High-strength pipe steel and method for manufacturing same

A technology for pipe fittings and controlled rolling, applied in the direction of manufacturing converters, improving process efficiency, furnace types, etc., can solve the problems of unfavorable welding performance and high C content in steel pipes, achieve low welding crack sensitivity index, inhibit grain size The effect of growing up and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

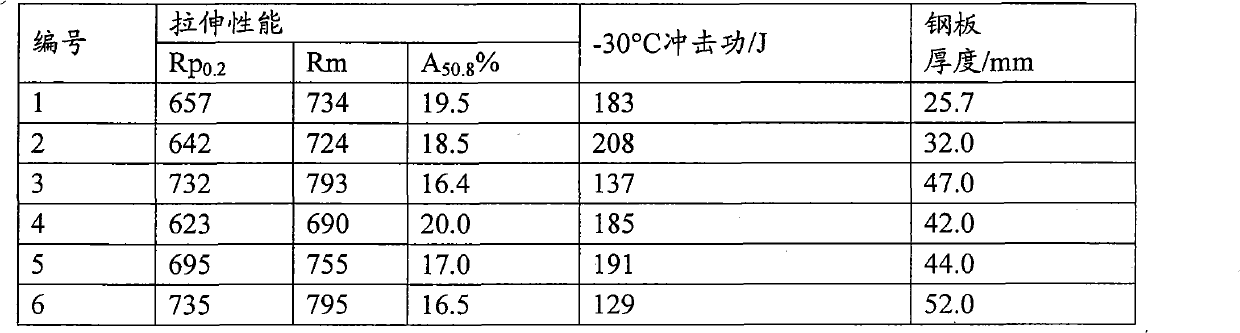

Embodiment 1

[0039] Example 1: For the manufacture of thick X80 pipeline steel plates with a thickness specification of 25.7 mm

[0040] Heating temperature: 1170±20°C, rolling temperature range in the recrystallization zone is 1130~980°C, the thickness of the billet to be heated in the middle (that is, the thickness of the billet after rolling in the recrystallization zone) is 110mm, and the temperature range in the non-recrystallization zone is 890~750°C . Stop cooling temperature 450 ~ 500 ℃. The cooling rate is 15-20°C / s. Quenching temperature: 910±10°C, quenching holding time: 40min; tempering temperature: 550±10°C; tempering holding time: 70min.

Embodiment 2

[0041] Example 2: Steel for high-strength pipe fittings with a thickness specification of 32.0 mm

[0042] Heating temperature: 1130±20°C, rolling temperature range in the recrystallization zone is 1120-950°C, the thickness of the billet to be heated in the middle is 120mm, and the temperature range in the non-recrystallization zone is 870-780°C. The termination cooling temperature is 580-620°C. The cooling rate is 12-17°C / s. Quenching temperature: 960±10°C, quenching holding time: 50min; tempering temperature: 600±10°C; tempering holding time: 90min.

Embodiment 3

[0043] Embodiment 3: Steel for manufacturing high-strength pipe fittings with a thickness specification of 47.0 mm

[0044] Heating temperature: 1150±20°C, rolling temperature range in the recrystallization zone is 1100-960°C, the thickness of the billet to be heated in the middle is 100mm, and the temperature range in the non-recrystallization zone is 890-750°C. Stop cooling temperature 450 ~ 500 ℃. The cooling rate is 8-12°C / s. Quenching temperature: 910±10°C, quenching holding time: 40min; tempering temperature: 580±10°C; tempering holding time: 100min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com