Patents

Literature

1134 results about "Low activity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reducing blocking and ringing artifacts in low-bit-rate coding

InactiveUS6983079B2Increase speedReducing blocking and artifactPicture reproducers using cathode ray tubesPicture reproducers with optical-mechanical scanningPattern recognitionLow activity

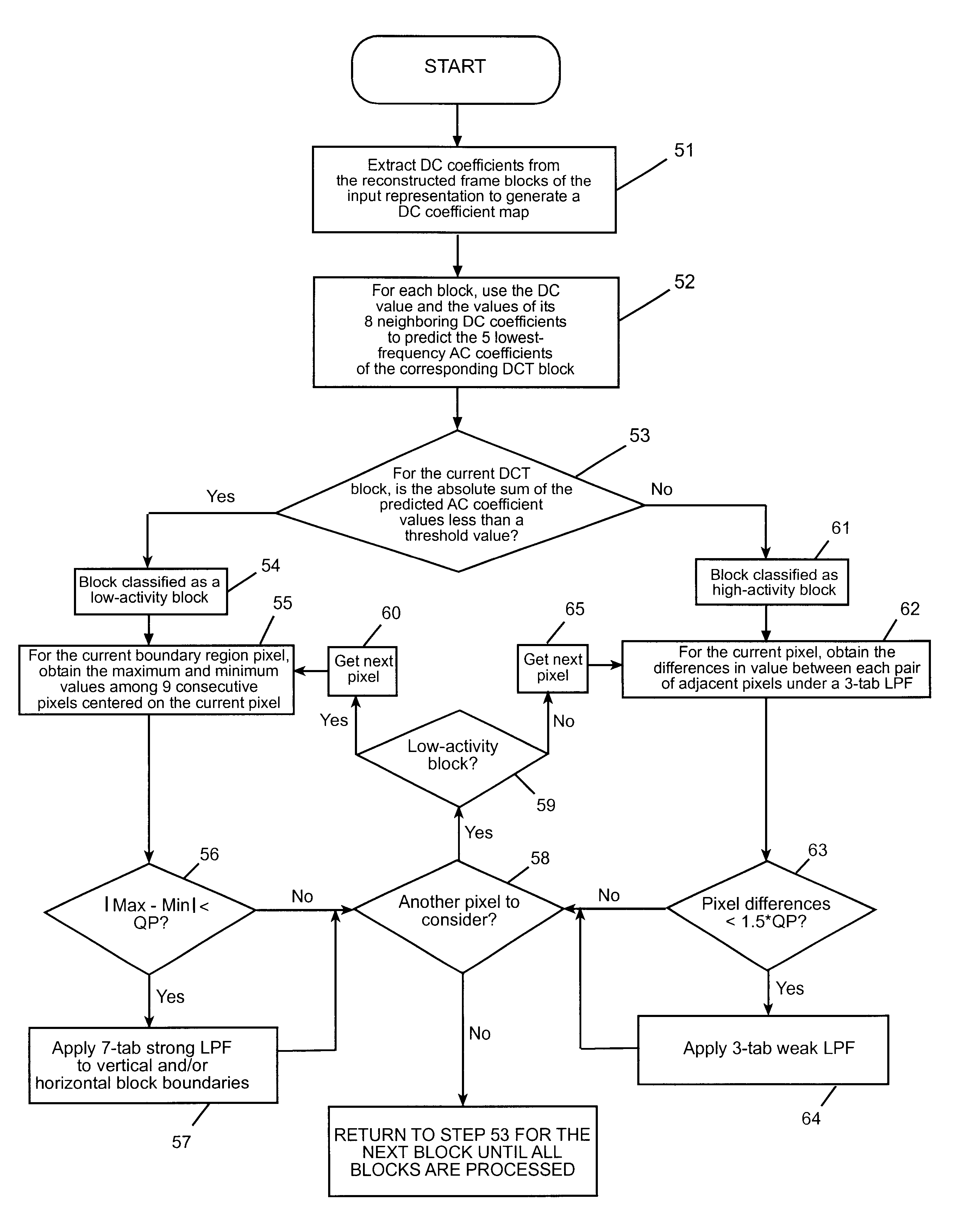

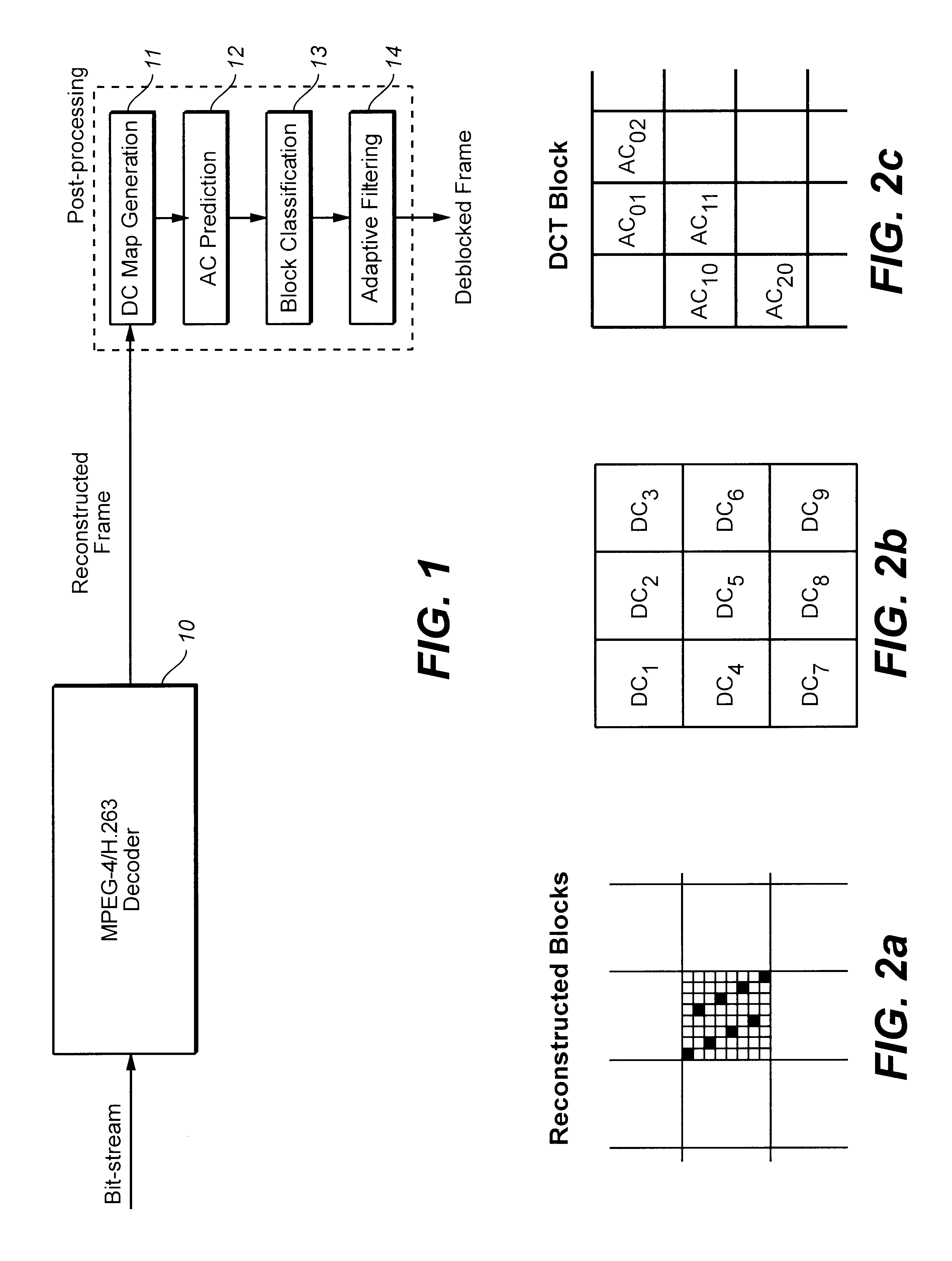

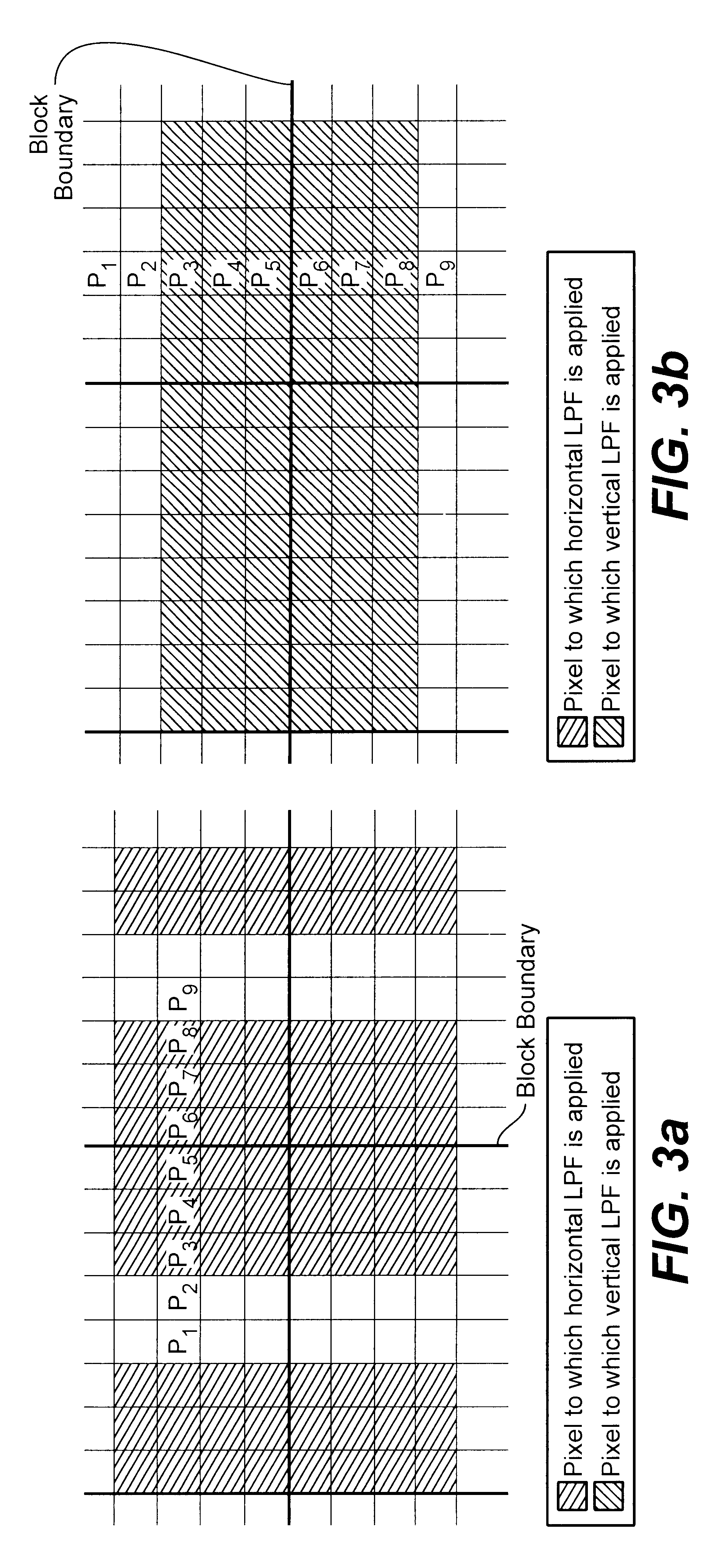

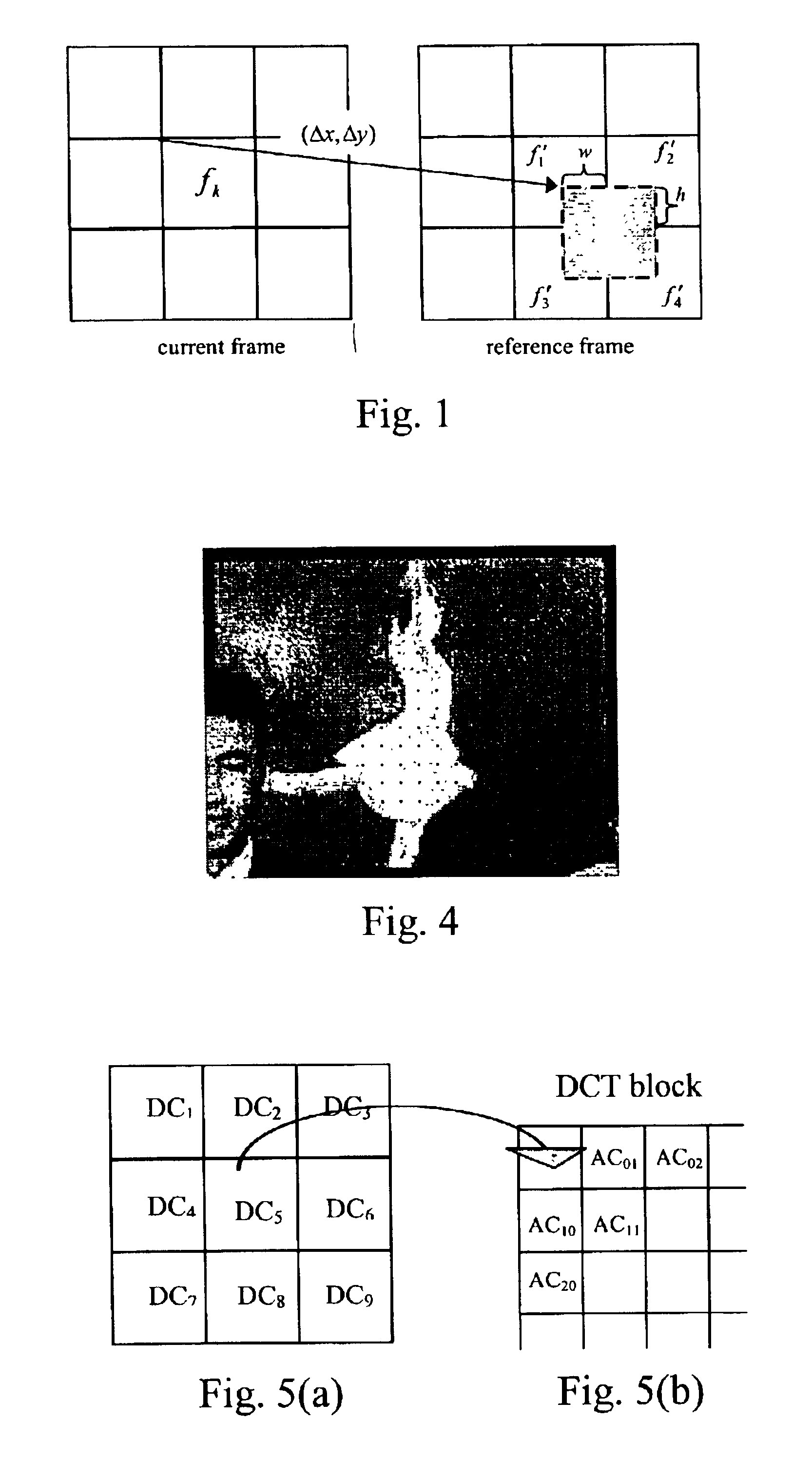

A technique to reduce blocking and ringing artifacts in low bit-rate block-based video coding is applied to each reconstructed frame output from the decoder. For each pixel block of a reconstructed frame, its DC value and DC values of the surrounding eight neighbor blocks are exploited to predict AC coefficients which might be lost in the quantization stage in the encoding process. The predicted AC coefficients are used to classify each reconstructed block as either a low-activity or a high-activity block. Low-pass filtering is then adaptively applied according to the classification of the block. Strong low-pass filtering is applied in low-activity blocks where the blocking artifacts are most noticeable, whereas weak low-pass filtering is applied in high-activity blocks where ringing noise as well as blocking artifacts may exist. The adaptive filtering reduces ringing noise as well as blocking artifacts without introducing undesired blur. In low activity blocks, the blocking artifacts are reduced by one dimensional horizontal and vertical low-pass filters which are selectively applied in either the horizontal and / or vertical direction depending on the locations and absolute values of the predicted AC coefficients. In high activity blocks, de-blocking and de-ringing is conducted by a single filter, applied horizontally and / or vertically, which makes the architecture simple.

Owner:SEIKO EPSON CORP

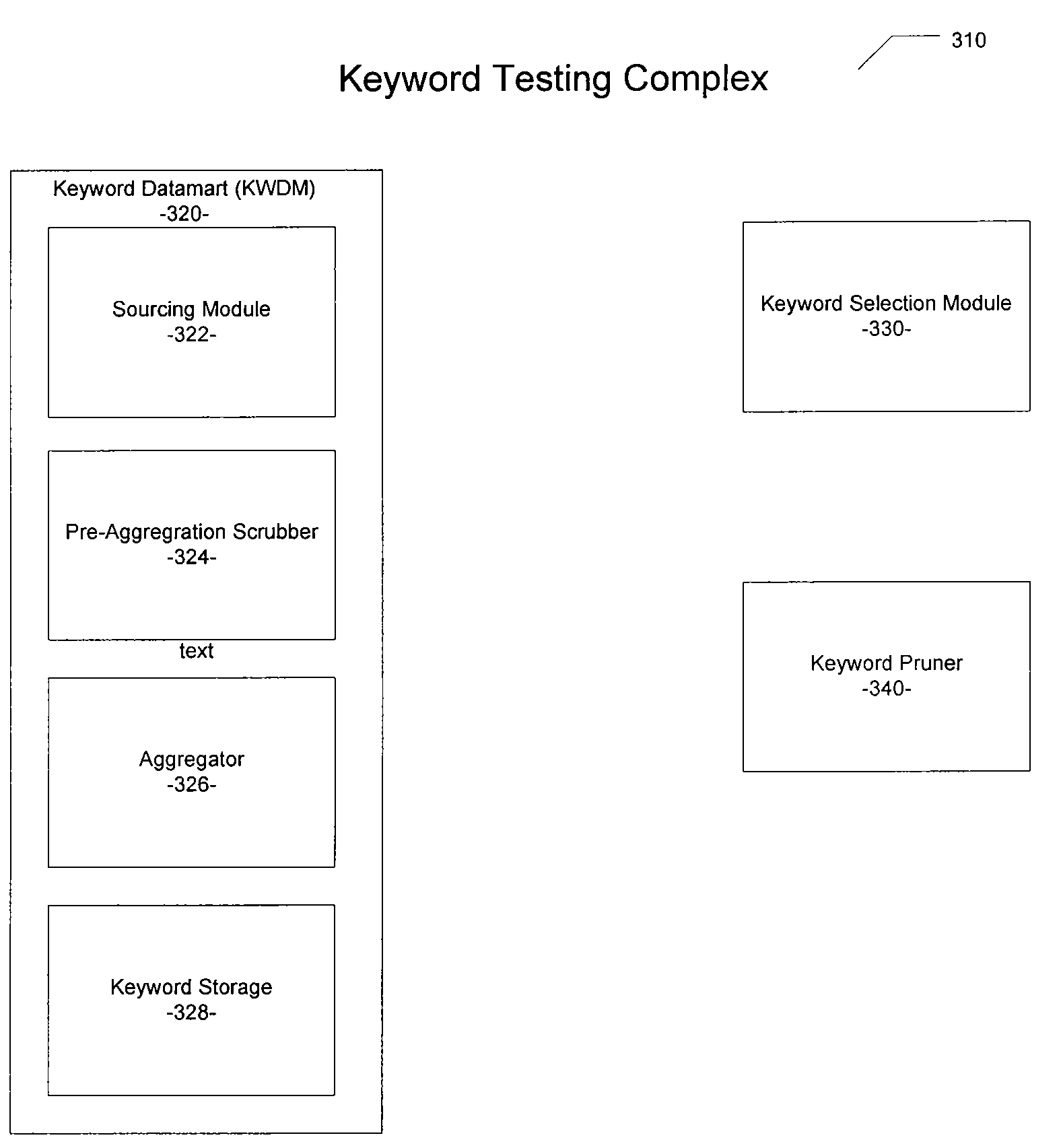

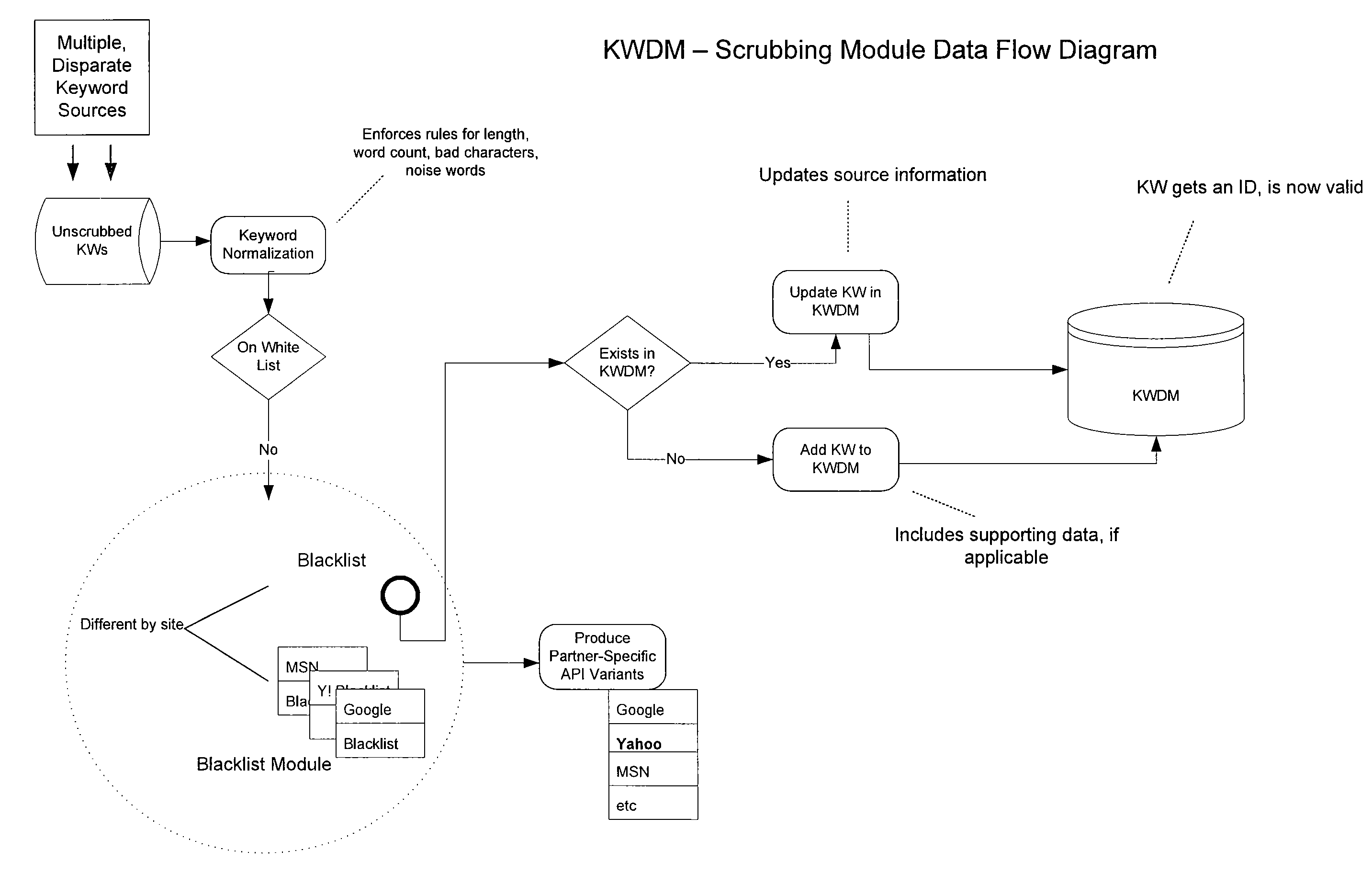

Computer-implemented method and system for combining keywords into logical clusters that share similar behavior with respect to a considered dimension

A computer-implemented method and system for combining keywords into logical clusters that share a similar behavior with respect to a considered dimension are disclosed. Various embodiments are operable to order a list of keywords from high activity to low activity, partition the list into at least two sets, a head partition including keywords with an activity level above a predefined threshold, a tail partition including the remainder of the keywords in the list, model the keywords in the head partition based on a set of variables, score the keywords in the head partition based on the modeling, and cluster head partition keywords with tail partition keywords having at least one common variable into at least one keyword cluster.

