Patents

Literature

3680 results about "Prefabrication" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Prefabrication is the practice of assembling components of a structure in a factory or other manufacturing site, and transporting complete assemblies or sub-assemblies to the construction site where the structure is to be located. The term is used to distinguish this process from the more conventional construction practice of transporting the basic materials to the construction site where all assembly is carried out.

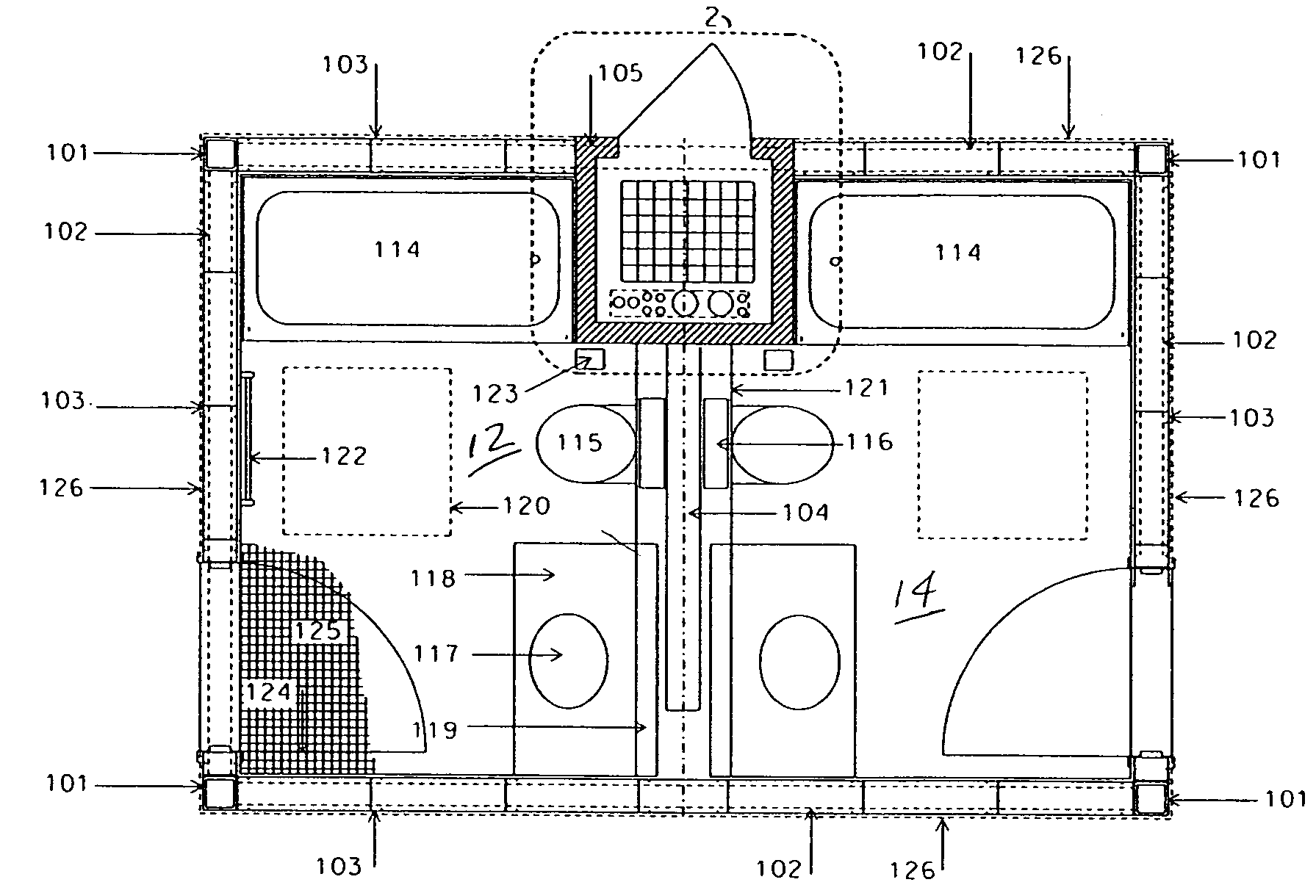

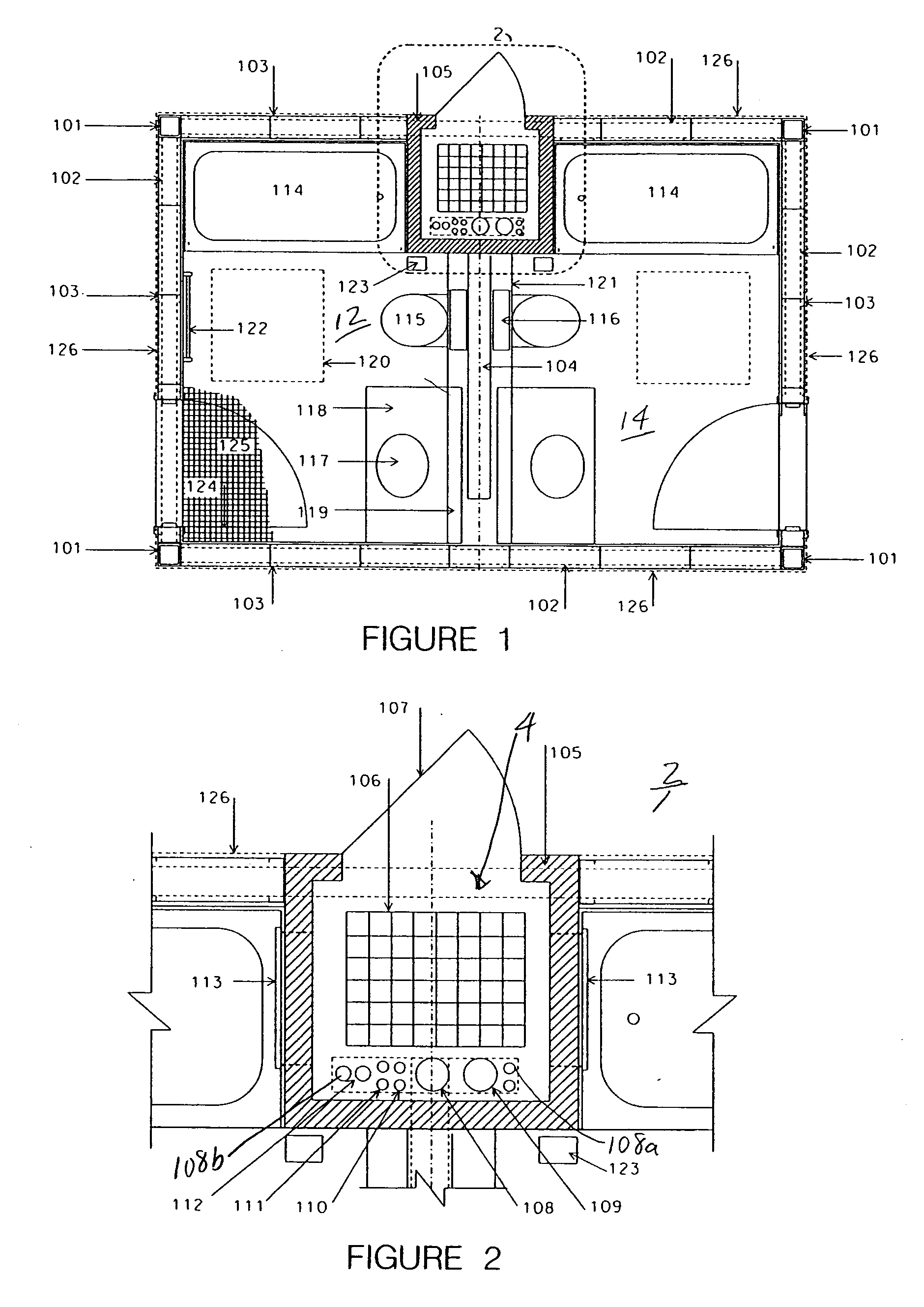

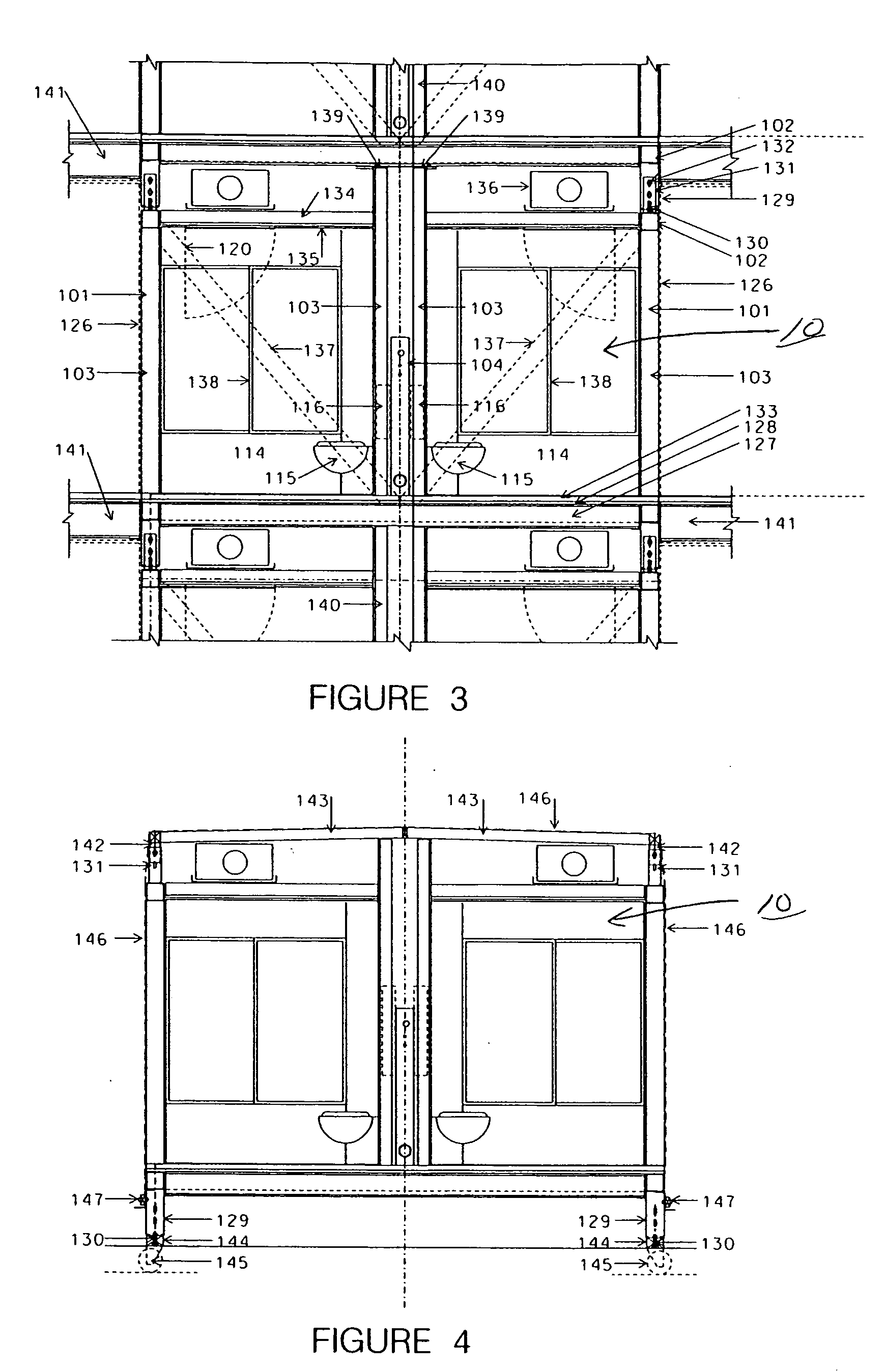

Pre-fabricated building modules and method of installation

InactiveUS20050108957A1Low costCompact designSpecial buildingExtraordinary structuresVentilation shaftPrefabrication

A pre-fabricated building module containing components of a typical multi-story housing project and a corresponding method of installation. Each module is configurable to provide one of a variety of room and dual-room layouts. The module's design allows for road transportation and installation by a tower crane typically found in most multi-story construction projects. Module embodiments are provided for enabling drop-in, stack-in, or slide-in installation in most buildings. Each module is preferably stackable with another module of the same type and configured to provide a predetermined amount of support for loads in the surrounding structure. Each module preferably provides all necessary mechanical and electrical components including their section of risers and ventilation shaft, as well as fixtures, fittings, appliances, cabinets, etc. except for the exterior cladding of perimeter walls which are designed for on-site installation. Each module preferably includes panelized interior cladding for built-in room items enabling sub-assembly prefabrication.

Owner:QUESADA JORGE DE

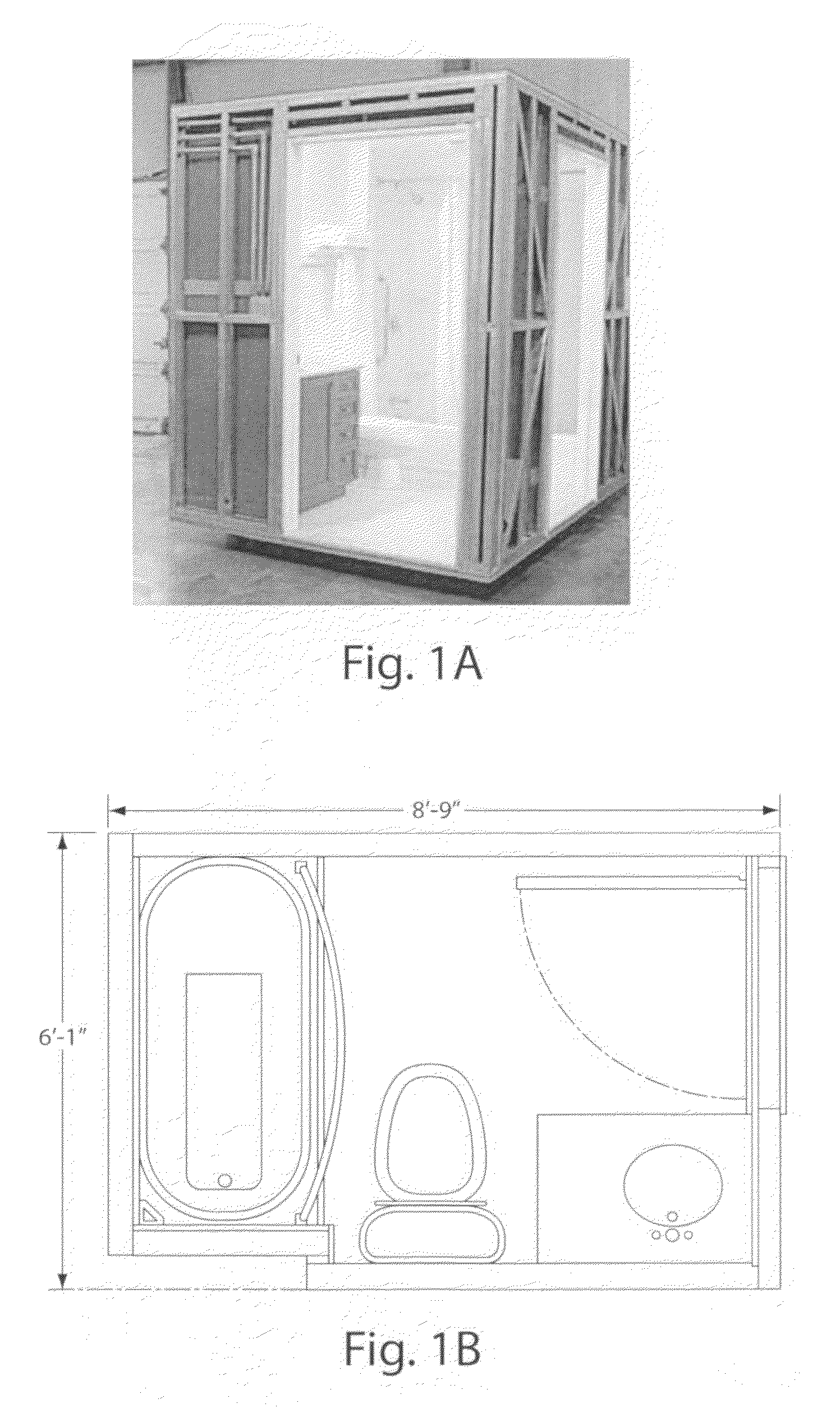

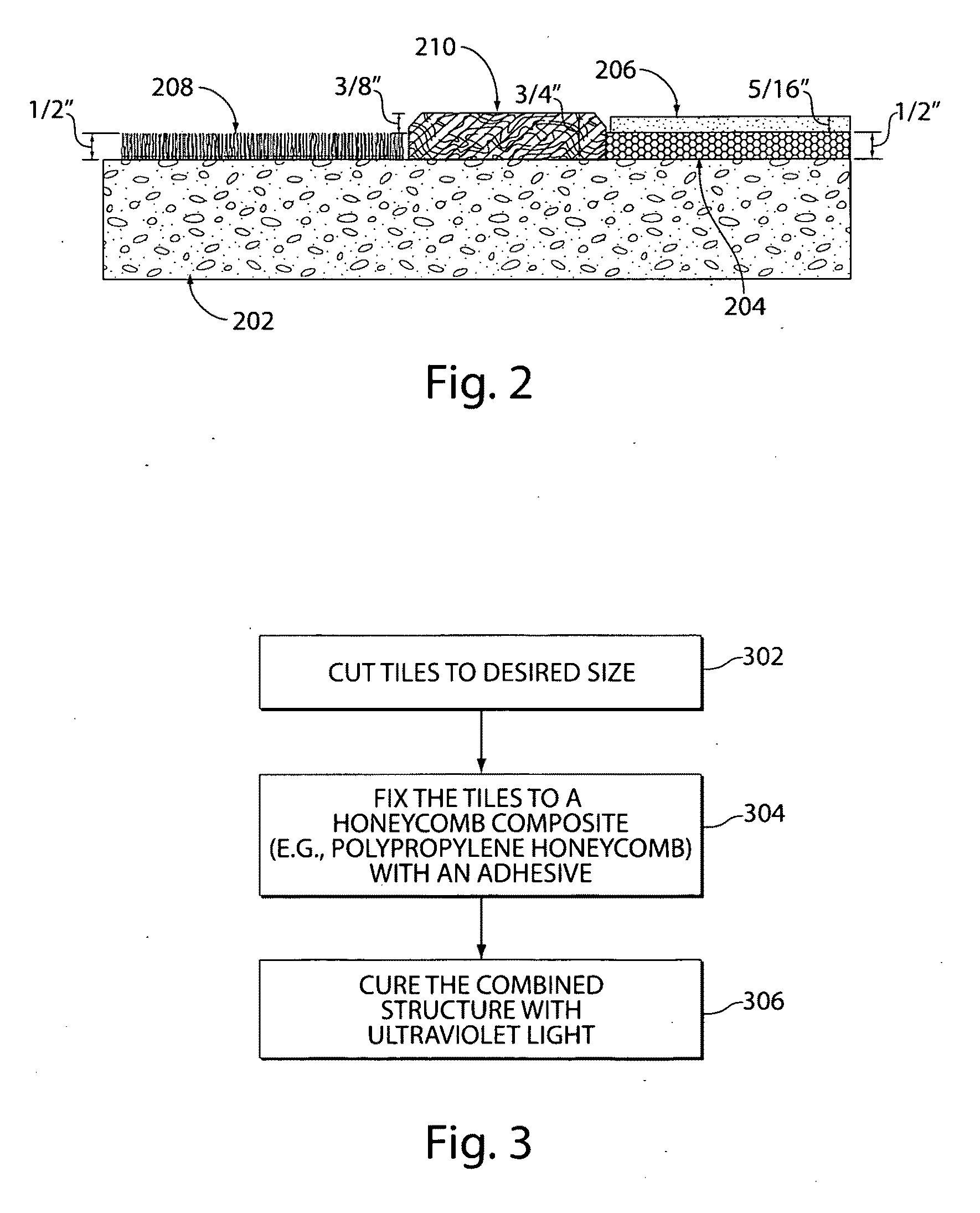

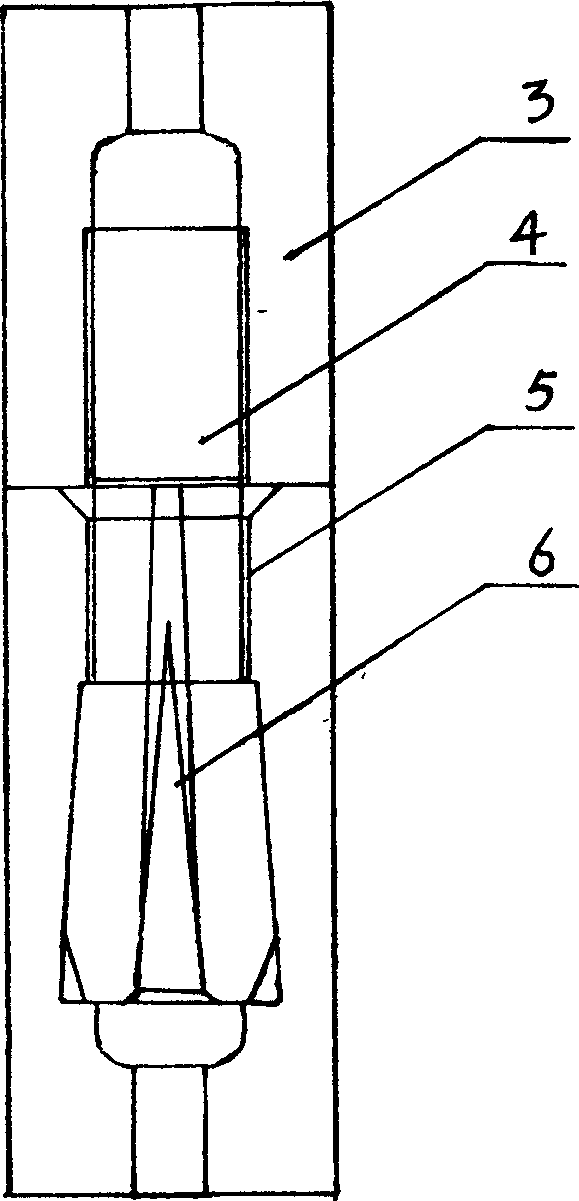

Prefabricated bathroom assembly and methods of its manufacture and installation

InactiveUS20090100769A1Maximal aesthetic qualityMaximum comfortBathsDouchesEngineeringPrefabrication

A prefabricated bathroom assembly and methods for its manufacture and installation are disclosed. For example, a prefabricated tub and / or shower assembly may be provided. In some embodiments, the prefabricated assembly may include at least a bathtub or a shower pan, tile surround(s), and a ceiling. The prefabricated assembly may be constructed substantially entirely off-site relative to a construction site and shipped to the construction site, for example, in substantially a single piece. Finishing face trim for making a seamless transition from the prefabricated assembly to the adjoining walls and ceiling may also be provided. In other embodiments, at least partially prefabricated panels (e.g., 3 wall panels and 1 ceiling panel), a tub or shower pan, the face trim, and / or other components may be shipped separately to the construction site for on-site assembly.

Owner:EGGROCK

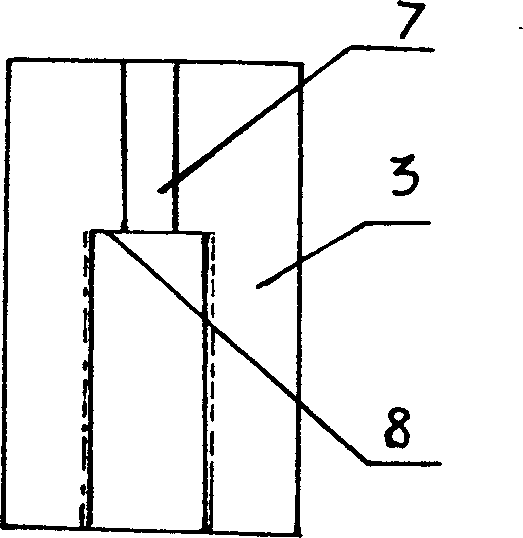

Upper screw lower connecting pile fastener and precast member

InactiveCN1603523AReduce manufacturing costAchieve consistencyBuilding constructionsBulkheads/pilesNosePre stress

The invention involves a kind of tube column to meet the buckle, as well as uses with the time mouth constitution pre-stressed high strength pre- workpiece and -odd in view of the fact that with the between between connection structure and the connection method, is the pre- workpiece to meet buckles with the pre- workpiece manufacture domain. On under the spiral goes against pile extension buckles by pulls the cap nut, inflates the screw and goes against pulls the cap nut constitution, pulls the cap nut screw together in the spiral which inflates the screw wire shorts, inflates the screw the inflation measure expansion in to go against pulls in the cap nut in the inflation cavity, when pile extension, demands the collection attire two maybe certain to pull the cap nut with the between nose minute to buckle goes against pulls the cap nut mouth which corresponds with the prefabrication, inflates the screw the spiral wire shorts screw together in pulls the cap nut screw thread in, Inflates the screw the inflation to carefully examine like goes against pulls the cap nut the inflation cavity also the inflation sells under the function in its nose to inflate in goes against pulls the cap nut in the inflation cavity, completes docking between the pre- workpiece and pre- workpiece.

Owner:周兆弟

BIM (Building Information Model)-based pipe prefabrication method

InactiveCN103218492AImprove the accuracy of prefabricationQuality improvementSpecial data processing applicationsCollision detectionDimensional modeling

The invention relates to a BIM (Building Information Model)-based pipe prefabrication method, which comprises the followingsteps: (1) performing three-dimensional modeling, i.e., converting a two-dimensional design drawing into a corresponding BIM three-dimensional model; (2) performing collision detection, i.e., performing collision detection on the three-dimensional model by using a pipeline model-based collision detection algorithm until the collision result is zero collision, and outputting a final three-dimensional model; (3) prefabricating and pretreating, i.e., numbering all pipe sections in the three-dimensional model according to an assembly sequence and outputting and printing a prefabrication drawing and a numbering result; and (4) prefabricating, i.e., manufacturing a pipe prefabricated part according to the prefabrication drawing and the numbering result. Compared with the prior art, the pipe prefabrication method has the advantages that the prefabrication accuracy can be improved, the field working efficiency is improved and the like.

