Patents

Literature

488 results about "Glyceryl triacetate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

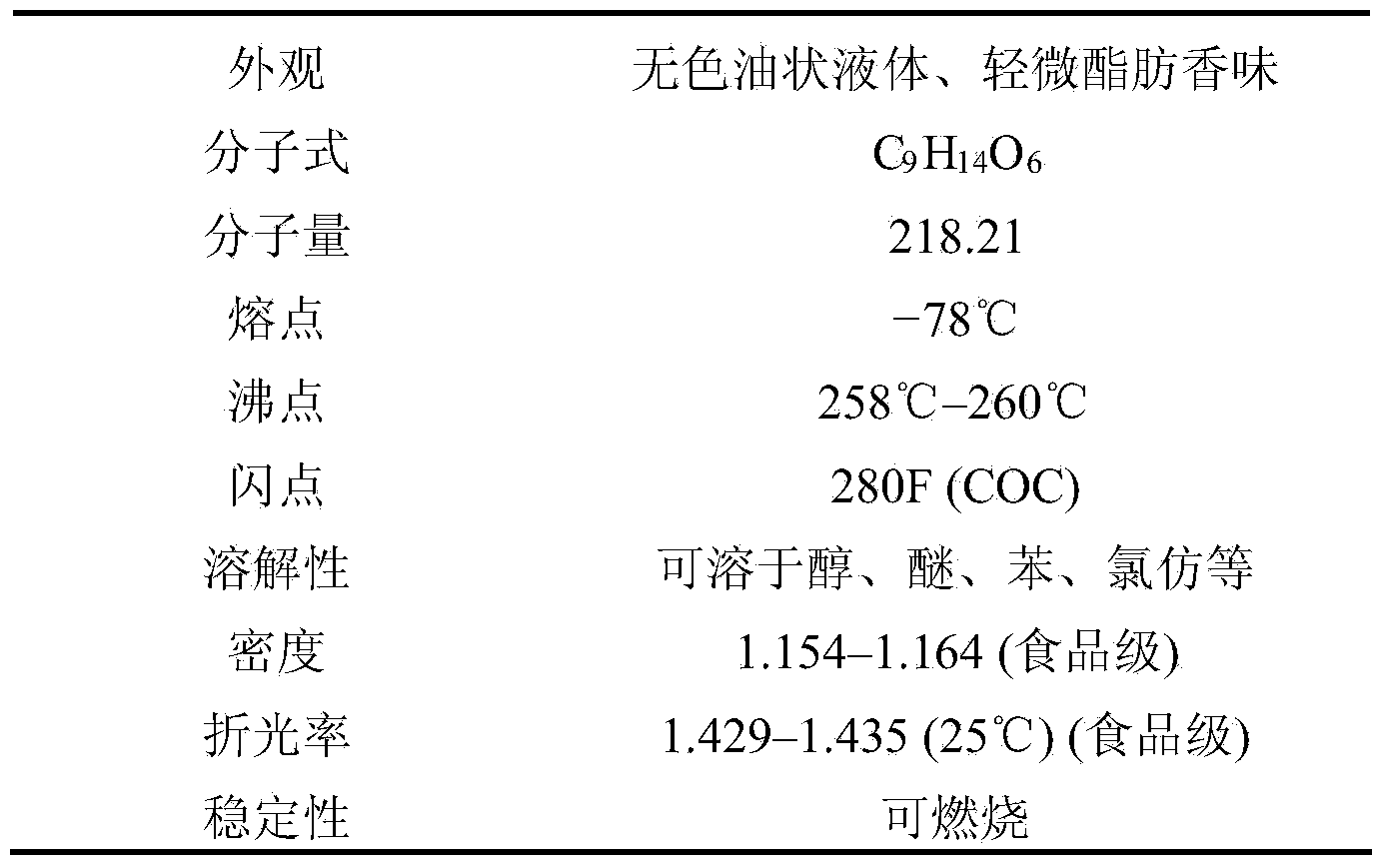

Triacetin (C9H14O6), also known as glyceryl triacetate, is pharmaceutical excipient used in manufacturing of capsules and tablets, and has been used as a humectant, plasticizer, and solvent.

Microporous PVDF films and method of manufacturing

Shaped microporous articles are produced from polyvinylidene fluoride (PVDF) and nucleating agents using thermally induced phase separation (TIPS) processes. The shaped microporous article is oriented in at least one direction at a stretch ratio of at least approximately 1.1 to 1.0. The shaped article may also comprise a diluent, glyceryl triacetate. The shaped microporous article may also have the micropores filled with a sufficient quantity of ion conducting electrolyte to allow the membrane to function as an ion conductive membrane. The method of making a microporous article comprises the steps of melt blending polyvinylidene fluoride, nucleating agent and glyceryl triacetate; forming a shaped article of the mixture; cooling the shaped article to cause crystallization of the polyvinylidene fluoride and phase separation of the polyvinylidene fluoride and glyceryl triacetate; and stretching the shaped article in at least one direction at a stretch ratio of at least approximately 1.1 to 1.0.

Owner:3M INNOVATIVE PROPERTIES CO

Additive agent for reducing harmful constituents in flue gas and method for preparing same

ActiveCN101199363ARefreshingWith anti-greasy weight lossTobacco smoke filtersFiberPolyethylene glycol

The invention discloses an additive which can reduce harmful components in smoke and the preparation method. The invention is mainly characterized in that the materials include jasmine tea, liquorice, Beta-cyclodextrin, polyethylene glycol, honey, lactic acid and glyceryl triacetate and the materials are processed into cigarette filter additive, and then are evenly sprinkled on the polypropylene or acetate fiber cigarette filter rod and at last are rolled into a cigarette; the weight of the additive is 0.5-5% of the weight of the cigarette filter rod. Compared with a reference cigarette, the cigarette filter rod additive is balanced in tea aroma, flower fragrance, cigarette aroma and drug aroma and can improve the taste of the cigarette, enabling the cigarette to have balanced aroma, comfortable aftertaste and slender and soft smoke; the invention also reduces total particulate matter in the cigarette by 3.0-5.6%, tar by 2.9-6.6%, carbon monoxide by 2.5-10% and nicotinamide by 0.9-1%, and effectively reduces peppery irritation to the respiratory system of the smoker from the smoke, reduces respiratory diseases as well as harm to the smoker.

Owner:CHINA TOBACCO GUANGXI IND

Barrier film

InactiveUS7854994B2Improve the level ofImprove homogeneityFibre treatmentBottlesPolyethylene terephthalate glycolPolyethylene oxide

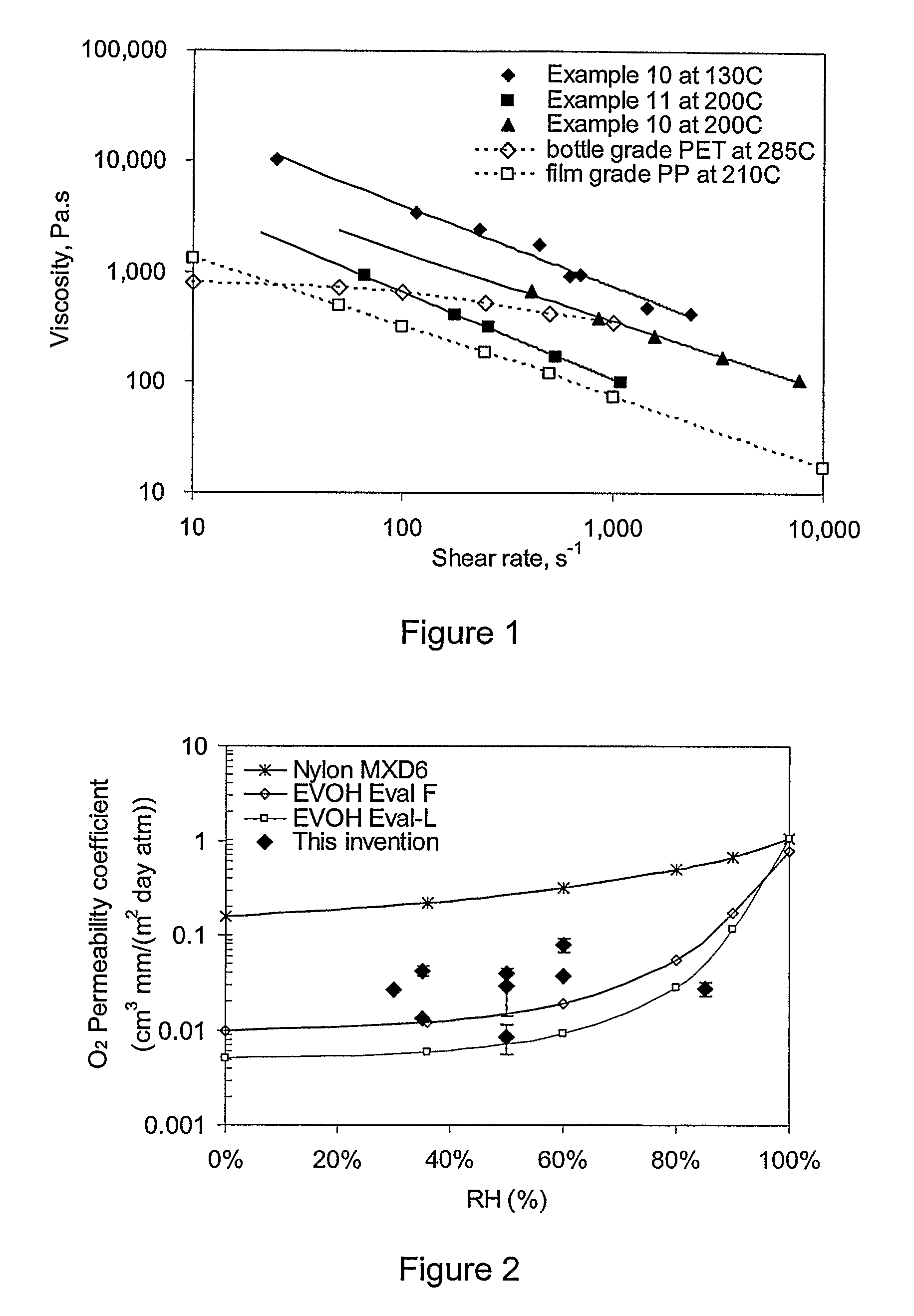

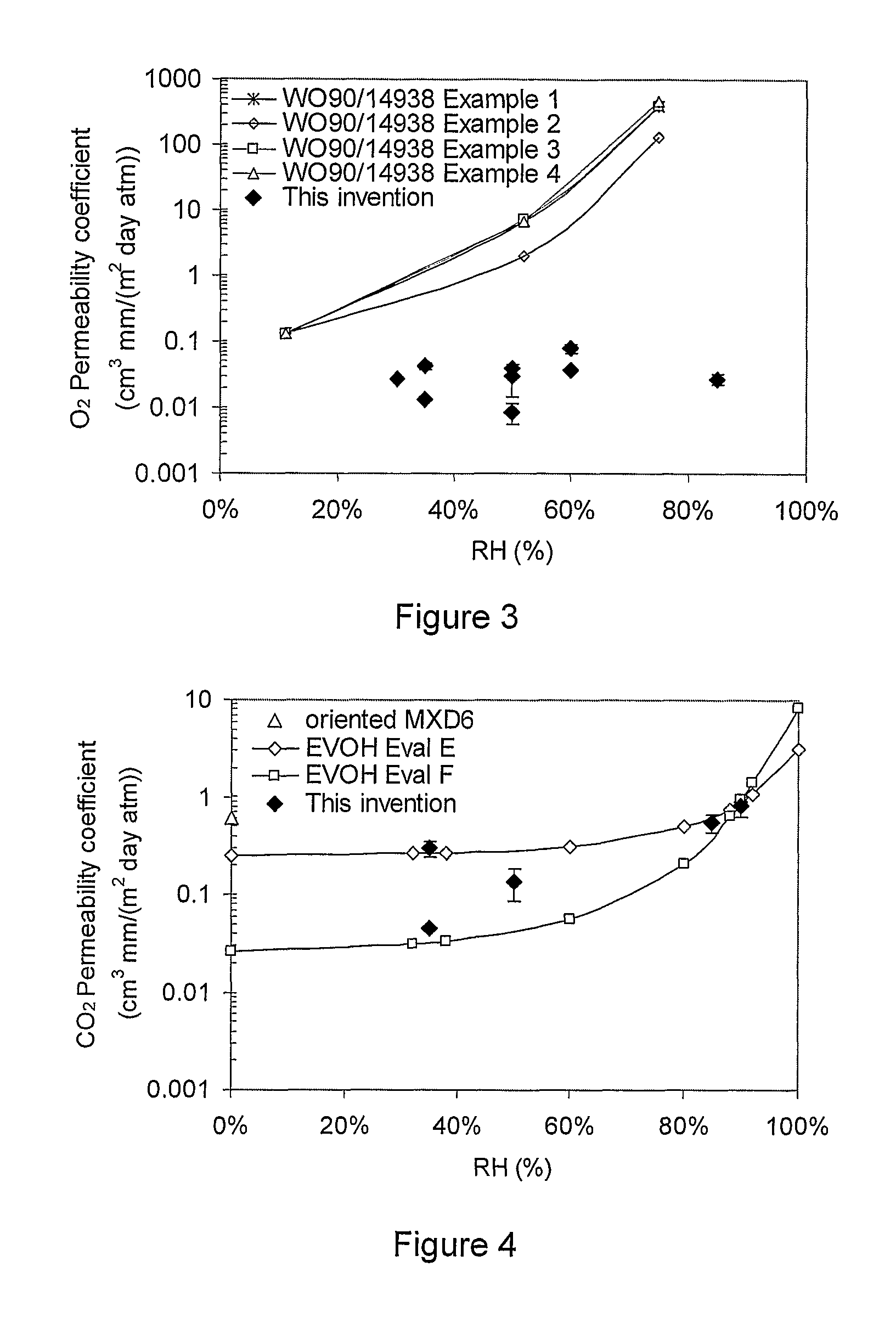

A barrier composition which is injection mouldable and able to be made into a transparent film or incorporated (by co-extrusion and / or lamination) into multi-layer film products, the composition on dry basis: a) from 45 to 90% by weight of a starch and / or a modified starch selected from starches modified by reaction with a hydroxyl alkyl group, an acetate or a dicarboxylic acid anhydride or a grafting polymer; b) from 4 to 12% by weight of a water soluble polymer selected from polyvinyl alcohol, polyvinylacetate, and copolymers of ethylene and vinylalcohol which have a melting point compatible with the molten state of the starch components c) from 5 to 45% by weight of a non-crystallising mixture of sorbitol and at least one other plasticizer selected from glycerol, maltitol, xylitol, mannitol, glycerol trioleate, epoxidised linseed or soybean oil, tributyl citrate, acetyl tri-ethyl citrate, glyceryl triacetate, 2,2,4-trimethyl-1,3-pentanediol diisobutyrate; polyethylene oxide or polyethylene glycol; d) from 0.3 to 2.5% by weight of a C12-22 fatty acid or salt; e) from 0.25% to 3% of an emulsifier system having a hydrophilic lipophilic balance value between 2 and 10. The barrier film may be co-injection moulded with polyethylene terephthalate (PET) or polylactic acid (PLA) for blow moulding into beverage bottles, with polyethylene (PE) or polypropylene (PP) or biodegradable polymers for high gas-barrier containers or closures, or may be co-extruded with polyethylene, polypropylene or polylactic acid for thin film packaging applications or for blow-moulded containers.

