Patents

Literature

6550results about How to "Prevent precipitation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

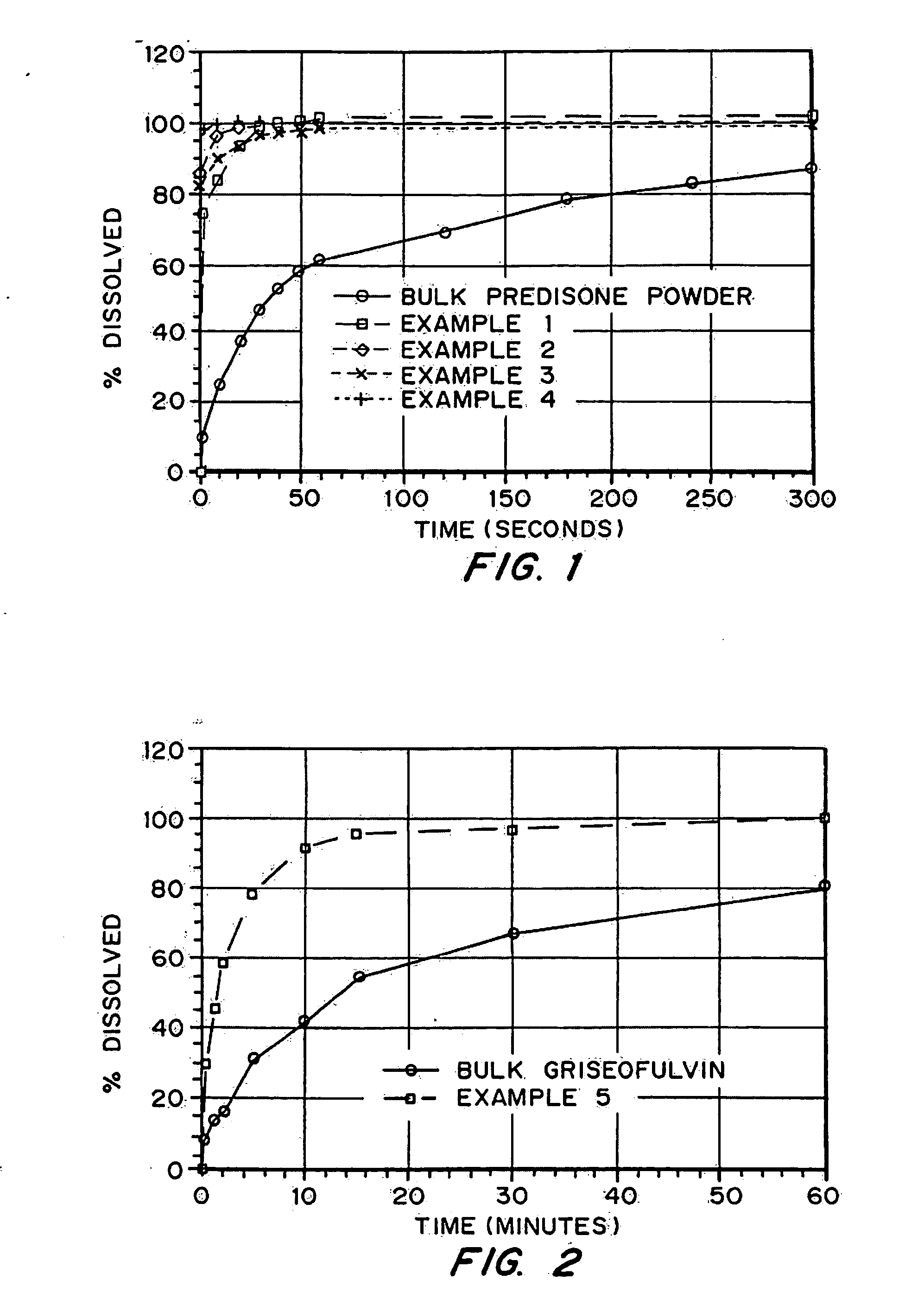

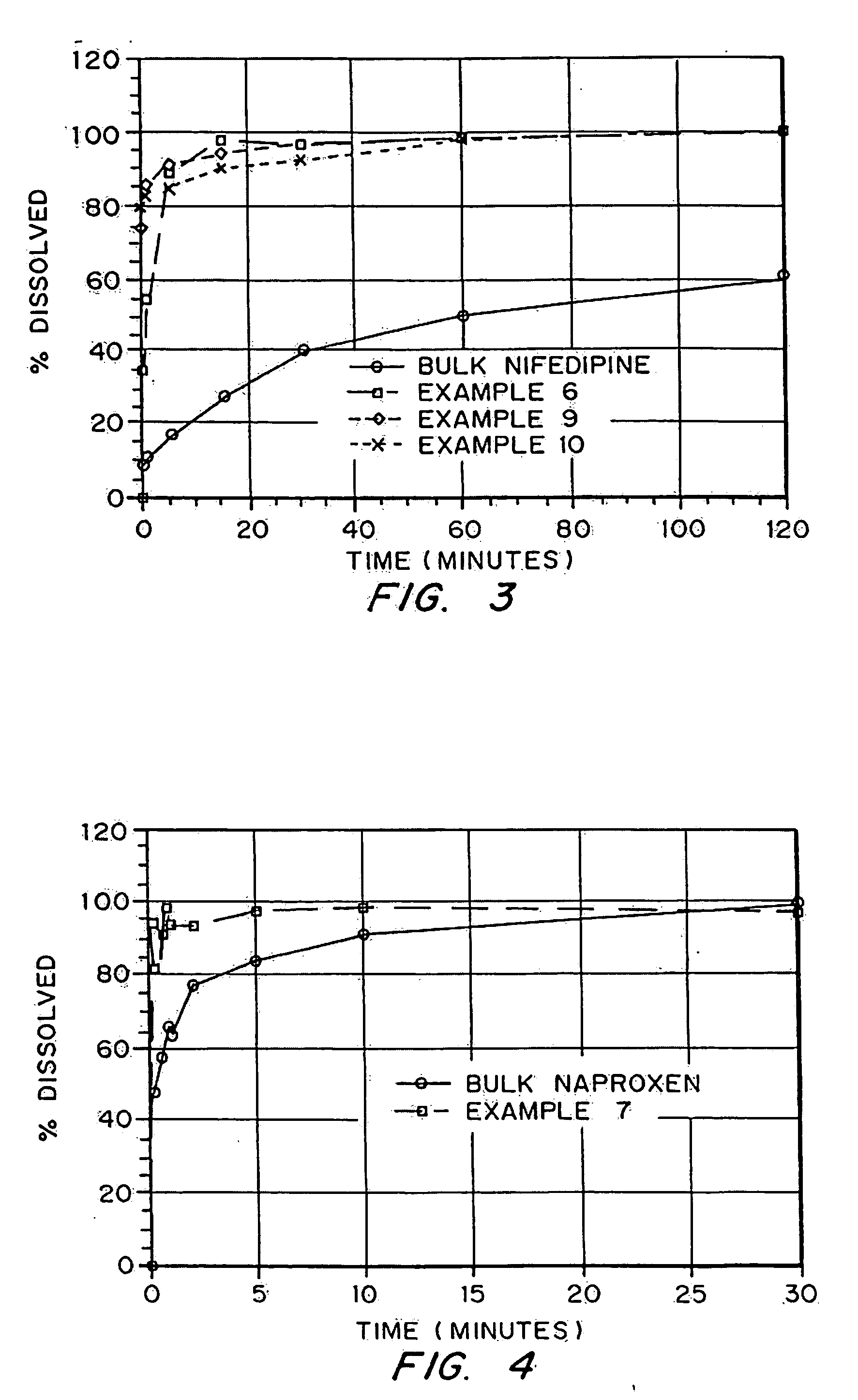

Porous drug matrices and methods of manufacture thereof

InactiveUS6932983B1Lower the volumePrevent precipitationPowder deliveryNanotechDrugs solutionWater soluble drug

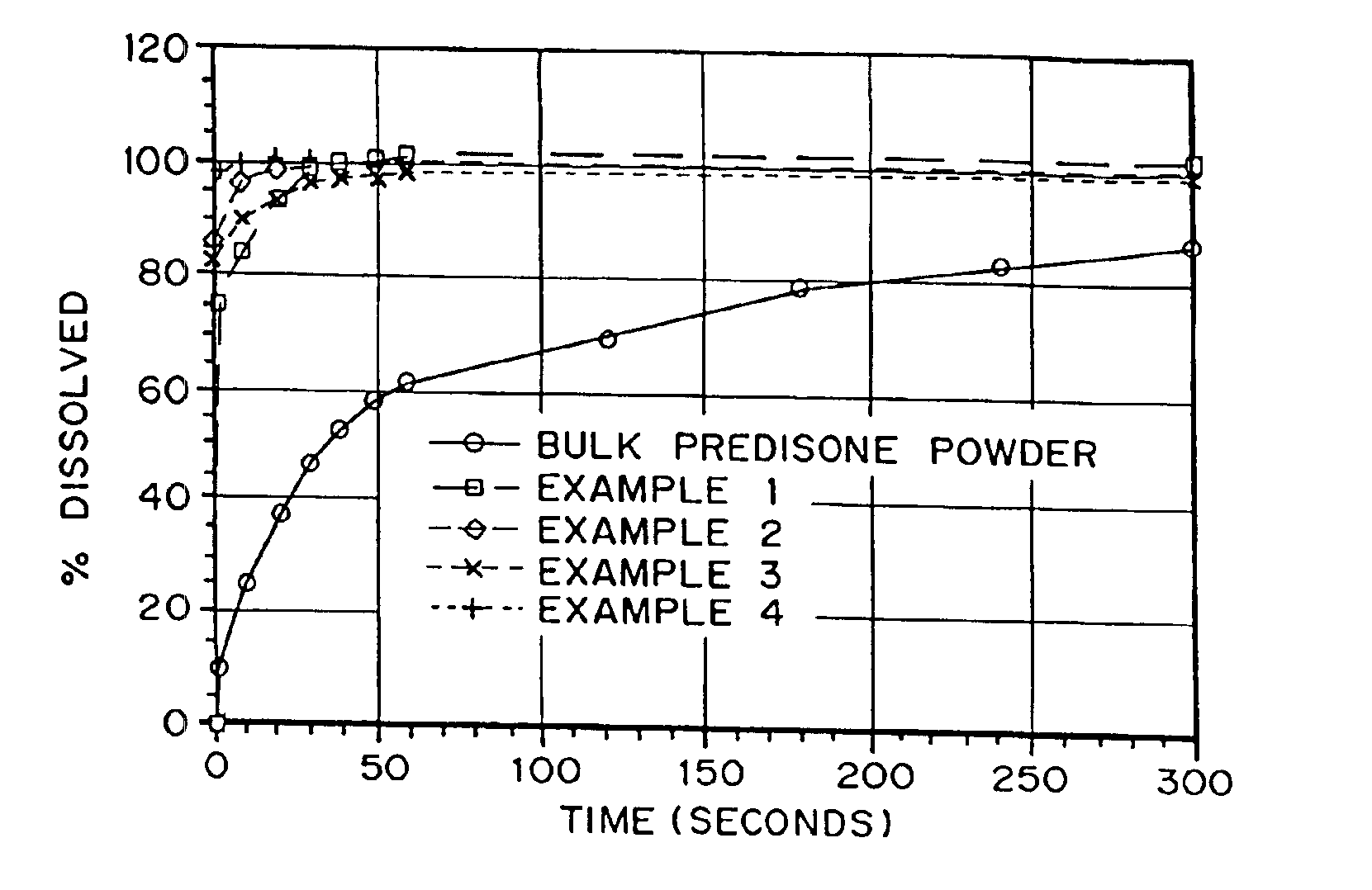

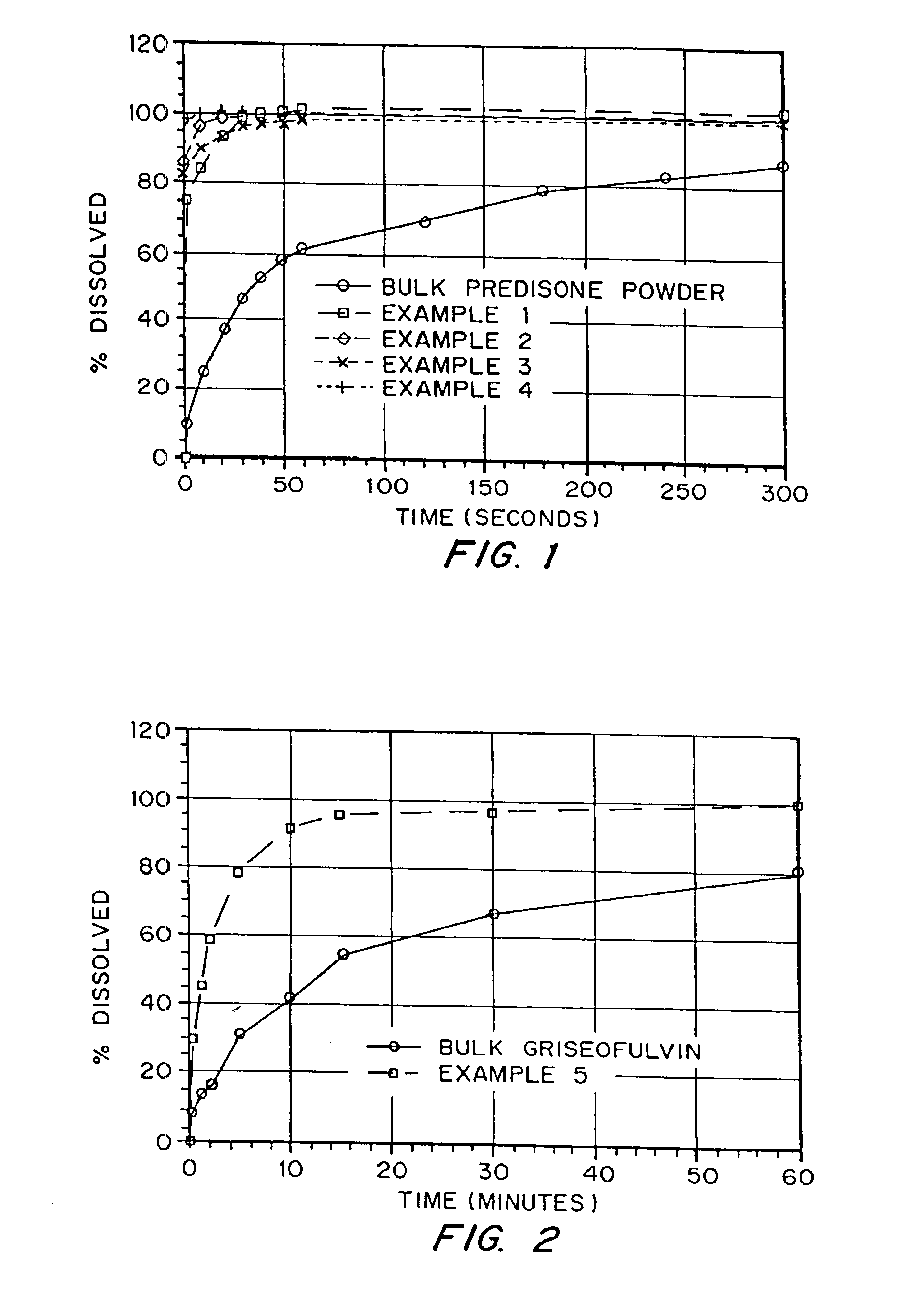

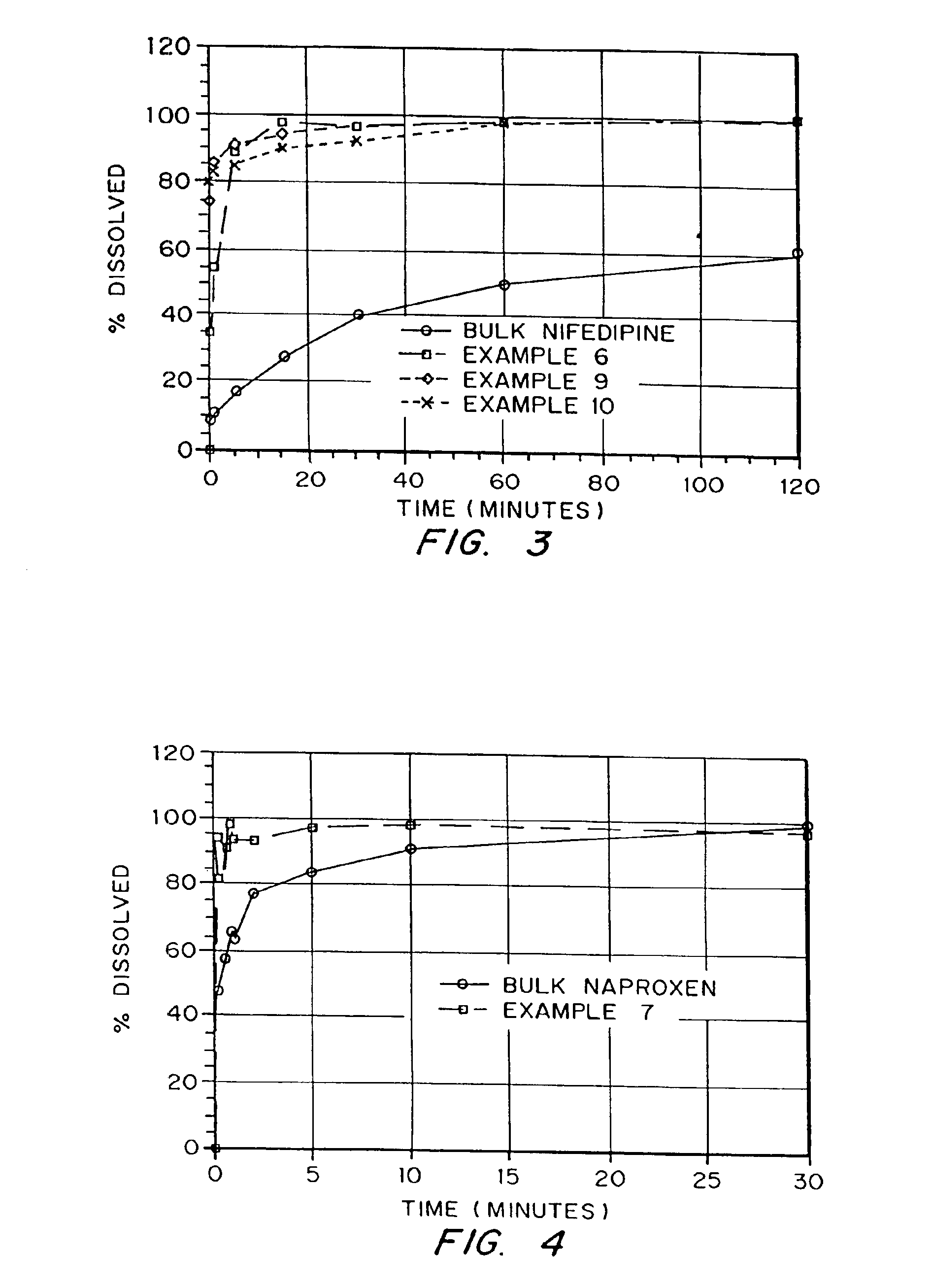

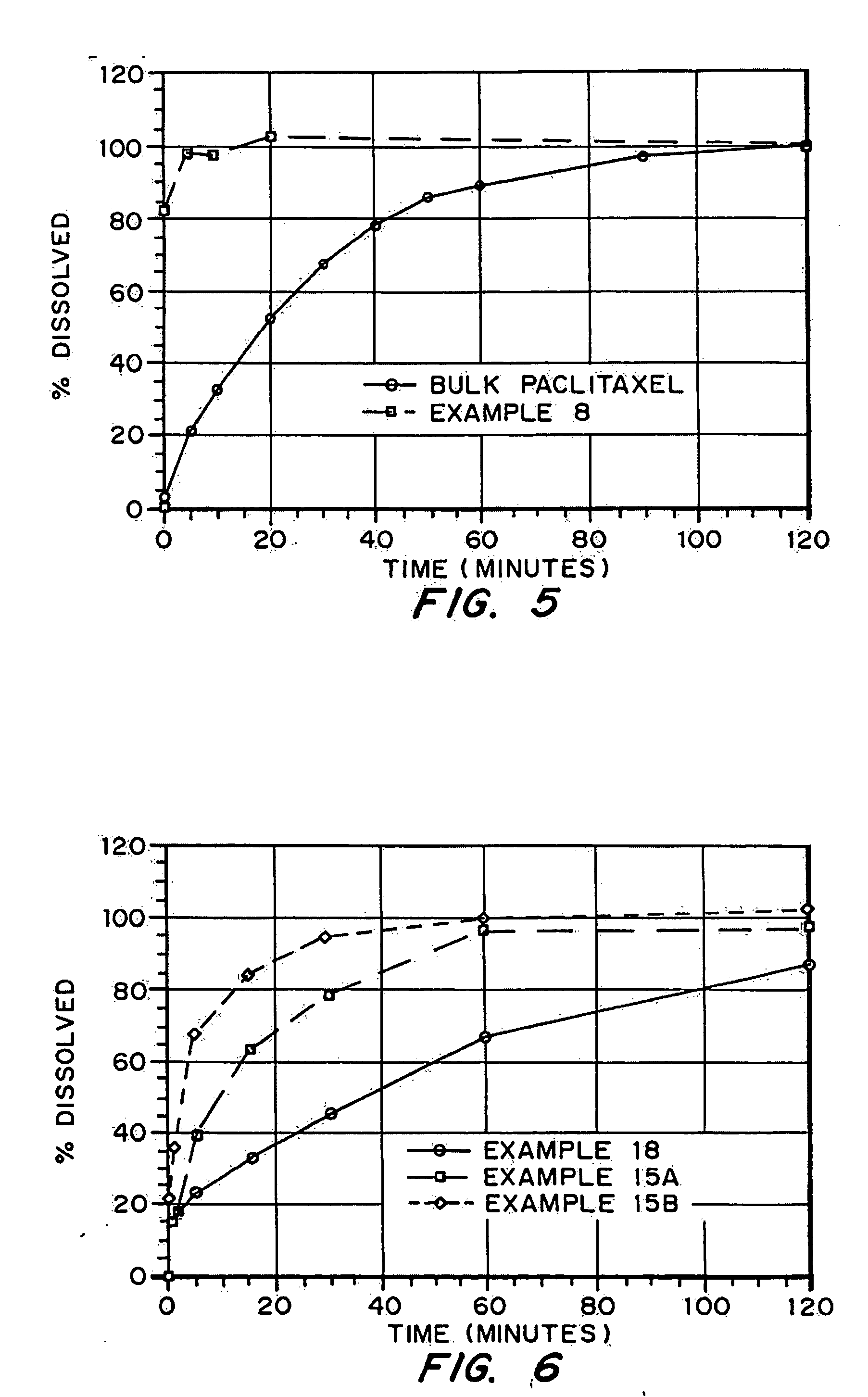

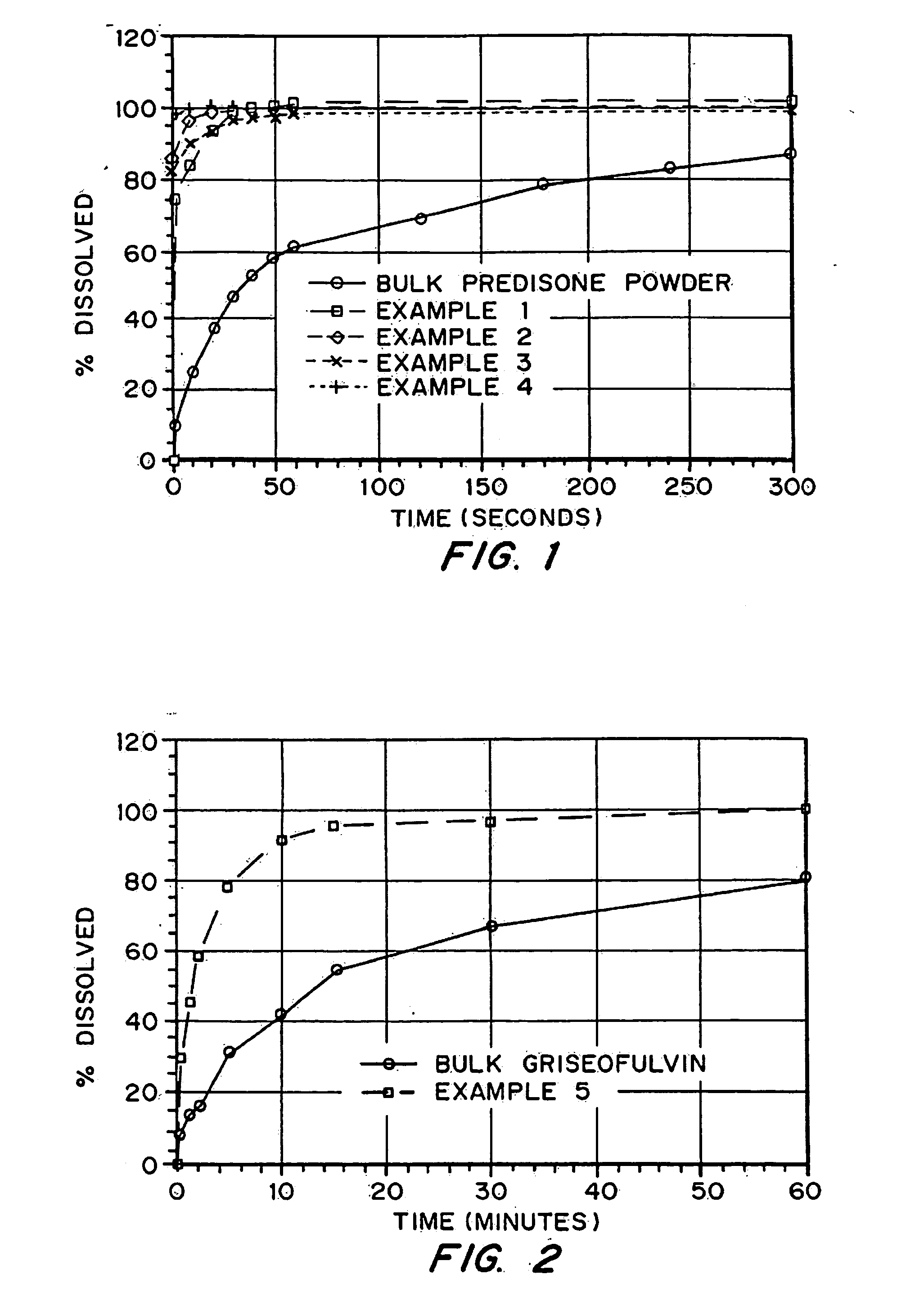

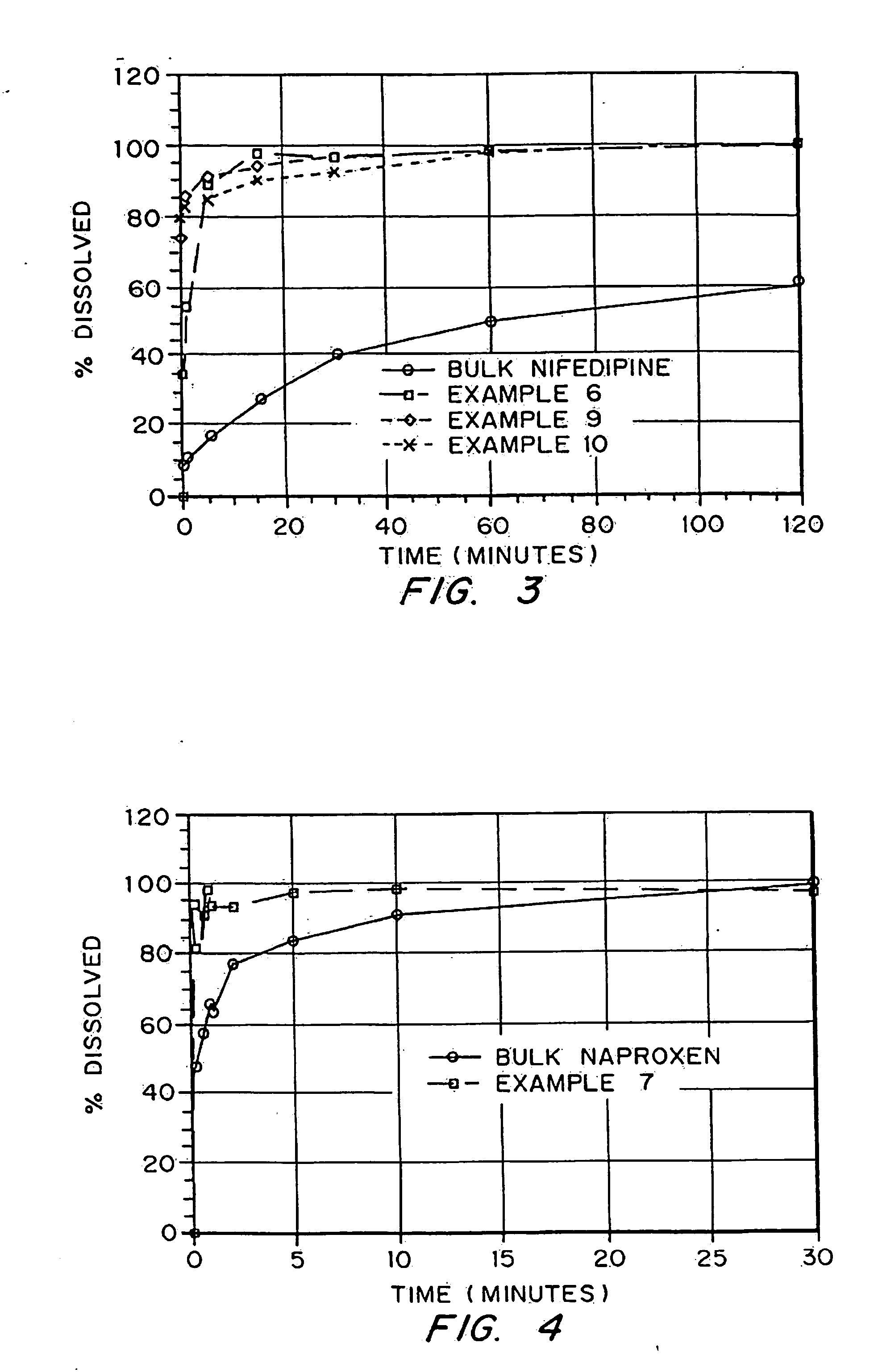

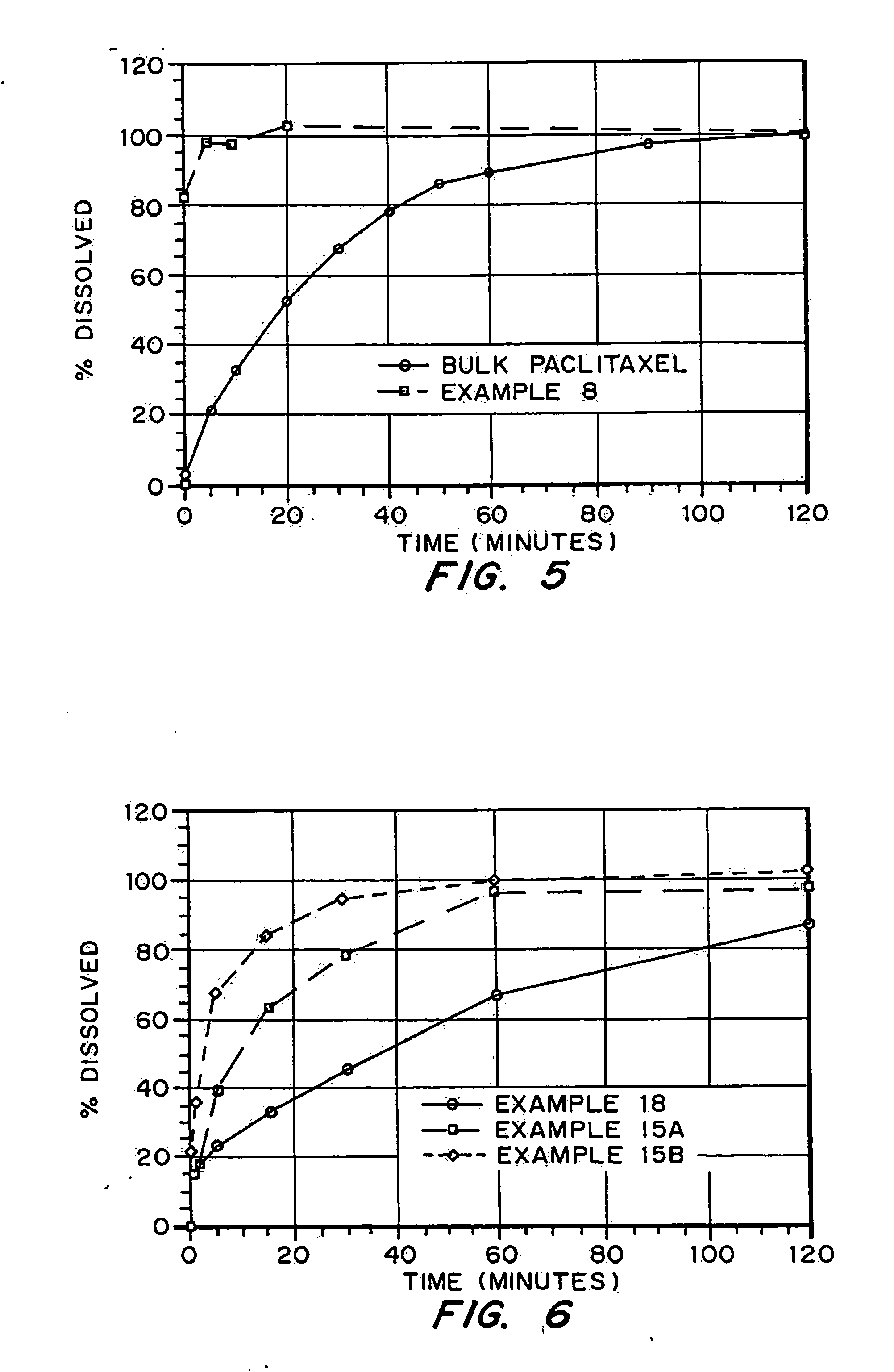

Drugs, especially low aqueous solubility drugs, are provided in a porous matrix form, preferably microparticles, which enhances dissolution of the drug in aqueous media. The drug matrices preferably are made using a process that includes (i) dissolving a drug, preferably a drug having low aqueous solubility, in a volatile solvent to form a drug solution, (ii) combining at least one pore forming agent with the drug solution to form an emulsion, suspension, or second solution, and (iii) removing the volatile solvent and pore forming agent from the emulsion, suspension, or second solution to yield the porous matrix of drug. The pore forming agent can be either a volatile liquid that is immiscible with the drug solvent or a volatile solid compound, preferably a volatile salt. In a preferred embodiment, spray drying is used to remove the solvents and the pore forming agent. The resulting porous matrix has a faster rate of dissolution following administration to a patient, as compared to non-porous matrix forms of the drug. In a preferred embodiment, microparticles of the porous drug matrix are reconstituted with an aqueous medium and administered parenterally, or processed using standard techniques into tablets or capsules for oral administration.

