Patents

Literature

564results about How to "Realize green production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

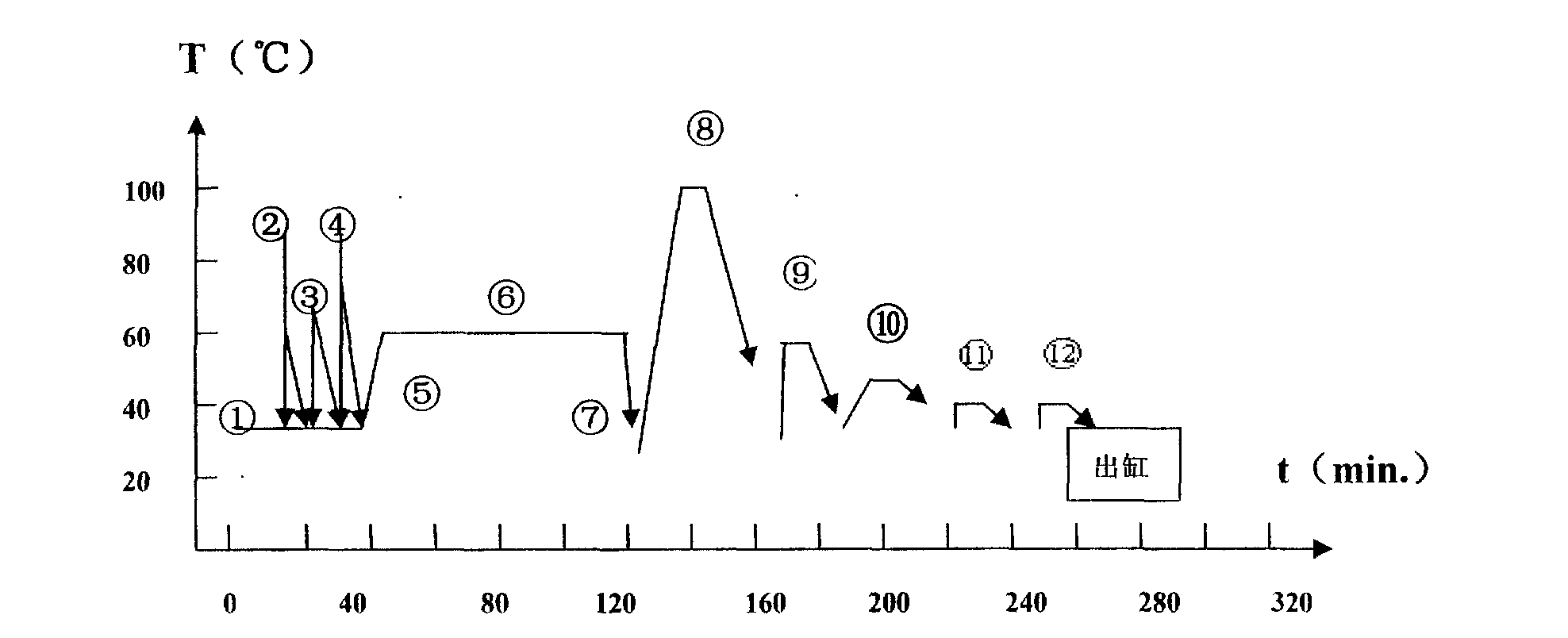

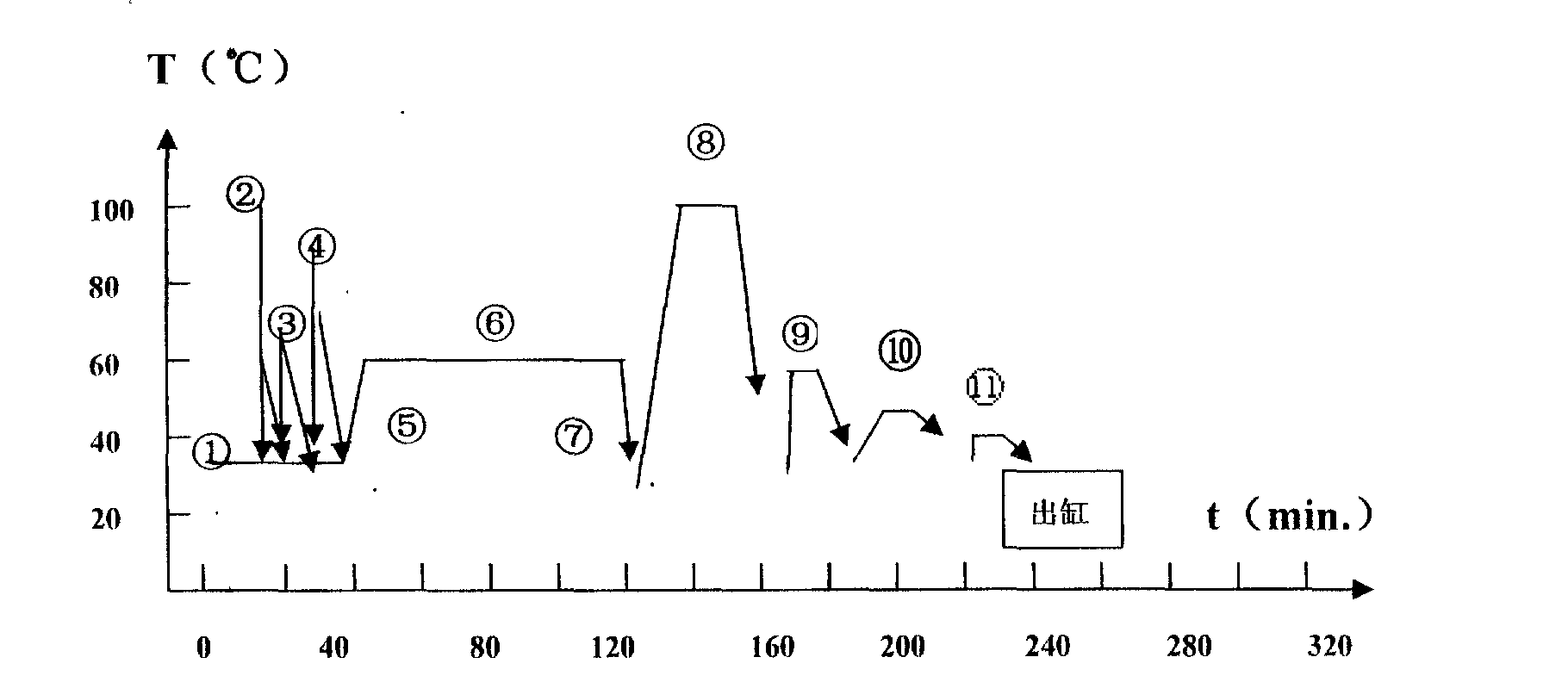

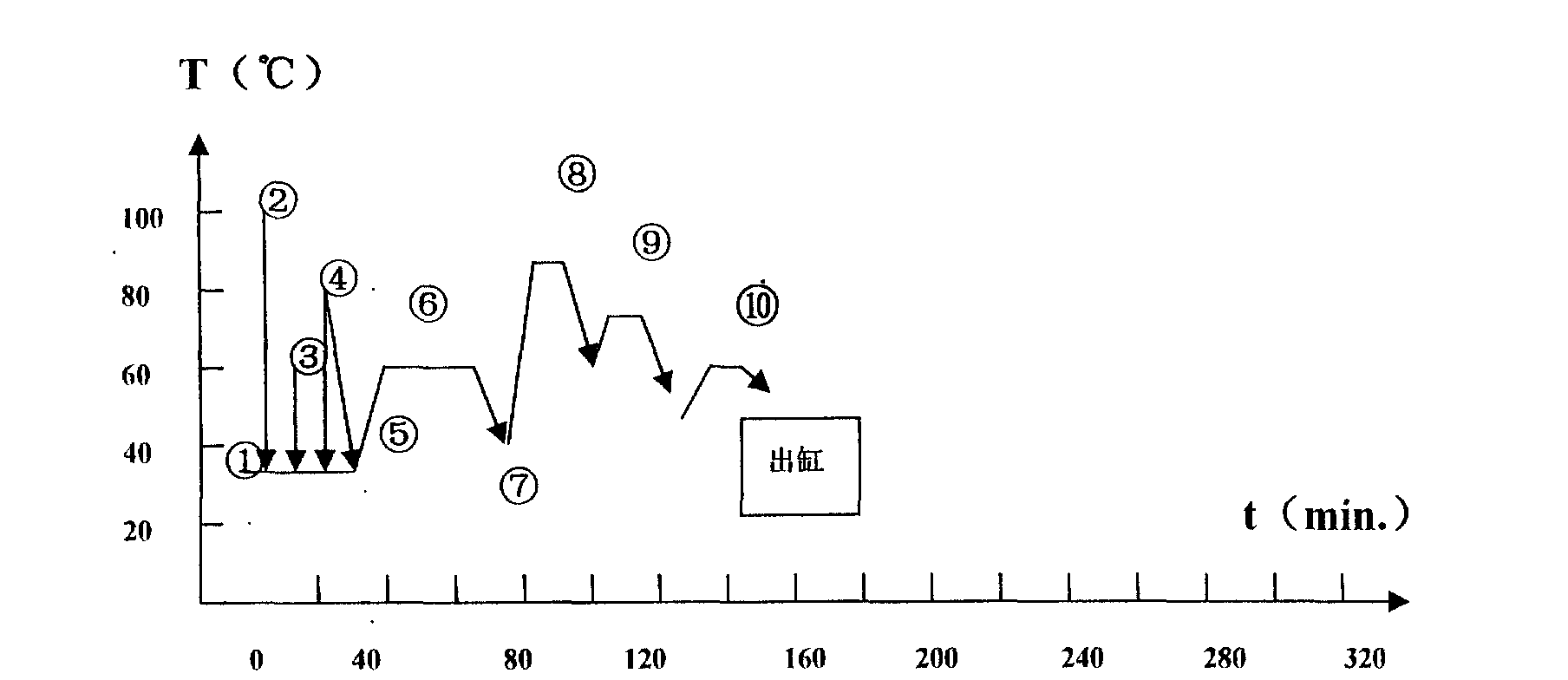

Reactive dye ultra-short rapid dyeing and fixation technology method

The invention relates to a reactive dye ultra-short rapid dyeing and fixation technology method. The method is realized by effectively minimizing auxiliary time such as feeding, shortening and optimizing post-processing processes, especially carrying soap boiling (one bath color mending) only once in advance to the greatest extend, merging washing, using less hot water and controlling the use of water aiming at various substances to be dyed according to dyeing requirements and the conditions of normal or abnormal and with the help of various accessory ingredients, thereby the reactive dye normal or abnormal dyeing conditions (especially mediate high color with a dye usage higher than 1percent of o. W. f) by the single one bath process, the multifunction composite one bath process, or the like, comprising pre-processing, dyeing, polishing with enzyme, and color mending, and even the pre-processing and the whole dyeing procedure in conventional equipment in an ultra-low bath ratio limit state can be completed well within 2.5-8h. The effects of thorough energy saving and emission reduction, efficiency increasing and consumption reduction, cleaner production and environmental protection are achieved.

Owner:罗海航 +1

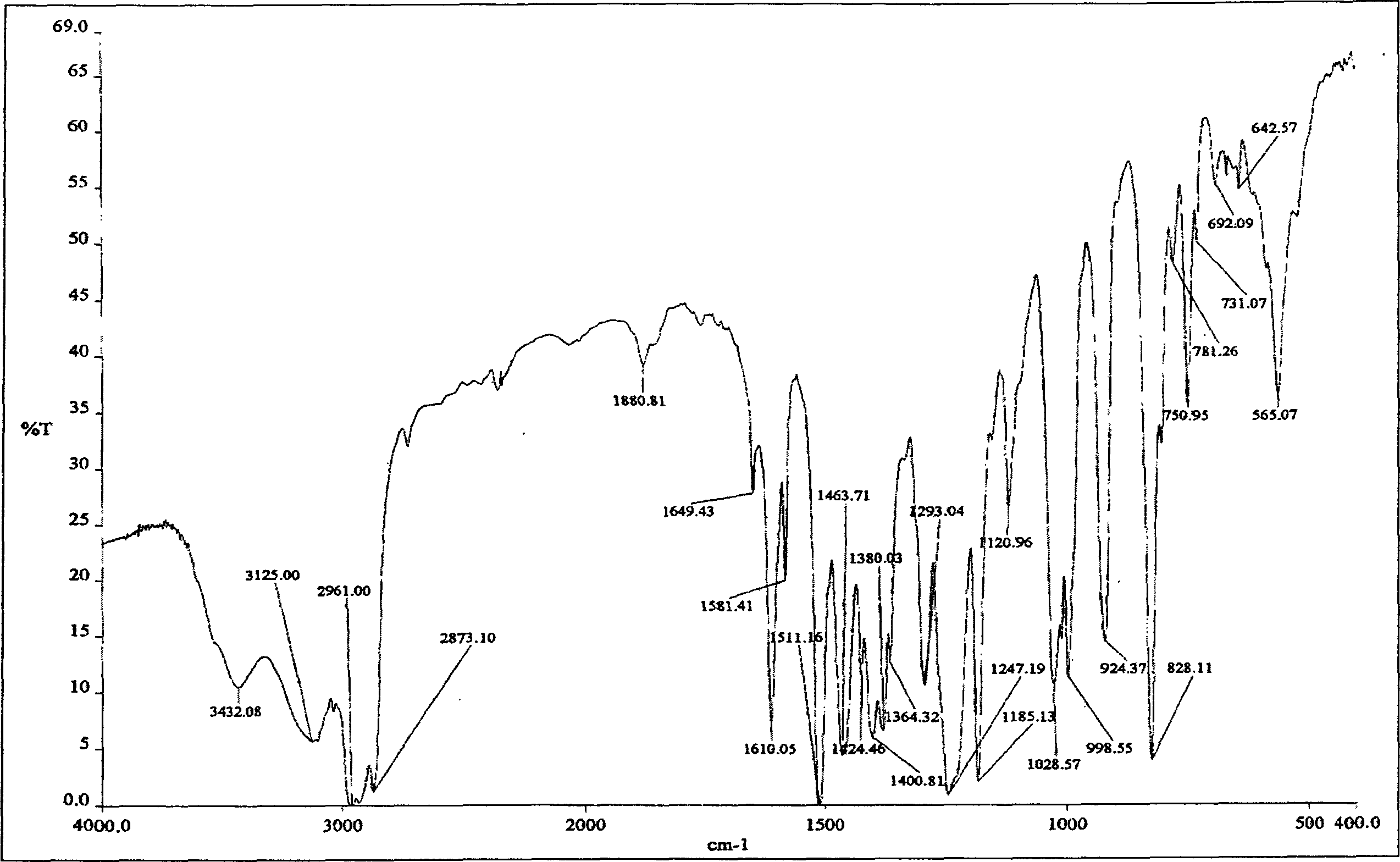

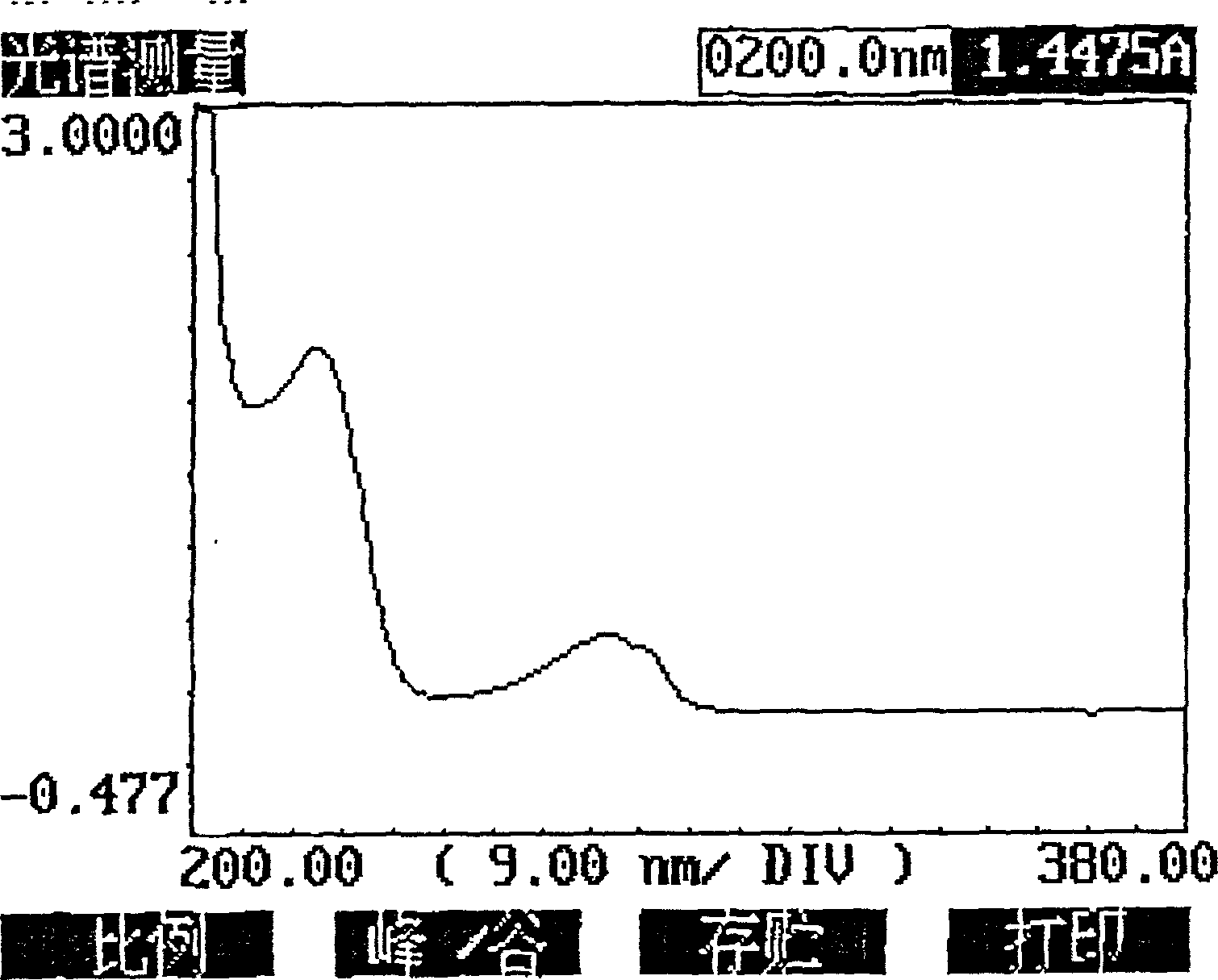

Water-solubility molecule associatad three-construction units hydrophobic associated polymer and synthesizing process thereof

InactiveCN1793189AThe synthesis process conditions are simpleEase of industrial productionAlkylphenolSolubility

The invention relates to a compounding method to form water solubility intermolecular association ternary hydrophobic association polymer that includes acrylamide, sodium acrylate, and allyl-alkylphenyl aether three constructions. The method includes the following steps: using acetone as reacting solvent, alkylphenols and allyl chloride as raw material, benzyl triethyl ammonium chloride as phase-transfer catalyst, reacting for 4-8 hours at 40-60 degree centigrade to form drainage monomer allyl-alkylphenyl aether; adding sodium acrylate, acrylamide and allyl-alkylphenyl aether monomer into reactor according to the mol ratio as 20-30:69.2-79.2:0.8, adding inducing agent, sealing reacting for 2-6 hours to gain terpolymer. The terpolymer has good temperature resistance, saline tolerance, dissolubility and high temperature stability. The invention is easy to compound and has mild condition.

