Patents

Literature

1326results about How to "Prevent seepage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

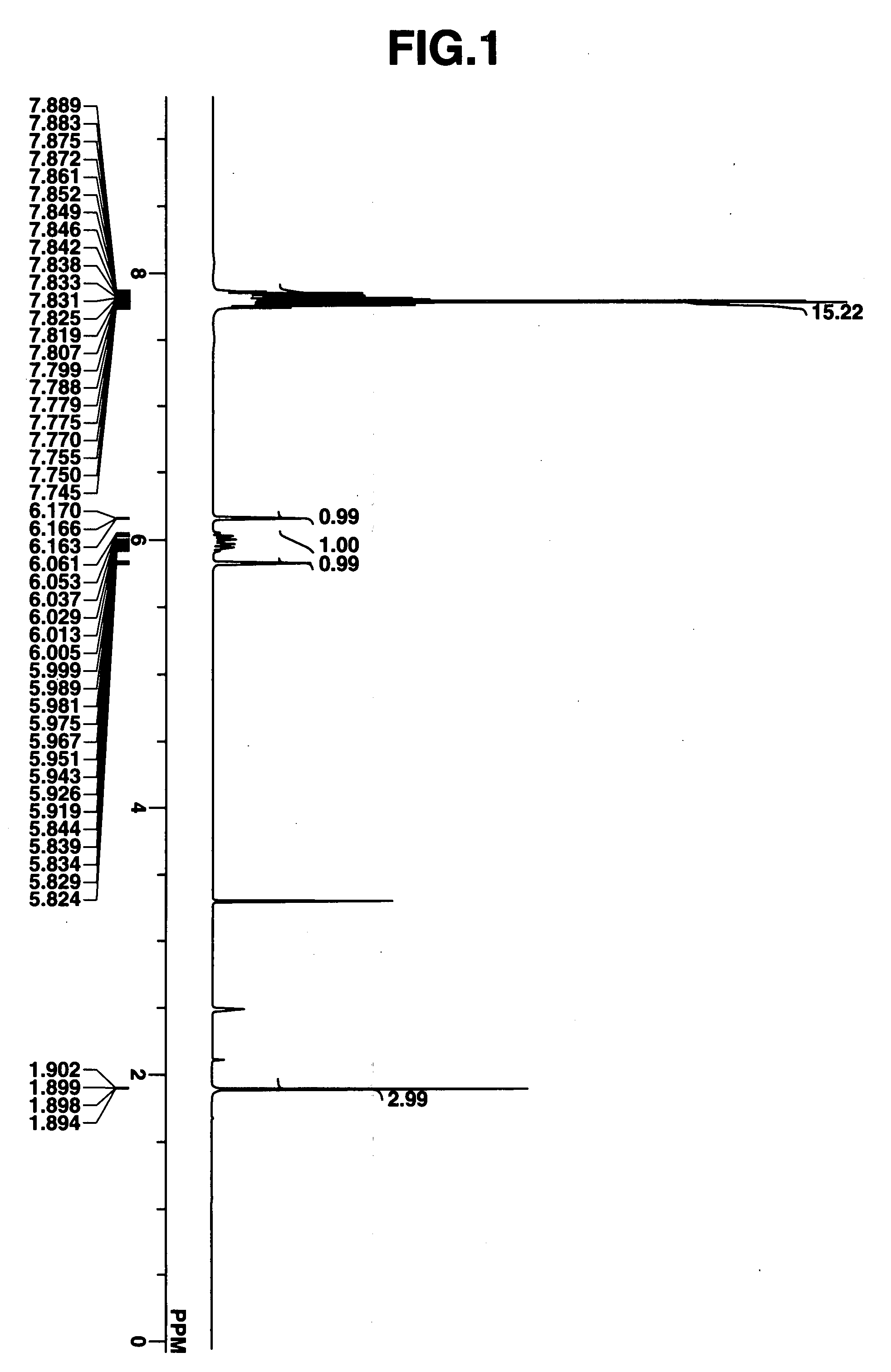

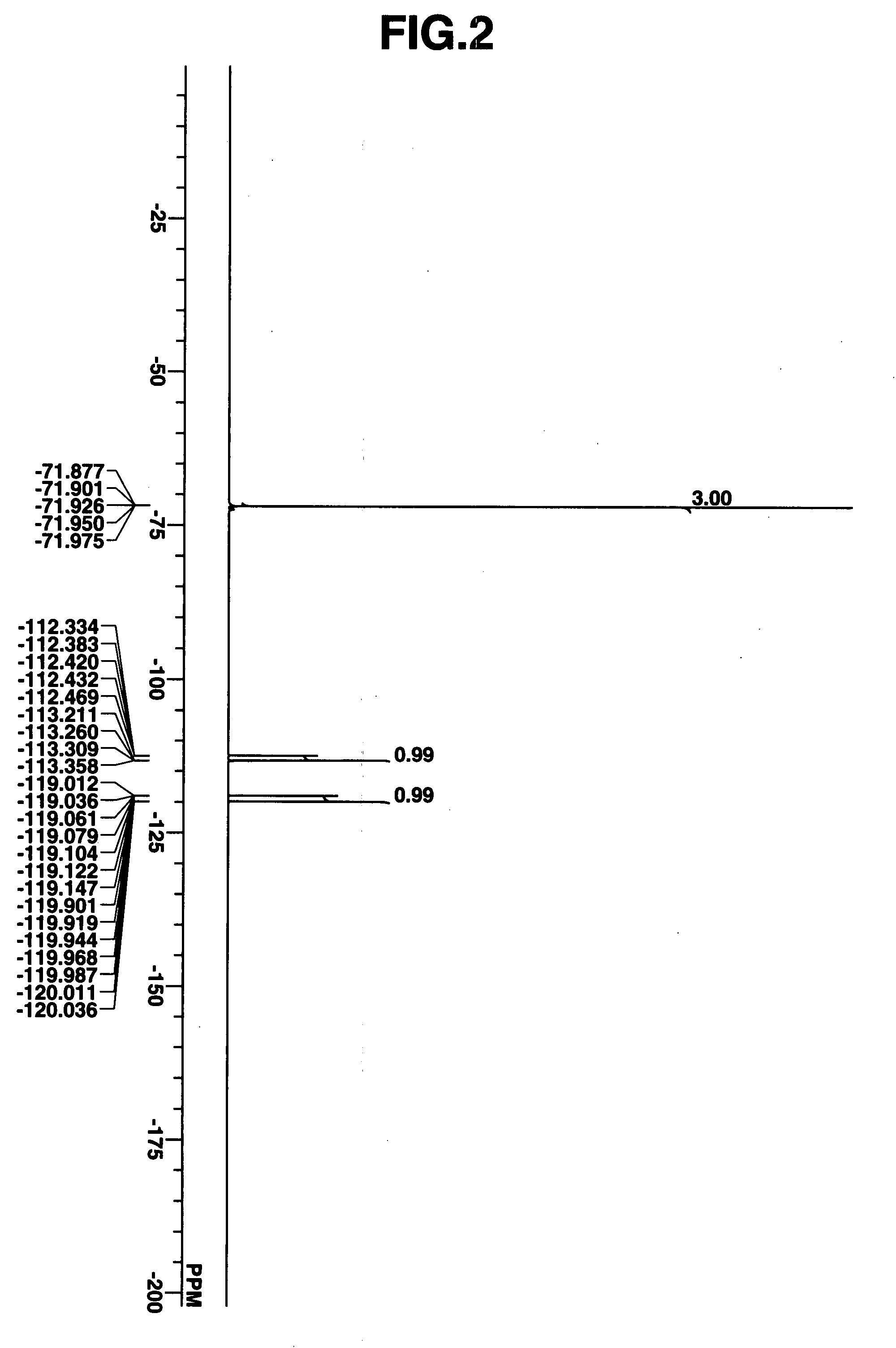

Sulfonium salt having polymerizable anion, polymer, resist composition, and patterning process

ActiveUS20080102407A1Feature size of to decreaseSmall feature sizeOrganic chemistryPhotosensitive materialsResistHigh energy

A sulfonium salt having a polymerizable anion generates a strong sulfonic acid upon exposure to high-energy radiation so that it facilitates effective scission of acid labile groups in chemically amplified resist compositions. It is useful as a monomer from which a base resin for use in radiation-sensitive resist compositions is derived.

Owner:SHIN ETSU CHEM IND CO LTD

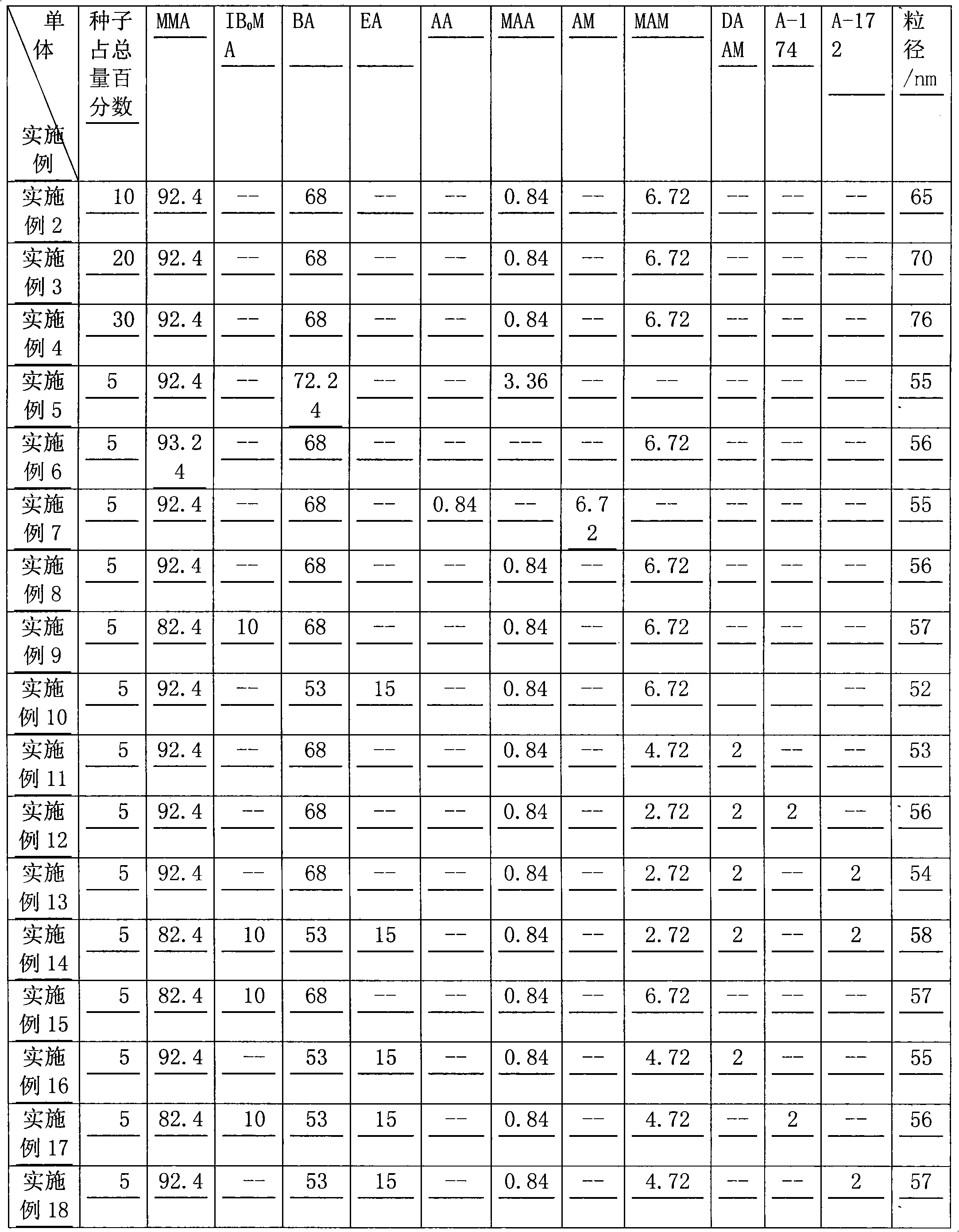

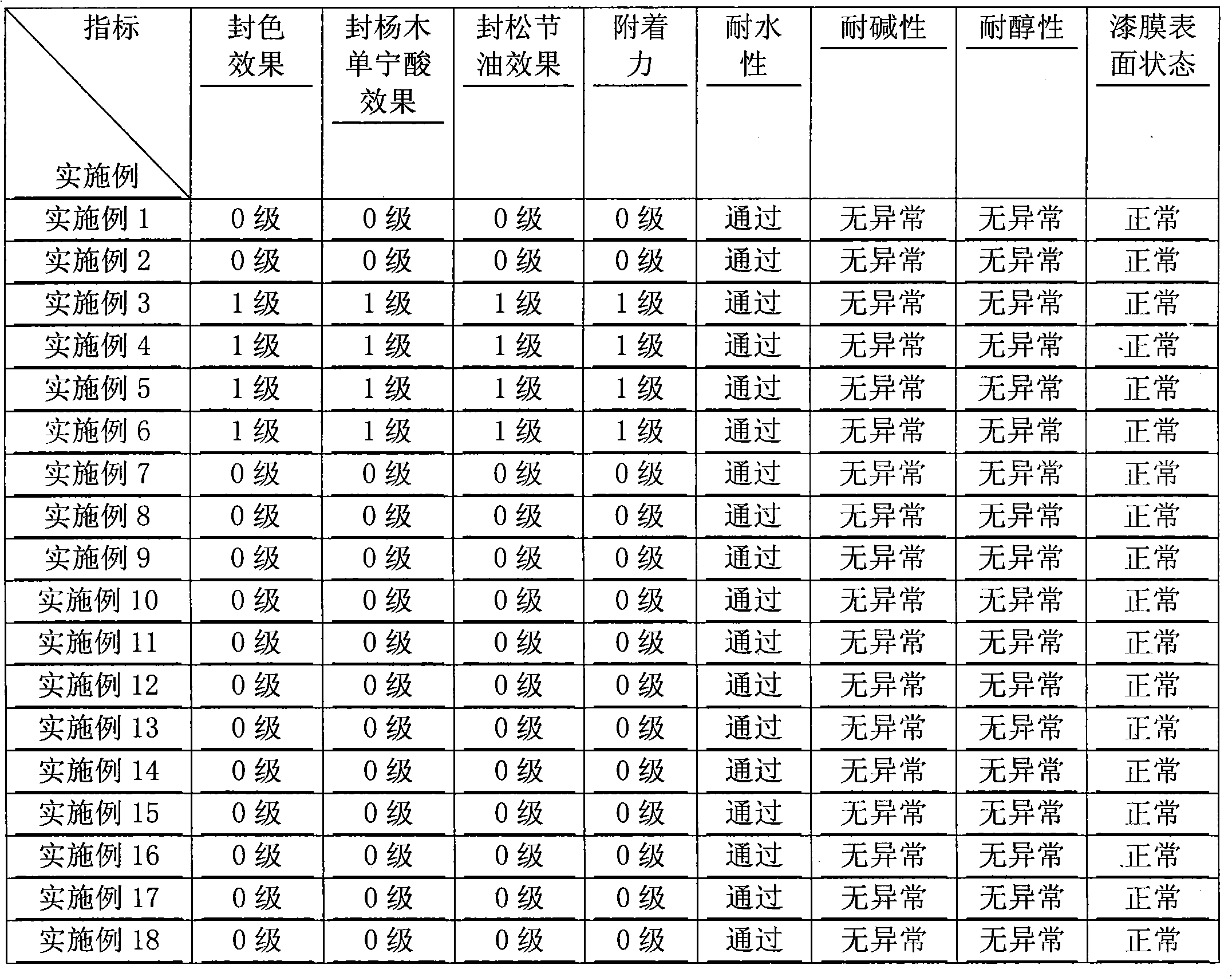

Aqueous acrylic acid series wooden ware sealing paint and method for preparing special emulsion thereof

InactiveCN101817906ASmall particle sizeImprove permeabilityCoating impregnationCoatingsFiberCoating system

The invention relates to aqueous acrylic acid series wooden ware sealing paint and a method for preparing special emulsion thereof. Nano emulsion with small particle diameter and narrow distribution is prepared by using an acrylic acid monomer containing multiple polar groups as a raw material. Multiple aids are added into the emulsion serving as a basic film-forming substance to form the novel aqueous wooden ware sealing paint. The polar functional groups on polymer molecule chains have good wetting property on wood, emulsion particles are easy to permeate into wood fiber conduits and quickly form films in conduit holes, and the paint can effectively prevent the moisture in the aqueous wooden ware paint from permeating into the wood and solves the problem of surface gully caused by the water-swelling wood; and meanwhile, the paint also can effectively seal the substances which are extremely easy to permeate to the outside such as turpentine, tannin and the like acknowledged in the wooden ware industry, and solves common problems for wide application of the aqueous wooden ware paint. The aqueous sealing paint also can be used for a solvent type paint coating system, and effectively prevents a large amount of solvent in the solvent type paint from penetrating into the wood during coating.

