Smashing and hitting material for blast furnace iron outlet groove

A blast furnace tapping and ramming material technology, which is applied in the field of iron trough ramming material, can solve the problems of high cost, high iron volume, complicated prefabrication process, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

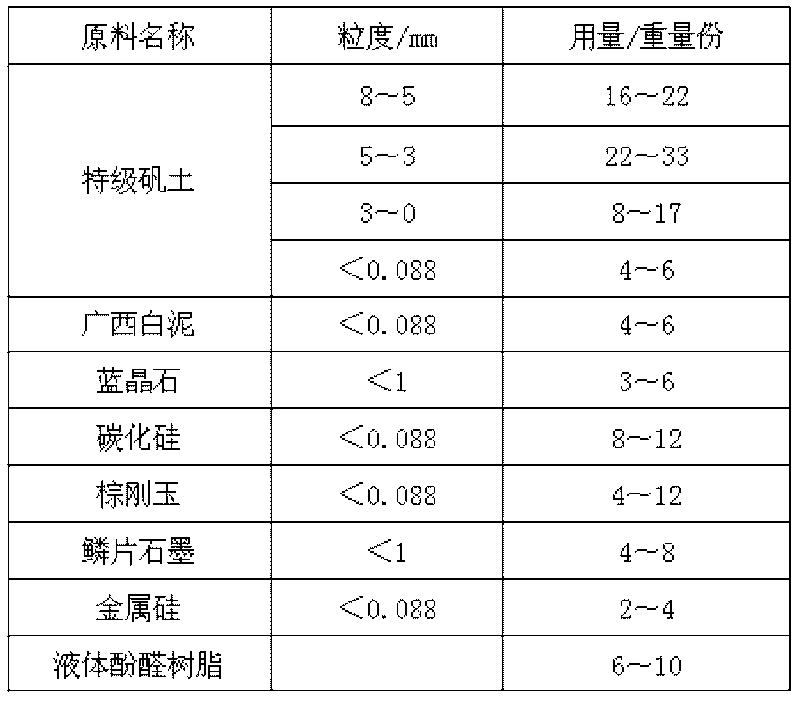

Method used

Image

Examples

Embodiment 1

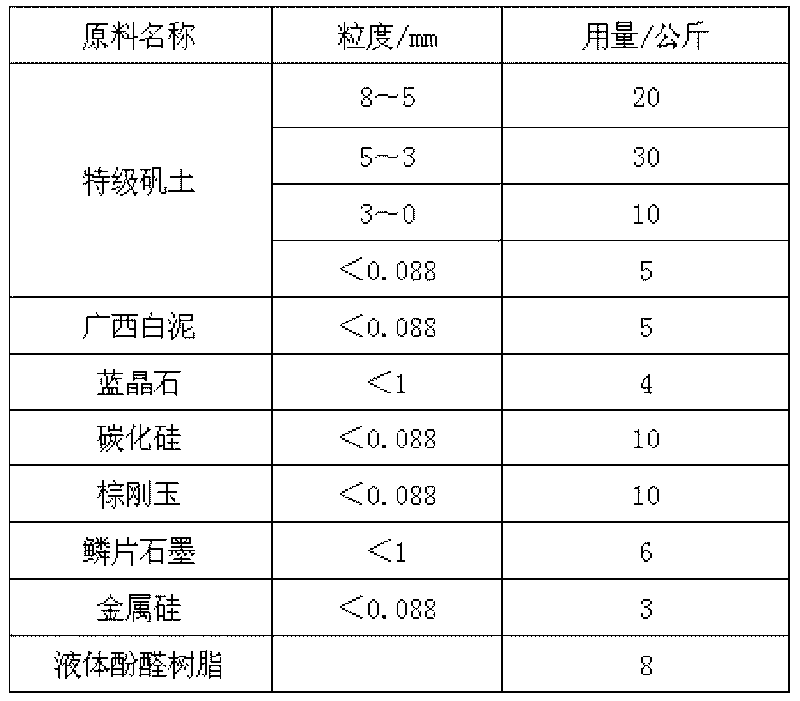

[0035] 1. The types and proportions of raw materials are shown in Table 2:

[0036] Table 2

[0037]

[0038] 2. Preparation of ramming material

[0039] 1. Weigh various raw materials according to the ratio in Table 2.

