Patents

Literature

387 results about "Thermal mechanical" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal Mechanical is a full-service, union mechanical contractor providing. Design Build, Plan & Spec, Fabrication, Installation and Maintenance services.

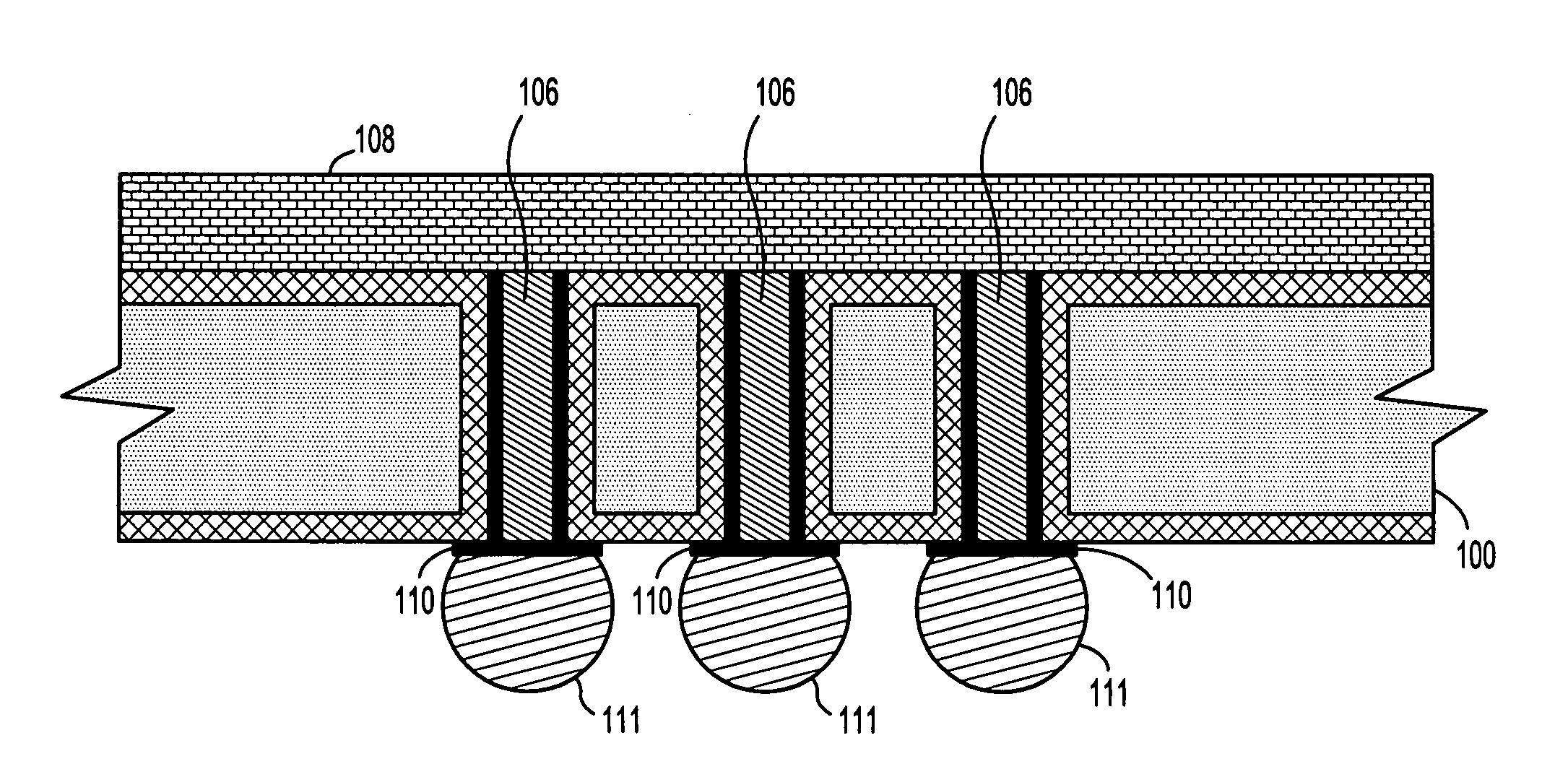

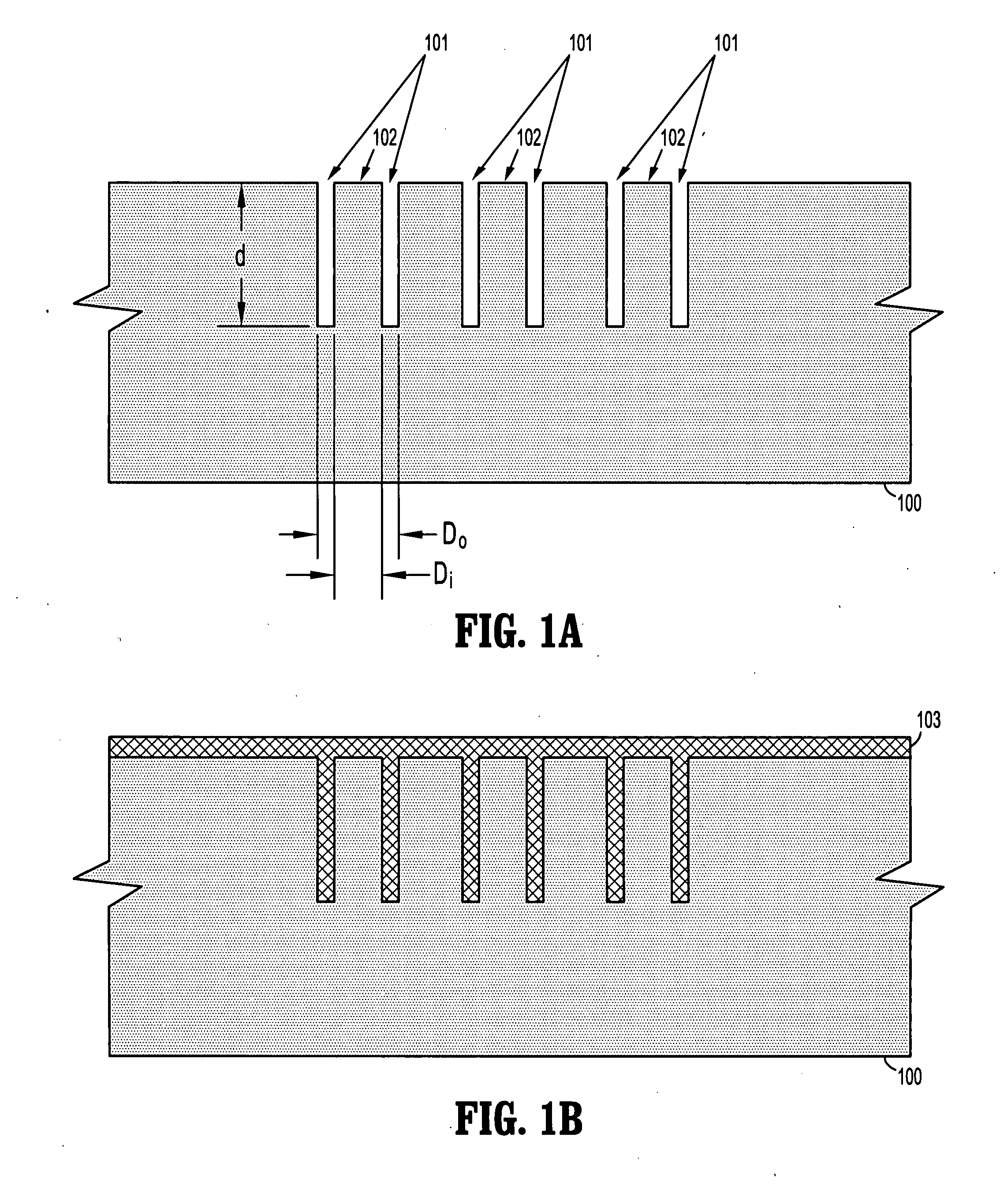

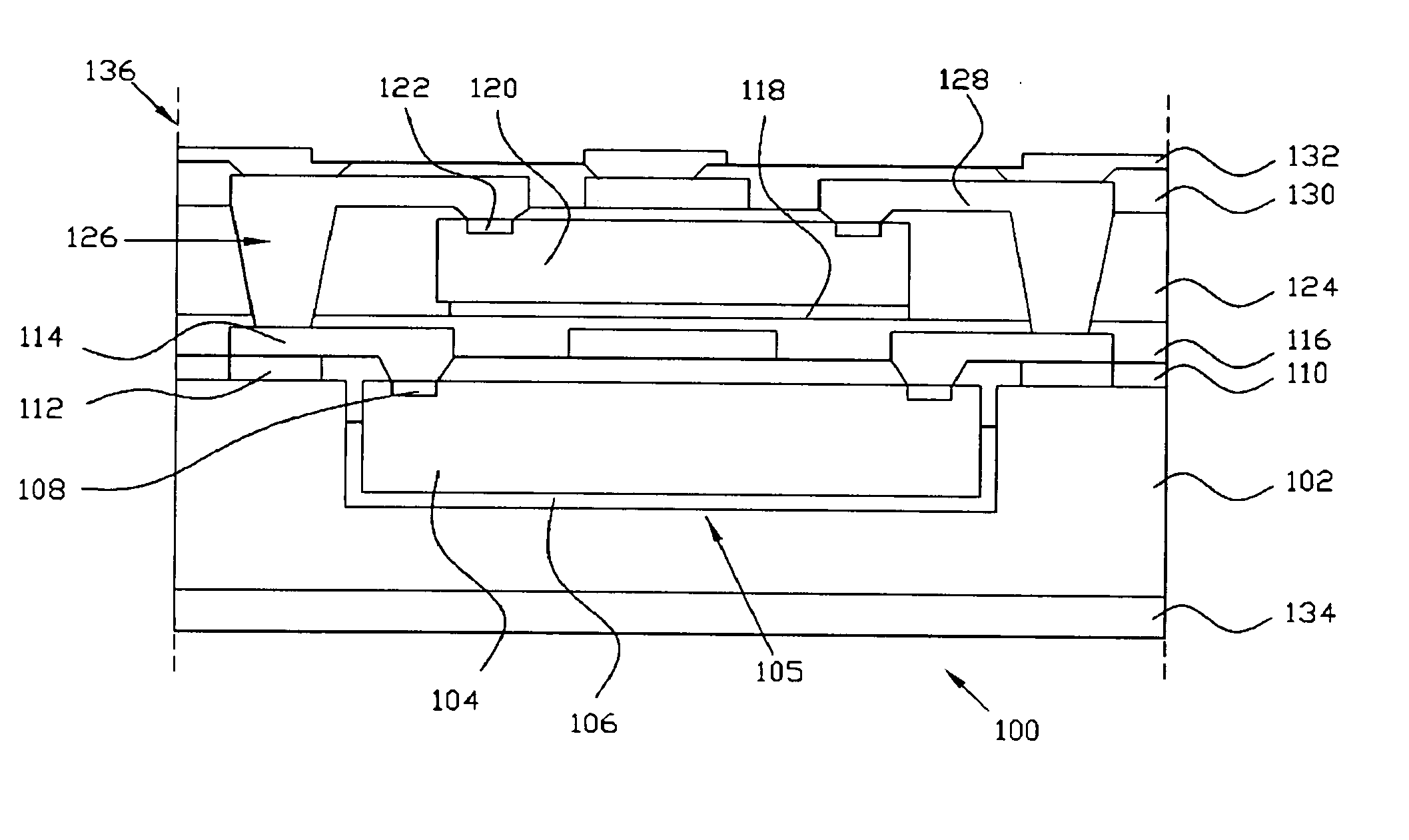

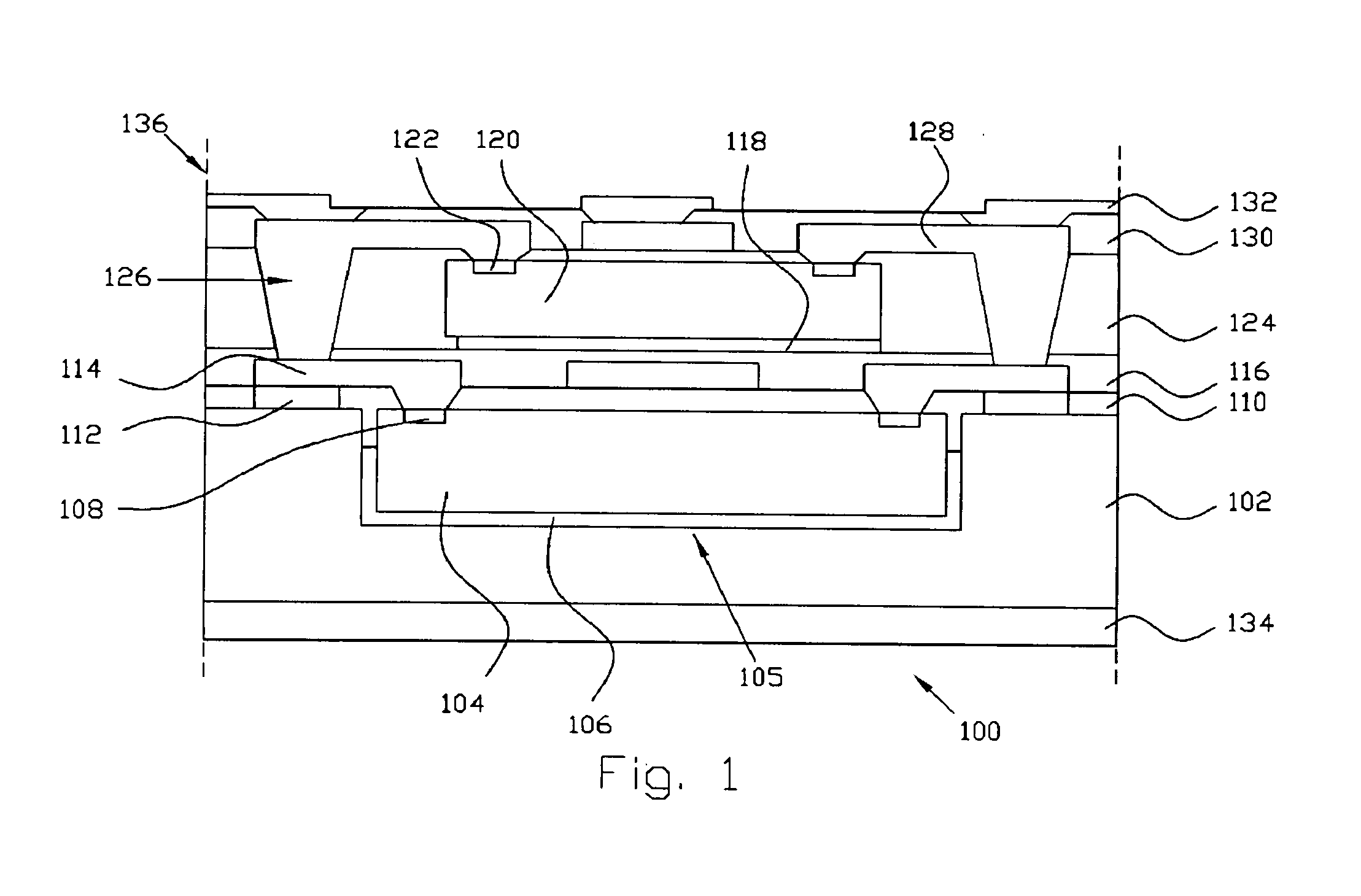

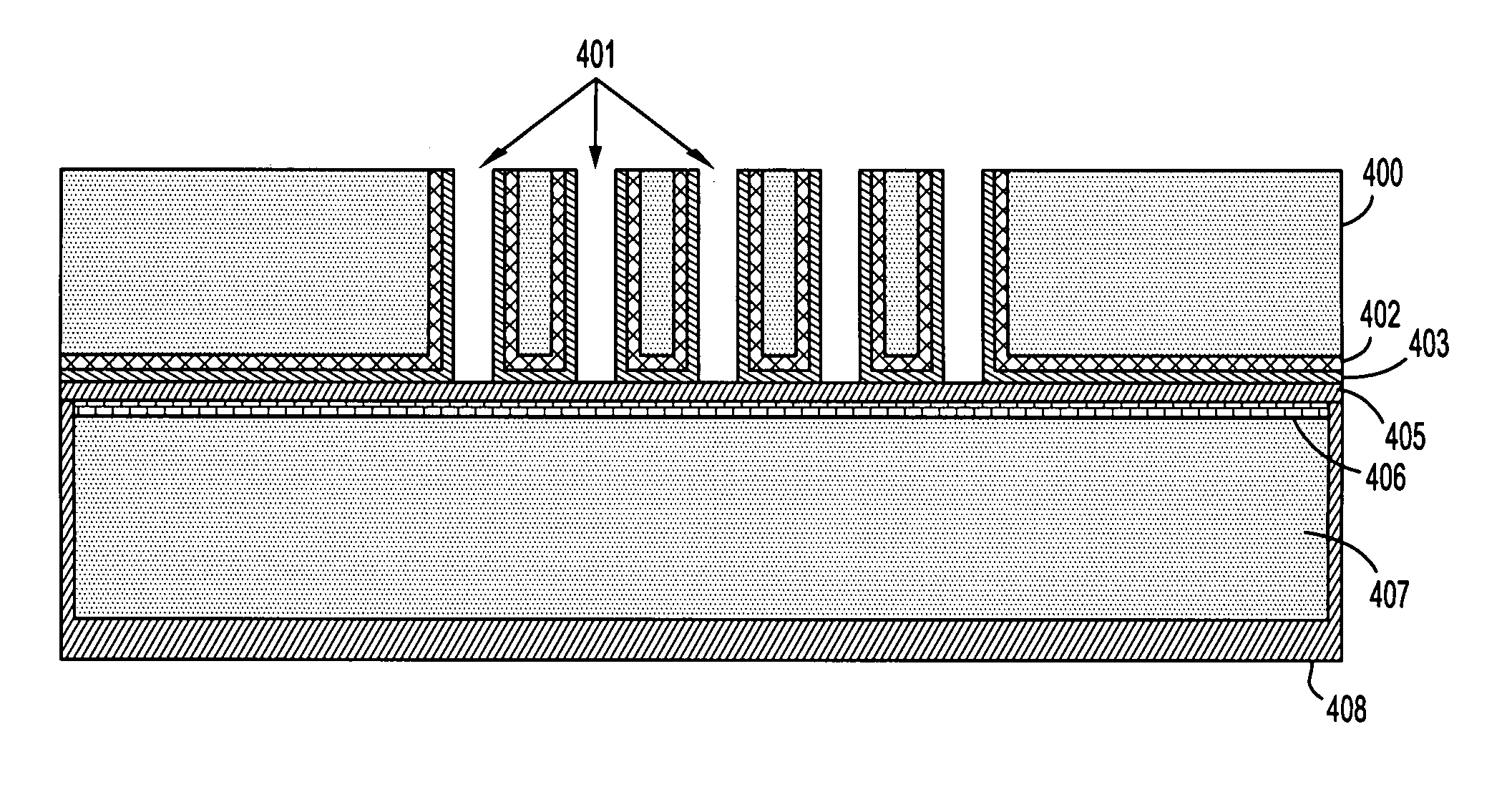

Methods for fabricating silicon carriers with conductive through-vias with low stress and low defect density

InactiveUS20080164573A1High-density packagingReduce stressSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorMicrometer

Methods are provided for fabricating silicon carriers with conductive through-vias that allow high-yield manufacture of silicon carrier with, low defect density. In particular, methods are provided which enable fabrication of silicon, carries with via diameters such as 1 to 10 microns in diameter for a vertical thickness of less than 10 micrometers to greater than 300 micrometers, which are capable robust to thermal-mechanical stresses during production to significantly minimize the thermal mechanical movement at the via sidewall interface between the silicon, insulator, liner and conductor materials.

