Patents

Literature

584results about "Discharge devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

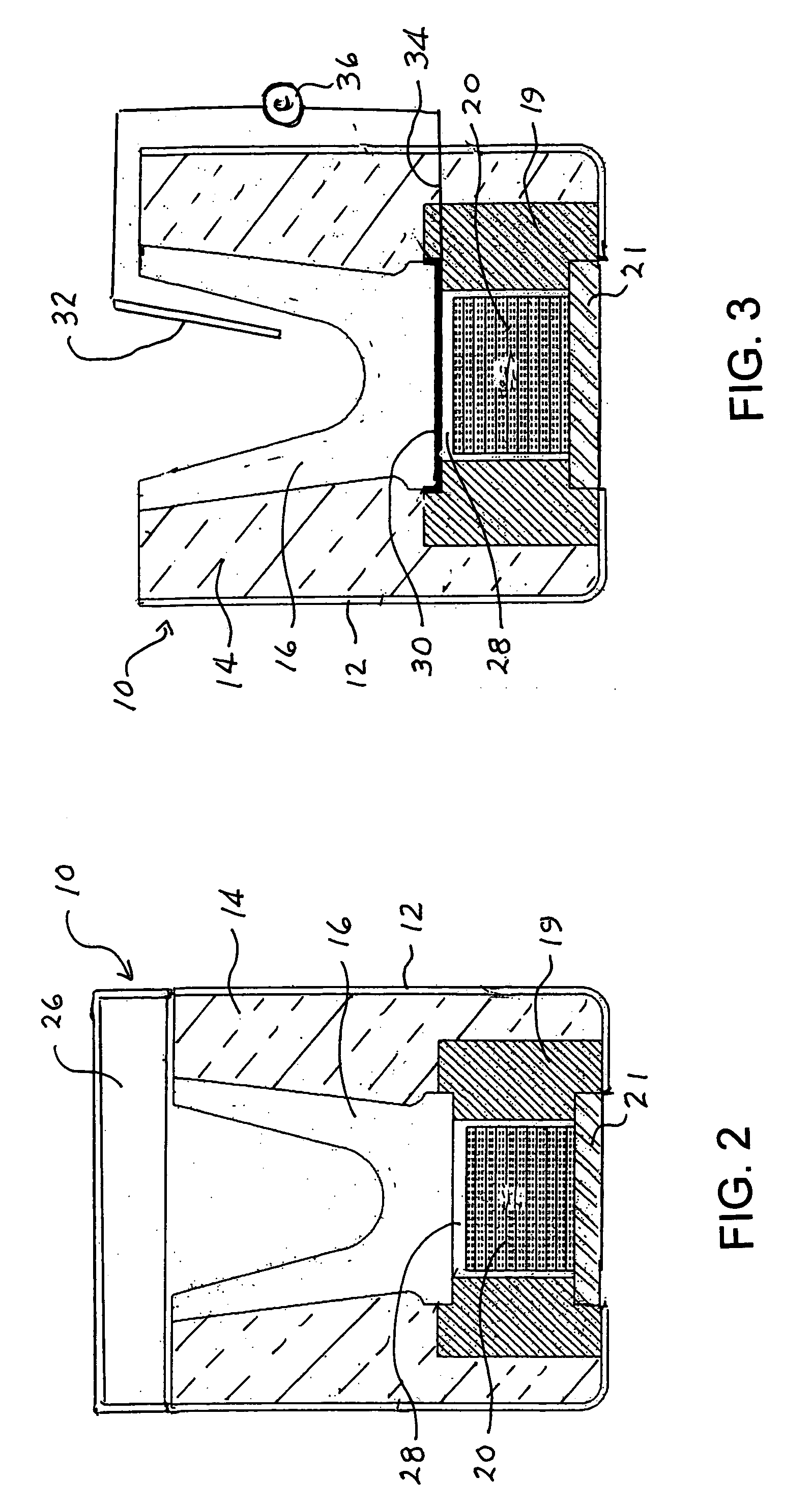

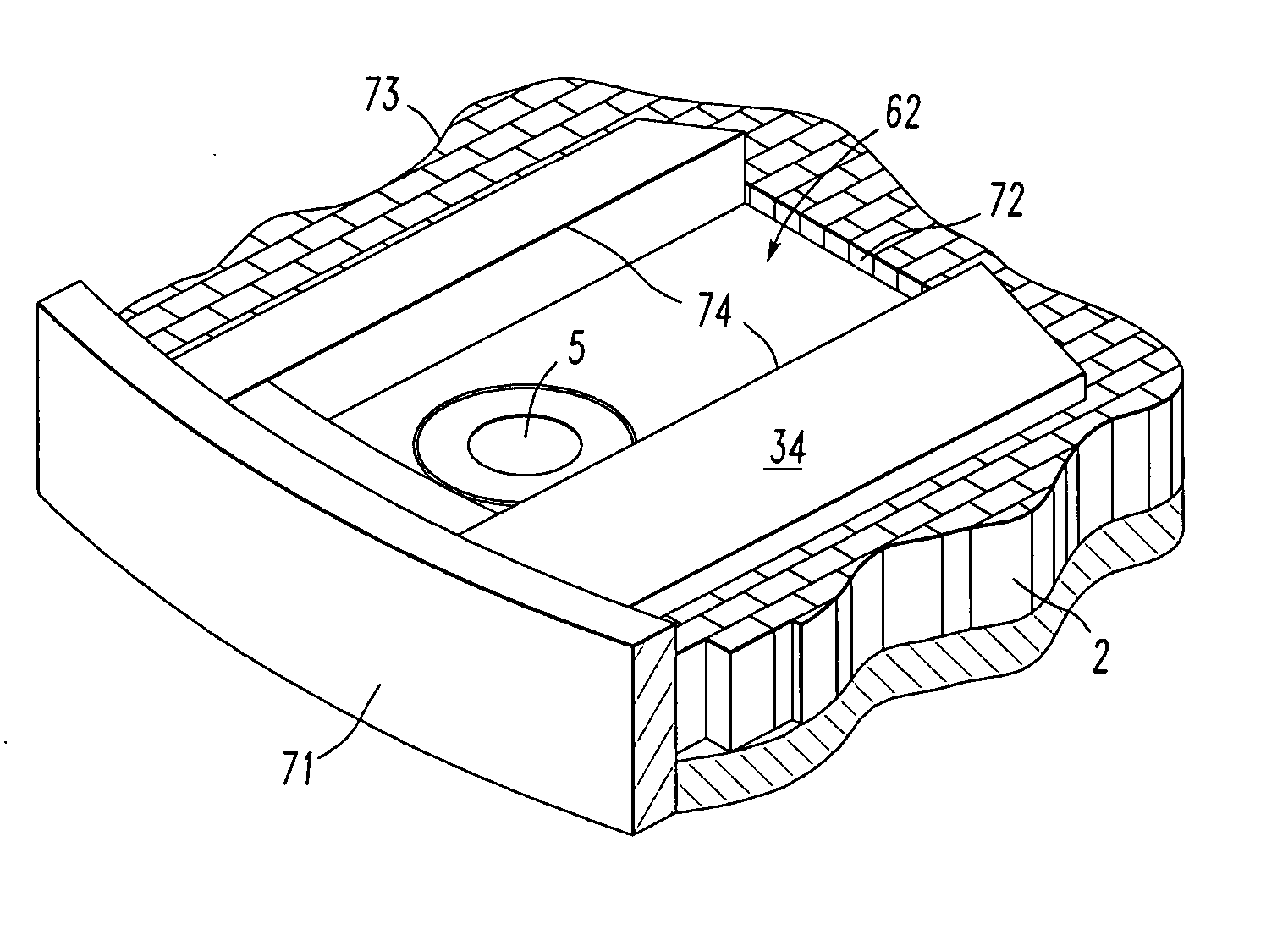

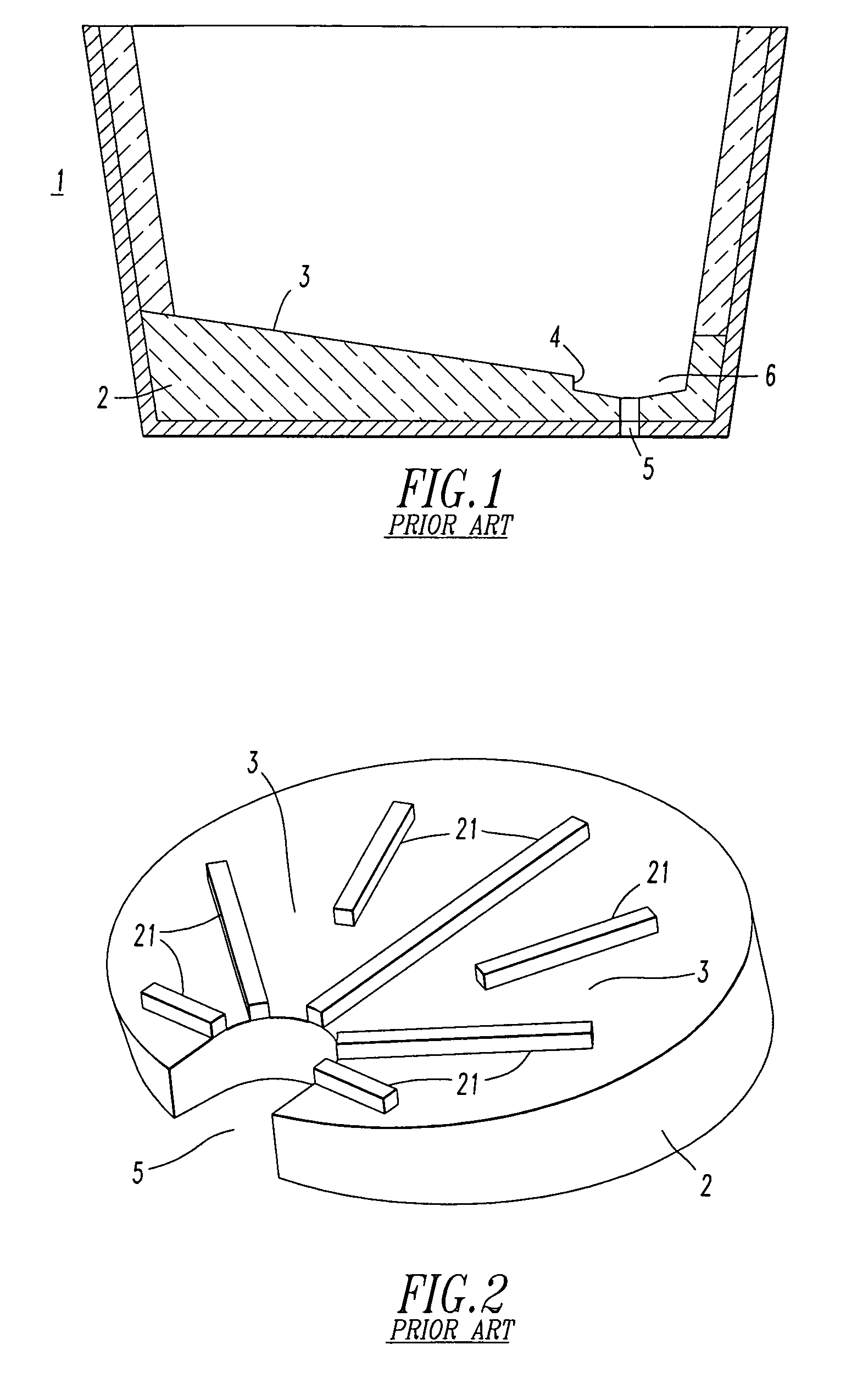

Bonded particle filters

InactiveUS7157043B2Significant portionMelt-holding vesselsMolten metal pouring equipmentsMolten metalMaterials science

