Patents

Literature

1732 results about "Propylene glycol methyl ether" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Propylene glycol methyl ether (PGME or 1-methoxy-2-propanol) is an organic solvent with a wide variety of industrial and commercial uses. Similar to other glycol ethers, it is used as a carrier/solvent in printing/writing inks and paints/coatings. It also finds use as an industrial and commercial paint stripper. It is used as an antifreeze in diesel engines.

Water-based two-pack polyurethane preservative coating and preparation method thereof

ActiveCN101701128AHigh glossGood chemical resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedDipropylene glycol monomethyl ether acetate

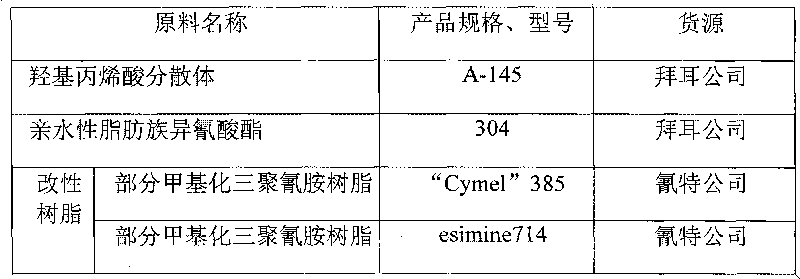

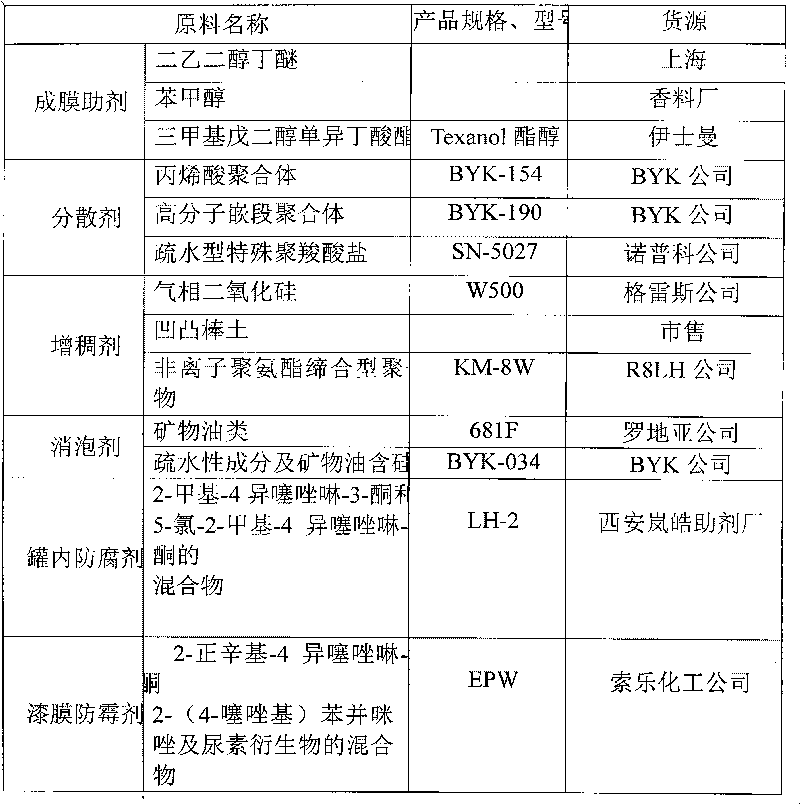

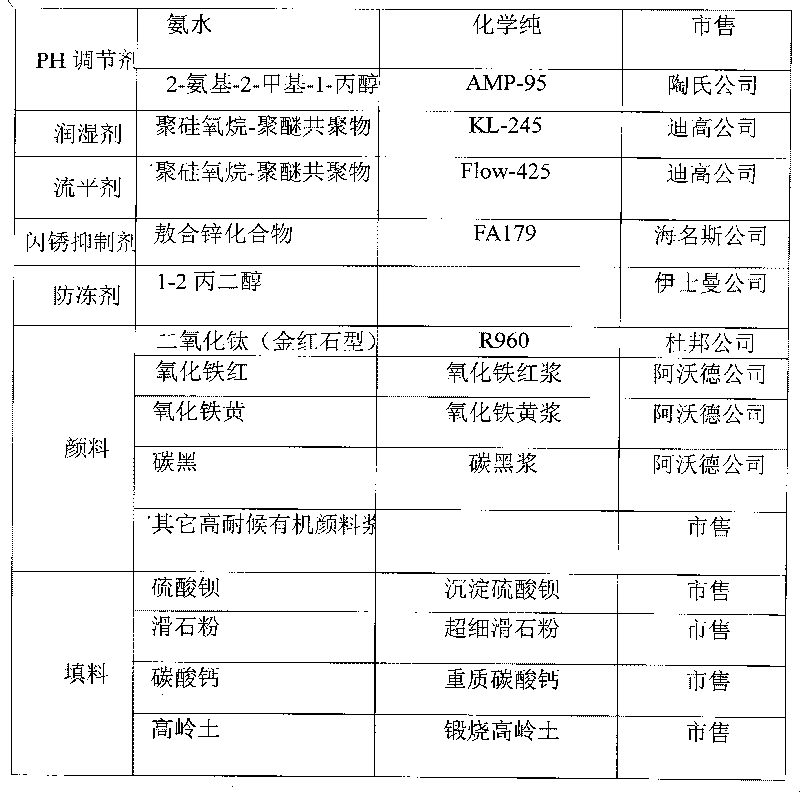

The invention relates to the preservative coating technology, in particular to a water-based two-pack polyurethane preservative coating and a preparation method thereof. The water-based two-pack polyurethane preservative coating comprises two parts, namely paint vehicle and curing agent, wherein the paint vehicle is prepared from water-based hydroxylated acrylic dispersion, modified resin, pigment, filler, additive and water, the curing agent part comprises hydrophilic aliphatic isocyanate, dodecyl ester and propylene glycol methyl ether acetate. When using the coating of the invention, the weight ratio of the paint vehicle to the curing agent is 74-85:15-26 and the coating can solve the defects of the existing preservative coating.

Owner:JIANGSU LANLING POLYMER MATERIAL CO LTD

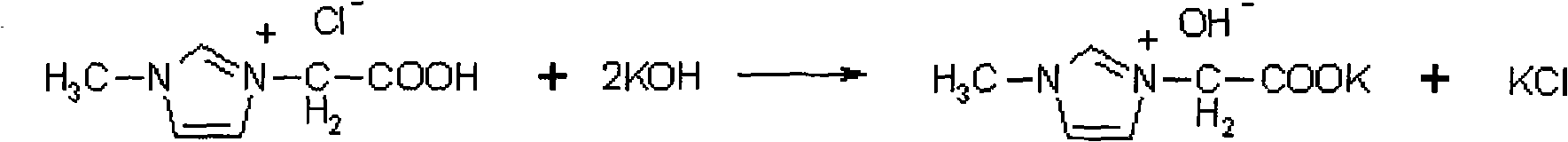

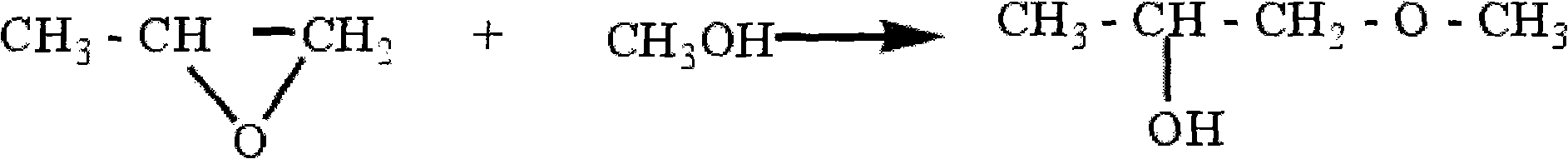

Method for synthesizing propylene glycol methyl ether

InactiveCN101550069ANo pollutionMild reaction conditionsOrganic-compounds/hydrides/coordination-complexes catalystsEther preparation from oxiranes1-PropanolReaction temperature

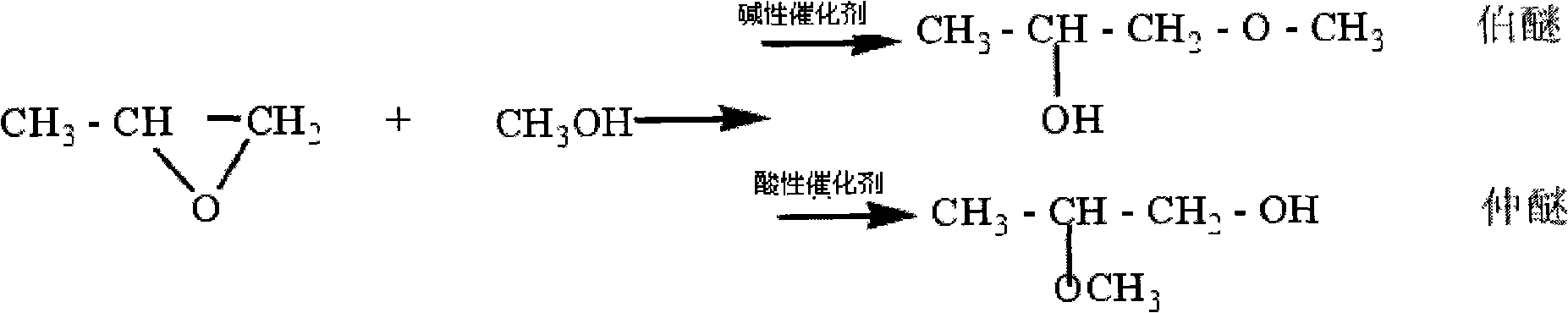

A method for synthesizing propylene glycol methyl ether relates to a method for synthesizing propylene glycol methyl ether. The method of the invention settles the problems of high reaction temperature, high pressure, low activity of catalyst and low selectivity existing in the prior method for preparing propylene glycol methyl ether. The method comprises the following steps: 1. preparing a compound A; 2. preparing a compound B; and 3. after naturally cooling the mixed solution B to a room temperature, atmospherically distilling and obtaining the propylene glycol methyl ether. The method of the invention has the advantages of simple process, applicable whole reaction in the condition of normal pressure and low-temperature, 93.3%-94.2% of epoxy propane conversion rate, 98.1%-99.1% of product selectivity, and no environment pollution as the whole reaction process is executed under the condition of no dissolvent. The propylene glycol methyl ether (1-methoxy-2-propanol or 2-methoxy-1-propanol) synthesized according to the invention can be synthesized by regulating the mixed liquid of acetate methyl glyoxaline hydroxide or acetate methyl glyoxaline chloride and ferric trichloride.