Owner:SICHUAN GUANGYA POLYMER CHEM

Microwave synthesis method of fiber carbamate

The invention discloses a technology of a microwave heating synthesis method of fiber carbamate; the method is that: firstly, the fiber is soaked in carbamide aqueous solution for completely adsorbing the carbamide, the fiber / carbamide even mixture is obtained by filtering and drying, and then the fiber / carbamide mixture is placed in a microwave oven for being heated, thereby obtaining the fiber carbamate. The synthesis technology of the fiber carbamate provided by the invention has no solvent pollution, organic solvents and any catalyzers do not need, the reacting time is speed, and the energy consumption is low. The synthesized fiber carbamate products has good dissolubility in 6 to 10 wt% of NaOH aqueous solution within the temperature range of -10 to 5 DEG C, and the concentrated solution which is stable, transparent and is suitable for industrial spinning and membrane manufacturing can be prepared.

Owner:WUHAN UNIV

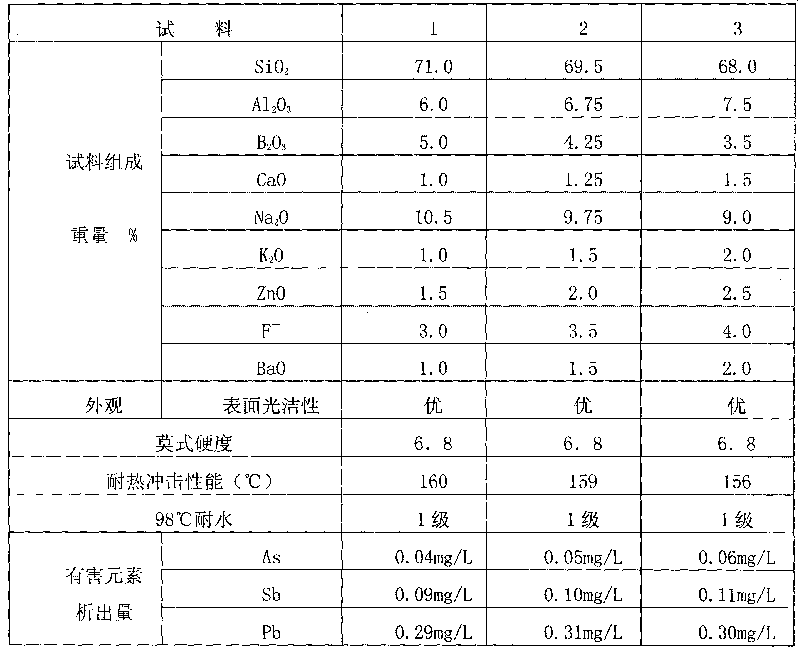

Opal glass suitable for full electrofusion forming and preparation process thereof

InactiveCN101717191AUniform chemical compositionReduce dosageElectric furnaceThermal dilatationPhysical chemistry

The invention discloses an opal glass suitable for full electrofusion forming and a preparation process thereof. The opal glass is prepared by composing a batch mixture by mixing a base material, an auxiliary material and an additive and adopting a full electrofusion method at the temperature of 1480-1520 DEG C; and the components of the batch mixture comprise the following components expressed as oxides in percentage by weight: 68.0-71.0% of SiO2, 6.0-7.5% of Al2O3, 1.0-1.5% of CaO, 9.0-10.5% of Na2O, 3.0-4.0% of F-, 1.5-2.5% of ZnO, 3.5-5.0% of B2O3, 1.0-2.0% of BaO and 1.0-2.0% of K2O. The opal glass prepared by the process has thermal expansion coefficient alpha less than or equal to 7.8*10-6 / DEG C, saves the energy by 50 percent as compared with the transitional method, achieves the mohs hardness of 6.8, the thermal shock resistance more than 125 DEG C and the water resistance of a primary standard, has main performance indexes all achieving or exceeding the level of similar imported products, meets the requirements for environmental protection and health and is an ideal substitute of the transitional porcelain product.

Owner:CHINA HOUSEHOLD ELECTRIC APPLIANCE RES INST

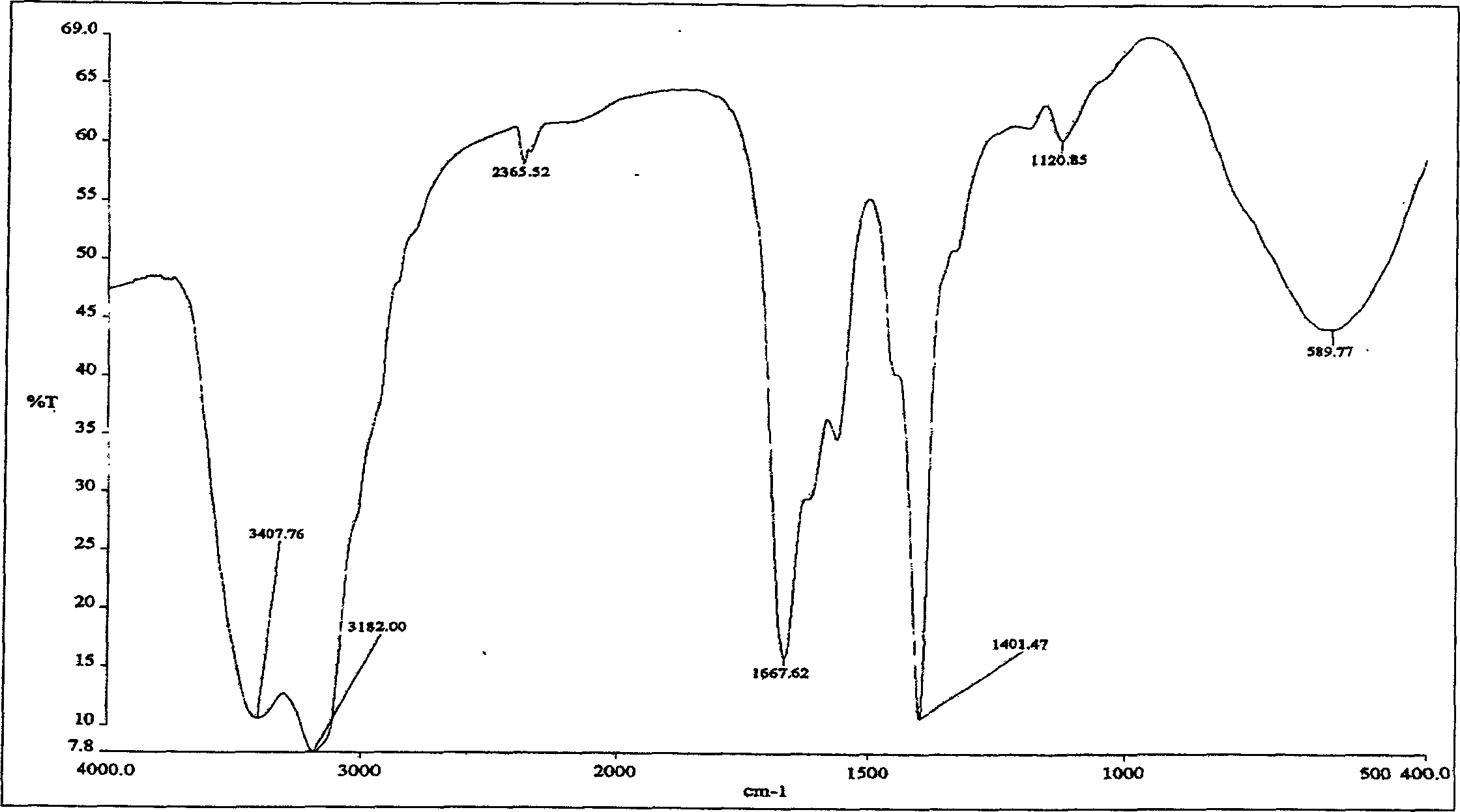

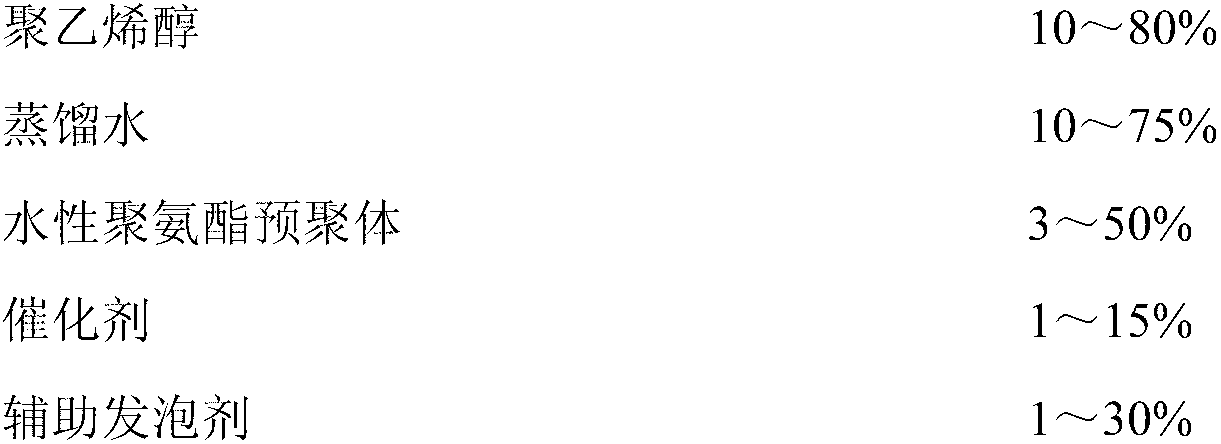

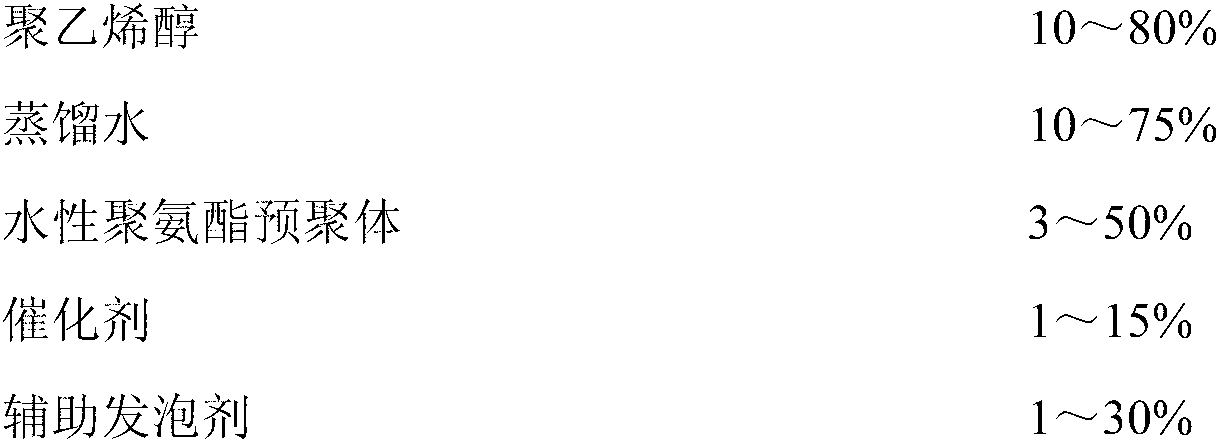

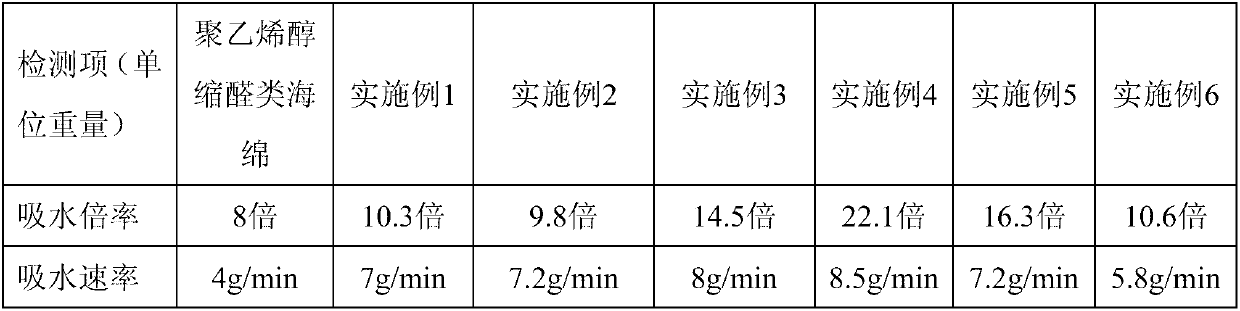

Method for preparing polyvinyl alcohol and polyurethane super absorbent sponge

The invention discloses a method for preparing a polyvinyl alcohol and polyurethane super absorbent sponge. The method includes mixing polyvinyl alcohol with distilled water at first, dissolving the polyvinyl alcohol for 20 to 30 minutes under the condition that the water bath temperature ranges from 50 DEG C to 95 DEG C and rotational speed ranges from 400r / min to 600r / min to obtain polyvinyl alcohol aqueous solution; and then heating the polyvinyl alcohol aqueous solution until the temperature of the polyvinyl alcohol aqueous solution ranges from 30 DEG C to 100 DEG C, adding water-based polyurethane prepolymer, catalysts and auxiliary foaming agents into the polyvinyl alcohol aqueous solution, stirring and uniformly mixing the mixture under the condition of rotational speed ranging from 400r / min to 600r / min, enabling the mixture to react for 5 minutes to 10 minutes, and solidifying the mixture for 2 to 4 hours at the temperature ranging from 30 DEG C to 100 DEG C to obtain the sponge with the water absorbent rate higher than 9.8. The water absorbent rate of the obtained sponge is increased to 10-20 times from the original 6-8 times of an existing polyvinyl acetal sponge, the water absorbing velocity of the sponge is increased to 8g / ming from the original 4g / ming, and the polyvinyl alcohol and polyurethane super absorbent sponge has a broad development prospect in fields of aquatic product processing, food, clinical medicine, water treatment and the like.

Owner:SOUTH CHINA UNIV OF TECH

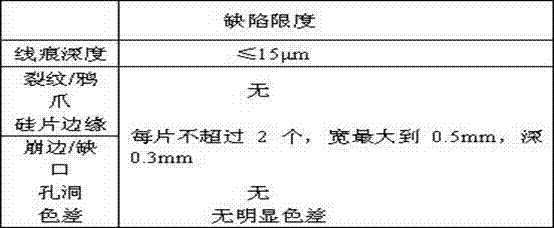

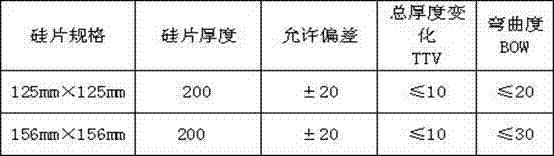

Solar-grade silicon wafer being cut by diamond wire and cutting method thereof

InactiveCN102390094AFast cutting speedSave silicon resourcesFine working devicesDiamond cuttingMicrometer

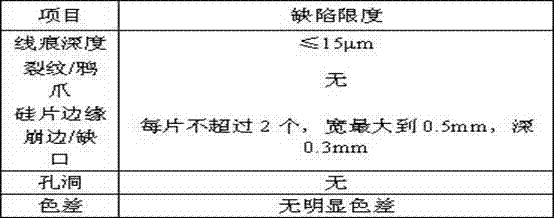

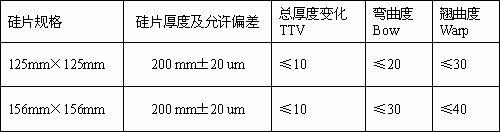

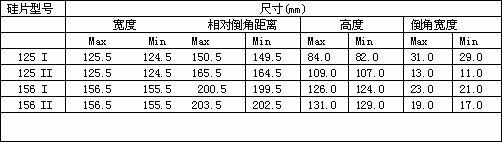

The invention discloses a solar-grade silicon wafer being cut by a diamond wire and a cutting method thereof. A mono-crystalline silicon square rod is cut by a diamond wire. The cutting method comprises the following steps that: the mono-crystalline silicon square rod which is formed by squaring, grinding and sharpening a mono-crystalline silicon circular rod, the mono-crystalline silicon square rod is fixed on a resin strip through an adhesive bar, the resin strip is fixed on an adhesive plate, then the adhesive plate and the mono-crystalline silicon square rod are collectively placed into a working cabin to be preheated, cutting liquid is circulated in the working cabin to work, then the diamond cutting is performed, the cut mono-crystalline silicon wafer is inversely arranged on a degumming device to degum, and the mono-crystalline silicon wafer is washed by ultrasonic and then is centrifugally dehydrated. Due to the adoption of the cutting method, the photoelectric conversion efficiency and the cutting efficiency of the mono-crystalline silicon wafer can be improved, a silicon wafer with the thickness of 140 to 200 micrometers can be produced, the qualification rate of the product can reach more than 98 percent; and silicon powder is recyclable, so valuable silicon resource can be saved, and the environment-friendly production can be really realized during the production process.

Owner:江西金葵能源科技有限公司

A method of using diamond wire cut solar grade polysilicon wafers

InactiveCN102285011AImprove photoelectric conversion efficiencyFast cutting speedFine working devicesPolycrystalline diamondWire cutting

The invention discloses a method for cutting solar-grade polysilicon wafers using diamond wire cutting. The polysilicon rods are glued to the sticks after being squared, ground and ground. The resin strip is fixed on the bonding board, and then the bonding board and the polysilicon rod are put into the working cabin, the cutting fluid is preheated and circulated in the working cabin, and the diamond wire is cut into polysilicon wafers, and the polysilicon wafers are placed upside down on the degumming equipment It is made by degumming, ultrasonic cleaning, and drying. The present invention does not produce indole-like cut marks on the surface of the polycrystalline silicon sheet, improves the photoelectric conversion efficiency of the polycrystalline silicon sheet, has high diamond wire cutting speed, high dimensional accuracy of the cut polycrystalline silicon sheet, small error, and a qualified rate of more than 95%. The silicon powder produced by cutting can be recycled, saving precious silicon resources.