Owner:BEIJING UNIV OF CHEM TECH

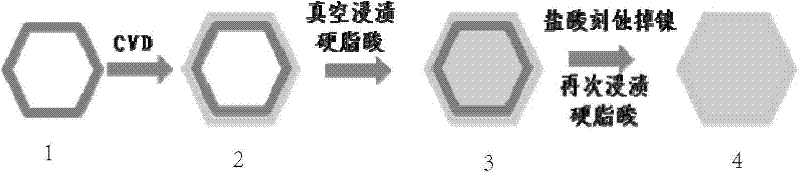

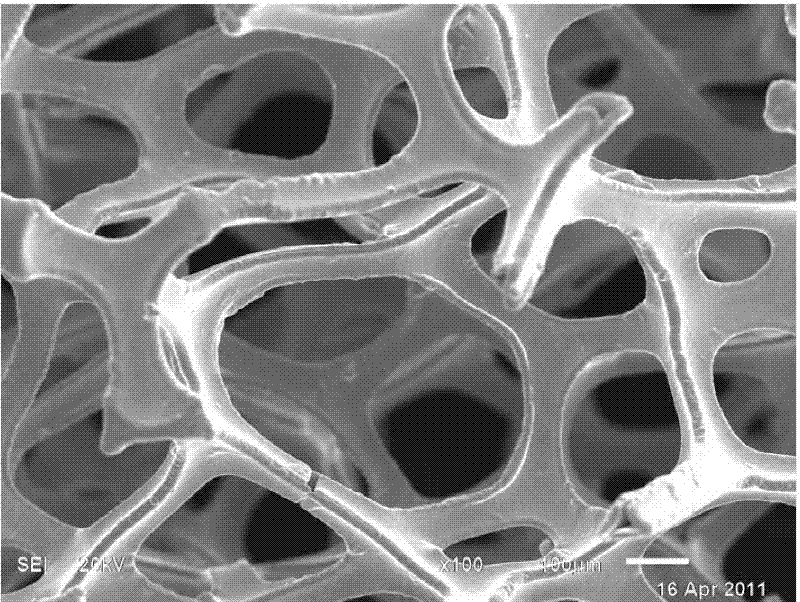

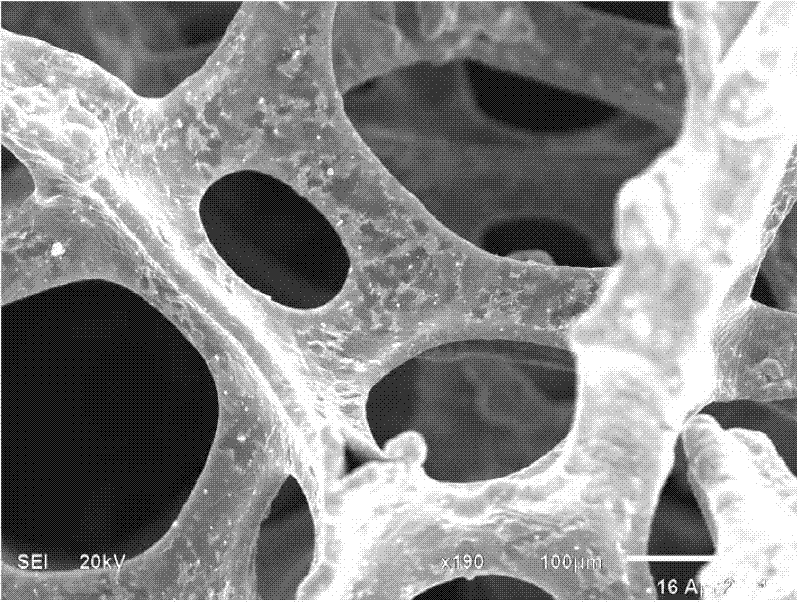

Three-dimensional graphene/phase change energy storage composite material and preparation method thereof

InactiveCN102585776AImprove thermal conductivityLow densityHeat-exchange elementsPorous grapheneLiquid state

The invention provides a three-dimensional graphene / phase change energy storage composite material and a preparation method thereof. The technical scheme is as follows: graphene and a phase change energy storage material are in situ compounded, wherein porous graphene with a three-dimensional structure is used as a heat conductor and a compound die, and a solid-liquid phase change organic material is used as the energy storage material and filler. The three-dimensional porous graphene is compounded with the phase change material, the phase change energy storage material is partitioned in a plurality of pore spaces and is in tight joint with the graphene wall so as to greatly increase the effective heat contact area, and the highly linked graphene three-dimensional heat conduction network channels can realize rapid system heat exchange. In addition, due to the capillary adsorption capacity of porous graphene, the liquid-state phase change energy storage material is localized, so as to effectively prevent seepage. Therefore, the three-dimensional graphene foam has good designability, and becomes a lighter and more effective heat dissipation material for electronic devices.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

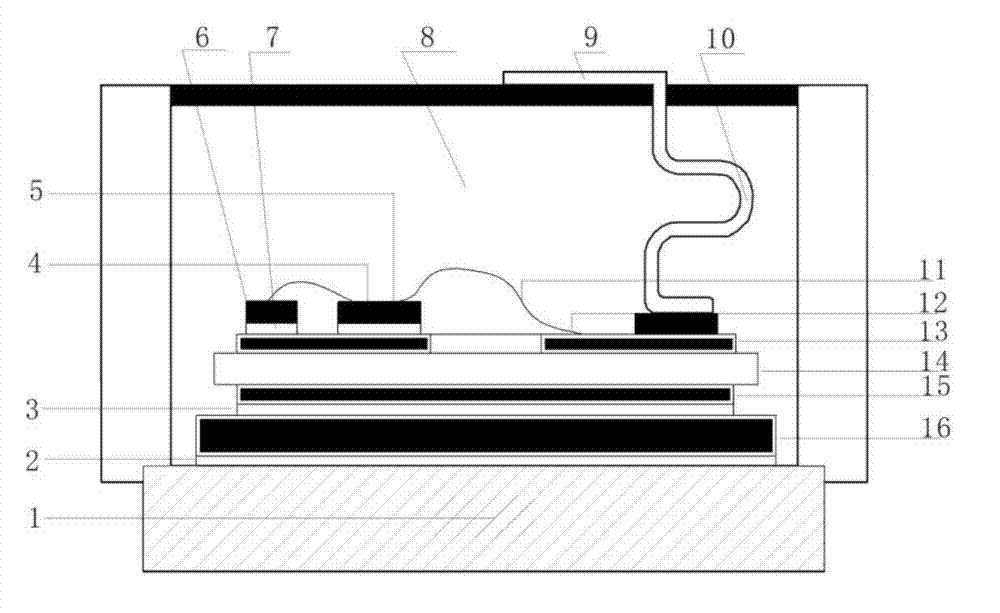

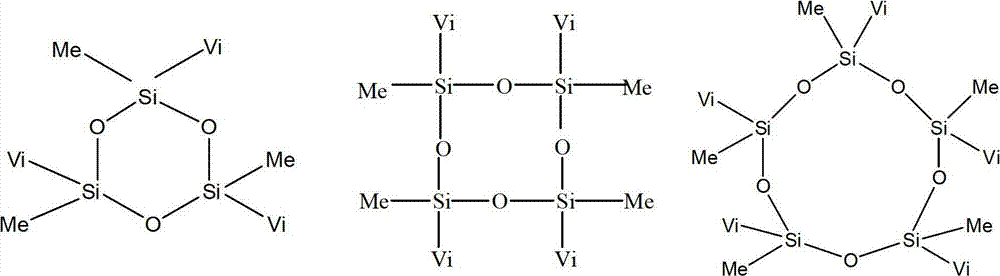

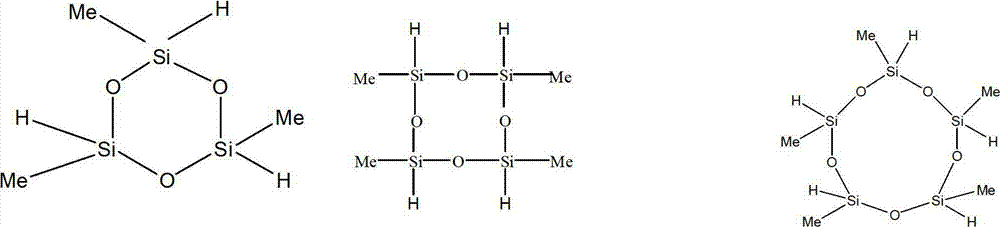

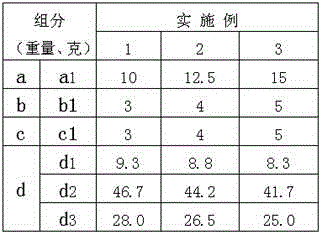

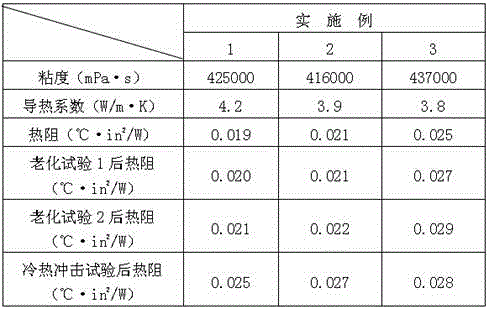

Organic silica gel used for packaging IGBT (insulated gate bipolar translator) module, and preparation method of organic silica gel

InactiveCN102807757AViscosity is convenient and controllableHigh reactivitySemiconductor/solid-state device detailsSolid-state devicesOptical propertyHigh intensity

The invention relates to an organic silica gel used for packaging an IGBT (insulated gate bipolar translator) module and a preparation method of the organic silica gel. The organic silica gel comprises a component A and a component B according to the weight proportion of 1:1, wherein the component A comprises the following raw materials by weight part: 94 to 99.89 parts of base material, 0.01 to 5 parts of silane coupling agent, and 0.1 to 1 part of catalyst; the component B comprises the following raw materials by weight part: 79 to 95 parts of base material, 5 to 15 parts of crosslinking agent, 0.01 to 5 parts of fire retardant and 0.1 to 1 part of inhibitor. The organic silica gel used for packaging the IGBT module has excellent optical property, high strength, low oil leakage, and fire resistance, is transparent, is solidified fast at high temperature, is capable of satisfying the long-term operating requirements under high and / or low temperature environments, and is mainly beneficial to sealing and encapsulation protection of the IGBT modules.

Owner:YANTAI DEBANG ADVANCED SILICON MATERIALS

Emergency wound dressing and its preparation method

InactiveCN1830409AImprove breathabilityGood moisture permeabilityAdhesive dressingsAbsorbent padsWound dressingInter layer

A dressing for the first aid to wound is a composite non-woven cloth consisting of an internal layer made of the mixture of chitosan fibers and alginate fibers, a middle layer made of the hydroscopic fibers mixed with high-hydroscopicity resin, and an external layer made of hydrophobic fibers. Its preparing process is also disclosed.

Owner:SANITARY EQUIP INST ACAD OF MILITARY MEDICAL SCI PLA

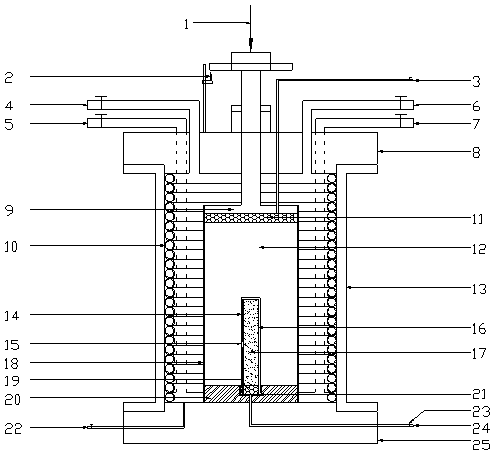

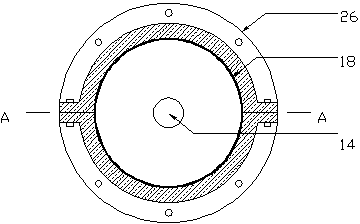

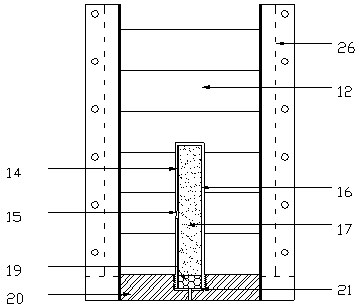

Device and method for clay core wall hydraulic fracturing experiments

ActiveCN103389249AReduce distortionReduce intensityPreparing sample for investigationMaterial strength using tensile/compressive forcesWater volumeAxial pressure

The invention relates to a device and a method for clay core wall hydraulic fracturing experiments under simulated coupling conditions. The method is characterized in that two semi-cylindrical molds are specially made and assembled into a sample mold which is easy to assemble and disassemble; the internal temperature of a pressure chamber is controlled through changing the temperature and amount of water in a copper water pipe; internal water pressure is applied to a sample by a water flow passing through a base of the pressure chamber, a permeable plate, coarse sand and finally a blowhole; and hydraulic fracturing features of the clay sample under different conditions are studied through changing the water temperature and loading schemes of the fracturing water pressure, the axial pressure and the confining pressure, etc. The method overcomes the defects of hydraulic fracturing experiments in the prior art on core walls of earth and rock-fill dams, simulates features, force conditions, influencing factors and the like of clay core walls more accurately, and thus can be widely applied in hydraulic engineering and geotechnical engineering.