Owner:EBAY INC

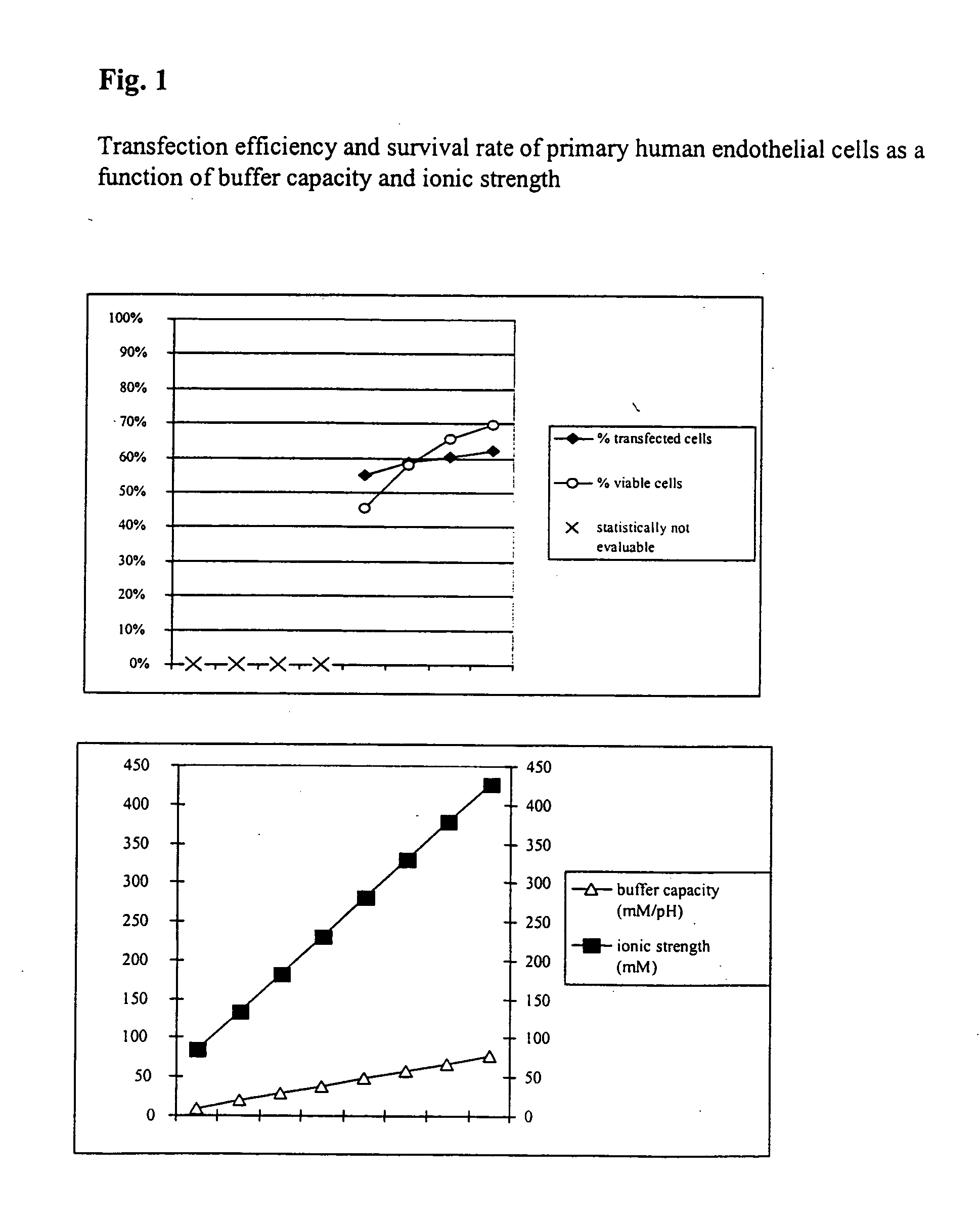

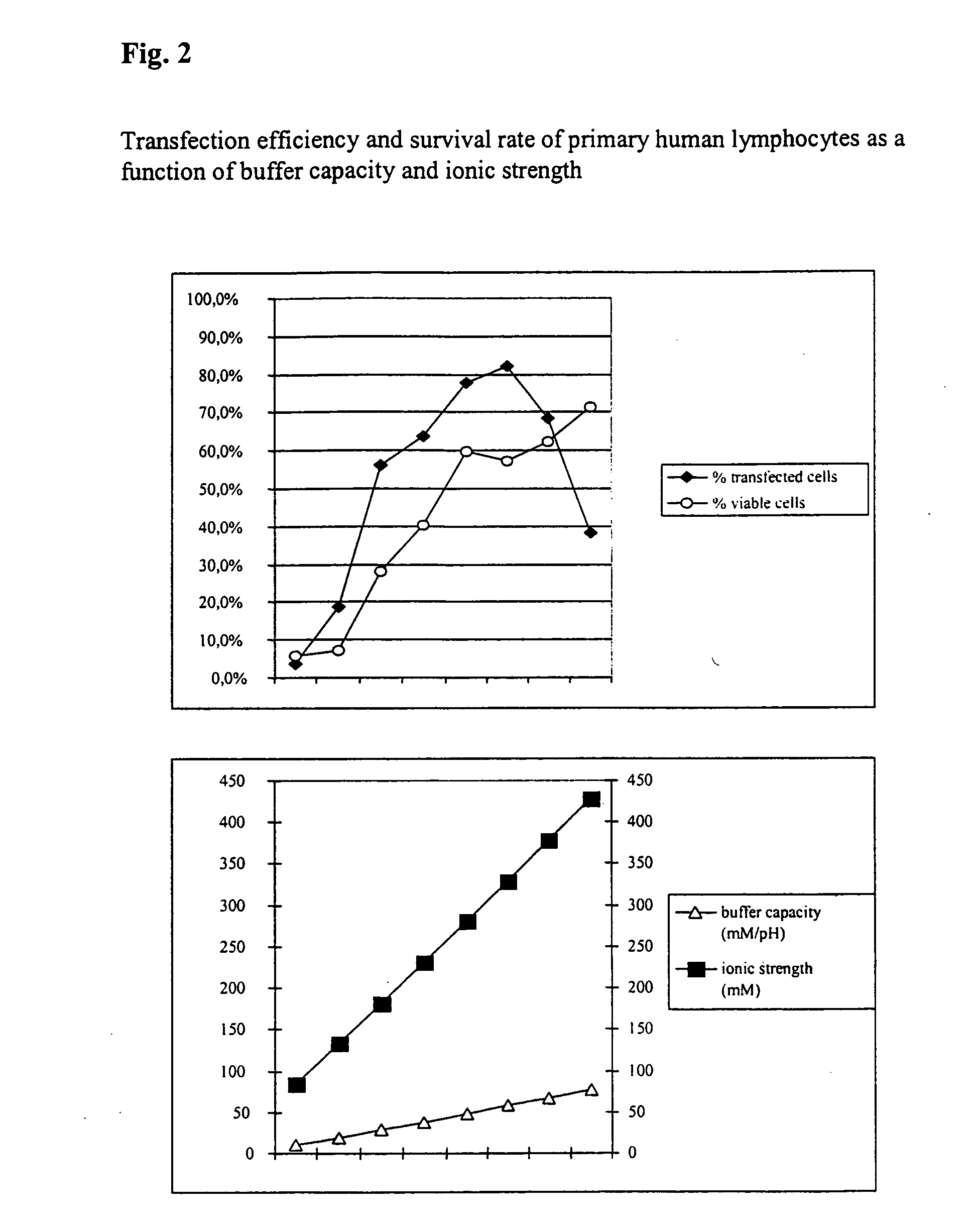

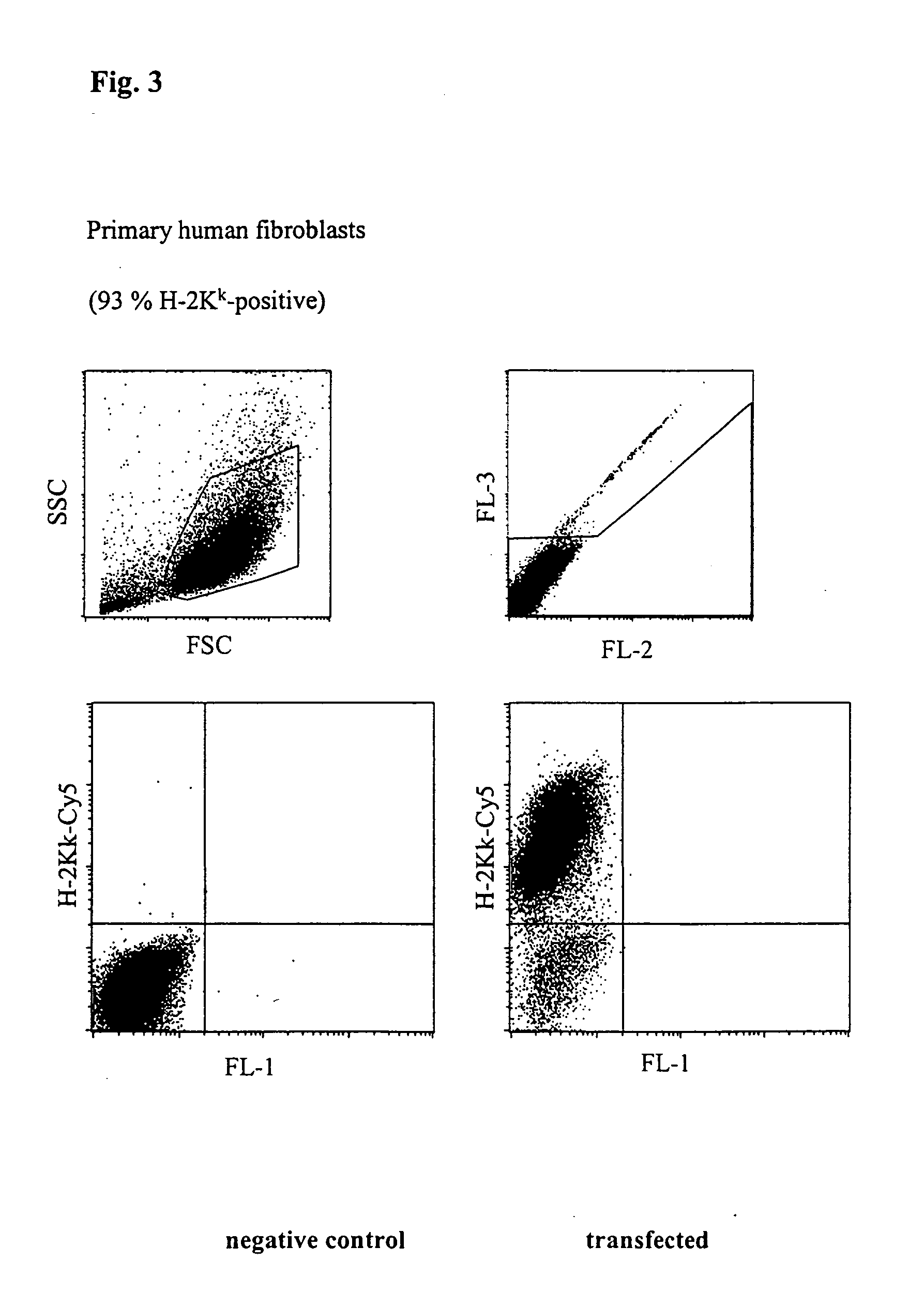

Buffer solution for electroporation and a method comprising the use of the same

InactiveUS20050064596A1High transfection efficiencyReduce cell deathPeptide/protein ingredientsGenetic material ingredientsElectroporationIon

The invention relates to a buffer solution for suspending animal or human cells and for dissolving biologically active molecules in order to introduce said biologically active molecules into the cells using an electric current and to a method for introducing biologically active molecules into animal or human cells using an electric current and a buffer solution. The inventive buffer solution has a buffering capacity of at least 20 mmol*I−1*pH−1 and an ionic strength of at least 200 mmol*I−1 during a change to the pH value from pH 7 to pH 8 and at a temperature of 25° C. The use of a buffer solution of this type in the corresponding method allows biologically active molecules to be introduced into animal and human cells with a high degree of transfection efficiency and at the same time a low cell mortality. Different cell types, in particular dormant and actively dividing cells of low activity, can be successfully transfected in said buffer solution.

Owner:LONZA COLOGNE

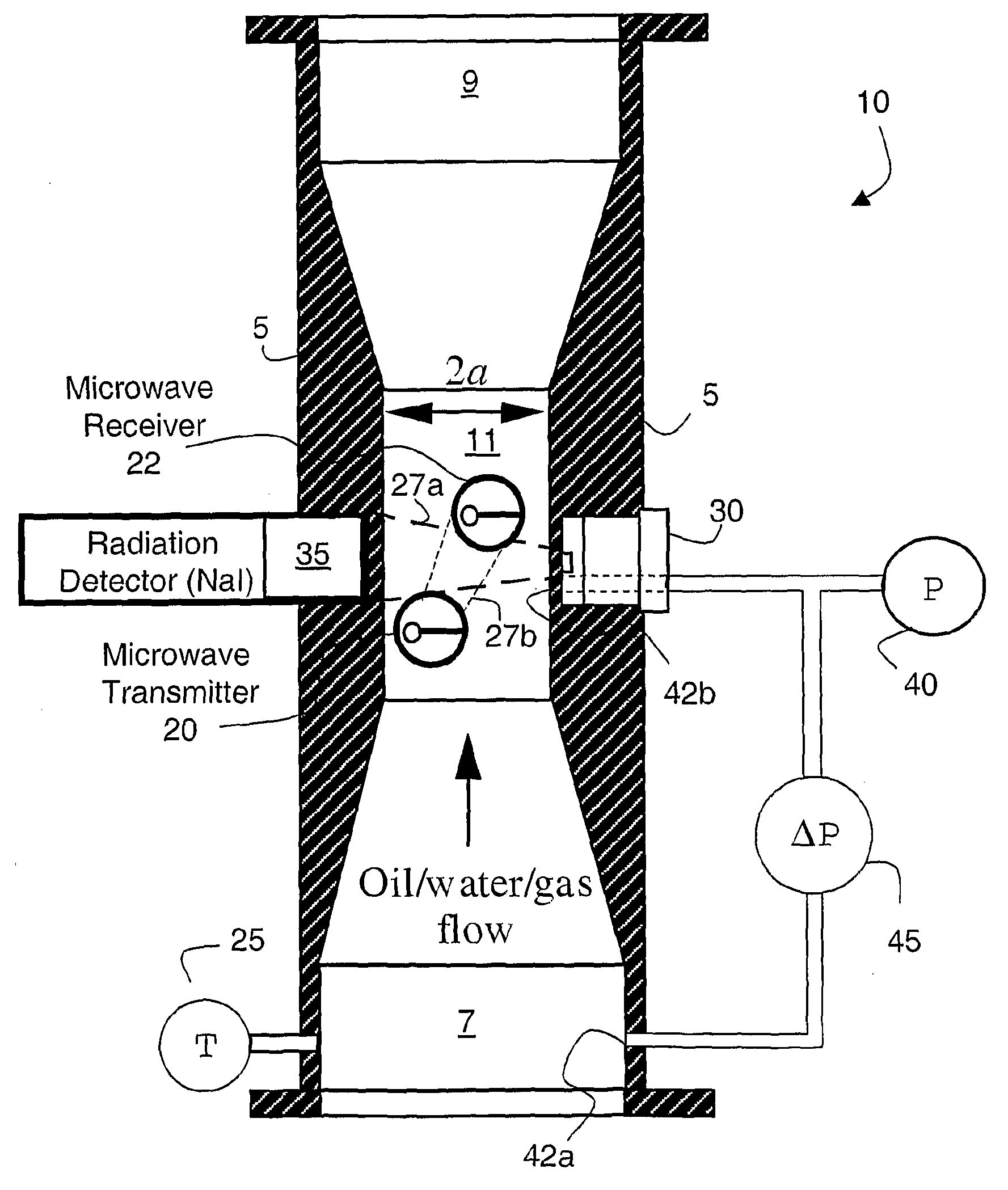

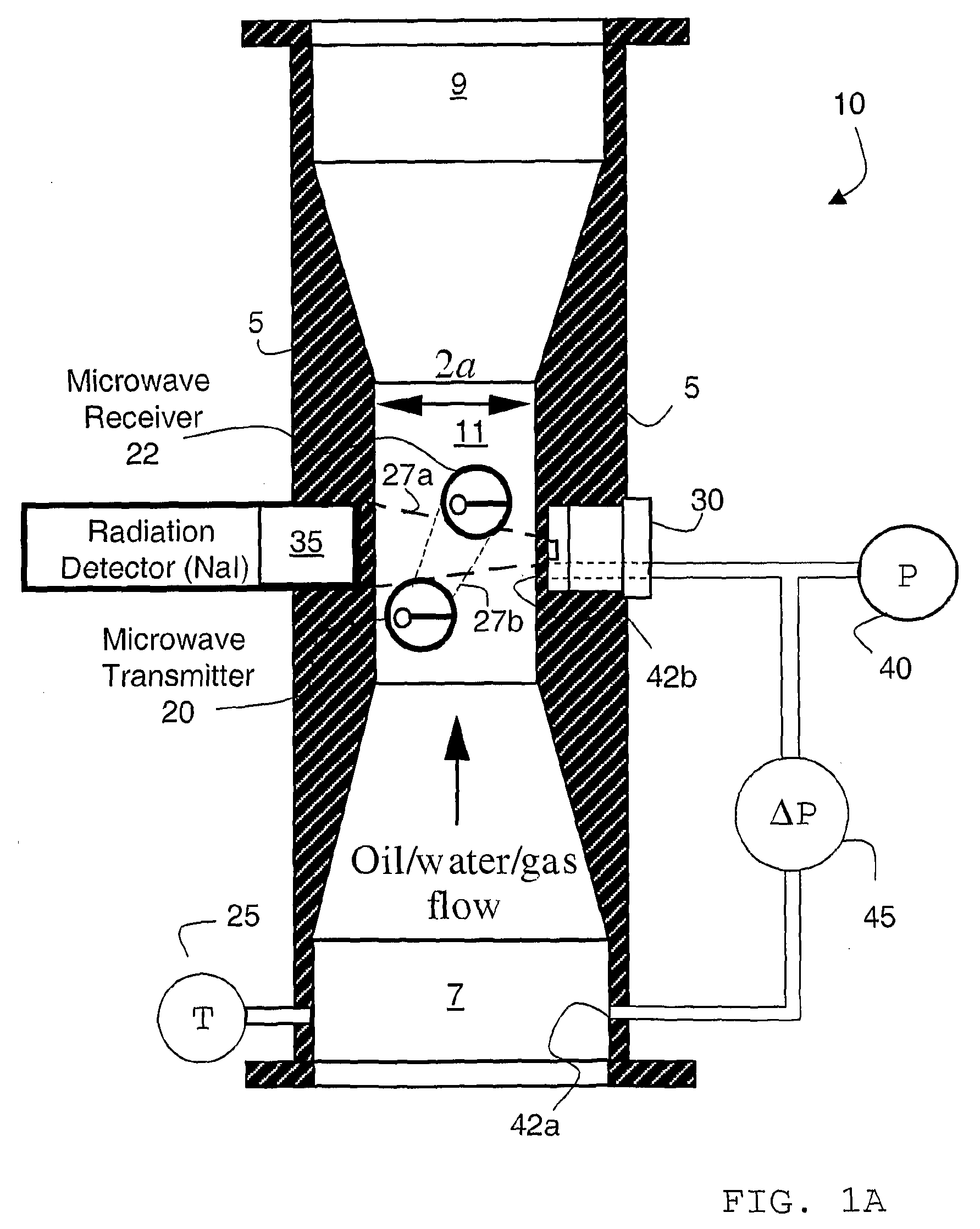

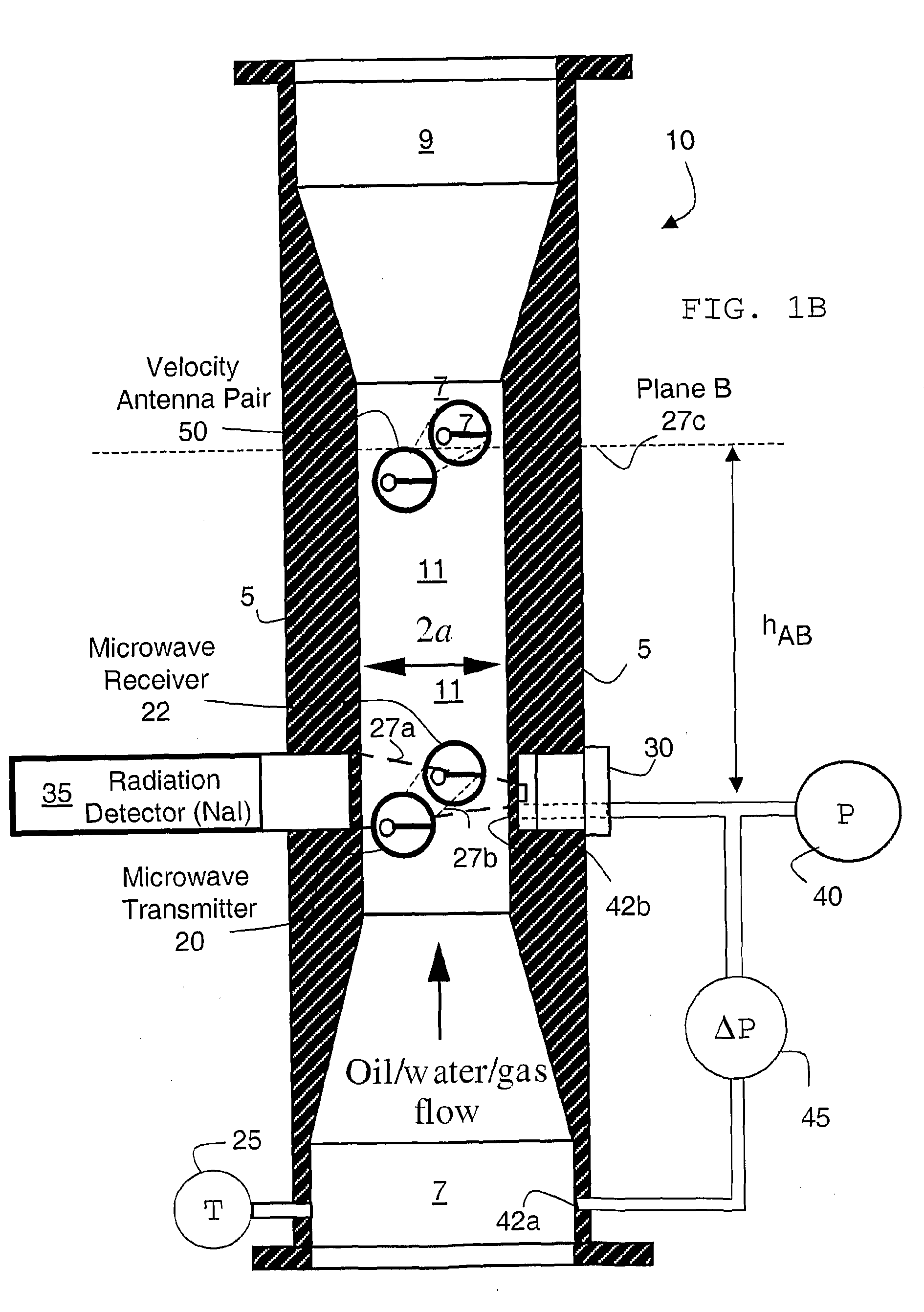

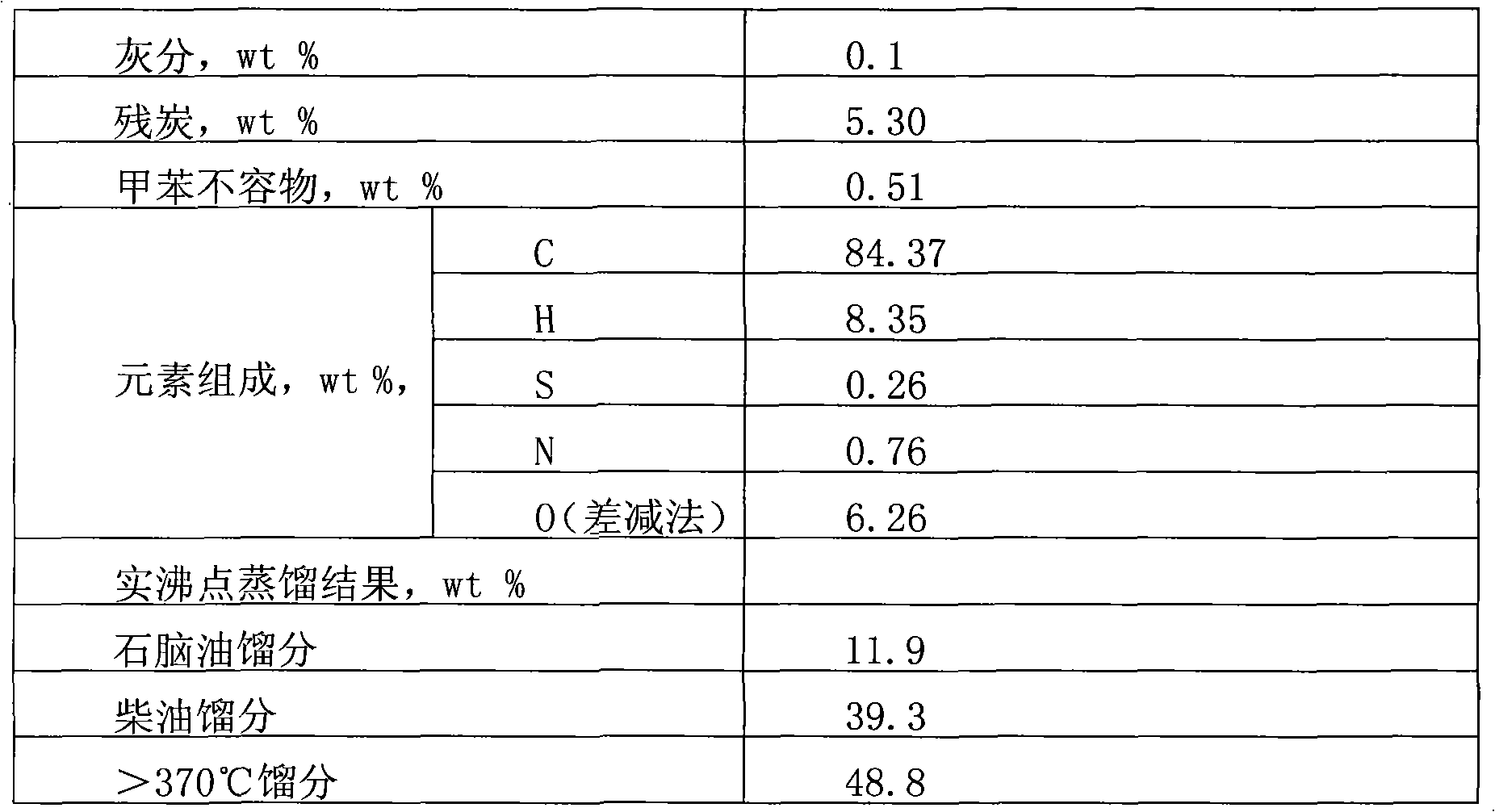

Systems and Methods For Measuring Multiphase Flow in a Hydrocarbon Transporting Pipeline

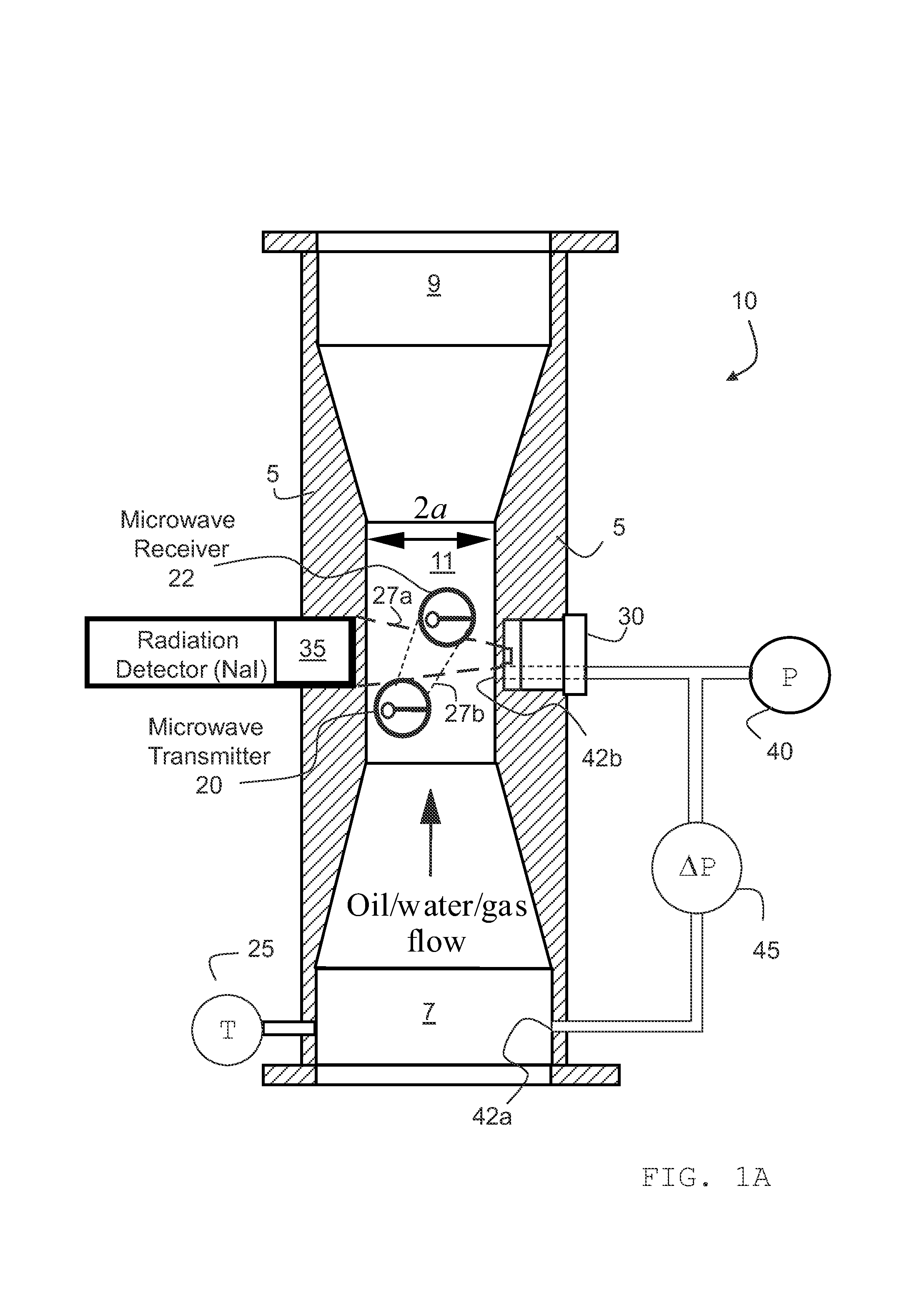

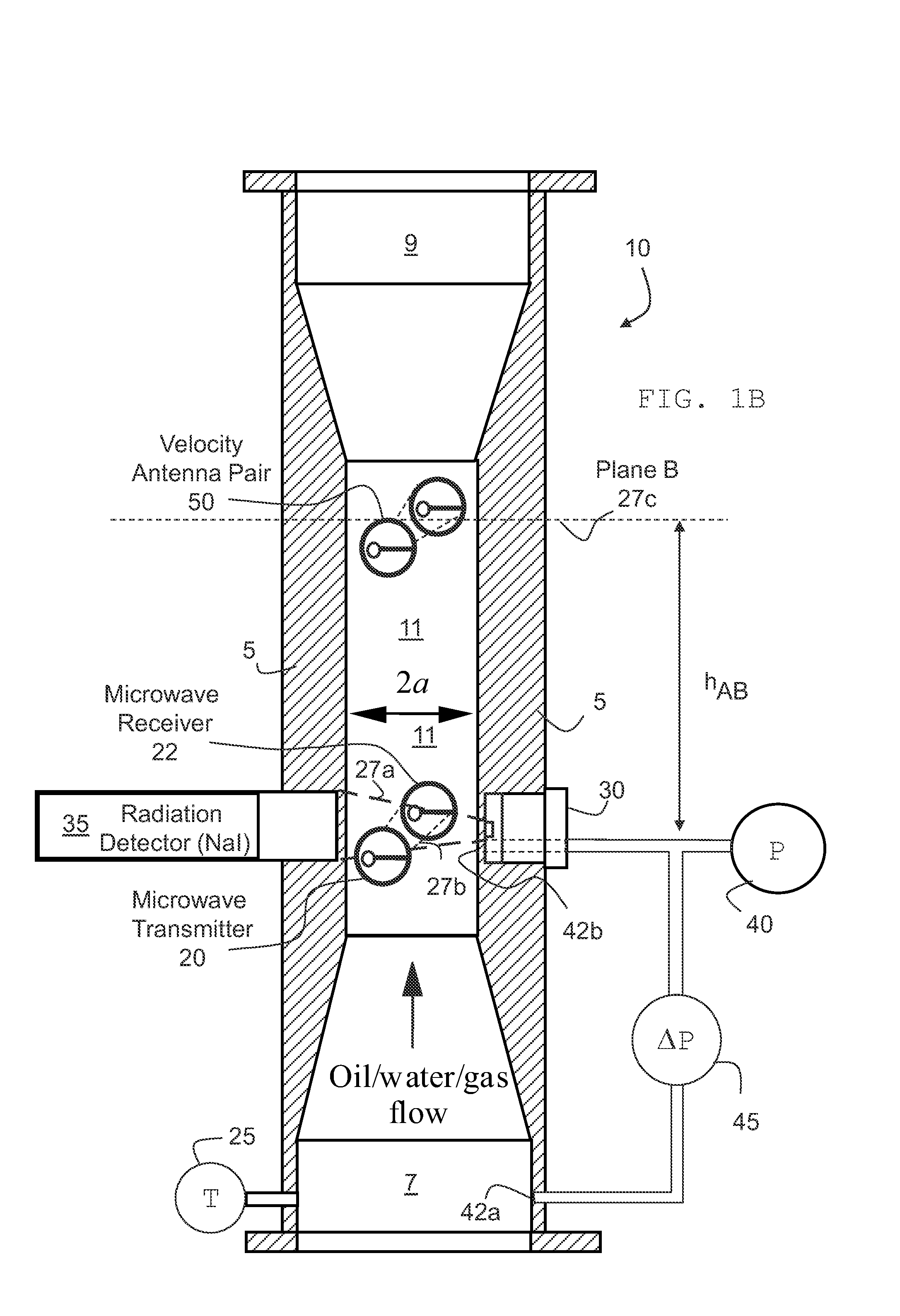

ActiveUS20080319685A1Material analysis using microwave meansMaterial testing goodsLow activityPressure difference

This disclosure relates in general to methods and systems for measuring multiphase flows in a pipeline using a combination of venturi, microwave and radiation techniques, where the pipeline is configured to transport hydrocarbons. More specifically, but not by way of limitation, certain embodiments of the present invention provide methods and systems in which low activity radiation sources may be used in combination with one or more microwave transmitter-receiver pairs and pressure differential sensors to measure the flow rates and fractions of phases in multiphase flows in a pipeline, such as may be encountered in producing hydrocarbon wells. Additionally, other embodiments of the present invention provide for the arrangement of one or more microwave transmitter-receiver pairs, one or more radiation source-detector pairs and / or one or more pressure sensor ports in the same cross-section of the throat of a venturi to measure multiphase flow in a hydrocarbon transporting pipeline.