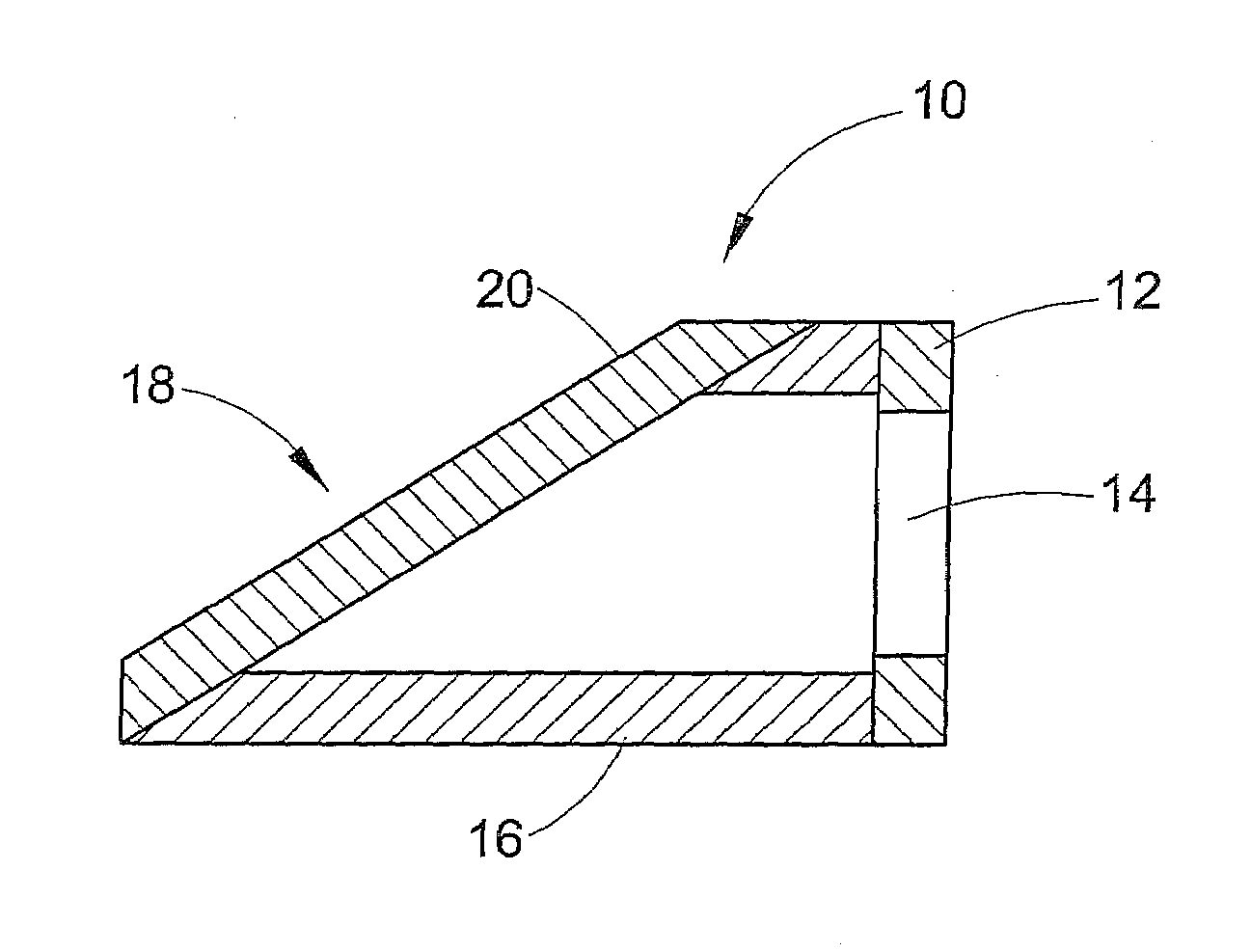

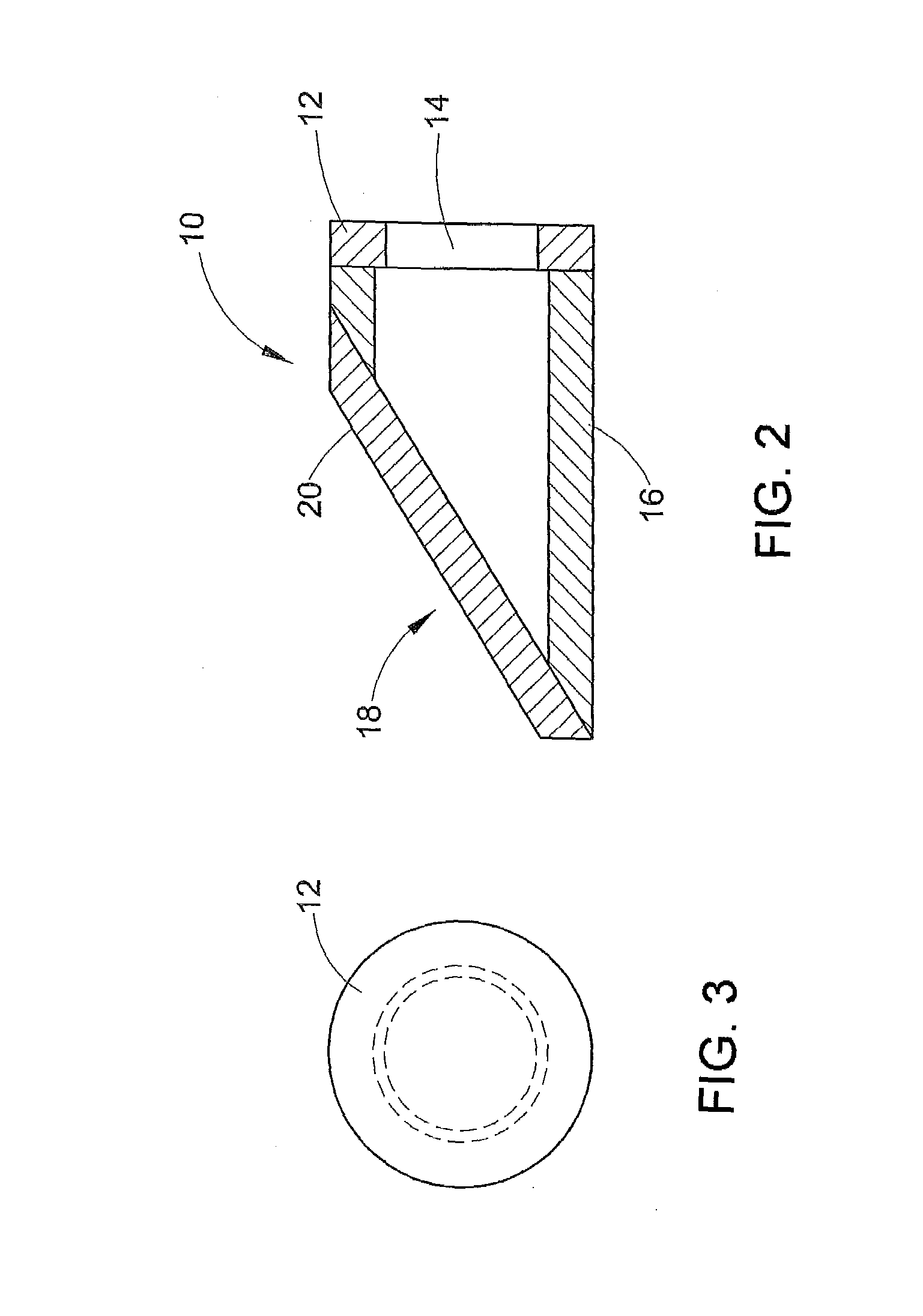

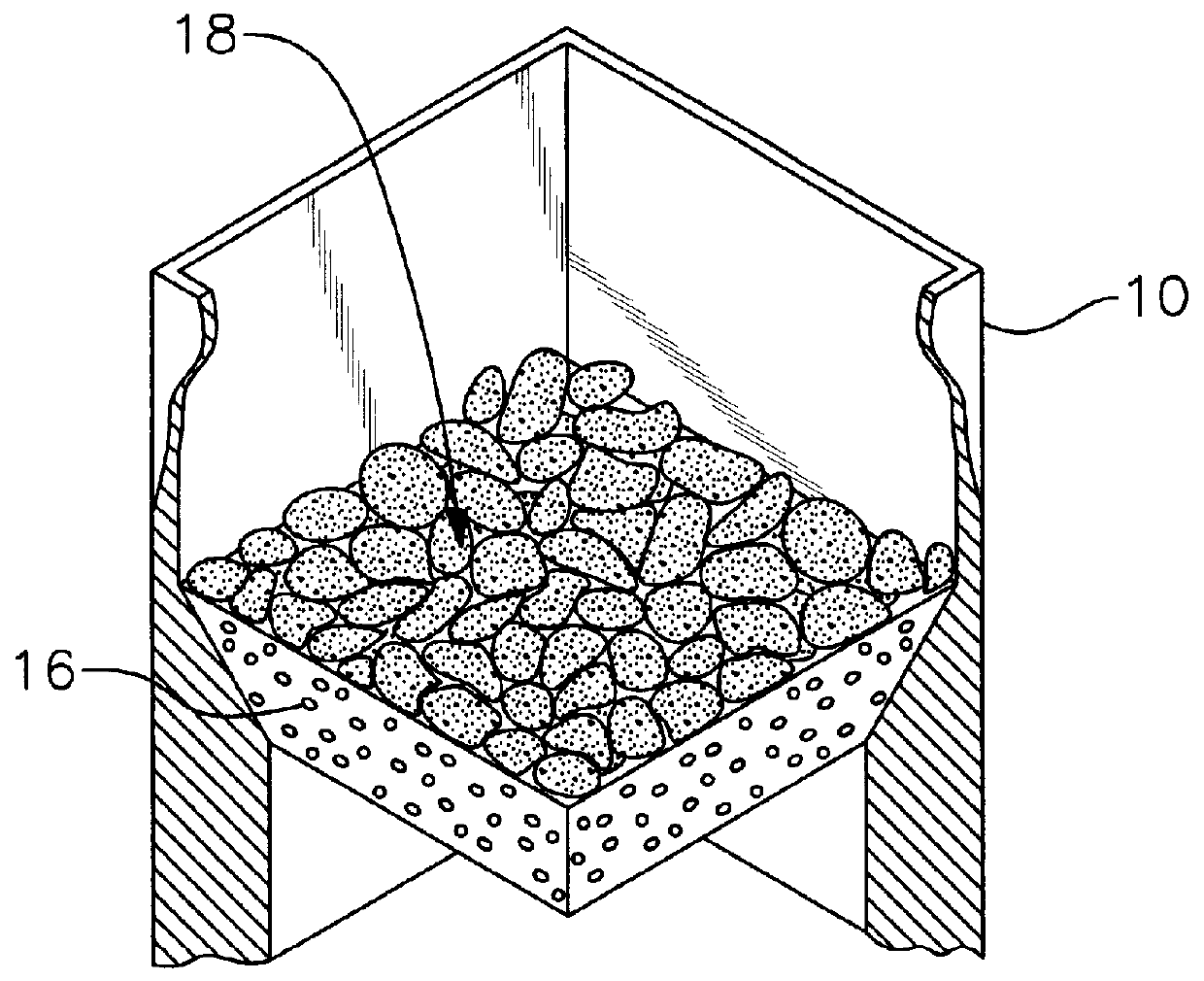

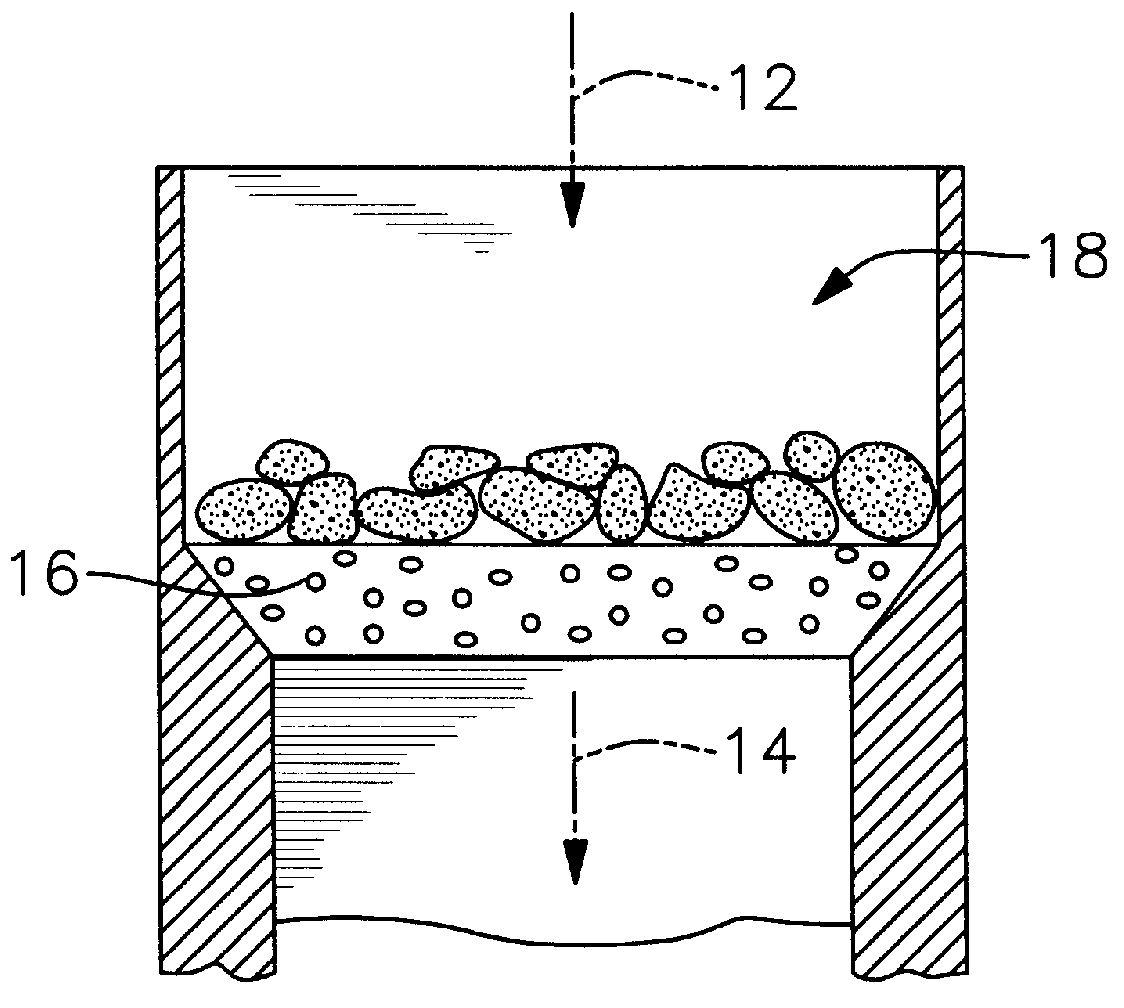

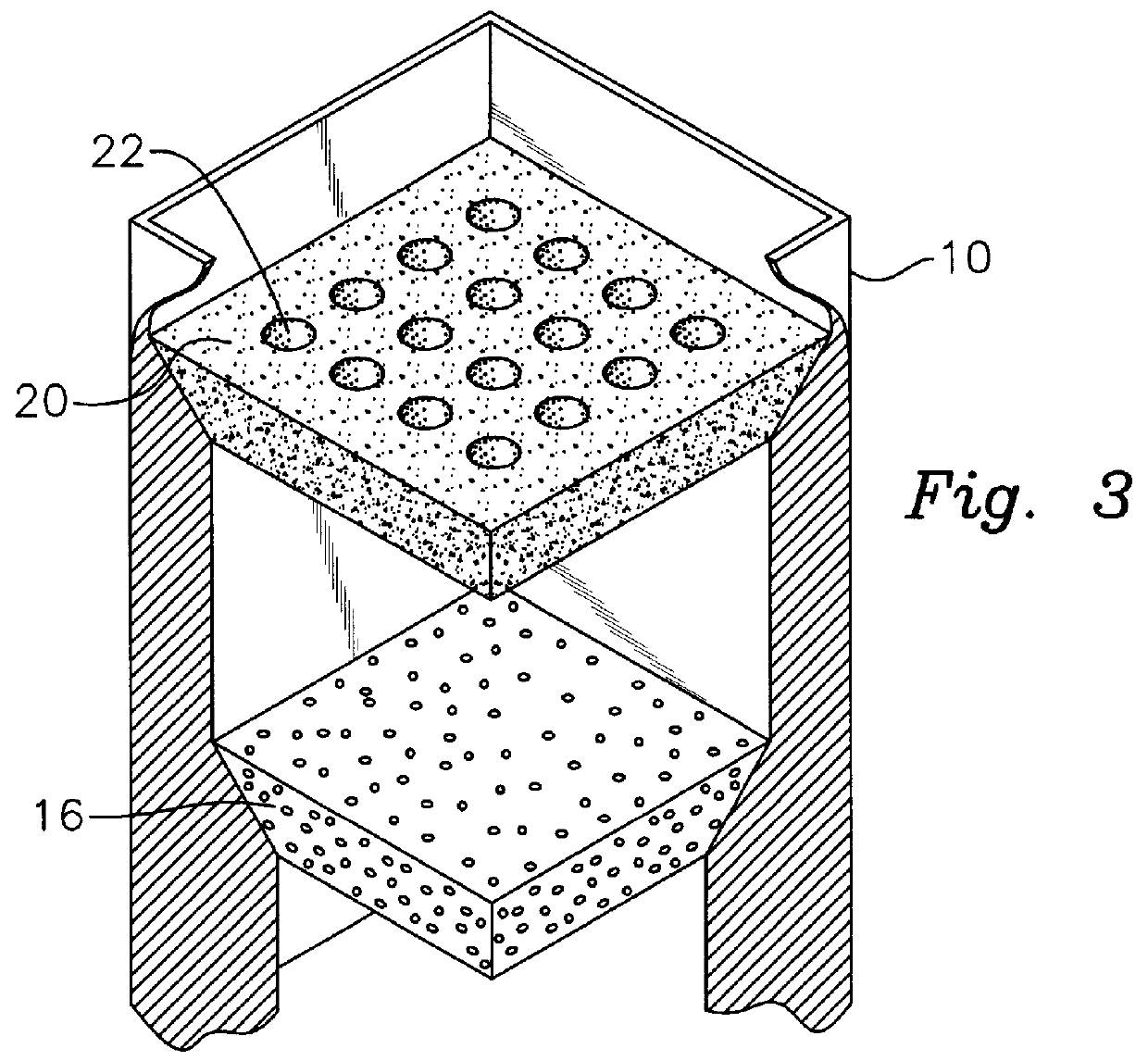

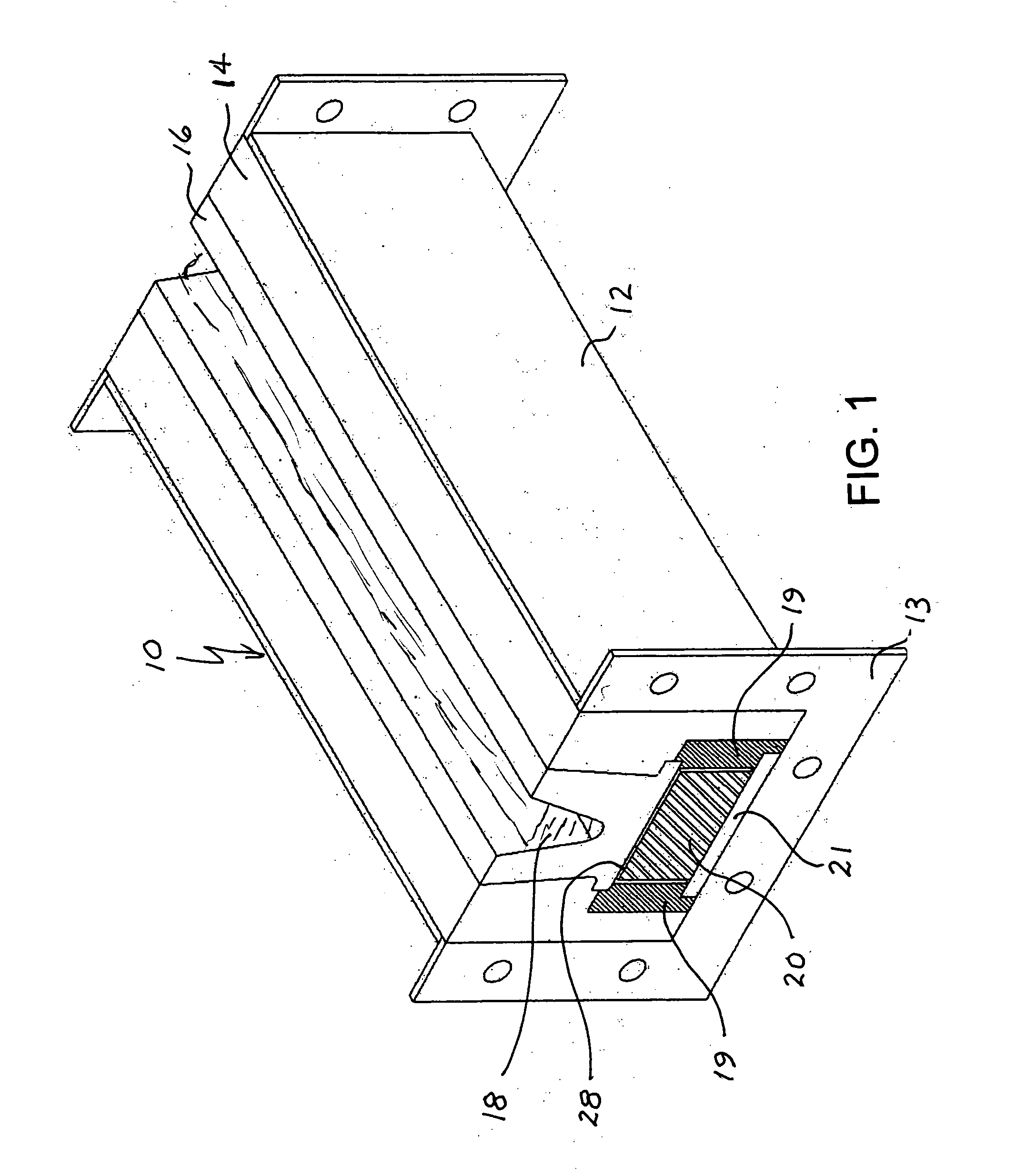

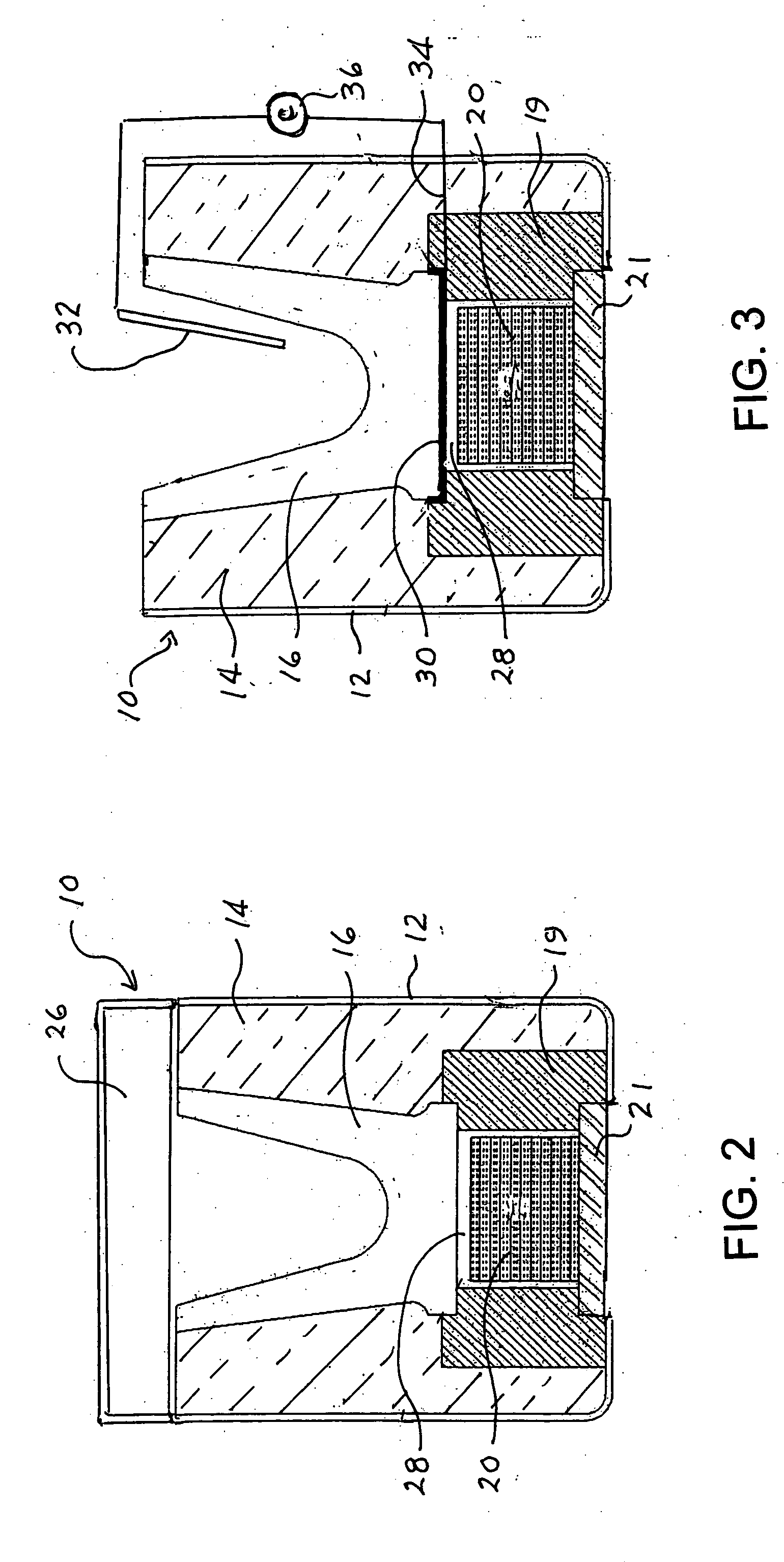

An apparatus for filtering molten metal held in a vessel before the metal enters the dosing tube. The filtering apparatus includes an attachment portion that mounts to the dosing tube, a filter body connected to the attachment portion and a planar surface attached to an end of the filter body opposite the attachment portion. The filter body can include a beveled end opposite the attachment portion where the planar surface is attached. The apparatus can be made from a bonded-particle material made from silicon carbide or aluminum oxide held together by an aluminum-resistant binder.

Owner:METAULLICS SYST +1

Heated trough for molten metal

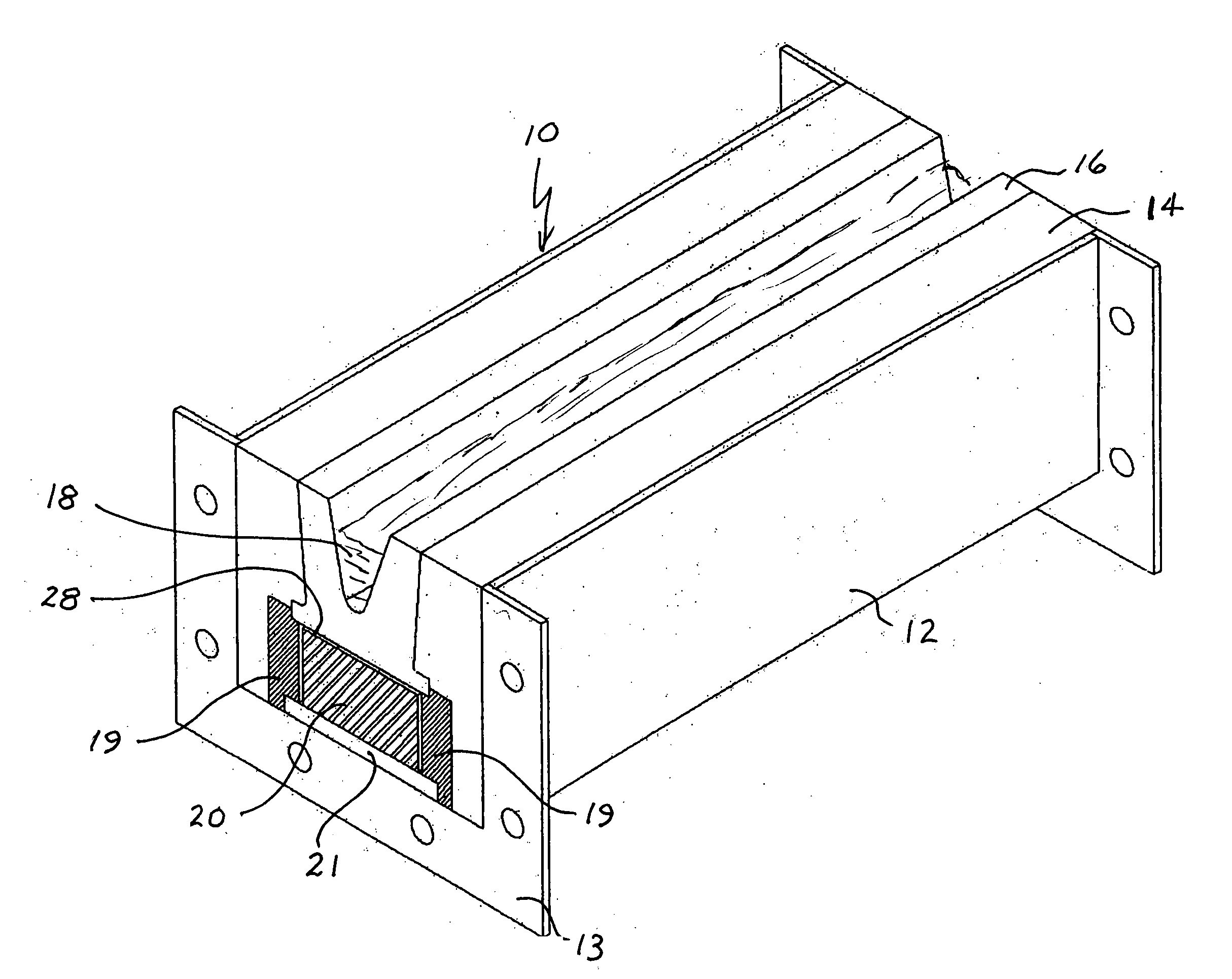

A trough is described for carrying molten metal, comprising an outer shell defined by a bottom wall and two side walls, an insulating layer filling the outer shell and a conductive U-shaped refractory trough body for carrying molten metal, the trough body being embedded in the insulating layer. At least one heating element is positioned in the insulating layer, adjacent to but spaced apart from the trough body, to provide an air gap between the heating element and the trough body.

Owner:NOVELIS INC

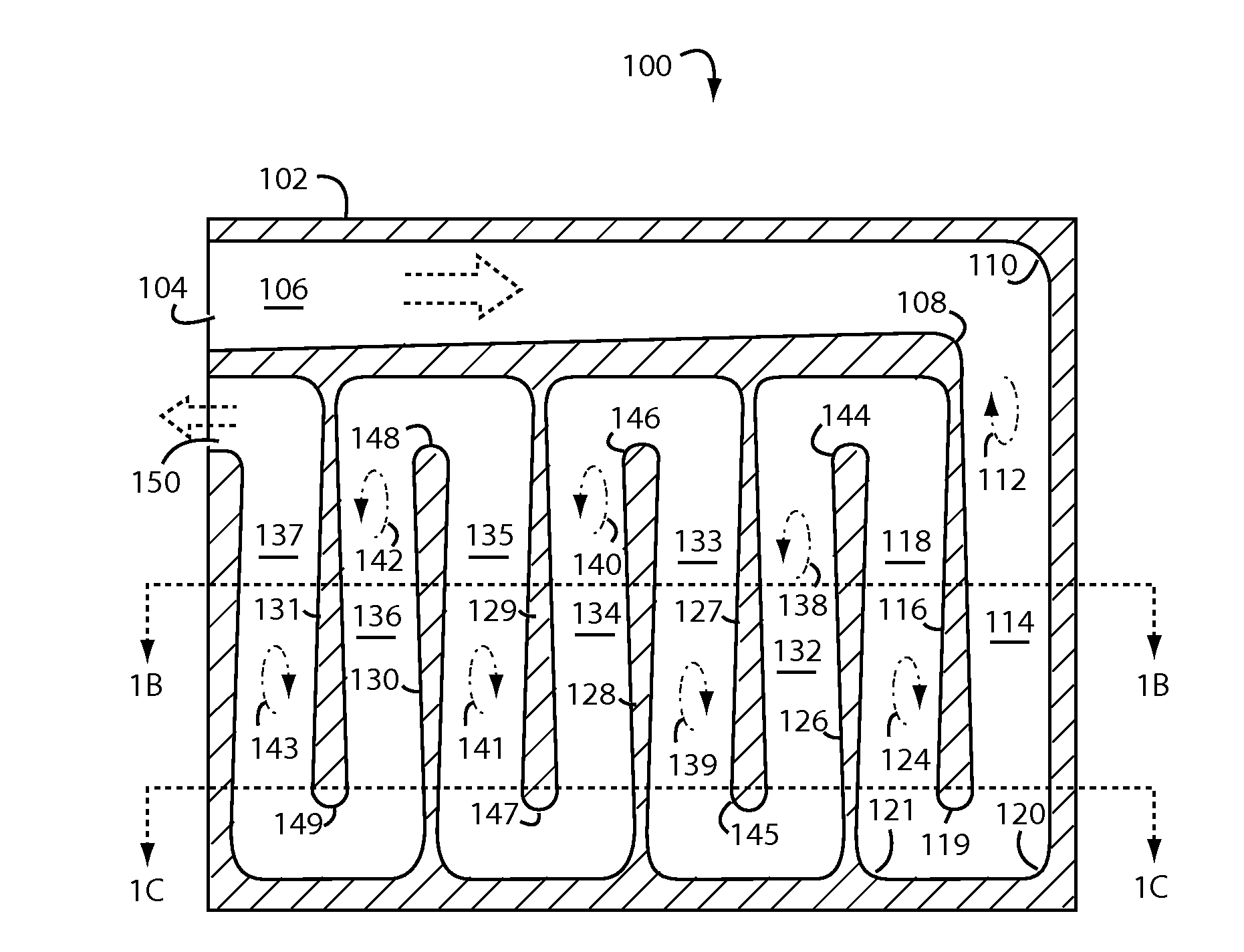

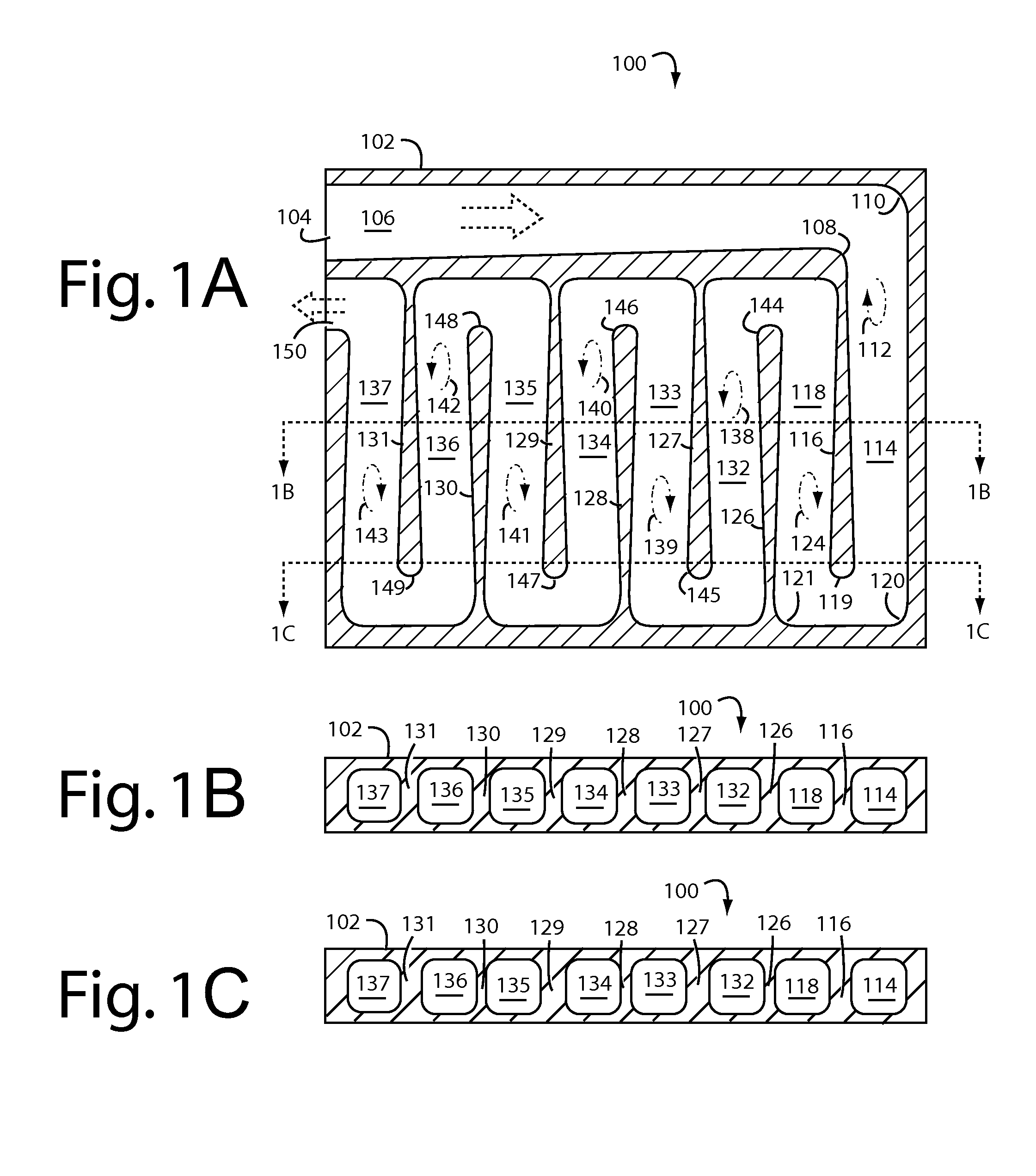

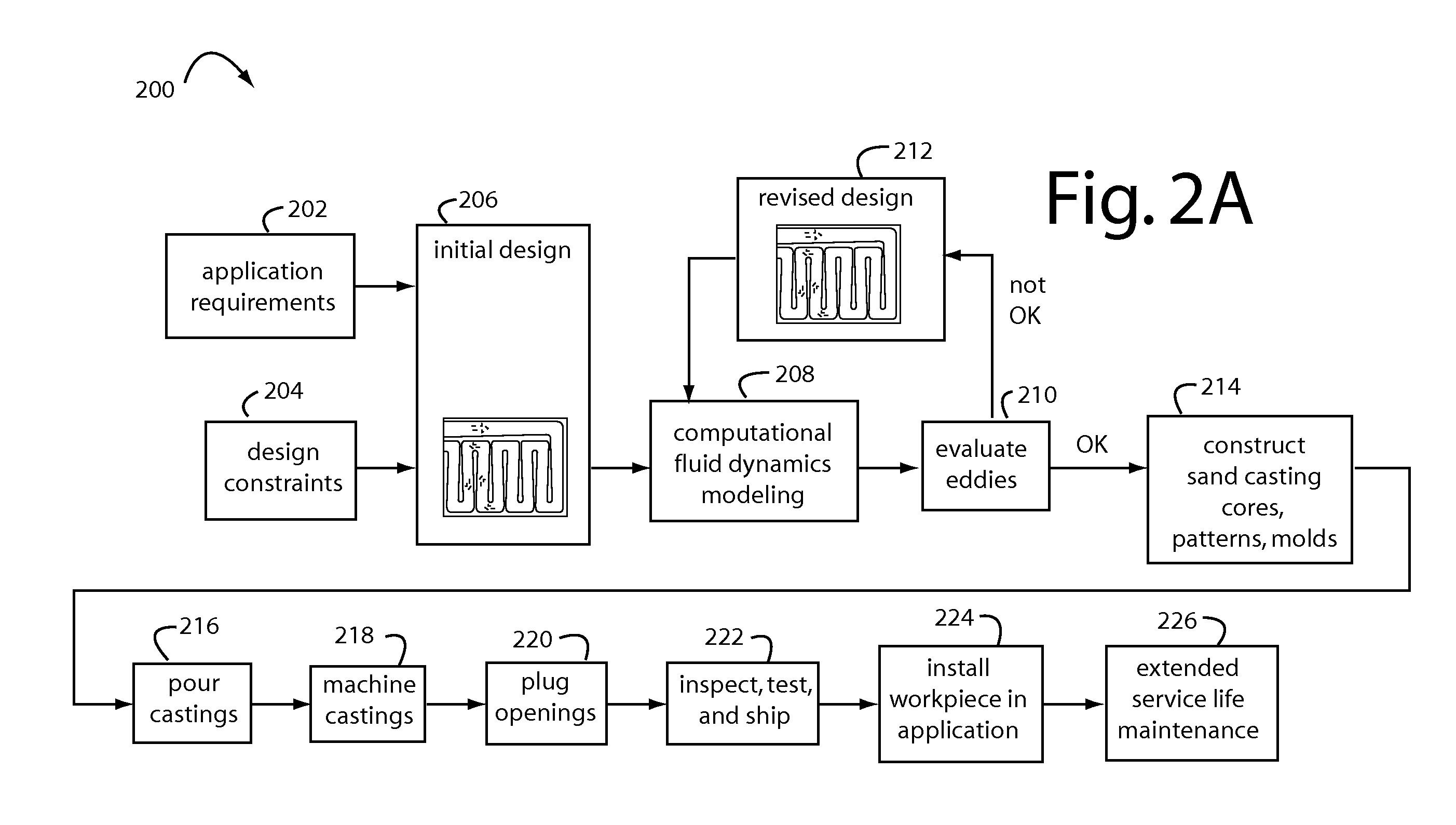

Eddy-free high velocity cooler

A cooling system comprises serpentine cooling fluid passages cast into a work piece with carefully controlled turning radii and profiles. Individual interdigitated baffles are contoured in the plane of coolant flow to have walls that thicken and then round off at their distal ends. The outside radii at these turns is similarly rounded and controlled such that the coolant flow will not be swirled into eddies.

