Patents

Literature

2989 results about "N-Butyl Alcohol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Butyl alcohol (C4H9OH), also known as butanol, is a clear, colorless and flammable liquid used as an organic solvent. It has four isomers, n-butyl, isobutyl, secondary butyl, and tertiary butyl alcohol.

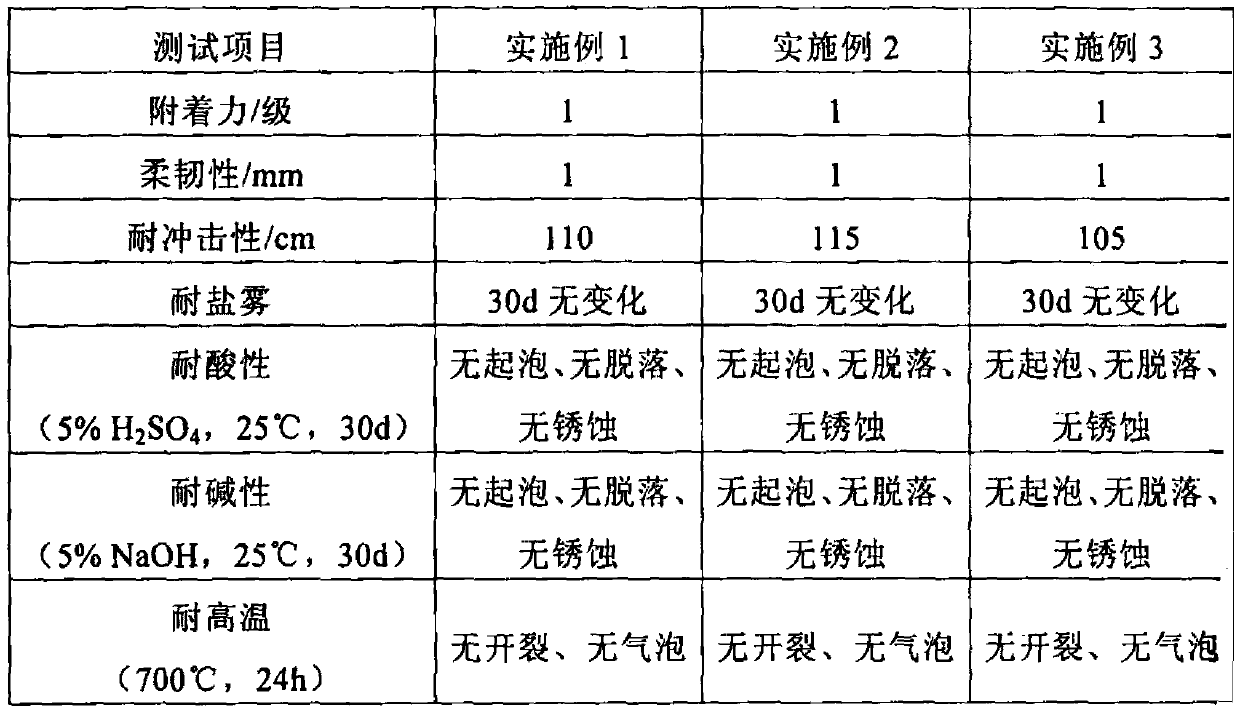

High temperature resistant anticorrosion coating based on graphene and preparation method thereof

InactiveCN103589281AImprove high temperature resistanceImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxySodium Bentonite

The invention relates to a high temperature resistant anticorrosion coating based on graphene and a preparation method thereof. The high temperature anticorrosion coating comprises the following components by the mass percentage: 5-60% of epoxy resin, 3-30% of polyphenylene sulfide resin, 3-30% of amino resin, 1-10% of a pigment, 1-20% of graphene, 3-50% of n-butyl alcohol, 0.1-0.3% of a defoaming agent, 0.1-10% of polyhydroxy acid sodium salt, 0.1-5% of benzenedicarboxylic acid dibutyl ester, 0.5-1.0% of bentonite, and 0.2-0.5% of a leveling agent. Compared with the prior art, the prepared coating has the advantages of quite excellent waterproof and anticorrosion performance, high temperature resistance, weather resistance, alkali resistance, impact resistance, artificial aging resistance and the like, and the preparation method has the advantages of good controllability, simple operation, low production cost, and easy industrialized production.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Leadless electronic slurry composition for solar silicon photovoltaic cell and preparation method thereof

InactiveCN101345263AHigh electrical conductivityRefined nanocrystalline structureFinal product manufactureSemiconductor devicesAdhesiveSlurry

The invention discloses a compounding and a preparation method for lead-free electronic slurry used for a solar silicon photocell; according to the mass percentage, the slurry is obtained by preparing 70 to 75 percent of aluminium powders, 20 to 25 percent of organic adhesive, 1 to 5 percent of inorganic glass powders and 1 to 5 percent of additives; the aluminium powder is ball-shaped aluminium powder with the surface covered by an aluminium nitride protection layer, with the purity not less than 99.9 percent and the average grain size of 2 to 6 microns; simultaneously, organic adhesives consisting of ethyl cellulose, resin, hexadecanol, diethyleneglycol monomethyl ether, diethyleneglycol monobutyl ether, terpineol and n-butyl alcohol are added into the aluminium powder; the inorganic glass powder is silicon dioxide, boracic acid, alumina, antimony oxide and zirconia; the additive consists of Span and pump oil. The product prepared by the method of the invention has no dust generation or aluminium peeling phenomenon and achieves the requirement of no lead and environmental protection.

Owner:NANTONG UNIVERSITY

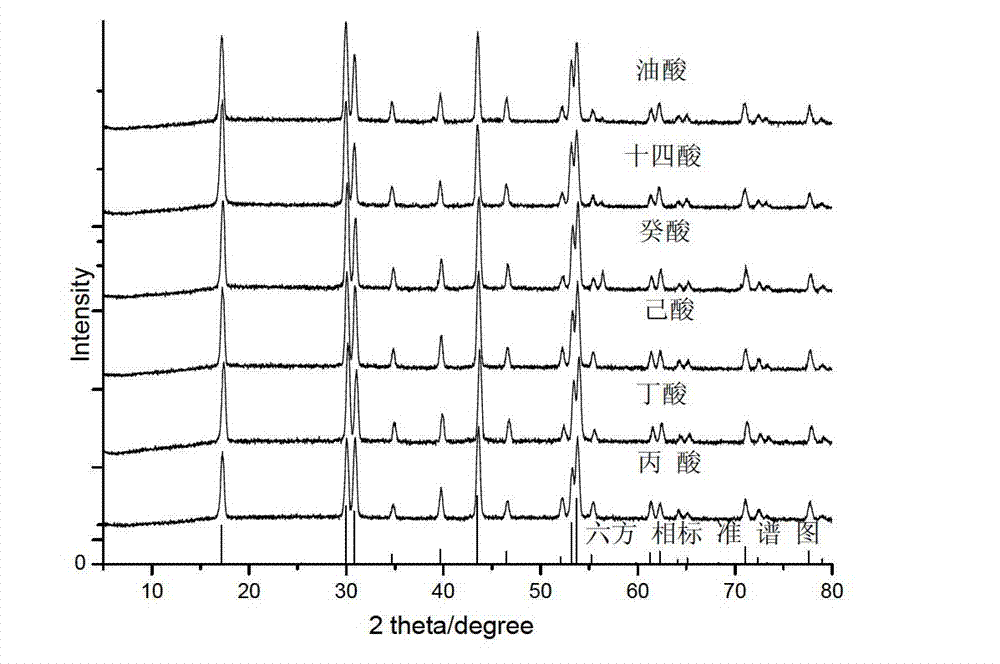

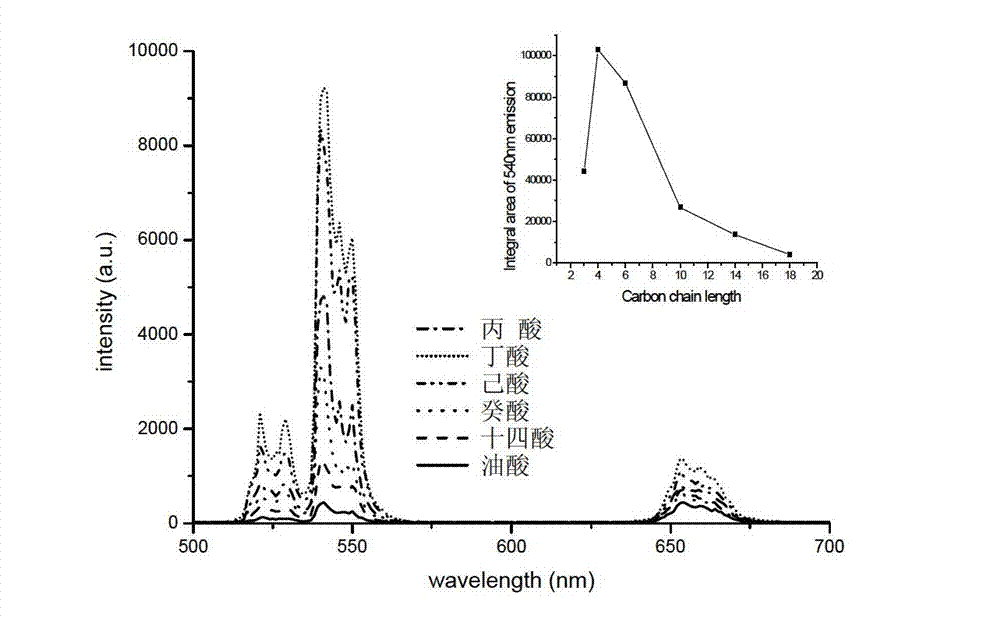

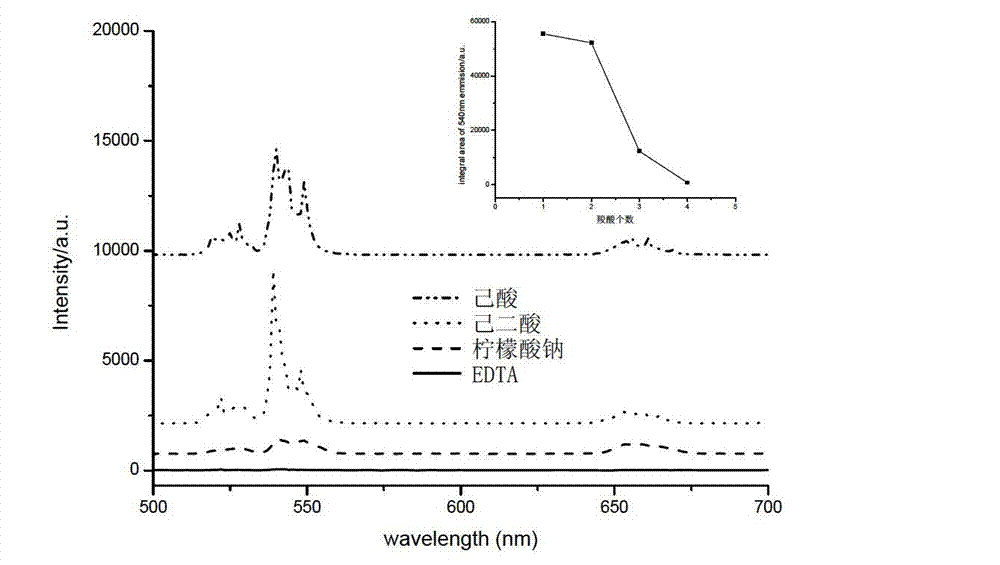

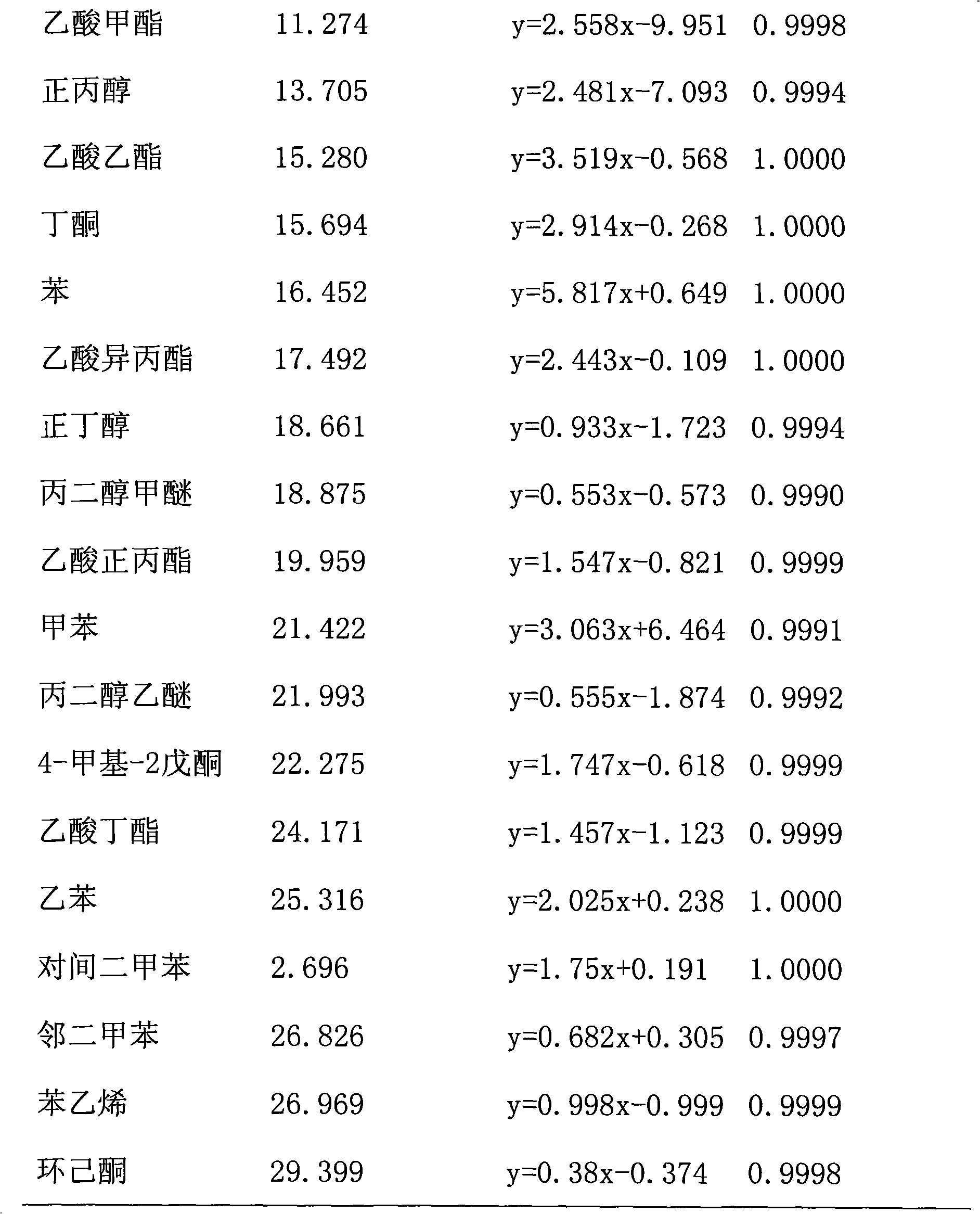

High-strength rare earth-doped up-conversion luminescence nanometer material and preparation method thereof

The invention provides a method of improving luminous efficiency of a rare earth-doped up-conversion luminescence nanometer material through changing the usage of a ligand. According to the method, the synthesis adopts a hydrothermal-solvothermal method, an organic ligand is an organic compound such as monocarboxylic acid, dicarboxylic acid or polycarboxylic acid, and amine, the molar ratio of rare earth ions to the ligand is 2:1-1:100, the molar ratio of NaOH to the ligand is 0:1-1:1, water / alcohol, water / n-propanol alcohol, water / isopropyl alcohol, water / n-butyl alcohol, water / acetone or water / ethylene glycol is used as a solvent, the temperature ranges from 180-240 DEG C, the reaction time is 2-24h, and the F<-> / Re value ranges from 4-12. With the method, the problems of selecting various ligands for synthesizing the up-conversion luminescence nanometer material, improving the luminous efficiency of the rare earth-doped up-conversion luminescence nanometer material, synthesizing the water-soluble up-conversion luminescence nanometer material, and the like can be mainly solved.

Owner:DALIAN UNIV OF TECH

Method for extracting refined cordycepin and cordycepin polysaccharide from cordyceps mititaris

ActiveCN101124988ALow costReduce pollutionSugar derivativesSugar derivatives preparationAmylaseAdditive ingredient

The present invention relates to a method for extracting the purificatory cordycepin and the cordyceps amylase from the cordyceps militaris, belonging to the fields of medicines and health protection and chemical engineering. The cordyceps militaris powder is extracted and filtrated by a cooling seep method, the filter residue is mixed with ethanol, the supersonic wave assists to extract and offcenter, the supernatant has the processes of concentration and alcohol-precipitating, then the alcohol-precipitated supernatant has the processes of decompression, concentration and elution, the eluted liquid has the processes of concentration and crystallization and recrystallization using the n-butyl alcohol, at last the purificatory amylase is obtained after freezing and drying. The preparation progress of the present invention only uses water and ethanol as the solvent, thus reducing the pollution, the resin is capable of being reused a plurality of times with low cost. The present invention fully exploits the biological activity ingredients of the cordyceps militaris, realizes the coextraction of the cordycepin and the cordyceps amylase, guarantees the biological activities of the cordycepin and the cordyceps amylase, farthest increases the utilization rate of the raw material to the largest extent, reduces the manufacturing cost. The present invention is suitable for the large-scale industrialized manufacture.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

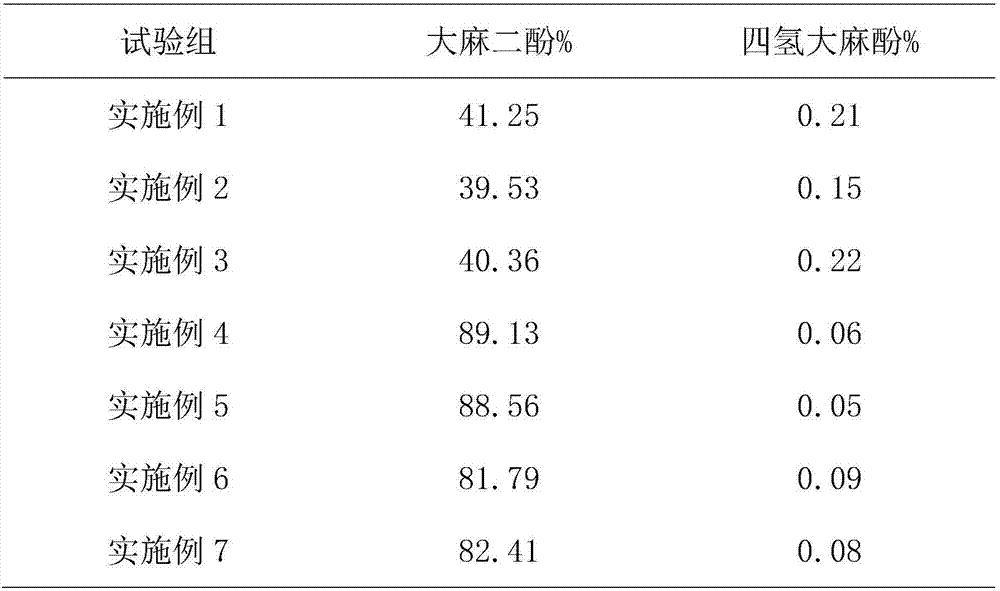

Method for enriching cannabidiol

ActiveCN107011125AIncrease contentOrganic chemistryOrganic compound preparationChemical industryGradient elution

The invention belongs to the technical field of chemical industry, and particularly relates to a method for enriching cannabidiol. The method includes steps of S1, drying Cannabis sativa flower and leaf for 0.5-4 hours at 120 DEG C, and smashing until the particle size of the smashed material meets the requirement of over 50 meshes; performing carbon dioxide supercritical extraction for 1-9 hours under the conditions of 30-55 DEG C and 13-30 MPa, and recycling carbon dioxide to obtain initial extractive of Cannabis sativa flower and leaf; S2, dissolving the initial extractive of Cannabis sativa flower and leaf in ethanol or methanol, refining, filtering and removing impurities, distilling and drying the solvent for future use; S3, filling a chromatographic column with the pretreated filler, sampling by a wet method or a dry method, wherein the sampling amount is 3-15 wt%; S4, performing gradient elution or isocratic elution by one or mixture of water, methanol, ethanol, n-butyl alcohol, acetone or chloroform; collecting the dilution section with enriched cannabidiol. The method is simple in technique; content of cannabidiol is improved, and tetrahydrocannabinol content is reduced.

