Patents

Literature

4422results about "Separation devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

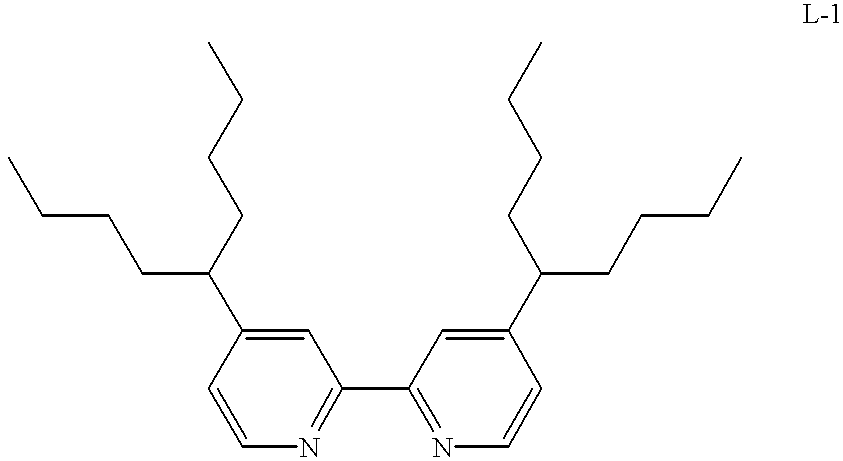

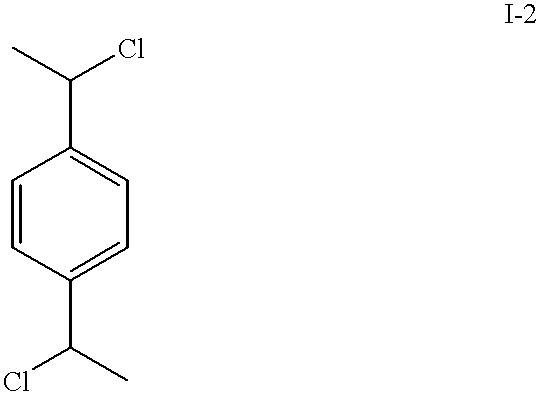

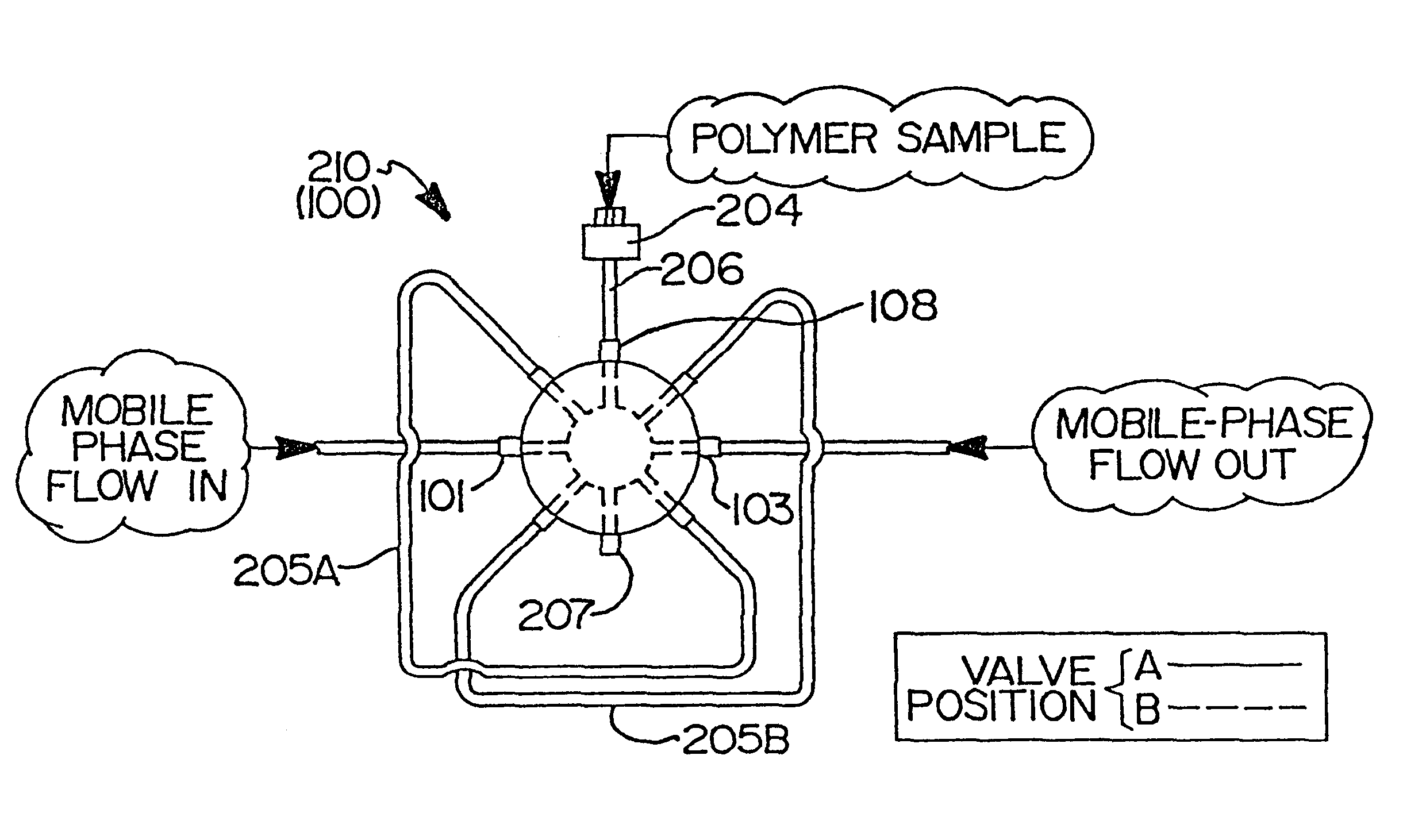

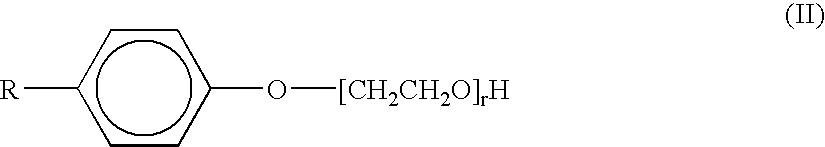

High-temperature characterization of polymers

InactiveUS6260407B1Avoid backlogImprove throughputSequential/parallel process reactionsComponent separationElutionChromatography column

Rapid characterization and screening of polymer samples to determine average molecular weight, molecular weight distribution and other properties is disclosed. Rapid flow characterization systems and methods, including liquid chromatography and flow-injection analysis systems and methods are preferably employed. High throughput, automated sampling systems and methods, high-temperature characterization systems and methods, and rapid, indirect calibration compositions and methods are also disclosed. In preferred high-temperature embodiments, the polymer sample is maintained at a temperature of not less than about 75° C. during sample preparation, loading into a liquid chromatography or flow-injection analysis system, injection into a mobile phase of a liquid chromatography or flow-injection analysis system, and / or elution from chromatographic column. The described methods, systems, and device have primary applications in combinatorial polymer research and in industrial process control.

Owner:INTERMOLECULAR

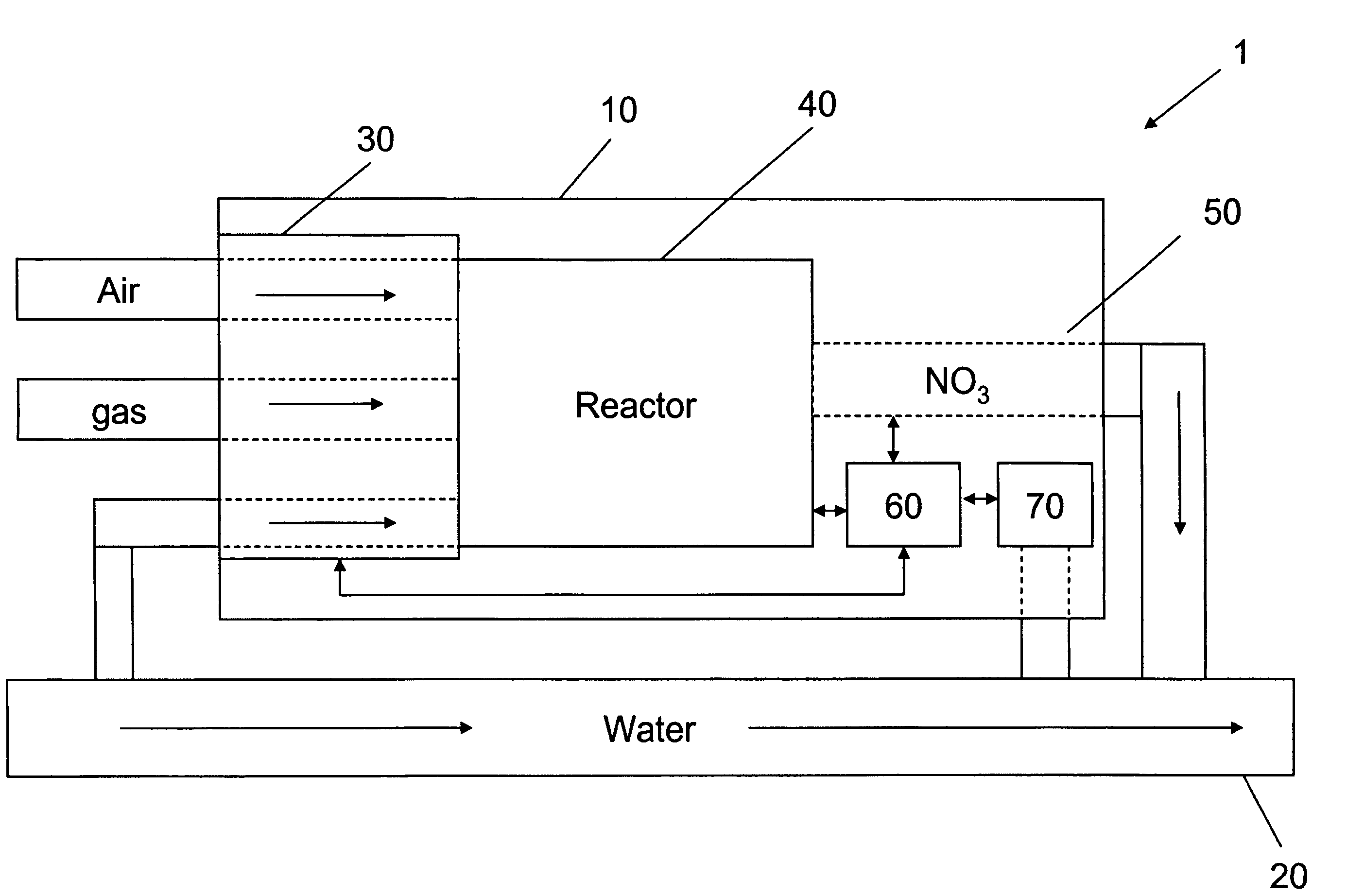

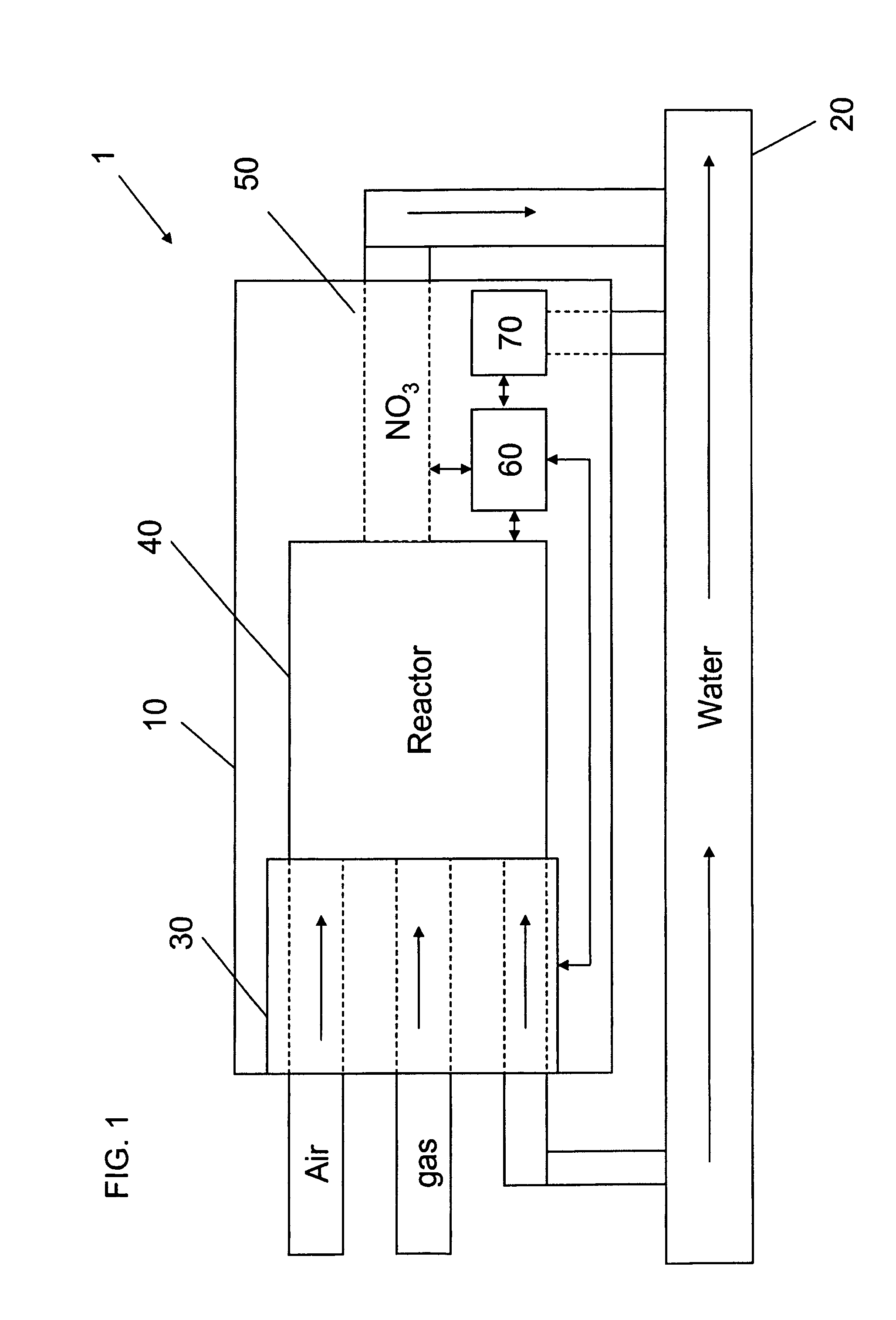

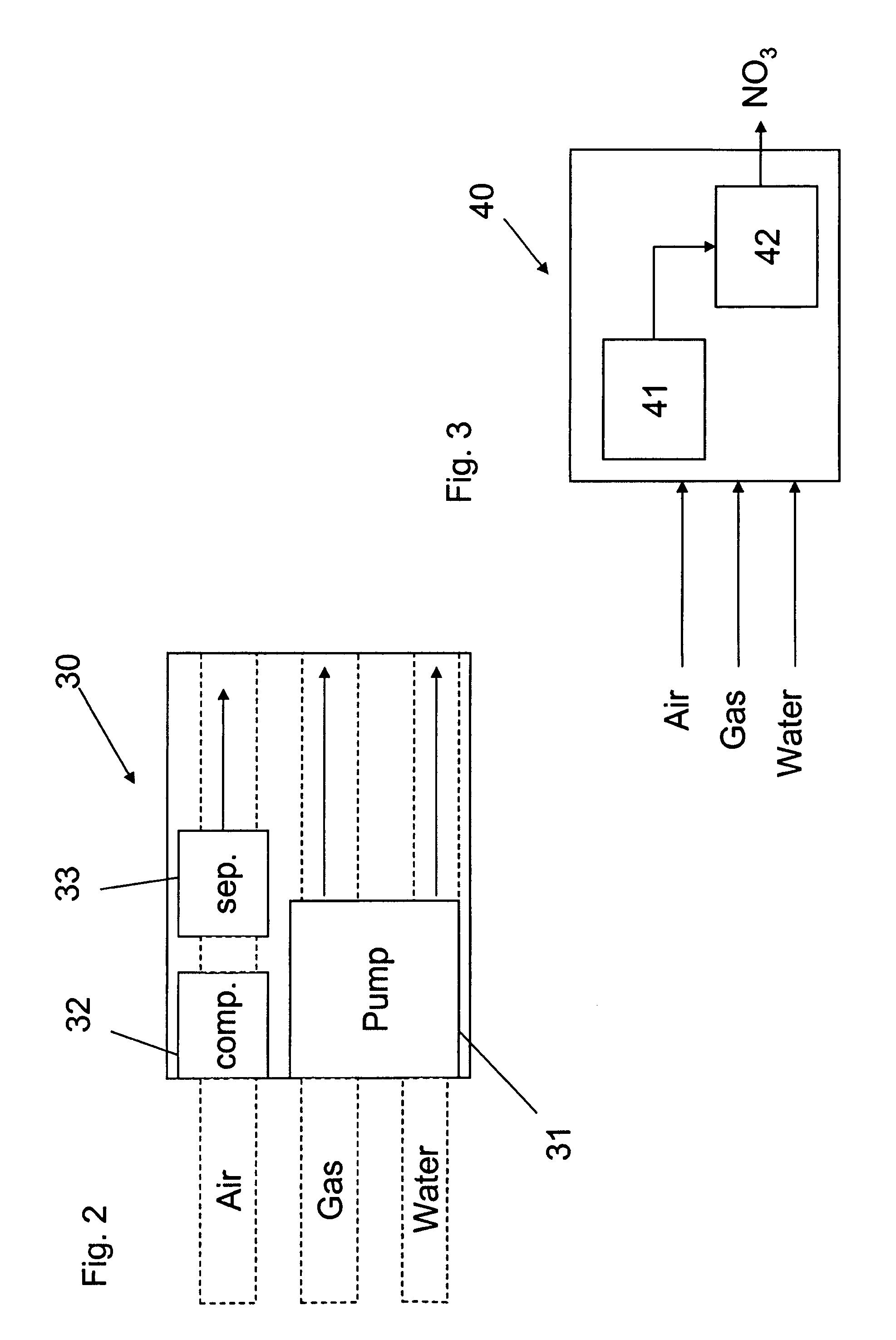

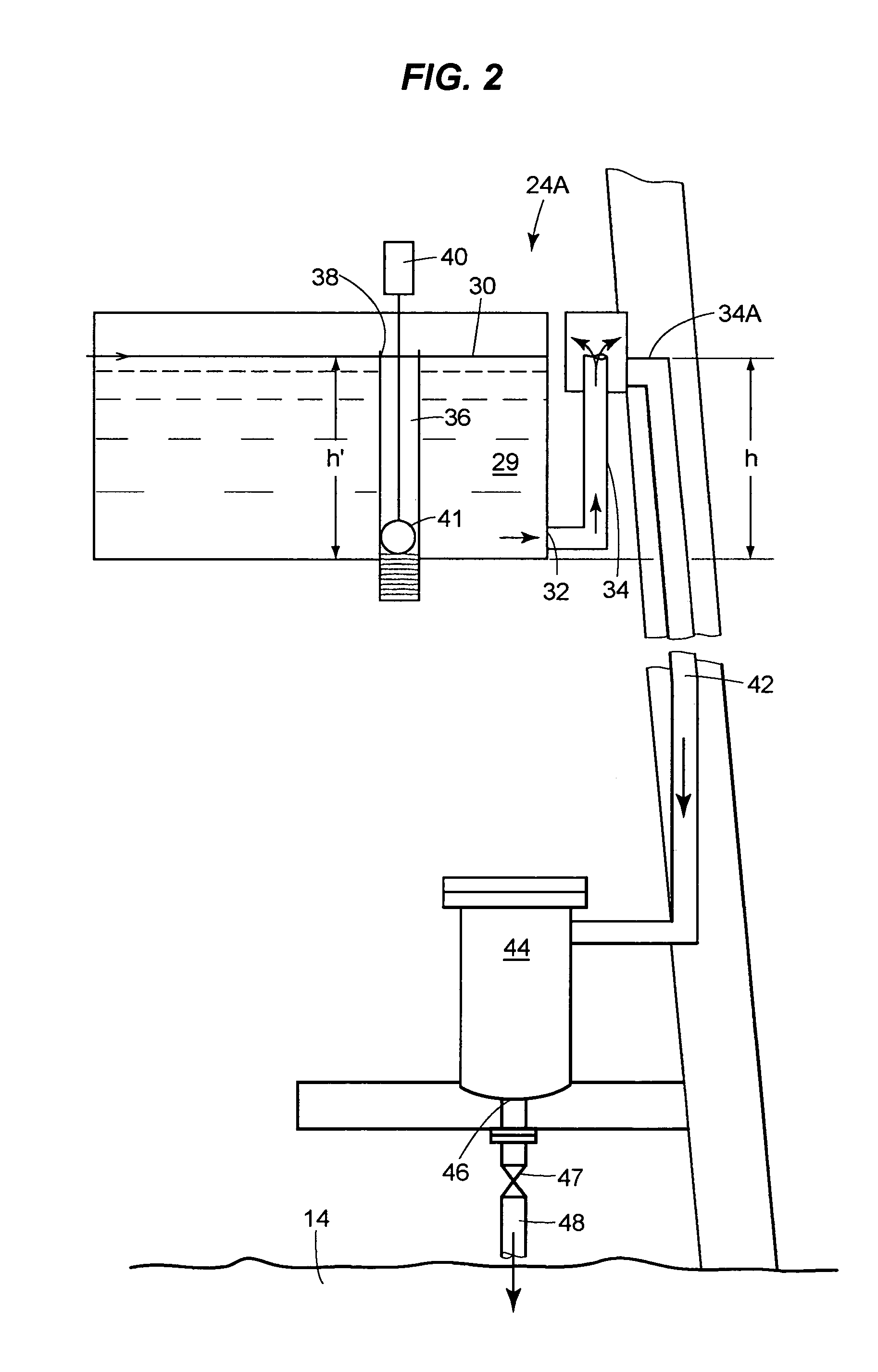

Apparatus for on-site production of nitrate ions

InactiveUS7514058B1Enhanced overall recoveryWater treatment parameter controlWater treatment compoundsMicrobial enhanced oil recoverySulfate-reducing bacteria

An apparatus and method produces nitrate ions on-site from water, natural gas and air extracted in proximity to the apparatus. The apparatus generates nitrate ions and brings the nitrate ions into contact with an aqueous system. Hydrogen sulfide present in the aqueous system is removed and the production of hydrogen sulfide by sulfate-reducing bacteria (SRB) is eliminated by introducing into the system nitrate ions, whereby denitrifying microorganisms, using nitrate, outcompete the sulfate-reducing bacteria for the available carbon nutrients, thus preventing the SRB from producing hydrogen sulfide. Nitrate ions generated by the apparatus and added to the aqueous system which contains the denitrifying microorganisms can enhance oil recovery by means of microbial enhanced oil recovery mechanisms.