Owner:江西金葵能源科技有限公司

Cleaning cocoon cooking method

InactiveCN103225112ANo emissionsThe total amount is controllableSilk filament obtainingChemical preparationDissolution

The invention discloses a cleaning cocoon cooking method. The method comprises the processes of: external vacuum infiltration, cooking by an automatic cooker, cocoon steaming, and adjustment, wherein a reelability agent originally used for cocoon cooking replaces a penetrating agent for penetrating to be used in the external vacuum infiltration cocoon cooking process; in the condition with 30-50 DEG C water temperature, the reelability agent can only have infiltration function with water to be adsorbed between cocoon layers and on the surface of a cocoon filament; and in the cocoon cooking process and in the condition with 60-80 DEG C water temperature, the reelability agent can promote the cocoon filament sericin dissolution to reduce adhesion between cocoon filaments for the smooth dissociation of the cocoon filaments, so that the reelability agent has the reelability function in the cocoon cooking process. One chemical preparation achieves two functions, the chemical preparation is less and easily controlled in dose, process is simple, operation is convenient, and production cost is low.

Owner:安徽绩溪县花神丝绸有限公司

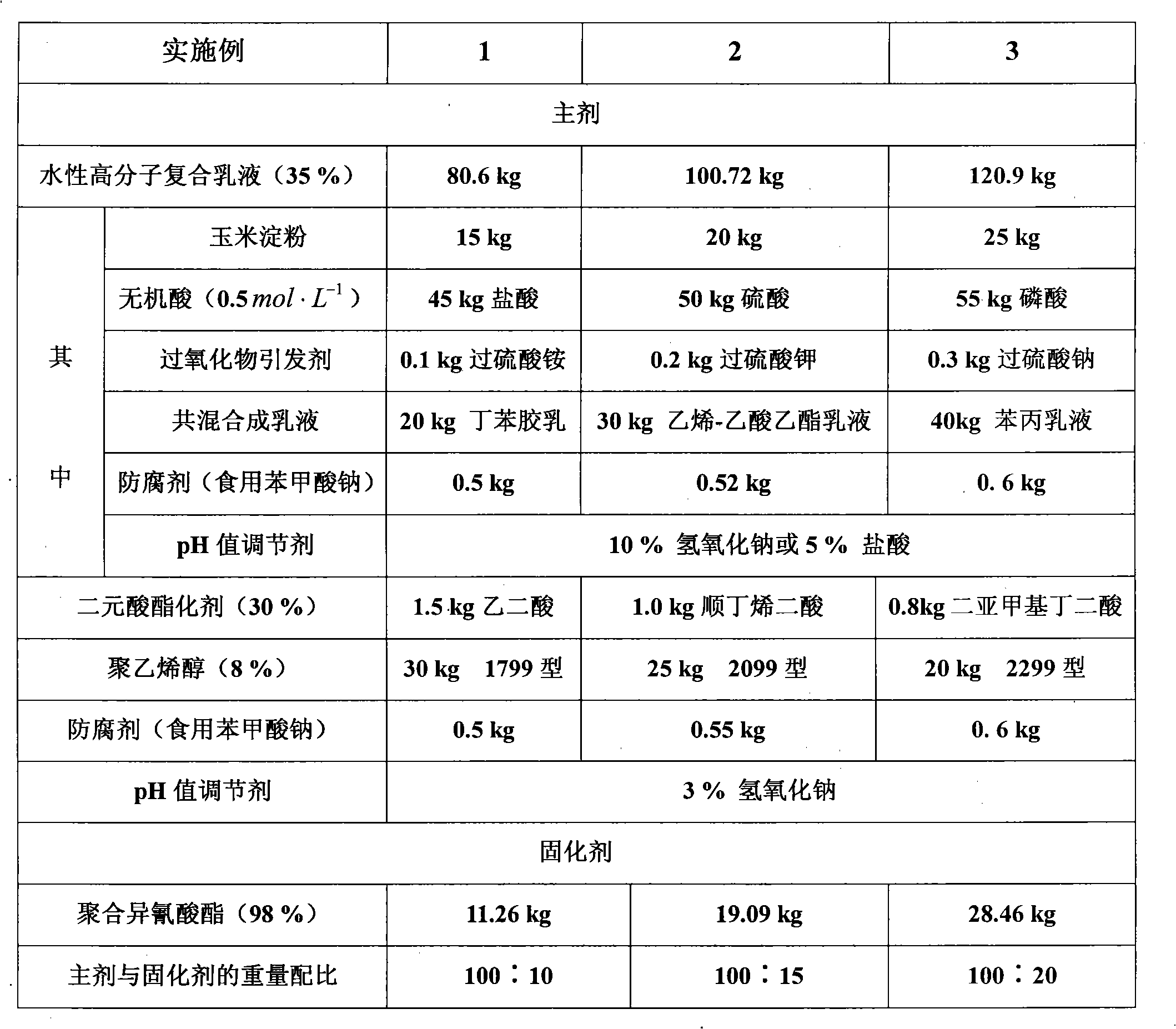

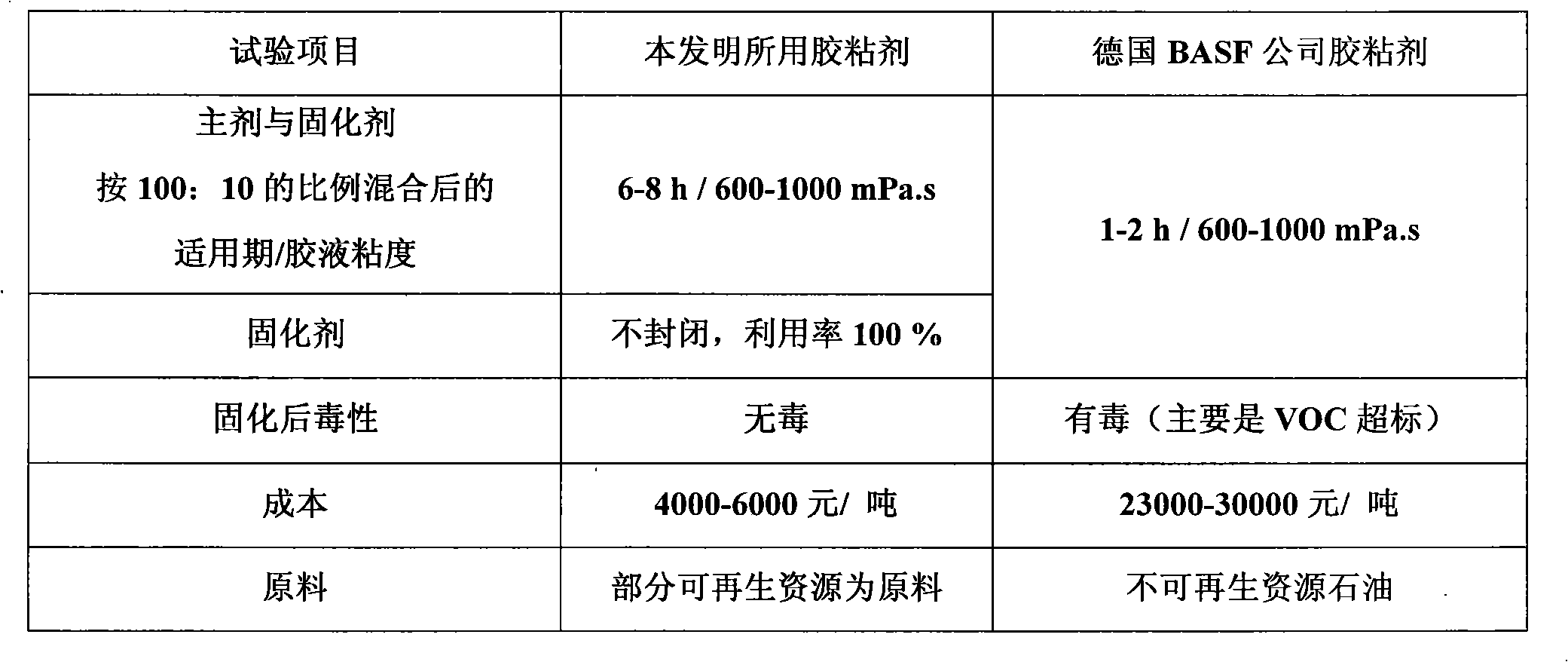

Aqueous macromolecule-isocyanic ester stalk artificial board and preparation thereof

ActiveCN101314235ARealize green productionGood workmanshipPolyureas/polyurethane adhesivesFlat articlesWater basedVolatiles

The invention relates to a water-based macromolecule-isocyanate straw hard board and a preparation method thereof. Straws of rice, wheat, corn or other crops, a water-based macromolecule-isocyanate adhesive and a straw interface performance modifying agent are used as raw materials, and the straws are treated by section cutting, kneading and modification, adhesive application and heat pressing to produce the water-based macromolecule-isocyanate straw hard board. A mixture ratio of the absolute dry straws to the water-based macromolecule-isocyanate adhesive to the straw interface performance modifying agent by weight is 100 to 10-16 to 0.05-0.15. The straw hard board uses the water-based macromolecule-isocyanate adhesive to replace a pure isocyanate adhesive, radically improves the problems of toxic organic volatiles, poor prepressing performance, adhesion on boards, etc., remarkably reduces cost and really realizes green production, and the raw materials after the treatment of kneading and modification have good prepressing and molding performances and high one-off qualified rate. The water-based macromolecule-isocyanate straw hard board has the characteristics of unique design, long active period, excellent aging, water and heat resisting performances, simple operation, easy availability of equipment, no environmental pollution, easy implementation, etc., and produces huge entironmental, social and economical benefits after the water-based macromolecule-isocyanate straw hard board is popularized.

Owner:BEIHUA UNIV

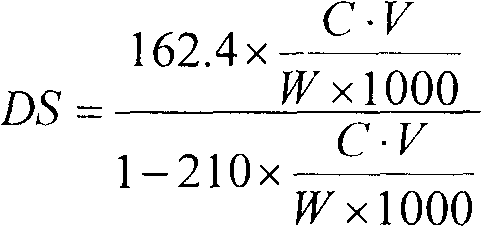

Method for preparing starch ester by recycling octenyl succinic anhydride

The invention discloses a method for utilizing octenyl succinic anhydride to produce starch ester in circulation. The method comprises steps that: water is added to 100 parts of dry basis starch; the starch is homogenized and emulsified; the pH value of the starch is regulated to 8 to 10; the starch is added to an octenyl succinic anhydride solution containing 3 parts of octenyl succinic anhydride, and is subject to a reaction; when the reaction is finished, the pH value of a reaction liquid is regulated to 5.5 to 6.5; the reaction liquid is filtered, and is processed from processes of washing, drying, crushing and sieving three times, such that white starch sodium octenyl succinate is obtained; a residual from the filtering process is mixed with the filtered washing solution, such that an octenyl succinic anhydride mixed solution is obtained; the solution is distilled, octenyl succinic anhydride is supplemented, and a solvent is added for dissolving, such that an octenyl succinic anhydride solution is obtained; water and ethanol obtained from distillation are fractionated, ethanol concentration is adjusted, and the materials can be repeatedly used. The method provided by the invention is advantaged in that: the technology is simple and is easy to control; recycling of octenyl succinic anhydride and recycling of the solvent can both be realized.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Preparation method of macroporous strong-alkaline anion exchange resin for removing nitrate in water

ActiveCN103524657AUniform distribution of poresGood physical and chemical propertiesWater/sewage treatment by ion-exchangeAnion exchangersPore distributionDichloromethane

The invention discloses a preparation method of styrene macroporous strong-alkaline anion exchange resin for removing nitrate in water. Styrene, divinyl benzene, benzoyl peroxide, liquid paraffin, polyvinyl alcohol, gelatin, methylene blue, dichloromethane, 1,4-bis(chloromethoxy)butane, anhydrous tin tetrachloride and triethylamine are used as main raw materials; the macroporous strong-alkaline anion exchange resin is prepared through suspension polymerization reaction, chloromethylation reaction and amination reaction. The preparation comprises the following steps: synthesis of styrene divinyl benzene cross-linked polymer by the suspension polymerization method, chloromethylation reaction of styrene divinyl benzene cross-linked polymer, and amination reaction of chloromethylated styrene divinyl benzene cross-linked polymer. The particle size of the prepared resin is 0.5-1.5mm; the resin has the advantages of uniform pore distribution, strong adsorbability against nitrate, high selectivity on nitrate and the like; the physicochemical properties of the resin are good. The resin can be applied to the nitrate removal treatment process of water, and has good development prospect and practical significance.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