Owner:HOHAI UNIV

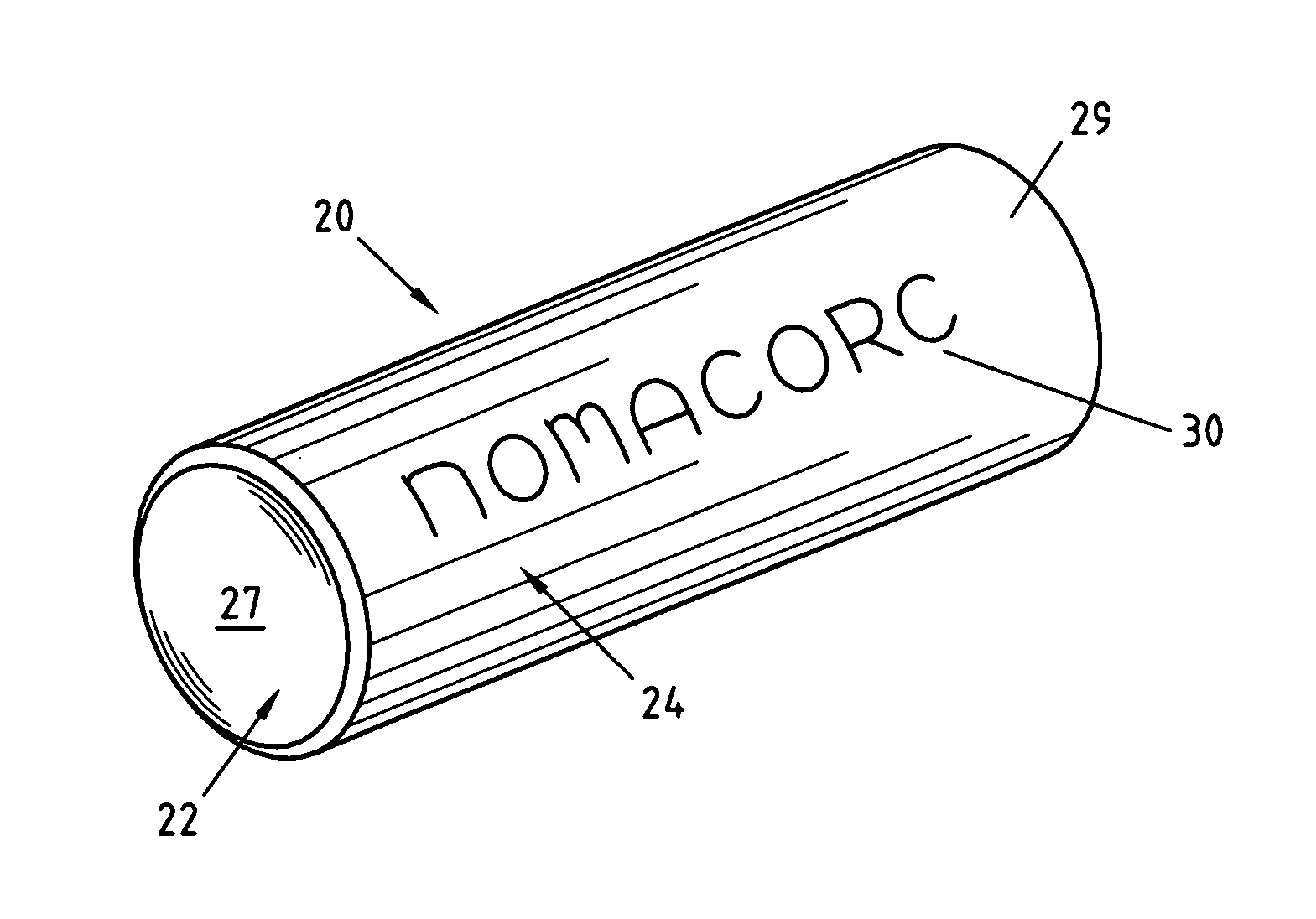

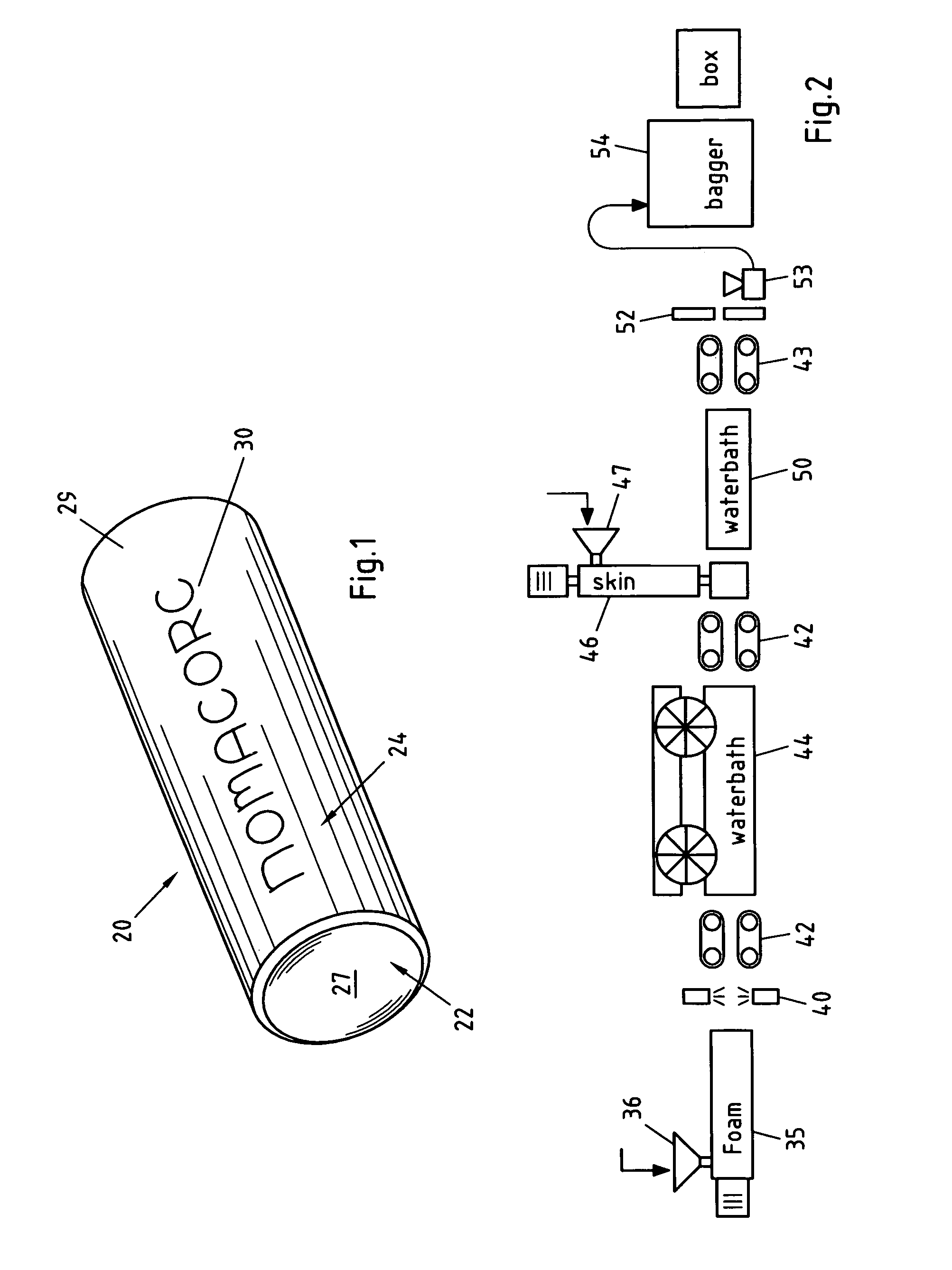

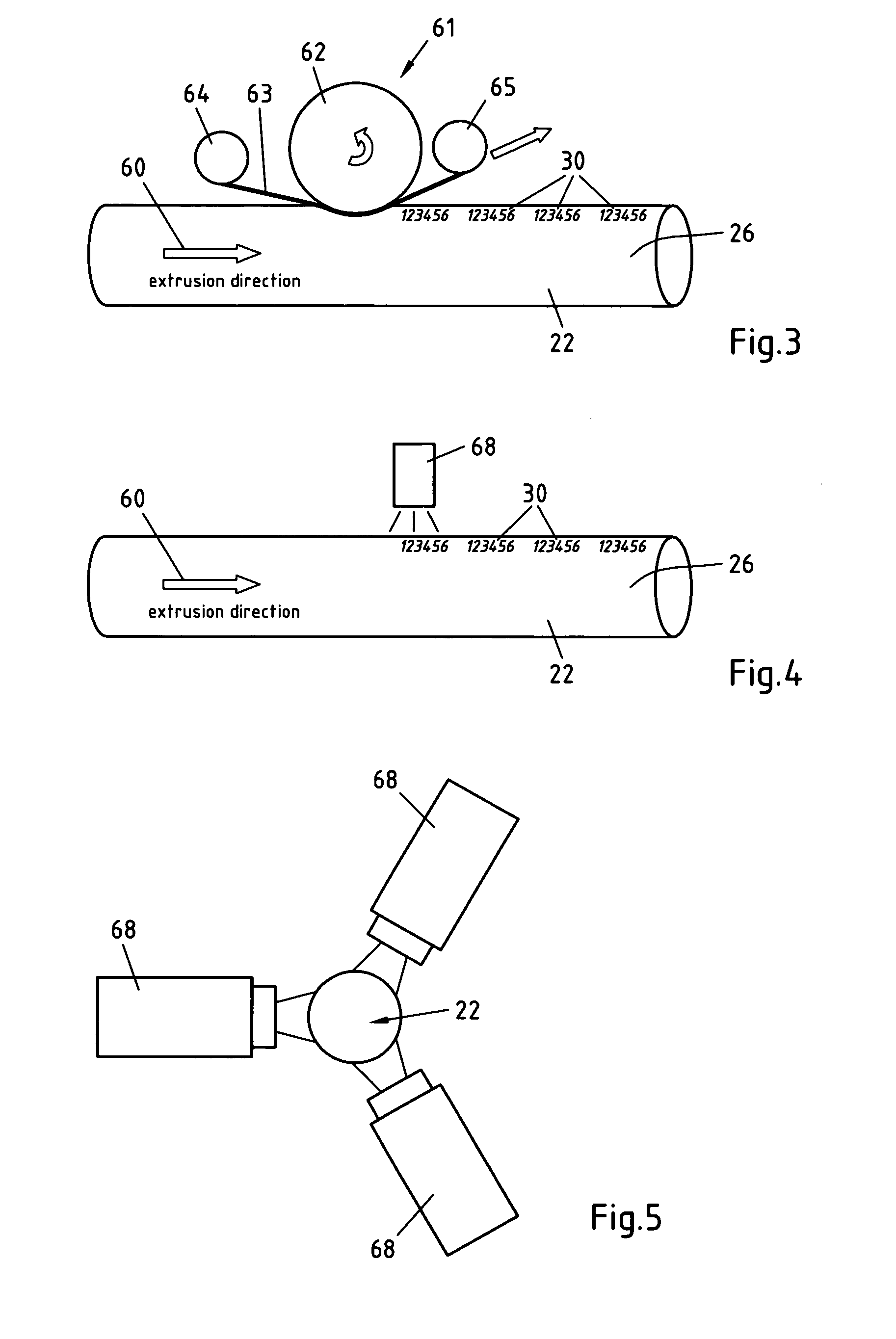

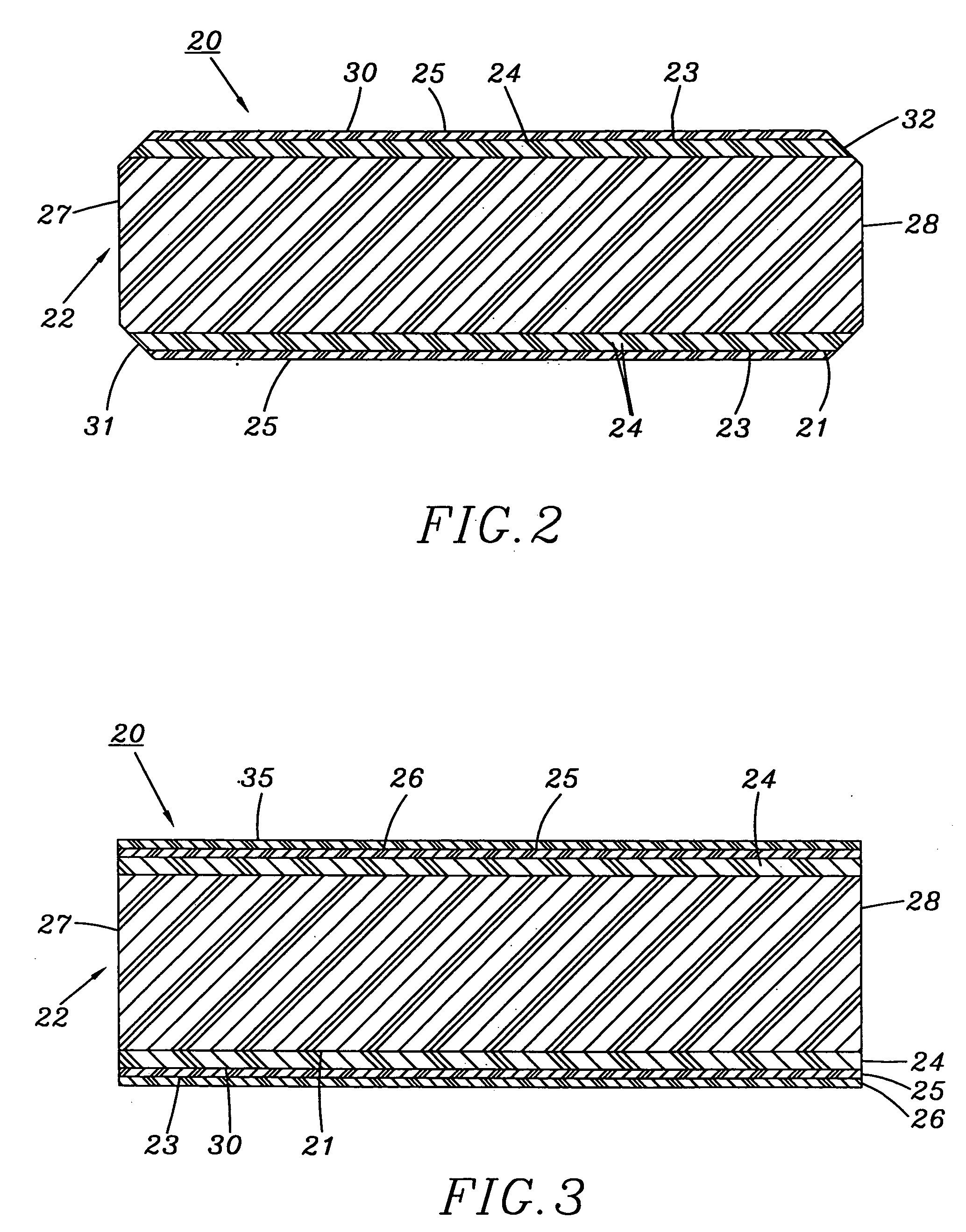

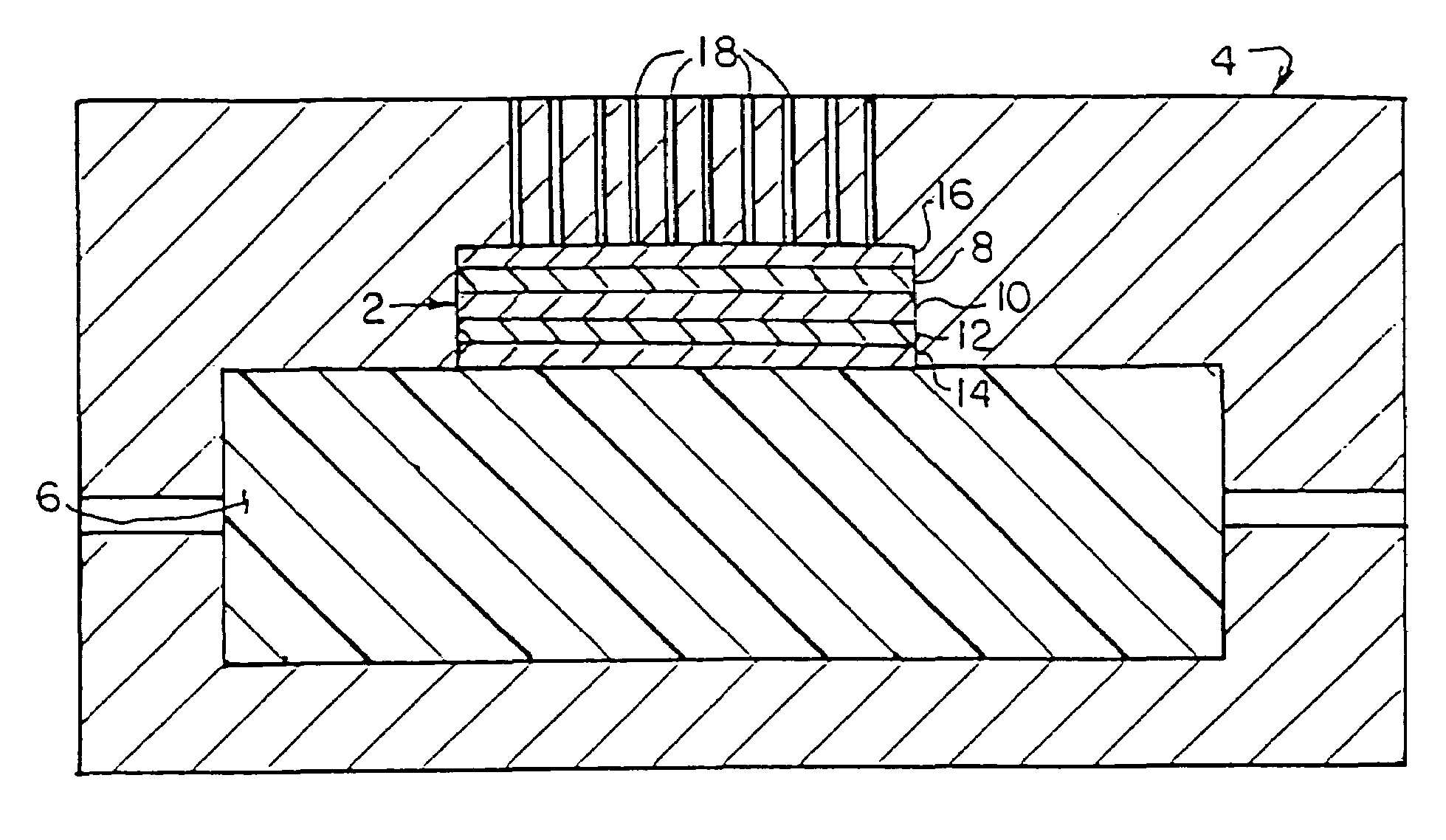

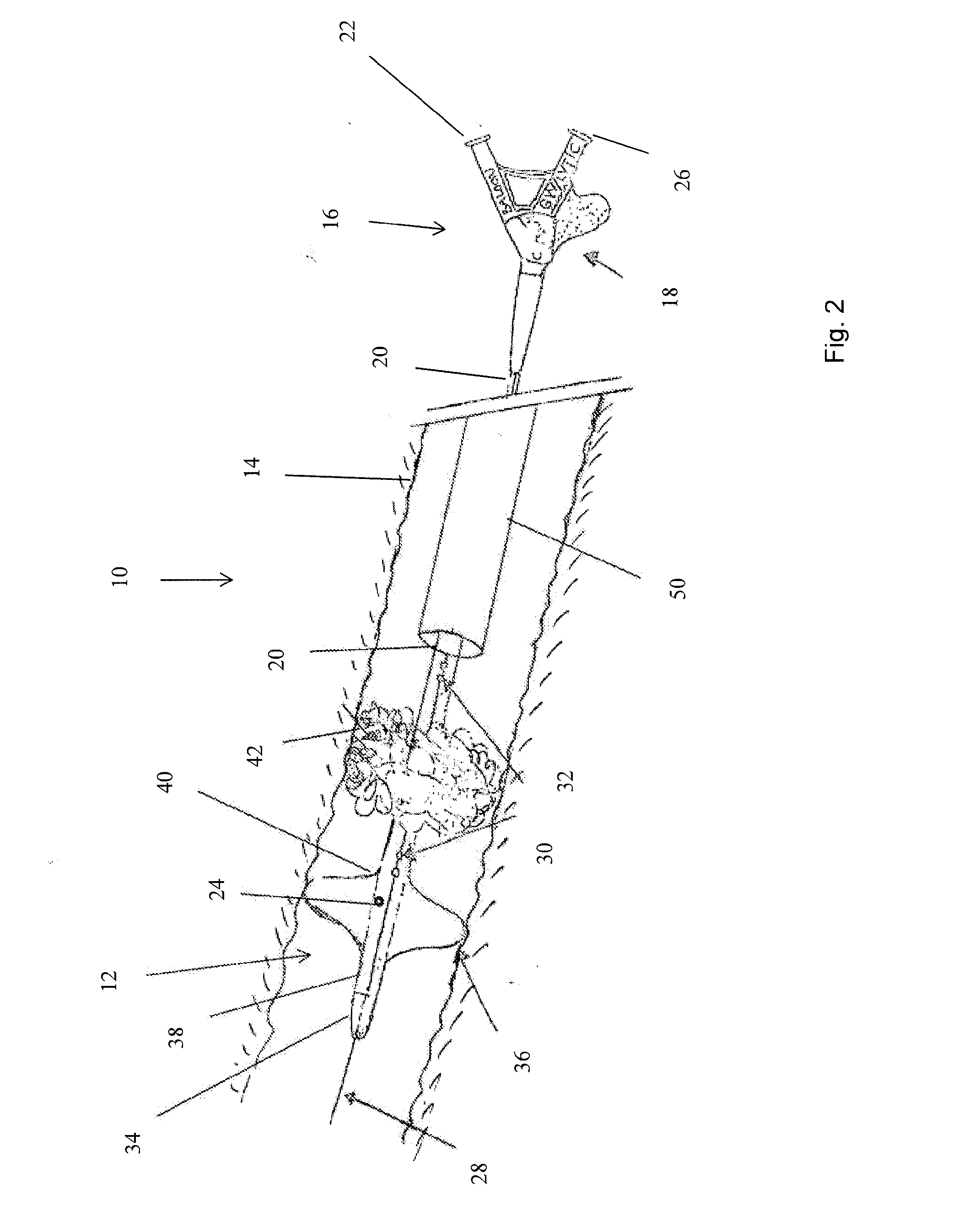

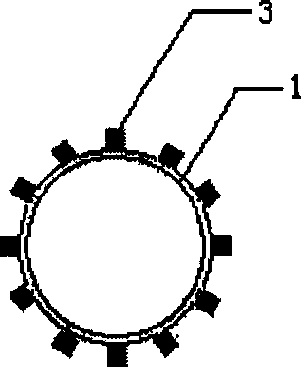

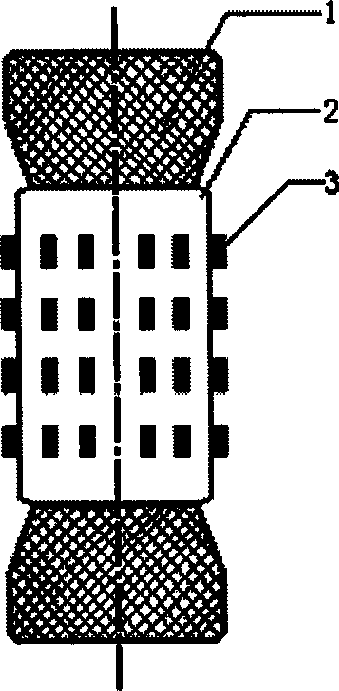

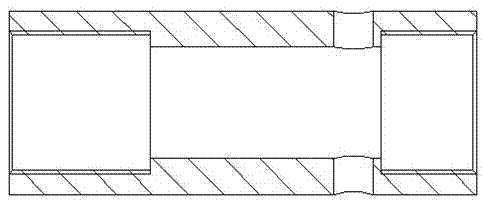

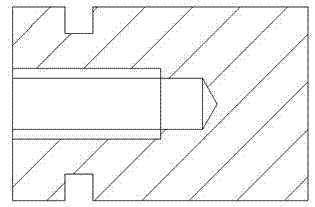

Multi-component synthetic closure and method of manufacture

InactiveUS9314953B2Prevent seepagePrevent leakageEnvelopes/bags making machineryElectric discharge heatingEngineeringExtrusion

In the present invention, a manufacturing process is provided in which a complete multi-component synthetic closure is achieved which incorporates printed indicia formed thereon, in a continuous, in-line manufacturing operation. In the preferred embodiment of the present invention, the core member of the synthetic closure is formed by a continuous extrusion process which enables the core to be manufactured as an elongated, continuous length of material. As the continuous elongated length of extruded material forming the central core is advanced from the extruder towards an outer skin forming station, the central core passes through a printing station for forming any desired indicia on the outer surface of the central core prior to the application of the outer skin layer.

Owner:NOMACORC LLC

Stabilization and solidification method of highly toxic waste residues

The invention relates to a stabilization and solidification method of highly toxic waste residues containing one or more of mercury, arsenic, chromium, cadmium and cyanide. Heavy metal is stabilized through chemicals, and then the highly toxic waste residues are sequentially wrapped with gypsum plus paraffin and epoxy resin. After four times of wrapping and two times of solidification, highly toxic substances in the waste residues are fully solidified into a solidified body, and the generated solidified body is high in strength and long in stability, and can be buried conveniently later.