Owner:NITRA GEN LLC

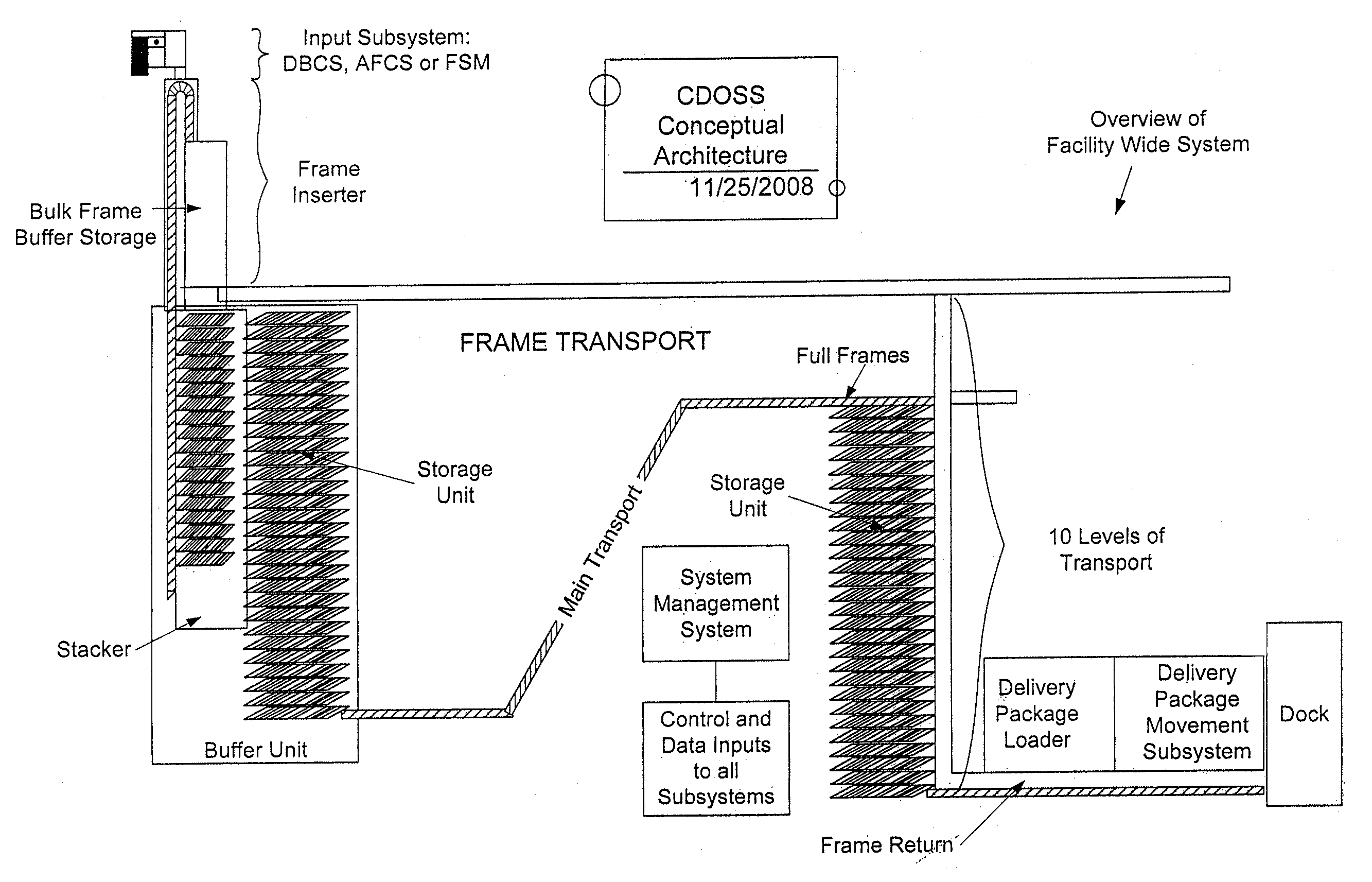

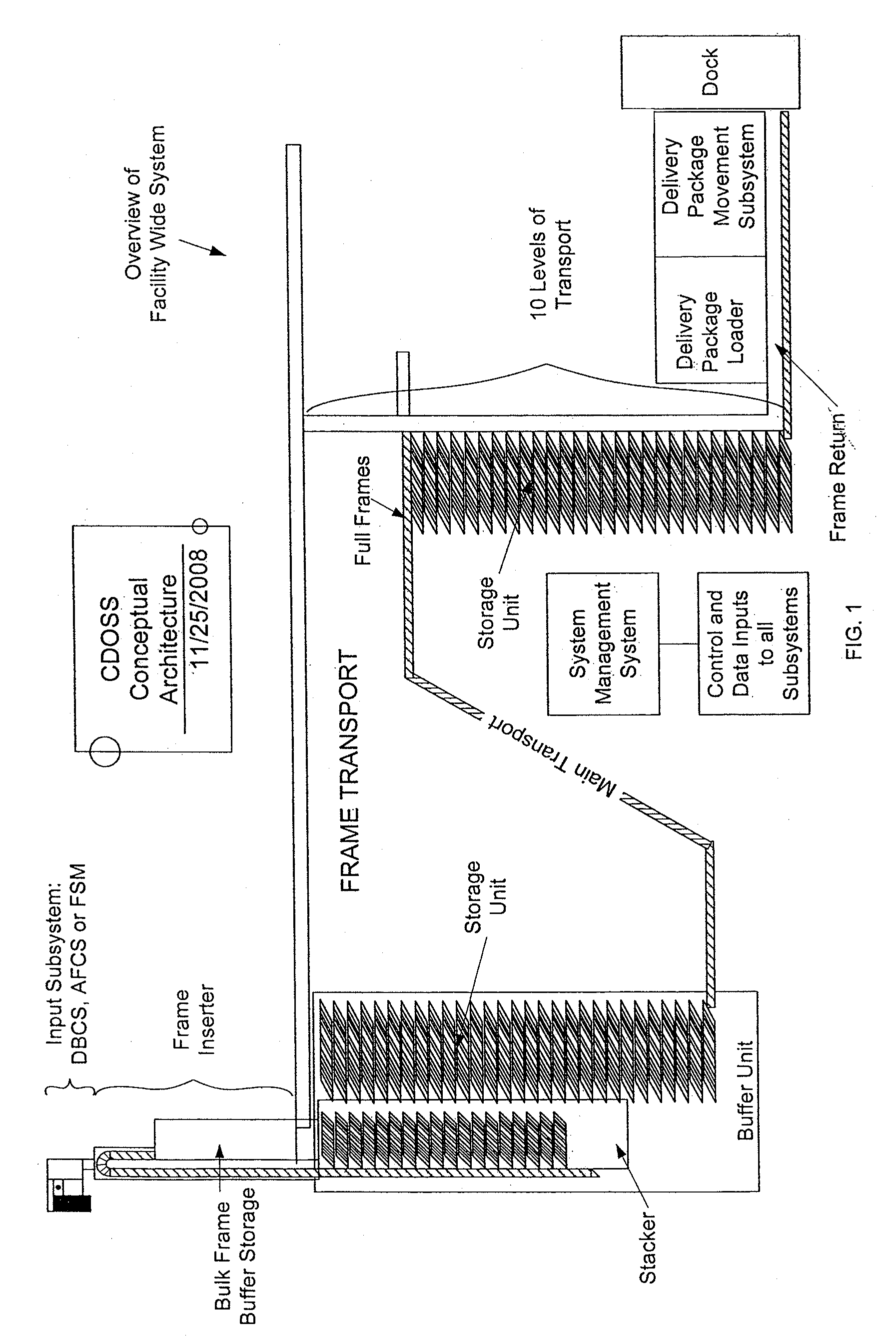

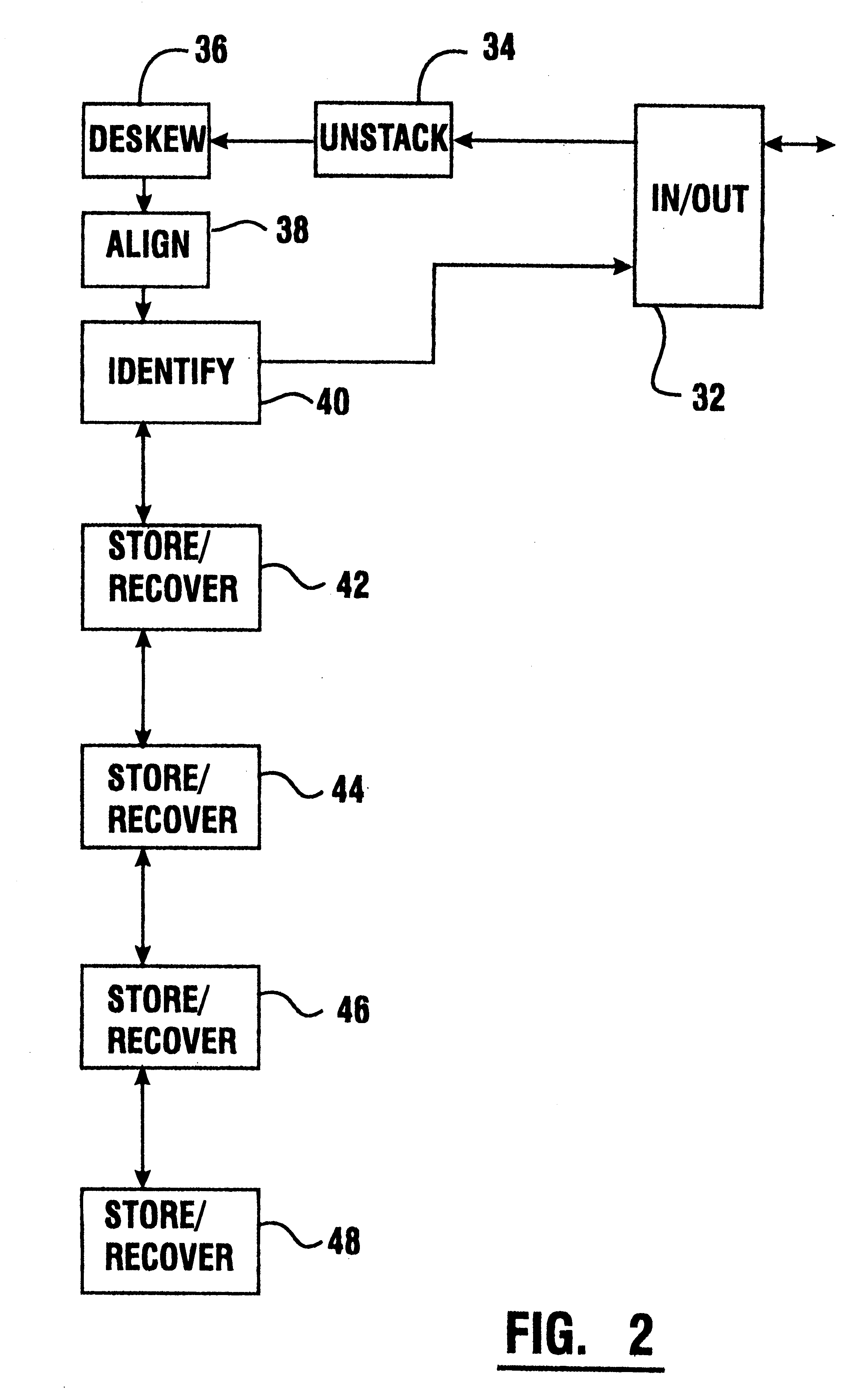

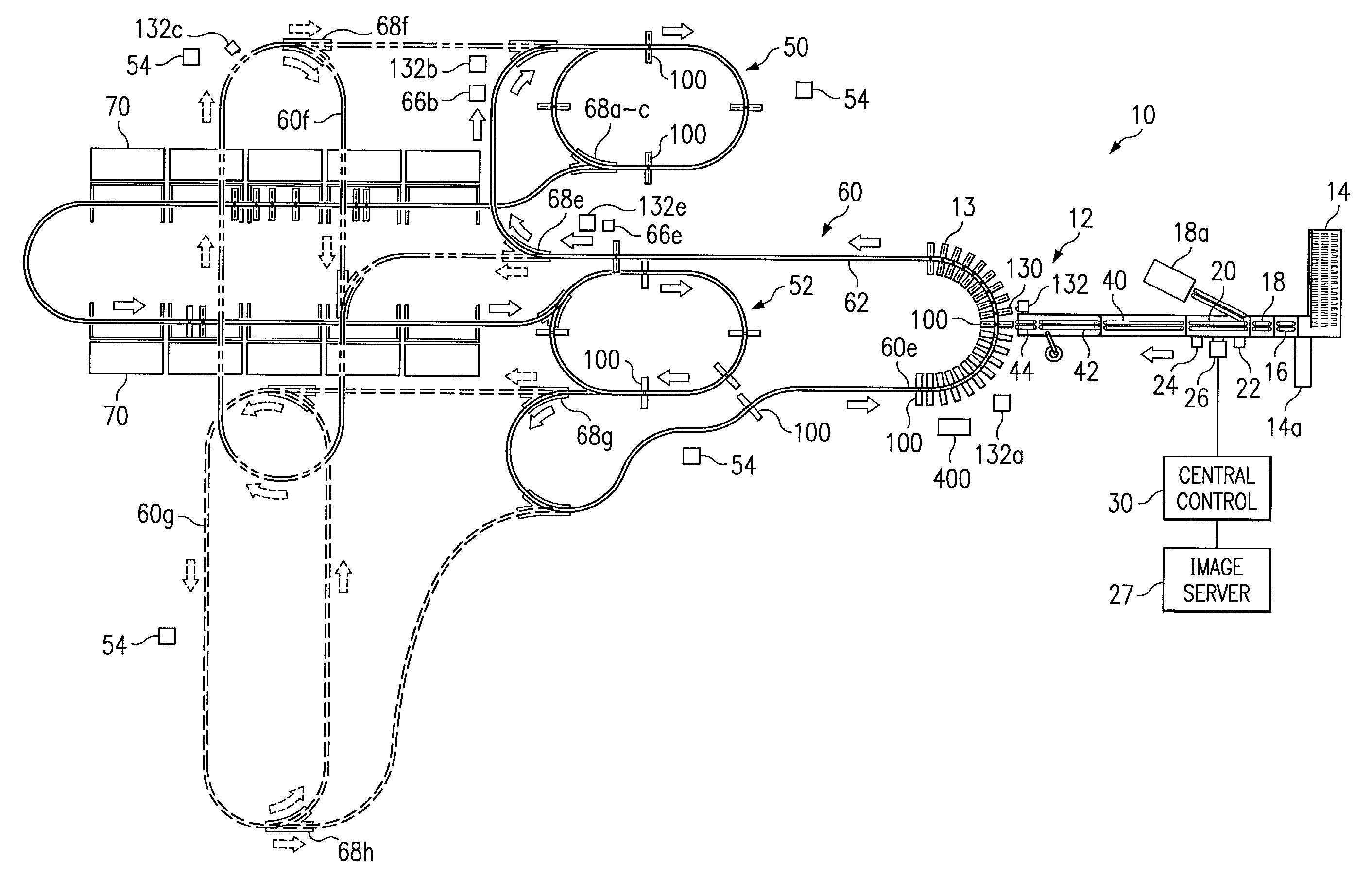

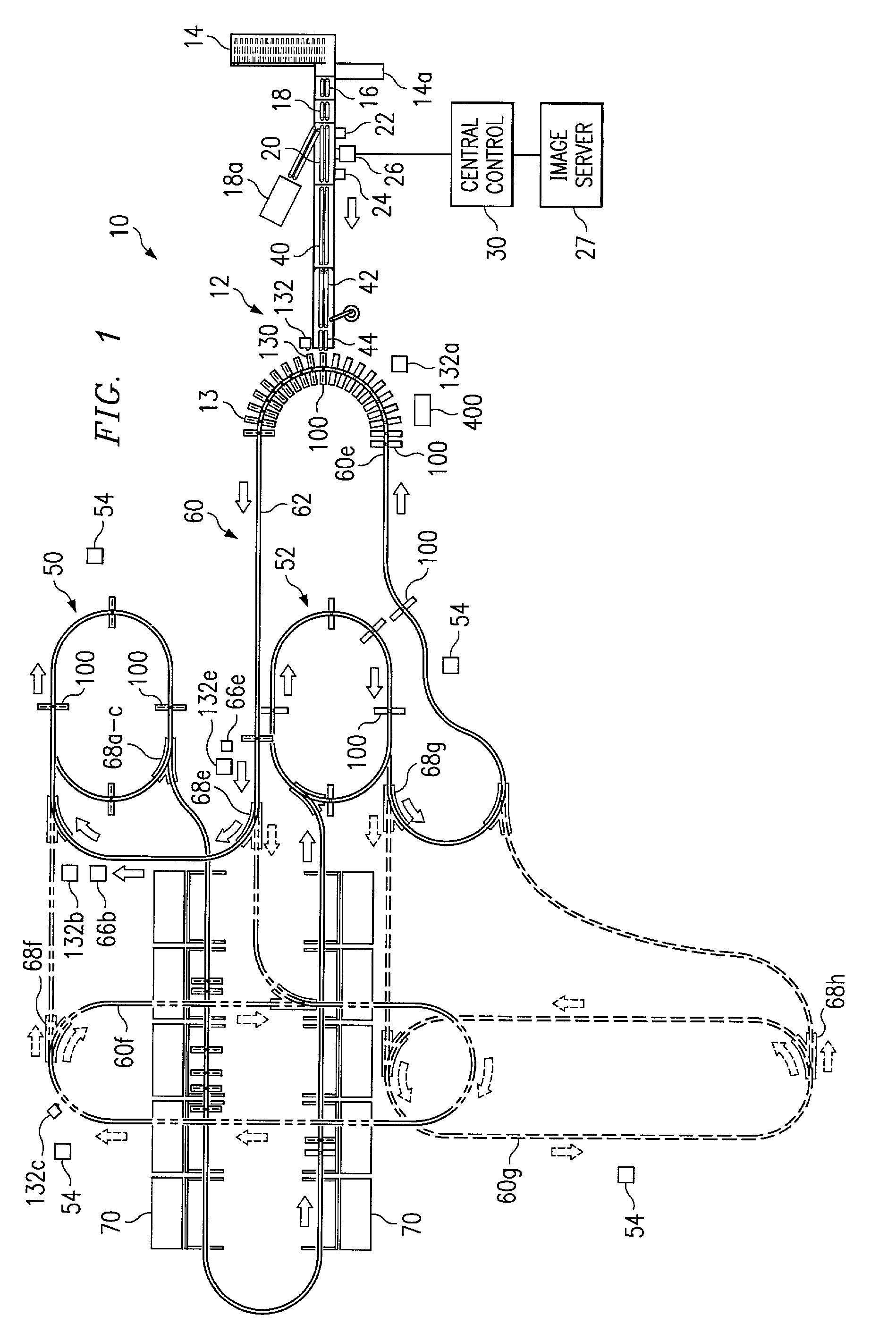

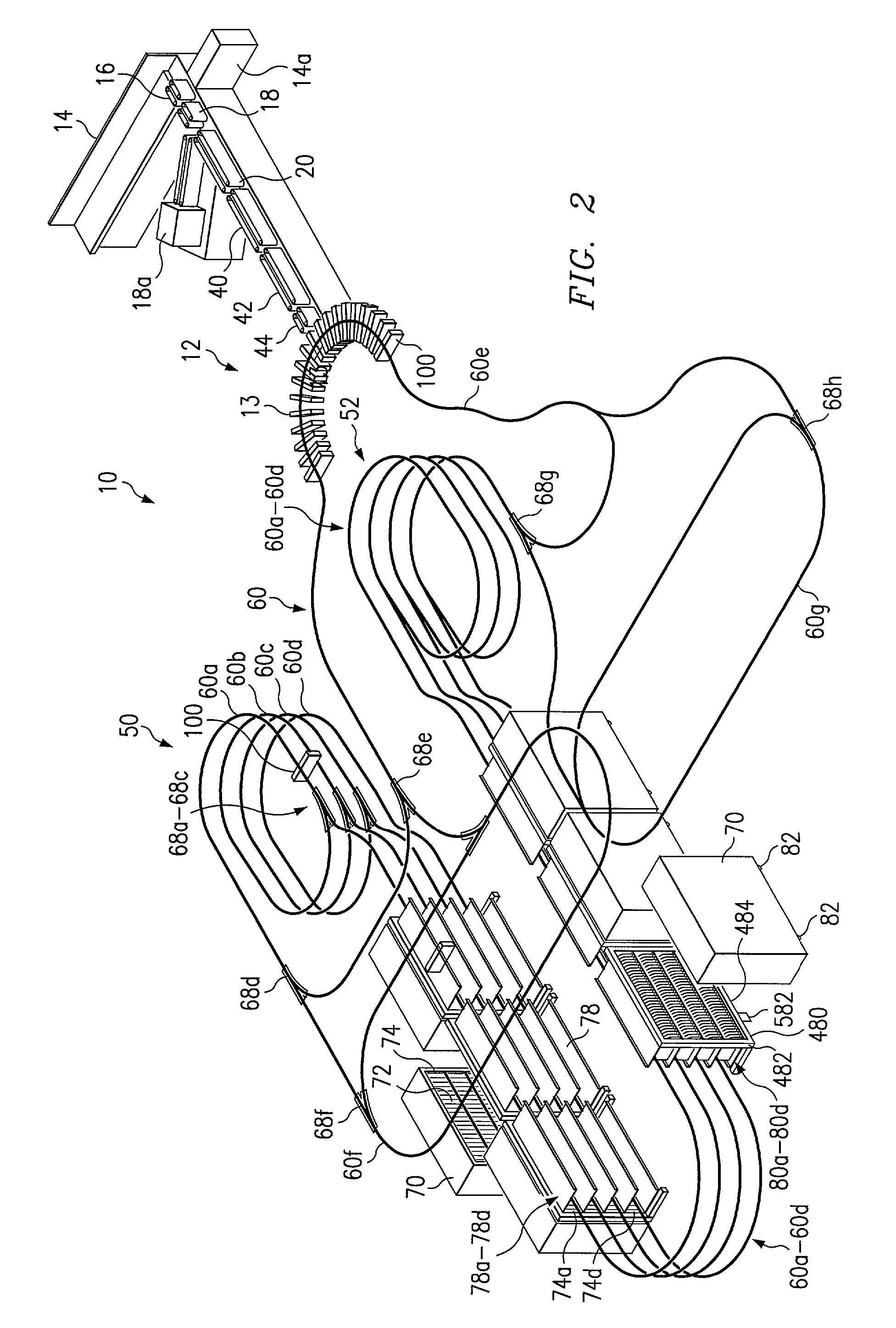

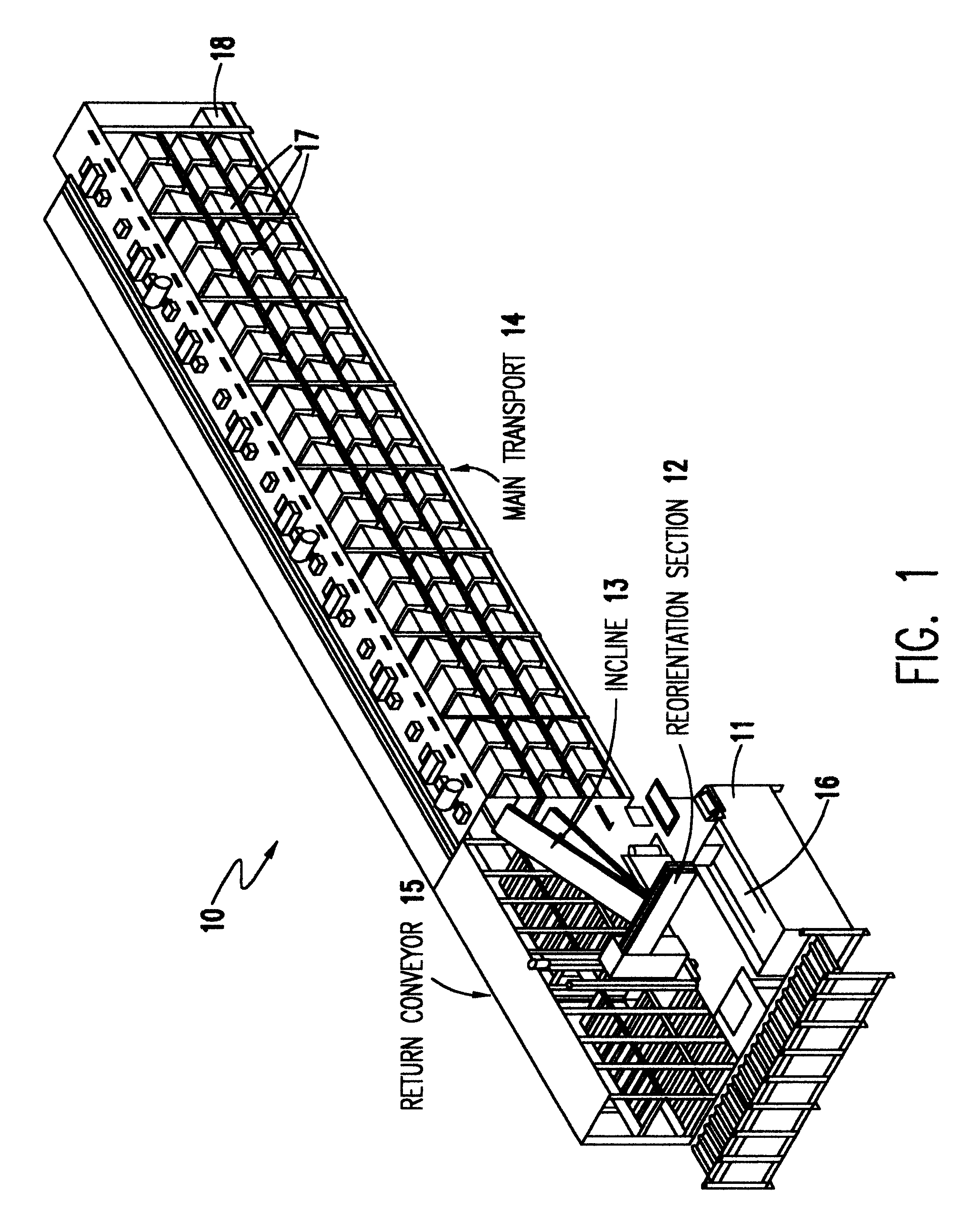

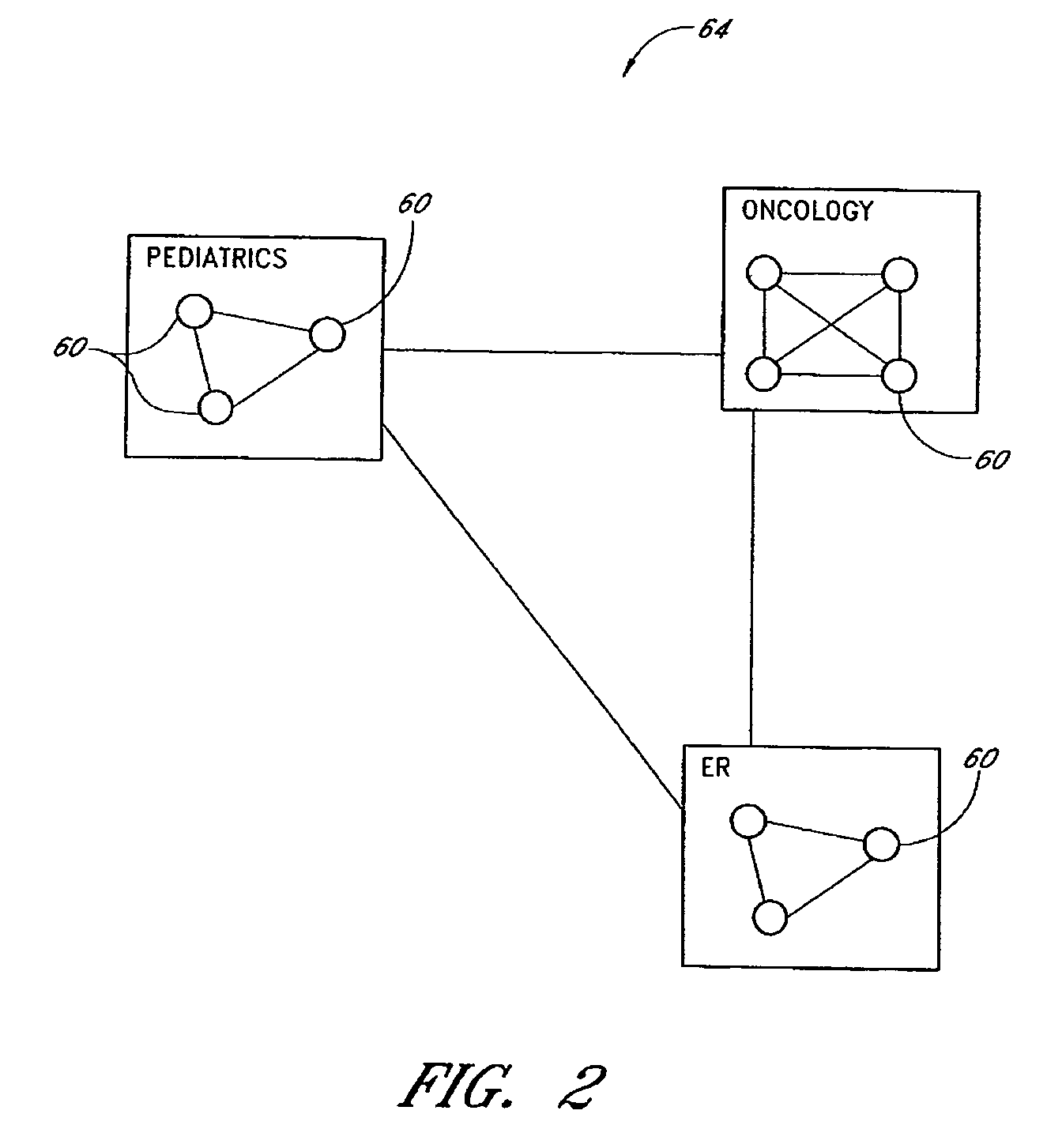

Facility Wide Mixed Mail Sorting and/or Sequencing System and Components and Methods Thereof

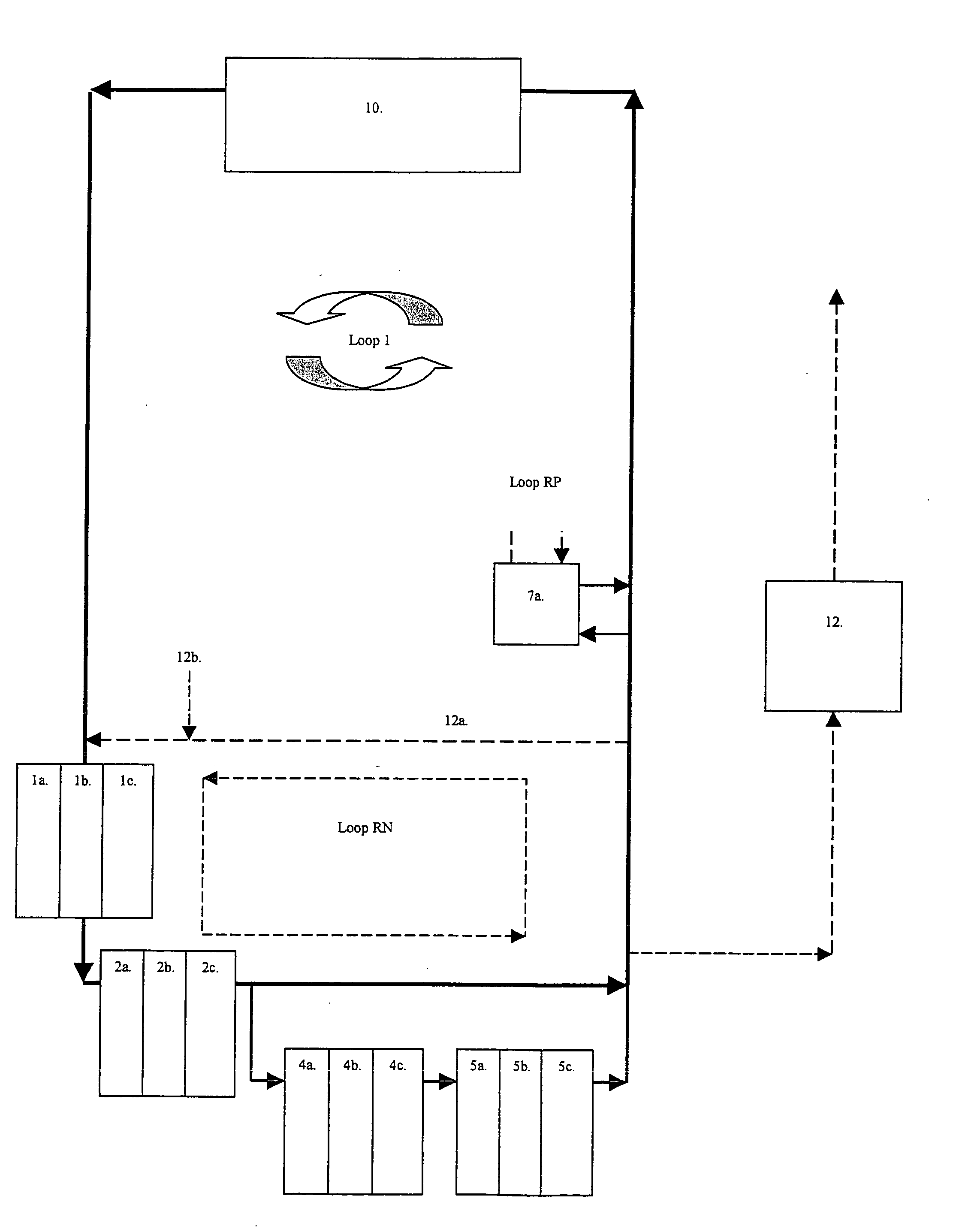

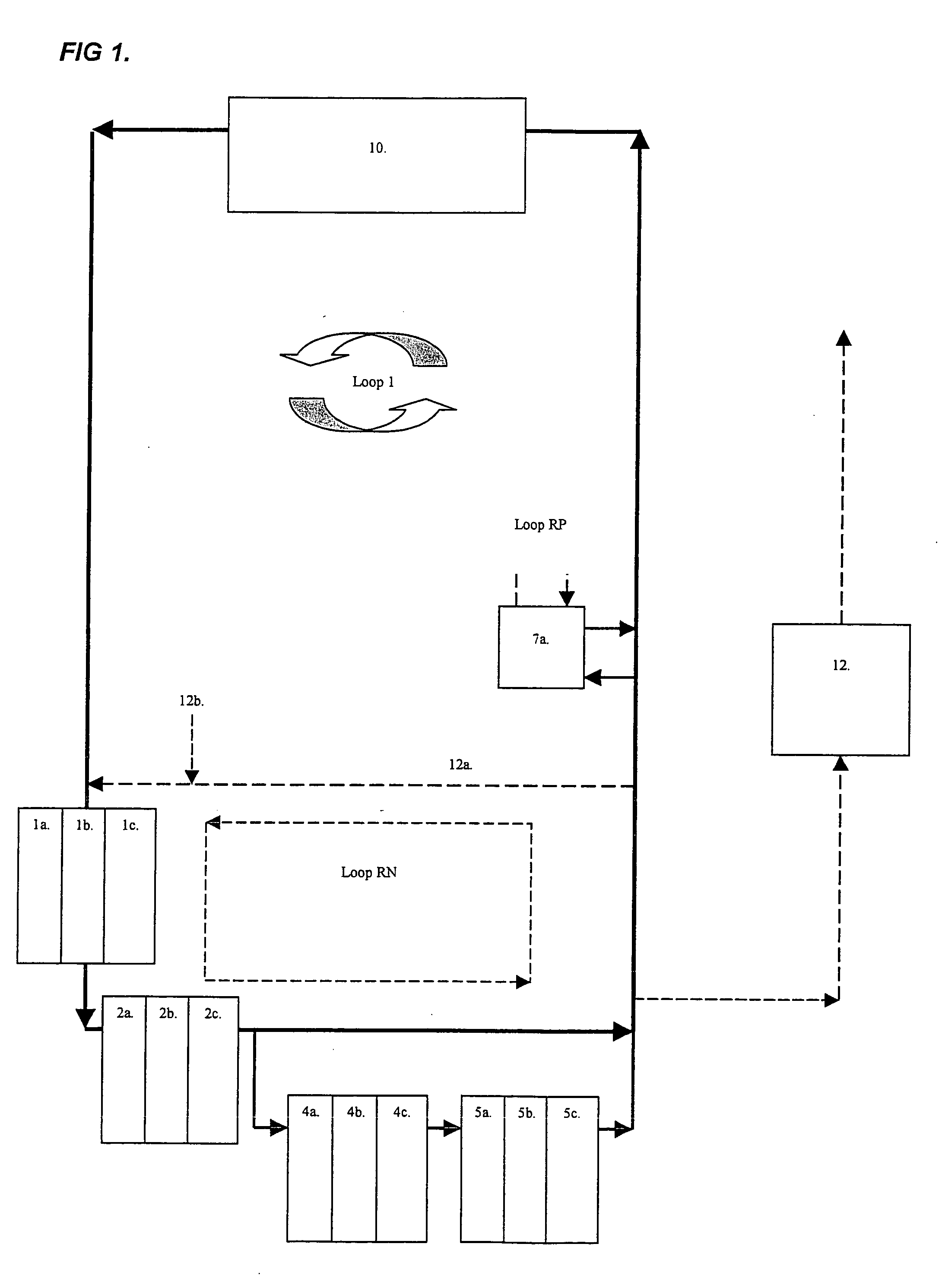

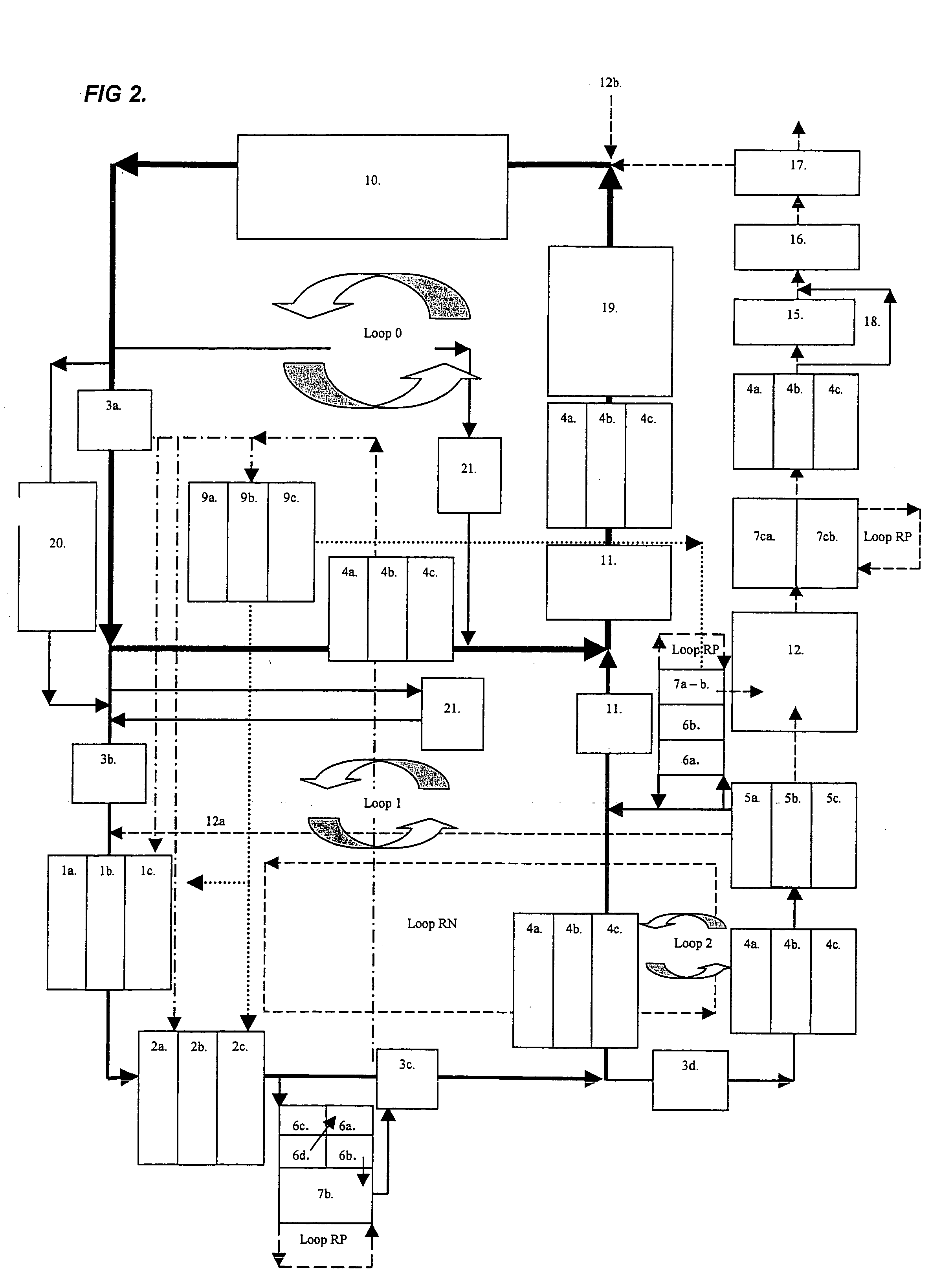

ActiveUS20110046775A1Reduce network congestionWidth minimizedConveyorsData processing applicationsEngineeringProduct processing

The invention generally relates to a facility wide sorting and / or sequencing system for improving product processing operations and, more particularly, to a facility wide system and related functionality for simultaneously sorting and sequencing mixed mail pieces such as, for example, flats and letter mail pieces. The flats and letter mail pieces are placed in frames so that all types of mail pieces can be sorted and / or sequenced simultaneously through merging and diverting a stream of filled trays into and out of different streams at a full or substantially full transport speed.

Owner:LOCKHEED MARTIN CORP

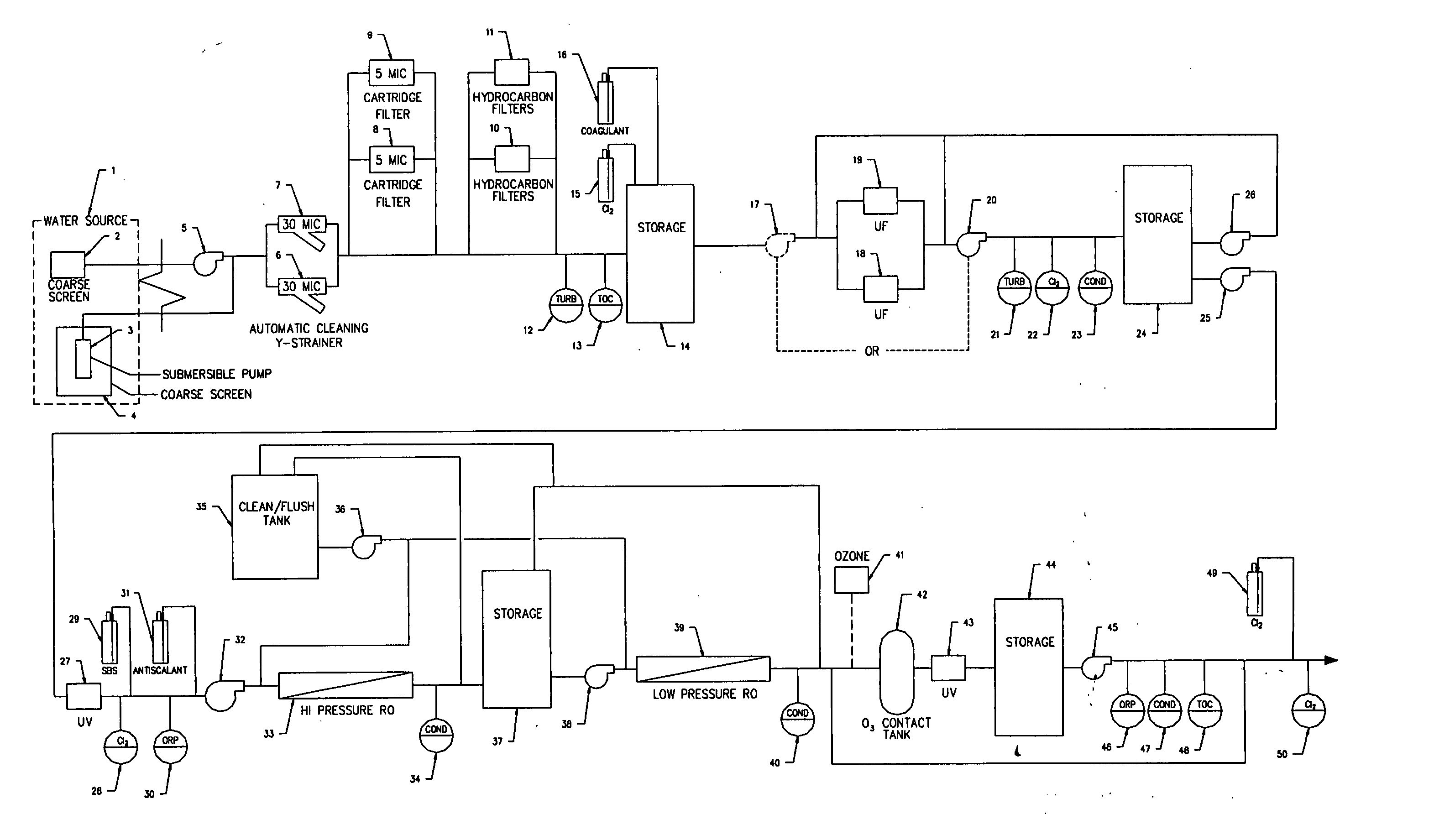

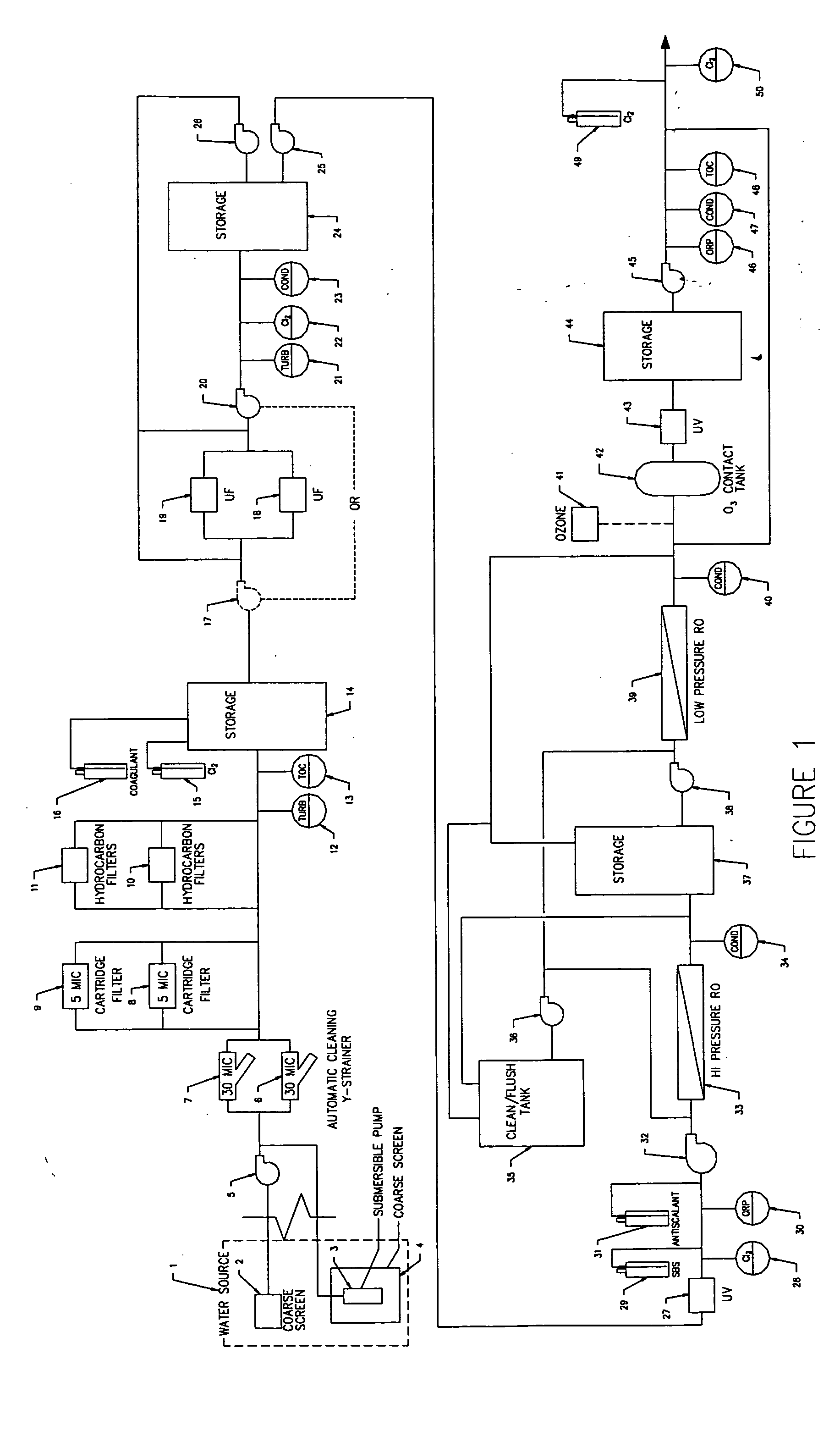

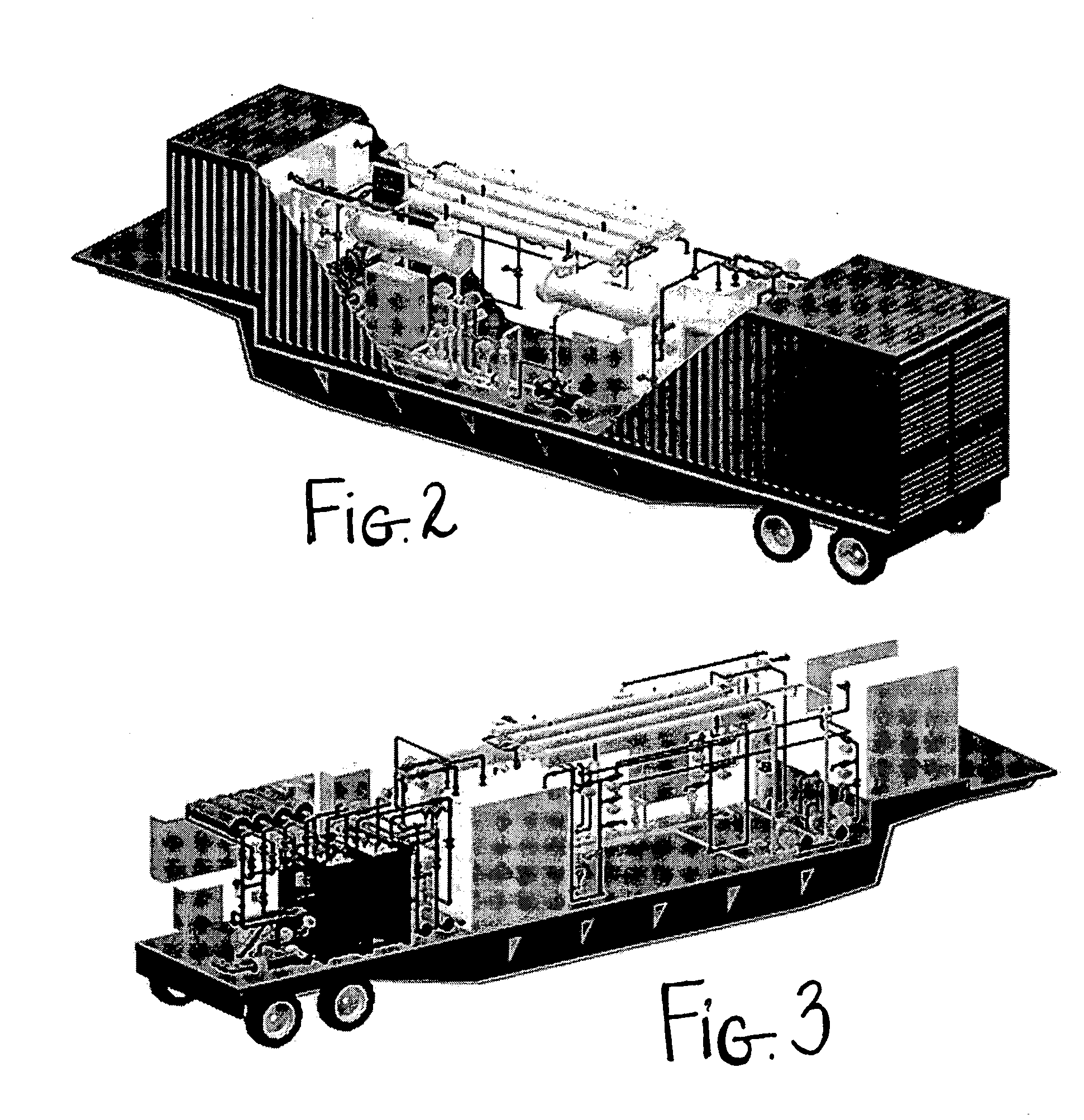

Water purifier and method of making and using the same

ActiveUS20050139530A1Fully removedGeneral water supply conservationTreatment involving filtrationHigh concentrationPurification methods

A method of producing safe drinking water from virtually any water source utilizing a water purification system is disclosed. The method includes a combination of water purification methods with a control system that evaluates water quality and functional processing parameters, such as pressure and flow. The control system determines what water processing methods to utilize and how most efficiently to operate them. The system is capable of treating highly contaminated water to the necessary degree to produce safe drinking water. Furthermore, the system regulates and cleans itself to maintain functionality despite receiving high concentrations of various contaminants from the feed water source.