Owner:SCHLUMBERGER TECH CORP

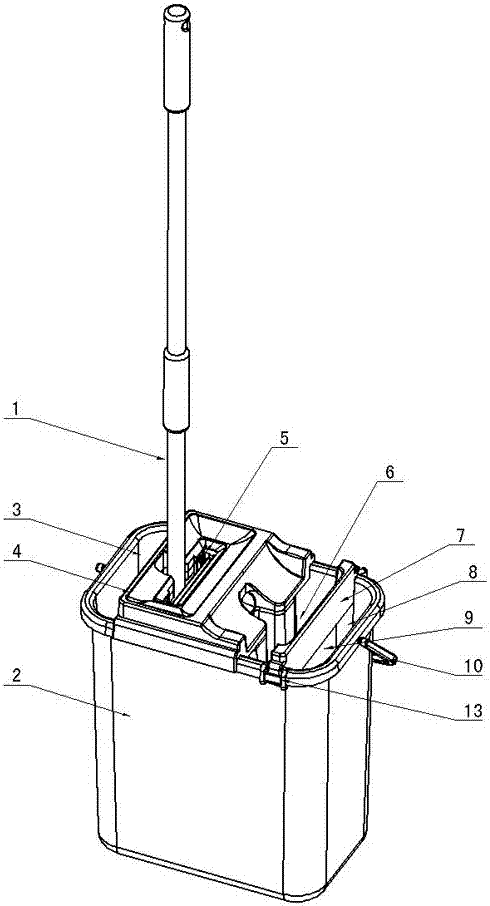

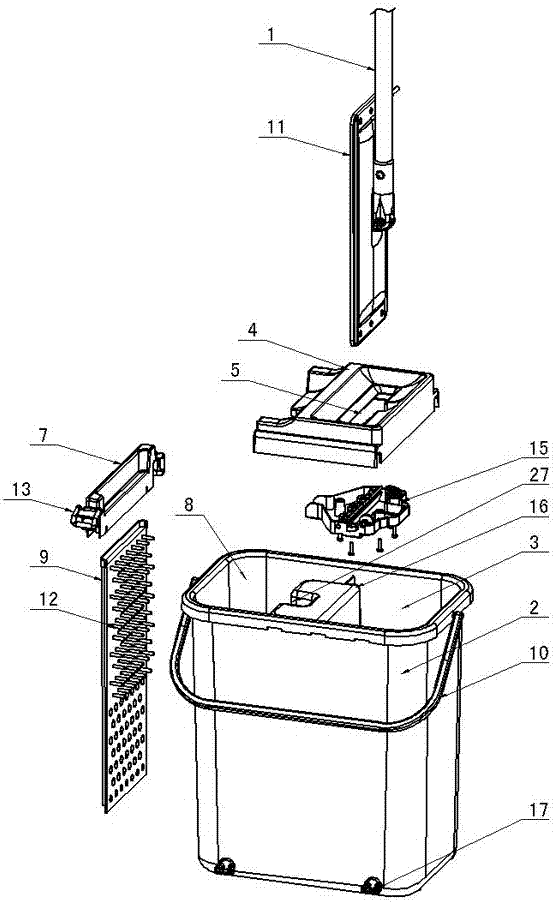

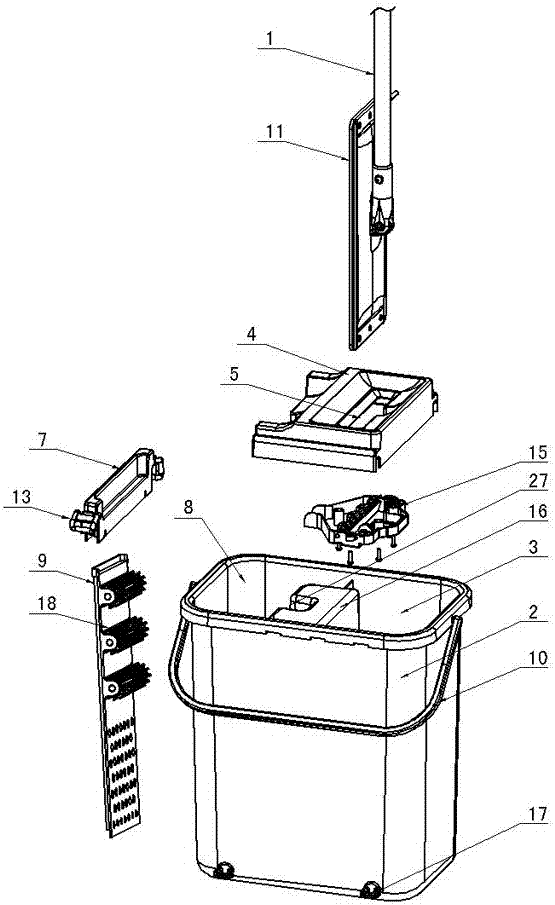

Plate mop and mop bucket

The invention creatively discloses a plate mop and mop bucket. The plate mop and mop bucket comprises a plate mop and a mop bucket (2); the lower side of a mop rod (1) is movably connected with a flat mop plate (11); the flat mop plate (11) is provided with mop cloth; the mop bucket (2) is provided with a water squeezing cavity (3) and a cleaning cavity (8) which are mutually separated from each other; the water squeezing cavity (3) is provided with a water squeezing device; the cleaning cavity (8) is internally provided with a cleaning device; during water squeezing, the flat mop plate (11) rotates to a position parallel to the mop rod (1), is mutually positioned to the mop rod (1) and moves up and down relative to the water squeezing device to wring the mop cloth to squeeze water; and a cleaning component used for cleaning the mop cloth is arranged in the cleaning device, and during cleaning, a part of the cleaning component is placed in water, the flat mop plate (11) rotates to the position parallel to the mop rod (1), is mutually positioned to the mop rod (1) and washes the mop cloth through mutual friction between the cleaning component and the mop cloth in the water. After adopting the structure, the plate mop and mop bucket has the advantages of simple and reasonable structure, convenience to operate and use, capability of alternatively carrying out cleaning and dewatering, saving labor by being cleaned in the water with rapid speed, good water squeezing and cleaning effects and the like.

Owner:ZHEJIANG XINGHAO PLASTIC

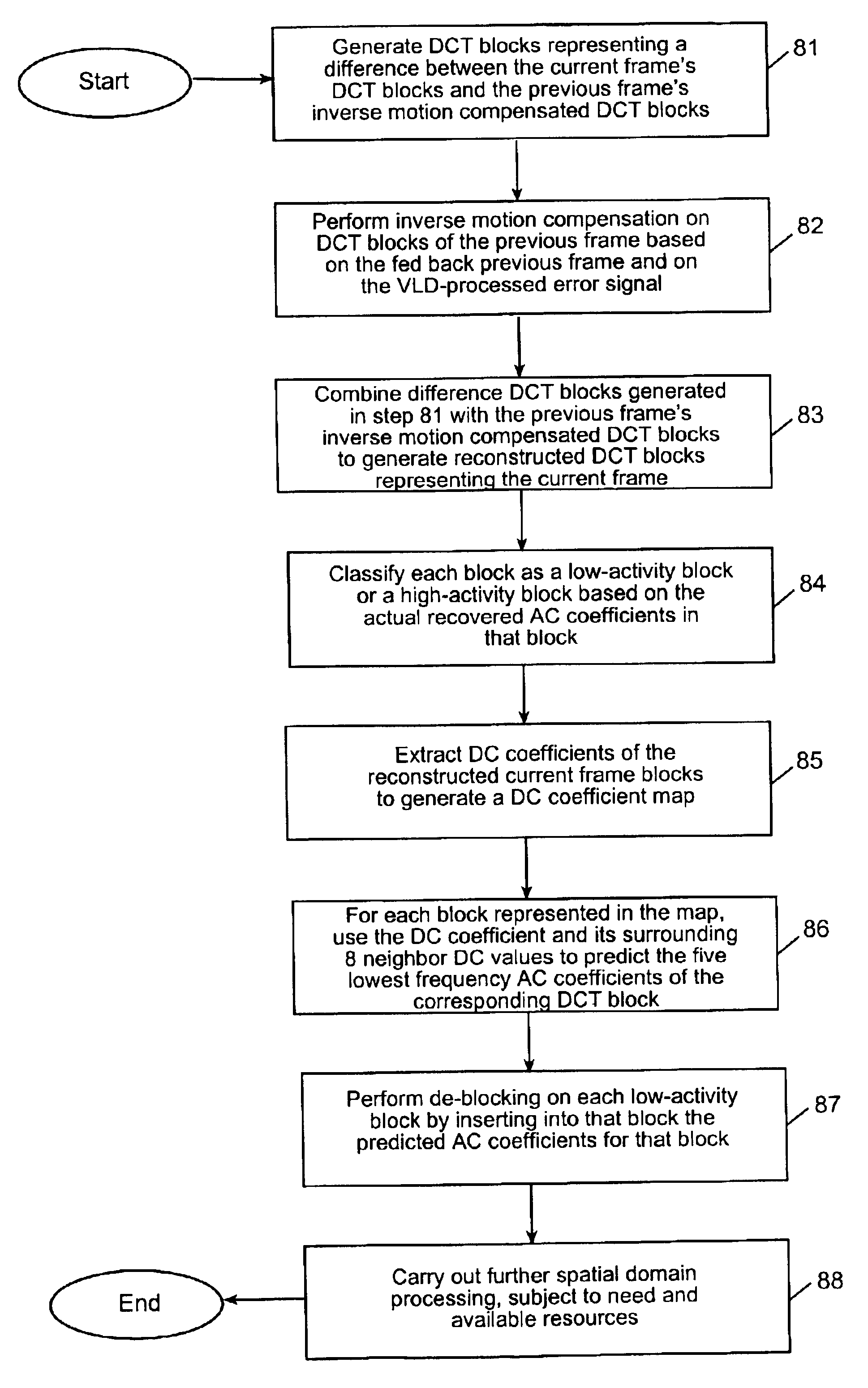

Hybrid technique for reducing blocking and ringing artifacts in low-bit-rate coding

ActiveUS6950473B2Efficient and effective power-scalableReduce blockingColor television with pulse code modulationColor television with bandwidth reductionLow activityDct coefficient

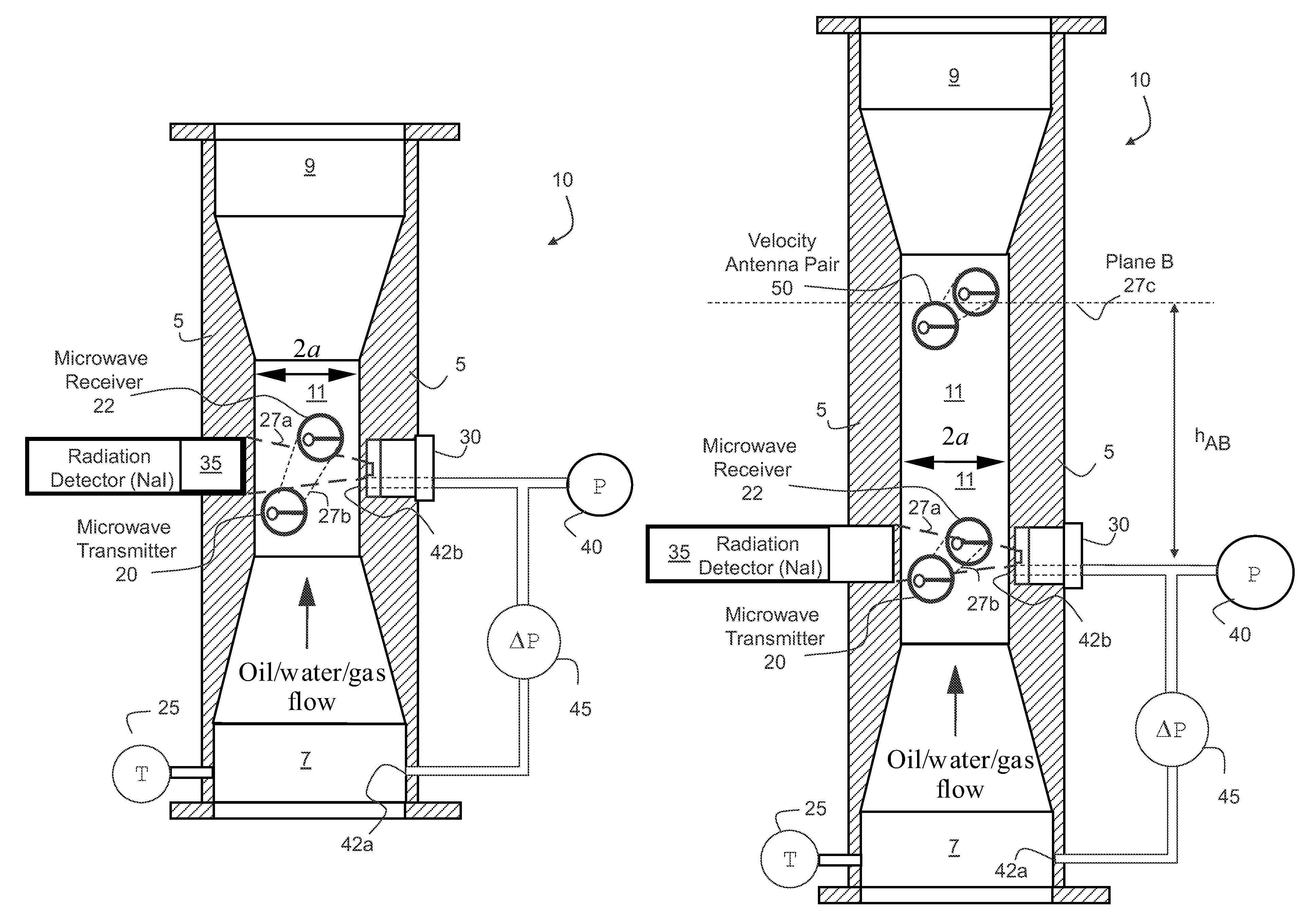

A power-scalable hybrid technique to reduce blocking and ringing artifacts in low bit-rate block-based video coding is employed in connection with a modified decoder structure. Fast inverse motion compensation is applied directly in the compressed domain, so that the transform (e.g., DCT) coefficients of the current frame can be reconstructed from those of the previous frame. The spatial characteristics of each block is calculated from the DCT coefficients, and each block is classified as either low-activity or high-activity. For each low-activity block, its DC coefficient value and the DC coefficient values of the surrounding eight neighbor blocks are exploited to predict low frequency AC coefficients which reflect the original coefficients before quantization in the encoding stage. The predicted AC coefficients are inserted into the low activity blocks where blocking artifacts are most noticeable. Subject to available resources, this may be followed by spatial domain post-processing, in which two kinds of low-pass filters are adaptively applied, on a block-by-block basis, according to the classification of the particular block. Strong low-pass filtering is applied in low-activity blocks where the blocking artifacts are most noticeable, whereas weak low-pass filtering is applied in high-activity blocks where ringing noise as well as blocking artifacts may exist. In low activity blocks, the blocking artifacts are reduced by one dimensional horizontal and vertical low-pass filters which are selectively applied in either the horizontal and / or vertical direction depending on the locations and absolute values of the predicted AC coefficients. In high activity blocks, de-blocking and de-ringing is conducted by 2- or 3-tap filters, applied horizontally and / or vertically, which makes the architecture simple.

Owner:SEIKO EPSON CORP

Systems and methods for measuring multiphase flow in a hydrocarbon transporting pipeline

ActiveUS7908930B2Material analysis using microwave meansMaterial testing goodsLow activityPressure difference

This disclosure relates in general to methods and systems for measuring multiphase flows in a pipeline using a combination of venturi, microwave and radiation techniques, where the pipeline is configured to transport hydrocarbons. More specifically, but not by way of limitation, certain embodiments of the present invention provide methods and systems in which low activity radiation sources may be used in combination with one or more microwave transmitter-receiver pairs and pressure differential sensors to measure the flow rates and fractions of phases in multiphase flows in a pipeline, such as may be encountered in producing hydrocarbon wells. Additionally, other embodiments of the present invention provide for the arrangement of one or more microwave transmitter-receiver pairs, one or more radiation source-detector pairs and / or one or more pressure sensor ports in the same cross-section of the throat of a venturi to measure multiphase flow in a hydrocarbon transporting pipeline.

Owner:SCHLUMBERGER TECH CORP

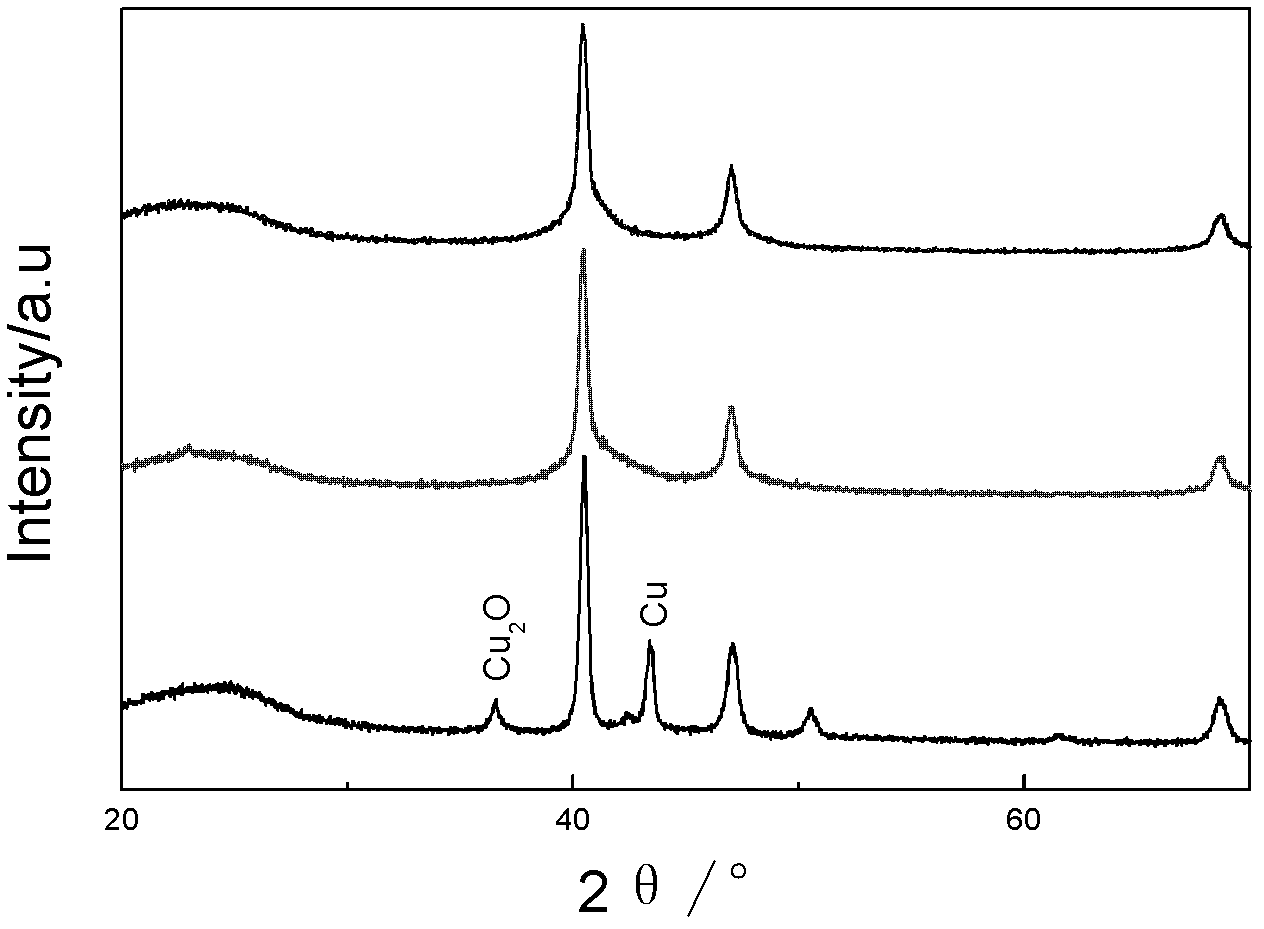

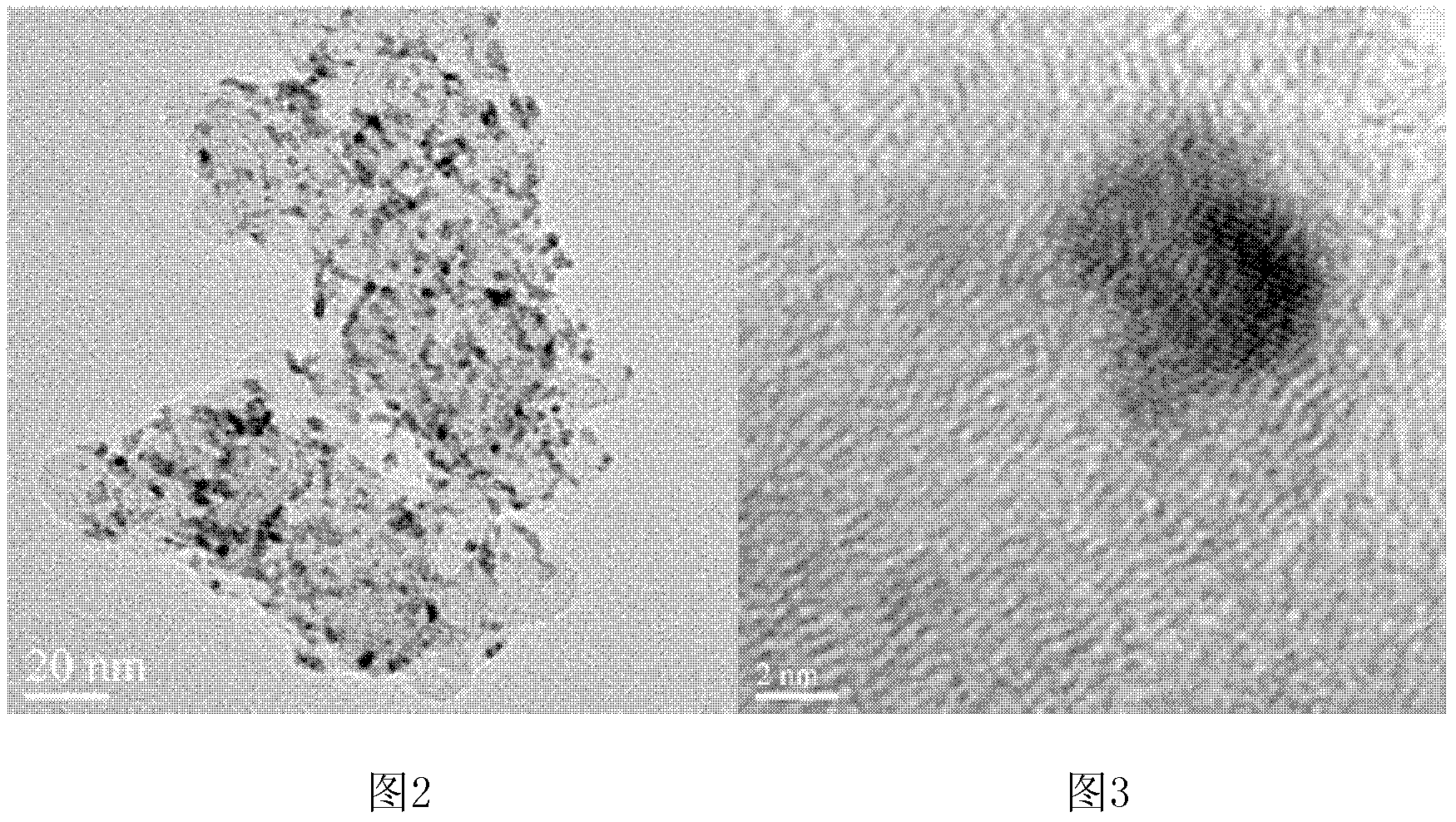

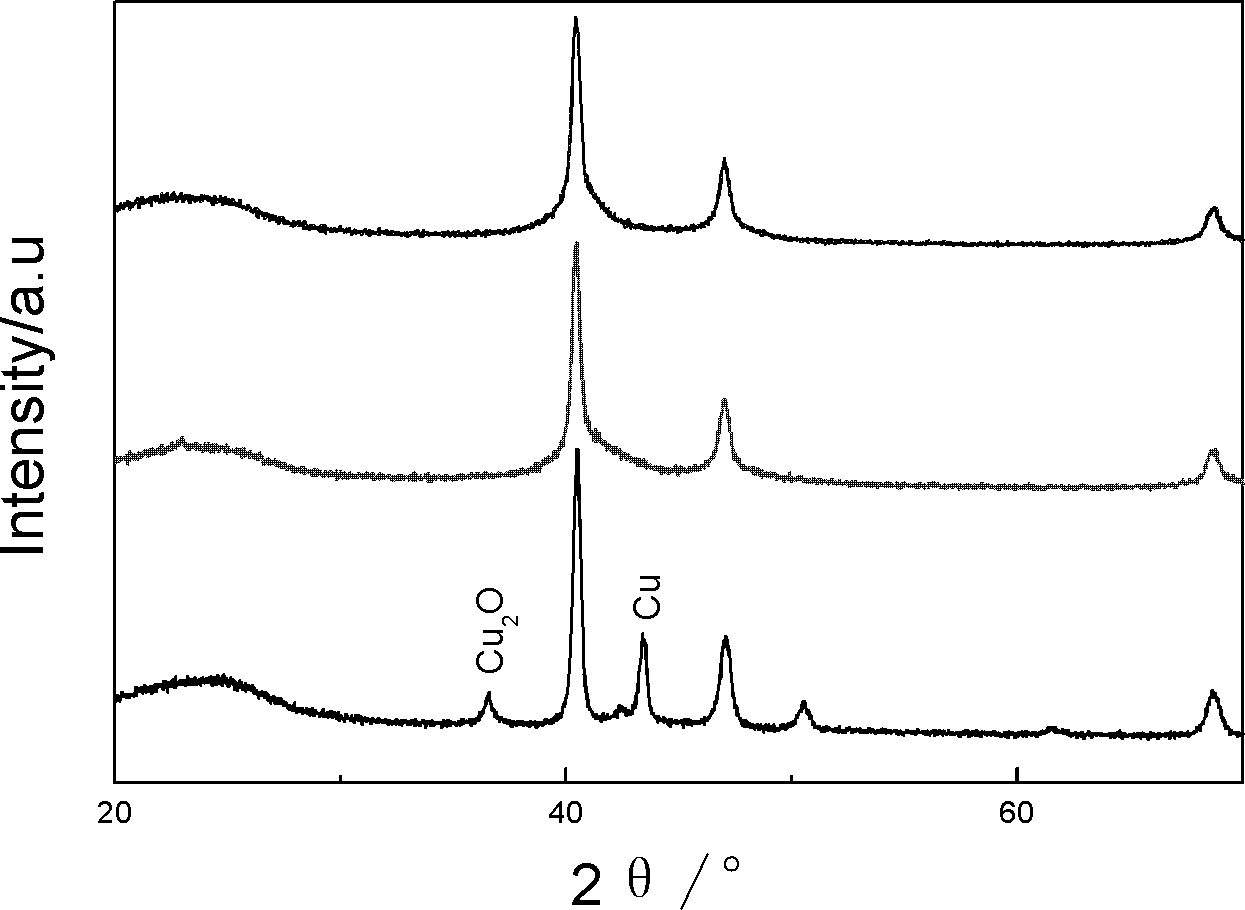

Catalyst for producing ethylene glycol from hydrogenation of oxalic ester

ActiveCN101474561AImprove stabilityImprove technical effectMolecular sieve catalystsMetal/metal-oxides/metal-hydroxide catalystsLow activityMolecular sieve