Owner:GLOBALFOUNDRIES US INC

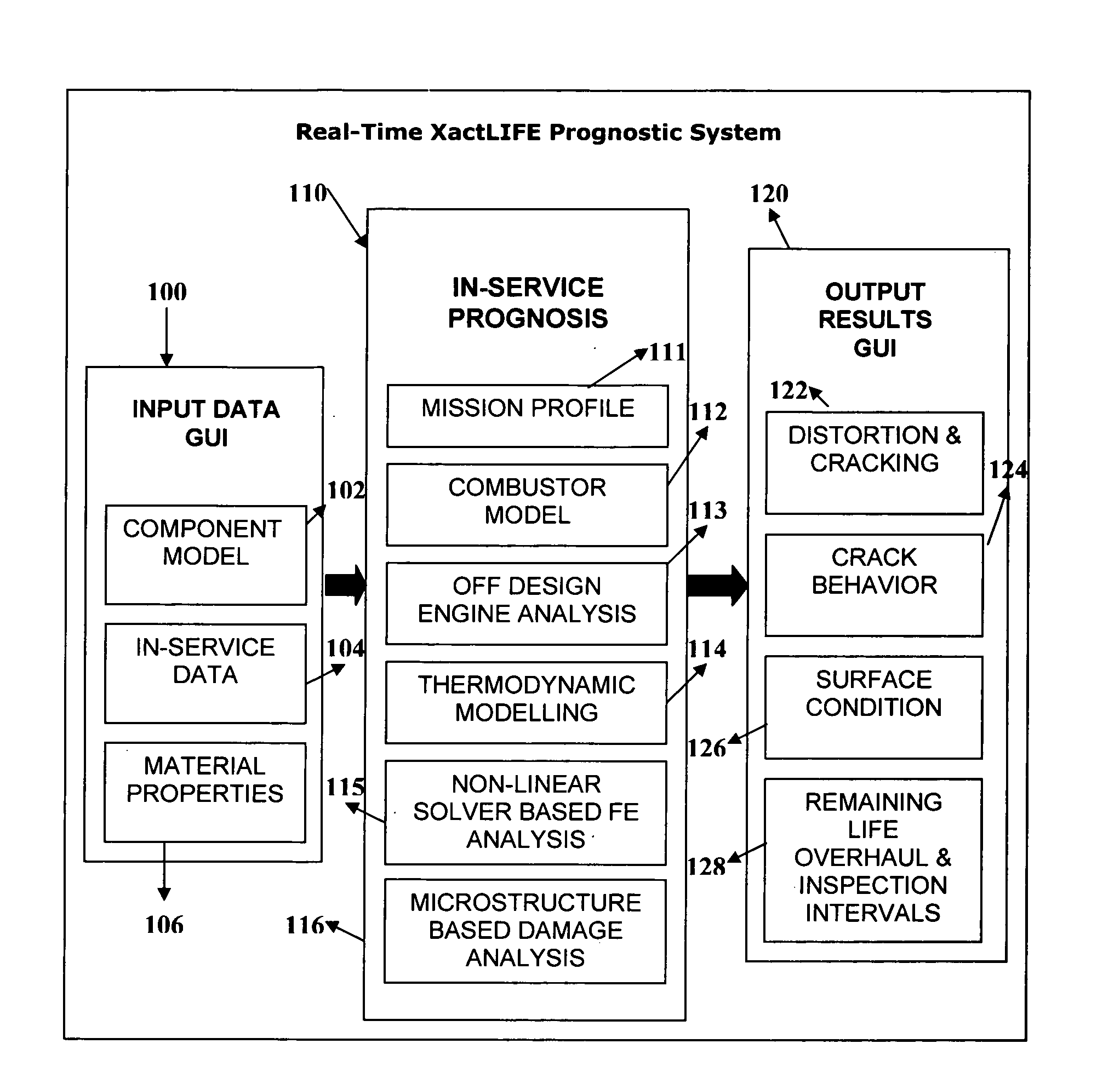

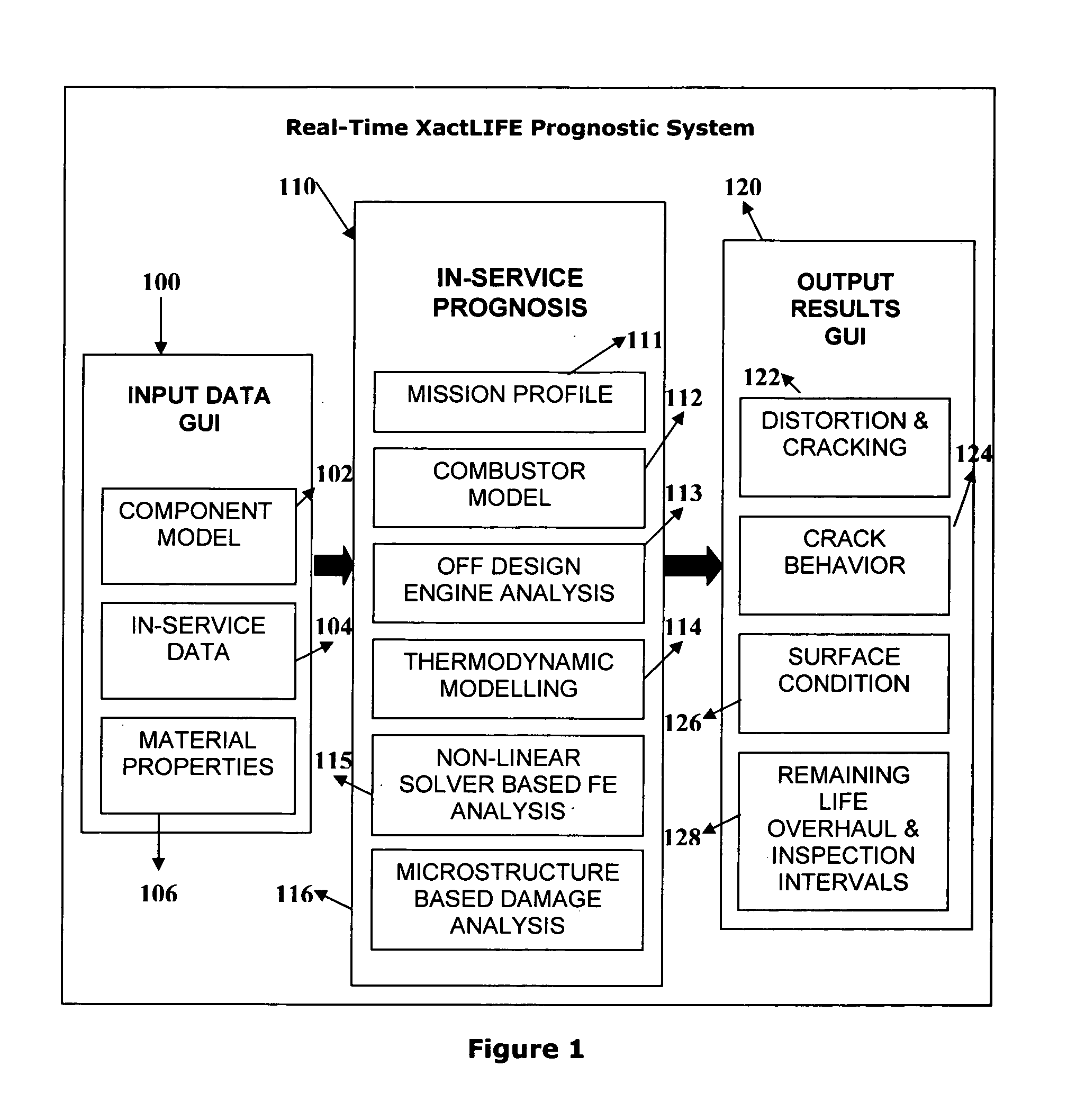

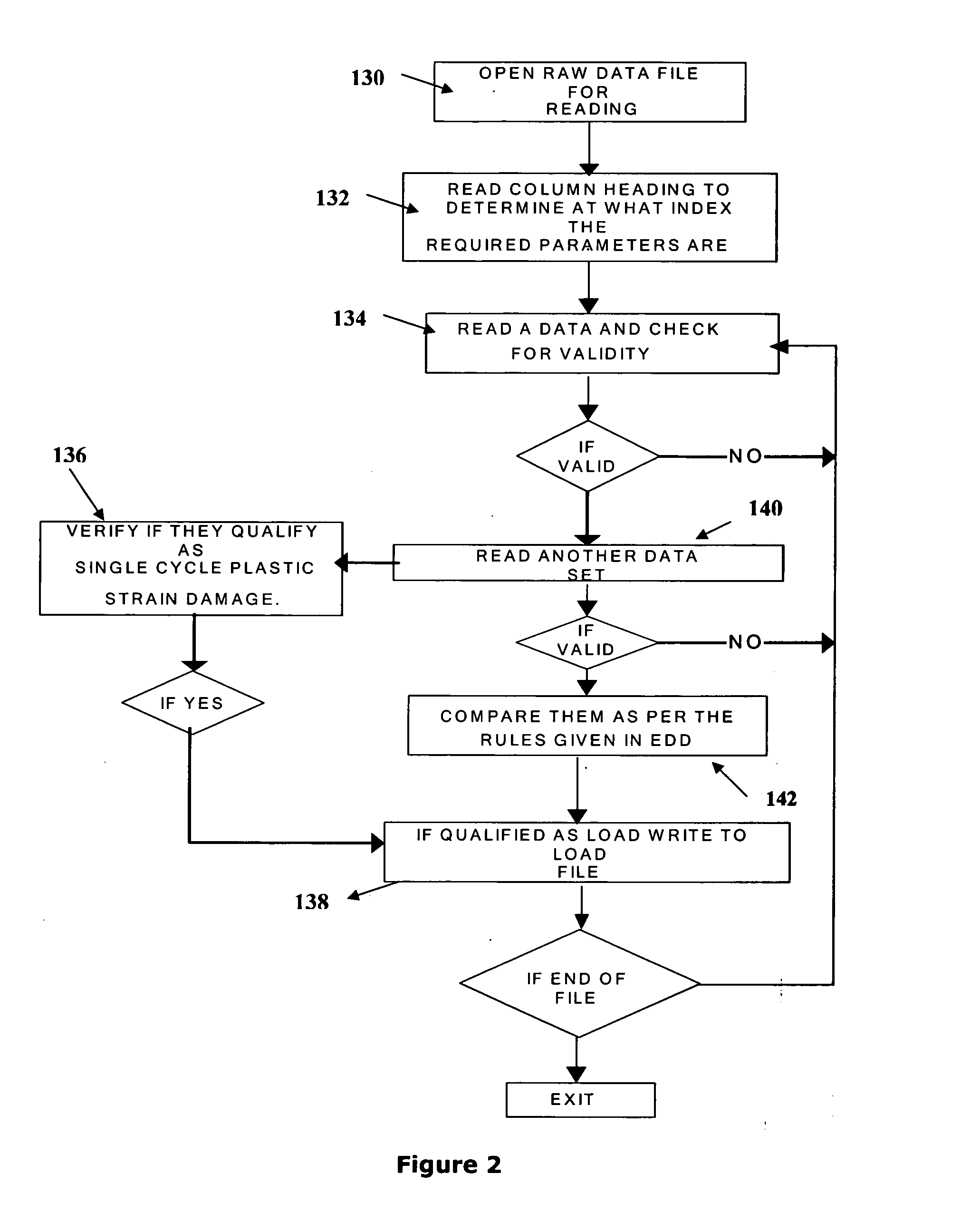

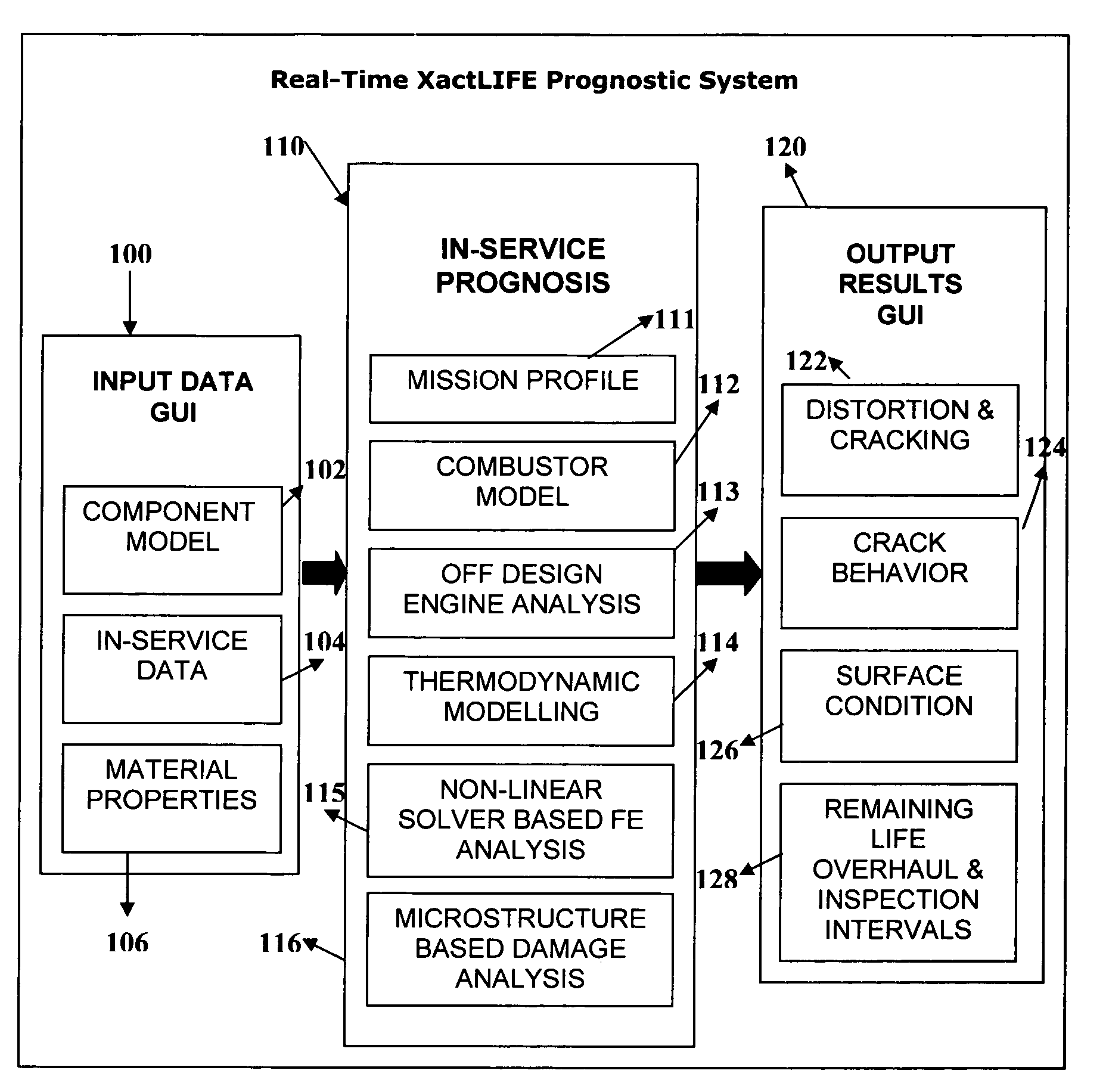

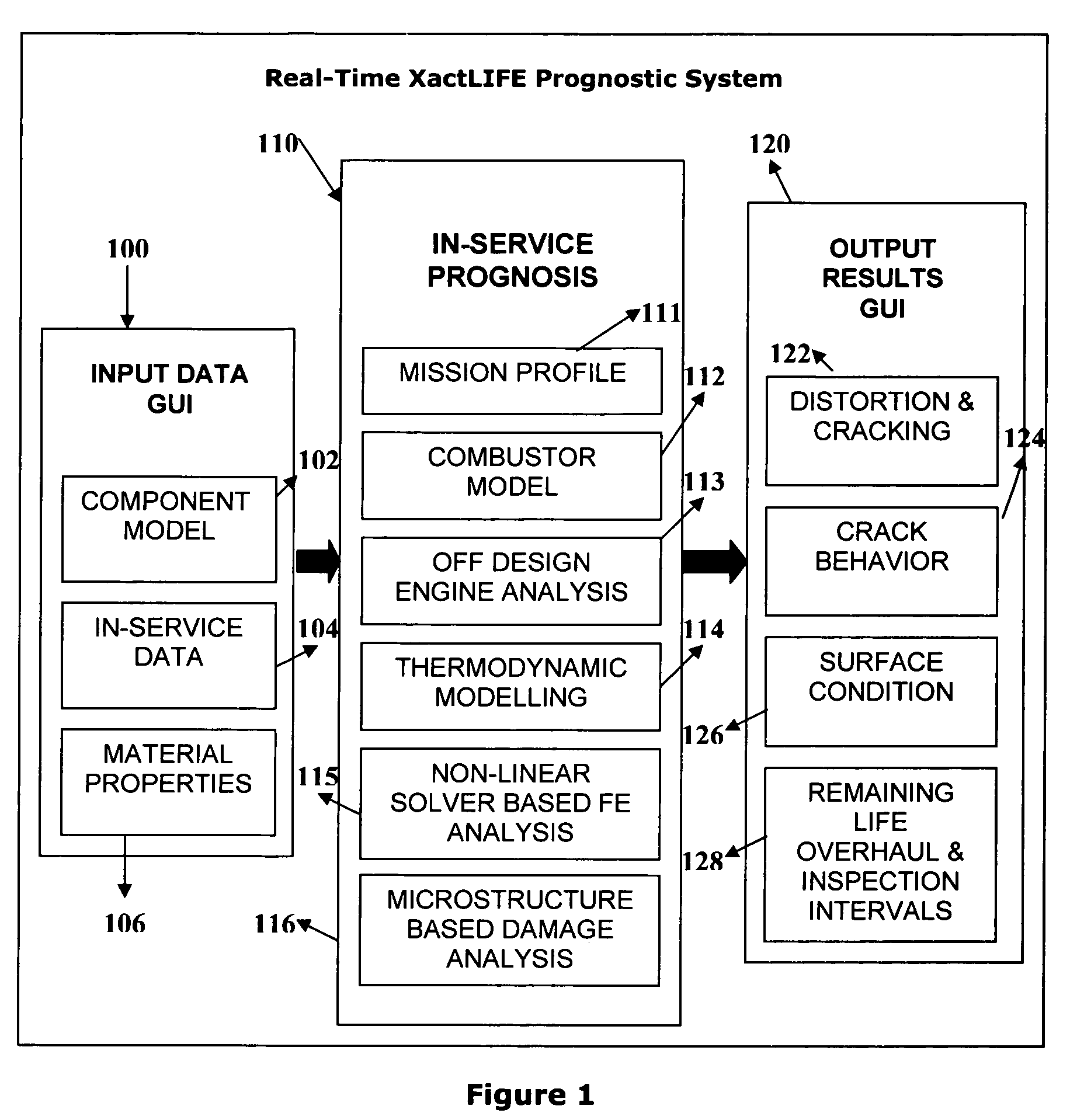

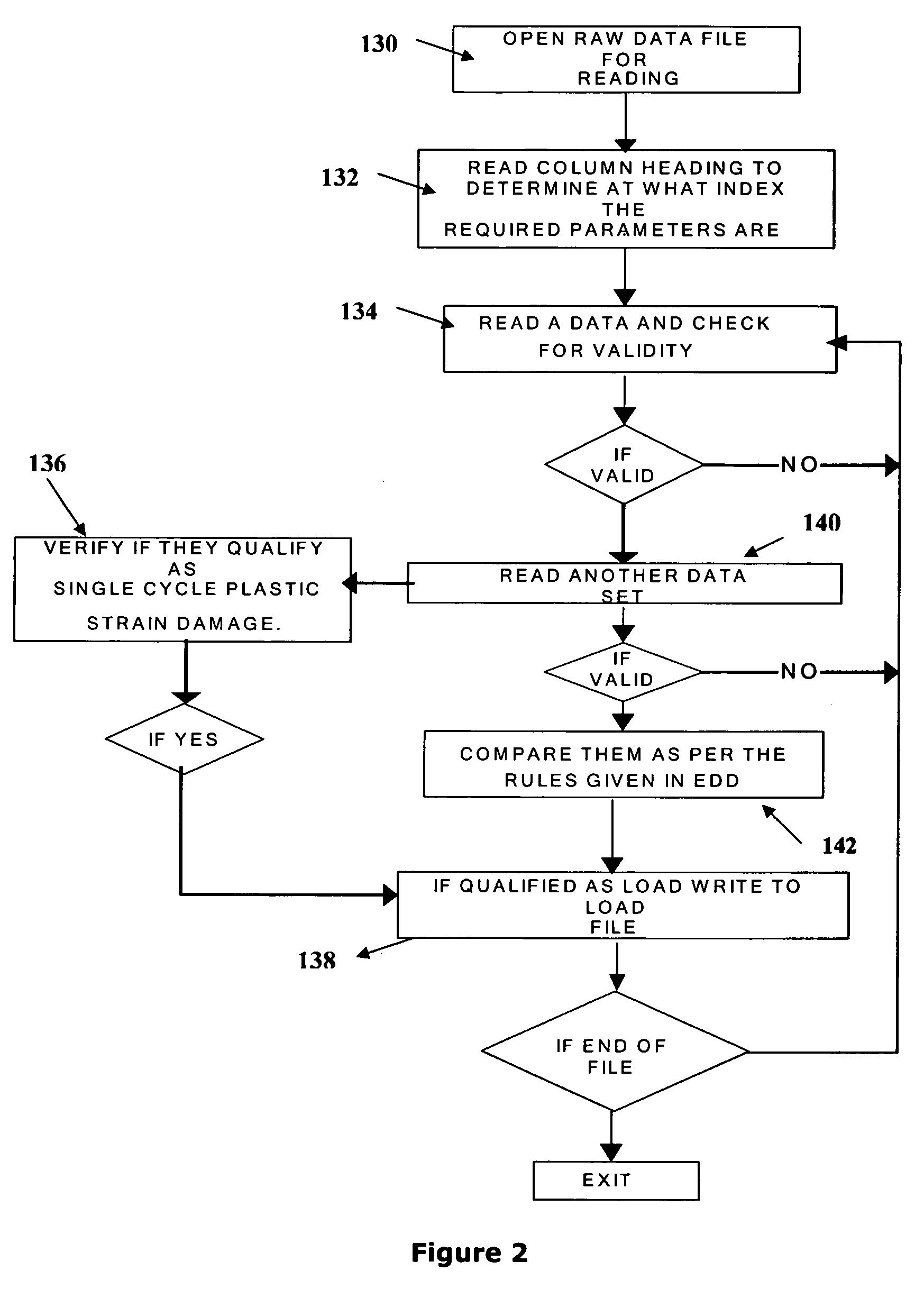

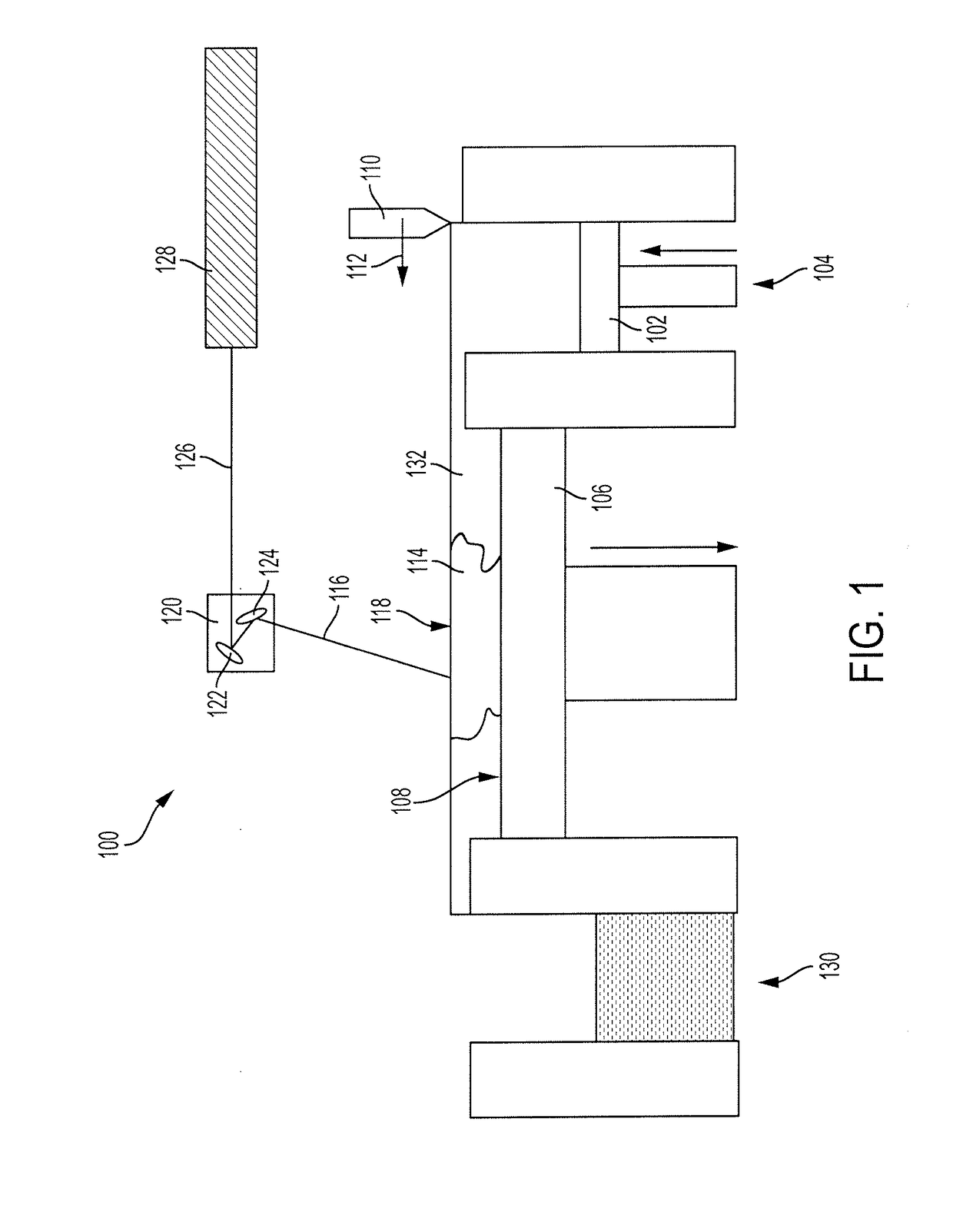

Method and system for real-time prognosis analysis and usage based residual life assessment of turbine engine components and display

ActiveUS20110137575A1Low costFacilitate decisionsPlug gaugesTesting dielectric strengthCombustion chamberOff design

A method and system for performing continuous (real-time) physics based prognostics analysis as a function of actual engine usage and changing operating environment. A rule-based mission profile analysis is conducted to determine the mission variability which yields variability in the type of thermal-mechanical loads that an engine is subjected to during use. This is followed by combustor modeling to predict combustion liner temperatures and combustion nozzle plane temperature distributions as a function of engine usage which is followed by off-design engine modeling to determine the pitch-line temperatures in hot gas path components and thermodynamic modeling to compute the component temperature profiles of the components for different stages of the turbine. This is automatically followed by finite element(FE) based non-linear stress-strain analysis using an real-time FE solver and physics based damage accumulation, life consumption and residual life prediction analyses using microstructural modeling based damage and fracture analysis techniques.