Owner:扬州杰嘉工业固废处置有限公司

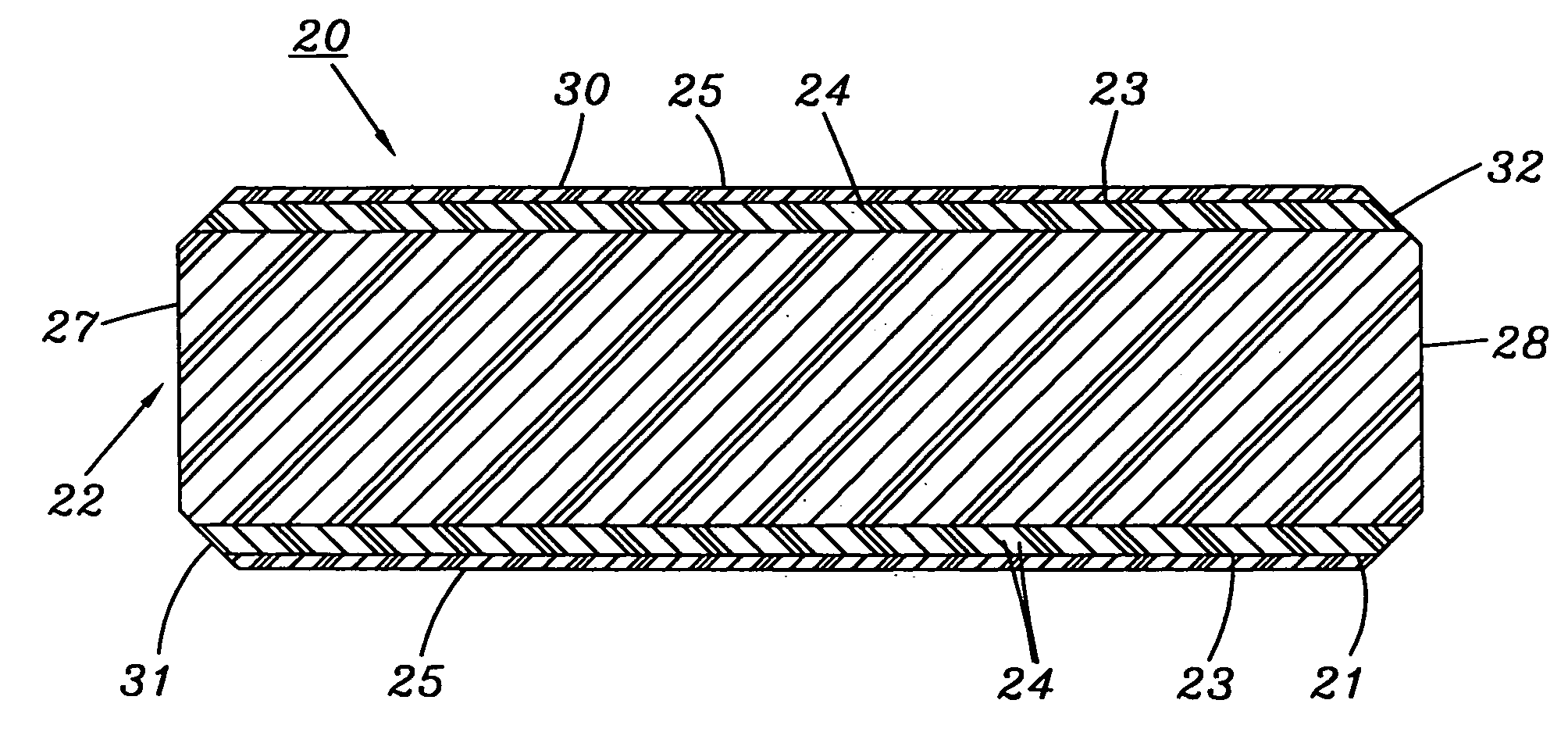

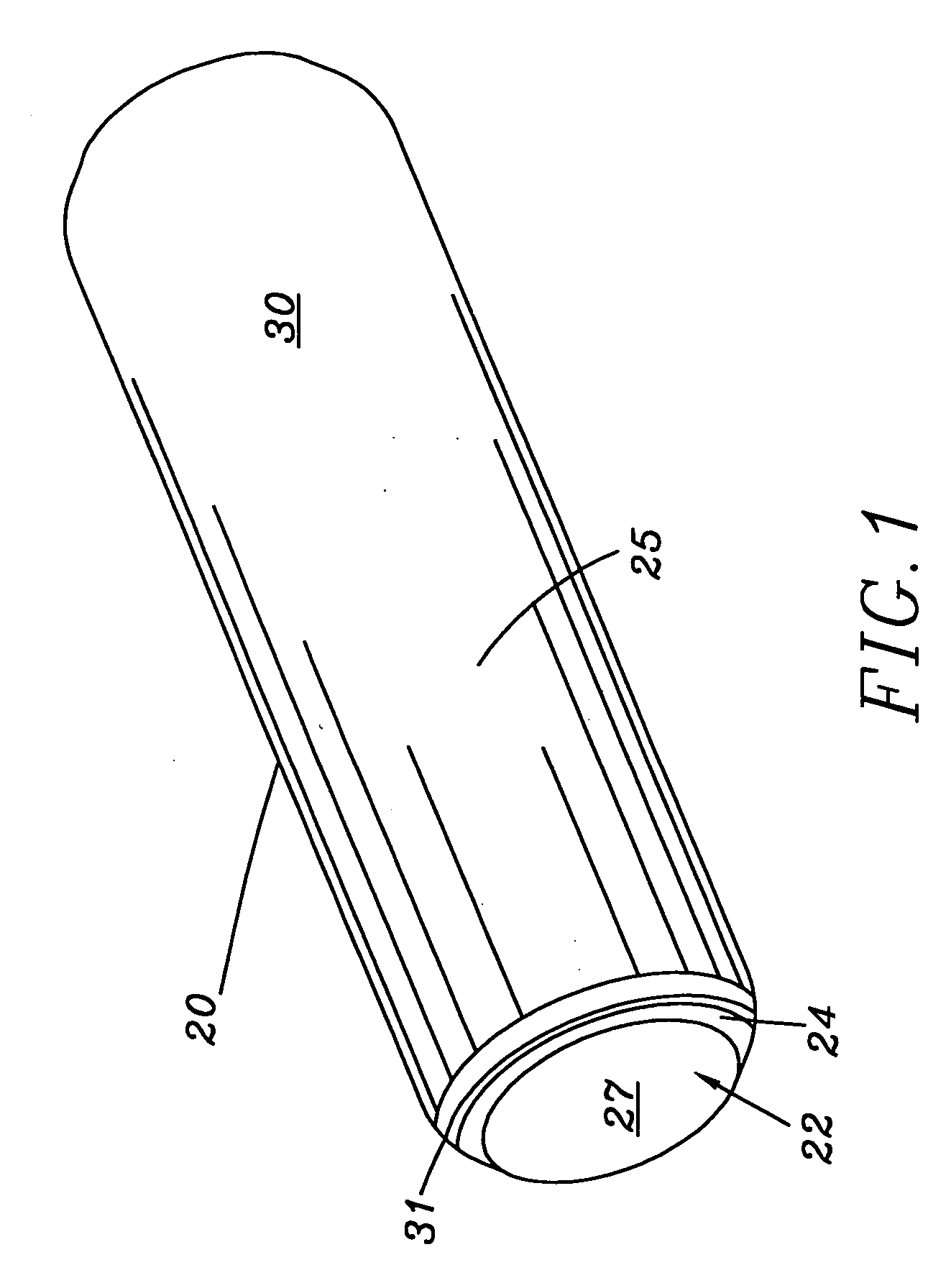

Synthetic closure

InactiveUS20060006132A1Prevent seepagePrevent leakageClosure using stoppersRemovable lids/coversPlastic materialsWine bottle

By achieving an extruded, foamed core formed from plastic material peripherally surrounded and integrally bonded with a plurality of cooperating synthetic, plastic, extruded, outer layers, a unique, multi-component, multi-layer synthetic closure is provided which may be employed as a bottle closure or stopper for any desired product, whether the product is a liquid, a viscous material, or a solid distributed in a bottle or container and dispensed through the open portal of the container neck. The present invention achieves a mass producible, resilient, synthetic bottle closure which is employable for any desired bottle, including wine. By employing the present invention, a multi-component or multi-layer synthetic closure is attained which possesses physical properties substantially equal to or better than the physical properties found in cork material, which has caused such cork material to be the principal closure material for wine bottles.

Owner:BANK OF AMERICA N A

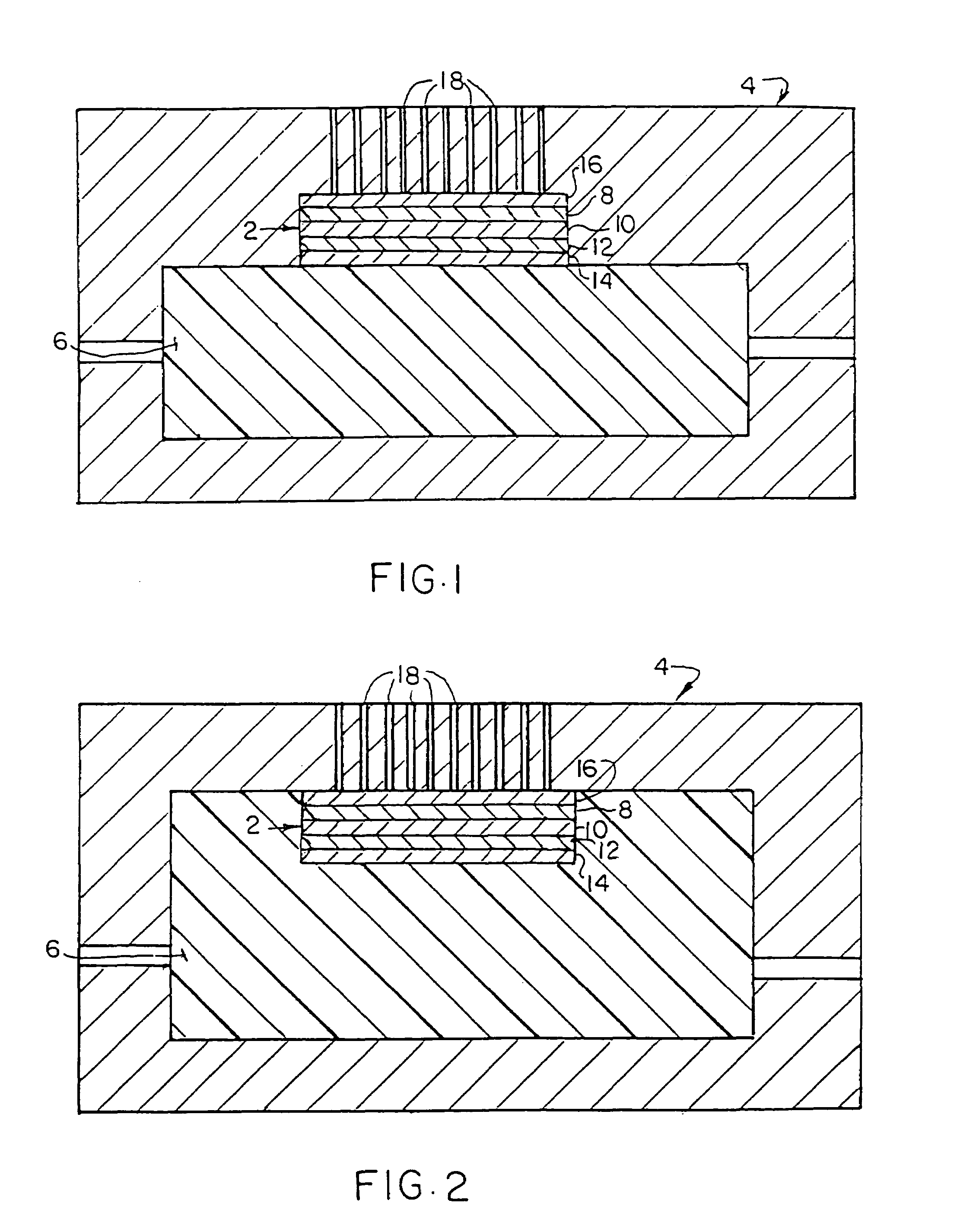

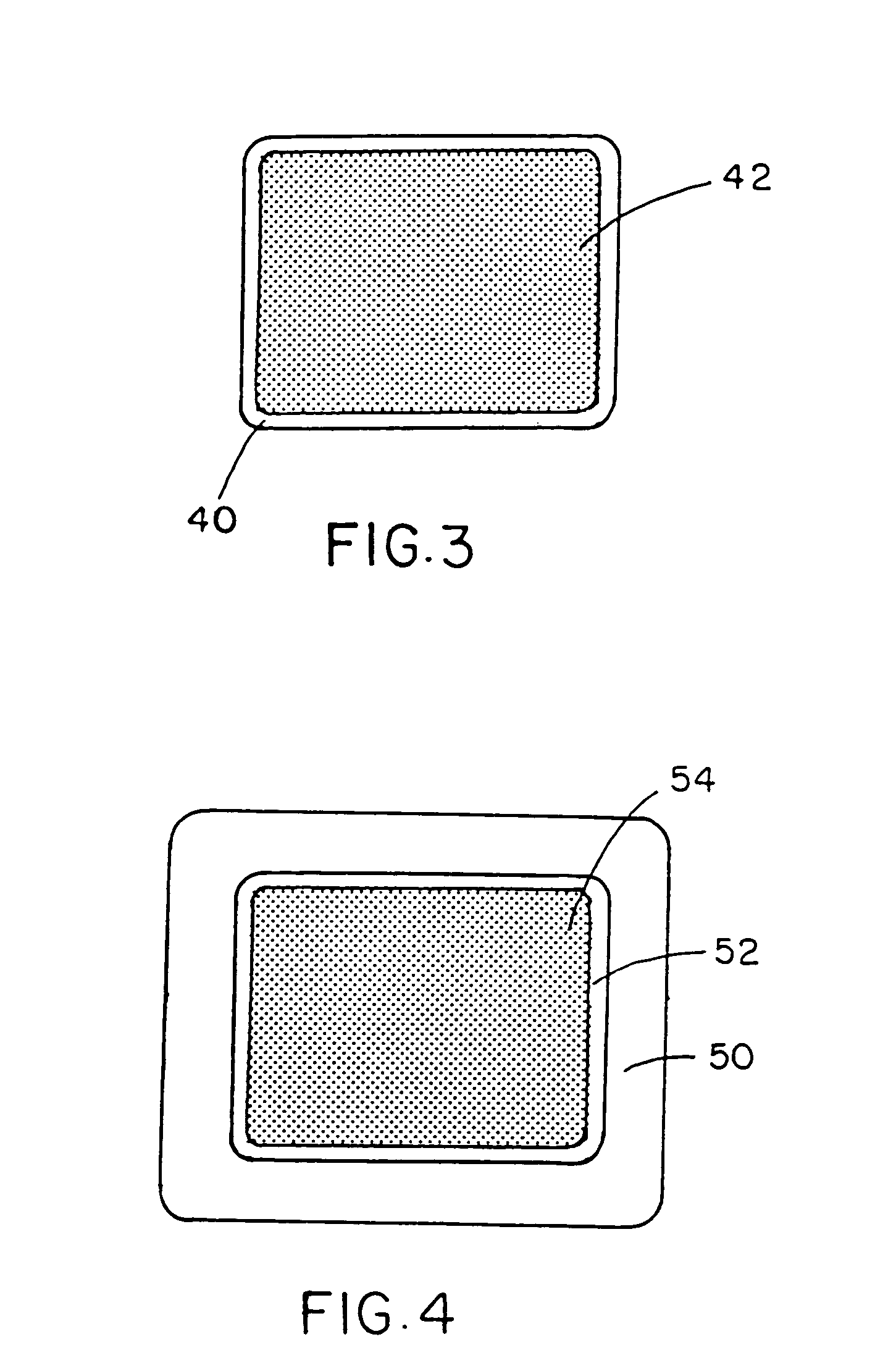

Method of decorating a molded article

InactiveUS6929771B1Prevent seepageEasy adhesionLamination ancillary operationsBristlePolymer scienceShell molding

Owner:HIGH VOLTAGE GRAPHICS

Dry heat transfer printing paper and preparation method thereof for textiles

ActiveCN102864688AImprove transfer rateAchieve transferNon-fibrous pulp additionSpecial paperWastewaterWater soluble

The invention discloses dry heat transfer printing paper and a preparation method thereof for textiles. The method includes preparing viscous fluid with a solid content of 2-10% w / w from a high polymer thickener and a water-soluble hot melt adhesive according to a mass ratio of (1:5)-(5:1); adding assistants such as acid, alkali, an absorbent and a fixing agent into the viscous fluid according to categories of fabric and dye so as to produce a transfer substrate; and subjecting the transfer substrate to coating, drying and press polishing processing for the paper to obtain the dry heat transfer printing paper for the textiles. The paper can generate strong adhesive force on the surface under a certain temperature and pressure and can be tightly attached to the fabric. If the paper is used for printing of non-thermoplastic fabric, modified or dewing treatment is not required any more before the printing, transfer printing can be directly performed on dry-state fabric, the dye transfer stability is guaranteed, and clean and high-quality printed patterns can be obtained; and simultaneously, the processing time is shortened, waste water emission of the printing and dyeing industry is reduced, and energy saving and environment protection are facilitated.

Owner:SUZHOU UNIV

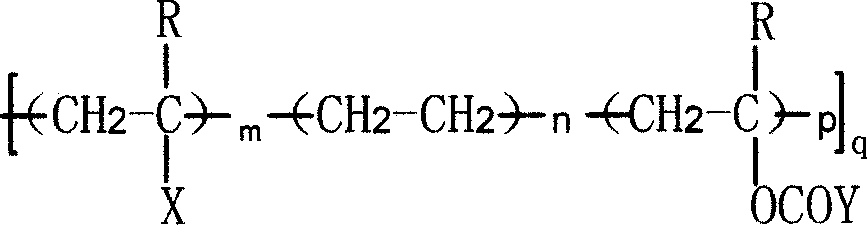

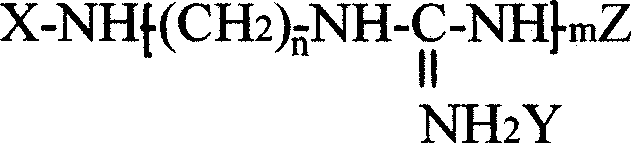

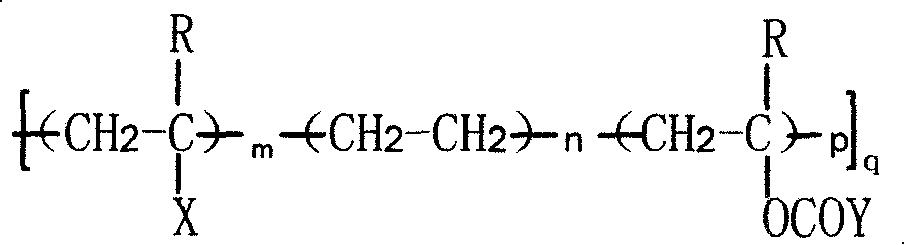

Functional olefin copolymers and its preparing process and application

The invention relates to a functionalized olefin copolymer, a preparation method and application thereof. The structural formula of the functionalized olefin copolymer is that: X is chlorine, methyl, ethenyl or hexyl; Y is alkane group such as methyl, ethenyl, propyl, butyl, etc.; R is polyamine and guanidinium oligomer; m, n and p are integers that are more than or equal to zero; q is integer that is more than zero; the functionalized olefin copolymer is obtained from olefin copolymer resin, polyamine, guanidinium oligomer, olefin monomer, evocating agent and antioxidant through solution reaction, frit reaction and solid phase reaction; the functionalized olefin copolymer can be used singly for preparing olefin copolymer products with antibiosis function and also can be mixed with resin together for preparing products with antibiosis function. Compared with the prior art, the invention has the advantages of safety, good antibiosis effect and long residual action, etc.