The invention relates to a catalyst for ethanediol production by oxalic ester hydrogenation, which solves the problems of small specific surface, low activity and poor stability of the catalyst in the previous technique. The catalyst used in the invention is composed of the following active components, assistants and carriers in terms of parts by weight: (a) 5-80 parts of active components; (b) 0-40 parts of assistants and (c) 1-30 parts of carriers, wherein the active component is copper, copper oxide or mixture thereof, the assistant is selected from at least one of Zn, Mn, Ba, Cr, Ni or Fe or oxides thereof and the carrier is selected from at least one of the alumina, silica, zirconia or molecular sieve. When the active component is copper, the technical scheme that the value of (b) is more than zero solves the problem in a good way. The catalyst can be used for ethanediol production in the industry.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for producing sweet gas for poor-quality gasoline distillate

ActiveCN101307255AReduce lossesTreatment with hydrotreatment processesLow activityHydrodesulfurization

The invention discloses a method for producing low-sulfur gasoline by inferior gasoline fractions. Firstly, full-range inferior gasoline raw material is oxidized and deodorized by a fixed bed, mercaptan sulfur is transformed into disulfide, then an oxidized and deodorized product is fractionated into light cut and heavy cut, the heavy cut is subject to the selective hydrodesulfurization through combining high-activity / low-activity and hydrodesulfurization catalyst, and a desulfurization product is mixed with the light cut to produce a clean gasoline product. Compared with the prior art, the method can effectively desulfurize the inferior gasoline fractions and has less octane number loss at the same time; under the preferable condition, the sulfur content of the gasoline product can reach less than 10 mu g / g.

Owner:CHINA PETROLEUM & CHEM CORP +1

Oxide dispersion strengthening low activity martensitic steel material and preparation thereof

The invention discloses an oxide dispersion strengthened low-activation martensitic steel. A substrate is a CLAM steel and contains 0.2 to 0.5 percent of Y2O3 and 0.10 to 0.50 percent of Ti. The method comprises the following steps that: CLAM steel powder, Y2O3 powder and Ti powder are evenly mixed and put in a sealed container for degassing, subjected to mechanical alloying, hot isostatic pressing or hot-pressing sintering and densification molding under the protection of high-purity argon gas, then subjected to hot squeezing or forging and rolling and other machining and molding processes, and the needed section material is prepared; and finally, the section material is subjected to the treatment of quenching and tempering to prepare the oxide dispersion strengthened low-activation martensitic steel ODS-CLAM. The oxide dispersion strengthened low-activation martensitic steel has the advantages that: the low-activation martensitic steel realizes a martensite-based alloy with oxide strengthening phases evenly dispersed and distributed and crystal grains of a reasonable size, can be used as a structural steel material, has the characteristics of strong neutron irradiation resistance, good high-temperature performance, low activation, etc. and is suitable for a fusion reactor and other environments with strong neutron irradiation and high-temperature.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

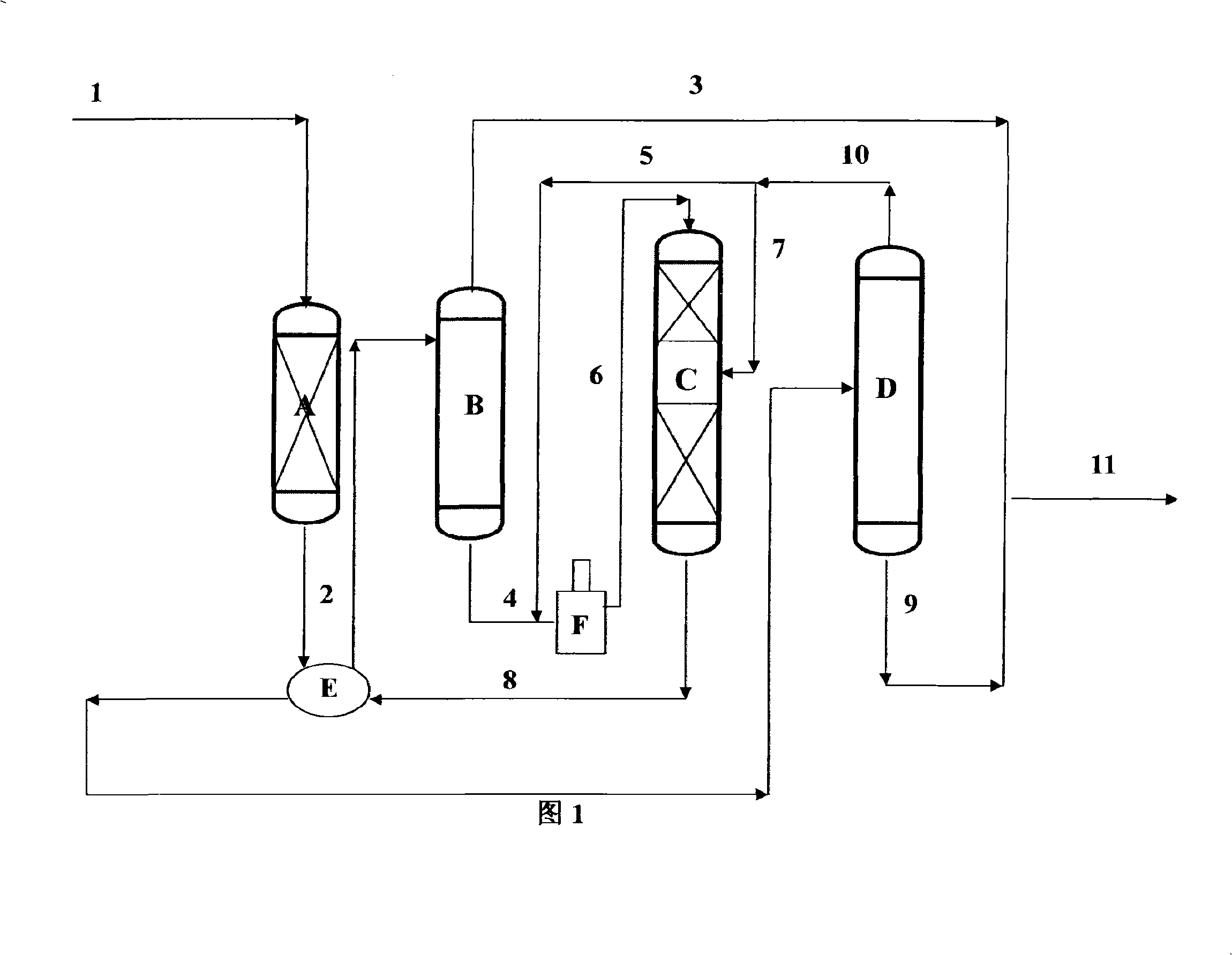

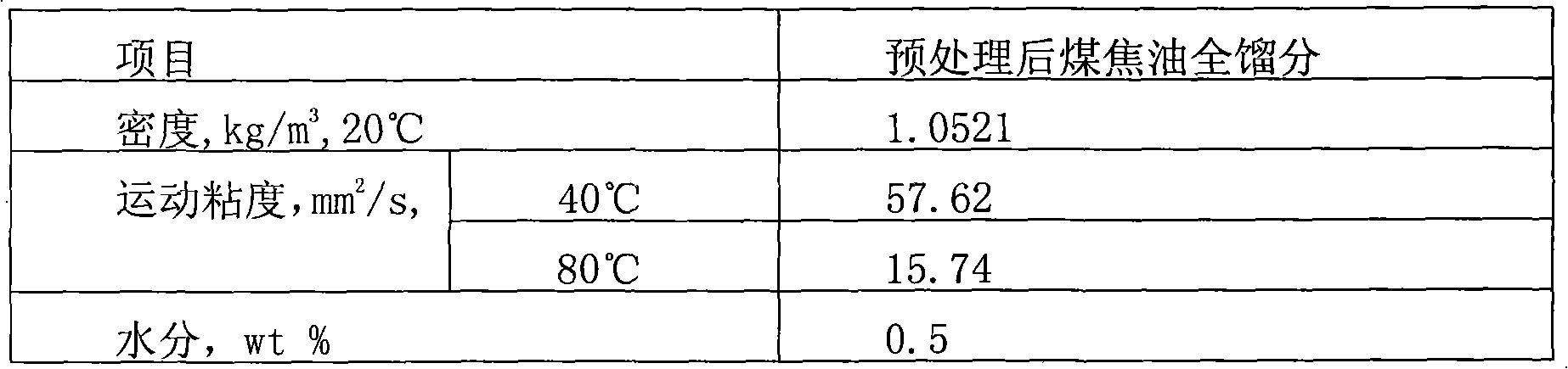

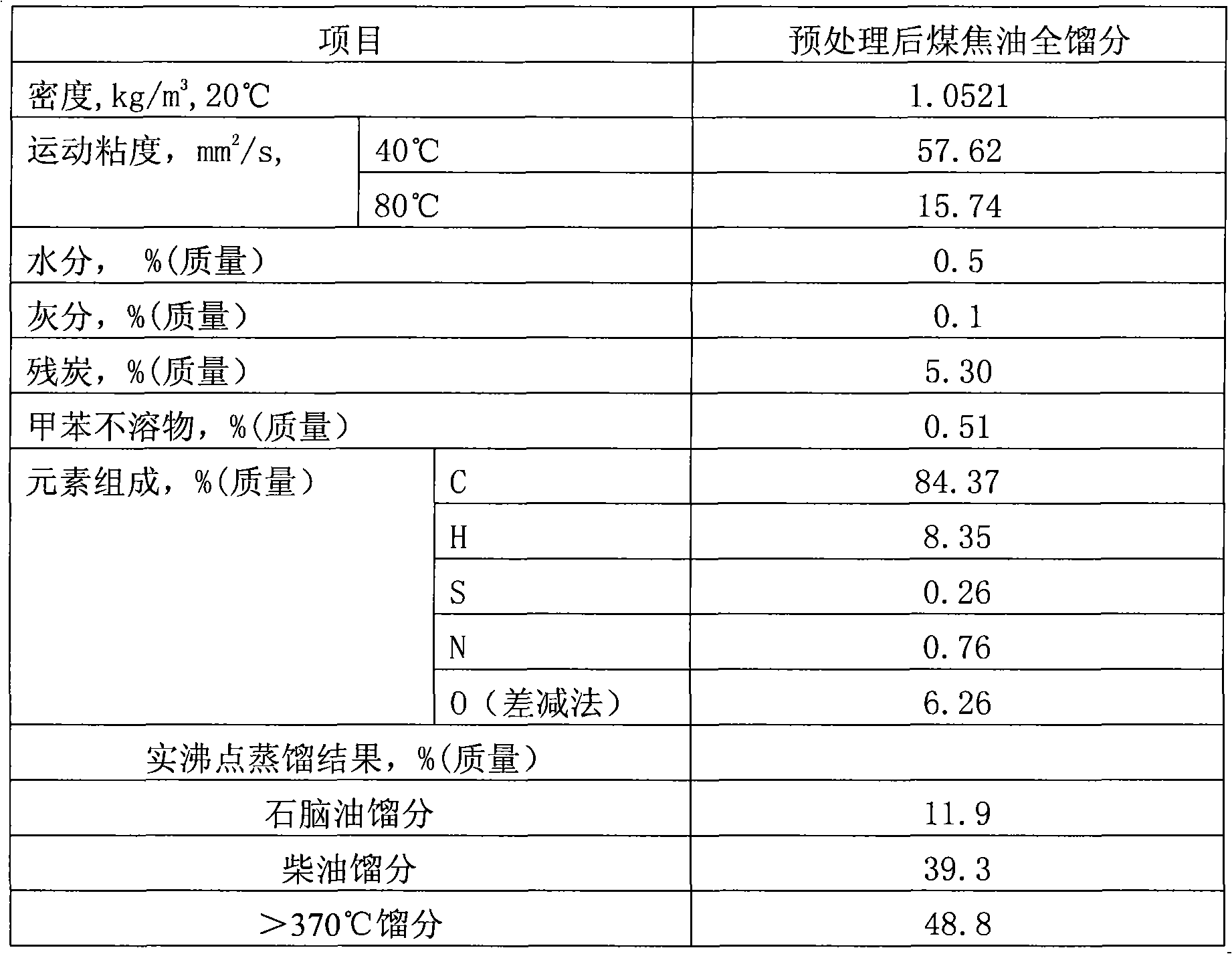

Compound coal tar hydrogenation catalyst and preparation method thereof

ActiveCN101927167AReduce manufacturing costReduce use costHydrocarbon oil crackingMetal/metal-oxides/metal-hydroxide catalystsLow activityIron sulfide

The invention relates to a compound coal tar hydrogenation catalyst and a preparation method thereof. The catalyst comprises a high-activity component of water-soluble salts of molybdenum, nickel, cobalt or tungsten and comprises a low-activity component of iron oxide ore or iron sulfide ore, wherein the mass ratio of the metals in the high-activity component to the metals in the low-activity component is 1:1,000 to 1:10; iron accounts for more than or equal to 40 weight percent of the ore; and water accounts for less than 2 weight percent of the catalyst. The catalyst is used for the coal tar hydrocracking technical process in a suspension bed, has higher hydrogenation activity and the lightweight oil yield of over 94 percent, and can be recycled; the preparation and use cost of the catalyst can be greatly reduced, the consumption of the catalyst is reduced in the process, the coke deposition of the reaction system is avoided simultaneously and the operation cycle is prolonged.

Owner:CCTEG CHINA COAL RES INST

Method and apparatus for real-time tumor tracking

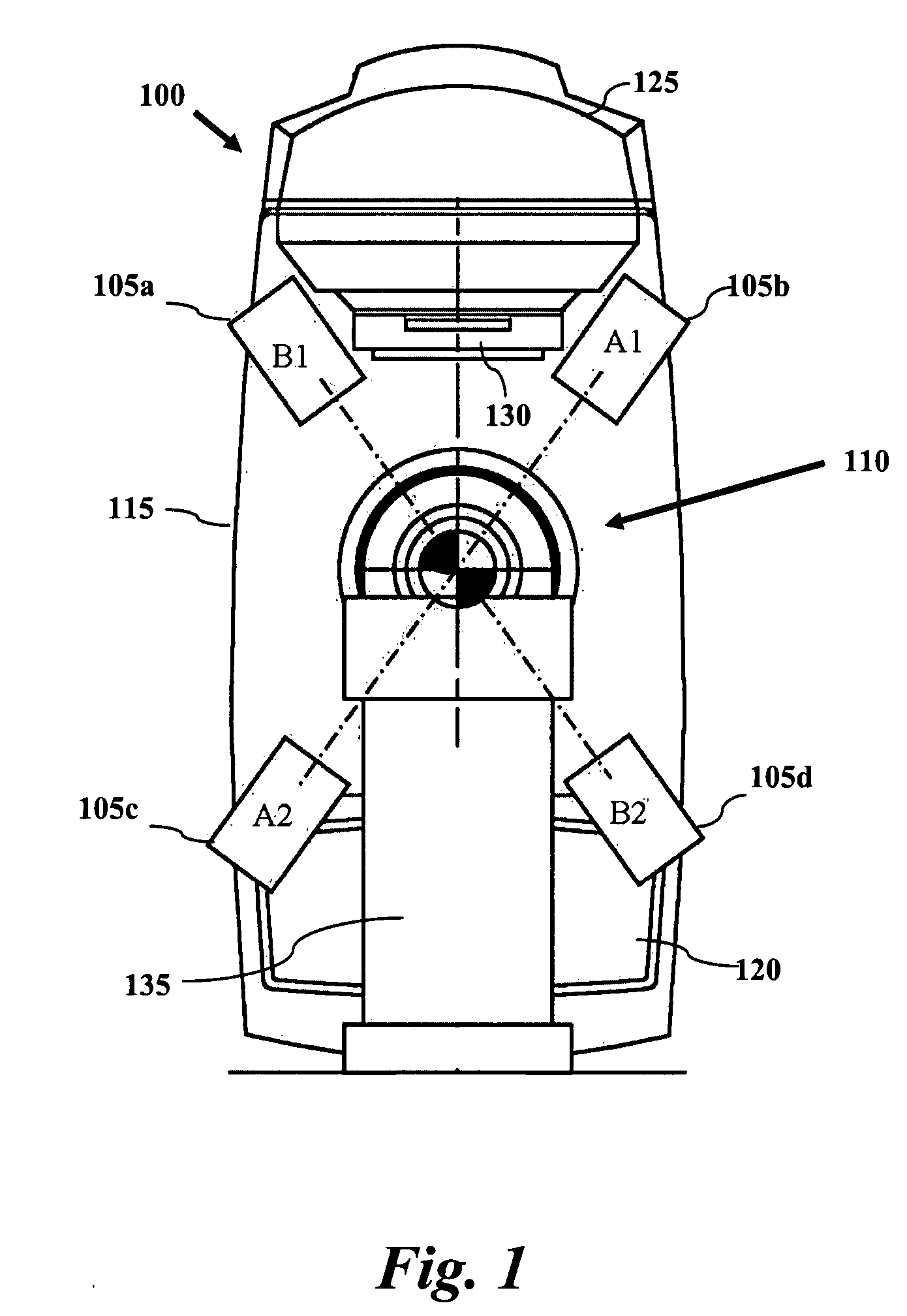

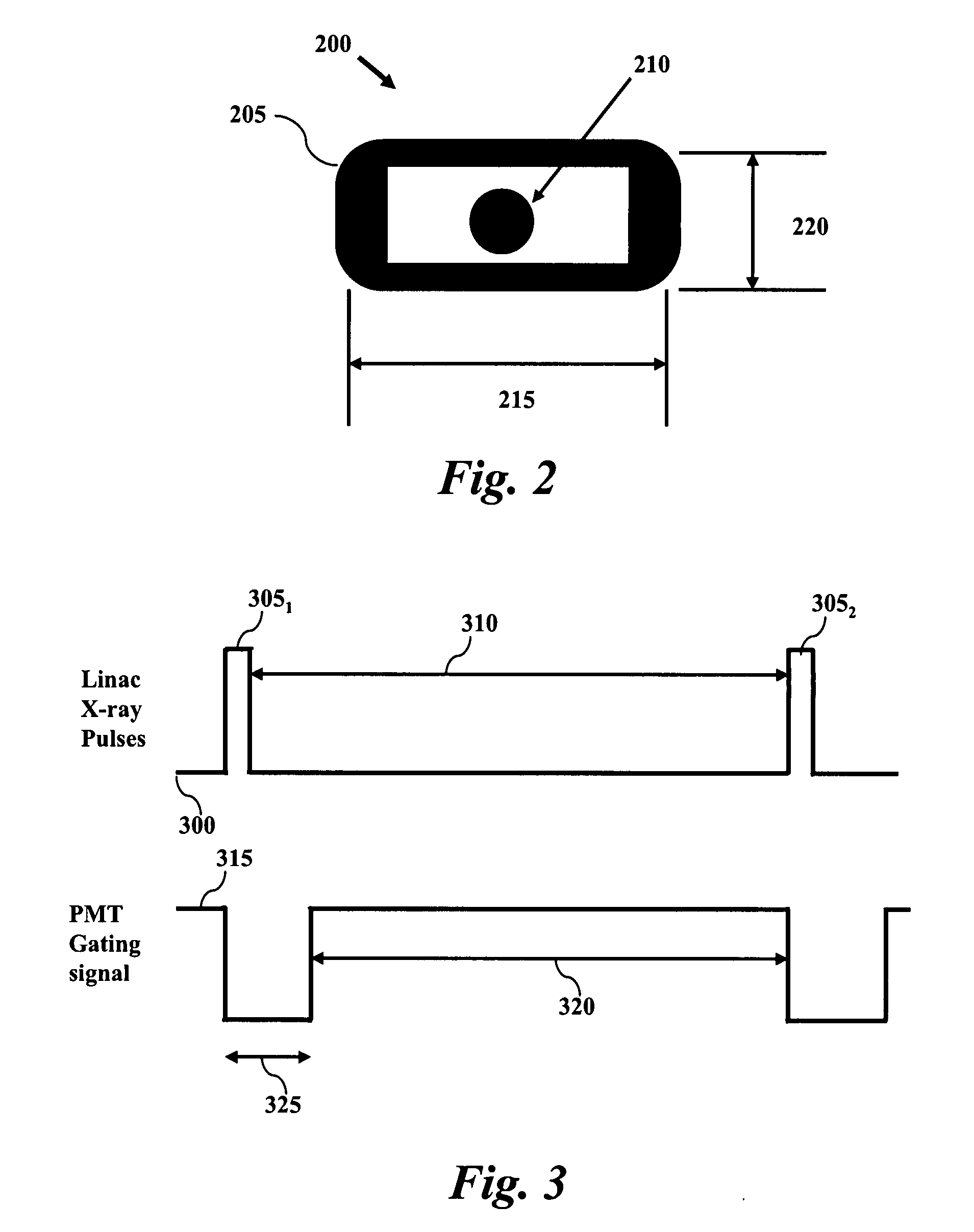

Method and apparatus for real-time tracking of a target in a human body. In one embodiment of the invention, positron emission marker may be implanted into a target, the positron emission marker having a low activity positron isotope. In one embodiment, annihilation gamma rays associated with the low activity positron isotope may be detected using a plurality of position-sensitive detectors. In another embodiment, the target may be tracked in real-time based on a position of the positron emission marker.