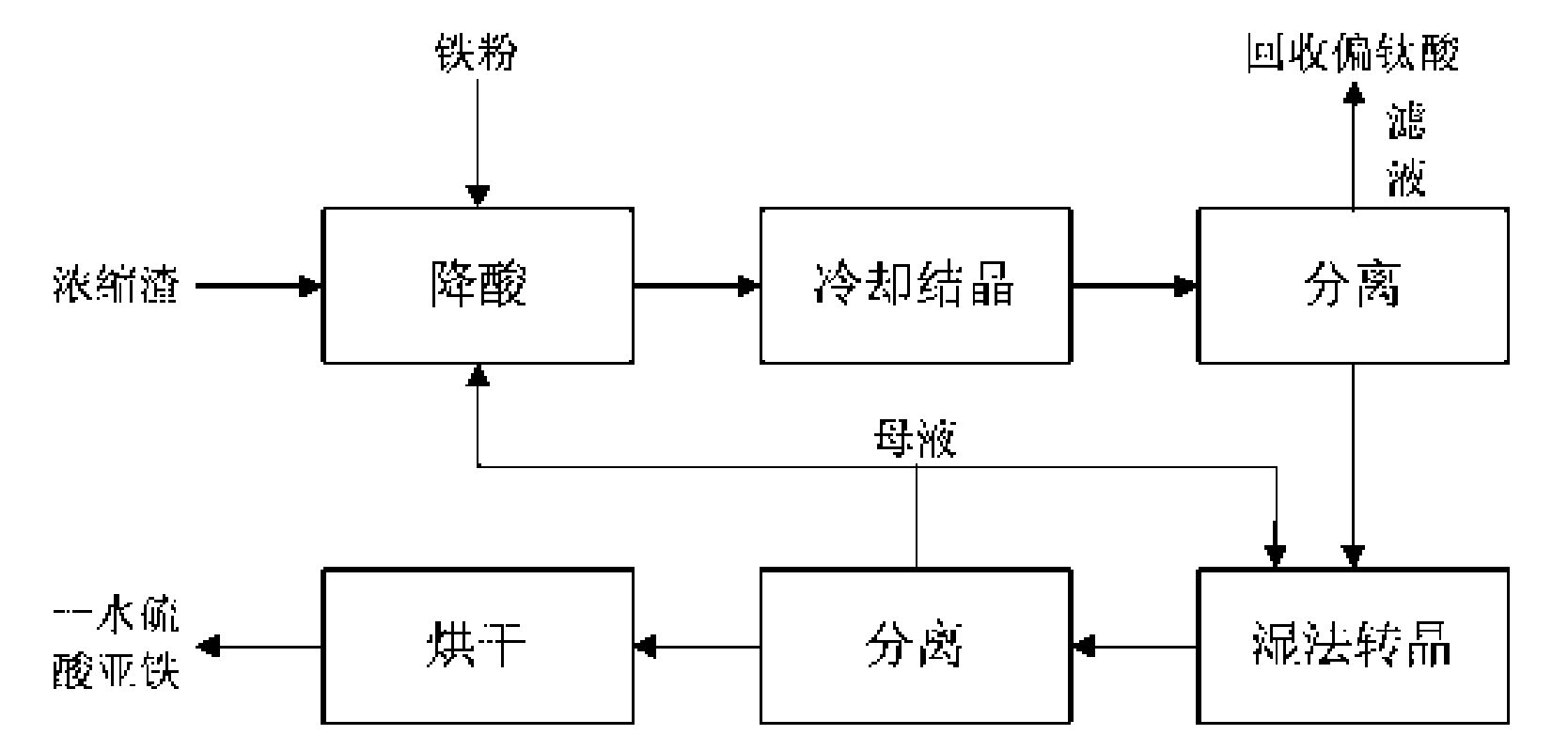

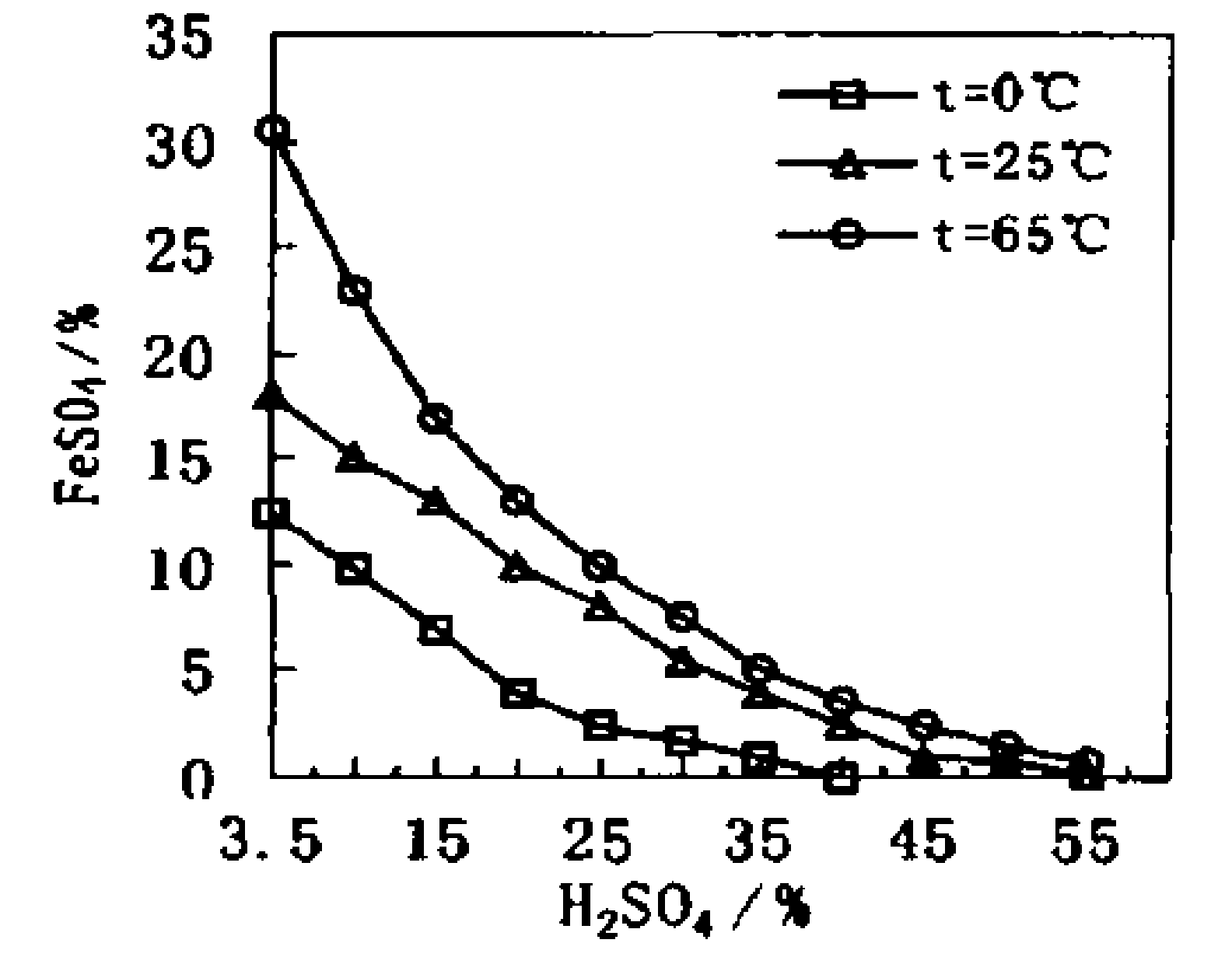

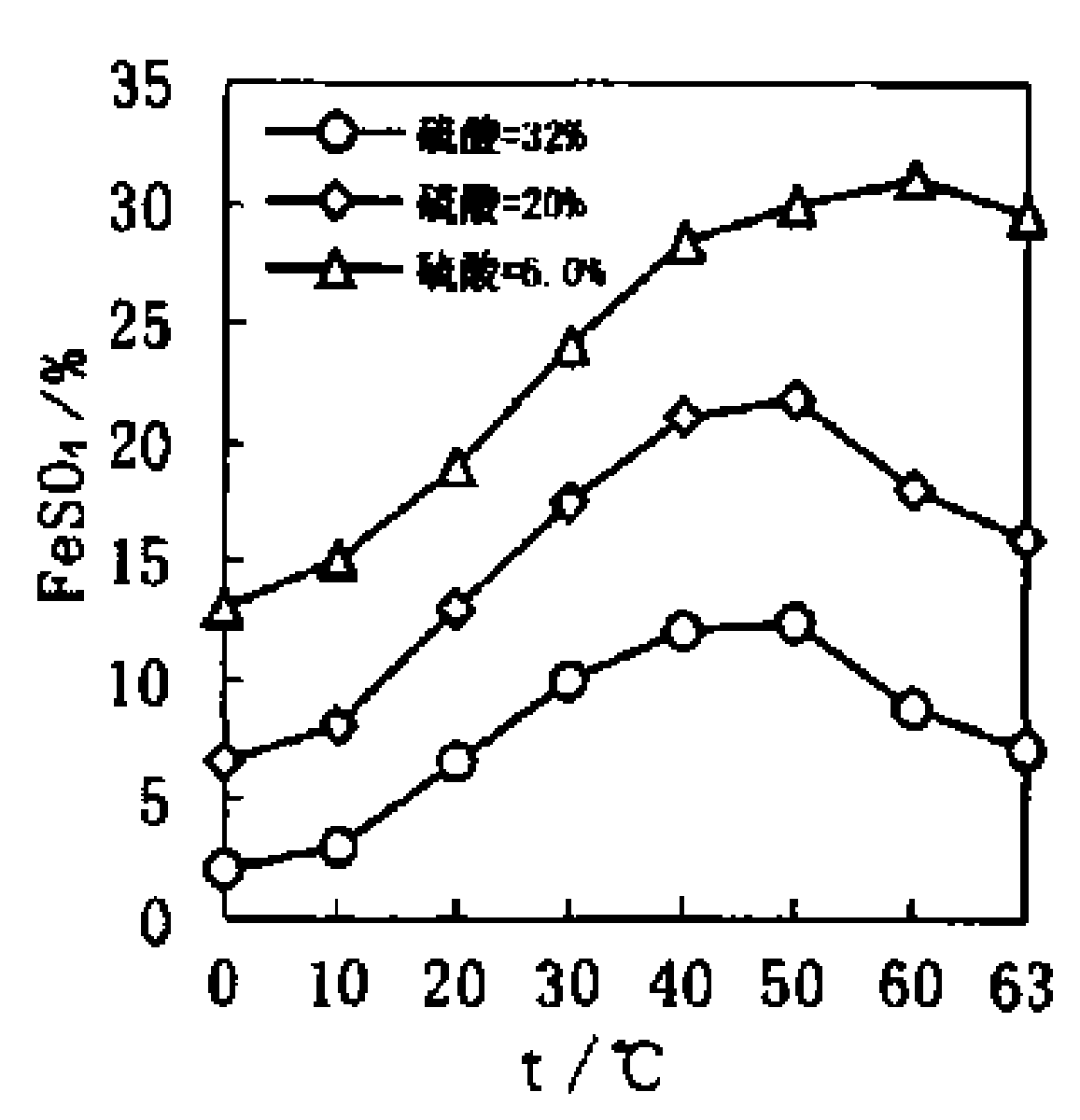

Method for producing feed grade ferrous sulfate monohydrate from titanium pigment waste acid condensed slag

The invention discloses a production method of feed grade ferrous sulfate monohydrate. Titanium white waste acid condensed slag is used as the raw material, and is subject to the processes of deacidification, pexitropy, separation, crystal transform and the like to produce the feed grade ferrous sulfate monohydrate, thereby realizing the comprehensive utilization of the titanium pigment waste acid condensed slag as the byproduct for the sulfuric acid method. The method comprises the following steps: mixing mother solutions generated in the ferrous sulfate monohydrate production processes by condensed slag and wet method, using iron powder to reduce the sulfuric acid content to 4% or so, slowly cooling and crystallizing the slurry to generatecoarse ferrous sulfate heptahydrate crystals, and separating impurities from the ferrous sulfate by using the particle size differences between the ferrous sulfate heptahydrate crystals and the impurity particles, thereby purifying the ferrous sulfate in the condensed slag and widening the application field of the condensed slag. The ferrous sulfate heptahydrate is transformed into ferrous sulfate monohydrate at high temperature to produce the qualified feed grade ferrous sulfate monohydrate in huge market demands, thereby changing the waste slag into valuable resources.

Owner:SICHUAN LOMON TITANIUM IND CO LTD

Frog artificial breeding and rearing method

InactiveCN1709049ARealization of captive breedingShorten breeding timeAnimal husbandryZoologyWater depth

Owner:刘国民

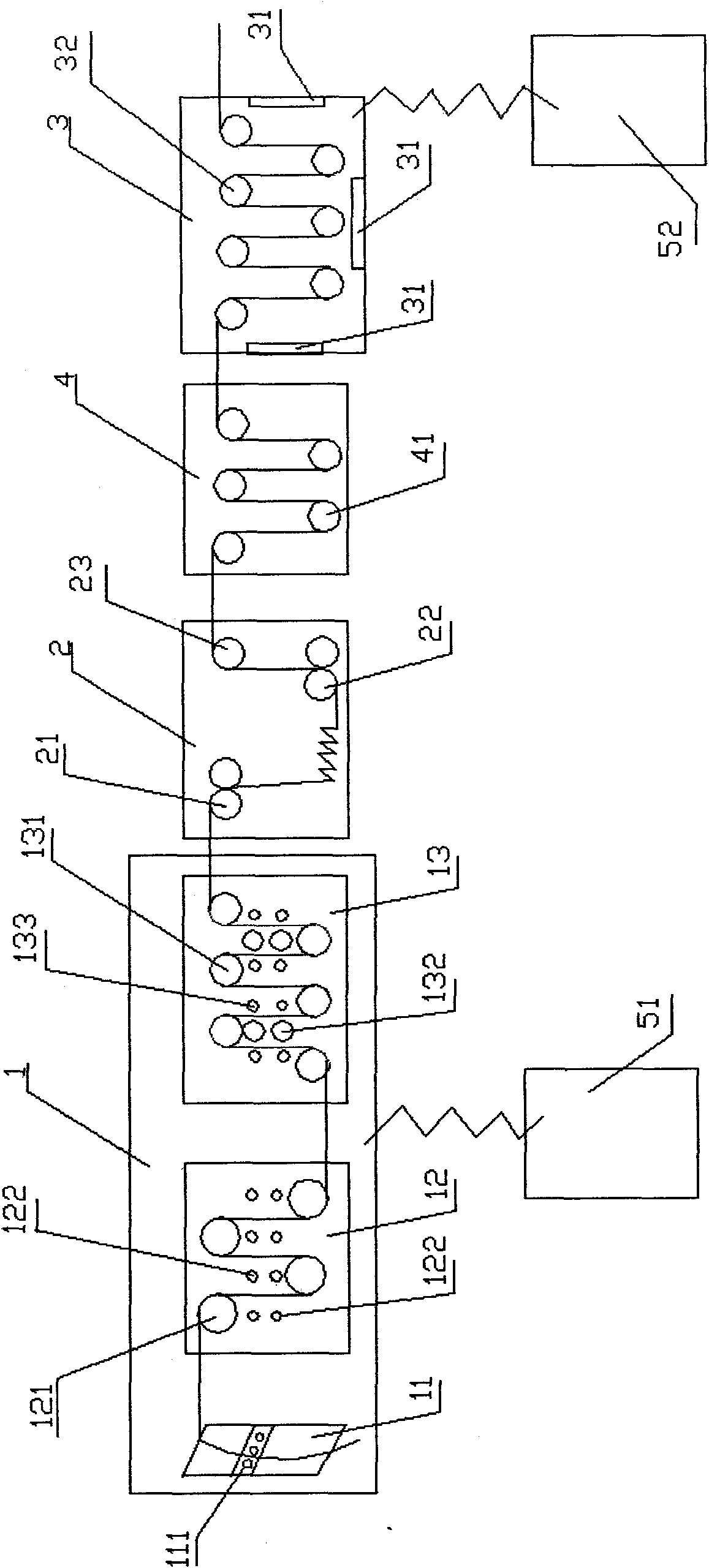

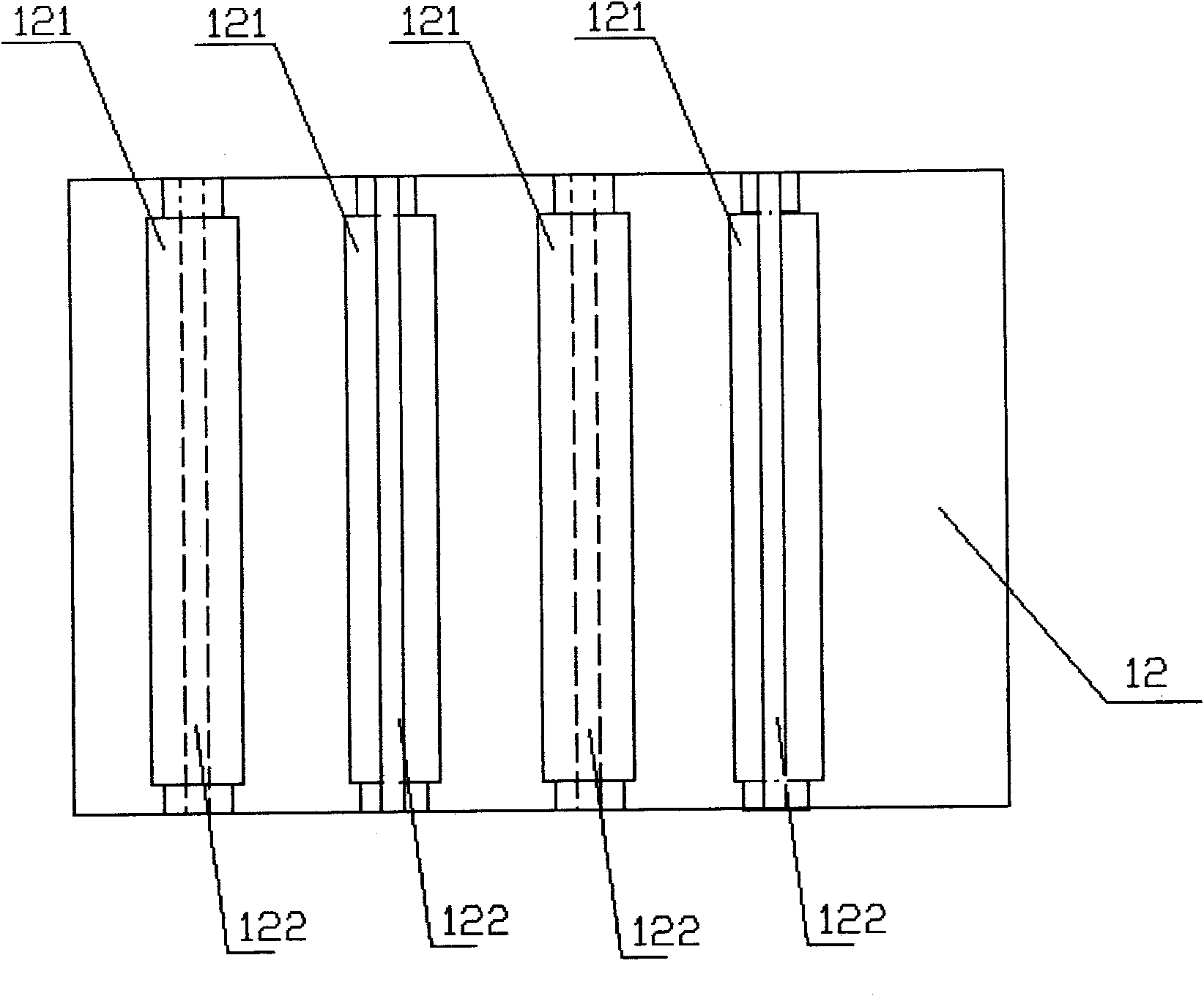

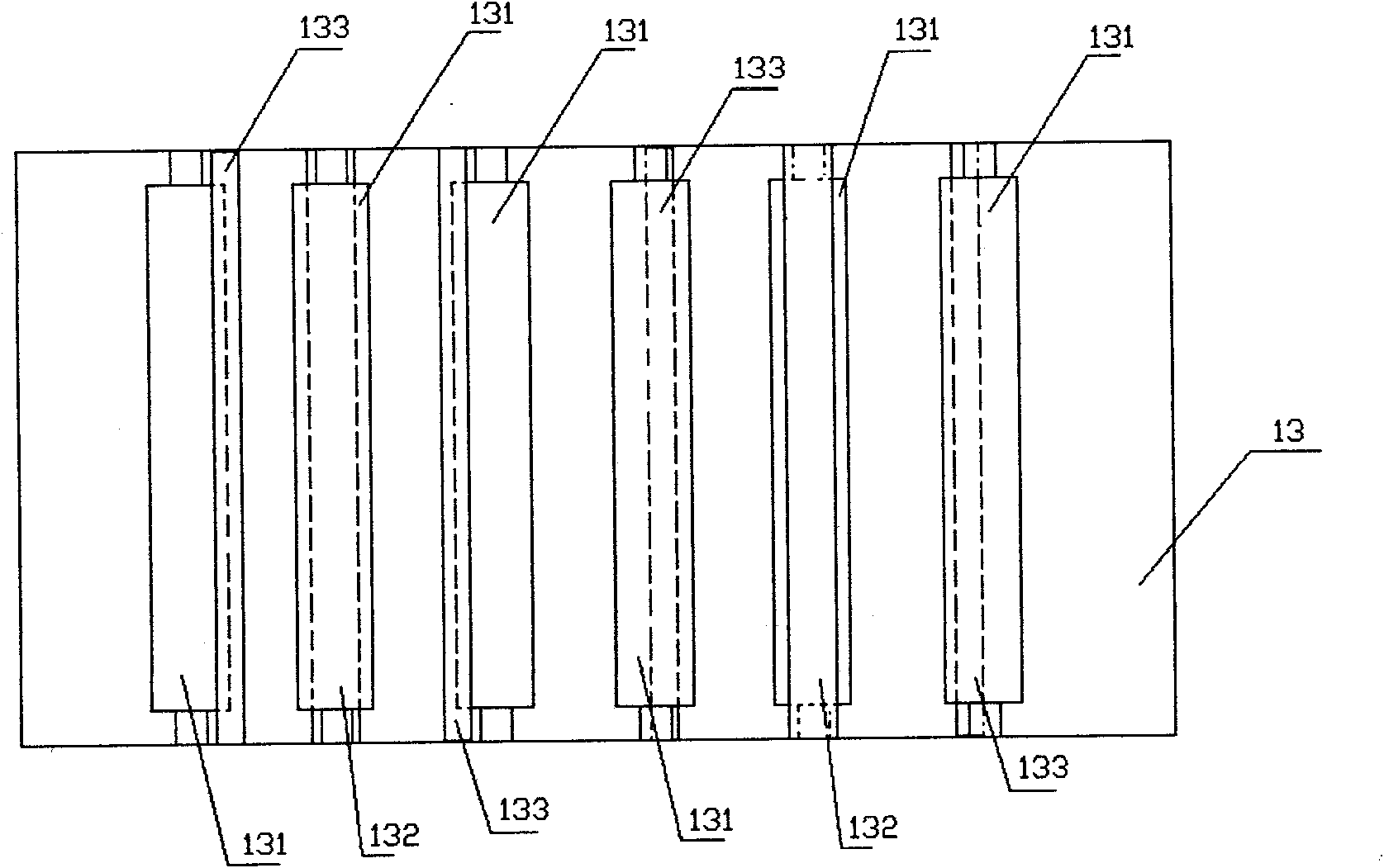

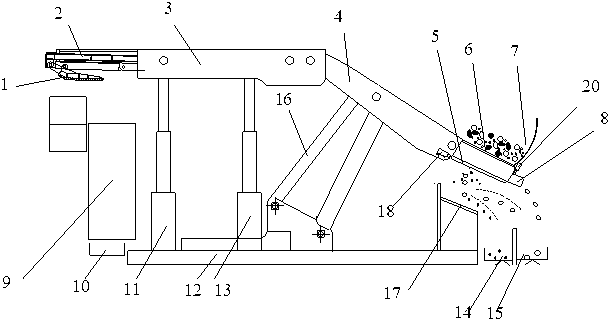

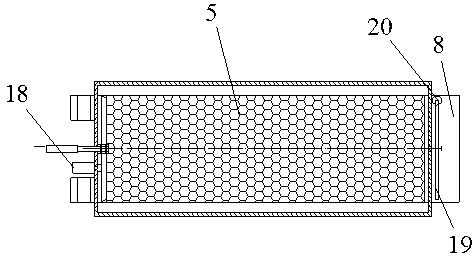

Process for dyeing fabrics by combining with plasma and ultrasonic and special device thereof

InactiveCN101880960AImprove dye uptakeReduce dosageDry-cleaning apparatus for textilesUltrasonic/sonic fibre treatmentControl systemGraft reaction

The invention relates to the field of fabrics dyeing and finishing processes, in particular to a process for dyeing fabrics by combining with plasma and ultrasonic and a special device thereof. The special device comprises low-temperature normal-pressure plasma equipment, grafting reaction equipment, ultrasonic dyeing equipment, a rinsing bath and two groups of control systems, wherein the low-temperature normal-pressure plasma equipment, the grafting reaction equipment, the rinsing bath and the ultrasonic dyeing equipment are sequentially connected, one group of control systems is connected with the low-temperature normal-pressure plasma equipment, and the other group of control systems is connected with the ultrasonic dyeing equipment. The invention organically combines the low-temperature normal-pressure plasma equipment and the ultrasonic dyeing equipment, solves the problem that the dye uptake and the dyeing quality can not improved in a process of dyeing fabrics in a high crystalline region or solves the problem of high energy consumption and high pollution in the dyeing process, and can effectively realize that the dye uptake and the dyeing quality can be improved while realizing environmental-friendly production with low energy consumption and low pollution.