Owner:HEISS CHRISTOPHER

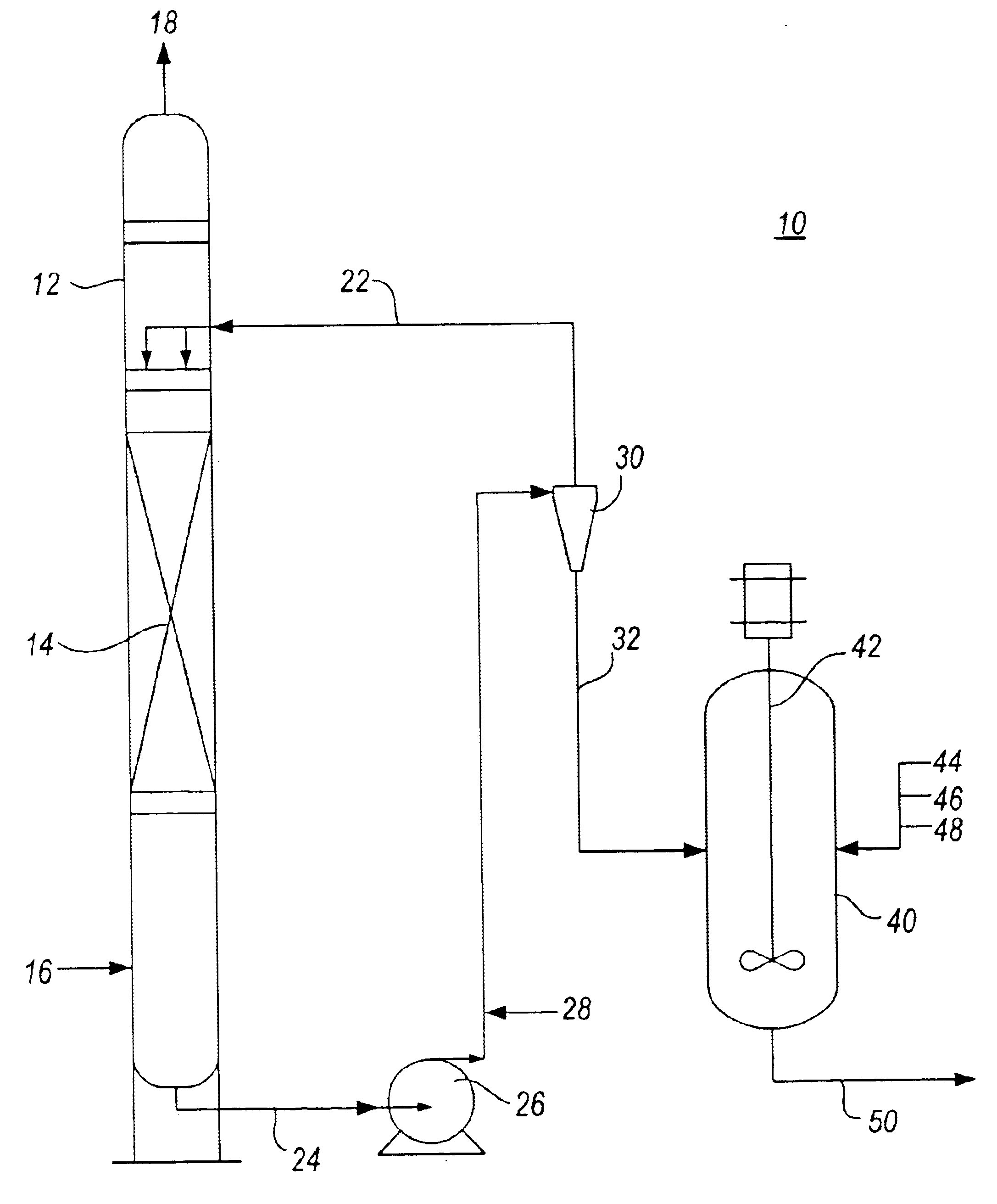

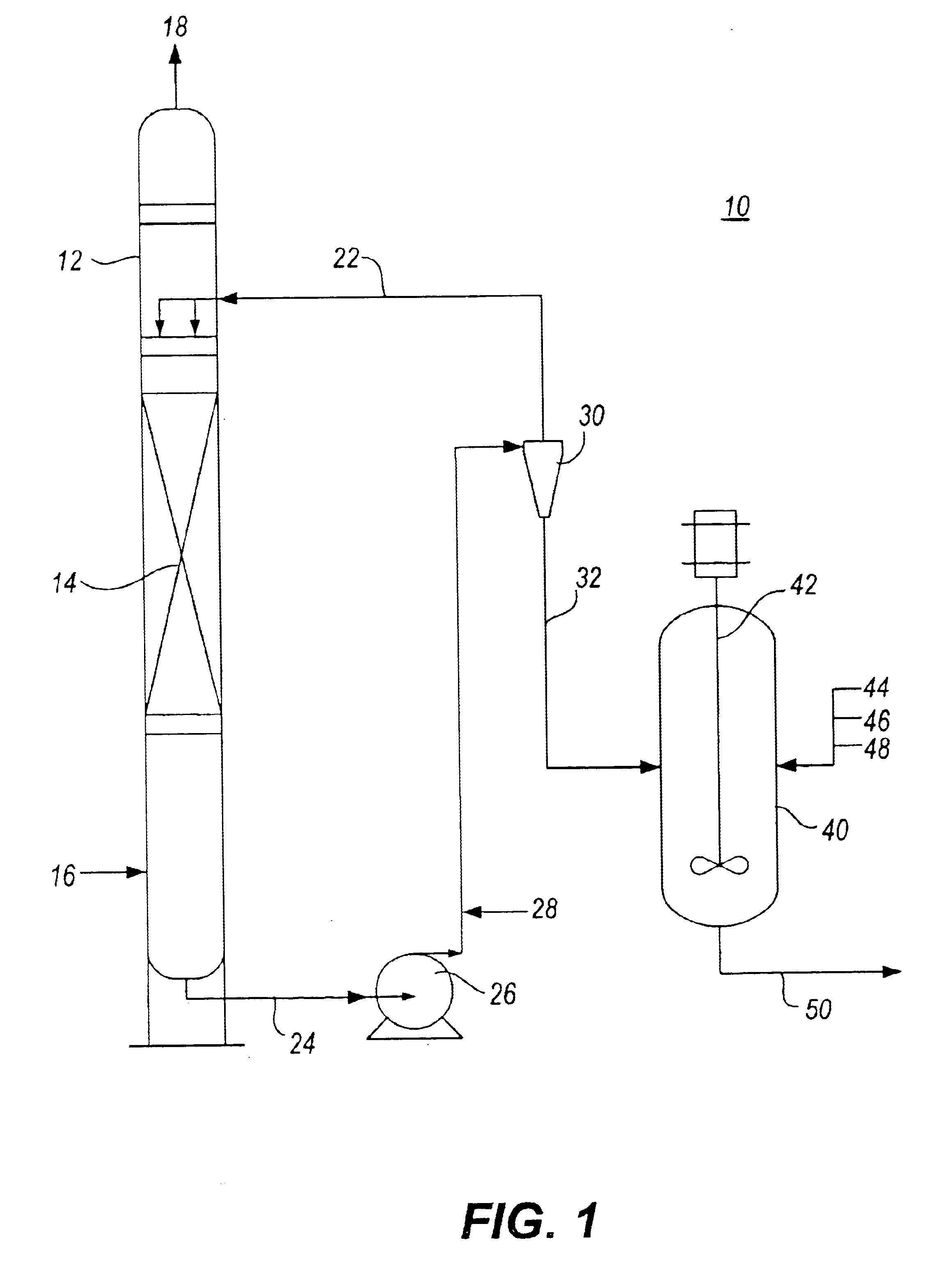

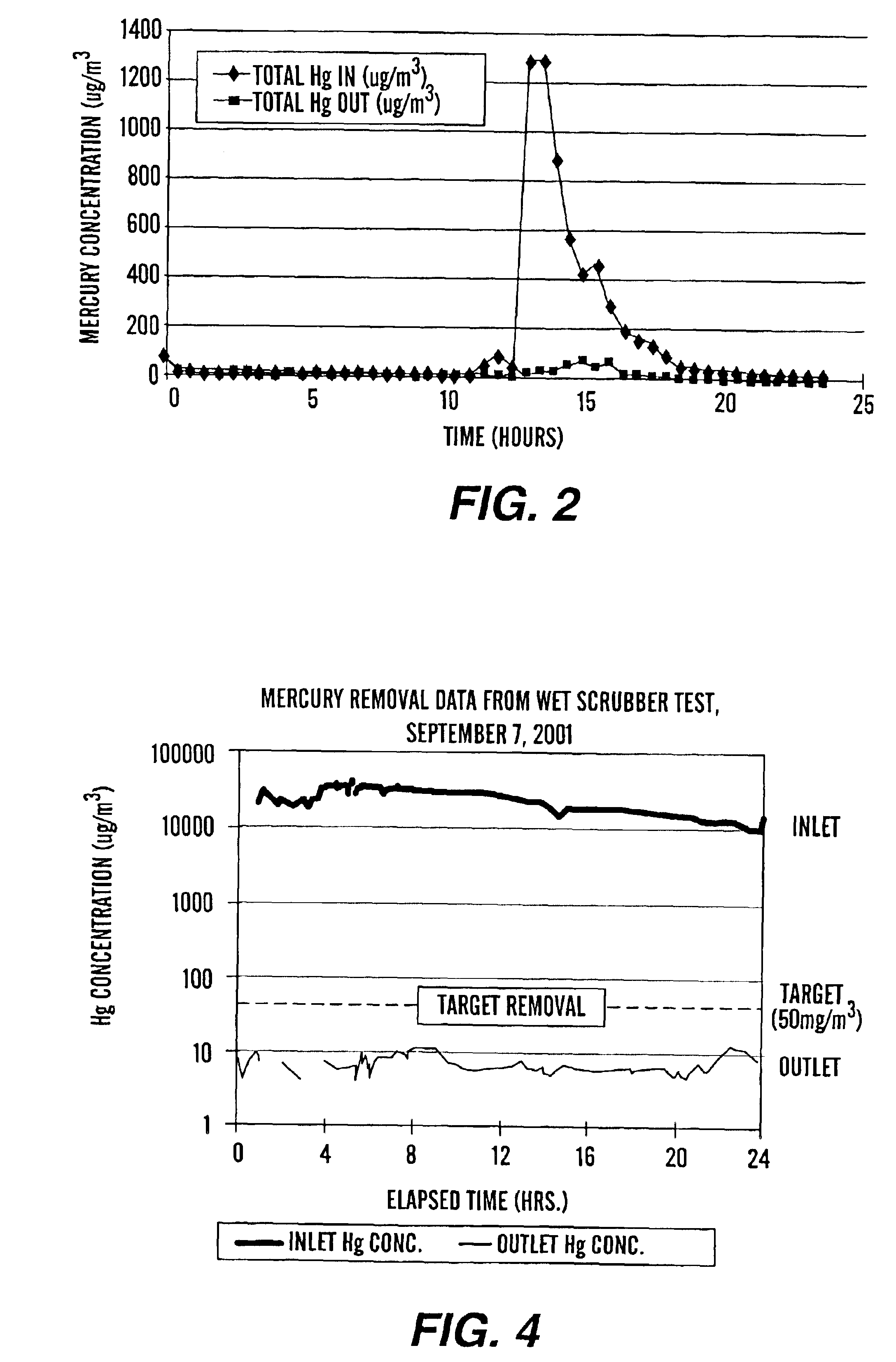

Method for removal and stabilization of mercury in mercury-containing gas streams

InactiveUS6942840B1Improve scalabilityCombination devicesDispersed particle filtrationOxygenVapor phase

The present invention is directed to a process and apparatus for removing and stabilizing mercury from mercury-containing gas streams. A gas stream containing vapor phase elemental and / or speciated mercury is contacted with reagent, such as an oxygen-containing oxidant, in a liquid environment to form a mercury-containing precipitate. The mercury-containing precipitate is kept or placed in solution and reacts with one or more additional reagents to form a solid, stable mercury-containing compound.

Owner:MERCURY CONTROL TECH

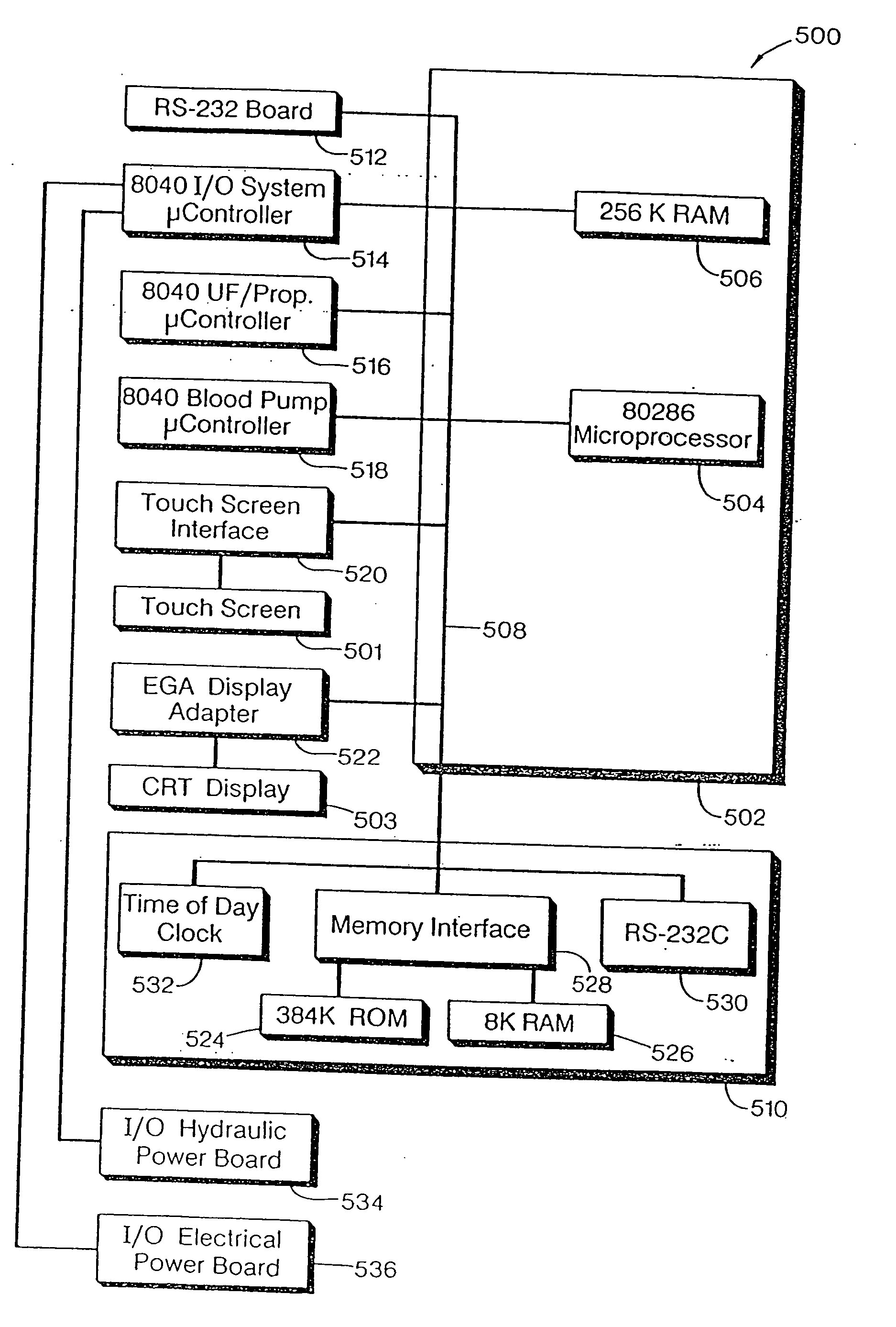

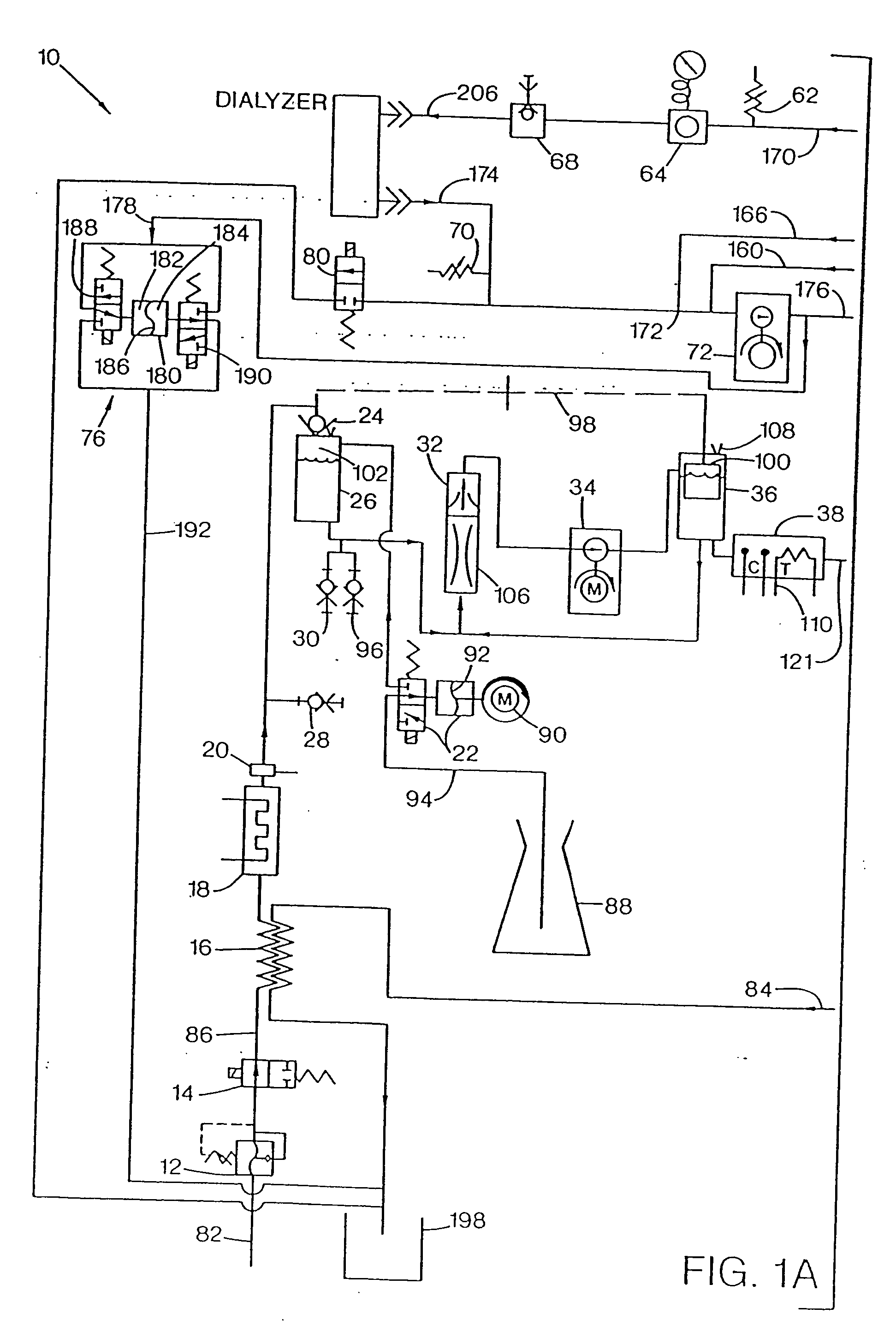

Method and apparatus for kidney dialysis

InactiveUS20050242034A1Mechanical/radiation/invasive therapiesOther blood circulation devicesUltrafiltrationDischarge measurements

