Nitrosyl sulfuric acid production method and system

A technology of nitrosyl sulfuric acid and production methods, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of incomplete tail gas absorption, increased energy consumption, emissions, cumbersome processes, etc., and reduce tail gas treatment Cost and raw material cost, reduction of raw material cost, effect of increasing reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

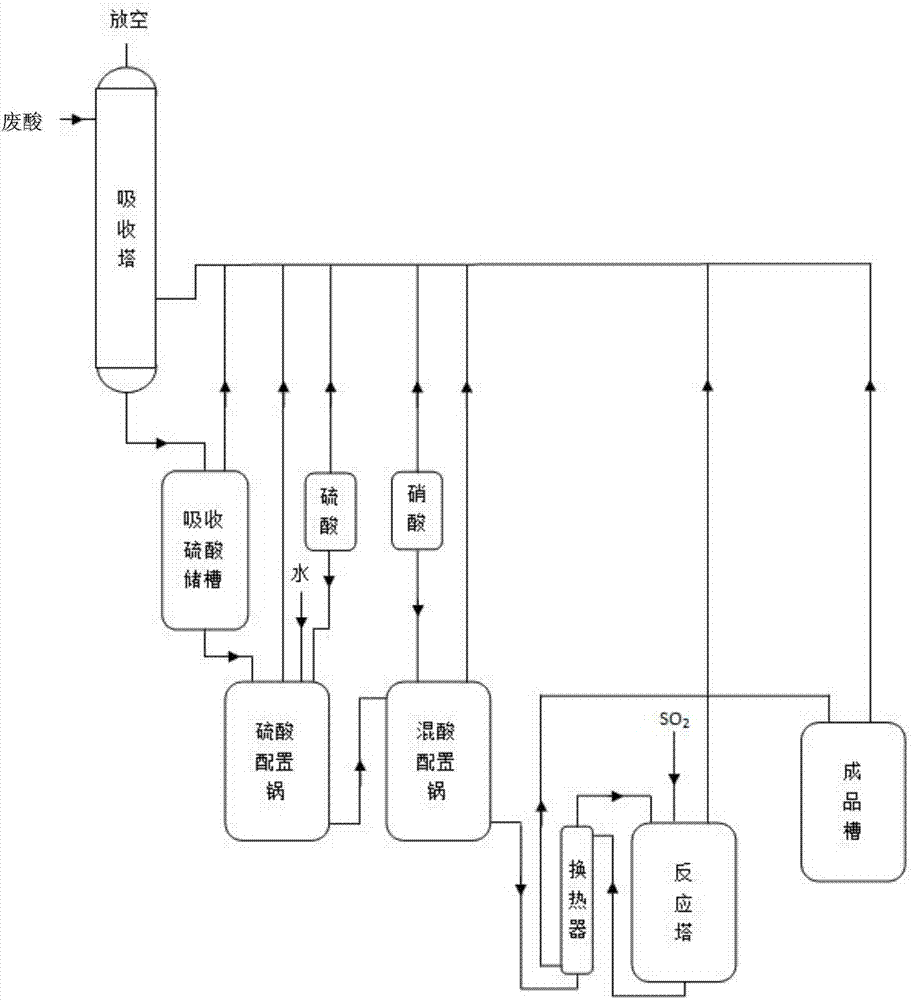

[0045] A kind of production method of nitrosyl sulfuric acid, comprises the following steps:

[0046] (1) waste acid is concentrated waste acid that obtains sulfuric acid mass fraction as 30% through concentration;

[0047] (2) flow is that the concentrated waste acid of 1.0t / h is passed into absorption tower continuously from top to bottom, absorbs the mixed tail gas that produces in the production process of nitrosyl sulfuric acid, and mixed tail gas enters absorption tower from bottom to top, obtains absorption sulfuric acid, The massfraction of sulfuric acid at the outlet of the absorption tower is 31.5%;

[0048]The absorption tower is a packed tower reactor, and the filler is aluminum silicate. The absorption tower is vented on the top of the absorption tower and connected to the waste gas treatment device for treatment; absorption sulfuric acid storage tank, sulfuric acid storage tank, nitric acid storage tank, and sulfuric acid configuration pot , The mixed acid confi...

Embodiment 2

[0052] A kind of production method of nitrosyl sulfuric acid, comprises the following steps:

[0053] (1) waste acid is concentrated waste acid that obtains sulfuric acid mass fraction as 85% through concentration;

[0054] (2) Concentrated waste acid is continuously fed into the absorption tower from top to bottom with a flow rate of 355kg / h to absorb the mixed tail gas produced in the production process of nitrosyl sulfuric acid, and the mixed tail gas enters the absorption tower from bottom to top to obtain absorbed sulfuric acid. The massfraction of sulfuric acid is 87.5%;

[0055] The absorption tower is a packed tower reactor, and the filler is aluminum silicate. The absorption tower is vented on the top of the absorption tower and connected to the waste gas treatment device for treatment; absorption sulfuric acid storage tank, sulfuric acid storage tank, nitric acid storage tank, and sulfuric acid configuration pot , The mixed acid configuration pot, the reaction tower...

Embodiment 3

[0059] A kind of production method of nitrosyl sulfuric acid, comprises the following steps:

[0060] (1) the waste acid is pretreated and concentrated to obtain a concentrated waste acid with a mass fraction of 60%;

[0061] (2) Concentrated waste acid is continuously fed into the absorption tower from top to bottom with a flow rate of 555kg / h to absorb the mixed tail gas produced in the production process of nitrosyl sulfuric acid, and the mixed tail gas enters the absorption tower from bottom to top to obtain absorbed sulfuric acid. The massfraction of sulfuric acid is 61.6%;

[0062] The absorption tower is a packed tower reactor, and the filler is aluminum silicate. The absorption tower is vented on the top of the absorption tower and connected to the waste gas treatment device for treatment; absorption sulfuric acid storage tank, sulfuric acid storage tank, nitric acid storage tank, and sulfuric acid configuration pot , The mixed acid configuration pot, the reaction tow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com