Patents

Literature

173results about How to "Reduced deformability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

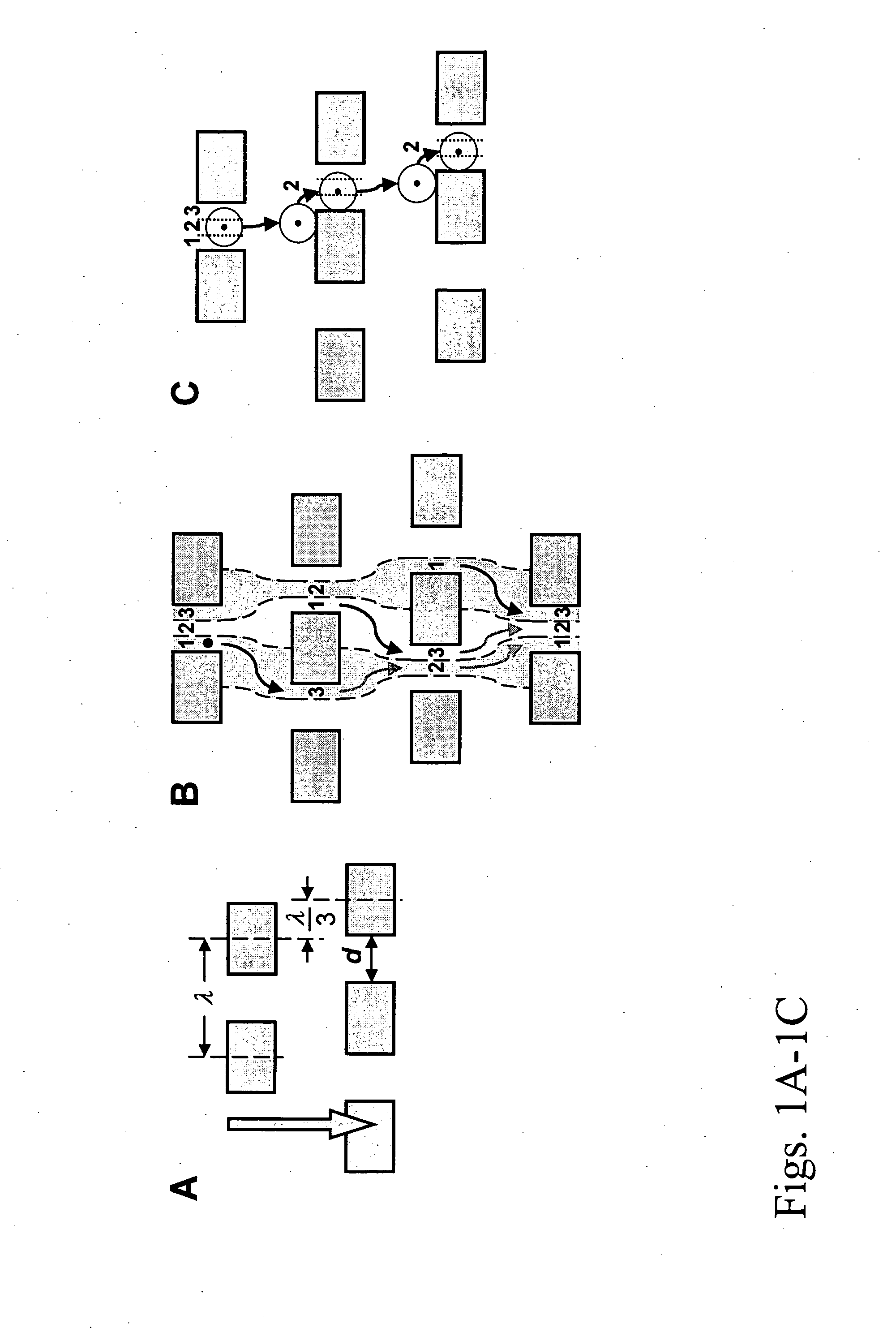

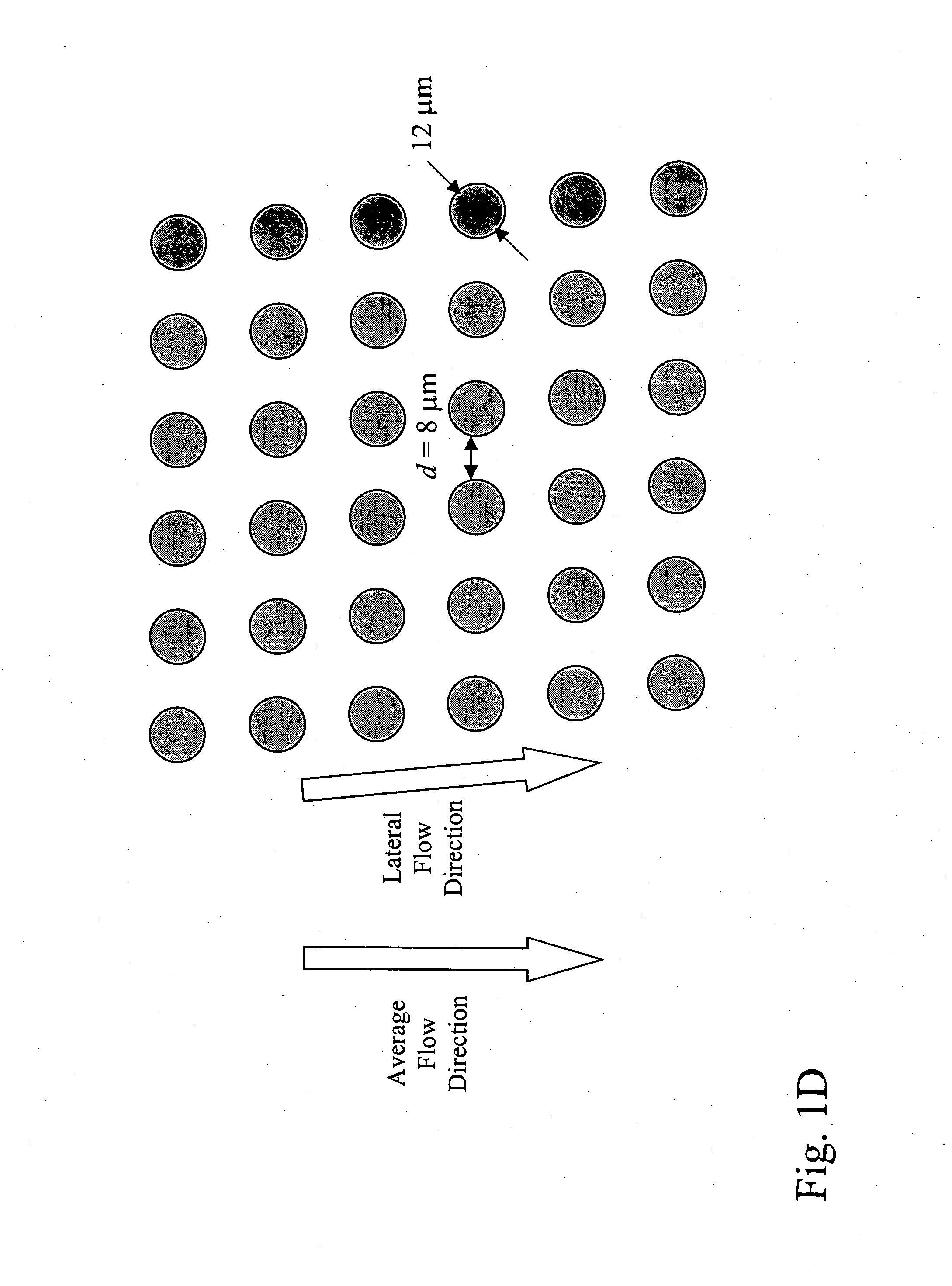

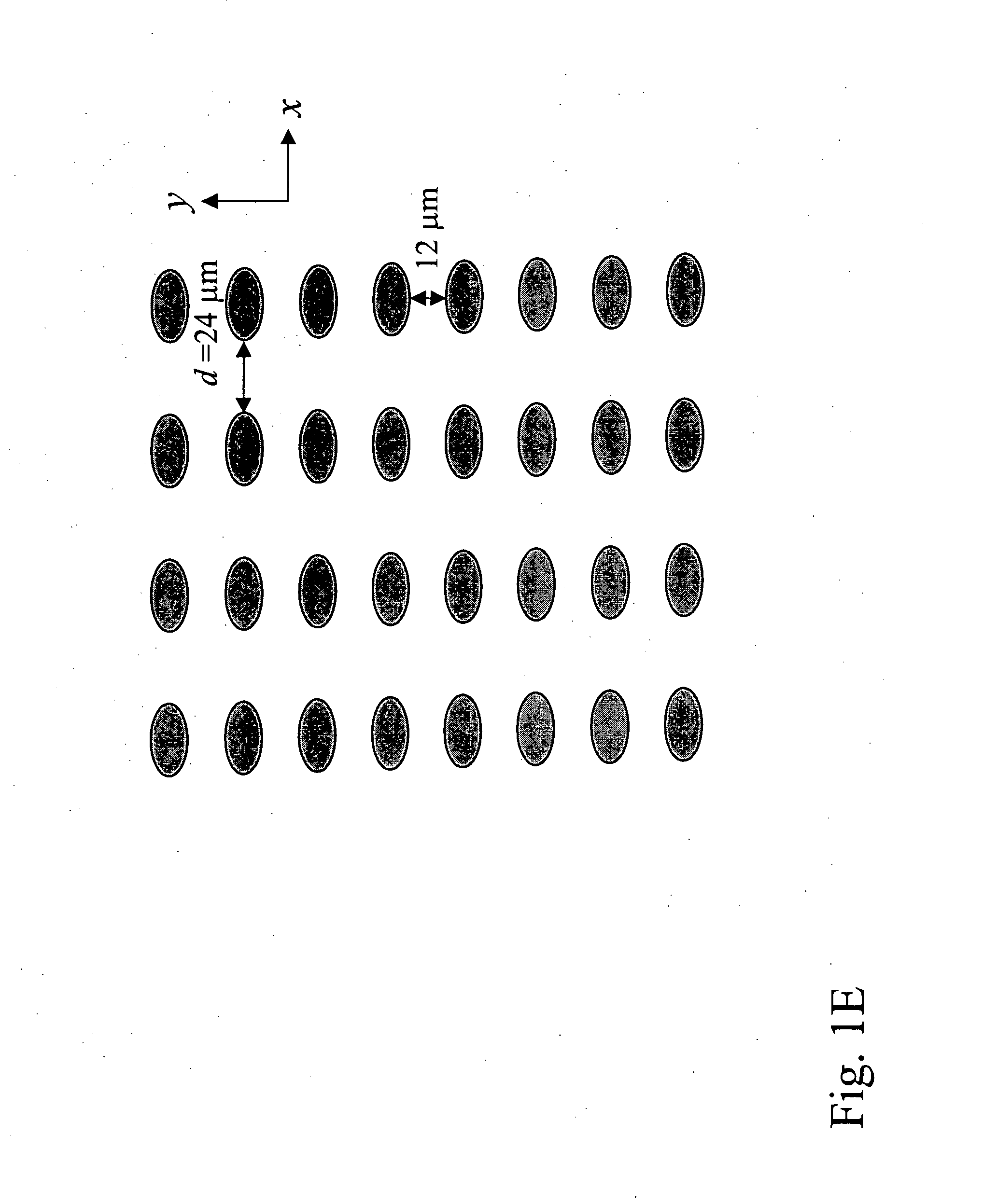

Devices and methods for magnetic enrichment of cells and other particles

InactiveUS20060223178A1Small particle sizeLower the volumeArtificial cell constructsLaboratory glasswaresAnalyteMedicine