Owner:YUNNAN HEMPSON BIO-TECH CO LTD

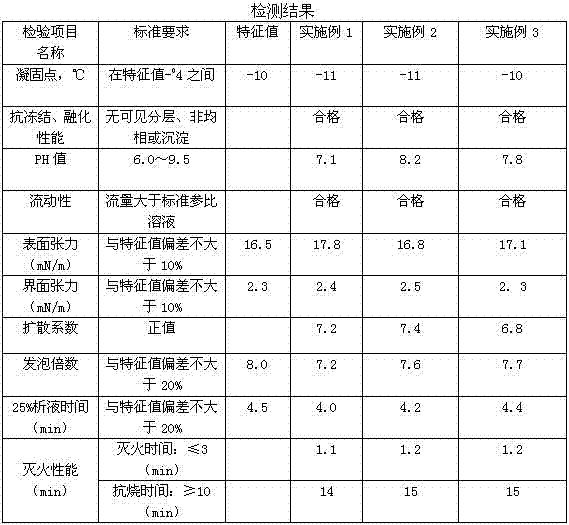

Aqueous film-forming foam extinguishing agent special for fire extinguishing bullet and throwing type fire extinguisher

InactiveCN104117176AImprove fire extinguishing effectPrevent re-ignitionFire extinguisherDiethylene glycol diethyl etherAmmonium dodecyl sulfate

The invention provides an aqueous film-forming foam extinguishing agent special for a fire extinguishing bullet and a throwing type fire extinguisher. The aqueous film-forming foam extinguishing agent has the advantages of being small in additive amount, rapid in fire extinguishing, good in recrudescence resisting effect, environmentally friendly, efficient and the like. The aqueous film-forming foam extinguishing agent comprises, by weight, 8 percent to 12 percent of main foaming agents, 8 percent to 20 percent of auxiliary foaming agents, two percent to 10 percent of antifreeze agents, 12 percent to 22 percent of cosolvents, 0.1 percent to one percent of stabilizers, 8 percent to 20 percent of fire retardants, two percent to five percent of burning-resistance agents and the balance water. The main foaming agents are selected from F1157N, F1203 and F1460, the auxiliary foaming agents are selected from lauryl sodium sulfate, ammonium lauryl sulfate, alkyl glycoside, dodecyl dimethyl betaine and cocamidopropyl betaine. The antifreeze agents are selected from ethylene glycol, glycerol and the like. The cosolvents are selected from dodecanol, n-butyl alcohol and diethylene glycol diethyl ether. The stabilizing agents are selected from xanthan gum, Arabic gum, guar gum and sodium alginate tech grade. The fire retardants are selected from ammonium polyphosphate and ammonium dihydrogen phosphate.

Owner:ANHUI TIANYUAN FIRE PROTECTION TECH

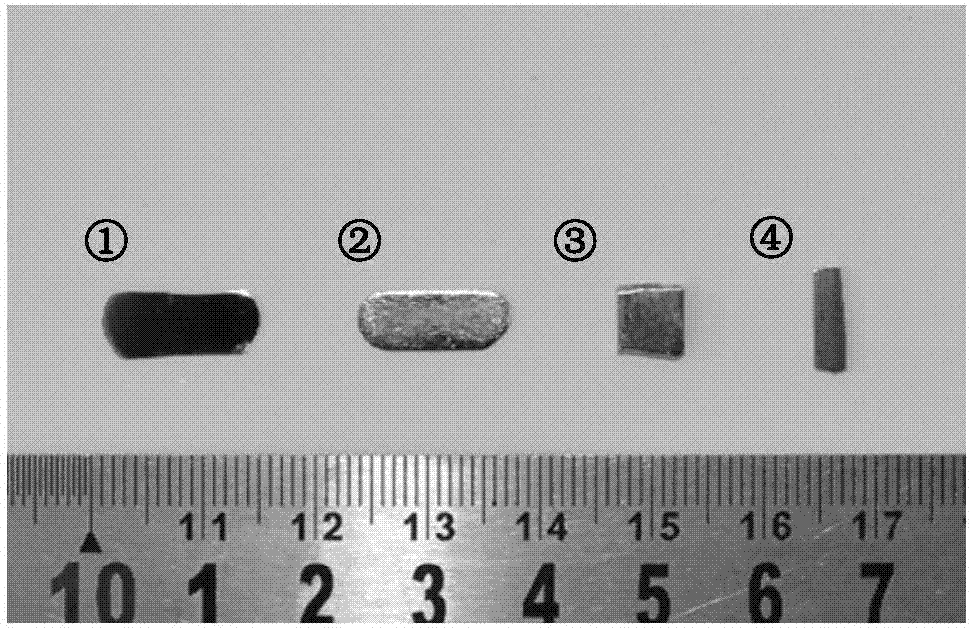

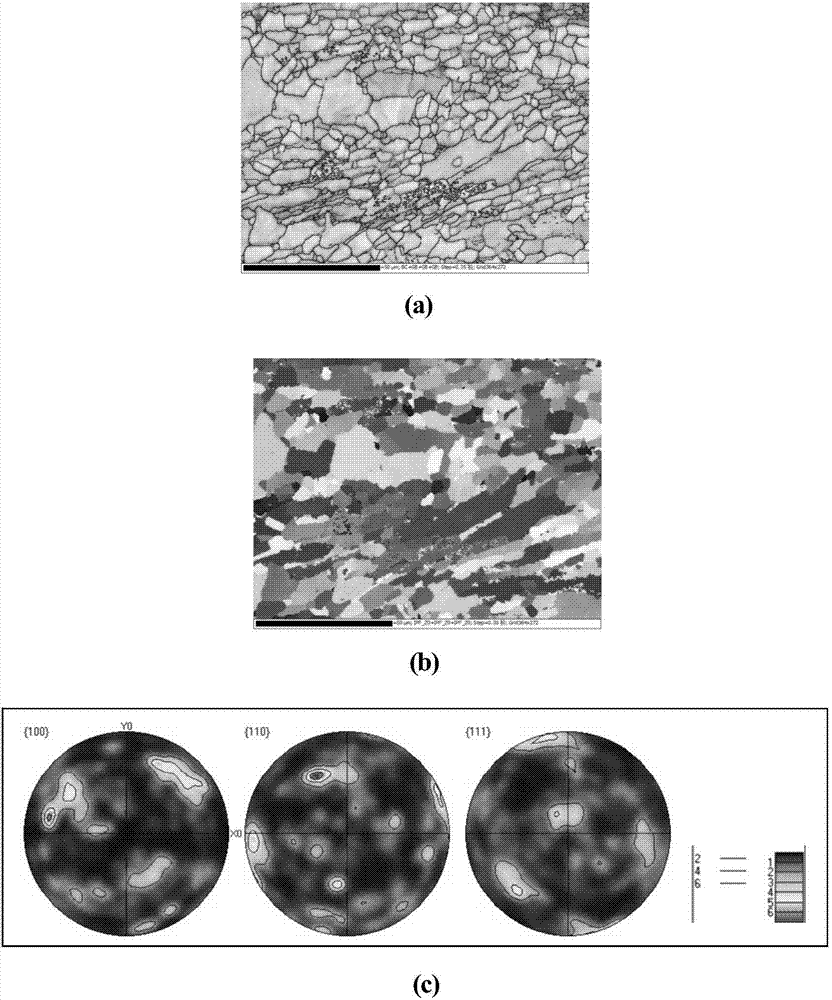

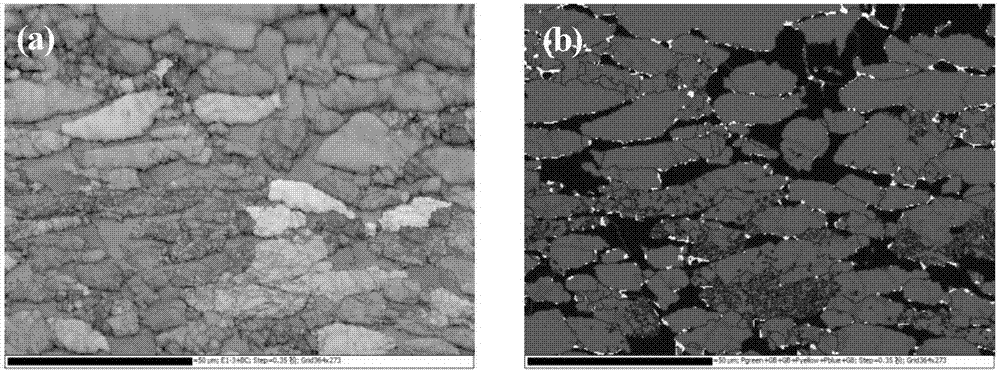

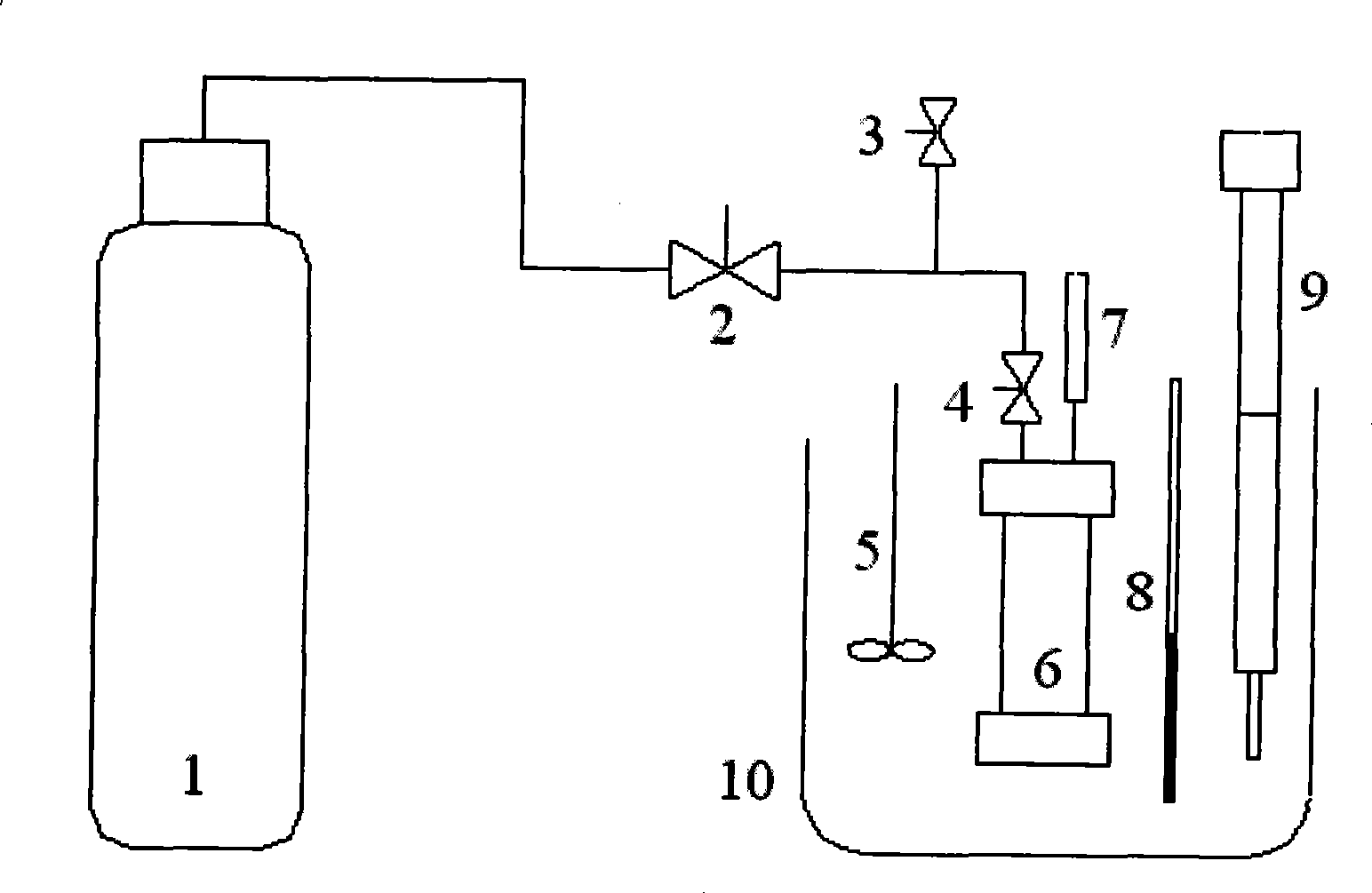

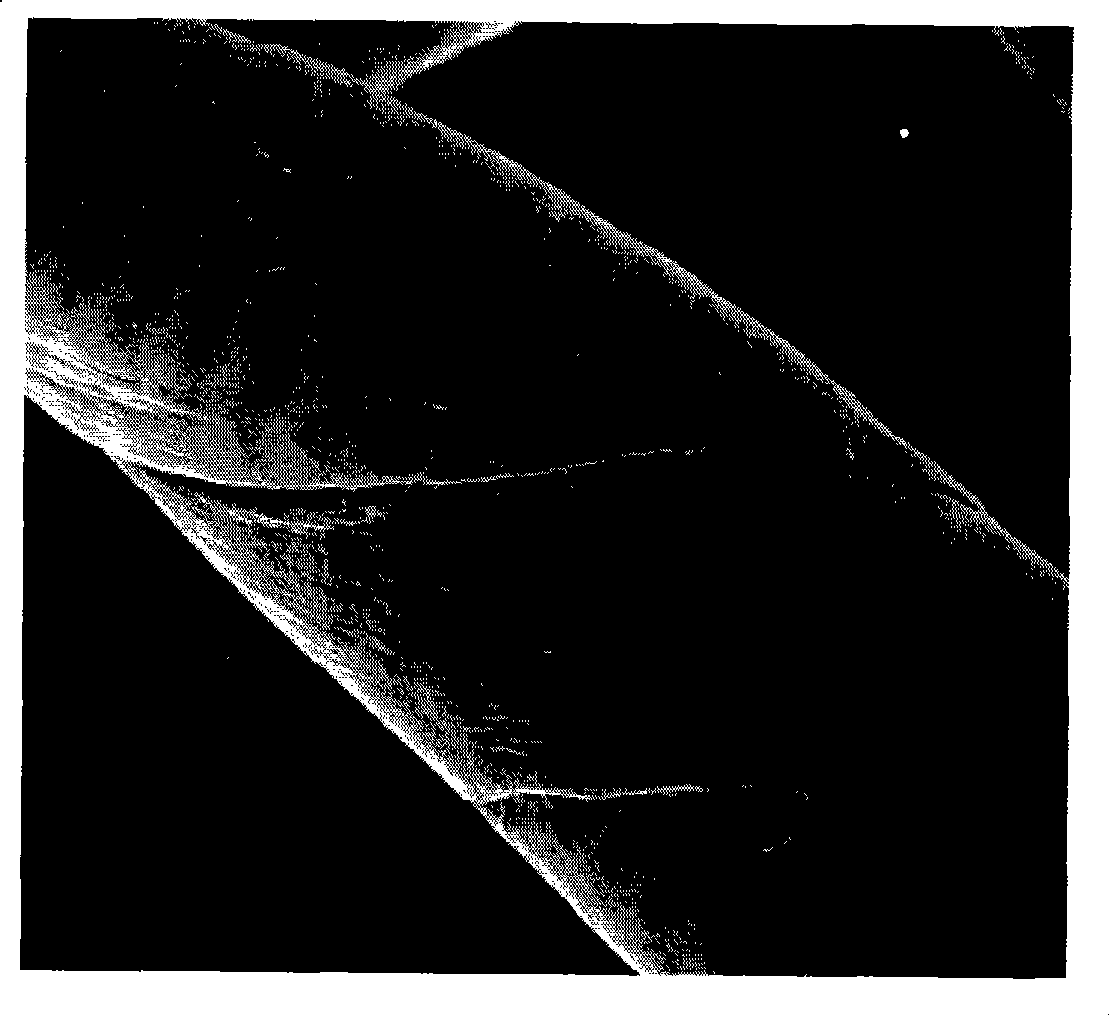

Electropolishing preparation method of sample for EBSD (Electron Back-Scattered Diffraction) analysis of titanium-aluminum alloy

InactiveCN107402150AIncrease the areaEasy and flexible operationPreparing sample for investigationElectrolysisHigh rate

The invention belongs to the technical field of non-ferrous metal analysis and particularly relates to an electropolishing preparation method of a sample for EBSD (Electron Back-Scattered Diffraction) analysis of a titanium-aluminum alloy. The electropolishing preparation method comprises the following steps: firstly, carrying out earlier stage treatment on the sample: determining the size of the sample to be smaller than 7mm*6mm*4mm, and carrying out standard metallographic treatment and mechanical polishing on the testing surface; secondly, setting up a portable device: connecting the sample with a positive pole of a power supply, connecting a stainless steel plate with a negative pole of the power supply and matching the bottom end of electrolyte with a magnetic stirrer; thirdly, preparing the electrolyte: selecting 4 to 12 percent of perchloric acid, 55 to 65 percent of methyl alcohol and the balance of n-butyl alcohol according to the volume ratio, wherein the total amount of the electrolyte is 700ml; putting the electrolyte into a beaker with the volume of 1L; fourthly, carrying out electrolysis treatment, washing and drying: controlling the temperature to be 30 DEG C below zero to 20 DEG C below zero, controlling the voltage to be 25 to 35V and controlling the polishing time to be 40 to 55 seconds. The electropolishing preparation method disclosed by the invention has the advantages of large surface area for treating the sample and suitability for preparing titanium-aluminum alloy samples with various components and various test purposes, which are prepared by different processing method. In addition, the electropolishing preparation method has the advantages of easiness and flexibility in operation, no restriction from site facilities and the like, good polishing effect and high rate of finished products; the device has the characteristics of high mobility, low cost, easiness in promotion and wide application prospect.

Owner:NORTHEASTERN UNIV

Centrifugal casting roller coatings and preparation method thereof

ActiveCN101491823AImprove heat resistanceGood chemical stabilityFoundry mouldsFoundry coresFatty alcoholN-Butyl Alcohol

The invention relates to a centrifugal casting roller coating and a preparation method thereof. The centrifugal casting roller coating is characterized by comprising the following compositions in percentage by mass: 12 to 15 percent of zircon powder, 8 to 10 percent of quartz powder, 8 to 10 percent of bauxite, 0.3 to 0.6 percent of silica sol, 0.1 to 0.4 percent of sodium carboxymethyl cellulose, 0.15 to 0.35 percent of alkyl benzene sodium sulfonate, 0.15 to 0.35 percent of sodium sulfate, 0 to 0.02 percent of n-butyl alcohol, 0 to 0.02 percent of n-octyl alcohol, 0.10 to 0.18 percent of fatty alcohol polyethenoxy ether, and the balance being water, wherein the mass percentage of the zircon powder + the quartz powder + the bauxite is more than or equal to 30 percent and less than or equal to 35 percent, the mass percentage of the alkyl benzene sodium sulfonate + the sodium sulfate is more than or equal to 0.35 percent and less than or equal to 0.55 percent, and the mass percentage of the n-butyl alcohol + the n-octyl alcohol is more than or equal to 0.02 percent and less than or equal to 0.03 percent. The coating is used for centrifugal casting roller production after stirring, grinding and sieving, and has good use effect.

