Patents

Literature

281results about How to "Reduce path length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

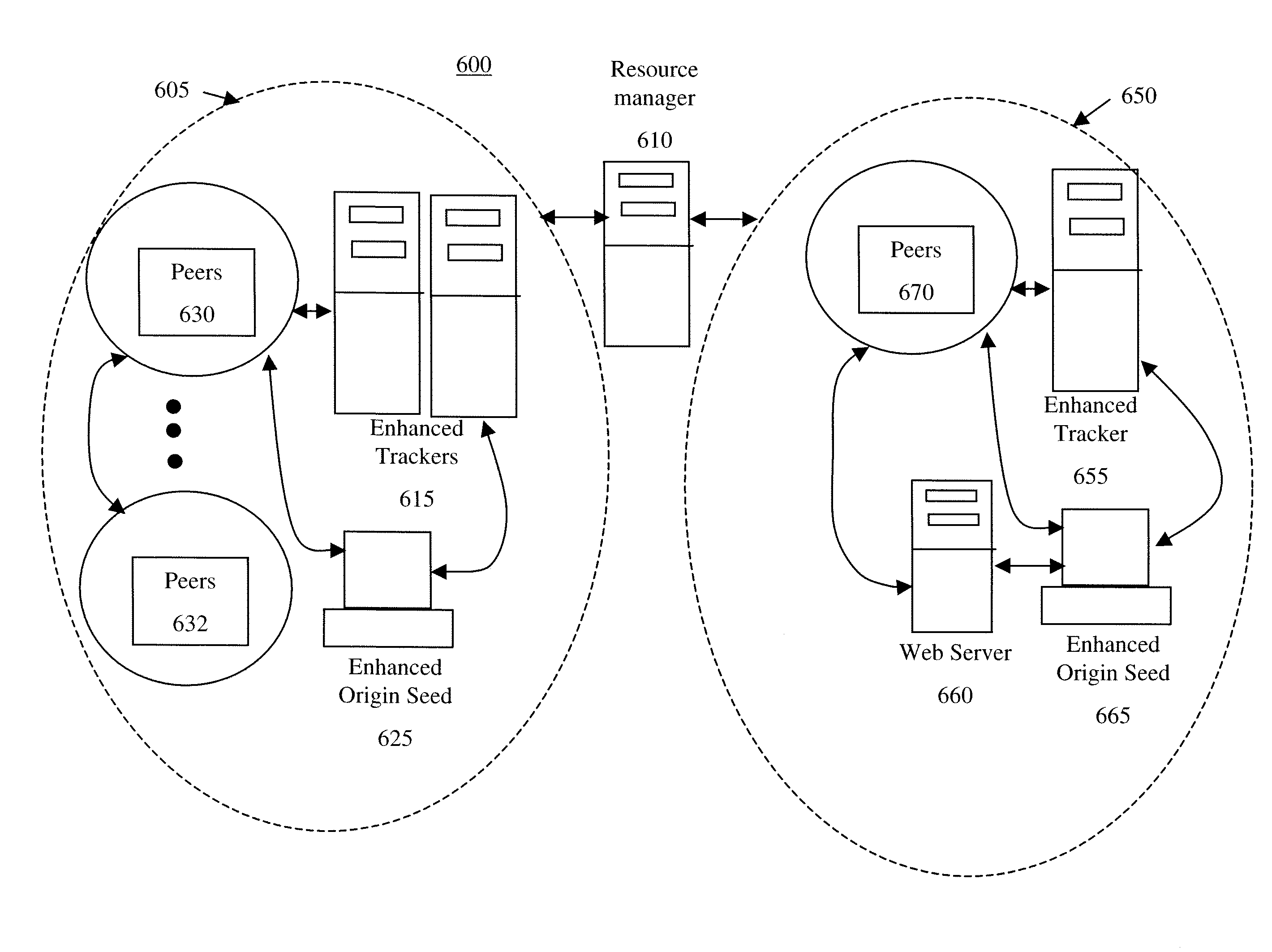

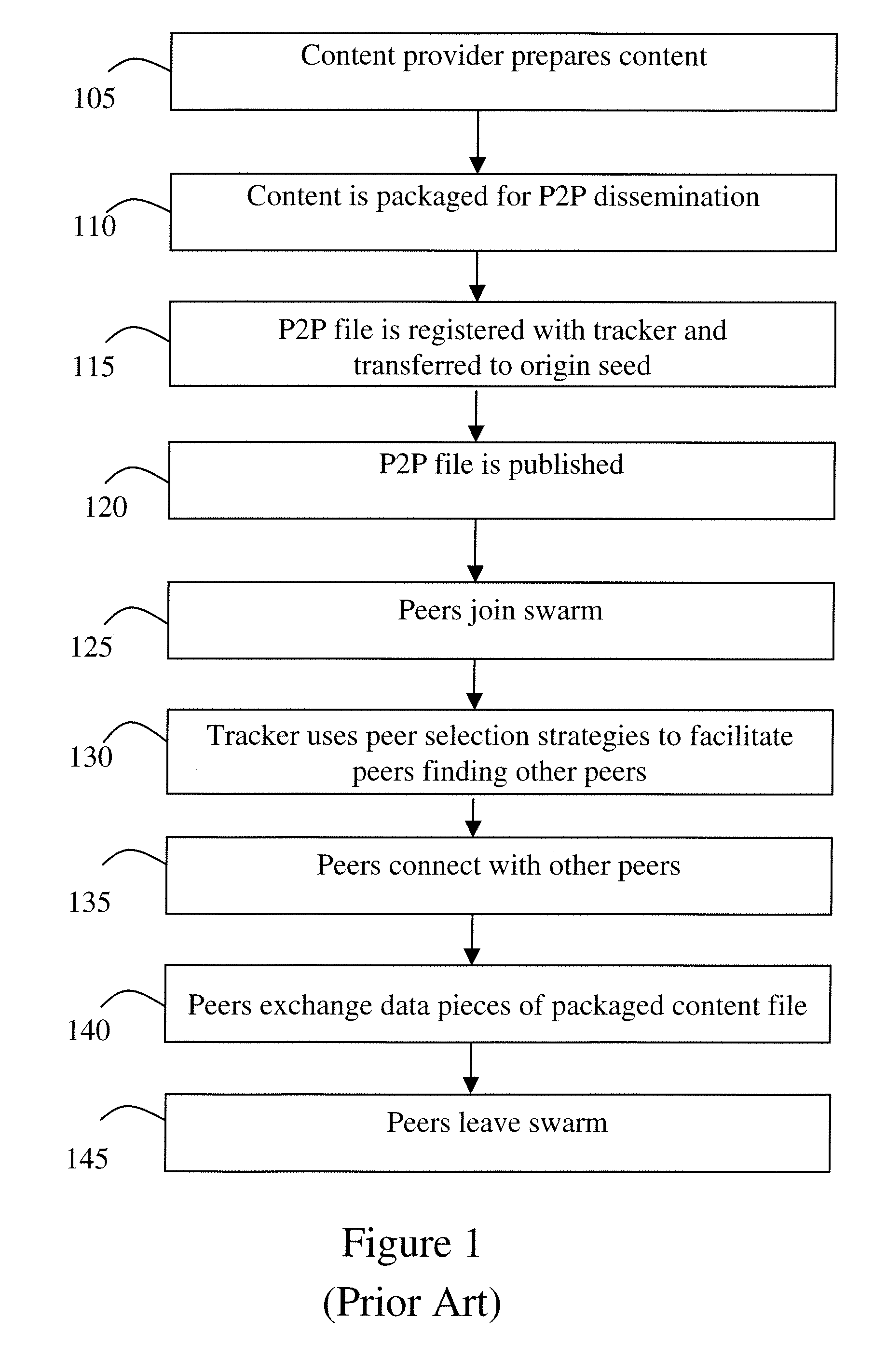

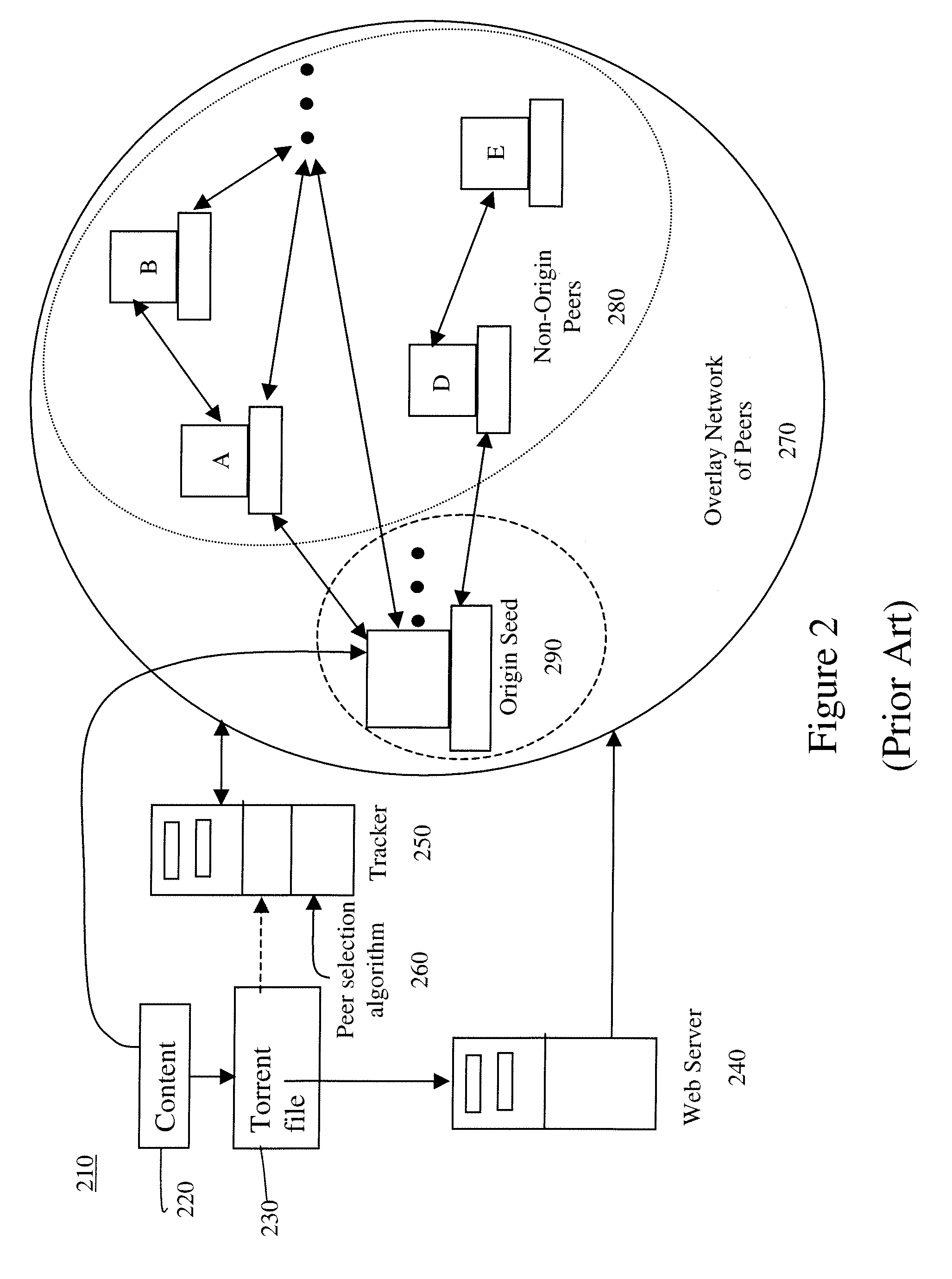

Accelerating peer-to-peer content distribution

ActiveUS20090182815A1Improving P2P performanceImprove service qualityMultiple digital computer combinationsElectric digital data processingContent distributionDistributed computing

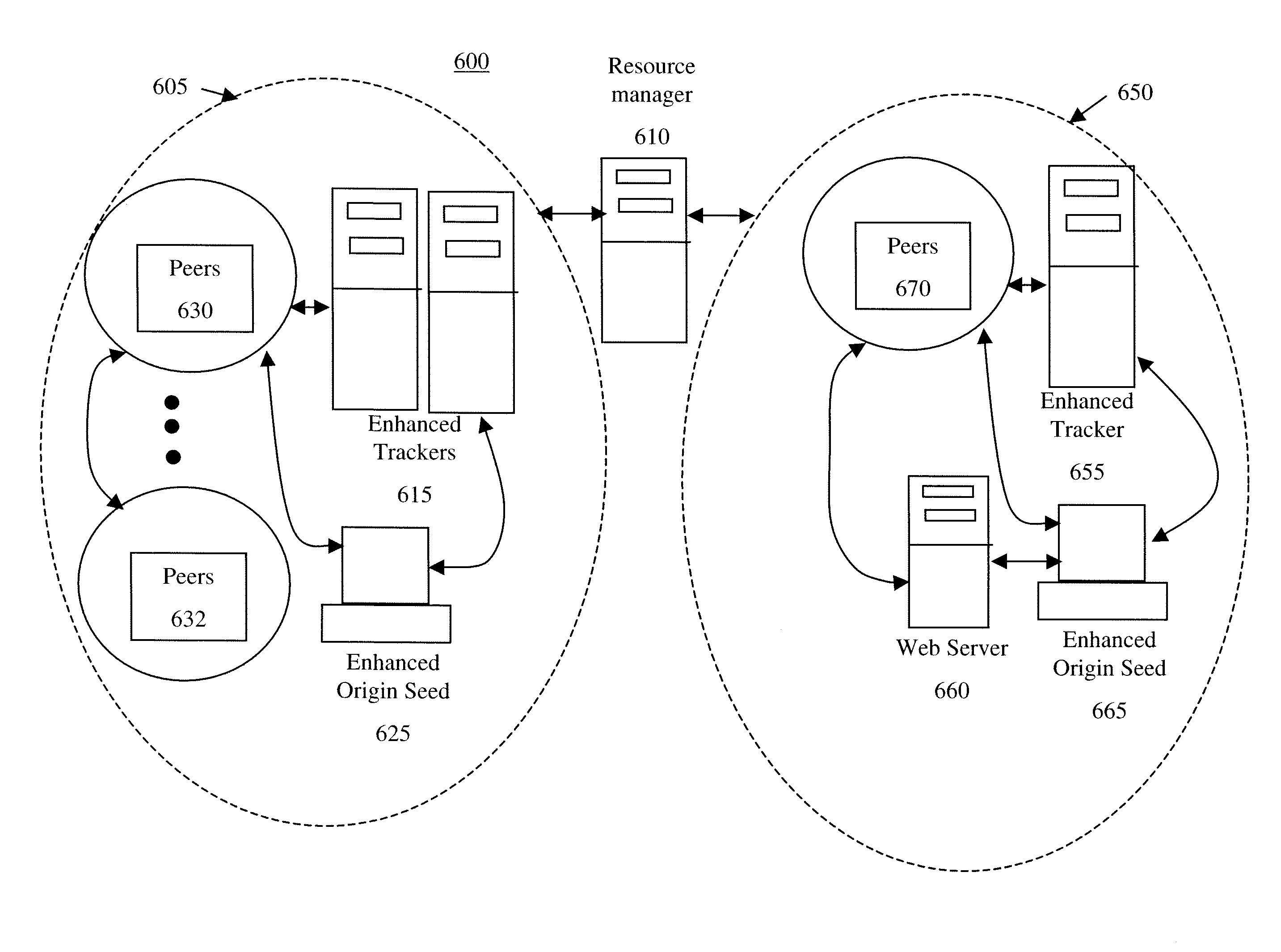

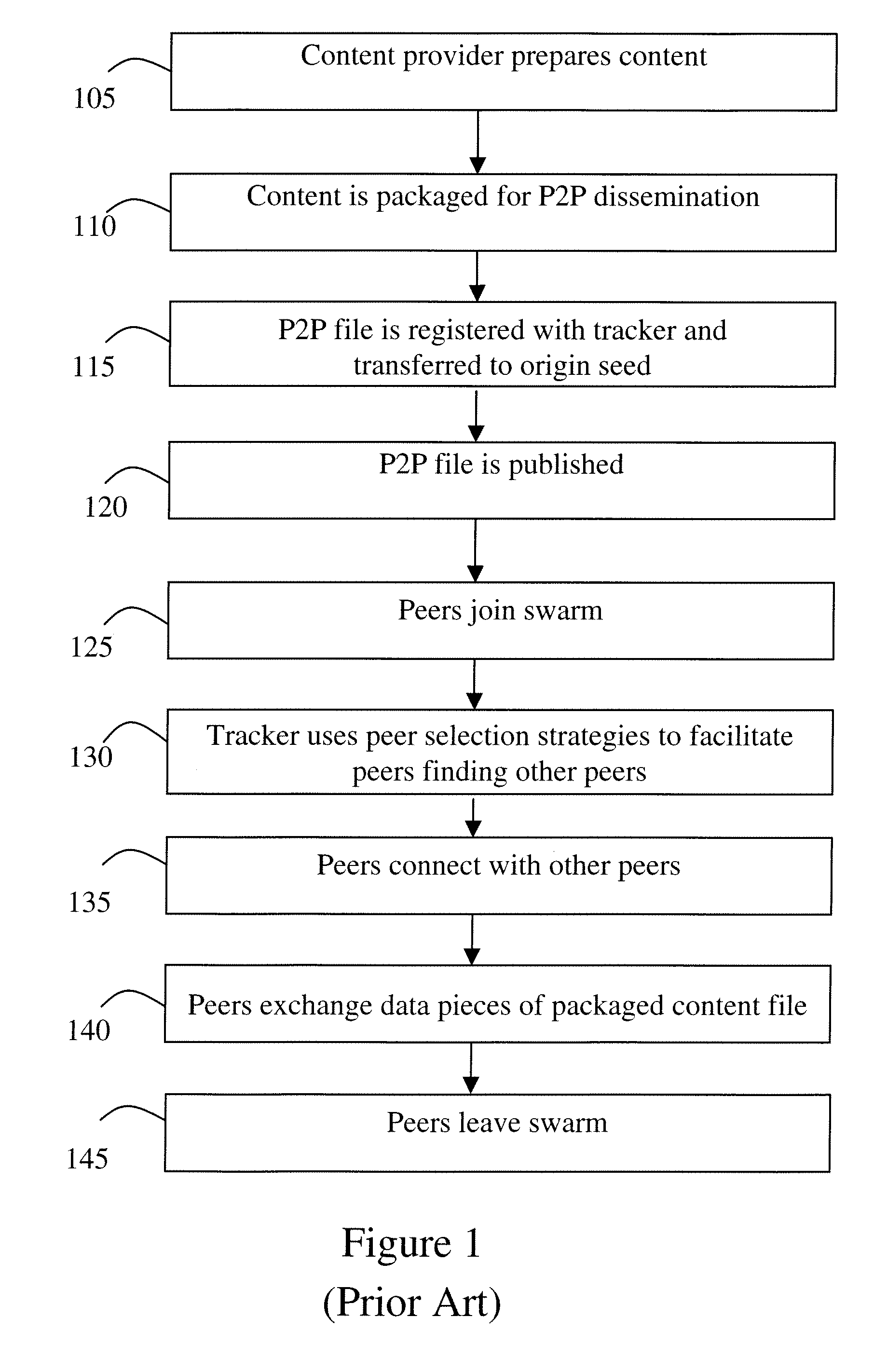

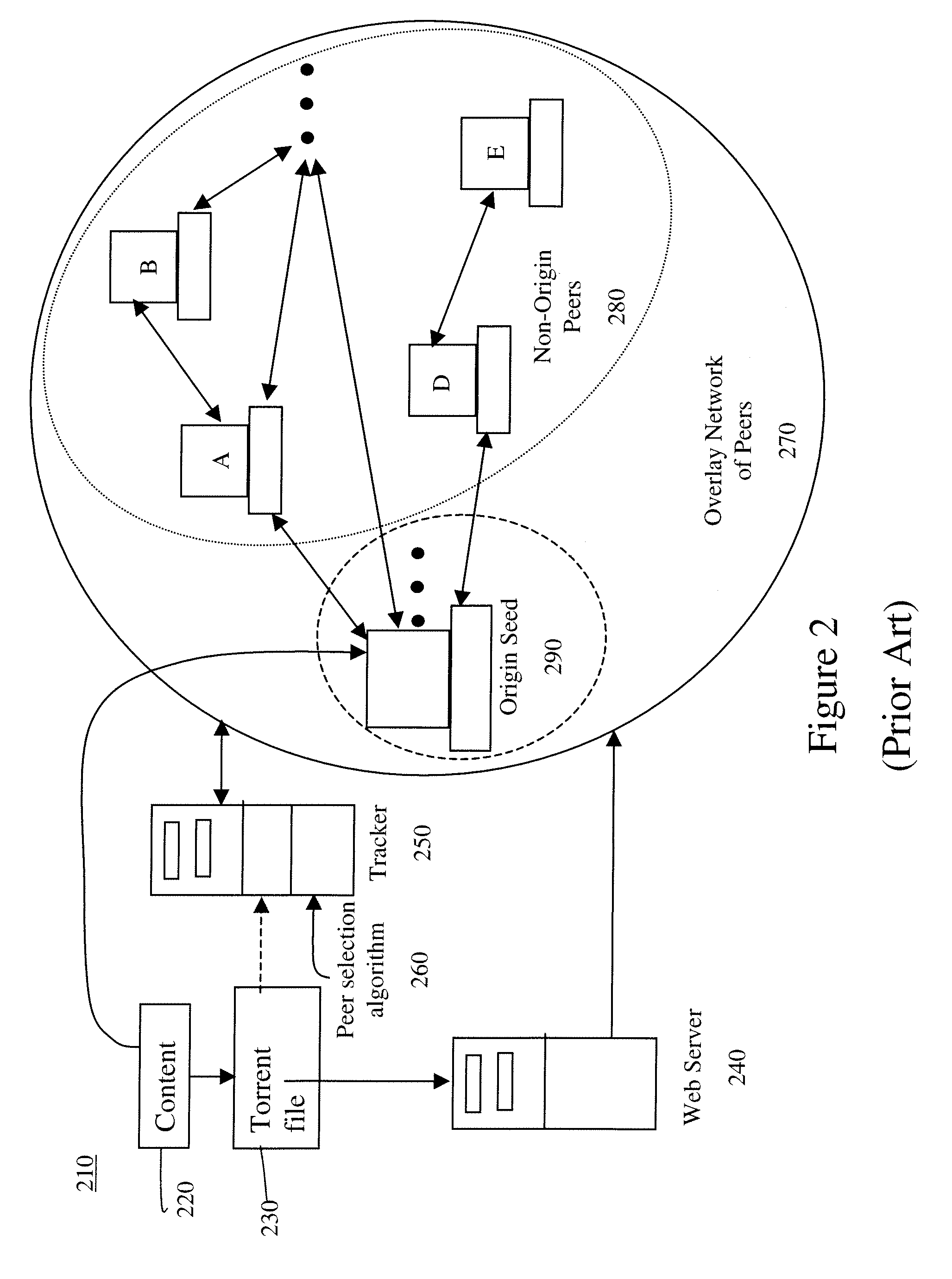

The acceleration of peer-to-peer downloads of content files wherein a tracker performs a condition based peer selection that is dynamically adjustable. A further feature relates to the use of enhanced message scheme for communications. One embodiment is a system in a swarm having at least one origin seed capable of at least initially storing the content files with at least one tracker maintaining a list of peers wherein the tracker uses at least one dynamically adjusting peer selection algorithm to generate a condition based peer-list and provides the condition based peer-list to a requesting peer.

Owner:NBCUNIVERSAL

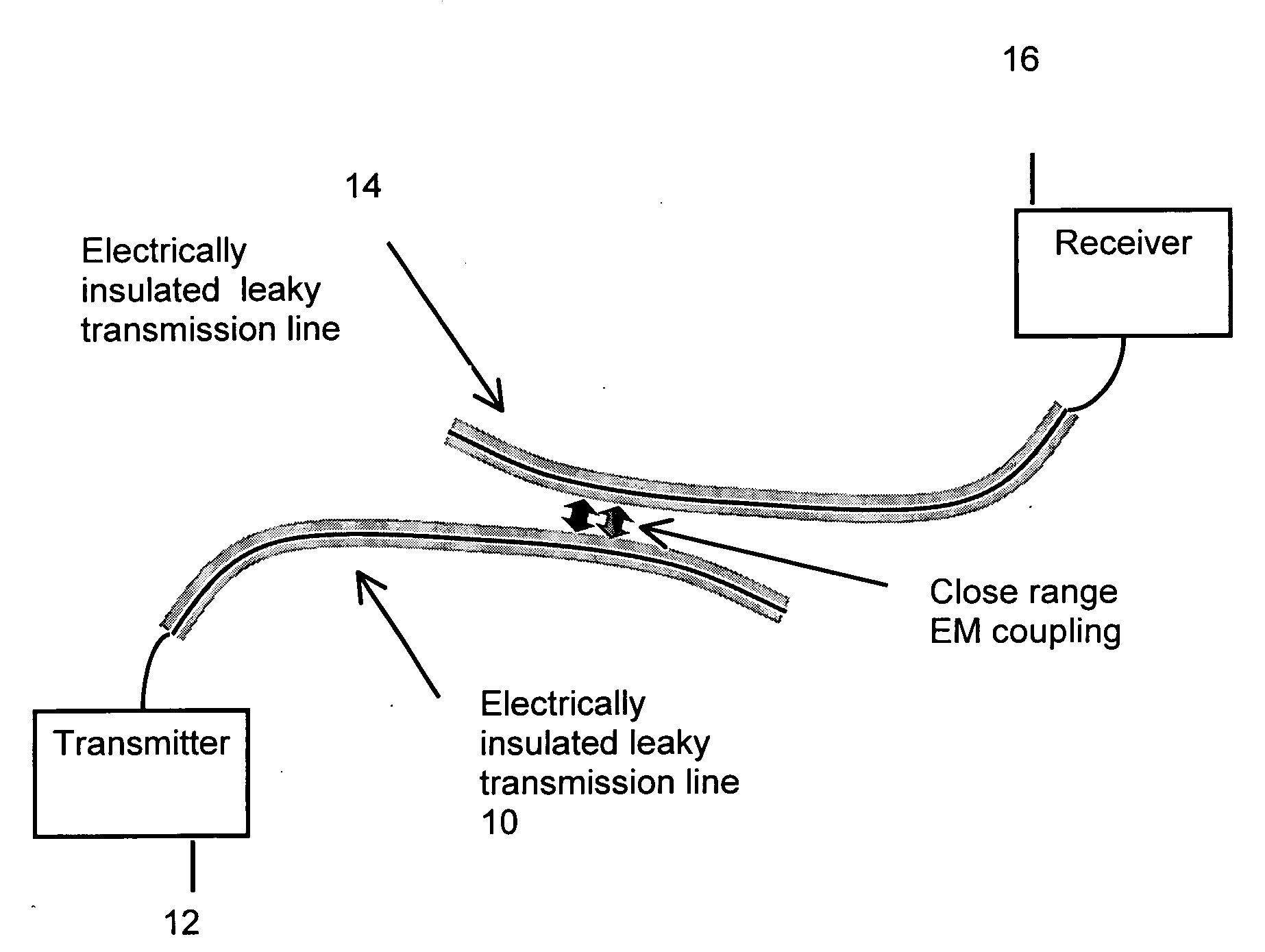

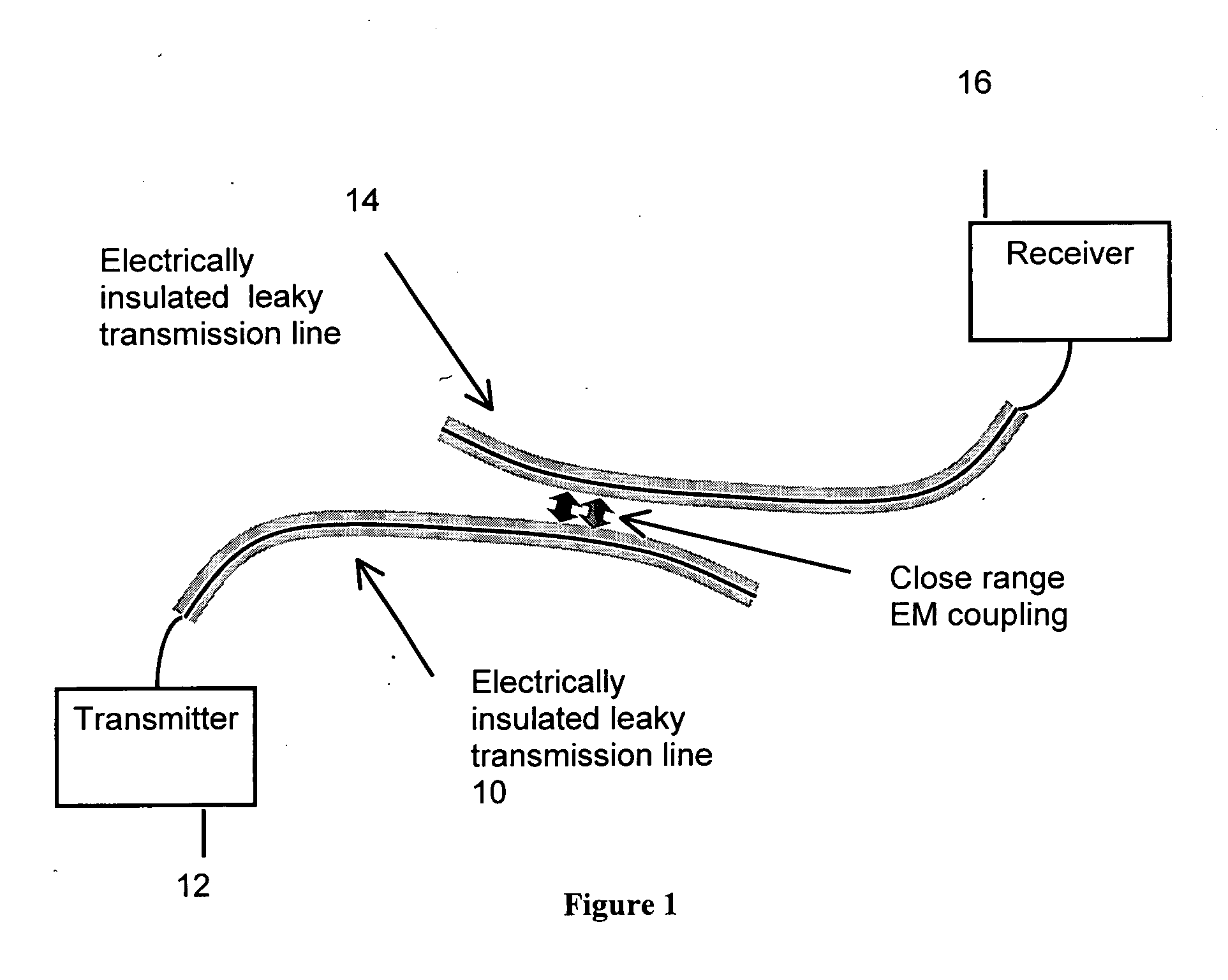

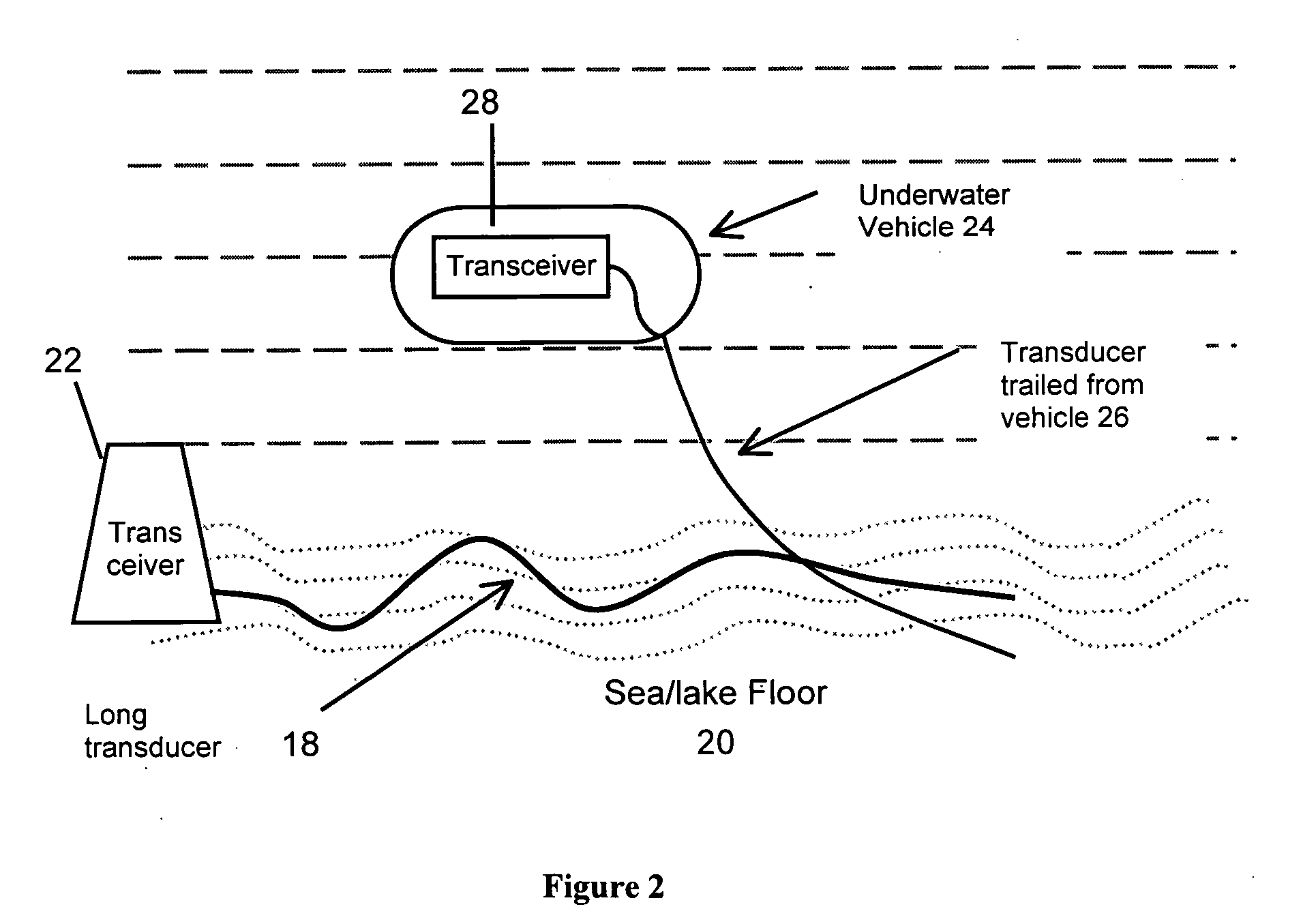

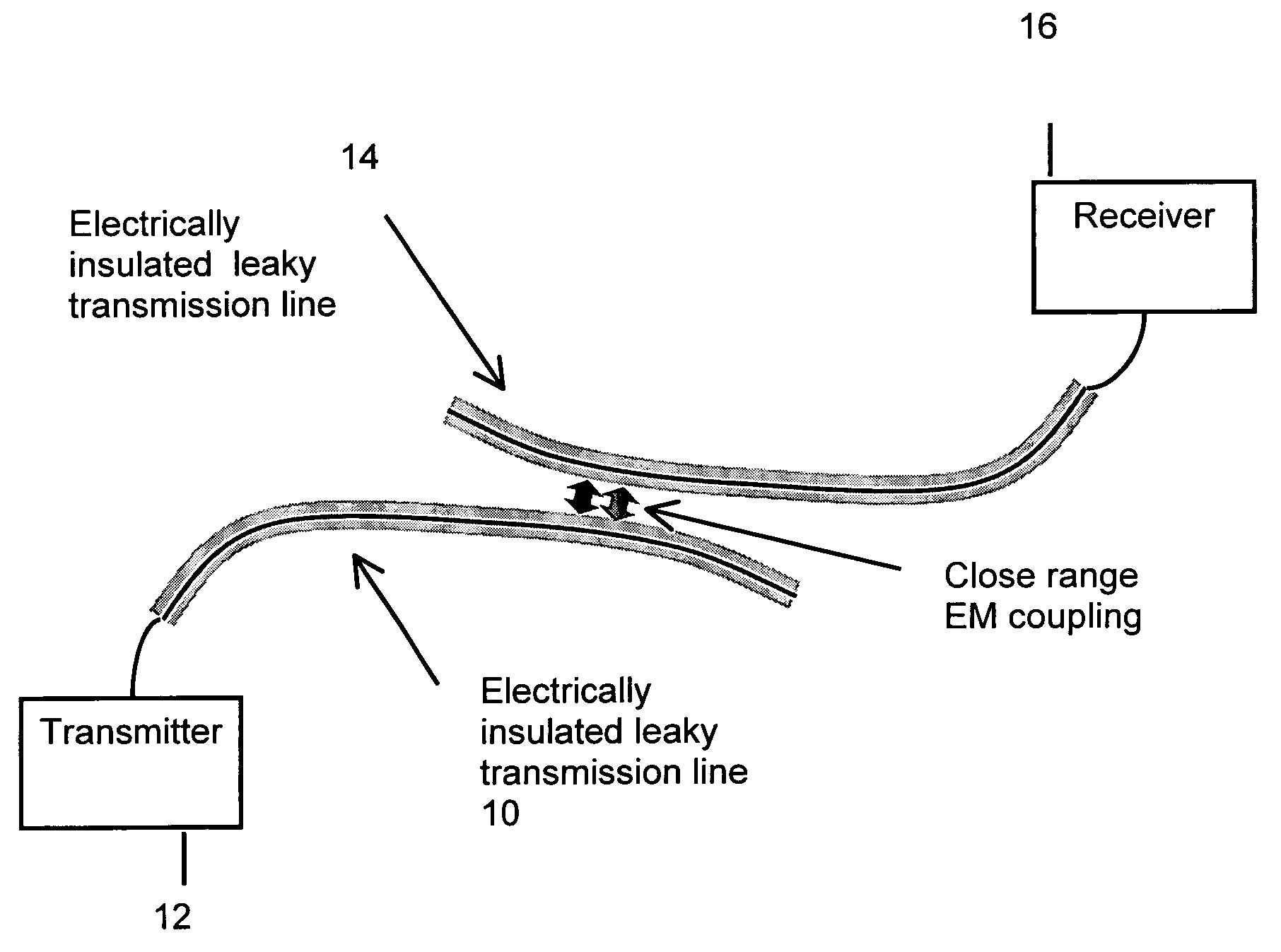

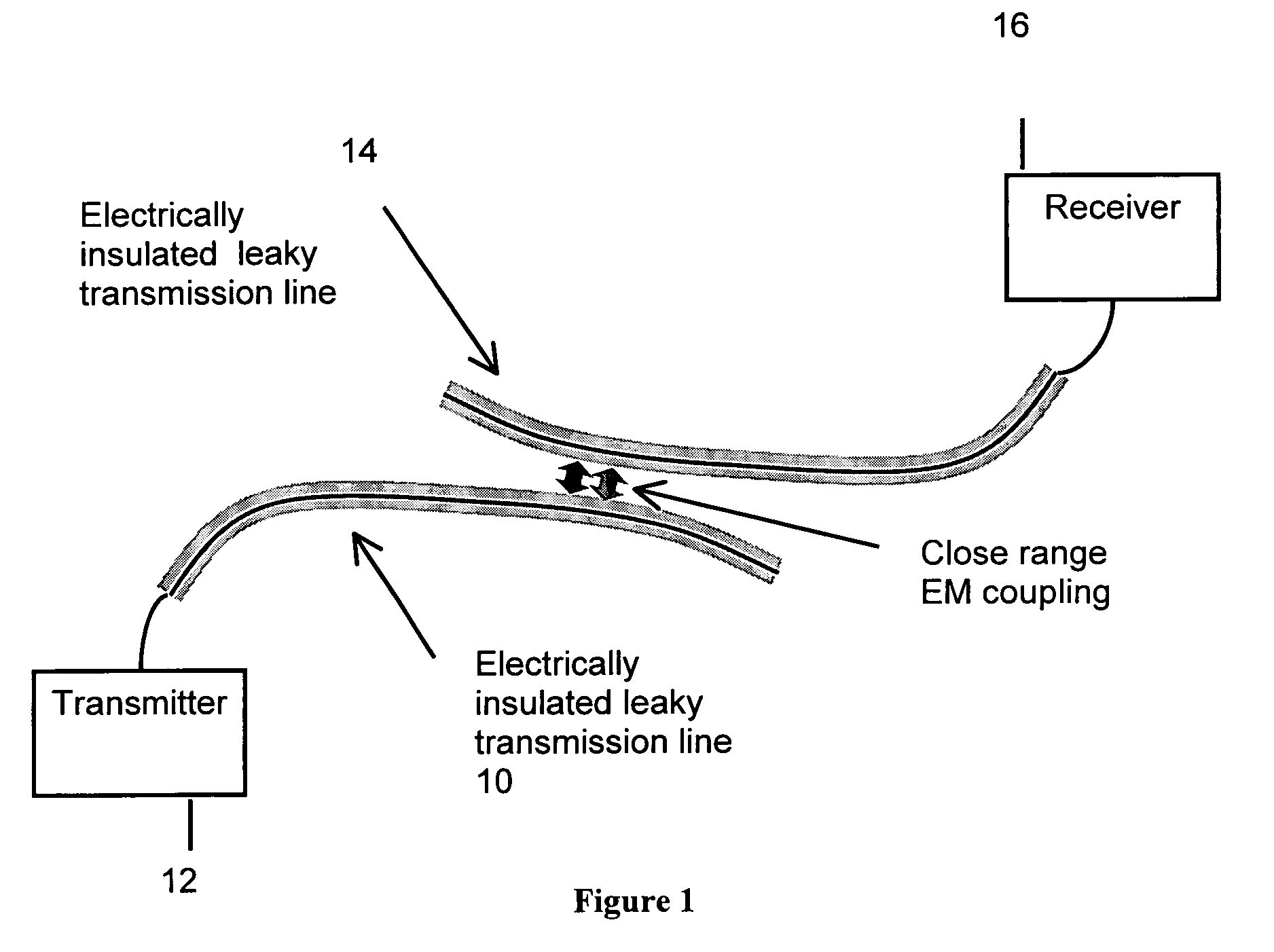

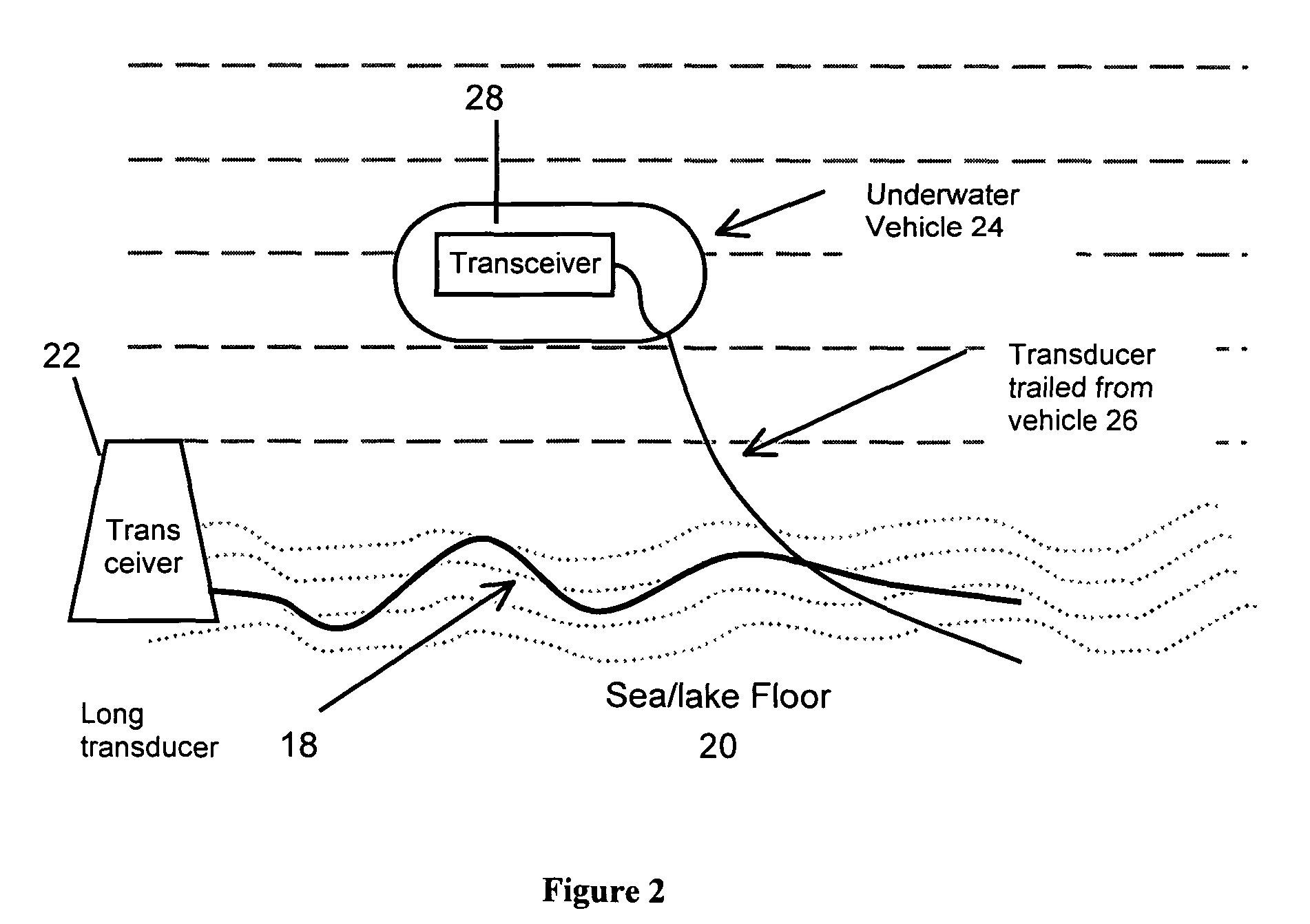

Distributed underwater electromagnetic communication system

InactiveUS20070135044A1Speed up the descentIncrease lossNear-field transmissionElectric signal transmission systemsElectricityCommunications system

An extended underwater electromagnetic transducer is provided with an electrically insulated transmission line typically connected to a transmitter or receiver or transceiver system. The transmission line allows near-field communications with another transmitter or receiver or transceiver system. The transmission line provided is relatively long, the through water signal path length can be significantly reduced.