Owner:上海上安机电设计事务所有限公司

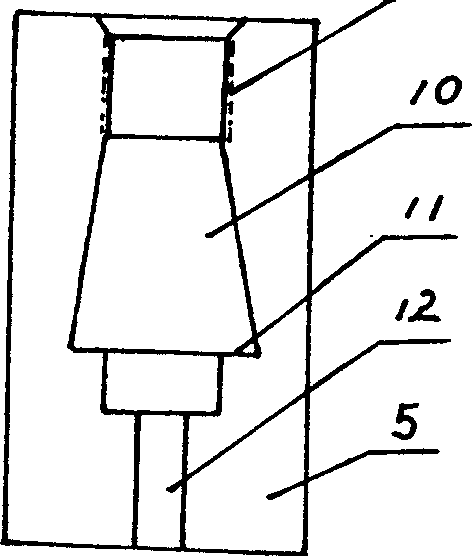

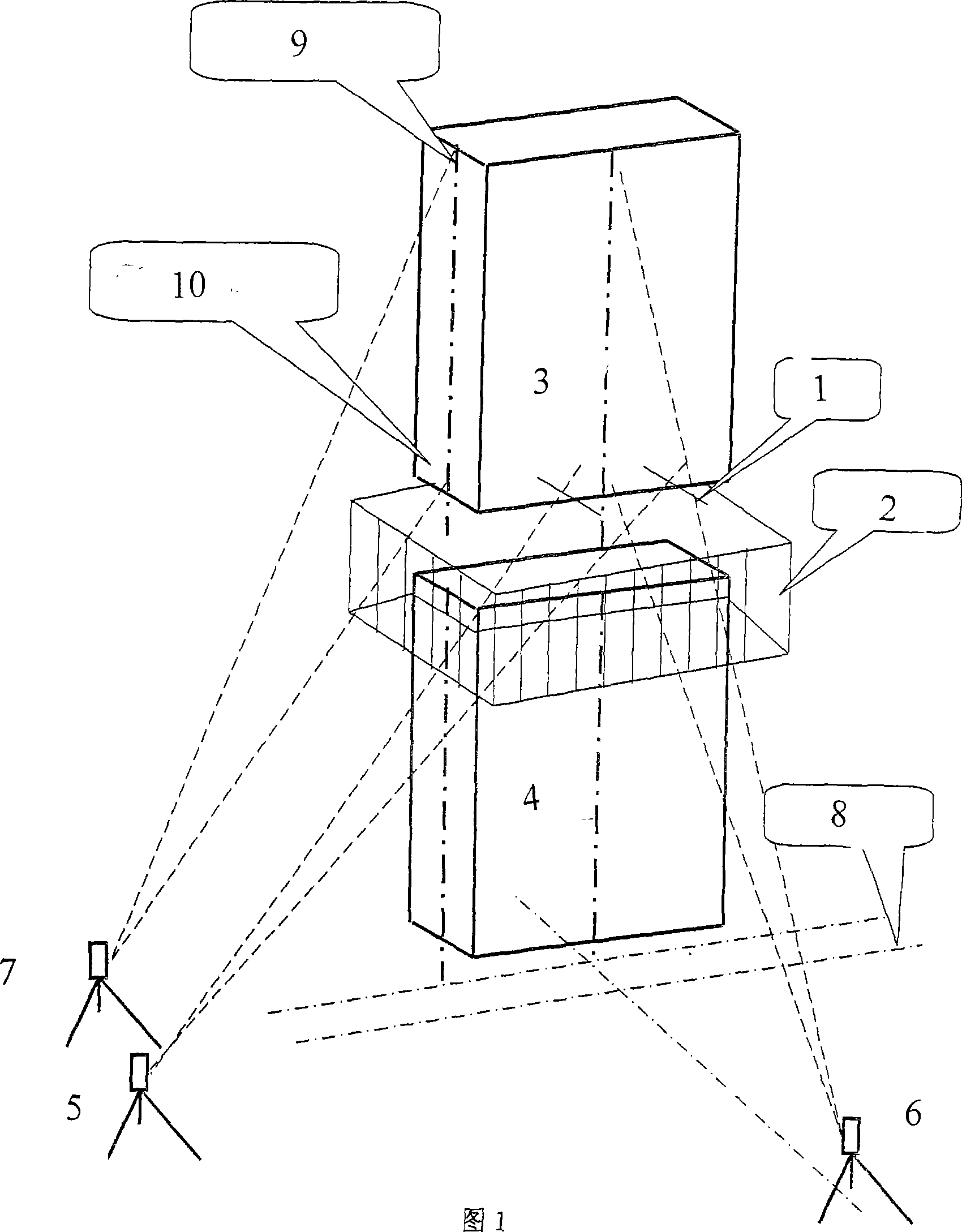

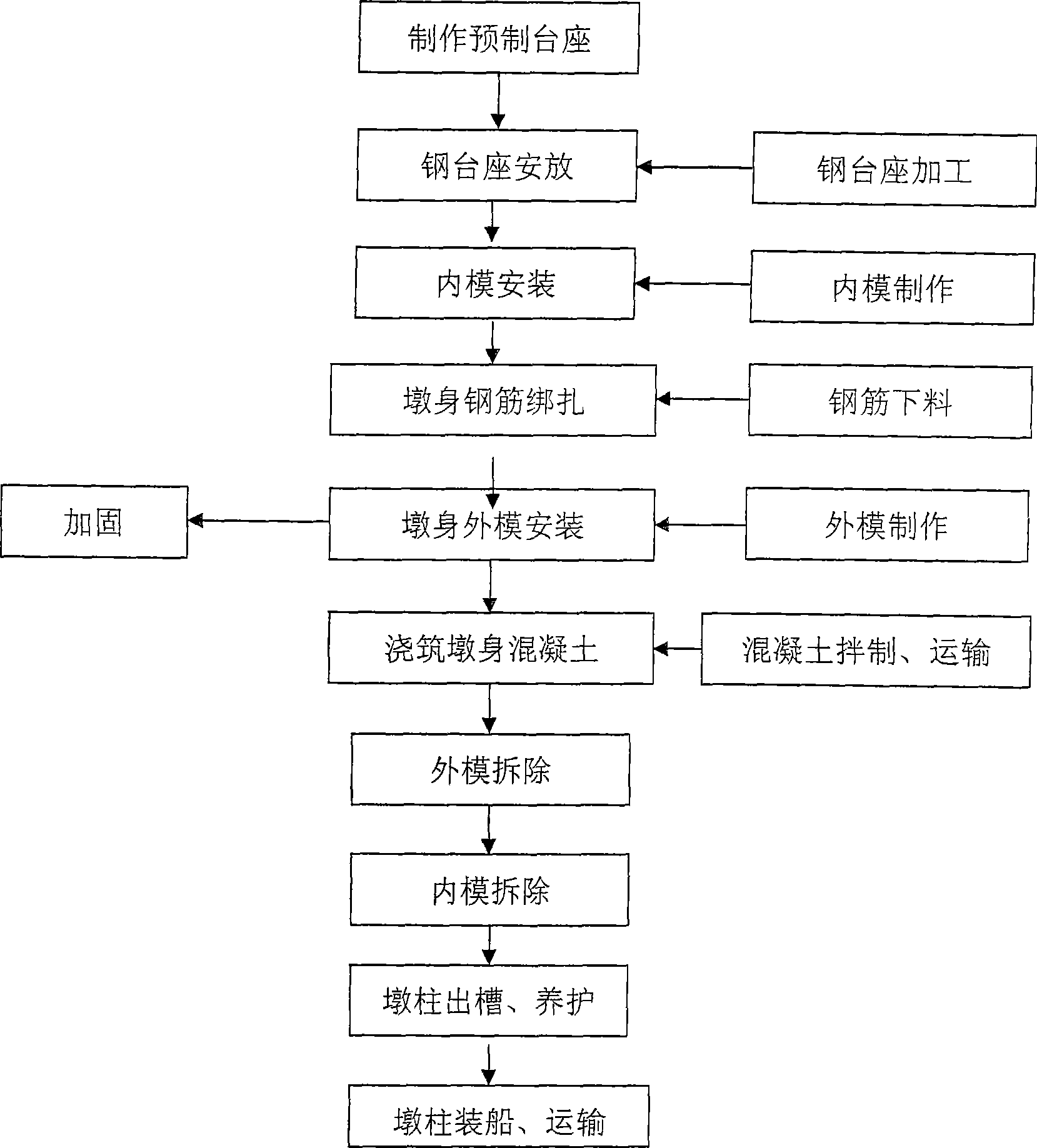

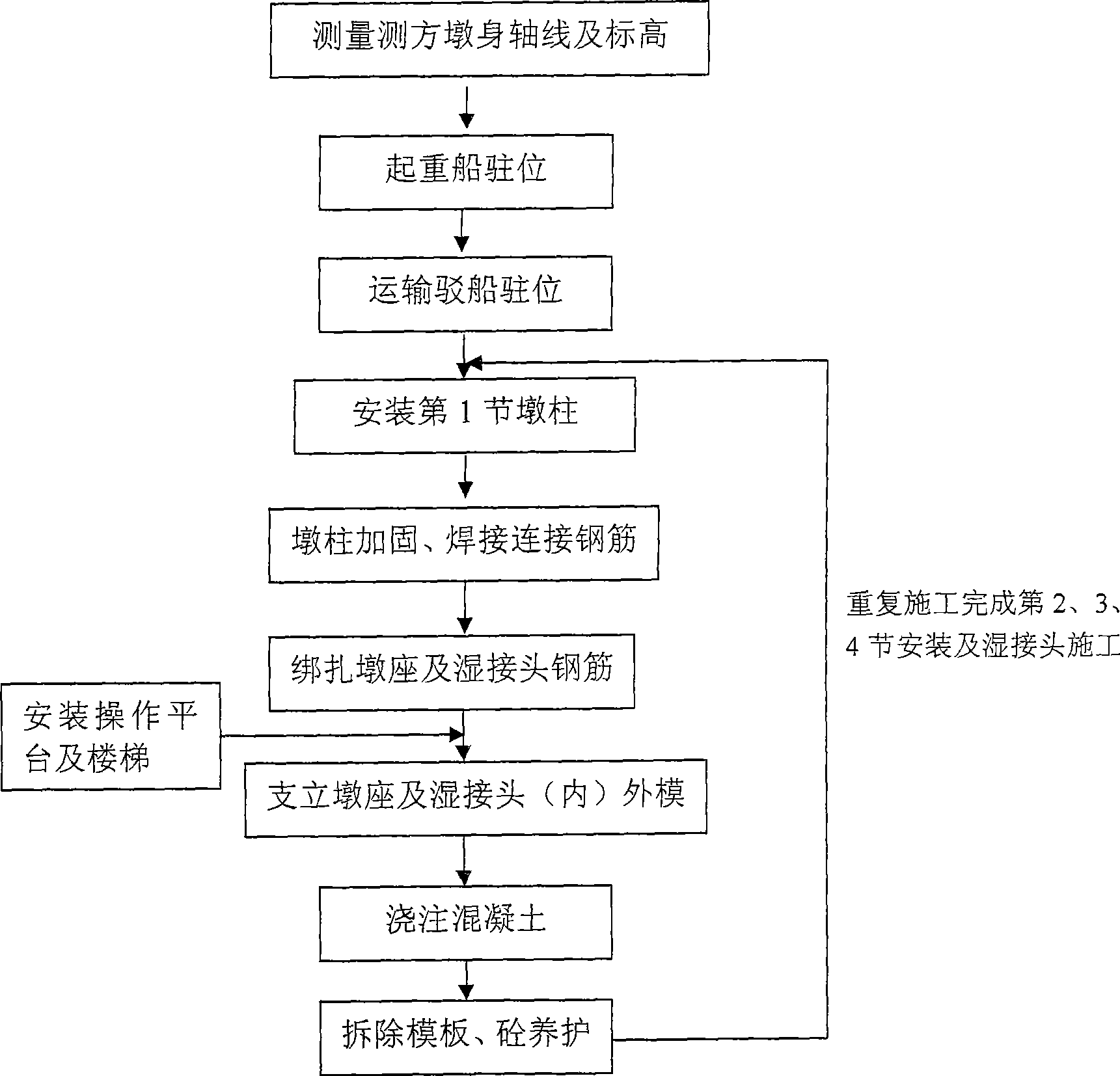

Pier column prefabrication splicing building technology

ActiveCN101429752AInspection is easy to implementImprove construction qualityBridge structural detailsBridge erection/assemblyHigh strength concreteBridge engineering

Owner:NO 1 ENG COMPANY CO LTD OF CCCC FIRST HARBOR ENG COMPANY +1

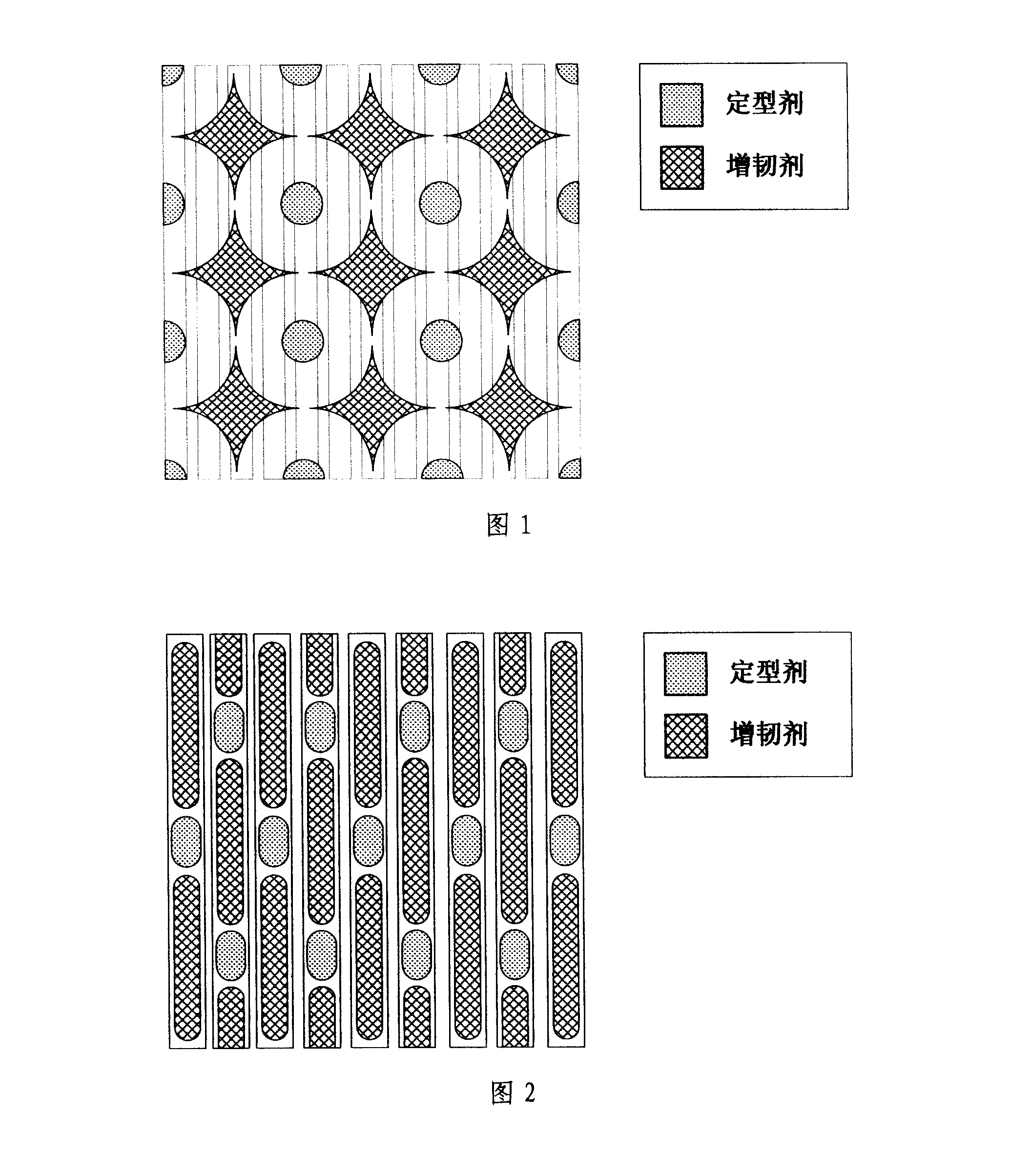

Prefabricated fabric for liquid condition shaping composite material and preparation thereof

ActiveCN101220561AGood presetting propertiesMaintain liquid formabilityLayered productsTextile decorationFiberManufacturing technology

The invention belongs to a composite material manufacturing technology which relates to a liquid molding prefabrication fabric and a preparation method thereof. The prefabrication fabric of the invention comprises a basal fiber fabric and is characterized in that: a toughening layer is adhered on one surface or two surfaces of the basal fiber fabric. The preparation method of the invention includes the steps: the toughening layer is conglutinated; a molding layer is conglutinated. The prefabrication fabric of the invention has both the interlayer selectivity toughening and molding functions, and realizes the high toughness modification of the composite material while keeping the composite material liquid molding performance and the good fabric prefabrication molding performance.

Owner:BEIJING AVIATION MATERIAL INST NO 1 GRP CORP CHINA AVIATION IND

BIM (Building Information Modelling) technology based municipal pipeline factory prefabrication and installation method

InactiveCN105046359AOptimize layoutMaximize space utilizationForecastingCollision detectionDimensional modeling

The present invention relates to pipeline prefabrication and installation technologies, in particular to a BIM (Building Information Modelling) technology based municipal pipeline factory prefabrication and installation method. The method comprises the following steps of step 1, three-dimensional modeling: performing municipal pipeline three-dimensional modeling in each specialty of buildings by using Revit MEP software; step 2, scheme optimization: performing comparative analysis on different schemes according to the established three-dimensional integrated pipeline model, and selecting an optimal arrangement scheme; step 3, collision detection: performing collision detection on the three-dimension model by using a pipeline model based collision detection algorithm, and outputting a final three-dimension model until a collision result is zero collision; step 4, preprocessing of prefabrication processing: performing numbering on all pipe sections in the three-dimensional model according to an assembly sequence, and outputting and printing a prefabrication processing diagram and a numbering result; and step 5, prefabrication processing: manufacturing pipeline preforms according to the prefabrication processing diagram and the numbering result. The method has the advantages that the precision of prefabrication processing can be improved, the field working efficiency can be improved, and the like.