Owner:EAST CHINA UNIV OF SCI & TECH

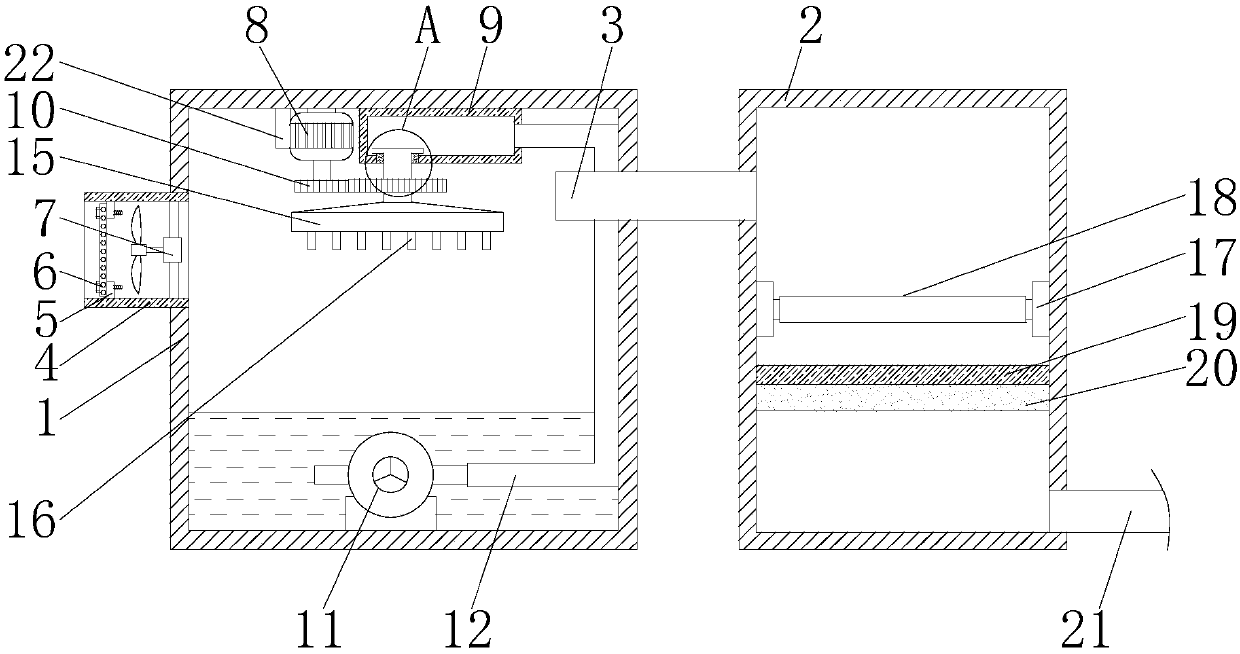

Environment-friendly equipment for purifying waste gas

InactiveCN107551802AImprove disinfection efficiencyImprove purification effectDispersed particle filtrationEnvironmental resistanceUltraviolet

The invention discloses environment-friendly equipment for purifying waste gas. The environment-friendly equipment comprises a disinfection box and a purification box, wherein the disinfection box islocated at the left side of the purification box; the top of the left side of the purification box is communicated with a connection tube; one end, away from the purification box of the connection tube passes through the disinfection box and extends into the inner cavity of the disinfection box; the top of the left side of the disinfection box is communicated with a gas inlet tube; the top and thebottom of the inner cavity of the gas inlet tube are fixedly connected with cushion blocks; the left sides of the cushion blocks are fixedly connected with filtering plates through bolts. According to the environment-friendly equipment for purifying waste gas, a rotary disc is used for driving atomization nozzles to rotate, so that the spraying area of the atomization nozzles is increased; the disinfection efficiency of the waste gas is improved; through cooperation of ultraviolet lamps, a photocatalyst plate and an active carbon adsorption layer, the poisonous and harmful gas in the air canbe effectively degraded; a plurality of bacteria can be effectively killed; toxins released by the bacteria or fungi can be decomposed and harmlessly treated; the purification performance of the wastegas is improved; the below-standard emission of the waste gas is avoided.

Owner:NANJING CHINA UNIV INTPROP CO LTD

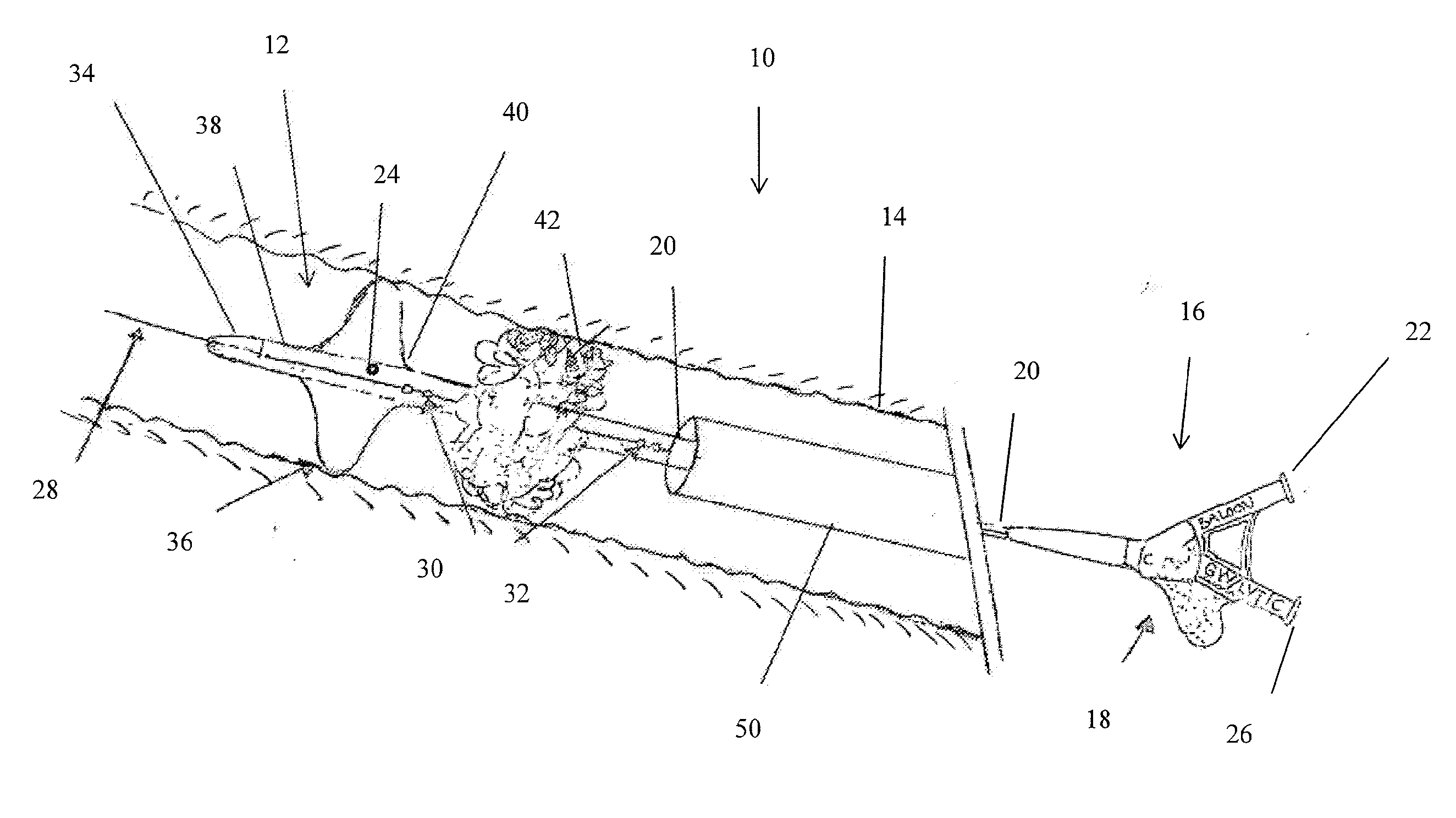

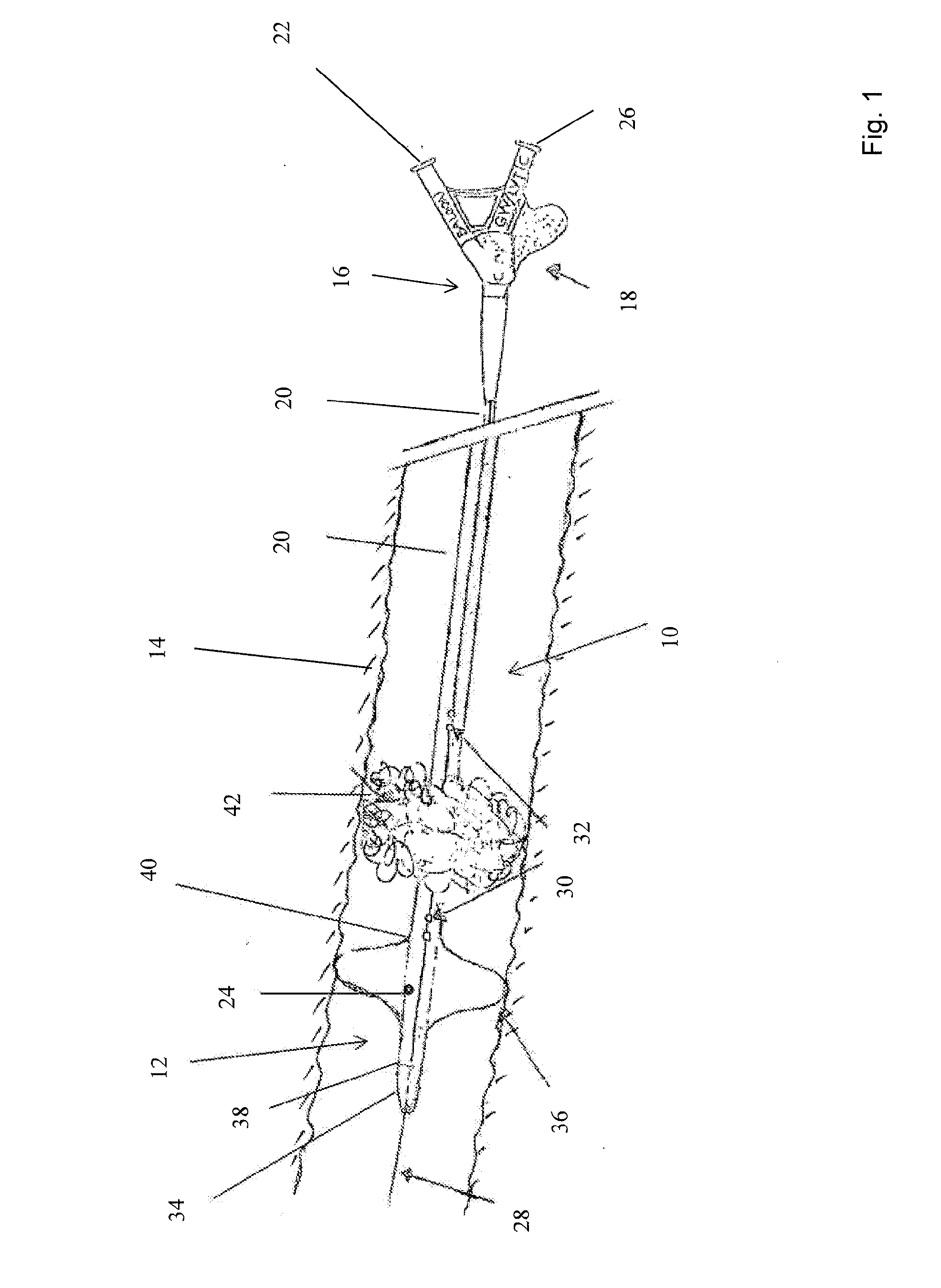

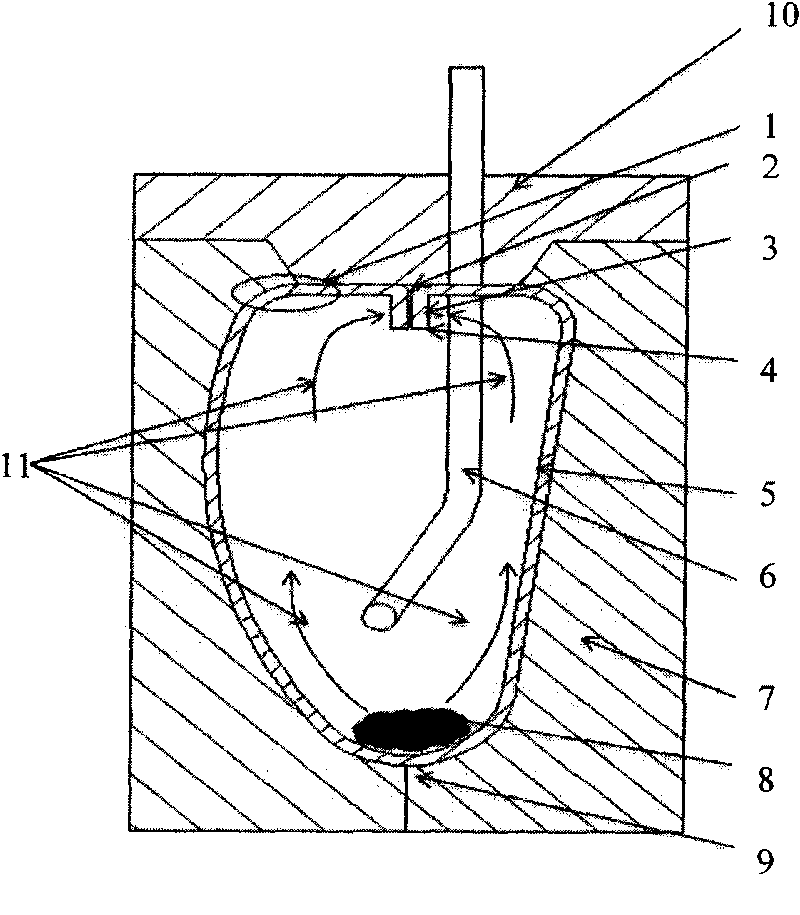

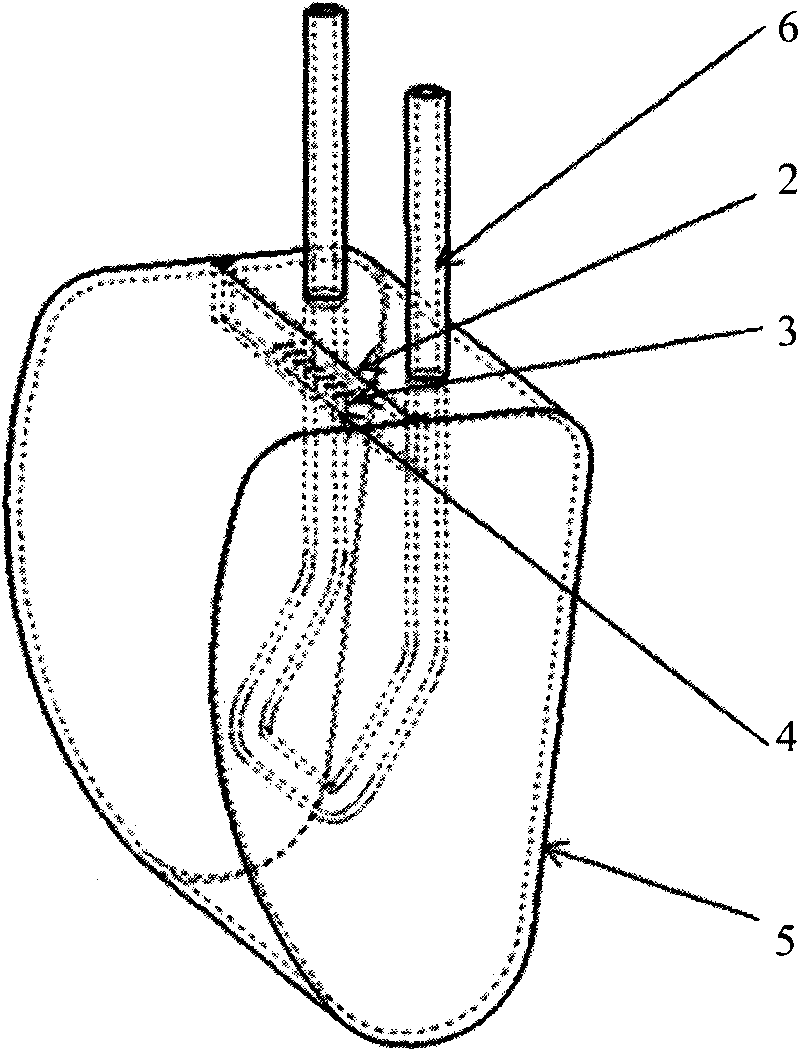

Thrombus removal apparatus and method

ActiveUS20130158511A1Prevent seepageInhibit transferBalloon catheterMedical devicesBalloon catheterBlood vessel

Thrombus removal apparatus includes a balloon catheter with a short balloon at a distal end thereof. An aspiration catheter is disposed coaxially over the balloon catheter. The balloon catheter includes a plurality of holes for the administration of lytic agent. The apparatus does not seal off completely the zone of the vessel around the thrombus, thereby allowing movement of blood within the vessel. The balloon is shaped so that it can be pulled along the vessel in an upstream direction so as to drag against the vessel walls for assisting in the removal of the thrombus.

