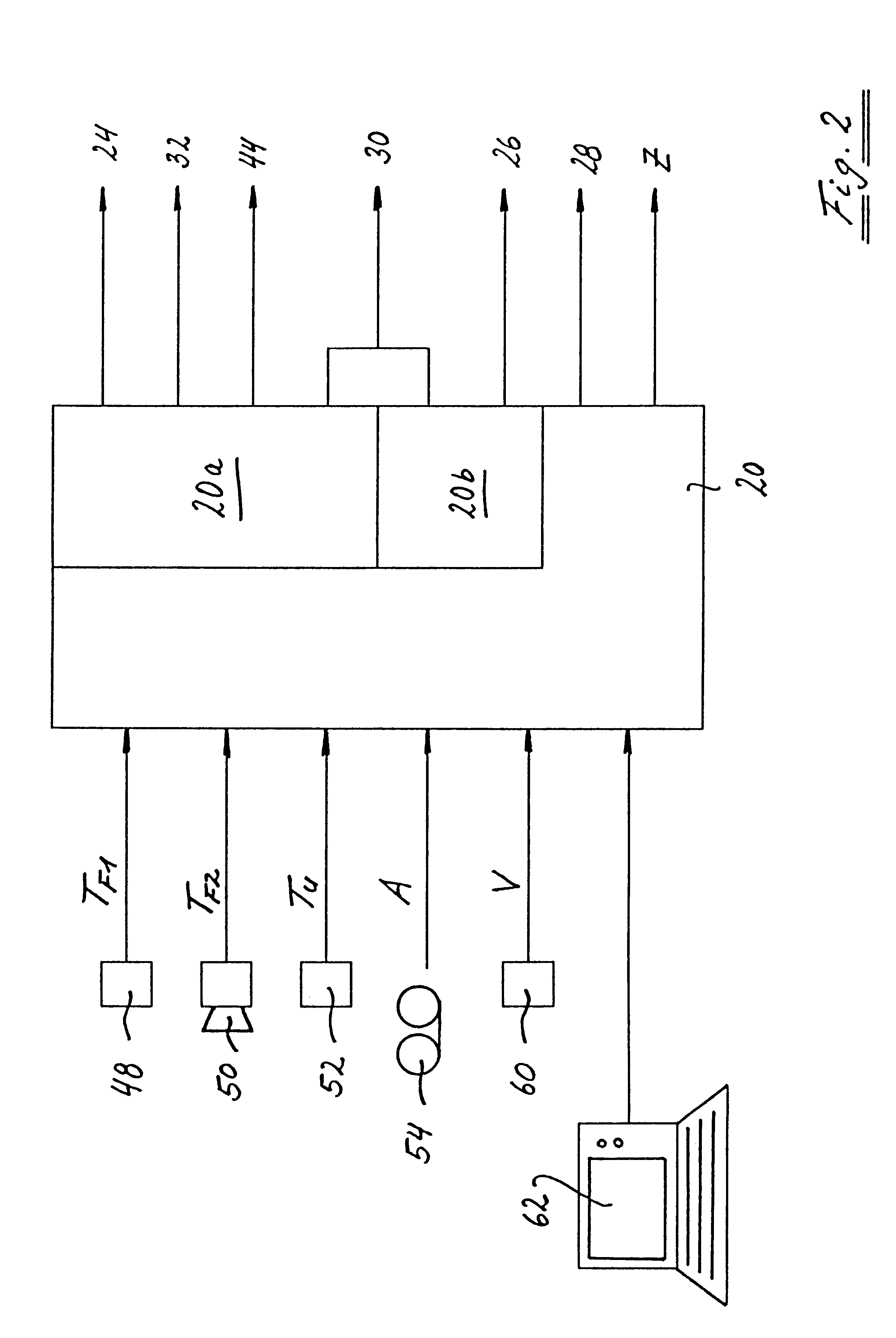

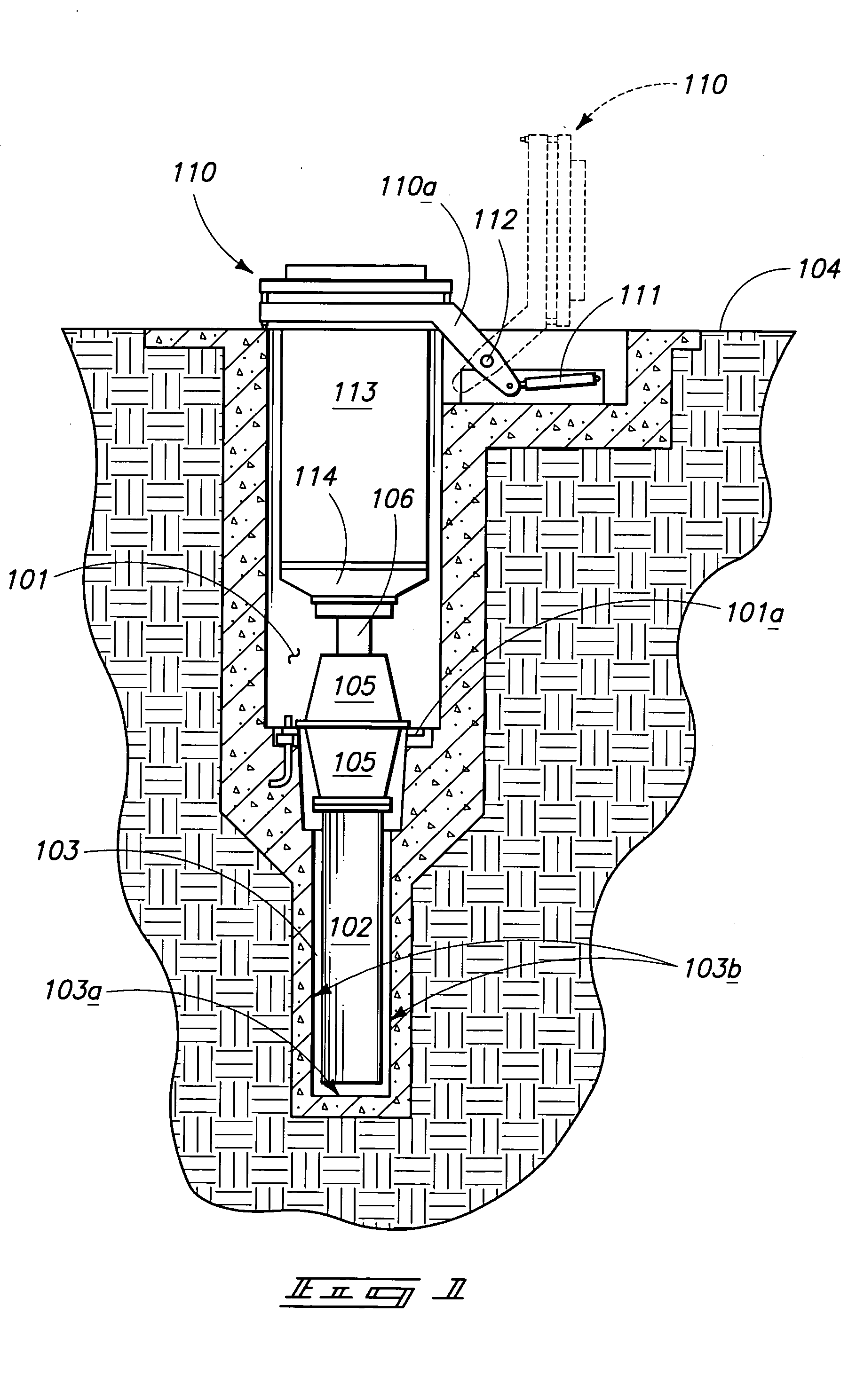

A system for transferring molten metal from a vessel and into one or more of a ladle, ingot mold, launder, feed die cast machine or other structure is disclosed. The system includes at least a vessel for containing molten metal, an overflow (or dividing) wall, and a device or structure, such as a molten metal pump, for generating a stream of molten metal. The dividing wall divides the vessel into a first chamber and a second chamber, wherein part of the second chamber has a height H2. The device for generating a stream of molten metal, which is preferably a molten metal pump, is preferably positioned in the first chamber. When the device operates, it generates a stream of molten metal from the first chamber and into the second chamber. When the level of molten metal in the second chamber exceeds H2, molten metal flows out of the vessel and into another structure, such as into one or more ladles and / or one or more launders.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

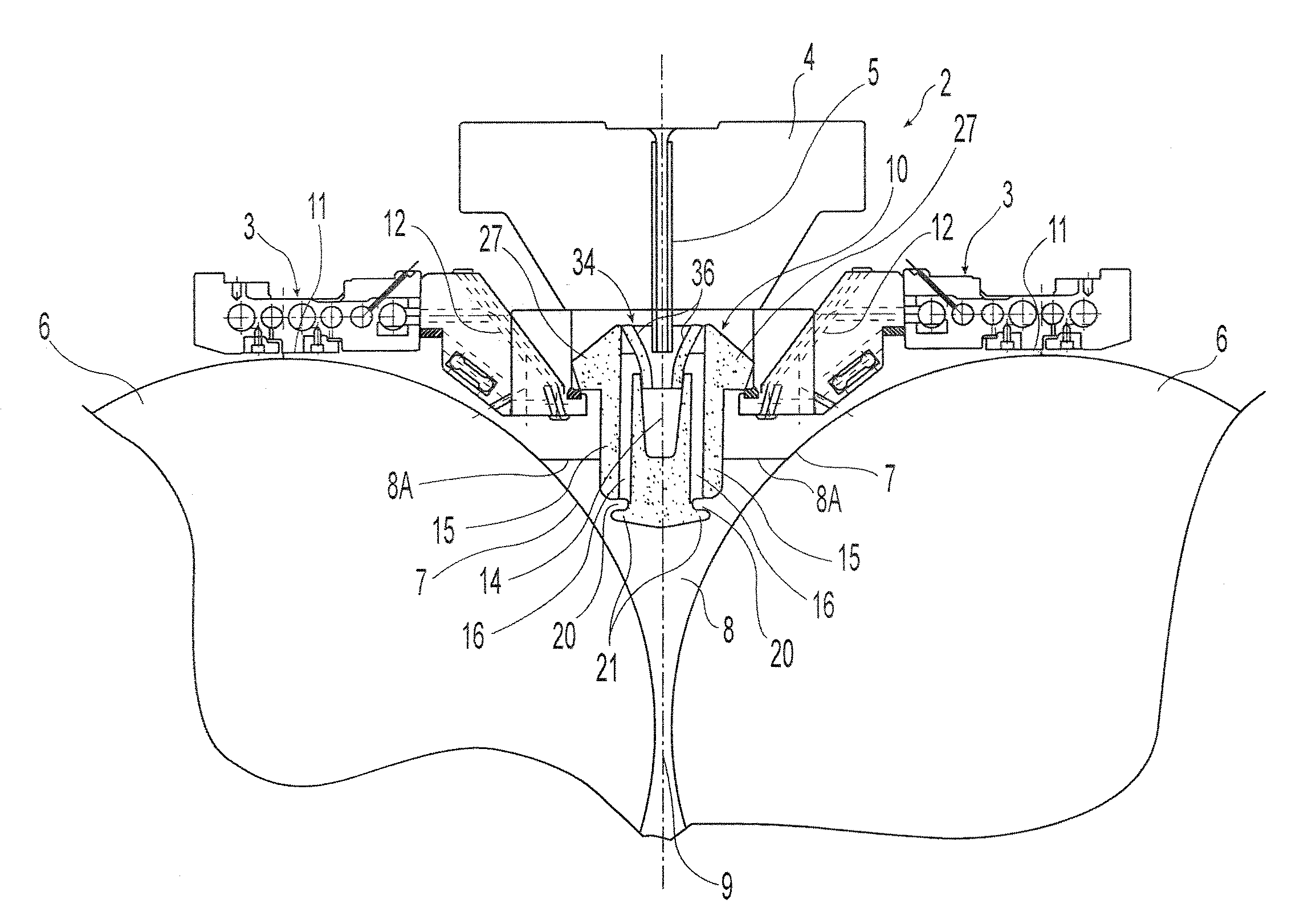

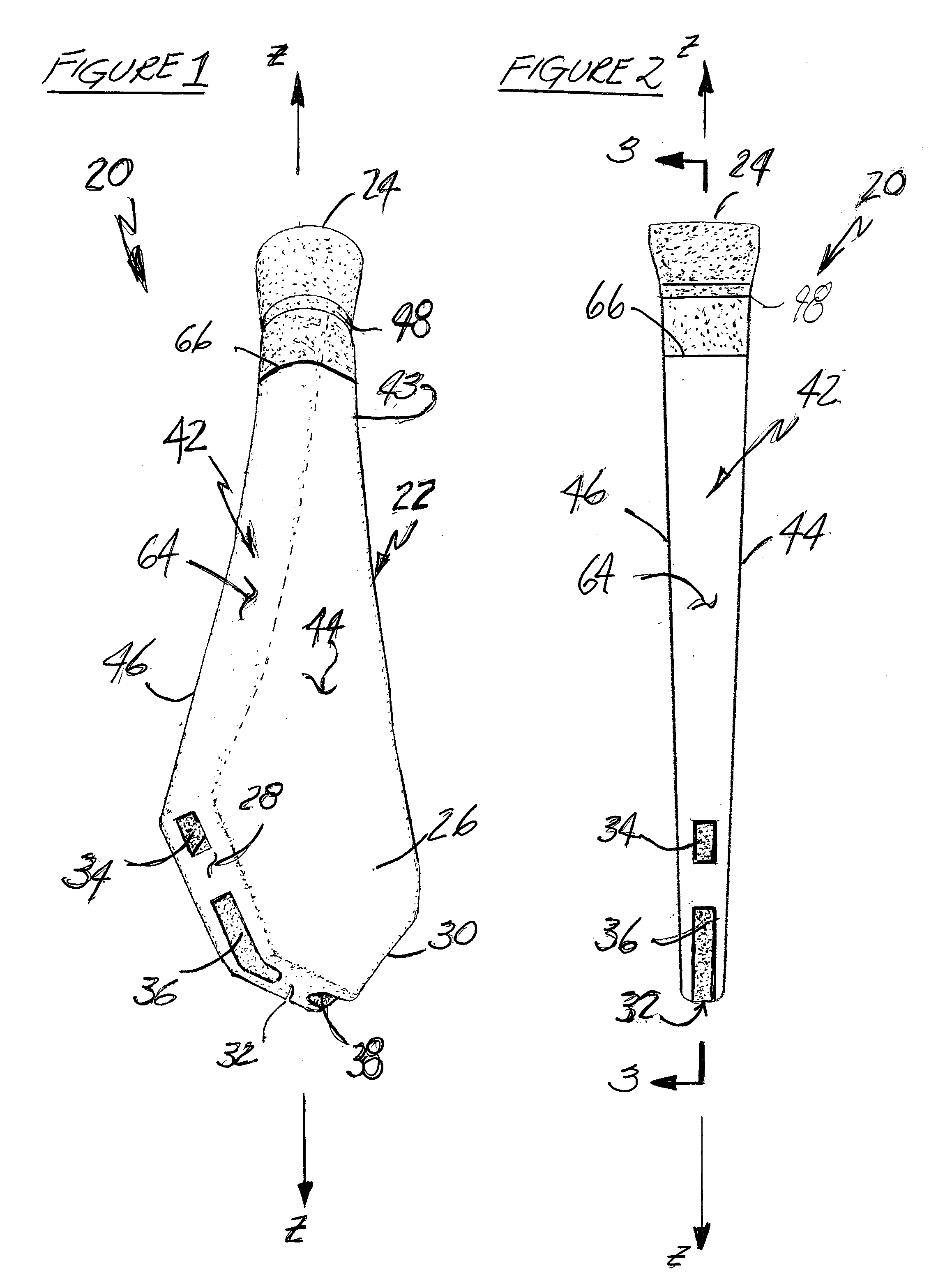

Bonded particle filters

InactiveUS7157043B2Significant portionMelt-holding vesselsMolten metal pouring equipmentsMolten metalMaterials science

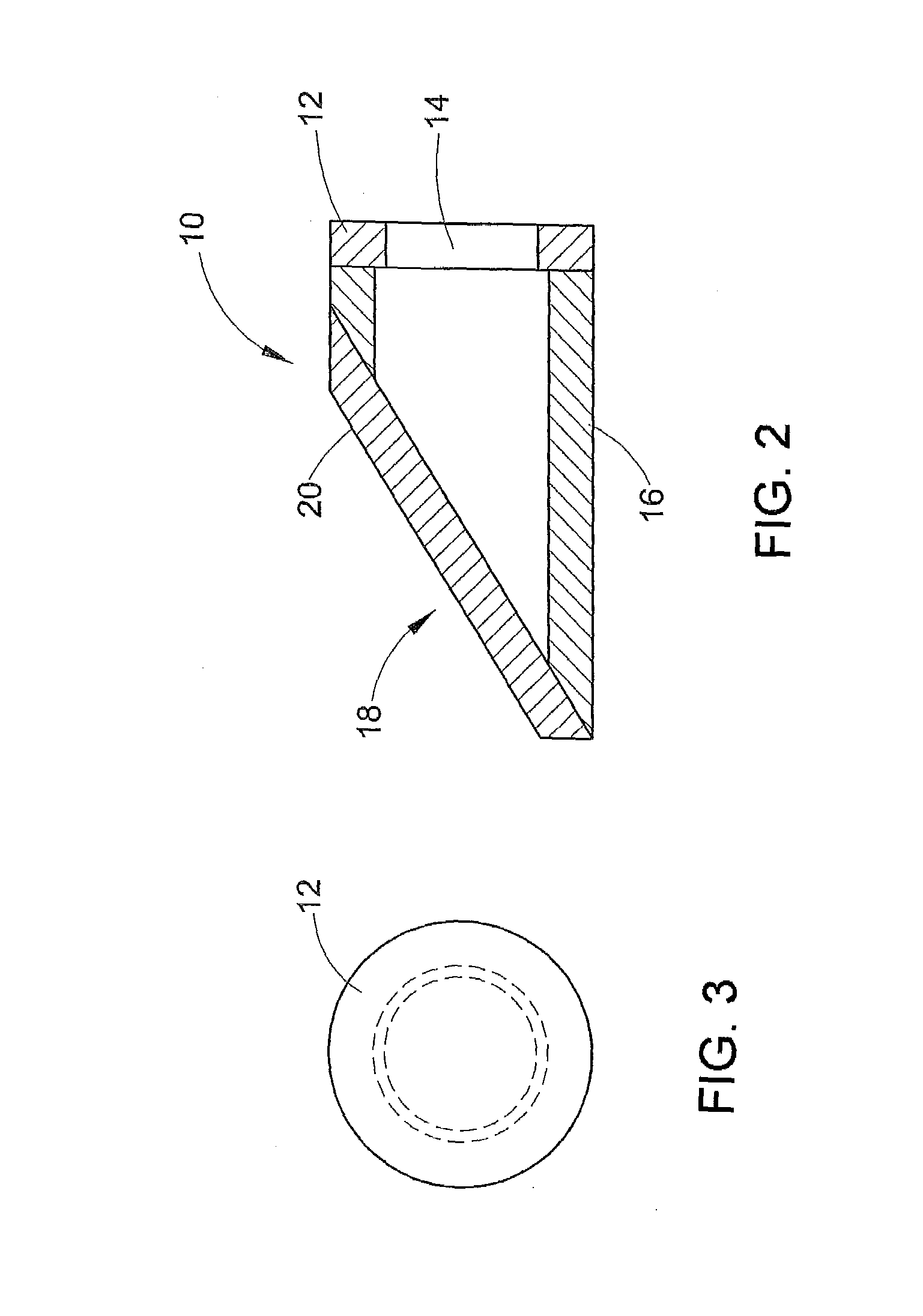

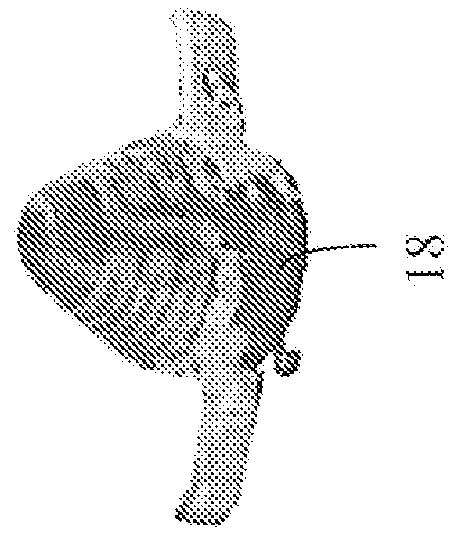

An apparatus for filtering molten metal held in a vessel before the metal enters the dosing tube. The filtering apparatus includes an attachment portion that mounts to the dosing tube, a filter body connected to the attachment portion and a planar surface attached to an end of the filter body opposite the attachment portion. The filter body can include a beveled end opposite the attachment portion where the planar surface is attached. The apparatus can be made from a bonded-particle material made from silicon carbide or aluminum oxide held together by an aluminum-resistant binder.

Owner:METAULLICS SYST +1

Investment casting mold design and method for investment casting using the same

ActiveUS7231955B1Molten metal pouring equipmentsMolten metal supplying equipmentsInvestment castingCasting mold

A method for investment casting includes the steps of positioning a base plate relative to a die; molding a first material between the die and at least a first surface portion of the base plate; securing one or more patterns to the base plate, the one or more patterns comprising a second material; applying one or more coating layers over at least portions of the one or more patterns and at least a portion of the first material; substantially removing the first material through an interior receptacle of a manifold body and the second material through an exterior receptacle of the manifold body to leave one or more shells formed by the coating layers; removing said base plate; introducing molten metal to the one or more shells through the interior receptacle of the manifold body; permitting the molten metal to solidify; and destructively removing one or more investment casting molds.

Owner:RTX CORP

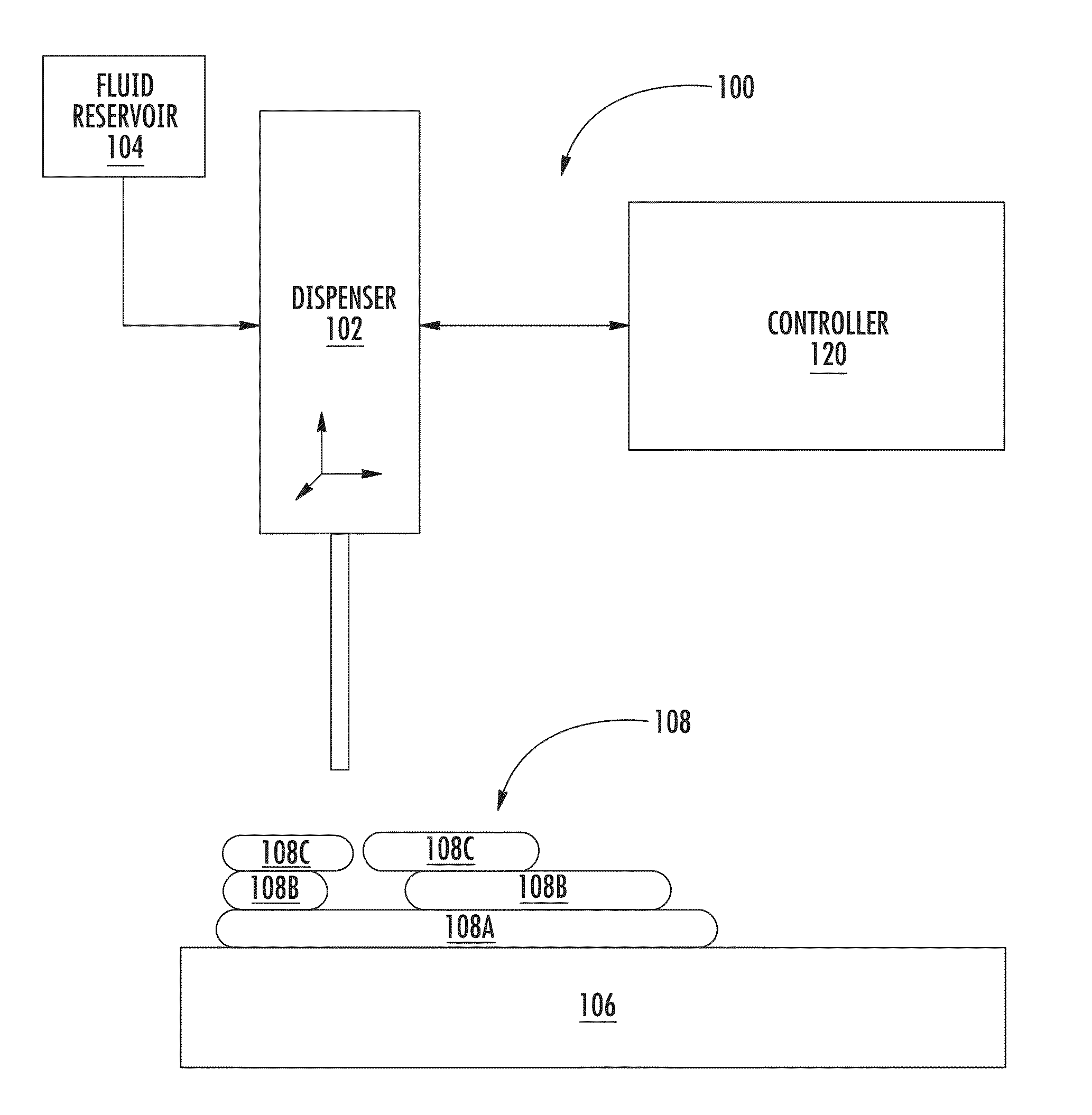

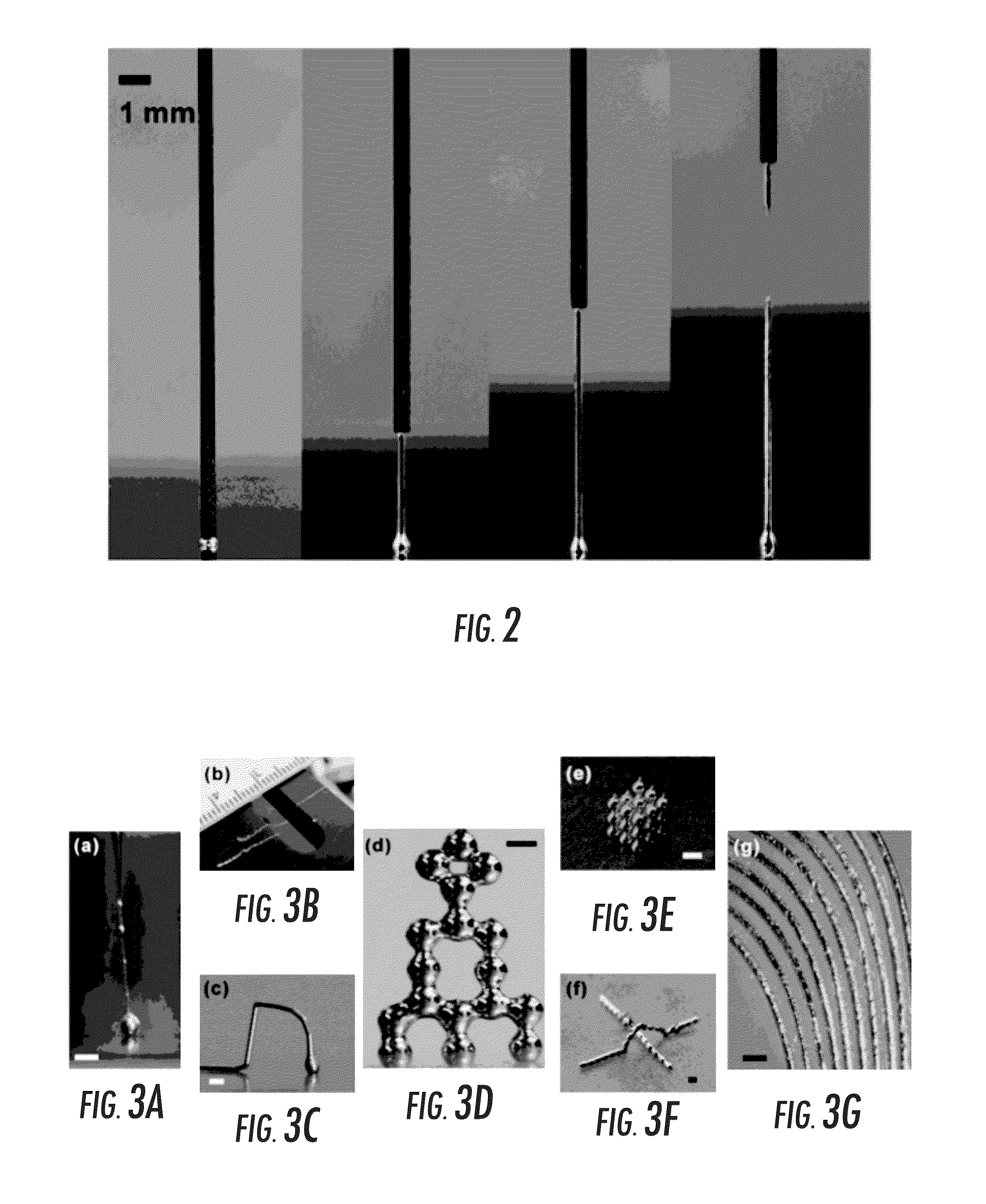

Method and apparatus for 3D fabrication

ActiveUS20160031159A1Preventing the high temperature from spreading into undesirable areasEasy to disassembleConfectioneryManufacturing heating elements3d fabricationEngineering

An apparatus for use in 3D fabrication includes a heat sink, a melt tube extending through the heat sink, the melt tube having a first end and an opposite second end and adapted for melting filament or other material as the material is conveyed from the first end to the second end, a pen tip having an opening therein for ejecting melted material, the pen tip at the second end of the melt tube, and a pen tip holder for securely holding the pen tip during printing, the pen tip holder having a heater element associated therewith.