Owner:NANNING MUNICIPAL ENG GRP

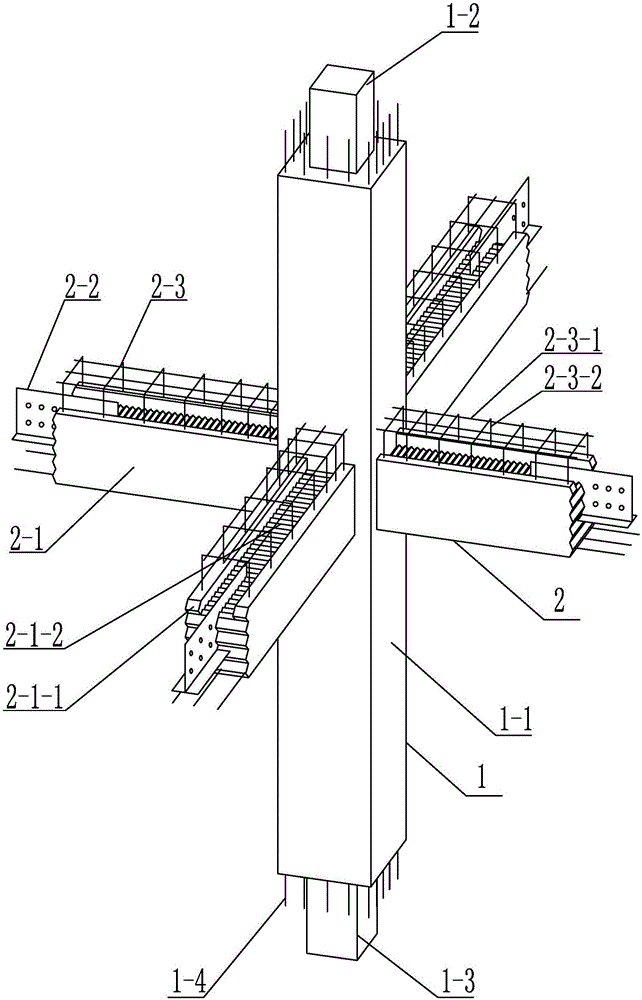

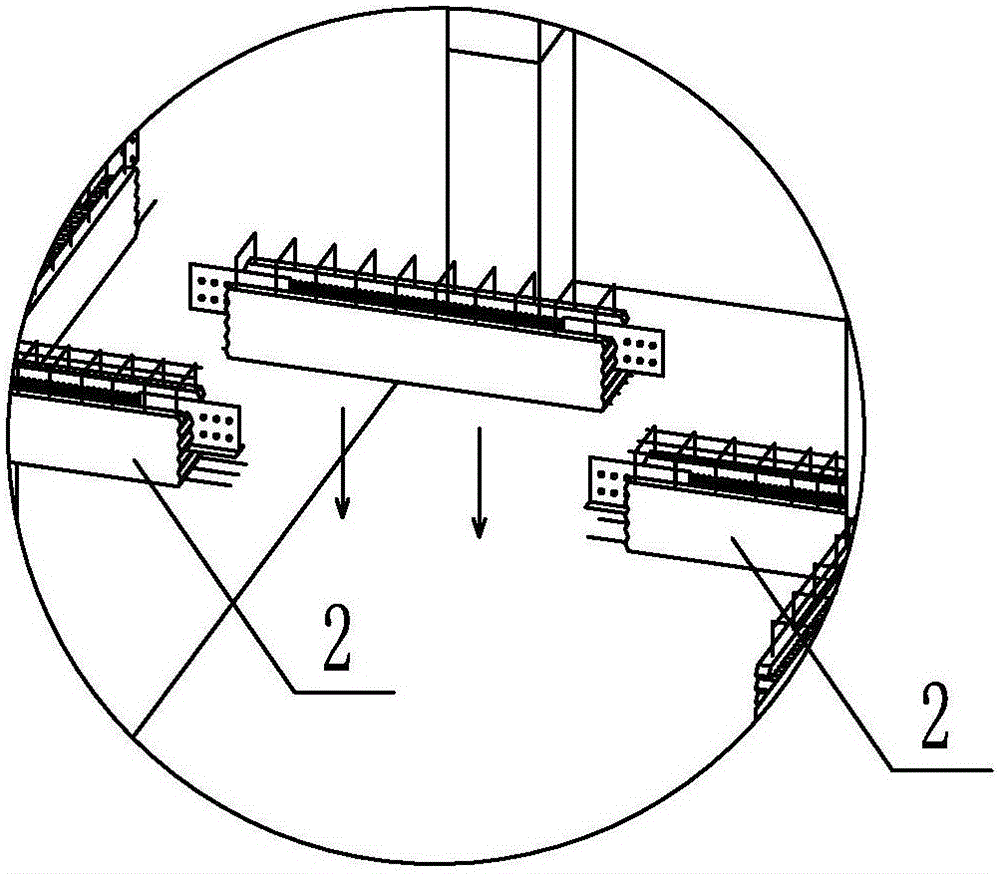

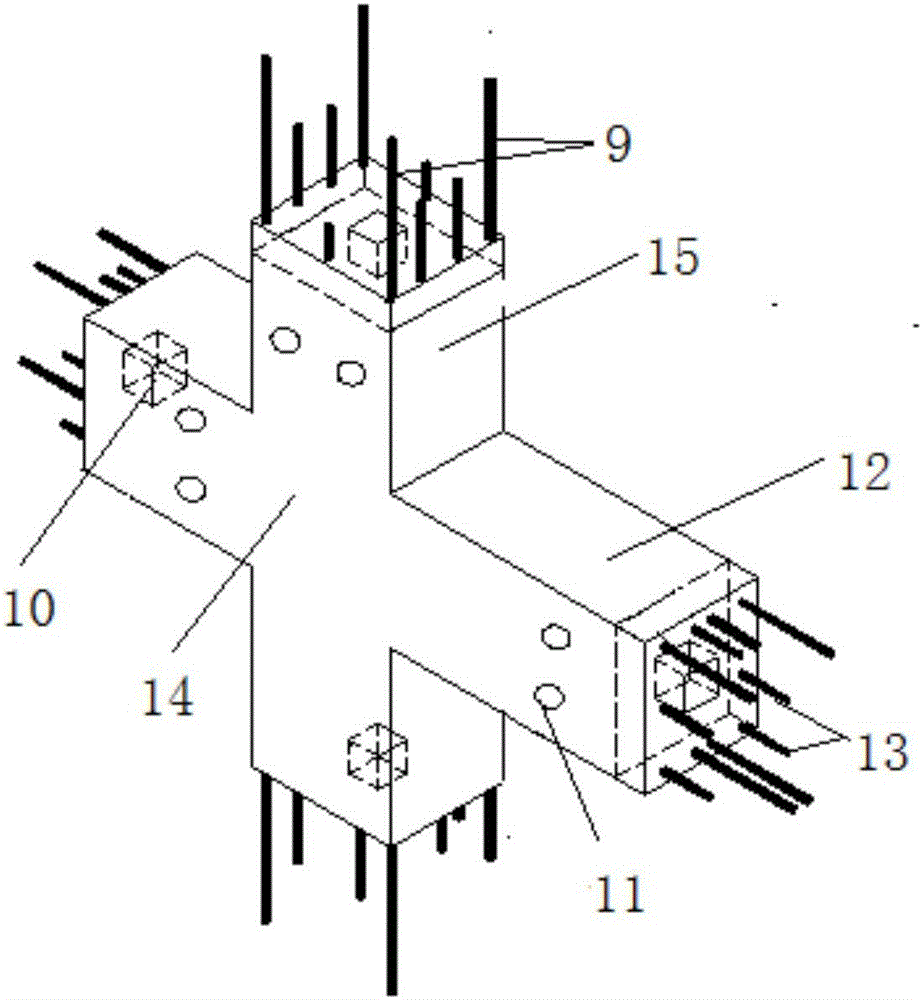

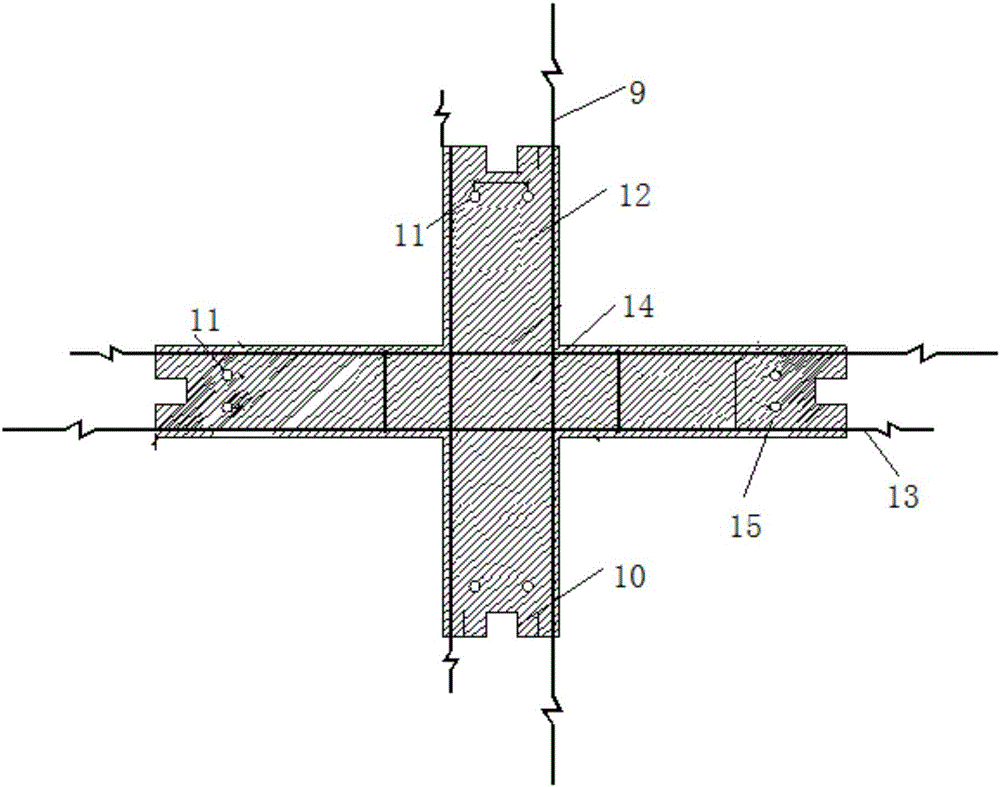

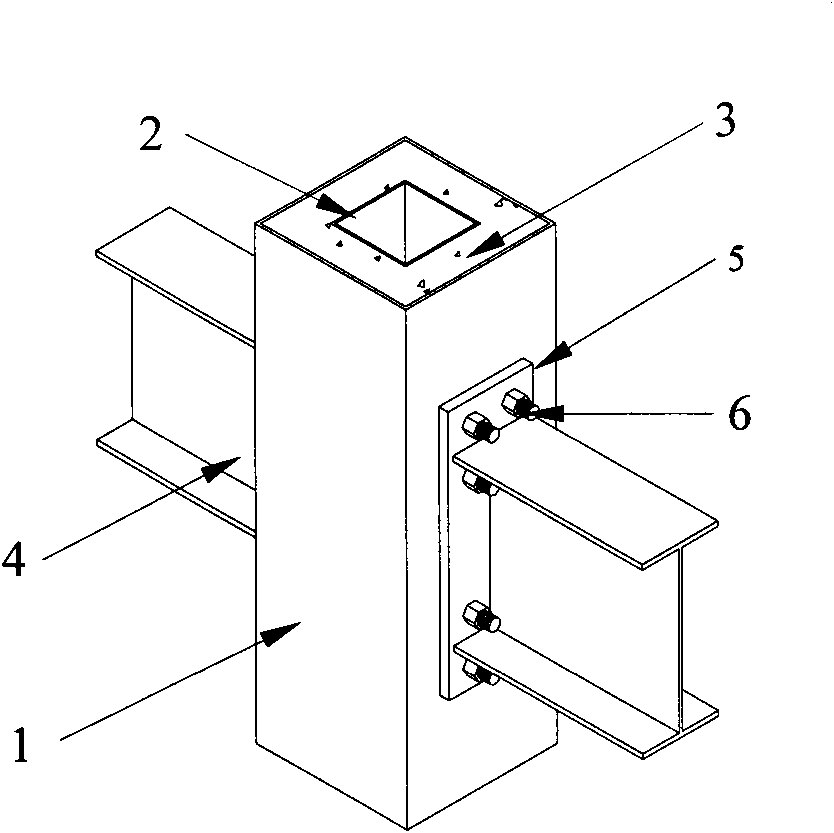

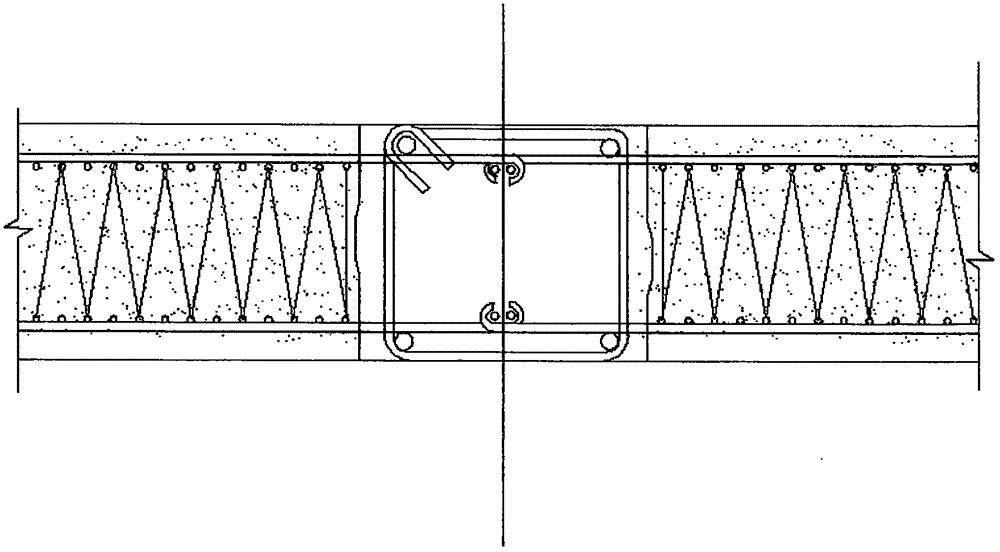

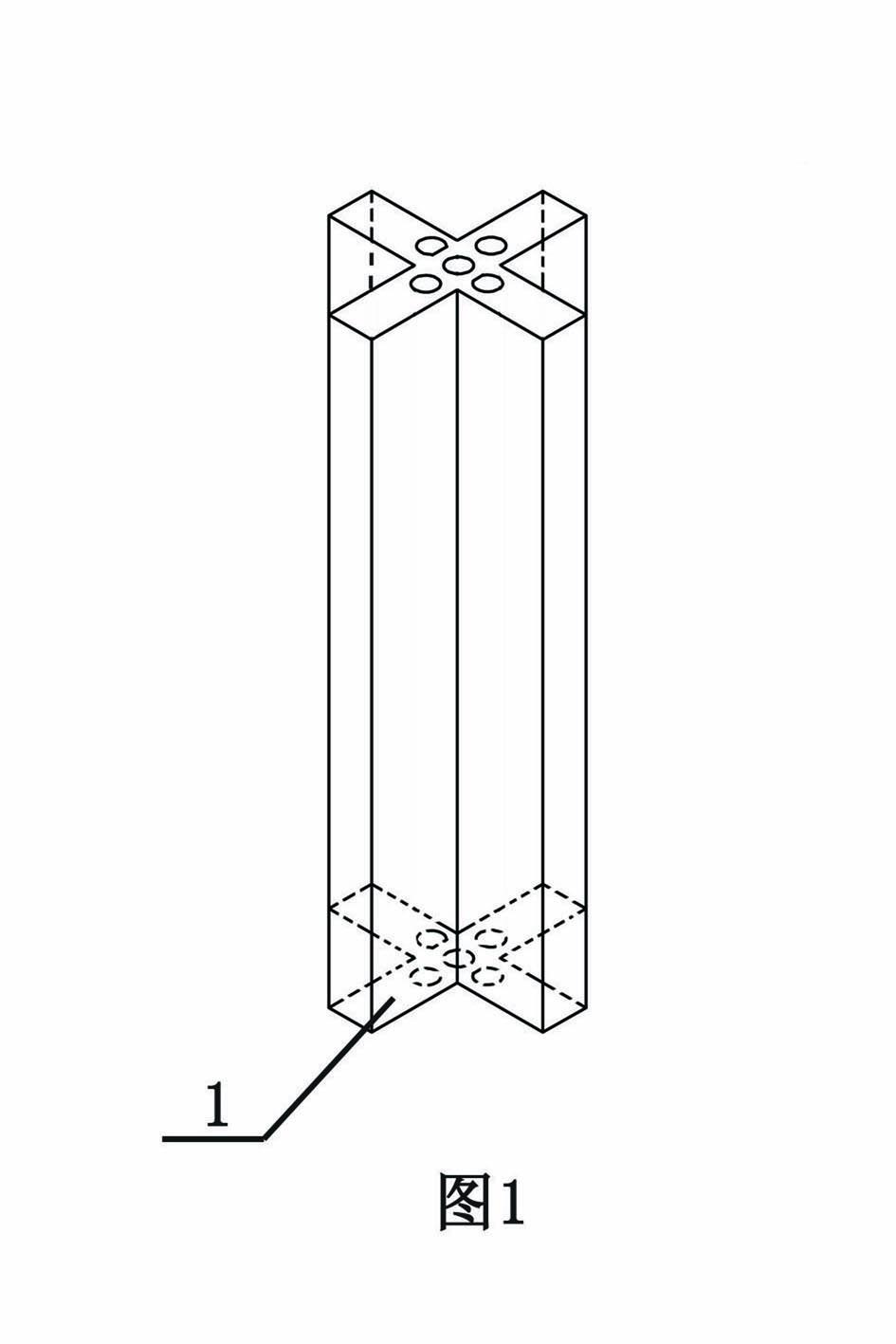

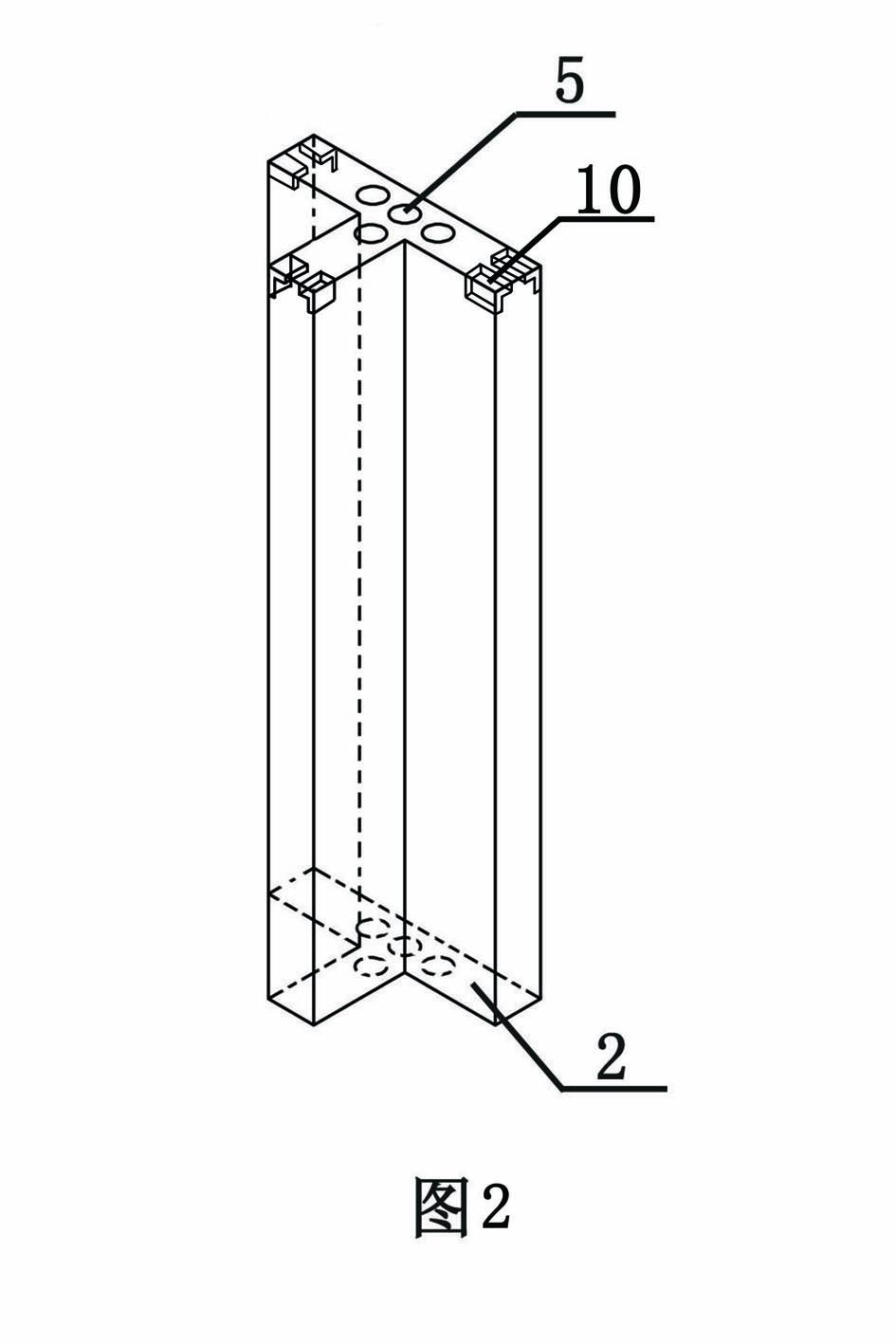

Single-layer prefabricated assembly type reinforced concrete beam-column joint

The invention relates to a prefabricated reinforced concrete beam-column joint, in particular to a single-layer prefabricated assembly type reinforced concrete beam-column joint. In order to solve the problem that the connection integrity of existing prefabricated beams and prefabricated columns is hard to guarantee, the prefabricated joint for one-piece casting manufacturing of a column section and part of beam sections is provided according to the concept of the point of inflection. The single-layer prefabricated assembly type reinforced concrete beam-column joint is formed by overall manufacturing of a vertical column section (1) and joint superposed beam sections (2) in a factory for prefabrication. A manufacturing method comprises the steps of beam-column longitudinal bar and stirrup binding, connector pre-burying, formwork erecting and concrete pouring and curing. The height of the vertical column section (1) of the joint is 1 / 2 of the storey height, and the length of each joint superposed beam section (2) is 1 / 3 of the span of adjacent columns. The vertical column section (1) comprises a pouring section (1-1), a concrete filled steel tube connector (1-2), a steel tube connector (1-3) and column section longitudinal bars (1-4). Each joint superposed beam section (2) comprises a groove-shaped pouring section (2-1), inverted-T-shaped structural steel connectors (2-2) and a reinforcement cage framework (2-3). The single-layer prefabricated assembly type reinforced concrete beam-column joint is applied to the construction industry.

Owner:HARBIN INST OF TECH

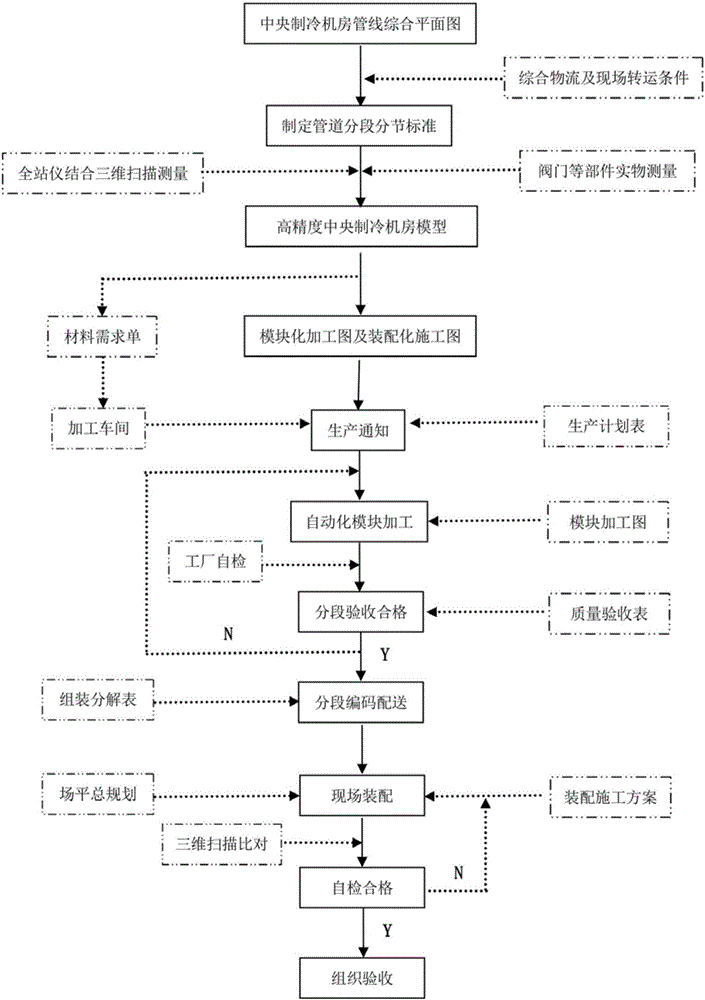

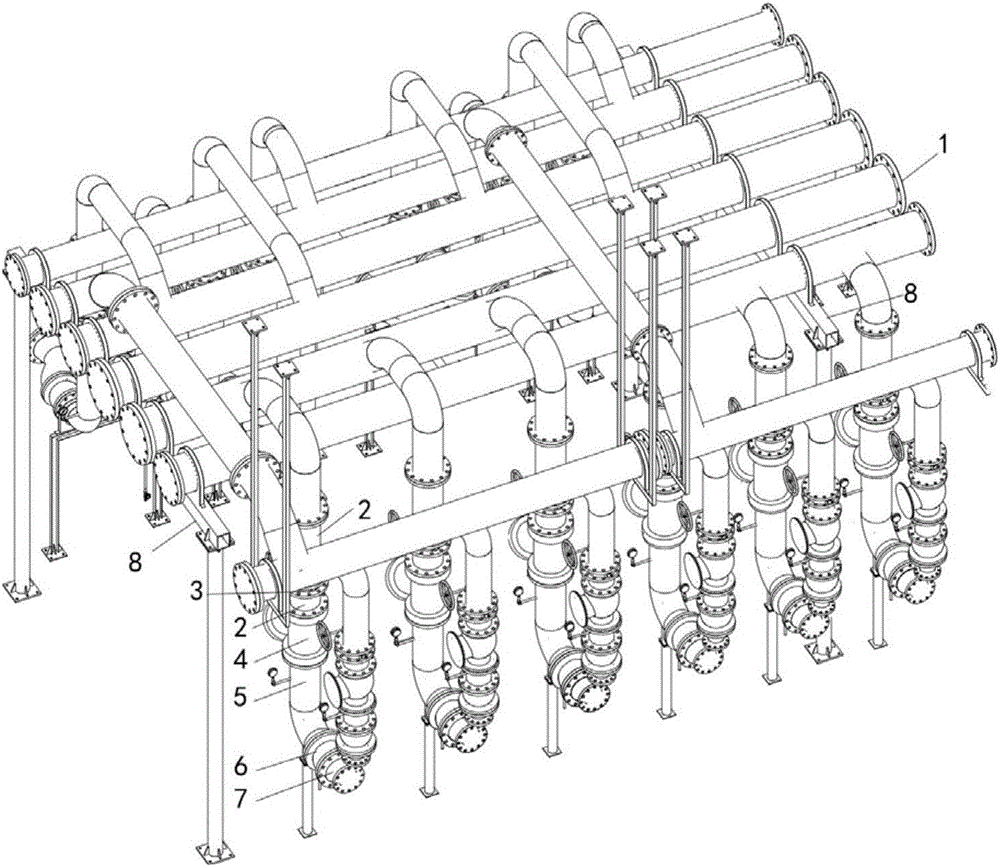

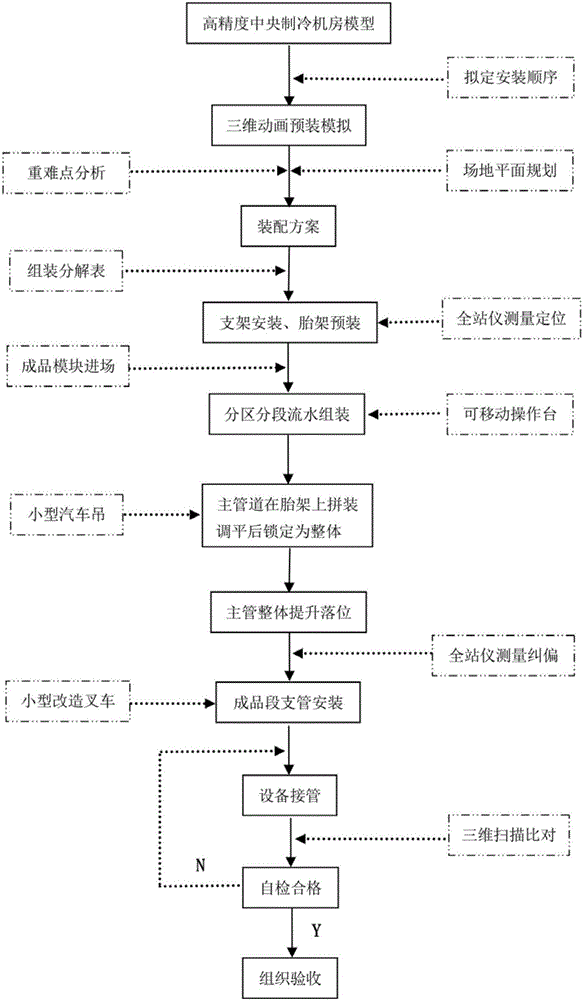

Central refrigeration machine room modular prefabrication and assembled construction method

ActiveCN105888317AError controllableImprove assembly efficiencyGeometric CADSpecial data processing applicationsComputer moduleRefrigeration

The invention discloses a central refrigeration machine room modular prefabrication and assembled construction method. The method comprises: refrigeration machine room standard family storehouse establishment, digital module design, three-dimensional precision control, factory full-automation prefabrication and assembled construction. A standard family storehouse is a central refrigeration machine room complete device, valve and component family storehouse created based on the size of an entity. A digital module is generated after a high-precision BIM model is subjected to scientific segmented encoding. The three-dimensional precision control comprises: rechecking and measuring a central refrigeration machine room building structure, constructing an absolute coordinate system, and ensuring that the model design precision, the processing precision and the field assembly precision are controlled uniformly and reliably. The factory full-automation prefabrication comprises factory production performed according to a digital module processing diagram. The assembled construction comprises segmented flange connection, and integrated lifting and mounting. The central refrigeration machine room modular prefabrication and assembled construction method has the advantages that mounting efficiency of a central refrigeration machine room can be improved, mounting quality and precision are improved, the reproduction and transplantation performances of a standard module design are high, and industrial production conditions are met.