Owner:BAXTER INT INC

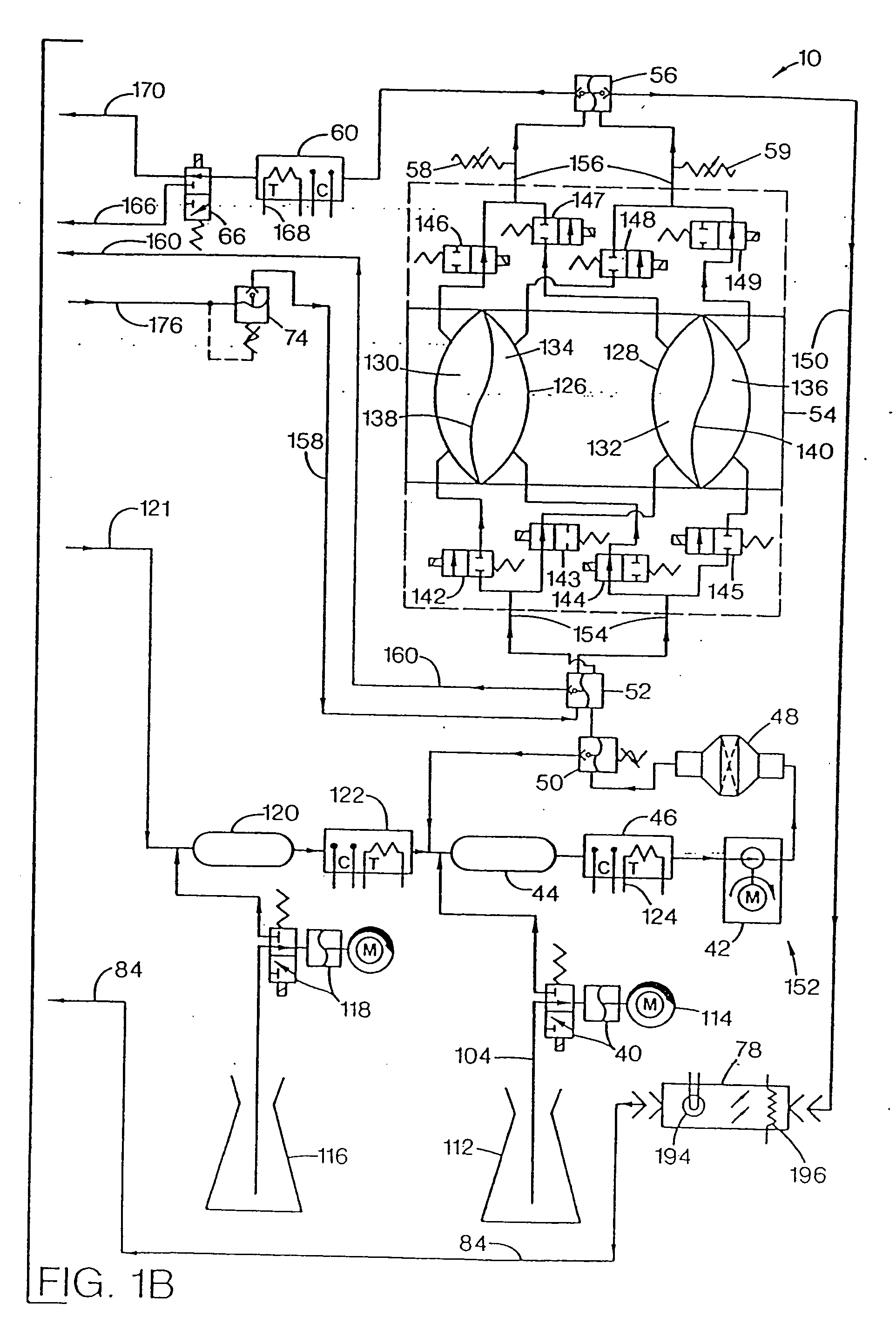

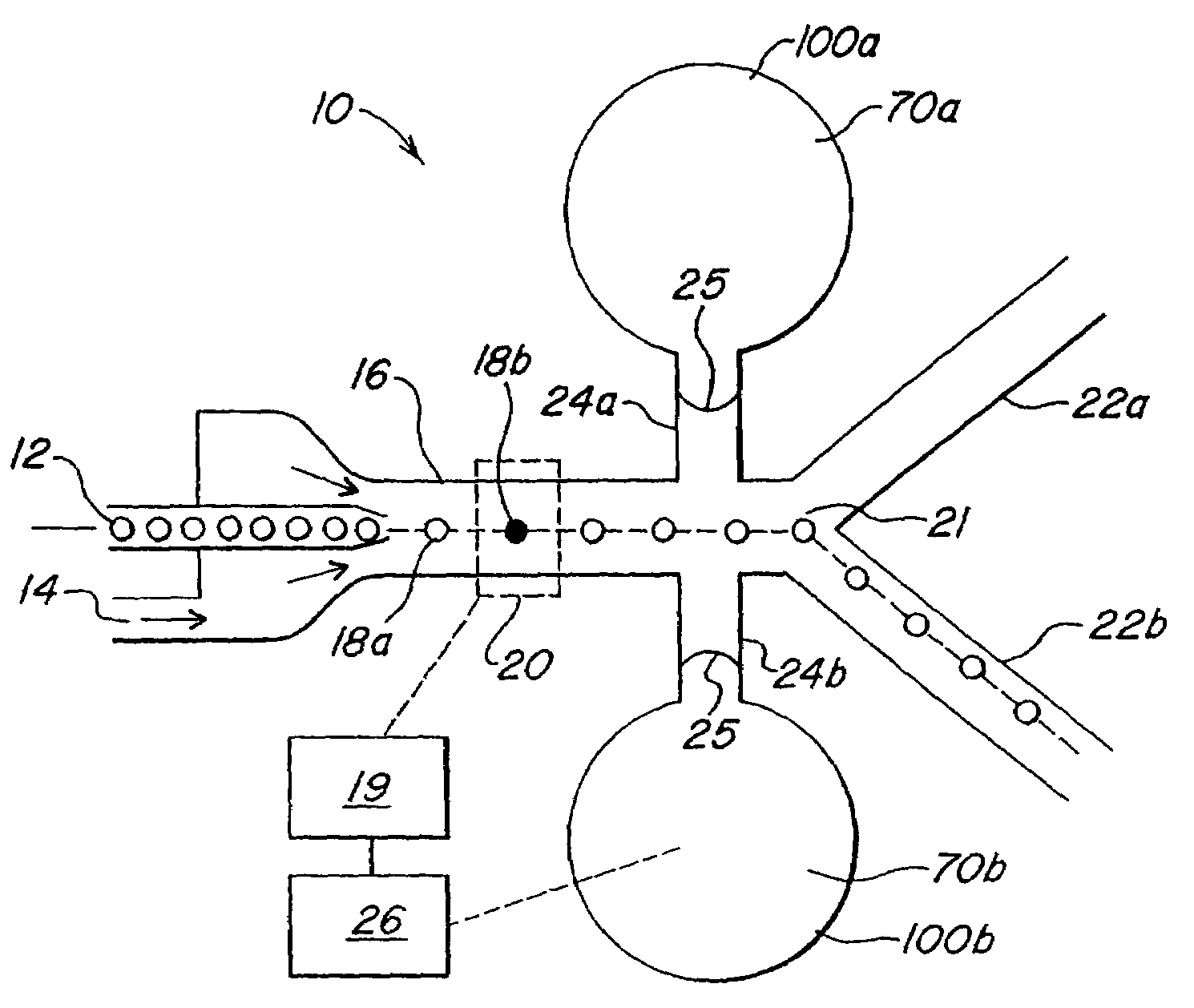

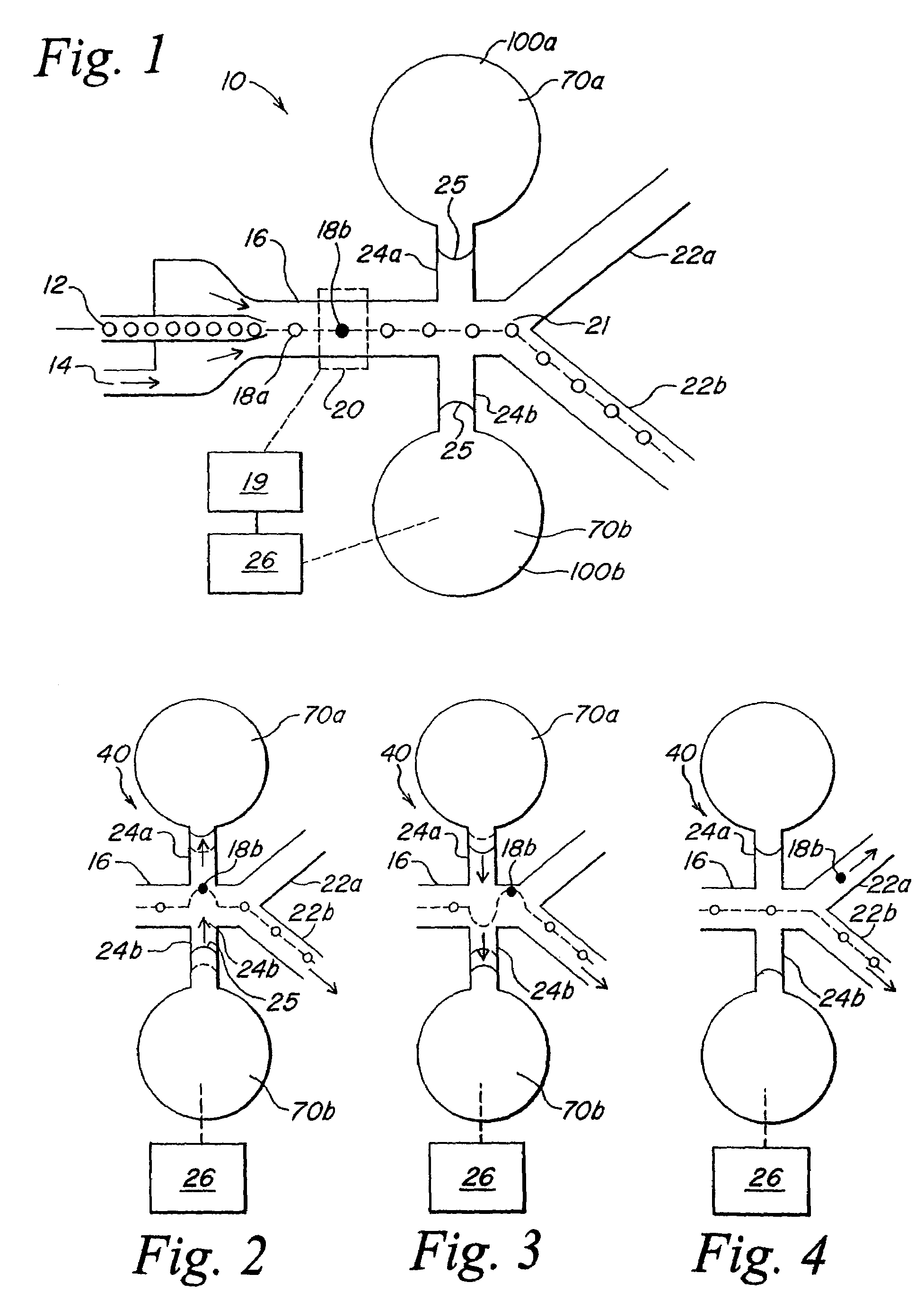

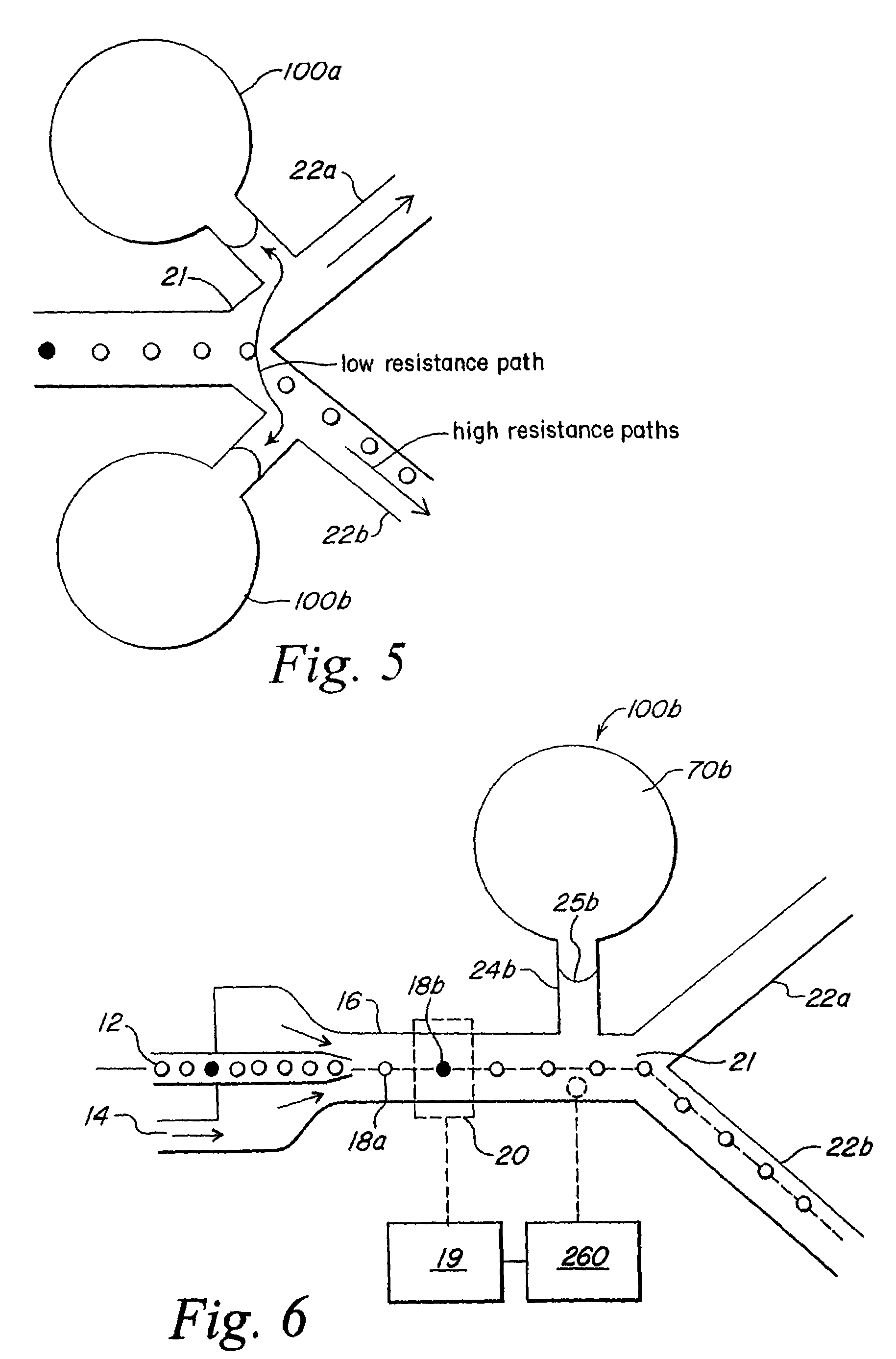

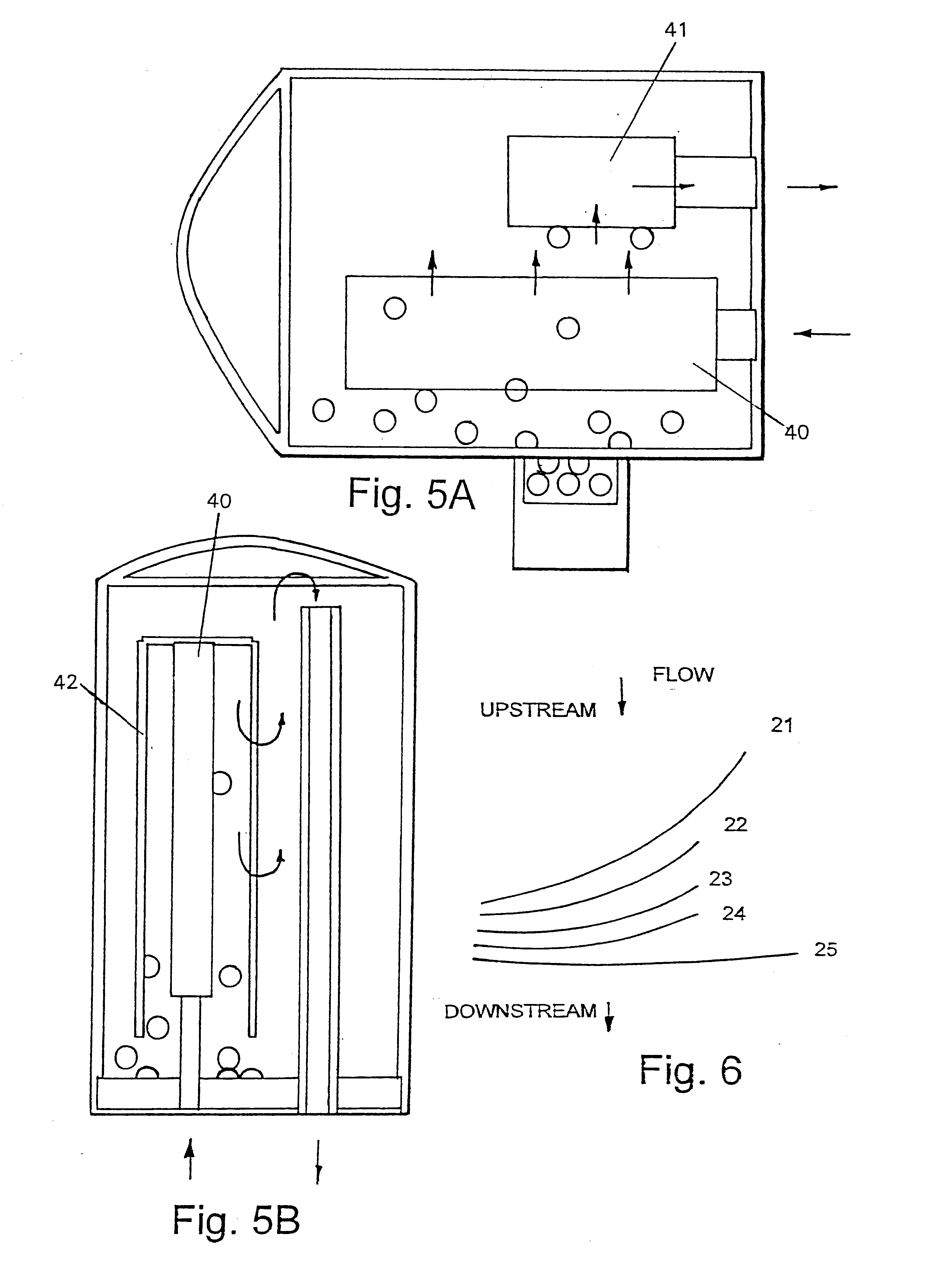

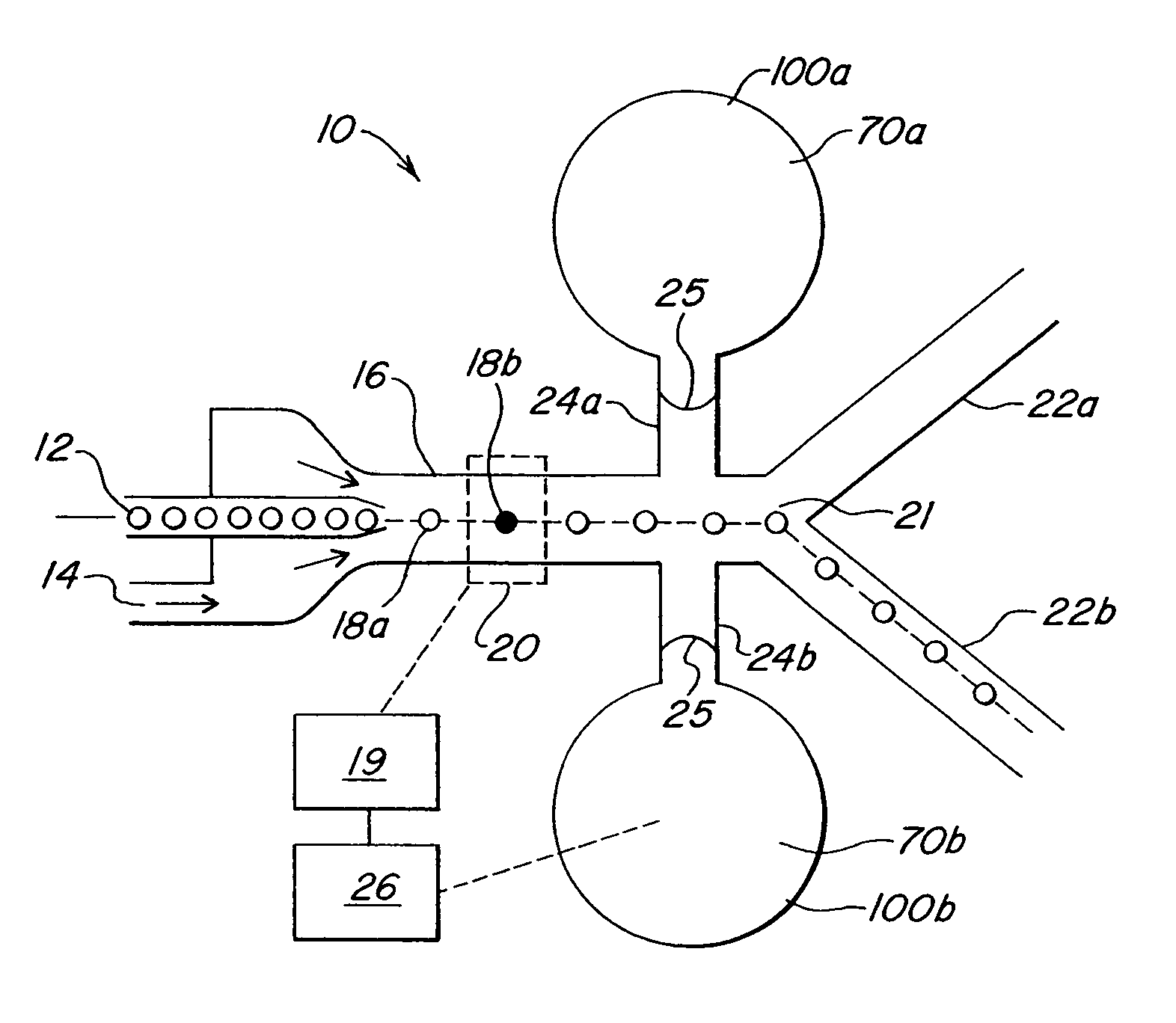

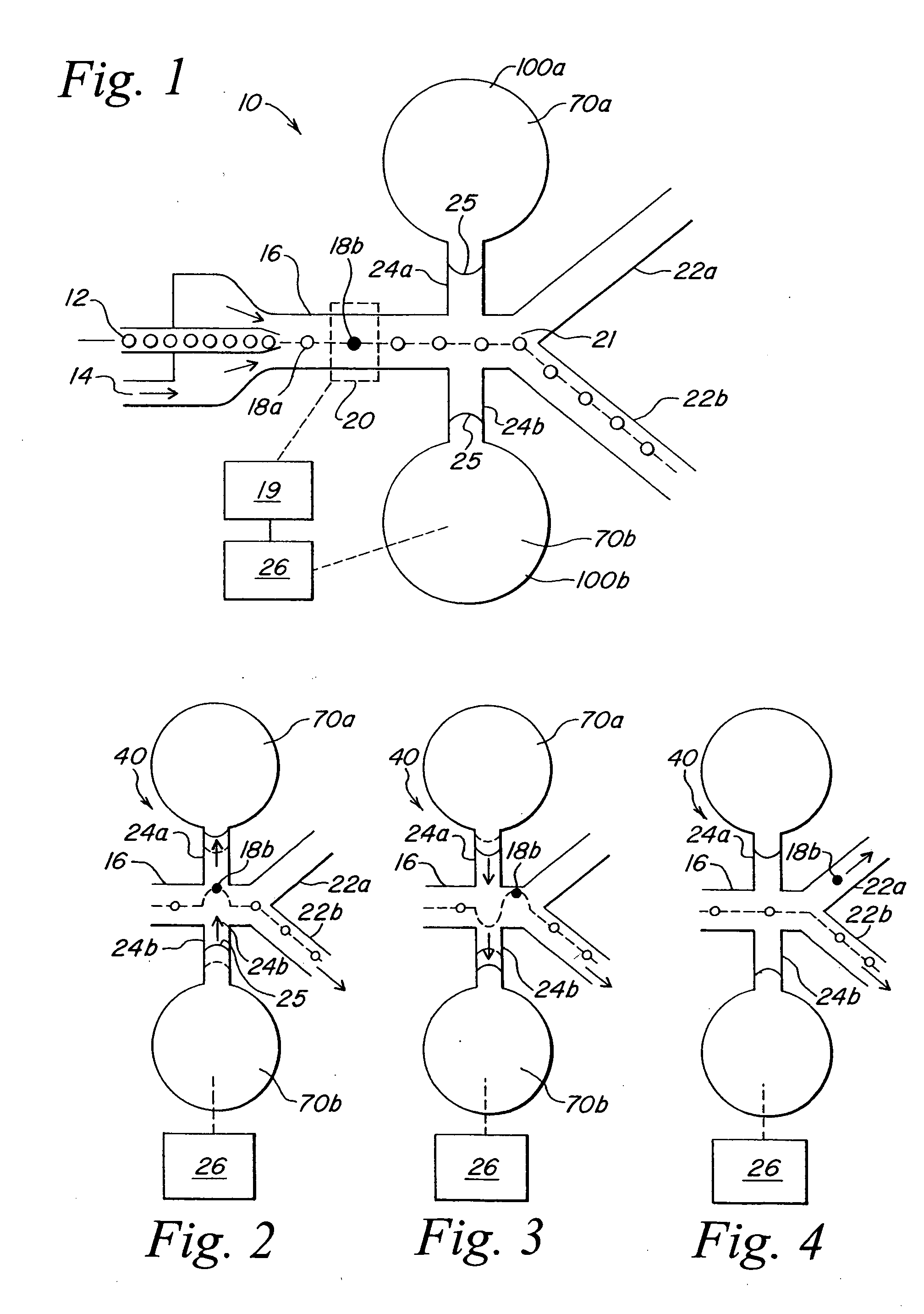

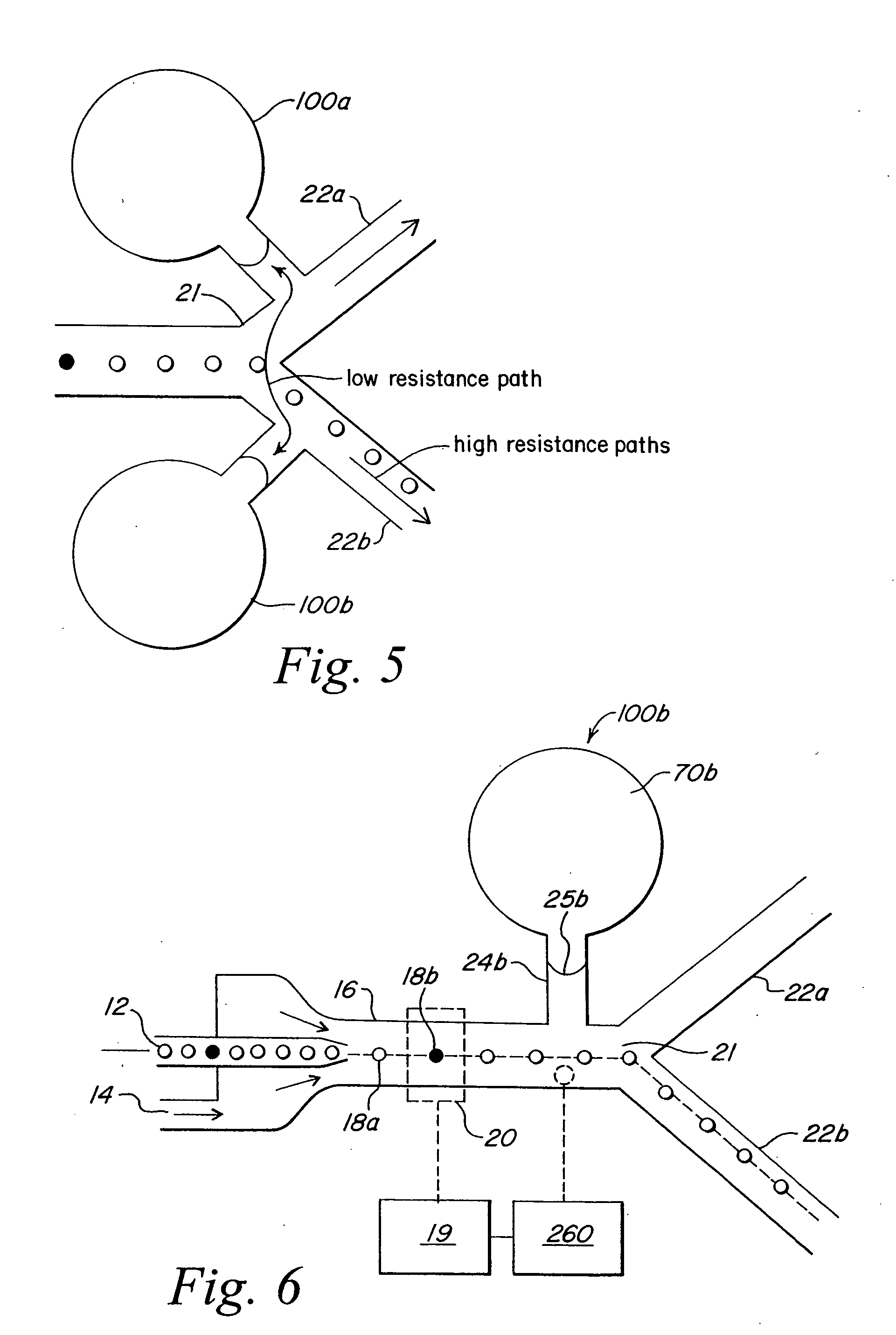

Method and apparatus for sorting particles

InactiveUS7157274B2Low costImprove sorting rateBioreactor/fermenter combinationsBiological substance pretreatmentsParticle sortingComputer module

A method and apparatus for sorting particles moving through a closed channel system of capillary size comprises a bubble valve for selectively generating a pressure pulse to separate a particle having a predetermined characteristic from a stream of particles. The particle sorting system may further include a buffer for absorbing the pressure pulse. The particle sorting system may include a plurality of closely coupled sorting modules which are combined to further increase the sorting rate. The particle sorting system may comprise a multi-stage sorting device for serially sorting streams of particles, in order to decrease the error rate.

Owner:CYTONOMEST

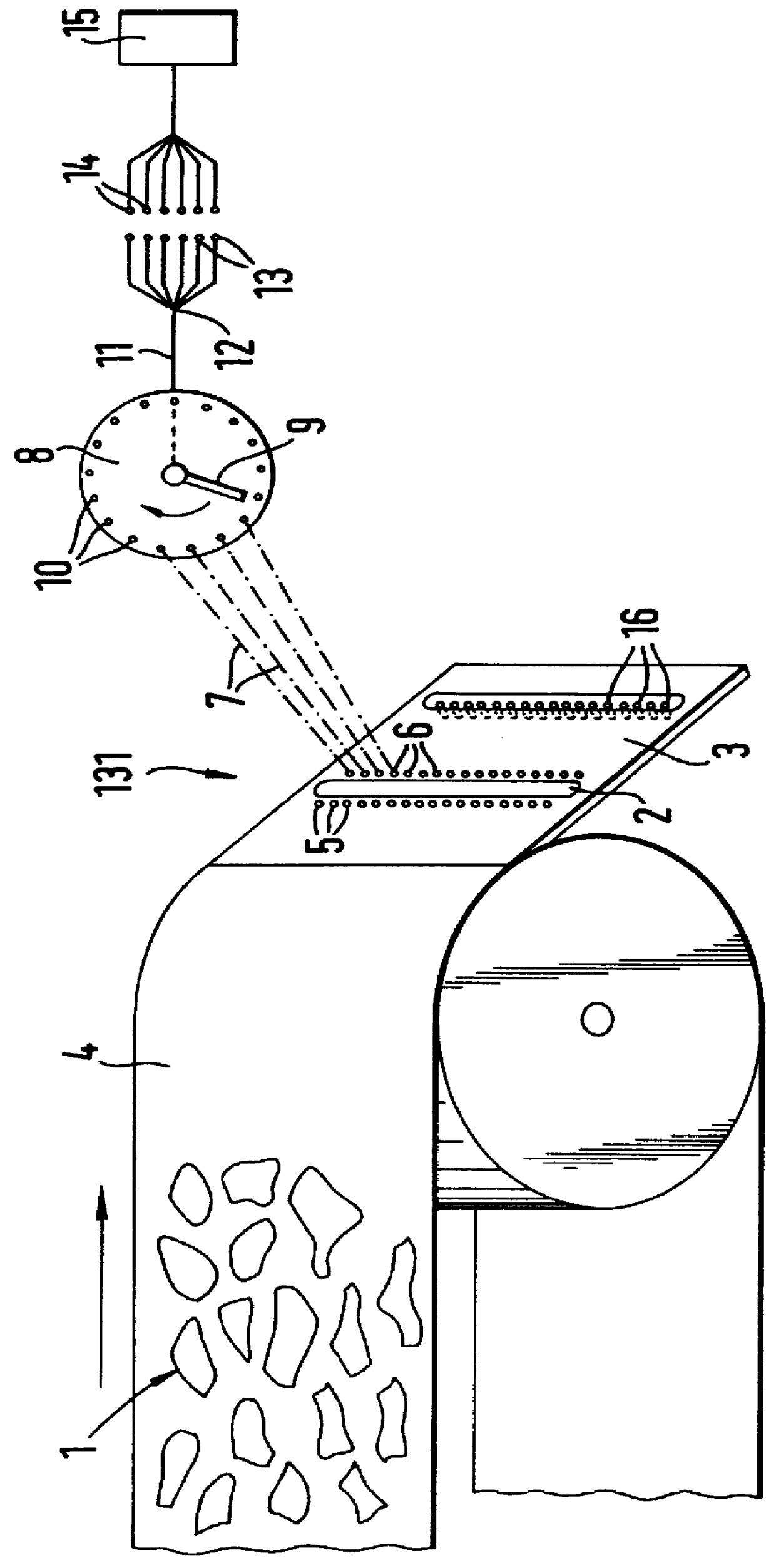

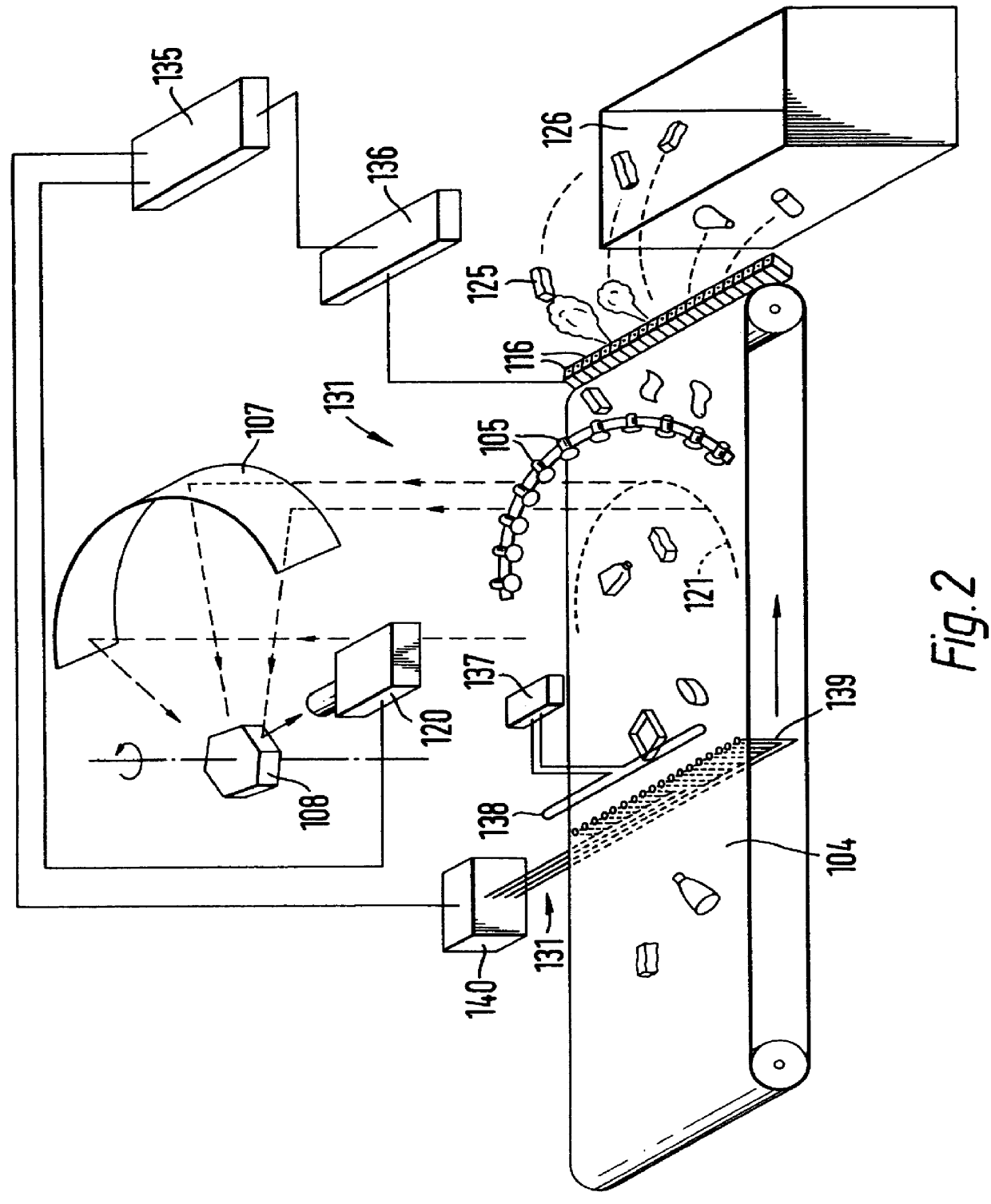

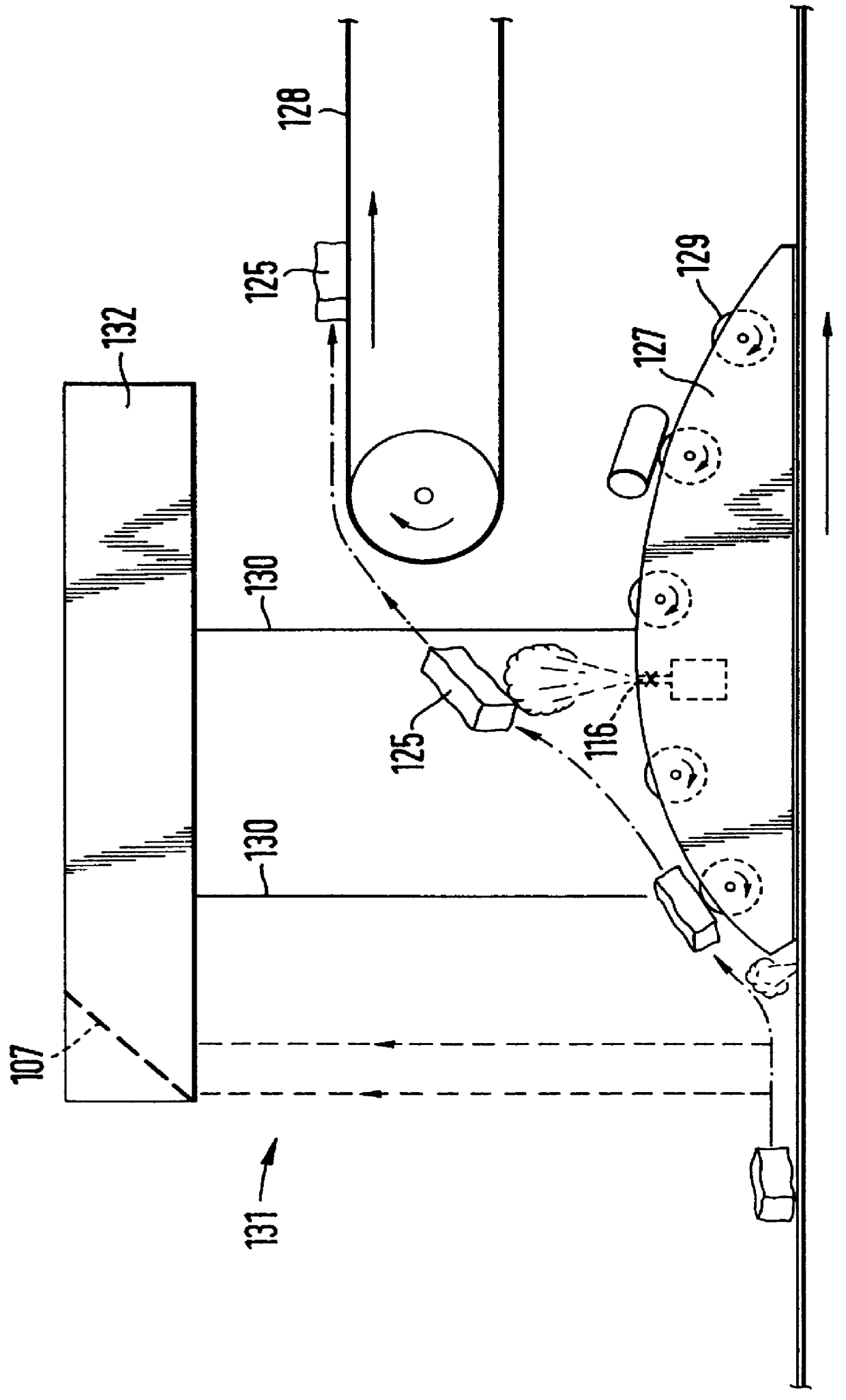

Determination of characteristics of material

InactiveUS6060677ALow costReduce runningSolid waste disposalOptical detectionSolenoid valveLength wave

A system for automatically inspecting matter for varying composition comprises one or more detection stations through which one or more streams of matter are advanced and particular materials therein are detected through their diffusely reflected IR spectra, if any, and / or through their variation of an electromagnetic field by their metallic portions, if any. A row of light sources distributed across the overall width of one or more belt conveyors may cause desired portions of the stream to reflect light diffusely onto a part-toroidal mirror extending over that overall width, whence the light is reflected, by a rotating, polygonal mirror through optical filters dedicated to differing IR wavelengths, onto detectors the data output of which is utilized in controlling solenoid valves operating air jet nozzles which separate-out the desired portions. Alternatively or additionally, an oscillator and an antenna which extends over that overall width generate an electromagnetic field through the belt and sensing coils sense variations therein produced by metallic portions of the stream passing through the detection station and the detection data produced by the sensing coils is used to control the solenoid valves operating the nozzles to separate-out the metallic portions.