Owner:WIRELESS FIBER SYST

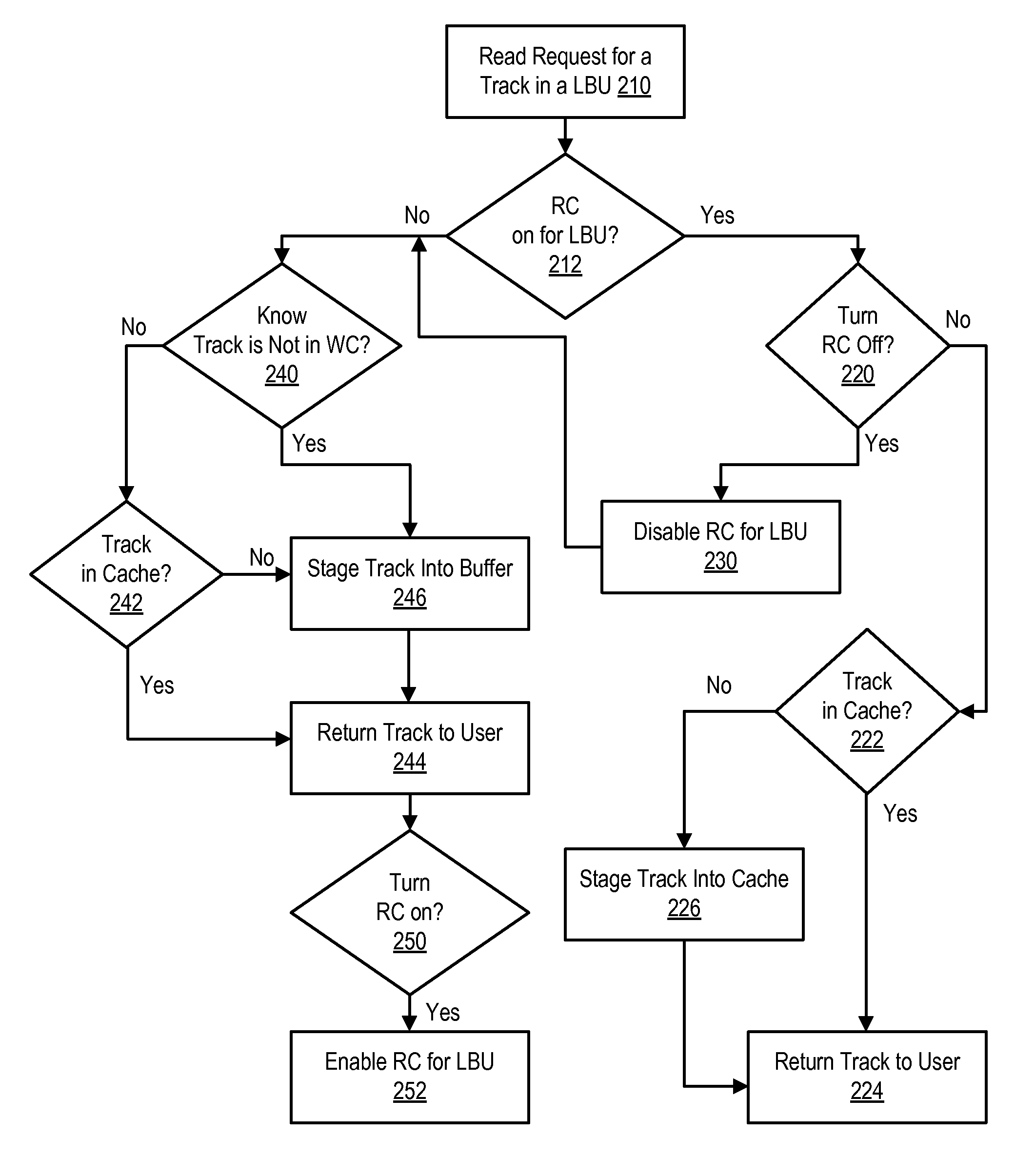

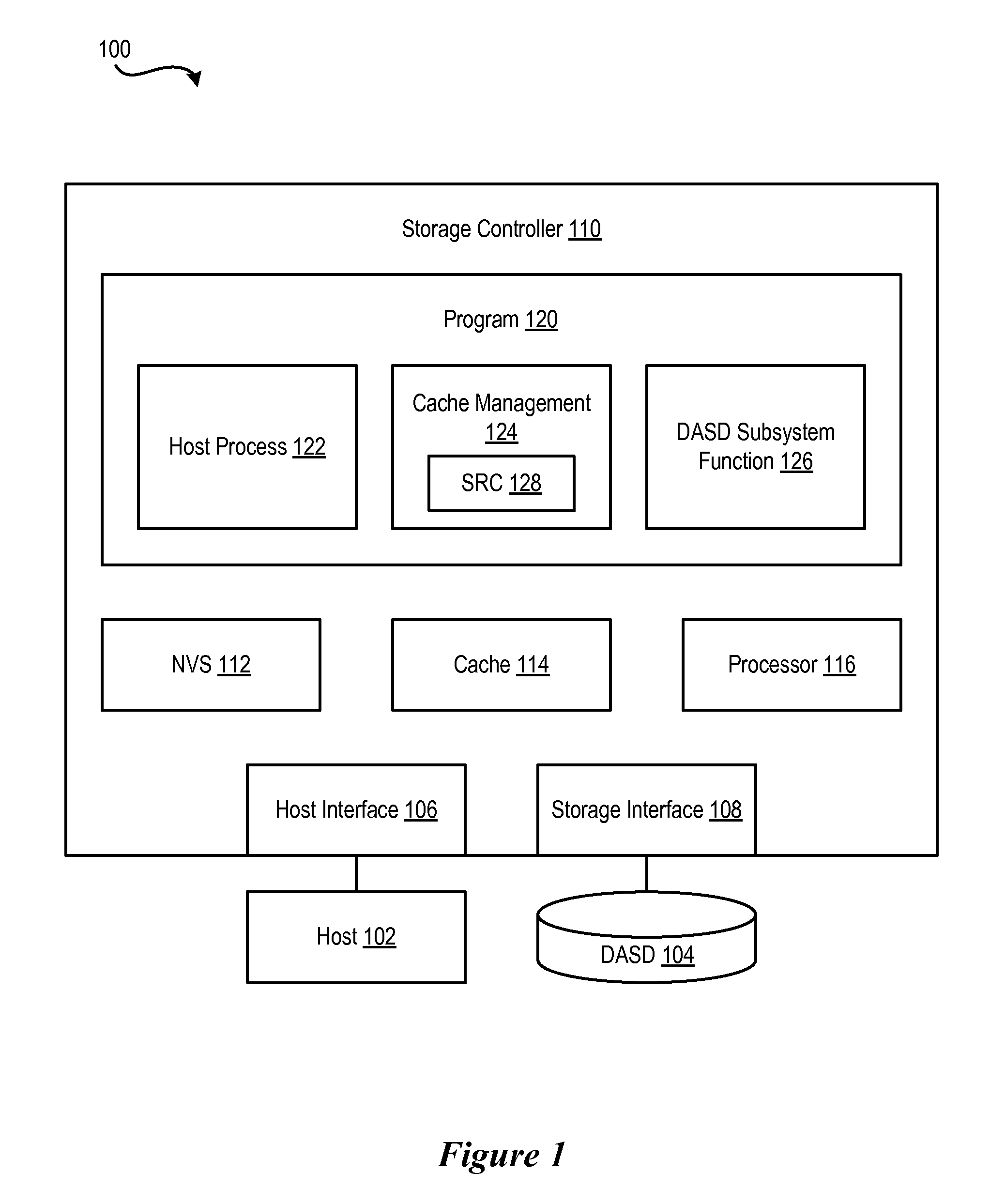

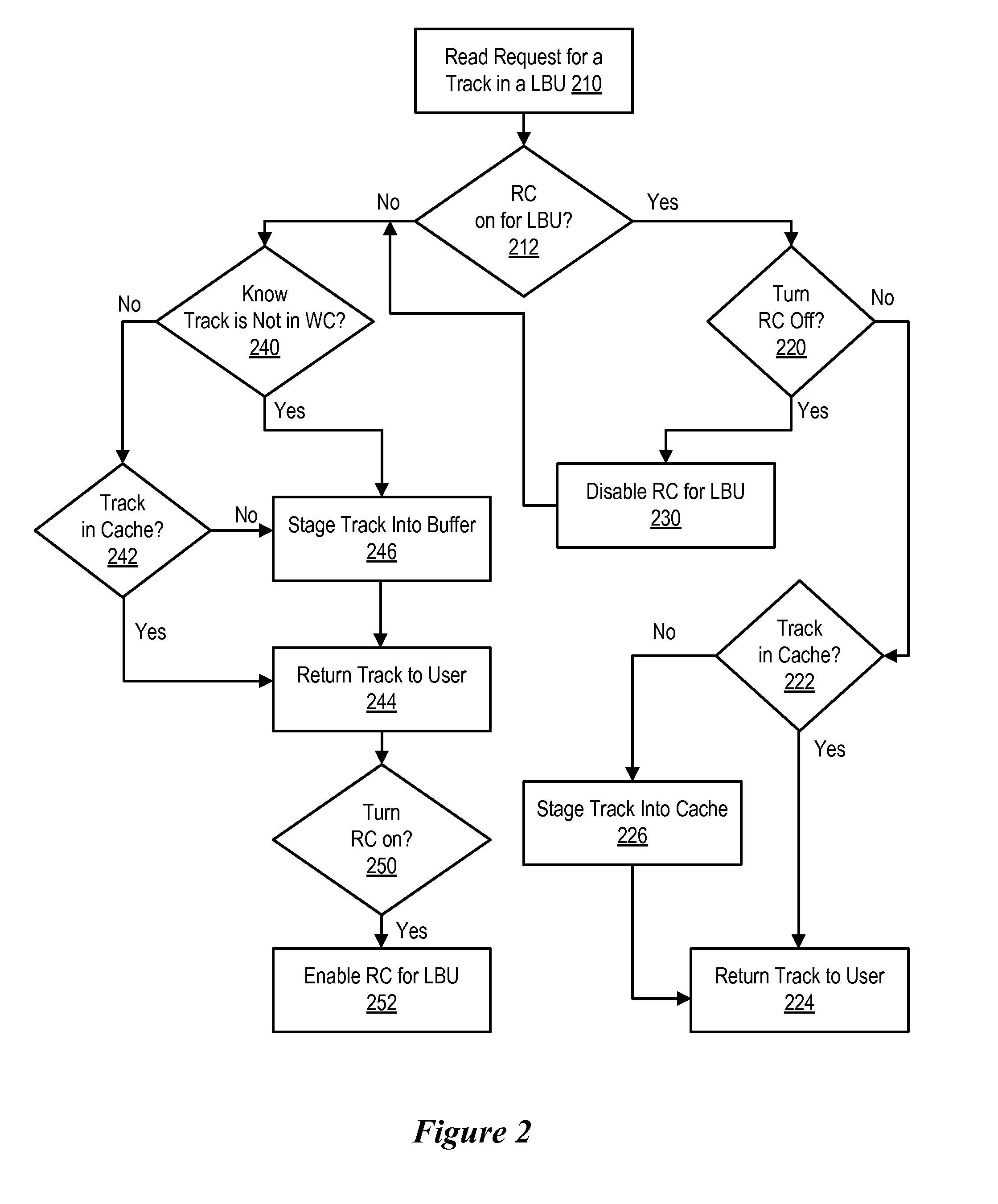

Method for Selectively Enabling and Disabling Read Caching in a Storage Subsystem

InactiveUS20090037662A1Improve performanceLow cache hit ratioMemory adressing/allocation/relocationCache hit rateWorkload

A mechanism for selectively disabling and enabling read caching based on past performance of the cache and current read / write requests. The system improves overall performance by using an autonomic algorithm to disable read caching for regions of backend disk storage (i.e., the backstore) that have had historically low cache hit ratios. The result is that more cache becomes available for workloads with larger hit ratios, and less time and machine cycles are spent searching the cache for data that is unlikely to be there.

Owner:IBM CORP

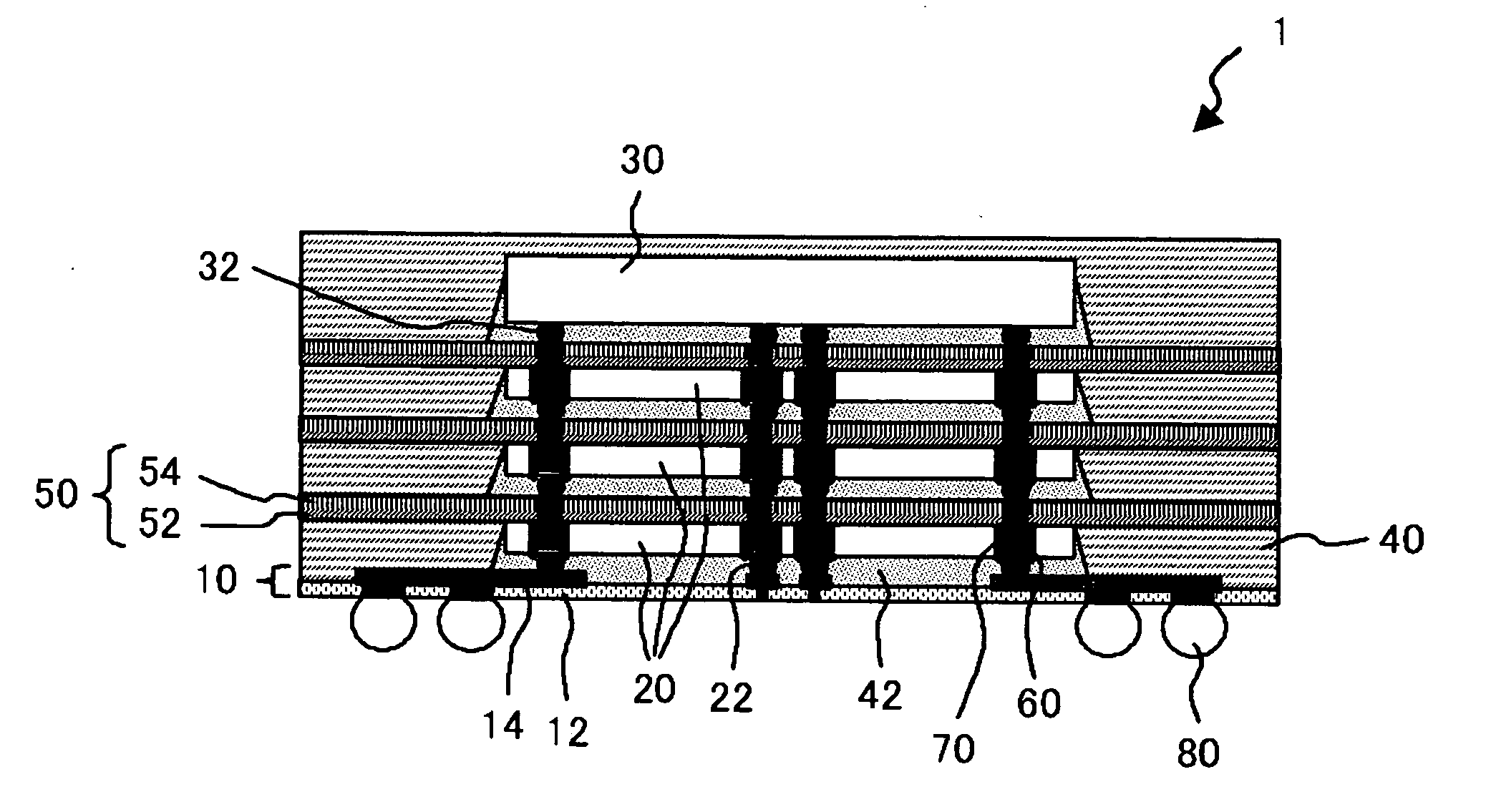

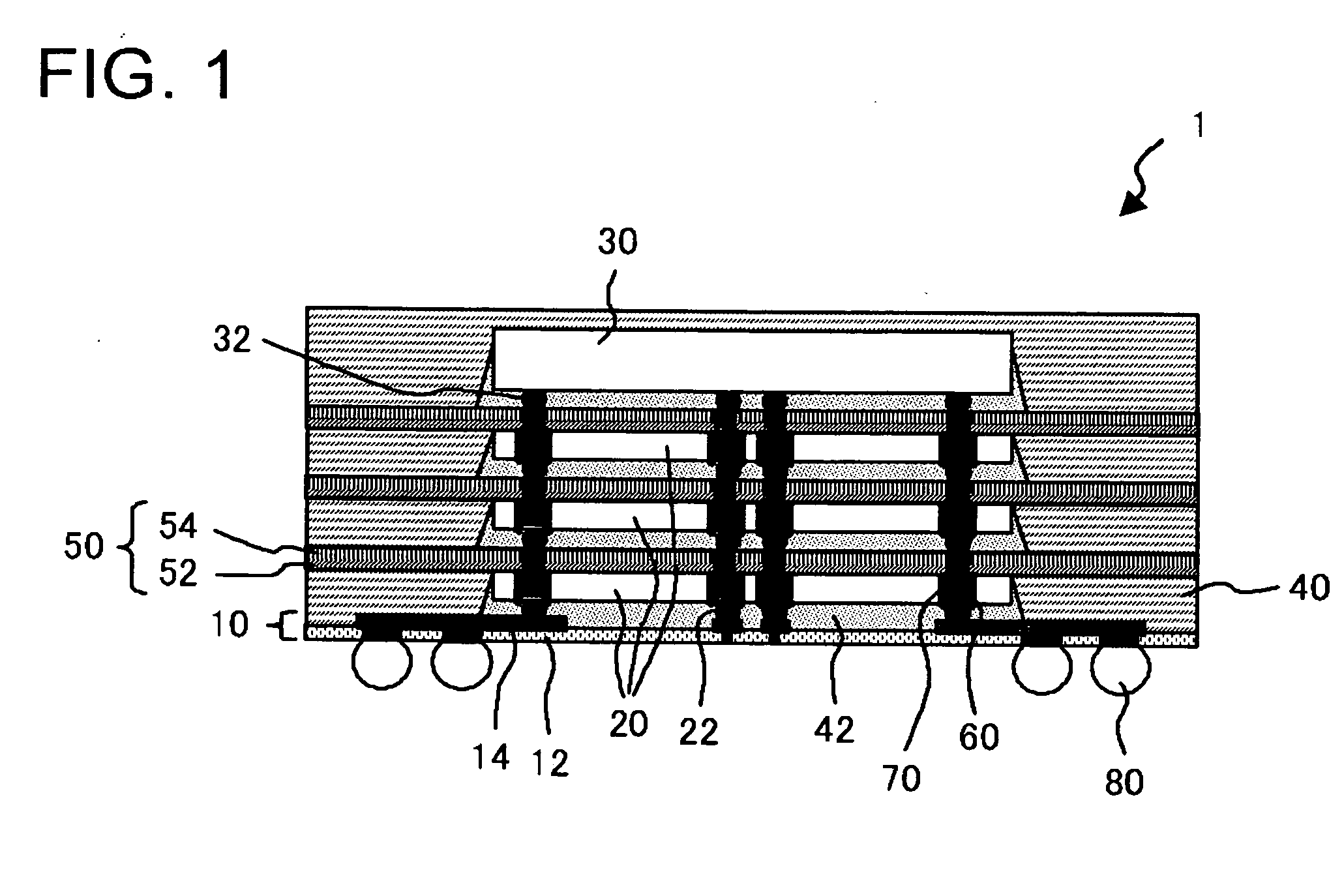

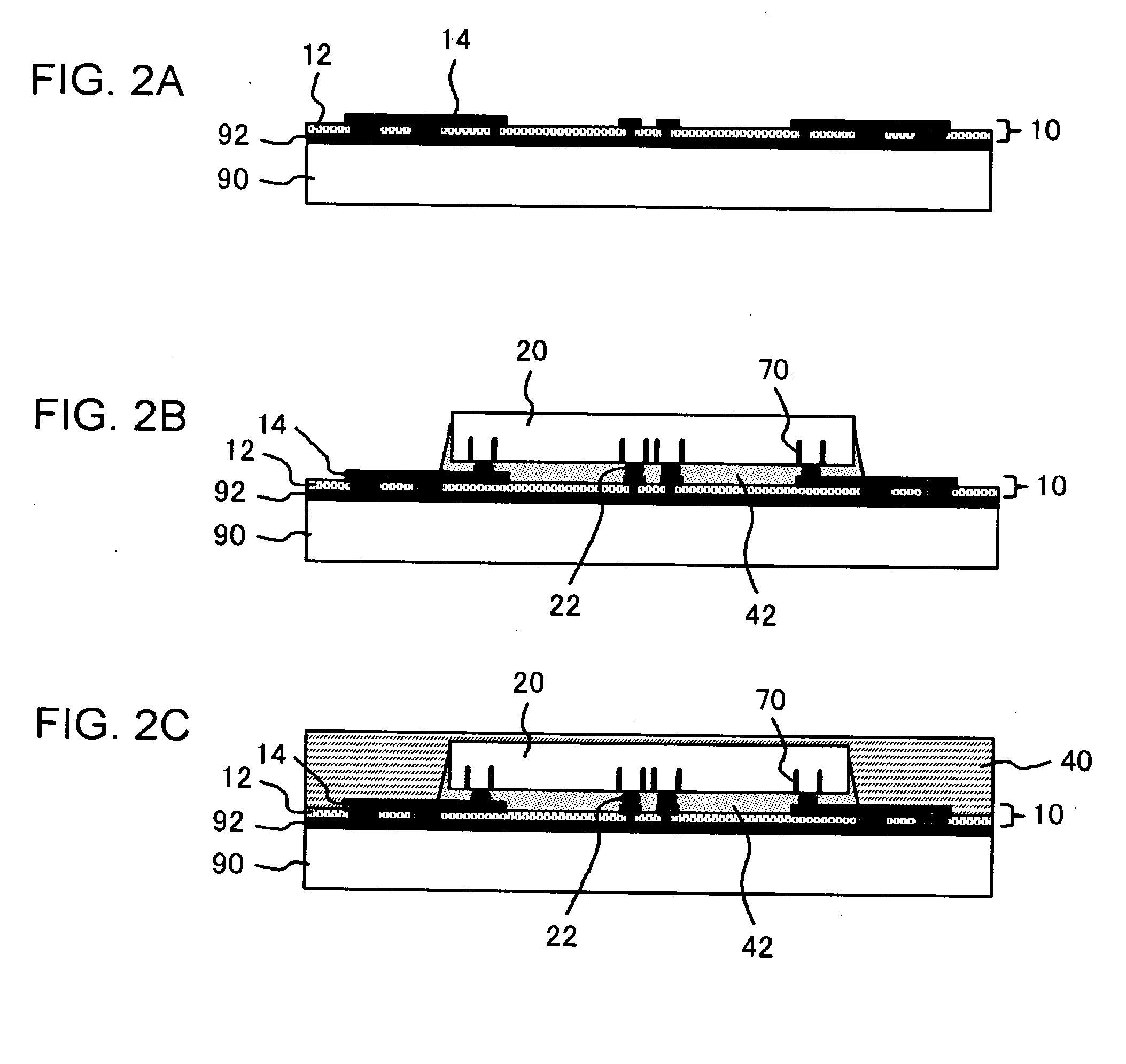

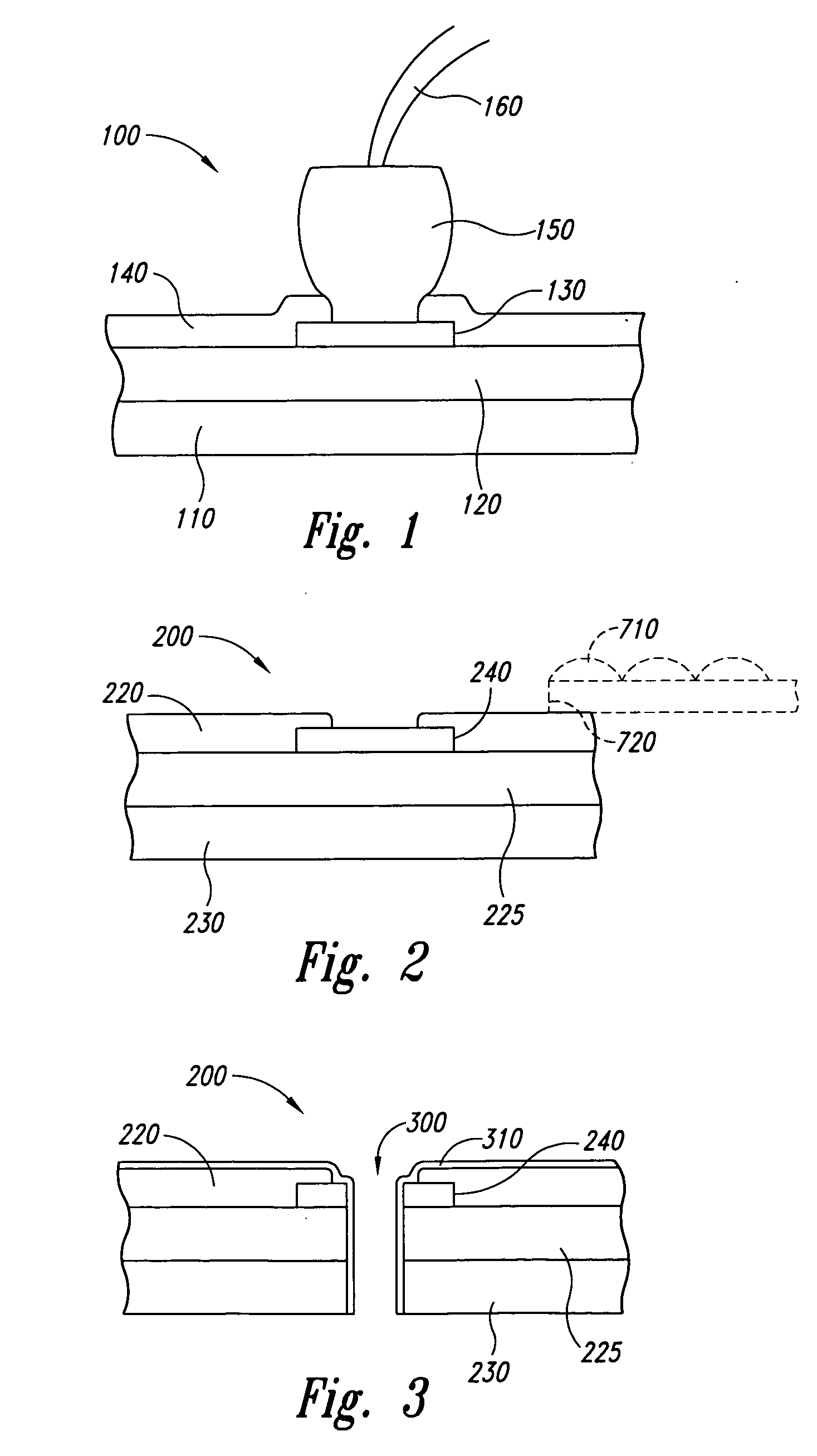

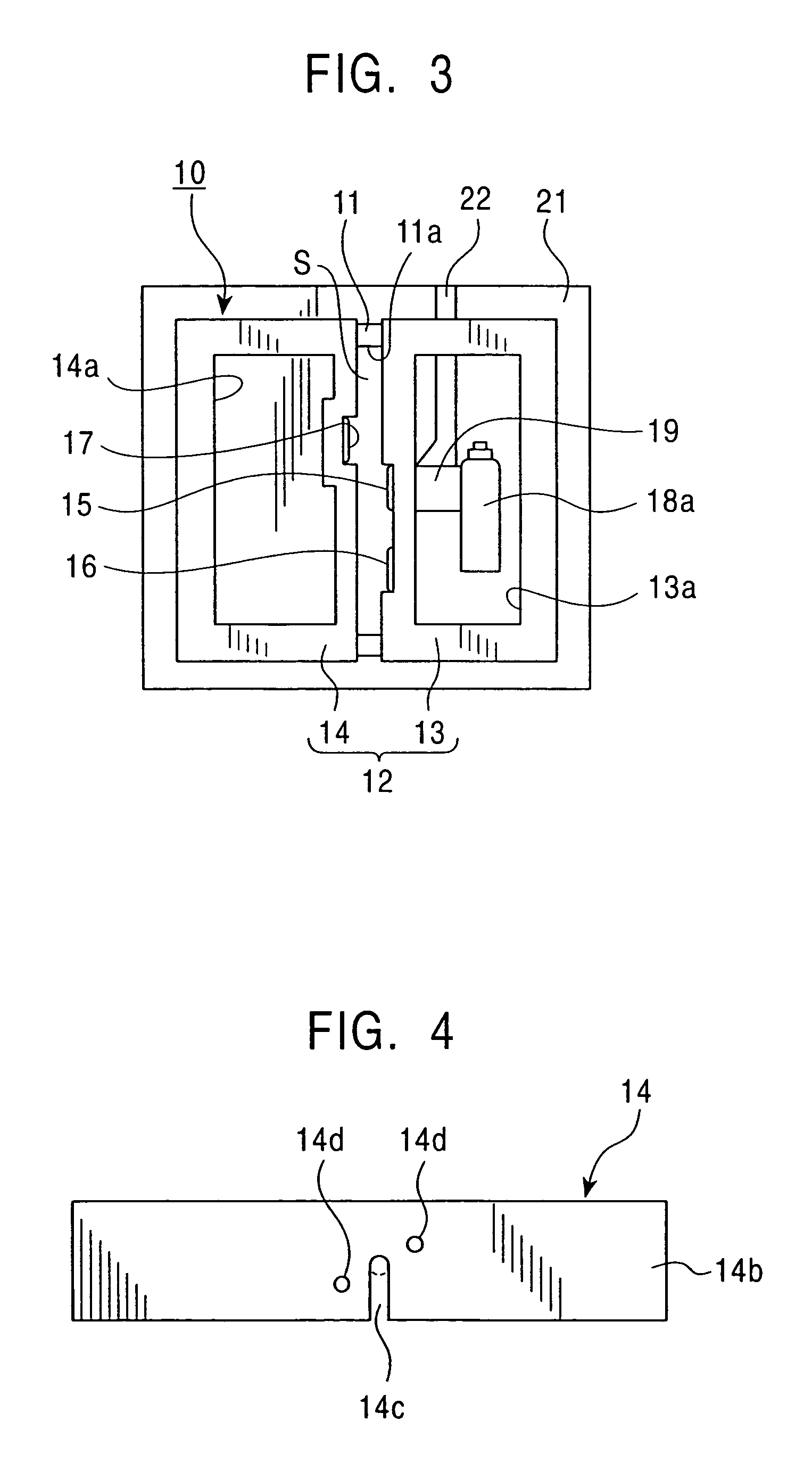

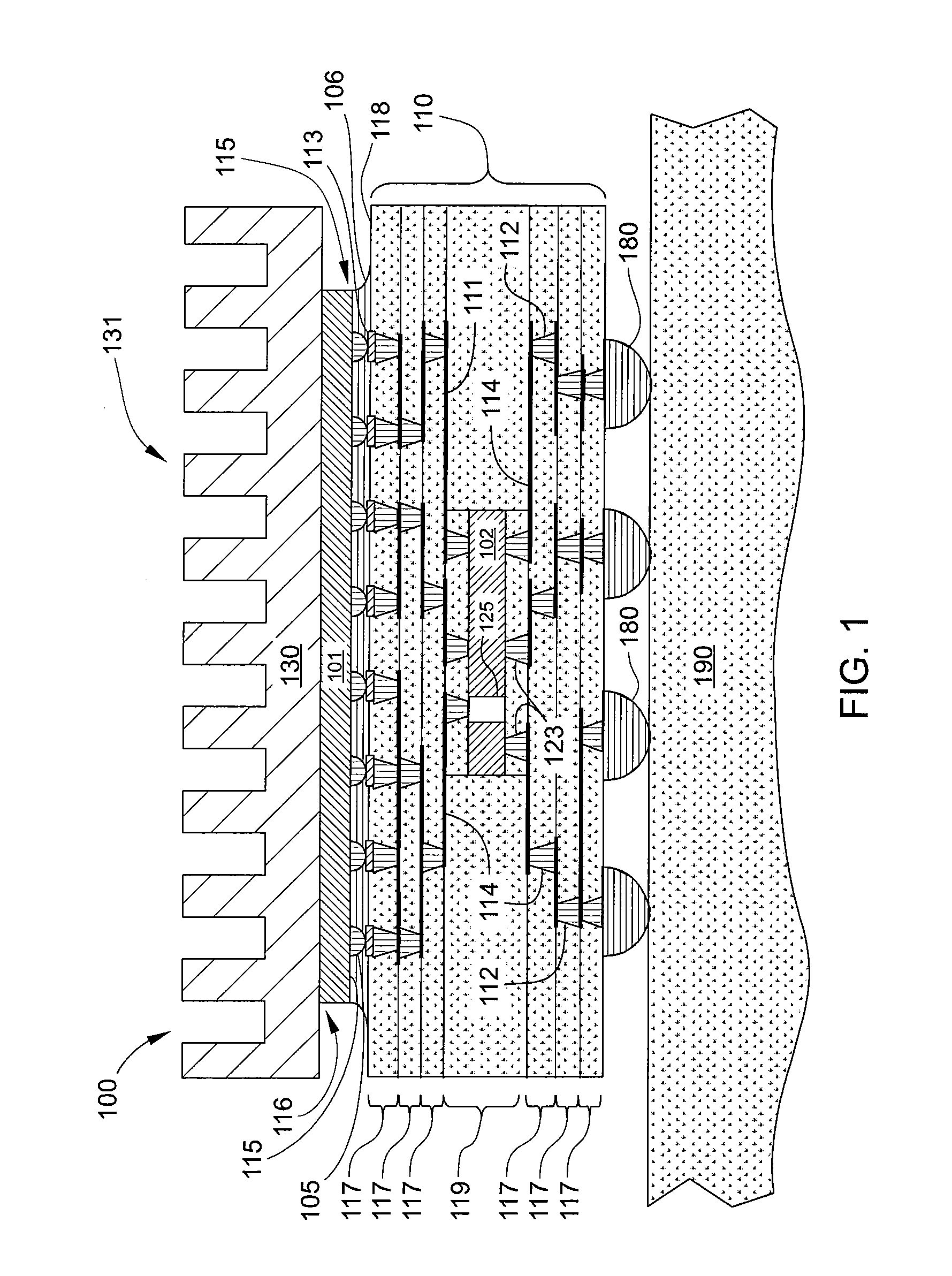

Semiconductor device and method of manufacturing the same

InactiveUS20070126085A1Reduce path lengthRun at high speedSemiconductor/solid-state device detailsSolid-state devicesDevice materialSemiconductor chip

A semiconductor device includes an interconnect member, a first semiconductor chip, a second semiconductor chip, a resin layer, an inorganic insulating layer, and a through electrode. The first semiconductor chip is mounted in a face-down manner on the interconnect member. The resin layer covers the side surface of the first semiconductor chip. This inorganic insulating layer is in contact with the back surface of the first semiconductor chip, and directly covers the back surface. Also, the inorganic insulating layer extends over the resin layer. The through electrode penetrates the inorganic insulating layer and the semiconductor substrate of the first semiconductor chip. The second semiconductor chip is mounted in a face-down manner on the inorganic insulating layer that covers the back surface of the first semiconductor chip in the uppermost layer.