Owner:XU TONG +2

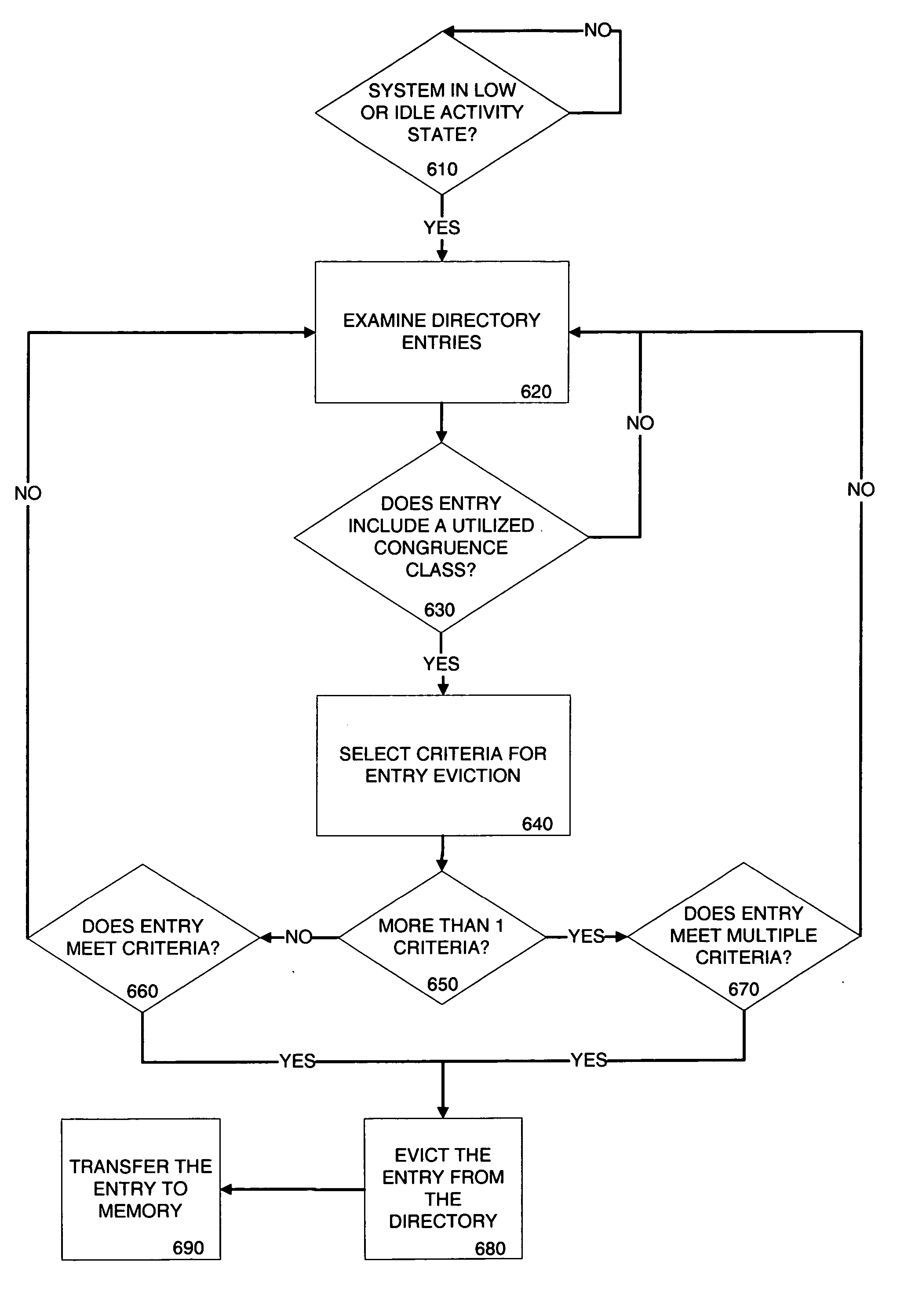

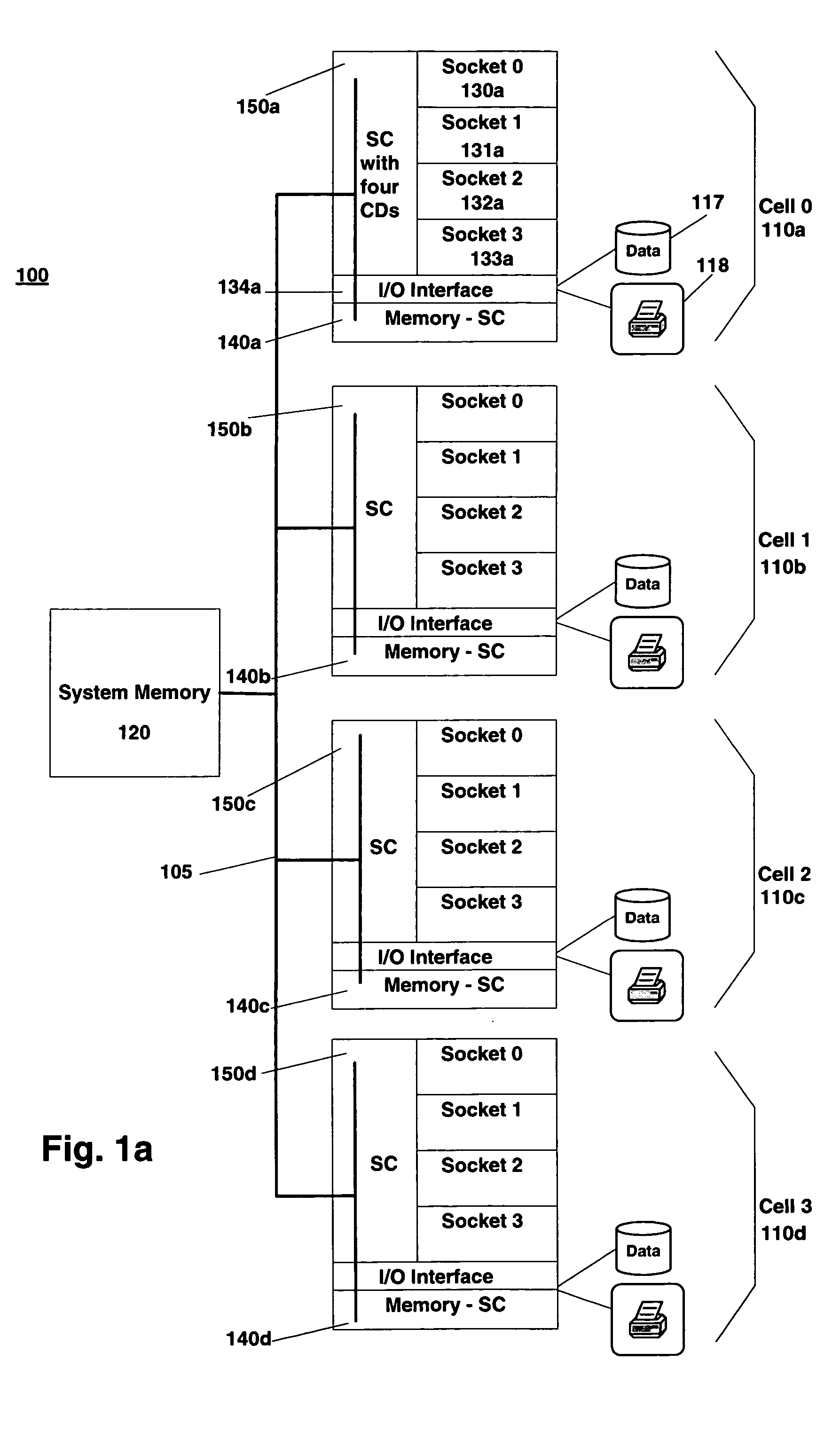

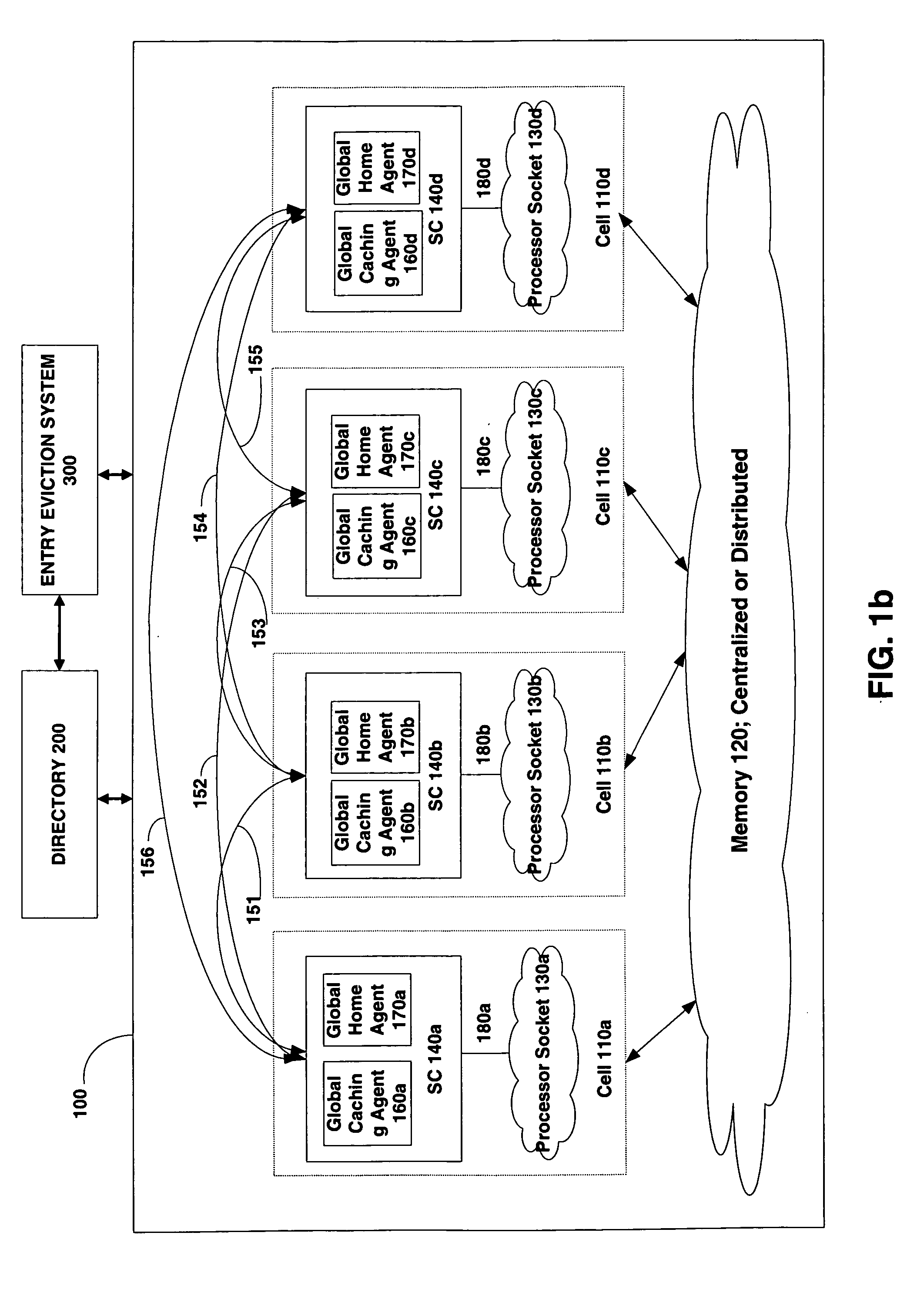

Preemptive eviction of cache lines from a directory

InactiveUS20070079072A1Memory architecture accessing/allocationMemory systemsLow activityTerm memory

A directory for maintaining cache line entries may include a limited amount of space for the entries. A preemptive eviction of an entry of the directory is performed so that adequate space for a new entry may be created. The eviction may be performed when a system is in a low-activity state or an idle state in order to conserve system resources. Such a state may also ensure that the new entry does not have to wait to be entered into the directory. The eviction may include the examination of entries to determine if the contents may be eliminated from the directory. The system may establish certain criteria to aid in this determination. Once evicted from the directory, any modified data associated with the entry is transferred to a memory location.

Owner:UNISYS CORP

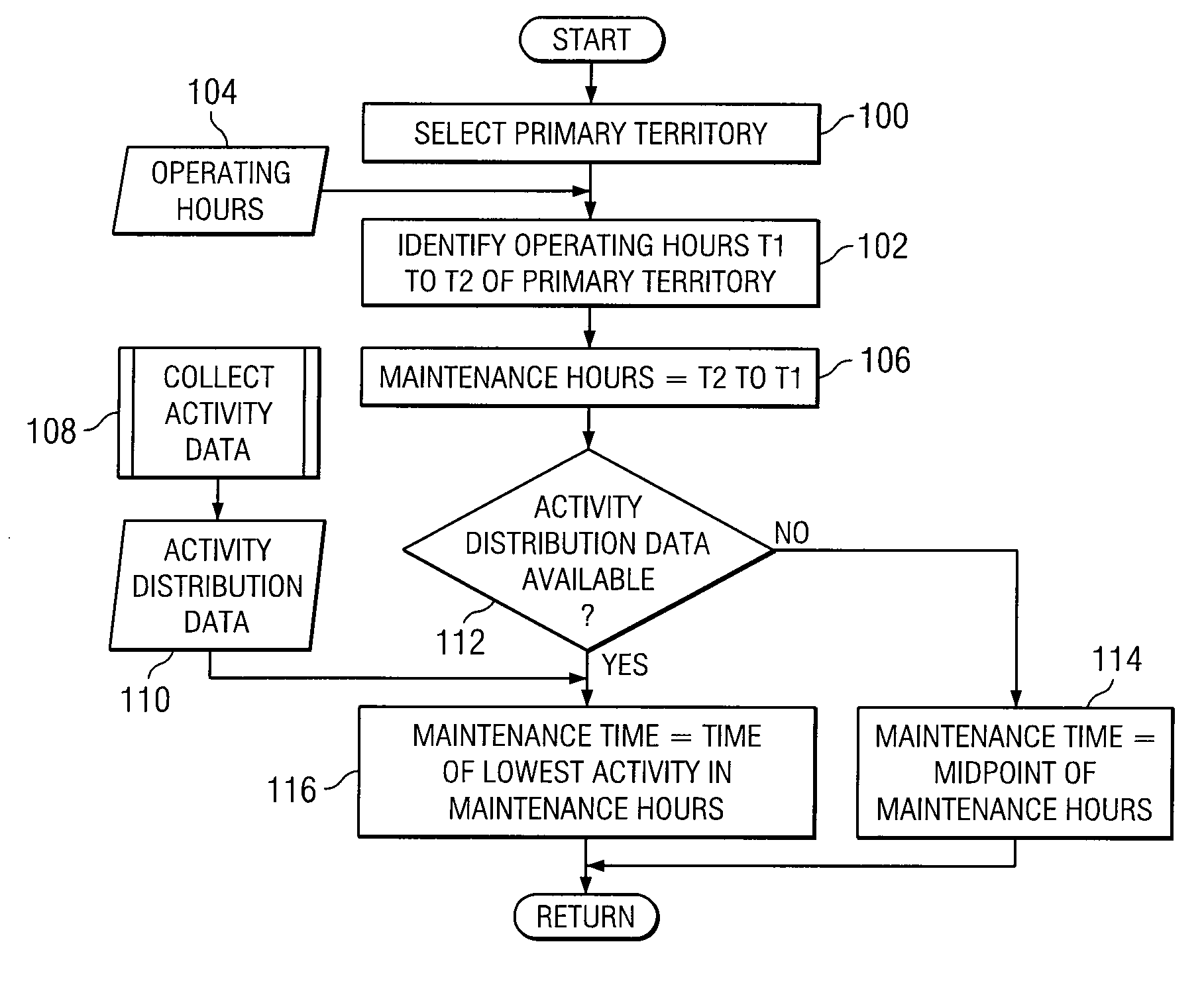

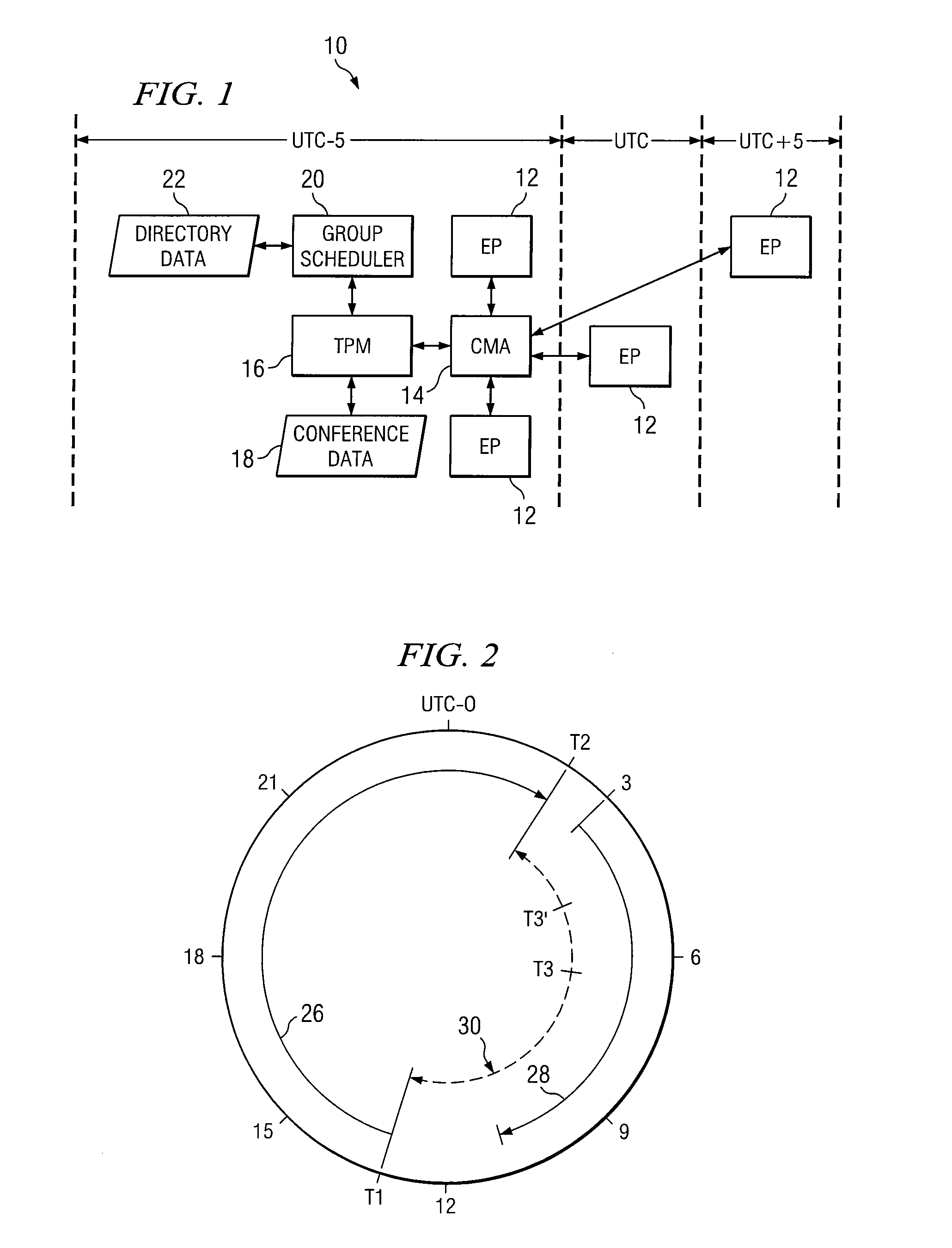

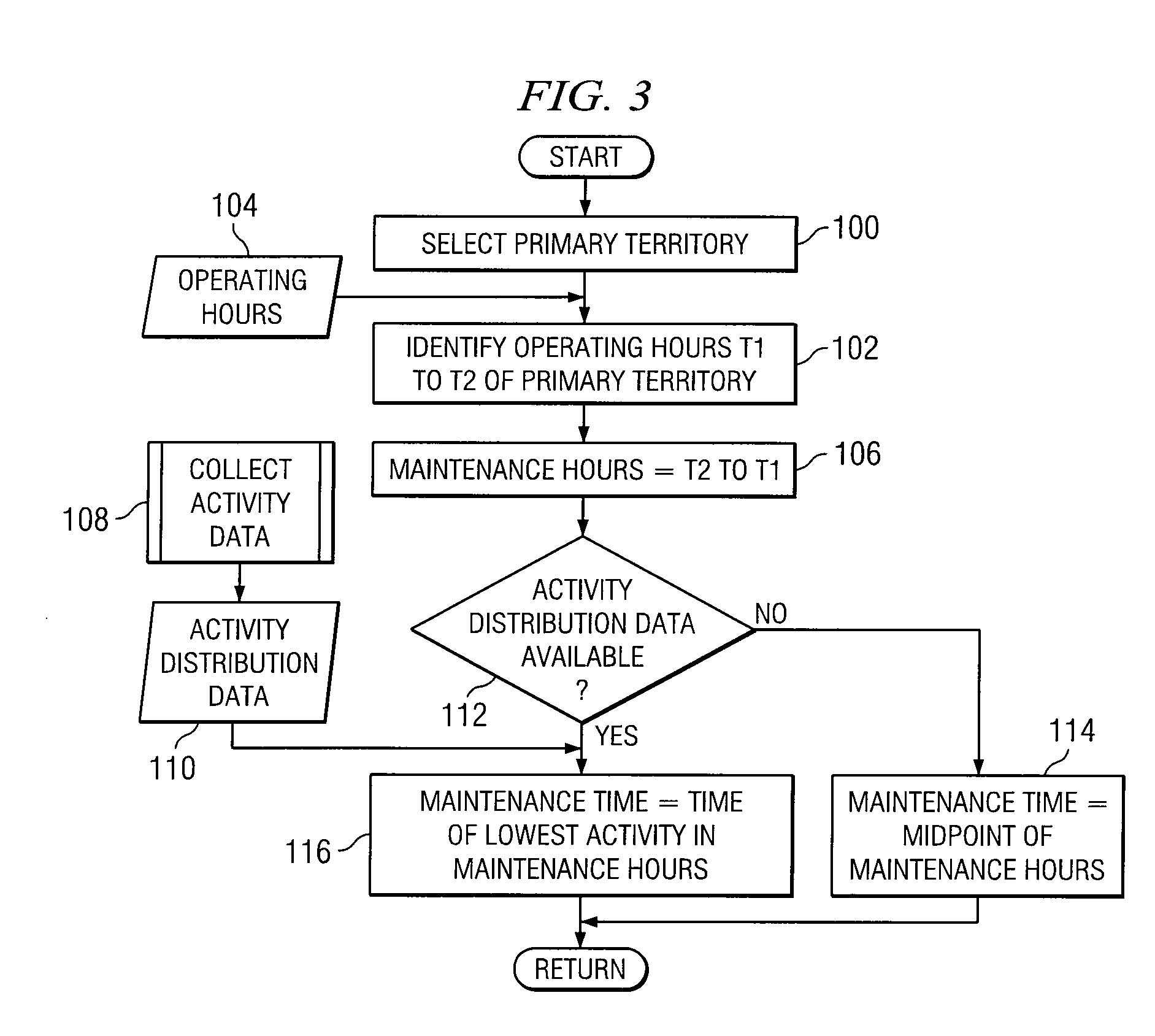

System and Method for Optimizing Maintenance of Geographically Distributed Processing Units

ActiveUS20070250620A1Data reduced eliminatedDisadvantages and reduced eliminatedDigital computer detailsResourcesData processing systemLow activity

A system and method are provided for optimizing maintenance of a geographically distributed data processing system. The method comprises selecting a primary territory having associated operating hours, identifying maintenance hours that exclude the operating hours, and selecting a maintenance time within the available maintenance hours. The midpoint of the maintenance hours may be selected as the maintenance time, or activity distribution data may be analyzed to select a maintenance time corresponding to a low activity time.

Owner:CISCO TECH INC

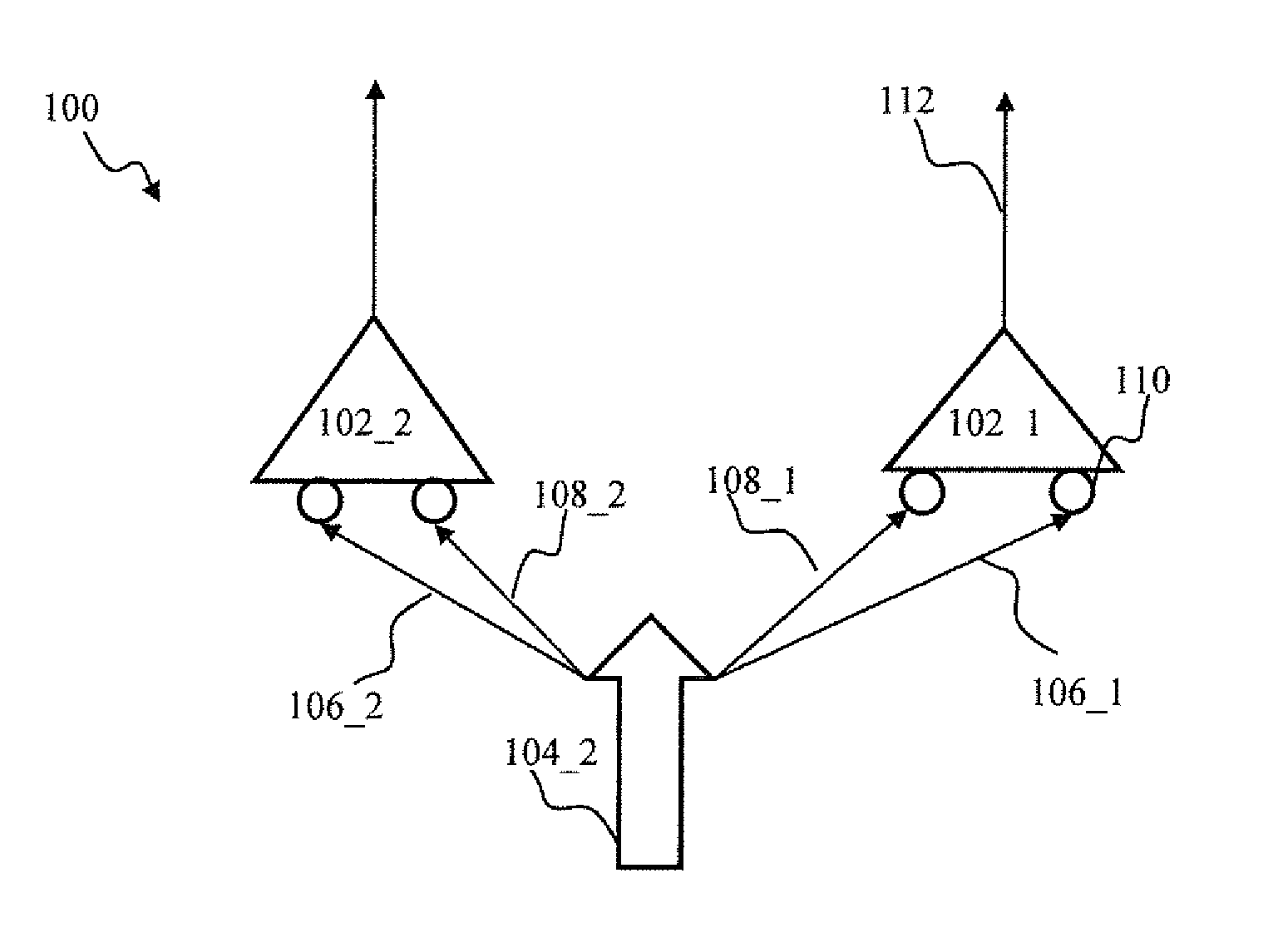

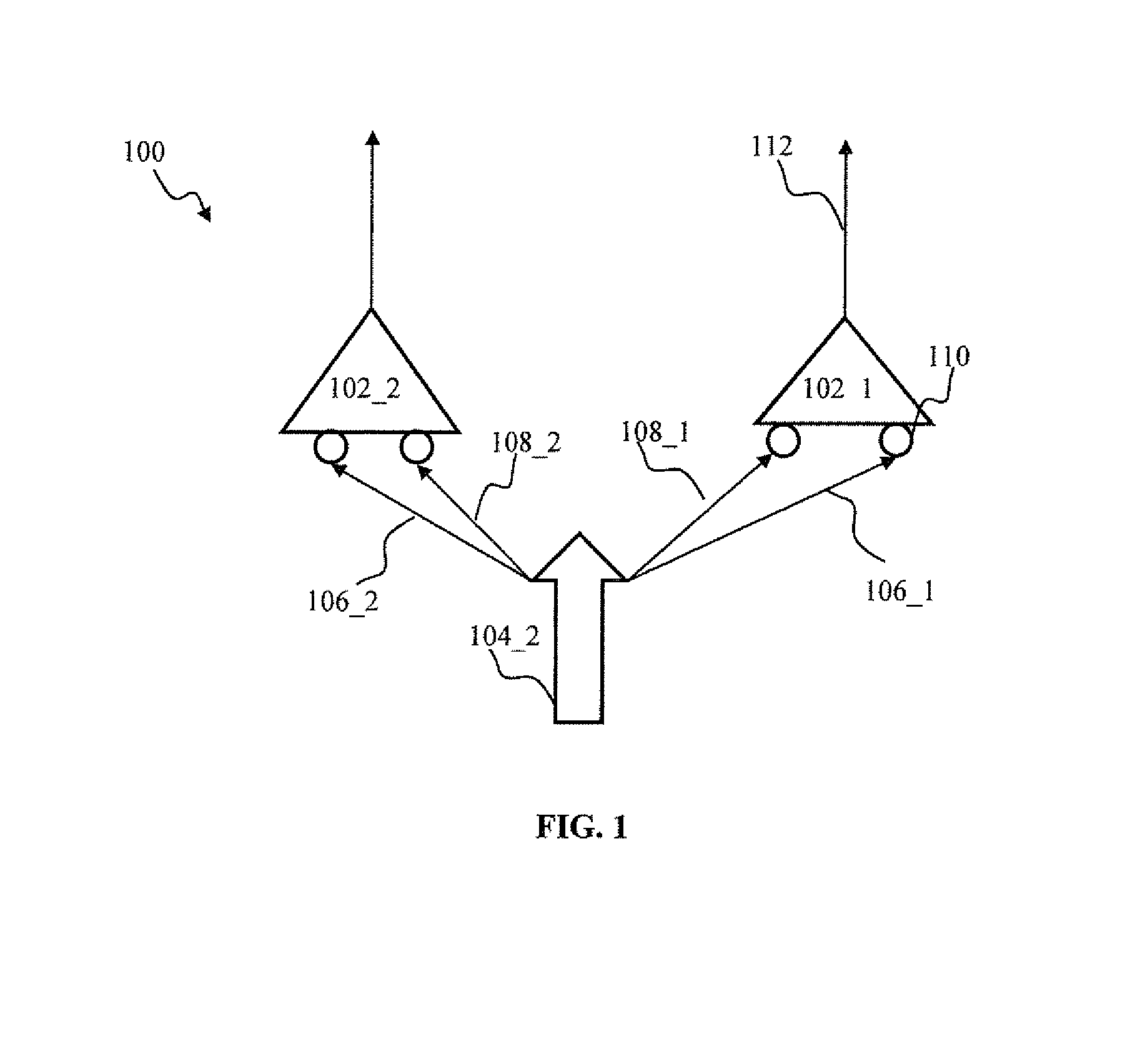

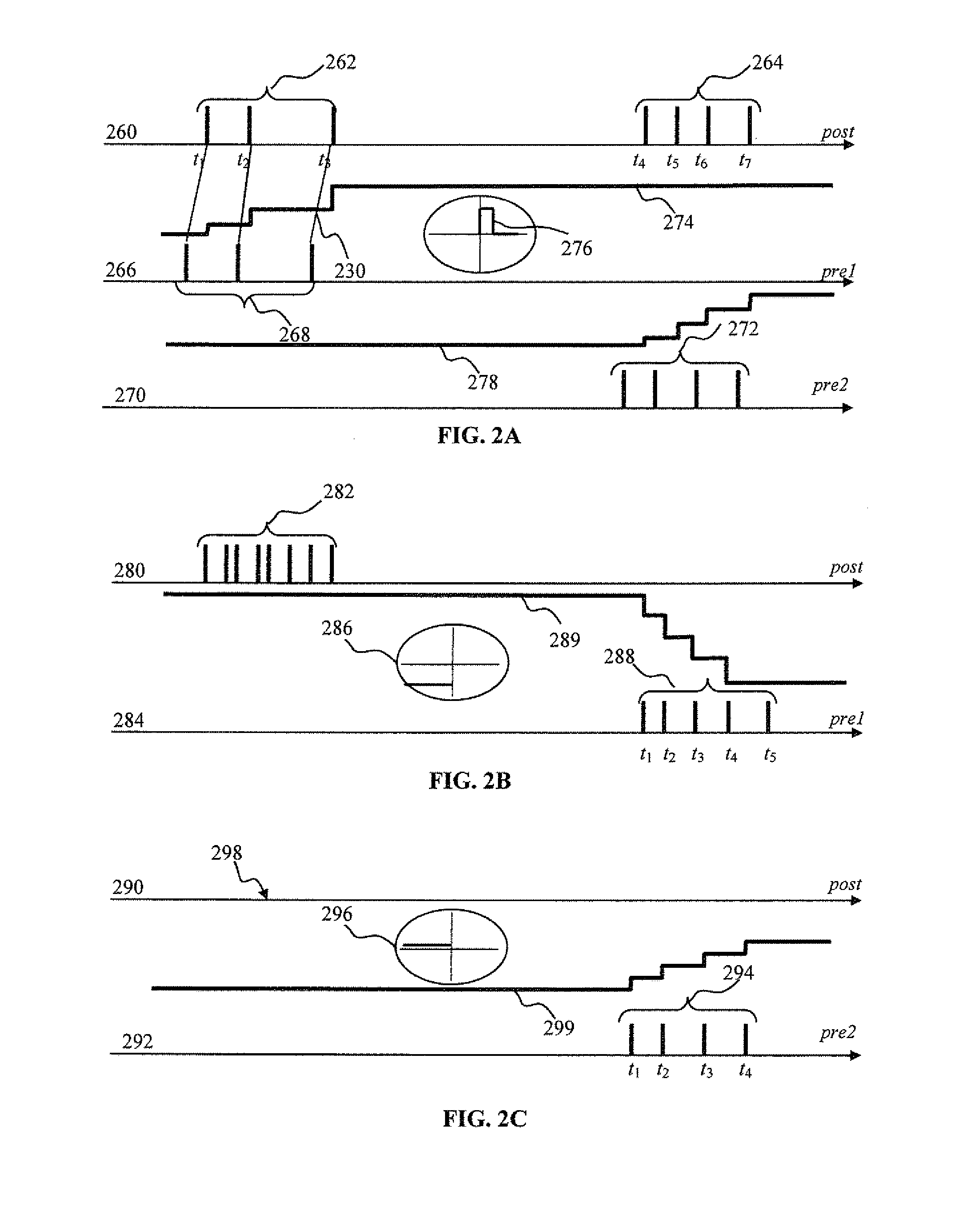

Apparatus and methods for rate-modulated plasticity in a spiking neuron network

ActiveUS20140244557A1Respond effectivelyGood curative effectDigital computer detailsDigital dataLow activityRate modulation