Owner:CHINA TEXTILE ACAD JIANGNAN BRANCH

Method utilizing nitric acid type solder stripping waste water to synthetize zinc hexahydroxystannate

InactiveCN102515259AAchieve recyclingTurn waste into treasureTin compoundsWater/sewage treatmentZinc compoundsSludge

The invention discloses a method utilizing nitric acid type solder stripping waste water to synthetize zinc hexahydroxystannate, which comprises the following steps that: (1) strong electrolyte and settling agent are added in the nitric acid type solder stripping waste water, so the tin compound in the waste water is precipitated, and then the tin sludge is obtained through filtration; (2) the obtained tin sludge is reacted with the concentrated hydrochloric acid to make the tin sludge convert into the tin ionic condition; (3) the tin ion which is in the ionic condition is reacted with the zinc salt under a certain condition to synthetize the zinc hexahydroxystannate compound; (4) the solution is cooled to the room temperature after the reaction is completed, the supernatant liquor is removed through centrifugal separtion, so the obtained material is cleaned via the distilled water; and (5) after the cleaning, the final zinc hexahydroxystannate is obtained through filtration and drying at intermediate temperature. No harmful substances to the environment are generated during the whole synthetization process, and the obtained material is the synthetic material of an environment-friendly plastic fire retardant, a smoke inhibitor and a sensor. The purposes of resource cyclic utilization, low emission and green and environmental-friendly production are realized.

Owner:GUANGDONG UNIV OF TECH

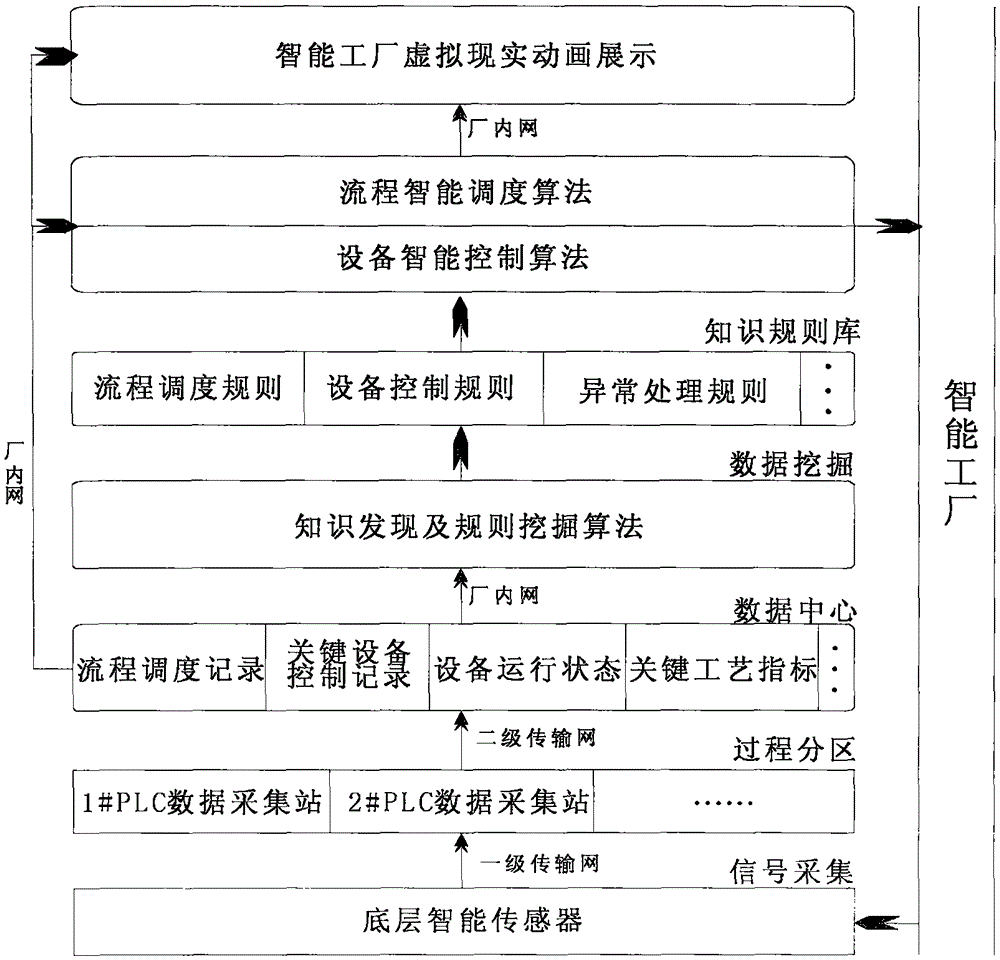

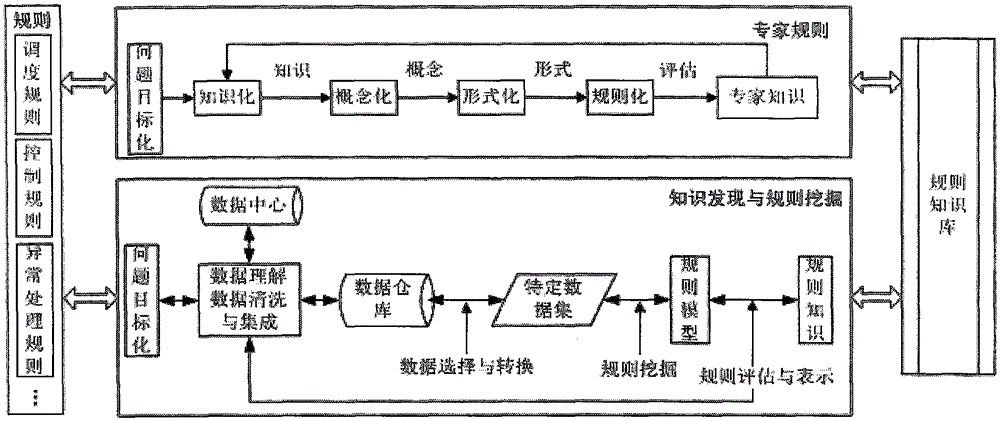

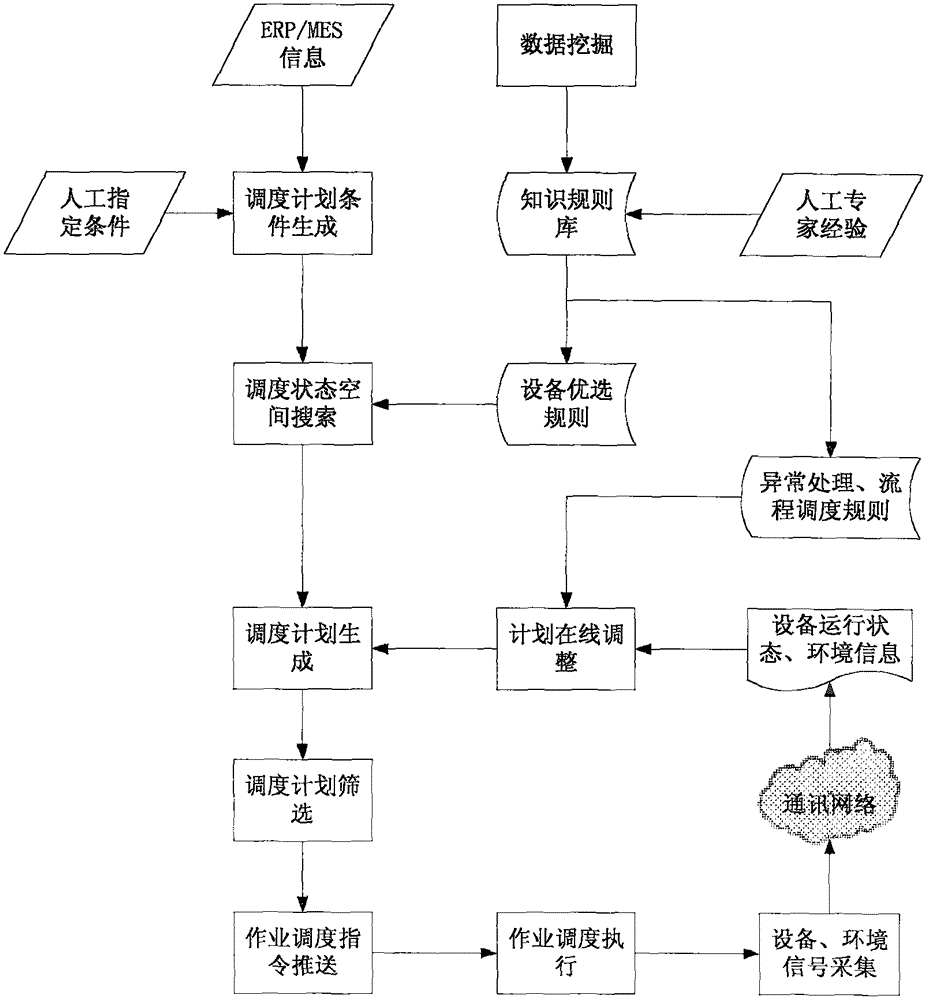

Factory intelligent scheduling method

ActiveCN105302096ARealize human-computer friendly interactive application and experienceReal, timely and reliable transmissionTotal factory controlProgramme total factory controlSmart transducerIntelligent sensor

The invention discloses a factory intelligent scheduling method which mainly comprises the following steps that equipment state information and factory environmental information are acquired via intelligent sensors; the equipment state information and the environmental information are respectively transmitted to corresponding PLC data acquisition stations; each PLC data acquisition station divides data into flow scheduling record data, key equipment control record data, equipment operation state data and key technological index data to be uploaded to a data center through data preprocessing; the data center performs extraction of knowledge rules so as to obtain a knowledge rule base formed by flow scheduling rules, equipment control rules and abnormity processing rules; and the corresponding rules are respectively read via an equipment intelligent control algorithm and a flow intelligent scheduling algorithm so that optimized configuration and scheduling of resources in an intelligent factory can be realized. Upgrading and reconstruction of conventional factory production modes can be realized so that production efficiency can be enhanced, production energy consumption can be reduced, environmental pollution can be reduced and production cost can be saved, and thus green production can be truly realized.

Owner:HUNAN CHAIRMAN IOT INFORMATION TECH CO LTD

Casting technology of engine cylinder cover and core assembling structure

InactiveCN105478677AHigh dimensional accuracyImprove efficiencyFoundry mouldsFoundry coresEngineeringSurface smoothness

The invention discloses a casting technology of an engine cylinder cover and a core assembling structure, and relates to a casting technology. A sand mold is manufactured through the cold core box core manufacturing technology, an intra-cavity inner sand core is manufactured through the precoated sand hot core box core manufacturing technology, vertical casting is carried out after the appearance is locked through sand core discharging, and a good solution is provided for cylinder cover air holes, sand holes, leakage, inner cavities and surface smoothness. By means of implementation of the technology, the casting yield is increased to be more than 98%.

Owner:JINAN FOUNDRY PATTERN

Preparing technology of Ni-Fe-P alloy-based compound coating

The invention provides a preparing technology of a Ni-Fe-P alloy-based compound coating. The matrix material of the compound coating is amorphous / nanocrystalline Ni-Fe-P alloy, the Ni content is 80-90wt% of the compound coating, the Fe content is 5-20wt% of the compound coating, and the P content is 5-15wt% of the compound coating. A second phase in the compound coating is a grain growth inhibitor, such as VC<1-x> and TiC, and the content of the second phase is 0-5wt% of the compound coating. The preparing technology of the compound coating comprises: 1, pretreating a metal plated surface; 2, activating second phase particles; 3, carrying out electric brushing plating on a Ni-Fe-P amorphous compound coating; and 4, carrying out partial crystallization transformation on the compound coating.

Owner:刘志红

Process for producing xylose

InactiveCN102586496AReduce energy consumptionReduce manufacturing costSaccharides productionXyloseIon exchange

The invention discloses a process for producing xylose and belongs to the technical field of the production of functional sugar. According to the process, a primary ion exchange liquid in the process for producing the xylose is treated by a membrane concentration technology, wherein a membrane core of a membrane system is a reverse osmosis membrane or a nanofiltration membrane of materials, and prevents sugar from being leaked; and a feed liquid is concentrated by the membrane system and then is not subjected to circular concentration. The process comprises the following steps of: hydrolyzing, neutralizing, performing primary decolorization, primary ion exchange, membrane concentration, multi-effect concentration, secondary decolorization, secondary ion exchange and vacuum concentration, crystallizing and centrifuging, drying, screening, and packaging to obtain a qualified xylose product. The process is energy-saving and consumption-reducing, so that the production cost of the xylose is greatly reduced, and the environment-friendly production of the xylose is realized; and meanwhile, the problems that the xylose is leaked in a membrane concentration process, the membrane is easy to pollute and the flux is easy to attenuate are solved.

Owner:FUTASTE PHARM CO LTD

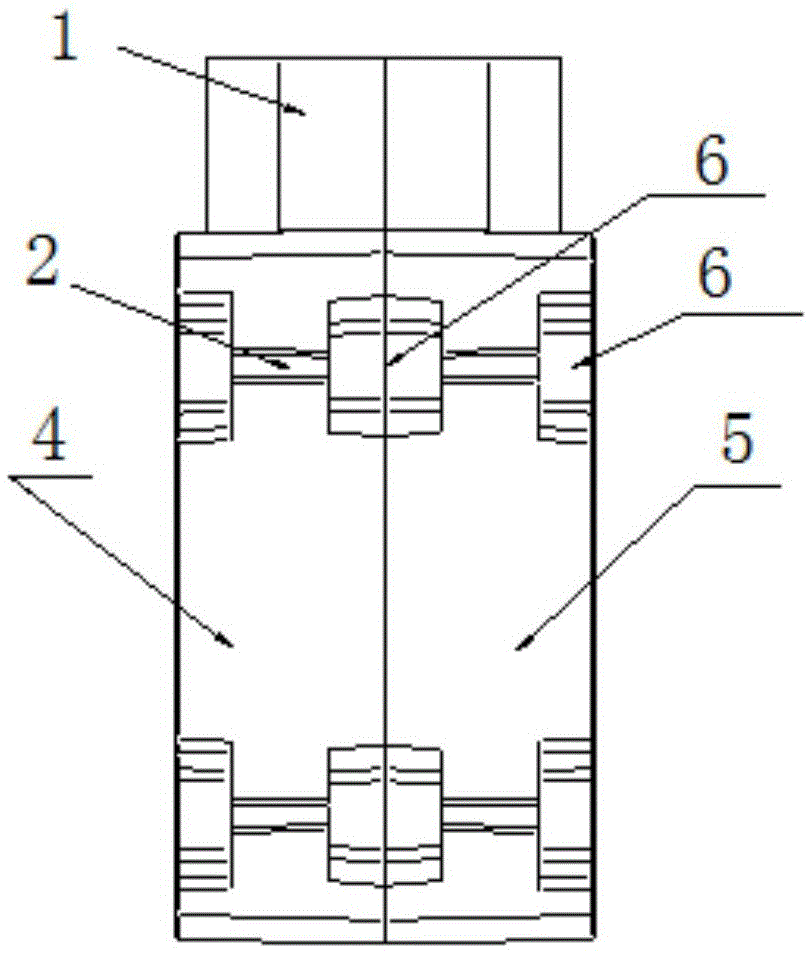

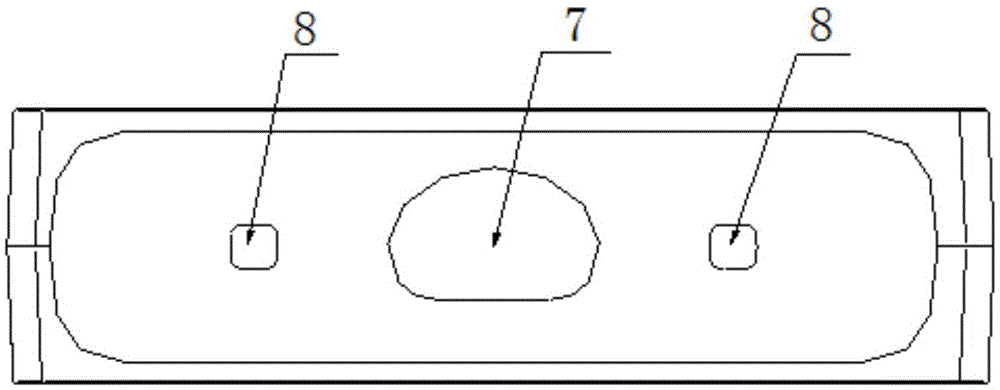

Coal-dressing hydraulic bracket for caving coal working face

ActiveCN102704975ARealize cleaner productionRealize green productionSievingScreeningElastic modulusCoal

The invention discloses a coal-dressing hydraulic bracket for a caving coal working surface. The coal-dressing hydraulic bracket comprises a face guard, a front beam, a top beam, an upright post, a connecting rod mechanism, a caving shield, a coal caving tail beam, a coal caving plate, a motor, a vibration screen, a belt conveyor, a rear scraper conveyor, a gangue transportation warehouse, a baffle plate and a base, wherein the connecting rod mechanism is supported on the lower end of the caving shield; the scraper conveyor and the gangue transportation warehouse are arranged on the base; a gangue vibration motor is arranged on the caving shield, so that coal blocks drop through a vibration mesh below; a gangue discharge gate is controlled to be opened or closed so as to separate the gangues to the gangue transportation warehouse at the lower part through a side gangue sieve, so that the gangues and coal blocks are preliminarily separated underground; according to the differences in elastic modulus and hardness of the coals and gangues, the coals and the gangues are secondarily separated by an elastic plate. The coal-dressing hydraulic bracket has a simple structure and the advantages of reliable operation, practicality and convenience, easiness in underground application and the like, and can remarkably reduce the underground coal transportation cost.