Owner:NEC ELECTRONICS CORP

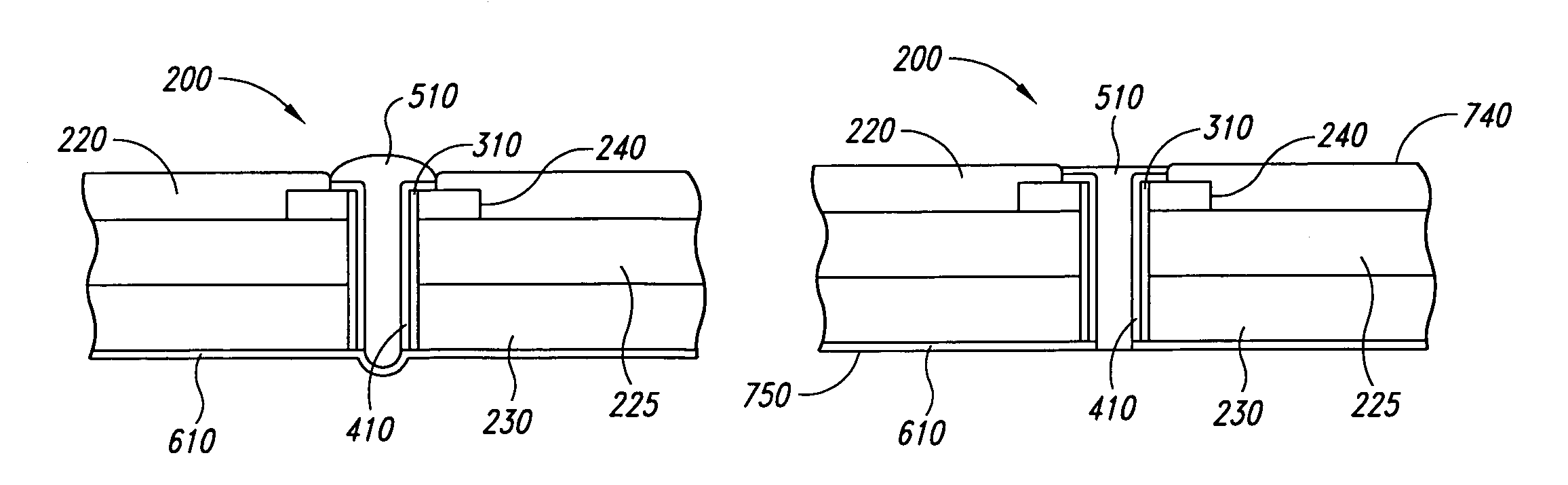

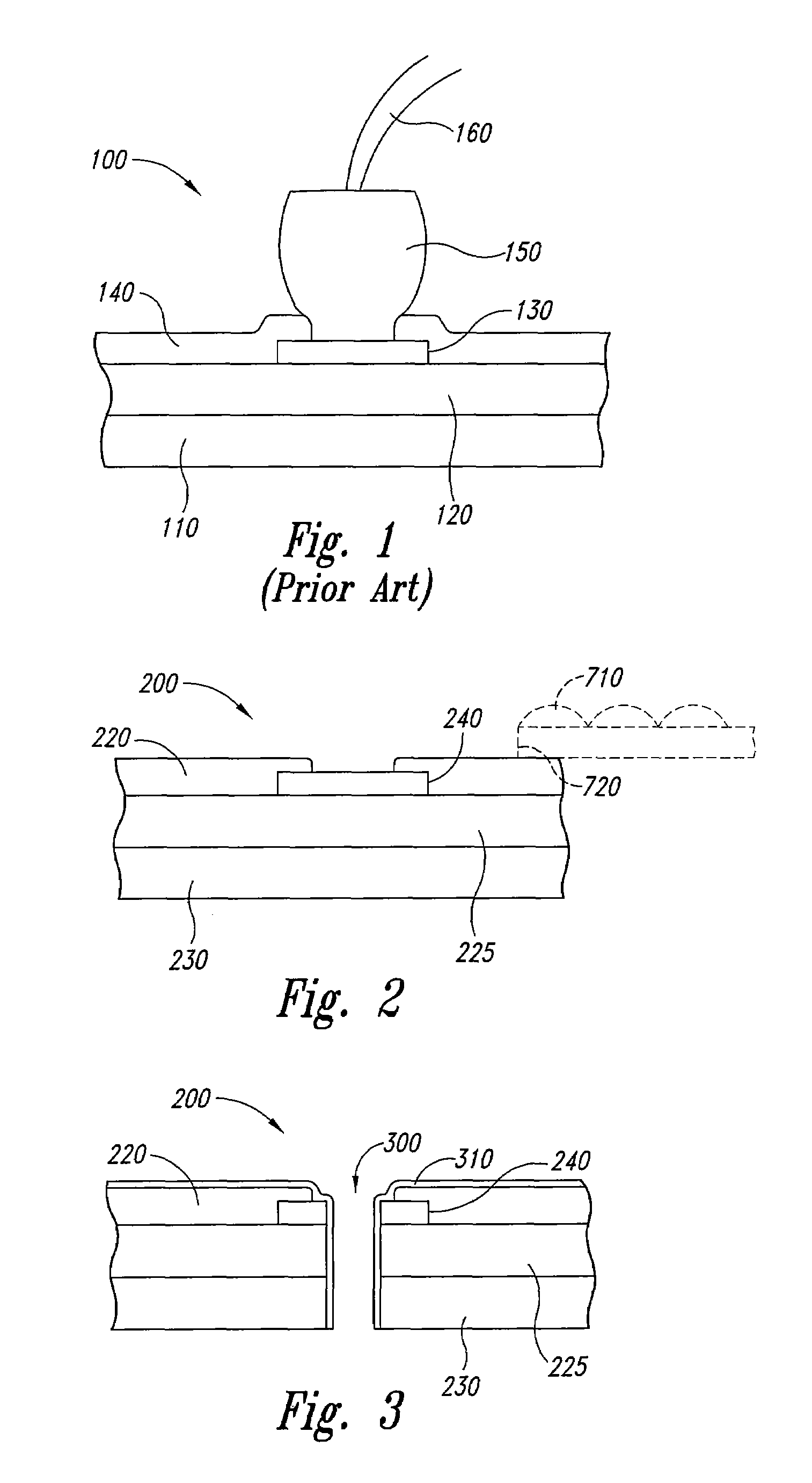

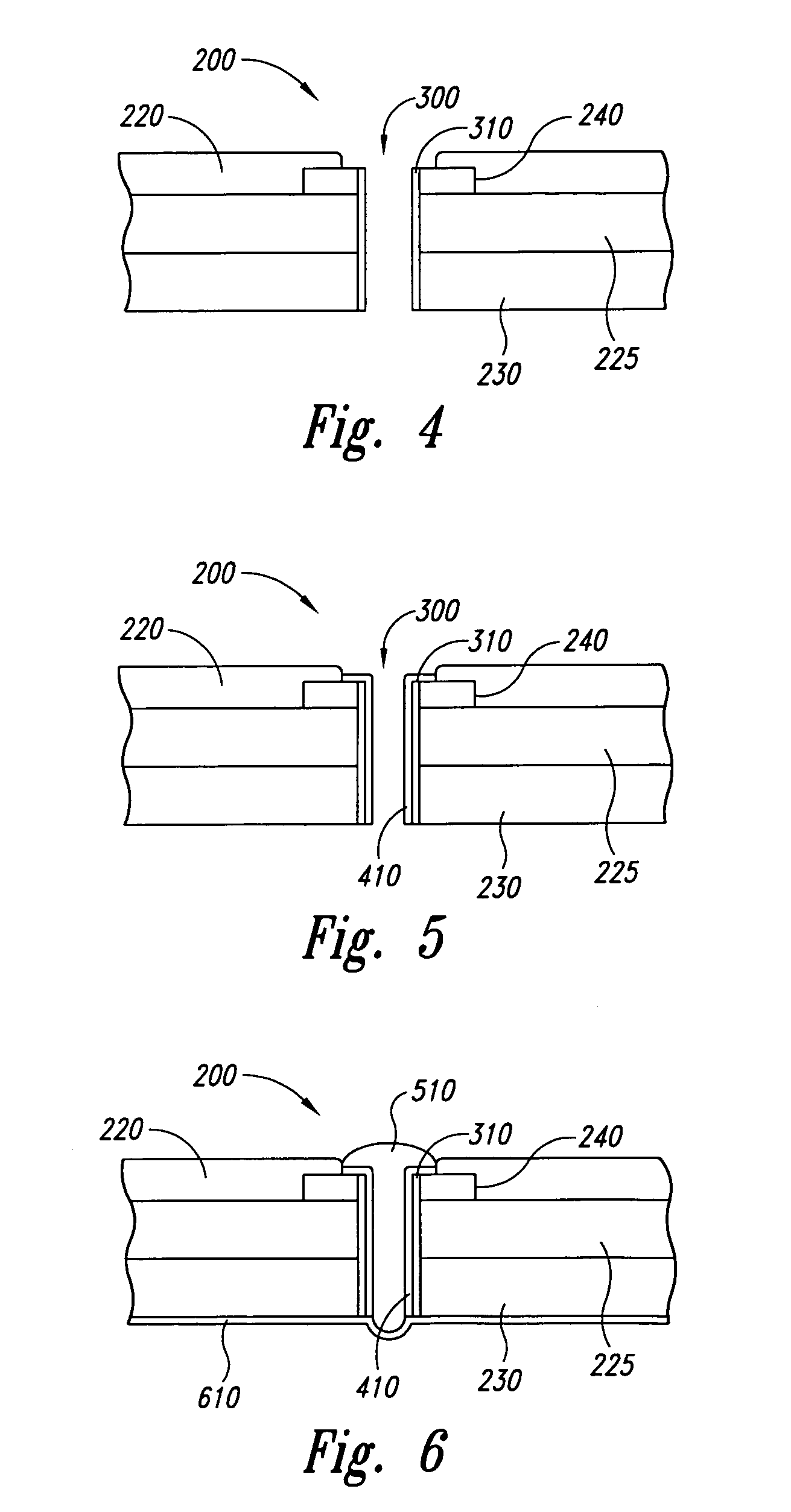

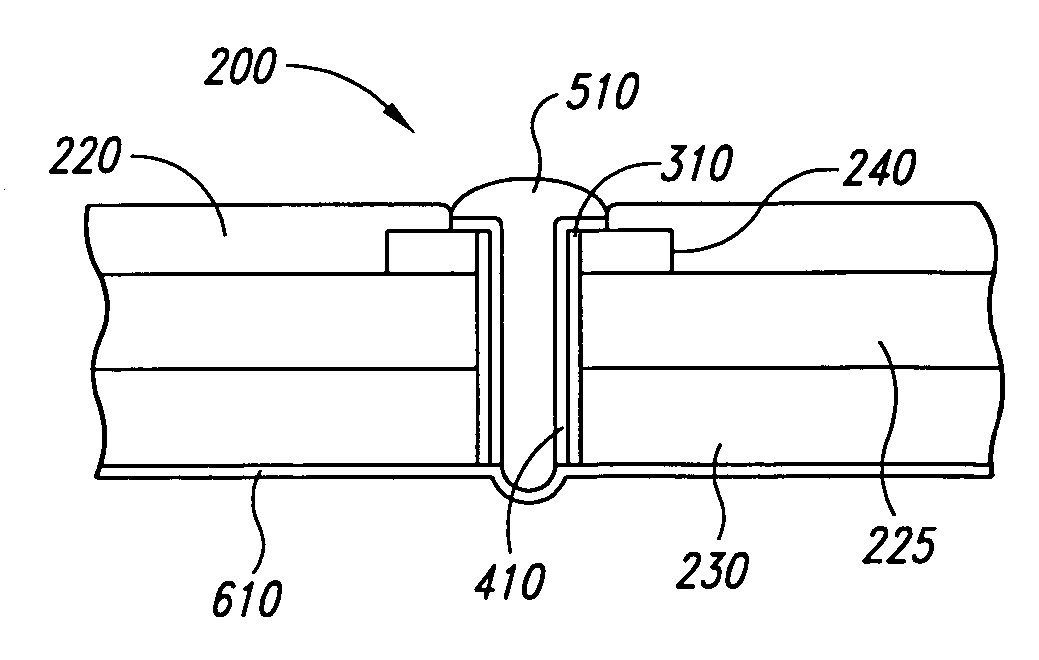

Through-wafer interconnects for photoimager and memory wafers

InactiveUS7300857B2High densityImprove functionalitySemiconductor/solid-state device detailsSolid-state devicesPath lengthLead bonding

A through-wafer interconnect for imager, memory and other integrated circuit applications is disclosed, thereby eliminating the need for wire bonding, making devices incorporating such interconnects stackable and enabling wafer level packaging for imager devices. Further, a smaller and more reliable die package is achieved and circuit parasitics (e.g., L and R) are reduced due to the reduced signal path lengths.

Owner:ROUND ROCK RES LLC

Through-wafer interconnects for photoimager and memory wafers

InactiveUS20060043599A1Small and reliableReduce path lengthSemiconductor/solid-state device detailsSolid-state devicesIntegrated circuitWafer-level packaging

A through-wafer interconnect for imager, memory and other integrated circuit applications is disclosed, thereby eliminating the need for wire bonding, making devices incorporating such interconnects stackable and enabling wafer level packaging for imager devices. Further, a smaller and more reliable die package is achieved and circuit parasitics (e.g., L and R) are reduced due to the reduced signal path lengths.

Owner:ROUND ROCK RES LLC

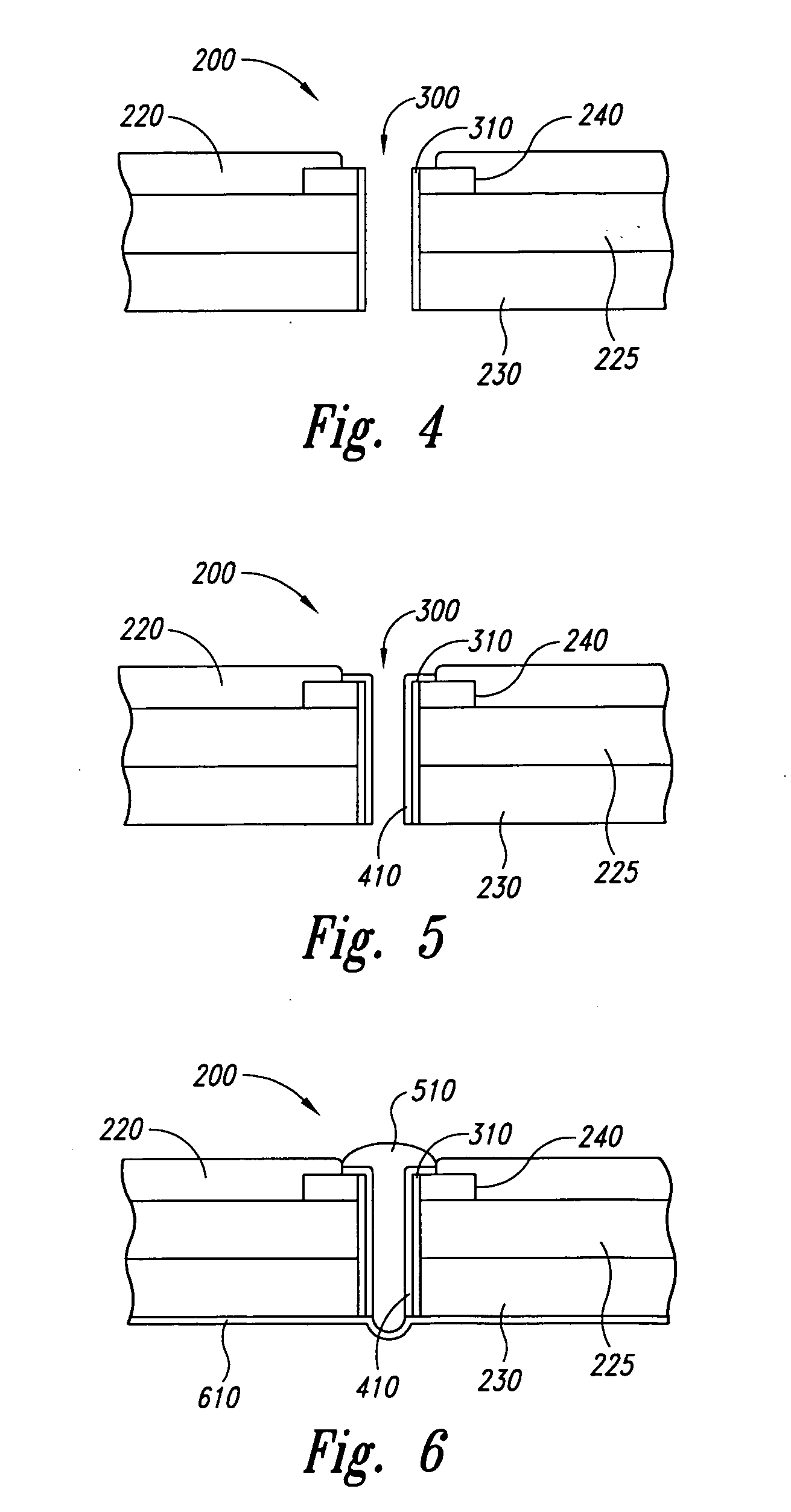

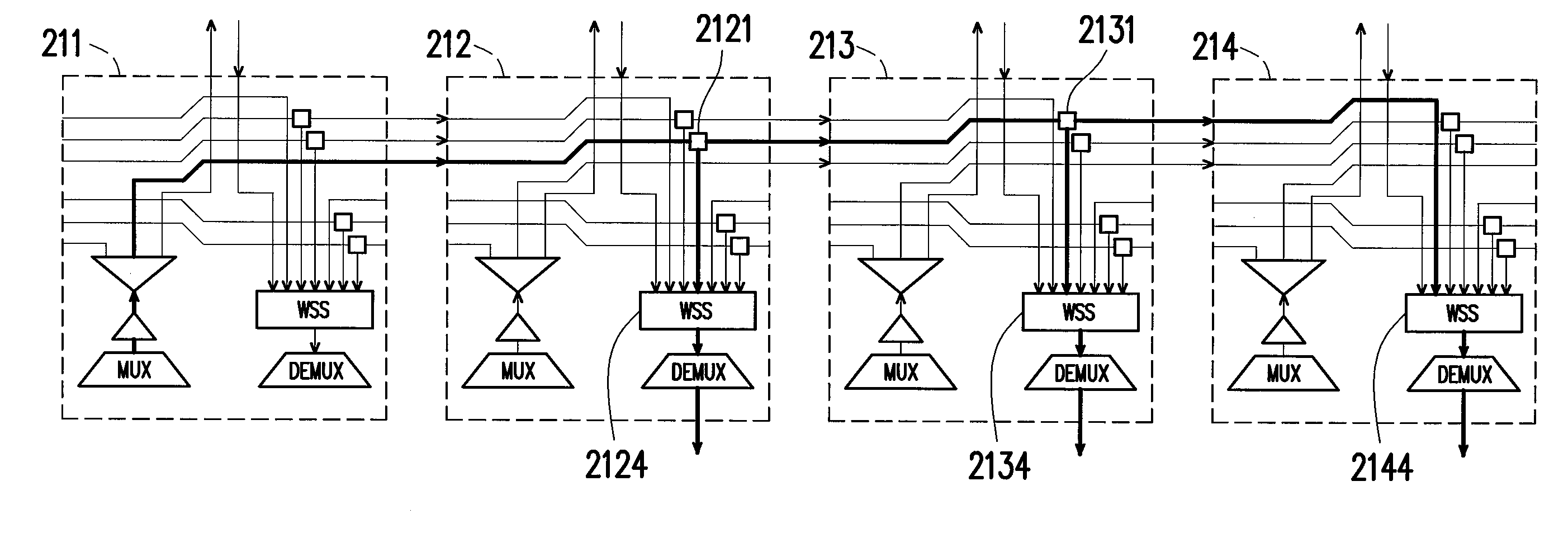

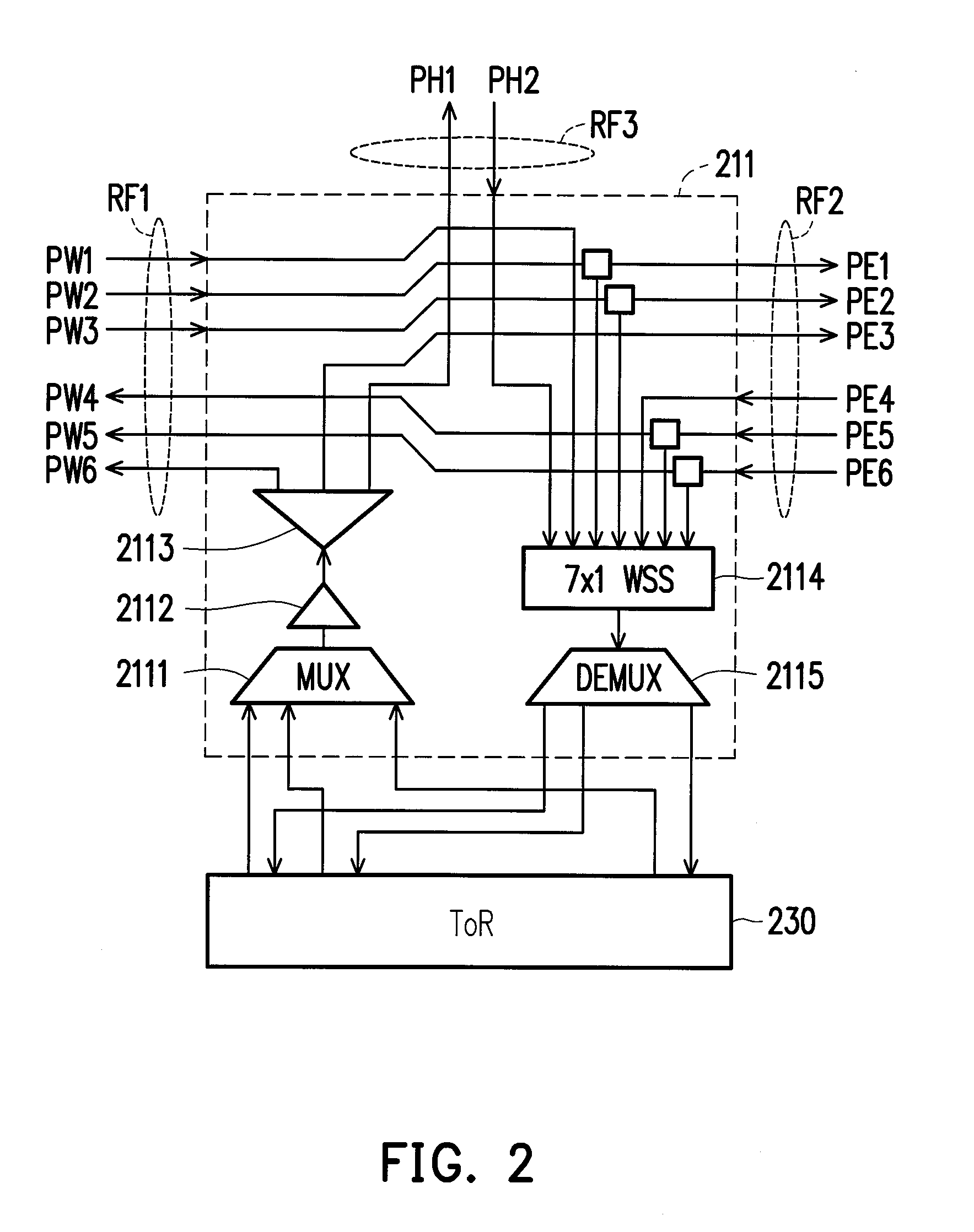

Optical data center network system and optical switch

ActiveUS20160277816A1High bandwidthLower latencyMultiplex system selection arrangementsWavelength-division multiplex systemsFiberData center

An optical data center network system including multiple tier-1 optical switches, multiple tier-2 optical switches and multiple tier-3 optical switches is provided. A pod is formed by the tier-1 optical switches connected to each other through ribbon fibers. A macro pod is formed by the tier-2 optical switches connected to each other through ribbon fibers, and each of the tier-2 optical switches is connected to all of the tier-1 optical switches in one pod. The tier-3 optical switches are connected to each other through ribbon fibers, and each of the tier-3 optical switches is connected to all of the tier-2 optical switches in one macro pod. Each optical switch in each tier is implemented by using the Wavelength Selective Switch (WSS) as a basic element, which has been commercialized numerously.

Owner:GENOPSYS TECH INC

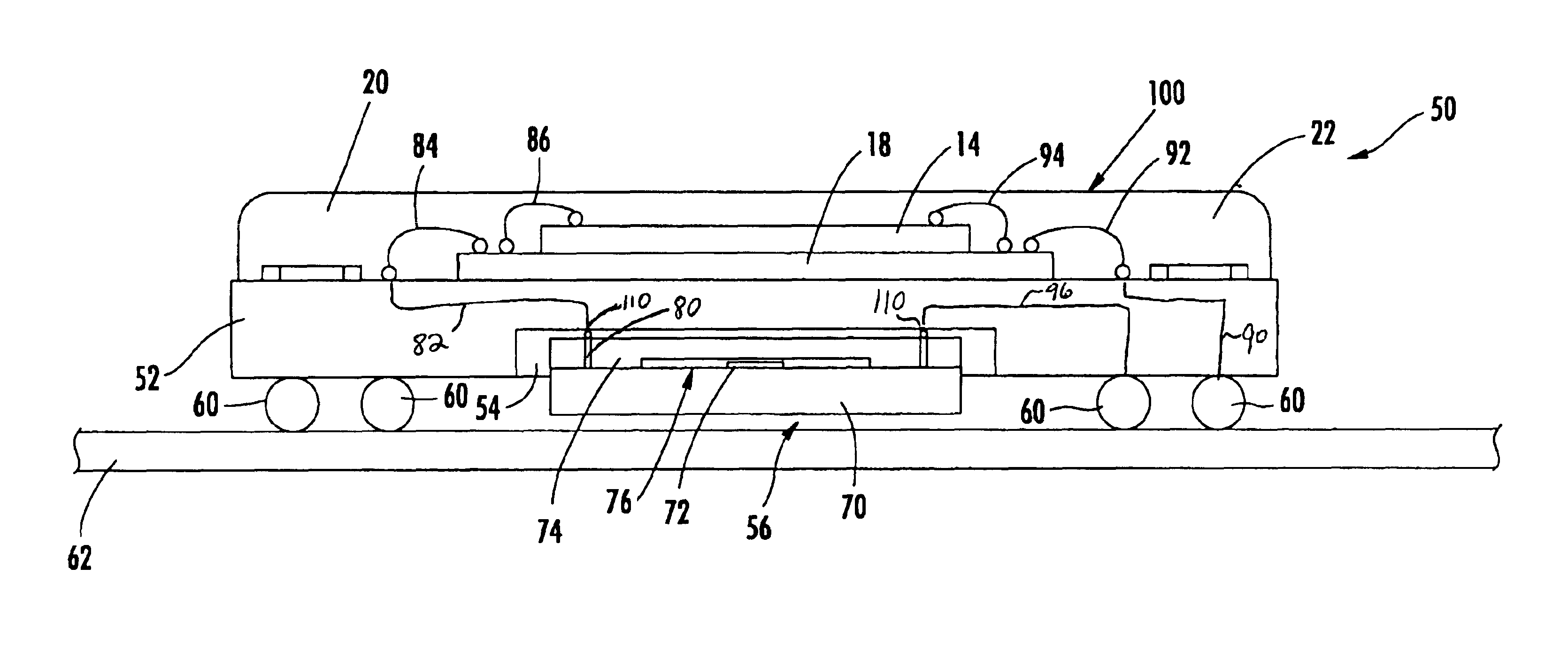

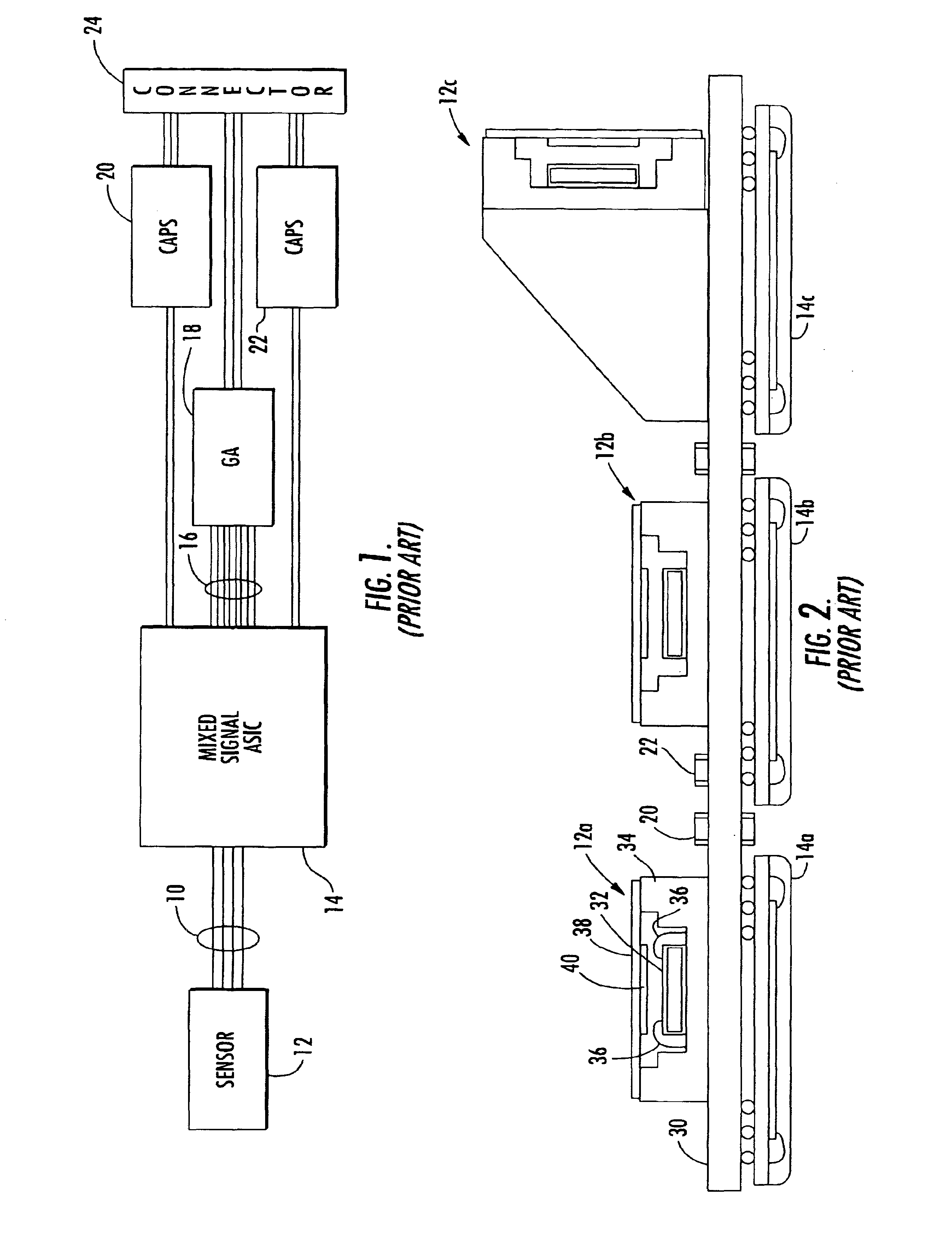

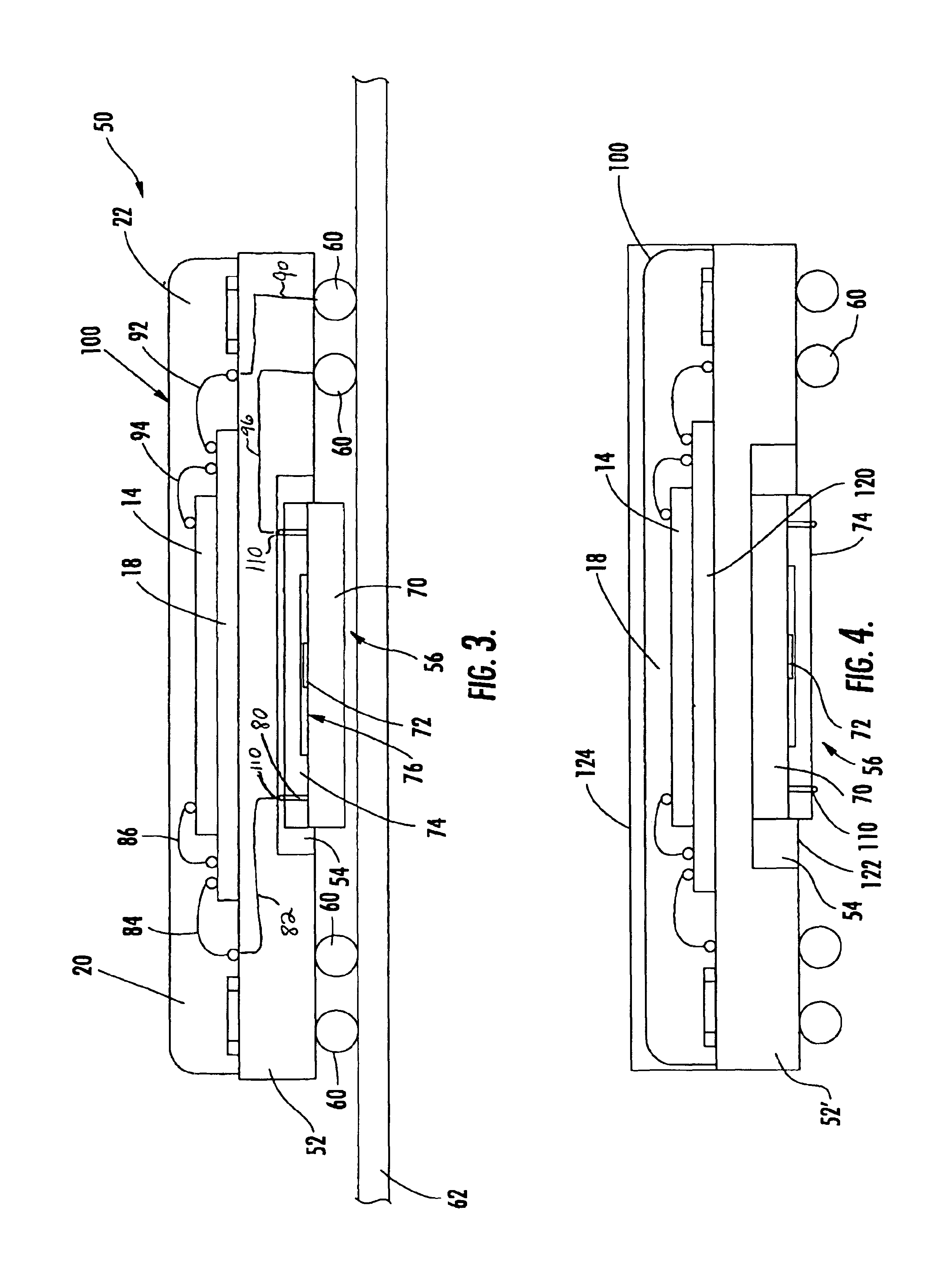

Integrated sensor and electronics package

InactiveUS6891239B2Reduce path lengthReduce capacitanceSemiconductor/solid-state device detailsSolid-state devicesElectrical connectionEngineering

An integrated sensor and electronics package wherein a micro-electromechanical sensor die is bonded to one side of the package substrate, one or more electronic chips are bonded to an opposite side of the package substrate, internal electrical connections run from the sensor die, through the package substrate, and to the one or more electronic chips, and input / output connections on the package substrate are electrically connected to one or more of the electronic chips.