Owner:MACRAE ALLAN J

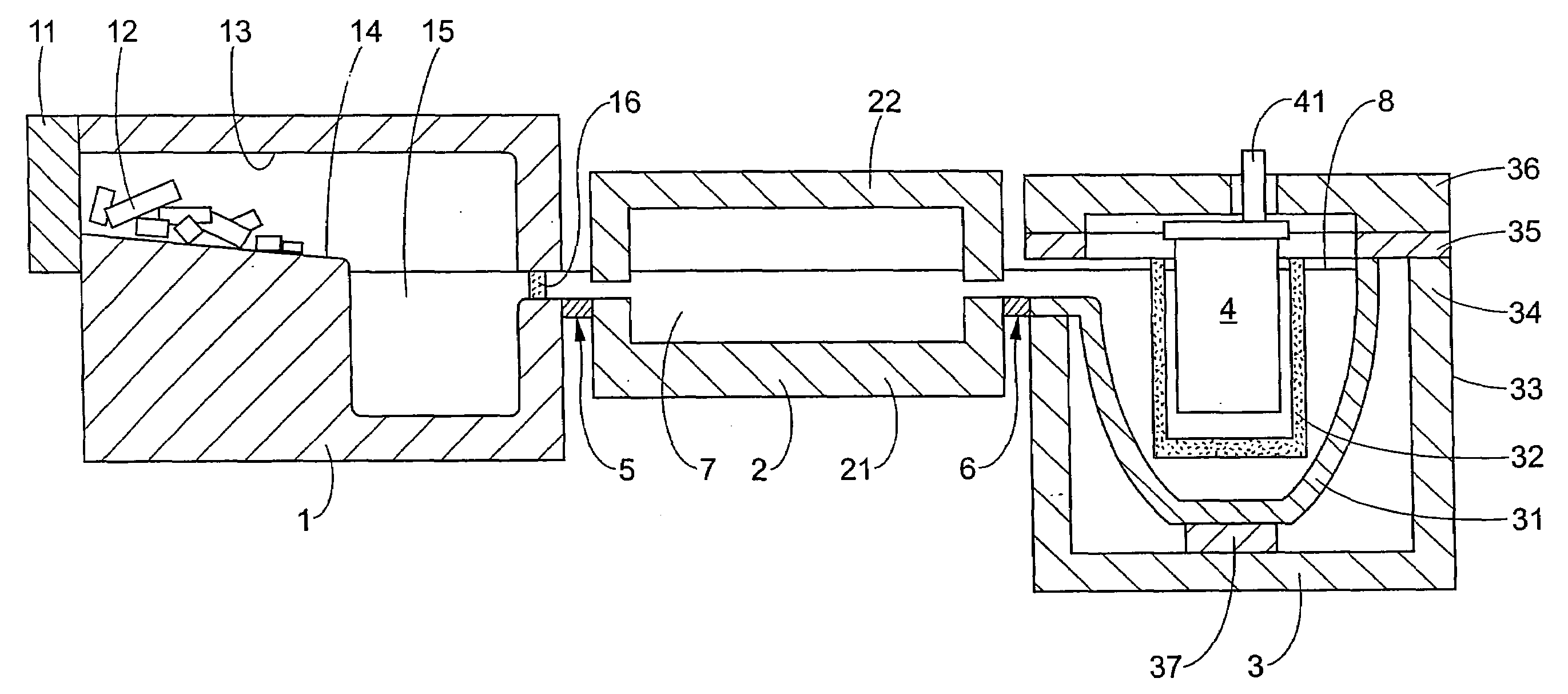

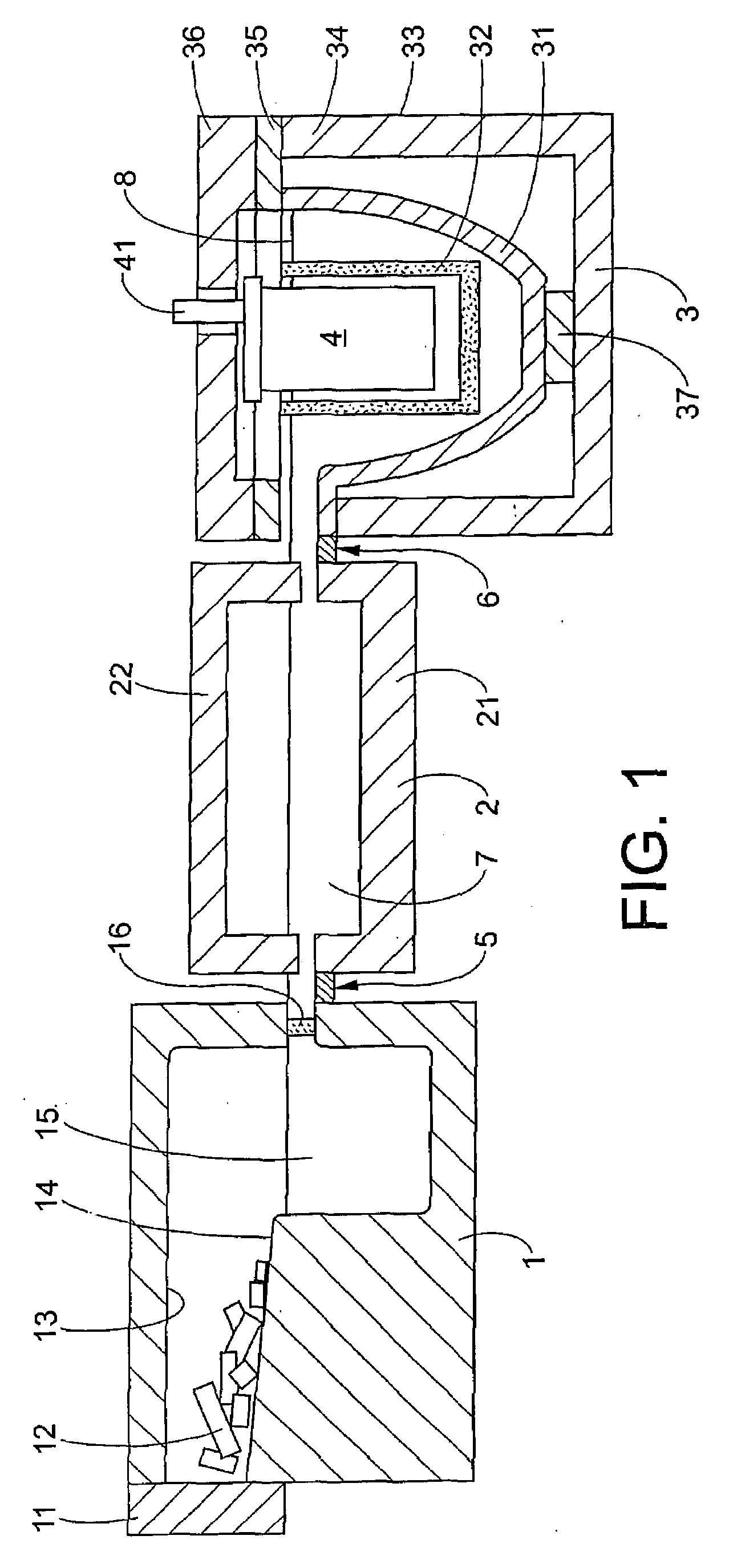

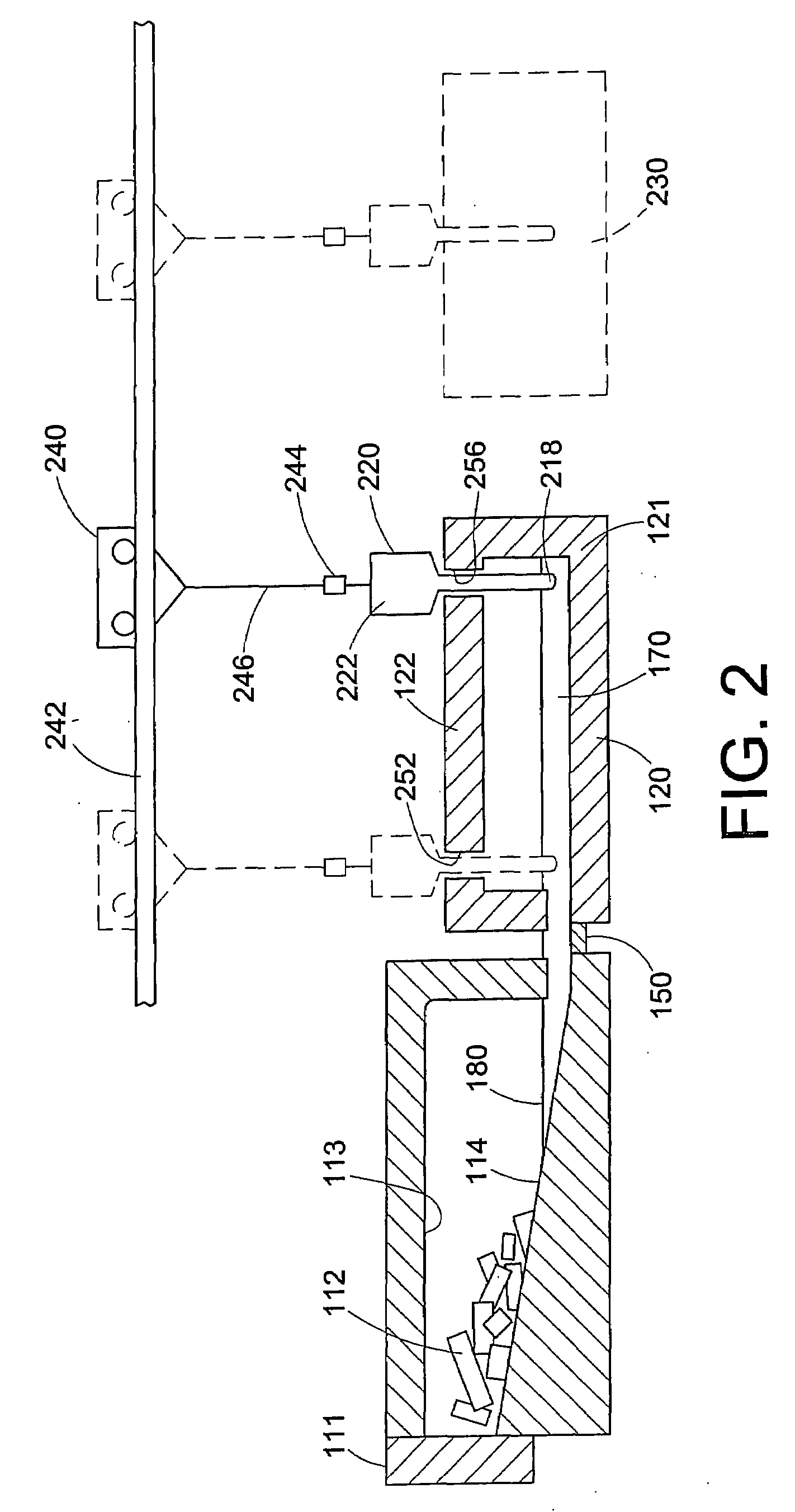

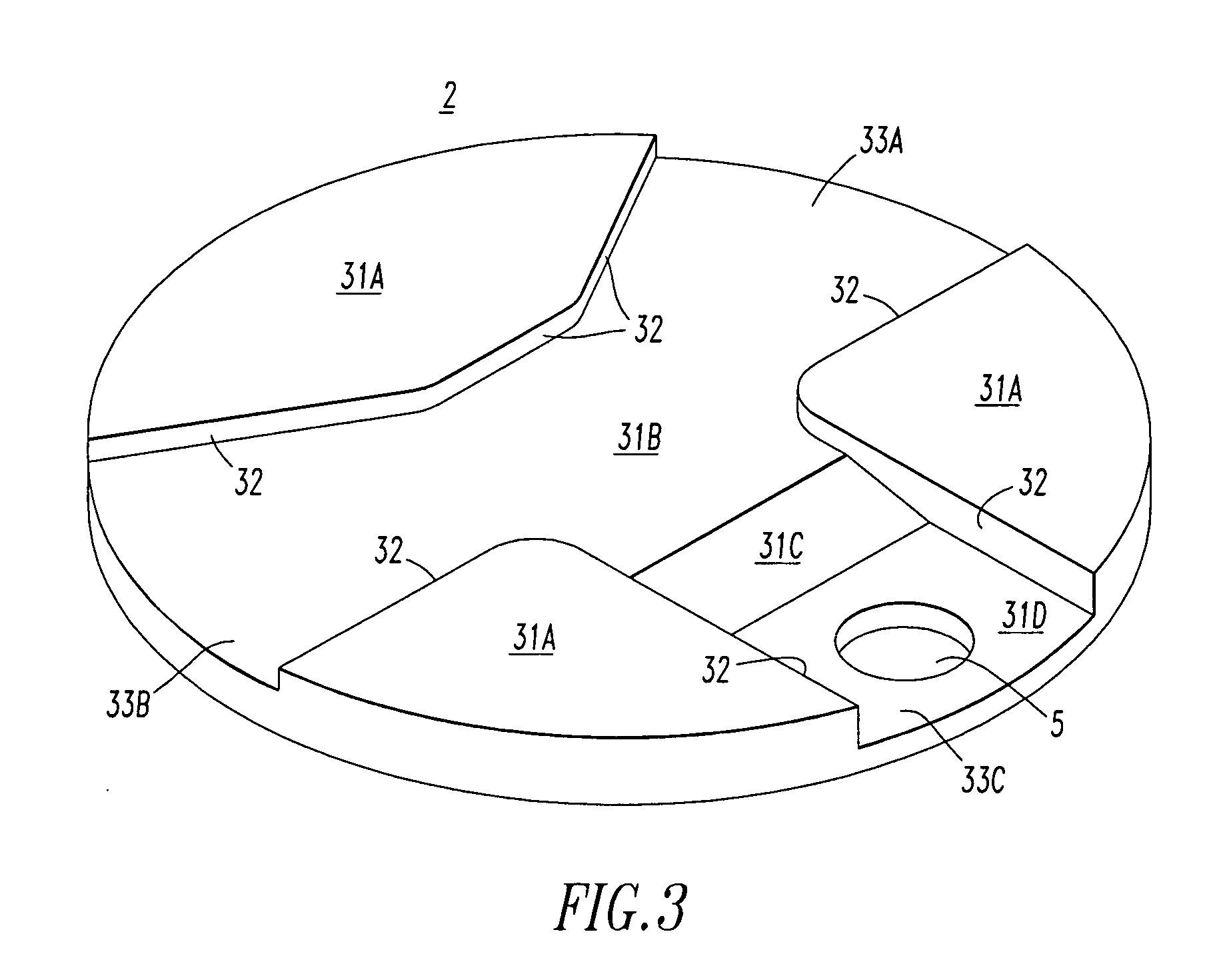

Quiescent transfer of melts

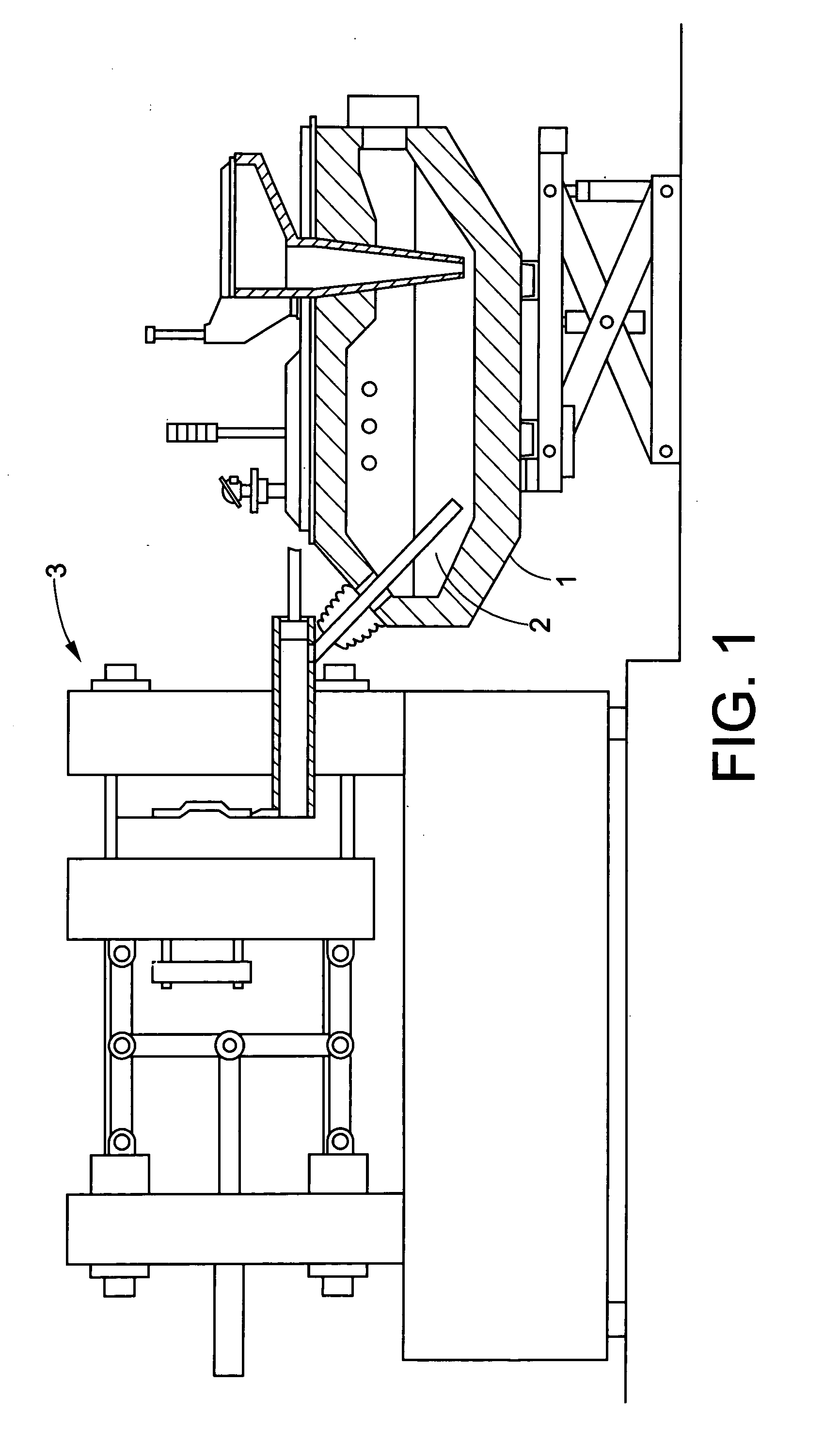

InactiveUS20080202644A1Easy to cleanBlast furnace detailsCharge manipulationHydrogen contentHandling system

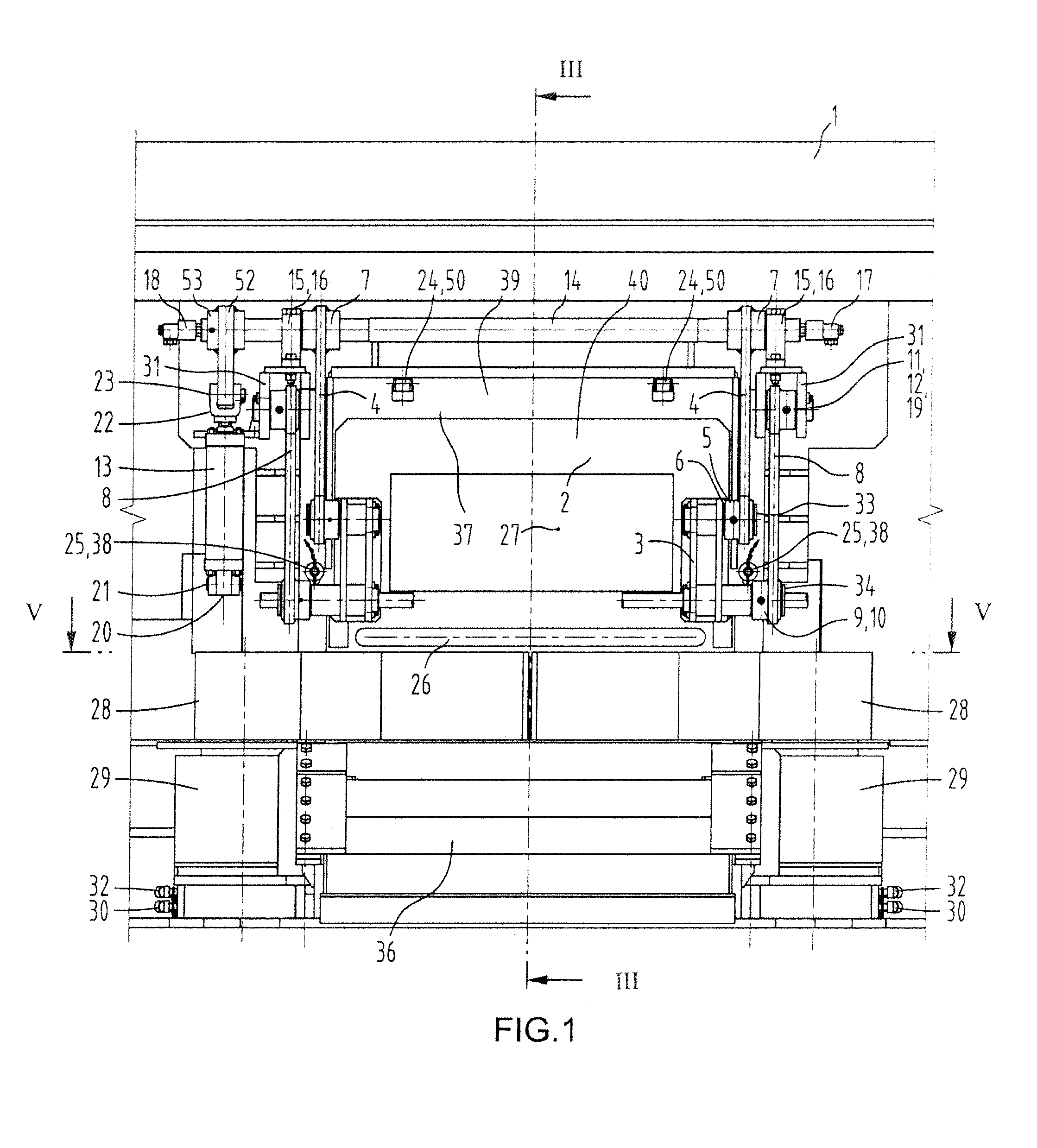

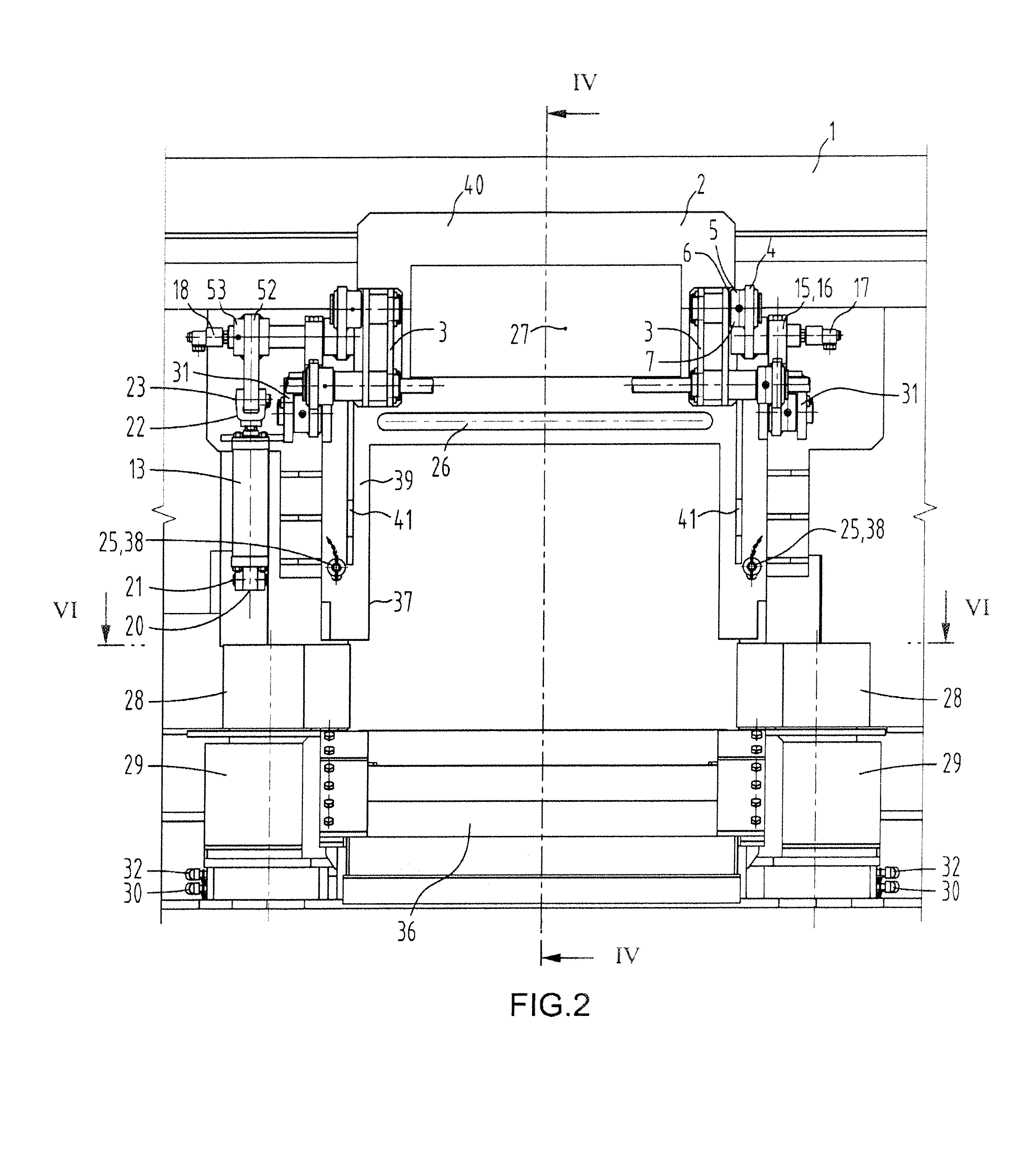

A quiescent melt handling system includes a holding furnace (2, 120, 320-720) for a molten metal melt. The holding furnace has a relatively large surface area and a relatively shallow depth, having a width to depth ratio in the range of 4-100 to 1. Also provided is structure (650-680) in the holding furnace for separating inclusions from the melt in the holding furnace. A quiescent transfer casting method includes melting a metal to form a melt and transferring the melt into a holding furnace. A hydrogen content in the melt is passively equilibrated with a dry atmosphere maintained in the holding furnace. Subsequently, the melt is withdrawn from the holding furnace.

Owner:ALOTECH LTD

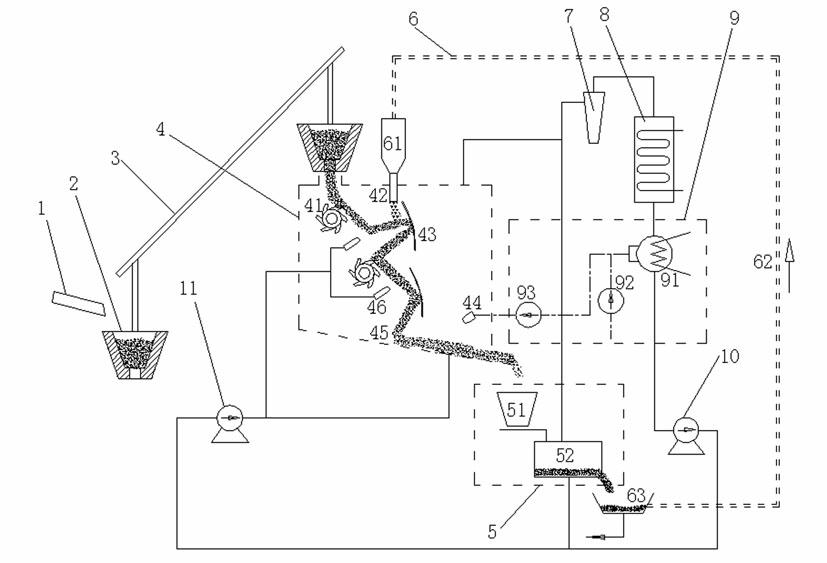

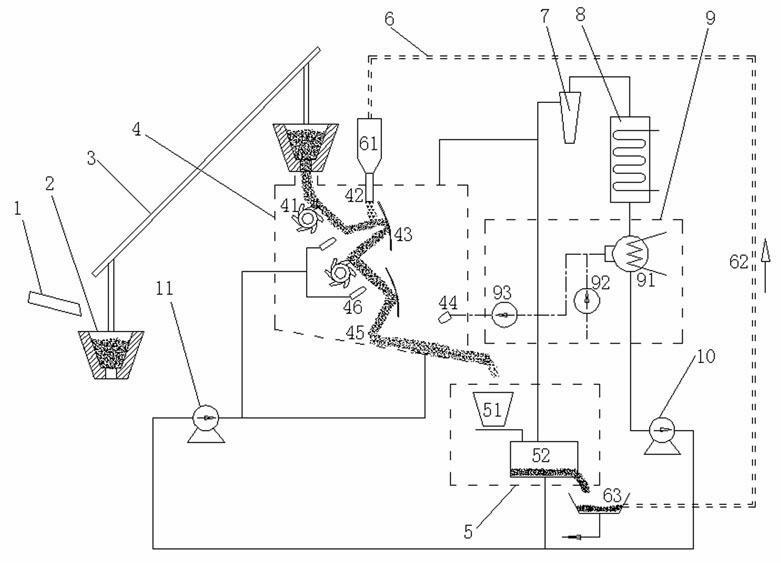

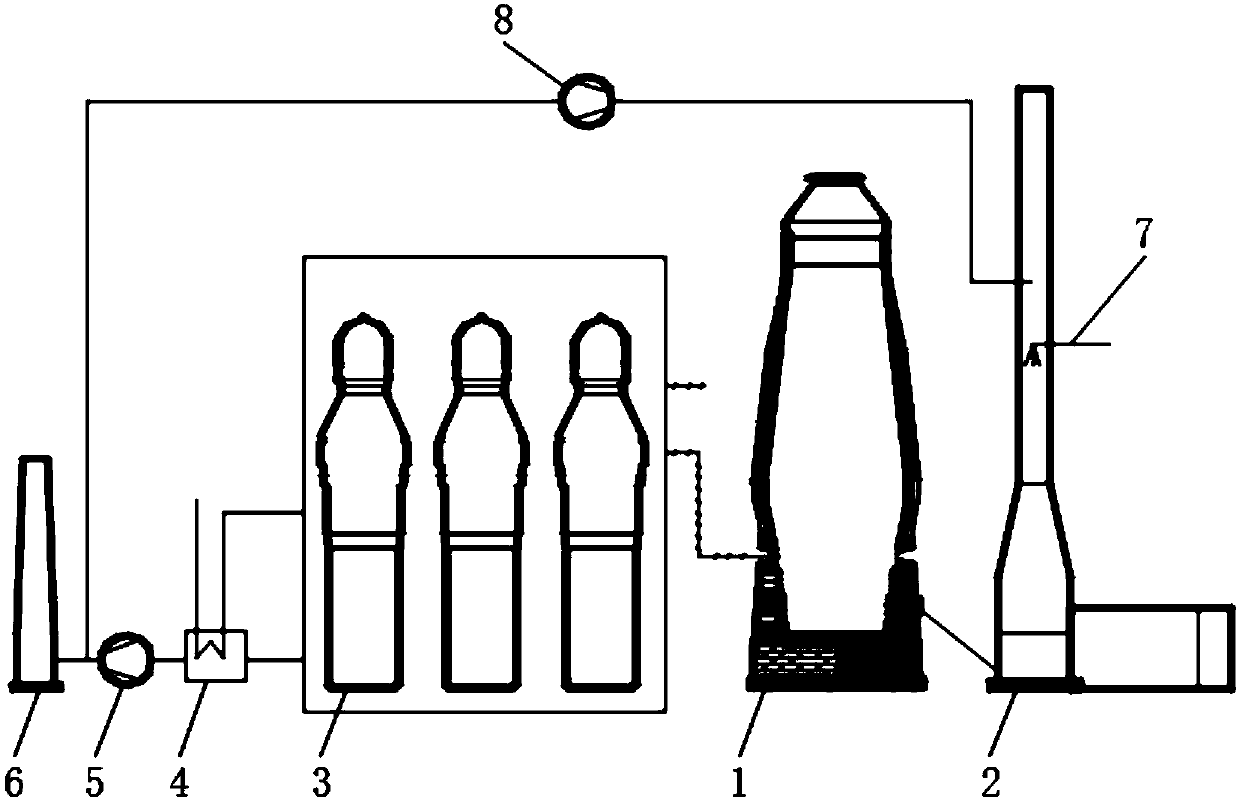

Method and system for recovering high-temperature sensible heat of molten blast furnace slag

ActiveCN102162016ADoes not affect activityImprove waste heat qualityIncreasing energy efficiencyDischarge devicesSlagSlow cooling

The invention discloses a method and a system for recovering high-temperature sensible heat of molten blast furnace slag. The system comprises a blast furnace slag runner, a slag hopper, a slag hopper lifting mechanism, a quenching unit, a slow cooling unit, a cold slag particle circulation unit, a cyclone dust collector, a waste heat boiler, a condensing unit, a circulating fan, and a booster fan. The method for recovering waste heat comprises the following steps of: crushing and quickly cooling the molten blast furnace slag in the quenching unit in a composite way of a rotary crushing wheel, high-pressure cold air, a slag trap, cold slag particles and cooling water, and fully exchanging heat with solidified blast furnace slag in the slow cooling unit by using cooling air; and allowing high-temperature air which comes out of the quenching unit and the slow cooling unit to enter the waste heat boiler and performing heat exchange, transforming into steam or electric power and then outputting. The subsequent utilization of blast furnace slag and the waste heat recovery efficiency are synchronously considered, condensed water is recycled, finished slag does not contain water or only contains a small amount of water, the granulation effect of the slag is better, and the contradiction between intermittent slagging and continuous heat production of blast-furnace ironmaking is resolved.