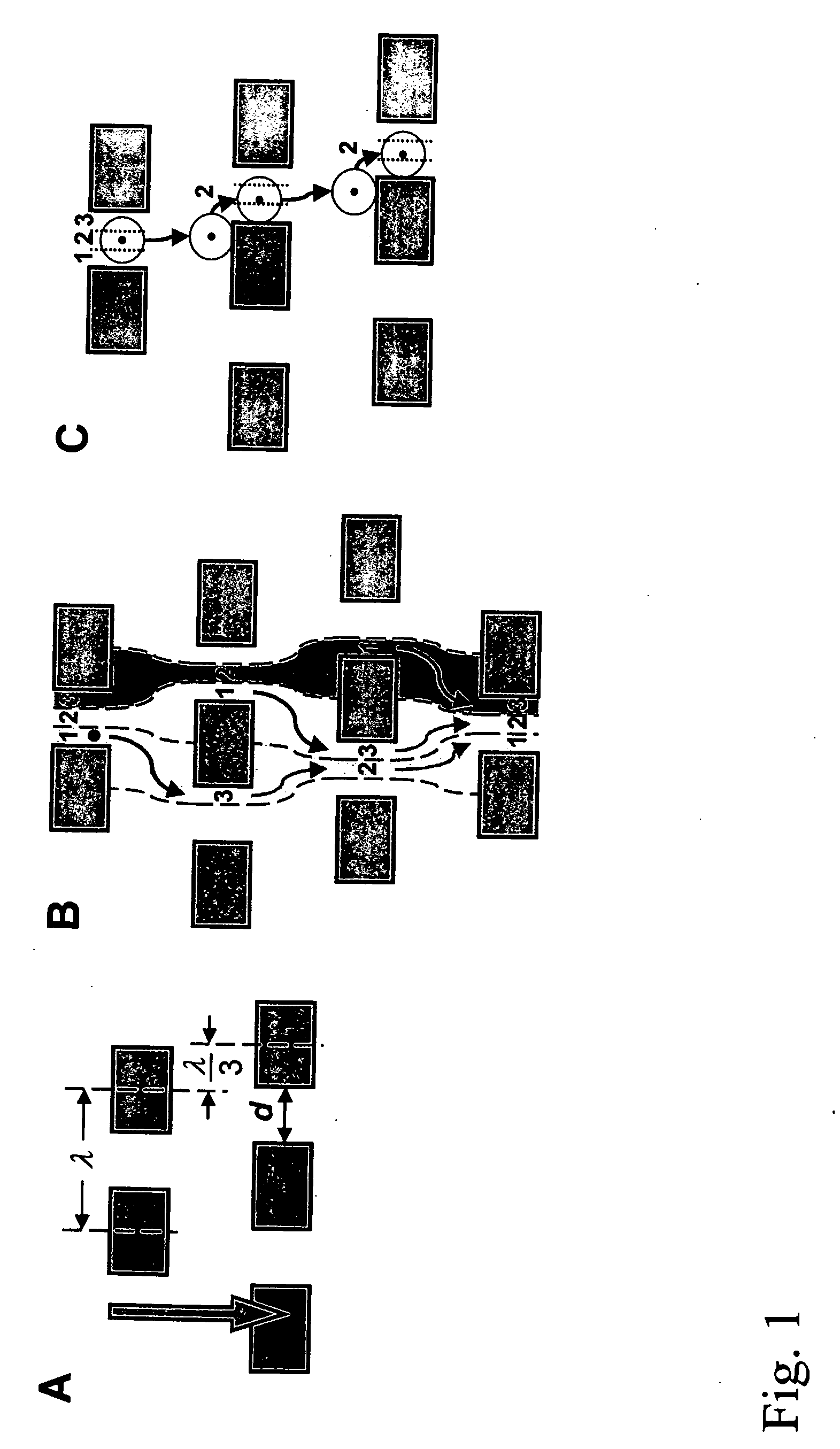

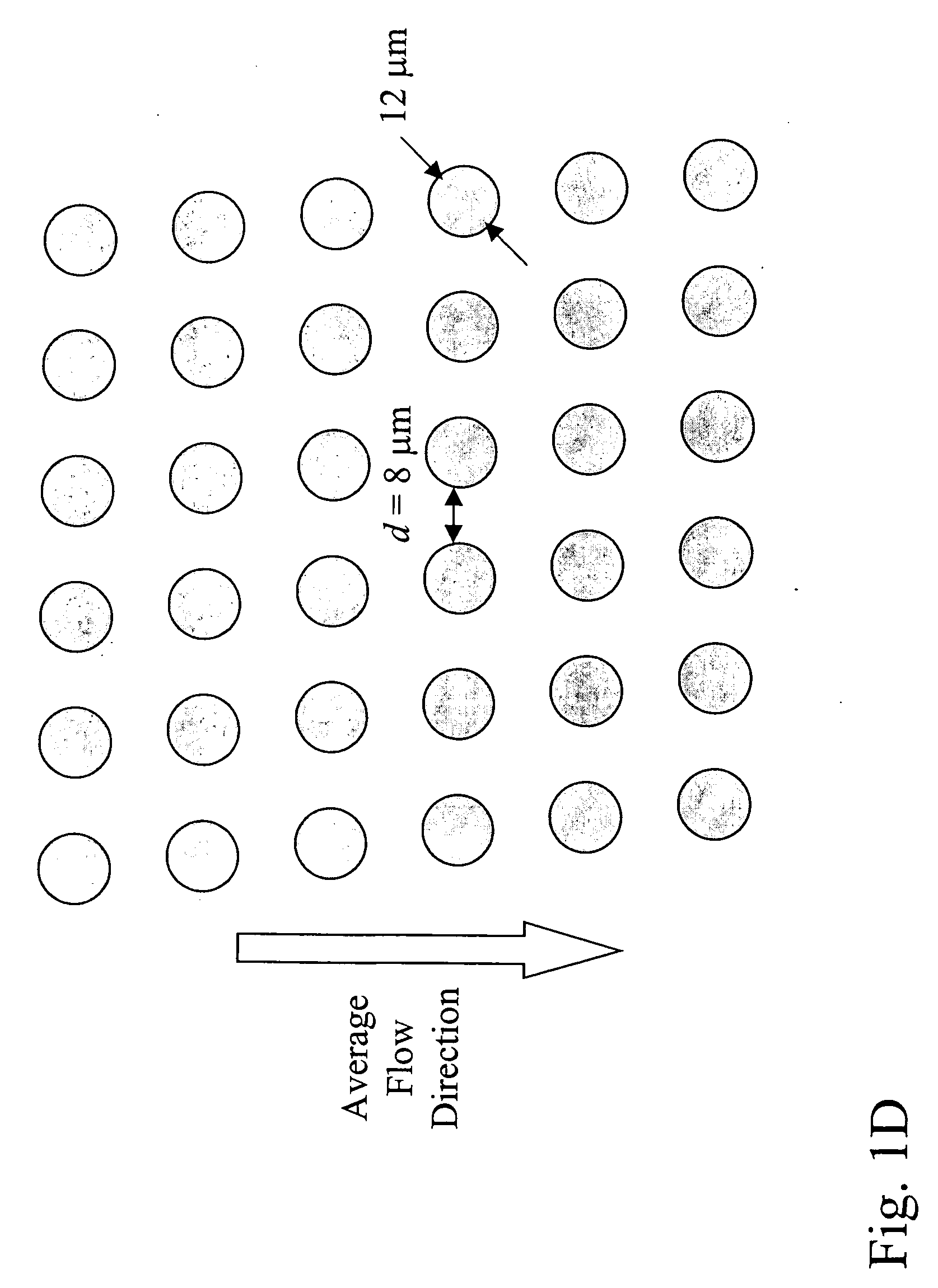

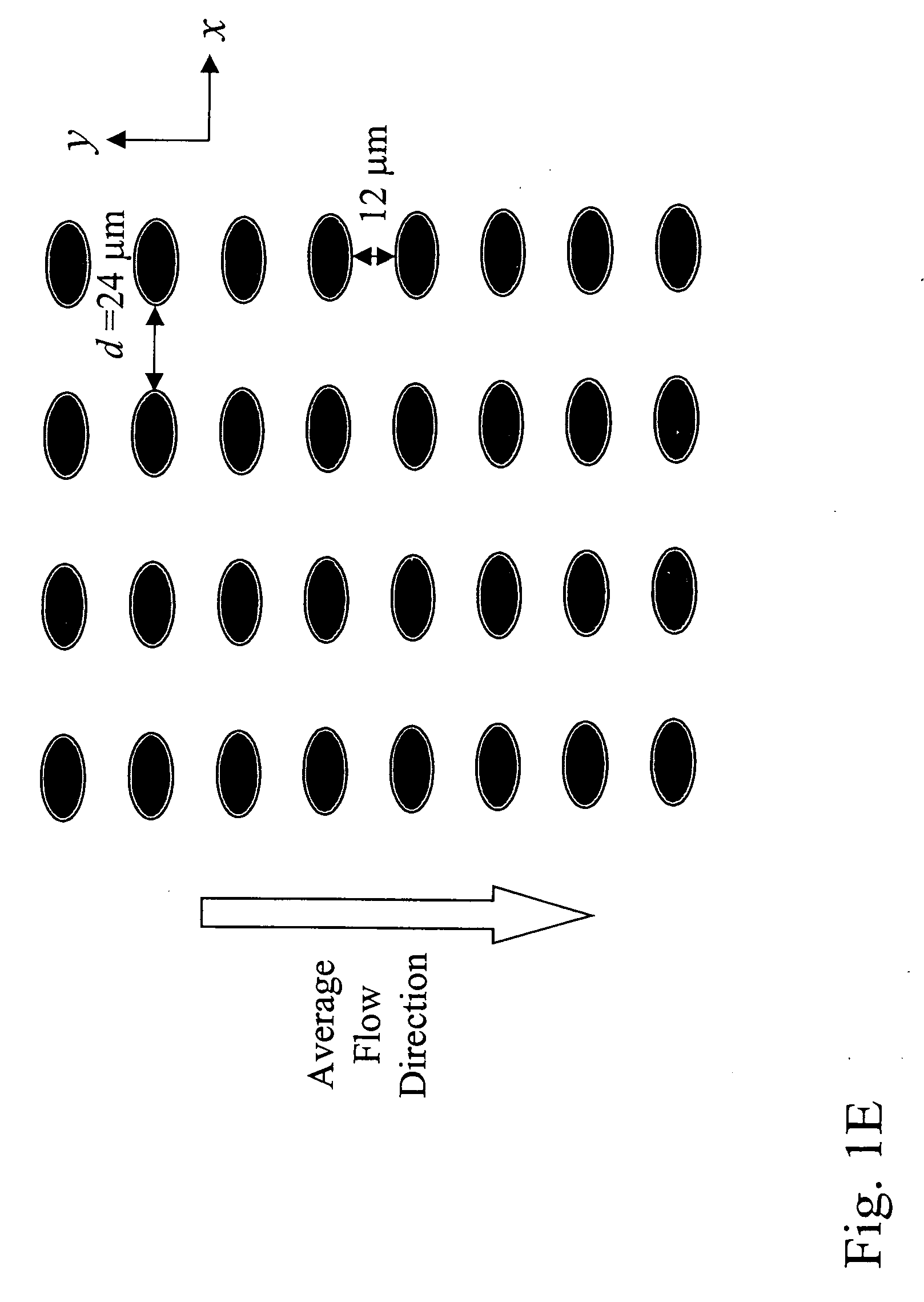

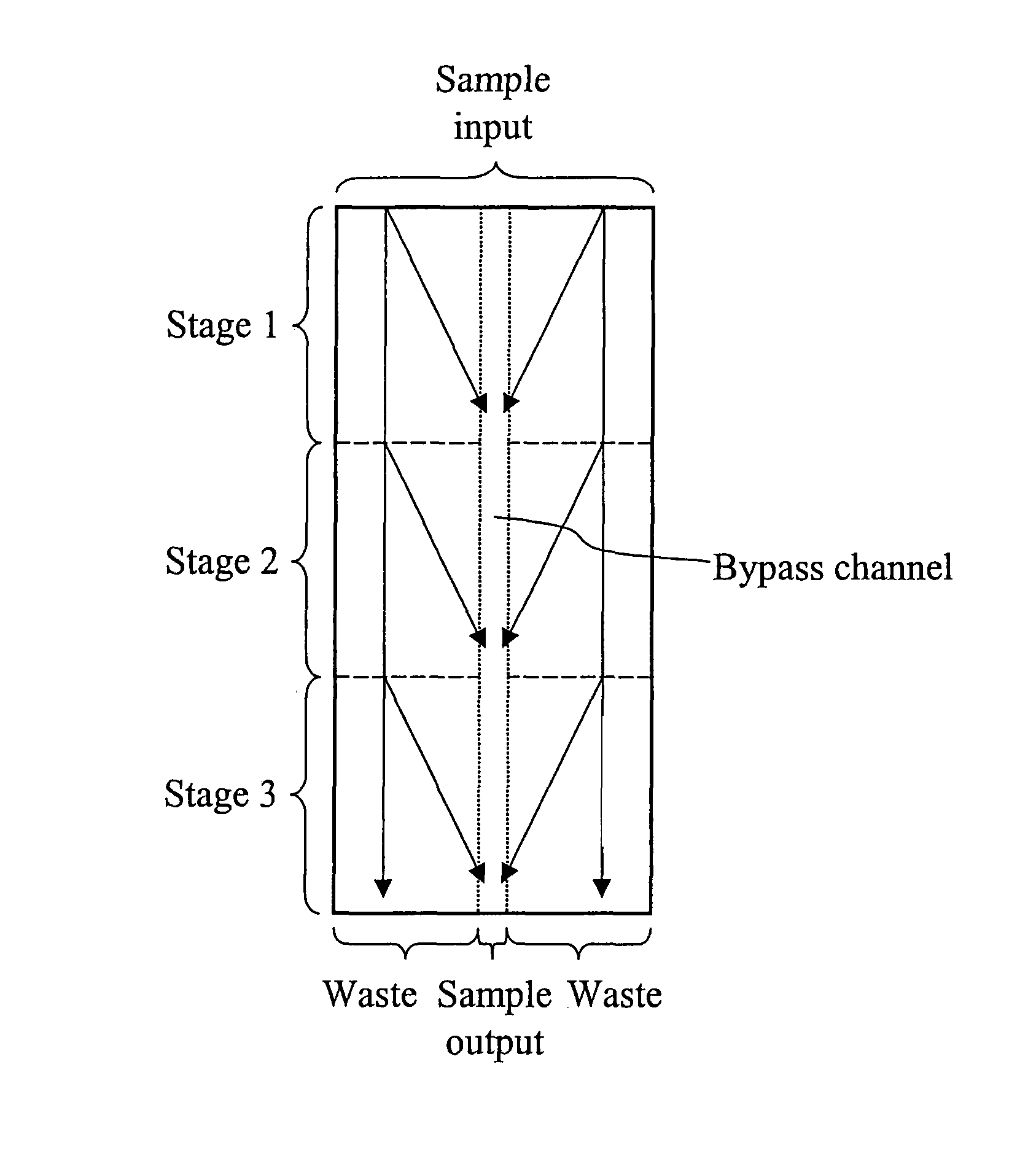

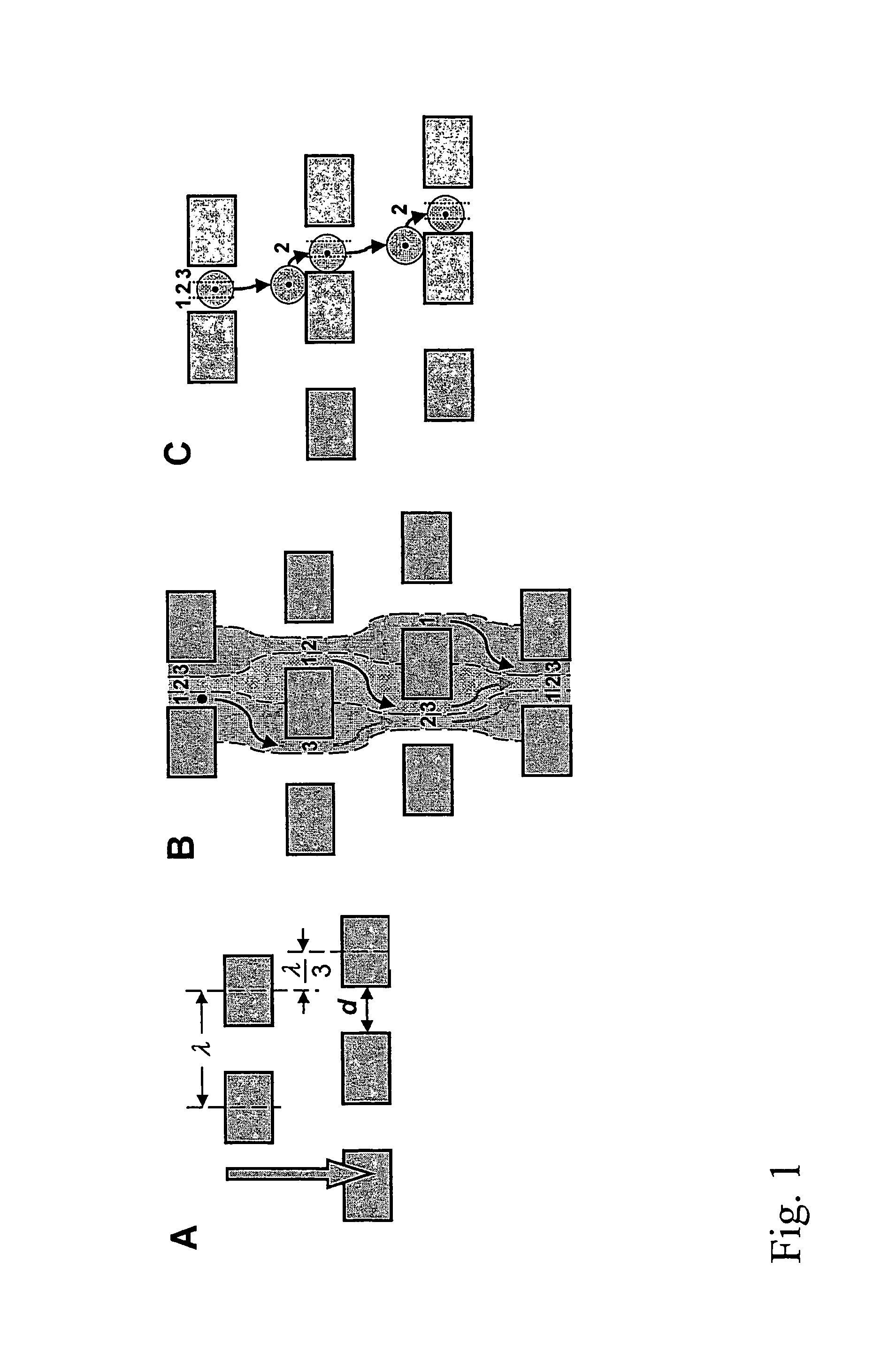

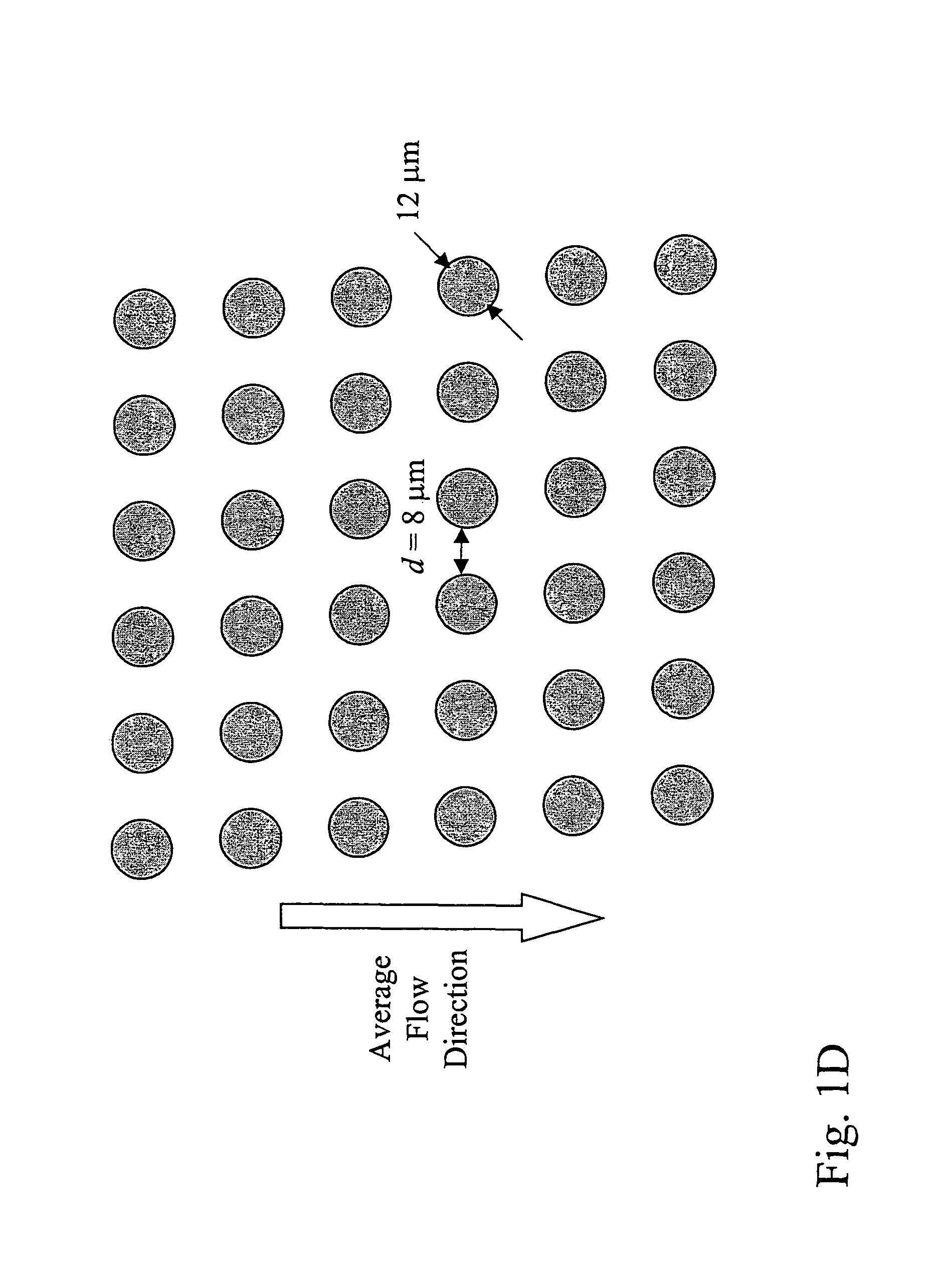

The invention features devices and methods for the enrichment of cells and other desired analytes by employing a magnetic field, alone or in conjunction with size-based separation. The devices and methods may be advantageously employed to enrich for rare cells, e.g., fetal cells or epithelial cells, present in a sample, e.g., maternal blood.

Owner:THE GENERAL HOSPITAL CORP +1

Devices and methods for enrichment and alteration of cells and other particles

ActiveUS8021614B2Increases the hydrodynamic radius of a particleIncrease volumeBioreactor/fermenter combinationsBiological substance pretreatmentsCellular componentClinical information

The invention features devices and methods for the deterministic separation of particles. Exemplary methods include the enrichment of a sample in a desired particle or the alteration of a desired particle in the device. The devices and methods are advantageously employed to enrich for rare cells, e.g., fetal cells, present in a sample, e.g., maternal blood and rare cell components, e.g., fetal cell nuclei. The invention further provides a method for preferentially lysing cells of interest in a sample, e.g., to extract clinical information from a cellular component, e.g., a nucleus, of the cells of interest. In general, the method employs differential lysis between the cells of interest and other cells (e.g., other nucleated cells) in the sample.

Owner:THE GENERAL HOSPITAL CORP +1

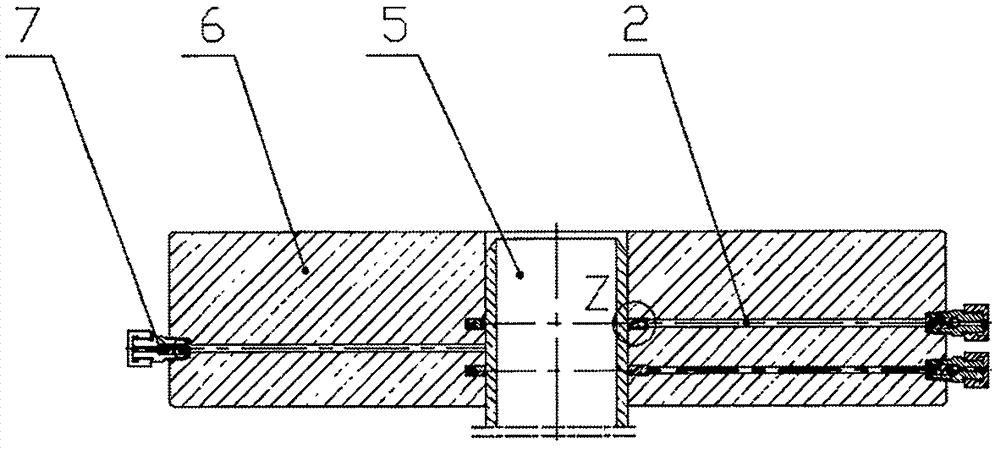

Petroleum wellhead annular space sealing device

PendingCN107143298AGood corrosion resistanceDirectionalSealing/packingWellheadMechanical engineering

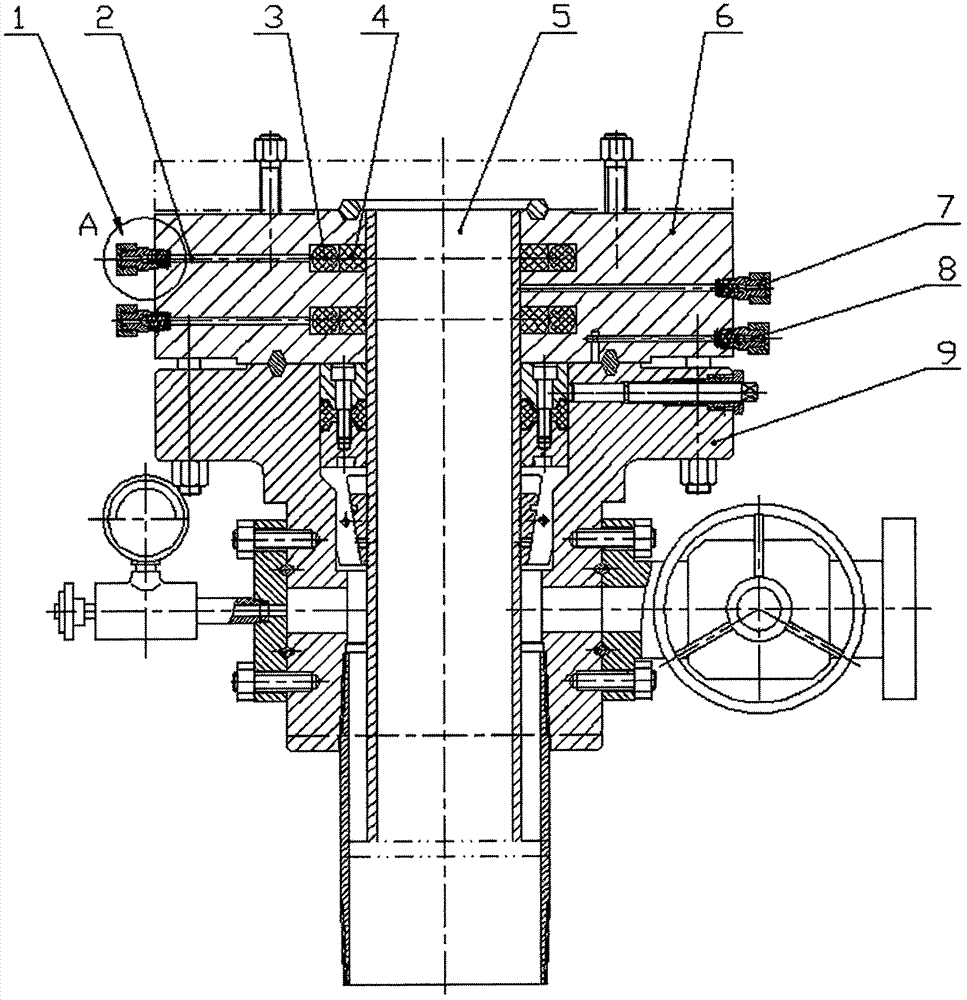

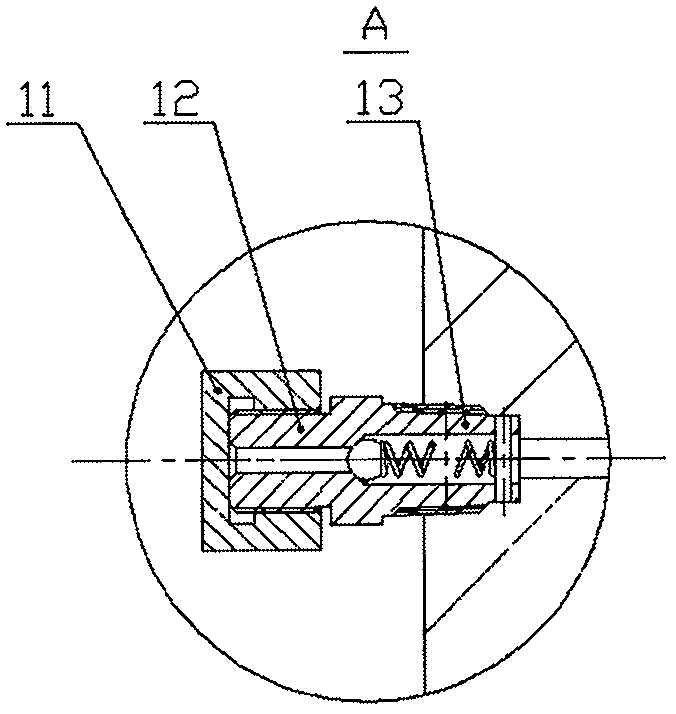

The invention discloses a petroleum wellhead annular space sealing device. The petroleum wellhead annular sealing device is used for sealing an annular space between a wellhead sealing body and a petroleum pipe, at least one annular groove is formed in the inner wall surface of the sealing body, and the sealing body is provided with an injection hole which is communicated to a centrifugal end of the annular groove; the petroleum wellhead annular space sealing device further comprises a sealing ring, a power ring, and an injection component, wherein the sealing ring is embedded into the annular groove, the sealing ring is used for sealing the groove in the radial direction by being jointed to the wall surface of the annular groove, and is used for sealing the annular space by being jointed to the outer wall of the petroleum pipe, the power ring is installed in the annular groove and is located between the groove bottom of the annular groove and the sealing ring, and the injection component is installed in an inlet of the injection hole, and is used for injecting fluid with given pressure so as to make the power ring push the sealing ring to tightly press the petroleum pipe. In the petroleum wellhead annular space sealing device, the requirement for deformation capability of a sealing part is low, and meanwhile the sealing capability can be effectively improved.

Owner:DEZHOU UNITED GASOLINEEUM MACHINERY

Devices and methods for enrichment and alteration of circulating tumor cells and other particles

InactiveUS20070026414A1Small particle sizeLower the volumeBioreactor/fermenter combinationsBiological substance pretreatmentsCirculating cancer cellTumor cells

The invention features devices and methods for detecting, enriching, and analyzing circulating tumor cells and other particles. The invention further features methods of diagnosing a condition, e.g., cancer, in a subject by analyzing a cellular sample from the subject.

Owner:THE GENERAL HOSPITAL CORP +2

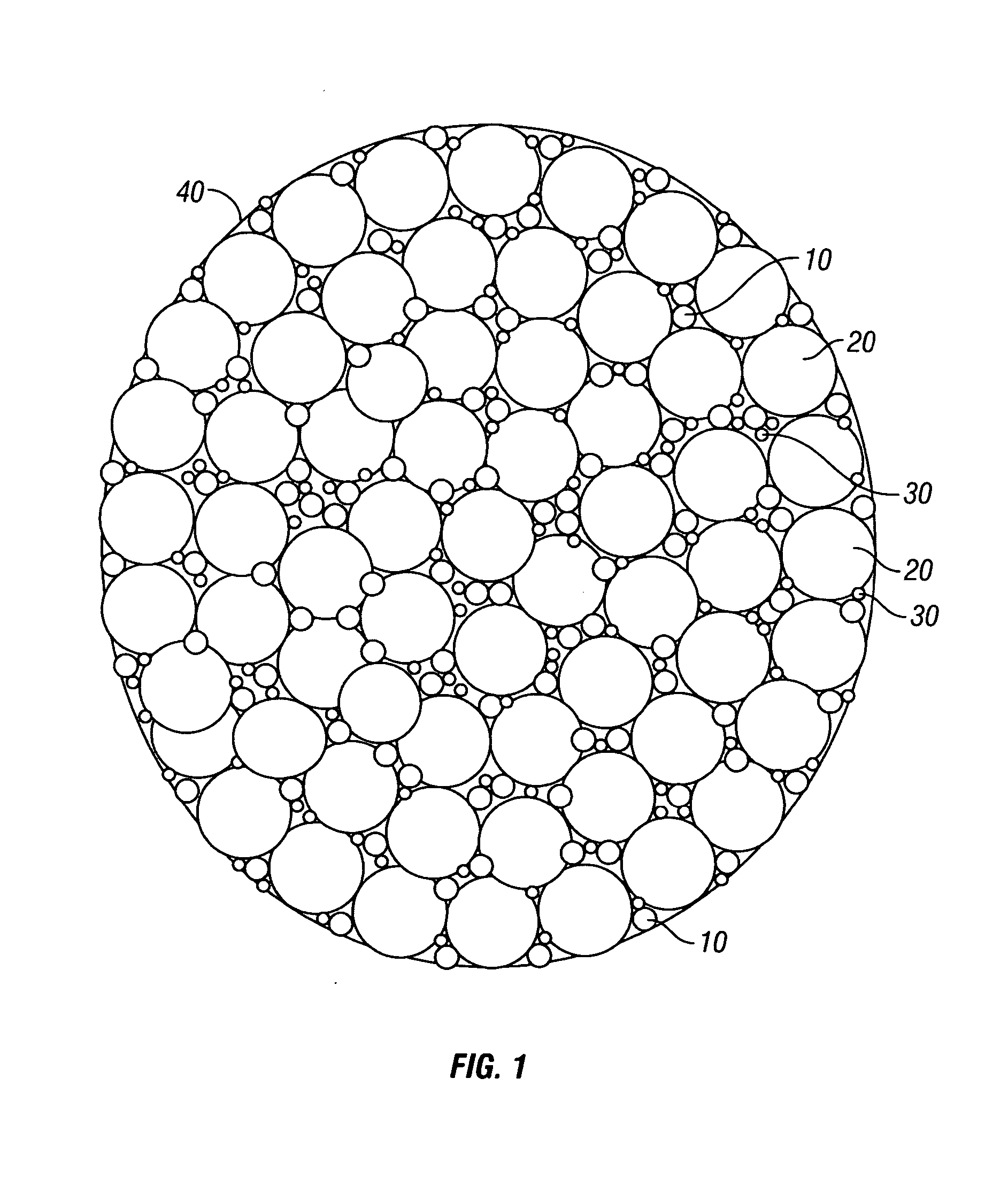

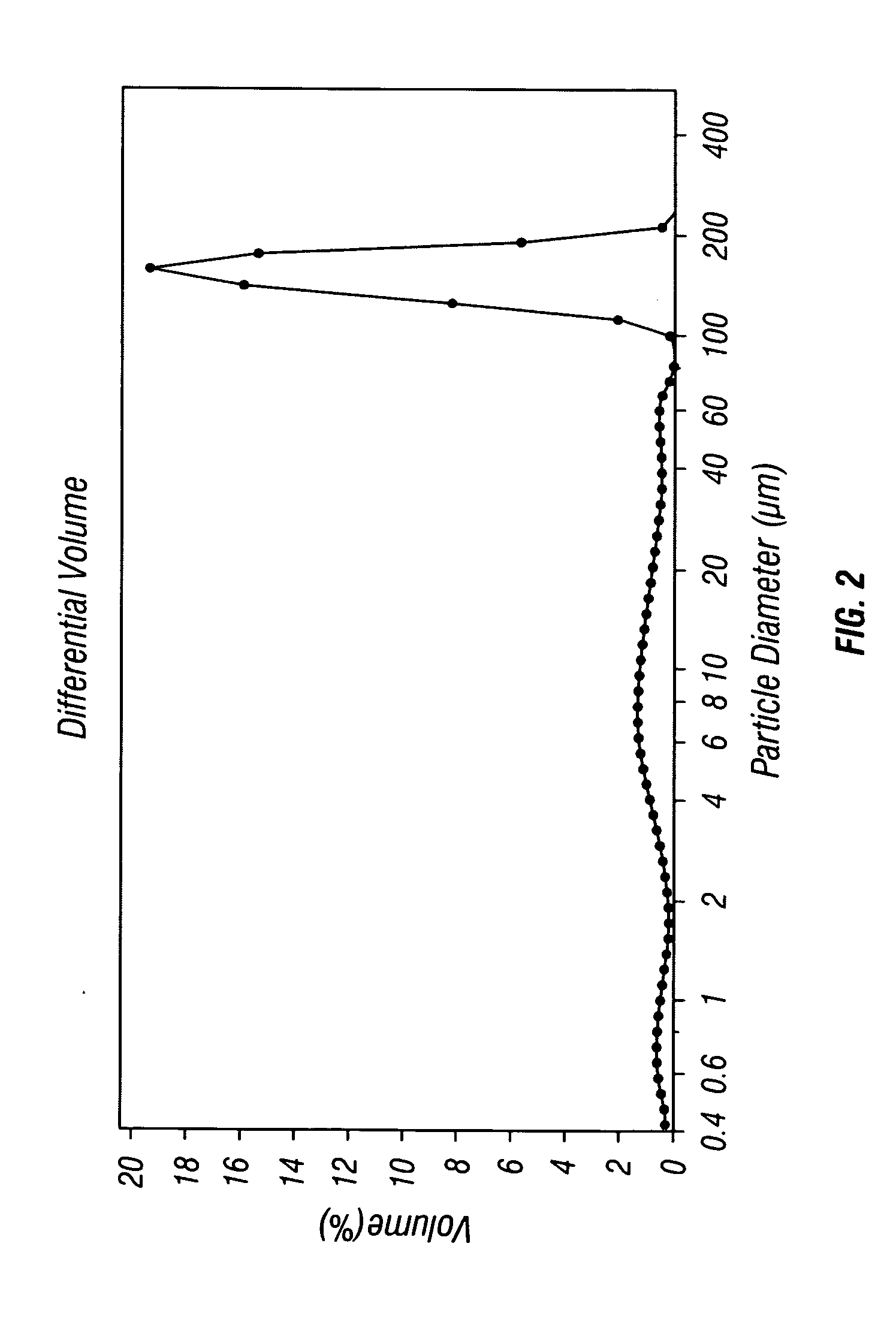

Structured composite compositions for treatment of subterranean wells

ActiveUS20060258546A1Reinforce strength (or modulus)Improve stress resistancePretreated surfacesFlushingParticulatesBi modal

A structured composite is comprised of particulates having particle size distribution of at least two modes and a binder. The particle size distribution is preferably bi-modal or tri-modal. The composite may further contain a density-modifying agent for modifying the density of the composite. The particulates are preferably substantially spherical and may be ultra lightweight (ULW) materials. The resulting composites exhibit the requisite strength to survive downhole imposed stresses and temperatures.

Owner:BJ SERVICES CO

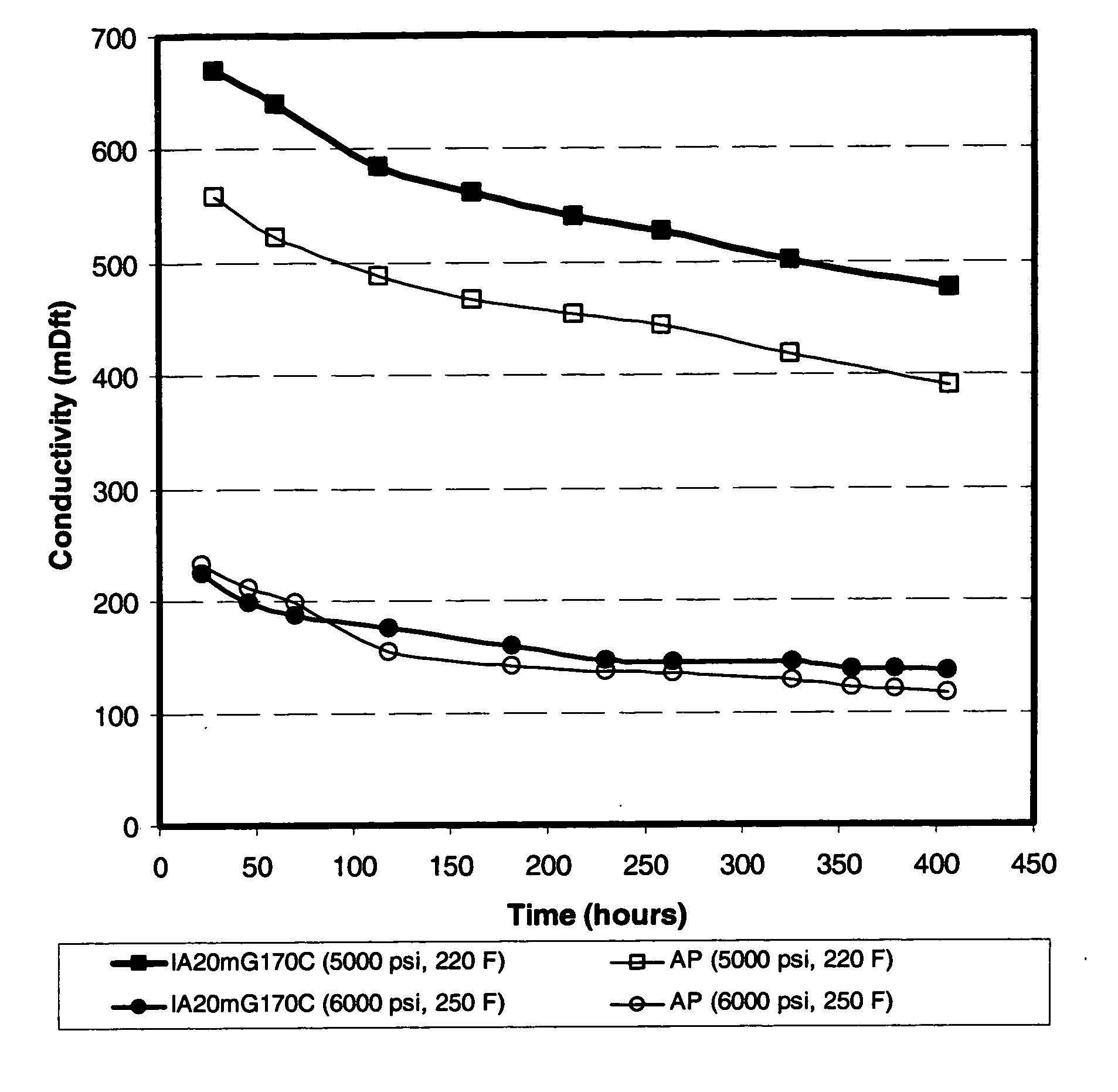

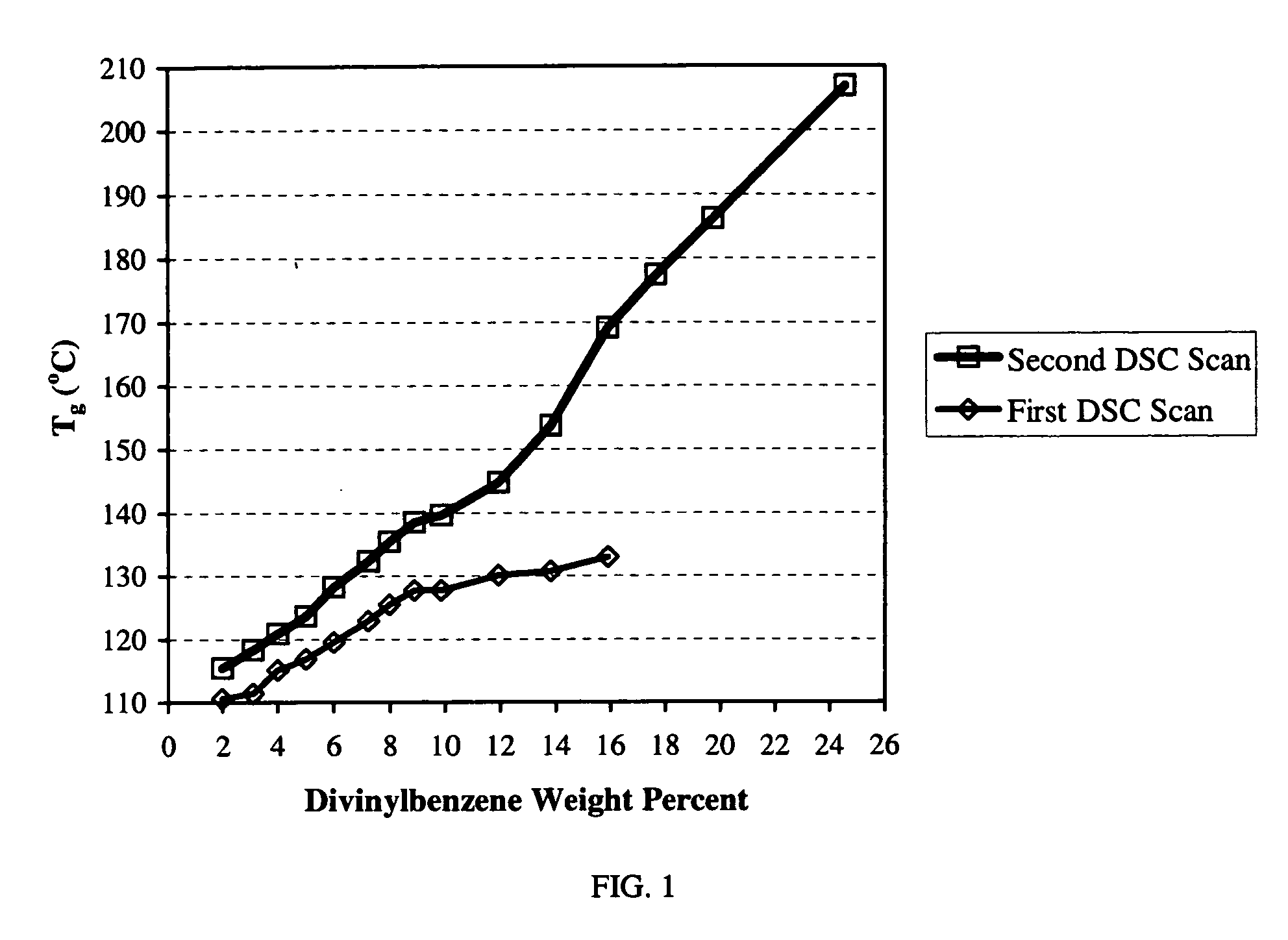

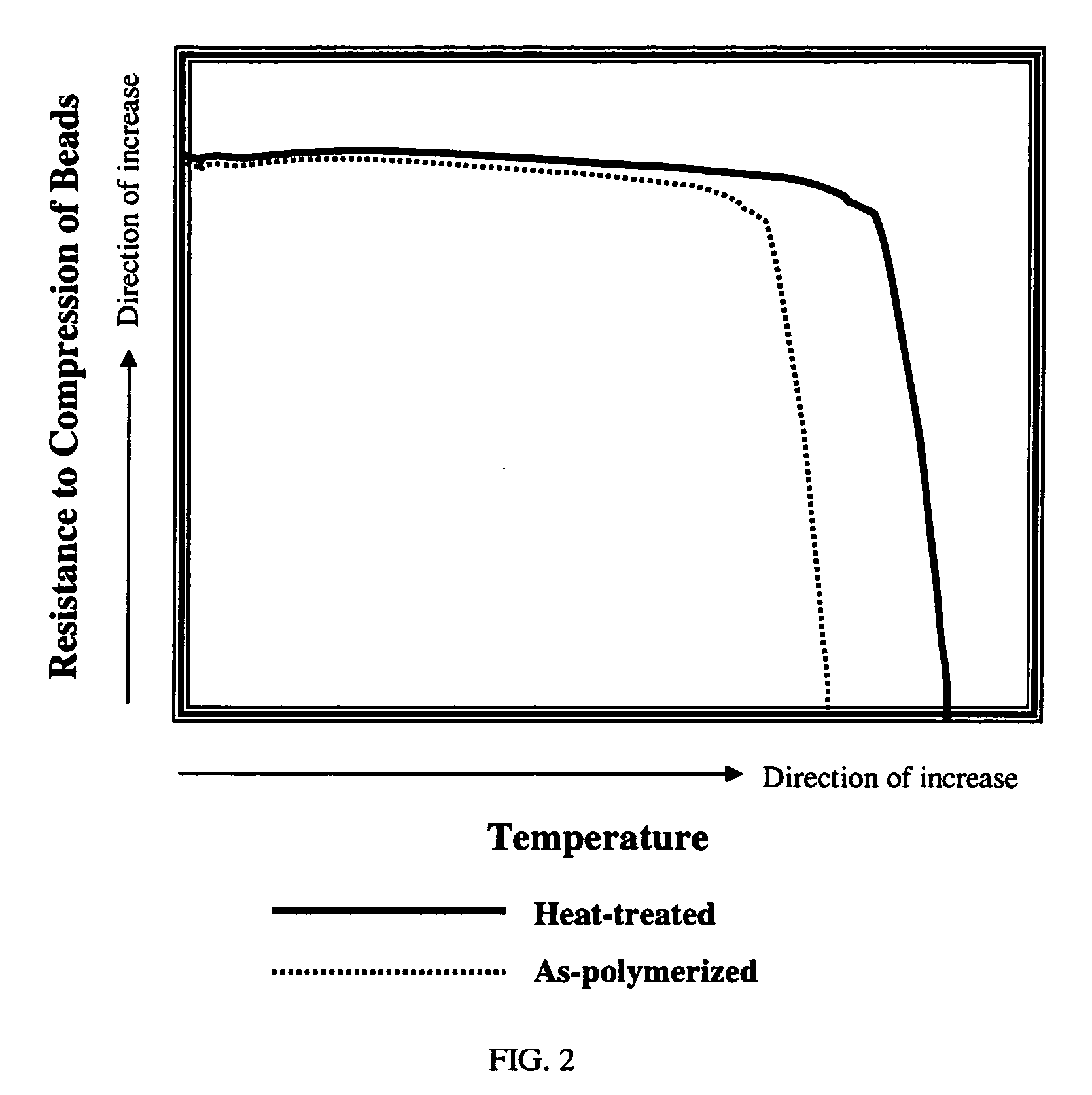

Thermoset particles with enhanced crosslinking, processing for their production, and their use in oil and natural gas driliing applications

