Patents

Literature

7041 results about "Polyvinylidene fluoride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyvinylidene fluoride or polyvinylidene difluoride (PVDF) is a highly non-reactive thermoplastic fluoropolymer produced by the polymerization of vinylidene difluoride. PVDF is a specialty plastic used in applications requiring the highest purity, as well as resistance to solvents, acids and hydrocarbons. Compared to other fluoropolymers, like polytetrafluoroethylene (Teflon), PVDF has a low density (1.78 g/cm³).

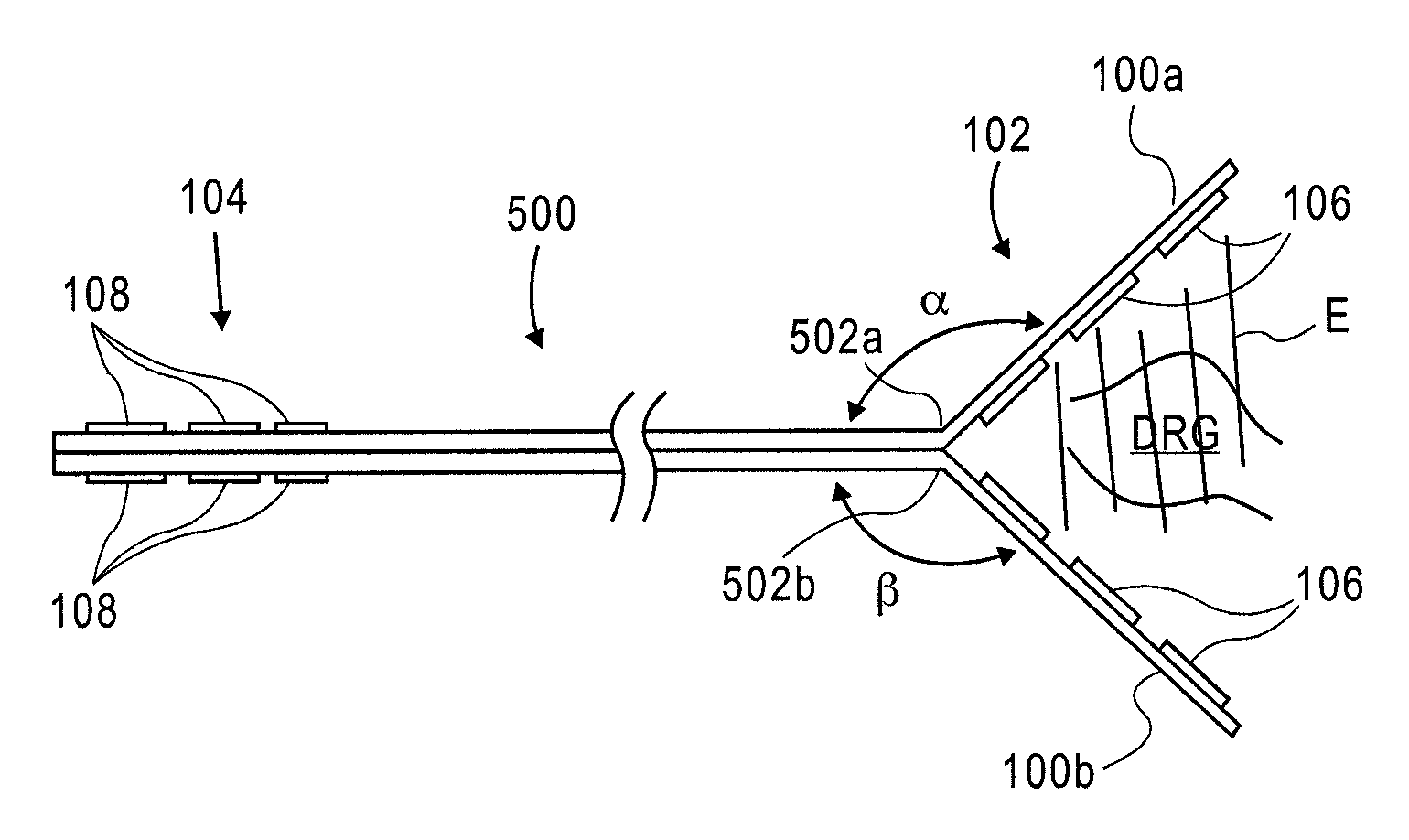

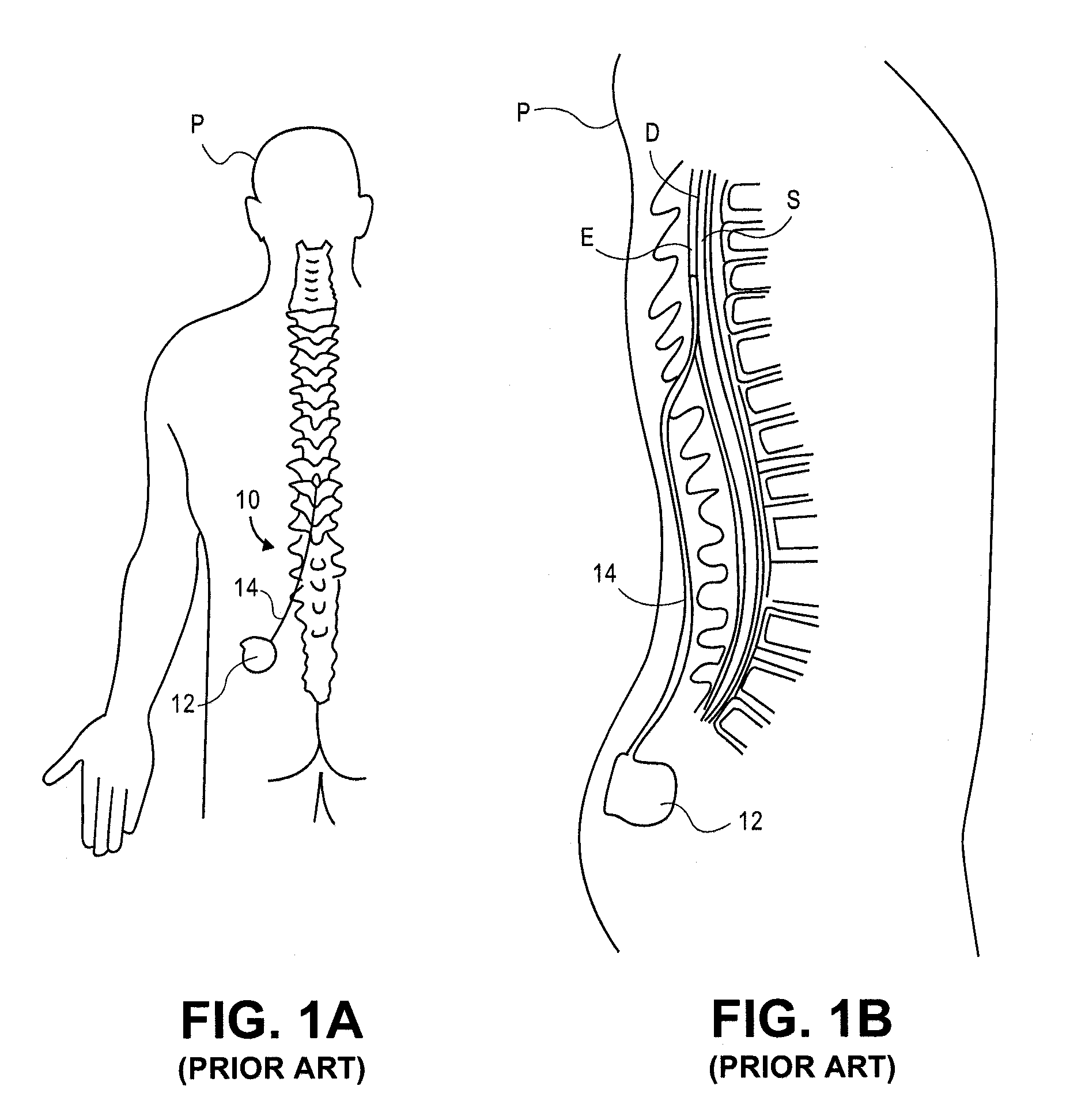

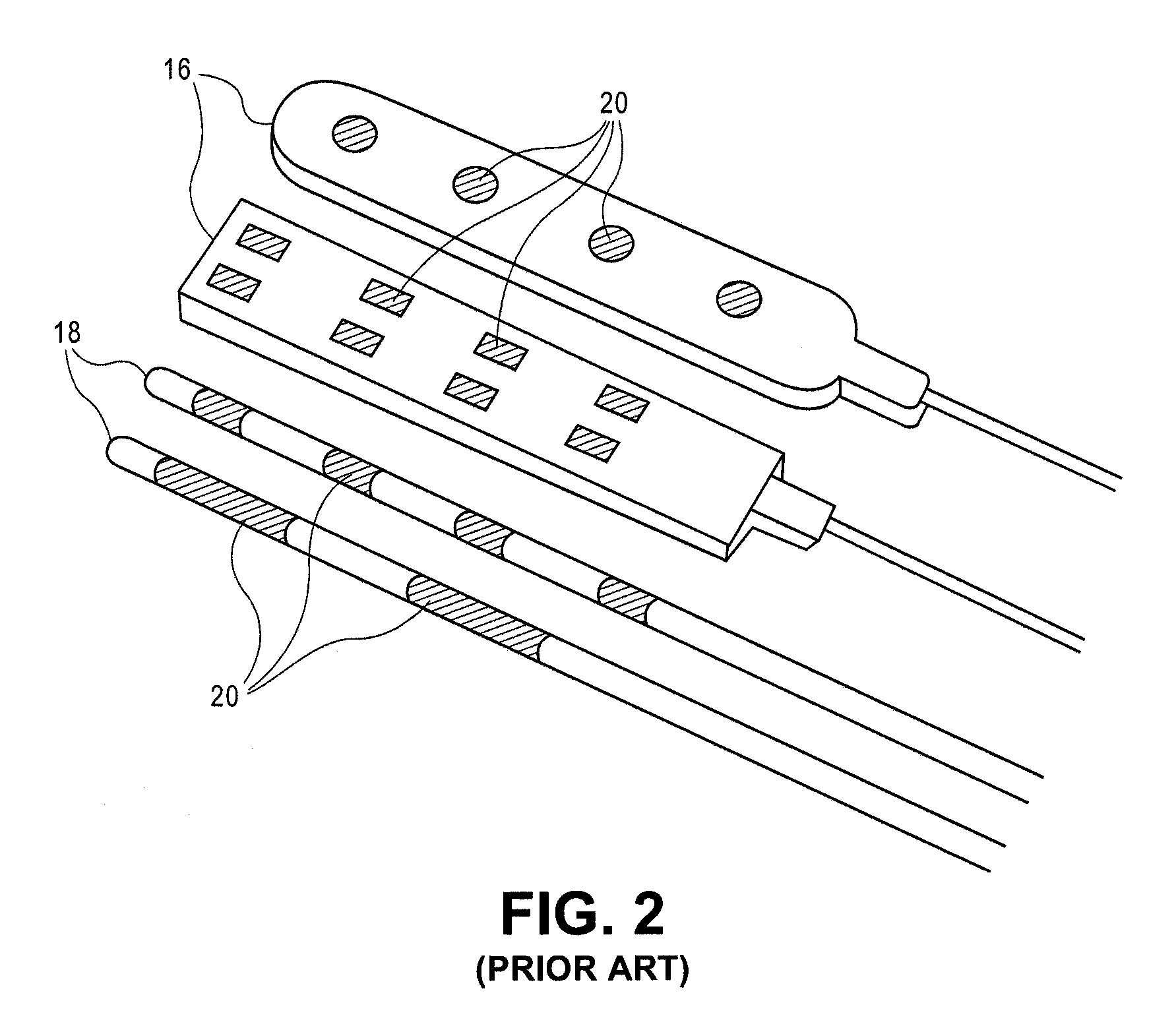

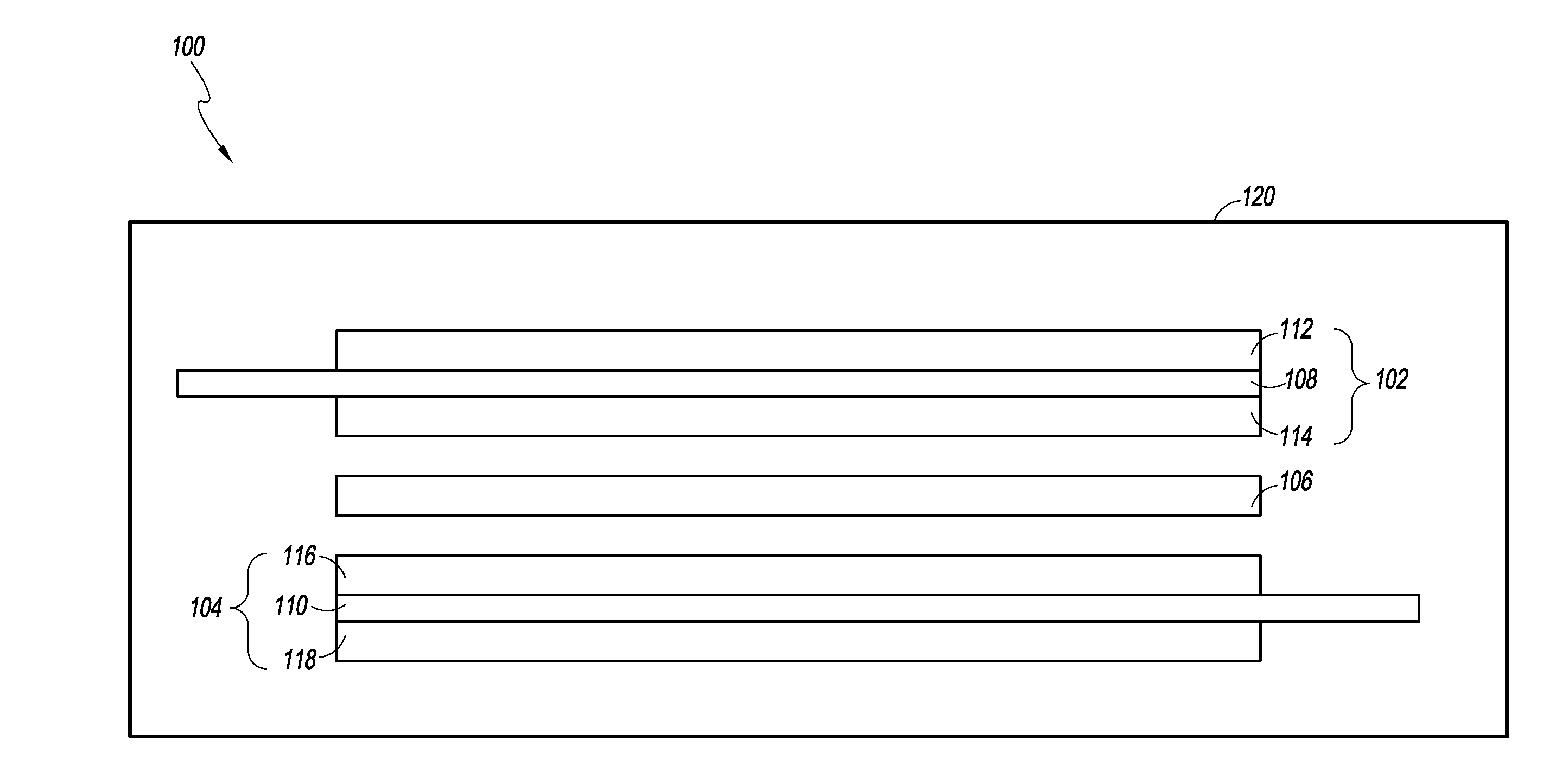

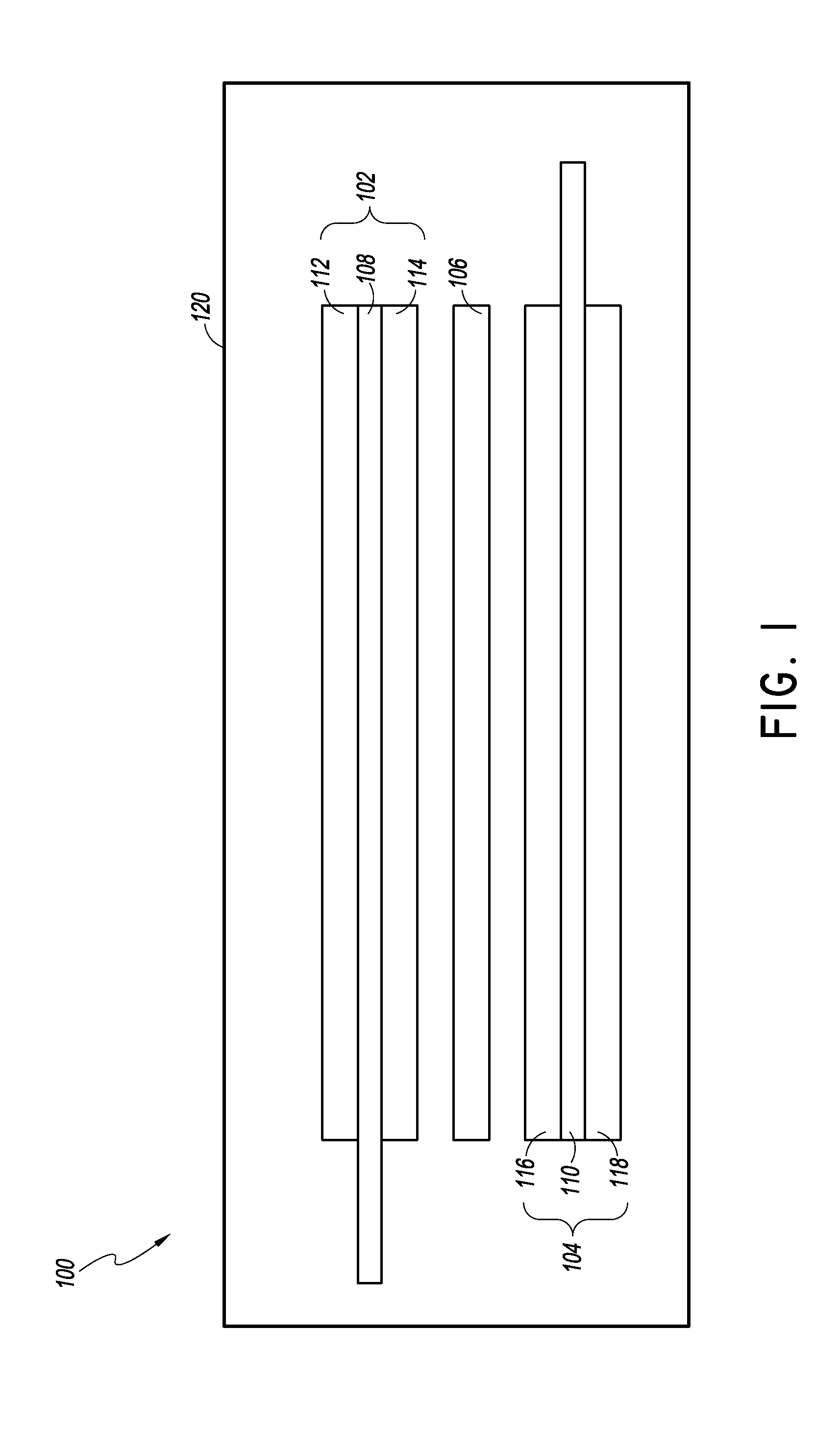

Implantable flexible circuit leads and methods of use

InactiveUS20080140152A1Easy to manufactureStrong specificitySpinal electrodesExternal electrodesDielectricFlexible circuits

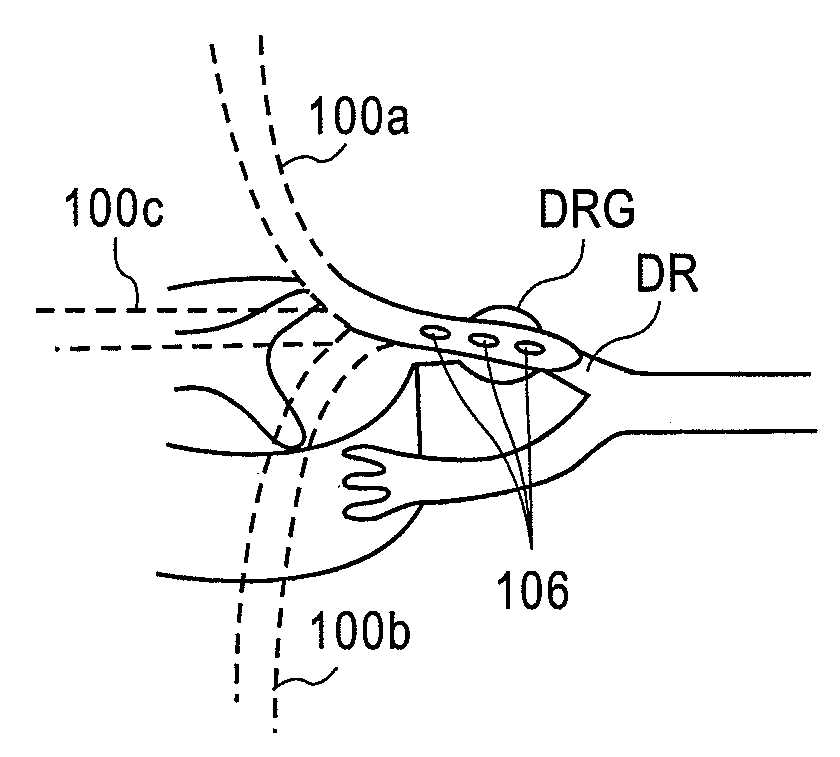

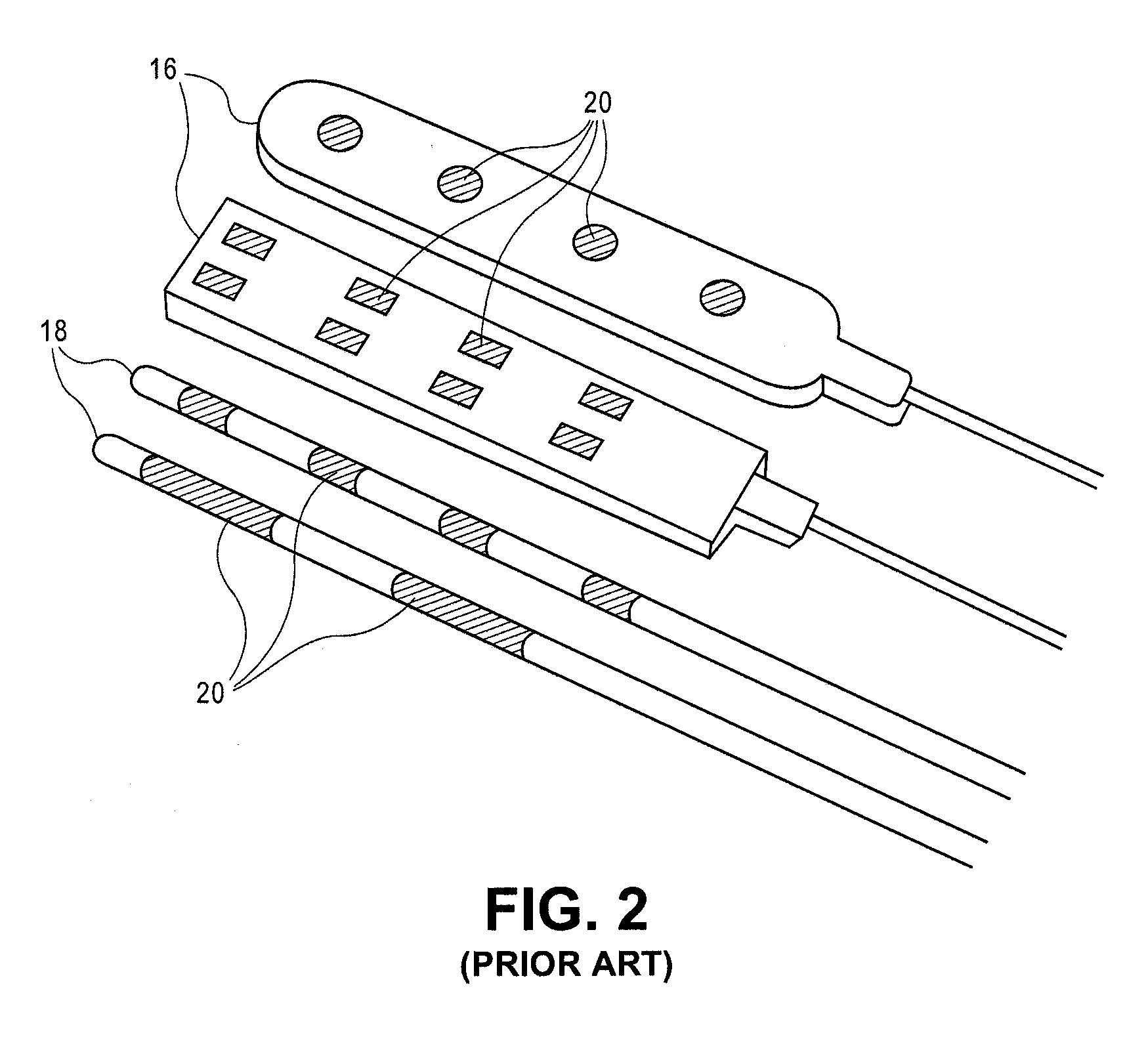

Devices, systems and methods are provided for stimulation of tissues and structures within a body of a patient. In particular, implantable leads are provided which are comprised of a flexible circuit. Typically, the flexible circuit includes an array of conductors bonded to a thin dielectric film. Example dielectric films include polyimide, polyvinylidene fluoride (PVDF) or other biocompatible materials to name a few. Such leads are particularly suitable for stimulation of the spinal anatomy, more particularly suitable for stimulation of specific nerve anatomies, such as the dorsal root (optionally including the dorsal root ganglion).