Owner:TITECH VISIONSORT +1

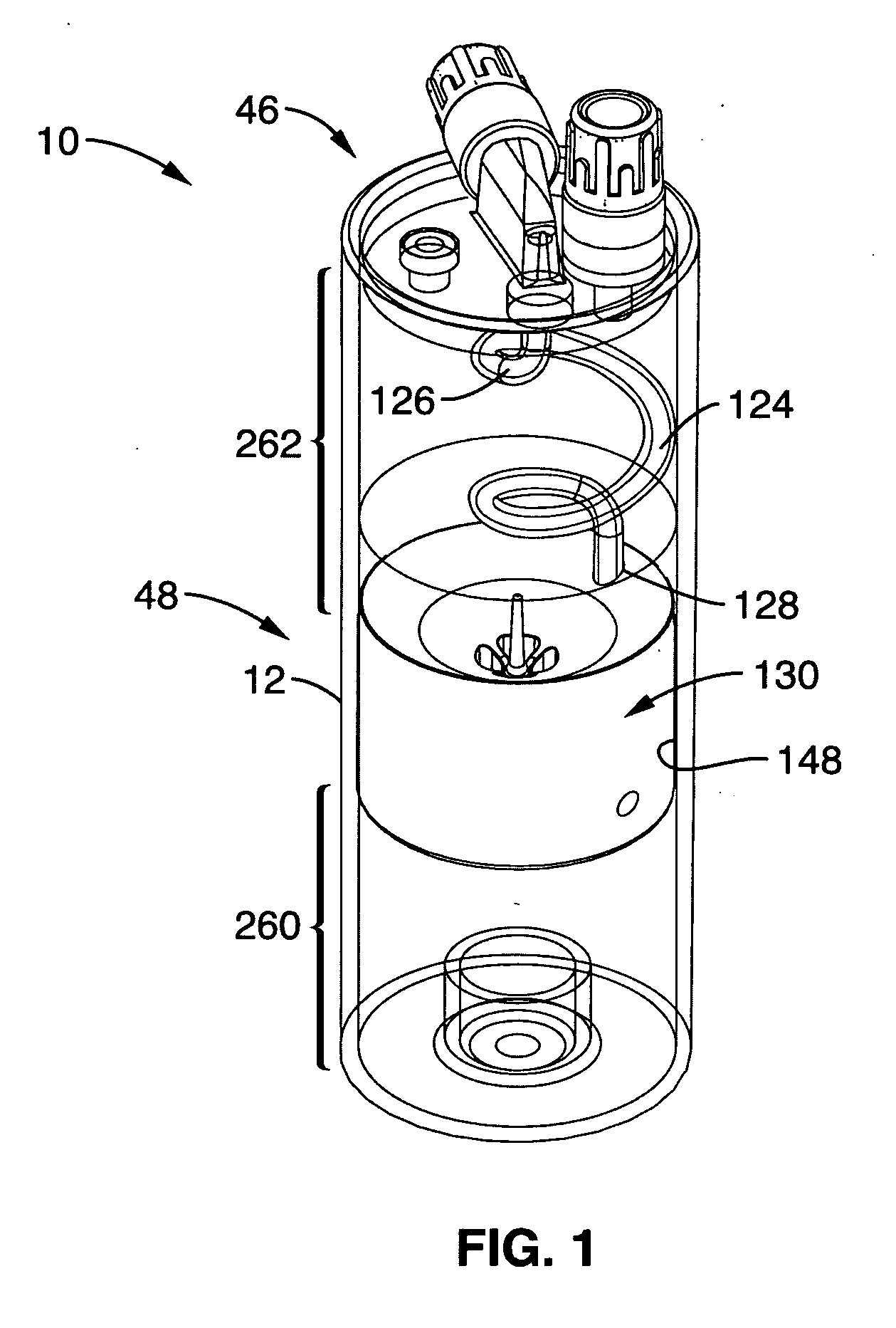

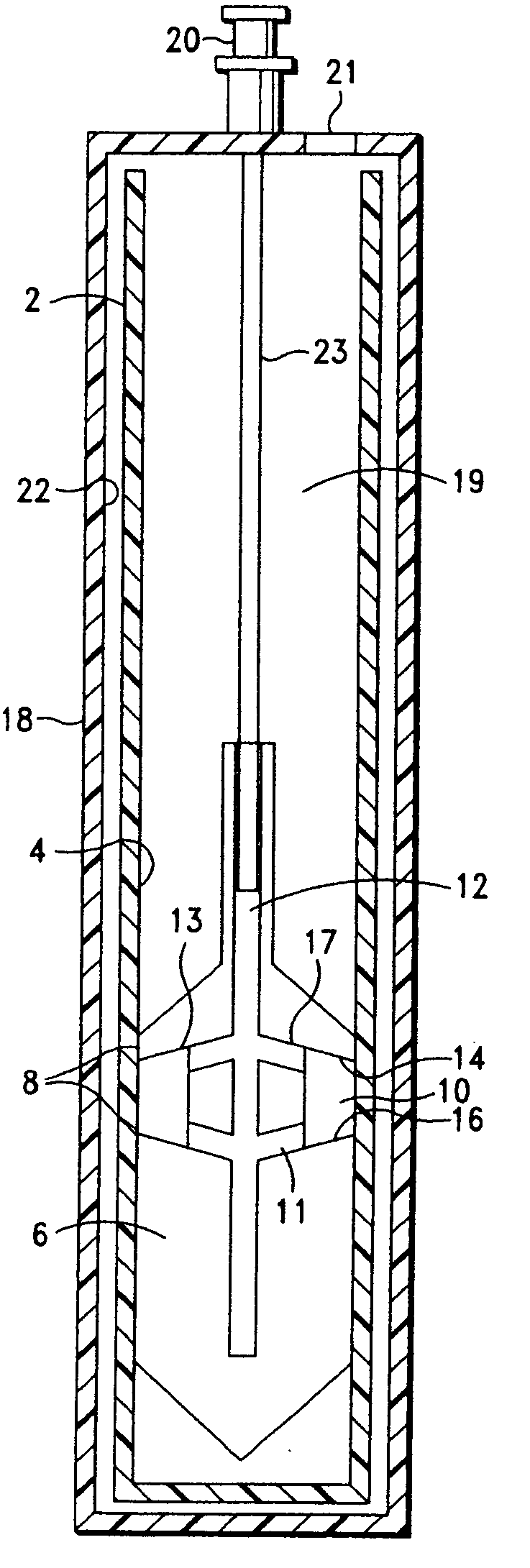

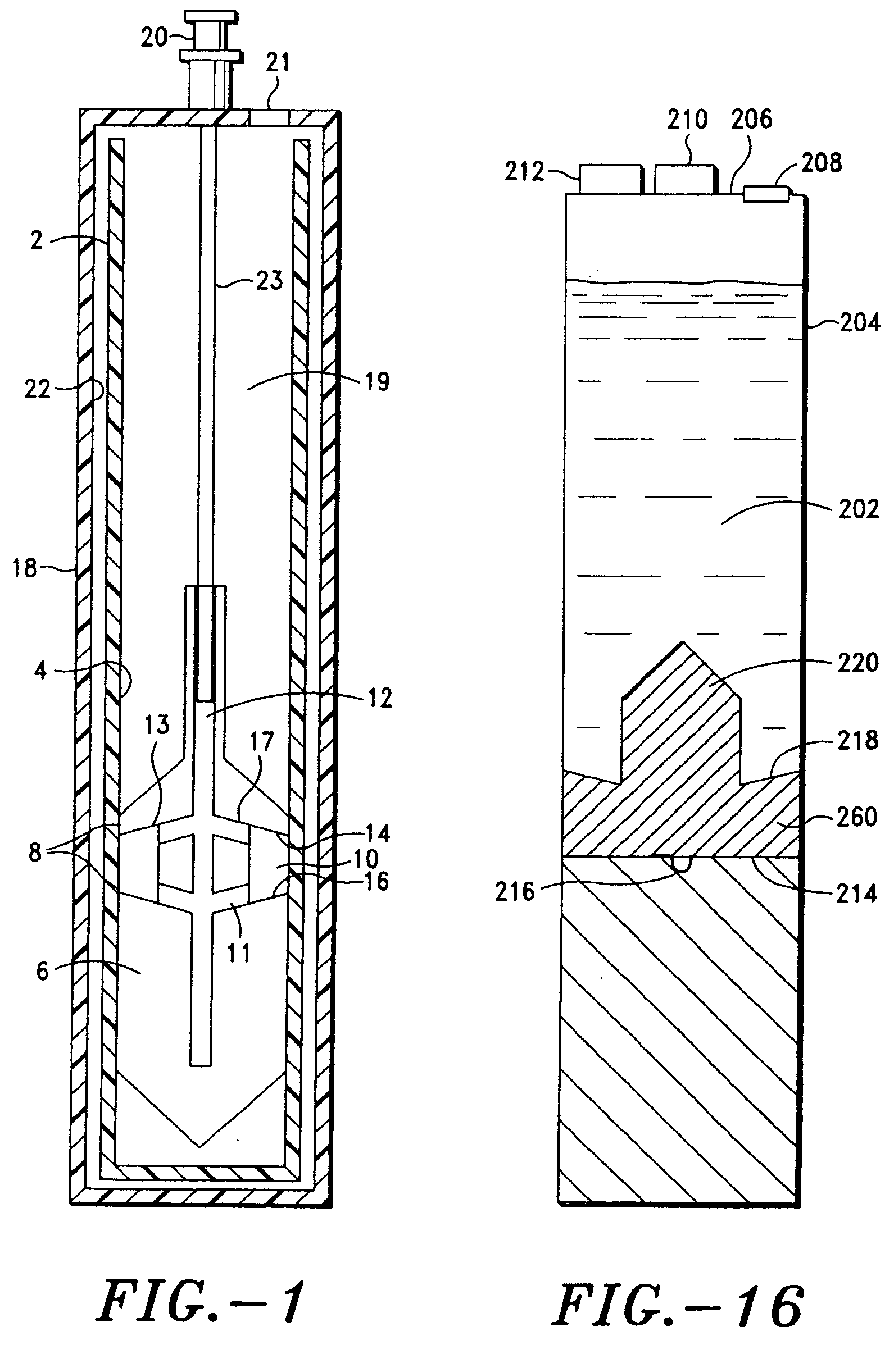

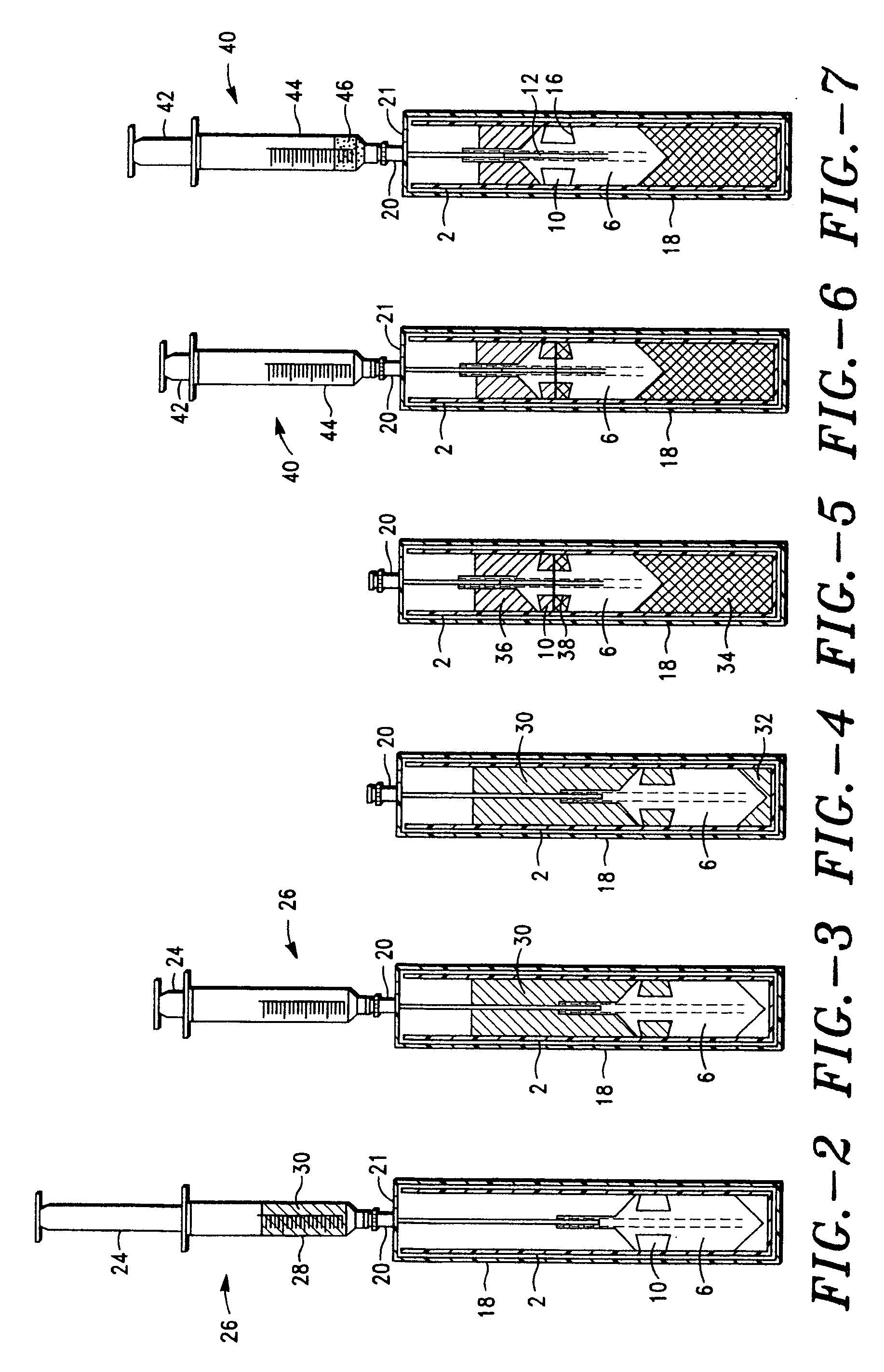

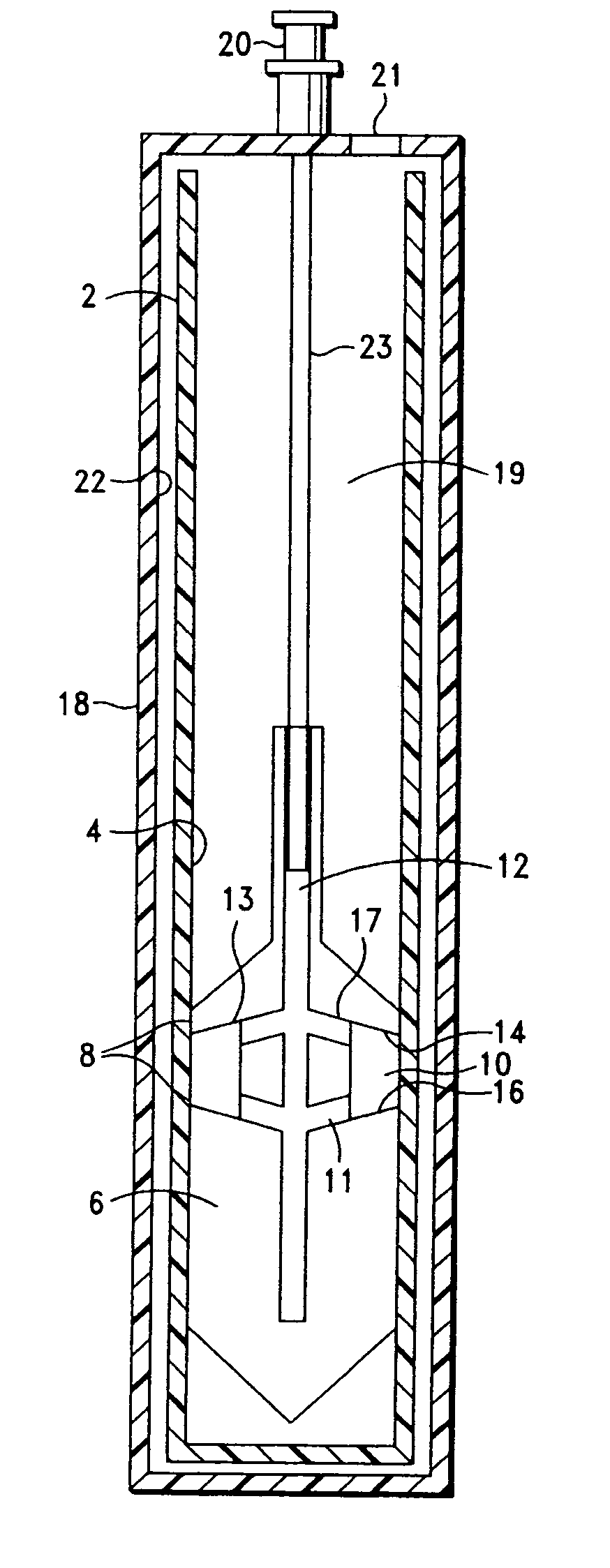

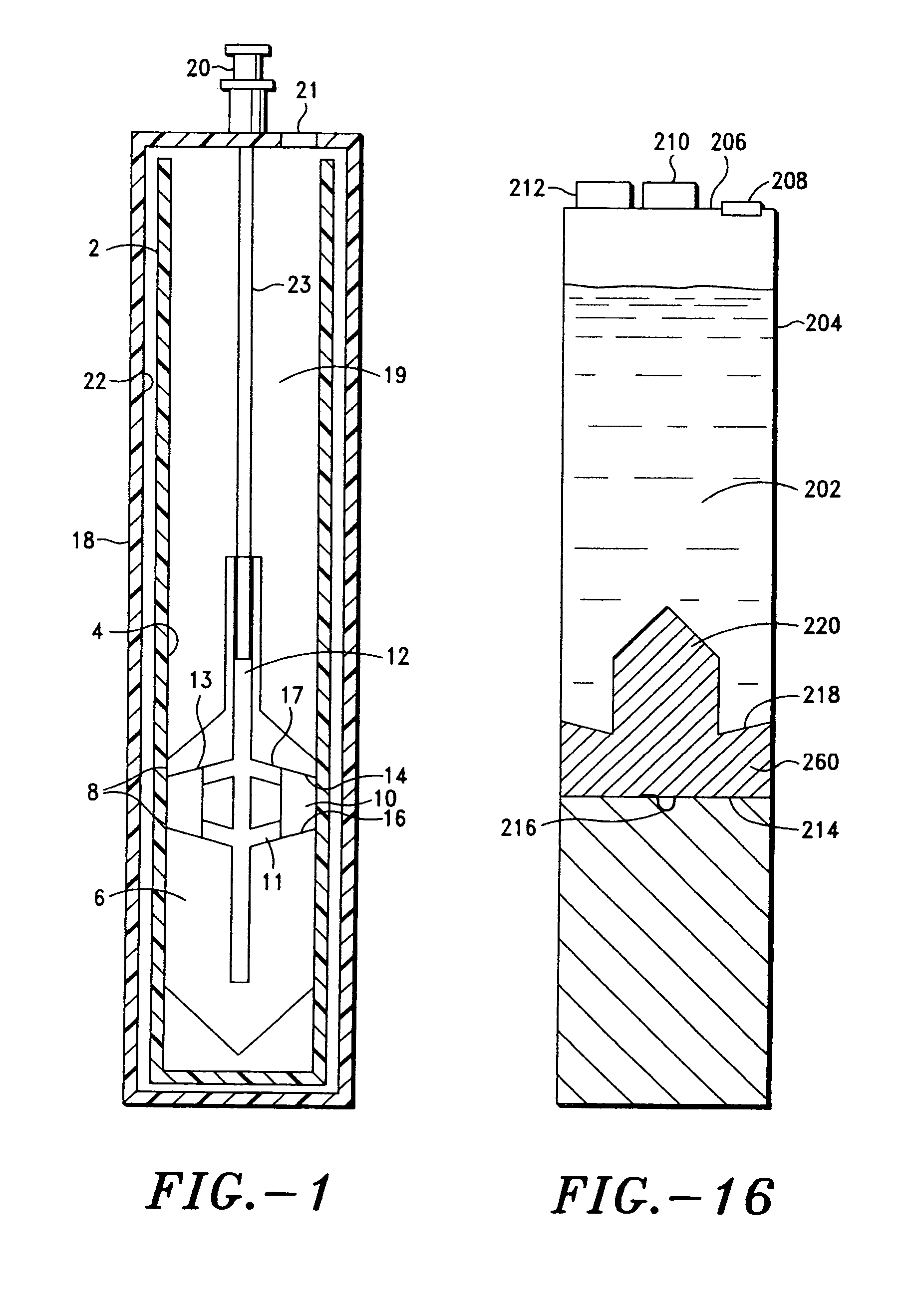

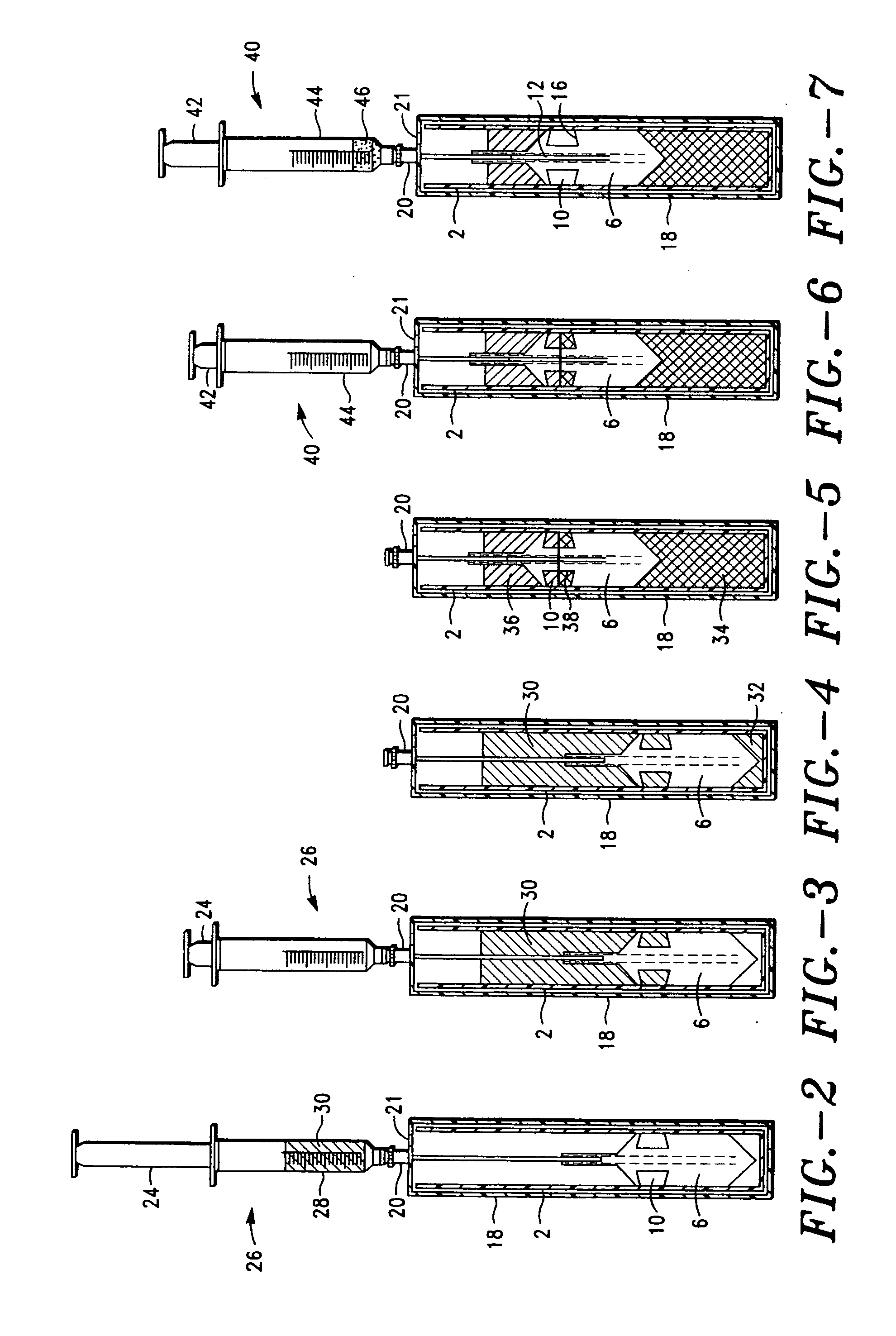

Apparatus and method for separating and isolating components of a biological fluid

A device for separating and isolating components of a biological fluid comprising a container for containing the fluid to be processed, a tube cap assembly for closing the container while providing filling and extraction communication therewith, a float assembly disposed within the container for funneling and controlling biological fluid flow into an inverted domed shaped isolation chamber within the float and controlling the biological fluid flow out of the isolation chamber for effecting an encapsulation or a sealed isolation of at least one component or fraction of the biological fluid flow within the isolation chamber during a centrifugation process. The device further comprising a flexible tube for connecting an extraction passageway disposed within the float assembly and an extraction valve of the tube cap assembly for allowing extraction of at least the one component or fraction encapsulated or isolated within the chamber.

Owner:THERMOGENESIS HLDG INC

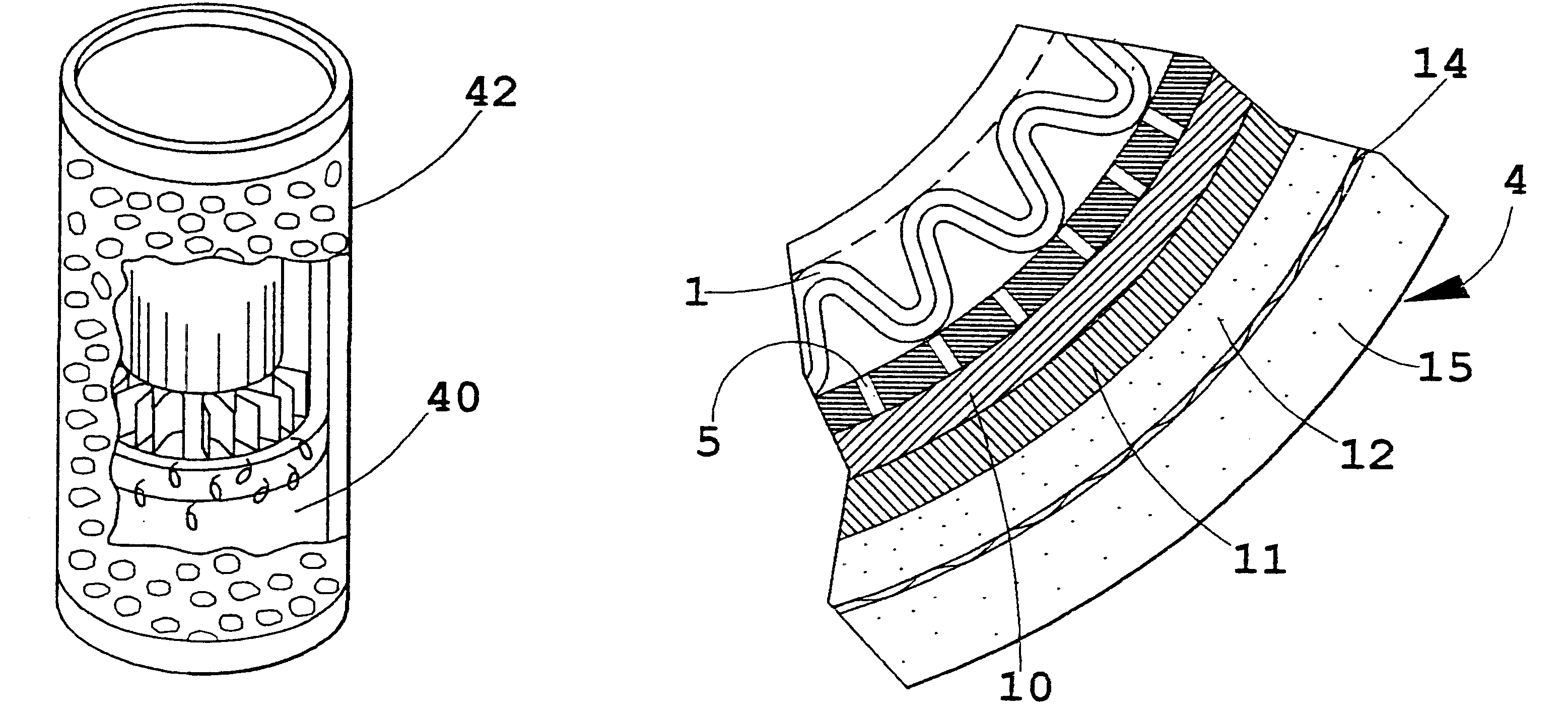

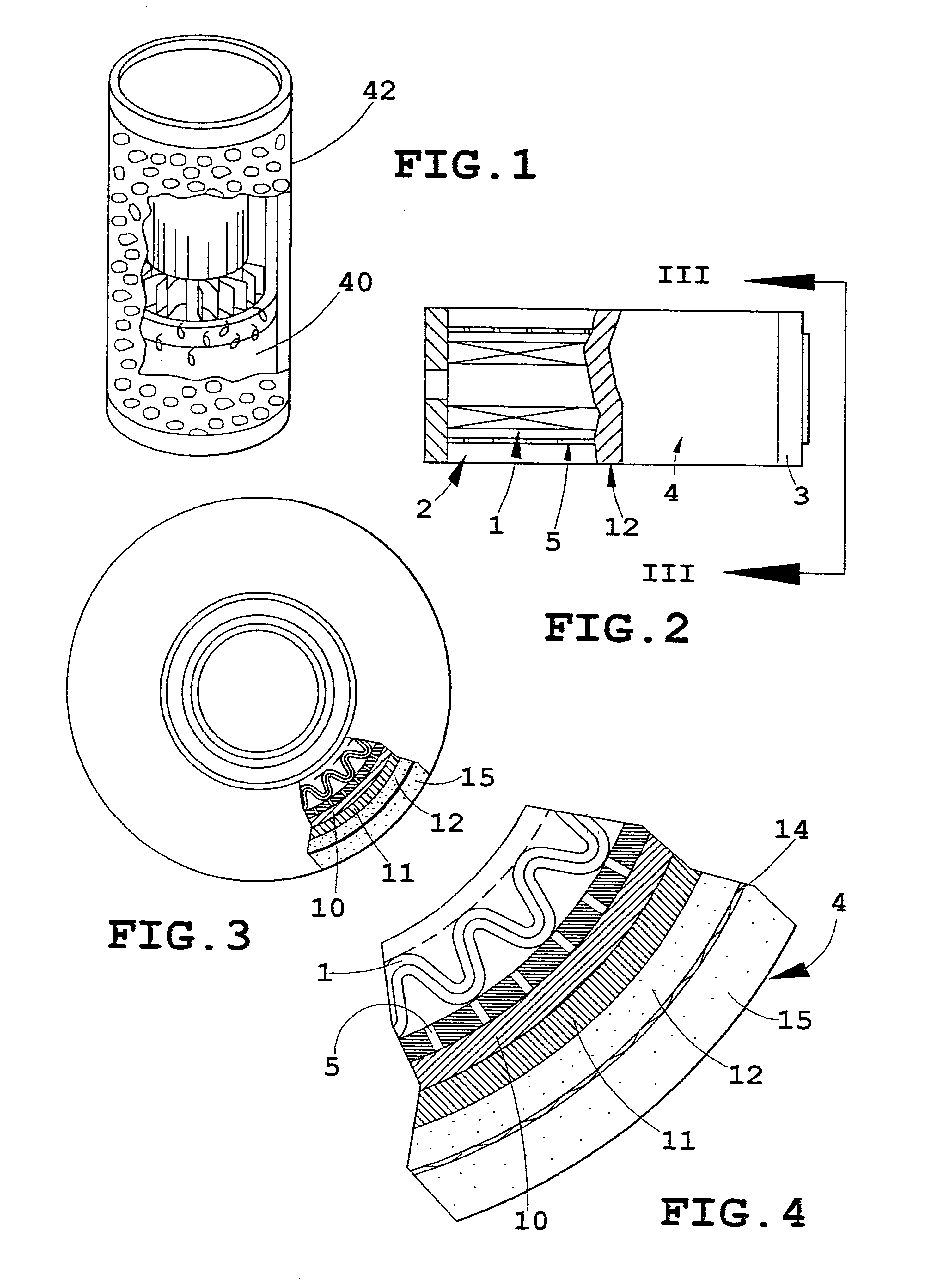

Coalescer for hydrocarbons containing surfactant

A coalescer filter element for the separation of water from hydrocarbon fluids, such as kerosene, jet fuel, diesel fuel, and gasoline under surfactant conditions such as thermal stability additive and dispersant. Coalescer fibrous material has hydrophobic properties which resist surfactant coating of the fibers thereby allowing breakdown of water emulsion in the hydrocarbon fluids. The coalescer has a negative media density gradient in the liquid flow direction.

Owner:KAYDON CUSTOM FILTRATION CORP

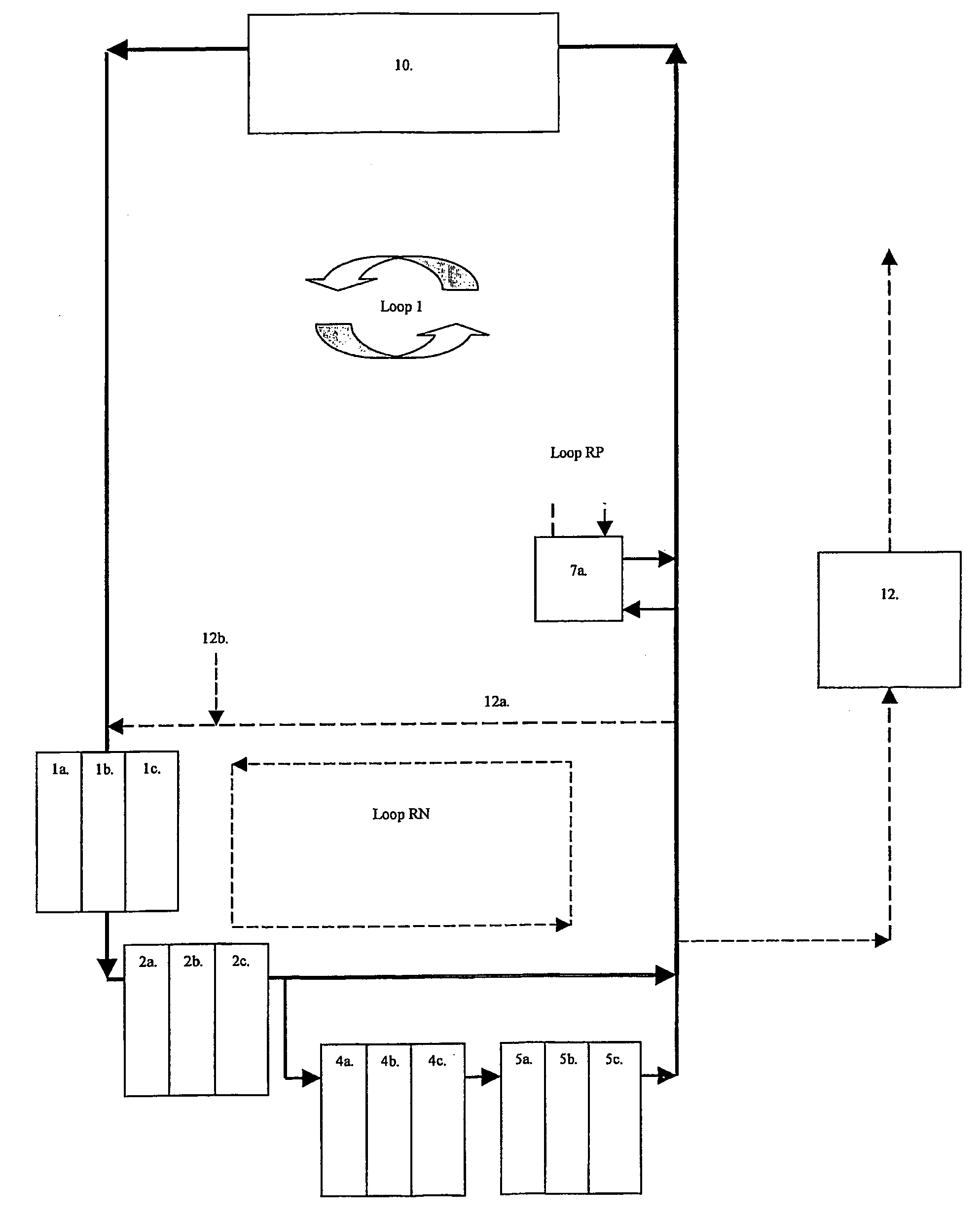

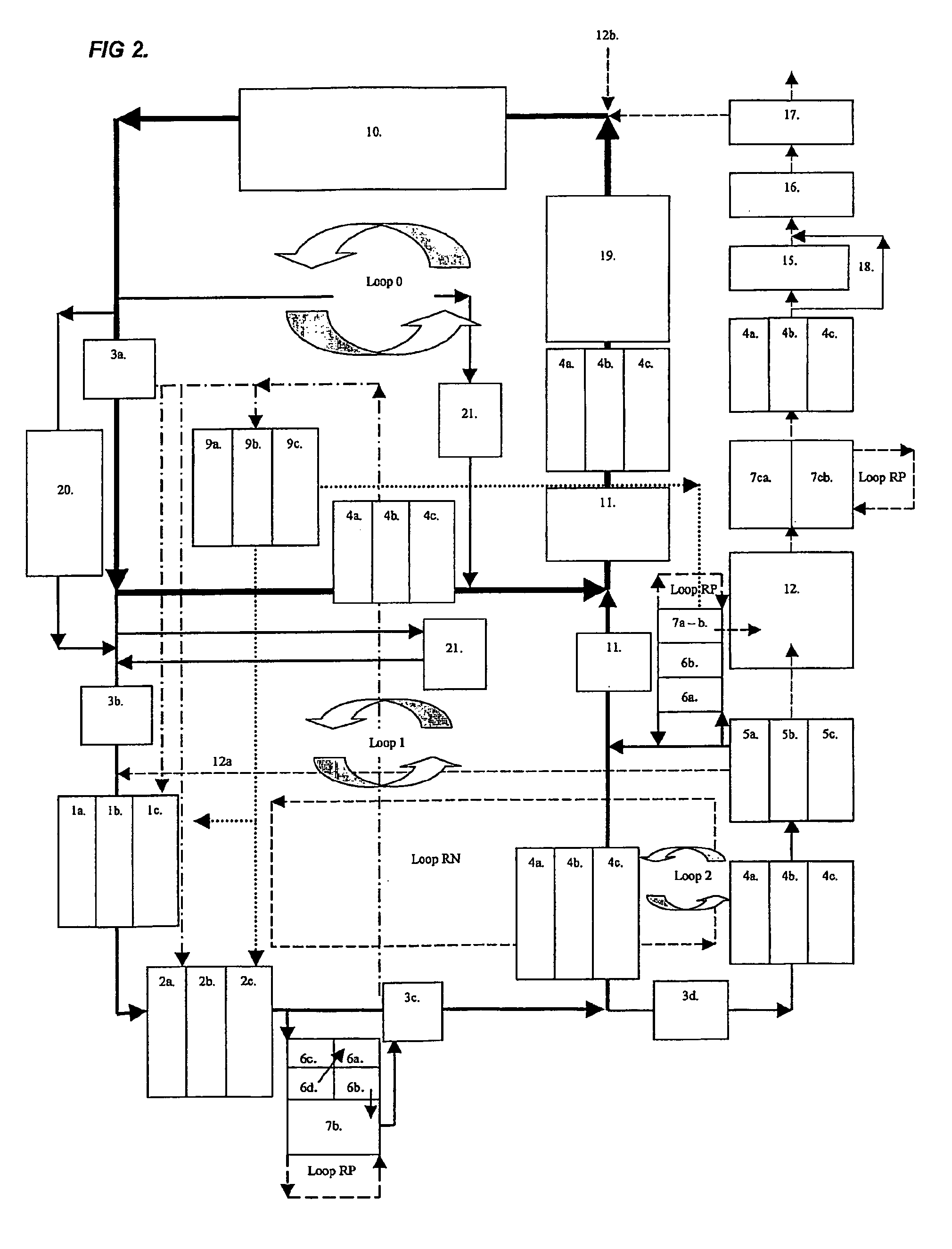

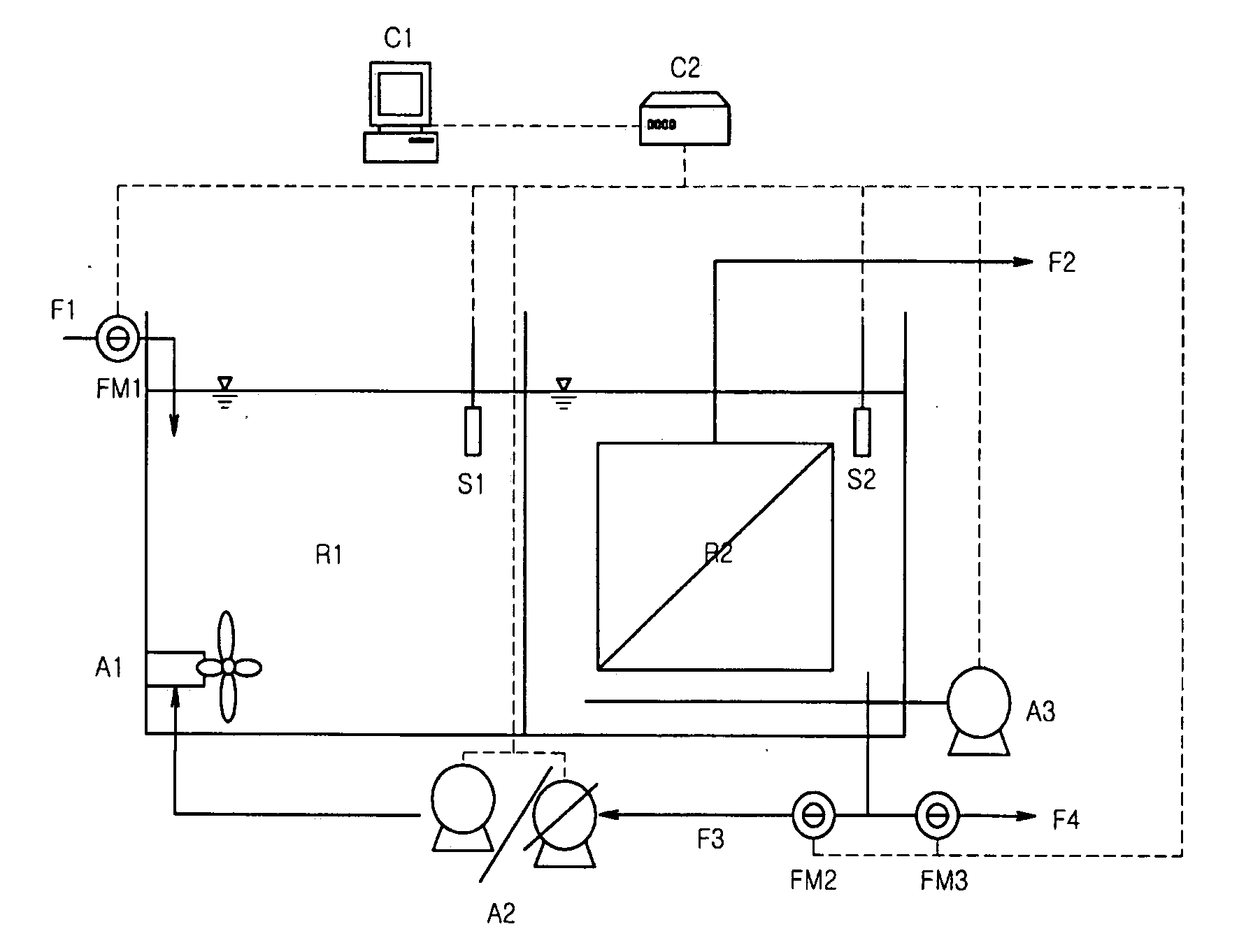

Integrated closed loop system for industrial water purification

InactiveUS7001519B2Improve purification efficiencyTreatment using aerobic processesWater/sewage treatment by irradiationOrganic matterIndustrial water

The present invention relates to an integrated closed loop system for aquaculture in at least one culturing tank and using continuous bioreactor technology for the biological treatment and removal of organic material, nitrogen and phosphorous, comprising: an integrated, partially or wholly closed loop system for waste water treatment, where the water contains nitrogen containing compounds and / or substances, comprising at least one production unit of such nitrogen containing compounds and / or substances and using continuous bioreactor technology for the biological treatment and removal of organic matter, nitrogen and phosphorous from the said water at continuous flow, comprising: a) at least one suspended carrier bioreactor for bacterial growth under anoxic conditions to cause anaerobic denitrification, with one or several compartments, preceding b) at least one suspended-carrier bioreactor for bacterial growth under oxic conditions to cause aerobic nitrification, c) the denitrification taking place after the production unit, and d) the nitrification taking place prior to the production unit in a by-pass mode as part of the continuous flow.

Owner:GREENFISH

Method for treating wastewater in a membrane bioreactor to produce a low phosphorus effluent

ActiveUS20050045557A1Minimizing space requirementMinimizing attendant costTreatment using aerobic processesOther chemical processesActivated sludgeMembrane bioreactor

Removal of biological nutrients from a wastewater yielding a low phosphorous (e.g., less than 0.25 mg / L) output includes providing a serial multistage bioreactor containing activated sludge having in hydraulic series an anaerobic zone and a downstream aerobic zone, with each zone having an upstream inlet and a downstream outlet. The wastewater is provided to the anaerobic zone inlet. A quantity of chemical sufficient to precipitate soluble and particulate phosphorous is added to the downstream aerobic zone in an amount sufficient to yield a low phosphorous output. Treated water is separated from the activated sludge and precipitated phosphorous and a return activated sludge separated from the treated water is recycled to the anaerobic zone.