Owner:HARBIN NORMAL UNIVERSITY

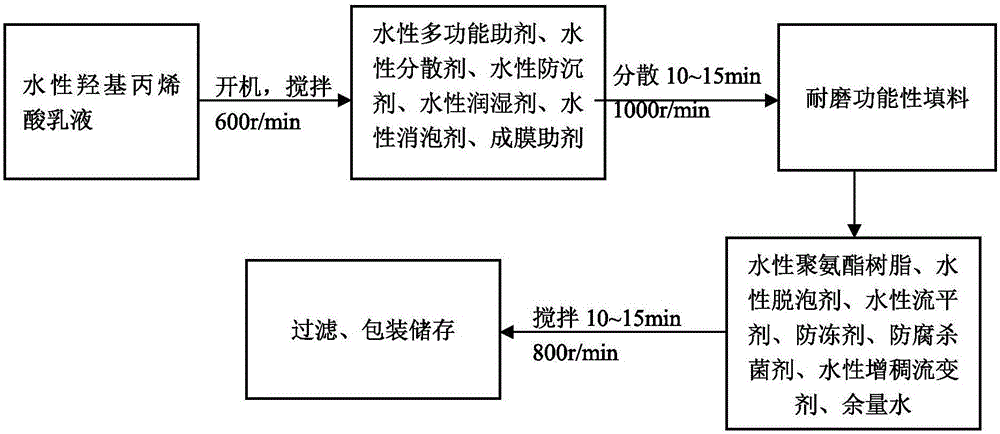

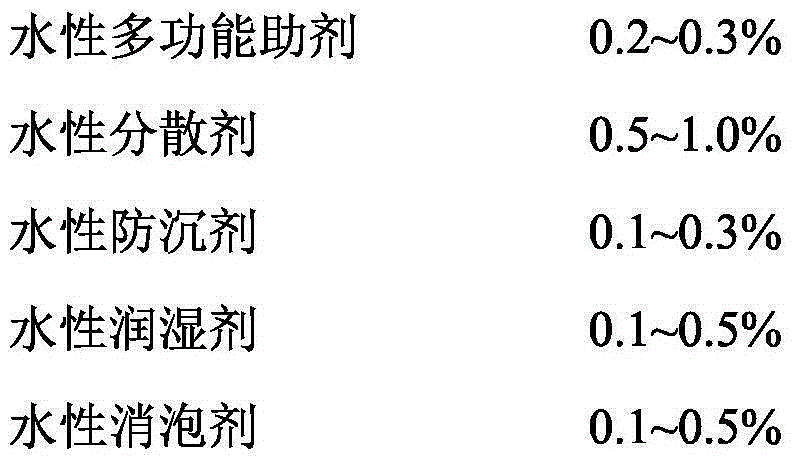

High-hardness water-borne double-component wood-ware varnish with high wear resistance and preparing method thereof

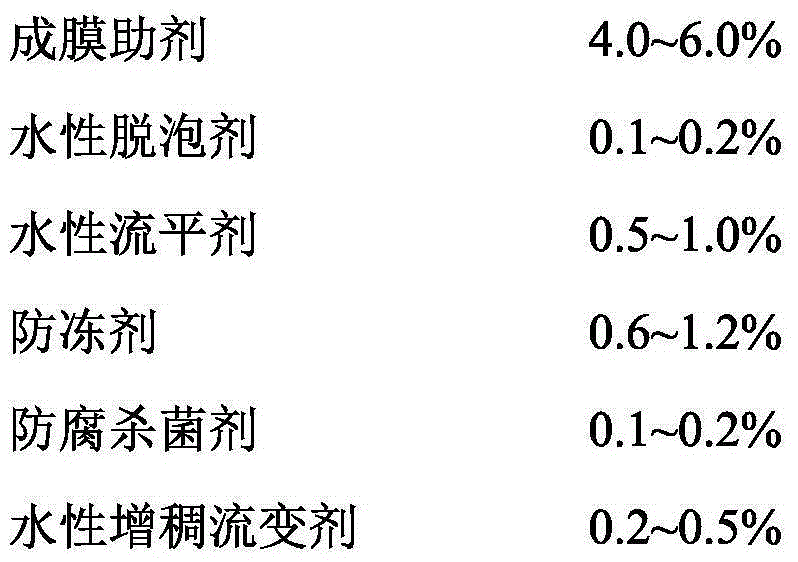

The invention provides high-hardness water-borne double-component wood-ware varnish with high wear resistance. The varnish is composed of main agent A and a curing agent B. The main agent A is composed of, by weight, 50-70% of water-borne hydroxyl acrylic emulsion, 10-30% of water-borne polyurethane resin, 4.0-8.0% of water-borne wear-resisting functionality filler, 6.5-11.7% of adjuvant and the balance water; the curing agent B is composed of, by weight, 80% of water dispersing modified polyisocyanate and 20% of propylene glycol monomethyl ether acetate. According to a coating method for the high-hardness water-borne double-component wood-ware varnish with the high wear resistance, the main agent A, the curing agent and the water are mixed according to the weight ratio of 100:20:20-30. The varnish has the advantages of being high in hardness and wear resistance, drying fast, resisting scratching, being good in water resistance and excellent in alcohol resistance, and resisting adhesion, and can be widely applied.

Owner:中山吕邦新材料科技有限公司

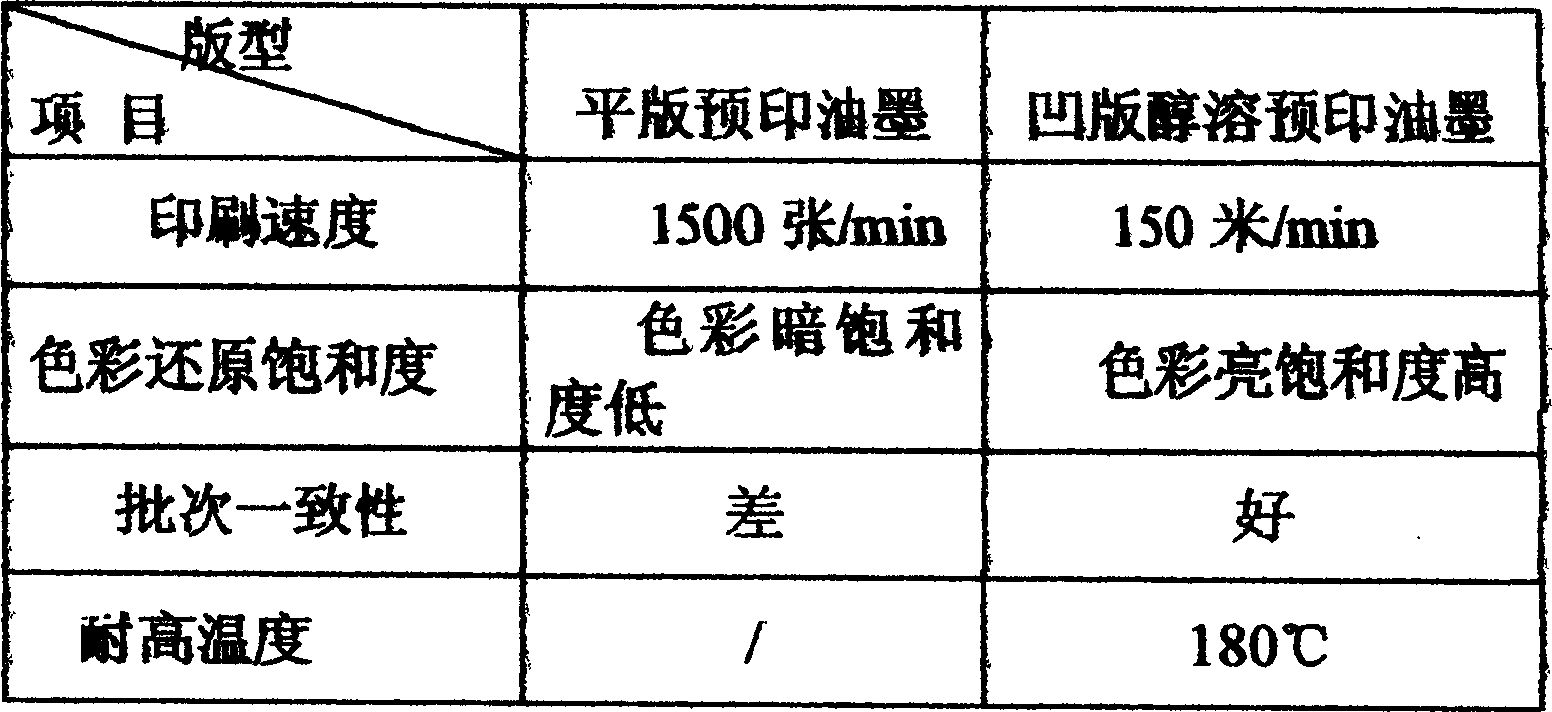

Alcohol soluble notch board paper box preprinting ink

An alcohol-soluble preprinting ink on gravure carton is composed of 6-10% nitrocellulose, methacrylate ester7-13%, propylene glycol methylether acetate 4-12%, dioctyl phthalate 2-6%, the dyestuff 15-25%, acetic ester 12-23%,absolute ethyl alcohol 32-43%. The ink has good glossiness, colour saturation degree and recurrence of halftone dot. It can defend the fake and resist to 180deg.C.

Owner:山西精华科工贸有限公司

Adhesive remover and preparation method thereof

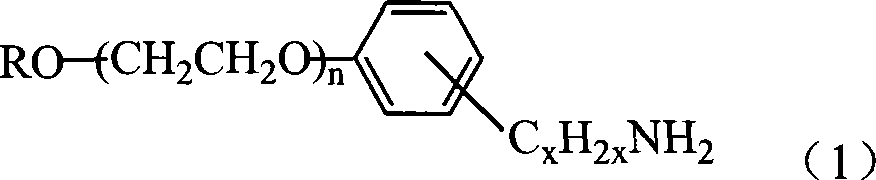

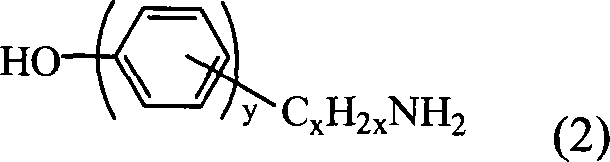

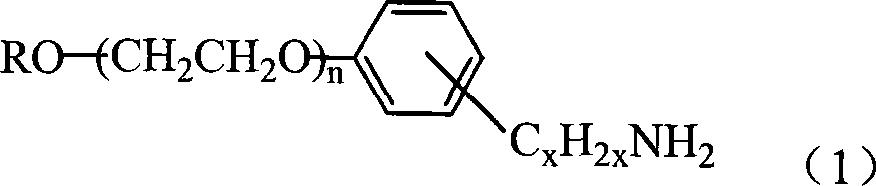

ActiveCN101899365ASmall smellEasy to removeOrganic detergent compounding agentsNon-ionic surface-active compoundsSilanesAlkylphenol

The invention relates to an adhesive remover and a preparation method thereof. The basic composition of the adhesive remover formula is as follows in percentage by weight: 12-25% of fatty alcohol-polyoxyethylene ether sodium sulfate and fatty alcohol-polyoxyethylene ether silane, 20-30% of alkylphenol polyoxyethylene ether, 4-5% of ethylene oxide / propane segmented copolymer, 5-7.9% of sodium chloride, 10-12% of triethyl phosphate and dimethyl adipate, 5-10% of tricarboxyl triethylamine, triethylamine, diethanol amine, EDTA, urea, triethanolamine and hexamethylene tetramine, 2-10% of ethylene glycol, butyl cellosolve, propylene glycol methyl ether, ethanol, isopropanol, benzyl alcohol and methyl isoamyl ketone and 0.1-42% of deionized water. Compared with the prior art, the invention has the advantages that the adhesive remover is aqueous and low irritating, is wide in application range, can rapidly remove various trade mark adhesives, eliminate adhesiveness, degrease, remove adhesive and deliquate adhering oil stain in the aspect of removing advertising posters on the surfaces of glass, ceramics, marbles, stainless steel, etc. The invention also provides an environment-friendly and safe method for preparing the adhesive remover.

Owner:NINGBO PASCO UNITED IND

Polyurethane matt varnish for benzene-free odor-less furniture

ActiveCN101684388AImprove mechanical propertiesGood gloss and color retentionPolyurea/polyurethane coatingsCyclohexanoneFoaming agent

The invention provides a polyurethane matt varnish for benzene-free odor-less furniture, which is composed of a main agent, a curing agent and a diluent. The main agent comprises 66.5-75.5% of hydroxyacrylic resin, 16.0-25.0% of solvent, 0.1-0.3% of defoarming agent, 0.05-0.1% of flatting agent, 0.1-0.5% of anti-settling agent, 0.1-0.5% of dispersing agent, and 4-8% of delustering agent; the curing agent comprises40.0-50.0% of toluene diisocyanate tripolymer, 20.0-30.0% of toluene diisocyanate-trimethylolpropane affixture, and 20.0-30.0% of butyl acetate; the diluent comprises 60.0-70.0% of butyl acetate, 15.0-20.0% of cyclohexanone, and 15.0-25.0% of propylene glycol methyl ether acetate. The product of the invention is favorable for construction, and no odor exists after the construction of the previous night.