Owner:CHINA UNIV OF MINING & TECH

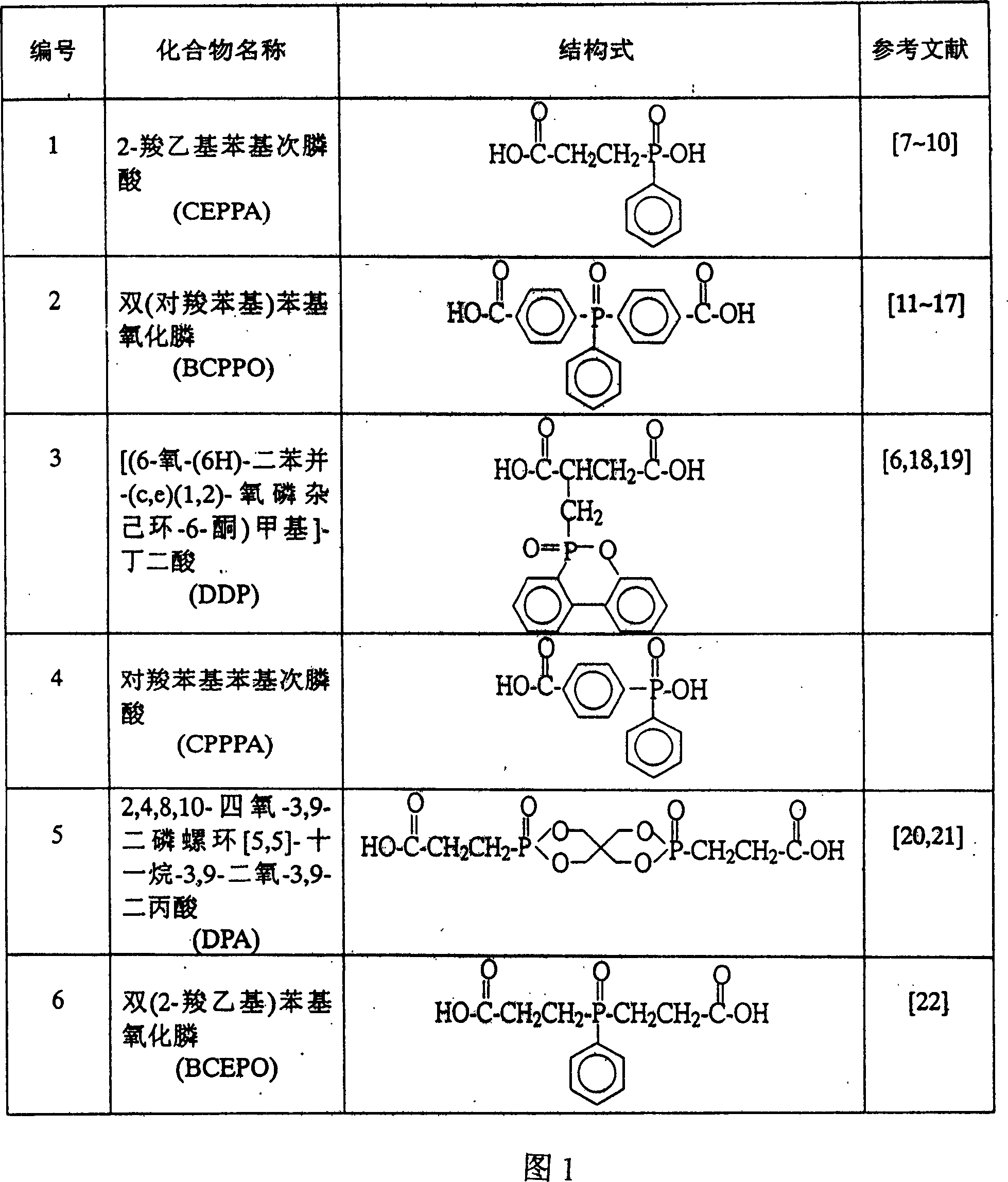

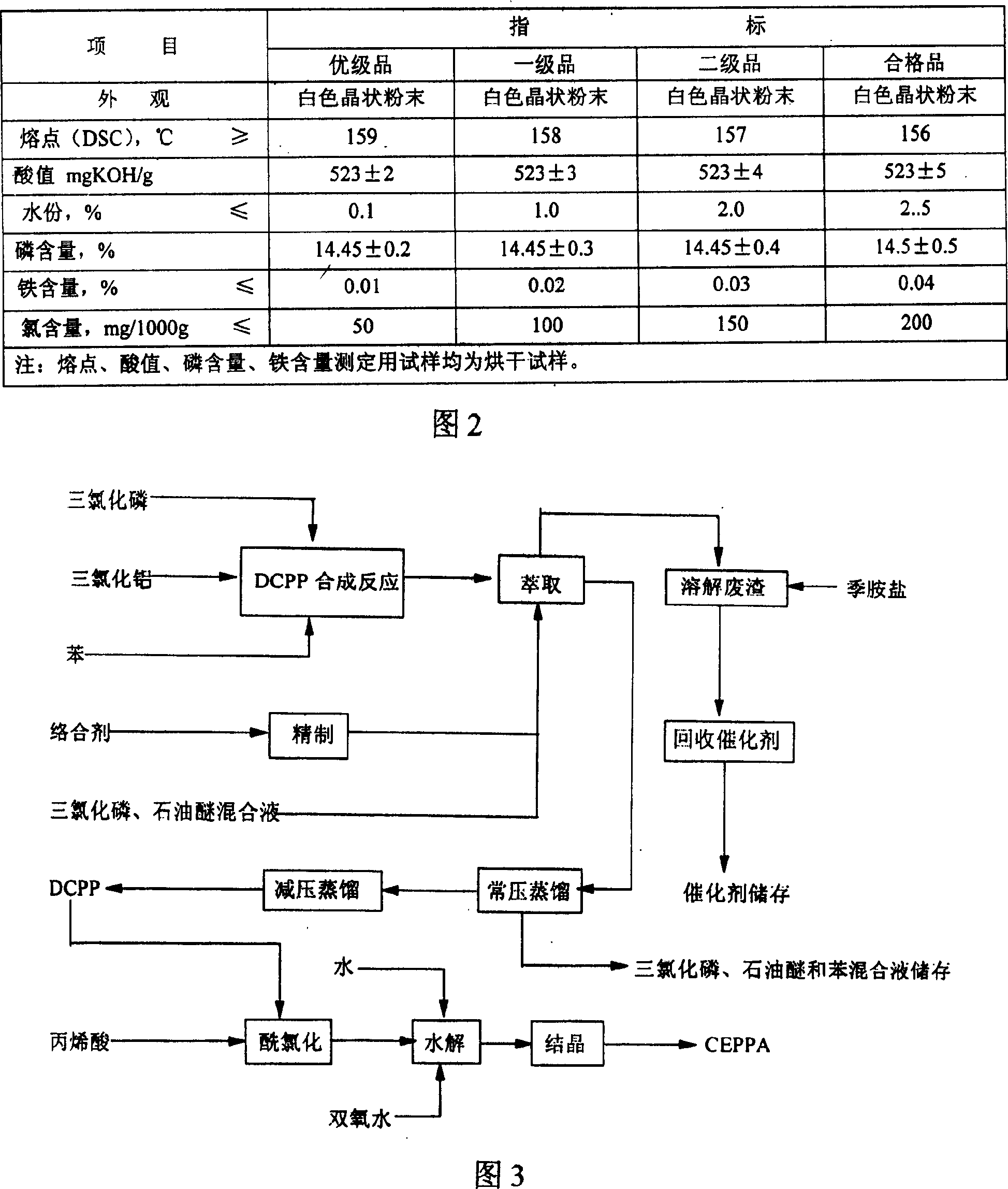

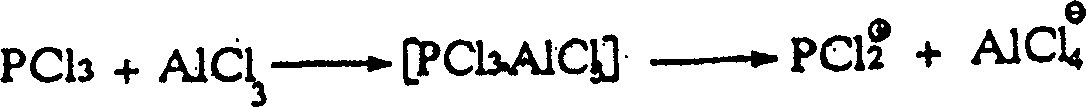

2-carboxyethylphenylphisphinic acid flame-proof agent production method

InactiveCN1952040AReduce consumptionRealize green productionFireproof paintsAluminum trichloridePhosphinic Acids

Owner:云南泰京化工有限公司

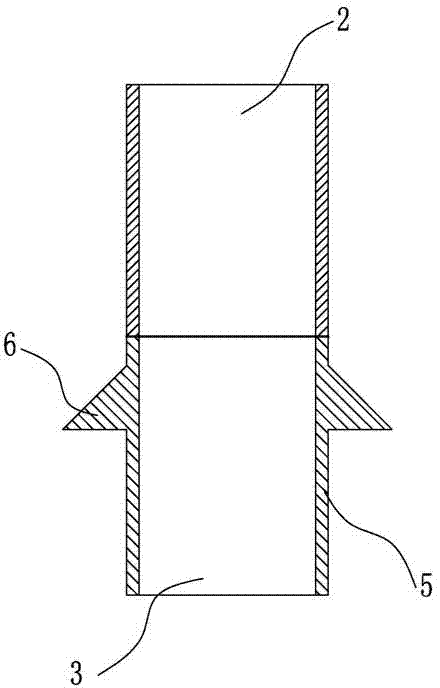

Compressor exhaust pipe and manufacturing method and application of compressor exhaust pipe

ActiveCN103032640ASimple structureRealize green productionNon-disconnectible pipe-jointsResistance welding apparatusButt weldingElectric resistance welding

The invention relates to the field of a compressor, in particular to a compressor exhaust pipe and a manufacturing method and application of the compressor exhaust pipe. The compressor exhaust pipe is arranged on an upper cover of the compressor and comprises a copper pipe section and an iron pipe section, the copper pipe section and the iron pipe section are in butt welding through flash welding, and the iron pipe section is connected with the upper cover of the compressor through electric resistance welding. The manufacturing method of the compressor exhaust pipe comprises preheating and upset-forging. The compressor exhaust pipe can be applied to an air conditioning compressor, a refrigerator compressor and a scroll compressor. The connection between the copper pipe section and the iron pipe section of the compressor exhaust pipe and the connection between the iron pipe section and the upper cover of the compressor adopt a welding method without welding materials, the use of the welding materials is completely eradicated, thus the environment cannot be polluted by waste gases such as carbon dioxide generated during a production process, the technology is simplified while the green production is realized, and the manufacturing cost is lowered; and the compressor exhaust pipe has the advantages that the welding quality is good, the welding strength is more reliable, the welding quality is increased, and the service life is prolonged.

Owner:DONGGUAN JINRUI HARDWARE PROD

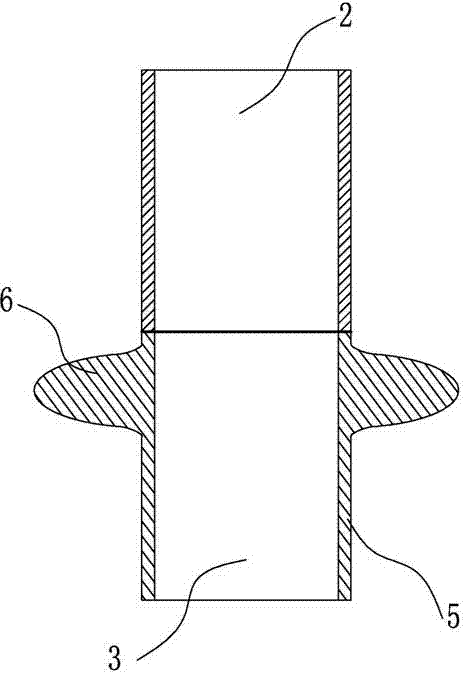

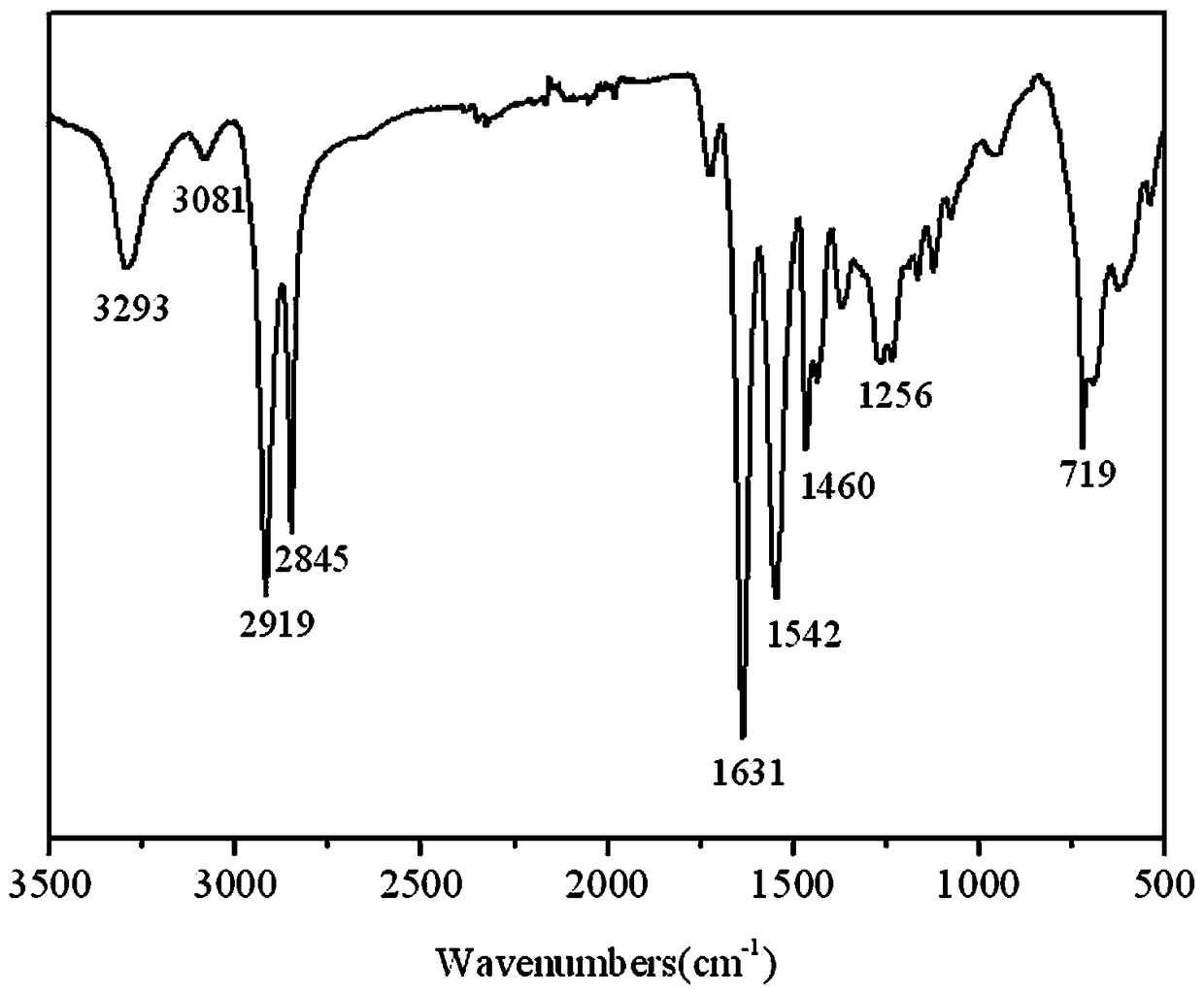

Preparation method for long carbon chain nylon PA1313 and product

ActiveCN109180931AReduce use costImprove solubilityOrganic compound preparationAmino compound preparationAlcoholWastewater

The invention discloses a preparation method for long carbon chain nylon PA1313. The preparation method comprises the following steps: taking 1,13-tridecanedioic acid as a raw material; preparing 1,13-tridecylamine through cyanation and amination; preparing PA1313 salt by taking 1,13-tridecylamine and 1,13-tridecanedioic acid as raw materials and water as a solvent; putting PA1313 salt and water at a certain ratio into a polymerizing kettle; performing melt polymerization, thereby acquiring PA1313 with a certain molecular weight. In the cyanation step of the method, an ammonia gas recycling technique is adopted, so that the use ratio of ammonia gas is greatly increased and the emission of wastewater and exhaust gas is reduced; in the salt forming and polymerizing process, water is used forreplacing ethyl alcohol as a reaction medium, so that the safety of industrial production is promoted, the safety level of equipment is reduced, the investment in equipment is reduced and the recycling cost of solvent is lowered.

