Patents

Literature

14941results about How to "Small particle size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

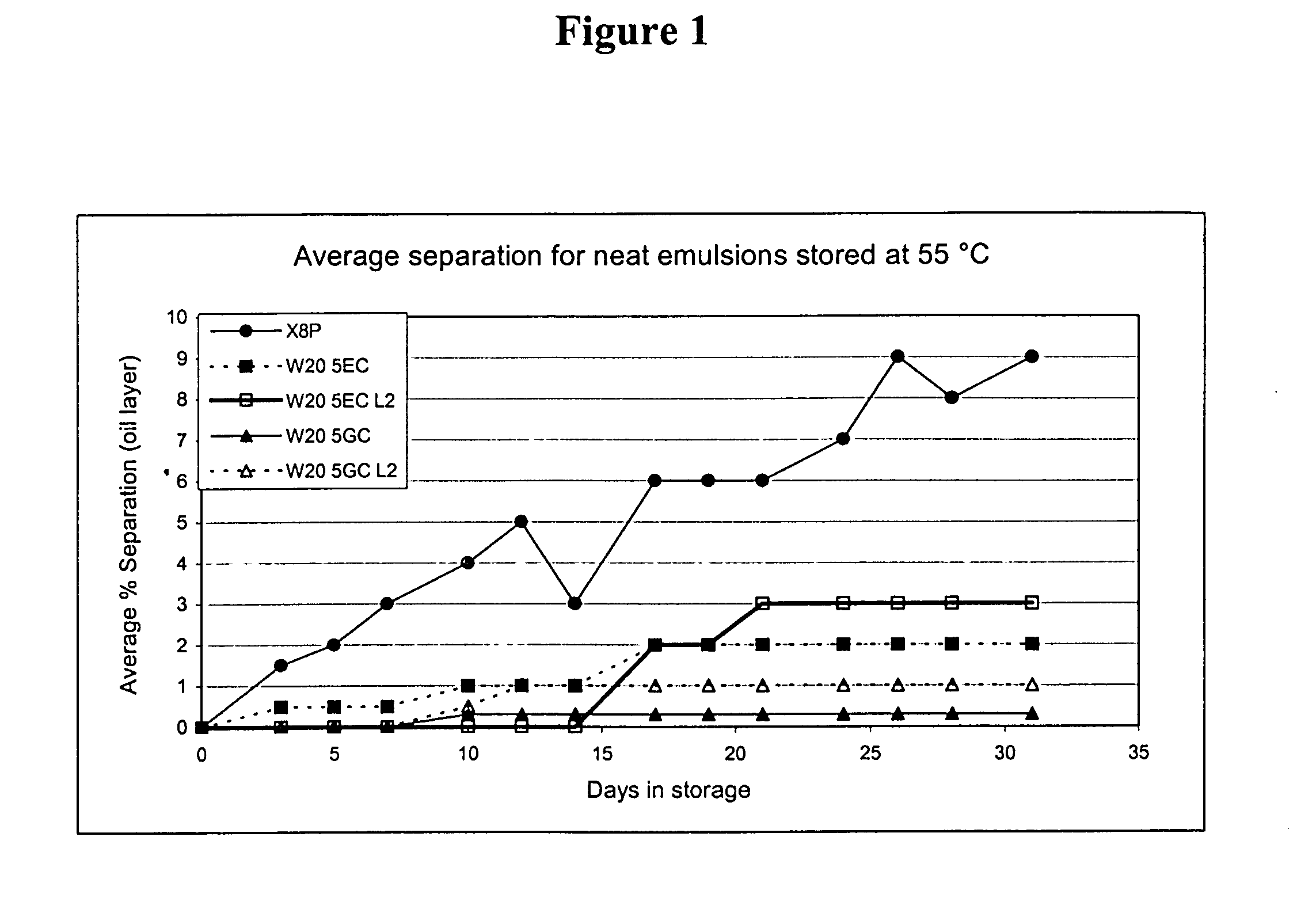

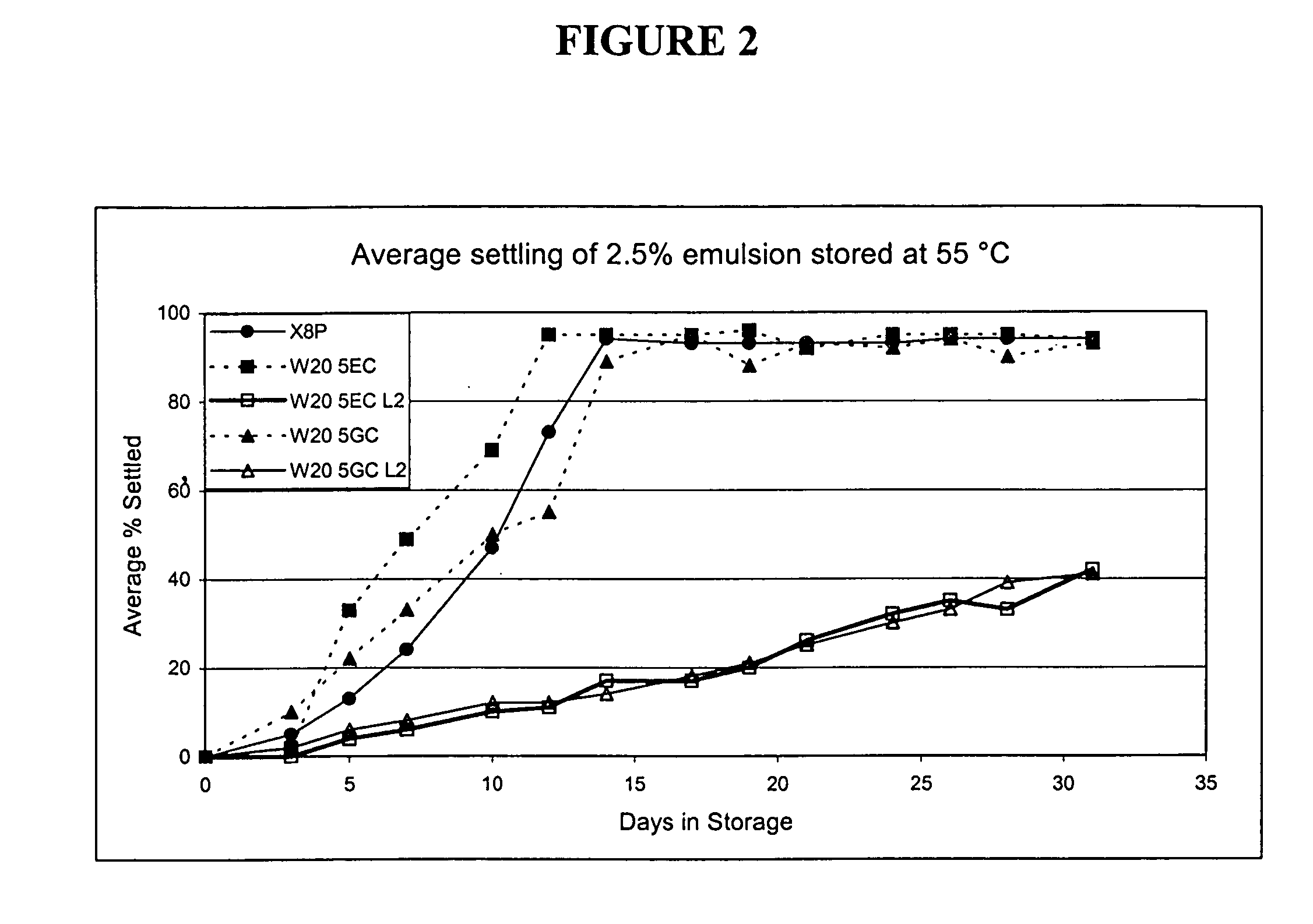

Nanoemulsion compositions having anti-inflammatory activity

InactiveUS20070036831A1Minimizing microbial resistanceMinimize ToxicityAntibacterial agentsBiocidePathogenic microorganismDisease

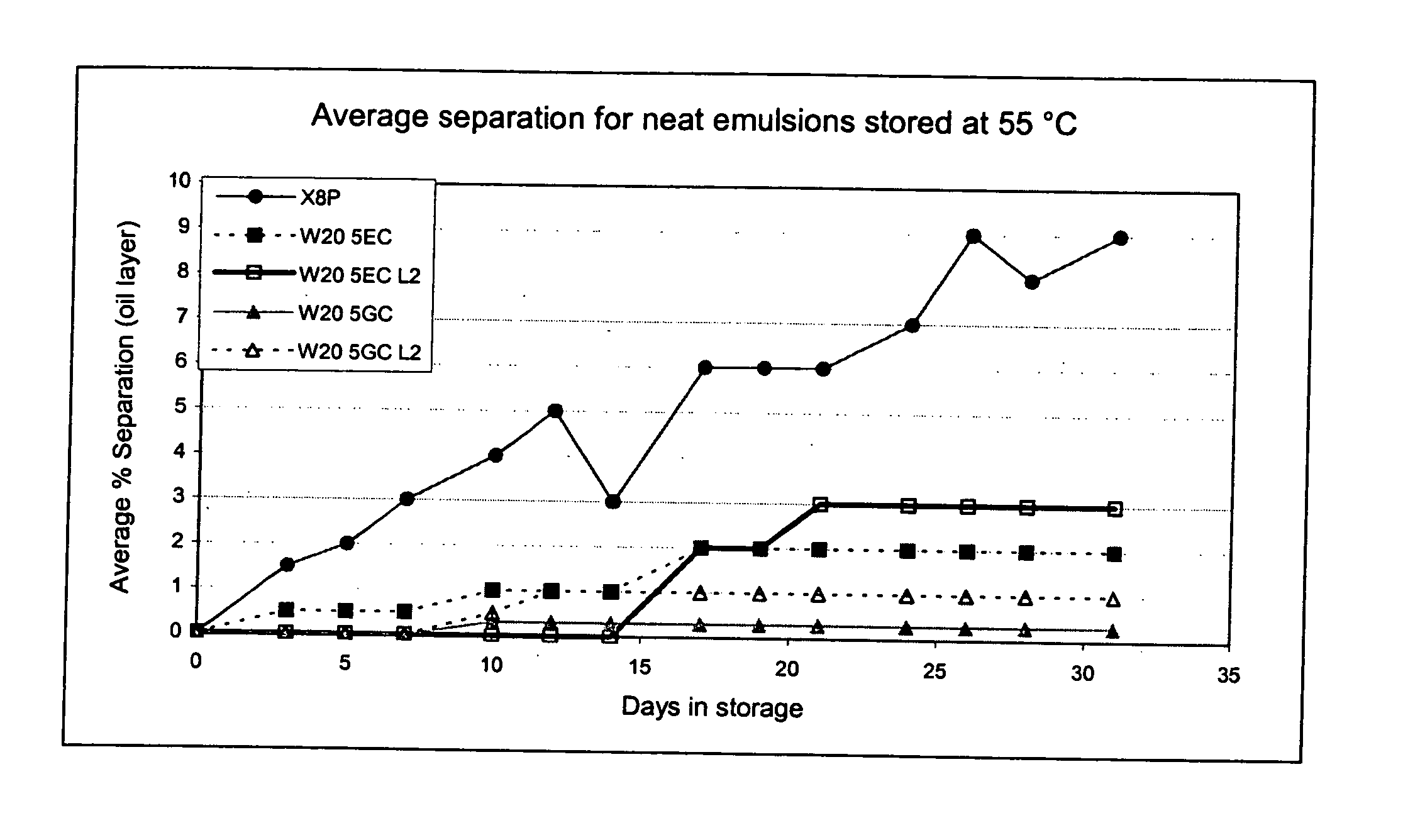

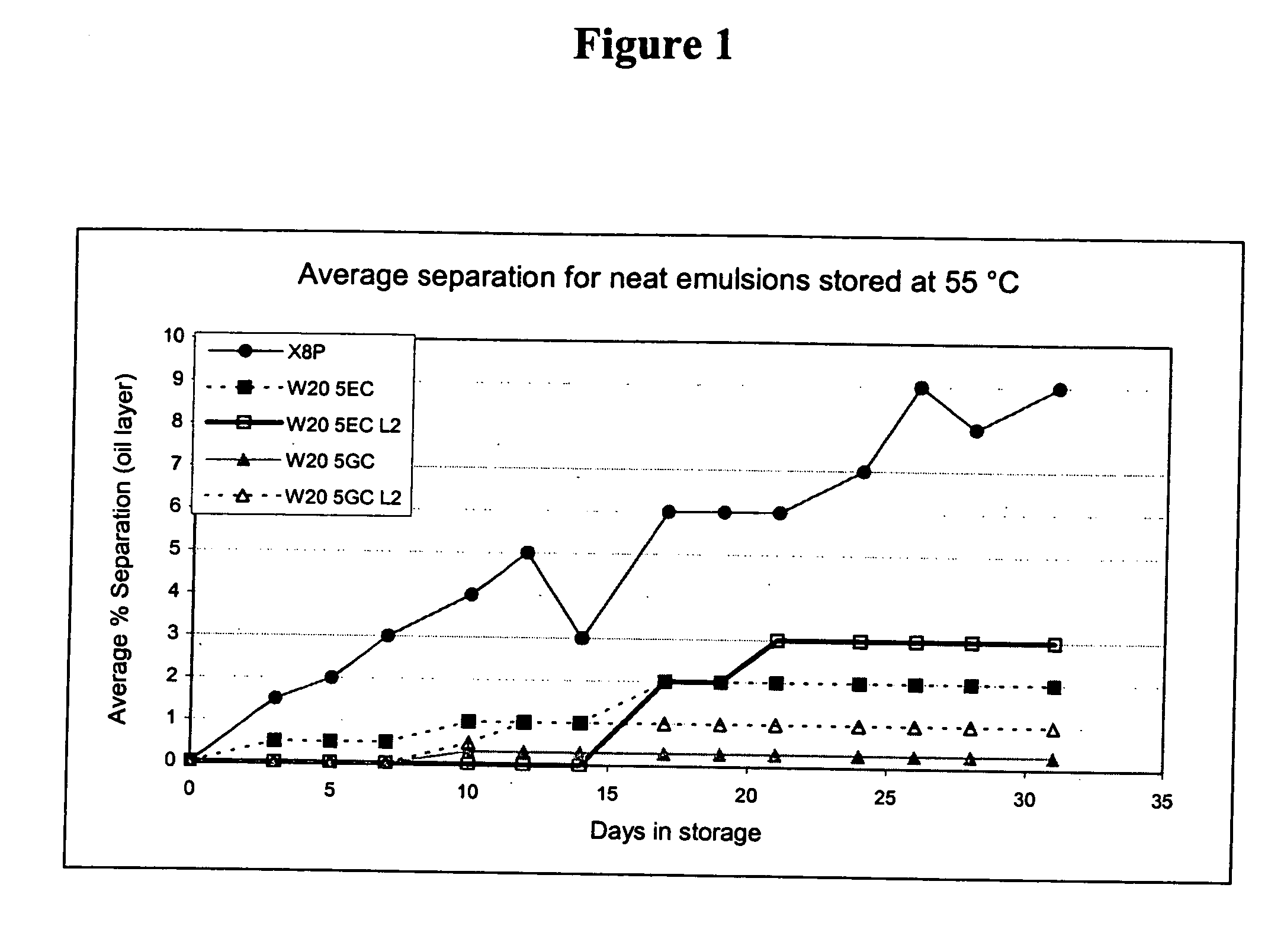

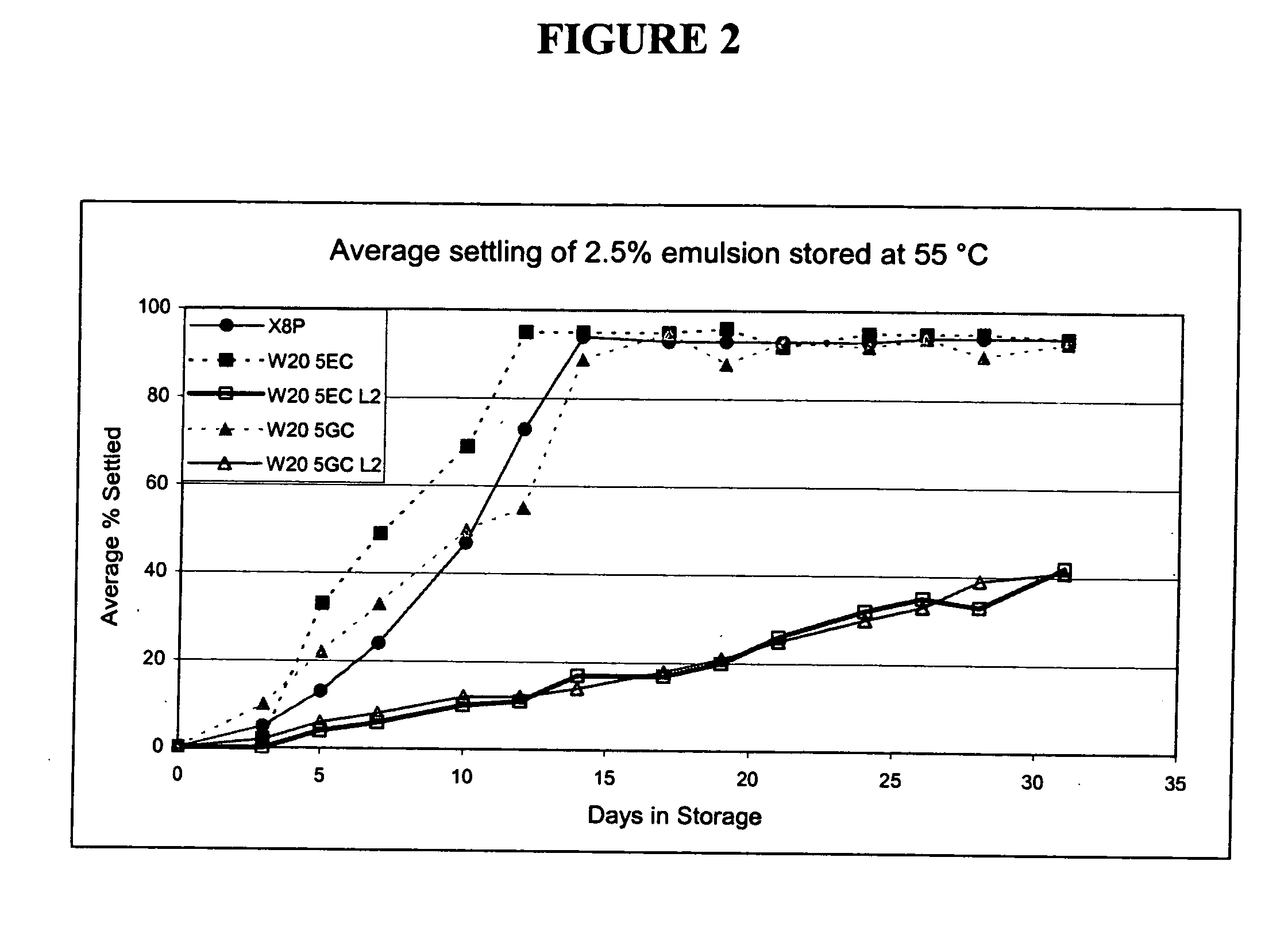

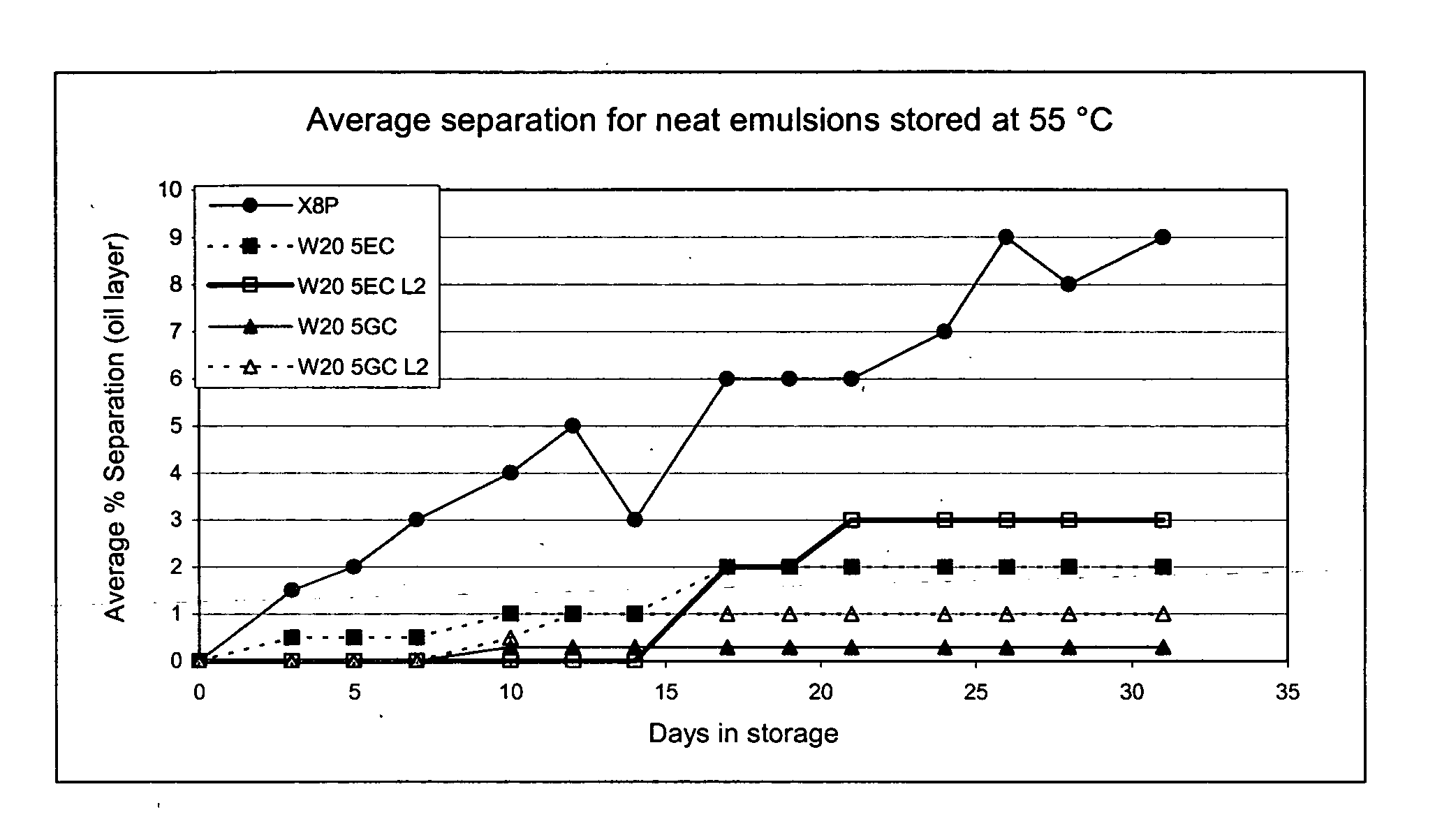

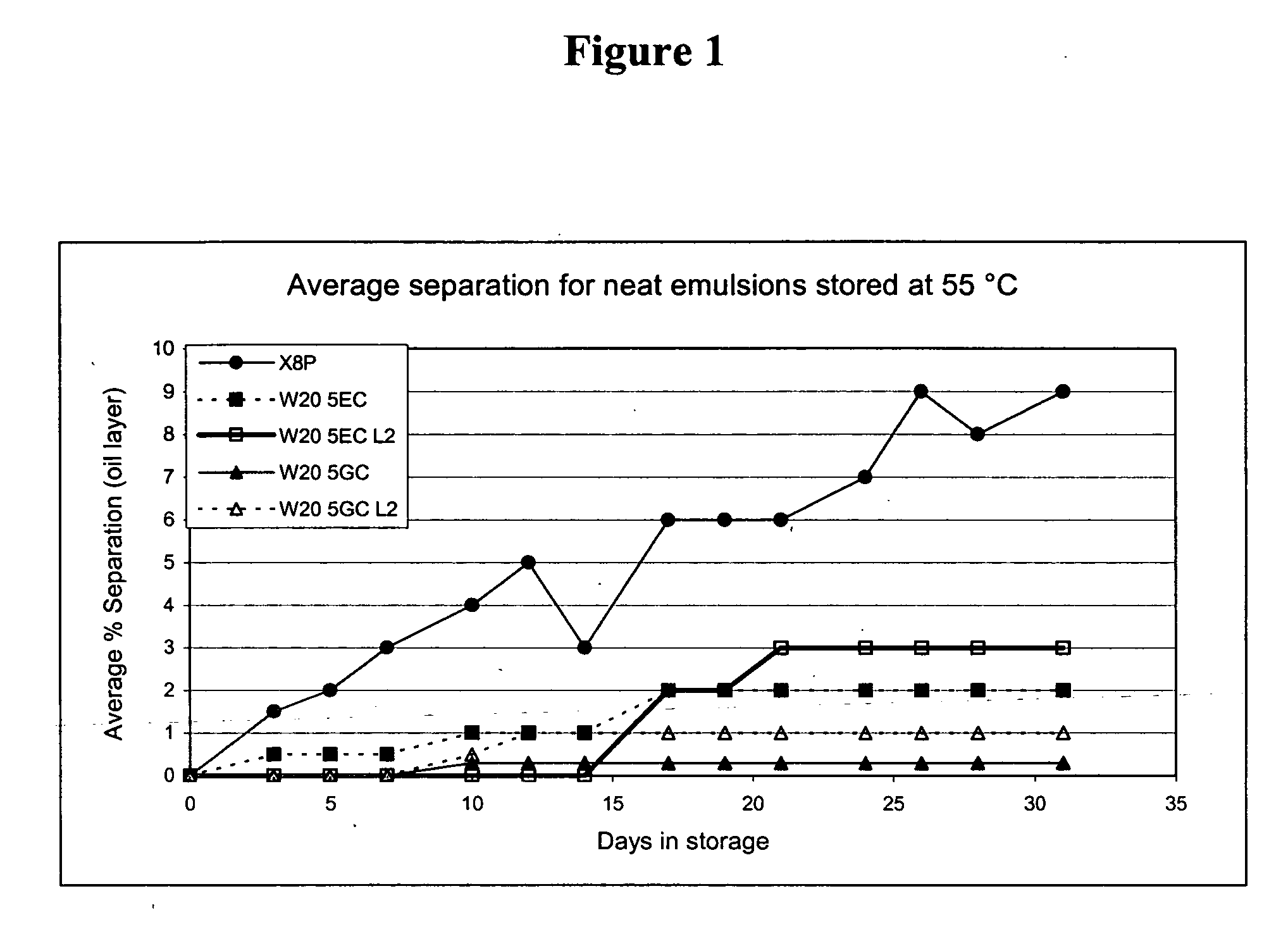

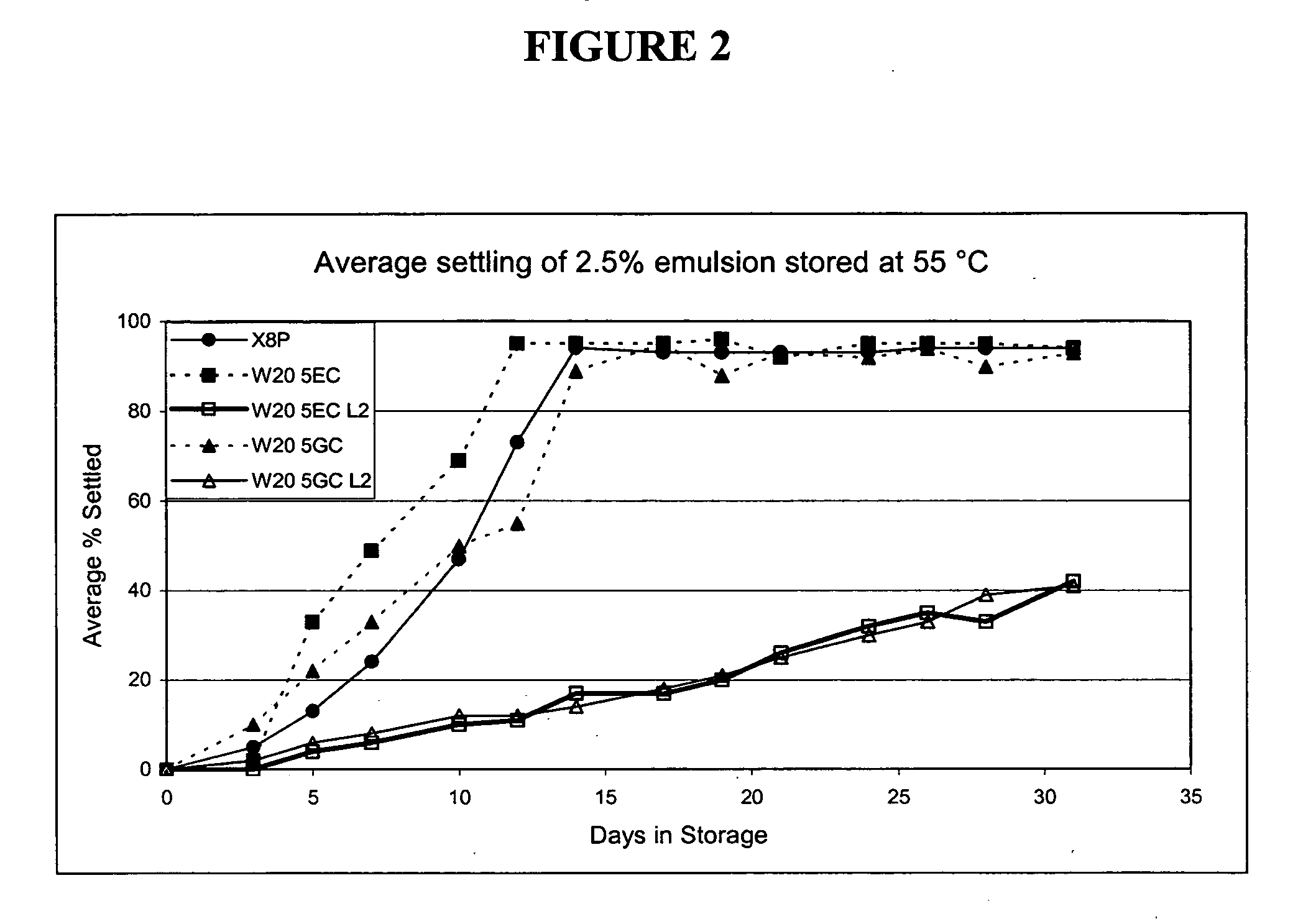

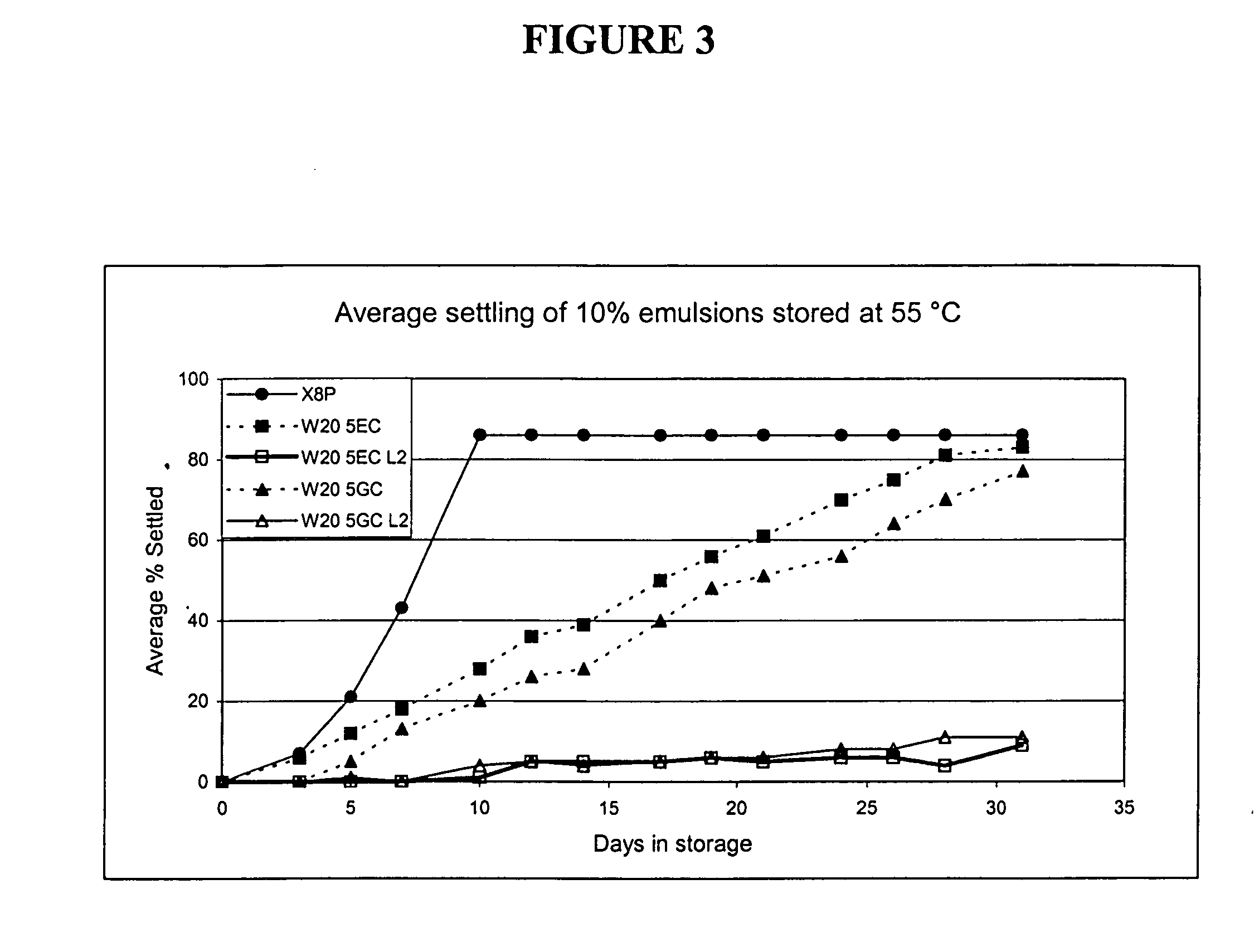

Nanoemulsion compositions with low toxicity that demonstrate broad spectrum inactivation of microorganisms or prevention of diseases are described. The nanoemulsions contain an aqueous phase, an oil phase comprising an oil and an organic solvent, at least one anti-inflammatory agent, and one or more surfactants. Methods of making nanoemulsions and inactivating pathogenic microorganisms are also provided.