Owner:上海展辰涂料有限公司 +1

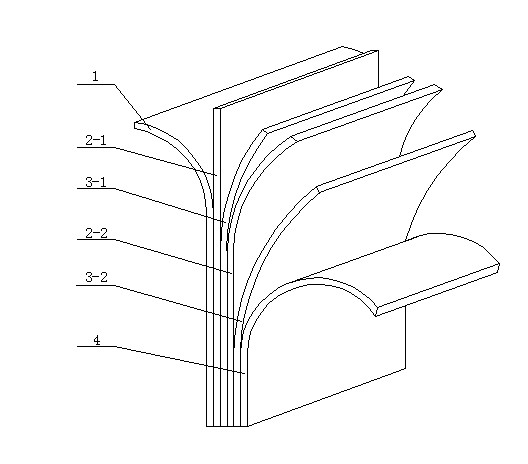

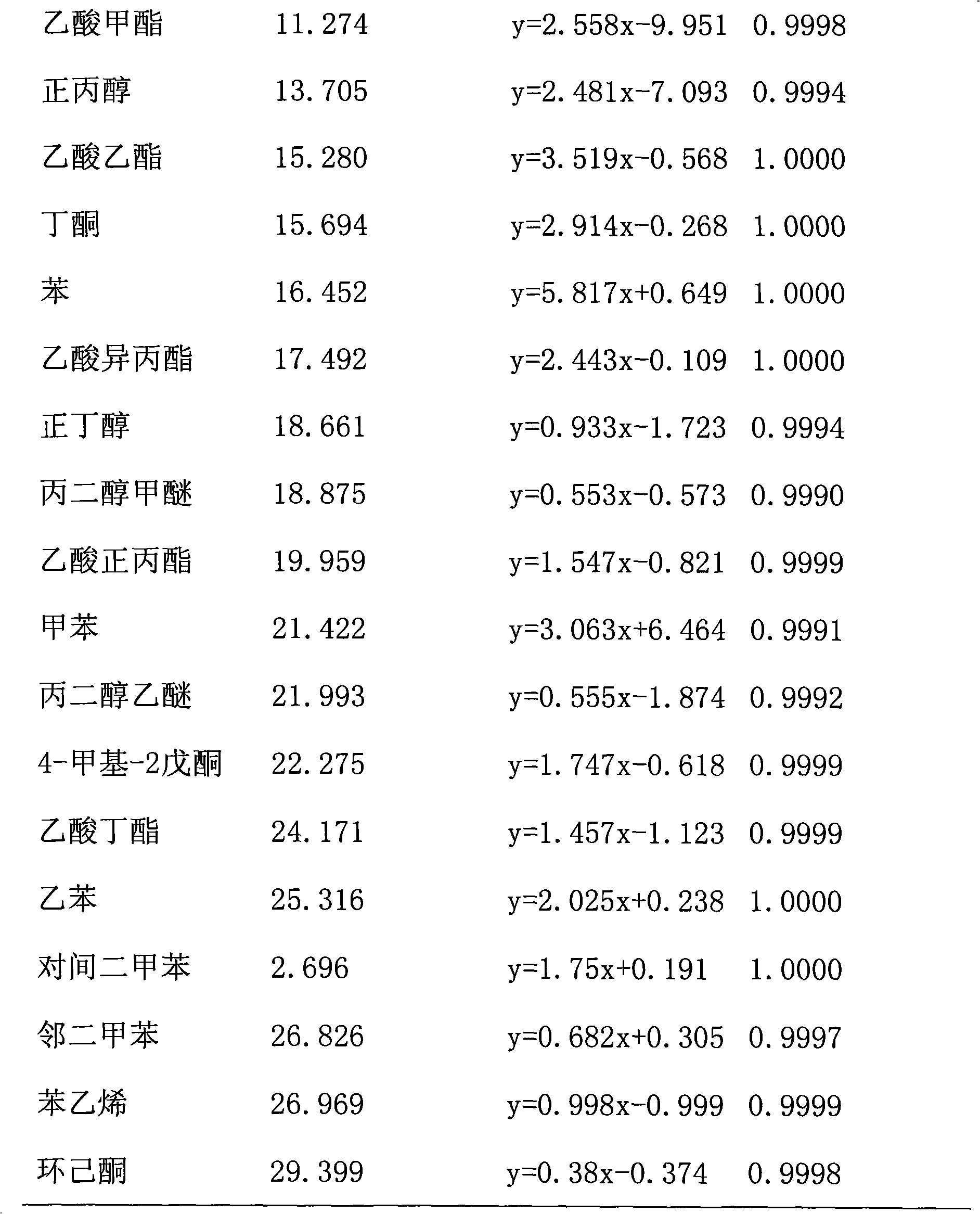

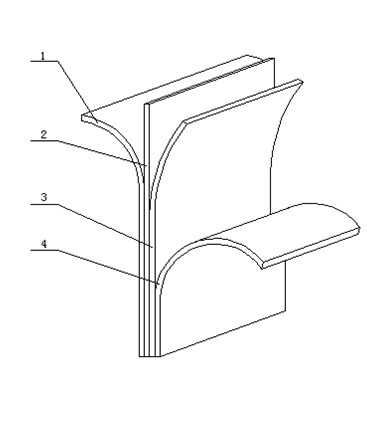

Anti-fogging agent composition and anti-fogging insulation window film formed thereby

InactiveCN102604460AGood anti-fog durabilityEasy to prepareFilm/foil adhesivesSynthetic resin layered productsPolyesterMonomethyl ether

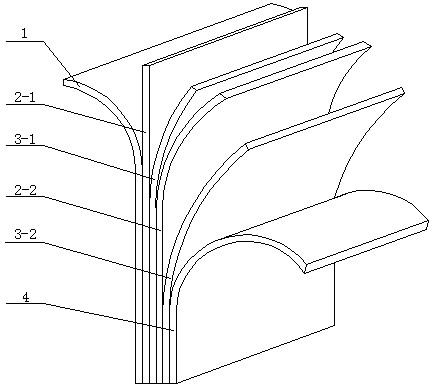

The invention relates to an anti-fogging agent composition and an anti-fogging insulation window film formed thereby, wherein the anti-fogging agent composition comprises 9 to 14 wt% of hydrophilic resin, 55 to 76 wt% of propylene glycol monomethyl ether, 3 to 10 wt% of dimethyl methylamine, 1 to 5 wt% of triethylene diamine, 1 to 5 wt% of leveling agent, 5 to 26wt% of isopropanol and 5 to 24wt% of ethanol; the anti-fogging insulation window film comprises a first transparent polyester film or transparent polyethylene film substrate (2-1), a heat insulation acrylic adhesive layer (3-1), a second transparent polyester film or transparent polyethylene film substrate (2-2), an acrylic adhesive layer (3-2) and a release film (4), which are composited as a whole, wherein the anti-fogging coating (1) is formed by the anti-fogging agent composition; and the heat insulation acrylic adhesive layer (3-1) contains a specific insulation material. According to the invention, the anti-fogging insulation window film is anti-fogging, insulating and safe.

Owner:西安航天三沃化学有限公司

Environment protective polyurethanes hammer paint

ActiveCN101353550AGood solvent resistanceGood acid and alkali resistancePolyurea/polyurethane coatingsOleoresinDimethyl siloxane

The invention discloses an environmental-protection polyurethane hammer paint which is applied to wood surface decoration and protection and consists of a component A, a component B and a component C; when in use, the component A, the component B and the component C can be evenly mixed by the weight ratio that component A: component B: component C is equal to 1: 0.4 to 0.6: 0.5 to 0.6; wherein, the component A consists of: short oil alkyd resin, 40 to 60 parts; long oleoresin, 2 to 5 parts; dispersing agent, 0.2 to 0.5 part; anti-sedimentation agent, 0.4 to 0.9 part; propylene glycol ether acetate 3 to 6 part; divalent ester 1 to 3 parts; pigment, 0 to 30 parts; defoamers, 0.2 to 0.5 part; leveling agent, 0.2 to 0.7 part; non-floating-type aluminum paste, 1 to 5 parts; n-butyl acetate 5 to 15 parts, polydimethylsiloxane, 0.1 to 0.5 part; the component B consists of the following materials by weight ratio: HDI trimer poly isocyanate: HDI-TDI trimer: n-butyl acetate is equal to 2 to 4: 3 to 5: 1 to 4; the component C consists of the following materials by weight ratio: n-butyl acetate: propylene glycol methyl ether acetate is equal to 7 to 9: 1 to 3. The invention has the advantagesof: 1. good paint film solvent resistance and acid and alkaline resistance, bright color, clear texture, and good hammer effective; 2. high paint film hardness and wide application range, not only being applicable to wood surface, but also being applicable to metal surface decoration and protection; and 3. triphenyl-free, low VOC, and high solid content, and meeting the requirements on environmental protection.

Owner:GUANGDONG SANVO CHEM IND TECH

Water-soluble single component aliphatic polyurethane floor coatings and manufacturing method thereof

InactiveCN101362922AGood anti-sinking effectSolve the problem of difficult film formationPolyurea/polyurethane coatingsEmulsion paintsPolymer scienceUltra fine

The invention provides a waterborne single-component aliphatic polyurethane floor coating, relating to the technical field of polyurethane coating. The waterborne single-component aliphatic polyurethane floor coating consists of waterborne single-component aliphatic polyurethane latex, deionized water, waterborne dispersant, polyether modified siloxane defoamer, no-dissolve polyurethane associative thickener, filling material, pigment, waterborne antiseptic, cosolvent compounded by propylene glycol methyl ether and N-methyl pyrrolidone according to the proportion of 1:1, pH regulator and ultra-fine SiO2 extinction powder compatibility, is a floor coating type of high performance, high performance / price ratio and friendly environment, has more excellent wearability and weathering resistance performance correspondingly to coatings such as epoxy, and the like, and can achieve and exceed the mechanical performance and chemical medium resistance of the products such as epoxy, etc.