Owner:靖江市黎明铸造材料厂

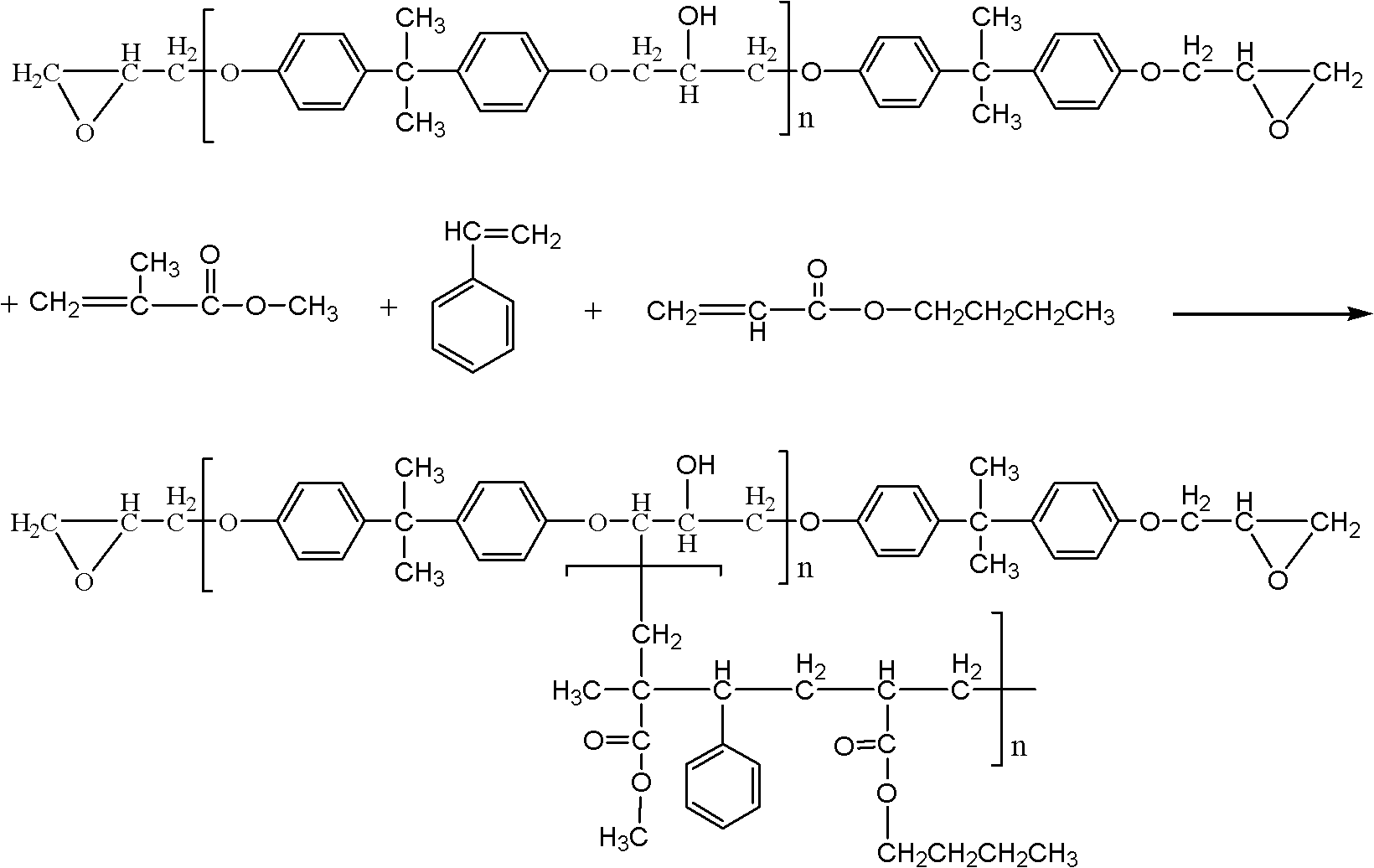

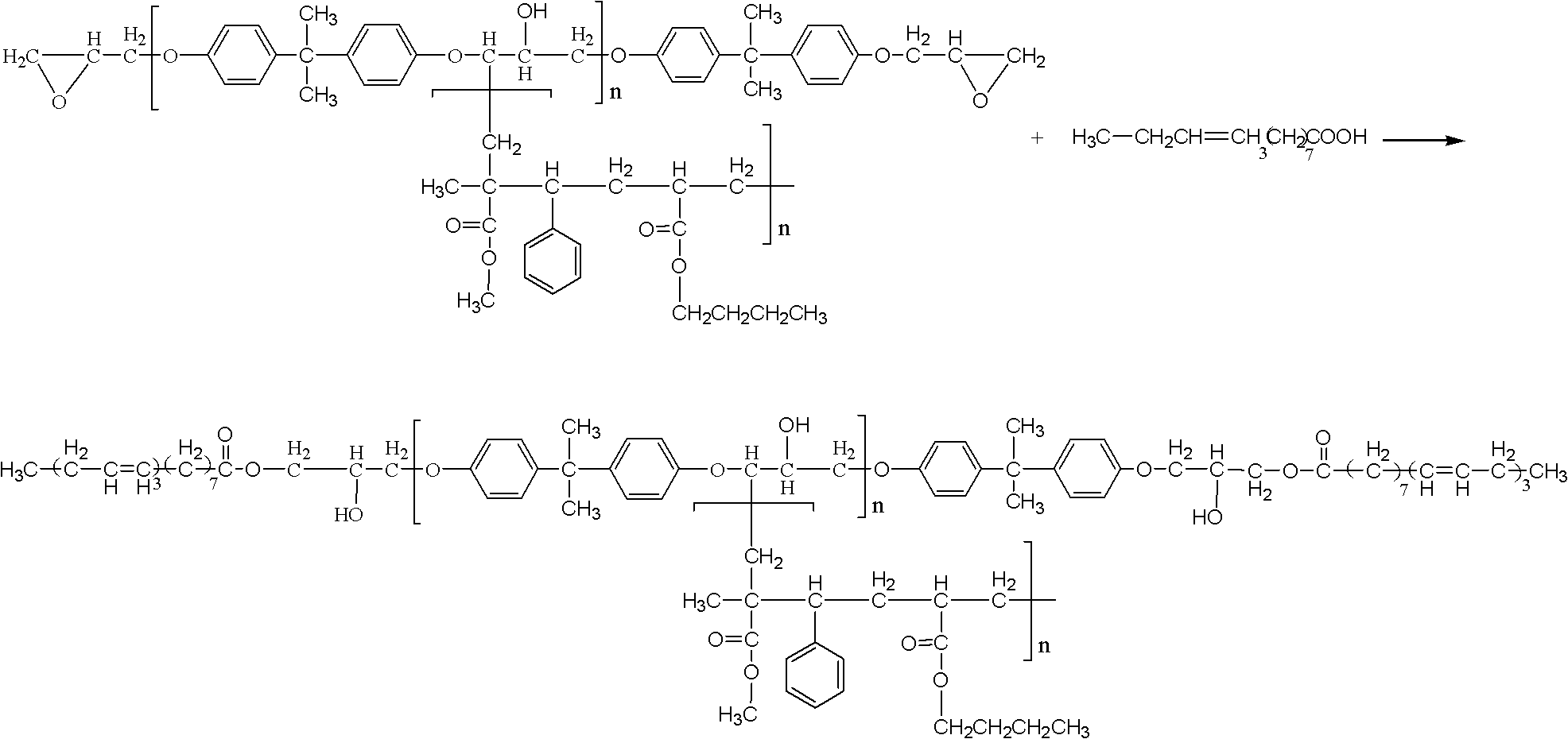

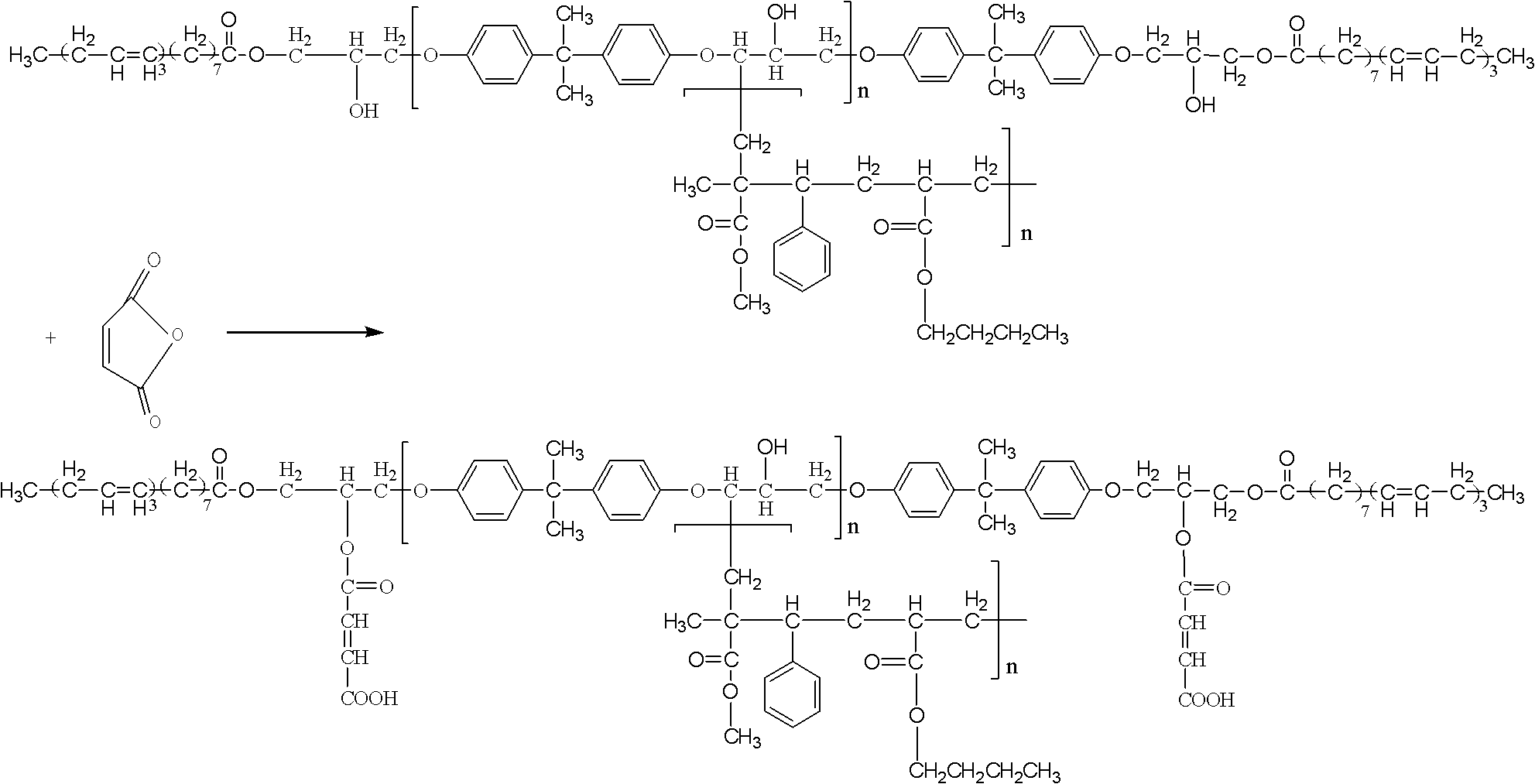

Single-component aqueous epoxy resin emulsion capable of being self-cured at normal temperature, and preparation method thereof

The invention discloses single-component aqueous epoxy resin emulsion capable of being self-cured at normal temperature, and a preparation method thereof. The method comprises the following steps of: adding epoxy resin, n-butyl alcohol, and ethylene glycol monobutyl ether into a reactor, heating to form a homogeneous phase, controlling temperature to be 110 to 120 DEG C, and dripping acrylic ester monomers in which initiator benzoyl peroxide (BPO) is dissolved to obtain an acrylic ester monomer modified epoxy resin; and heating the acrylic ester monomer modified epoxy resin to 120 to 150 DEG C, adding unitary unsaturated fatty acid and catalyst triphenylphosphorus, adding maleic anhydride, reacting for 1.0 to 2.0 hours, reducing temperature to 50 to 55 DEG C, adding triethylamine, neutralizing for 0.5 to 1.0 hour, adding water and dispersing for 0.5 to 1.0 hour to obtain the single-component aqueous epoxy resin emulsion capable of being self-cured at normal temperature. The aqueous epoxy resin emulsion which is obtained by the method can be cured at normal temperature to form a film under the condition of not adding a curing agent, is convenient to use, and high in water resistance and corrosion resistance, and can be used for metal corrosion-resistant paint and the like.