Owner:THE SECOND CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU

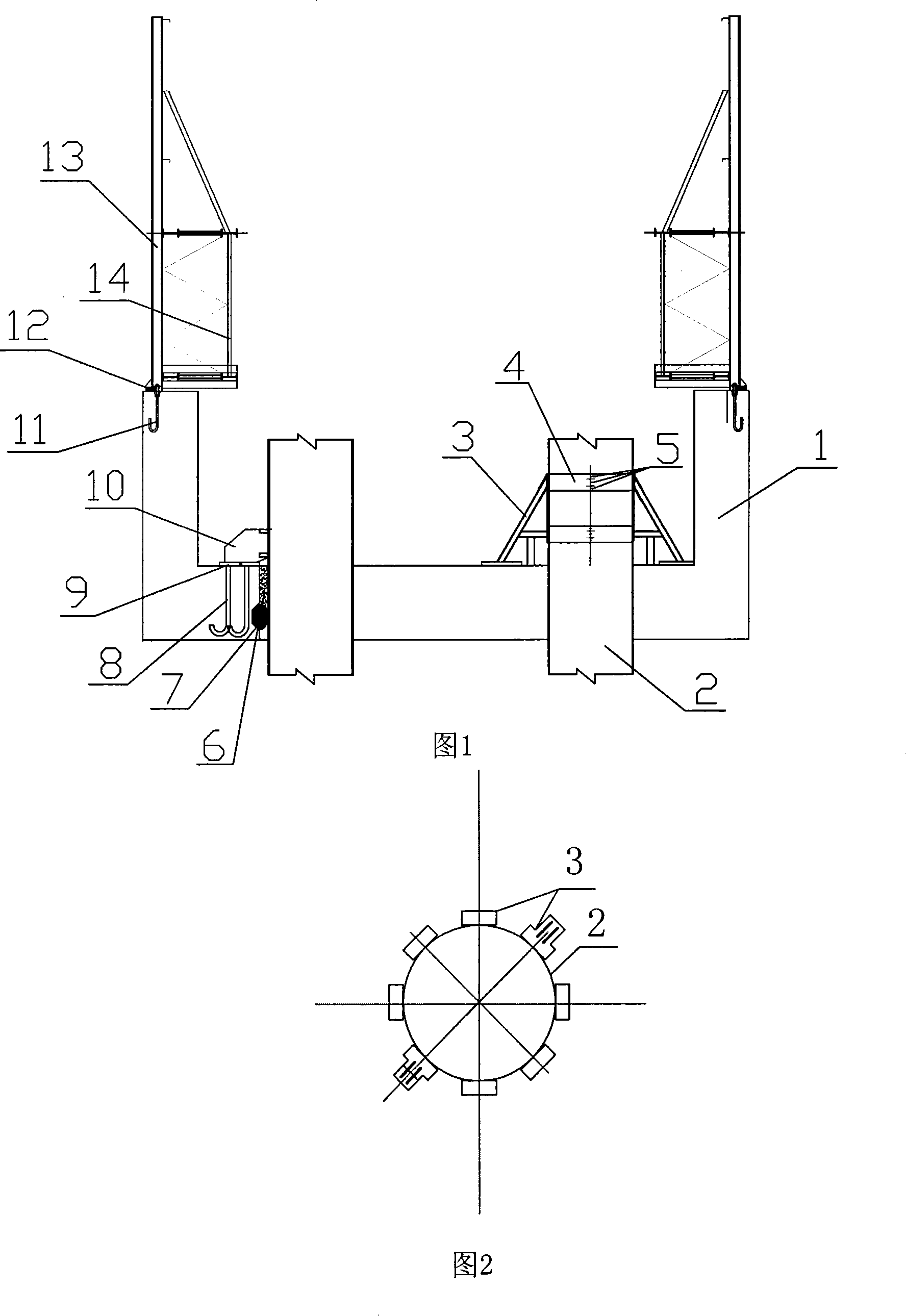

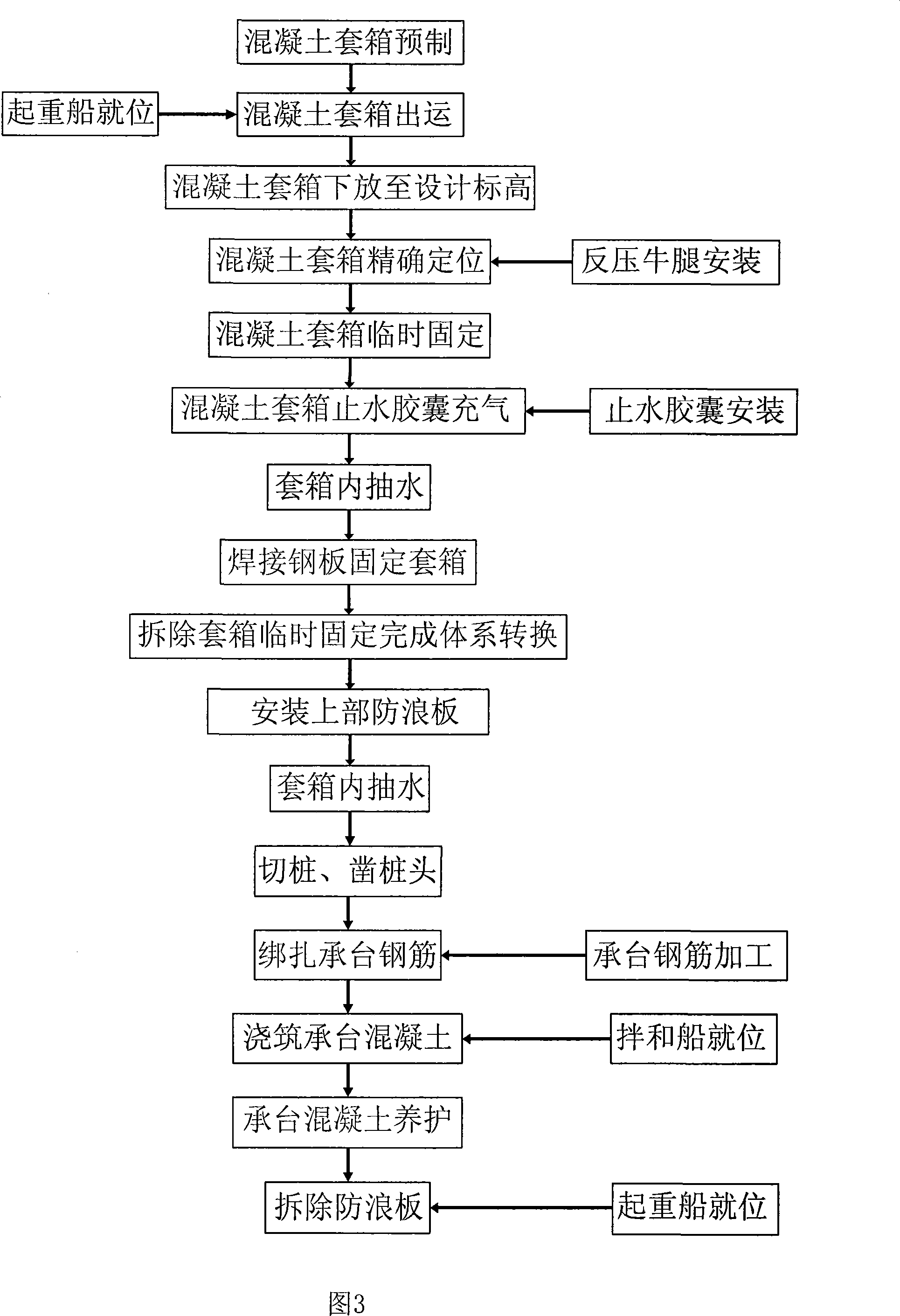

Underwater no-bottom closing concrete boxed cofferdam and method of use thereof

An underwater concrete boxed cofferdam without bottom sealing and an application method solves the shortcomings that the traditional steel cofferdam construction requires to pour thick concrete to seal the bottom; the consumption of steel material is large; the construction period is long; and the bearing platform quality is not easy to be controlled. The underwater concrete boxed cofferdam without bottom sealing is poured together with the concrete bearing platform; an upper part of the concrete boxed cofferdam is provided with a contemporary surf board cofferdam; and the surf board is dissembled after the concrete bearing platform is poured and completed. The concrete boxed cofferdam can be produced by factory prefabrication; the construction quality is easy to be controlled; the installation is convenient, simple and quick, which can accelerate the construction progress; the construction period is shortened reasonably and economically with reliability and safety; at the same time, the boxed cofferdam can play a seawater erosion prevention effect, which improves the durability of the engineering. The invention is mainly suitable for working in shallow water.

Owner:SHANDONG HI SPEED QINGDAO HIGHWAY

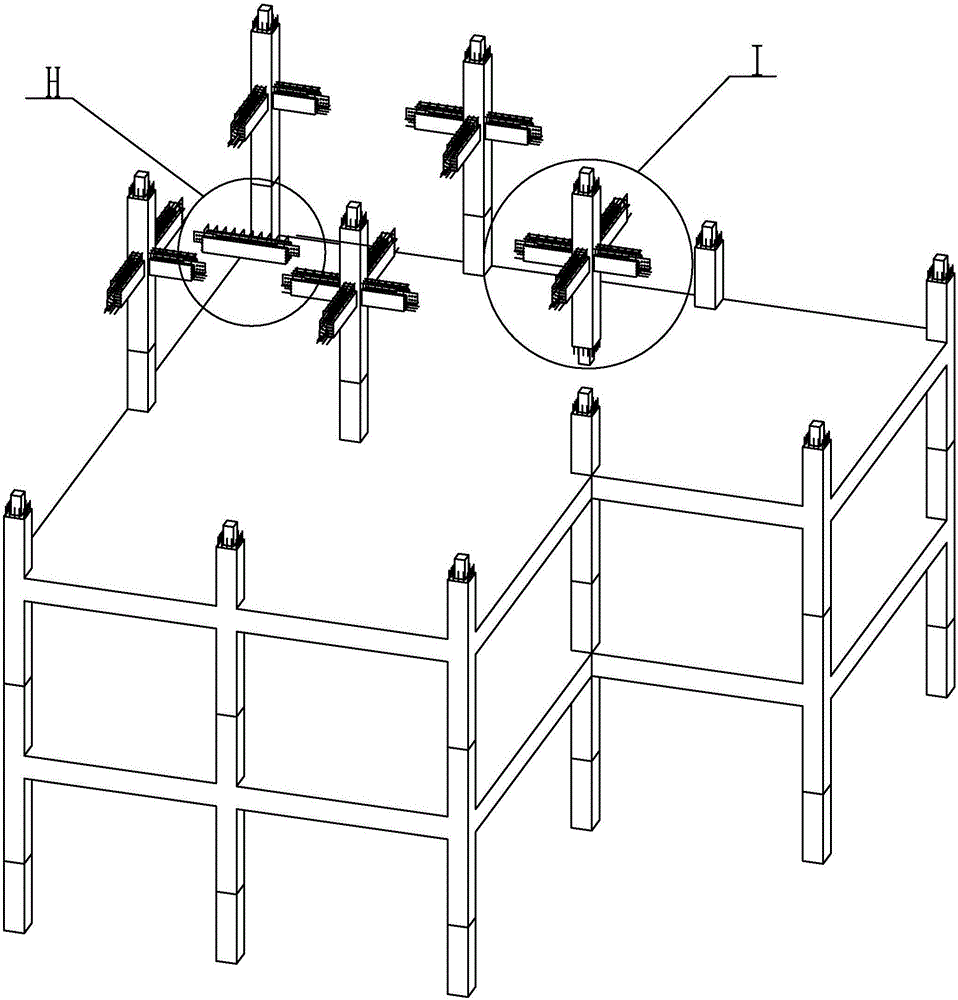

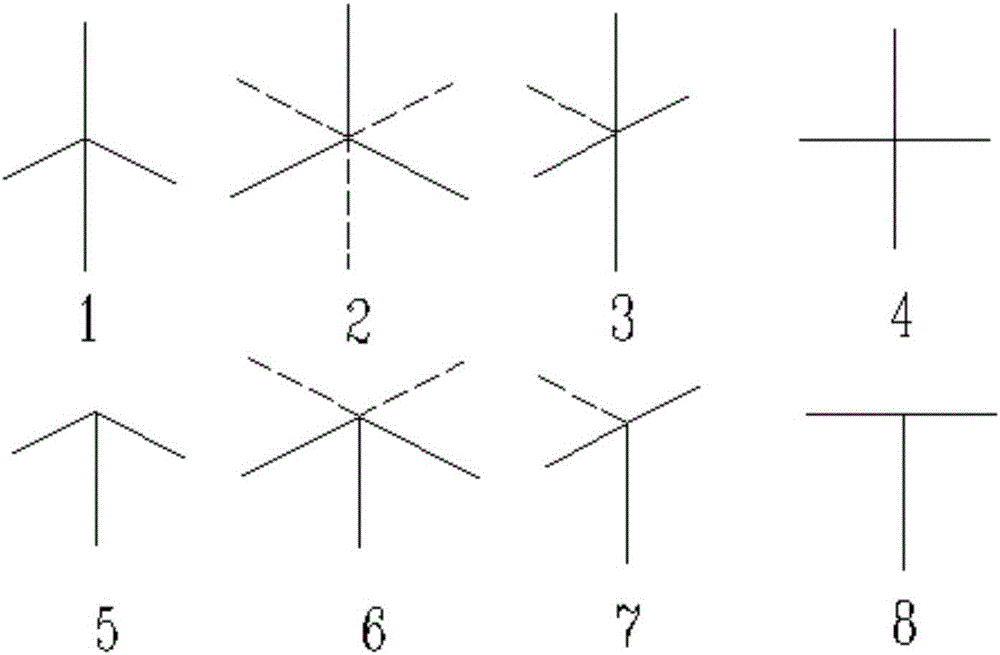

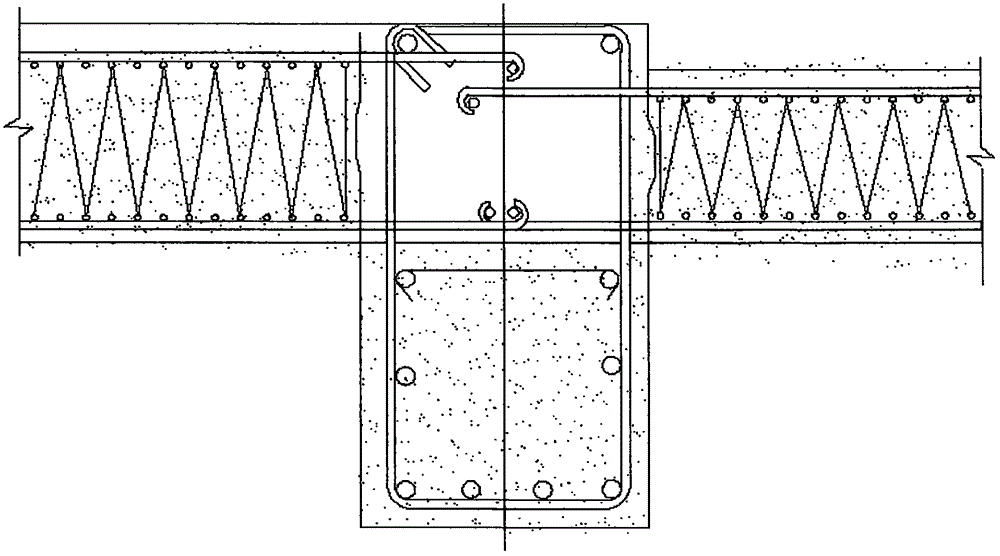

Prefabricated node and prefabricated frame structure and construction method thereof

ActiveCN106223463ARealize factory productionBuild fastBuilding constructionsReinforced concreteArchitectural engineering

The invention discloses a prefabricated node and a prefabricated frame structure and a construction method thereof. The prefabricated node can be subjected to workshop prefabrication according to the structure. The prefabricated frame structure is mainly characterized in that the prefabricated node with a node overhanging beam section and a node overhanging column section is prefabricated, prefabricated nodes of various kinds are designed according to a graph, the prefabricated nodes are accurately mounted, and the overall prefabricated assembled integral type structure is constructed by means of connecting beams or columns of the prefabricated nodes in site. The construction method includes the steps of 1), positioning, lifting and correcting the prefabricated nodes in site; 2), fixing and mounting the prefabricated nodes; 3), casting a beam connection portion and a column connection portion in site. A novel construction mode is innovatively put forward for the prefabricated frame structure, and the node prefabricated structure with the beams and the columns is put forward; unfavorable situation that durability and reliability of the nodes are pool due to conventional prefabricated beams and columns and in-site casting of reinforced concrete nodes is favorably improved, construction time is saved, and construction cost is reduced.

Owner:赵挺生

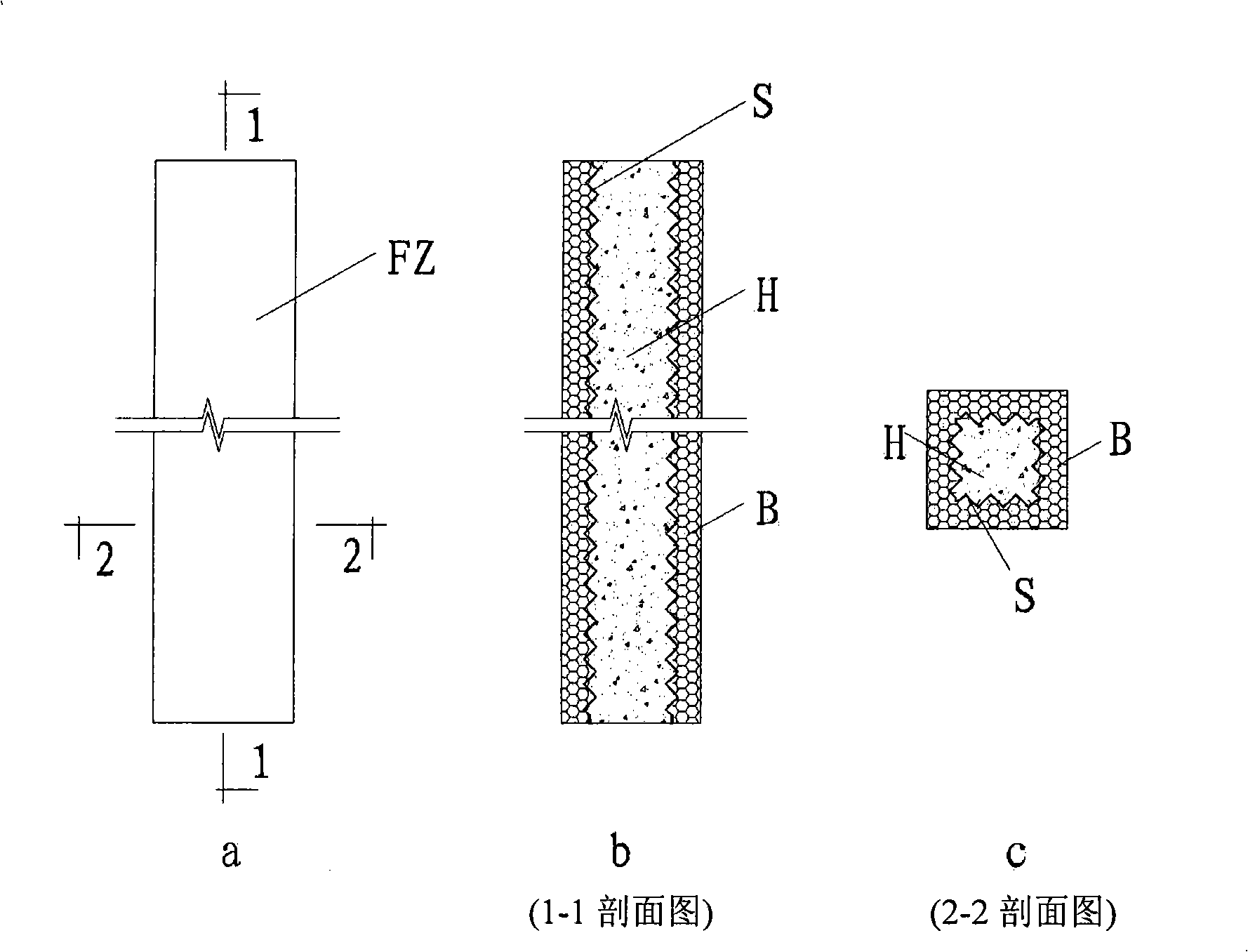

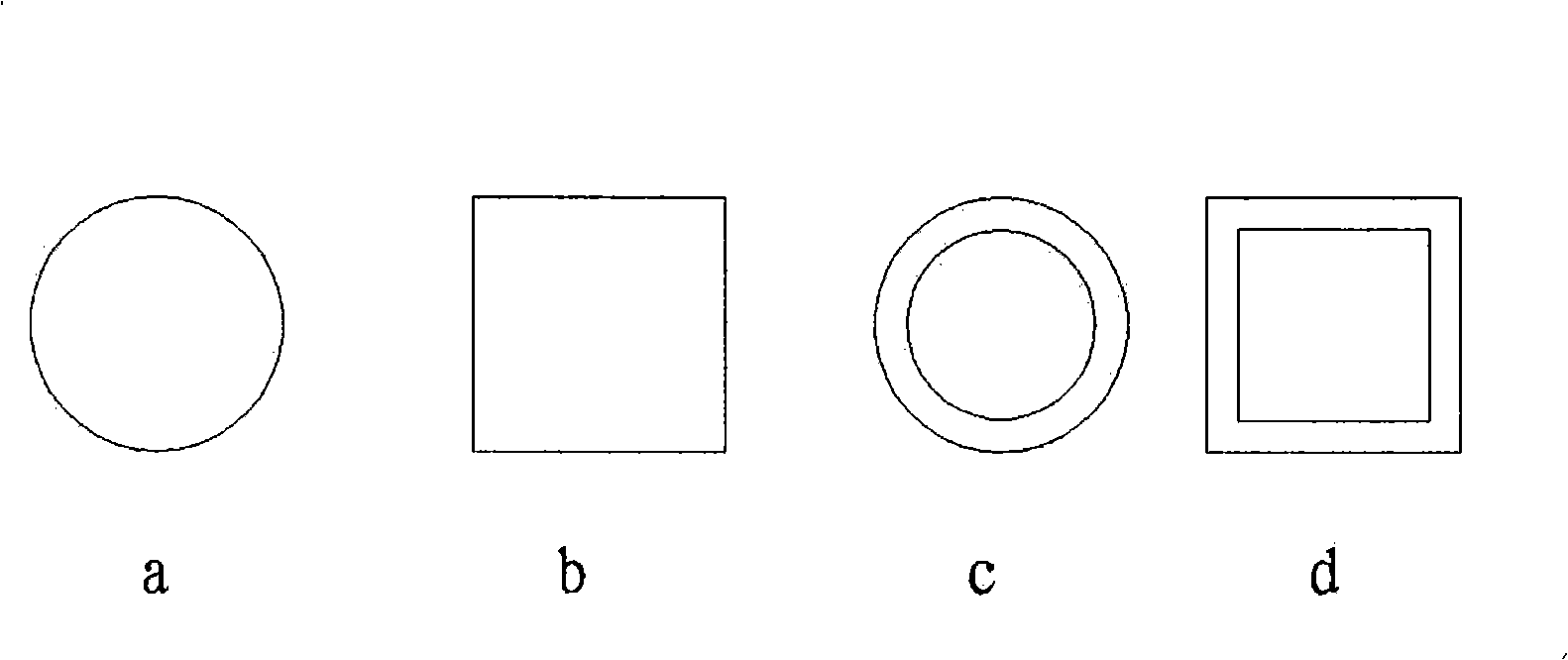

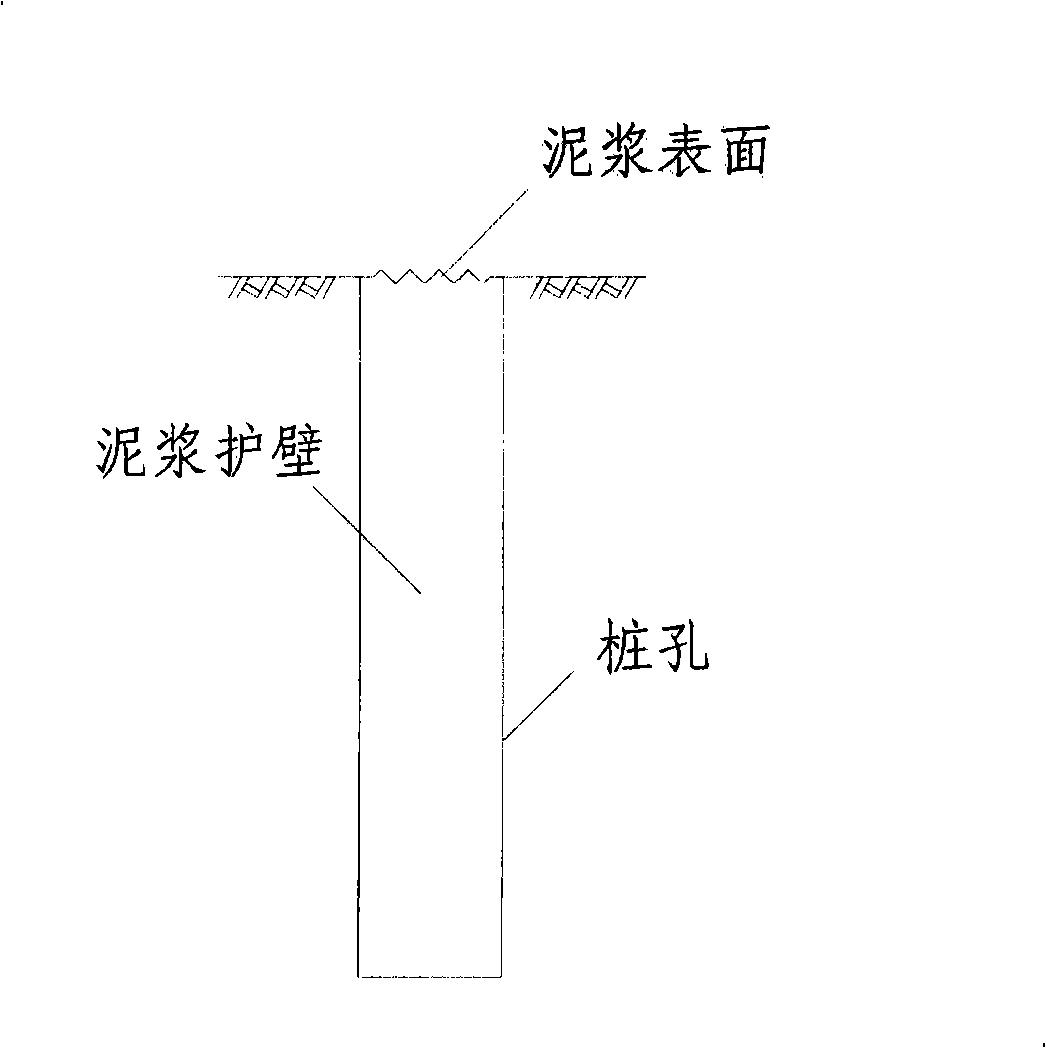

Composite pile with high permanent stability protection layer and its production and construction method

InactiveCN101343871AIncreased durabilityExtended service lifeClimate change adaptationBulkheads/pilesAlkali activatedGeopolymer

Disclosed is a high-durability protective layer compound pile. The structure of high-durability protective layer compound pile comprises: the compound pile is composed of a core bearing structure which is wrapped with a high-durability protective layer, the material of the protective layer adopts plastic or other modified products, asphalt and mortar or concrete, alkali activated material and the mortar or the concrete, geopolymer and the mortar or the concrete, reactive powder concrete, fiber reinforcement concrete base material, and resin mortar or concrete; The manufacturing and the construction can adopt six methods: firstly, site-casting can be performed to the protective layer and a core structure simultaneously; secondly, after the site-casting is performed to the protection wall of the protective layer, the site-casting is performed to the site-cast protective wall; thirdly, prefabrication is performed to the sleeve of the protective layer, and site-casting is carried out to the prefabricated sleeve of the site cast core structure of the sunk tube; fourthly, prefabrication is performed to the sleeve of the protective layer, the sleeve is taken as an outer mould plate to prefabricate the prefabricated sleeve of the core structure; fifthly, prefabrication is performed to the core structure, the core structure is taken as an inner mould plate to prefabricate the prefabricated sleeve of the core structure; and sixthly, site-casting is implemented to the protective layer and the core structure simultaneously.