Owner:无锡市南雅化工有限公司

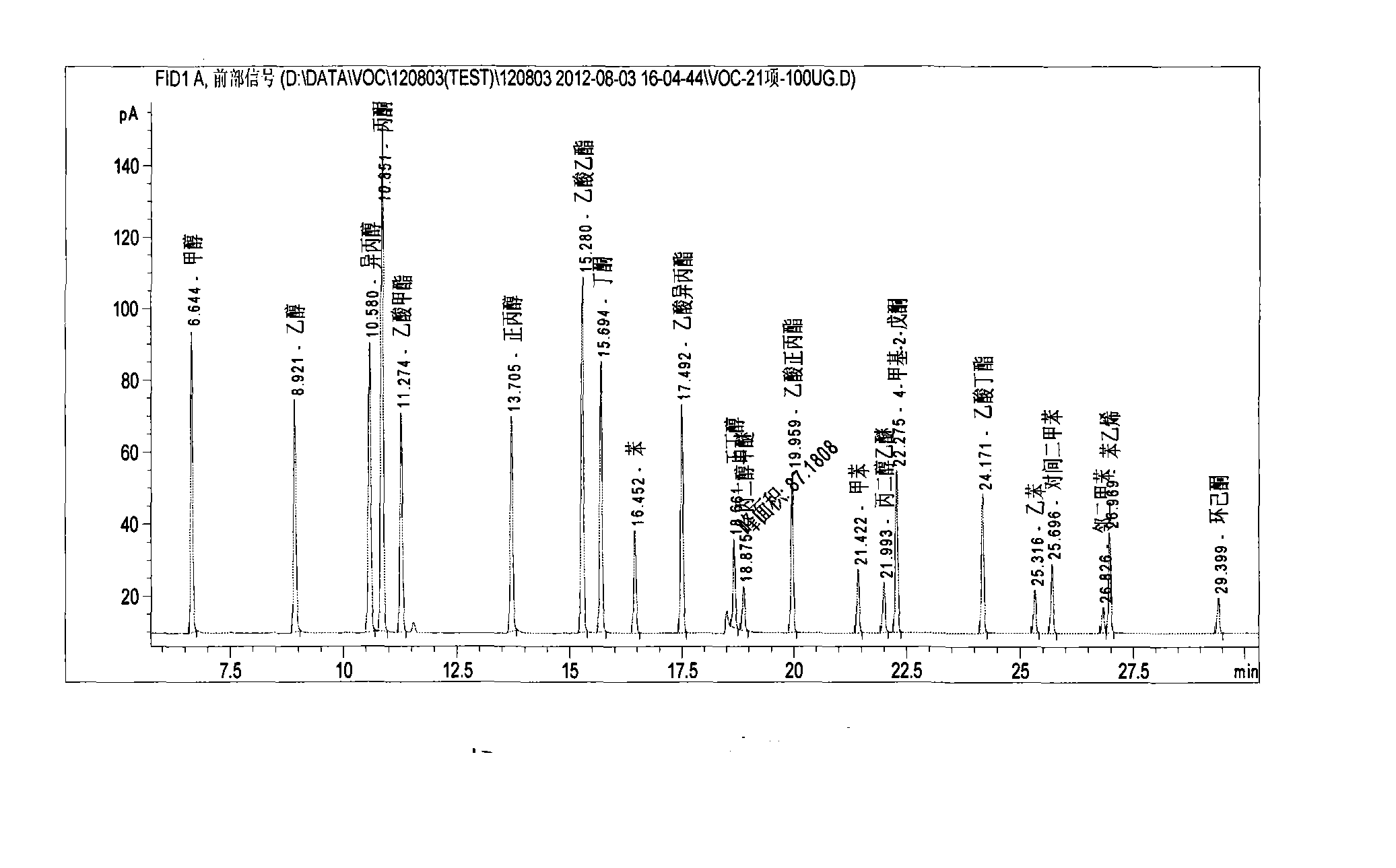

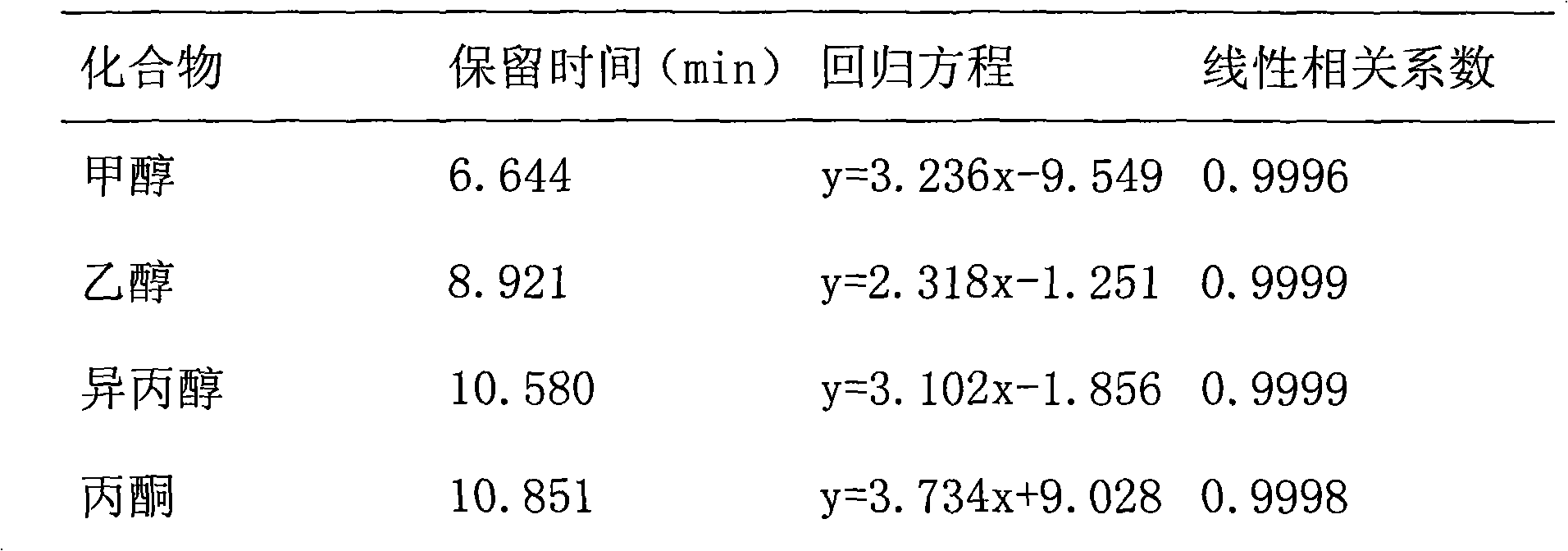

Method for detecting 21 volatile organic compounds (VOC) in tobacco packing box

The invention belongs to the technical field of tobacco packing box, and in particular relates to a method for detecting contents of 21 volatile organic compounds (VOC), including benzene, methyl benzene, p-xylene, m-xylene, o-xylene, styrene, methanol, ethanol, acetone, isopropyl alcohol, methyl acetate, normal propyl alcohol, ethyl acetate, butanone, acetic acid isopropyl ester, n-butyl alcohol, propylene glycol monomethyl ether, n-propyl acetate, propylene glycol monoethyl ether, 4-methyl-2-pentanone, butyl acetate, cyclohexanone in a tobacco packing box. The method for detecting 21 volatile organic compounds in the tobacco packing box disclosed by the invention comprises the following steps of: sample pretreatment: preparing a piece of hard box packing paper; cutting and reserving a main packing surface by an area of 22.0cm*5.5cm; rolling the printing surface of the sample inwards to obtain a barrel-shaped part; putting the barrel-shaped part in a headspace bottle; adding 1000mu l of glycerol triacetate; sealing, and implementing a headspace-gas chromatography detection. The method disclosed by the invention is high in sensitivity, high in recovery rate, and excellent in precision of detecting result.

Owner:GUANGZHOU PONY TESTING TECH

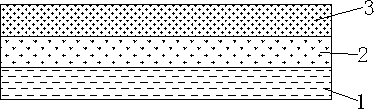

Antifogging agent composition and antifogging colored window film formed by same

ActiveCN102618102AEasy to prepareReduce manufacturing costOther chemical processesSynthetic resin layered productsPolyesterDiamine

The invention relates to an antifogging agent composition and an antifogging colored window film formed by the same. The antifogging agent composition comprises 9-14wt% of hydrophilic resin, 55-76wt% of propylene glycol methyl ether, 3-10wt% of dimethyl methylamine, 1-5wt% of triethylene-diamine, 1-5wt% of leveling agent, 5-26wt% of isopropanol and 5-24wt% of ethanol. The antifogging colored window film comprises an antifogging agent coating layer (1), a first transparent polyester film or transparent polyethylene film substrate (2-1), a dyed acrylic acid adhesive layer (3-1), a second transparent polyester film or transparent polyethylene film substrate (2-2), an acrylic acid adhesive layer (3-2) and a releasing film (4) which are integrally composited, wherein the antifogging agent coating layer (1) is formed by the antifogging agent composition. The antifogging colored window film is antifogging, attractive, transparent and safe.

Owner:CHANGZHOU SANYOU DISSAN PROTECTIVE MATERIAL MFG

Polyurethane matte white finish coat for non-benzene and odor-free furniture

ActiveCN102061123AFacilitated releaseReduce harmPolyurea/polyurethane coatingsCyclohexanoneAromatic solvent

The invention relates to polyurethane matte white finish coat for non-benzene and odor-free furniture, which consists of a main agent, a curing agent and a diluent, wherein the main agent comprises hydroxyl acrylic resin, titanium white, solvent, a defoaming agent, a flatting agent, an anti-settling agent, a dispersing agent and a flatting agent; the curing agent comprises a toluene diisocynate tripolymer, toluene diisocynate-trimethylolpropane addition product and butyl acetate; and the diluent comprises the butyl acetate, cyclohexanone and propylene glycol monomethyl acetate. By adopting the technical scheme, the polyurethane matte white finish coat has the advantages that: an obtained paint film has less residual solvent and is tasteless after 12 hours; a formula does not contain chemical substances harmful to body health of human beings, such as benzene, methylbenzene, dimethylbenzene, other aromatic solvents and derivatives, methanol, glycol ether ester solvents, halogenated hydrocarbon and the like, and the excellent decorative and protective effects of the conventional polyurethane (PU) dual-component furniture paint are reserved in the formula; and the polyurethane matte white finish coat is easy to construct and is applicable to various construction modes such as spraying, electrostatic spraying and brush coating.

Owner:上海展辰涂料有限公司

Gravure transparent ink and preparation method thereof

The invention discloses a gravure ink and a preparation method thereof. The ink consists of the following substances of modified polyurethane, a vinyl chloride acetic acid copolymer resin, a modified chlorinatedpolypropylene resin, a dye, an erucidic acid amide wax, an antifoaming agent, an adhesion promoter, propylene glycol methyl ether, acetic ether, ethanol and dimethyl carbinol. The preparation method of the invention includes the following sequential working procedures: a) the dye diluting; b) the resin diluting; c) the blending. Compared with the present technology, the invention is low in solvent residue, and printing products have no version fogs of knife wires with very good adhesion fastness on BOPP and PET and are especially suitable for package printing of PET aluminium-plated products. Metallic lustre of composite packaged products is fully shown, and the visual effect is very good and the adhesion fastness of the ink is equal to or more than 98 percent. The composite sealing strength is 45N per 15mm.

Owner:HUANGSHAN SHINING INK TECH

Self-emulsifying aqueous epoxide resin paint and method for producing the same

InactiveCN101220237AImprove hydrophilicityImprove brittlenessEmulsion paintsEpoxy resin coatingsAlkaneEpoxy

The invention relates to a self-emulsifiable water epoxide resin coating mainly consisting of water epoxide resin and a water curing agent; wherein, the water epoxide resin is the product obtained by the reaction of epoxide resin with Alpha-amino-Omega-alkyl polyether, or can be obtained by taking the product as epoxide resin emulsifier to carry out emulsification on the low molecular weight epoxide resin by adding water. The preparation method of the coating is as follows: preparing end alkoxy polyether at a chlorine end capping which is then put into well mixed mixture of hydroxyphenyl aliphatic amine, sodium hydroxide and tetrabutylammonium bromide; stirring, extracting, filtering and distilling the mixture to remove the solvent, thus getting the end alkane oxyl polyether; taking propylene glycol methyl ether as solvent, evenly mixing the epoxide resin and the end alkane oxyl polyether, and removing the solvent by being distilled after being stirred. The self-emulsifiable water epoxide resin coating has good storage stability, no toxity, and high packing ratio of filler, can be solidified under indoor temperature, has high adhesive force, high flexibility, good water resisting property and solvent resisting property.