Owner:KOUL ASHOK

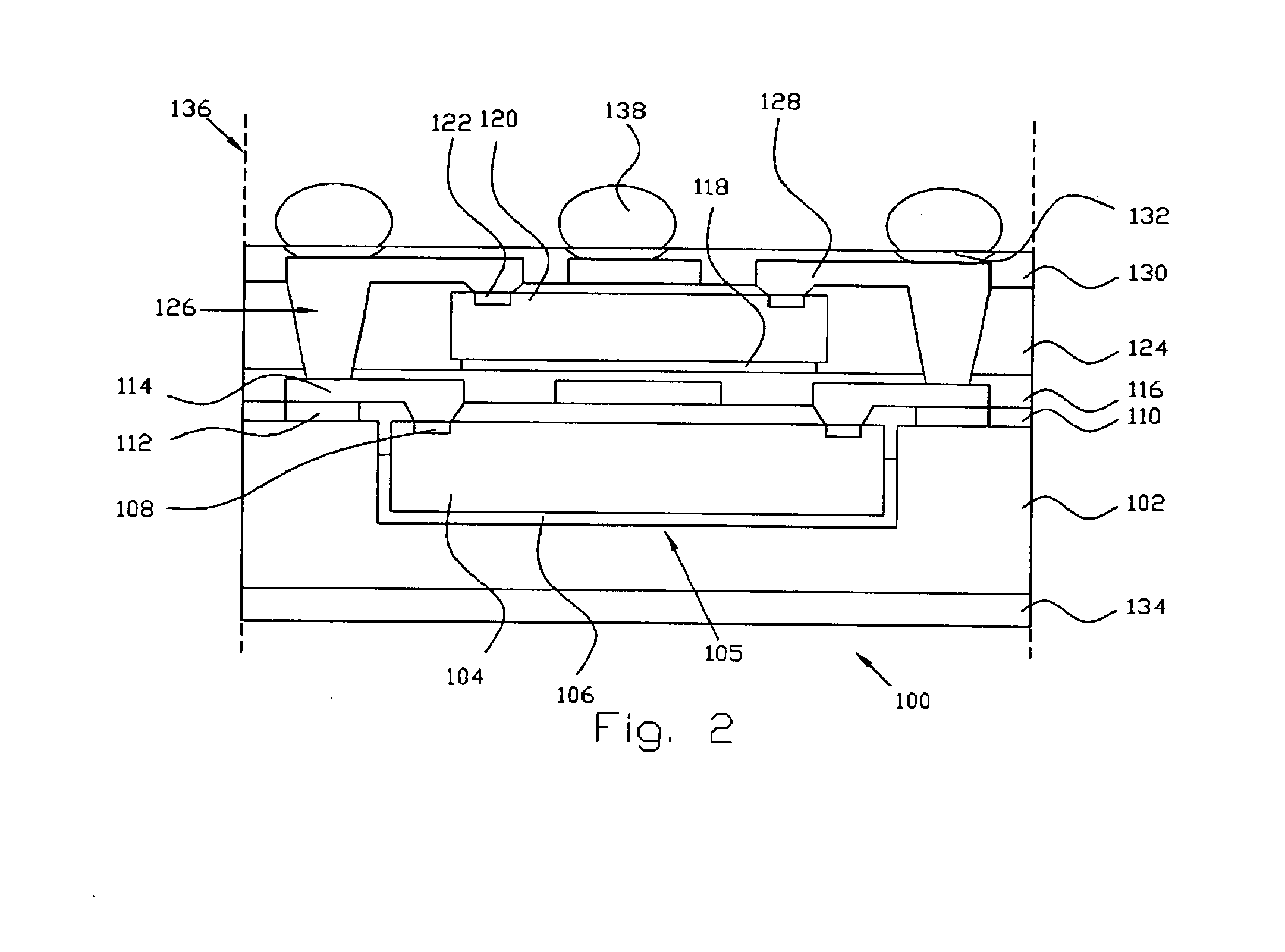

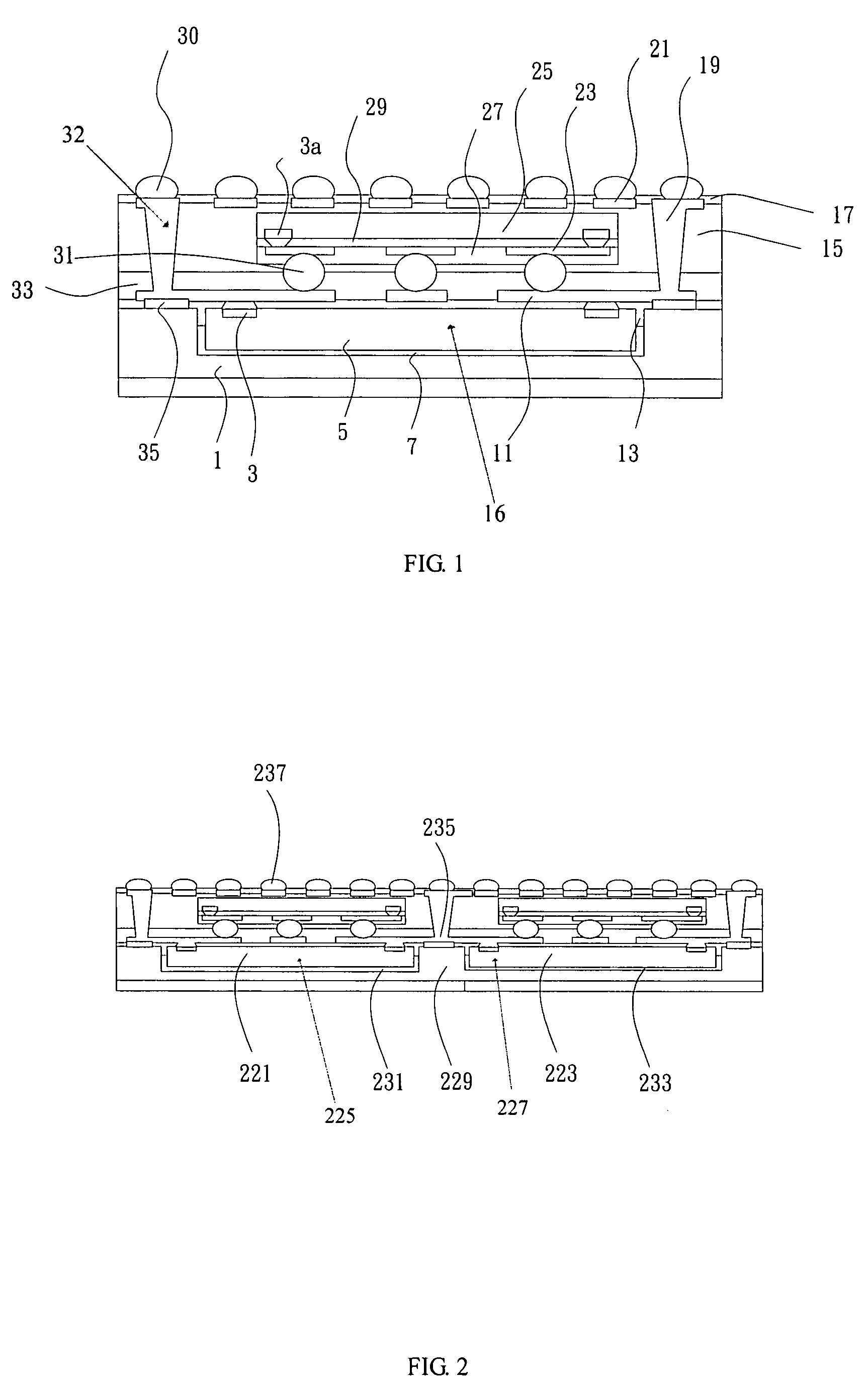

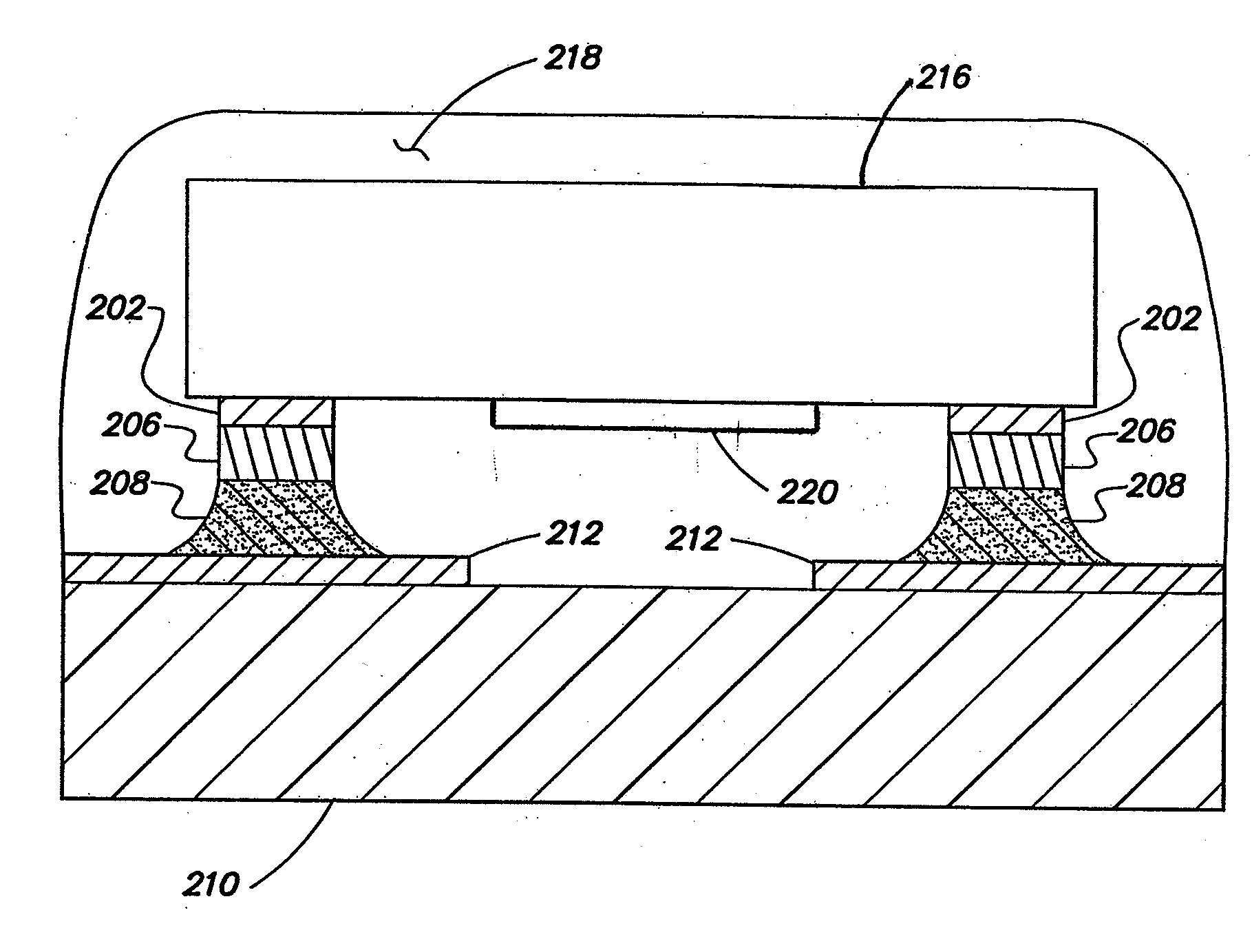

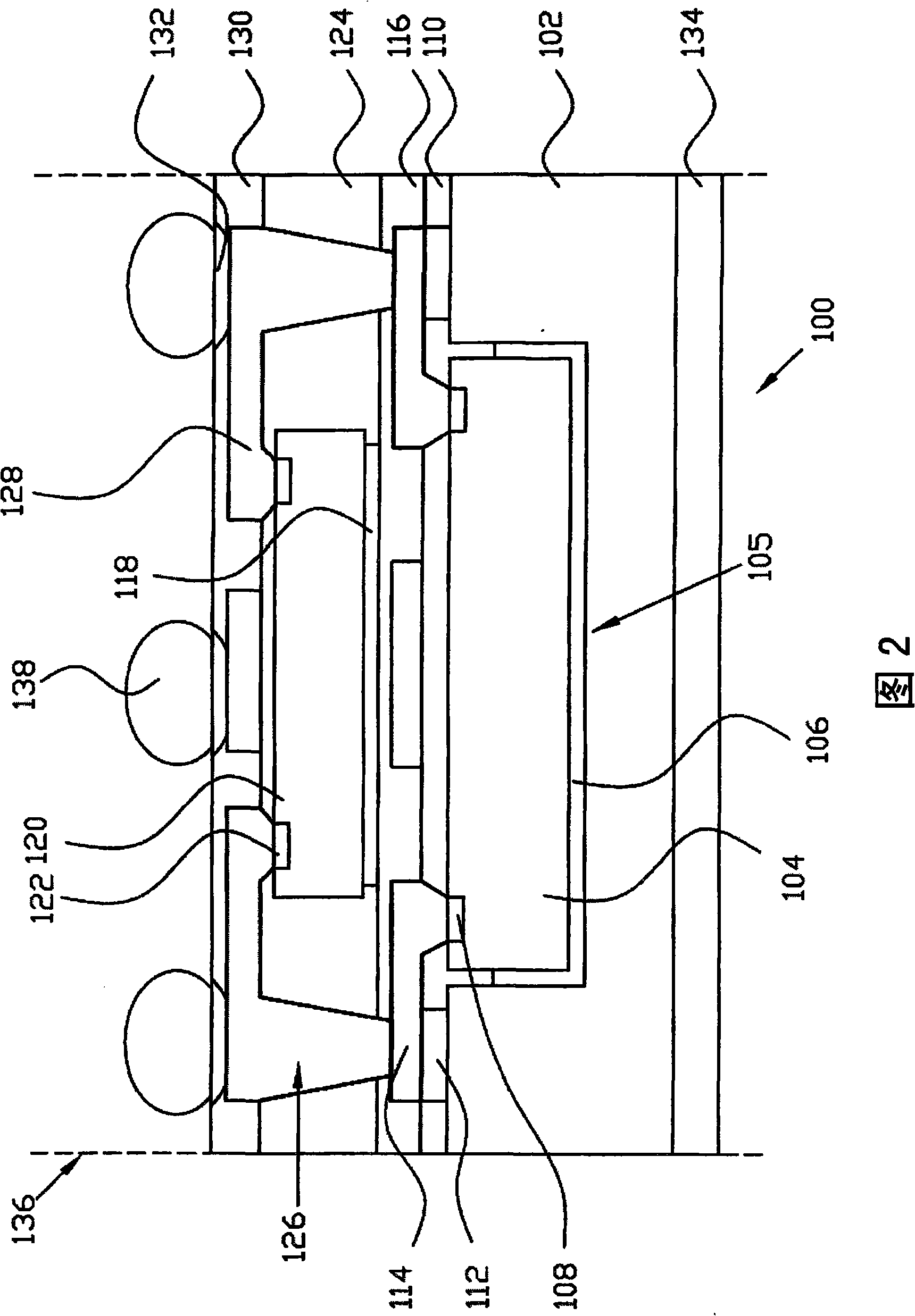

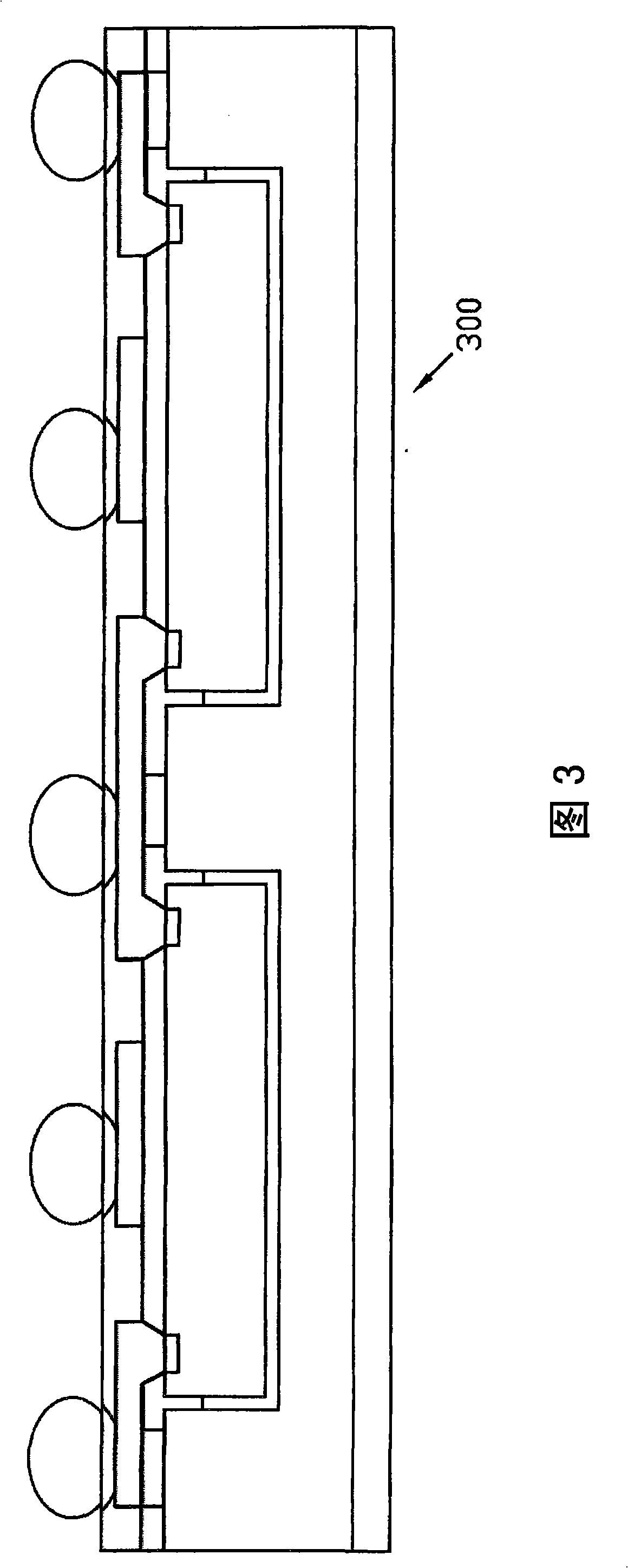

Structure of semiconductor device package and method of the same

InactiveUS20080217761A1Avoid warpingReduce processing stepsSemiconductor/solid-state device detailsSolid-state devicesEngineeringDielectric layer

The present invention provides a semiconductor device package comprising a substrate with at lease a pre-formed die receiving cavity formed and terminal contact metal pads formed within an upper surface of the substrate. At lease a first die is disposed within the die receiving cavity. A first dielectric layer is formed on the first die and the substrate and refilled into a gap between the first die and the substrate to absorb thermal mechanical stress there between. A first re-distribution layer (RDL) is formed on the first dielectric layer and coupled to the first die. A second dielectric layer is formed on the first RDL, and then a second die is disposed on the second dielectric layer and surrounded by core pastes having through holes thereon. A second re-distribution layer (RDL) is formed on the core pastes to fill the through holes, and then a third dielectric layer formed on the second RDL.

Owner:ADVANCED CHIP ENG TECH

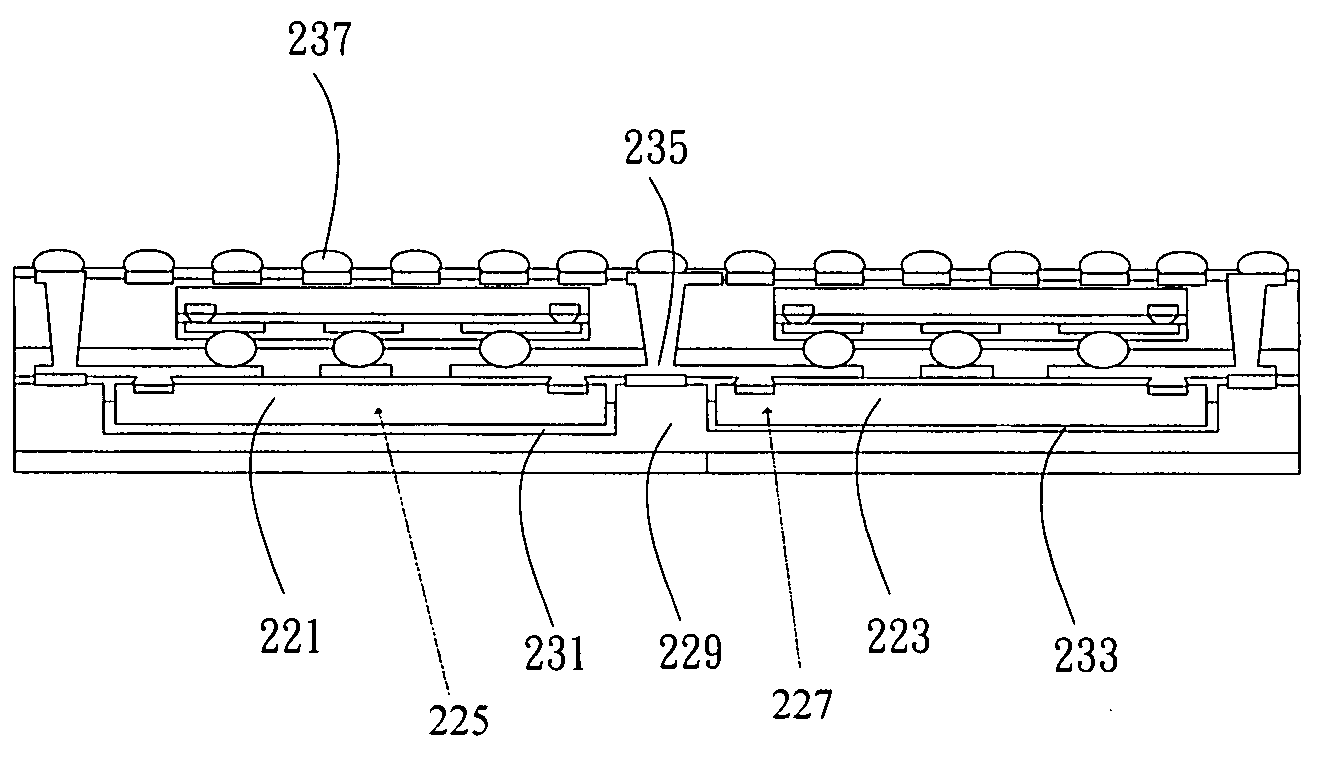

Multi-chips package with reduced structure and method for forming the same

InactiveUS20080197469A1Improve reliabilityReduce manufacturing costSemiconductor/solid-state device detailsSolid-state devicesEngineeringDielectric layer

The present invention provides a structure of multi-chips package and Method of the same comprising a substrate with a pre-formed die receiving cavity formed within an upper surface of the substrate. A die is disposed within the die receiving cavity by adhesion and an elastic dielectric layer filled into a gap between the die and the substrate to absorb thermal mechanical stress; therefore the thickness of the package is reduced and the CTE mismatch of the structure is reduced. The present invention also provides a structure for SIP with higher reliability and lower manufacturing cost. the process is simpler and it is easy to form the multi-chips package than the traditional one. Therefore, the present invention discloses a fan-out WLP with reduced thickness and good CTE matching performance.

Owner:ADVANCED CHIP ENG TECH

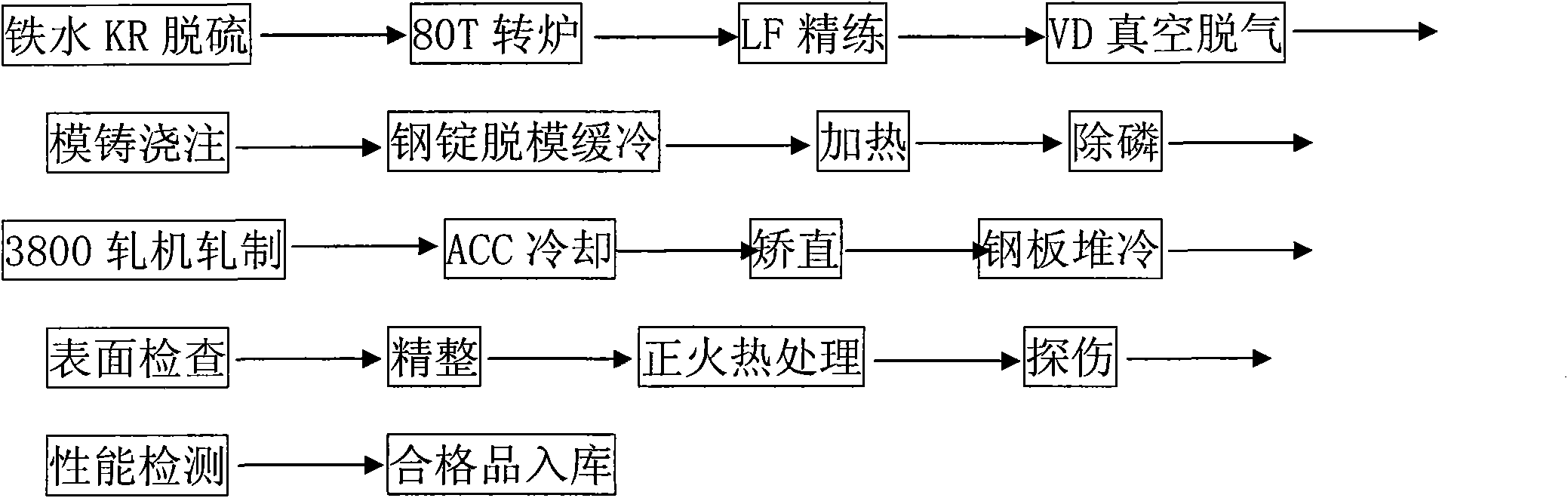

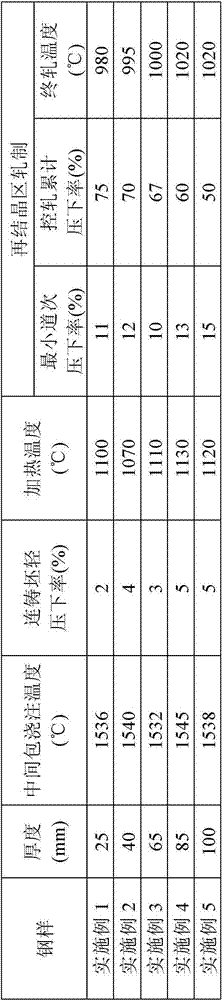

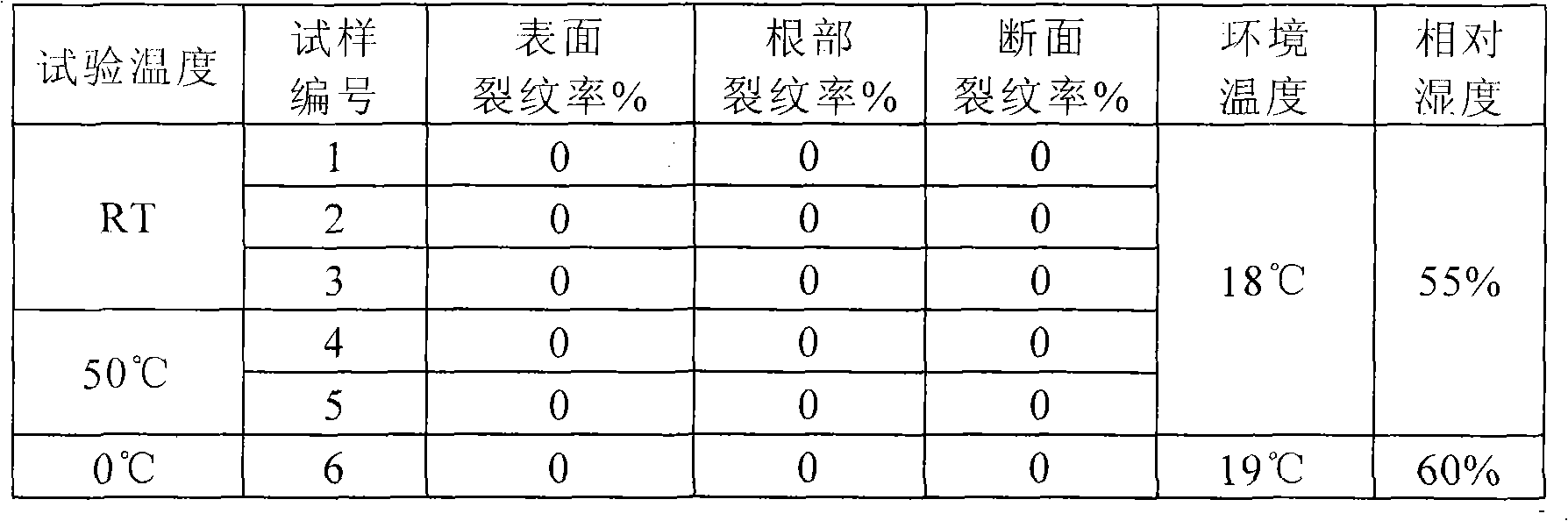

Q345q-series super-thick bridge steel plate and production method thereof

ActiveCN101880824AHigh standardRoll force/gap control deviceTemperature control deviceProduction lineChemical composition

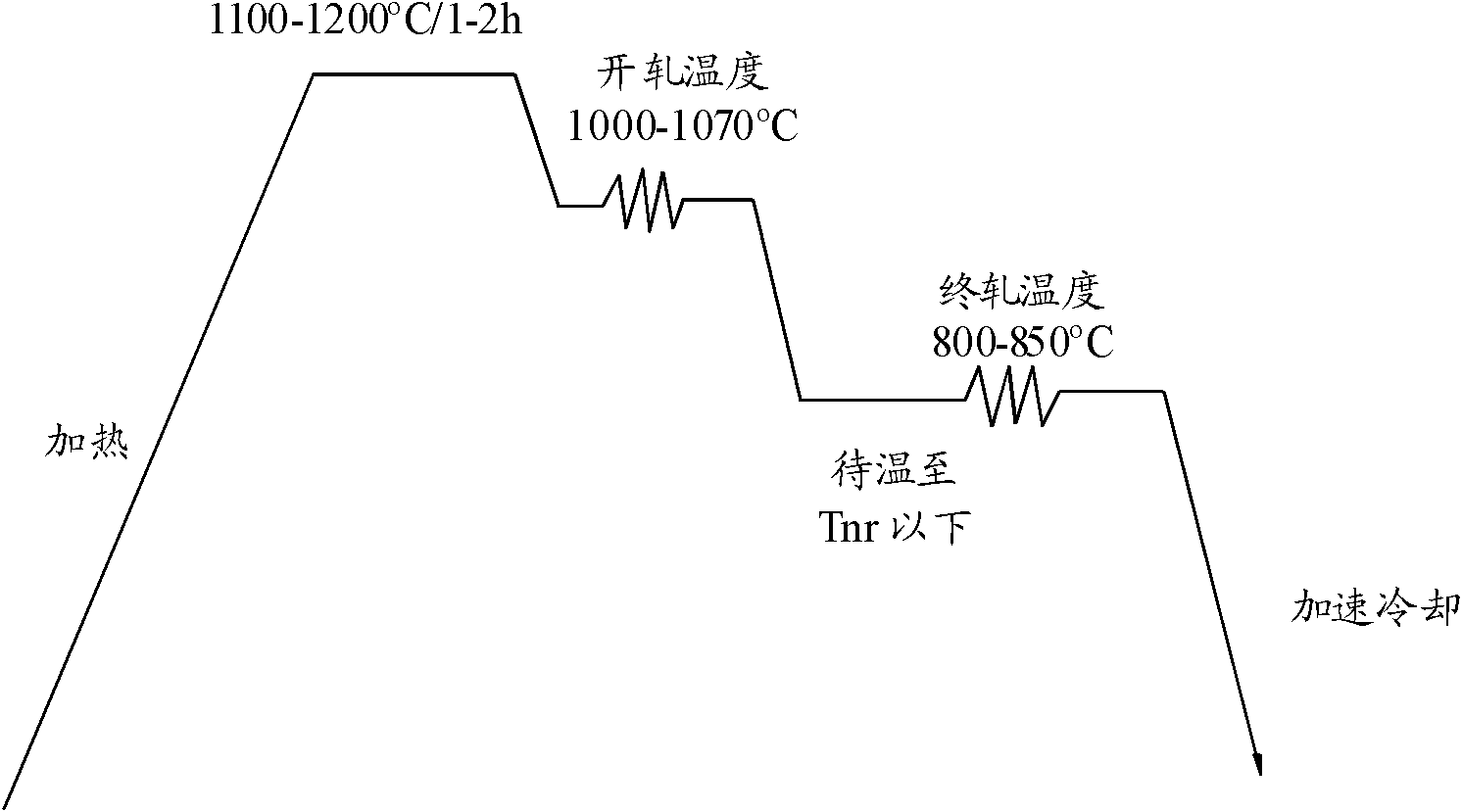

The invention discloses a Q345q-series super-thick guaranteed performance and flaw detection bridge steel plate comprising the following chemical components in percentage by mass: 0.08-0.16 percent of C, 0.20-0.50 percent of Si, 1.15-1.60 percent of Mn, not more than 0.020 percent of P, not more than 0.010 percent of S, not more than 0.12 percent of microalloyed element (V+Nb+Ti+Ni), 0.010-0.050 percent of AlS and the balance of Fe and residual elements; and carbon equivalent is not more than 0.43. The invention also discloses a production method of the steel plate, comprising the steps of rolling, cooling, straightening, cooling in pile and thermal treatment. In the rolling, the cooling and the straightening, the 130 mm super-thick Q345qD(E) steel plate is successfully developed in the production line of a converter, die casting, mill rolling and normalization thermal treatment through carrying out reasonable composition design, die casting, TMCP (Thermal Mechanical Control Process) rolling and thermal treatment; the secondary flaw detection qualification rate reaches 90 percent, the performance initial test qualification rate reaches 100 percent, and the Z-direction performance of the entity of the steel plate can reach Z15 level. The development of the super-thick steel plate satisfies the higher requirements on bridge industry.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