Apparatus and methods for activity based plasticity in a spiking neuron network adapted to process sensory input. In one approach, the plasticity mechanism of a connection may comprise a causal potentiation portion and an anti-causal portion. The anti-causal portion, corresponding to the input into a neuron occurring after the neuron response, may be configured based on the prior activity of the neuron. When the neuron is in low activity state, the connection, when active, may be potentiated by a base amount. When the neuron activity increases due to another input, the efficacy of the connection, if active, may be reduced proportionally to the neuron activity. Such functionality may enable the network to maintain strong, albeit inactive, connections available for use for extended intervals.

Owner:QUALCOMM INC

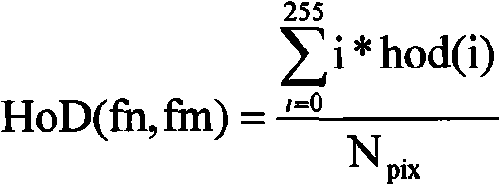

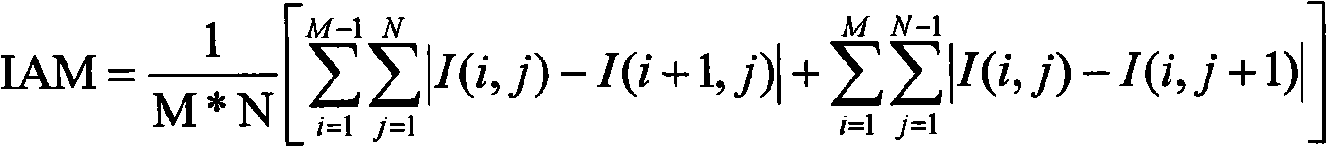

Video quality automatic evaluation system oriented to wireless network and evaluation method thereof

InactiveCN101312544AGuaranteed evaluation performanceReduce reference dataImage analysisTelevision systemsLivenessWireless mesh network

The invention relates to a video quality automatic evaluation method and an evaluation method, relating to the evaluation of wireless video communication, which can confirm the evaluation property, reduce needed reference data and reduce calculation complexity, therefore, the evaluation mode is adaptive to the evaluation application facing wireless network. The method comprises: processing content pre-check on the reference video not compressed; according to the average activity of each activity region, dividing the check on the video characters into high and low activity region character checks, to attain the check parameters representing the spatial domain and time domain characters which express the characters of the video sections in each activity region; weighting the check parameters of the spatial domain and time domain characters of each activity region to build the spatial domain and time domain character parameters of the whole video, realizing the projection between the check parameters and the subjective quality expression according to a preset video quality evaluation database, to realize the automatic evaluation on the video quality facing wireless network.

Owner:XIAMEN UNIV +1

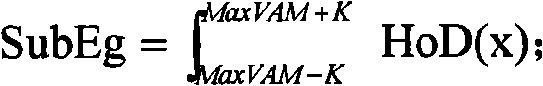

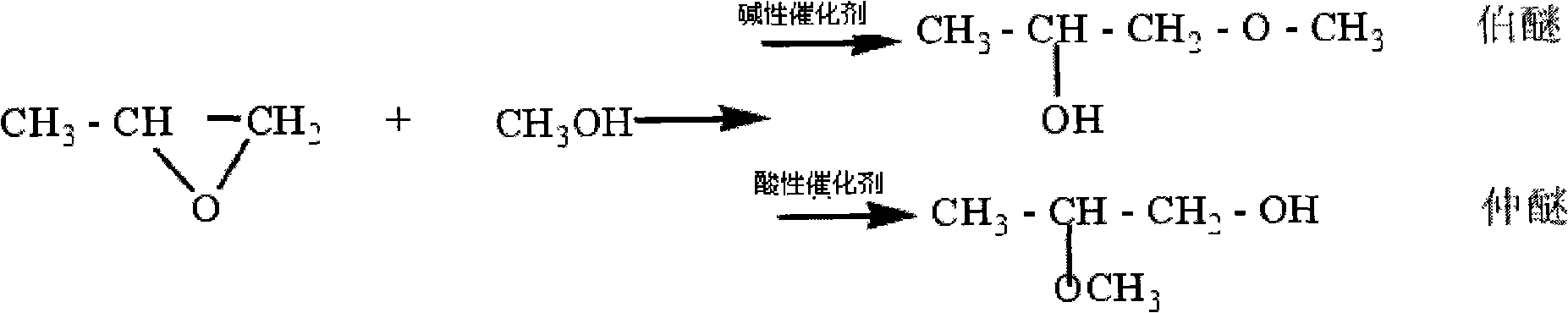

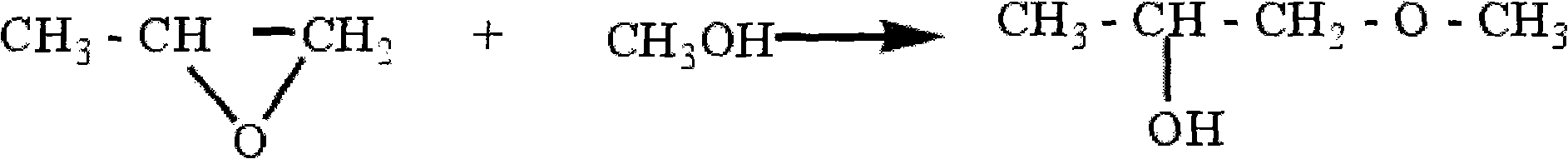

Method for synthesizing propylene glycol methyl ether

InactiveCN101550069ANo pollutionMild reaction conditionsOrganic-compounds/hydrides/coordination-complexes catalystsEther preparation from oxiranes1-PropanolReaction temperature

A method for synthesizing propylene glycol methyl ether relates to a method for synthesizing propylene glycol methyl ether. The method of the invention settles the problems of high reaction temperature, high pressure, low activity of catalyst and low selectivity existing in the prior method for preparing propylene glycol methyl ether. The method comprises the following steps: 1. preparing a compound A; 2. preparing a compound B; and 3. after naturally cooling the mixed solution B to a room temperature, atmospherically distilling and obtaining the propylene glycol methyl ether. The method of the invention has the advantages of simple process, applicable whole reaction in the condition of normal pressure and low-temperature, 93.3%-94.2% of epoxy propane conversion rate, 98.1%-99.1% of product selectivity, and no environment pollution as the whole reaction process is executed under the condition of no dissolvent. The propylene glycol methyl ether (1-methoxy-2-propanol or 2-methoxy-1-propanol) synthesized according to the invention can be synthesized by regulating the mixed liquid of acetate methyl glyoxaline hydroxide or acetate methyl glyoxaline chloride and ferric trichloride.

Owner:HARBIN NORMAL UNIVERSITY

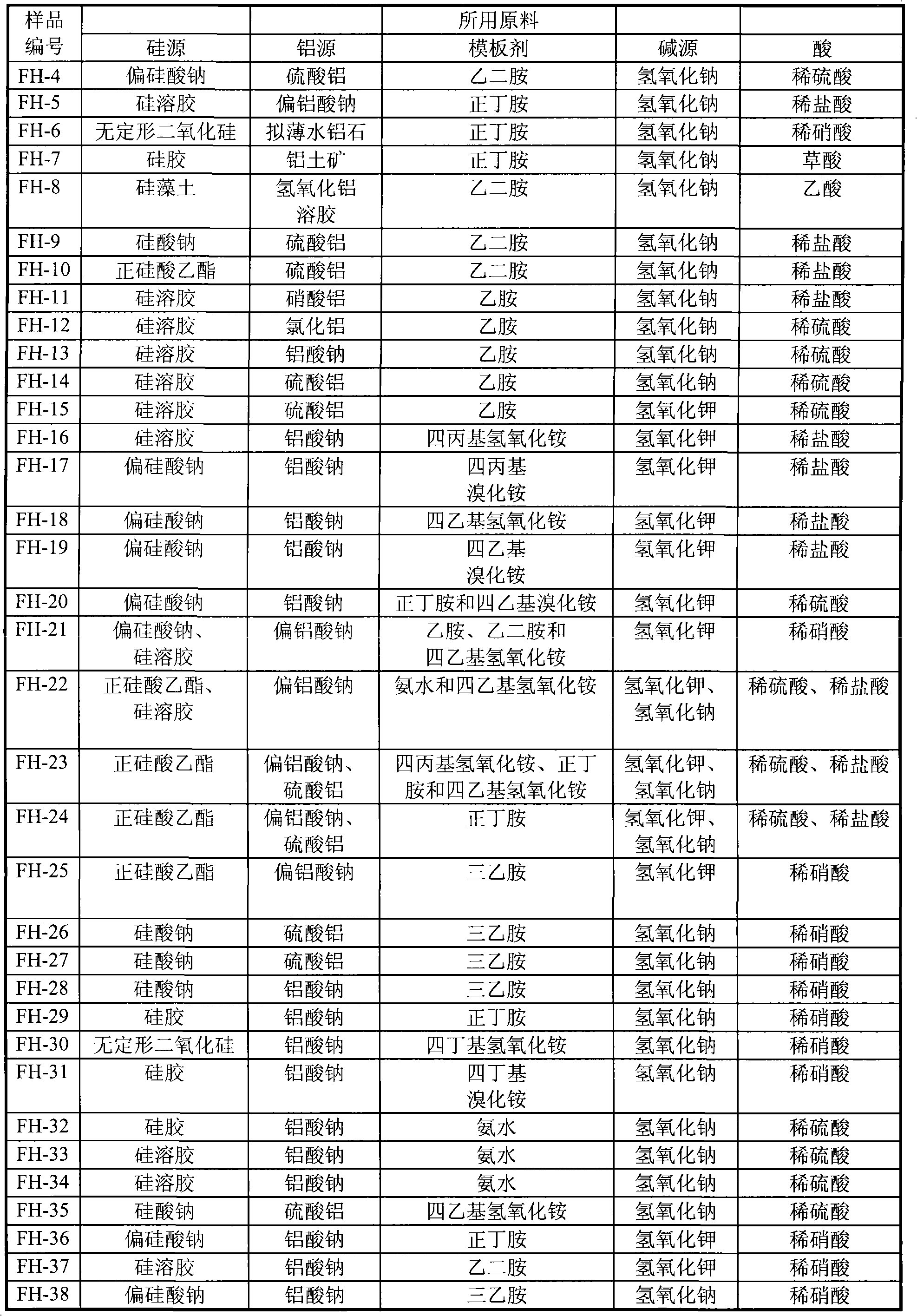

Synthetic method of SAPO-5 and SAPO-34 symbiotic molecular sieves

InactiveCN102372290AImprove catalytic performanceMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesState of artMolecular sieve

The invention relates to a synthetic method of SAPO-5 and SAPO-34 symbiotic molecular sieves and mainly solves the problems of single aperture and low activity of a porous material synthesized by the prior art. The synthetic method provided by the invention comprises the following steps of: using a phosphor source, an aluminium source, a silicon source and an organic template as raw materials, mixing the raw materials according to a certain proportion to form a mixed solution, and carrying out hydrothermal crystallization to obtain a series of SAPO-5 and SAPO-34 symbiotic molecular sieves. The synthesized symbiotic molecular sieves have the following molar ratio: AlO3: P2O5: SiO2: R: H2O=1: 0.2-1-2: 0.1-2.0: 0.5-2.5: 20-100, wherein R is the organic template. The technical scheme provided by the invention greatly solves the problems, and can be used in the industrial production of low carbon olefin prepared by methanol.

Owner:CHINA PETROLEUM & CHEM CORP +1

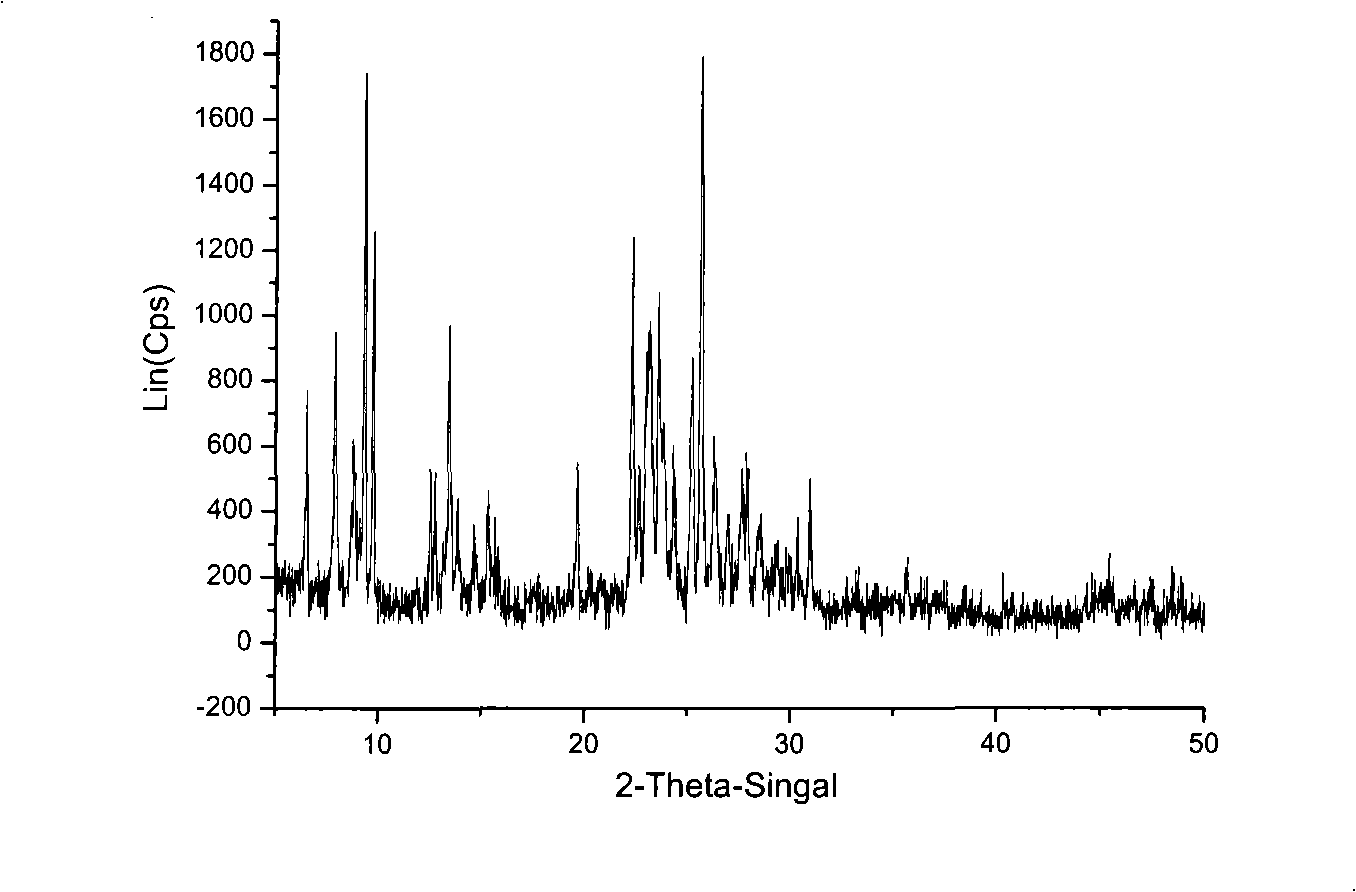

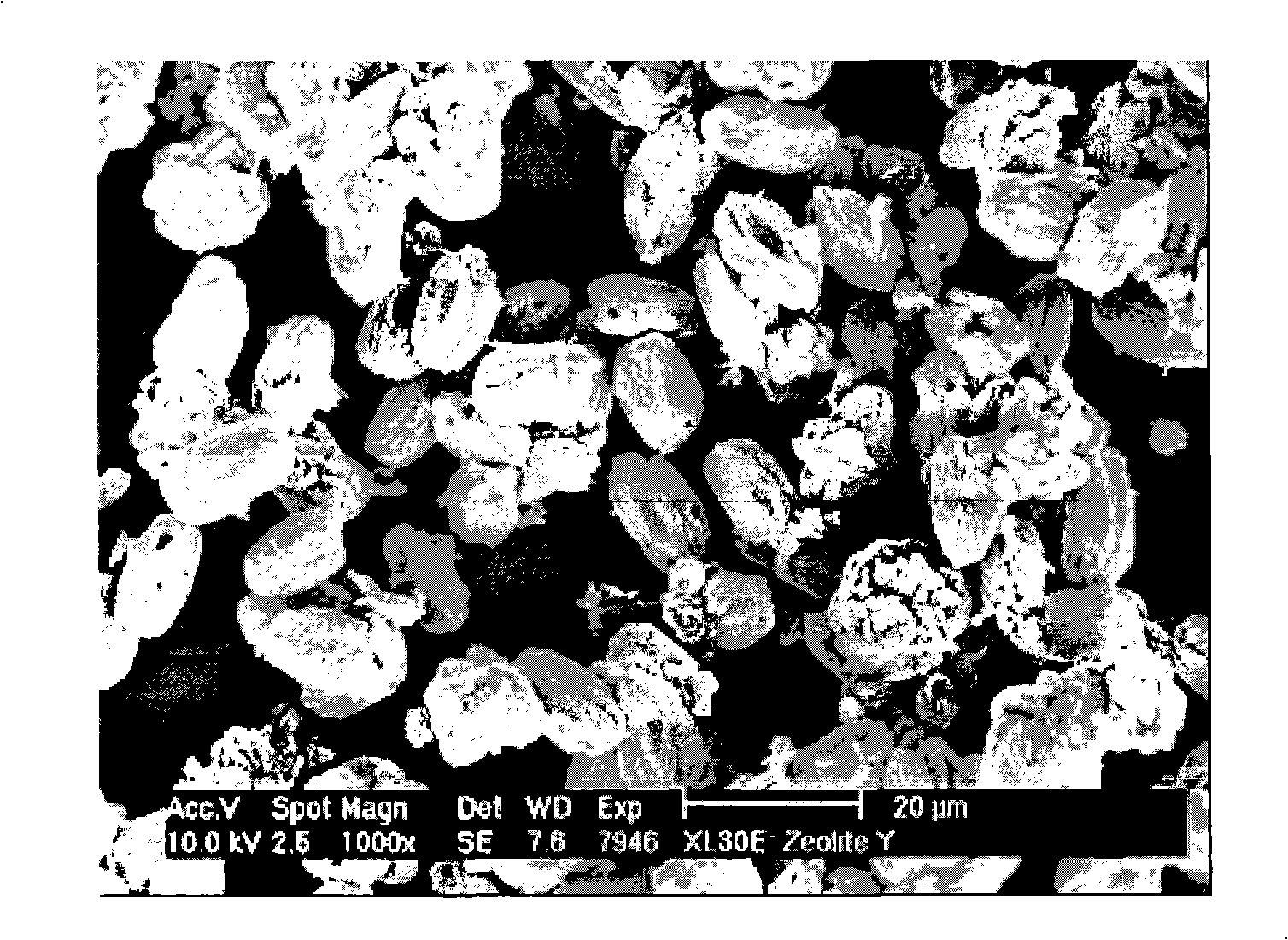

ZSM-5/mordenite/Yzeolite intergrowth molecular sieve and synthetic method thereof

ActiveCN101279747AIncrease acidityStrong acidFaujasite aluminosilicate zeoliteMordenite aluminosilicate zeoliteLow activityChemistry

The invention relates to a ZSM-5 / mordenite / zeolite Y intergrowth molecular sieve and a synthetic method thereof, which mainly solves the problems of singular aperture, rather weak acidity and low activity of porous materials synthesized by the prior art. The invention adopts the technical proposal that the nucleation and process of growth of the molecular sieve are controlled properly by adding crystal seeds containing zeolite Y precursors in the synthetic process of the intergrowth molecular sieve for producing the ZSM-5 / mordenite / zeolite Y intergrowth molecular sieve, wherein the proportion of intergrowth phases is adjustable, and the synthesized ZSM-5 / mordenite / zeolite Y intergrowth molecular sieve adopts the compositions including the following mole relation: nSiO2:Al2O3, where n is between 4 and 400 in the formula, and the method is characterized in that the ZSM-5 / mordenite / zeolite Y intergrowth molecular sieve has more than two phases and an XRD diffraction pattern thereof has the d-space maximum value at the lengths of 14.3+-0.1, 13.58+-0.1, 11.21+-0.1, 10.04+-0.1, 9.47+-0.1, 9.09+-0.1, 6.6+-0.1, 5.7 +-0.1, 4.5+-0.1, 3.98+-0.05, 3.76+-0.04, 3.64+-0.04, 3.53+-0.04, 3.38+-0.02, 3.19+- 0.05 and 2.88+-0.1 angstroms, thereby solving the problems properly. The ZSM-5 / mordenite / zeolite Y intergrowth molecular sieve can be used for preparing ethylene and propylene by catalytic-cracking naphtha in the industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Carbon-loaded kernel-shell copper-palladium-platinum catalyst for fuel battery and preparation method thereof

InactiveCN102664275AGood effectImprove stabilityCell electrodesMetal/metal-oxides/metal-hydroxide catalystsAdditive ingredientReaction temperature

The invention provides a carbon-loaded kernel-shell copper-palladium-platinum catalyst for a fuel battery and a preparation method thereof. Conductive carbon black is used as a carrier, an active component is a copper-palladium-platinum alloy with a nuclear-shell structure, wherein the copper palladium is a kernel, the platinum is a shell, and the catalyst comprises the following ingredients by mass percent: 70 to 91 percent of conductive carbon black, 2 to 10 percent of copper, 2 to 10 percent of palladium and 5 to 10 percent of platinum. A two-step reduction method is utilized, namely, low-activity metal is firstly reduced, then the active precious metal is reduced, the precious metal is precipitated on the surface of the non-precious metal by controlling the reaction temperature and the pH value, and a kernel-shell catalyst is formed through a dealloying step; and in addition, the carbon carrier is added in the preparation process, so that the nano metal particles can directly grow on the carrier, the combination of the catalyst particles and the carbon carrier can be enhanced, and the catalyst is more stable. Due to the adoption of the preparation method, the catalyzing efficiency of the catalyst and the utilization rate of the precious metal can be greatly improved, and the development of the fuel battery can be promoted.