Owner:WUHAN UNIV OF TECH

Composite multi-functional two-component aqueous wood white top coat and preparation method thereof

ActiveCN106243966AExcellent antibacterial and aldehyde removal functionReasonable materialsAntifouling/underwater paintsPaints with biocidesCross-linkSlurry

The invention discloses a composite multi-functional two-component aqueous wood white top coat, which comprises a component A, a component B and water according to a mass part ratio of 100:20-25:10-20, wherein the component A is prepared from the following raw materials by mass: an aqueous hydroxy acrylic acid resin, a compound modified self-cross-linking acrylic acid polymer, an aqueous titanium white slurry, an aqueous matting agent, a defoamer, a wetting agent, a thickening agent, a dispersant, a leveling agent, an anti-mildew bactericidal agent, and the balance of water, and the component B is prepared from the following raw materials by mass: hydrophilic aliphatic polyisocyanate and propylene glycol methyl ether acetic acid ester. The composite multi-functional two-component aqueous wood white top coat of the present invention has advantages of good antibacterial effect, good aldehyde removing effect, good stain resistance, environmental protection, good hardness, high fullness, and moderate cost.

Owner:广东伊思曼新材料科技有限公司

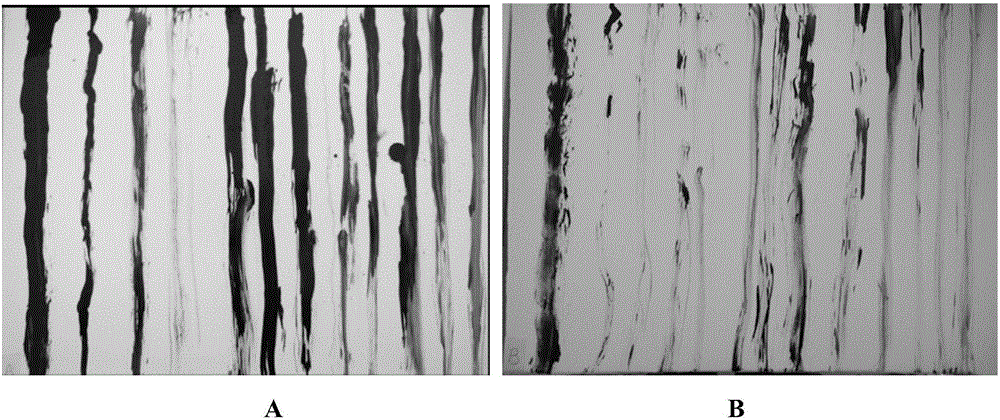

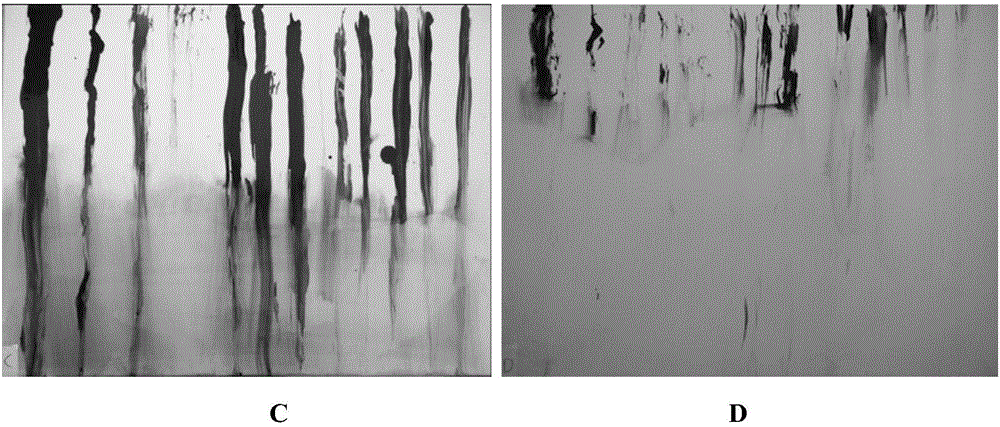

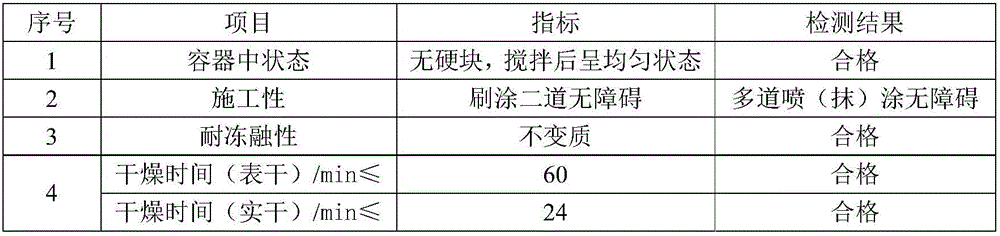

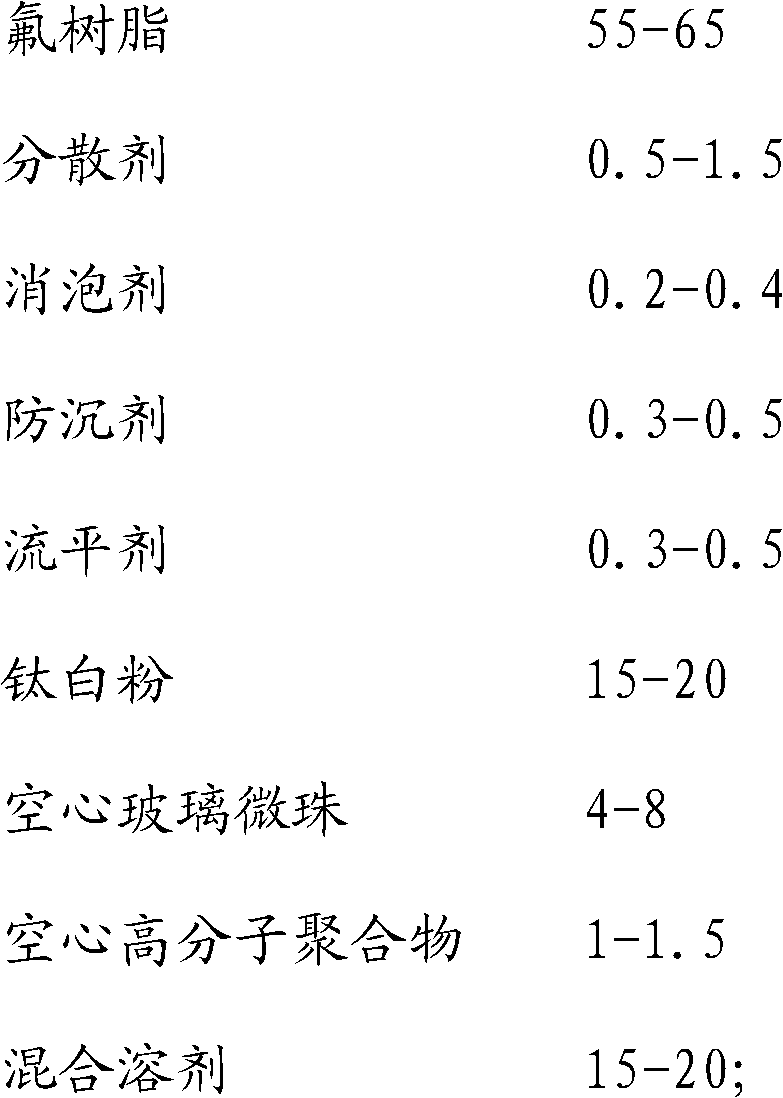

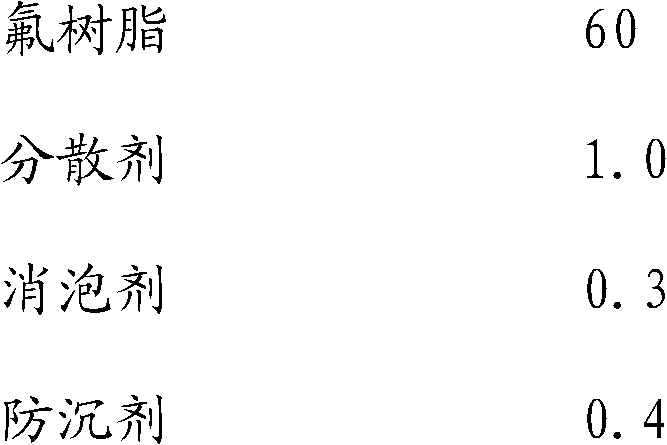

Elastic heat-insulation fluorocarbon coating and preparation method and use method thereof

InactiveCN102492338AGood weather resistanceGood gloss and color retentionReflecting/signal paintsButyl acetateTitanium

An elastic heat-insulation fluorocarbon coating consists of a host and curing agent. The host is prepared by the following components, by weight, 55 to 65 parts of fluororesin, 0.5 to 1.5 parts of dispersant, 0.2 to 0.4 part of defoamer, 0.3 to 0.5 part of anti-settling agent, 0.3 to 0.5 part of flatting agent, 15 to 20 parts of titanium white, 4 to 8 parts of hollow glass microballs, 1 to 1.5 parts of hollow macromolecular polymer and 15 to 20 parts of mixed solvent. The curing agent is manufactured by the following components, by weight, 90 parts of E405 to 80T, 5 parts of butyl acetate and 5 parts of propylene glycol methyl ether acetate. The weight proportion of the host and the curing agent can be calculated according to the hydroxyl value of the fluororesin and the NCO (isocyanate) content of the curing agent, namely OH / NCO=1:(1.05 to 1.15). The elastic heat-insulation fluorocarbon coating has the advantages of excellent weatherability, stain resistance, washability, decoration performance, excellent normal-temperature and low-temperature elasticity, capability of resisting to fine fissures, improved heat insulation effect and benefits to transport and settlement.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

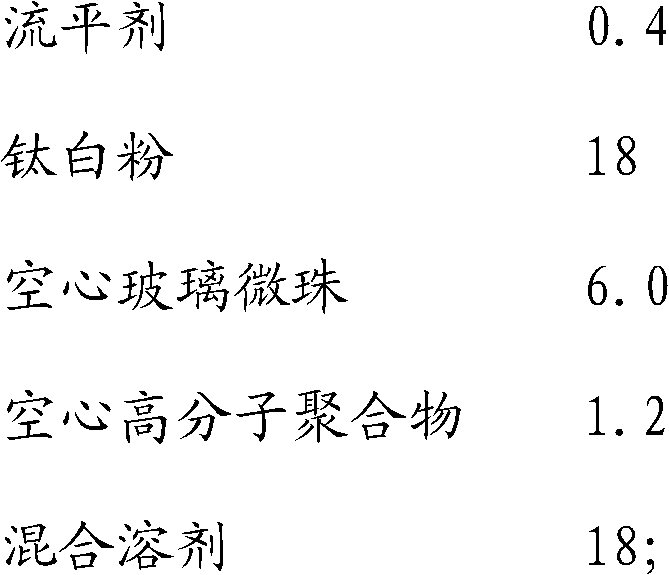

Method for producing propylene glycol methyl ether acetate

ActiveCN101693661AImprove reaction efficiencyPositive responseOrganic compound preparationCarboxylic acid esters preparationAcetic acidGas phase

The invention relates to a method for producing propylene glycol methyl ether acetate. The method is characterized in that a reactive kettle made of an acid-resisting material is applied to a reactive fractionating tower and the front passage of a material kettle on the lower part of the reactive fractionating tower; under the existence of a catalyst, when the number of moles of propylene glycol methyl ether is excessive compared with that of the acetic acid, the esterification is carried out concentratively in the reactive kettle; the obtained product and the unreacted material are evaporated and pass an acid catcher so that the acidic catalyst with a high boiling point is collected in liquid phase; the material of gas phase enters the reactive fractionating tower through a material inlet; an entrainer is added at the upper part of the reactive fractionating towel so as to remove the water in the material by azeotropy; under the action of the layered solid acid catalyst, the residual acetic acid in the material continues to react at the reaction section of the lower part of the material inlet of the reactive fractionating towel so that the material finally dropped in the material kettle of the reactive fractionating towel has no acidic compositions, thus avoiding the corrosion on the equipment in the subsequent separating and refining process; and the obtained product has low acidity and completely meets the requirement of the product standard.