[0040] 2. Put the weighed raw materials into the mud mill and grind them in turn. The order of feeding the raw materials is: super bauxite with a particle size of 5-8mm, super bauxite with a particle size of 3-5mm, super bauxite with a particle size of 0-3mm, blue The spar and flake graphite are first mixed and milled for 5 minutes, then 1 / 3 of the liquid phenolic resin is added and then milled for 5 minutes, and then Guangxi white mud, silicon carbide, brown corundum, metal silicon and special-grade alumina with a particle size of <0.088mm and the remaining The liquid phenolic resin was ground for 8 minutes and discharged.

[0041] 3. Pack in woven bags lined with plastic film, each bag is 25kg, and the seal should be tight. The warranty period is one...

Embodiment 2

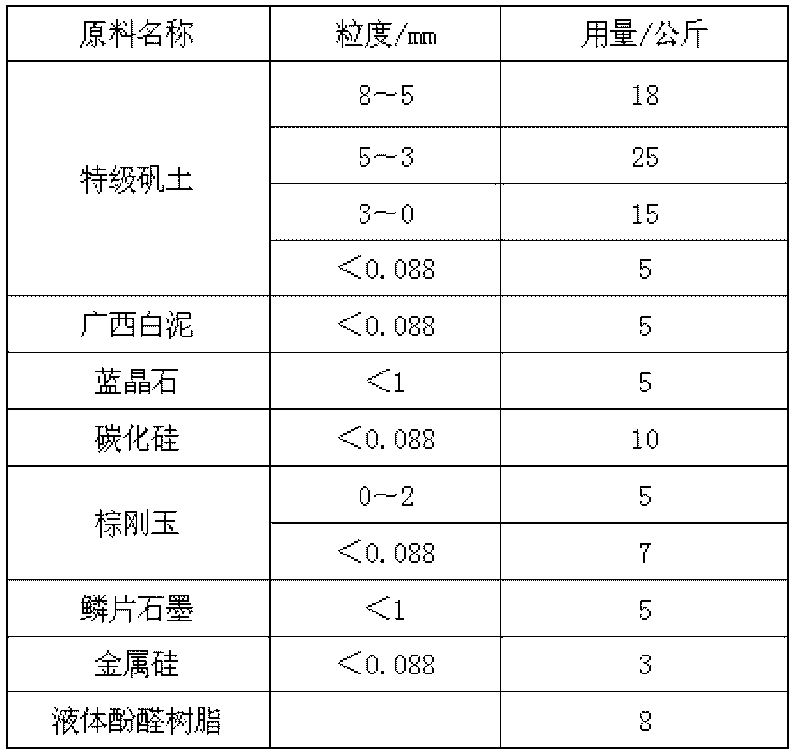

[0047] 1. The types and proportions of raw materials are shown in Table 3:

[0048] table 3

[0049]

[0050] 2. Preparation

[0051] 2. Preparation of ramming material

[0052] 1. Weigh various raw materials according to the ratio in Table 3.

[0053] 2. Put the weighed raw materials into the mud mill and grind them in turn. The order of feeding the raw materials is: super bauxite with a particle size of 5-8mm, super bauxite with a particle size of 3-5mm, super bauxite with a particle size of 0-3mm, blue The spar and flake graphite are first mixed and milled for 5 minutes, then 1 / 3 of the liquid phenolic resin is added and then milled for 5 minutes, and then Guangxi white mud, silicon carbide, brown corundum, metal silicon and special-grade alumina with a particle size of <0.088mm and the remaining The liquid phenolic resin was ground for 8 minutes and discharged.

[0054] 3. Pack in woven bags lined with plastic film, each bag is 25kg, and the seal should be tight. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com