Owner:NANOBIO CORP

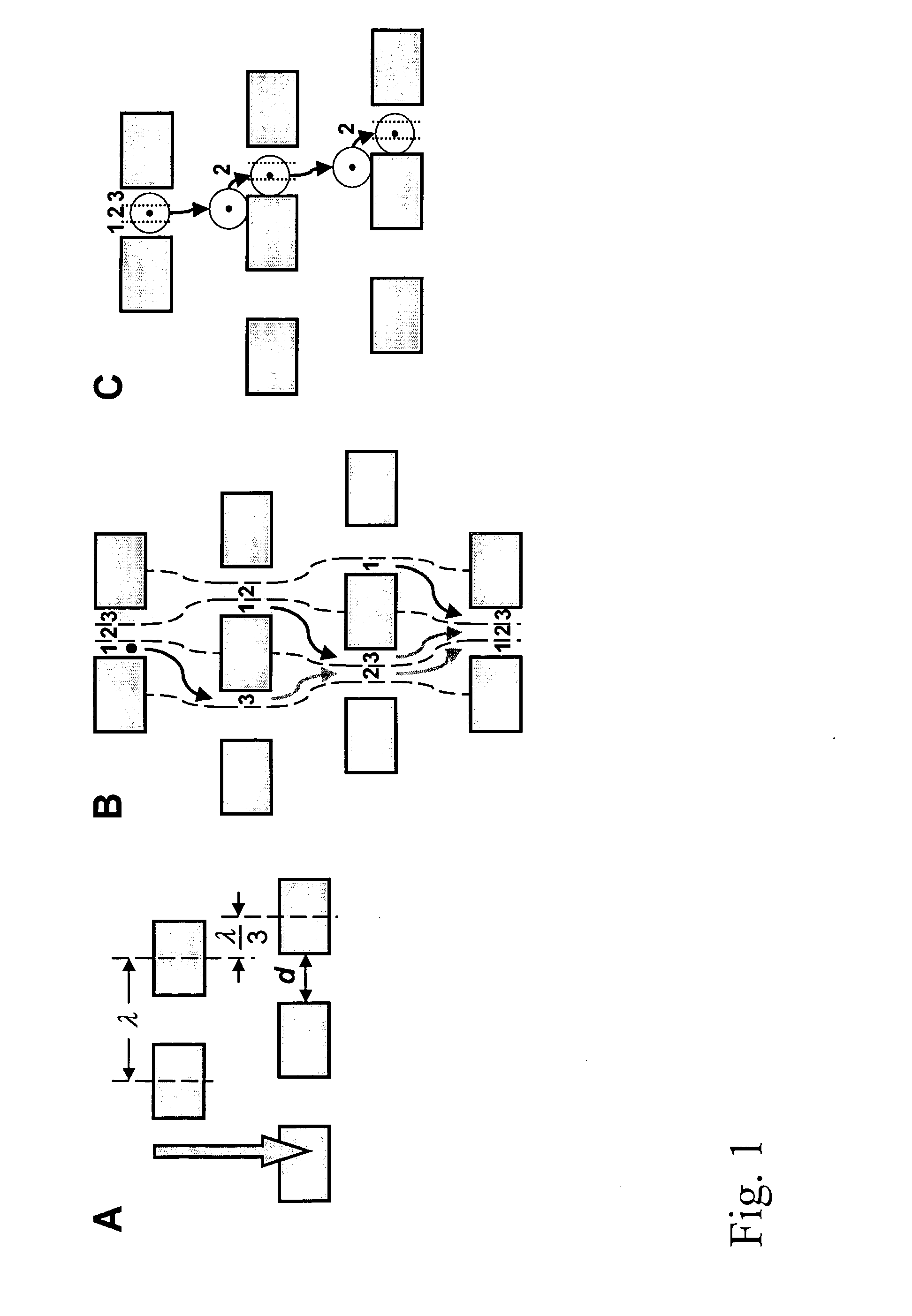

Devices and methods for magnetic enrichment of cells and other particles

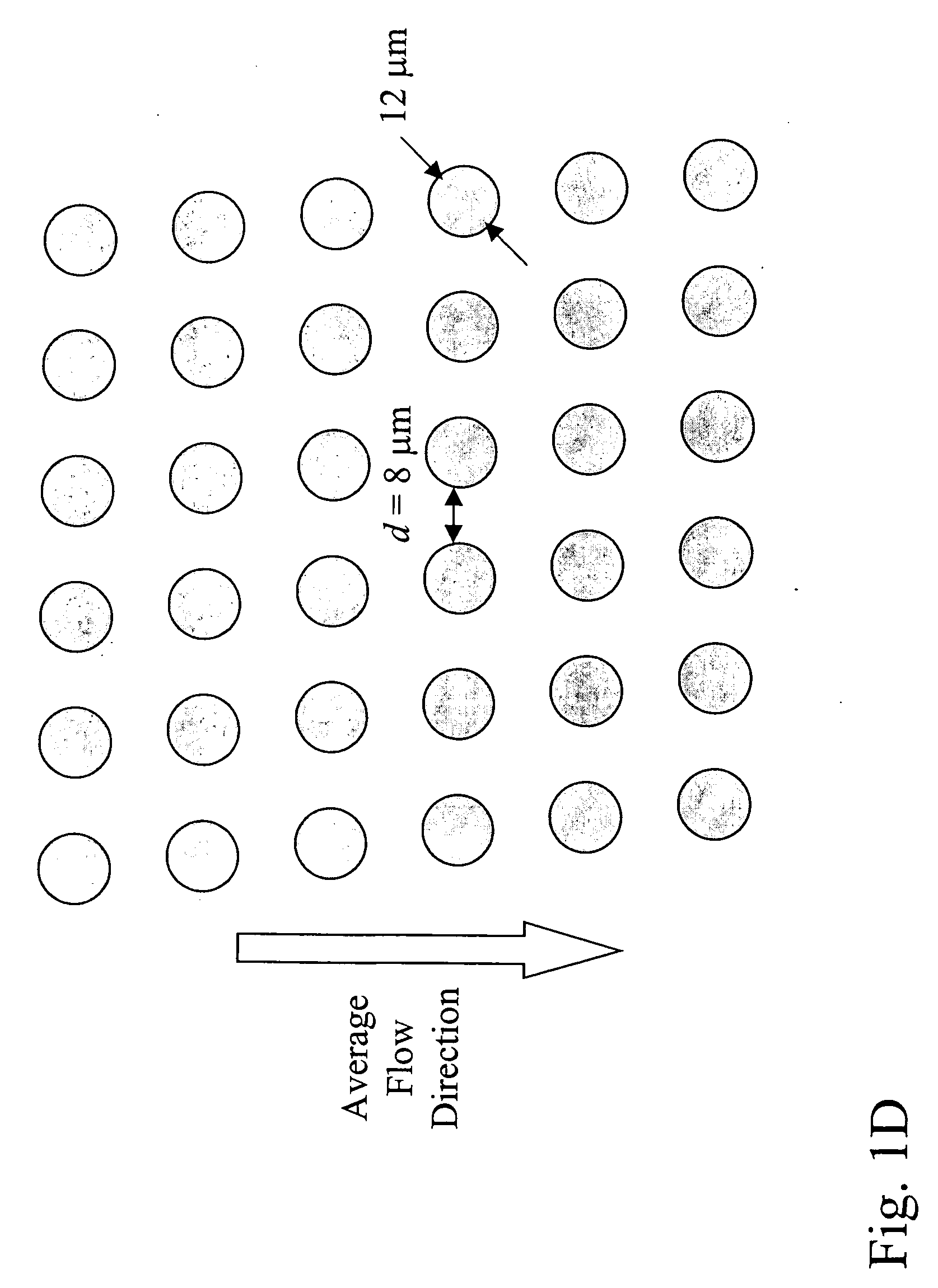

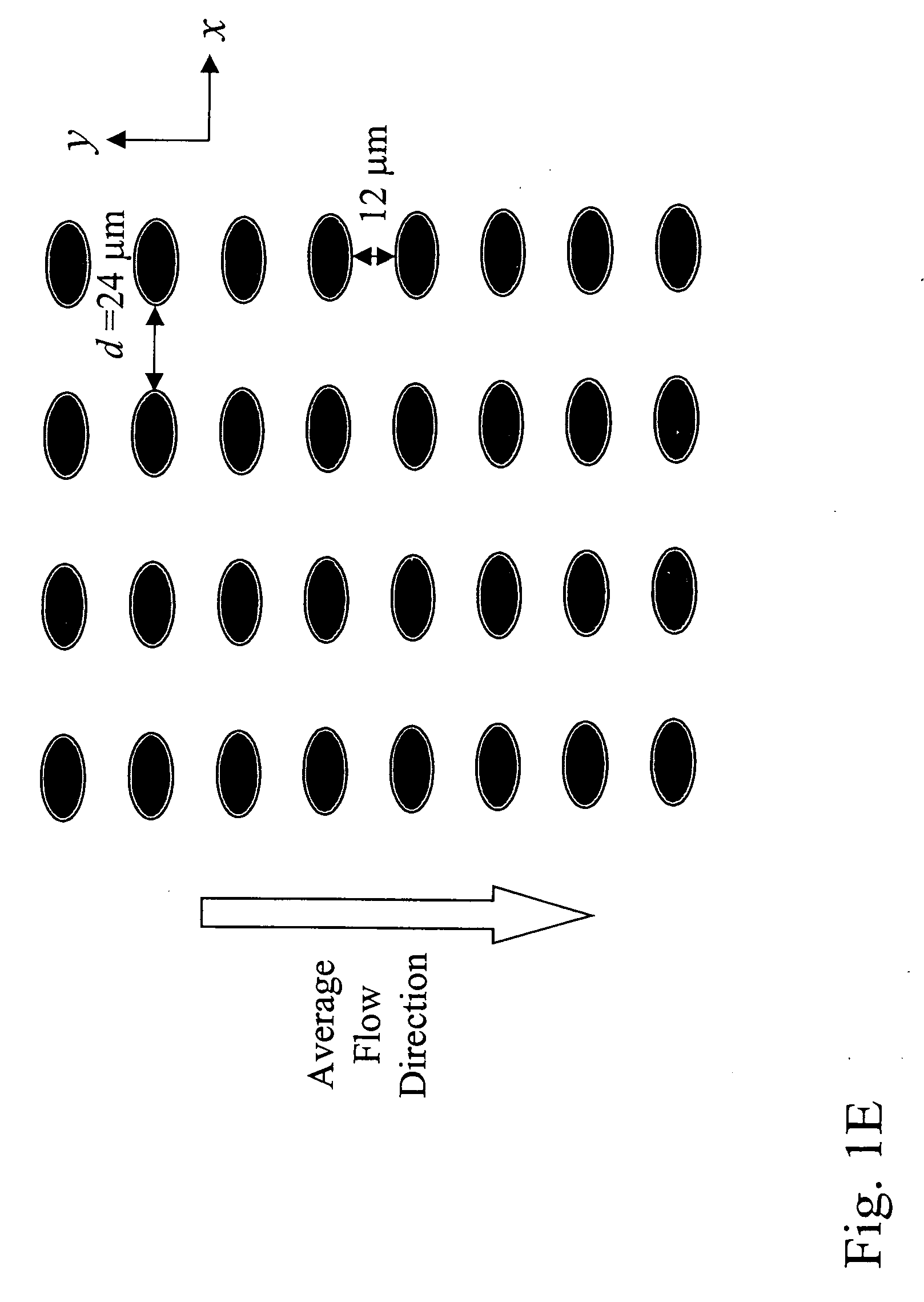

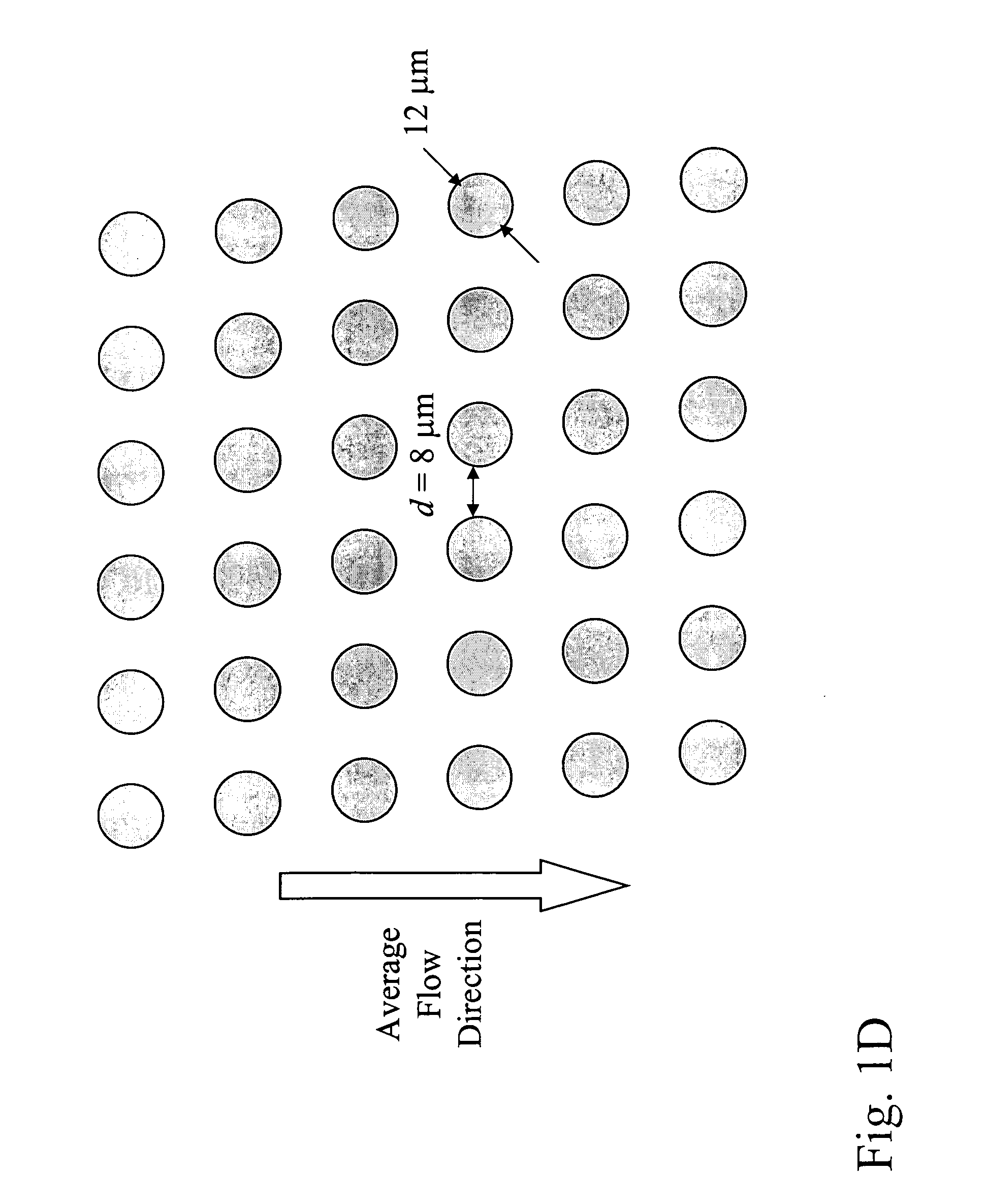

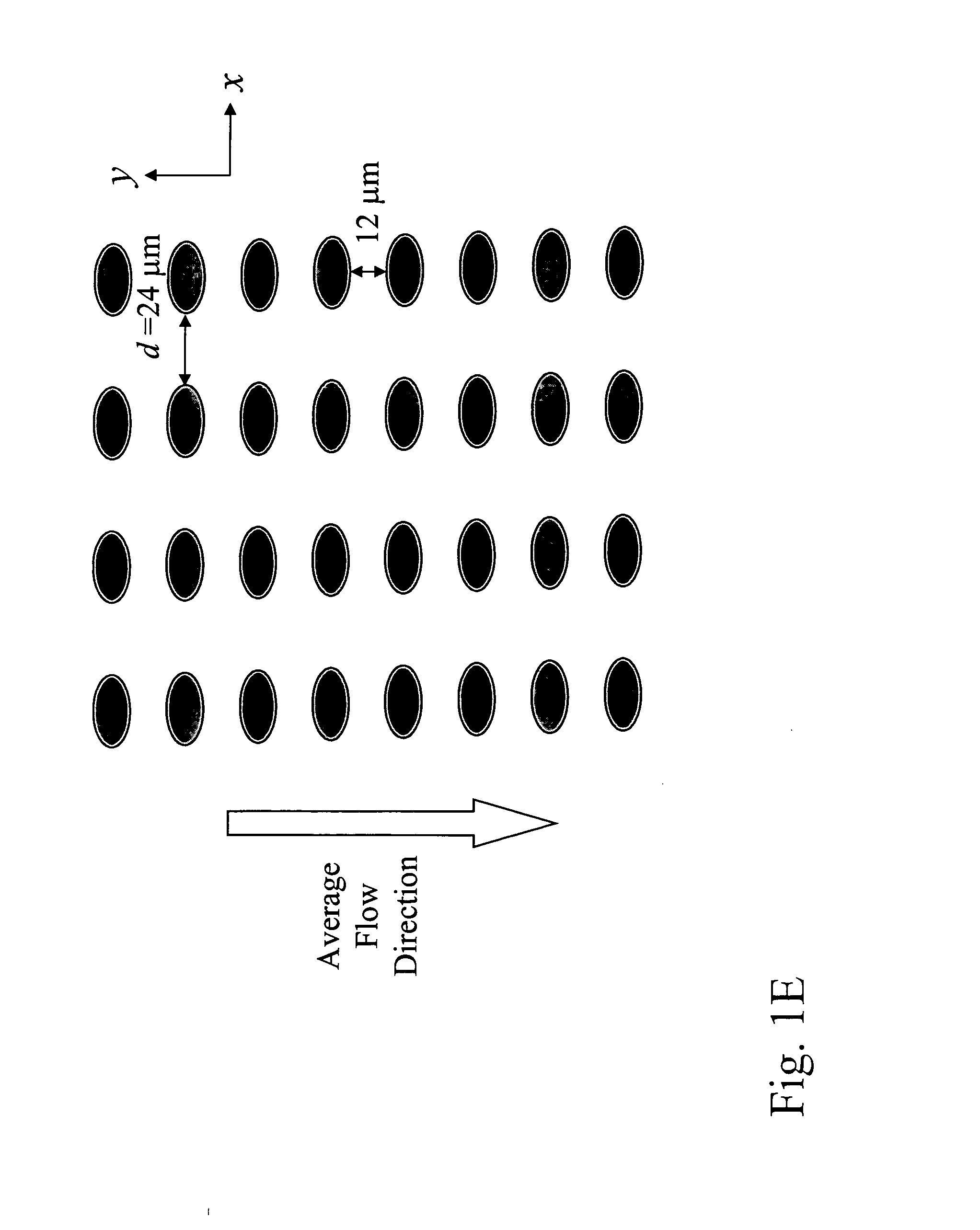

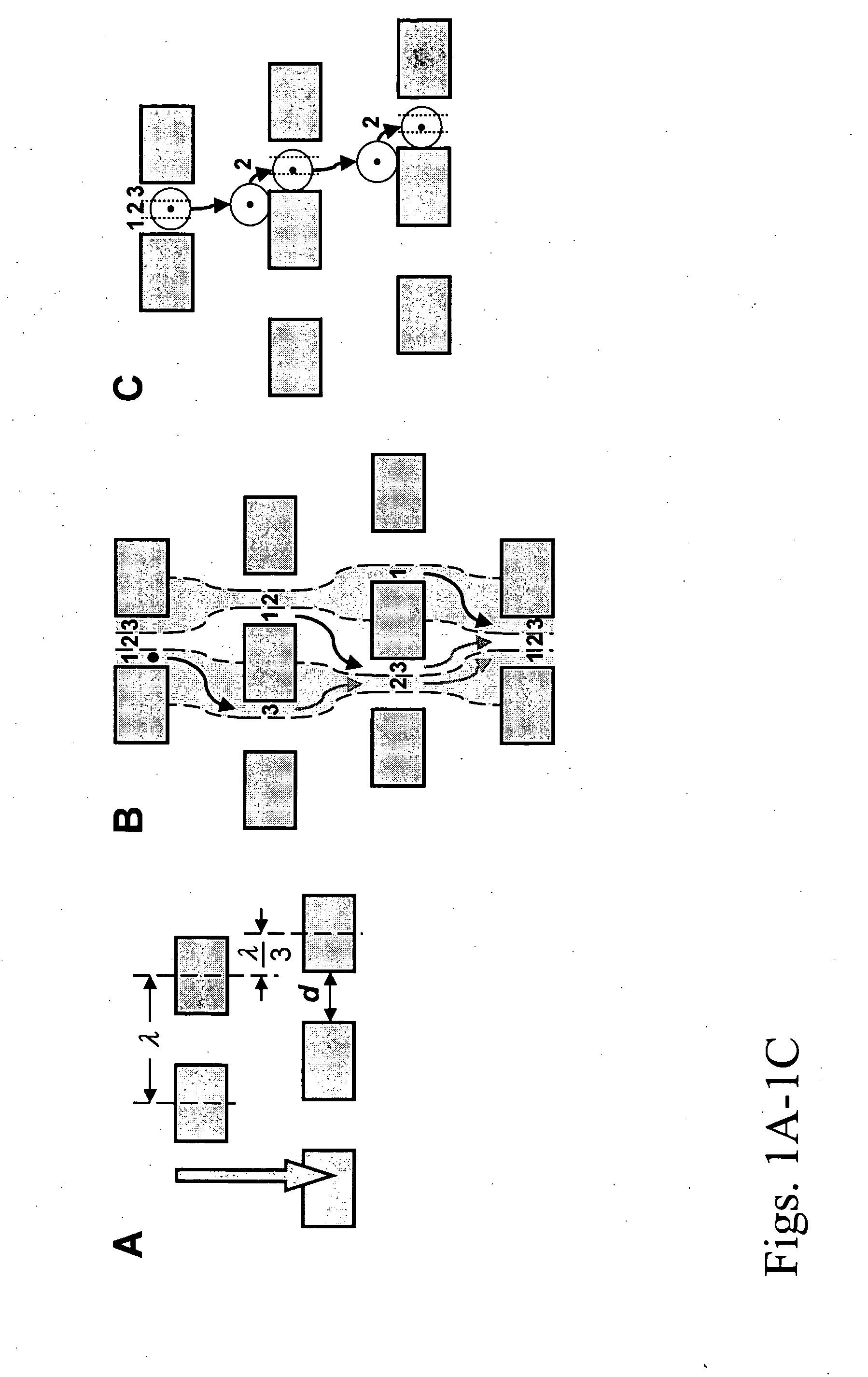

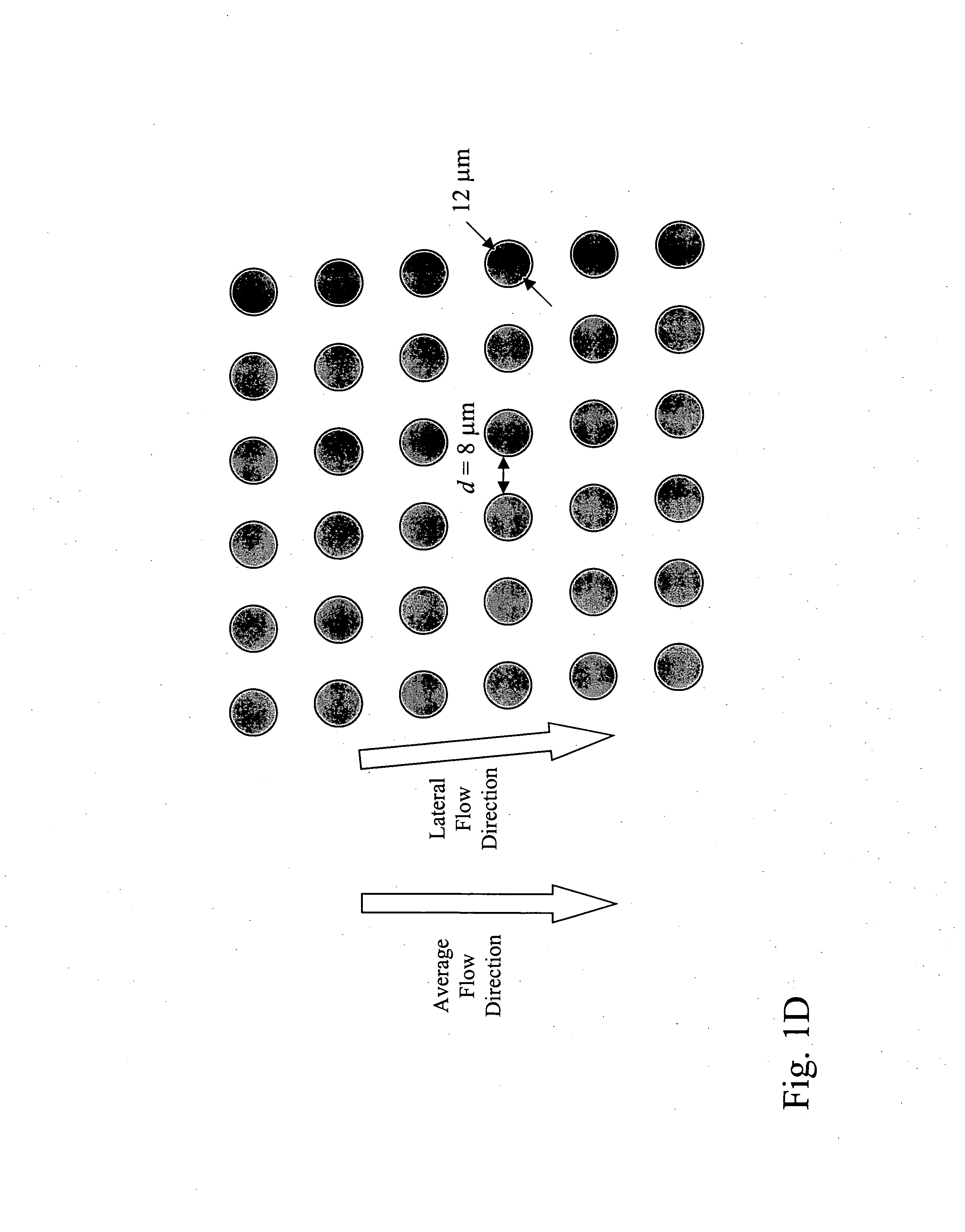

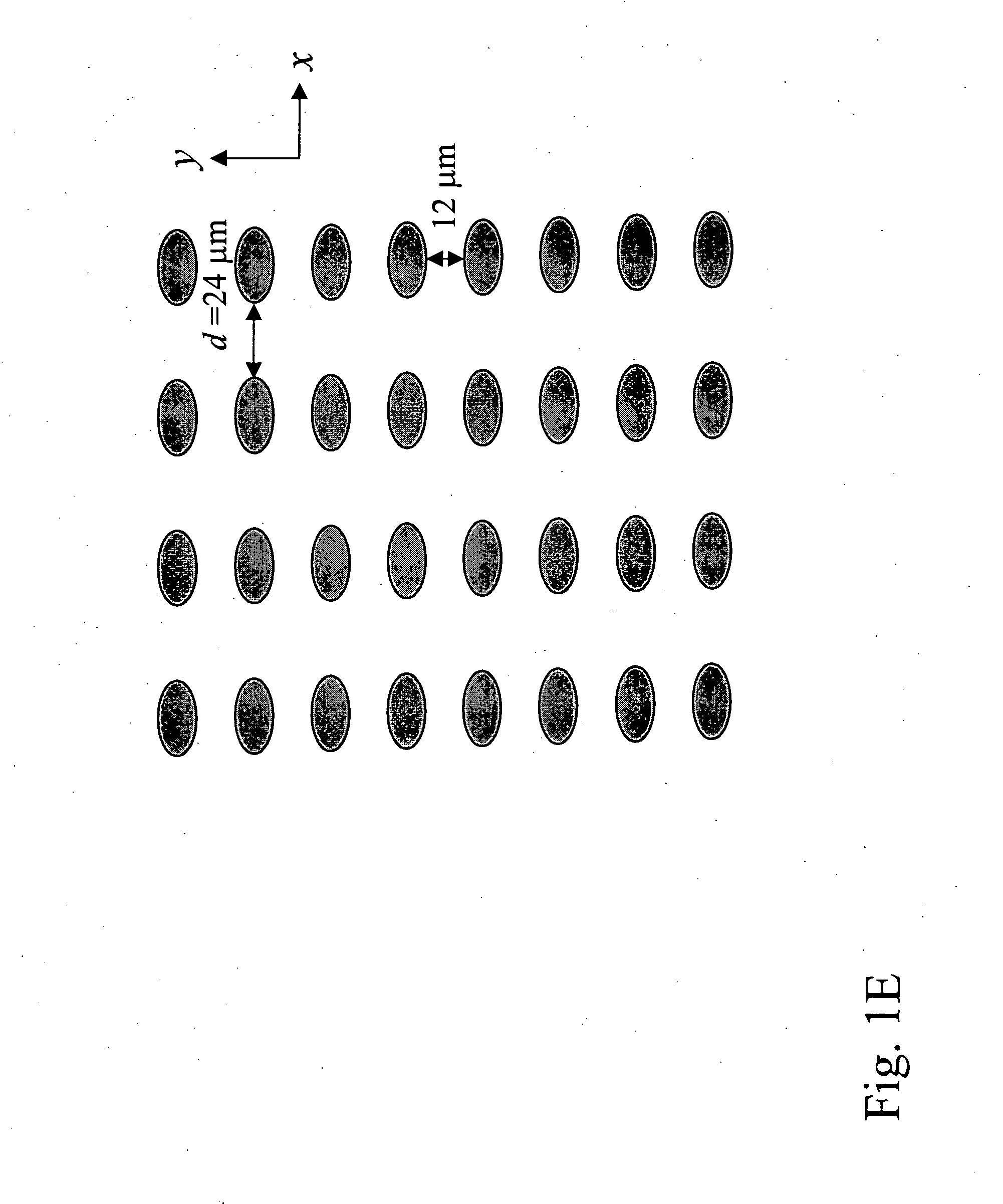

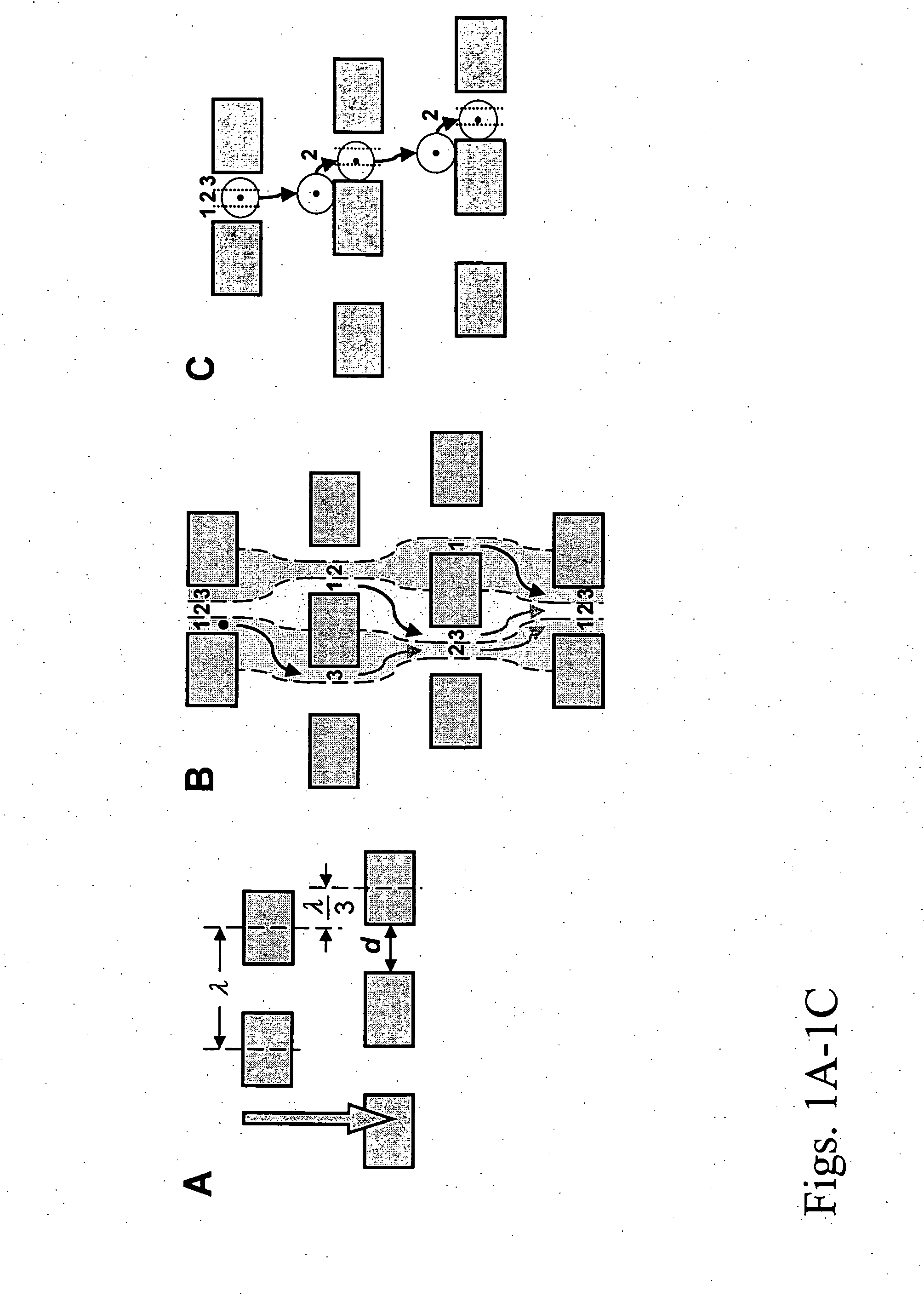

InactiveUS20060223178A1Small particle sizeLower the volumeArtificial cell constructsLaboratory glasswaresAnalyteMedicine