Owner:SCIPERIO

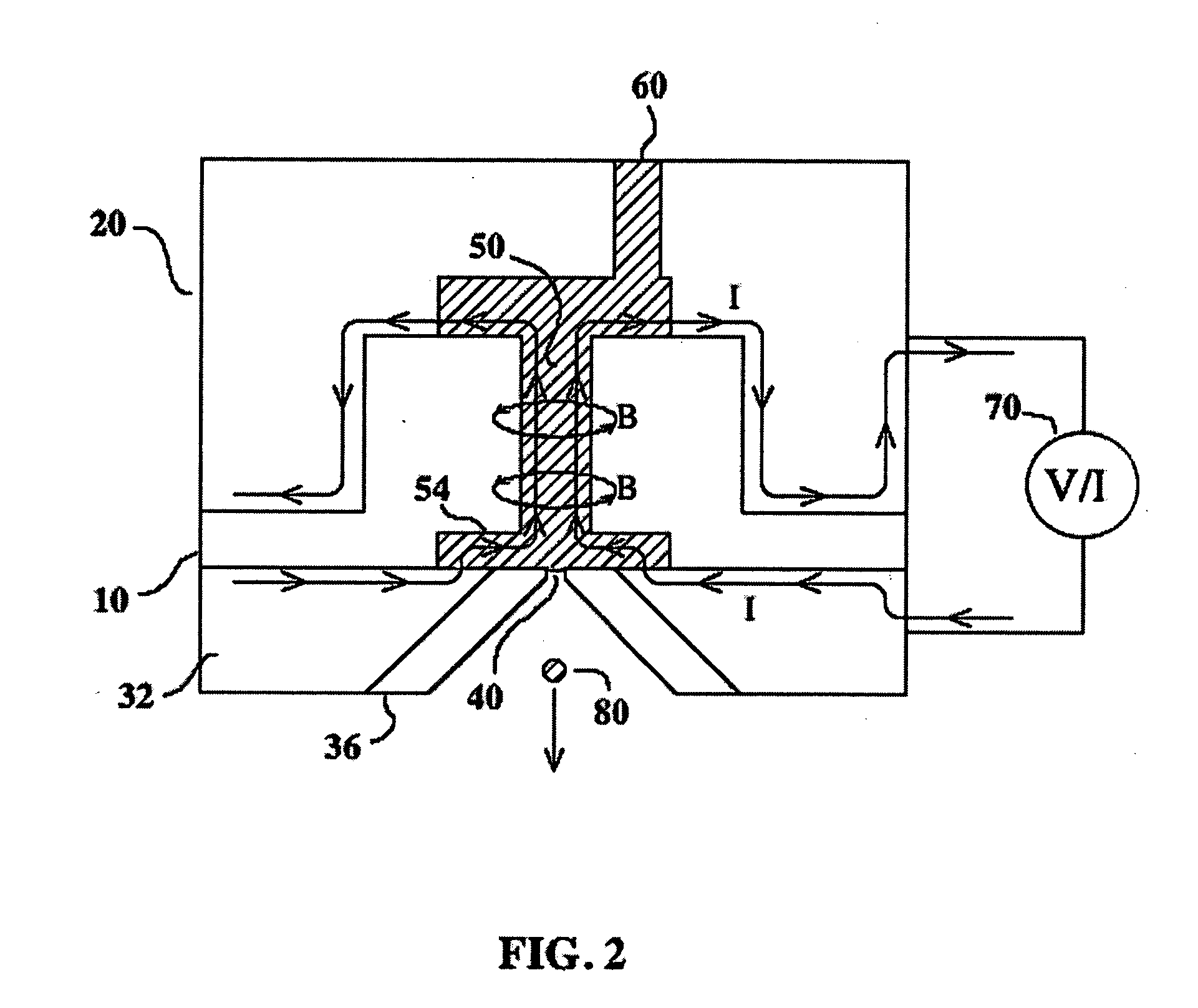

Transferring molten metal from one structure to another

ActiveUS8337746B2Formation of dross in the ladle or launder are greatly reduced or eliminatedEliminate useMolten metal pouring equipmentsStirring devicesDie castingMolten metal

A system for transferring molten metal from a vessel and into one or more of a ladle, ingot mold, launder, feed die cast machine or other structure is disclosed. The system includes at least a vessel for containing molten metal, an overflow (or dividing) wall, and a device or structure, such as a molten metal pump, for generating a stream of molten metal. The dividing wall divides the vessel into a first chamber and a second chamber, wherein part of the second chamber has a height H2. The device for generating a stream of molten metal, which is preferably a molten metal pump, is preferably positioned in the first chamber. When the device operates, it generates a stream of molten metal from the first chamber and into the second chamber. When the level of molten metal in the second chamber exceeds H2, molten metal flows out of the vessel and into another structure, such as into one or more ladles and / or one or more launders.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Receptacle for handling molten metal, casting assembly and manufacturing method

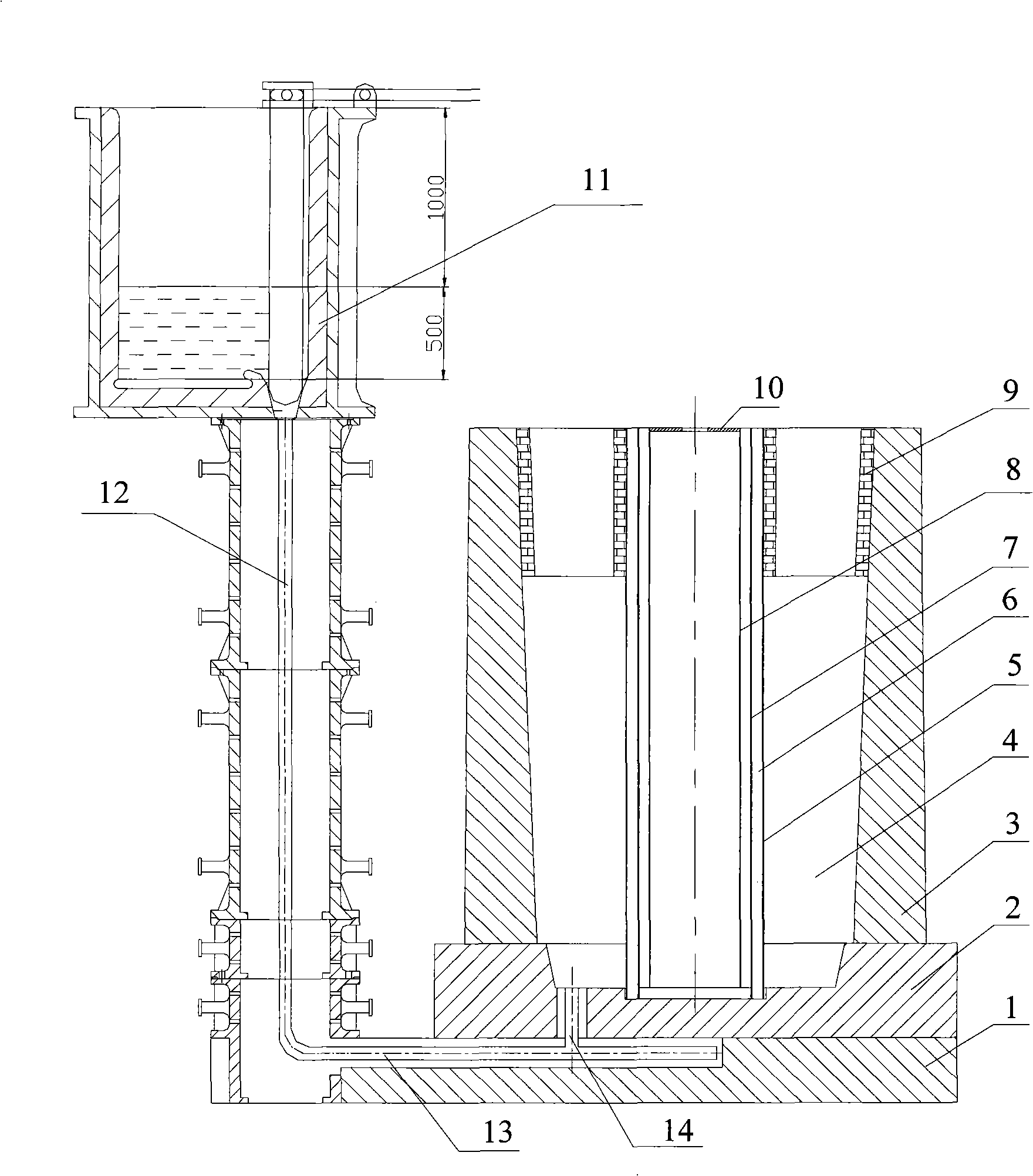

InactiveUS20130334744A1Simpler and less cumbersomeEasy to manufactureMelt-holding vesselsDischarging arrangementRefractoryEngineering

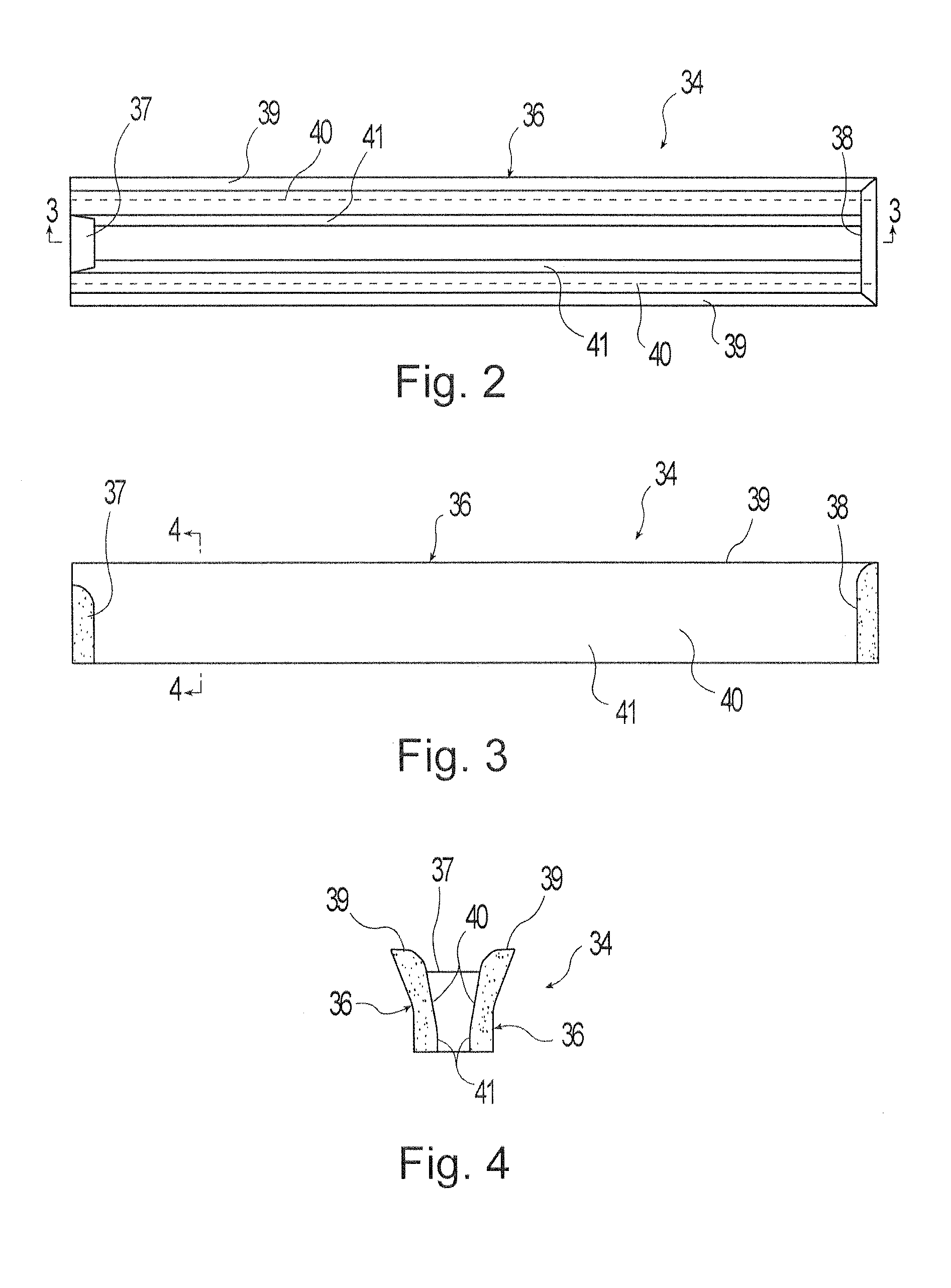

A receptacle for handling molten metal is provided. The receptacle has bottom and side walls and includes a refractory defining a cavity within which the molten metal is conveyed or contained. The receptacle has at least one channel extending within at least one of its walls. The channel has an inlet and an outlet. The inlet is connectable to a source for circulating a fluid within the channel. The outlet allows the fluid to be expelled from said channel. The channel allows, when the fluid is circulated in it, to regulate the temperature of the refractory and thereby of the metal conveyed or contained. A casting assembly and a method for casting the refractory are also provided.