Owner:ST JUDE MEDICAL LUXEMBOURG HLDG SMI S A R L SJM LUX SMI

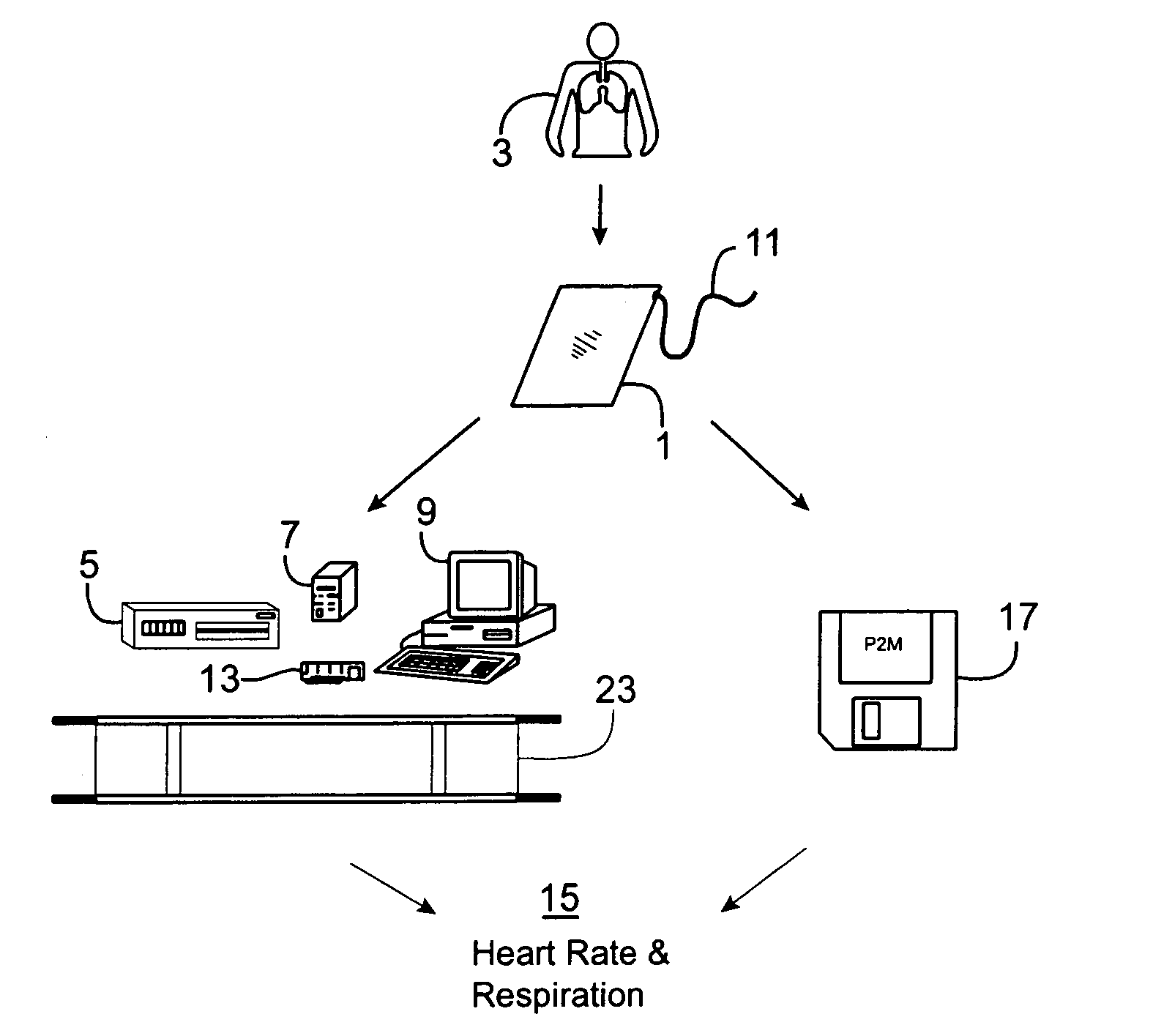

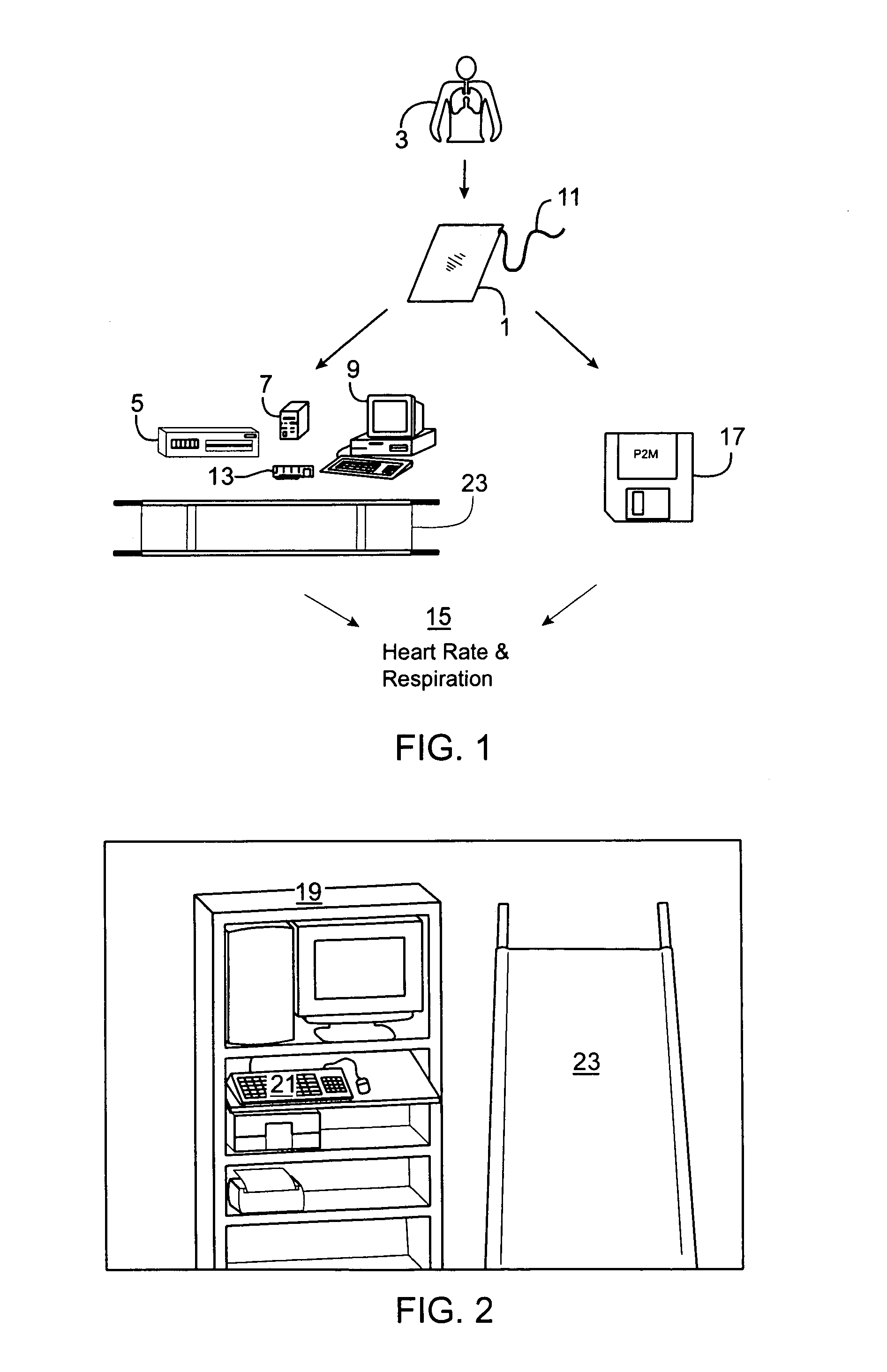

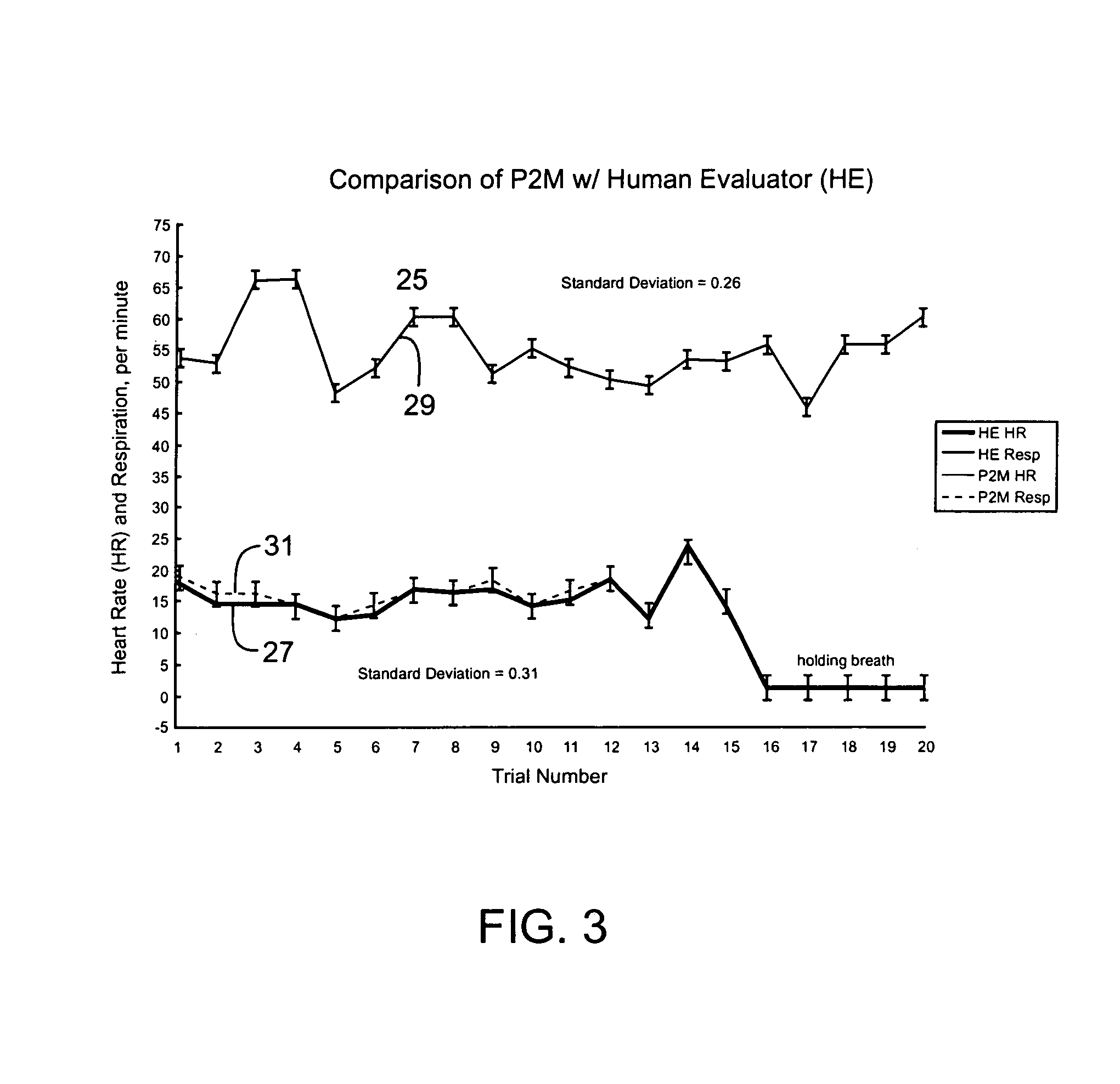

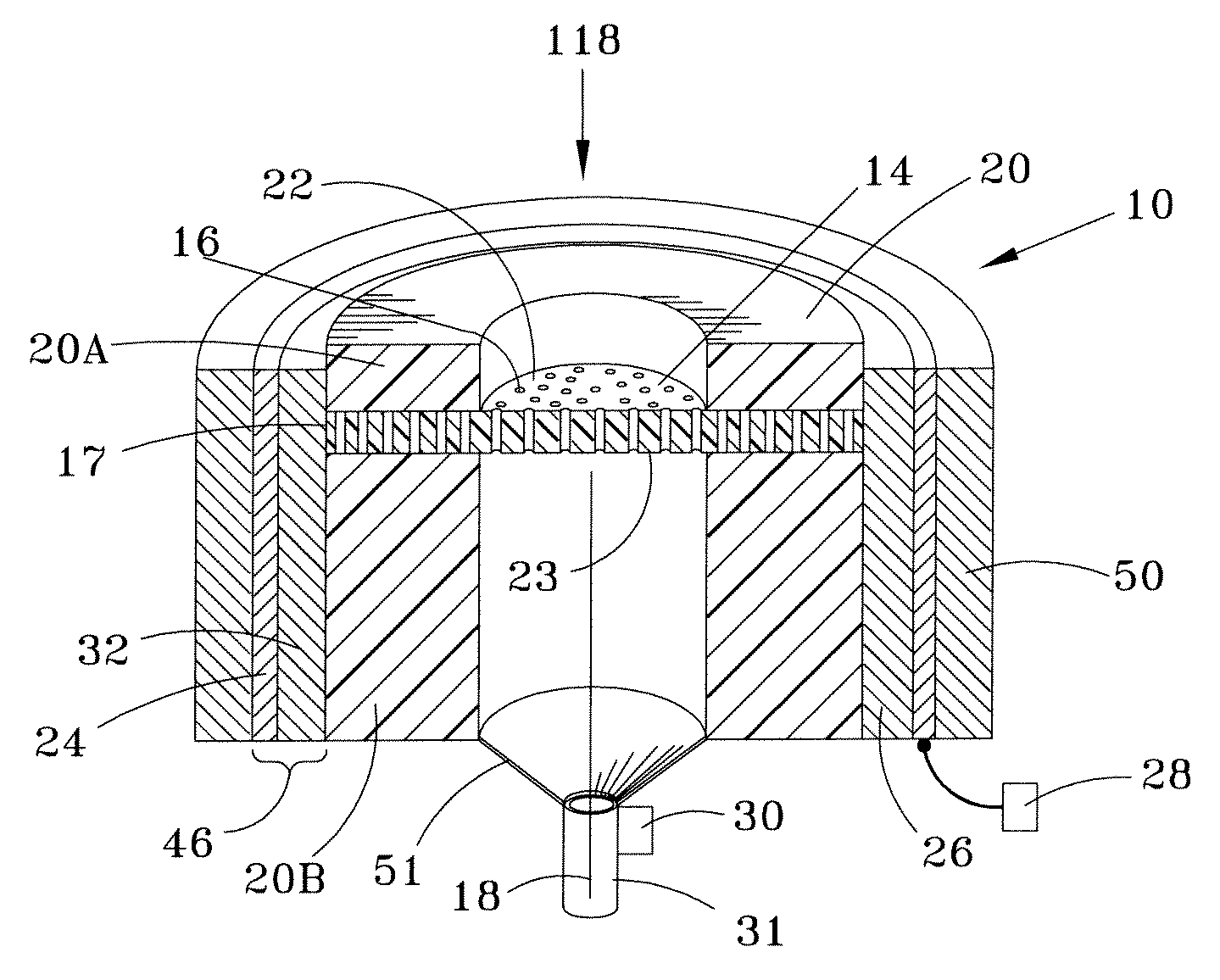

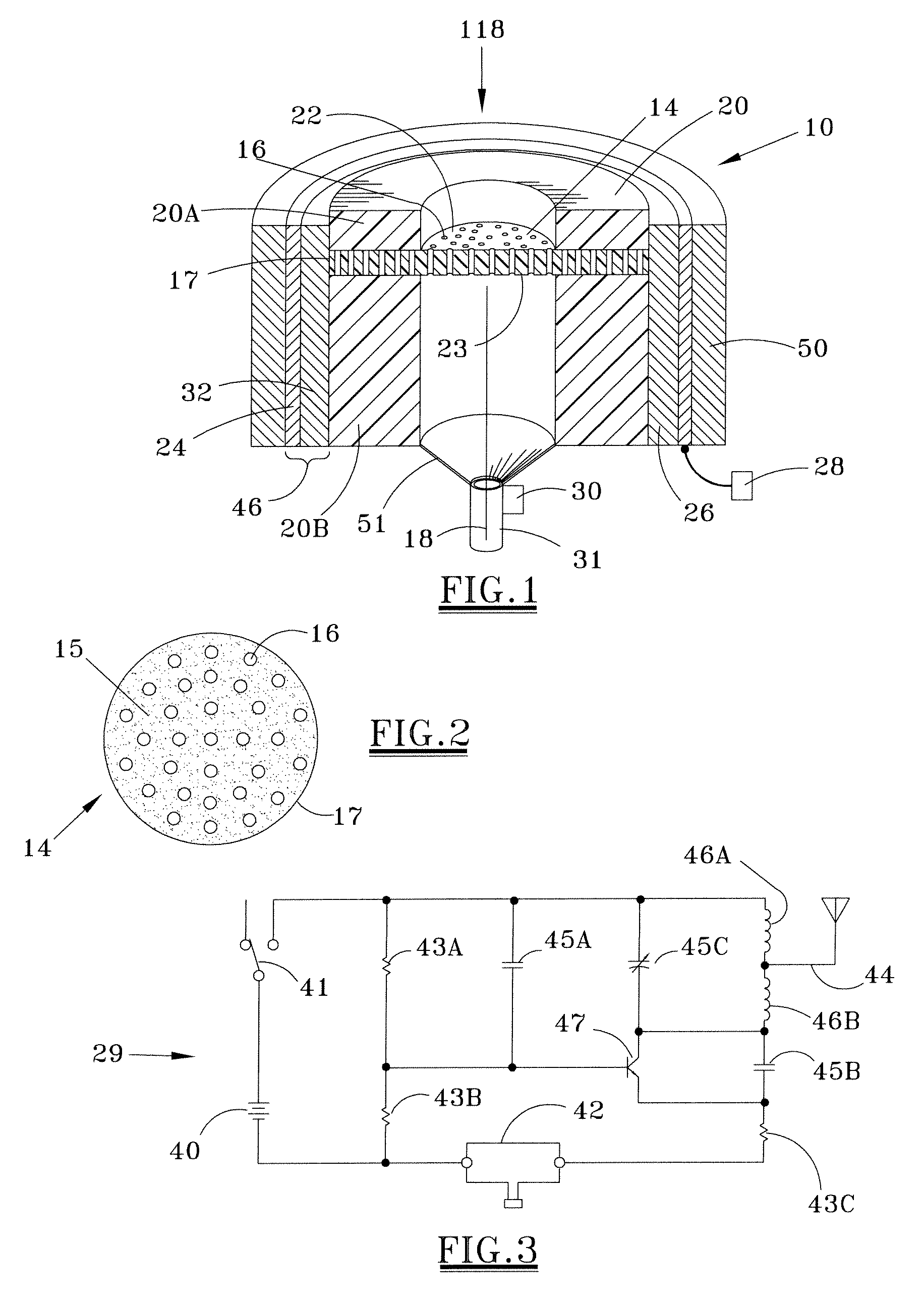

Passive physiological monitoring (P2M) system

InactiveUS6984207B1Easy to deployEvaluation of blood vesselsCatheterInternal bleedingBand-pass filter

Passive Physiological monitoring apparatus and method have a sensor for sensing physiological phenomenon. A converter converts sensed data into electrical signals and a computer receives and computes the signals, and outputs computed data for real-time interactive display. The sensor is a piezoelectric film of polyvinylidene fluoride. A band-pass filter filters out noise and isolates the signals to reflect data from the body. A pre-amplifier amplifies signals. Signals detected include mechanical, thermal and acoustic signatures reflecting cardiac output, cardiac function, internal bleeding, respiratory, pulse, apnea, and temperature. A pad may incorporate the PVDF film and may be fluid-filled. The film converts mechanical energy into analog voltage signals. Analog signals are fed through the band-pass filter and the amplifier. A converter converts the analog signals to digital signals. A Fourier transform routine is used to transform into the frequency domain. A microcomputer is used for recording, analyzing and displaying data for on-line assessment and for providing realtime response. A radio-frequency filter may be connected to a cable and the film for transferring signals from the film through the cable. The sensor may be an array provided in a MEDEVAC litter or other device for measuring acoustic and hydraulic signals from the body of a patient for field monitoring, hospital monitoring, transport monitoring, home, remote monitoring.