Owner:HANGZHOU BOILER GRP CO LTD

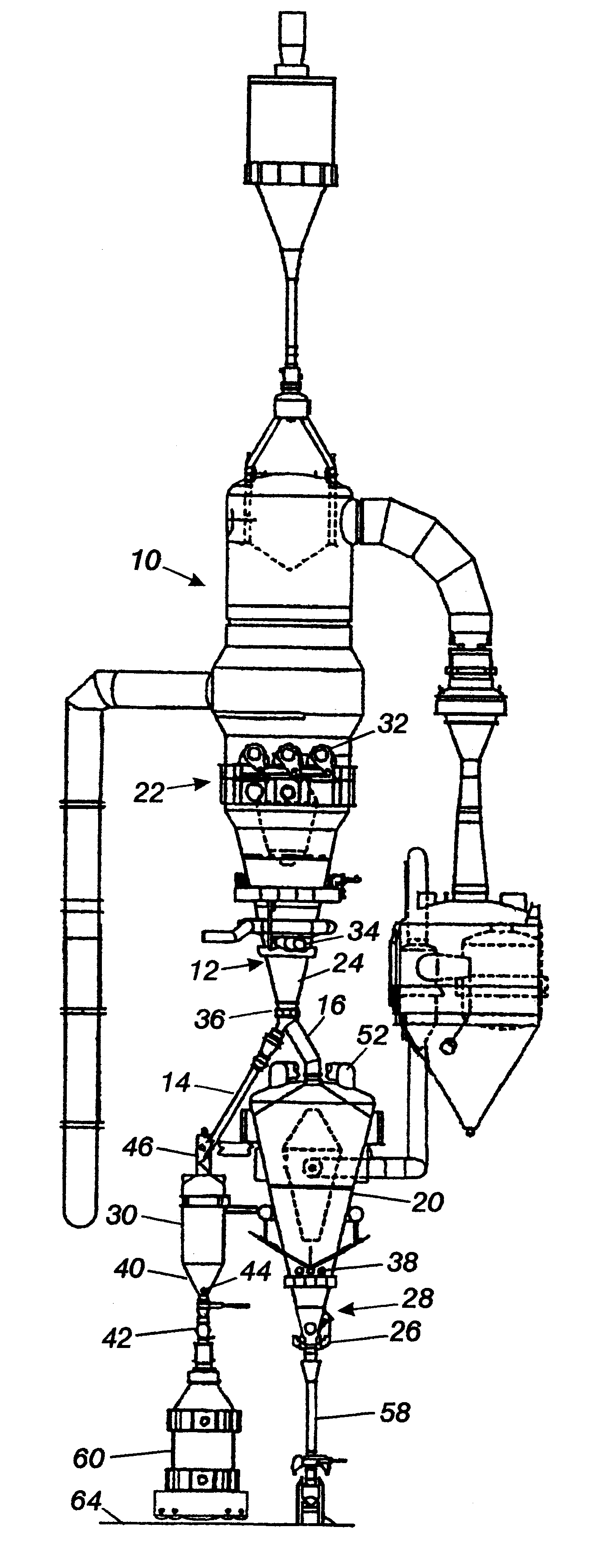

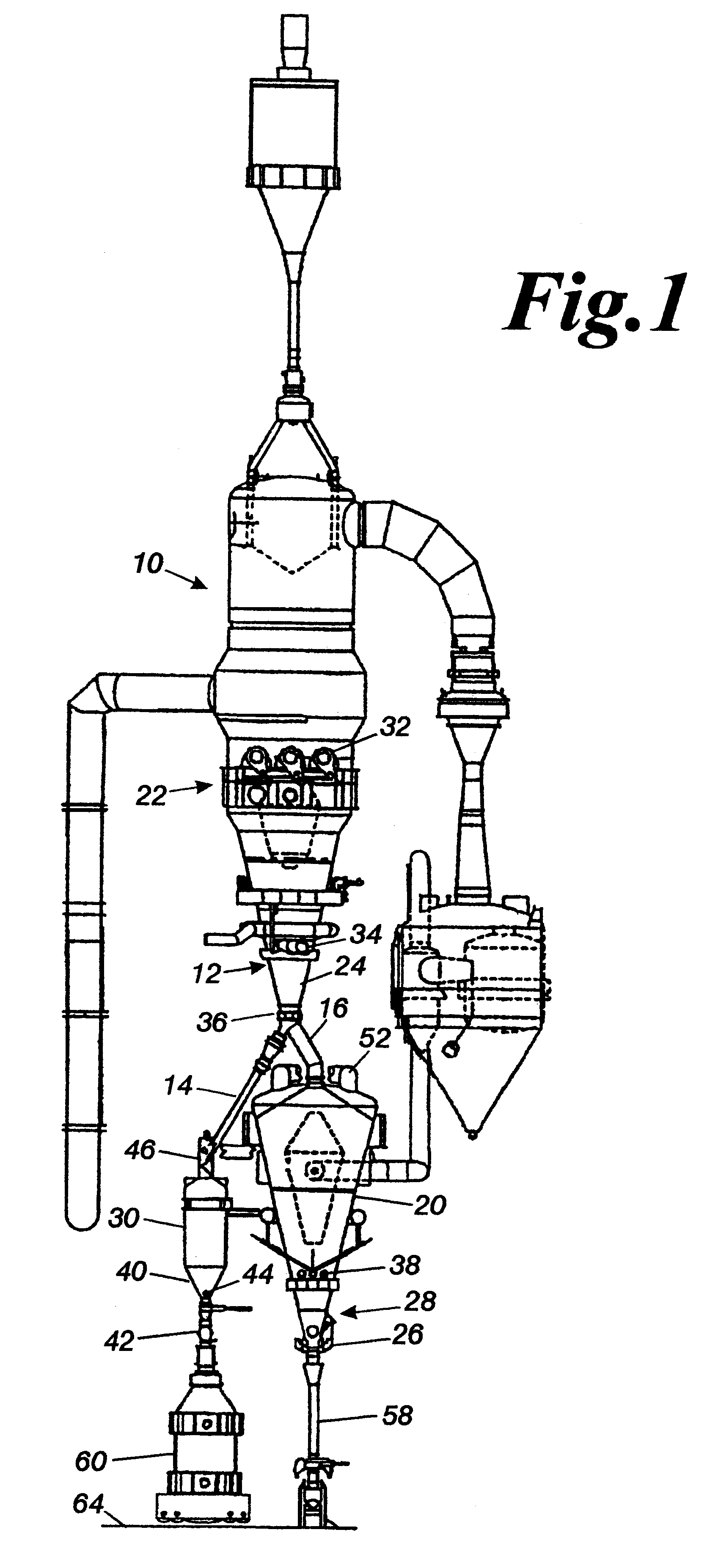

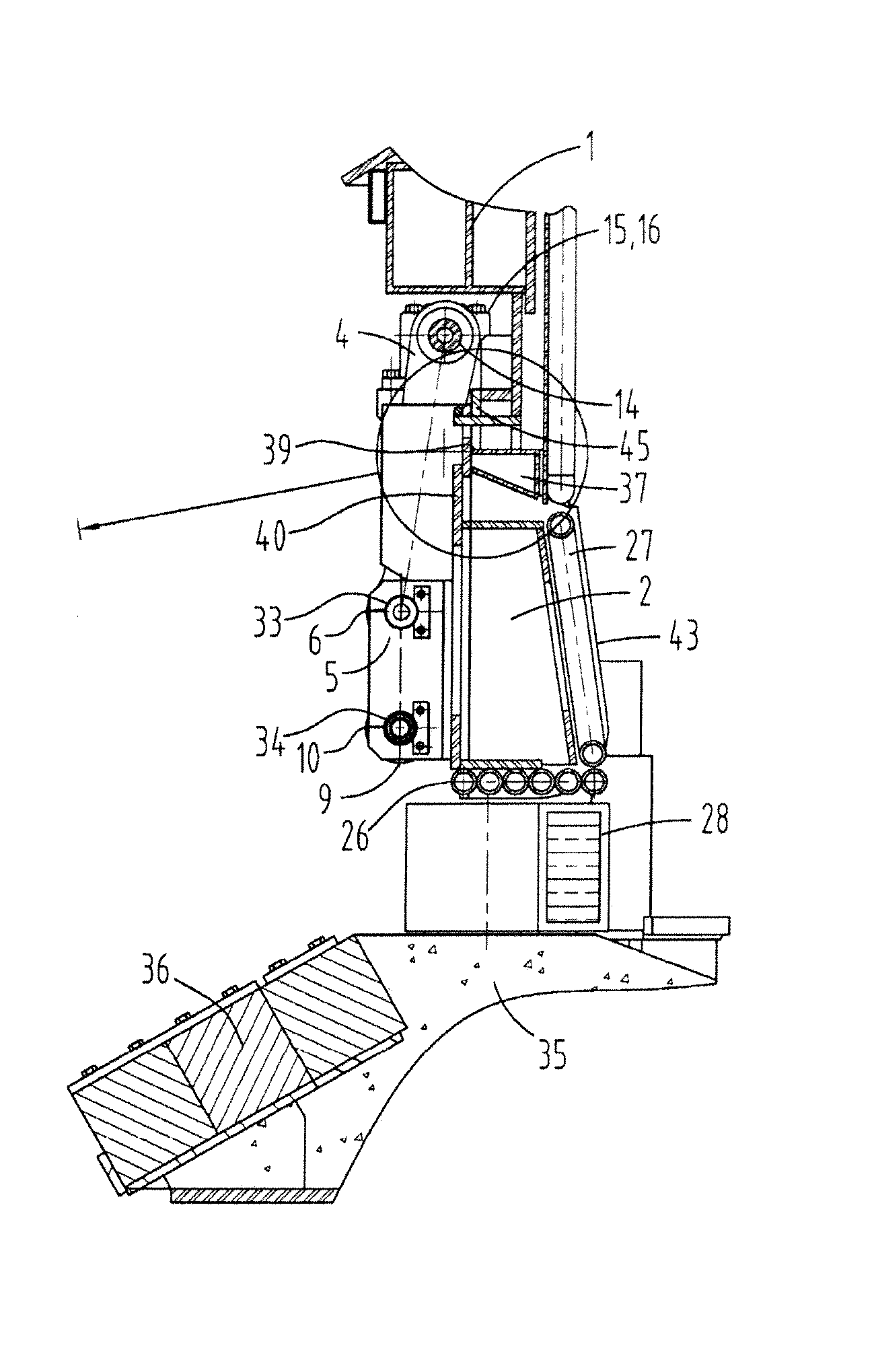

Direct reduced iron discharge system and method

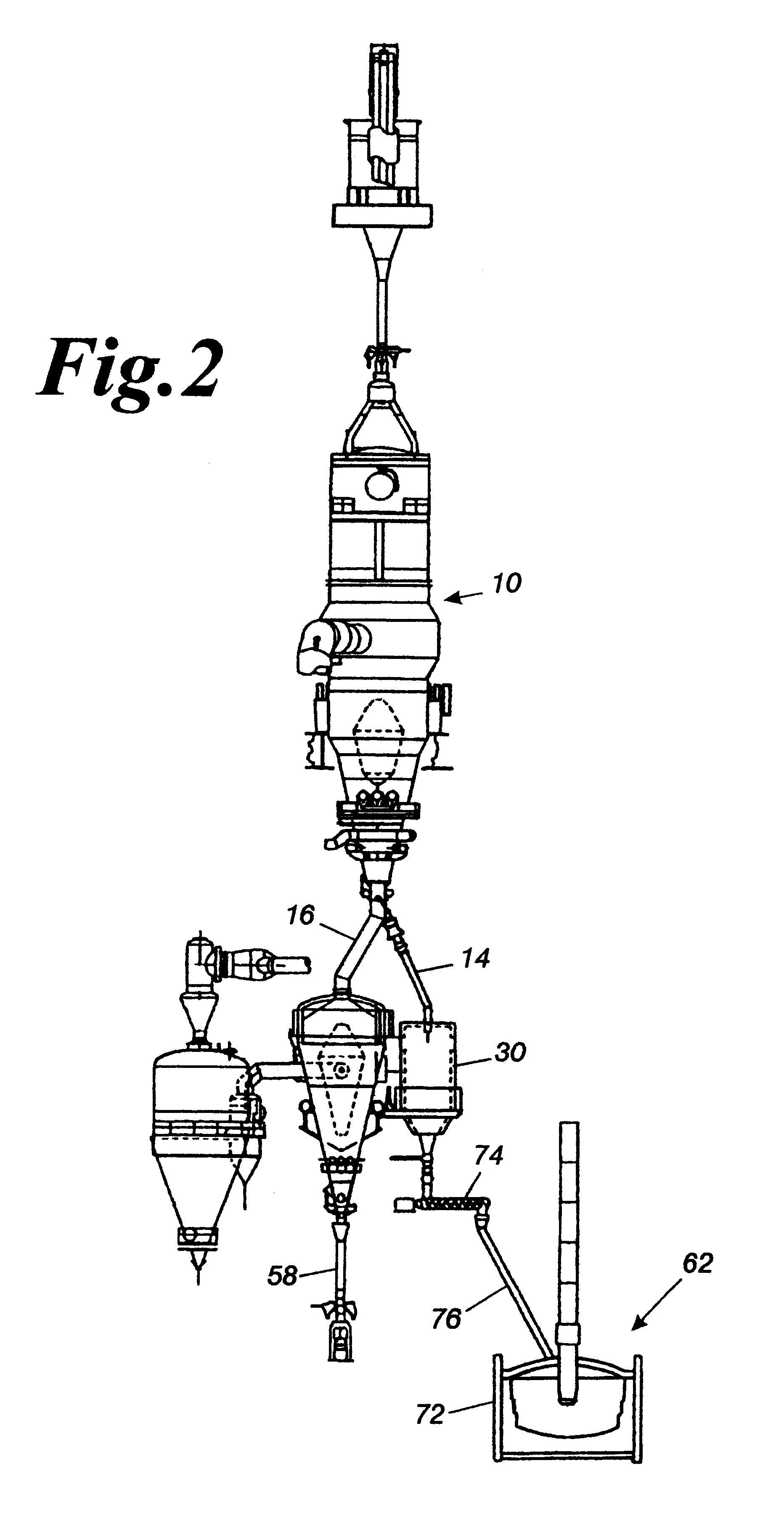

InactiveUS6214086B1No loss in metallizationWide range of sizesMolten spray coatingNuclear energy generationEngineeringDirect reduced iron

A method and apparatus for simultaneously supplying varying proportions of hot and cold direct reduced iron(DRI) material from a source of hot DRI for melting, storage, briquetting, or transport. The system uses gravity to transport hot DRI material from a reduction furnace to a furnace discharge section, which transports desired amounts to a cooling receptacle and to a hot DRI vessel. The cooling section of the apparatus is connected to the furnace discharge section through a dynamic seal leg. The hot section is also connected to the furnace discharge section through separate a dynamic sealing leg and can feed a surge vessel, a briquetter, a storage vessel or a melting furnace. The method of operation is also disclosed.

Owner:IDREX INT BV ROTTERDAM ZURICH BRANCH

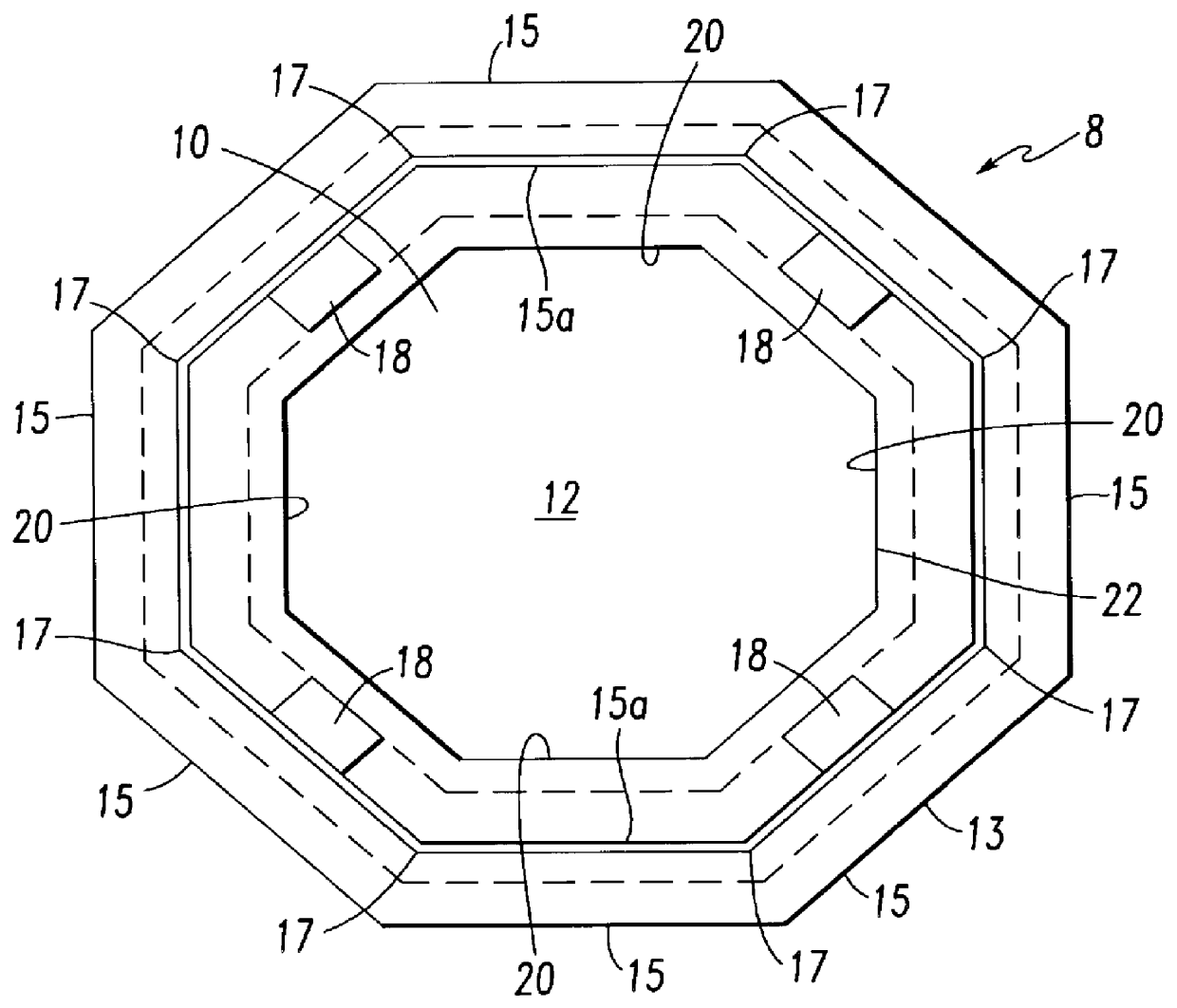

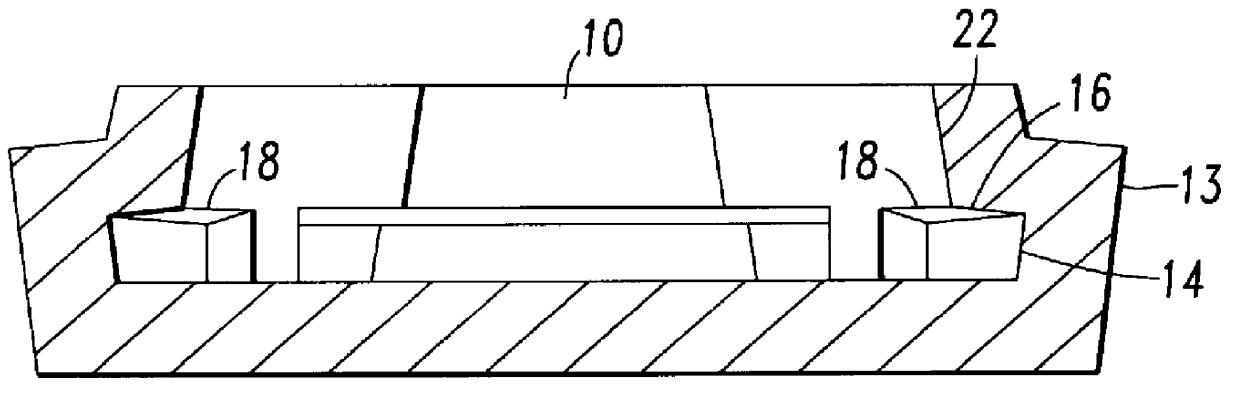

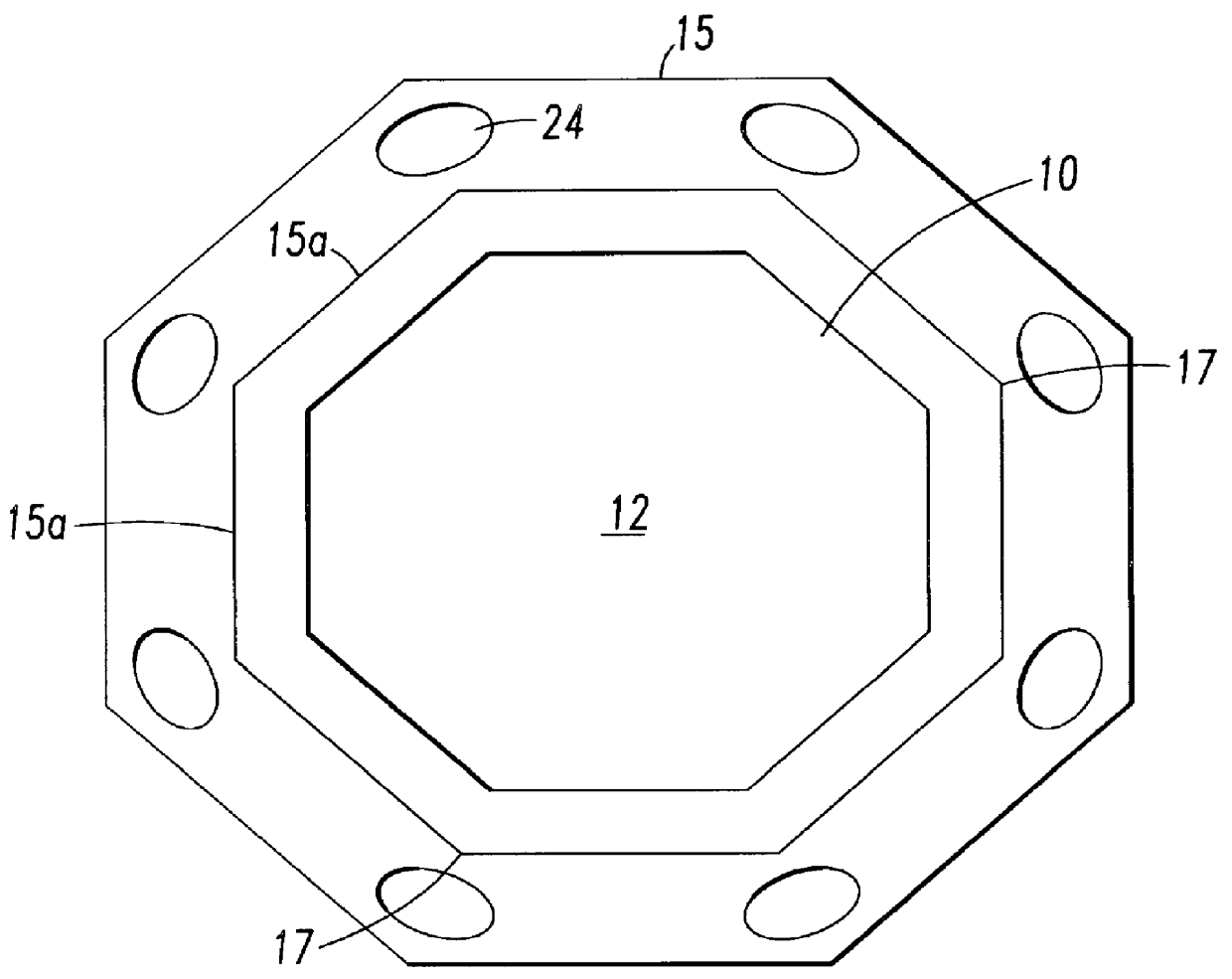

Molten metal containment structure having flow through ventilation

Exemplary embodiments of the invention provide a molten metal containment structure including a refractory molten metal containment vessel having an external surface, and a metal casing for the vessel having an internal surface at least partially surrounding the external surface of the vessel at a distance therefrom forming a spacing between the vessel and the casing. The spacing includes an unobstructed upwardly extending gap that is vented to the exterior of the structure by upper and lower openings in the casing. A layer of insulating material is preferably positioned in the spacing between the internal surface of the casing and the external surface of the vessel, with the layer of insulating material being narrower than the spacing at least at upwardly extending sides of the casing, thereby forming the unobstructed gap. The vessel may be a metal conveying trough, a housing for a metal filter, a container for a metal degasser unit, a crucible, or the like.

Owner:NOVELIS INC

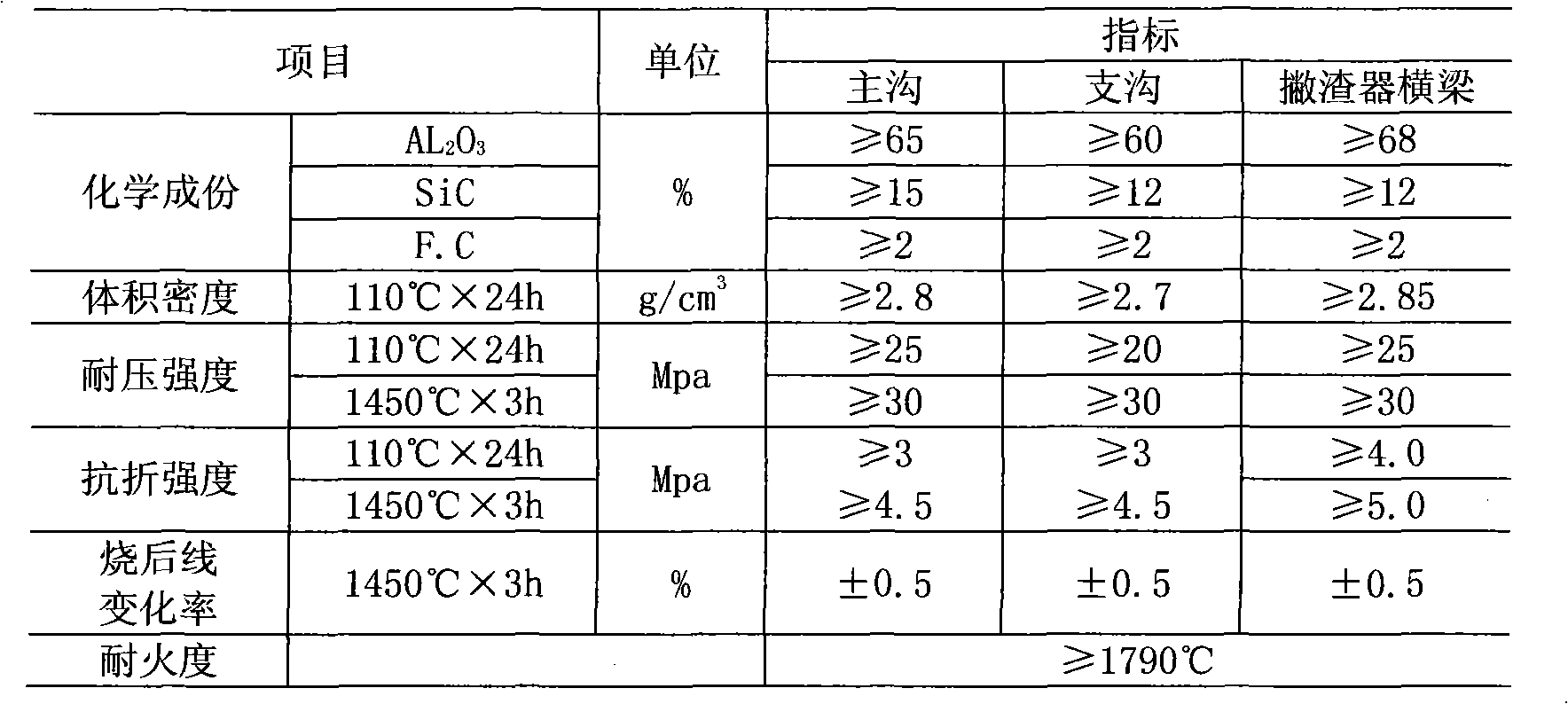

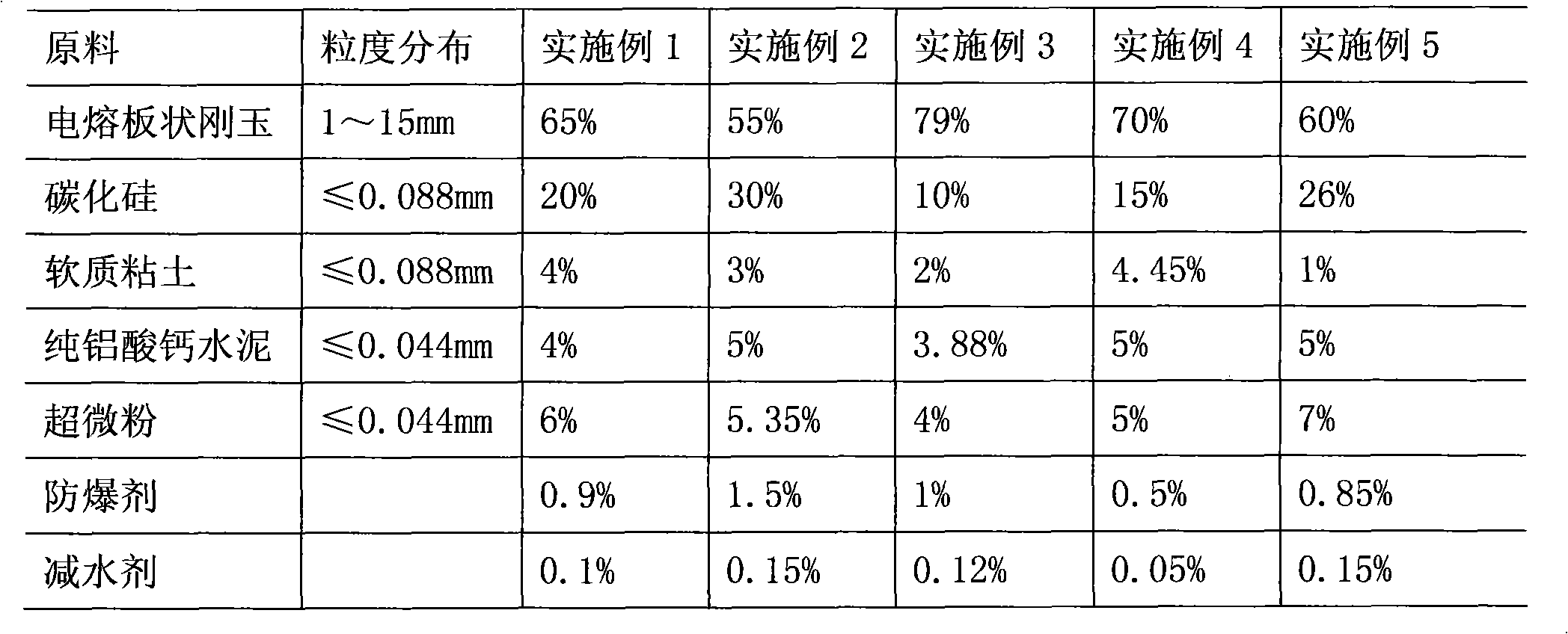

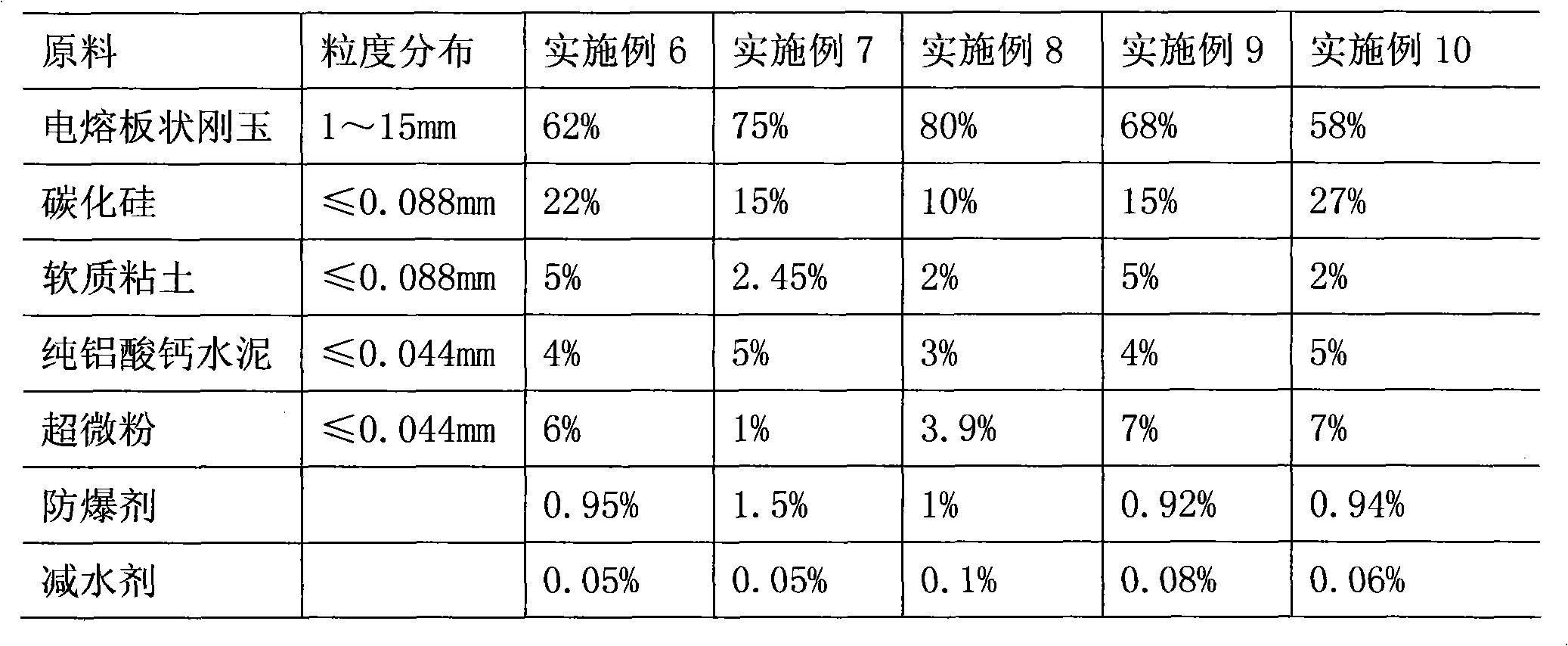

Explosion-proof iron runner castable

The invention relates to an explosion-proof iron runner castable which comprises the following raw materials in percentage by weight: 55-80 percent of fusion tabular corundum, 10-30 percent of silicon carbide, 1-5 percent of soft clay, 2-5 percent of pure calcium aluminate cement, 1-7 percent of submicron powder, 0.5-1.5 percent of explosion-proof agent and 0.05-0.15 percent of water reducing agent, wherein the explosion-proof agent is a mixture of aluminum powder, aluminum lactate, explosion-proof fiber and boron carbide powder with the weight ratio of 1-2:2.5-4:1-2.5:2-4. The castable of the invention has no cracks after demoulding and drying and no spalling during baking, has the safe explosion-proof temperature of 800 DEG C increased from 500 DEG C, can be subjected to construction under heat state and rapid temperature rise without spalling and can meet the operating requirements of rapid construction of middle and small size blast furnace iron runner. The castable has long service life, can improve the environment of a casting house, greatly reduces the labor intensity of the workers, improves the quality of molten iron and enhances the application safety factor of the iron runner.