Owner:PYROTECK INC

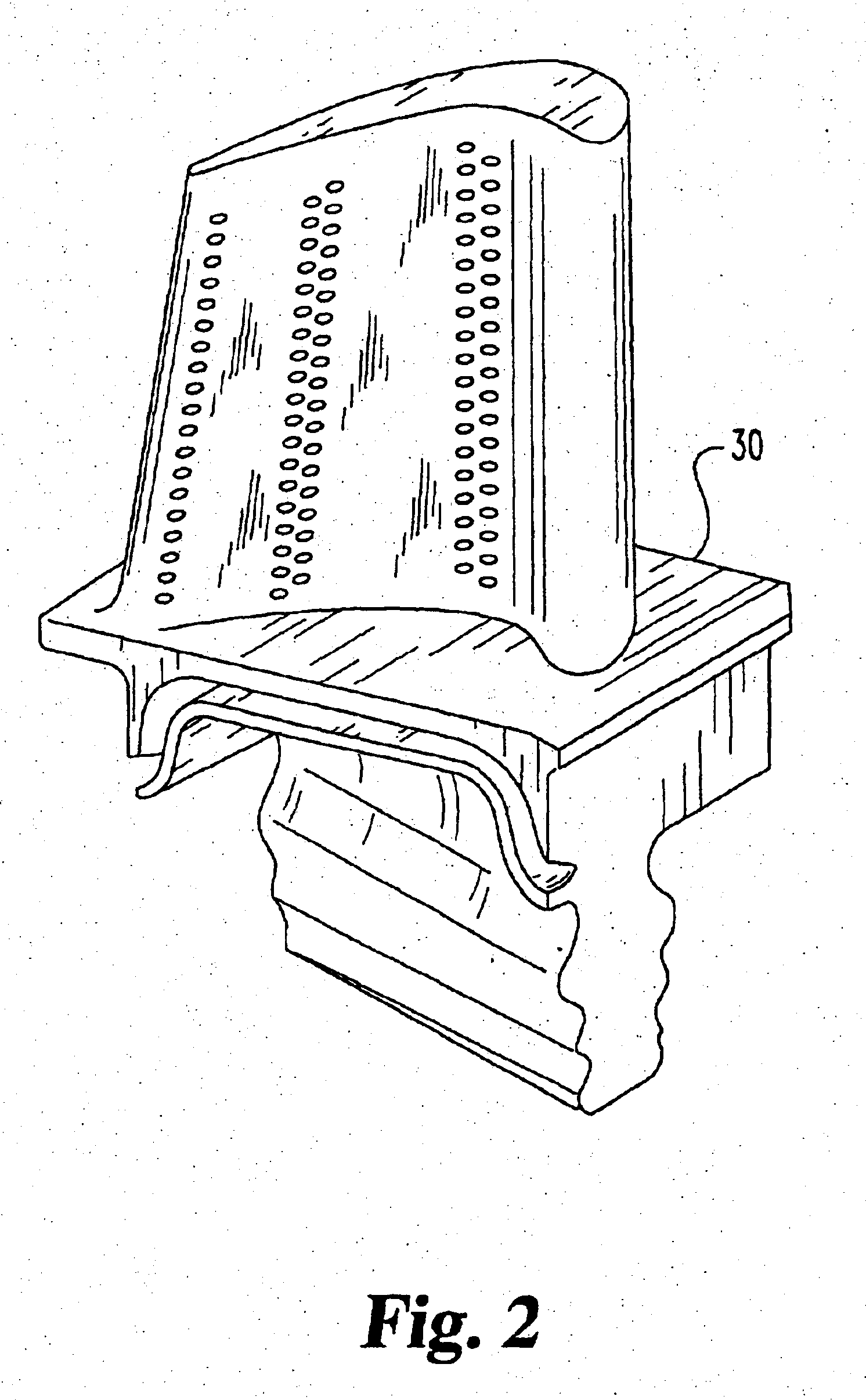

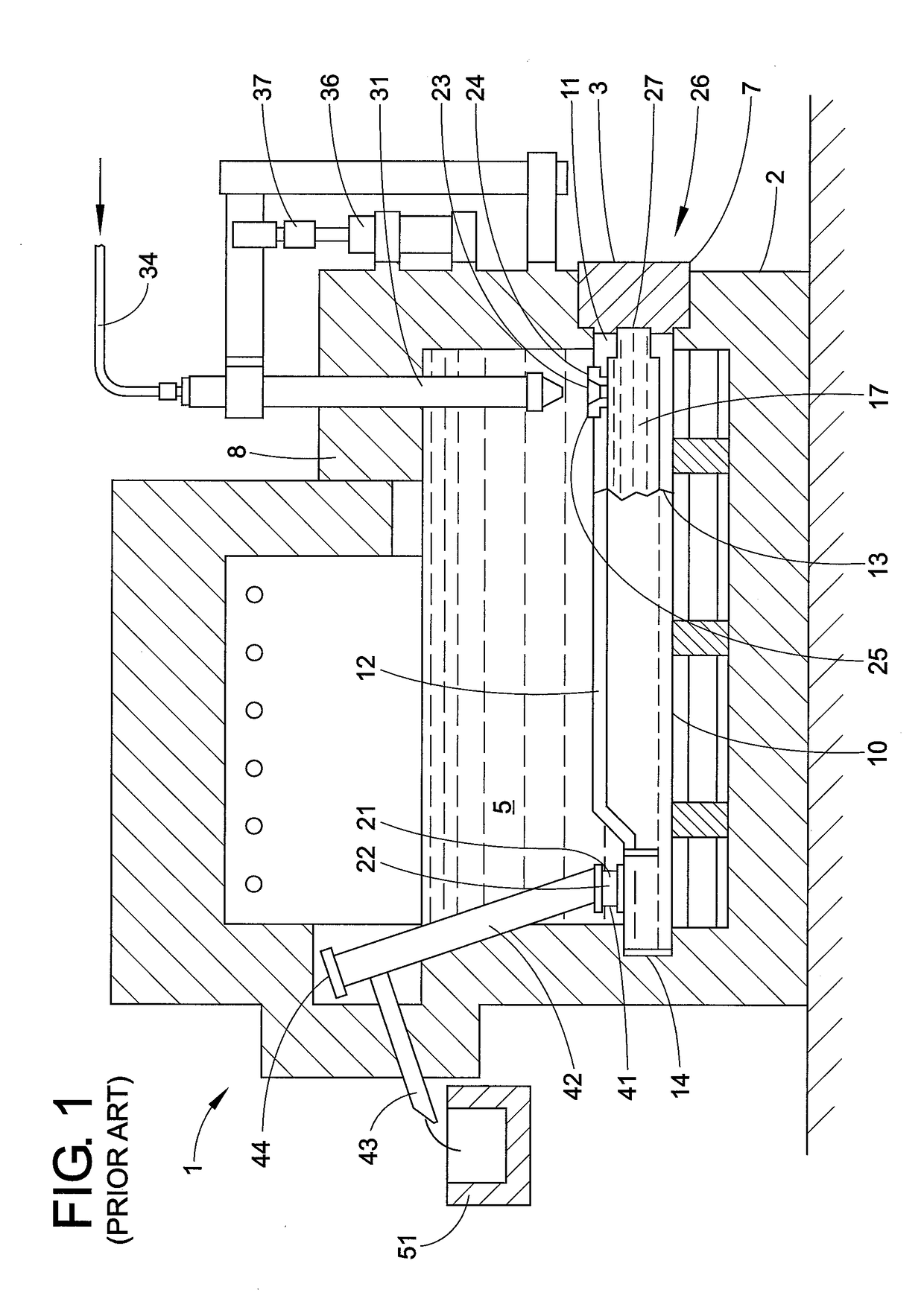

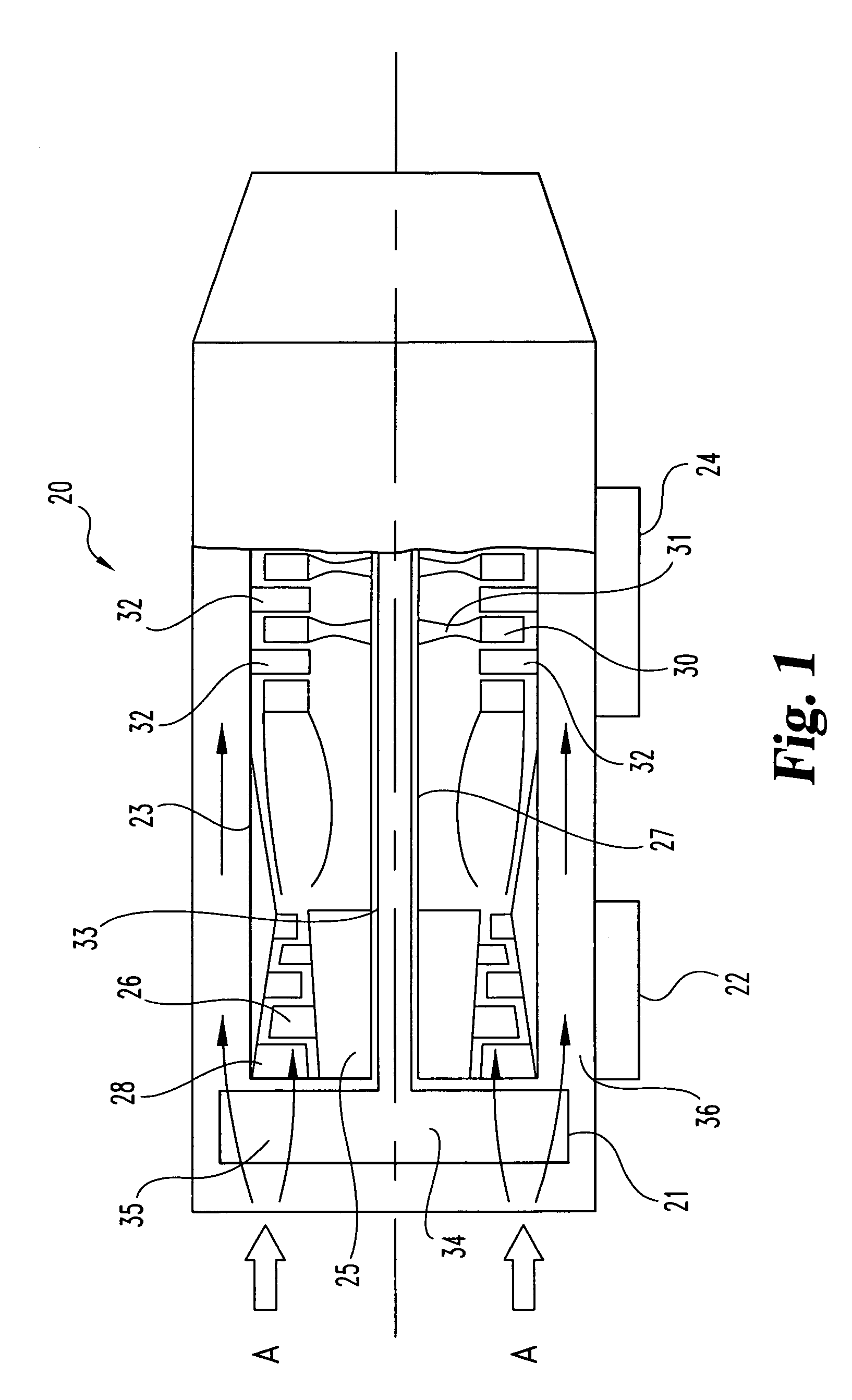

Method and apparatus for production of a cast component

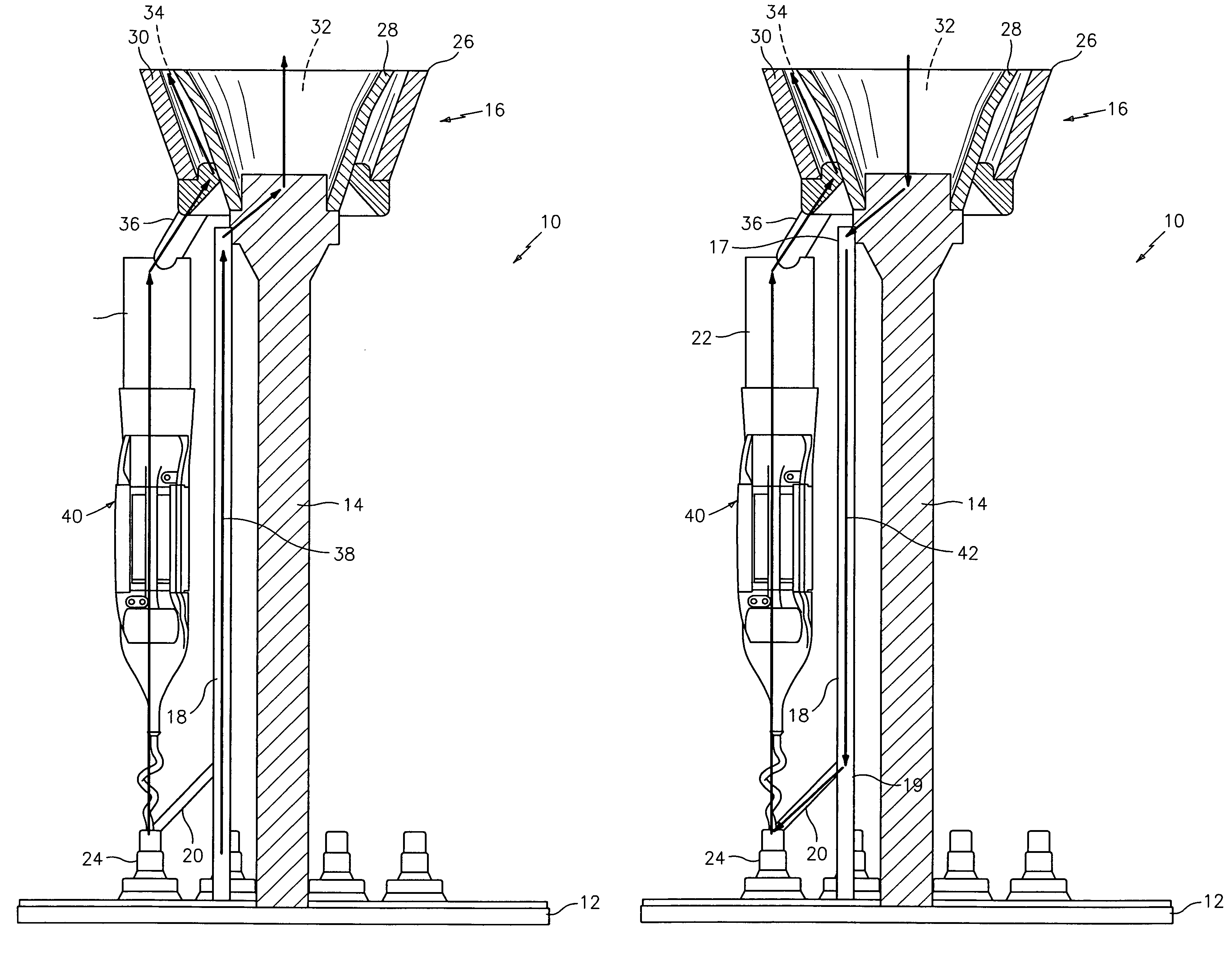

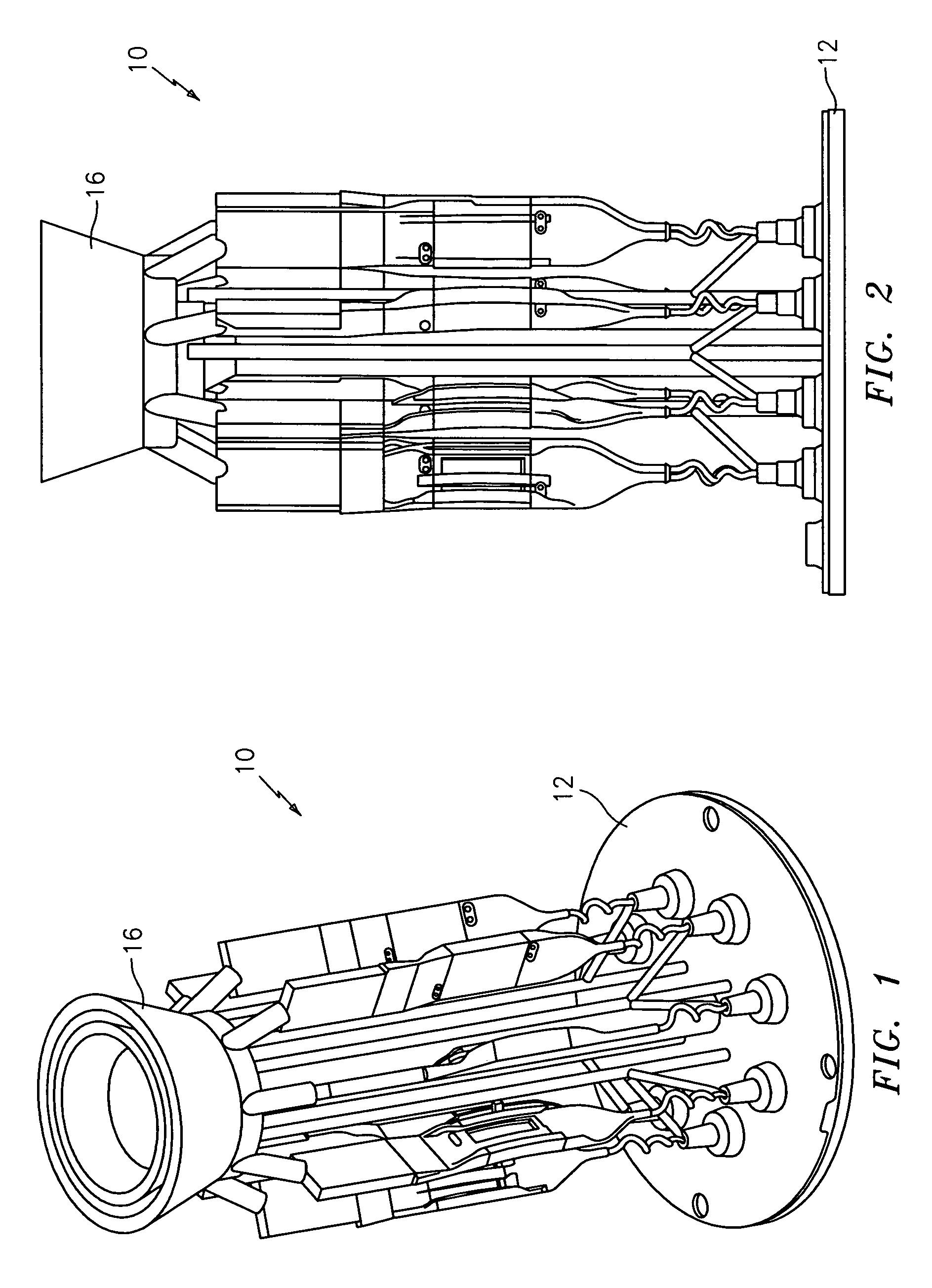

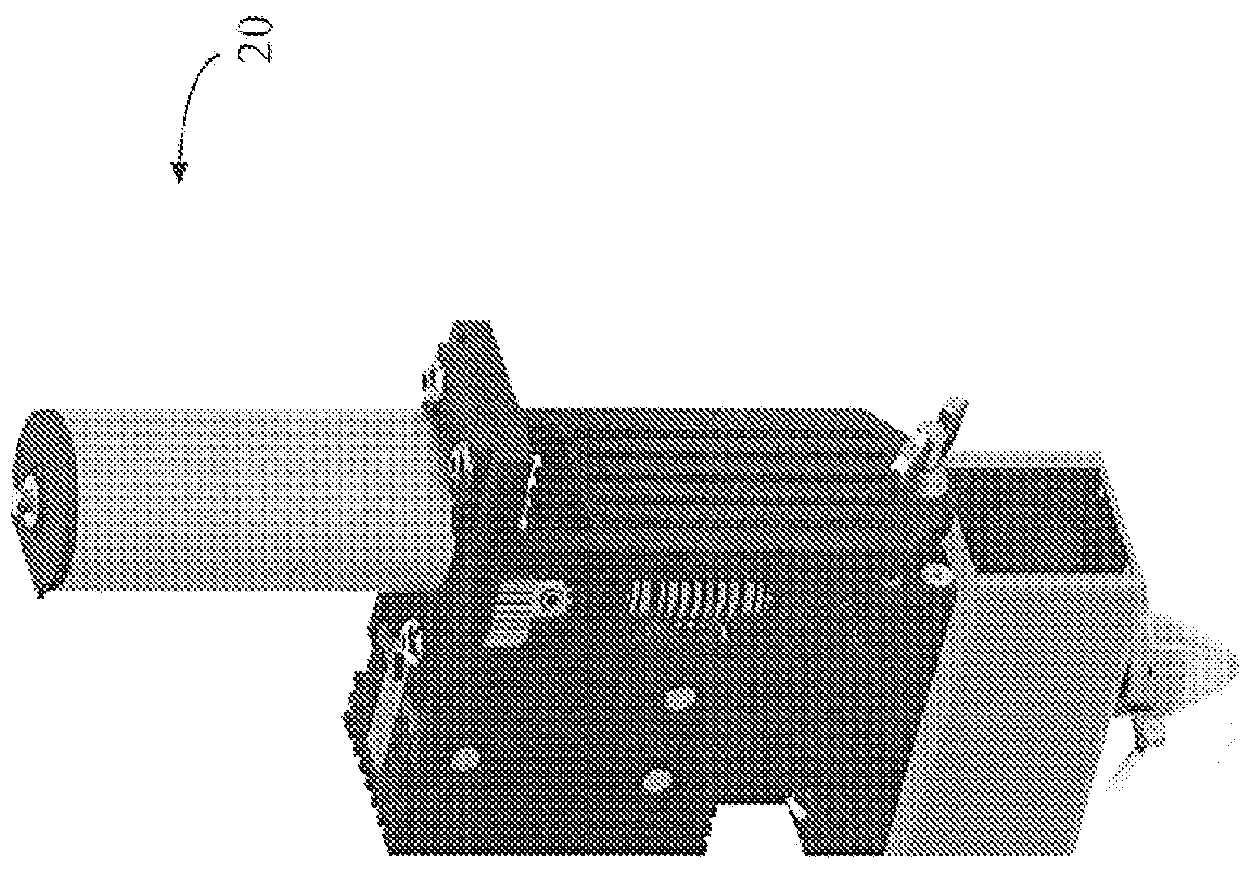

InactiveUS6932145B2Minimize transmission of heatGas turbine plantsFrom frozen solutionsCasting moldMolten metal

A system for producing cast components from molten metal. One form of the present invention includes a system for the precision pouring of molten metal within a casting mold.

Owner:ROLLS ROYCE CORP

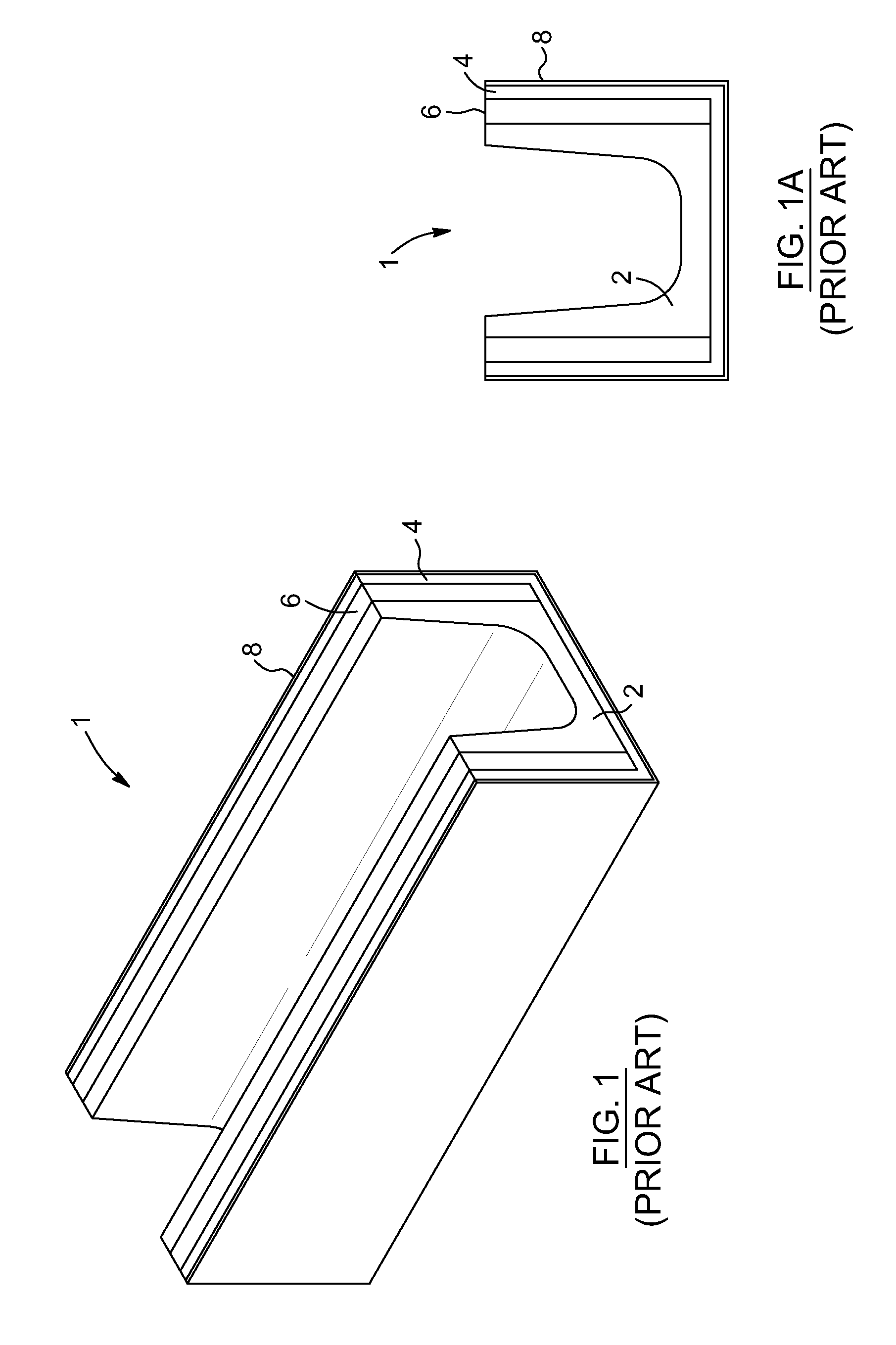

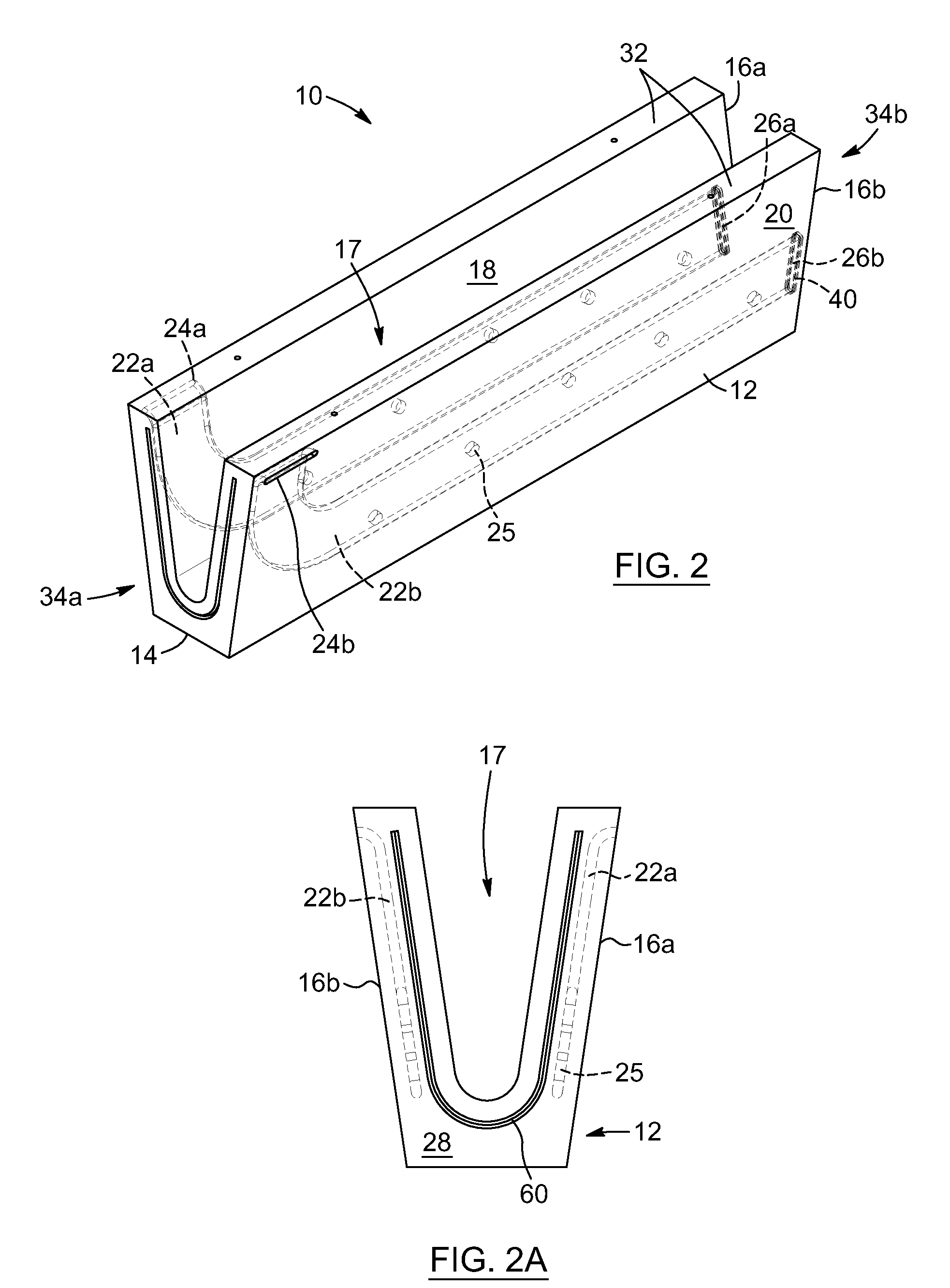

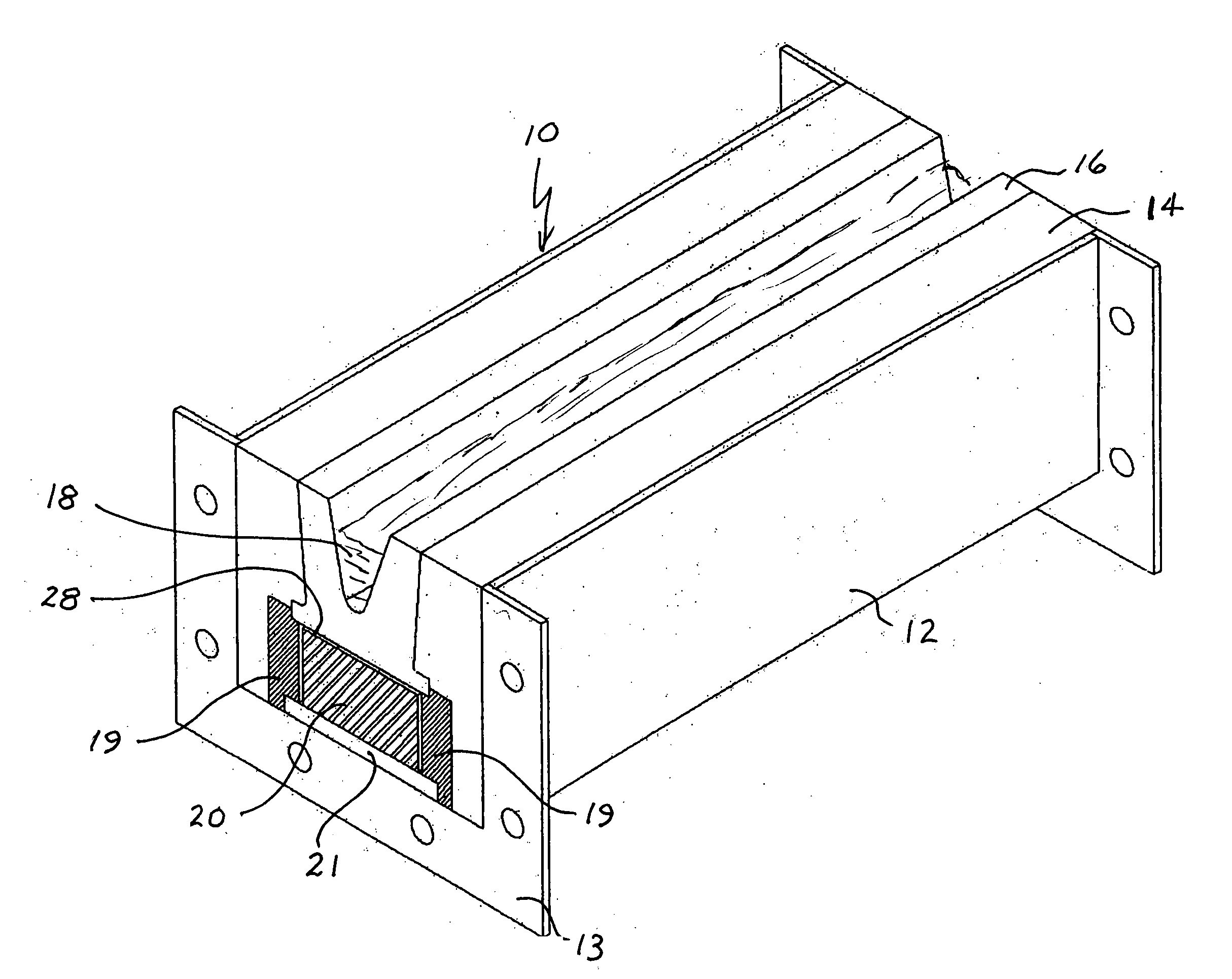

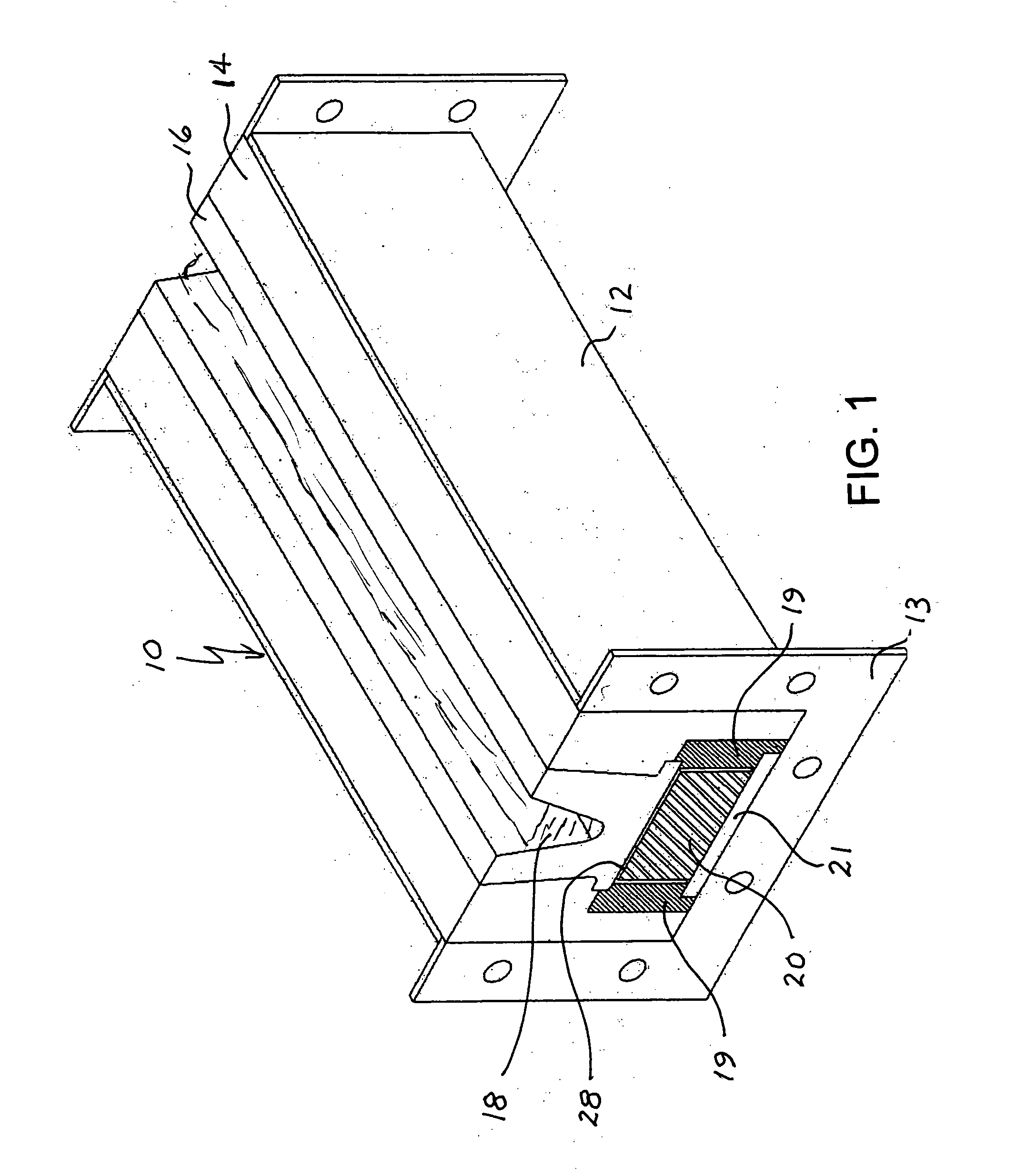

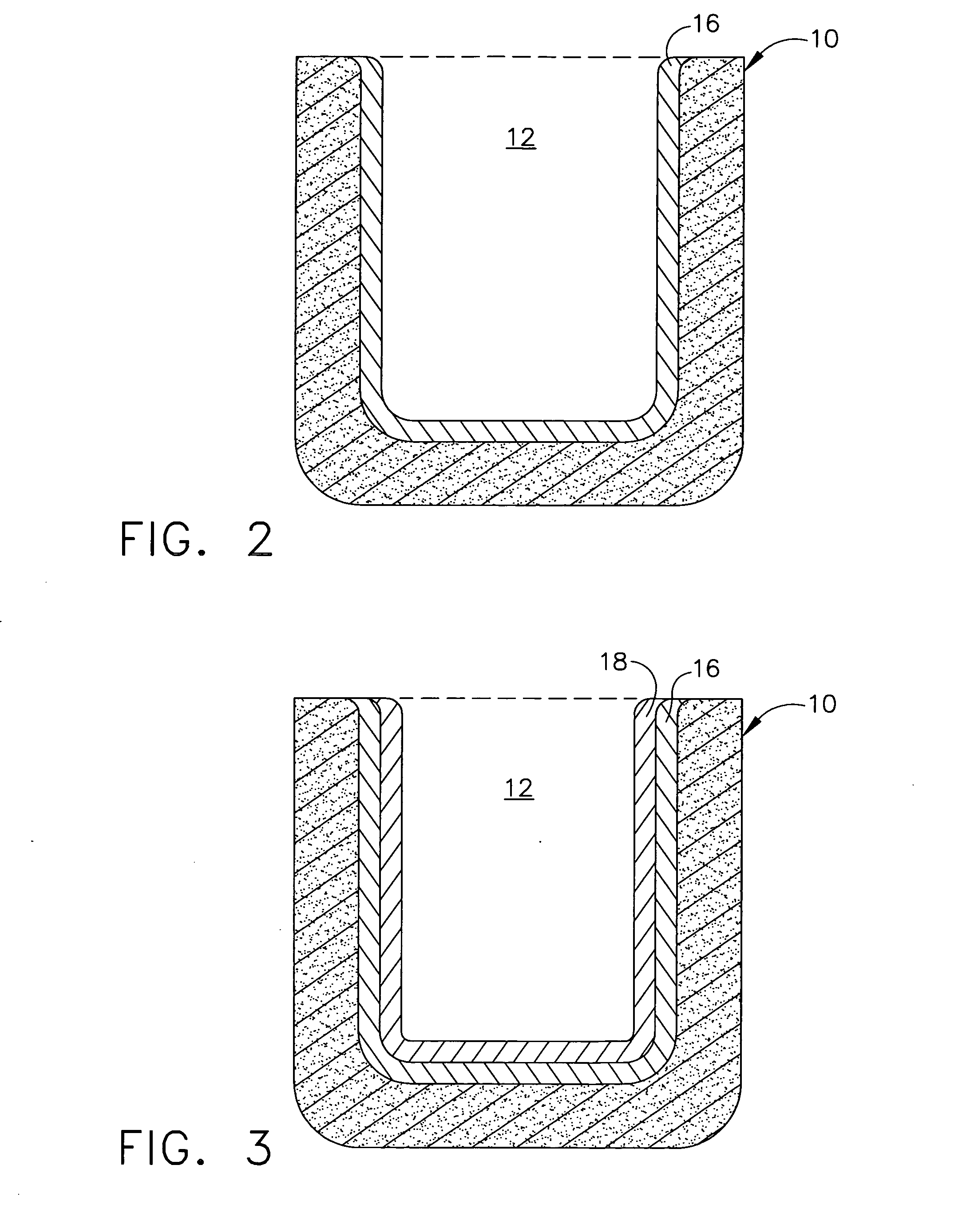

Heated trough for molten metal

A trough is described for carrying molten metal, comprising an outer shell defined by a bottom wall and two side walls, an insulating layer filling the outer shell and a conductive U-shaped refractory trough body for carrying molten metal, the trough body being embedded in the insulating layer. At least one heating element is positioned in the insulating layer, adjacent to but spaced apart from the trough body, to provide an air gap between the heating element and the trough body.

Owner:NOVELIS INC

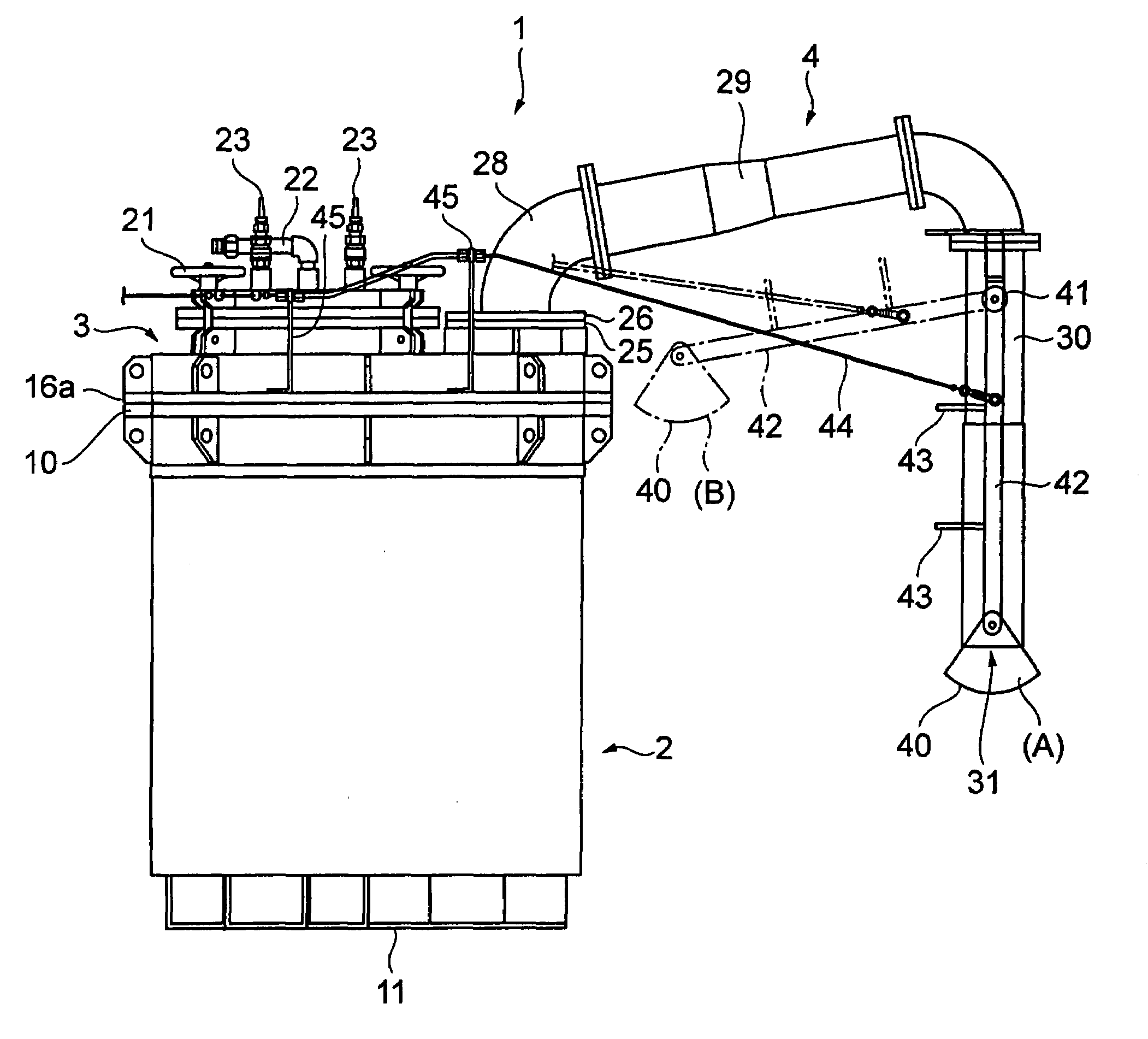

System for supplying molten metal, container and a vehicle

InactiveUS7481966B2Low costMelt-holding vesselsMolten metal supplying equipmentsWire rodHermetic seal

A molten metal supplying system comprising a container having a main body capable of being hermetically sealed and having a passage through which compressed gas is received, a pipe having an outlet supplying molten metal in the container to the outside, the outlet downwardly extending, a reception dish receiving the molten metal capable of being placed below the pipe outlet, a holding member having a fulcrum to the pipe rotatably holding the reception dish, a wire with a first and second end, the first end connected to the reception dish or holding member, a pair of channel members at the outer bottom of the container main body, and a vehicle having a fork that can be inserted and removed from the channel members, a carriage on which the fork is mounted, a lift mechanism for lifting up and down the carriage, and a wire pull and return mechanism mounted on the carriage pulling and returning the wire with it's second end.