Owner:HOANA MEDICAL

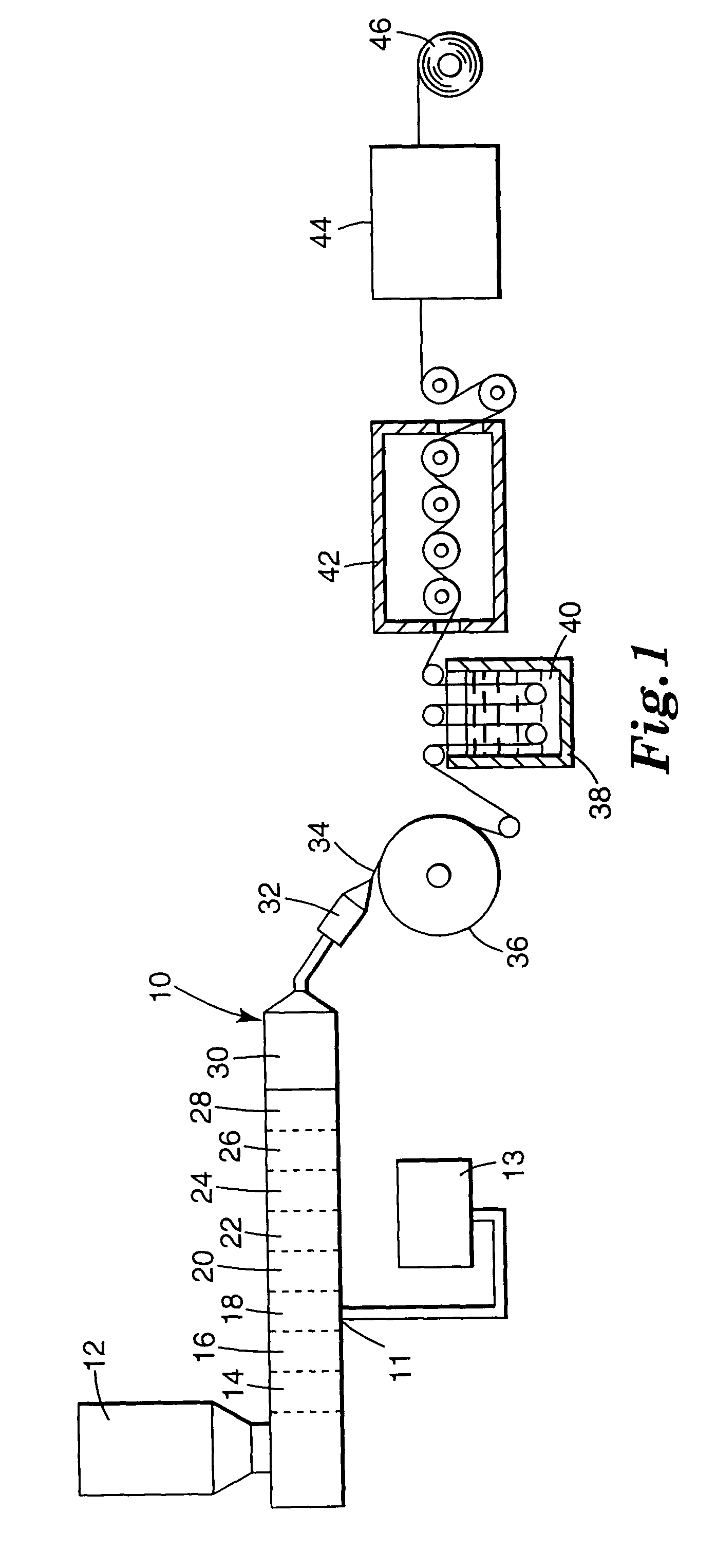

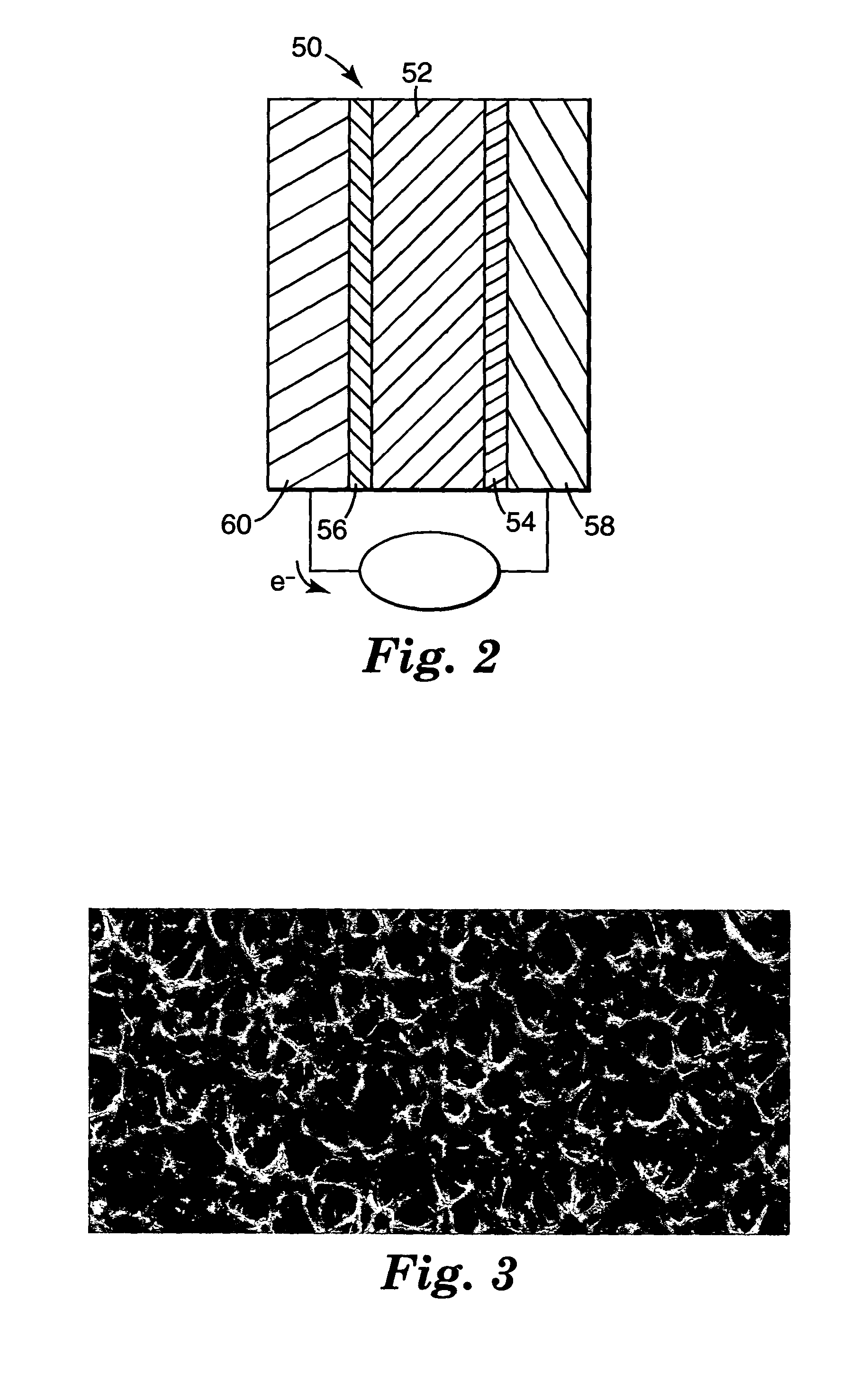

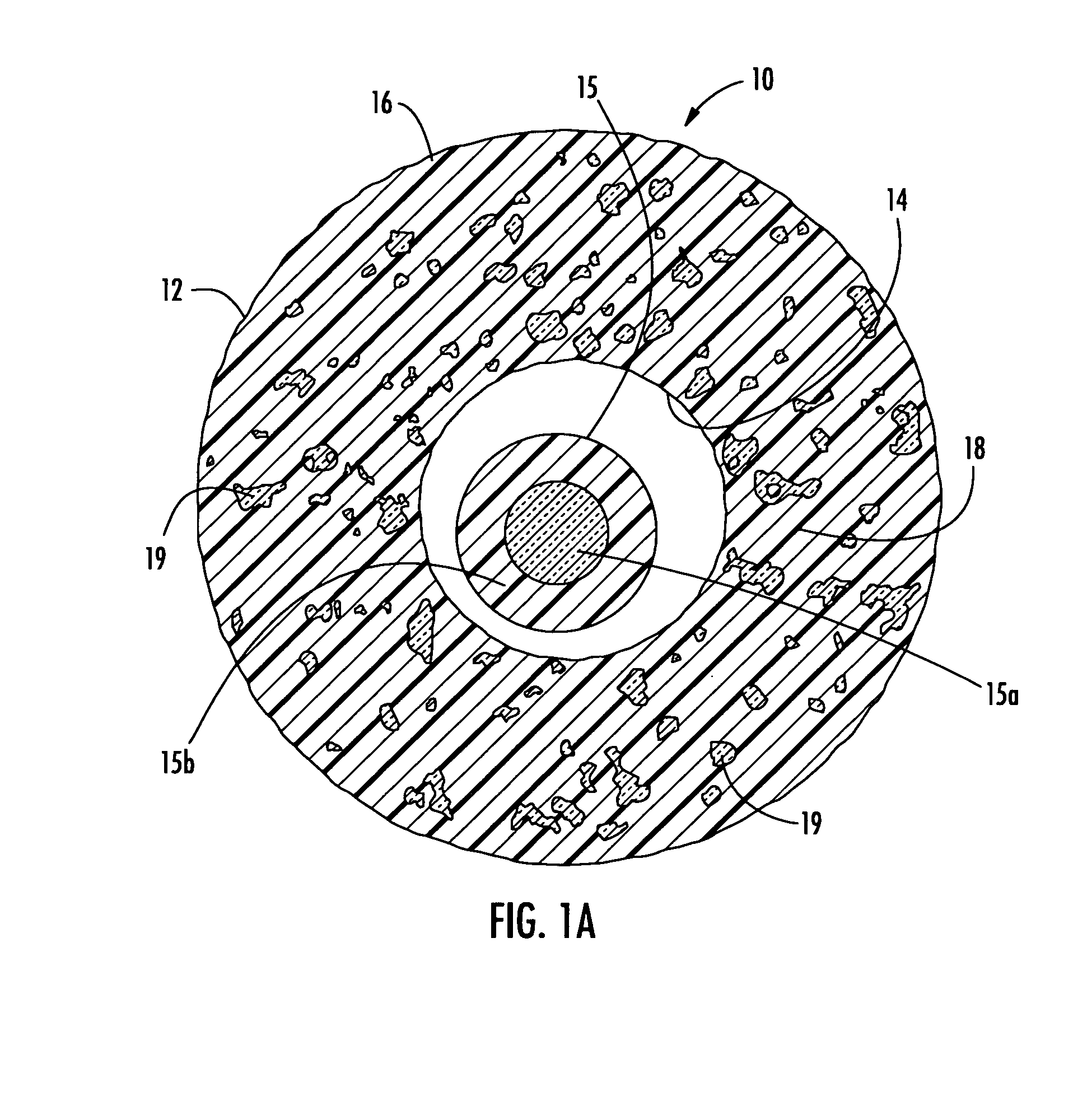

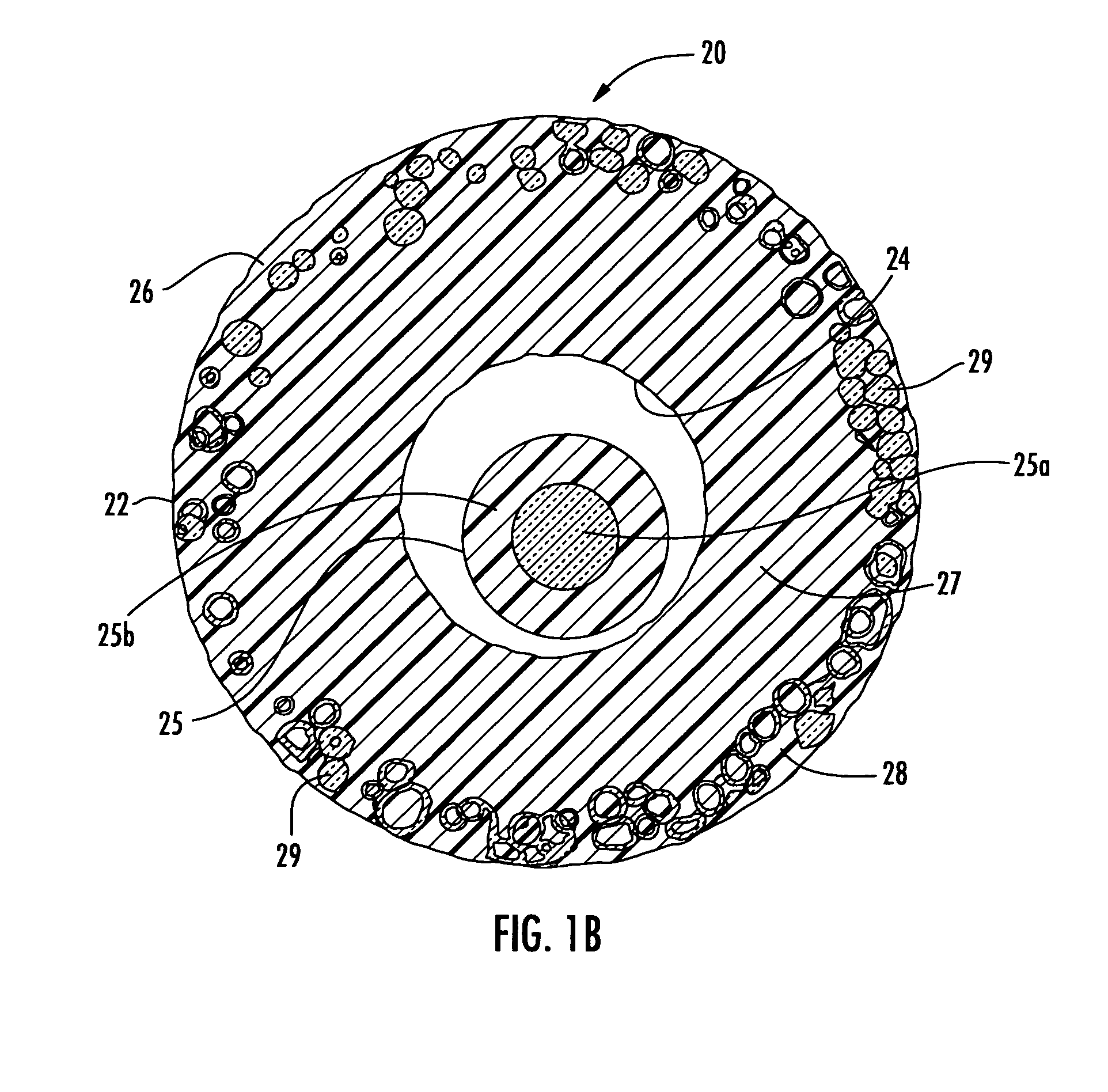

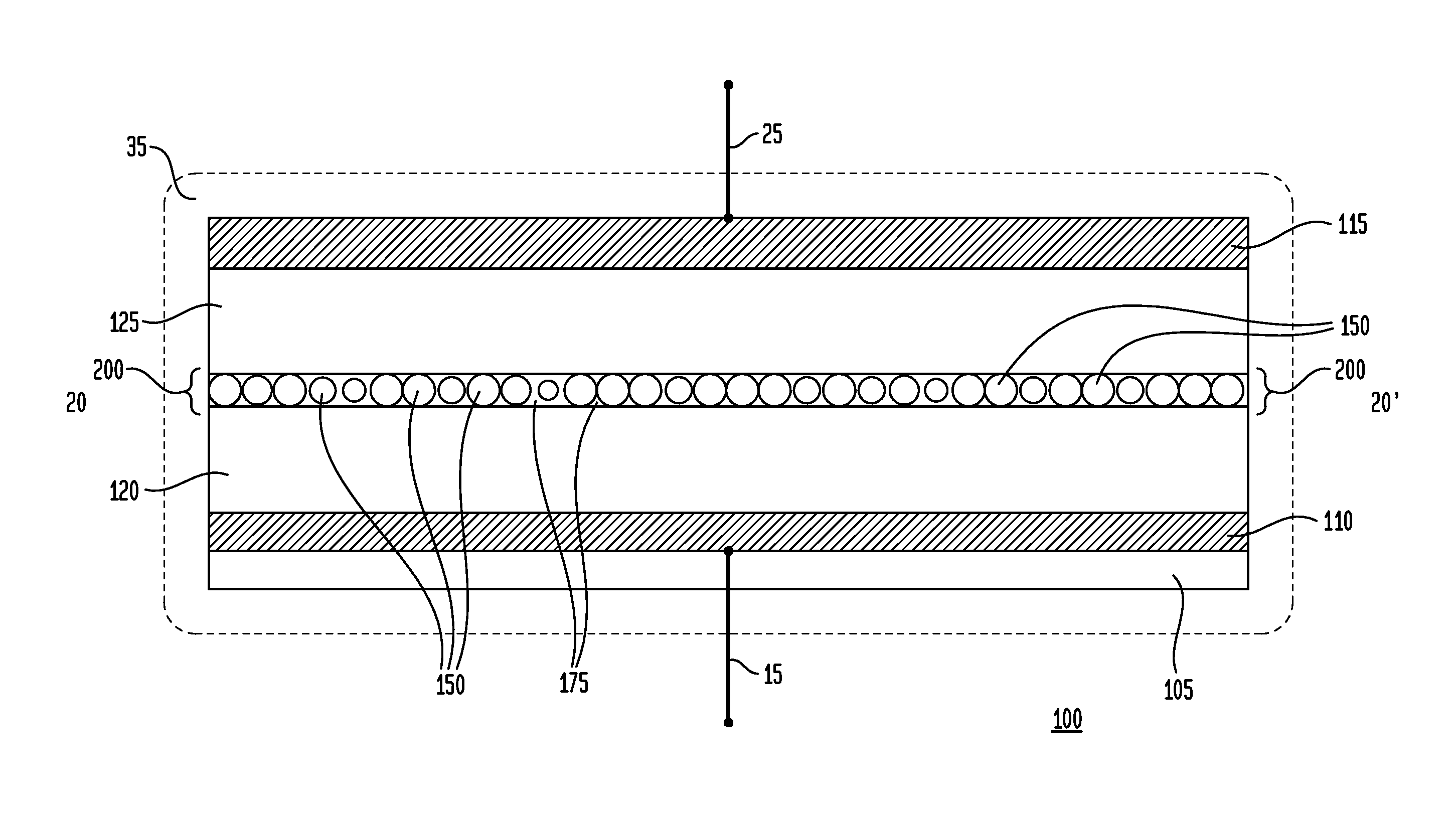

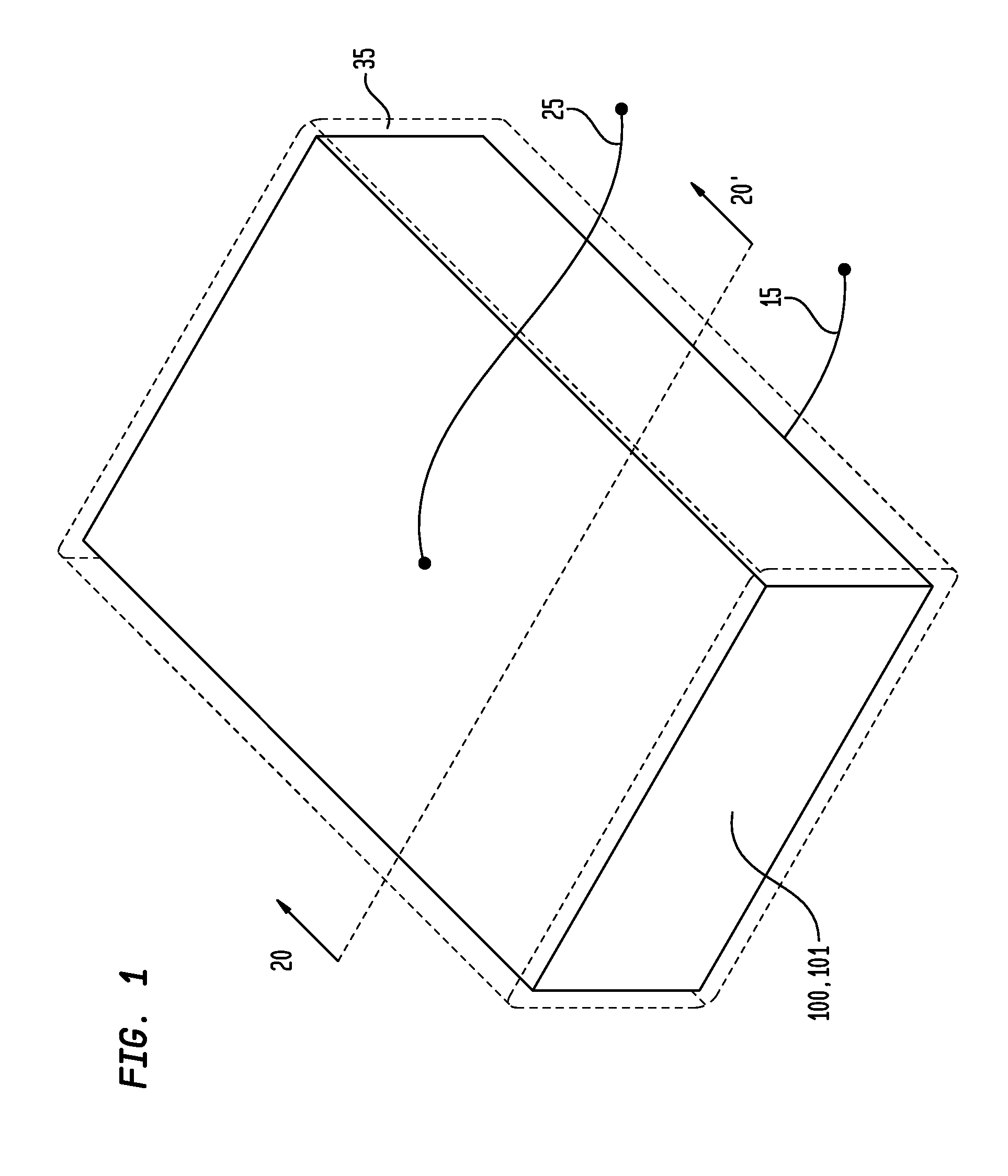

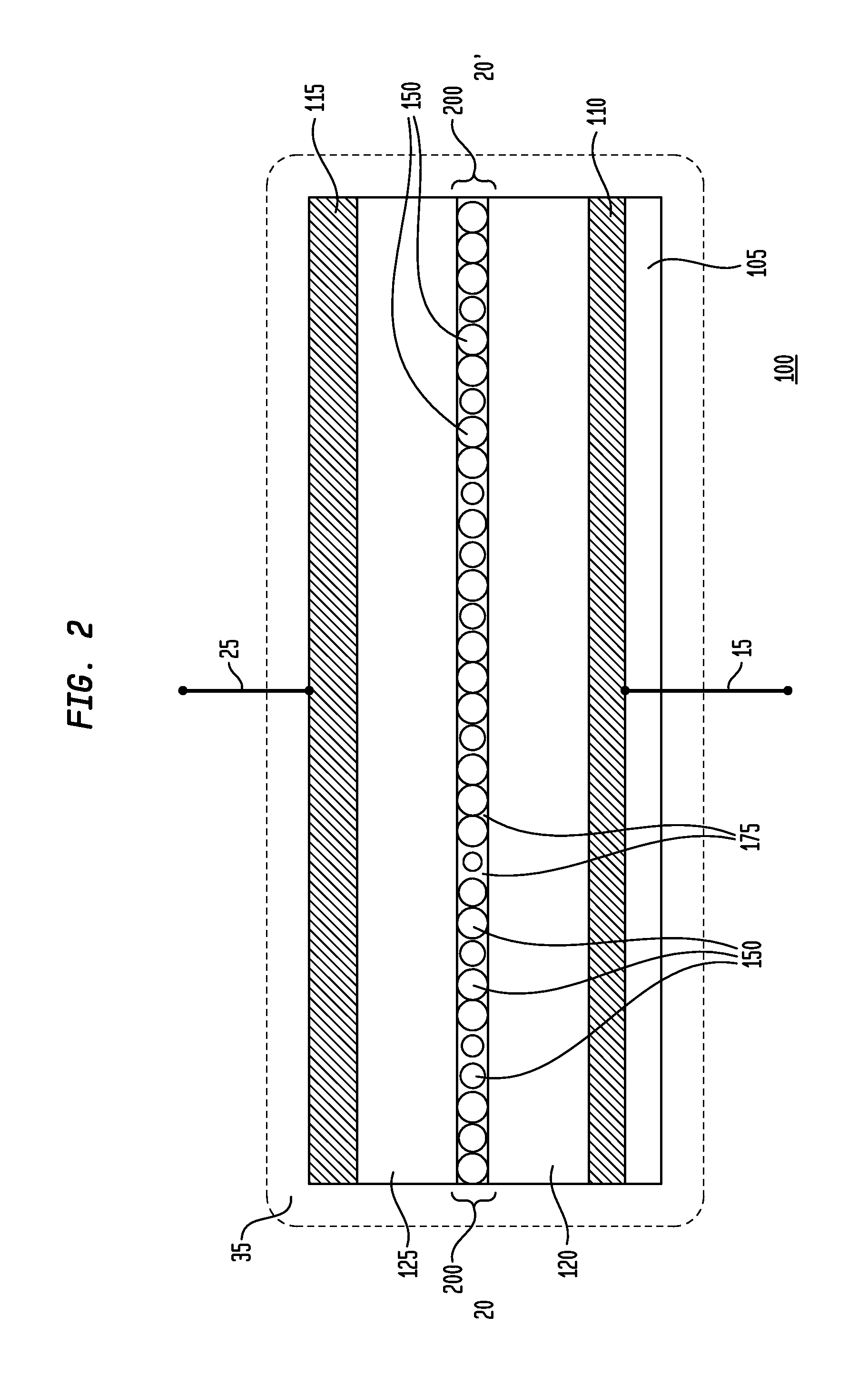

Microporous PVDF films

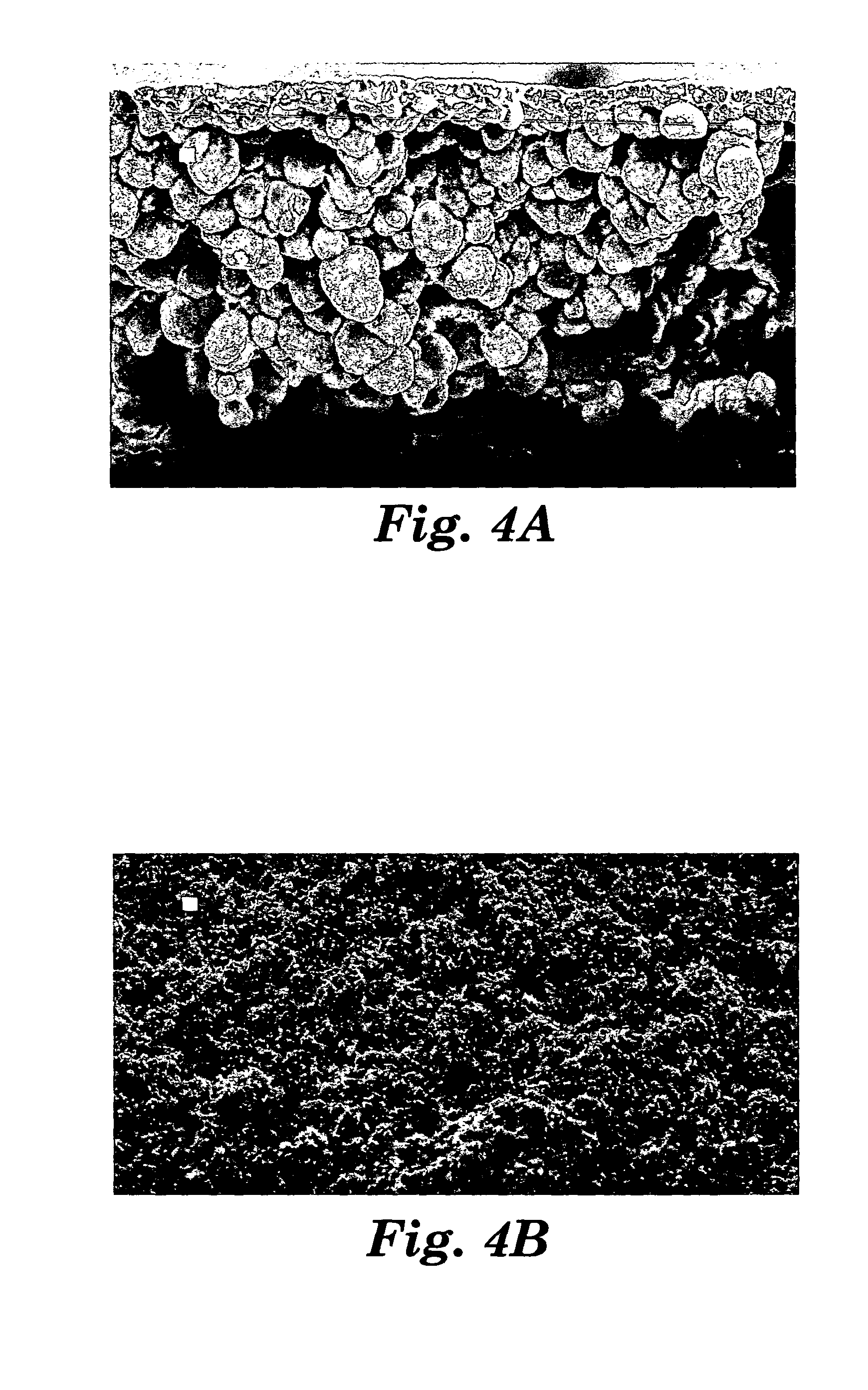

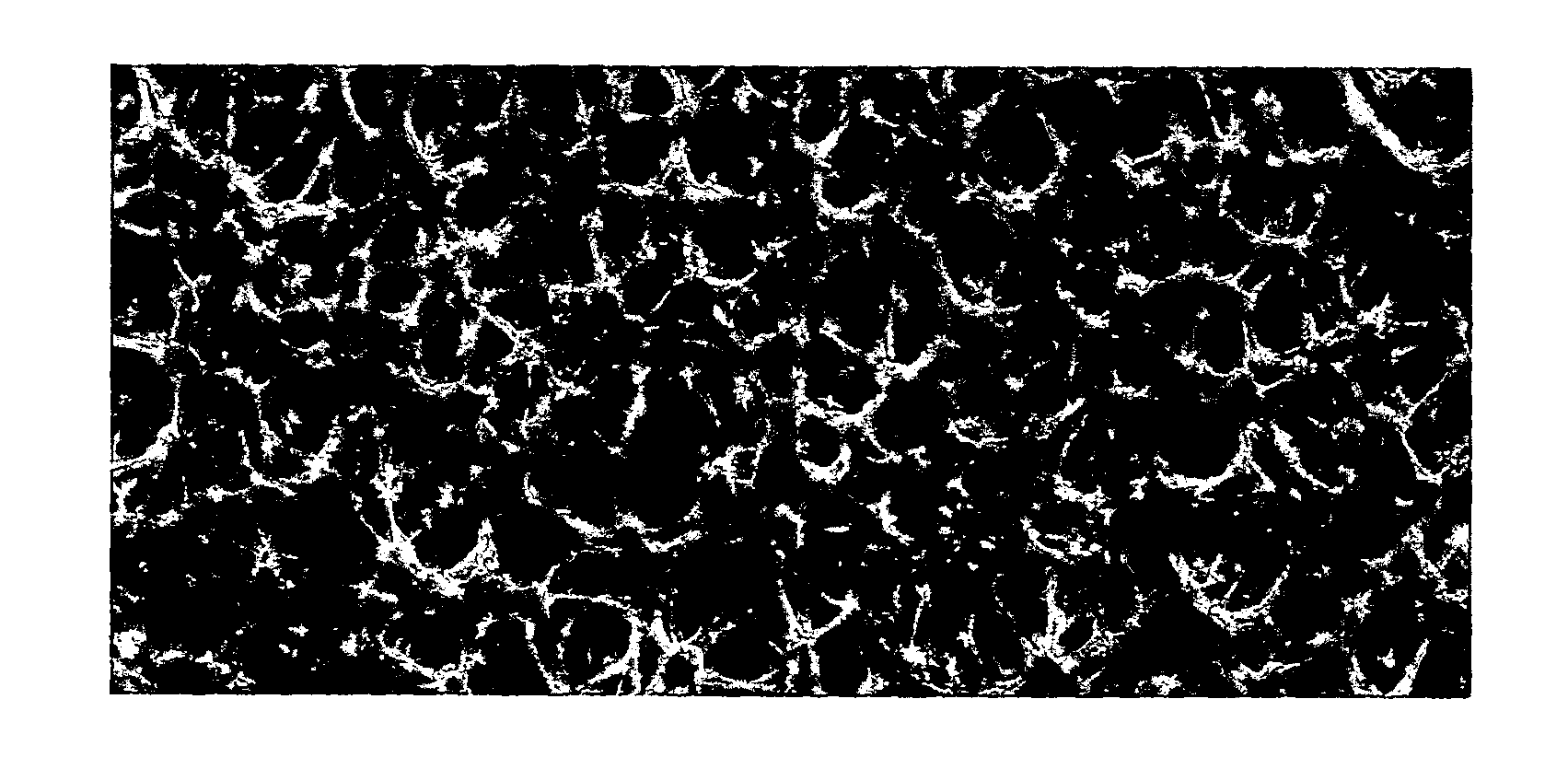

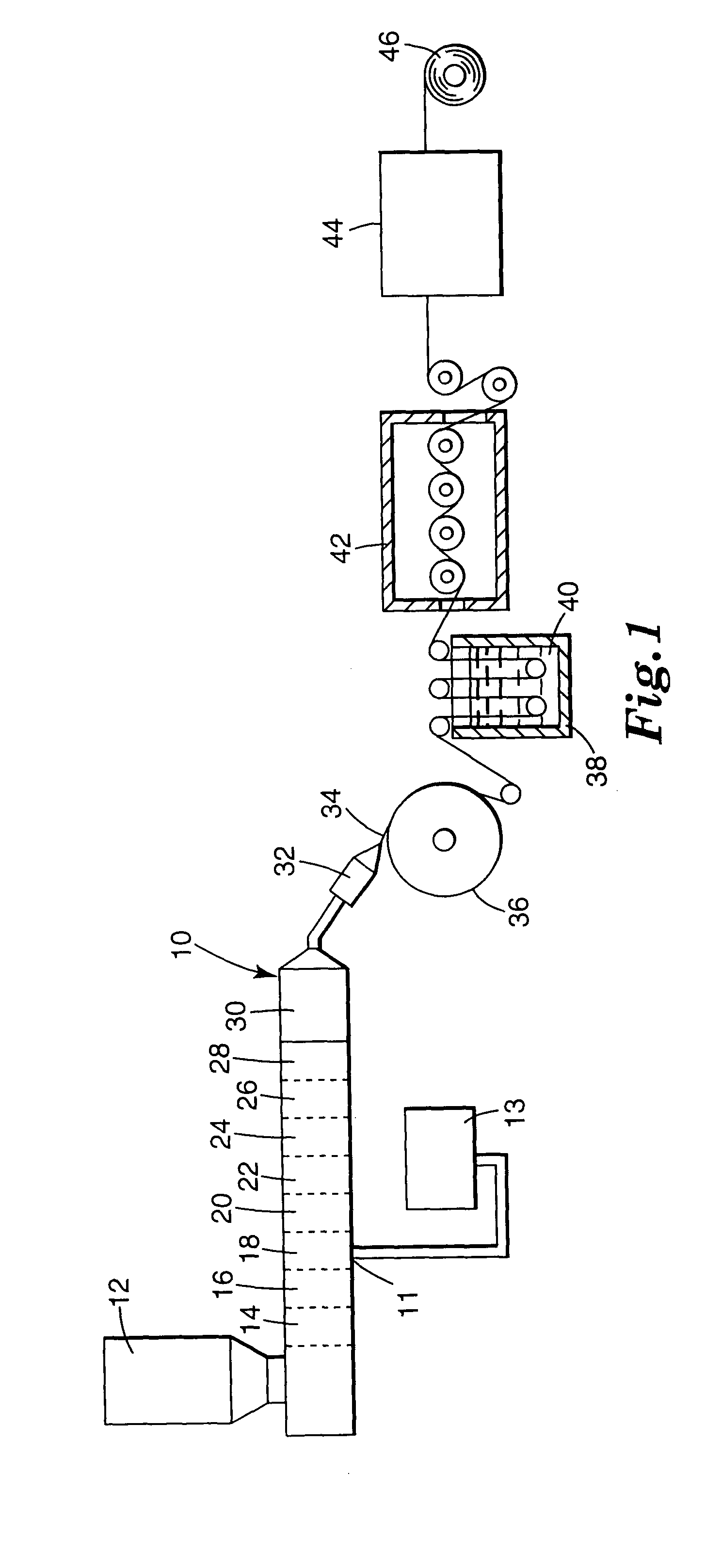

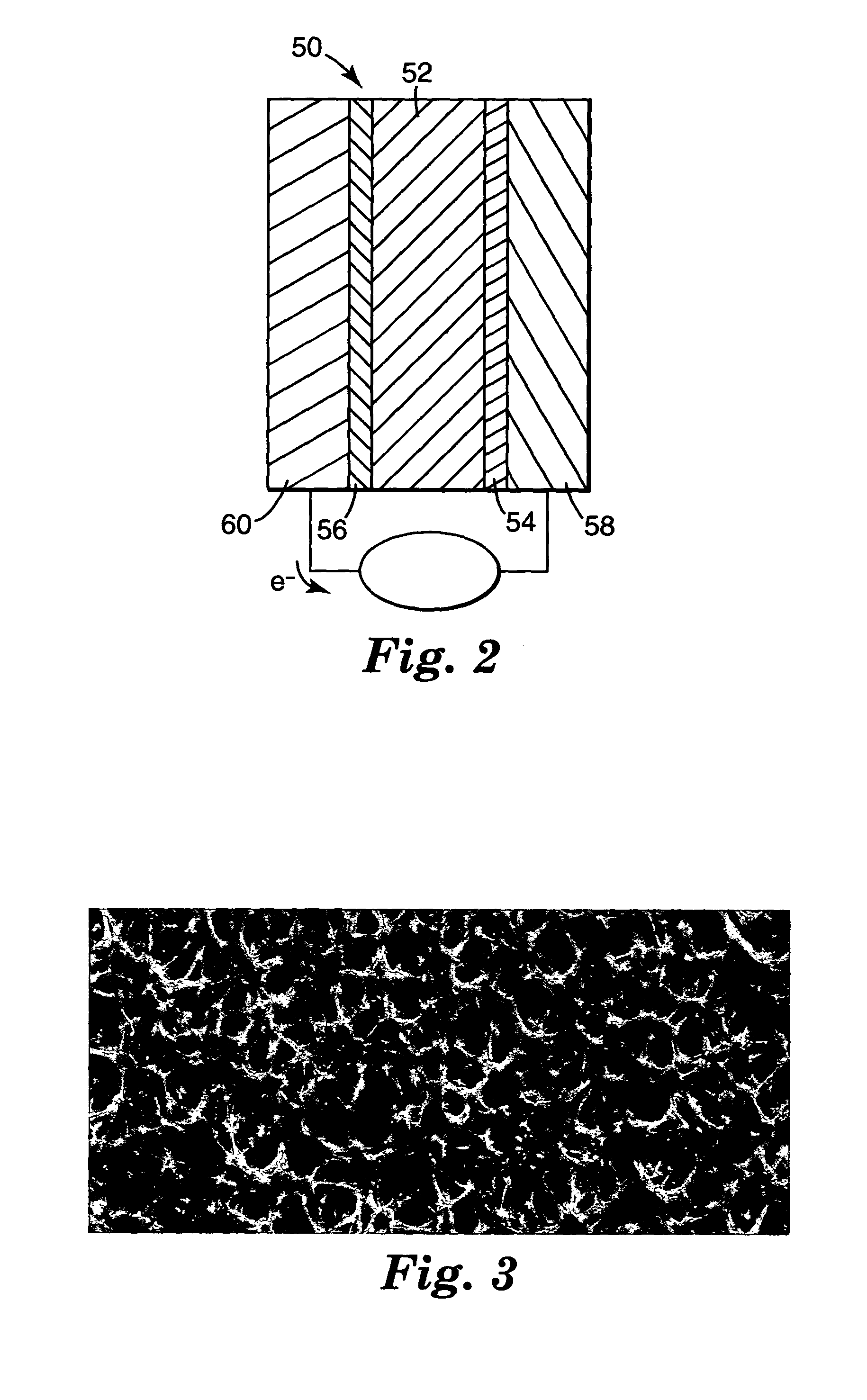

Shaped microporous articles are produced from polyvinylidene fluoride (PVDF) and nucleating agents using thermally induced phase separation (TIPS) processes. The shaped microporous article is oriented in at least one direction at a stretch ratio of at least approximately 1.1 to 1.0. The shaped article may also comprise a diluent, glyceryl triacetate. The shaped microporous article may also have the micropores filled with a sufficient quantity of ion conducting electrolyte to allow the membrane to function as an ion conductive membrane. The method of making a microporous article comprises the steps of melt blending polyvinylidene fluoride, nucleating agent and glyceryl triacetate; forming a shaped article of the mixture; cooling the shaped article to cause crystallization of the polyvinylidene fluoride and phase separation of the polyvinylidene fluoride and glyceryl triacetate; and stretching the shaped article in at least one direction at a stretch ratio of at least approximately 1.1 to 1.0.