Owner:广州玖盈化工材料有限公司

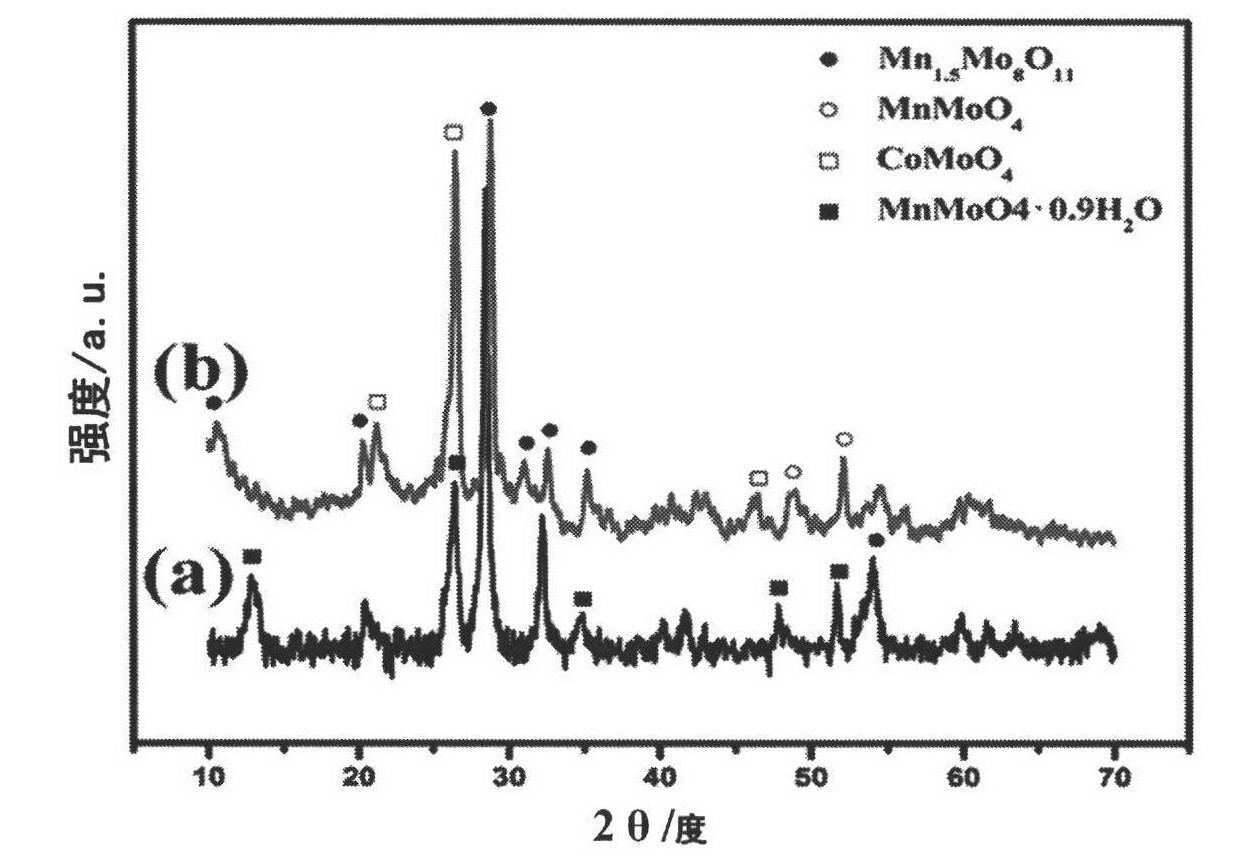

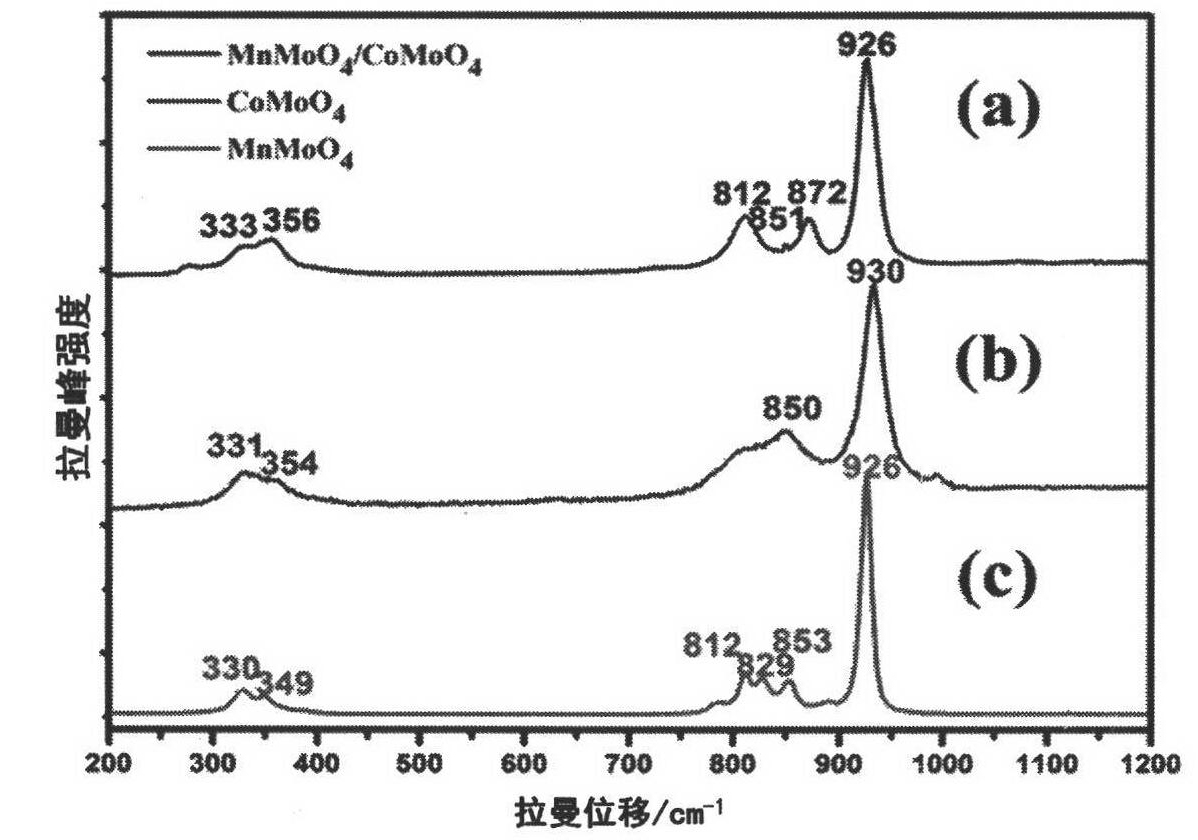

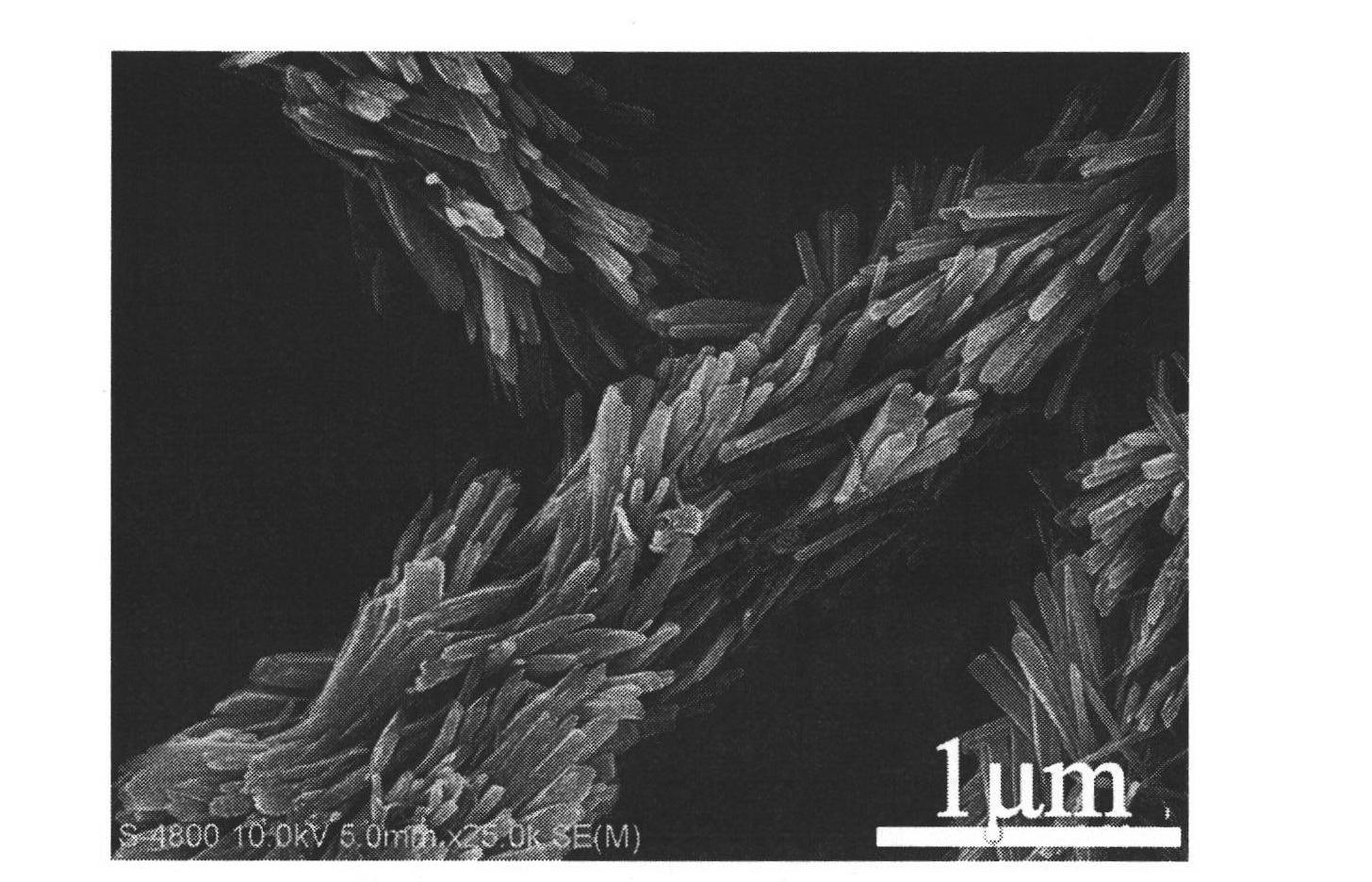

Method for preparing manganese molybdate/cobalt molybdate hierarchical heterostructure nanowires

ActiveCN102154701AAchieving controllable synthesisHigh specific capacitancePolycrystalline material growthFrom normal temperature solutionsNanowireMolybdate

The invention discloses a method for preparing manganese molybdate / cobalt molybdate hierarchical heterostructure nanowires. The method comprises the following steps of: preparing a NaMoO4 aqueous solution and a MnCl2aqueous solution; proportioning in a certain ratio of the NaMoO4aqueous solution to the MnCl2 aqueous solution to CTAB (Cetyltrimethyl Ammonium Bromide) to n-butyl alcohol to isooctane and preparing manganese molybdate nanorods by using a microemulsion method; adding the manganese molybdate nanorods into distilled water, stirring and ultrasonically cleaning to obtain transparent liquid; and adding the liquid into a flask, placing the flask in an oil bath of between 60 and 80 DEG C, condensing and refluxing, adding a CoCl2 solution and a Na2MoO4 solution with different concentrations in turn every certain time, stirring to react so as to obtain a product, separating and drying the product to obtain the manganese molybdate / cobalt molybdate hierarchical heterostructure nanowires, wherein the lengths of the nanowires reach 10 microns and the diameters of the nanowires are between 500 and 1,000nm; the manganese molybdate nanorods in the hierarchical heterostructure nanowires are used as a main material and the diameters of the manganese molybdate nanorods are between 300 and 500; and the cobalt molybdate is branch nanorods which orderly grow on the surfaces of the manganese molybdate nanorods and the diameters of the cobalt molybdate nanorods are between 30 and 50nm. The material has excellent electrochemical performance and can be used as an active material for electrodes of electrochemical super capacitors. The method has the advantages of low-cost raw materials, simple process and environmental friendliness.

Owner:武汉经开科创运营有限公司

Special high-property coating for chemical equipment

InactiveCN104946082AIncrease viscosityIncrease crosslink densityFireproof paintsEpoxy resin coatingsPyrophylliteMelamine phosphate

The invention discloses a special high-property coating for chemical equipment. The special high-property coating comprises the following raw materials: novolac epoxy resin, phosphorus-containing acrylic resin, boric acid modified organic silicon resin, polytetrafluoroethylene resin, polyvinylidene fluoride, a carbon nano tube, ammonium polyphosphate, pentaerythritol, alumina powder, pyrophyllite powder, graphite, expanded perlite, modified attapulgite, cerium oxide, n-butyl alcohol, n-amyl alcohol, ethanediol, water, amine resin, melamine polyphosphate, N-phenyl-N'-cyclohexyl p-phenylene diamine, dodecanol, dipropylene glycol mono butyl ether, dimethyl phthalate, a coupling agent and an auxiliary agent. The special high-property coating for the chemical equipment, which is disclosed by the invention, has the advantages of good corrosion resistance and high-temperature resistance, high adhesive power and excellent flame-retardant property, can be used for the chemical equipment, is difficult to desquamate, good in protection effect and capable of prolonging the service life of the chemical equipment.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

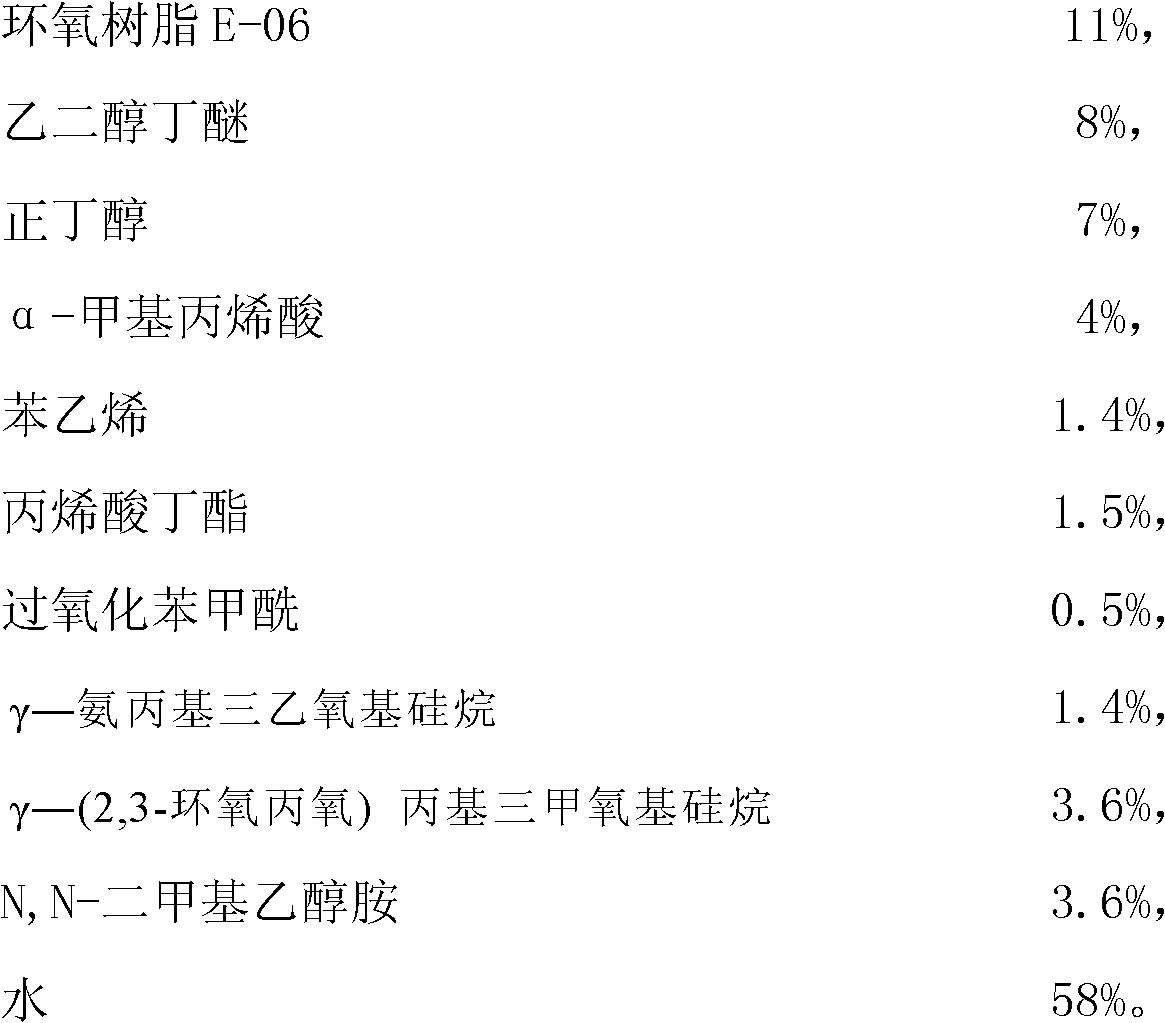

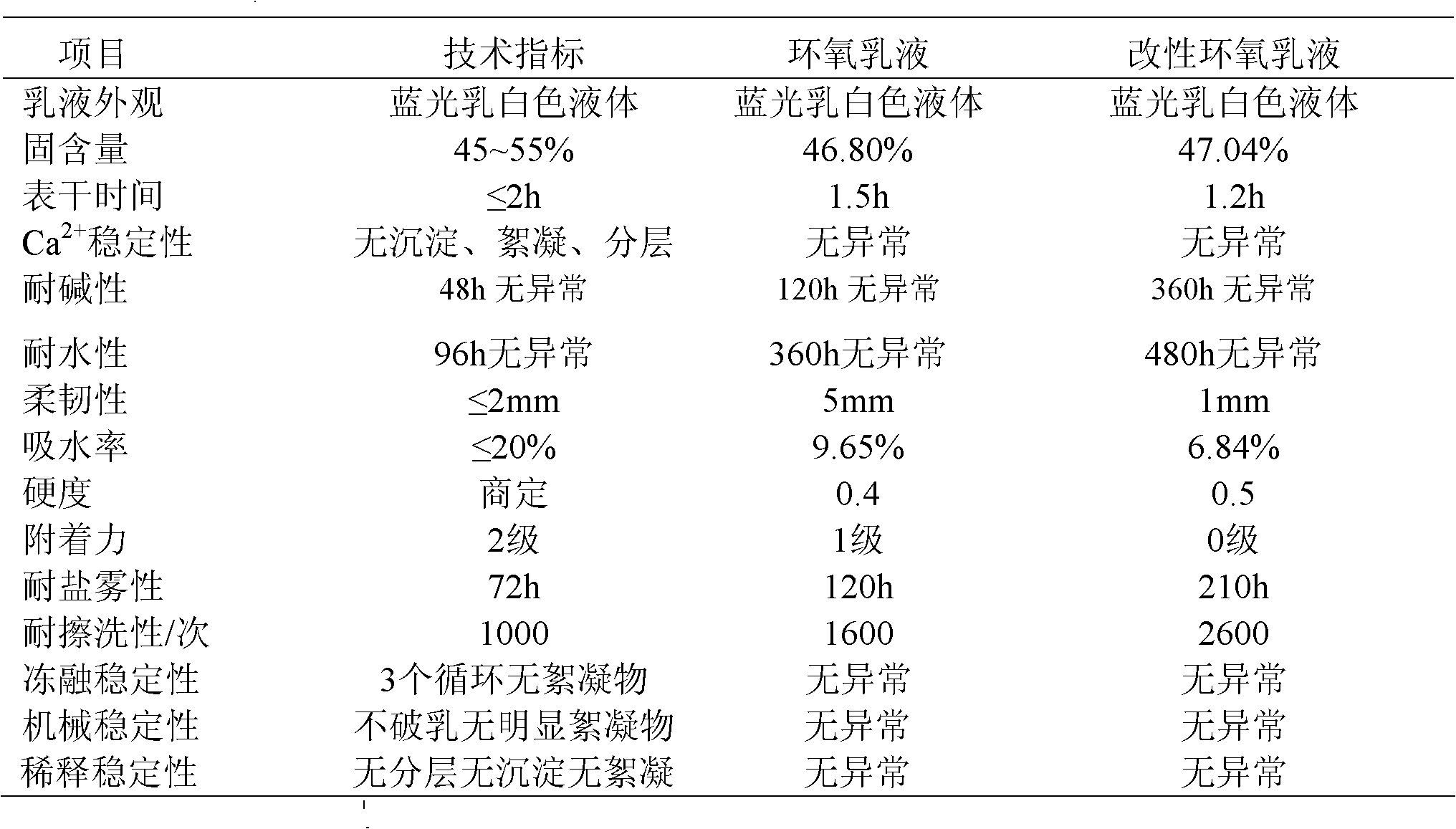

Modified epoxy emulsion and preparation method thereof

InactiveCN102585111AGood film formingGood physical and mechanical propertiesCoatingsHydrophilic monomerEpoxy

The invention discloses a modified epoxy emulsion and a preparation method thereof. The emulsion comprises the following components in percentage by weight: 10-15 percent of epoxy resin E-06, 8-10 percent of ethylene glycol monobutyl ether, 7-8 percent of n-butyl alcohol, 4-4.5 percent of alpha-methacrylic acid, 1-1.5 percent of styrene, 1-1.5 percent of butyl acrylate, 0.4-0.8 percent of benzoyl peroxide, 1-1.5 percent of gamma-aminopropyl triethoxy silane, 3.2-4 percent of gamma-trimethoxypropylsilane, 3.2-4.2 percent of N,N-dimethylethanolamine and 50-60 percent of water. The preparation method comprises the following steps of: preparing for graft copolymerization; then, introducing hydrophilic monomers by utilizing the graft copolymerization method; and adding a mixture for further modification to obtain the modified epoxy emulsion. The modified epoxy emulsion has the characteristics of strong adhesion, good flexibility, hardness, corrosion resistance, water resistance, alkali resistance, scrub resistance and simple preparation process.

Owner:JIANGSU UNIV OF SCI & TECH

Method for processing cellulose by supercritical carbon dioxide, products and use thereof

The invention relates to a method for utilizing supercritical carbon dioxide to process cellulose; firstly, the cellulose and a cosolvent or an inorganic sol or a former body of the inorganic sol are arranged in a high pressure container; carbon dioxide is pumped by a pumping pressure; the reaction condition is 15 to 200 DEG C; the pressure is 4 to 40MPa; the reaction time is 0.5 to 24 hours; then the activated cellulose is manufactured; the cosolvent relates to carbinol, ethanol, normal butanol, isobutyl alcohol, acetone, tetrahydrofuran, formaldehyde, n-butyl aldehyde and isobutyraldehyde; the cellulose is a natural cellulose and a ramification thereof; the natural cellulose relates to chopped cotton fibers, cotton fabrics, bagasse, straws, paper products, bamboo, flax and wood. The method for utilizing the supercritical carbon dioxide to process the cellulose has the advantages that: the processing method is simply and easily operated; the supercritical carbon dioxide is adopted, thus having no burning, no pollution and no toxic action and being conveniently recycled and being repeatedly used; the content of the mixed inorganic oxide in a compound fiber material is high; the product is easily separated and purified; the characteristic is uniform and stable; the method for utilizing the supercritical carbon dioxide to process the cellulose has broad application prospects in the fields of catalyzing, chemical engineering, packaging, weaving, etc.

Owner:FUDAN UNIV

Method for extracting oligomeric proanthocyanidins

InactiveCN101845035AHigh purityHigh yieldOrganic chemistryOther chemical processesGradient elutionSolvent

The invention discloses a method for extracting oligomeric proanthocyanidins, which comprises the following steps of: extracting a plant raw material containing the oligomeric proanthocyanidins with a solvent; enabling a crude extract to pass through a macroporous adsorbent resin column; eluting with water to remove protein and polysaccharide impurities; carrying out gradient elution with water and one or more selecting from alcohol, methyl alcohol and acetone as an eluant; collecting mixed solution with the volume ratio of n-butyl alcohol, acetic acid and water of 4:1:5; standing for demixing, wherein the solution at upper layer is a developing solvent; and carrying out silica gel thin-layer chromatography, wherein the elution part with the Rf value of 0.2-0.5 on a thin-layer chromatography plate is the oligomeric proanthocyanidins extract. Compared with the prior art, the invention has the advantages that the purity and the yield are both remarkably improved, the yield of the oligomeric proanthocyanidins can reach more than 80 percent, the product purity is no less than 50 percent and is basically more than 80 percent, and the method has simple and convenient process, low cost and easy industrialization.