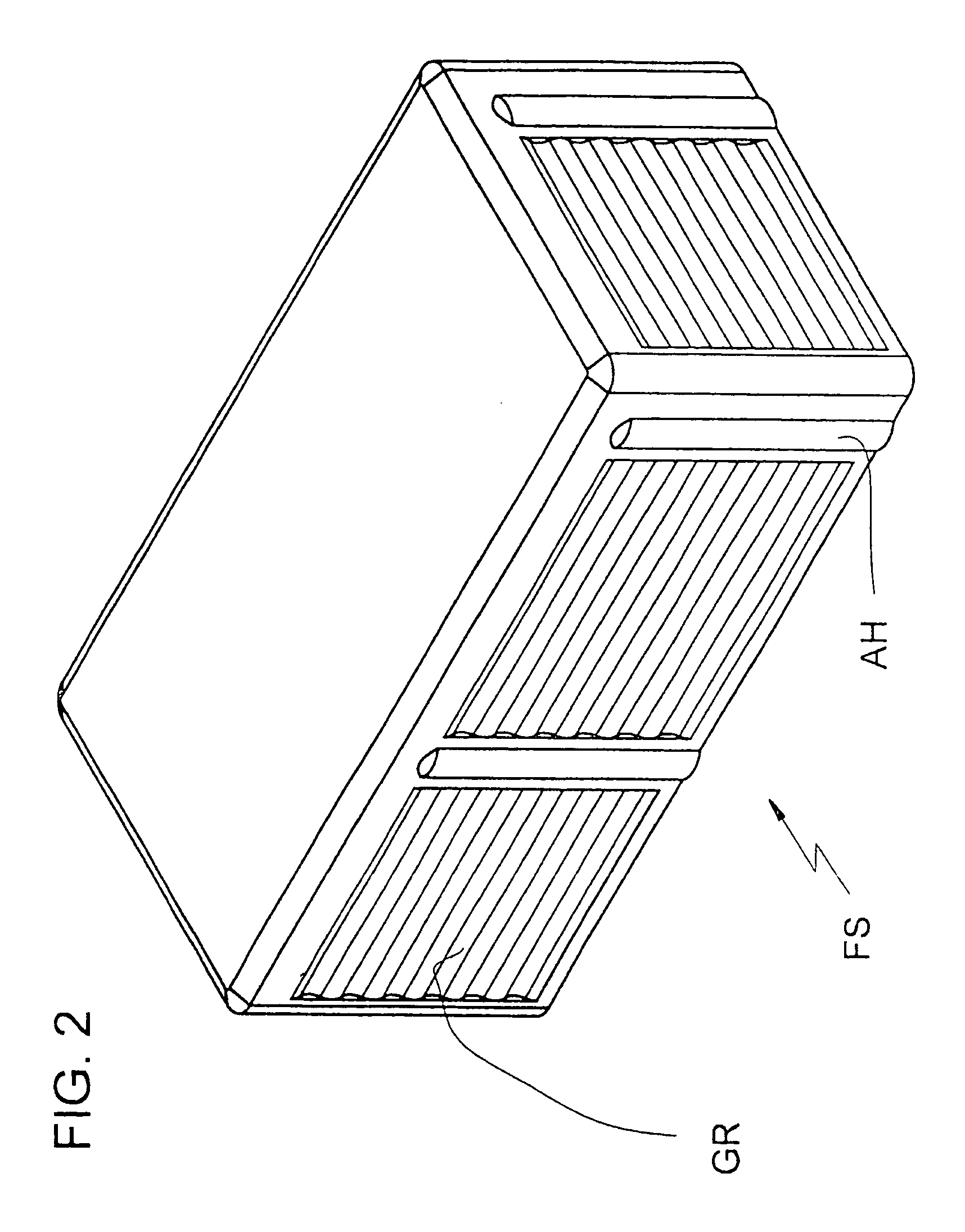

InactiveUS20070021309A1Increase compressive elastic modulusReduced deformabilitySynthetic resin layered productsCellulosic plastic layered productsEnvironmental resistancePetroleum

Thermoset polymer particles are used in many applications requiring lightweight particles possessing high stiffness, strength, temperature resistance, and / or resistance to aggressive environments. The present invention relates to the use of methods to enhance the stiffness, strength, maximum possible use temperature, and environmental resistance of such particles. One method of particular interest is the application of post-polymerization process step(s) (and especially heat treatment) to advance the curing reaction and to thus obtain a more densely crosslinked polymer network. The most common benefits of said heat treatment are the enhancement of the maximum possible use temperature and the environmental resistance. The present invention also relates to the development of thermoset polymer particles. It also relates to the further improvement of the key properties (in particular, heat resistance and environmental resistance) of said particles via post-polymerization heat treatment. Furthermore, it also relates to processes for the manufacture of said particles. Finally, it also relates to the use of said particles in the construction, drilling, completion and / or fracture stimulation of oil and natural gas wells; for example, as a proppant partial monolayer, a proppant pack, an integral component of a gravel pack completion, a ball bearing, a solid lubricant, a drilling mud constituent, and / or a cement additive.

Owner:SUN DRILLING PRODS

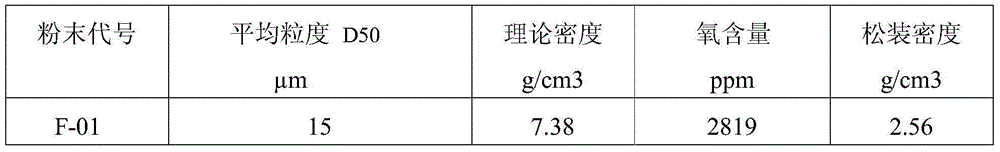

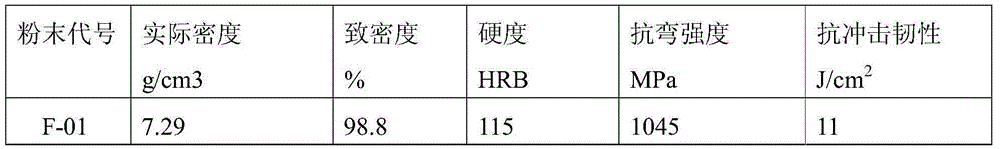

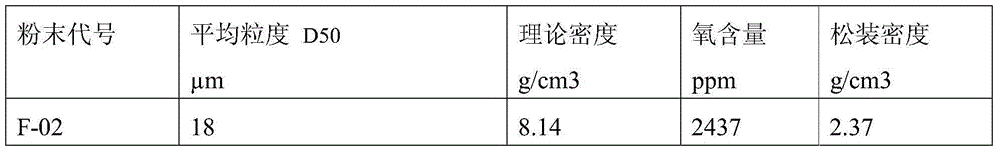

Circular diamond saw blade bit and manufacturing method thereof

The invention discloses a circular diamond saw blade bit and a manufacturing method thereof. The circular diamond saw blade bit is made of diamond particles and matrix powder used for consolidation of the diamond particles. The matrix powder comprises, by mass percent, 40%-80% of Fe, 15%-30% of Cu, 0%-10% of Ni, 2%-8% of Sn, 0%-10% of Co, 0%-5% of Me and the balance inevitable impurities. Me is at least one of Mn, Ti, Si, Cr, P and Al. The manufacturing method comprises the steps of mixing raw materials, conducting cold-press molding and free sintering. The manufacturing method is simple and can effectively avoid the loss of a graphite mould and reduce manufacturing cost. Meanwhile, a volume production requirement can be met, and blade bits in complicated shapes can be produced; production efficiency is prolonged, and the service life of the tool is similar to that of a tool manufactured through a hot-press sintering method; the purpose that high-quality diamond cutting tools are produced under the condition of low cost can be achieved; and the circular diamond saw blade bit and a manufacturing method thereof are easy to popularize in an industrialized manner.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

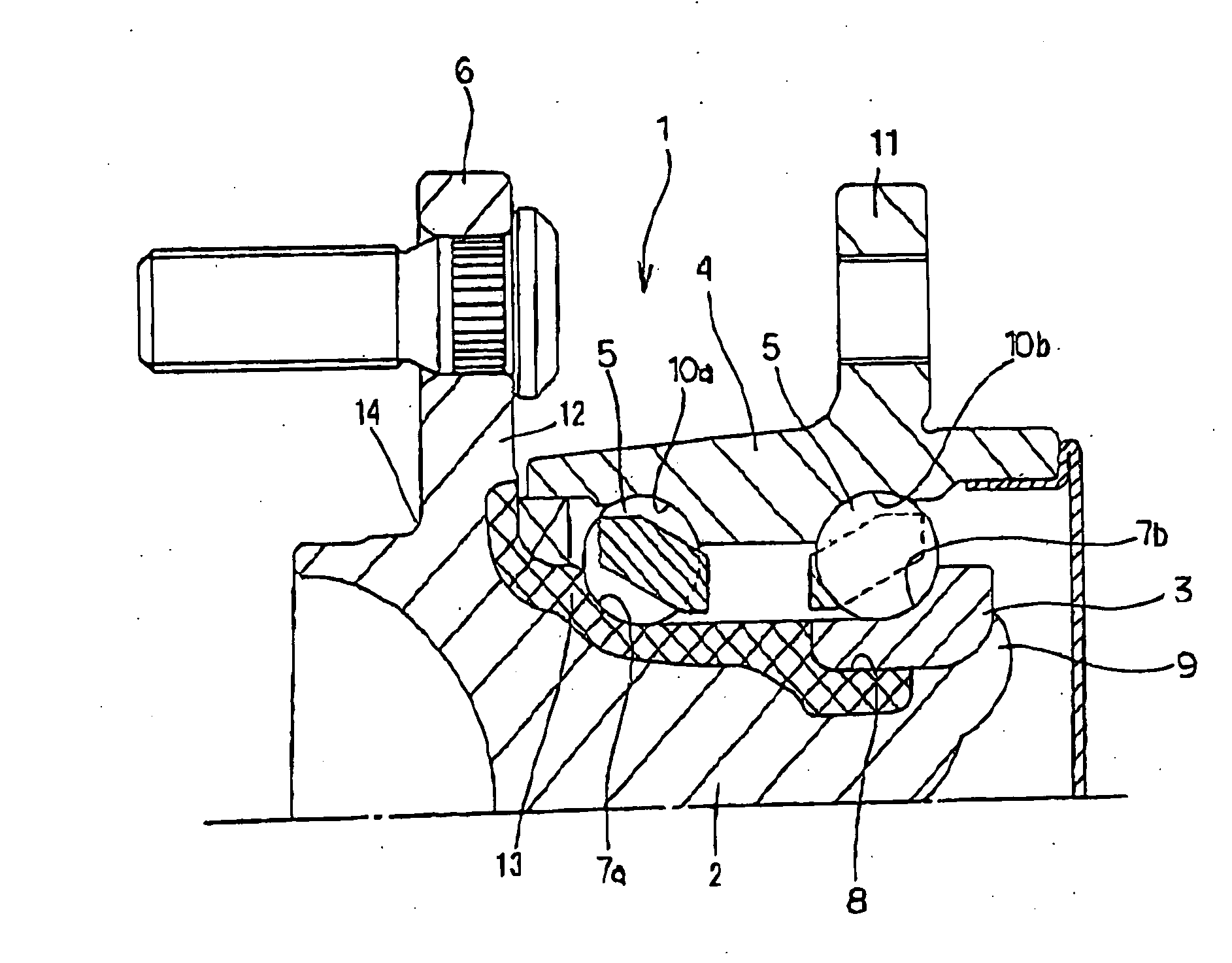

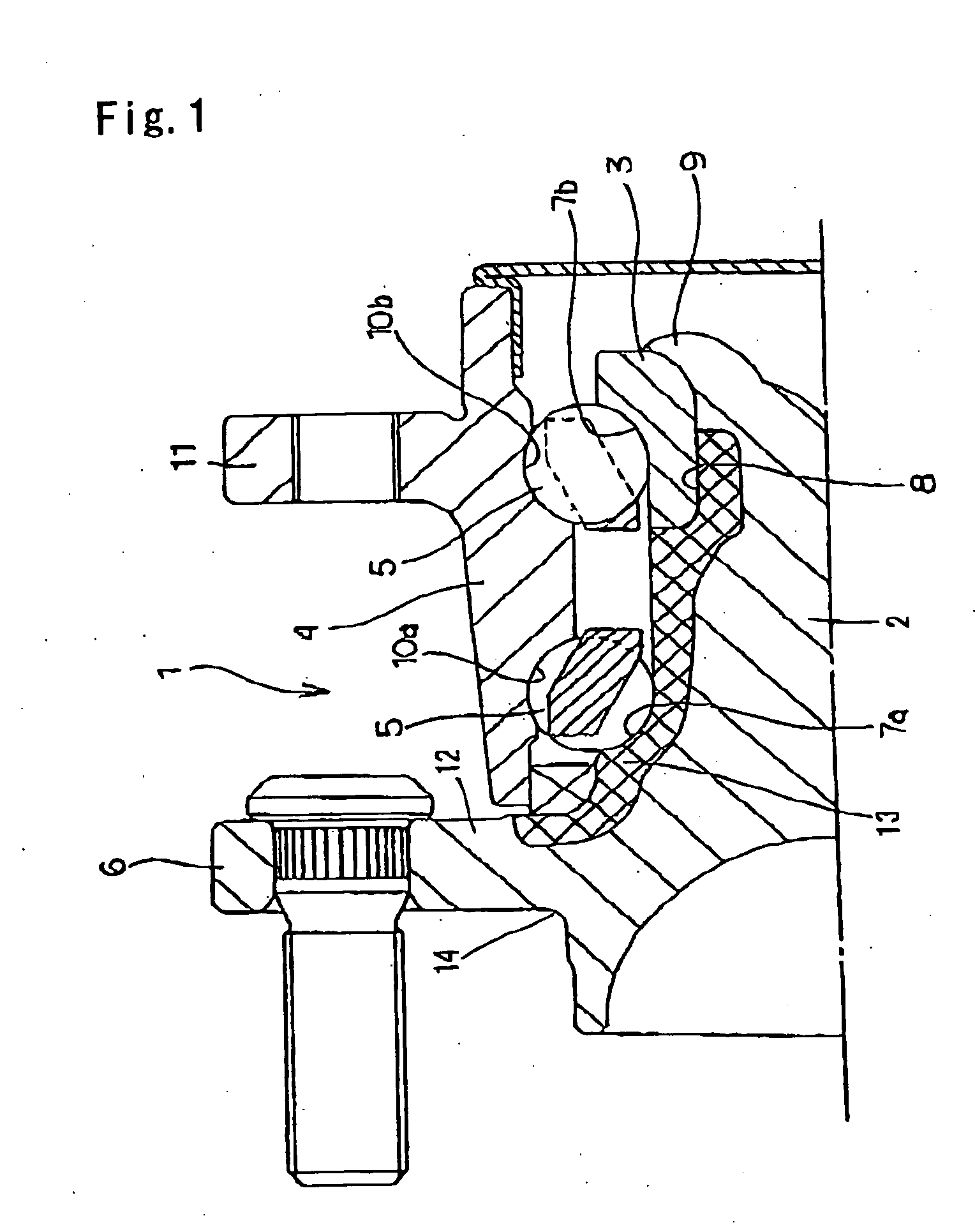

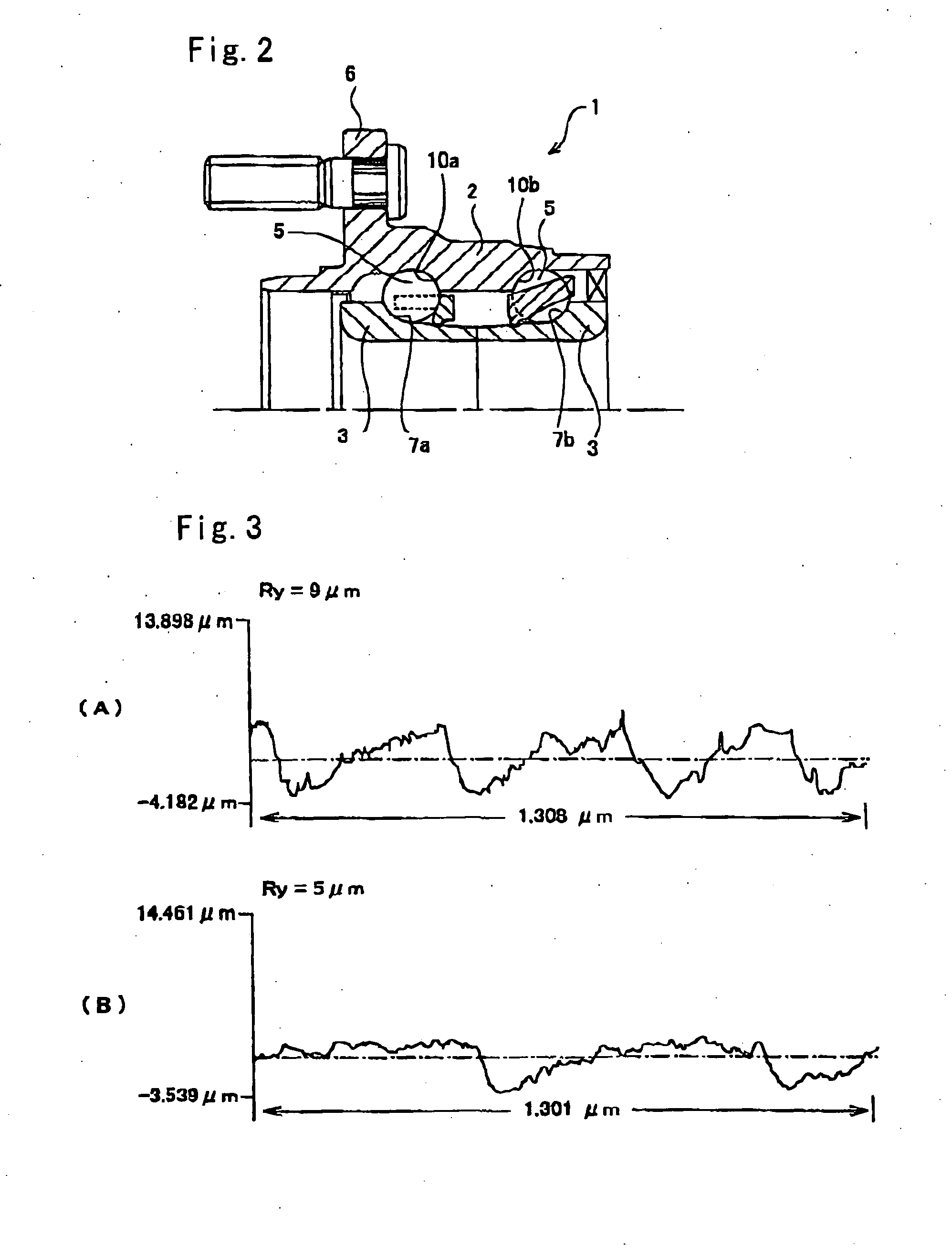

Wheel-support rolling bearing unit

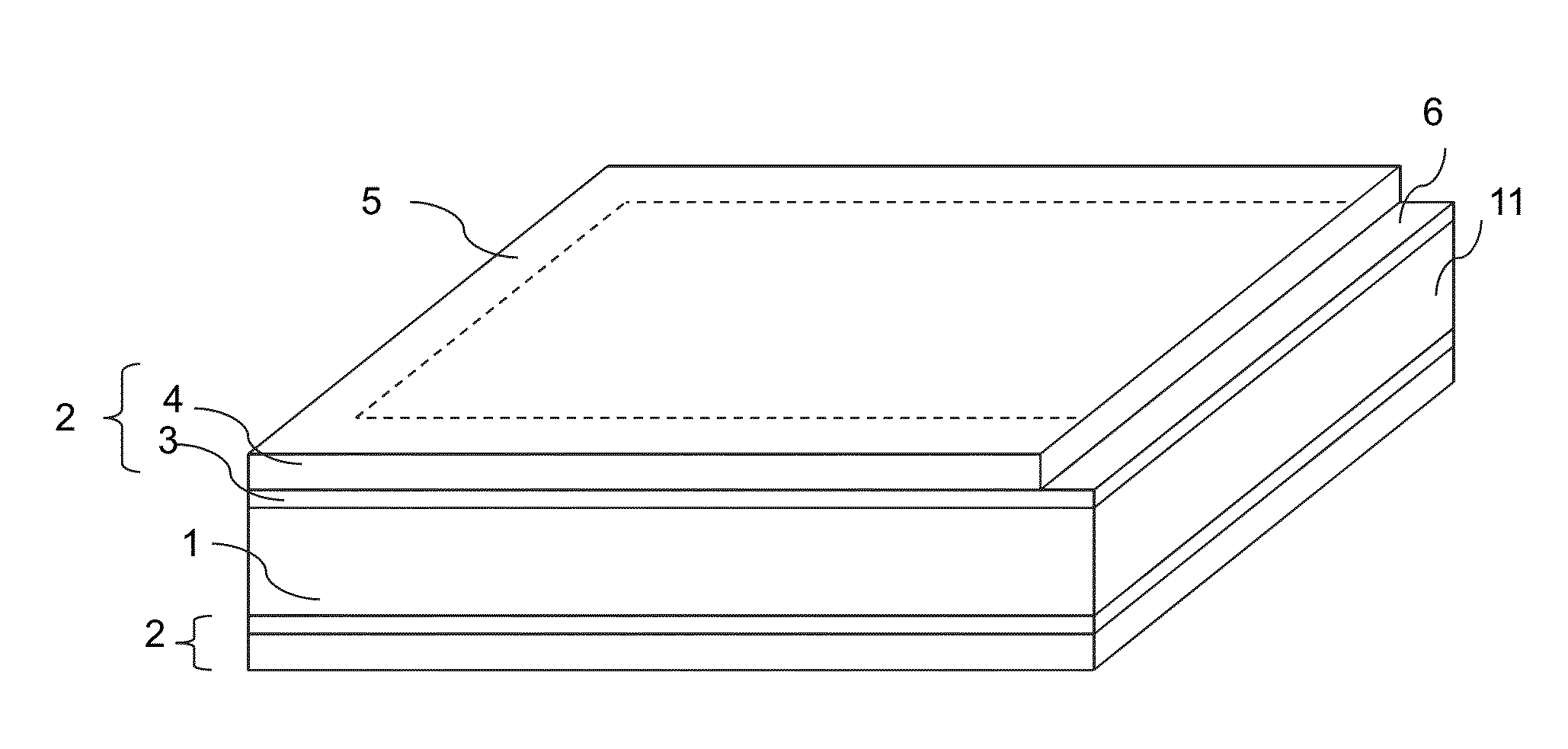

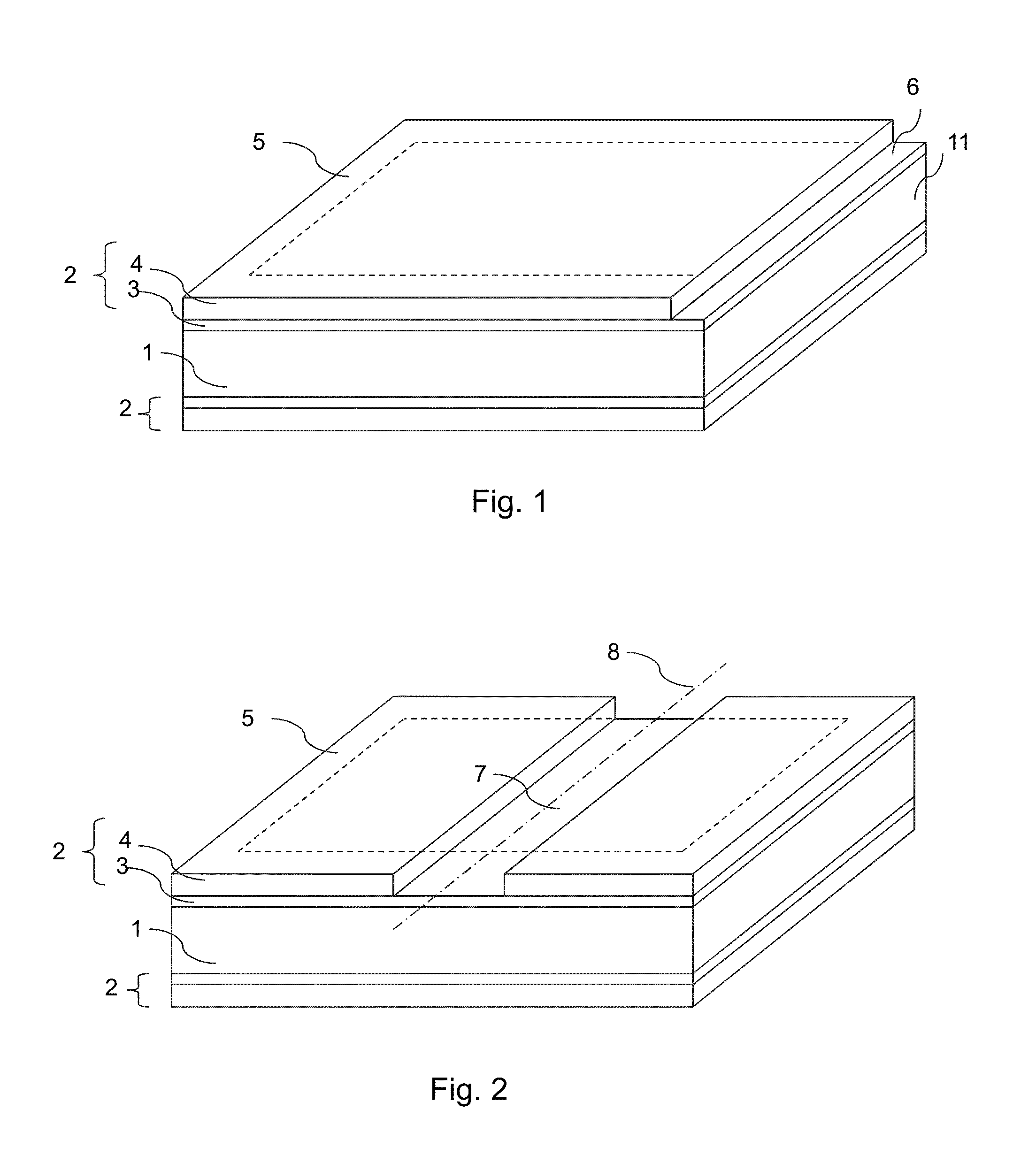

InactiveUS20050141799A1Reduced deformabilityEasy to crackRolling contact bearingsBearing assemblySurface roughnessHardness

In a wheel-support rolling bearing unit, in order to made a flange 6 thinner and thus lighten the bearing unit without impairing fatigue strength, machinability, and workability after forging, the composition of the alloy steel constituting the flange attached member (hub ring 2), the surface hardness of the root portion 14 on the axial outside surface side of the flange 6, and the surface roughness, are stipulated to thereby improve the durability ratio (fatigue limit strength / tensile strength) of the flange 6. In one aspect, the member is made from an alloy steel containing C: 0.5 to 0.65 weight %, Mn: 0.3 to 1.5 weight %, Si: 0.1 to 1.0 weight %, Cr: 0.01 to 0.5 weight %, S: 0.35 weight % or less, and any one type or more selected from 0.01 to 0.2 weight % of V, 0.01 to 0.15 weight % of Nb, and 0.01 to 0.15 weight % of Ti, with the rest being Fe and inevitable impurities, and the oxygen contents is 15 ppm or less. Moreover, the surface hardness of the inner raceway 7a formed with the hardened layer, is between Hv 650 and 780, and the surface hardness of a portion not formed with the hardened layer is between Hv 230 and 300.