Owner:HOEI SHOKAI CO LTD

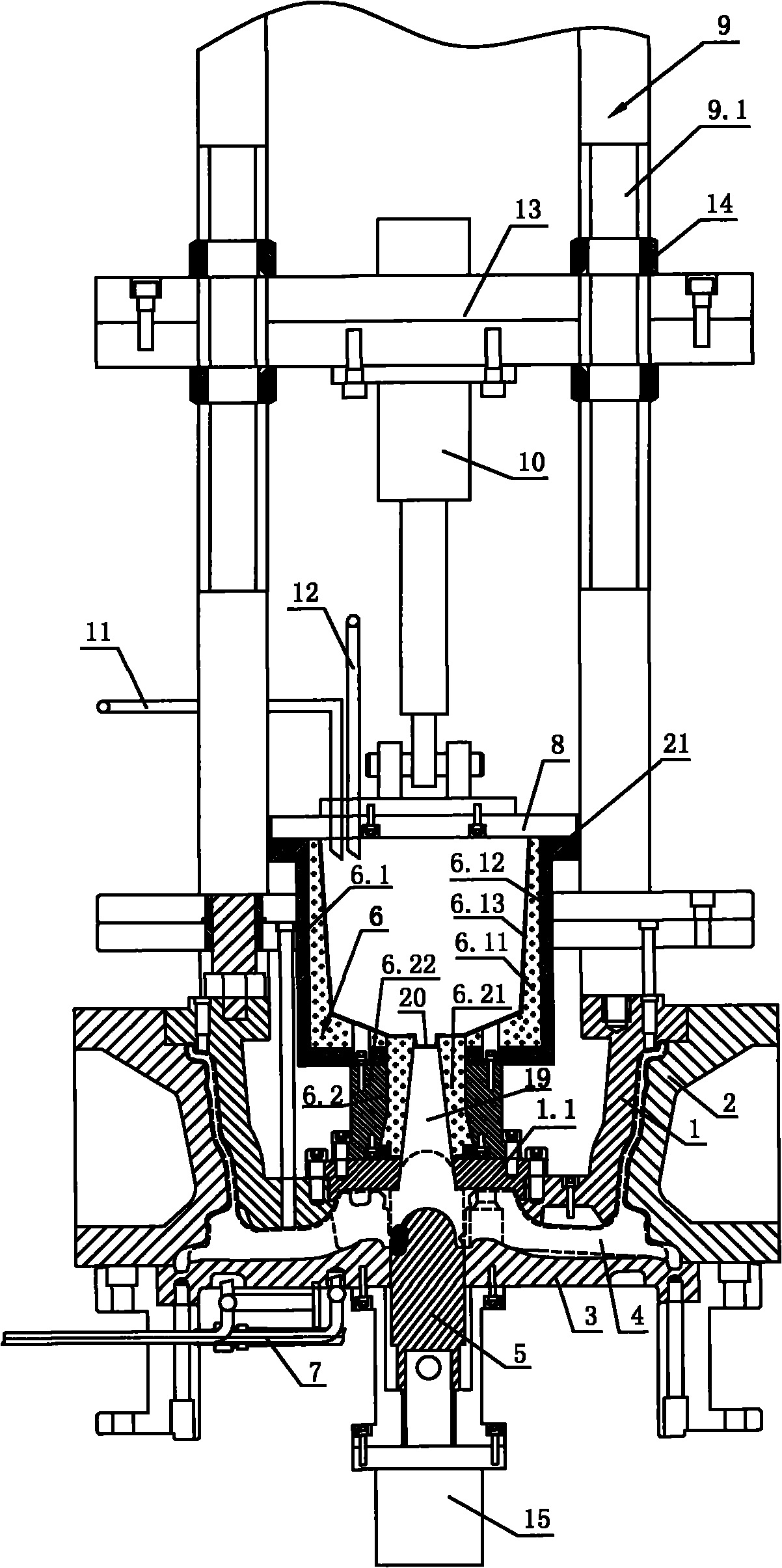

Amorphous alloy diecasting equipment and amorphous alloy diecasting process

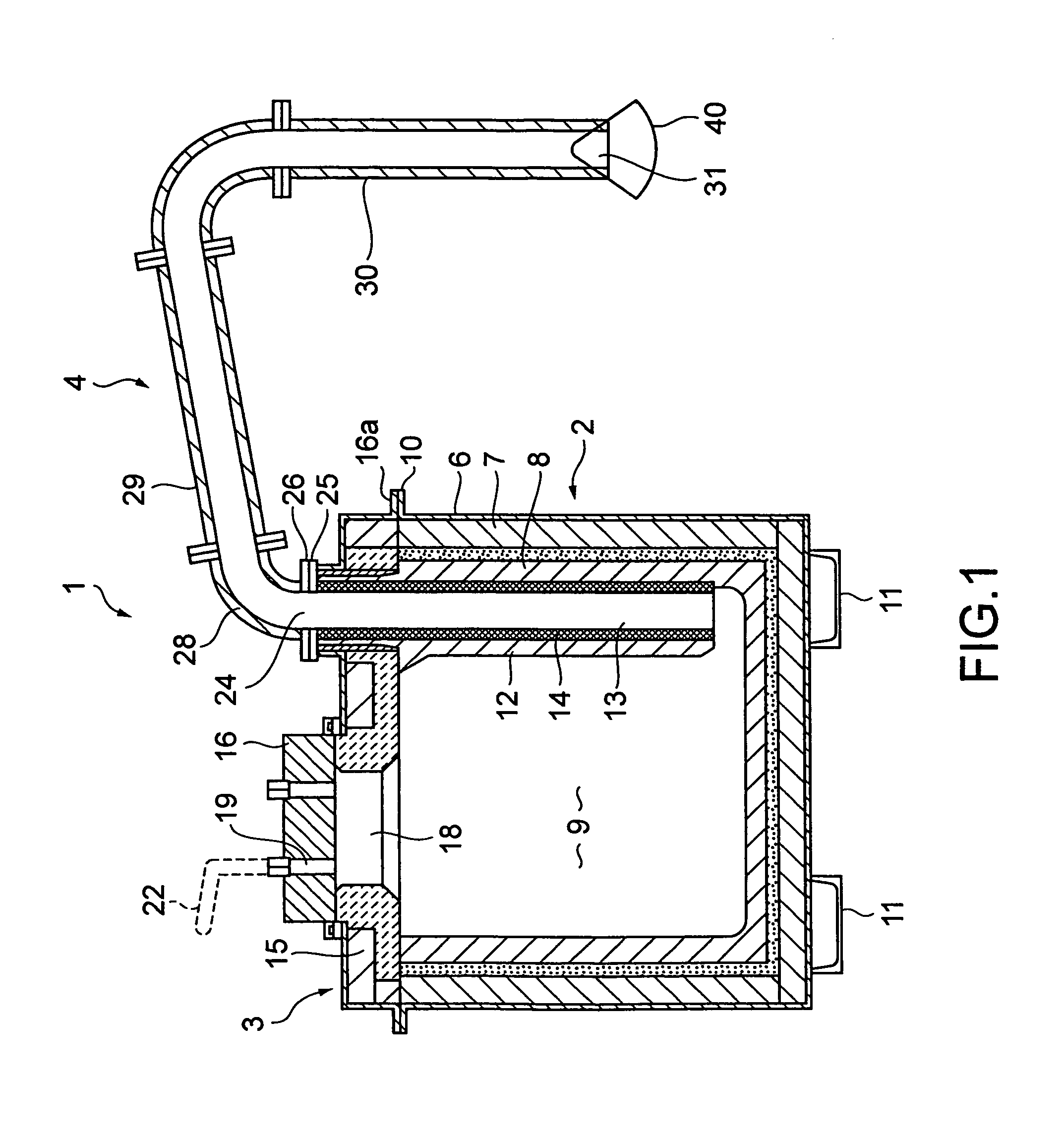

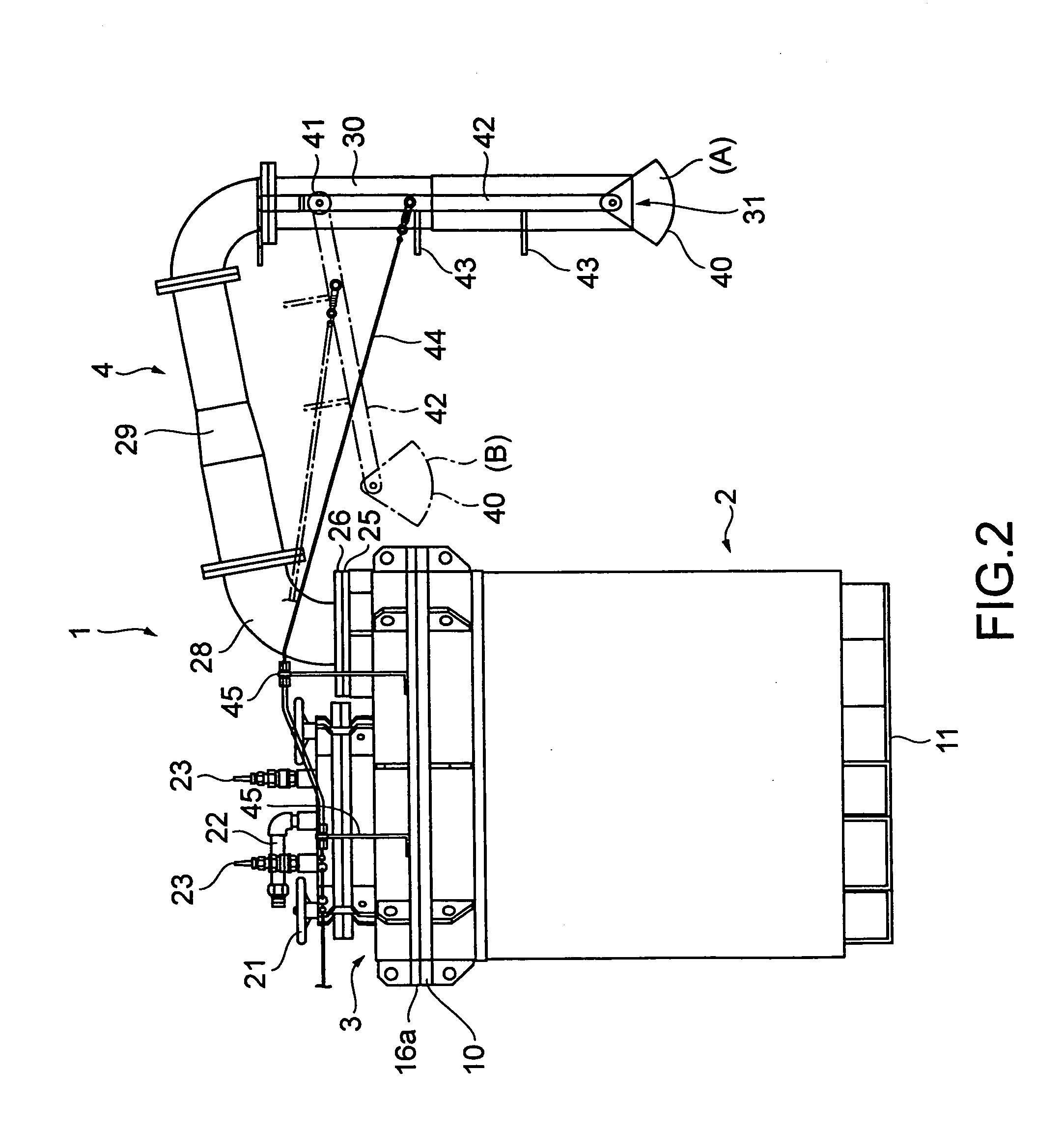

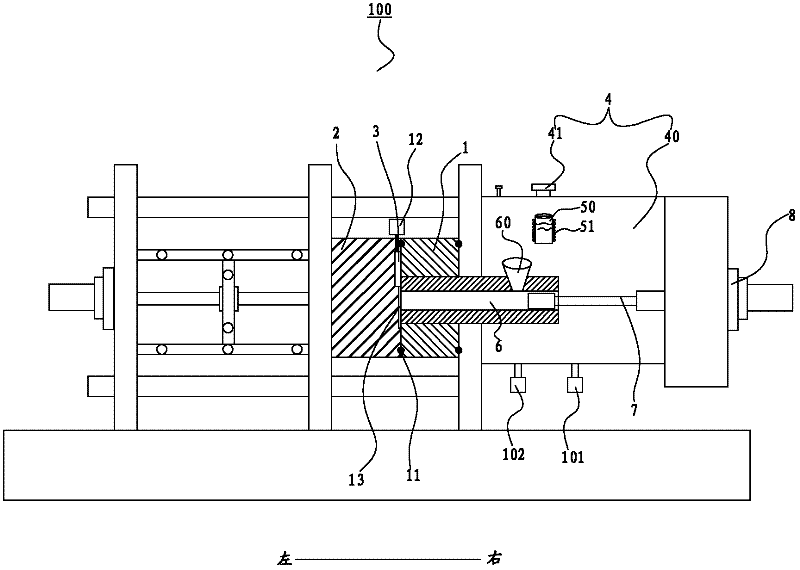

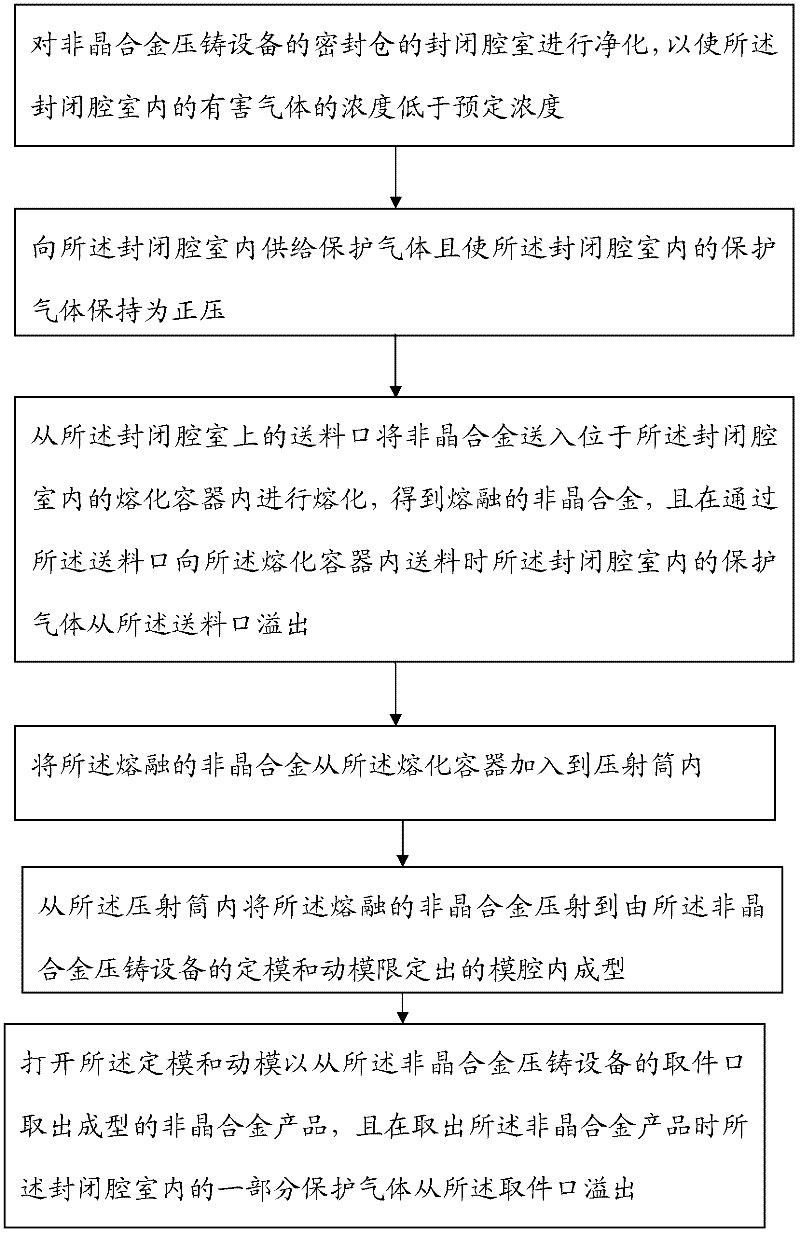

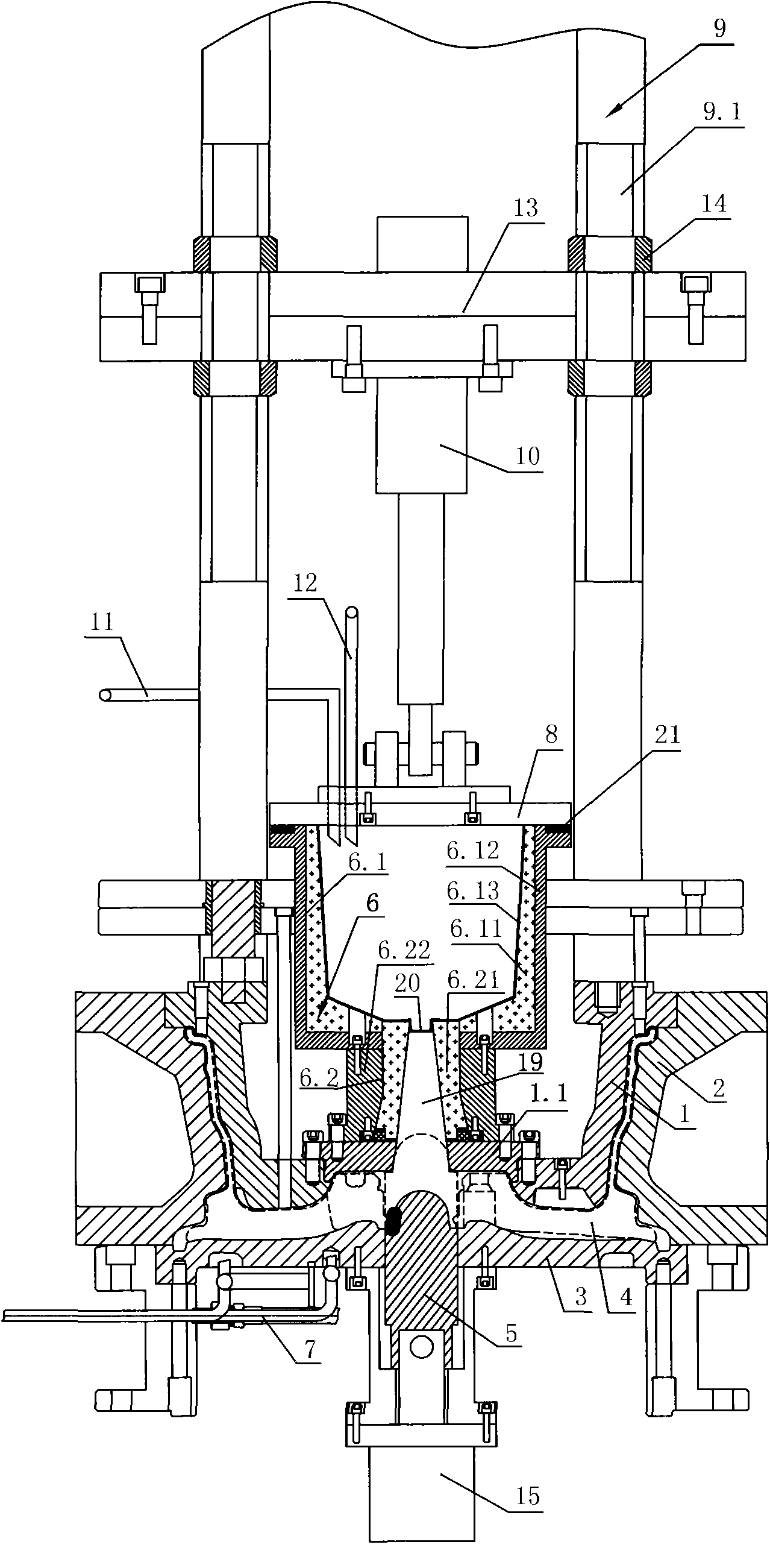

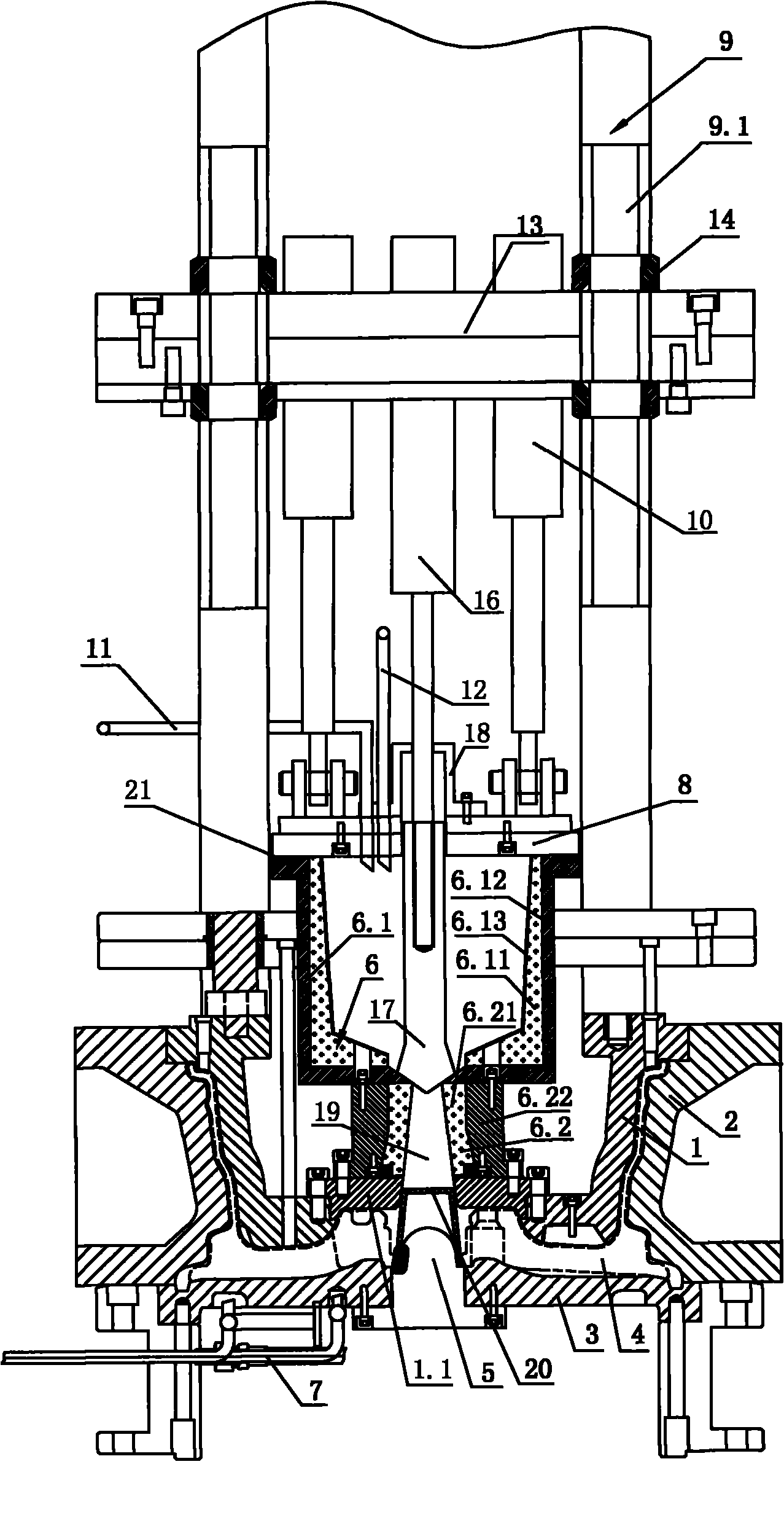

ActiveCN102527982ACritical dimension reductionSimple structureMelt-holding vesselsMolten metal conveying equipmentsPositive pressureShielding gas

The invention discloses an amorphous alloy diecasting equipment and an amorphous alloy diecasting process. The amorphous alloy diecasting equipment comprises a fixed die, a movable die, a sealed bin, a protection-gas supplying device, a melting container, a pressing and ejecting cylinder, a driving device and a harmful-gas purifying device; the fixed die and the movable die can be opened and closed, and a die cavity is formed between the fixed die and the movable die in a defining way when the fixed die and the movable die are closed; a sealed chamber is formed in the sealed bin in a defining way, and the sealed bin is provided with a feeding opening; the protection-gas supplying device is connected with the sealed chamber and used for supplying a protection gas to the sealed chamber, wherein the protection gas in the sealed chamber is at positive pressure; the melting container is arranged in the sealed bin; the pressing and ejecting cylinder is communicated with the die cavity and provided with a melt inlet; the pressing and ejecting cylinder is internally provided with a pressing and ejecting piston used for ejecting the melted amorphous alloy into the die cavity; and the harmful-gas purifying device is connected with the sealed chamber and used for purifying the harmful gas in the sealed chamber. The amorphous alloy diecasting equipment disclosed by the embodiment of the invention has a simple structure, adopts the protective gas at positive pressure, does not need to establish a high vacuum degree and has low manufacturing and maintaining cost.