Owner:PLANTIC TECH

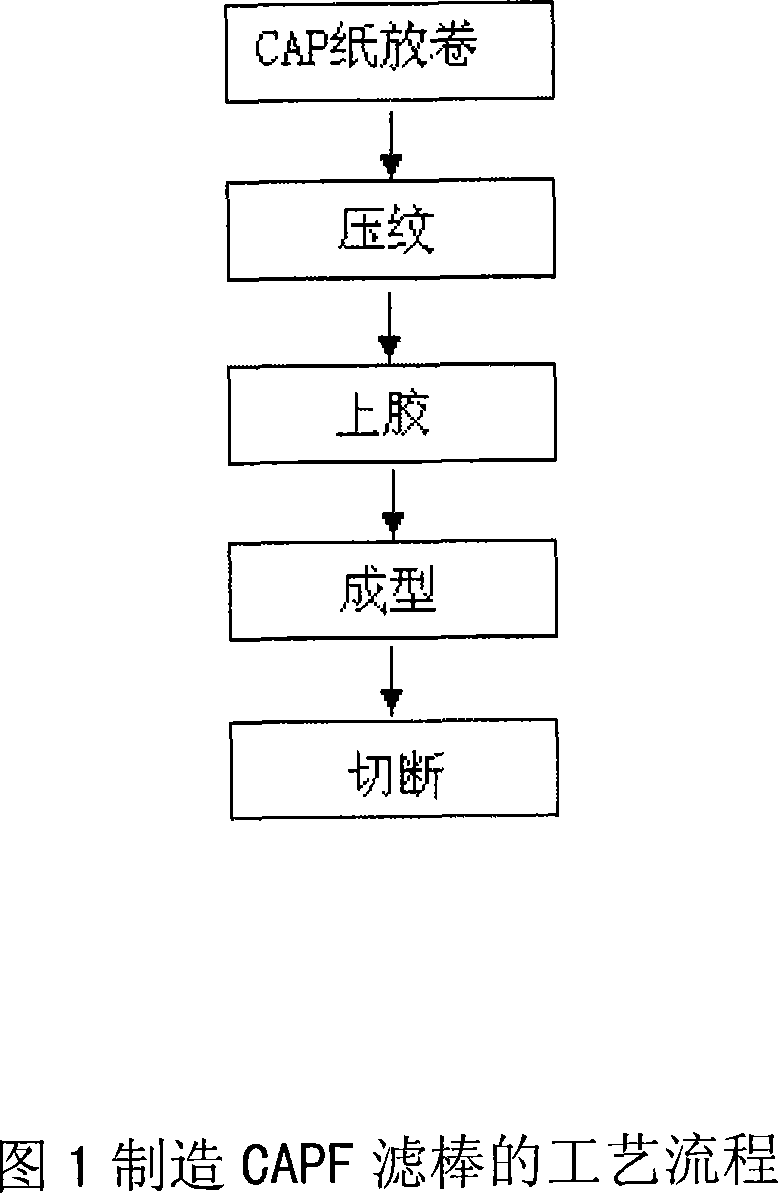

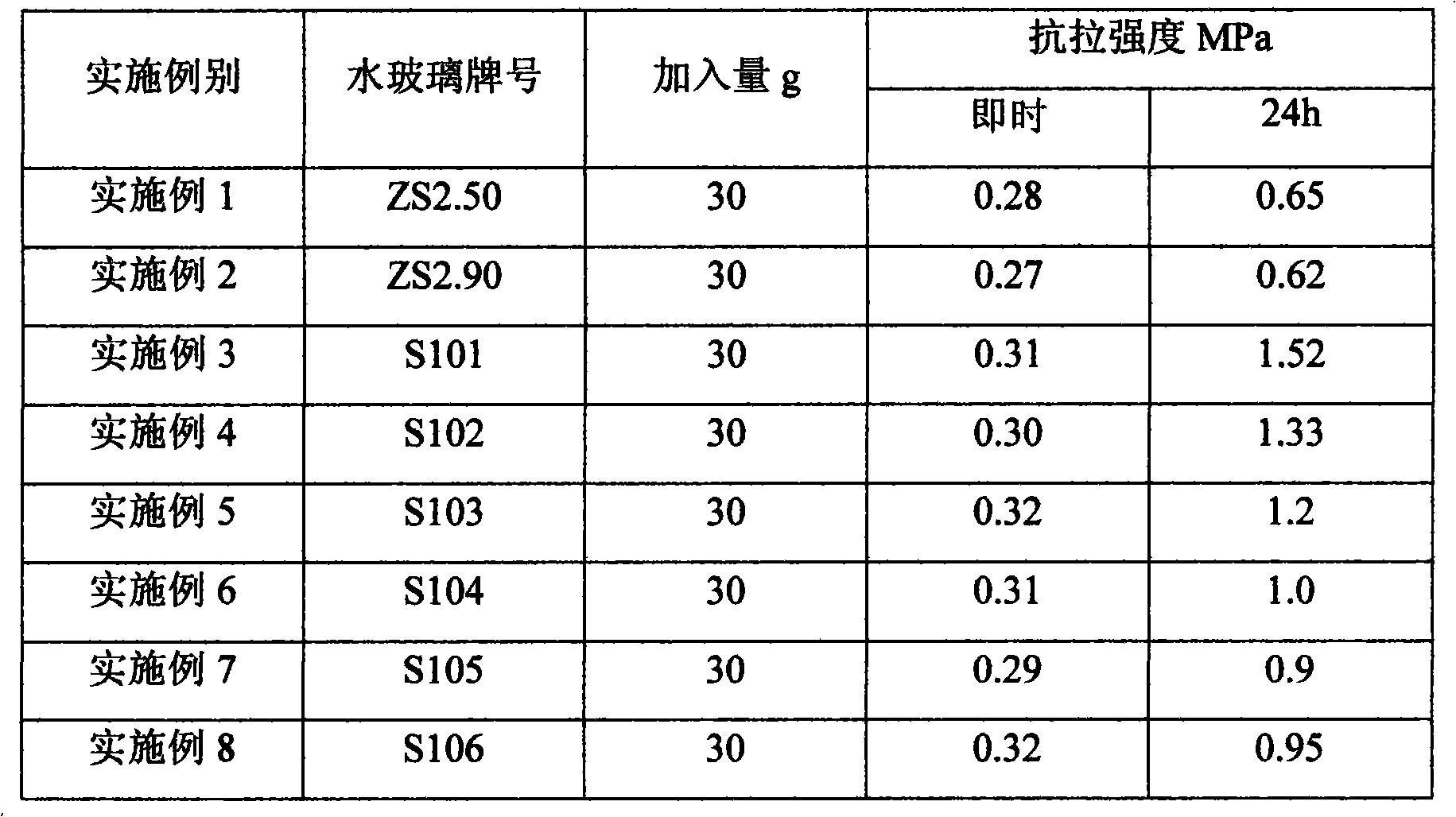

Producing technique of filter tip bar for filling material including acetate fibre paper to cigarette

The present invention relates to cigarette filter tip making technology, and is especially one kind of cigarette filter tip with cellulose acetate paper as the filling and filtering material. The cellulose acetate paper filter tip may be filter tip made of cellulose acetate paper or composite filter tip made of composite material with cellulose acetate paper. During the formation of the cellulose acetate paper filter tip, triglycreyl acetate or other cellulose acetate is applied as the plasticizer, and the filter tip may be 'cured' or 'non-cured'.

Owner:NANTONG CIGARETTE FILTER +1

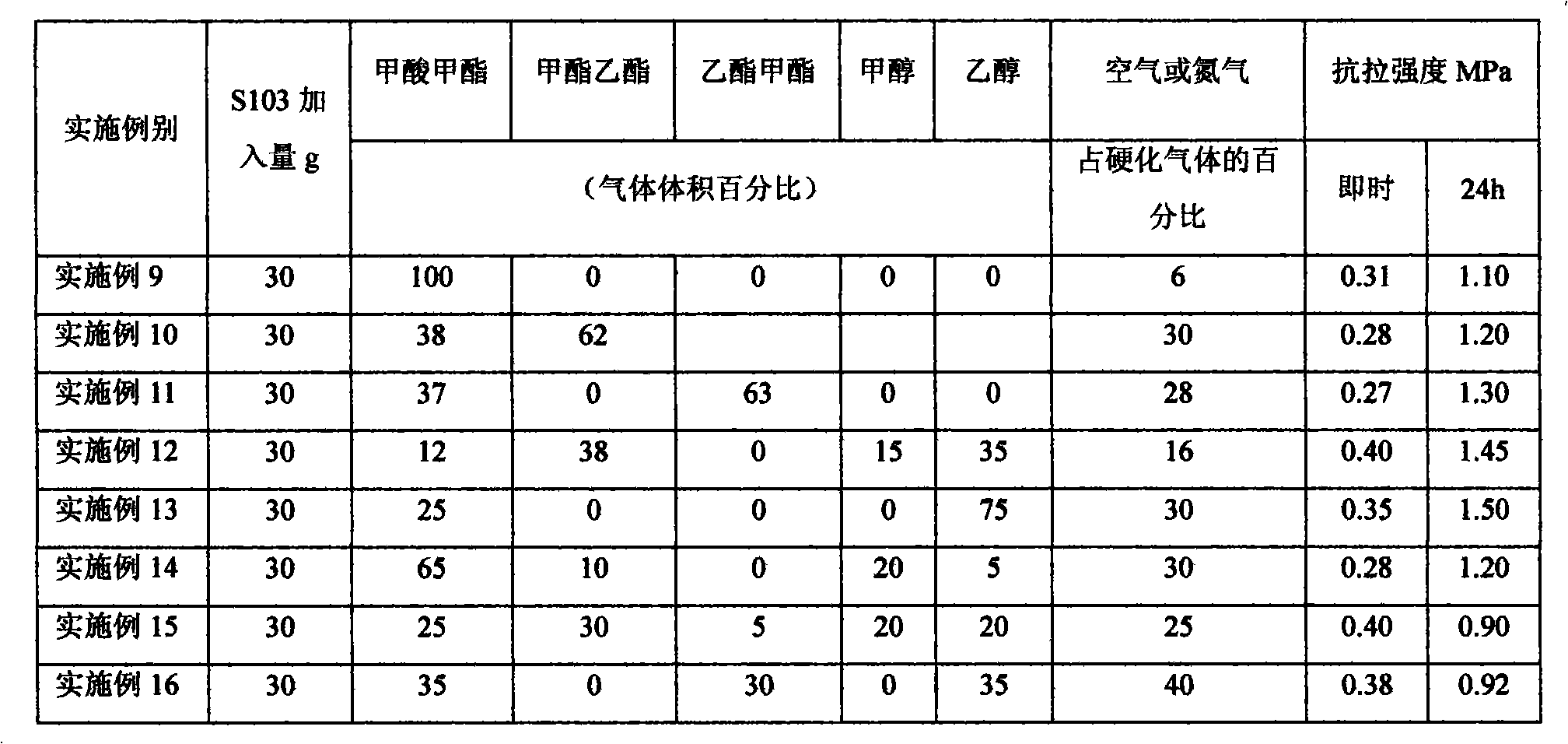

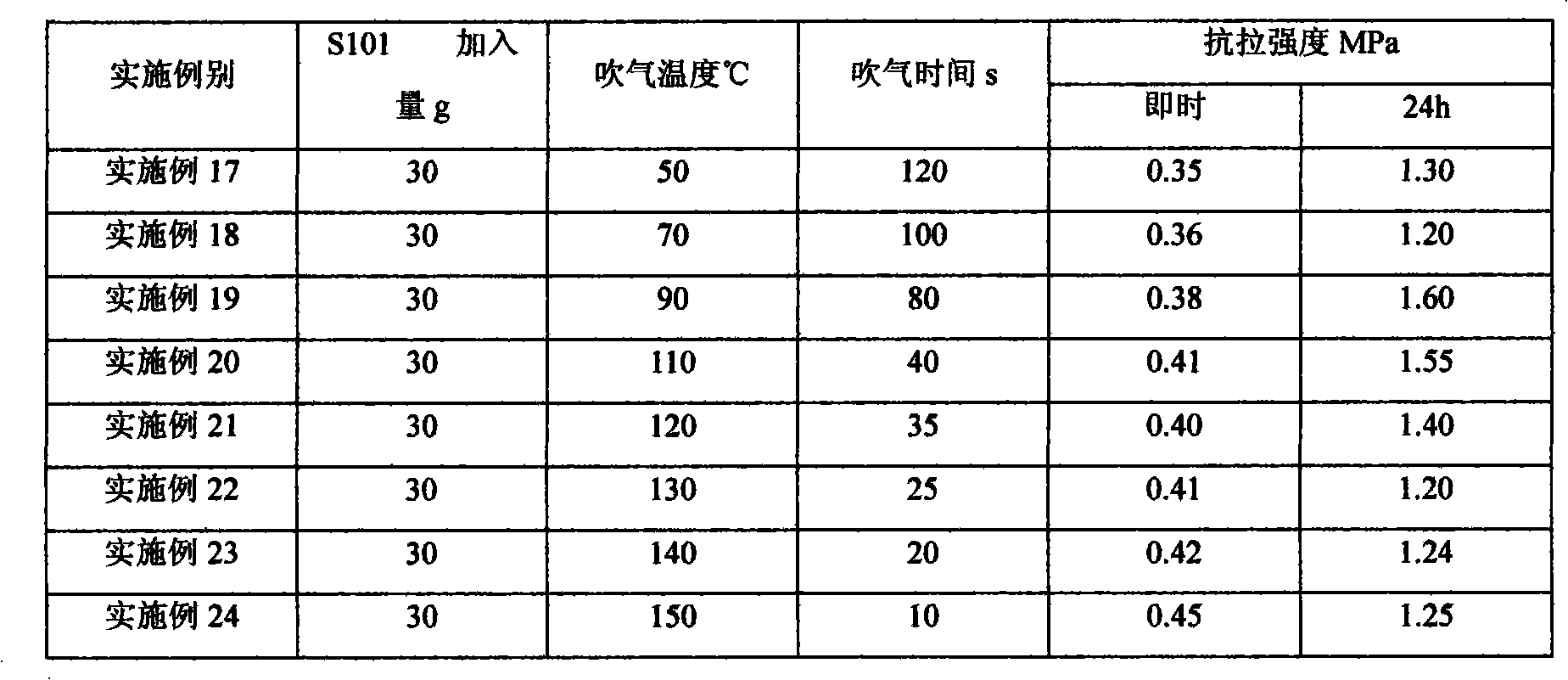

Method for making core with aeration ossification

InactiveCN101293271AWide variety of sourcesLow priceFoundry mouldsFoundry coresSoluble glassGlycerol

The invention discloses a core making method by gas-blowing hardening, which is characterized in that the mass percentage of mixing materials of the making core sand is as follows: 0.9-7.0 percent of soluble glass, 0.1-1.0 percent of moisture absorption resistant agent and raw sand for the rest; the used moisture absorption resistant agent can be triacetyl glycerine, diacetin, glycerol mono acetate bulk, diethylene glycol acetic ester, propylene glycol acetic ester, other polylol organic acid ester or the mixture thereof; the volume percentage of the blowing gas for hardening is as follows: 25-100 percent of C2-C4 organic ester and 0-75 percent of C1-C2 alcohols. The method of the invention has no toxicity and odor in production process, and the produced cores have better stripping strength.