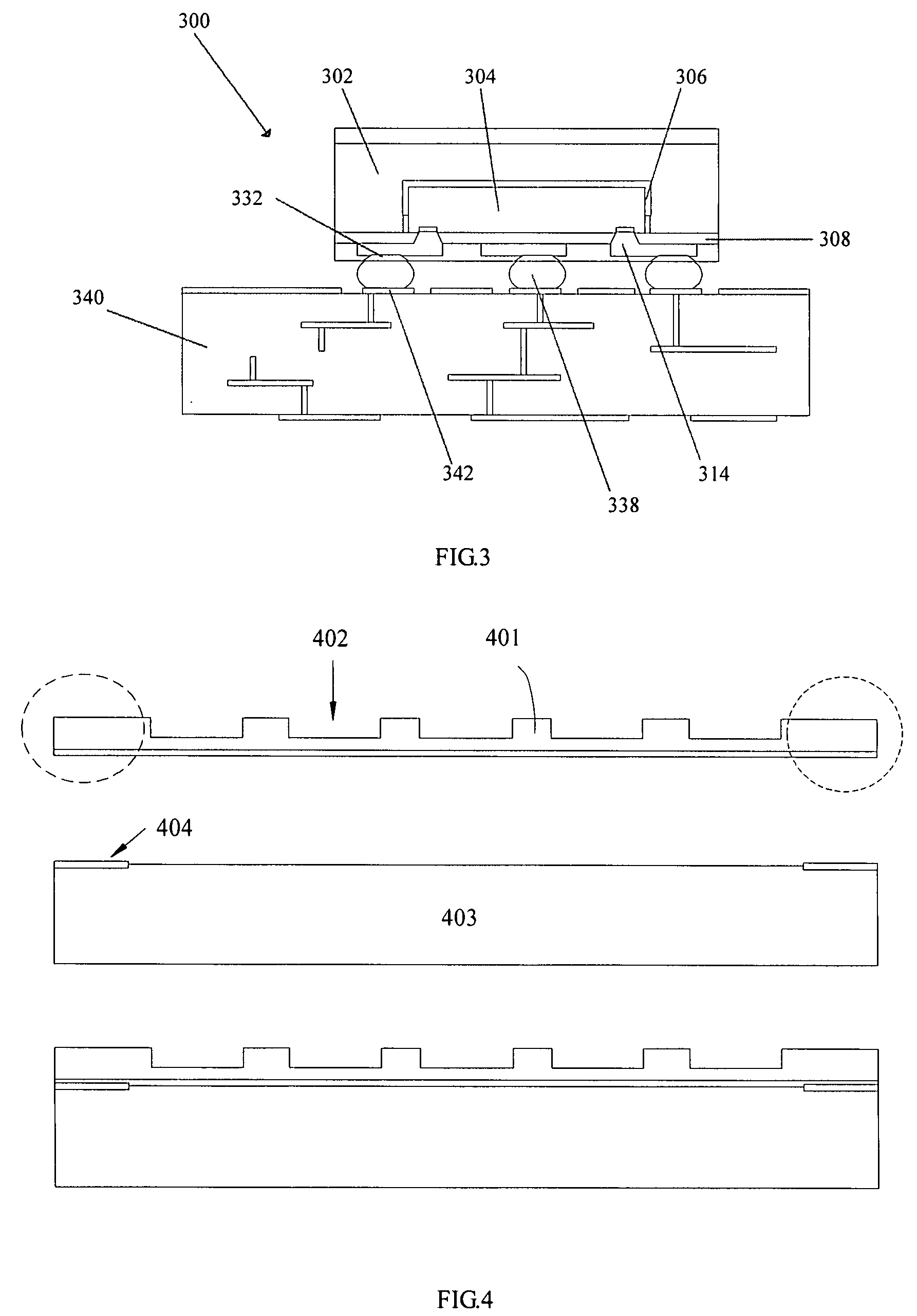

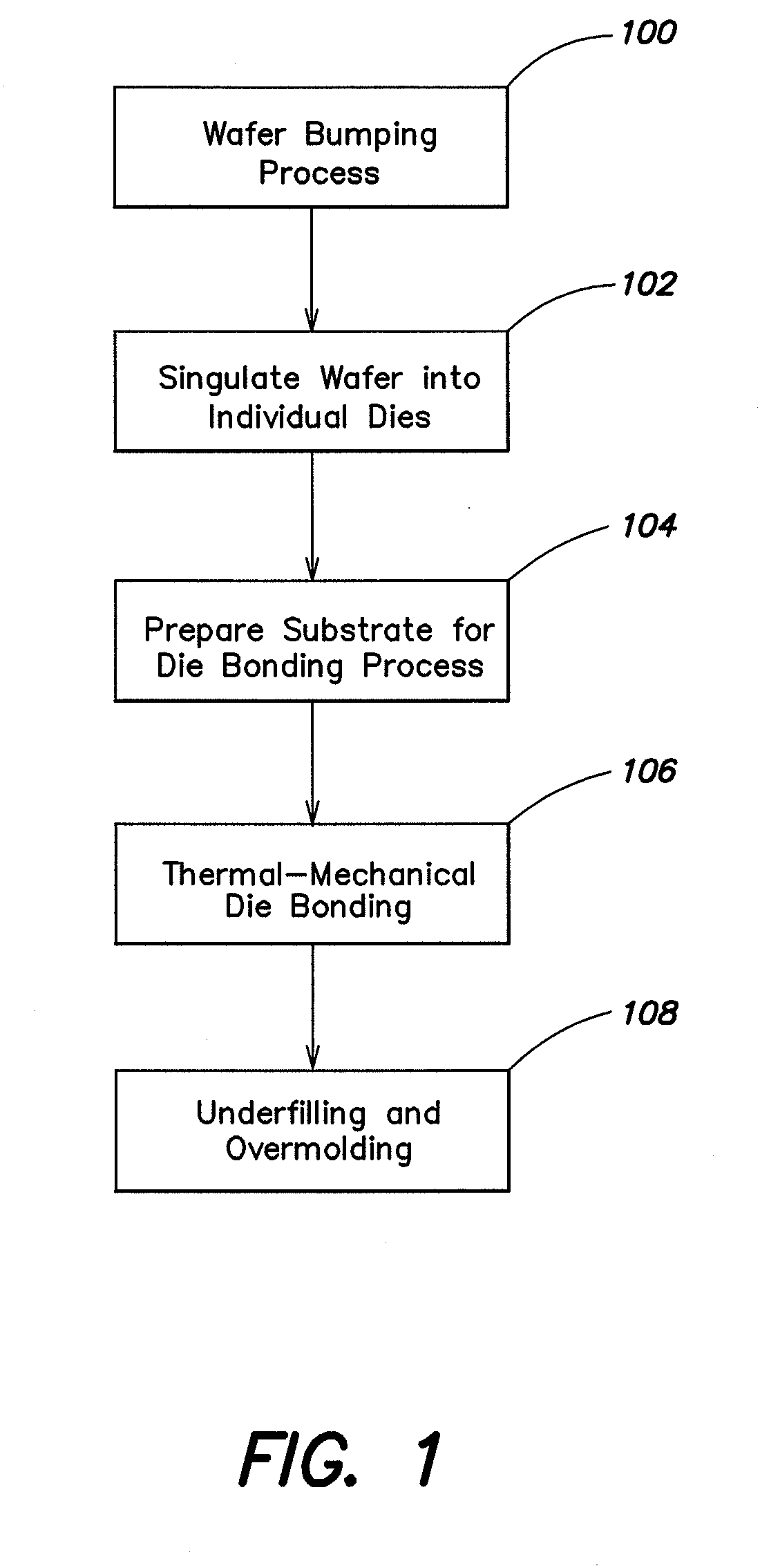

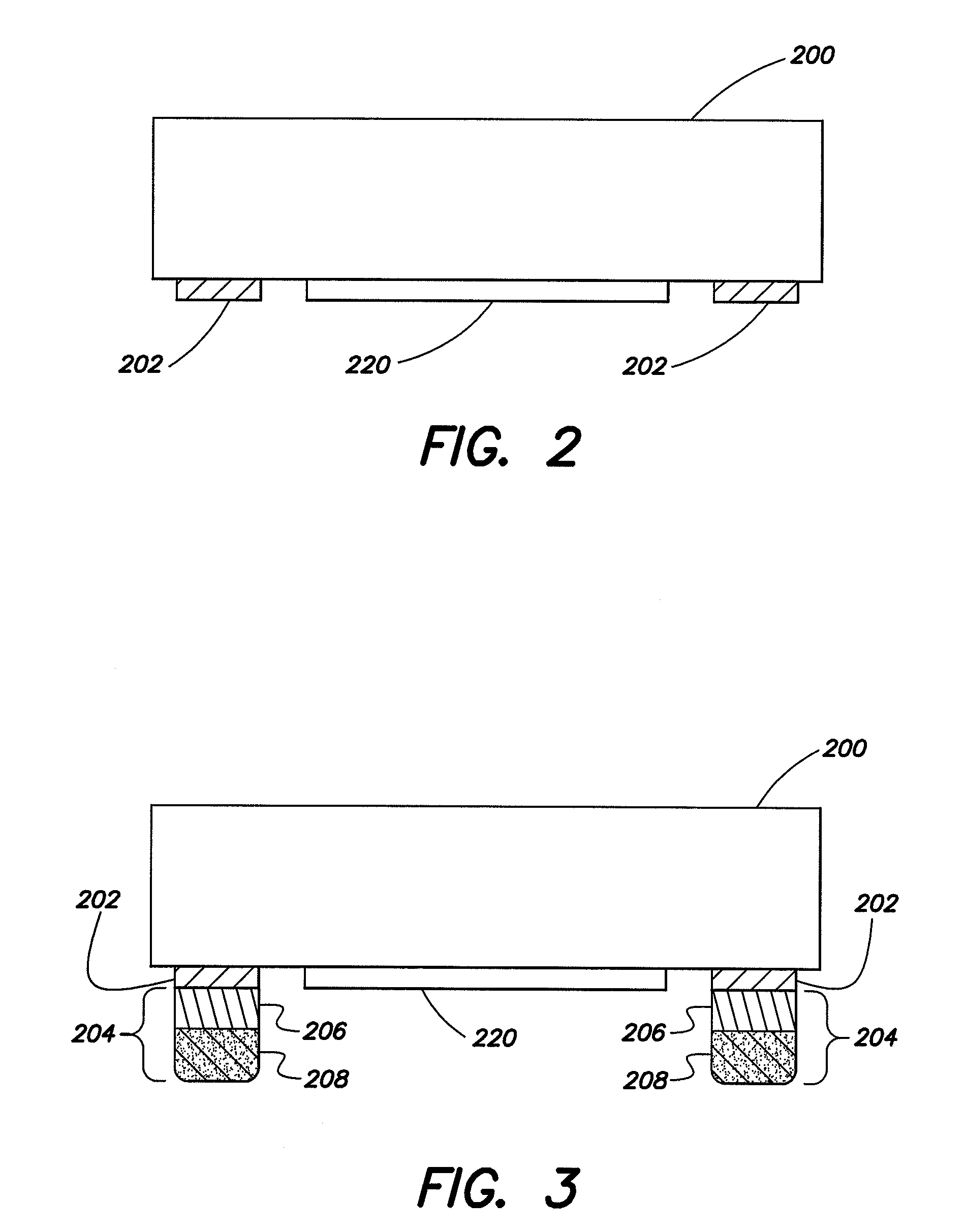

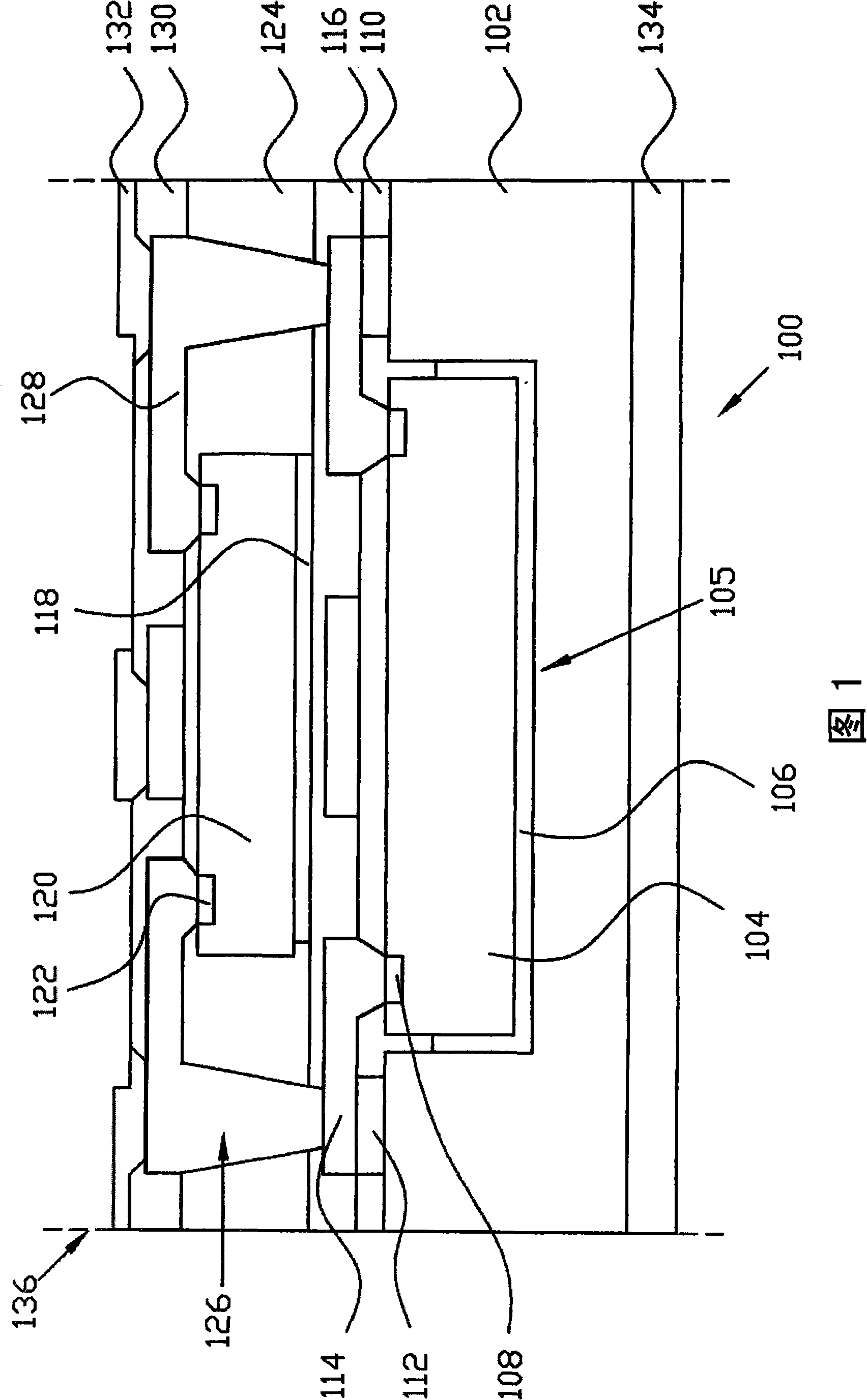

Thermal mechanical flip chip die bonding

ActiveUS20090155955A1High bonding strengthImprove electrical performanceSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsEngineeringCopper

A thermal mechanical process for bonding a flip chip die to a substrate. The flip chip die includes a plurality of copper pillar bumps, each copper pillar bump of the plurality of copper pillar bumps having a copper portion attached to the die and a bonding cap attached to the copper portion. The process includes positioning the die on the substrate such that the bonding cap of each copper pillar bump of the plurality of copper pillar bumps contacts a corresponding respective one of a plurality of bonding pads on the substrate, and thermosonically bonding the die to the substrate.

Owner:SKYWORKS SOLUTIONS INC

Structure of semiconductor device package and the method of the same

InactiveCN101261984ARoughness is easy to controlThickness is easy to controlSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

The present invention provides a semiconductor device package comprising a substrate with at lease a pre-formed die receiving cavity formed and terminal contact metal pads formed within an upper surface of the substrate. At lease a first die is disposed within the die receiving cavity. A first dielectric layer is formed on the first die and the substrate and refilled into a gap between the first die and the substrate to absorb thermal mechanical stress there between. A first re-distribution layer (RDL) is formed on the first dielectric layer and coupled to the first die. A second dielectric layer is formed on the first RDL, and then a second die is disposed on the second dielectric layer and surrounded by core pastes having through holes thereon. A second re-distribution layer (RDL) is formed on the core pastes to fill the through holes, and then a third dielectric layer formed on the second RDL.

Owner:ADVANCED CHIP ENG TECH INC

Mixture containing fluororesin and prepreg prepared from same, and copper clad laminate

ActiveCN106854330AEasy to operateMild preparation conditionsSynthetic resin layered productsGlass/slag layered productsPolymer scienceResin matrix

The invention specifically relates to a mixture containing fluororesin and a preparation method thereof, belonging to the field of communication materials. A prepreg prepared by impregnating a glass fabric in dispersion liquid of the mixture containing fluororesin and then carrying out drying and the like has uniform glue content, good impregnation quality, strong resin adhesion, smooth surface and appropriate toughness and viscosity. The invention also relates to a high-frequency copper clad laminate prepared from the prepreg, or a film or copper foil made of the mixture containing fluororesin. The prepared copper clad laminate has good thermal-mechanical properties, excellent dielectric properties and high copper foil strength, and can meet requirements on the comprehensive properties of substrate materials in the field of high-frequency communication. According to the invention, the processing properties of traditional fluororesin are greatly improved by using fluorine-containing resin with a low melting point; and a coupling agent is cooperatively used, so interaction between an inorganic filling material and glass fabric and a resin matrix is improved, dispersibility of the inorganic filling material, processing aids and the like in the fluororesin is enhanced, and the overall performance of the copper clad laminate is made more stable.

Owner:CHANGZHOU ZHONGYING SCI & TECH CO LTD

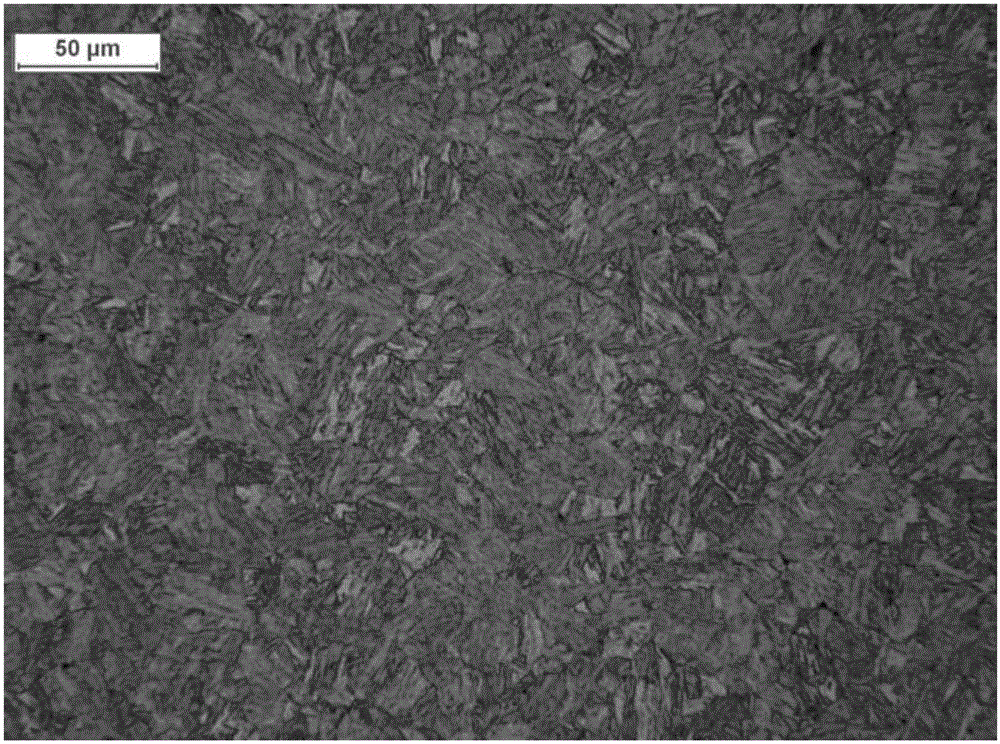

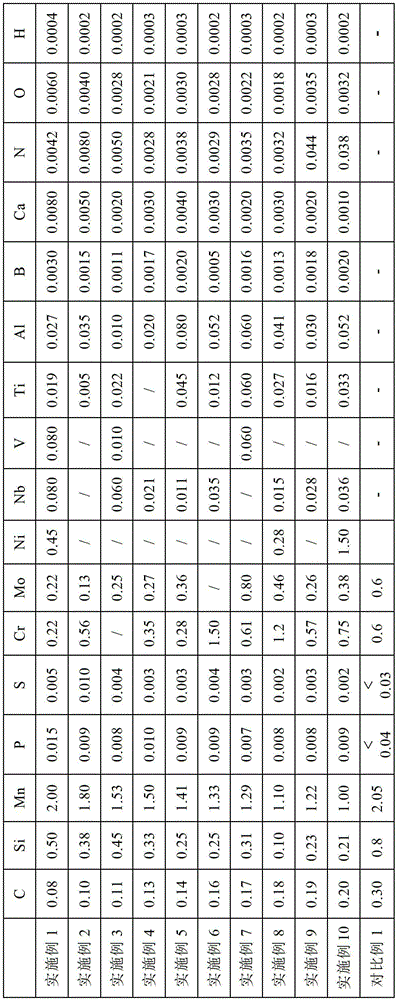

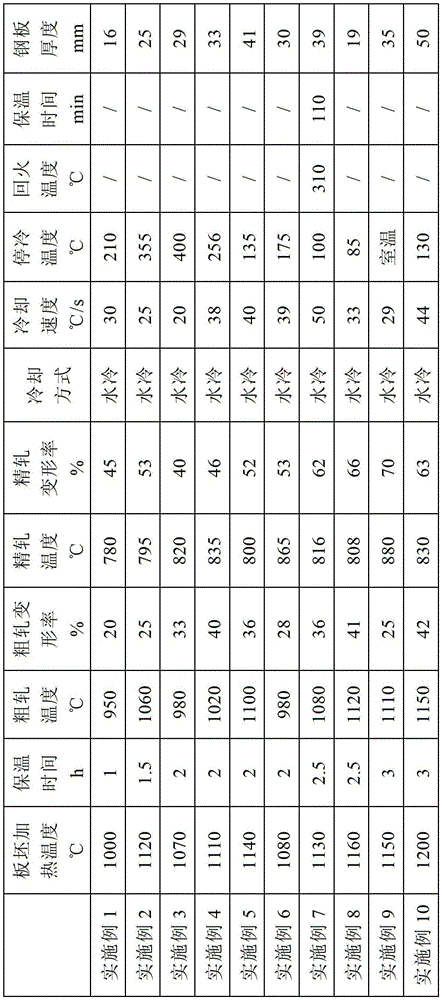

Low-alloy high-toughness wear resistant steel plate and manufacturing method thereof

ActiveCN103146997AGood mechanical propertiesHigh strengthFurnace typesQuenching agentsChemical compositionWear resistant

The invention relates to a low-alloy high-toughness wear resistant steel plate and a manufacturing method thereof. The steel plate contains the following chemical components (wt%): C: 0.08-0.20%, Si: 0.10-0.60%, Mn: 1.00-2.00%, B: 0.0005-0.0040%, Cr<=1.50%, Mo<=0.80%, Ni<=1.50%, Nb<=0.080%, V<=0.080%, Ti<=0.060%, Al: 0.010-0.080%, Ca: 0.0010-0.0080%, N<=0.0080%, O<=0.0080%, H<=0.0004%, P<=0.0015% and S<=0.010%, wherein the following relationships are satisfied: 0.20%<=(Cr / 5+Mn / 6+50 B)<=0.55%, 0.02%<=(Mo / 3+Ni / 5+2Nb)<=0.45%, and 0.01%<=(Al+Ti)<=0.13%; and the balance of Fe and inevitable impurities. The contents of both carbon and alloy elements are reduced, the characteristics of refining, strengthening and the like of micro-alloy elements such as Nb and Ti are fully utilized, and a TMCP (thermal mechanical control processing) technology is adopted, so that the wear resistant steel plate is high in hardness, good in toughness, easy to weld, perfect in wear resistance, and applicable to easily-worn components in various types of mechanical equipment.

Owner:BAOSHAN IRON & STEEL CO LTD

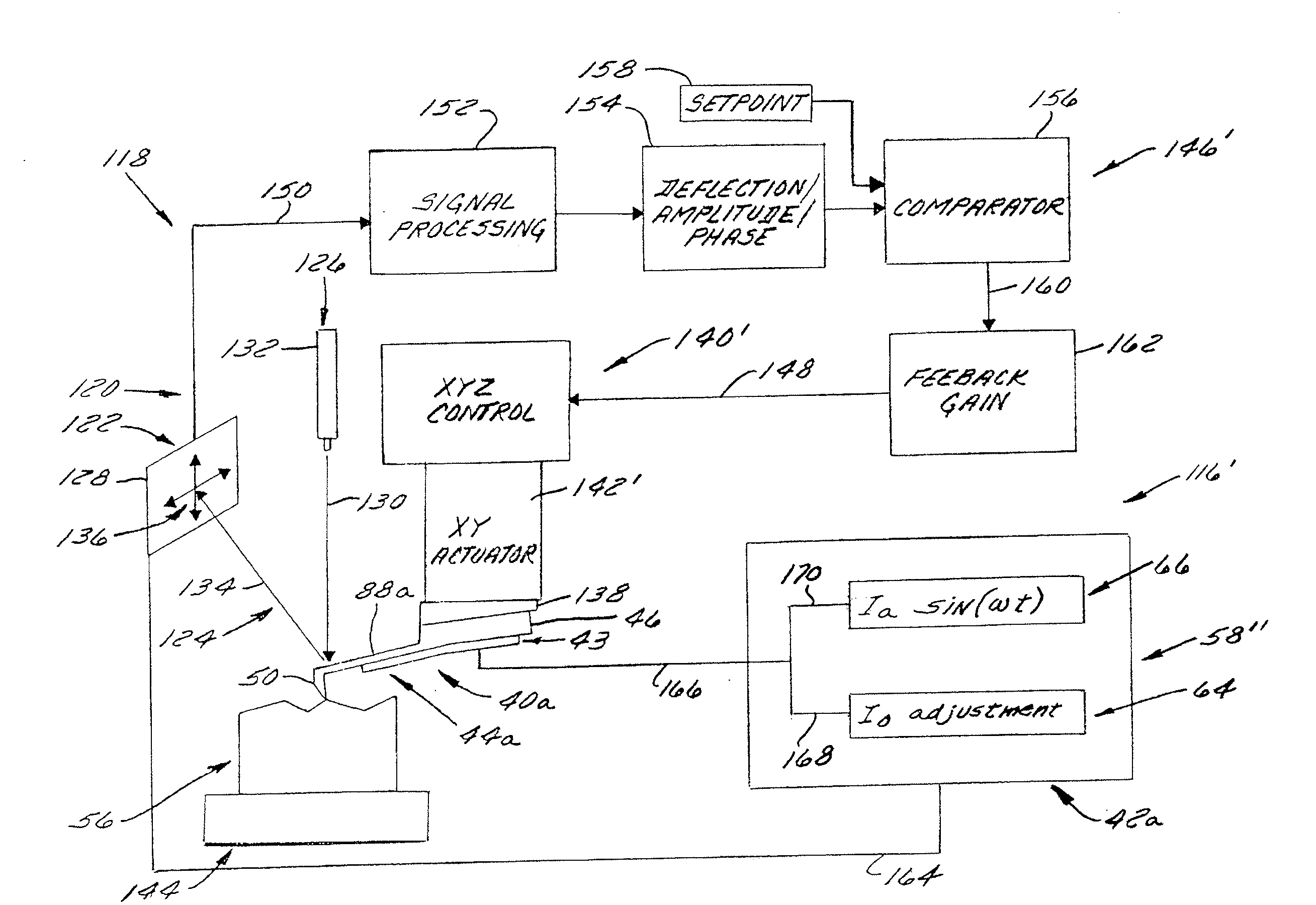

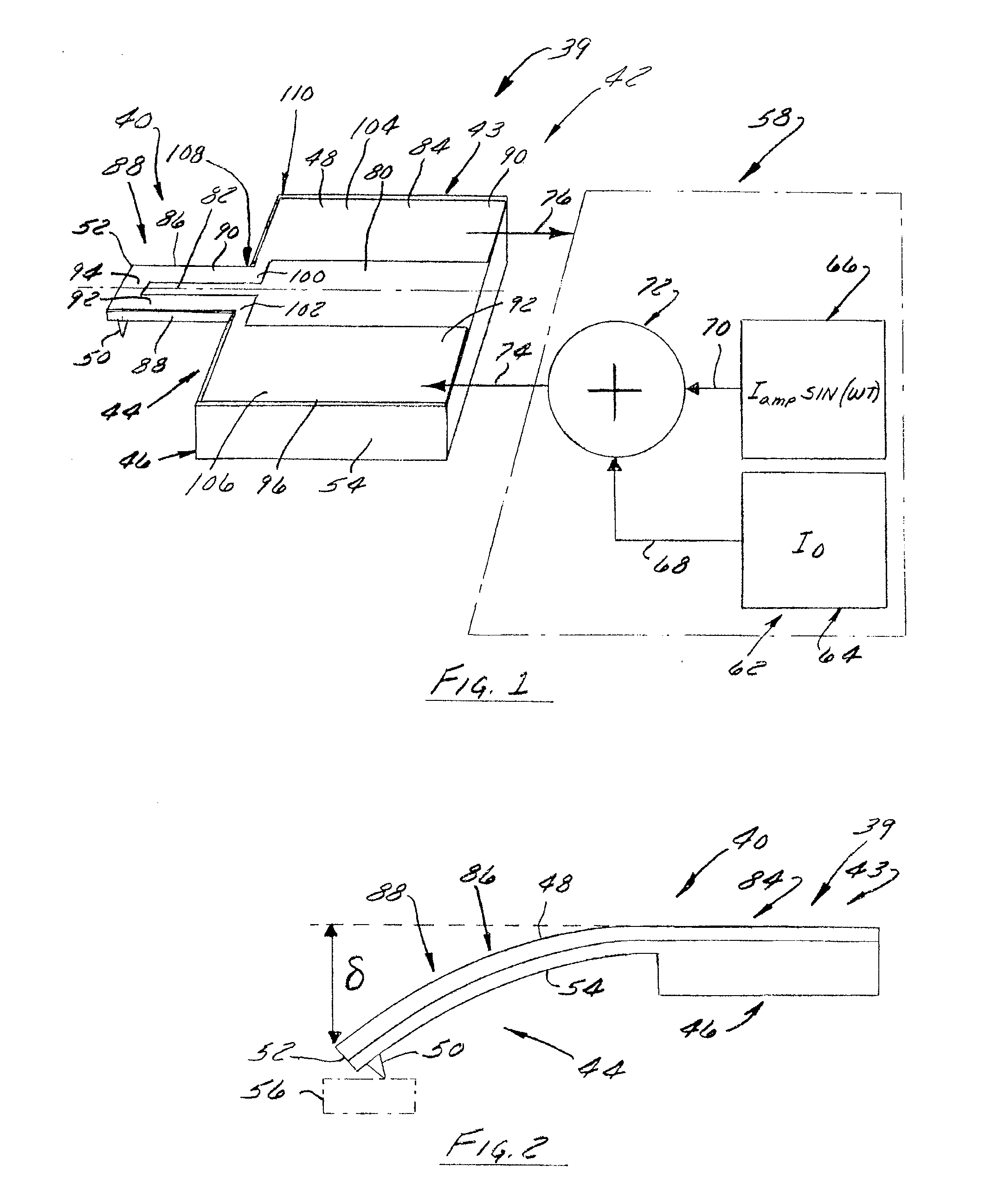

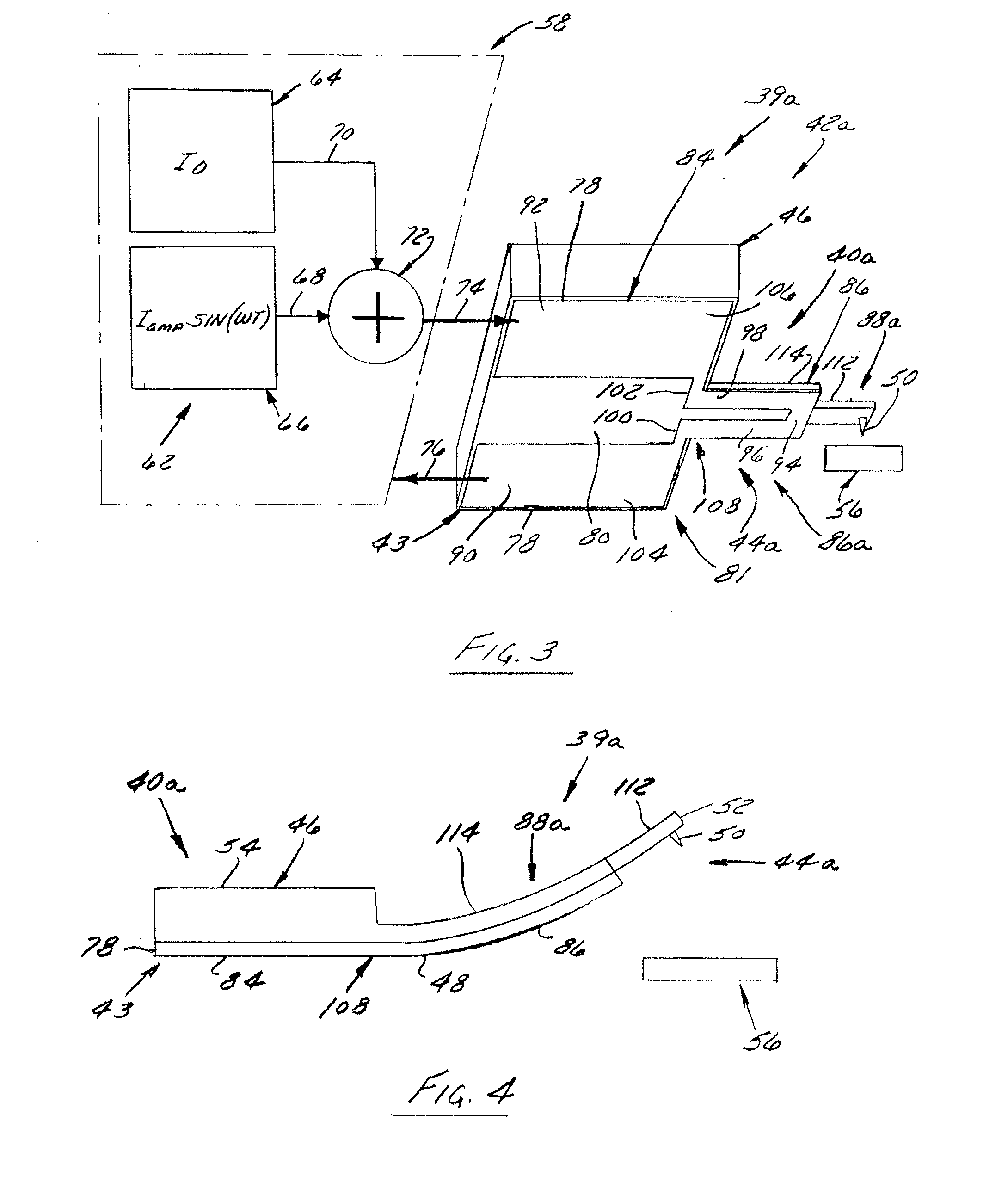

Thermal mechanical drive actuator, thermal probe and method of thermally driving a probe

ActiveUS20080011065A1Improve cooling effectIncrease convective coolingNanotechnologyMechanical roughness/irregularity measurementsThermal dilatationMeasuring instrument

A drive actuator for a measurement instrument having a probe, the drive actuator including a heating element in a thermally conductive relationship with the probe such that application of electric current to the heating element modifies a characteristic of the probe. The probe device includes a probe including a cantilever having a lever made of a material having a selected thermal expansivity and a drive actuator in operable cooperation with the cantilever lever made of a material having a thermal expansivity different than the thermal expansivity of the material of which the cantilever lever is made.