Owner:NSK LTD

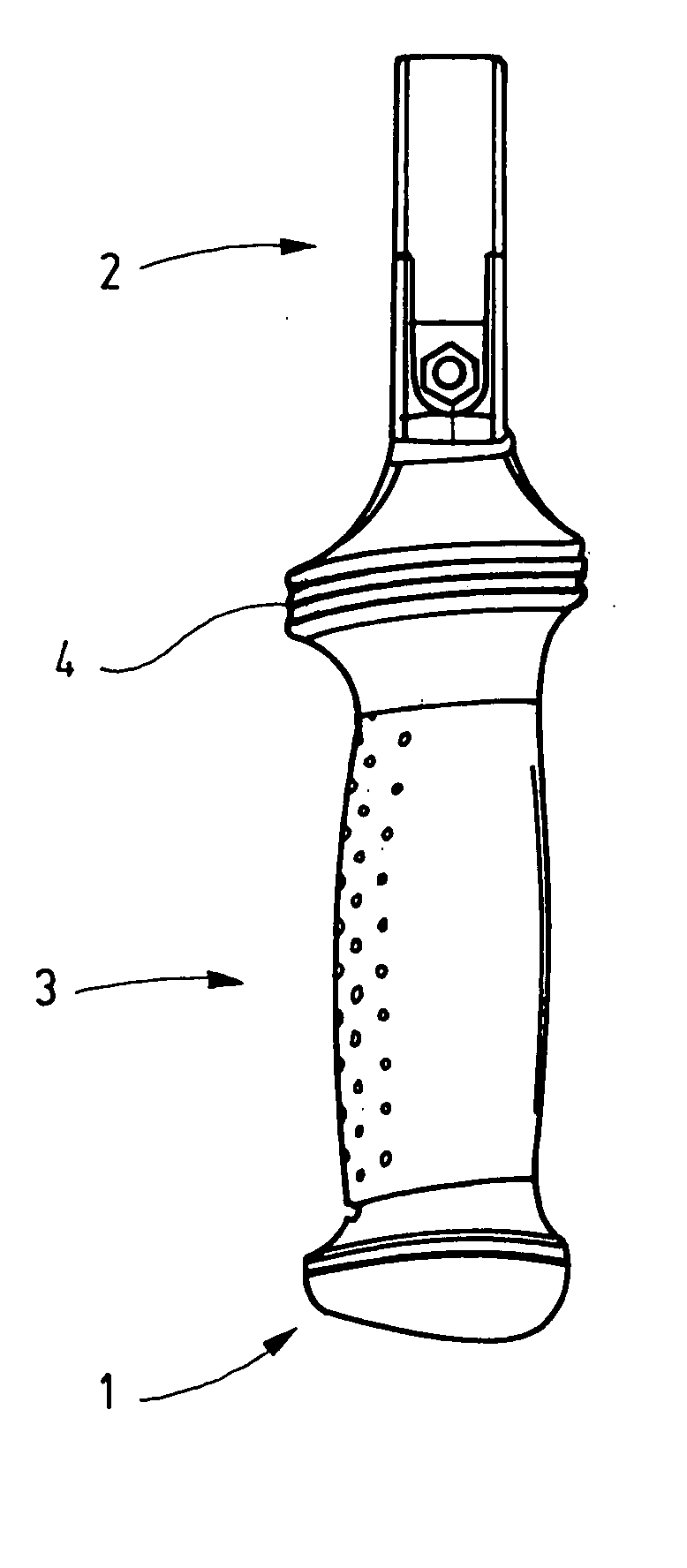

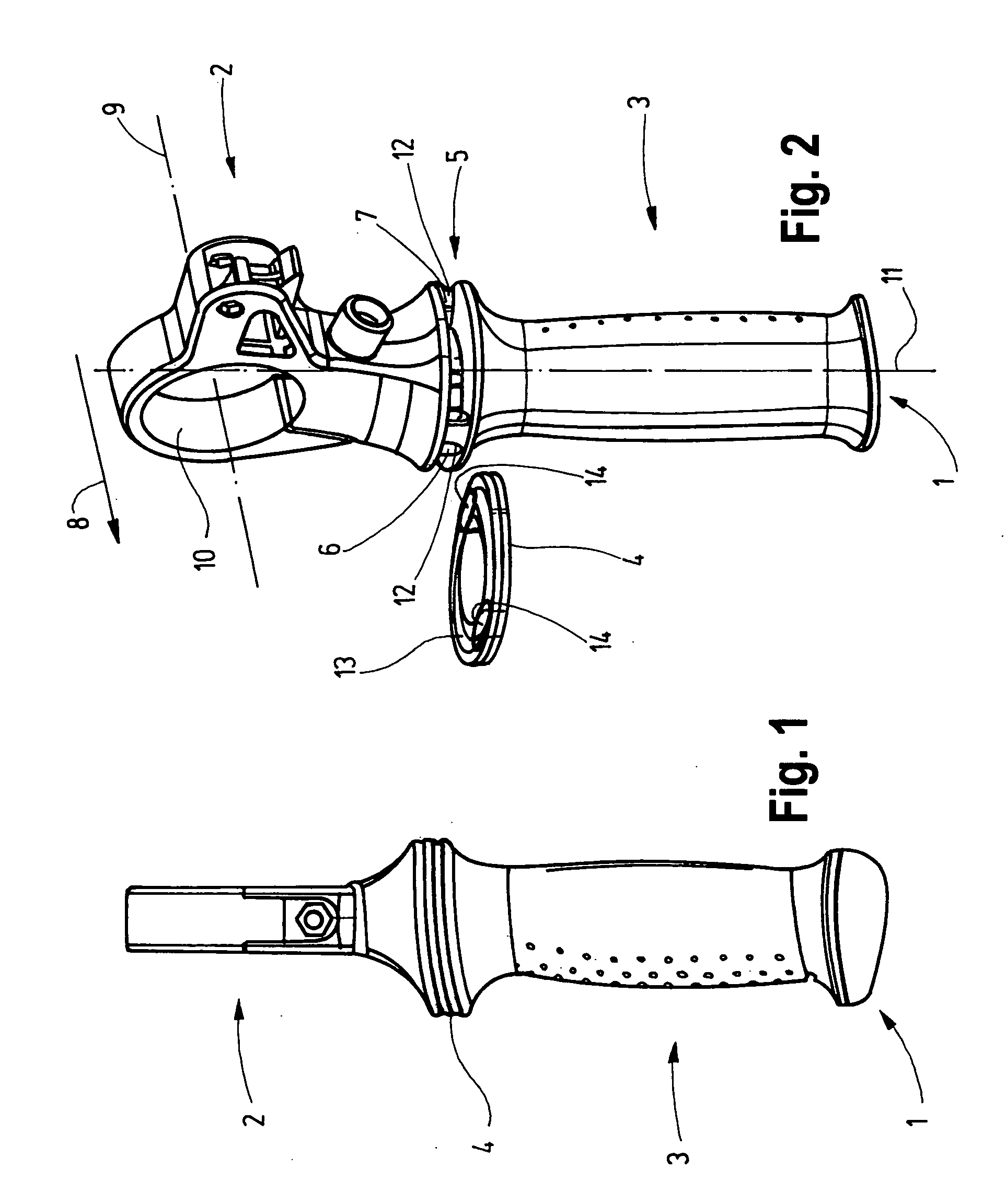

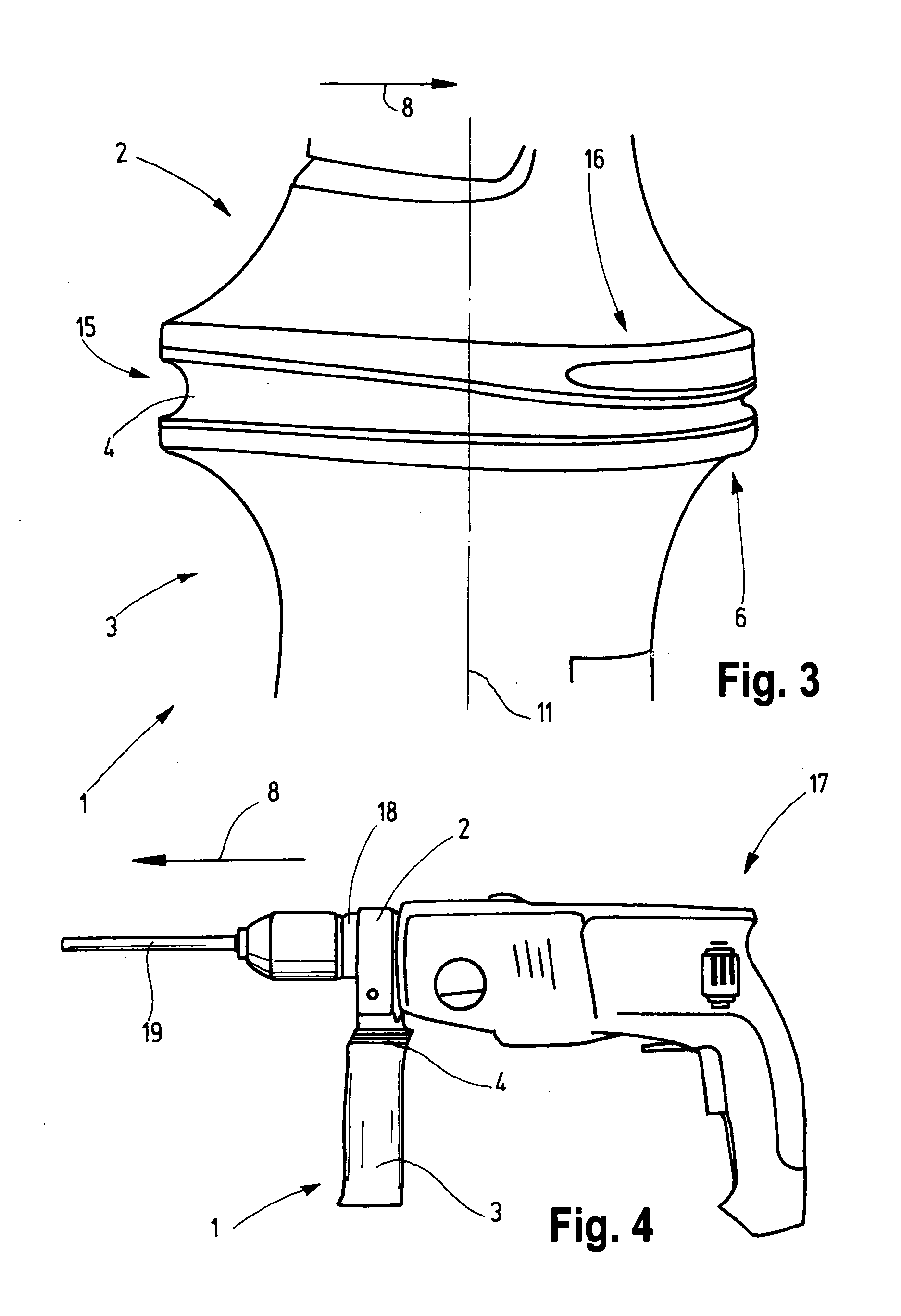

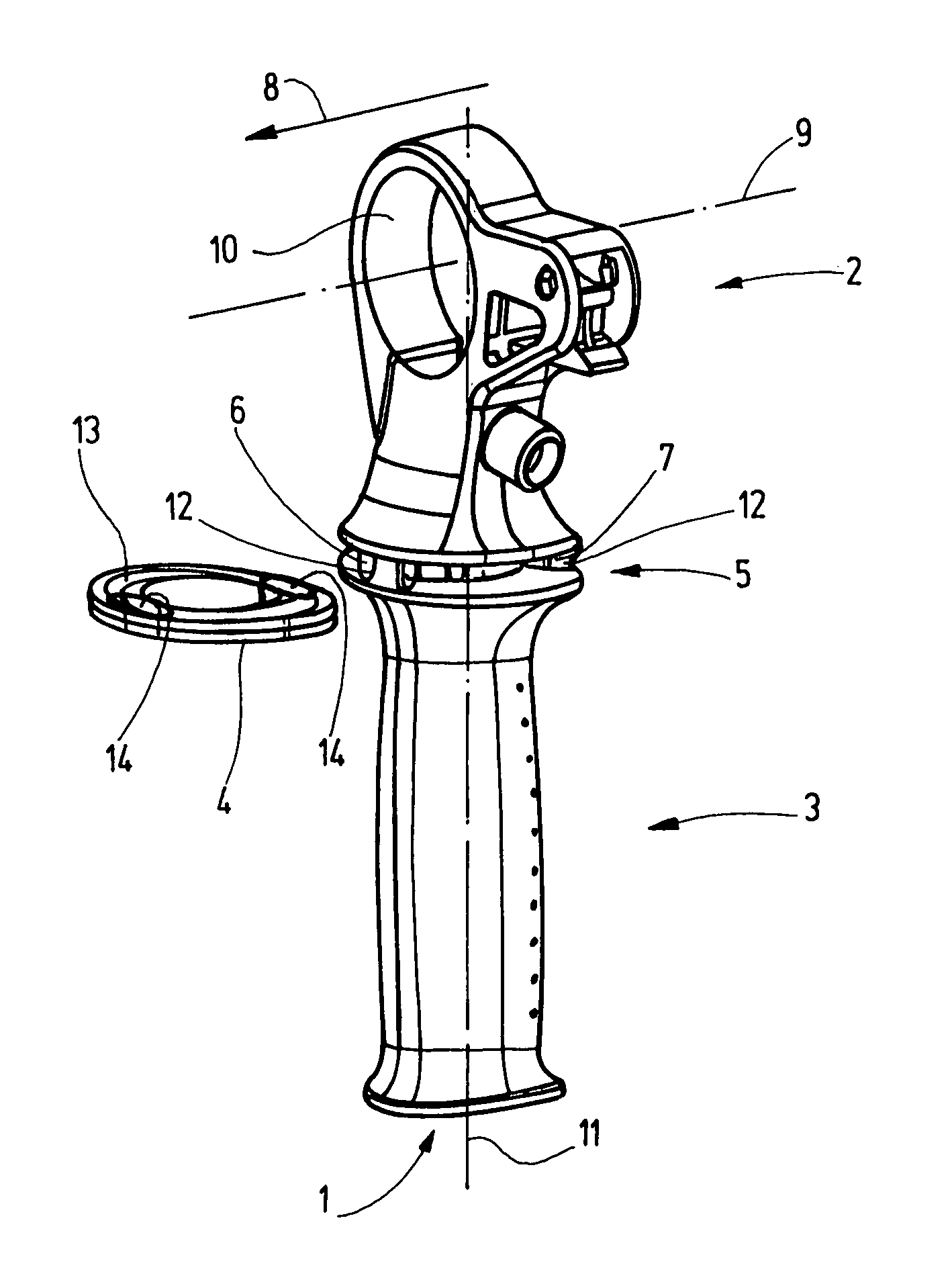

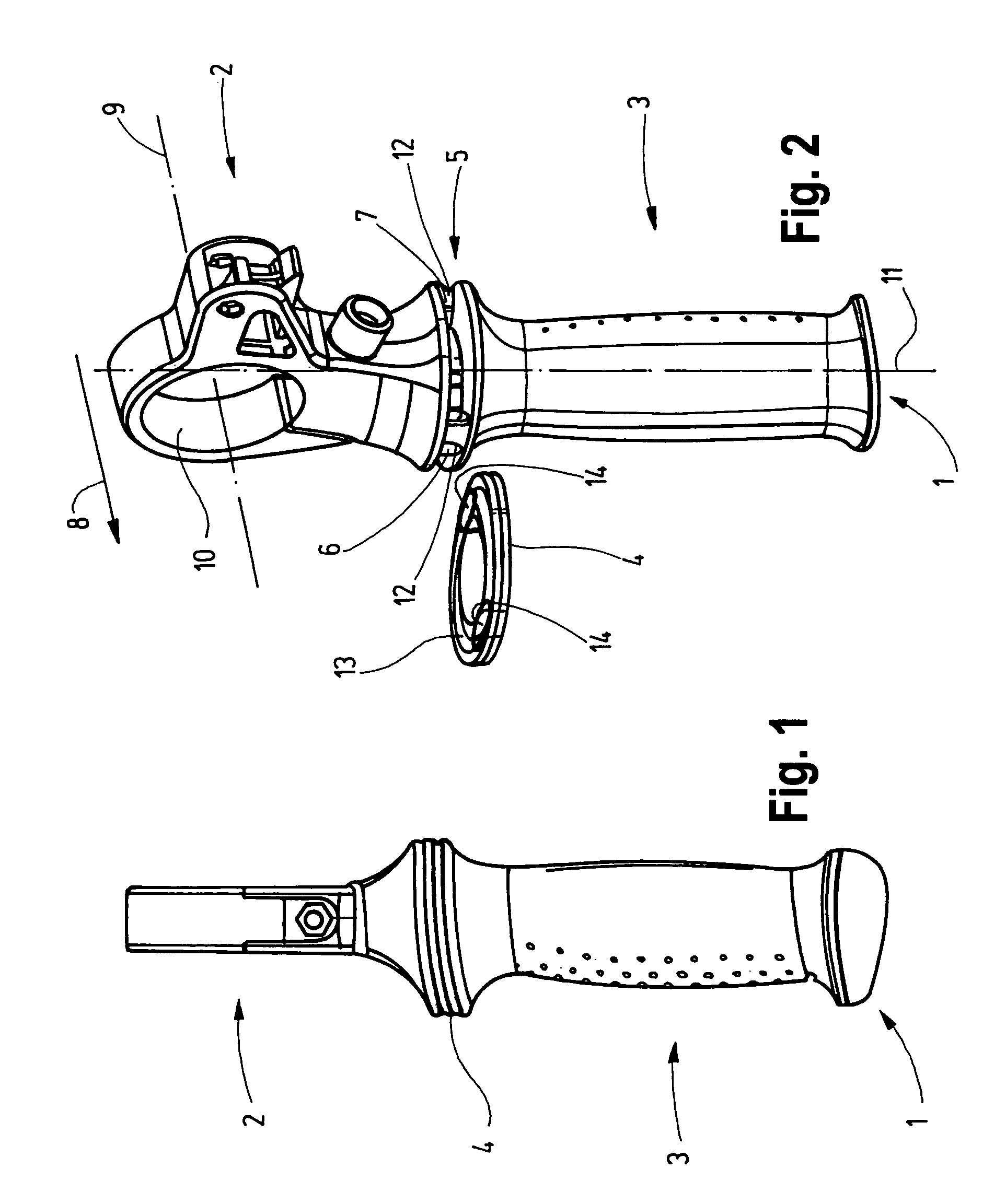

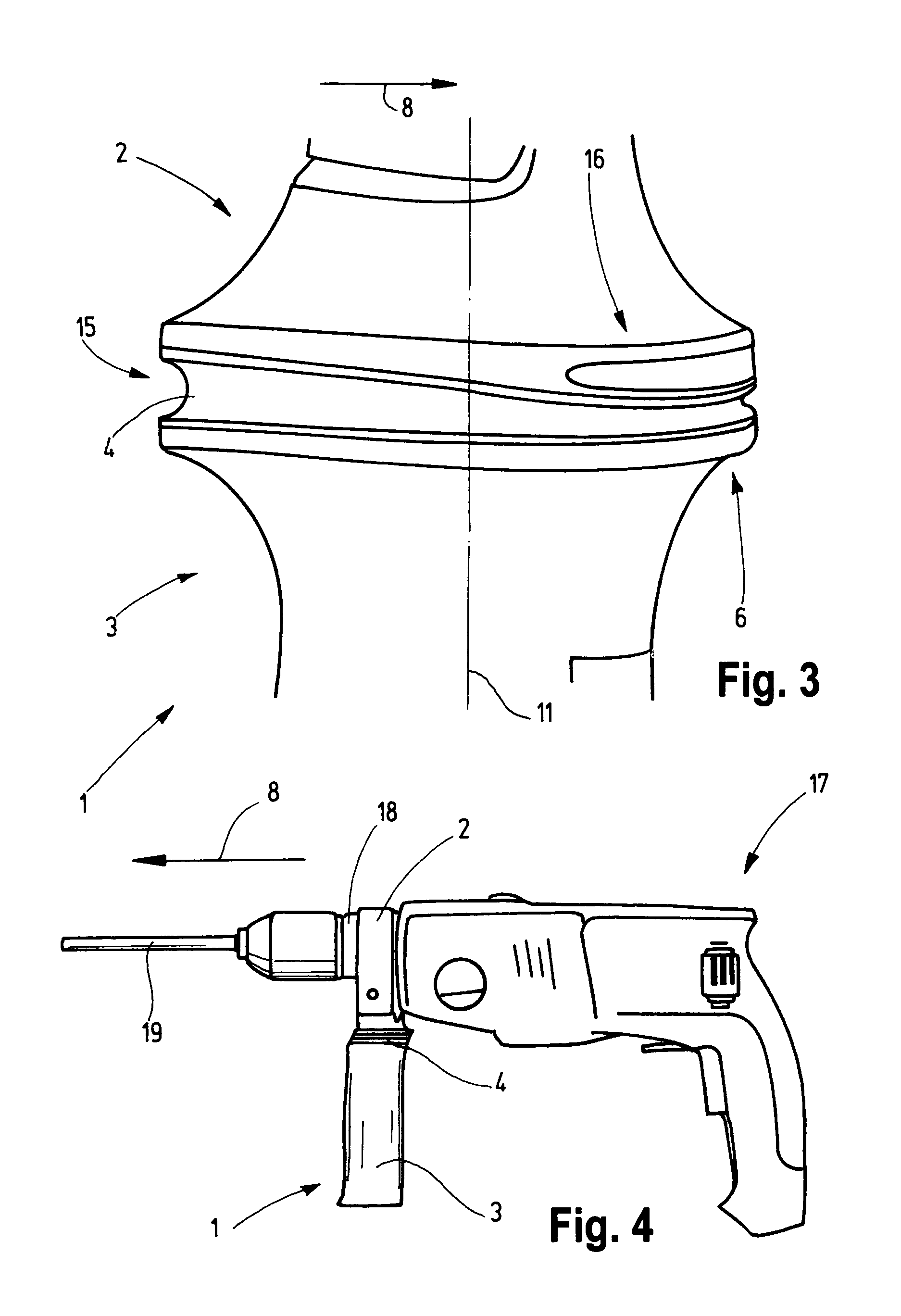

Auxiliary handle, and hand power tool provided therewith

InactiveUS20050082072A1Reduced deformabilityReduce vibrationOperator-supported drilling machinesPortable percussive toolsMotor driveEngineering

An auxiliary handle for a motor-driven hand tool has a mounting device which forms an upper region and provides a force-transmitting and / or form-locking connection to a hand tool; a handle forming a lower region, a damping element forming an intermediate region and located at least locally between the mounting device and the handle, the damping element having a damping material with which, during an operation of a hand tool, it dampens vibration transmitted through the mounting device to the handle, the damping element in its damping region acting for damping having at least one reinforcing region that has a lower deformability than a remaining part of the damping region and during deviations of the handle in at least two different directions relative to the mounting device causes differently great elastic counter forces.

Owner:ROBERT BOSCH GMBH

Halogen-Free Flame-Retardant Polyolefin Composite Foam Material And Preparation Method Thereof

This present invention discloses a halogen-free flame retardant polyolefin foam composite, which is comprises: 80-125 parts by weight of ethylene / vinyl acetate copolymer (EVA), 8-13 parts by weight of high density polyethylene (HDPE) or low density polyethylene (LDPE), 15-25 parts by weight of polyolefin elastomer (POE), 60-77 parts by weight of acid source material, 17-22 parts by weight of carbon source material, 8-11 parts by weight of gas source material, 1-8 parts by weight of retardant synergist, 5.5-8 parts by weight of composite foaming agent, 0.7-1.0 parts by weight of crosslinking agent, 4.0-5.5 parts by weight of plasticizer, 0.5-1.6 parts by weight of surface treatment agent, 20-35 parts by weight of compatibility, 6-14 parts by weight of inorganic filler, and 1.6-4.6 parts by weight of additive. This halogen-free flame retardant polyolefin foam composite has the advantages of good softness, flexibility, impact resistance, low density, low compressibility and deformability, good shock absorbability, and so on.

Owner:FUZHOU UNIV

Rolling technique of ultra-fine grained magnesium alloy sheet

ActiveCN101422784AHigh yield strengthHigh tensile strengthFurnace typesMetal rolling arrangementsMicrometerUltra fine

The invention relates to a rolling technique used for producing superfine crystal magnesium alloy plate band materials. The rolling technique is characterized in that a thin near-net shaped magnesium alloy cast-rolled plate is fast heated to hot rolling temperature, then treated with hot rolling with first pass great deformation magnitude, and then treated with low-temperature softening annealing; and a hot rolling machine is used for regulating the plate to a regulated thickness by multi-pass cold rolling, and the plate is treated with controlled hot treatment to form a finished magnesium alloy plate with crystal grains less than 10 micrometer. The cost of the production method of the invention is low, the technical procedure is short, and the product quality is high.