Owner:JIANGSU BAICHUAN GAOKE NEW MATERIAL CO LTD +1

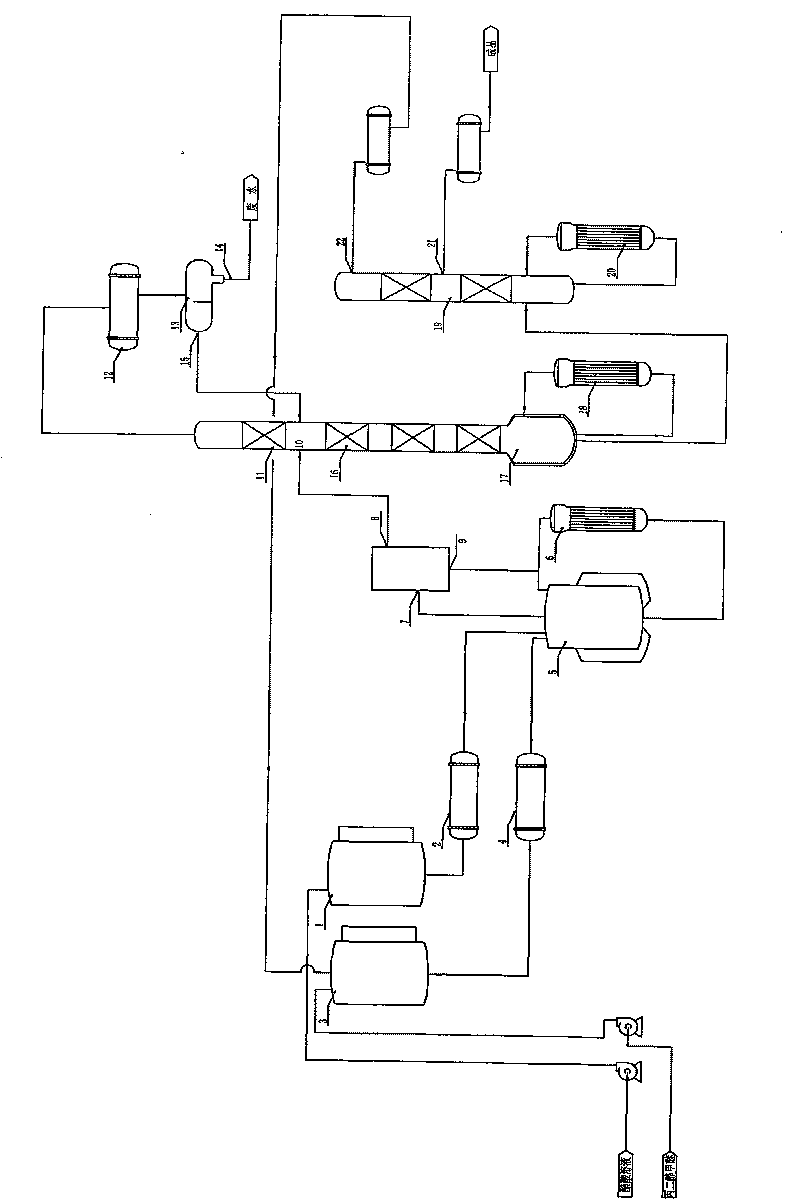

Method for preparing 1-Methoxy-2-propyl acetate by continuous esterification reaction

ActiveCN101337885ARealize industrial productionEmission reductionOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAcetic acidFixed bed

The invention discloses a process for preparing propylene glycol methyl ether acetate by continuous esterification reaction, which adopts propylene glycol methyl ether and acetic acid as the raw materials. The process is characterized in that a solid acid catalyst is adopted to carry out two-section fixed bed continuous esterification reaction at the esterification temperature of 70 to 150 DEG C; water generated in the sterification reaction is removed by azeotropic distillation; and the result of the esterification reaction is rectified to remove and recover unreacted propylene glycol methyl ether and acetic acid to obtain propylene glycol methyl ether acetate. The method can achieve continuous production of propylene glycol methyl ether acetate, and has the advantages of simple operation manner, greatly improved production efficiency of propylene glycol methyl ether acetate, lowered production cost, reduced emission of solid contaminants and wastewater, and excellent large-scale industrial application value.

Owner:江苏德纳化学股份有限公司

Halogen-free low temperature solidified silver paste and preparation method thereof

InactiveCN101950596AReduce pollutionSuitable process conditionsNon-conductive material with dispersed conductive materialCable/conductor manufactureLow temperature curingEthylene glycol monoethyl ether acetate

The invention provides a halogen-free low temperature solidified silver paste, which comprises the following raw materials in percentage by mass: 40 to 50 percent of conductive powder, 37 to 46 percent of solvents, 8 to 20 percent of high polymer resin and 1 to 3 percent of additives, wherein the conductive powder is a mixture of flake silver powder and silver coated nickel powder; the solvent is one or more of DBE, diethylene glycol monoethyl ether acetate, propylene glycol methyl ether acetate and ethylene glycol monoethyl ether acetate; the high polymer resin is one or more of polyester resins and polyurethane resins; and the additives comprise one or more of coupling agents, thickening agents and leveling agents. In the halogen-free low temperature solidified silver paste of the invention, the conductive powder is successfully used for replacing silver powder, which not only can reduce the cost, but also satisfies European safety standards, and reduces environment pollution.

Owner:IRICO

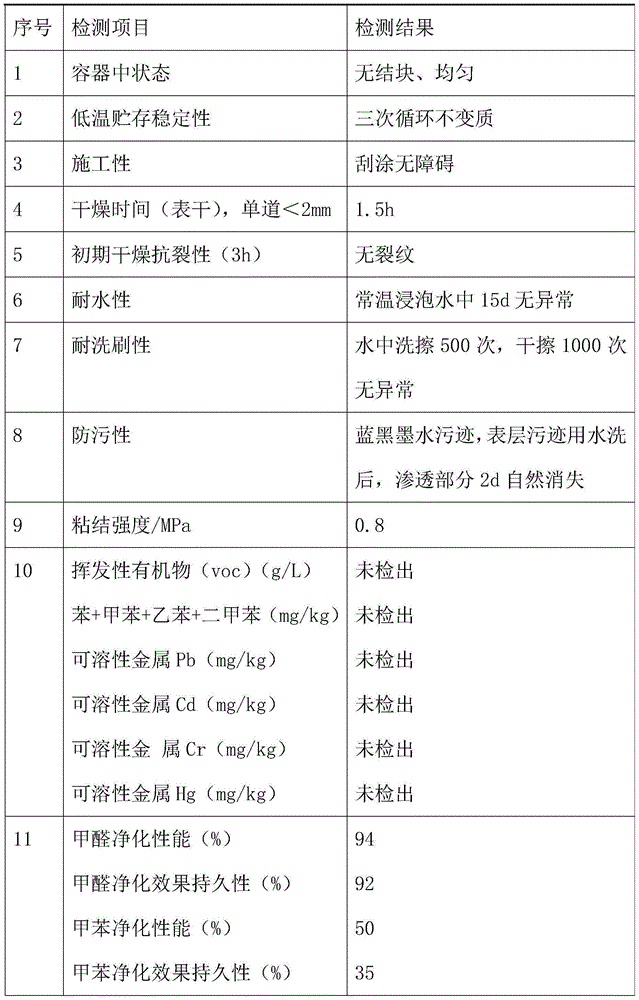

Multifunctional inner wall paint

InactiveCN105131774AGood scrub resistanceImprove rheologyCoatingsAcrylic resinHydroxyethyl cellulose

The invention discloses a multifunctional inner wall paint. The multifunctional inner wall paint comprises raw materials: modified acrylic resin emulsion, pure acrylic emulsion, light calcium carbonate, diatomite, lithopone, ultrafine talcum powder, water absorption composite materials, negative ion-anti-microbial additives, hydroxyethyl cellulose, a dispersant SN-5040, a wetting agent AP-680, 2,2,4-Trimethyl-1,3-pentanediol monoisobutyrate, propylene glycol monomethyl ether, an antifoaming agent TSP-01, sodium hexametaphosphate, a leveling agent L-150, a stain-resistant agent JZM-1, glycol, a multifunctional auxiliary agent AMP-95, mildew inhibitors and deionized water. The multifunctional inner wall paint has good scrubbing resistance, rheological property and brushing performance, can absorb harmful components in air indoors, adsorbs moisture, releases moisture, refreshes air, releases negative ions and is environmentally friendly and is helpful for health.

Owner:TIANCHANG YINHU PAINT

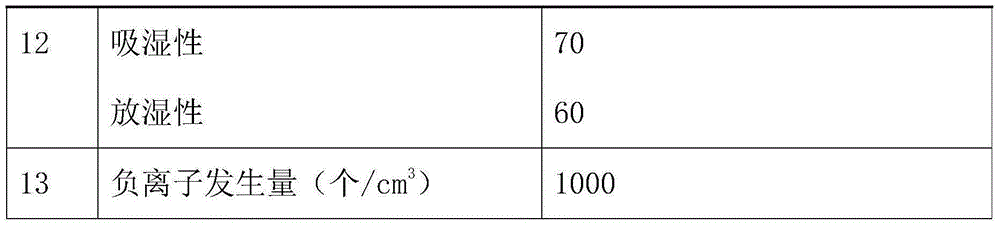

Salt-storage sustained-release snow-melt deicer and preparation method thereof

ActiveCN108949109AAvoid contactGood ice melting effectOther chemical processesRelease timeSnow melting

The invention provides a salt-storage sustained-release snow-melt deicer and a preparation method thereof. The method comprises the following steps: firstly, respectively preparing an anticoagulationchloride saturated solution and a nano-silicon dioxide modified diatomite suspension; then, adding the anticoagulation chloride saturated solution into the nano-silicon dioxide modified diatomite suspension, stirring, filtering in vacuum, drying and grinding to obtain sustained-release inorganic salt; preparing a polymer monomer solution, sequentially adding the sustained-release inorganic salt, isopropyl alcohol or propylene glycol monomethyl ether solution into a flask, putting the flask in an oil bath, and uniformly stirring, adding the polymer monomer solution and a mixed solution of KH570and gAIBN, keeping on stirring, reducing the temperature, adding triethylamine into the flask, stirring, and adding water to obtain the salt-storage sustained-release snow-melt deicer. According to the salt-storage sustained-release snow-melt deicer, snow-melt substances are not limited by temperature-control molecules, and have long release time and relatively high ice melting capacity.