Owner:CHARLES STARK DRAPER LABORATORY

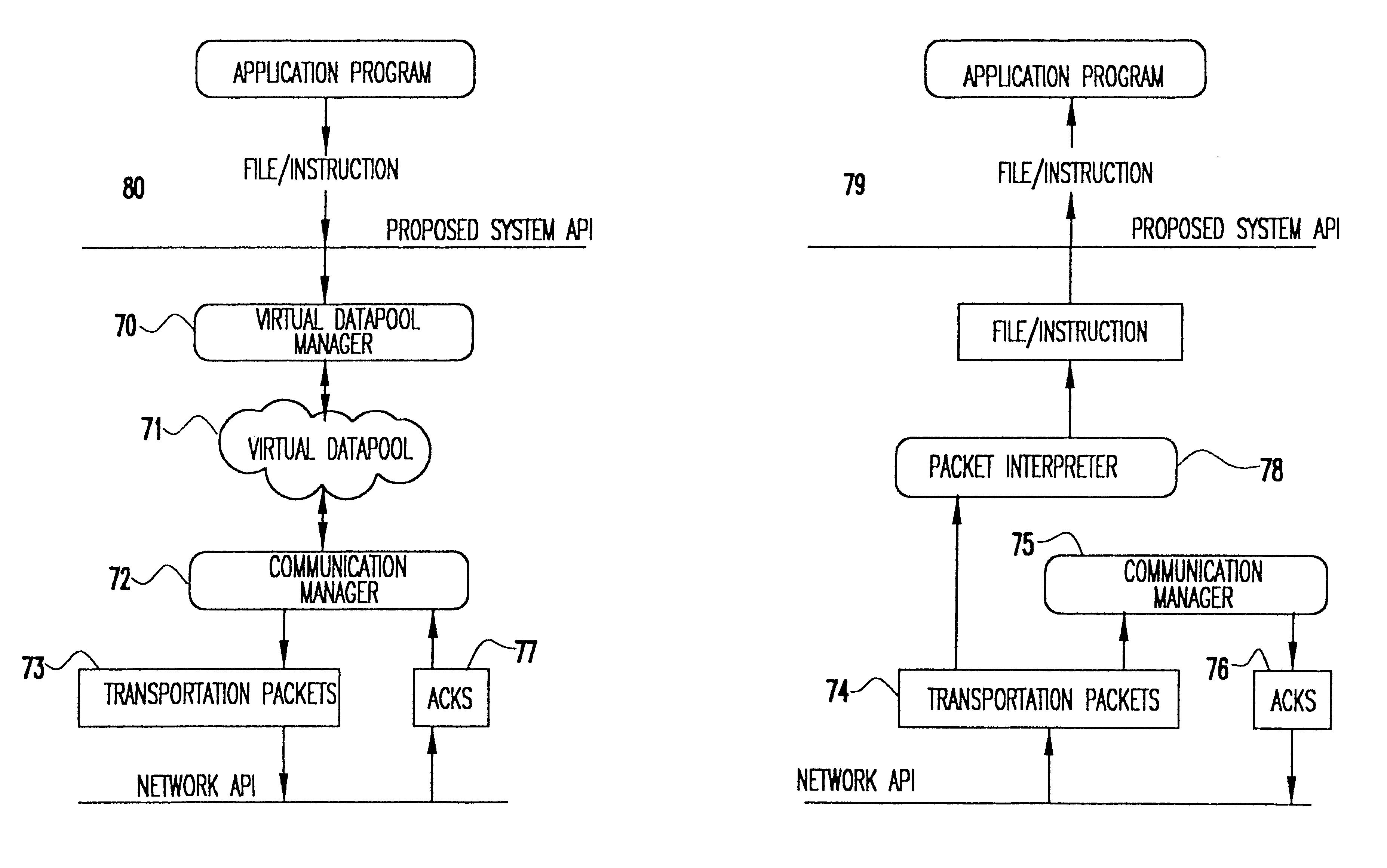

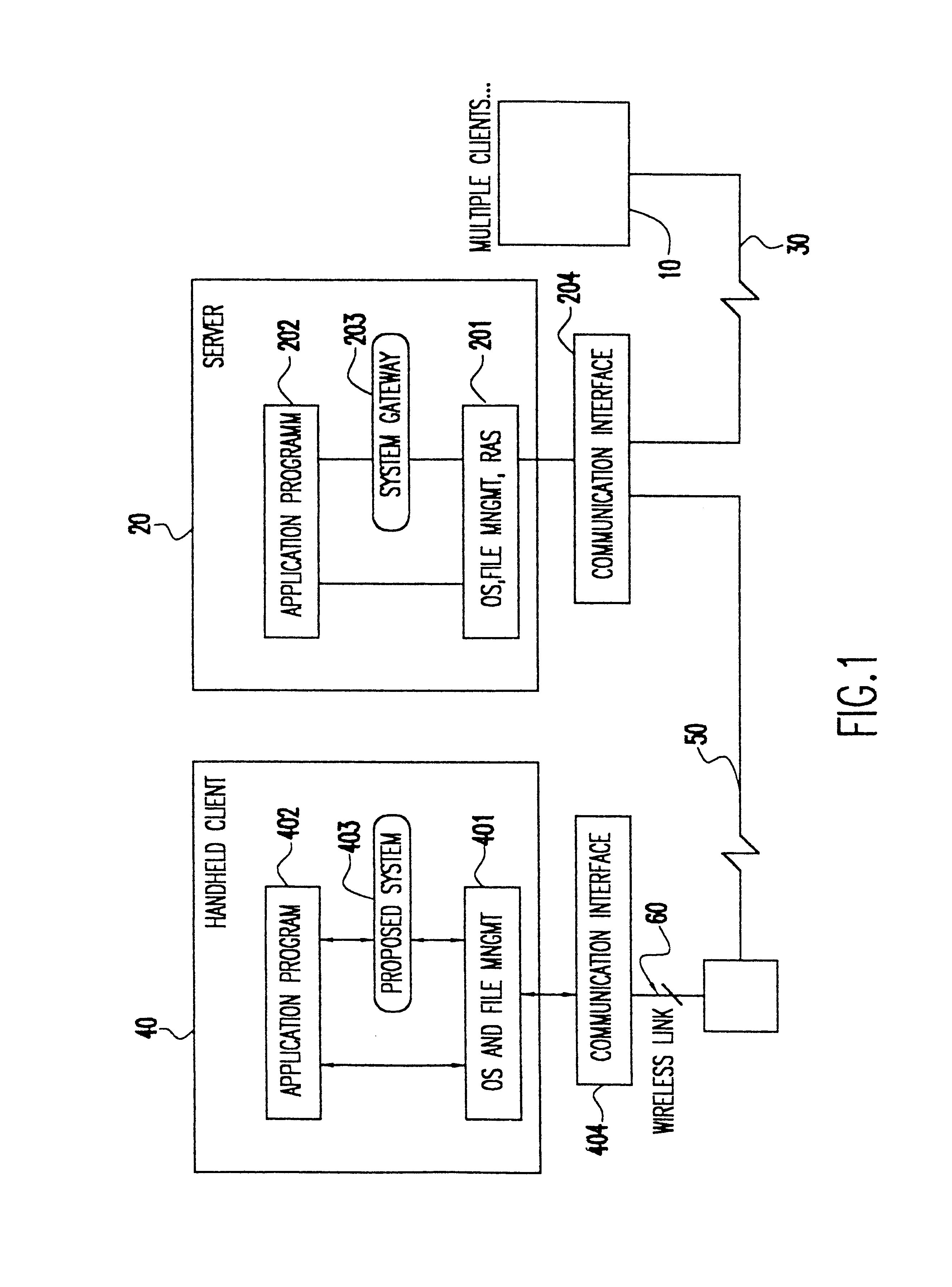

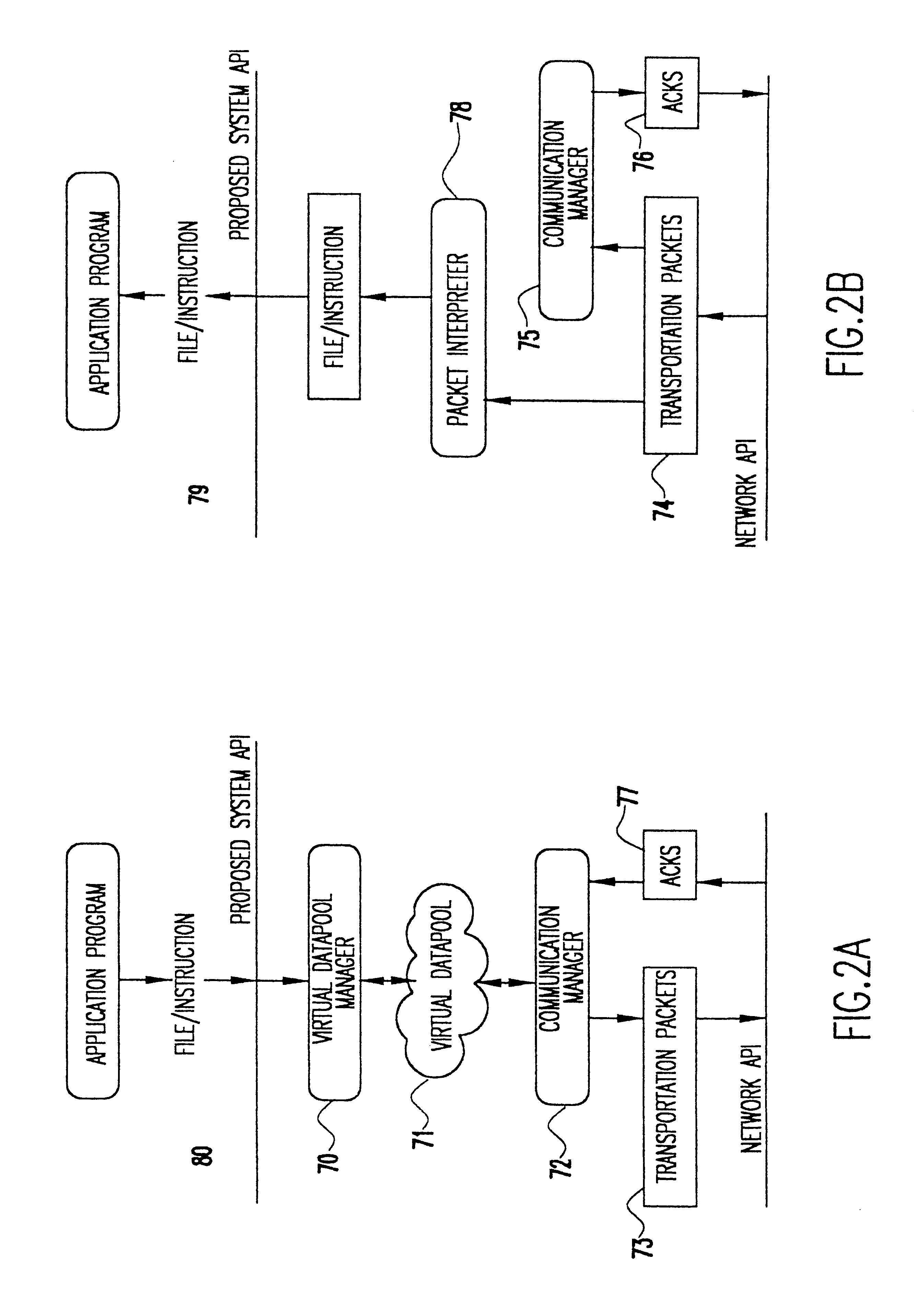

Data transfer mechanism for handheld devices over a wireless communication link

InactiveUS6775298B1Bandwidth is not as inexpensiveReduce battery power consumptionError preventionFrequency-division multiplex detailsTelecommunications linkNetwork packet

A method and apparatus for transferring data between a handheld device and a network over a wireless communications link. A datapool manager breaks files into virtual blocks and adds the virtual blocks to a datapool. A communications manager converts the virtual blocks into transportation packets and controls the transfer of the transportation packets between the handheld device and the network. After a transportation packet is transferred, an acknowledgment is returned indicating that the transfer was successful. If the transfer of a file is interrupted, then, upon reestablishing the wireless link, only those transportation packets for which an acknowledgment has not been returned are transferred. To properly reconstruct the file, a pointer indicates the location of each transportation packet in the file. Furthermore, to enable the use of a partially transferred file, a table of information is maintained indicating the validity of the partially transferred file. Transportation packets are identified as instruction packets or data packets. When determining the order of transfer, priority is placed on the transfer of instruction packets.

Owner:IBM CORP

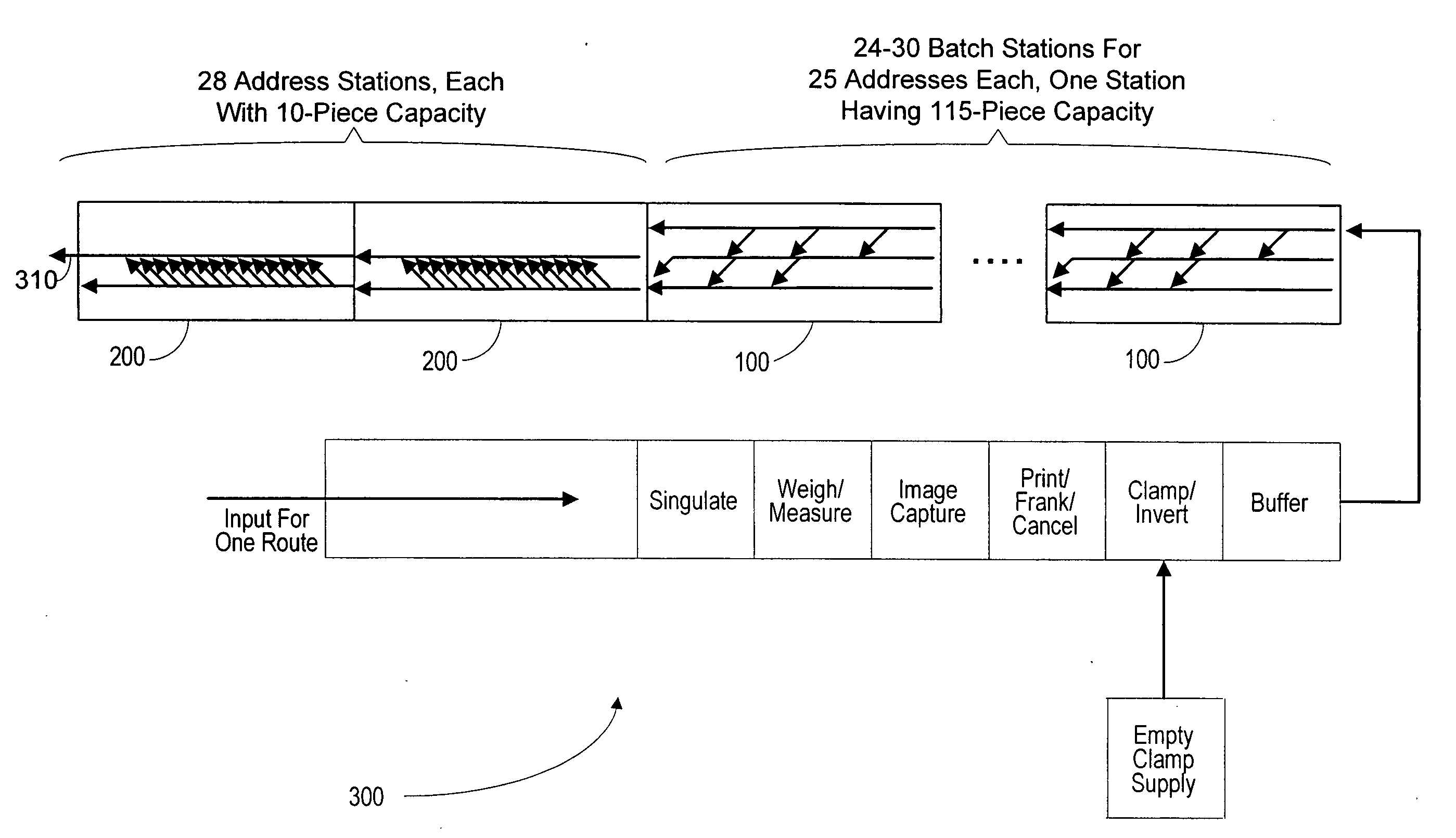

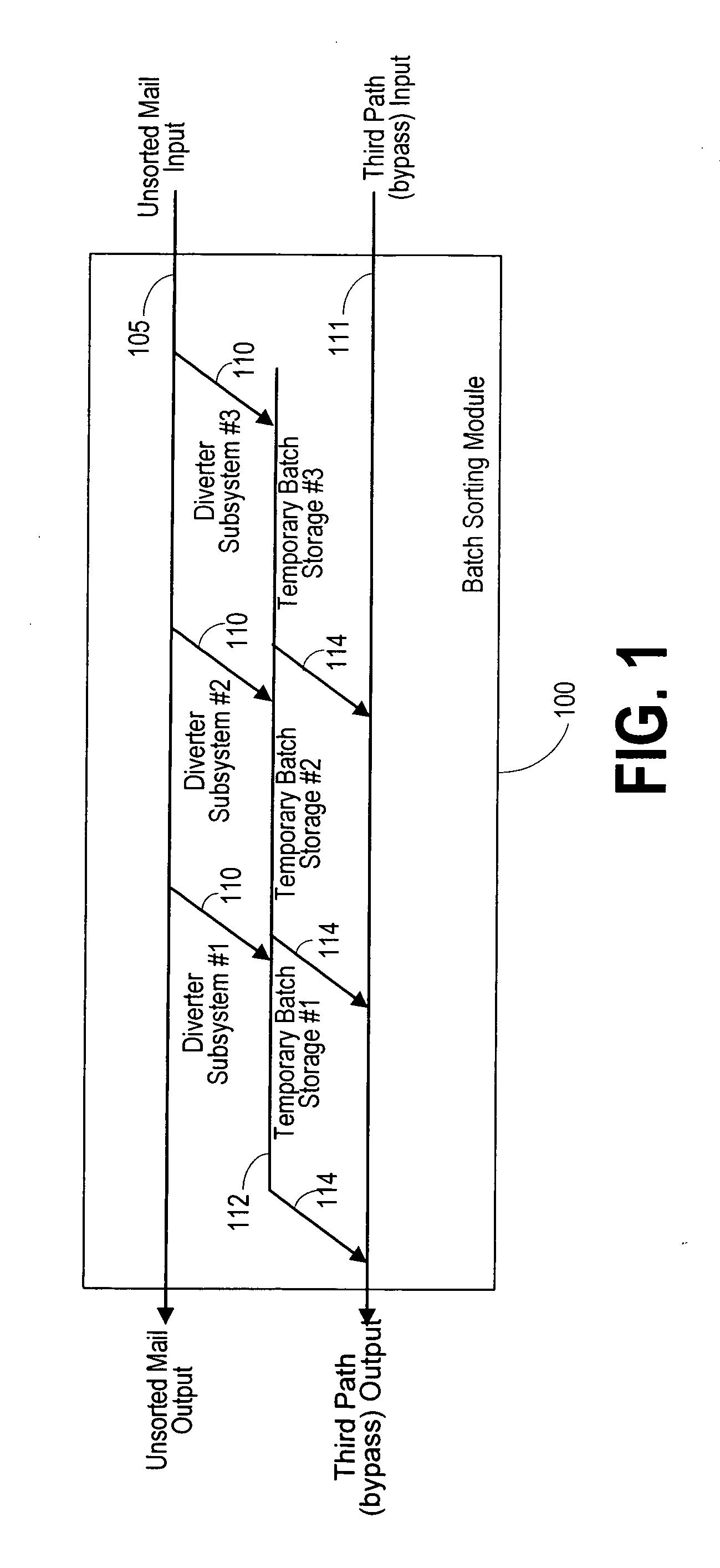

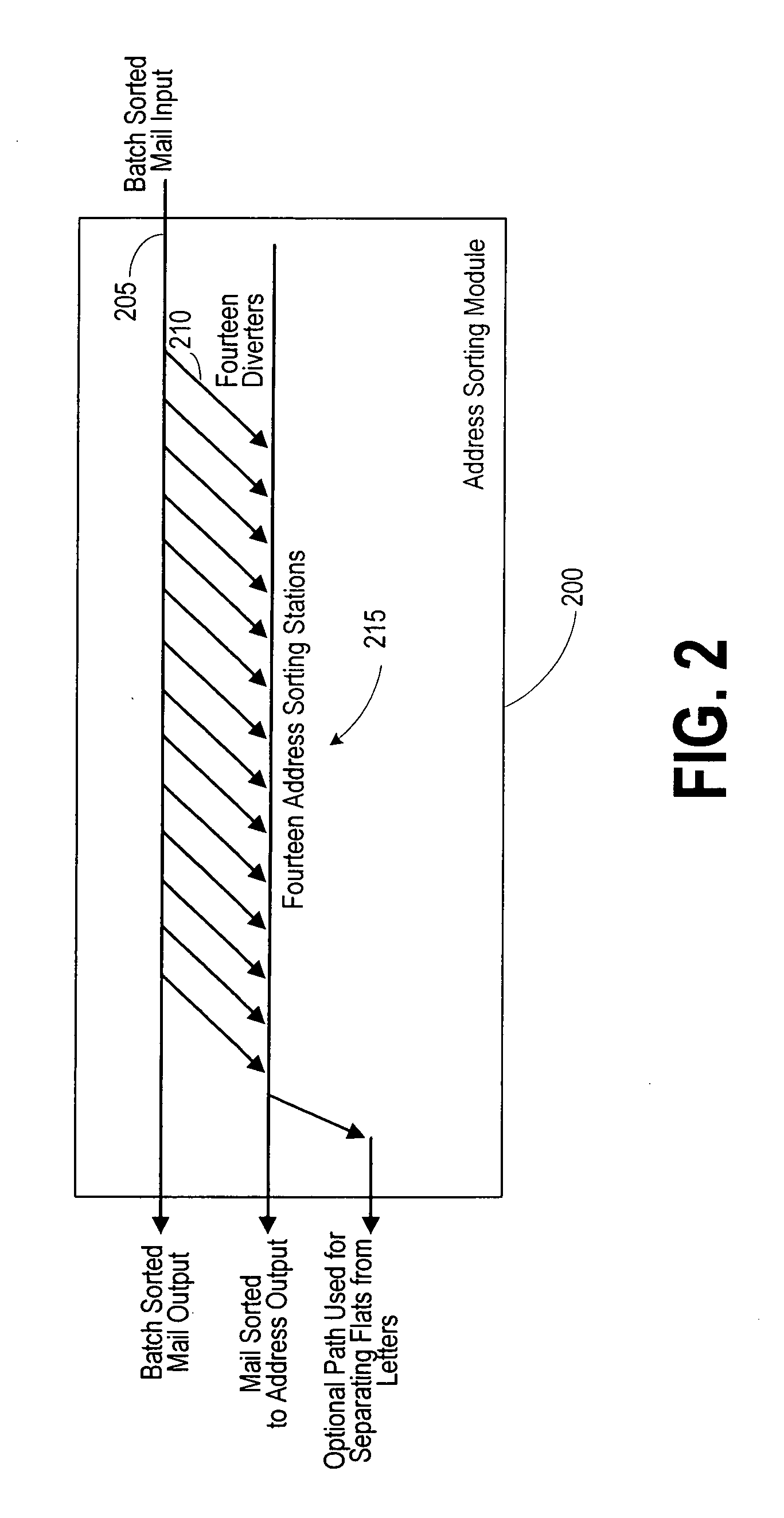

Mail sorter, method, and software product for a two-step and one-pass sorting algorithm

InactiveUS20080011653A1Short working hoursReduce path lengthSeparation devicesCharacter and pattern recognitionSorting algorithmSoftware product line

A sorter, method, and software product are used for sorting objects into a sequence of destination addresses, in at most a single pass through the sorter. In a first stage of the single pass through the sorter, the objects are sorted into a plurality of batches corresponding to groups of the destination addresses. The batches are then eventually advanced from the first stage to a second stage of the single pass through the sorter. During that second stage, objects in each of the batches are sorted into the sequence of destination addresses.

Owner:LOCKHEED MARTIN CORP

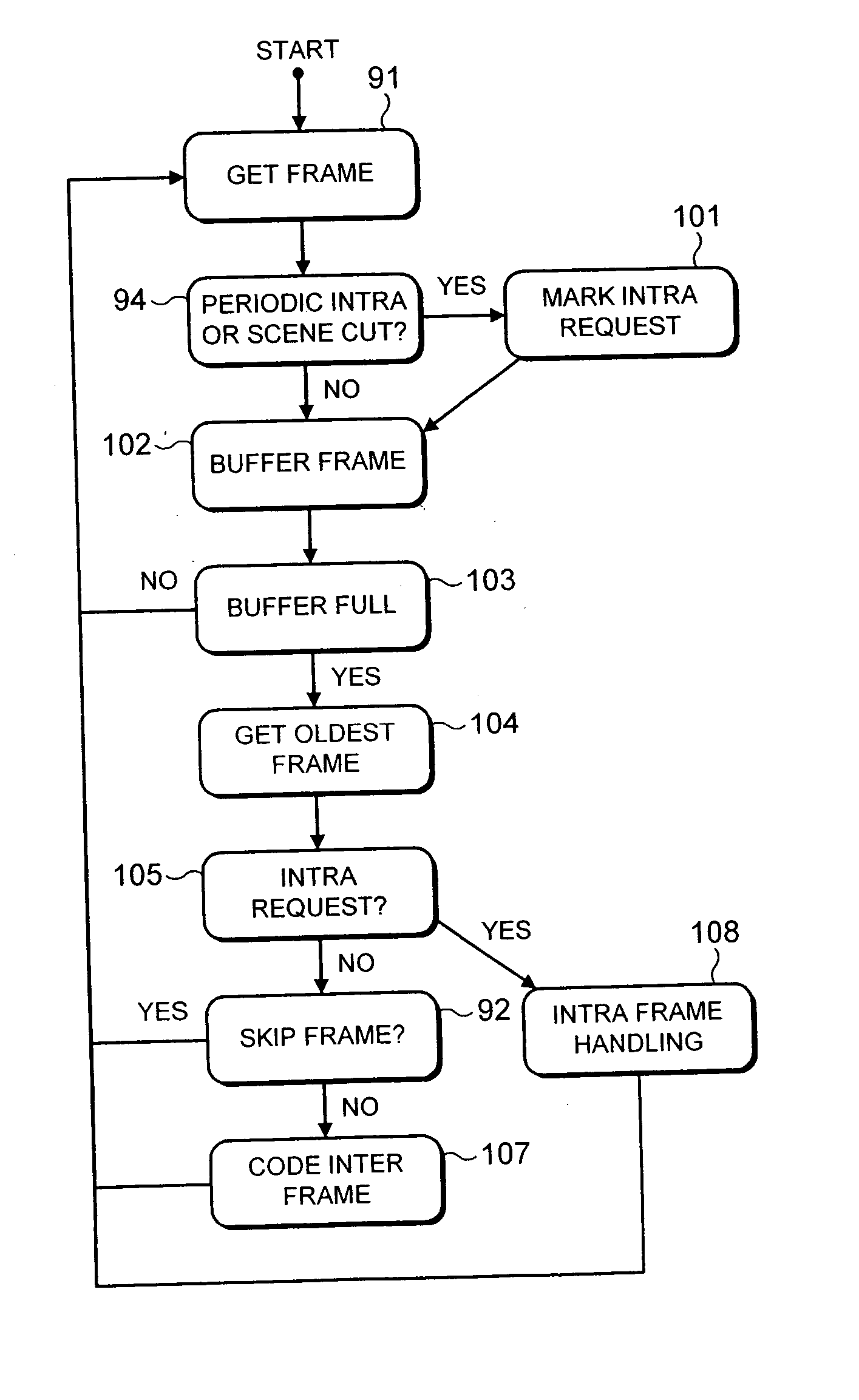

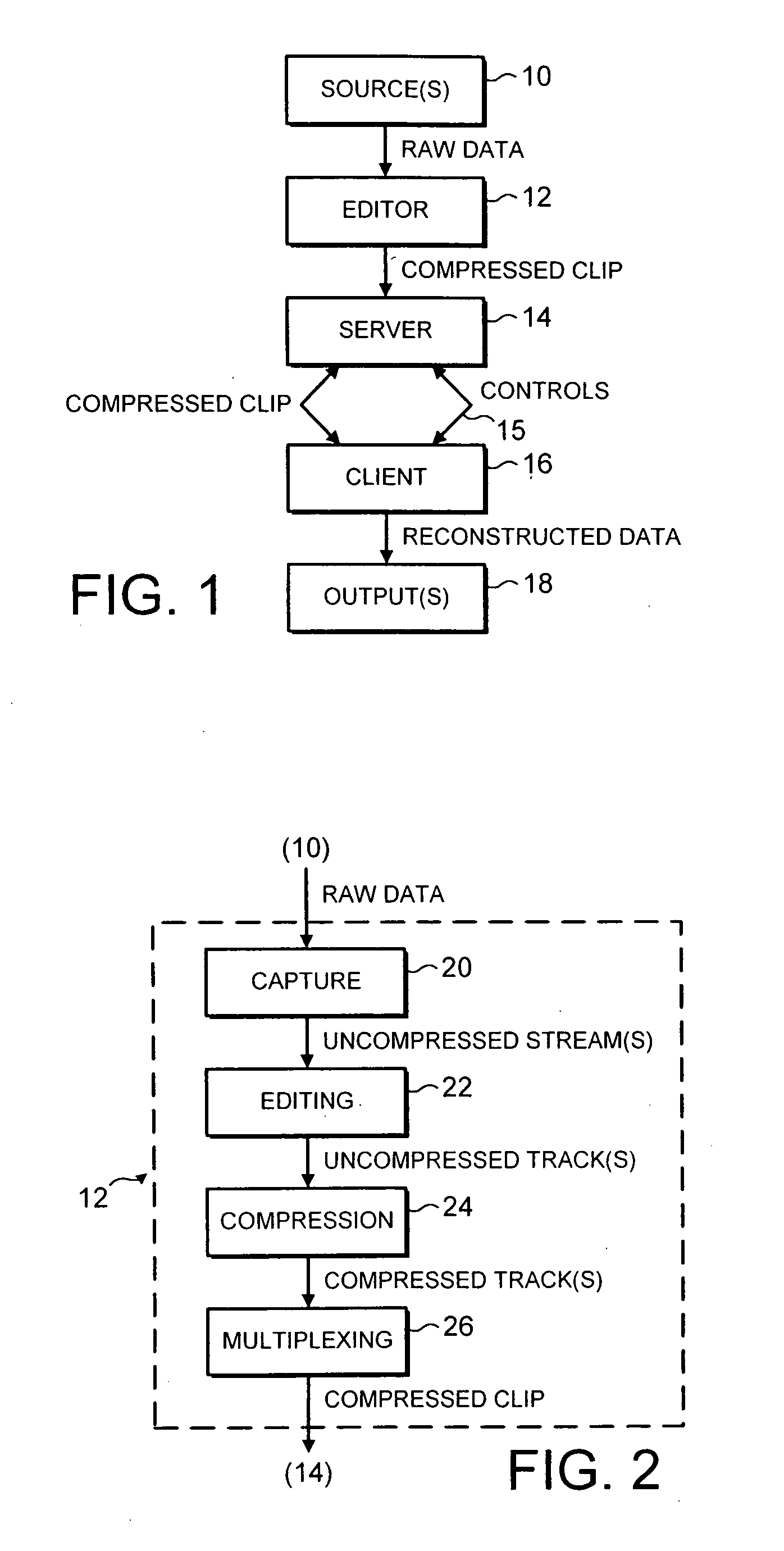

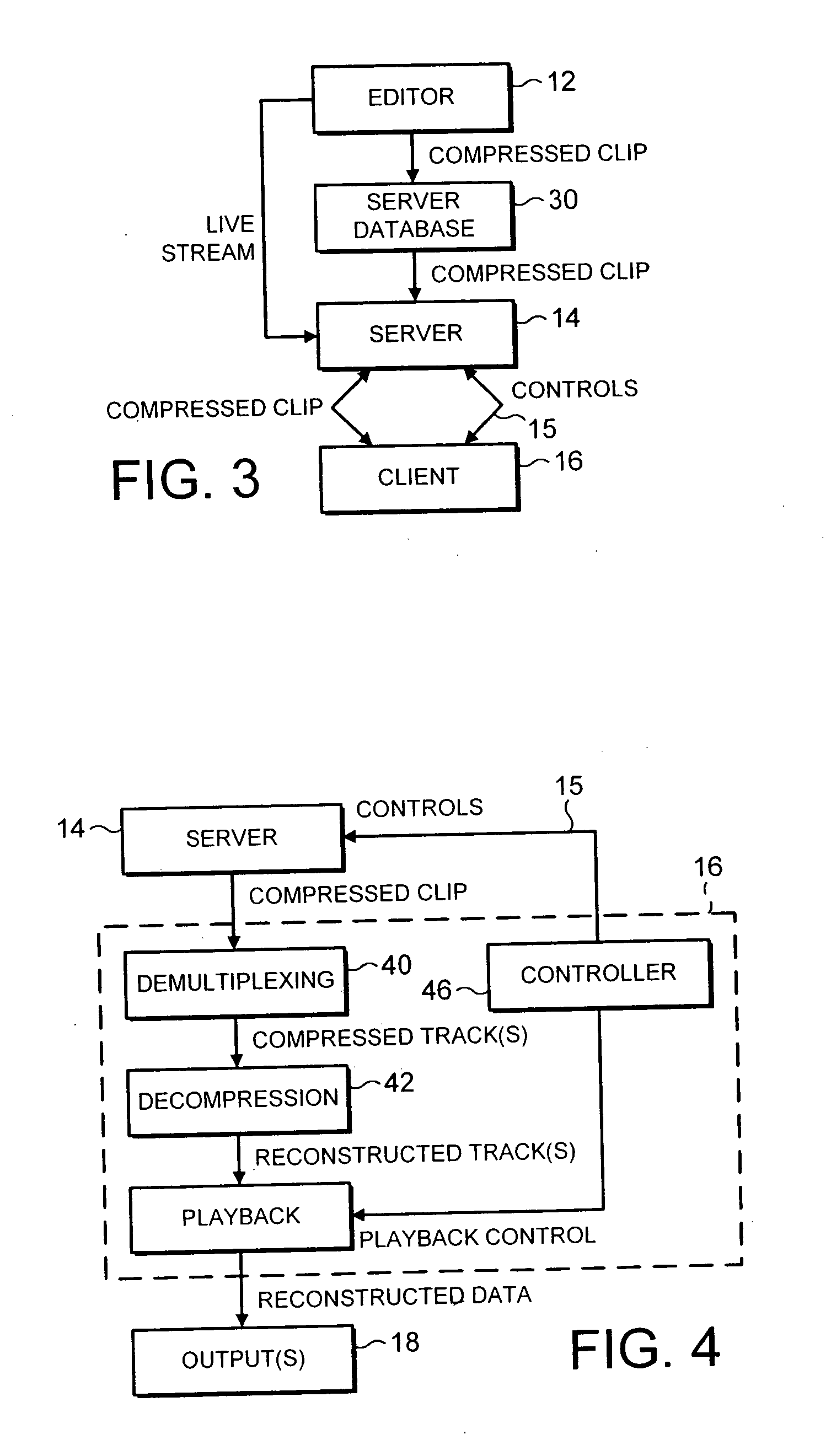

Video error resilience

ActiveUS20050123045A1Reduce path lengthGreat error resilienceColor television with pulse code modulationColor television with bandwidth reductionReal-time computingReverse order

The invention provides a method that reduces degradation in the perceived quality of images in a video sequence due to data loss. This effect is achieved by effectively delaying the insertion of an INTRA coded frame after a periodic INTRA frame refresh, INTRA update request, or scene cut. Frames associated with INTRA frame requests are not themselves coded in INTRA format, but instead a frame occurring later in the video sequence is chosen for coding in INTRA format. Preferably, the actual INTRA frame is selected such that it lies approximately mid-way between periodic INTRA requests. Frames occurring prior to the actual INTRA coded frame are encoded using temporal prediction, in reverse order, starting from the actual INTRA frame, while those frames occurring after the INTRA coded frame are encoded using temporal prediction in the forward direction.

Owner:NYTELL SOFTWARE LLC

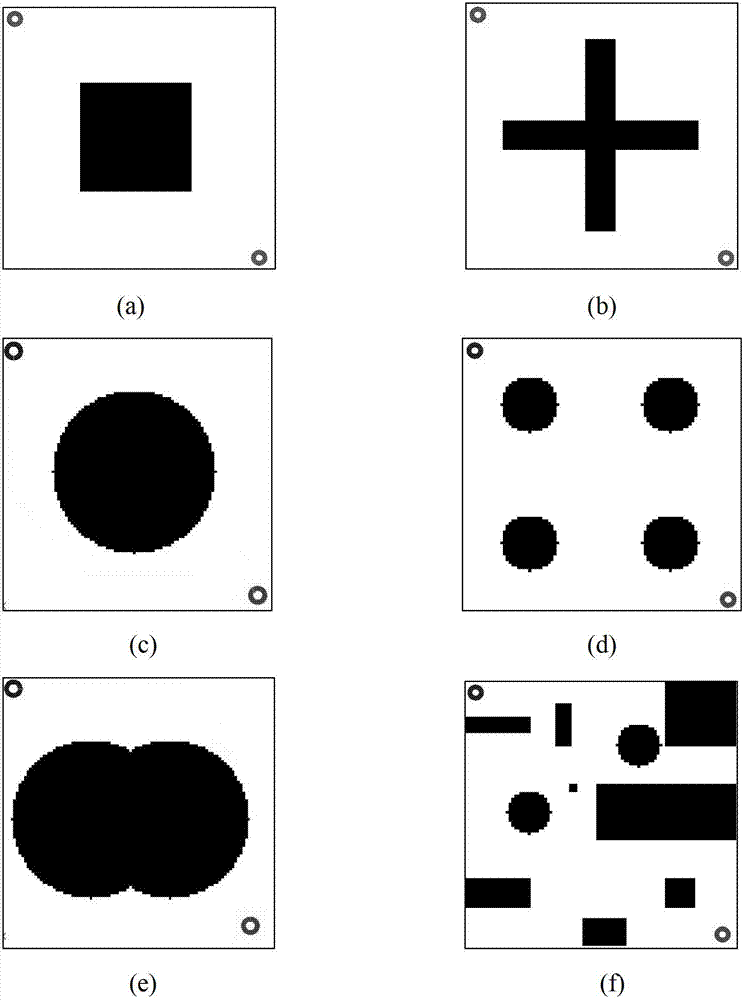

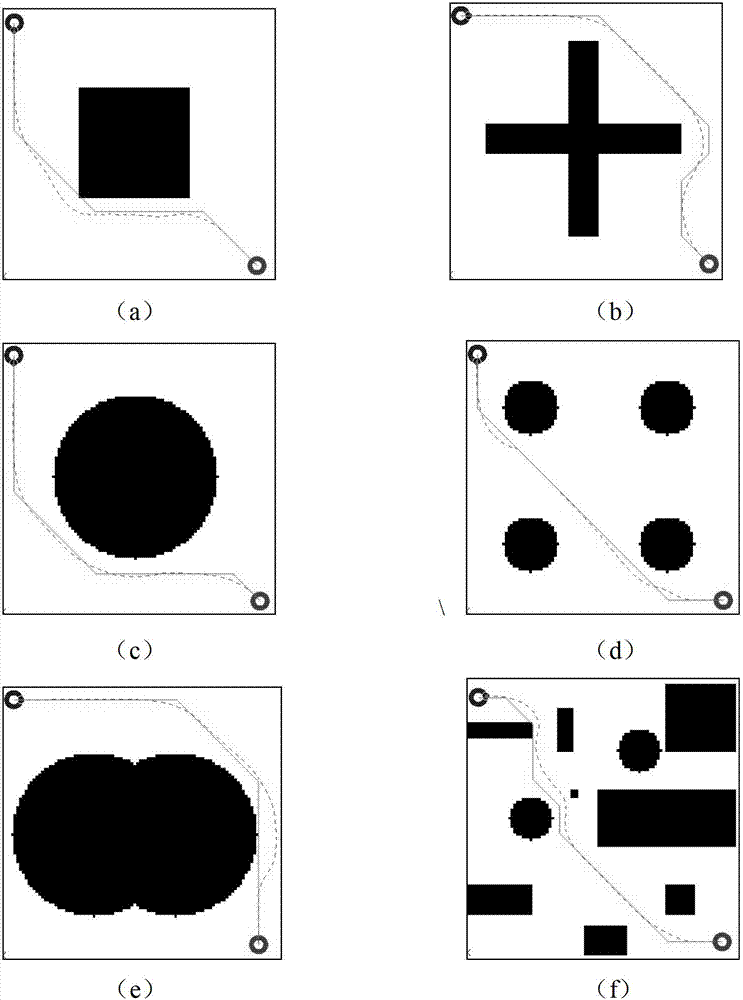

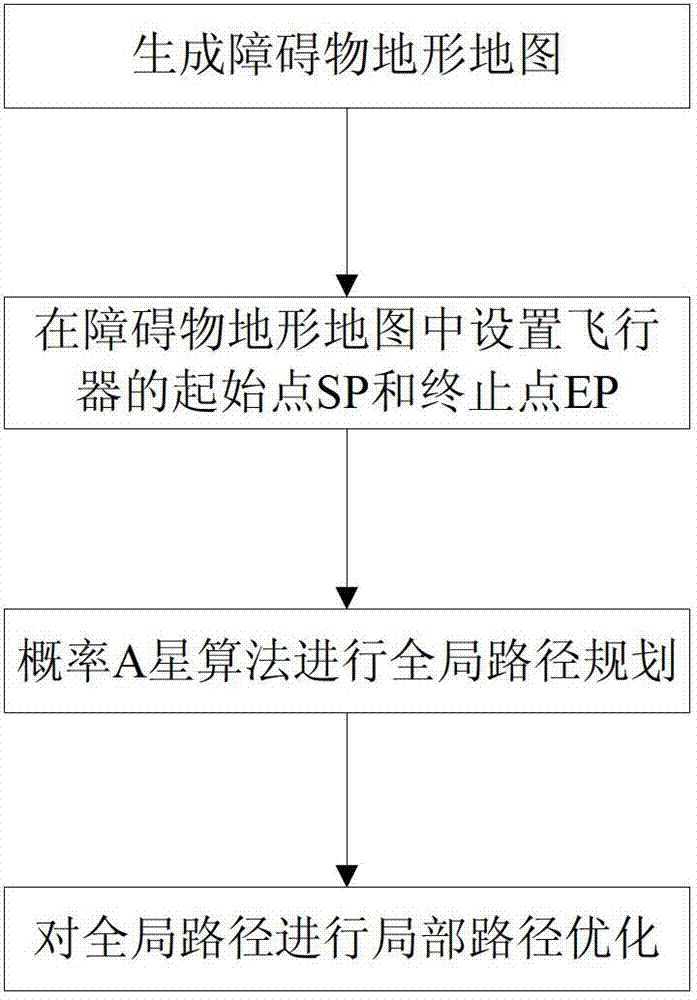

Aircraft optimal path determination method based on mixed probability A star and agent

InactiveCN102901500AShorten the lengthShorten the pathNavigational calculation instrumentsPath lengthLandform

The invention discloses an aircraft optimal path determination method based on mixed probability A star and agent. The method is mainly used to solve problems of too long path length and too large thread value of obstacles to the aircraft. The method comprises steps of: (1) generating a topographical map of the obstacles; (2) arranging a start point SP and a stop point EP of the aircraft in the topographical map of the obstacles; (3) planning a global path of the aircraft by using a probability A star algorithm in accordance with the positions of the start point SP and the stop point EP of the aircraft; and (4) locally optimizing the planned path by using an agent algorithm. The method has advantages of short path length and low thread value, and can be used for determining the optimal path of the aircraft.