Owner:ZHENGZHOU UNIV

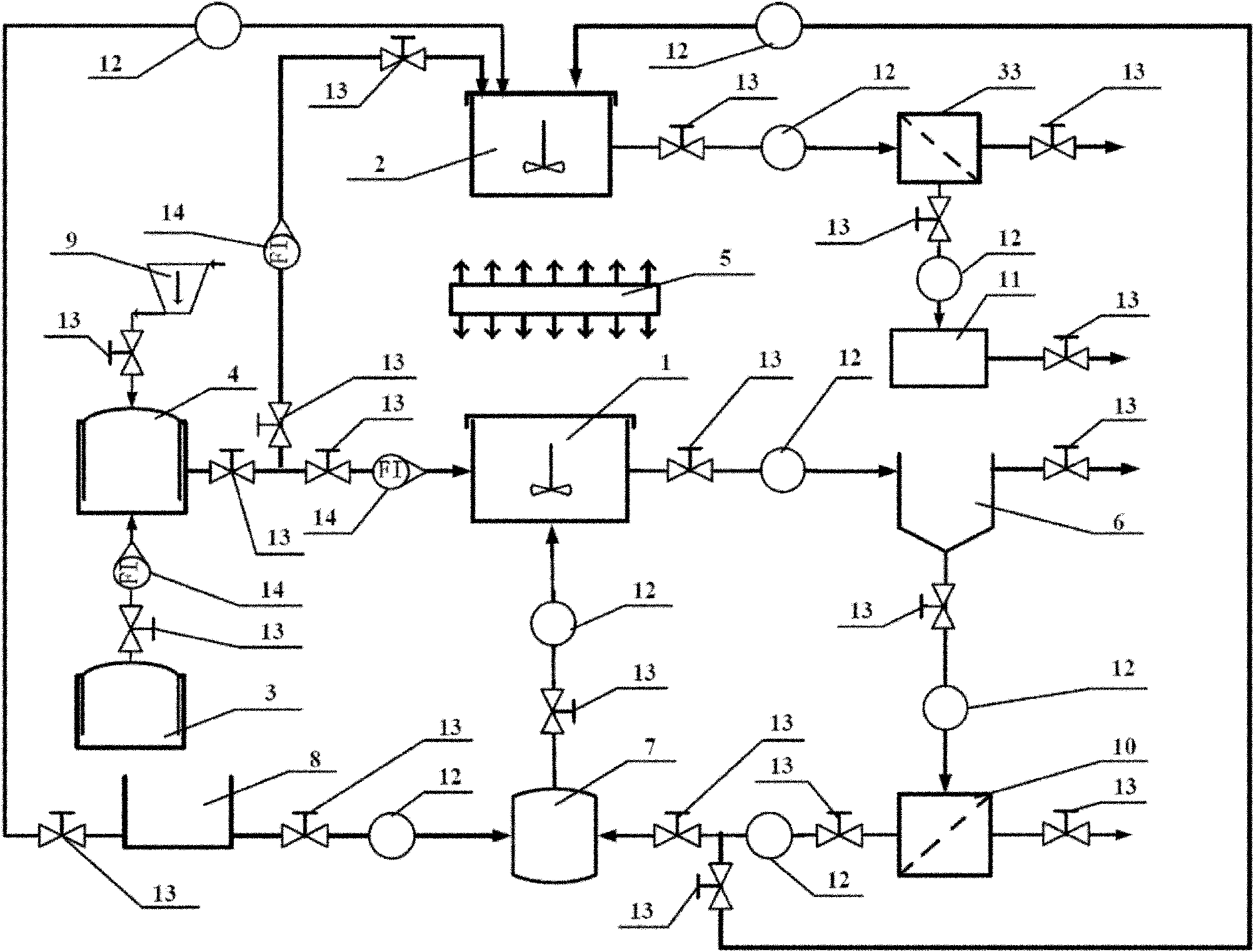

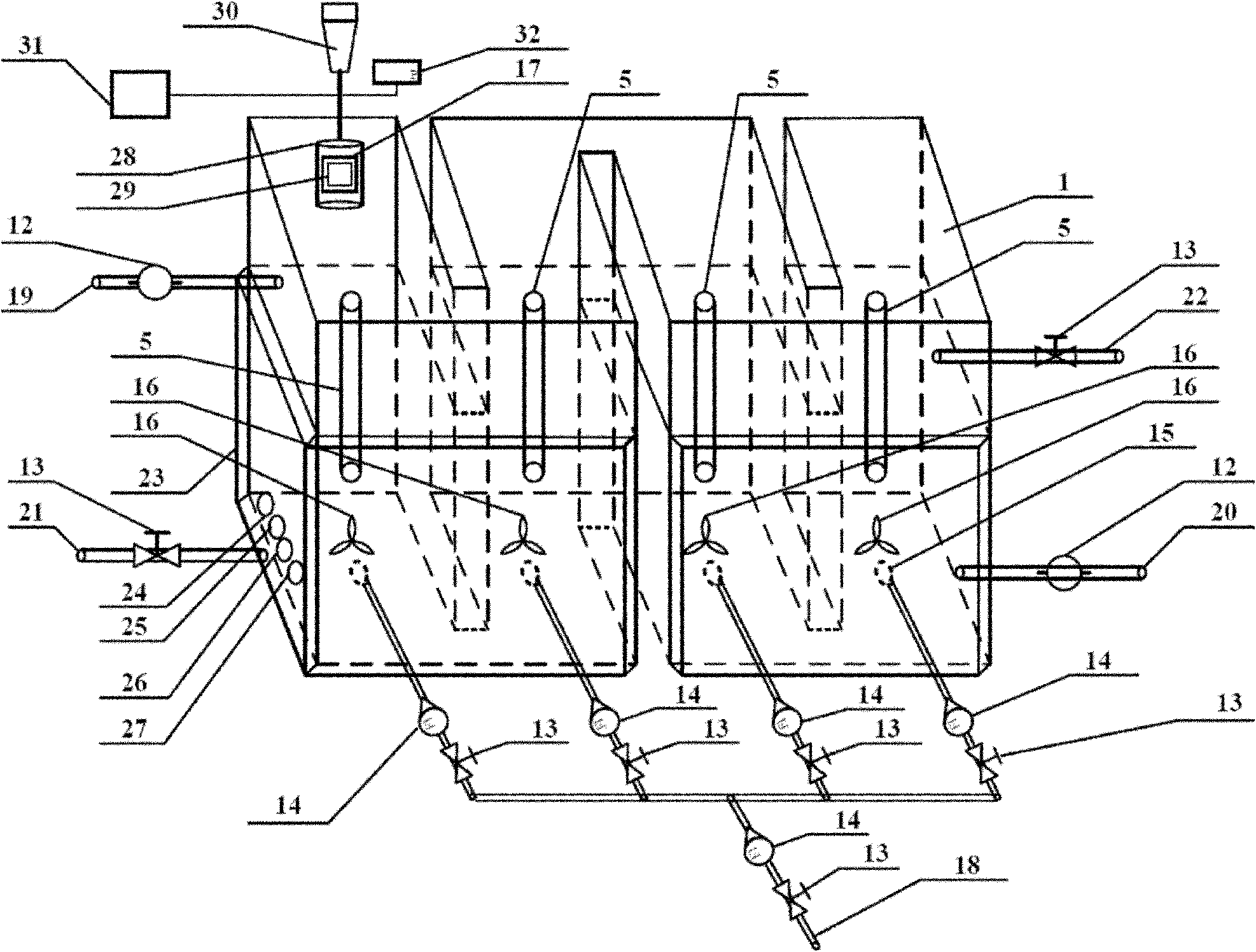

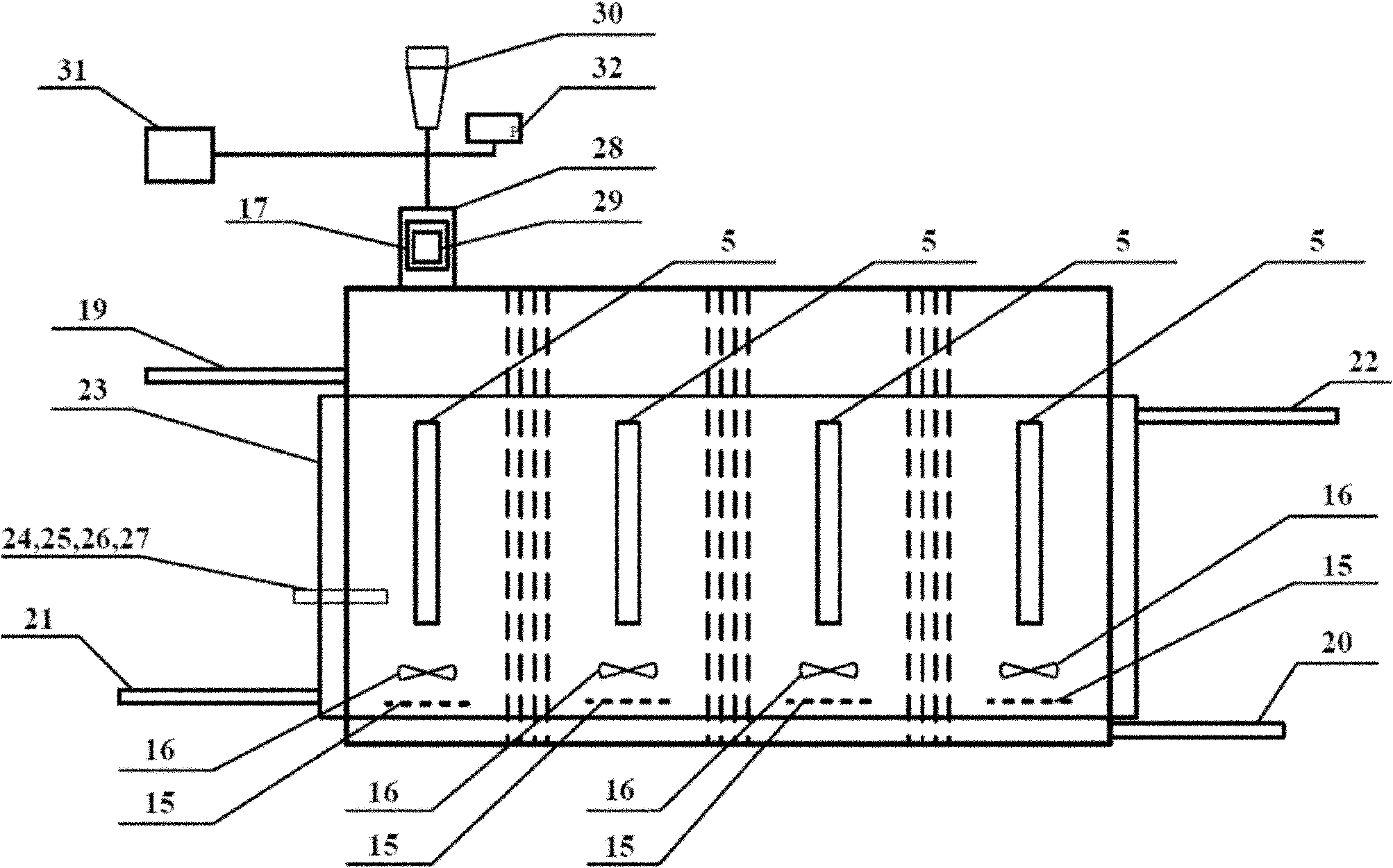

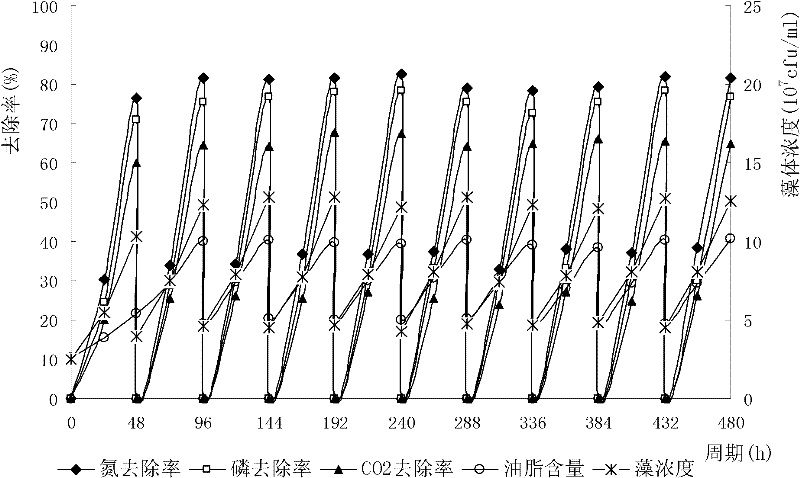

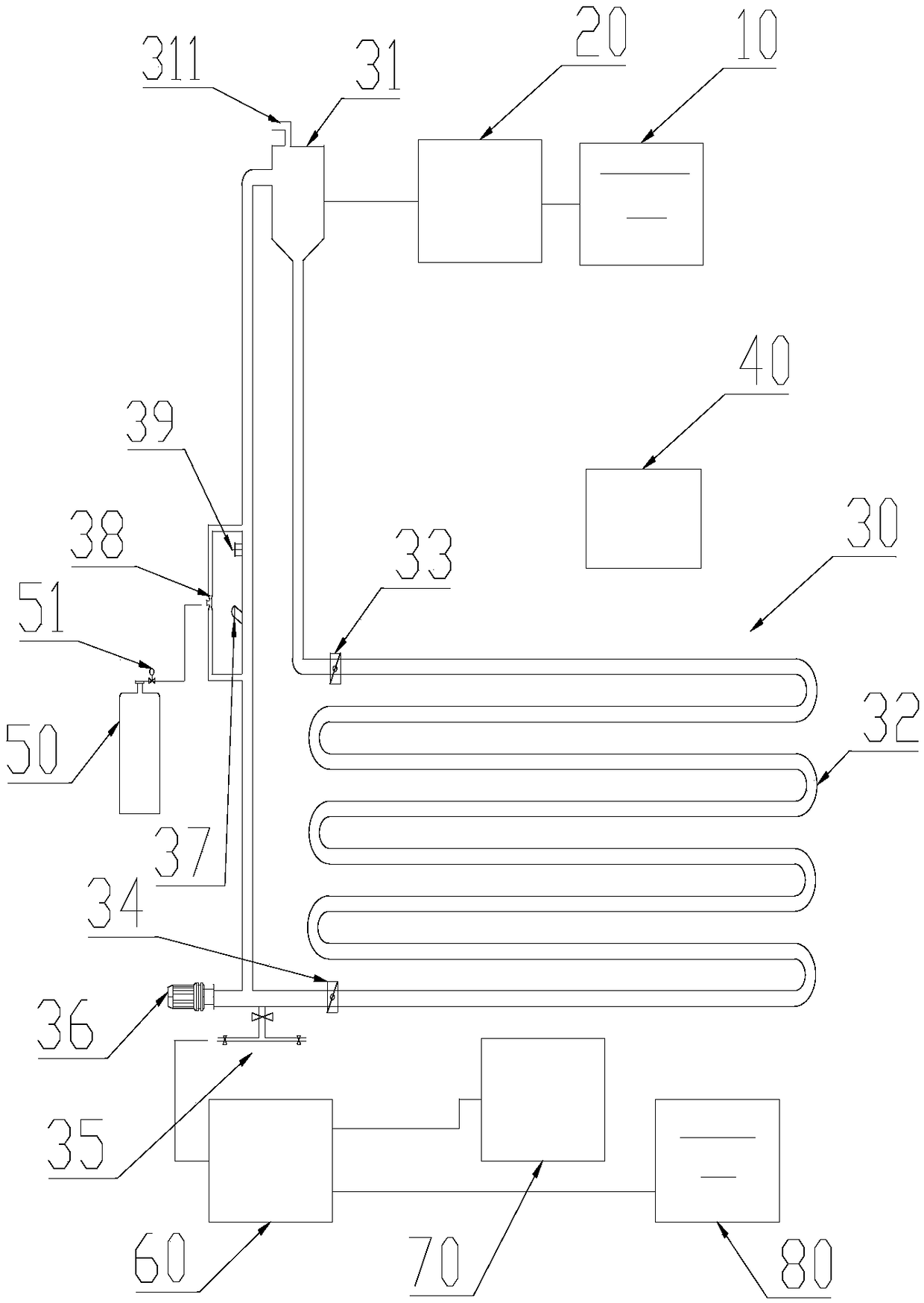

System for treating sewage and producing biological oil by using microalgae and method

ActiveCN102583767AReduced batch processing timeImprove utilization efficiencyEnergy based wastewater treatmentFermentationOil and greaseMixing tank

The invention provides a system for treating sewage and producing biological oil by using microalgae. A first light source device and a second light source device of the system are respectively arranged in a photo-biological reactor and an oil accumulating tank; a CO2 gas supply device is respectively connected with the photo-biological reactor and the oil accumulating tank through air passages; a sewage sedimentation tank is connected with the oil accumulating tank through a pipeline and connected with the photo-biological reactor via a pipeline through a microalgal liquid mixing tank; the photo-biological reactor is respectively connected with the microalgal liquid mixing tank and the oil accumulating tank via pipelines through a first microalgal liquid separating device; and the oil accumulating tank is connected with a second separating device through a pipeline. The invention further provides a method for using the system to treat sewage and produce biological oil. Through the use of the invention, the production of biological energy sources and other byproducts (such as protein, cosmetic raw materials, animal feed and the like) is realized while sewage is treated, so that the production cost is lowered, and the comprehensive utilization of waste resources and the energy-saving and emission-reducing green production are achieved. The invention is suitable for cultivating microalgae from a laboratory to a factory, is skillful and unique in design, and is applicable to large-scale promotion and application.

Owner:JIANGNAN UNIV

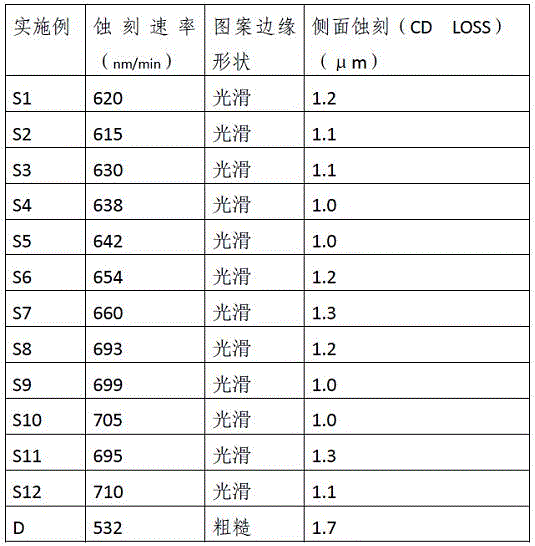

ITO-Ag-ITO etching liquid for AMOLED

ActiveCN105463463AHigh viscosityReasonable concentration gradientSurface treatment compositionsPhosphoric acidDecomposition

The invention discloses ITO-Ag-ITO etching liquid for an AMOLED. The liquid comprises, by weight percentage, 3% to 10% of nitric acid, 10% to 25% of acetic acid, 30% to 60% of a mixture of phosphoric acid and soluble orthophosphate, 1% to 5% of an additive and the balance deionized water, wherein the additive comprises nitrate. The soluble orthophosphate is added so that the viscosity of the etching liquid can be properly increased, it is guaranteed that the etched surface has the reasonable reactant and product concentration gradient in the etching process, and compared with the prior art, the silver etching speed can be properly reduced, the even etching effect can be achieved, and the controllable electrode shape is obtained; and decomposition of the acetic acid, the nitric acid and nitrous acid in the etching process can be remarkably reduced, and environment-friendly production of the etching process can be achieved conveniently.