Owner:HENAN HUAXI FURNACE REFRACTORY

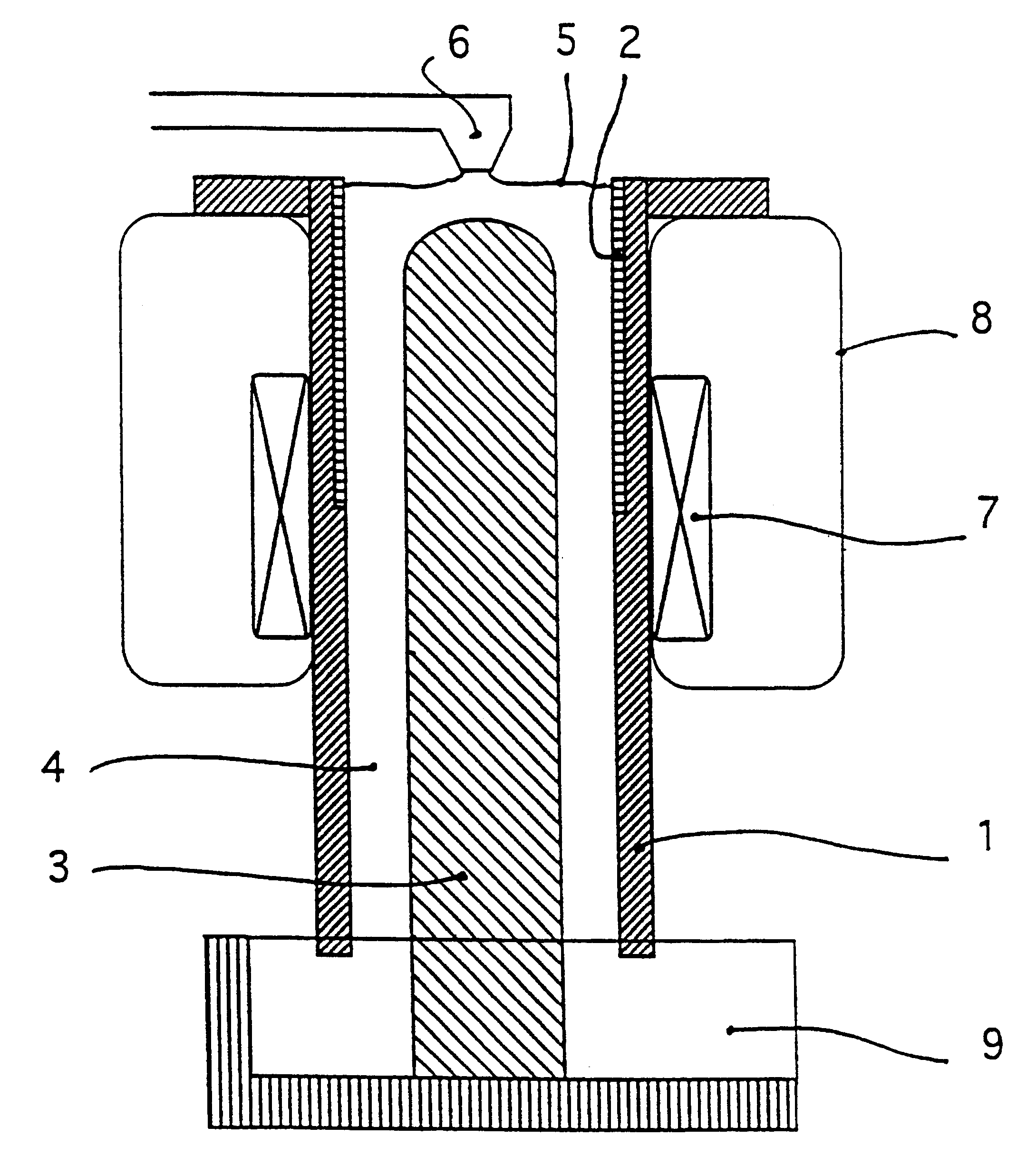

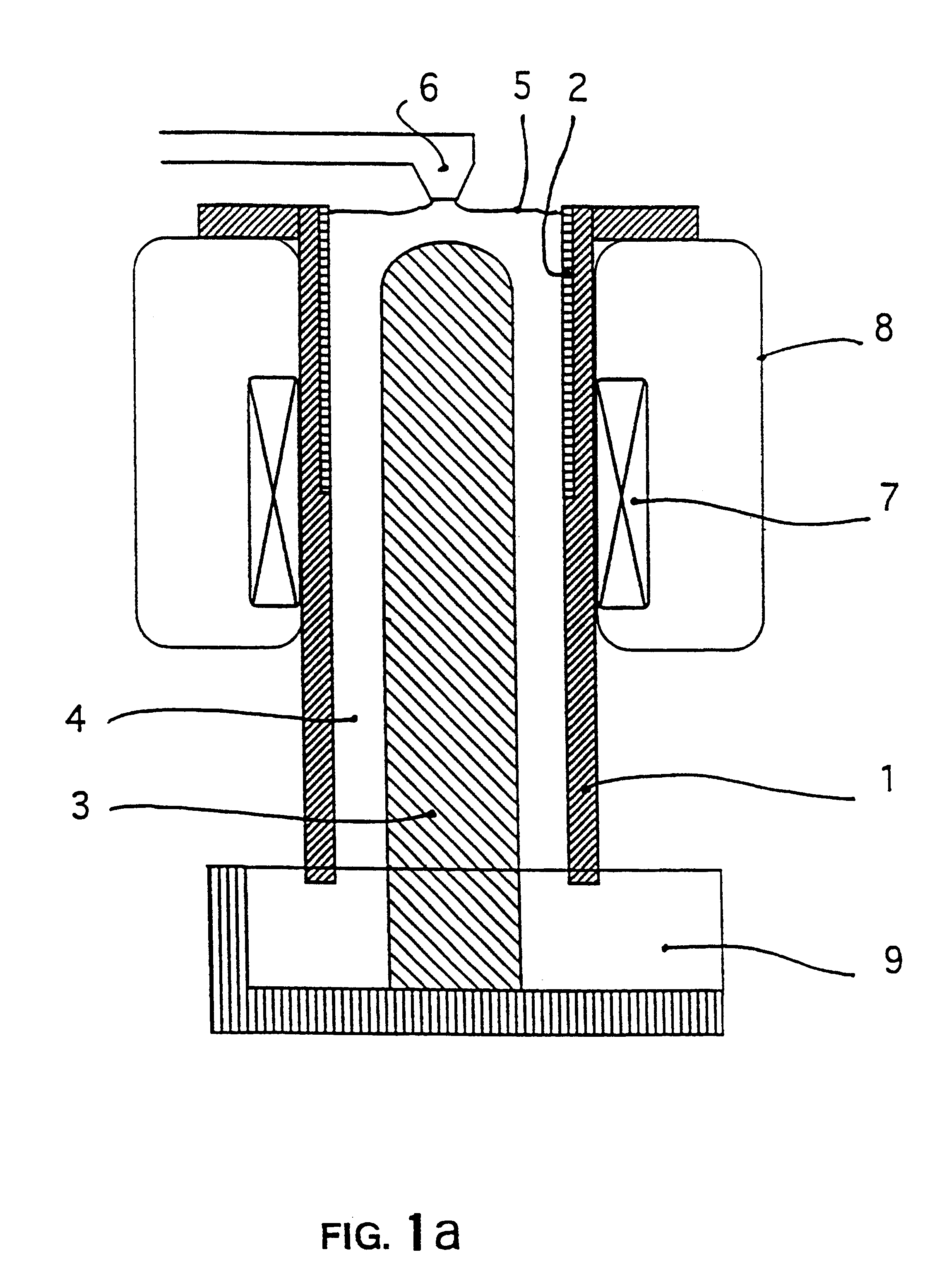

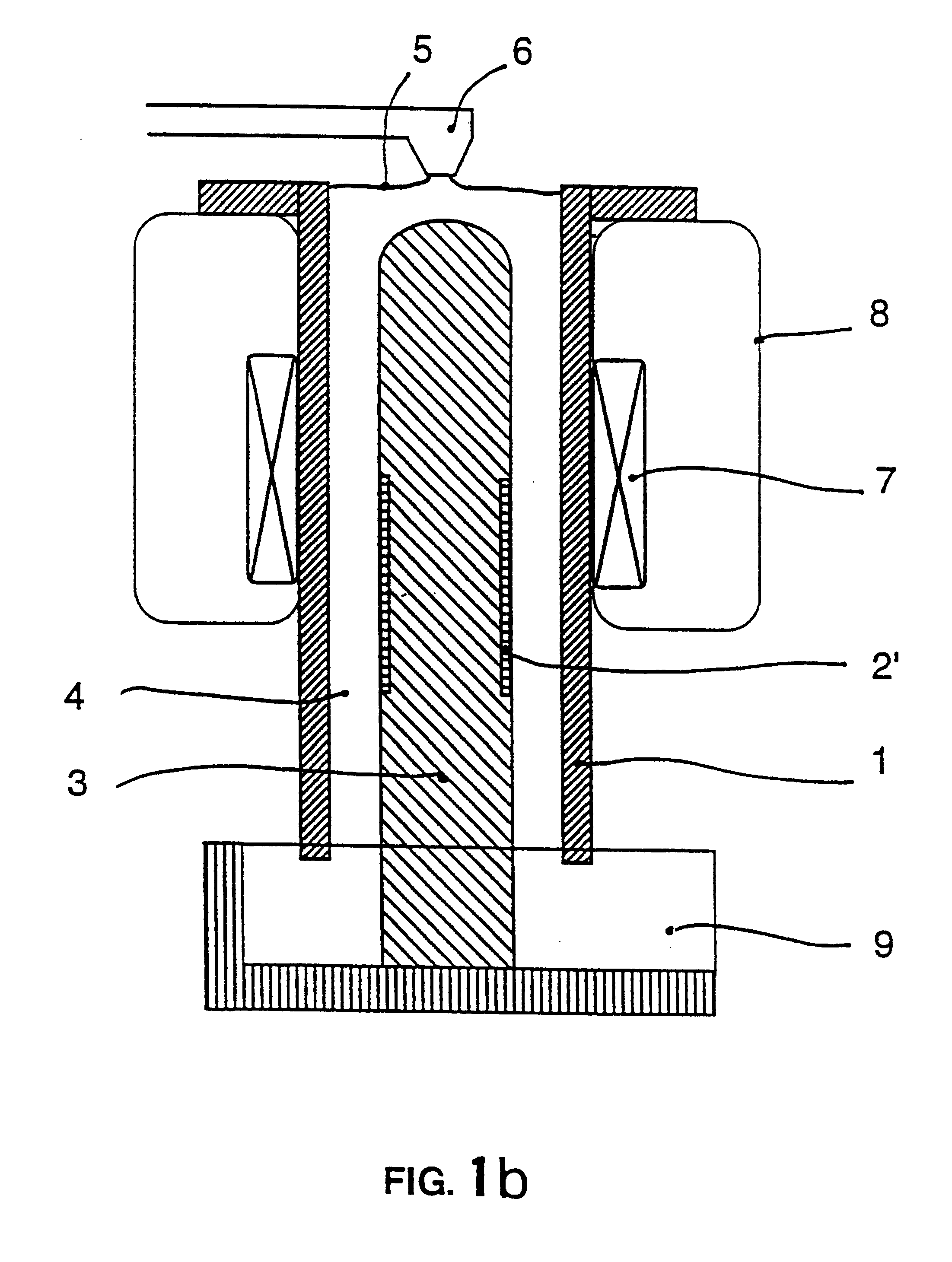

Method and device for separating particles from an electrically conductive liquid flow using electromagnetic forces

InactiveUS6355085B1Easy to separateDistance minimizationWater/sewage treatment by magnetic/electric fieldsOpen gradient mangetic separatorsElectromagnetic interferenceMagnetic flux

A method for separating inclusions from an electrically conductive liquid flow using electromagnetic forces, wherein the inclusions and the liquid have differing electrical conductivities. The flow is exposed to a spatially heterogeneous magnetic flux produced by a continuous static magnetic field.

Owner:CENT NAT DE LA RECHERCHE SCI

Slag washing water steam recycling and white fog removing system and recycling method

PendingCN107815514ADesaturationAvoid it happening againBlast furnace detailsDischarge devicesSlagDihydrogen oxide

The invention provides a slag washing water steam recycling and white fog removing system and a recycling method. The slag washing water steam recycling and white fog removing system comprises a slagwashing water steam chimney close to a blast furnace, at least one cooling spraying device and a hot air furnace assembly; the lower portion of the slag washing water steam chimney can contain waste slag discharged out of the blast furnace and carries out slag washing operation, the cooling spraying devices are arranged in the middle of the slag washing water steam chimney and spray atomized waterto the lower portion of the slag washing water steam chimney, the hot air furnace assembly is communicated with the blast furnace and the upper portion of the slag washing water steam chimney, the hot air furnace assembly can convey generated hot air into the blast furnace, and conveys the treated waste gas to the upper portion of the slag washing water steam chimney, the mist spraying cooling direct heat exchange manner is adopted, the cooling efficiency is high, in combination with the humidity and condensation effect of atomized water, a small amount of water is sprayed, and therefore a large amount of water steam can be recycled, water steam which is not condensed is subject to waste gas temperature rise dilution, the water steam saturability is reduced, and white smoke is prevented from being generated.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

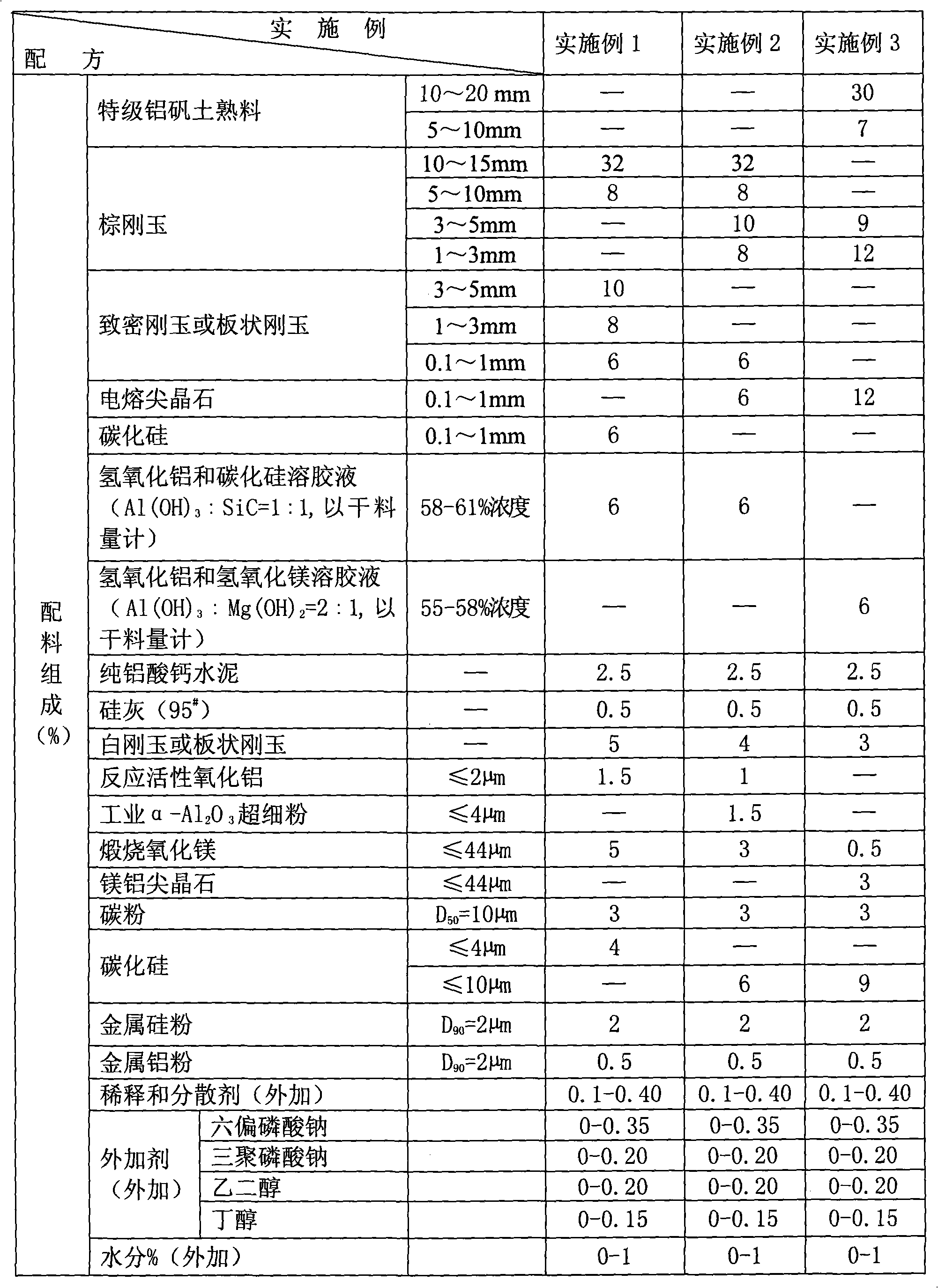

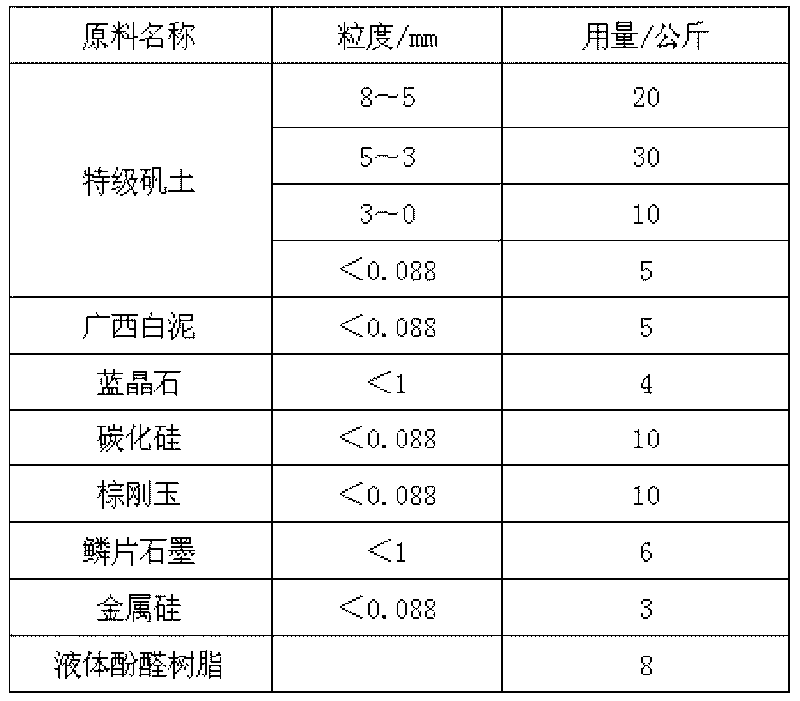

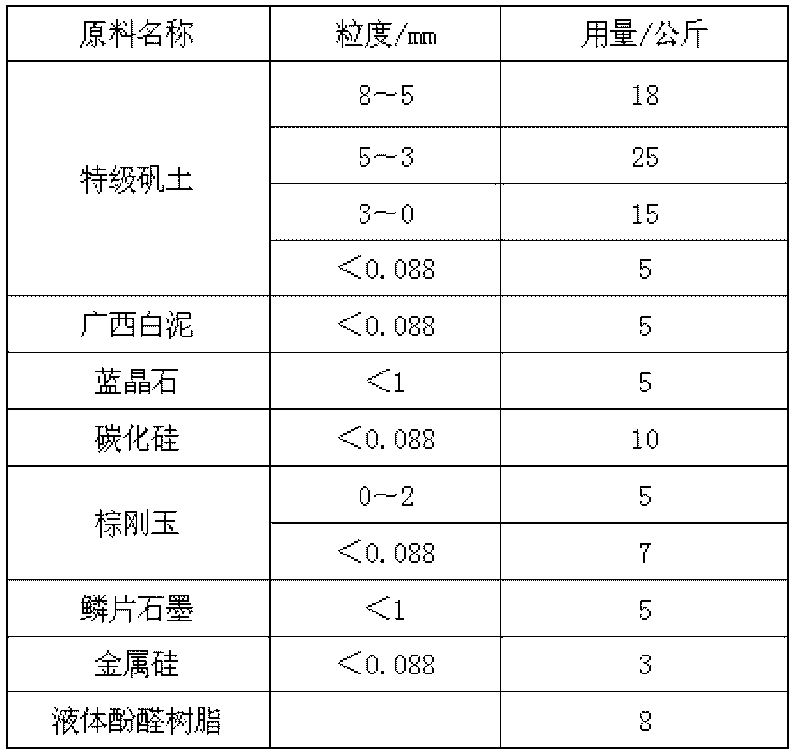

Al2O3-MA-SiC-C refractory castable material with carbon wrapped by nano Al2O3-SiC film and preparation method thereof

The invention relates to an Al2O3-MA-SiC-C refractory castable material with carbon wrapped by nano Al2O3-SiC film or nano Al2O3-MgO film, and a preparation method thereof. The preparation method of the nano carbon-containing castable material comprises: preparing carbon-containing sol suspension with Al(OH)3-SiC or Al(OH)3-Mg(OH)2 through a high-speed impact mixer, coating the carbon-containing sol suspension on the surface of carbon powder to form a compact carbon wrapping layer with complete coverage and no crack, and carrying in-situ synthesis of nano gel particles of Al2O3 and SiC or Al2O3 and MgO generated during transformation from sol to gel so as to generate a nano-sized matrix with carbon-containing nano secondary spinellite, Al2O3 and SiC as main crystalline phases, thereby completing the preparation of the Al2O3-MA-SiC-C refractory castable material made of nano material. The castable material has particularly excellent resistance against erosion and scouring of molten iron slag, and can satisfy the requirements for use in the iron tapping channel of the modern large-scale blast furnace. Moreover, the invention significantly prolongs the service life, reduces the cost and facilitates the environmental protection.

Owner:高树森

Aluminiferous casting material for blast furnace tapping and preparation method thereof

The invention relates to an aluminiferous casting material for blast furnace tapping and a preparation method thereof, belonging to the technical field of fire-proof material. The main raw materials of the casting material contain industrial corundum powder, Si powder, high-temperature pitch grain powder, alumina concrete or calcium aluminum concrete, Aplha-Al2O3 superfine powder, SiO2 superfine powder and metallic silicon powder. Sodium tripolyphosphate or sodium hexametaphosphate is used as dispersing agent. Explosion-proof organic fiber and aluminum ash are added to acquire the casting material for blast furnace tapping. The casting material can be used, after adding 4% to 6% of water and mixing in the casting material, molding the mixture by pouring into a mould for blast furnace tapping, naturally hardening, drying, de-molding, drying at a temperature of 85 DEG C to 700 DEG C and removing water by performing thermal treatment. The casting material has high blast furnace slag resistant property and usability. By adopting the components Al2O3, Al, SiO2, etc., in the aluminum ash instead of the aluminum material and siliceous material in the casting material for blast furnace tapping, the invention can efficiently lower the cost of the casting material and find a new way to comprehensively use aluminum ash.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Waterless taphole mix for blast furnace taphole

The invention discloses a waterless tamping for blast furnace tapping comprising 80-120 weight portions of component A and 15-25 weight portions of component B, wherein the component A comprises (by weight portions) brown fused alumina with grain size of 1-3mm 20-40 parts, brown fused alumina powder with grain size <=0.074mm 15-25 parts, kyanite with grain size <=1mm 2-7 parts, SiC with grain size <=0.074mm 8-15 parts, Guangxi clay wash with grain size <=0.088mm 5-20 parts, mica powder with grain size <=0.074mm 5-10 parts, coke with grain size <=2mm 10-20 parts, metallic silicon powder with grain size of 0.044mm 0.5-3 parts, carbon black 0.1-2 parts, the component B being conjugation agent. The waterless tamping has good high-temperature strength and slag erosiveness resistance.

Owner:PUYANG REFRACTORIES GRP CO LTD

Ceramic capacitor mounting structure and ceramic capacitor

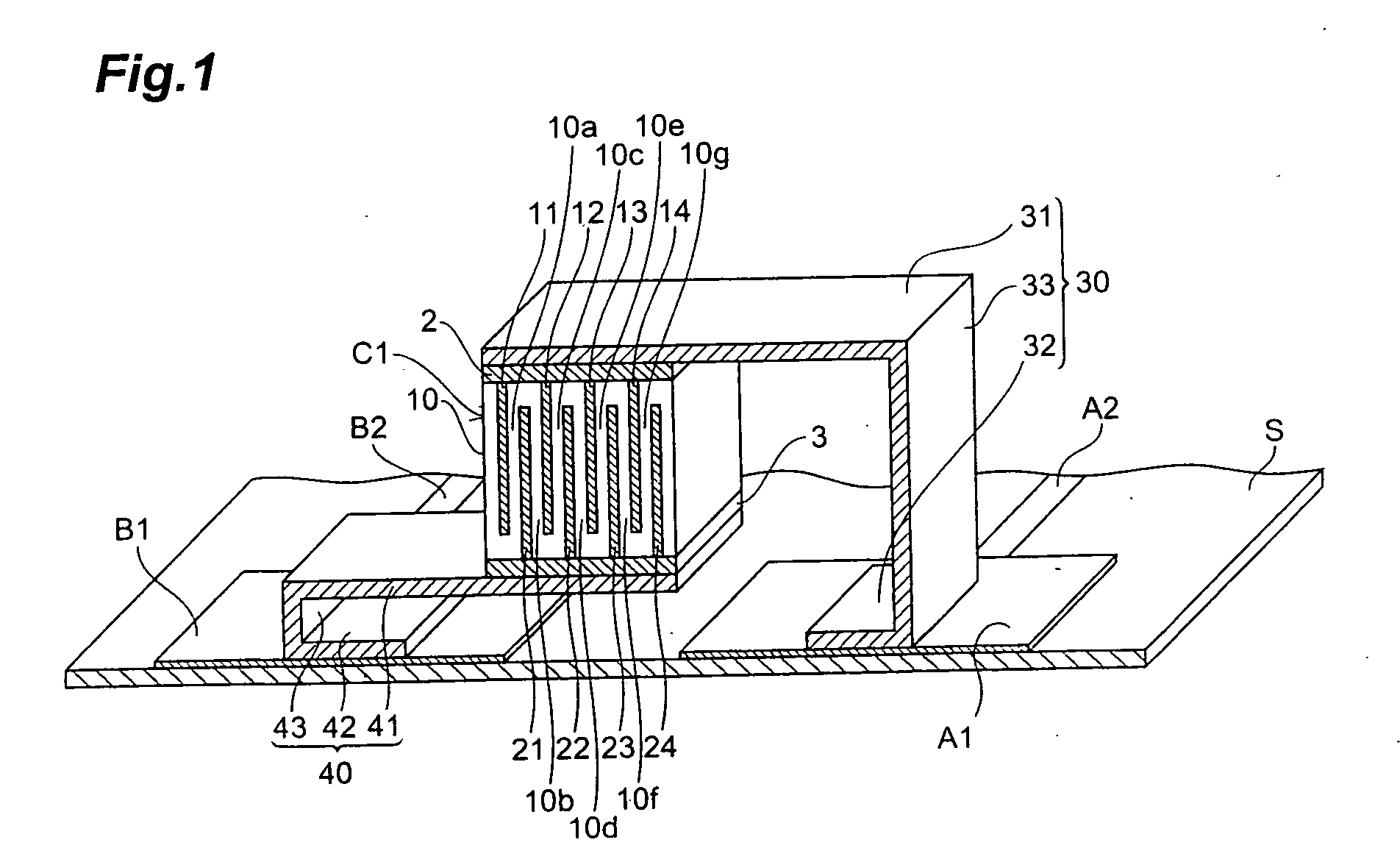

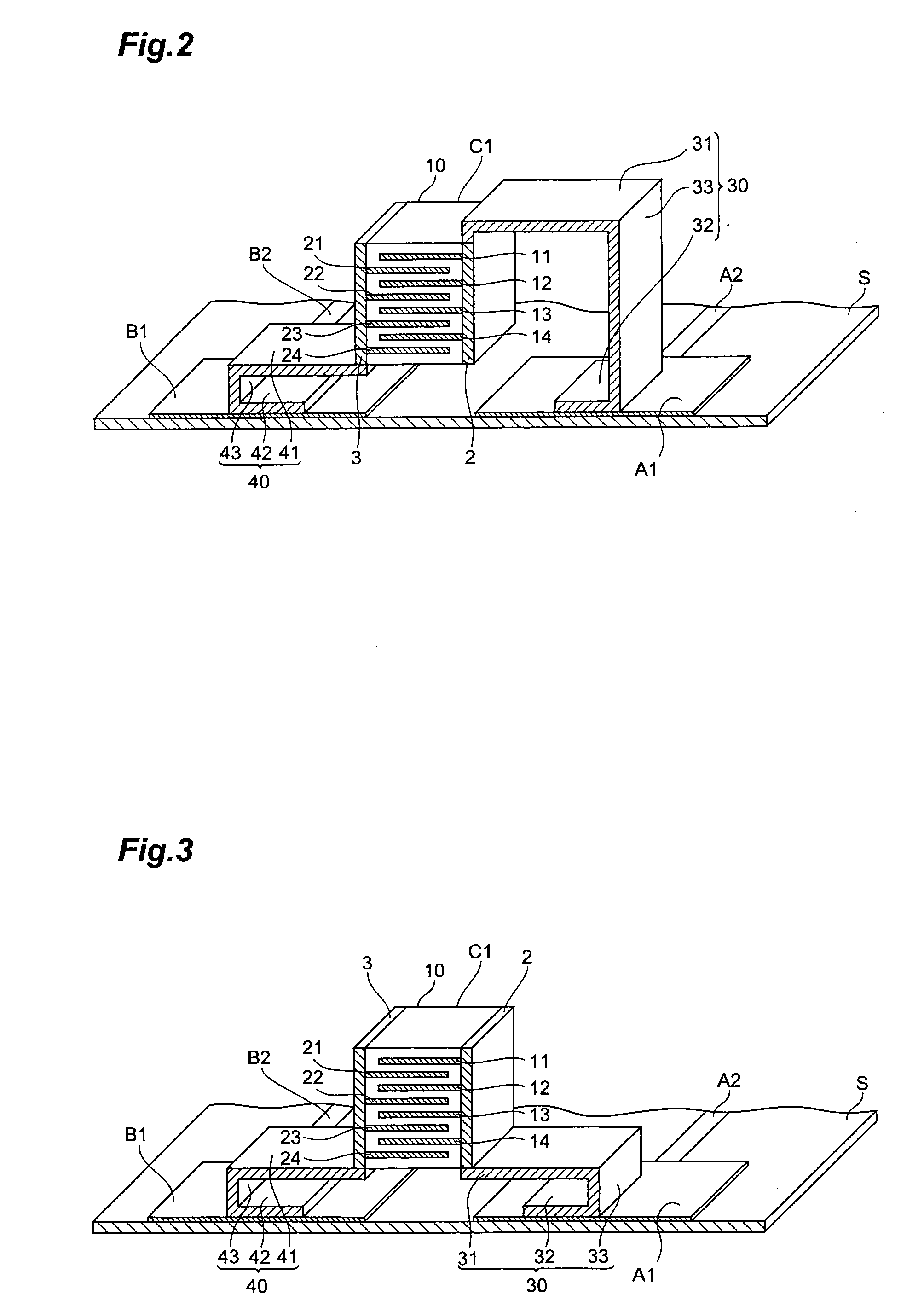

ActiveUS20070188975A1Reduce the soundAbsorb vibrationFurnace safety devicesFinal product manufactureCeramic sinteringCeramic capacitor

A ceramic capacitor comprises a ceramic sintered body, and first and second terminal electrodes formed on outer surfaces of the ceramic sintered body. The first terminal electrode is electrically connected to a land formed on a substrate through a first metal terminal. The first metal terminal has a first capacitor connecting portion mechanically connected to the first terminal electrode, a first terminal portion mechanically connected to the land, and a first intermediate portion electrically connecting the first capacitor connecting portion and the first terminal portion to each other. The first capacitor connecting portion of the first metal terminal is parallel to the substrate.

Owner:TDK CORPARATION

Method and apparatus for removing liquid salts from liquid metal

InactiveUS6036743ALow production costEasy to useBlast furnace detailsDischarge devicesPorous substrateLiquid state

There is provided a method and apparatus for removing liquid salts from liquid metal utilizing at least one porous substrate which is wettable by liquid salts and is not wettable by liquid metal. The porous substrate is inserted into a container having a quantity of liquid metal which is contaminated with an amount of liquid salt. The salt contaminated liquid metal contacts the substrate so that the liquid salt is absorbed into the porous substrate. The salt wetted porous substrate is then removed from the container.

