Composite porous current collector, and preparation method and application thereof

A technology of porous current collector and pore size, applied in electrical components, battery electrodes, circuits, etc., can solve problems affecting battery safety performance, battery short circuit, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

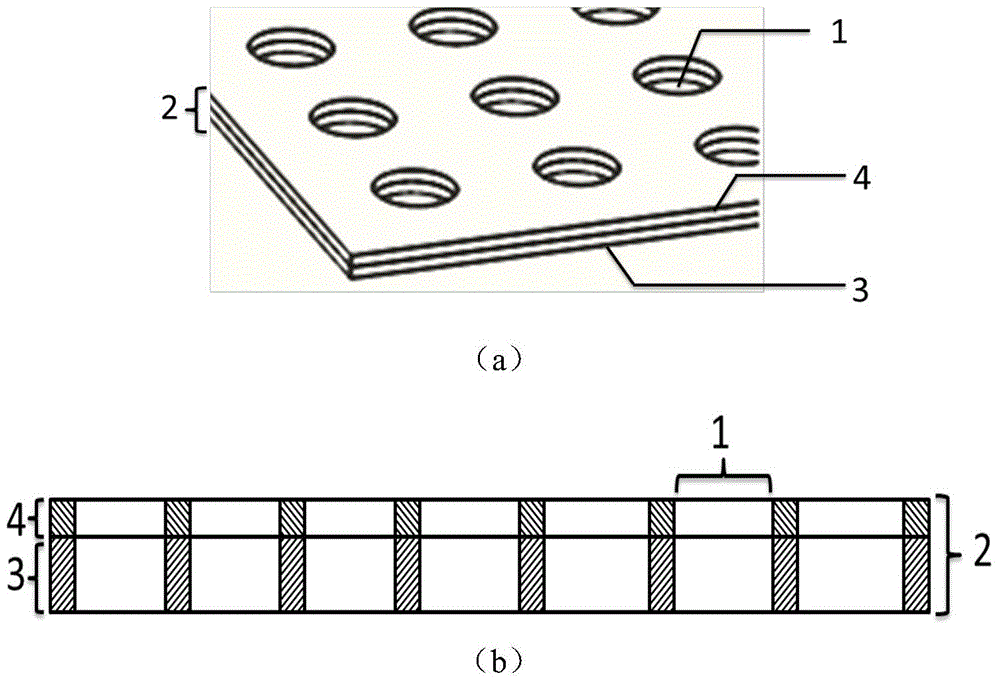

Embodiment 1

[0043] In this embodiment, the composite porous current collector includes: the electronic insulating layer 4 is a polyethylene film with a thickness of 30 μm, the porous electronic conductive layer 3 is a porous PET conductive cloth with a pore diameter of 300 to 800 μm, a porosity of 80%, and a thickness of 500 μm coated with carbon. .

[0044] The preparation method of the composite porous current collector of this embodiment is as follows:

[0045] 1) Pretreatment, specifically including:

[0046] a. Cleaning and drying: At room temperature, soak the carbon-coated porous PET conductive cloth in ethanol, acetone and dimethyl carbonate respectively and ultrasonically for 10 minutes to remove oil, dust and soluble impurities, and then rinse with deionized water Clean and dry under hot air at 90°C for 60 minutes.

[0047] At room temperature, soak the polyethylene film in acetone for 10 minutes to remove oil and dust on the surface, then rinse it with deionized water, and dr...