Owner:XIDIAN UNIV

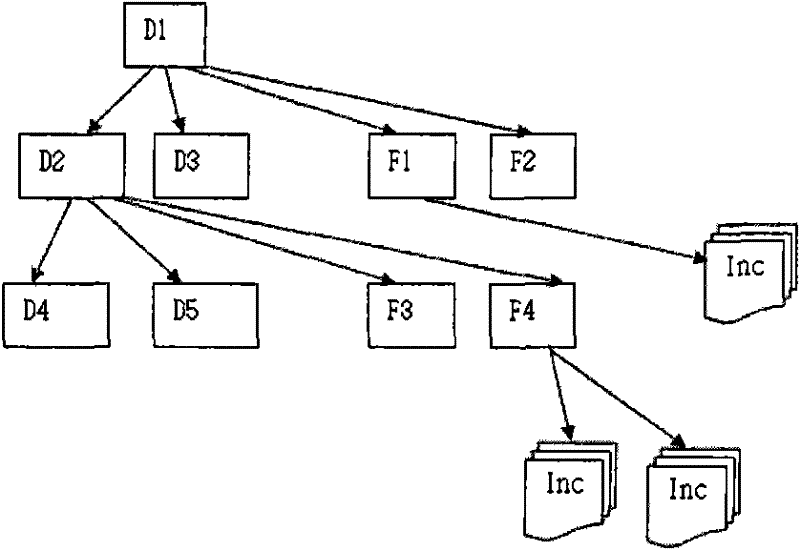

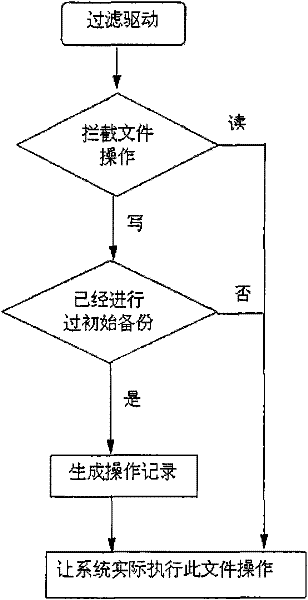

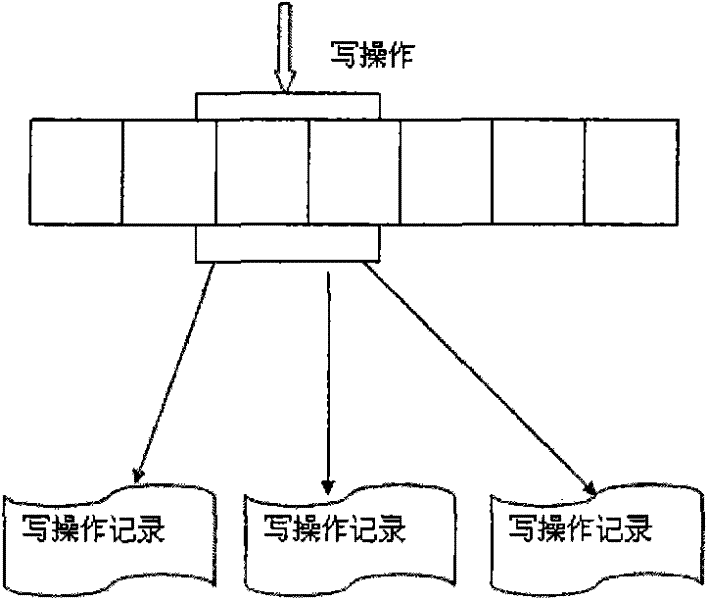

Data protection method for managing increment file based on digital identifiers

ActiveCN102236589AReduce path lengthPrevent leakageRedundant operation error correctionSpecial data processing applicationsDatabase indexData store

The invention relates to a data protection method for managing an increment file by using digital identifiers, and belongs to the technical field of data storage and backup. The method comprises the following steps of: numbering a catalogue and representing the catalogue by using the digital identifiers; numbering files under the catalogue and representing the files by using the digital identifiers; and synthesizing operating records into the increment file and representing the synthesized increment file by using the digital identifiers. An index is created for fields of the digital identifiers by using a database indexing technology. During recovery, all increment information of the file to be recovered can be quickly found, so that the file version at any modification time can be quickly recovered.

Owner:NANJING UNARY INFORMATION TECH

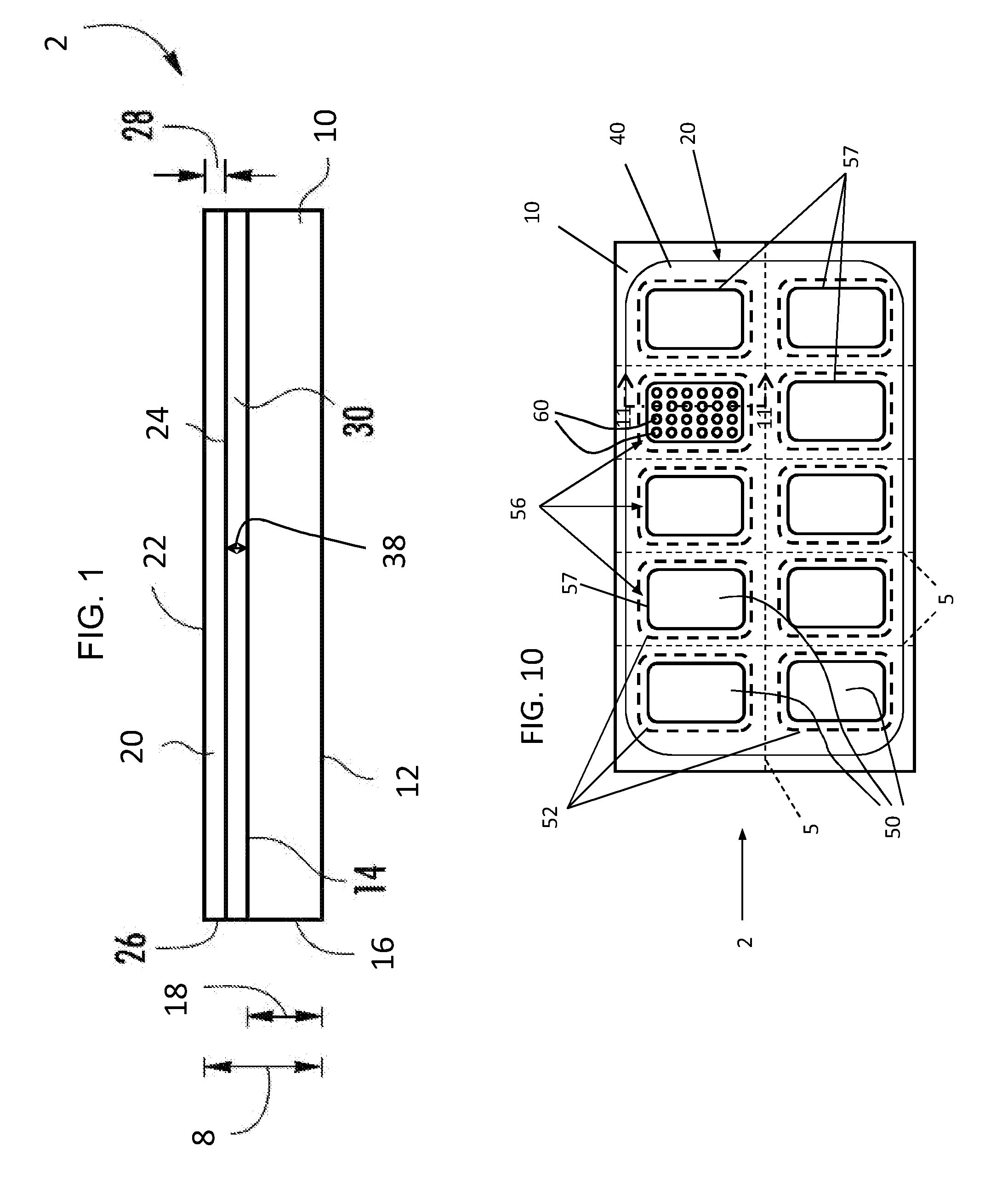

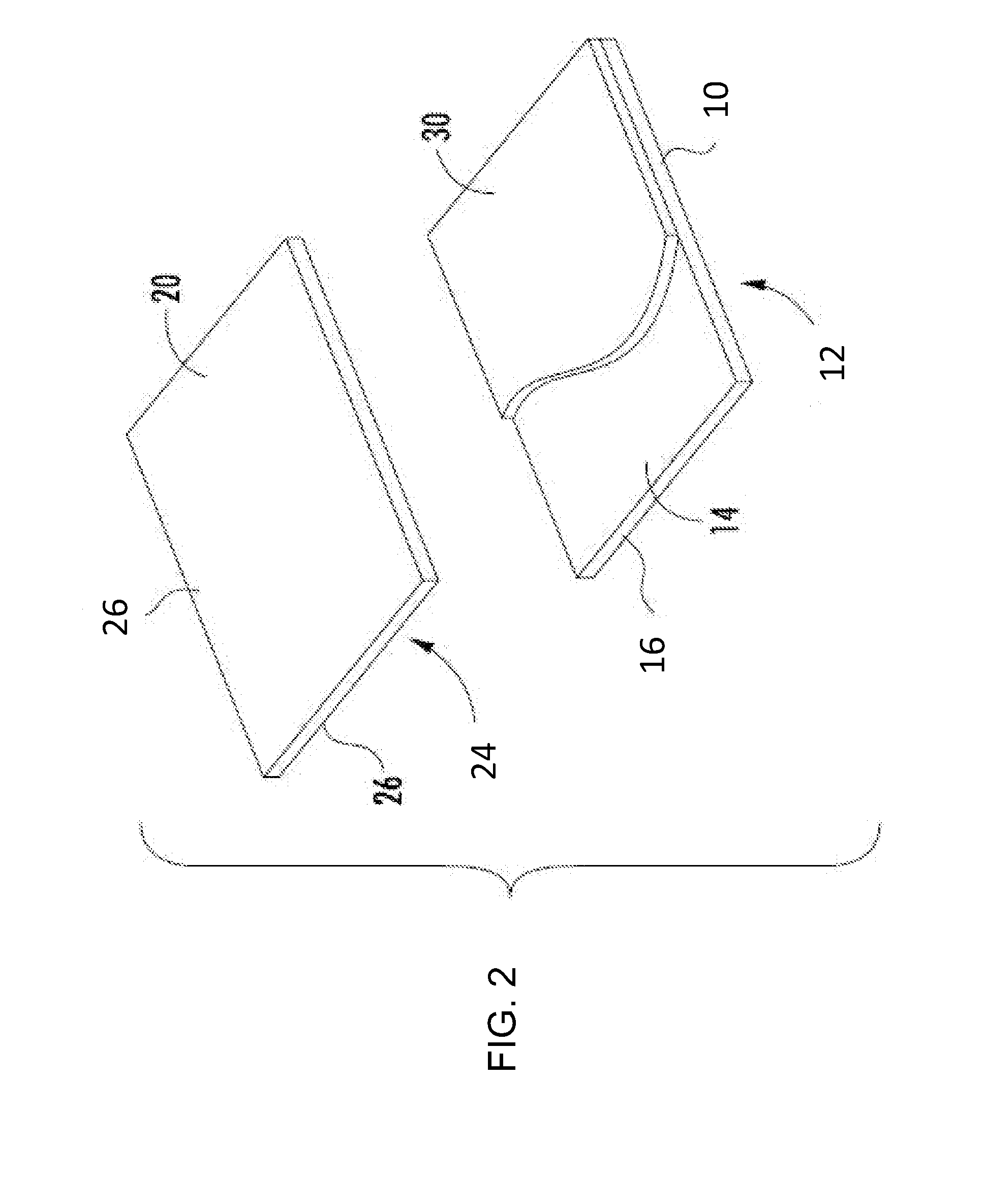

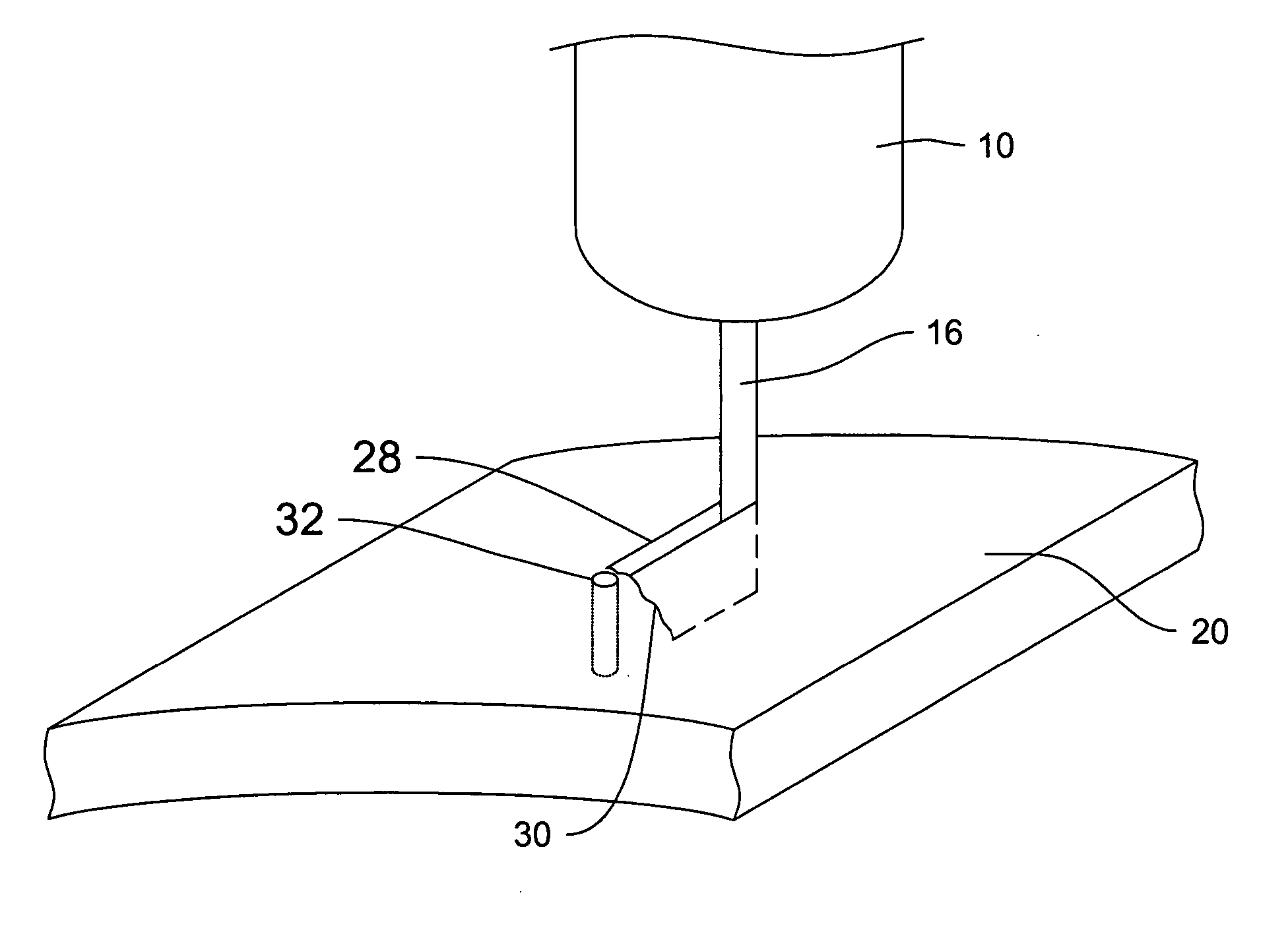

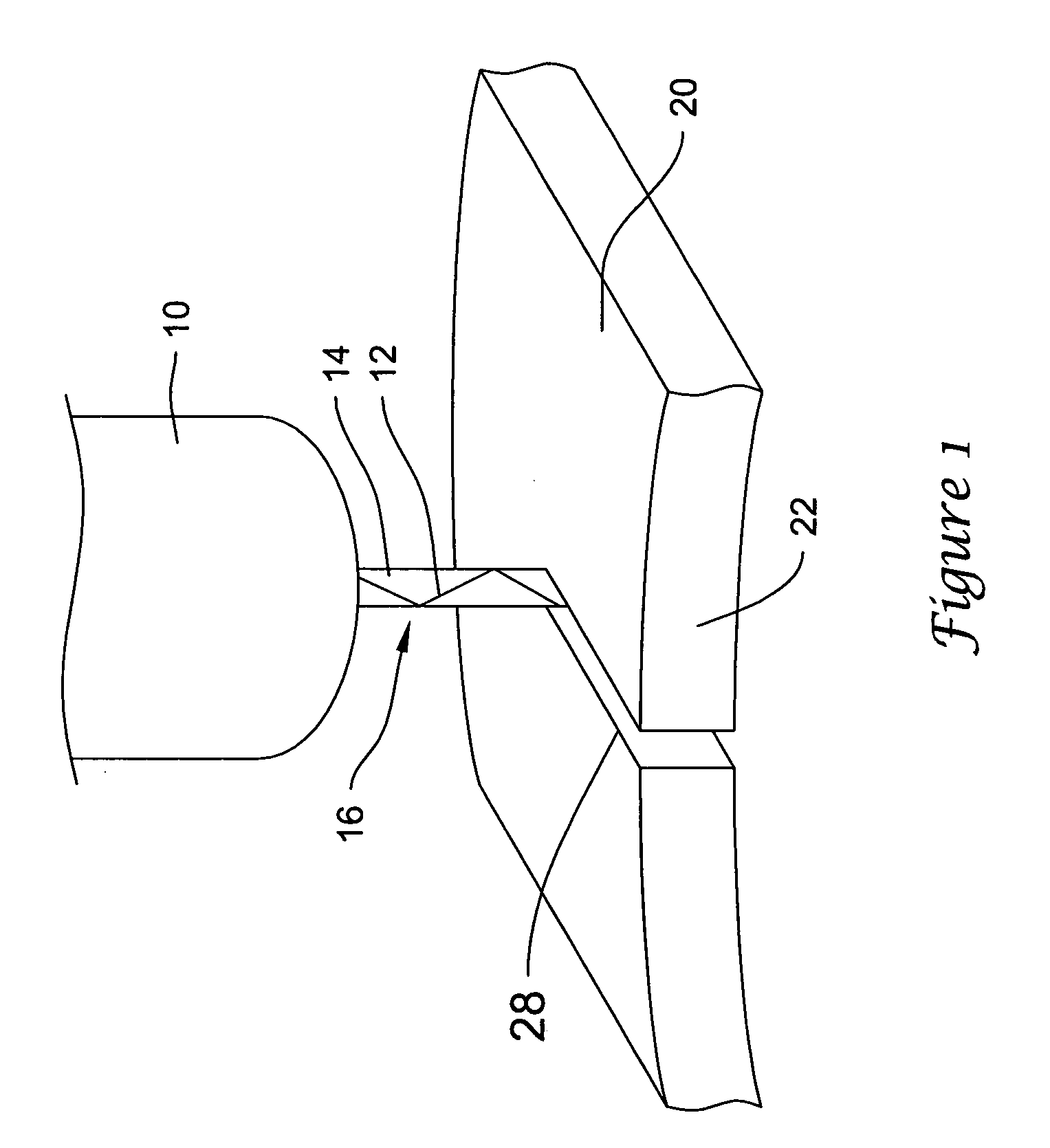

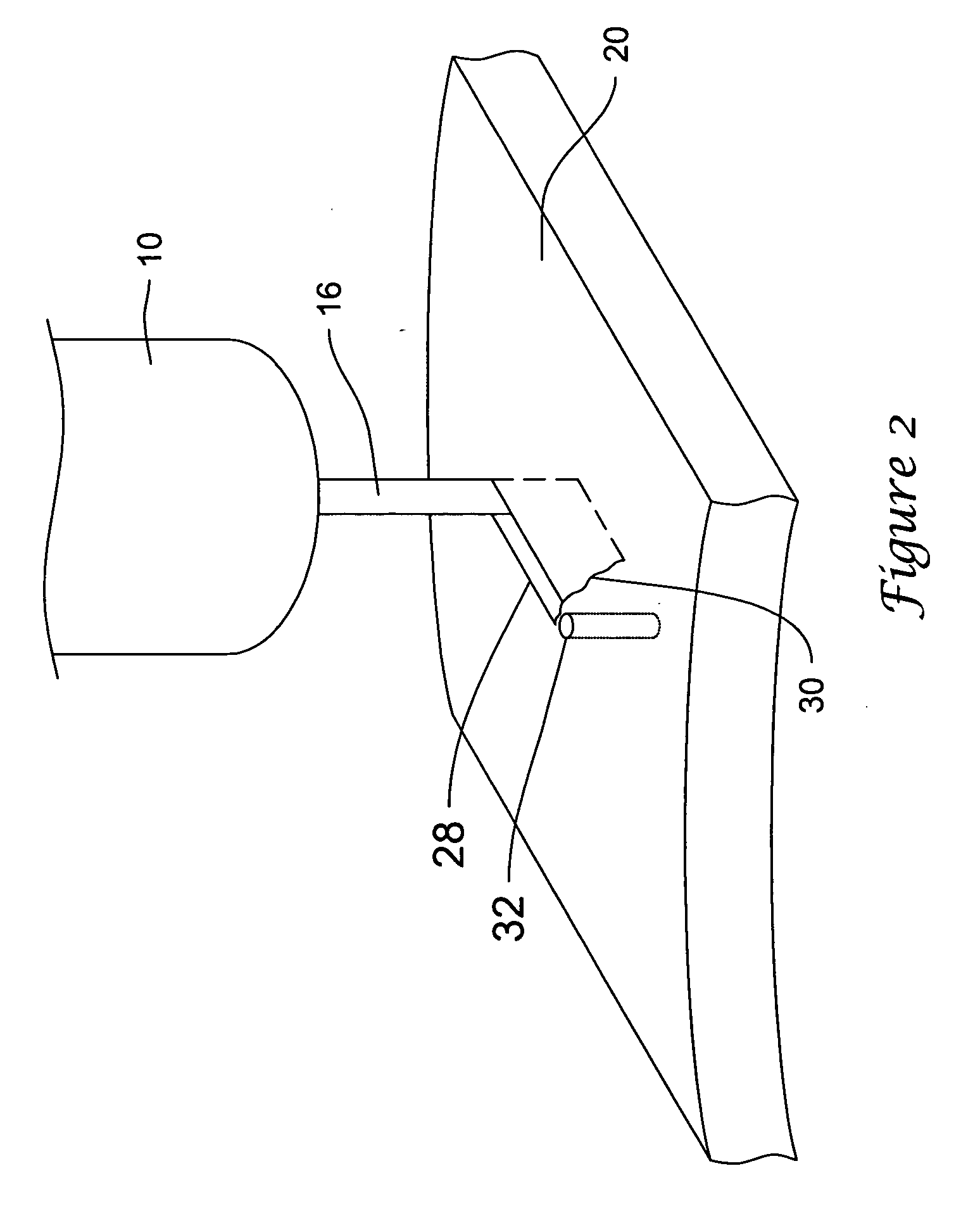

Carrier-bonding methods and articles for semiconductor and interposer processing

ActiveUS20150102498A1Avoiding waste and potential yield reductionPrevent removalSemiconductor/solid-state device detailsSolid-state devicesRoom temperatureInterposer

A thin sheet (20) disposed on a carrier (10) via a surface modification layer (30) to form an article (2), wherein the article may be subjected to high temperature processing, as in FEOL semiconductor processing, not outgas and have the thin sheet maintained on the carrier without separation therefrom during the processing, yet be separated therefrom upon room temperature peeling force that leaves the thinner one of the thin sheet and carrier intact. Interposers (56) having arrays (50) of vias (60) may be formed on the thin sheet, and devices (66) formed on the interposers. Alternatively, the thin sheet may be a substrate on which semiconductor circuits are formed during FEOL processing.

Owner:CORNING INC

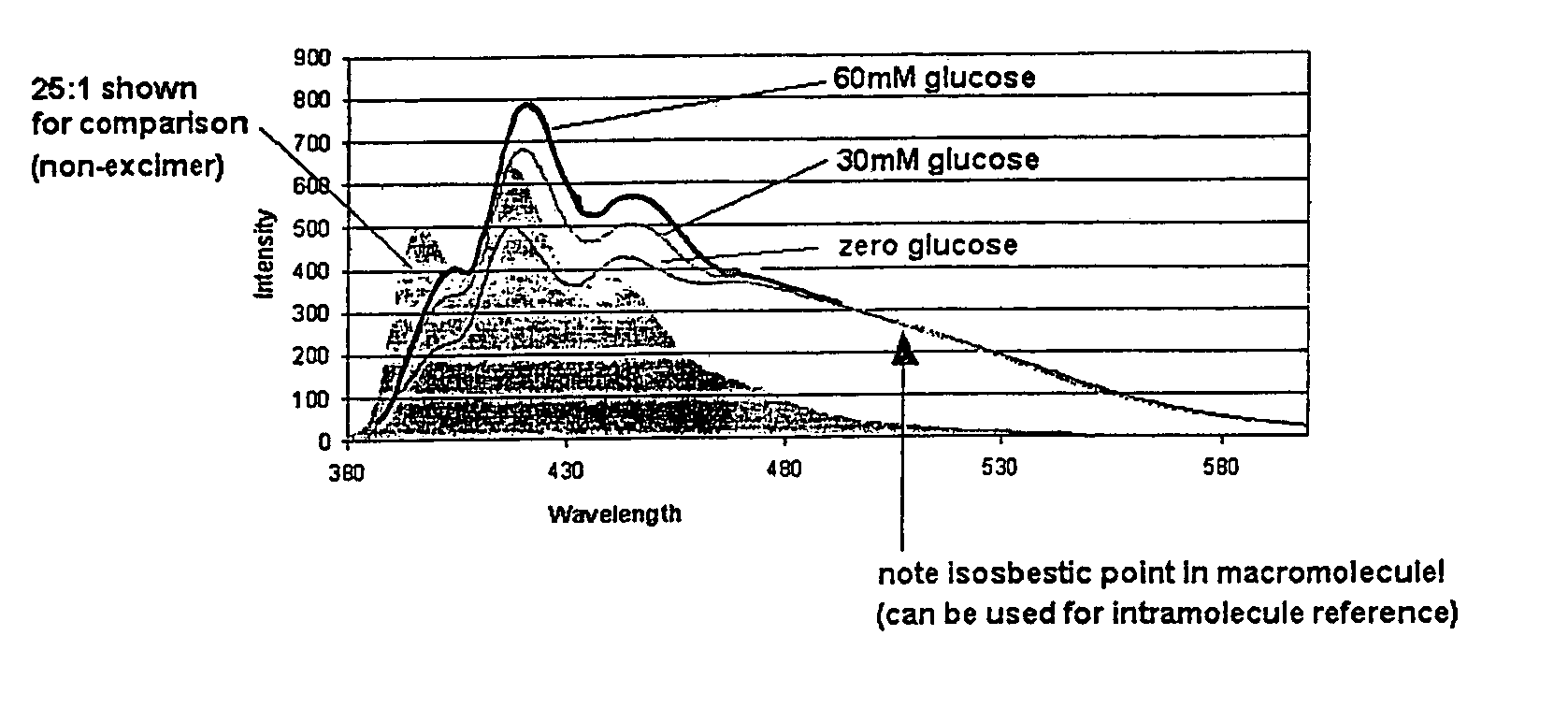

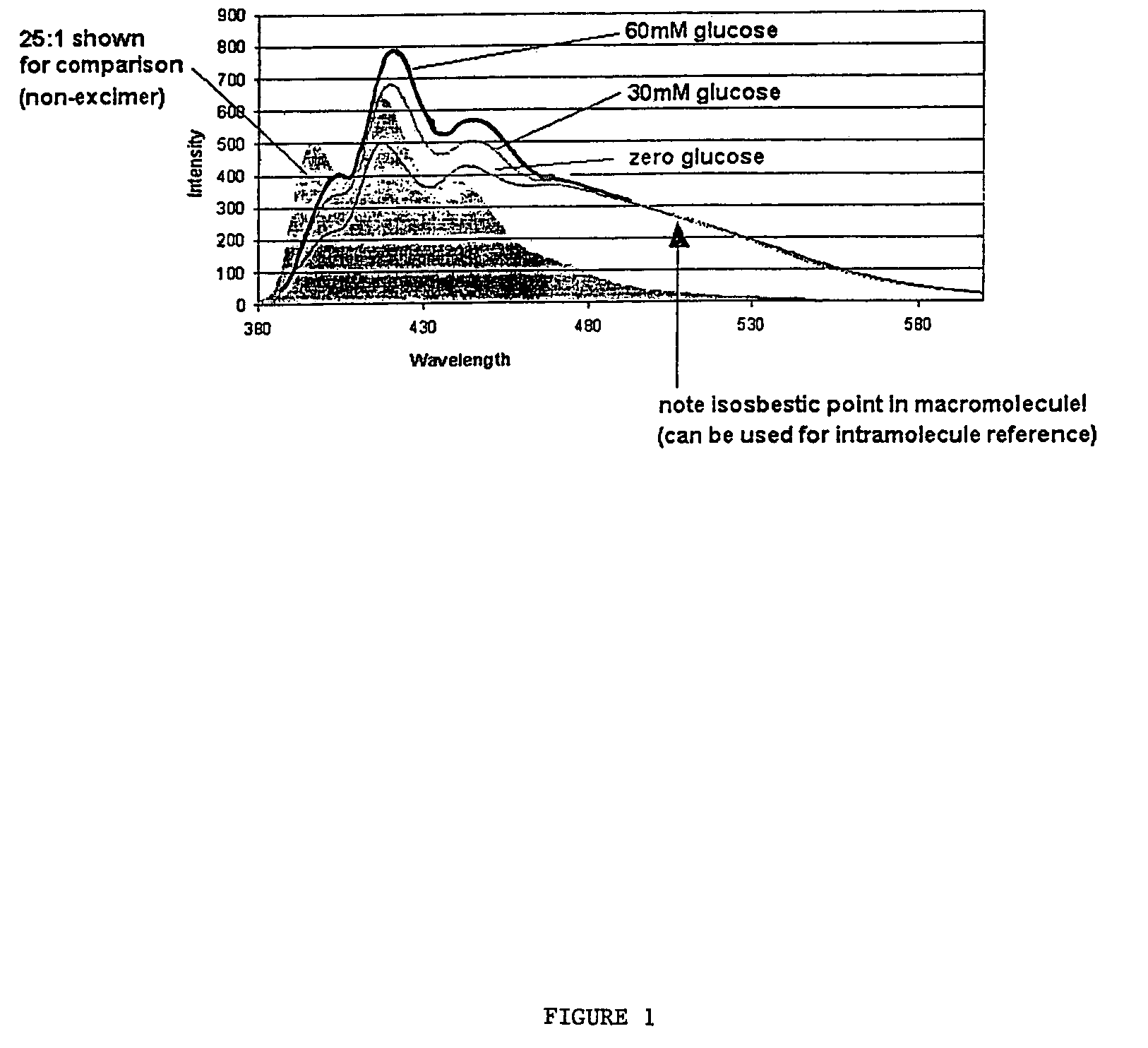

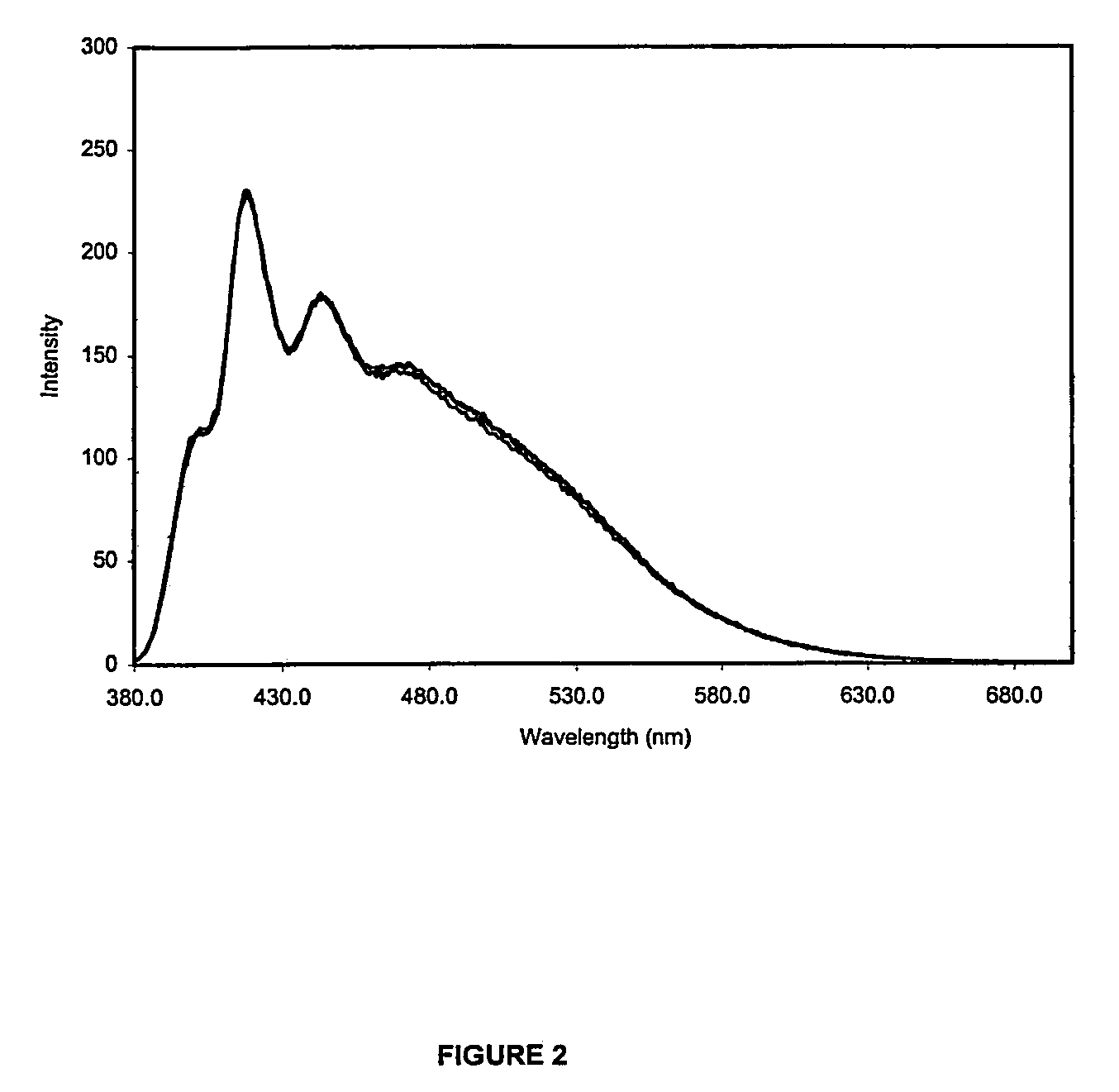

Detection of Analytes in aqueous environments

InactiveUS7060503B2Increase local concentrationHigh extinctionSilicon organic compoundsAnalysis using chemical indicatorsHydrophilic monomerAnalyte

The invention relates to indicator molecules for detecting the presence or concentration of an analyte in a medium, such as a liquid, and to methods for achieving such detection. More particularly, the invention relates to copolymer macromolecules containing relatively hydrophobic indicator component monomers, and hydrophilic monomers, such that the macromolecule is capable of use in an aqueous environment.