Owner:山西银光华盛镁业股份有限公司

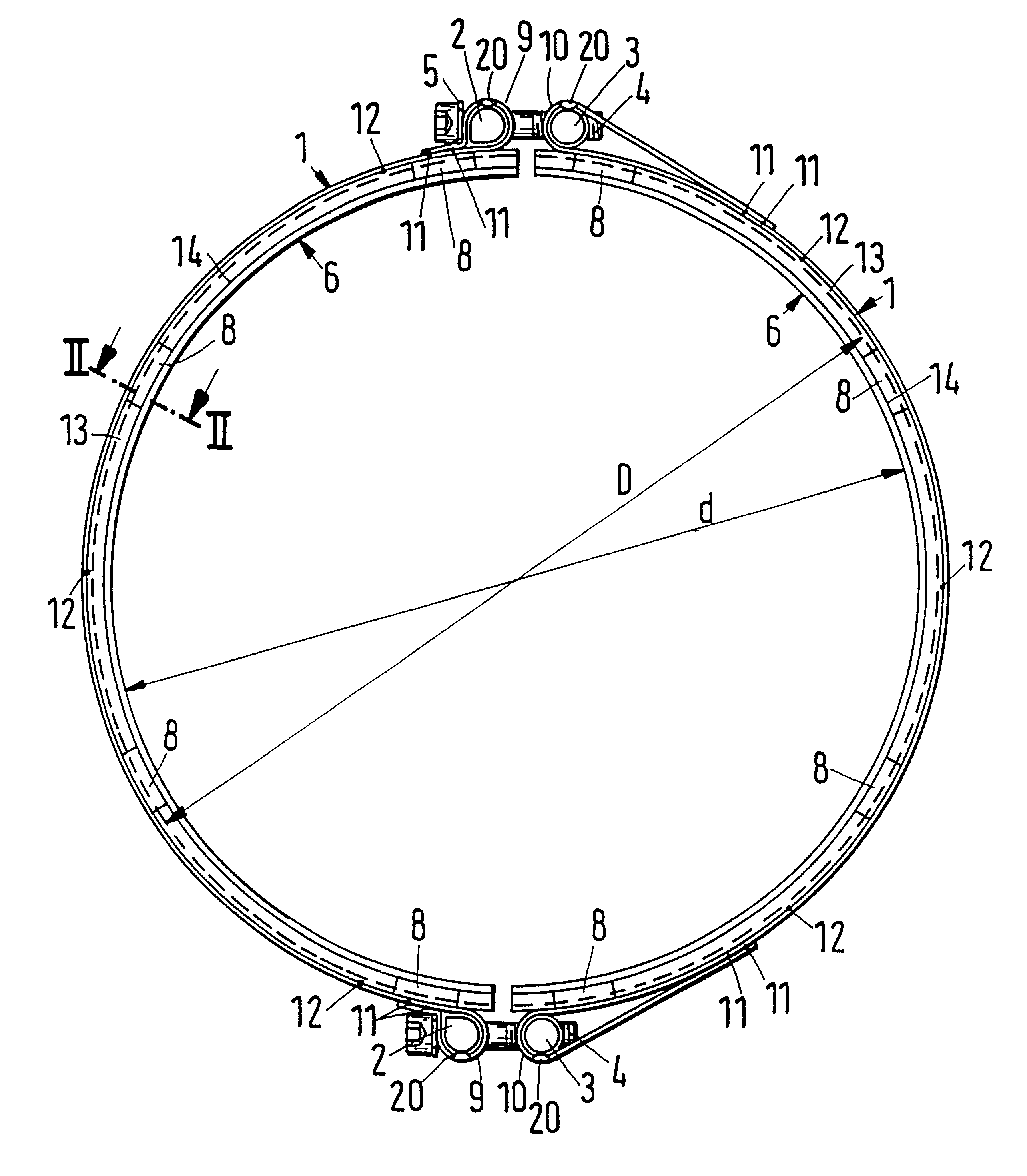

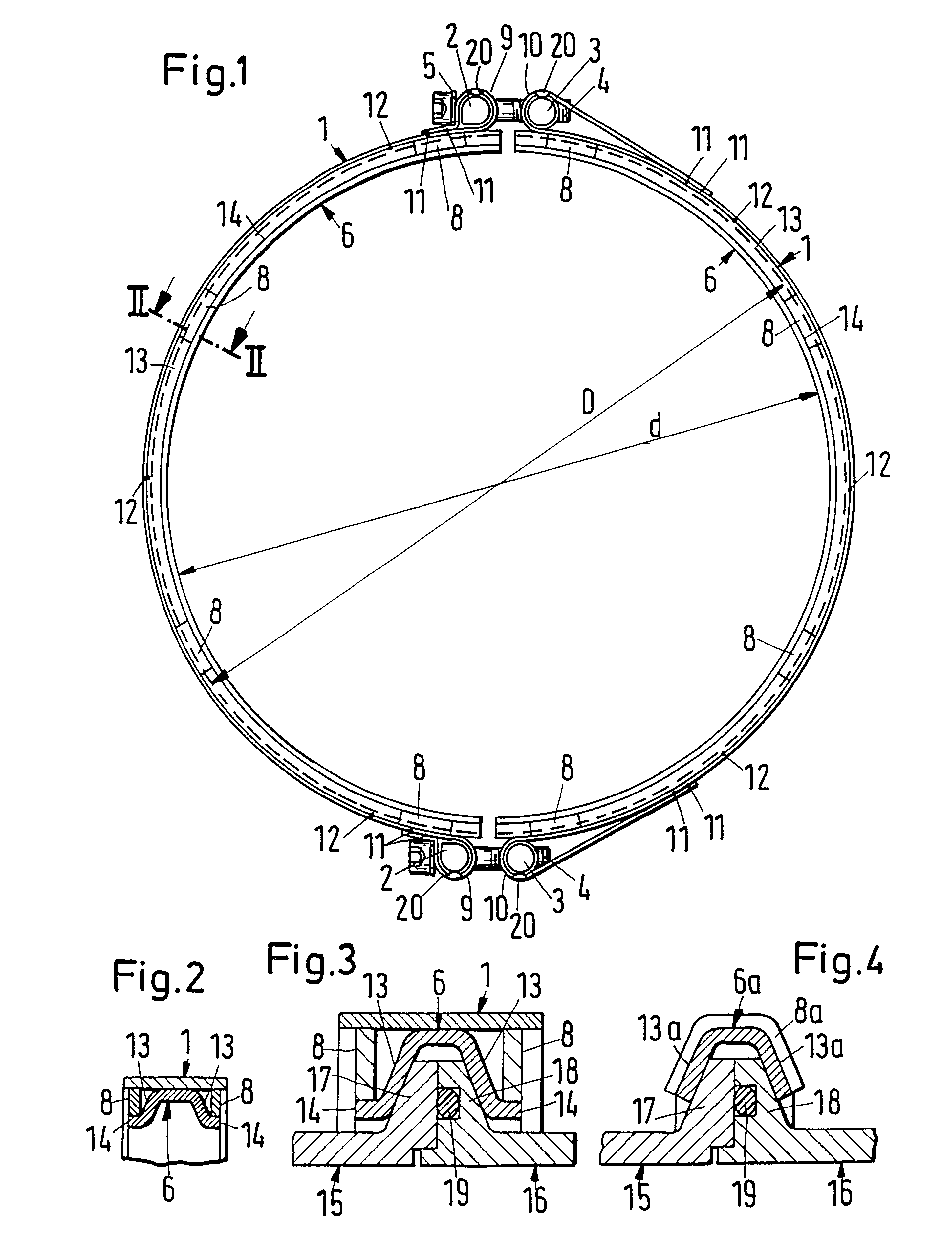

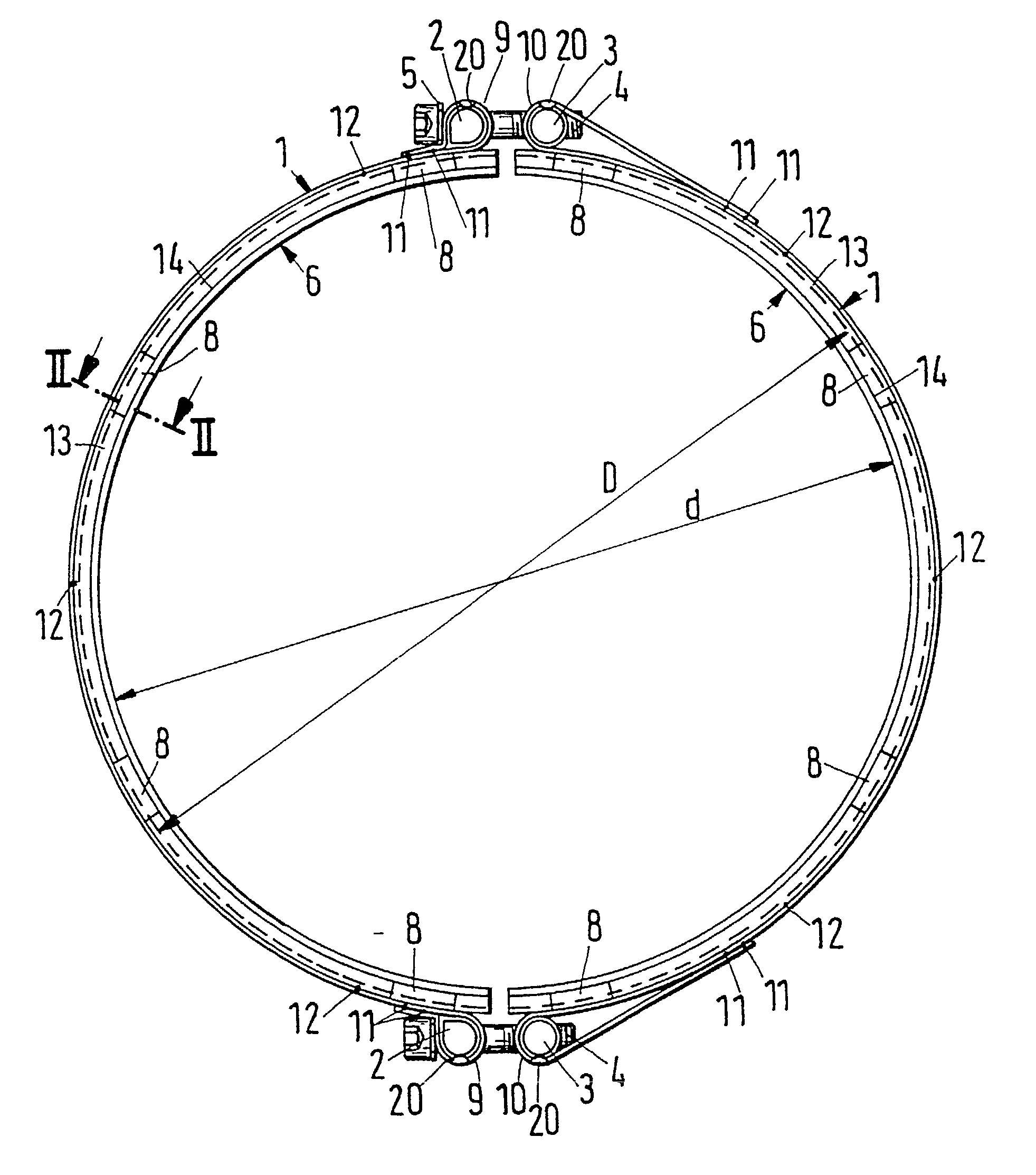

Profile clamp and method for manufacturing a profile clamp

InactiveUS6383315B1High hardnessHigh strengthFlanged jointsExhaust apparatusCarrying capacityThermal expansion

A steel profile clamp is used to join flanged component parts. The profile clamp has at least partially conical side walls that are bent radially inwardly. The profile clamp has welding joints to maintain the shape of the clamp. The steel is martensitic for increased load-carrying capacity of the joint. The steel material, in an ambient temperature range of 20° C. to 750° C., has a coefficient of thermal expansion that is at least 0.3x10-6 m / m° C. lower than that of the coefficient of thermal expansion of a ferritic casting material. The method for manufacturing the profile clamp includes prequenching and tempering the material of the profile clamp when it is in the form of a strip. After forming and welding the profile clamp, the weld is subject to induction tempering.

Owner:ABB (SCHWEIZ) AG

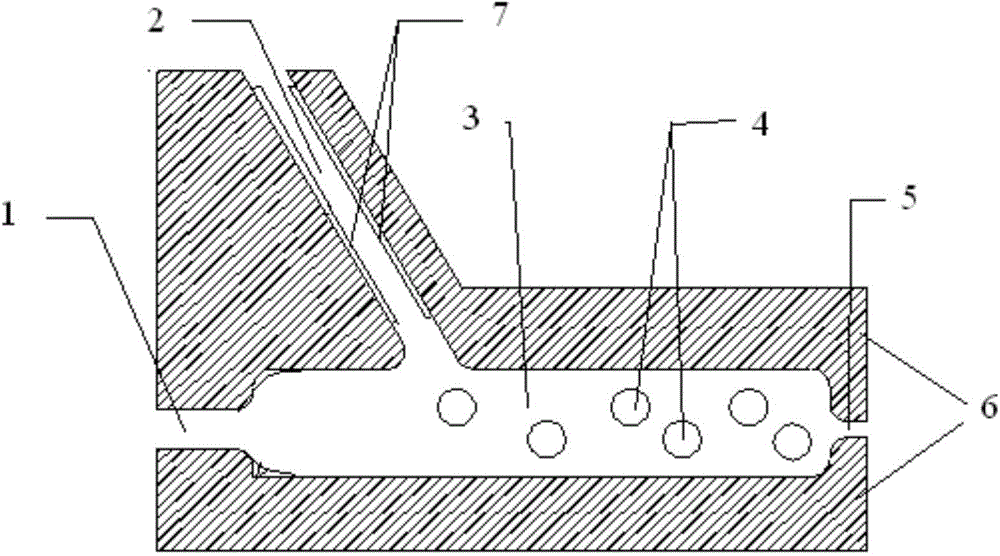

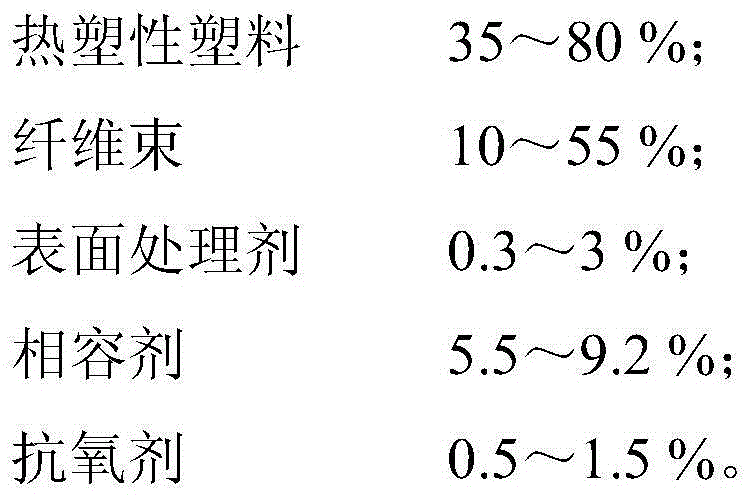

High-rigidity creep-resistant long-fiber-reinforced master batch for wood plastic products, and preparation and mold thereof

ActiveCN104356511AImprove appearance and performanceStrong rigidity and creep resistanceThermoplasticSurface finishing

The invention belongs to the technical field of preparation of long-fiber-reinforced master batches, and particularly relates to a high-rigidity creep-resistant long-fiber-reinforced master batch for wood plastic products and a preparation method thereof, and an impregnation mold for the preparation method. The master batch comprises the following components in percentage by mass: 35-80% of thermoplastic, 10-55% of fiber bundle, 0.3-3% of surface treating agent, 5.5-9.2% of compatilizer and 0.5-1.5% of antioxidant. By adopting the specific thermoplastic, compatilizer and other materials and utilizing the specific impregnation mold, the long fiber bundle is sufficiently impregnated in the master batch so as to lower the porosity and provide impregnation effect, and thus, the master batch has higher rigidity and creep resistance. After being added into the wood plastic profile product, the master batch enhances the bending modulus, strength and creep resistance, and can perform the function of reducing deformation in the profile use process, so that the application performance and long-term usage stability of the obtained WPC profile are improved.

Owner:GUANGZHOU ZAISEN NEW MATERIAL TECH CO LTD

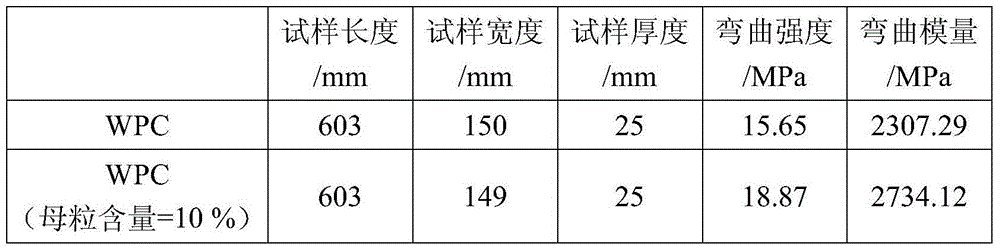

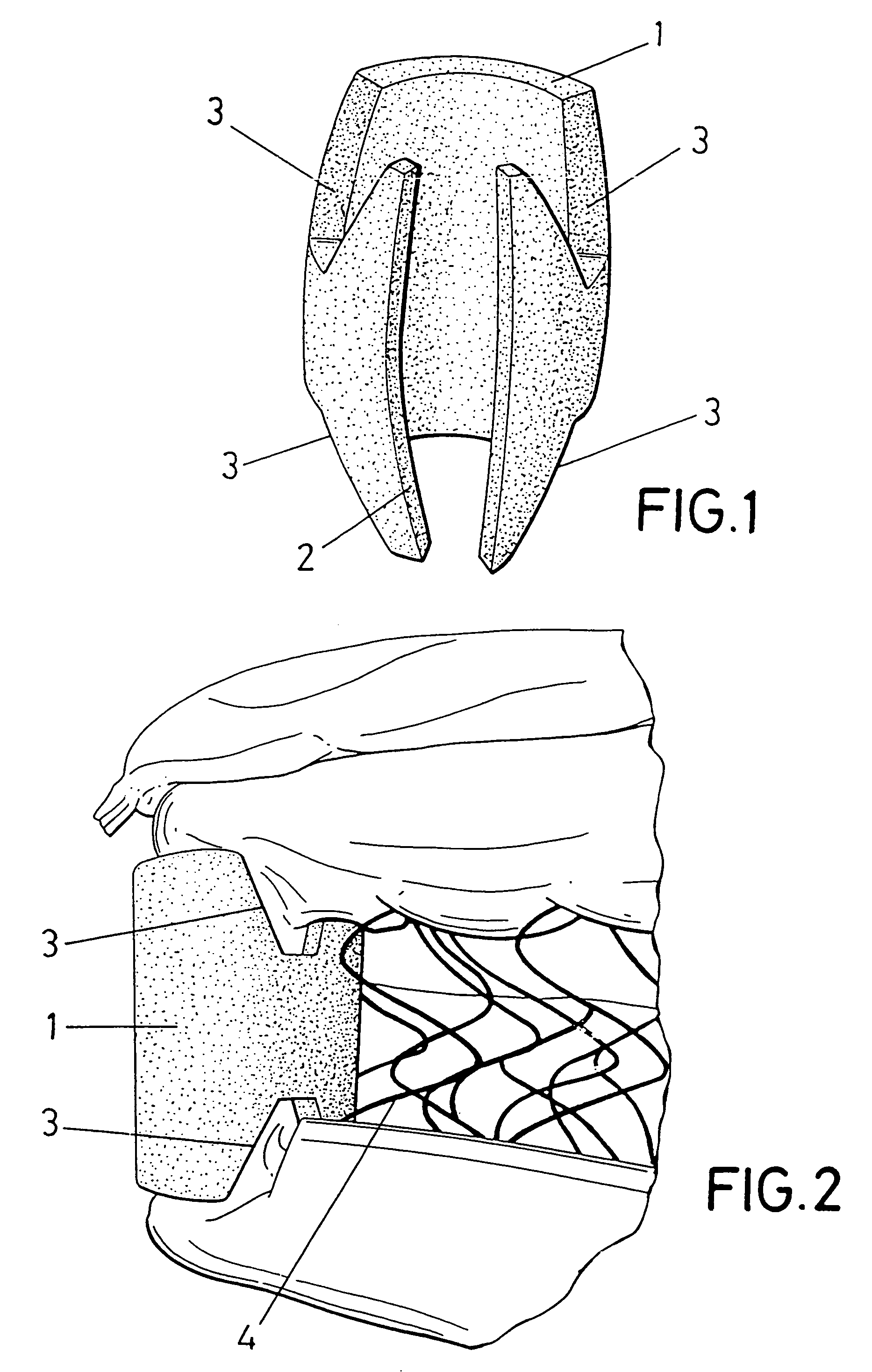

Corner piece for mattresses and the production method thereof

InactiveUS7127765B2Reduced deformabilityStuffed mattressesSpring mattressesIsosceles trapezoidCoupling

Specifically conceived for mattresses with springs (4), the mattress consists of a cylindrical tubular body (1, 1′) with a longitudinal cut line (2) in correspondence with one of its lines of symmetry, that connects its two open ends, towards which open a number of wide notches (3, 3′), with an isosceles trapezoid configuration that, together with the longitudinal opening (2) allow the male-female coupling of the corner piece to the springs (4) of the mattress, externally closing the set of springs at the corresponding corner to provide a smooth, continuous surface without any bulges, recesses or deformations.

Owner:FLEX EQUIPOS DE DESCANSO

Method for producing magnesium alloy anode plate of torpedo battery

ActiveCN101623699AFine grainUniform tissueElectrode carriers/collectorsMetal rolling arrangementsElectrical batteryMicrometer

The technology of rolling a magnesium alloy anode plate of a military torpedo battery aims to obtain a magnesium alloy anode with high potential, high specific energy, high specific power and good storage status and operative mode. A thin magnesium alloy anode plate blank of the torpedo battery without gravity segregation is prepared by directly cooling a liquid metal and immediately applying plastic deformation with a high deformation degree. The finish rolling of the thin rolled cast plate blank adopts the rolling technology of cold-rolling of a heat roller under high pressure for the production of fine crystalline magnesium alloy plates and strips, and then the thin rolled cast plate blank is subjected to heat treatment under control to form the finished magnesium alloy plate with crystalline grains less than 10 micrometers. The production method has the advantages of low cost and short process flow; and the product quality of the magnesium alloy anode plate of the torpedo battery is high.

Owner:山西银光华盛镁业股份有限公司

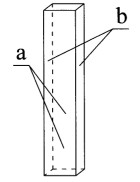

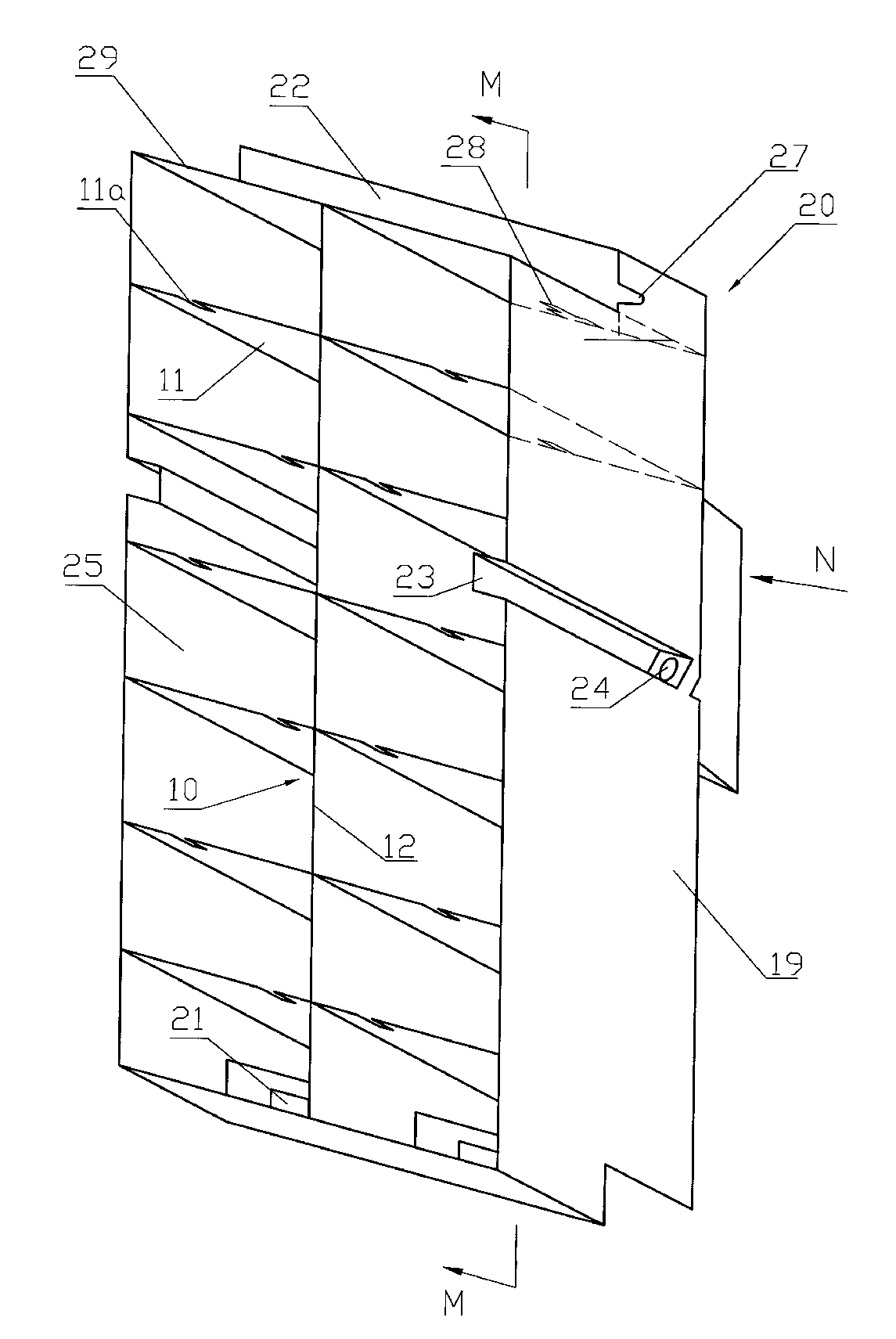

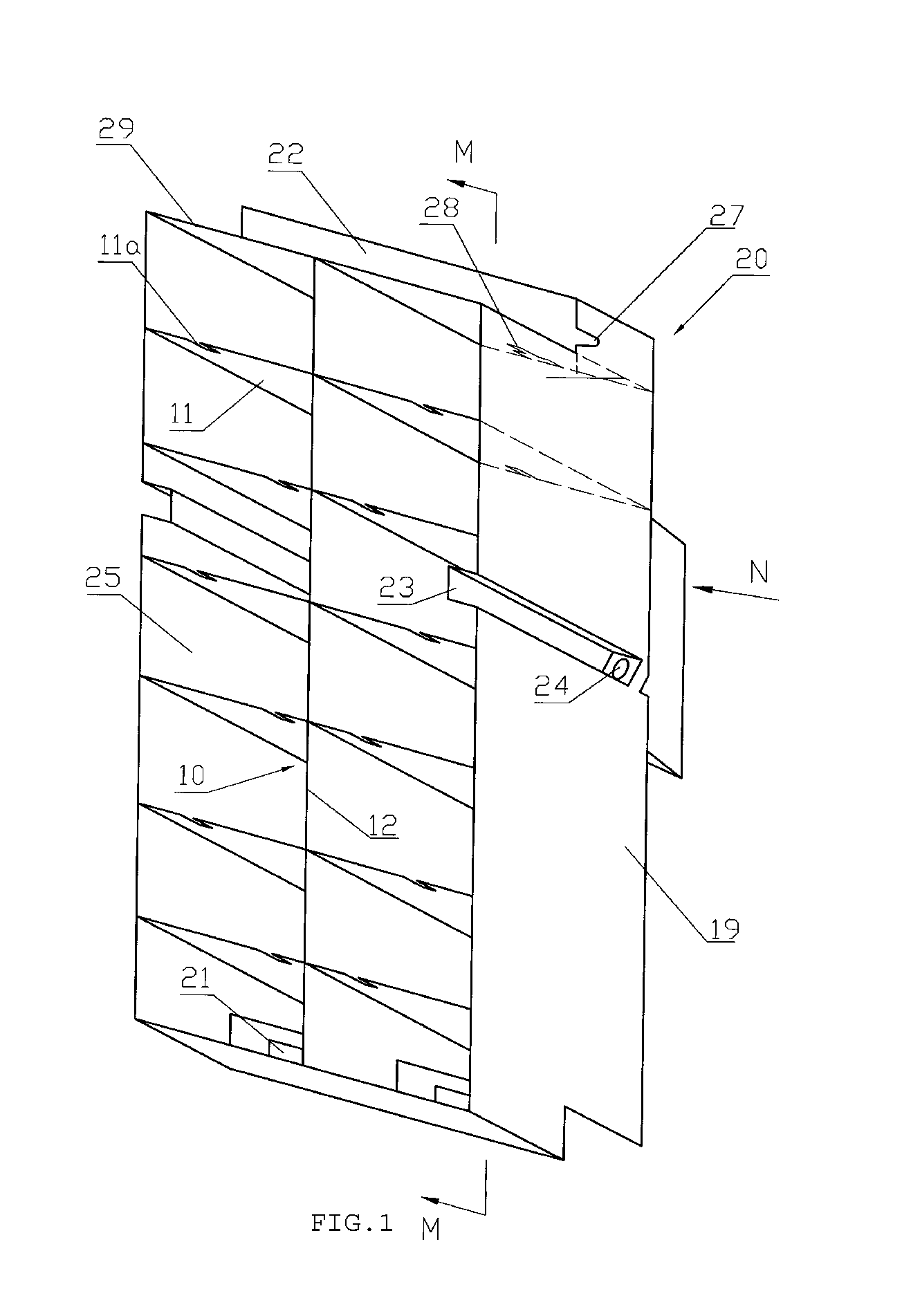

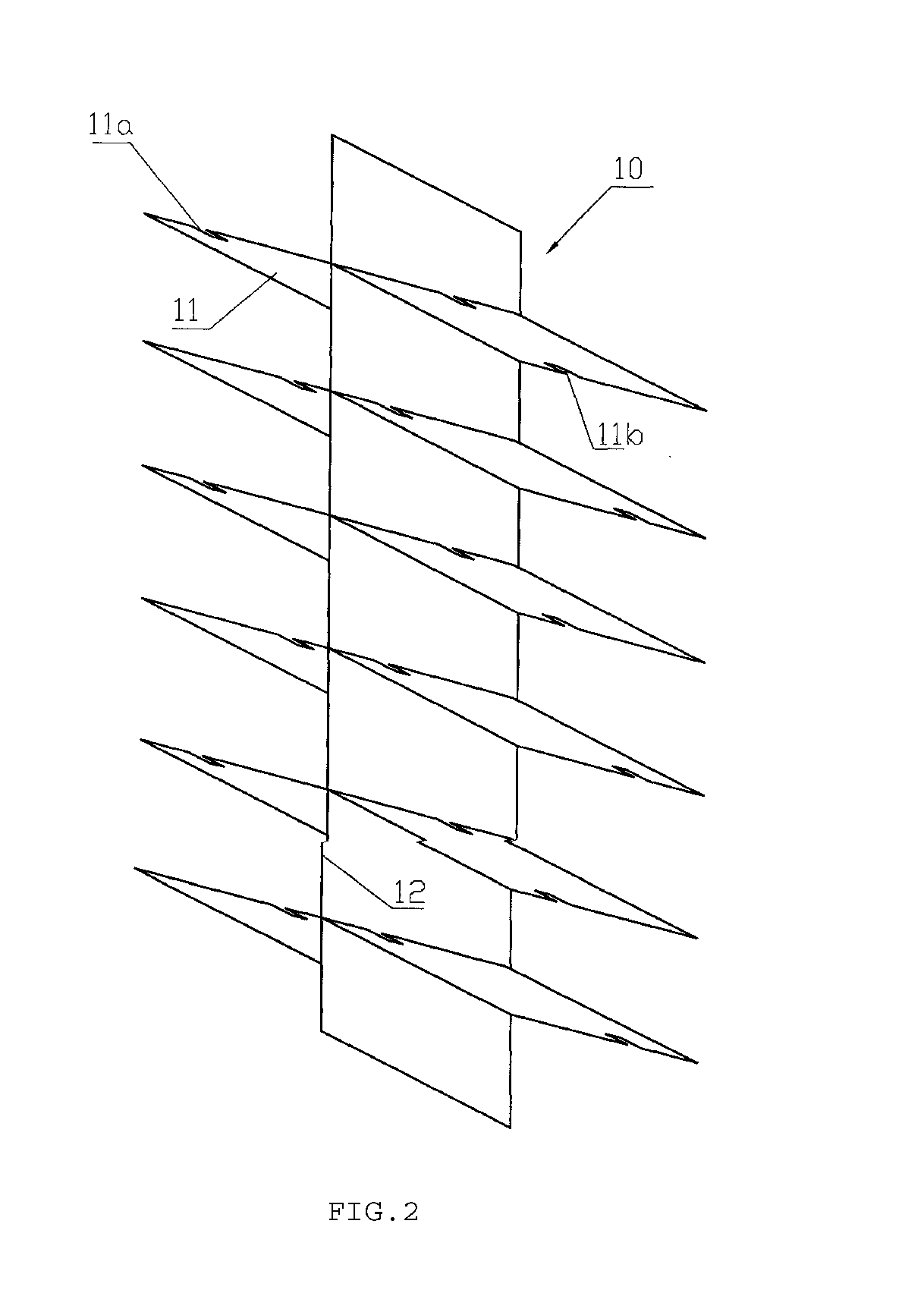

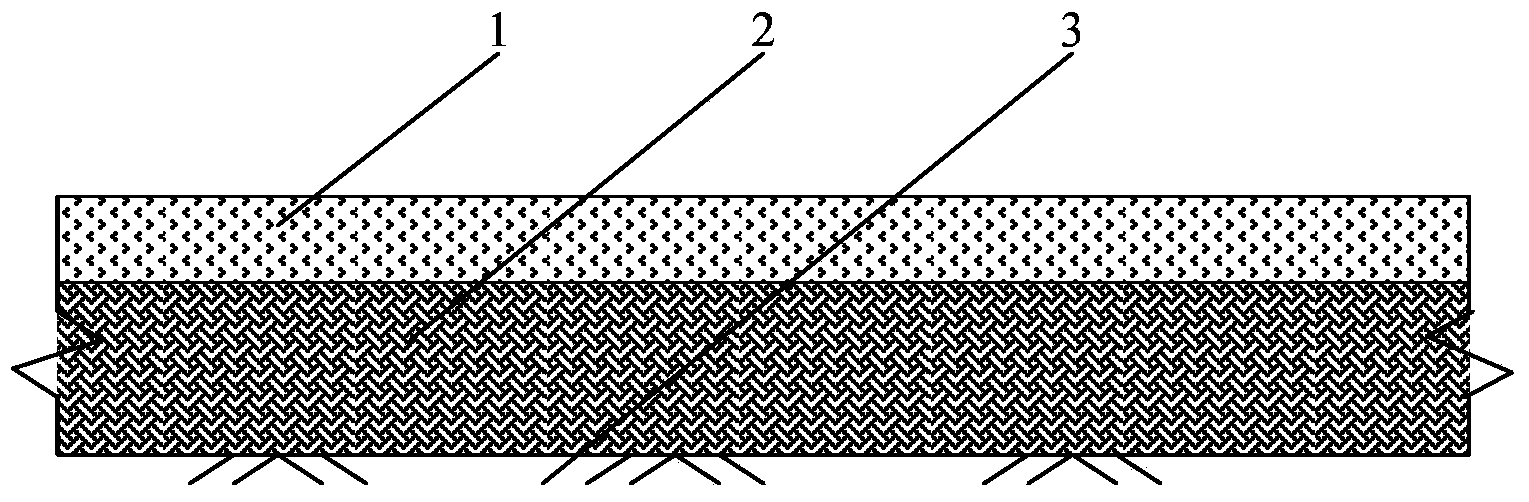

Bamboo flooring with cut surfaces in staggered flat compression and lateral compression and processing technology of bamboo flooring