Owner:BYD CO LTD

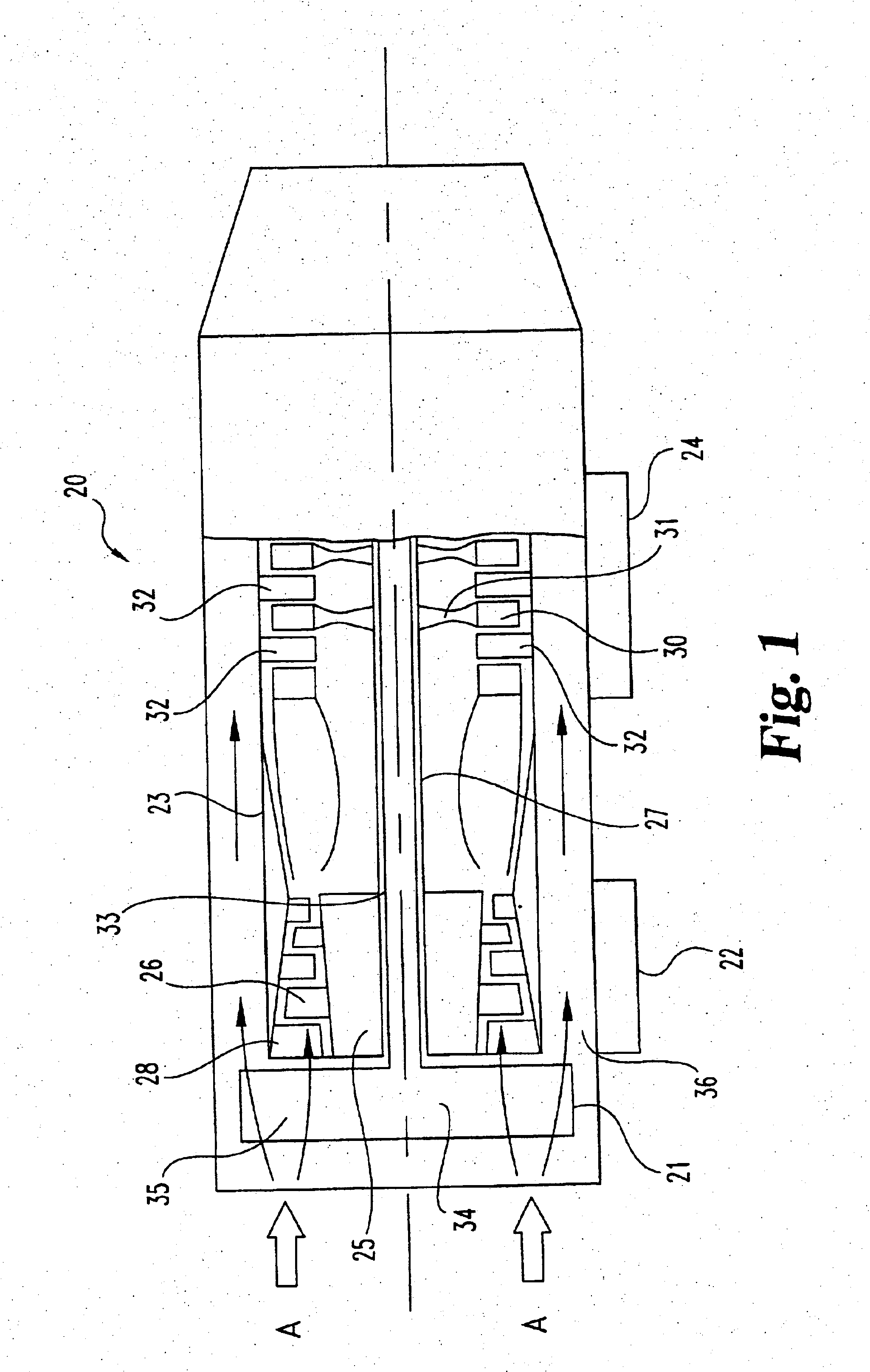

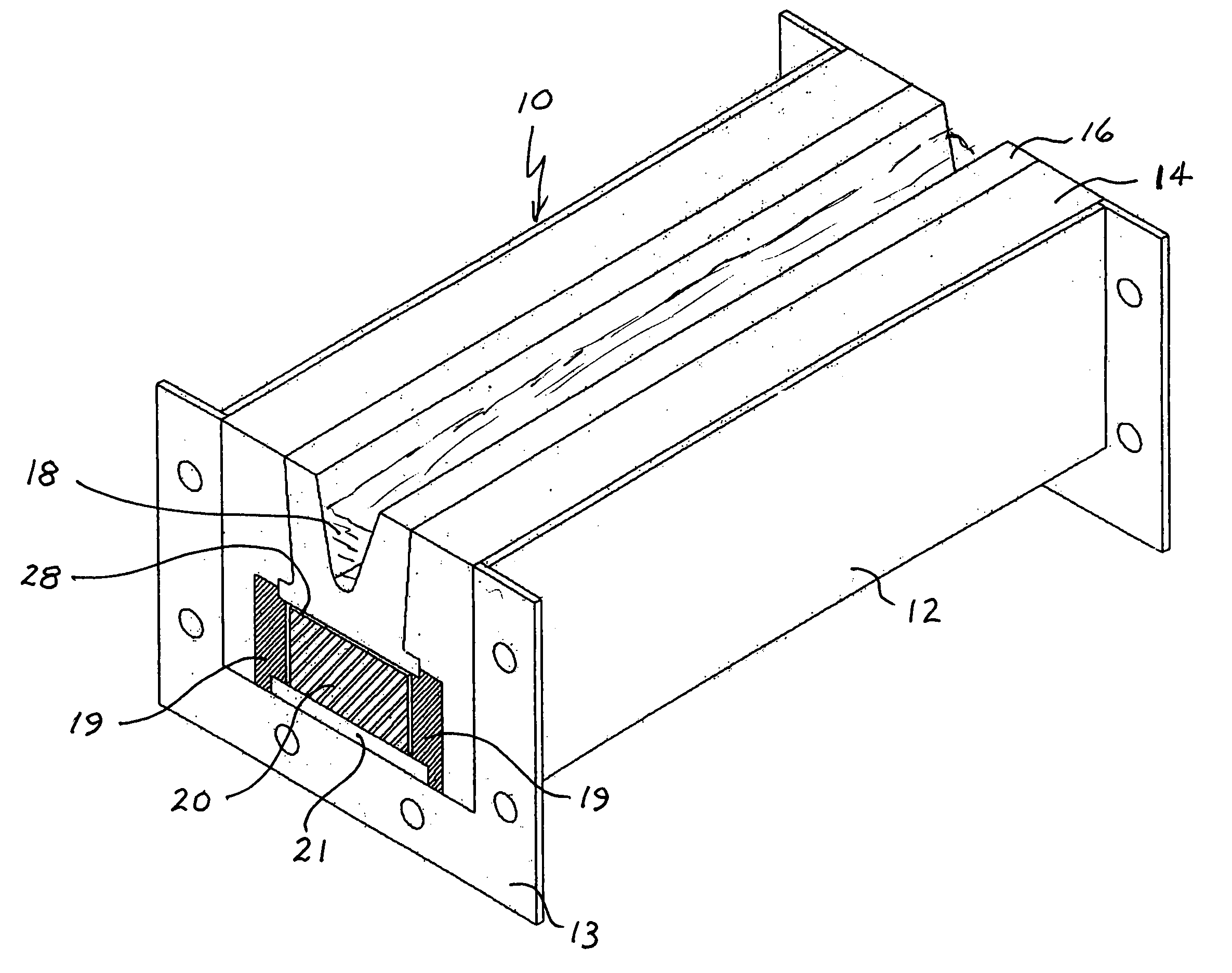

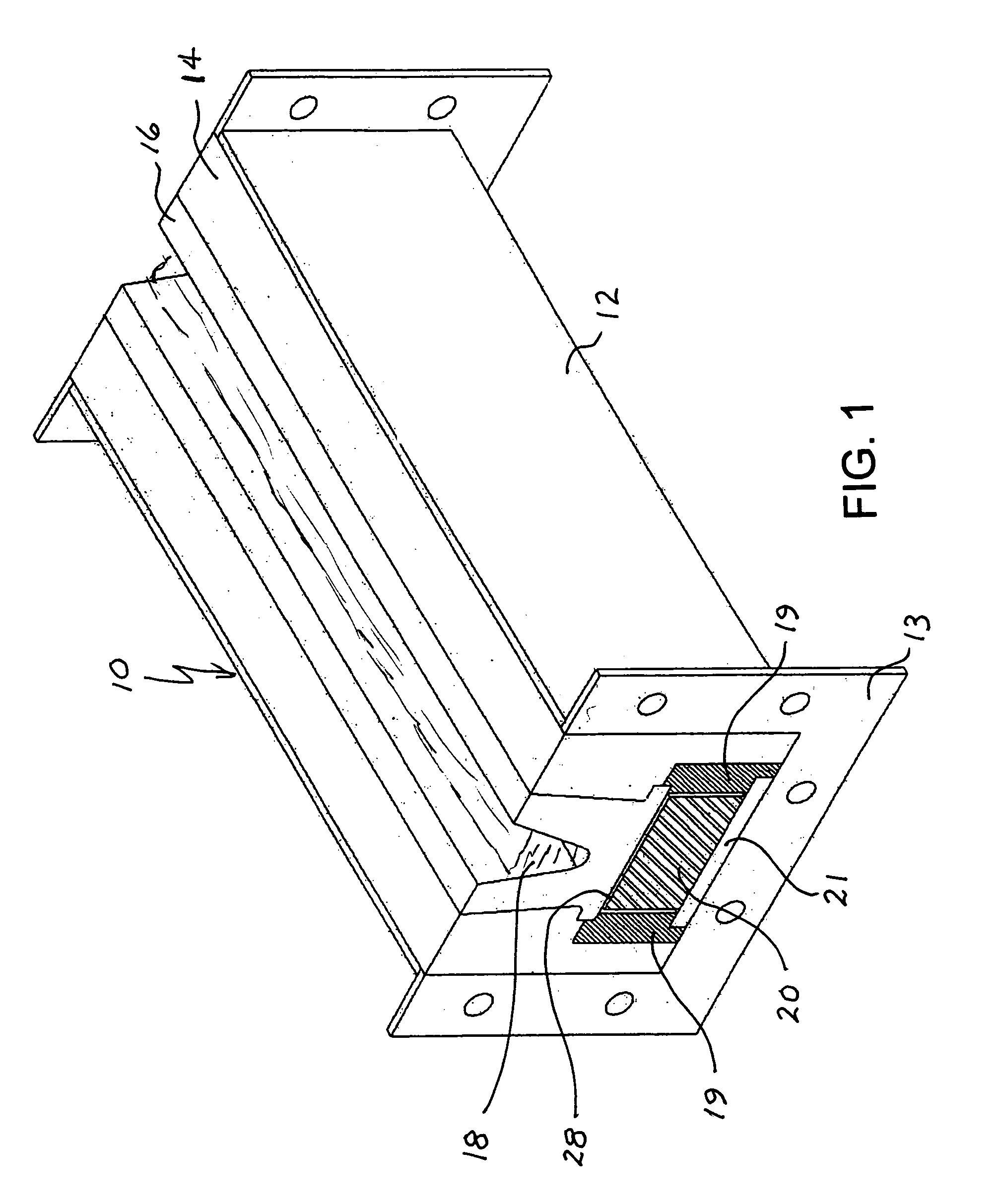

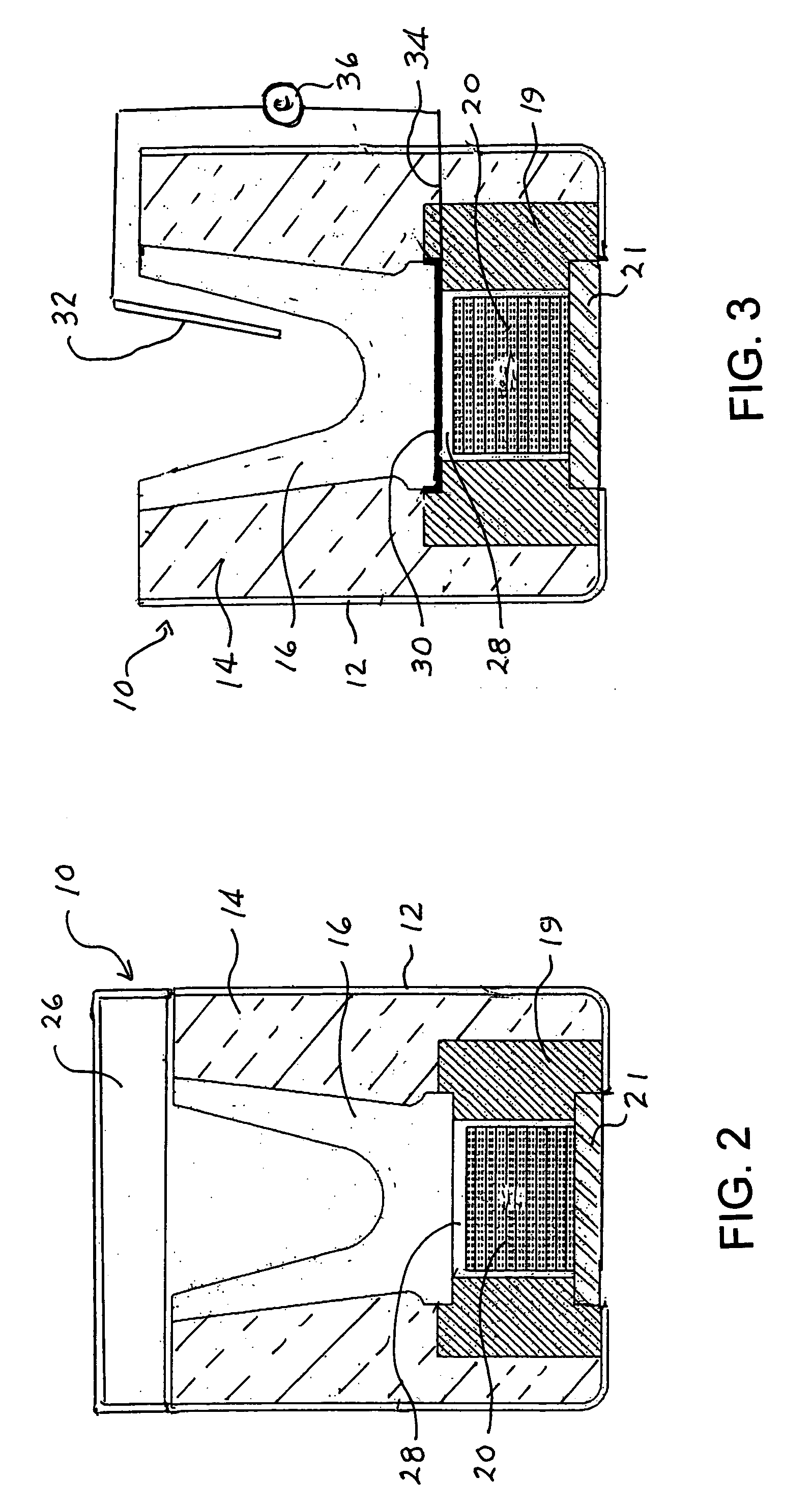

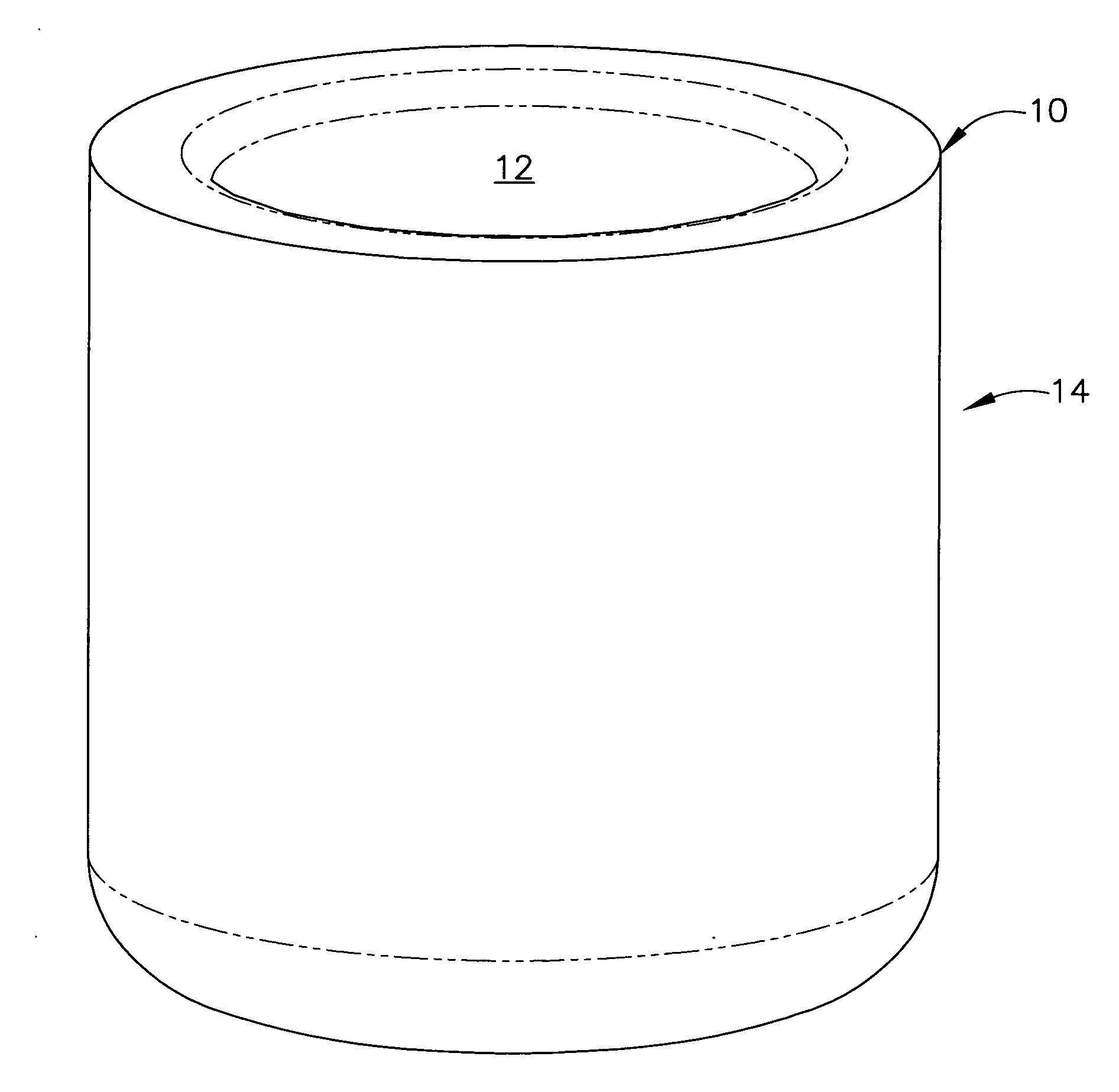

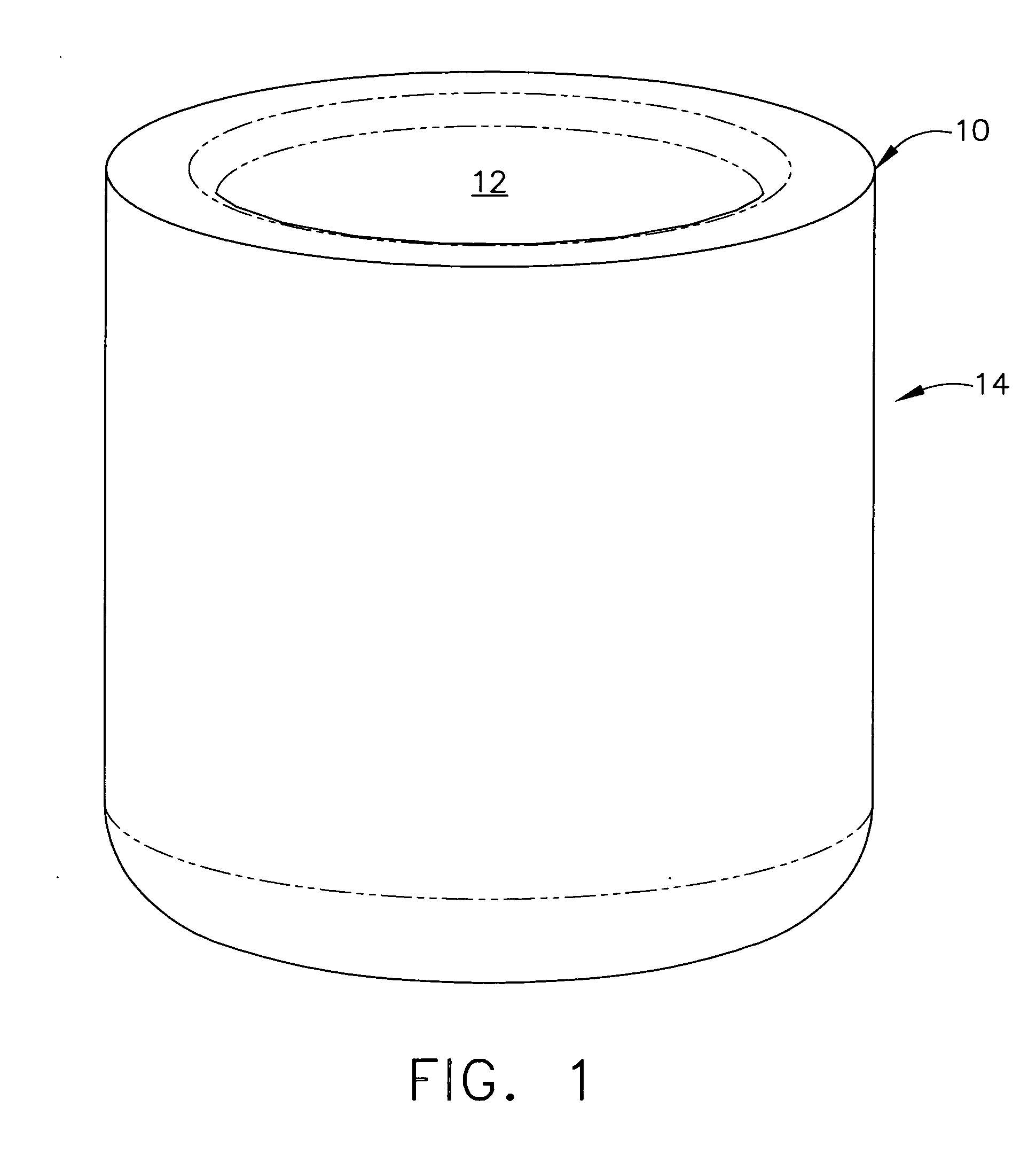

Molten metal containment structure having flow through ventilation

Exemplary embodiments of the invention provide a molten metal containment structure including a refractory molten metal containment vessel having an external surface, and a metal casing for the vessel having an internal surface at least partially surrounding the external surface of the vessel at a distance therefrom forming a spacing between the vessel and the casing. The spacing includes an unobstructed upwardly extending gap that is vented to the exterior of the structure by upper and lower openings in the casing. A layer of insulating material is preferably positioned in the spacing between the internal surface of the casing and the external surface of the vessel, with the layer of insulating material being narrower than the spacing at least at upwardly extending sides of the casing, thereby forming the unobstructed gap. The vessel may be a metal conveying trough, a housing for a metal filter, a container for a metal degasser unit, a crucible, or the like.