Owner:SELEE

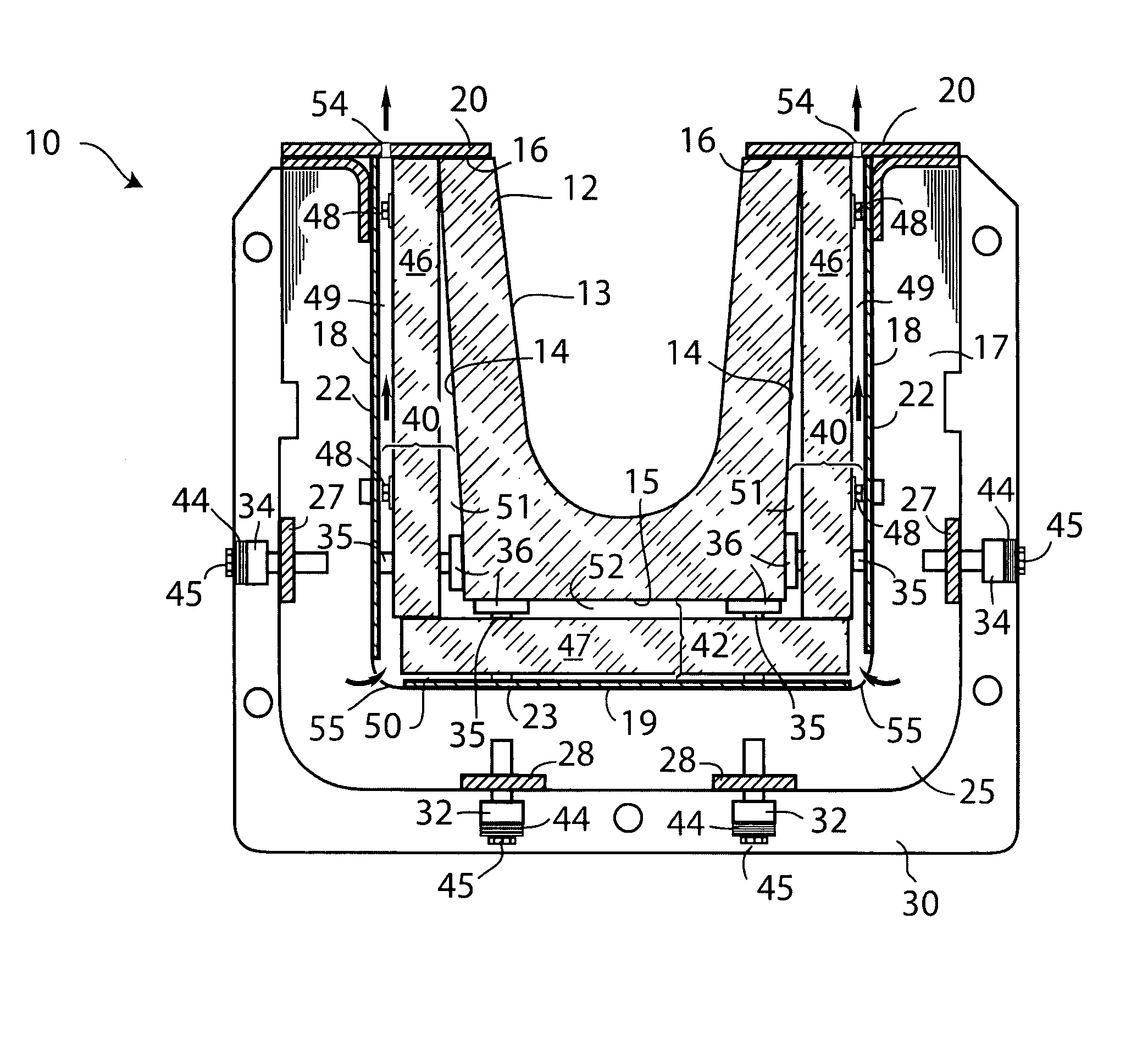

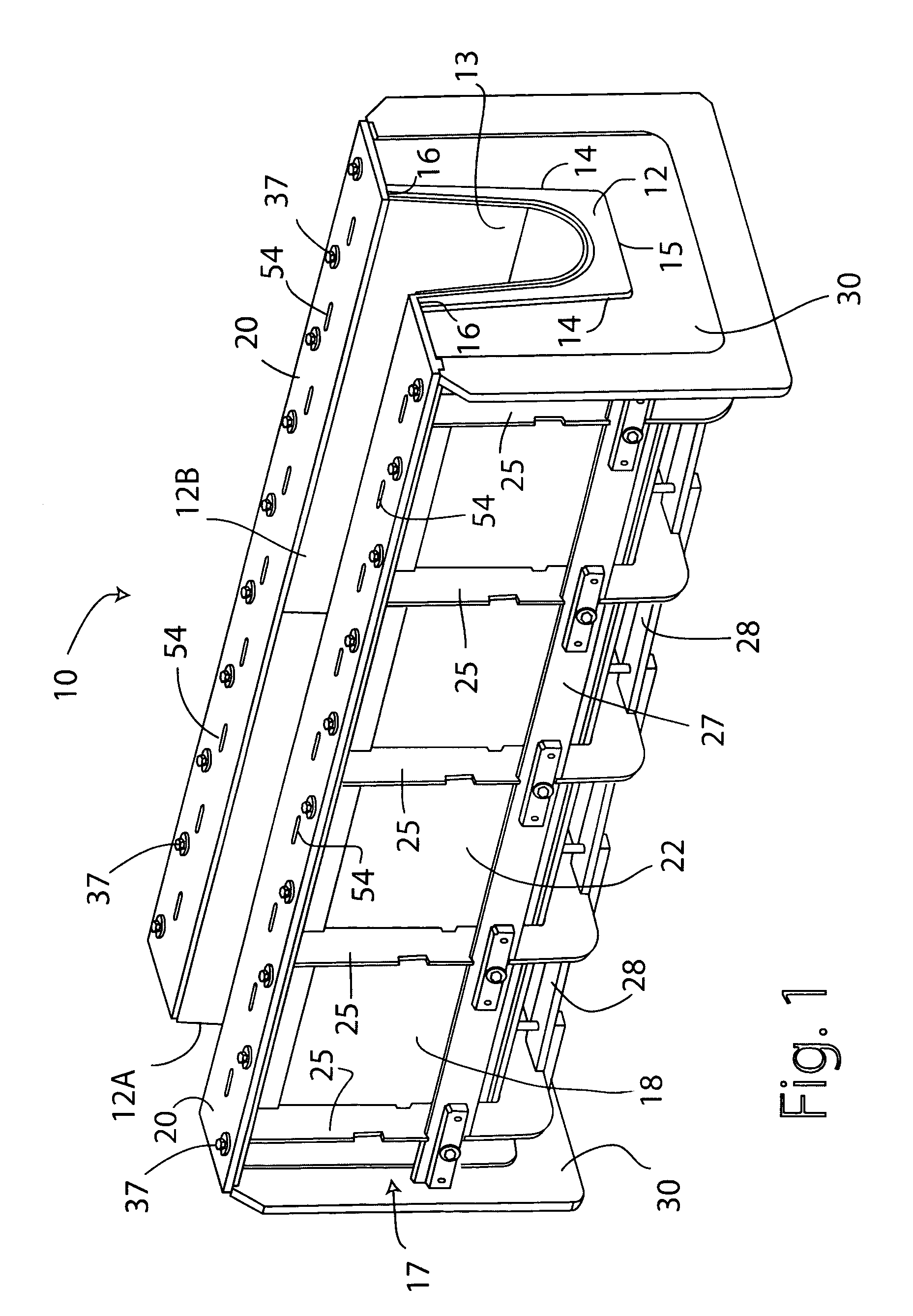

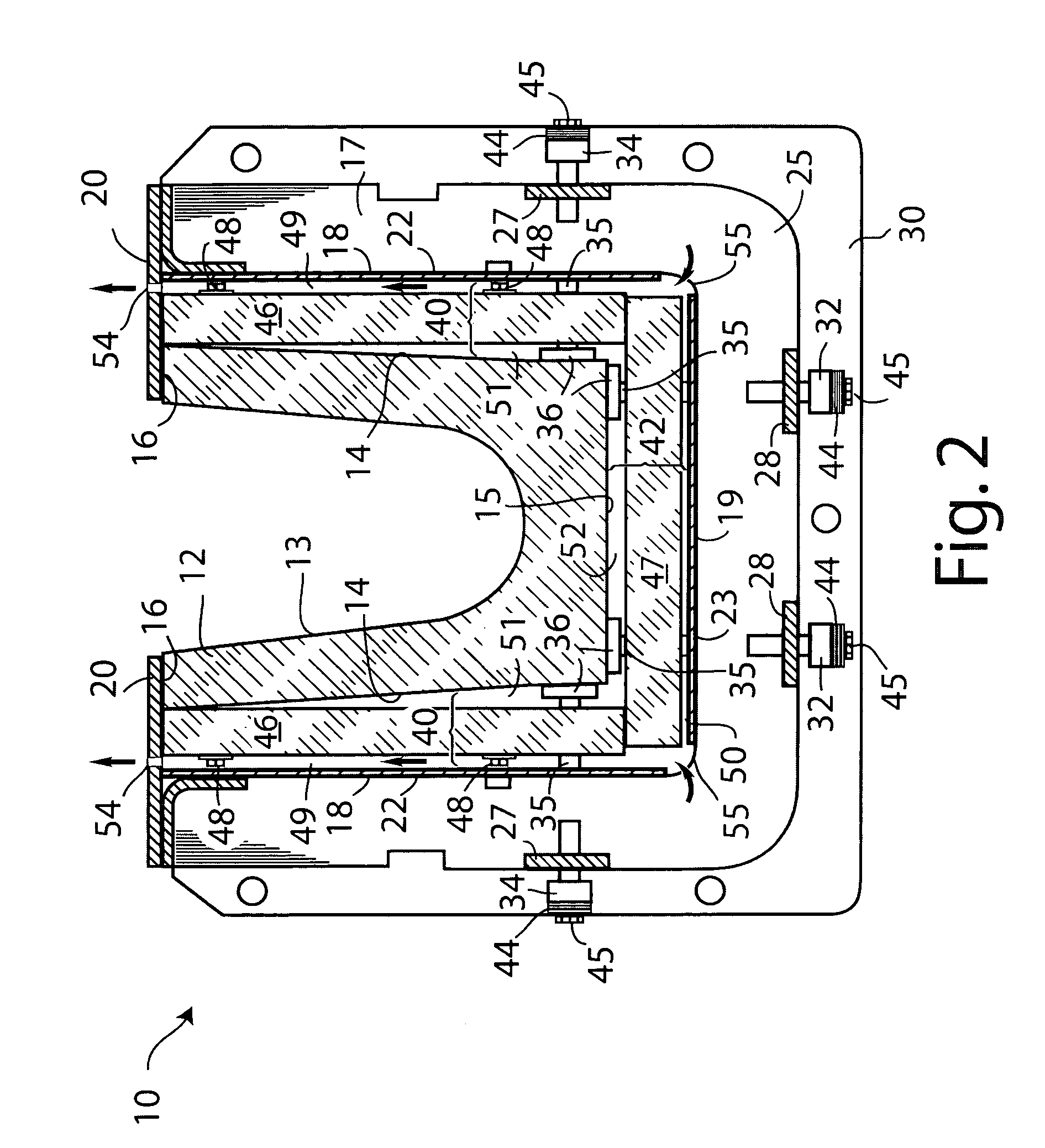

Heated trough for molten metal

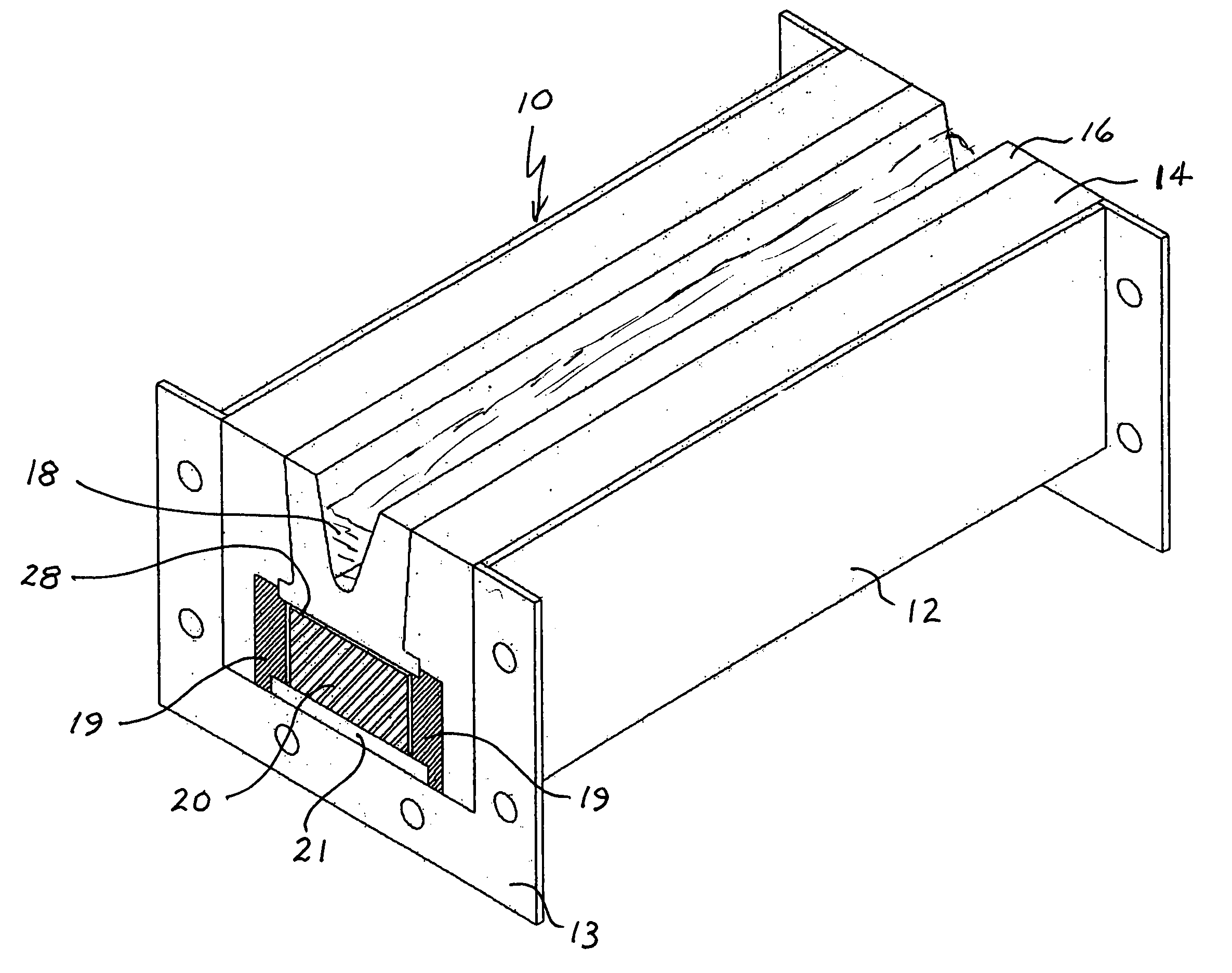

ActiveUS20050126738A1Melt-holding vesselsMolten metal pouring equipmentsMaterials scienceMolten metal

A trough is described for carrying molten metal, comprising an outer shell defined by a bottom wall and two side walls, an insulating layer filling the outer shell and a conductive U-shaped refractory trough body for carrying molten metal, the trough body being embedded in the insulating layer. At least one heating element is positioned in the insulating layer, adjacent to but spaced apart from the trough body, to provide an air gap between the heating element and the trough body.

Owner:NOVELIS INC

Liner making technique for casting lander of blast furnace with single iron notch, and free from baking casting material for iron notch

Owner:北京联合荣大工程材料股份有限公司

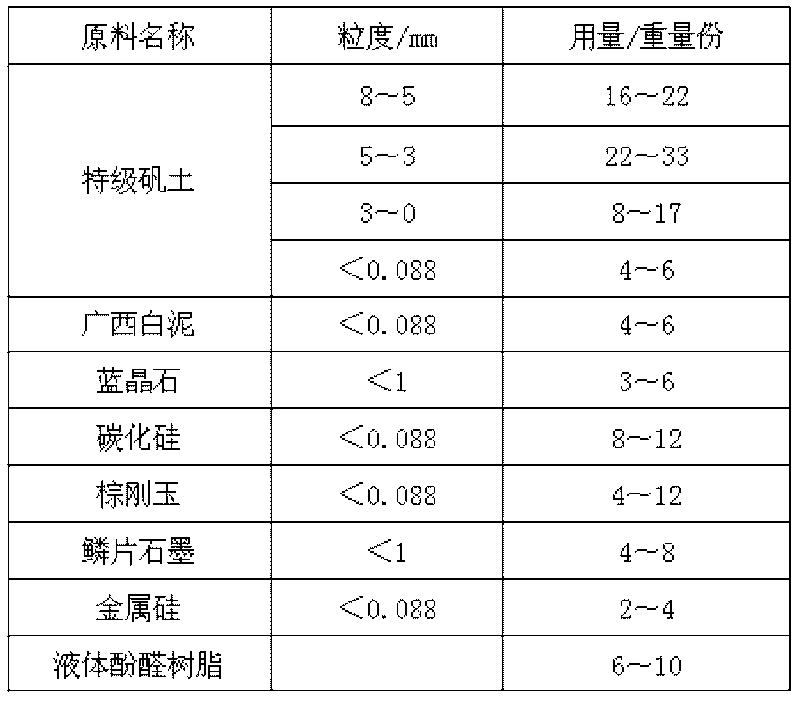

Smashing and hitting material for blast furnace iron outlet groove

The invention belongs to the technical field of iron groove smashing and hitting materials, in particular to a smashing and hitting material for a blast furnace iron outlet groove. The smashing and hitting material for the blast furnace iron outlet groove is prepared by the following materials according to part by weight: alumina 50-78 shares, plasticity agent 3-7 shares, swelling agent 3-6 shares, carborundum 8-12 shares, brown fused alumina 4-12 shares, graphite 4-8 shares, metallic silicon 2-4 shares and phenol resin 6-10 shares. The smashing and hitting material for the blast furnace iron outlet groove is tried through a blast furnace iron outlet groove, the primary iron passing amount is more than 160 thousand tons, and the using effect is better than the precast members or casting materials in the prior art.

Owner:PANZHIHUA UNIV

Method for preparing cast material of AL2O3-SiC-Ciron runner

InactiveCN1661117AIncrease binding rateHigh viscosityDischarge devicesRefractoryConstruction aggregate

Owner:WUHAN UNIV OF SCI & TECH

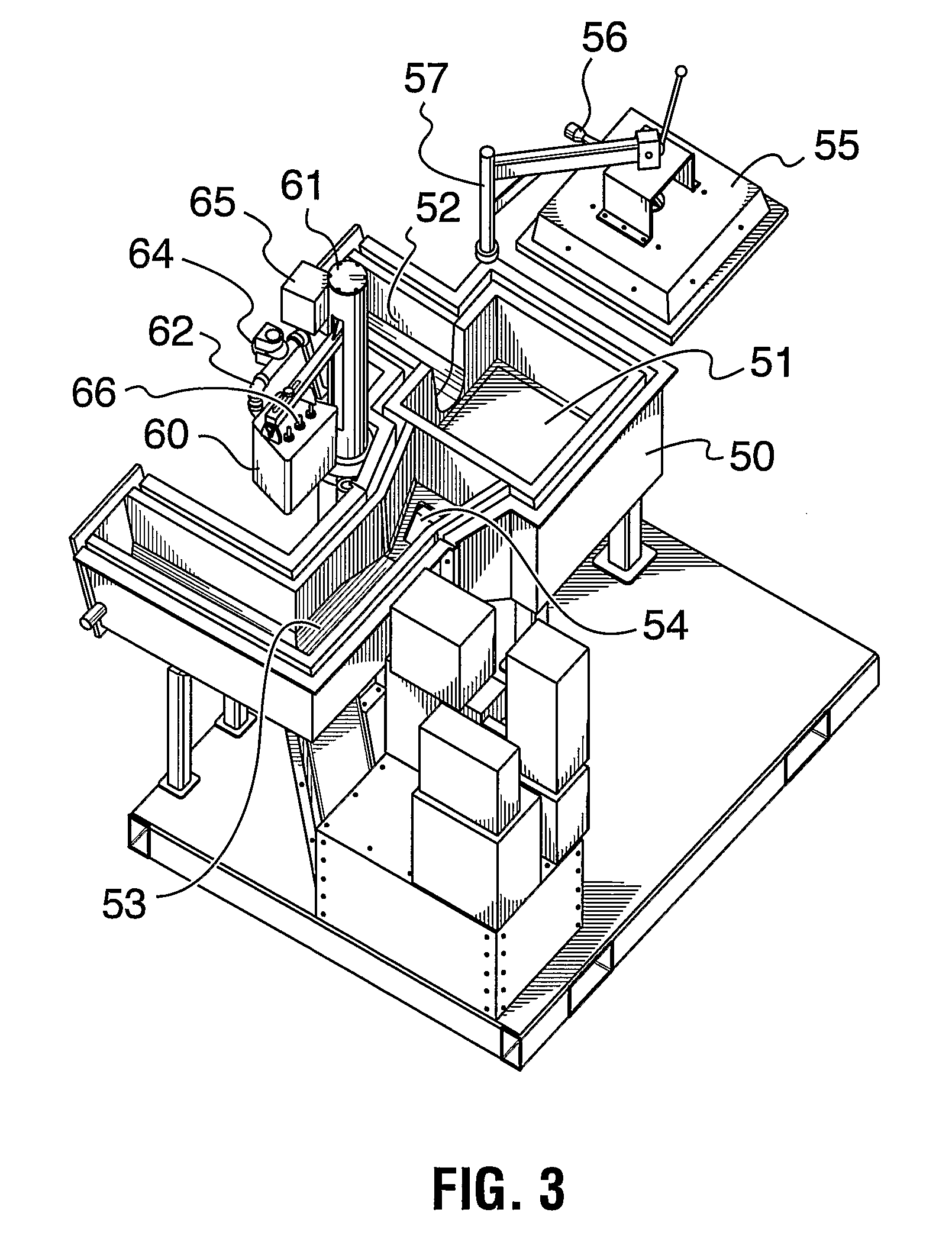

Single iron-port blast furnace tapping main channel gunning material and gunning technology

InactiveCN101555152AImprove wear resistanceImprove corrosion resistanceDischarge devicesSlagMain channel

The invention discloses a single iron-port blast furnace tapping main channel gunning material and a gunning technology, comprising the components with the weight percentages as follows: 44 to 52 percent of brown aluminum oxide or dense aluminum oxide, 24 to 32 percent of 98 silicon carbide, 6 to 12 percent of white aluminum oxide, 6 to 12 percent of Alpha-Al2O3, 1 to 3 percent of silicon powder, 1 to 4 percent of pure calcium aluminate cement, 1 to 4 percent of spherical asphaltum, and 1.5 to 3.5 percent of complex additive. The gunning material is prepared according to the material mixture ratio; compressed air is connected to a gunning machine; the gunning machine is connected with a hose used for a sponging gun; the sponging gun is connected with a tap water pipe and a regulating valve; the inner diameter of the sponging gun is about 4-6cm; the pressure of the compressed air is controlled to be about 0.7MPa; the gunning material is added; the compressed air is used for spraying the gunning material and water mixed in the sponging gun to the part of the tapping main channel needing to be gunned; and the water pressure can be regulated by the water valve on the sponging gun during gunning. The single iron-port blast furnace tapping main channel gunning material and the gunning technology not only can ensure the performances of erosion resistance, oxidization resistance and slag attack resistance and the like after repair, but also can be quickly executed to ensure the smooth use of the single iron-port blast furnace tapping main channel after improvement.

Owner:畲成明

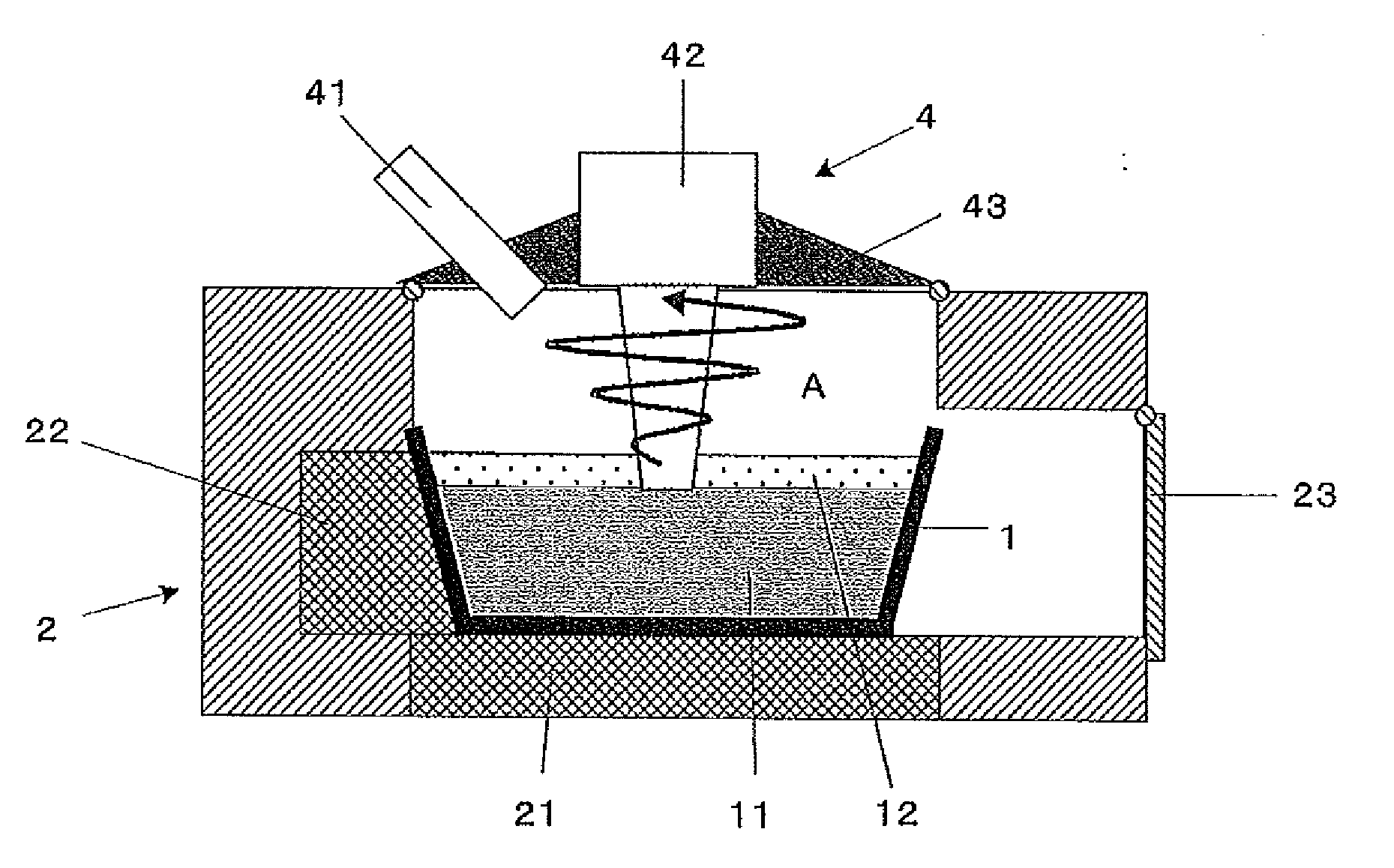

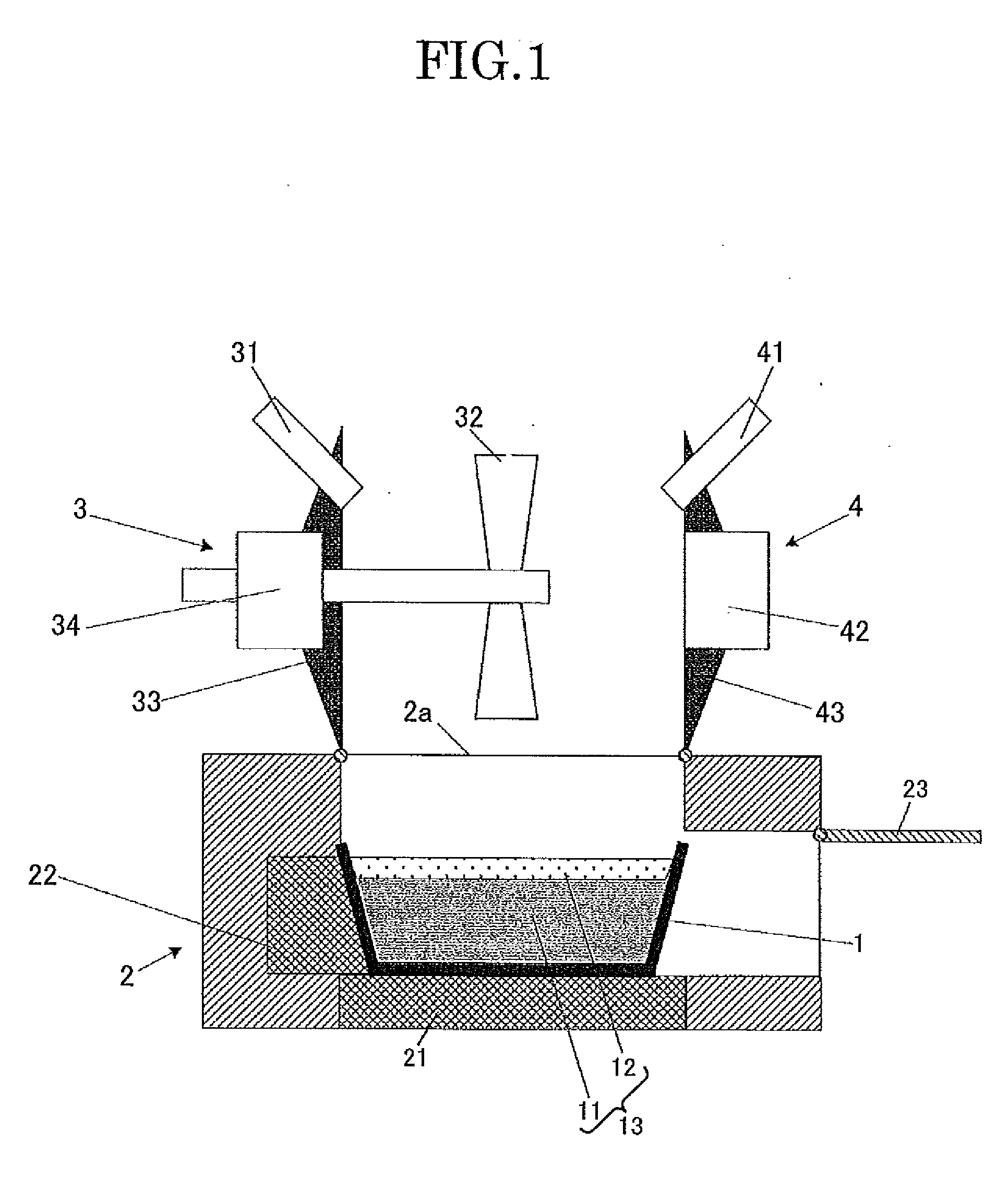

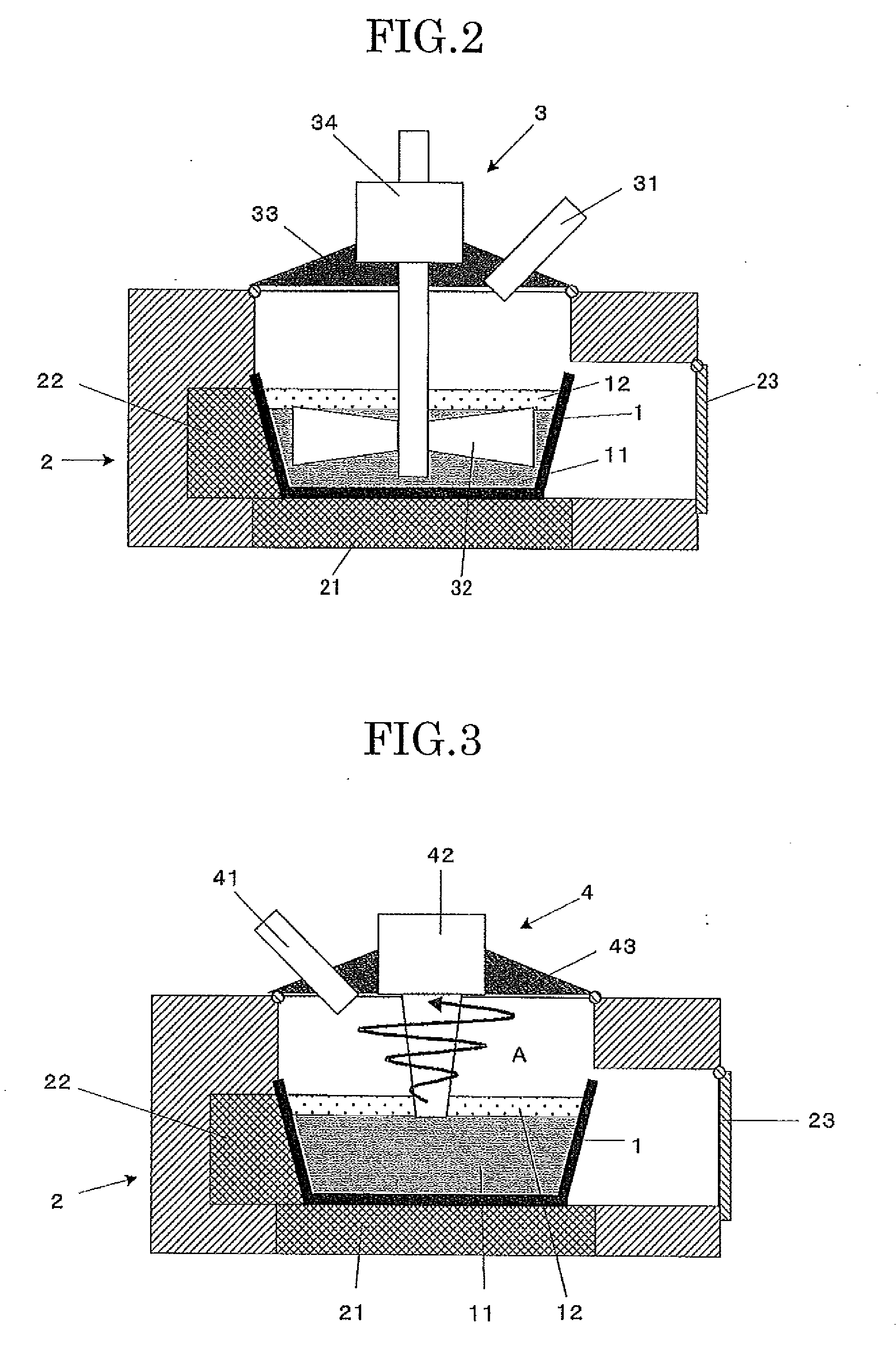

Solder recovery device

InactiveUS20100187732A1Operation efficiency be improvedImprove securityBlast furnace detailsDischarge devicesCrucibleDross

A solder recovery device includes a melter which melts solder dross stored in a melting crucible, an agitation unit which agitates the melted solder dross, so as to separate the melted solder dross up and down into an oxidized residue and a recycled solder in the melting crucible, and a suction unit which sucks the oxidized residue generated by the agitation, the suction unit sucking the oxidized residue in an upper portion of the melting crucible to be removed.