Owner:CH2M HILL

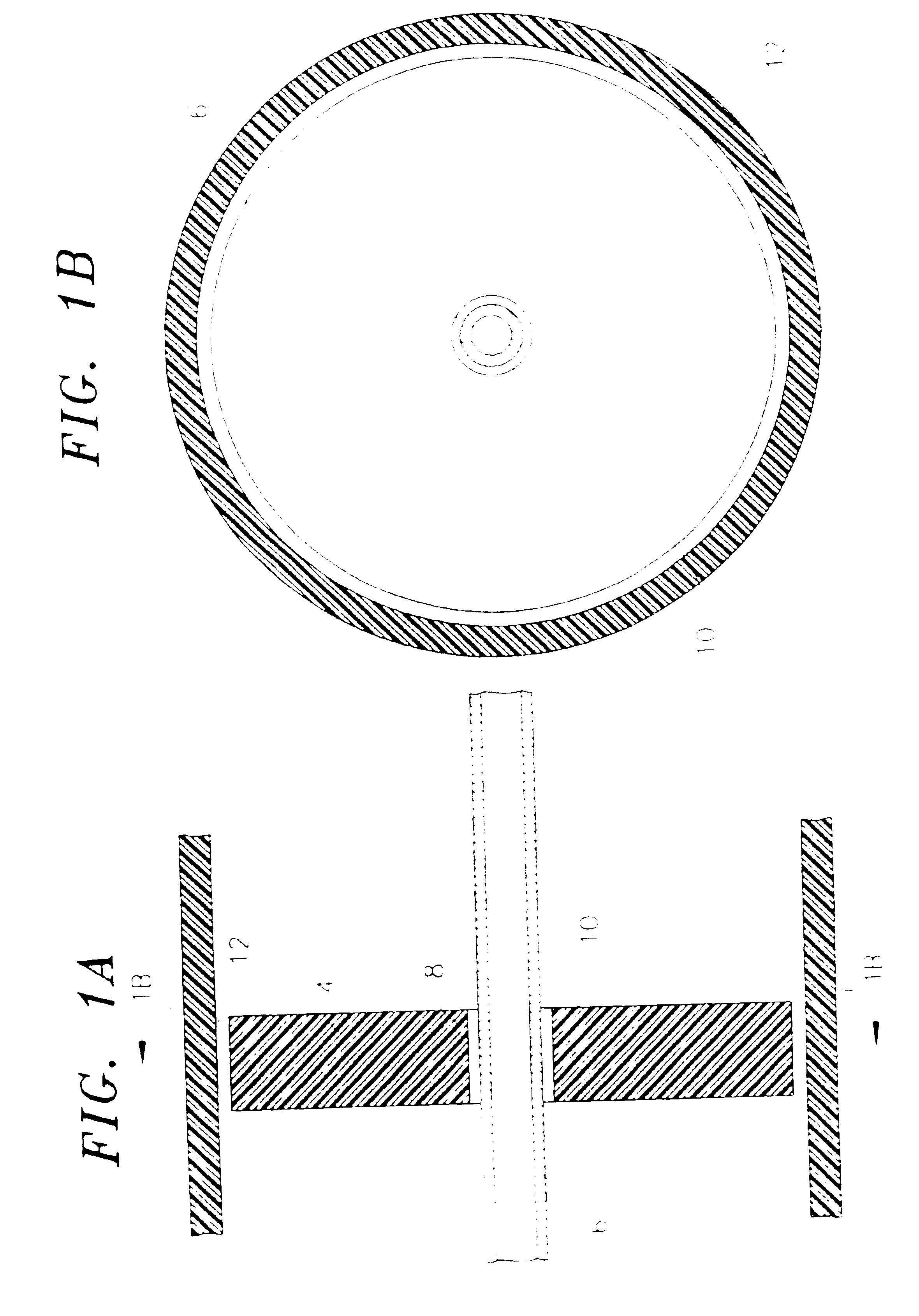

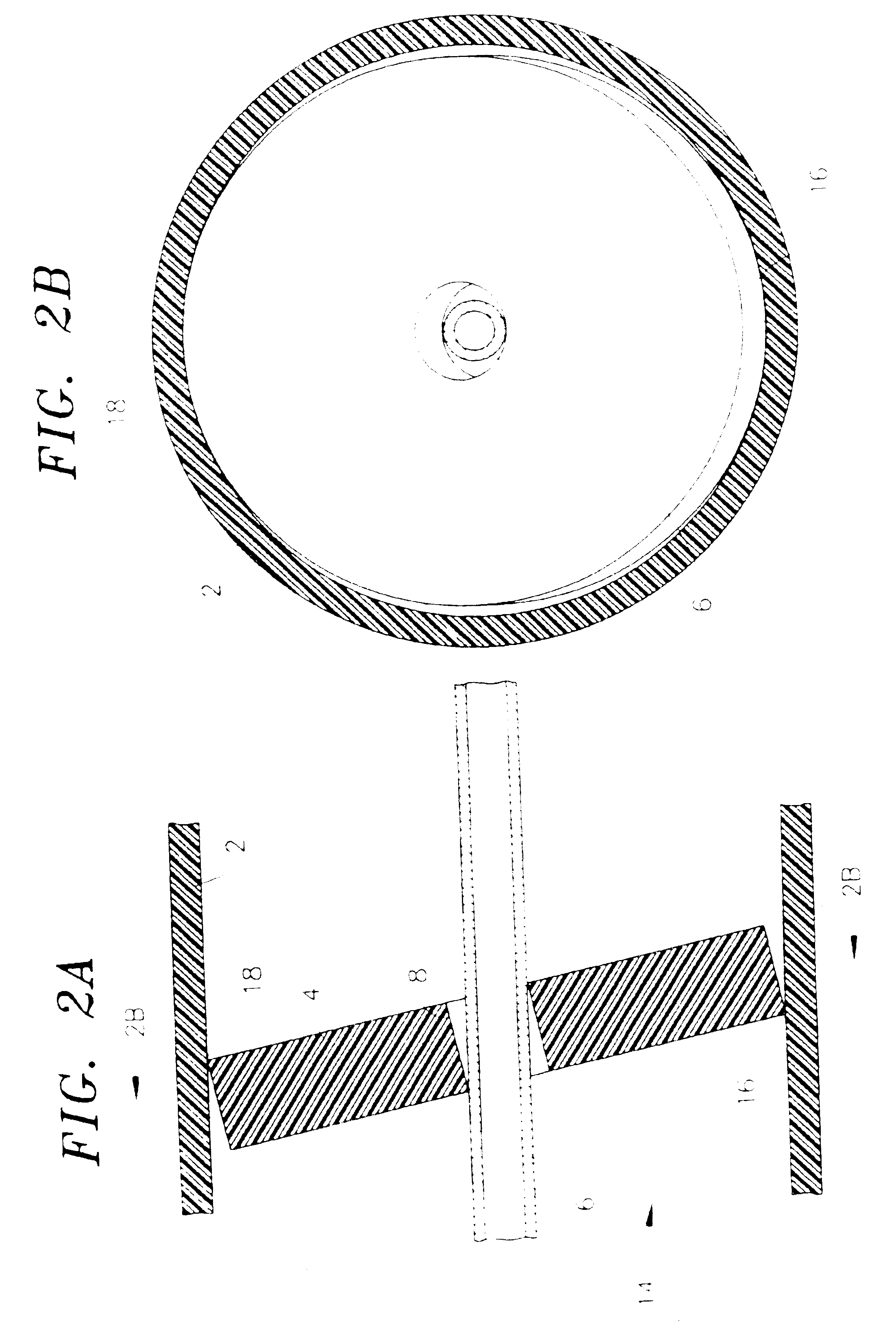

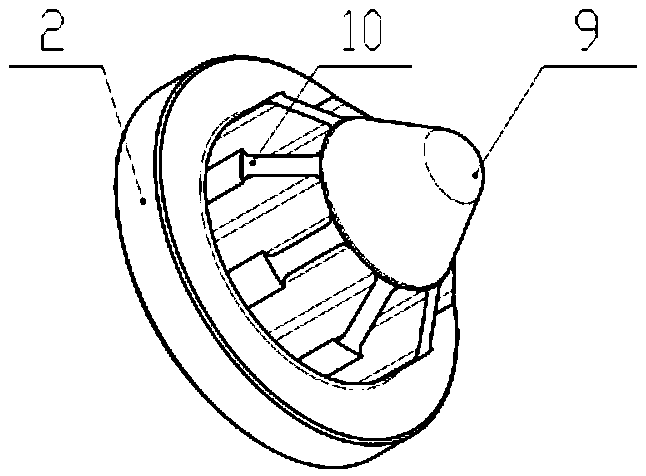

Blood component separator disk

InactiveUS7077273B2Improve processing efficiencyControl flowOther blood circulation devicesDispersed particle separationBlood component separatorRed blood cell

A separator disk (4) for use in centrifugal separation of components is designed to automatically position itself during separation at the interface between the supernatant and the remaining components. Preferably the interface is between plasma and red blood cells.

Owner:HARVEST TECH

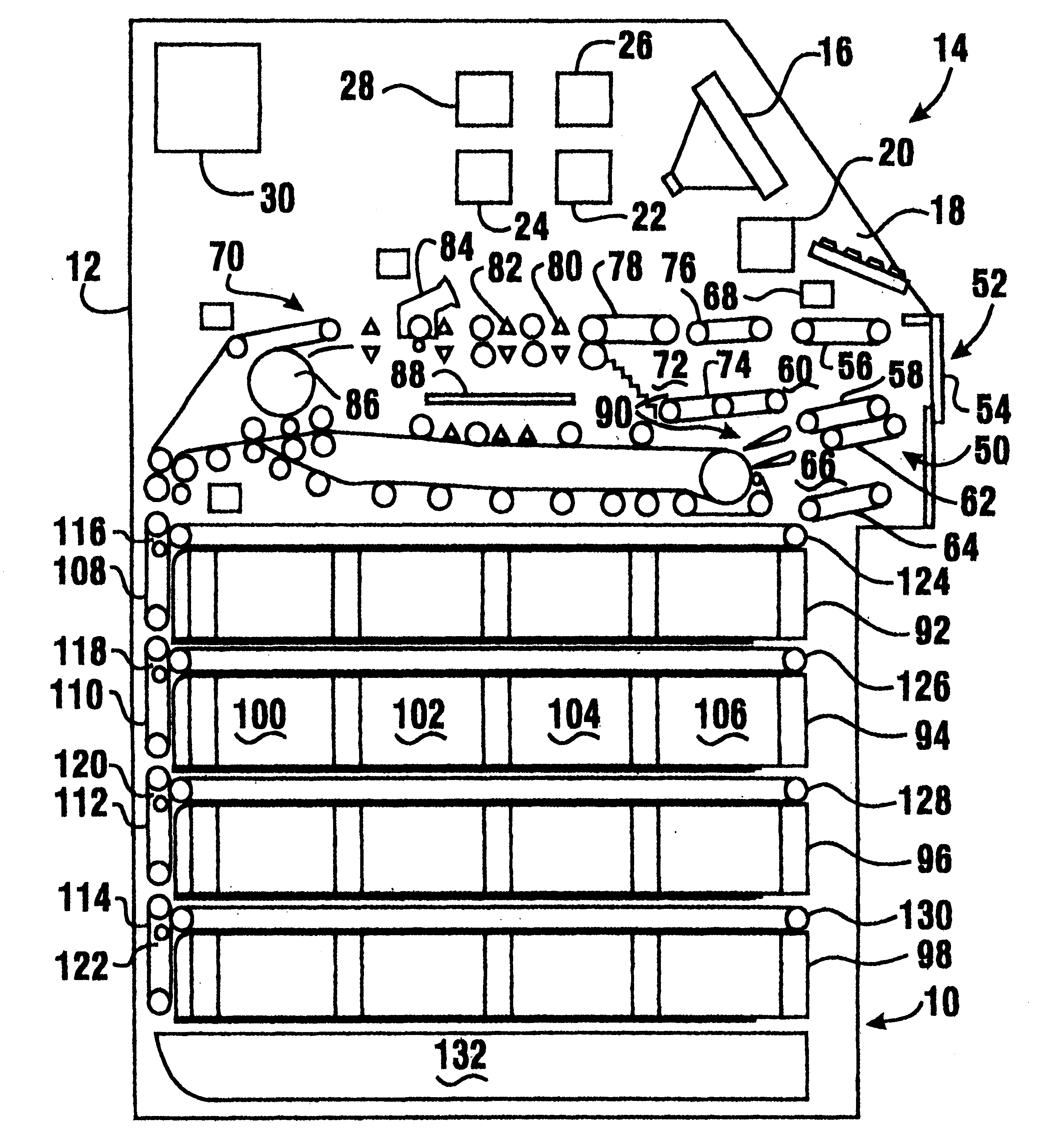

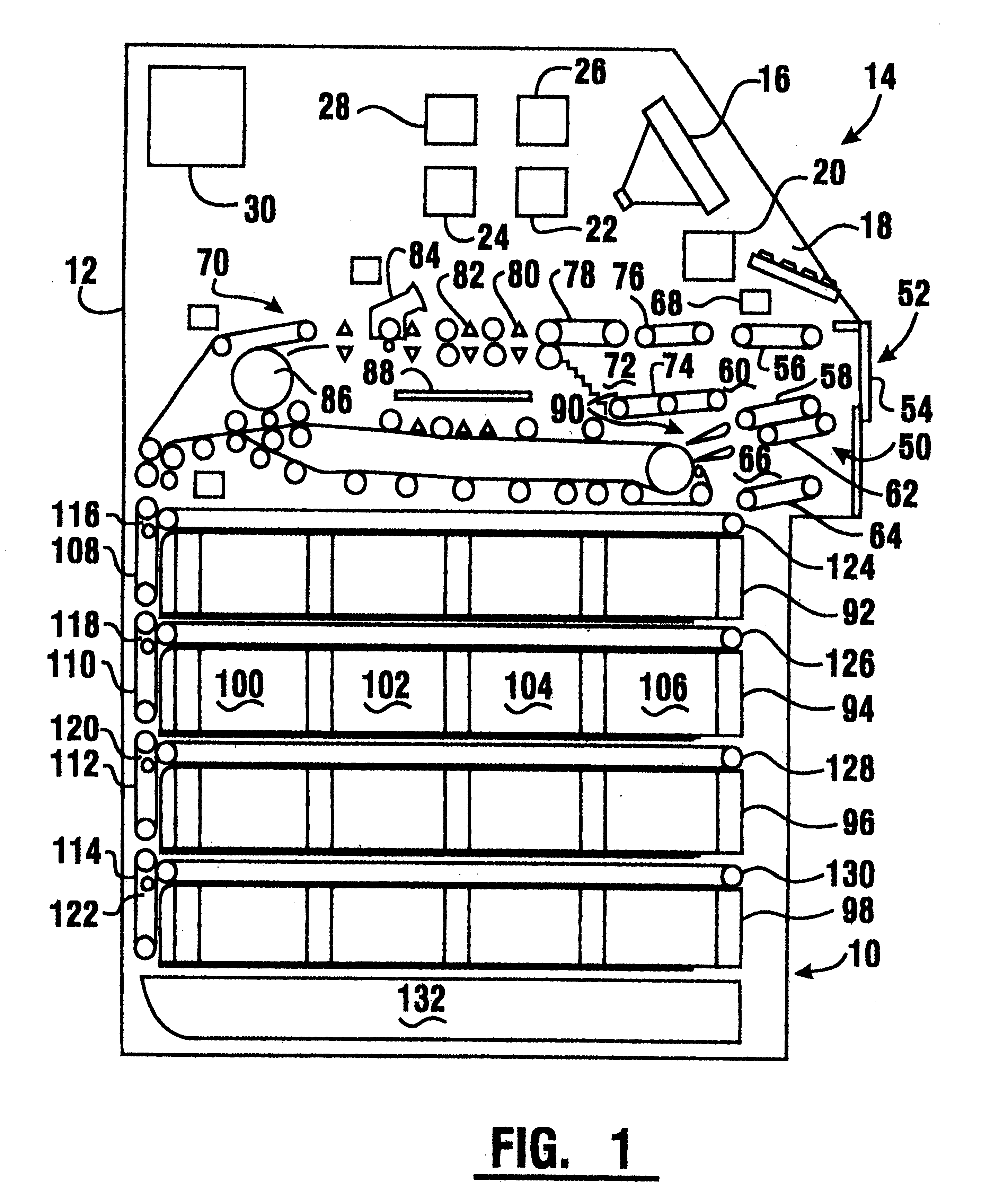

Currency recycling automated banking machine

InactiveUS6290070B1Easy to operateFacilitate rapid operation of machinePayment architectureSortingMachine selectionDocumentation

An automated banking machine (10) identifies and stores documents such as currency bills deposited by a user. The machine then selectively recovers such documents from storage and dispenses them to other users. The machine includes a central transport (70) wherein documents deposited in a stack are unstacked, oriented and identified. Such documents are then routed to storage areas in recycling canisters (92, 94, 96, 98). When a user subsequently requests a dispense, documents stored in the storage areas are selectively picked therefrom and delivered to the user through an input / output area (50) of the machine.

Owner:DIEBOLD NIXDORF

Removal of fluorinated surfactants from waste water

The present invention provides a method of removing a fluorinated surfactant from waste water comprising fluoropolymer particles. The method comprises (i) adding a non-fluorinated surfactant to the waste water (ii) contacting the thus obtained waste water with adsorbent particles to adsorb at least a portion of the fluorinated surfactant to the adsorbent particles and (iii) separating the waste water and the adsorbent particles.

Owner:3M INNOVATIVE PROPERTIES CO

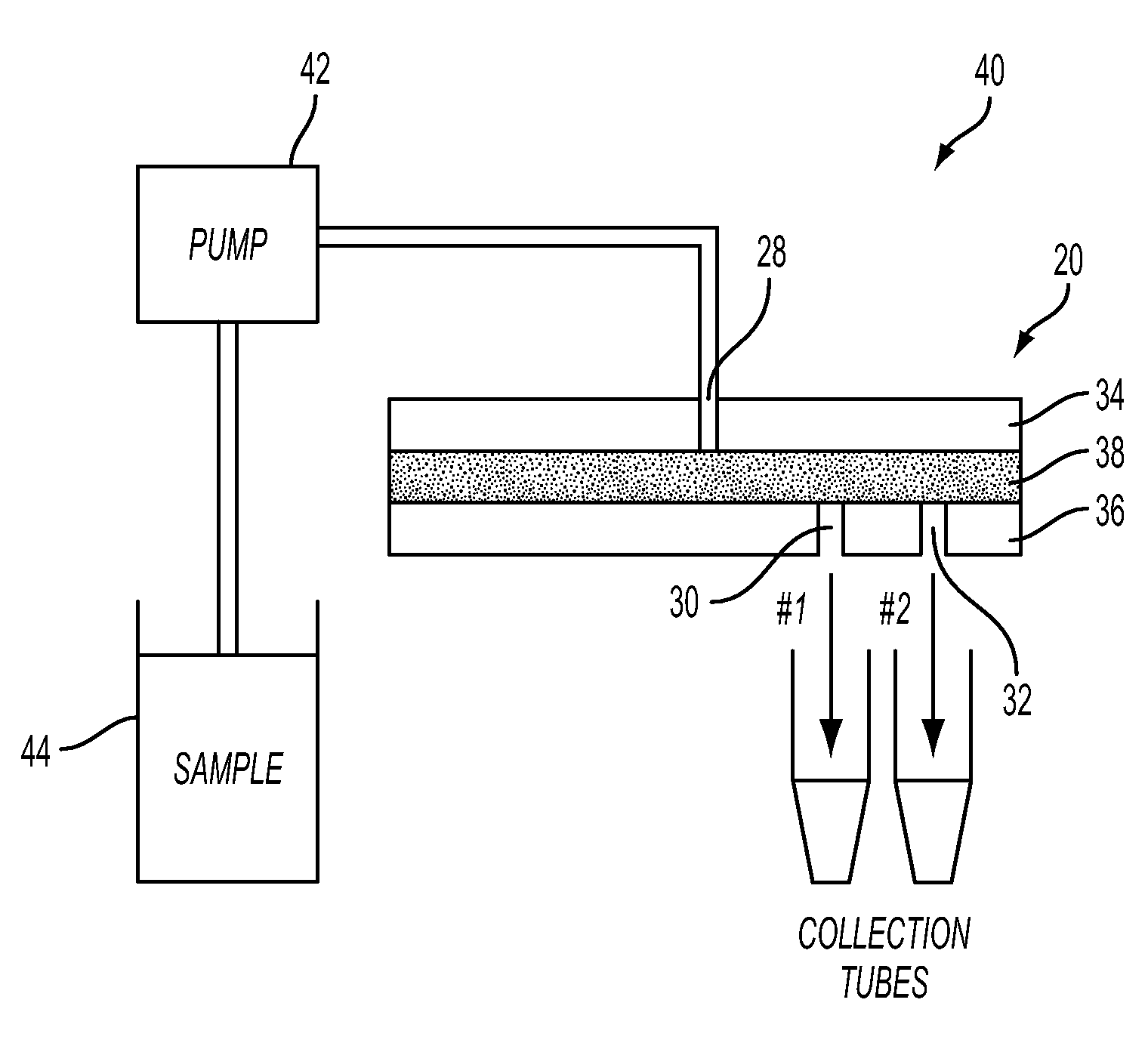

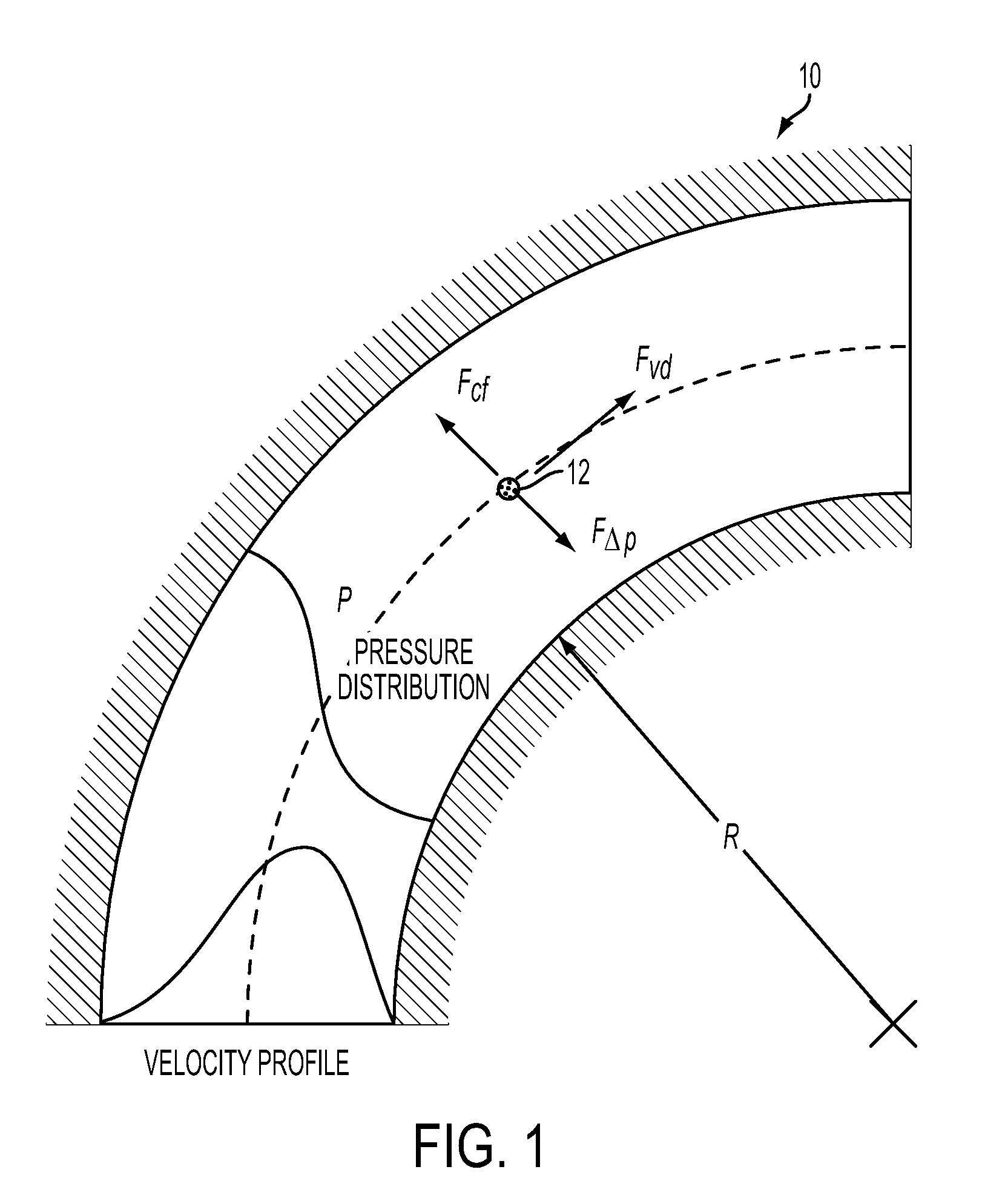

Particle separation and concentration system

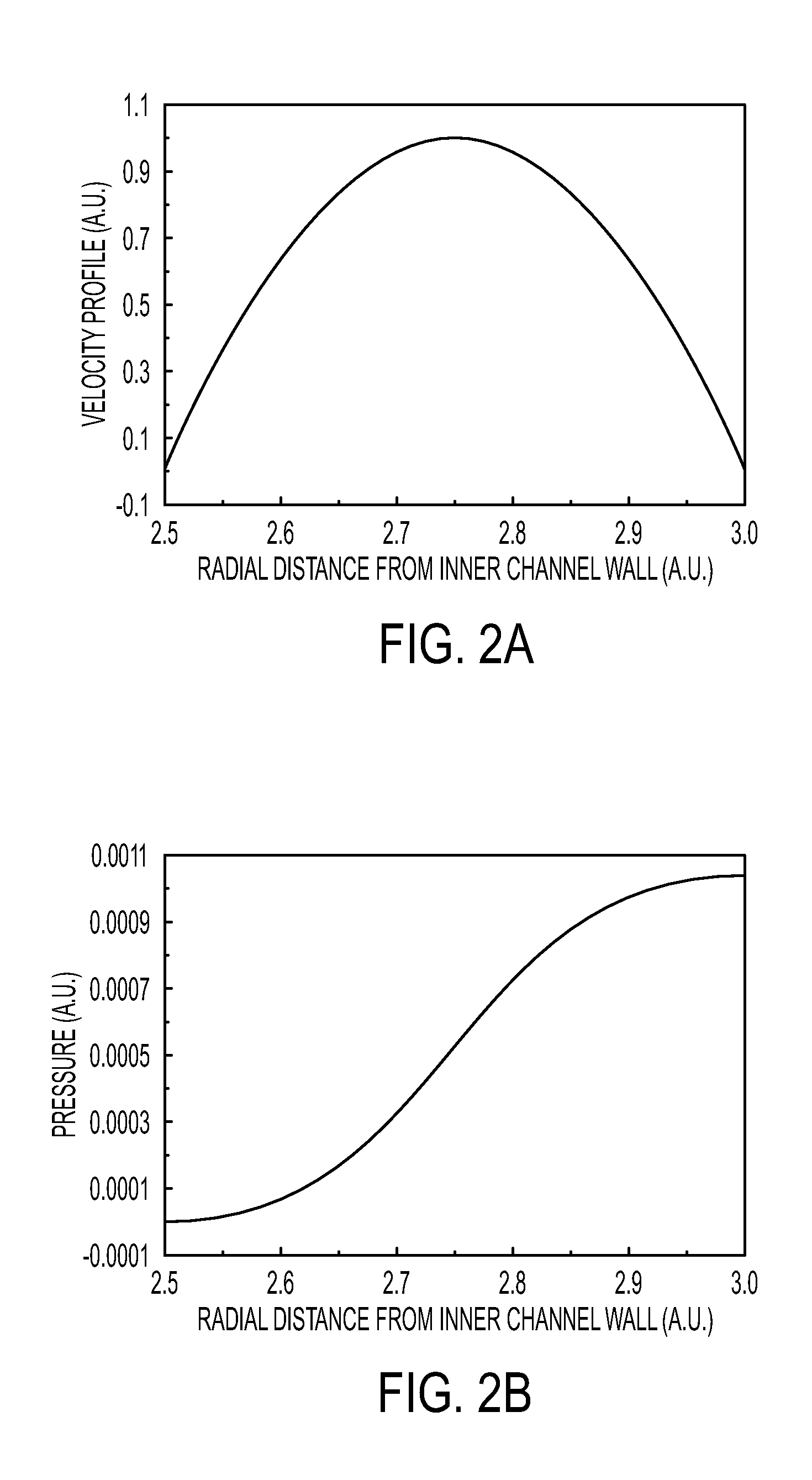

This invention is based on size and mass separation of suspended particles, including biological matter, which are made to flow in a spiral channel. On the spiral sections, the inward directed transverse pressure field from fluid shear competes with the outward directed centrifugal force to allow for separation of particles. At high velocity, centrifugal force dominates and particles move outward. At low velocities, transverse pressure dominates and the particles move inward. The magnitudes of the two opposing forces depend on flow velocity, particle size, radius of curvature of the spiral section, channel dimensions, and viscosity of the fluid. At the end of the spiral channel, a parallel array of outlets collects separated particles. For any particle size, the required channel dimension is determined by estimating the transit time to reach the side-wall. This time is a function of flow velocity, channel width, viscosity, and radius of curvature. Larger particles may reach the channel wall earlier than the smaller particles which need more time to reach the side wall. Thus a spiral channel may be envisioned by placing multiple outlets along the channel. This technique is inherently scalable over a large size range from sub-millimeter down to 1 μm.

Owner:XEROX CORP

Treatment of wastewater containing phosphorous and nitrogen

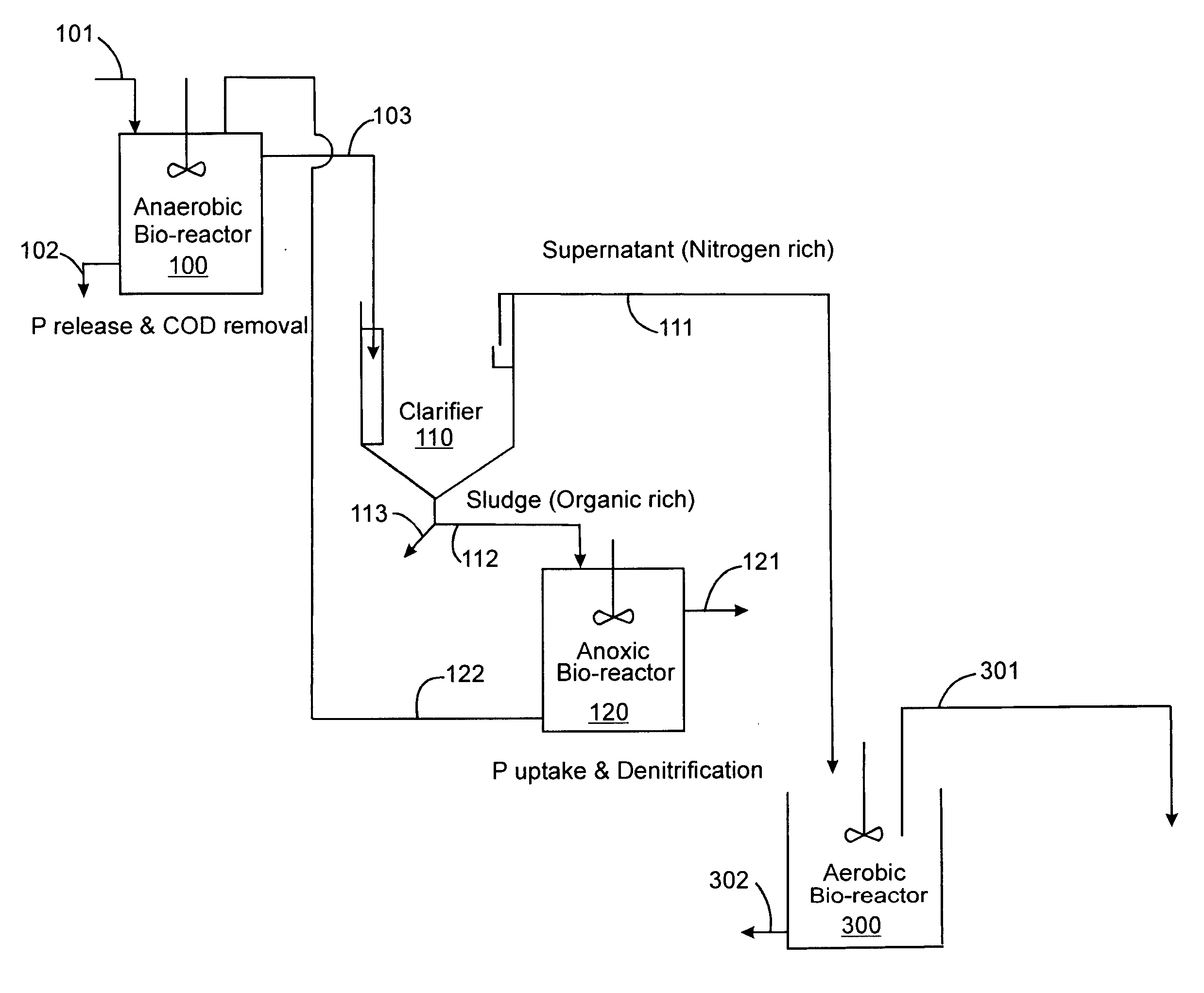

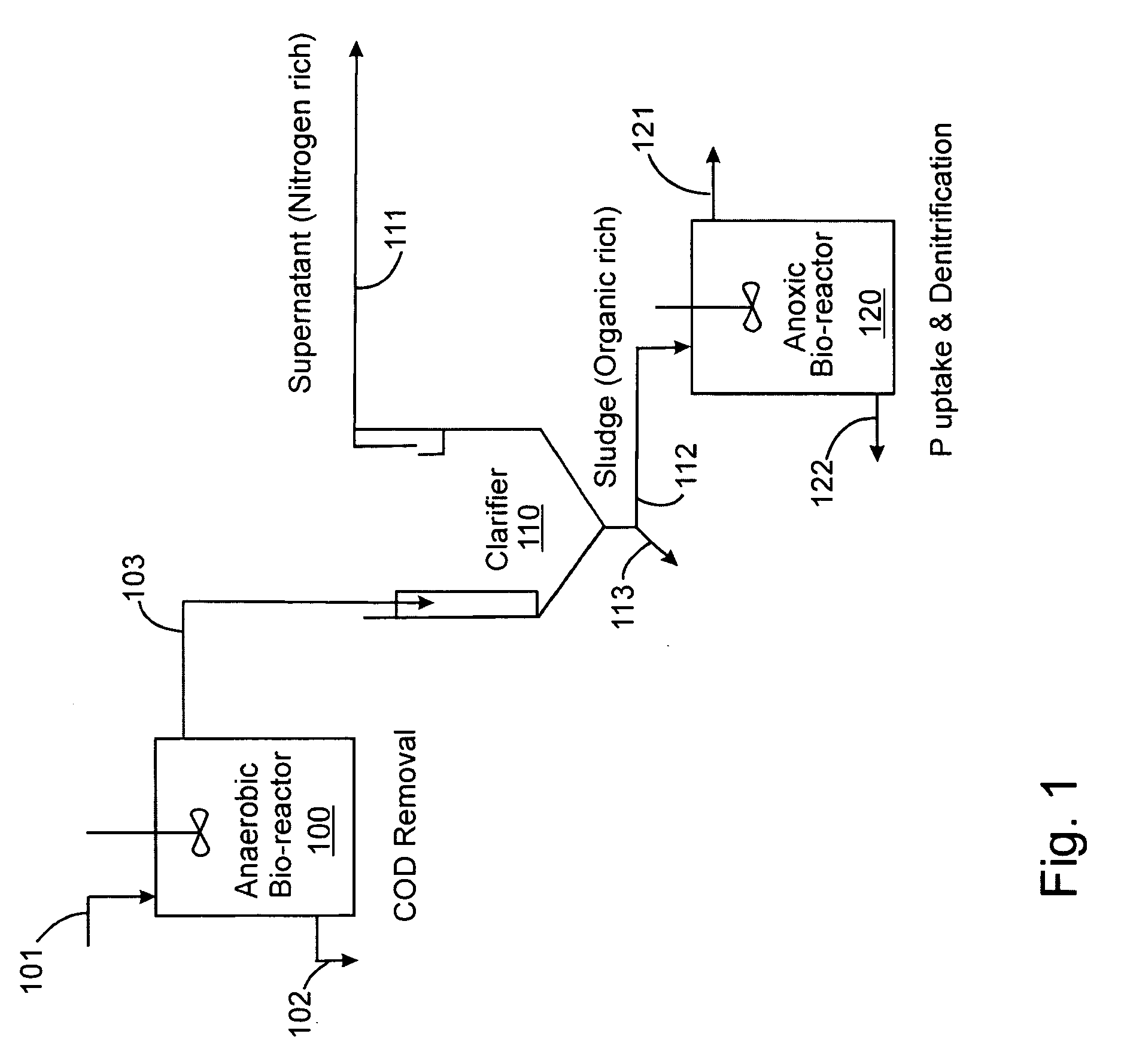

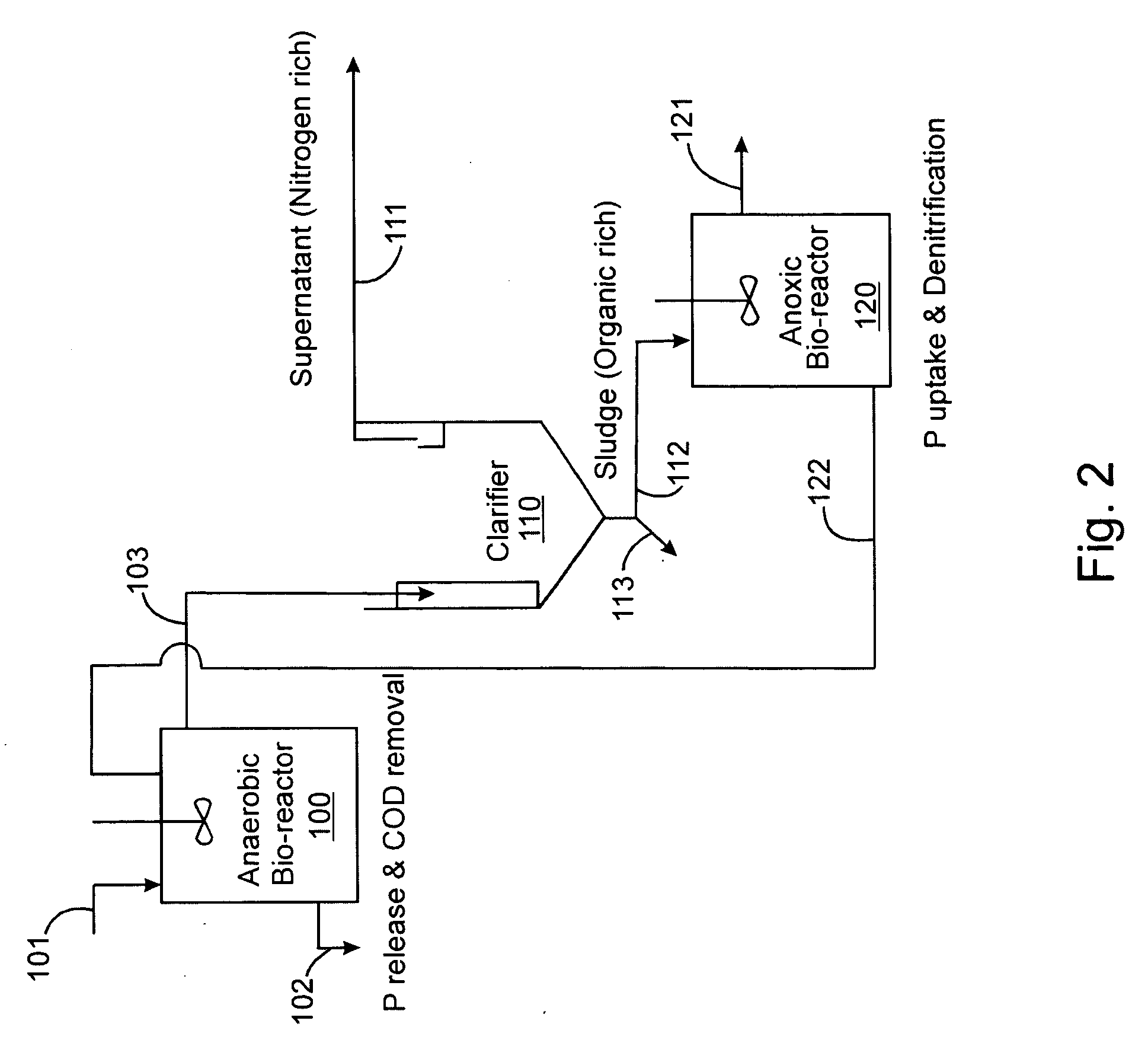

InactiveUS20060249449A1Great extent of P releaseHigh P uptakeTreatment using aerobic processesSeparation devicesOxygenClarifier

A method and process for the treatment of wastewater containing phosphorous and nitrogen. The wastewater is first anaerobically treated to produce an anaerobic effluent from which insoluble organic carbon is separated to form a sludge rich in organic carbon that is used as a substrate during anoxic treatment of the wastewater by de-nitrifying phosphorous accumulating organisms (DPAO's) and ordinary de-nitrifying organisms. The separation of insoluble organic carbon is normally conducted using a clarifier located intermediate the anaerobic and anoxic bio-reactors. In one embodiment, the ammonia rich clarifier supernatant is directed to an aerobic reactor for nitrification and the nitrate produced is recycled to the anoxic bio-reactor. The final effluent may be membrane filtered to retain nitrifying biomass within the aerobic bio-reactor. The invention reduces overall hydraulic residence time and sludge volume, which results in a smaller, less expensive wastewater treatment system.