Owner:BEIHANG UNIV

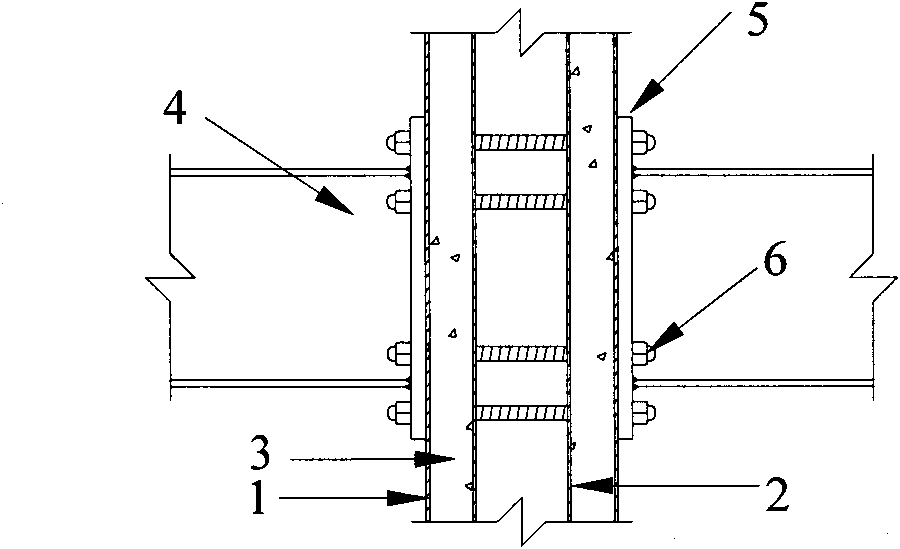

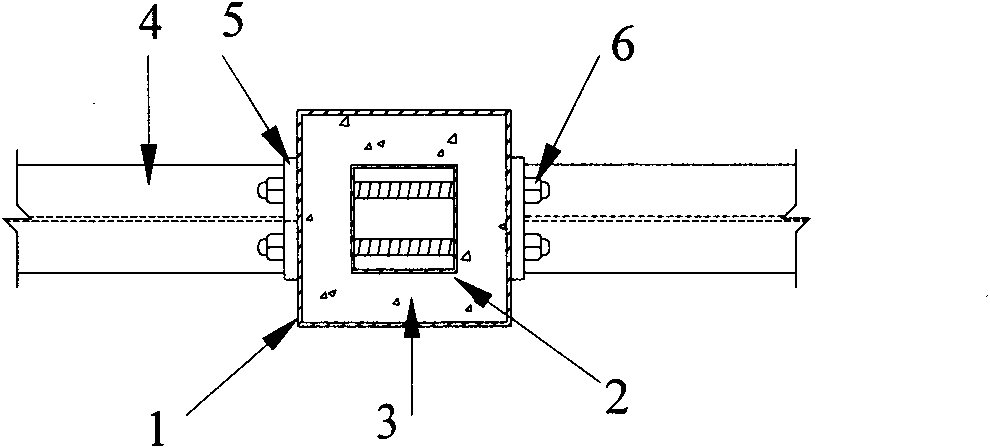

Connecting joint between hollow steel tube concrete column and steel girder and construction method thereof

InactiveCN101914952AImprove seismic performanceAvoid destructionBuilding material handlingPre stressShock resistance

The invention discloses a connecting joint between a hollow steel tube concrete column and a steel girder and a construction method thereof. The joint comprises a hollow steel tube concrete column, a steel girder, an end plate and a high-strength bolt, wherein the end plate is welded at the steel girder end; the steel girder end at the joint is connected with the hollow steel tube concrete column through the end plate and a bolt and is connected with a column through the prestressed high-strength bolt. In the construction method, the concrete in the steel tube can be prefabricated or cast in situ; the end plate can be welded in a factory; bolt holes on the end plate and the steel tube are preformed in the factory; and only bolt connection needs on-site construction. The joint structure has the advantages of economy, practicality, definite force transmission, simple manufacture, high prefabrication degree, convenient construction, and capacities of avoiding on-site welding and improving joint shock resistance and construction benefit.

Owner:SOUTH CHINA UNIV OF TECH

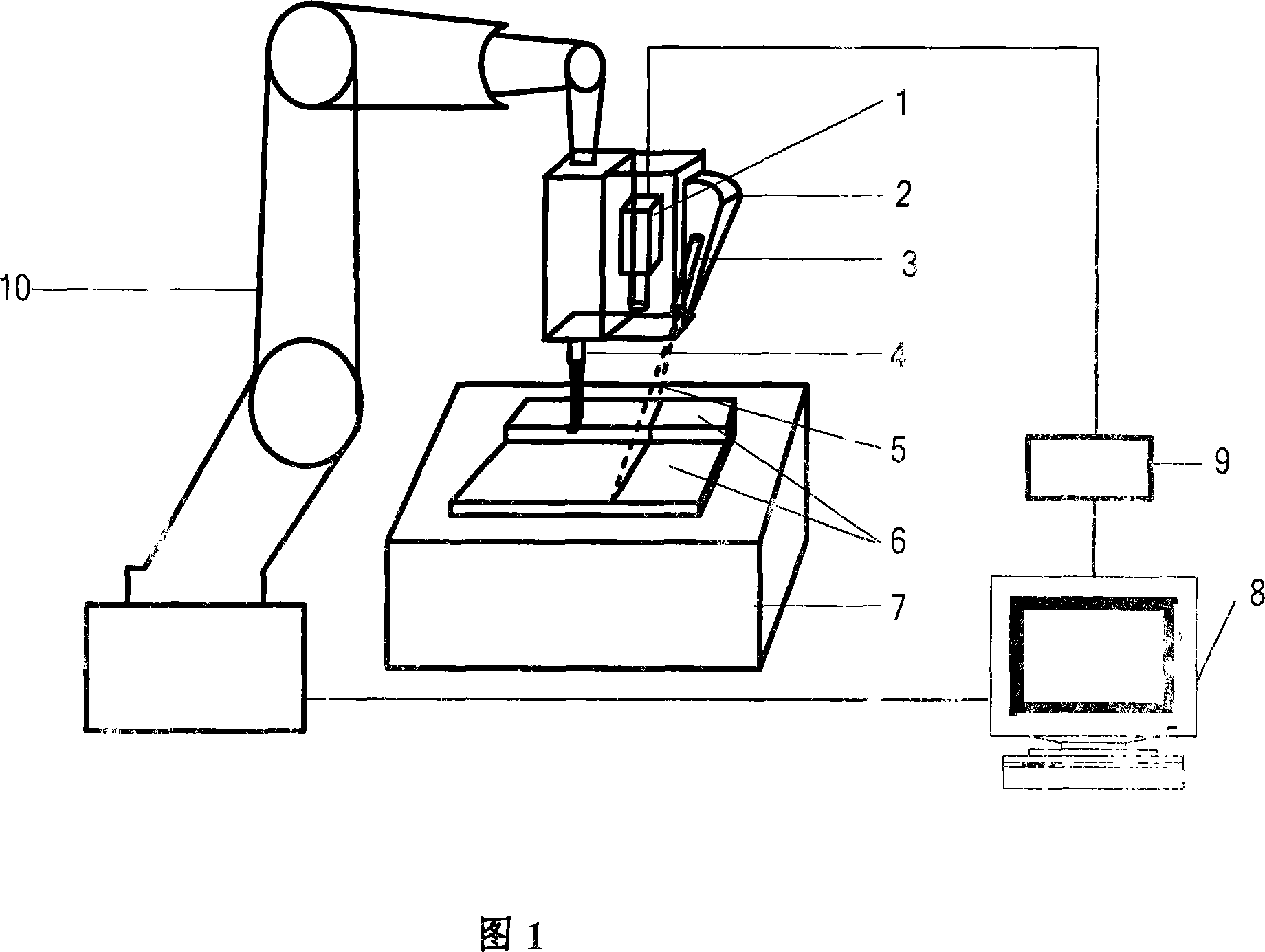

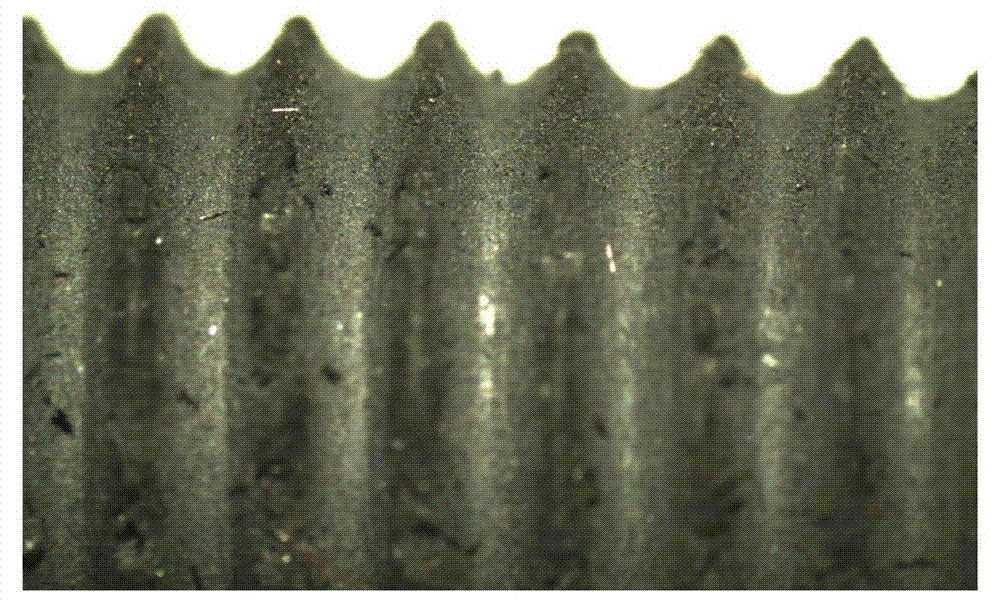

Robot sewing system for three-dimensional composite material perform

InactiveCN101205662AOvercome flexibilityOvercome errorProgramme-controlled manipulatorSewing apparatusImage post processingEngineering

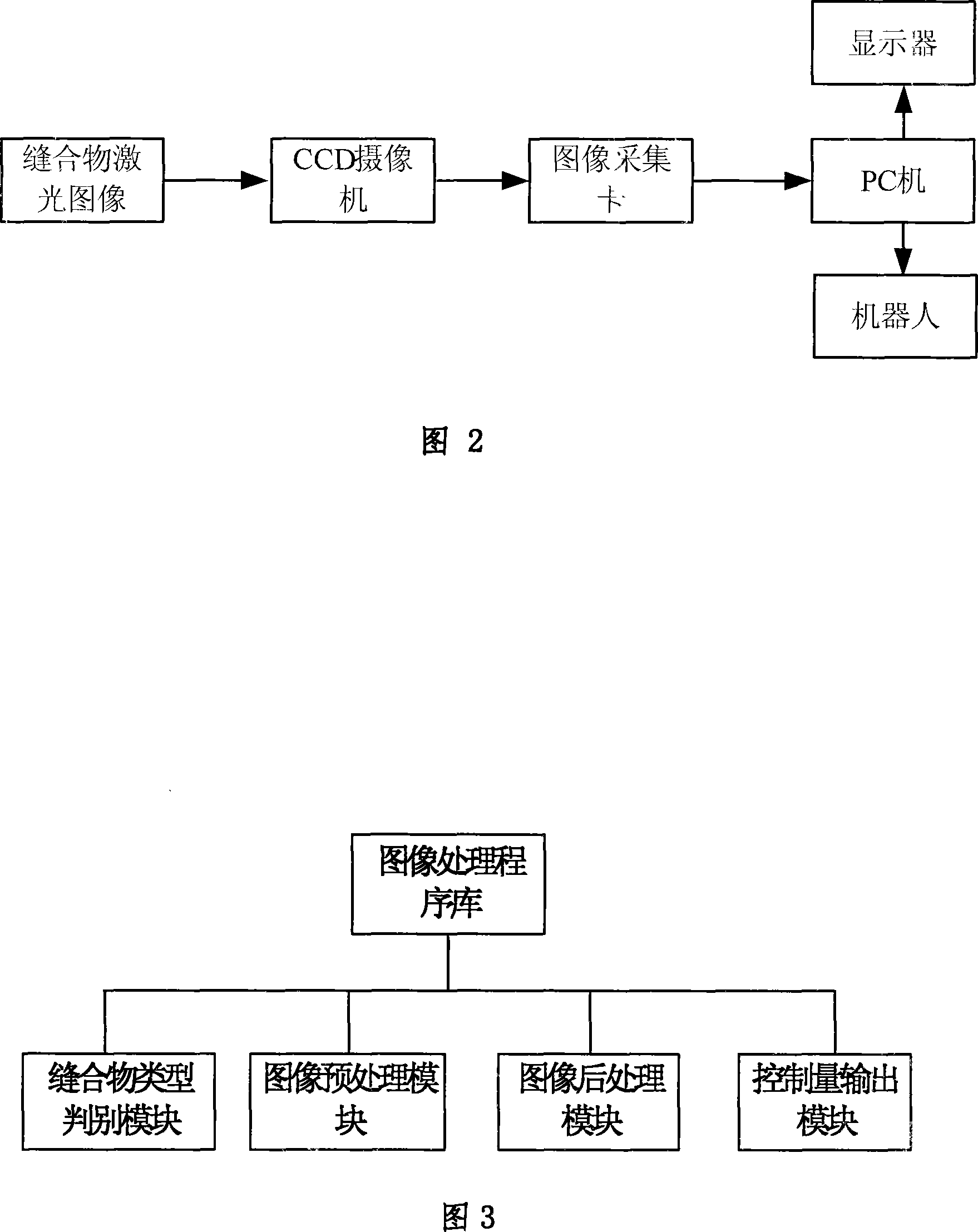

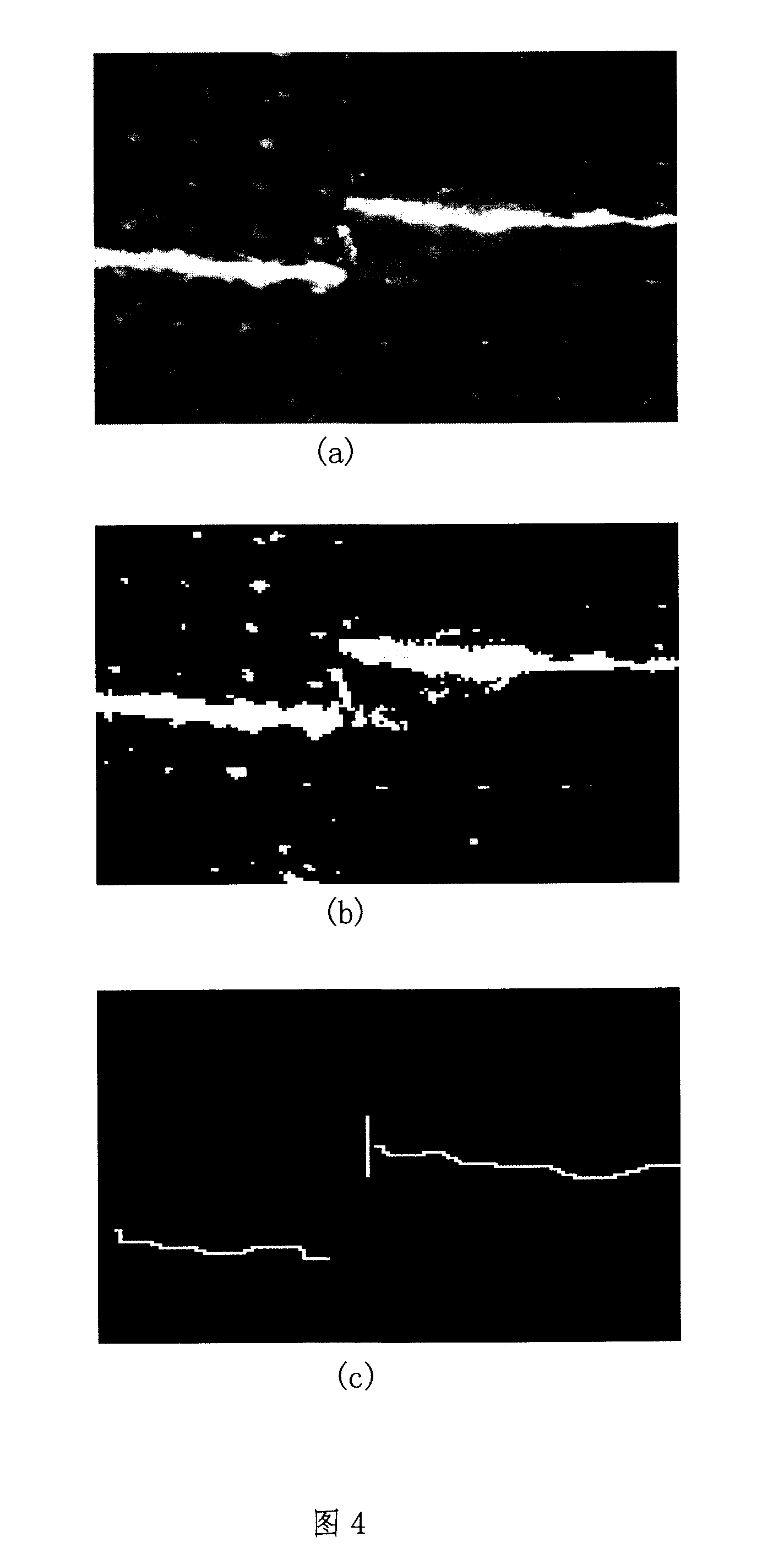

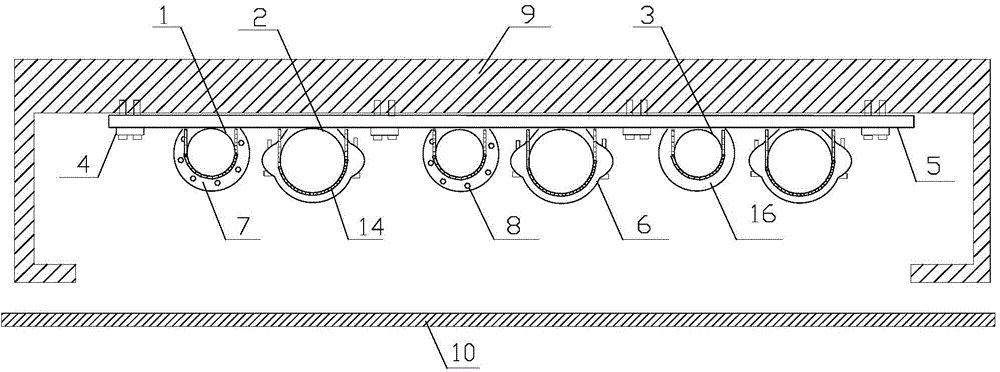

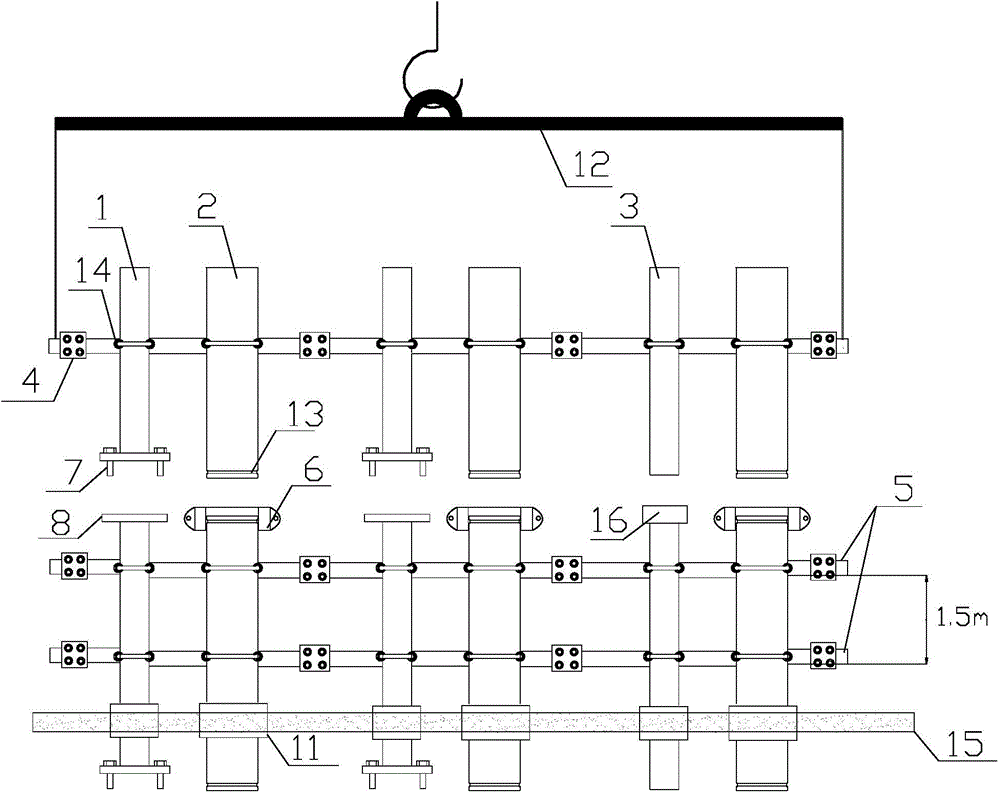

The invention relates to a 3D composite material prefabrication piece robot sewing system, which comprises a robot, a single-face sewing machine, a structured light vision sensor and an image processing unit; the single-face sewing machine is connected with a shell of the structure light vision sensor and fixed at the tail end of an arm of the robot; the structured light vision sensor comprises a laser and a CCD video camera which are respectively fixed inside an shell of the structured light vision sensor, the included angle of a light axis centerline of the CCD video camera and a laser structure light surface of the laser is 30 to 60 degrees, which is perpendicular with the work-piece surface of a sewing material; the image processing unit comprises an image acquisition card, a PC machine and an image processing program library, the image processing program library comprises a sewing material type identification module, an image pre-processing module, an image post-processing module and a control capacity output module; the CCD video camera is connected with the image acquisition card through an video data line, the image acquisition card is arranged inside a main board slot of the PC machine, the PC machine is connected with the robot through a serial port.