Owner:COOK MEDICAL TECH LLC

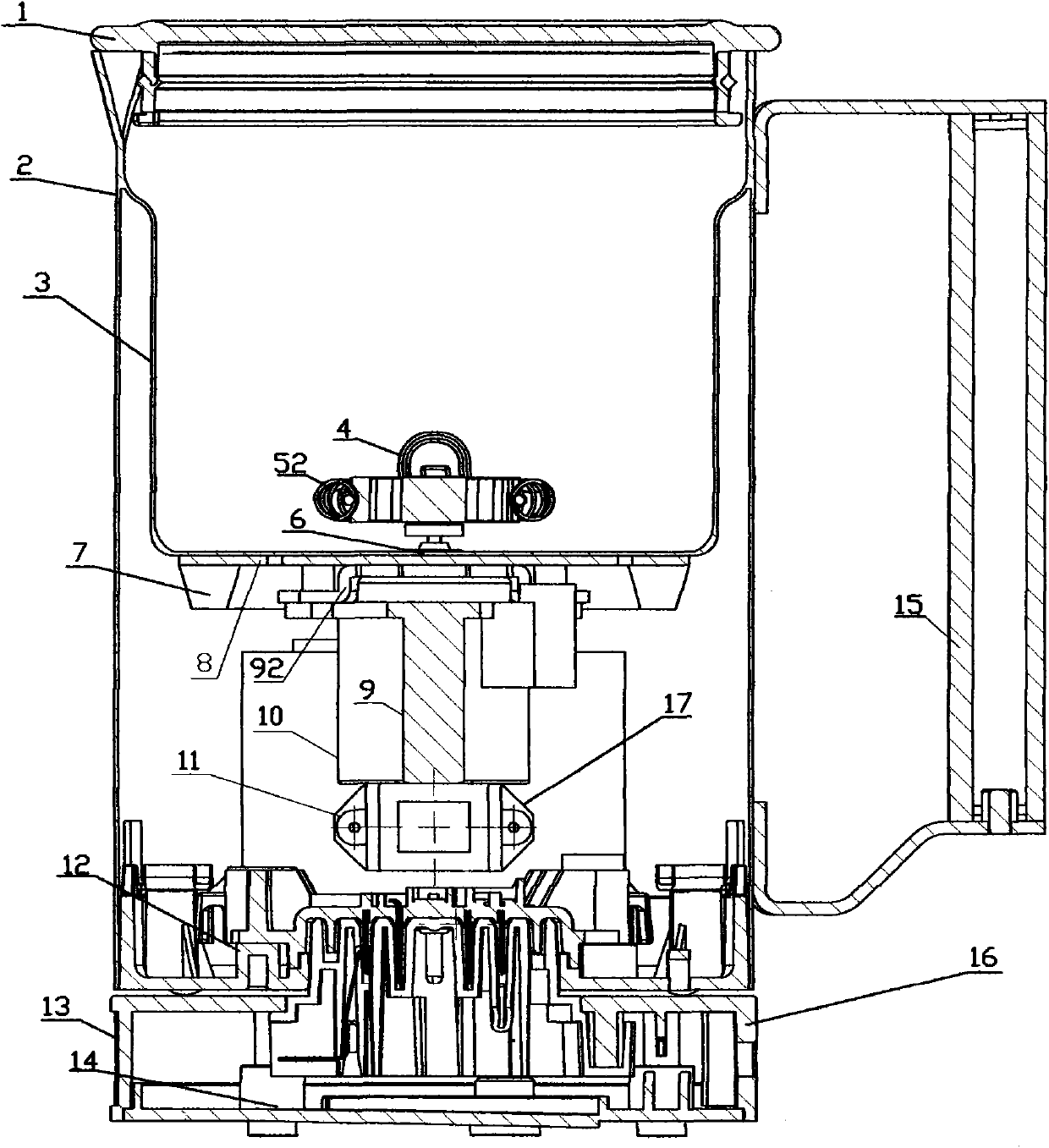

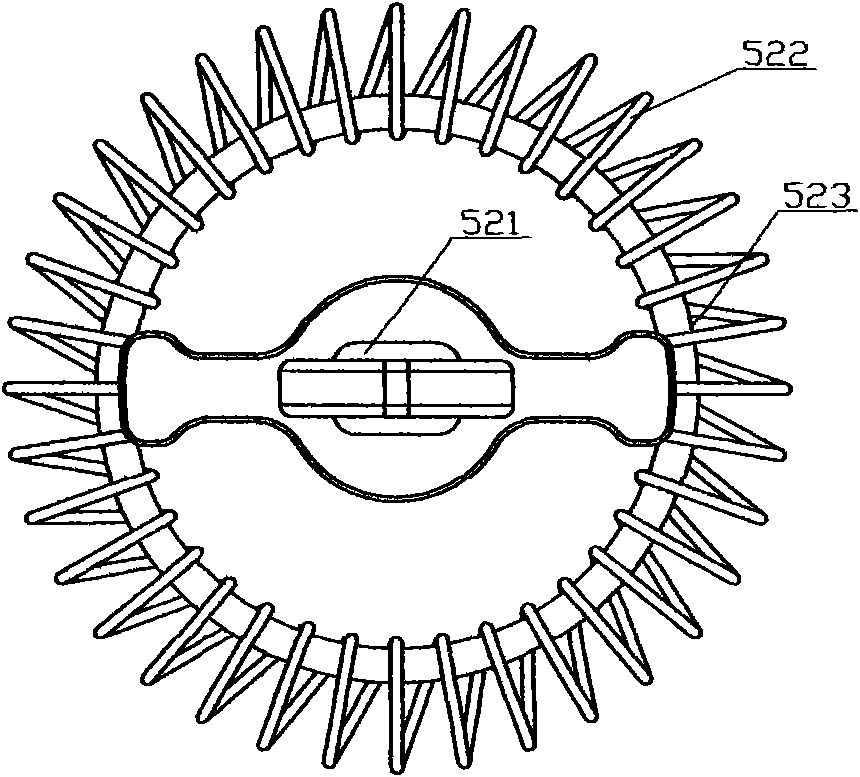

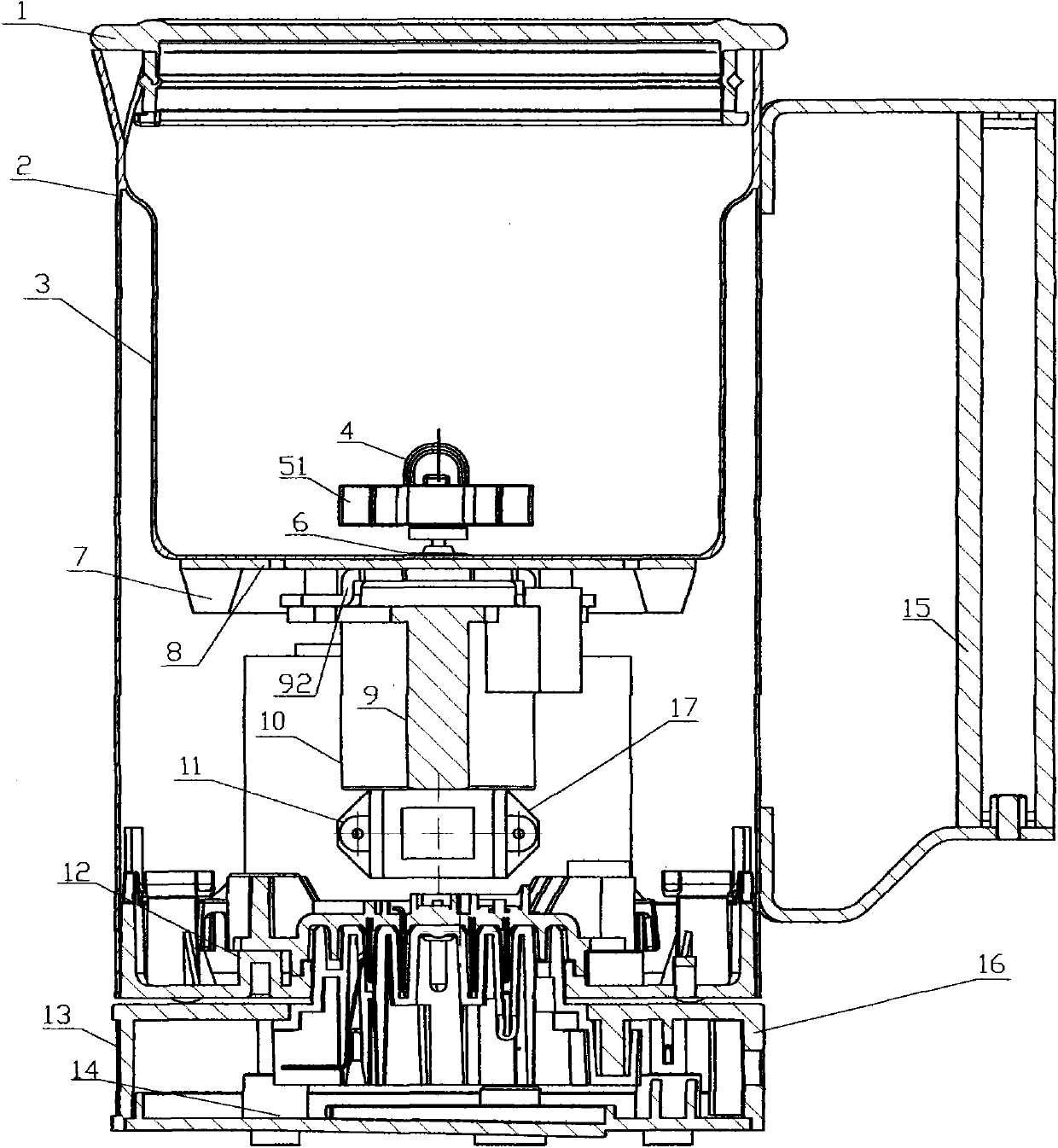

Milk foam machine directly driven by motor

ActiveCN101904700ASimple structureGood shaft seal performanceKitchen equipmentElectric machineLiquid state

Owner:GUANGDONG MASTER ELECTRICAL APPLIANCE CO LTD

Pretreatment liquid for direct injection of polyester fiber through dispersive ink and direct injection digital printing process

The invention discloses a pretreatment liquid for direct injection of polyester fiber through dispersive ink and a direct injection digital printing process. The pretreatment liquid comprises, by mass, 0.2-5 parts of thickener, 1-10 parts of dispersion promoter, 2-5 parts of sodium chloride and 76-95 parts of water. The pretreatment liquid is semi-thick liquid, polyester fabric after going through impregnation or padding treatment liquid is dried, injection printing of dispersive dye ink is performed, high-temperature steaming baking is performed for color fixing after drying, water washing is performed, and then drying is performed to obtain a printing finished product. The pretreatment liquid is simple to prepare, convenient to use and suitable for direct injection process digital printing of all fabric high in polyester content, and the pretreatment liquid is easy to wash away after printing, so that hand feel of fabric is unaffected. Conventional heat transfer printing is replaced by the dispersive direct injection process, and transfer printing paper is not used, so that the direct injection digital printing process is environment-friendly. The pretreatment liquid can effectively prevent ink from spreading around on the polyester fabric, so that patters are ensured to be exquisite and lines are ensured to be clear after printing; color yield rate is high, printing is saturated and bright in color, and visual three-dimensional sense is high.

Owner:深圳市墨库图文技术有限公司

Solidified agent for drilling well waste mud

InactiveCN1792898APrevent seepageHigh strengthSludge treatment by de-watering/drying/thickeningSludgeWell drilling

Owner:刘茂平

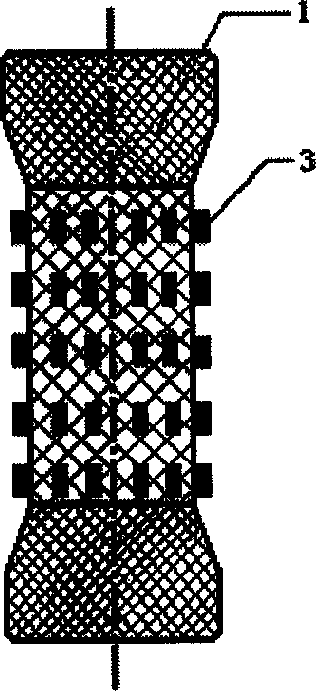

Digestive tract stent with anti-cancer medicinal particles

InactiveCN1792380AFree from pollutionControl drug loadingOrganic active ingredientsSurgeryTopical treatmentTubular stenosis

A scaffold of the granular anticancer medicine for treating the benign or malignant stenosis of esophagus and digestive tract is disclosed, which has 4 structures consisting of scaffold, granular anticancer medicine, selective coated film on the surface of scaffold, and selective external protective layer.

Owner:SHANGHAI JIAO TONG UNIV

Method for molding headrest of vehicle

The invention provides a molding method for manufacturing a headrest of a vehicle by applying an improved pour in place method. The headrest comprises a preassembled trim cover and a framework, wherein the trim cover is formed by compounding a fabric surface, a PU layer and a TPU film layer; the preassembled trim cover and the framework are placed in a die; a foaming raw material is poured through an opening of the trim cover which penetrates the framework; and the die is closed to manufacture a final product through a curing process, wherein the highest point of the headrest is selected as an exhaust position which is provided with a plurality of fine, narrow and long linear notches. The fabric surface is made of a permeable material, when the opening of the trim cover is not the highest point of the product, an invisible position on a flange of the trim cover is selected as the exhaust position; and the exhaust position is provided with a plurality of impermeable holes.

Owner:YANFENG ADIENT SEATING CO LTD

Underground gas plugging coating in coal mine

This invention provides an underground gas plugging coating in coal mine, consisting of an individually packaged liquid material and a powder material in the weight ratio of 0.3 to 0.45: 1; wherein the powder material comprises the following components by weight percentage: 30% to 45% of concrete, 30% to 40% of quartz powder, 5% to 10% of talcum powder, 5% to 10% of flyash, 7% to 13% of aluminium hydroxide, 0% to 4% of magnesium hydroxide, 2% to 4% of ammonium polyphosphate, 1% to 2% of melamine, 1% to 2% of pentaerythritol and 1% to 1.5% of carbon fiber; the liquid material is flexible styrene-acrylate emulsion or flexible pure acrylic emulsion. The coating is characterized by flame retardancy, antistatic property, watertightness, tight bonding with the coal wall and elasticity, further more, can prevent the gas from leaking after being sprayed on the coal wall, and reduce the gas concentration in the laneway.

Owner:SHANXI LUAN ENVIRONMENTAL ENERGY DEV +1

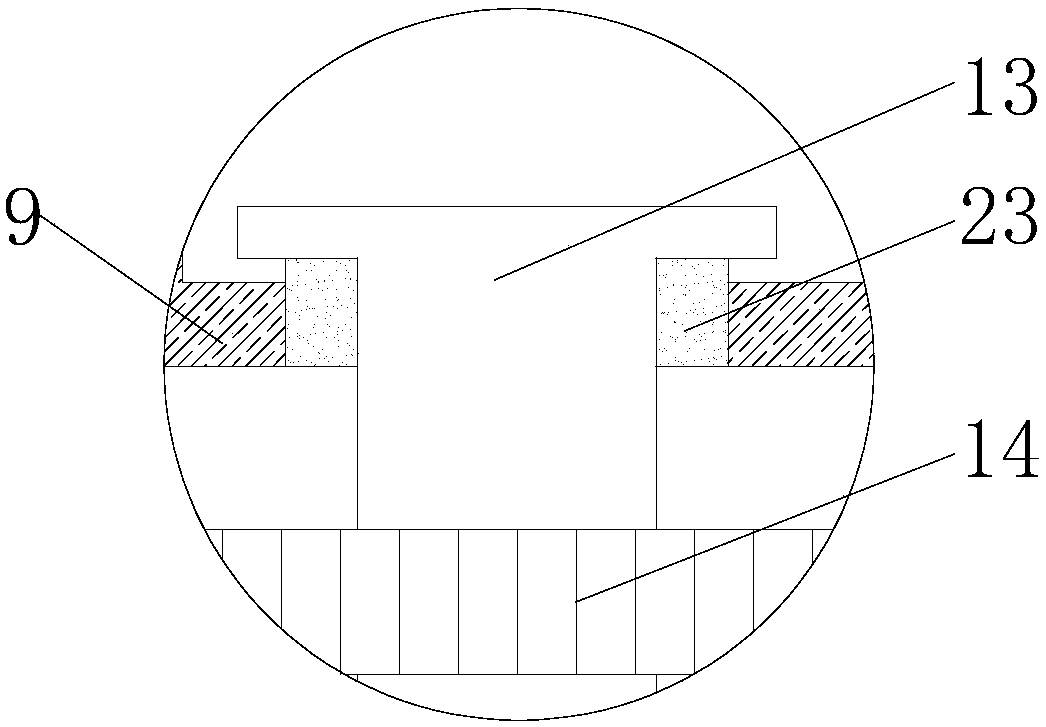

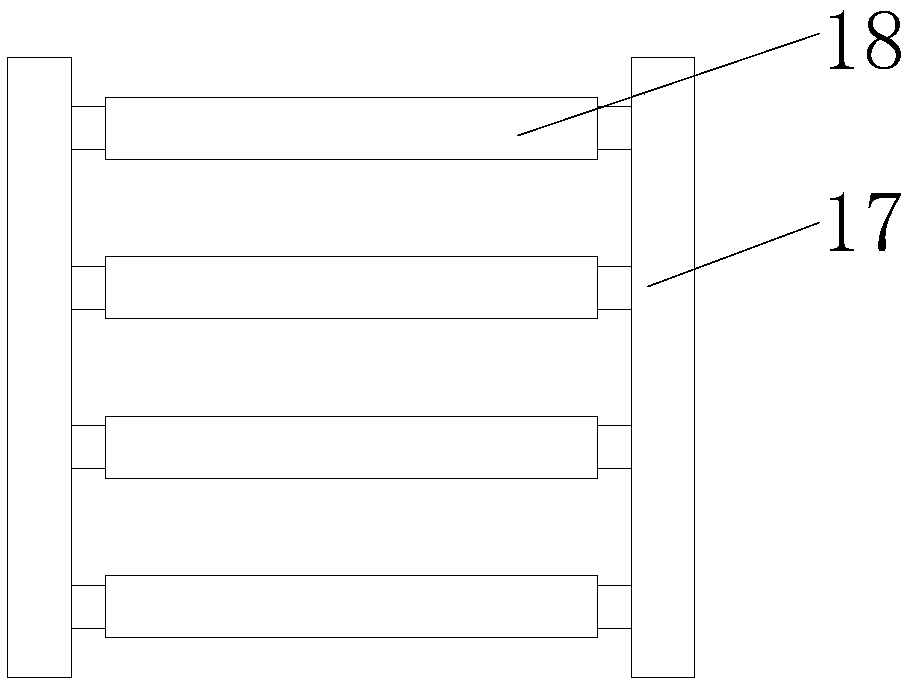

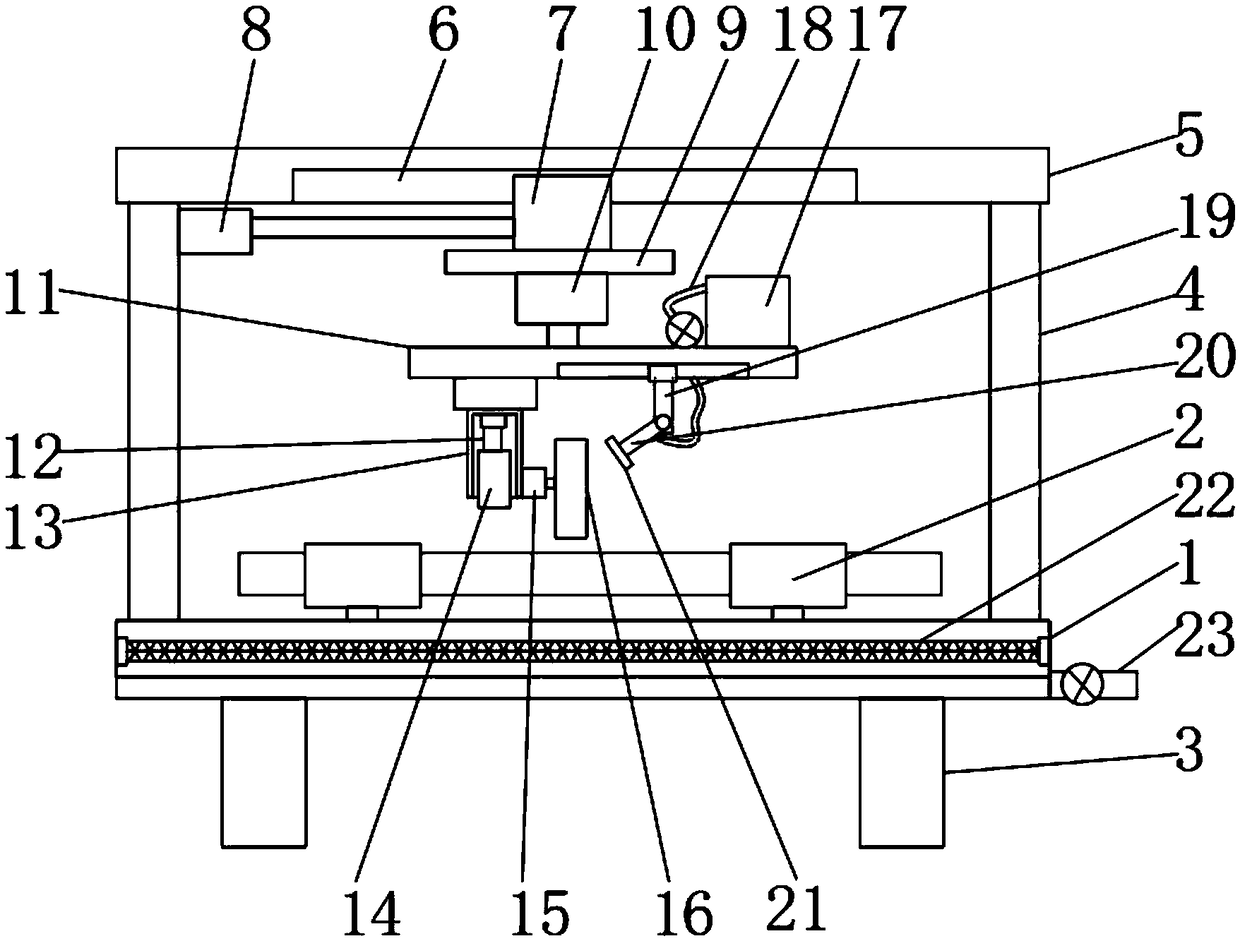

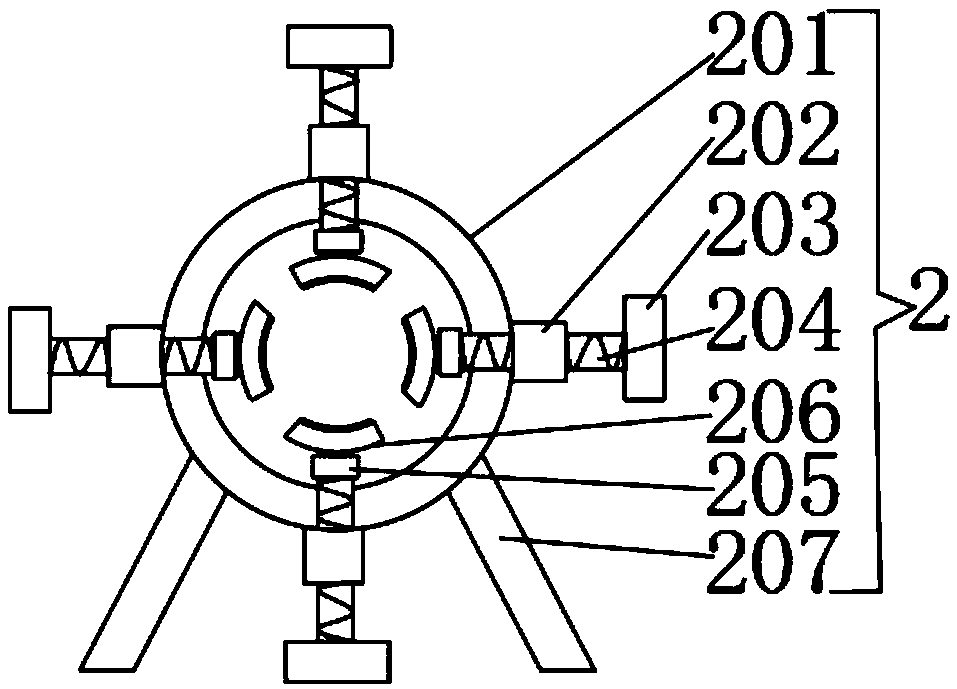

Rock fracture frost heaving deformation testing device

ActiveCN105334240AImprove test accuracyPrecise frost heave displacementMaterial thermal analysisEngineeringFrost heaving