Owner:ACUSPHERE INC

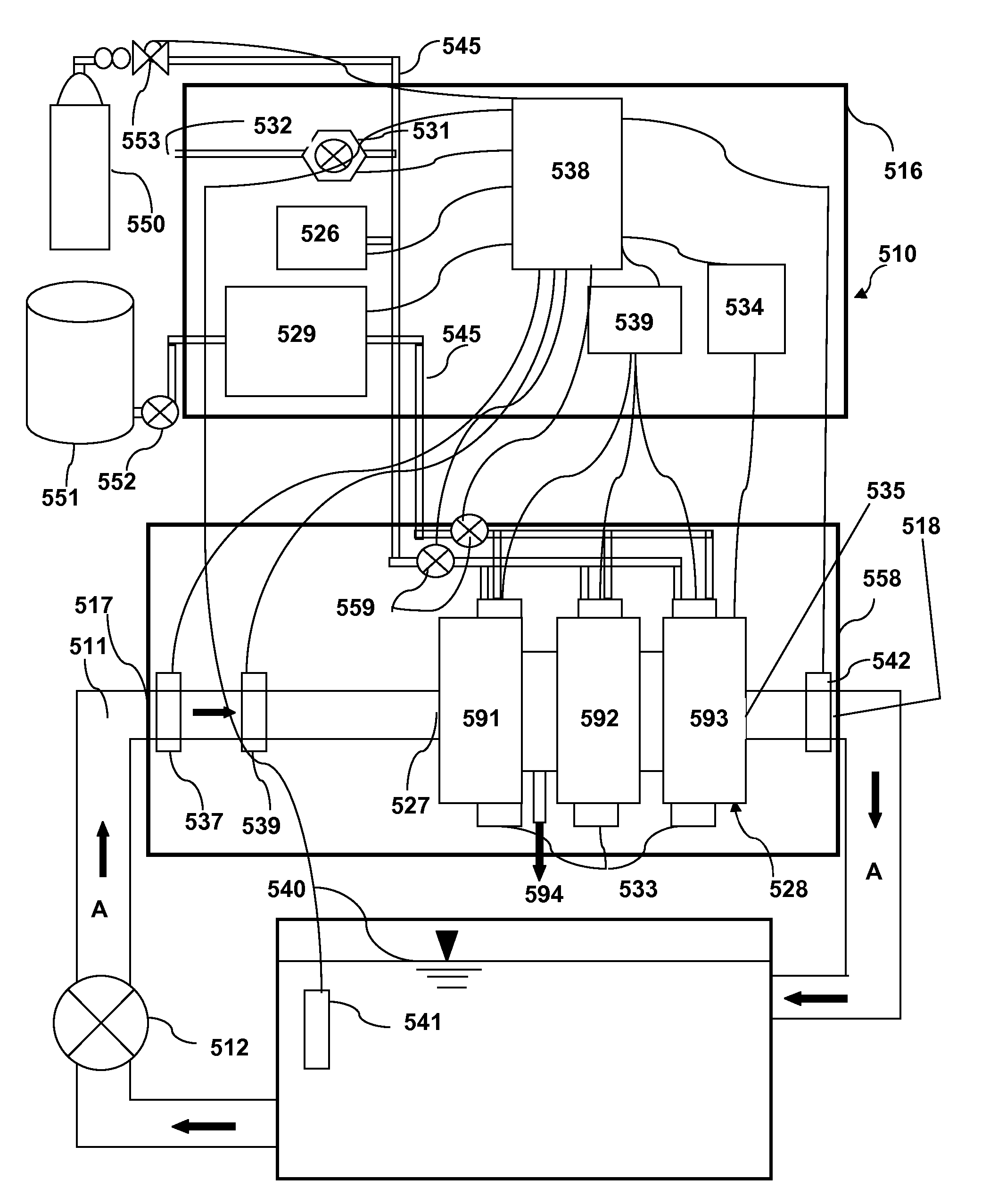

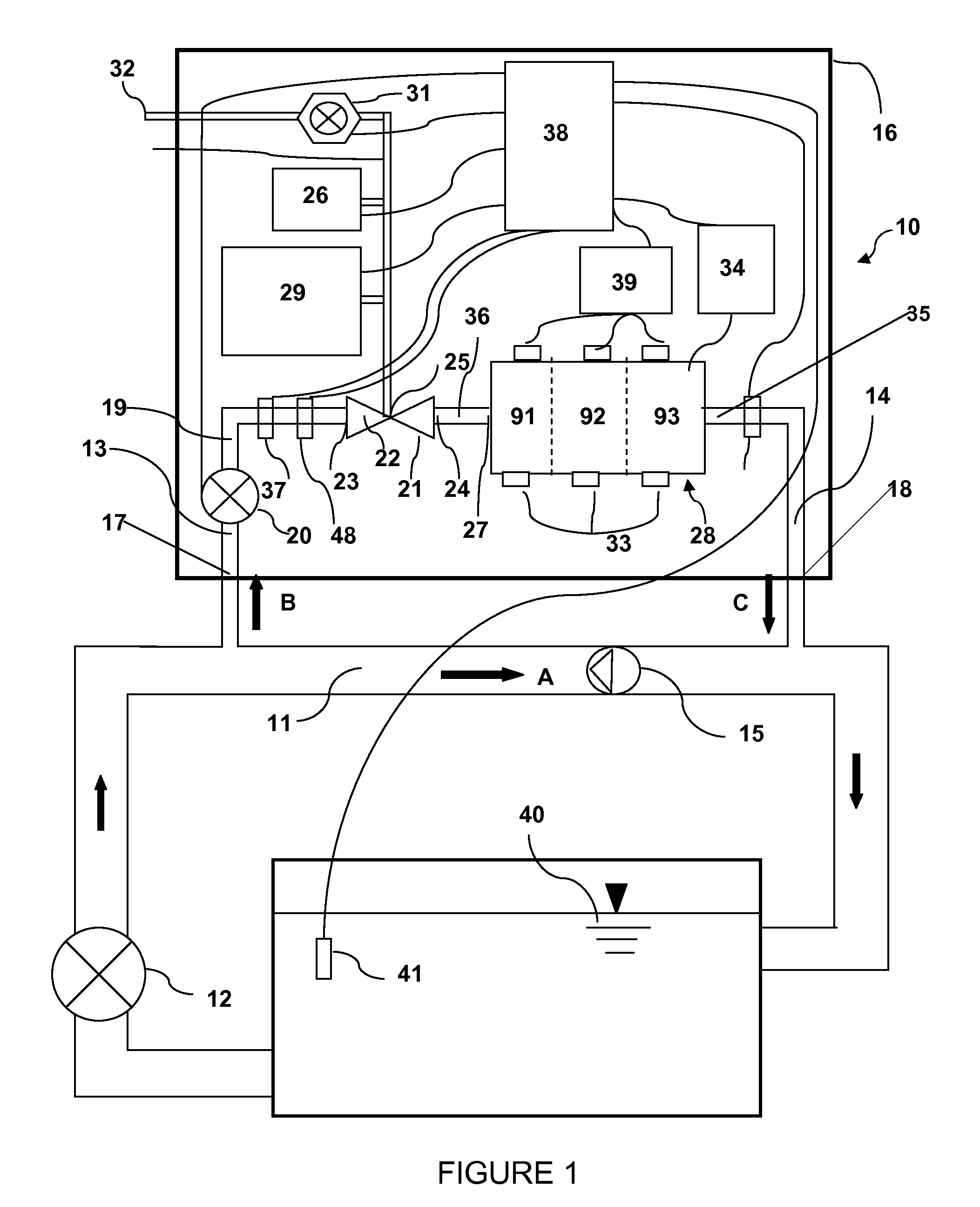

Aqueous treatment apparatus utilizing precursor materials and ultrasonics to generate customized oxidation-reduction-reactant chemistry environments in electrochemical cells and/or similar devices

ActiveUS20110024361A1Prevent precipitationReduce maintenance costsFrom normal temperature solutionsLiquid separation by electricityEnvironmental chemistrySet point

An electrochlorination and electrochemical system for the on-site generation and treatment of municipal water supplies and other reservoirs of water, by using a custom mixed oxidant and mixed reductant generating system for the enhanced destruction of water borne contaminants by creating custom oxidation-reduction-reactant chemistries with real time monitoring. A range of chemical precursors are provided that when acted upon in an electrochemical cell either create an enhanced oxidation, or reduction environment for the destruction or control of contaminants. Chemical agents that can be used to control standard water quality parameters such as total hardness, total alkalinity, pH, total dissolved solids, and the like are introduced via the chemical precursor injection subsystem infrequently or in real time based on sensor inputs and controller set points.

Owner:GLOBAL WATER INVESTMENTS LLC

Porous drug matrices and methods of manufacture thereof

InactiveUS20050048116A1Fast dissolutionHigh dissolution ratePowder deliveryGranular deliveryDrugs solutionMicroparticle

Drugs, especially low aqueous solubility drugs, are provided in a porous matrix form, preferably microparticles, which enhances dissolution of the drug in aqueous media. The drug matrices preferably are made using a process that includes (i) dissolving a drug, preferably a drug having low aqueous solubility, in a volatile solvent to form a drug solution, (ii) combining at least one pore forming agent with the drug solution to form an emulsion, suspension, or second solution and hydrophilic or hydrophobic excipients that stabilize the drug and inhibit crystallization, and (iii) removing the volatile solvent and pore forming agent from the emulsion, suspension, or second solution to yield the porous matrix of drug. Hydrophobic or hydrophilic excipients may be selected to stabilize the drug in crystalline form by inhibiting crystal growth or to stabilize the drug in amorphous form by preventing crystallization. The pore forming agent can be either a volatile liquid that is immiscible with the drug solvent or a volatile solid-compound, preferably a volatile salt. In a preferred embodiment, spray drying is used to remove the solvents and the pore forming agent. The resulting porous matrix has a faster rate of dissolution following administration to a patient, as compared to non-porous matrix forms of the drug. In a preferred embodiment, microparticles of the porous drug matrix are reconstituted with an aqueous medium and administered parenterally, or processed using standard techniques into tablets or capsules for oral administration.

Owner:ACUSPHERE INC

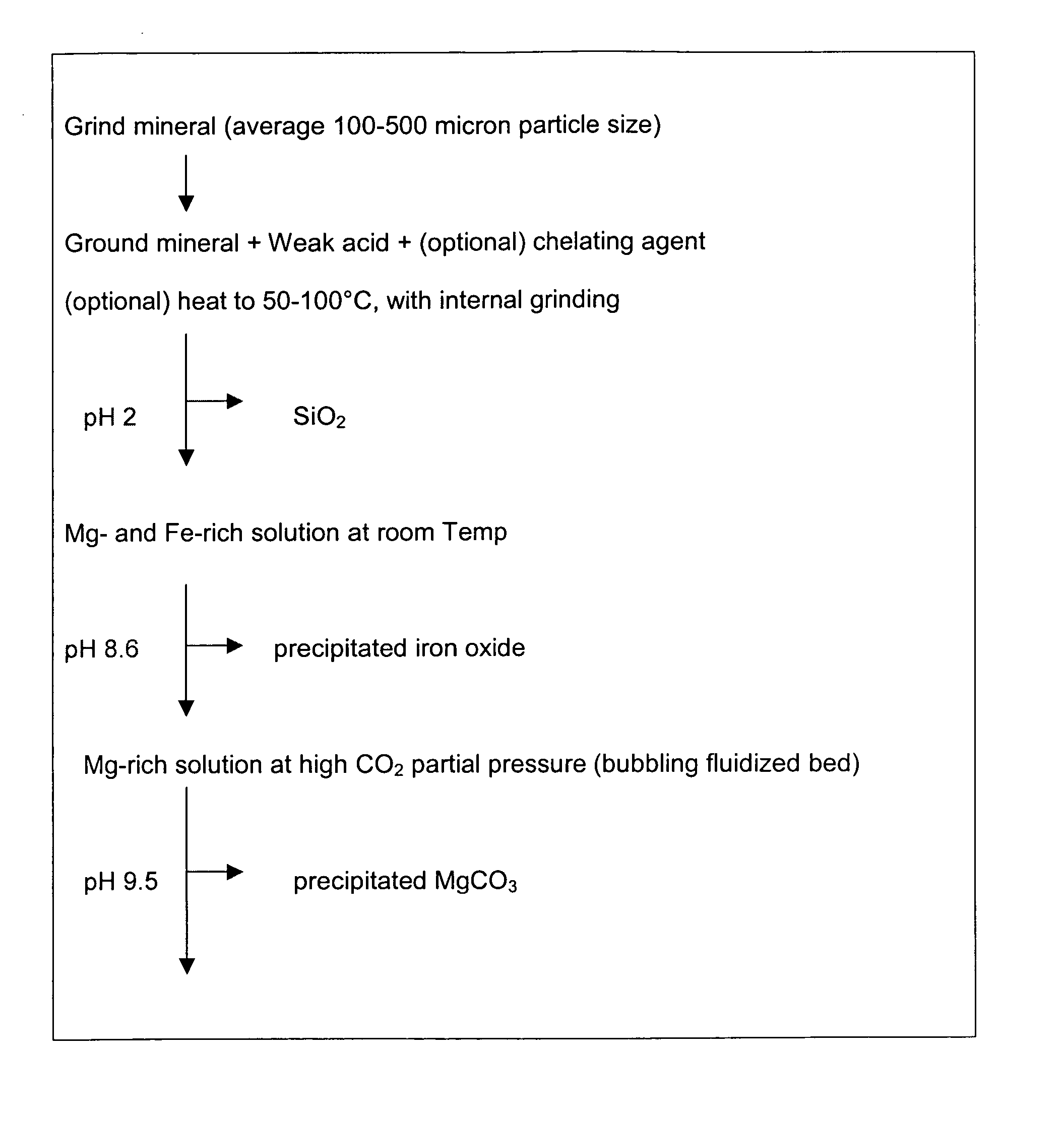

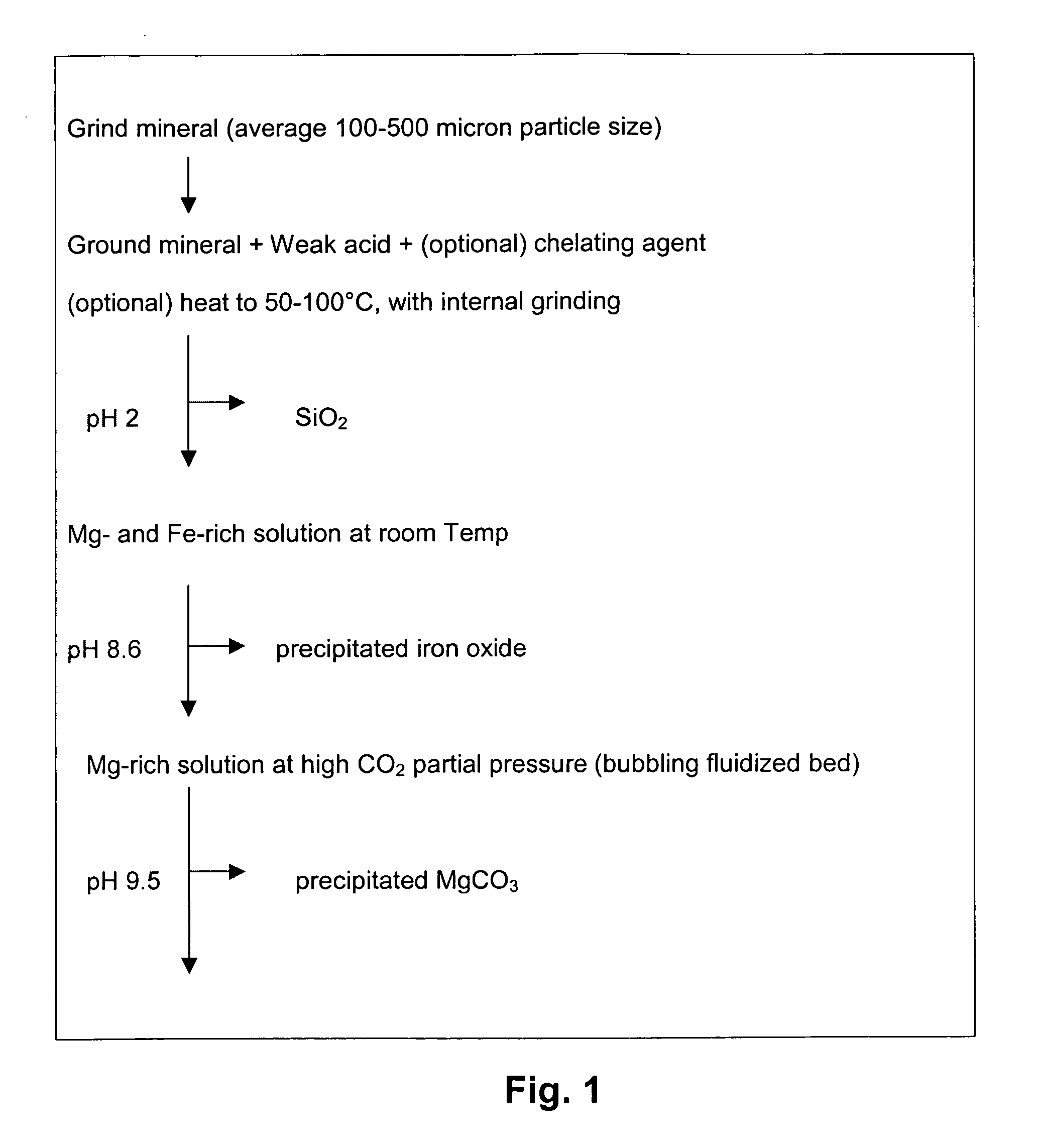

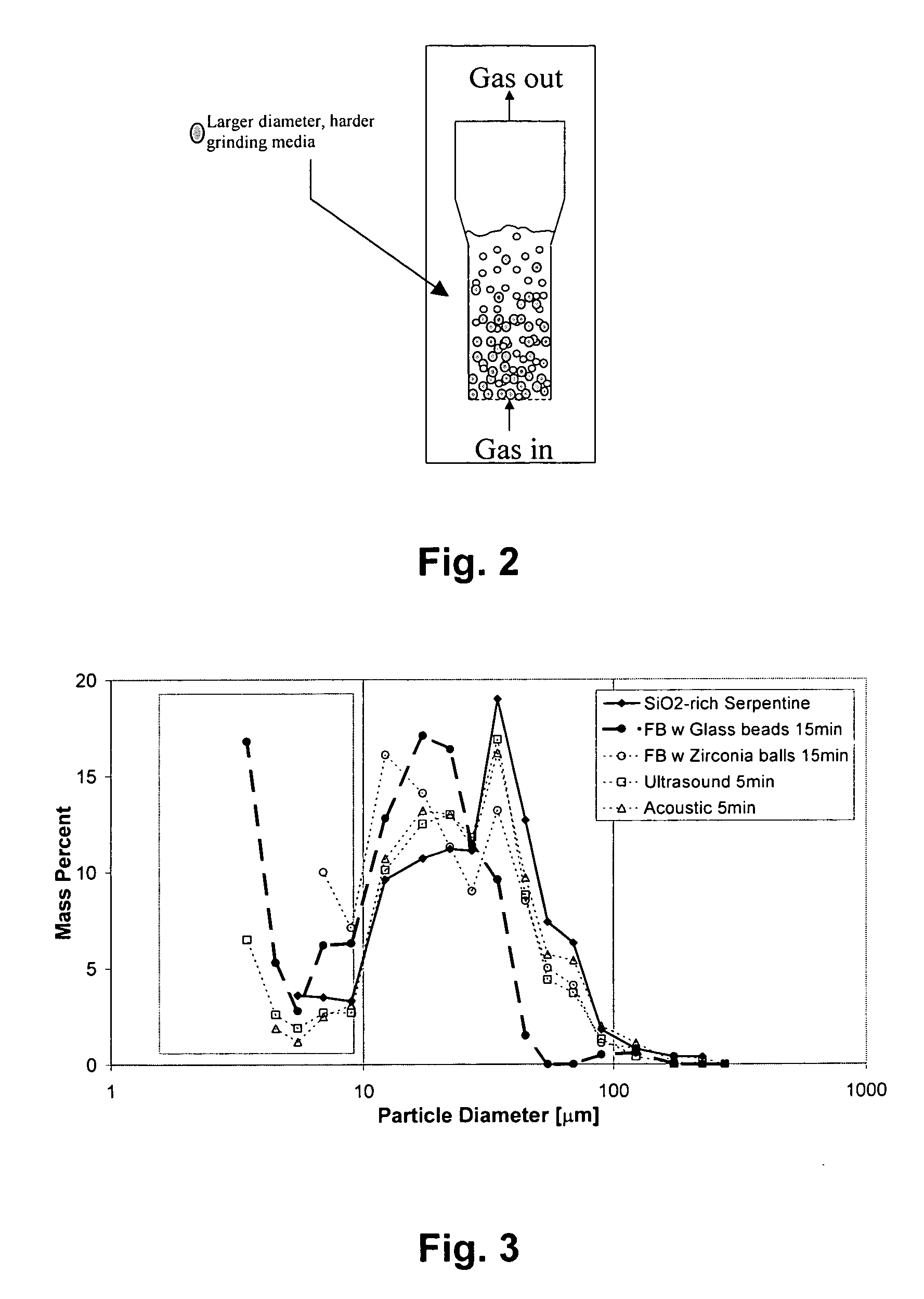

Carbon dioxide sequestration using alkaline earth metal-bearing minerals

ActiveUS20050180910A1High dissolution rateEfficient removalCalcium/strontium/barium carbonatesProductsParticulatesAlkaline earth metal

A method for mineral sequestration of pollutant gases resulting from the combustion of carbon-based fuels such as carbon and sulfur dioxides is provided and includes, providing a particulate magnesium-containing mineral and exposing the magnesium-containing mineral to a weak acid to dissolve magnesium from the mineral and form a magnesium-containing solution. The surface of the particulate magnesium-containing mineral is physically activated to expose and dissolve additional magnesium into the solution. Pollutant gases such as carbon dioxide are mixed with the magnesium-containing solution. When the pH of the magnesium-containing solution is increased, solid magnesium carbonate is formed.

Owner:THE OHIO STATES UNIV

Porous drug matrices and methods of manufacture thereof

InactiveUS20050058710A1Fast dissolutionExtended half-lifePowder deliveryGranular deliveryDrugs solutionMicroparticle

Drugs, especially low aqueous solubility drugs, are provided in a porous matrix form, preferably microparticles, which enhances dissolution of the drug in aqueous media. The drug matrices preferably are made using a process that includes (i) dissolving a drug, preferably a drug having low aqueous solubility, in a volatile solvent to form a drug solution, (ii) combining at least one pore forming agent with the drug solution to form an emulsion, suspension, or second solution and hydrophilic or hydrophobic excipients that stabilize the drug and inhibit crystallization, and (iii) removing the volatile solvent and pore forming agent from the emulsion, suspension, or second solution to yield the porous matrix of drug. Hydrophobic or hydrophilic excipients may be selected to stabilize the drug in crystalline form by inhibiting crystal growth or to stabilize the drug in amorphous form by preventing crystallization. The pore forming agent can be either a volatile liquid that is immiscible with the drug solvent or a volatile solid compound, preferably a volatile salt. In a preferred embodiment, spray drying is used to remove the solvents and the pore forming agent. The resulting porous matrix has a faster rate of dissolution following administration to a patient, as compared to non-porous matrix forms of the drug. In a preferred embodiment, microparticles of the porous drug matrix are reconstituted with an aqueous medium and administered parenterally, or processed using standard techniques into tablets or capsules for oral administration.