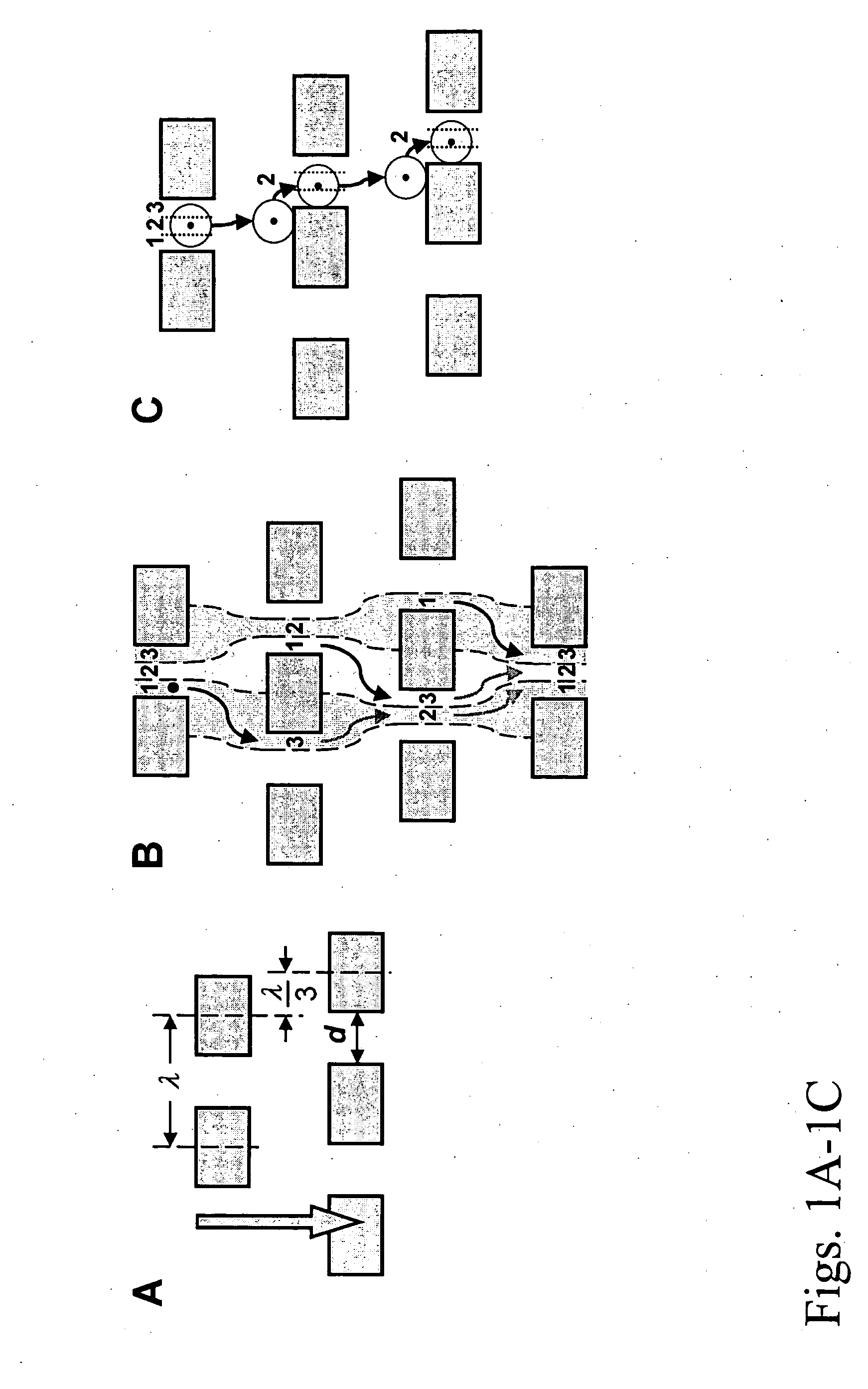

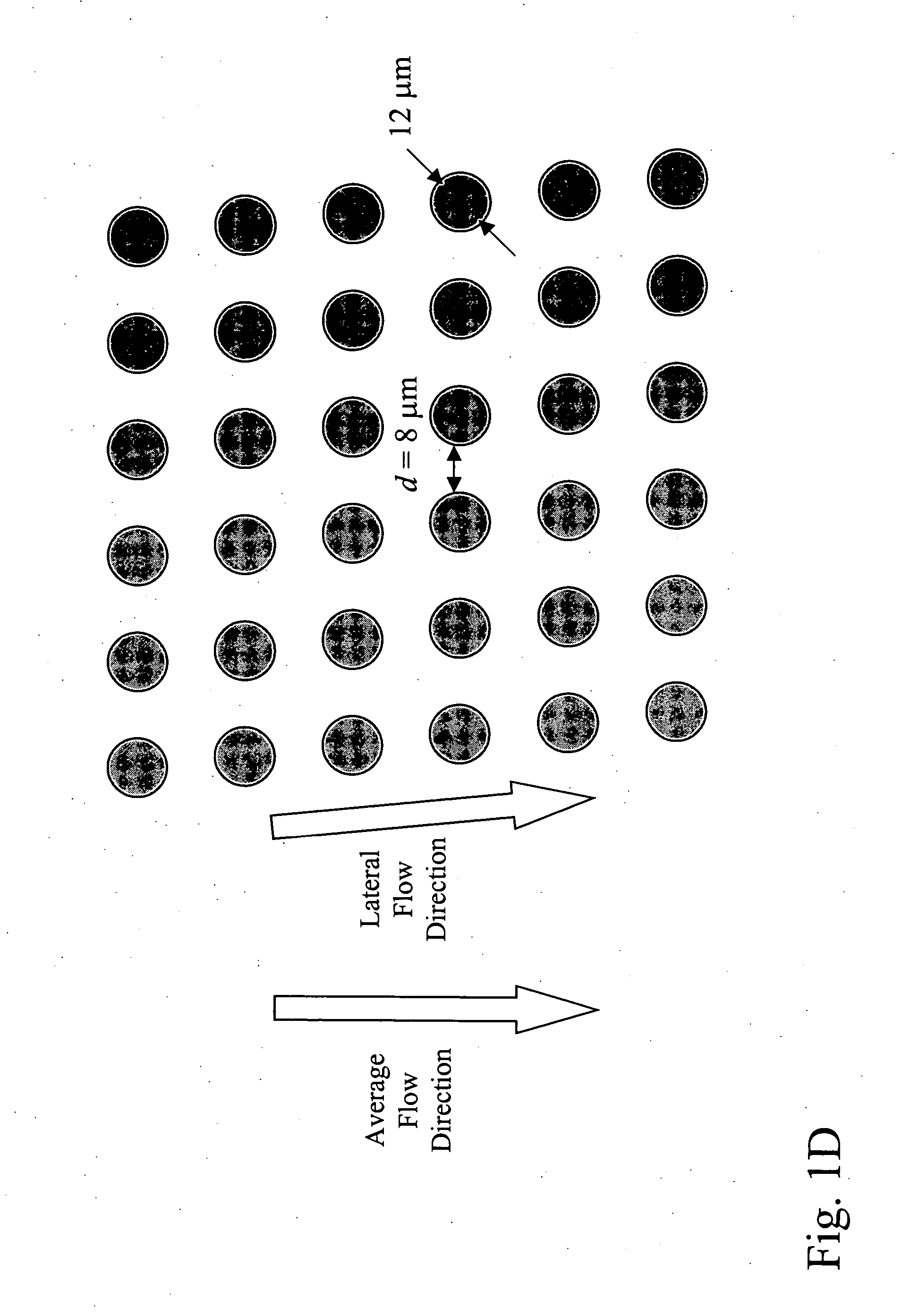

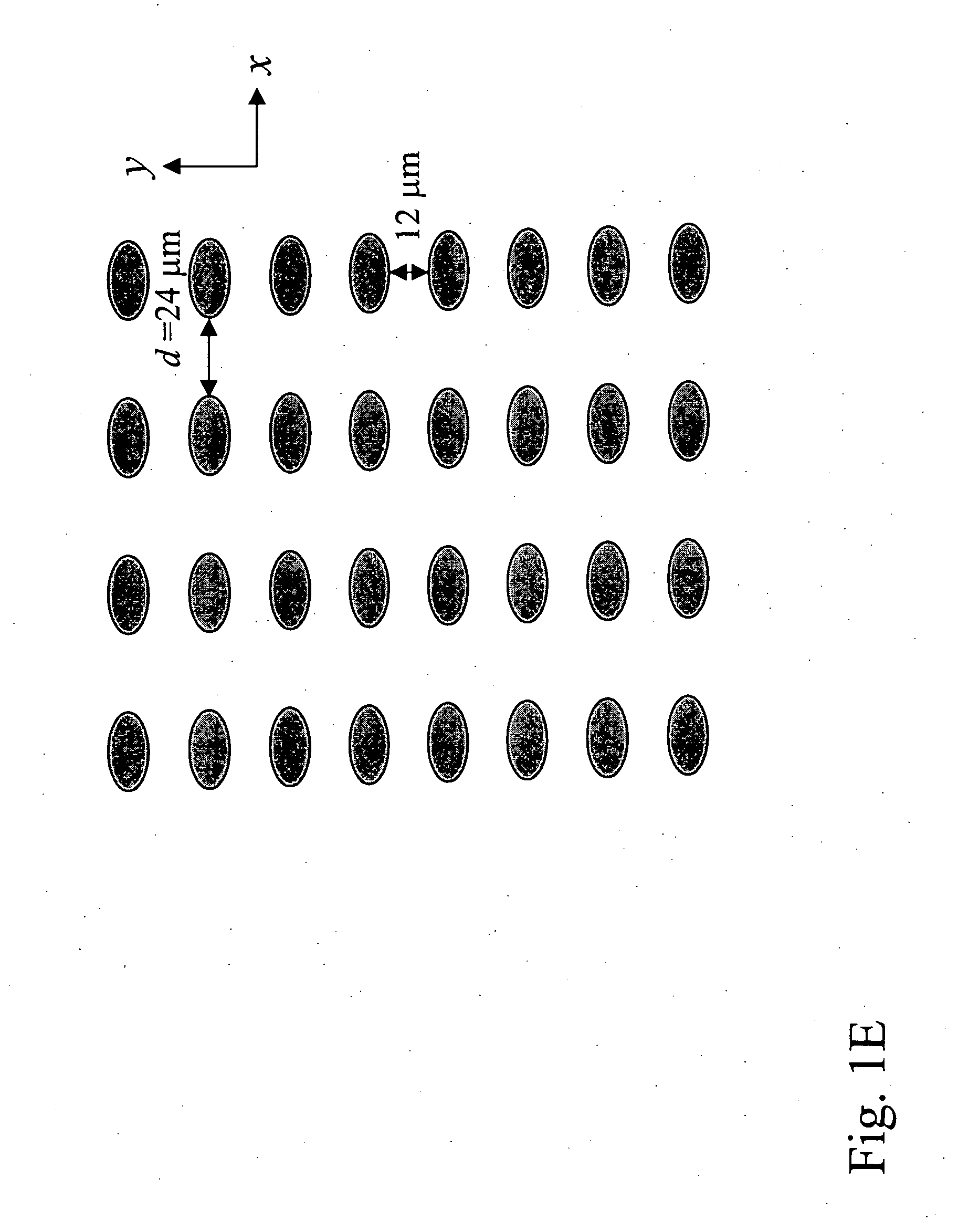

The invention features devices and methods for the enrichment of cells and other desired analytes by employing a magnetic field, alone or in conjunction with size-based separation. The devices and methods may be advantageously employed to enrich for rare cells, e.g., fetal cells or epithelial cells, present in a sample, e.g., maternal blood.

Owner:THE GENERAL HOSPITAL CORP +1

Compositions for inactivating pathogenic microorganisms, methods of making the compositions, and methods of use thereof

InactiveUS20060251684A1Reduce infectivityReduce morbiditySsRNA viruses negative-senseAntibacterial agentsPathogenic microorganismOrganic solvent

Nanoemulsion compositions with low toxicity that demonstrate broad spectrum inactivation of microorganisms or prevention of diseases are described. The nanoemulsions contain an aqueous phase, an oil phase comprising an oil and an organic solvent, and one or more surfactants. Methods of making nanoemulsions and inactivating pathogenic microorganisms are also provided.

Owner:NANOBIO CORP

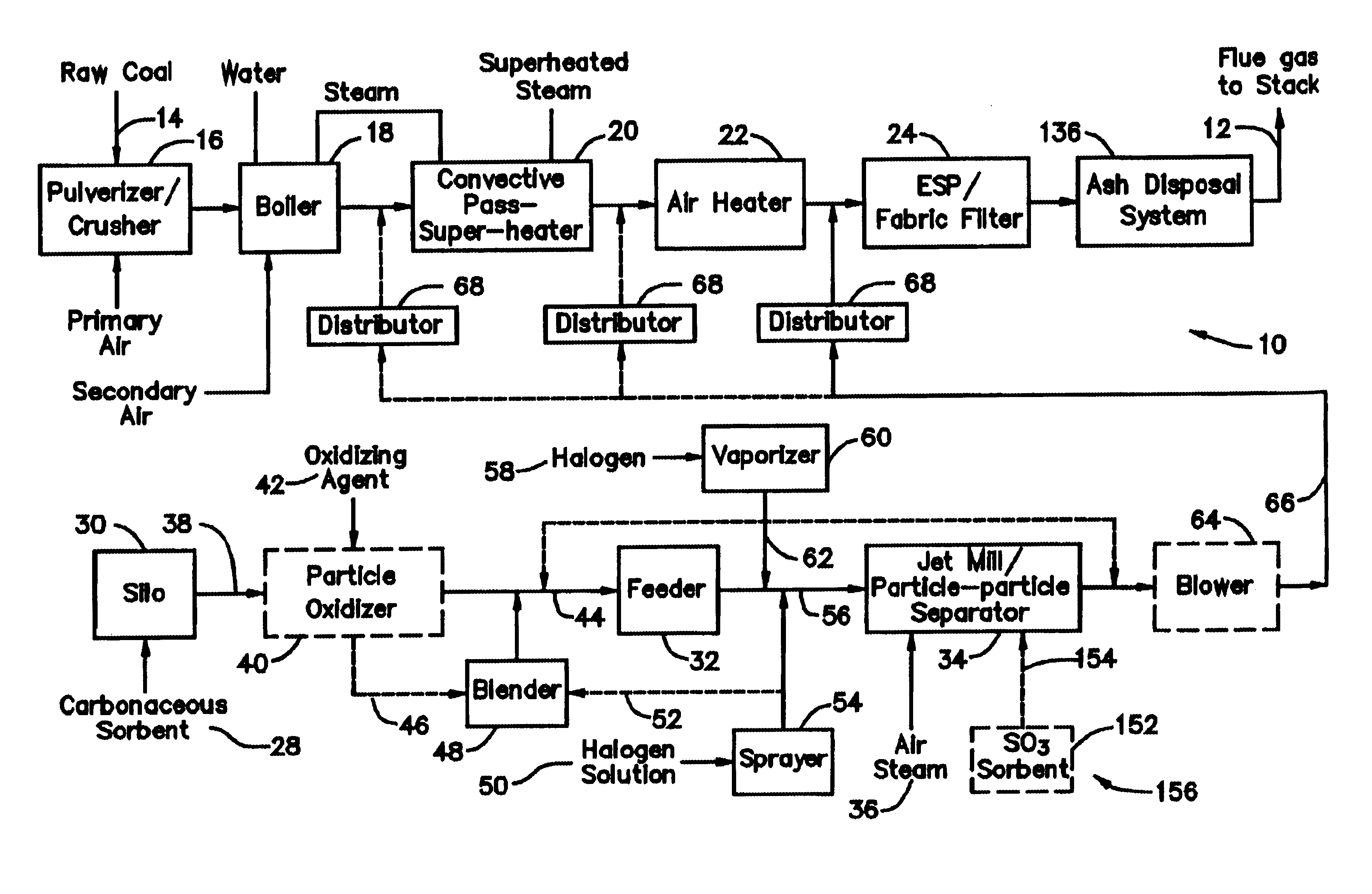

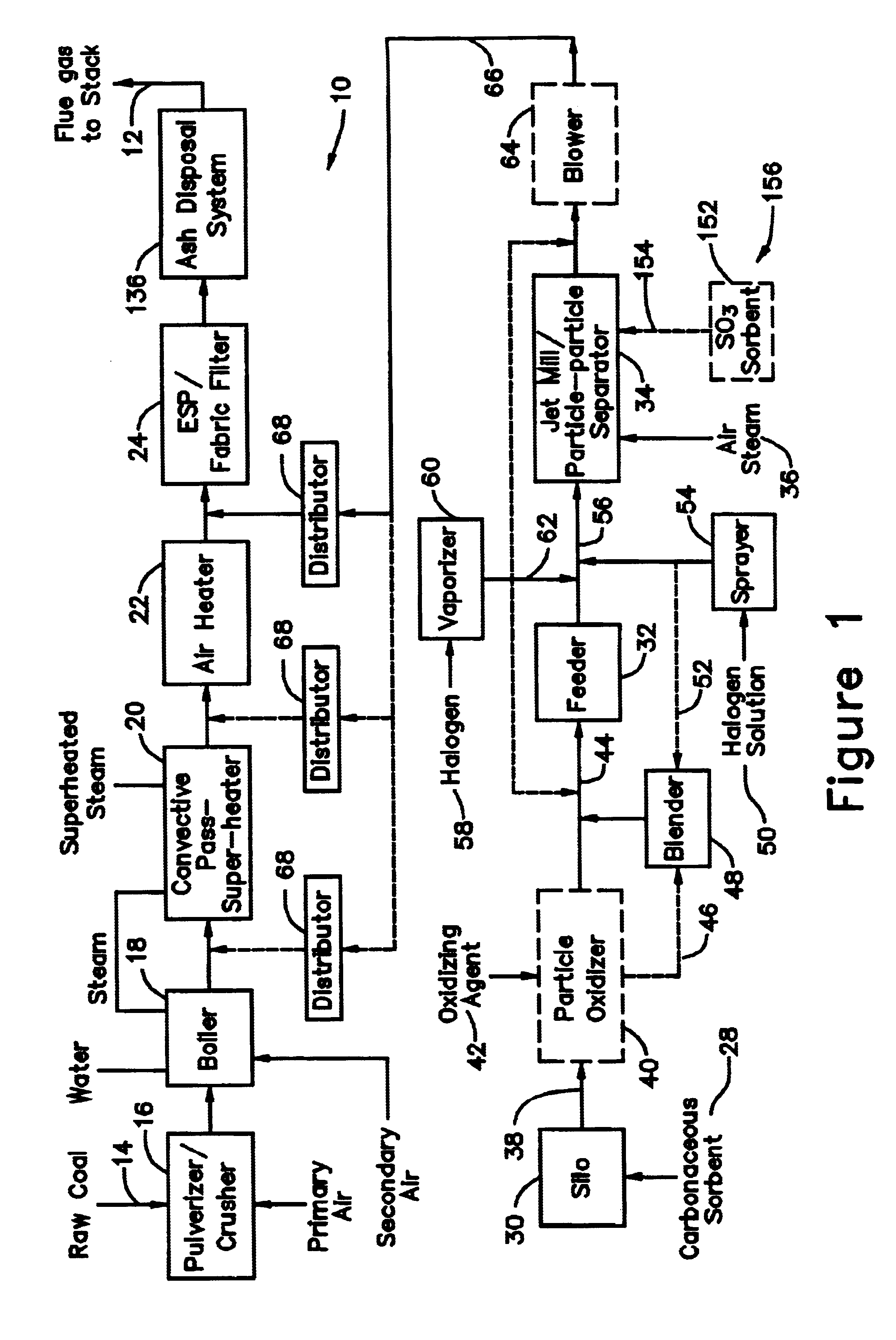

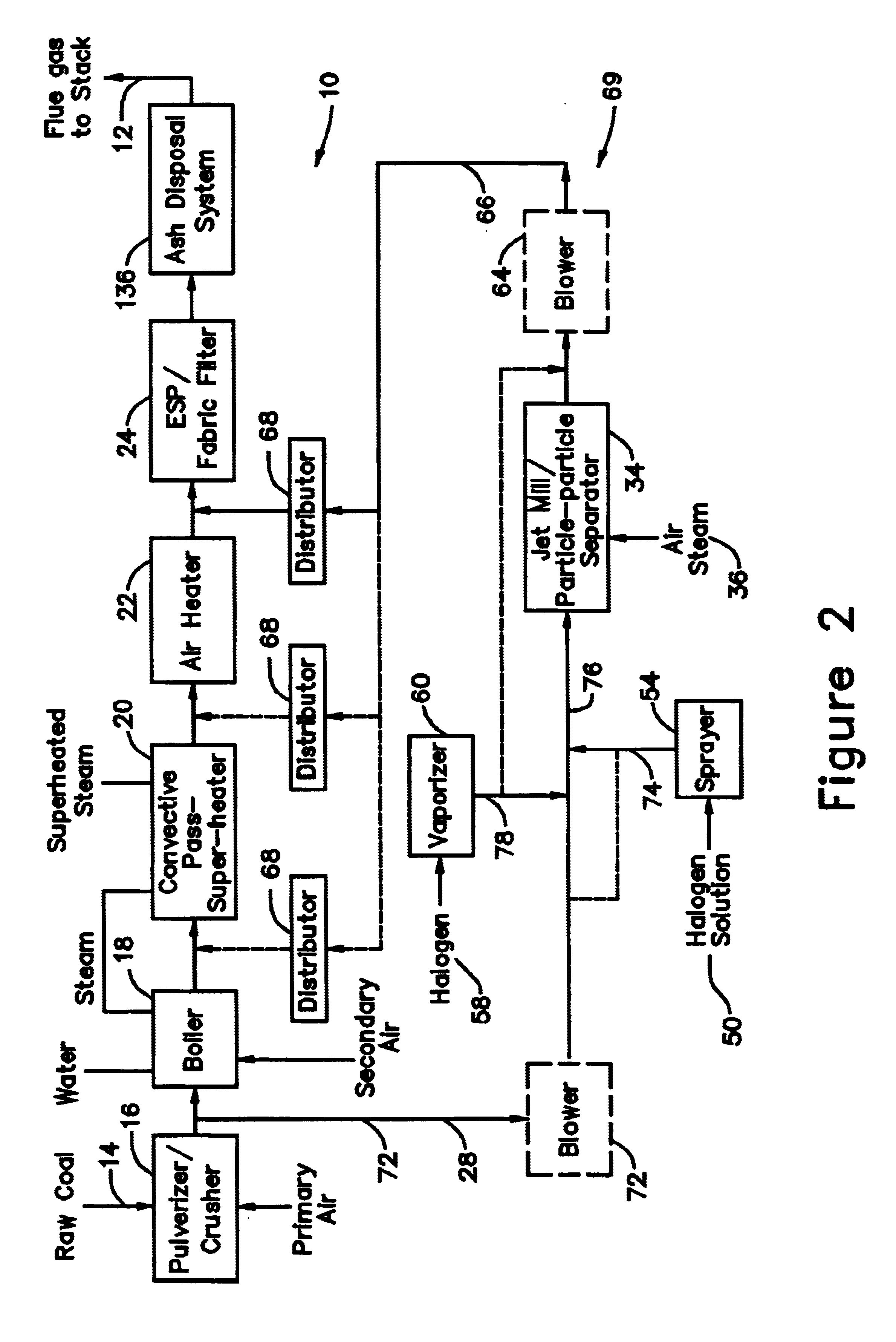

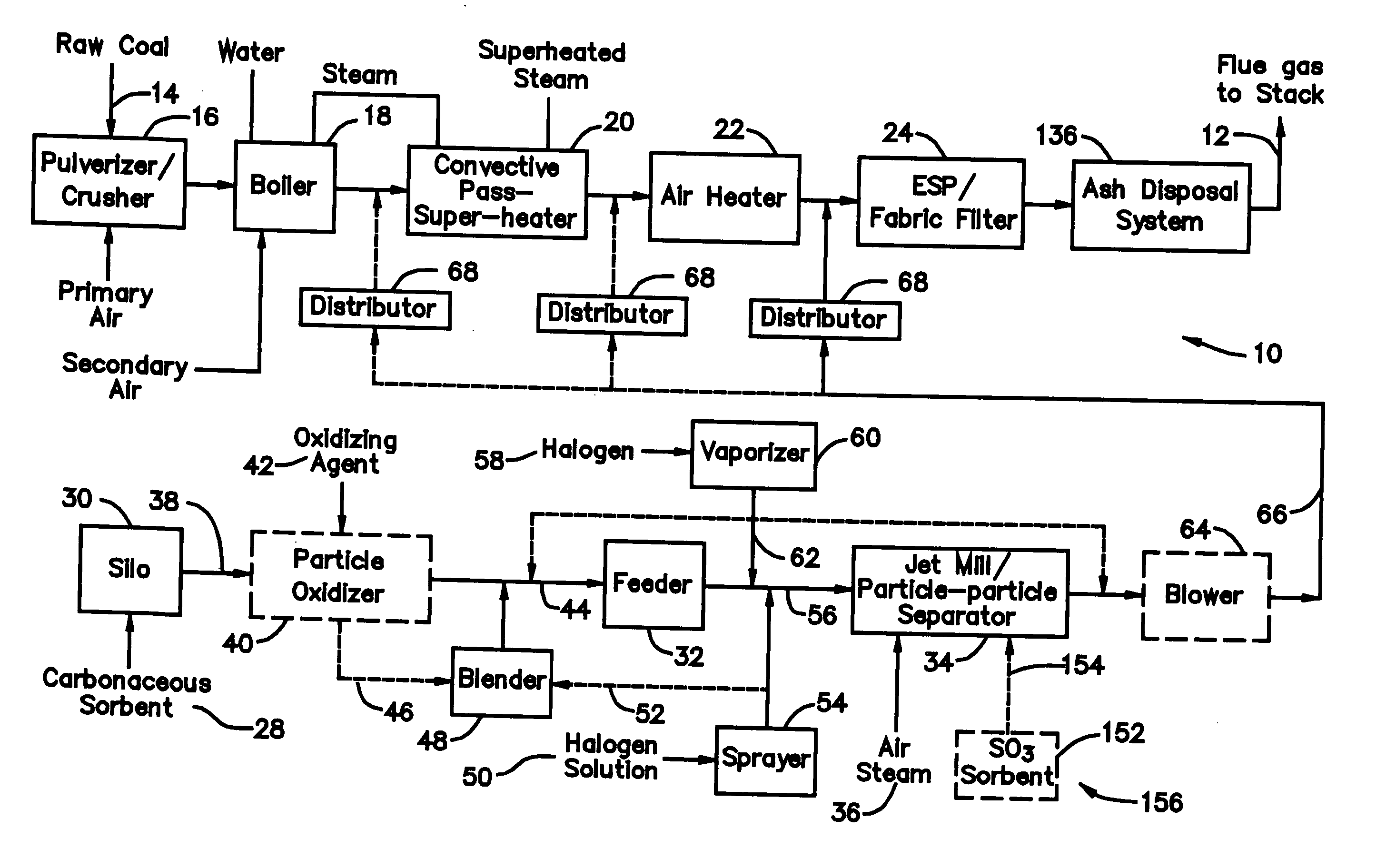

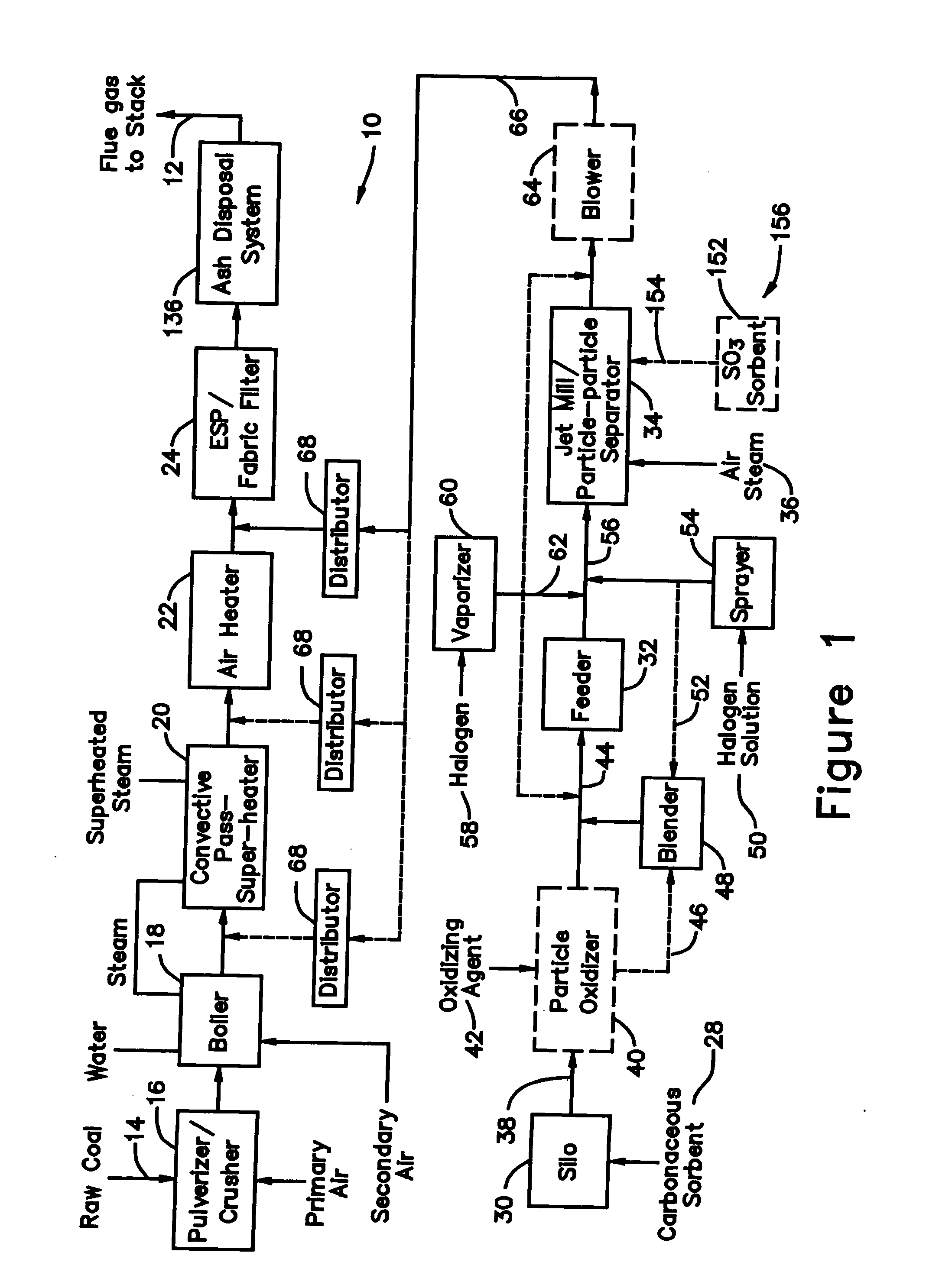

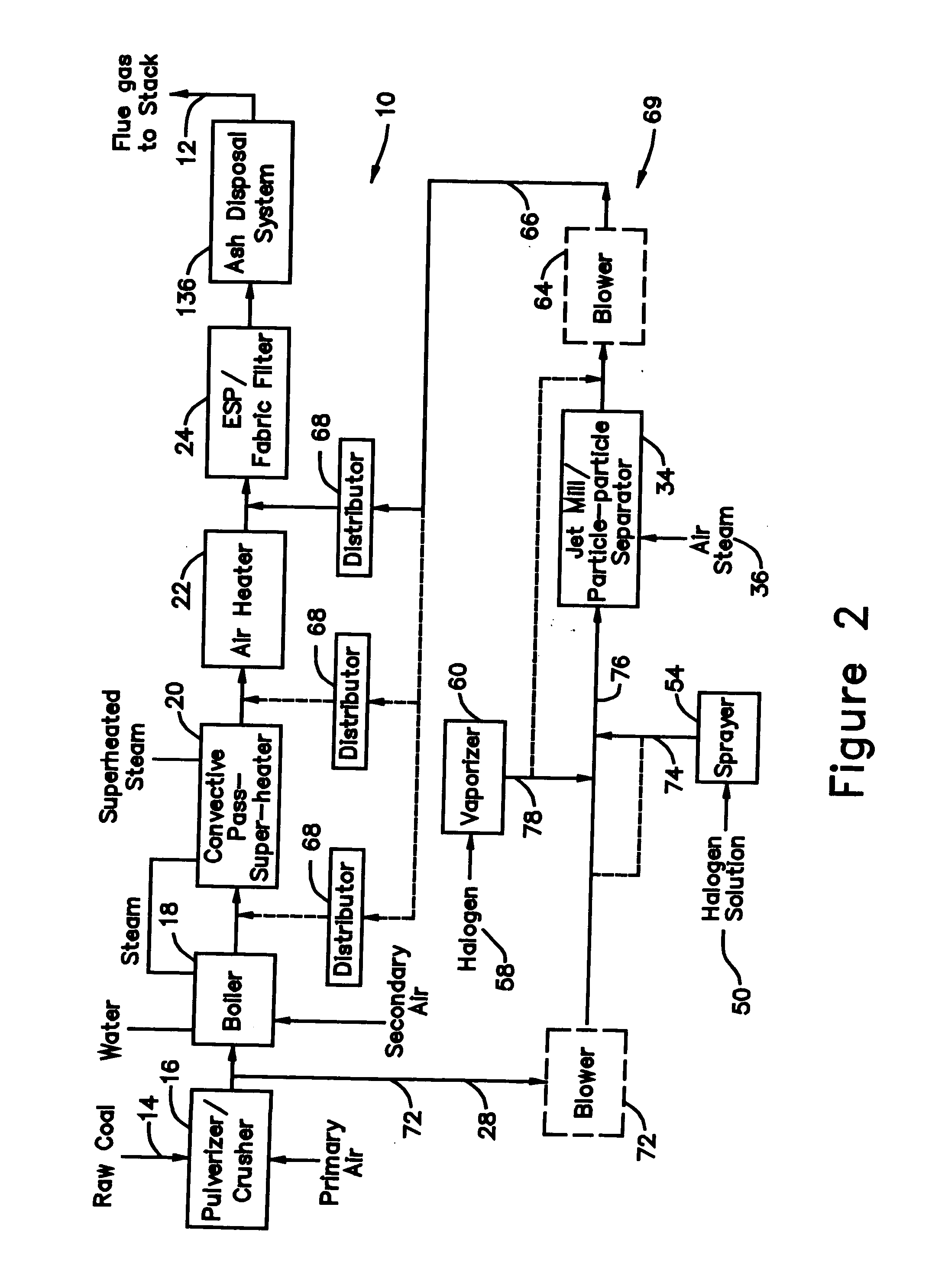

Control of mercury emissions from solid fuel combustion

InactiveUS6848374B2Remove pollutantsEasy to captureCombination devicesGas treatmentSorbentSolid fuel

A system 26 for removing elemental mercury or mercury compounds handles carbonaceous sorbent 28 of a starter batch stored in a silo 30 in an agglomerated state. The sorbent 28 is fed by a feeder 32 to a separation device 34, which comminutes (if necessary) and de-agglomerates the sorbent particles 28 to their primary size distribution. This device 34 may be a particle-particle separator or a jet mill, where compressed air or high-pressure steam is the energy source. The de-agglomerated sorbent 28 of a contact batch created from the starter batch is conveyed by an airsteam for injection at a contact location 66 in a flue gas duct whereat carbonaceous sorbent of the contact batch adsorbs mercury from the flue gas.