Owner:TIANJIN POLYTECHNIC UNIV

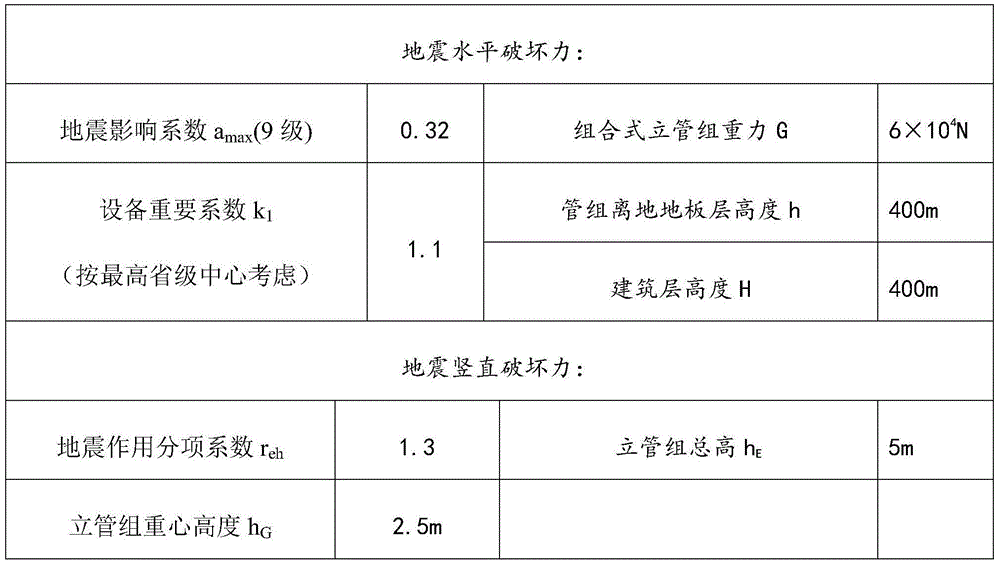

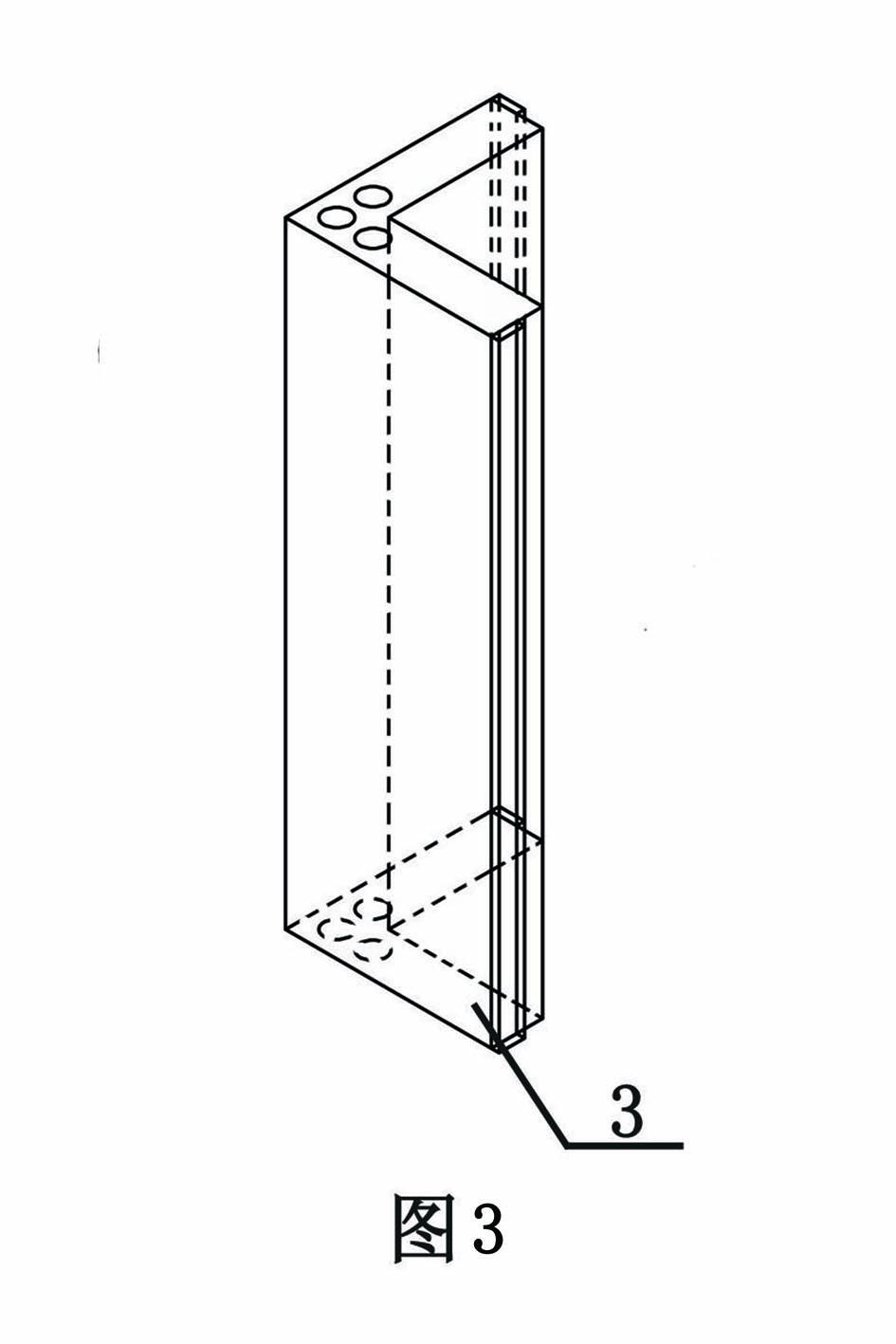

Combined type stand pipe and modularized installation method thereof

ActiveCN104806822ARealize segmented factory prefabricationShorten the installation periodPipe supportsPipe laying and repairEngineeringPrefabrication

The invention discloses a combined type stand pipe and a modularized installation method thereof for solving the problems of difficult welding, low installation efficiency and low precision of stand pipes in tube wells in the prior art. The combined type stand pipe comprises at least two sections of prefabricated pipe groups; each section of prefabricated pipe group comprises brackets, a plurality of pipelines and a plurality of bracket fixing plates, wherein the pipelines are fixedly arranged on the brackets at intervals; the bracket fixing plates are fixedly arranged on the brackets at intervals; the pipelines are divided into a plurality of units by the bracket fixing plates; the corresponding pipelines of the adjacent fabricated pipe groups are detachably connected; each section of the prefabricated pipe group can be fixed in a tube well through the bracket fixing plates. The combined type stand pipe comprises a plurality of prefabricated pipe groups; compared with the conventional on-site manufacturing and installing technology of a single stand pipe, the industrialized prefabrication of the prefabricated pipe groups reduces the on-site welding, shortens the installation period, reduces the installation difficulty, improves the installation efficiency and precision, avoids cross influences from other construction professional and meets the demand of the environment-friendly construction.

Owner:SHANGHAI INSTALLATION ENG GRP

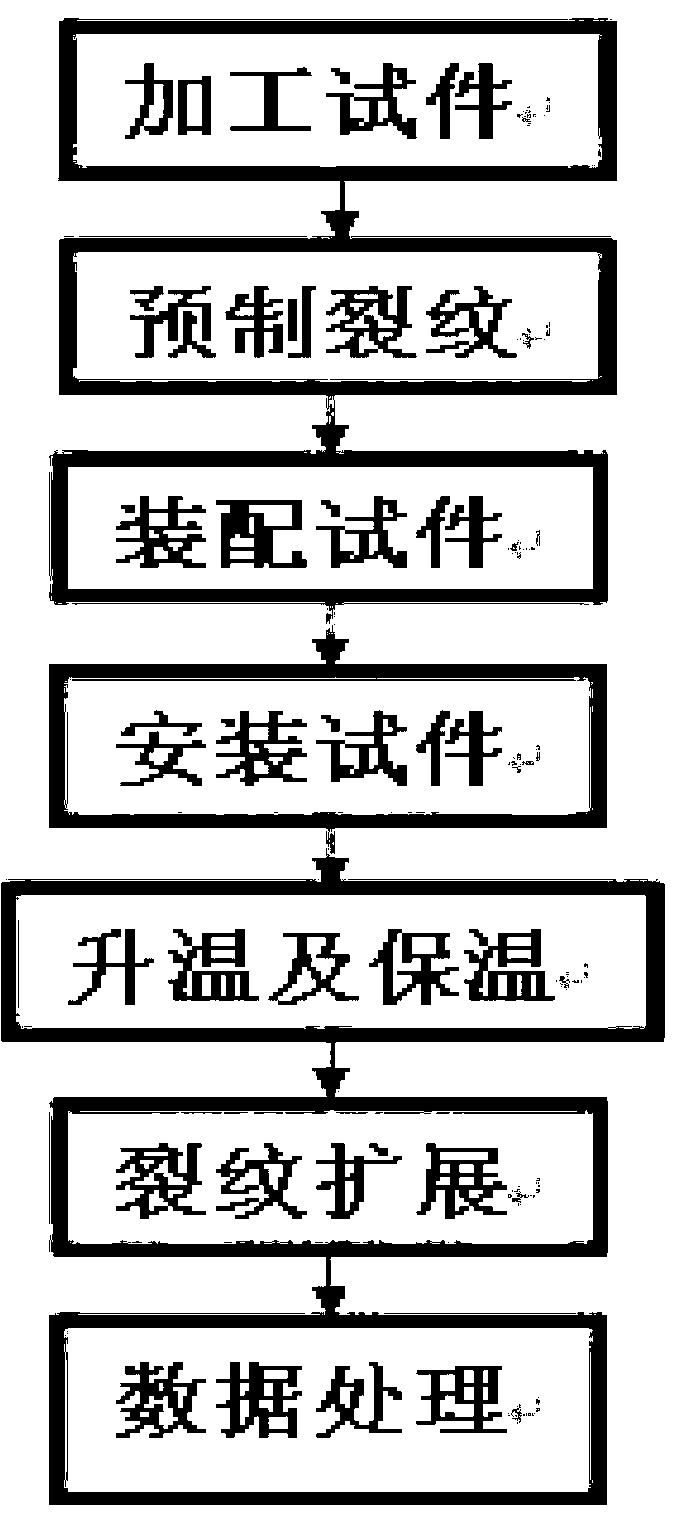

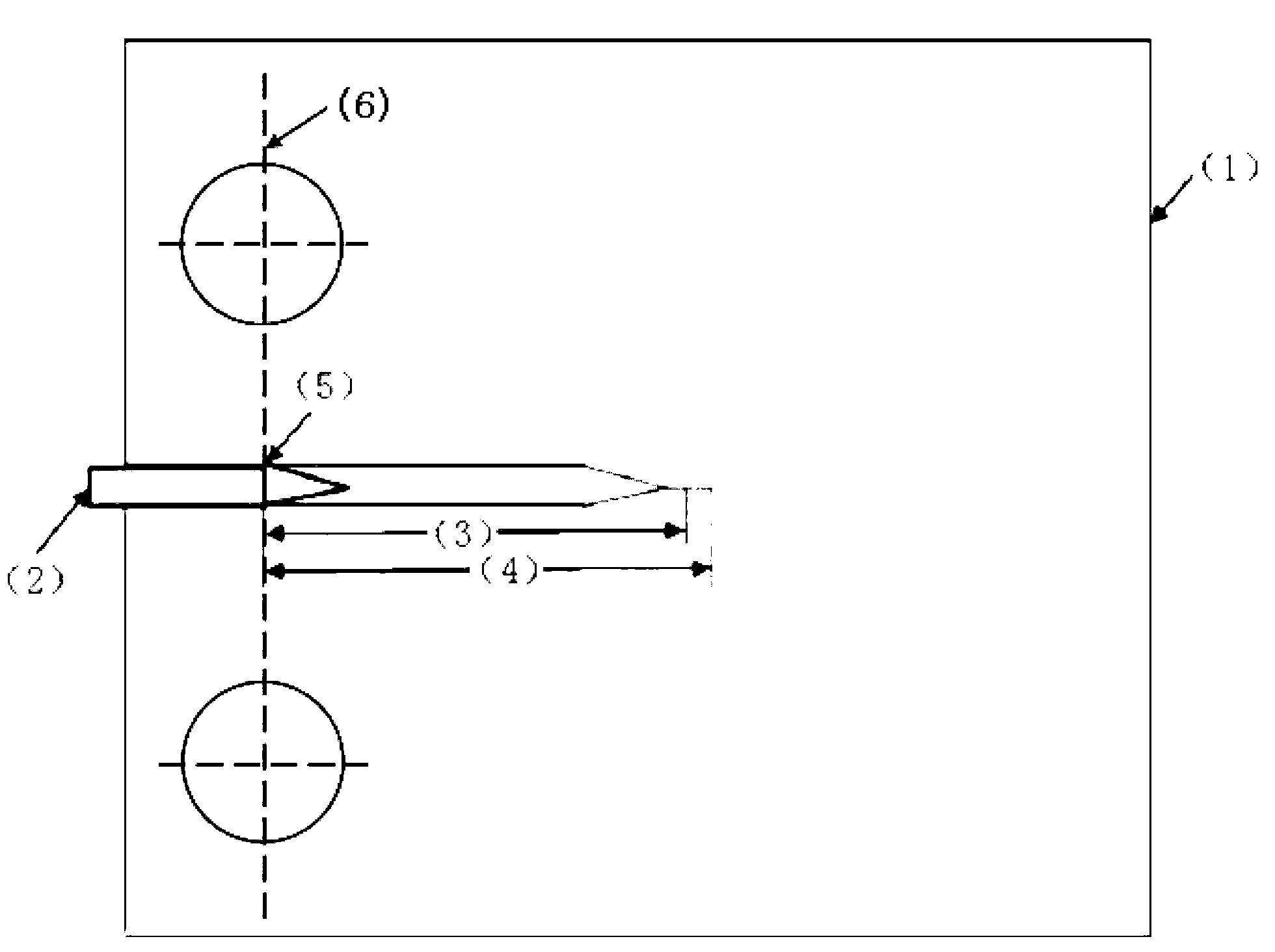

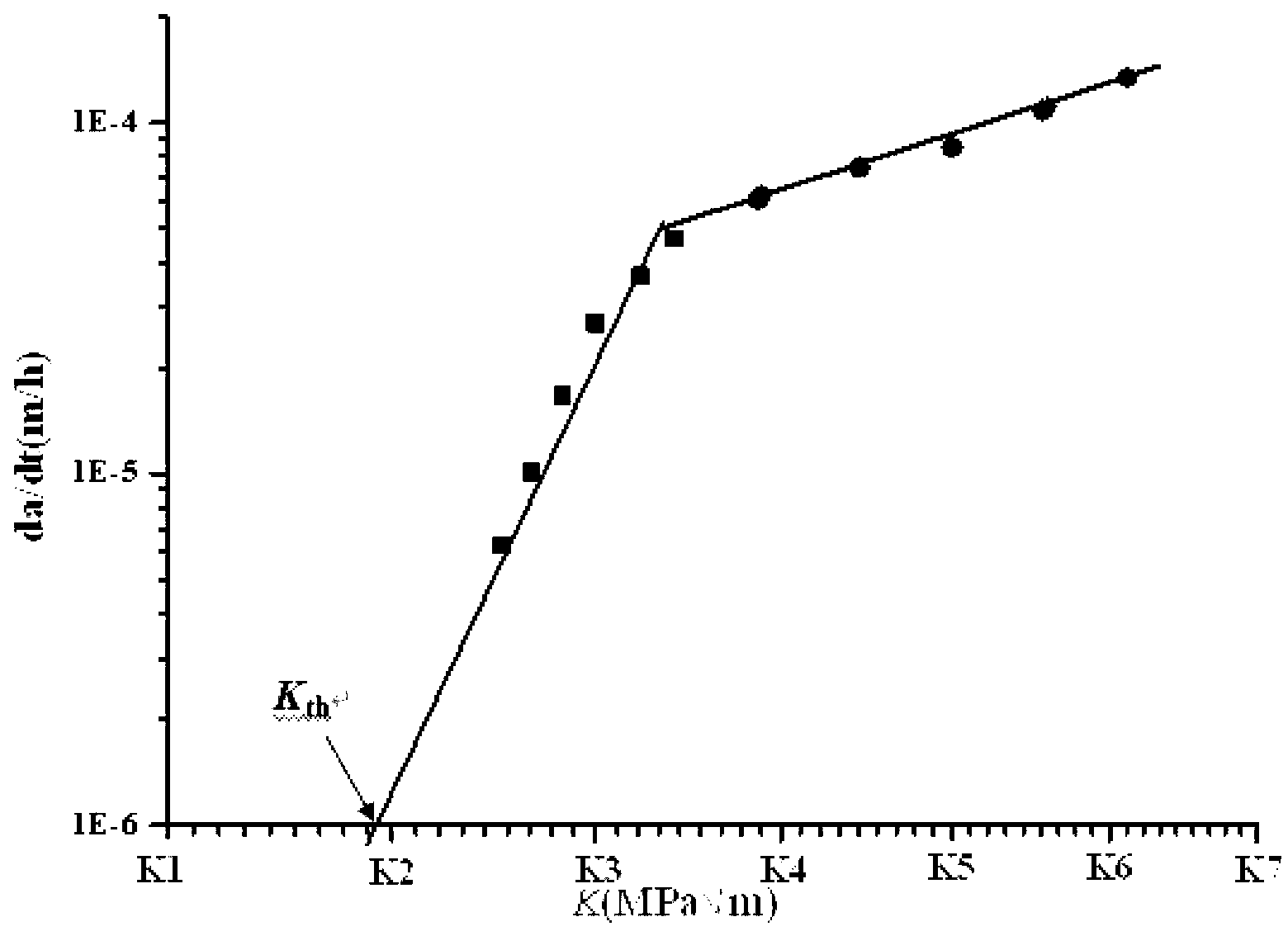

Method for measuring high-temperature creep crack growth threshold value of material

ActiveCN103217346AImprove scalabilityIncrease costInvestigating material ductilityStress intensity factorTest requirements

The invention discloses a method for measuring high-temperature creep crack growth threshold value of material. The method comprises the following steps of: for a specific material, according to the creep crack growth test requirement, processing at least 6 standard compact tension specimens, performing crack prefabrication for the well processed at least 6 specimens on a fatigue performance tester, wherein the prefabricated crack length is 0.5 times of the width of each specimen; wedging a wedge-shaped block into an initial notch of each specimen, placing the headmost end of the straight part of the wedge-shaped block at the position of a loading line, providing displacement for the loading line, forming a stress-strain field characterized by a stress strength factor at the tip of the specimen crack, and providing a driving force for the creep crack growth, wherein the specimens with different initial stress strength factors grow after certain time under creep effect in high-temperature environment, and in the same time interval, the crack growth lengths are different; drawing for the different stress strength factors and the corresponding crack growth rates, and solving the creep crack growth threshold value of the material through an extrapolation method. According to the method provided by the invention, multiple specimens can be tested for one time, and thus, the test cost is greatly reduced and the test time is greatly shortened.

Owner:BEIHANG UNIV

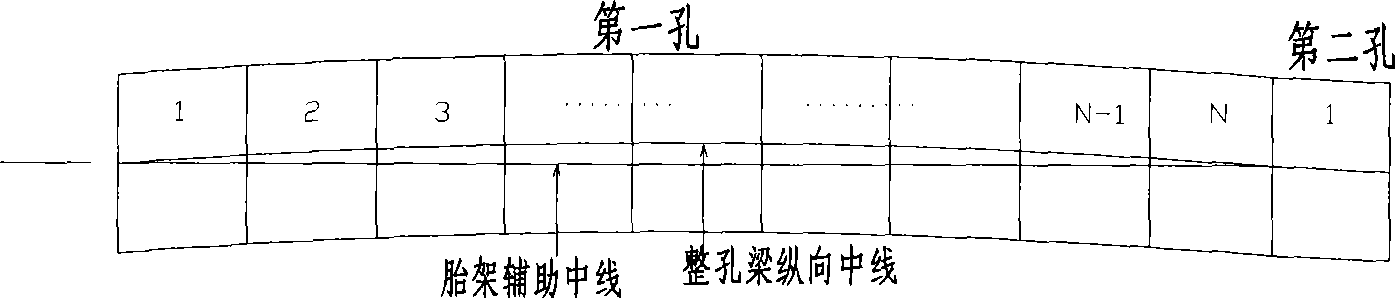

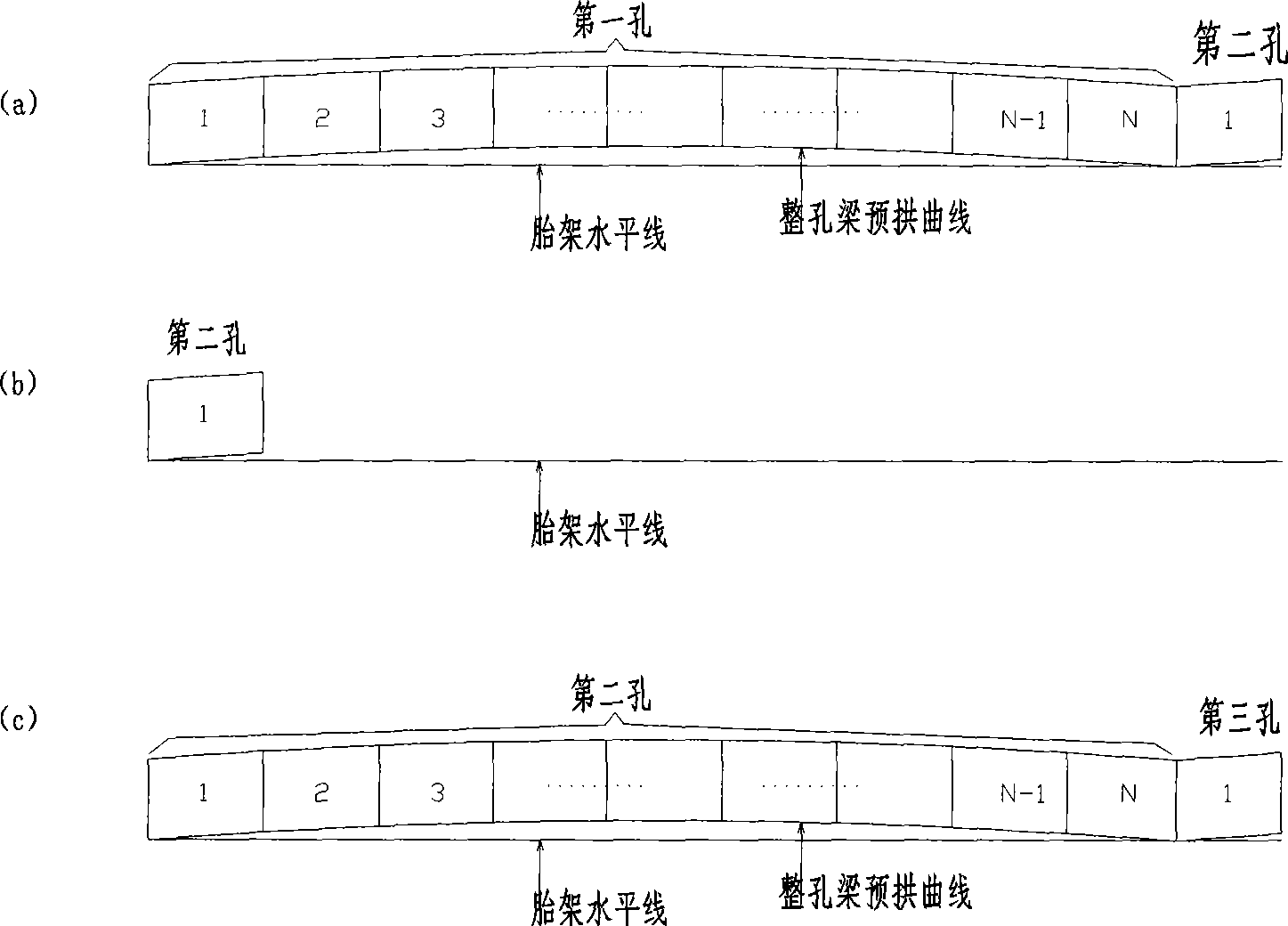

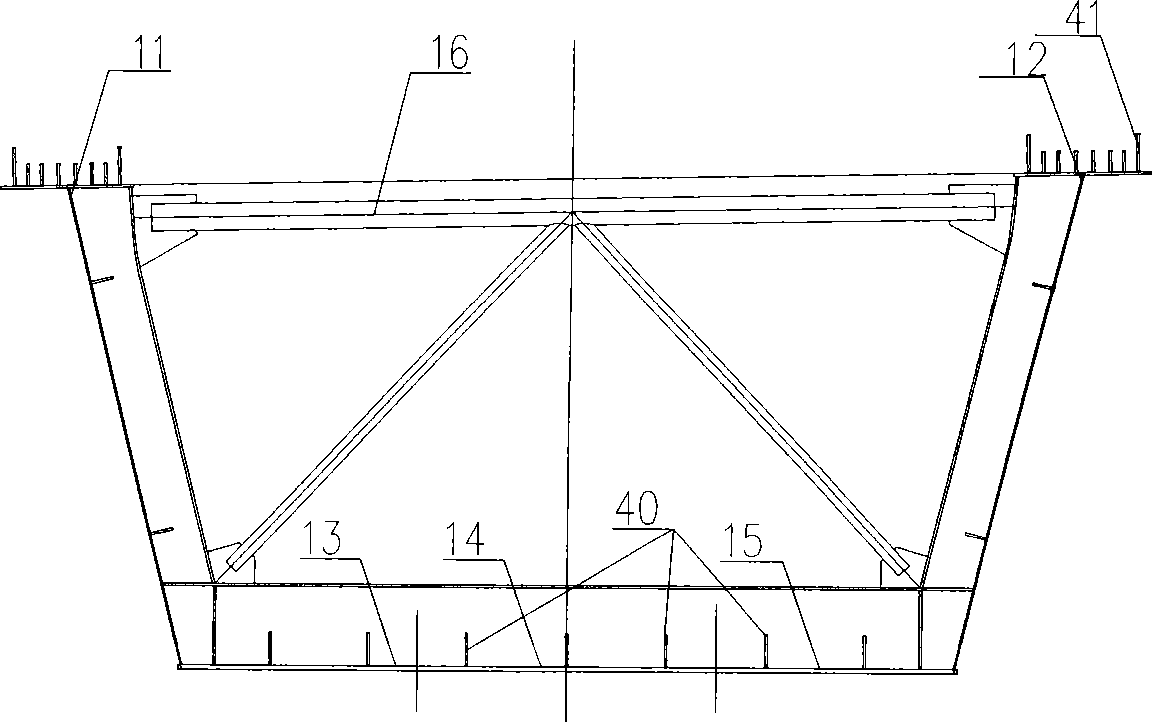

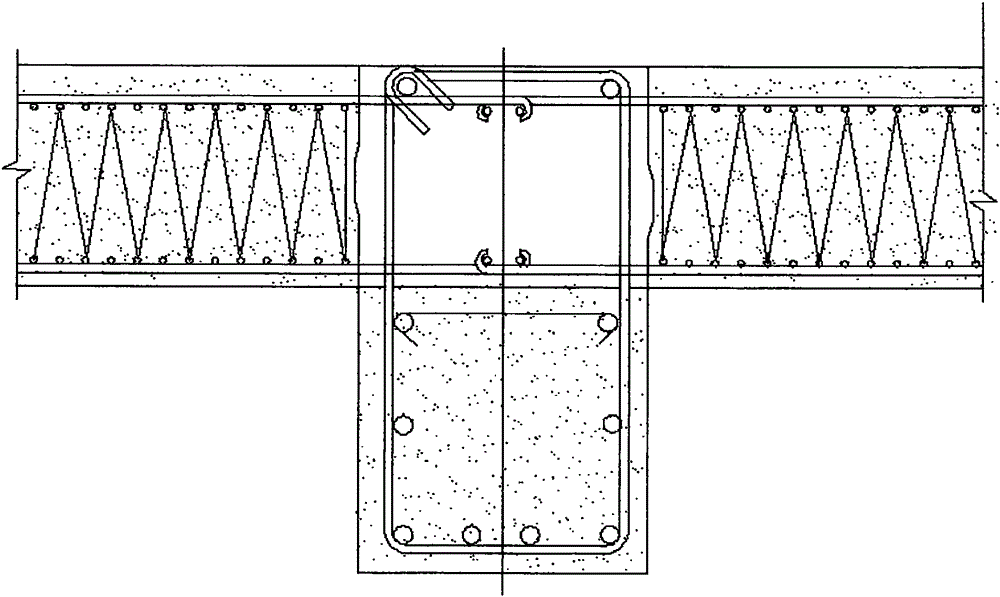

Long continuous structural steel box beam or combination box beam construction method

InactiveCN101368373AReduce welding workloadSatisfy \"Light Large Span\"Bridge erection/assemblyBridge materialsButt weldingEngineering

The invention discloses a long continuous steel box girder or combined box girder construction method, including the following steps: 1, segment division and plate unit division; 2, butt welding the fulcrum segmental box girders and standard segmental box girders at a prefabrication plant, namely, pre-splicing the segmental box girders of a full span box girder and the first box girder segment of the adjacent span box girder through long line method on a segmental box girder molding bed on which plane curves and pre-camber are arranged; marking the box girder segments, taking away the segmental box girders of the full span box girder, leaving the first box girder segment of the adjacent span box girder, and continuing to splice and weld the segmental box girders of the rest full span box girders; 3, generally assembling the full span box girders in the prefabrication plant. The invention adopts full span prefabrication and arrangement to construct a long continuous steel box girder or combined box girder, thus greatly reducing welding work load at the site. The invention ensures that the adjacent spans close smoothly after the steel girders are arranged and meets the requirements of light large span, precast assembly and quick construction.