Owner:NOVELIS INC

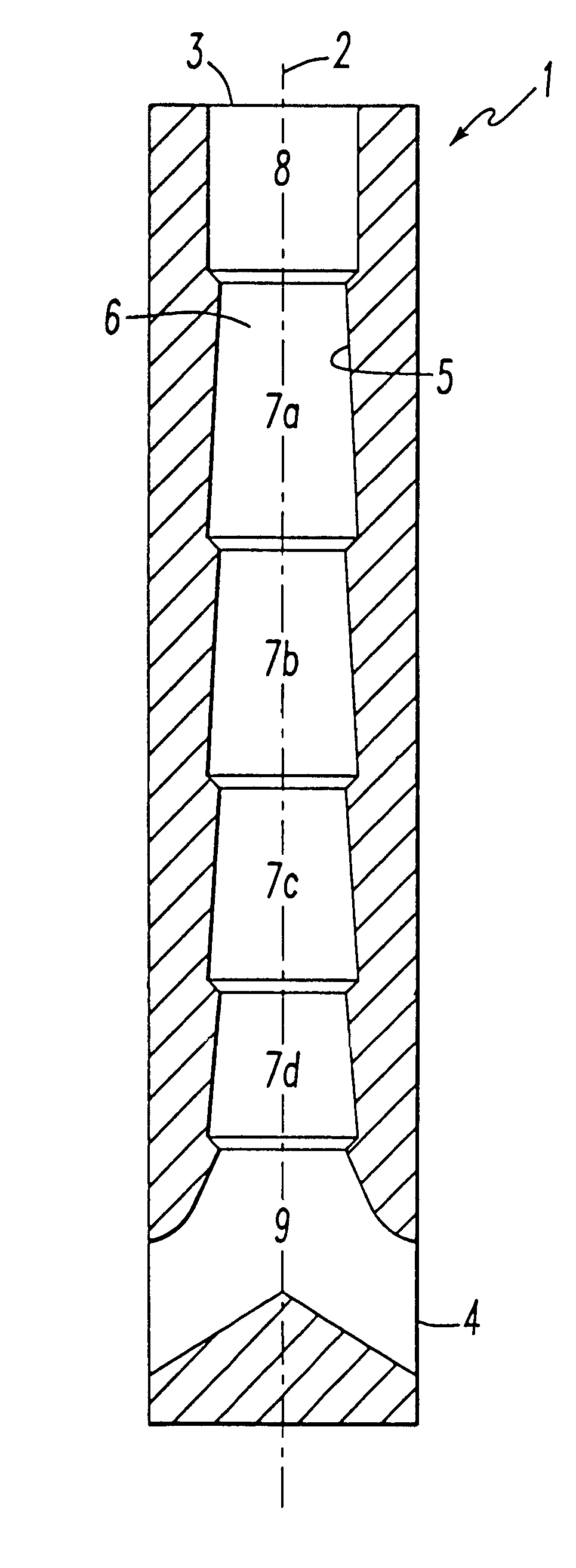

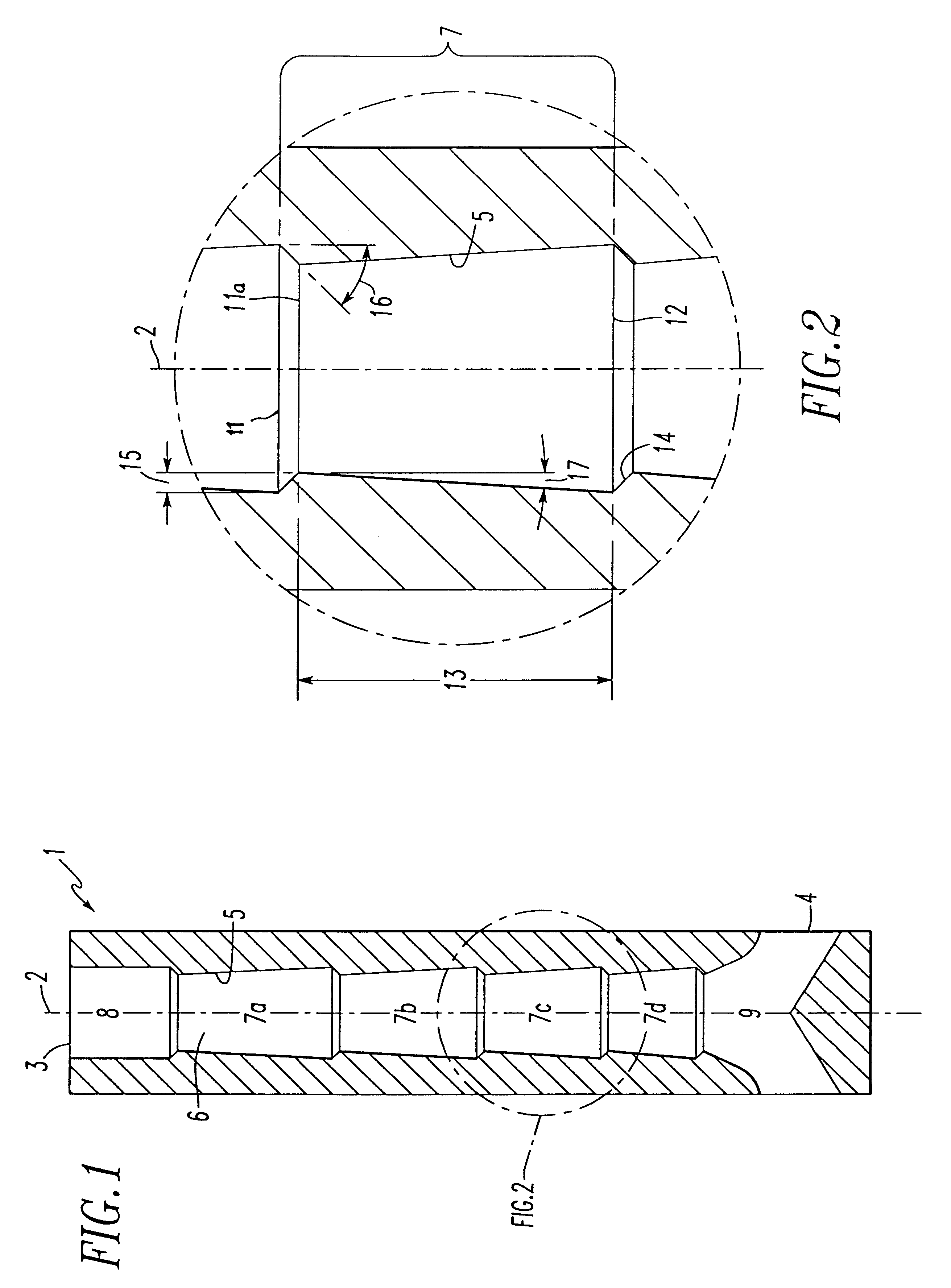

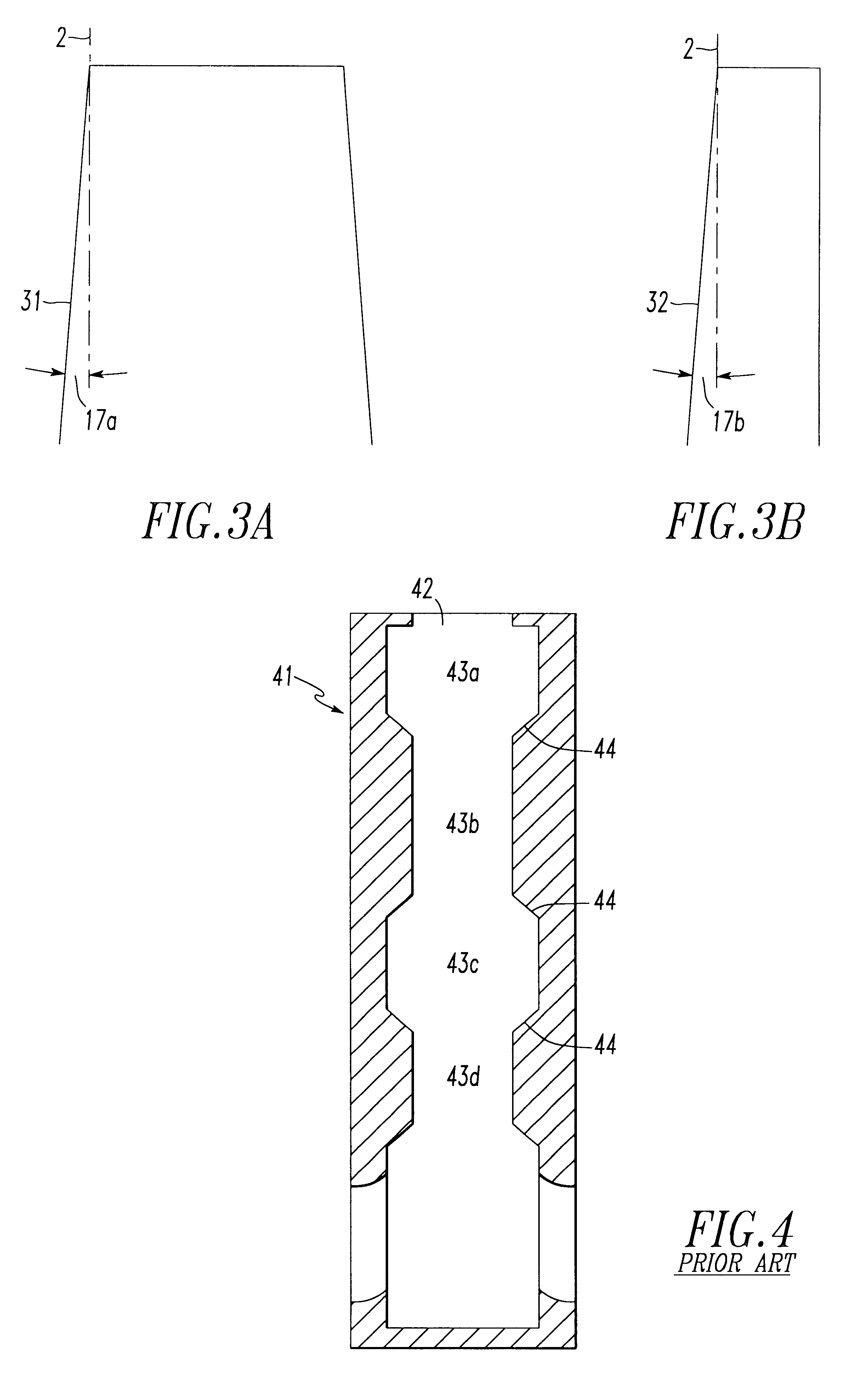

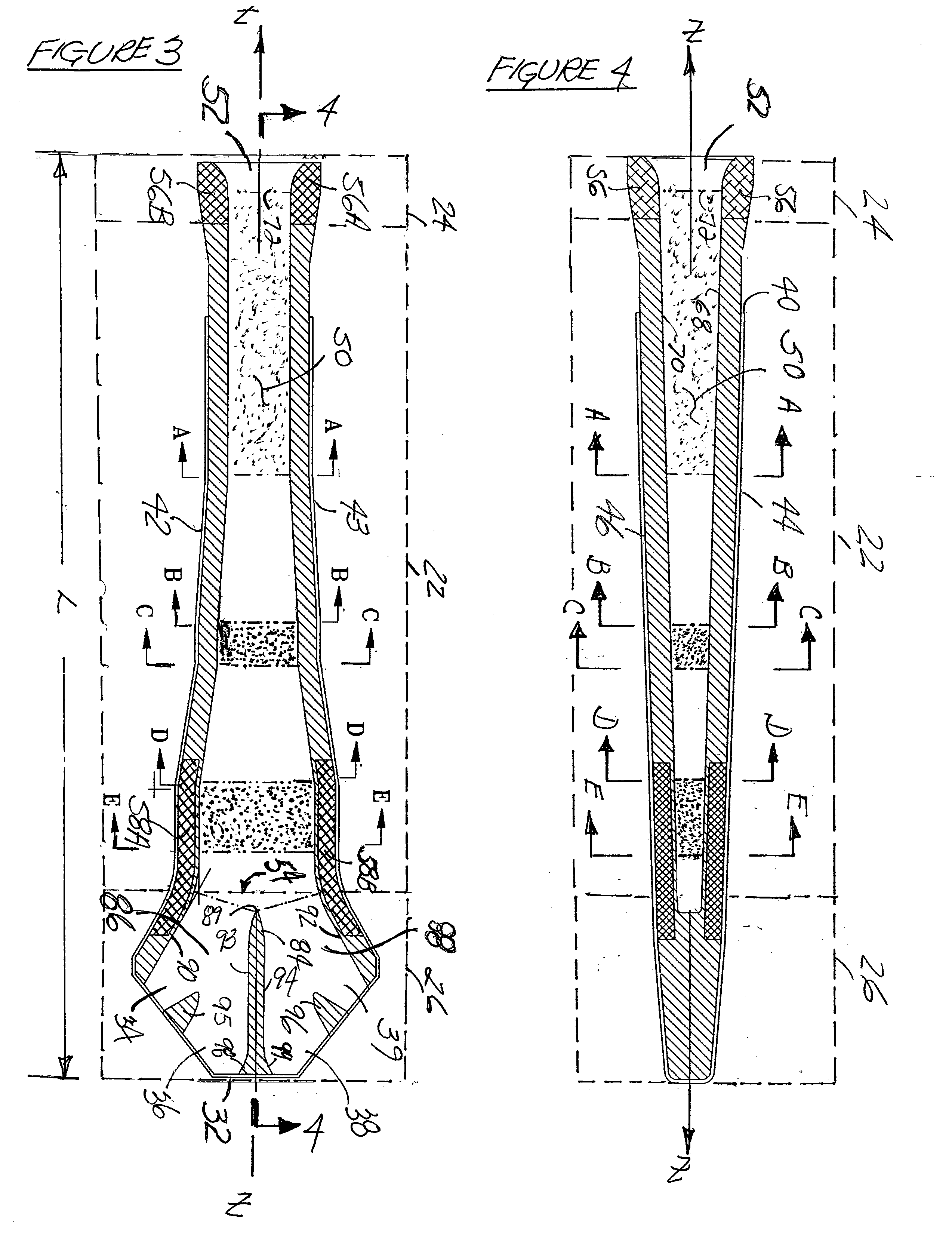

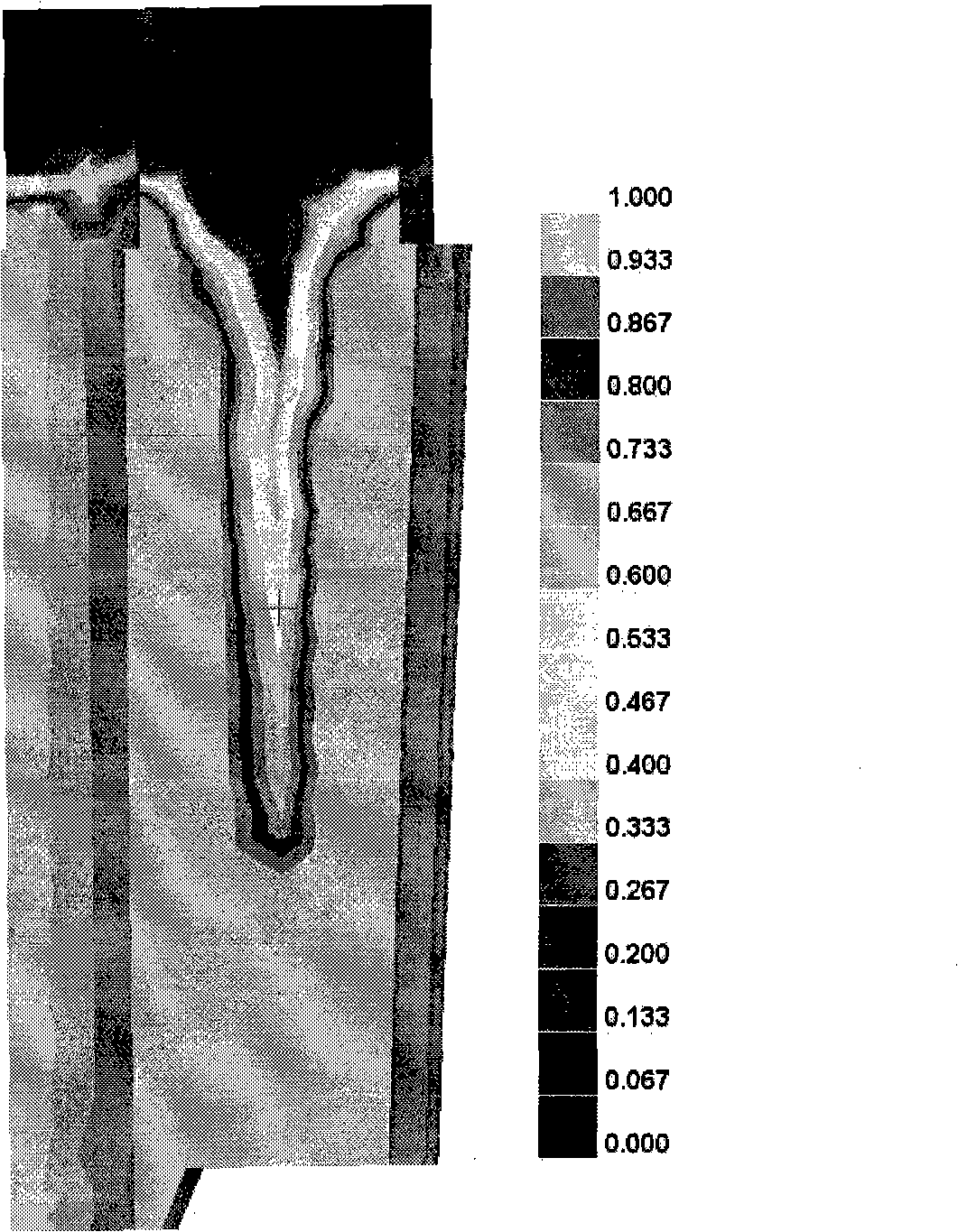

Pour tube with improved flow characteristics

A pour tube for use in the continuous casting of a stream of molten metal has a bore comprising a plurality of fluidly connected sections that improve the flow of molten metal through the bore. The sections reduce asymmetric flow of the molten metal stream and the likelihood of precipitates clogging the bore. Each section comprises a converging portion and a diverging portion. The converging portion deflects the stream toward the center of the bore, while the diverging portion diffuses the stream. The sections may comprise a plurality of frusto-conical sections. The cross-sectional areas of the sections may increase, decrease, or remain the same size from an upstream to a downstream position.

Owner:VESUVIUS USA CORP

Three-Dimensional Printing of Metallic Materials

InactiveUS20150217367A1Additive manufacturing apparatusMolten metal pouring equipmentsSolid regionMetallic materials

Methods of printing metallic objects include providing parameters of an object for printing, and controlling a deposition of a fluid metallic material to form the object. At least an outer surface region of the fluid metallic material is converted to a solid region after deposition.

Owner:NORTH CAROLINA STATE UNIV

Mold pump

PendingUS20170246681A1Specific fluid pumpsMolten metal supplying equipmentsMolding machineGuide tube

A molding machine for molding material is provided. The machine includes a cavity to be filled with molten metal and a conduit system leading to the cavity, thus forming a system of interconnected hollow spaces. At least one pressure member is moveable in at least part of the conduit system. A centrifugal pump in fluid communication with a reservoir of molten metal is provided, the pump providing molten metal to the hollow space receiving the at least one pressure member.

Owner:PYROTECK INC

Method of and apparatus for conveying molten metals while providing heat thereto

InactiveUS20080163999A1High heat conductivityPrevent oxidationHot-air central heatingLighting and heating apparatusCombustionEngineering

The invention relates to a method of and apparatus for providing heat to a molten metal flowing through metal-conveying apparatus. The apparatus includes a molten metal-conveying channel, an enclosure for receiving and circulating combustion gases while preventing entry of the gases into said channel, a heat-conductive body of material separating at least part of the channel from the enclosure; and a combustion device for generating combustion gases and delivering the gases to the enclosure. Heat from the combustion gases is used to heat molten metal held in the channel, while preventing contact between the combustion gases and the molten metal. The body of material may be a trough used to form the channel, a tube for conveying the molten metal, or a tube acting as the enclosure, or the like.

Owner:NOVELIS INC

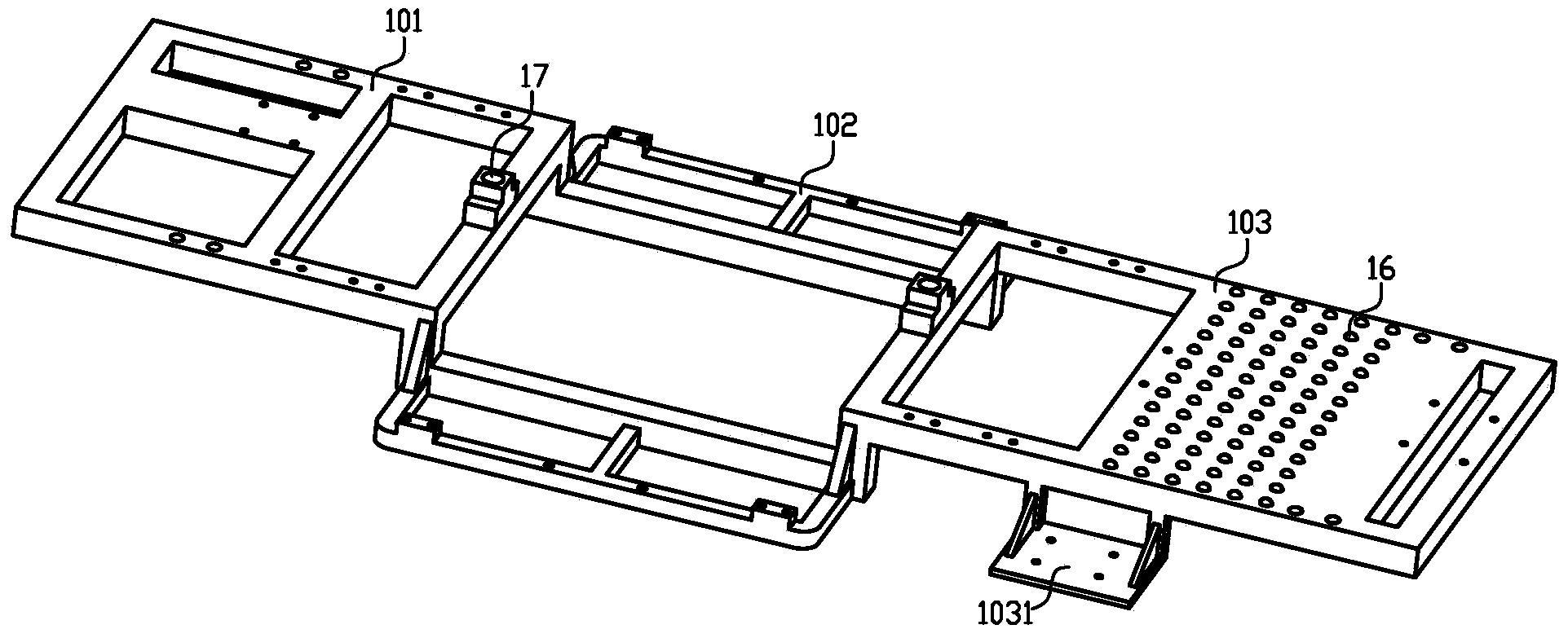

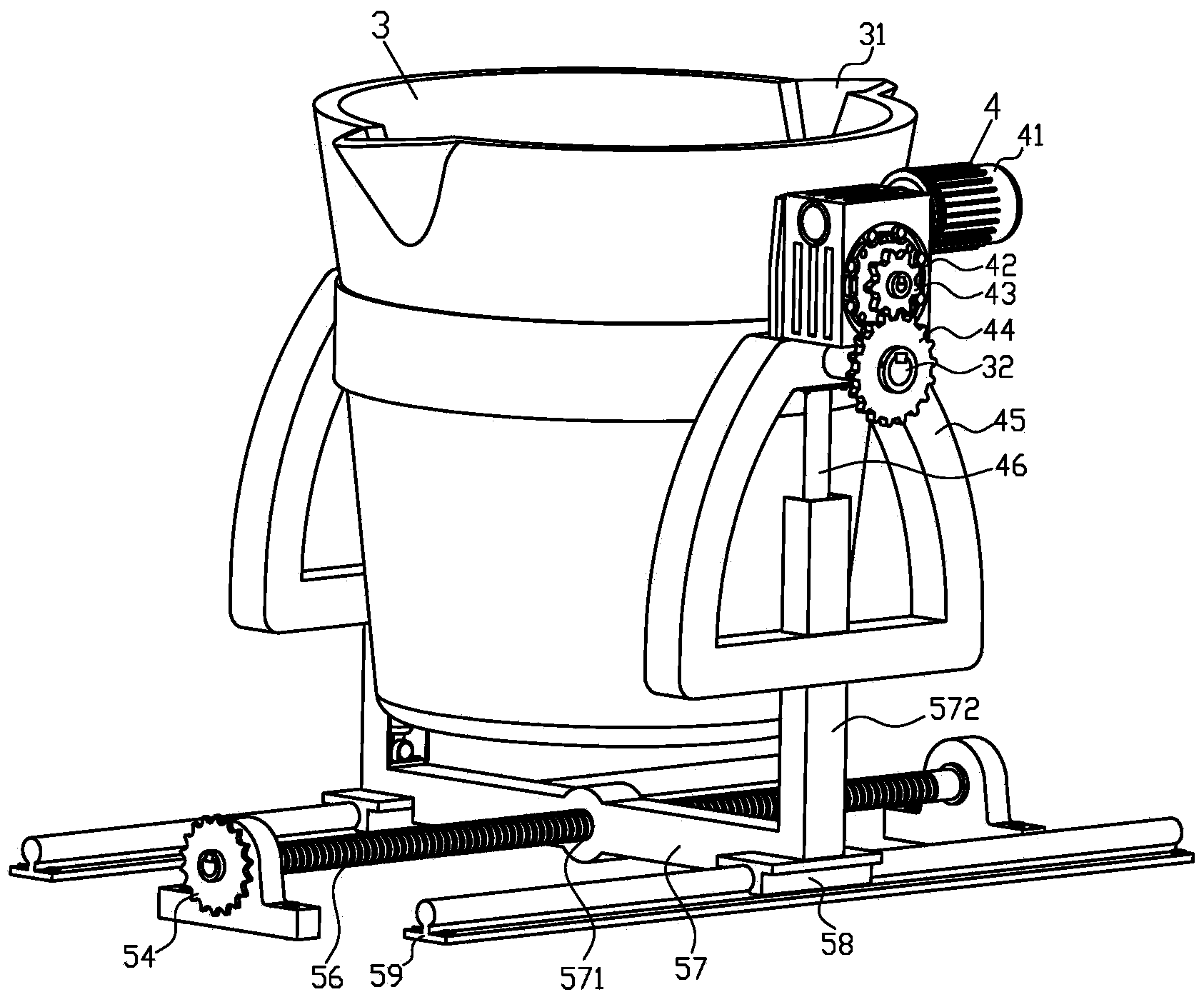

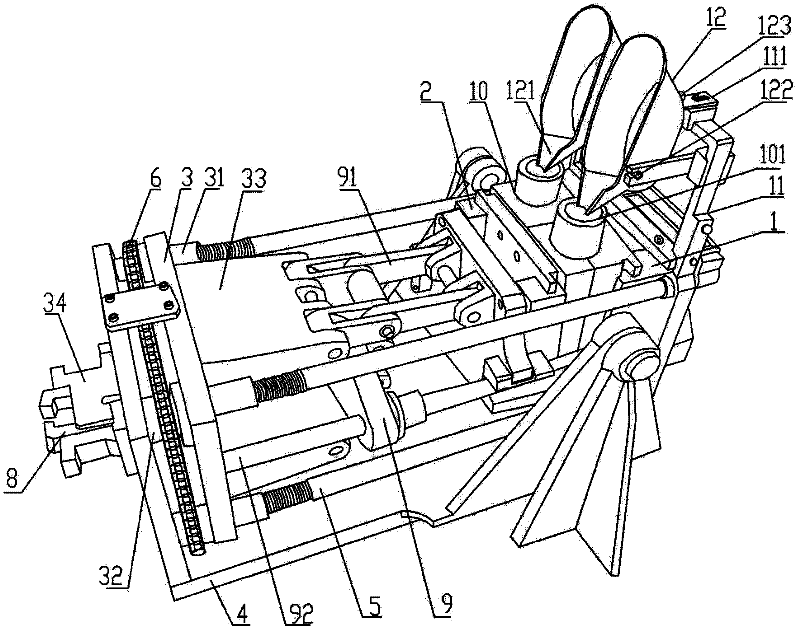

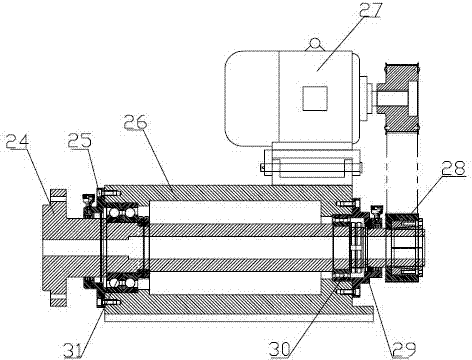

Rail-wheel type semi-automatic bilateral casting machine

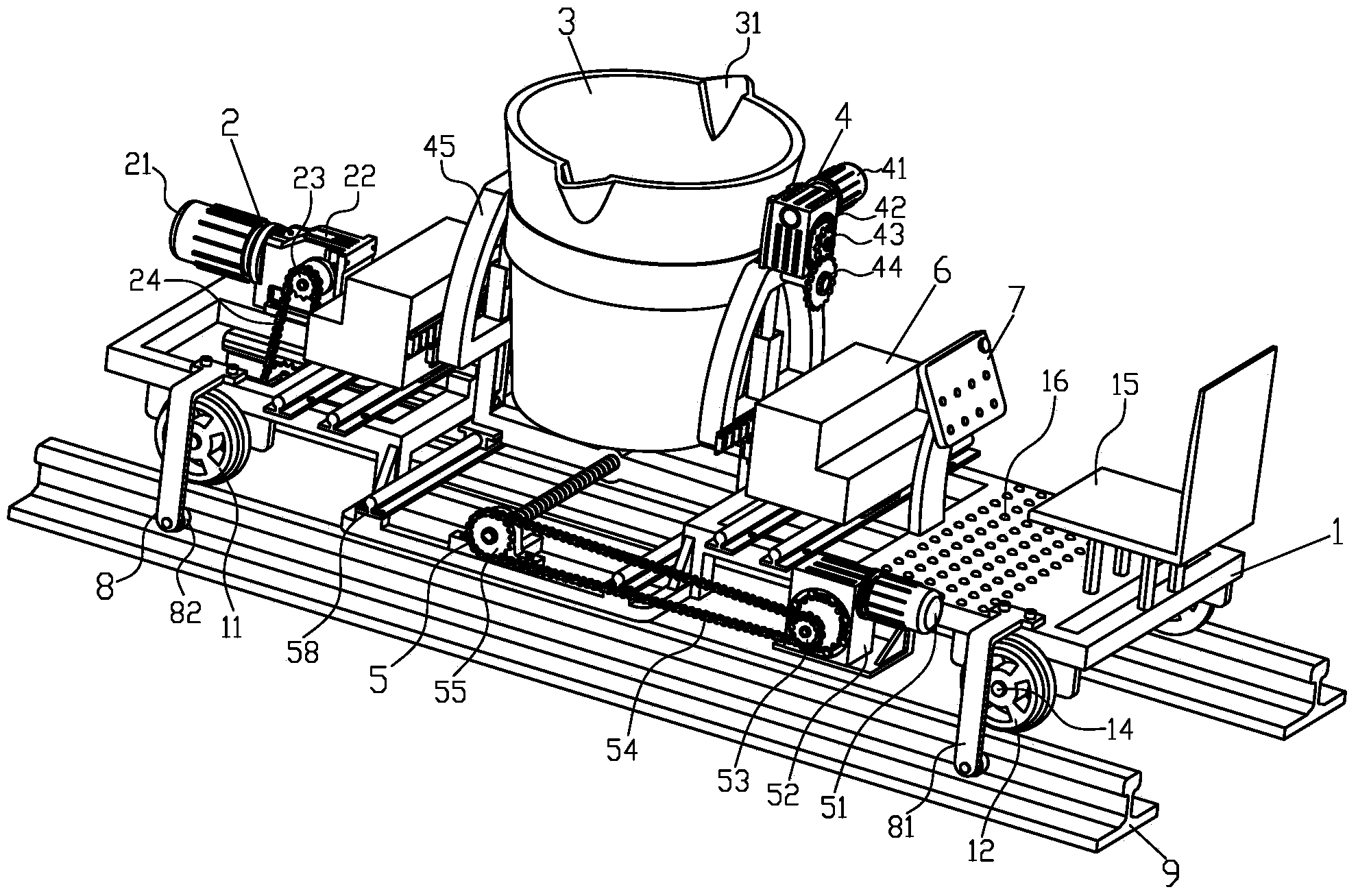

InactiveCN104308135AOvercoming technical deficienciesPrecise positioningMelt-holding vesselsMolten metal conveying equipmentsDrive wheelSemi automatic

The invention discloses a rail-wheel type semi-automatic bilateral casting machine which comprises a frame body, a travel driving unit, a casting ladle, a tilting unit, a side shifter, a counterweight unit, a controller and four tilting prevention units. The travel driving unit located at the front end of the frame body is used for driving the casting machine to travel along an H-shaped guide rail, and a seat and the controller are mounted at the rear end of the frame body; the tilting unit is used for driving the casting ladle to tilt to pour over liquid metal in the casting ladle, two sprues are arranged in the top of the casting ladle, and the casting ladle is mounted on the tilting unit through a rotating shaft of the same; the side shifter can drive the casting ladle to move laterally and can enable the counterweight unit to move backwardly synchronously; the tilting prevention units are respectively mounted on outer sides of driving wheels and driven wheels. By the arrangement, technical defects of an existing casting machine can be overcome; the rail-wheel type semi-automatic bilateral casting machine is used for batch casting situations and has functions of synchronous counterweight, safety tilting prevention, bilateral casting and the like, and has the advantages of accurate positioning, reliable operation, convenience in operation and maintenance and the like.

Owner:ANHUI UNIV OF SCI & TECH +1

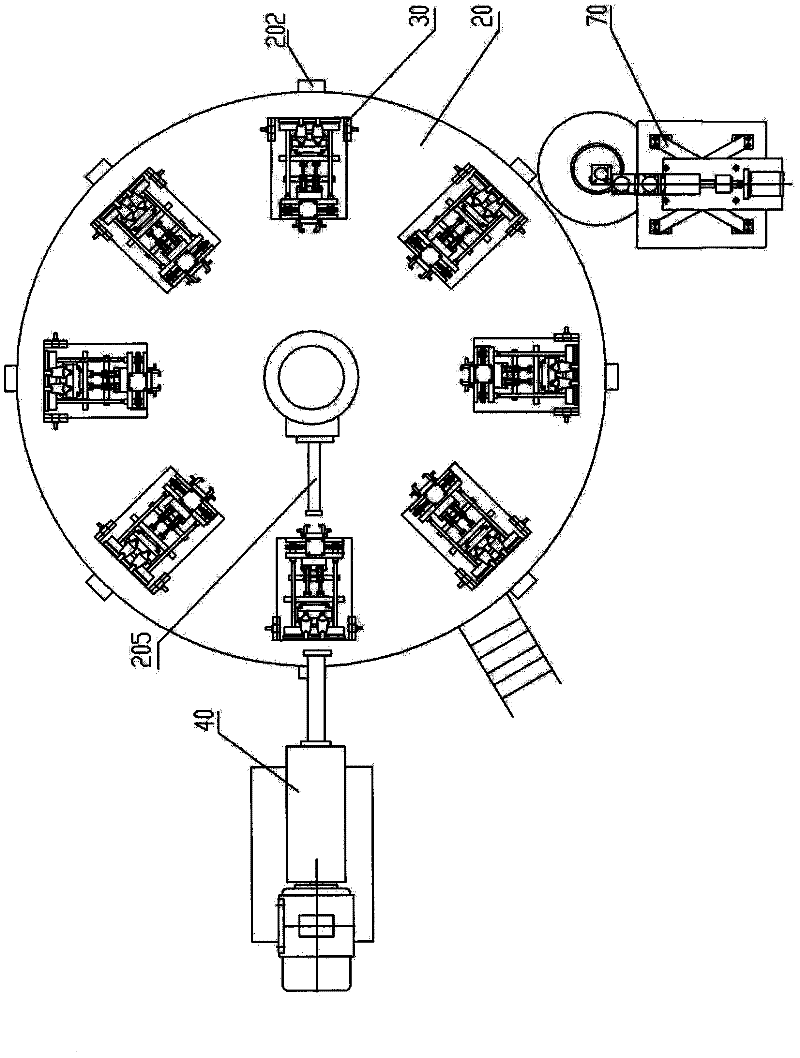

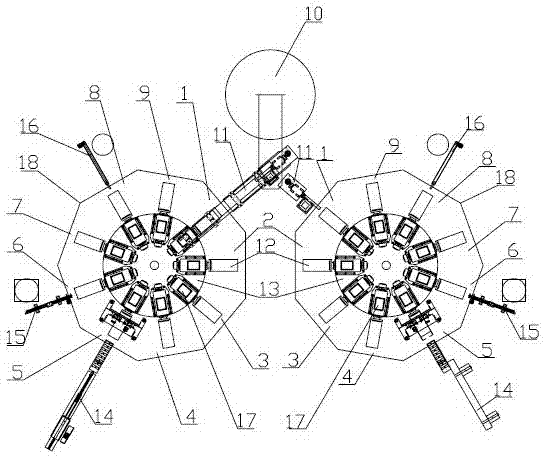

A multi-station automatic pouring machine

ActiveCN102259183AEasy to adjustAccurate adjustmentPig casting plantsMolten metal conveying equipmentsMotor driveGear wheel

The invention discloses a multi-station full-automobile casting machine comprising a casting robot. The casting robot is fixed on one side of a workbench on a mainframe, at least three casting units are annularly distributed on the workbench, and a hydraulic pushrod mechanism is arranged face to face at one casting unit on one side of the workbench; the hydraulic pushrod mechanism supports the casting unit, a bull gear is arranged at the bottom of the workbench, pulley supports are fixed on the edge of the workbench corresponding to the casting units, each pulley support is provided with a pulley, a guide rail table is arranged on the mainframe and is provided with a motor, the motor drives a small pinion to rotate, the small pinion is meshed with the bull gear, and the pulleys acts circular movement along the guide rail table. With the multi-station full-automobile casting machine, a whole lower mould fixture moves to be regulated through the regulation of a guide rod so as to meet the requirement of an upper casting mould and a lower casting mould on compact matching; simultaneously, the casting units rotate through a hydraulic system, thus the manufactured castings have higher degree of crystallization and higher strength.

Owner:浙江文源智能科技有限公司

Liquid metal droplet generator

Small, high velocity liquid metal droplets are produced for applications that require the accurate and remote placement of small quantities of a metal. The magnetic pressure of current flowing through liquid metal is used to force small quantities of liquid metal through an orifice. Examples of applications are to feed metal fuel into plasma extreme ultraviolet sources, and to place solder bumps on an integrated circuit prior to the attachment of connections.

Owner:PUREX

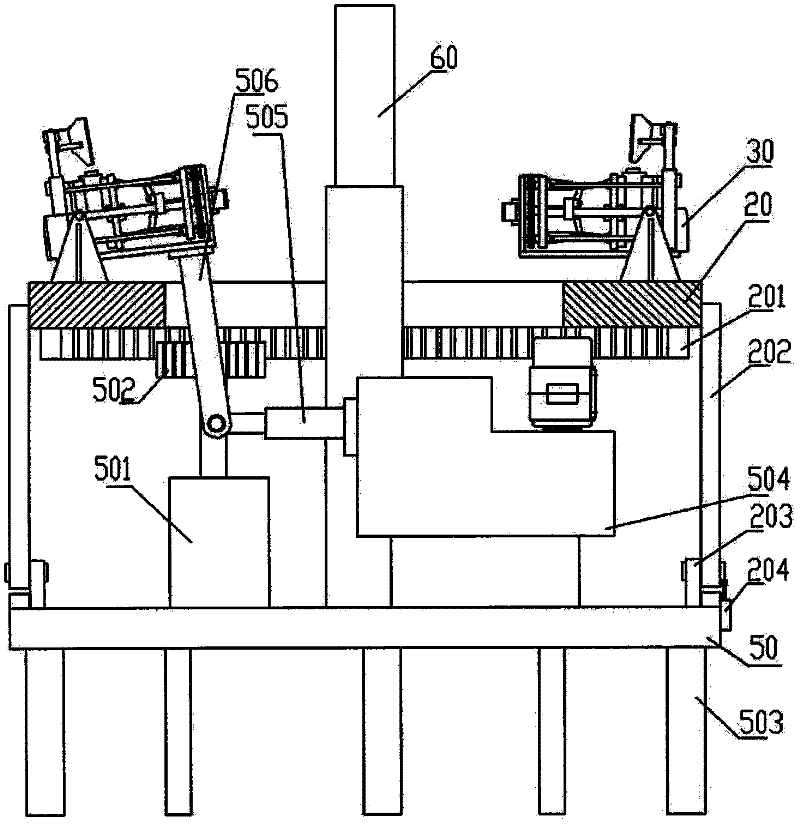

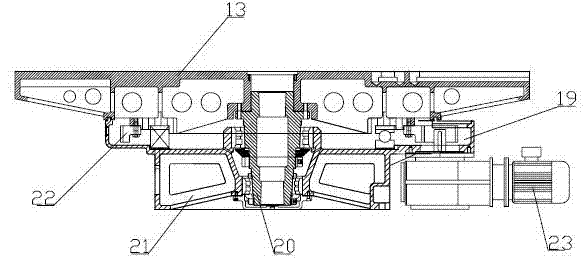

Automatic nine-station casting machine for engine cylinder liner blank

InactiveCN102441659AImprove work efficiencyReduce labor intensityMolten metal conveying equipmentsEngineeringMechanical engineering

The invention discloses an automatic nine-station casting machine for an engine cylinder liner blank, which comprises a nine-station rotating worktable connected with a power device. Nine stations comprising nine casting power heads and nine centrifugal casting dies are mounted on the rotating worktable, and a smelting furnace is arranged on one side of the rotating worktable. By means of the principle of centrifugal casting, the nine-station casting machine for the engine blank is provided with a power turntable, the casting power heads, an automatic casting system, an automatic water shocking system, an automatic cylinder drawing system, an automatic cleaning system, an automatic coating spraying system and the like, the working efficiency of the casting machine is high, one blank is averagely cast in 35-40 seconds and can be made into at least one cylinder liner blank and at most four cylinder liner blanks, and 300-360 thousand of cylinder liner blanks can be produced in a year.