The invention discloses a rock fracture frost heaving deformation testing device. The bottom of a bottom plate is provided with screw holes, and bases are mounted at the bottom of the bottom plate. A frame is welded to the bottom plate. A fastening support and a fastening stop dog are welded to the bottom plate. A fastening bolt is mounted on the fastening support. A rubber gasket is arranged at the tail end of the fastening bolt. Locating stop dogs are welded to the bottom plate. The two ends of each test point fixing web are welded to the bottom plate and the frame respectively. The fixing webs are provided with slide grooves and compensation block containing grooves. Slide blocks are arranged at the two ends of a strain sheet laying strip and embedded in the slide grooves. Test point locating screws are arranged on the slide blocks. A strain sheet is pasted to the strain sheet laying strip and connected with a wire. A temperature compensation strain sheet is pasted to quartz glass. A wire laying plate is mounted between the bottom plate and the frame. The wire is led out of the wire laying plate. The rock fracture frost heaving deformation testing device is simple in structure, high in test accuracy and capable of accurately and continuously testing frost heaving deformation of rock mass factures in the frost heaving process to obtain fracture deformation characteristics at different frost heaving stages.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

Ink-jet oil painting canvas and manufacturing method thereof

The invention discloses an ink-jet oil painting canvas. The oil painting canvas comprises a base material, a bottom coating layer and a surface coating layer from bottom to top in sequence, wherein the bottom coating layer comprises the following components in parts by weight: 35-45 parts of filler, 1-3 parts of polyvinyl alcohol, 30-40 parts of a bonding agent, 0.5-2 parts of an additive and 10-30 parts of water; the surface coating layer comprises the following components in parts by weight: 10-15 parts of silicon dioxide, 1-3 parts of polyvinyl alcohol, 30-40 parts of a special bonding agent, 0.5-2 parts of an additive, 1-5 parts of an anti-bleeding agent, and 30-50 parts of water. The ink-jet oil painting canvas disclosed by the invention has the advantages that the matching and the bonding strength of the ink-jet oil painting canvas with latex used in Latex ink are good, and when the Latex ink is used for ink-jet printing, the ink can be cured on the surface coating layer at low temperature, and high color fastness can be obtained; simultaneously, the extra anti-bleeding agent is added into the surface coating layer, so that the bleeding of ink can be prevented, the edges of a painting are clear and the color expressiveness is excellent.

Owner:JIANGSU GEMEIGAO DEV CO LTD +1

High-performance silicon-based thermal-conducting gel and preparation method thereof

The invention discloses high-performance silicon-based thermal-conducting gel and a preparation method thereof. The silicon-based thermal-conducting gel is prepared from organic silicone gel, hydrogen-containing silicone oil, hydroxyl silicone oil and thermal conductive powder, wherein the thermal conductive powder is prepared by polar matching of different kinds of powder according to large, medium and small particle sizes. The high-performance silicon-based thermal gel has excellent thixotropy, high thermal conductivity and good blocking property and is capable of replacing a thermal gel gasket; operation can be carried out by a dispensing machine in application; the production efficiency is greatly improved; a macromolecular structure in thermal conductive mud is connected into a mesh in the fabrication process; seepage of low molecular silicone oil is effectively blocked; and the high-performance silicon-based thermal gel has relatively high high-temperature resistance, is simple and feasible in preparation method, simple to operate in application, safe and reliable.

Owner:江苏晶河电子科技有限公司

Room-temperature curing epoxy resin pouring sealant for permanent magnet motor as well as preparation method and process thereof

ActiveCN102304275ALong operating timeHigh heat resistance indexManufacturing dynamo-electric machinesHeat resistanceFatty amine

The invention discloses a room-temperature curing epoxy resin pouring sealant for a permanent magnet motor as well as a preparation method and process thereof. According to the invention, the resin comprises an epoxy resin A component and a curing agent B component, wherein the epoxy resin A component comprises the following ingredients in parts by weight: 100 parts of bisphenol A epoxy resin, 10-15 parts of active diluent and 5-10 parts of thixotropic agent; the curing agent B component comprises the following ingredients in parts by weight: 15-25 parts of fatty amine, 10-15 parts of modified aromatic amine and 5-10 parts of polyether amine. According to the invention, when in use, the epoxy resin A component and the curing agent B component are mixed in a proportion of (3-4):1 and then poured into the pretreated permanent magnet motor. The epoxy resin pouring sealant has the characteristics of high heat resistance, high strength and long operation time, and can be cured at room temperature; and the sealant pouring process is unique and novel, is simple and safe to operate, and the fixation problem of magnetic steel in a permanent magnet motor rotor can be well solved by the sealant pouring process.

Owner:ZHUZHOU TIMES ELECTRIC INSULATION

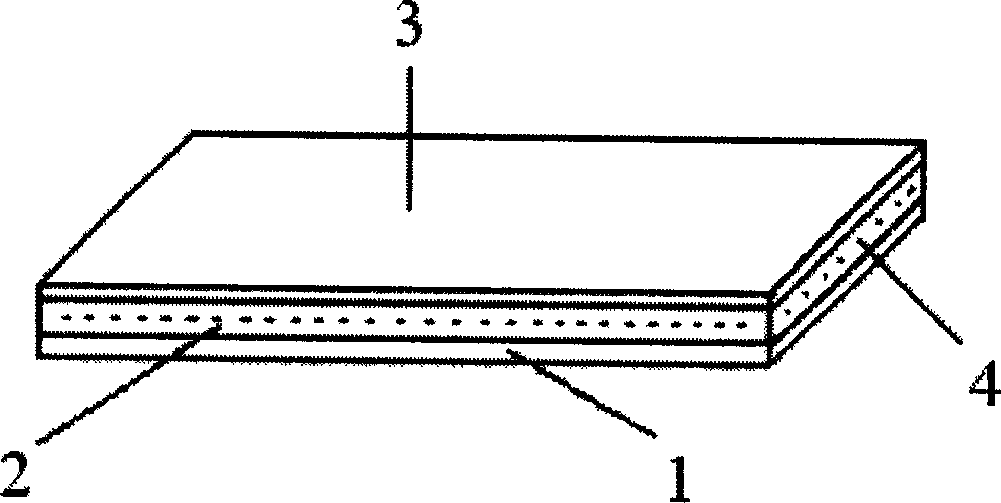

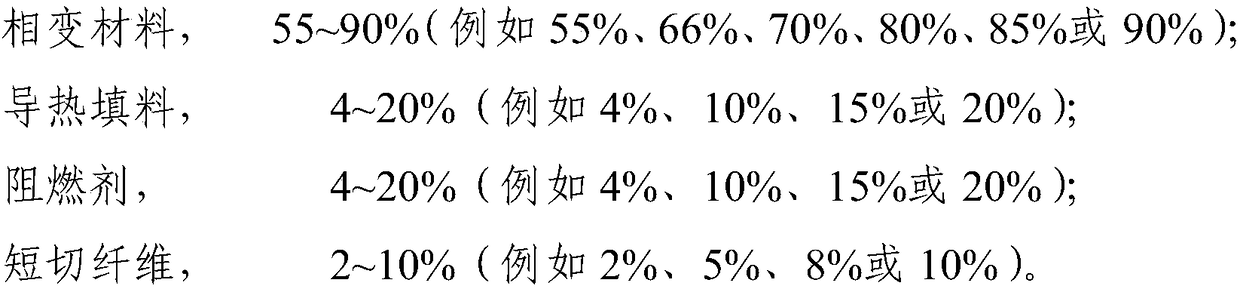

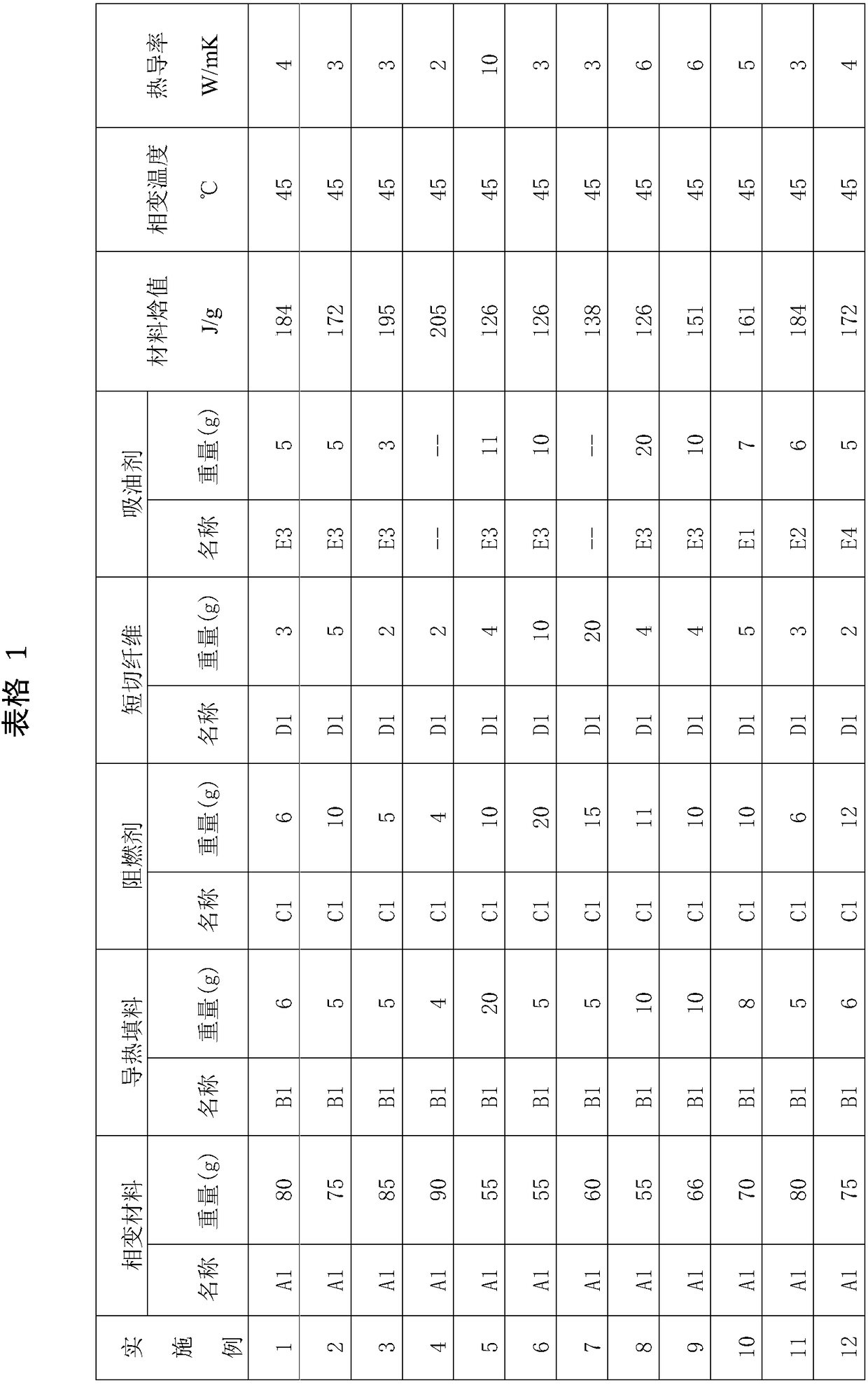

Phase-change-material-based thermal management material, preparation method and applications thereof

ActiveCN108199113AImprove thermal conductivityGood temperature control functionSecondary cellsHeat-exchange elementsFiberPhase-change material

The invention relates to a phase-change-material-based thermal management material, a preparation method and applications thereof, wherein the thermal management material comprises, by mass, 55-90% ofa phase change material, 4-20% of a thermal conduction filler, 4-20% of a flame retardant, and 2-10% of chopped fiber. According to the present invention, by adding an appropriate amount of the chopped fibers, the deformation of the phase change material due to volume expansion or contraction can be effectively prevented, such that the content of the phase change material in the thermal management material can be substantially increased so as to improve the heat storage capacity of the thermal management material and stably regulate and control the temperature.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Curing agent and curing method for titanium-extracted tail slag

InactiveCN107098614APrevent harmful elements from seeping outReasonable ratioSolid waste disposalSlagFirming agent

The invention discloses a curing agent and a curing method for titanium-extracted tail slag and relates to the field of environment protection. The curing agent comprises 5-30 parts of excitant, 5-30 parts of enhancer and 0.5-1 part of waterproof agent, a main ingredient of the excitant is active calcium oxide, and a main ingredient of the enhancer is calcium sulfate. The calcium oxide and the calcium sulfate in the curing agent can react with glass in the titanium-extracted tail slag to efficiently generate a cured body. The waterproof agent forms a hydrophobic protection layer on the surface of the cured body, so that harmful elements can be effectively prevented from seeping. The curing agent is reasonable in proportion, and the cured body has the advantages of high strength and low harmful element seepage. Using the curing agent to cure the titanium-extracted tail slag is convenient to operate and needless of complex equipment, the titanium-extracted tail slag can be efficiently cured to obtain the high-strength cured body through simple mixing and standing, and the curing agent is suitable for instant use on an operation site and fit for being popularized and applied in industrial production.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

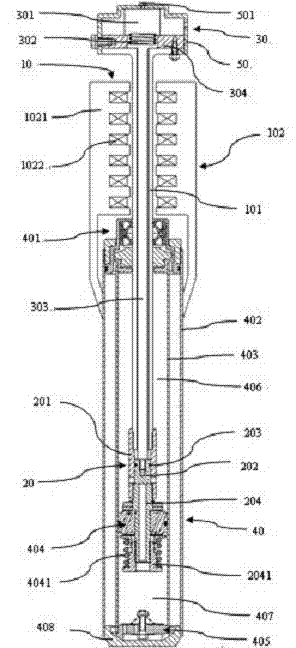

Semi-active suspension energy-regenerative device of hybrid vehicle

InactiveCN103192673APrevent seepageSpringsResilient suspensionsAutomotive engineeringElectric generator

The invention relates to a semi-active suspension energy-regenerative device of a hybrid vehicle and belongs to the technical field of energy saving and emission reduction of vehicles. A barrel-type straight line generator is integrated in a traditional passive shock absorber, and a throttling port is arranged on a piston rod to enable damping force of the shock absorber to be adjustable. When a vehicle is driven normally, the piston rod serving as an active cell and a stator perform relative motion, alternating current power is sensed in a armature winding, a battery is charged through an energy-regenerative circuit, and accordingly a part of vibration energy of a suspension system is recovered in the vehicle running process. In addition, the size of the throttling port can be adjusted according to vehicle running work conditions so as to change the damping force of the shock absorber and improve smoothness, operation stability and safety of the vehicle.

Owner:JIANGSU UNIV

PE pipe cutting device

InactiveCN108705583AEasy to fixEasy to grindEdge grinding machinesMetal working apparatusHydraulic cylinderSpray nozzle

The invention discloses a PE pipe cutting device in the technical field of building materials. The PE pipe cutting device comprises a base. Clamping devices of the same structure are arranged on two sides of the top of the base. Supporting rods are symmetrically arranged on two sides of the top of the base. A top plate is arranged at the tops of the two sets of supporting rods. A first sliding block is arranged at the bottom of the top plate. A hydraulic cylinder is arranged at the bottom of an installing plate. The bottom of the hydraulic cylinder is connected with a connecting plate througha push rod. A cutting motor is fixedly arranged at the bottom of the right side of a shell. A cutter blade is arranged at the output end of the cutting motor. A hollow rod is arranged at the bottom ofa connecting rod through a rotary shaft. A spraying nozzle is arranged at the bottom of the hollow rod. A cooling liquid box is arranged at the right side of the top of the connecting plate. The clamping devices can fix a pipe conveniently, and therefore the situation that the pipe is misplaced during cutting, and a cutting opening is not flat is avoided. A first hydraulic telescopic rod pushes the first sliding lock, so that the position of the cutter blade is adjusted conveniently, and pipes with different lengths can be cut conveniently.