Owner:GENERAL ELECTRIC TECH GMBH

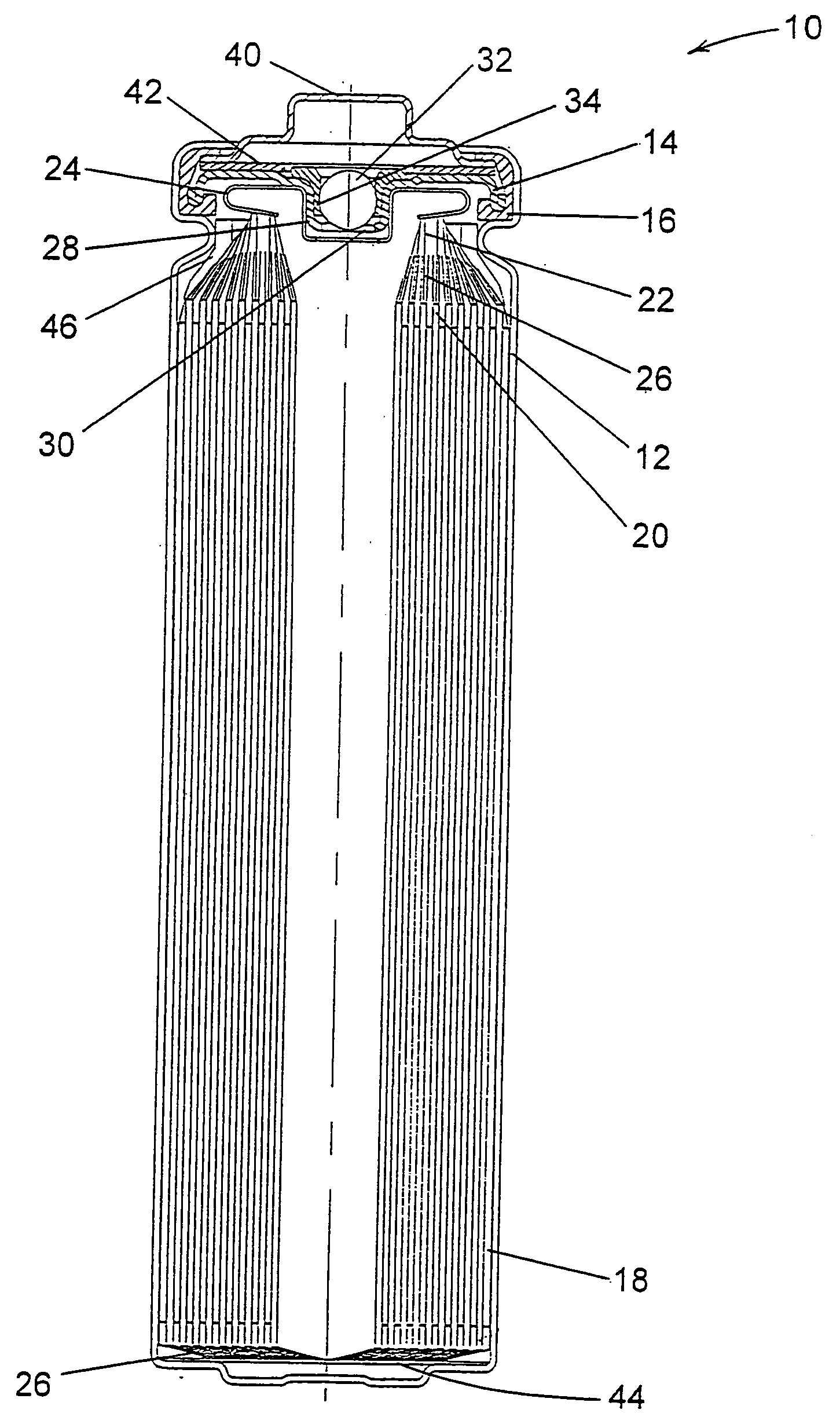

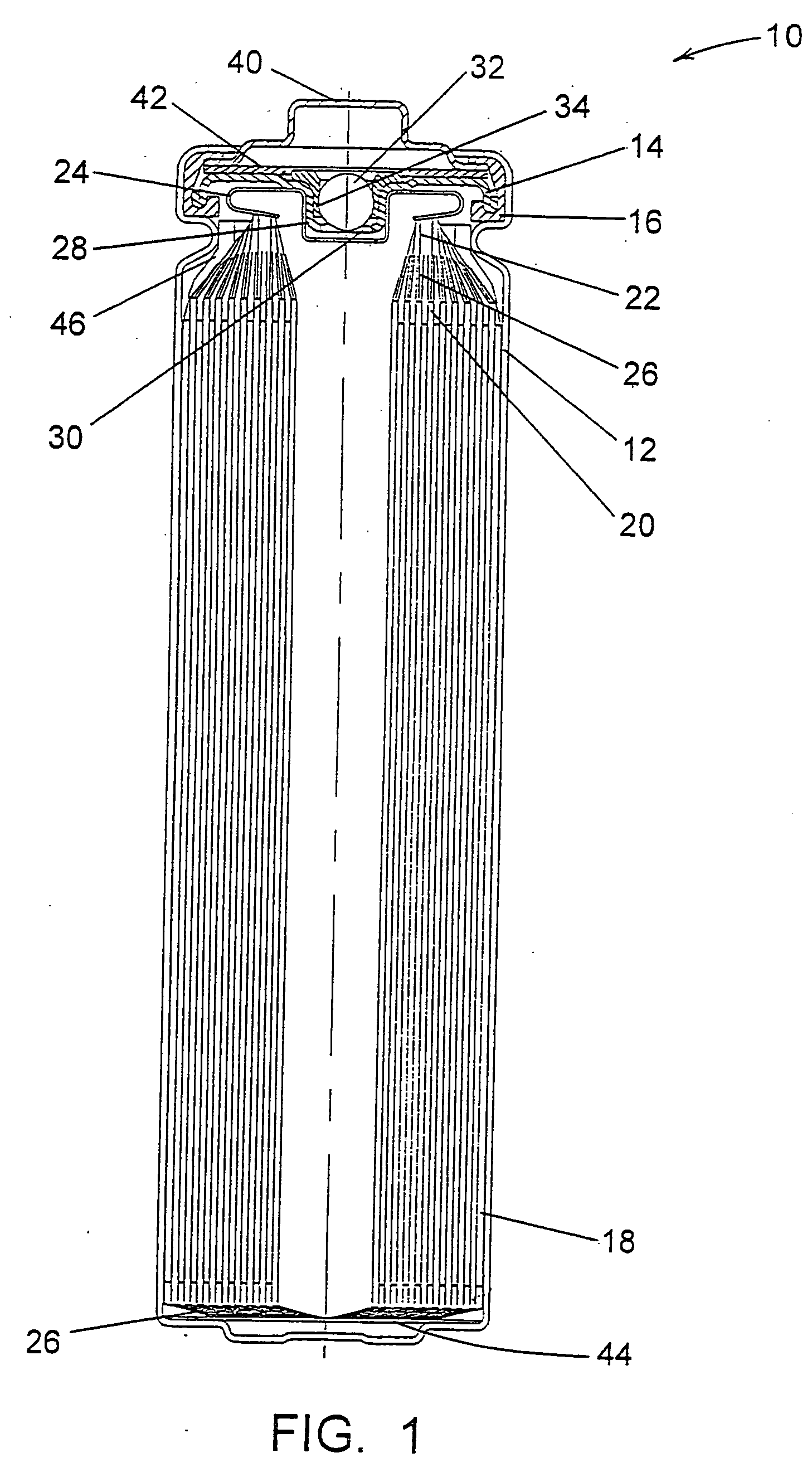

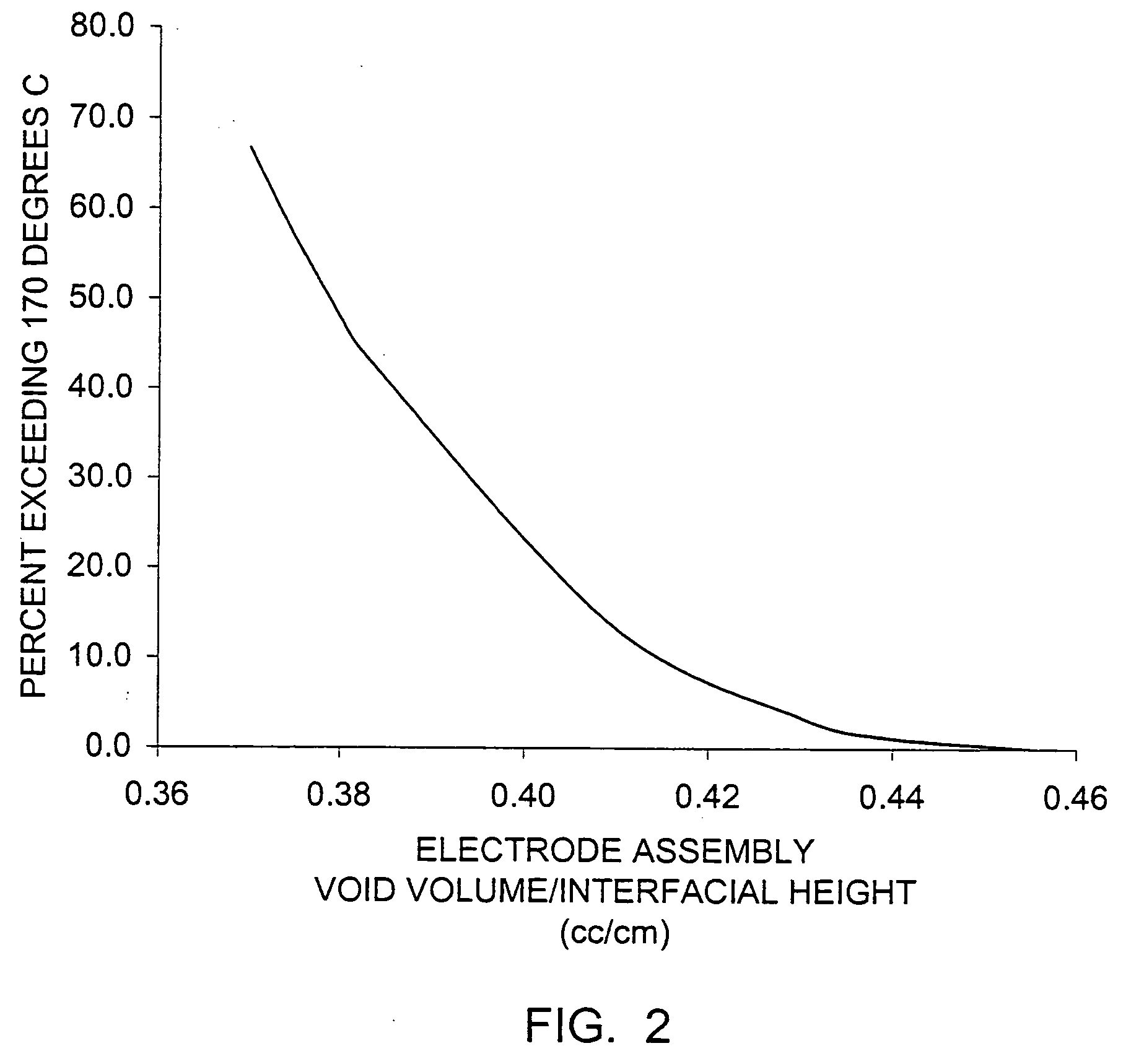

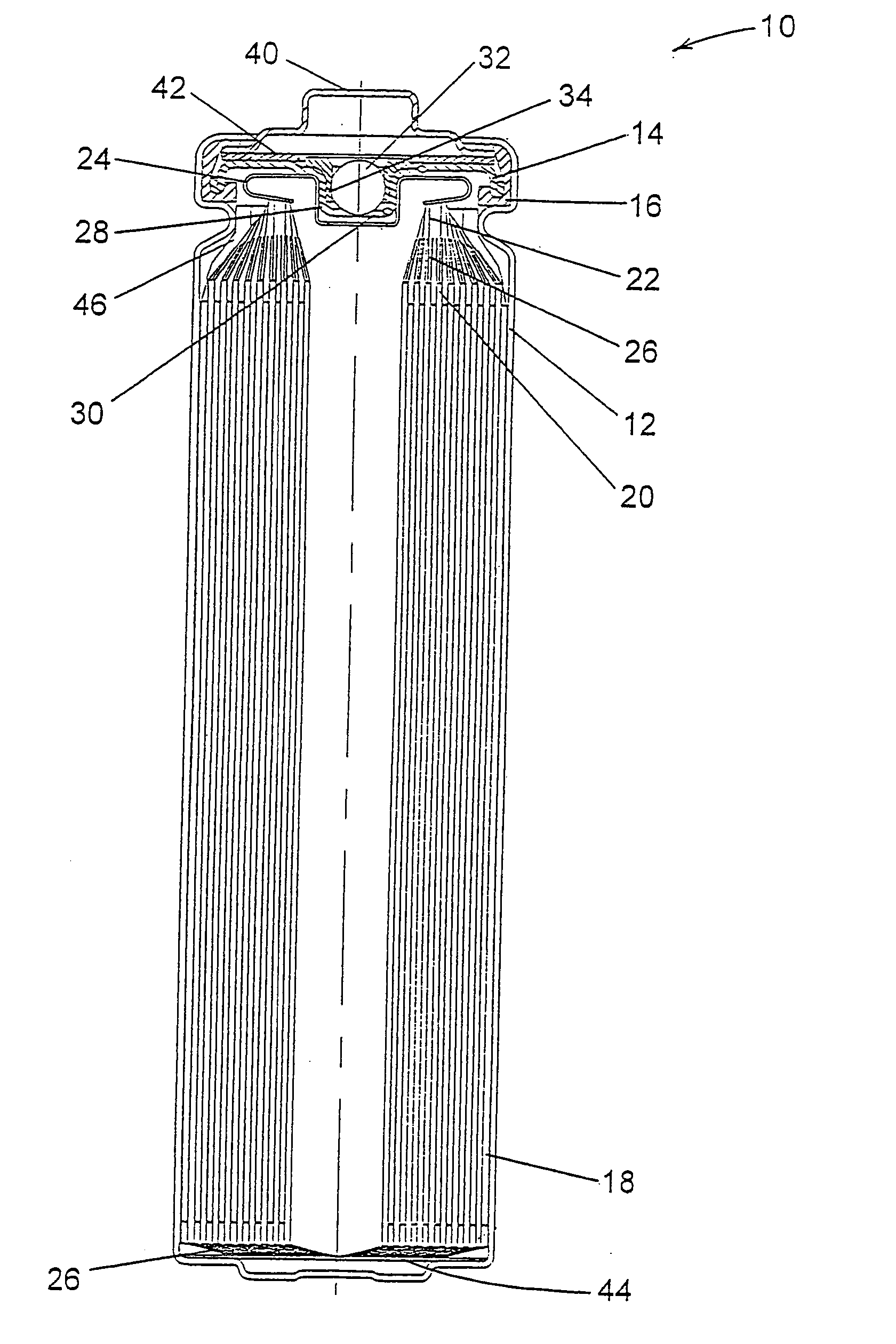

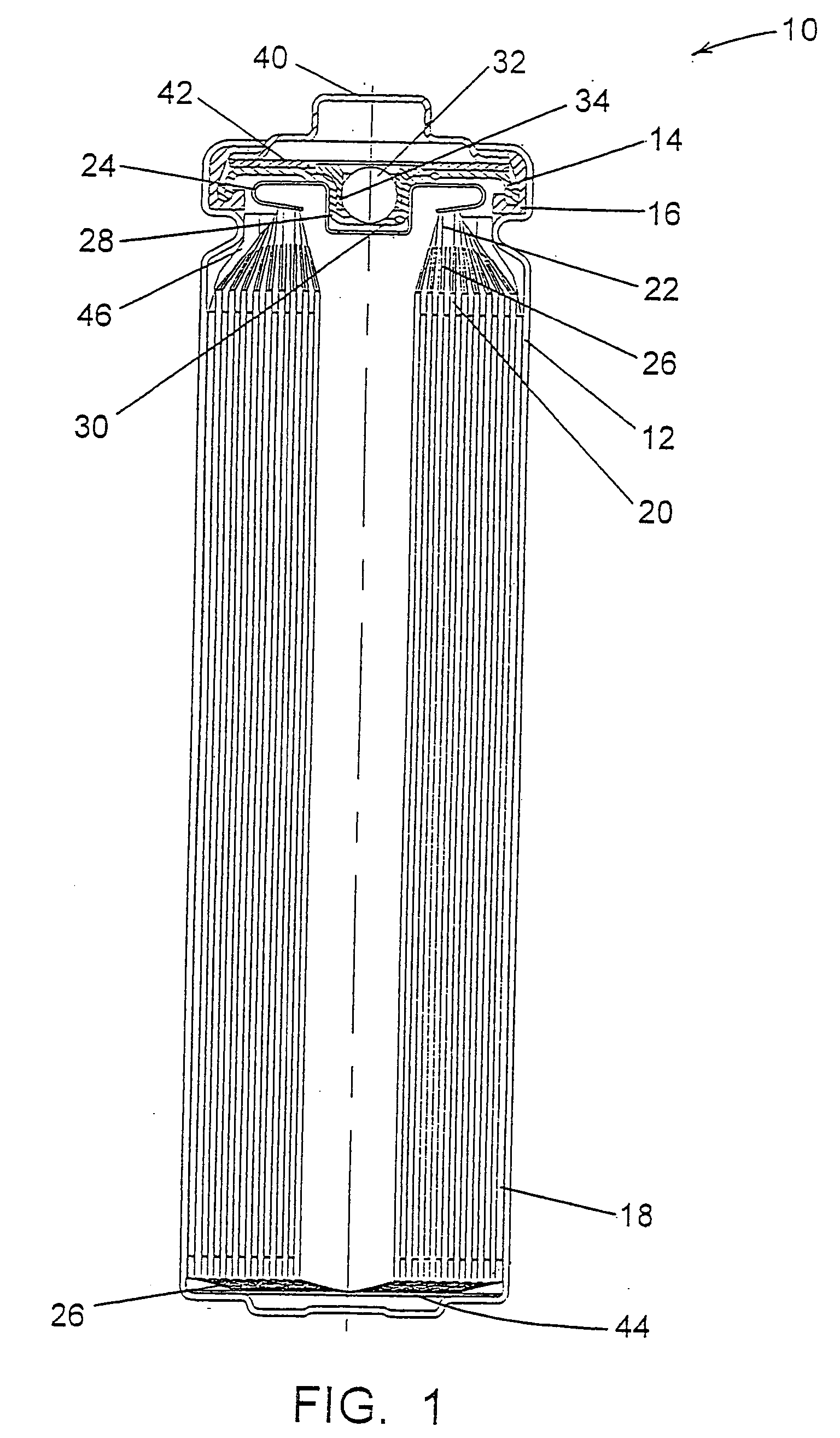

High discharge capacity lithium battery

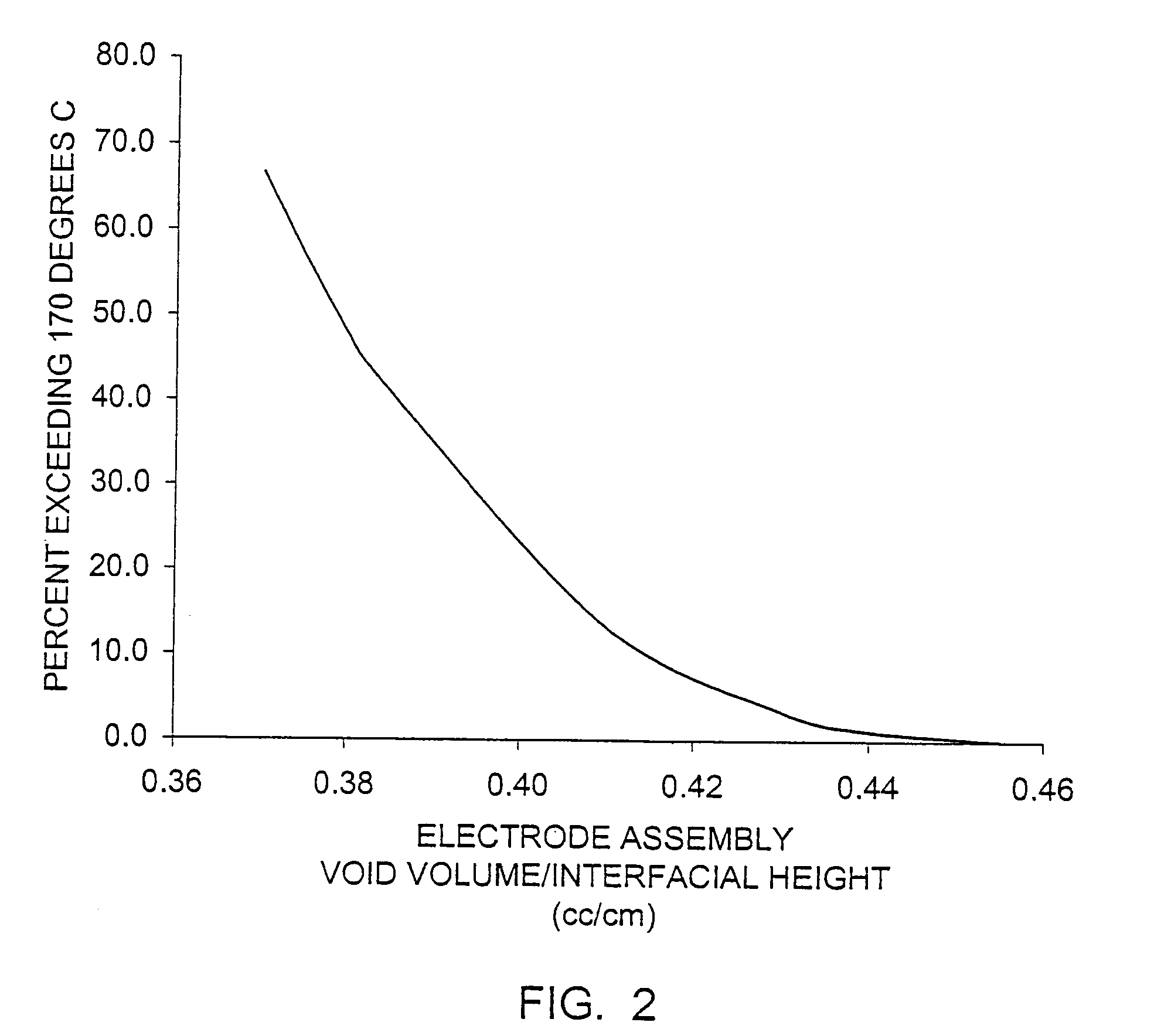

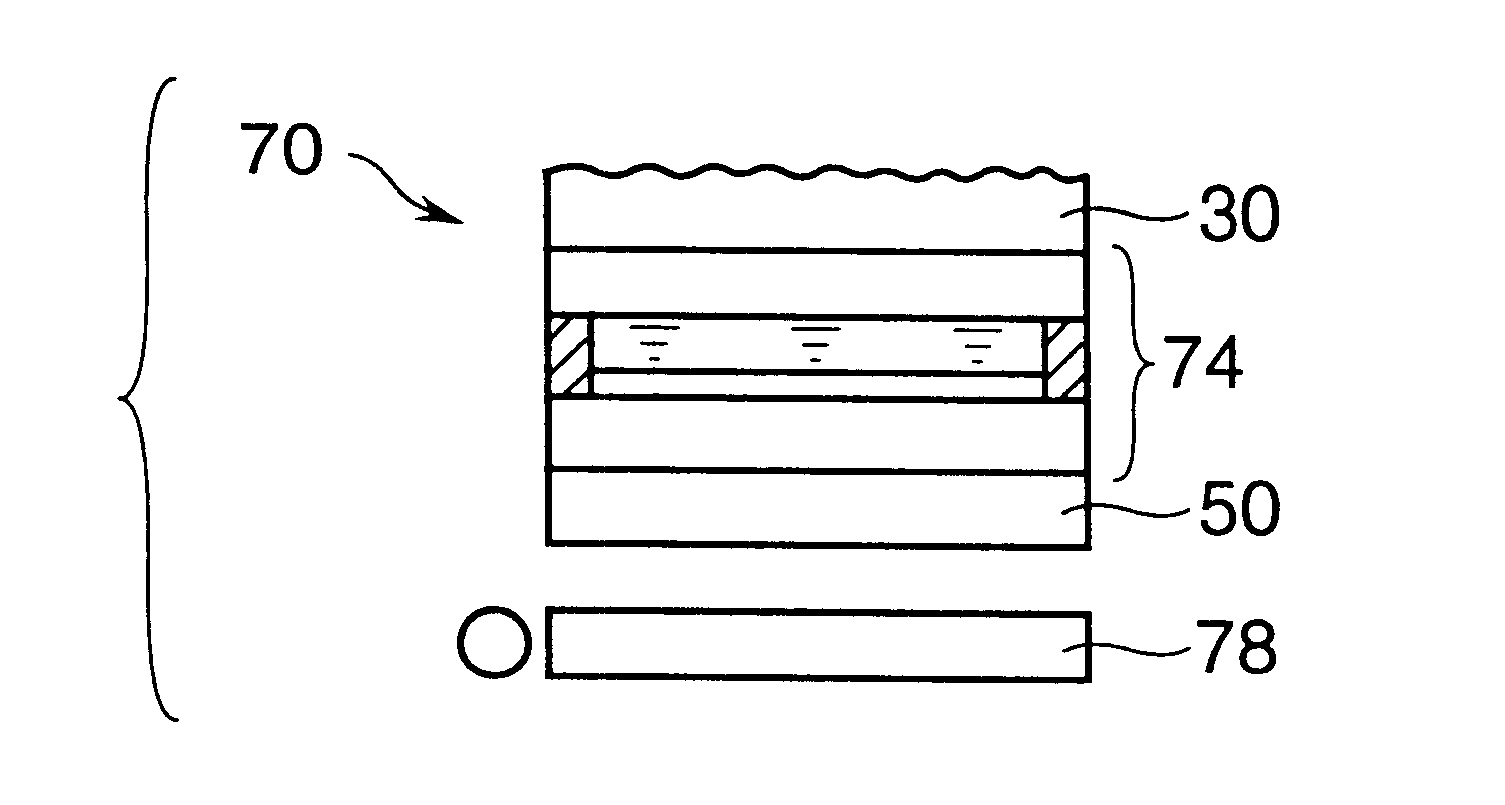

InactiveUS20050233214A1Improve discharge performanceIncrease energy densityFinal product manufactureOrganic electrolyte cellsHigh rateIron disulfide

A lithium / iron disulfide electrochemical battery cell with a high discharge capacity. The cell has a lithium negative electrode, an iron disulfide positive electrode and a nonaqueous electrolyte. The iron disulfide of the positive electrode has a controlled average particle size range which allows the electrochemical cells to exhibit desired properties in both low and high rate applications. In various embodiments, the iron disulfide particles are wet milled, preferably utilizing a media mill or milled utilizing a non-mechanical mill such as a jet mill, which reduces the iron disulfide particles to a desired average particle size range for incorporation into the positive electrode.