Owner:ACUSPHERE INC

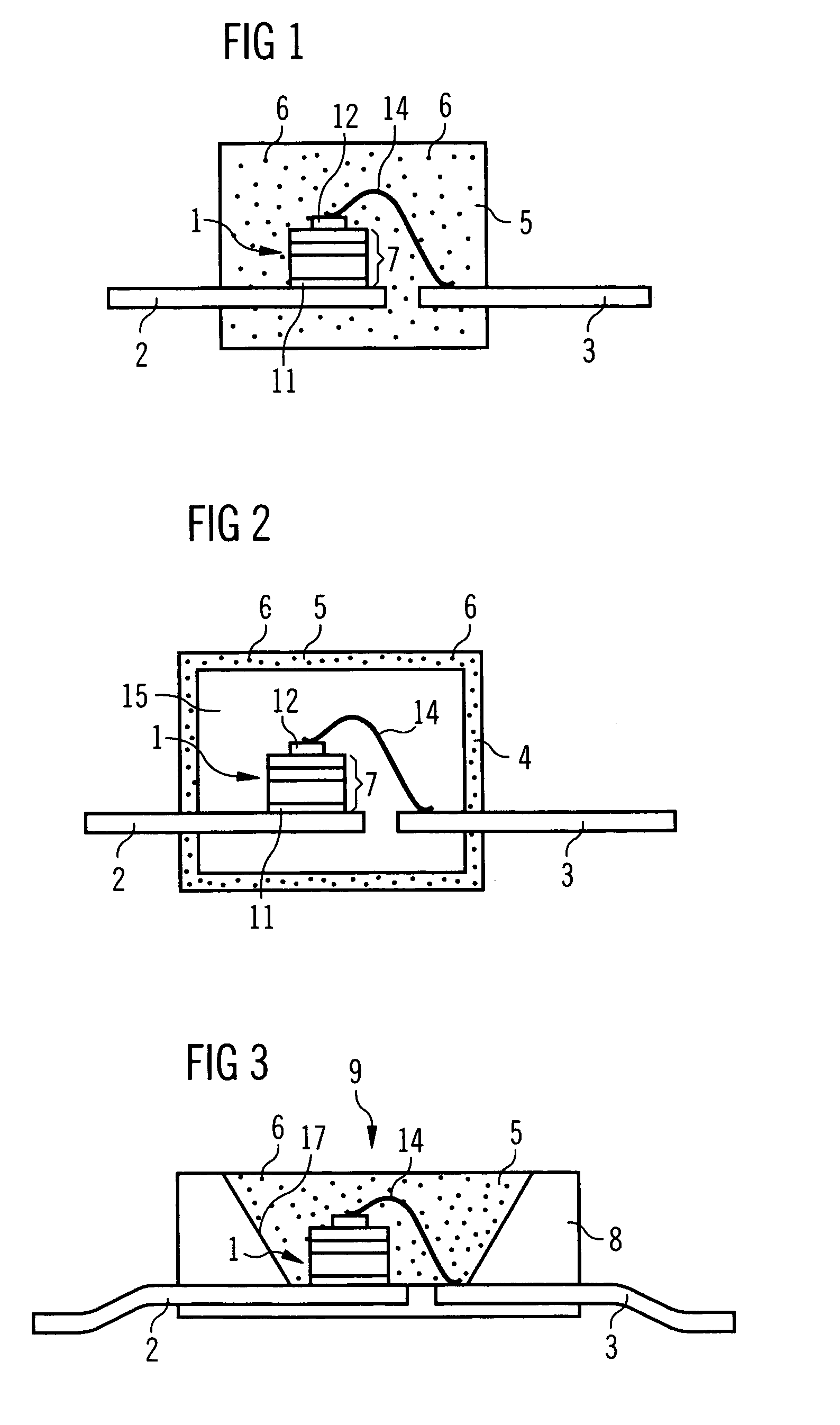

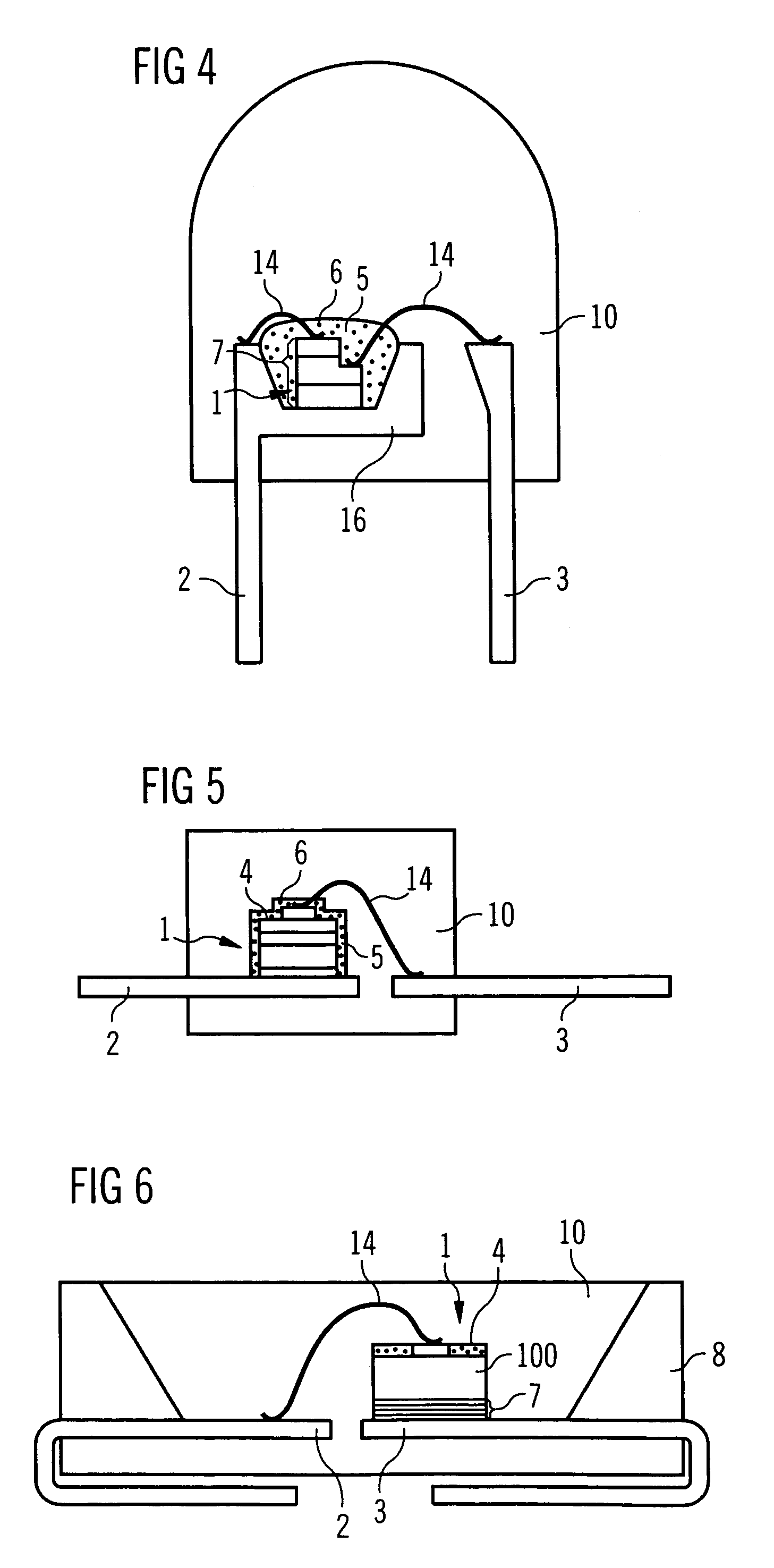

Light emitting diode with wavelength conversion

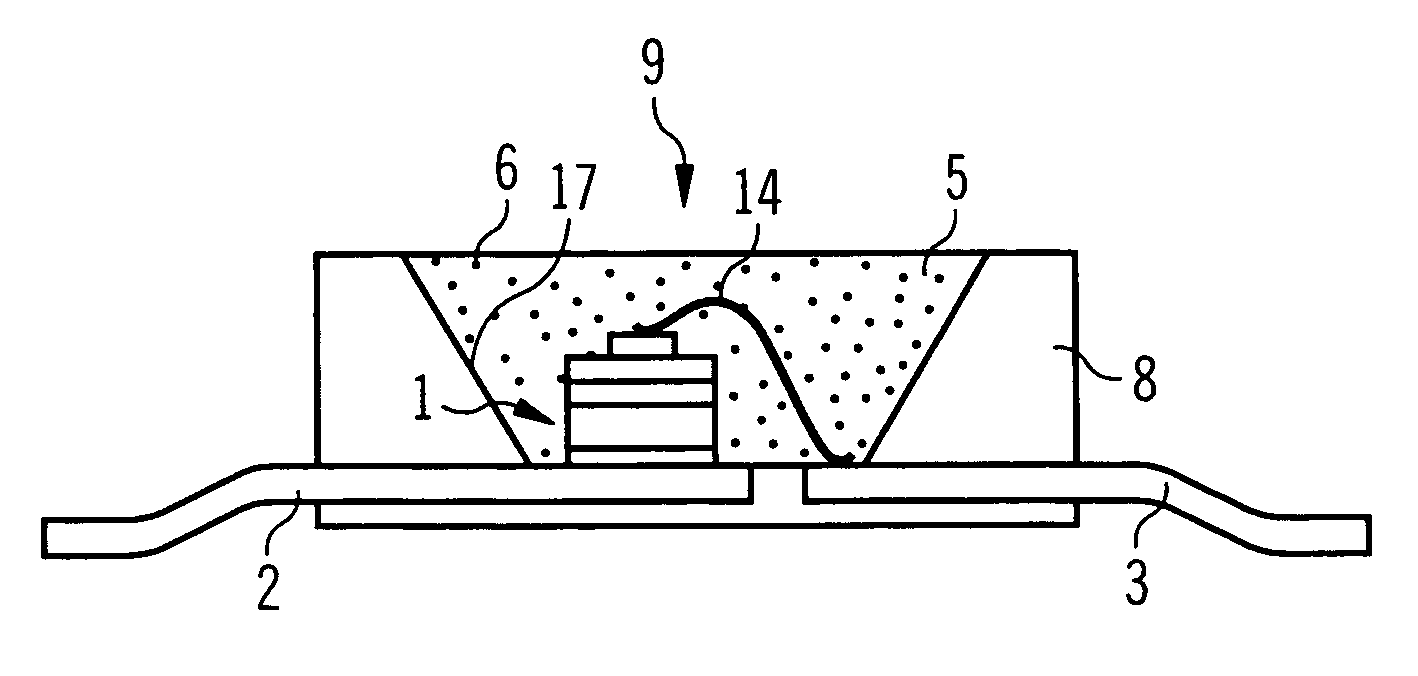

InactiveUS7045956B2Increase lighting brightnessEasy to convertDischarge tube luminescnet screensElectroluminescent light sourcesNanoparticleLength wave

The invention relates to a wavelength-converting reaction resin compound into which a wavelength-converting luminescent material and a thixotroping agent are mixed, wherein the luminescent material contains inorganic luminescent particles. The thixotroping agent is present, at least in part, in the form of nanoparticles. Methods of producing the reaction resin compound and light-emitting diode elements having such reaction resin compounds are indicated.

Owner:OSRAM GMBH

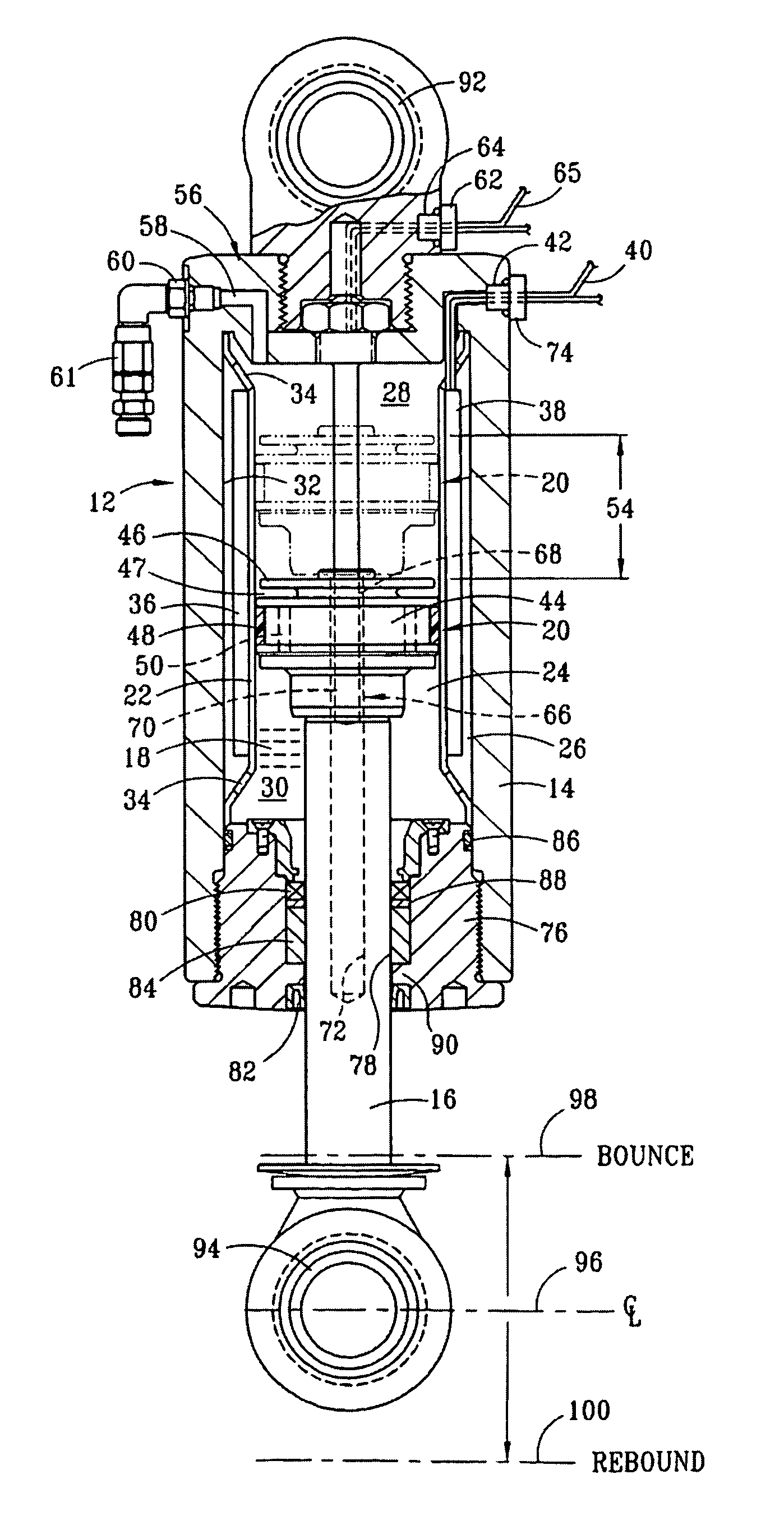

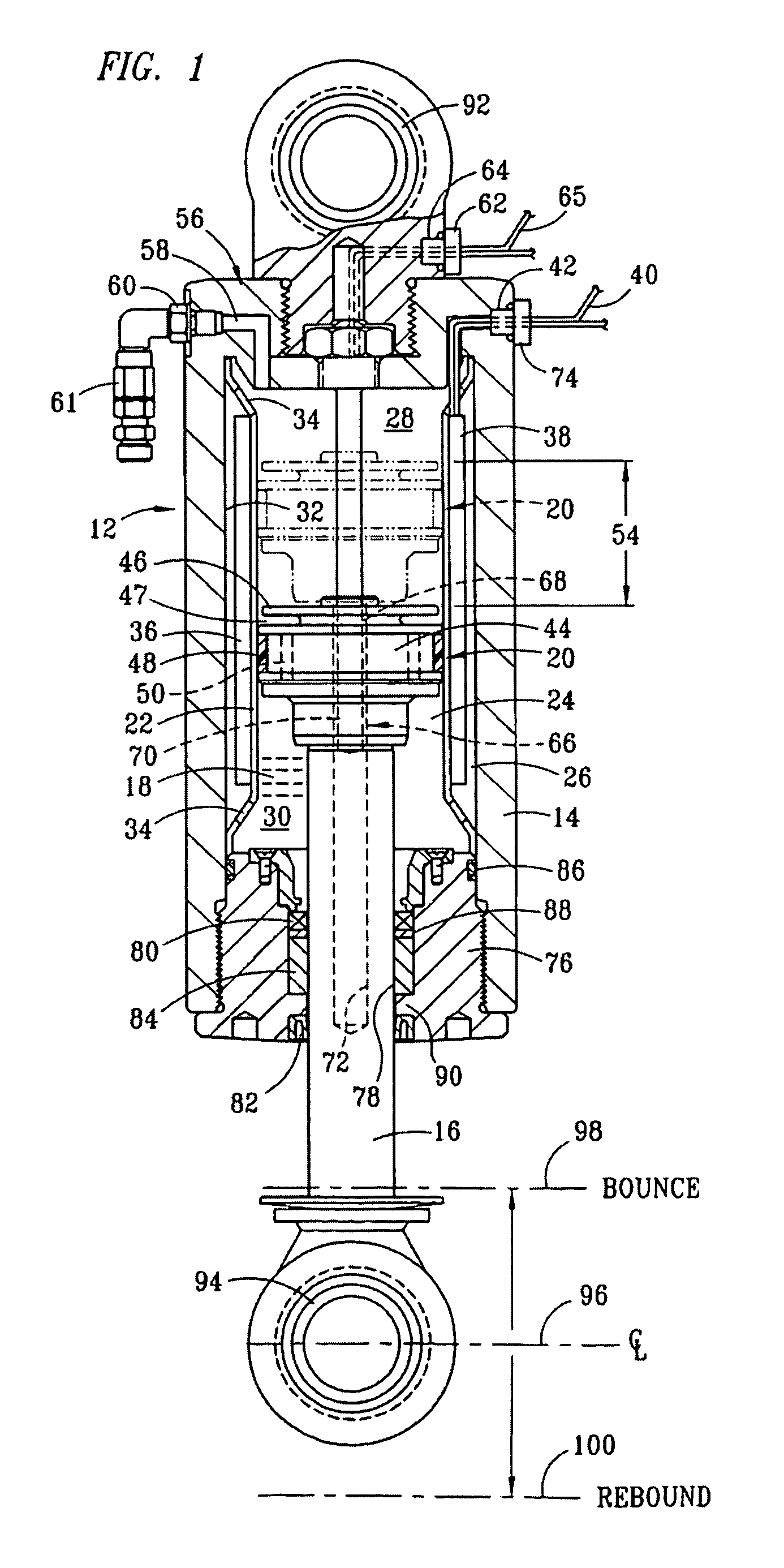

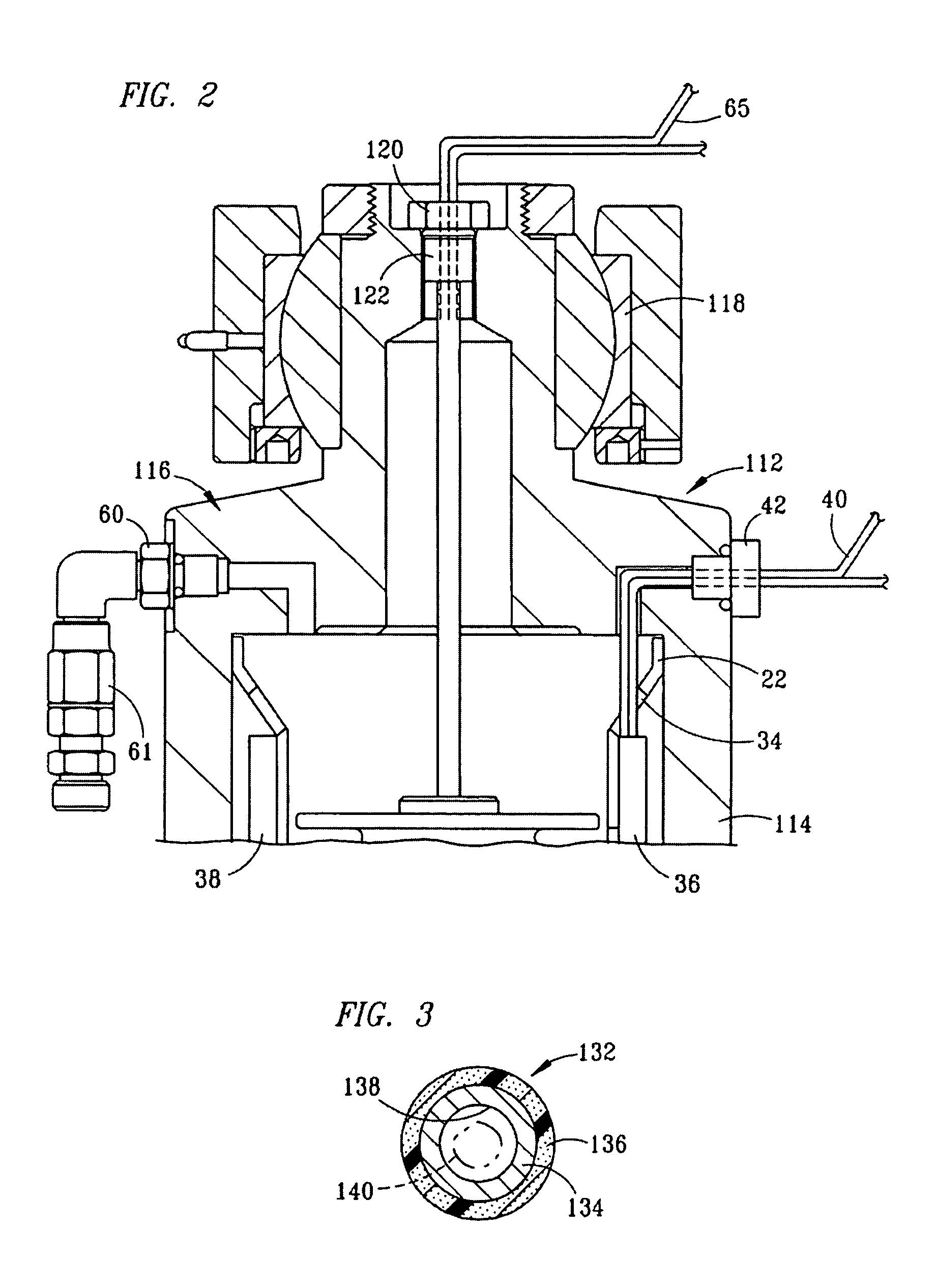

Suspension strut for use with a compressible magnetorheological fluid

ActiveUS7770701B1Prevent precipitationStay flexibleSpringsNon-rotating vibration suppressionMagnetorheological fluidVolumetric Mass Density

A strut (12) is configured for an active suspension system (142) which provides electronic control for both the force applied by the strut (12) and the dampening characteristics of the strut (12). A compressible fluid (18) is used within the strut (12), and preferably includes a compressible base fluid and electromagnetic field responsive particles (132) which are suspended in the compressible base fluid. The electromagnetic field responsive particles (132) are preferably closely matched in density and modulas of elasticity to that of the compressible base fluid to prevent sedimentation of the particles (132) and to maintain the elasticity of the compressible fluid (18). The amount compressible fluid (18) within the strut (12) is electronically controlled to determine the force applied by the strut (12) and a field strength applied to the compressible fluid in a fluid flow passage is electronically controlled to determine the dampening characteristics of the strut (12).

Owner:HORSTMAN

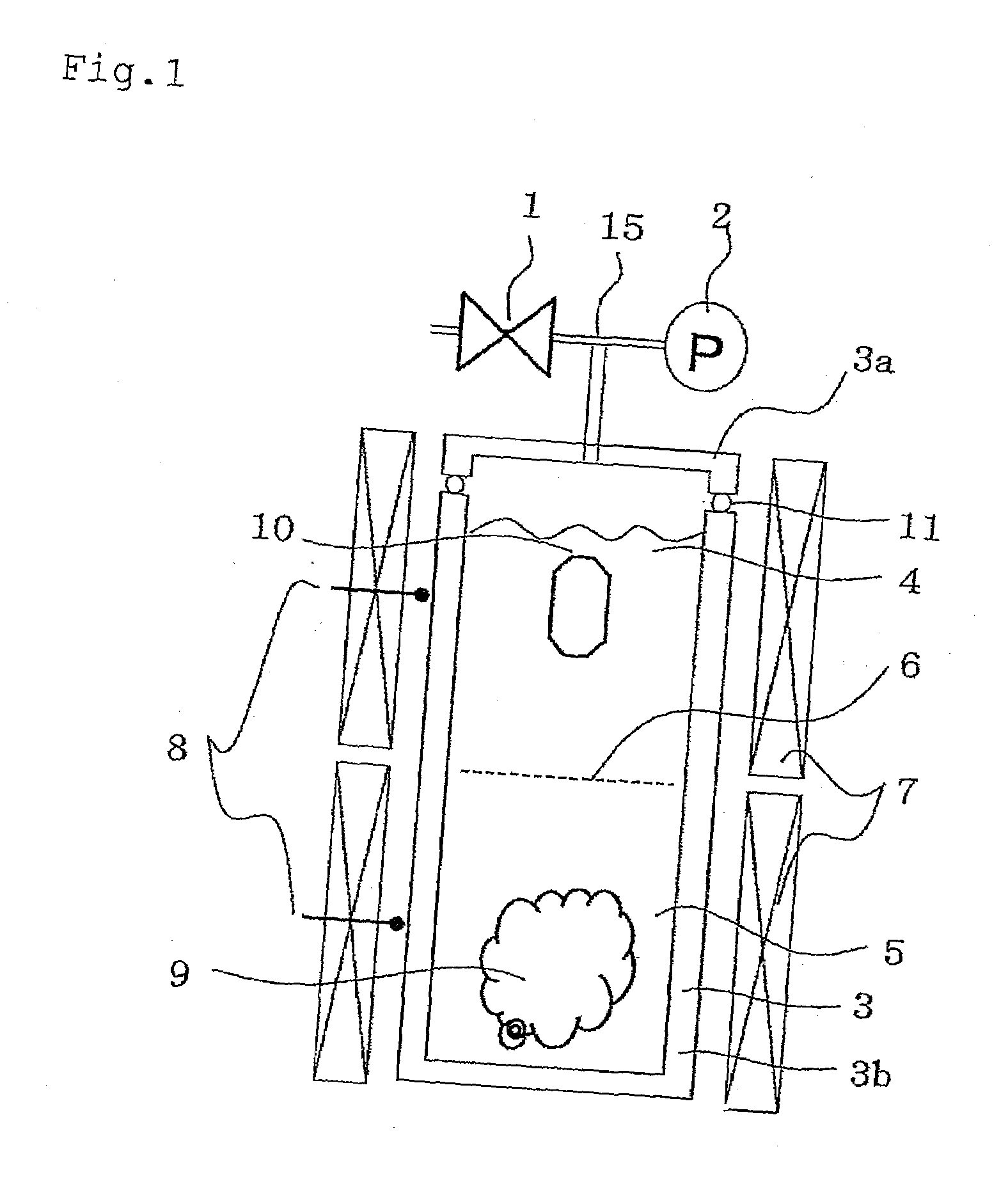

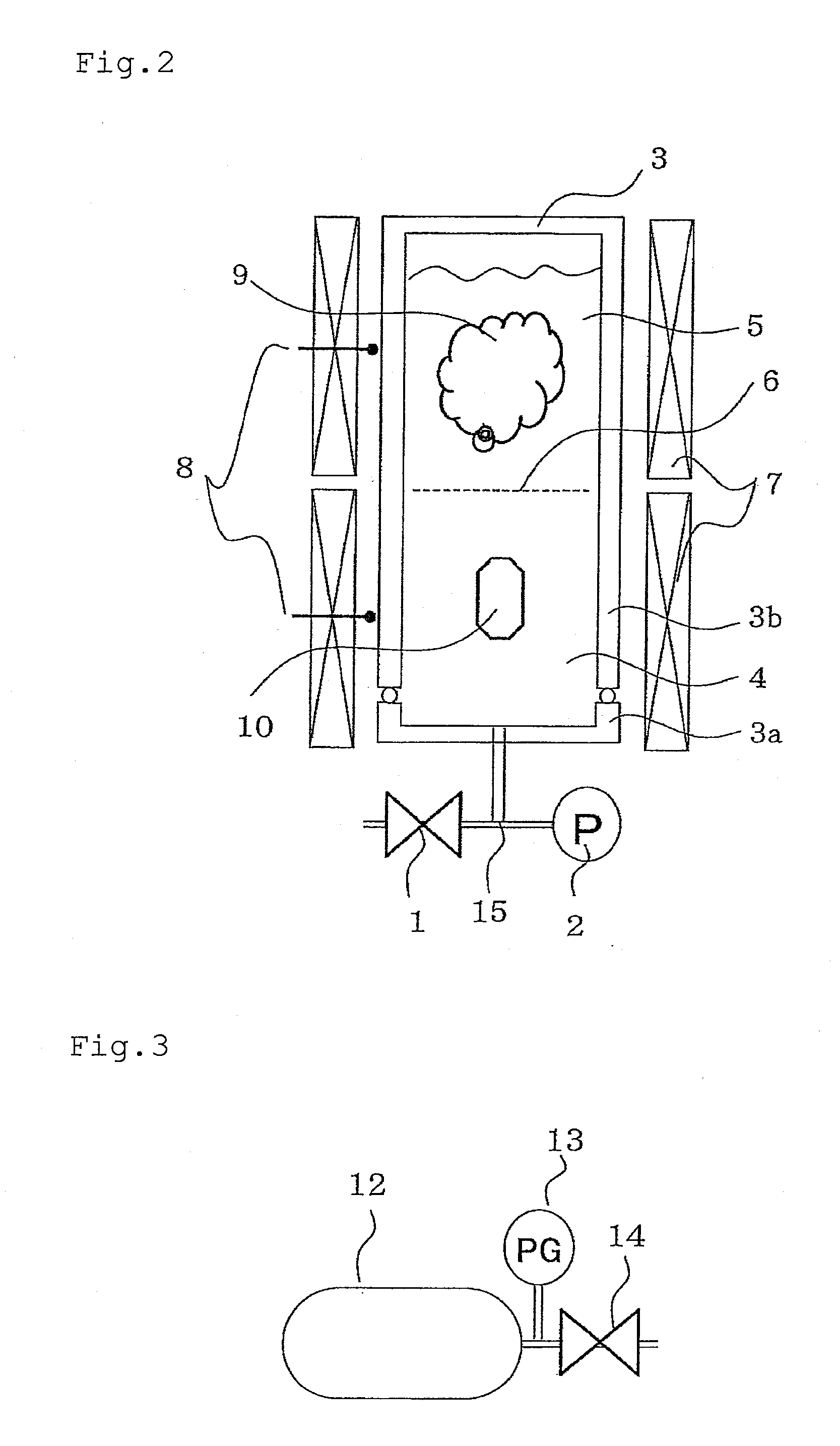

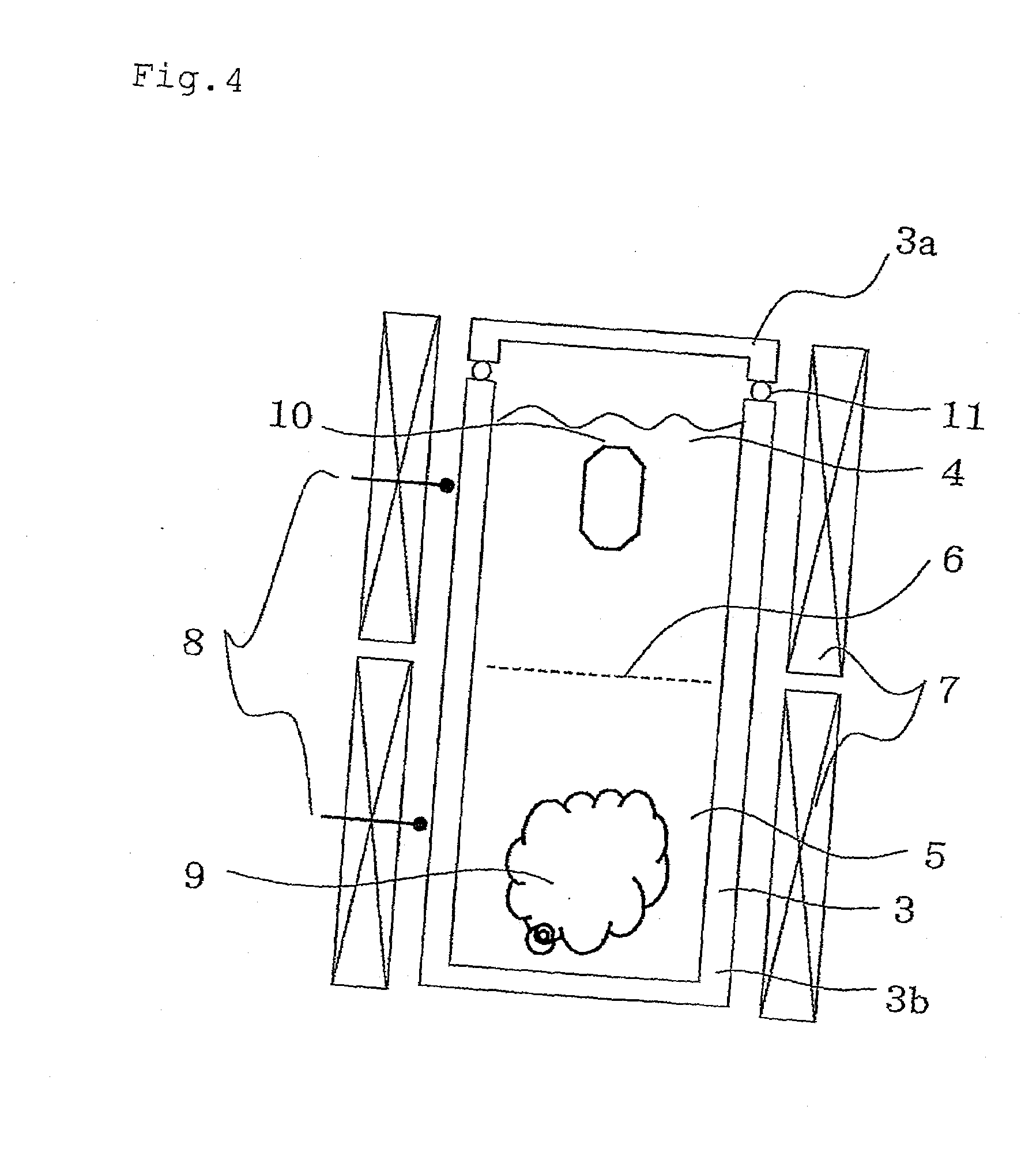

Crystal production process using supercritical solvent, crystal growth apparatus, crystal and device

InactiveUS20090092536A1Efficient productionEasy to controlPolycrystalline material growthFrom normal temperature solutionsSolventCrystal growth

To control the precipitation position of a crystal and increase the yield of the crystal by performing the crystal growth according to the solvothermal method while allowing a predetermined amount of a substance differing in the critical density from the solvent to be present in the reaction vessel; and to prevent mixing of an impurity into the crystal and improve the crystal purity.

