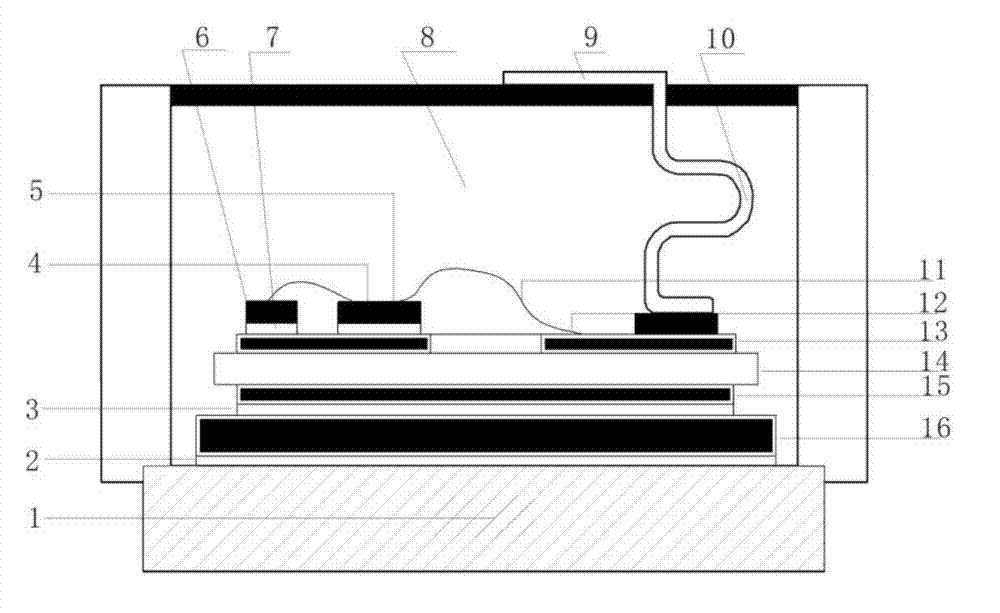

Organic silica gel used for packaging IGBT (insulated gate bipolar translator) module, and preparation method of organic silica gel

A technology of module encapsulation and silicone, which is applied in the direction of circuits, electric solid devices, semiconductor devices, etc., can solve the problems of inability to achieve transparent flame retardancy, low adhesion of substrate materials, and poor adhesion, so as to maintain automatic repairability, Good flame retardant performance and easy pouring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