Owner:SHANGHAI INST OF PHARMA IND

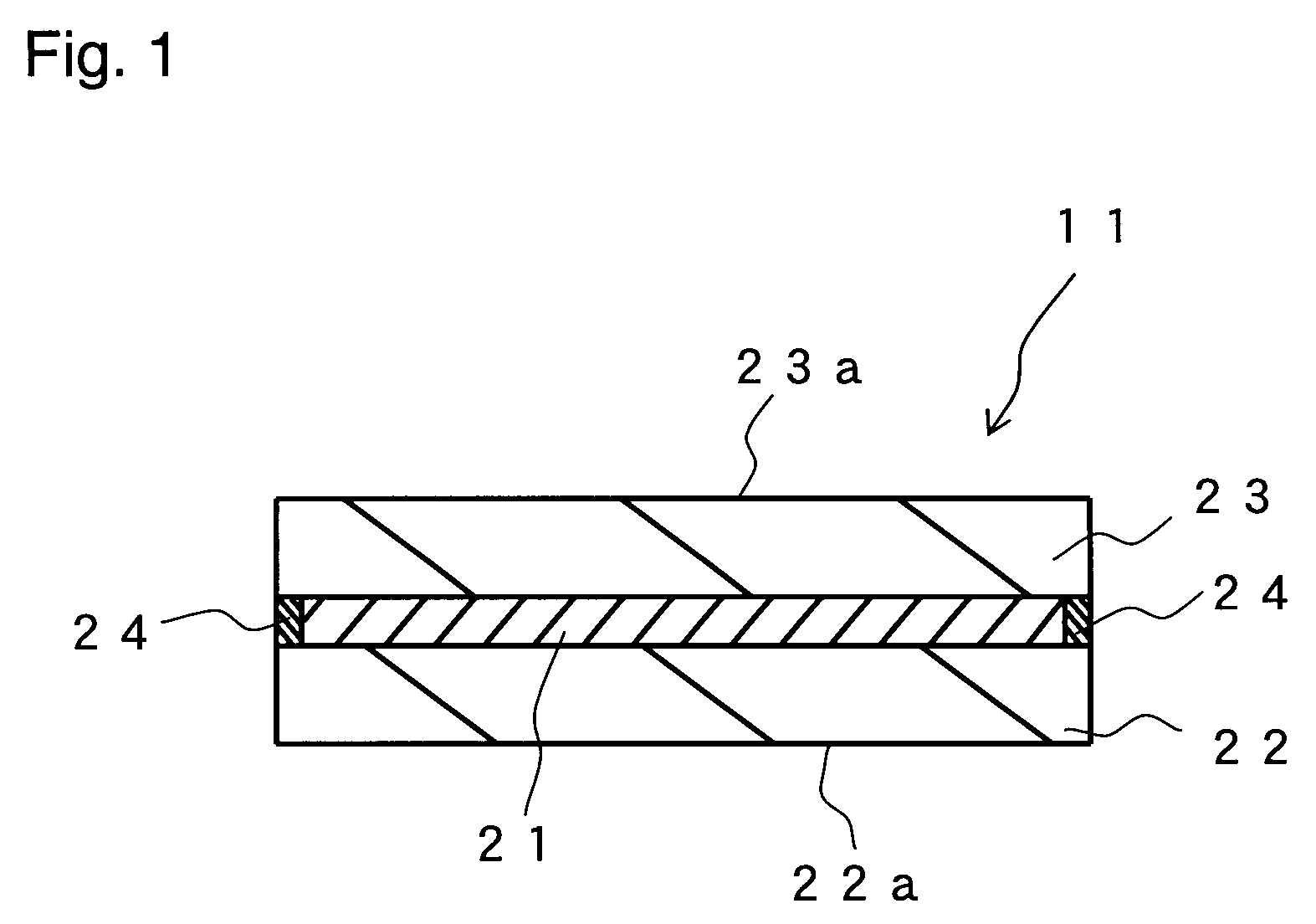

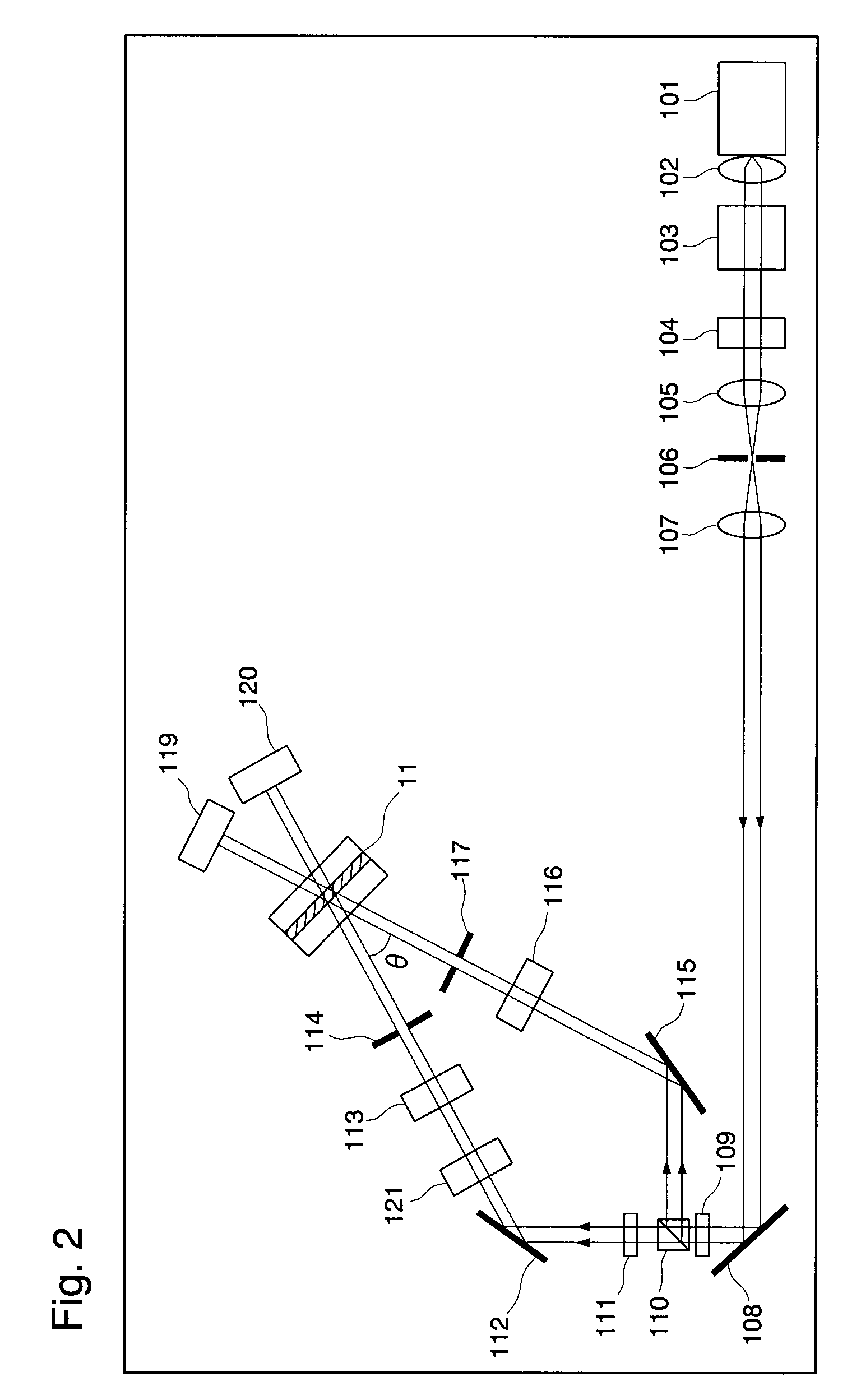

Hologram recording medium

InactiveUS20080160421A1High mechanical strengthGood holographic memory recording propertyPhotomechanical apparatusHolographic storageRefractive index

The present invention provides a hologram recording medium which is suitable for volume hologram record and can attain high refractive index change, flexibility, high sensitivity, low scattering, environment resistance, durability, low dimensional change (low shrinkage) and high multiplicity in holographic memory record using not only a green laser but also a blue laser. A hologram recording medium (11) comprising at least a hologram recording layer (21), wherein the hologram recording layer contains a metal oxide matrix comprising metal oxide fine particles, and a photopolymerizable compound; the metal oxide fine particles comprise metal oxide fine particles containing Ti as a metallic element; and at the time of subjecting the hologram recording layer before exposure to light to an extraction operation in n-butyl alcohol having a mass 100 times the mass (W) of said recording layer, thereby yielding a sol solution; filtrating the sol solution to obtain a filtrated sol solution; and measuring particle diameter distribution of sol particles in the filtrated sol solution by a dynamic light scattering method; and obtaining an average particle diameter thereof, the average particle diameter of the sol particles is in the range of 5 nm or more and 50 nm or less.

Owner:TDK CORPARATION

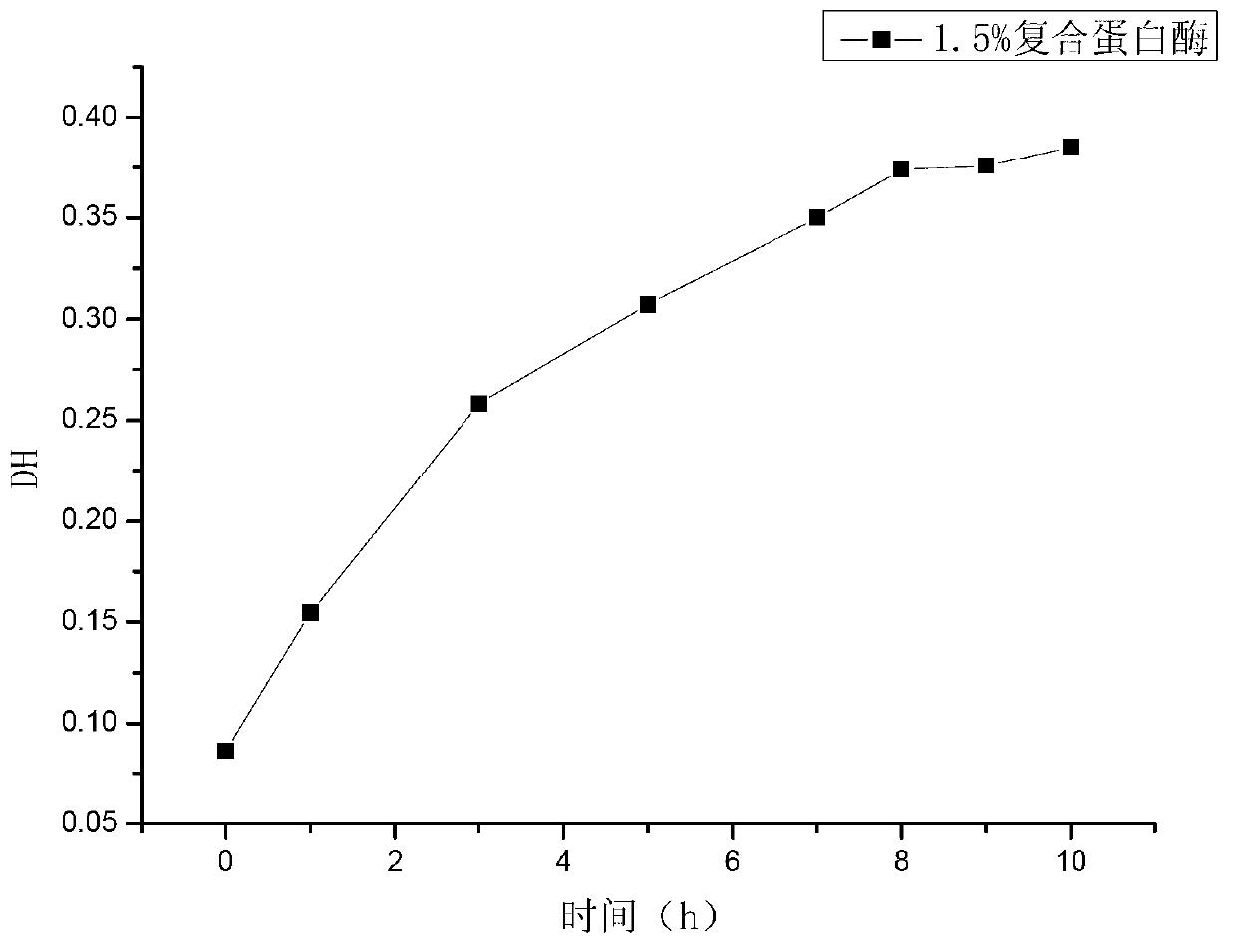

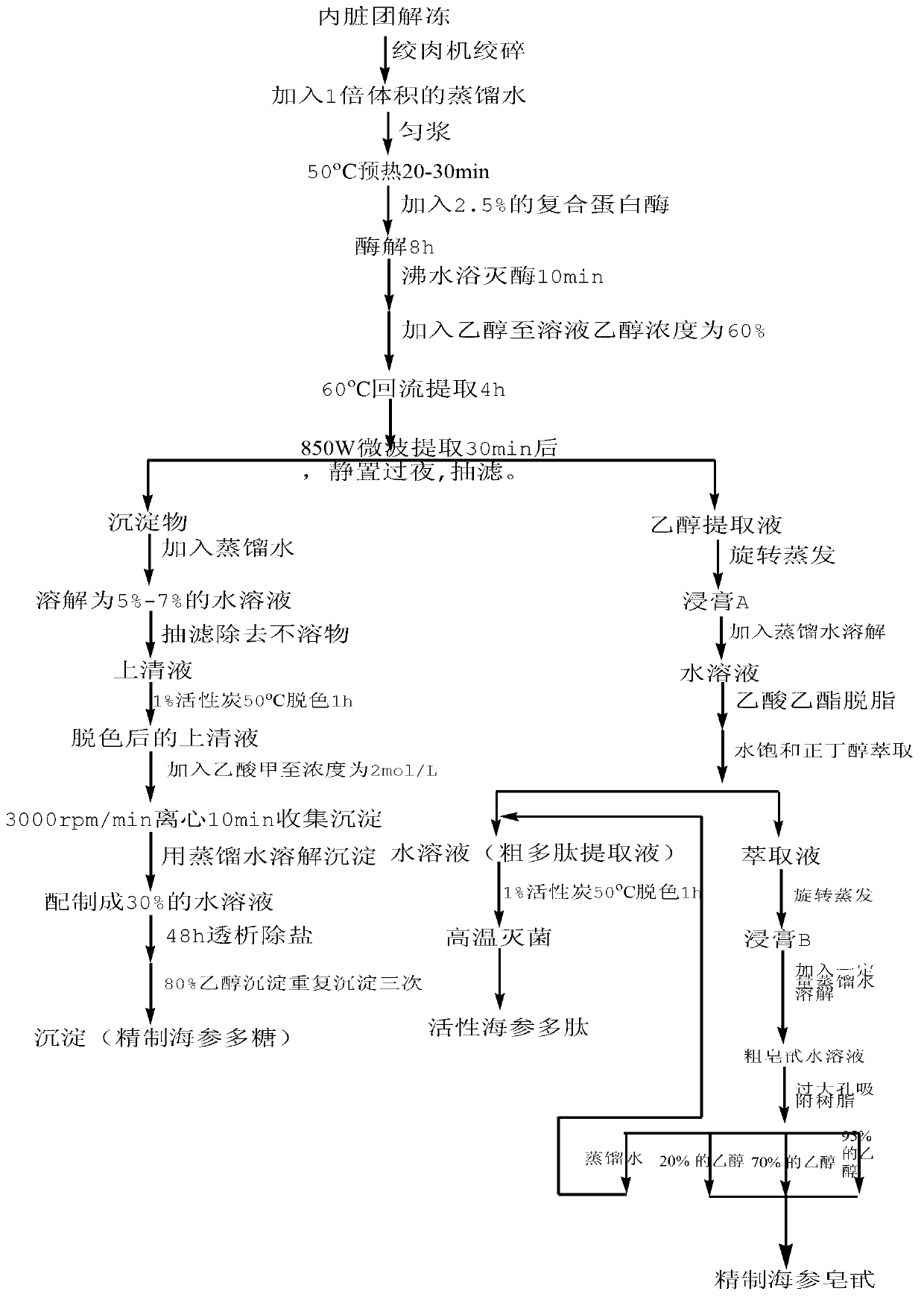

Method for extracting active substance from sea cucumber processing waste

ActiveCN103265642AIncrease the degree of hydrolysisHigh extraction rateAntinoxious agentsSteroidsEvaporationN-Butyl Alcohol

The invention relates to an extraction method of an active substrate, and in particular relates to a method for extracting an active substance from the sea cucumber processing waste. By taking the viscera of sea cucumber as a raw material, the method is used for preparing refined sea cucumber polysaccharide through the processes of pretreatment, enzymolysis, reflux extraction, microwave extraction, alcohol precipitation, decoloration, centrifugation, salt precipitation, dialysis, refining and the like; the supernate after alcohol precipitation is subjected to the processes of rotary evaporation, extraction degreasing, water saturation n-butyl alcohol extraction, rotary evaporation, macroporous adsorption resin chromatography and the like to obtain refined sea cucumber total saponins; and the aqueous solution after the water saturation n-butyl alcohol extraction is processed by the technologies of decoloration, sterilization and the like to obtain antioxidant active sea cucumber polypeptide. The method provided by the invention turns the waste of sea cucumber viscera into wealth so as to obtain three products including sea cucumber polysaccharide, sea cucumber total saponins and antioxidant active sea cucumber polypeptide.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Green making technology of animal tissue paraffin section

A green making technology of animal tissue paraffin section disclosed in the invention aims at providing a technique of making a paraffin section of animal tissue applied to the agricultural university medicine and other majors, characterized by that the type of chemical reagents that are used is limited, the chemical reagents have no toxicity, and dehydrate the tissue thoroughly, accelerate making sections but not lead to excessive contraction and increasement of hardness of the tissue, and substitute dimethyl benzene used in the traditional making technology of the paraffin section which isharmful to human body, so as to eliminate the occupational diseases and environmental pollution caused by dimethyl benzene. The making technology comprises the following steps: carrying out fixation with a fixative solution (100ml of the fixative solution comprises 91 ml 85% alcohol, 4 ml methanol and 5 ml glacial acetic acid ), dehydrating the tissue with graded ethanol, then putting the fixative and dehydrated tissue in a mixed transparent reagent (comprising 14wt% of analytically pour n-butanol, 29wt% of acetone and 57wt% of absolute alcohol ) for standing for 3 hours, then carrying out normal waxing and embedding, using analytically pour turpentine (60 DEG C) for section staining, carrying out dewaxing twice, carrying out hydration under normal temperature, using haematoxylin for staining nuclei, decoloration and bluing, and using eosin for staining, dehydrating until get absolute alcohol, then carrying out air drying, and directly using the gum diluted by turpentine to sealing the section.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

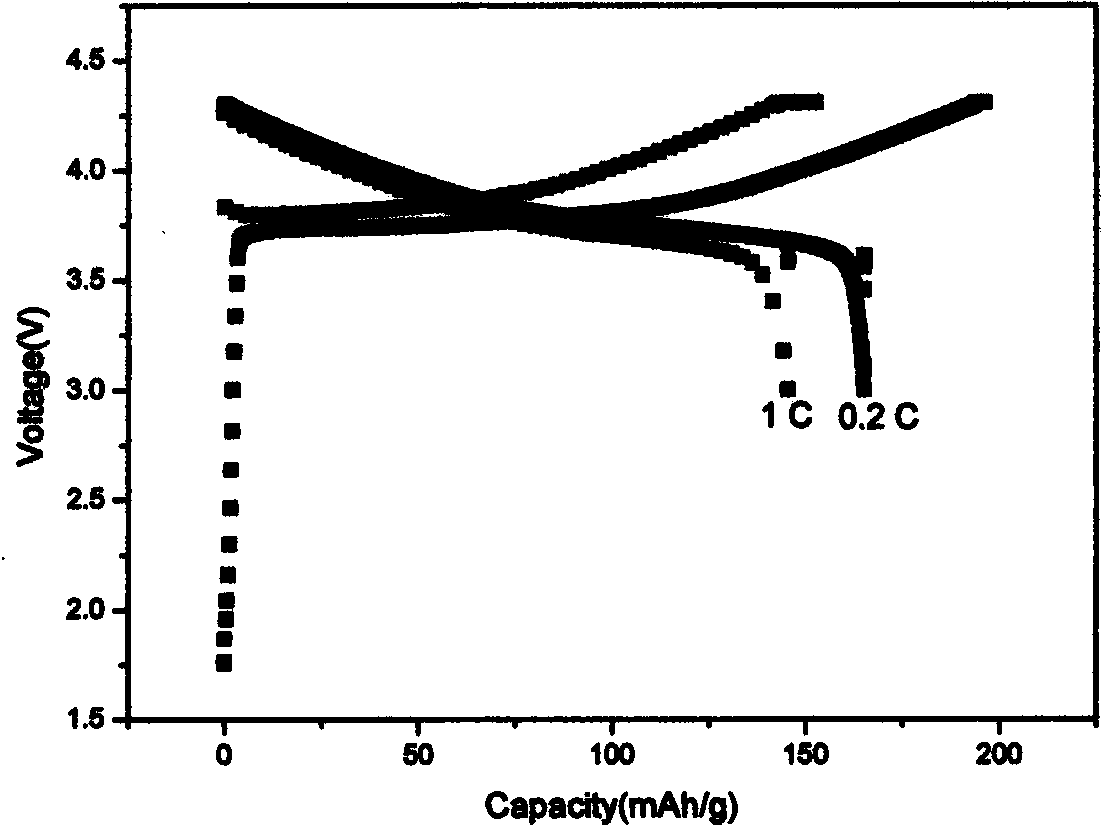

Method for preparing nano ternary composite lithium ion anode material by utilizing microemulsion

ActiveCN103811746AHigh discharge specific capacityImprove cycle stabilityMaterial nanotechnologyCell electrodesNickel saltManganese

The invention belongs to a method for preparing a nano ternary composite lithium ion anode material by utilizing a microemulsion. The method comprises the following steps: firstly, mixing a surfactant triton X-100 and a cosurfactant n-butyl alcohol with cyclohexane so as to prepare an emulgator; secondly, dissolving nickel salt, cobalt salt and manganese salt into deionized water; thirdly, preparing nickel, cobalt and manganese salt microemulsion; fourthly, preparing complexing agent aqueous alkali; fifthly, preparing alkali microemulsion; sixthly, adding the nickel, cobalt and manganese salt microemulsion into a reaction kettle; seventhly, adding alkali microemulsion dropwise into the nickel, cobalt and manganese salt microemulsion so as to prepare a turbidimetric solution; eighthly, standing the turbidimetric solution still so as to prepare a NixCoyMn(1-x-y)(OH)2 precursor; ninthly, carrying out ball-milling on the NixCoyMn(1-x-y)(OH)2 precursor and a lithium compound, mixing uniformly, and sieving; and tenthly, preparing the sieved mixture into a nano spherical LiNixCoyMn(1-x-y)(OH)2 anode material. The nano ternary composite lithium ion anode material has favorable cycle stability.