Owner:MITSUBISHI CHEM CORP +1

Aqueous liquid pharmaceutical composition comprised of gatifloxacin

InactiveUS6333045B1Prevent from colorationReduce calcium concentrationAntibacterial agentsSenses disorderDisodium EdetateChemistry

There is provided an aqueous liquid pharmaceutical composition which comprises Gatifloxacin (chemical nomenclature: (±)-1-cyclopropyl-6-fluoro-1,4-dihydro-8-methoxy-7-(3-methyl-1-piperazinyl)-4-oxo-3-quinoline carboxylic acid) or its salt and disodium edetate. Further, there are provided a method for raising corneal permeability of Gatifloxacin, a method for preventing precipitation of Gatifloxacin crystals, and a method for preventing coloration of Gatifloxacin by incorporating disodium edetate into an aqueous liquid preparation containing Gatifloxacin or its salt.

Owner:SENJU PHARMA CO LTD +1

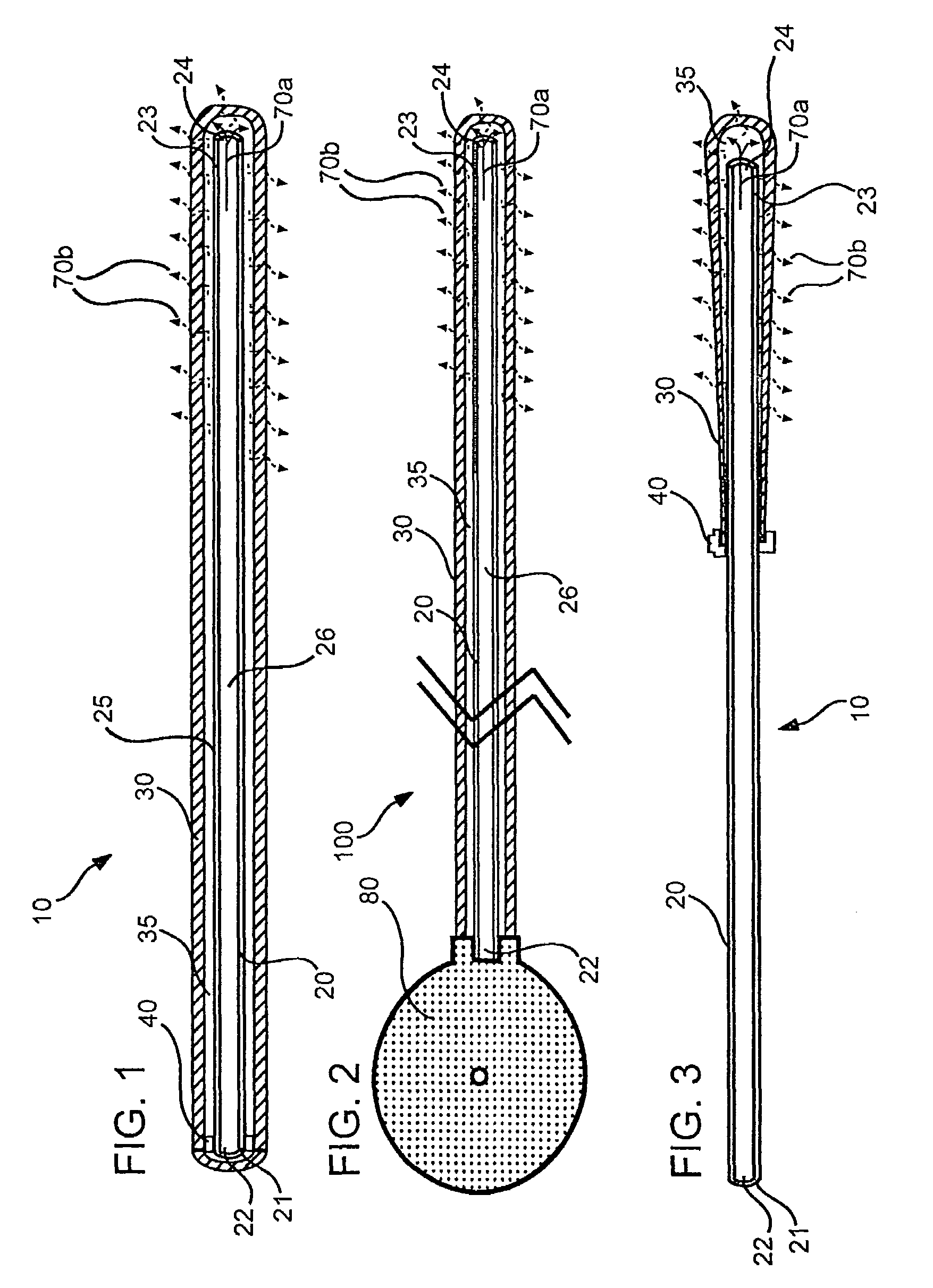

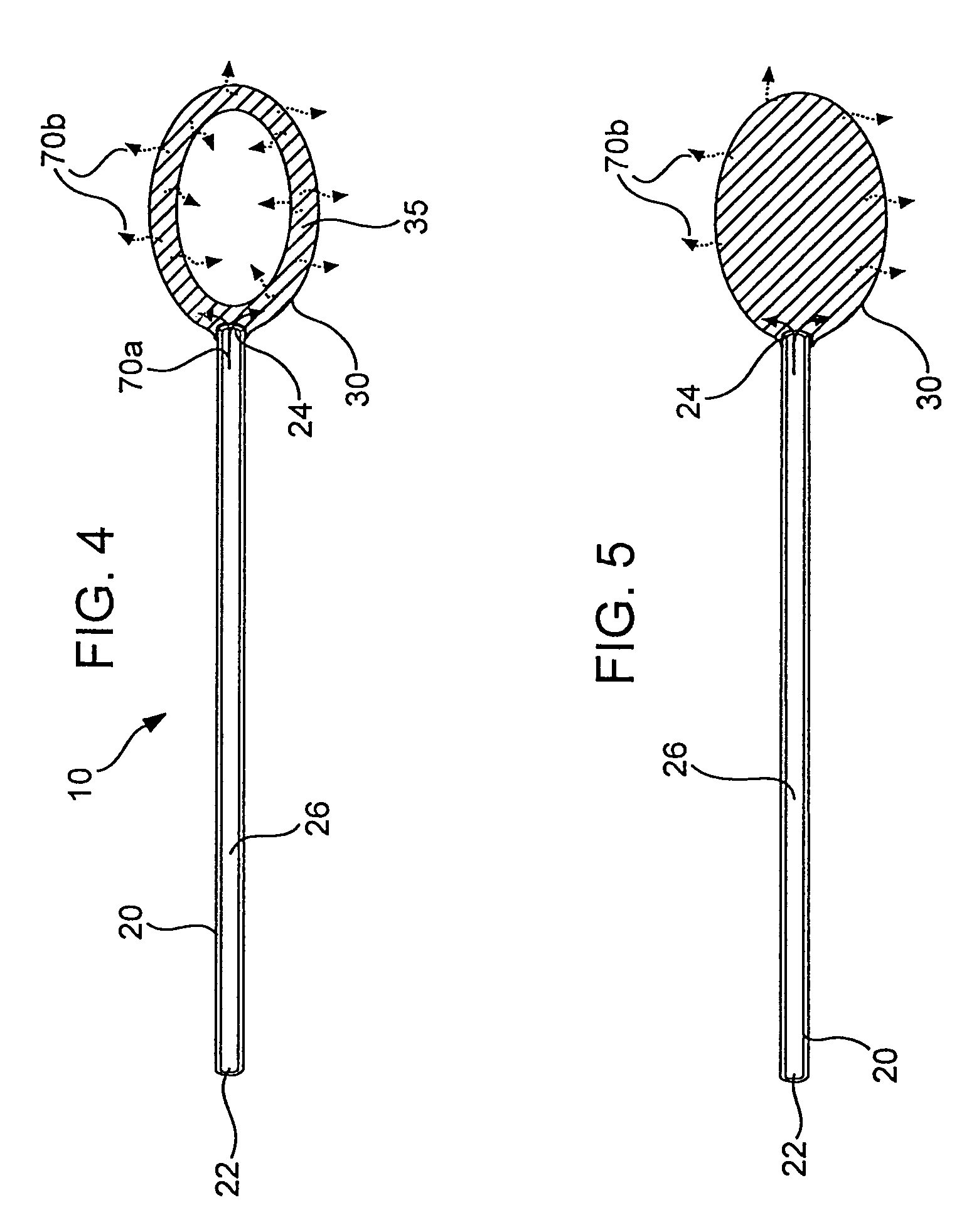

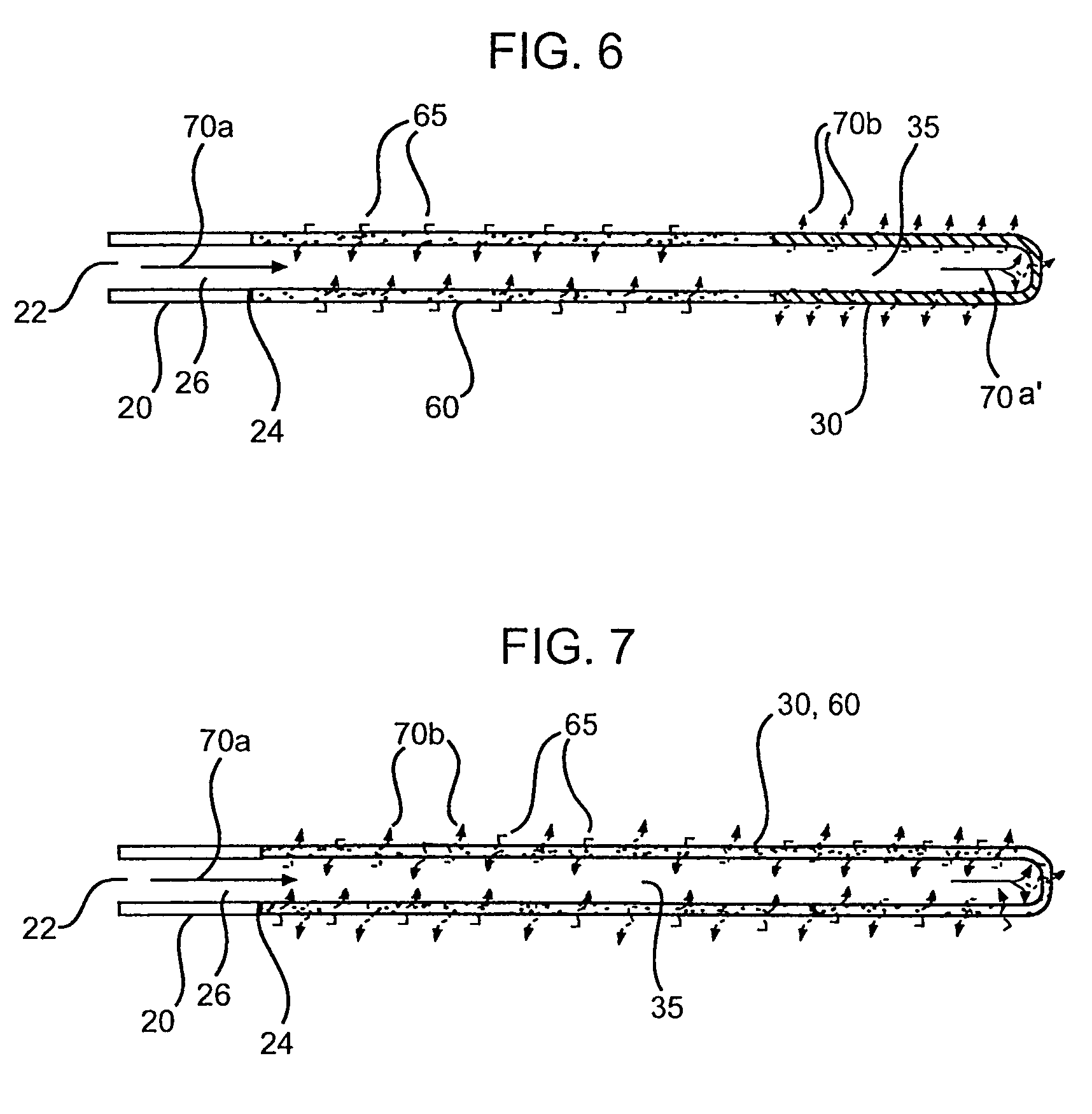

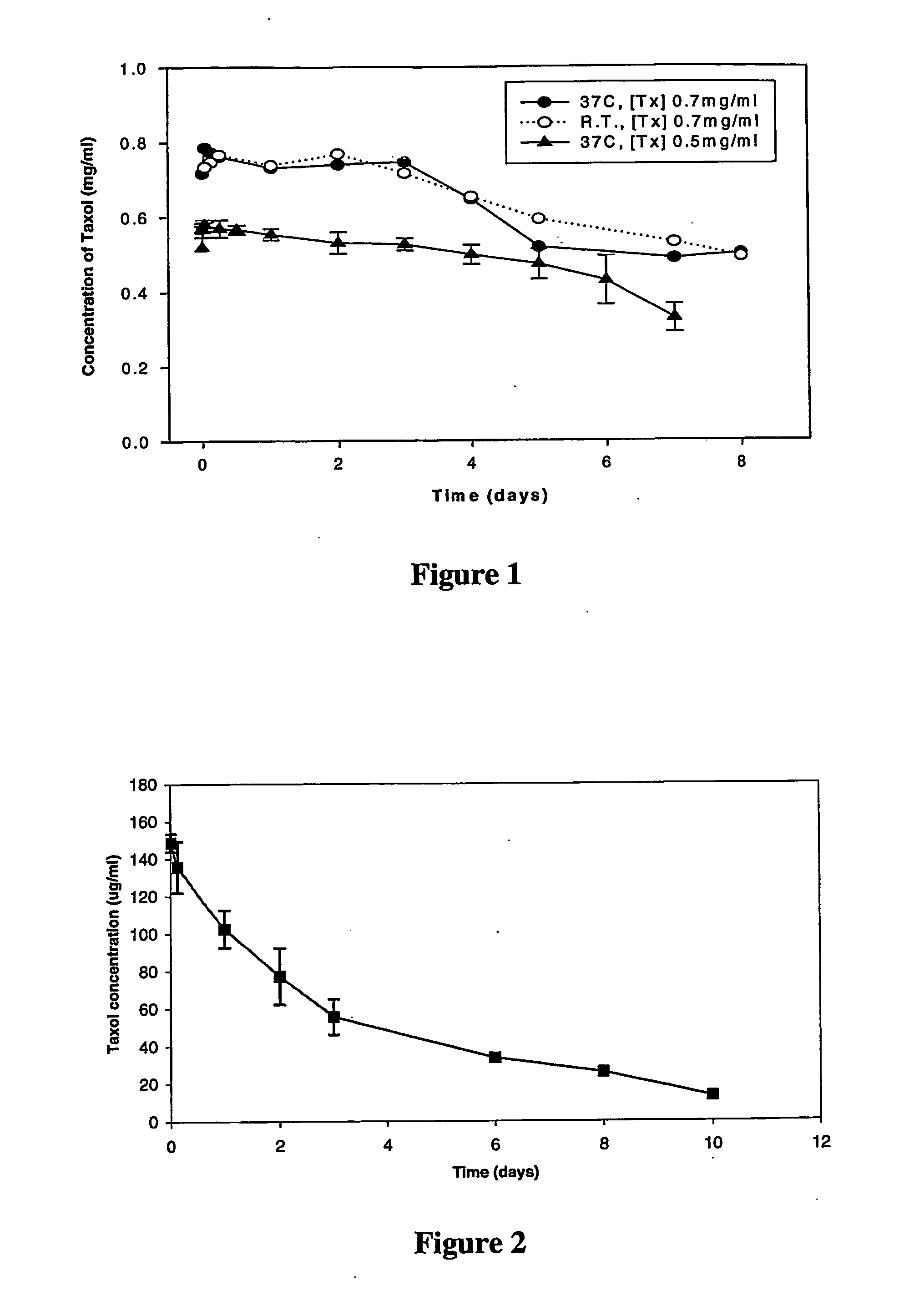

Local concentration management system

InactiveUS7438701B2Reduce deliveryEasy to handleBalloon catheterSurgeryMedicineCentralized management

The invention provides a local concentration management system (LCMS) for delivery of highly concentrated therapeutic agent formulations. The LCMS comprises a device comprising an elongate body defining a lumen between its proximal and distal ends, and a diffuser element, a dilutor element, or both. The diffuser element, which is selectively permeable to the agent, is operatively associated with the elongate body so that agent flows through the elongate body, and into and through the diffuser element to exit the system. The dilutor element can be operatively associated with the system to be in fluid communication with the elongate body lumen, a diffusion space defined by a diffuser element inner wall, or both. The dilutor element is selectively water permeable, but substantially impermeable to agent, to provide for dilution of the agent during transit through the system. The LCMS system is designed to disperse and / or dilute the drug delivery stream.

Owner:DURECT CORP

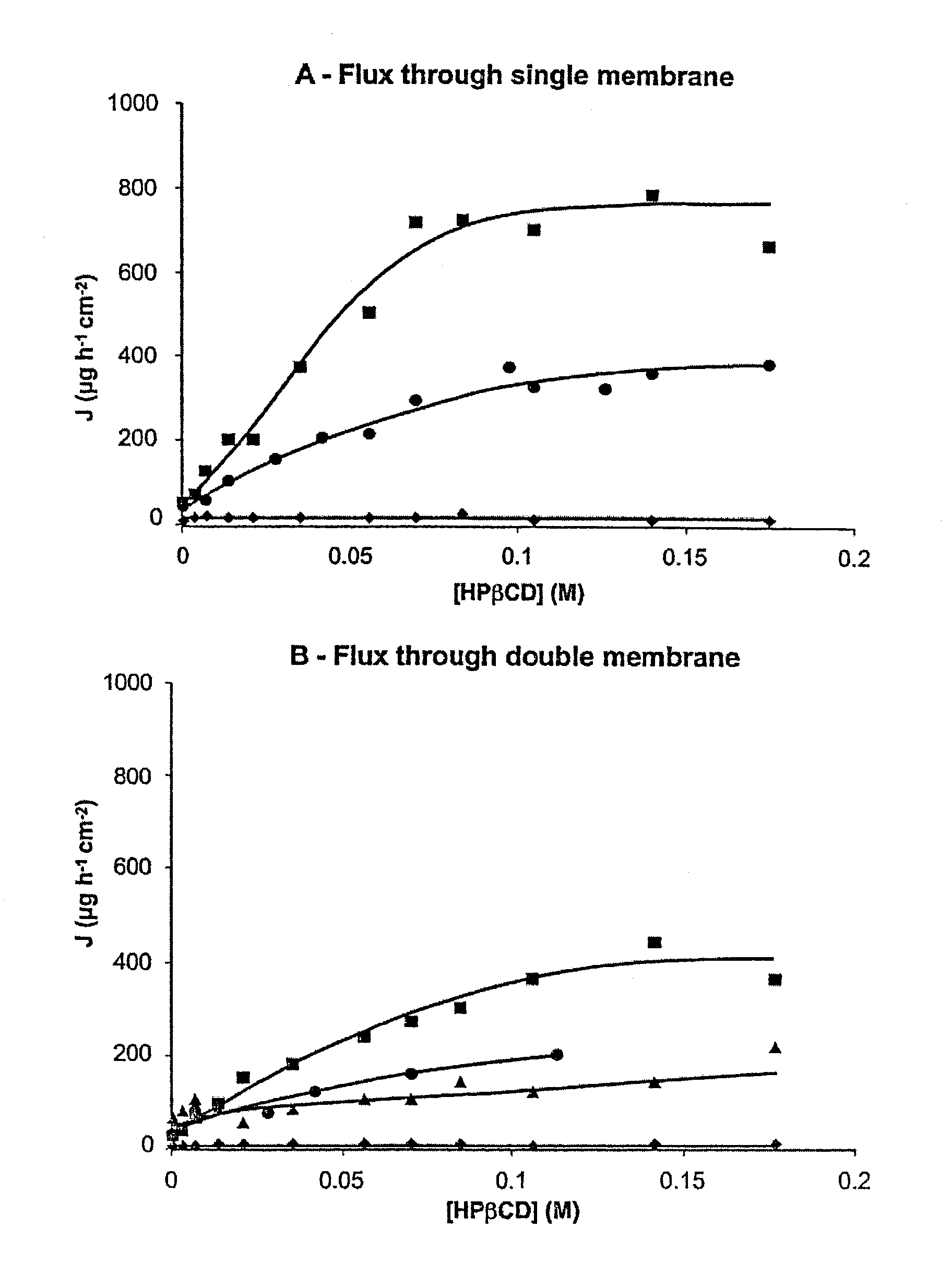

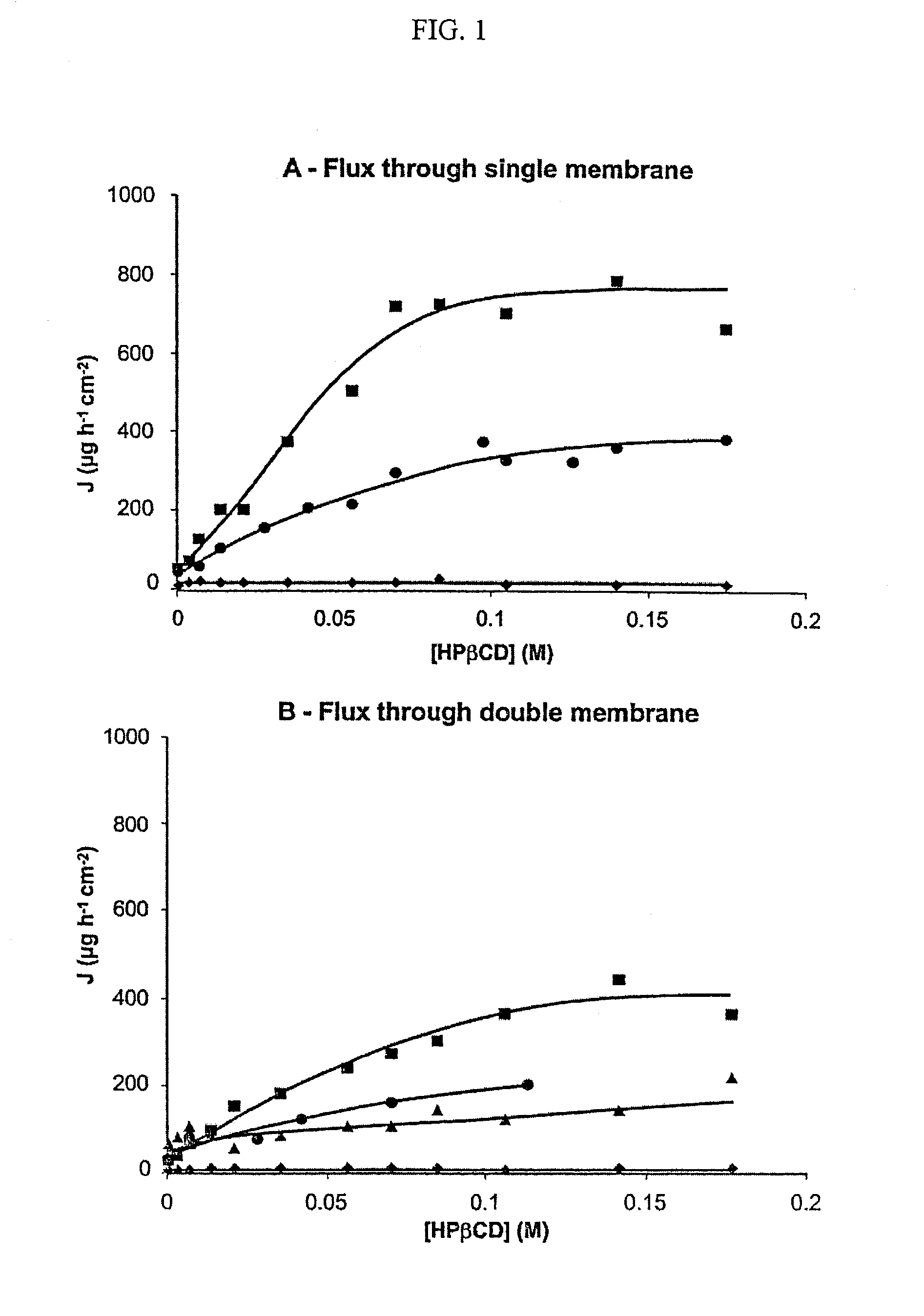

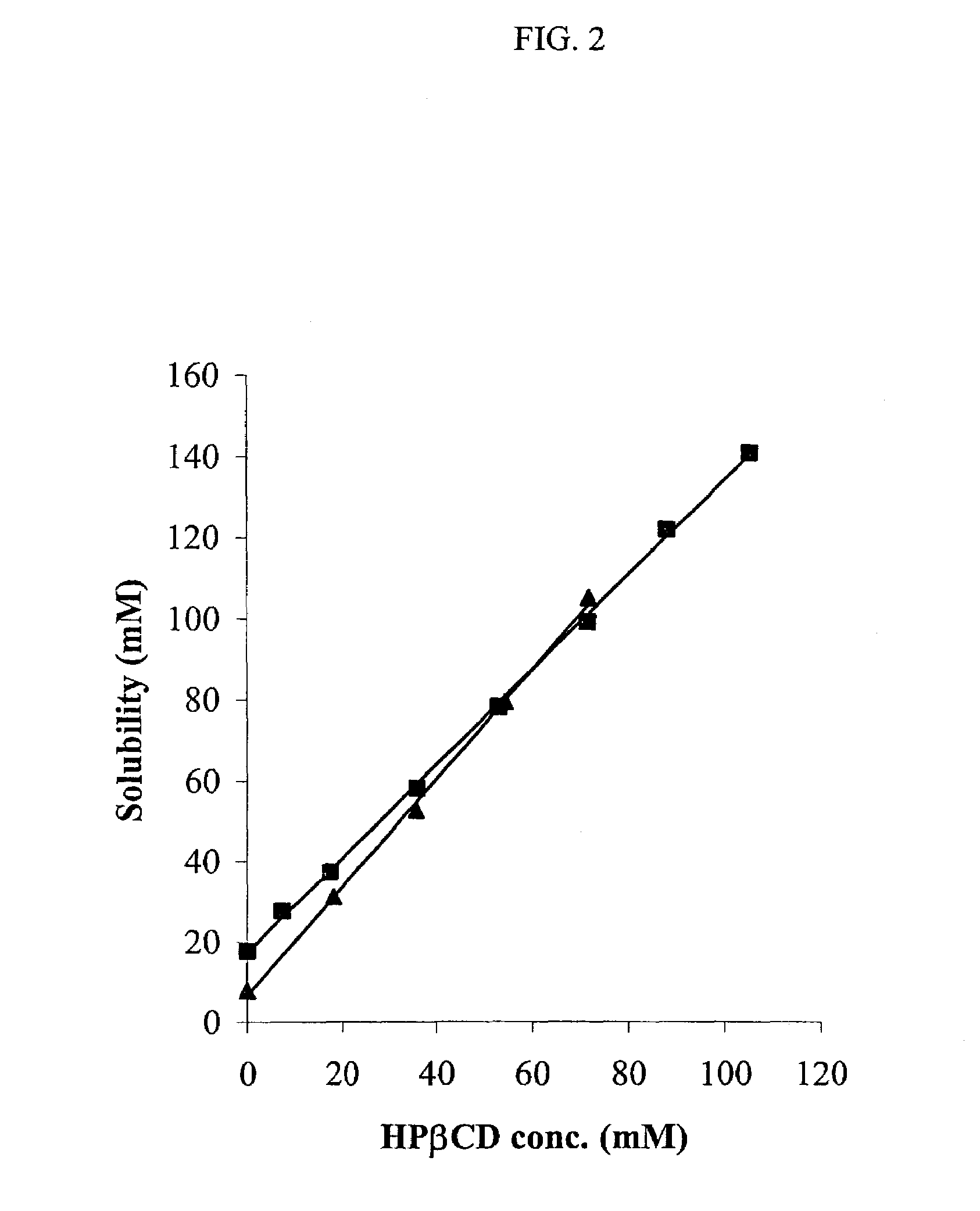

Non-inclusion cyclodextrin complexes

InactiveUS7115586B2Improve stabilityInhibit aggregationBiocideSugar derivativesWater solubleBULK ACTIVE INGREDIENT

The invention provides a number of methods for enhancing the aqueous solubility of an active ingredient which is insoluble or sparingly soluble in water. In one preferred embodiment, solubilization of the active ingredient is enhanced by combining it with β-cyclodextrin in an aqueous complexation medium comprising β-cyclodextrin and a negatively- or positively-charged compound which forms an inclusion or non-inclusion complex with β-cyclodextrin and its inclusion complexes.