Owner:SHENYANG HYATON FOUNDRY MATERIAL

Polylactic acid degradable film

The invention relates to a polylactic acid degradable film with controllable degradable time, belonging to the technical field of medical appliances. The polylactic acid degradable film comprises the following components in percentage by weight: 1%-35% of plasticizer and 65%-99% of polylactic acid, polylactic acid-glycollic acid copolymer, polyglycollic acid-epsilon-caprolactone copolymer, polylactic acid-epsilon-caprolactone copolymer or polylactic acid-glycollic acid-epsilon-caprolactone copolymer, wherein the plasticizer is more than one of citrate ether, glucose monoester ether, fatty acid ester ether, polyethylene glycol 400-2,000, low-molecular weight polylactic acid, glycerol, glycerol triacetate and ethylene glycol monobutyl ether acetate. The manufactured polylactic acid degradable film of the invention has good strength and controllable degradable time, can be used for a human body, such as an anti-adhesion film in a surgical operation, a digestive stent, a biliary stent, a prostate stent, an endovascular stent, an intrauterine stent and a medical appliance fitting, and can be used for preparing the required controllable polylactic acid degradable film according to the clinical requirements.

Owner:山东省医疗器械研究所

Use of lactide acid polymer

Use of lactate polymer is for filter tip material of cigarette, their molecular weight is between 5-200,000, smelting point is between140-170 degrees C, melt flowing index is 5-30g / 10min at 190 degrees C and 2.16kg load, binding strength at room temperature is 4-12Mpa by triacetate glyceride. It has proper crystallinity, dissolubility, adsorptive performance and mechanical strength and can satisfy requirement of spinning, after-treatment and shearing.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

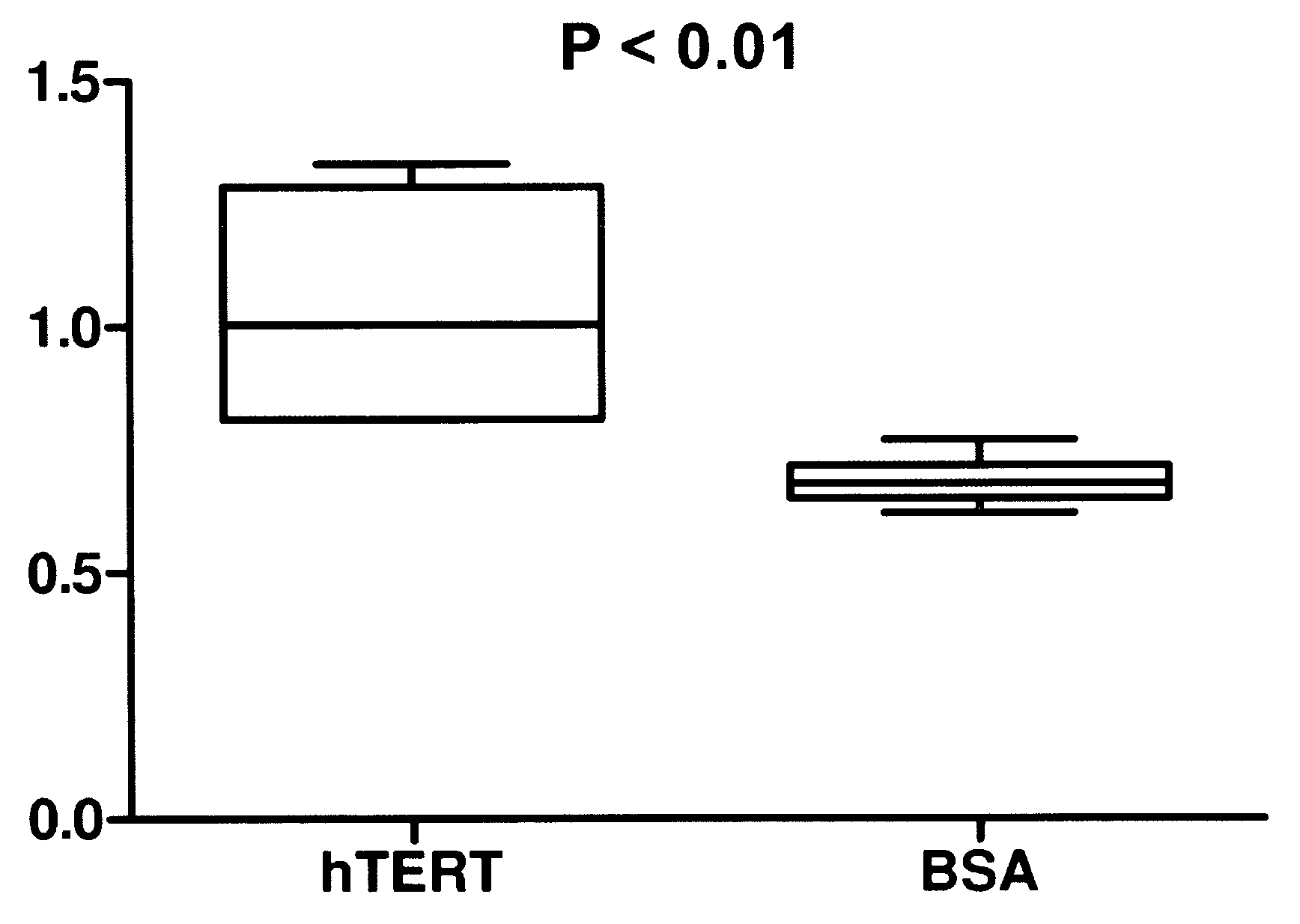

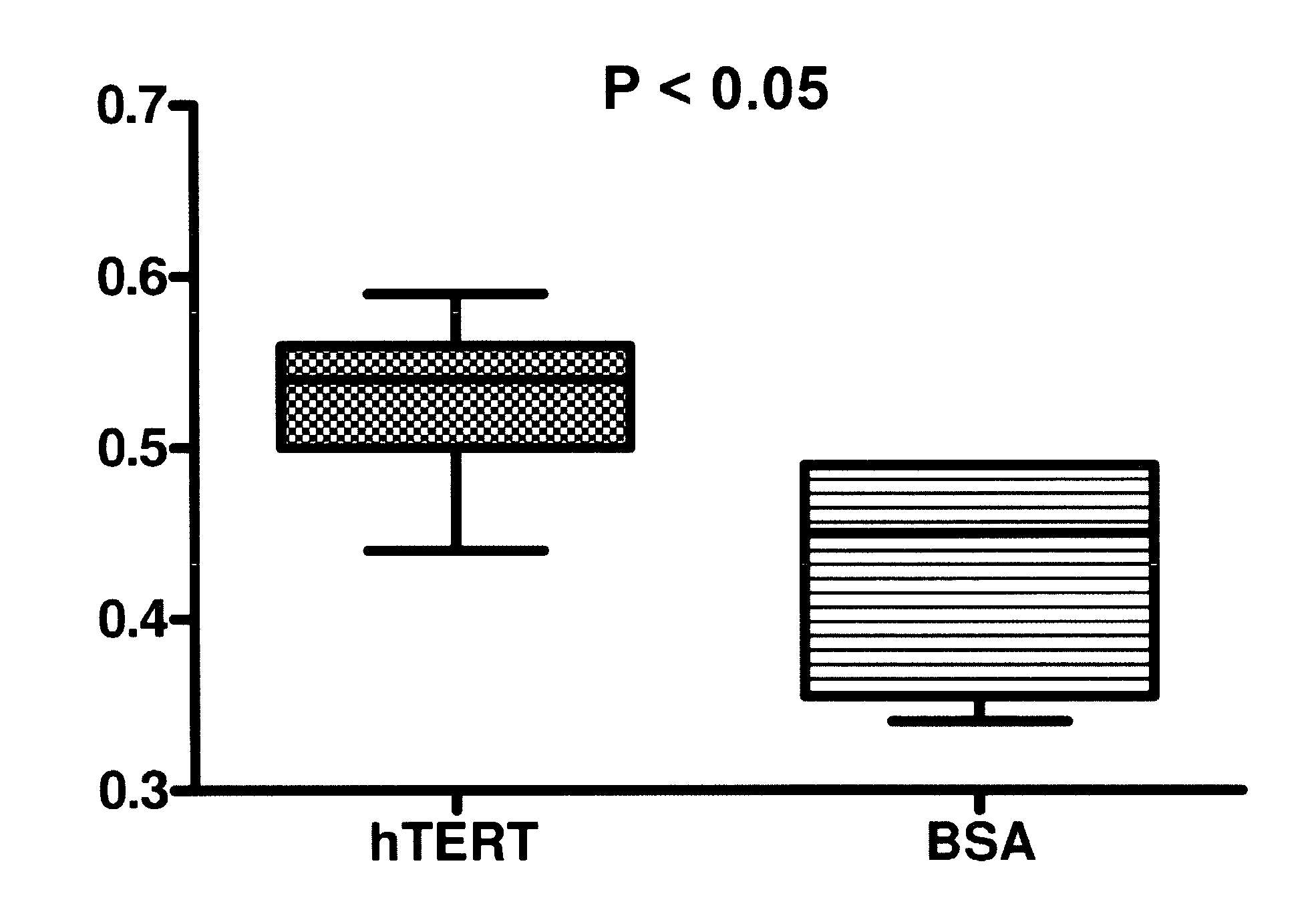

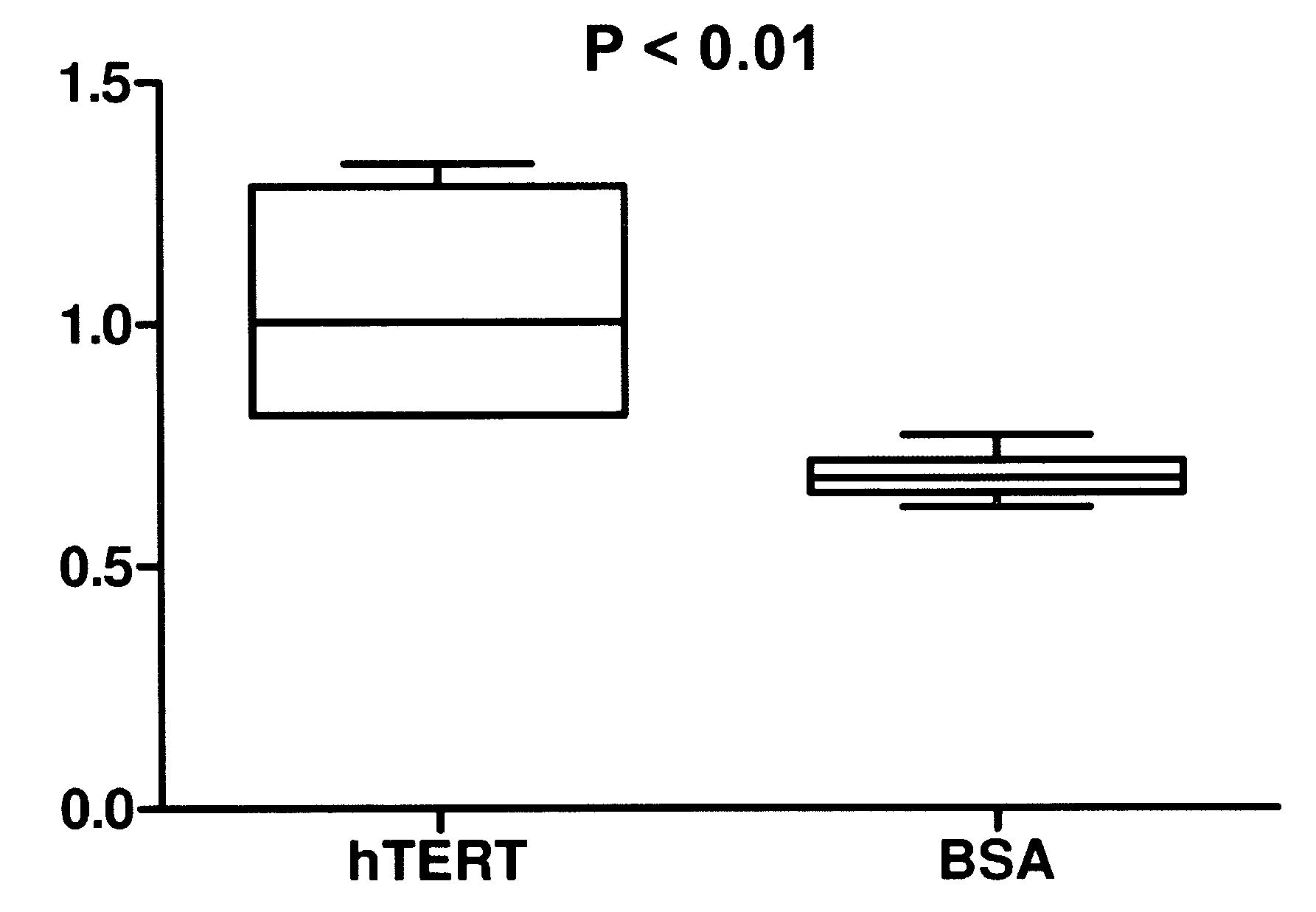

Telomerase delivery by biodegradable Nanoparticle

InactiveUS20090142408A1Effectively crossControl releasePowder deliveryPeptide/protein ingredientsAge related diseaseHydrophilic polymers

A therapeutic compound consisting of human telomerase, its catalytic subunit hTert, or a known variant of either, and a biodegradable nanoparticle carrier, which can be administered to cells in a cell culture or in a living animal, is provided herein. The therapeutic compound is envisioned as a method for treating a wide variety of age-related diseases such as idiopathic pulmonary fibrosis, aplastic anemia, dyskeratosis congenita, arteriosclerosis, macular degeneration, osteoporosis, Alzheimer's, diabetes type 2, and any disease that correlates with telomere shortening and may be corrected or ameliorated by lengthening telomeres. The therapeutic compound is also envisioned as method for potentially treating more generic problems of human aging. The nanoparticle carrier is comprised of certain biodegradable biocompatible polymers such as poly(lactide-co-glycolide), poly(lactic acid), poly(alkylene glycol), polybutylcyanoacrylate, poly(methylmethacrylate-co-methacrylic acid), poly-allylamine, polyanhydride, polyhydroxybutyric acid, polycaprolactone, lactide-caprolactone copolymers, polyhydroxybutyrate, polyalkylcyanoacrylates, polyanhydrides, polyorthoester or a combination thereof. The nanoparticle may incorporate a targeting moiety to direct the nanoparticle to a particular tissue type or a location within a cell. The nanoparticle may incorporate a plasticizer to facilitate sustained release of telomerase such as L-tartaric acid dimethyl ester, triethyl citrate, or glyceryl triacetate. A nanoparticle of the present invention can further contain a polymer that affects the charge or lipophilicity or hydrophilicity of the particle. Any biocompatible hydrophilic polymer can be used for this purpose, including but not limited to, poly(vinyl alcohol).