Owner:3M INNOVATIVE PROPERTIES CO

Microporous PVDF films and method of manufacturing

Shaped microporous articles are produced from polyvinylidene fluoride (PVDF) and nucleating agents using thermally induced phase separation (TIPS) processes. The shaped microporous article is oriented in at least one direction at a stretch ratio of at least approximately 1.1 to 1.0. The shaped article may also comprise a diluent, glyceryl triacetate. The shaped microporous article may also have the micropores filled with a sufficient quantity of ion conducting electrolyte to allow the membrane to function as an ion conductive membrane. The method of making a microporous article comprises the steps of melt blending polyvinylidene fluoride, nucleating agent and glyceryl triacetate; forming a shaped article of the mixture; cooling the shaped article to cause crystallization of the polyvinylidene fluoride and phase separation of the polyvinylidene fluoride and glyceryl triacetate; and stretching the shaped article in at least one direction at a stretch ratio of at least approximately 1.1 to 1.0.

Owner:3M INNOVATIVE PROPERTIES CO

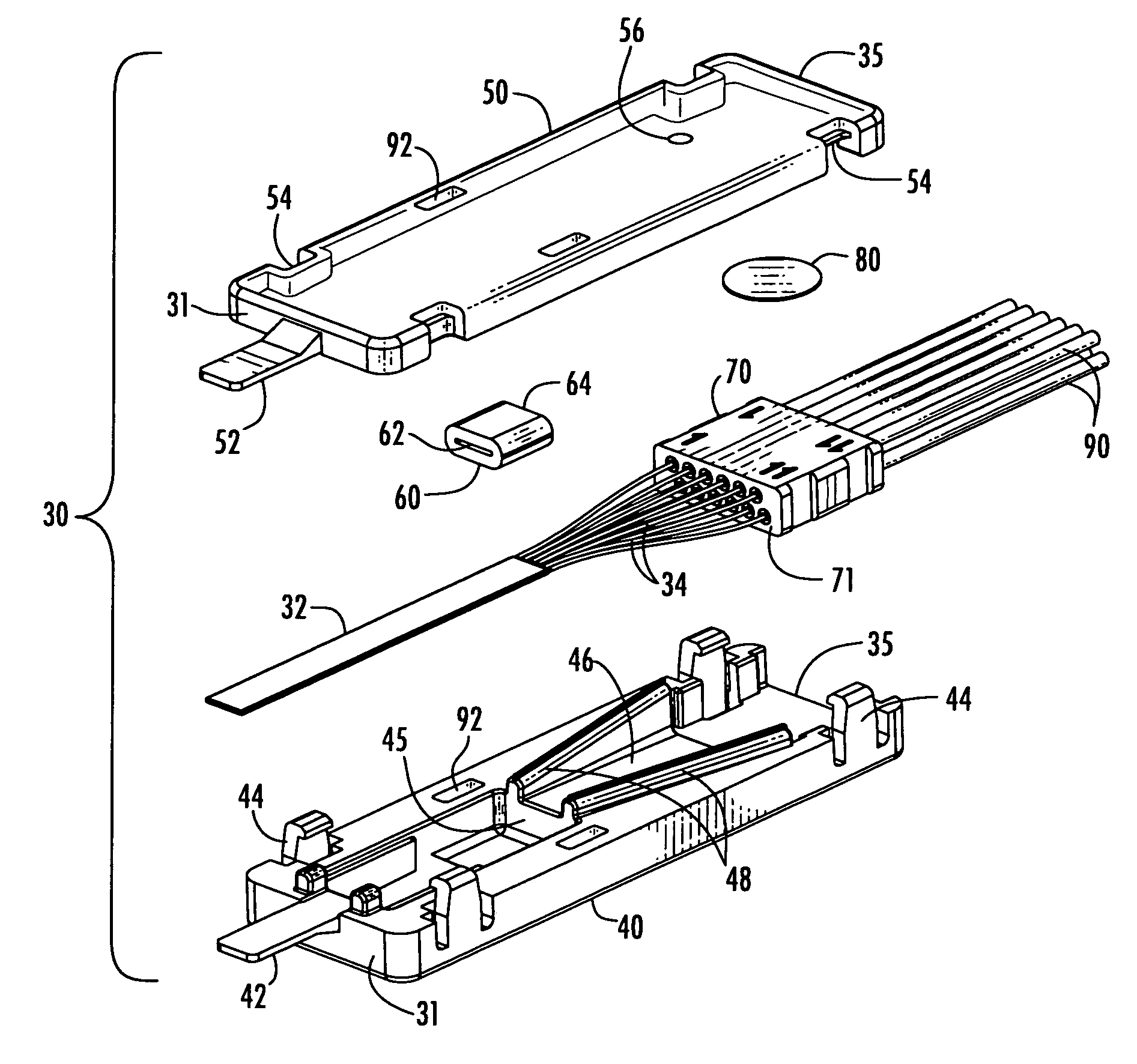

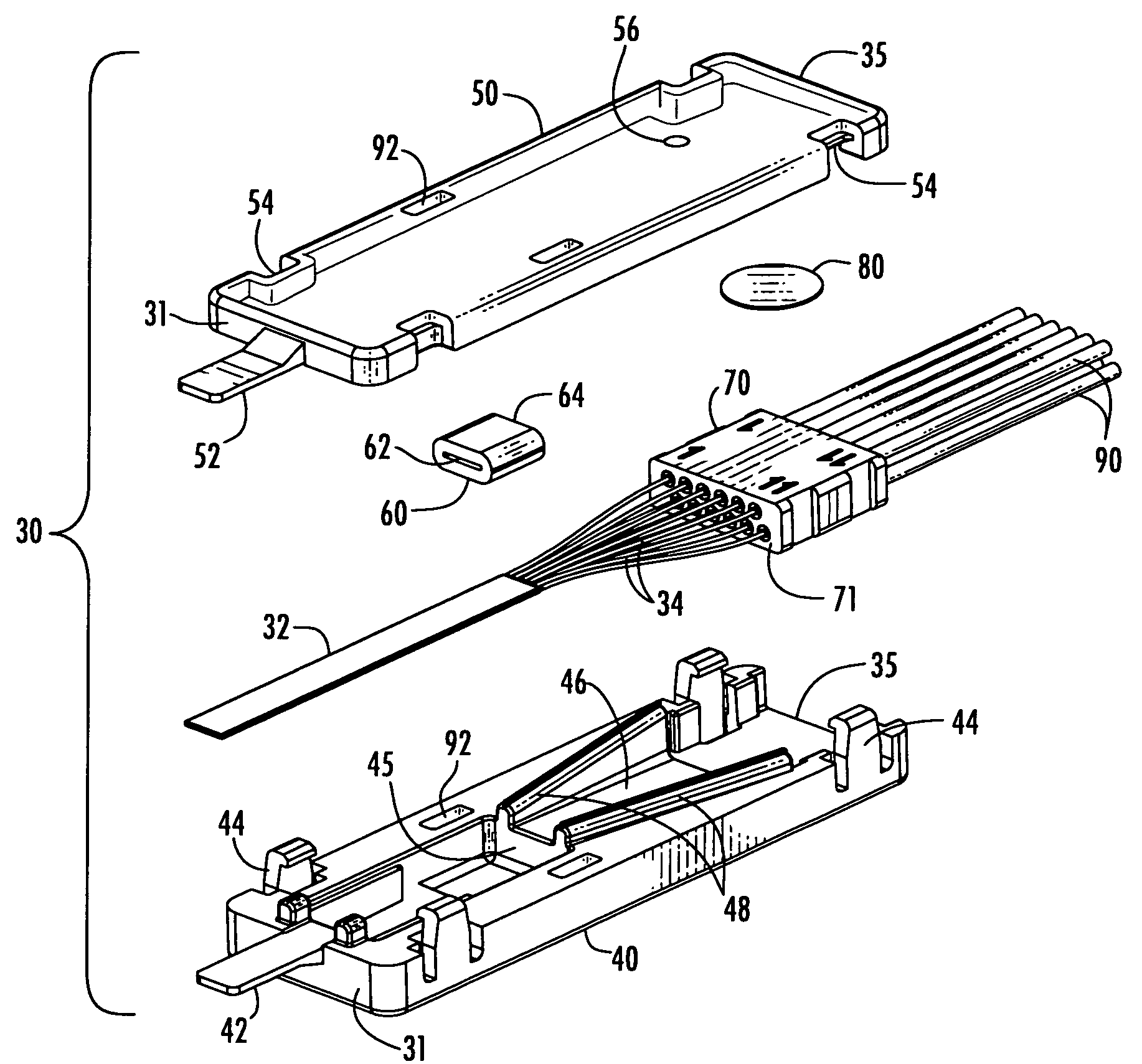

Furcation tubing and fanout furcation kit

ActiveUS20080138026A1Reduced longitudinal shrinkageIncreased tensile bond strengthCoupling light guidesOptical light guidesFiberUltrasound attenuation

Furcation tubing is made of glass-filled Teflon (PTFE) that provides reduced longitudinal shrinkage and increased tensile bond strength in the standard colors utilized for fiber identification. The furcation tubing experiences no more longitudinal shrinkage than furcation tubing made of polyvinylidene fluoride (PVDF) and has a tensile bond strength no less than furcation tubing made of clear, etched Teflon (PTFE). A fanout furcation kit prevents movement of the separated optical fibers in a funnel area of a lower furcation body. The funnel area is bathtub shaped with an increasing depth in the direction of an insert block having at least two rows of passageways in a staggered array. Guide walls defining the funnel area form a seal with an upper furcation body. Use of the furcation tubing and fanout furcation kit significantly reduces unacceptable attenuation and micro-damage to optical fibers deployed in an outdoor fiber optic network.

Owner:CORNING OPTICAL COMM LLC

Aqueous polyvinylidene fluoride composition

ActiveUS20100304270A1Dry fastUseful electrodeLiquid electrolytic capacitorsConductive materialInterconnectivityPolyvinylidene difluoride

The invention relates to an aqueous fluoropolymer, and preferably polyvinylidene fluoride (PVDF), composition for manufacturing electrodes for use in non-aqueous-type electrochemical devices, such as batteries and electric double layer capacitors. The composition contains aqueous PVDF binder, and one or more powdery electrode-forming materials. In one embodiment, the composition is free of fluorinated surfactant In another embodiment, one or more fugitive adhesion promoters are added. The electrode formed from the composition of the invention exhibits interconnectivity and irreversibility that is achieved from the use of aqueous PVDF binder.

Owner:ARKEMA INC

Furcation tubing and fanout furcation kit

ActiveUS7461981B2Reduced longitudinal shrinkageIncreased tensile bond strengthCoupling light guidesFiberUltrasound attenuation

Furcation tubing is made of glass-filled Teflon (PTFE) that provides reduced longitudinal shrinkage and increased tensile bond strength in the standard colors utilized for fiber identification. The furcation tubing experiences no more longitudinal shrinkage than furcation tubing made of polyvinylidene fluoride (PVDF) and has a tensile bond strength no less than furcation tubing made of clear, etched Teflon (PTFE). A fanout furcation kit prevents movement of the separated optical fibers in a funnel area of a lower furcation body. The funnel area is bathtub shaped with an increasing depth in the direction of an insert block having at least two rows of passageways in a staggered array. Guide walls defining the funnel area form a seal with an upper furcation body. Use of the furcation tubing and fanout furcation kit significantly reduces unacceptable attenuation and micro-damage to optical fibers deployed in an outdoor fiber optic network.

Owner:CORNING OPTICAL COMM LLC

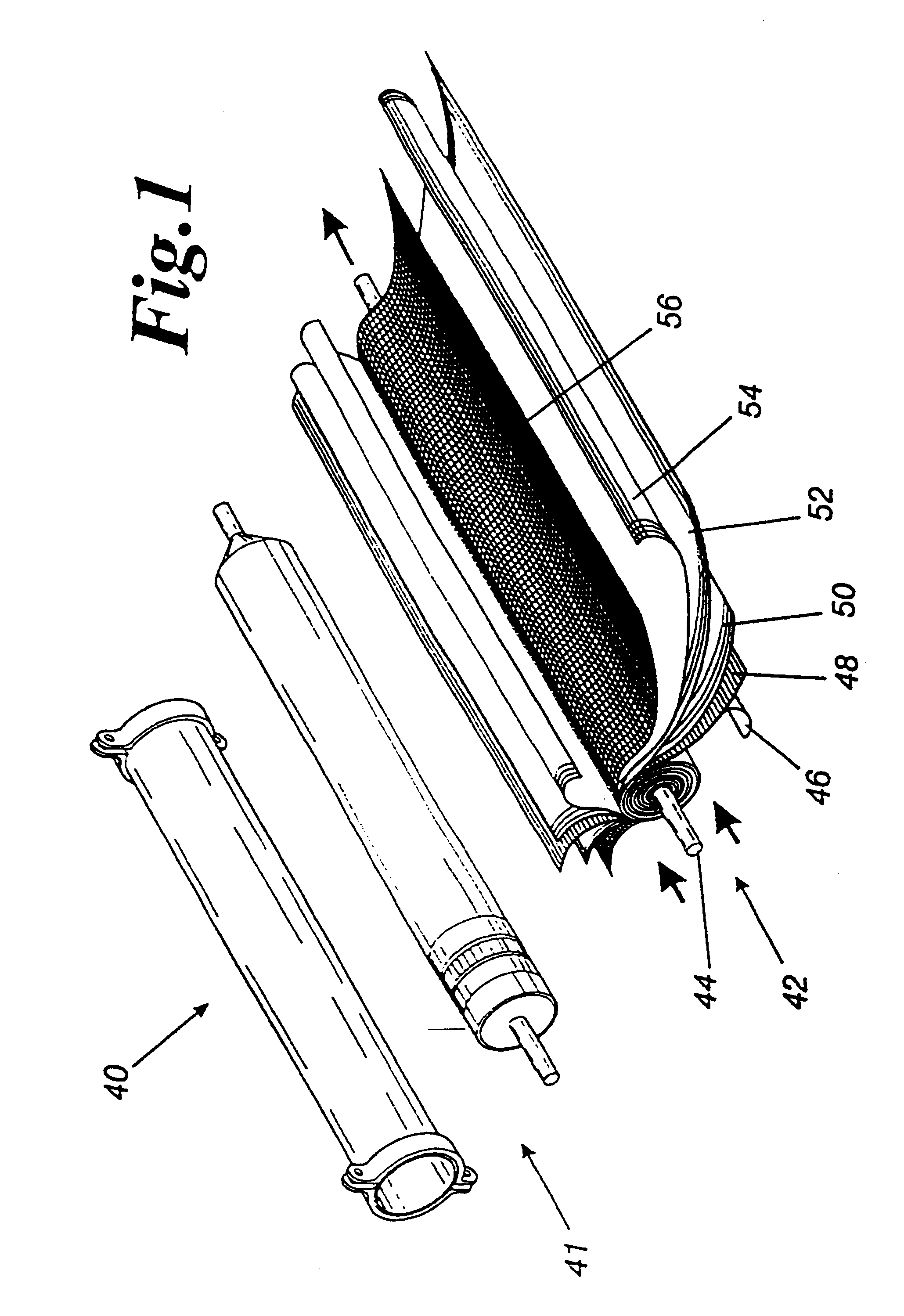

Method of fabricating a lithium ion secondary battery

To provide a process for producing a lithium ion secondary battery which can have any arbitrary shape, such as thin shape, and yet exhibits high performance. In a method of fabricating a battery comprising a positive electrode 1, a negative electrode 4, and a separator 7, a binder resin solution mainly comprising polyvinylidene fluoride is applied to the separator 7, and the positive electrode 1 and the negative electrode 4 are laid thereon, followed by drying to form a battery laminate, which is then impregnated with an electrolytic solution.

Owner:MITSUBISHI ELECTRIC CORP

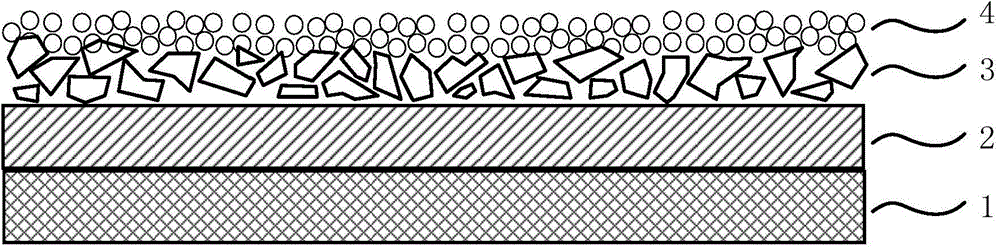

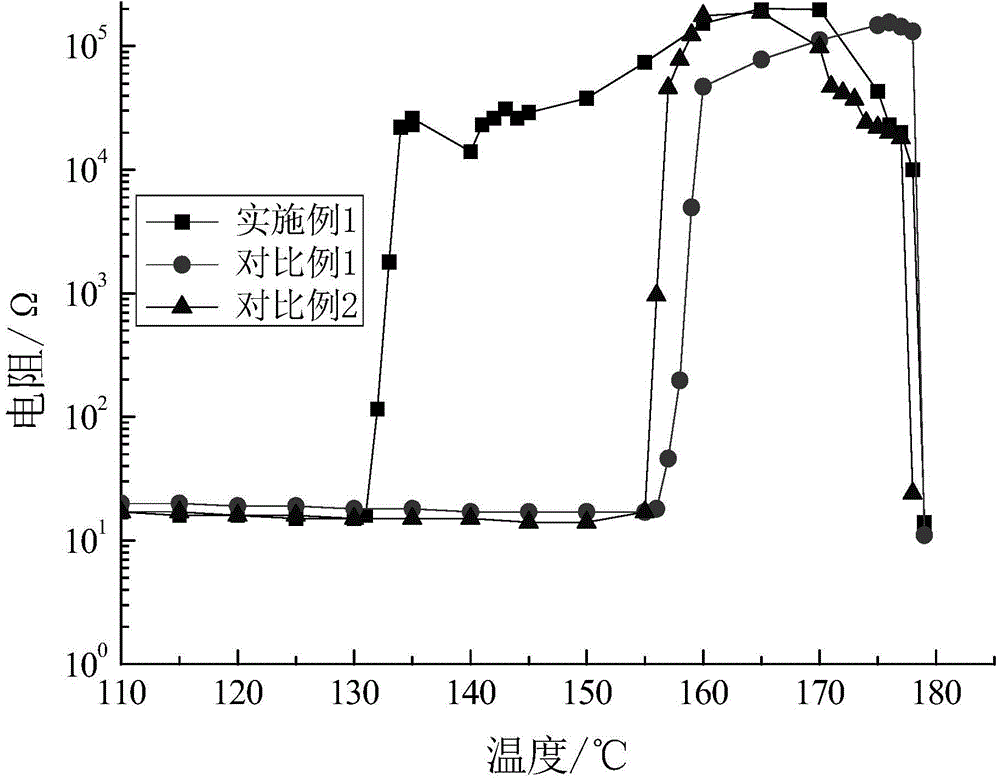

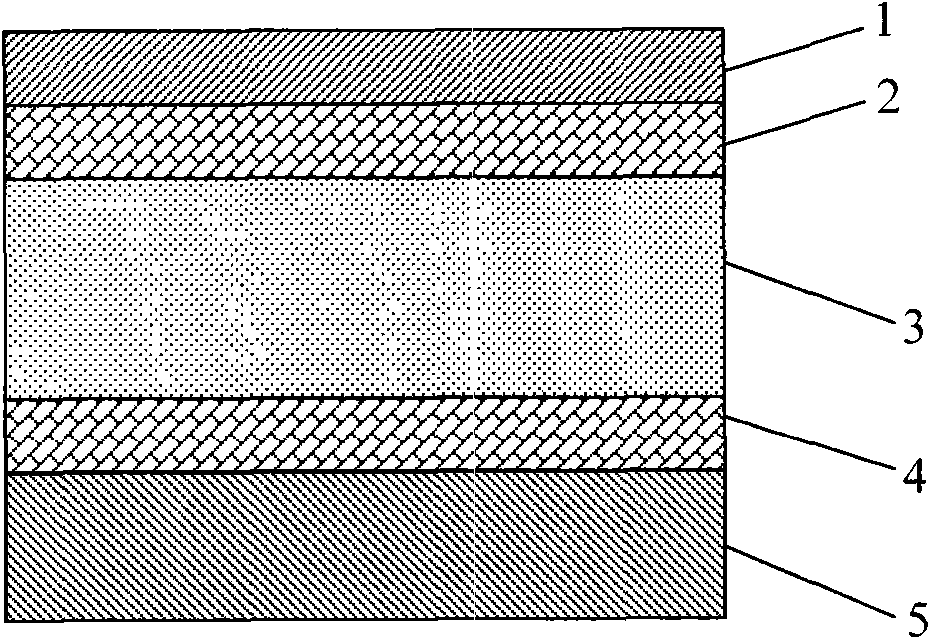

Ceramic-gel polymer multilayer composite lithium battery diaphragm and preparation method thereof

InactiveCN104157819AImprove thermal safetyImprove wettabilitySecondary cellsCell component detailsCompound aSlurry

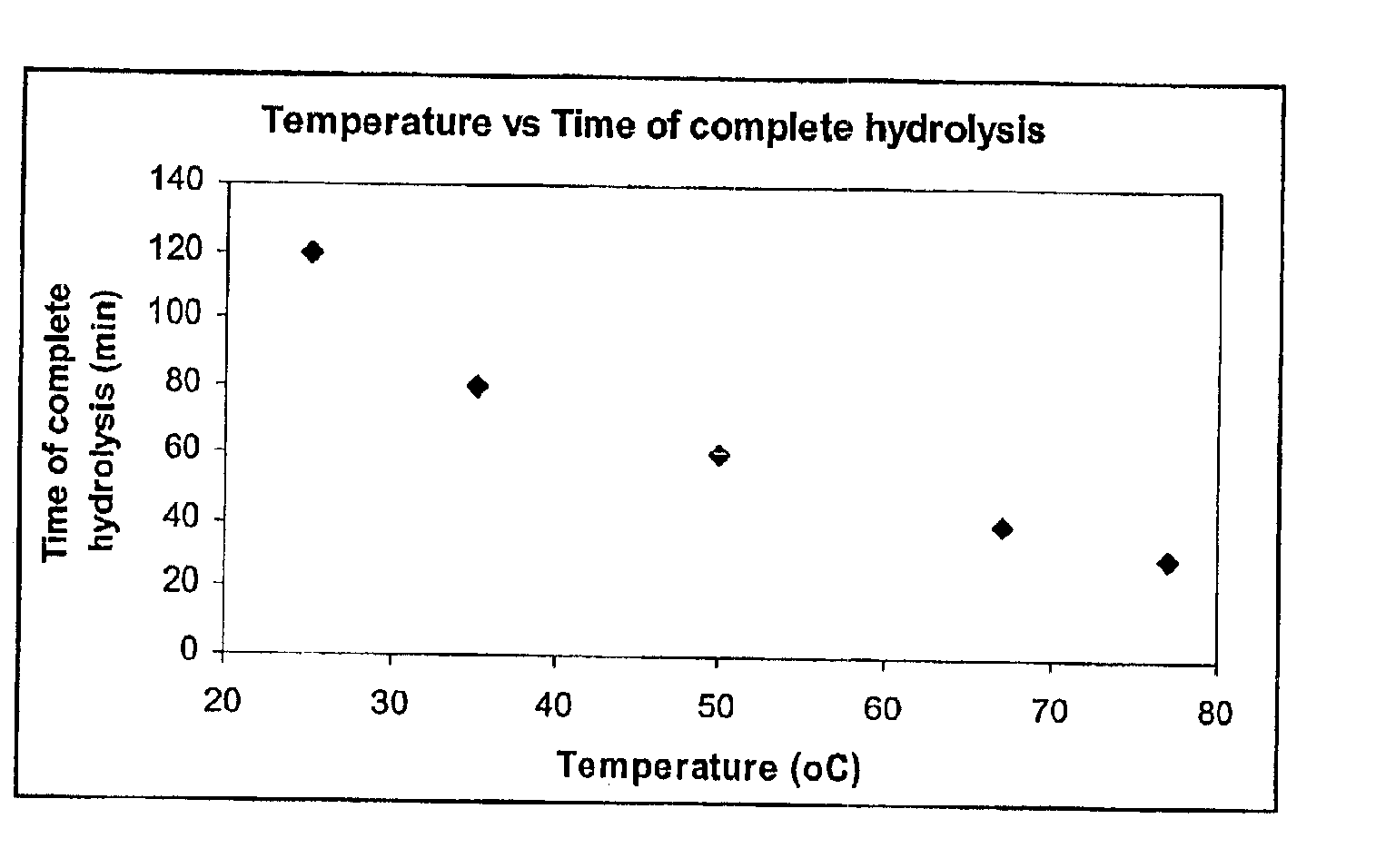

The invention discloses a preparation method of a ceramic-gel polymer multilayer composite lithium battery diaphragm. The preparation method comprises the following steps: 1, preparing aqueous PVDF (polyvinylidene fluoride) slurry and aqueous ceramic slurry; 2, thermally compounding a polypropylene diaphragm and a polyethylene diaphragm at 50-100 DEG C to obtain PP / PE (polypropylene / polyethylene) composite diaphragm; 3, with the PP / PE composite diaphragm obtained in the step 2 as a coating substrate, coating the aqueous slurry prepared in the step 1 onto the PE surface of the substrate: coating the aqueous ceramic slurry to form a ceramic layer first and then coating the aqueous PVDF slurry to form a gel polymer layer, with the coating speed of 5-100m / min, and drying in a drying box with the temperature of 30-100 DEG C to obtain a final four-layer composite diaphragm. The invention further discloses a ceramic-gel polymer multilayer composite lithium battery diaphragm prepared by the preparation method. The prepared ceramic-gel polymer multilayer composite lithium battery diaphragm has the advantages of high thermal safety and high capability of keeping electrolyte.