Owner:DECODE GENETICS EHF

Cyanide-free pyrophosphoric acid bath for use in copper-tin alloy plating

InactiveUS6416571B1Changeable colorEasy to separateAnti-corrosive paintsLiquid/solution decomposition chemical coatingAlloyAmine derivatives

The present invention provides a pyrophosphoric acid bath for use in Cu-Sn alloy plating without containing a cyanic ion comprising a reaction product (A) of an amine derivative and an epihalohydrin in a 1:1 mole ratio and a cationic surfactant (B) and, when necessary, further comprising a surface tension adjusting agent (C), a bath stabilizer (D) and an N-benzylpyridinium derivative (E) as additives. According to the bath of the present invention, by changing a bath composition of copper and tin or by employing a characteristic additive, a stable film with a silver-white, gold, copper or light black color can be obtained. By increasing tin contents in the bath, the bath can be used for lead-free solder plating. The bath is safe in handling and hygienic and, moreover, has no sewage process and environmental problems since it contains neither cyanic compound nor formaldehyde derivative.

Owner:NIHON NEW CHROME

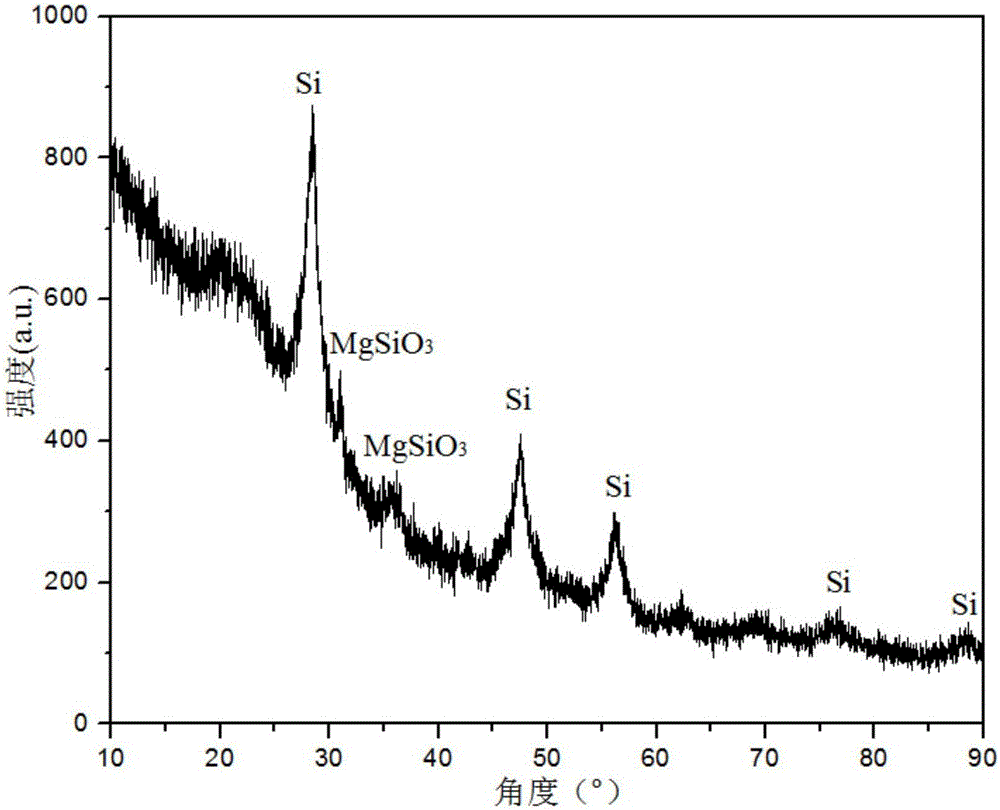

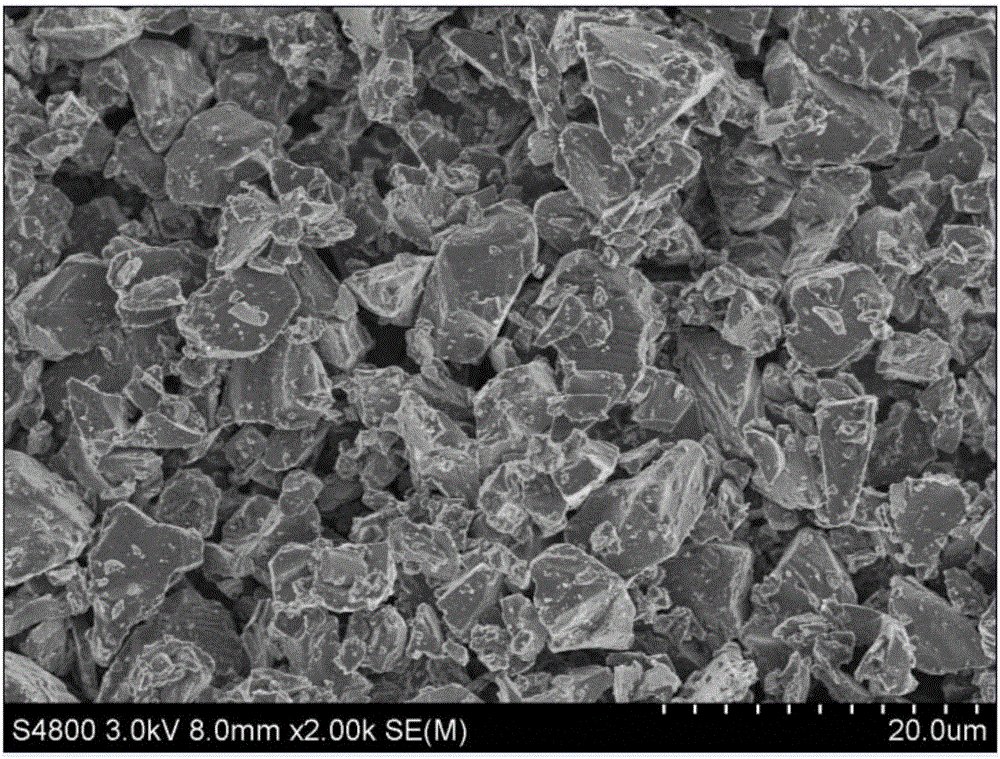

Compound and preparation method thereof as well as negative electrode prepared by adopting compound and lithium ion battery

ActiveCN106356508AImprove consistencyImprove dispersion uniformityCell electrodesSecondary cellsElectrical batterySilicon oxygen

The invention relates to a compound and a preparation method thereof as well as a negative electrode prepared by adopting the compound and a lithium ion battery. The compound comprises silicon, silicon oxide SiOx (x is greater than 0 and is less than or equal to 2) and silicate, wherein positive ion elements of the silicate are reductant elements, and Si, O and the reductant elements in the compound are uniformly distributed. Reductants used in the compound are heated and insulated in the environment of negative pressure, so that SiO steam reacts with reductant steam in the form of a gas phase so as to condense to obtain the compound, and then the compound is further used as a raw material so as to prepare a modified silica negative electrode material. The negative electrode material is suitable for the lithium ion battery, the prepared lithium ion battery has high charge and discharge specific capacity and excellent first coulombic efficiency, the charge capacity is 1447 mAh / g or above, the discharge capacity is 1213 mAh / g or above, and the first coulombic efficiency is 83.8% or above.

Owner:BTR NEW MATERIAL GRP CO LTD

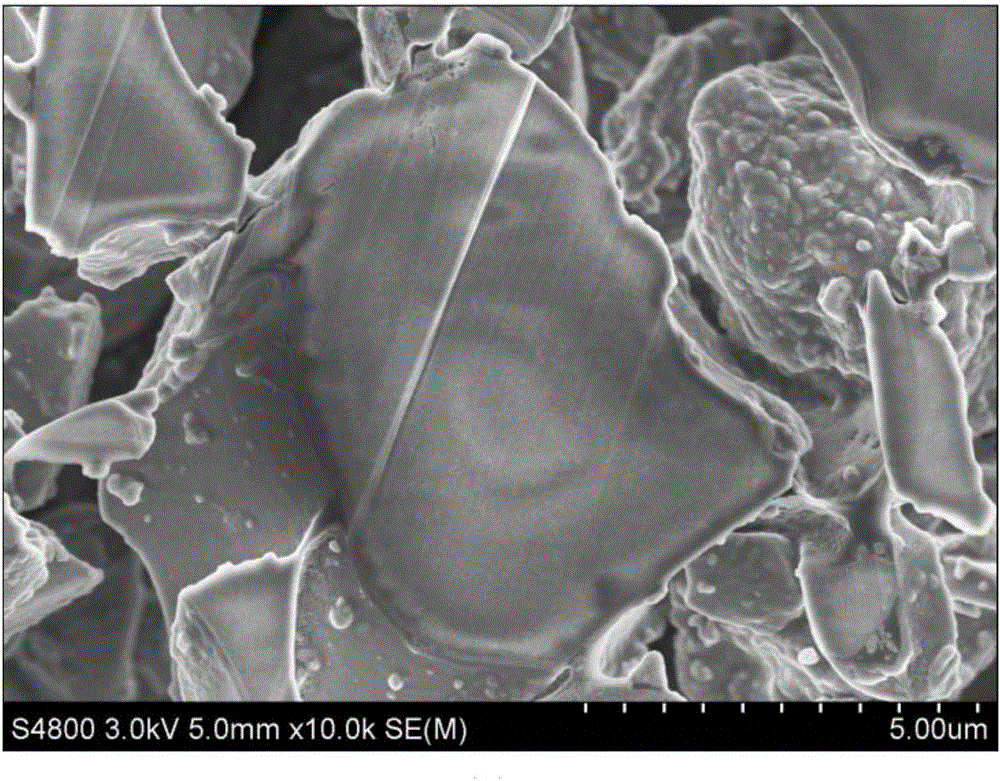

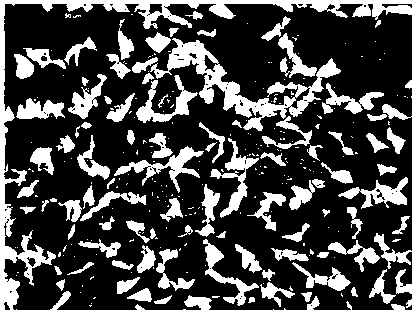

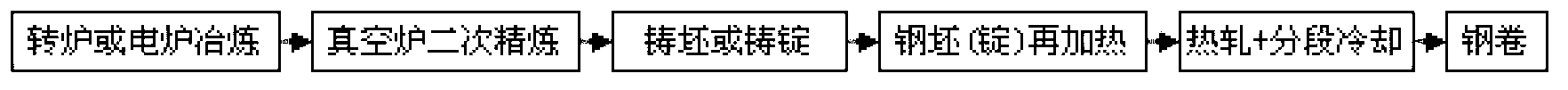

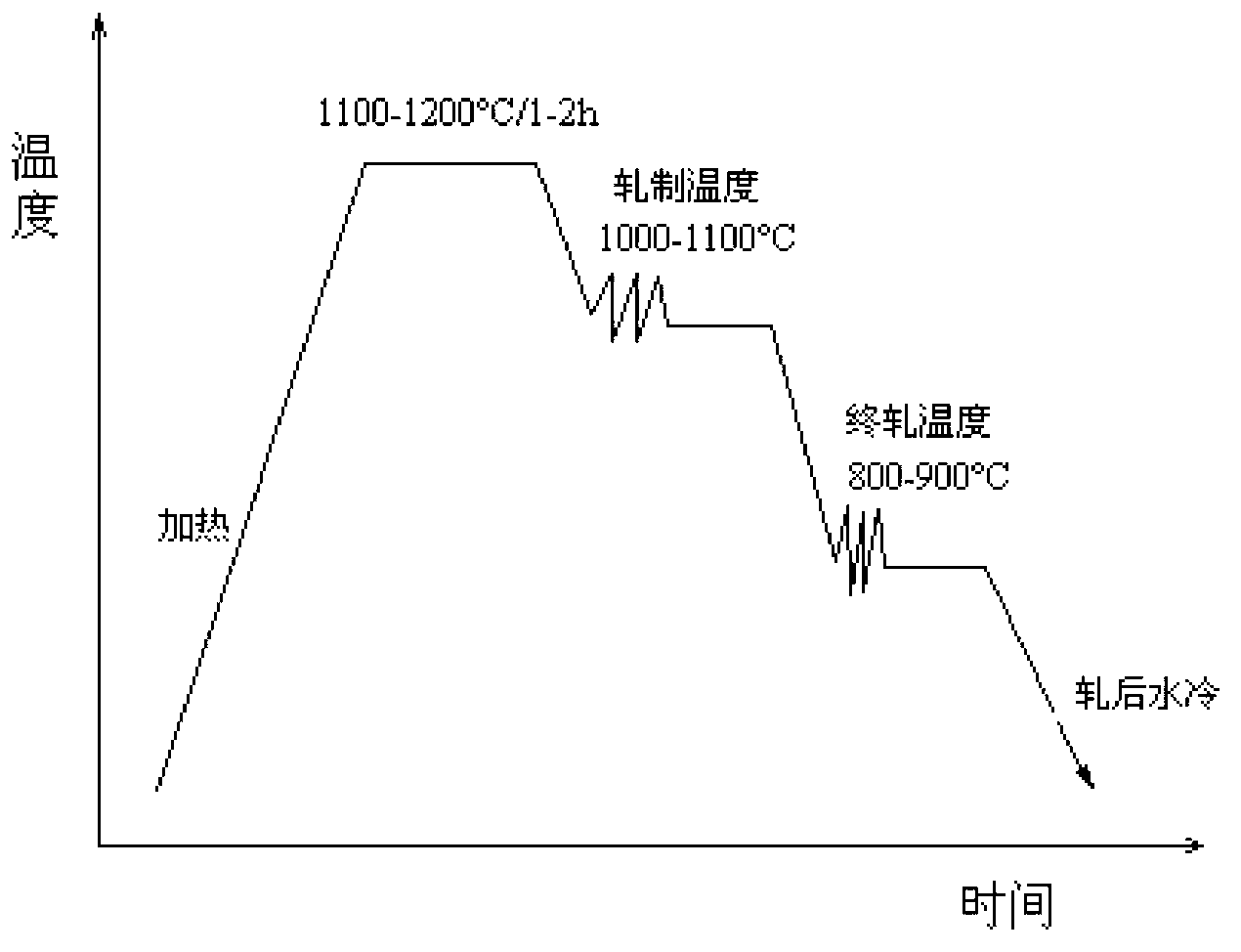

700MPa high strength hot rolling Q&P steel and manufacturing method thereof

ActiveCN103215516AHigh strengthPrevent precipitationFurnace typesHeat treatment furnacesAustenite grainChemical composition

The invention relates to 700MPa high strength hot rolling Q&P steel and a manufacturing method thereof. The steel has the following chemical components in percentage by weight: 0.15-0.40% of C, 1.0-2.0% of Si, 1.5-3.0% of Mn, less than or equal to 0.015% of P, less than or equal to 0.005% of S, 0.3-1.0% of Al, less than or equal to 0.0065% of N, 0.005-0.015% of Ti and the balance of Fe. The yield strength is greater than or equal to 70MPa, the strength of extension is greater than or equal to 1300MPa, and the ductility is greater than 10%. According to the invention, through a reasonable compound design, based on common C-Mn steel components, austenite crystal is refined by micro Ti treatment by improving the content of Si to inhibit separation of cementite, so that the austenite transformation kinetics in the air cooling process is accelerated by improving the content of Al. Meanwhile, a hot continuous rolling process is matched with a sectional cooling process, so that proeutectoid ferrite+martensite+retained austenite tissues are obtained. The cost of the alloy is greatly lowered.

Owner:BAOSHAN IRON & STEEL CO LTD

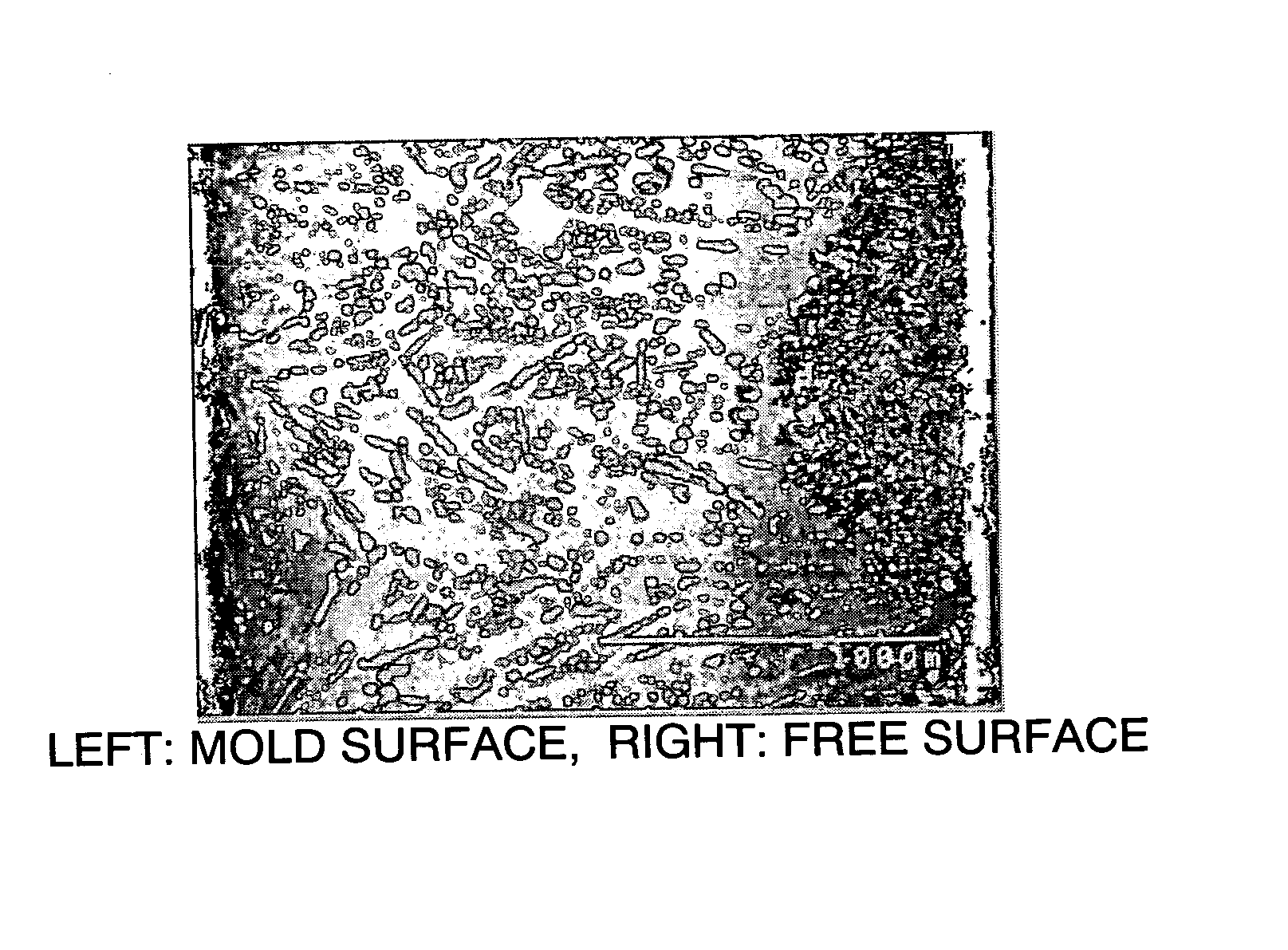

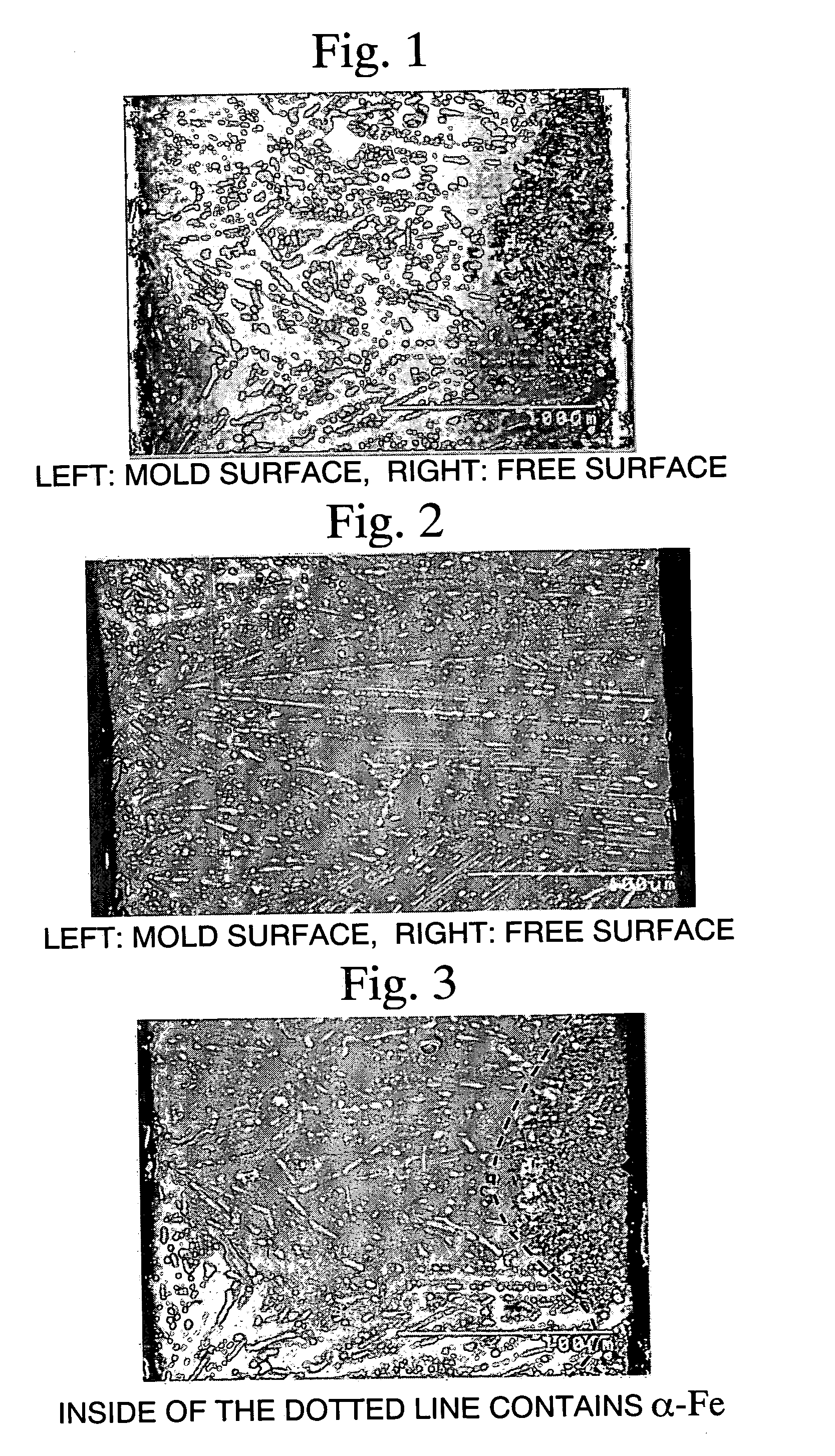

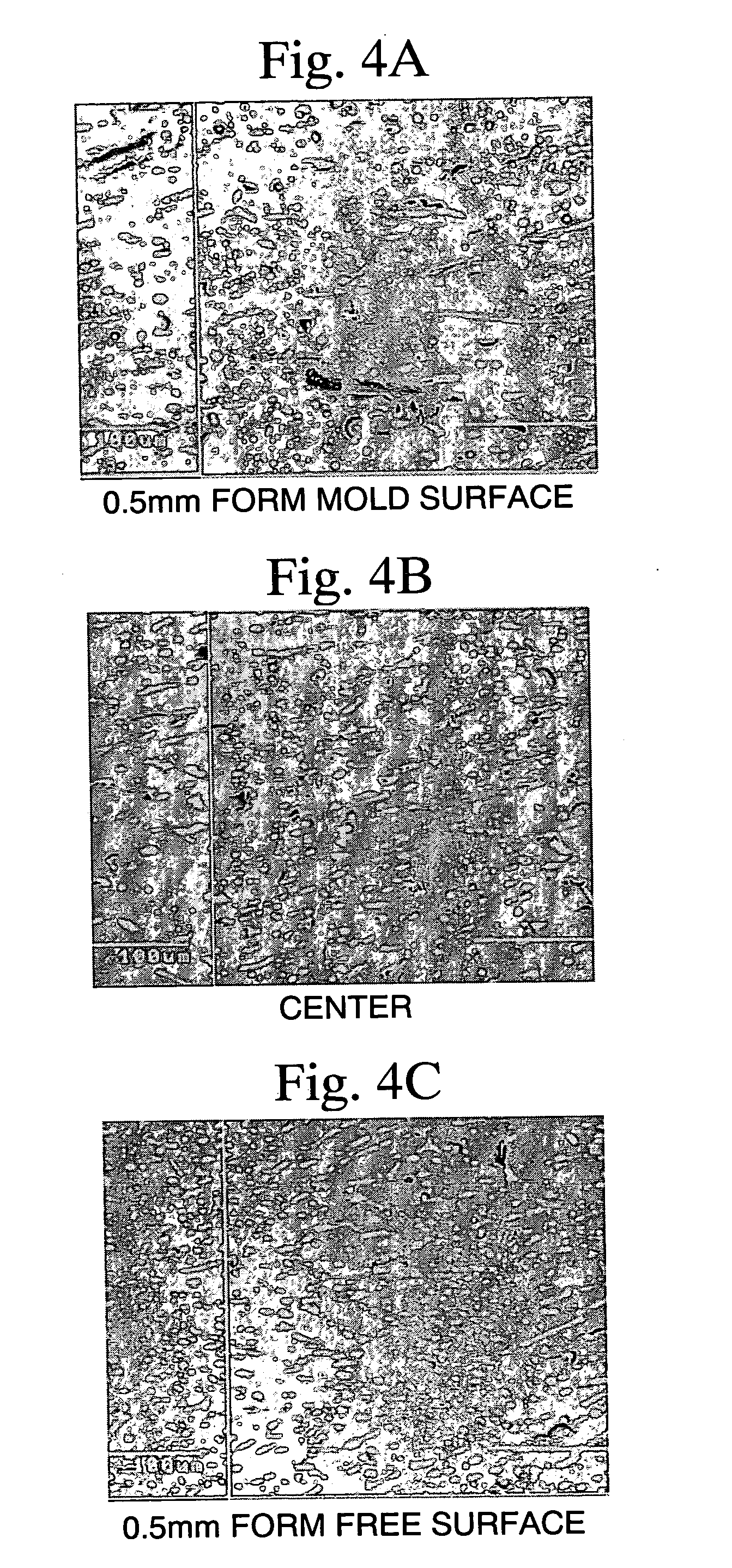

Alloy flake for rare earth magnet, production method thereof, alloy powder for rare earth intered magnet, rare earth sintered magnet, alloy powder for bonded magnet and bonded magnet

ActiveUS20050028892A1Low amountLow costTransportation and packagingMetal-working apparatusRare-earth elementThin sheet

Disclosed is a rare earth magnet in the R-T-B (rare earth element-transition metal-boron) system that is made from an improved composition and properties of main phase alloy in the R-T-B system containing Pr and a boundary alloy. Disclosed also is a manufacturing method of the rare earth magnet alloy flake by a strip casting method with improved rotating rollers such that the alloy flake has a specified fine surface roughness and has a small and regulated amount of fine R-rich phase regions. Consequently, the alloy flake for the rare earth magnet does not containing α-Fe and has a homogeneous morphology so that the rare earth magnet formed by sintering or bonding the alloy flakes exhibits excellent magnetic properties.

Owner:TDK CORPARATION

Solar water evaporation purification and decomposition device

ActiveCN107879405AAchieve fadeAchieve purificationGeneral water supply conservationSeawater treatmentWater desalinationEvaporation Purification

The invention discloses a solar water evaporation purification and decomposition device which comprises a water supply line, a float and heat insulation layer, an evaporation layer and a photothermalconversion and solute barrier layer which are connected in sequence from bottom to top. The water supply line enables water to pass through the float and heat insulation layer, and the water is pumpedinto the evaporation layer by virtue of a capillary action; solar energy absorbed by the photothermal conversion and solute barrier layer is converted into heat, and water is heated to be vaporized into water vapor from the evaporation layer; due to pore channel volatilization of the photothermal conversion and solute barrier layer, partial water vapor is decomposed to produce hydrogen and oxygen; since the photothermal conversion and solute barrier layer contains a hydrophobic part and is not infiltrated by water, the solar energy can directly heat a heat-absorbing material only, but not heat water, so that high photothermal conversion efficiency is realized; and meanwhile, the solute in the water is prevented from being separated out on the membrane, and sea water desalination, sewage purification and water decomposition can be realized. Due to the design of a hydrophilic / hydrophobic double-layer evaporation structure, the solar water evaporation purification and decomposition device with high photothermal conversion efficiency and high stability is obtained.