Owner:SARAD MATTHEW

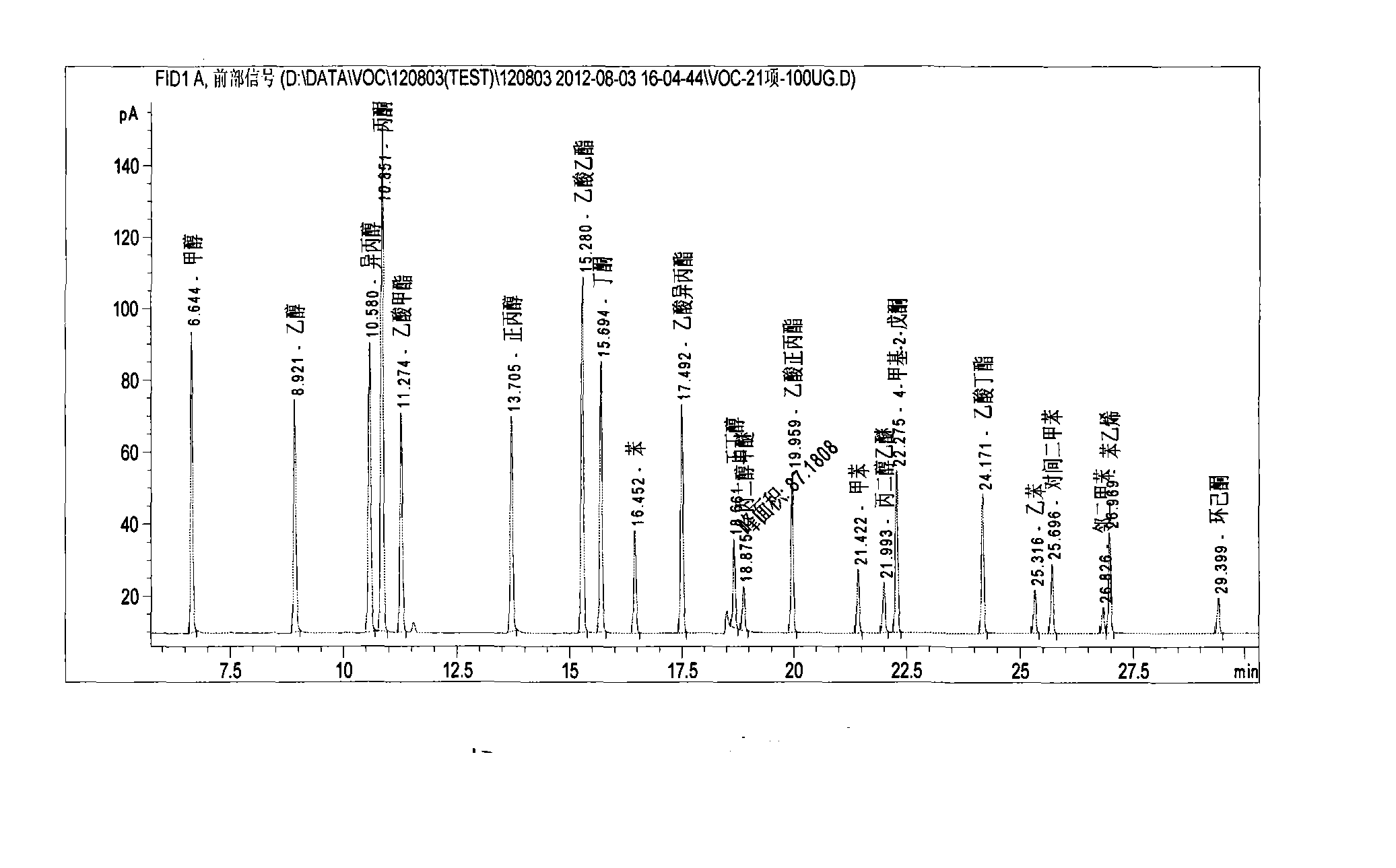

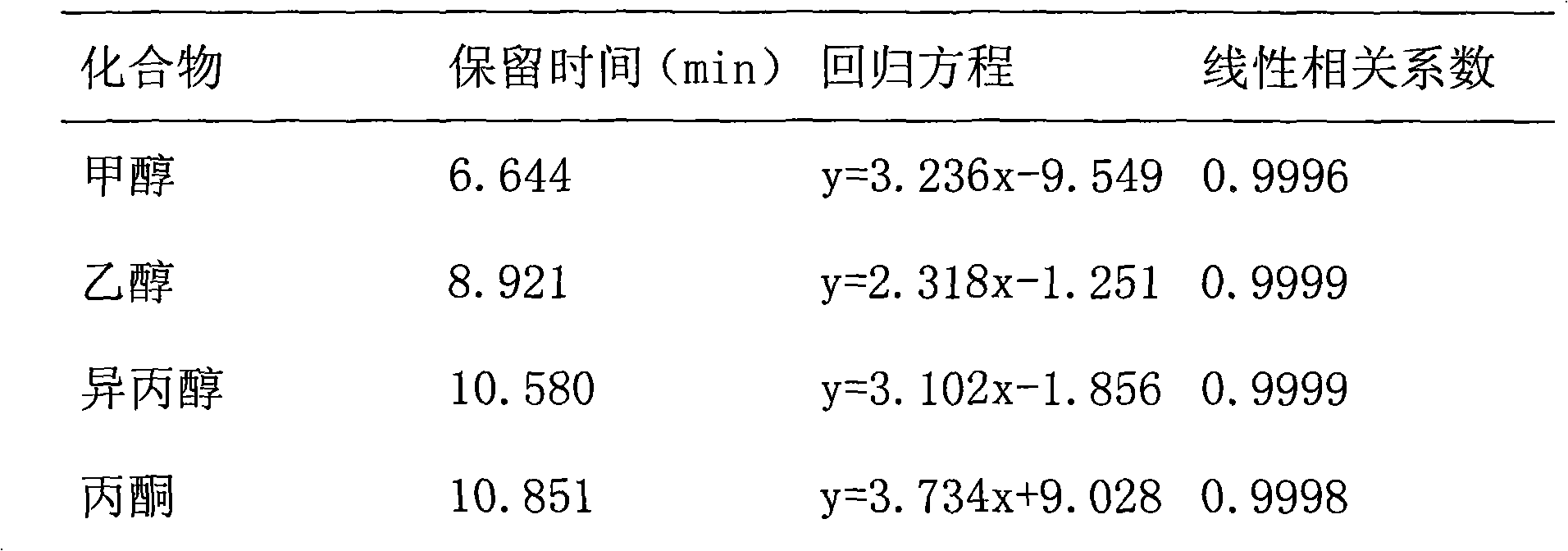

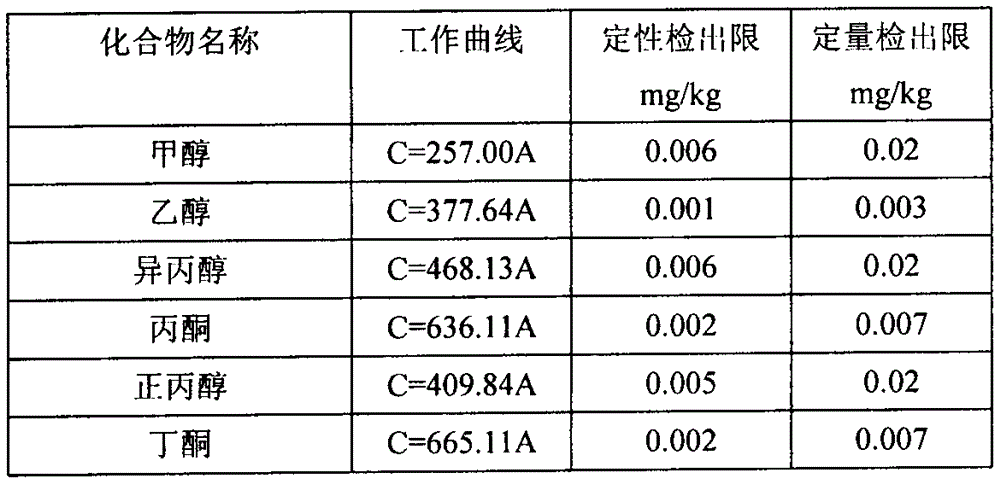

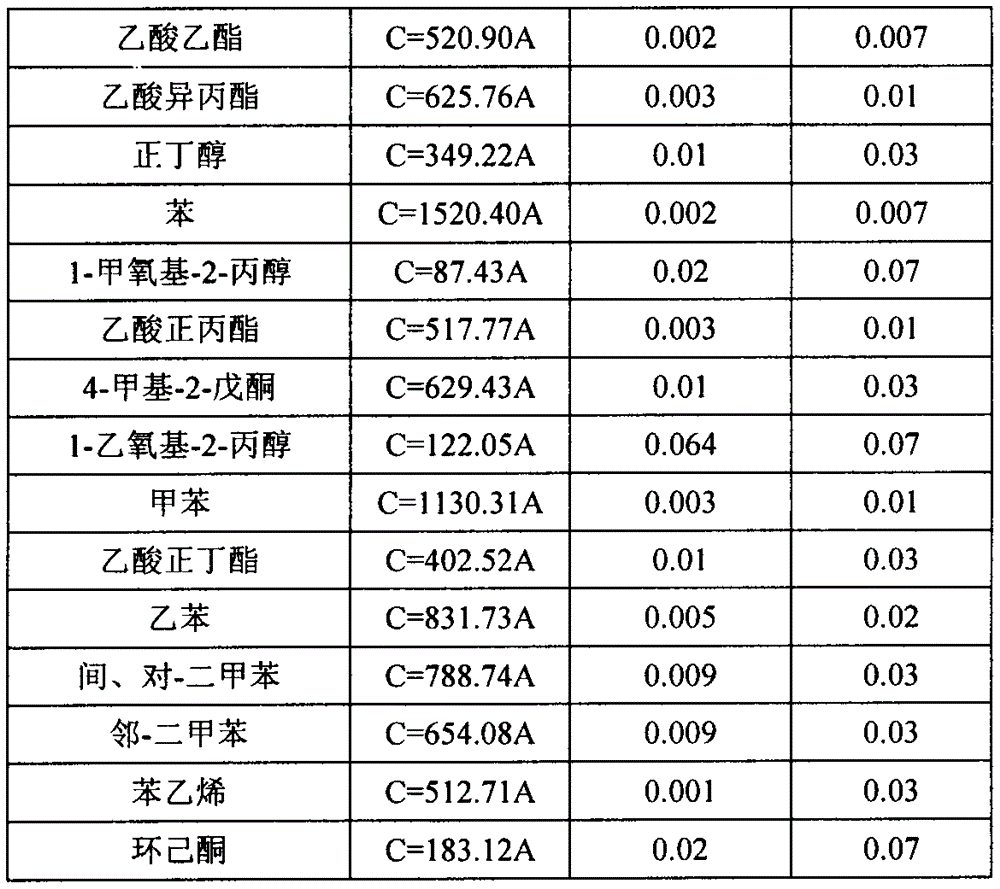

Method for detecting 21 volatile organic compounds (VOC) in tobacco packing box

The invention belongs to the technical field of tobacco packing box, and in particular relates to a method for detecting contents of 21 volatile organic compounds (VOC), including benzene, methyl benzene, p-xylene, m-xylene, o-xylene, styrene, methanol, ethanol, acetone, isopropyl alcohol, methyl acetate, normal propyl alcohol, ethyl acetate, butanone, acetic acid isopropyl ester, n-butyl alcohol, propylene glycol monomethyl ether, n-propyl acetate, propylene glycol monoethyl ether, 4-methyl-2-pentanone, butyl acetate, cyclohexanone in a tobacco packing box. The method for detecting 21 volatile organic compounds in the tobacco packing box disclosed by the invention comprises the following steps of: sample pretreatment: preparing a piece of hard box packing paper; cutting and reserving a main packing surface by an area of 22.0cm*5.5cm; rolling the printing surface of the sample inwards to obtain a barrel-shaped part; putting the barrel-shaped part in a headspace bottle; adding 1000mu l of glycerol triacetate; sealing, and implementing a headspace-gas chromatography detection. The method disclosed by the invention is high in sensitivity, high in recovery rate, and excellent in precision of detecting result.