Owner:RICOH KK

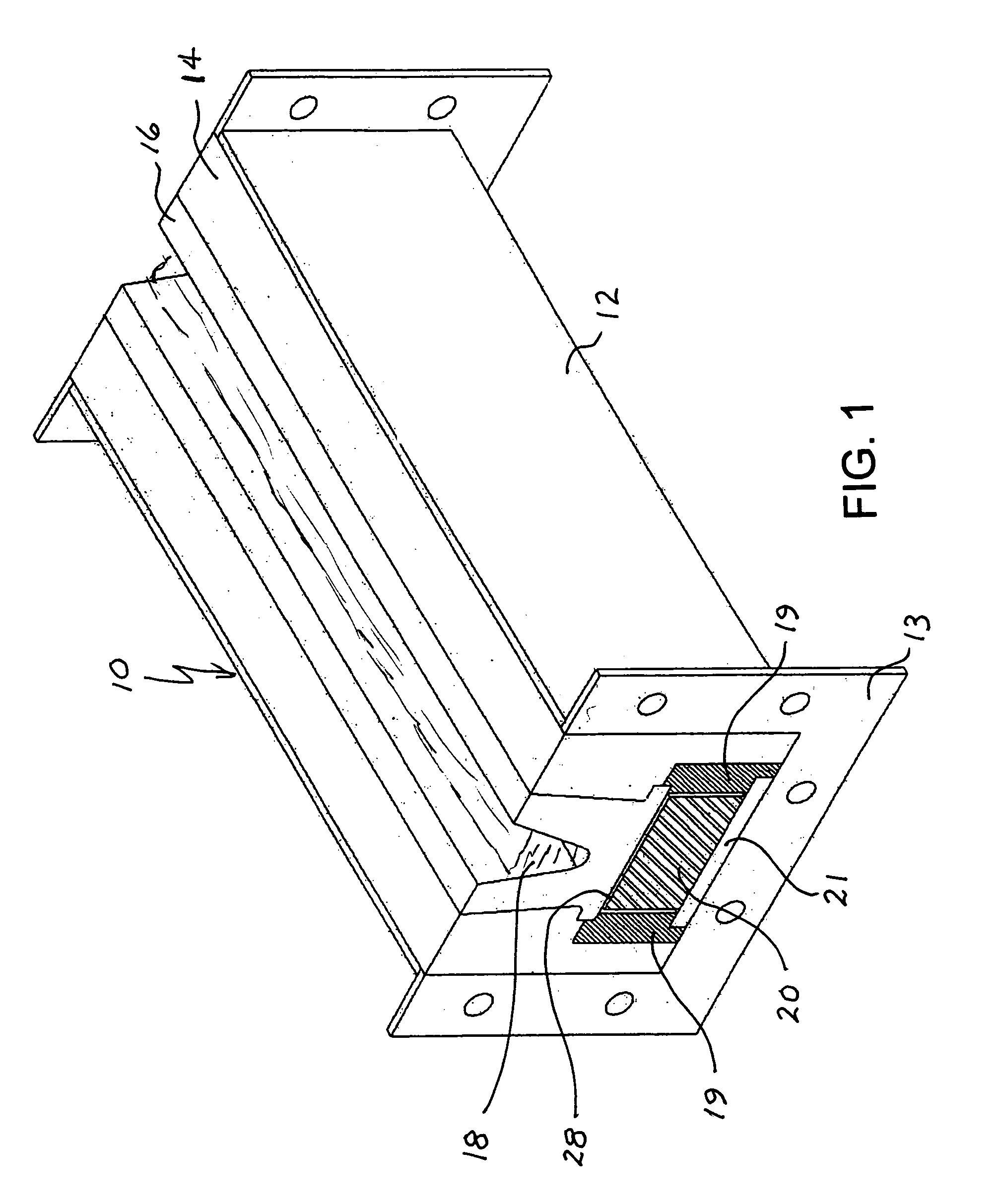

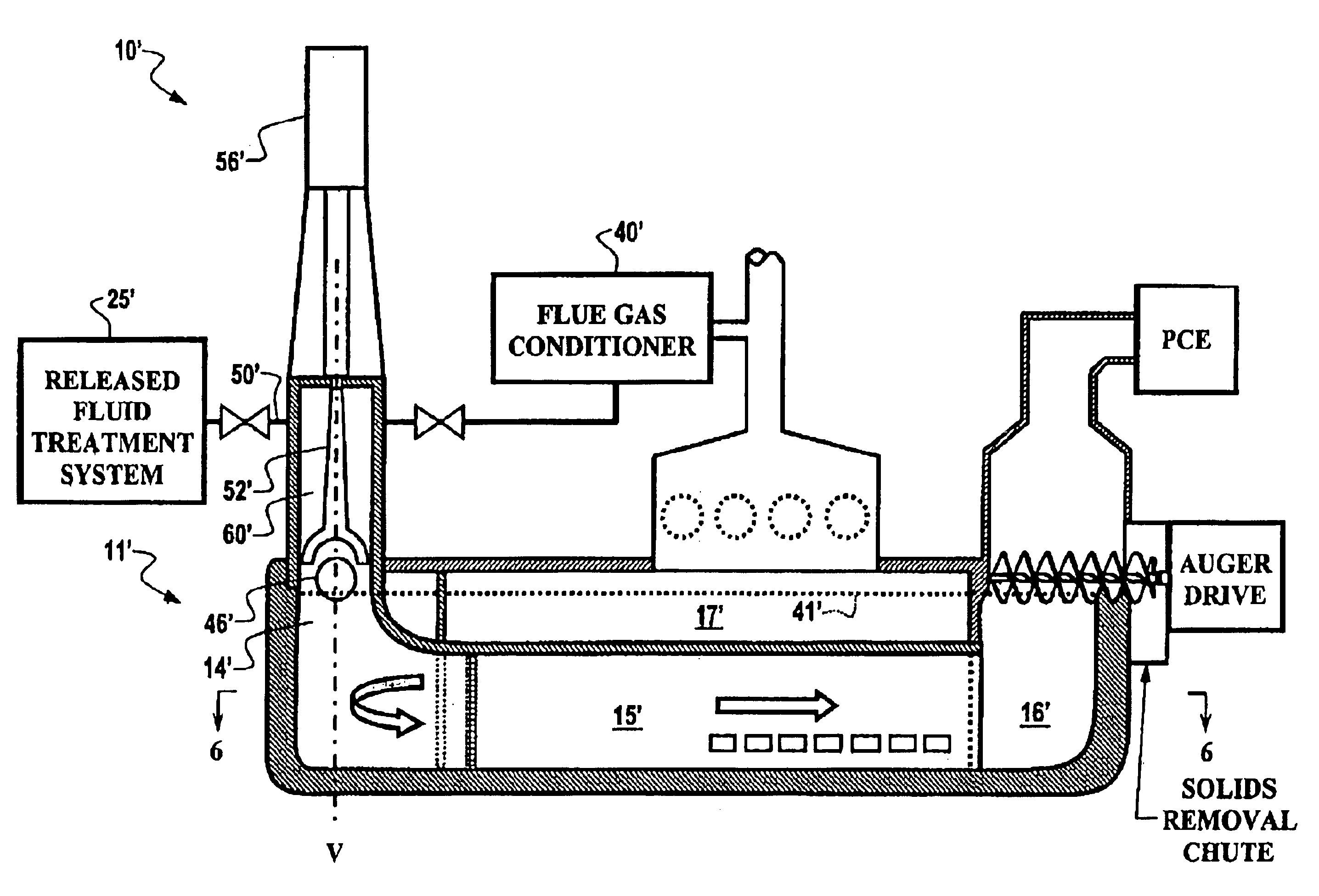

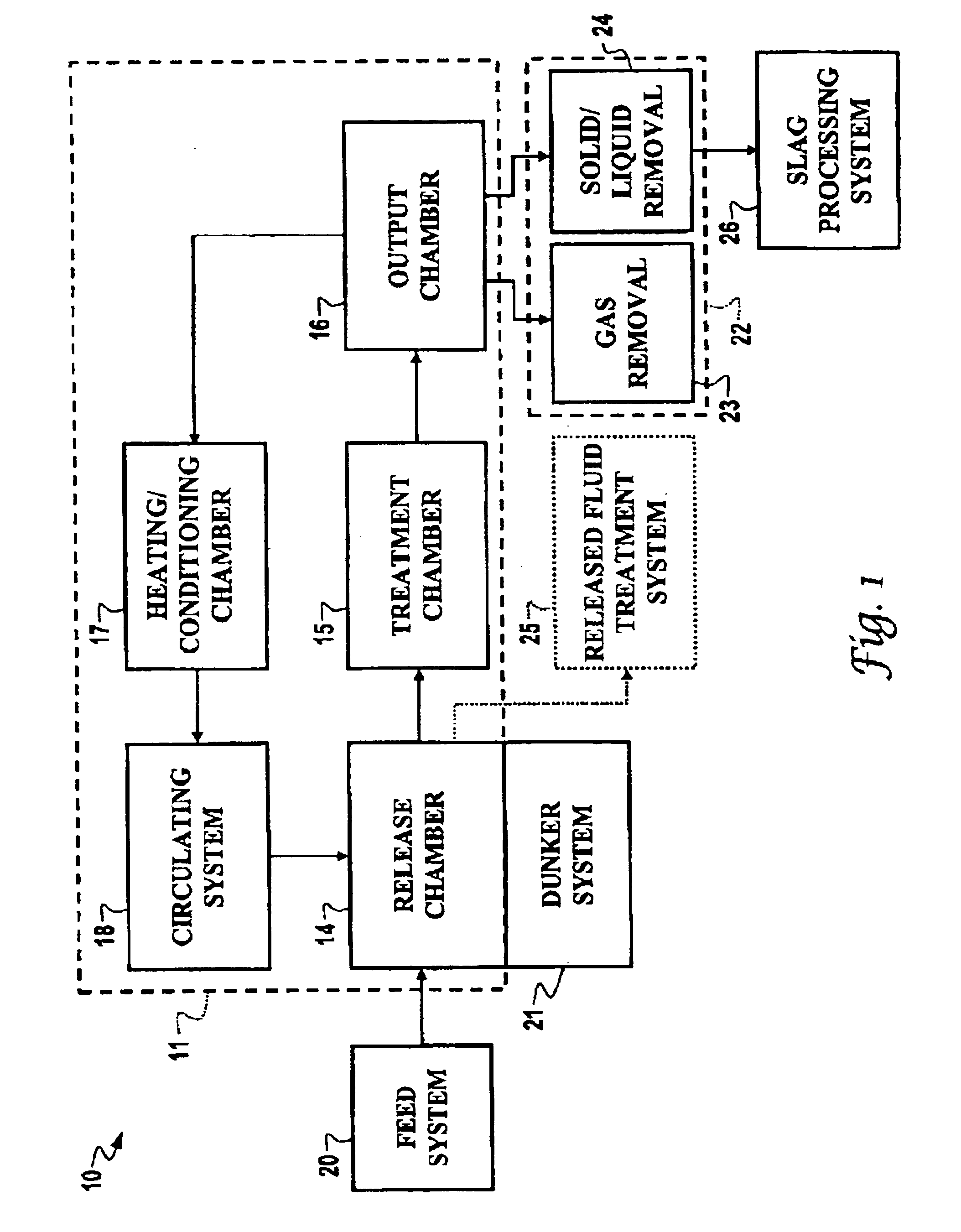

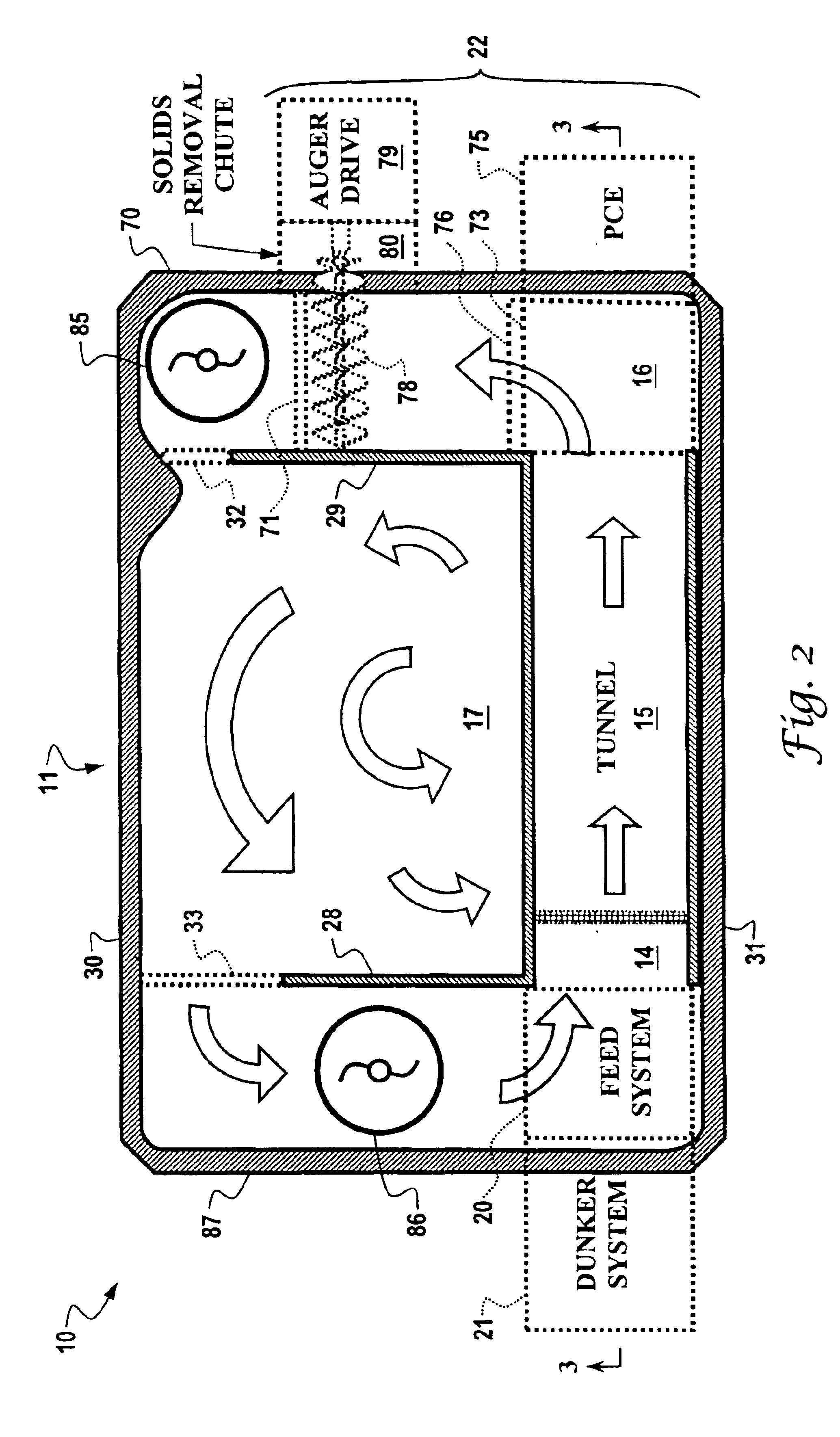

Apparatus and method for treating containerized feed materials in a liquid reactant metal

A treatment apparatus (10) includes a liquid reactant metal containment vessel (11) for containing a first liquid reactant metal and isolating the reactant metal from the atmosphere. A release chamber (14) is adapted to receive the first liquid reactant metal from the containment vessel (11) and a submerging arrangement (21) is adapted to dunk or submerge a container (46) of feed material into the liquid reactant metal and move the container to a release location within the release chamber (14). Relatively light materials rising from the submerged container (46), including unreacted feed material, intermediate reaction products, and perhaps final reaction products collect in a collection area (60) having an upper surface defined by an upper surface of the release chamber (14). A treatment arrangement included in the apparatus places the fluids collected in the collection area (60) in contact with the first liquid reactant metal or a second liquid reactant metal for a sufficient period of time to effect the desired reduction reactions.

Owner:CLEAN TECH INT

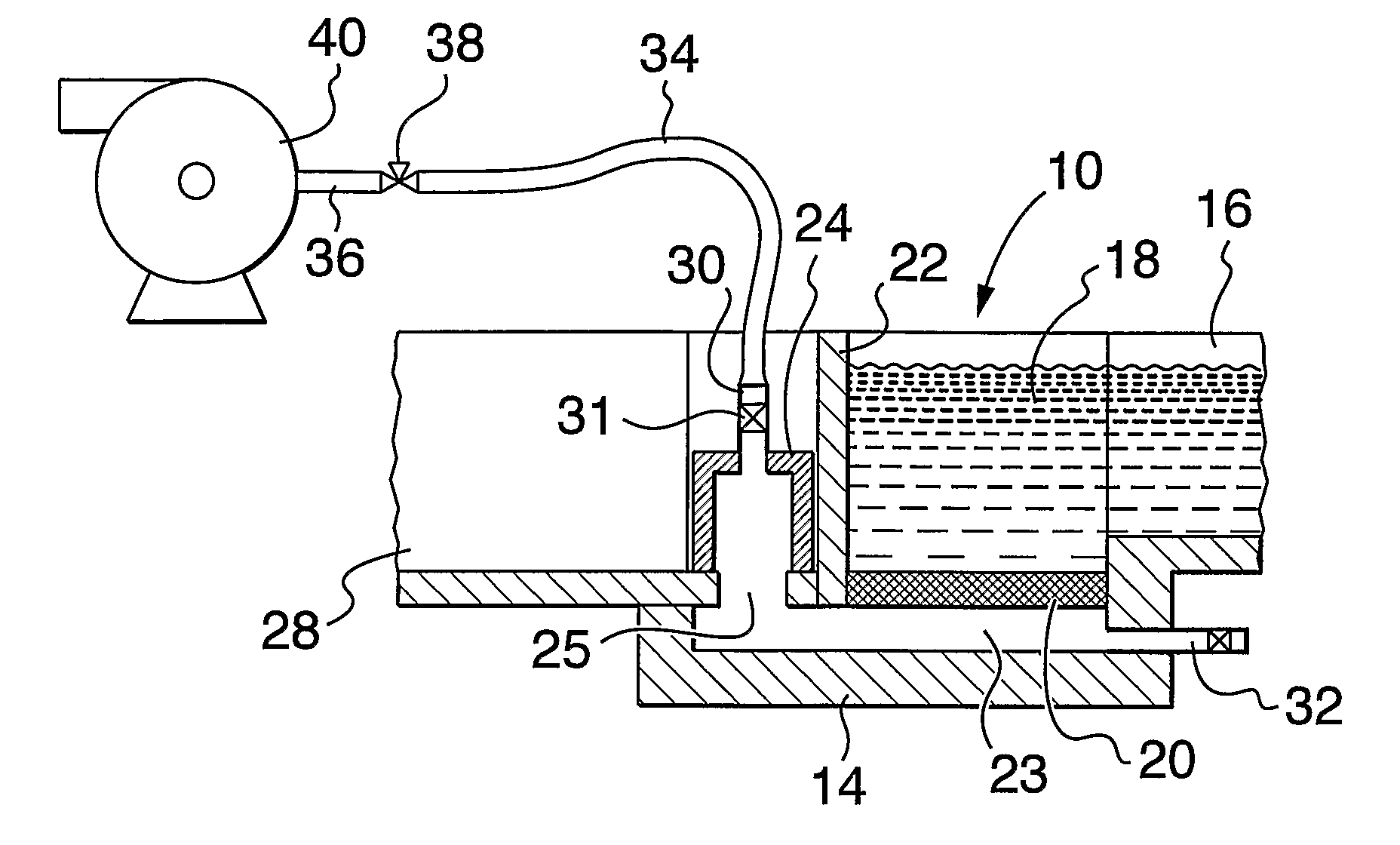

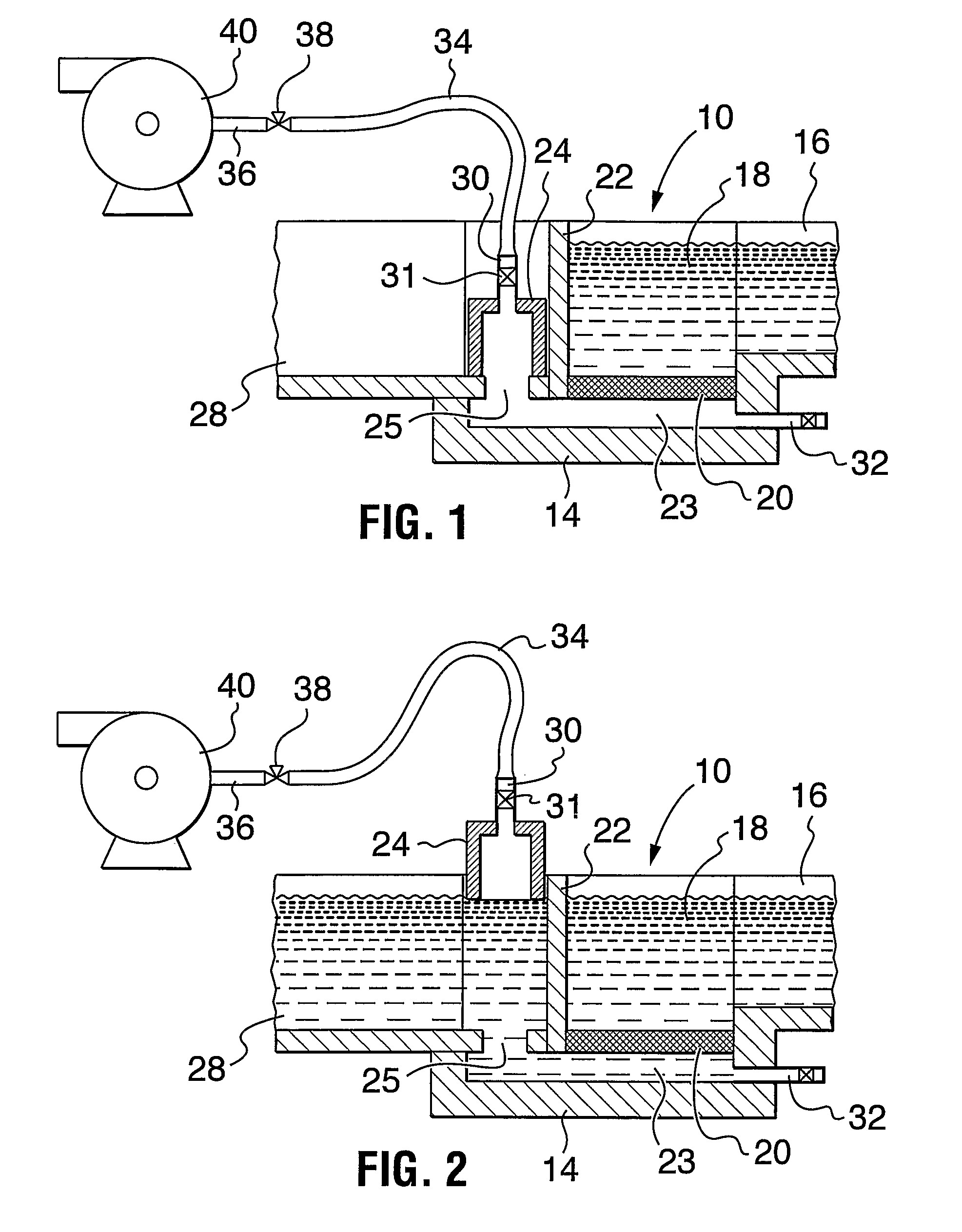

Method of priming filter for molten metal

ActiveUS7666248B2Quickly release withoutLevel of vacuumBlast furnace detailsCasting cleaning apparatusFiltrationPorous ceramics

A method is described for priming an in-line molten metal filtration unit having a porous ceramic or refractory filter mounted substantially horizontally in a filter box. This filter box has an inlet for molten metal and an outlet for molten metal, the outlet being a closeable outlet in an exit well connecting to the downstream side of the filter. The method of the invention comprises the steps of adding a molten metal to the filter box sufficient to entirely cover the upstream side of the filter with a depth of molten metal and temporarily sealing the outlet in the exit well. A steadily increasing vacuum is then applied to the closed exit well at a rate between 0.1 and 10 kPa per second by withdrawing a stream of air from the exit well by means of a fan or air venturi until molten metal begins to flow through the filter. At that point the vacuum is quickly released and the molten metal outlet is opened. Once the filter has been primed in this manner, flow of metal through the filter continues while requiring only a relatively low head of molten metal on the inlet side of the filter.

Owner:ALCAN INT LTD

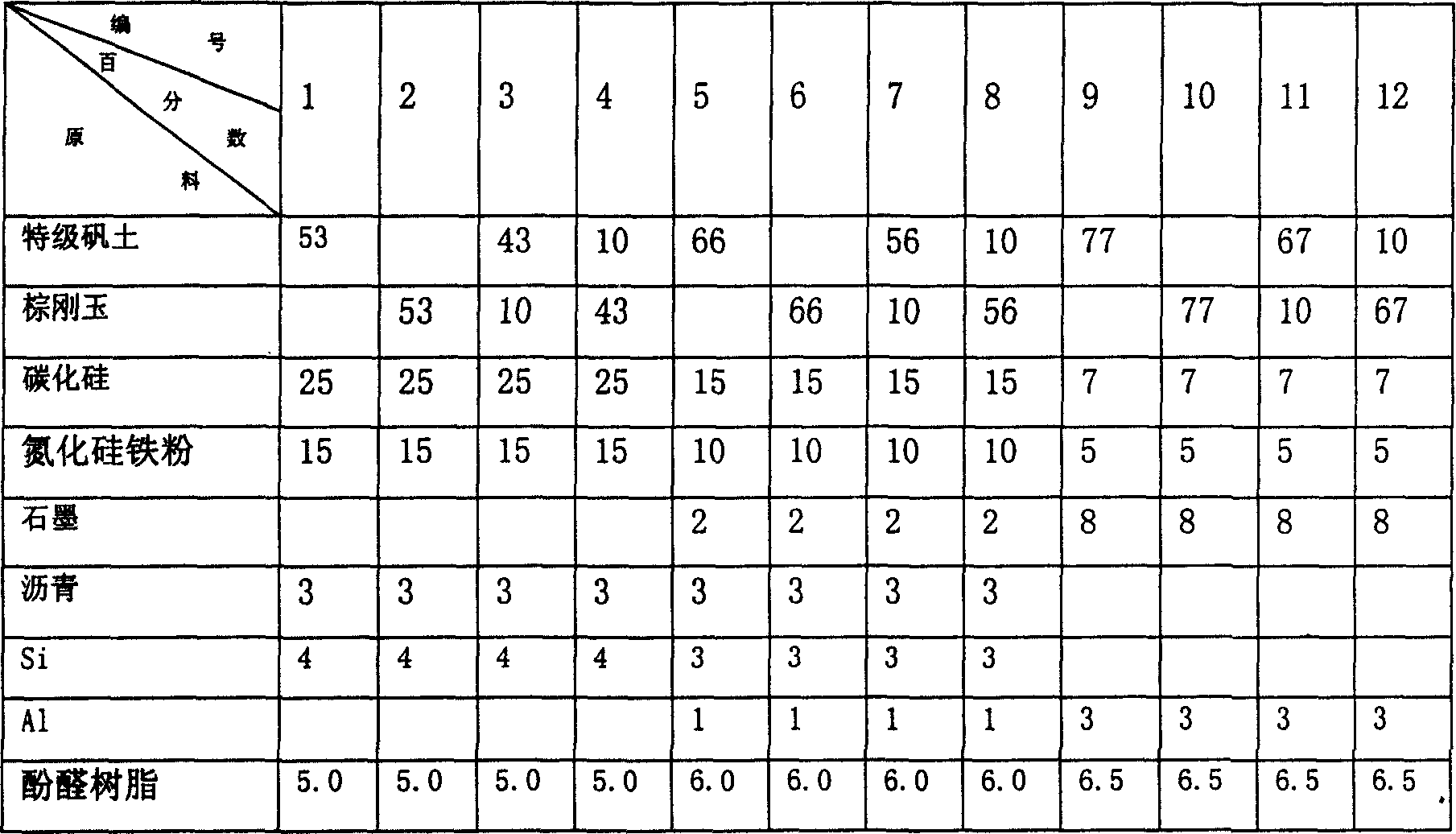

Bake-free iron runner ramming mass containing ferrosilicon nitride

InactiveCN1544389AImprove high temperature strengthImprove erosion abilityDischarge devicesAl powderFerrosilicon

The invention provides a baking free iron groove tamping material containing ferrum silicon nitride which comprises aluminium silicate material, silicon carbide, carbon material, ferrum silicon nitride and bonding agent, their weight portions are, aluminium silicate material 43-80%, silicon carbide 7-25%, carbon material 2-10%, ferrum silicon nitride 5-15%, Si powder 0-4%, Al powder 0-3%, and phenolic resin 2-7%. The invention realizes increased tamping material high-temperature strength, high temperature molten slag erodibility resistance and penetrability, and improved material oxidation resistance property.