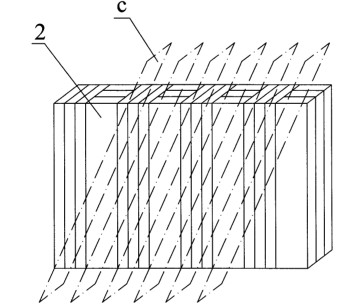

InactiveCN102581907AReduced deformabilityImprove viewingOther plywood/veneer working apparatusWood veneer joiningComposite materialEngineering

The invention relates to a bamboo flooring and processing technology thereof, in particular to a bamboo flooring with cut surfaces in staggered flat compression and lateral compression and processing technology of the bamboo flooring. The technology includes cutting floorings which are arrayed by means of staggered flat compression and lateral compression by certain angles; and then adopting the cut surfaces as surface patterns of the bamboo flooring and manufacturing the bamboo flooring. Blank strips used as units are glued and pressed to form the bamboo flooring, the blank strips are cuboid-shaped, and transverse bamboo blocks and vertical bamboo blocks are alternately arrayed, glued and pressed to form the blank strips. Deformation force among bamboo chips is mutually offset, a unique angular cutting mode is adopted, original internal stress of the bamboo chips is destroyed, and deformation capacity of the bamboo flooring is greatly reduced. In addition, various different surface patterns can be processed, ornamental property of the bamboo flooring is greatly enhanced, and the additional value of a product is increased.

Owner:JIANGXI BUYANG WOOD PROD

Precoated steel plate, welded blank, part and methods

ActiveUS20160008924A1DeformabilityReduced deformabilityHot-dipping/immersion processesRadiation applicationsSheet steelMetal alloy

Owner:ARCELORMITTAL INVESTIGACION Y DESARROLLO SL

Connecting structure for assembly type concrete shear wall edge member

InactiveCN102691365AImprove the anchoring effectGuaranteed carrying capacityWallsShock resistanceRebar

The invention discloses a connecting structure for an assembly type concrete shear wall edge member. vertical connecting reinforcing steel bar, which can be provided with an upset head, is reserved through a hole reserved in a large-diameter metal bellows, and is sleeved with a continuous spiral stirrup; then the vertical connecting reinforcing steel bar and the continuous spiral stirrup are commonly inserted into the large-diameter metal bellows; and fine aggregate concrete (or a grounding material) is poured into the metal bellows, so that the reliable connection of the edge member is realized. Due to reliable anchoring of the vertical connecting reinforcing steel bar, the optimization of the diameter, the quantity and the plane arrangement of the vertical connecting reinforcing steel bar, and the increase of the wet joint area on a splicing surface, full exertion of the bearing capacity of the shear wall is ensured; and multiple effective restrain for the subsequentlly-poured fine aggregate concrete (or the grouting material) is formed by the shear wall stirrup, a horizontal tie bar, the metal bellows and the continuous circular spiral stirrup, and thus the integral performance of the part is remarkably improved. According to the connecting method for the edge member, which is provided by the invention, the stress continuousness of the vertical steel reinforcing bar is ensured, the deformaility and the ductility performance of the vertical steel reinforcing bar are remarkably improved, and the shock resistance of the assembly type concrete shear wall is improved. Meanwhile, the method is simple in manufacturing process and facilitates the practice and application.

Owner:SOUTHEAST UNIV

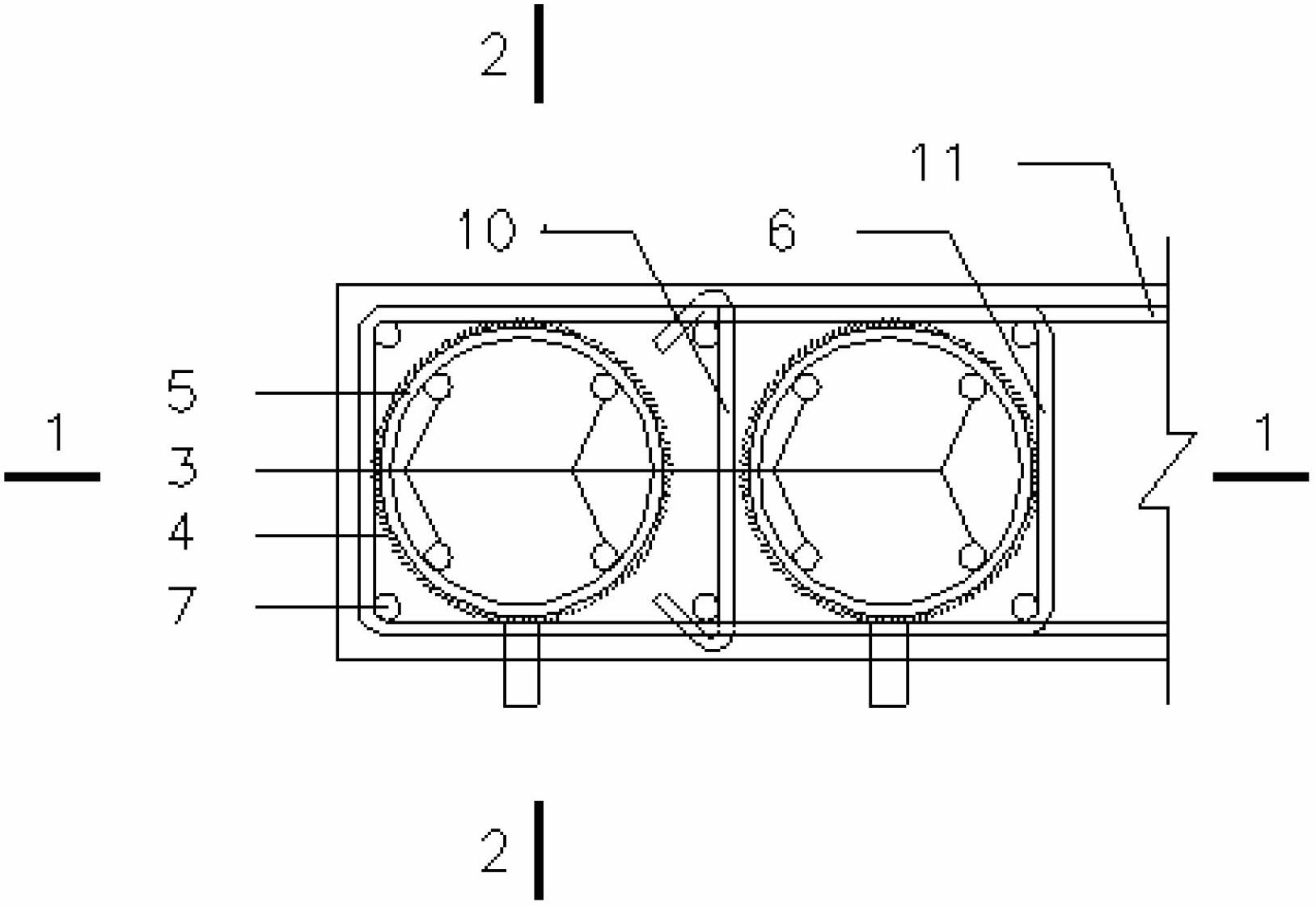

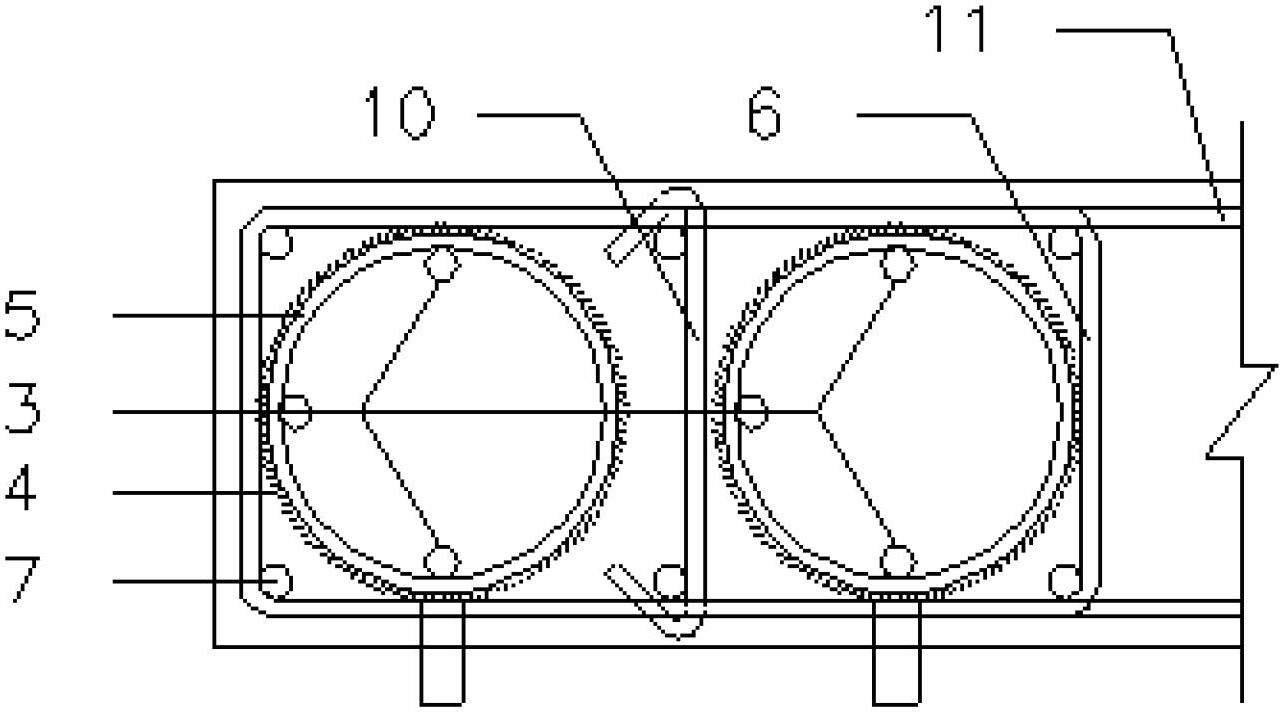

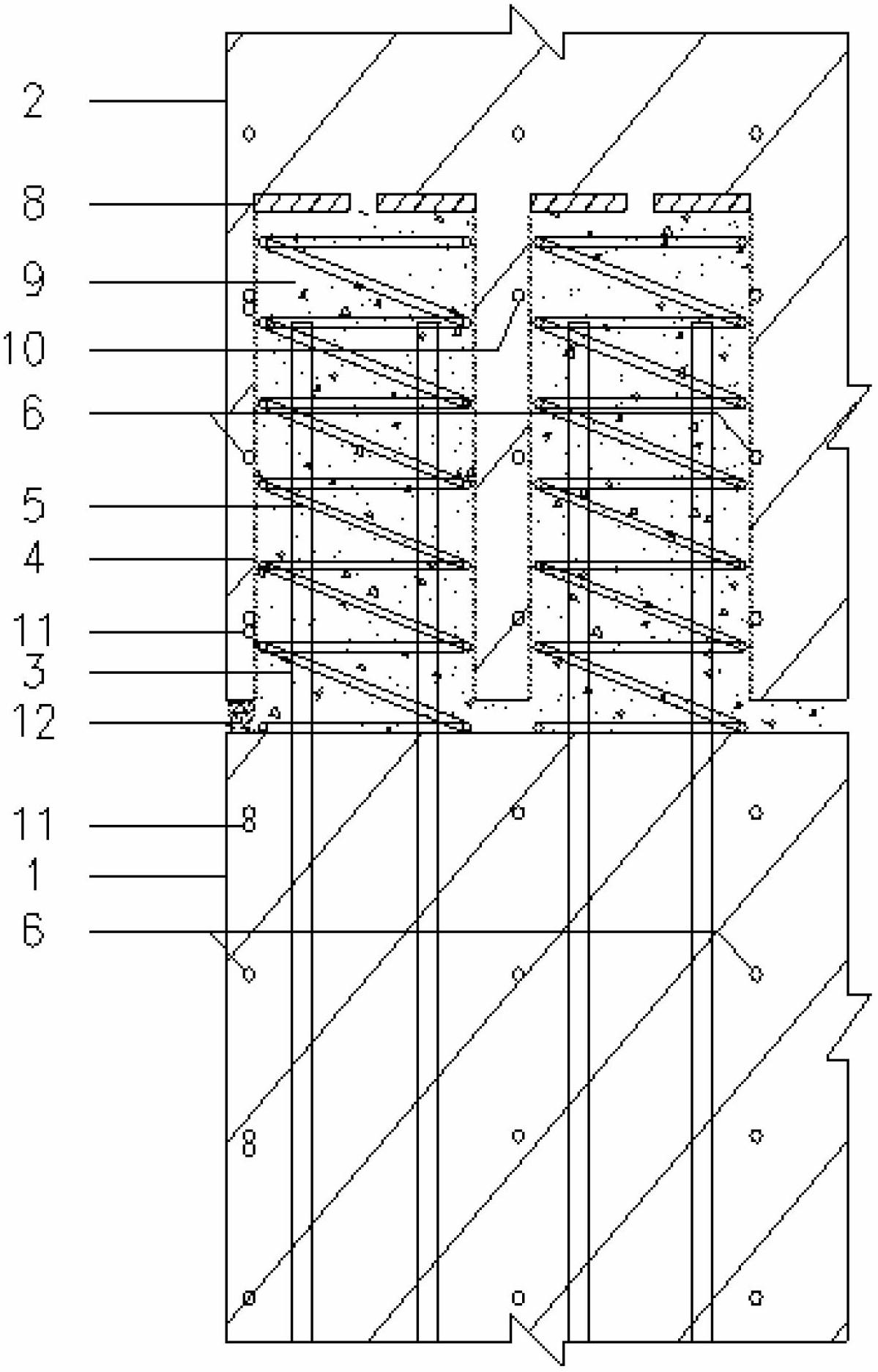

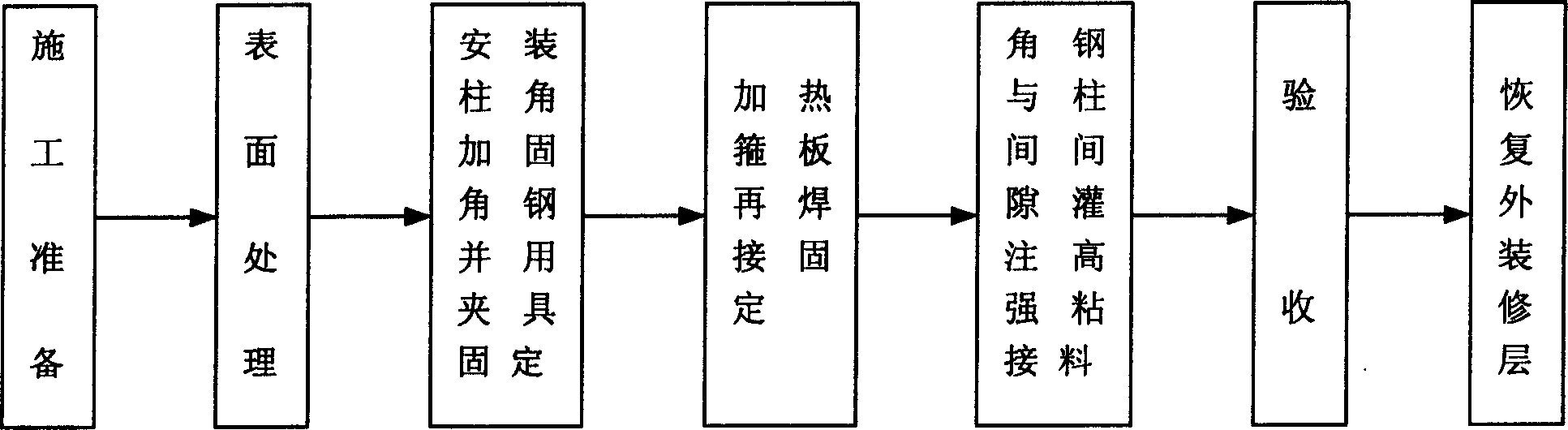

Prestressed steeling reinforcement method for concrete column

InactiveCN1546823AGood anchoring effectReduce stress hysteresisBuilding repairsBuilding reinforcementsPre stressHigh intensity

The invention provides a kind of prestress steeling reinforcement method for a kind of concrete pile, the method includes following steps: (1) construction preparing; (2) surface preprocess; (3) sets pile corner reinforcing steel and uses clamp to fix them; (4) heats and stretch-draw the banding board, then welds and fixes; (5) pours with high intensity adhesive material between the steel angle and the intervals among the piles; (6) checking; (7) restores the outer decoration layer. The invention uses the improvement of intensity and deformation performance in condition of three-axis pressed to upgrade the bearing of component, it doesn't increases the cross section, thus it won't affect the visible effect in the room; reduces the stress delaying effect. The shake resisting grade is upgraded, the cost is low.

Owner:GUANGDONG PROVINCIAL ACAD OF BUILDING RES GRP CO LTD

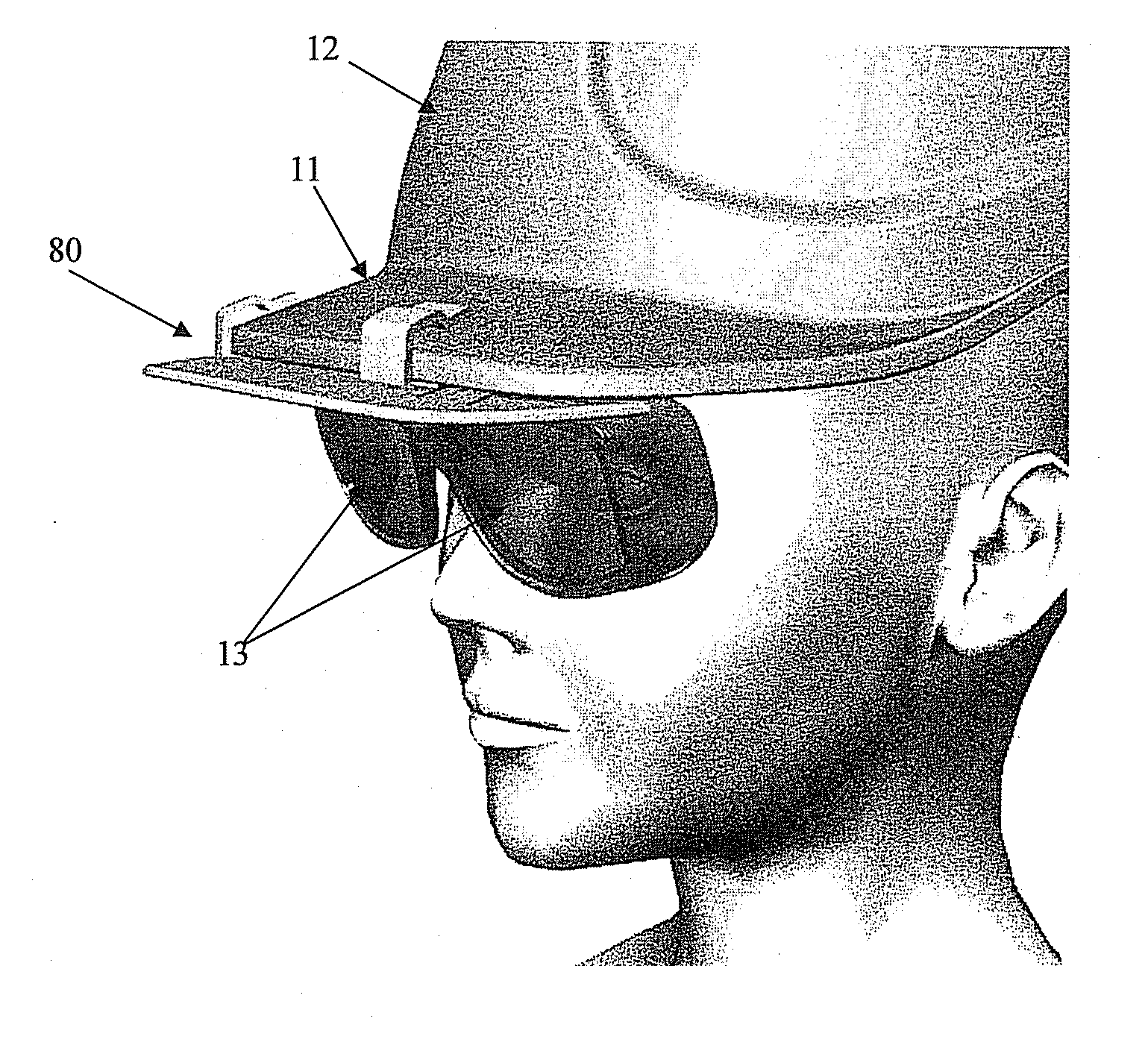

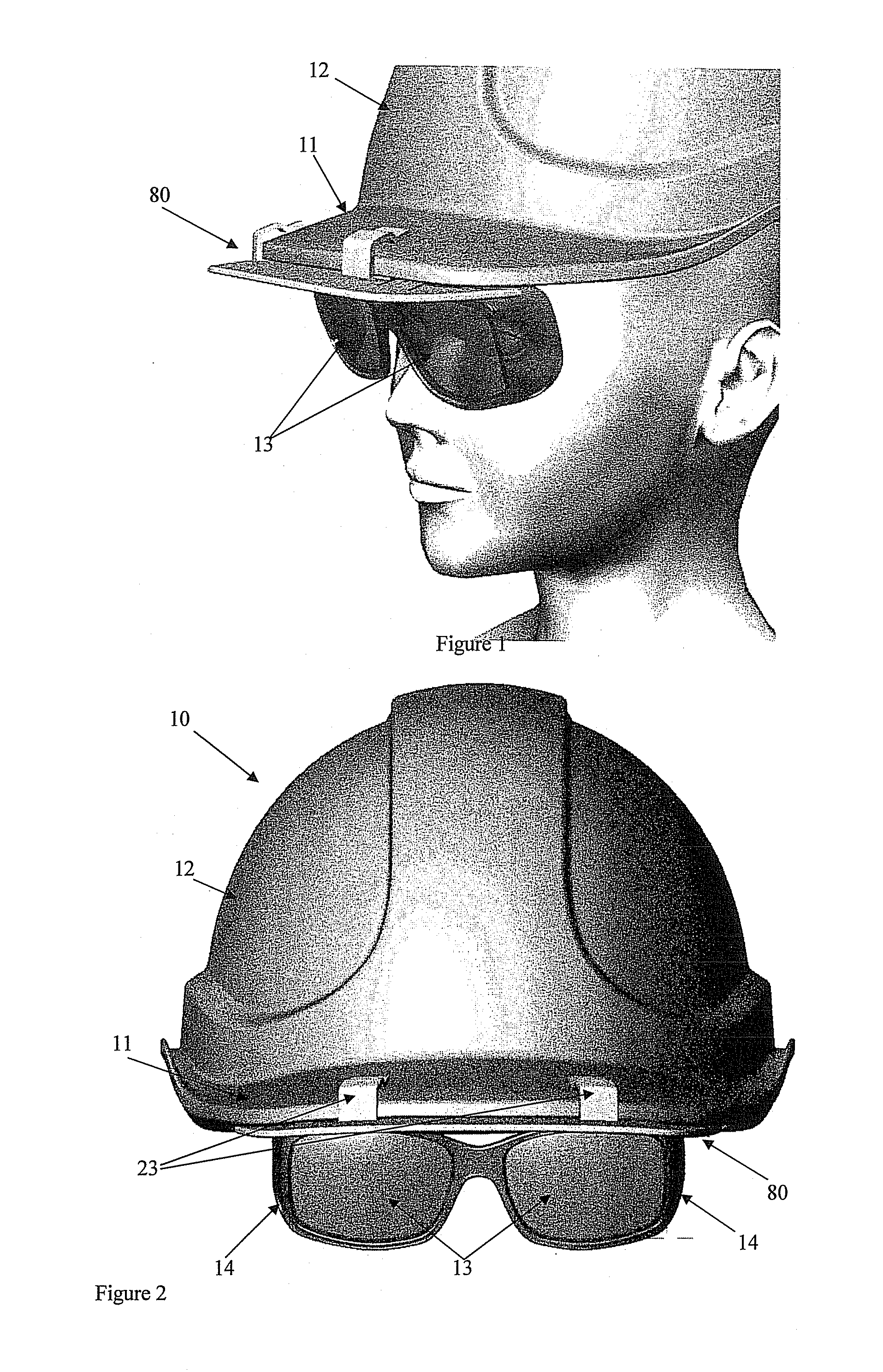

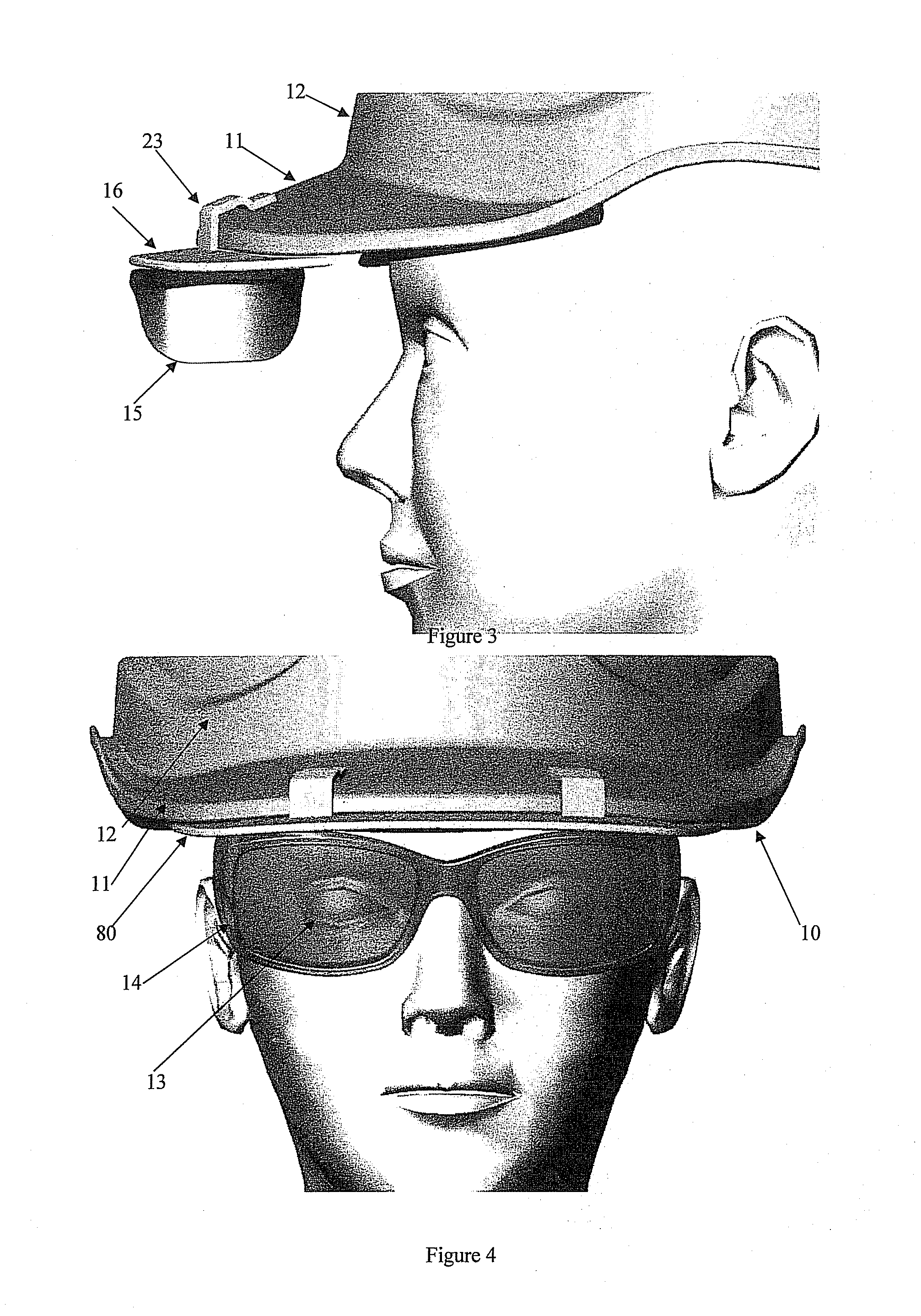

Eyewear assembly for attachment to a hard hat

An eyewear assembly for attachment to a hard hat, the hard hat including a main body and a visor, the eyewear assembly including at least one eyewear member, a mounting means to attach the set of eyewear to the headwear including an arcuate body adapted to substantially correspond to the shape of the visor of the hard hat, a rearwardly projecting locating tongue and at least one deformable attachment portion such that the mounting means is clamped to the visor of the hard hat by the at least one deformable attachment portion and at least one rotation mechanism associated with the mounting means and the eyewear to allow movement of the at least one eyewear member relative to the at least one mounting means between a use position in front of a wearer's eyes and a stored position adjacent the visor of the headwear.