Owner:SENSEONICS INC

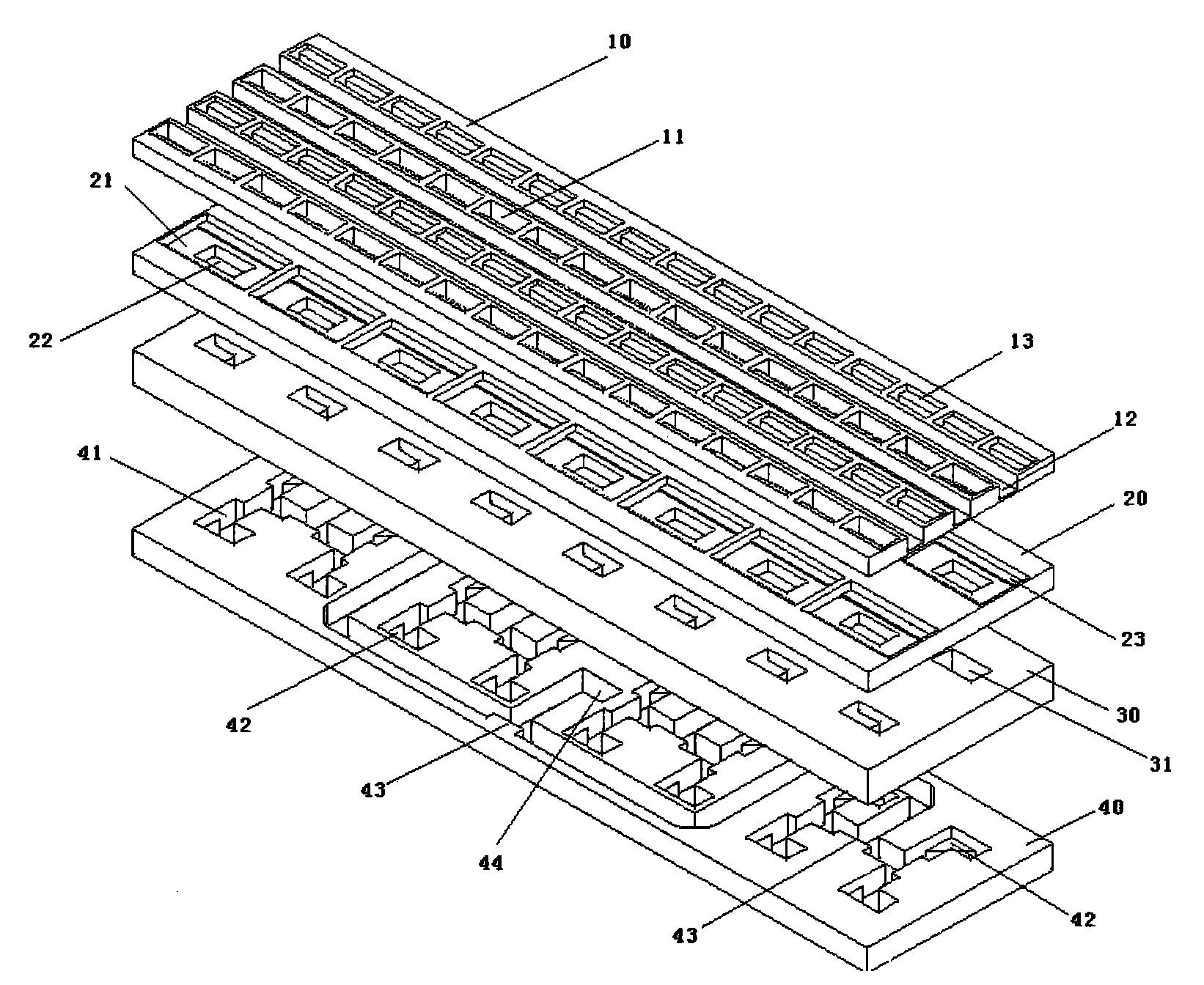

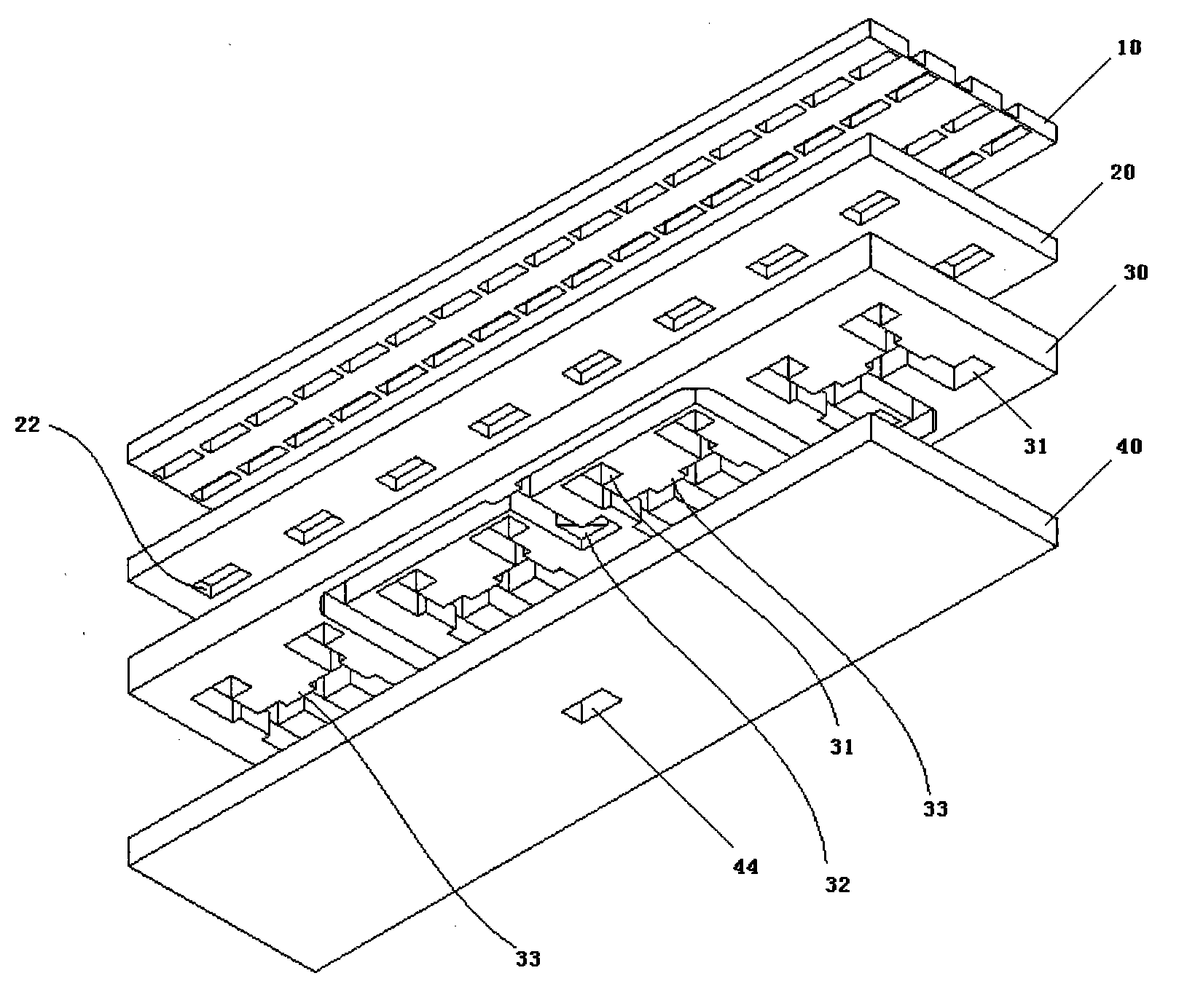

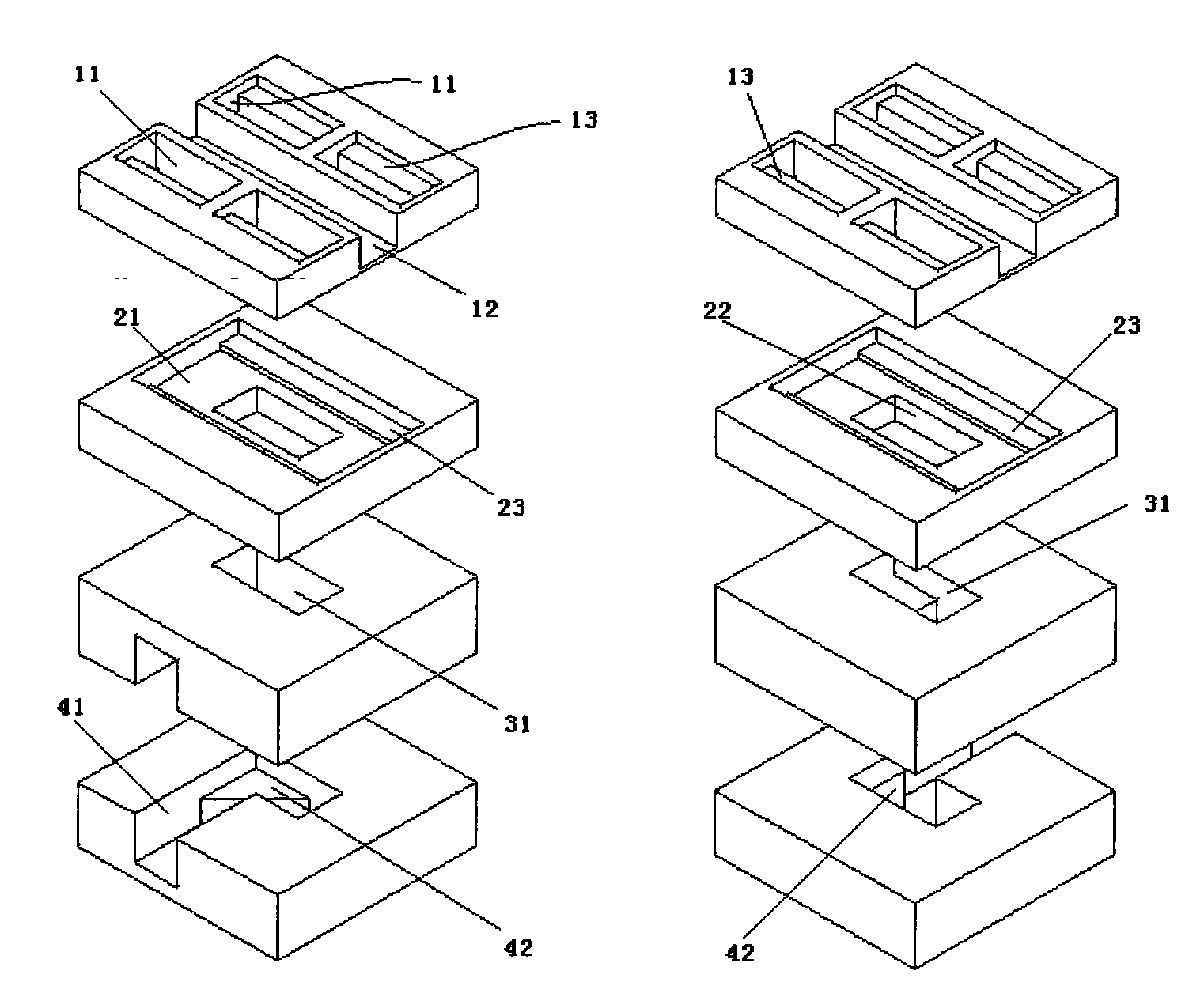

Waveguide flat array antenna

InactiveCN102064380AAvoid complex welding processesExpand standing wave bandwidthWaveguide mouthsAntenna arraysElectricityWaveguide

The invention provides a waveguide flat array antenna, which has the characteristics of broadband and high-efficiency feed. Rectangular open waveguides 11 are used as radiation units; four rectangular open waveguides in one group form a sub array, and are arranged in a 2*2 rectangle and supplied with broadband equal-amplitude in-phase feed by a rectangular cavity 21; and in order to ensure efficient transmission of electromagnetic wave, the joint of each rectangular open waveguide 11 and the rectangular cavity 21 is provided with matched steps 13 and 23. The center of the rectangular cavity 21 is provided with a rectangular window 22 which is connected with a feed network of the next layer. In order to ensure smooth signals, a rectangular matching block 42 is arranged at the feed network corner connected with each rectangular window 22. The feed network consists of multistage parallel E-T so as to ensure that the antenna has enough bandwidth. The transceiving capacity of circularly polarized wave is realized by arranging a circularly polarized cover. Compared with the conventional flat antenna, the waveguide flat array antenna has broader bandwidth and higher feed efficiency.

Owner:李峰

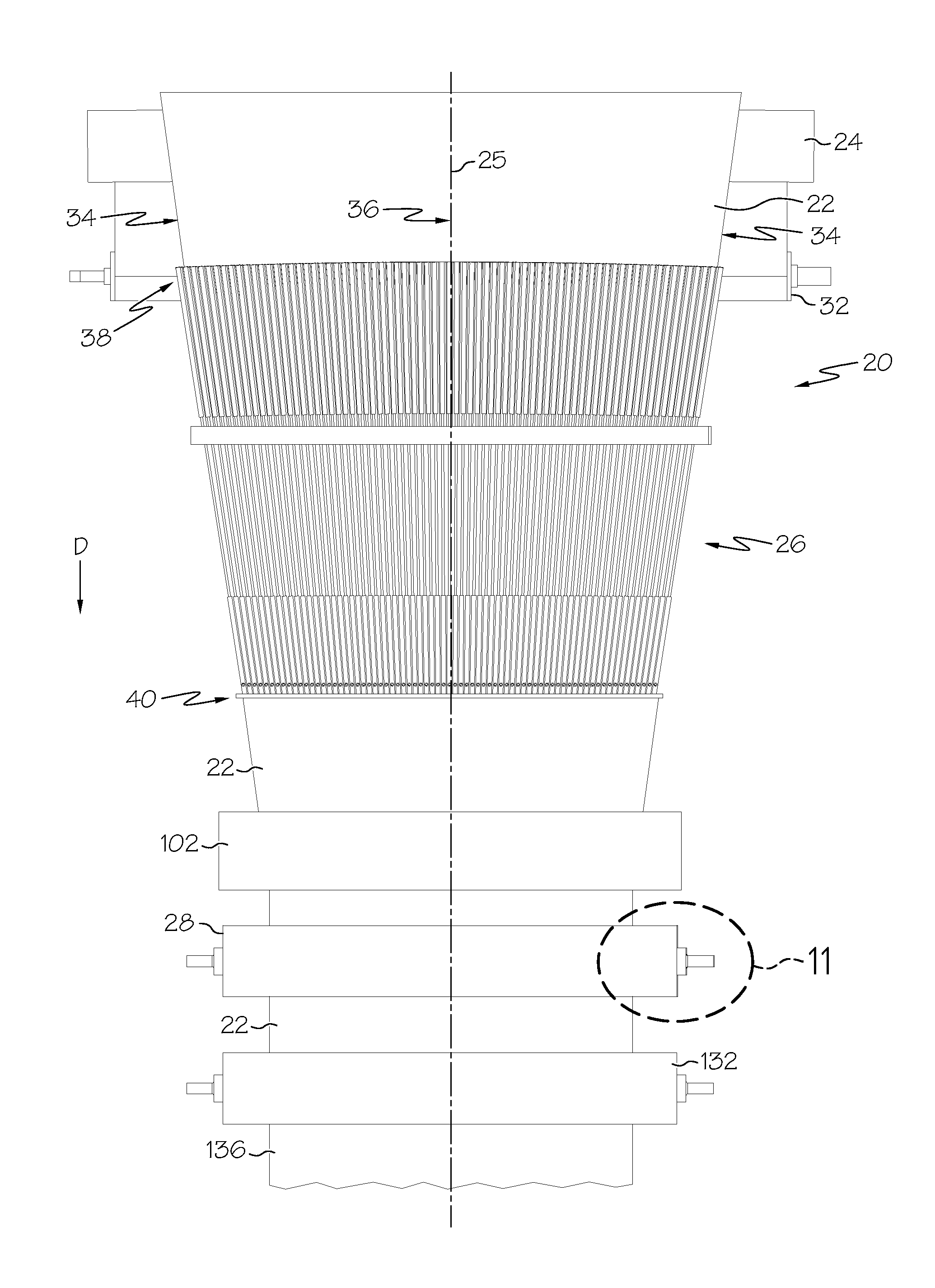

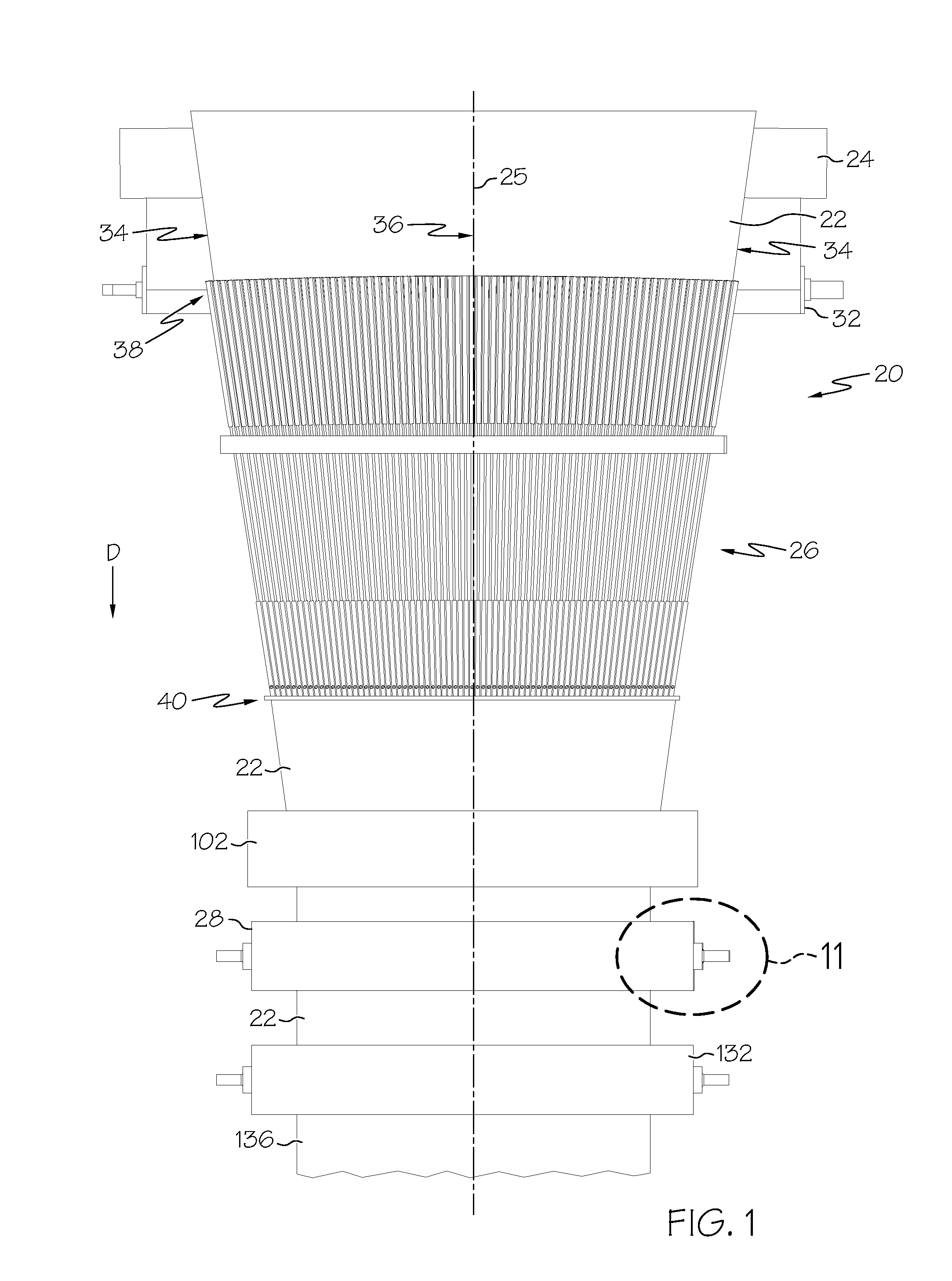

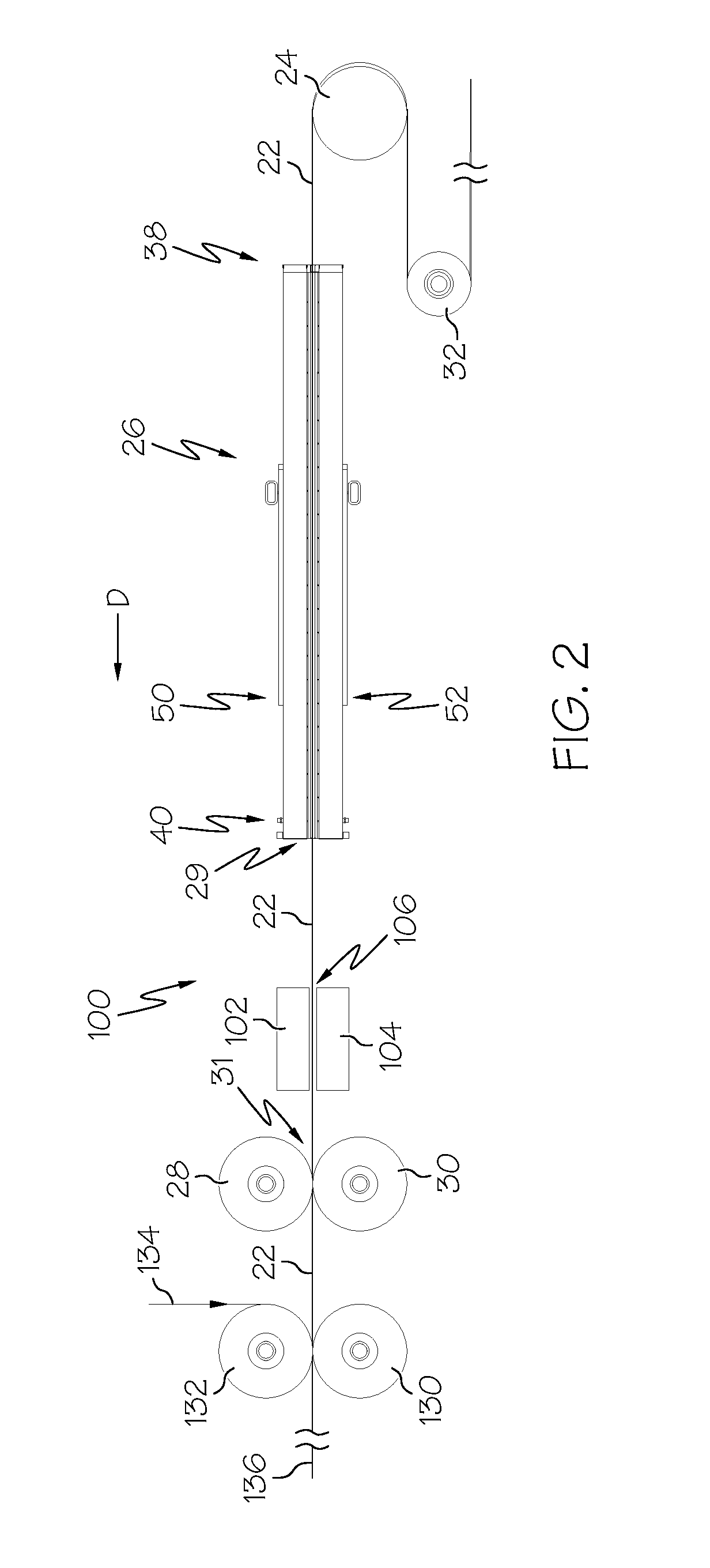

Apparatus for producing corrugated board

ActiveUS20100331160A1Well formedReduce path lengthMechanical working/deformationLamination ancillary operationsFluteMechanical engineering

An apparatus is provided for producing longitudinally corrugated product. The apparatus includes a guide roll for guiding a web of medium material, wherein at least a portion of the guide roll is adapted to be arranged at an angle relative to another portion of the guide roll. The apparatus further includes a plurality of flute forming bars oriented generally along a longitudinal axis of the web to define a first corrugating labyrinth effective to longitudinally corrugate the web to an intermediate geometry. The apparatus further includes a pair of corrugating rollers that cooperate to define, at a nip therebetween, a second corrugating labyrinth effective to longitudinally corrugate the web to a substantially final geometry. The apparatus further includes a web travel pathway for the web that follows a path around a portion of the guide roll, through the first corrugating labyrinth, and through the second corrugating labyrinth.

Owner:INT PAPER CO

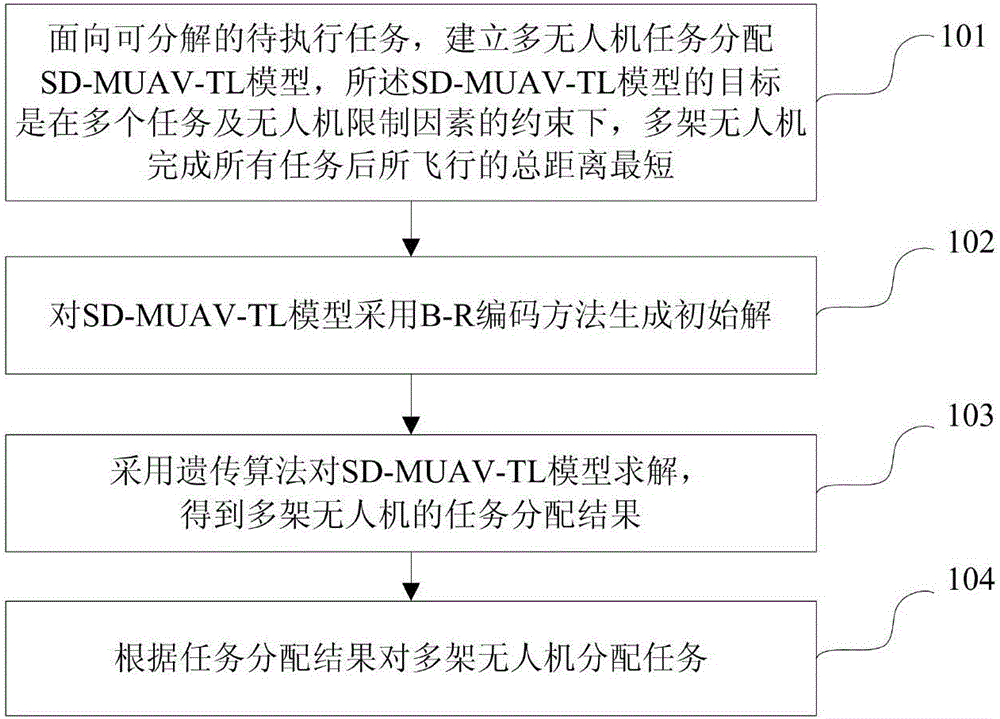

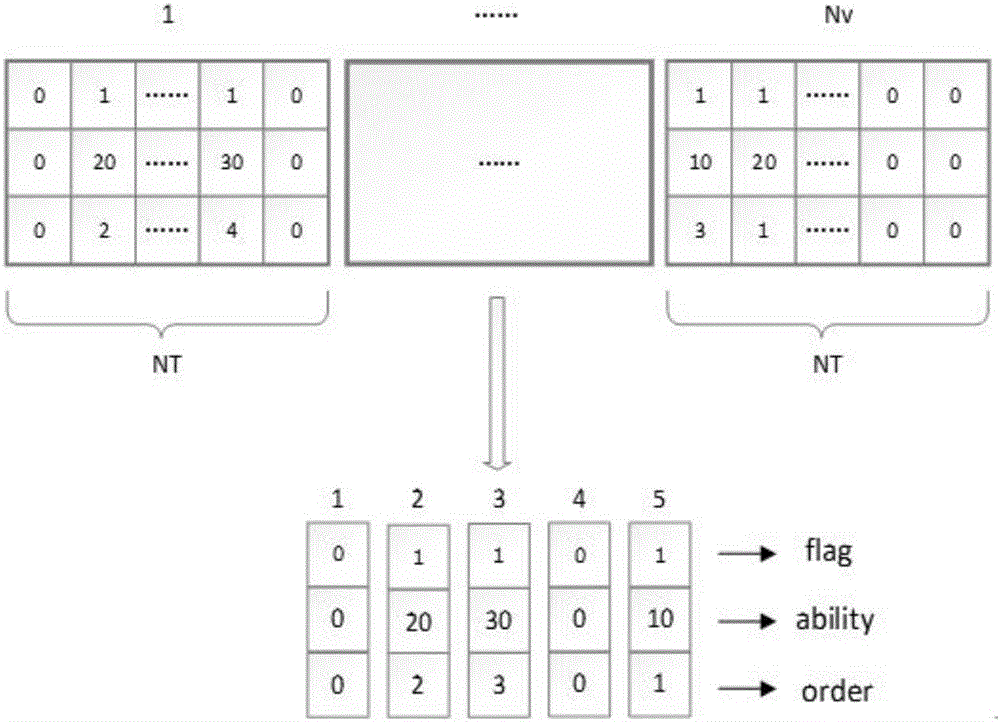

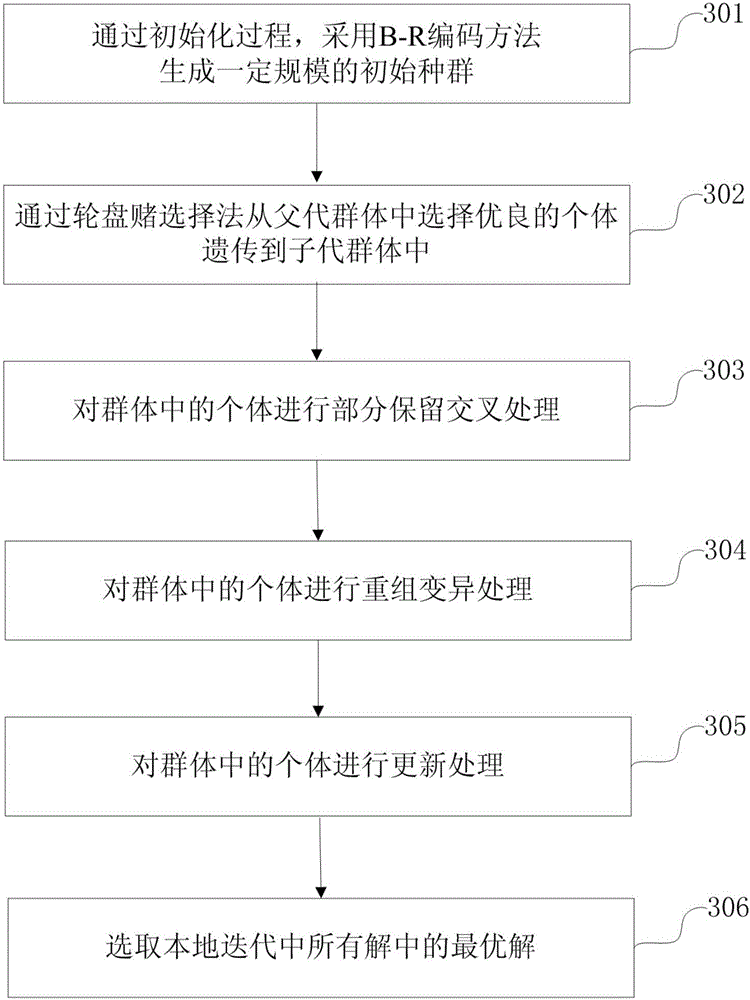

Resolvable task oriented task assigning method and apparatus for multiple unmanned aerial vehicles

InactiveCN106600147ALow costReduce path lengthForecastingResourcesGenetic algorithmReal-time computing

The embodiments of the invention provide a resolvable task oriented task assigning method and apparatus for multiple unmanned aerial vehicles. The method comprises the following steps: establishing an SD-MUAV-TL model for the task assigning of the multiple unmanned aerial vehicles in terms of a to-be-executed resolvable task wherein the goal of the SD-MUAV-TL model is to ensure that the total distance traveled by the multiple unmanned aerial vehicles is the shortest after they complete their task under the constraints of a plurality of tasks and the limiting factors of the unmanned aerial vehicles; adopting a B-R coding method to the SD-MUAV-TL model to generate an initial solution; using a genetic algorithm to solve the SD-MUAV-TL model to obtain a task assigning result for the multiple unmanned aerial vehicles; and according to the task assigning result, assigning the task to the multiple unmanned aerial vehicles. The embodiments of the invention assign task to a cluster of unmanned aerial vehicles of the same structure. The cluster of unmanned aerial vehicles need to transverse all search objects and complete corresponding search task and with the invention, the total cost for all search tasks is the smallest.

Owner:HEFEI UNIV OF TECH

Dual-band antenna with easily and finely adjustable resonant frequency, and method for adjusting resonant frequency

InactiveUS6995720B2Reduce path lengthIncrease path lengthSimultaneous aerial operationsAntenna supports/mountingsElectromagnetic couplingDual band antenna