Owner:XI AN JIAOTONG UNIV

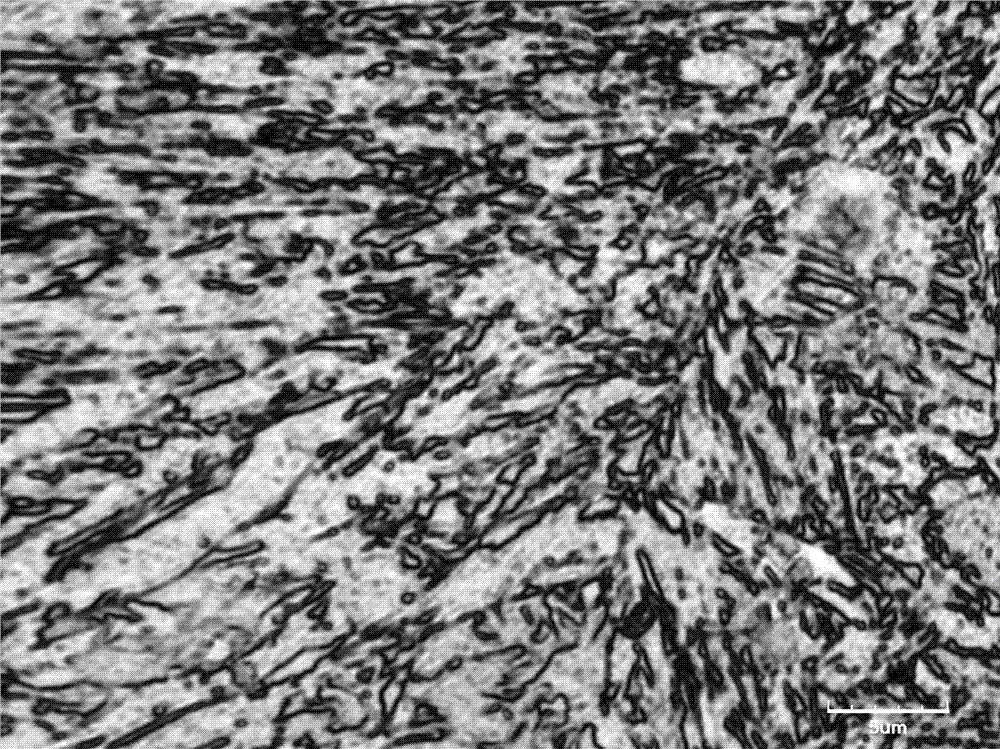

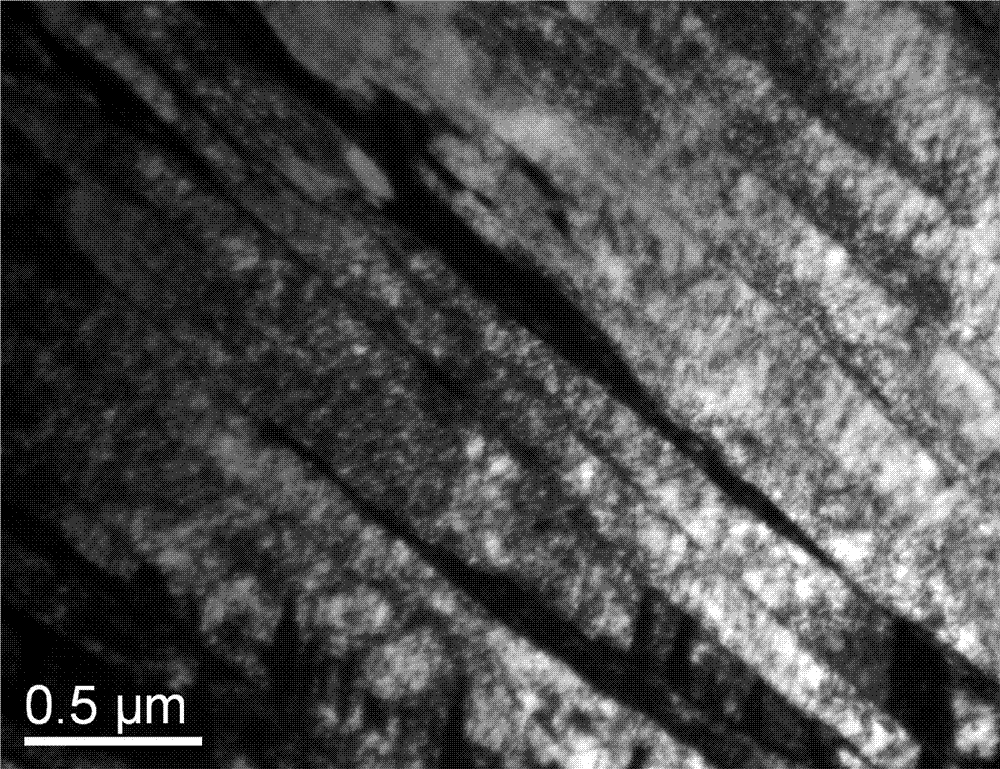

High-strength, high-toughness and high-plasticity martensitic stainless steel and preparation method thereof

ActiveCN103614649AImprove the level of toughness and plasticityImprove stabilityMartensitic stainless steelRoom temperature

The invention discloses high-strength, high-toughness and high-plasticity martensitic stainless steel, and belongs to the technical field of metallurgy. The martensitic stainless steel comprises the following components in percentage by weight: 0.15 to 0.4 percent of C, 0 to 0.12 percent of N, 0.2 to 2.5 percent of Si, 0.4 to 3.0 percent of Mn, less than or equal to 0.02 percent of S, less than or equal to 0.02 percent of P, 13.0 to 17.0 percent of Cr, 0 to 5.0 percent of Ni, 0 to 2.0 percent of Mo, 0 to 0.3 percent of V, 0 to 0.2 percent of Nb, 0 to 0.05 percent of Ti, 0 to 0.8 percent of Al and the balance of Fe and inevitable impurities. A preparation method comprises the following steps of (1) smelting molten steel according to the set components, and solidifying the molten steel to form an ingot blank by using a continuous casting machine or a casting mold; (2) hot-rolling the ingot blank to form a hot-rolled plate blank; (3) heating the hot-rolled plate blank to 950 to 1100 DEG C, preserving heat for 0.5 to 2 hours, cooling the plate blank to 25 to 200 DEG C, heating the plate blank to 350 to 500 DEG C, preserving heat for 10 to 60 minutes, and air-cooling the plate blank to room temperature. According to the martensitic stainless steel prepared by the method, dispersed remaining martensite is introduced into a microscopic structure, so that the strength, toughness and plasticity of the martensitic stainless steel are greatly improved.

Owner:NORTHEASTERN UNIV

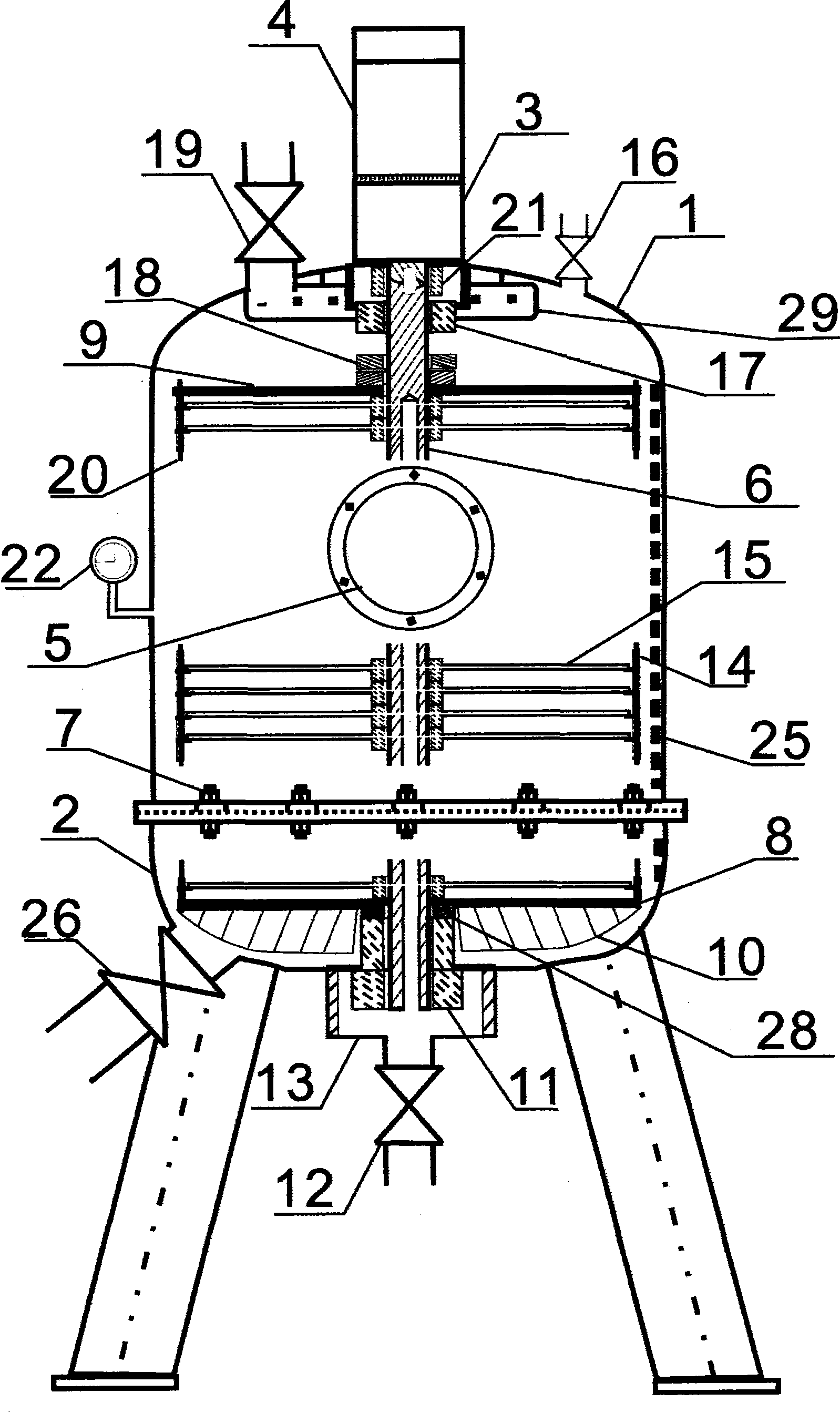

High-efficiency energy-saving disk type filtering equipment

ActiveCN101850197AEasy to recyclePrevent precipitationMoving filtering element filtersExhaust valveInlet valve

The invention relates to high-efficiency energy-saving disk type filtering equipment which is a whole set of equipment comprising an upper cover, a shell, a speed reducer, an explosion-proof motor, a pair of sight glasses, a mandrel, a capping bolt, a tray, a pressure disk, a scraping plate, a sealing device, a liquid outlet valve, a sealing device, a supporting column sleeve, a filtering piece, an exhaust valve, a pressure disk locking nut, a liquid inlet valve, a supporting column, a shaft sleeve, a pressure gage, a liquid rotation directional column, a residue discharge valve, a bearing device, an inlet liquid separating buffer and the like. The high-efficiency energy-saving disk type filtering equipment has convenient operation, practicality, product quality improvement, environmental protection, high efficiency and energy saving.

Owner:高云芝

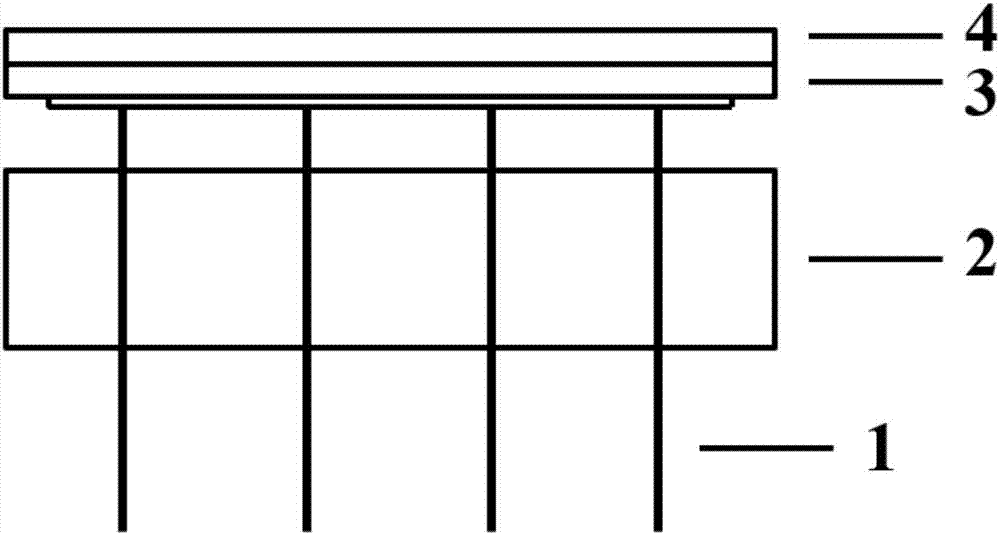

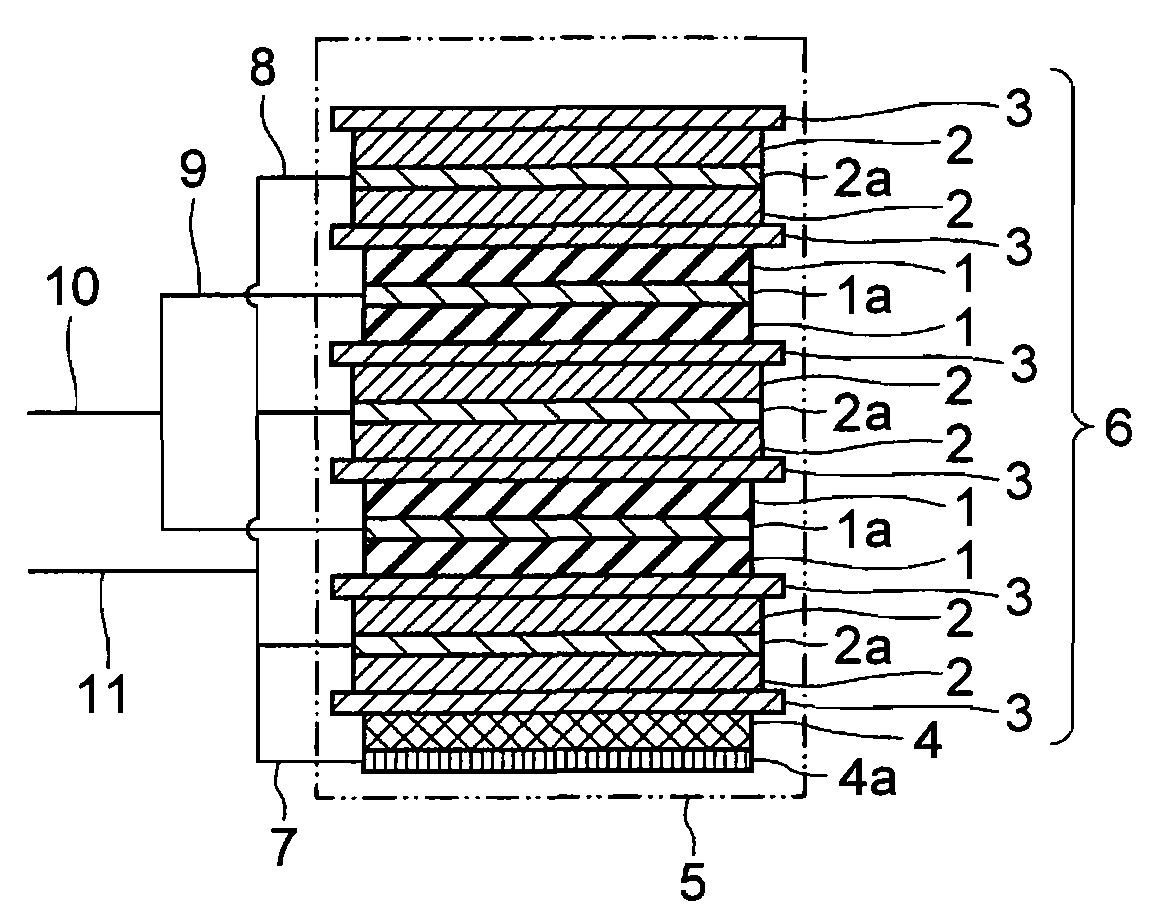

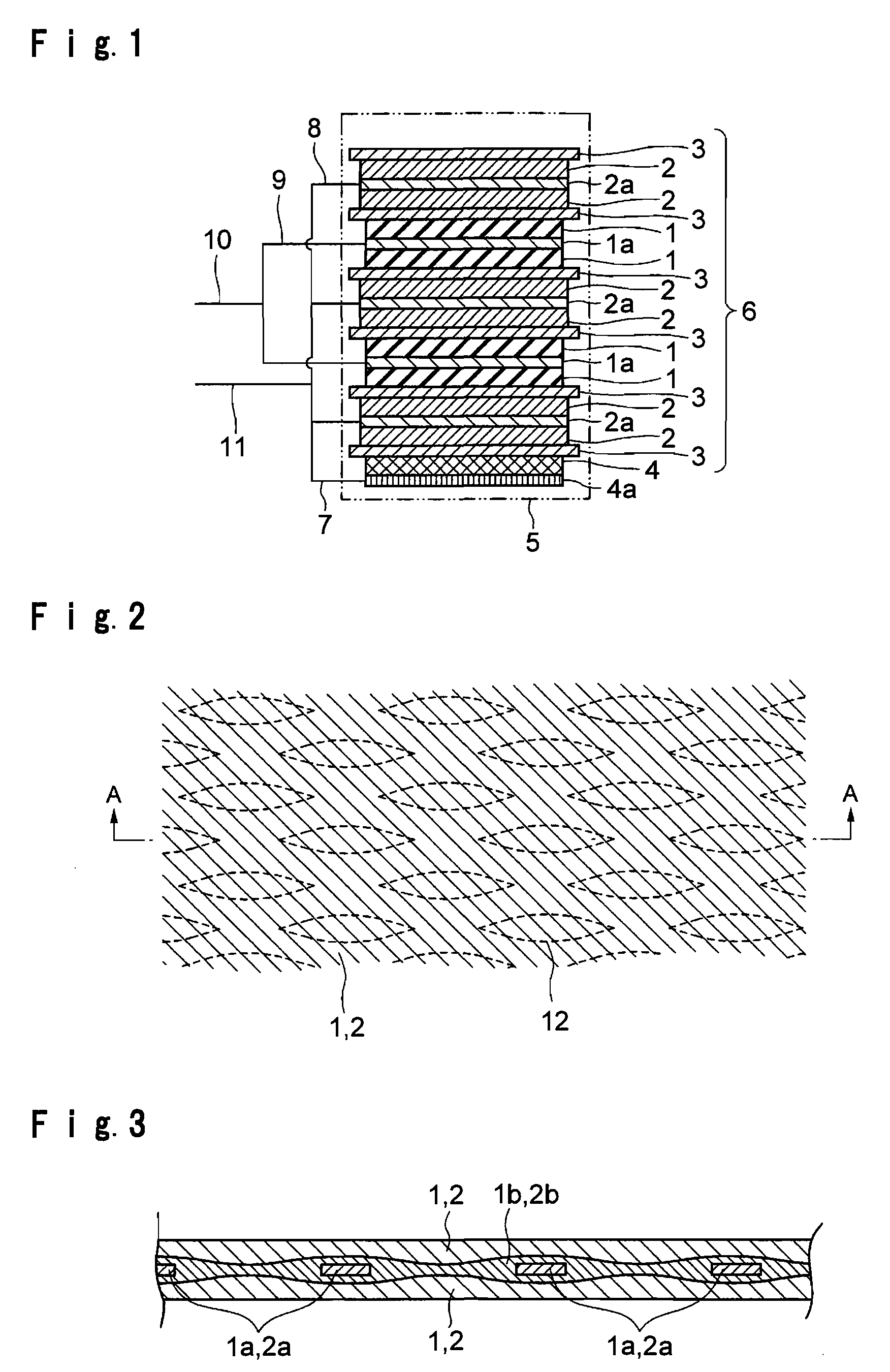

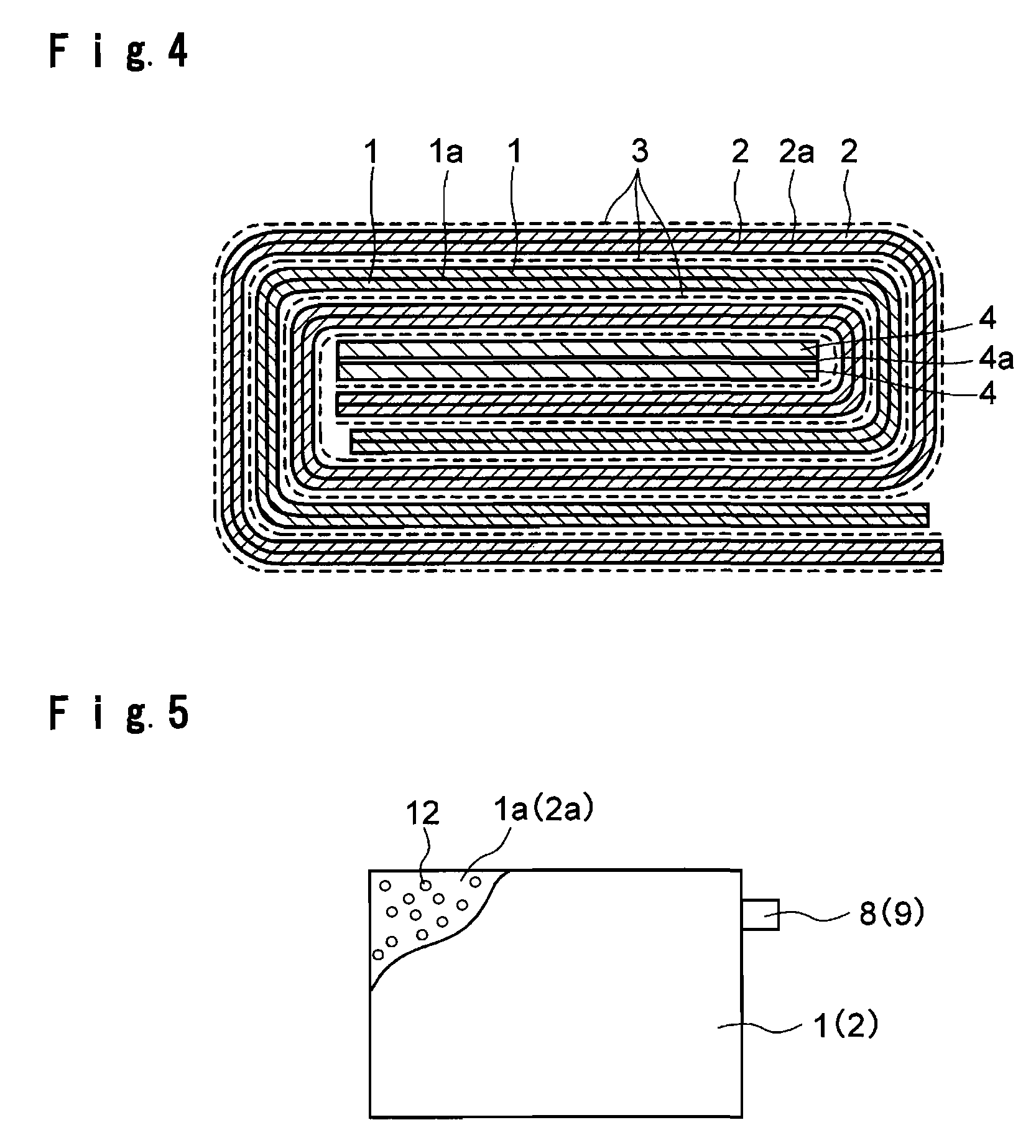

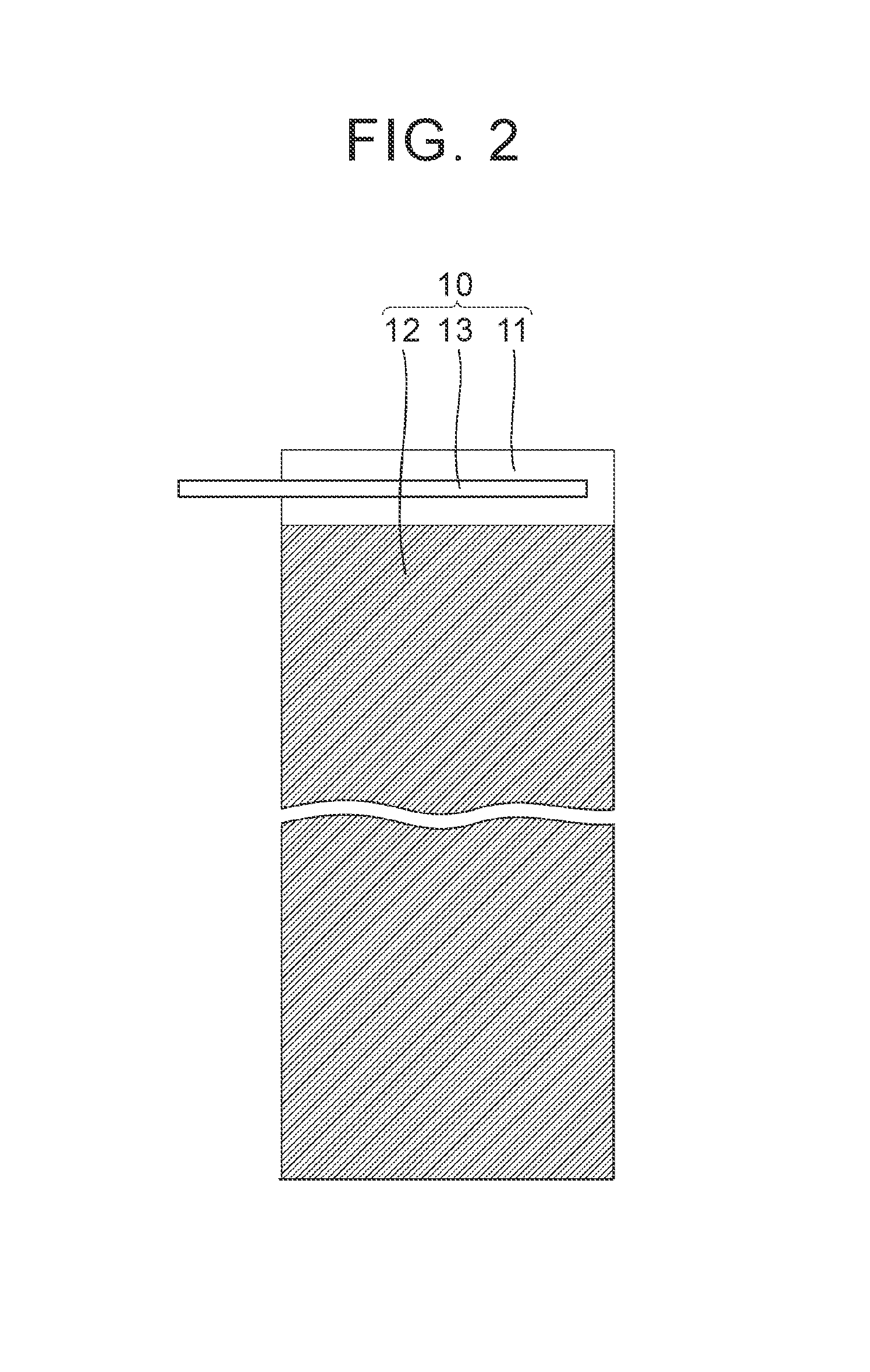

Lithium ion capacitor

ActiveUS20090097189A1Prevent increase of positive electrode potentialQuality improvementHybrid capacitor separatorsLiquid electrolytic capacitorsHigh energyPhysical chemistry

A lithium ion capacitor having high energy density, high output density, high capacity and high safety is provided.A lithium ion capacitor comprising a positive electrode 1 made of a material capable of being reversibly doped with lithium ions and / or anions, a negative electrode 2 made of a material capable of being reversively doped with lithium ions, and an aprotic organic solution of a lithium salt as an electrolytic solution, wherein the positive electrode 1 and the negative electrode 2 are laminated or wound with a separator interposed between them, the area of the positive electrode 1 is smaller than the area of the negative electrode 2, and the face of the positive electrode 1 is substantially covered by the face of the negative electrode 2 when they are laminated or wound.