Owner:SHENZHEN SENIOR TECH MATERIAL

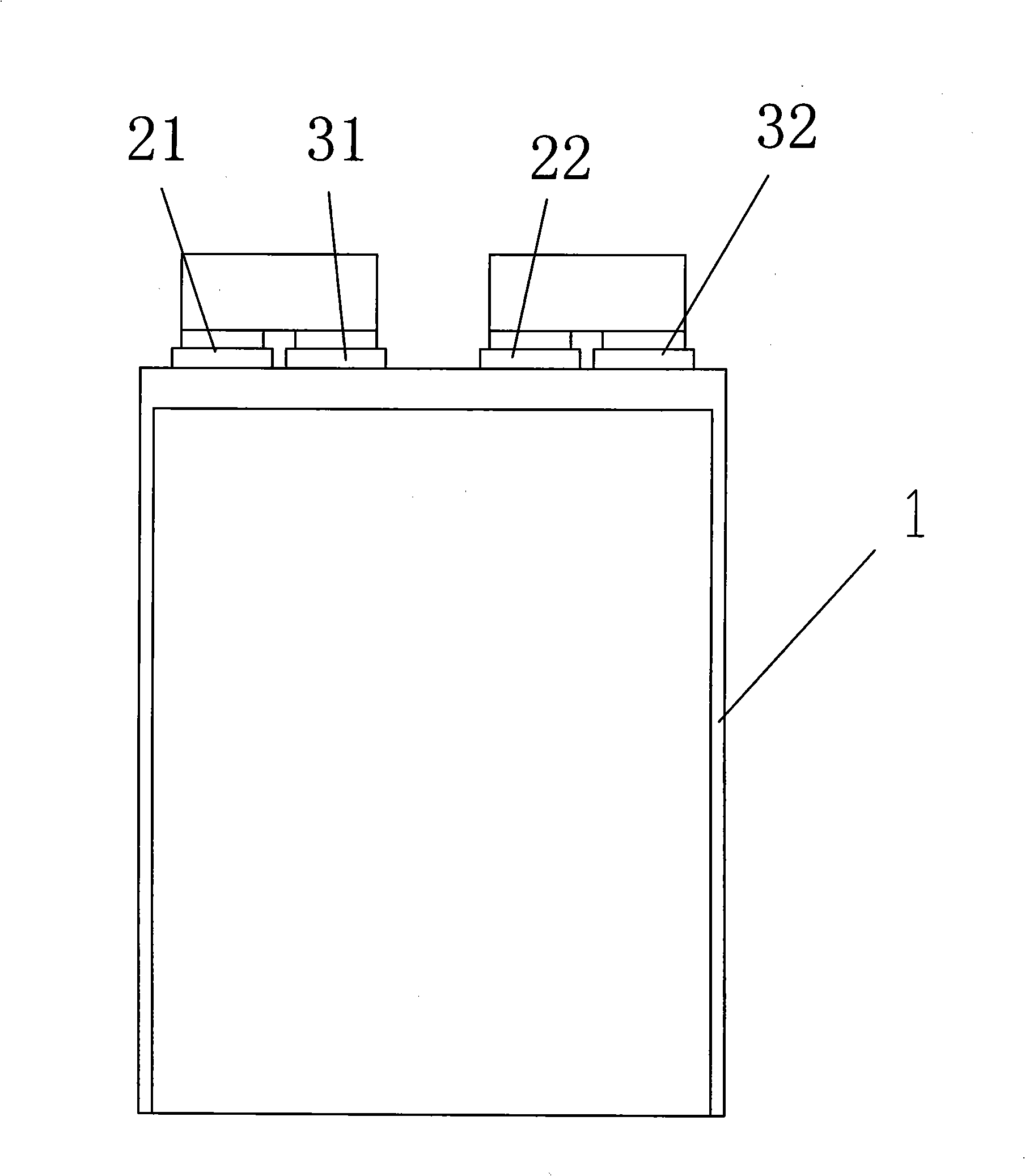

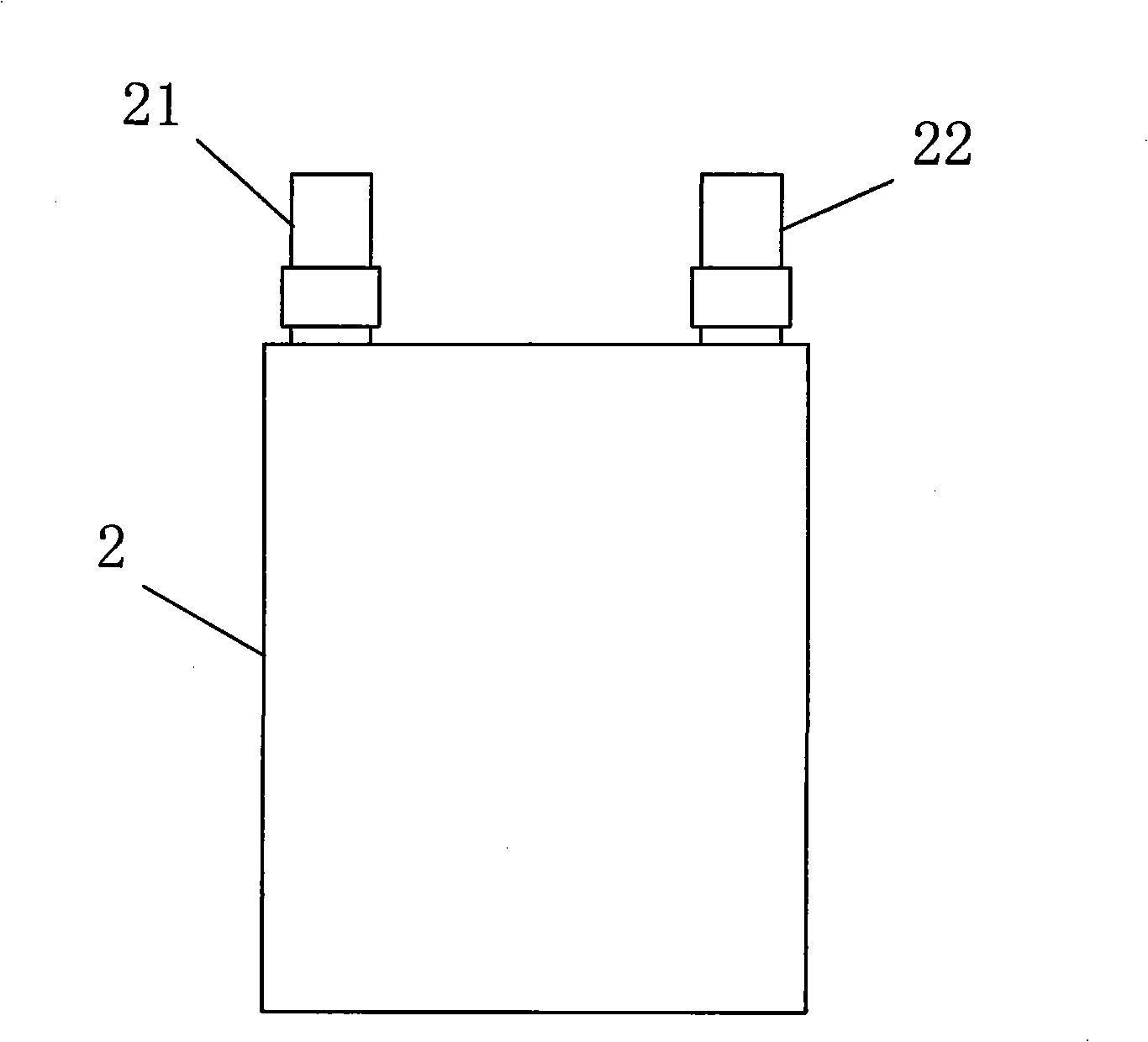

Large-capacity high power polymer ferric lithium phosphate power cell and preparation method thereof

InactiveCN101409369AImprove securityIncrease capacityElectrode manufacturing processesFinal product manufactureSlurryElectric vehicle

The invention discloses a large-capacity high-power polymer lithium iron phosphate power battery. The weight ratio of anode slurry is as follows: 81 to 85 percent of lithium iron phosphate, 1 to 5.5 percent of superconduction carbon, 0 to 2.5 percent of conductive carbon soot, 0 to 4 percent of conductive black lead, 0 to 2.5 percent of crystalline flake graphite, 0 to 2 percent of carbon nanometer tube as well as 6 to 7.5 percent of polyvinylidene fluoride; the weight ratio of cathode slurry is as follows: 89 to 91 percent of cathode material, 1 to 3.5 percent of superconduction carbon, 0 to 2 percent of conductive carbon soot, 0 to 4 percent of conductive black lead, 2.5 to 3.5 percent of styrene-butadiene rubber as well as 1.5 to 2 percent of sodium carboxymethyl cellulose; the steps for preparing the battery are as follows: preparing slurry, coating the anode and the cathode, rolling and pressing a polar plate, transversely and separately cutting the polar plate, baking the polar plate, welding the polar ears of the anode and the cathode, preparing a battery cell, putting the electric core into a shell and sealing, baking the electric core, injecting liquid into the battery as well as forming the battery and dividing the volume of the battery. The invention relates to a lithium-ion secondary battery which can provide drive energies for electric tools, electric bicycles, motor cars and electric vehicles.

Owner:MCNAIR TECH

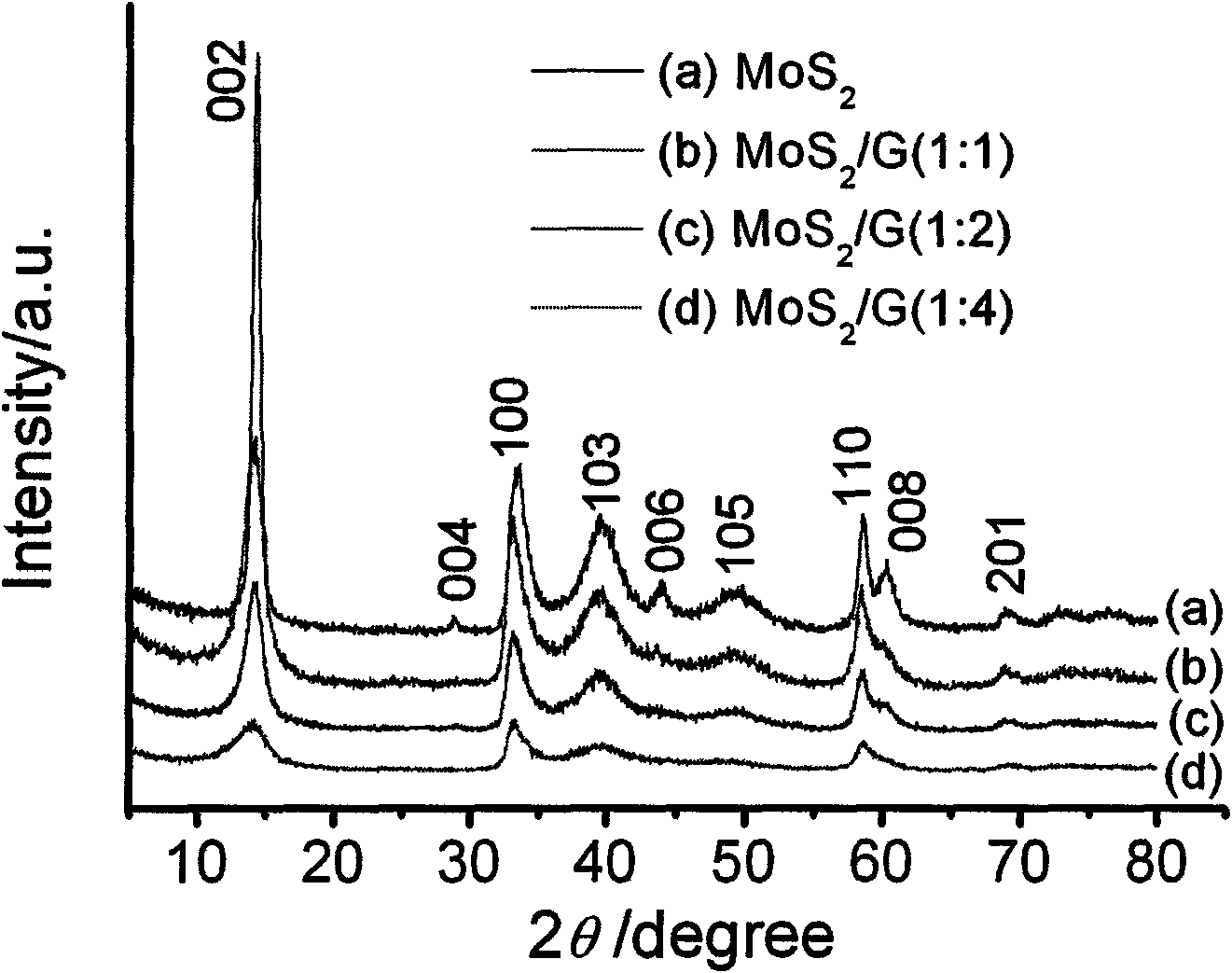

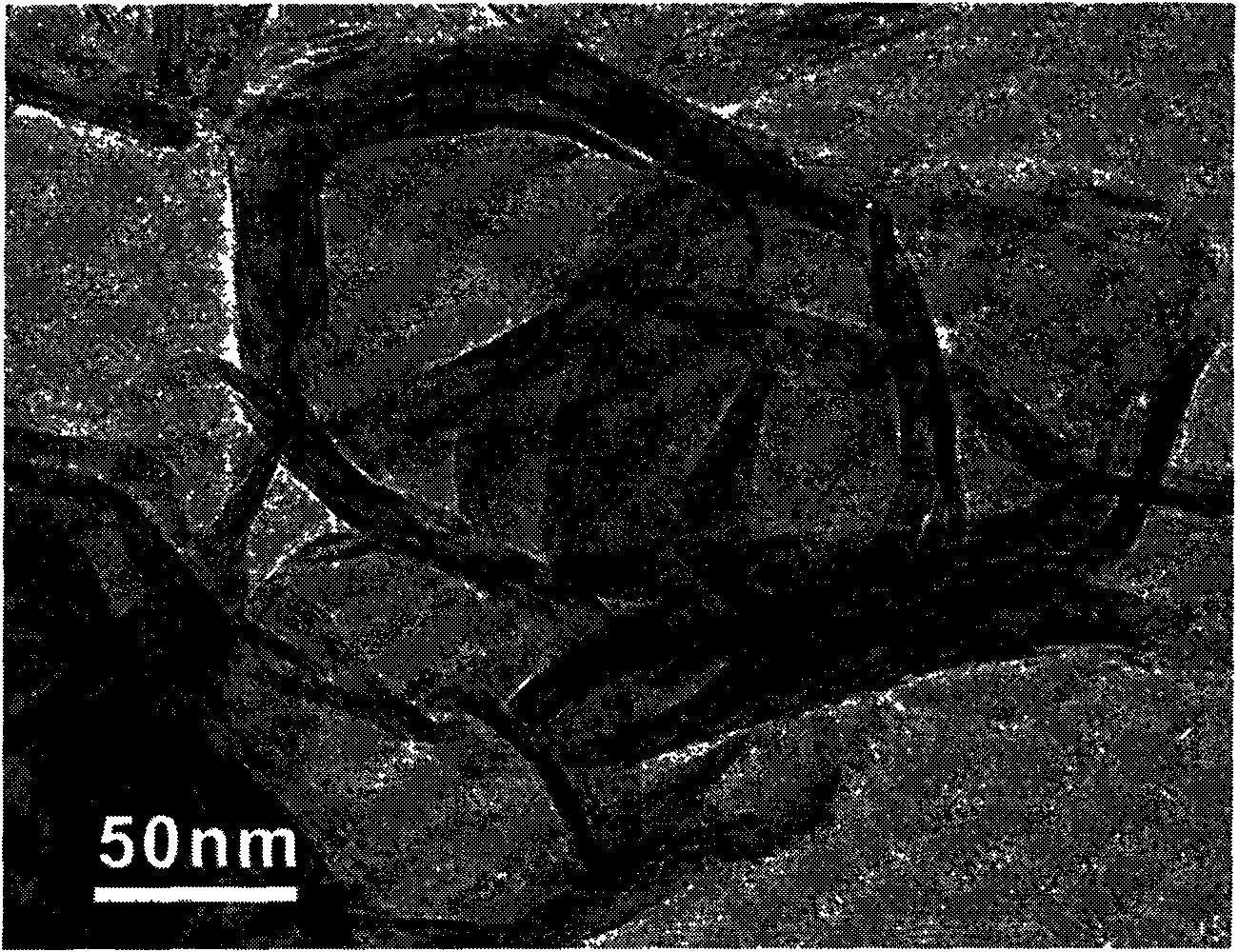

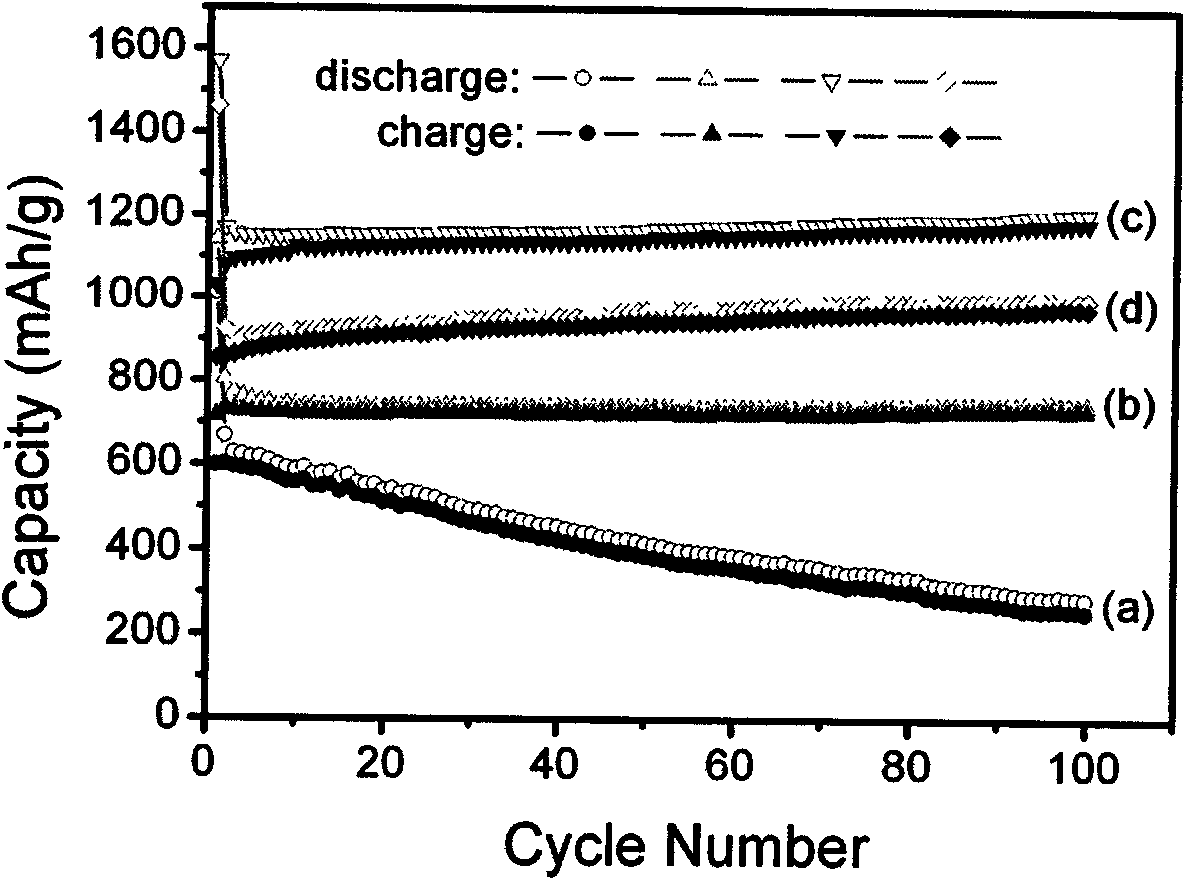

Graphene/MoS2 compound nano material lithium ion battery electrode and preparation method thereof

InactiveCN102142537ALarge specific surface areaImprove mechanical propertiesNon-aqueous electrolyte accumulator electrodesLithium-ion batteryMaterials science

The invention discloses a graphene / molybdenum disulfide (MoS2) compound nano material lithium ion battery electrode and a preparation method thereof. The electrode comprises the following components in percentage by mass: 75 to 85 percent of compound nano material serving as an active substance, of a graphene nano slice and MoS2, and 5 to 10 percent of acetylene black and 10 percent of polyvinylidene fluoride; and the mass ratio of the graphene nano slice to the MoS2 nano material in the compound nano material active substance is (1 to 1)-(4 to 1). The preparation method of the electrode comprises the following steps of: preparing an oxidized graphite nano slice by using graphite as a raw material by a chemical oxidization method; synthesizing by a one-step hydrothermal in-situ reduction method in the presence of the oxidized graphite nano slice to obtain a graphene nano slice / MoS2 compound nano material; and finally, preparing the electrode by using the graphene nano slice / MoS2 compound nano material as the active substance. The electrode has high electrochemical lithium storage reversible capacity and cyclic stabilization performance, and can be widely applied to new generation lithium ion batteries.