Owner:EVEREADY BATTERY CO INC

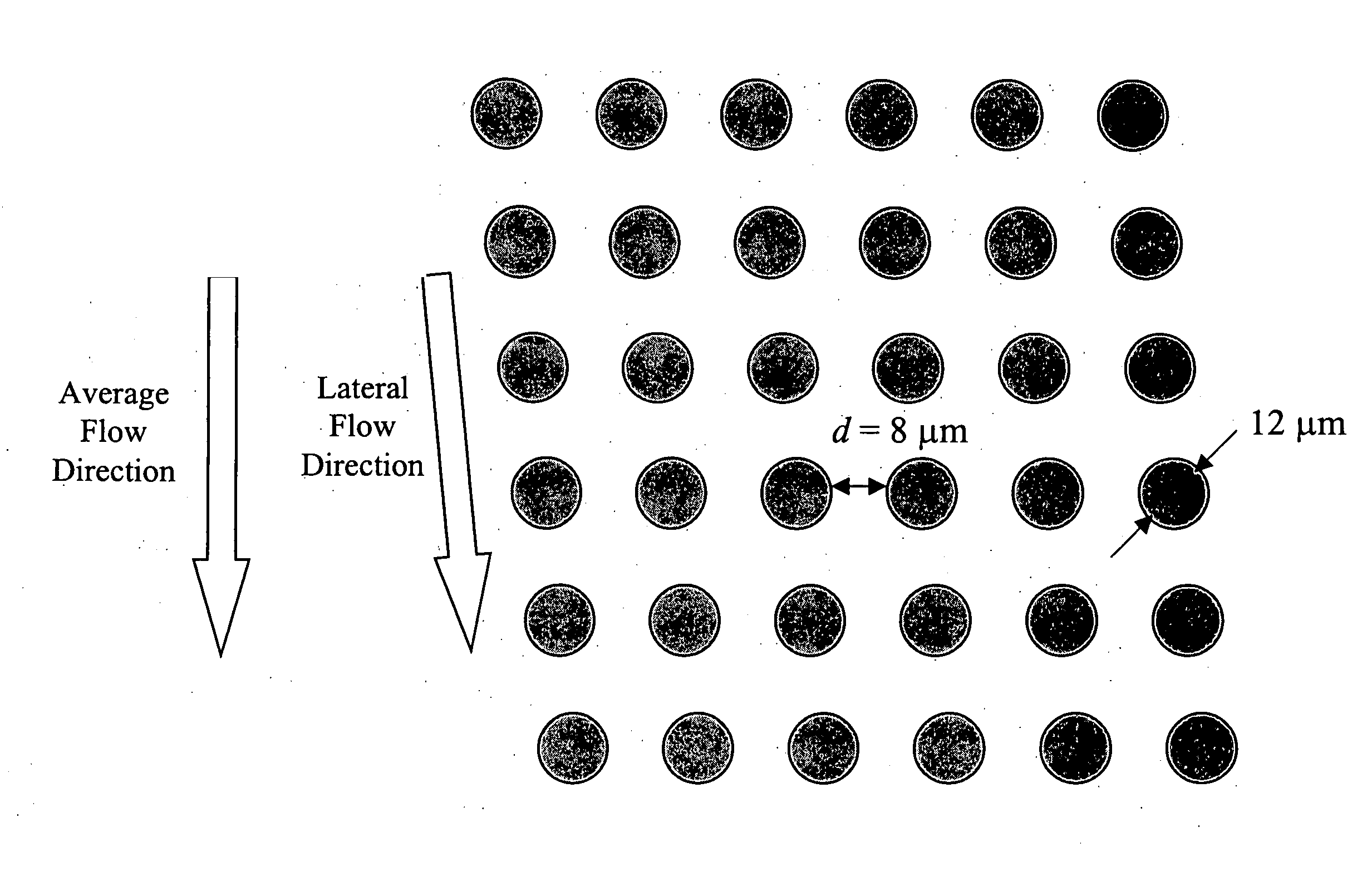

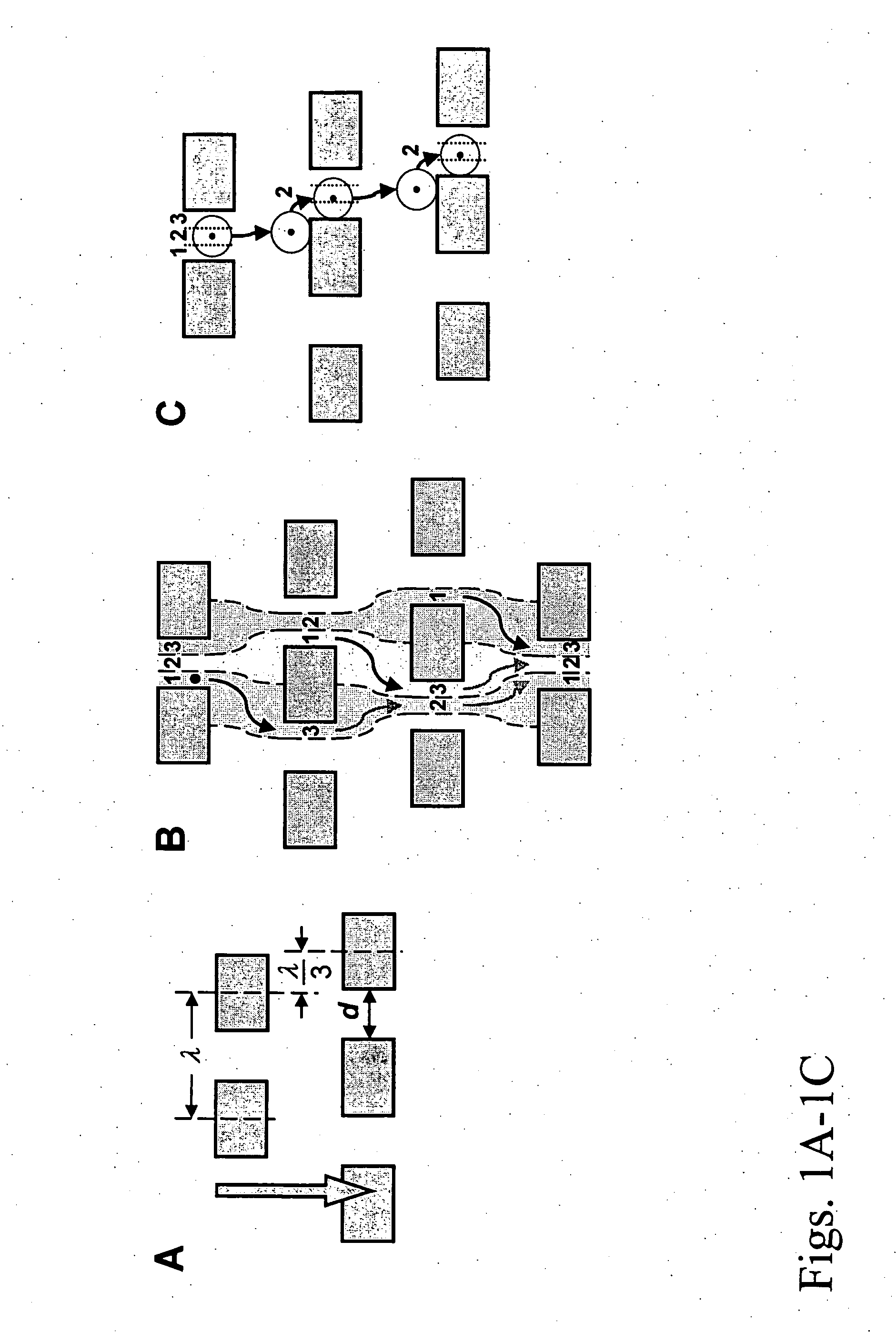

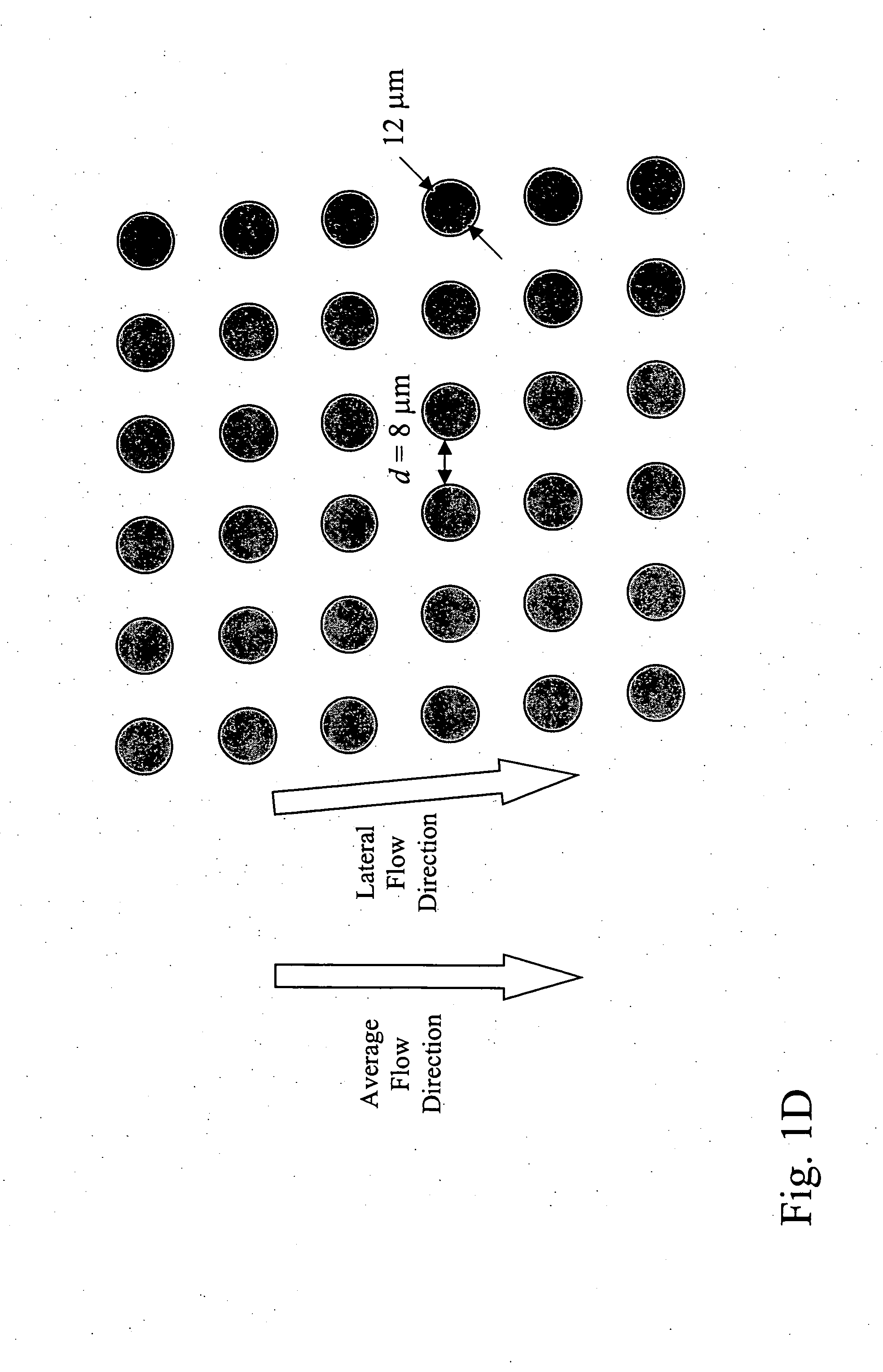

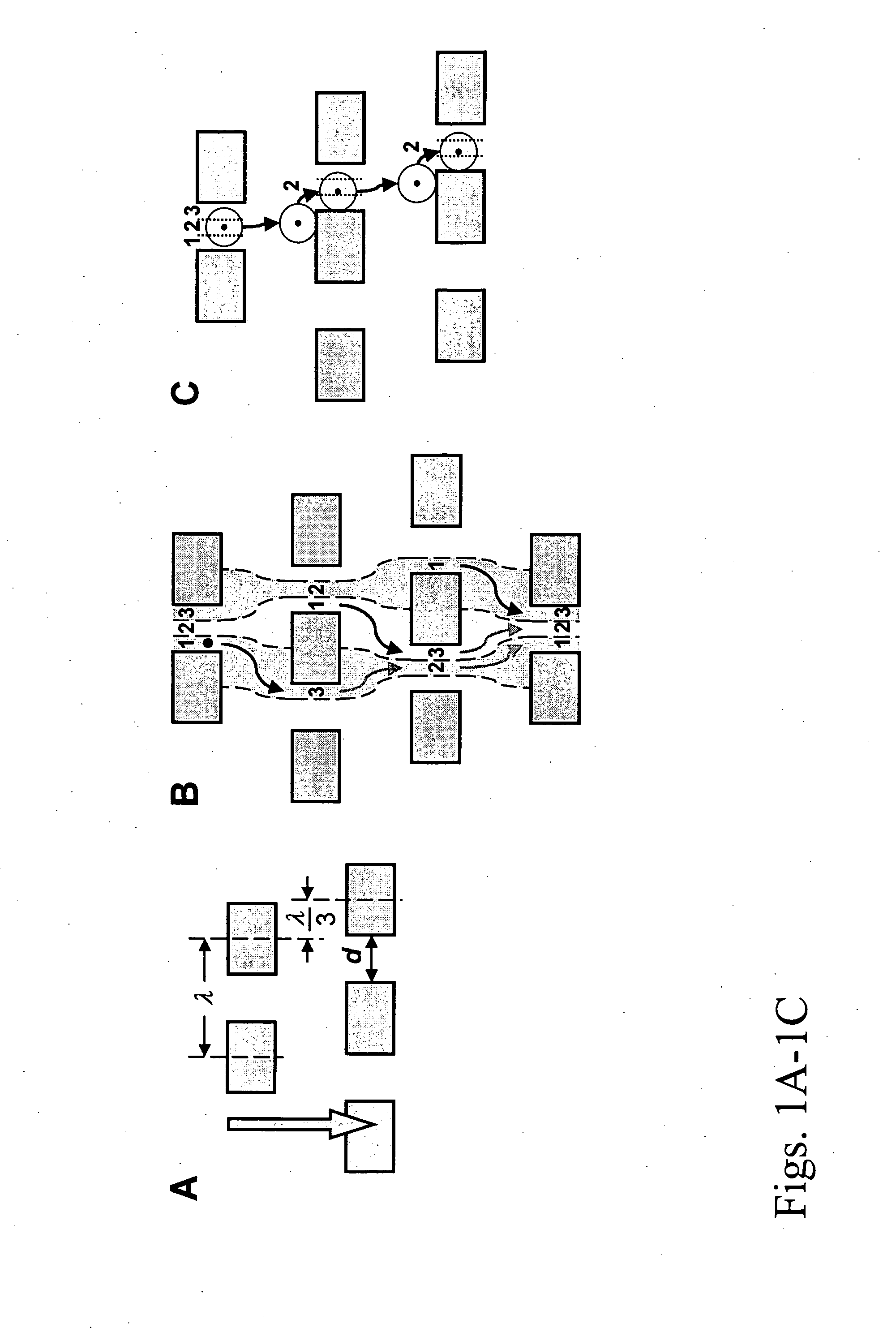

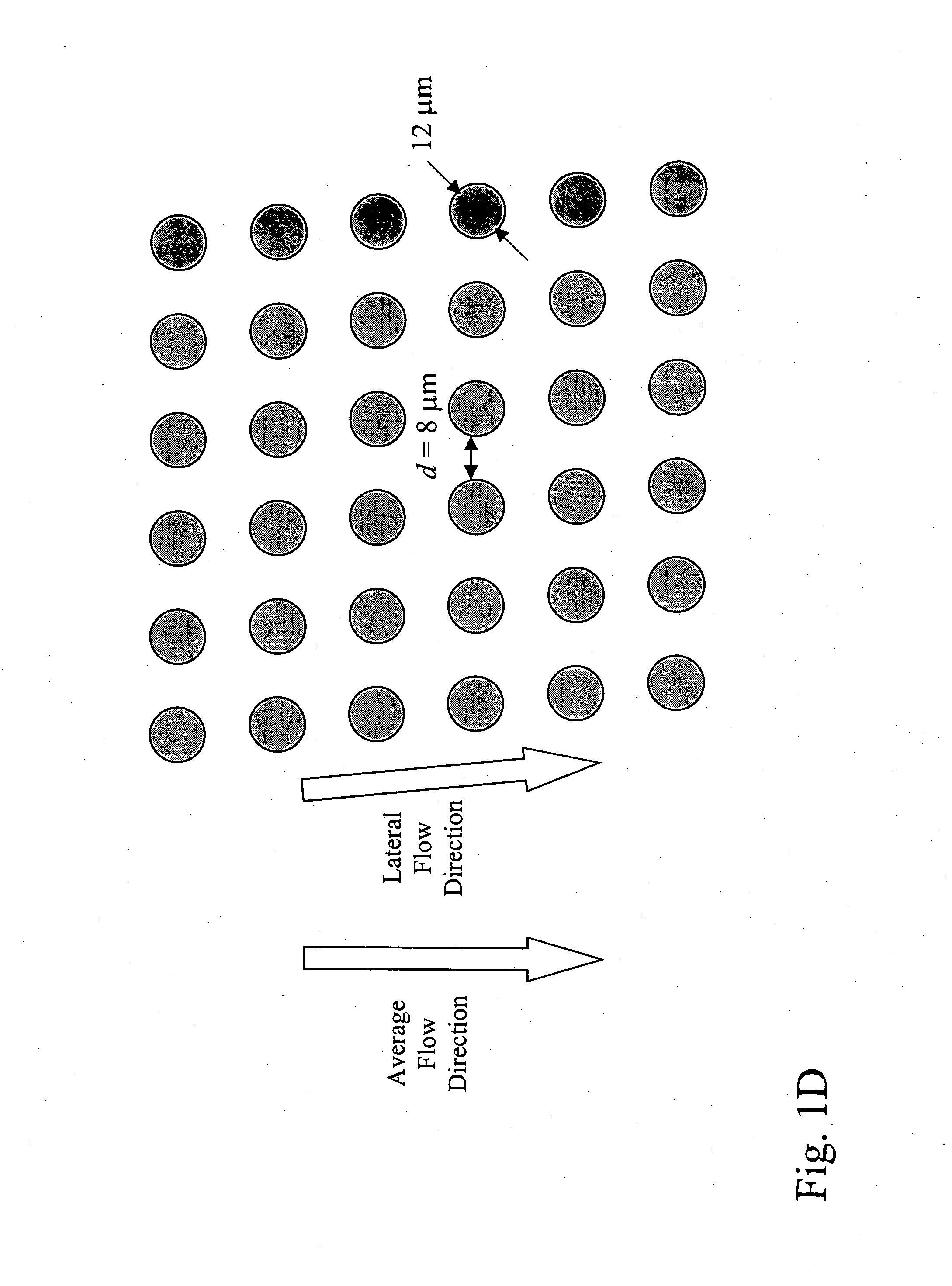

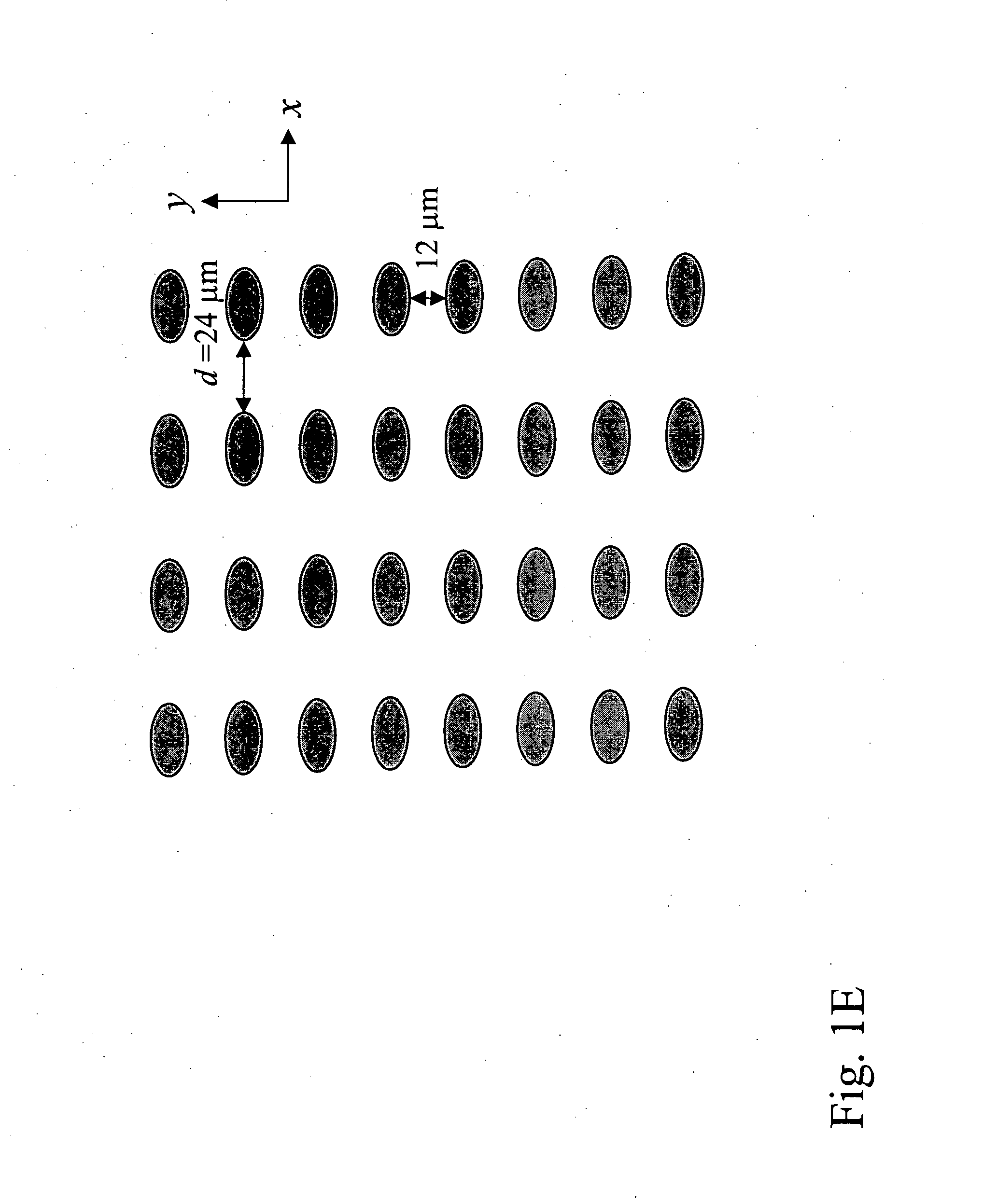

Devices and methods for enrichment and alteration of cells and other particles

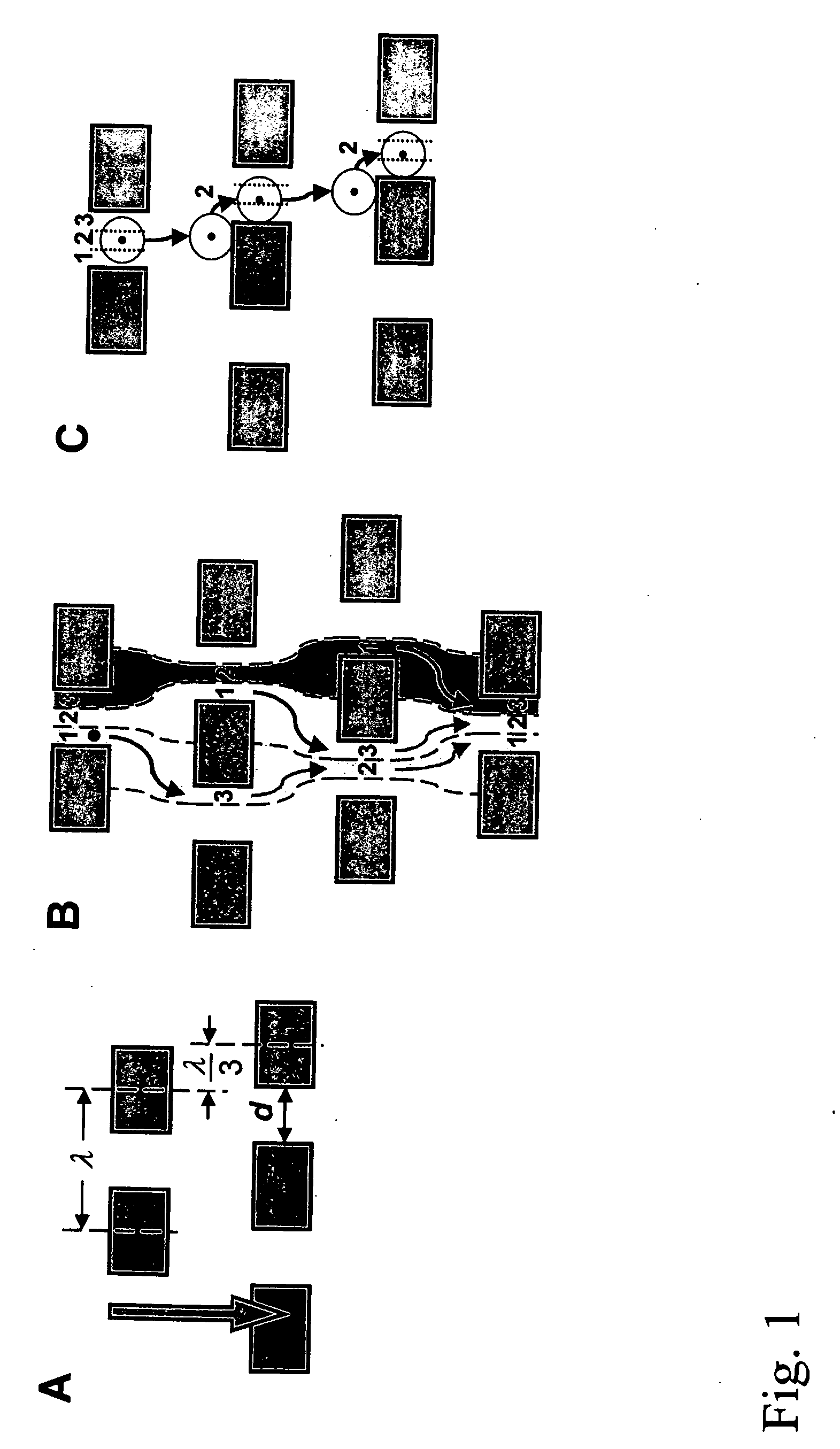

InactiveUS20070196820A1High magnetic responsivenessSmall particle sizeBioreactor/fermenter combinationsBiological substance pretreatmentsAnalyteRare cell

The invention features a device for the deterministic separation of analytes coupled to a reservoir containing a reagent that alters a magnetic propert of the analyte. Exemplary methods include the enrichment of a sample in a desired analyte (e.g., using deterministic separation) or the alteration of a desired analyte in the device. The devices and methods may be advantageously employed to enrich for rare cells, e.g., fetal cells or epithelial cells, present in a sample, e.g., maternal blood.

Owner:THE GENERAL HOSPITAL CORP +1

High discharge capacity lithium battery

InactiveUS20050277023A1High capacityLong storage lifeElectrode manufacturing processesFinal product manufactureScavengerCycloaliphatic epoxy

Electrochemical battery cells, and more particularly, to cells comprising a lithium negative electrode and an iron disulfide positive electrode. Before use in the cell, the iron disulfide has an inherent pH, or a mixture of iron disulfide and an pH raising additive compound have a calculated pH, of at least a predetermined minimum pH value. In a preferred embodiment, the pH raising additive compound comprises a Group IIA element of the Periodic Table of the Elements, or an acid scavenger or pH control agent such as an organic amine, cycloaliphatic epoxy, amino alcohol or overbased calcium sulfonate. In one embodiment, the iron disulfide particles utilized in the cell have a specific reduced average particle size range. Methods for preparing cathodes and electrochemical battery cells comprising such cathodes including (a) iron disulfide or (b) a mixture of iron disulfide and the pH raising additive compound, having (a) an inherent pH or (b) a calculated pH greater than or equal to a predetermined minimum value are disclosed.

Owner:ENERGIZER BRANDS

Non-glare film, polarizing device and display device

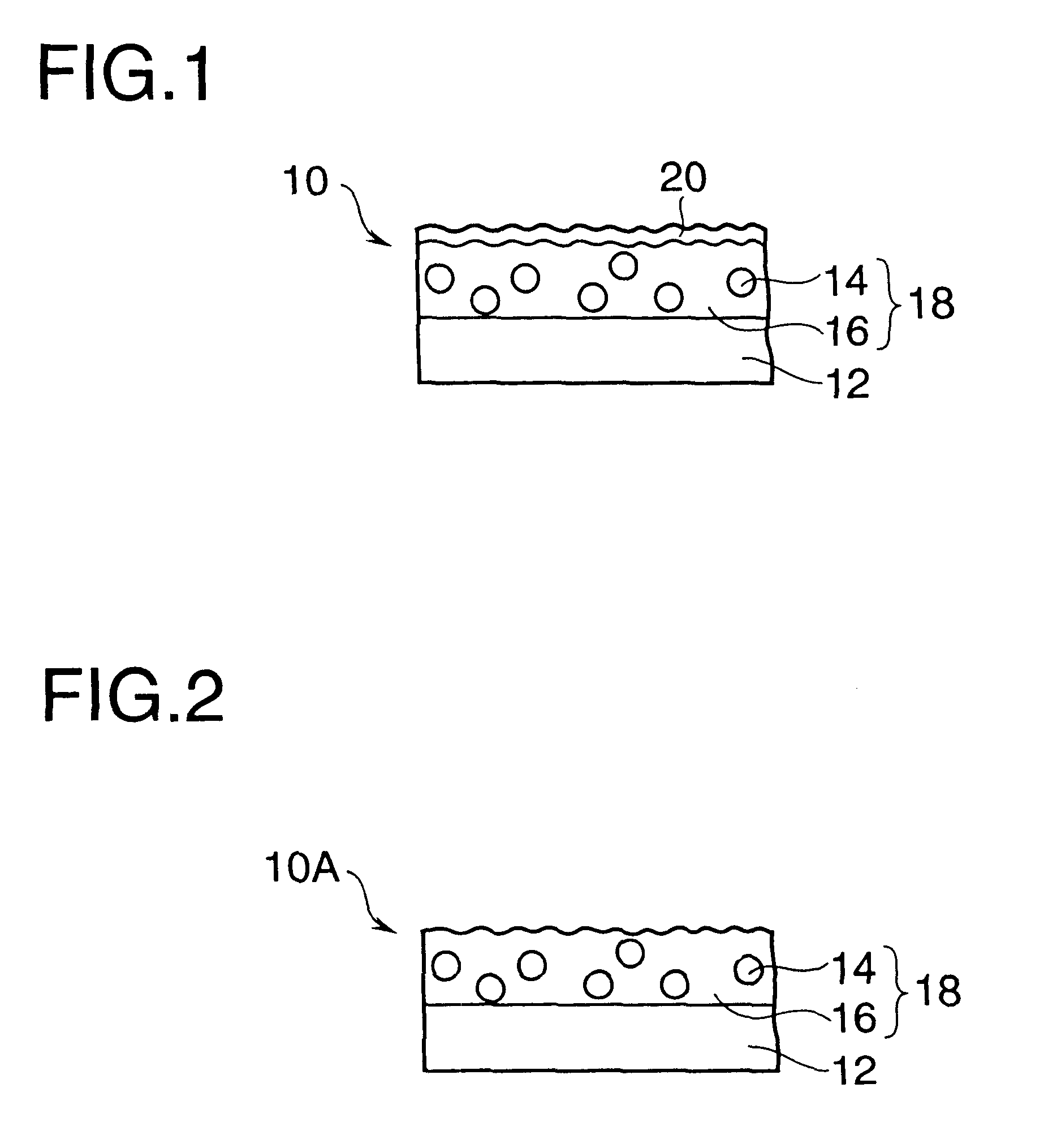

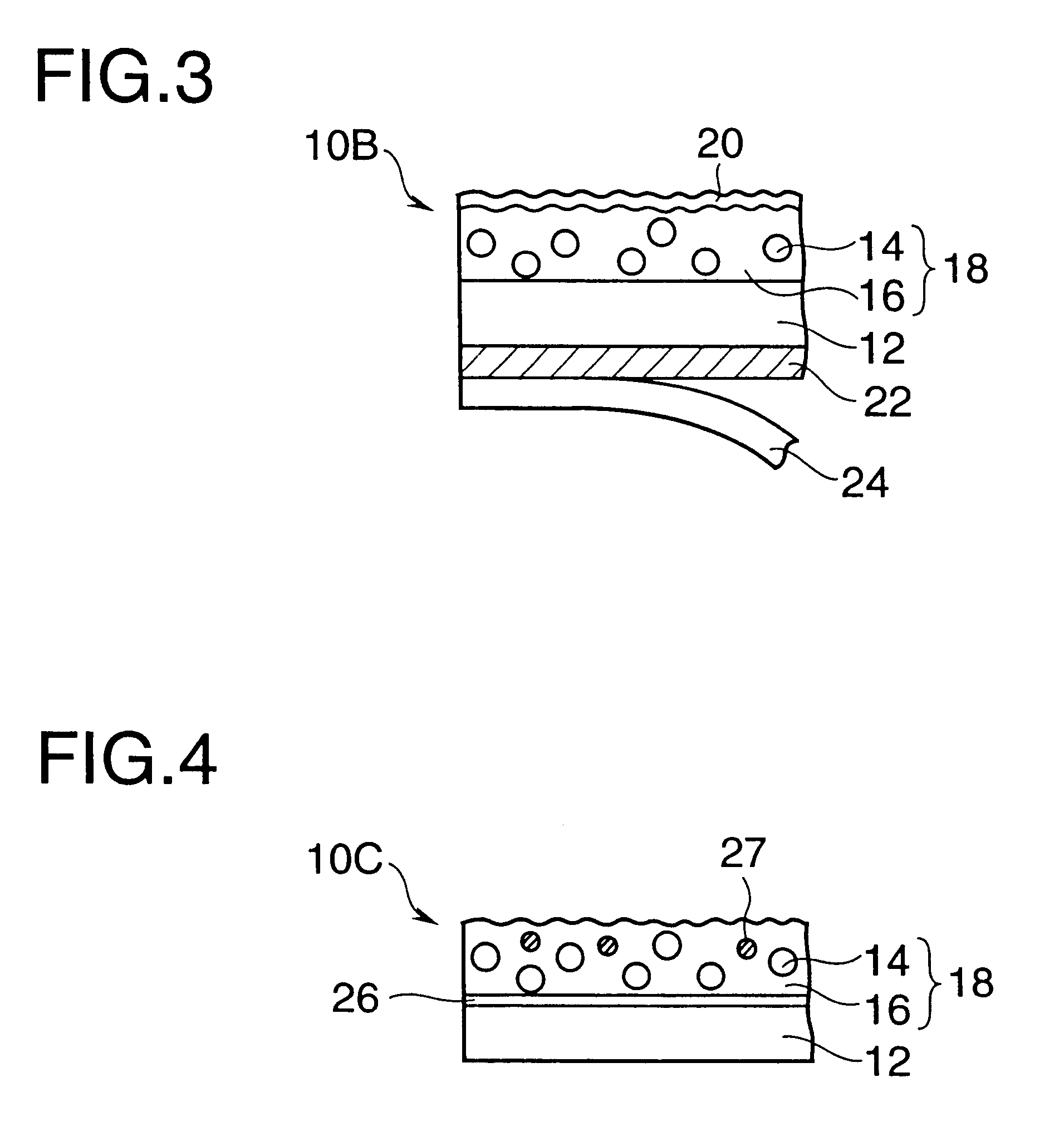

InactiveUS6343865B1Small particle sizeImprove display qualityMirrorsDiffusing elementsRefractive indexDisplay device

A non-glare film 10 is composed of a non-glare layer 18 formed by coating a transparent base film 12 of TAC or the like with a coating material obtained by mixing a light transmissive diffusing material 14 of resin beads and the like in a light transmissive resin 16, and a low refractive index layer 20 composed of a silicon-containing vinylidene fluoride copolymer, said low refractive index layer 20 being laminated onto the surface of the non-glare layer, in which the haze value on the surface of the non-glare layer 18 is 7 to 30 and the haze value inside the non-glare layer 18 is 1 to 15, and when the non-glare film is attached onto the surface of a display panel, it suppresses degradation in contrast and furthermore prevents face-glare, reflecting-in and whitening.

Owner:DAI NIPPON PRINTING CO LTD

Devices and methods for enrichment and alteration of circulating tumor cells and other particles

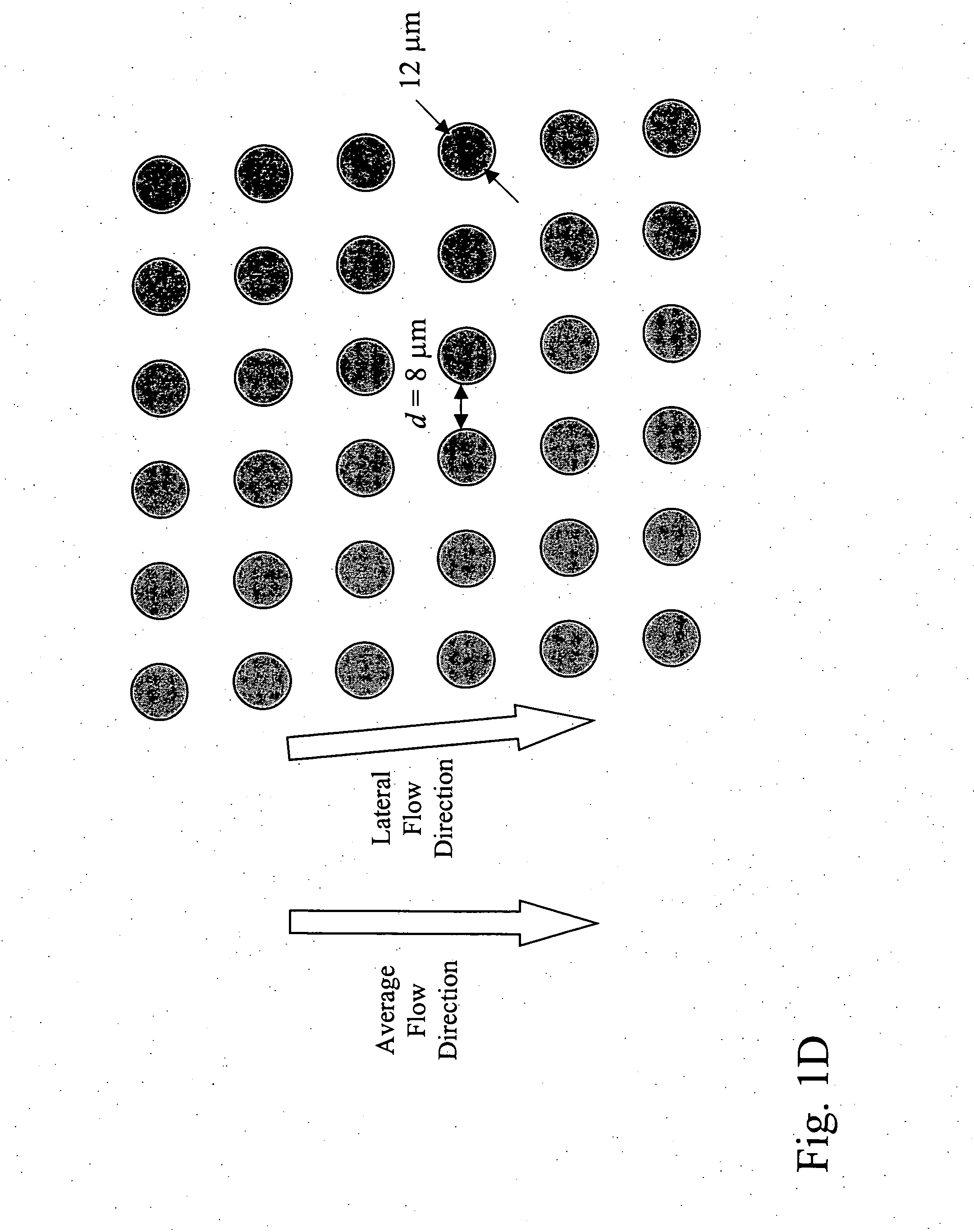

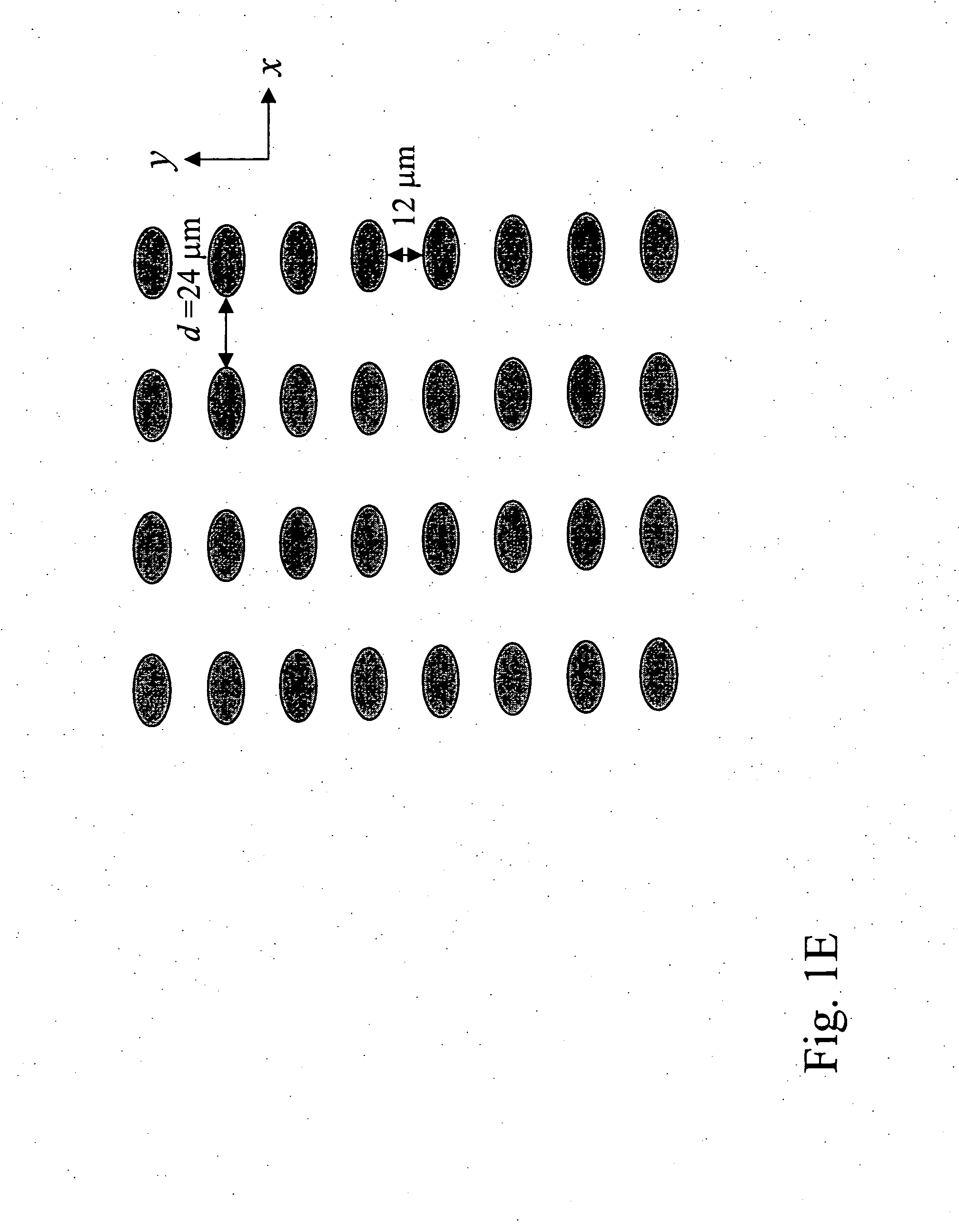

InactiveUS20070026415A1Increase array densitySmall particle sizeBioreactor/fermenter combinationsBiological substance pretreatmentsCirculating cancer cellTumor cells

The invention features devices and methods for detecting, enriching, and analyzing circulating tumor cells and other particles. The invention further features methods of diagnosing a condition, e.g., cancer, in a subject by analyzing a cellular sample from the subject.

Owner:THE GENERAL HOSPITAL CORP +2

Devices and methods for enrichment and alteration of circulating tumor cells and other particles

InactiveUS20070026413A1Increase array densitySmall particle sizeBioreactor/fermenter combinationsBiological substance pretreatmentsCirculating cancer cellTumor cells

The invention features devices and methods for detecting, enriching, and analyzing circulating tumor cells and other particles. The invention further features methods of diagnosing a condition, e.g., cancer, in a subject by analyzing a cellular sample from the subject.

Owner:THE GENERAL HOSPITAL CORP +2

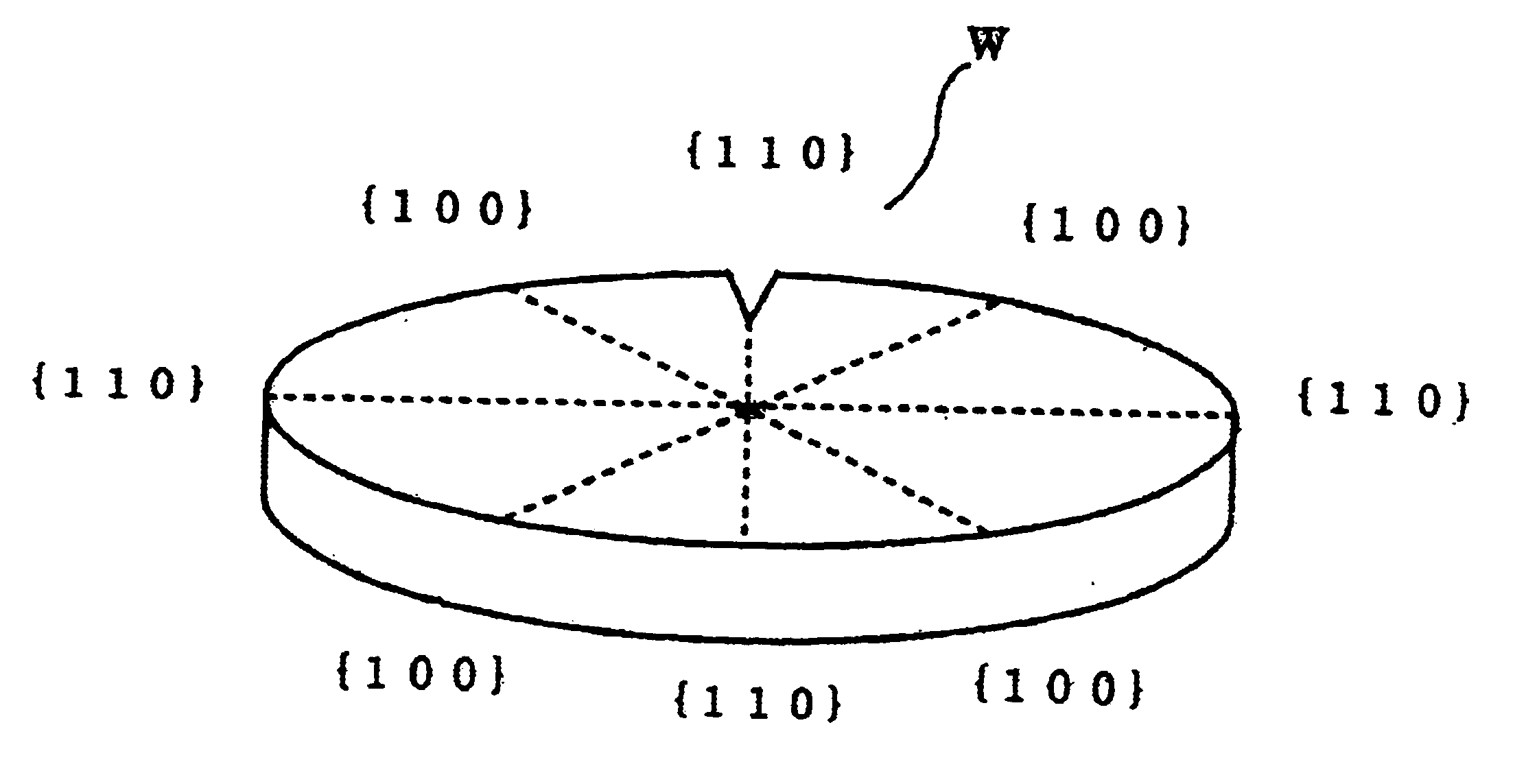

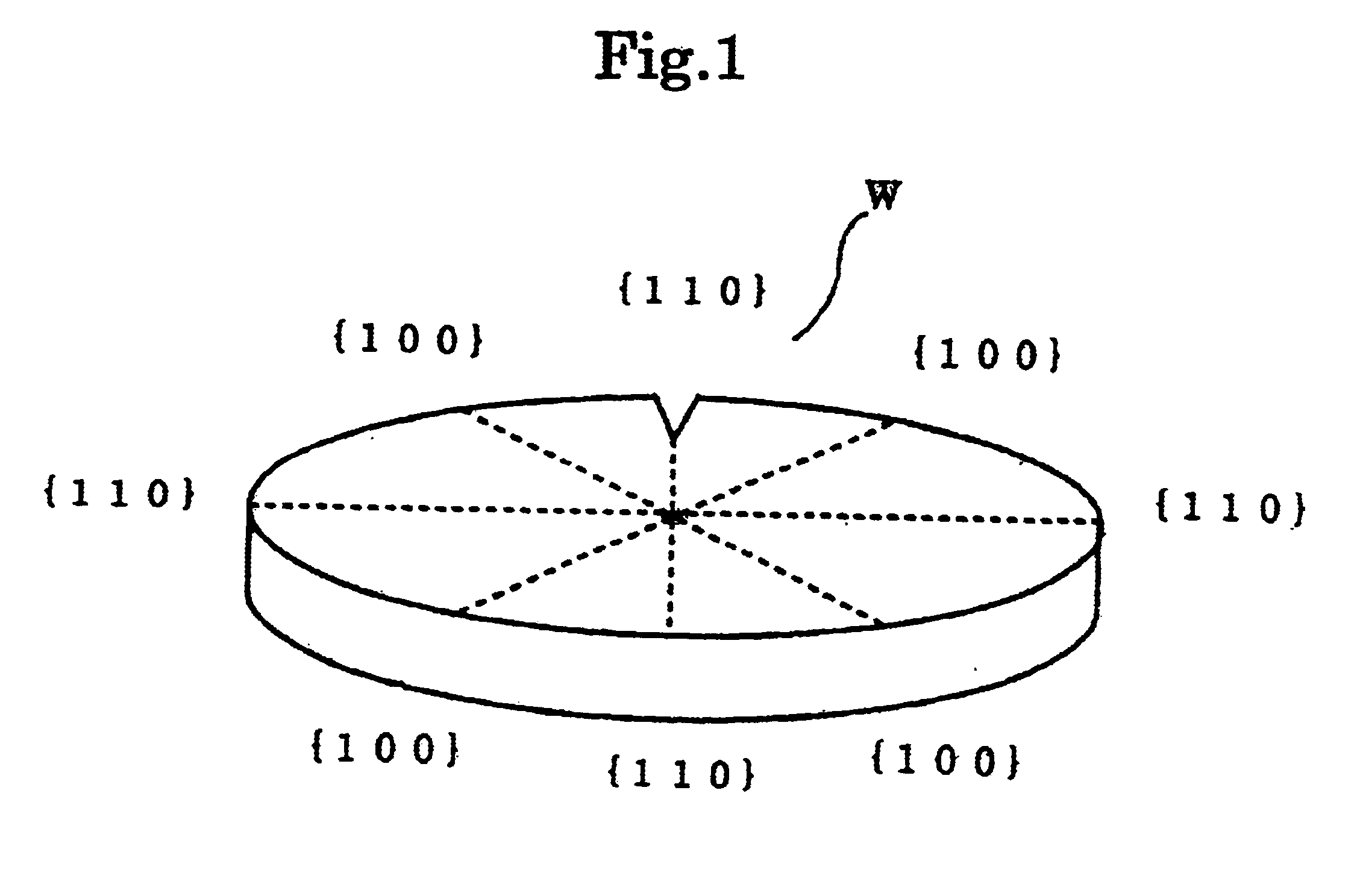

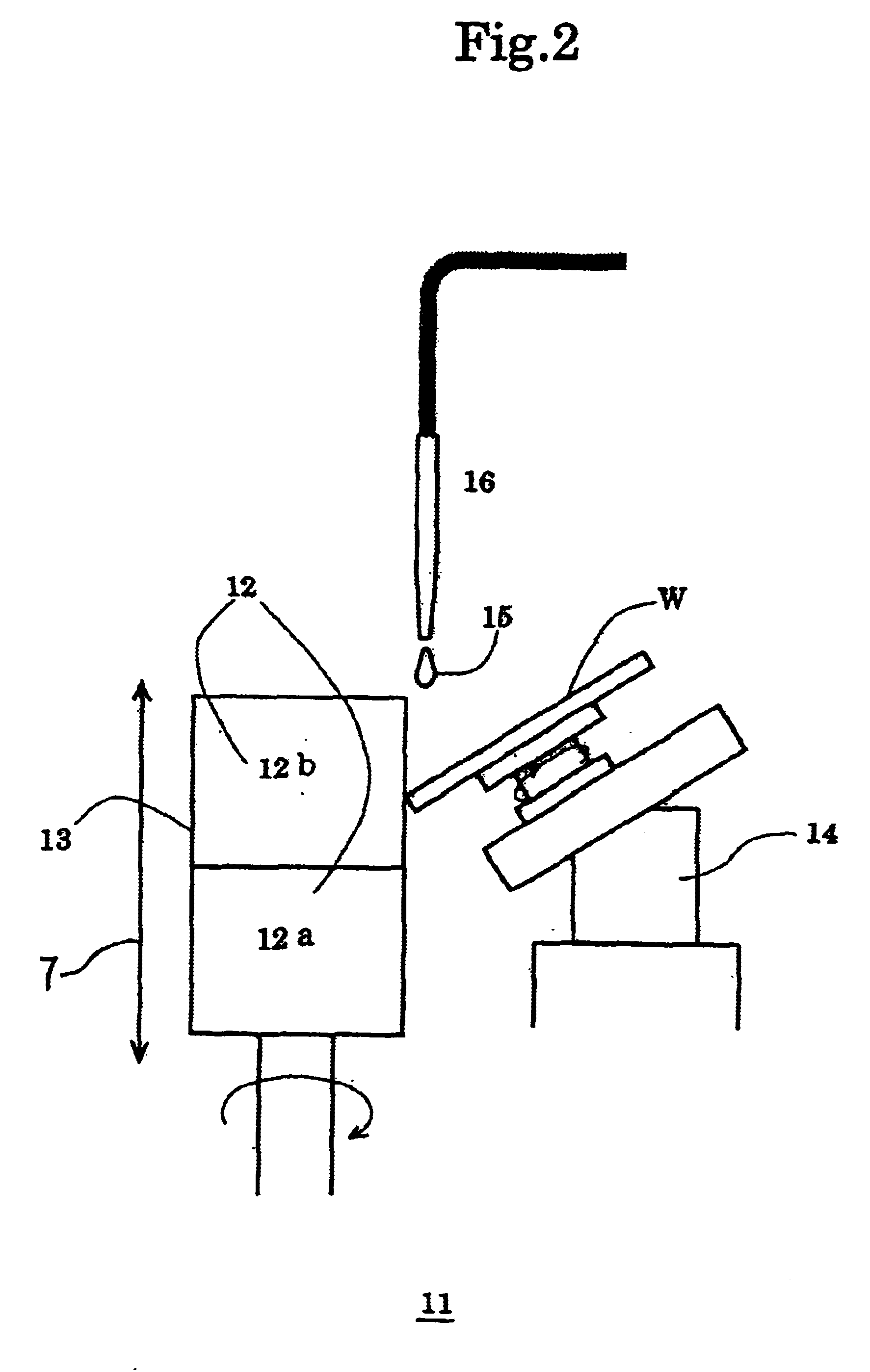

Method for apparatus for polishing outer peripheral chamfered part of wafer

InactiveUS6884154B2Improve productivityShorten polishing timeEdge grinding machinesPolishing machinesProduction rateHardness

In a process for polishing the chamfered peripheral part of a wafer using a polishing cloth while supplying a polishing slurry in order to improve productivity of the process by reducing a polishing time, at least two steps of polishing processes are performed in sequence. The process comprises a first polishing process to polish a particular part, e.g. the part corresponding to the {110} plane of a peripheral part of the wafer and a second polishing process in which the whole part of a peripheral part of the wafer is polished for finishing by means of varying a hardness of the polishing clothes and / or a particle size of abrasives in the slurry such as the hardness of the polishing cloth in the second polishing process being softer than that of in the first polishing process and a particle size of abrasives in the slurry in the second polishing process being finer than that of in the first polishing process.