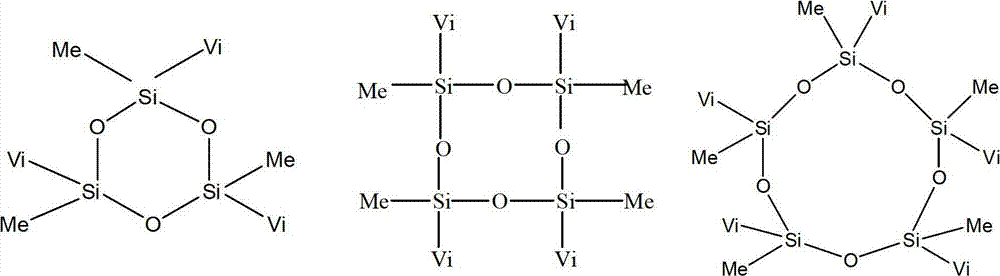

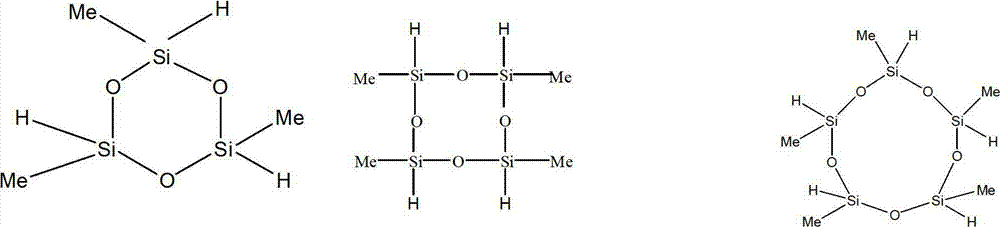

[0081] Preparation of component A: Weigh double-ended vinyl polysiloxane with a viscosity of 500cps (vinyl content: 0.3wt%), such as structural formula 1, 86.7g, with a viscosity of 100cps, end and side vinyl polydimethylsiloxane Oxylkane (vinyl content 6wt%) such as structural formula 2, 6.0g, vinyl liquid MQ resin, such as molecular formula 1 (vinyl content 1.3wt%, a=1.28, b=0.02), 4.0g, γ-(methyl Acryloyloxy)propyltrimethoxysilane 3.0g, platinum-vinylsiloxane complex catalyst 0.3g, content 7000ppm, were added into the mixer in sequence, mixed and stirred evenly, and the A component was obtained;

[0082] Preparation of component B: Weigh double-ended vinylpolysiloxane with a viscosity of 100cps (vinyl content 0.7wt%), such as structural formula 1, 83.47g, vinyl liquid MQ resin, such as molecular formula 1 (vinyl content = 1.3wt%, a=1.28, b=0.02), 6.0g, polymethylhydrogensiloxane, such as structural formula 6, 10.0g, 0.5g of triaryl phosphate, 0.3g of 1-ethynyl cyclohexanol,...

Embodiment 2

[0086] Preparation of component A: Weigh double-ended vinyl polysiloxane (vinyl content 0.42wt%) with a viscosity of 500cps, such as structural formula 1, 83.6g, vinyl ring body (vinyl content 30wt%), such as structural formula 4 , 8.0g, vinyl liquid MQ resin, such as molecular formula 1 (vinyl content 3wt%, a=1.25, b=0.05), 3.0g, γ-(2,3-epoxypropoxy)propyltrimethoxy 2.0g of silane, 0.4g of platinum-vinylsiloxane complex catalyst, content of 5000ppm, were sequentially added into the mixer, mixed and stirred evenly, and the A component was obtained;

[0087] Preparation of component B: Weigh double-ended vinylpolysiloxane with a viscosity of 500cps (vinyl content 0.12wt%), such as structural formula 1, 79.9g, vinyl liquid MQ resin such as molecular formula 1 (vinyl content 3wt%) , a=1.25, b=0.05), 4.0g, terminal and side group polymethylhydrogen siloxane, such as structural formula 8, 15.0g, 1.0g triphenyl phosphate, 0.1g ethynyl cyclohexanol, add to the mixer in turn Inside, ...

Embodiment 3

[0091] Preparation of component A: Weigh double-ended vinylpolysiloxane (vinyl content: 0.1wt%) with a viscosity of 10000cps (vinyl content: 0.1wt%), such as structural formula 1, 83g of terminal and side vinylpolydimethylsiloxane with a viscosity of 2000cps (vinyl content 0.5wt%) such as structural formula 2, 5.0g, vinyl ring body (vinyl content 30wt%) such as structural formula 5, 7.0g, vinyl liquid MT resin such as molecular formula 2 (vinyl content 3.6wt%, a =1.23, b=0.07), 3.0g, 1.0g of vinyltriethoxysilane, 1.0g of complex catalyst of chloroplatinic acid and divinyltetramethyldisiloxane, content 2000ppm, add to the mixer in turn , mix and stir evenly to obtain the A component;

[0092]Preparation of component B: Weigh double-ended vinylpolysiloxane with a viscosity of 450cps (vinyl content 1.2wt%), such as structural formula 1, 85.98g, vinyl liquid MT resin such as molecular formula 2 (vinyl content 3.6wt%) , a=1.23, b=0.07), 5.0g, polymethylhydrogensiloxane, such as st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| dielectric strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com