Owner:XINXIANG JINRUN TECH

Method for preparing aqueous alkyd resin

ActiveCN103788340AIncrease crosslink densityHigh hardnessPolyurea/polyurethane coatingsCross-linkBenzoic acid

The invention provides a method for preparing an aqueous alkyd resin. The preparation method comprises the following steps: preparing the alkyd resin from vegetable oil acid, polyhydric alcohol, benzoic acid and polyatomic acid, subsequently cooling, adding organic polyatomic acid, controlling the acid value of the system, further cooling, adding isocyanate and a catalyst, controlling the content of an isocyanate group, adding methyl ethyl ketoxime and reacting at constant temperature, controlling the content of urethane, and adding butyl cellosolve and n-butyl alcohol to reduce the temperature so as to obtain the alkyd resin. According to the method, methyl ethyl ketoxime is adopted to seal up the isocyanate group, so that the defect that isocyanate is not applicable to storage and application as a single component system because of the high reaction activity is overcome, and moreover after the resin is made into a coating for filming, the sealed isocyanate group is opened and subsequently is subjected to irreversible cross-linking reaction with water in air or hydroxyl of the aqueous alkyd resin, and the cured aqueous alkyd resin is high in cross-linking density, high in hardness and excellent in water resisting and chemical medicine resistance.

Owner:ZHUHAI CHANGXIAN CHEM TECH

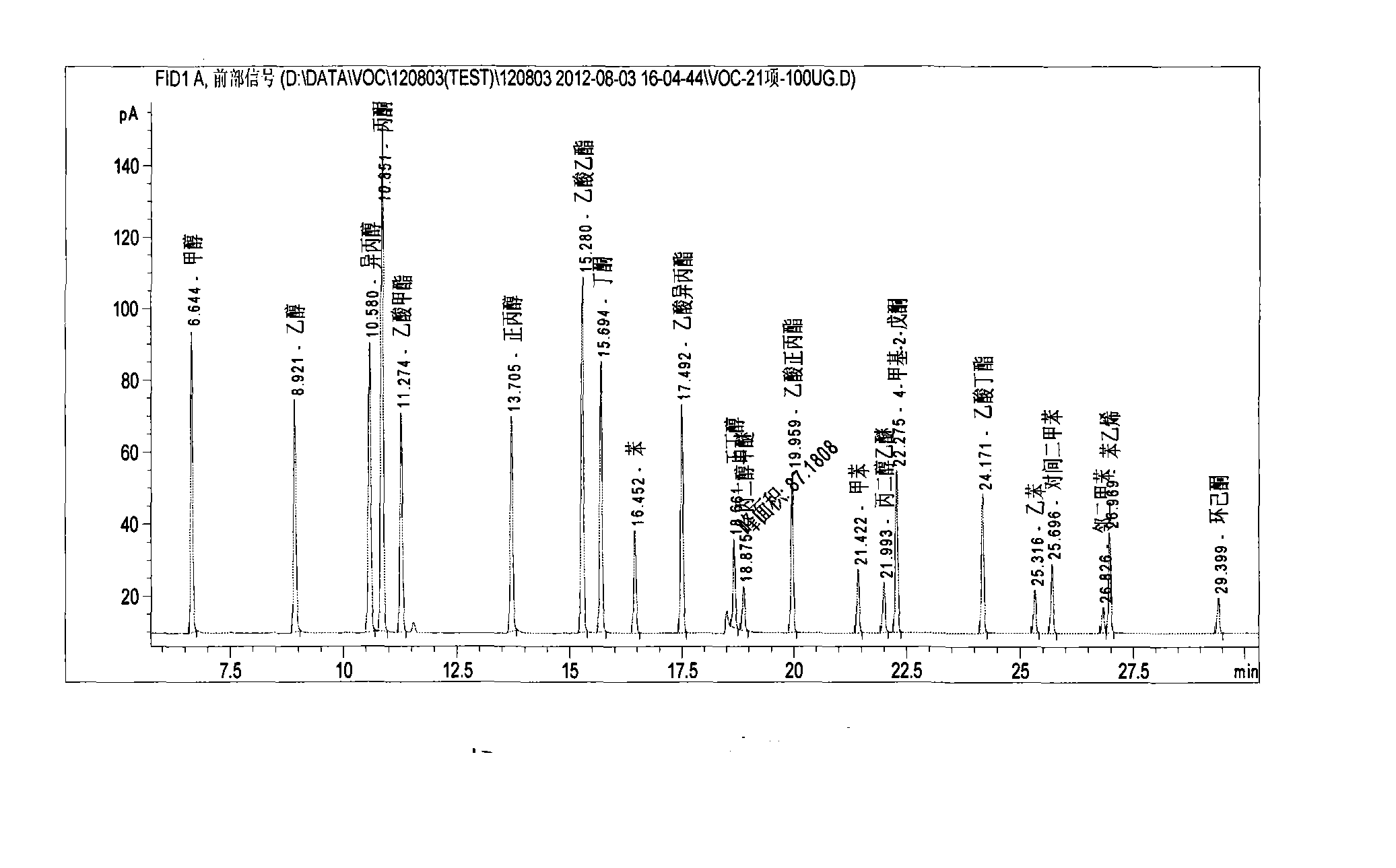

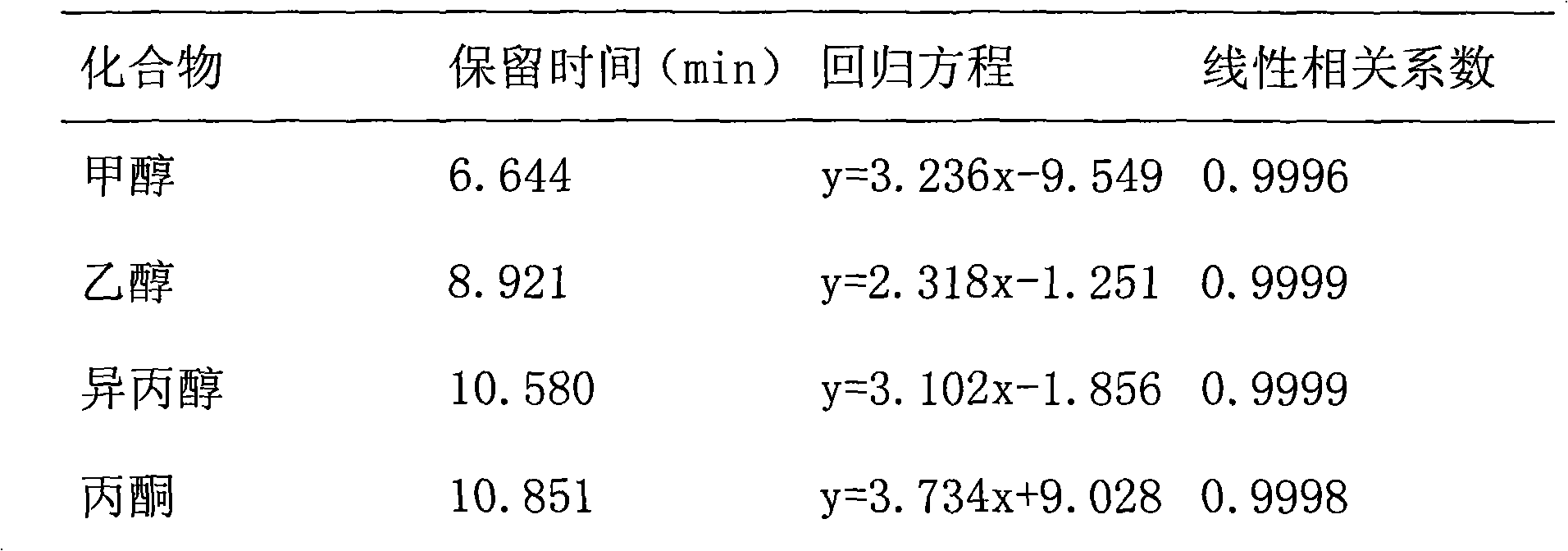

Method for detecting 21 volatile organic compounds (VOC) in tobacco packing box

The invention belongs to the technical field of tobacco packing box, and in particular relates to a method for detecting contents of 21 volatile organic compounds (VOC), including benzene, methyl benzene, p-xylene, m-xylene, o-xylene, styrene, methanol, ethanol, acetone, isopropyl alcohol, methyl acetate, normal propyl alcohol, ethyl acetate, butanone, acetic acid isopropyl ester, n-butyl alcohol, propylene glycol monomethyl ether, n-propyl acetate, propylene glycol monoethyl ether, 4-methyl-2-pentanone, butyl acetate, cyclohexanone in a tobacco packing box. The method for detecting 21 volatile organic compounds in the tobacco packing box disclosed by the invention comprises the following steps of: sample pretreatment: preparing a piece of hard box packing paper; cutting and reserving a main packing surface by an area of 22.0cm*5.5cm; rolling the printing surface of the sample inwards to obtain a barrel-shaped part; putting the barrel-shaped part in a headspace bottle; adding 1000mu l of glycerol triacetate; sealing, and implementing a headspace-gas chromatography detection. The method disclosed by the invention is high in sensitivity, high in recovery rate, and excellent in precision of detecting result.

Owner:GUANGZHOU PONY TESTING TECH

Method for preparing lead zirconate titanate ceramics fibre

The invention provides a preparation method of lead zirconate-titante ceramic fiber, which relates to a ceramic fiber. The fiber obtained with the diameter less than 30Mum and the length about 1cm has a single perovskite phase and comparatively high consistency and the invention can be a preparation method of lead zirconate-titante ceramic fiber of ceramic fiber for 1-3 piezoelectric composites. The preparation of lead zirconate-titante precursor solution is : lead acetate trihydrate is added into n-Butyl alcohol, complexing agent glacial acetic acid is added then; the mixture is heated, dissolved and cooled to obtain solution A; zirconium butoxide and titanium butoxide are poured into the n-Butyl alcohol in sequence to obtain the binary mixed solution of zirconium and titanium, and then acetyl acetone is added into the binary mixed solution and solution B is obtained after backflowing; the solution A and the solution B are mixed and the lead zirconate-titante precursor solution is obtained after backflowing. The preparation of lead zirconate-titante precursor sol is: the lead zirconate-titante precursor solution is steamed, concentrated and stirred, rod winding is carried out and the lead zirconate-titante precursor sol is obtained after concentration; lead zirconate-titante gel fiber is obtained through fiber drawing; after aging, the lead zirconate-titante gel fiber is dried and carried out by heat treatment.

Owner:XIAMEN UNIV

Method for preparing tert-butyl hydrogen peroxide and tert-butyl alcohol by oxidating isobutane

InactiveCN102391167AImprove conversion rateHigh selectivityPreparation by oxidation reactionsOrganic compound preparationCatalytic oxidationSolvent

The invention discloses a method for preparing tert-butyl hydrogen peroxide and tert-butyl alcohol by oxidating isobutene. Molecular oxygen is taken as an oxygen source; N-hydroxy phthalimide (NHPI) or a derivative thereof is taken as a catalyst; in the presence of a polar solvent, carrying out catalytic oxidation on the liquid phase of the isobutane to prepare the tert-butyl hydrogen peroxide and the tert-butyl alcohol; after finishing the reaction and rapidly cooling, the catalyst and the products are subjected to solid-liquid separation; and the catalyst is recycled through centrifugal sedimentation and washing. Compared with the existing process without catalytic optimization, the method disclosed by the invention has mild reaction conditions, the temperature and the pressure needed in the reaction can be remarkably lowered; and in addition, under the condition of having higher rate of conversion of the isobutane, the high selectivity of the tert-butyl hydrogen peroxide and the tert-butyl alcohol can be maintained.

Owner:XIANGTAN UNIV

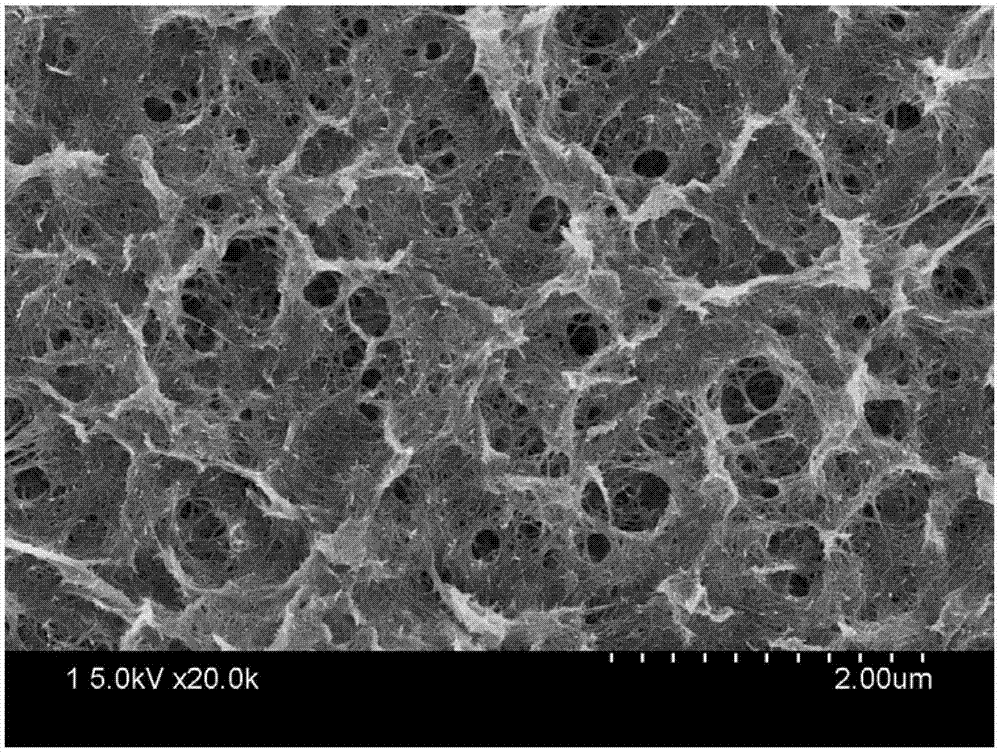

Method for preparing composite material of stannic oxide/polyaniline

The invention discloses a method for preparing composite material of stannic oxide / polyaniline. The method comprises the steps of taking stannic chloride as material and ethylene glycol as solvent, preparing nano stannic oxide powder material of which the mean grain size is about 1.5nm by a sol-gel process; taking aniline and prepared nano stannic oxide as materials, using sodium dodecyl sulfate,n-butyl alcohol and ammonium persulfate, and preparing the composite material of stannic oxide / polyaniline by adopting a microemulsion in-situ polymerization method. The method disclosed by the invention is easy to obtain the material, simple in synthesis and low in cost; the conductive polymer polyaniline in the prepared composite material not only can improve the conductive property of stannic oxide, but also can restrain agglomeration of nano stannic oxide at a certain extent. In addition, the existence of a conductive polymer network structure can effectively ensure electric contact between stannic oxide particles when electrode reacts, so that the composite material is expected to be excellent lithium ion battery negative electrode material.

Owner:SHANDONG UNIV

Method for extracting theabrownin crude product from Liupu tea

InactiveCN102334574AProcess requirements are not harshEquipment requirements are not strictTea extractionUltrasonic assistedLow demand

The invention discloses a method for extracting a theabrownin crude product from Liupu tea. The method comprises the following steps: utilizing an ultrasonic auxiliary aqueous solvent extraction process to extract Liupu tea powder; treating a tea extracting solution by utilizing chloroform, ethyl acetate and n-butyl alcohol to respectively extract and remove tea polyphenol, theaflavin and thearubigins; and finally acquiring the theabrownin crude product by evaporating the acquired water layer which is a theabrownin crude product solution. The method provided by the invention has the following beneficial effects: 1) the method has low demands on process and equipment for extracting theabrownin from the Liupu tea and is easily performed, and 2) the research shows that the method is capable of enriching research data of the Liupu tea and theabrownin, providing necessary assistance in identifying properties of the theabrownin of the Liupu tea and providing theoretical reference to the deep processing of the Liupu tea and the sale of middle and low-class Liupu tea.