Owner:GUANGZHOU PONY TESTING TECH

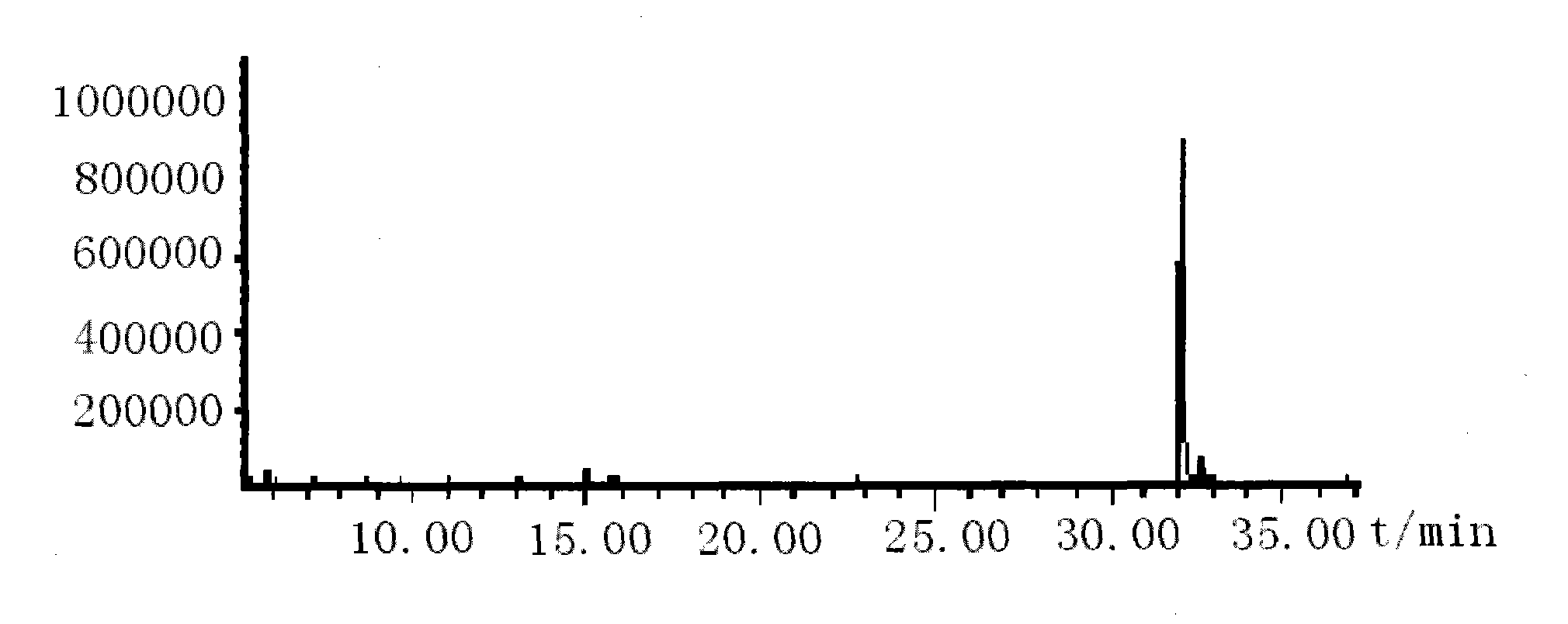

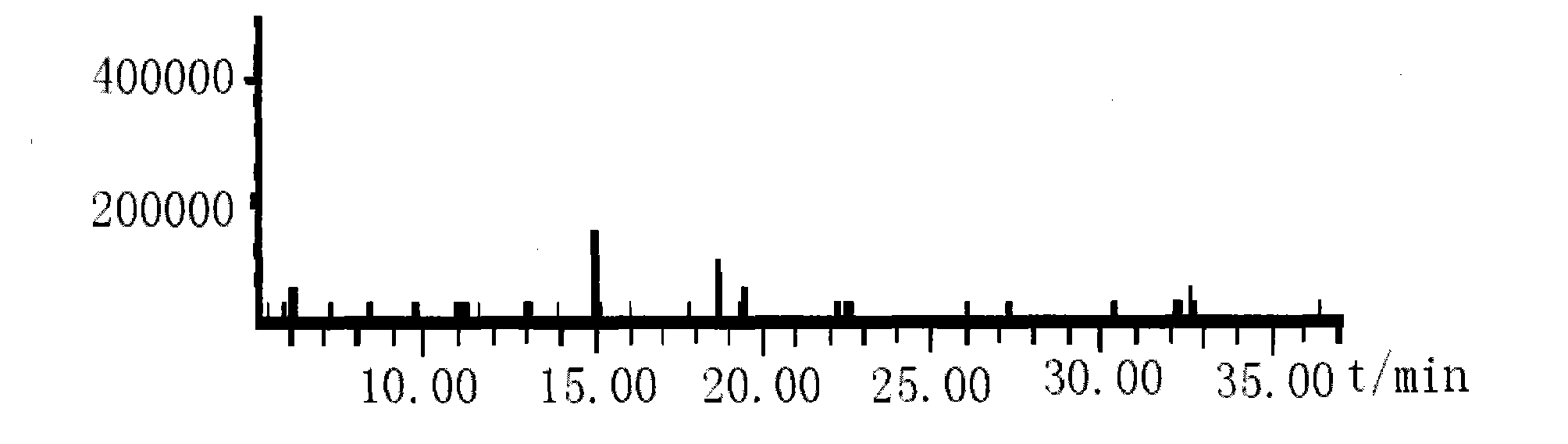

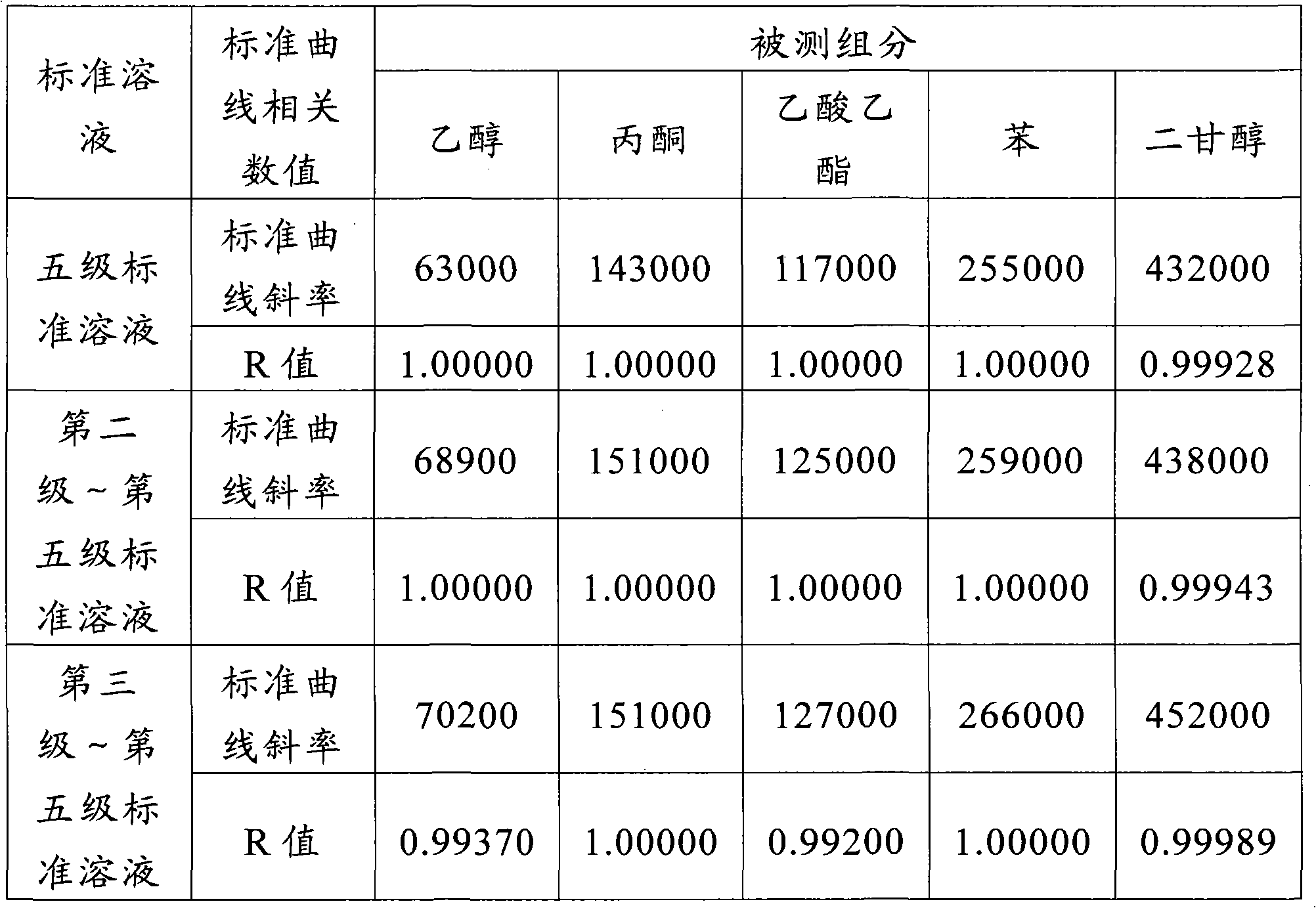

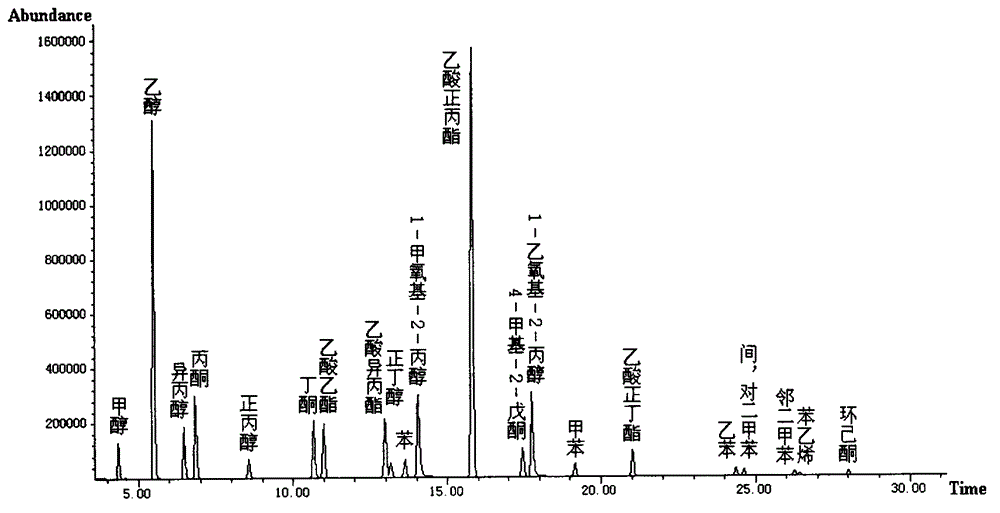

Quantitive detection method of volatile organic compounds in additive of cigarette filter stick

InactiveCN101650280AControl contentGuaranteed qualityComponent separationStrength propertiesCigarette filterStandard solution

The invention provides a quantitive detection method of volatile organic compounds in an additive of a cigarette filter stick, comprising the following steps: (1) determining the volume by triacetyl glycerine; preparing different concentrations of standard solutions of detected components in the additive of the cigarette filter stick; (2) analyzing the standard solutions by a chromatograph; plotting standard curves of the detected components; (3) analyzing a sample to be detected by the chromatograph and computing the concentrations of the detected components in the sample to be detected by the standard curves. The provided quantitive detection method can accurately detect the content of volatile organic compounds in the additive of the cigarette filter stick, thereby controlling the content of the volatile organic compounds in the additive of the cigarette filter stick according to a detection result and ensuring the quality of cigarette gas.

Owner:CHINA TOBACCO GUANGDONG IND

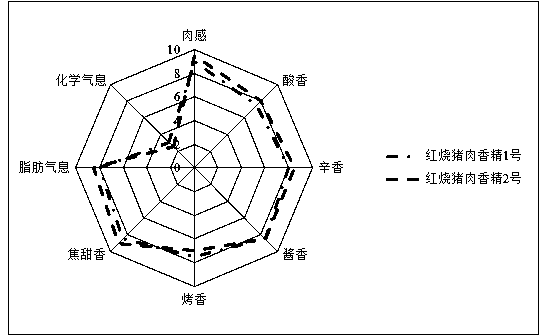

Mixed stewed pork essence and making method thereof

InactiveCN104026546AHigh concentration of fragranceRealistic aromaFood preparation2-methyl-3-furanthiolFuran

The invention discloses mixed stewed pork essence which consists of furanone, ethyl maltol, 2-acetylpyrazine, methyl cyclopentenolone, difurfuryl sulfide, 3-sulfydryl-2-butanol, 2-methyl-3-furan mercaptan, di(2-methyl-3-furan mercaptan)-disulfide, methyl(2-methyl-3-furan mercaptan)-disulfide, acetic acid, 3-sulfydryl-2-butanone, 3-propionaldehyde, thiophane-3-acetone, 2,3,5-trimethyl pyrazine, counter,counter-2,4-decadiene aldehyde, furfuryl disulfide, furfurylmercaptan, anise camphor, anisic aldehyde, pepper essential oil, 2-acetyl thiazole, delta-dodecalactone, 4-methyl-5(beta)-hydroxyethyl thiazole acetate, onion oil alcohol, 4-methyl-4-bran sulfenyl-2-pentanone and glycerol triacetate. The mixed stewed pork essence is high in biofidelity and mellow and fine in fragrance, has a good application effect and is economical and practical.

Owner:SHANGHAI INST OF TECH

Water-soluble film coated premix agent

ActiveCN102512401ACombination is firm and tightUniform colorPharmaceutical delivery mechanismPolyethylene glycolFilm coating

The invention relates to a water-soluble film coated premix agent, which comprises the following components: cellulose derivatives or acrylic acid derivatives, polyvinyl alcohol, povidone K30, polyethylene glycol 6000, glyceryl triacetate, talcpowder and water. According to the water-soluble film coated premix agent, a coated layer and medicinal tablets are combined firmly and closely, so that the tablets are uniform in coloring, and uniform in thickness and smooth; and the coated premix agent with different colors can be obtained by different ratios of titanium dioxide and a colorant, so that colorless and transparent coating, white coating and the colored coating can be obtained; and therefore, the appearance of medicines is improved. The polyvinyl alcohol is added into the water-soluble film coated premix agent, so the solid content of the film coated premix agent can be improved; and therefore, coating time is shortened.

Owner:BEIJING YINGMAO PHARMA

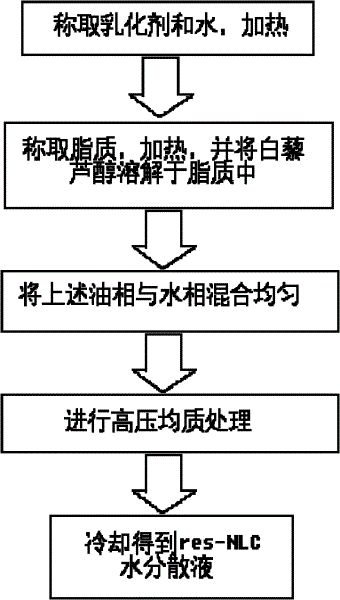

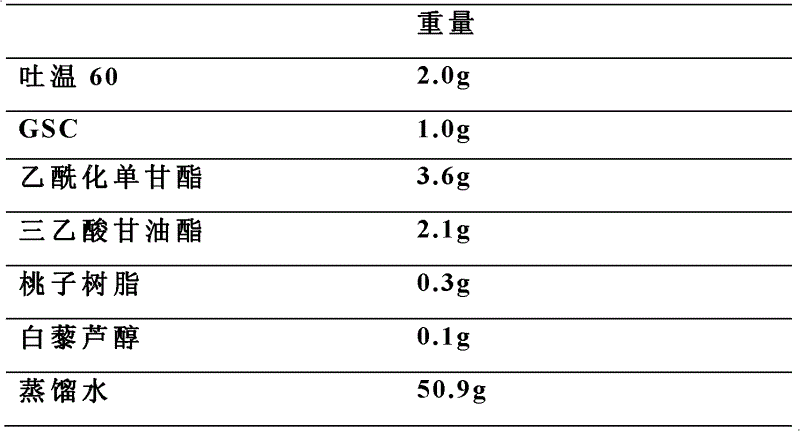

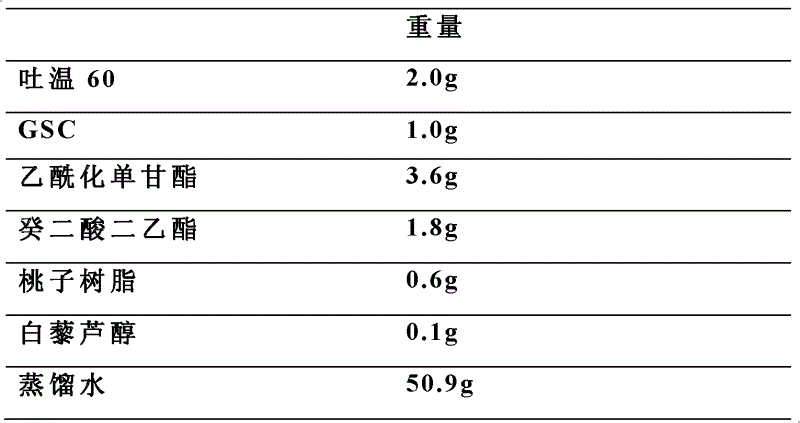

Resveratrol nanostructured lipid carrier and preparation method thereof

InactiveCN102614091AStructural disorderImprove stabilityCosmetic preparationsToilet preparationsLipid formationSolubility

The invention discloses a resveratrol nanostructured lipid carrier. The resveratrol nanostructured lipid carrier is loaded with active pharmaceutical ingredients of resveratrol and is characterized by comprising 0.1 to 1wt% of resveratrol, 2 to 20wt% of at least one emulsifier, 2 to 30wt% of a composite lipid material and the balance water, wherein the composite lipid material is a mixture of at least one solid lipid material and at least one liquid lipid material. The at least one solid lipid material and the at least one liquid lipid material are selected from glyceryl triacetate, acetylated monoglyceride, diethyl sebacate, diisopropyl adipate, diisopropyl sebacate, glycerol monolaurate, peach resin and an octadecyl alcohol. The resveratrol nanostructured lipid carrier has good stability and water-solubility. The preparation method of the resveratrol nanostructured lipid carrier is simple and controllable and has good repeatability. The resveratrol nanostructured lipid carrier can be utilized in preparation of resveratrol-containing cosmetics.