Owner:SHIN-ETSU HANDOTAI CO LTD

Devices and methods for enrichment and alteration of circulating tumor cells and other particles

ActiveUS20070026469A1Increase array densitySmall particle sizeBioreactor/fermenter combinationsBiological substance pretreatmentsCirculating cancer cellTumor cells

The invention features devices and methods for detecting, enriching, and analyzing circulating tumor cells and other particles. The invention further features methods of diagnosing a condition, e.g., cancer, in a subject by analyzing a cellular sample from the subject.

Owner:GPB SCI

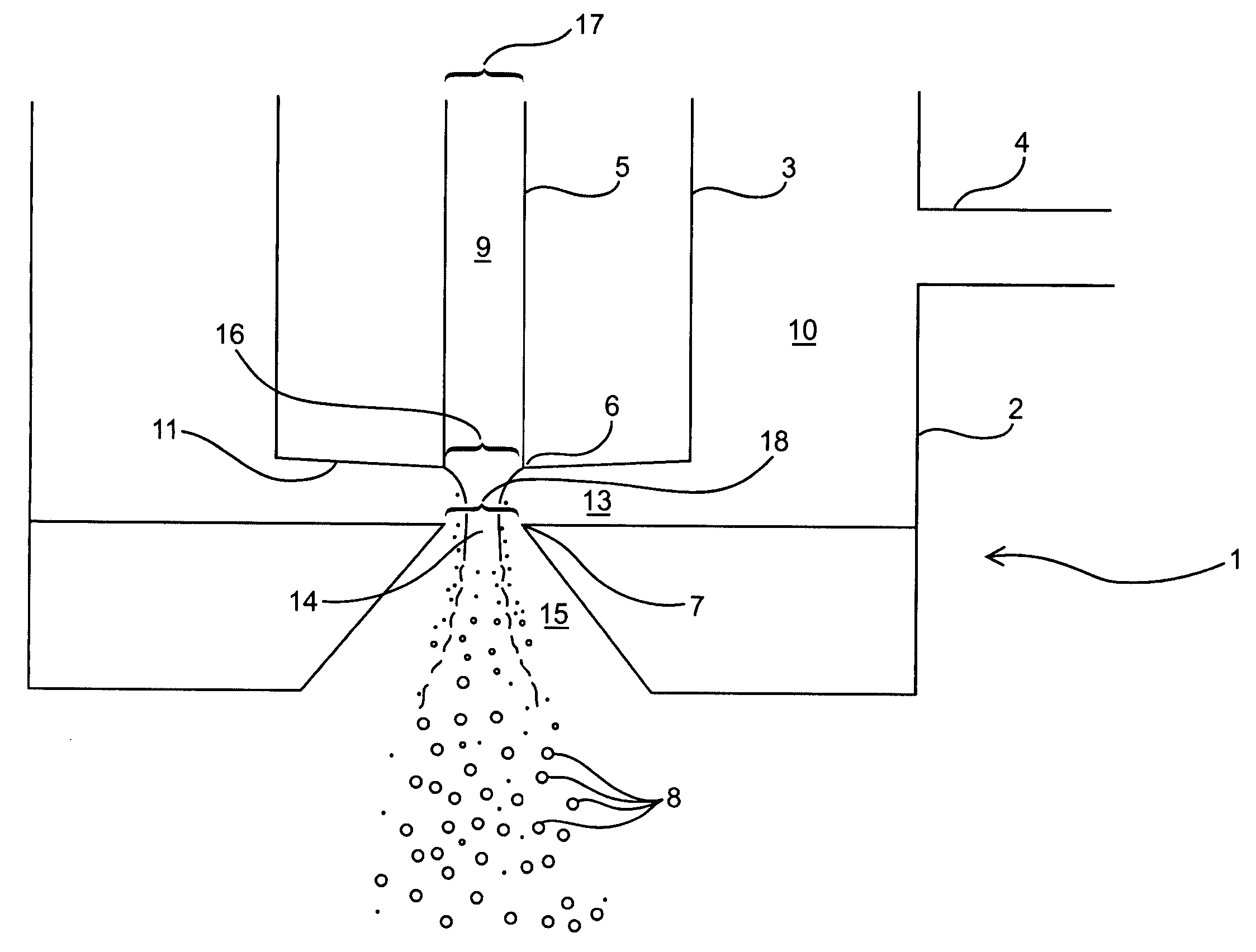

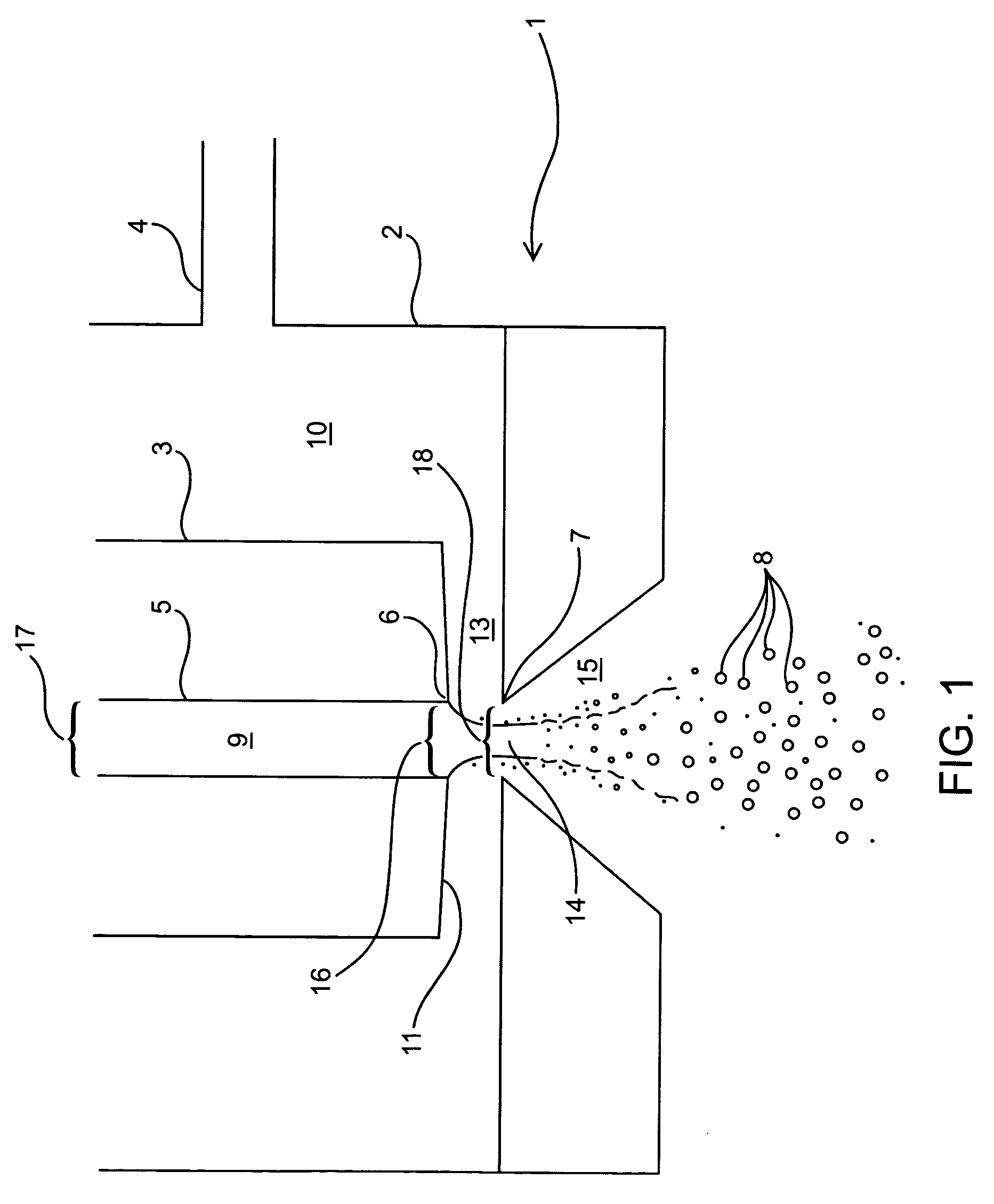

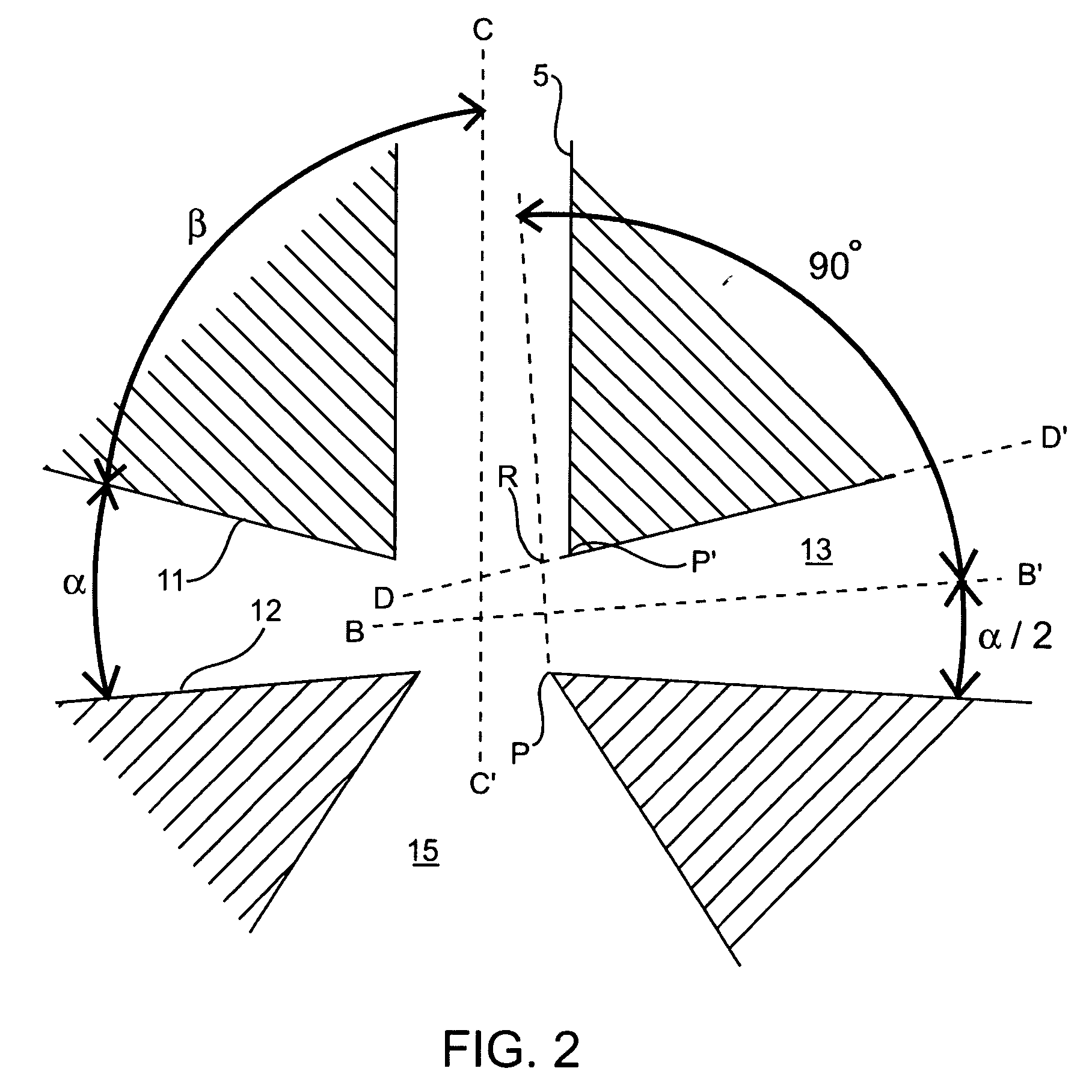

Aerosol created by directed flow of fluids and devices and methods for producing same

InactiveUS20060169800A1Efficient deliveryEasy to manufactureSpray nozzlesLiquid spraying apparatusEngineeringSmall particle

A method of creating small particles by a technology referred to here as “violent focusing” is disclosed, along with devices for generating such violent focusing. In general, the method comprises the steps of forcing a first fluid out of an exit opening of the feeding channel to create a fluid stream. The exit opening is positioned such that the fluid flowing out of the channel flows toward and out of an exit orifice of a pressure chamber which surrounds the exit opening of the feeding channel, and is filled with an atomizing fluid. An atomizing fluid such as a gas is directed towards the first fluid stream in approximately orthogonal directions and surrounding the circumference of the first fluid stream from all sides. The first fluid flow is broken into particles which have dimensions which are smaller than the dimensions of this fluid stream.

Owner:ARADIGM +1

Control of mercury emissions from solid fuel combustion

ActiveUS20050039598A1Remove pollutantsEasy to captureGas treatmentEmission preventionSorbentSolid fuel

A system 26 for removing elemental mercury or mercury compounds handles carbonaceous sorbent 28 of a starter batch stored in a silo 30 in an agglomerated state. The sorbent 28 is fed by a feeder 32 to a separation device 34, which comminutes (if necessary) and de-agglomerates the sorbent particles 28 to their primary size distribution. This device 34 may be a particle-particle separator or a jet mill, where compressed air or high-pressure steam is the energy source. The de-agglomerated sorbent 28 of a contact batch created from the starter batch is conveyed by an airsteam for injection at a contact location 66 in a flue gas duct whereat carbonaceous sorbent of the contact batch adsorbs mercury from the flue gas.

Owner:GENERAL ELECTRIC TECH GMBH

Compositions for inactivating pathogenic microorganisms, methods of making the compositons, and methods of use thereof

InactiveUS20050208083A1Reduce infectivityReduce morbidityAntibacterial agentsSsRNA viruses negative-sensePathogenic microorganismOrganic solvent

Nanoemulsion compositions with low toxicity that demonstrate broad spectrum inactivation of microorganisms or prevention of diseases are described. The nanoemulsions contain an aqueous phase, an oil phase comprising an oil and an organic solvent, and one or more surfactants. Methods of making nanoemulsions and inactivating pathogenic microorganisms are also provided.

Owner:NANOBIO CORP

Devices and methods for enrichment and alteration of circulating tumor cells and other particles

InactiveUS20070026417A1Decrease size of particleDecrease in volumeMicrobiological testing/measurementNanoinformaticsCirculating cancer cellCirculating tumor cell

The invention features devices and methods for detecting, enriching, and analyzing circulating tumor cells and other particles. The invention further features methods of diagnosing a condition, e.g., cancer, in a subject by analyzing a cellular sample from the subject.

Owner:CELLECTIVE DX CORP +2

Anti-bacterial thermoplastic composite and preparation method thereof

The invention relates to an anti-bacterial thermoplastic composite, which comprises the following mixed components: 100 parts of thermoplastic by weight and 0.1-40 parts of composite antibacterial agent by weight, wherein the composite antibacterial agent comprises micronano inorganic / organic particles and guanidinesalt polymers which are coated on the surfaces of the micro / nano particles and / or embedded among pores and layers of the micronano particles; the weight ratio of the guanidinesalt polymers to the micro / nano particles is 1:1-1:50; and the micro / nano particles have at least a one-dimensional average size of 1nm-1000mum. The anti-bacterial thermoplastic composite is obtained by melting and mixing the components such as the thermoplastic, the composite antibacterial agent, and the like, therefore the antibacterial rate of the anti-bacterial thermoplastic composite is higher and the preparation method is simple.

Owner:CHINA PETROLEUM & CHEM CORP +1

Magnetic recording medium and coating composition for magnetic recording medium

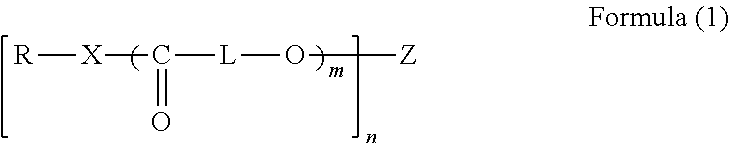

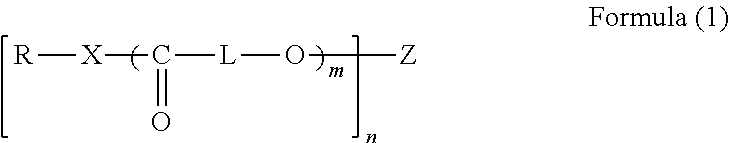

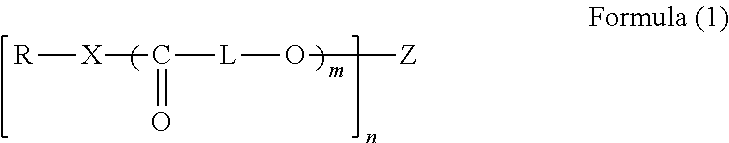

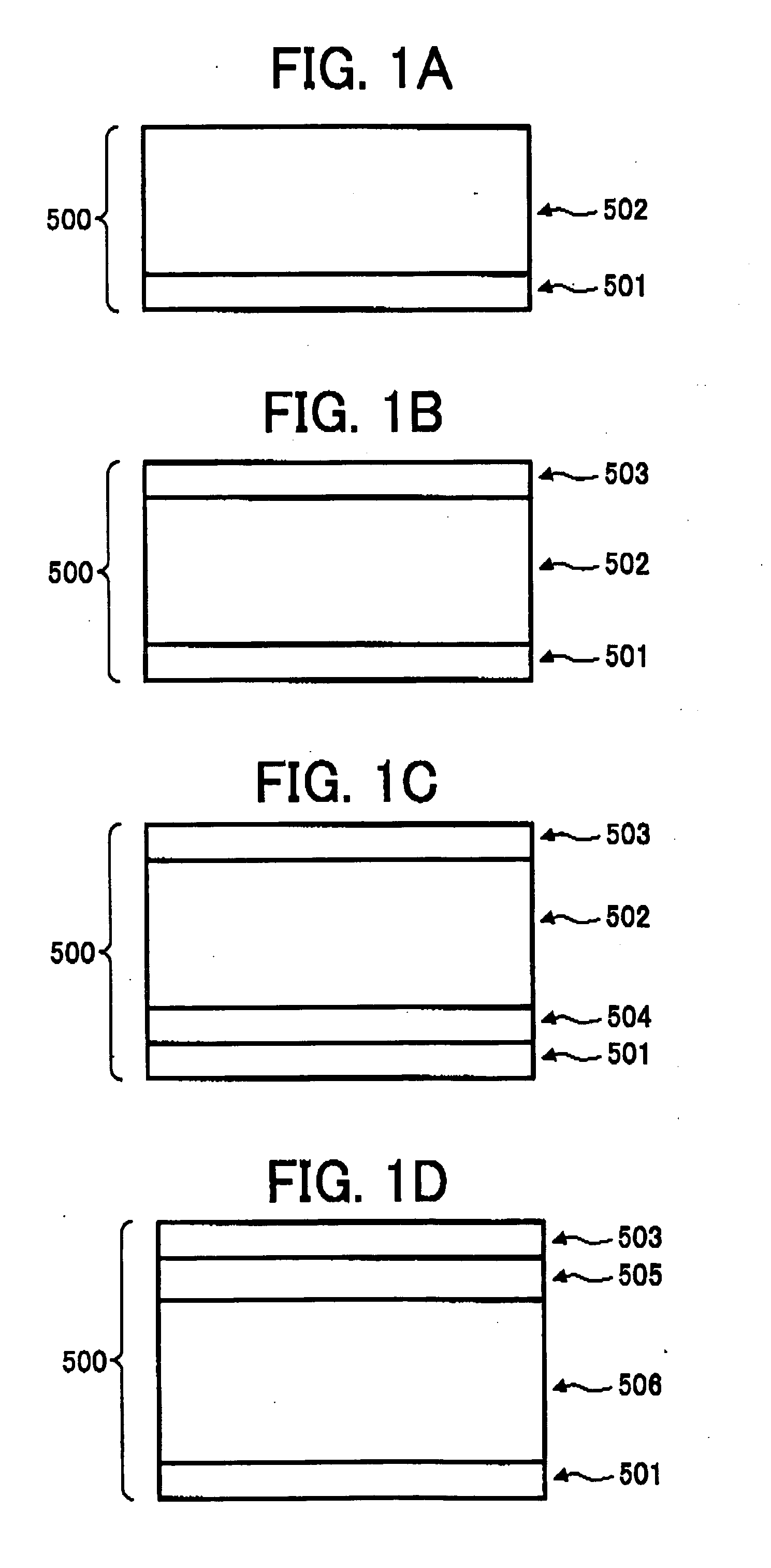

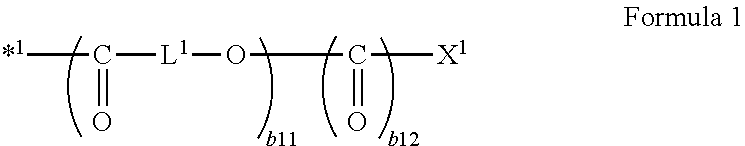

ActiveUS20160093321A1Increased durabilitySmall particle sizeInorganic material magnetismRecord information storageHydrogen atomMagnetic layer

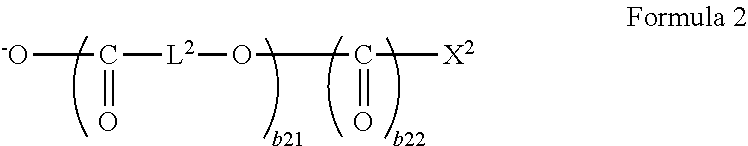

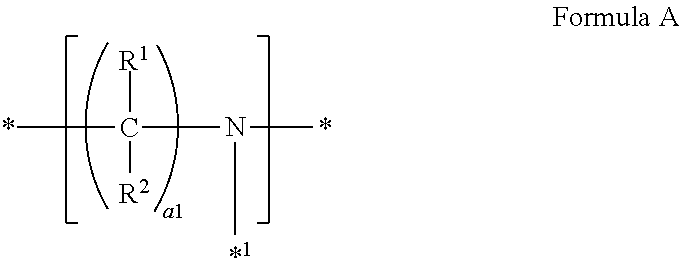

The magnetic recording medium comprises a magnetic layer comprising ferromagnetic powder and binder on a nonmagnetic support, and further comprises a compound denoted by Formula (1):wherein, in Formula (1), X denotes —O—, —S—, or NR1—; each of R and R1 independently denotes a hydrogen atom or a monovalent substituent; L denotes a divalent connecting group; Z denotes a partial structure of valence n comprising at least one group selected from the group consisting of carboxyl groups and carboxylate groups; m denotes an integer of greater than or equal to 2, and n denotes an integer of greater than or equal to 1.

Owner:FUJIFILM CORP

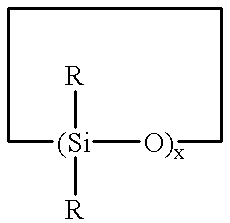

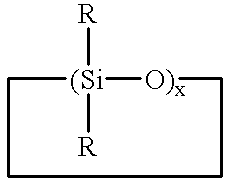

Method for making polysiloxane emulsions

A method for making oil free polysiloxane standard, fine and microemulsions using emulsion polymerization is disclosed. The method comprises reacting a cyclicsiloxane in the presence of a catalyst, ionic surfactant and nonionic surfactant within a certain operating window. Emulsions containing silicone copolymers can also be produced using the method of the instant invention.

Owner:DOW SILICONES CORP

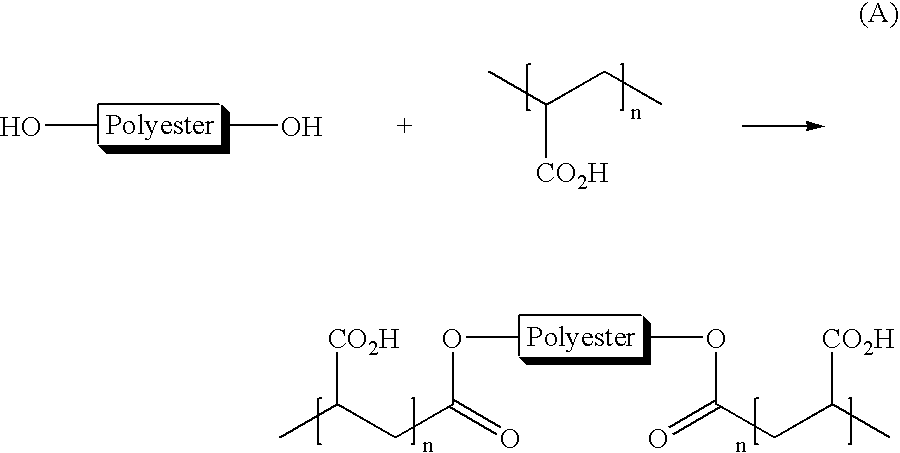

Toner compositions

Toner compositions comprising low-melt toner particles and methods of preparing such toner compositions are provided. The toner particles include a polyester-containing binder, a colorant and an optional wax. The binder includes at least one crystalline polyester resin and at one amorphous acidic polyester resin.

Owner:XEROX CORP

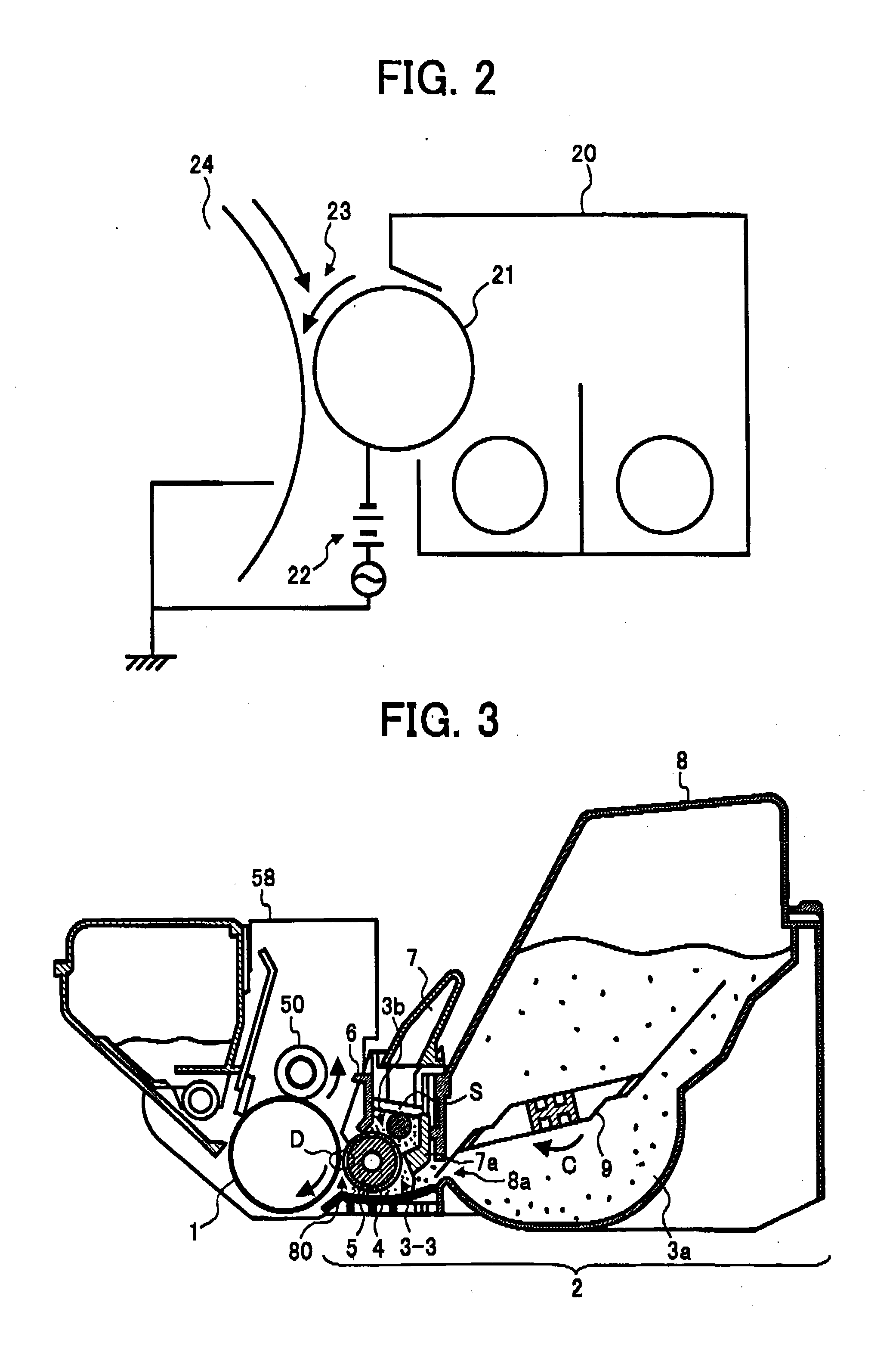

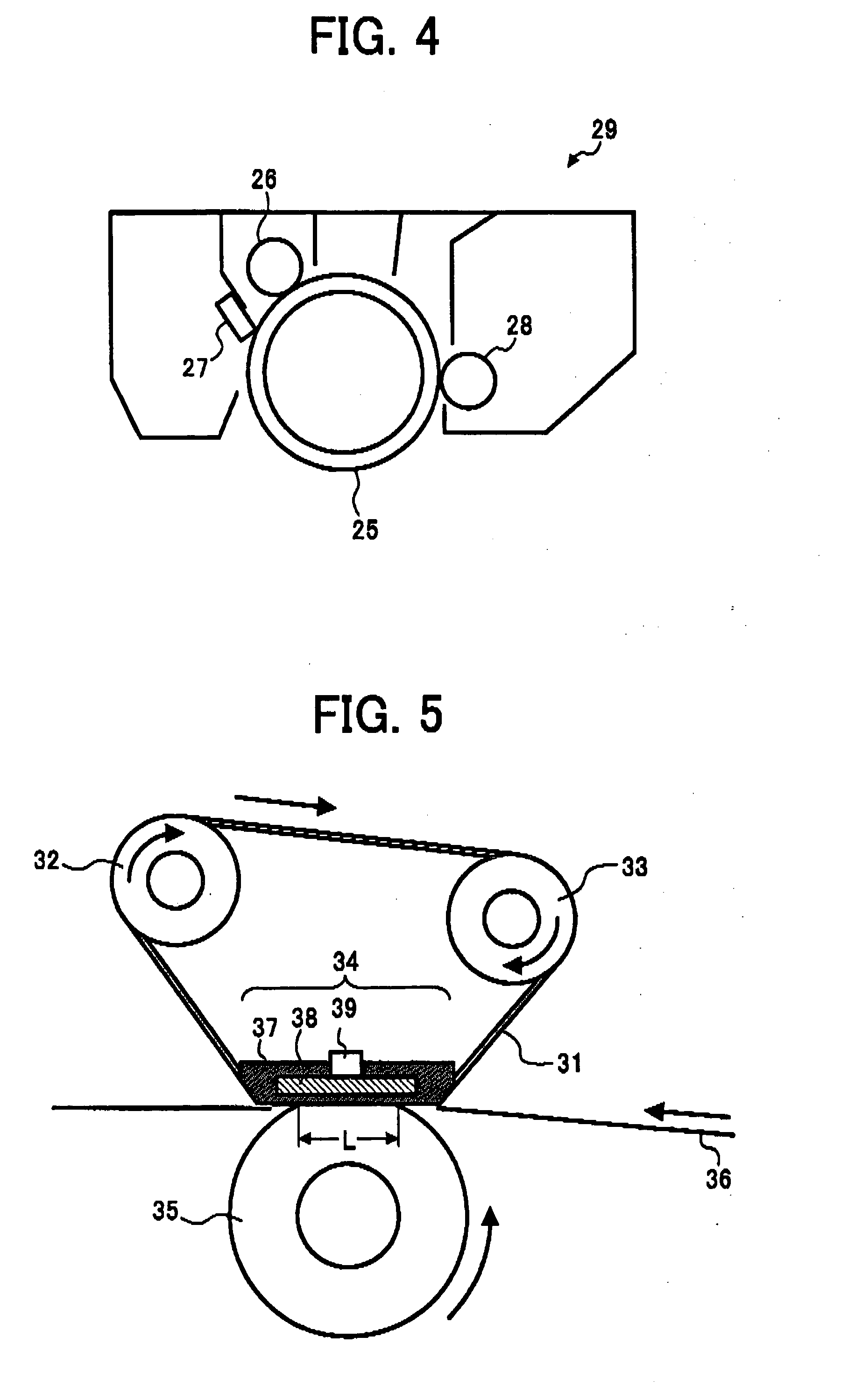

Toner and developer, and image forming method and apparatus using the developer

A toner is provided that contains a particulate toner material (mother toner) having an average circularity of from 0.93 to 0.99, and including a modified polyester resin and a colorant; and an external additive in an amount of from 0.3 to 5.0 parts by weight per 100 parts by weight of the mother toner, wherein the toner has a melting viscosity of from 70 to 140 Pa·s at 160° C., a weight-average particle diameter of from 3 to 7 μm, a ratio thereof to a number-average particle diameter of from 1.91 to 1.25, wherein particles satisfy at least one of (I) and (II): (I) particles having a diameter of 4 μm or less in an amount less than 10% by number; or (II) particles having a diameter of 8 μm or more in an amount less than 2% by volume, along with a one or two component developer containing the toner, a cartridge containing the toner, an image forming method using the toner and an image forming apparatus using the toner.