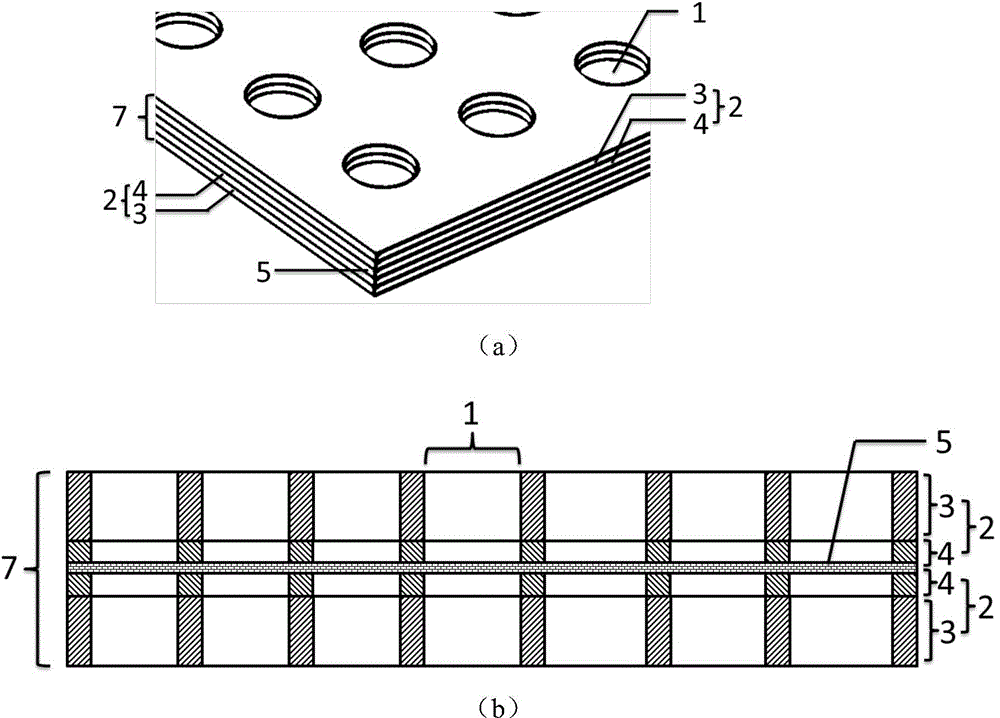

Embodiment 2

[0053] In this embodiment, the composite porous current collector includes: the electronic insulating layer 4 is a polyvinylidene fluoride film after the solution has been volatilized, and the thickness is 40 μm; Carbon porous PET conductive cloth.

[0054] The preparation method of the composite porous current collector of this embodiment is as follows:

[0055] 1) Pretreatment, specifically including:

[0056] a. Cleaning and drying: At room temperature, soak the carbon-coated porous PET conductive cloth in ethanol, acetone and dimethyl carbonate respectively and ultrasonically for 10 minutes to remove oil, dust and soluble impurities, and then rinse with deionized water Clean and dry under hot air at 90°C for 60 minutes.

[0057] b. Surface treatment: In order to increase the bonding strength between the porous PET conductive cloth and the polyvinylidene fluoride film and improve the interface performance, the cleaned and dried porous PET conductive cloth was treated in a...

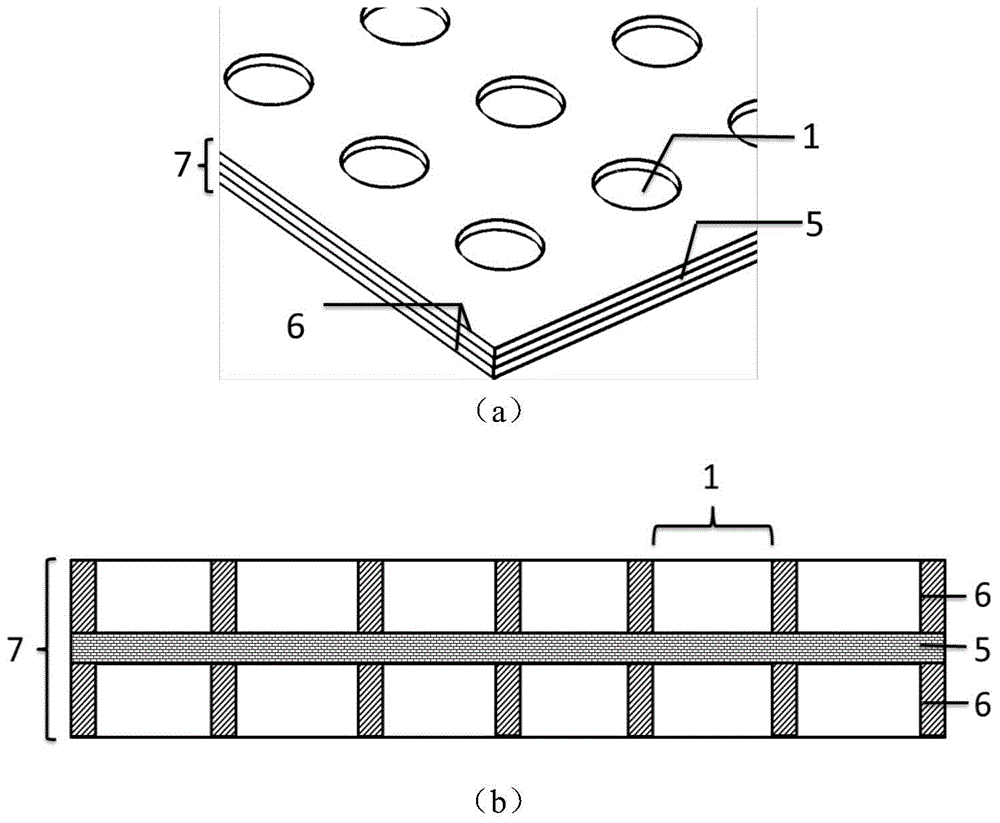

Embodiment 3

[0062]In this embodiment, the composite porous current collector includes: the electronic insulating layer 4 is a polyethylene film with a thickness of 50 μm, and the porous electronic conductive layer 3 is a 200-mesh stainless steel mesh.

[0063] The preparation method of the composite porous current collector of this embodiment is as follows:

[0064] 1) Pretreatment, specifically including:

[0065] a. Cleaning and drying: Soak the stainless steel mesh in acetone at 40°C for 10 minutes to remove oil and dust on the surface, then rinse it with deionized water, and dry it under hot air at 90°C for 30 minutes.

[0066] At room temperature, soak the polyethylene film in acetone for 10 minutes to remove oil and dust on the surface, then rinse it with deionized water, and dry it under hot air at 60°C for 30 minutes.

[0067] b. Surface treatment: In order to increase the bonding strength between the stainless steel mesh and the polyethylene film and improve the interface perfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com