Owner:UNIV OF WESTERN ONTARIO

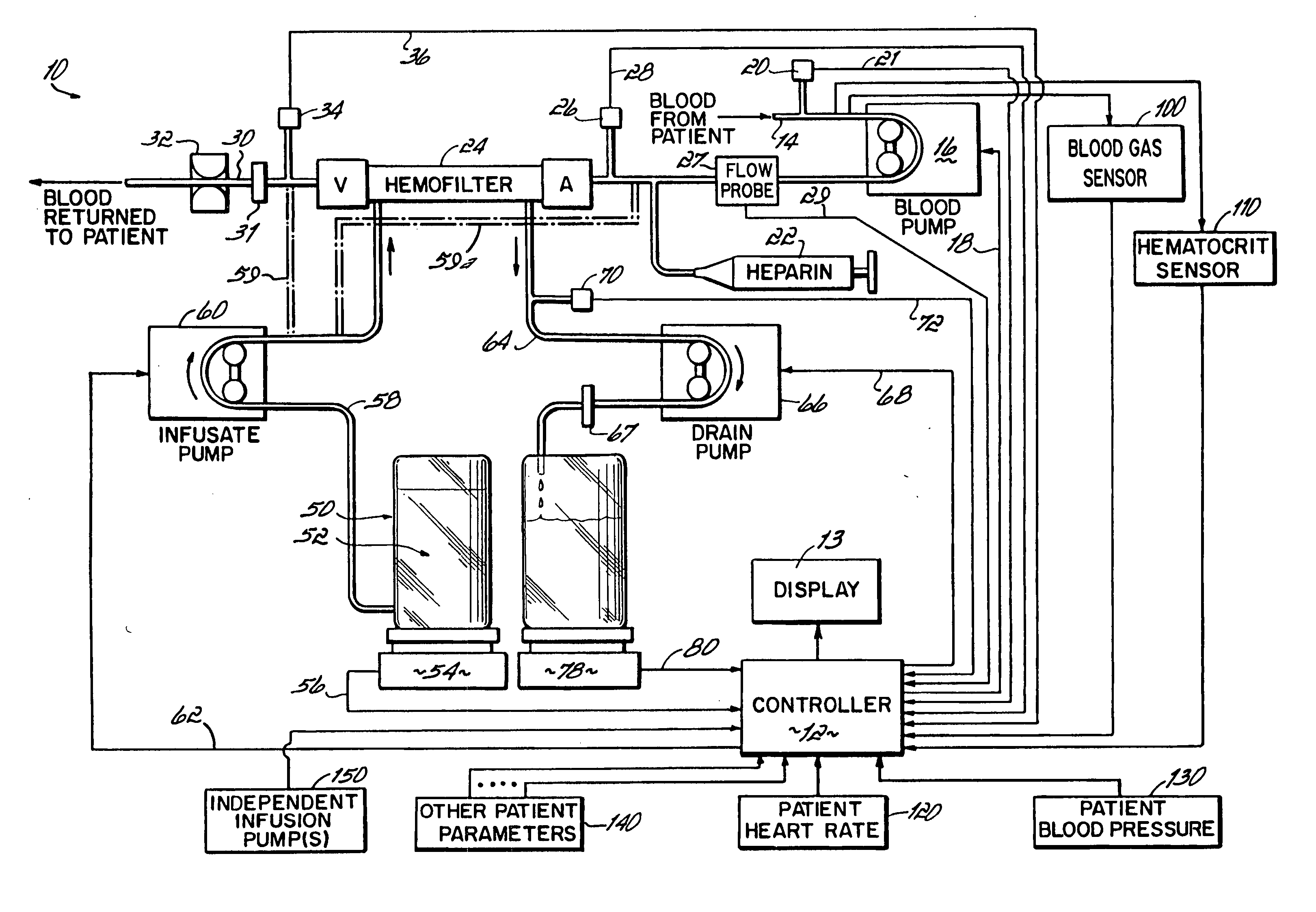

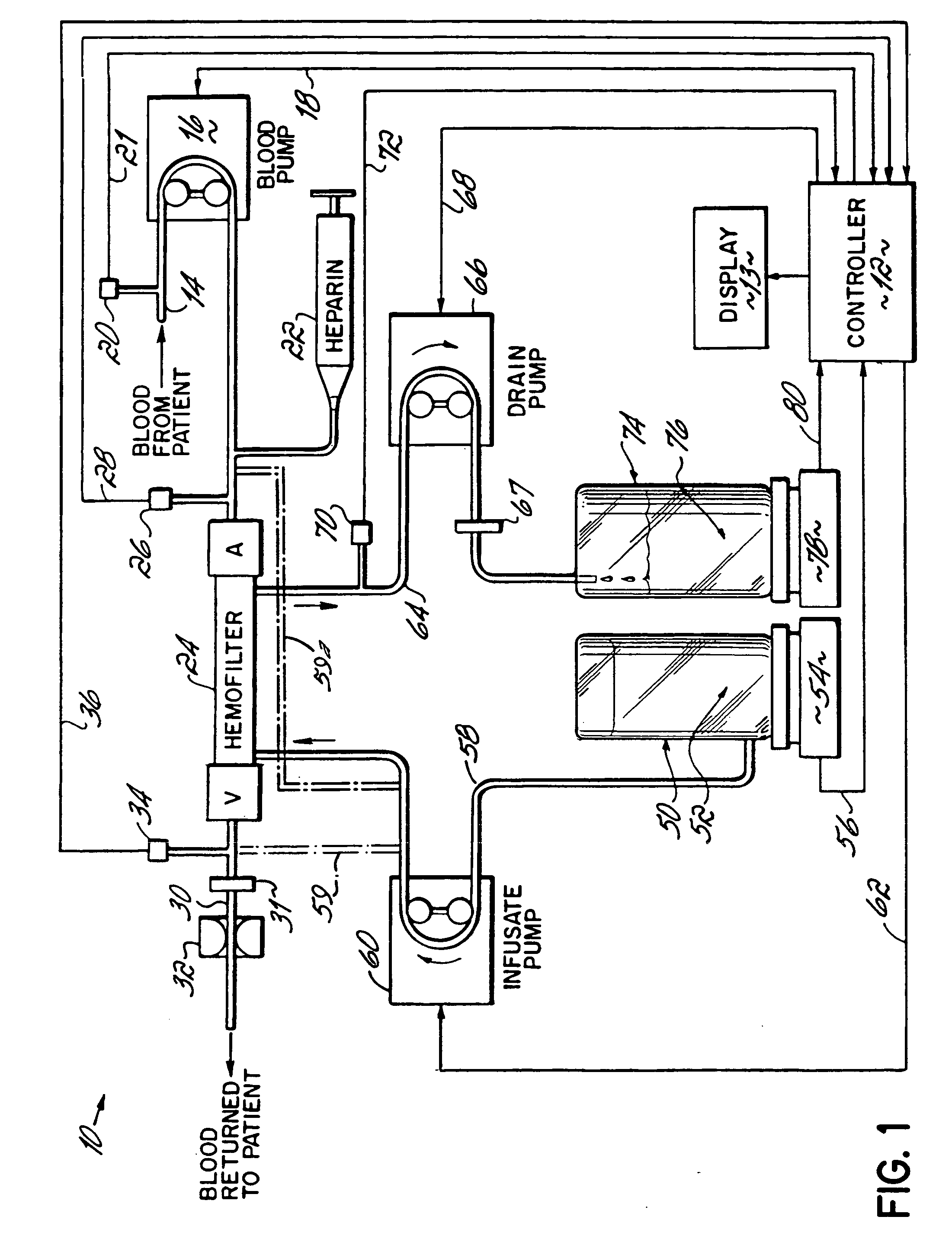

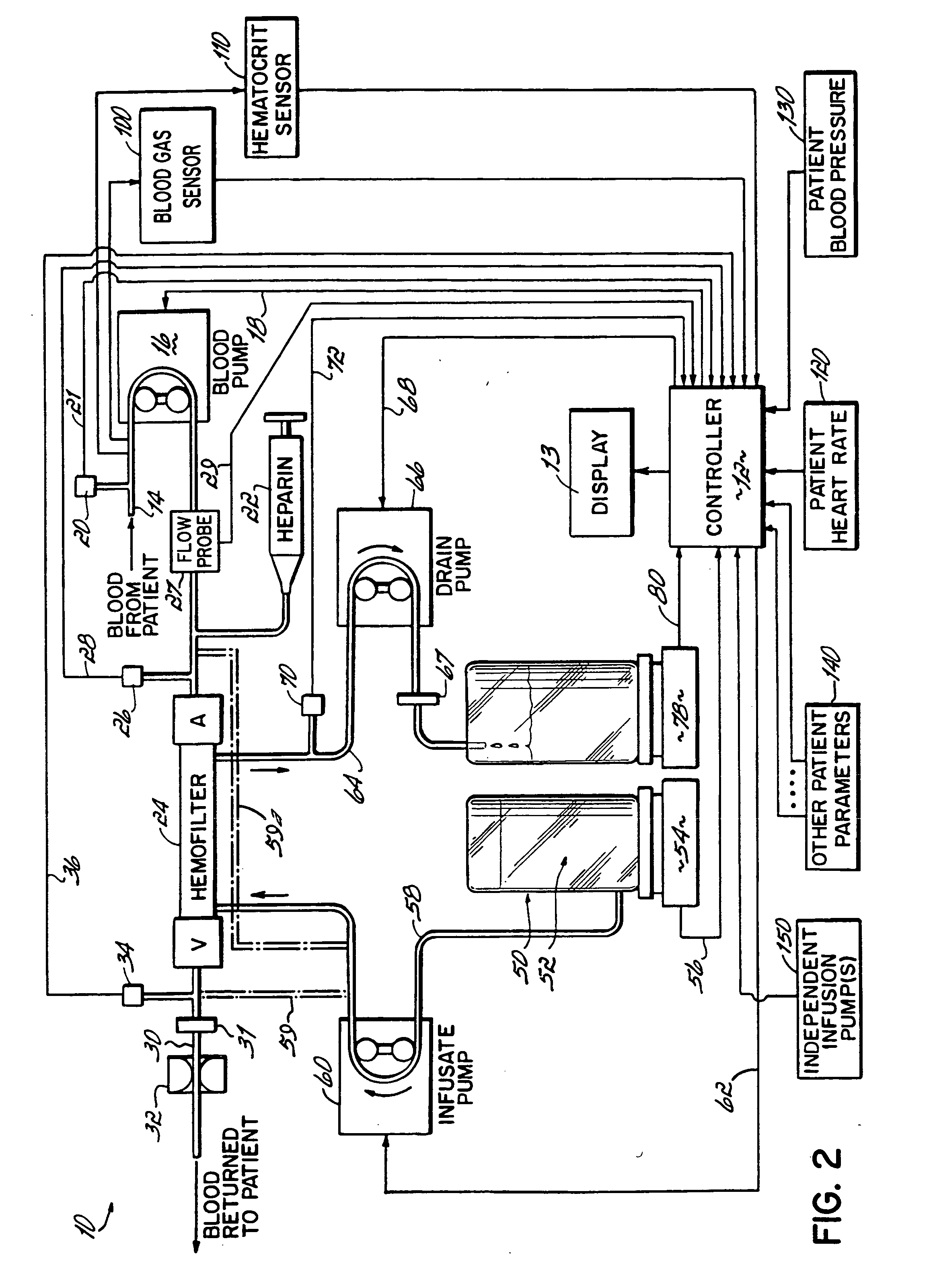

Hemofiltration system and method based on monitored patient parameters, supervisory control of hemofiltration, and adaptive control of pumps for hemofiltration

InactiveUS20050126961A1Reliable and long-term operationImprove accuracyHaemofiltrationUltrafiltrationMedicineTime changes

Owner:CHILDRENS HOSPITAL MEDICAL CENT CINCINNATI

Methods and apparatus for isolating platelets from blood

InactiveUS20050186120A1Simple and fast preparationIncrease productionMedical devicesLaboratory glasswaresMedicineRed blood cell

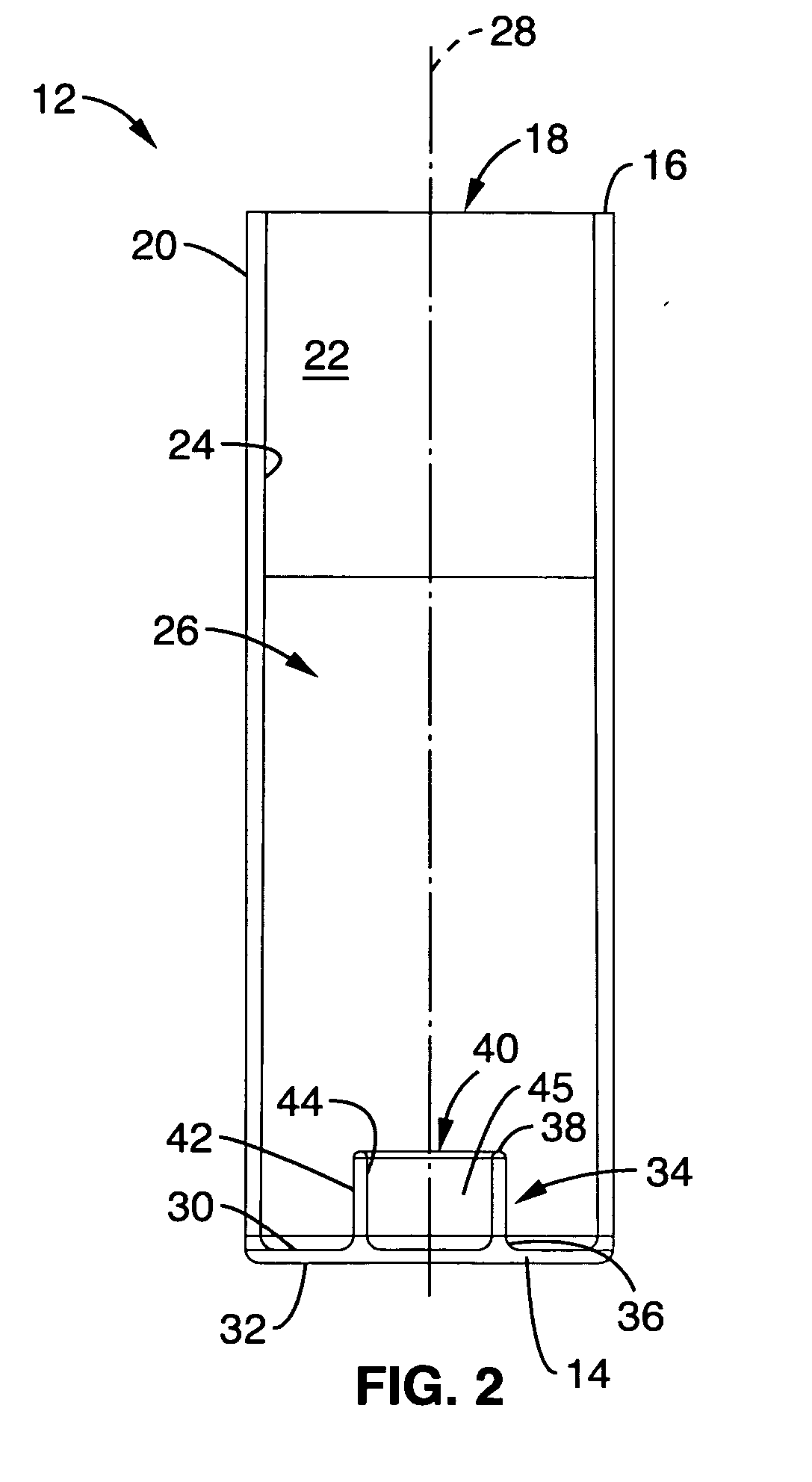

A platelet collection device comprising a centrifugal spin-separator container with a cavity having a longitudinal inner surface. A float in the cavity has a base, a platelet collection surface above the base, an outer surface. The float density is below the density of erythrocytes and above the density of plasma. The platelet collection surface has a position on the float which places it below the level of platelets when the float is suspended in separated blood. During centrifugation, a layer of platelets or buffy coat collects closely adjacent the platelet collection surface. Platelets are then removed from the platelet collection surface. Movement of a float having a density greater than whole blood through the sedimenting erythrocytes releases entrapped platelets, increasing the platelet yield.

Owner:DORIAN RANDEL +2

Apparatus and method for mail sorting

InactiveUS7138596B2Efficient drawingReduce capacityDigital data processing detailsSeparation devicesCommon railEngineering

A method for sorting mail to a case having a plurality of slots is described, wherein each slot corresponds to a destination. The method includes steps of loading a mail piece to be sorted into a delivery robot, determining for the mail piece a destination slot the mail piece is to be delivered to, moving the delivery robot along a rail disposed at the front of the case near the slots into proximity with an open end of the destination slot, inserting the mail piece from the delivery robot into the associated slot, and returning the delivery robot to a loading station whereby the cycle may be repeated. Such a method, when using a large number of robots moving along a common rail system, can sort a large volume of mail in carrier delivery order.

Owner:SIEMENS LOGISTICS LLC

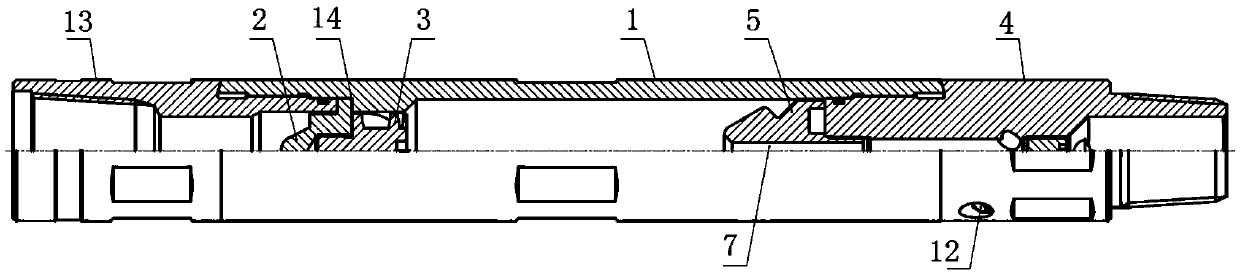

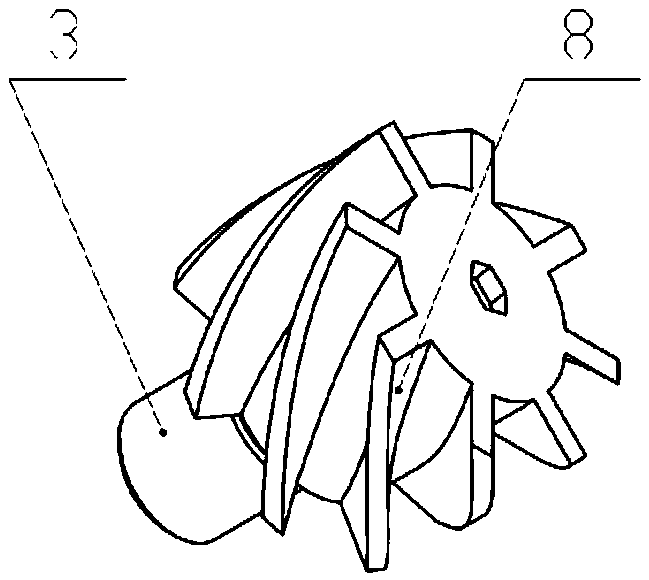

Downhole gas-liquid separation device and working method thereof

ActiveCN105536299AReduce in quantitySimple structureLiquid degasificationSeparation devicesEngineeringProduct gas

A downhole gas-liquid separation device comprises a barrel-shaped body, and a positioning wheel is fixedly installed in the body. A rotatable swirling wheel is installed on the positioning wheel and provided with spiral wheel blades, and the positioning wheel is provided with fluid channels. A lower connector is connected to the body, a diverting joint is arranged at the inner end, located in an inner cavity of the body, of the lower connector, a gas outlet channel is formed in the center of the diverting joint in a coaxial mode, and the outer side of the diverting joint is provided with liquid drainage channels. An interval is formed between the swirling wheel and the diverting joint. The downhole gas-liquid separation device is small in part number, simple in structure and lower in cost; the swirling wheel is driven to rotate when liquid passes through the swirling wheel to enable the liquid to generate centrifugal force and swirlingly flow in the inner cavity in the mode of being attached to the wall, the liquid in gas is gathered to the center, and then the liquid and the gas flow out through the liquid drainage channels formed in the outer side and the gas outlet channel formed in the center respectively, so that gas and liquid separation is achieved; accordingly, the liquid sent to a motor does not contain the gas, damage to the motor is avoided, and the service life of the motor is prolonged.