Owner:BEIJING UNIV OF CHEM TECH

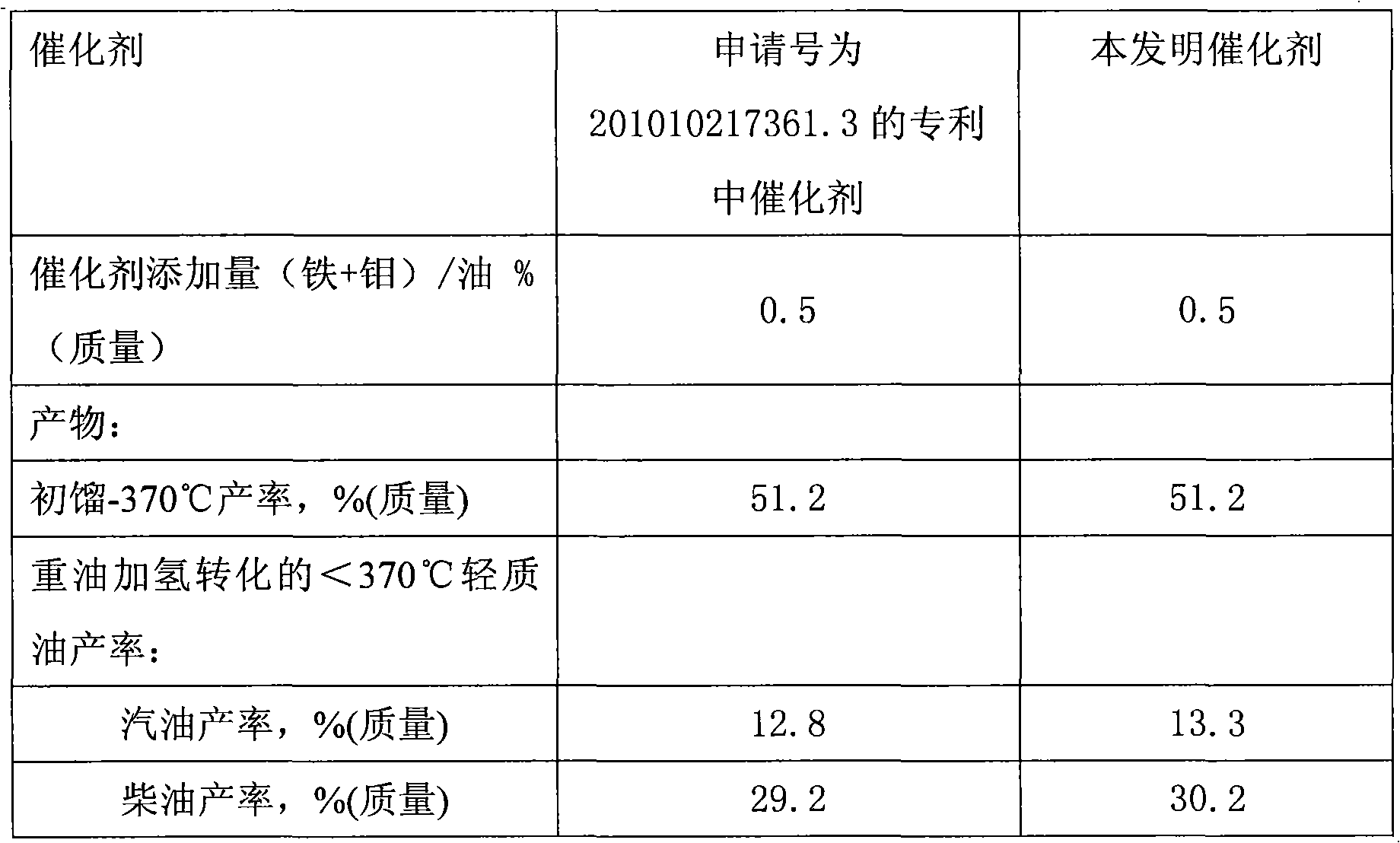

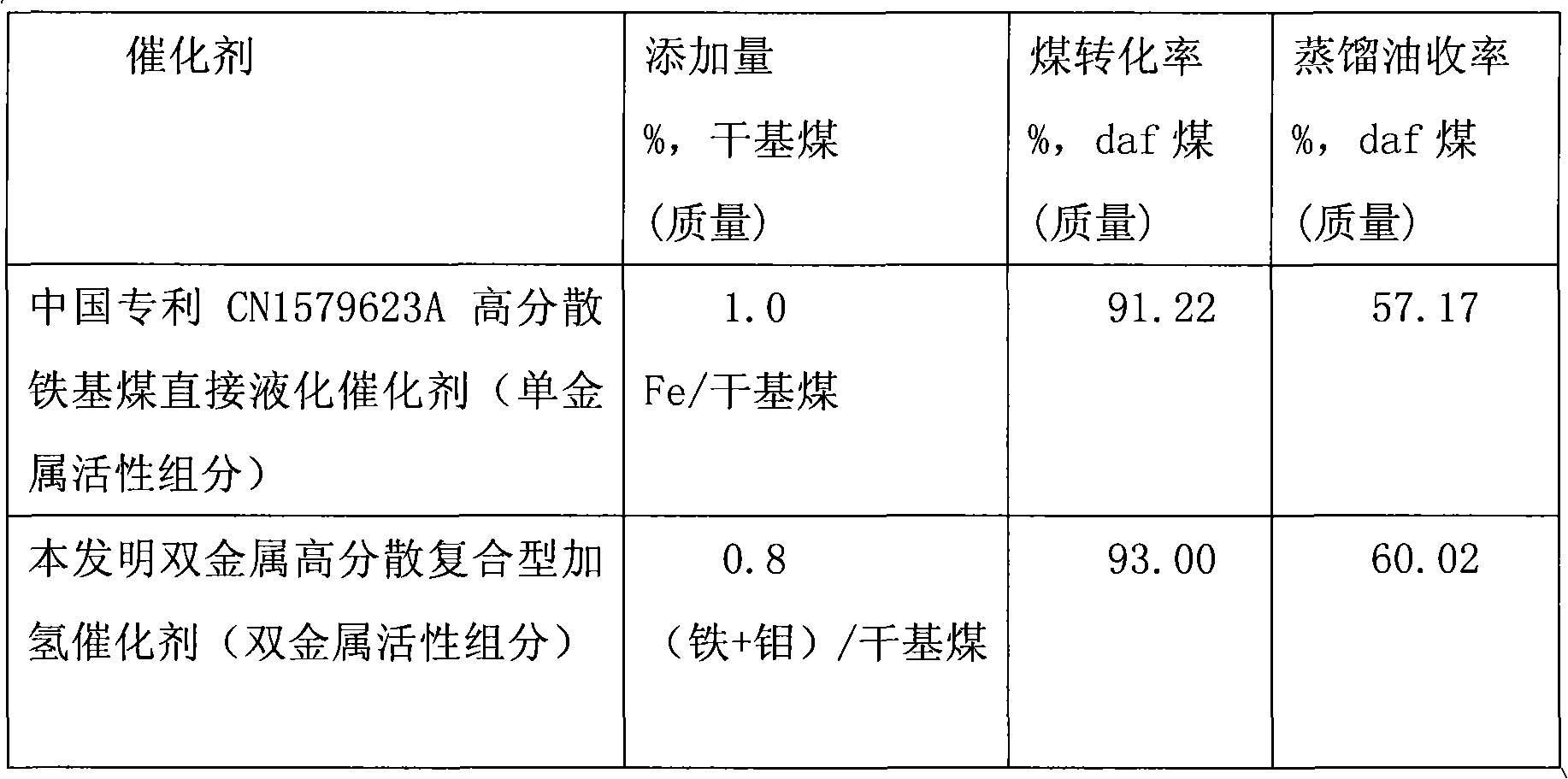

Bimetal or multi-metal high-dispersion composite coal tar hydrogenation catalyst and preparation method thereof

ActiveCN102380396AHigh activityReduce manufacturing costLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesSolubilityCobalt

The invention relates to a bimetal or multi-metal high-dispersion composite coal tar hydrogenation catalyst and a preparation method thereof. The catalyst comprises molecular high-activity components of one or a plurality of mixtures of water-solubility salt compounds of metal from molybdenum, nickel, tungsten or cobalt, nanometer low-activity components gamma-FeOOH grains and micro or sub nanometer carrier pulverized coal, the activity components are uniformly and highly dispersed on the surfaces of the carrier pulverized coal, the catalyst is micro or sub nanometer fine powder and is high in activity, particles of the activity components are small and are highly uniformly dispersed on the surface of a carrier, the utilization quantity of the catalyst is low, cost is reduced, and the bimetal or multi-metal high-dispersion composite coal tar hydrogenation catalyst can be widely applied to coal tar hydrogenation or coal liquefaction.

Owner:CCTEG CHINA COAL RES INST

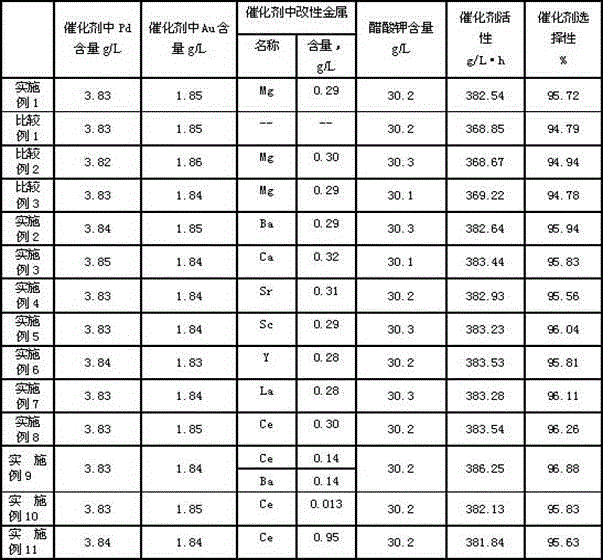

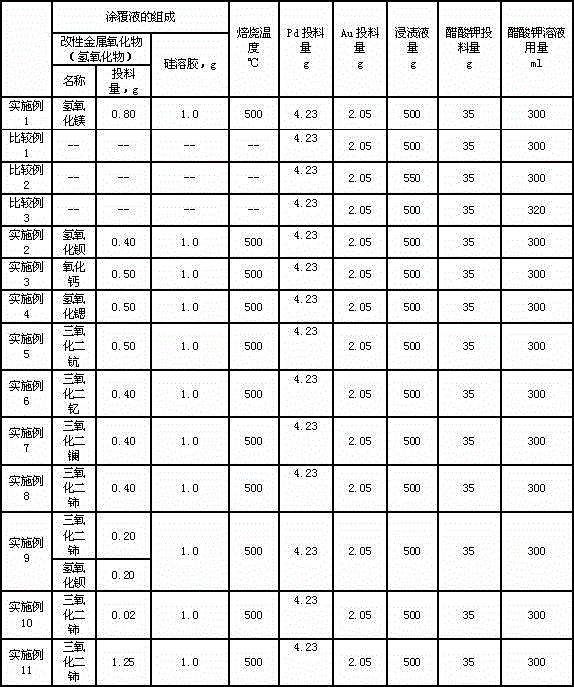

Vinyl acetate catalyst and application thereof

ActiveCN104549517AHigh activityHigh selectivityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsLow activityPtru catalyst

The invention relates to a vinyl acetate catalyst, a preparation method thereof and a method for synthesizing vinyl acetate in order to mainly solve the problem of low activity and selectivity of a catalyst in the prior art. The problem is better solved through the technical scheme that the vinyl acetate catalyst comprises a carrier, active components and a catalyst promoter, wherein the active components include metal Pd and metal Au; the catalyst promoter is alkali metal acetate; the carrier is silicon dioxide provided with a coating on the surface; the coating is prepared from modified metal elements and a silicon dioxide adhesive for adhering the modified metal elements on the surface of the carrier; 0.01-1.00g / L of the modified metal elements are contained; the modified metal elements are at least one selected from IIA metal elements and IIIB metal elements. The vinyl acetate catalyst can be used for industrial production of vinyl acetate.

Owner:CHINA PETROLEUM & CHEM CORP +1

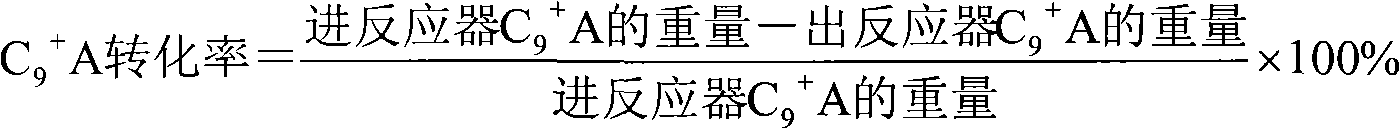

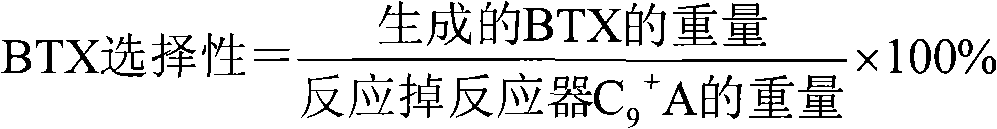

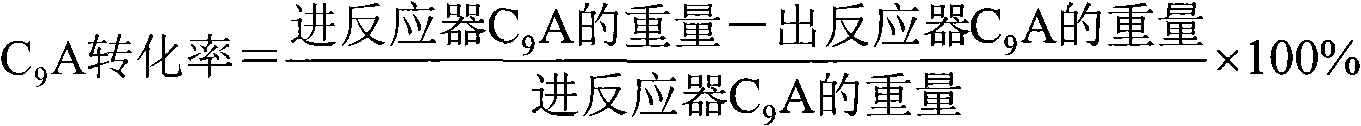

Method for converting heavy aromatics to light aromatics and transferring alkyl radical

The invention relates to a method for converting heavy aromatics to light aromatics and transferring an alkyl radical, which mainly solves the problem of low activity during the reaction of converting the heavy aromatics to the light aromatics and transferring the alkyl radical in the presence of a conventional catalyst. In the invention, a new method for converting the heavy aromatics to the light aromatics and transferring the alkyl radical is adopted, wherein the catalyst comprises the following components in part by weight: a) 5 to 95 parts of nuclear-shell molecular sieve material and b)95 to 5 parts of adhesive; the nuclear phase of the nuclear-shell molecular sieve is ZSM-5; and the shell layer is beta zeolite grains with coverage of between 50 and 100 percent. The technical scheme solves the problem better and the method can be used in the industrial production of converting the heavy aromatics to the light aromatics and transferring the alkyl radical.

Owner:CHINA PETROLEUM & CHEM CORP +1

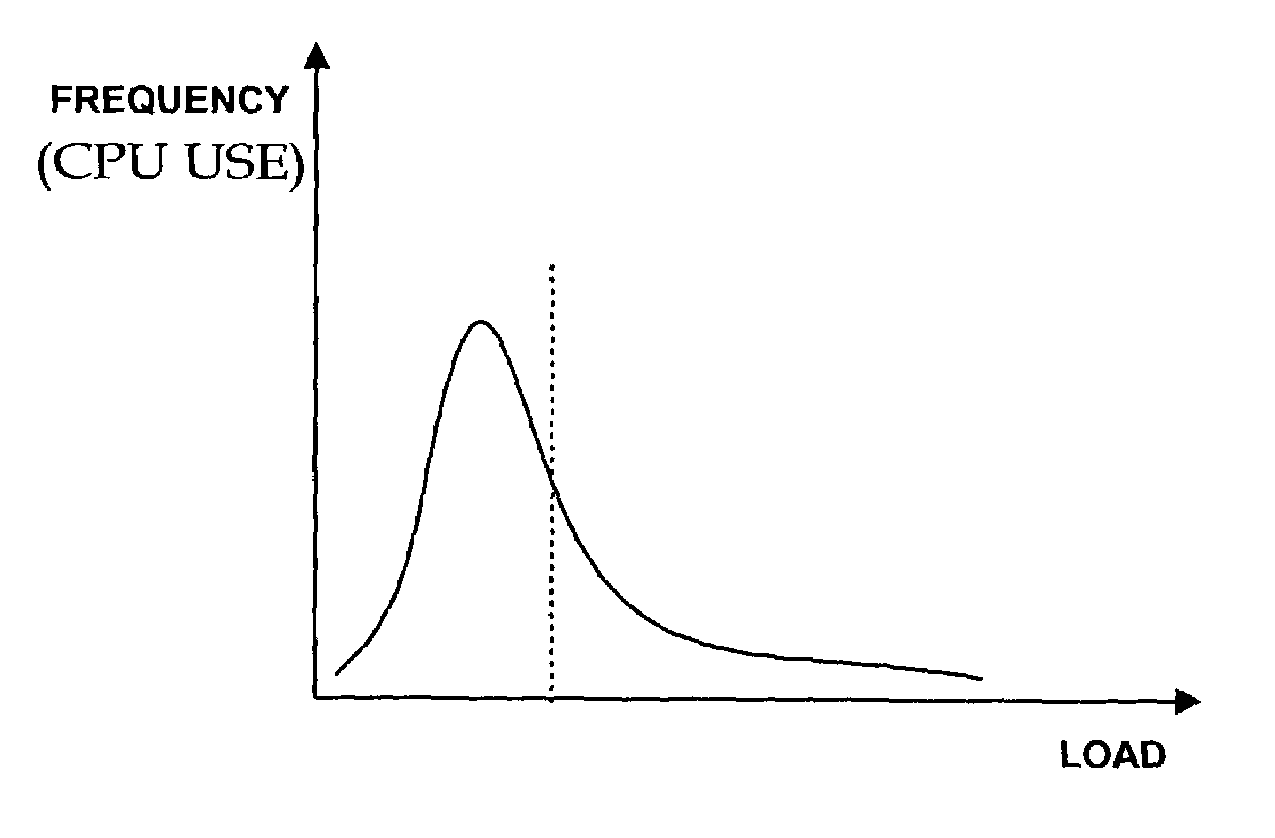

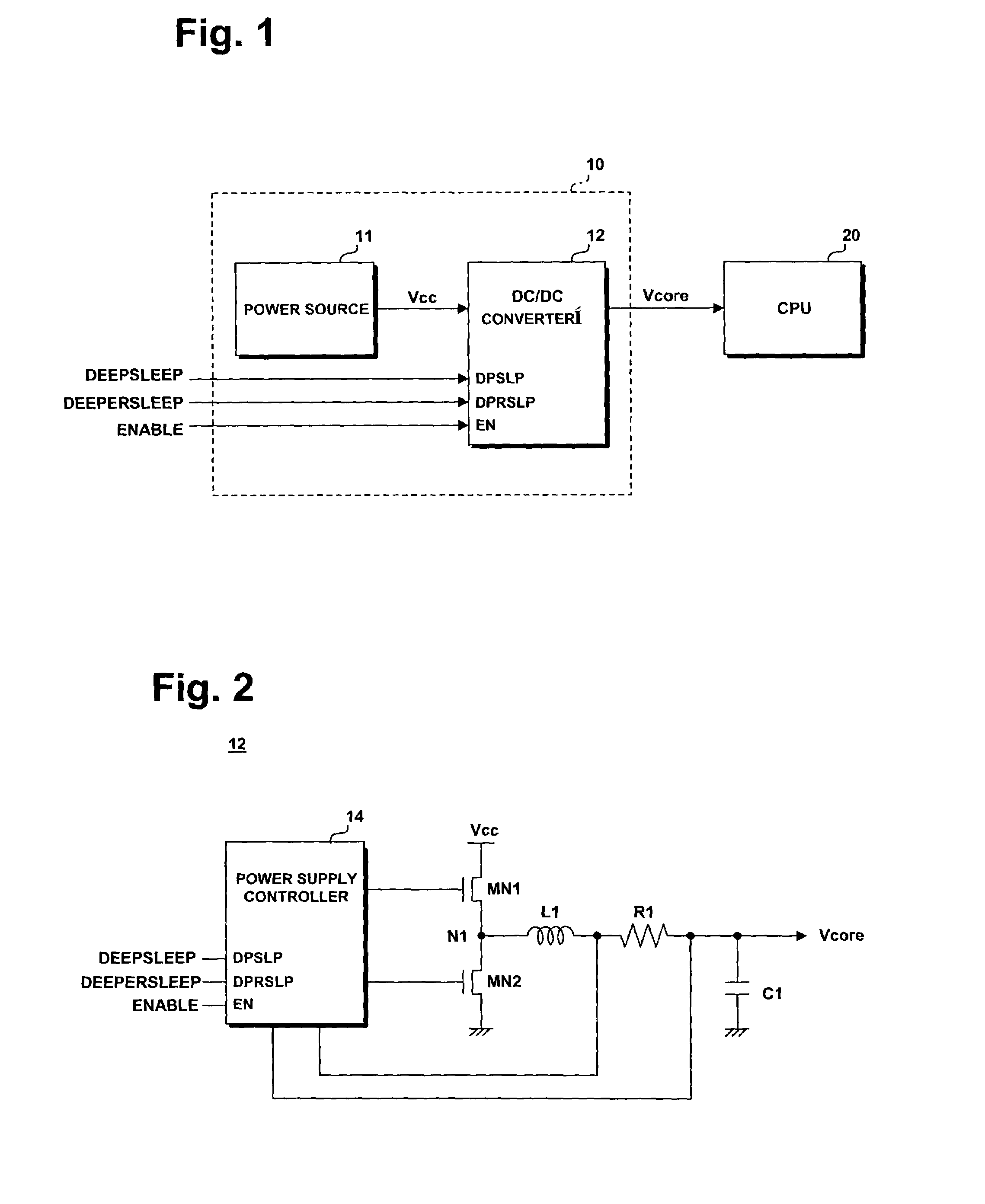

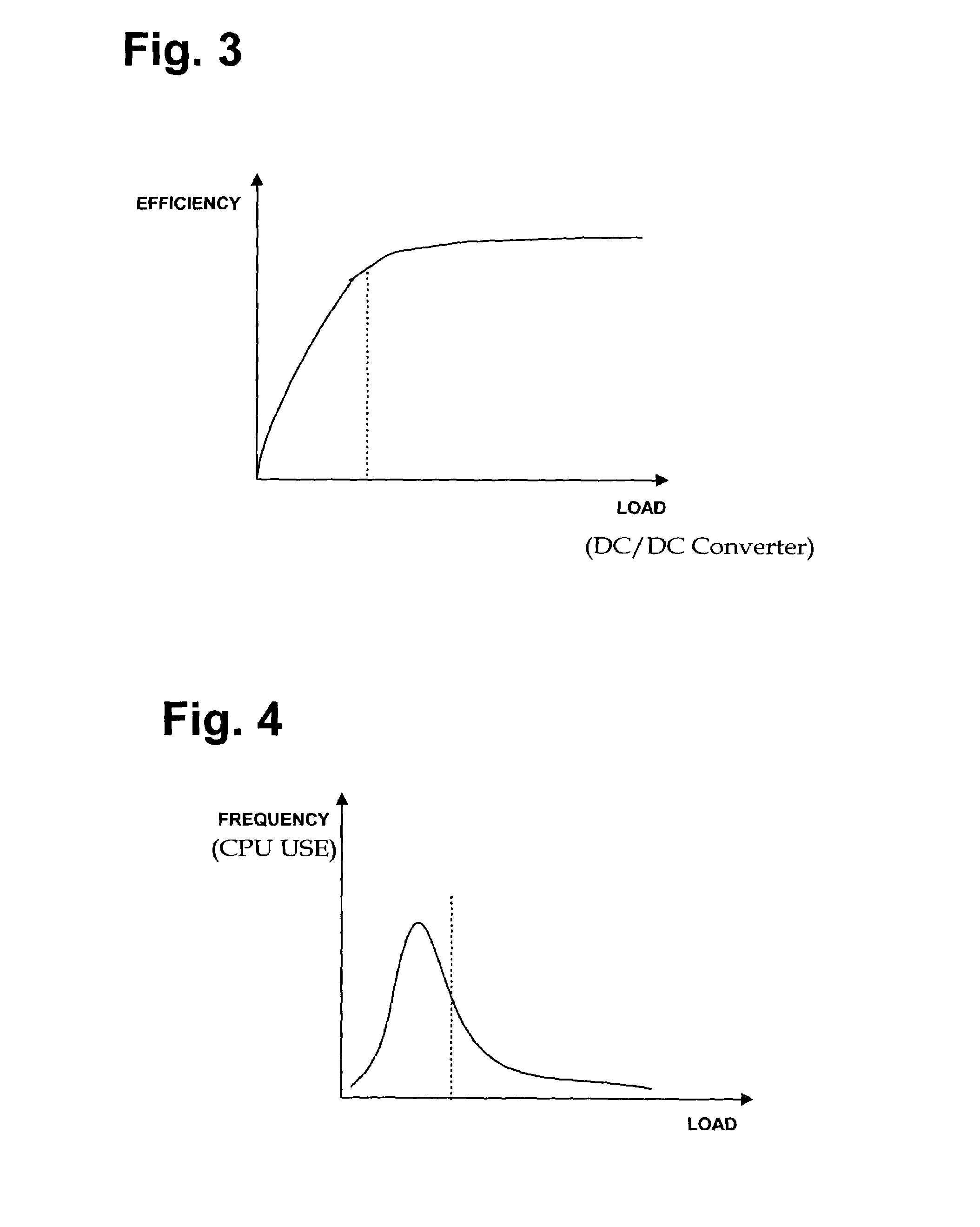

Power supply for central processing unit

ActiveUS7203847B2Improve power efficiencyReduces and prevents efficiencyVolume/mass flow measurementPower supply for data processingLow activityLow load

A power supply and method for a central processing unit (CPU). The power can include a first power supply circuit such as a DC / DC converter for supplying a voltage of a first level to the CPU when the CPU is in a high activity mode, and a second power supply circuit such as an LDO regulator circuit for supplying a voltage of a second level lower than the first level to the CPU when the CPU is in a low activity mode. The second power supply circuit is preferably efficient when the CPU is in a low load or low activity mode. In such a power supply, when the CPU is in the low activity mode, the LDO regulator circuit is operated to reduce or prevent the efficiency from being degraded, reduce a CPU power consumption and extend a CPU battery lifetime.

