Sheet steel with tensile strength of 1500 MPa levels and used for hot stamping forming and cast steel plate (CSP) production method thereof

A technology of hot stamping and tensile strength, applied in the field of ultra-high-strength hot-forming steel, can solve the problems of high price of the final thin steel plate product, achieve the suppression of austenite grain growth, and reduce repeated uncoiling and coiling , the effect of refining the austenite grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

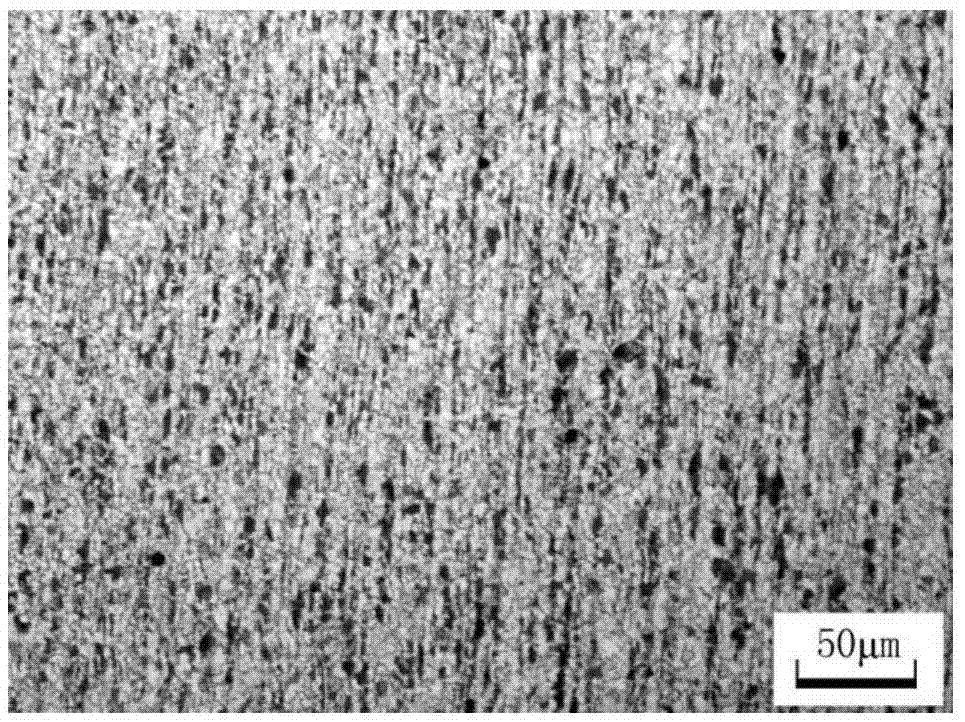

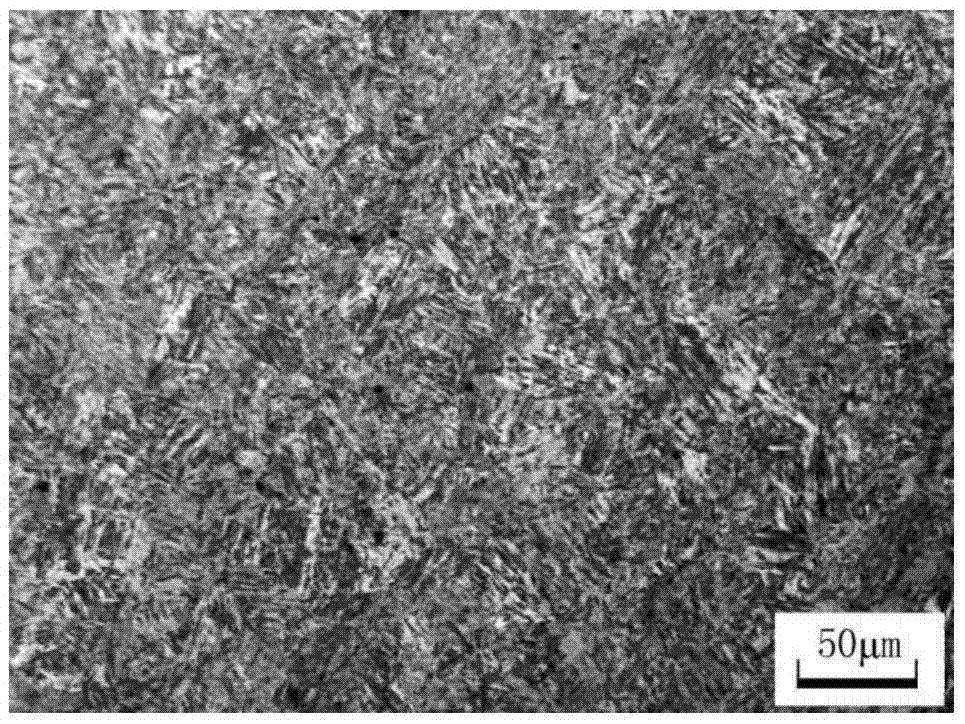

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with accompanying drawing:

[0026] Table 1 is a list of chemical components and weight percentage values of each embodiment of the present invention;

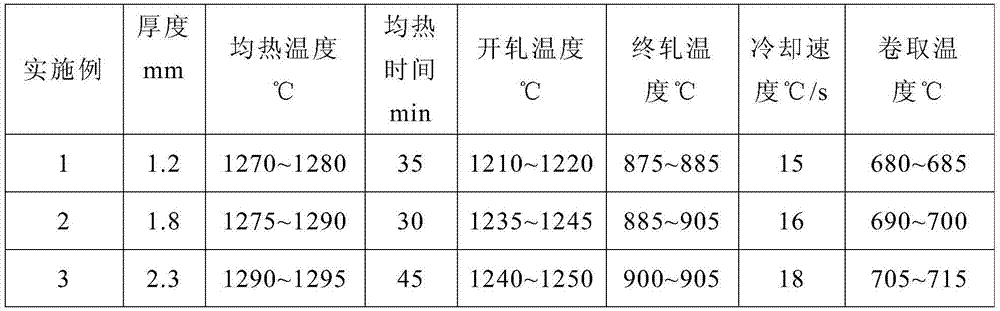

[0027] Table 2 is the list of main process parameters of each embodiment of the present invention;

[0028] Table 3 is a list of experimental results of mechanical properties of each embodiment of the present invention after quenching treatment.

[0029] The process route of the present invention includes: molten steel smelting, vertical curved CSP thin slab continuous casting, descaling, roller hearth tunnel furnace soaking, TMCP six-stand hot continuous rolling, laminar cooling, coiling, decoiling pickling, leveling , Rolling into storage.

[0030] Each embodiment of the present invention is produced according to the following steps:

[0031] 1) Molten steel smelting: using converter smelting and LF furnace refining;

[0032] 2) CSP thin slab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com