Owner:夏强 +1

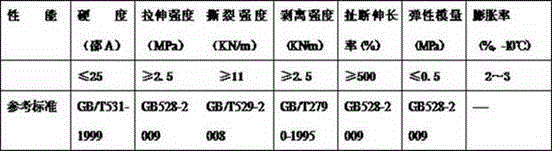

Polymer material for quickly repairing cracks of asphalt pavement and preparation method thereof

The invention relates to a polymer material for quickly repairing cracks of an asphalt pavement and a preparation method thereof. The polymer material is prepared by mixing two components A and B and quickly solidifying the mixed components, wherein the component A comprises the following ingredients in parts by weight: 41-60 parts of polyoxypropylene diol N220, 25-20 parts of polyoxypropylene diol N210, 1-0.4 part of carbon black, 2-1 part of a catalyst, 20.5-15.5 parts of glycerol triacetate, 8-1 part of a chain extender, 2 parts of a latent curing agent, 0.5-0.1 part of a BYK-535 defoaming agent and 50-80 parts of water absorbent microcapsules; the component B is 100 parts of polyether urethane prepolymers; mixing the component A with the component B according to the mass ratio of (1.5-1.8) : 1 to solidify so as to obtain the polymer material for quickly repairing the cracks of the asphalt pavement. The non-flowing time of the prepared polymer material is shorter than 5 min at 20 DEG C, and if being applied to repair the cracks of the asphalt pavement, the prepared polymer material can be solidified after 30 min and the asphalt pavement has the transportation service. The asphalt pavement repairing polymer material has a self-repairing function so as to prevent a situation that the repaired pavement is cracked again due to the reduced temperature; the crack repairing process is simple, the repairing speed is high, the construction efficiency is high, the application effect is good, no pollution generates, the production is clean, and the polymer material is green and environment-friendly.

Owner:北京艾施姆科技有限公司

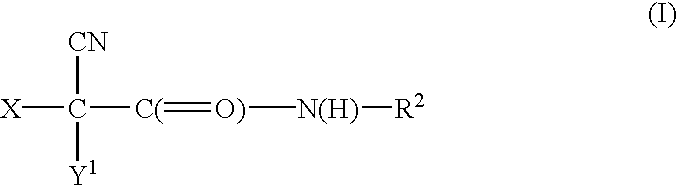

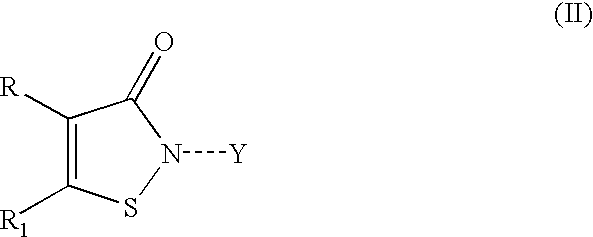

Halocyanoacetamide antimicrobial compositions

A stabilized halocyanoacetamide composition in the form of a solution or emulsifiable concentrate using selected ester solvents is disclosed. Preferred ester solvents include glyceryl triacetate, ethyl acetate and diethyl phthalate. Particularly preferred are stabilized compositions containing 2,2-dibromo-3-nitrilopropionamide, glyceryl triacetate and optional non-ionic surfactants or additional antimicrobial compounds, particularly 3-isothiazolone compounds.

Owner:GIRONDA KEVIN F +5

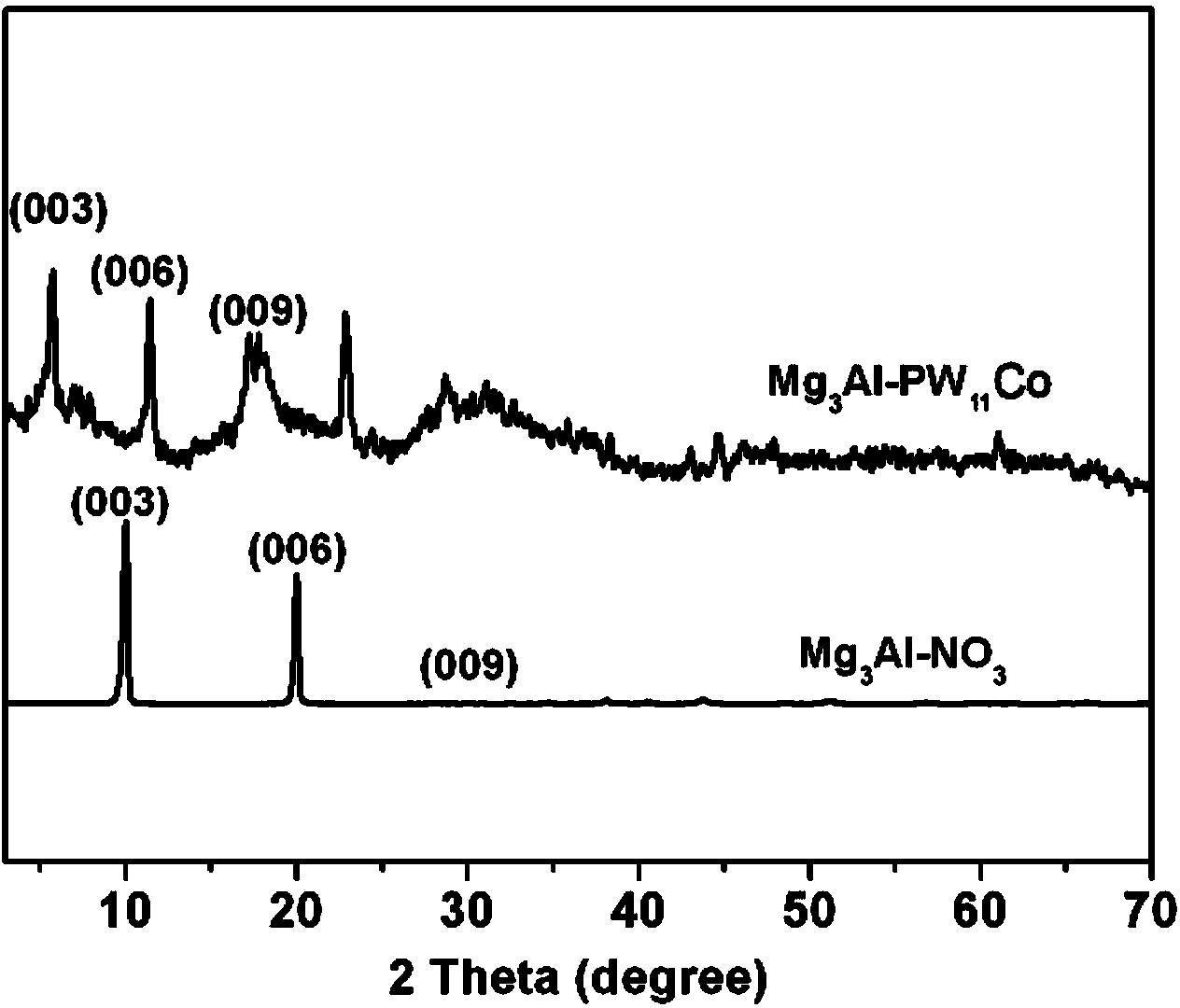

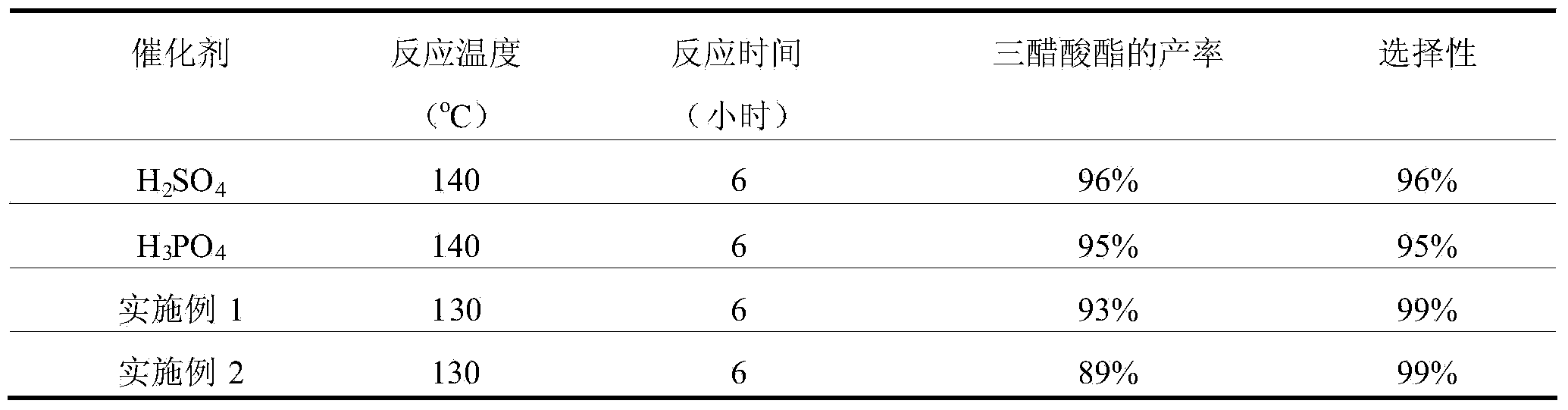

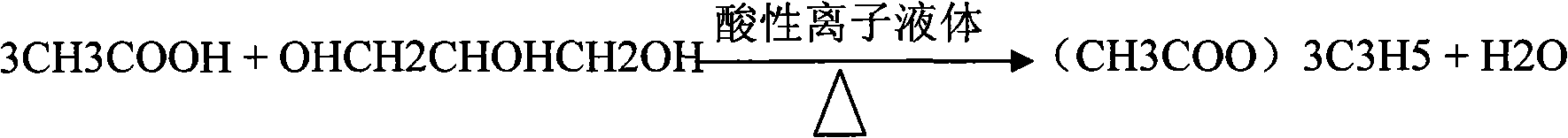

Application of polyacid intercalated hydrotalcite catalyst in preparing glyceryl triacetate

ActiveCN103706403ARealize green productionReduced activityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsReaction temperatureIon exchange

The invention discloses a polyacid intercalated hydrotalcite catalyst and application of the polyacid intercalated hydrotalcite catalyst to preparation of environment-friendly toxic-free glyceryl triacetate, which belong to the technical field of catalyst preparation. Polyacid is intercalated into hydrotalcite through an ion exchanging method and firstly used for producing the glyceryl triacetate. The prepared polyacid intercalated hydrotalcite catalyst has a supermolecular lamella structure and a nano-grade size; the glyceryl triacetate is prepared through the catalysis of the polyacid intercalated hydrotalcite catalyst. Compared with concentrate sulfuric acid and phosphoric acid, the polyacid intercalated hydrotalcite catalyst has the advantages that the high-efficient catalytic activity and catalytic selectivity can be maintained under the situation that the reaction temperature is lowered; the corrosion on equipment is small, and no waste liquid with high acidity is produced; easiness in recycling can be realized, the stability is good, and after the catalyst is continuously used for 3 months, the poisoning phenomenon of the catalyst does not occur and the activity of the catalyst is not obviously reduced.

Owner:BEIJING UNIV OF CHEM TECH +1

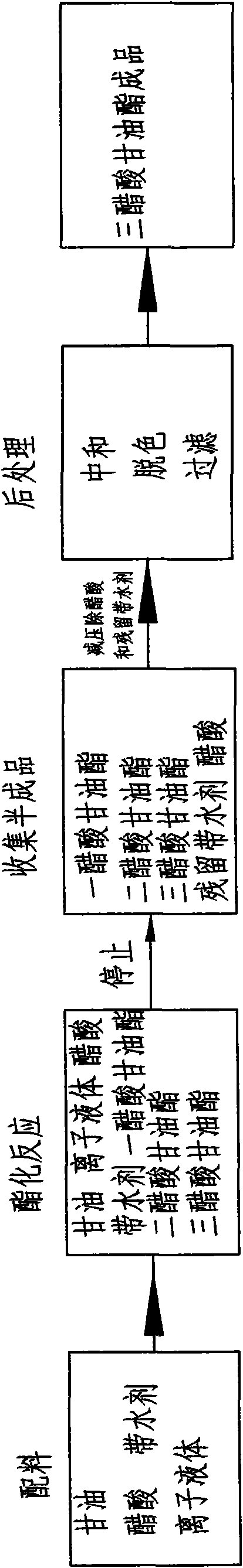

Acetate plasticizer for improving smoking property of cigarette and method for preparing same

InactiveCN1994164AQuality improvementHigh fullnessTobacco smoke filtersVegetal fibresFlavorPlasticizer

Owner:YUNNAN REASCEND TOBACCO TECH GRP +1

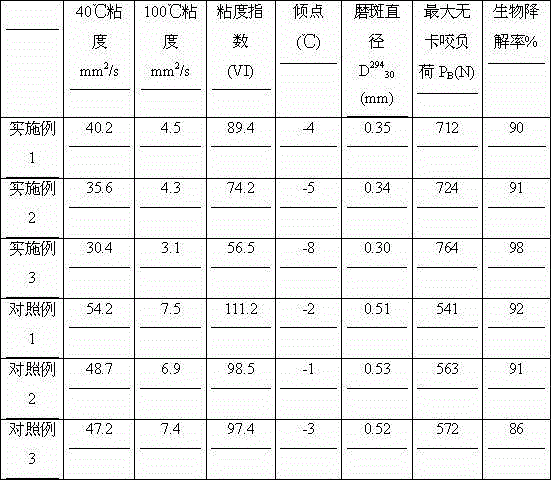

Method of preparing biodegradable lubricating oil

The invention relates to a method of preparing biodegradable lubricating oil. The method of preparing biodegradable lubricating oil belongs to the technical field of lubricating oil and comprises the steps: uniformly mixing polyhydric alcohols, vegetable oil, catalysts and organic solvent, heating to perform reaction and obtaining polyol ester; decompressing and distilling the obtained polyol ester, evaporate the organic solvent, adding formic acid, heating and dripping 20-40 parts of hydrogen peroxide; after the dripping is finished, keeping warm, standing and delaminating, removing a water layer, distilling an oil layer, collecting fractions to obtain modified polyol ester; and uniformly mixing the modified polyol ester with base oil, glyceryl triacetate, an xanthan gum, an antirust agent, an anti-wear reagent at extreme pressure and a surfactant to obtain the biodegradable lubricating oil. The lubricating oil provided by the invention keeps better biodegradability and has good anti-wearing property.