Owner:LG ELECTRONICS INC

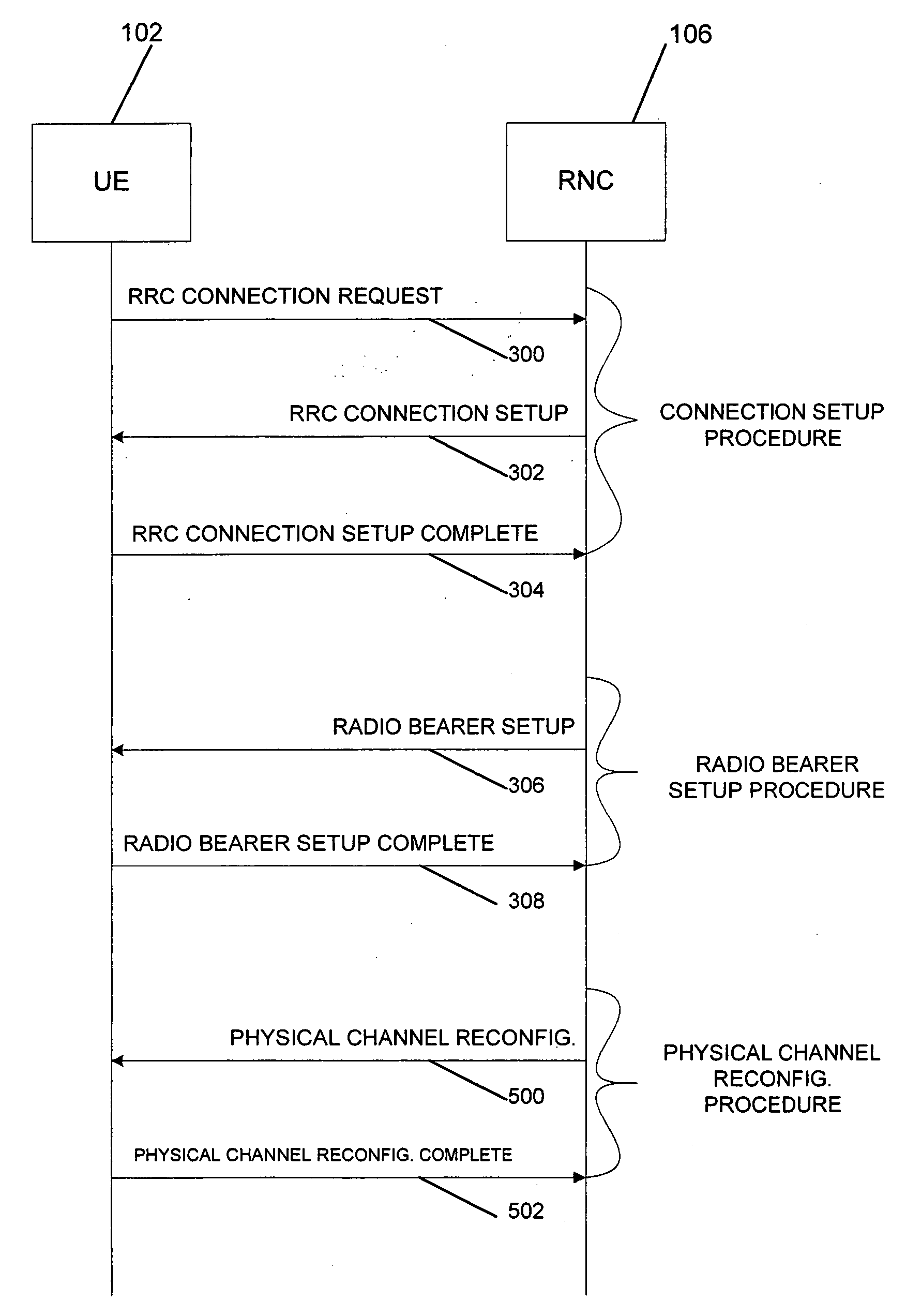

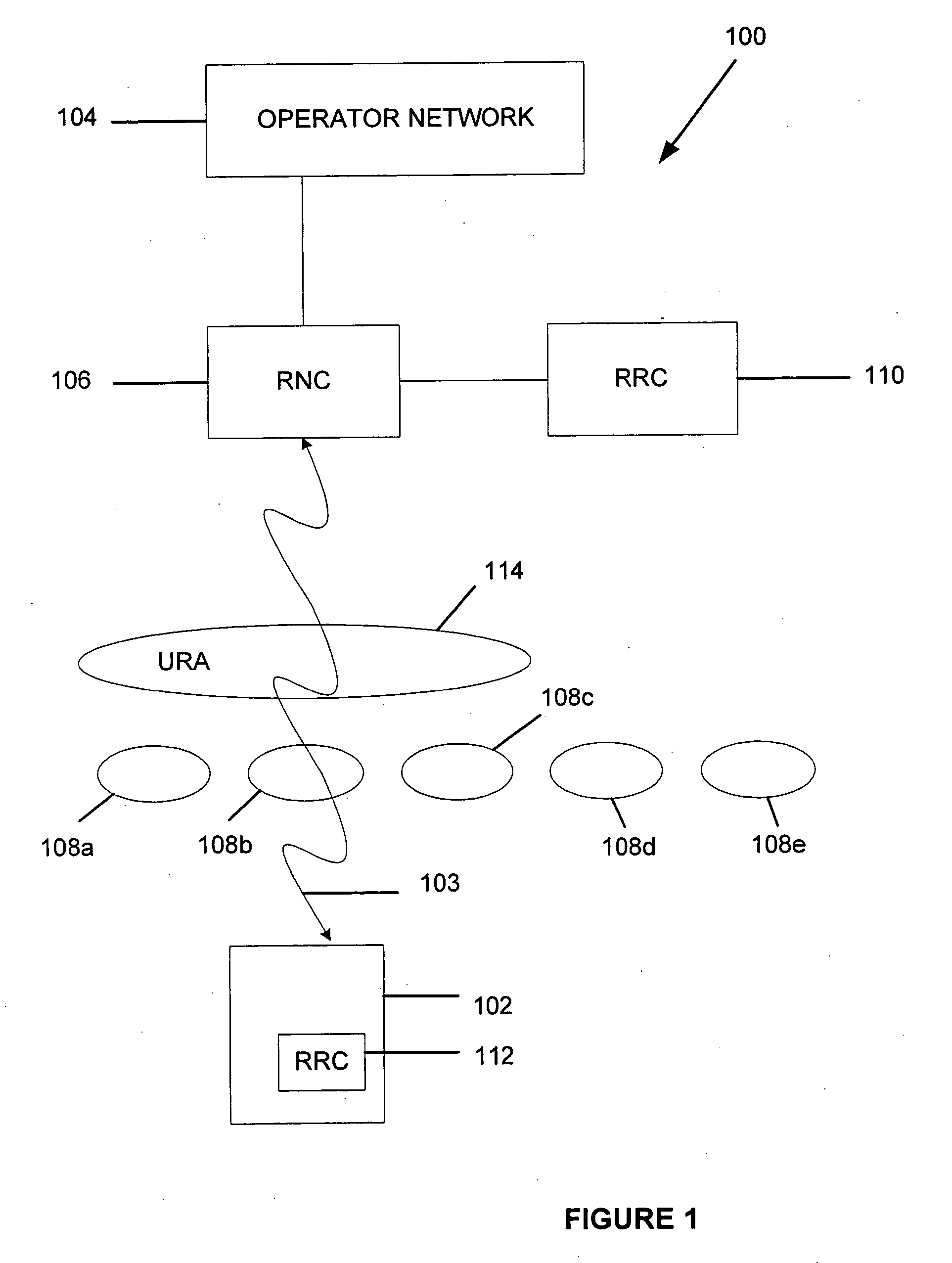

Method for maintaining transparent mode radio bearers in a radio access network

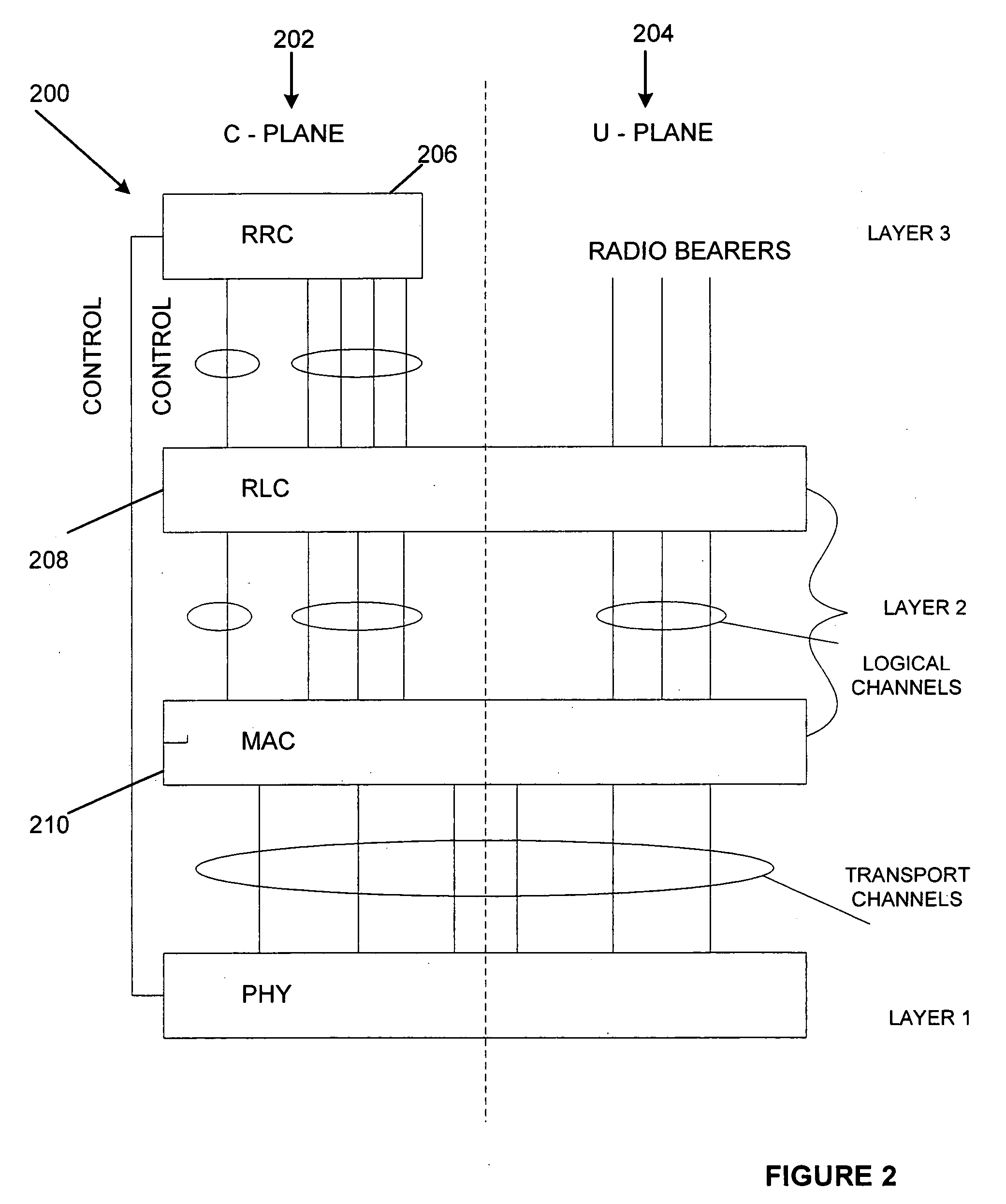

The present invention concerns a method for maintaining transparent mode radio bearers in a Radio Access Network (RAN) of a third generation mobile telecommunications network. The method relates to managing the radio resources allocated to a user equipment (UE) in said radio access network (RAN). The method generally comprises communicating a message from a radio resource controller (RRC) of the RAN to the UE where said message is arranged to instruct the UE to transition from a dedicated channel connection state to a lower activity connection state and to store in its memory transparent mode (TM) radio bearer (RB) information associated with said dedicated channel connection state. By storing TM RB information associated with the dedicated channel connection state, the UE can be reconfigured to the dedicated channel connection state without the RAN having to perform a radio bearer setup procedure.

Owner:MALIKIE INNOVATIONS LTD

Catalyst for dehydrogenating light alkane

The invention relates to a catalyst for dehydrogenating light alkane in order to mainly solve the problem of relatively-low activity of a dehydrogenating catalyst prepared in the prior art. The problem is better solved through the technical scheme that the catalyst for dehydrogenating light alkane comprises the following components in parts by weight: 1-30 parts of a Cr element or an oxide of the Cr element (a), 0.1-5 parts of alkali metal oxides or alkaline earth metal oxides (b), 0.001-1 part of the group VA elements selected from a periodic table of elements or oxides of the group VA elements (c), 0.001-1 part of the group IIIA elements selected from the periodic table of elements or oxides of the group IIIA elements (d), and 54-99 parts of Al2O3 or SiO2 (e). The catalyst can be used for industrial production of light olefin prepared by dehydrogenating light alkane.

Owner:CHINA PETROLEUM & CHEM CORP +1

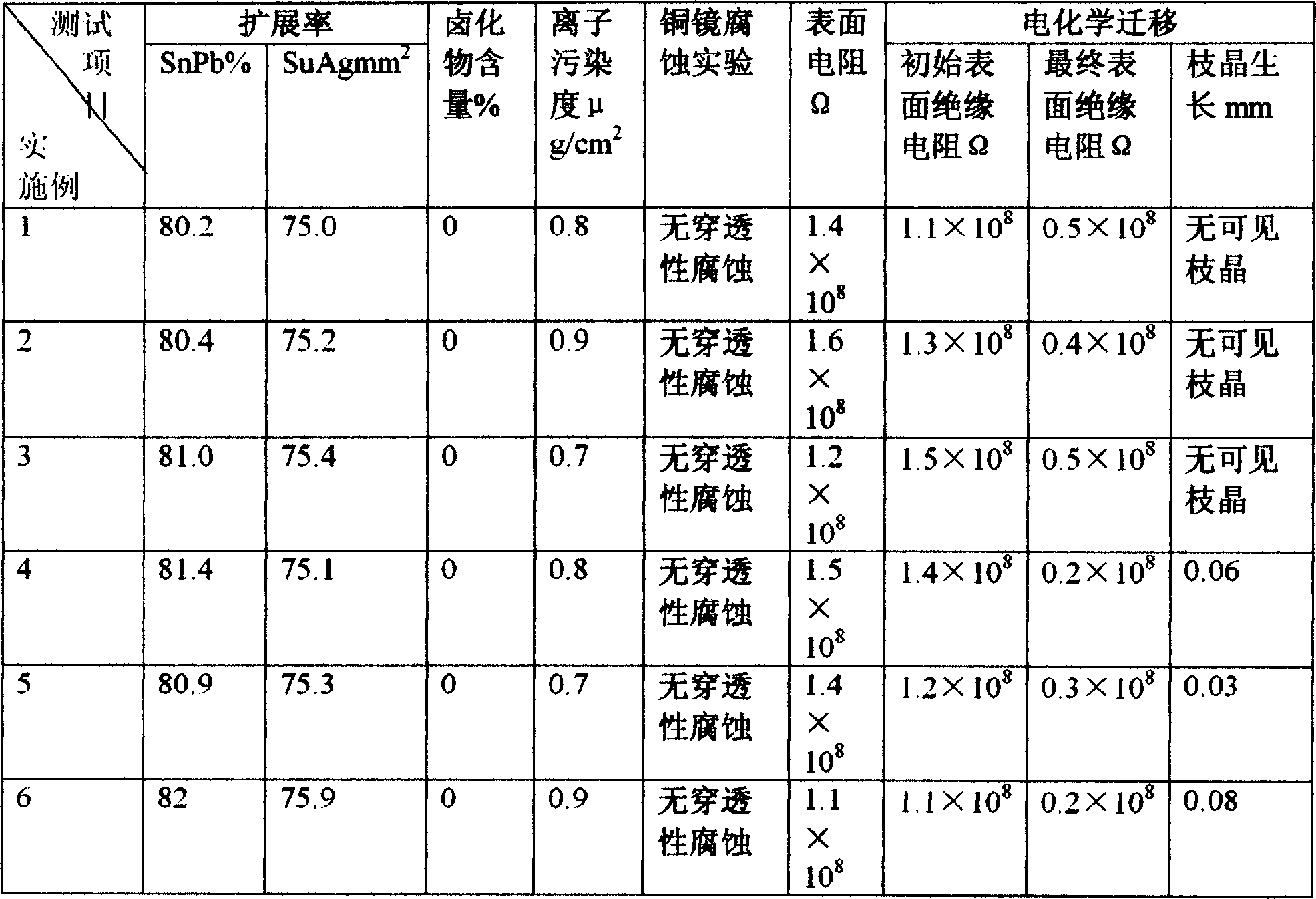

Low-solid content water based clean-free welding flux without volatile organic substance and halogen

InactiveCN1843684ANo penetrating corrosionGood solder spreadabilityWelding/cutting media/materialsSoldering mediaWater basedSolvent

The invention relates to a organic non-halogen low-solid water-based washing-free welding flux with low activity and non-volatility, which can be coated on the welding surface of PCB plate via spraying, foaming and dipping. It comprises following components: organic acid organic amine activator in 1.0-4.0; film former in 0.5-1.0; wetting agent in 0.03-0.20; inhibitor in 0.04-0.10, some water, and assisting solvent in 2.0-6.0 and / or vesicant in 0.04-0.10. The invention has better spreading property; and with it, the PCB plate has better tin transparent property; the surface has no left matter after welding, since the activator is decomposed or sublimed in welding temperature; and it can avoid VOC material. And it is environment friendly.

Owner:广东中实金属有限公司

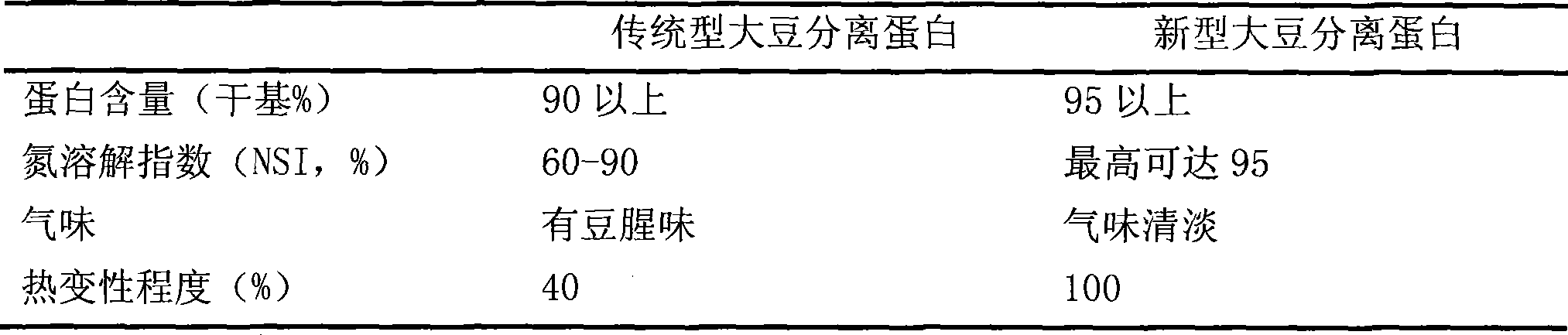

Preparation of soy protein isolate

InactiveCN101372501AAdditional preparation stepsEasy to handlePeptide preparation methodsSolubilityLow activity

The invention provides a method for preparing separated soy protein and comprises the following steps: (1) the preparation of concentrated soybean albumen powder by vacuum drying alcoholic method; (2) solution preparation and heat treatment; (3) acid coprecipitate and neutrality adjustment; (4) instantaneous heating and sterilizing as well as sponging drying. The separated soy protein prepared by the method not only has the advantages of high solubility and high protein content of common protein isolate, but also has the advantages of low beanyflavor, light color, low activity of nutrition resistant substance, easy treatment on discharged sewage, and the like which are not possessed by common separated soy protein; therefore, the invention is an ideal preparation method for producing beverage type separated soy protein.

Owner:SOUTH CHINA UNIV OF TECH

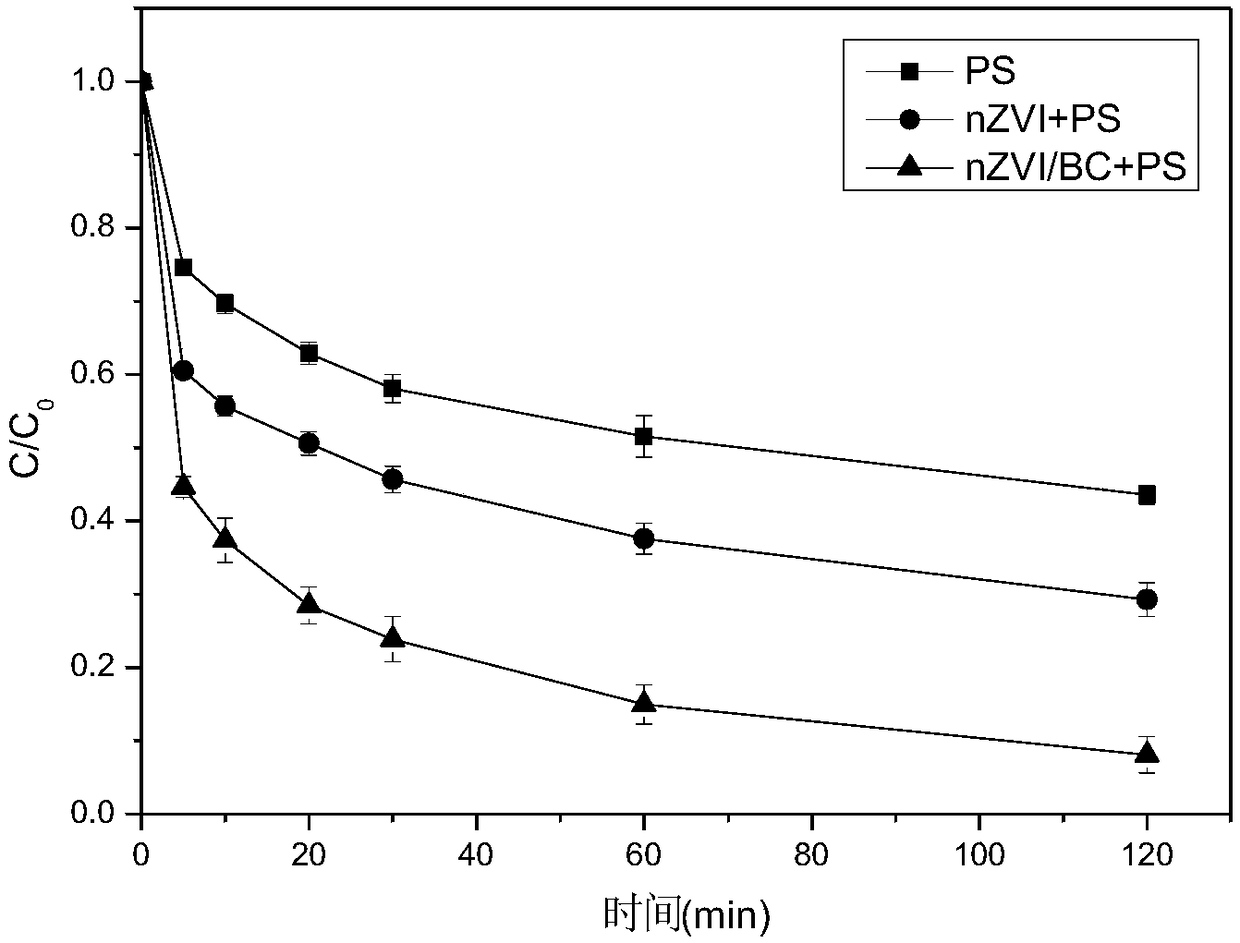

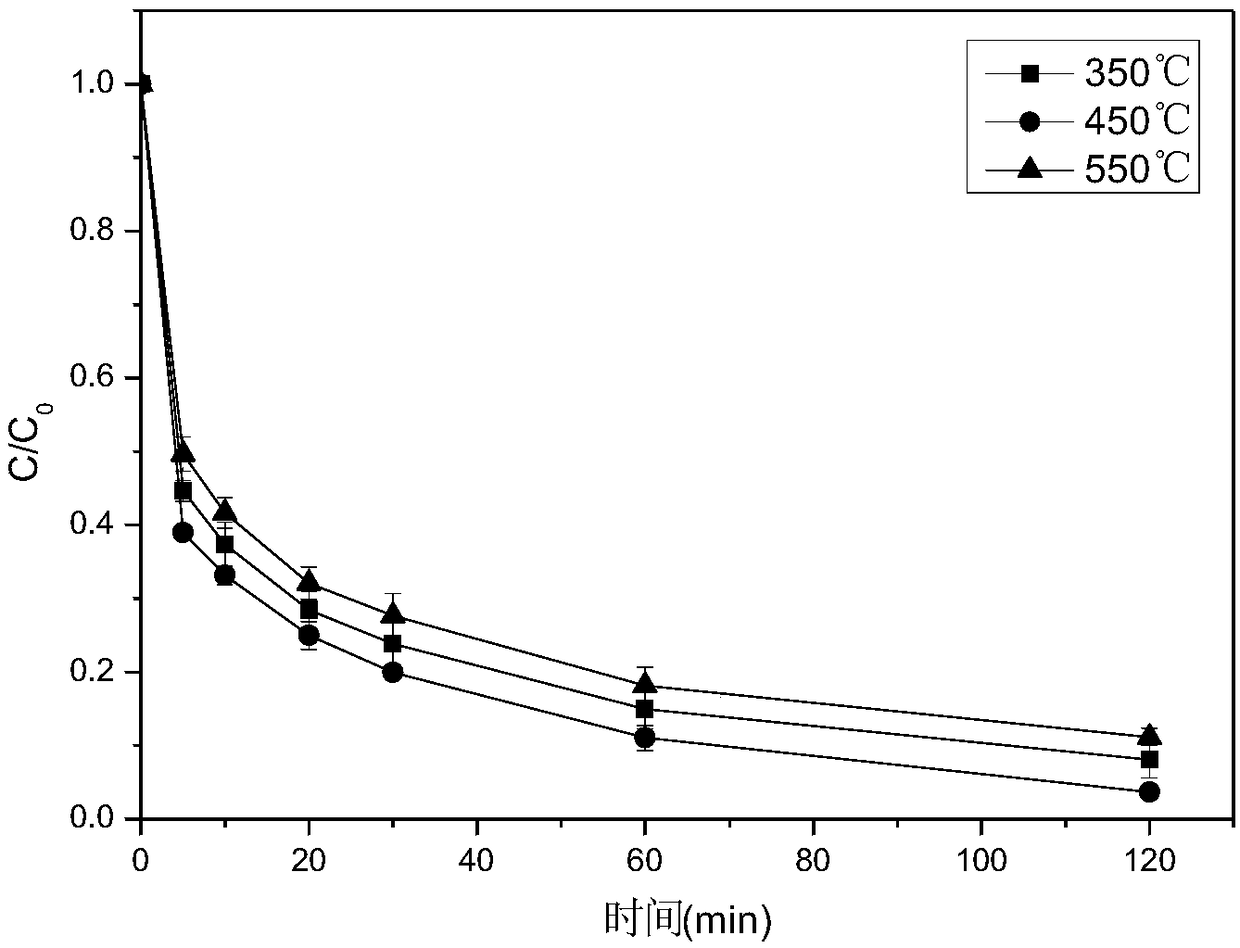

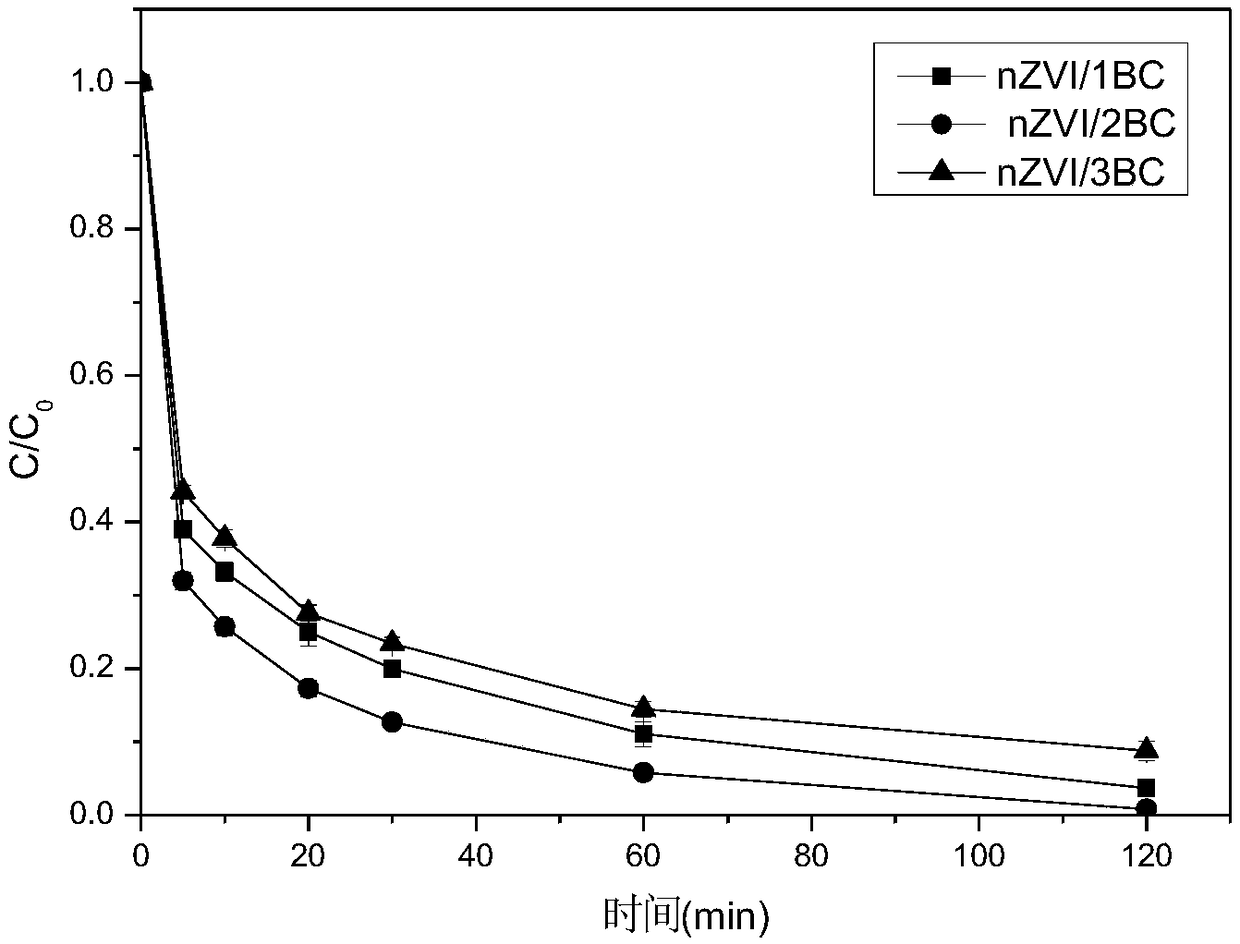

Charcoal load nanometer zero-valent iron activated sodium persulfate system and preparation and application thereof

InactiveCN108439570ASimple processEasy to prepareWater treatment compoundsTreatment of wastewater with pathogenic microorganismsEarth surfaceSodium sulfate

The invention relates to a charcoal loading nanometer zero-valent iron activated sodium persulfate system and preparation and application thereof. Firstly, biomass is burned into charcoal, the charcoal is cleaned and dried after being acidized, and added into a ferrous sulphate solution taking absolute ethyl alcohol and water as a dispersing agent for being stirred fully, then a sodium borohydridesolution is added dropwise to generate the charcoal loading nanometer zero-valent iron; lastly, a composite material prepared with pure water and ethyl alcohol is washed and dried, the obtained charcoal loading nanometer zero-valent iron activated material is placed in the solution, after ultrasonic treatment is carried out, the material is uniformly dispersed in the solution, at the moment, a sodium persulfate solution is added, the mixture is mixed evenly to obtain the charcoal loading nanometer zero-valent iron activated sodium persulfate system. The oxidation system is used for reducing waste, polluted surface water and target pollutants in the underground water, and the problems of the agglomeration and lower activity of sodium persulfate during the use of the nanometer zero-valent iron are solved.

Owner:徐建

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com