Owner:BRUKER NANO INC

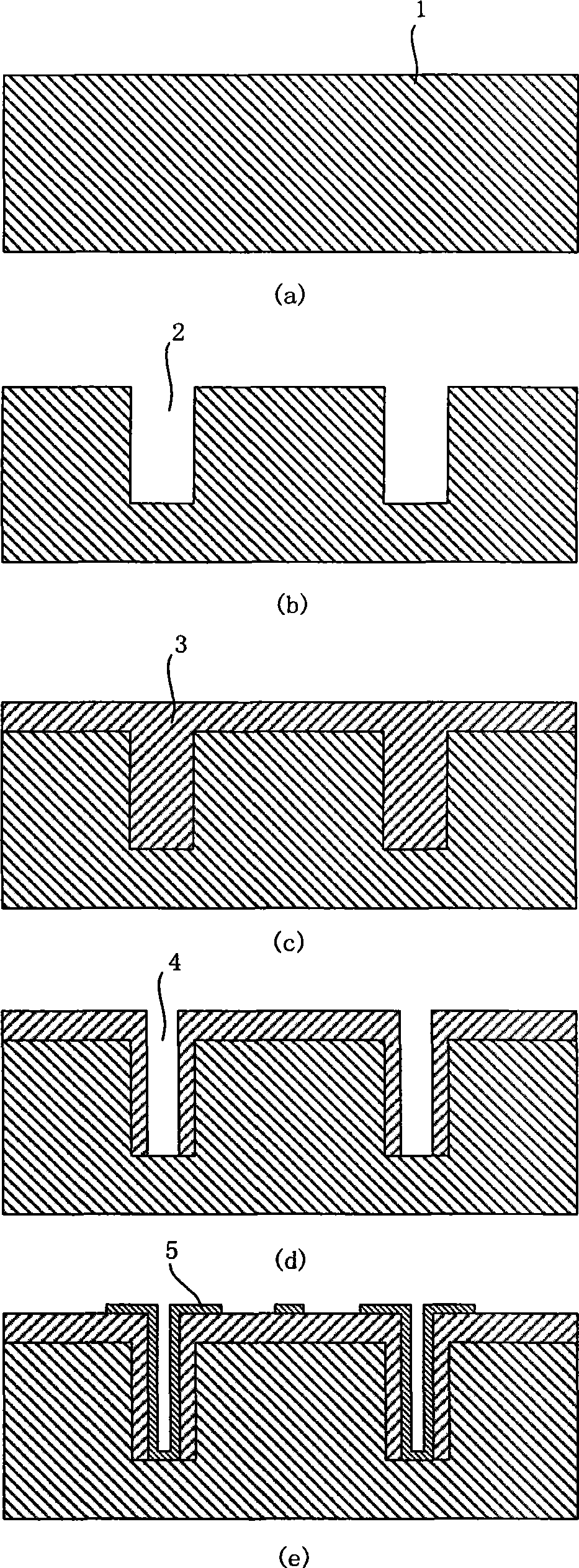

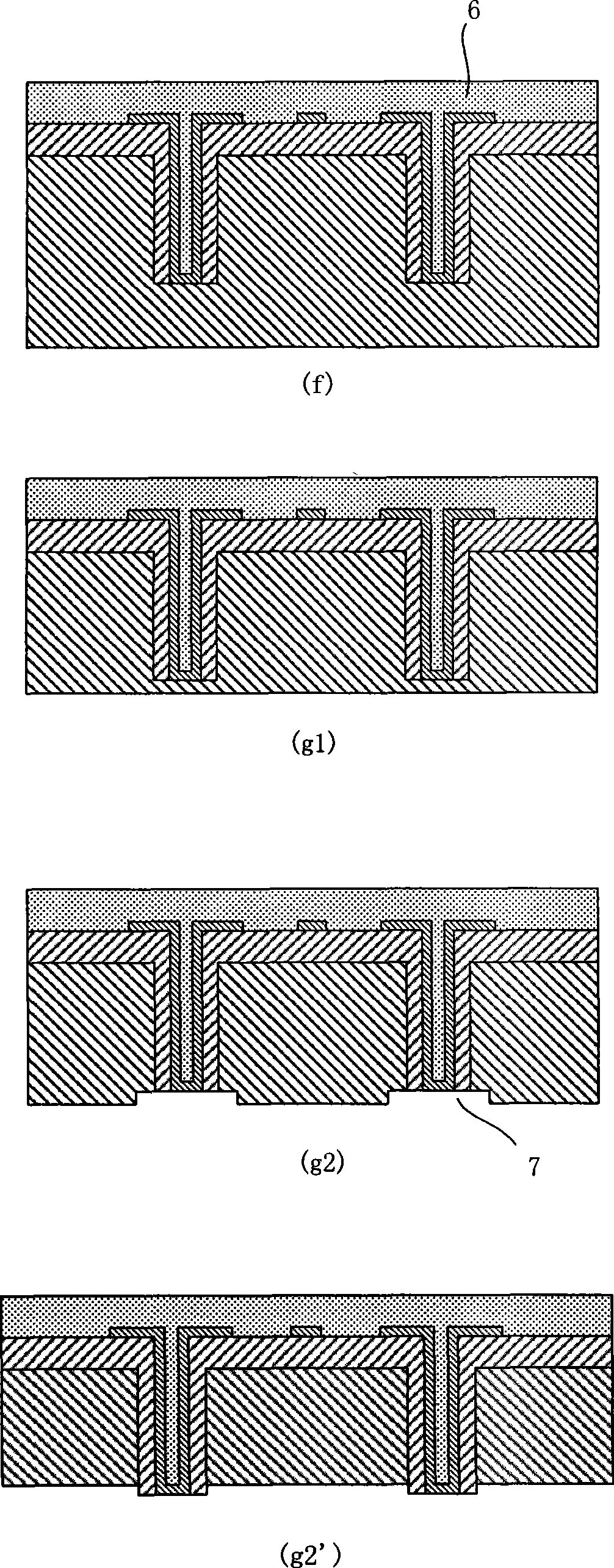

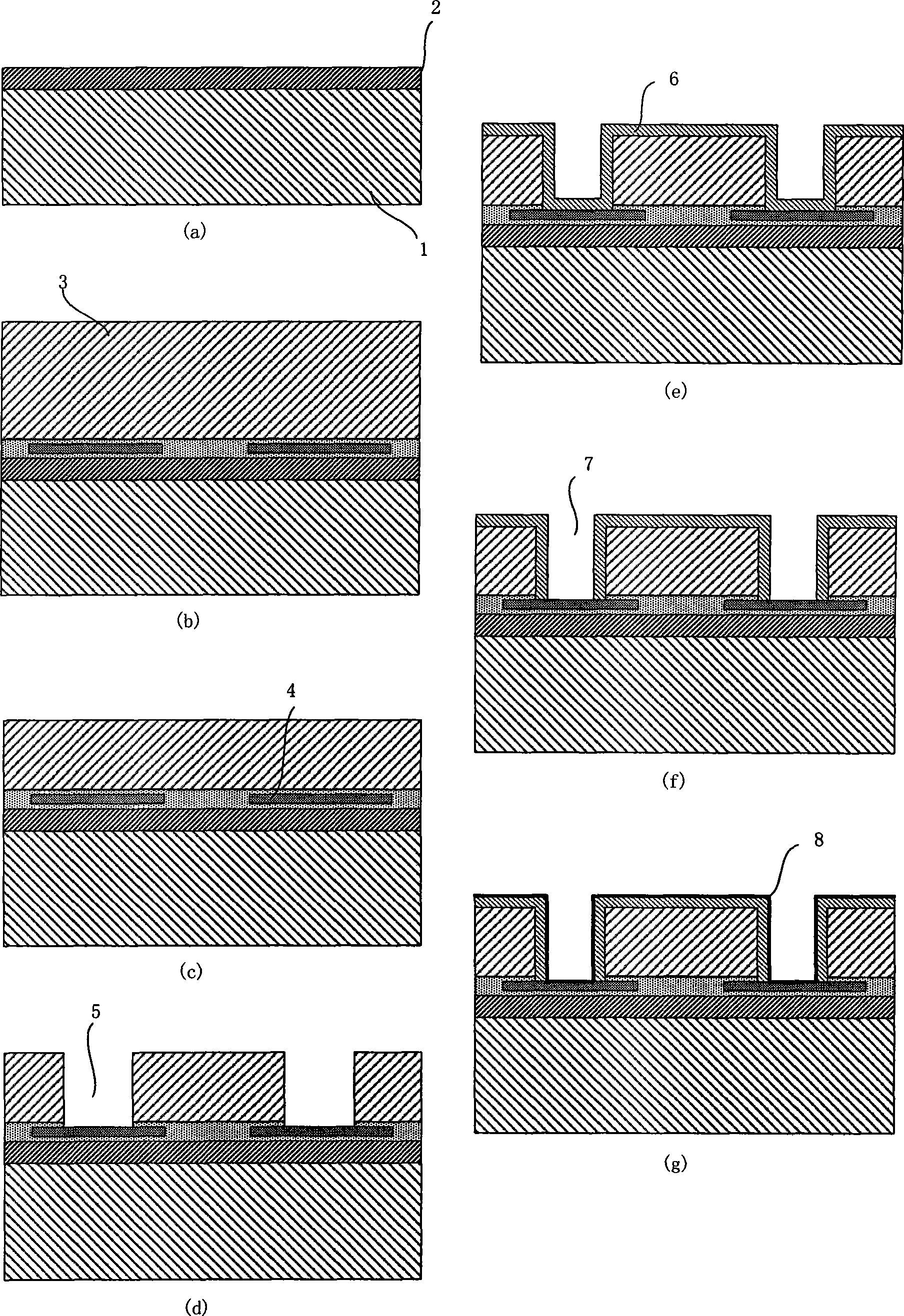

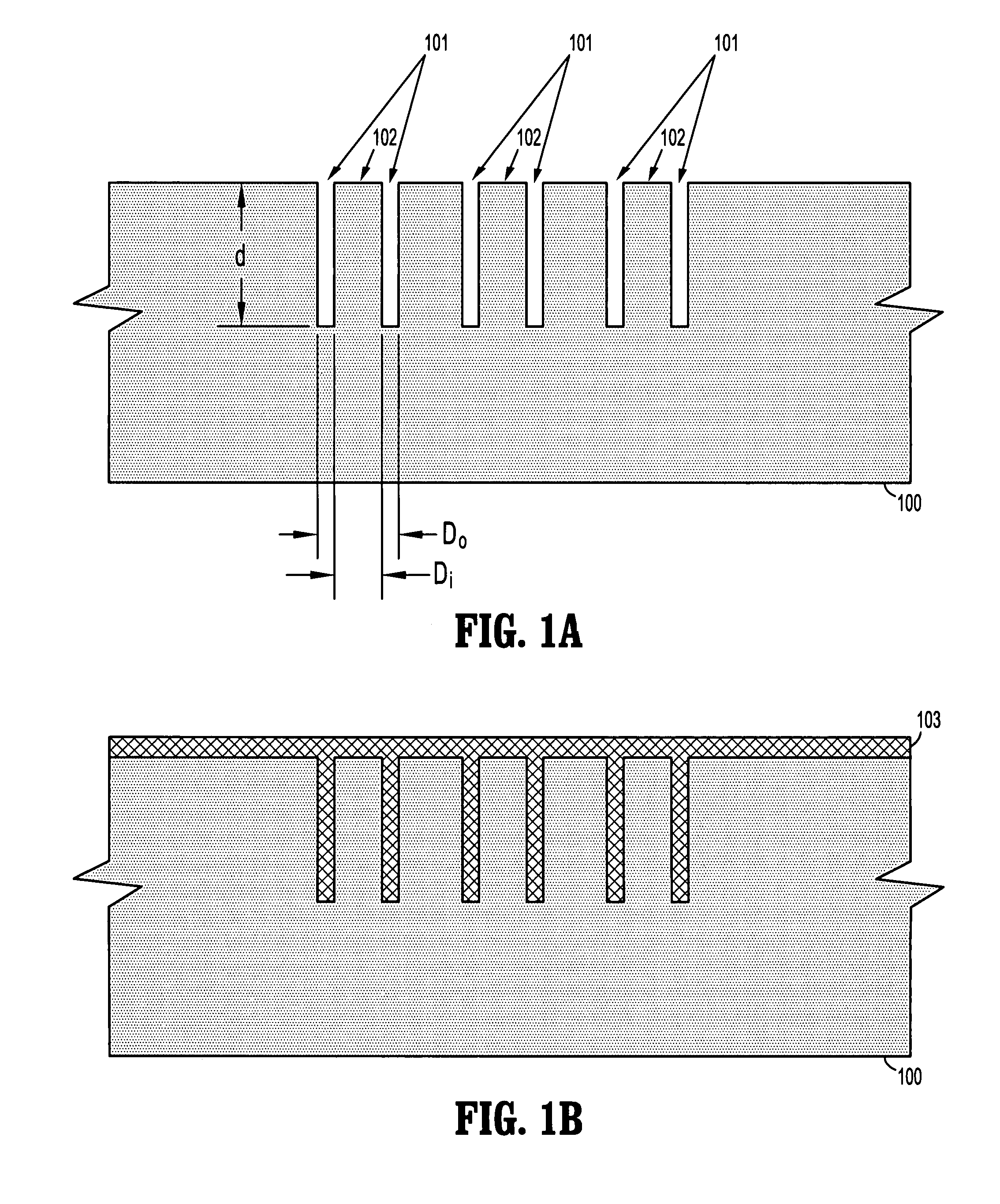

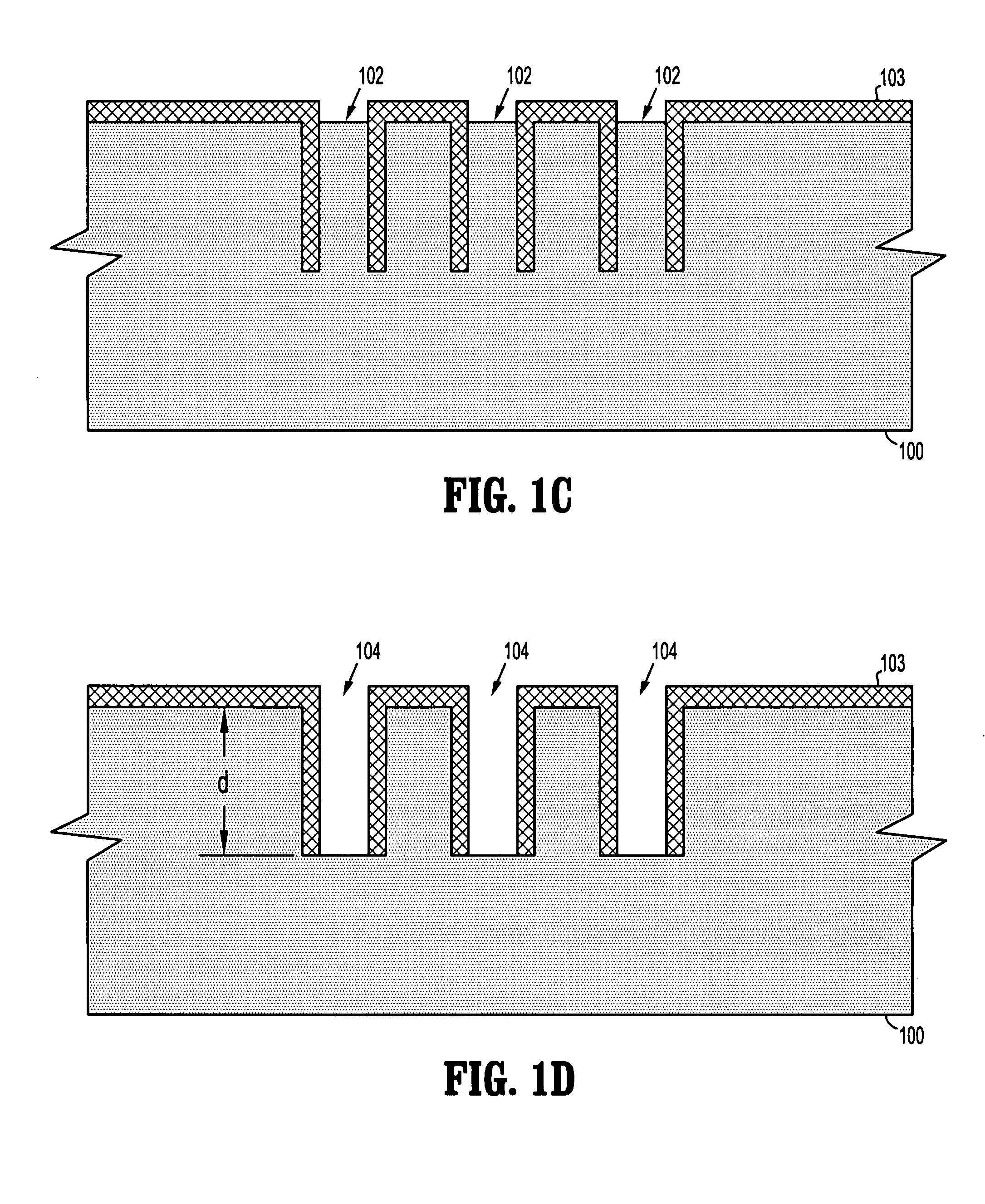

Process for treating through wafer interconnection construction

ActiveCN101483150AMitigate Thermal MismatchThe process steps are simpleSemiconductor/solid-state device manufacturingParasitic capacitanceInterconnection

The invention discloses a through wafer interconnect structure processing method comprising: 1. etching a blind hole on a substrate; 2. etching a pattern dielectric substance layer on the substrate; 3. etching the pattern dielectric substance layer and the dielectric material at the bottom of the blind hole, keeping the dielectric material of a blind hole side wall; forming a dielectric substance hole on the substrate; 4. depositing a layer of conductive material on the dielectric substance hole and forming a conductive hole; 5. re-depositing a layer of pattern dielectric substance on the conductive layer and filling the conductive hole; 6. etching the back side of the plate to expose the conductive layer and forming a solder micro-convex point on the conductive layer, wherein the pattern dielectric substance material is preferable poly-p-xylene. The invention simplifies the process steps, reduces the process time and the cost; depresses a parasitic capacitance by using two layers of the pattern dielectric substance layers, improves a interconnect electrical behavior, suits for the high speed and RF three-dimensional interconnection structure; releases the thermal mismatch between the conductive material and the silicon and greatly reduces the thermal mechanical stress.

Owner:HUAZHONG UNIV OF SCI & TECH

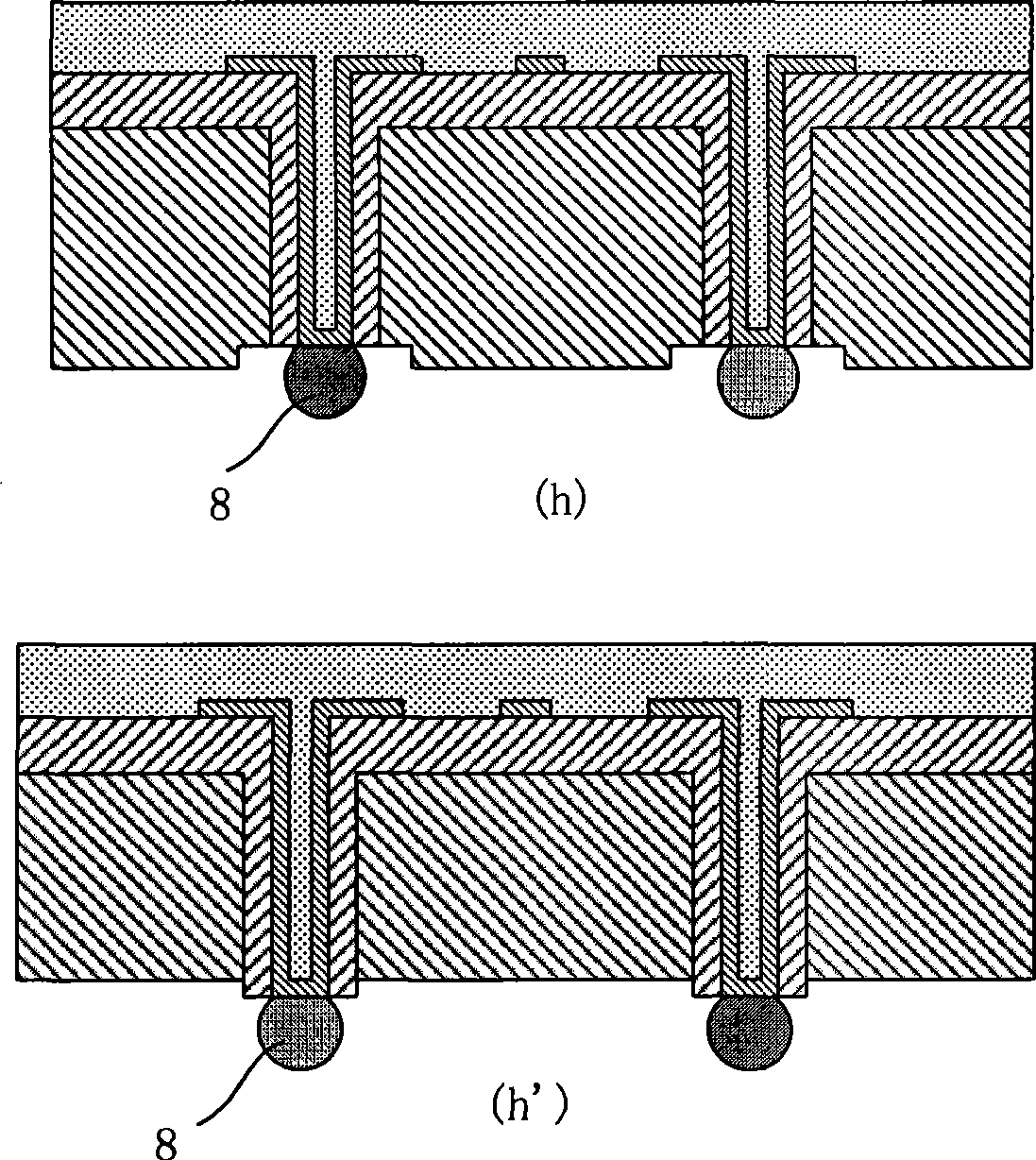

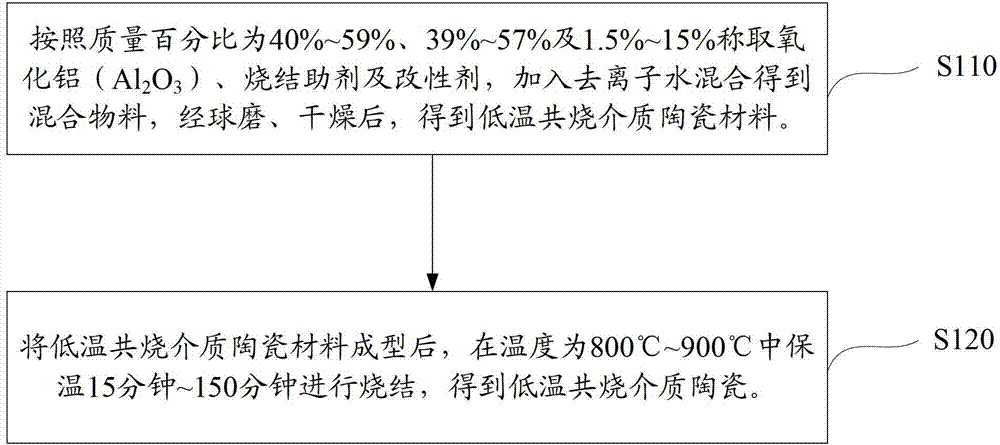

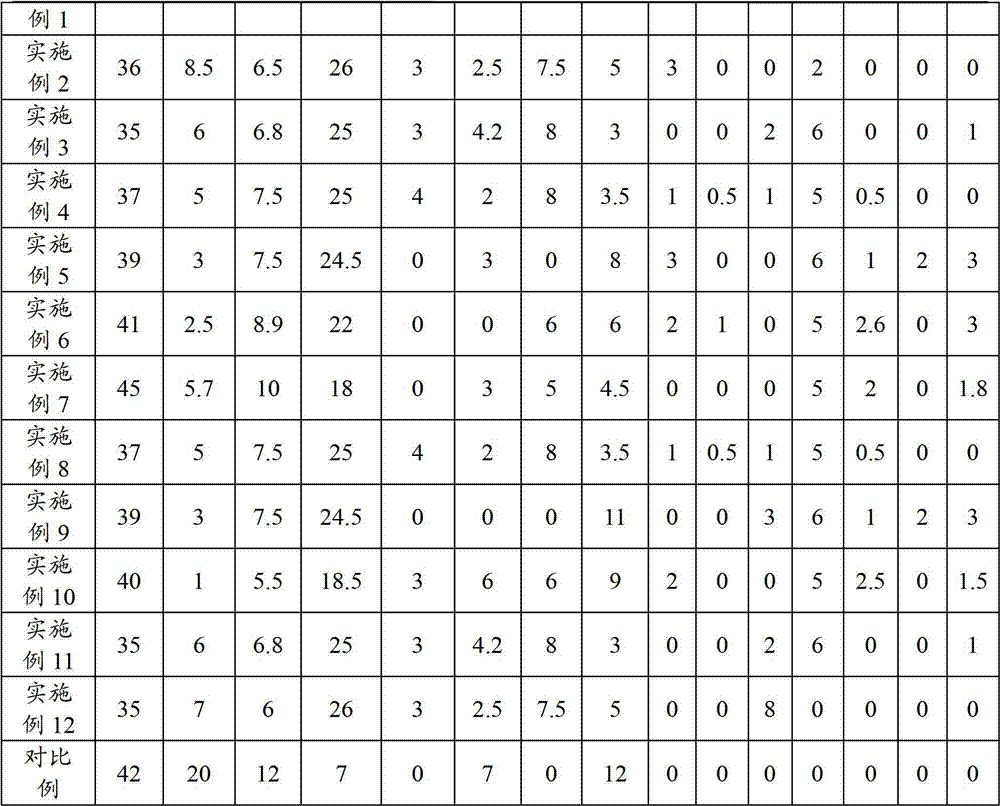

Method, sintering aid and materials for preparation of low-temperature cofired medium ceramic and application

A sintering aid for a low-temperature cofired medium ceramic material is composed of, by weight, 31%-45% of silicon dioxide, 1%-10% of boron oxide, 5.1%-10% of zinc oxide, 18%-30% of aluminum oxide, 11%-24% of alkaline earth metallic oxide and 5%-15% of oxide with the general formula of R2O3, wherein R refers to at least one of lanthanum, cerium, praseodymium, neodymium, samarium, europium and dysprosium, and the alkaline earth metallic oxide refers to one of magnesium oxide, calcium oxide, barium oxide and strontium oxide. Adding the sintering aid into the low-temperature cofired medium ceramic material enables the prepared low-temperature cofired medium ceramic to have excellent thermal mechanical performance and dielectric performance. In addition, the invention provides the low-temperature cofired medium ceramic material and application thereof and a method for preparing the low-temperature cofired medium ceramic.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

Production method for through wafer interconnection construction

ActiveCN101483149AMitigate Thermal MismatchThe process steps are simpleSemiconductor/solid-state device manufacturingParyleneParasitic capacitance

The invention discloses a through wafer interconnect structure preparation method comprising: 1. bonding a bonding silicon device wafer on a silicon wafer substrate; 2. thinning the silicon device wafer, etching the silicon device and forming a blind hole; 3. coating a layer of pattern dielectric material (such as poly-p-xylene) on the silicon device wafer; 4. etching the pattern dielectric substance layer, etching the dielectric material at the bottom of the blind hole, keeping a blind hole side wall; forming a dielectric substance hole on the substrate and enabling the dielectric substance hole and the blind hole coaxial; 5. depositing a layer of conductive material on the dielectric substance hole as a conductive layer and forming a conductive hole; 6. re-depositing a layer of pattern dielectric substance on the conductive layer; 7. forming a solder micro-convex point on the conductive layer. The invention simplifies the process steps, reduces the process time and the cost; depresses a parasitic capacitance, improves a interconnect electrical behavior, suits for the RF three-dimensional interconnection structure; releases the thermal mismatch between the conductive material and the silicon and greatly reduces the thermal mechanical stress.