Owner:RPS INT MARKETING

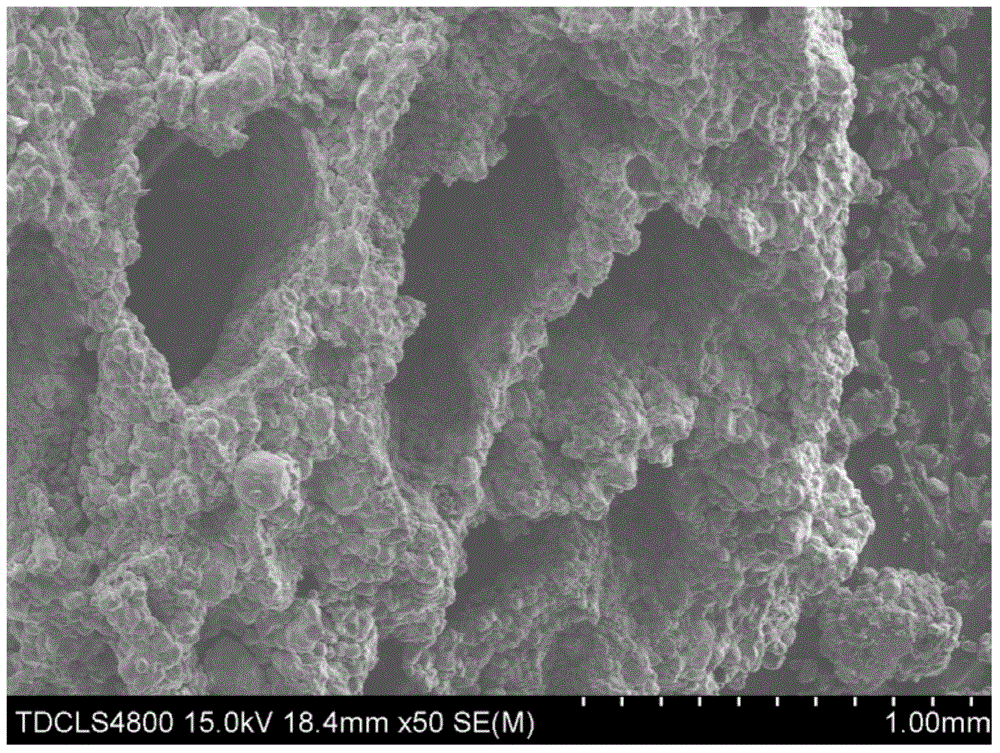

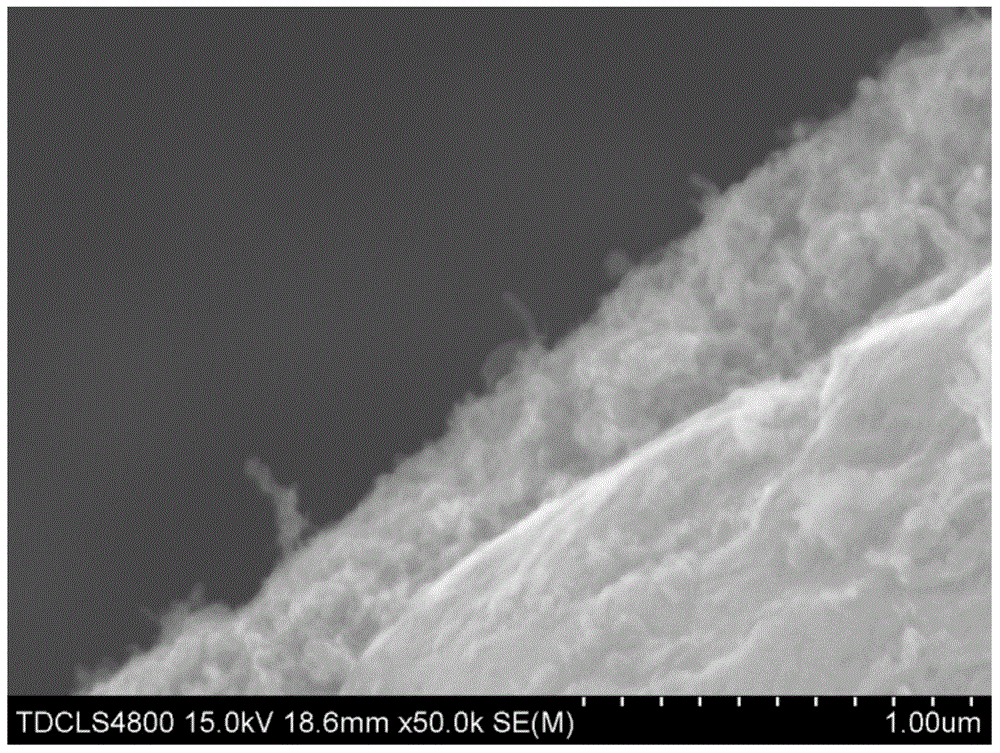

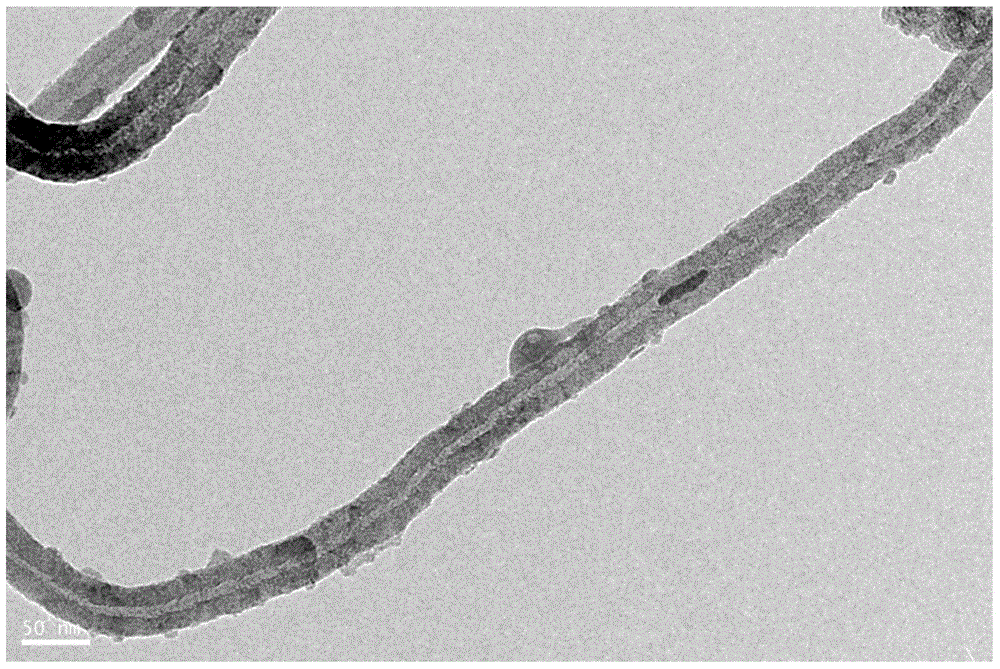

Preparation method of carbon nanotube reinforced foamed aluminum composite material for vibration attenuation and energy absorption

ActiveCN104911388AHighlight substantiveGood deformabilityChemical vapor deposition coatingVibration attenuationNitrate

The invention provides a preparation method of a carbon nanotube reinforced foamed aluminum composite material for vibration attenuation and energy absorption, relates to the manufacturing of an alloy with open or closed pores, and specifically relates to the preparation method of the carbon nanotube reinforced foamed aluminum composite material for vibration attenuation and energy absorption with urea as a pore-forming agent and nickel as a carbon nanotube synthesis catalyst; the preparation method comprises the following steps: preparing the mixed powder of nickel nitrate, urea and aluminum powder; preparing a foamed aluminum blank; and preparing the carbon nanotube reinforced foamed aluminum composite material. The method is used for overcoming the defects of structural defect, low mechanical properties and low buffer energy-absorption property, large density and no lightweight property of the foamed aluminum materials prepared in the prior art, complex preparation process, relatively high cost and difficult realization of functional structure integration of the foamed aluminum serving as an energy-absorption material.

Owner:HEBEI UNIV OF TECH

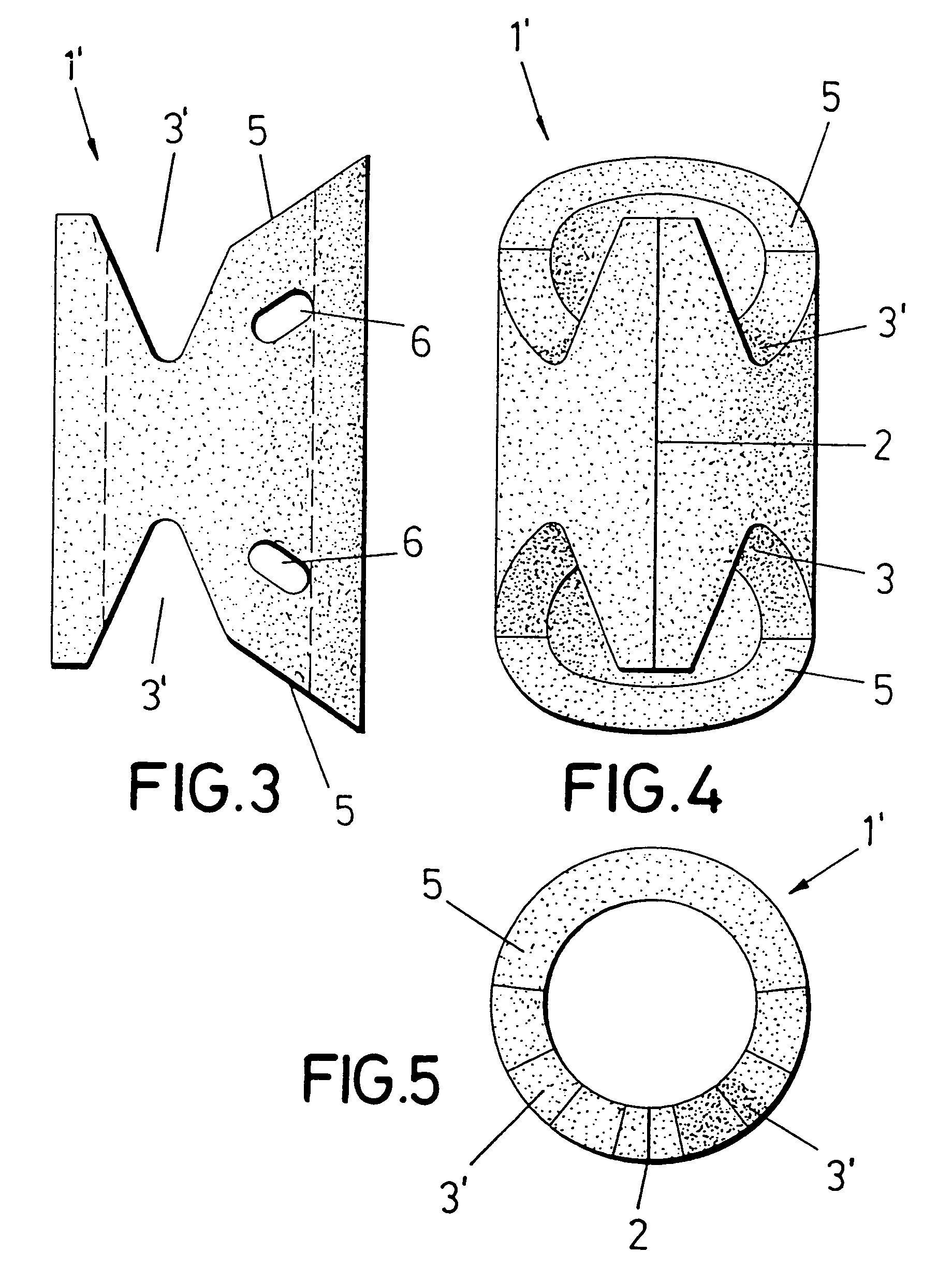

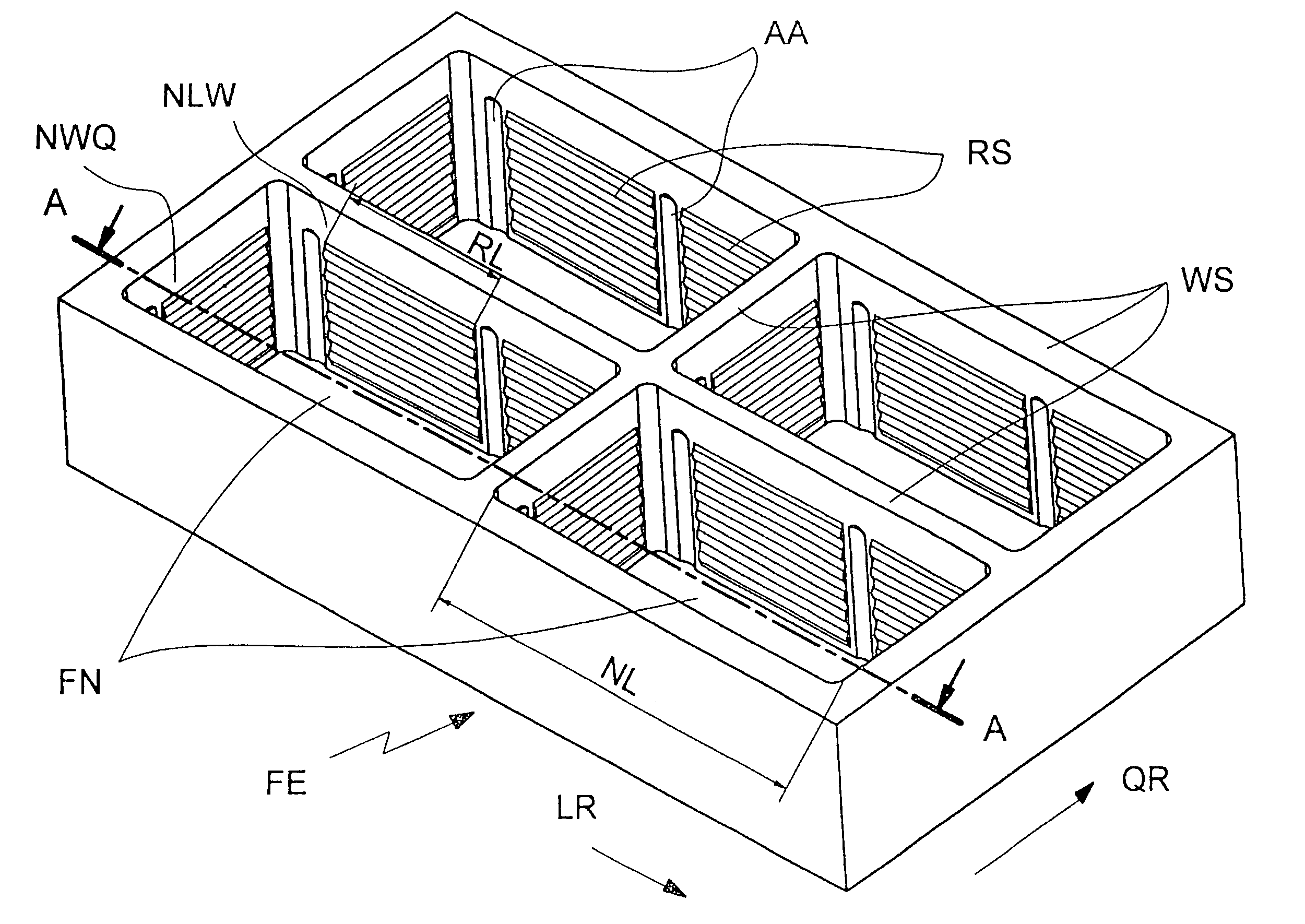

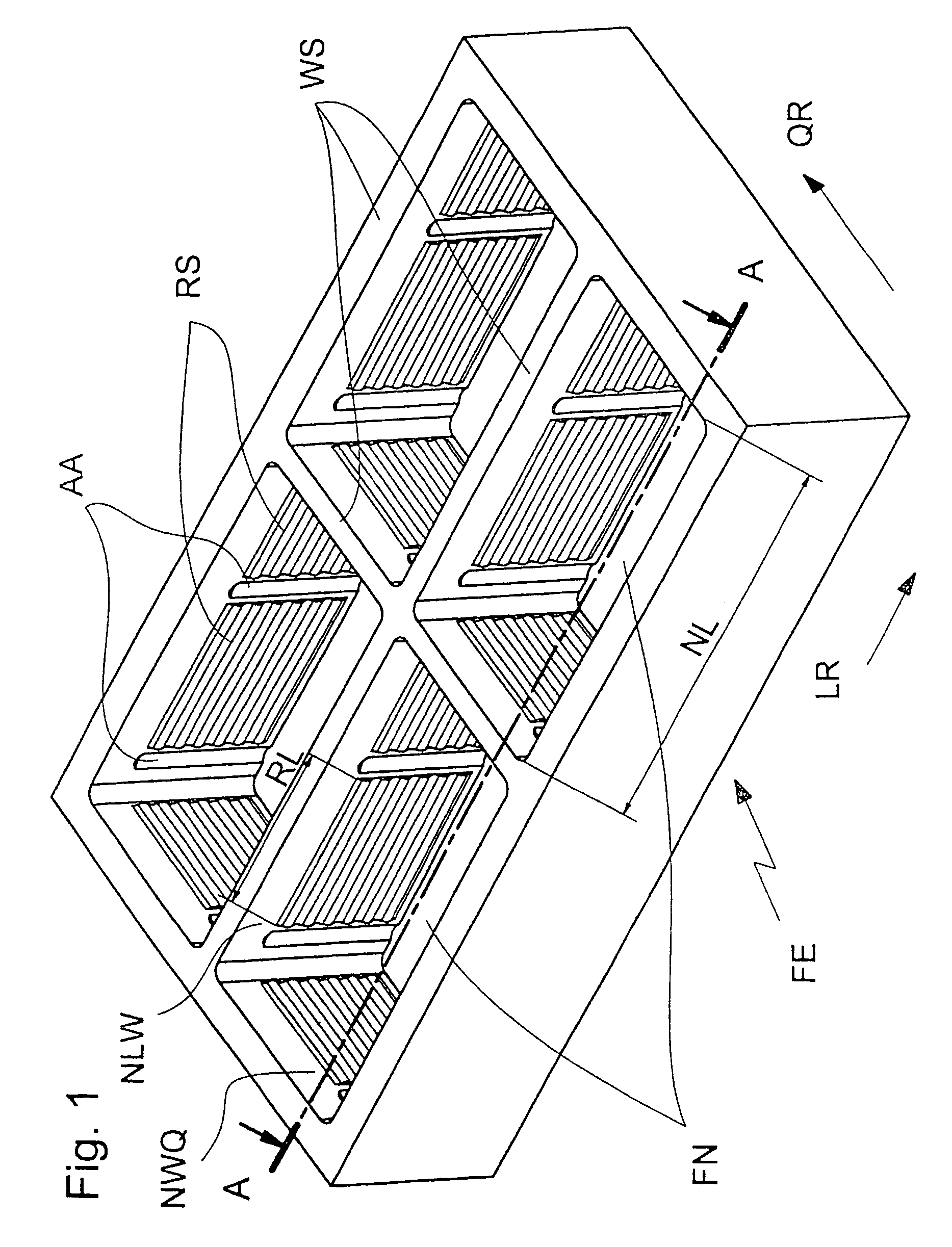

Molding insert for molding machines

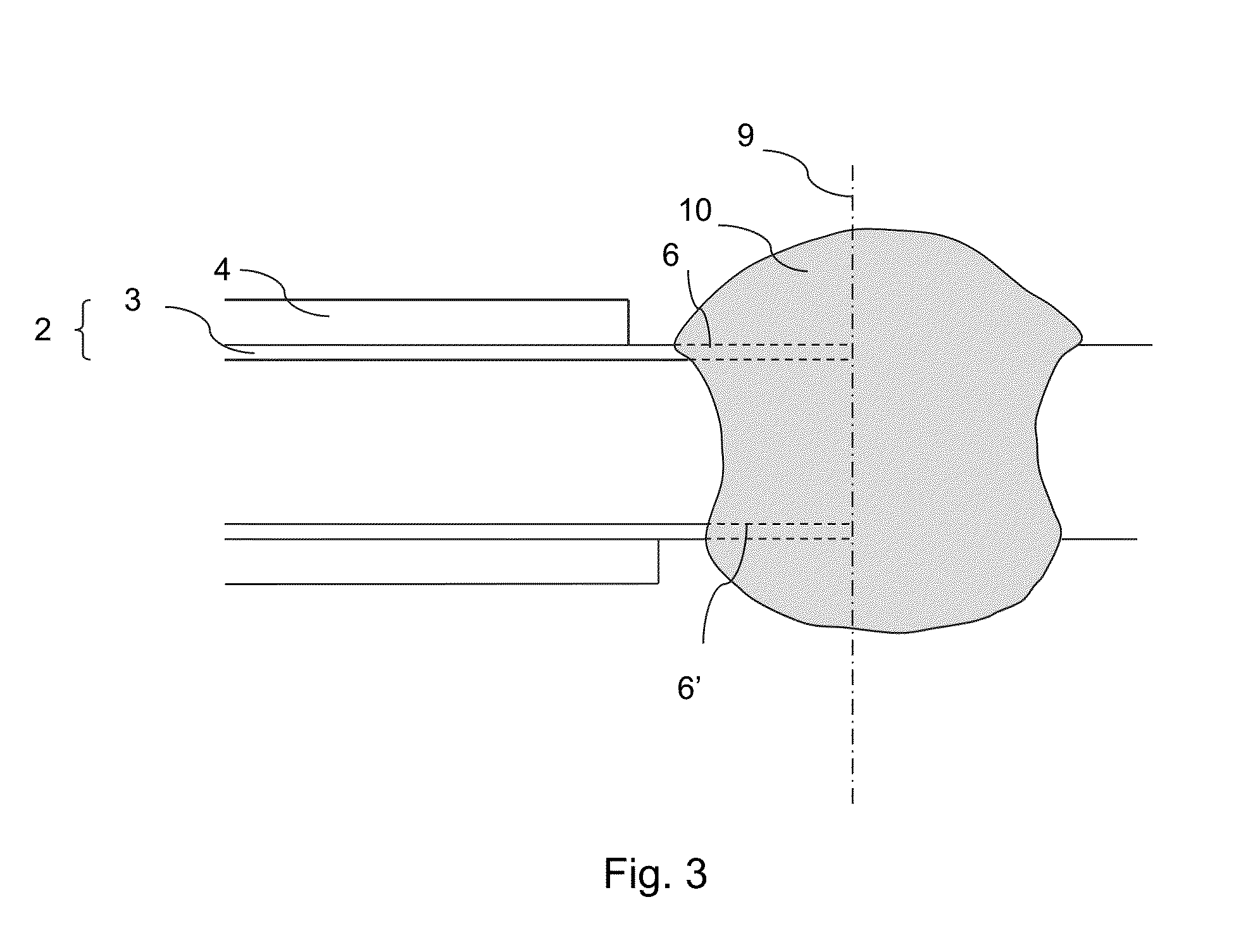

InactiveUS7172404B2Reduced deformabilityEasy deformabilitySingle unit pavingsMouldsShell moldingMolding machine

The invention relates to the production of multi-layered concrete moulded bodies in a moulding machine comprising a moulding insert having a plurality of mould cavities. Relief structures are arranged in the lateral walls of the mould cavities and are dimensioned in such a way that projections formed on the moulded body when the filled concrete material is compacted engage in the relief structures, thereby creating sufficient retaining force for compensating the net weight of the moulded body and enabling the moulded bodied to be extracted from the mould cavities as a result of additional demoulding forces and causing elastic deformation of the projections without any material being cut off from the projections.