Owner:ZHEJIANG UNIV

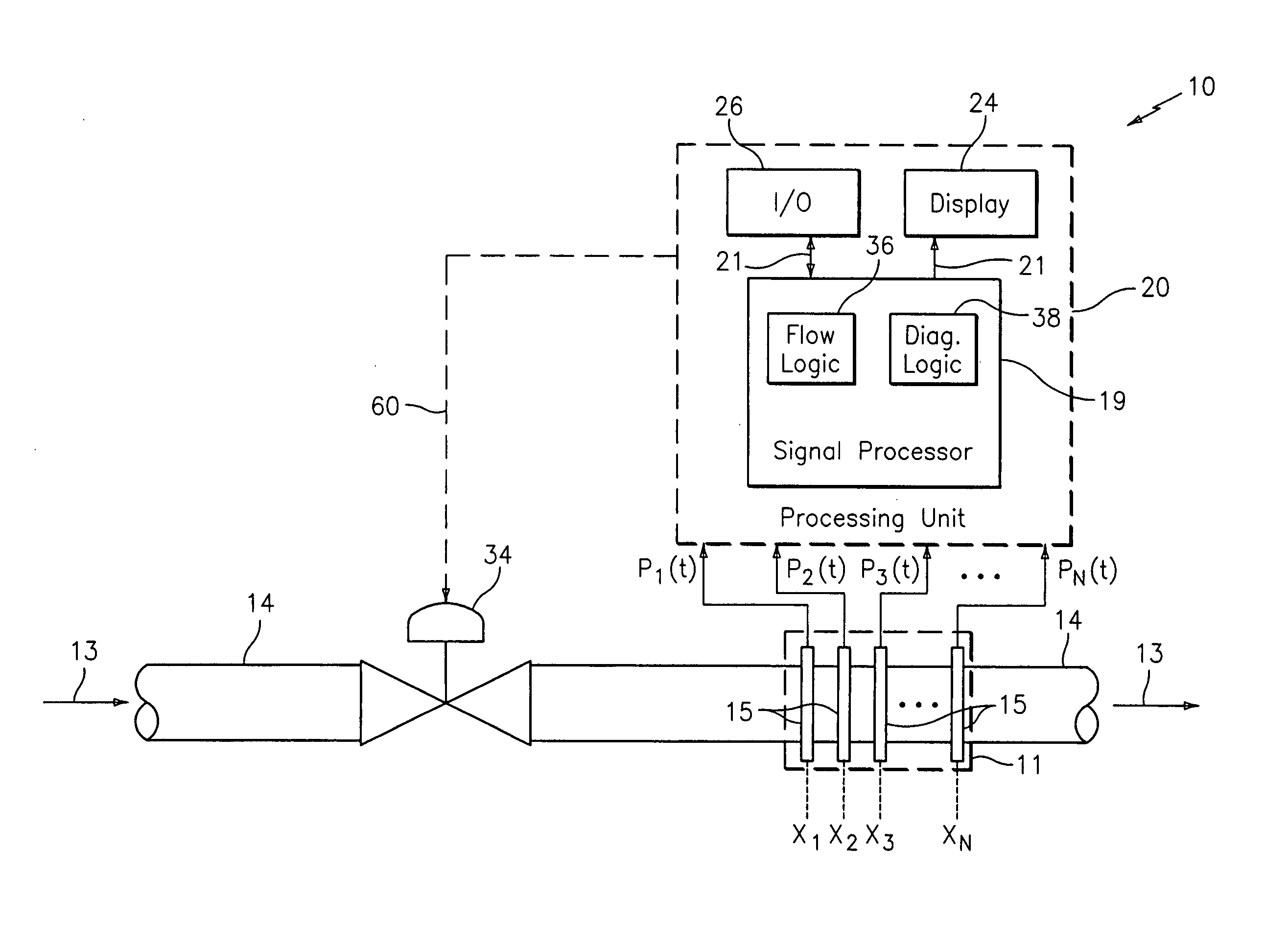

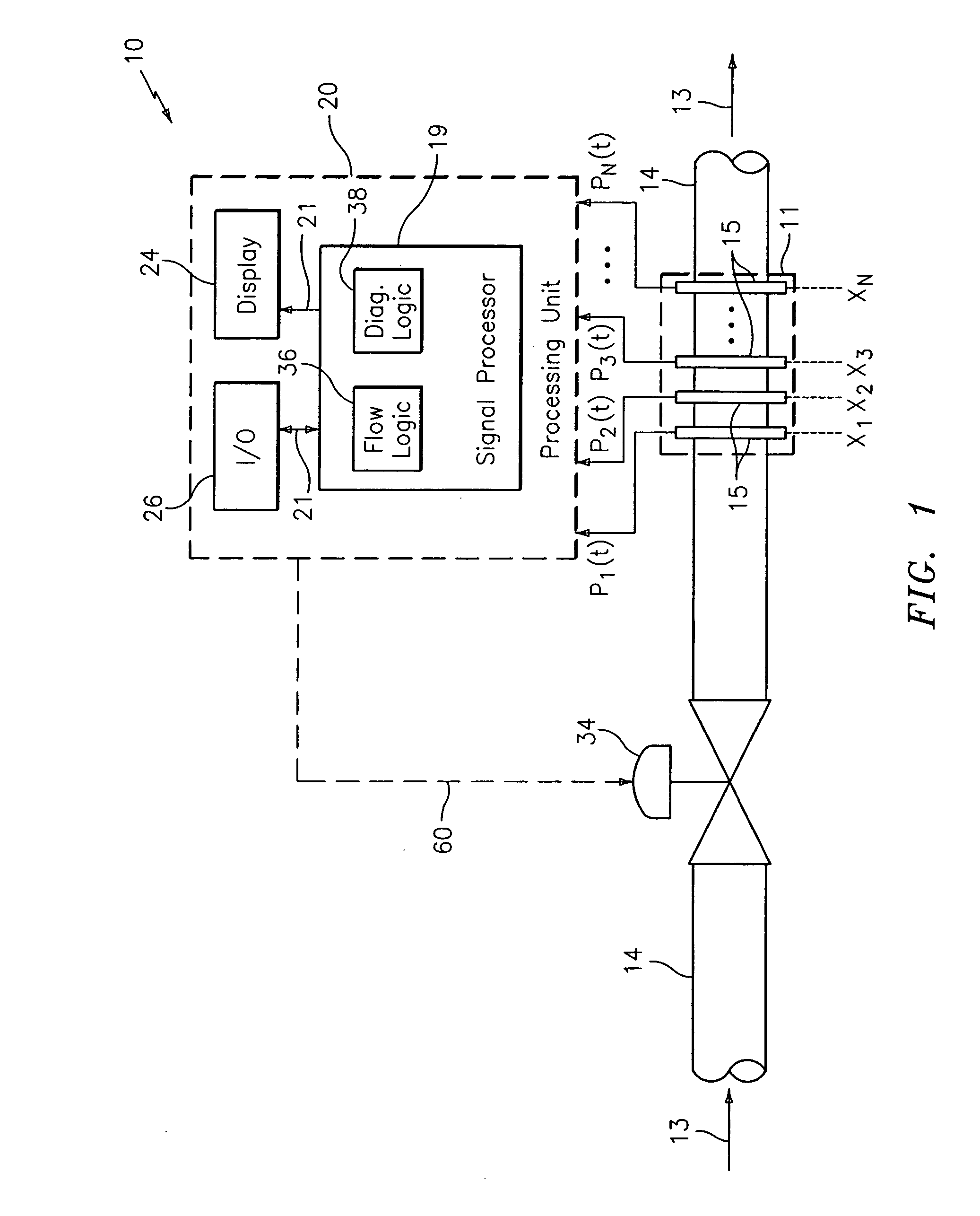

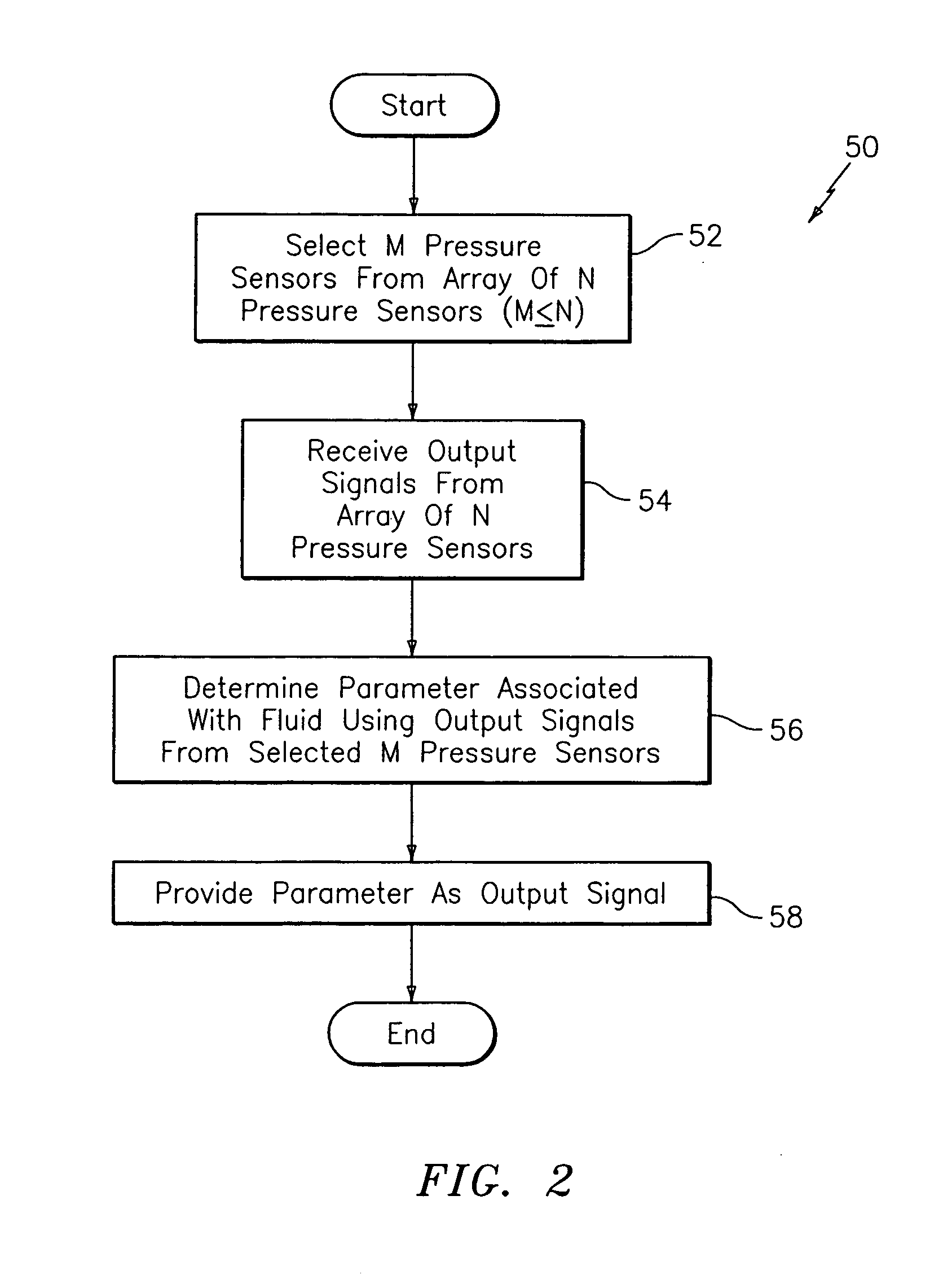

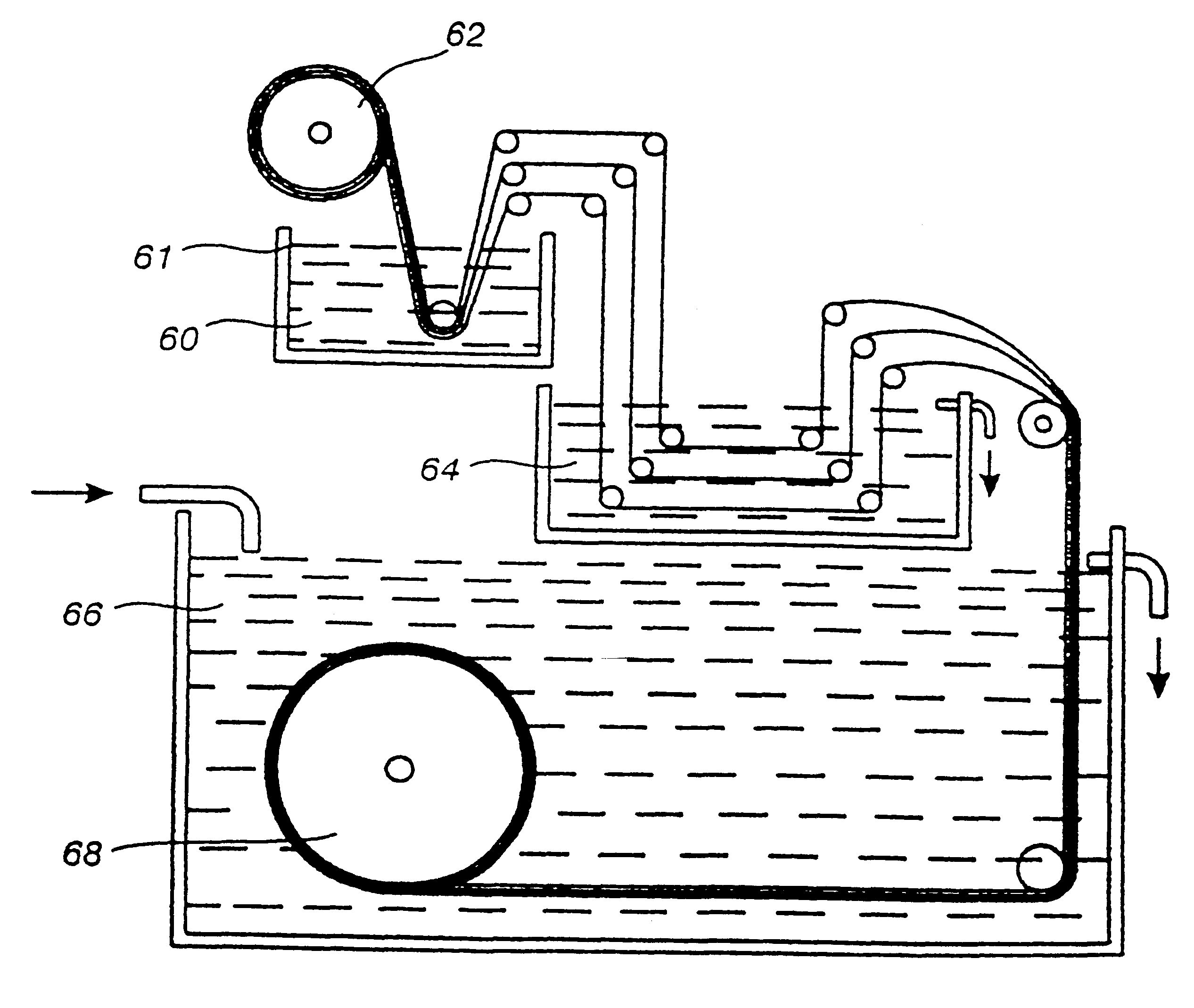

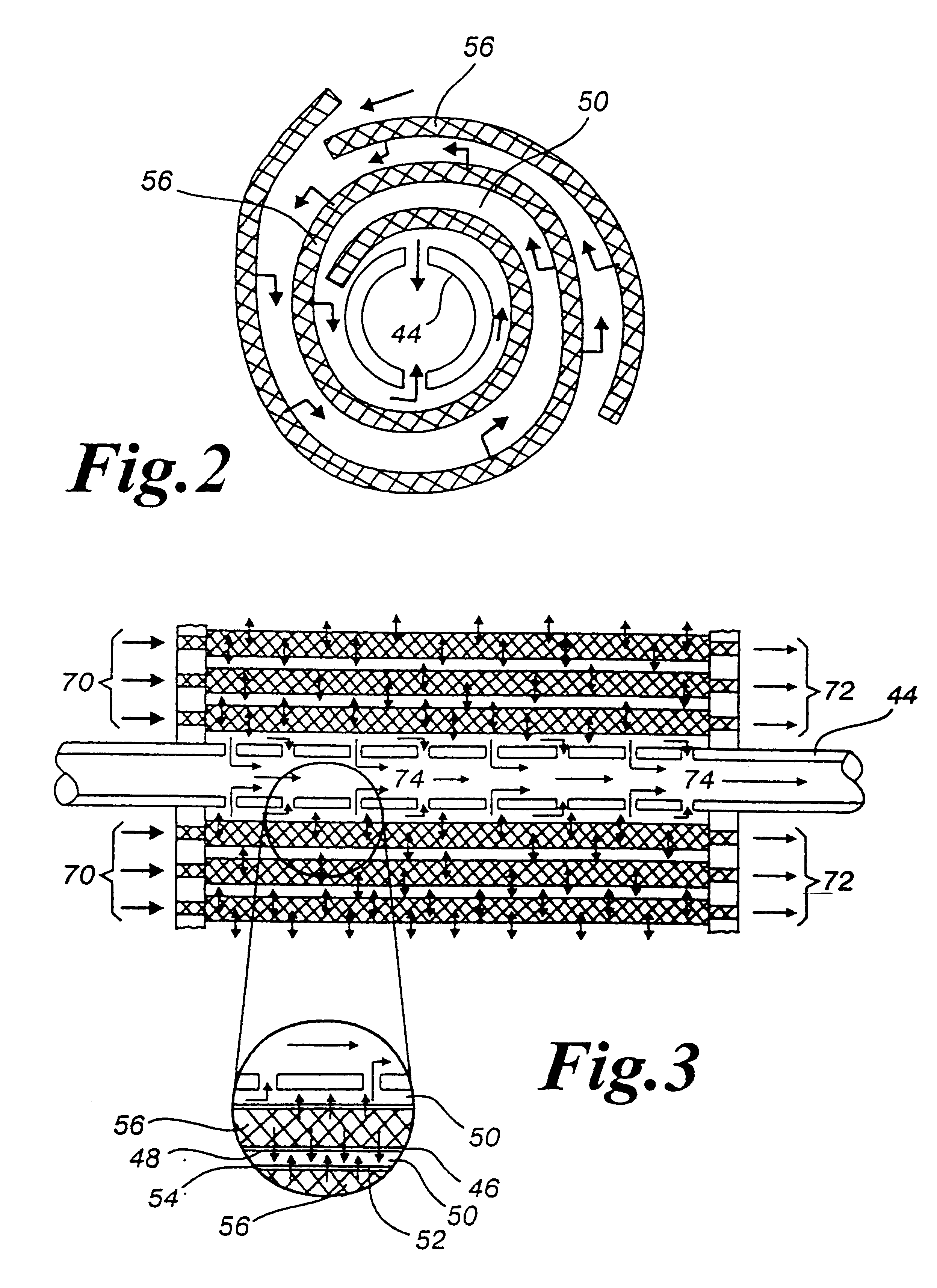

Method and apparatus for measuring parameters of a fluid flowing within a pipe using a configurable array of sensors

ActiveUS20050039520A1Detection of fluid at leakage pointMaterial analysis using sonic/ultrasonic/infrasonic wavesSensor arrayEngineering

An apparatus for measuring at least one parameter associated with a fluid flowing within a pipe includes a spatial array of pressure sensors disposed at different axial locations x1. . . xN along the pipe. Each of the pressure sensors provides a pressure signal P(t) indicative of unsteady pressure within the pipe at a corresponding axial location of the pipe. A signal processor receives the pressure signals from each of the pressure sensors and determines the parameter of the fluid using pressure signals from selected ones of the pressure sensors. By selecting different pressure sensors, the signal processor can configure the array to meet different criteria. In one embodiment, the array of pressure sensors may be formed on a single sheet of polyvinylidene fluoride (PVDF) that is wrapped around at least a portion of an outer surface of the pipe. This arrangement allows a large number of pressure sensors to be quickly and economically installed.

Owner:EXPRO METERS

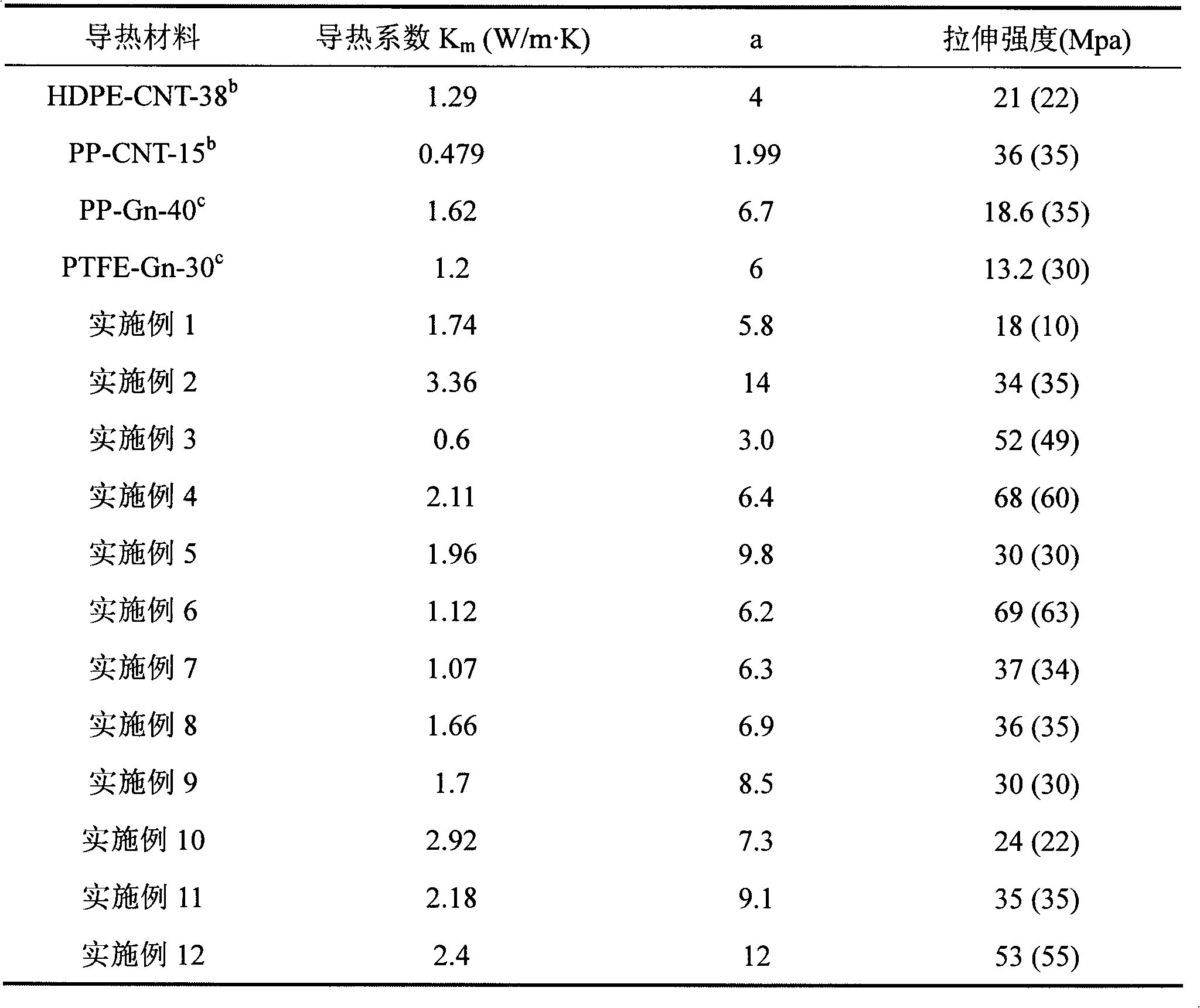

High-heat-conductivity composite material and preparation method thereof

InactiveCN102040761AImprove thermal conductivitySmall amount of thermally conductive fillerFiberCarbon fibers

The invention discloses a high-heat-conductivity composite material and a preparation method thereof. The preparation method comprises the following steps: evenly mixing fibrous heat-conduction filler and high-heat-conductivity filler graphene in a mass ratio of 1:1-1:200 with thermoplastic polymer, dispersing for 0.5-24 hours, granulating to obtain high-heat-conductivity composite grains, and putting the grains in a die to carry out hot molding at 170-280 DEG C under the pressure of 10-18 MPa. The thermoplastic polymer is any one of polyethylene, polypropylene, polyvinylidene fluoride, polytetrafluoroethylene, polyperfluoroalkoxy ester, nylon, polymethyl methacrylate, polycarbonate and polyvinyl chloride. The fibrous heat-conduction filler is carbon fiber or carbon nanotube, and the high-heat-conductivity filler accounts for 5-35 wt% of the high-heat-conductivity composite material. The high-heat-conductivity composite material has the advantages of excellent heat-conduction property, low consumption of heat-conduction filler, favorable mechanical properties, simple preparation technique and low cost.

Owner:SOUTH CHINA UNIV OF TECH

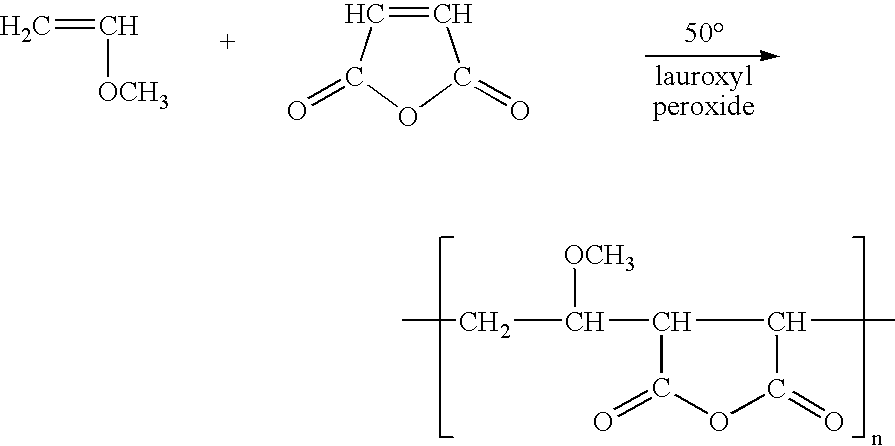

Modified membranes

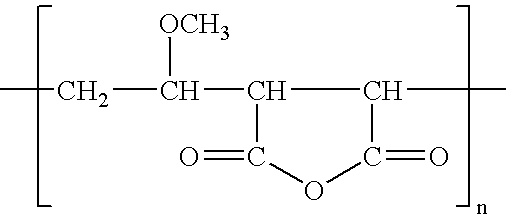

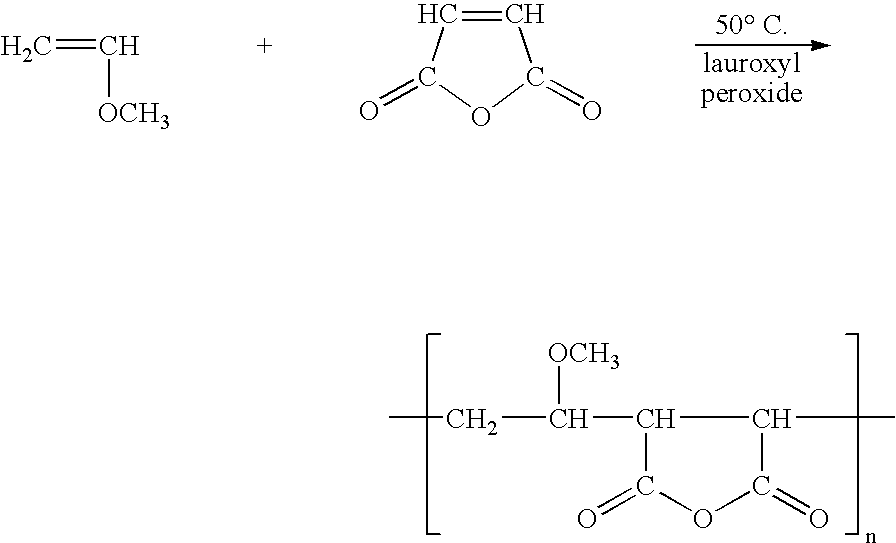

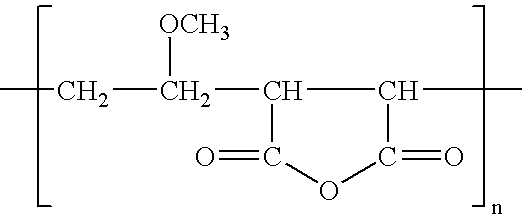

InactiveUS20050029186A1Reduce dirtEssential mechanical properties of the membranesSemi-permeable membranesMembranesVinyl etherReverse osmosis

A porous polymeric membrane formed from a blend of a polymeric membrane forming material, such as polyvinylidene fluoride or polysulfone and a polymeric reactivity modifying agent adapted to modify the surface active properties of the porous polymeric membrane. The reactivity modifying agent is preferably a linear polymeric anhydride, such as poly(alkyl vinyl ether / maleic anhydride). The surface activity modifications include modification of the hydrophilicity / hydrophobicity balance of the membrane, or hydrolysis followed by reaction with a polyamine to form a crosslinked polyamide layer. Such modified membranes have use as reverse osmosis membranes.

Owner:EVOQUA WATER TECH LLC

Filtering Apparatus and Method of Use

A filtering apparatus comprises a microporous membrane and an actuator. The membrane is positioned to traverse across the hollow interior of a conduit used for the transport of molecules in bulk. In one example, the pores of the membrane comprise a plurality of open-ended carbon nanotubes. The actuator comprises a transducing material such as a polyvinyledene fluoride film that is operatively positioned in contact with the membrane and is capable of propagating acoustic vibration onto the membrane at a particular frequency so as to hasten the movement of the molecules through the membrane. Similarly, a method of filtering water comprises the steps of: (a) sifting molecules of water through the membrane, the pores of the membrane comprising a plurality of carbon nanotubes; and (b) propagating acoustic vibration onto the microporous membrane at a libration frequency of ice so as to hasten movement of the water molecules within the carbon nanotubes.

Owner:NASA

Printable Composition for an Ionic Gel Separation Layer for Energy Storage Devices

InactiveUS20140017557A1Low vapor pressureHybrid capacitor separatorsHybrid capacitor electrolytesIonPolyvinylidene fluoride

Representative embodiments provide a composition for printing a liquid or gel separator utilized to separate and space apart first and second conductors or electrodes of an energy storage device, such as a battery or a supercapacitor. A representative composition comprises a plurality of particles, typically having a size (in any dimension) between about 0.5 to about 50 microns; a first, ionic liquid electrolyte; and a polymer or polymeric precursor. In another representative embodiment, the plurality of particles comprise diatoms, diatomaceous frustules, and / or diatomaceous fragments or remains. Another representative embodiment further comprises a second electrolyte different from the first electrolyte; the plurality of particles are comprised of silicate glass; the first and second electrolytes comprise zinc tetrafluoroborate salt in 1-ethyl-3-methylimidazolium tetrafluoroborate ionic liquid; and the polymer comprises polyvinyl alcohol (“PVA”) or polyvinylidene fluoride (“PVFD”). Additional components, such as additional electrolytes and solvents, may also be included.

Owner:NTHDEGREE TECH WORLDWIDE

Implantable flexible circuit leads and methods of use

InactiveUS9314618B2Easy to manufactureStrong specificitySpinal electrodesDiagnostic recording/measuringDielectricAnatomical structures

Owner:ST JUDE MEDICAL LUXEMBOURG HLDG SMI S A R L SJM LUX SMI

Modified membranes

InactiveUS6884350B2Reduce dirtEssential mechanical properties of the membranesMembranesSemi-permeable membranesVinyl etherPolyamide

A porous polymeric membrane formed from a blend of a polymeric membrane forming material, such as polyvinylidene fluoride or polysulfone and a polymeric reactivity modifying agent adapted to modify the surface active properties of the porous polymeric membrane. The reactivity modifying agent is preferably a linear polymeric anhydride, such as poly(alkyl vinyl ether / maleic anhydride). The surface activity modifications include modification of the hydrophilicity / hydrophobicity balance of the membrane, or hydrolysis followed by reaction with a polyamine to form a crosslinked polyamide layer. Such modified membranes have use as reverse osmosis membranes.