Owner:RICOH KK

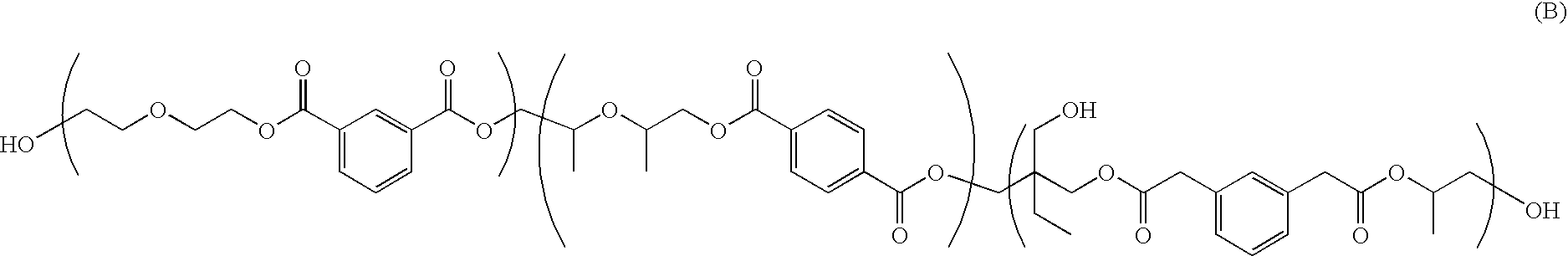

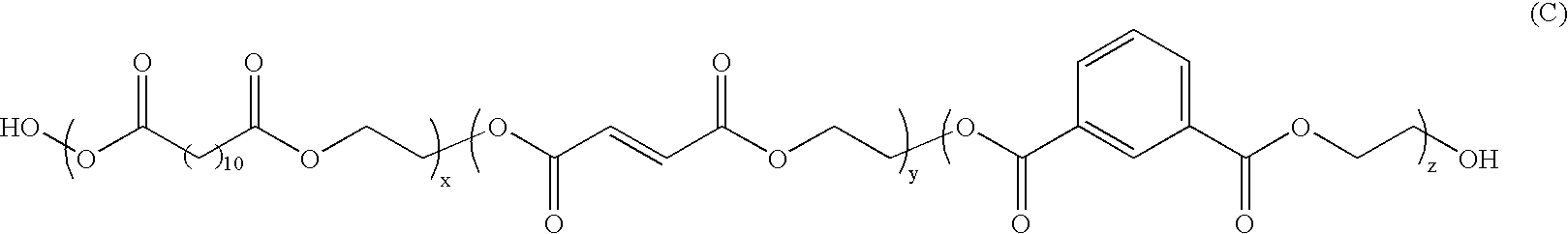

Magnetic recording medium and coating composition for magnetic recording medium

InactiveUS20140374645A1Good dispersionSmall particle sizeInorganic material magnetismRecord information storagePolyesterNon magnetic

An aspect of the present invention relates to a magnetic recording medium comprising a magnetic layer comprising ferromagnetic powder and binder on a nonmagnetic support, wherein an average particle size of the ferromagnetic powder is equal to or less than 50 nm, the magnetic layer further comprises a compound, and the compound comprises at least one polyalkyleneimine chain and at least one polyester chain, with a proportion in the compound accounted for by the polyalkyleneimine chain being less than 5.0 weight percent and a number average molecular weight of the polyalkyleneimine chain ranging from 300 to 3,000.

Owner:FUJIFILM CORP

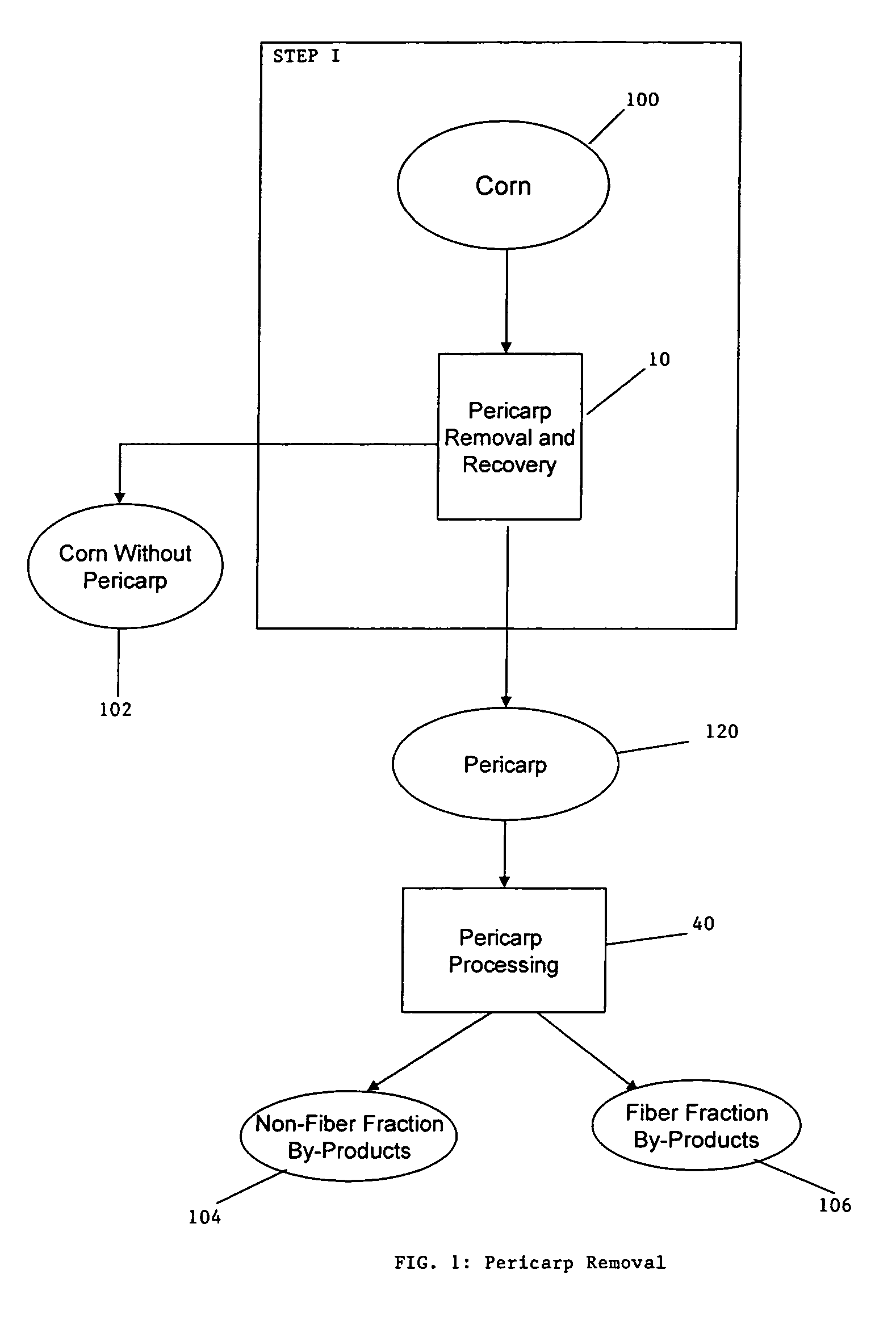

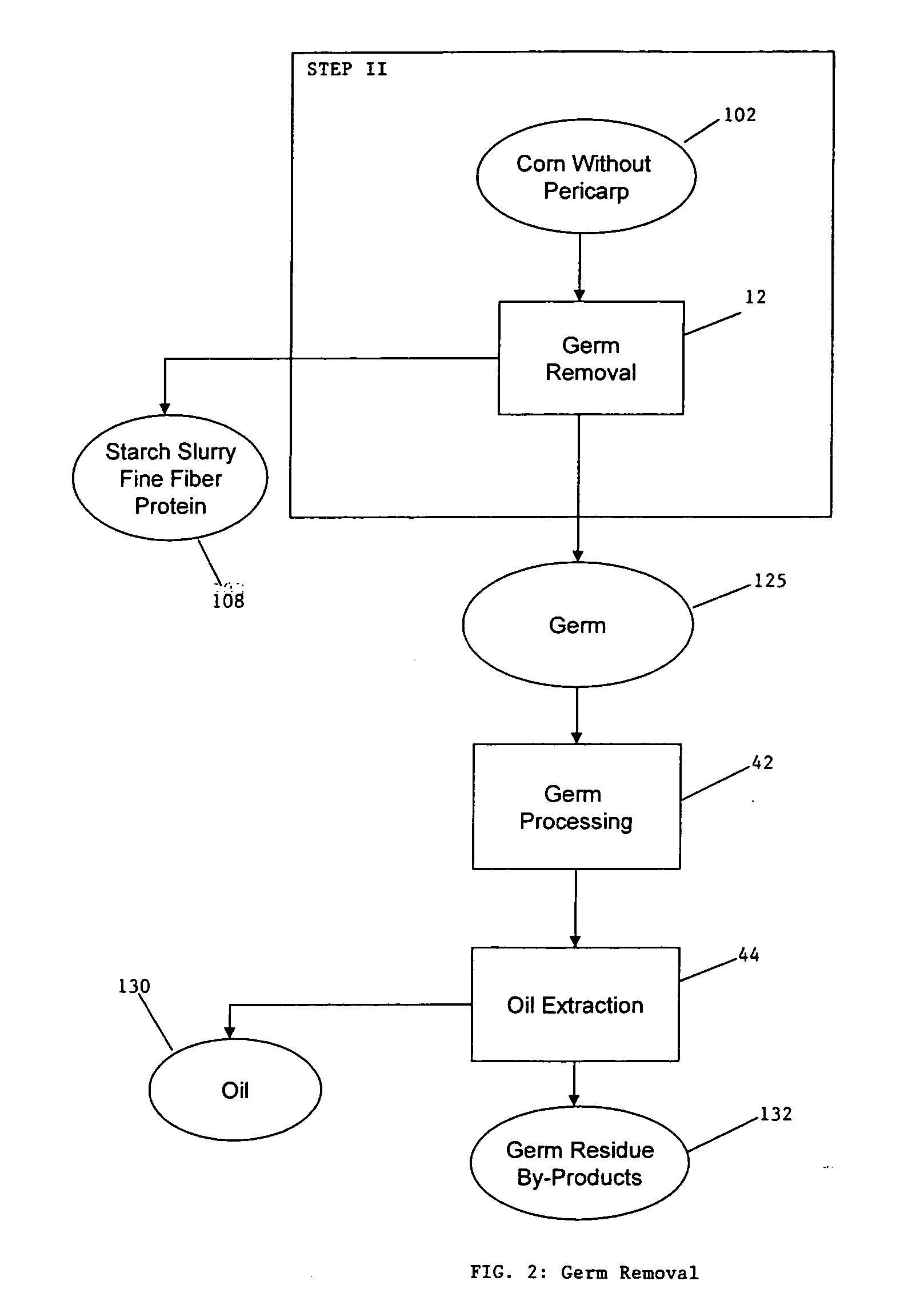

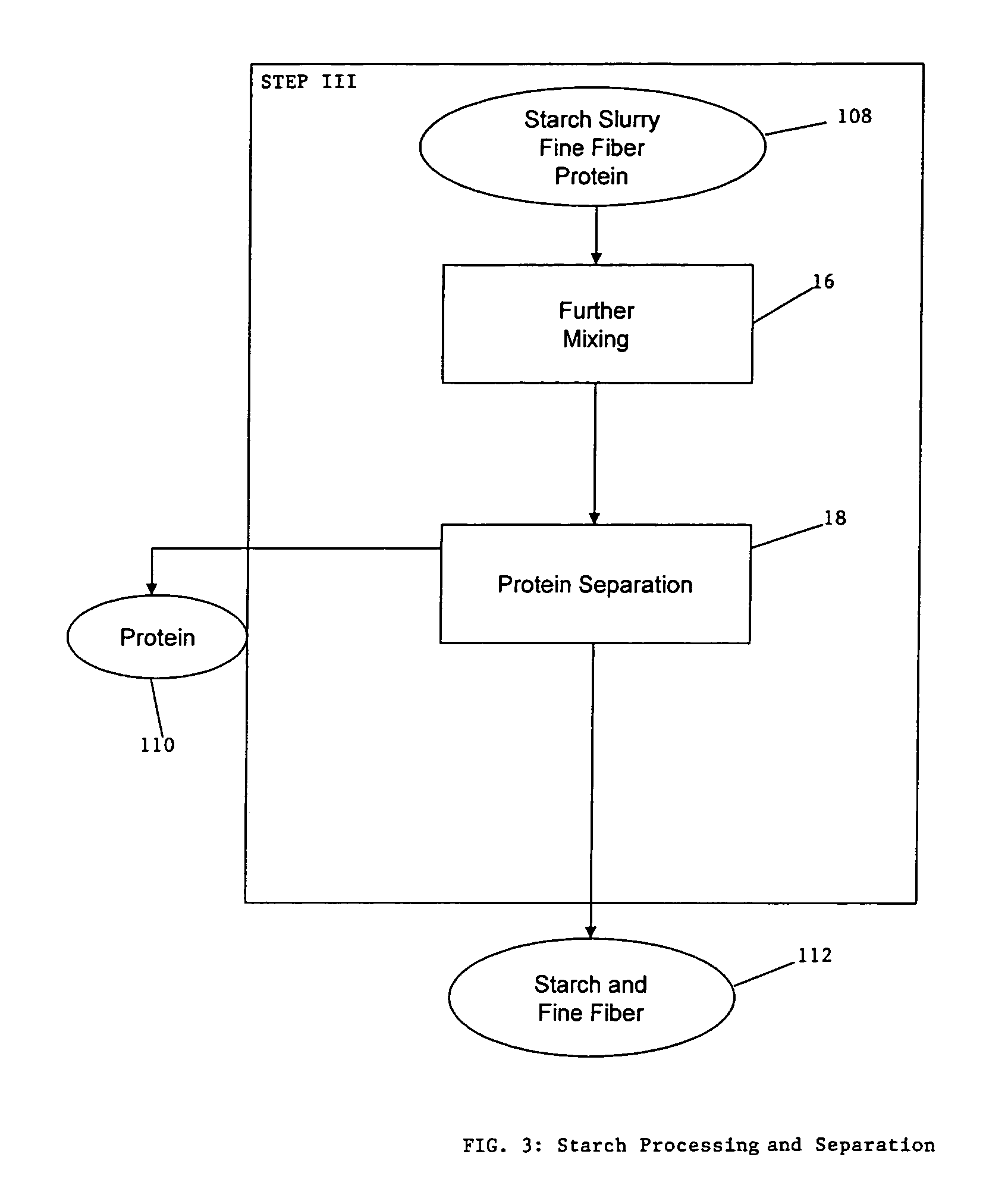

Process for the production of animal feed and ethanol and novel animal feed

ActiveUS20060251764A1Enhance digestibilityDecrease in crystallinityGrain huskingBiocideChemistryBiomass

A method for the production of ethanol and a modified animal feed is provided. The method replaces the starch in known corn-based animal feed with biomass fiber treated to make it more digestible by animals. The process includes wherein the pericarp and germ are removed from the corn kernel and processed for by-products. The starch and protein are also removed and separated. The starch is then fermented and distilled to ethanol and stillage. The bioavailable modified animal feed comprises the pericarp and germ removed from corn kernels and optionally by-products of the pericarp and germ processing, and lignocellulosic materials. The modified animal feed may optionally include energy materials such as animal and vegetable fats, vegetable soapstocks, or glycerin, and combinations thereof.

Owner:ARCHER DANIELS MIDLAND CO

Devices and methods for enrichment and alteration of circulating tumor cells and other particles

InactiveUS20070026414A1Small particle sizeLower the volumeBioreactor/fermenter combinationsBiological substance pretreatmentsCirculating cancer cellTumor cells

The invention features devices and methods for detecting, enriching, and analyzing circulating tumor cells and other particles. The invention further features methods of diagnosing a condition, e.g., cancer, in a subject by analyzing a cellular sample from the subject.

Owner:THE GENERAL HOSPITAL CORP +2

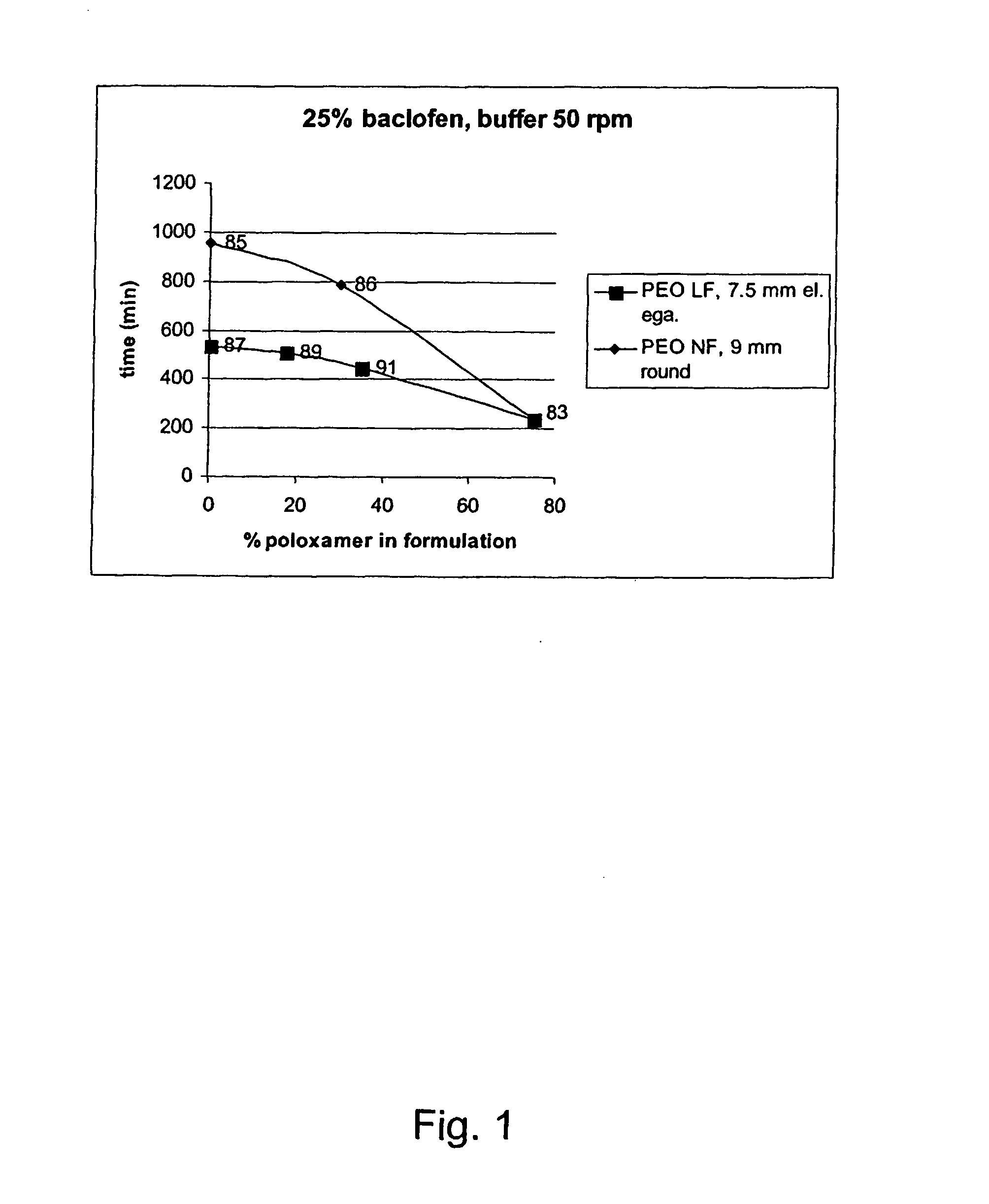

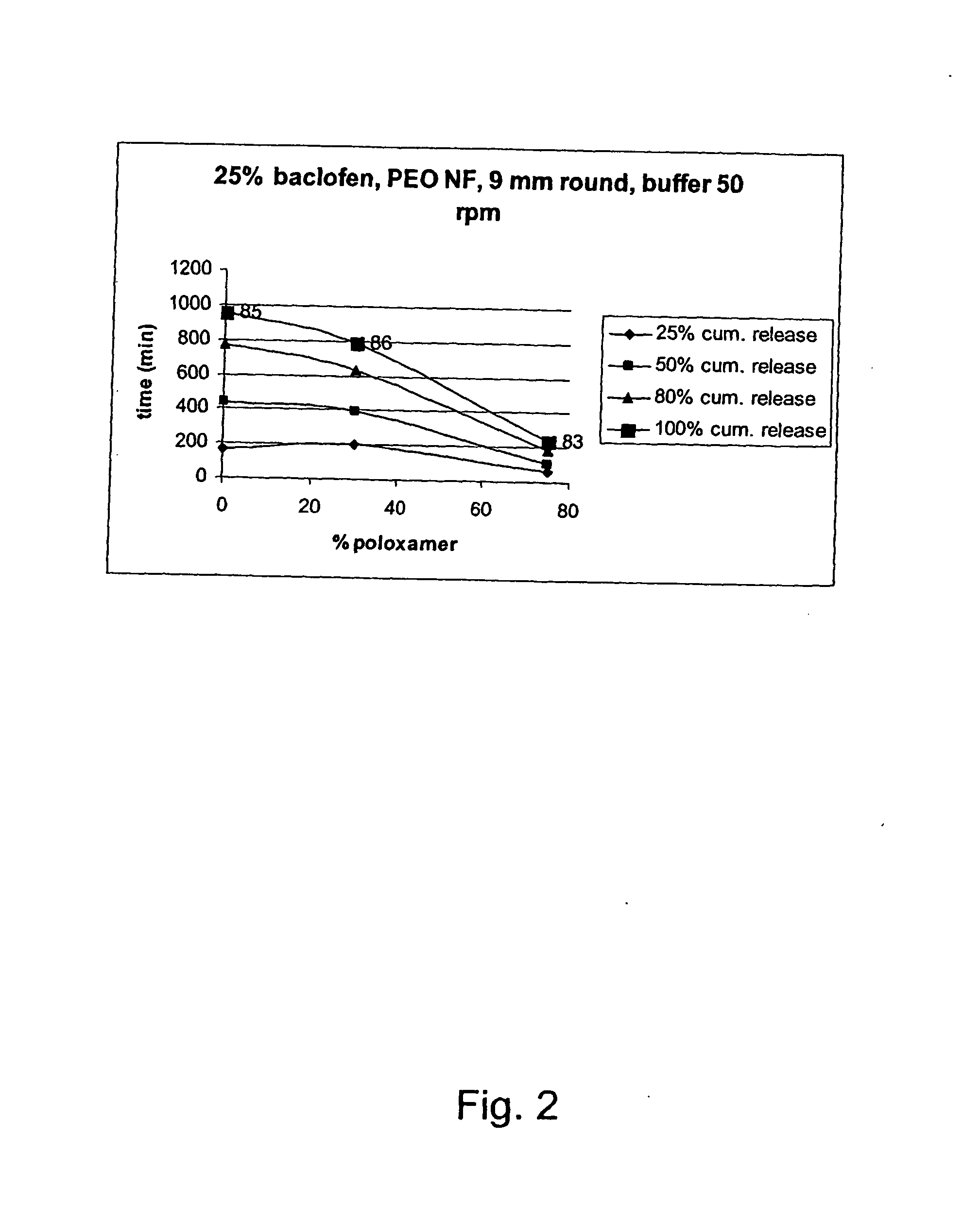

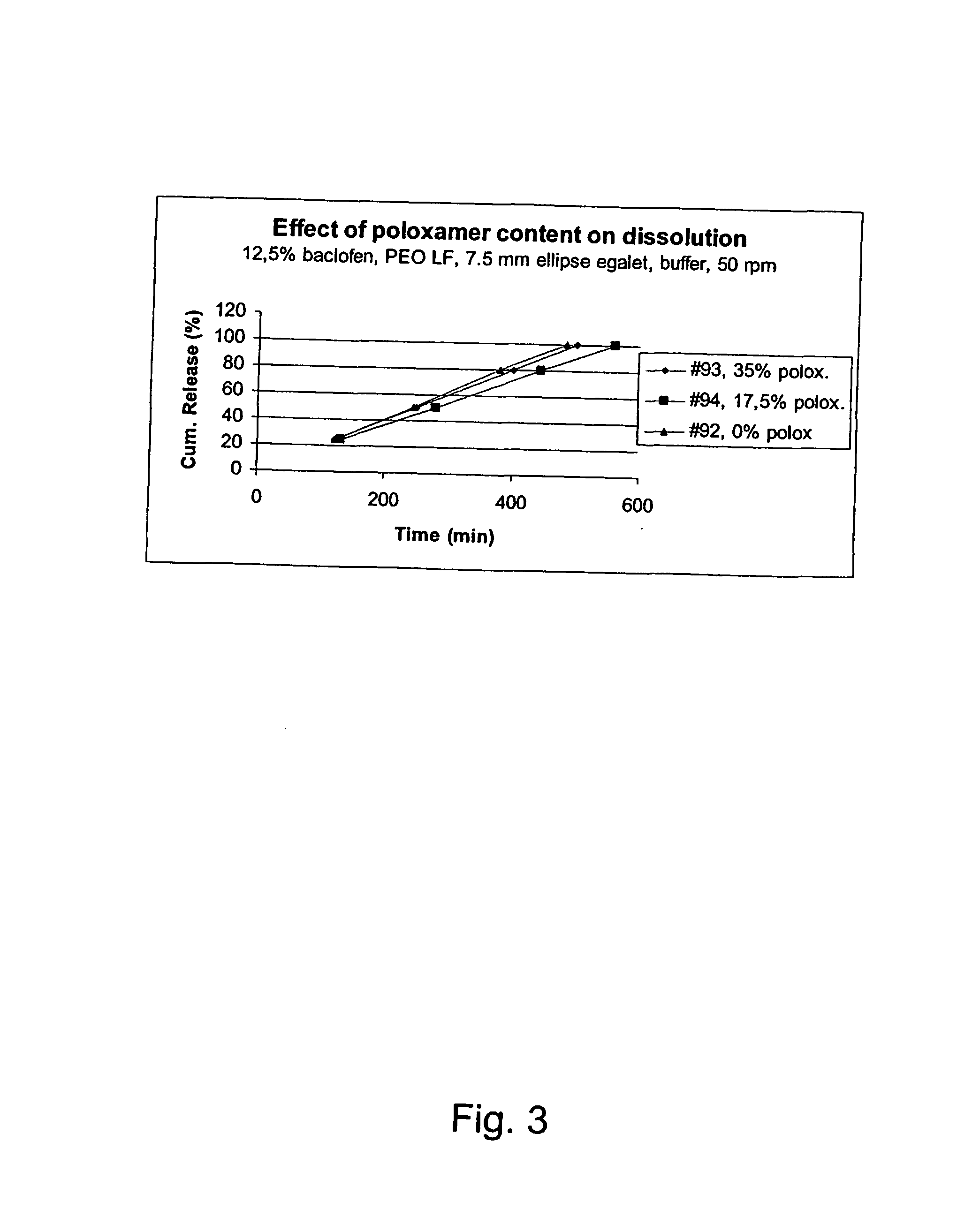

Matrix compositions for controlled delivery of drug substances

InactiveUS20070042044A1Improve solubilityImprove oral bioavailabilityBiocidePowder deliveryPolyethylene oxidePEG-PLGA-PEG

A novel matrix composition for pharmaceutical use. The matrix composition has been designed so that it is especially suitable in those situation where an improved bioavailability is desired and / or in those situation where a slightly or insoluble active substance is employed. Accordingly, a controlled release pharmaceutical composition for oral use is provided in the form of a coated matrix composition, the matrix composition comprising i) a mixture of a first and a second polymer that have plasticizing properties and which have melting points or melting intervals of a temperature of at the most 200° C., the first polymer being selected from the group consisting of polyethylene glycols and polyethylene oxides, and the second polymer being selected form block copolymer of ethylene oxide and propylene oxide including poly(ethylene-glycol-b-(DL-lactic acid-co-glycolic acid)-b-ethylene glycol (PEG-PLGA PEG), poly((DL-lactic acid-co-glycolic acid)-g-ethylene glycol) (PLGA-g-PEG), poloxamers and polyethylene oxide-polypropylene oxide (PEO-PPO), ii) a therapeutically, prophylactically and / or diagnostically active substance, the matrix composition being provided with a coating having at least one opening exposing at one surface of said matrix, wherein the active substance is released with a substantially zero order release.

Owner:EGALET LTD

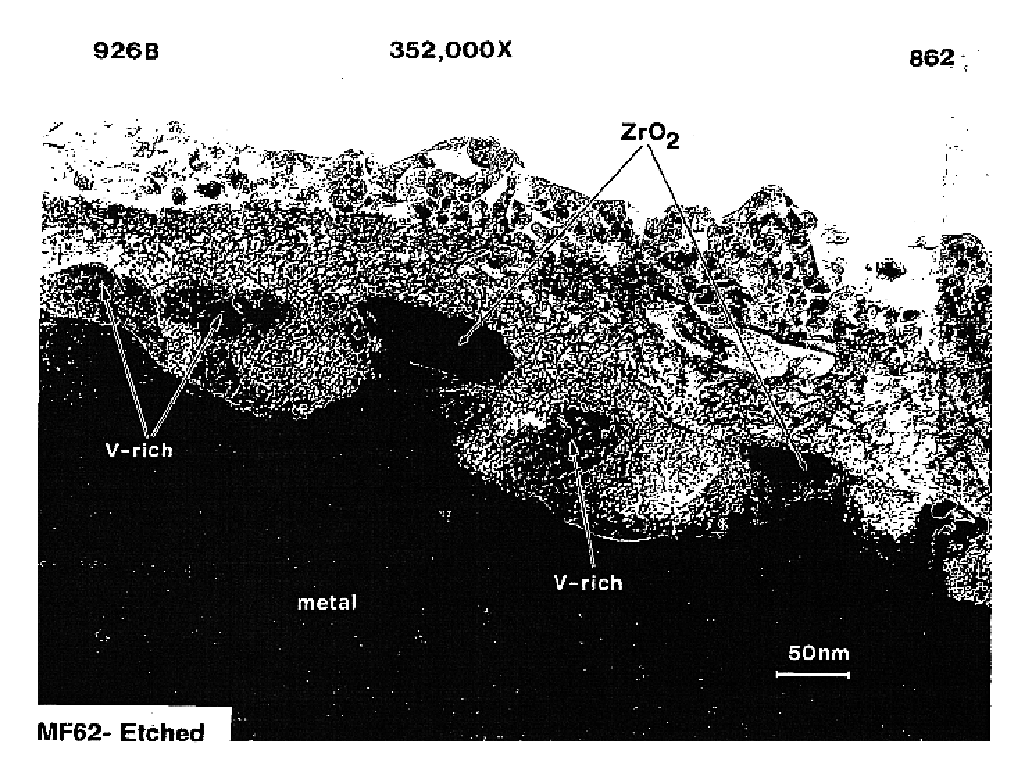

Finely divided metal catalyst and method for making same

InactiveUS6841512B1Facilitating hydrogen consumptionSmall particle sizeReactant parameters controlReversible hydrogen uptakeParticulatesMetal catalyst

An inexpensive, highly catalytic material preferably formed by a leaching process. The catalyst comprises a finely divided metal particulate and a support. The active material may be a nickel and / or nickel nickel alloy particulate having a particle size less than about 100 Angstroms. The support may be one or more metal oxides.

Owner:CHEVRONTEXACO TECH VENTURES

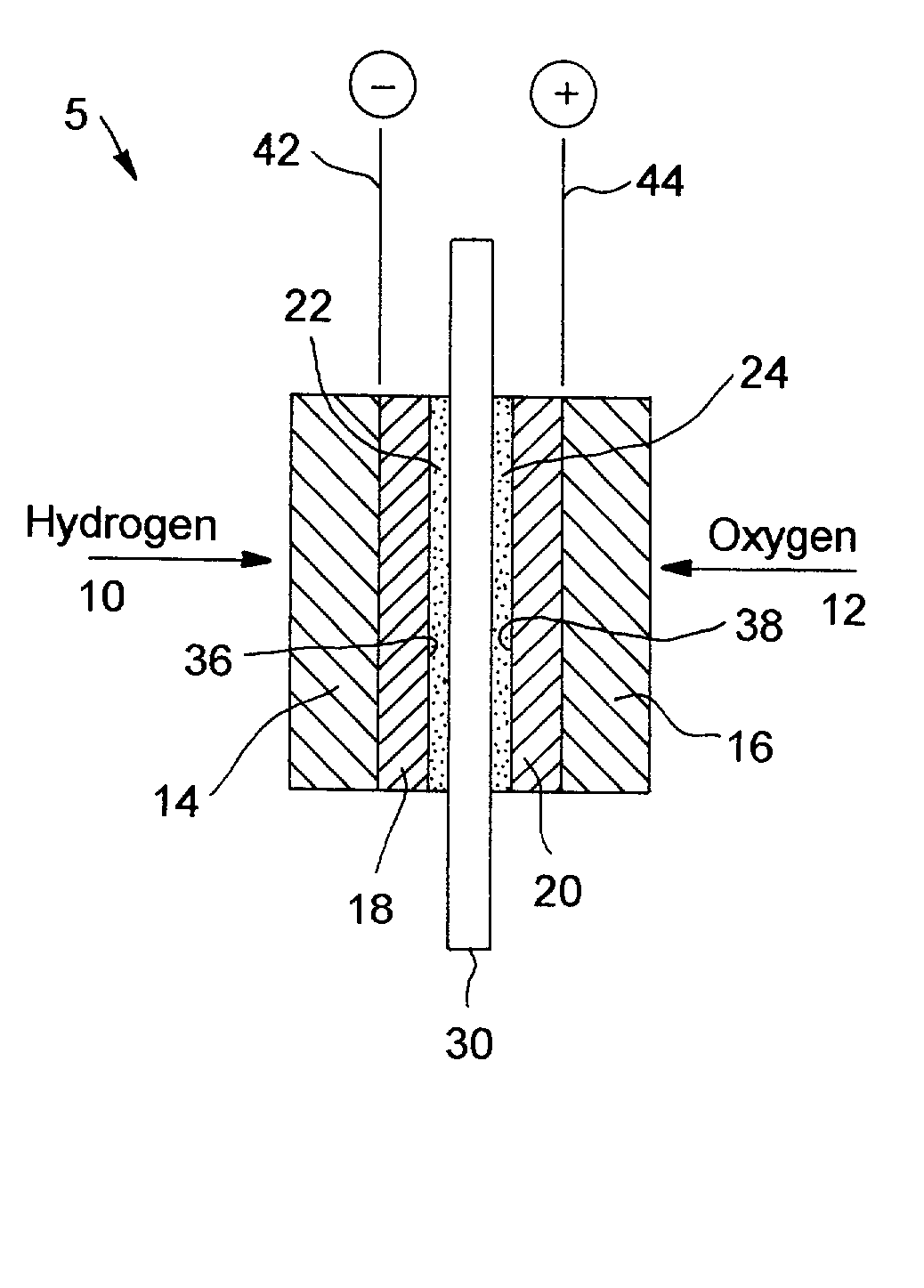

Fuel cells and other products containing modified carbon products

InactiveUS20030017379A1Decrease electrode performanceReduction of gas mass transport efficiencyOrganic diaphragmsAlkali metal halidesFuel cellsModified carbon

Fuel cells are described and contain a gas diffusion electrode, a gas diffusion counter-electrode, an electrolyte membrane located between the electrode and counter-electrode. The electrode or counter-electrode or both contain at least one modified carbon product. The electrolyte membrane can also or alternatively contain modified carbon products as well. The modified carbon product is a carbon product having attached at least one organic group. Preferably the organic group is a proton conducting group and / or an electron conducting group. The present invention preferably permits the elimination of fluoropolymer binder in the active or catalyst layer and further preferably leads to a thinner active layer and / or a thinner electrolyte membrane. Other uses and advantages are also described.