Owner:HUAZHONG UNIV OF SCI & TECH

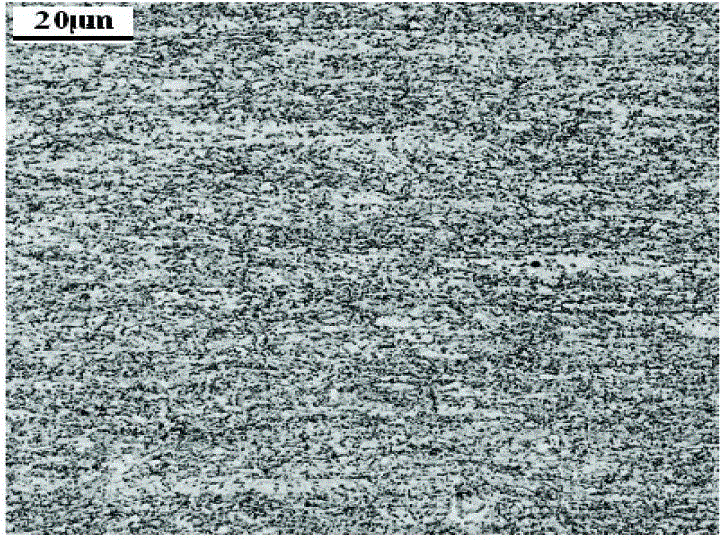

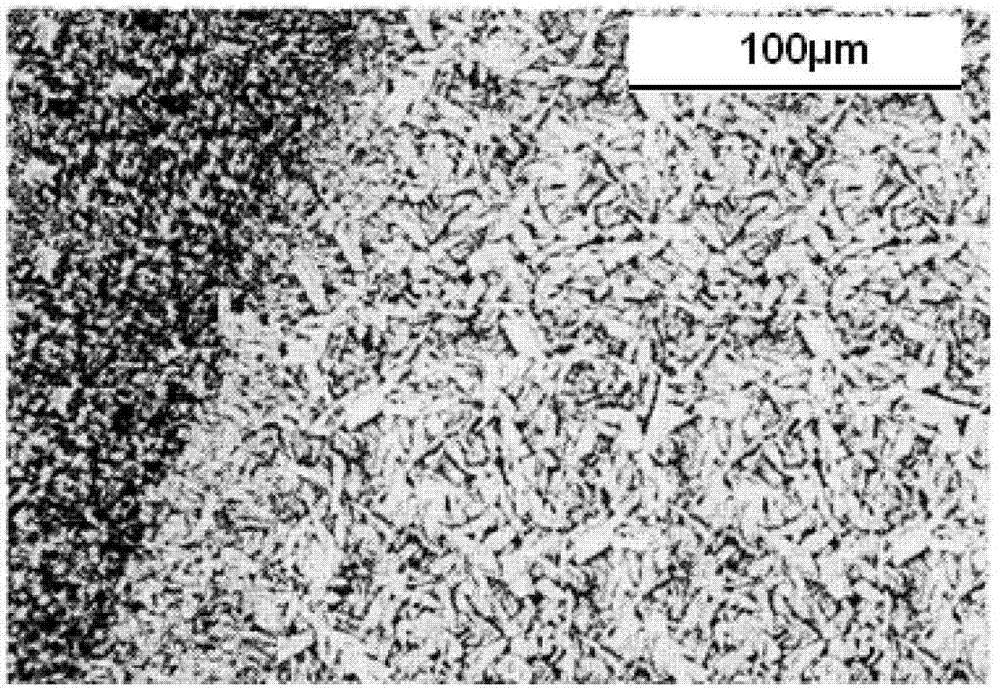

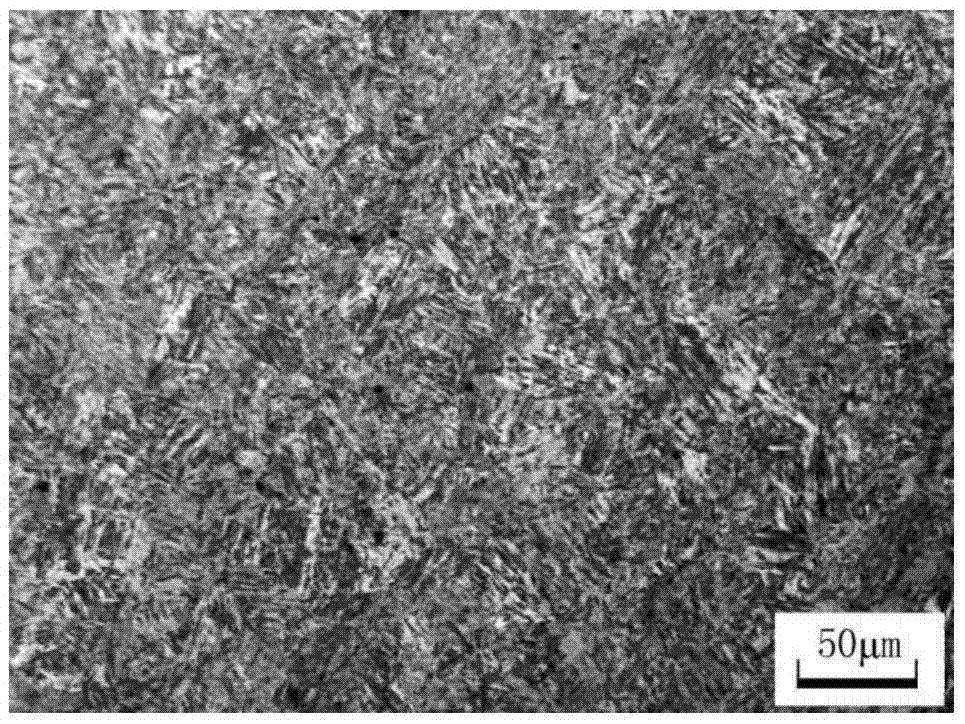

High-strength low-temperature steel with high hydrogen induced cracking (HIC) and sulfide stress corrosion cracking (SSC) resistance and manufacturing method thereof

ActiveCN102719745AReduce consumptionReduce difficultyHeat treatment process controlStress corrosion crackingSteel tube

The invention relates to high-strength low-temperature steel with high hydrogen induced cracking (HIC) and sulfide stress corrosion cracking (SSC) resistance and a manufacturing method thereof. A low alloy steel component system with ultra-low C content, low Si content, medium Mn content, low Als content, low N content, a little alloyed Ni and Mo and trace Ti and Nb is adopted, Mn / C is more than or equal to 22, the segregation index 1.32 (percent C)*[(1.53 (percent Mn)+1.37 (percent Si)+1.15 (percent Mo)+1.06 (percent Cr)+(percent Cu)+0.86 (percent Ni)]*[(30 (percent P)+10 (percent S)] is less than or equal to 0.060, [(percent Si)+(percent Als)]*(percent C) is less than or equal to 0.0035, Pcm is less than or equal to 0.018 percent, Nib / Ti is 1.5 to 3.5, Ca treatment is performed, Ca / S is 0.80 to 3.00, the microstructure of a finished steel plate product consists of uniform and fine acicular ferrites and a few upper bainites by optimizing a thermal mechanical control processing (TMCP) technology, and the average particle size is less than 10mu m; and the characteristics of high strength, toughness and HIC and SSC resistance are achieved, high heat input welding can be performed, and the steel is particularly suitable for manufacturing a low temperature storage tank, a low temperature pressure steel pipe, an ocean platform in an ice sea area, and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

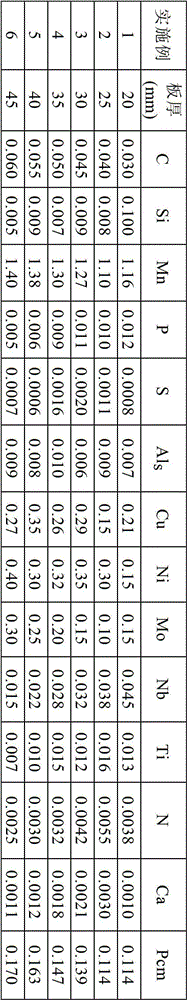

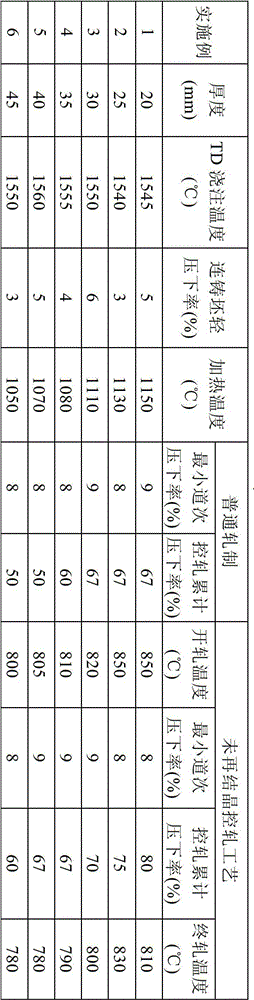

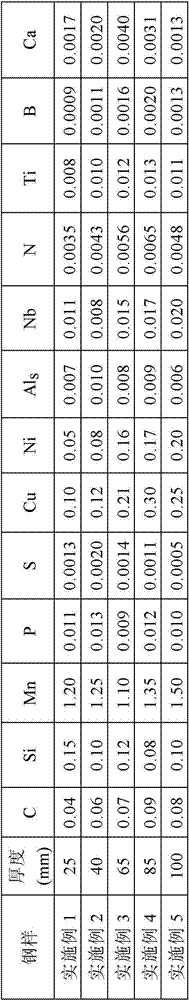

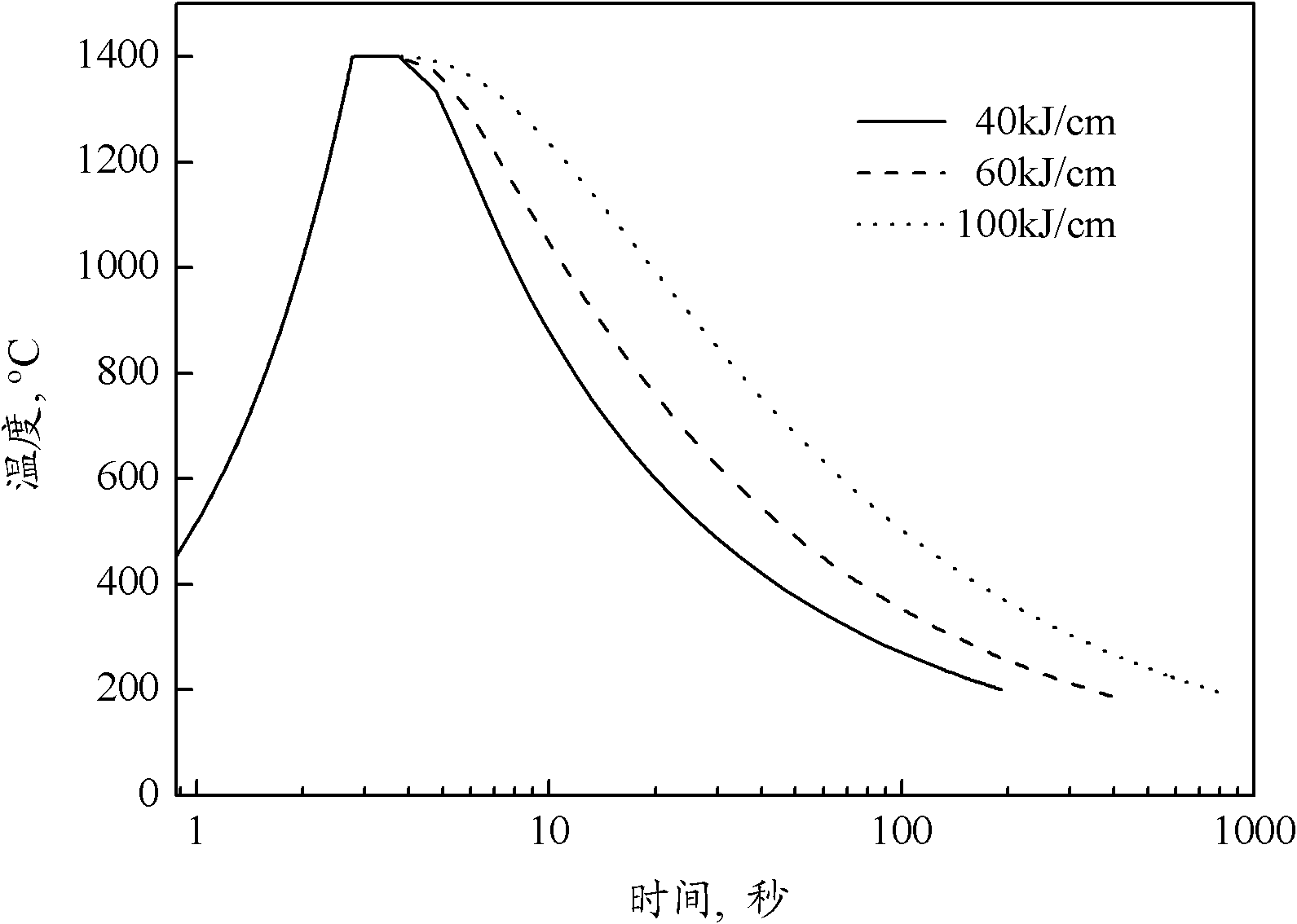

Ultra-low temperature steel in great heat input welding and manufacturing method of steel

The invention discloses ultra-low temperature steel in great heat input welding and a manufacturing method of the steel. The steel disclosed by the invention comprises the following components in percent by weight: 0.040-0.090% of C, less than or equal to 0.15% of Si, 1.10-1.50% of Mn, less than or equal to 0.013% of P, less than or equal to 0.0020% of S, 0.10-0.30% of Cu, 0.05-0.20% of Ni, 0.008-0.020% of Nb, less than or equal to 0.010% of Als, 0.008-0.013% of Ti, 0.0035-0.0065% of N, 0.001-0.004% of Ca, 0.0008-0.0020% of B and the balance of Fe and inevitable impurities. By adopting the simple combined design of alloy elements in the steel disclosed by the invention, the TMCP (Thermal Mechanical Control Processing) technology is optimized without the requirement of adding a great number of noble elements such as Ni and Cu, the excellent patent steel plate low-temperature tenacity is acquired and simultaneously the low-temperature tenacity of the HAZ (Heat Affected Zone) during large line energy welding is also excellent; and the uniform and excellent mechanical property, good welding property and marine atmosphere corrosion resistance are acquired, so that the steel disclosed by the invention is specially applicable to wind tower structures on the sea, low-temperature pressure vessels, ocean platforms and bridges.

Owner:BAOSHAN IRON & STEEL CO LTD

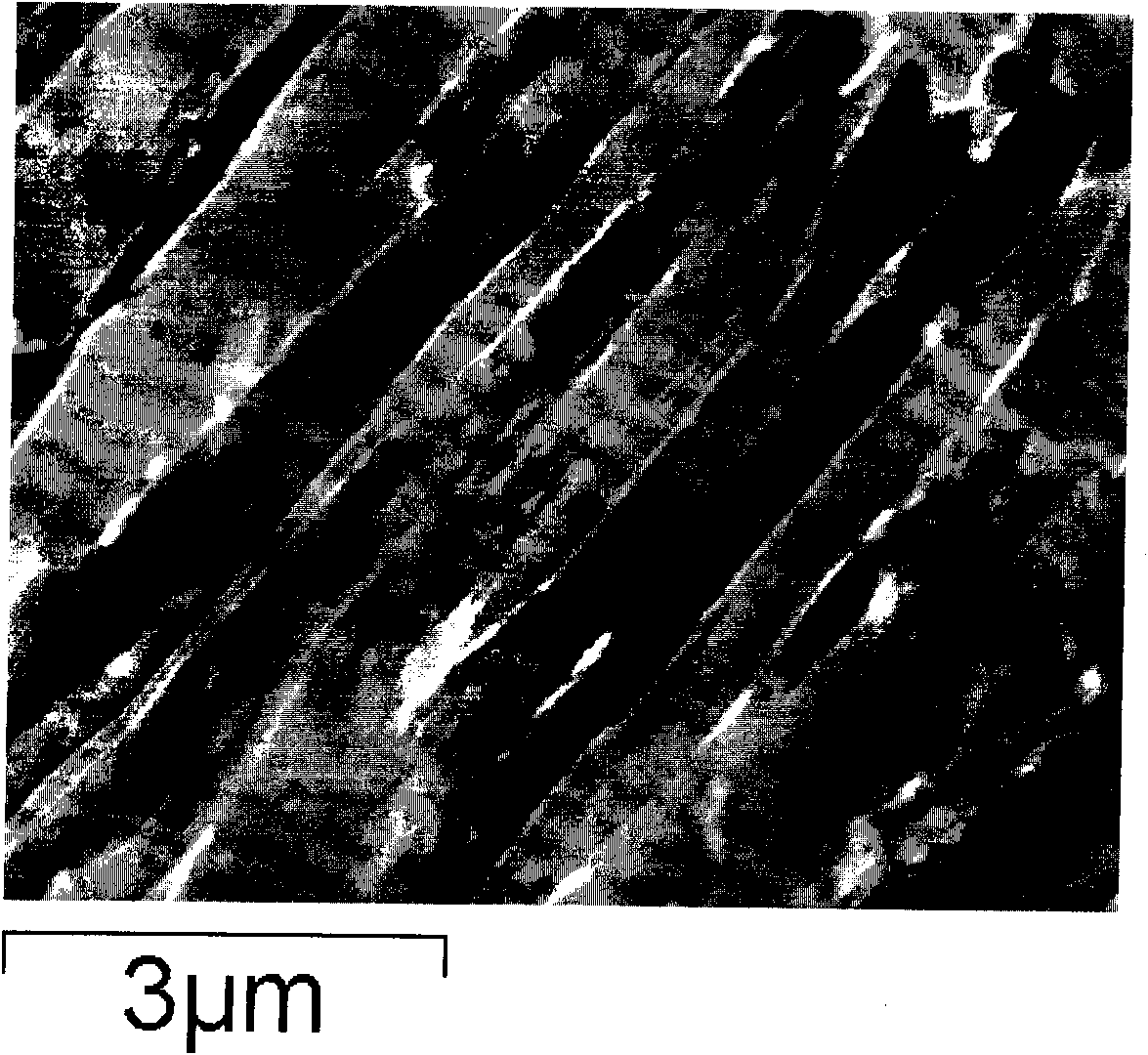

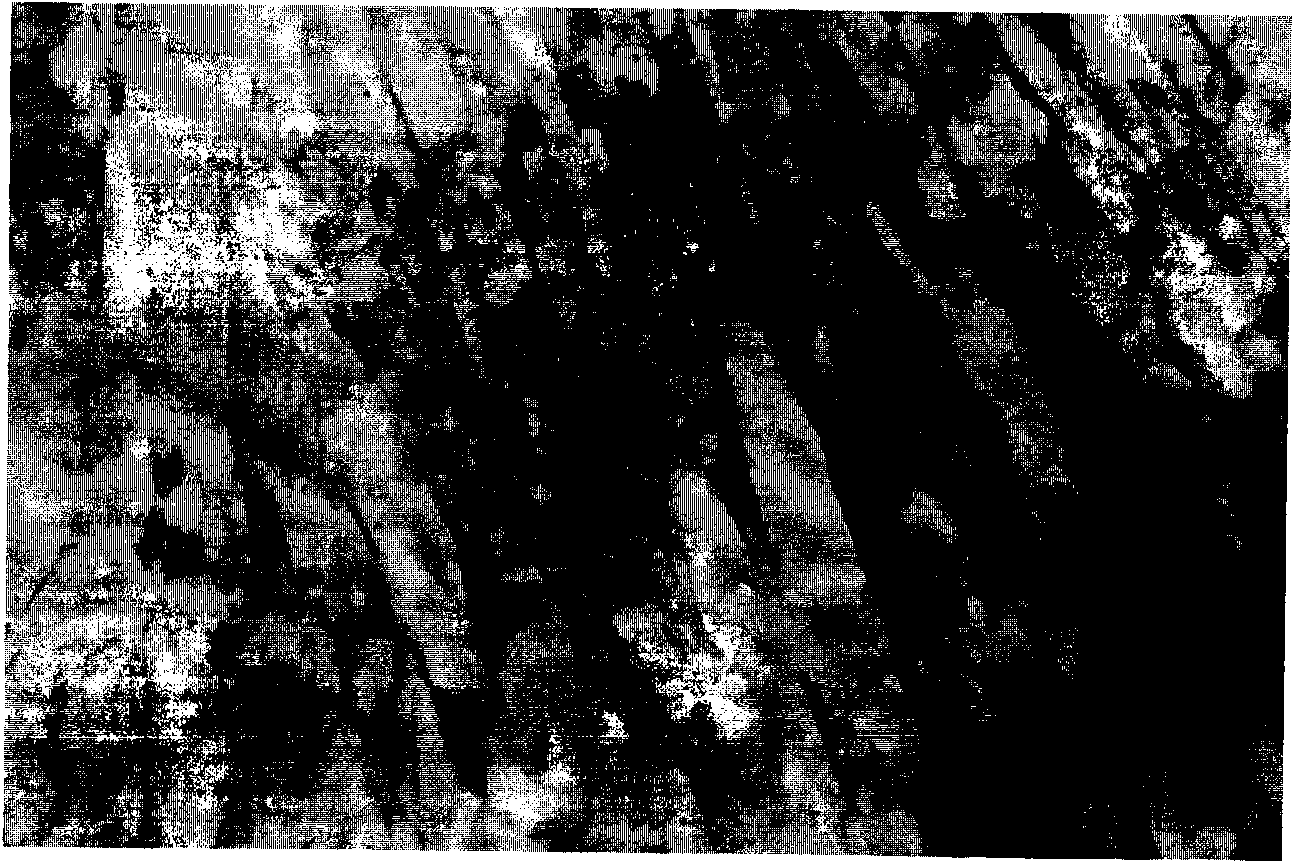

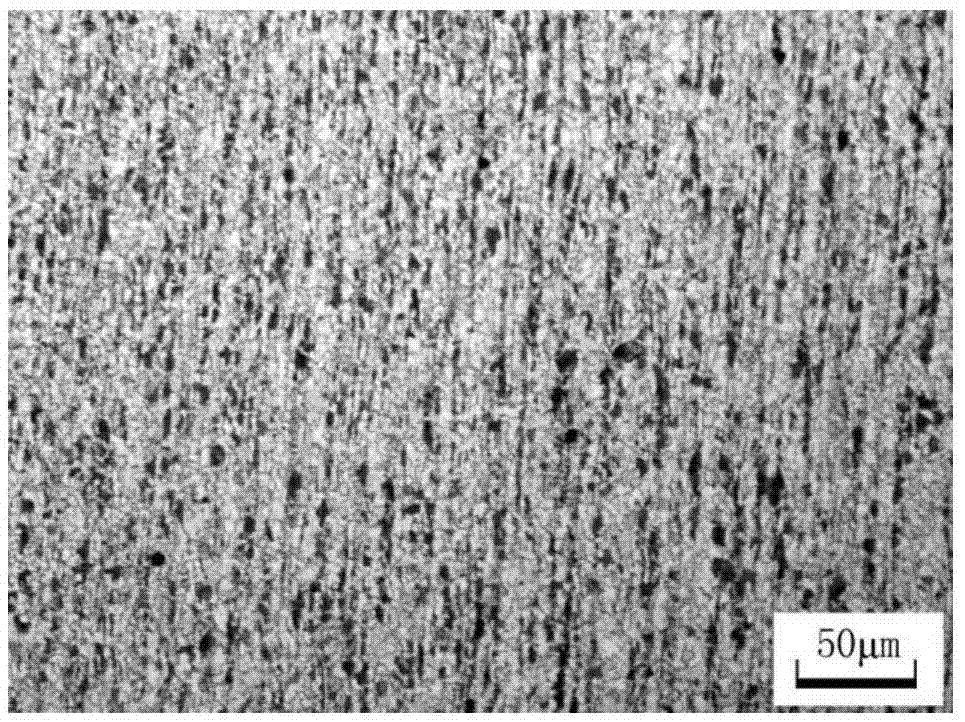

Ultrafine crystal bainite high-strength steel and manufacturing method thereof

The invention relates to ultrafine crystal bainite high-strength steel and a manufacturing method thereof. The ultrafine crystal bainite high strength steel comprises the components by mass percent: 0.03-0.06% of C, 0.05-0.90% of Si, 1.00-2.00% of Mn, 0.05-0.25% of Cr, 0.03-0.08% of Nb, 0.02-0.04% of Al, 0.004-0.020% of Ti, 0.0010-0.0020% of B, 0.01-0.03% of Zr as well as balance of Fe and inevitable impurities, and P cm is<=0.20%. 13.14C+14.21Nb+6.32Cr+680B-1.98Mn<(Si)<12.22C+9.87Nb+8.11Cr+1210B-1.25Mn. By adopting control thermal mechanical rolling and accelerated cooling technology, the invention can obtain an ultrafine bainite ferrite lath and structure with mahaud components distributed along the interface of the lath; and the yield strength is more than 690MPa, the tensile strength is more than 780MPa, and the Charpy impact power Akv (-20 DEG C) is>=120J. A steel plate has good welding performance, is welded at the room temperature and has no welding cold crack after being placed for 48h.