Owner:EVOQUA WATER TECH LLC

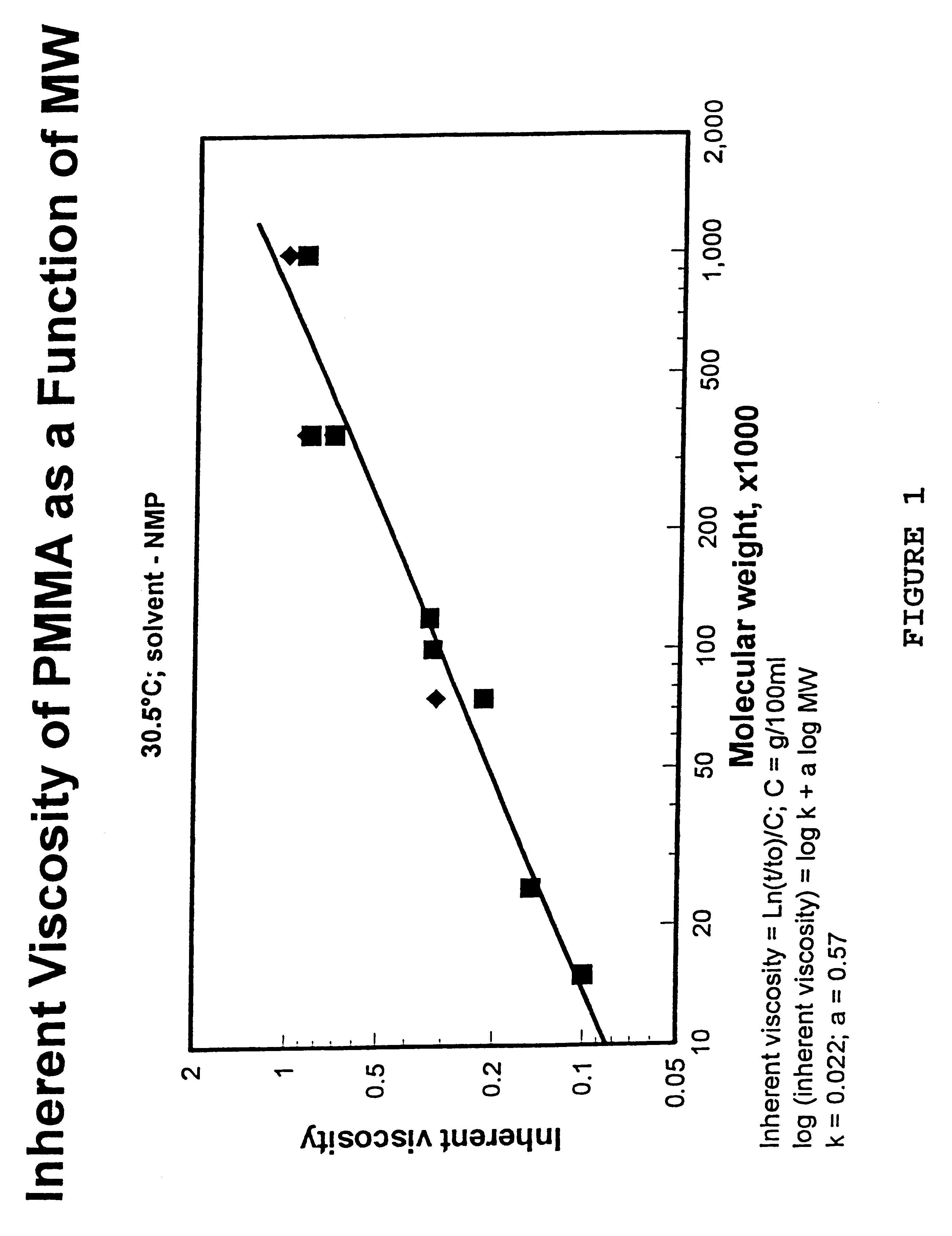

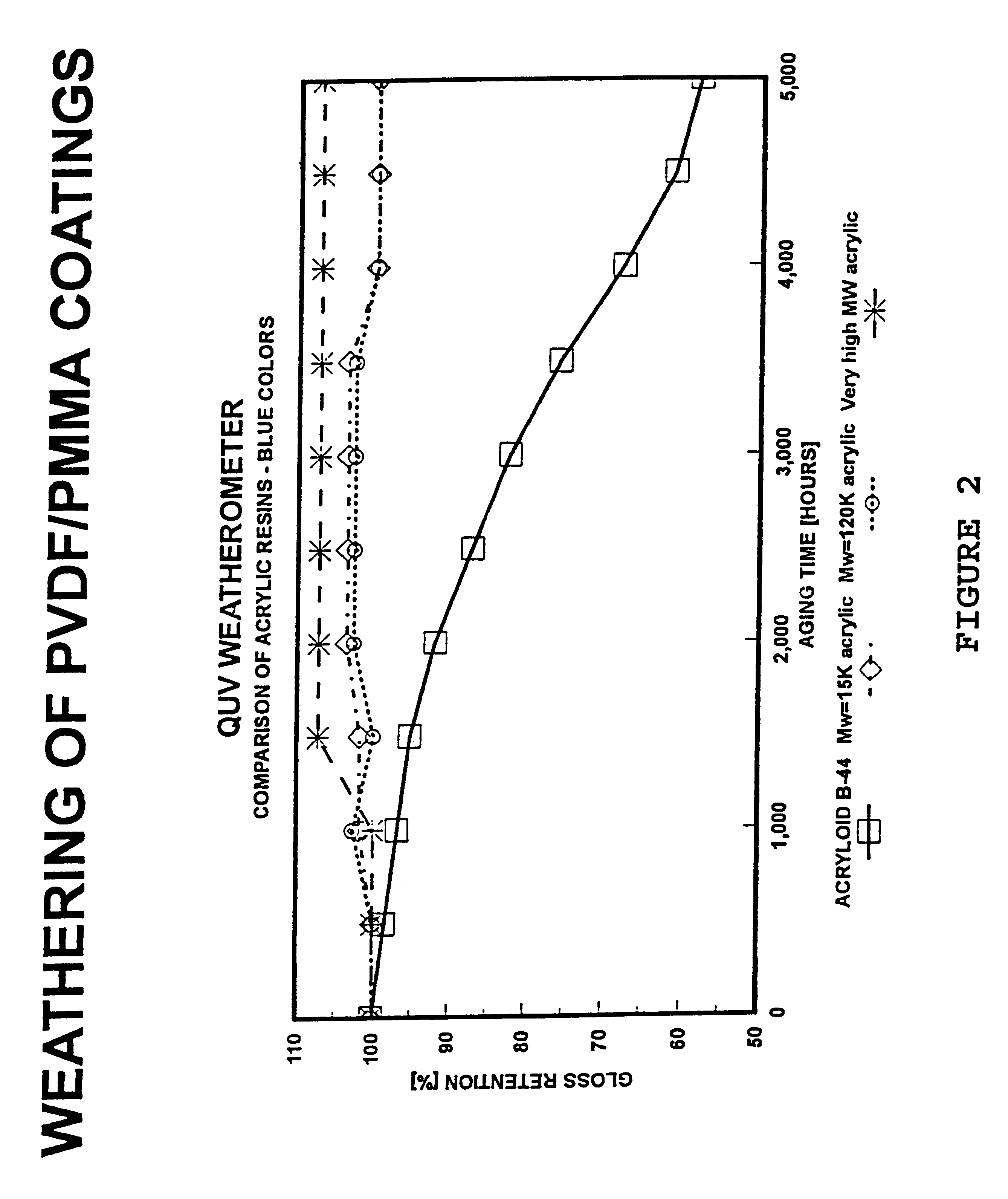

Polyvinylidene fluoride weather resistant coating compositions including polymethyl methacrylate

InactiveUS6362271B1Improve adhesionReduce the shrinkage of the polyvinylidene fluorideMixing methodsCoatingsMethacrylatePolymethyl methacrylate

A weather resistant coating composition comprising a miscible polymer blend of highly crystalline polyvinylidene fluoride polymer and polyalkyl methacrylate, such as PVDF and PMMA. The miscible blend comprises from about 50 weight percent to about 90 weight percent polymer comprising polyvinylidene fluoride and from about 10 weight percent to about 50 weight percent polyalkyl methacrylate. The polyalkyl methacrylate having a molecular weight within the range of about 25,000 grams per mole to about 200,000 grams per mole. The crystallinity of the polyvinylidene fluoride polymer is about 20% to about 70%. The weather resistant coating has excellent and unexpected physical characteristics, including solvent resistance and gloss retention.

Owner:SOLVAY SOLEXIS

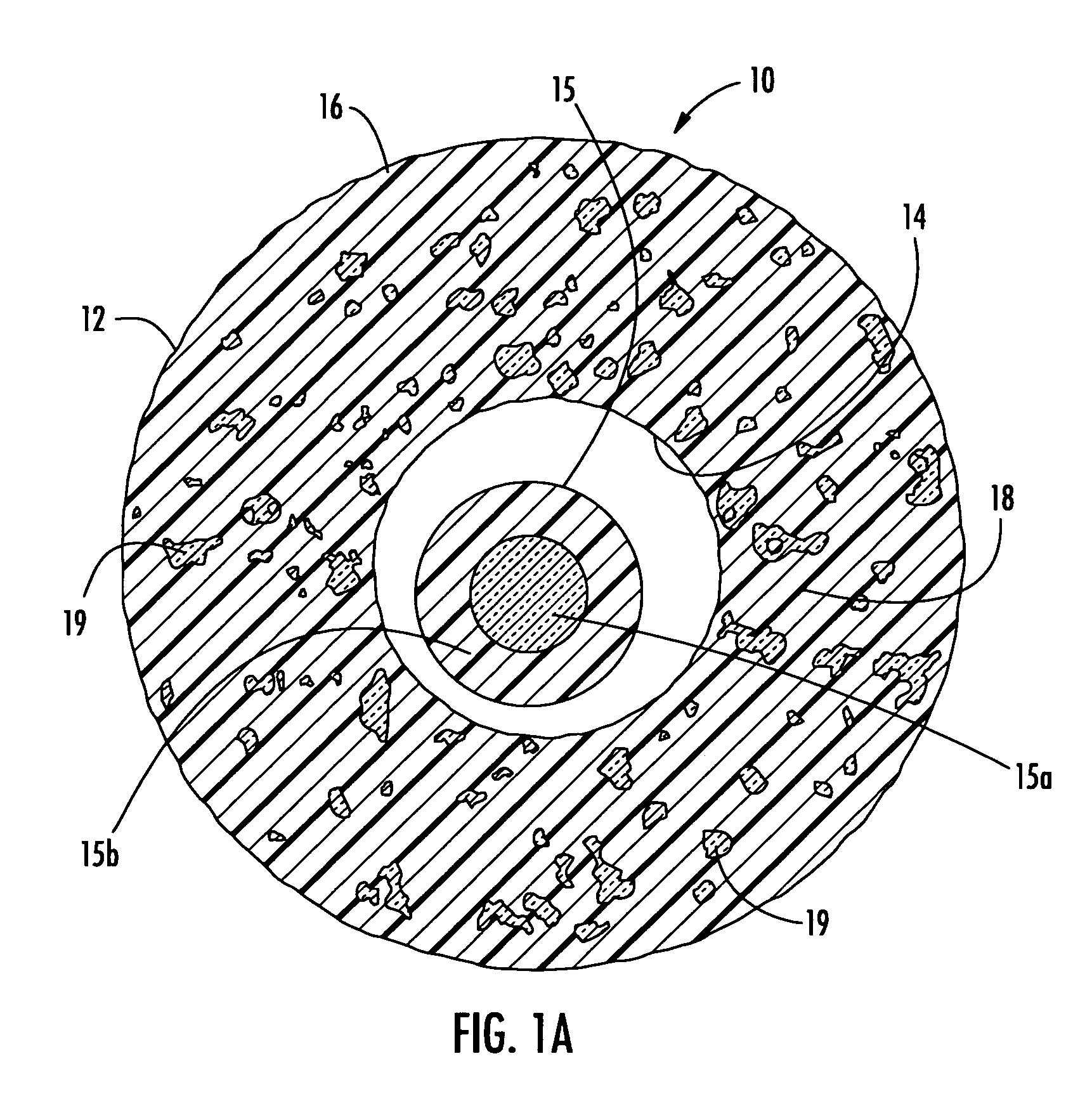

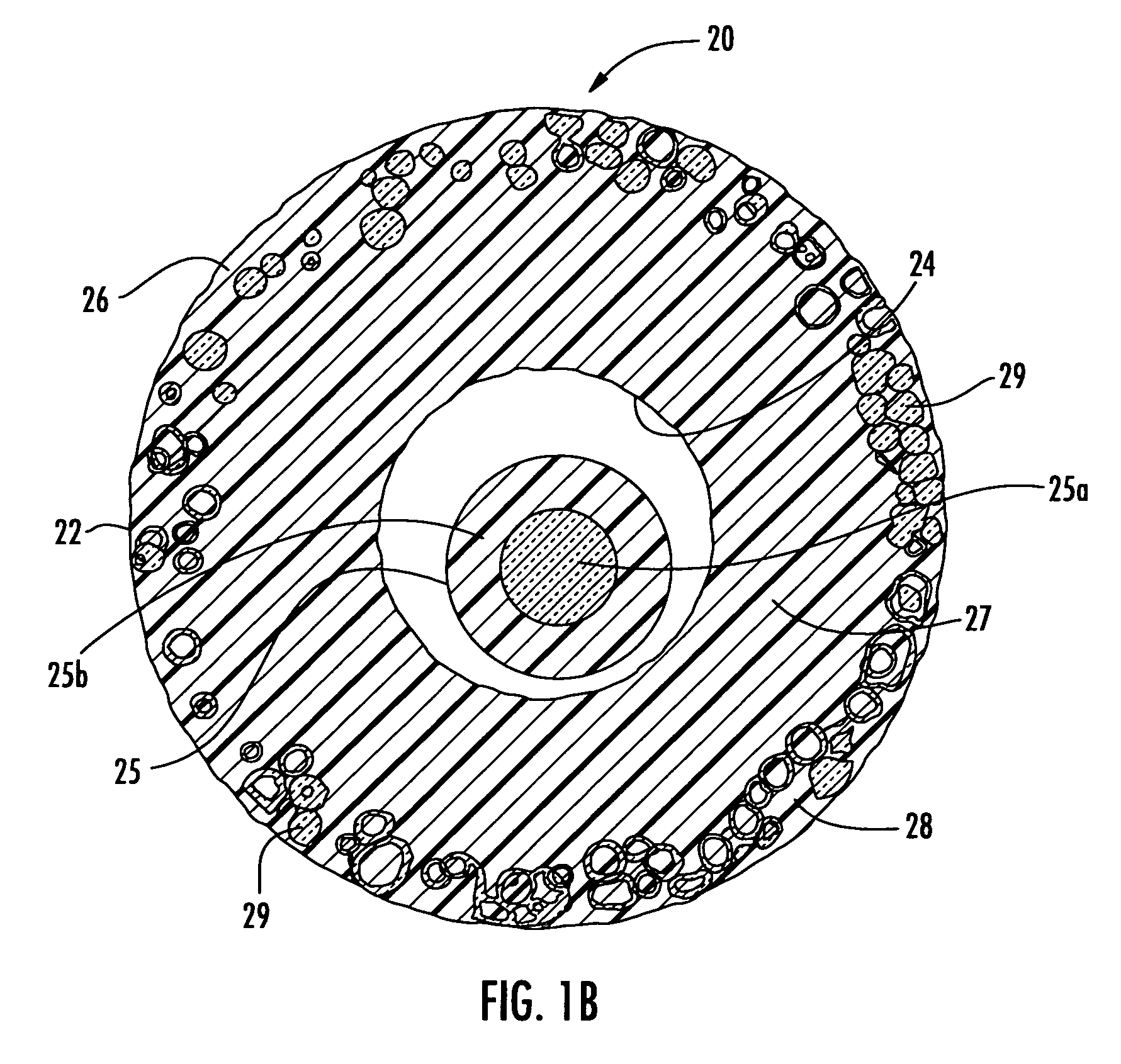

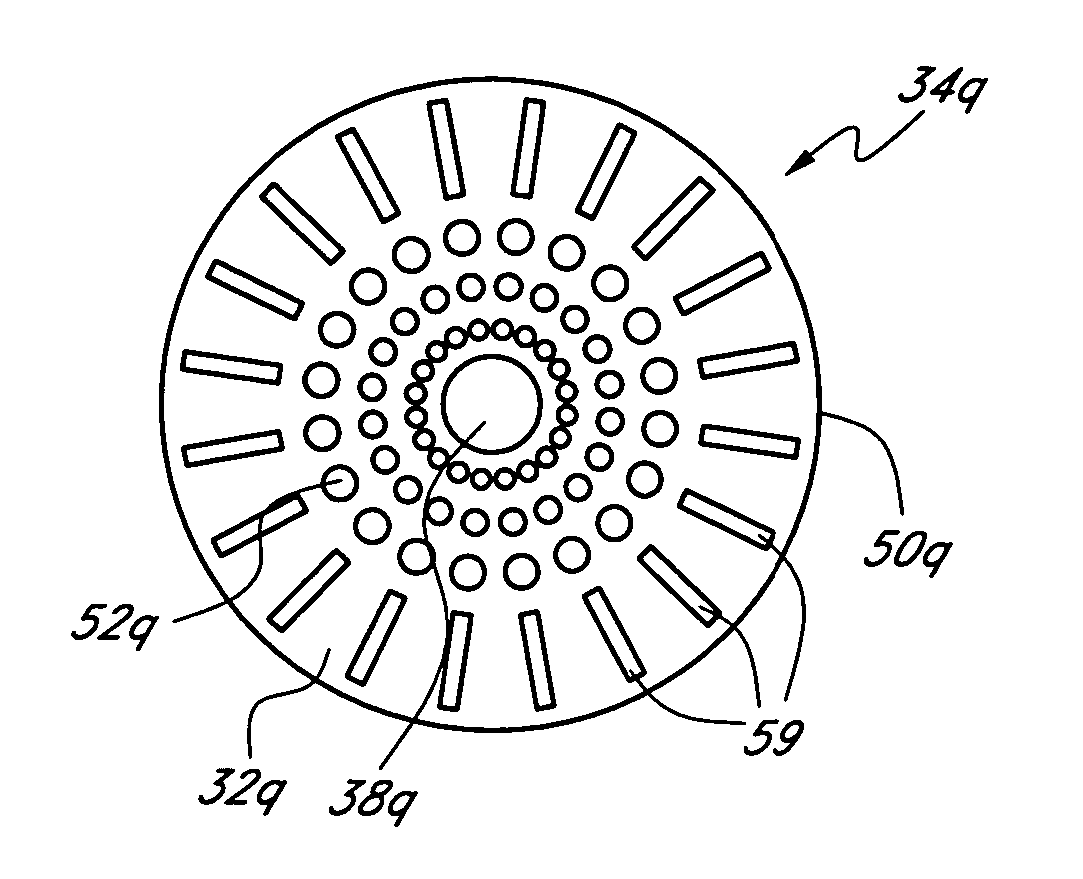

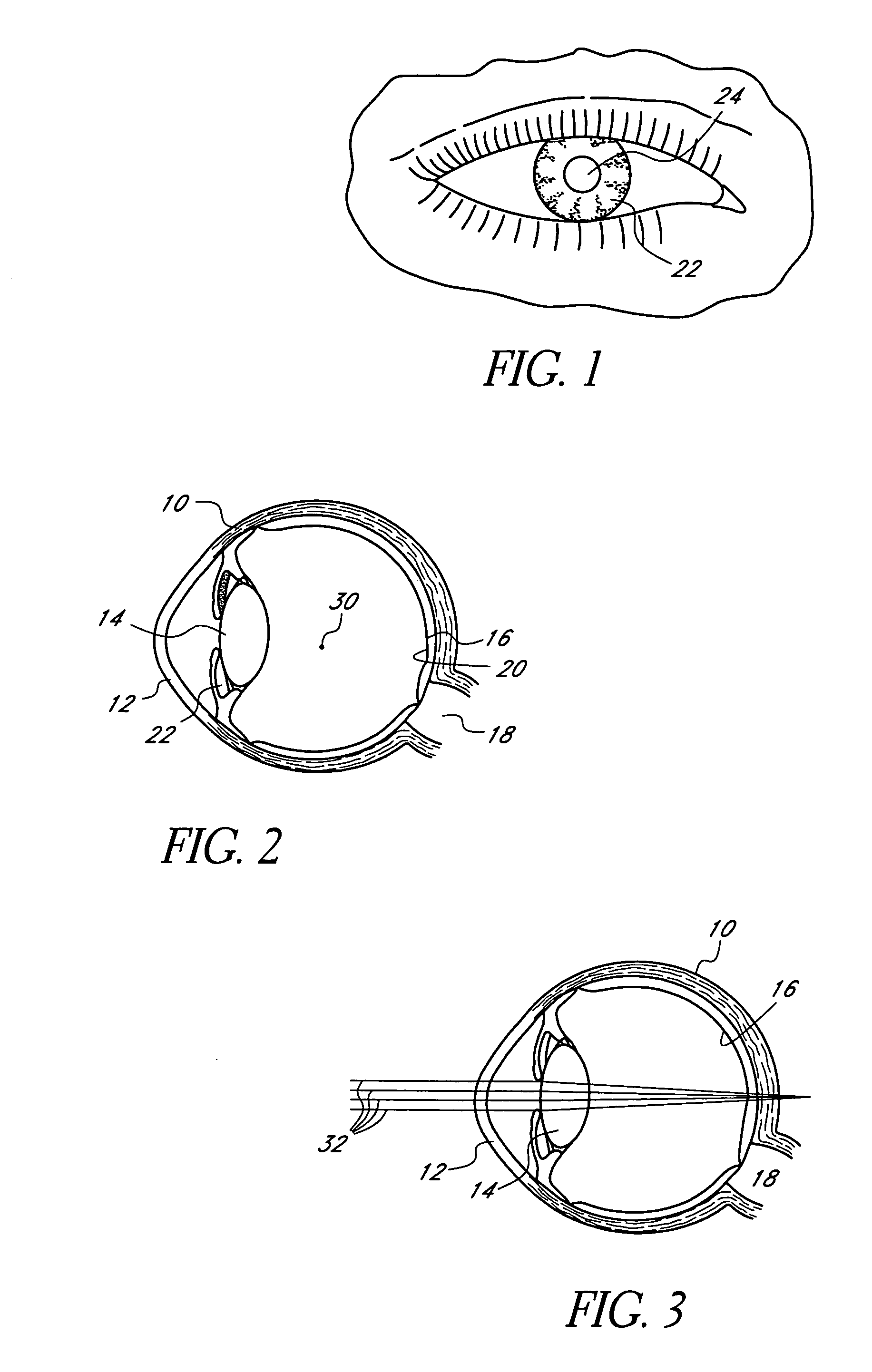

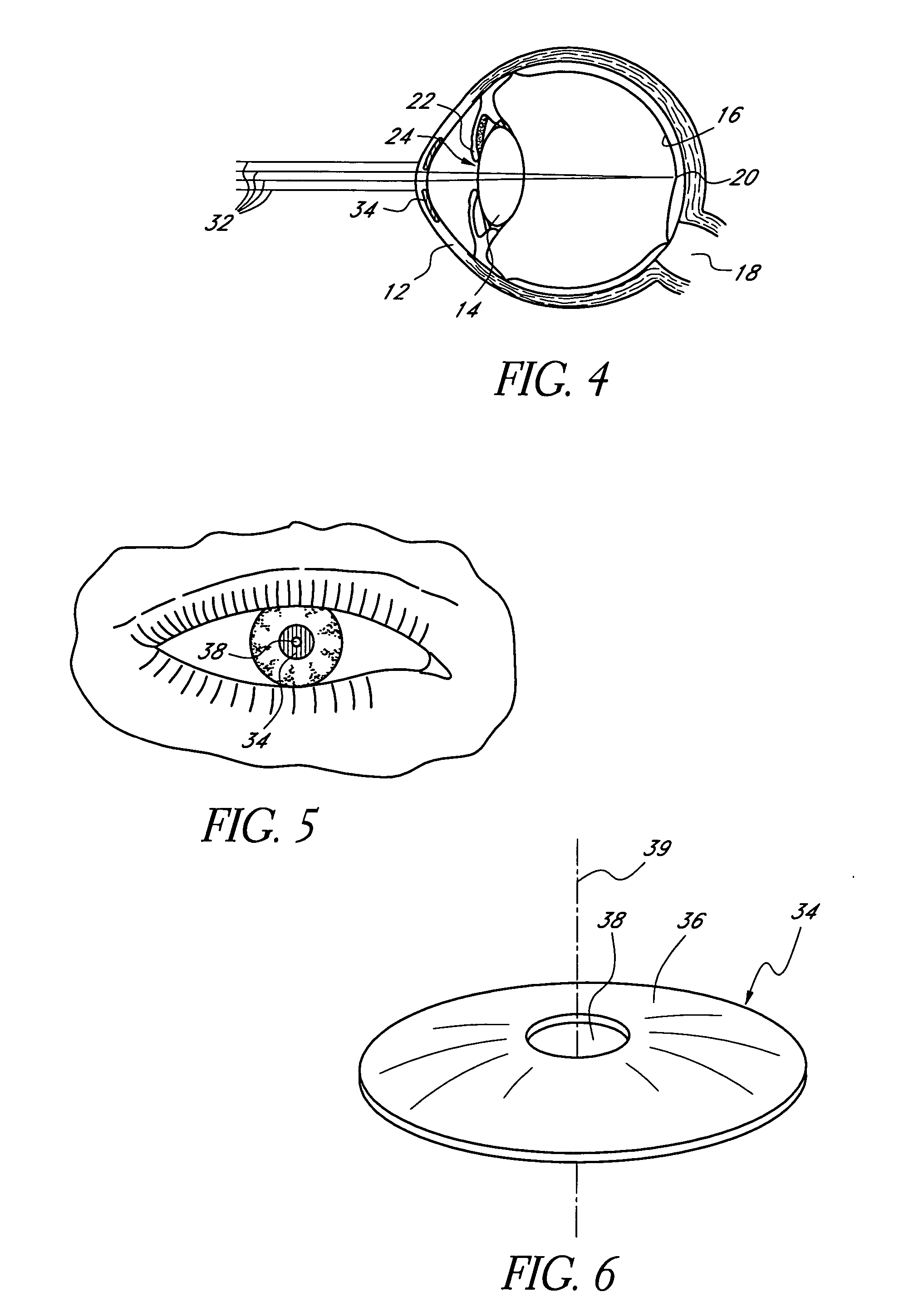

Corneal optic formed of degradation resistant polymer

Disclosed are mask optics configured to be implanted in a cornea of a patient. In one embodiment, the body of the optic has a light transmitting portion, a light blocking portion disposed about the light transmitting portion, and an outer periphery surrounding the light blocking portion. The optic is adapted to reside between two intracorneal layers of a cornea. The mask optic may be formed from a material comprising a highly fluorinated polymeric material and an opacification agent. Preferred highly fluorinated polymeric materials include polyvinylidene fluoride (PVDF) and preferred opacification agents include carbon. The highly fluorinated polymeric material is preferably resistant to degradation upon exposure to ultraviolet light.

Owner:ACUFOCUS

Composite thermotropic phase separation film-making method

The invention relates to a composite thermotropic phase isolated membrane preparation method which is characterized in that used composite diluent is the mixture of water-soluble good solvent and water-soluble additive of polymers. The membrane forming separation is a composite process which mainly takes the thermotropic membrane phase separation as the dominant role and non-solvent induced phaseseparation as the subsidiary role. The membrane prepared through the method has the advantages of high abruption strength, high abruption elongation and high water flux. The method is applicable to the preparation of membranes which are made of a plurality of polymers, including polyvinylidene fluoride, polysulfone, polyether sulfone, polyvinyl chloride and polyacrylonitrile. The performances of the membranes are improved greatly. Thus, the membranes can be widely applied to the fields of drinking water advanced treatment, pretreatment before reverse permeation, membrane bioreactor wastewatertreatment, reclaimed water reuse, etc.

Owner:湖南坎普尔环保技术有限公司

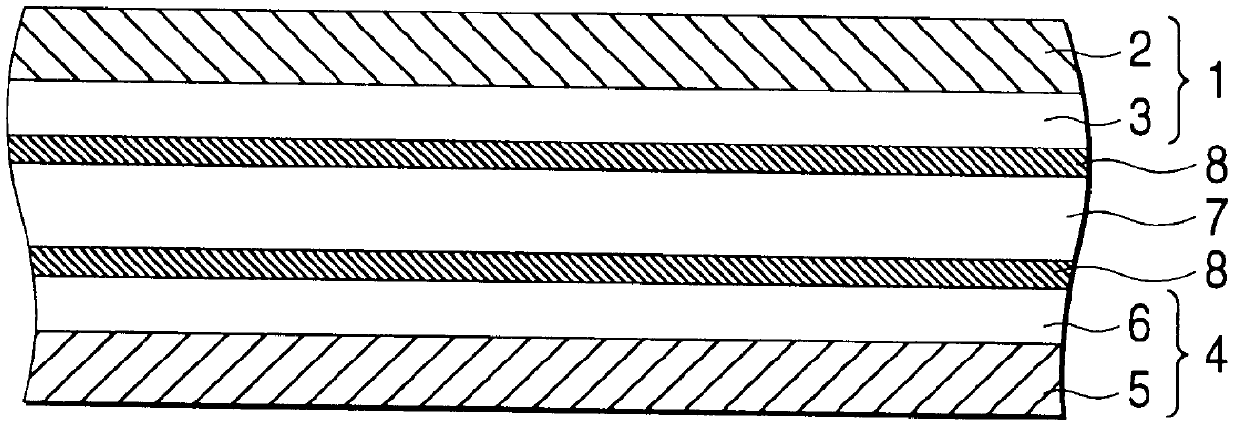

Novel solar battery backboard

ActiveCN101582458ANovel structureMaterials are readily availableSynthetic resin layered productsPhotovoltaic energy generationPolyurethane adhesiveAlloy

The invention relates to a novel solar battery backboard, which comprises the following components according to the adhesion in turn: a weathering layer, a first adhesive layer, a structure-enhancing layer, a second adhesive layer and an adhesive reflecting layer; wherein, the weathering layer is a polyvinylidene fluoride alloy layer modified by inorganic materials; the adhesive reflecting layer is a white polyethylene layer; preferably, the polyvinylidene fluoride alloy layer is a plastic alloy layer formed by the polyvinylidene fluoride and the inorganic materials with the thickness of 4-40 mum; the white polyethylene layer is a plastic alloy layer in which polyethylene is mixed with inorganic white pigment, anti-ultraviolet stabilizer and hot-oxygen ageing resistance stabilizer with the thickness of 10-300mum; the structure-enhancing layer is a polyethylene qlycol terephthalate layer; the first adhesive layer and the second adhesive layer can be one of the following three, namely, a polyurethane adhesive layer, an acrylic ester adhesive layer or an epoxy adhesive layer with the thickness of 1mum-30mum. The invention features novel structure, easily obtained materials, greatly reduced cost and good performance, conforms to the requirements of the backboard, and has important significance on solar energy industry.

Owner:SHANGHAI HIUV NEW MATERIALS

Modified membranes

InactiveUS20050032982A1Reduce dirtEssential mechanical properties of the membranesSemi-permeable membranesMembranesVinyl etherReverse osmosis

A porous polymeric membrane formed from a blend of a polymeric membrane forming material, such as polyvinylidene fluoride or polysulfone and a polymeric reactivity modifying agent adapted to modify the surface active properties of the porous polymeric membrane. The reactivity modifying agent is preferably a linear polymeric anhydride, such as poly(alkyl vinyl ether / maleic anhydride). The surface activity modifications include modification of the hydrophilicity / hydrophobicity balance of the membrane, or hydrolysis followed by reaction with a polyamine to form a crosslinked polyamide layer. Such modified membranes have use as reverse osmosis membranes.

Owner:MULLER HEINZ JOACHIM

Multi-layer sheet having a weatherable surface layer

InactiveUS20060057392A1Synthetic resin layered productsElectrical equipmentPolymer scienceWeather resistance

A multi-layer sheet and a process for producing the sheet are disclosed. The sheet can comprise a first polymer layer comprising a film of polyvinyl fluoride (PVF) or polyvinylidene fluoride (PVDF) having an adhesive coating on one side; second optionally pigmented polymer layer extruded onto the adhesive coating of the first polymer layer; and optionally a third polymer layer. Also a photovoltaic module comprising a prebonded backskin that comprises the multi-layer sheet.