Owner:GUANGXI TEACHERS EDUCATION UNIV

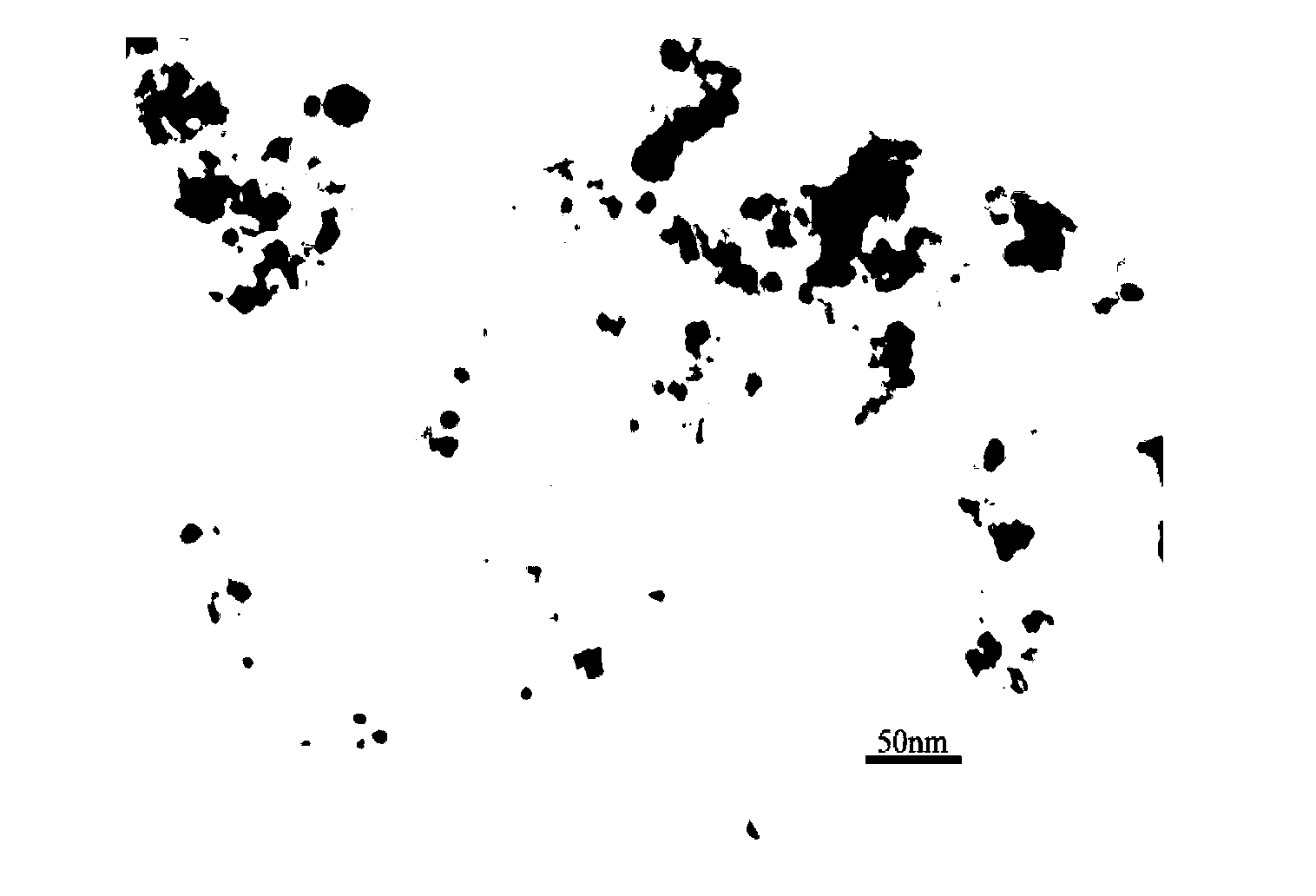

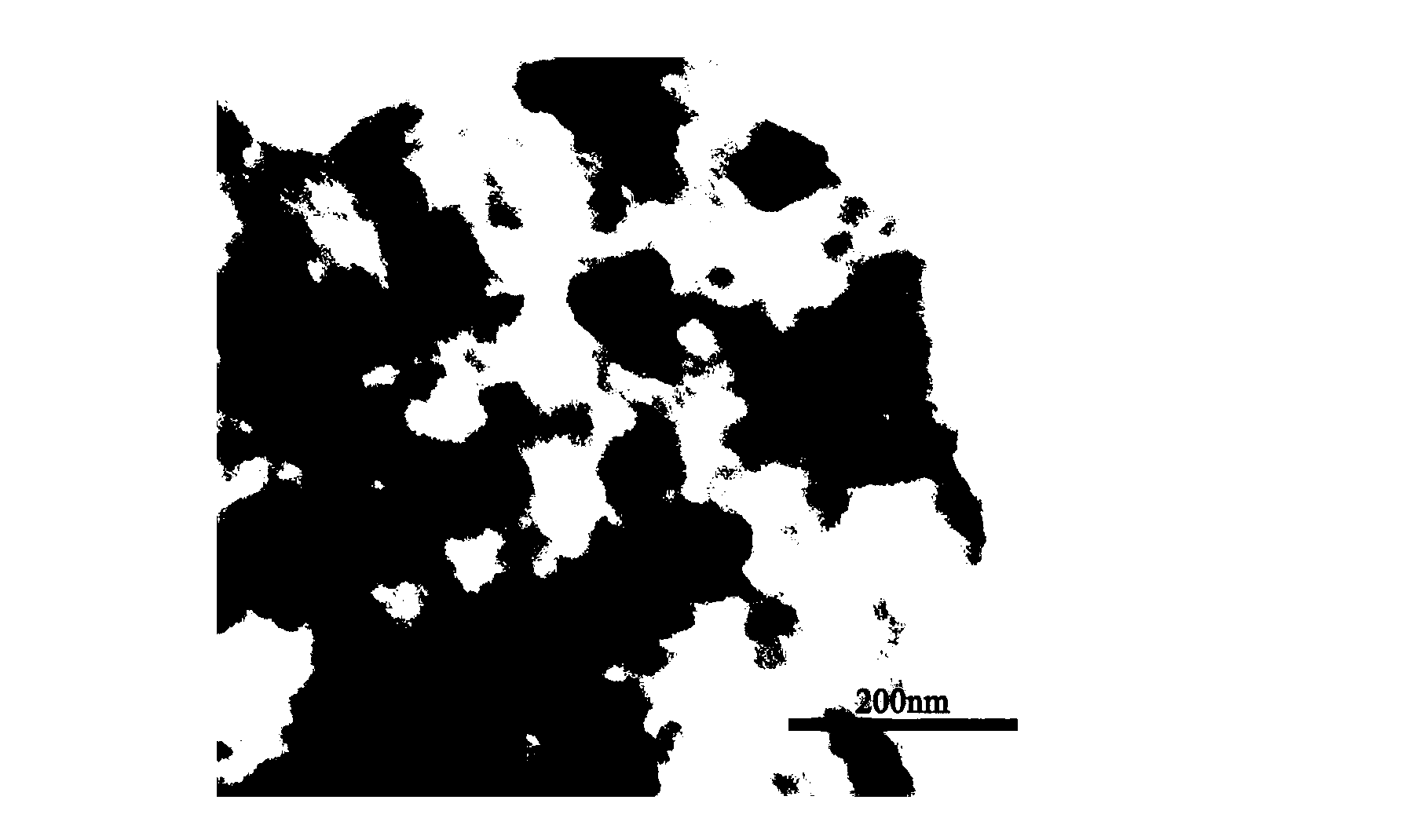

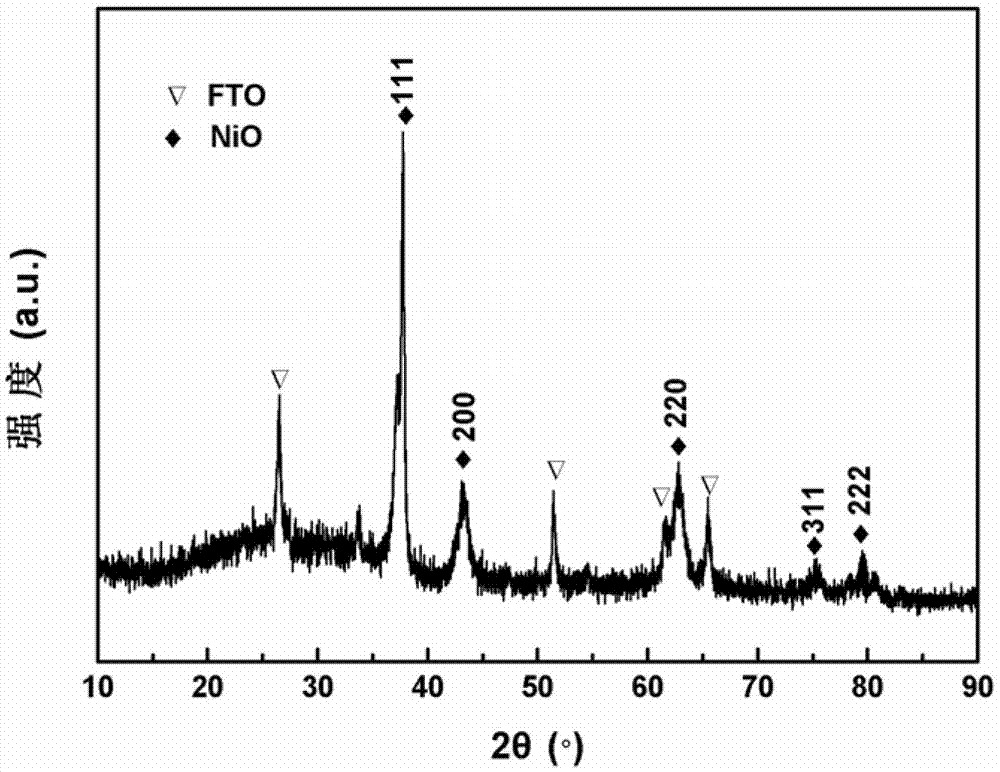

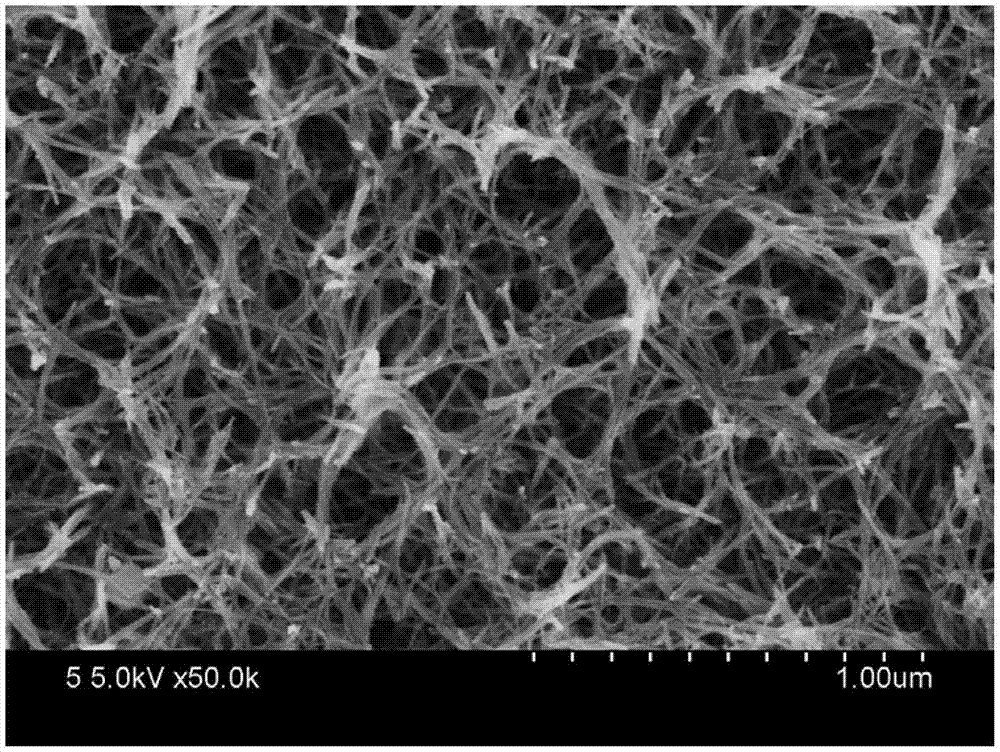

Method for preparing nickel oxide electrochromic film by hydrothermal method

ActiveCN103172273ALarge specific surface areaReduce path lengthNickel oxides/hydroxidesNickel acetate tetrahydrateSolvent

The invention relates to a method for preparing a nickel oxide electrochromic film by a hydrothermal method. The method comprises the following steps of: dissolving nickel acetate tetrahydrate in a mixed solution of alcohol and n-butyl alcohol, dropwise adding ammonia water to the mixed solution after the nickel acetate tetrahydrate is dissolved to obtain sol; coating the sol to the surface of FTO (Fluorine-doped Tin Oxide) conductive glass in a rotary manner, drying the sol to obtain the FTO conductive glass with a crystal seed layer; mixing the nickel acetate tetrahydrate, urea and a solvent to obtain a reaction solution; immersing the FTO conductive glass with the crystal seed layer to the reaction solution for carrying out hydrothermal reaction; keeping the reaction solution for 6 hours to 12 hours under the condition of 160 DEG C to 180 DEG C, cooling the reaction solution to the room temperature, cleaning, drying and roasting to obtain the nickel oxide electrochromic film. The preparation method disclosed by the invention is simple, low in cost and likely applied to the glass surface film-making industry. The nanometer structure nickel oxide film directly grows on the surface of the FTO conductive glass by a hydrothermal method, so that the nickel oxide and the substrate have better binding force for being beneficial to electron conduction. Meanwhile, the electrochemical stability of the film is also improved.

Owner:DONGHUA UNIV

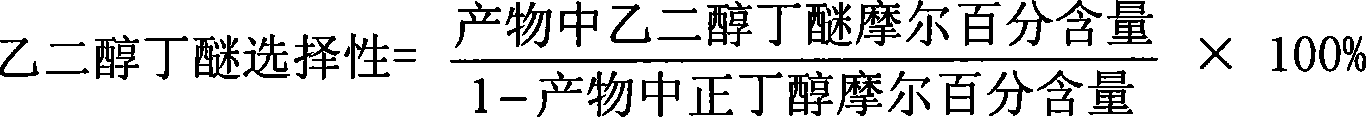

Method for preparing ethylene glycol monobutyl ether

The present invention discloses a method for preparing glycol butyl ether with one step reaction taking ethylene, hydrogen peroxide and n-Butyl alcohol as the raw material; the method makes ethylene, hydrogen peroxide and n-Butyl alcohol mix under titanium silicon molecule screen or alkaline titanium silicon molecule screen; the molar ratio between n-Butyl alcohol and hydrogen peroxide is 1-20; the temperature and the pressure are respectively 5-280 Celsius system and 0.1-5.0 Mpa; the contact time is 0.2-10 hours; the dose of the titanium silicon molecule screen or alkaline titanium silicon molecule screen should be the degree to make with 0.001-0.5 molecule screen in each gram of the reaction liquid. The method not only overcomes the problem in the traditional technical that: the flow is much longer; the device investment is much larger and the resource consumption is much higher and so on, but also the selectivity for the purposed product is much higher; the utilization ratio for hydrogen peroxide is much higher; the activity and the stability of the catalyzer is much higher; the product can be reused and recycled; hydrogen peroxide is oxidated to change water, which does not pollute the environment.

Owner:胡先念

Agrochemical formulation aid composition and uses thereof

InactiveUS6936572B2Improve biological activityEasy to storeBiocideDead animal preservationWaxChemistry

There is provided an agrochemical formulation aid composition for preparing bioactive and sprayable agrochemicals, wherein various components for the composition were selected from mineral oil paraffinic distillate and / or aromatic hydrocarbon distillate; 2N-octanol; oleyl-cetyl; alcohol polyoxyethylene (2) oleylether; polyoxyethylene (8) nonylphenolethin and / or ethoxylated tallow amine blend; lauryl sulphate; fatty alcohol alkoxylate; terpenes, diammonium phosphate; tetrasodium ethylene diamine tetracetate; cab-o-sil; fatty acid methyl ester; (C18) free fatty acid blend; N-butanol; and methyl alcohol. Also provided are methods of preparing the formulation aid composition on site by mixing various components and methods of preparing sprayable and bioactive agrochemical systems using the formulation aid and non-formulated or formulated agrochemicals. Also provided are uses of the formulation aid in preparing sprayable and bioactive agrochemical systems for controlling pests.

Owner:ADJUVANTS PLUS INC

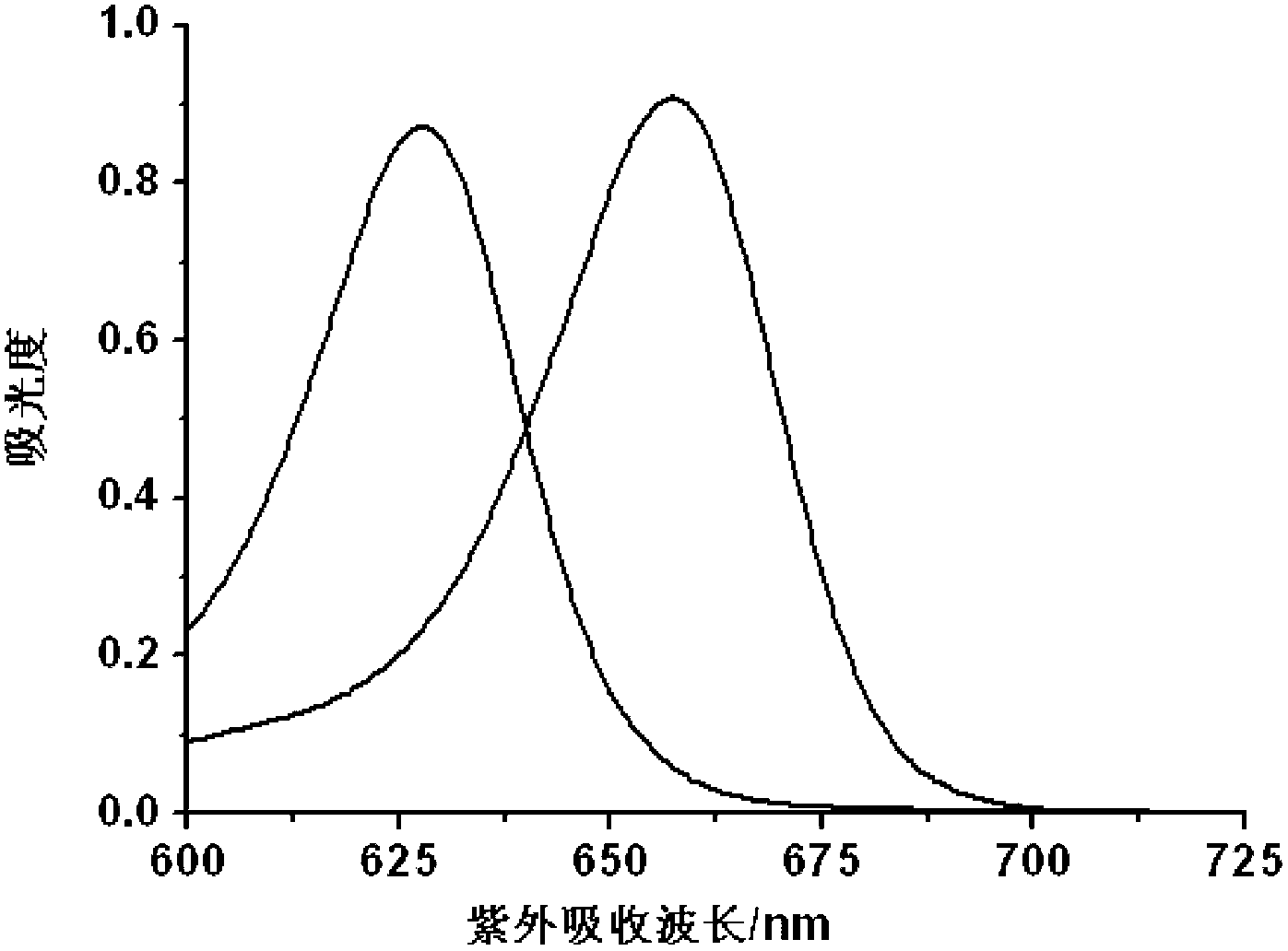

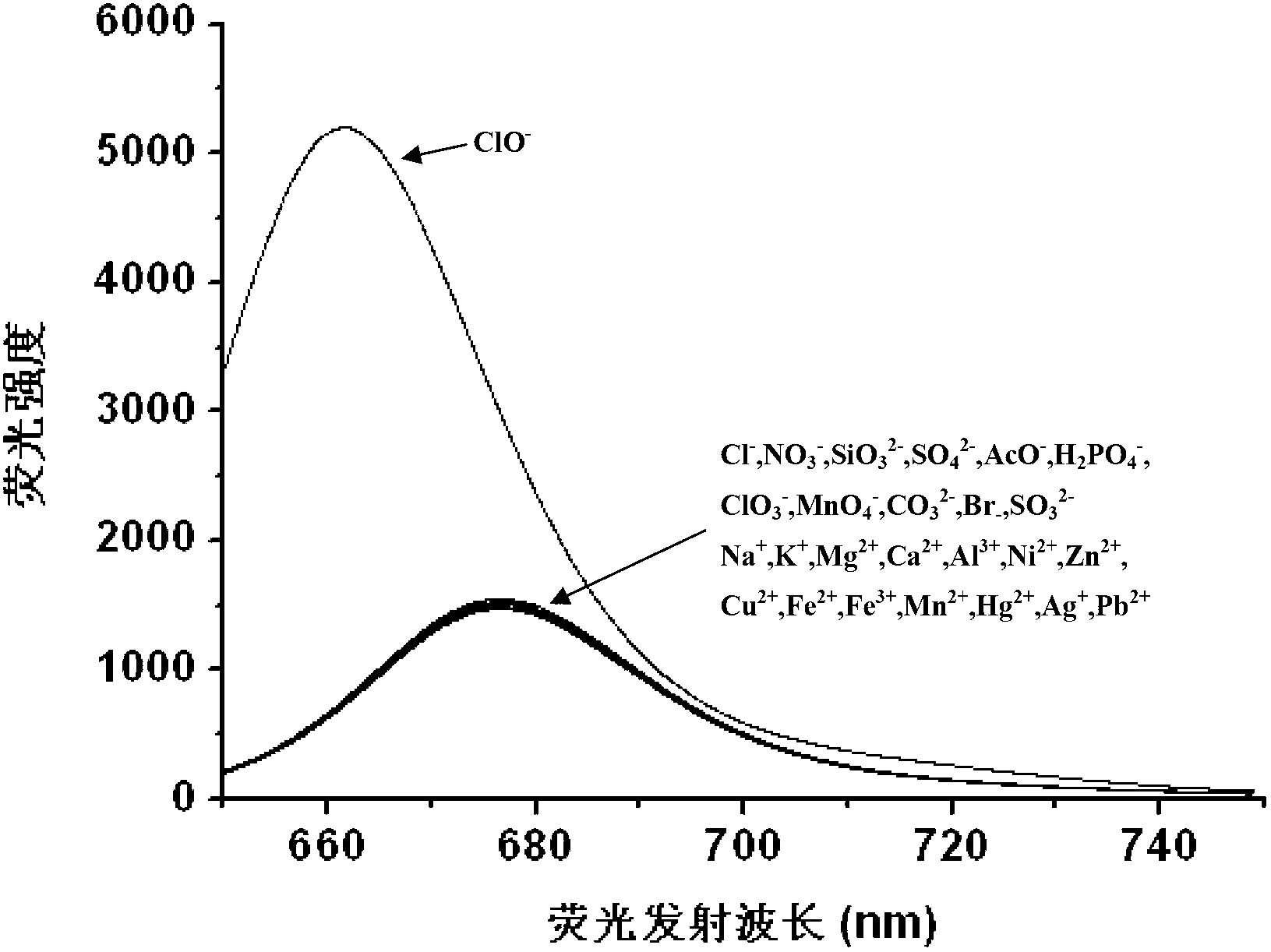

Hypochlorite ion fluorescence probe, and synthetic method and application thereof