Owner:BAOSHAN IRON & STEEL CO LTD

Method and system for real-time prognosis analysis and usage based residual life assessment of turbine engine components and display

ActiveUS8116990B2Facilitate decisionsPromote repairPlug gaugesTesting dielectric strengthCombustion chamberOff design

A method and system for performing continuous (real-time) physics based prognostics analysis as a function of actual engine usage and changing operating environment. A rule-based mission profile analysis is conducted to determine the mission variability which yields variability in the type of thermal-mechanical loads that an engine is subjected to during use. This is followed by combustor modeling to predict combustion liner temperatures and combustion nozzle plane temperature distributions as a function of engine usage which is followed by off-design engine modeling to determine the pitch-line temperatures in hot gas path components and thermodynamic modeling to compute the component temperature profiles of the components for different stages of the turbine. This is automatically followed by finite element (FE) based non-linear stress-strain analysis using an real-time FE solver and physics based damage accumulation, life consumption and residual life prediction analyses using microstructural modeling based damage and fracture analysis techniques.

Owner:KOUL ASHOK

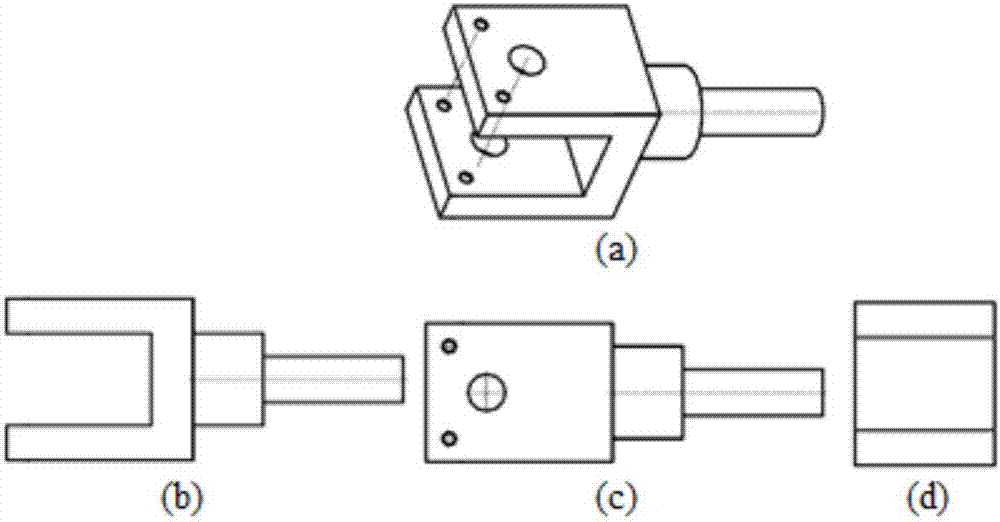

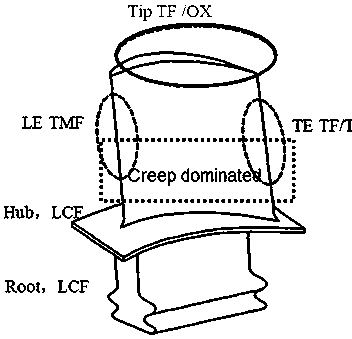

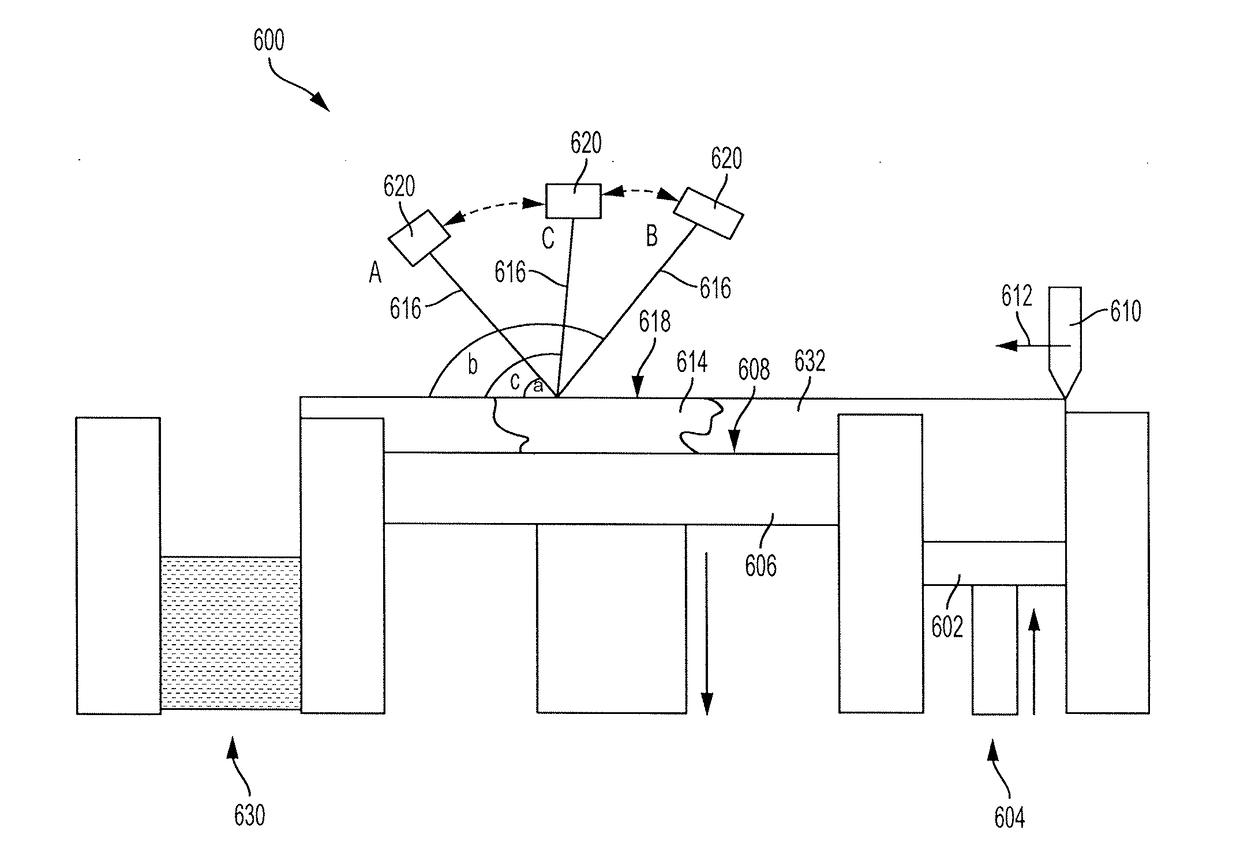

Thermal mechanical fatigue test system and method for performing hollow turbine blade superposed high-cycle vibration

ActiveCN107421984AAccurate test lifeEnsure safetyMaterial heat developmentTurbine bladeWater cooling

The invention relates to a thermal mechanical fatigue test system and method for performing hollow turbine blade superposed high-cycle vibration. The test system comprises a high / low-cycle load loading subsystem, a temperature load loading subsystem, a cooling subsystem and a load coordination control subsystem, wherein the high / low-cycle load loading subsystem is used for independently applying high / low-cycle loads to turbine blades which are stably clamped by a special fixture; the temperature load loading subsystem is used for heating assessment sections of the turbine blades; the cooling subsystem comprises a water cooling part and an air cooling part; the water cooling part is used for cooling in a test process; the air cooling part is used for coordinating a temperature cycle in the test and simulating cooling conditions inside the blades; and the load coordination control subsystem is used for controlling each system to operate in a coordinated manner. According to the test system disclosed by the invention, the stress field, temperature field and vibration conditions in the assessment section service process of the turbine blades and the cooling conditions inside the blades can be simulated, the thermal mechanical fatigue test for superposed high-cycle vibration of the turbine blades is performed, and a guarantee is provided for safe and reliable operations of aircraft engines.

Owner:BEIHANG UNIV

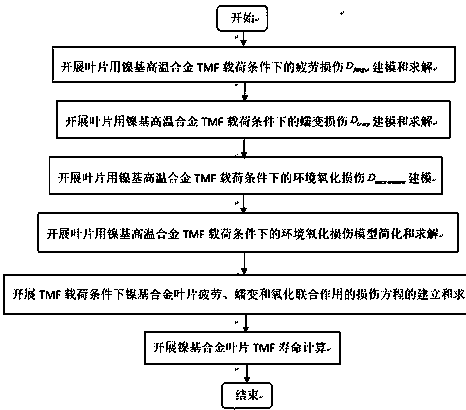

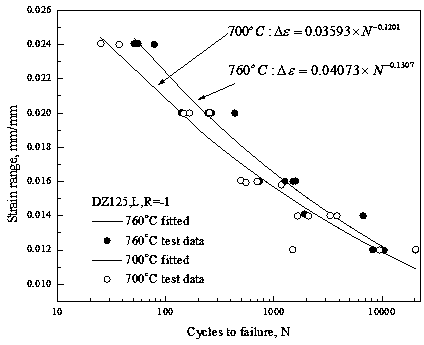

Life prediction method used for nickel-base superalloy blade under thermal mechanical fatigue load

InactiveCN108170905AThe modeling process is clearFully combine structural featuresDesign optimisation/simulationSpecial data processing applicationsFatigue damageTime function

The invention discloses a life prediction method used for a nickel-base superalloy blade under a thermal mechanical fatigue load. The problems of life prediction and joint representation of low cyclefatigue damage, creep damage and oxidation environment damage of the nickel-base superalloy blade under the TMF load are effectively solved; according to isothermal low cycle fatigue life data of nickel-base alloy under the condition of not causing high-temperature effects of creep, oxidation and the like, fitting is performed to obtain a strain life equation; in combination with a fatigue damagelinear accumulation theory, a fatigue damage model is obtained; a creep damage model is represented as temperature, stress and time functions; the oxidation environment damage is modeled based on an oxidation-cracking mechanism with a continuous oxidation layer at a crack tip; a continuous damage accumulation mechanism is adopted for the three models; and by virtue of stress, strain and temperature data of dangerous position points of the blade, accurate and reliable unified representation of fatigue, creep and oxidation interactive damage, and life prediction of a combined damage model to a nickel-base superalloy member under the thermal mechanical fatigue load is realized.

Owner:NANCHANG HANGKONG UNIVERSITY

Methods for fabricating silicon carriers with conductive through-vias with low stress and low defect density

InactiveUS7863189B2High-density packagingHigh-yieldSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorMicrometer

Methods are provided for fabricating silicon carriers with conductive through-vias that allow high-yield manufacture of silicon carrier with low defect density. In particular, methods are provided which enable fabrication of silicon carries with via diameters such as 1 to 10 microns in diameter for a vertical thickness of less than 10 micrometers to greater than 300 micrometers, which are capable robust to thermal-mechanical stresses during production to significantly minimize the thermal mechanical movement at the via sidewall interface between the silicon, insulator, liner and conductor materials.

Owner:GLOBALFOUNDRIES U S INC

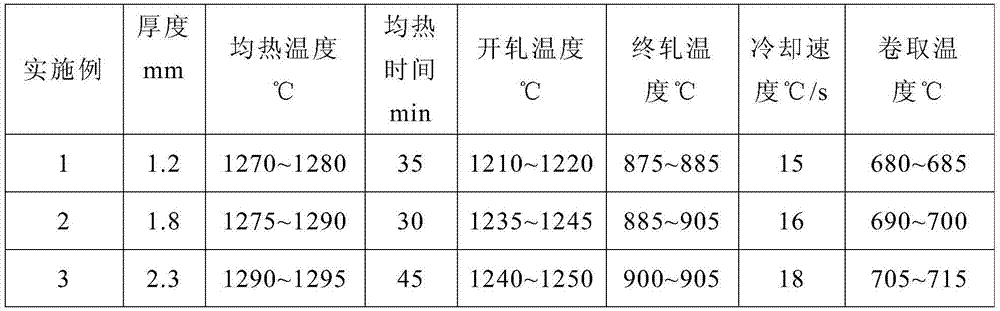

900MPa grade hot rolling non-tempering thin steel sheet and preparation method thereof

The invention relates to a 900MPa grade hot rolling non-tempering thin steel sheet and a preparation method thereof, belonging to the technical field of alloy steel. The steel sheet comprises the following chemical components in percentage by weight: 0.08-0.13wt% of C, less than or equal to 0.50wt% of Si, 1.0-2.0wt% of Mn, 0.08-0.20wt% of V, 0.08-0.15wt% of Ti, 0.15-0.40wt% of Mo, less than 0.015wt% of P, less than 0.005wt% of S, less than 0.005wt% of N, less than 0.002wt% of O and the balance of Fe and inevitable impurities. Through reasonable control of a V-Ti-Mo multielement microalloying and hot continuous rolling online TMCP (Thermal Mechanical Control Processing) process, a microstructure is obtained, wherein microalloy precipitated phases with grain size of about 5nm are dispersed and distributed on an ultra-fine grain ferrite matrix with grain size less than 5 mu m, so that the yield strength of the steel sheet can reach over 900MPa grade in a hot continuous rolling technical condition, thereby cancelling tempering thermal treatment after rolling. The steel sheet has the advantages that the production flow of the steel sheet is simplified, the energy consumption is reduced, the internal stress of the steel sheet is reduced, and the steel sheet has an important effect of improving the plate cut quality. The steel sheet can be widely applied to the field of mobile facilities such as automobiles, engineering machinery and containers.

Owner:CENT IRON & STEEL RES INST

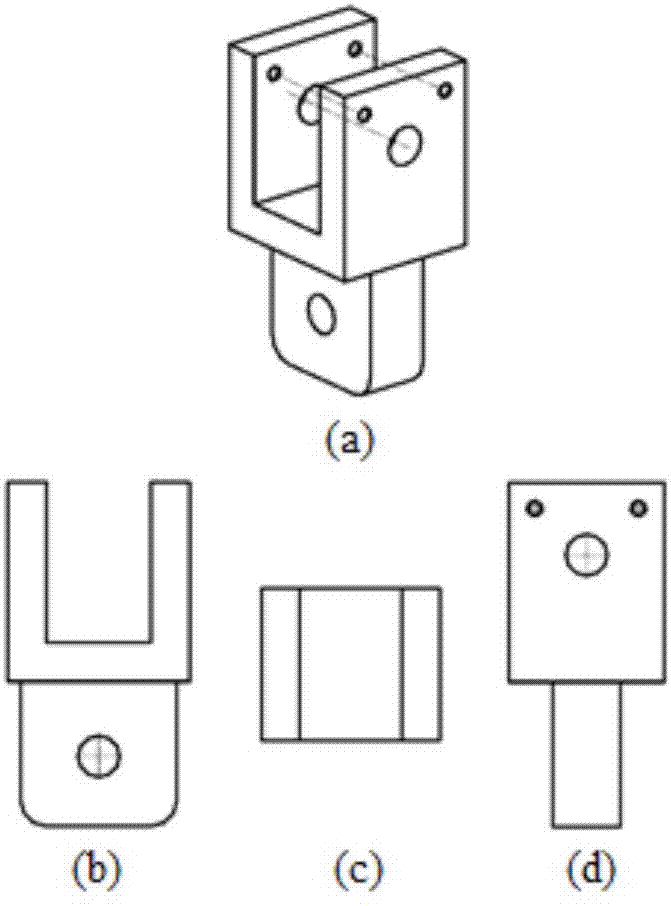

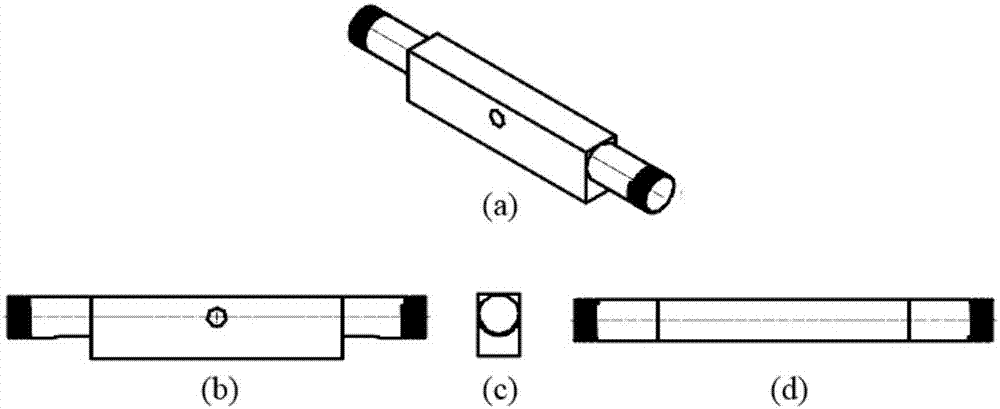

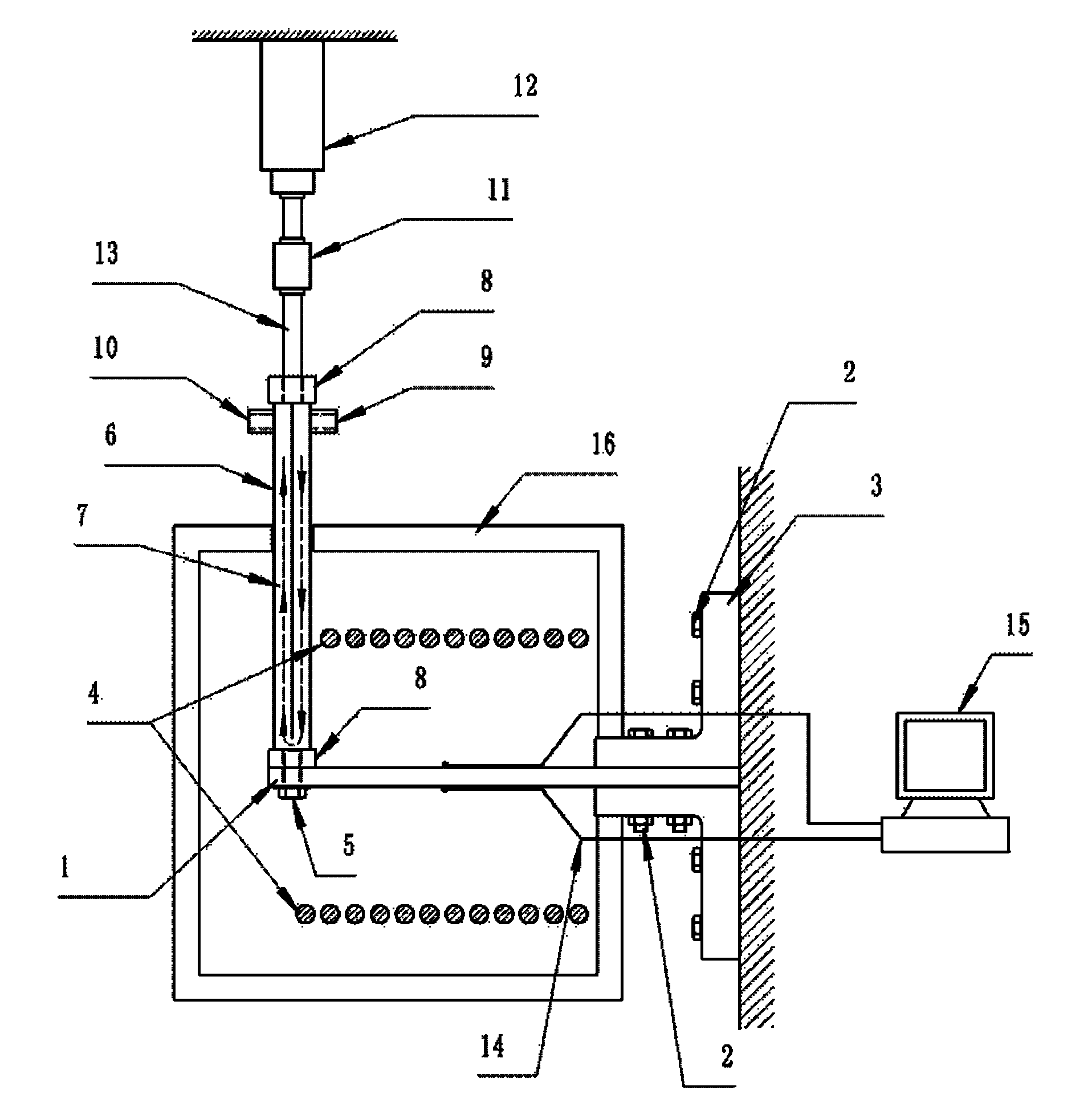

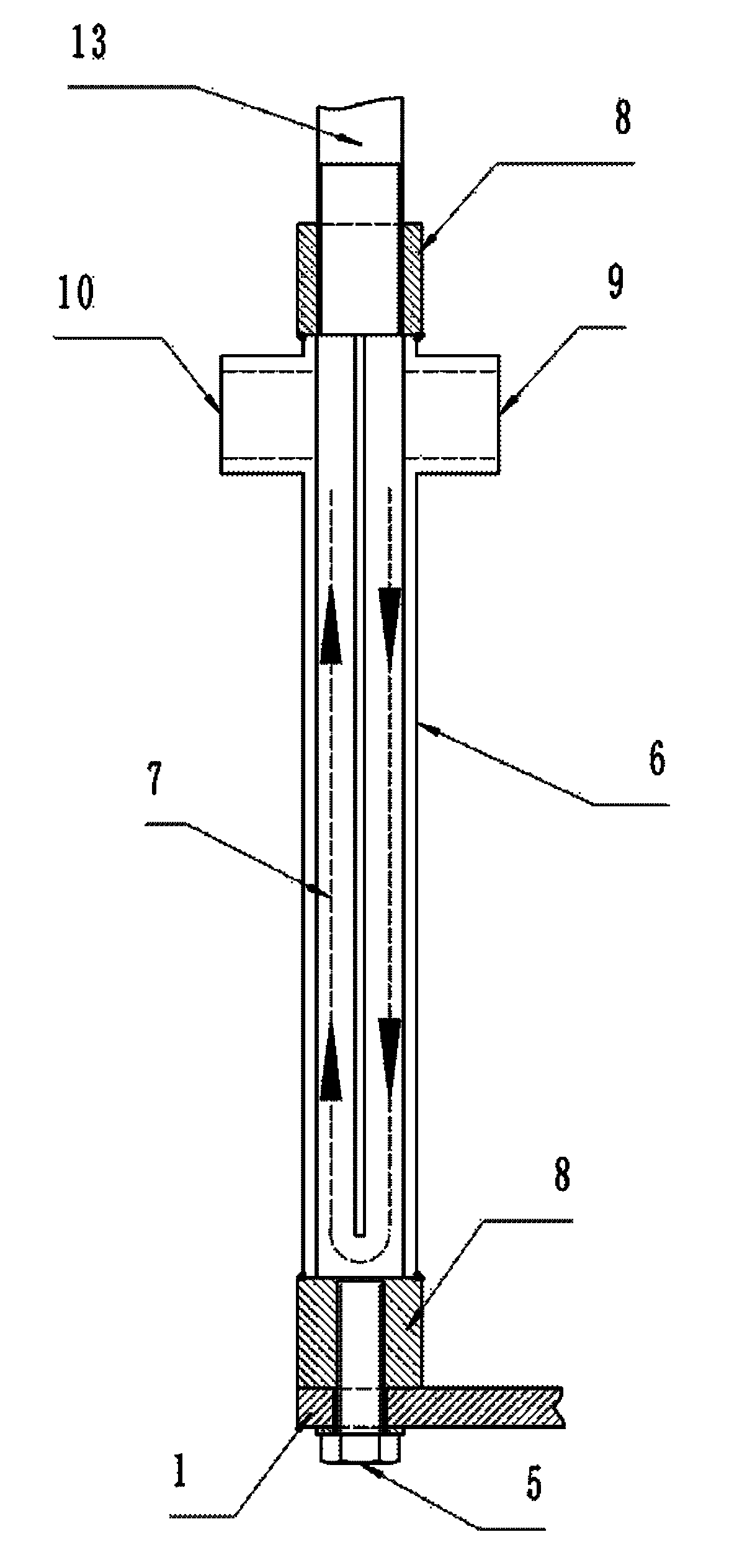

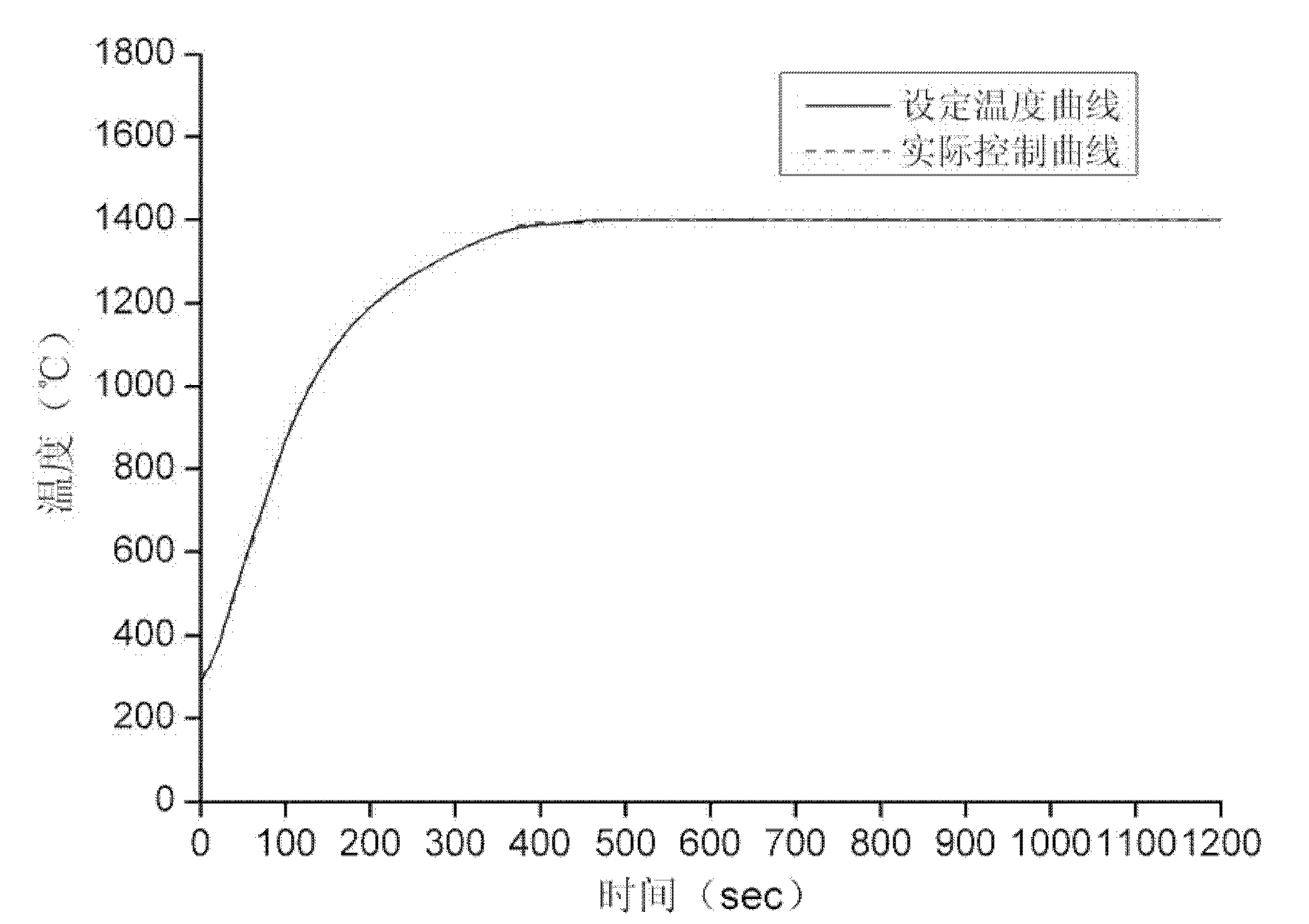

1400°C high temperature thermal-mechanical coupling test device for the airfoil structure of hypersonic aircraft

InactiveCN102262099AThermal-mechanical coupling test completedReduce the temperatureMachine part testingMaterial thermal analysisEngineeringActuator

The invention discloses a 1400-DEG C high-temperature thermal-mechanical coupling test device for the aerofoil structure of a hypersonic vehicle, which comprises a test sample of the aerofoil structure of the hypersonic vehicle, a silicon-molybdenum heating array, a water-cooled metal-loading component, a U-shaped water-cooled channel, a force sensor, a hydraulic actuator, a temperature sensor and a computer. Because the water-cooled metal-loading component is designed into a U-shaped hollow structure, the problems of high-temperature softening and deformation existing in the metal-loading component at 1400 DEG C are solved by using a method of cooling the inside of the metal loaded component with flowing liquid, the high-temperature (up to 1400 DEG C) thermal-mechanical coupling test on the aerofoil structure can be realized, and the ultimate strength of the aerofoil structure in high-temperature thermal-mechanical complex environment and other important parameters can be obtained, thereby providing a reliable basis for the safety design of a hypersonic vehicle structure in high-speed, high-temperature thermal-mechanical coupling environments.