Owner:ZYNP GRP

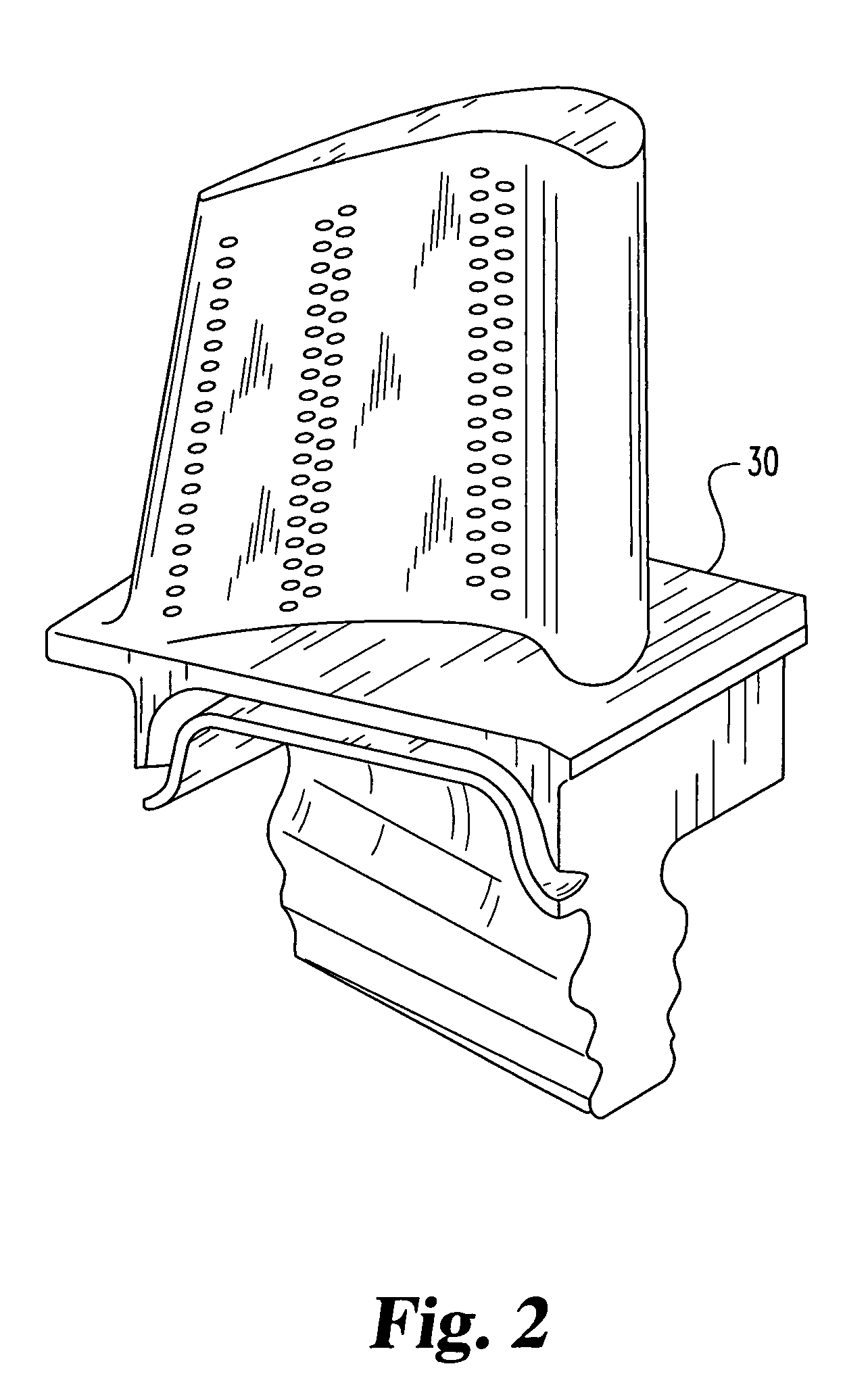

Casting delivery nozzle with insert

InactiveUS20080264599A1Easy to replaceReduces turbulence in flowMolten metal pouring equipmentsMolten metal supplying equipmentsMolten metalNozzle

A metal strip casting apparatus and a method of casting continuous metal strip includes assembling a pair of counter-rotatable casting rolls having casting surfaces positioned laterally forming a nip between for casting, and delivering molten metal through a delivery nozzle disposed above the nip capable to form a casting pool supported on the casting rolls. The delivery nozzle comprises segments each having elongate nozzle body with longitudinally extending side walls, end walls and a bottom part to form an inner trough, a nozzle insert disposed above bottom portions of the inner trough of each segment and supported relative to the nozzle body through which incoming molten metal may be delivered to the inner trough of each segment of the delivery nozzle, and the elongate nozzle body of each segment having passageways in fluid communication with the inner trough and outlet openings capable of discharging molten metal from the nozzle body outwardly into the casting pool.

Owner:NUCOR CORP

Aluminum alloy wheel gravity casting die and casting method thereof

InactiveCN102029383ARiser lessHigh weight yieldMolten metal conveying equipmentsMetallurgyAlloy wheel

The invention discloses an aluminum alloy wheel gravity casting die and a casting method thereof. The aluminum alloy wheel gravity casting die comprises a cooling device, a top die, a side die, a bottom die and a die cavity formed by the top die, the side die and the bottom die; the bottom die is provided with a sprue spreader; the aluminum alloy wheel gravity casting die also comprises a heat insulation cup communicated with the die cavity and capable of storing molten aluminum, a pressing device capable of enabling the molten aluminum stored in the heat insulation cup to be continuously injected into the die cavity, and a plugging device capable of stopping the molten aluminum stored in the heat insulation cup from flowing into the die cavity under the action of gravity; the heat insulation cup is arranged on a rack of a gravity casting machine, and the plugging device is arranged on the bottom die or the rack of the gravity casting machine; and the casting method for the aluminum alloy wheel gravity casting die comprises molten aluminum injection, pressing, continuous casting, filling, feeding, crystallization and solidification. The cast aluminum alloy wheel has the advantages of a few dead heads, high weight and yield, and good quality stability.

Owner:何丙军 +1

Heated trough for molten metal

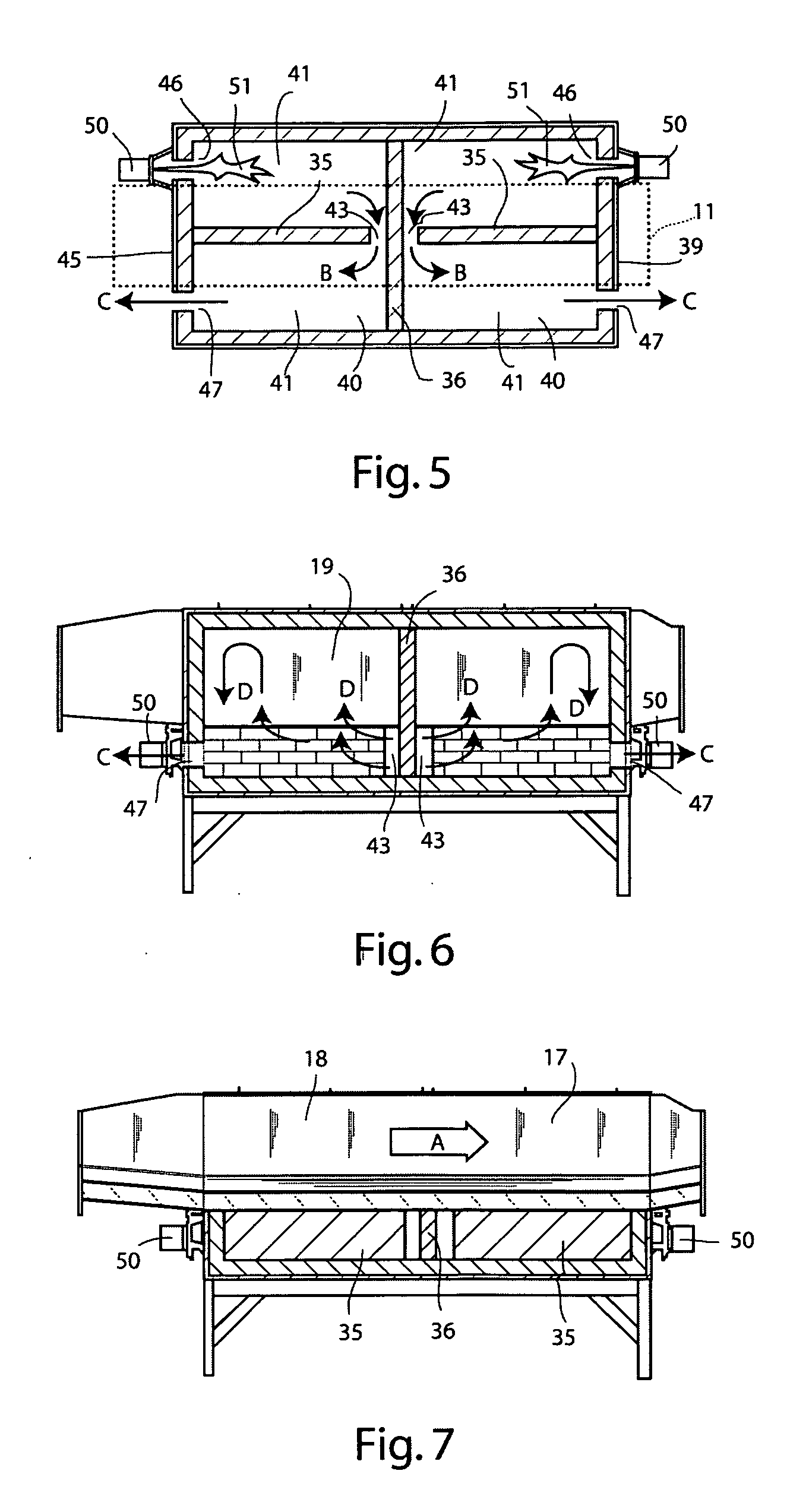

ActiveUS20050126738A1Melt-holding vesselsMolten metal pouring equipmentsMaterials scienceMolten metal

A trough is described for carrying molten metal, comprising an outer shell defined by a bottom wall and two side walls, an insulating layer filling the outer shell and a conductive U-shaped refractory trough body for carrying molten metal, the trough body being embedded in the insulating layer. At least one heating element is positioned in the insulating layer, adjacent to but spaced apart from the trough body, to provide an air gap between the heating element and the trough body.

Owner:NOVELIS INC

Process for preparing the walls of a mold for molding or shaping to make them ready for the next molding cycle

In a process for preparing the mold walls (12a, 12b) of a mold (12, 12) for the molding or shaping of a molded part after completion of the molding cycle and after removal of the molded part from the mold (12) to make the mold walls ready for the next molding cycle, the tempering of the mold walls (12a, 12b) and the coating of the walls with mold wall treatment agent are carried out independently of each other, i.e., without any time overlap, and in a controlled manner, preferably in a program-controlled manner. To apply the coating, preferably a spray element with centrifugal atomization and air control is used, the mold walls preferably being coated with essentially solvent-free mold wall treatment agent.

Owner:HENKEL IP & HOLDING GMBH

Control pin and spout system for heating metal casting distribution spout configurations

InactiveUS20100032455A1Melt-holding vesselsMolten metal pouring equipmentsDistribution systemEngineering

A control pin system, including an apparatus and method, for use in controlling the flow of molten metal in a molten metal distribution system for casting, with some aspects of the control pin including: a control pin body with an internal cavity and an outer surface, wherein the outer surface is sized and configured to operatively interact with an internal surface of a spout to effectively control the flow of molten metal through a spout aperture; and a heater element within the internal cavity of the control pin body. In other embodiments, the heater may be located within the spout body and transferring heat to the control pin.

Owner:WAGSTAFF INC

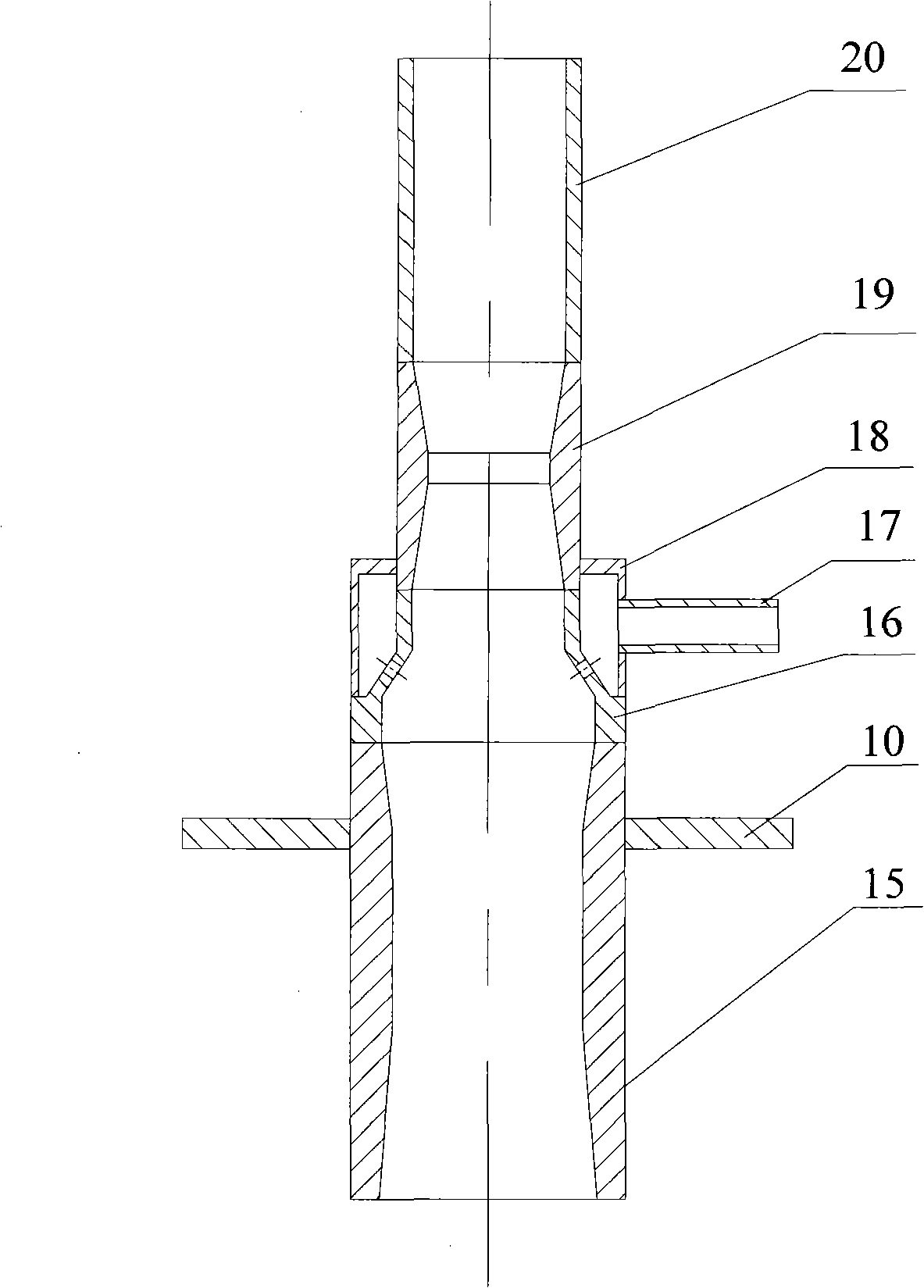

Submerged entry nozzle

InactiveUS20060243760A1Increase flow dynamicsMinimizing steel flow turbulenceMelt-holding vesselsMolten metal pouring equipmentsMetallurgyThin slab

A nozzle for transferring molten steel in a thin slab continuous casting machine from the tundish to the mold which provides at least two areas of stream compression below the major changes in section required to transition from the entry diameter to the rectangular submerged portion of the nozzle.

Owner:NUCOR CORP

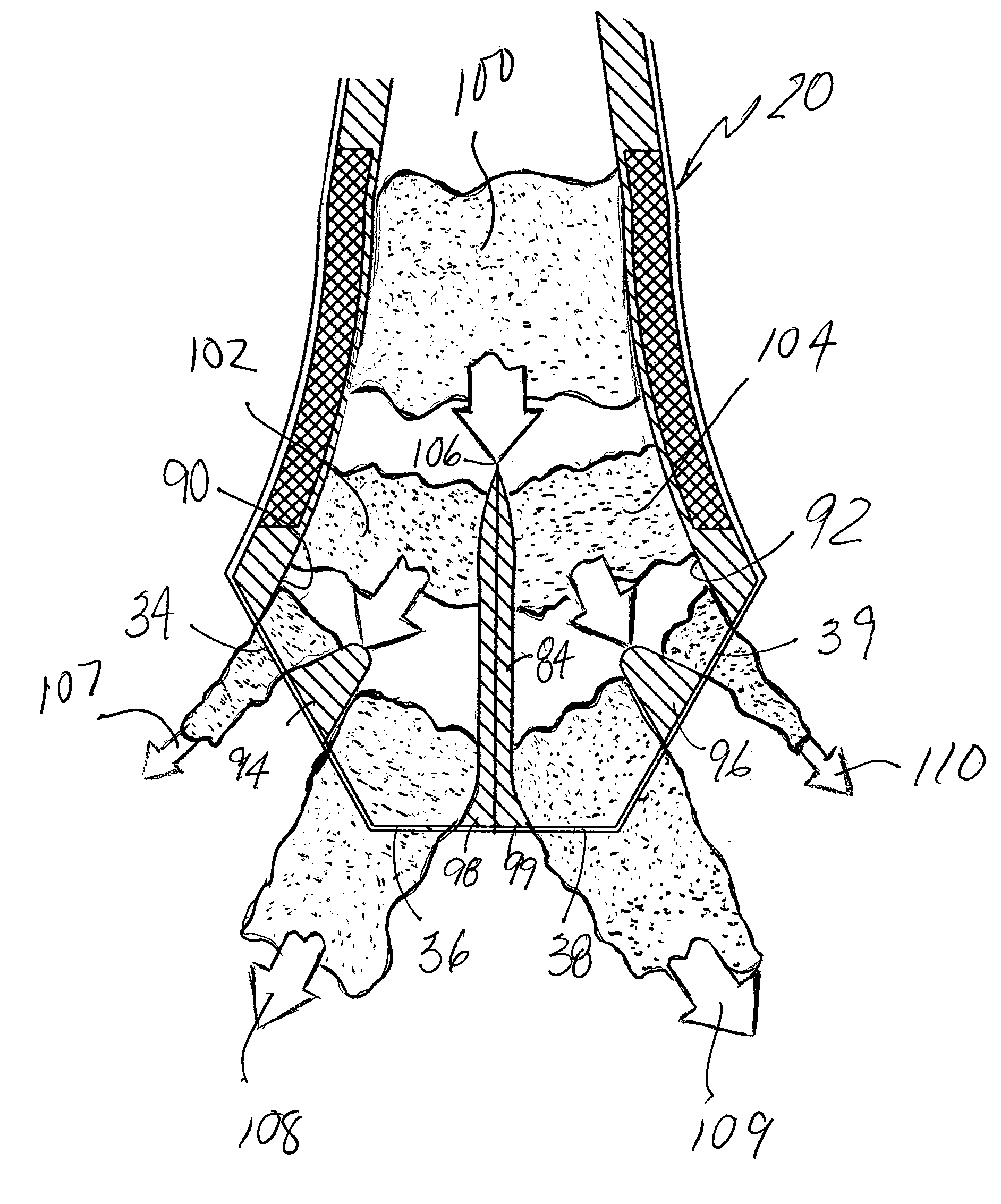

Method and apparatus for production of a cast component

InactiveUS7343960B1Minimize heat transferBlast furnace componentsBlast furnace detailsCasting moldPressure difference

A system for producing cast components from molten metal. One form of the present invention includes a system for the precision pouring of molten metal within a casting mold. The precision pouring system is driven by a pressure differential.

Owner:ROLLS ROYCE CORP

Method for manufacturing compound core low-segregation large-sized hollow steel ingot

InactiveCN101279359AGuaranteed sequential solidificationIncrease profitFoundry mouldsFoundry coresTemperature differenceIngot

The invention relates to a casting process of all levels of large-scale hollow ingots below 250-ton level, in particular to a manufacturing method of composite core low-segregation large-scale hollow ingots. The manufacturing method is applicable to the preparation process of all large-scale hollow ingots which adopt the composite core pouring, comprising the casting of the hollow ingots with various shapes, specifications and materials. In addition to the usage of the computer simulation means to reasonably design an ingot mold and a pouring system, the invention mainly adopts the composite core hole forming technology, the large temperature difference cooling technology, the narrow gap molding sand technology, the bottom pouring dispersible gate drainage technology, the thick and large chassis mandatory cooling technology and a liquid nitrogen ejector device etc., and the invention further designs the corresponding mold and the equipment, pours the steel water with the different materials and prepares the low-segregation hollow ingots. The invention can ensure the serial solidification of the hollow ingots, reduce the defects of shrinkage, loose and inclusion, control the segregation position, lead the segregation band of the hollow ingots to be positioned at the middle position and improve the utilization rate and the using range of the hollow ingots.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

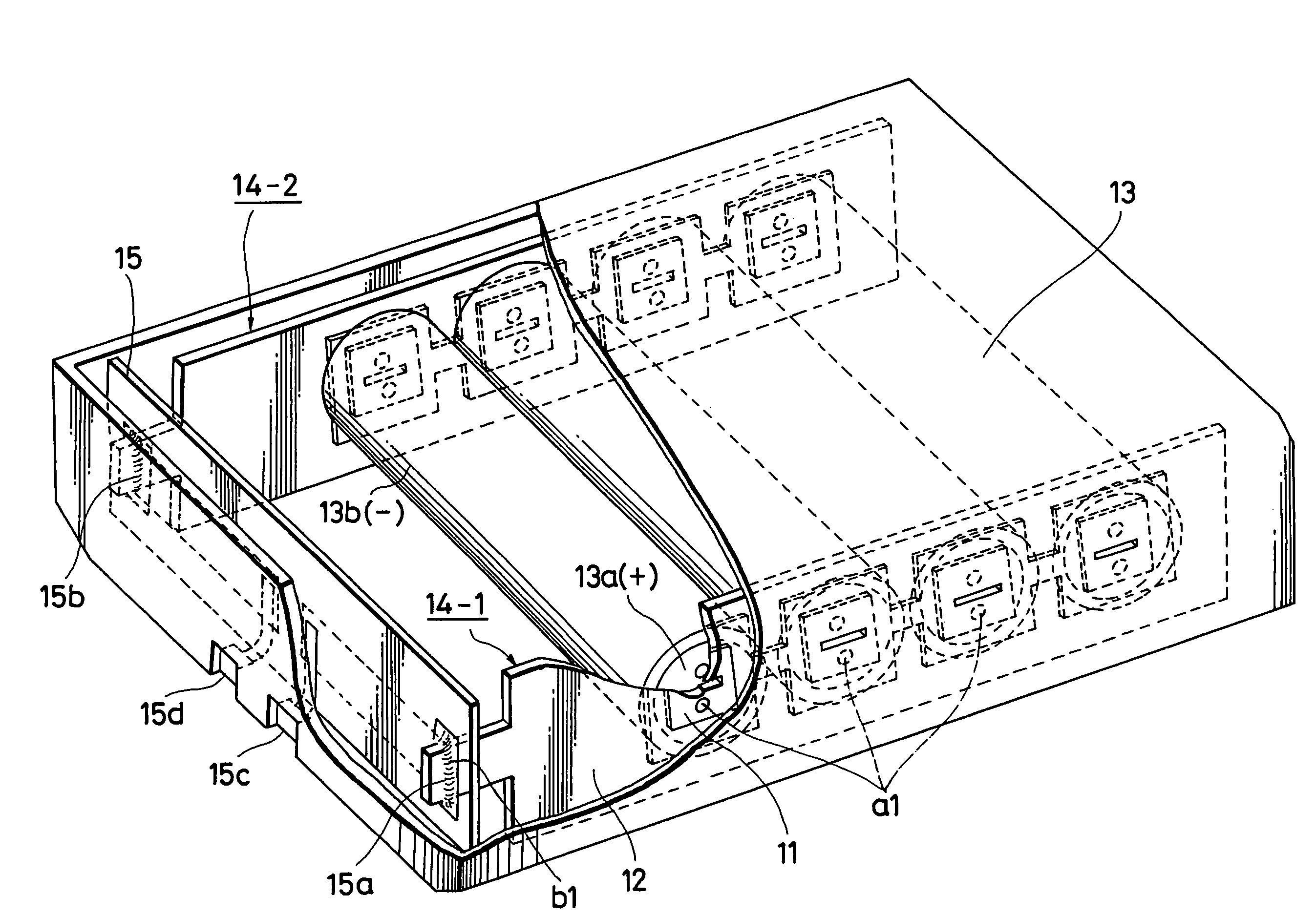

Battery pack having thin terminal board

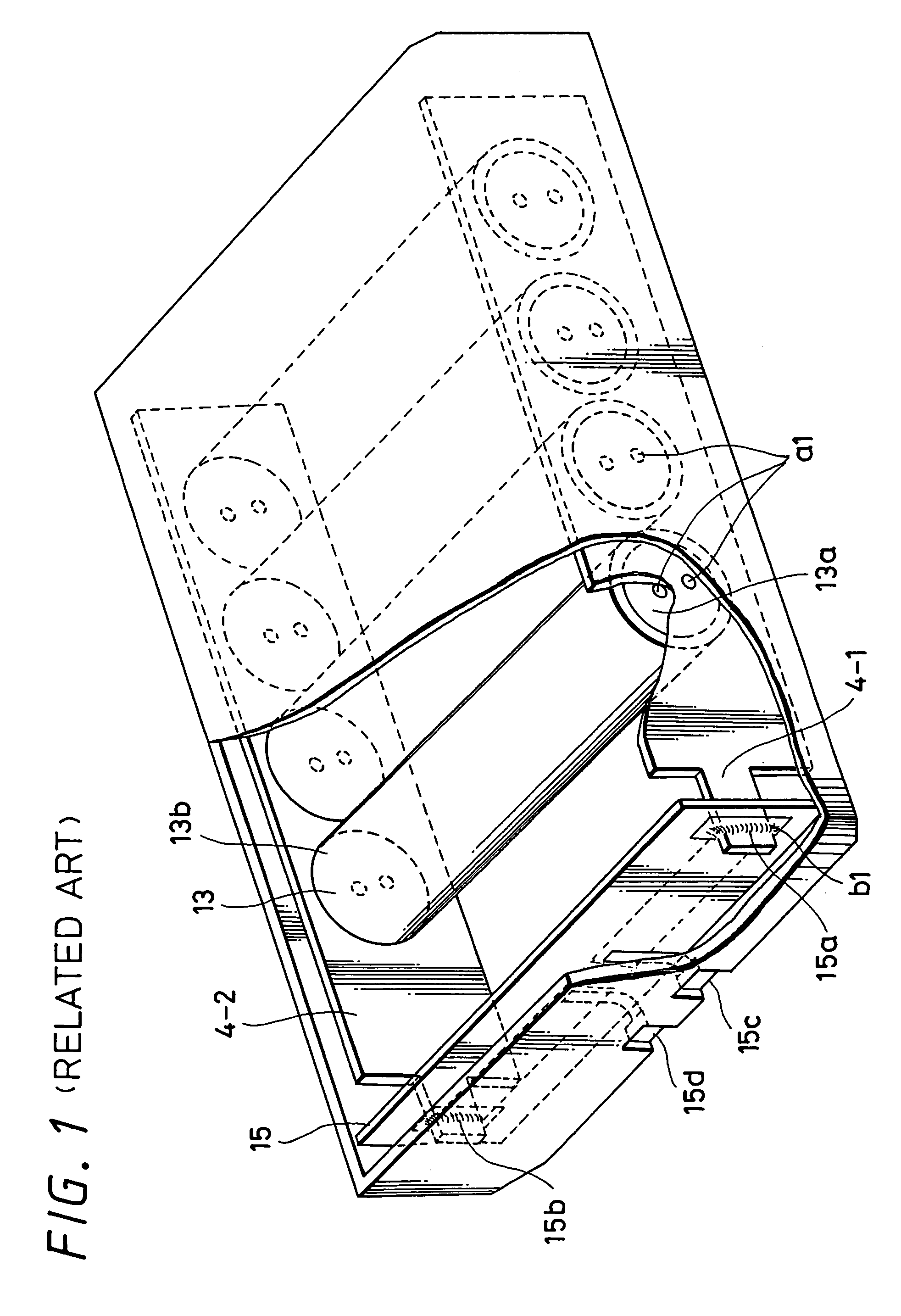

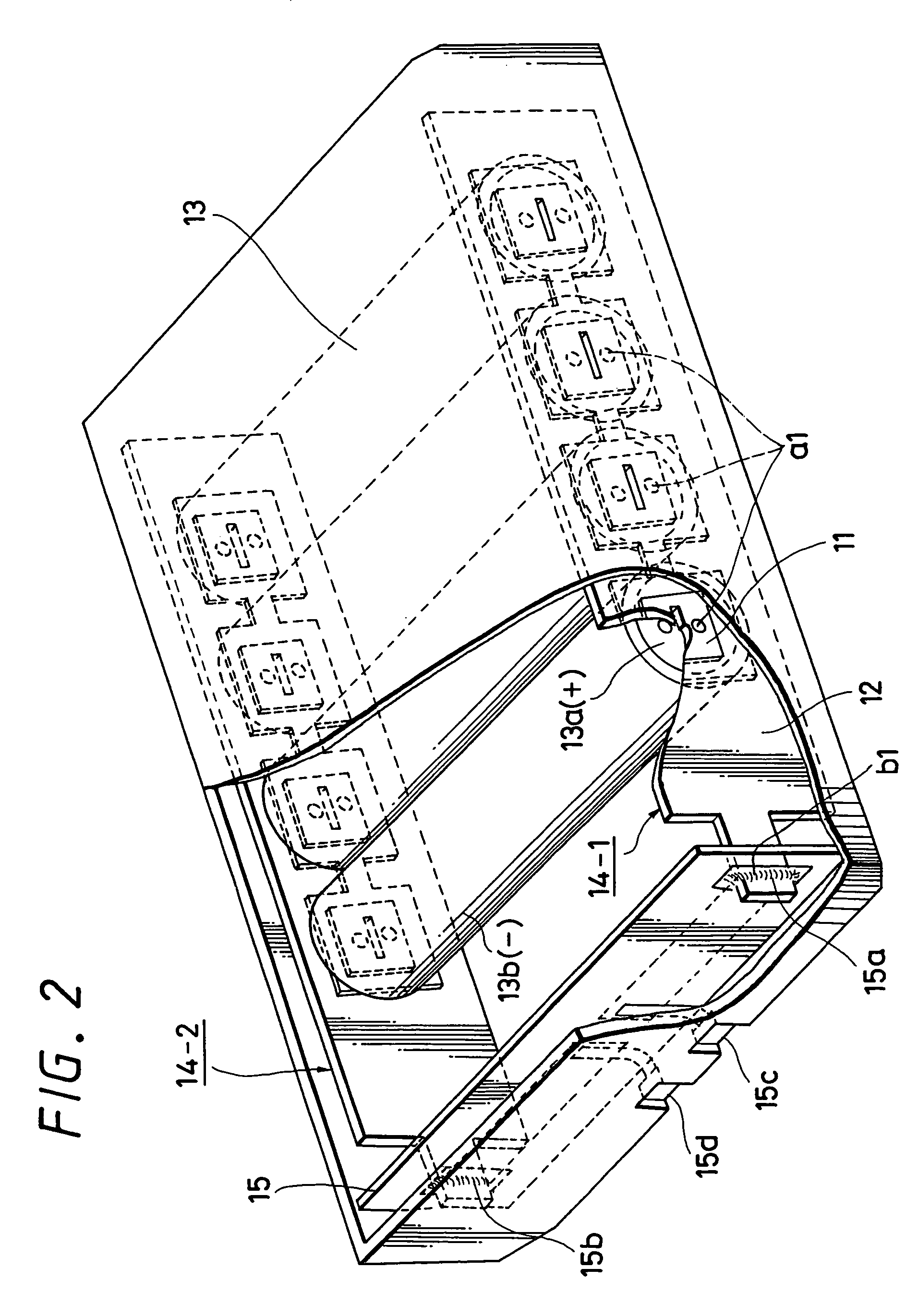

ActiveUS7316863B2Improve solderabilityLow resistance characteristicPrimary cell to battery groupingMelt-holding vesselsElectrical resistance and conductanceEngineering

A battery pack housing a plurality of battery cells in a case and respectively connecting the positive electrodes and the negative electrodes of the plurality of battery cells to conductive terminal boards to be led out to outside terminals is provided. The conductive terminal board has a structure in which a first member is joined with a second member such that the first member having excellent weldability is arrayed in a plurality-of-islands state in the second member having excellent conductivity, and the positive electrodes and the negative electrodes of the battery cell are welded to the first member of the conductive terminal board through resistance-welding, so that the battery pack capable of efficiently supplying a large amount of current is provided.