InactiveCN103173213AGood choiceLow detection limitThiol preparationFluorescence/phosphorescenceHypochloriteDistillation

The invention discloses a hypochlorite ion fluorescence probe, and a synthetic method and an application thereof. The synthetic method comprises the following steps: 1, adding 3,4-dihydroxy-3-cyclobutene-1,2-dione (squaric acid) and 3-N,N-diethylamino phenol to a solvent which is a mixed solution comprising toluene and n-butanol, carrying out a heating reflux reaction for 8-12h, filtering, washing the obtained reaction precipitate with methanol, and drying to obtain an intermediate squaric acid dye, wherein the molar ratio of 3,4-dihydroxy-3-cyclobutene-1,2-dione (squaric acid) to 3-N,N-diethylamino phenol is 1:1.8-2.2; and 2, carrying out the heating reflux reaction of the squaric acid dye and a Lawesson reagent in a solvent toluene under the protection of nitrogen for 6-24h, carrying out reduced pressure distillation to remove the solvent, and carrying out silica gel column chromatography to obtain the fluorescence probe. The probe has a simple synthetic process, has a very high selectivity and a very high sensitivity to hypochlorite ions, and has a good application prospect.

Owner:CENT SOUTH UNIV

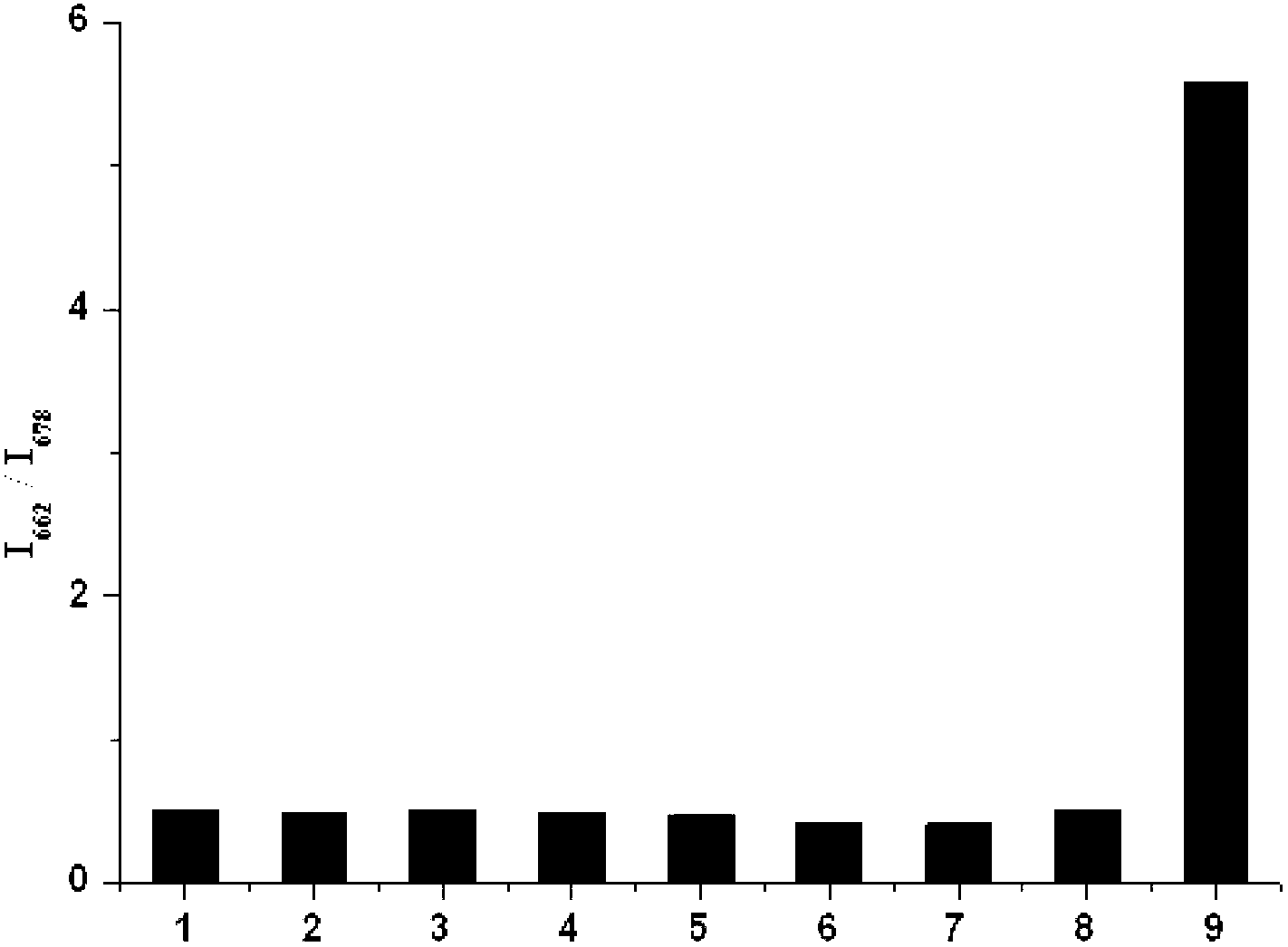

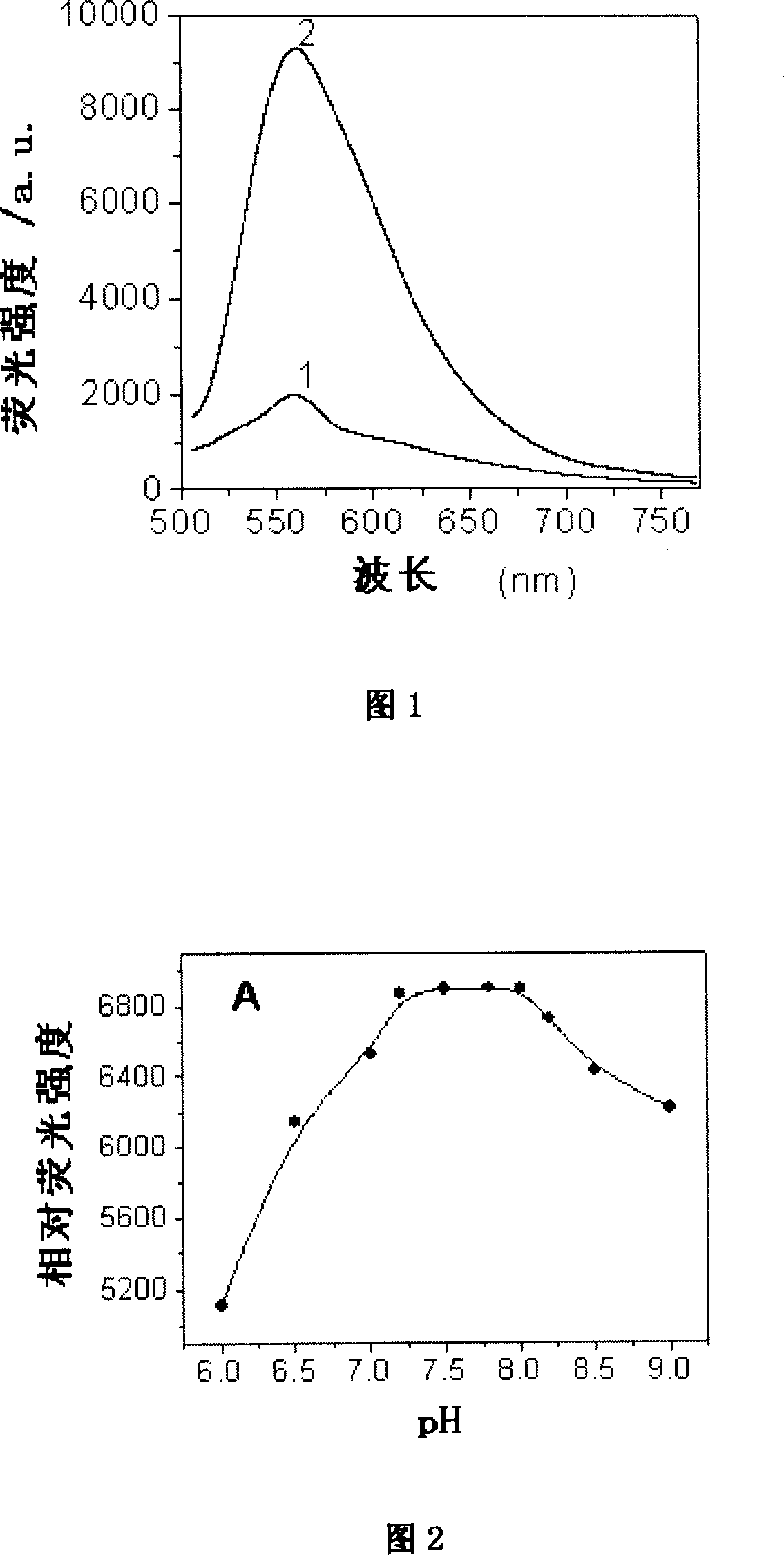

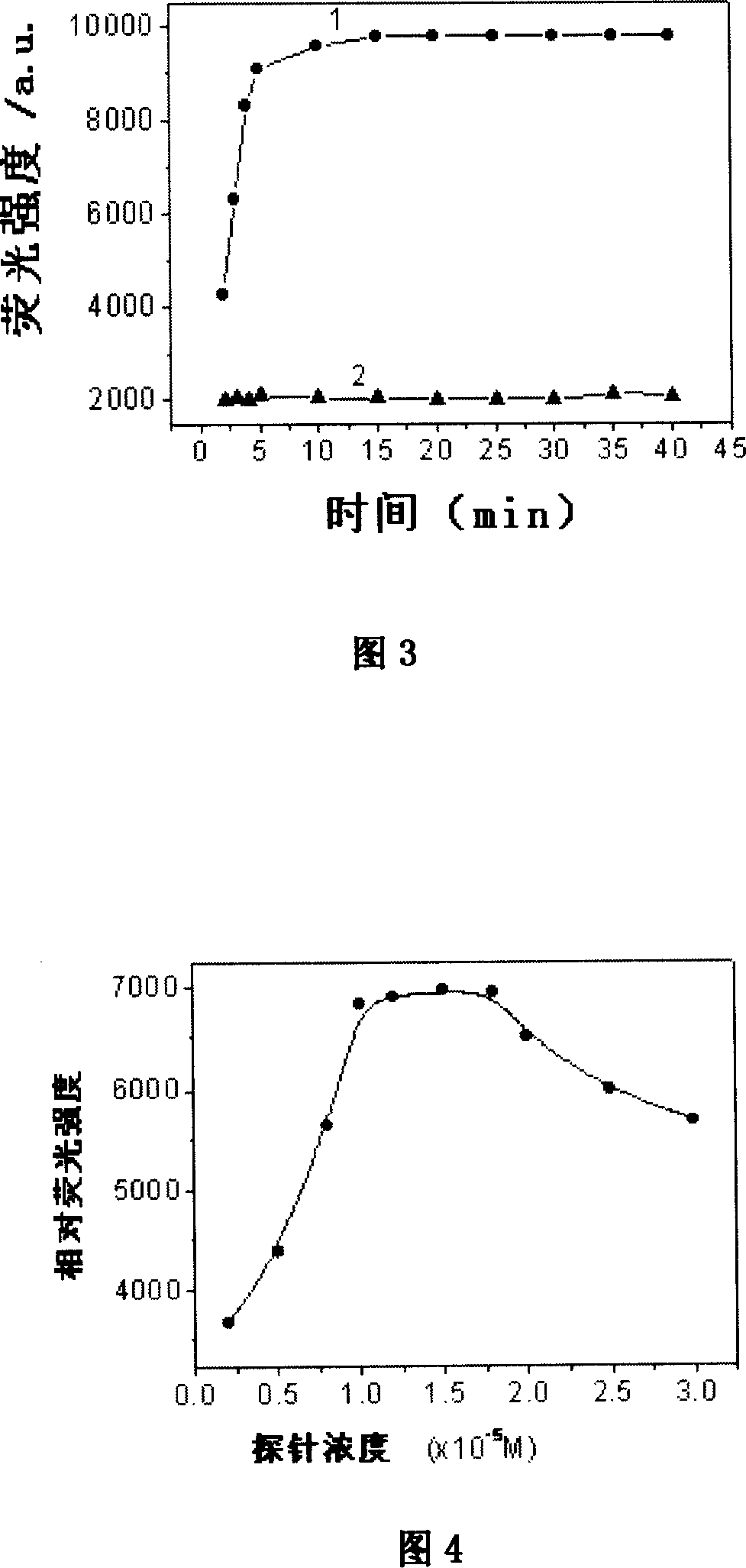

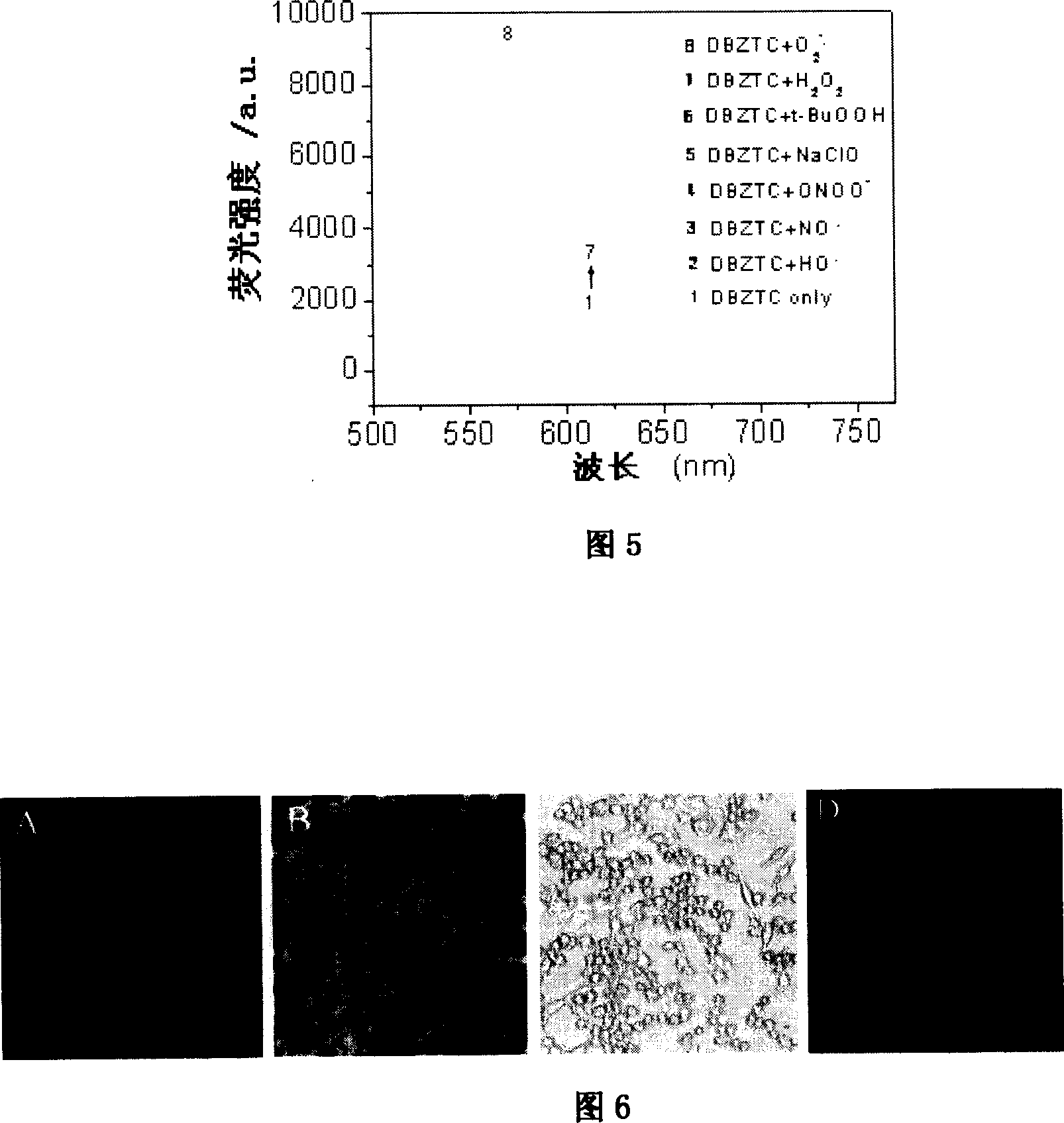

Fluorescent probe for detecting ultra-oxygen anion free radical, synthesis method and use

InactiveCN101012207AGood choiceLarge conjugated structureOrganic chemistryBiological testingAlcoholSynthesis methods

The invention discloses a new typed fluorescent probe and synthesizing method and application to detect hyperoxygen anion free radical in the cell selectively, which comprises the following steps: dissolving aromatic o-aminophenyl-sulfhydrate or aromatic o-aminophenyl-sulfhydrate derivant with weight rate at 1:2 -3.5 into composite solution with butanol and benzene with bulk rate at 1:0.3-0.6; heating the composite liquid to reflux 3-5h; decompressing to remove solvent; obtaining rough product; recrystallizing through alcohol; drying in the vacuum; obtaining pure product.

Owner:SHANDONG NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com