Owner:SUBARU CORP

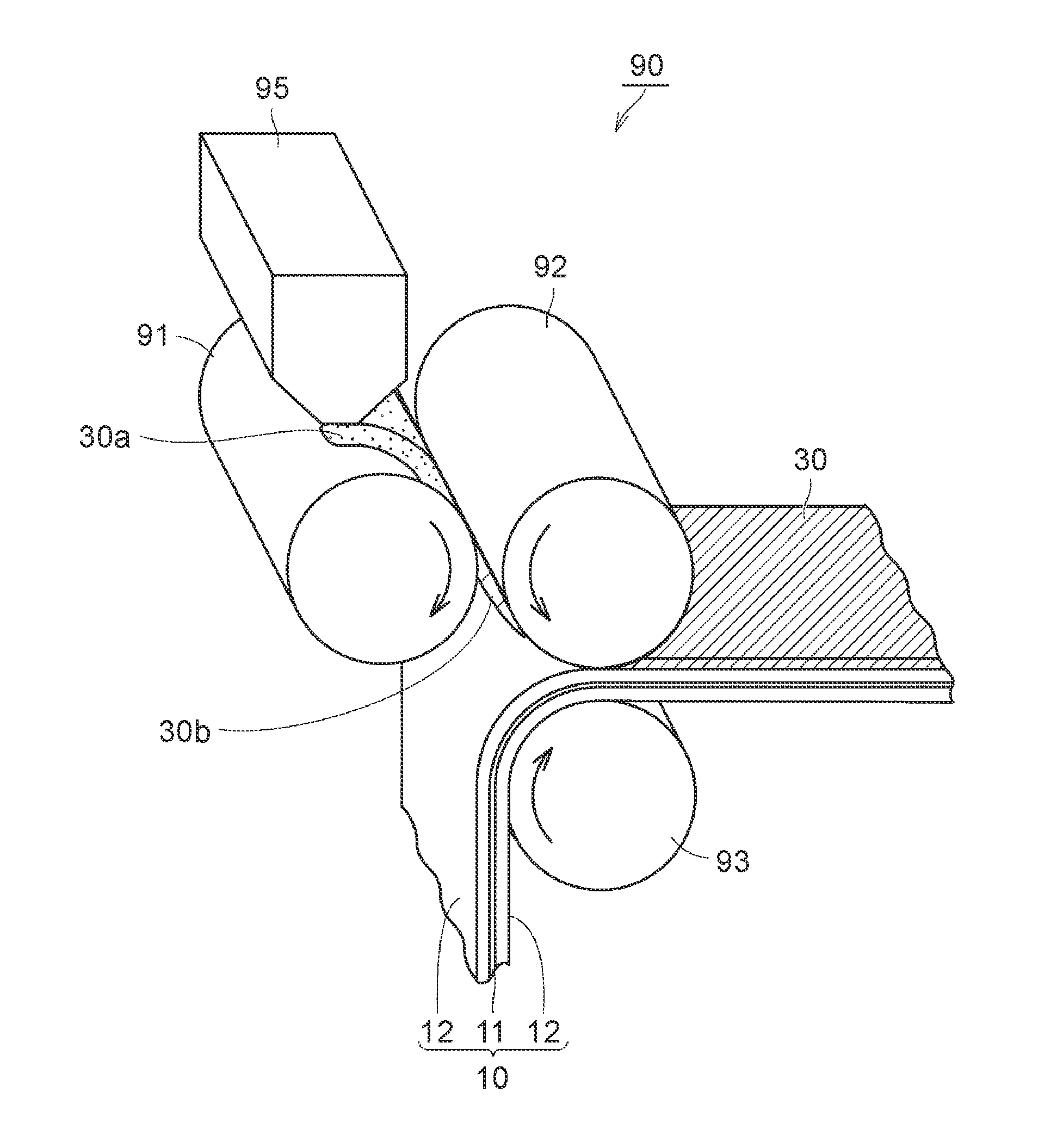

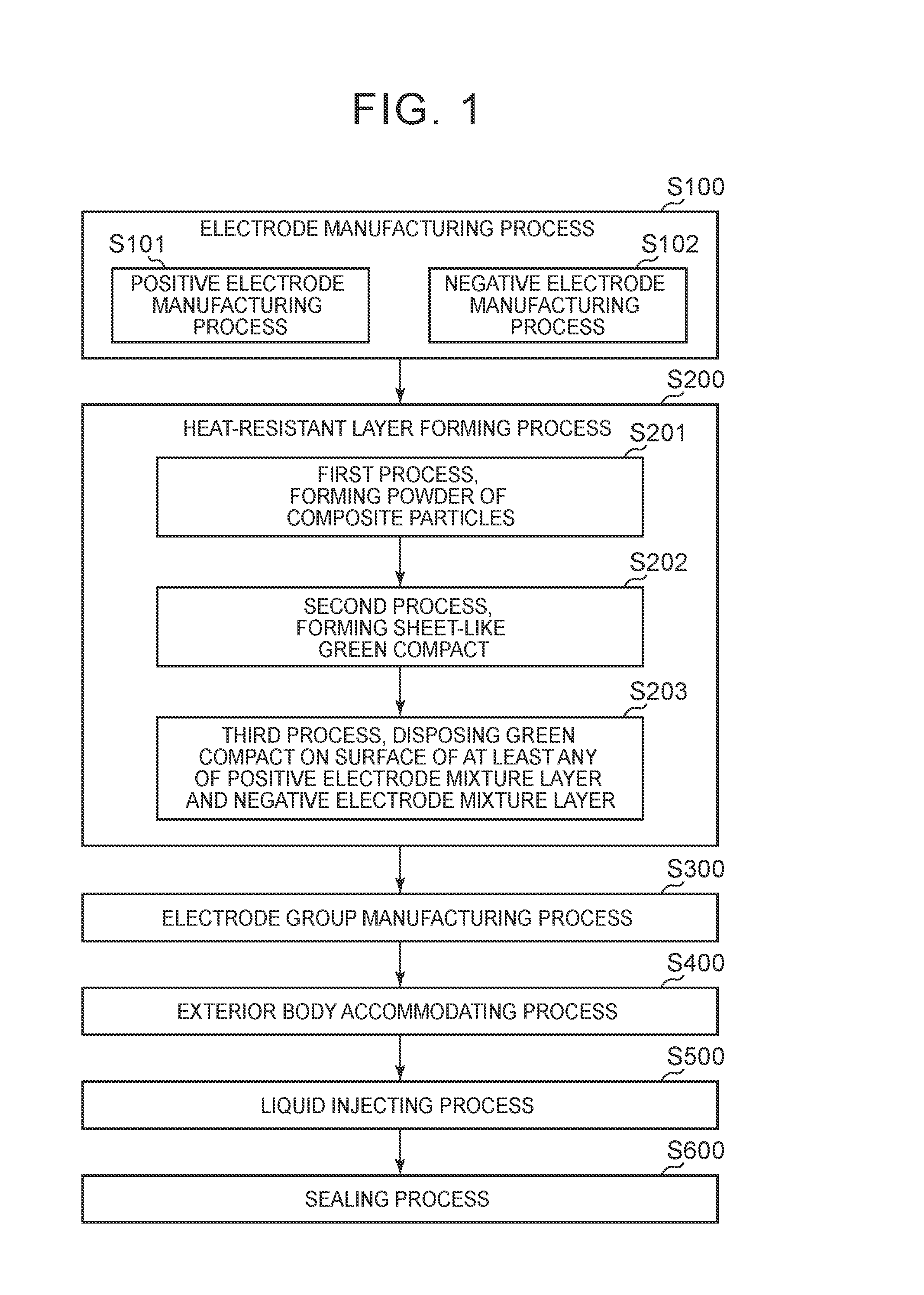

Manufacturing method for non-aqueous electrolyte secondary battery

ActiveUS20160240839A1Reduce the amount requiredHigh strengthElectrode rolling/calenderingNon-aqueous electrolyte accumulatorsSolventInorganic filler

A manufacturing method for a non-aqueous electrolyte secondary battery includes: forming a powder; forming a sheet-like green compact; and forming a heat-resistant layer. The powder contains composite particles and a solvent. The composite particles contain inorganic filler particles and a binder. The green compact is formed by pressing the powder in a state in which the solvent remains. The heat-resistant layer is formed by disposing the green compact on a surface of at least any of a positive electrode mixture layer and a negative electrode mixture layer after the green compact is formed.

Owner:TOYOTA JIDOSHA KK

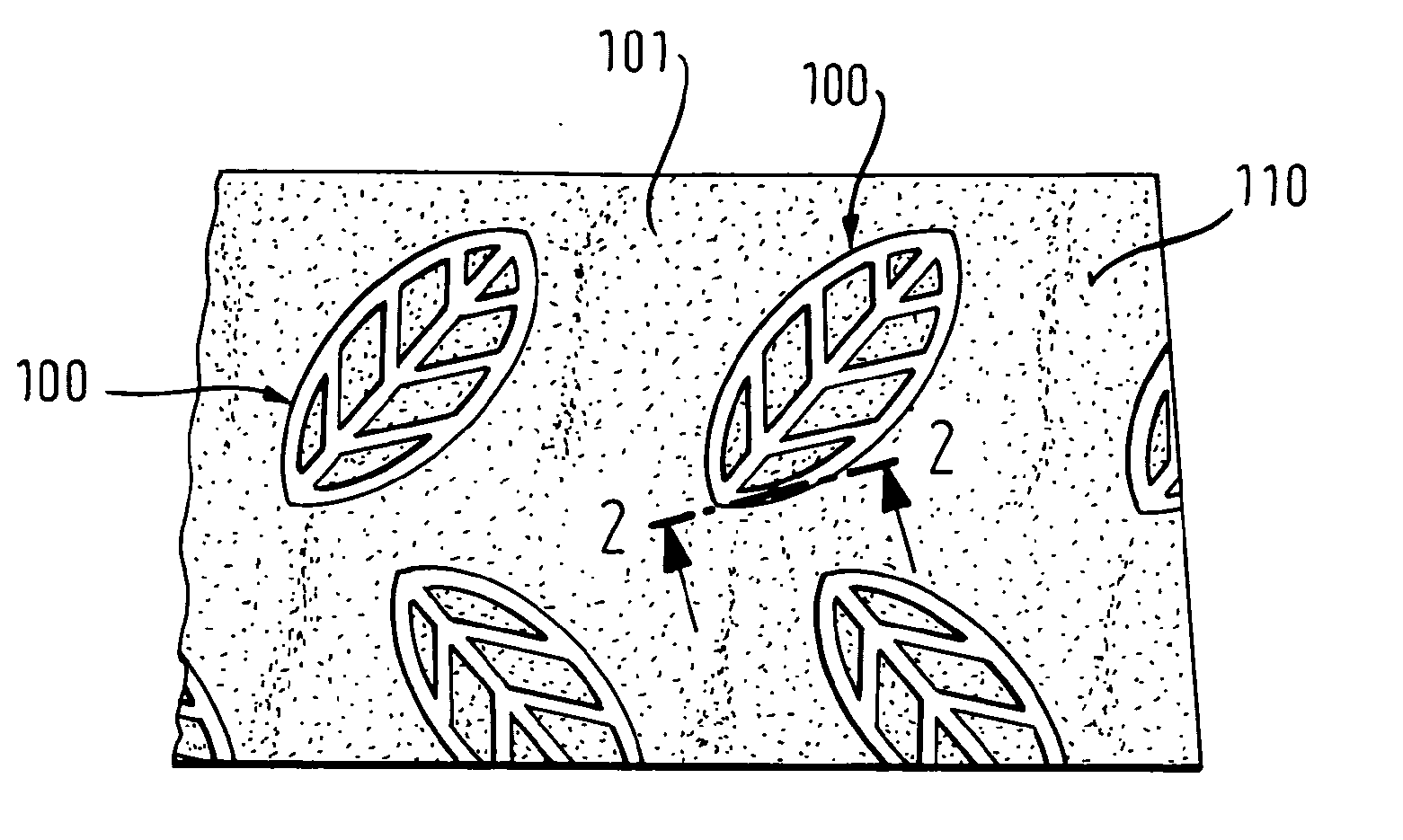

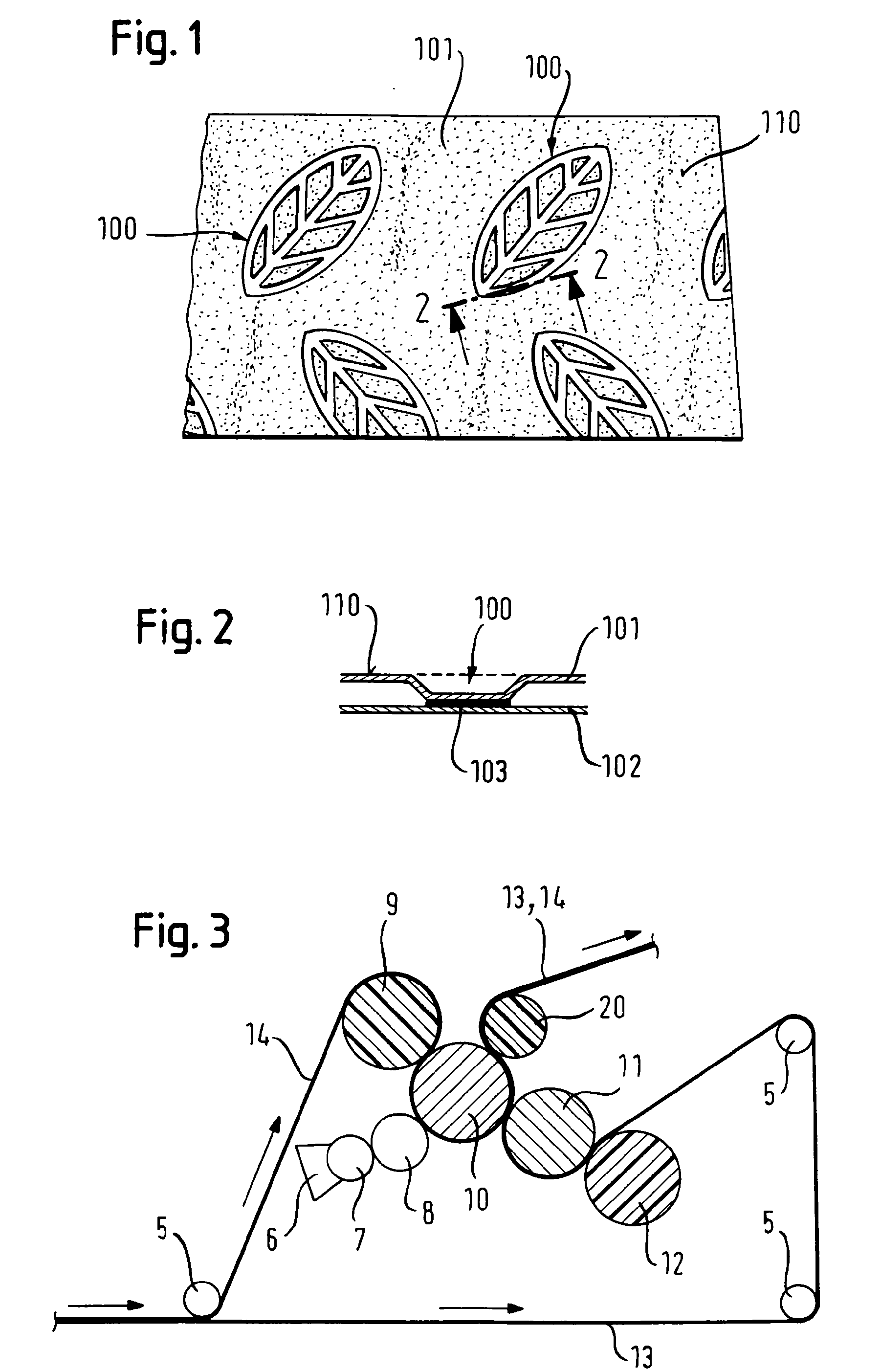

Hygiene or wiping product comprising at least one patterned ply and method for patterning the ply

InactiveUS20110027545A1Prevent precipitationLamination ancillary operationsDecorative surface effectsCellulose fiberEngineering

A hygiene or wiping product includes at least one ply of a fibrous web containing cellulose fibers and having a graphical pattern of at least first and second areas. The ply contains a coloring compound providing a coloration of the ply in the first area. The coloring compound is at least partly chemically destroyed in the second area so that the ply is less colored in the second area than in the first area. A method for producing such a ply includes the steps of providing a fibrous web containing a coloring compound, which provides a uniform coloration in at least a portion of the web, and applying a bleaching agent to a part of the colored portion of the web to at least partly decolor the web in the part generating a pattern of at least first colored and second less colored areas.

Owner:SCA HYGIENE PROD AB

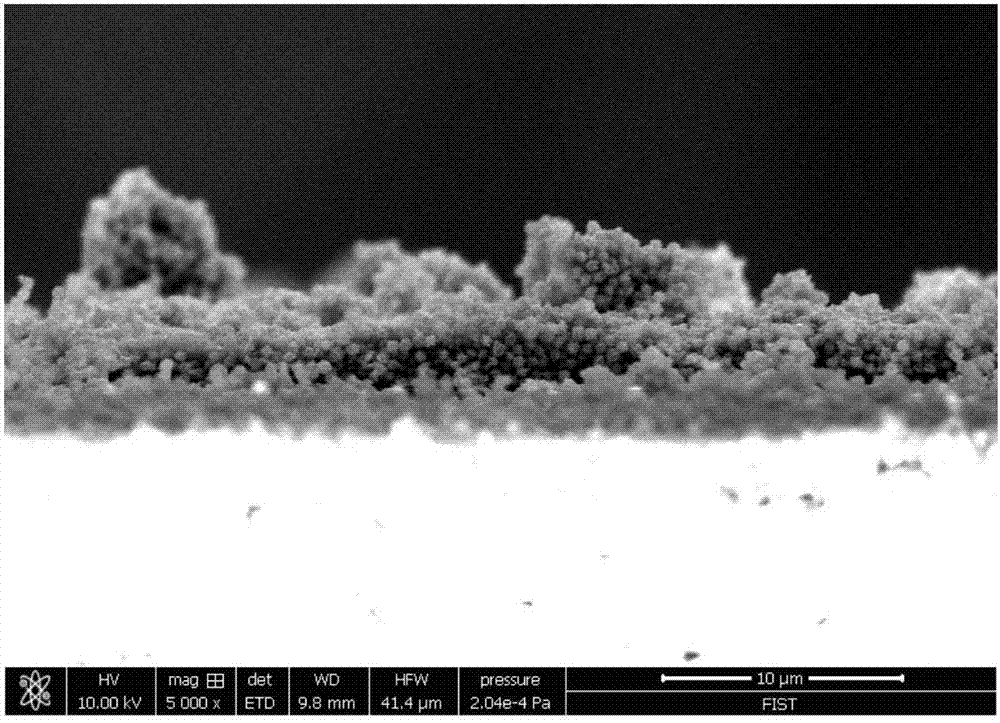

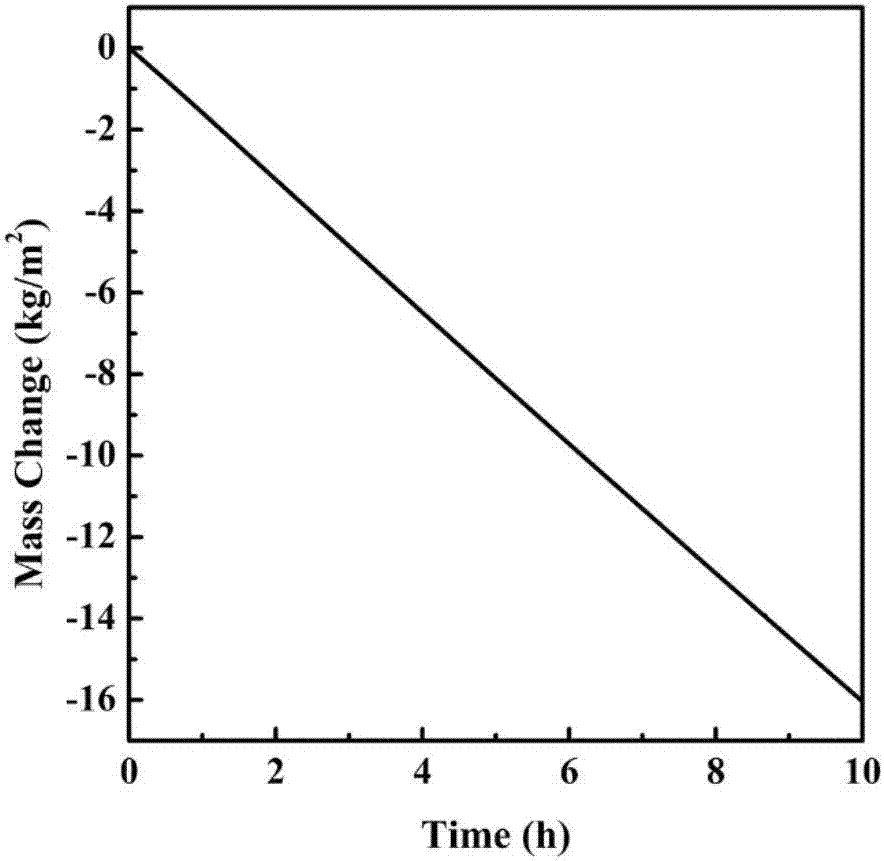

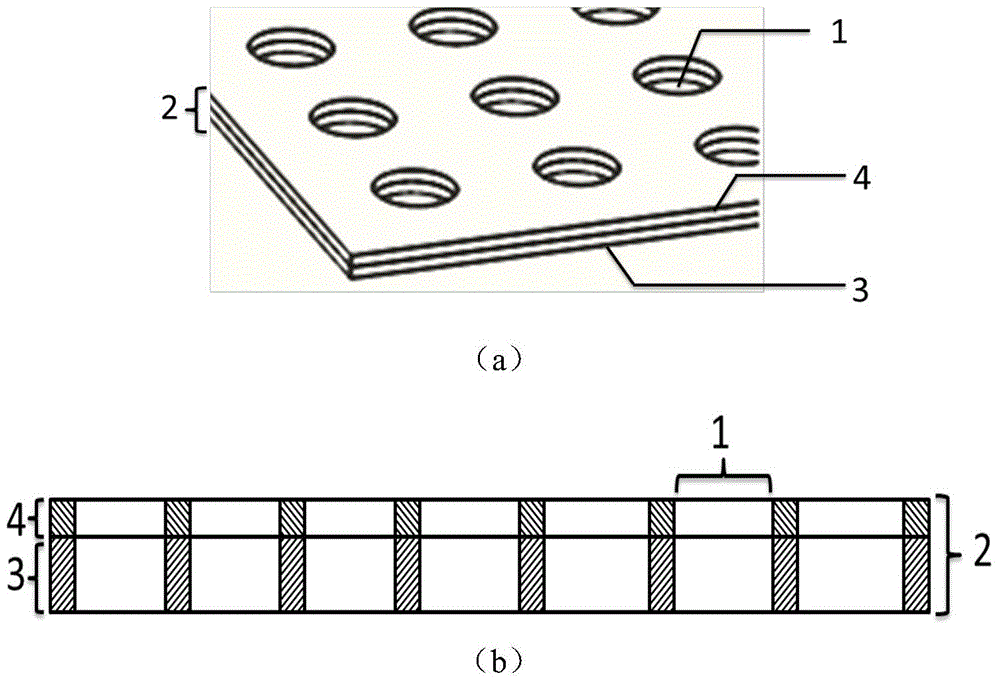

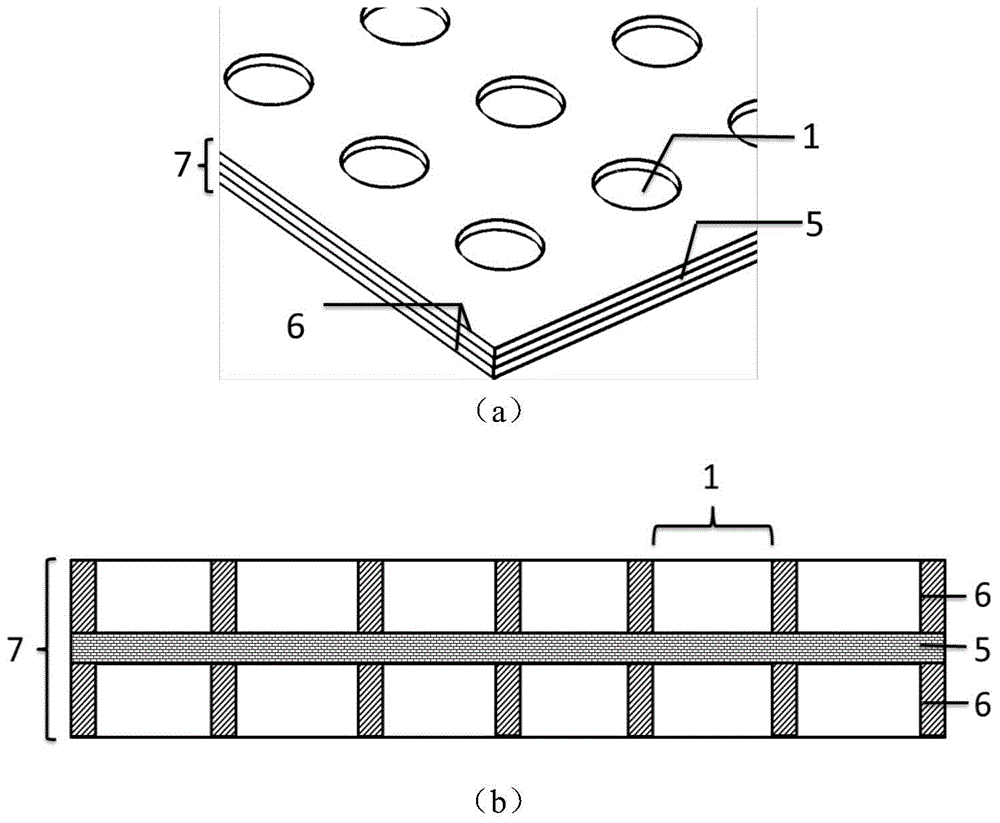

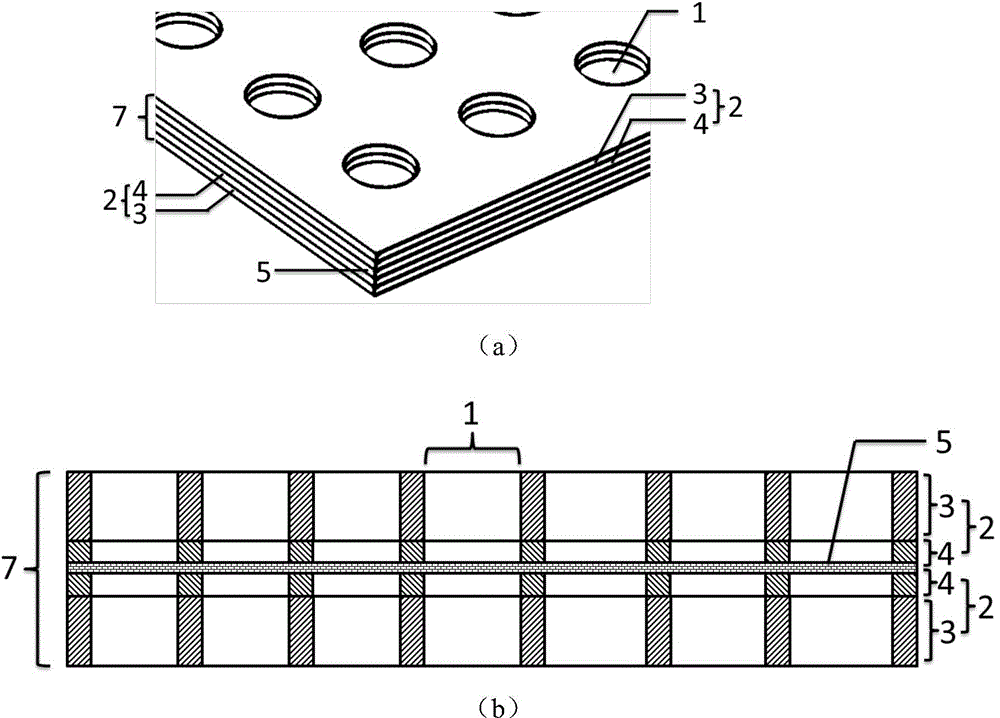

Composite porous current collector, and preparation method and application thereof

The invention provides a composite porous current collector, and a preparation method and an application thereof. The composite porous current collector comprises a porous electron conducting layer with through holes and an electron insulating layer with through holes, wherein the porosity of the through holes of porous electron conducting layer is not less than the porosity of the through holes of the electron insulating layer, a position of the porous electron conducting layer corresponding to the position of the through hole of the electron insulating layer is a through hole, and a position of the porous electron conducting layer corresponding to the position of the non-through hole of the electron insulating layer can be a through hole, and also can be a blind hole or a rough surface. The electron insulating layer is adjacent to an isolation layer, so puncture of precipitated lithium dendrite to a diaphragm is prevented, direct contact of the electron conducting layer is avoided, and the safety of a battery is improved; the above corresponding through hole structure is in favor of transferring lithium ions, so the internal resistance of the battery is reduced; the hole structure of the porous electron conducting layer and the homogeneous rough surface are in favor of full contact of an electrode active substance with the current collector, the current is uniformly distributed, and the current collection effect is improved; and the preparation method adopting airflow punching has the advantages of simplicity, easy implementation, cleanness, energy saving, combination of other various enforcement modes, and convenience for production and application.