Owner:CHINA MAJOR BRIDGE ENG

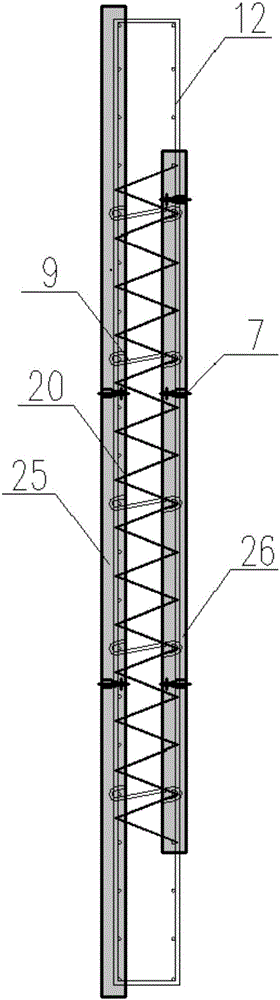

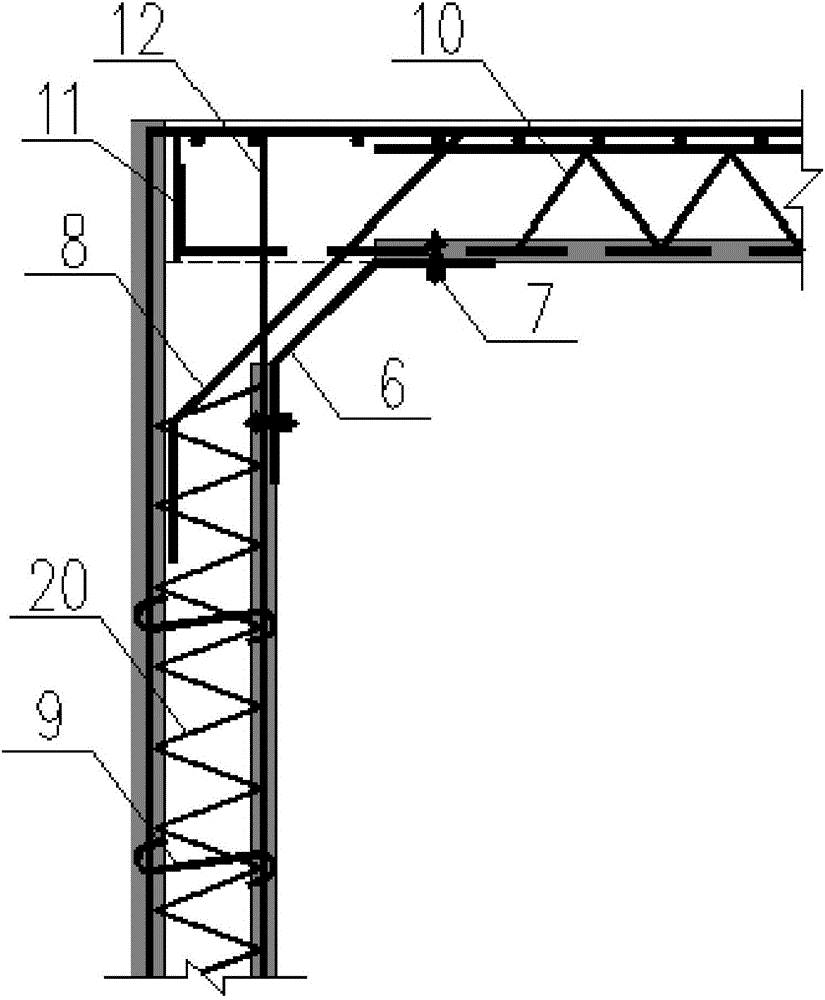

Mounting method of prefabricated building

ActiveCN106013811AImprove air tightnessImprove water tightnessFoundation engineeringBuilding material handlingEarthquake resistanceSewage

The invention discloses a mounting method of a prefabricated building, comprising the following steps: base level treatment, binding of basic steel bars, mounting of first level vertical members, pouring of basic concrete, mounting of first level top horizontal members, pouring of concrete, mounting of second level vertical members, pouring of concrete, mounting of second level horizontal members, pouring of concrete and sequential cyclic operation according to the mounting operation flow. The method disclosed by the invention has the advantages of good integrity of structural connection, good safety and earthquake resistance, good environmental friendliness and energy-saving performance, reliable quality and convenience of quality inspection; the prefabrication rate reaches over 95%; secondary large area pouring, leveling blanket, masonry and other field operation procedures are saved; labor and materials are saved; by virtue of continuous mounting, the efficiency is improved, and the construction period is shortened; precise mounting and one-step positioning can be realized; the safety risk is reduced, and the quality is upgraded; waste water, waste materials, garbage, dust and noise generated by site construction and pollution of transportation to the air environment are reduced; and the prefabricated building is safe, durable, energy-saving, efficient, green, environment-friendly, economical and applicable.

Owner:李藏柱

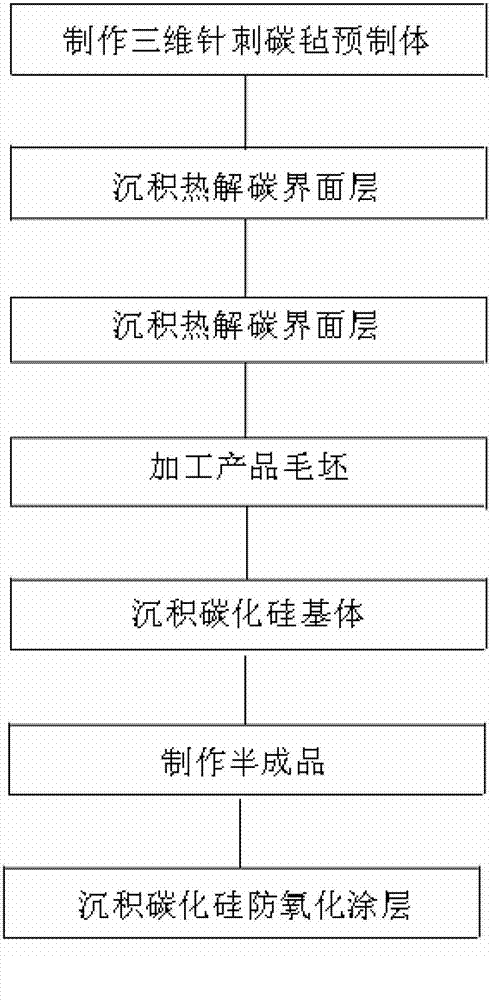

Preparation method of three-dimensional needling carbon/carborundum composite material bolt

ActiveCN102775176AIncreased shear strengthReduce wearScrewsChemical vapor infiltrationMaterials science

A preparation method of a three-dimensional needling carbon / carborundum composite material bolt adopts a three-dimensional needling fiber prefabrication body to prepare the composite material bolt. Pyrolytic carbon is deposited on the prefabrication body, carborundum substrates are deposited through chemical vapor infiltration (CVI), and a bolt bar blank and a bolt cap blank are obtained. The carborundum substrates of the bolt bar blank and the bolt cap blank which are obtained through machining are deposited through the CVI, a carborundum anti-oxidation coating is deposited through the CVI, and a three-dimensional needling C / SiC composite material bolt end product with the shear strength being 80-100MP is obtained. Compared with the prior art, the preparation method has the advantages that the number of times for getting into a furnace is reduced by 6-10, the densifying period is shorter, and the production cost is reduced. By means of a test of a CK6180-3000 numerically controlled lathe, the preparation method is small in diamond grinding wheel abrasion, hour norm for machining 30 bolt threads is reduced by about 10 hours, and as the abrasion of a grinding wheel is less, the working accuracy is improved, and industrialized batch production is achieved.

Owner:XIAN XINGUI CERAMIC COMPOSITE MATERIAL CO LTD

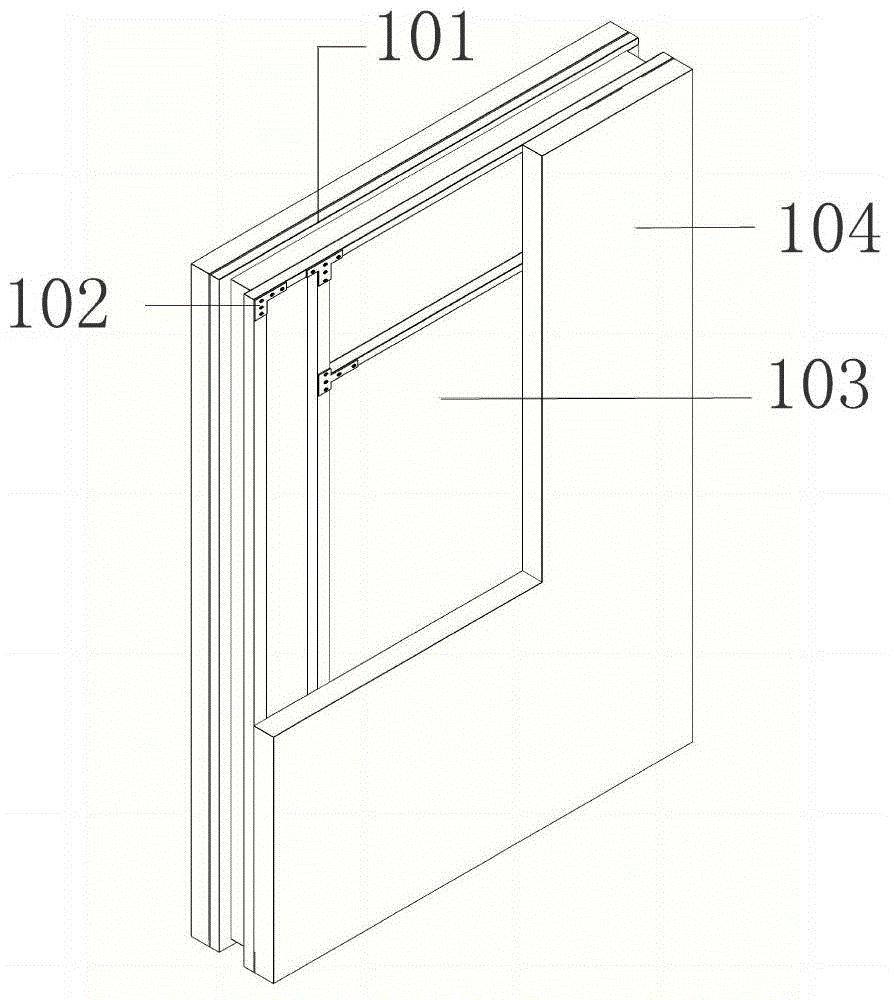

Simply-built green light steel fabricated building and installation method

ActiveCN104947792AImprove prefabrication rateEnsure structural safetyBuilding componentsBuilding material handlingPollutionPrefabrication

The invention provides a simply-built green light steel fabricated building and an installation method. The fabricated building comprises wall plates, main plates, composite frame columns and main connection pieces. The two wall plates are connected by means of the corresponding main connection pieces through self-tapping screws. The composite frame columns and the wall plates are connected by means of the corresponding main connection pieces through self-tapping screws. In the connection process, firstly the main connection pieces abut against the composite frame columns, the self-tapping screws are screwed into the composite frame columns to fix the composite frame columns, the wall plates are then arranged in place, and the main connection pieces are clamped into lateral side grooves of the wall plates. The main boards are connected with the composite frame columns, and body column sleeves of the portions, on the top layers of the main plates, of the composite frame columns are inserted in upwards-exposed tenon columns in a sleeved mode and are then fixed through bolts. By means of the full industrialized prefabrication of the wall plates and the main plates, the prefabrication rate of main components of the building is greatly increased, and therefore the structure safety and quality of the building are better facilitated, site workloads are reduced, the construction environment pollution is reduced, the construction period is shortened, and cost is saved.

Owner:江苏保力装配式住宅工业有限公司

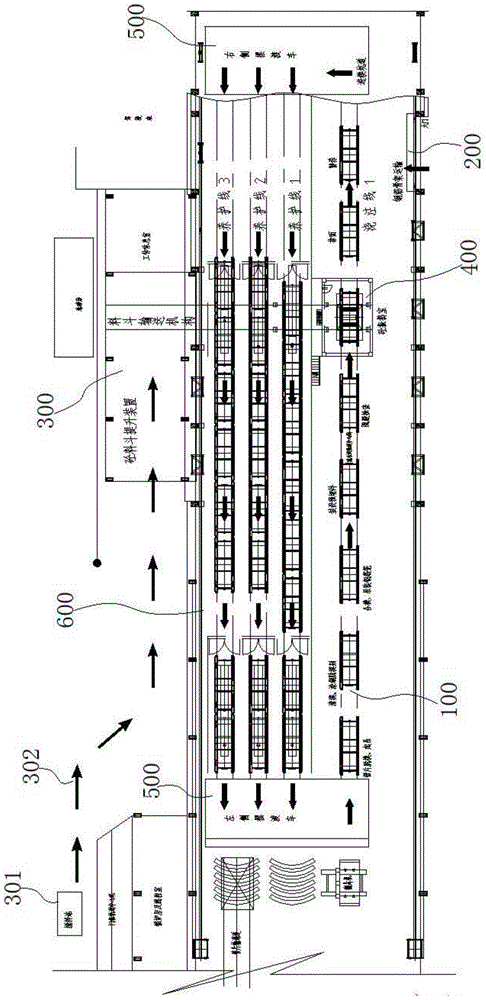

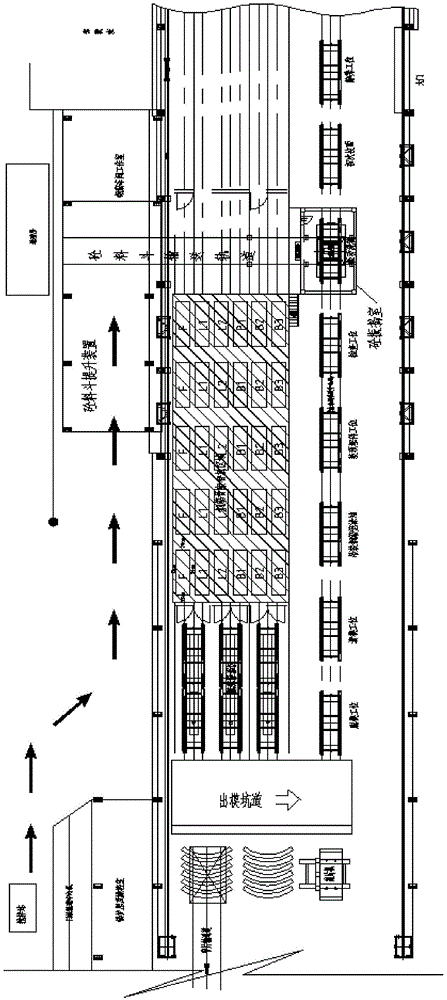

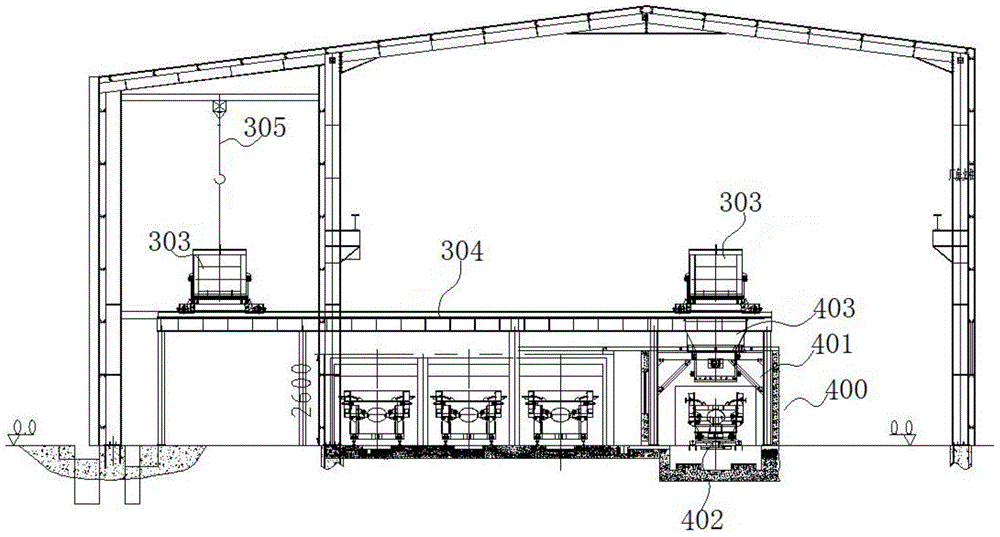

Intelligent flow production line for shield segment prefabrication

ActiveCN105082346AImprove precast production efficiencyReduce labor intensityCeramic shaping plantsProduction lineAutomatic control

The invention discloses an intelligent flow production line for shield segment prefabrication. Mold propelling systems in the production line are arranged on a pouring production line body and curing production line bodies respectively and push segment molds on the production line bodies to move. Transverse moving ferrying systems are matched with the pouring production line body and the curing production line bodies and used for conveying the molds from the pouring production line body to the curing production line bodies or conveying the molds from the curing production line bodies to the pouring production line body. A concrete feeding system is matched with a concrete pouring system and used for conveying concrete to the concrete pouring system. The concrete pouring system is arranged on the pouring production line body and used for completing segment pouring forming. An intelligent steam curing control system is used for conducting steam curing control on segments on the curing production line bodies. A programmable logic controller (PLC) automatic control system coordinates mutual matching among the systems, so that automation of shield segment prefabrication is achieved. The intelligent flow production line is stable in performance, good in reliability, easy to maintain and good in safety performance and meanwhile has the characteristics of being automatic and high in informationization degree and production efficiency.

Owner:CCCC THIRD HARBOR ENG +1

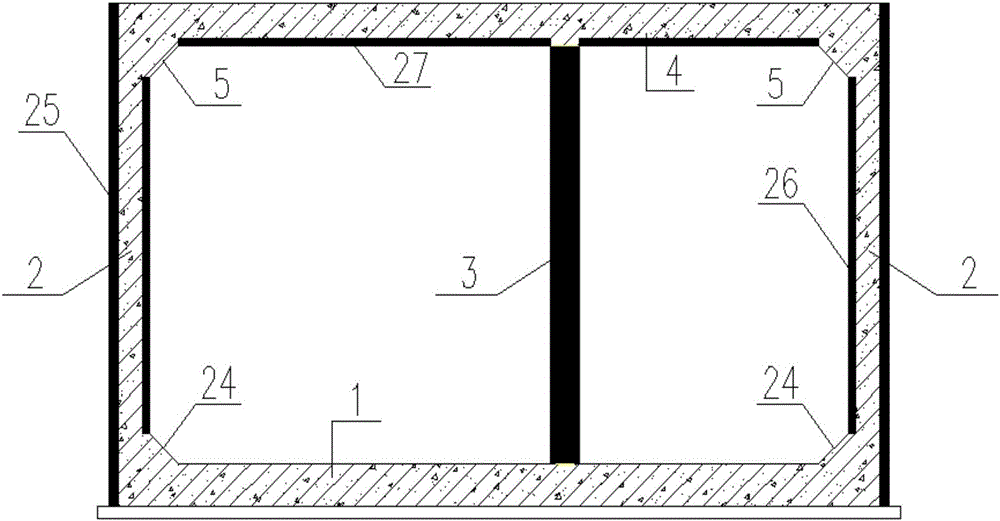

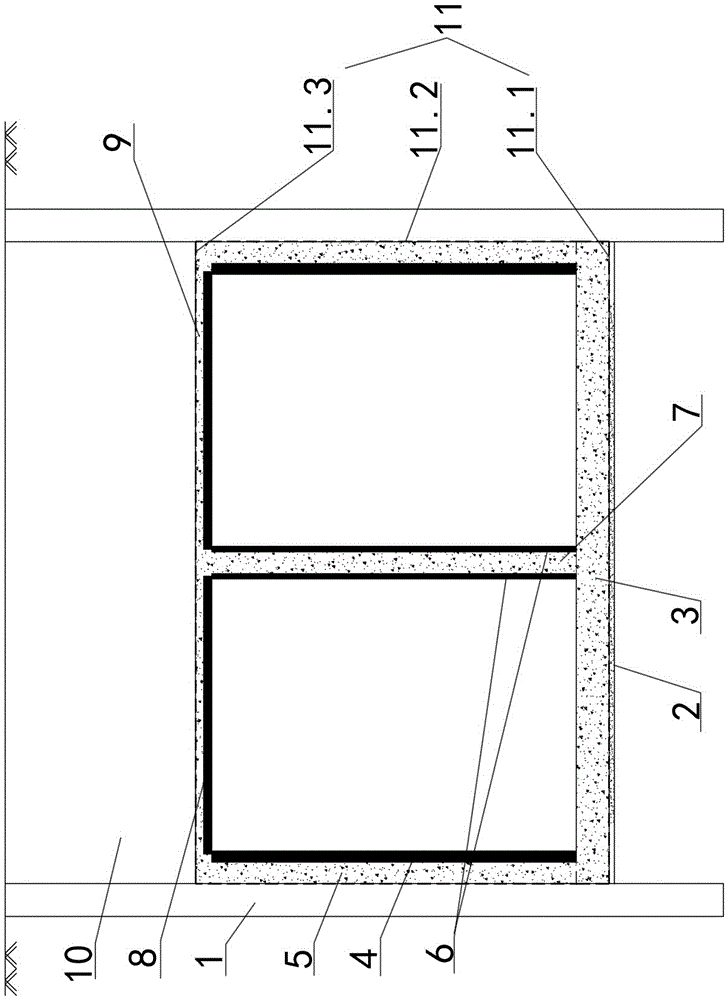

Air-cored wallboard mixed prefabrication assembly type compositive pipe gallery and construction method thereof

The invention discloses an air-cored wallboard mixed prefabrication assembly type compositive pipe gallery and a construction method thereof. The two ends of a cast-in-place bottom board are connected with the lower portions of two two-sided prefabricated hollow core-filling side walls correspondingly. The middle of the cast-in-place bottom board is connected with the lower portion of a total-prefabricated mid-partition. The two ends of a laminated top board are connected with the upper portions of the two two-sided prefabricated hollow core-filling side walls correspondingly. The middle of the laminated top board is connected with the upper portion of the total-prefabricated mid-partition. The advantages of prefabrication and cast-in-place techniques are combined, the self weight of prefabricated parts can be reduced through reasonable splitting, and the parts can be connected into a whole through cast-in-place core grouting, and the problem of prefabrication assembling of multi-cabin pipe galleries and pipe gallery nonstandard sections can be solved.

Owner:中建五局第三建设有限公司 +1

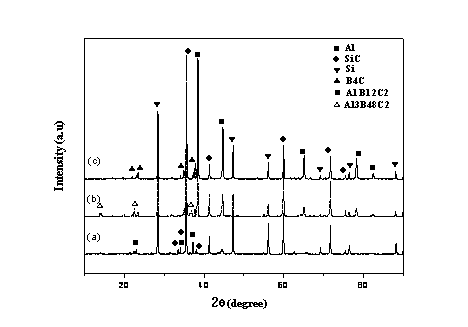

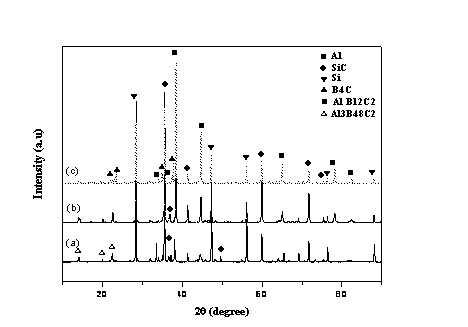

Boron carbide-silicon carbide complex ceramic and preparation method thereof

The invention relates to the field of ceramic materials and in particular relates to a boron carbide-silicon carbide complex ceramic and a preparation method thereof. The boron carbide-silicon carbide complex ceramic is prepared through the following steps: degreasing a boron carbide and carbon mixed powder preform and then carrying out alloy infiltration reactive sintering on the degreased preform, wherein the boron carbide and carbon mixed powder preform comprises 85wt%-98wt% of boron carbide, 1.0wt%-14.0wt% of carbon and an organic bonding agent with a use amount for prefabrication and formation; and alloy is composed of 12.5wt% of silicon and 5wt%-87.5wt% of aluminum. According to the invention, a technology combining infiltration with reactive sintering is adopted, and a bidirectional interconnection microstructure is formed, so that the product has high mechanical property and can resist shooting of bullets; and the complex ceramic is low in density, is an optimal bulletproof and armour material, and is mainly applied to low-density high-property materials in the bulletproof and armour fields.