Owner:BEIHANG UNIV

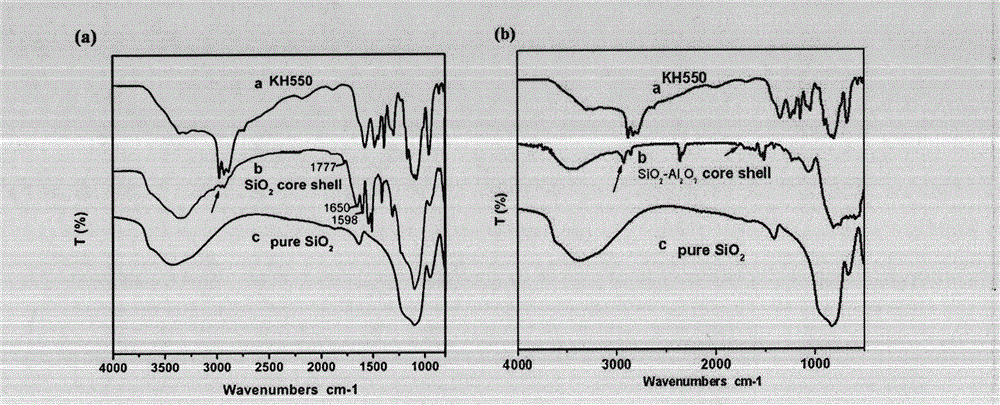

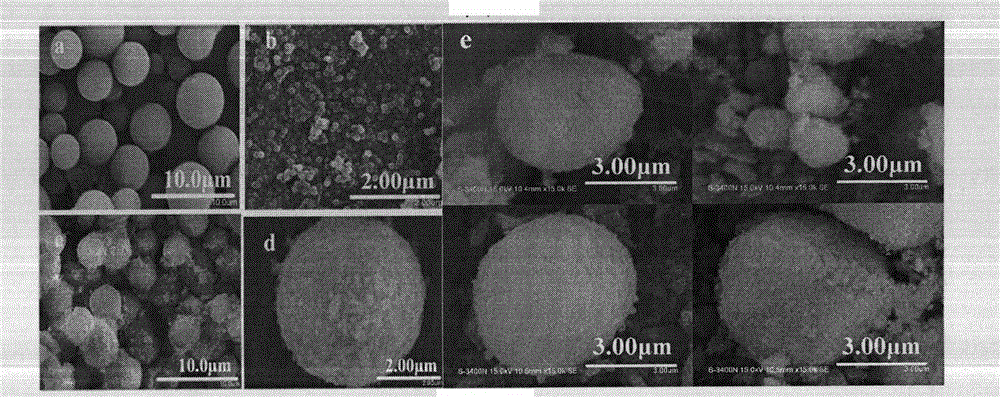

Method for preparing lyophobic heat conduction material with micro-nano core-shell structure

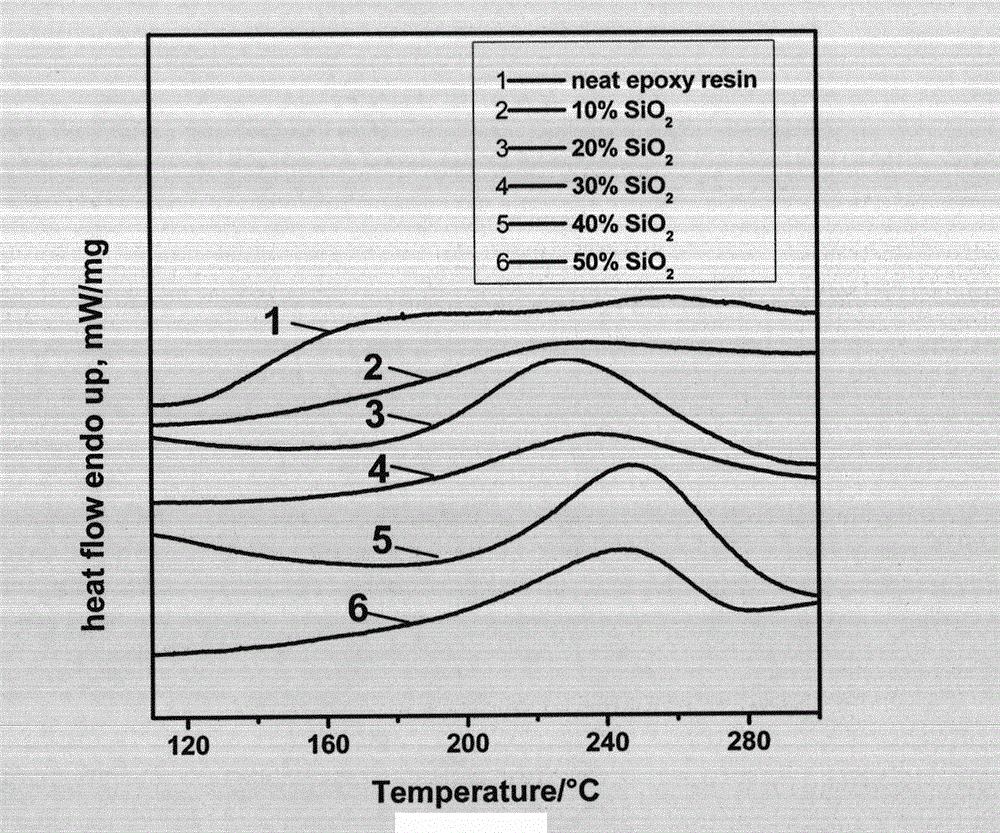

ActiveCN103146197AReduce the amount requiredHigh thermal conductivitySilicaOther chemical processesMicro nanoEpoxy

The invention discloses a method for preparing a lyophobic heat conduction material with a micro-nano core-shell structure. The method comprises the following steps of: preparing micro-nano particles with different particle sizes by adopting a colloidal sol method at first; utilizing organic matters containing special functional groups to wrap the nano particles on microparticles because nano particle surfaces comprise hydroxyls, and thus obtaining composite particles with core-shell structures; and filling the composite particles into epoxy resin or organic silicon resin so as to prepare a packaging material with high thermal conductivity, super hydrophobicity, good heat resistance and thermal mechanical performance. Compared with a conventional particle filling packaging material or thermal interface material, the material has more excellent performances.

Owner:东莞市维赛实业有限公司

460MPa anti-seismic and fire-resistant building steel and preparation method thereof

The invention relates to a 460MPa anti-seismic and fire-resistant building steel and a preparation method thereof, and belongs to the field of building steels. The 460MPa anti-seismic and fire-resistant building steel is prepared from the following components of 0.03 to 0.08% of C (carbon), 1.0 to 1.8% of Mn (manganese), 0.1 to 0.5% of Si (silicon), 0.2 to 0.7% of Cr (chromium), 0.1 to 0.3% of Mo(molybdenum), 0.05 to 0.12% of Ti (titanium), 0.04 to 0.12% of V (vanadium), 0.01 to 0.06% of Nb (niobium), 0.01 to 0.05% of Al (aluminum), 0.008% or less of P (phosphor), 0.002% or less of S (sulfur), and the balance of iron and unavoidable trace chemical elements. The preparation method comprises the following steps of performing conventional vacuum smelting, and casting into a blank; heating acasting blank, and performing conventional warming; coarsely rolling, and controlling temperature; finely rolling, and controlling finishing temperature; naturally cooling to certain temperature; performing water cooling until the temperature reaches room temperature; controlling the rolling and cooling, so as to obtain a martensite / bainite and ferrite double-phase tissue with fine crystal grains.The 460MPa anti-seismic and fire-resistant building steel and the preparation method have the advantages that by delivering in a TMCP (thermal mechanical control process) way, the complicated heat treatment technology is not needed; a process window is wider, the yield strength is greater than or equal to 460MPa, the tensile strength is 670 to 800MPa, the elongation rate at break is greater thanor equal to 26%, the KV2 at temperature of -40 DEG C is greater than or equal to 250J, and the yield ratio is smaller than 0.75; the 460MPa anti-seismic and fire-resistant building steel can be widelyapplied to high-rise and ultrahigh-rise buildings with high-strength, anti-seismic and fire-resistant steel requirements.

Owner:UNIV OF SCI & TECH BEIJING

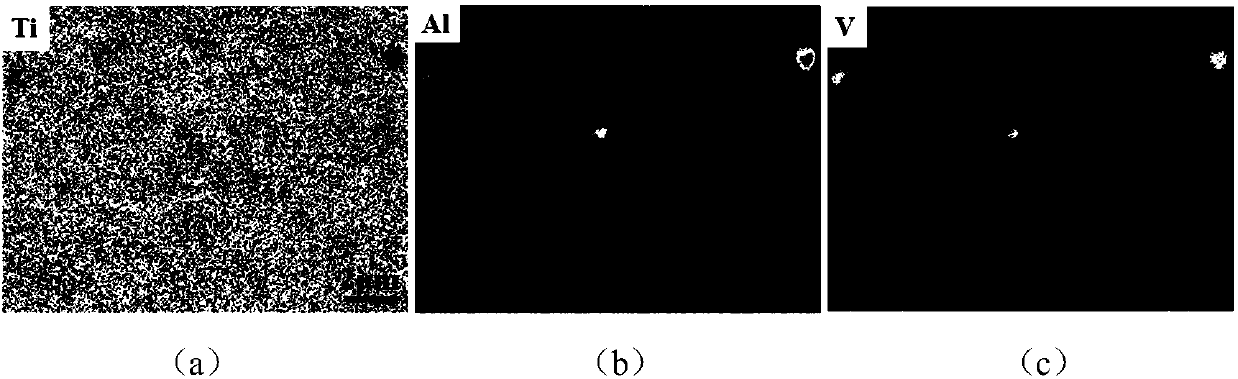

Method for manufacturing titanium and titanium alloy and part thereof by taking hydrogenated sponge titanium as raw material

InactiveCN107760897AGood for controlling oxygen contentImprove compactnessTransportation and packagingMetal-working apparatusTitanium alloyTitanium powder

The invention belongs to the technical field of preparing and processing of titanium and a titanium alloy, and particularly relates to a method for manufacturing titanium and titanium alloy and part thereof by taking hydrogenated sponge titanium as a raw material. The method comprises the following steps: hydrogenating sponge titanium; synchronously ball-milling to prepare hydrogenated titanium powder or mixed powder; pressing the powder; quickly sintering and synchronously dehydrogenizing; thermally mechanically solidifying or forming; performing complete vacuum dehydrogenizing; and obtainingan alloy product. The method realizes synchronously ball-milling to prepare mixed powder from hydrogenated sponge titanium and alloying raw materials, and the powder does not need to screen, so thatthe powder yield is greater than 96%; and under protection of inert atmosphere, pressing, quick heating and alloying, thermal mechanical solidifying and forming are completed. The method is short in process flow, is high in efficiency, can prepare the titanium and the titanium product with high compaction (greater than or equal to 99.8%) and low oxygen content (lower than or equal to 0.26%); mainmechanical properties of the alloy are higher than level of common deformed titanium alloy; and cost is obviously lower than that of conventional powder metallurgical titanium alloy.

Owner:NORTHEASTERN UNIV

800 Mpa high-strength thick plate for high heat input welding

Owner:BAOSHAN IRON & STEEL CO LTD

Zinc-induced-crack-resistant steel plate and manufacturing method thereof

ActiveCN103320693AExcellent resistance to zinc crackingImprove mechanical propertiesFurnace typesMetallic material coating processesMicro structureSpray coating

The invention discloses a zinc-induced-crack-resistant steel plate and a manufacturing method thereof. Low alloy steel subjected to low C-ultralow Si-high Mn-low Als-(Ti+Nb) micro alloying treatment is taken as a basis, the Als content of the steel is appropriately reduced, situations that Mn / C is greater than or equal to 15, [(%Mn)+0.75 (%Mo)]* (%C) is less than or equal to 0.16, Nb / Ti is greater than or equal to 1.8, Ti / N is 1.50-3.40, CEZ is less than or equal to 0.44%, the B content is less than or equal to 2 ppm, and Ni / Cu is greater than or equal to 1.50 are controlled, the Ca treatment is performed, the Ca / S ratio is controlled to be 1.0-3.0, (%Ca)*(%S)0.28 is controlled to be less than or equal to 1.0*10<-3>, and a TMCP (Thermal Mechanical Control Process) is optimized, so that the micro-structure of a finished steel plate is a ferrite-dispersedly distributed tiny bainitic colony, the average grain size is less than 10 mu m, and homogeneous excellent mechanical properties, excellent weldability and zinc-induced-crack-resistant properties are obtained, therefore, the zinc-induced-crack-resistant steel plate is especially suitable for being used as a zinc-spray coating anti-corrosion steel plate for marine structures, a zinc-spray anti-corrosion steel plate for extra-high voltage power transmission structures, a zinc-spray coating anti-corrosion steel plate for coast bridge structures, and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

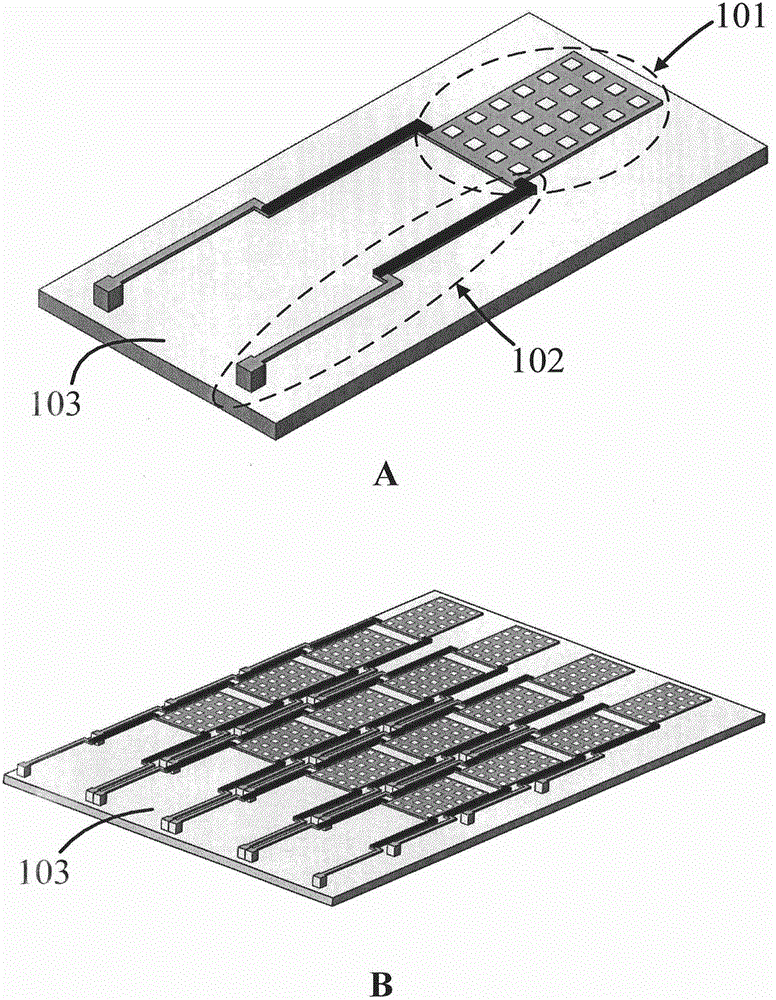

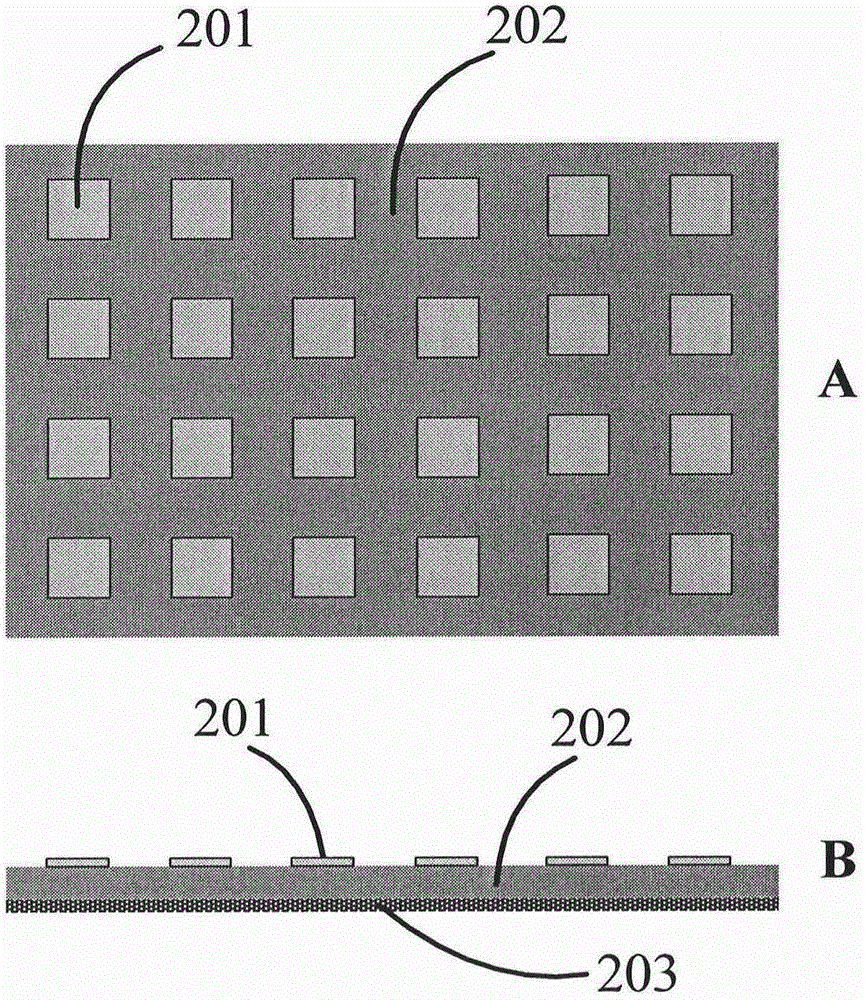

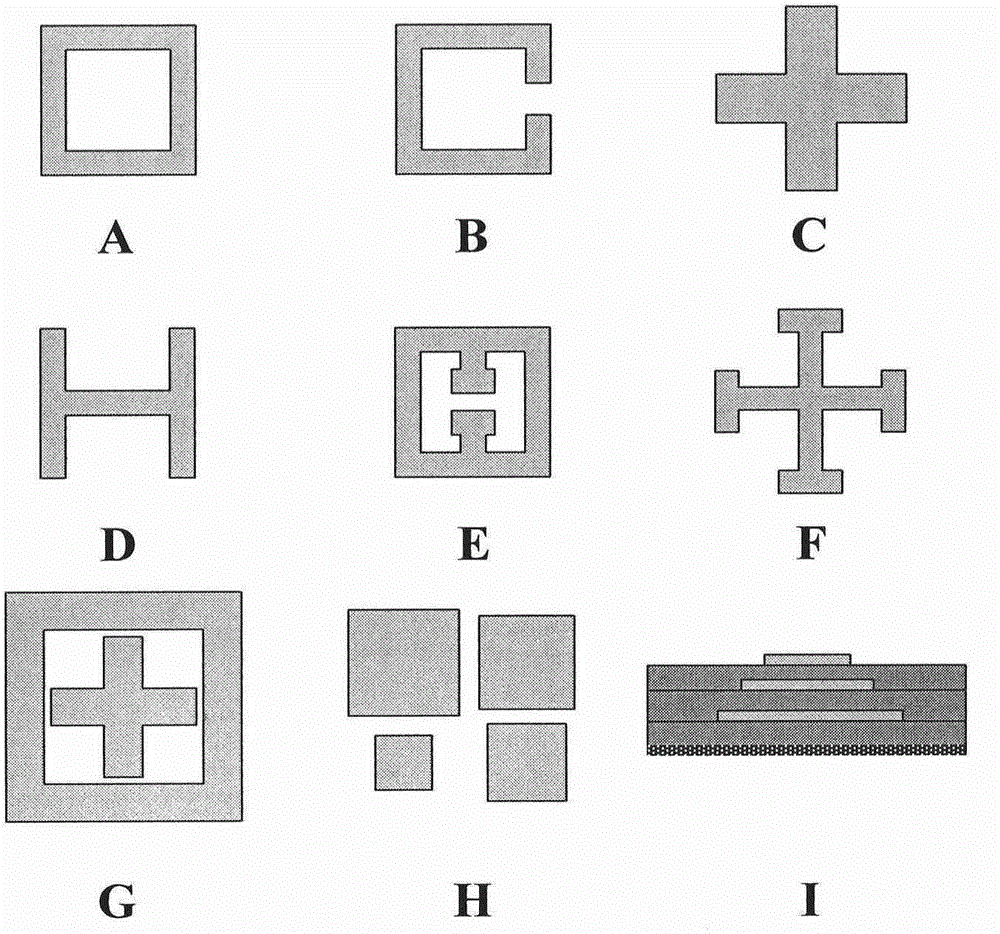

Thermal mechanical type electromagnetic radiation detector

ActiveCN105891609AFlexible designHigh sensitivityElectromagentic field characteristicsThermal energyImage resolution

The invention provides a thermal mechanical type electromagnetic radiation detector. The electromagnetic radiation detector is composed of a metamaterial wave absorber, supporting legs and a substrate. The electromagnetic radiation detector is prepared on a transparent substrate through adopting a surface sacrificial layer process, and a suspended movable structure according to which the supporting legs support the metamaterial wave absorber can be formed. In detection imaging, electromagnetic wave energy entering the metamaterial wave absorber is converted into thermal energy, and the supporting legs are bent after temperature changes; a beam of visible light passes through the transparent substrate and enters the reflecting mirror surface of the metamaterial wave absorber; an optical detection system is used for reading the deflection angle change and distribution of the metamaterial wave absorber; and therefore, detection imaging of electromagnetic waves can be realized. The thermal mechanical type electromagnetic radiation detector provided by the invention has the advantages of high sensitivity, high resolution, high reliability, high uniformity, low cost and simple preparation process and the like, can be used as a single detector to work independently, can also be distributed into an array to work as an imaging device, and can be flexibly designed according to the wavelength of detected electromagnetic waves and actual application requirements.

Owner:PEKING UNIV

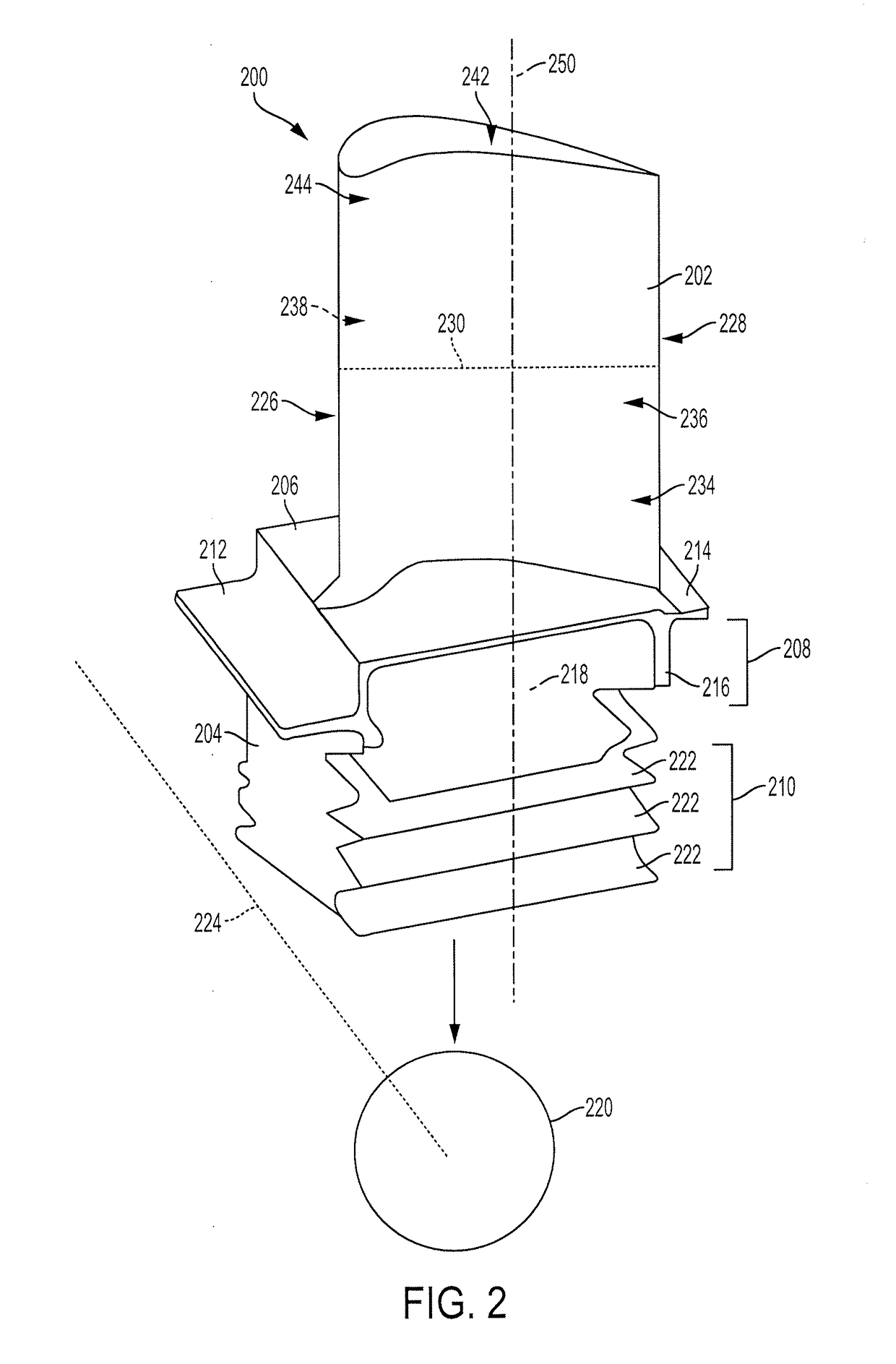

Turbine component having multiple controlled metallic grain orientations, apparatus and manufacturing method thereof

The present disclosure generally relates to turbine engine components having multiple controlled metallic grain orientations. In general, the primary grain orientation is aligned substantially perpendicular to the longitudinal axis of the turbine engine component while the secondary grain orientation is aligned substantially parallel to the longitudinal axis. Such controlled grain orientations provide the blades and vanes with increased strength to withstand the thermal-mechanical stresses of the turbine operation. The disclosure also relates to turbines having these fortified components, and methods of manufacturing the components.

Owner:GENERAL ELECTRIC CO

Sheet steel with tensile strength of 1500 MPa levels and used for hot stamping forming and cast steel plate (CSP) production method thereof

The invention discloses sheet steel with the tensile strength of 1500 MPa levels and used for hot stamping forming and a cast steel plate (CSP) production method thereof. The sheet steel comprises, by weight, 0.20-0.25% of C, 0.25-0.40% of Si, 1.00-1.30% of Mn, 0-0.025% of P, 0-0.01% of S, 0.015-0.035% of Als, 0-0.005% of N, 0-0.005% of B, 0.020-0.060% of Nb, 0.010-0.040% of Ti, and the balance Fe and inevitable microelements. According to the sheet steel with the tensile strength of 1500 MPa levels and used for hot stamping forming and the cast steel plate (CSP) production method thereof, the process steps comprises molten steel smelting, vertical bending type CSP sheet blank continuous casting, descaling, roller bottom type tunnel furnace soaking, thermal mechanical control processing (TMCP) six machine frame hot continuous rolling, laminar cooling, reeling, unreeling pickling, flattening and reeling; sheet material cold rolling and annealing heat treatment are omitted, and a traditional cold-rolled sheet product is replaced by a hot rolled sheet product; the comprehensive production cost is reduced, and the cost of the steel per ton can be reduced by over 600 yuan.

Owner:武汉钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com