Owner:ALPS ALPINE CO LTD

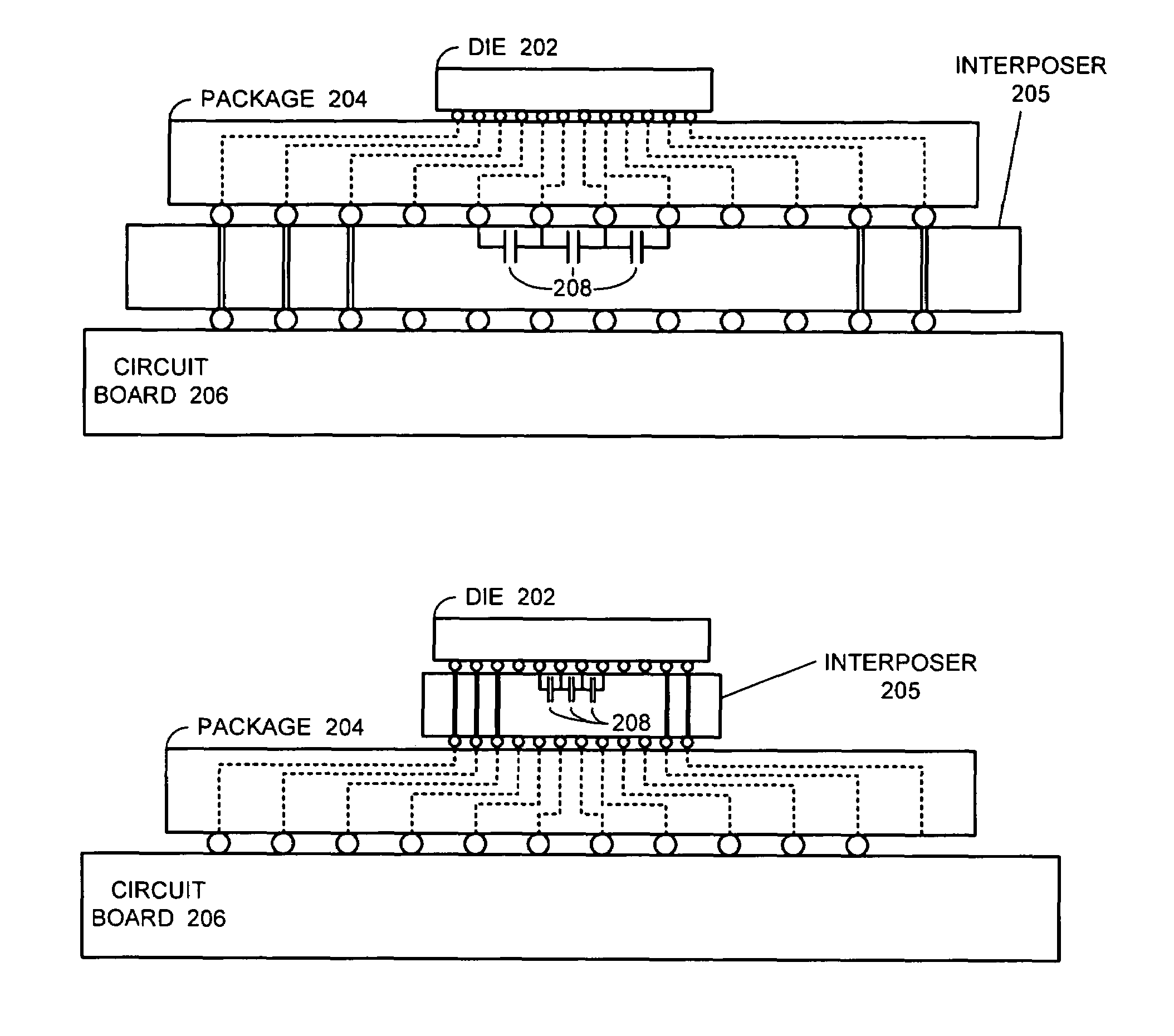

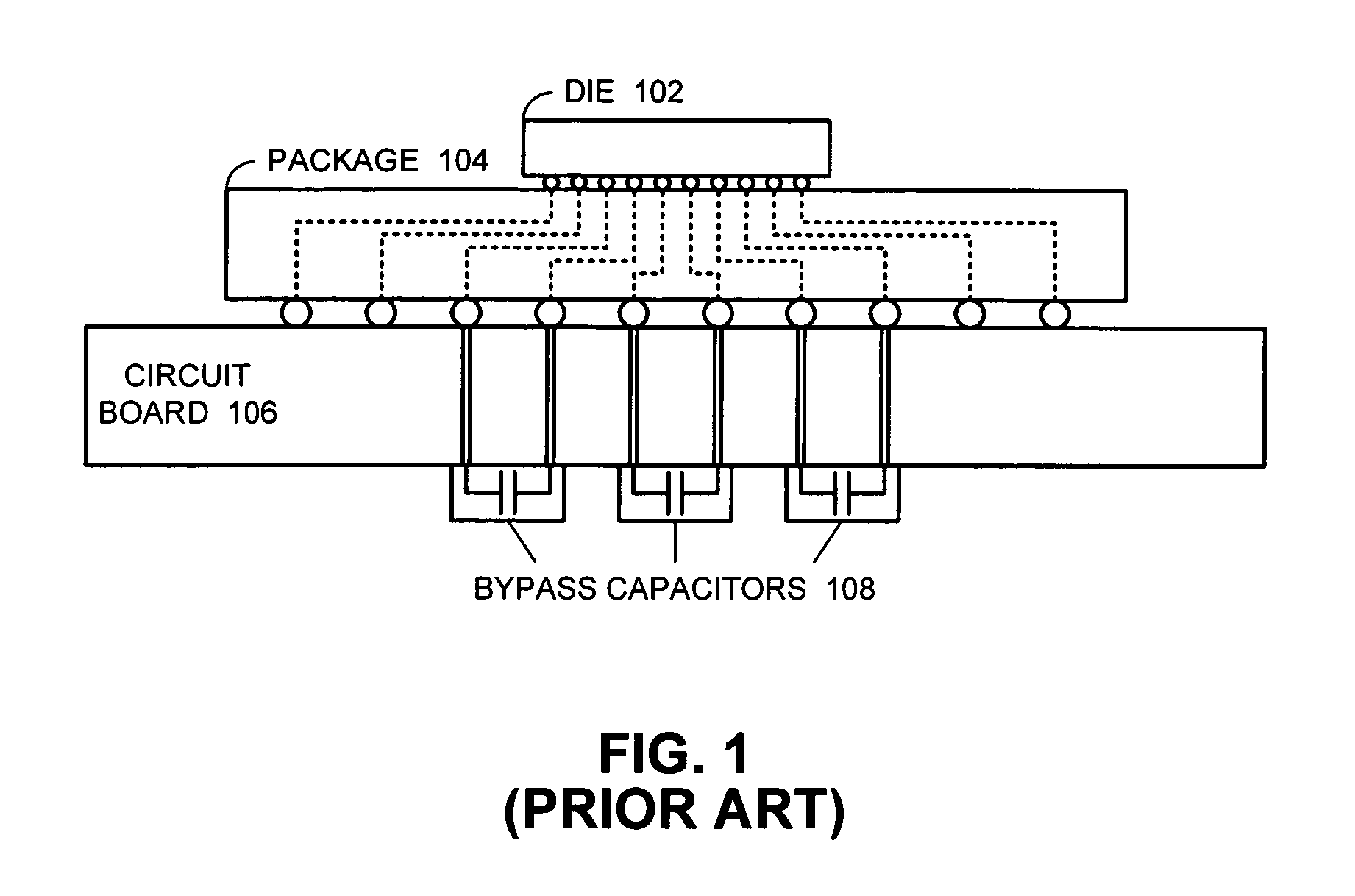

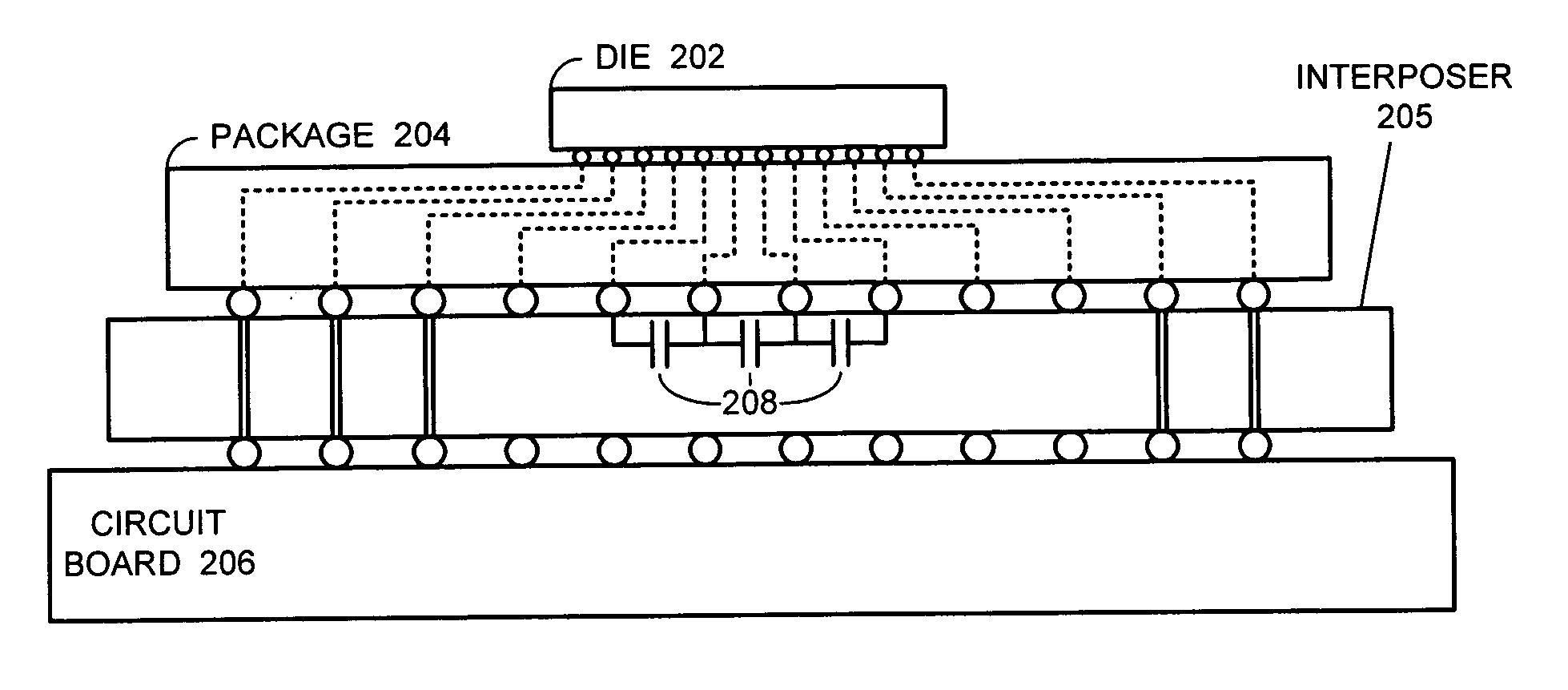

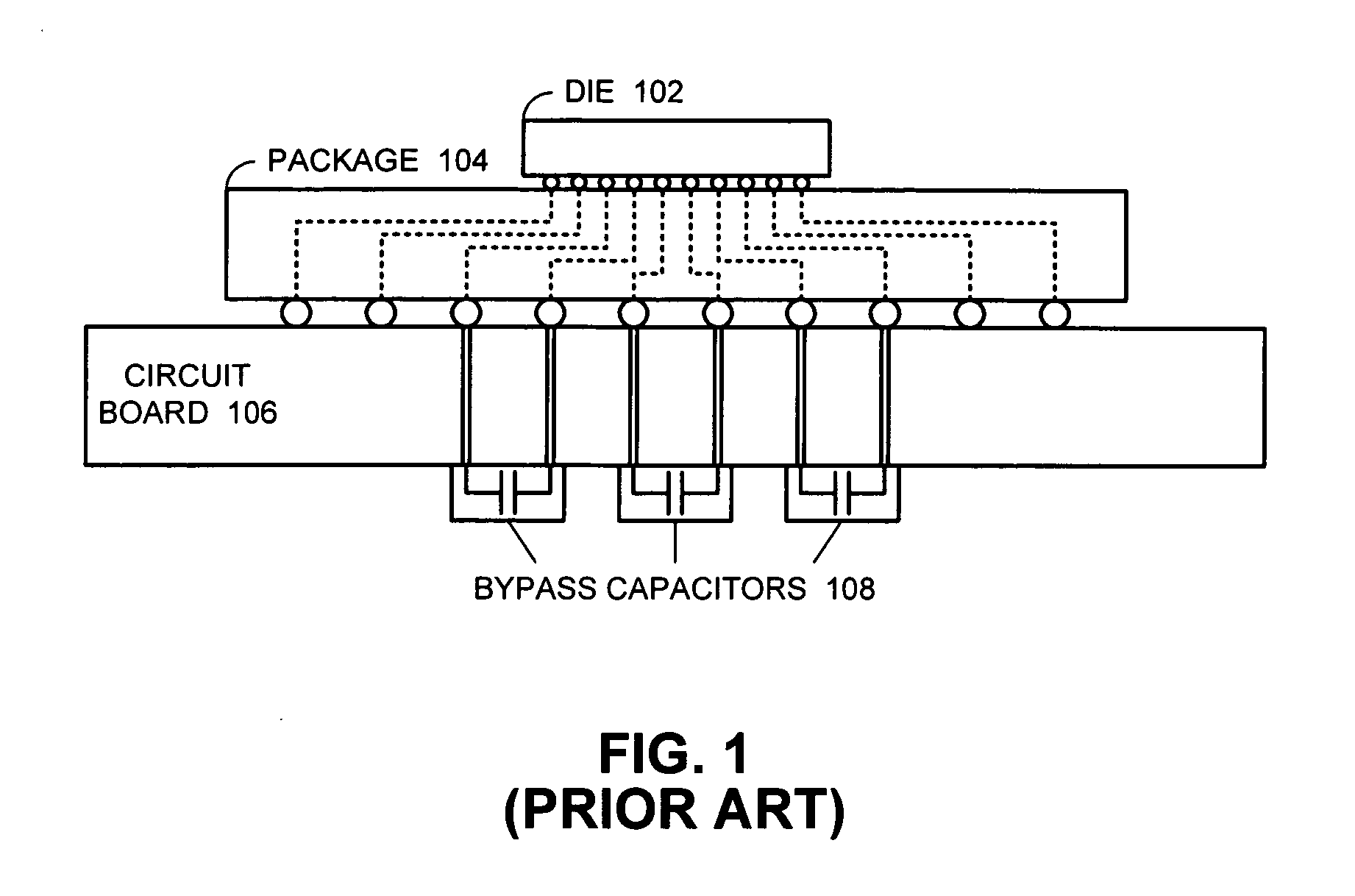

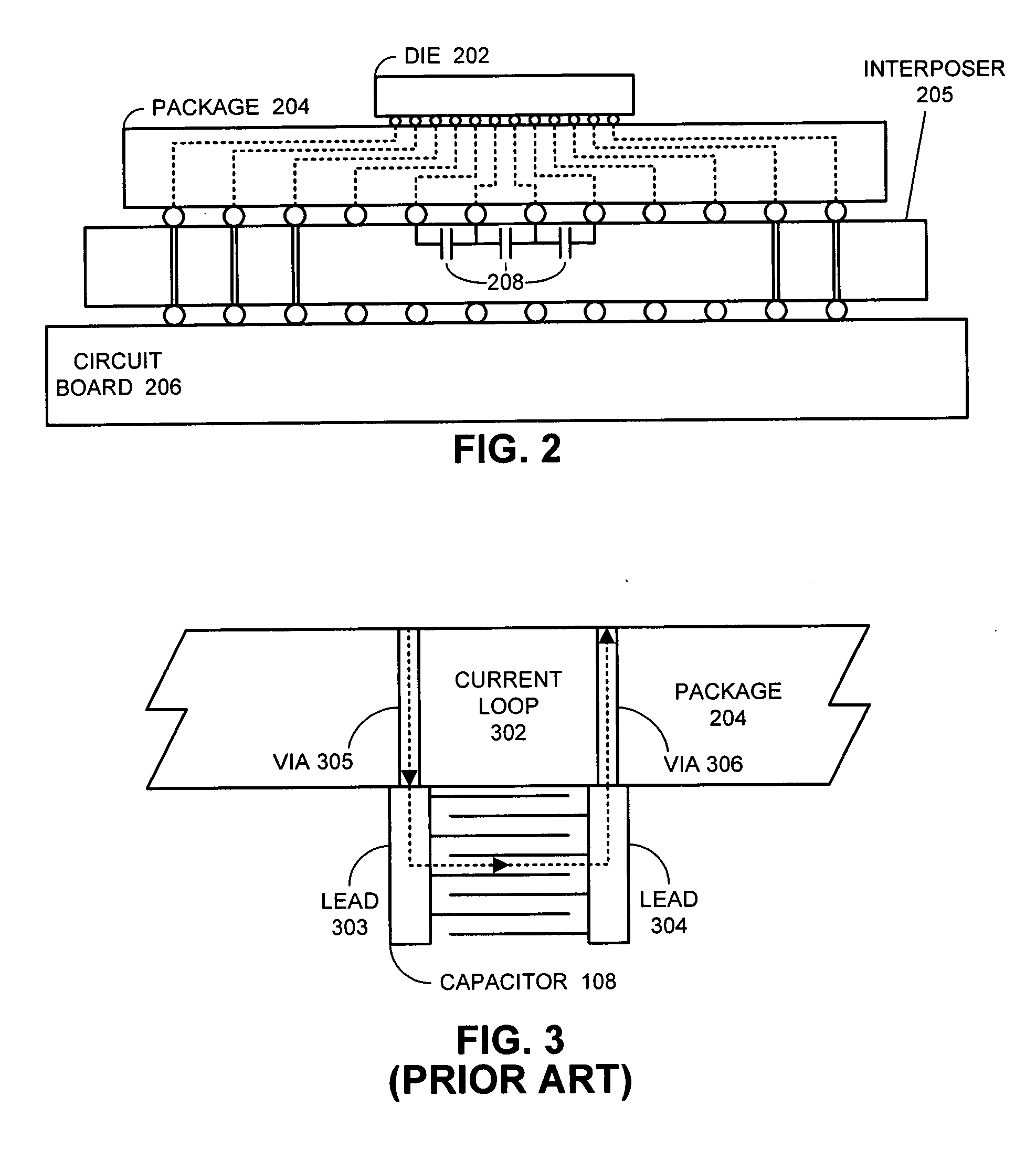

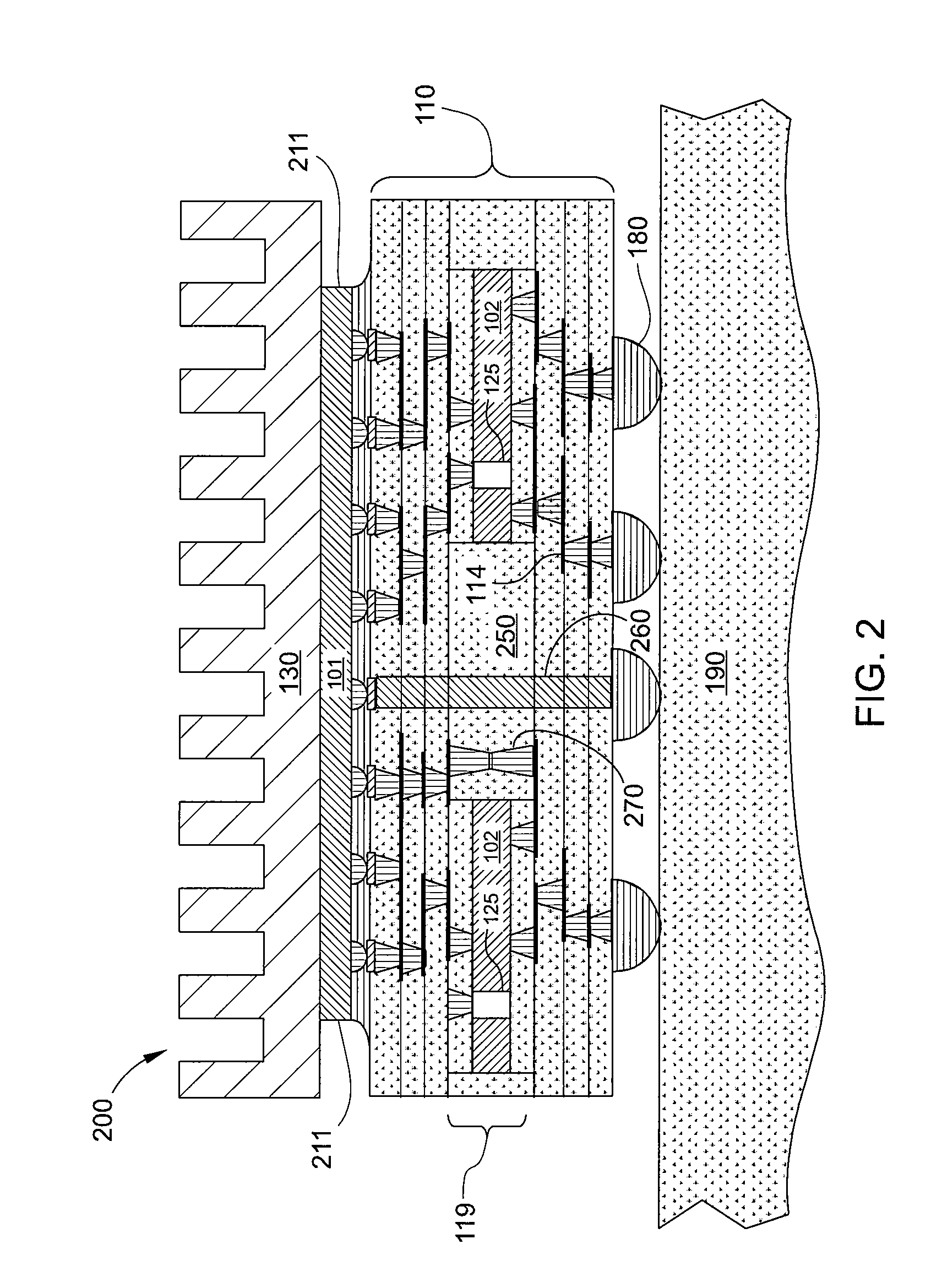

Interposer containing bypass capacitors for reducing voltage noise in an IC device

InactiveUS7268419B2Reduce voltageReduce noiseSemiconductor/solid-state device detailsSolid-state devicesElectricityElectrical connection

One embodiment of the present invention provides an apparatus that reduces voltage noise for an integrated circuit (IC) device. This apparatus includes an interposer, which is configured to be sandwiched between the IC device and a circuit board. This interposer has a bottom surface, which is configured to receive electrical connections for power, ground and other signals from the circuit board, and a top surface, which is configured to provide electrical connections for power, ground and the other signals to the IC device. A plurality of bypass capacitors are integrated into the interposer and are coupled between the power and ground connections for the IC device, so that the plurality of bypass capacitors reduce voltage noise between the power and ground connections for the IC device.

Owner:APPLE INC

Interposer containing bypass capacitors for reducing voltage noise in an IC device

InactiveUS20050280146A1Reduce voltage noiseReduce voltageSemiconductor/solid-state device detailsSolid-state devicesElectricityElectrical connection

One embodiment of the present invention provides an apparatus that reduces voltage noise for an integrated circuit (IC) device. This apparatus includes an interposer, which is configured to be sandwiched between the IC device and a circuit board. This interposer has a bottom surface, which is configured to receive electrical connections for power, ground and other signals from the circuit board, and a top surface, which is configured to provide electrical connections for power, ground and the other signals to the IC device. A plurality of bypass capacitors are integrated into the interposer and are coupled between the power and ground connections for the IC device, so that the plurality of bypass capacitors reduce voltage noise between the power and ground connections for the IC device.

Owner:APPLE INC

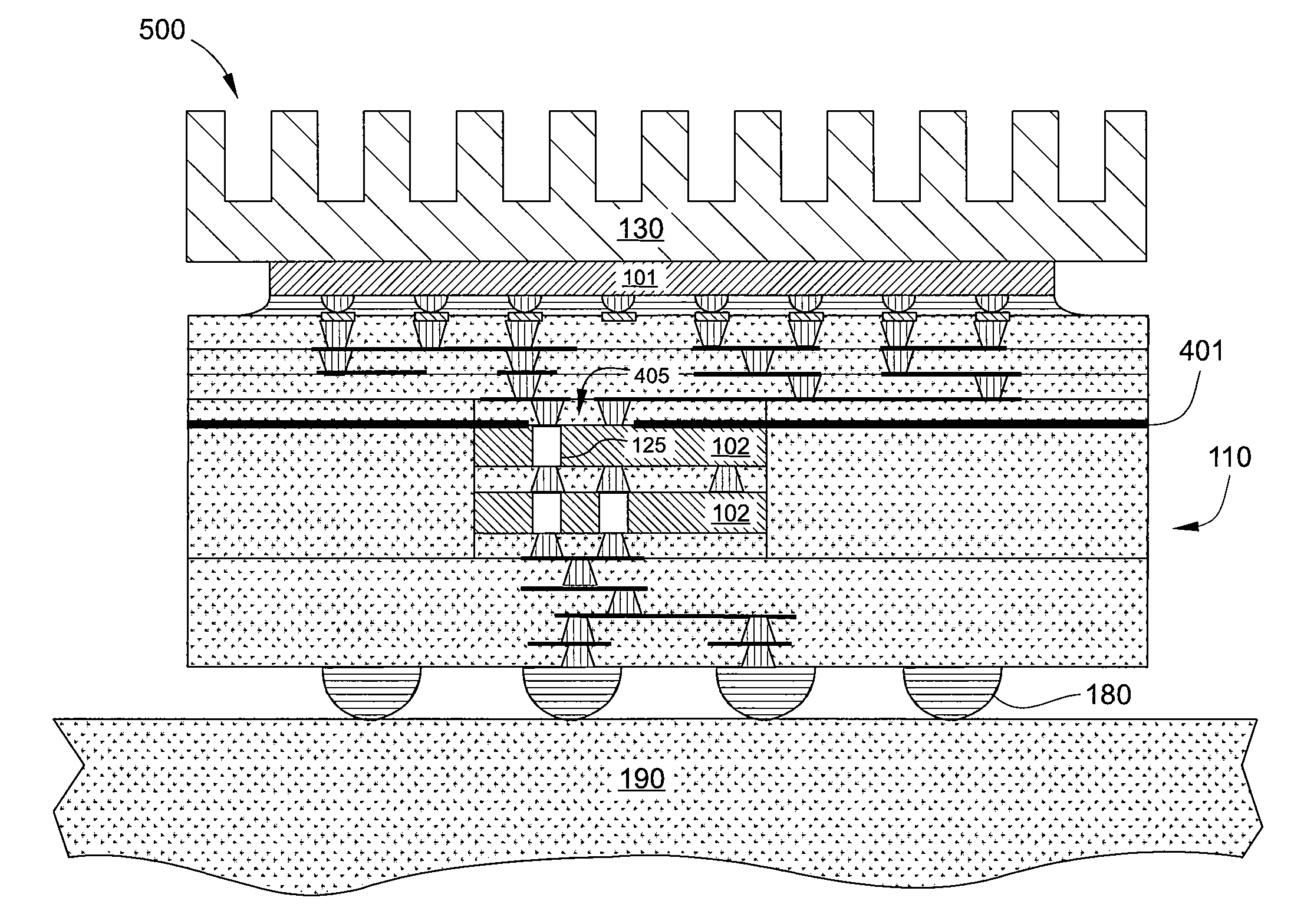

System with a high power chip and a low power chip having low interconnect parasitics

ActiveUS20130058067A1Improve device performanceReduces interconnect parasiticsSemiconductor/solid-state device detailsSolid-state devicesEngineeringMemory chip

An IC system includes low-power chips, e.g., memory chips, located proximate one or more higher power chips, e.g., logic chips, without suffering the effects of overheating. The IC system may include a high-power chip disposed on a packaging substrate and a low-power chip embedded in the packaging substrate to form a stack. Because portions of the packaging substrate thermally insulate the low-power chip from the high-power chip, the low-power chip can be embedded in the IC system in close proximity to the high-power chip without being over heated by the high-power chip. Such close proximity between the low-power chip and the high-power chip advantageously shortens the path length of interconnects therebetween, which improves device performance and reduces interconnect parasitics in the IC system.

Owner:NVIDIA CORP

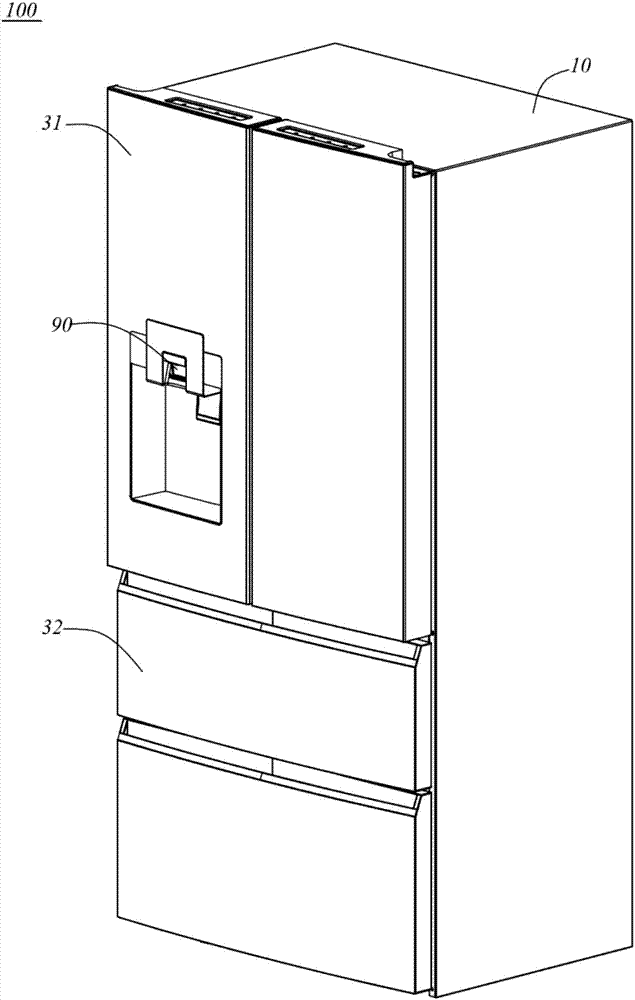

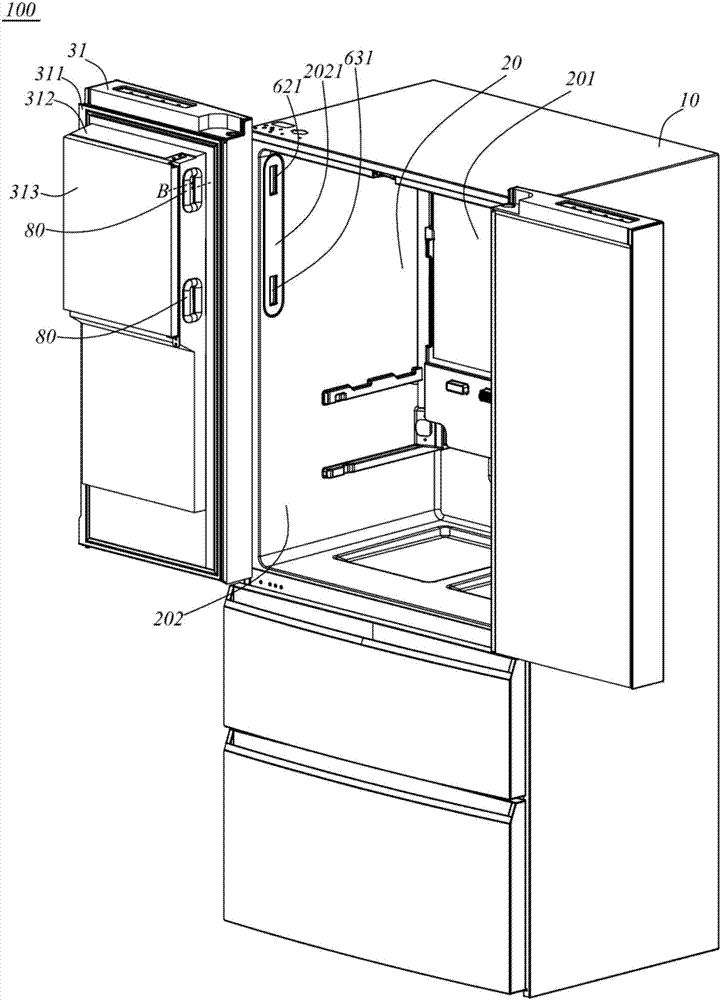

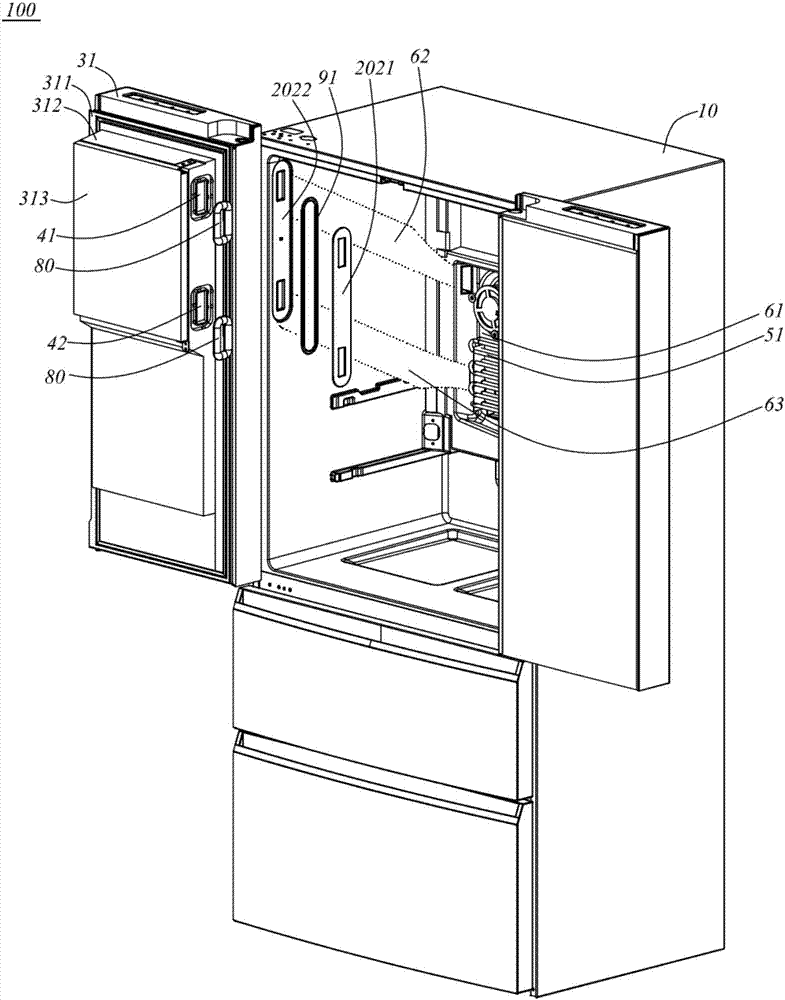

Refrigerator

ActiveCN106885420AGood eating experienceReduce path lengthLighting and heating apparatusDomestic refrigeratorsEngineeringCold store

The invention discloses a refrigerator comprising a refrigerator body, door bodies, an ice-making compartment, a cooling system and an ice-making air channel system. The refrigerator body is provided with a refrigerating room and a freezing room in a limiting mode. The door bodies are movably connected to the refrigerator body and comprise the refrigerating door body for opening and closing the refrigerating room and the freezing door body for opening and closing the freezing room. The ice-making compartment is limited to the refrigerating door body, and ice blocks can be formed in the ice-making compartment. The cooling system comprises a freezing evaporator for providing cooling capacity for the freezing room, a refrigerating evaporator for providing cooling capacity for the refrigerating room and an ice-making evaporator for providing cooling capacity for the ice-making compartment. The ice-making air channel system comprises an ice-making evaporator compartment, an ice-making air conveying channel and an ice-making air returning channel, wherein the ice-making evaporator compartment is arranged on the back wall of a liner of the refrigerating room and accommodates the ice-making evaporator; and the ice-making air conveying channel and the ice-making air returning channel are arranged on the side wall of the liner of the refrigerating room and communicate with an ice-making evaporator compartment and the ice-making compartment. Compared with the prior art, the ice-making efficiency is high, and serious frosting of the freezing evaporator and the peculiar smell of the ice blocks are avoided.

Owner:HAIER SMART HOME CO LTD

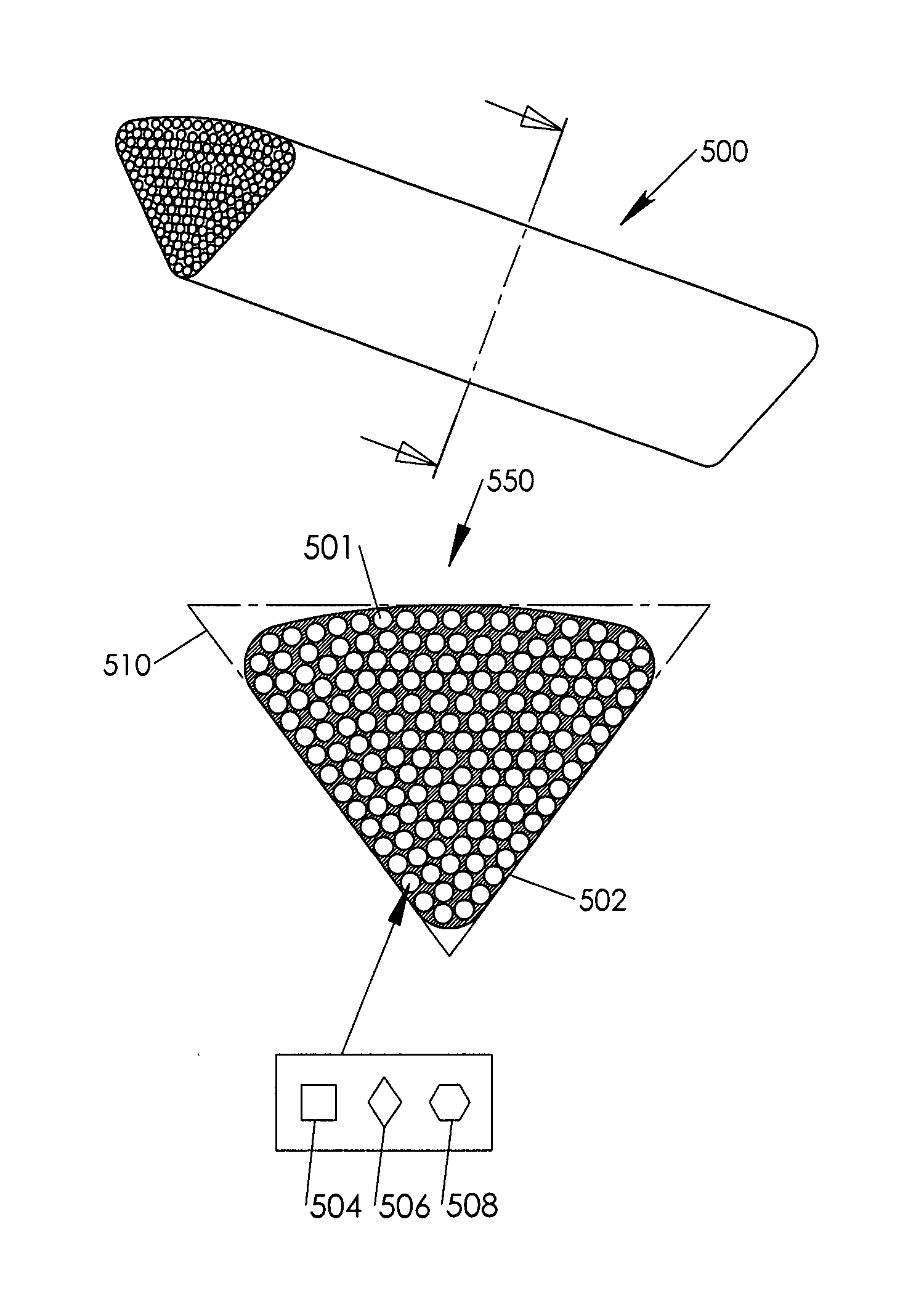

Method of cutting material with hybrid liquid-jet/laser system

InactiveUS20050160891A1Reduce lead-in path lengthReduce path lengthStentsMetal working apparatusLiquid jetInsertion stent

A hybrid liquid-jet / laser device may be used to remove material from a tube or sheet to form a medical device, such as a stent. The liquid-jet / laser stream may be impinged against the wall of the tube or sheet between the ends of the tube or sheet, wherein an aperture may be formed in the tube or sheet, followed by a lead-in, and then a full thickness cut. A full thickness cut should be achieved via a lead-in before moving the liquid-jet / laser stream along a final cut path.

Owner:BOSTON SCI SCIMED INC

Accelerating peer-to-peer content distribution

ActiveUS8606846B2Easy to manageReduce path lengthMultiple digital computer combinationsTransmissionContent distributionDistributed computing

Owner:NBCUNIVERSAL

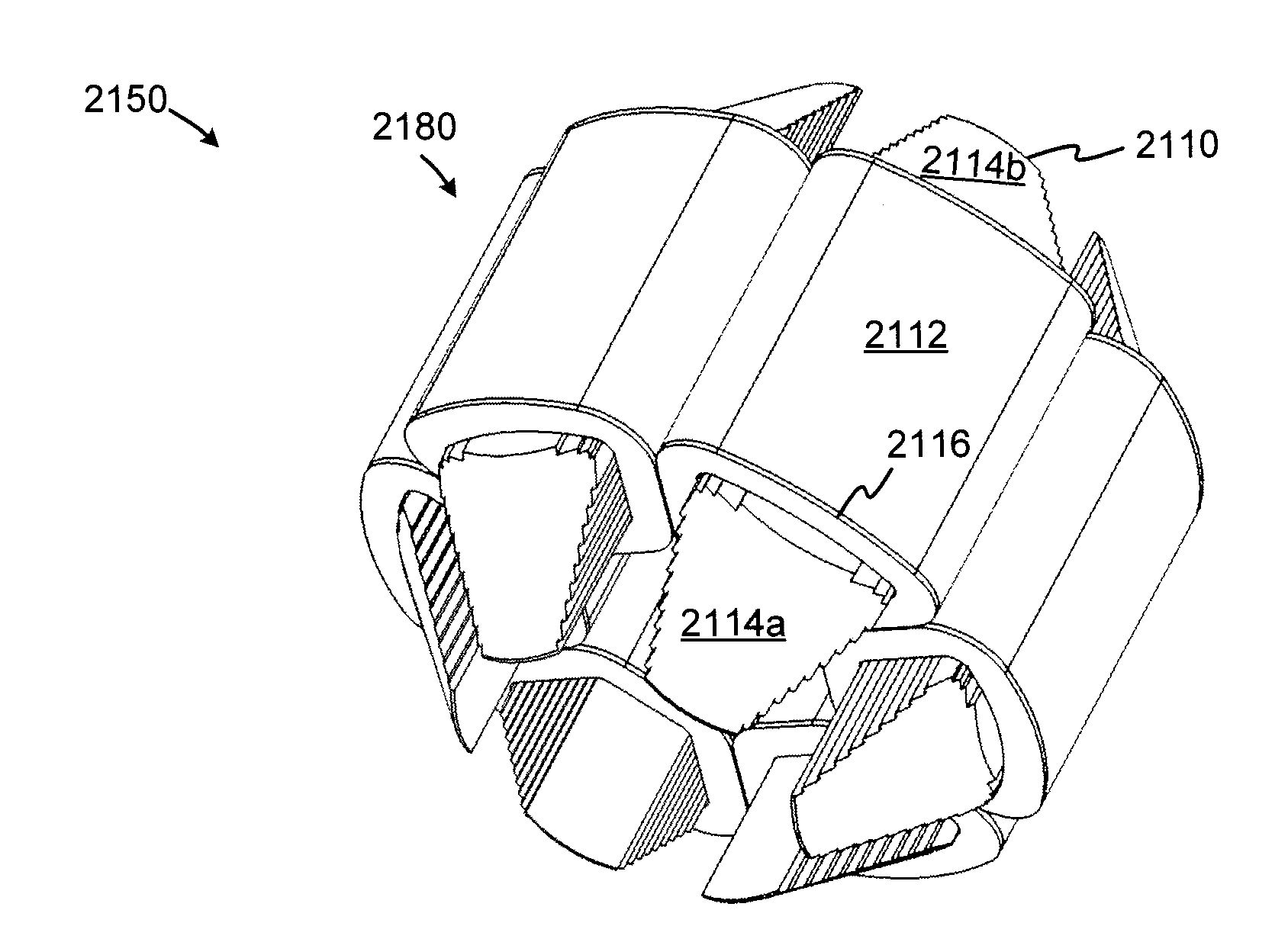

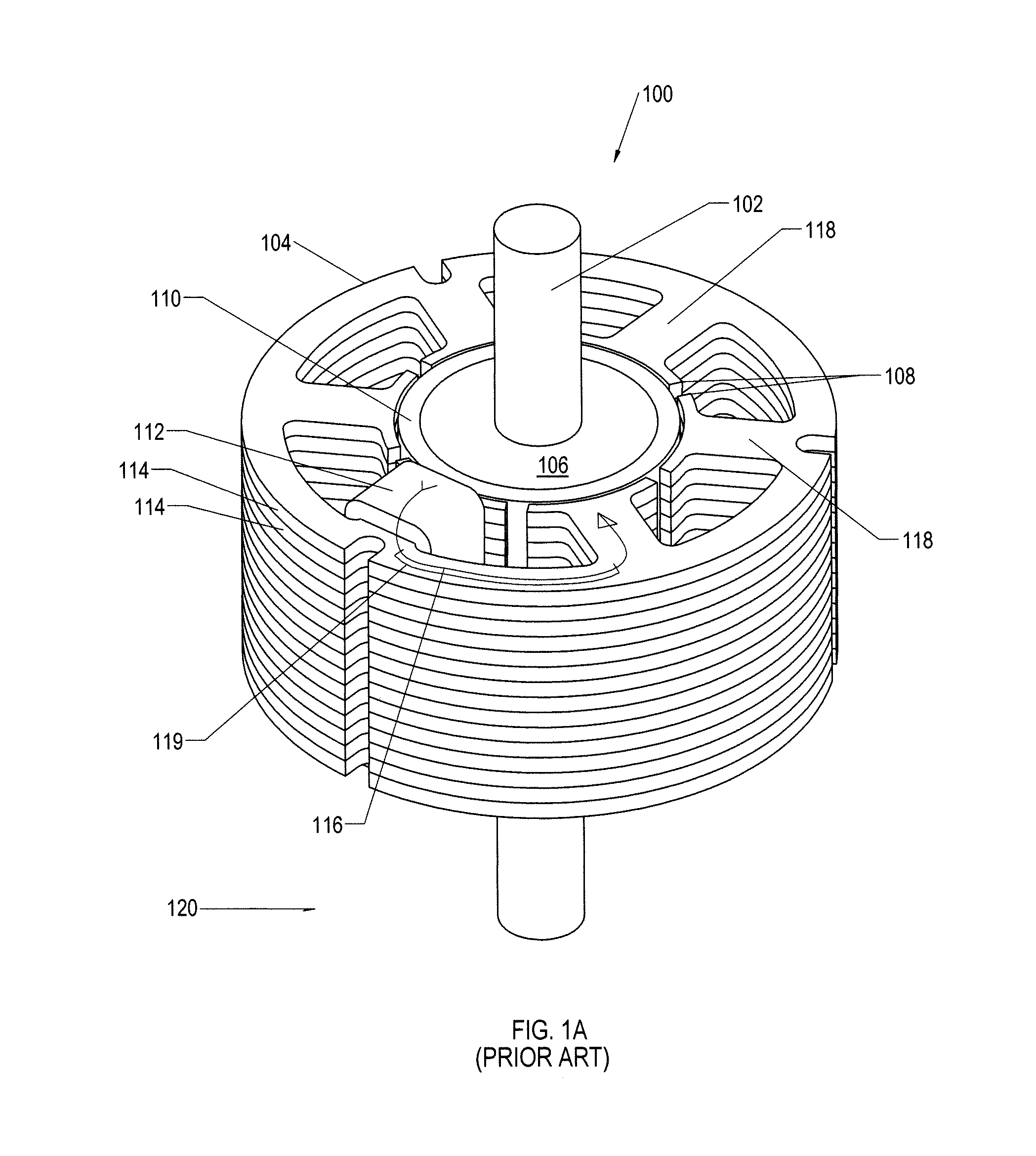

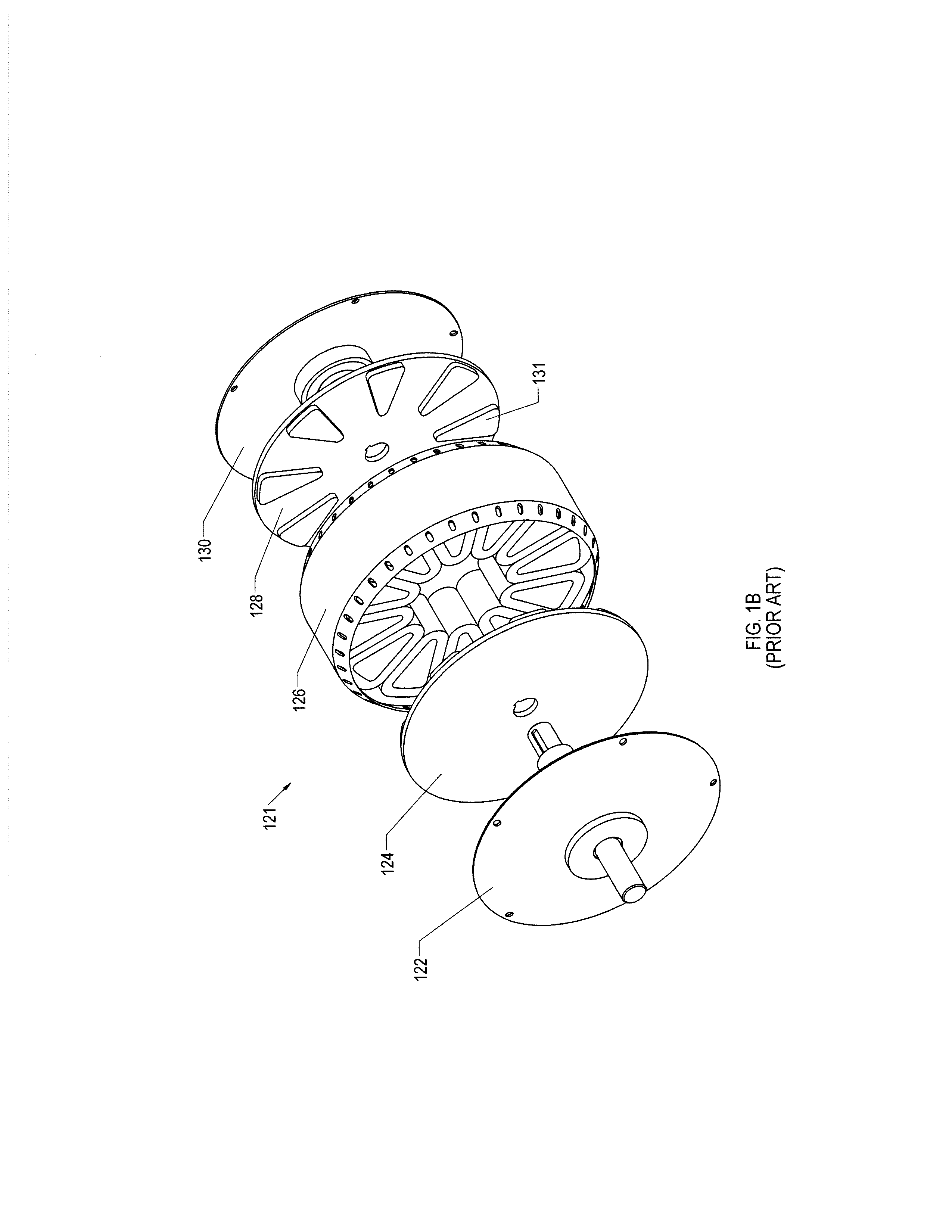

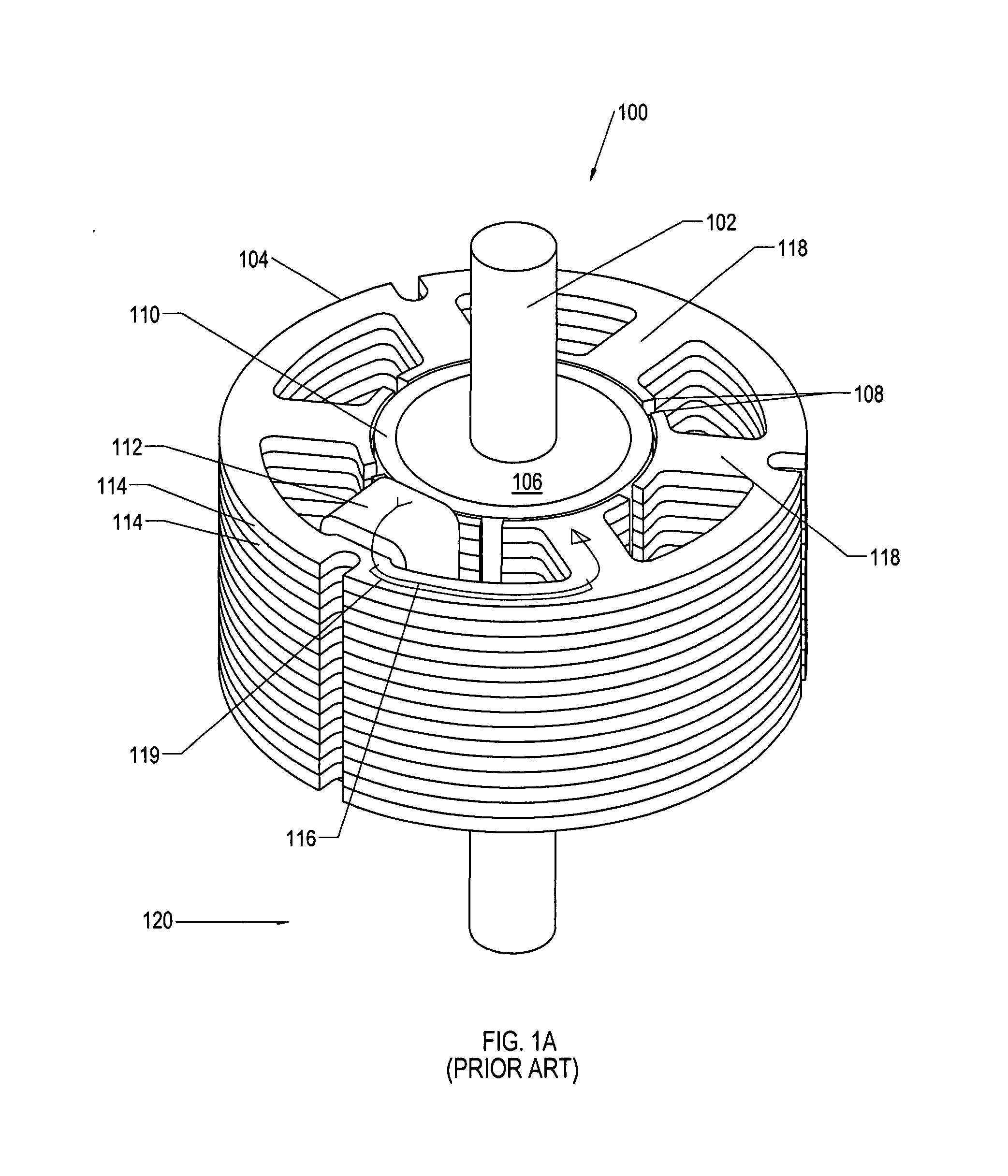

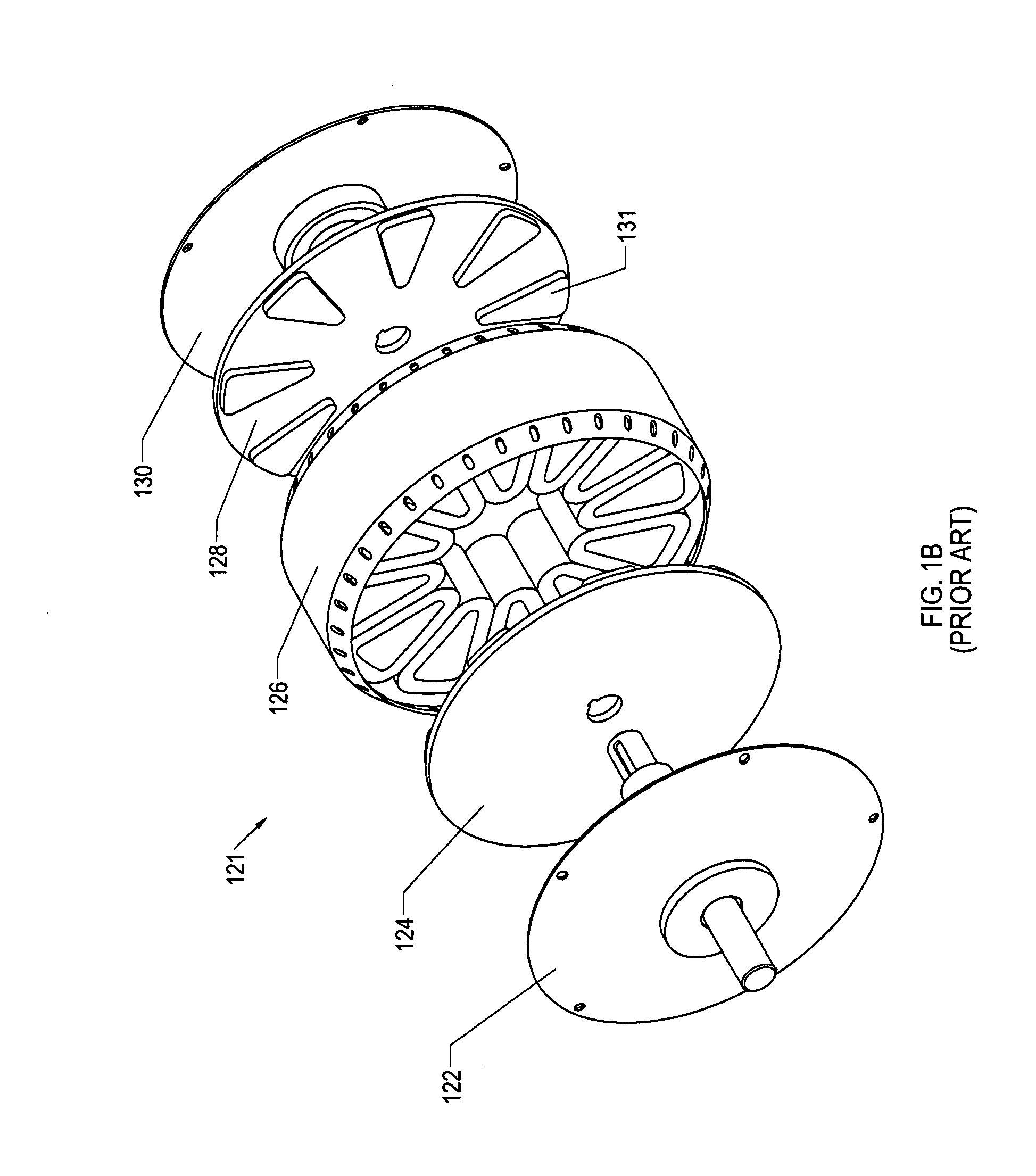

Sculpted field pole members and methods of forming the same for electrodynamic machines