Owner:ZHEJIANG LIGHT TOUGH COMPOSITE MATERIALS

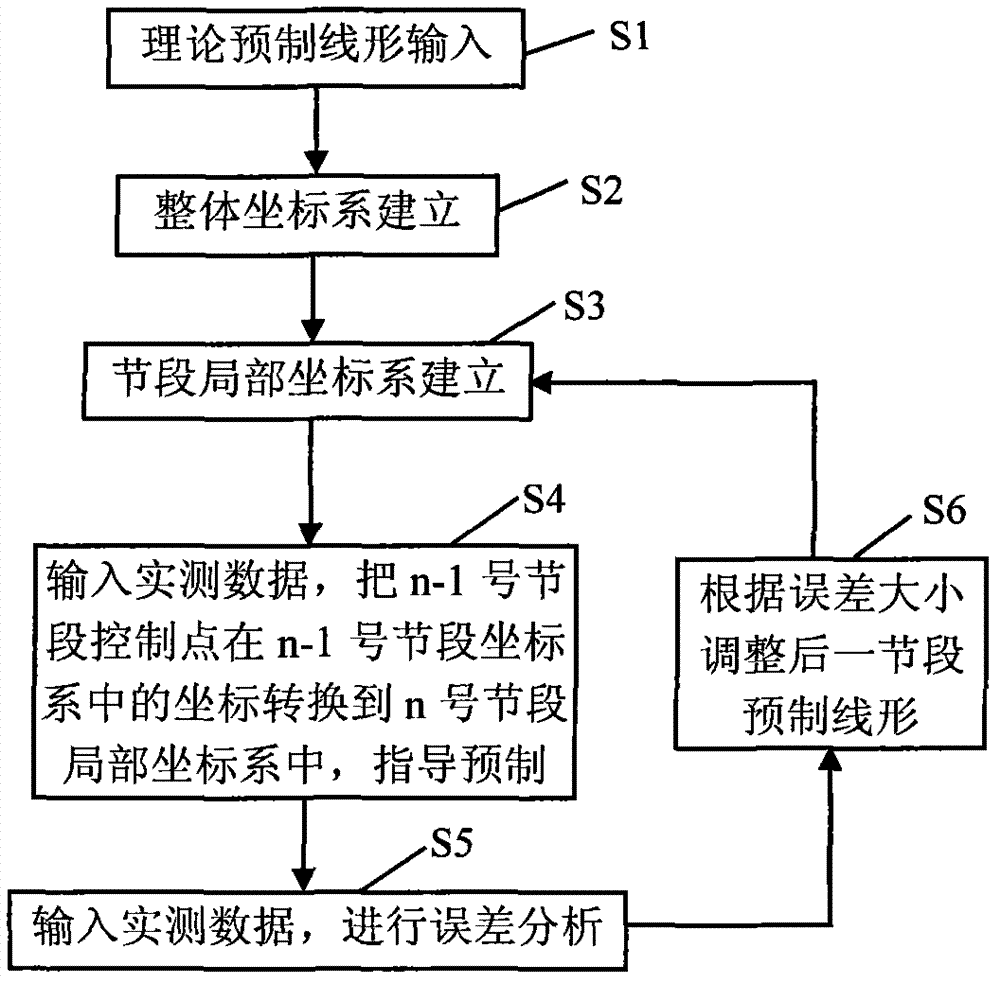

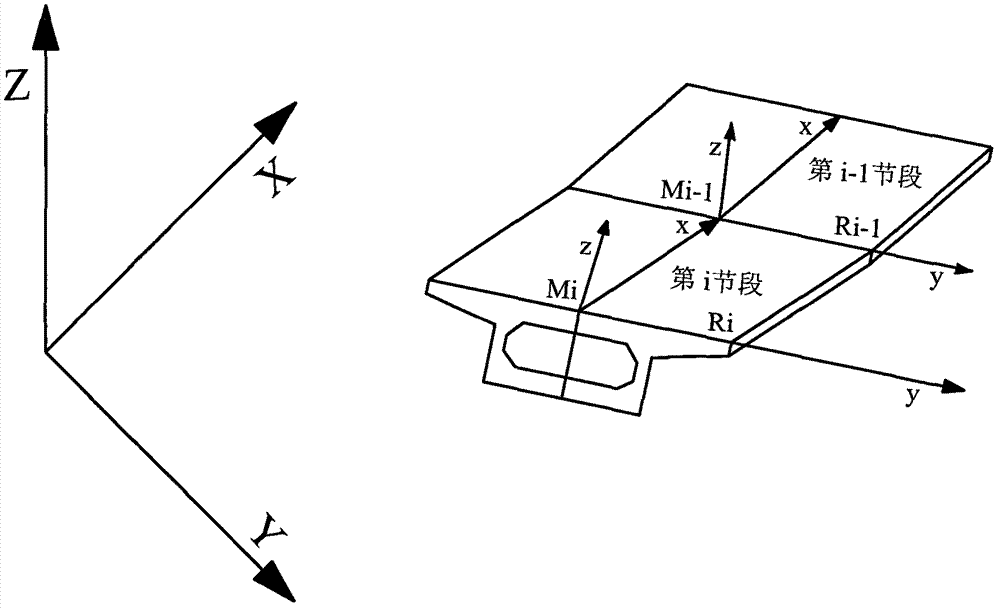

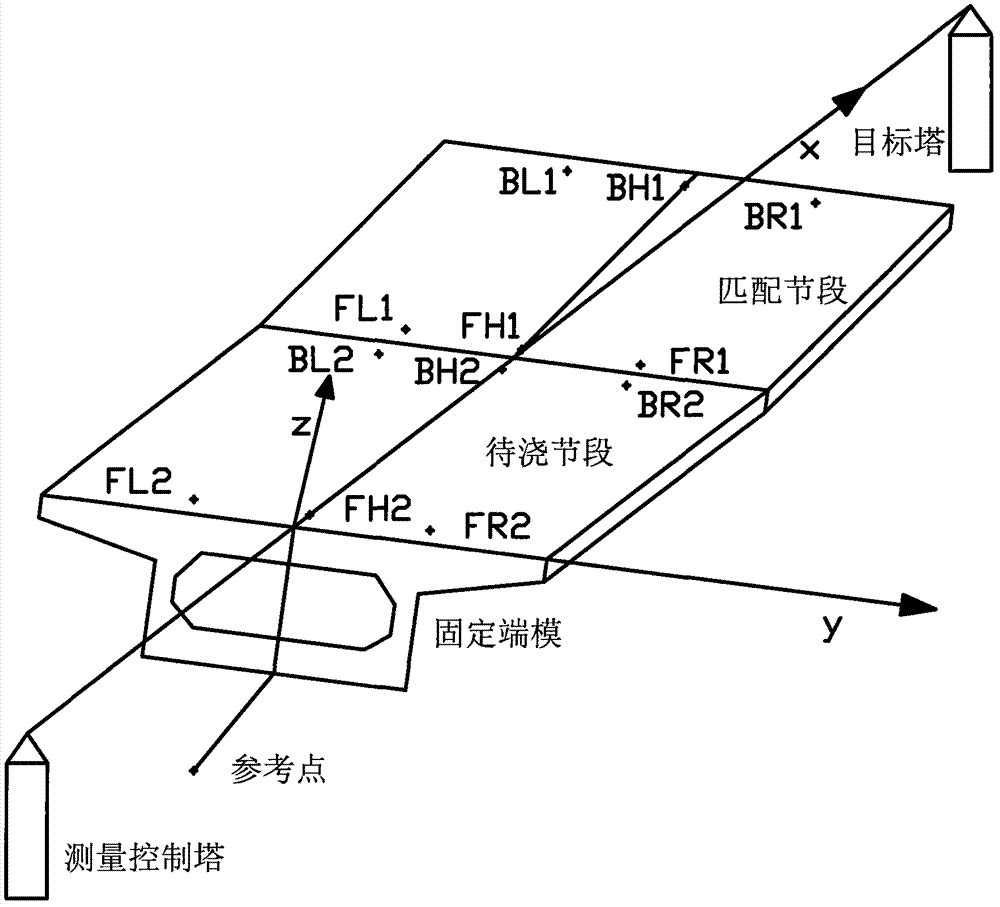

Line shape control method for short line method segment prefabrication construction

ActiveCN102733311AHigh control precisionCalculation speedBridge erection/assemblyObservational errorProcess error

The invention discloses a line shape control method for short line method segment prefabrication construction and relates to the field of control of bridge construction. The method comprises the following steps of: calculating a theoretical prefabrication line shape according to the line shape of bridge design and the construction sequence by a tangent displacement method; building the global coordinate system of the prefabrication line shape and the local coordinate systems of all prefabrication segments; converting segment control points between the local coordinate systems and the global coordinate system by a matrix calculation method; processing errors by a non-linear least square method, and correcting coordinates of segment nodes in the global coordinate system; and adjusting the line shapes of subsequent segments by a direct adjustment method or a segmentation adjustment method according to the errors. According to the method, the errors are processed by the non-linear least square method, so the method is high in calculation speed; the influence of position errors of matched segments, measurement errors of a control point coordinate, and template errors on the prefabrication line shape is comprehensively considered, the control accuracy of the line shape is improve obviously, and the popularization of a short line method segment construction method in China is accelerated.

Owner:CHINA RAILWAY BRIDGE SCI RES INST LTD +1

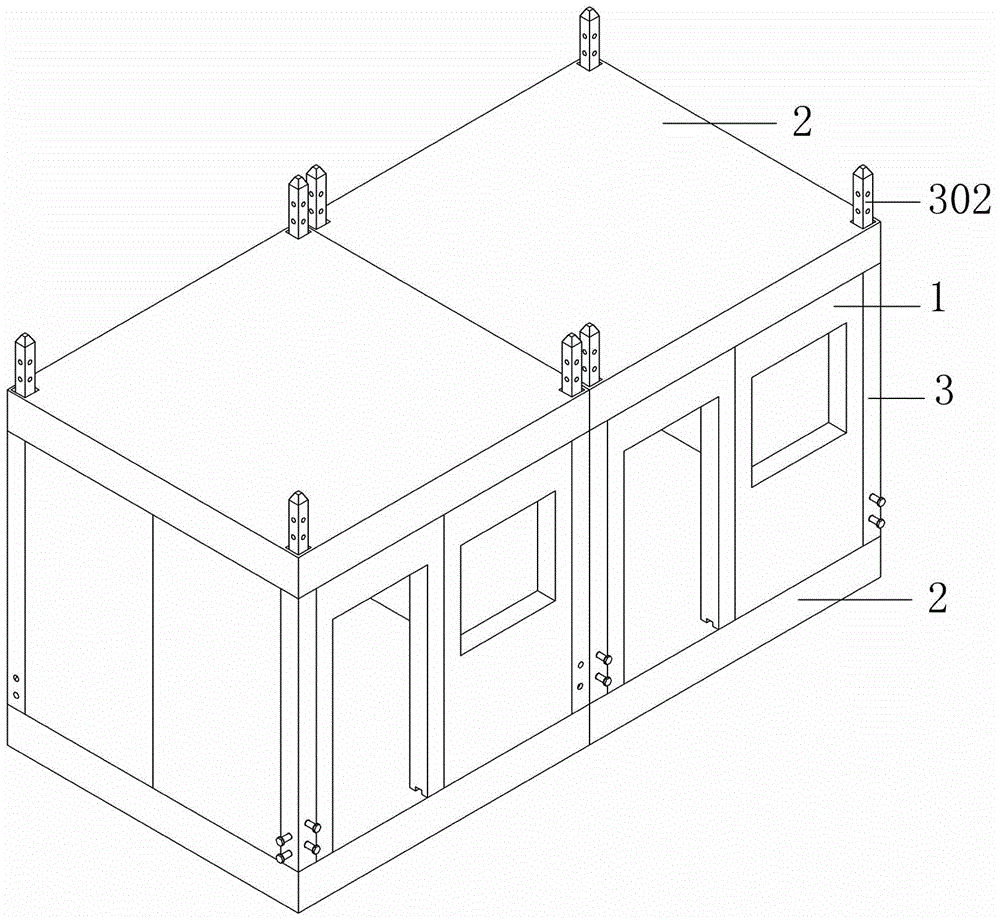

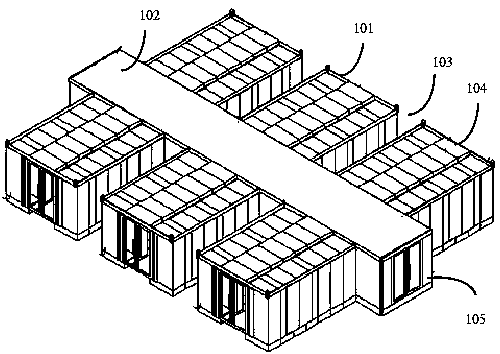

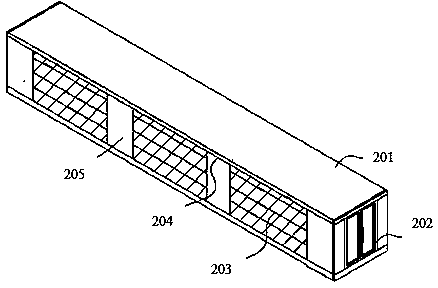

Modularized data center machine room provided with sealed channels

ActiveCN103806704AImprove construction efficiencyShort construction periodCooling/ventilation/heating modificationsIndustrial buildingsWater leakageData center

The invention discloses a modularized data center machine room provided with sealed channels. A wire routing channel and a pipe routing channel are arranged, so that factory prefabrication and productization installation are achieved, a construction period is shortened, and construction efficiency of a data center system is improved. By the adoption of hidden wire routing and pipe routing, the data center system is clean and tidy. Besides, the data center system is divided into a cold channel area, a hot channel area and a work maintenance channel area, wherein the cold channel area, the hot channel area and the work maintenance channel area are mutually isolated, the temperature of the three areas can be effectively controlled, comfortable environment is provided for workers, and the utilization rate of cool air is improved. A horizontal pipe routing channel is provided for a refrigerating unit, the water leakage risk is reduced, and engineering maintenance difficulty is reduced.

Owner:SHENZHEN XBROTHER TECH

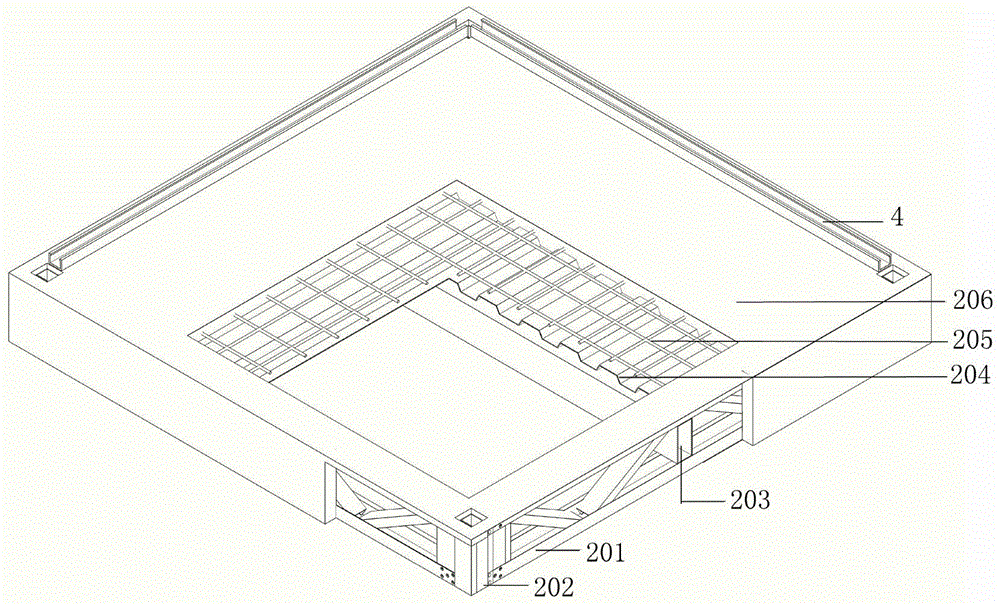

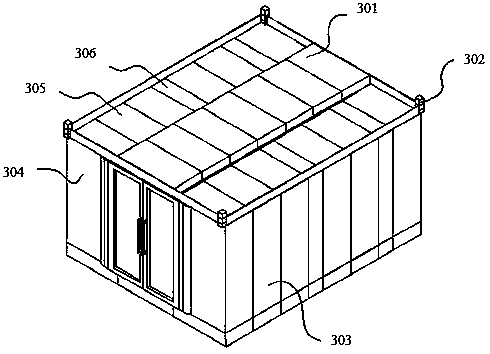

House construction building structure module, house and method for constructing same

InactiveCN108867875AGuaranteed StrengthDoes not affect structural strengthBuilding constructionsArchitectural engineeringPrefabrication

The invention relates to a house construction building structure module, a house and a method for constructing the same, and belongs to the technical field of prefabricated buildings. The house construction building structure module is of an integral structure formed by means of integral pouring prefabrication in factories and at least comprises a bottom surface, a left side surface, a top surfaceand a right side surface. The bottom surface, the left side surface, the top surface and the right side surface are sequentially connected with one another, and cavities are enclosed by the bottom surface, the left side surface, the top surface and the right side surface; the length of the house construction building structure module is the size of the house construction building structure modulealong the left-right directions, the width of the house construction building structure module is the size of the house construction building structure module along the front-rear directions, the height of the house construction building structure module is the size of the house construction building structure module along the up-down directions, and the length of the house construction buildingstructure module is larger than the width of the house construction building structure module; the design depth of the house is divided into a plurality of units in the width direction of the house construction building structure module according to restriction sizes not larger than the transport widths, and the sizes of the width of the house construction building structure module are the sizes of the widths of the divided units. The house construction building structure module, the house and the method have the advantages that use spaces of the house can be expanded by the house constructionbuilding structure module under the condition that the requirements of the transport sizes are met, and accordingly the limitation on the use spaces of the house due to the transport sizes can be broken.

Owner:张剑

Overlapping integral type prefabricated assembly structure for comprehensive pipe gallery and construction method thereof

ActiveCN106013228ALarge working spaceActive connectionArtificial islandsUnderwater structuresEngineeringAssembly structure

The invention discloses an overlapping integral type prefabricated assembly structure for a comprehensive pipe gallery and a construction method thereof. The overlapping integral type prefabricated assembly structure comprises envelop enclosures, a pipe gallery prefabricated assembly structure body, a bottom plate cushion course and a completely outer-cladding waterproof layer, wherein the envelop enclosures are located in a foundation pit; the pipe gallery prefabricated assembly structure body is arranged between the envelop enclosures; the bottom plate cushion course is arranged under the pipe gallery prefabricated assembly structure body; and the completely outer-cladding waterproof layer is arranged on the outer side surface of the pipe gallery prefabricated assembly structure body in a cladding mode. The upper portion of the pipe gallery prefabricated assembly structure body is filled with backfill earth, and the completely outer-cladding waterproof layer is arranged on the outer side surface of an outer side cast-in-situ part of the pipe gallery prefabricated assembly structure body in a cladding mode. The construction method of the overlapping integral type prefabricated assembly structure comprises the steps of prefabricated component machining, foundation pit excavation, bottom plate pouring, side wall construction, mid-partition construction, top plate construction, earth backfilling and the like. According to the overlapping integral type prefabricated assembly structure for the comprehensive pipe gallery and the construction method thereof, the prominent problems of force bearing of joints, water seepage of connection seams and the like in the underground engineering prefabrication process are solved; and the structural modes of bottom plate casting in situ, side wall single-layer overlapping, mid-partition double-layer overlapping, top plate overlapping, all-joint casting in situ and completely outer-side waterproof layer cladding are adopted, so that effective connection and the waterproof function of the joints are ensured.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

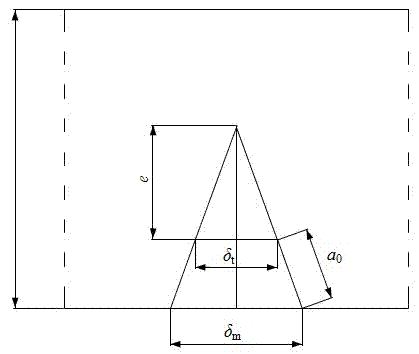

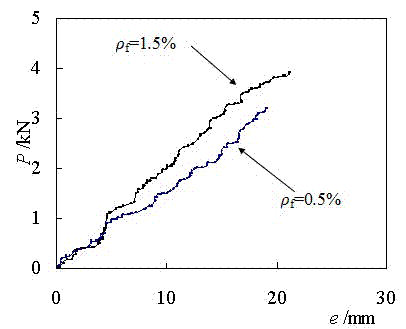

Testing method of steel fiber reinforced concrete fracture test crack initiation load

ActiveCN103760036AReduce test costsLower requirementMaterial strength using steady bending forcesStress intensity factorClassical mechanics

The invention relates to a testing method of steel fiber reinforced concrete fracture test crack initiation load, and belongs to the technical field of concrete cracking parameter testing. The testing method provided by the invention is characterized in that when a steel fiber reinforced concrete coped beam specimen cracks, a stress intensity factor of a prefabrication crack front edge achieves concrete fracture toughness, and the steel fibre blocking action is not exerted; the stress intensity factor generated by external load and concrete cracking toughness(i)K( / i) IC are equal, the external load value which is corresponding to a numerical value (i)K( / i)IC of the stress intensity factor generated by the external load can be used for determining the crack initiation load according to the curve relation graph of the external load and the stress intensity factor (i)K generated by the external load (img file='2014100081259100004dest_path_image002.TIF'wi='8'he='21' / )( / i)-(i)P( / i) curve relational graph. The testing method provided by the invenytion has the advantages that the required equipment, analyzing and processing method are simple, the cost is low, and the precision is high.

Owner:YELLOW RIVER INST OF HYDRAULIC RES YELLOW RIVER CONSERVANCY COMMISSION

Prefabricated column of reserved concealed column channel, concealed column type complete assembled earthquake-resistant building and its method

InactiveCN102493603AReduce usageShorten the construction periodStrutsPillarsFloor slabArchitectural engineering

The invention relates to a concealed column type complete assembled earthquake-resistant building and its method, the concealed column type complete assembled earthquake-resistant building comprises a base, a prefabricated column, a prefabricated beam, a prefabricated wall panel, a prefabricated floor slab and a prefabricated stair, at least one reserved concealed column channel with continuous length used for passing through a steel bar, casting the concrete and constructing the concealed column is provided on a core part of the prefabricated column along the direction of column length, a beam of concealed column steel bar is passed through in the reserved concealed column channel, and solidified with a casted fine aggregate concrete to form the concealed column in the column, the upper part of the prefabricated column of the reserved concealed column channel is connected to a beam column edged steel plate. According to the invention, the products can solve the technical problem that the assembly of nodes can not reach the earthquake-resistant requirements or installation requirements in a traditional assembly type building, and solve the technical problem that production with complete prefabrication and complete assembly of columns, beams and wall panels of the building can be simultaneously realized under the prerequisite that the tradition assembly type building can not guarantee the earthquake-resistant requirements.

Owner:王夏静 +1

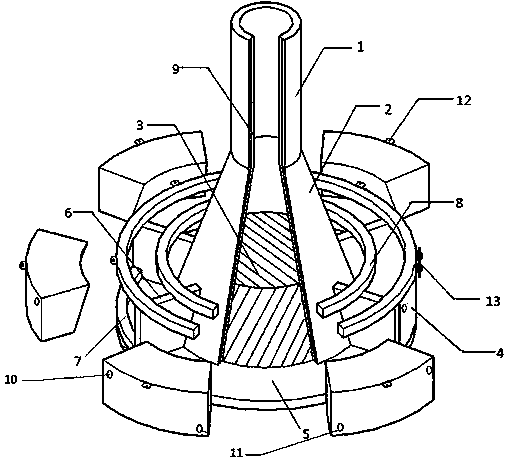

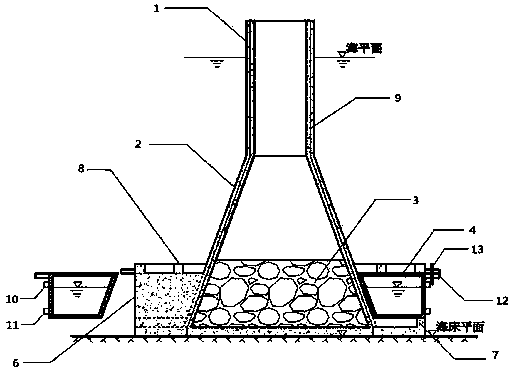

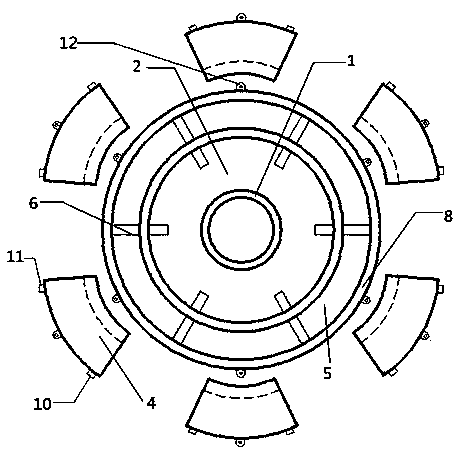

Gravity type offshore wind turbine generator set foundation and towing and sinking method thereof

ActiveCN103758147AEasy to disassembleEasy pre-installationFoundation engineeringElectricityWater discharge

A gravity type offshore wind turbine generator set foundation capable of being towed is composed of a connecting section, a foundation body, a gravel pile and a floating box. The foundation body is composed of a foundation base and a reinforced concrete conic cylinder, the foundation base comprises a bottom board and a rib board, the outer edge of the bottom board is provided with a bottom board ring beam, the circular bottom board is fixed to a rock foundation through grouting, and the top of the rib board is provided with a rib board ring beam; the top of a reinforced concrete circular cylinder at the connecting section is connected with a fan tower through a flange; the floating box is a closed box body welded through steel and the top of the floating box and the bottom of the floating box are provided with an air discharging valve and a water discharging valve respectively; the floating box and the outer side rib board ring beam are provided with connecting components and connected through hinge pins so that the floating box can be fixed or retracted. The gravity type offshore wind turbine generator set foundation has the advantages that the gravity center of the gravity type offshore wind turbine generator set foundation is low, the good stability and the safety are achieved in the towing transportation process and the sinking process, the material use amount of the foundation is small, prefabrication installation is convenient and rapid, the construction period is short, the construction cost is low, the economical efficiency is good, and popularization and application are facilitated.

Owner:THE FRONTIER TECH RES INST OF TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com