Owner:CHONGQING JIAOTONG UNIVERSITY +1

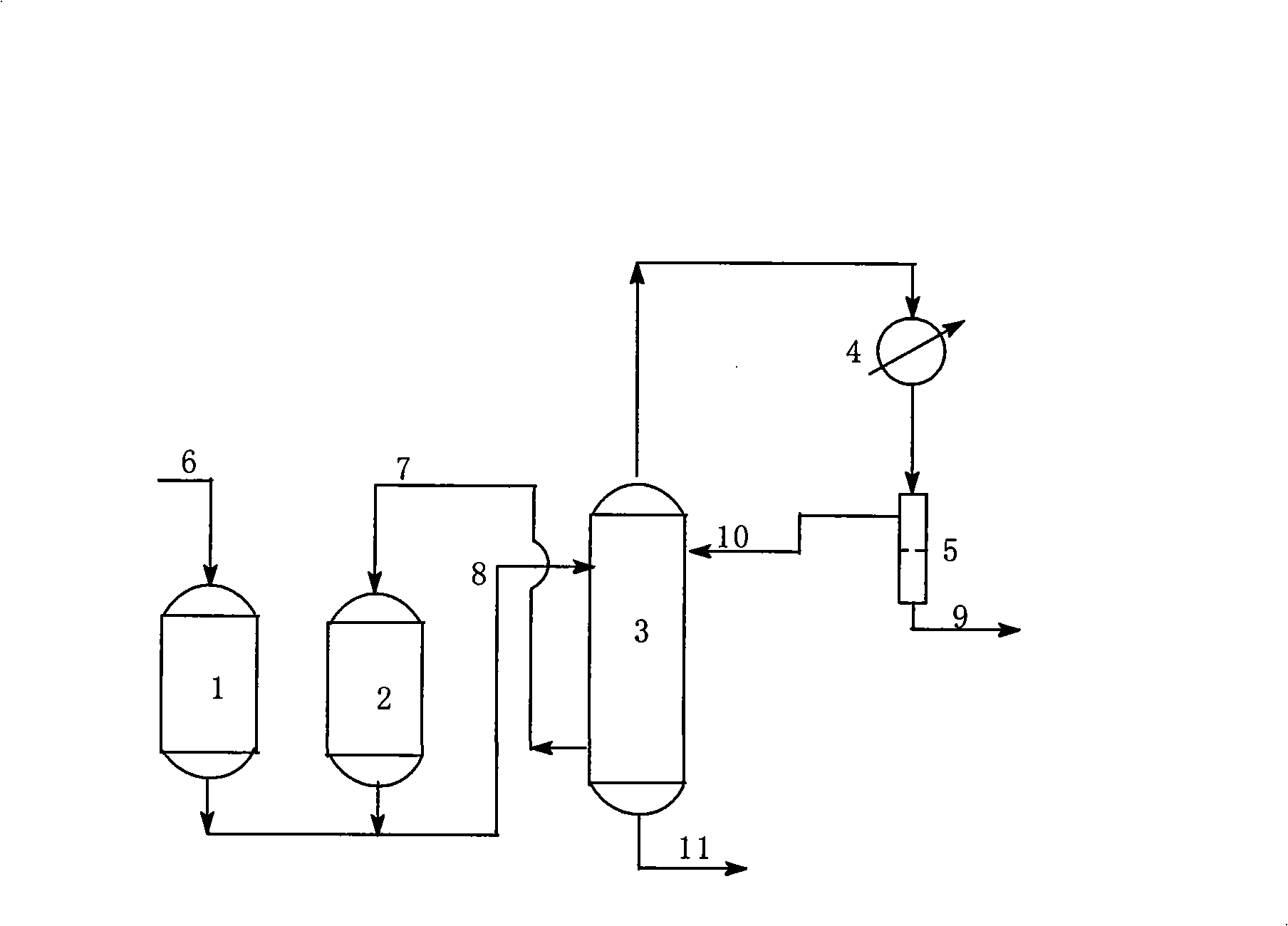

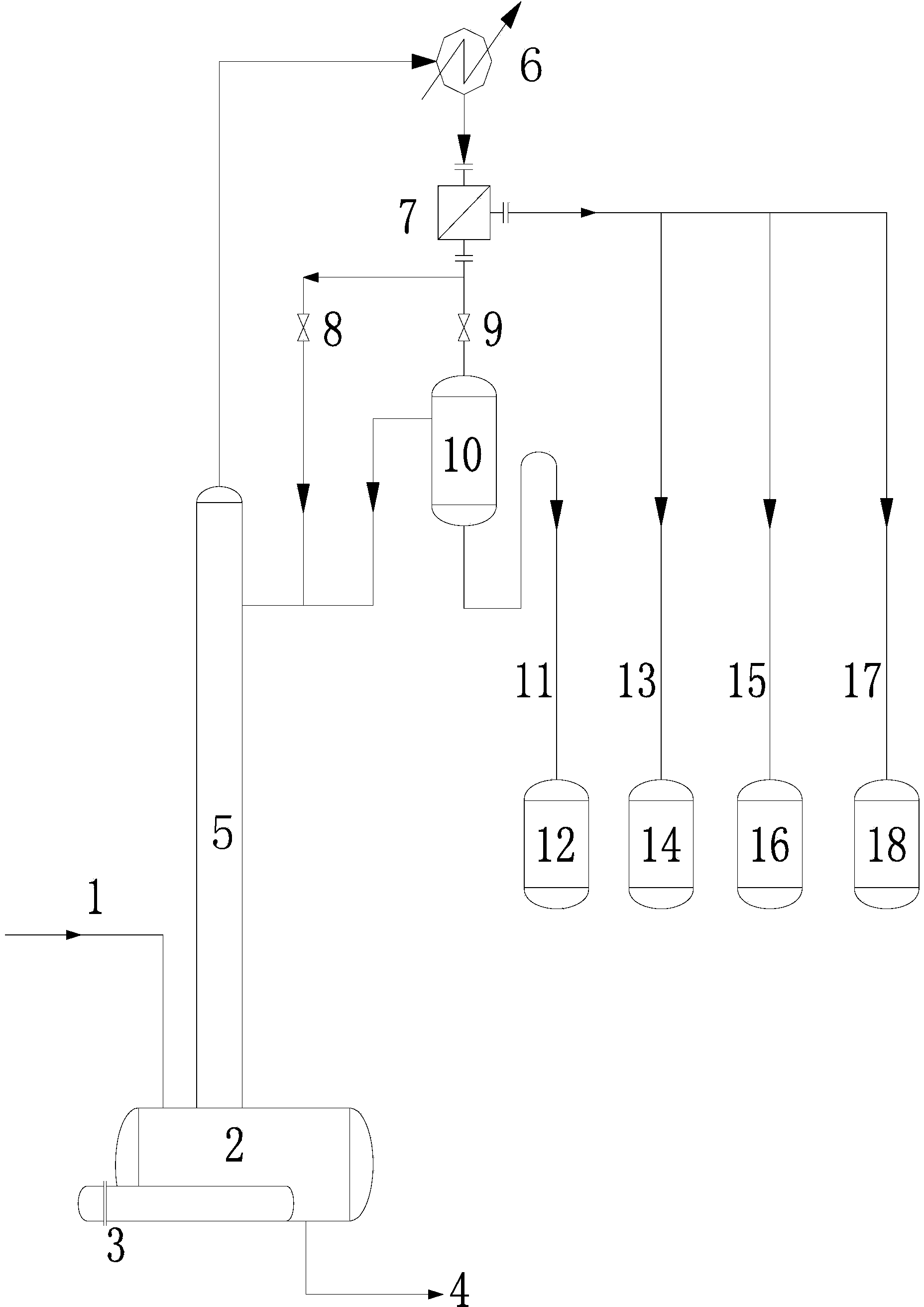

Azeotropic rectification device and method for separating propylene glycol monomethyl ether and water

ActiveCN103449981AEfficient recyclingReduce dosageEther separation/purificationAzeotropic distillationRefluxMonomethyl ether

The invention discloses an azeotropic rectification device and method for separating propylene glycol monomethyl ether and water. The azeotropic rectification device and method are characterized in that cyclohexane is adopted as an entrainer; waste liquor containing propylene glycol monomethyl ether, water and cyclohexane is added to a rectification kettle once; a rectification column is directly connected with the rectification kettle; a kettle-type reboiler is arranged on the rectification kettle; the waste liquor is heated into steam through the kettle-type reboiler and then enters the rectification column; the material at the top of the column is condensed and then transferred into the a reflux ratio controller; if the material at the top of the column is an azeotrope of cyclohexane and water, the material is fed into a phase splitting tank for phase splitting, a water phase is extracted, and cyclohexane reflows; if the material at the top of the column is cyclohexane, recovered cyclohexane is obtained; if the material at the top of the column is a transition fraction of cyclohexane and propylene glycol monomethyl ether, the material is extracted into a transition fraction storage tank; if the material at the top of the column is propylene glycol monomethyl ether, a propylene glycol monomethyl ether product can be obtained; once materials in the kettle of the column are basically the heavy components of the waste liquor, the extracting at the top of the column is stopped, and the residual materials in the kettle are discharged from the bottom part of the rectification kettle. The device and method for separating propylene glycol monomethyl ether and water are efficient and environment-friendly.

Owner:WUXI ZHONGTIAN SOLID WASTE DISPOSAL CO LTD

Preparation method of fluorin modified crylic acid resin for helicopter skining paint

the invention discloses a fluorine modified acrylic resin and preparing method for helicopter covering paint, which comprises the following steps: blending composite monomer methacrylic acid borneol ester, n-butyl methacrylate, hydroxyethyl methacrylate, butyl acrylate, methacrylic acid and fluorine monomer in the composite solvent with xylene, propylene glycol methyl ether acetic ester, methyl isobutyl ketone and 100# solvent oil; dripping carbonic glycide ester to polymerize acted by trigger pentaphen peroxide to obtain the product.

Owner:ZHEJIANG UNIV +1

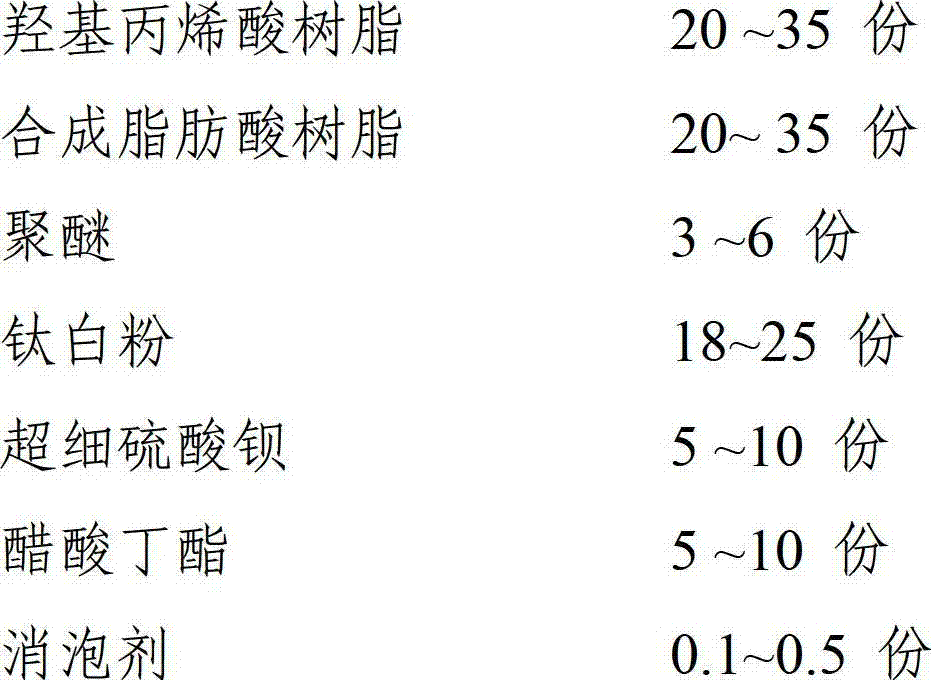

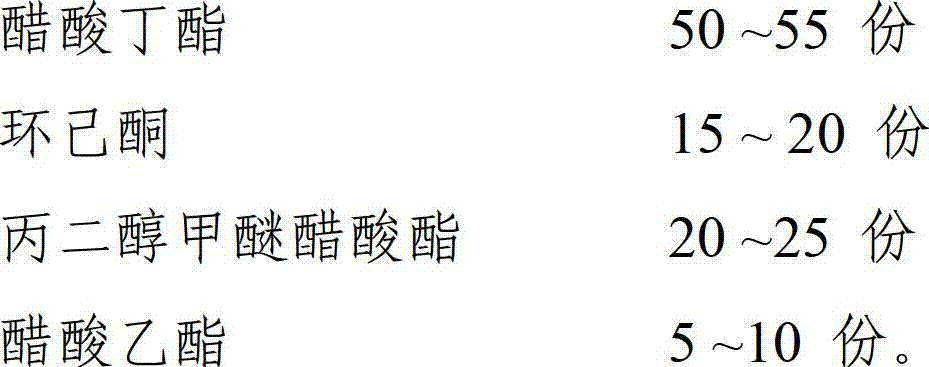

Highlight-dark-bubble-resistance white wood lacquer and preparation method and application thereof

ActiveCN102964953AStrong UV Absorbing PropertiesGood storage stabilityPolyester coatingsCyclohexanoneAcrylic resin

The invention provides a high-dark-bubble-resistance white wood lacquer which comprises a component A, a component B and a component C, wherein the weight ratio of the component A to the component B to the component C is 100:(80-100):(30-50), the component A comprises the following ingredients in parts by weight: 20-35 parts of hydroxy acrylic resin, 20-35 parts of synthetic fatty acid, 3-6 parts of polyether, 18-25 parts of titanium dioxide, 5-10 parts of superfine barium sulfate, 5-10 parts of n-butyl acetate, 0.1-0.5 part of defoaming agent, 0.1-0.5 part of dispersing agent, 0.1-0.5 part of flatting agent, 0.1-0.5 part of ultraviolet absorbing agent and 0.5-1.0 part of anti-settling agent; the component B comprises the following ingredients in parts by weight: 10-20 parts of polyisocyanate, 40-60 parts of co-polymer and 20-30 parts of n-butyl acetate; and the component C comprises the following ingredients in parts by weight: 50-55 parts of n-butyl acetate, 15-20 parts of cyclohexanone, 2-25 parts of propylene glycol monomethyl ether acetate and 5-10 parts of acetic ether. The invention also provides a preparation method of the wood lacquer. The high-dark-bubble-resistance white wood lacquer provided by the invention is high in gloss, strong in sand mark covering capacity, and good in dark bubble resistance.