Owner:领驰慧润滑科技(河北)有限公司

Flame-retardant polyethylene-polypropylene composite plastic

The invention discloses a flame-retardant polyethylene-polypropylene composite plastic and particularly relates to the field of preparation of a plastic formula. The flame-retardant polyethylene-polypropylene composite plastic includes following components, by weight, polyethylene, polyvinyl chloride, dimethylamino propylamine, melamine, antimony oxide, glycerol triacetate, an anti-oxidant, benzophenone, ammonium polyphosphate, triphenyl triphosphate and glass fibers. The composite plastic is high in mechanical strength, is good in flame-retardant performance, is excellent in corrosion-resistant performance and anti-static performance, is low in cost and is long in service life.

Owner:QINGDAO DTCN NEW MATERIAL TECH DEV

Preparation method of film coating pre-mixing agent and uses thereof

ActiveCN101380475AThe method is simple to prepareImprove stabilityInorganic non-active ingredientsPharmaceutical delivery mechanismPolyethylene glycolDrugs preparations

The invention discloses a method for preparing film coating premix and the application thereof. The film coating premix comprises the following components: cellulose derivative or acrylic derivative, povidone K30, polyethylene glycol 6000, glyceryl triacetate and talcum powders. The film coating premix has low cost and simple and controllable preparation method, and is suitable for scale production; the film coating premix also comprises titanium dioxide, pigment and color lake; a coating level and a drug tablet have firm and tight combination, uniform thickness and uniform and smooth coloring. The film coating premix with various colors can be obtained by different ratioes of the titanium dioxide, the pigment and the color lake to better satisfy various needs for solid drug preparation film coating, and meanwhile, the invention also discloses the preparation method for the solid drug preparation film coating and the application thereof.

Owner:BEIJING YINGMAO PHARMA

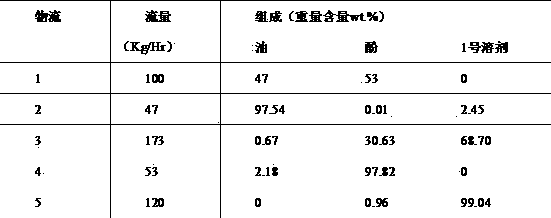

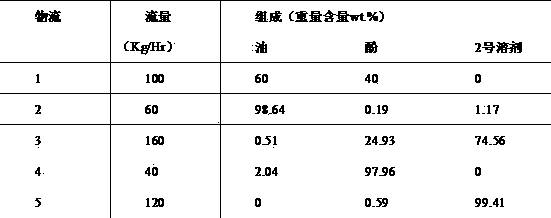

Method for extracting phenol compounds from direct coal liquefied oil through extractive distillation

ActiveCN103896739AHigh recovery rateIncrease relative volatilityOrganic chemistryOrganic compound preparationSulfolaneExtractive distillation

The invention relates to a method for extracting phenol compounds from direct coal liquefied oil through extractive distillation. An extractive distillation solvent (hereinafter referred to as solvent) adopted in the method is glyceryl triacetate and / or sulfolane, or a mixed solvent formed by mixing glyceryl triacetate and / or sulfolane and one or more selected from glycerol, triethanolamine, triethylene glycol, tetraethylene glycol, dimethyl sulfoxide and diethanol amine according to any proportion. The method is used for extracting phenol compounds from direct coal liquefied oil in an extraction distillation tower by using the solvent, then, a solvent flow rich in the phenol compounds enters a recovery tower and is separated, the phenol compounds discharged from the top of the recovery tower are recovered after being cooled to obtain phenol products, and the solvent is recycled after being discharged from the bottom of the recovery tower. The method has the characteristics of high product purity, low system energy consumption, no wastewater generation, no acid and alkaline waste and no corrosion to equipment.

Owner:TAIYUAN UNIV OF TECH

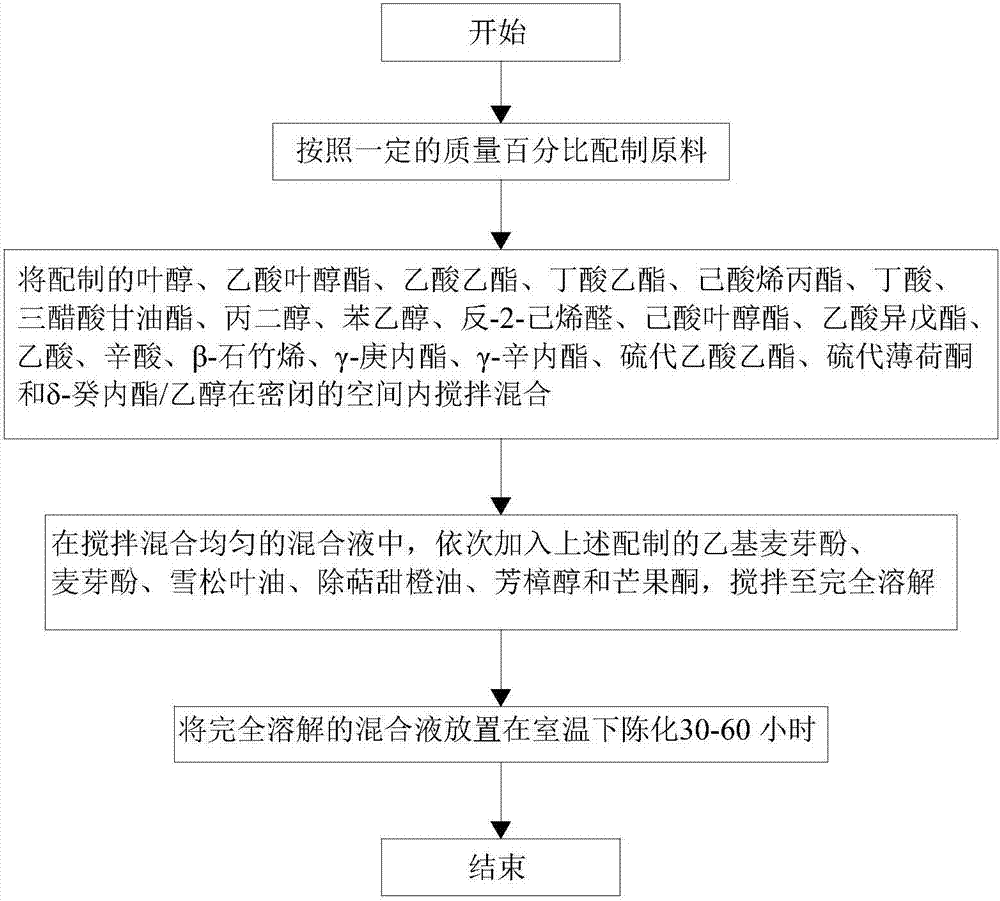

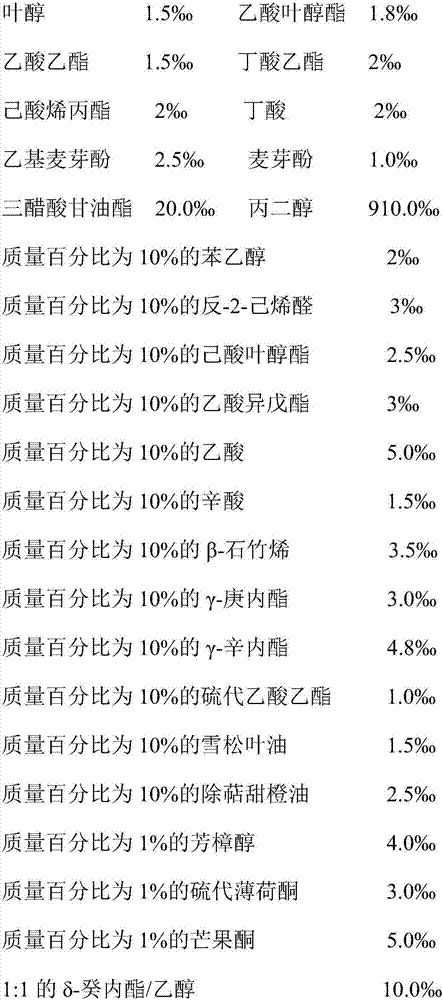

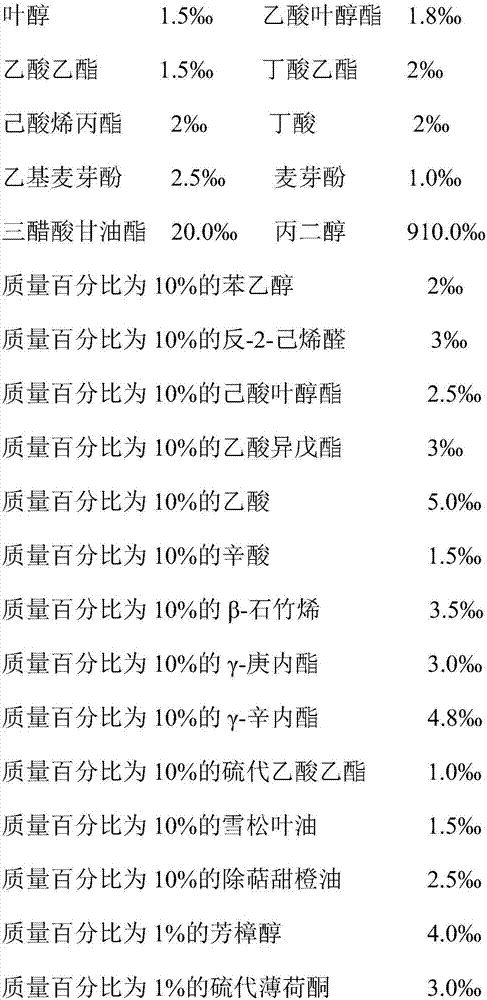

Preparation method of mango-flavored essence for electronic cigarettes

InactiveCN106995749ASimple processEasy to operateTobacco devicesEssential-oils/perfumesMint familyEthyl butyrate

The invention discloses a preparation method of mango-flavored essence for electronic cigarettes. The preparation method comprises the following preparation steps: step 1, preparing raw materials according to certain mass percent; step 2, stirring and mixing prepared cis-3-hexen-1-ol, cis-3-hexenyl acetate, ethyl acetate, ethyl butyrate, allyl hexanoate, butyric acid, glyceryl triacetate, propylene glycol, phenethyl alcohol, ethyl thioacetate, para-mentha-8-thiolone and delta-decalactone / ethanol in a sealed space; step 3, sequentially adding prepared ethyl maltol, maltol, cedar leaf oil, sweet orange oil terpeneless, linalool and mango ketone into the stirred mixed solution; stirring until all the raw materials are completely dissolved; step 4, putting a mixed solution at room temperature and ageing for 30h to 60h. According to the preparation method of mango-flavored essence for the electronic cigarettes, disclosed by the invention, the mango-flavored essence has a special rich and fresh mango flavor and the flavor is rich, mellow and lasting; the mango-flavored essence has no nicotine, has the mango flavor which is favored by the majority of female consumers and has the effect of refreshing breath of a user.

Owner:广东优尼克生物科技有限公司

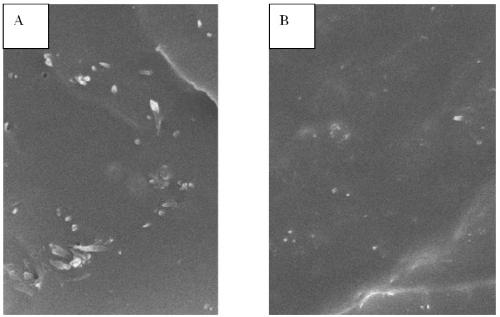

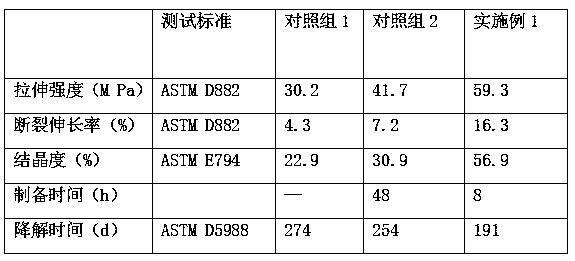

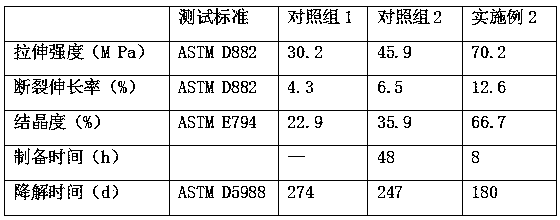

Environment-friendly toughening nano-cellulose-polylactic acid biodegradable material and preparation method thereof

The invention discloses an environment-friendly toughening nano-cellulose-polylactic acid biodegradable material and a preparation method thereof, and belongs to the field of polymer processing. The biodegradable material comprises polylactic acid, nano-cellulose, glycerol triacetate, polyvinyl alcohol water solution and additives. The invention further discloses a preparation method of the biodegradable material. The method includes the steps: coating and mixing the nano-cellulose and toughening agents in organic solvents in advance; placing mixed colloids, processing agents and polylactic acid in a twin-screw extruder to blend and compound the nano-cellulose and the polylactic acid through dual functions of solvent evaporation and melt blending to obtain the biodegradable material. The method is simple and convenient to operate, short in preparation time, dispersibility of the nano-cellulose in a polylactic acid substrate is achieved, and the prepared composite material improves toughness and has environmental safety.