Owner:CABOT CORP

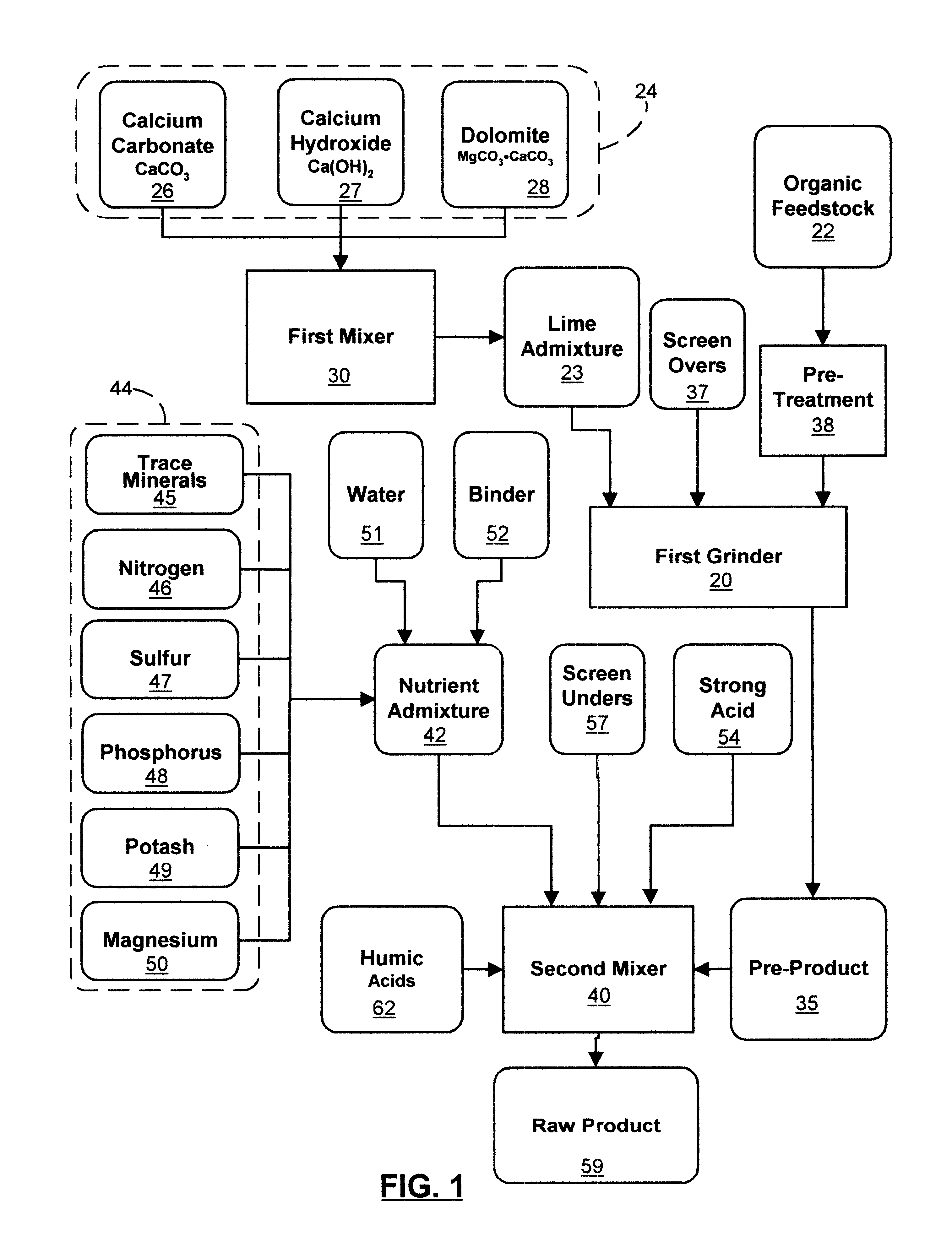

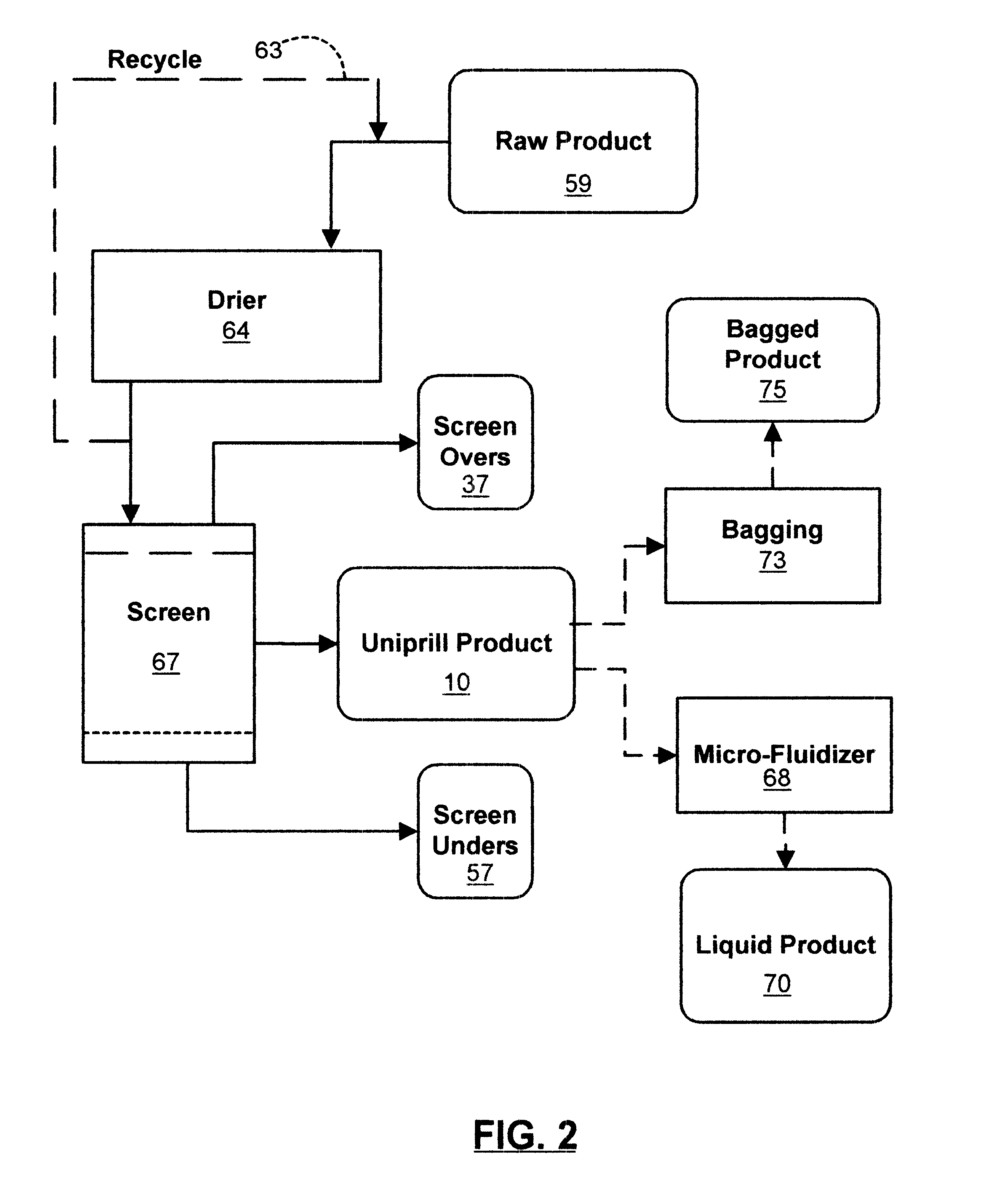

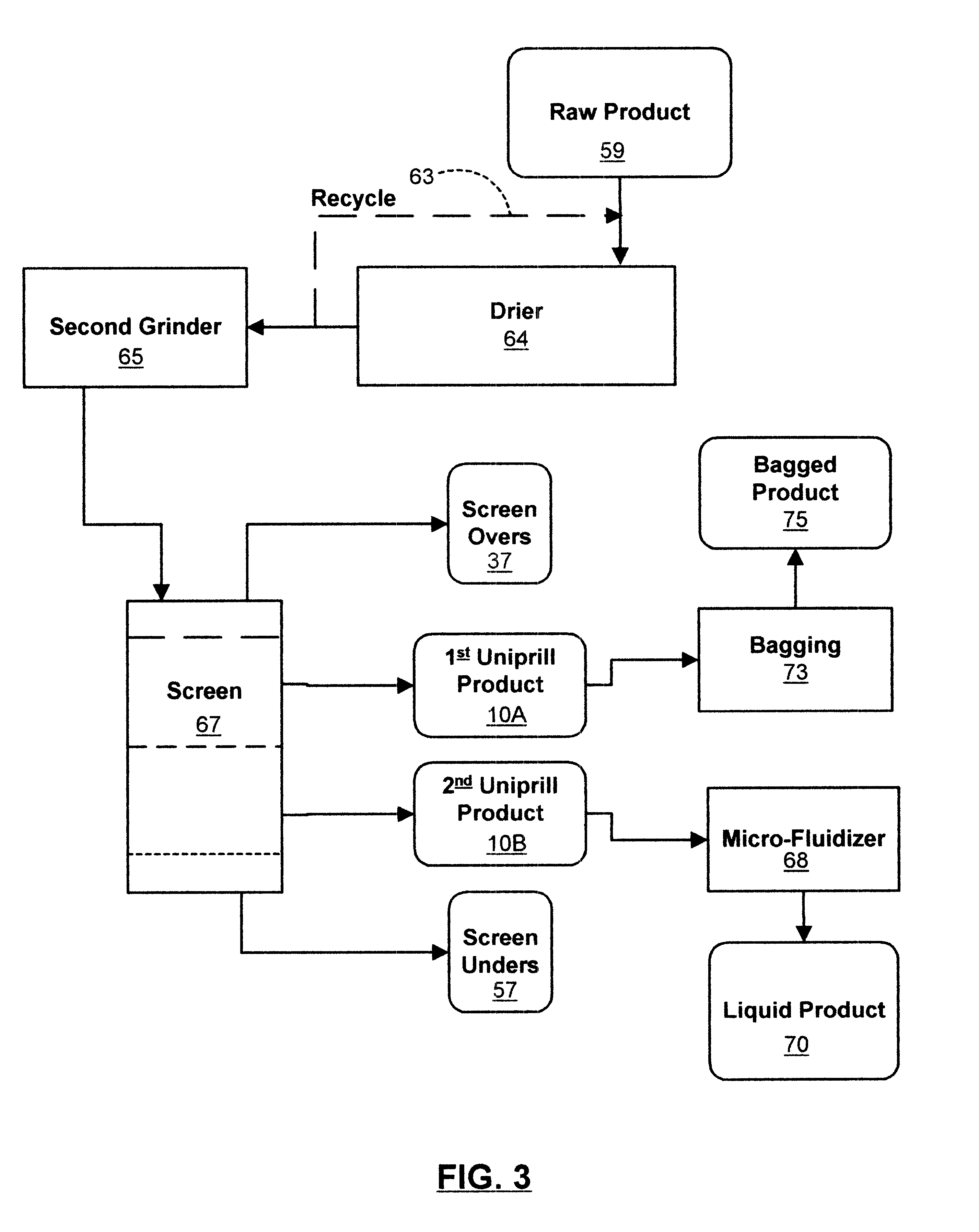

Organic material based uniprill fertilizer

InactiveUS6461399B1Reduce moisture contentIncrease speedCalcareous fertilisersBiocideOrganic basePhosphoric acid

An organic-based uniprill fertilizer is provided. To produce the fertilizer, organic matter is sequentially pre-treated by first mixing it in a first grinder with a lime admixture, then adding a slurry of reagents and binders, followed by a mixture of acids. The acids can include sulfuric and phosphoric acids, in addition to nitric acid and various organic acids such as citric and fulvic acid, depending on the end requirements of the fertilizer product. Following the mixing of the pre-product with the mixture of acids and reagents, the resultant raw product is preferably processed through a second grinder. This grinding further dries, mixes and granulates the raw product. The particle size of the completed fertilizer is reduced into a flowable, user safe uniprill product that can be further ground to reduce its moisture. Further drying may be necessary for bag or bulk product, or it can be liquified by high speed blending or micro-fluidized for sprinkler or drip applications. The uniprill fertilizer comprises small, preferably microscopic particles that are homogenous in nature, in that any single particle is substantially identical in composition to all other particles of the fertilizer. Additionally, each uniprill particle contains substantially all sixteen nutriments and minerals required for the growth of healthy plants.

Owner:GREEN TRIANGLE

Perpendicular magnetic recording medium and its manufacturing method

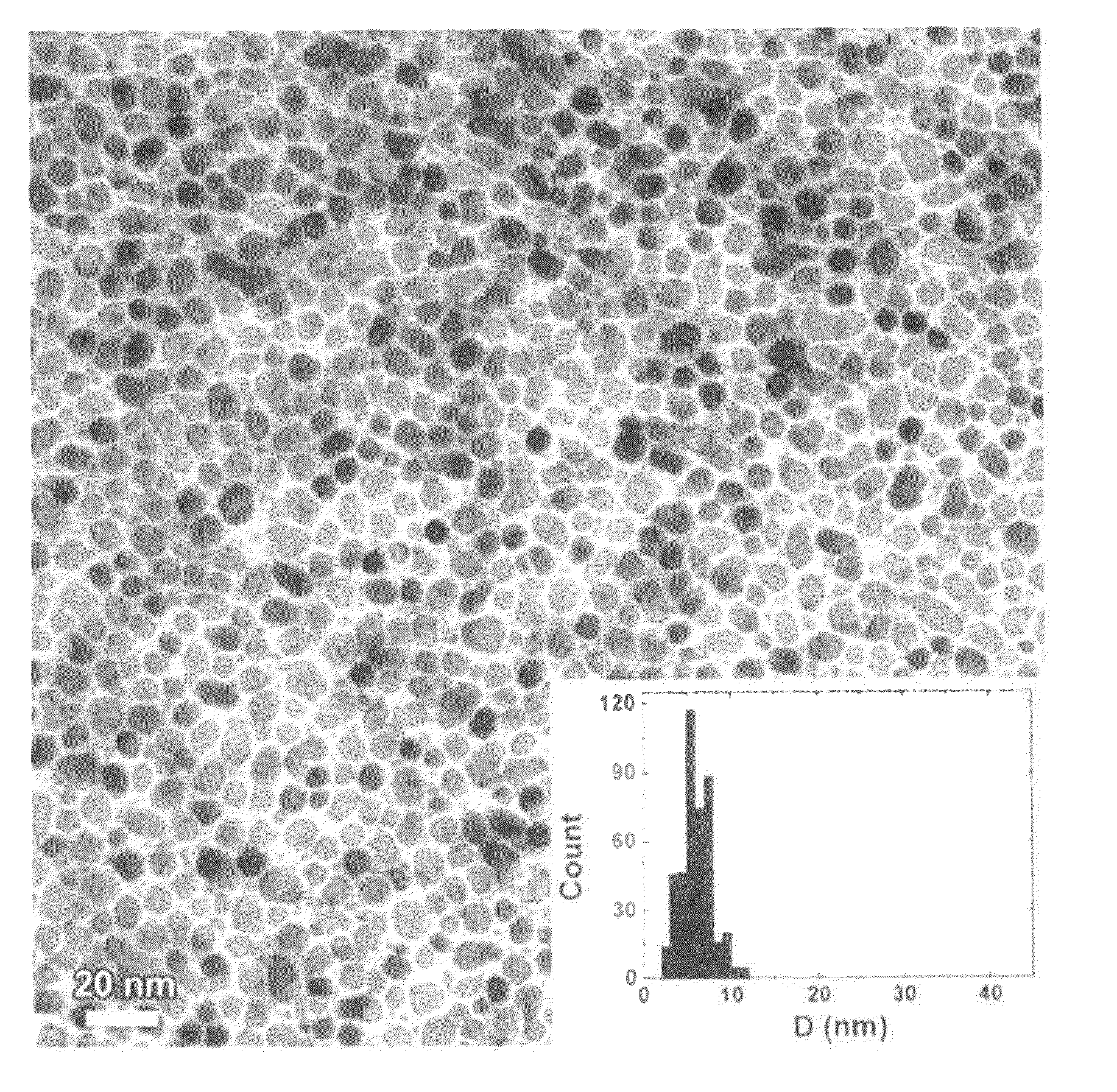

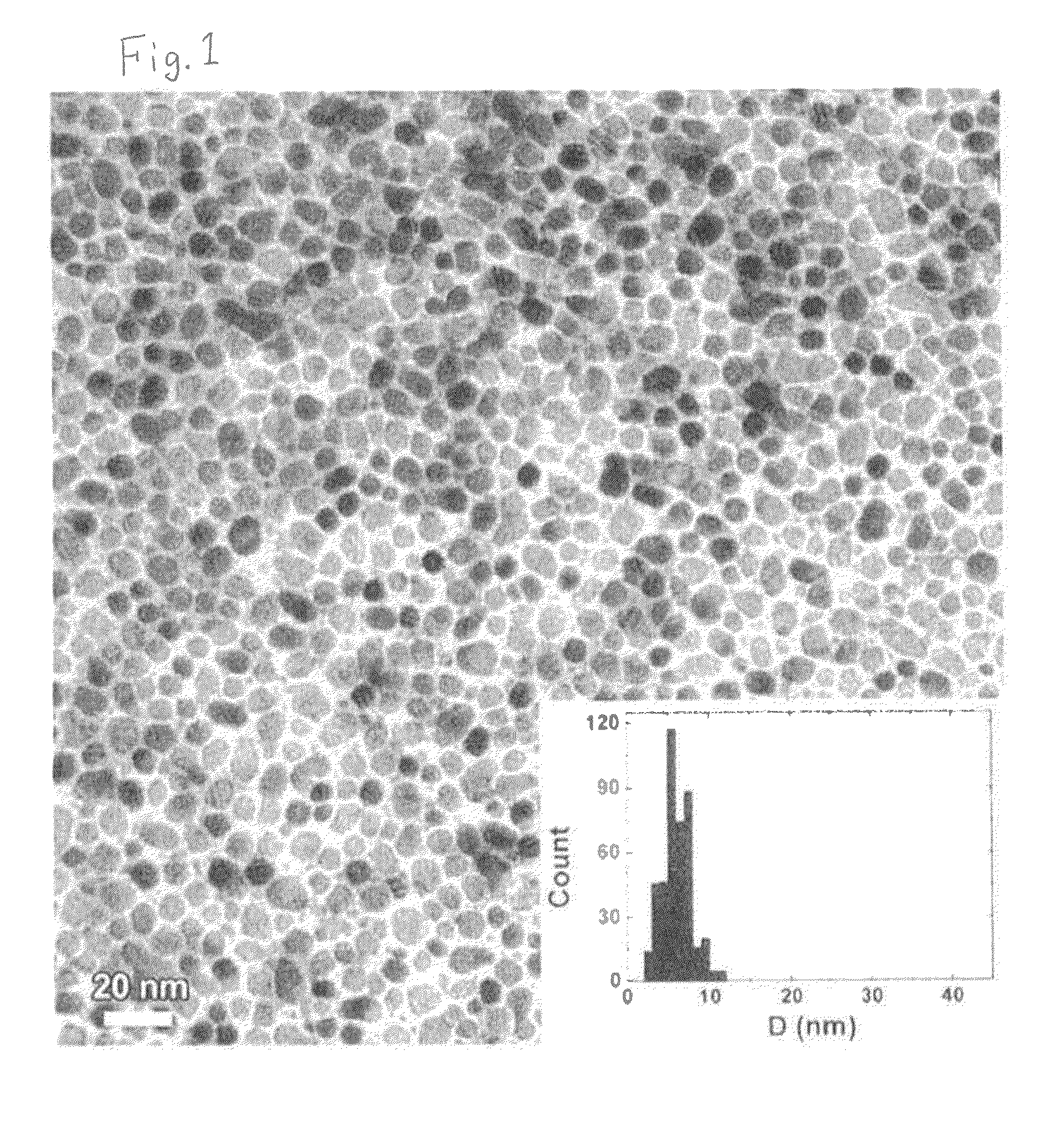

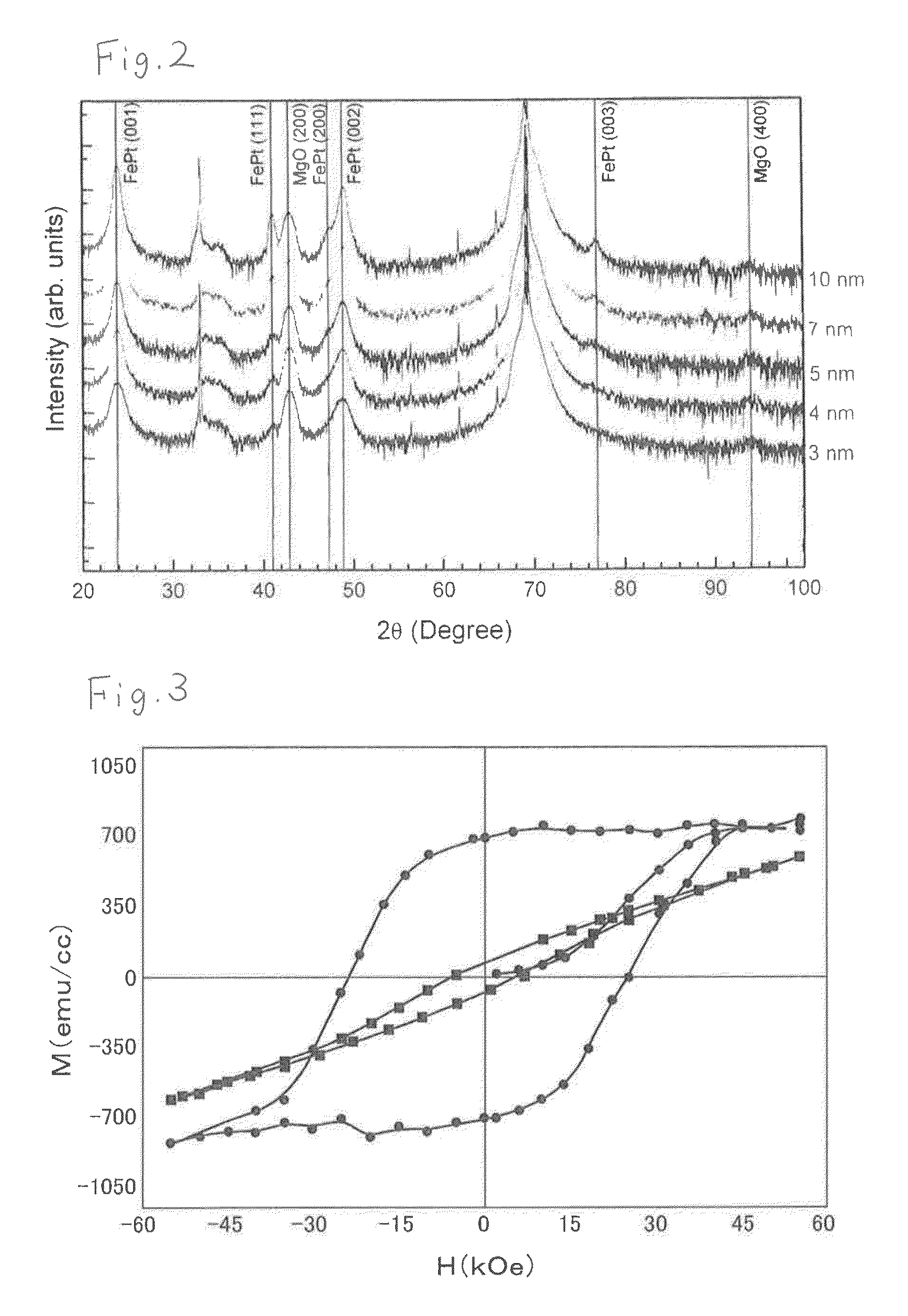

InactiveUS20130040167A1Suppress interferenceIncrease in ultra-high recording densityRecord information storageCoating by sputteringSputteringAlloy

It is aimed to provide a perpendicular magnetic recording medium capable of dealing with an ultra-higher recording density than before and its manufacturing method.The present invention concerns a perpendicular magnetic recording medium including at least a seed layer made of noncrystalline ceramic, a crystalline orientation control layer and a magnetic layer made of a material mainly containing a FePt alloy in this order on a substrate. This perpendicular magnetic recording medium is suitably manufactured by forming at least the seed layer, the orientation control layer and the magnetic layer made of the material mainly containing the FePt alloy in this order on the substrate by sputtering, wherein the magnetic layer is formed at a predetermined temperature of 500° C. or less.

Owner:WD MEDIA SINGAPORE PTE +1

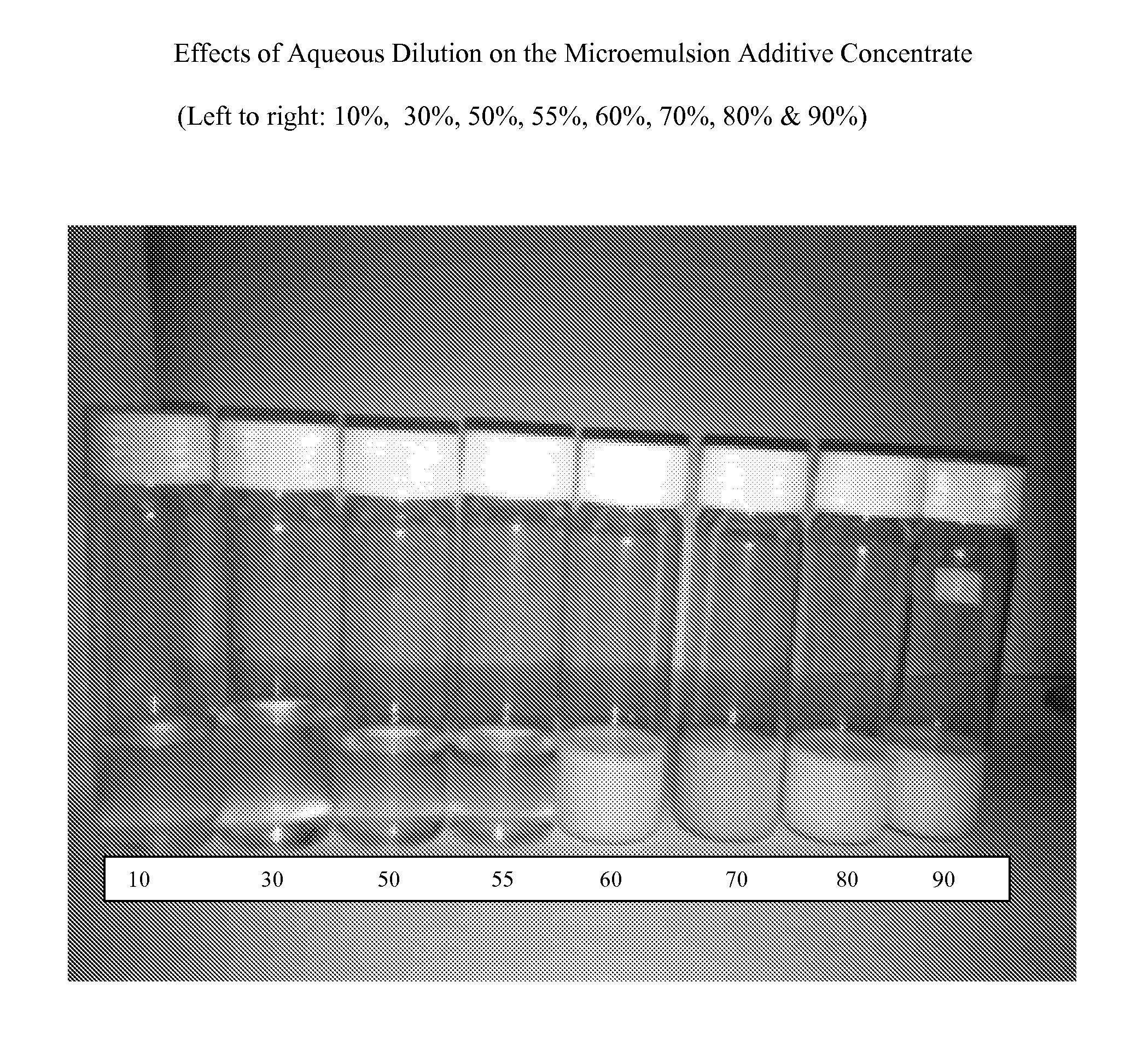

Composition and method of converting a fluid from oil external to water external for cleaning a wellbore

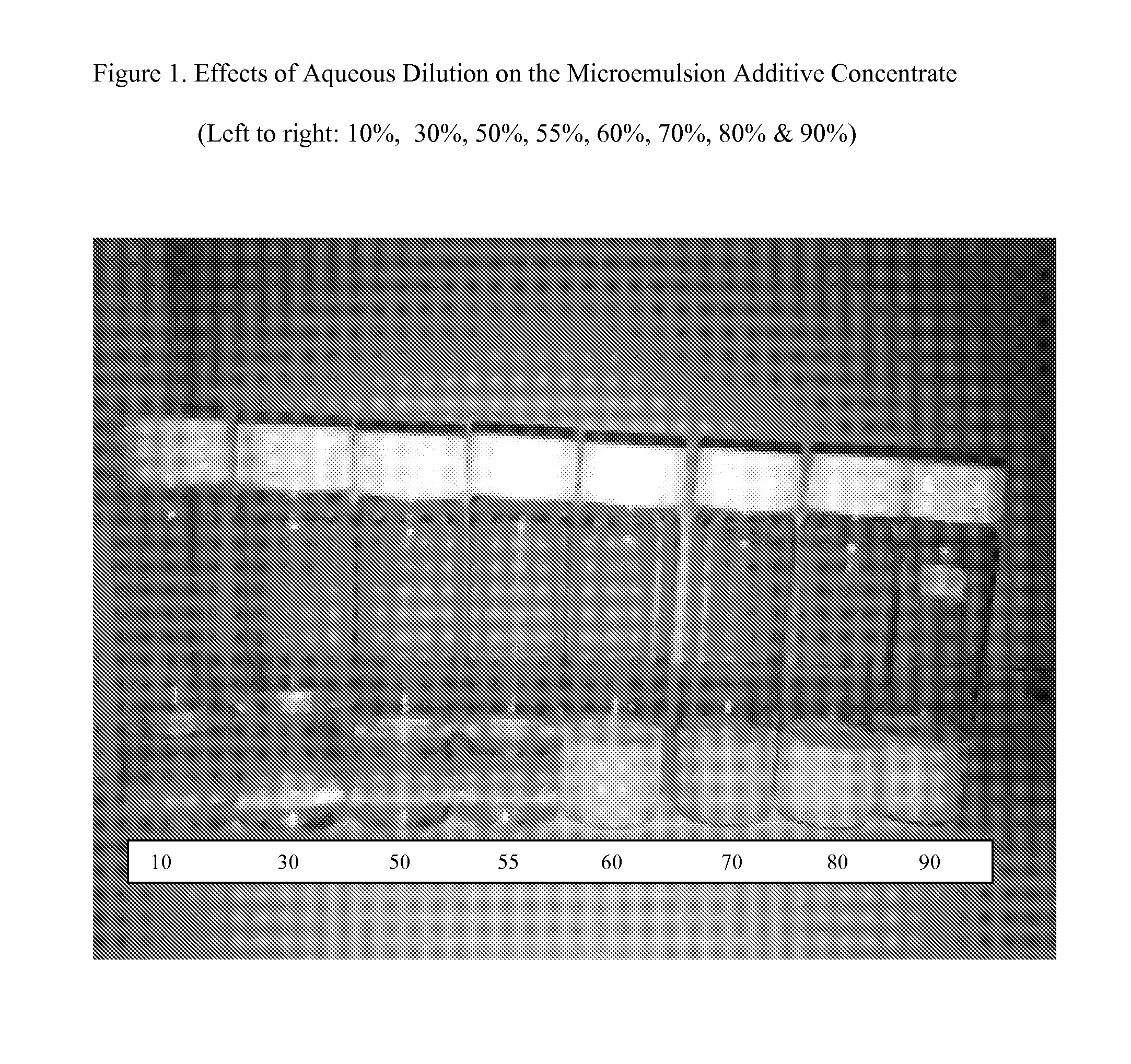

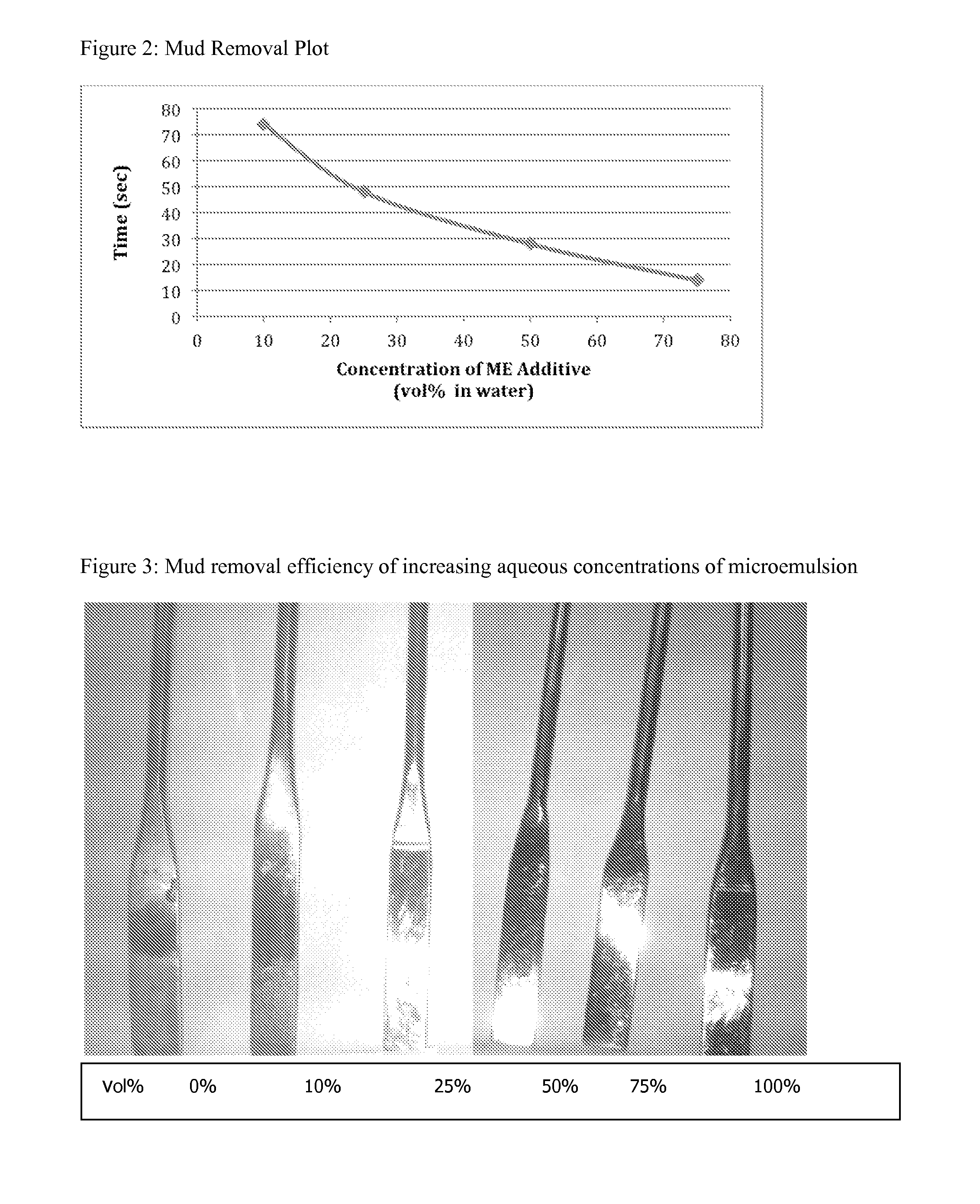

InactiveUS20130244913A1Effective mud removalGood dispersionFlushingDrilling compositionWater basedHydrocarbon solvents

An environmentally acceptable water-in-oil microemulsion composition includes at least one emulsifying surfactant, at least one biodegradable hydrocarbon solvent, at least one co-solvent, at least one hydrocarbon co-surfactant, and water. The microemulsion composition may be used in a method for rendering fluids from oil external to water external. The microemulsion composition may be combined with water or a water based fluid to produce a spacer fluid utilized in removing oil and oil-residues from a surface, particularly that of wellbores in the drilling of oil and gas wells.

Owner:BENCHMARK PERFORMANCE GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com