ActiveUS20130181565A1Increase torqueReduce manufacturing costMagnetic circuit stationary partsSalient polesUnit sizeManufacturing cost reduction

A method, apparatus, article of manufacture and system for producing a field pole member for electrodynamic machinery are disclosed to, among other things, reduce magnetic flux path lengths and to eliminate back-iron for increasing torque and / or efficiency per unit size (or unit weight) and for reducing manufacturing costs. For example, a field pole member structure can either reduce the length of magnetic flux paths or substantially straighten those paths through the field pole members, or both. In one embodiment, a method provides for the construction of field pole members for electrodynamic machines.

Owner:REGAL BELOIT AMERICA

Field pole members and methods of forming same for electrodynamic machines

ActiveUS20070205675A1Increase torqueReduce manufacturing costMagnetic circuit rotating partsMagnetic circuit stationary partsUnit sizeManufacturing cost reduction

A method, apparatus, article of manufacture and system for producing a field pole member for electrodynamic machinery are disclosed to, among other things, reduce magnetic flux path lengths and to eliminate back-iron for increasing torque and / or efficiency per unit size (or unit weight) and for reducing manufacturing costs. For example, a field pole member structure can either reduce the length of magnetic flux paths or substantially straighten those paths through the field pole members, or both. In one embodiment, a method provides for the construction of field pole members for electrodynamic machines.

Owner:REGAL BELOIT AMERICA

Distributed underwater electromagnetic communication system

InactiveUS7826794B2Speed up the descentIncrease lossNear-field transmissionElectric signal transmission systemsElectricityCommunications system

An extended underwater electromagnetic transducer is provided with an electrically insulated transmission line typically connected to a transmitter or receiver or transceiver system. The transmission line allows near-field communications with another transmitter or receiver or transceiver system. The transmission line provided is relatively long, the through water signal path length can be significantly reduced.

Owner:WIRELESS FIBER SYST

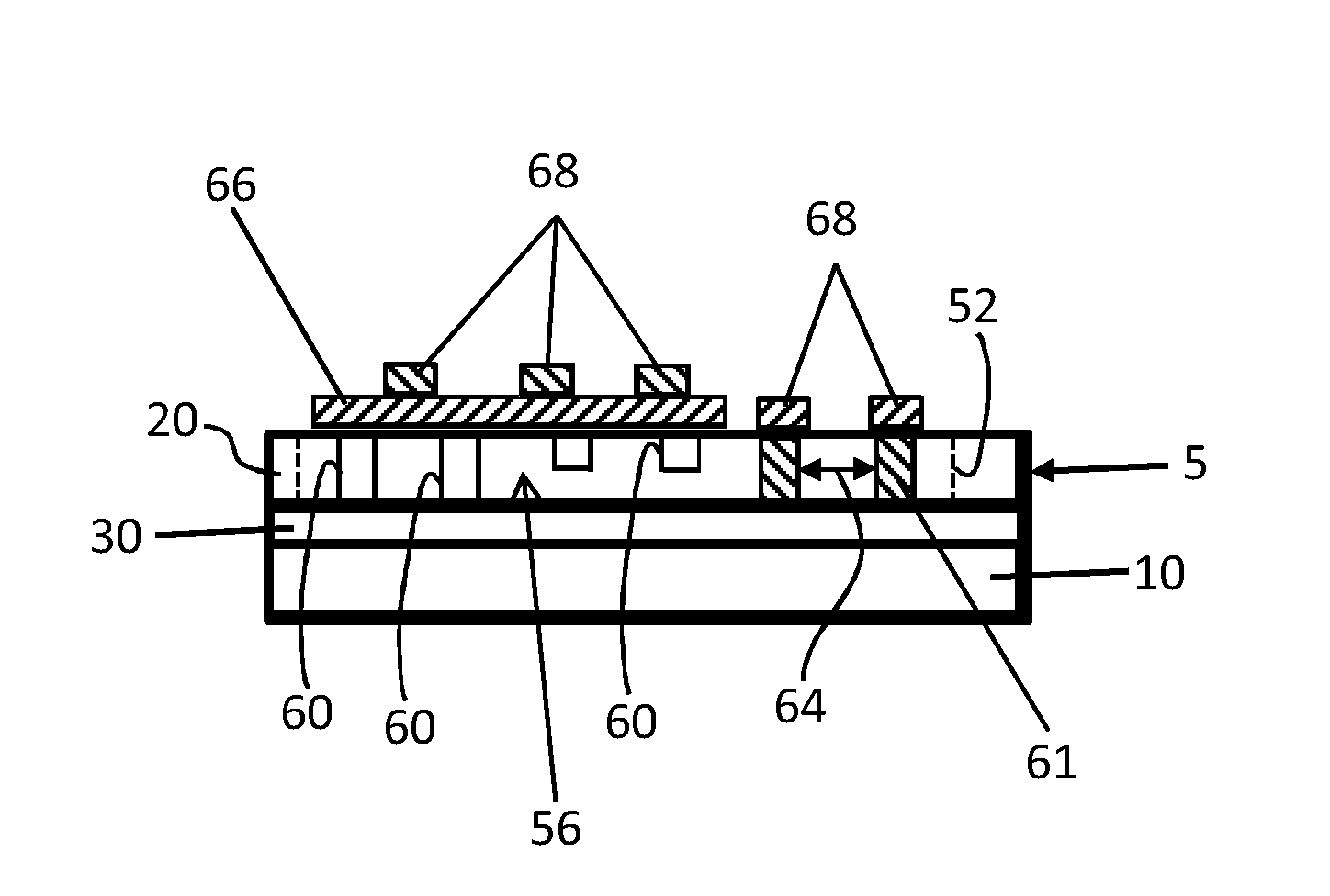

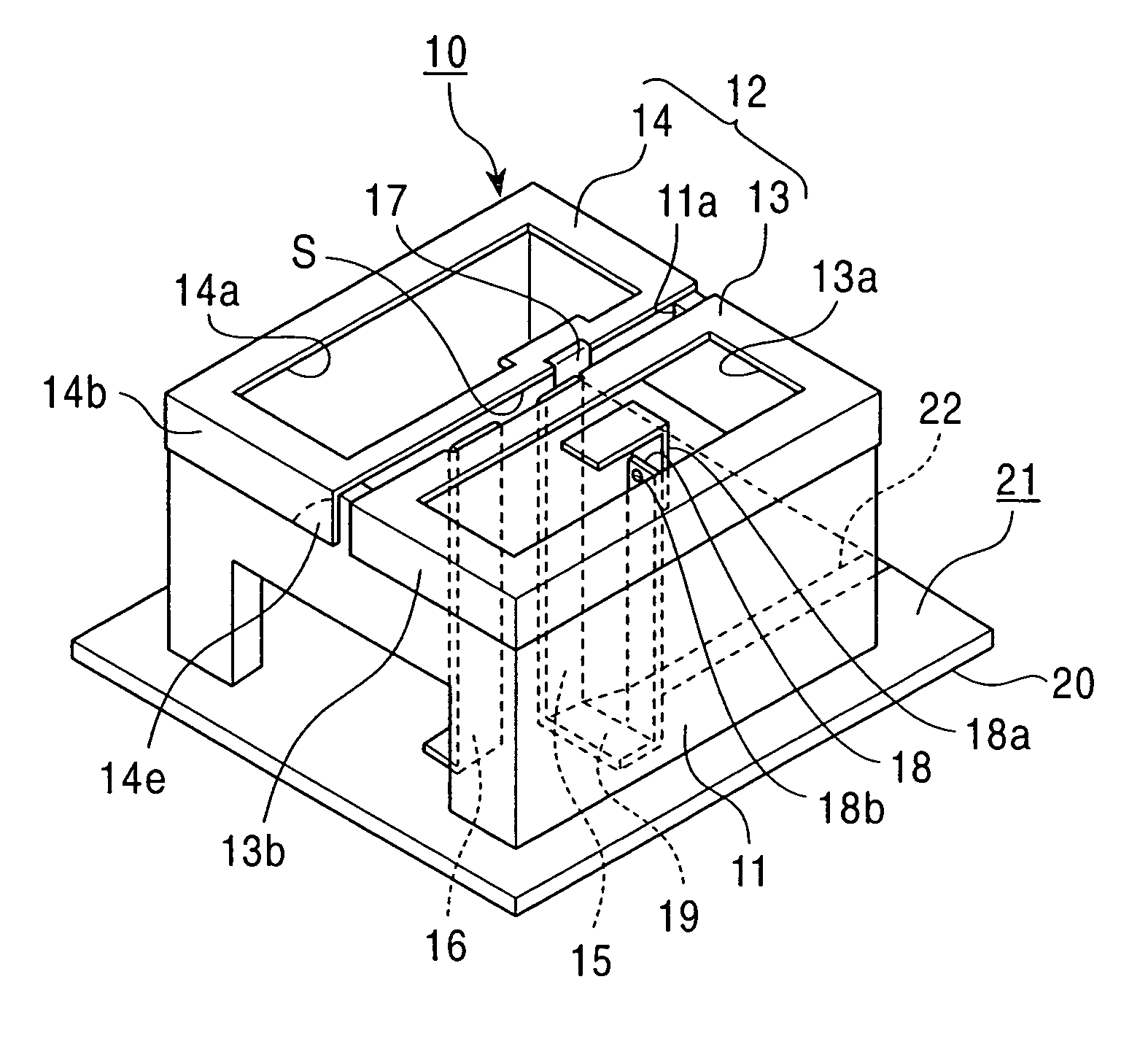

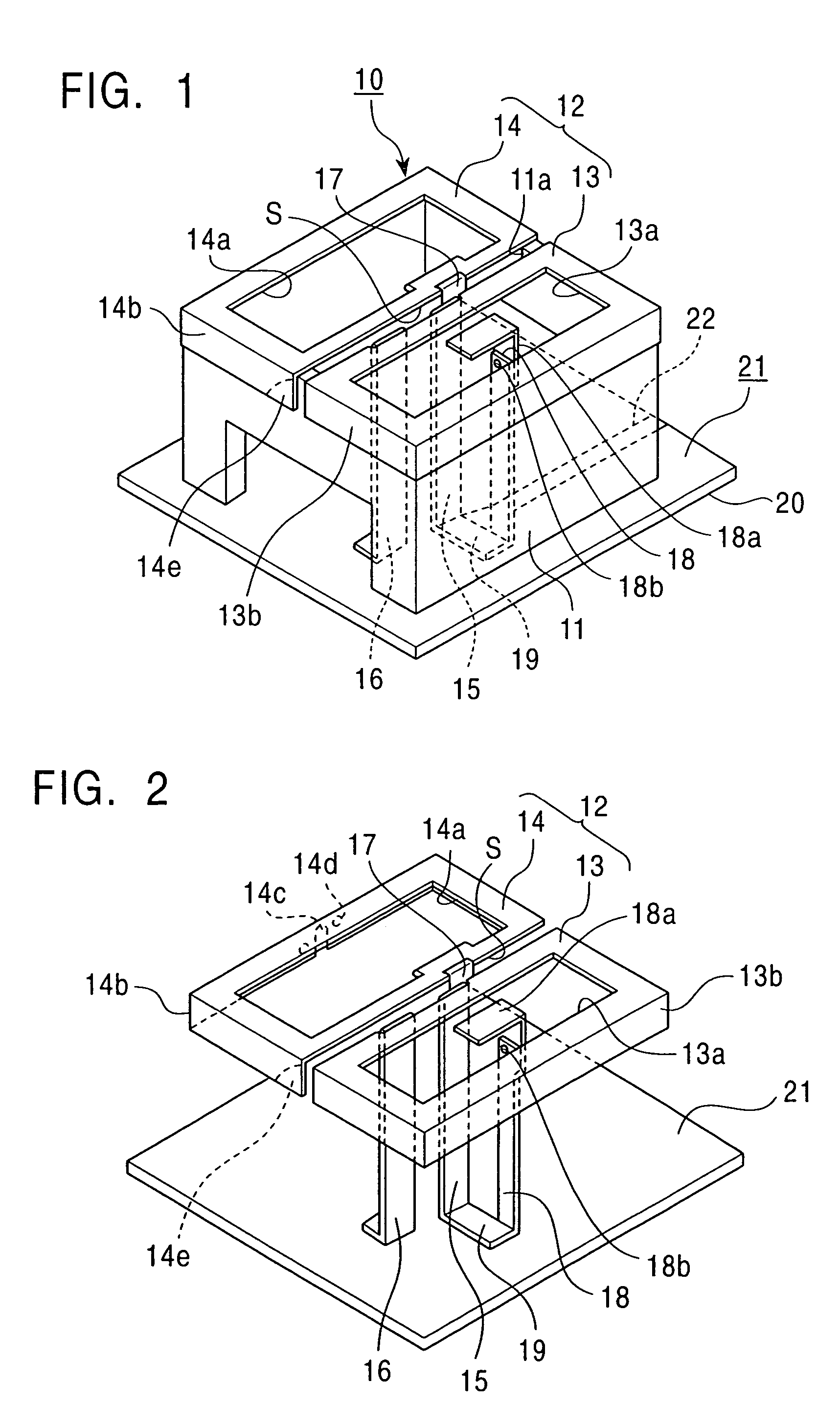

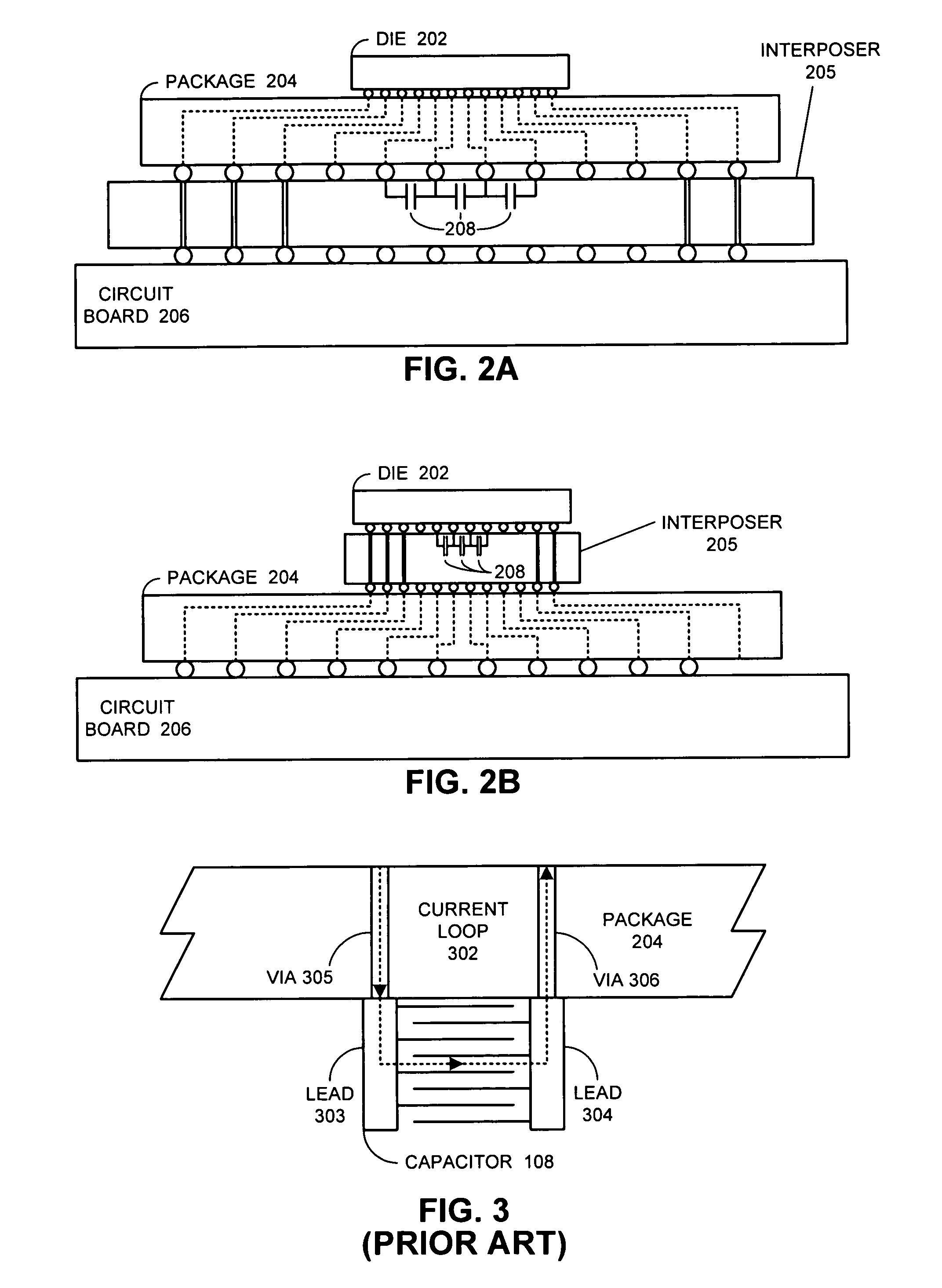

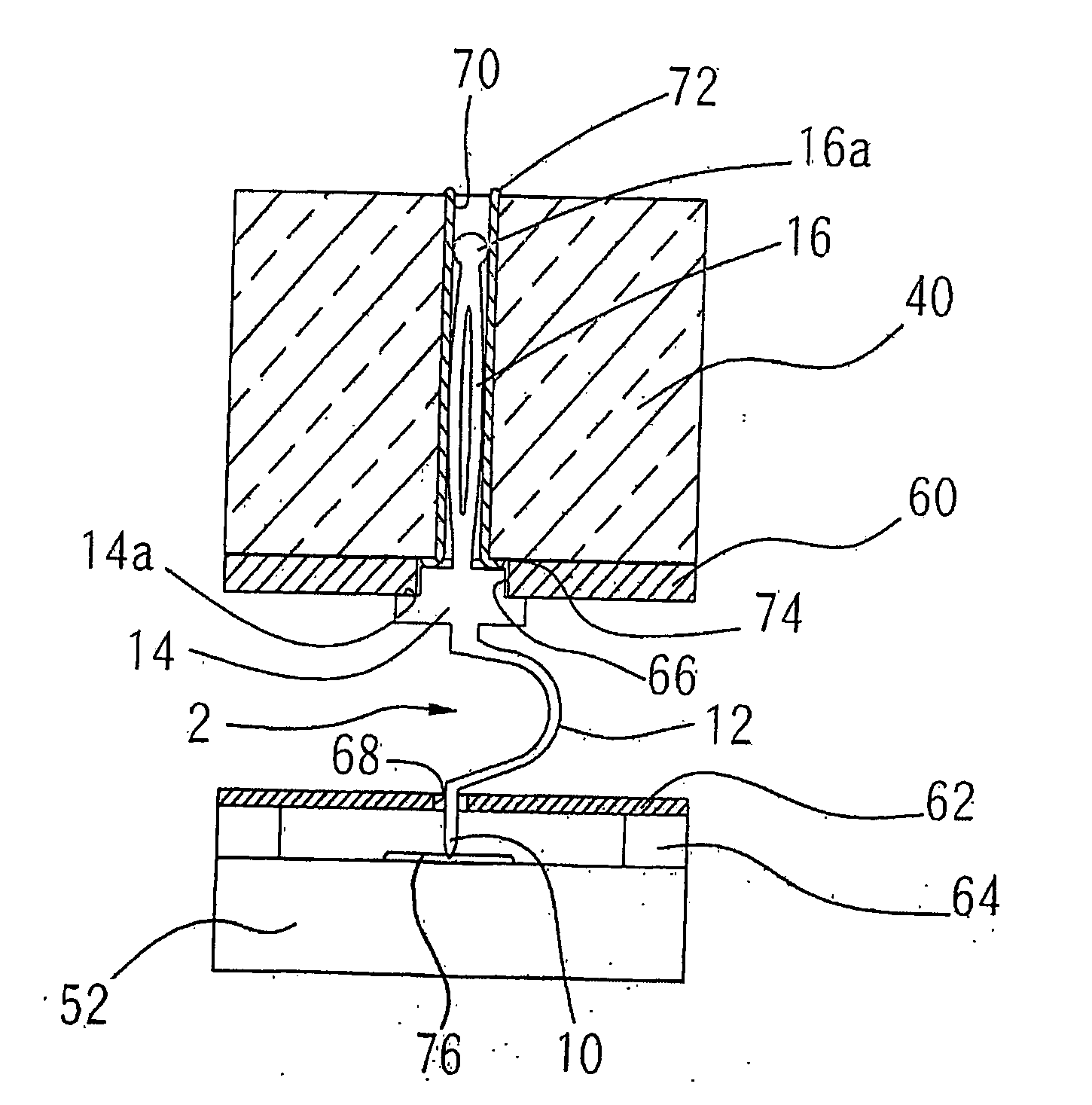

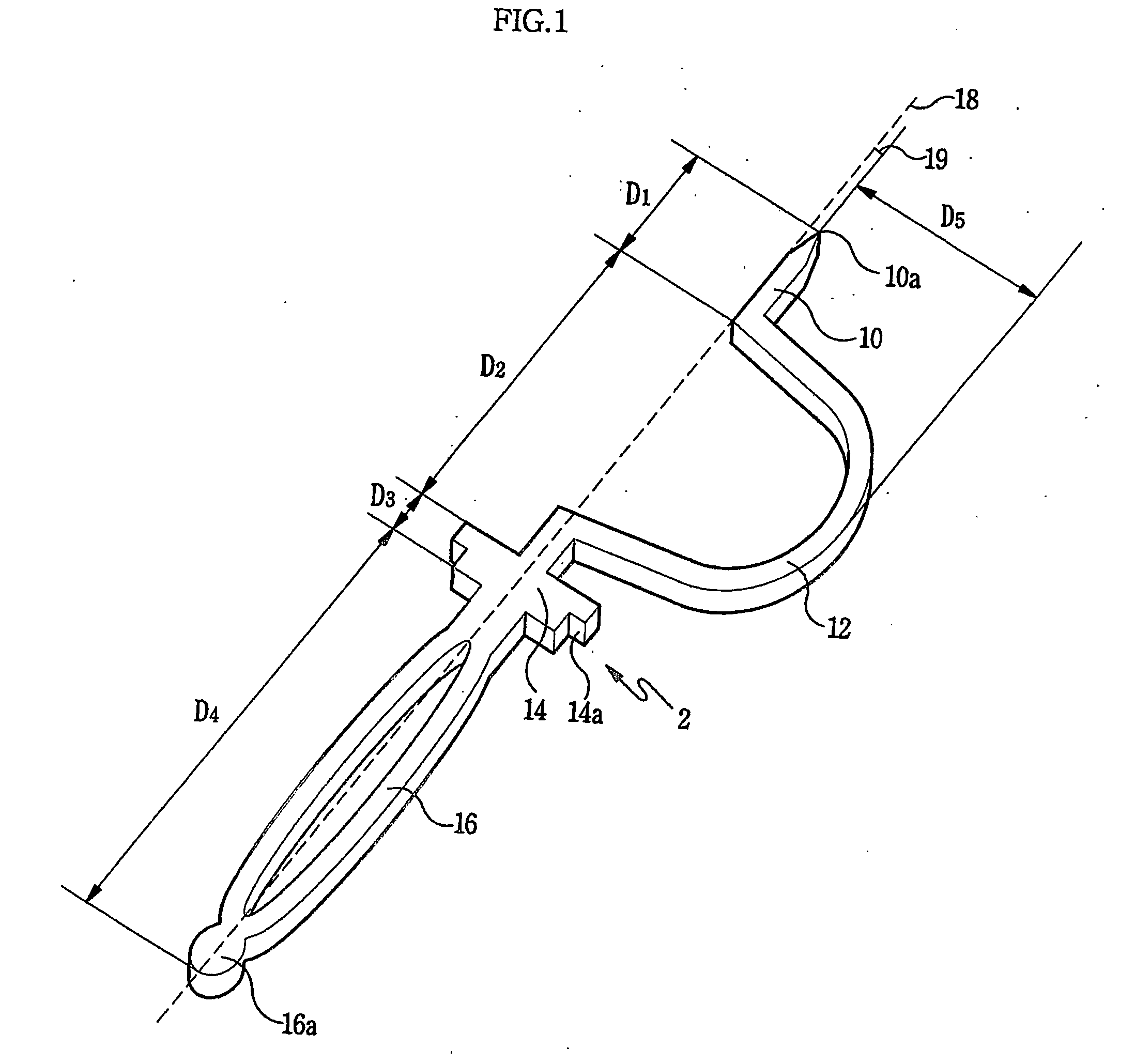

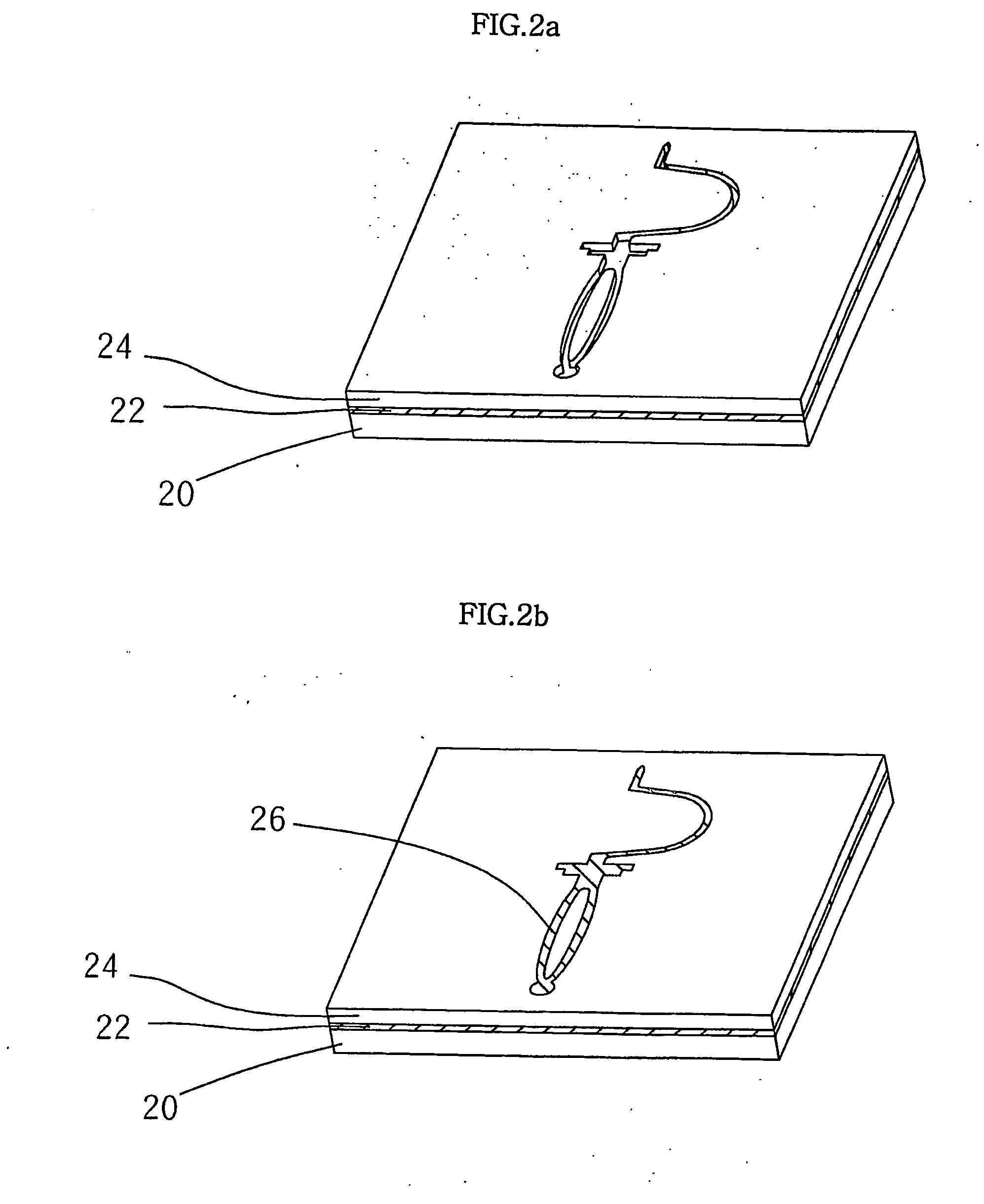

Interconnection device for a printed circuit board, a method of manufacturing the same, and an interconnection assembly having the same

ActiveUS20060166479A1Solve the real problemInhibit deteriorationContact member manufacturingElectronic circuit testingInterference fitTransformer

The present invention relates to an interconnect device for a printed circuit board, a method of manufacturing the same and an inter-connect assembly having the same. According to one aspect of the present invention, the interconnect device for a printed circuit board comprises: a first contact section 10 having a bar-like shape for making contact with a second contact terminal 76 in a space transformer 52; a connecting section 12 having an O-ring-like shape of which one side is opened and connected to one end of the first contact section 10 in an integrated manner; a support section 14 having an engaging protrusion 14a in a predetermined portion and connected to one end of the connecting section 12 in an integrated manner; and a second contact section 16 having an O-ring-like shape and connected to one end of the support section 14, wherein the whole inter-connect device is made up of an identical resilient material. According to still another aspect of the present invention, an interconnect assembly having an interconnect device for a printed circuit board, comprises: a printed circuit board 40 including a contact hole 70 in which a conductive film 72 connected to an internal circuitry is formed on the inside wall; a first guide film 60 fixed on a bottom surface of the printed circuit board 40 and having a first guide opening 66 to open the contact hole 70; a space transformer having a second contact terminal 76 on a top portion and a bump 64 in the vicinity of the second contact terminal 76; a second guide film 62 fixed on the space transformer 52, supported by the bump 64, and having a second guide opening 68 to be related with the bump 64; and an interconnect device 2 including a second contact section having an O-ring-like shape to be inserted into the contact hole 70 by an interference fit, a support section connected to the second contact section in an integrated manner to be inserted into the inside of the first guide opening, a connecting section having an O-ring-like shape of which one side is opened and connected to the support section in an integrated manner thereby being placed between the first guide film and the second guide film, and a first contact section connected to the connecting section in an integrated manner for making contact with the second contact section 76 through the second guide opening.

Owner:PHICOM CORP +1

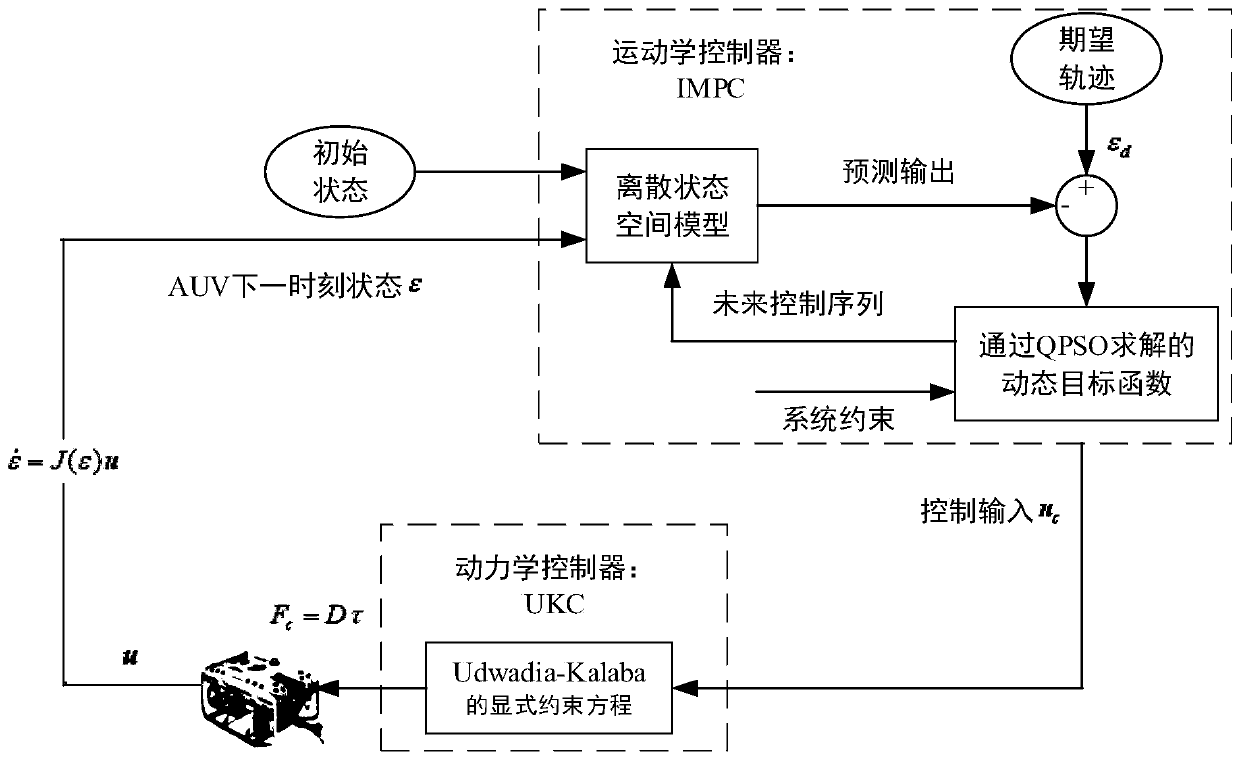

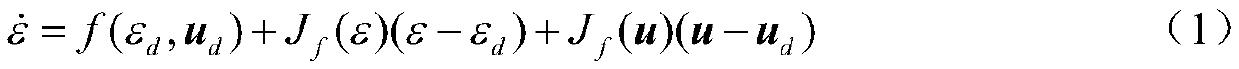

Trajectory tracking control method of underwater inspection robot

ActiveCN111324146ATrack tracking is smooth and stableSmall lagTotal factory controlPosition/course control in three dimensionsKinematic controllerPath length

The invention discloses a trajectory tracking control method of an underwater inspection robot. The method comprises the following steps: (1) presetting a reference trajectory for trajectory trackingof the underwater inspection robot, obtaining an optimal path from a starting point to a target point by using a navigation path planning algorithm according to the reference trajectory, and taking the optimal path as a preset reference trajectory of trajectory tracking of the robot; (2) designing a trajectory tracking kinematic controller in combination with the reference trajectory and a kinematic model; (3) carrying out stress analysis on the underwater inspection robot, establishing a dynamic model, and designing a trajectory tracking dynamic controller; and (4) taking a control value of the kinematic controller as input of the dynamic controller to obtain a thrust and a torque required by trajectory tracking, and realizing smooth and stable trajectory tracking control of the underwater inspection robot. By designing a dynamic target function, a problem of speed jump is solved, a lag between an actual trajectory and the reference trajectory is reduced, the shortest tracking step length optimization function item is added into the target function, the path length of the actual trajectory is reduced, and then trajectory tracking energy consumption is decreased; in addition, the influence of the actual underwater environment on trajectory tracking is also considered, and finally smooth and stable trajectory tracking control is realized.

Owner:HOHAI UNIV CHANGZHOU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com