Owner:濮阳展辰新材料有限公司

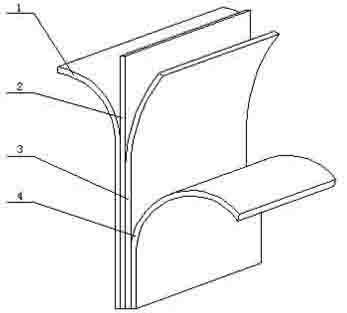

Antifogging agent composition and transparent antifogging window membrane formed therefrom

ActiveCN102627880AGood anti-fog durabilityEasy to prepareOther chemical processesFilm/foil adhesivesPolyesterPolymer science

The invention relates to an antifogging agent composition and a transparent antifogging window membrane formed from the composition. The antifogging agent composition consists of 9-14wt% of hydrophilic resin, 55-76wt% of propylene glycol methyl ether, 3-10wt% of dimethyl methylamine, 1-5wt% of triethylenediamine, 1-5wt% of a levelling agent, 5-26wt% of isopropanol, and 5-24wt% of ethanol. The antifogging window membrane is composed of an antifogging agent coating (1), a transparent polyester membrane or transparent polyethylene membrane base material (2), an acrylic adhesive layer (3) and a release membrane (4), and all layers are integrated. The antifogging agent coating (1) is formed by the antifogging agent composition, while the acrylic adhesive layer (3) is formed by a mixture of an acrylic adhesive, a curing agent, toluene and butanone. The transparent antifogging window membrane has effective antifogging function and high light transmittance, as well as a protection effect.

Owner:CHANGZHOU SANYOU DISSAN PROTECTIVE MATERIAL MFG

Alkaline paint remover

InactiveCN106497213AImprove working environmentNo pollution in the processChemical paints/ink removersLacquerPolyethylene glycol

The invention relates to an alkaline paint remover. The alkaline paint remover comprises the following components in percentage by weight: 8%-10% of sodium hydroxide, 13%-15% of propylene glycol methyl ether acetate, 5%-10% of ethylene glycol monobutyl ether, 0.5%-1% of sorbitol, 13%-17% of benzyl alcohol, 10%-13% of absolute ethyl alcohol, 3%-5% of polyethylene glycol and 30%-47.5% of deionized water. The alkaline paint remover is a medicament for removing various paints, powdered coatings and the like, is suitable for removing metal surface coatings of steel, copper, aluminum and various alloy components, and is high in utilization rate; after the paint removal is finished, residual paint residue is fished out, and the alkaline paint remover is covered with a lid and is sealed, so that the alkaline paint remover can be repeatedly used; and furthermore, the alkaline paint remover can be contained by virtue of containers made of stainless steel, PVC and the like, is wide in selection range and low in cost, does not contain phenol, dichloromethane, phosphorus or various heavy metals, meets the requirements of European Union WEEE&RoHS instructions and has good odor, so that the working environment of operators can be effectively improved, the environmental protection is realized, and the pollution is avoided.

Owner:粟飞

Coating composition with ceramic imitation effect

ActiveCN102585633AWear-resistantGood mechanical propertiesPolyurea/polyurethane coatingsSpecial surfacesXylyleneEthylic acid

The invention mainly relates to the field of paint coating, in particular to a coating composition with a ceramic imitation effect. The coating comprises primer coating, middle coating and top coating. The top coating mainly comprises a main agent and a curing agent, wherein the main agent mainly comprises the following components: 5-10 parts of butyl acetate, 4-10 parts of xylene, 80-85 parts of acrylic polyol resin, 4-8 parts of propylene glycol methyl ether acetate, 0.5-2 parts of an organosilicon leveling agent, and 0.1-0.5 parts of an organosilicon antifoaming agent; and the curing agent mainly comprises the following components: 15-30 parts of butyl acetate, 15-30 parts of xylene, and 40-65 parts of an isocyanate curing agent. The coating composition provided by the invention can be used on prefabricates of plastic, glass or other materials, so that the prefabricates have a high ceramic imitation effect, and the ceramic imitating products not only have various advantages of ceramic products, but also reduces mining and use of organic soil and saves consumption of natural resources. In addition, the coating composition can be dissolved in soil, so as to reduce the pollution and destroy to the environment and reduce the harm to human bodies.

Owner:DONGGUAN SUNLAND TECH CO LTD

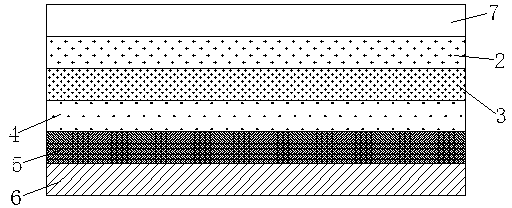

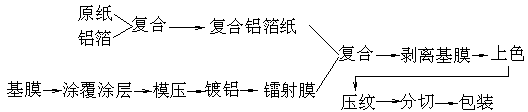

Die pressing coating capable of being transferred onto composite metal surface and laser film comprising die pressing coating

InactiveCN102912673AAvoid deformationImprove compactnessCoatingsCoatings without pigmentsCelluloseAcrylic resin

The invention discloses a die pressing costing capable of being transferred onto a composite metal surface. The die pressing costing comprises 6-10% of cellulose acetate butyrate, 4-8% of acrylic resin, 2-6% of nitrocotton liquid, 25-35% of butanone, 10-20% of propylene glycol monomethyl ether and 28-32% of ethyl acetate, and is 1.3-1.5 micrometers in thickness. The die pressing coating is compact in surface, not easy to erode by solvent utilized in follow-up processing, suitable in strength for die pressing, good in stripping, and particularly suitable for being transferred onto an aluminum foil surface of composite aluminum foil paper to be colored and embossed after the die pressing, so that the composite aluminum foil paper with laser effect can be obtained. The invention further provides a laser film comprising the die pressing coating. The laser film comprises a basic film, and the die pressing coating which is provided with laser patterns after die pressing treatment is coated on the basic film, and a vacuum aluminum coated layer is arranged on the die pressing coating. The composite aluminum foil paper with bright, smooth and massive laser effect can be obtained by compositing the laser film with the composite aluminum foil paper and peeling the same off, and the process is easy to control.

Owner:GUANGDONG XINRUI NEW MATERIAL TECH +1

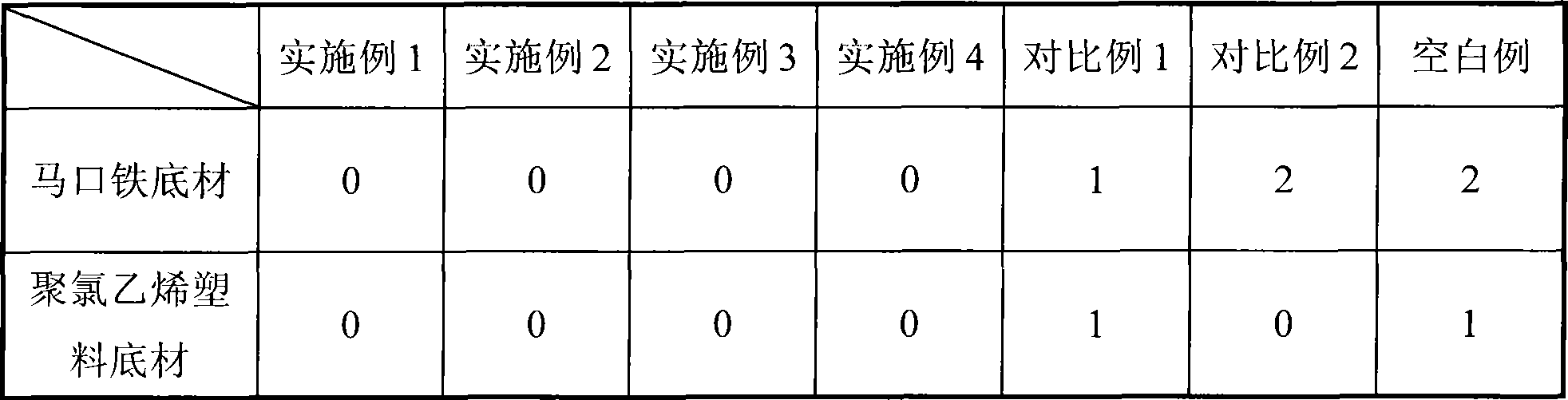

General adhesion promoter for paint and method of producing the same

The invention relates to an adhesive force accelerant for a universal coating and a preparation method thereof. The adhesive force accelerant consists of the following raw materials in weight percentage: 20 to 40 percent of epoxy resin, 10 to 30 percent of chlorinated polypropylene resin, 20 to 40 percent of propylene glycol methyl ether acetate, 10 to 20 percent of n-butyl alcohol, 2 to 5 percent of water and 5 to 20 percent of phosphoric acid. According to the proportion, the propylene glycol methyl ether acetate, the n-butyl alcohol and the water are sequentially added into a vessel, are started to stir and are added with the chlorinated polypropylene resin; and upon complete dissolve, the solution is added with the epoxy resin, is evenly stirred, is dripped with the phosphoric acid and is continuously stirred for 2 to 3 hours to obtain the adhesive force accelerant. The adhesive force accelerant has the advantages of strong universality, excellent intermiscibility, low cost, small use amount, simple production process and convenient use.

Owner:JINAN HUALIN CHEM

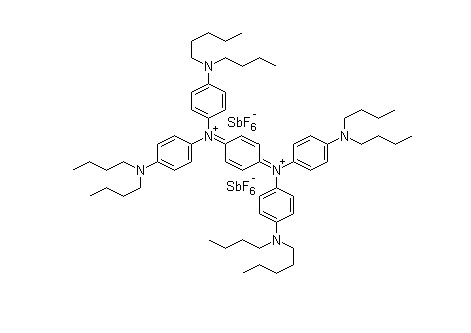

Fluorocarbon compound modified polyacrylate flow agent for coating ink and production method thereof

The invention discloses a fluorocarbon modified polyacrylate flow agent used for paint and ink and the production method, which is manufactured by the reaction of acrylate monomer, initiator, acrylic fluoride monomer, xylene, toluene and propylene glycol methyl ether. The fluorocarbon modified polyacrylate flow agent has the advantages of easily available materials, low production cost, simple preparation method, convenient use and increased surface glass of paint and ink.

Owner:ANHUI XOANONS CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com