Owner:朱巧珍

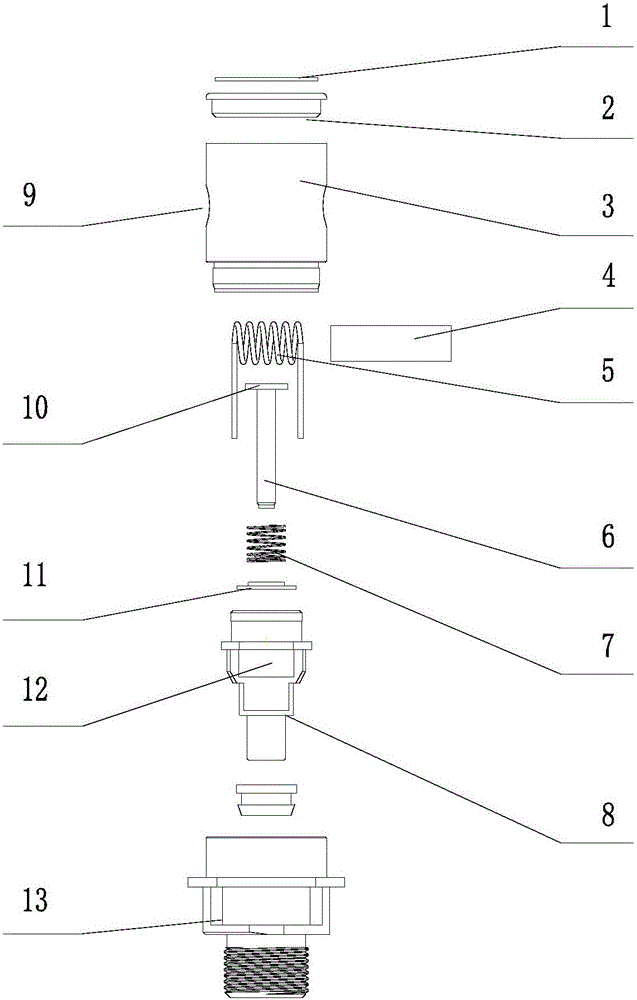

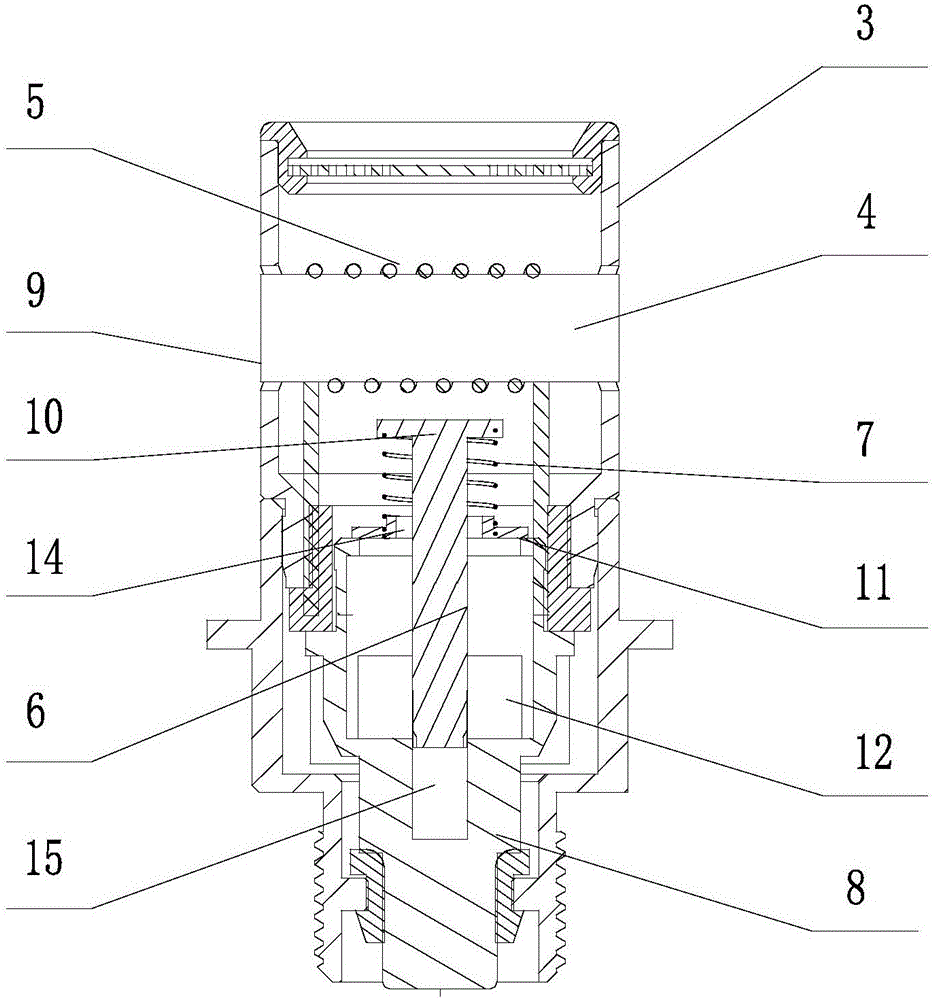

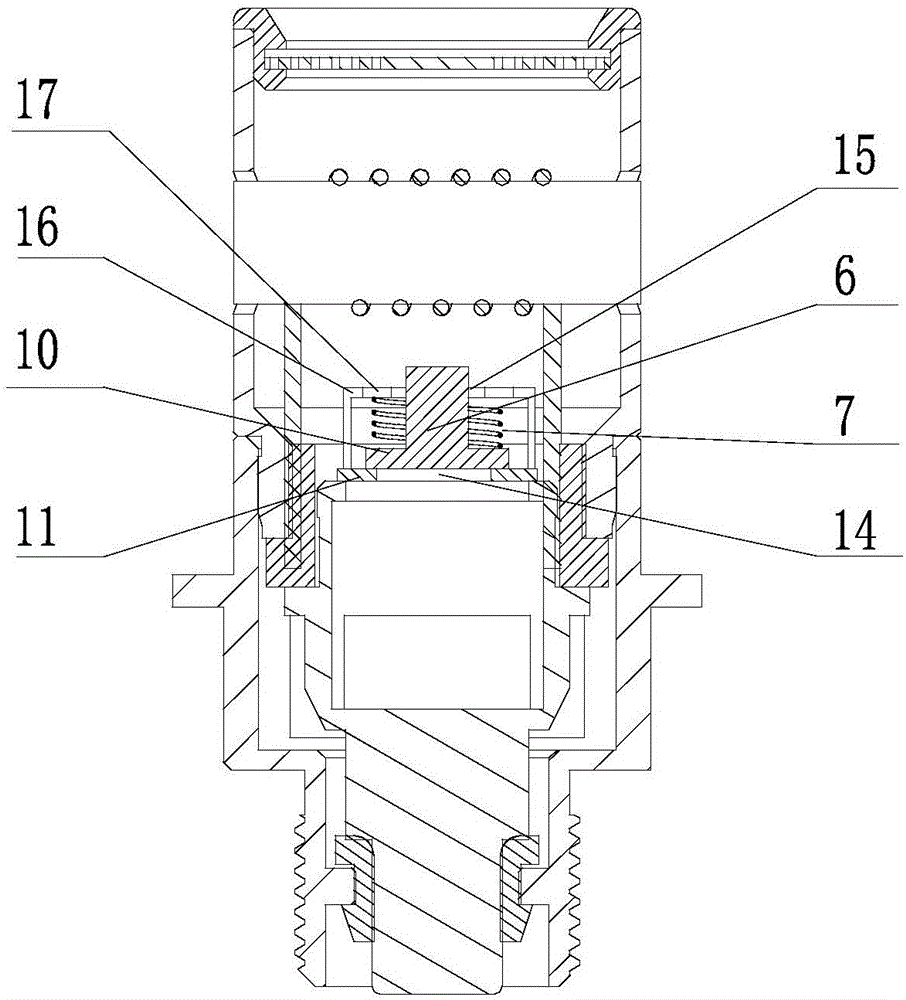

One-way ventilation electronic cigarette atomization core

ActiveCN105768233AOvercome the defect of leakagePrevent seepageTobacco devicesElectricityElectronic cigarette

The invention discloses a one-way ventilation electronic cigarette atomization core, comprising an atomization core outer barrel, a heater and a conductive connecting column, wherein the conductive connecting column is arranged at the bottom of the atomization core outer barrel in a connecting way; the heater is positioned in the atomization core outer barrel; an electrode of the heater is electrically connected with the conductive connecting column; an air inlet and an air outlet are formed in the atomization core; the air outlet is formed in the upper end of the atomization core outer barrel, the air inlet is formed in the conductive connecting column at the bottom of the atomization core outer barrel, an internal airflow channel of the atomization core is formed between the air inlet and the air outlet, and a one-way ventilation valve is arranged on the internal airflow channel. Due to the arrangement of the one-way ventilation valve, one-way ventilation is realized. The smoking airflow direction is only through, and the reverse direction is not through. An air inlet airflow channel is closed when not smoking, so that dirt is prevented from falling into the atomization core. The air inlet airflow channel can be sealed by the one-way valve when not smoking, so that the aim of avoiding leakage of electronic cigarette liquid is achieved.

Owner:INNOKIN TECH

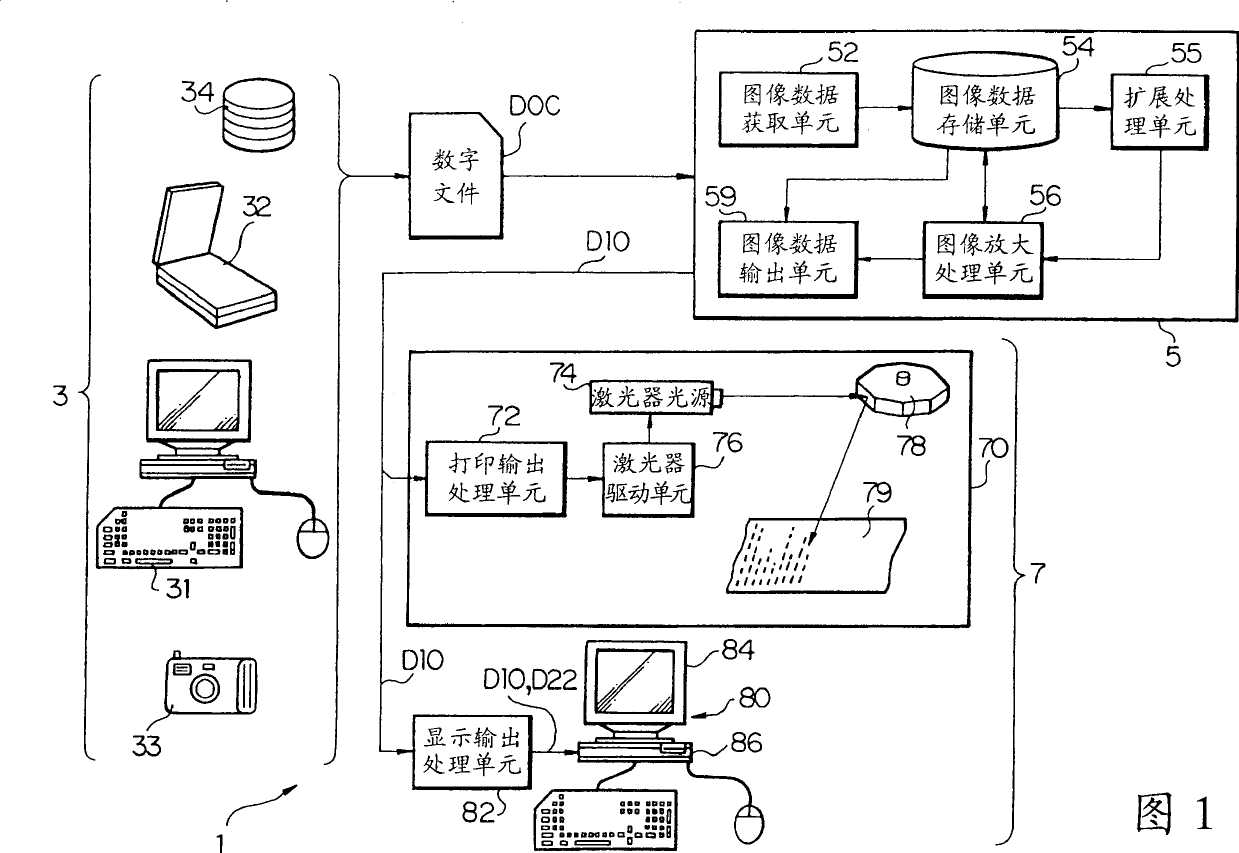

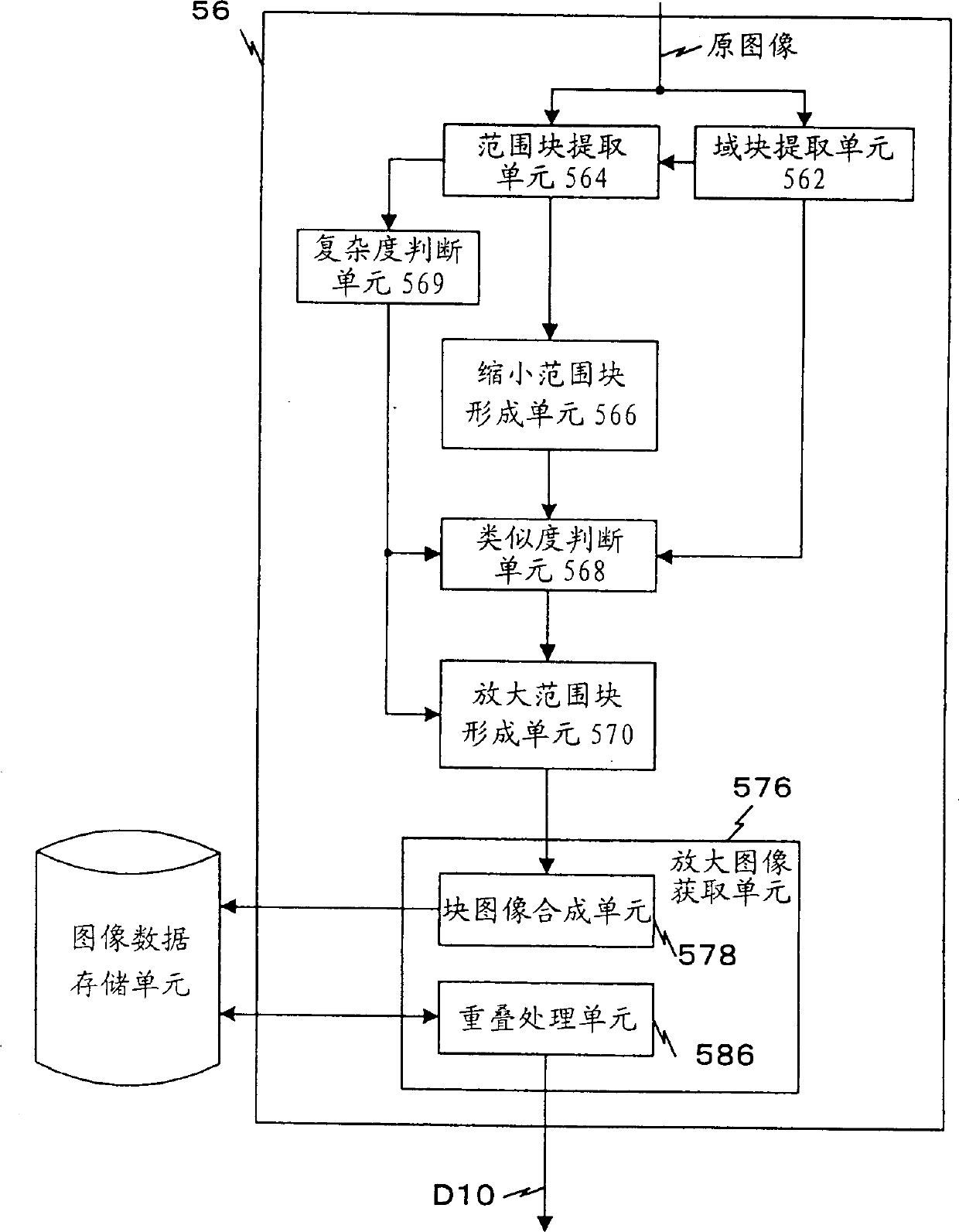

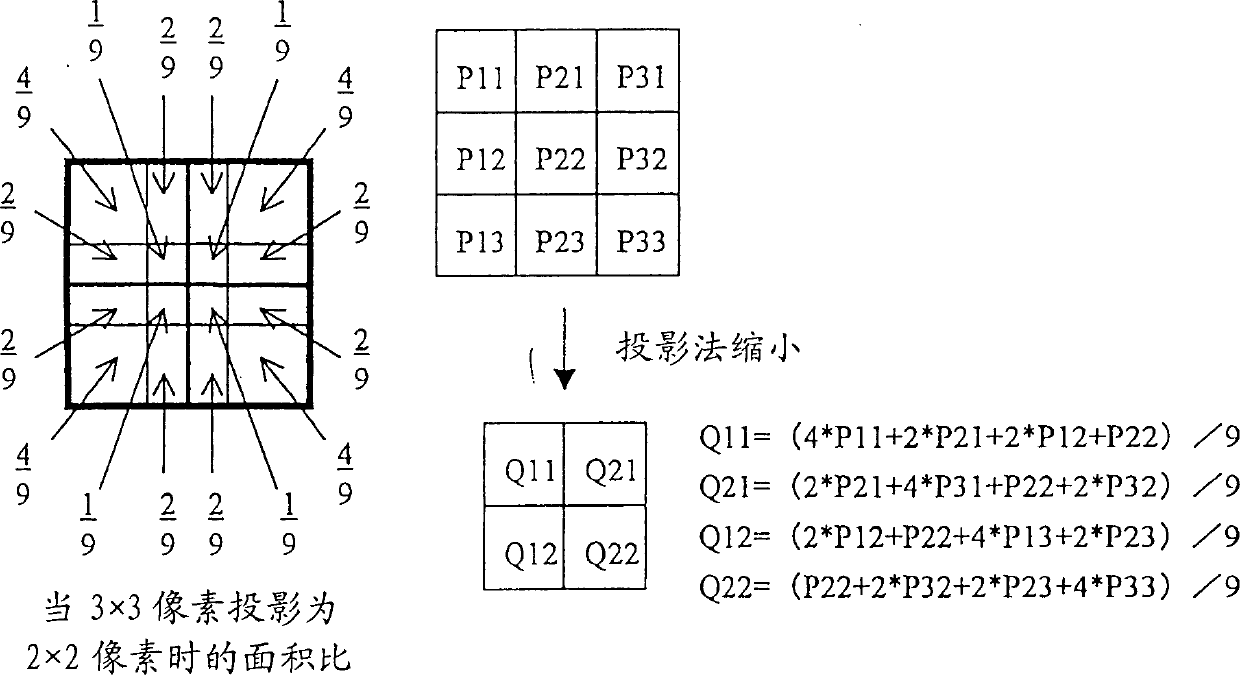

Image processing equipment and program

InactiveCN1417745ALarge blur componentSuppression of distortionTelevision system detailsGeometric image transformationPattern recognitionImaging processing

A domain block extracting unit extracts a domain block image from an original image. A range block extracting unit extracts a range block image from an area in the vicinity of the domain block image. The range block image has size being larger than a domain size and being smaller than an enlarged size. A reduced range block forming unit reduces the range block image to the domain size to produce a reduced range block image. A similarity judging unit compares each of the reduced range block images with the domain block image to select the highest similarity range block image. An enlarged range block forming unit forms an enlarged range block image by enlarging the size of the highest similarity range block image to an enlarged size thereof. An enlarged image acquiring unit produces an enlarged image of an original image by employing the respective enlarged range block images.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com