Owner:JIANGYIN JIANGHUA MICROELECTRONICS MATERIAL

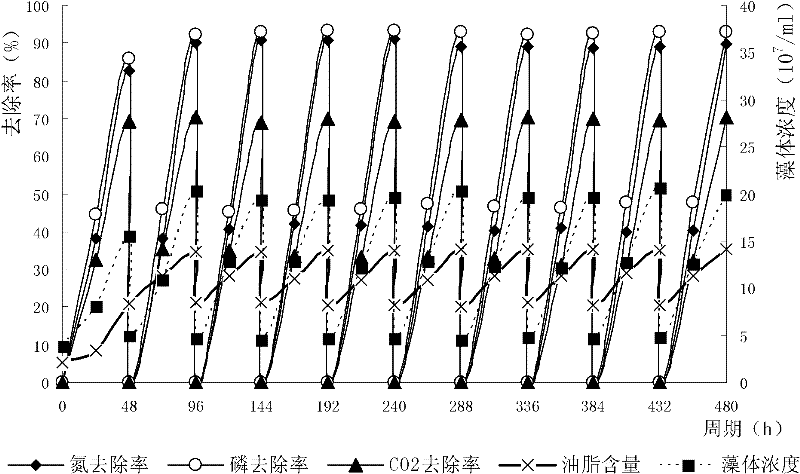

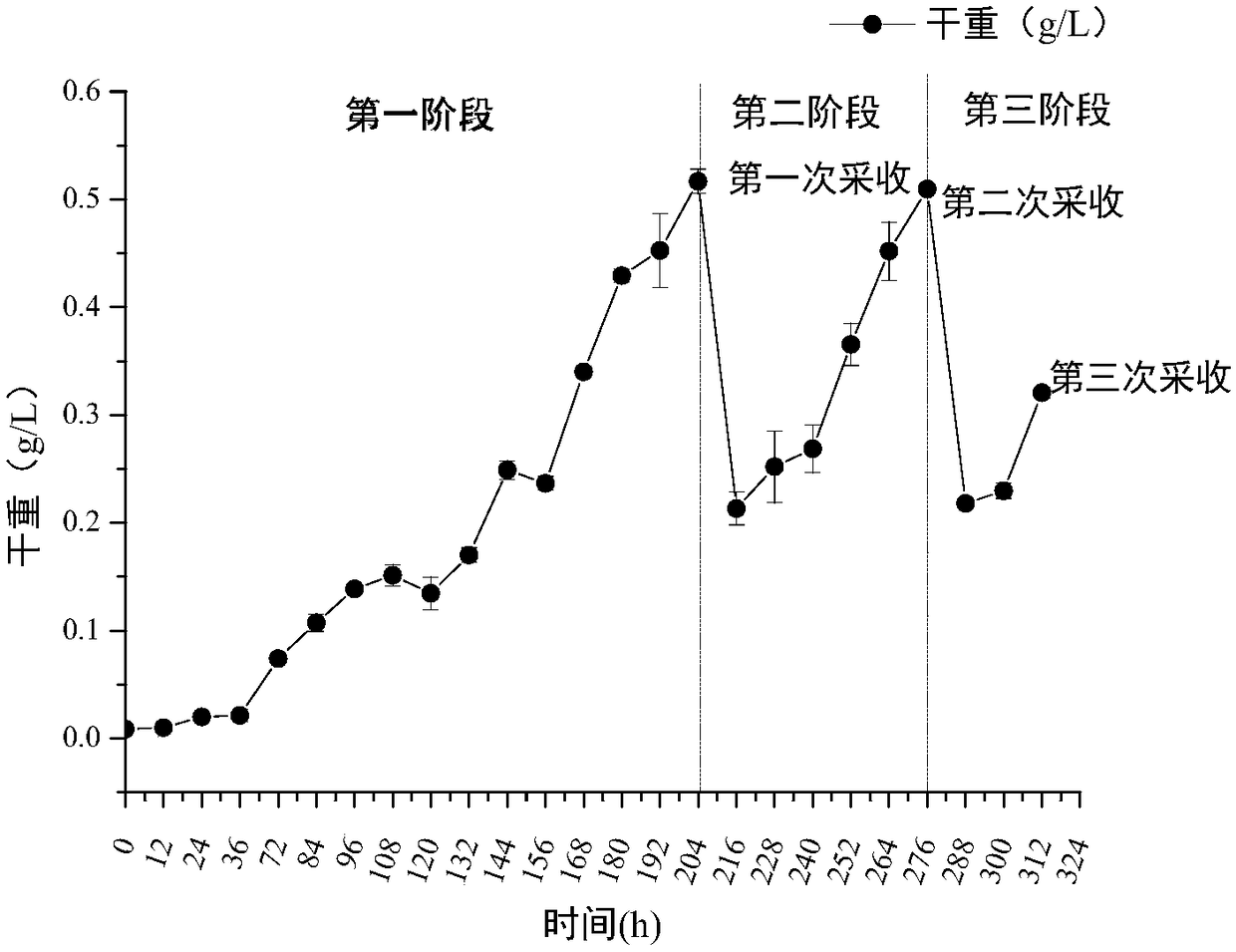

High-density culture process of autotrophic oil-producing microalgae

ActiveCN102443542AIncrease contentNo pollution in the processUnicellular algaeDispersed particle separationNitzschia closteriumSea salt

The invention relates to a high-density culture process of autotrophic oil-producing microalgae. A fermentation method combining a partition method and a two-step method is adopted, CO2 waste gas discharged from a thermal power plant is used as a carbon source, municipal sewage after living contaminant or miscellaneous algae filtering removal is used as a culture medium, the autotrophic oil-producing microalgae is cultured in a high-density way for growth, perfectly, sea salt is added into the municipal sewage for simulating sea water so that the permeation pressure is increased, the living contaminant or miscellaneous algae pollution is prevented, and the autotrophic oil-producing microalgae is selected from one kind or several kinds of materials from autotrophic chlorella, nannochloropsis salina, botryococcus braunii, chaetoceros gracile, marine green algae, isochrysis galbana, nitzschia closterium, phaeodactylum tricornutum, dunaliella and prism-shaped algae. When the high-density culture process is adopted, high removal efficiency of nitrogen, phosphorus and CO2 can be realized, in addition, the algae concentration, the grease content and the protein content are high, the double effects of environment protection and biological resources production are reached, the operation is simple, convenient and fast, the cost is low, no pollution is caused, social and economic integrated benefits are high, and the high-density culture process is suitable for large-scale popularization and application.

Owner:JIANGNAN UNIV

Preparation method of pseudoboehmite

ActiveCN103332716ALower synthesis costLow costAluminium oxides/hydroxidesPseudoboehmiteAluminium nitrate

The invention discloses a preparation method of pseudoboehmite, which comprises the steps that an alcohol water solution is prepared for standby; an aluminum nitrate solution and an ammonia water solution are prepared by taking the prepared alcohol aqueous solution as a solvent, and taking aluminum nitrate and ammonia water as solutes respectively; the ammonia water solution is dropwise added to the aluminum nitrate solution; a pH value is adjusted to be 7-10; reaction is performed for 10-50min at 20-50 DEG C; aging is performed for 1-8h at 30-80 DEG C; filtering is performed; washing is performed for 2-6 times by the alcohol water solution; drying is performed for 6-24h at 120 DEG C; and the pseudoboehmite is obtained. The preparation method is simple to operate; aluminum nitrate is taken as a raw material, so that the cost is lowered greatly; alcohol can be recycled, and a byproduct, namely ammonium nitrate has an industrial application value, so that green production can be realized; and a very good effect is obtained.

Owner:甘肃莱安能源有限公司

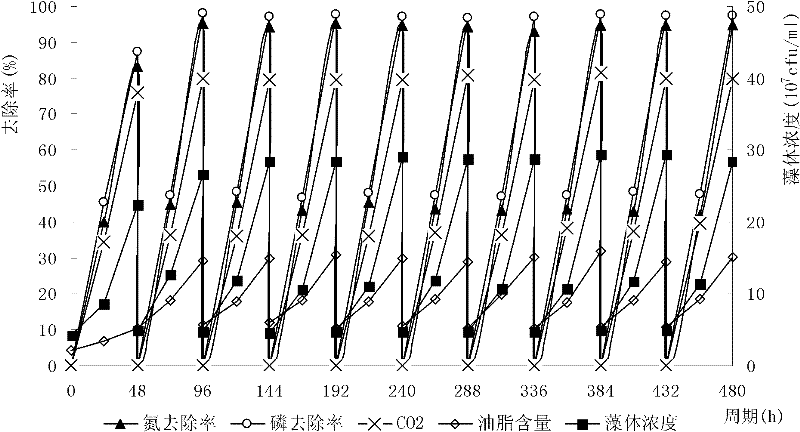

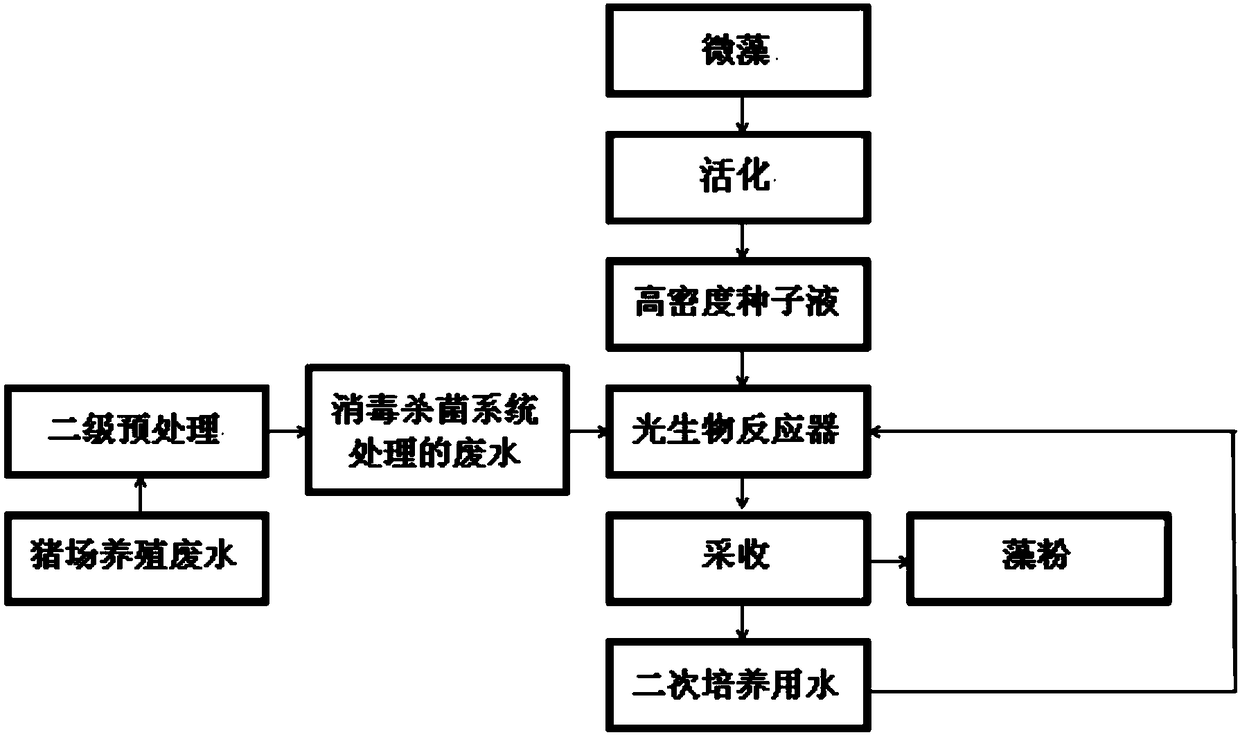

Apparatus and process for treating breeding wastewater in pig farm and producing algal powder by utilizing microalgae

InactiveCN108249574AShort processing cycleAchieve recyclingBioreactor/fermenter combinationsBiological substance pretreatmentsPig farmsUltrafiltration

The invention discloses apparatus and a process for treating breeding wastewater in a pig farm and producing algal powder by utilizing microalgae. The device comprises a wastewater pool, a filtering device, a pipeline type photobioreactor, a spraying device, a gas supply device, an ultrafiltration device, a centrifuge and a clear water pool; and the process comprises the following steps: (1) performing secondary pretreatment on the breeding wastewater in the pig farm, placing the treated wastewater into the photobioreactor, and performing treatment by using a disinfection sterilization system;(2) performing inoculation in the photobioreactor having the wastewater in the pig farm by using the microalgae, performing cultivation, and performing harvesting, wherein the photobioreactor includes an on-line detection water datum system: an in-situ carbon supplementation-pH feedback control device, a spray automatic cooling system and a dissolved-oxygen detection system; and (3) performing centrifugation on the harvested algal liquid to obtain algal mud, and performing drying to obtain the algal powder. The method provided by the invention eliminates or reduces discharge of waste to a maximum limit, achieves the purposes of energy conservation, emission reduction, efficiency enhancement and resource recovery, is applied to large-scale purification treatment of the wastewater in the pig farm and production of the algal powder, and realizes sustainable development and utilization of resources.

Owner:SOUTH CHINA UNIV OF TECH

Antiflaming straw big core board and manufacturing method thereof

ActiveCN105269642AAchieve recyclingFlame retardantNon-macromolecular adhesive additivesLaminationPolyvinyl alcoholChloride

The invention provides an antiflaming straw big core board. The antiflaming straw big core board comprises two wood single boards and a homogenization straw core board arranged between the two wood single boards. The homogenization straw core board comprises, by mass, 8 parts to 9 parts of straw particles and 1.8 parts to 2.4 parts of an antiflaming binding agent, wherein the antiflaming binding agent comprises raw material including magnesium chloride, magnesium oxide, polyvinyl alcohol, sodium silicate, tartaric acid and ammonium polyphosphate. The antiflaming straw big core board has the good chemical properties of inflaming retarding, water prevention, mosquito prevention and the like and has the good physical mechanical performance, a wood large core board can be replaced with the antiflaming straw big core board, and the antiflaming straw big core board can be applied to various fields. The invention further provides a manufacturing method of the antiflaming straw big core board. The manufacturing method is simple and environment-friendly.

Owner:信阳美丽真好秸秆新材科技有限公司

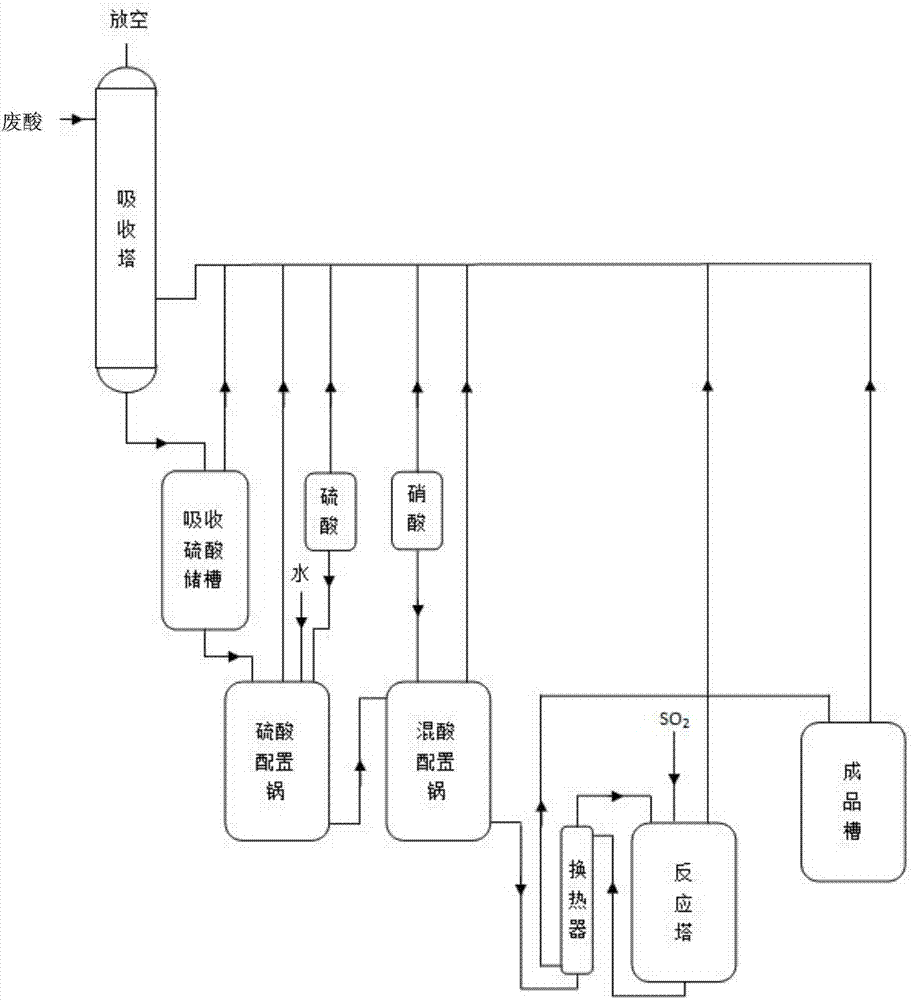

Nitrosyl sulfuric acid production method and system

ActiveCN107963617AEmission reductionRealize resource utilizationNitrogen compoundsResource utilizationControl manner

The invention discloses a green continuous production method of nitrosyl sulfuric acid. The production method includes the steps: (1) condensing waste acid to obtain condensed waste acid; (2) continuously leading the condensed waste acid in an absorption tower to absorb mixed tail gas generated in the production of the nitrosyl sulfuric acid to obtain absorbed sulfuric acid; (3) preparing the absorbed sulfuric acid and water and / or concentrated sulfuric acid into sulfuric acid solution with demand concentration, and mixing the sulfuric acid solution and the concentrated sulfuric acid into mixed acid; (4) continuously feeding the mixed acid and gas with sulfur dioxide into a reaction tower to perform reaction to obtain a nitrosyl sulfuric acid finished product. The invention further discloses a production system of the nitrosyl sulfuric acid. The tail gas generated in the production process of the nitrosyl sulfuric acid is absorbed and recycled by the aid of the condensed waste acid, the mixed acid is preheated by the nitrosyl sulfuric acid finished product, and the nitrosyl sulfuric acid is synthesized in a continuous and automatic chain control manner. According to automatic chaincontrol, heat exchange and tail gas resource utilization, emission reduction of tail gas is achieved, energy is saved, consumption is reduced, and yield is improved.

Owner:ZHEJIANG DIBANG CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com