Owner:UNIV OF SCI & TECH BEIJING +1

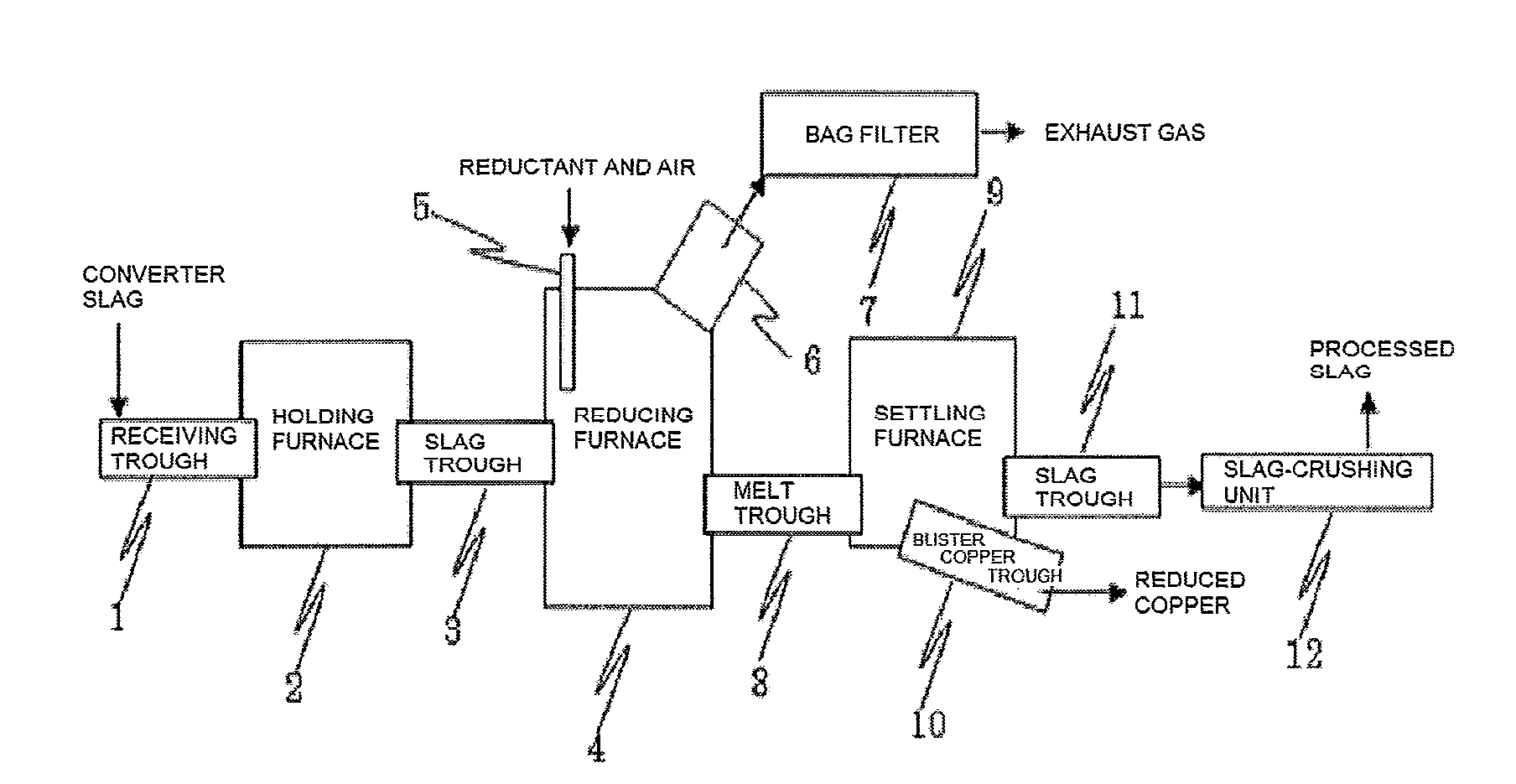

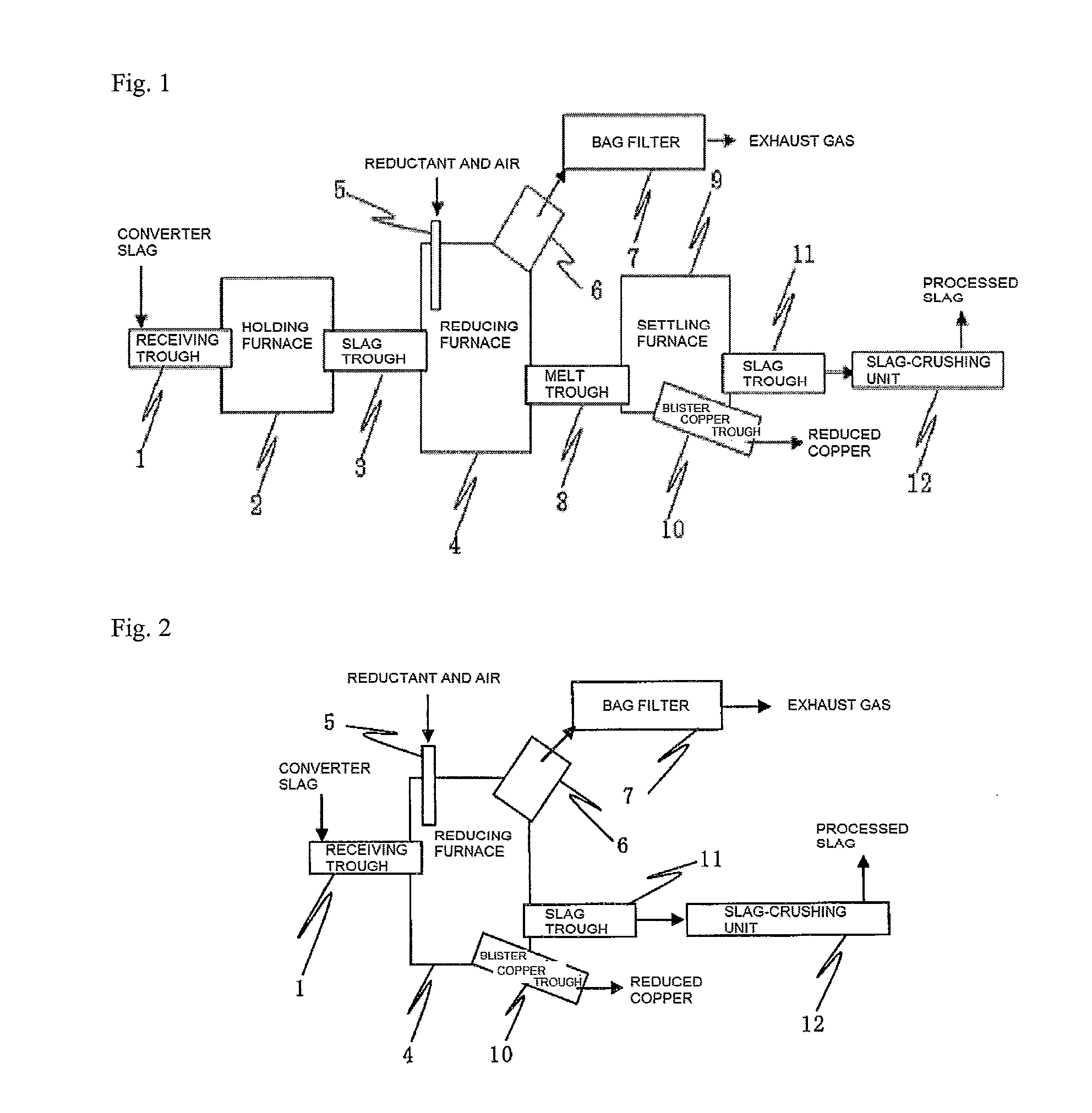

Method and system of dry processing of converter slag in copper smelting

A method for processing converter slag produced in copper smelting includes feeding the converter slag into a reducing furnace, reducing zinc and copper contained in the converter slag by heating and removing the reduced zinc through volatilization in a reducing furnace. The slag discharged from the converter is transformed into a raw material for iron making.

Owner:PAN PACIFIC COPPER CO LTD

Ladle bottom

InactiveUS20070029708A1Increase fractionImprove efficiencyMelt-holding vesselsBlast furnace detailsMolten slagMaterials science

The present invention relates to a ladle block for use in a bottom of a molten metal ladle. The ladle block reduces the amount of contaminants, particularly slag, exiting the ladle during casting operations. The ladle block includes a floor defining an outlet and sidewalls substantially orthogonal to the floor. The floor and sidewalls define a channel having dimensions of length, width and height. Channel dimensions are determined from the Froude number, which is based at least partially on the casting flow rate.

Owner:VESUVIUS USA CORP

Chamber for reception, lateral division and redirection of liquid metal flow

InactiveUS6156260AEasy to useEasy to manufactureMelt-holding vesselsBlast furnace detailsButtressInterior space

A chamber for receiving a downward flow of liquid metal includes a generally horizontal base having a generally planar impact surface. A first faceted sidewall having a plurality of facets formed therein, generally extends upwardly from and encompasses the planar surface to define an interior space. The interior space has an upper opening for receiving the downward flow of liquid metal. A second wall extends inwardly and upwardly from the first faceted wall toward the upper opening. A plurality of buttresses are spaced along the first faceted wall. Each of the buttresses extends between the impact surface and the second faceted wall. The buttresses form a plurality of discrete pockets including at least one facet. The pockets are defined by the buttresses, the impact surface, the first faceted wall and the second wall. The buttresses laterally deflect and divide the radial outward flow into a plurality of discrete flow patterns associated with the plurality of pockets.

Owner:PSC TECH

Sealing apparatus for a slag door of a metallurgical furnace

InactiveUS20070290420A1Aid removalObstruction in may takeBlast furnace detailsCharge manipulationSlagEngineering

A sealing apparatus for a slag door of a metallurgical furnace, having a mounting assembly for mounting the apparatus to the furnace, and at least one closure element, moveable from an open position that is exterior of the slag door opening, to a closed position that effectively seals against the slag door and extends into the slag door opening with the rear panel of the closure element(s) being proximally aligned with the interior wall of the furnace. The apparatus may also have at least one wiping component moveable so as to sweep across the lower surface of the slag door to remove obstructions.

Owner:EMPCO (CANADA) LTD

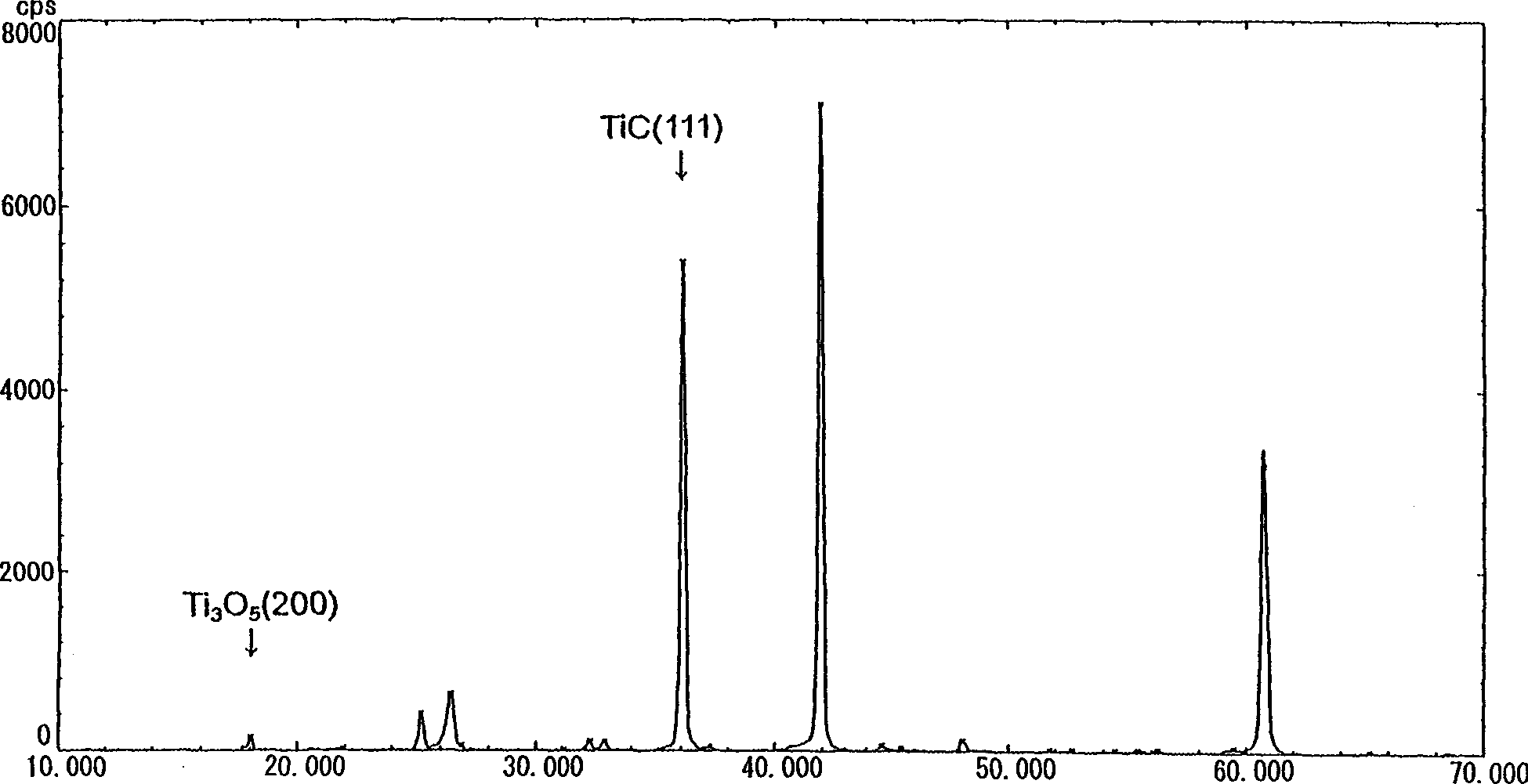

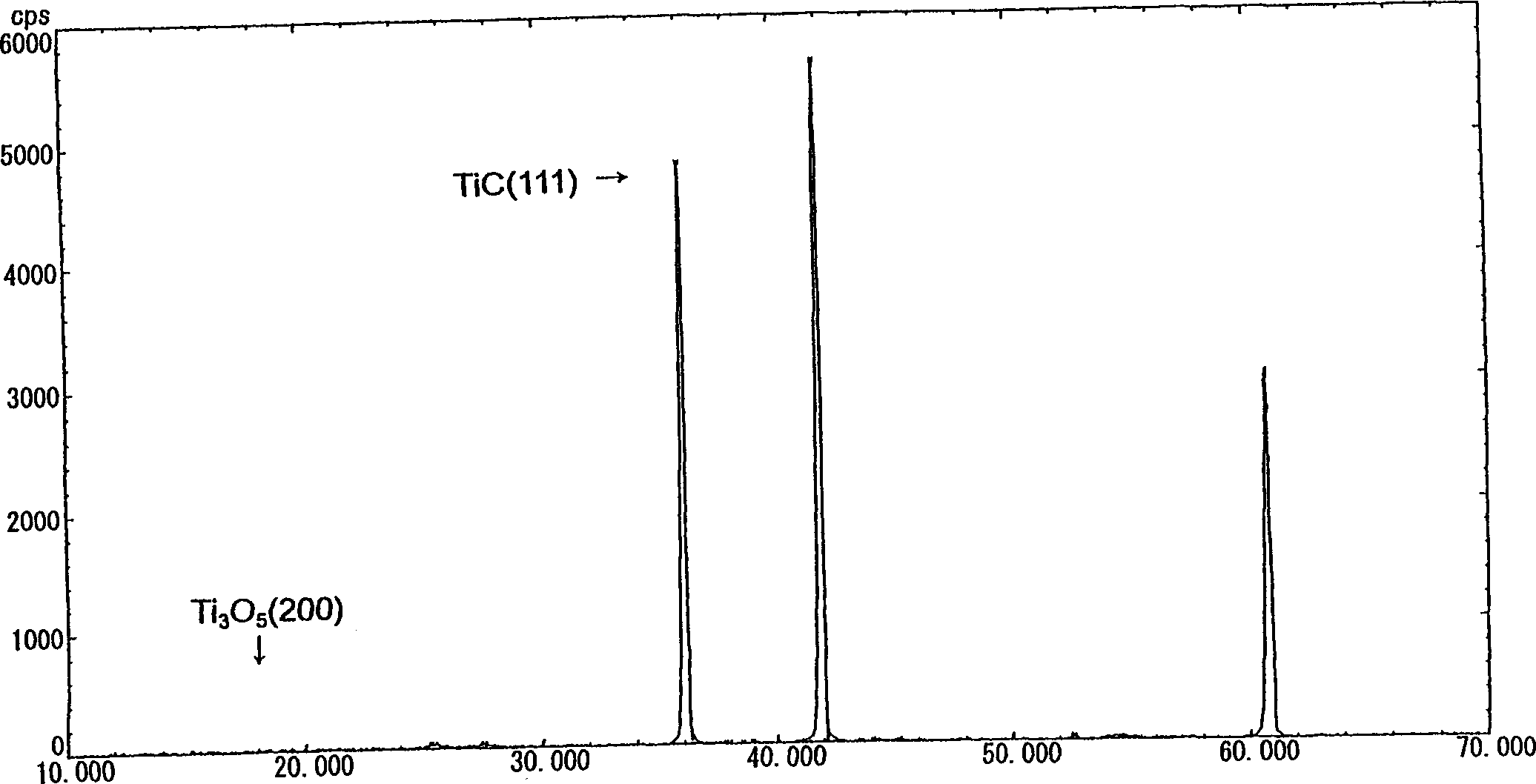

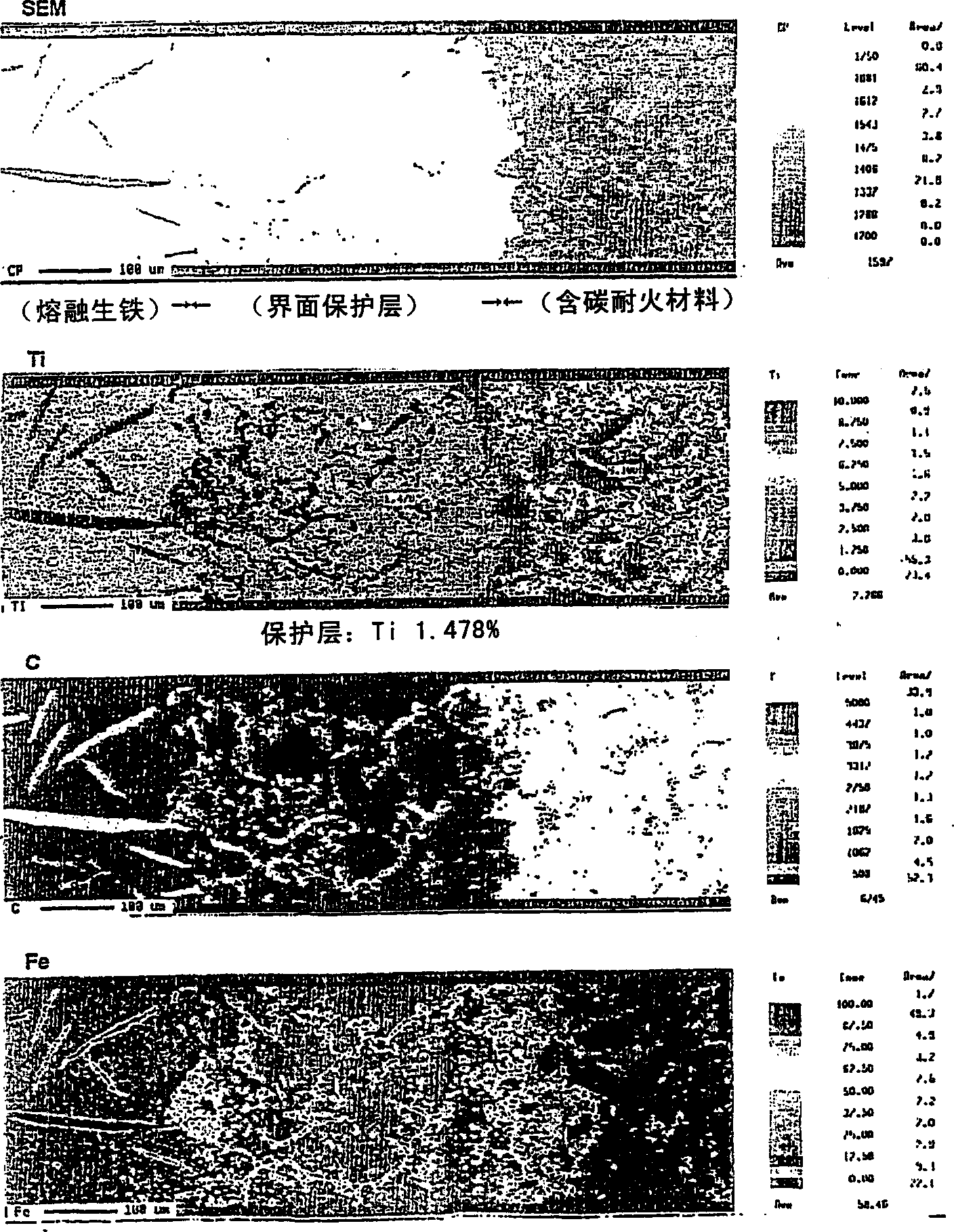

Carbonaceous refractory and method for preparing same

InactiveCN1366515AEasily wets molten ironImprove corrosion resistanceBlast furnace detailsCooling devicesTitanium nitrideCoke

Owner:NIPPON STEEL CORP +1

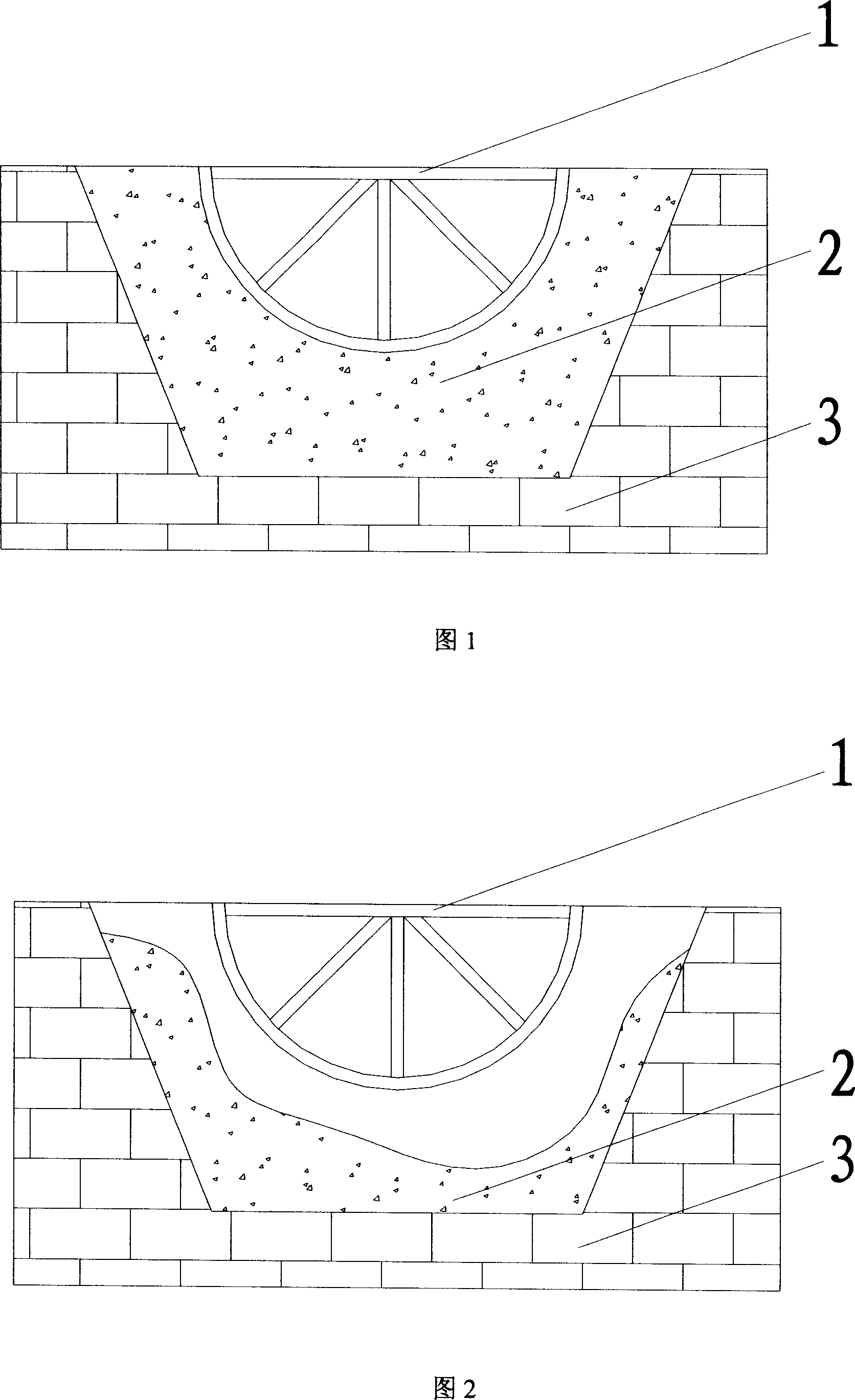

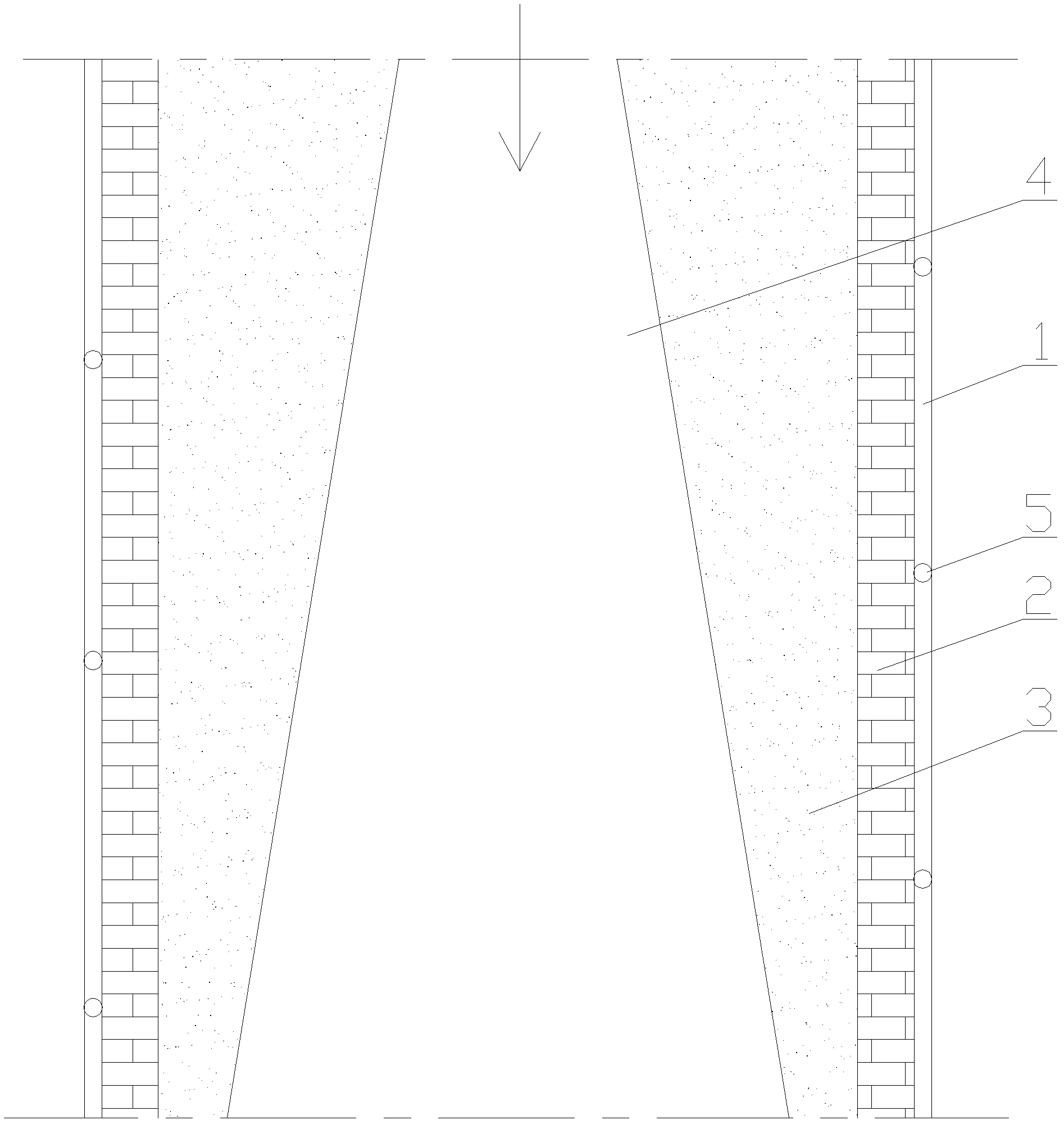

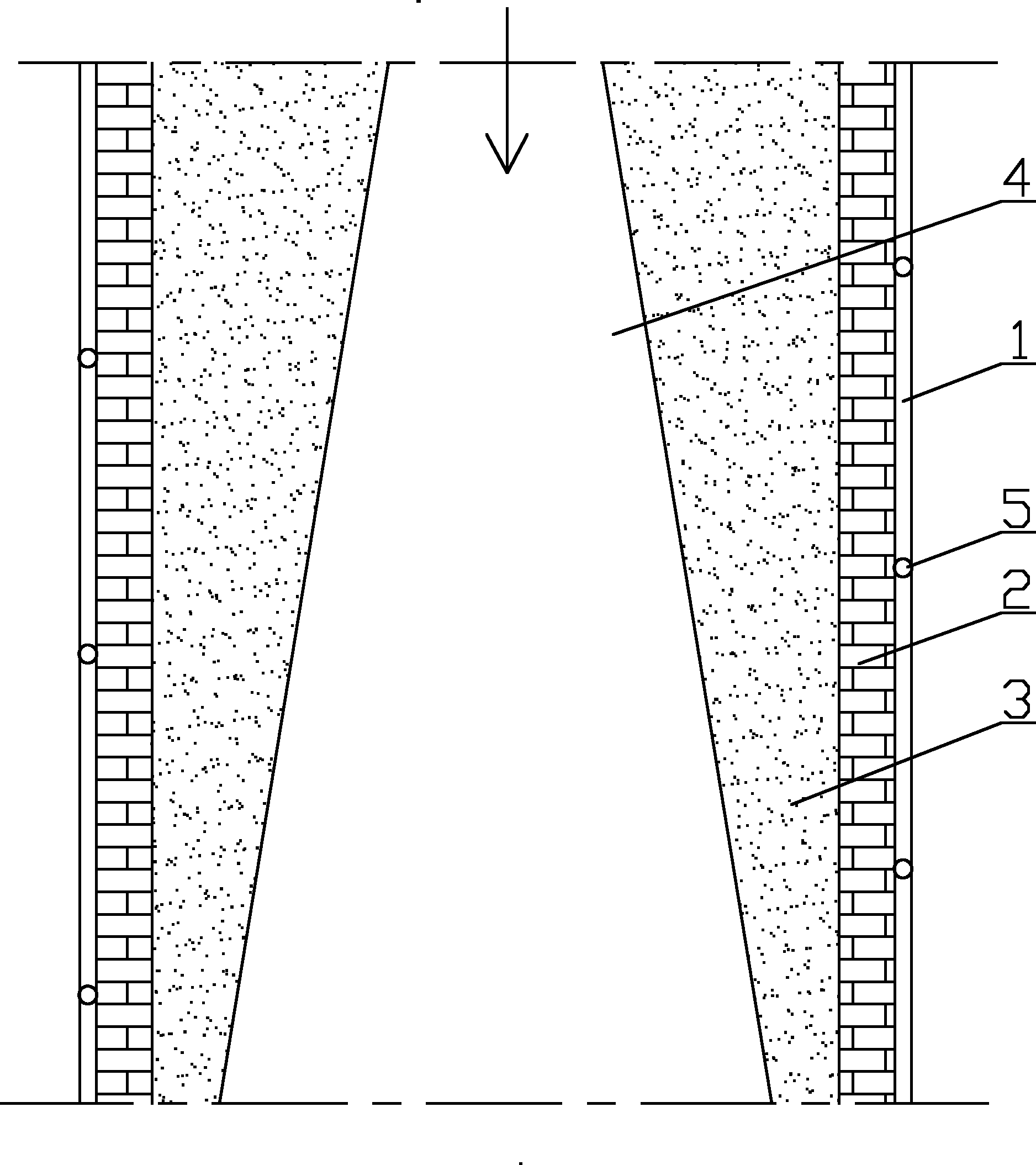

Pouring material and single-iron notch blast furnace iron storage type tapping main channel using same

The invention discloses a pouring material and a single-iron notch blast furnace iron storage type tapping main channel using the same; the single-iron notch blast furnace iron storage type tapping main channel comprises a steel mould, a brick layer and the pouring material, wherein the brick layer is laid at the inner side of the steel mould; and the pouring material is poured at the inner side of the brick layer. The single-iron notch blast furnace iron storage type tapping main channel is characterized in that a channel is arranged at the inner side of the pouring material, so that the width of the channel is gradually increased from front to back. According to the invention, the scouring force of molten iron for the main channel can be reduced, the labor intensity of workers pushing slag can be reduced, and the front half part and rear half part of the main channel can be repaired synchronously, so that the waste can be avoided. The repairing material can be saved by about 40-50 tons every year, so that the cost is greatly saved; and about 10 ton of material can be saved for a new main channel which is poured for the first time after the structural design is improved, so that the material cost is greatly saved, the annual total cost is greatly saved, and the economic benefit is greatly improved.

Owner:CHANGXING MINGTIAN FURNACE CHARGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com