Owner:PERFORMANCE MATERIALS NA INC

Modified membranes

InactiveUS20050029185A1Reduce dirtEssential mechanical properties of the membranesSemi-permeable membranesMembranesVinyl etherReverse osmosis

A porous polymeric membrane formed from a blend of a polymeric membrane forming material, such as polyvinylidene fluoride or polysulfone and a polymeric reactivity modifying agent adapted to modify the surface active properties of the porous polymeric membrane. The reactivity modifying agent is preferably a linear polymeric anhydride, such as poly(alkyl vinyl ether / maleic anhydride). The surface activity modifications include modification of the hydrophilicity / hydrophobicity balance of the membrane, or hydrolysis followed by reaction with a polyamine to form a crosslinked polyamide layer. Such modified membranes have use as reverse osmosis membranes.

Owner:EVOQUA WATER TECH LLC

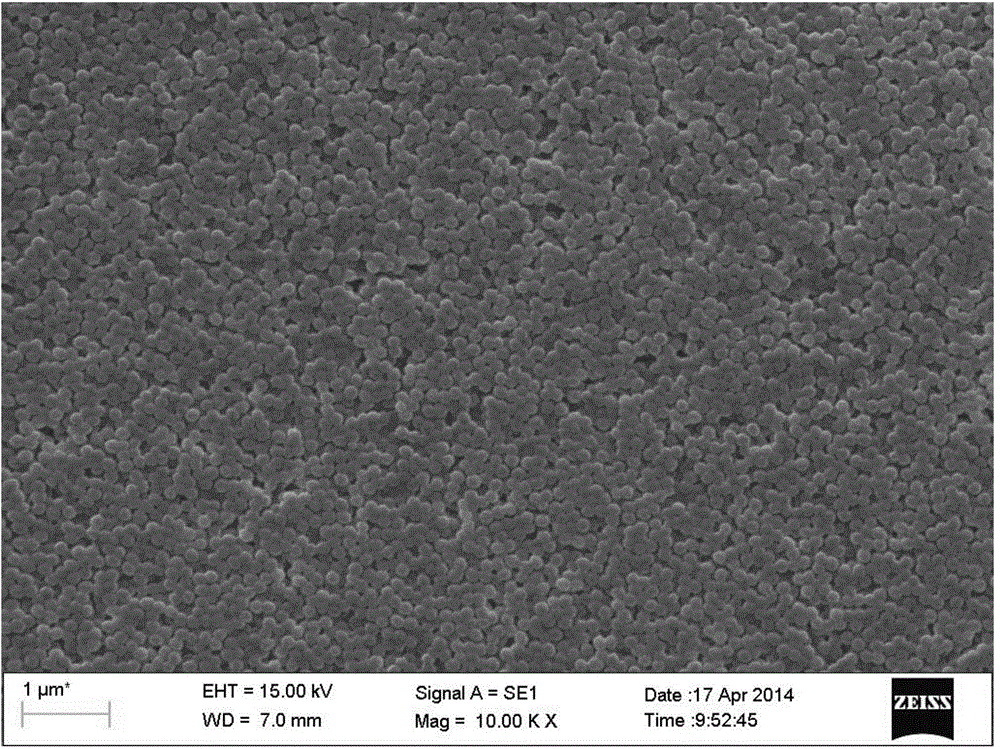

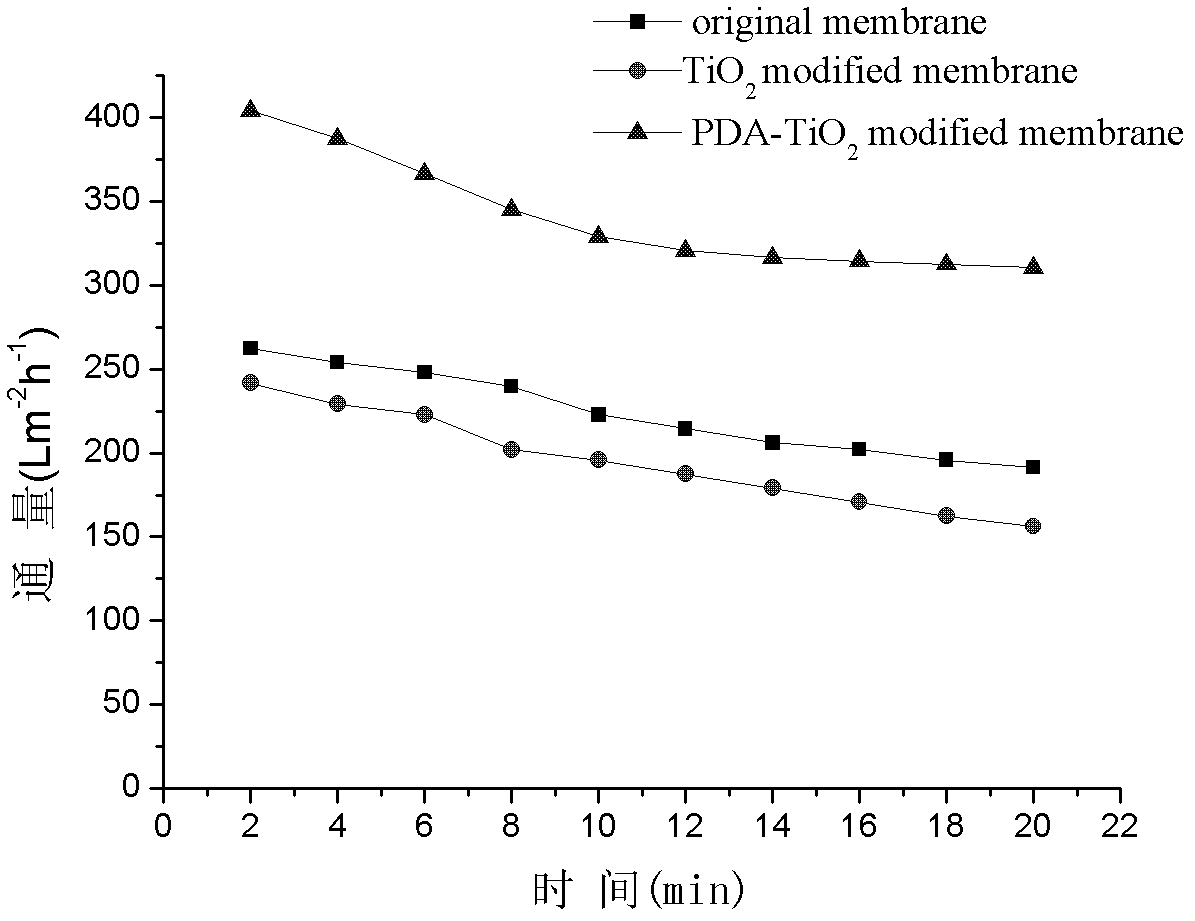

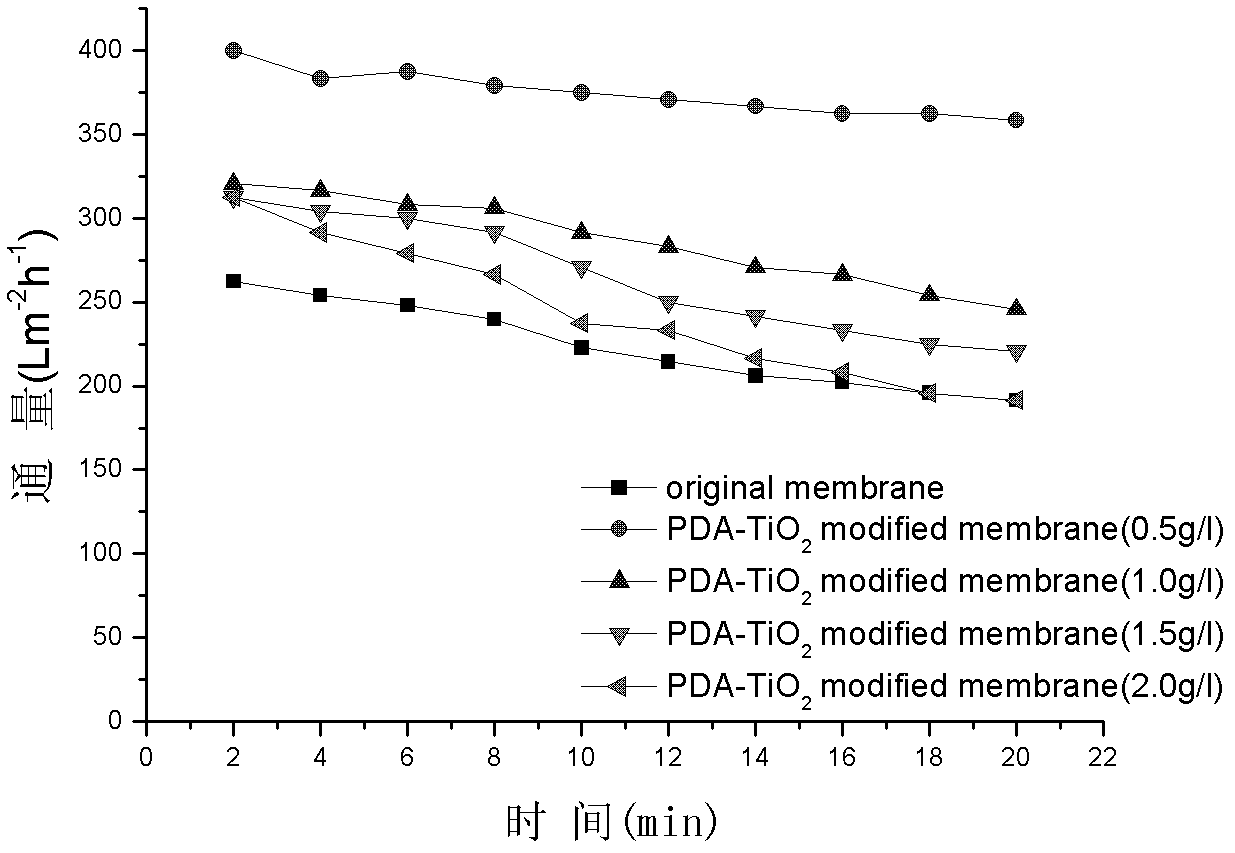

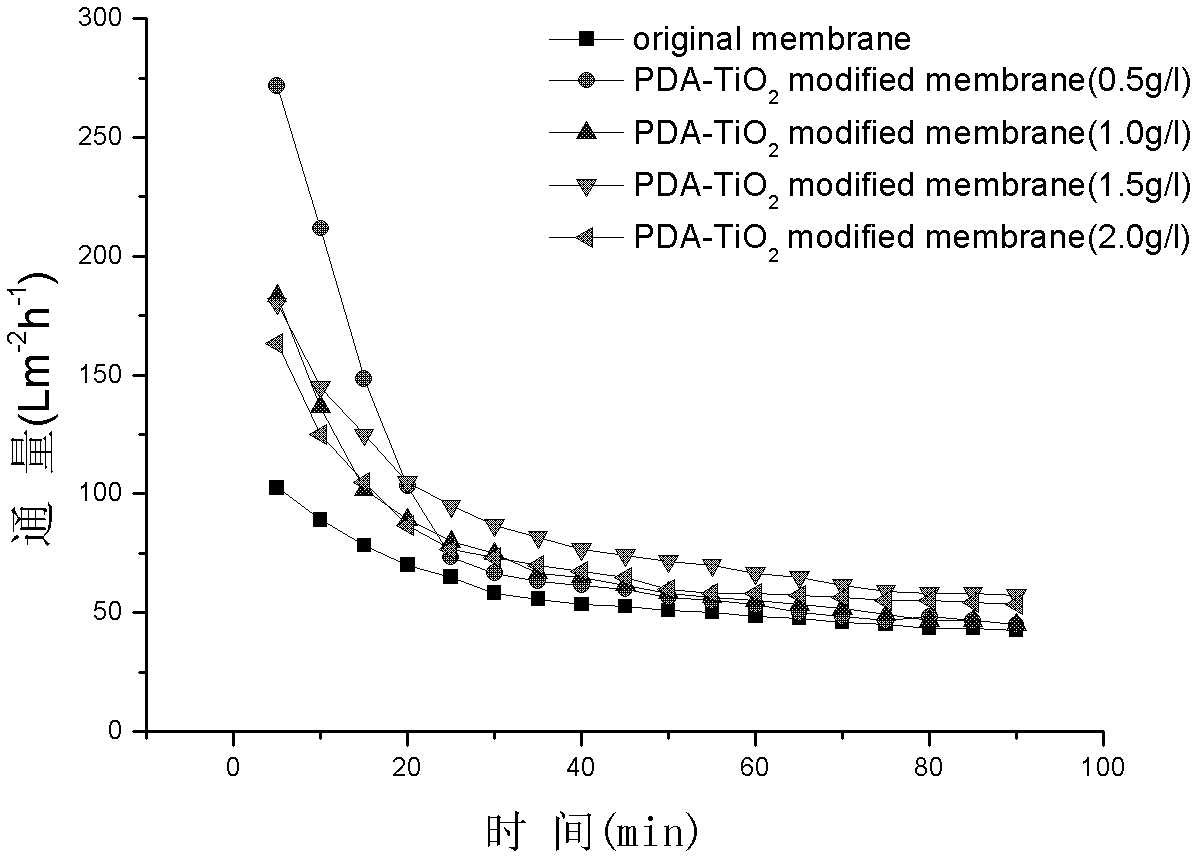

Method for preparing high-flux composite membrane from dopamine-modified nanometer material

InactiveCN102614783AImprove hydrophilicityImprove pollutionSemi-permeable membranesPigment treatment with macromolecular organic compoundsOrganic solventHigh flux

The invention relates to a method for preparing a high-flux composite membrane from a dopamine-modified nanometer material and belongs to the technical field of modification of membrane materials. The method is characterized by comprising the following steps of: forming an active poly-dopamine composite layer on the surfaces of titanium dioxide nanometer grains by utilizing automatic polymerization of dopamine, selecting different concentrations of dopamine-modified titanium dioxide grains, and adding the modified nanometer grains utilized as additives into a membrane casting solution, in which the mass fraction of PVDF (Polyvinylidene Fluoride) is 13% and the mass fraction of PVP (Polyvinyl Pyrrolidone) is 4%, so as to bend and modify according to different proportions, thus obtaining a composite membrane prepared from dopamine-modified nanometer titanium dioxide. The method for preparing the high-flux composite membrane from the dopamine-modified nanometer material, disclosed by the invention, has the advantages that dopamine-modified titanium dioxide can be greatly dispersed in an organic solvent to form a uniform dispersed phase; the additive can be used for effectively improving the hydrophilcity and anti-pollution capability of the high-flux composite membrane; and the dopamine modification method is simple, the condition is gentle, the flux of the prepared membrane is large and the anti-pollution capability is strong.

Owner:DALIAN UNIV OF TECH

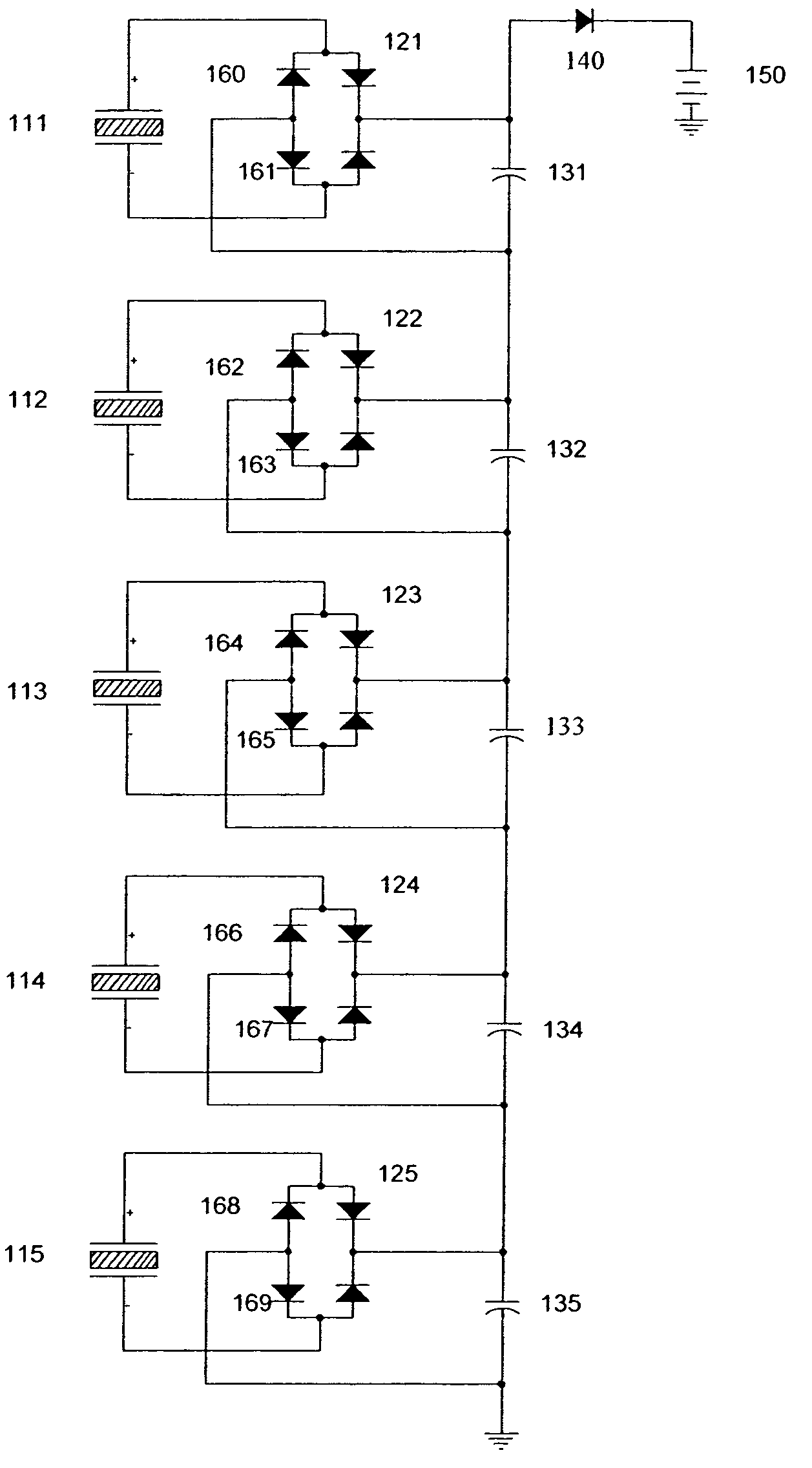

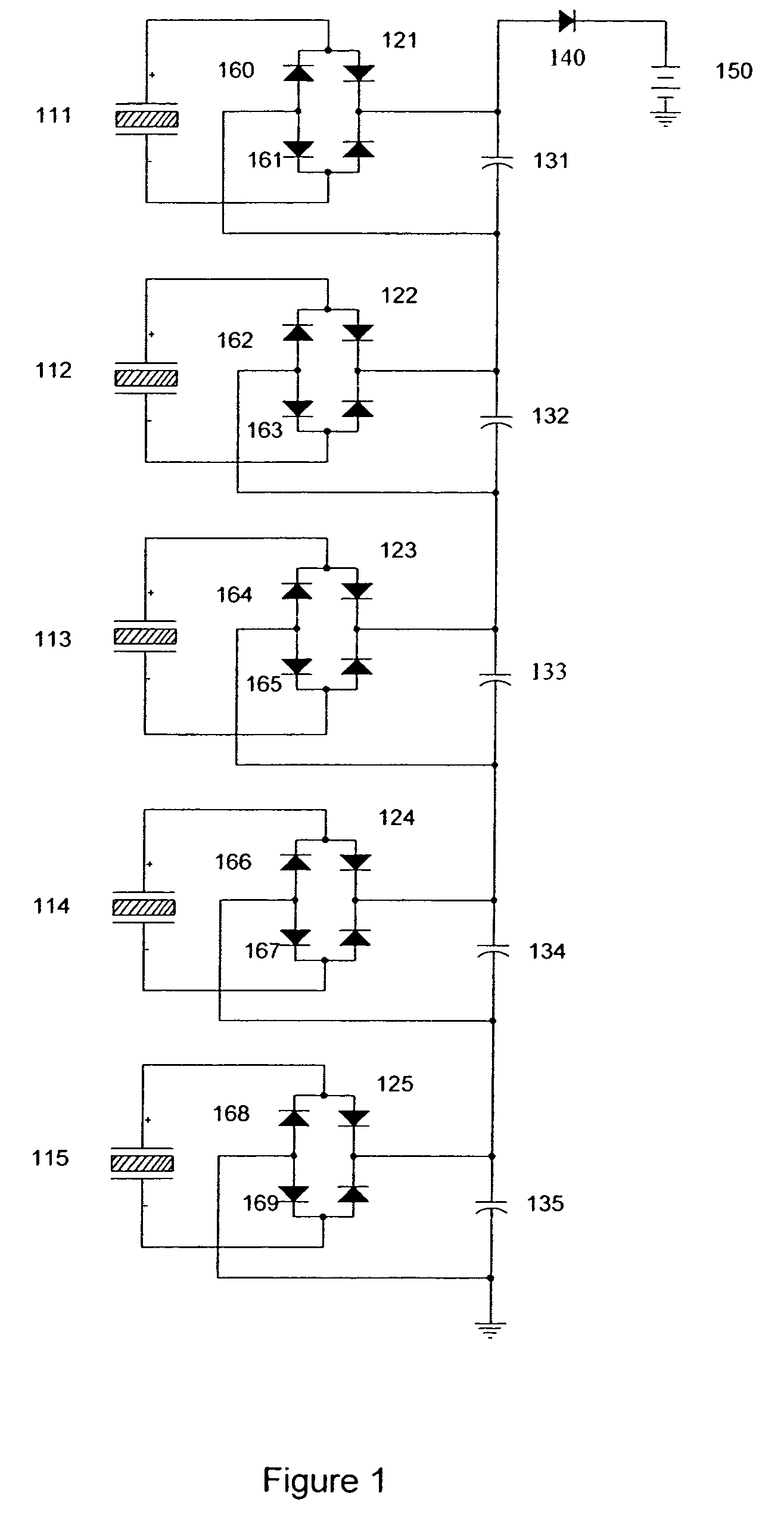

Method and apparatus for an ambient energy battery or capacitor recharge system

InactiveUS7088031B2Improve the environmentChange powerPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive devicesMassive gravityInfrared

The present invention relates to the field of battery and capacitor charging. In particular, the present invention provides pulsed current charging using changes, regardless of polarity, in the local energy environment to obtain power. The present invention relates, for example, to ambient energy charging thin film batteries, other batteries, or capacitors, via, for example, polyvinyladine fluoride homopolymer (PVDF), PVDF bi-axially poled, or other piezoelectric materials. Ambient energy may be defined as any change in energy within the local environment. Charging can be accomplished with, and is not limited to, positive or negative changes of the following energy types: thermal; visible light, including infrared and ultraviolet; mechanical motion or impact; triboelectric, including airflow or physical contact; movement in relation to a gravitational plane (increase or decrease in gravitational potential energy); and radio frequency (RF) electromagnetic energy, regardless of specific frequency.

Owner:SAPURAST RES

Membrane polymer compositions

InactiveUS7226541B2Good chemical stabilityBioreactor/fermenter combinationsBiological substance pretreatmentsHexafluoropropylenePolyvinylidene difluoride

Owner:EVOQUA WATER TECH LLC

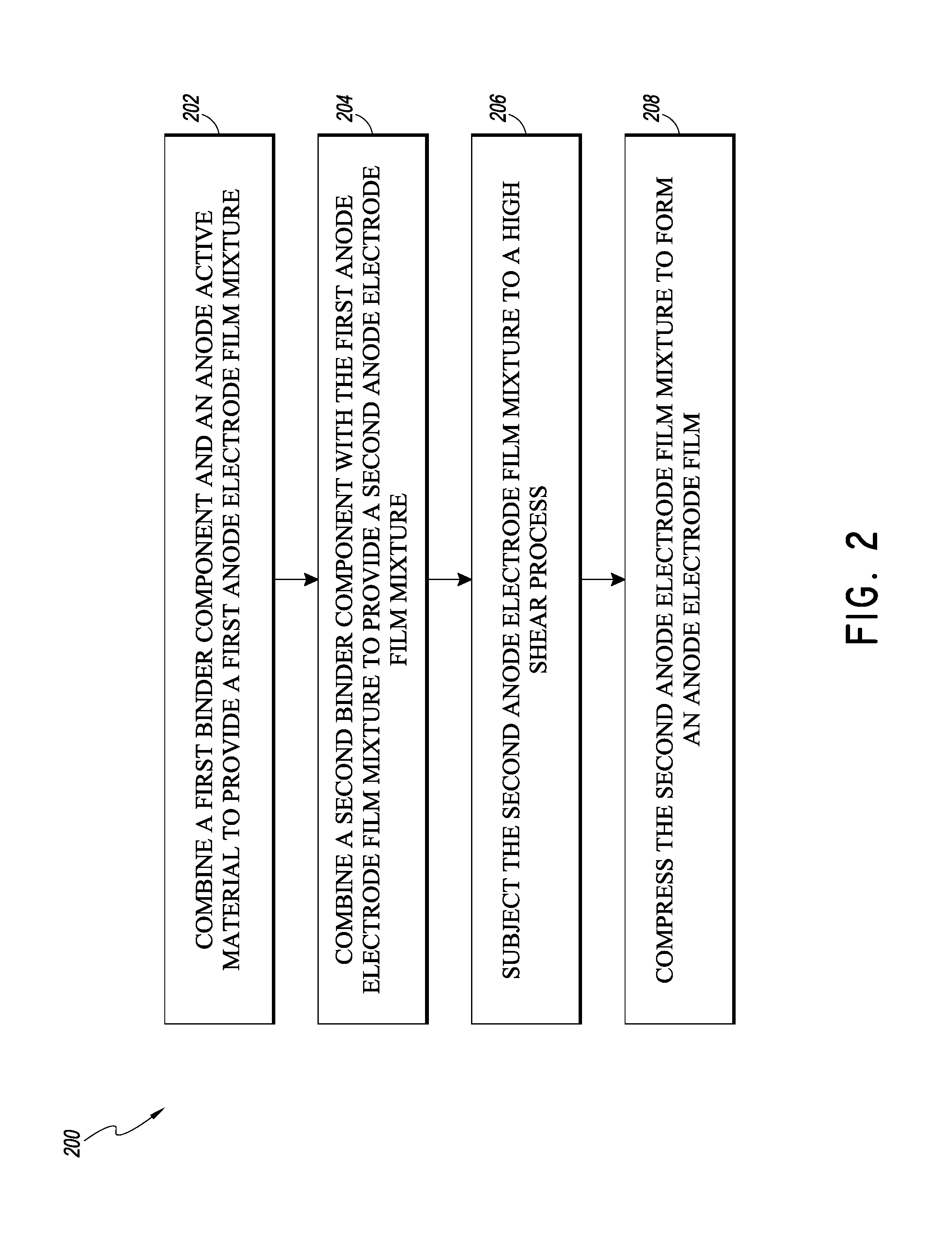

Dry energy storage device electrode and methods of making the same

ActiveUS20150303481A1Electrode rolling/calenderingSolid electrolytic capacitorsEthylene oxidePolyvinylidene difluoride

An energy storage device can include a cathode and an anode, where at least one of the cathode and the anode are made of a polytetrafluoroethylene (PTFE) composite binder material including PTFE and at least one of polyvinylidene fluoride (PVDF), a PVDF co-polymer, and poly(ethylene oxide) (PEO). The energy storage device can be a lithium ion battery, a lithium ion capacitor, and / or any other lithium based energy storage device. The PTFE composite binder material can have a ratio of about 1:1 of PTFE to a non-PTFE component, such a PVDF, PVDF co-polymer and / or PEO.

Owner:TESLA INC

Antimicrobial semi-permeable membranes

Cast semi-permeable membranes made from synthetic polymer used in reverse osmosis, ultrafiltration and microfiltration are treated with a non-leaching antimicrobial agent to prevent its bio-fouling and bacterial breakthrough. The semi-permeable membranes include a polymeric material and a non-leaching antimicrobial agent that is incorporated into and homogeneously distributed throughout the polymeric material. The polymeric material, in the case of one membrane, may be cellulose acetate. In the case of thin film composite polyamide membranes, the antimicrobial agent is incorporated in a microporous polysulfone layer that is sandwiched between a reinforcing fabric and an ultrathin polyamide material. The invention also includes a treatment of flat and hollow fiber semipermeable membranes made with polysulfones and polyvinylidene fluoride.

Owner:MICROBAN PROD CO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com