Owner:JIANGSU ACAD OF AGRI SCI

Preparation method for cellulose acetate porous microspheres and product applying preparation method

The invention discloses a preparation method for cellulose acetate porous microspheres and a product applying the preparation method. The method comprises the following steps: dissolving cellulose acetate containing glycerol triacetate into an organic solvent; and then adding a pore-foaming agent aqueous solution to obtain a water in oil type W / O emulsifiable solution; finally, adding the W / O emulsifiable solution into an outer aqueous phase aqueous solution to remove the organic solvent so as to obtain the cellulose acetate porous microspheres. The cellulose acetate porous microsphere provided has average particle diameter of 20.0-2000 micrometers, BET specific surface area of 1.0-50.0 m<2> / g, pore diameter of 50-20000 nm, pore volume of 0.5-10.0 mL / g and glycerol triacetate content of 1.0-20.0 percent. The porous microspheres have porous structures which are communicated to one another, and are large in pore volume; the pore structure and the particle diameter are adjustable. The structure is favorable for being applied to the fields of adsorptive separation and water treatment and biomedicine.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

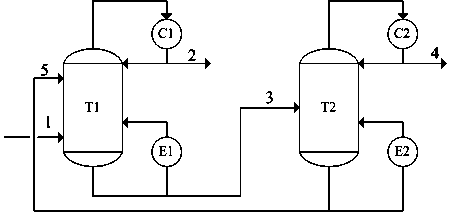

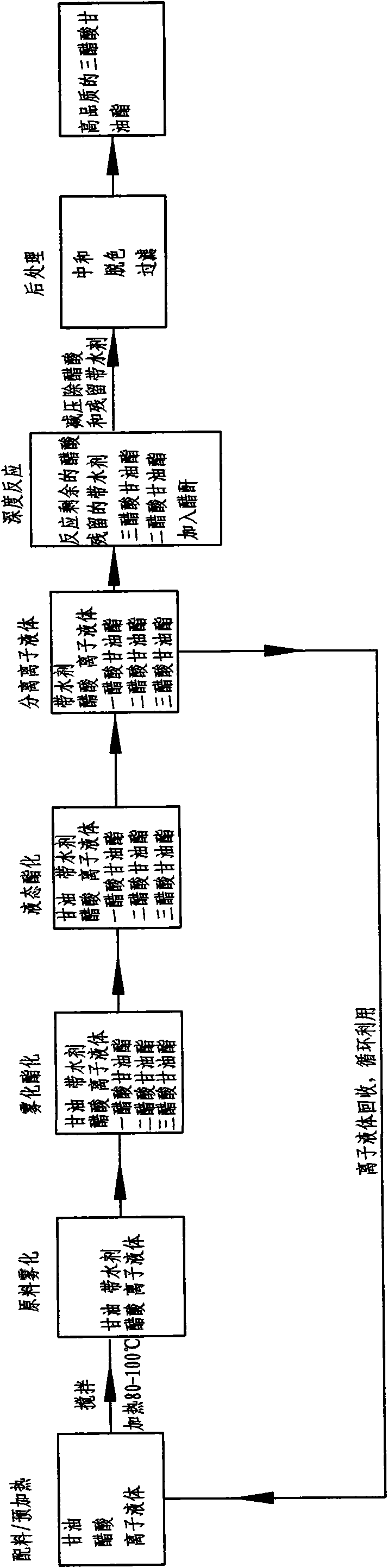

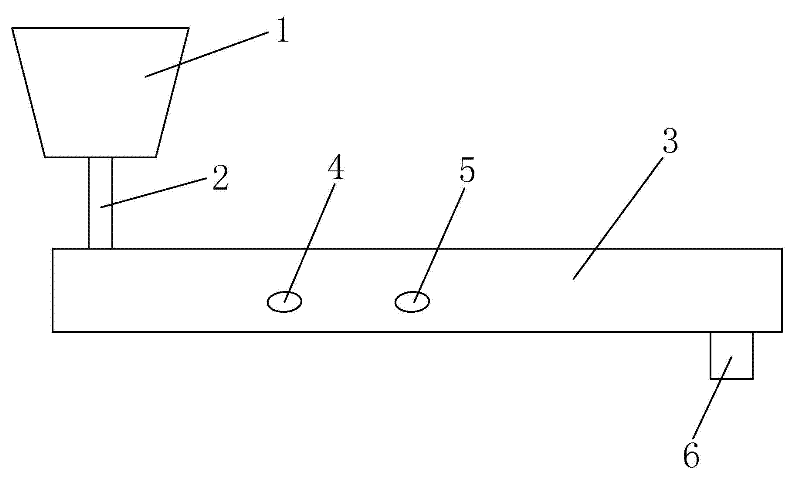

Method for producing glyceryl triacetate by atomizing raw materials

ActiveCN101613275AIncrease contentGood chromaOrganic compound preparationCarboxylic acid esters preparationAcetic acidAcetic anhydride

The invention discloses a method for producing glyceryl triacetate by atomizing raw materials. The production method can help shorten esterification reaction time and improve product yield, quality and chroma. The objective is achieved in virtue of the following technical scheme: mixing glycerol and acetic acid at a mol ratio of 1:6-9; adding a proper amount of a liquid catalyst and an entrainer,stirring and preheating to 80-100 DEG C; atomizing the mixture to allow the mixture to be subject to esterification reaction at 100-120 DEG C for 1-2h to obtain a liquid mixture containing 98-99% of glyceryl triacetate; adding 1-1.5% of acetic anhydride to the obtained liquid mixture for deep esterification reaction at the temperature of 90-110 DEG C for 10-20min to obtain a semi-finished product; removing the entrainer and the acetic acid, neutralizing, decoloring and filtering to obtain the glyceryl triacetate finished product.

Owner:云南玉溪环腾科工贸有限公司

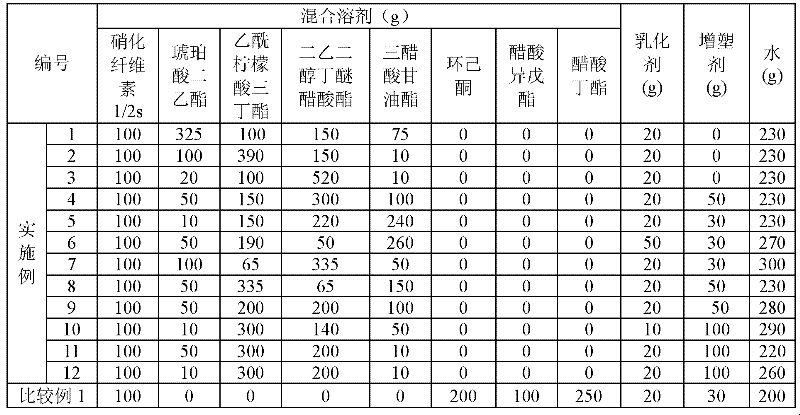

Mixed solvent used for dissolving nitrated cellulose and nitrated cellulose product containing mixed solvent

The invention provides a mixed solvent used for dissolving nitrated cellulose. The mixed solvent contains 1-50wt% of diethyl succinate, 10-60wt% of acetyl tributyl citrate, 10-80wt% of diethylene glycol butyl ether acetate and 1-40wt% of glycerol triacetate. The invention also provides a water-soluble nitrated cellulose product and a water-soluble nitrated cellulose product prepared by the mixed solvent provided by the invention. The nitrated cellulose product prepared by the mixed solvent is little in smell and low in toxicity, has good volatilization grade, and greatly improves the production environment of leather processing enterprises and alleviates the harm to the body health of workers on the basis of keeping the performances of the nitrated cellulose products.

Owner:德瑞(常州)特种材料有限公司

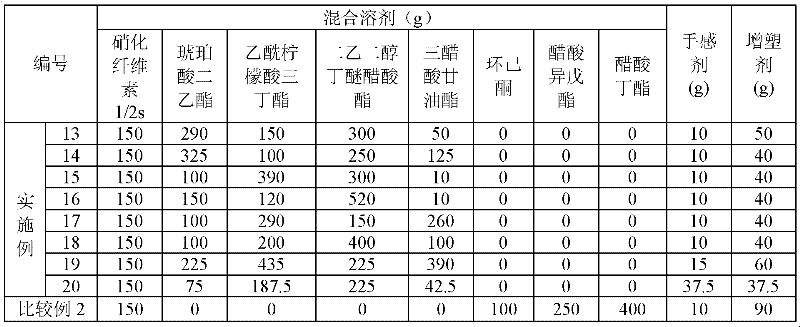

Method for detecting volatile organic compounds in cigarette tipping paper printing ink

InactiveCN104597166AEasy to handleAchieving Simultaneous DetectionComponent separationCyclohexanoneN-Propyl alcohol

The invention relates to a method for detecting the contents of 22 kinds of volatile organic compounds in cigarette tipping paper printing ink, including benzene, toluene, ethylbenzene, ortho / meta / para-xylene, phenethylene, methanol, ethanol, isopropyl alcohol, n-propyl alcohol, n-butanol, acetone, 4-methyl-2-pentanone, butanone, cyclohexanone, ethyl acetate, n-propyl acetate, n-butyl acetate, isopropyl acetate, 1-methoxy-2-propyl alcohol and 1-ethoxy-2-propyl alcohol. Detection is performed by headspace gas chromatography by taking glyceryl triacetate as a matrix rectifier. According to the method provided by the invention, a sample pretreatment process is simple, the automation degree of the whole operation is high, the simultaneous detection of various volatile organic compounds can be realized, and the detection sensitivity, the recovery rate and the result precision are high.

Owner:GUANGXI ZHENLONG IND

Preparation method of sand die material of fused zirconia corundum block

The invention relates to a preparation method of a sand die material of a fused zirconia corundum block, effectively solving the problems of flatness and fineness of the sand die, environmental pollution, the hazard to human body, and influence on the color of the fused zirconia corundum product. The method comprises the following steps: mixing silica sand and glycerol triacetate in a mixing unit, adding modified soluble glass and mixing to obtain the mixture. The method has the advantages of simple process, reasonable ingredients, and easy production, and the prepared product has high hardness and good quality. According to the invention, the flatness, fineness, precision and production efficiency of the sand die are effectively improved, and simultaneously no pollution to the color of the fused zirconia corundum product is generated.

Owner:郑州远东耐火材料有限公司

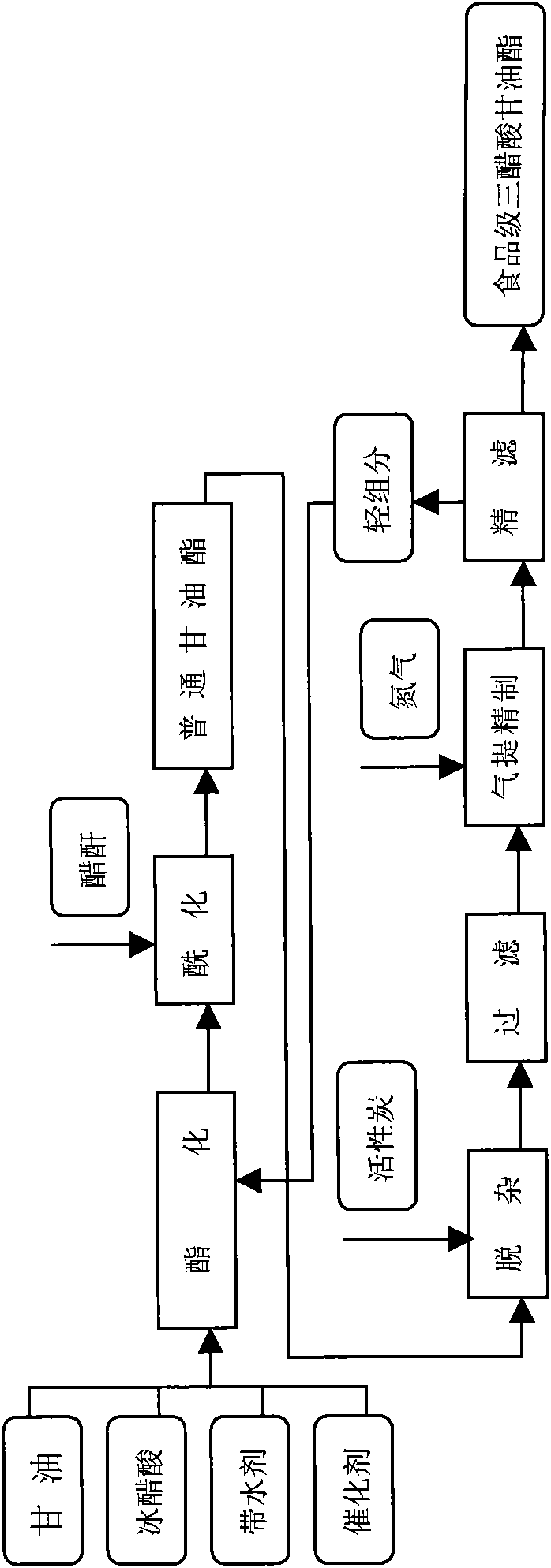

Method for preparing food grade triacetyl glycerine

ActiveCN101585765AIncrease contentGood chromaOrganic compound preparationCarboxylic acid esters preparationAcetic acidAcid value

The invention discloses a method for preparing food grade triacetyl glycerine, which comprises the following steps: after glycerin and glacial acetic acid are esterified and acylated, ordinary triacetyl glycerine is prepared; the ordinary triacetyl glycerine is pressed and filtered by a plate and frame filter press; active carbon is used for removing impurities so as to ensure that the chrominance of the triacetyl glycerine is smaller than No.10; and under the conditions of a vacuum degree of -0.098MPa and a temperature of 120-150 DEG C, nitrogen is used as shielding gas for carrying out gas purification on the product with the chrominance smaller than No.10 and fine filtering out a light component so as to ensure that the acid value of the triacetyl glycerine is smaller than or equal to 0.005 percent. The method greatly improves properties such as the content, the chrominance, the acid value, the water content, the heavy metal content, and the like of the triacetyl glycerine and the quality and the stability of the triacetyl glycerine.

Owner:JIANGSU RUIJIA CHEM

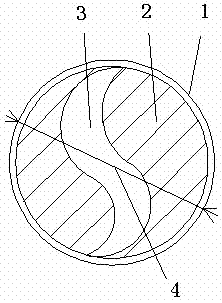

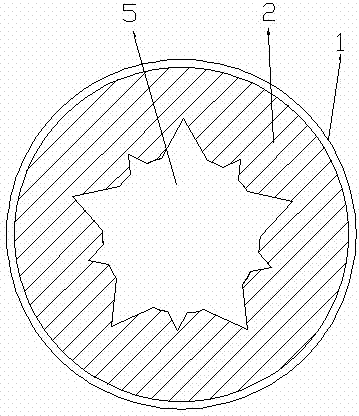

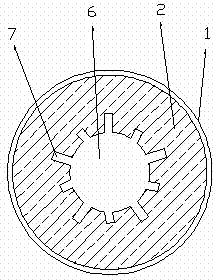

Hollow filter stick and production method thereof

ActiveCN104770874ASmall diameterGood flue gas condensation effectTobacco smoke filtersWater vaporMaterial consumption

The invention provides a hollow filter stick and a composite filter stick of the hollow filter stick. The hollow filter stick is formed by wrapping forming paper on a hollow filter cartridge; an axial hole extending in the length direction of the filter stick and in multiple shapes is formed inside the hollow filter cartridge, and the inner wall of the axial hole is smooth. The preferential shape of the axial hole is a gear, wherein teeth shapes of the gear are different or teeth dimensions are not completely same, but the teeth are rotational symmetric; radial holes can be formed in the filter cartridge. The invention also provides a production method of the hollow filter stick; the production method includes the following steps of spraying glycerol triacetate which accounts for 13-30% (according to weight ratio) of dry acetate tows, and then jetting with vapor at 120-160 degrees centigrade to heat the glycerol triacetate and dry acetate tows to be condensed and shaped. The hollow filter stick can not only ensure hardness, stiffness and resistance absorption but also is low in cost as filter cartridge material consumption is little.

Owner:NANTONG CIGARETTE FILTER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com