Owner:MURATA MFG CO LTD

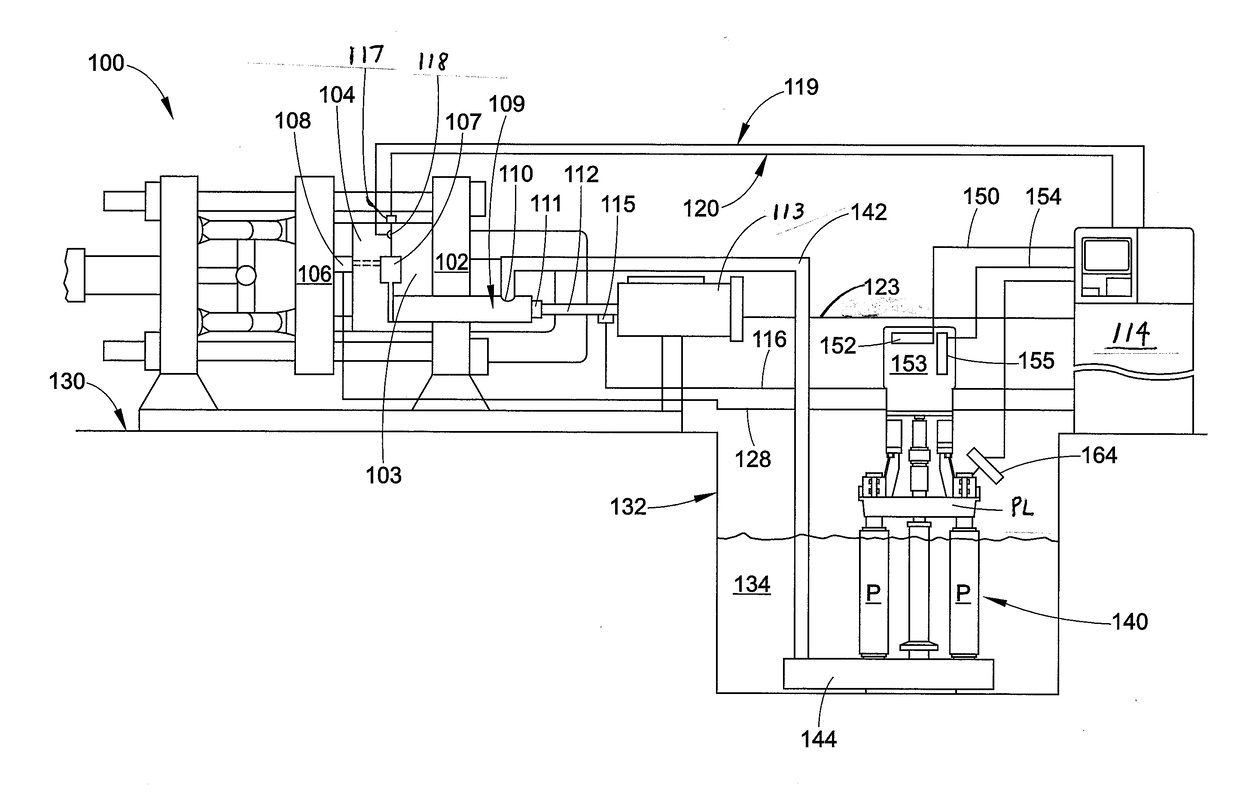

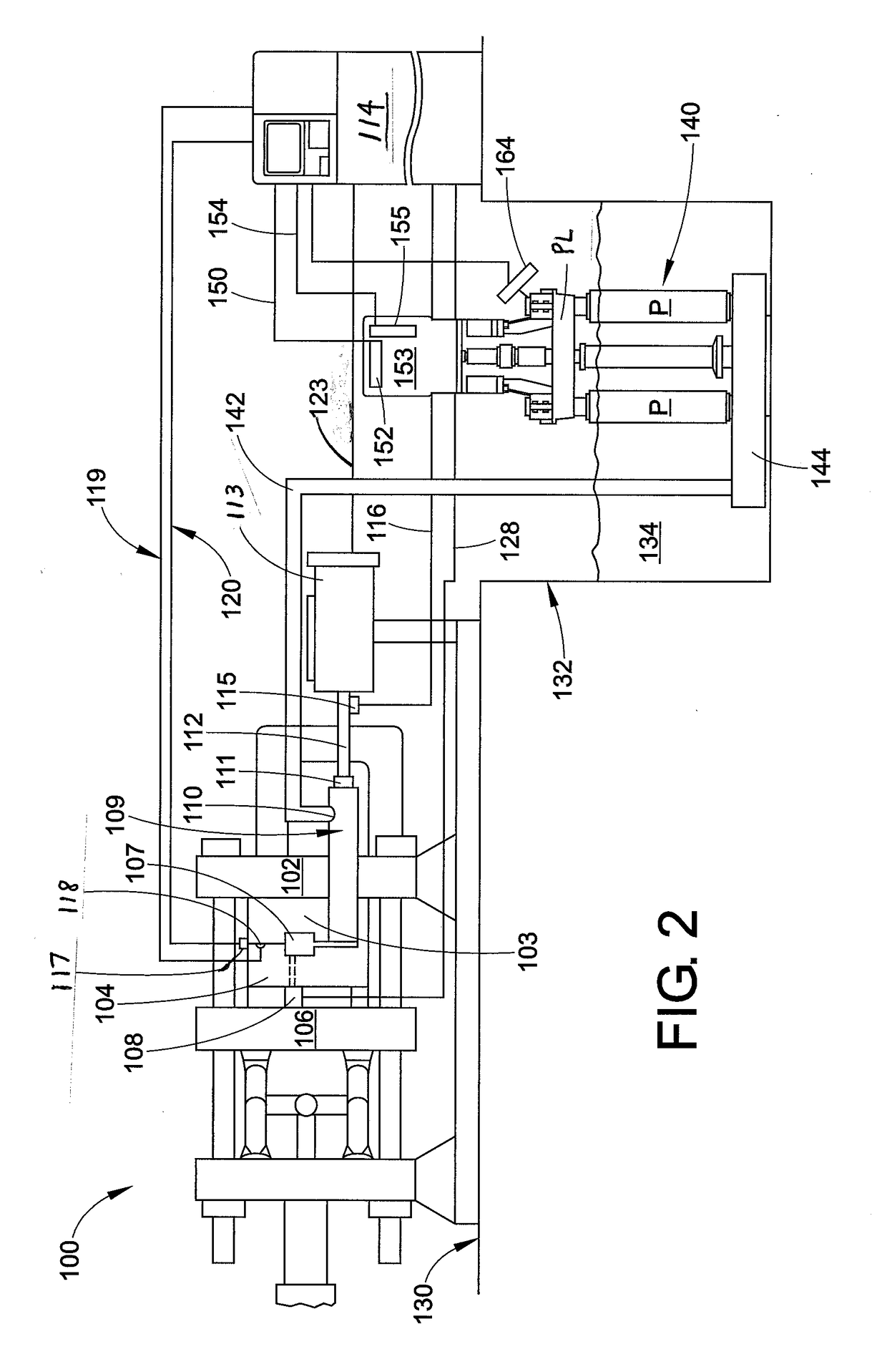

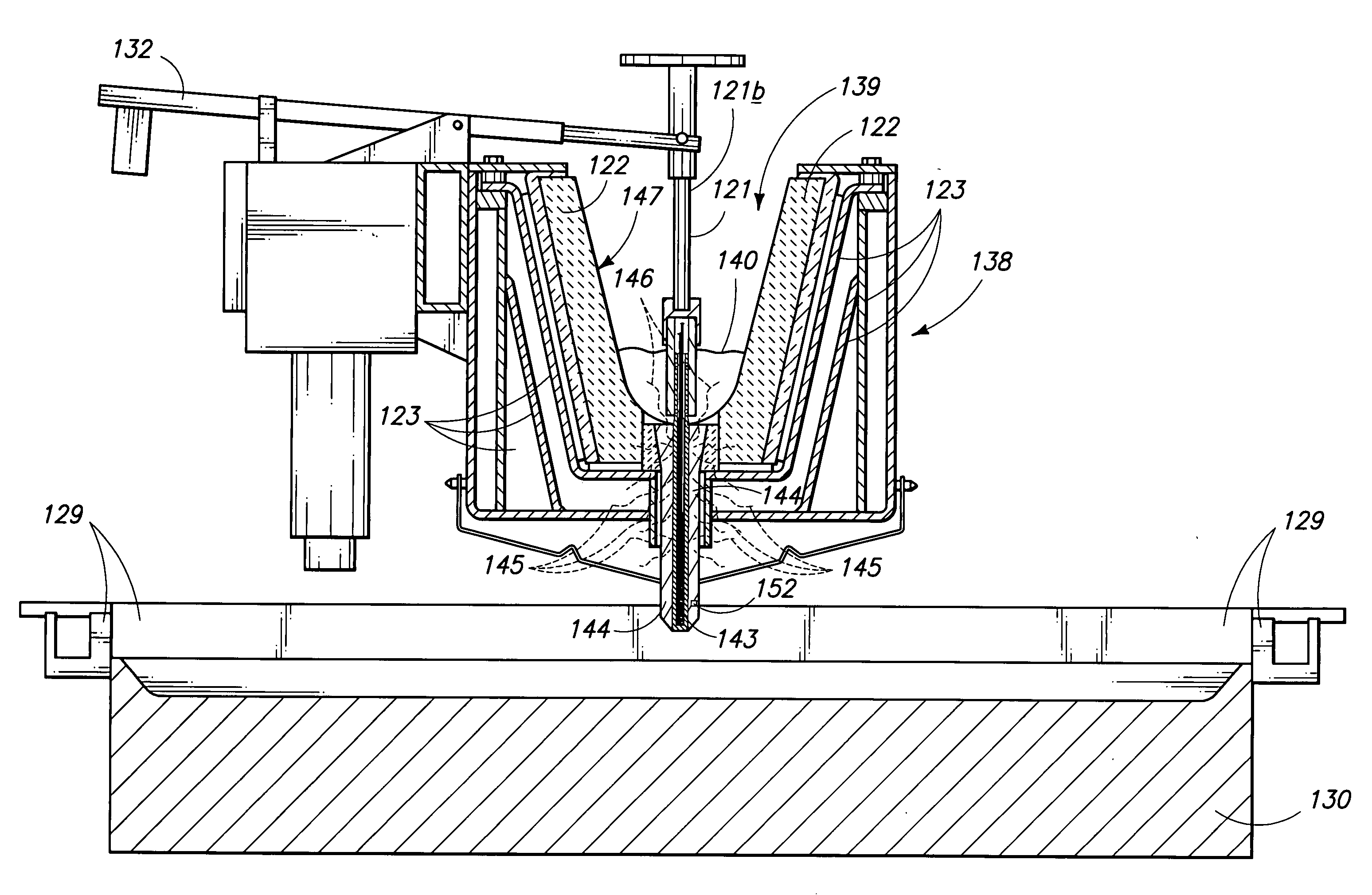

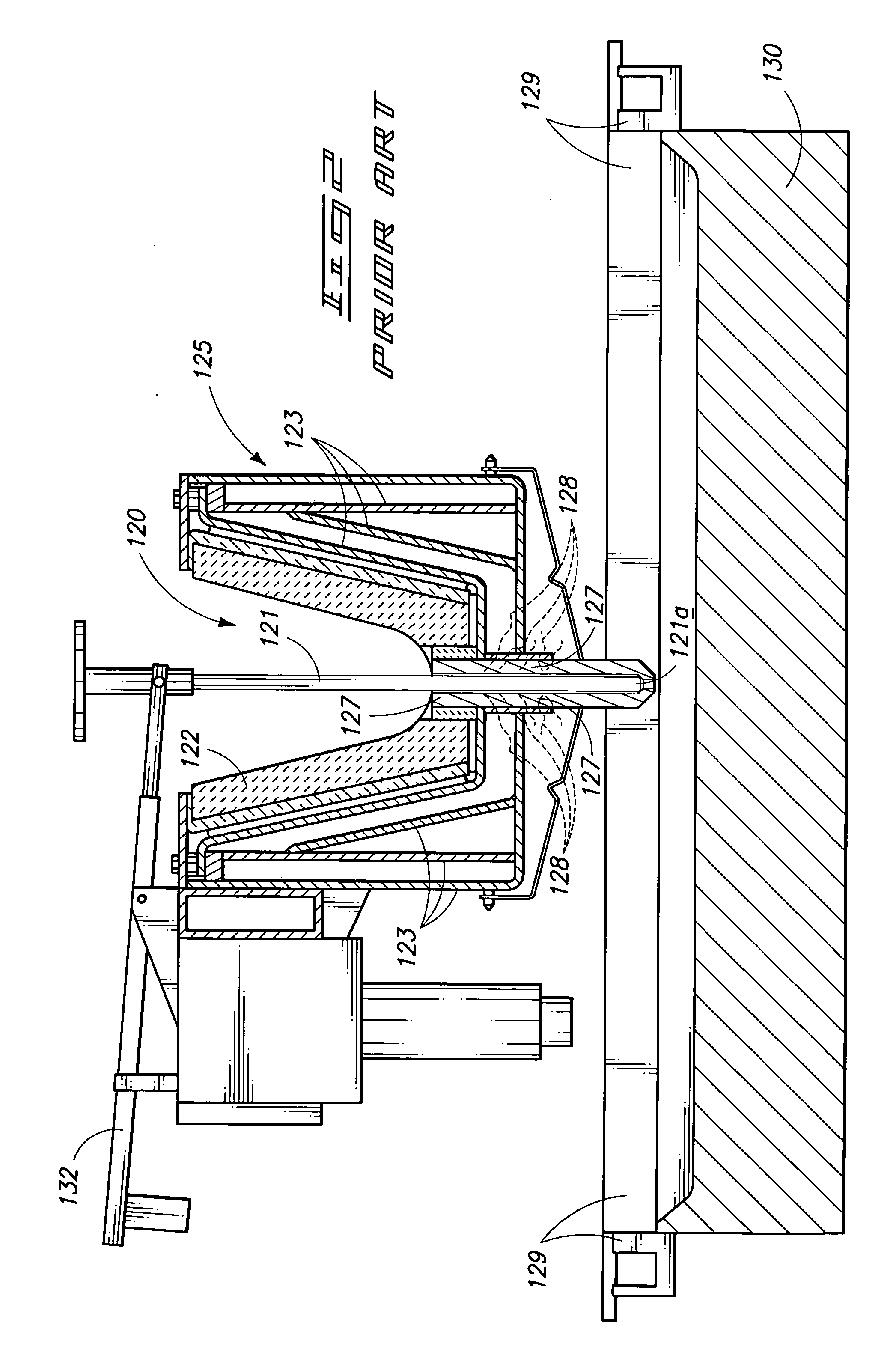

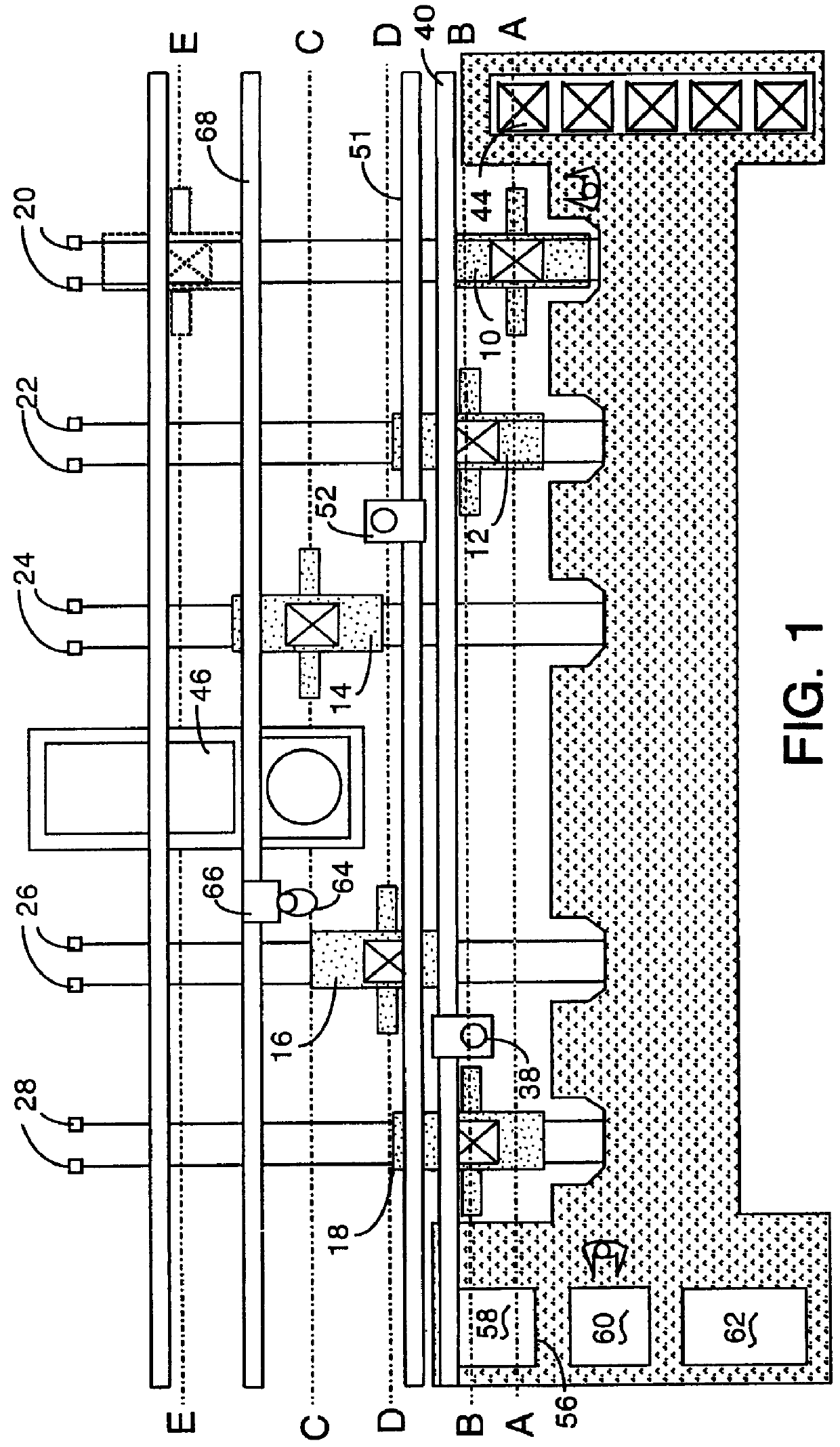

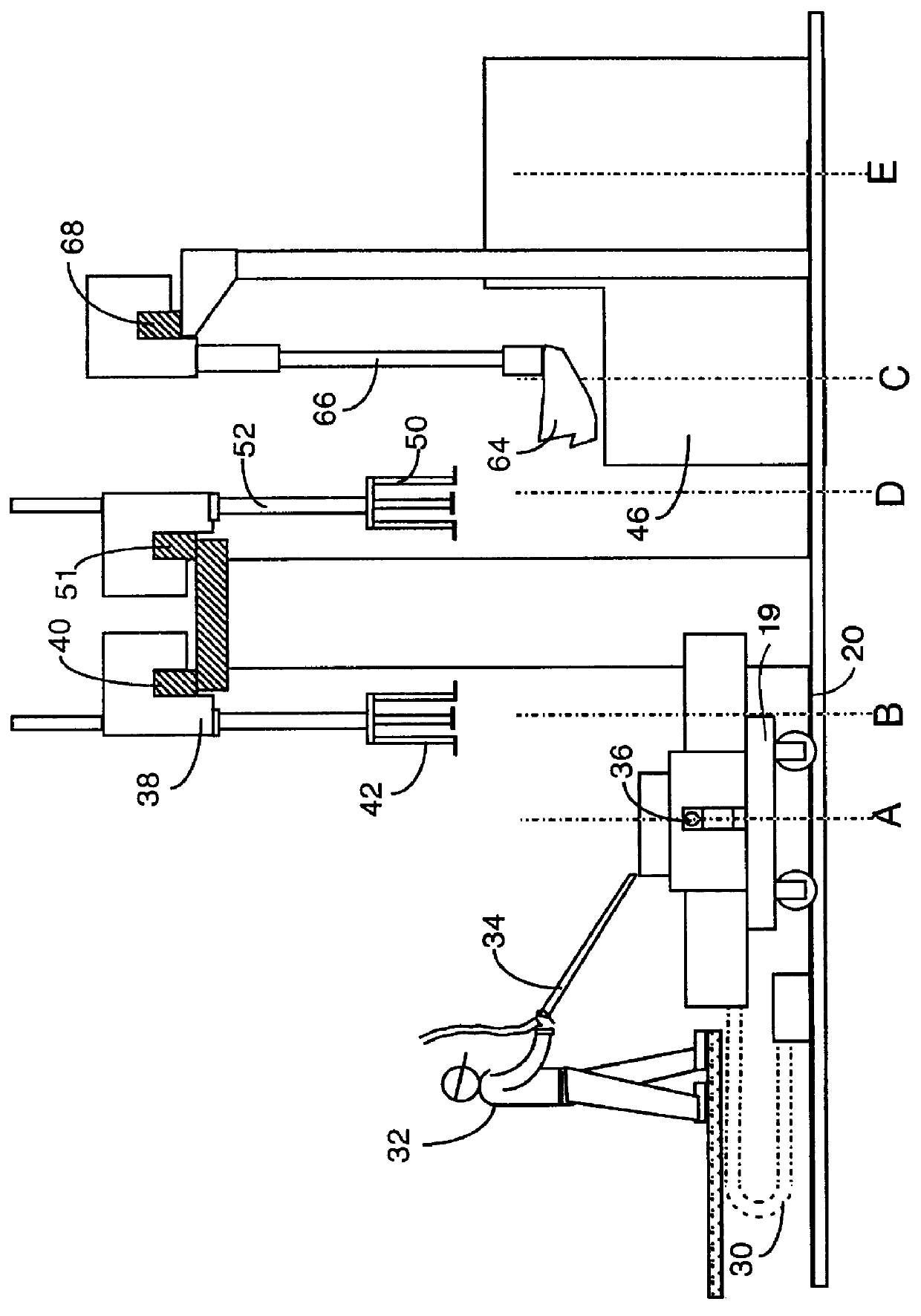

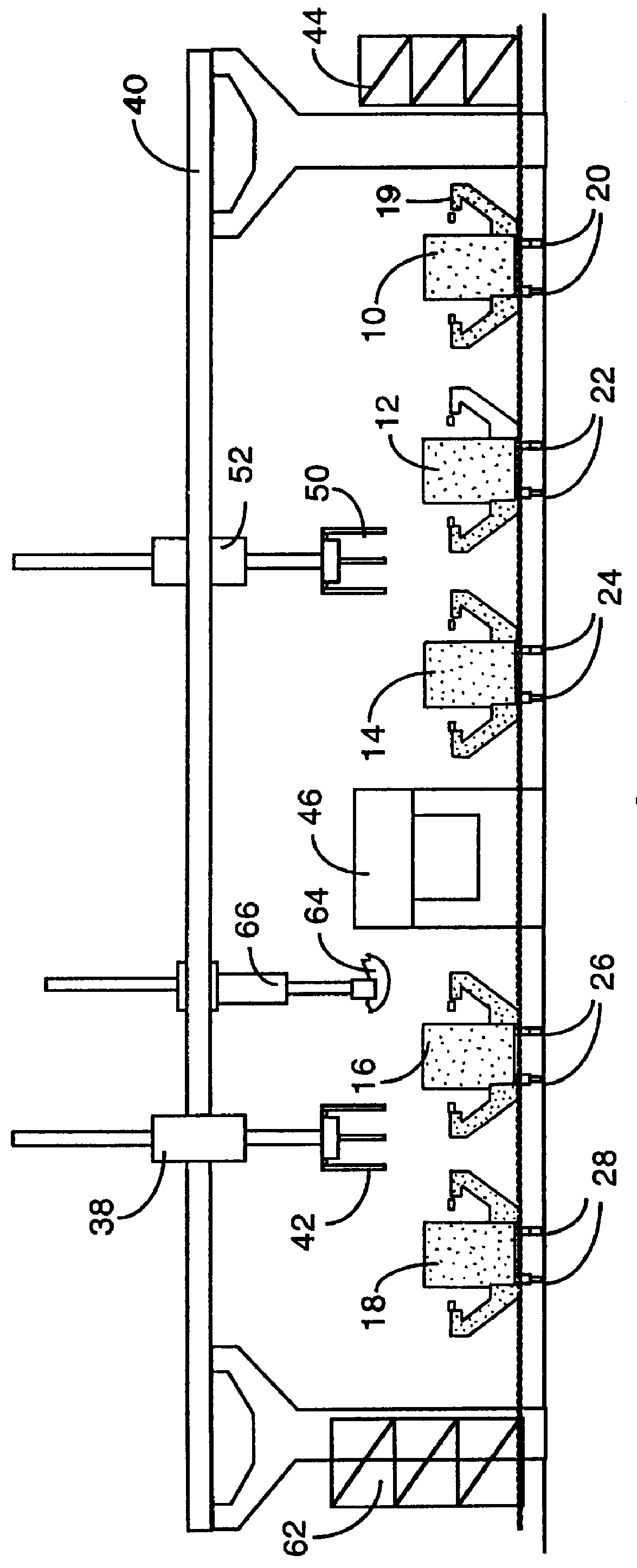

Method and apparatus for production of aluminum alloy castings

InactiveUS6073678AImprove productivityReduce operating costsMelt-holding vesselsPig casting plantsProduction rateCylinder head

Method and simplified apparatus for manufacturing aluminum alloys castings, for example those cast aluminum parts utilized in the manufacture of automobile engines: cylinder heads, engine blocks and the like; whereby the castings are cast in a plurality of semi-permanent-type molds, said molds each being movable to a plurality of processing positions along one of a plurality of preferably straight line paths (five in the preferred embodiment), wherein the operations of cleaning, core setting, casting, and casting extraction are performed on each mold at predetermined positions along its respective path and alternating said operations among the molds in order to permit minimization of the number of robot equipment and to increase the aggregate productivity of said molds, since any one processing operation can be handled by only a few (and preferably only one) robot arm moving across a plurality of mold paths (preferably seriatim), so that a given process step is performed at any one time only at one (or at least significantly fewer than all) of the plurality of mold paths.

Owner:TENEDORA NEMAK SA DE CV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com