Owner:南京竞予能源有限公司

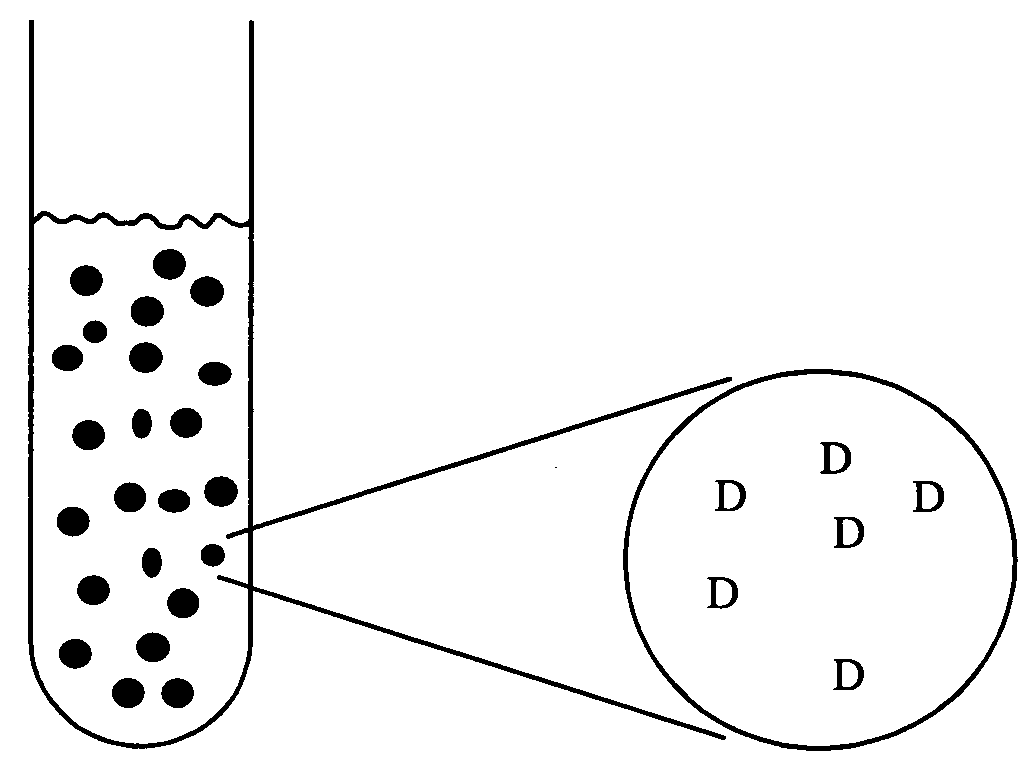

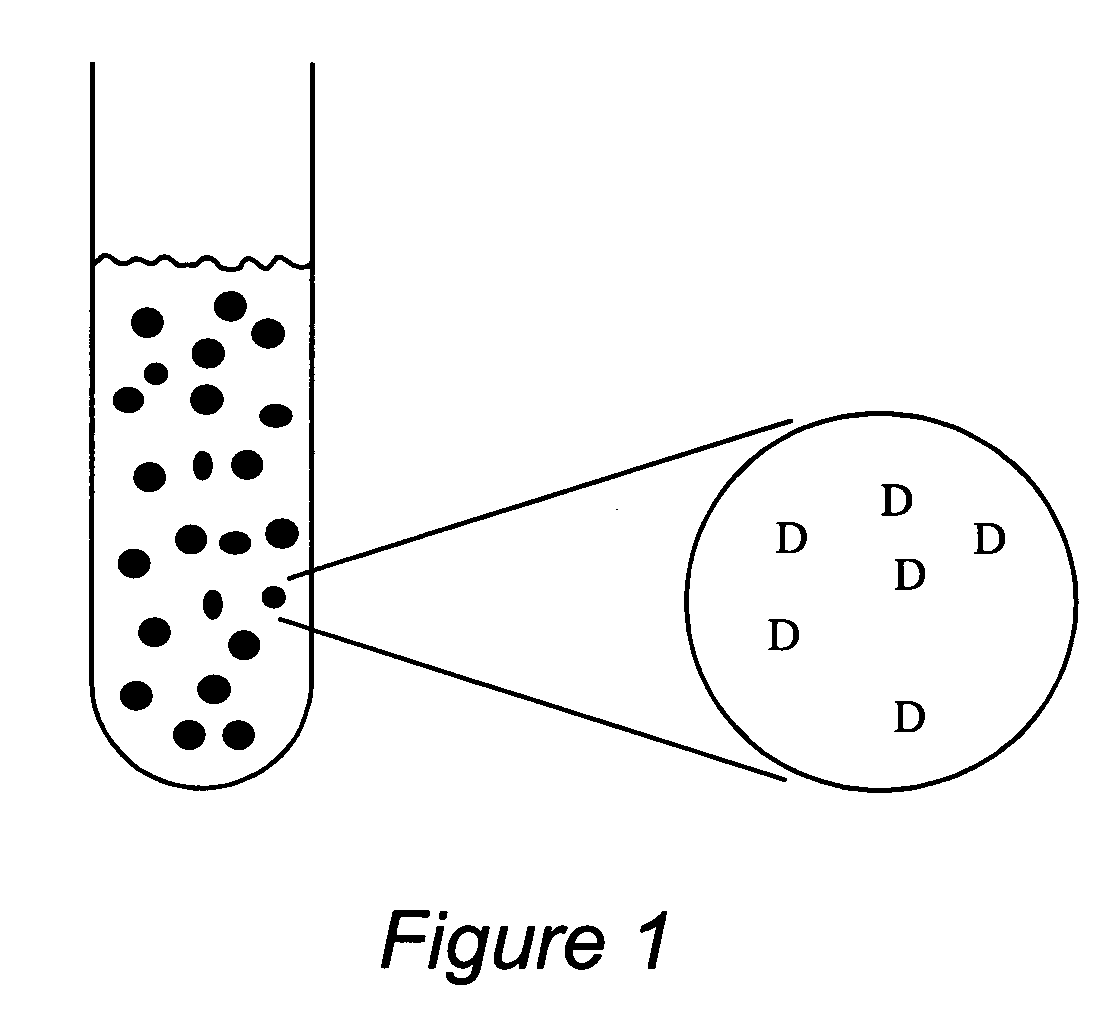

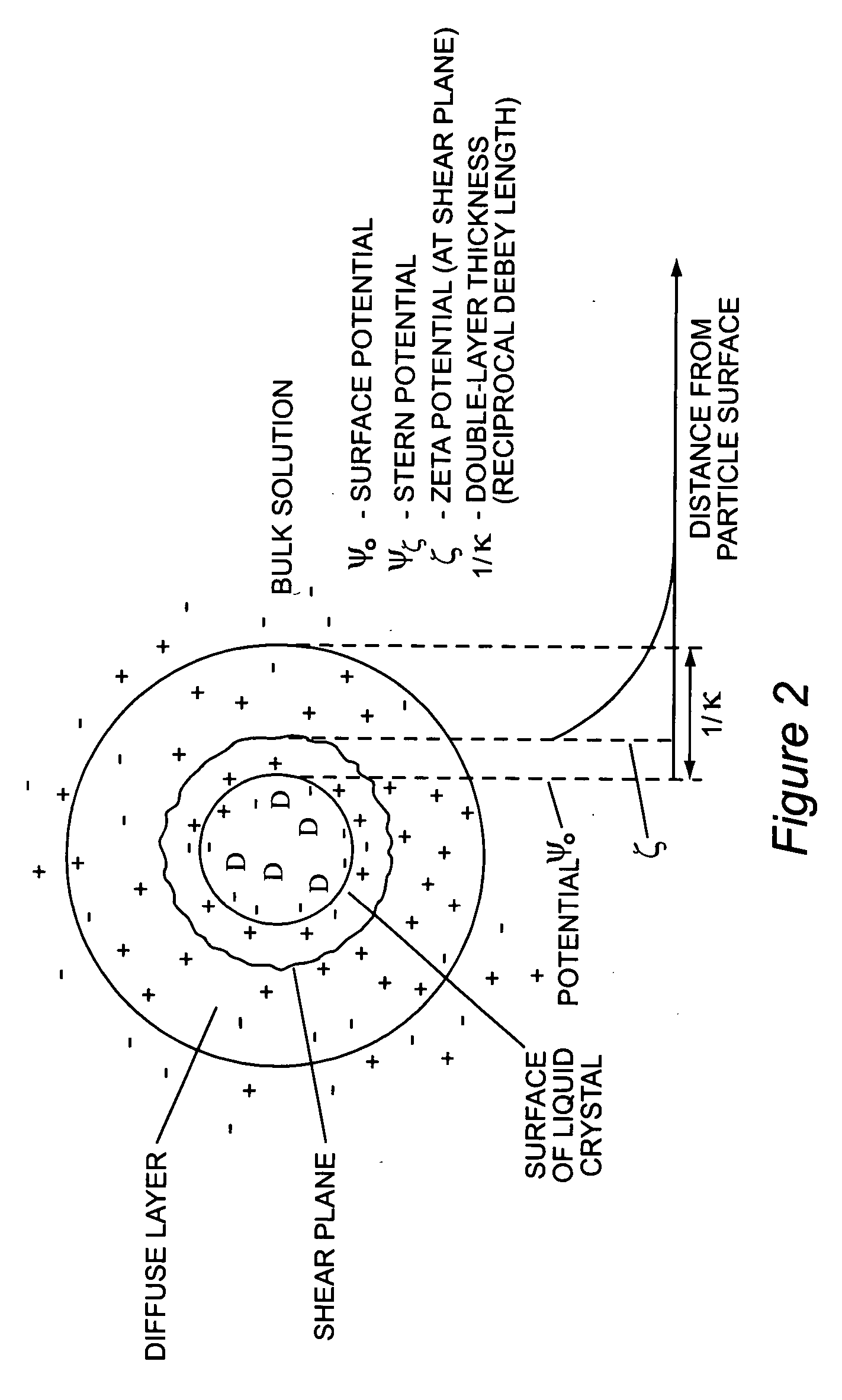

Stabilized uncoated particles of reversed liquid crystalline phase materials

ActiveUS20050077497A1High potential to transport active compoundLow water solubilityLiquid crystal compositionsPowder deliveryCrystallographyLiquid crystalline

Uncoated particles of reversed cubic phase or reversed hexagonal phase material containing an active disposed within are provided. The uncoated particles have an ionic charge that is sufficient to stabilize them in dispersion in a liquid, e.g. a polar solvent. The active that is disposed within the particles may be, for example, a pharmaceutical or nutriceutical compound.

Owner:LYOTROPICS THERAPEUTICS INC

Method for adsorption of phosphate contaminants from water solutions and its recovery

InactiveUS20100243571A1Prevent precipitationReduce concentrationMaterial nanotechnologyIon-exchanger regenerationSorbentSludge

Aqueous fluid polluted with phosphate contaminants is mixed with or passed through an adsorbent material selected from: (i) particles of oxides or hydroxides of transition metals, aluminum oxides or hydroxides, TiO2, or mixtures thereof, or (ii) particles of activated carbon, activated alumina, aluminum oxide, activated TiO2, TiO2, mineral clay, zeolite, or an ion exchanger loaded with nanoparticles of oxides or hydroxides of transition metals, aluminum oxides or hydroxides or TiO2, or mixtures thereof, to yield aqueous fluid purified from phosphate. The adsorbent material is further regenerated by increasing the pH of the adsorbent sludge, concentrated phosphate solution or a phosphate crystal slurry is recovered as well.

Owner:TECHNION RES & DEV FOUND LTD

Two-step hydroprocessing method for heavy hydrocarbon oil

ActiveUS20060011510A1Reduce the presence of impuritiesGreat degree of desulfurizationCatalyst activation/preparationHydrocarbon oil crackingHydrogenSulfur

A method is disclosed for hydroprocessing a heavy hydrocarbon oil, comprising a first hydroprocessing step of bringing a heavy hydrocarbon oil into contact with a Catalyst (1) with a certain specific surface area and pore size distribution in the presence of hydrogen in a first reaction zone containing the Catalyst (1), and a second hydroprocessing step of bringing the hydroprocessed oil obtained from the first reaction zone into contact with a Catalyst (2) with a certain specific surface area and pore size distribution in the presence of hydrogen in a second reaction zone containing the Catalyst (2). The method is an improvement in decreasing or inhibiting the sediment formation, while highly hydroprocessing a heavy hydrocarbon oil containing a large amount of impurities such as sulfur, micro carbon residue (MCR), metals, nitrogen and asphaltene, especially a heavy oil containing a large amount of heavy vacuum residue, to adequately remove the impurities.

Owner:EXXON RES & ENG CO

Total nutrient liquid fertilizer containing amino acids, and preparation method thereof

InactiveCN104311213AImprove frost resistanceImprove drought resistanceMagnesium fertilisersAlkali orthophosphate fertiliserBiotechnologyNutrition

A total nutrient liquid fertilizer containing amino acids comprises, by weights, 6-12 parts of N, 1-6 parts of P, 3-10 parts of K, 1-3 parts of Ca, 1-3 parts of Mg, 9-13 parts of Zn, 2-10 parts of Mn, 1-2 parts of B, 0.5-2 parts of Cu, 0.2-0.5 parts of Mo, 3-10 parts of Fe, 10-15 parts of amino acids, 1-10 parts of a plant growth regulator, 2-5 parts of an organic chelating agent and 30-40 parts of water. The liquid fertilizer provides comprehensive nutrition for plants, enhances the freeze, drought, salt and disease resistance of the plants, enhances the synthesis and translocation of substances in the plants, promotes the formation of adenosine triphosphate (ATP), promotes the photosynthesis and protein synthesis, induces the formation of chlorophyll, promotes the cell protoplasm flow, improves the cell vitality and accelerates the growth of the plants.

Owner:SICHUAN LUTIANHUA

Polychromic ink composition depending on viewing angle

InactiveUS20020033117A1Coating obtainedImprove dispersion stabilityPigmenting treatmentInksPolymer chemistryPigment

A polychromic ink composition depending on viewing angle comprises 0.5 to 40% by weight of cholesteric liquid crystal polymer particles whose maximum particle diameter is 1 to 200 mum, 1.0 to 30.0% by weight of binder resins, 0.05 to 20% by weight of pigments with a deep-colored coloring matter whose average particle diameter is 0.01 to 0.5 mum, 0.01 to 5.0% by weight of a shear-thinning property imparting agent, and water with respect to the total amount of the ink composition.

Owner:SAKURA COLOR PRODUCTS CORPORATION

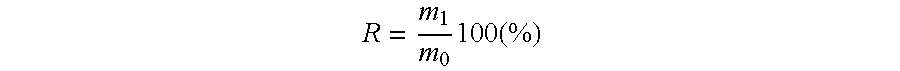

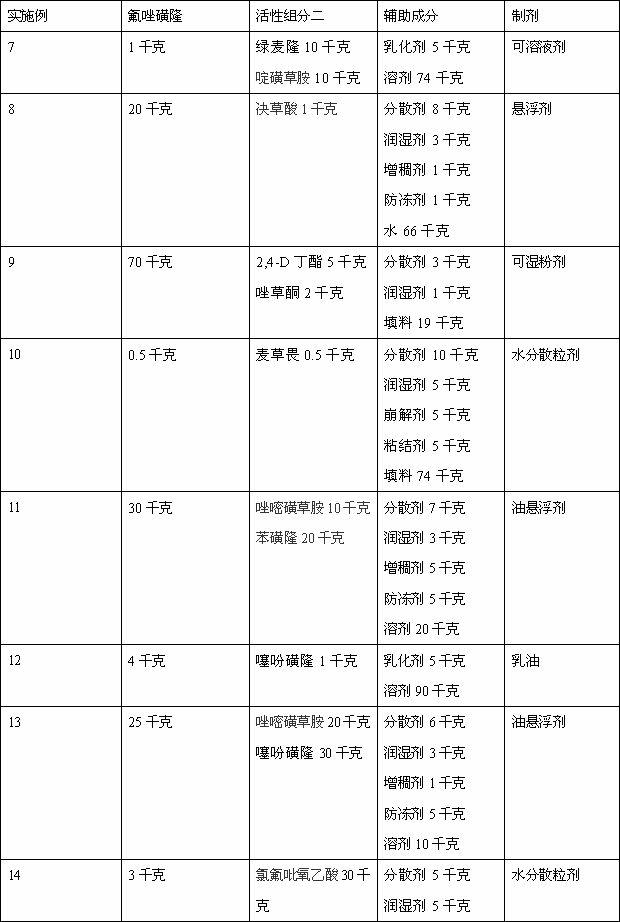

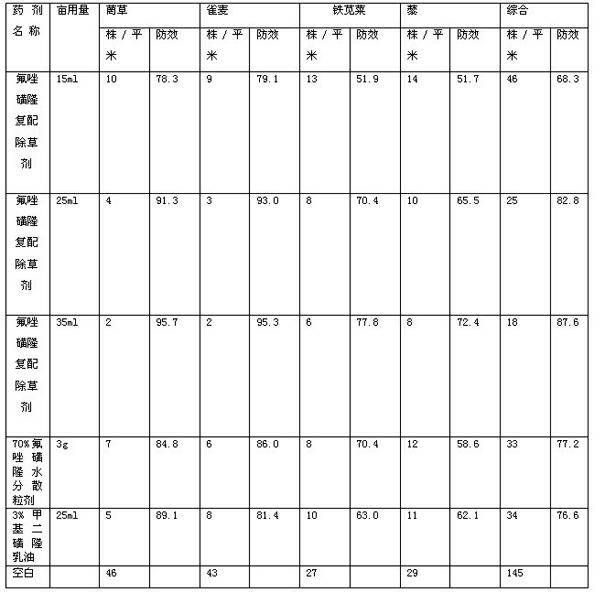

Flucarbazone-Na compounded herbicide

InactiveCN102428945APrevent flocculationAvoid layeringBiocideAnimal repellantsFluroxypyrFluoroglycofen-ethyl

The invention discloses a flucarbazone-Na compounded herbicide which comprises an active component I (flucarbazone-Na), an active component II and auxiliary components, wherein the active component II is one or a combination of several of mesosulfuron methyl, isoproturon, chlortoluron, pyroxsulam, Clodinafop-propargyl, carfentrazone-ethyl, tribenuron-methyl, fluroxypyr, methoxone, 2,4-D-butyl ester, dicamba, bromoxynil, thifensulfuron methyl, amidosulfuron, bensulfuron-methyl, flumetsulam, fluoroglycofen-ethyl and florasulam; the auxiliary components comprise an auxiliary agent and also comprise one of a filler and a solvent; the auxiliary agent is one or a combination of two of an emulsifying agent, a dispersant, a wetting agent, a disintegrant, an agglomerant, an antifreezing agent and a thickening agent; the mass sum of the active component I (flucarbazone-Na) and the active component II is 1%-85% of the total mass of the flucarbazone-Na compounded herbicide; and the mass ratio of the active component I to the active component II is (1:20)-(20:1). The flucarbazone-Na compounded herbicide disclosed by the invention is a novel herbicide for preventing and removing weeds in a wheatland.

Owner:河北博嘉农业有限公司

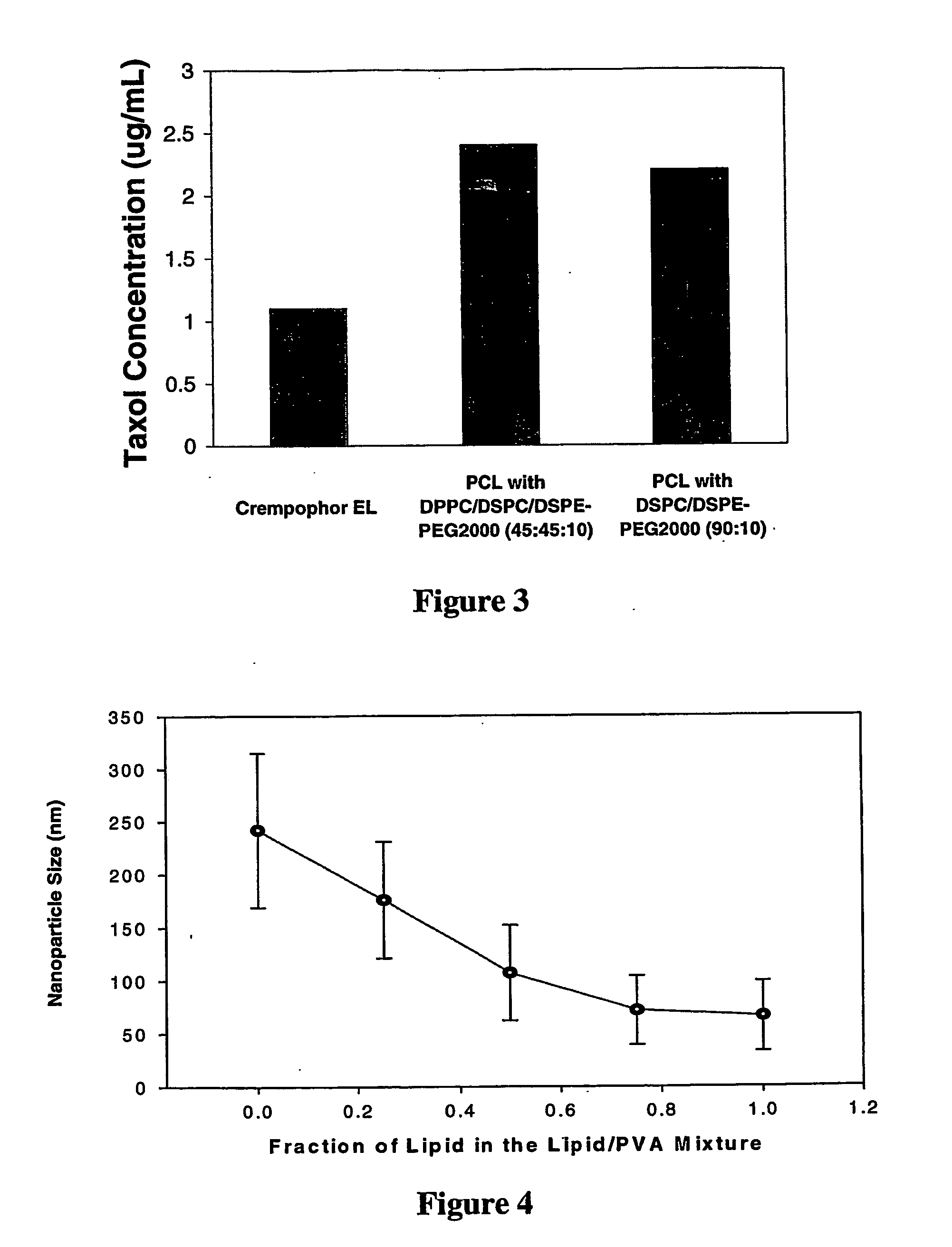

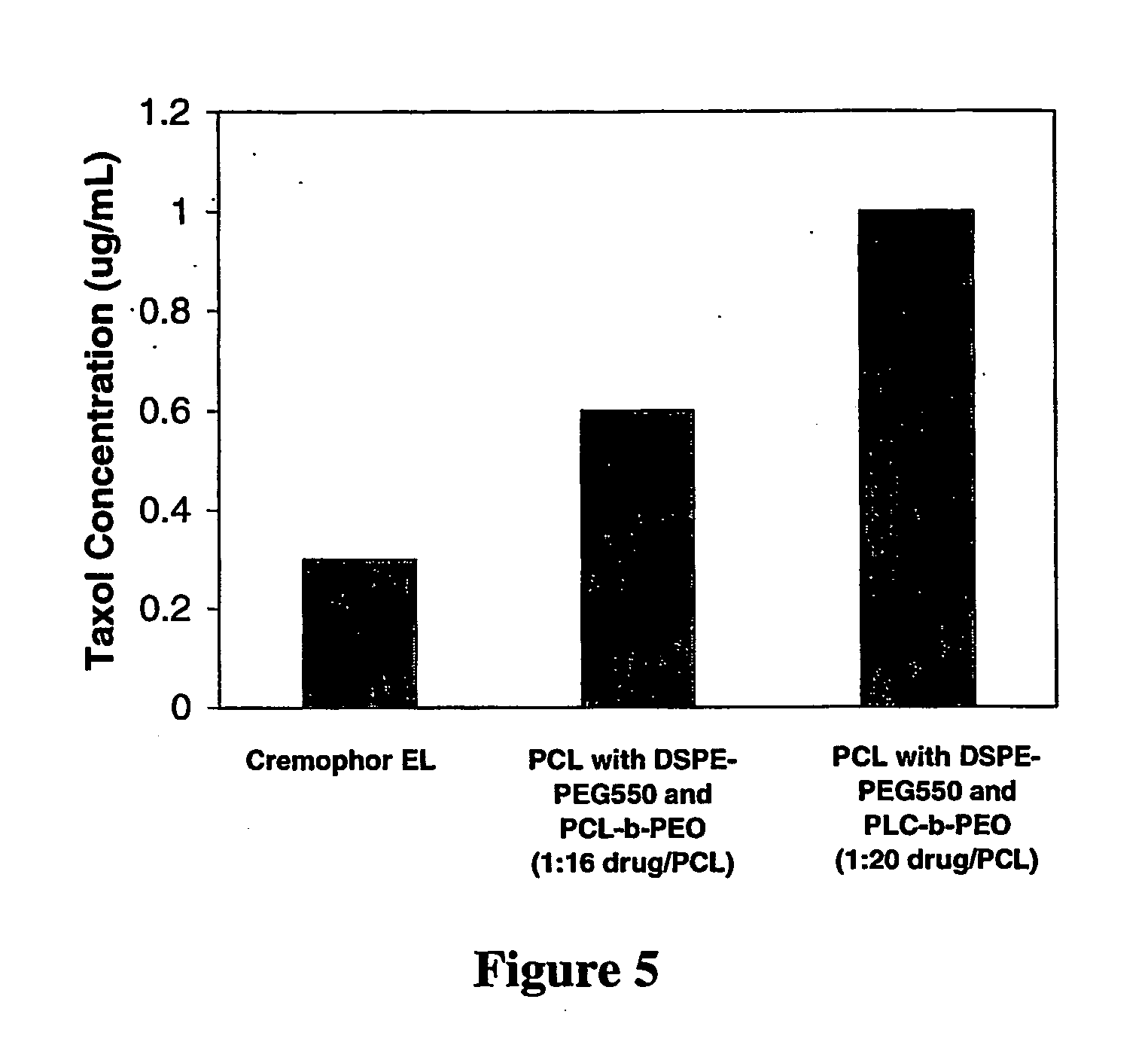

Polymer-lipid delivery vehicles

InactiveUS20060177495A1Improve pharmacokineticsEfficient deliveryHeavy metal active ingredientsOrganic active ingredientsLipid formationHydrophobic polymer

Delivery vehicles comprising nanoparticles which are composed of: (a) a biodegradable hydrophobic polymer forming a core, and; (b) an outer amphiphilic layer surrounding the polymer core containing a stabilizing lipid are suitable for delivering active agents.

Owner:CELATOR PHARMA INC

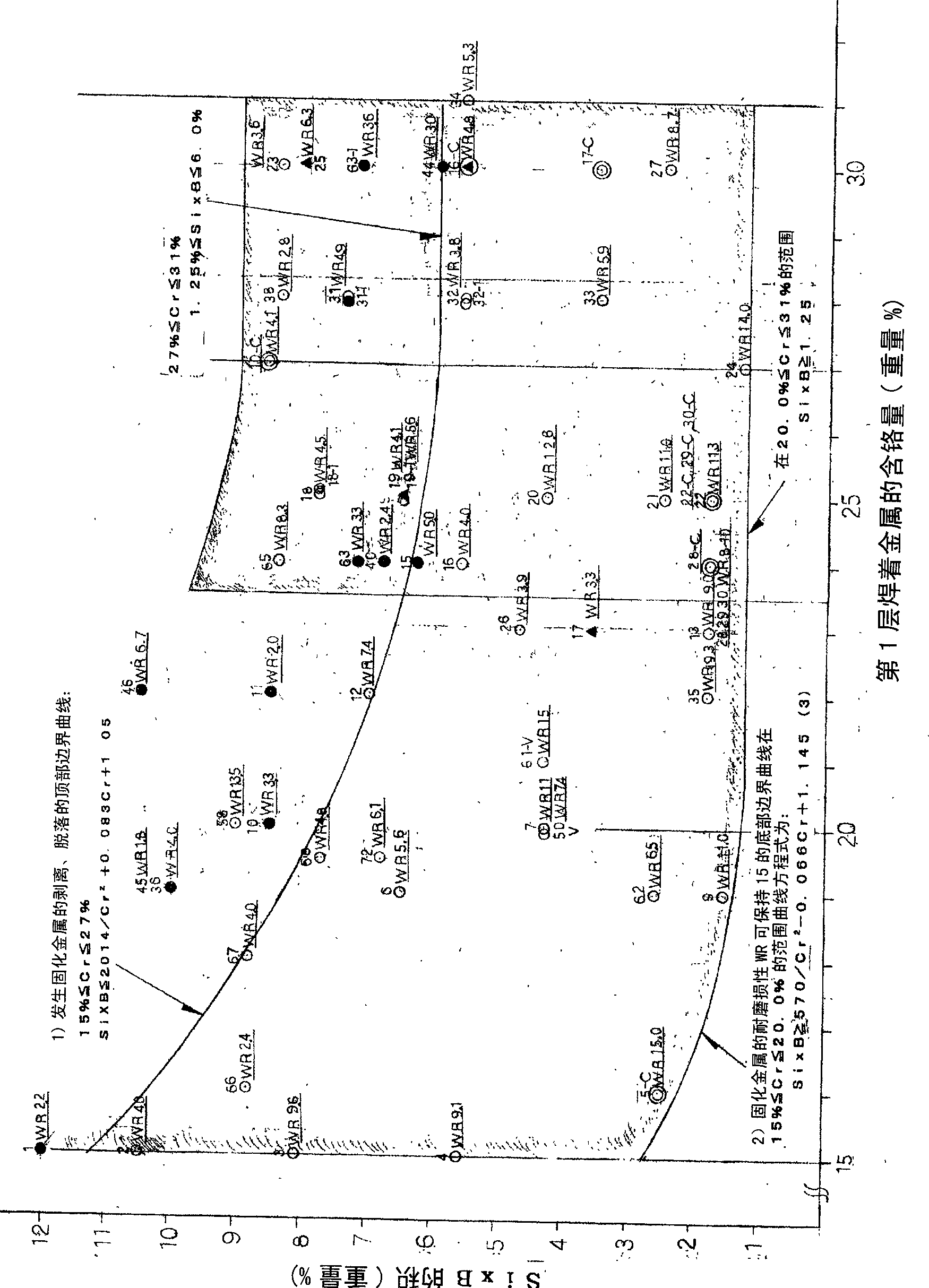

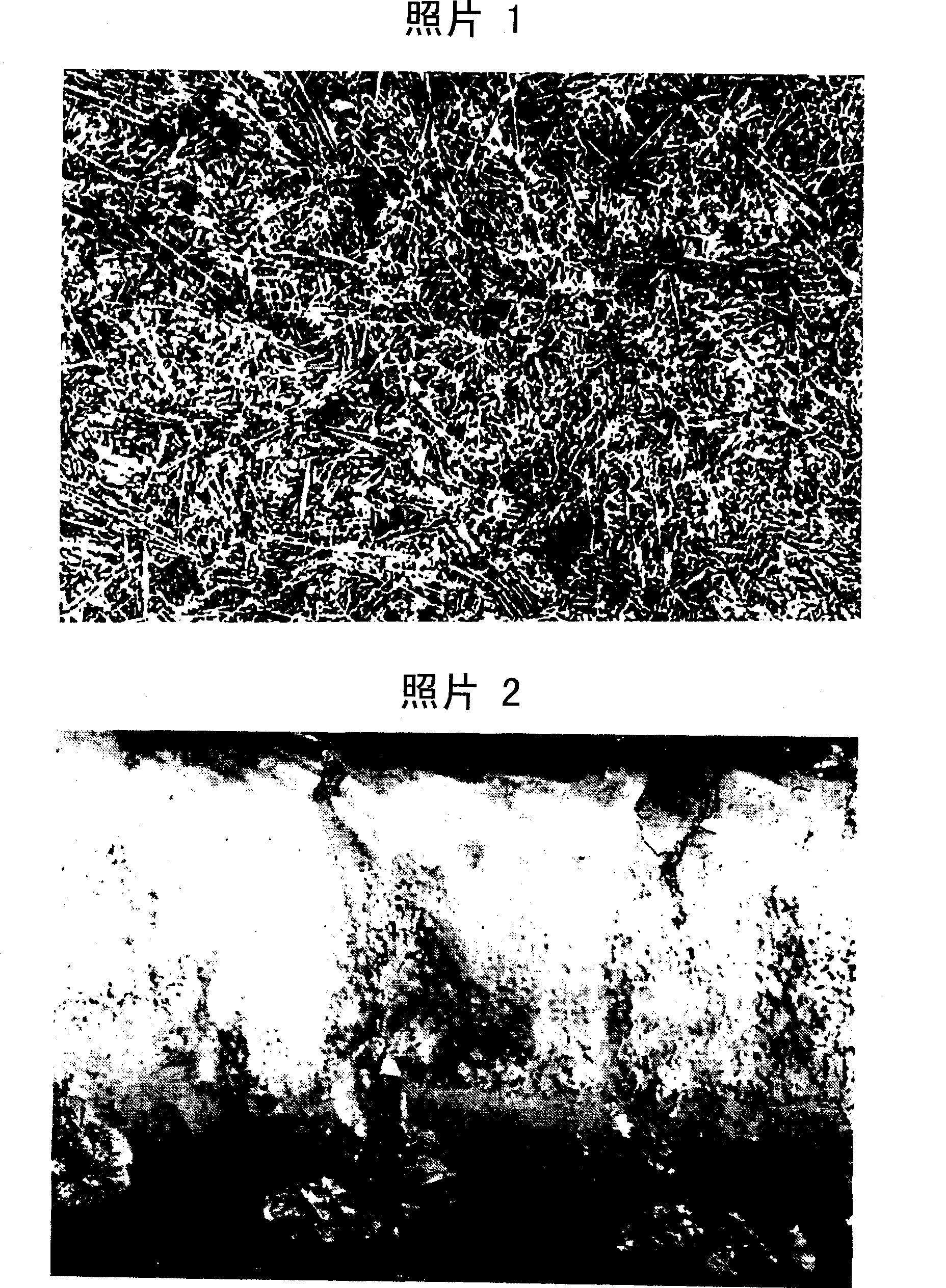

Iron-based corrosion resistant wear resistant alloy and deposit welding material for obtaining the alloy

InactiveCN101505910AOvercoming brittlenessOvercome vulnerabilityWelding/cutting media/materialsSoldering mediaChromium carbideWear resistant

To provide a high-performance, inexpensive low C-high Si-high Cr-B-Nb type iron-based corrosion-resistant and wear-resistant alloy that is extremely superior in corrosion resistance and wear resistance to 304 stainless steel, high-chromium cast iron and high carbon-high chromium cast-iron-type materials, has a high corrosion-resistant property that would never be obtained from a high carbon-high chromium carbide precipitation-type iron-based wear-resistant alloy and at the same time, a wear-resistant property that is superior to these metals, and further hardly causes brittle peeling that is inherent to high Si-containing steel. This alloy contains, all percentages by weight, C: 0.5 to 2.5% by weight, Si: 2.5 to 4.5%, Mn: 0 to 10% or less, Cr: 15% to 31%, Ni: 0 to 16%, Cu: 7% or less, Mo: 10% or less, B: 0.5% to 3.5%, and 0+0.083Cr+1.05 is satisfied, within a range of 27% / =570 / Cr-0.066Cr+1.145 is satisfied, and within a range of 20% / =1.25 is satisfied.

Owner:ING SHOJI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com