Owner:KOBRA FORMEN

Auxiliary handle, and hand power tool provided therewith

InactiveUS8430183B2Eliminate disadvantagesReduced deformabilityOperator-supported drilling machinesPortable percussive toolsMotor driveEngineering

Owner:ROBERT BOSCH GMBH

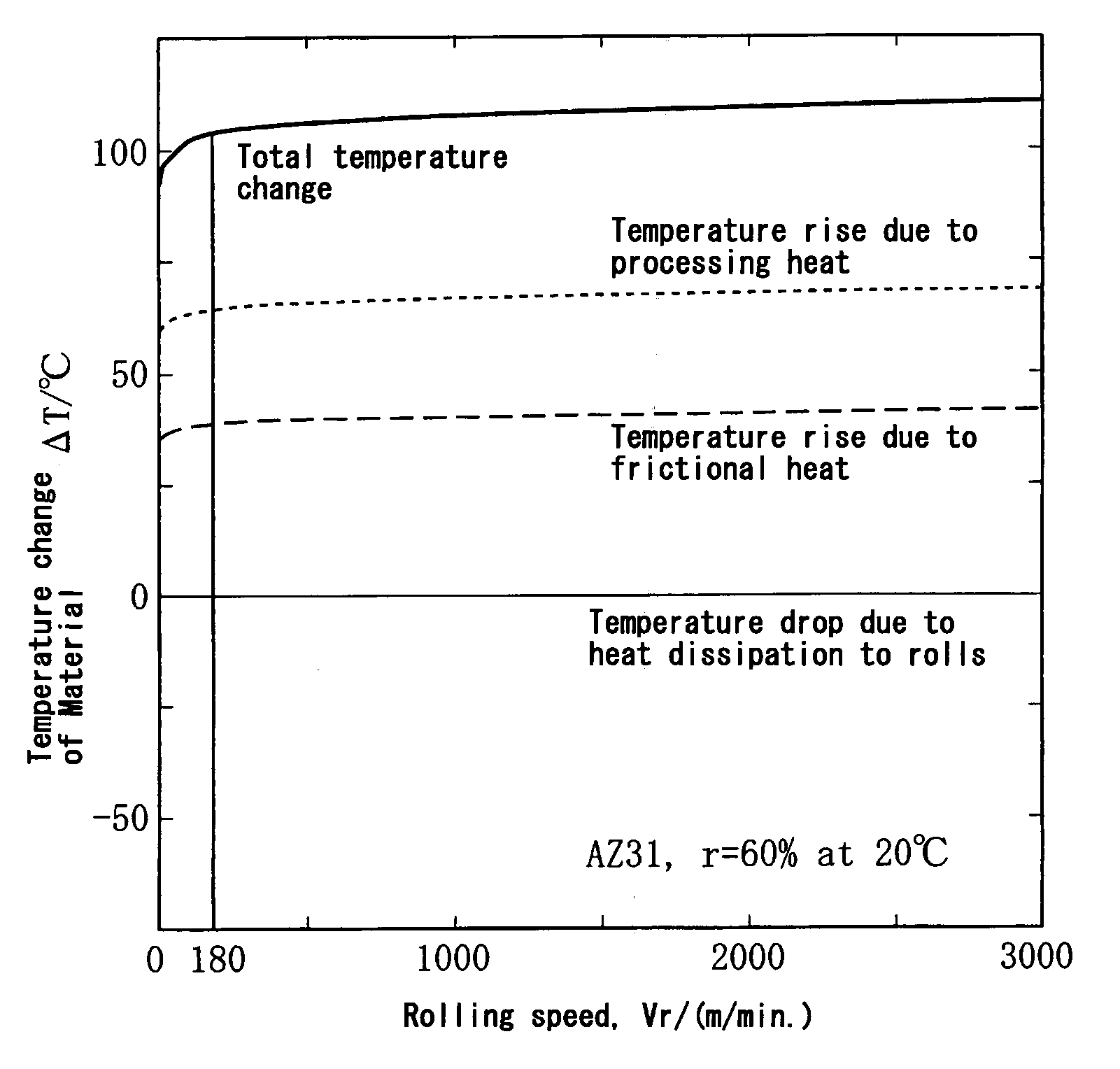

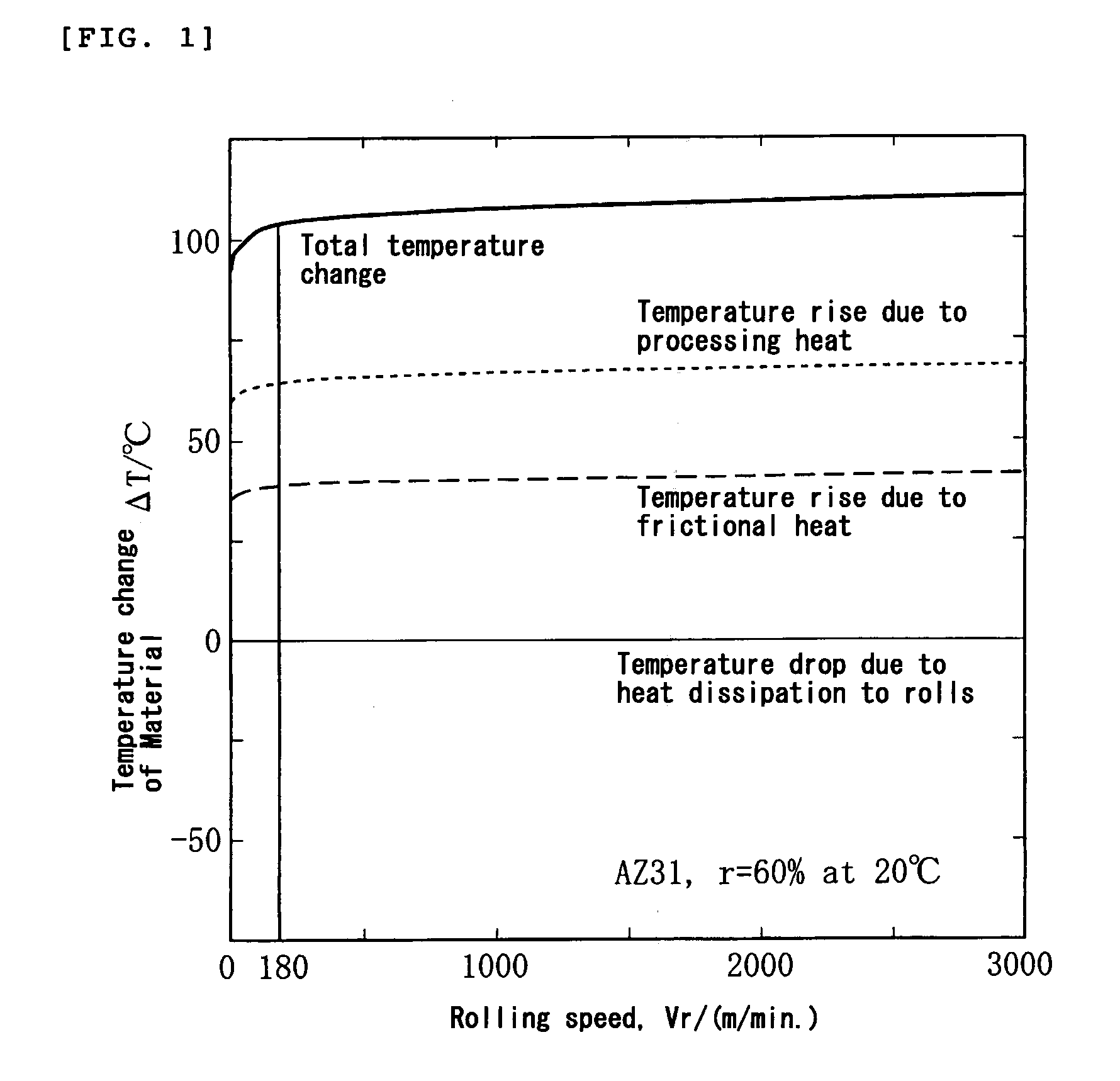

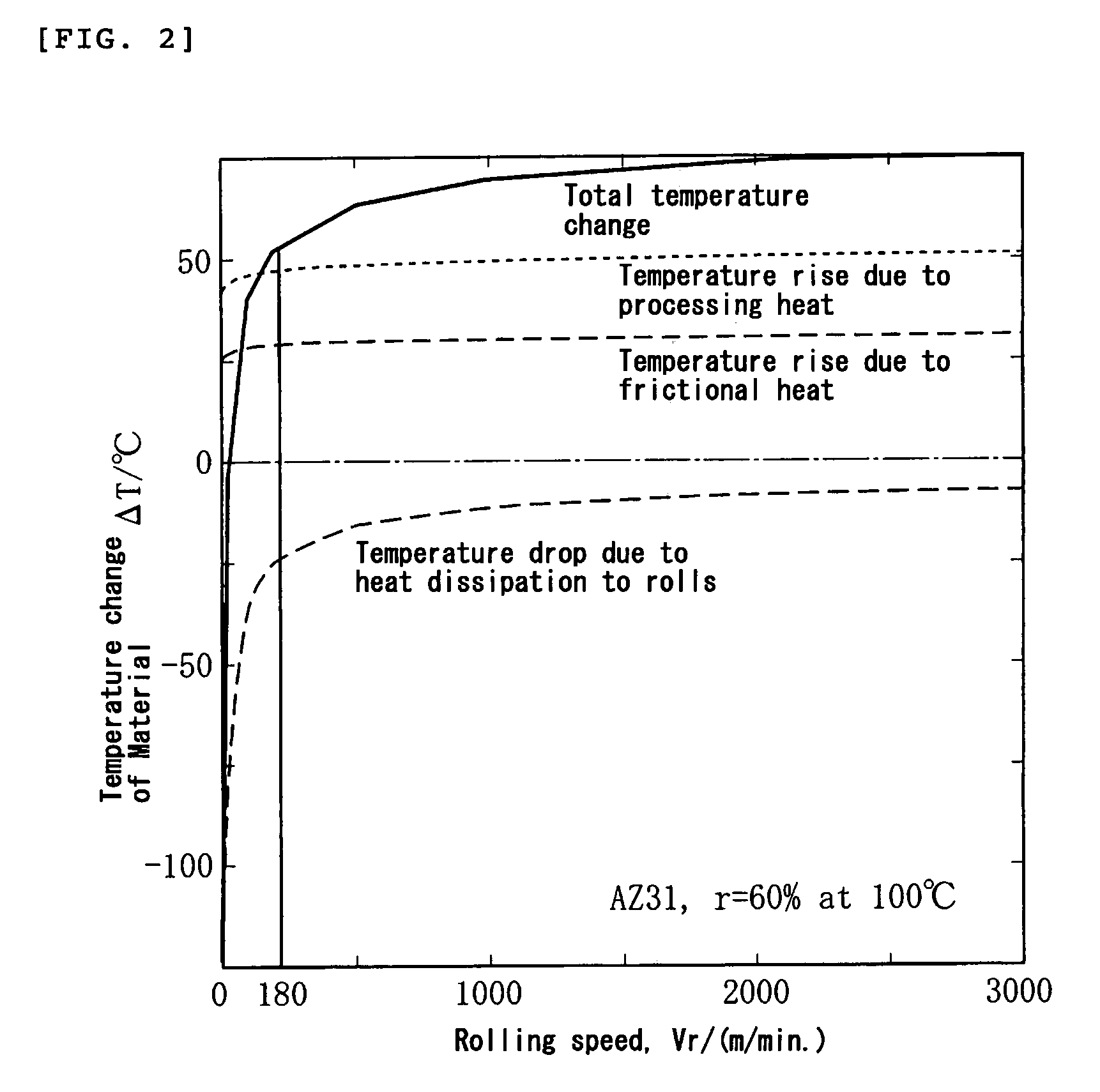

Magnesium alloy sheet processing method and magnesium alloy sheet

InactiveUS20080075624A1Increase the amount of cuttingReduced deformabilityMetal rolling arrangementsGrain boundaryMagnesium alloy

A magnesium alloy sheet processing method wherein a magnesium alloy sheet is rolled at a speed of 180 m / min or more. Particularly, a magnesium alloy sheet processing method, wherein the magnesium alloy sheet is rolled at a speed of 450 m / min or more. A magnesium alloy sheet processing method, wherein a rolling tool which is not heated is used. A magnesium alloy sheet processing method, wherein the temperature of the magnesium alloy sheet immediately before the rolling is in the range of 0° C. to 400° C. A magnesium alloy sheet, wherein the sheet has an average crystal grain of 4 μm or less, and does not internally include any unbonded interface in parallel with a direction of rolling. A magnesium alloy sheet, wherein the sheet has an average grain size of 4 μm or less, and has an internal grain boundary formed by a clean grain boundary.

Owner:OSAKA UNIV

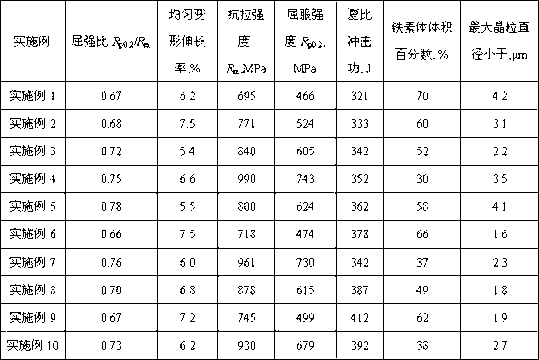

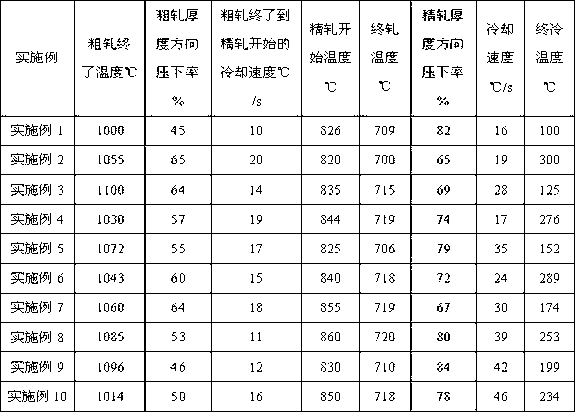

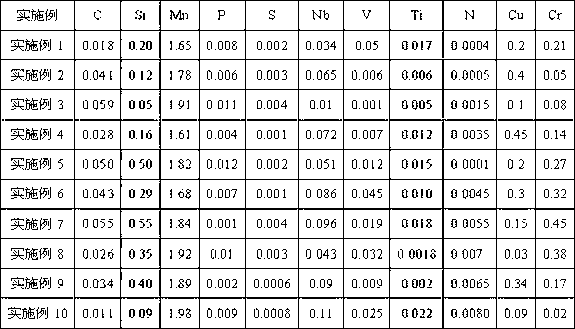

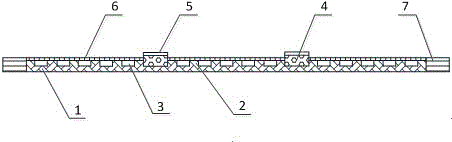

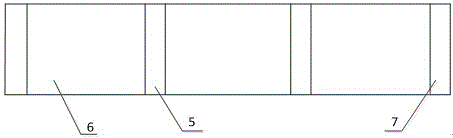

Manufacturing method of pipeline steel with high strength and toughness and high deformability

ActiveCN103160756AImprove toughnessImprove deformation abilityRoll mill control devicesMetal rolling arrangementsLine tubingYield ratio

The invention discloses a manufacturing method of pipeline steel with high strength and toughness and high deformability. The steel comprises the following components in percentage by weight: 0.01-0.06% of C, 0.05-0.55% of Si, 1.60-2.00% of Mn, not more than 0.012% of P, not more than 0.005% of S, not more than 0.11% of Nb, not more than 0.06% of V, not more than 0.025% of Ti, not more than 0.0080% of N, not more than 0.50% of Cu, not more than 0.50% of Cr and the balance of Fe and inevitable impurities. The manufacturing method comprises the following steps: performing pretreatment of molten iron, smelting, refining and continuous casting to prepare a plate blank comprising the components in percentage by weight, being in line with the requirements; and manufacturing a steel plate through thermal mechanical control of rolling and control of cooling process so as to get the pipeline steel. The pipeline steel disclosed by the invention is very small in crystal grains and appropriate in soft phase-hard phase proportion and can get higher strength and toughness and excellent deformability under the situation of not containing Ni, Mo and other alloy elements and containing lower C content. The tensile strength Rm is not less than 695 and not more than 990, the yield ratio Rp0.2 / Rm is not more than 0.8, the uniform deformation elongation rate is not less than 5%, and the Charpy impact energy is not less than 300J. The pipeline steel disclosed by the invention is low in cost, and the obtained steel plate has the advantages of excellent deformability, strength, toughness and excellent welding performance.

Owner:NANJING IRON & STEEL CO LTD

Bonded flexible water proof and drainage coiled material for road and railway tunnel and laying method thereof

The invention discloses a bonded flexible water proof and drainage coiled material for a road and a railway tunnel and a laying method thereof. The coiled material comprises a water proof and drainage part and more than one bonding belt vertically coated one side of the water proof and drainage part. The water proof and drainage part comprises a main board of a water proof board and a plurality of protruding strip ridges vertically arranged on one side of the main board of the water proof board. Drainage blind drains are formed by grooves between the protruding strip ridges. The bonding belts and the protruding strip ridges are arranged on the same side. The bonded flexible water proof and drainage coiled material can closely adhere to an initial support. Even if a secondary lining pouring method from bottom to top is utilized, the gap generation at an arch portion is avoided, the mountain water of the initial support is discharged easily, and the water proof effect is good through the combination of the water tightness and the drainage. The drainage blind drains can be easily formed by geotechnical cloth. The blocking of the drainage blind drains and the puncture for the main board of the water proof board caused by sands and stones can be avoided through the filtration of the geotechnical cloth. The water proof board can be extended and transformed easily under outside strong extrusion or extension, and the damage to the main board of the water proof board can be prevented.

Owner:SICHUAN HAODESI NEW MATERIAL TECH CO LTD

Vertical planting module

InactiveUS8438781B2Improve rigidityReduced deformabilityWatering devicesAgriculture gas emission reductionGrowth plantPlant roots

The invention includes a box, vertical and horizontal dividers, a plant-growth mat, and a mounting bar. The dividers are permanently linked to form an insert, which slides into insert grooves inside the box. Insert grooves have upper and lower rails. At the insert groove openings rail ends feature upward bends. The plant-growth mat is secured against the box inner-back by the insert which is prevented from sliding out by the upward bends of the lower rails. A support mount and a fastener on the back of the box and compatible groove surfaces on the mounting bar prevent box movement when mounted. The invention increases the rigidity of the dividers and reduces their deformability. It facilitates inserting the integrated dividers into the box with convenient insert grooves. The plant-growth mat can store water, prevent soil erosion, and provide aeration to plant roots. The mounting bar stabilizes the module for easy installation.

Owner:ZHAO FEIYUN +1

Road building method based on modified roller compacted concrete pavement on enzyme soil solidified base layer

ActiveCN103882788ANot easy to breakNo ruttingIn situ pavingsRoller-compacted concreteEnvironmental resistance

The invention relates to the technical field of road engineering construction, and particularly to a road building method which solves the problems that an existing road engineering construction road structure is relatively single, easy to damage, difficult in repairing, and high in building cost. The building method comprises the steps of mixing at least biological enzyme, broken stones, soil, an additive and water according to a certain ratio and rolling to form a biological enzyme soil solidified base layer and a subbase layer (enzyme soil solidified base layer for short), and then paving a cement mixing material of the biological enzyme, rubber powder and fibers modified for multiple times on the enzyme soil solidified base layer through a paving machine, rolling and forming to obtain a novel road pavement structure based on the enzyme soil solidified base layer and a multi-element repeated-modified roller compacted concrete pavement. By adopting the road building method of the novel road pavement structure, the difficulties such as high requirement on materials selected by building a road pavement, high cost, complicated construction, difficulty in maintenance, serious environment pollution and the like are solved, and the use performance of a road is greatly improved; the novel road pavement structure has the advantages of environment friendliness without pollution, resource saving, and the like, and is remarkable in economical benefits and social benefits.

Owner:HUNAN RUIBIN TECH

Profile clamp

InactiveUS20030005980A1Withstands high forceHigh hardnessFlanged jointsRopes and cables for vehicles/pulleyCarrying capacityThermal expansion

A steel profile clamp is used to join flanged component parts. The profile clamp has at least partially conical side walls that are bent radially inwardly. The profile clamp has welding joints to maintain the shape of the clamp. The steel is martensitic for increased load-carrying capacity of the joint. The steel material, in an ambient temperature range of 20° C. to 750° C., has a coefficient of thermal expansion that is at least 0.3x10-6 m / mK lower than that of the coefficient of thermal expansion of a ferritic casting material. The method for manufacturing the profile clamp includes prequenching and tempering the material of the profile clamp when it is in the form of a strip. After forming and welding the profile clamp, the weld is subject to induction tempering.

Owner:ABB (SCHWEIZ) AG +1

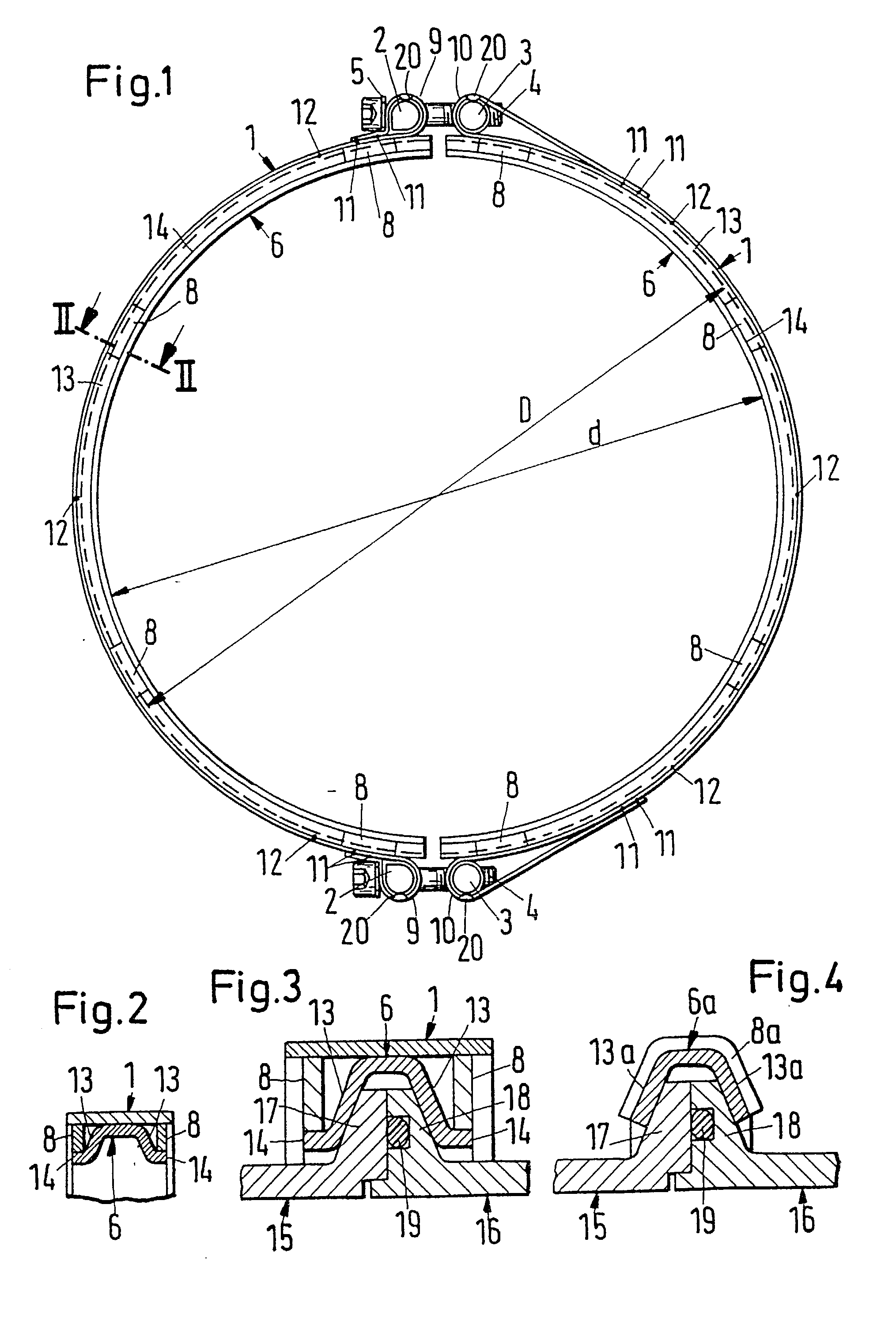

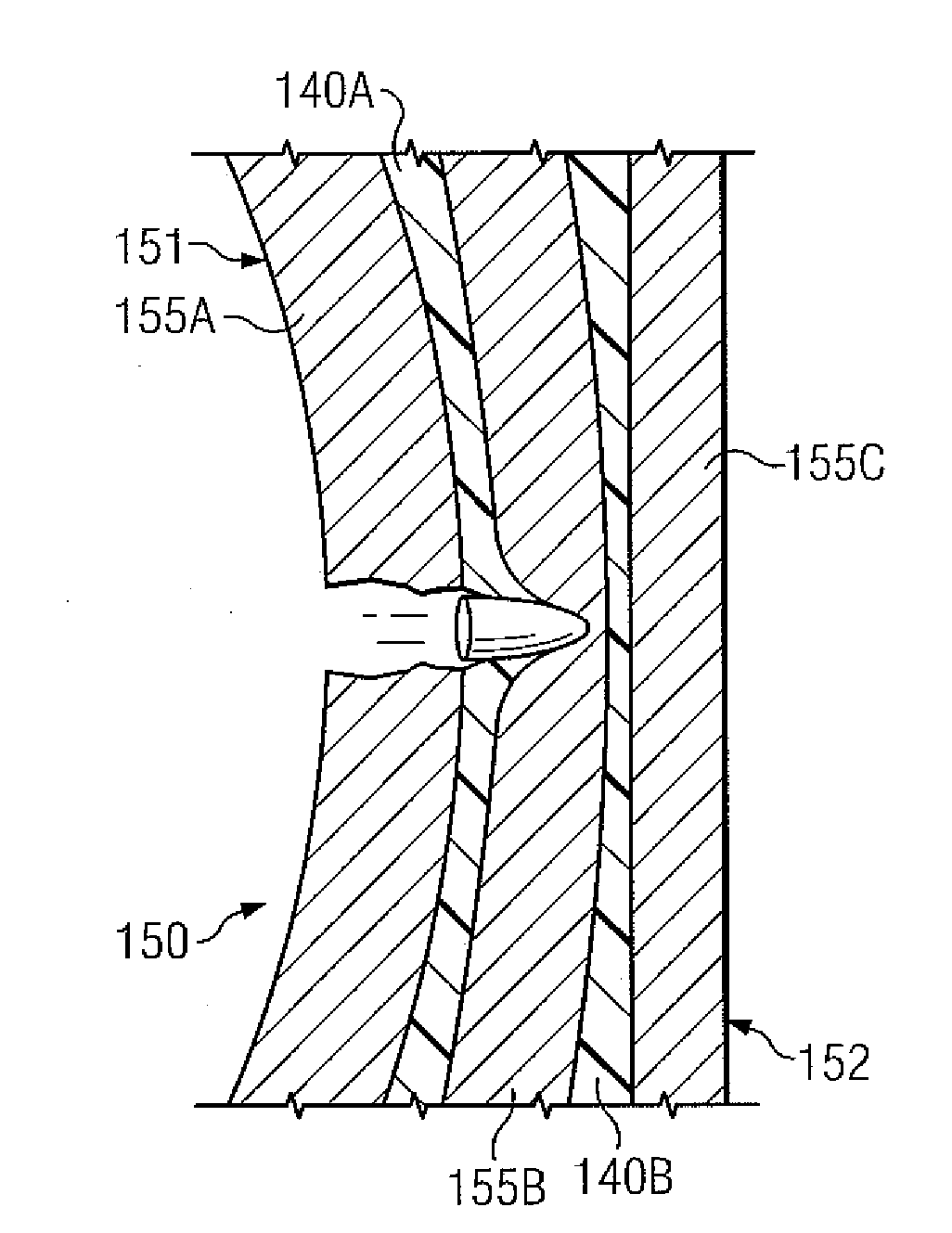

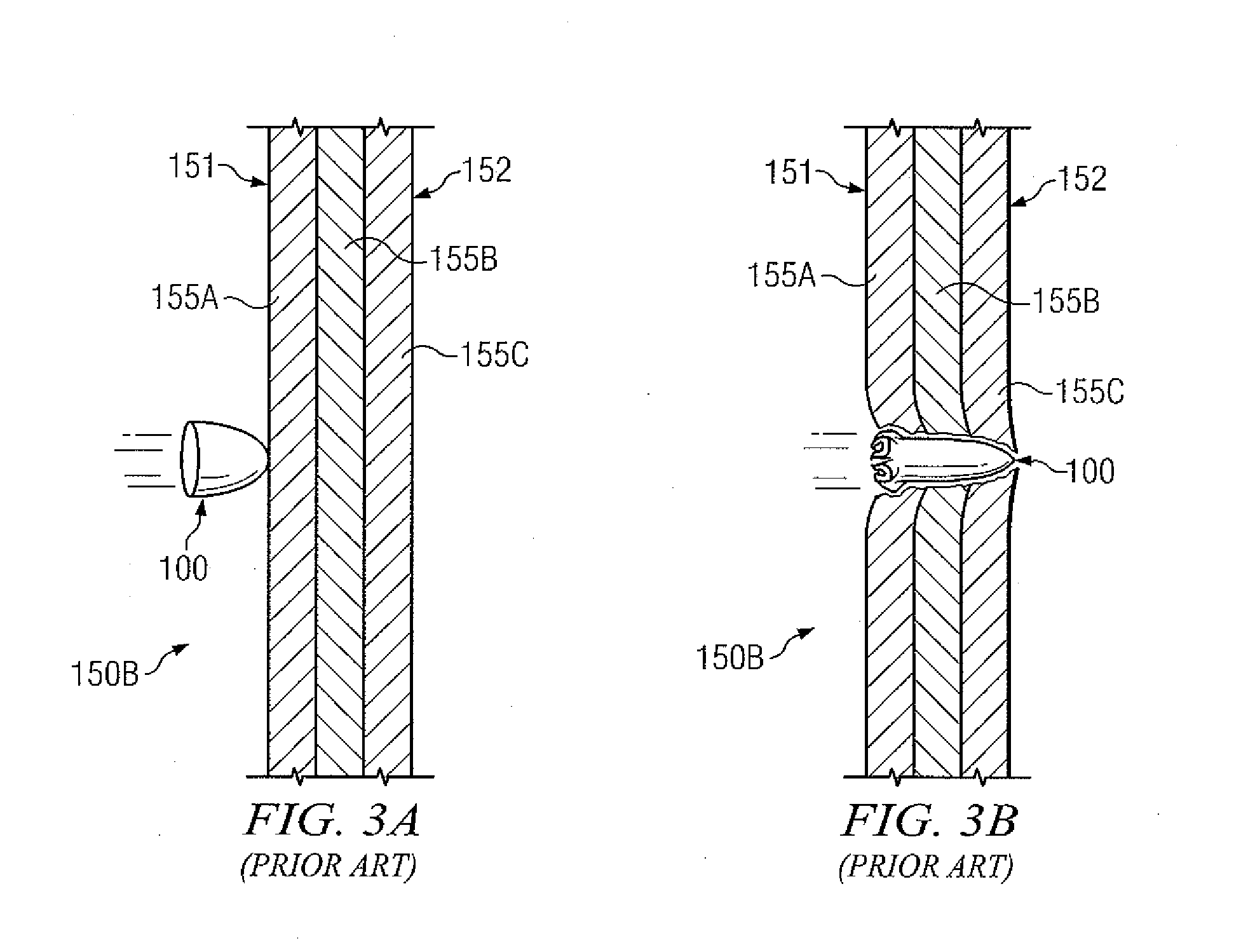

Layering Non-Metallic Layers Between Metallic Layers to Improve Armor Protection

According to one embodiment, an armor system comprises a plurality of metallic layers. The armor system further comprises a plurality of non-metallic layers located in between two or more metallic layers of the plurality of metallic layers, such that each non-metallic layer is located at a respective depth in the plurality of metallic layers.

Owner:RAYTHEON CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com