General adhesion promoter for paint and method of producing the same

An adhesion promoter, general-purpose technology, applied in the direction of coating, etc., can solve the problem of complex process, achieve the effect of less dosage, excellent compatibility and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

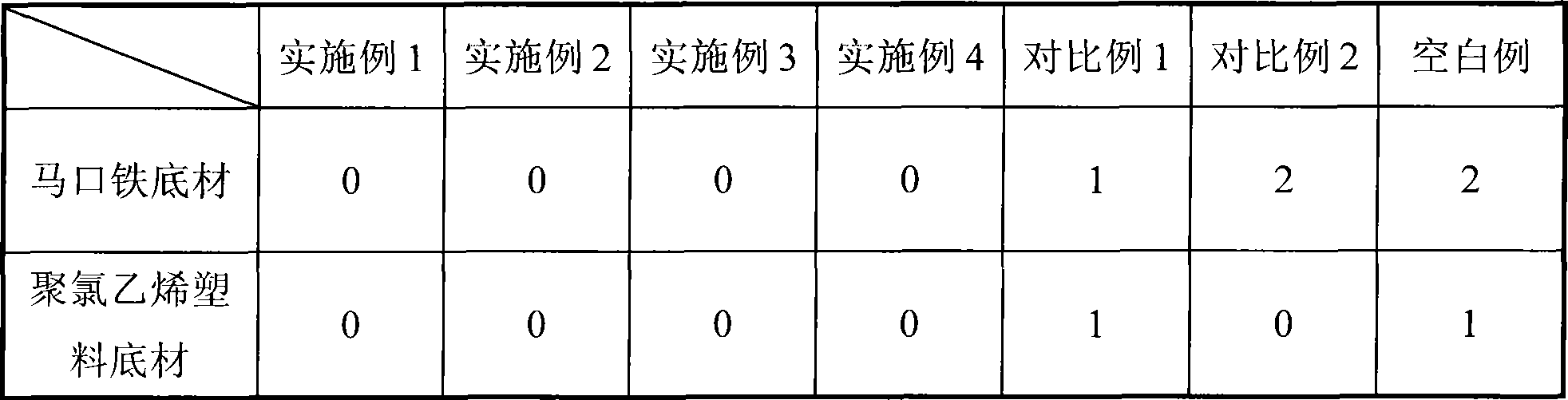

Examples

Embodiment 1

[0038] In a 500 ml three-necked flask, add 30% propylene glycol methyl ether acetate, 10% n-butanol, 5% deionized water, start stirring, add 15% chlorinated polypropylene resin, its chlorine content At 25℃, the viscosity in 20% toluene solution is 260mpa.s and the pH value is 6.3. After the chlorinated polypropylene resin is completely dissolved, add 30% epoxy resin with a value of 0.44 and a molecular weight of 380 After the phenol A epoxy resin is continuously stirred and dispersed uniformly, 10% phosphoric acid with a mass concentration of 85% is added dropwise, and the product of the present invention is obtained by continuing to stir for 2.5 hours.

Embodiment 2

[0040] In a 500 ml three-necked flask, add 20% propylene glycol methyl ether acetate, 20% n-butanol, 2% deionized water, start stirring, and add 20% chlorinated polypropylene resin. The chlorine content The viscosity is 680mpa·s and the pH value is 7.0 in a 20% toluene solution at 25℃. After the chlorinated polypropylene resin is completely dissolved, add 40% bisphenol with an epoxy value of 0.51 and a molecular weight of 210. After the A-type epoxy resin is continuously stirred and dispersed uniformly, 20% phosphoric acid with a mass concentration of 85% is added dropwise, and the product of the present invention is obtained by continuing to stir for 3 hours.

Embodiment 3

[0042] In a 500 ml three-necked flask, add 26% propylene glycol methyl ether acetate, 13% n-butanol, 3% purified water, start stirring, add 18% chlorinated polypropylene resin, the chlorine content is 30%, at 25℃, 20% toluene solution has a viscosity of 1340mpa·s and a pH of 5.3. After the chlorinated polypropylene resin is completely dissolved, add 20% bisphenol A with an epoxy value of 0.56 and a molecular weight of 180 After the epoxy resin is continuously stirred and dispersed uniformly, 5% phosphoric acid with a mass concentration of 83% is added dropwise, and stirring is continued for 2 hours to obtain the product of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com