Owner:JEREH ENERGY SERVICES

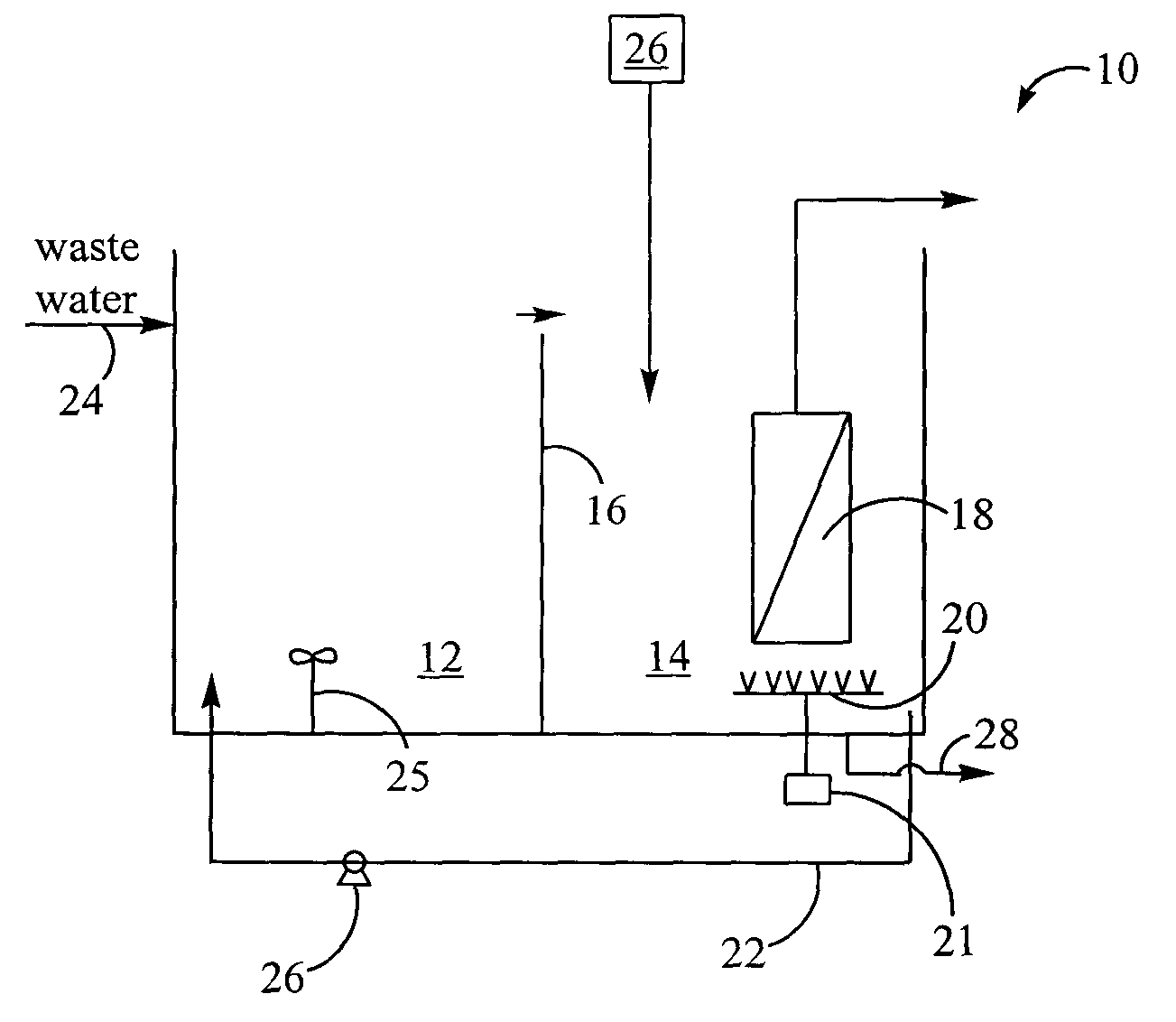

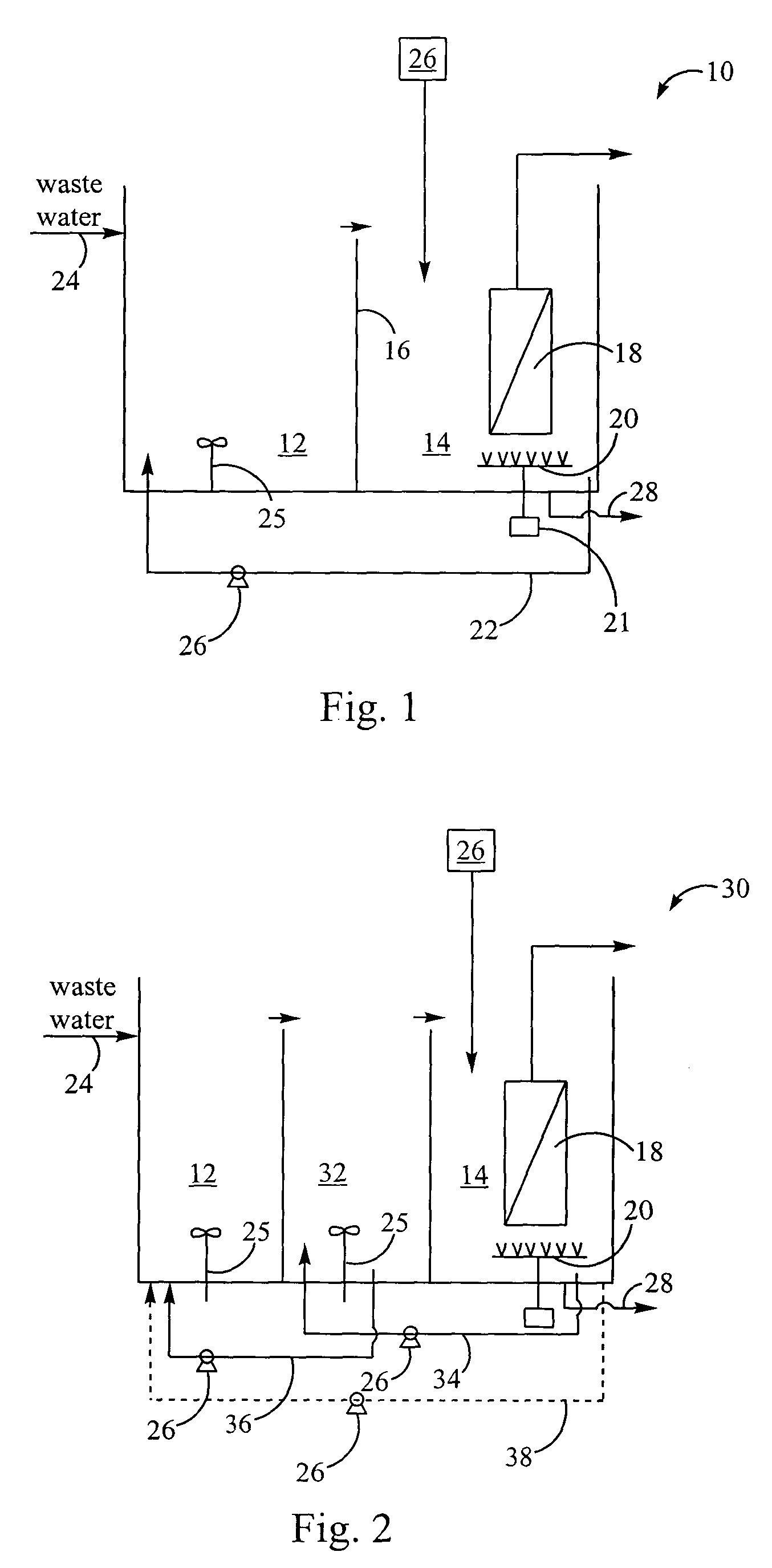

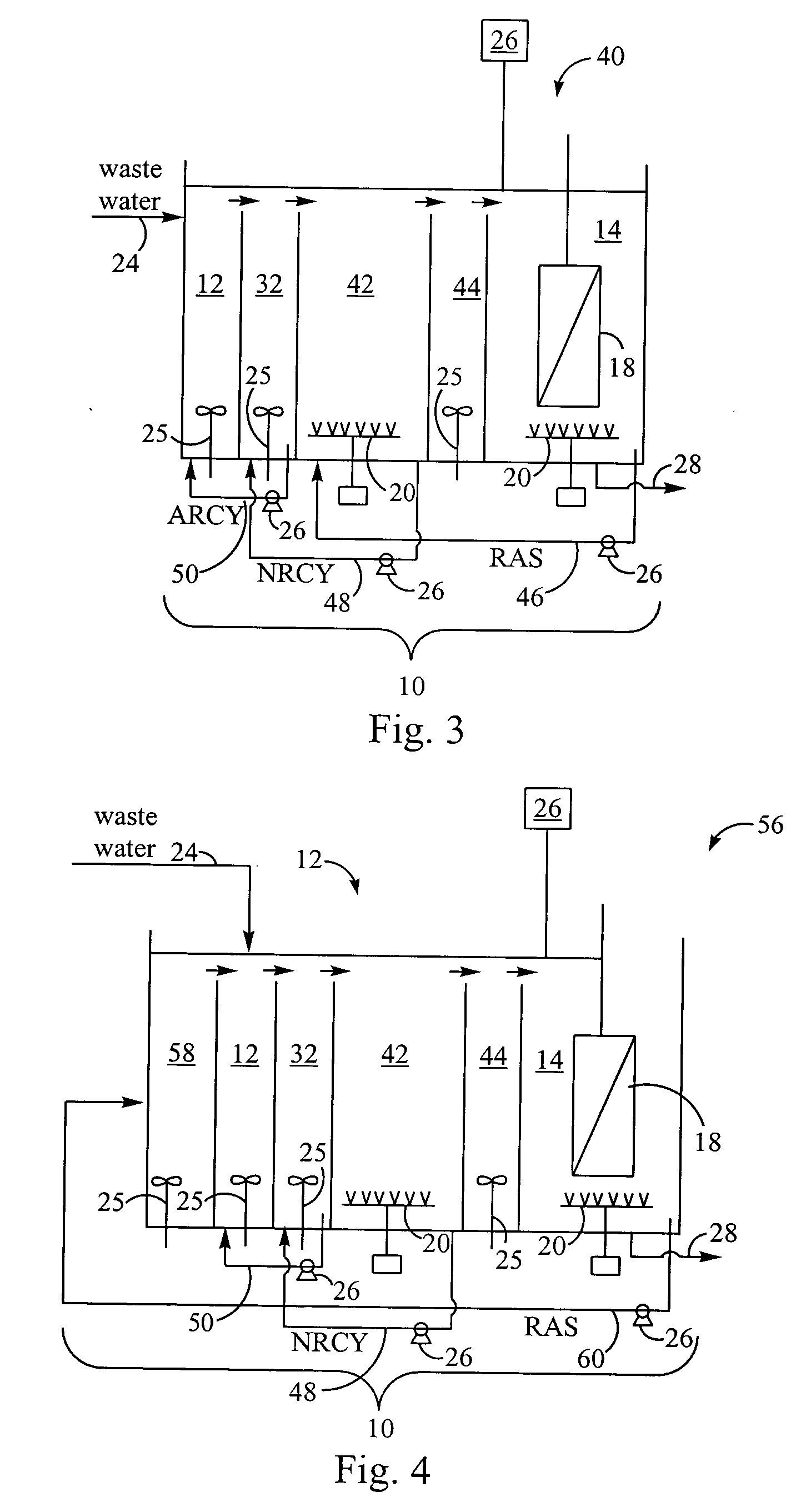

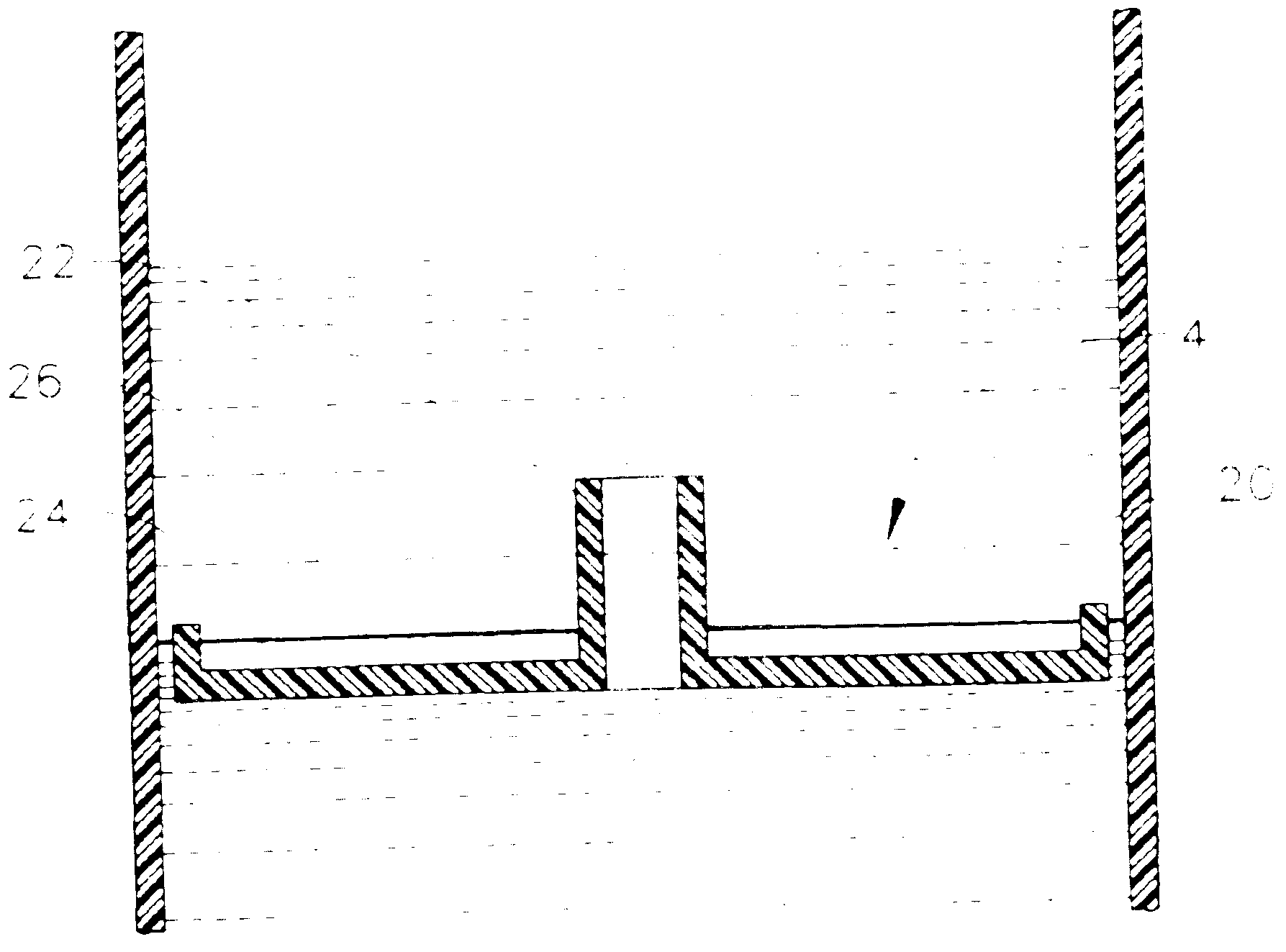

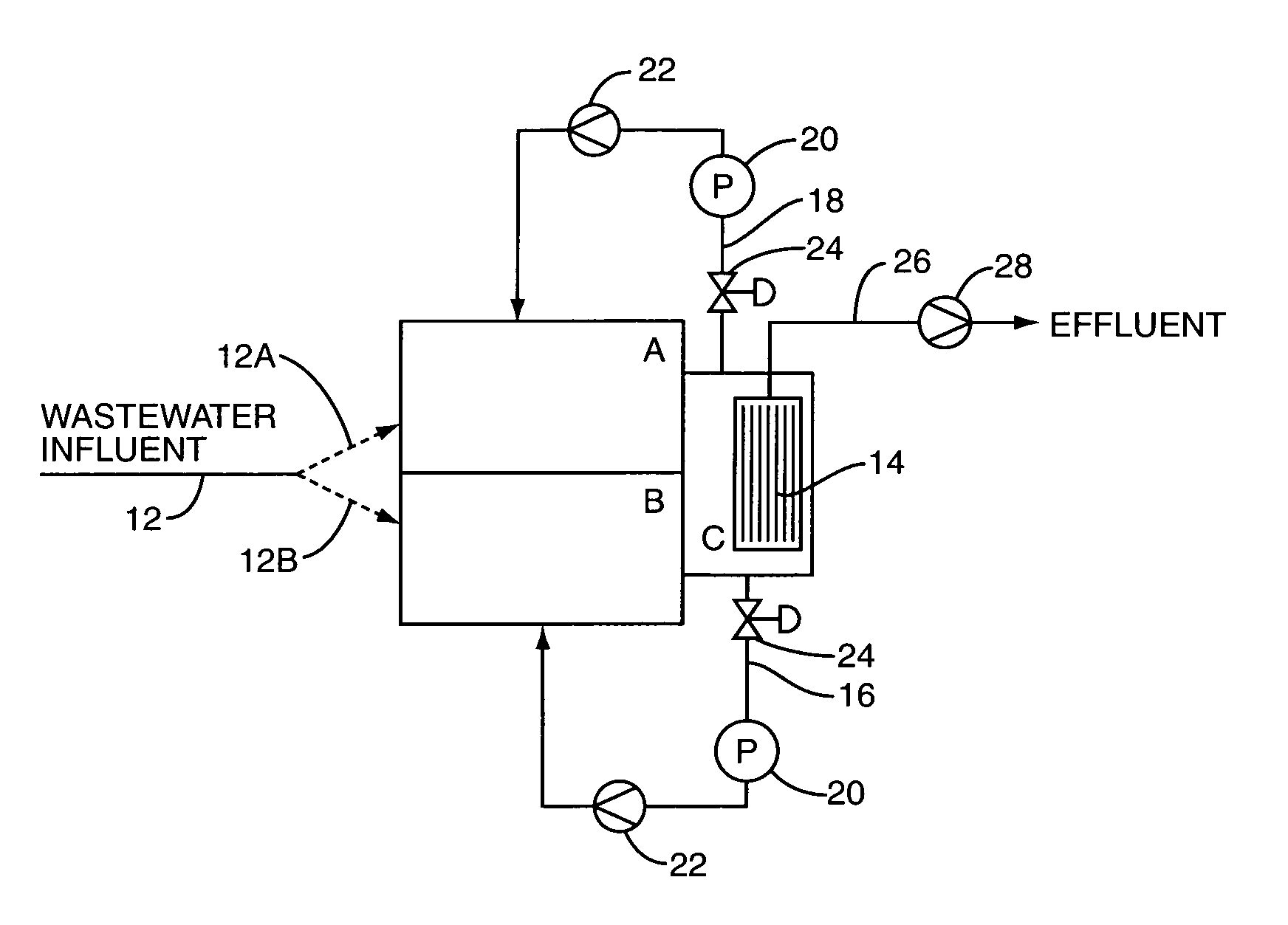

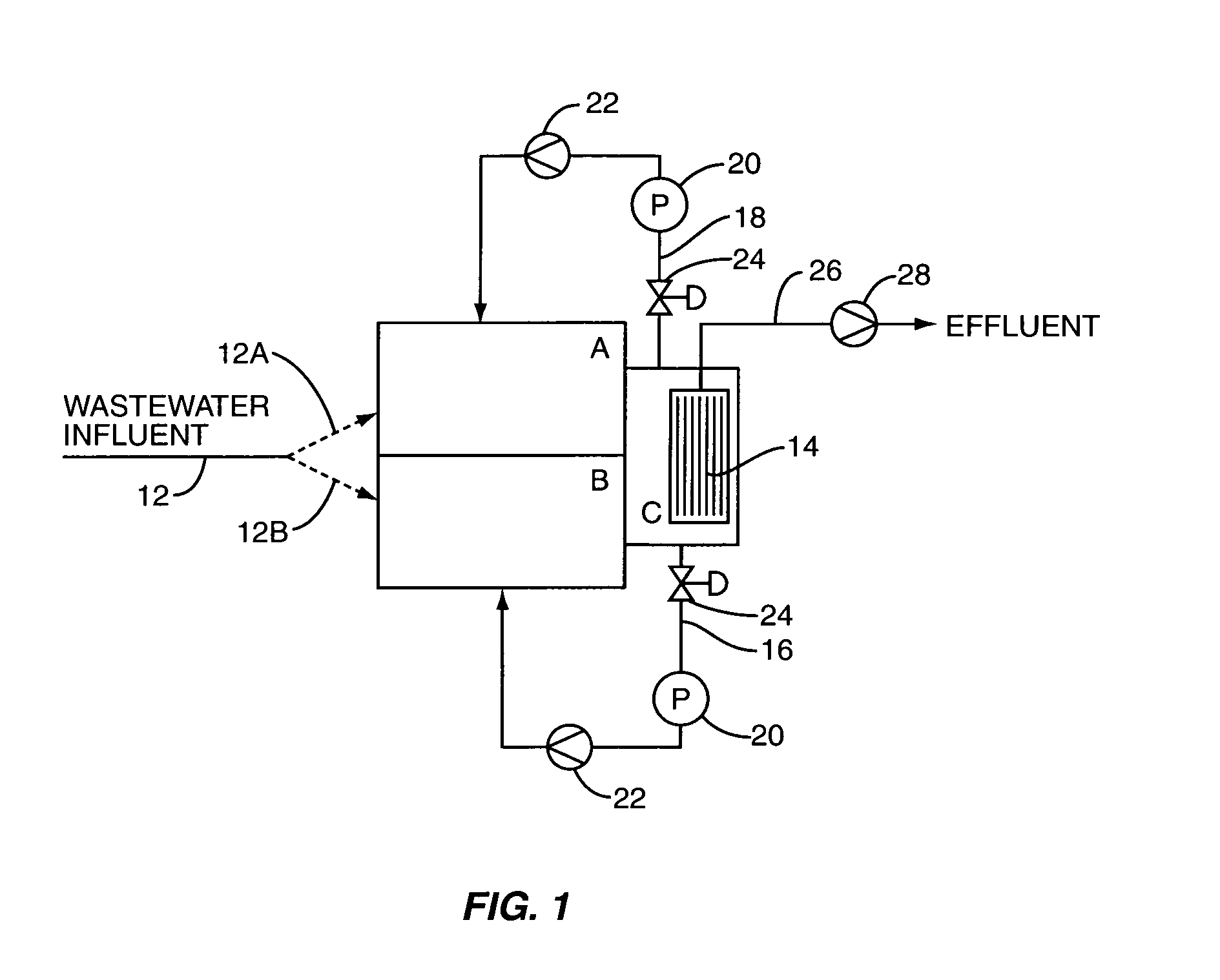

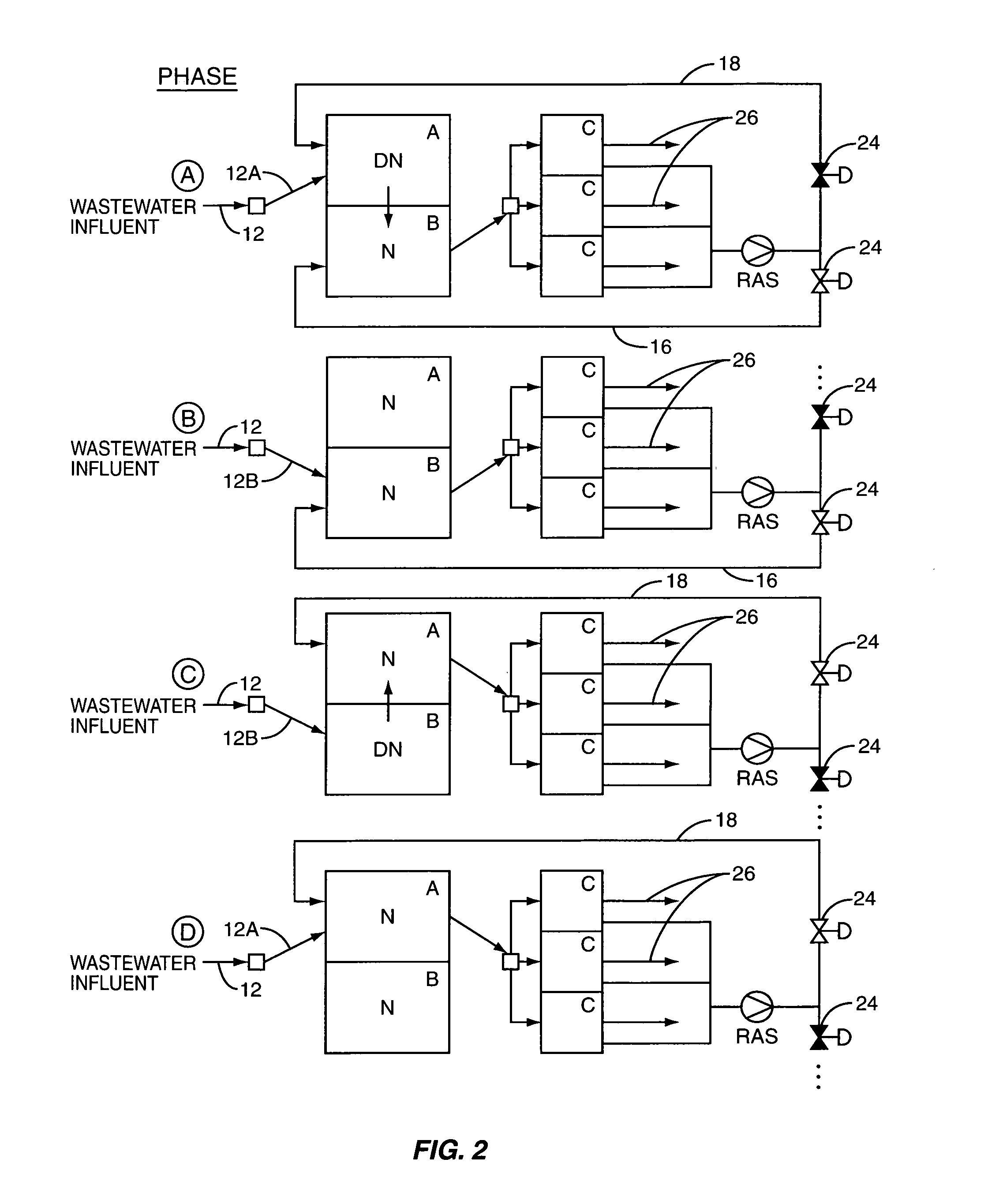

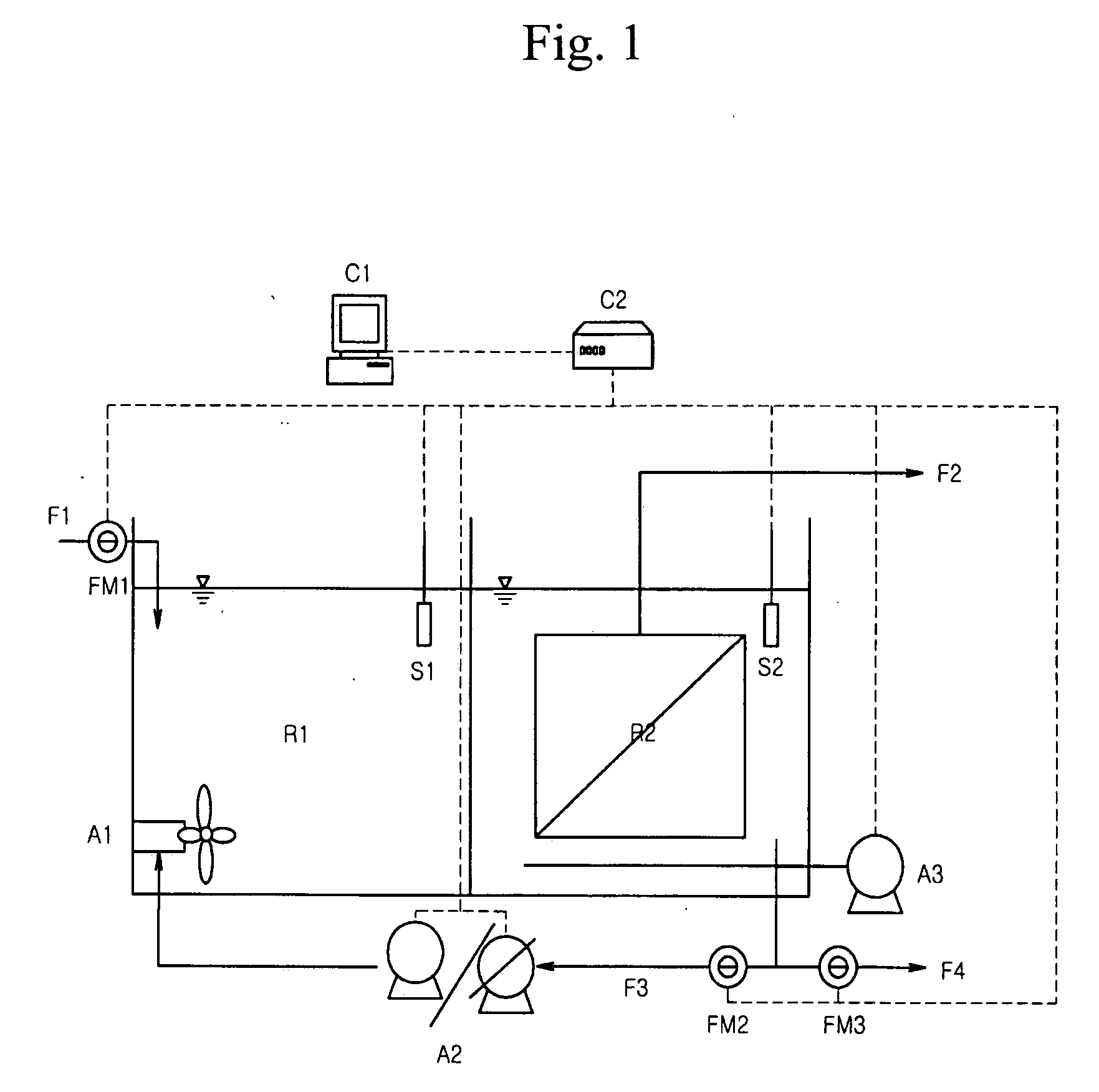

Method and system for nitrifying and denitrifying wastewater

ActiveUS7147778B1Reducing and minimizing dissolved oxygen concentrationReduces and minimizes dissolved oxygen concentrationTreatment using aerobic processesSeparation devicesActivated sludgeOxygen

A wastewater treatment system is provided that includes first and second reactors, each operative to nitrify or denitrify wastewater contained therein. Downstream from the first and second reactors is a membrane reactor that operates under aerobic conditions and includes one or more submersed membranes for separating solids. Extending between the membrane reactor and each of the first and second reactors is a return activated sludge line with appropriate controls for permitting return activated sludge to be directed to one of the reactors at a time. To nitrify and denitrify wastewater, a wastewater influent stream is alternatively directed to the anoxic reactors which are alternatively operated under aerobic and anoxic conditions so as to nitrify or denitrify the wastewater contained therein. To reduce or minimize the dissolved oxygen return from the membrane reactor to the first and second reactors, the flow of return activated sludge is controlled such that generally return activated sludge is returned to the reactor operating under aerobic conditions.

Owner:KRUGER I INC

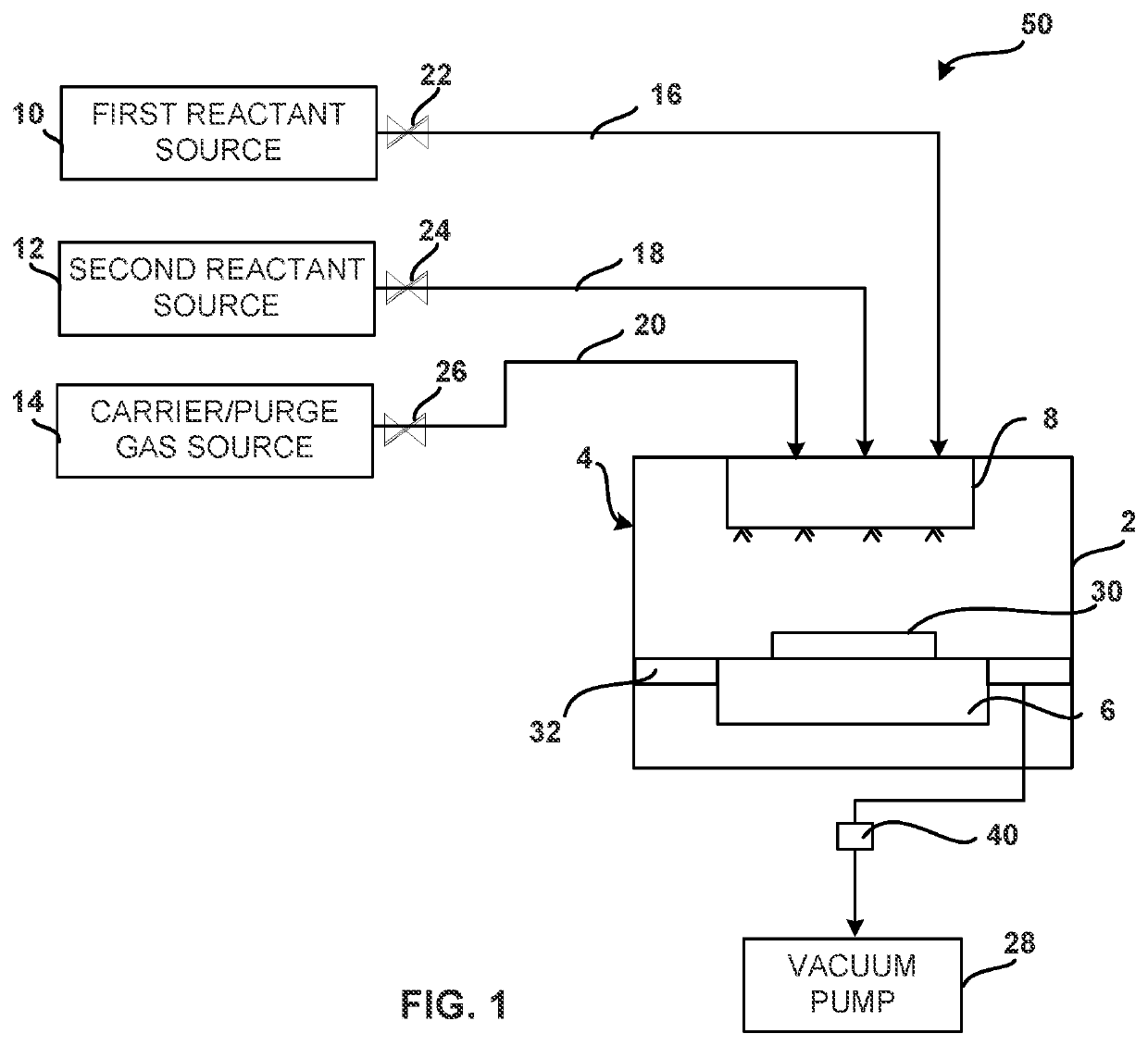

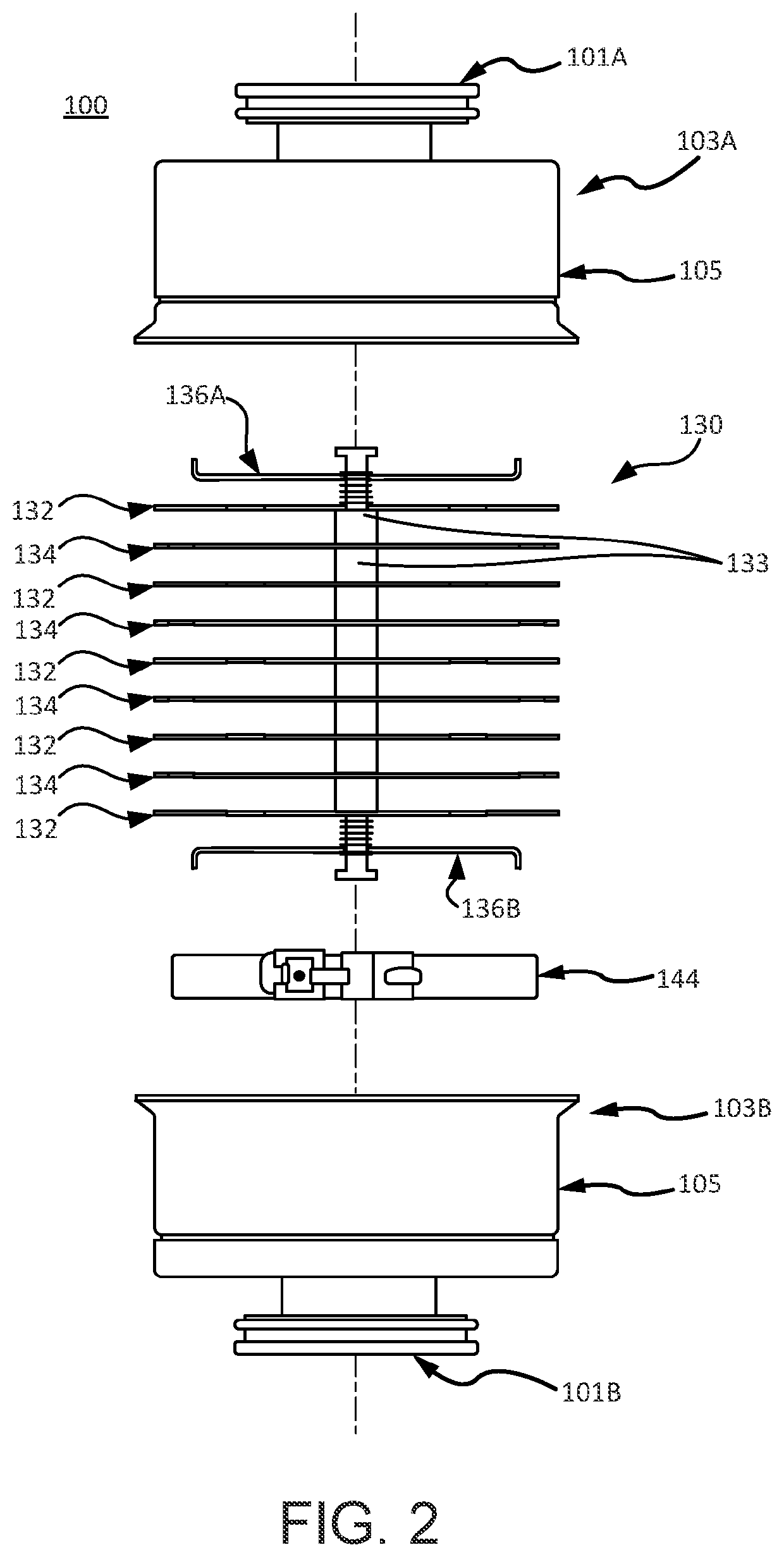

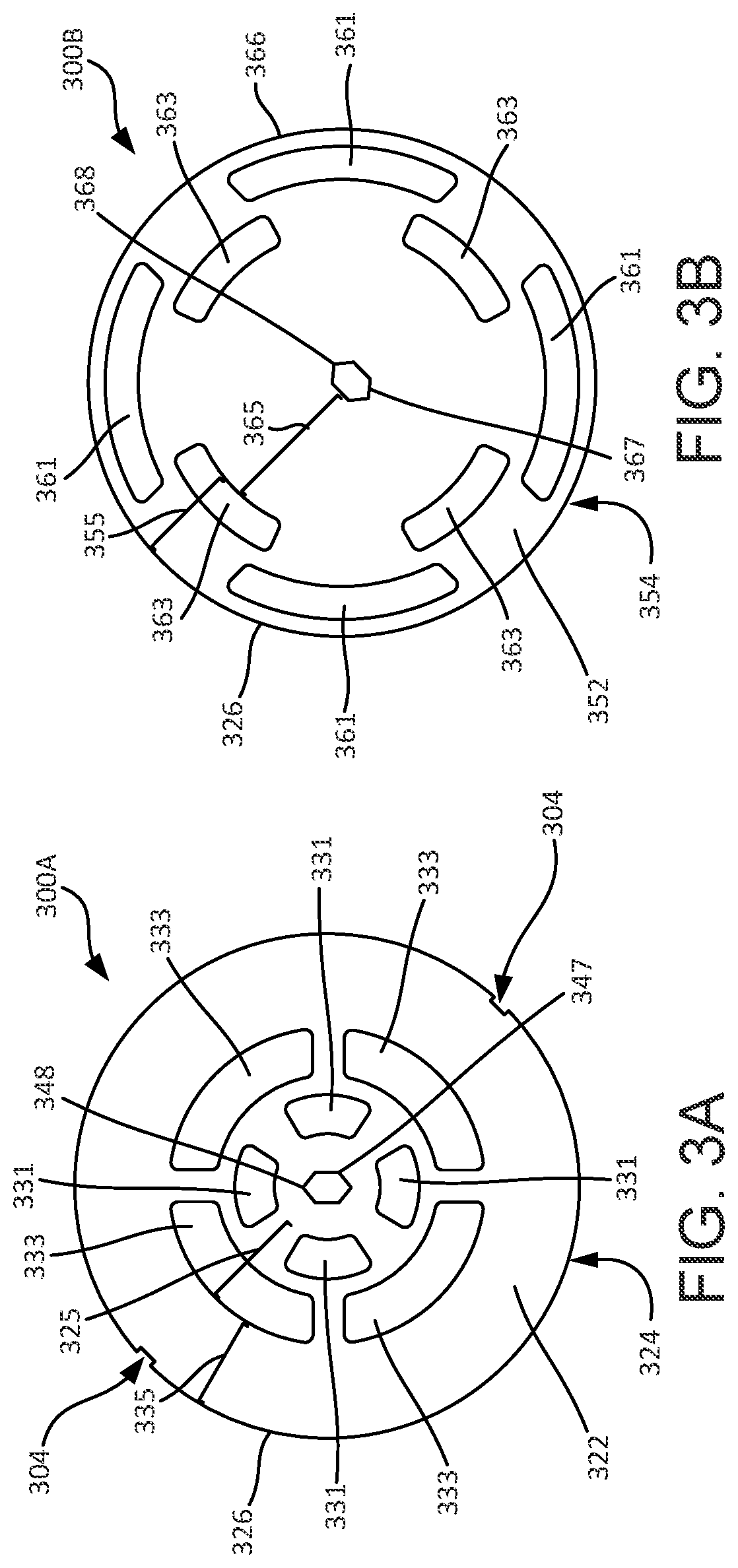

Contaminant trap system for a reactor system

PendingUS20210230744A1Reduce pollutionDispersed particle filtrationElectric discharge tubesReactor systemEngineering

A contaminant trap system of a reactor system may comprise a baffle plate stack comprising at least one baffle plate comprising an aperture spanning through a baffle plate body of the baffle plate, and a solid body portion; and at least one complementary baffle plate comprising a complementary aperture spanning through a complementary baffle plate body of the complementary baffle plate, and a complementary solid body portion. The at least one baffle plate and the at least one complementary baffle plate may be disposed in a baffle plate order between a first end and a second end of the baffle plate stack in which the baffle plates alternate with the complementary baffle plates, such that no two baffle plates or no two complementary baffle plates are adjacent in the baffle plate order.

Owner:ASM IP HLDG BV

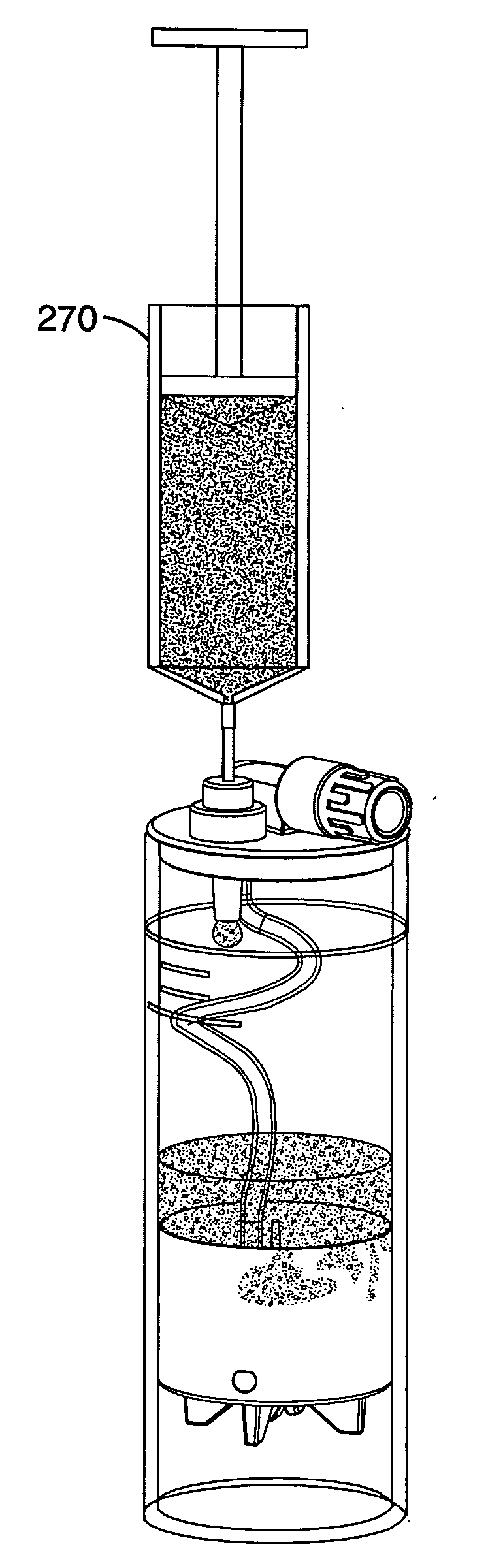

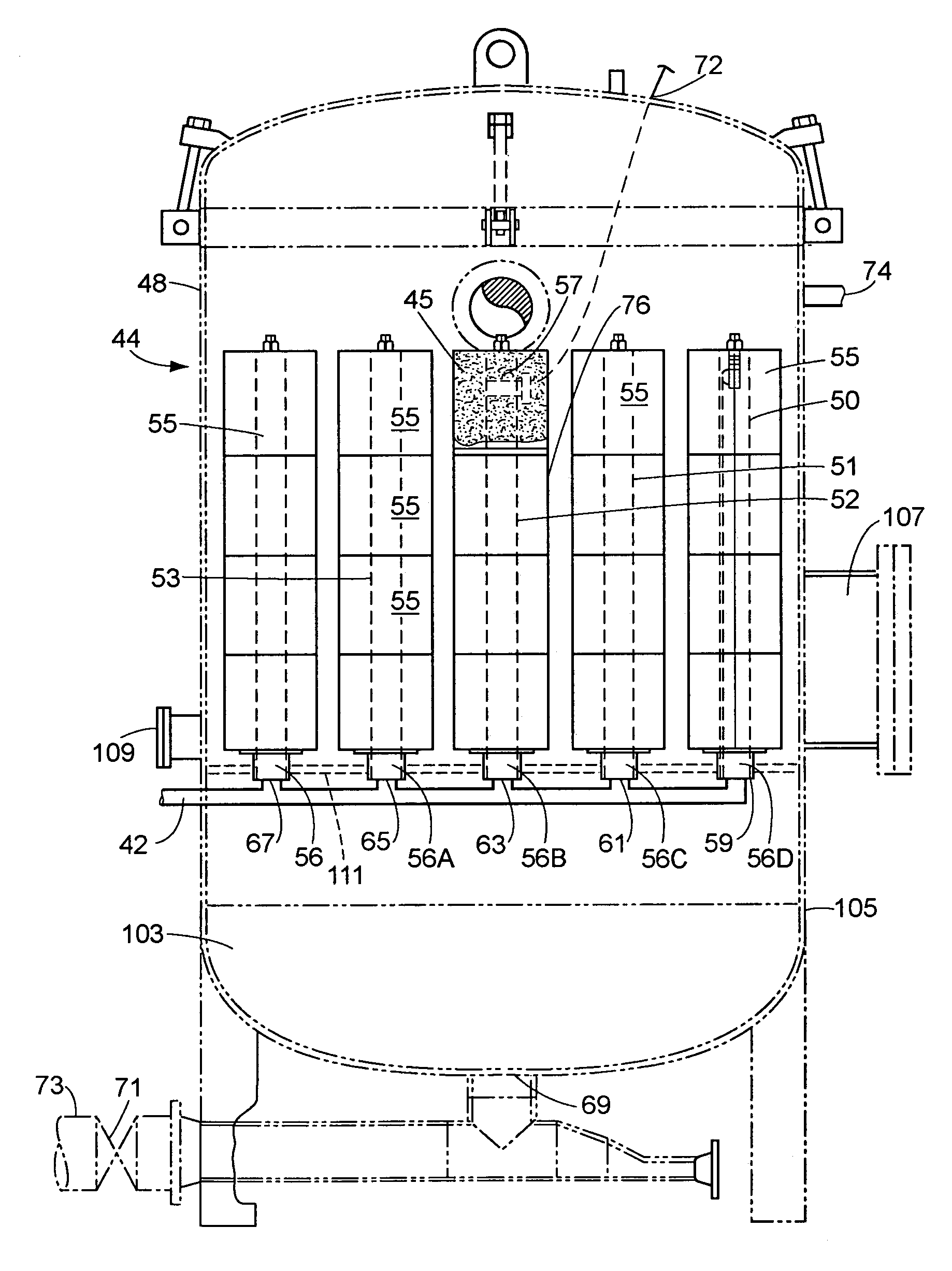

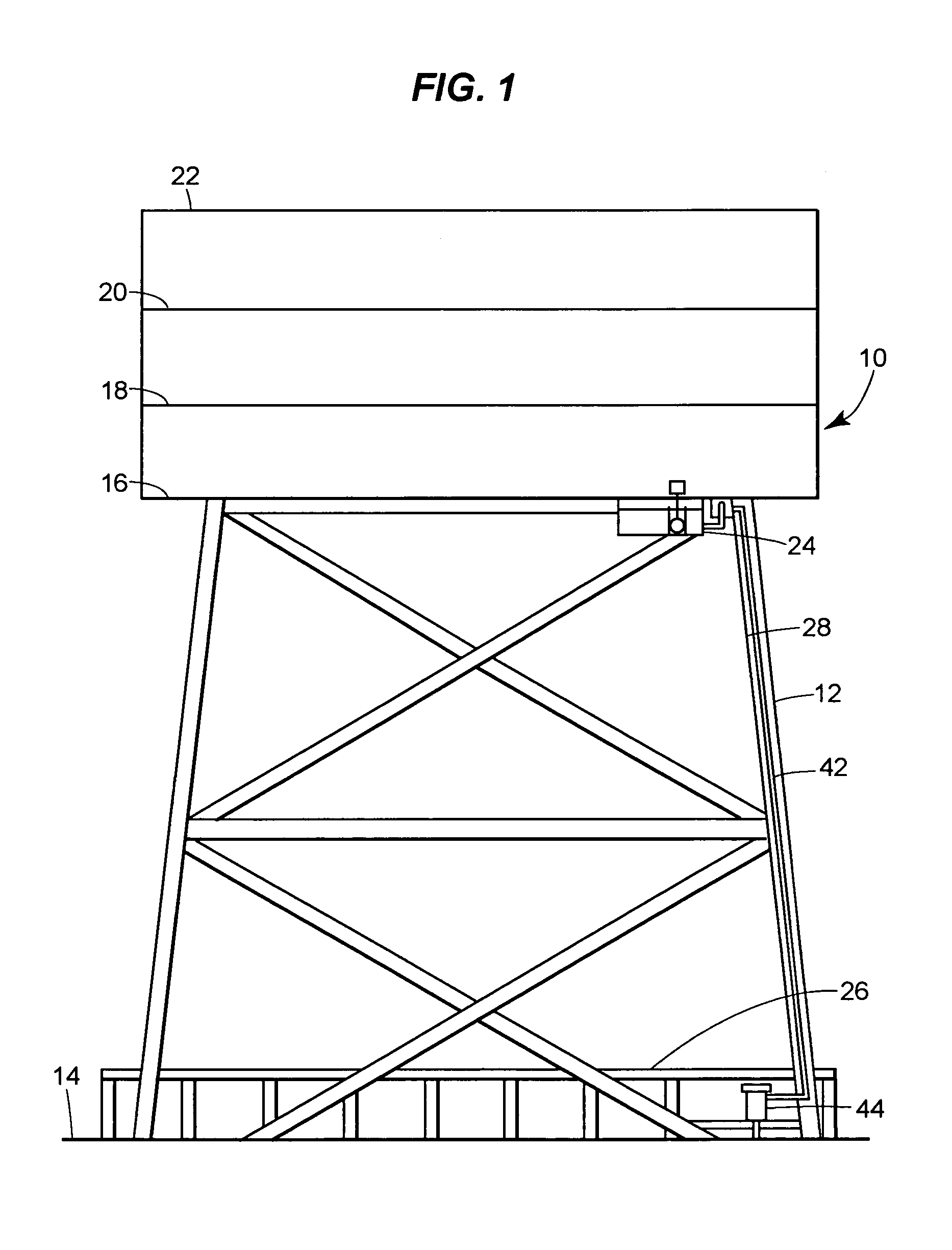

Method for removing oil from water coalescing in a polymer particle/fiber media

ActiveUS7297279B2Increase the liquid flow rateBig contactLiquid suspension thickening by filtrationSolid sorbent liquid separationFiberWater flow

Apparatus in fluid communication with a water leg portion of a hydrocarbon-contaminated water, e.g., a water leg portion of a produced water stream or an offshore drilling or production platform sump tank for conveying water, separated from oil, into contact with non-woven fiber / particulate polymer coalescing media-containing canisters such that the hydrocarbon droplets and other organic material droplets commingled with the sump tank or produced water will be coalesced by passage through the coalescing media. The canisters preferably are provided in a plurality of stacks in each vessel. Solids that do not pass through the canisters are accumulated at the bottom of the vessel and easily drained through a drain port. The water and hydrocarbons will pass through the coalescing media within the canisters and will be separated easily from each vessel, e.g., by gravity separation, sot that the water can be conveyed back to the ocean water without contamination.

Owner:AMCOL INTERNATIONAL CORPORATION

Methods and apparatus for isolating platelets from blood

InactiveUS20050196874A1Simple and fast preparationIncrease productionSurgeryVaccination/ovulation diagnosticsMedicineRed blood cell

A platelet collection device comprising a centrifugal spin-separator container with a cavity having a longitudinal inner surface. A float in the cavity has a base, a platelet collection surface above the base, an outer surface. The float density is below the density of erythrocytes and above the density of plasma. The platelet collection surface has a position on the float which places it below the level of platelets when the float is suspended in separated blood. During centrifugation, a layer of platelets or buffy coat collects closely adjacent the platelet collection surface. Platelets are then removed from the platelet collection surface. Movement of a float having a density greater than whole blood through the sedimenting erythrocytes releases entrapped platelets, increasing the platelet yield.

Owner:HANUMAN

Membrane coupled activated sludge method and apparatus operating anoxic/anaerobic process alternately for removal of nitrogen and phosphorous

ActiveUS20070108125A1Quality improvementSimple processTreatment using aerobic processesMixing methodsActivated sludgeNitrogen

Disclosed are a membrane coupled activated sludge method and apparatus operating anoxic / anaerobic processes alternately for removal of nitrogen and phosporus, wherein nitrogen and phosphorous together with organics in the sewage, wastewater, filthy water etc. can be simultaneously removed with an economic and efficient manner, an operation thereof is easy and efficient, a capacity thereof is high and the method is economic due to the reduced operating costs with performing measurement and control of a recycle rate, a recycle time of alternate operation of the anoxic and anaerobic process, an amount of sludge, an amount of aeration and an operation of a blower for an intermittent membrane cleaning.

Owner:KOREA INST OF SCI & TECH

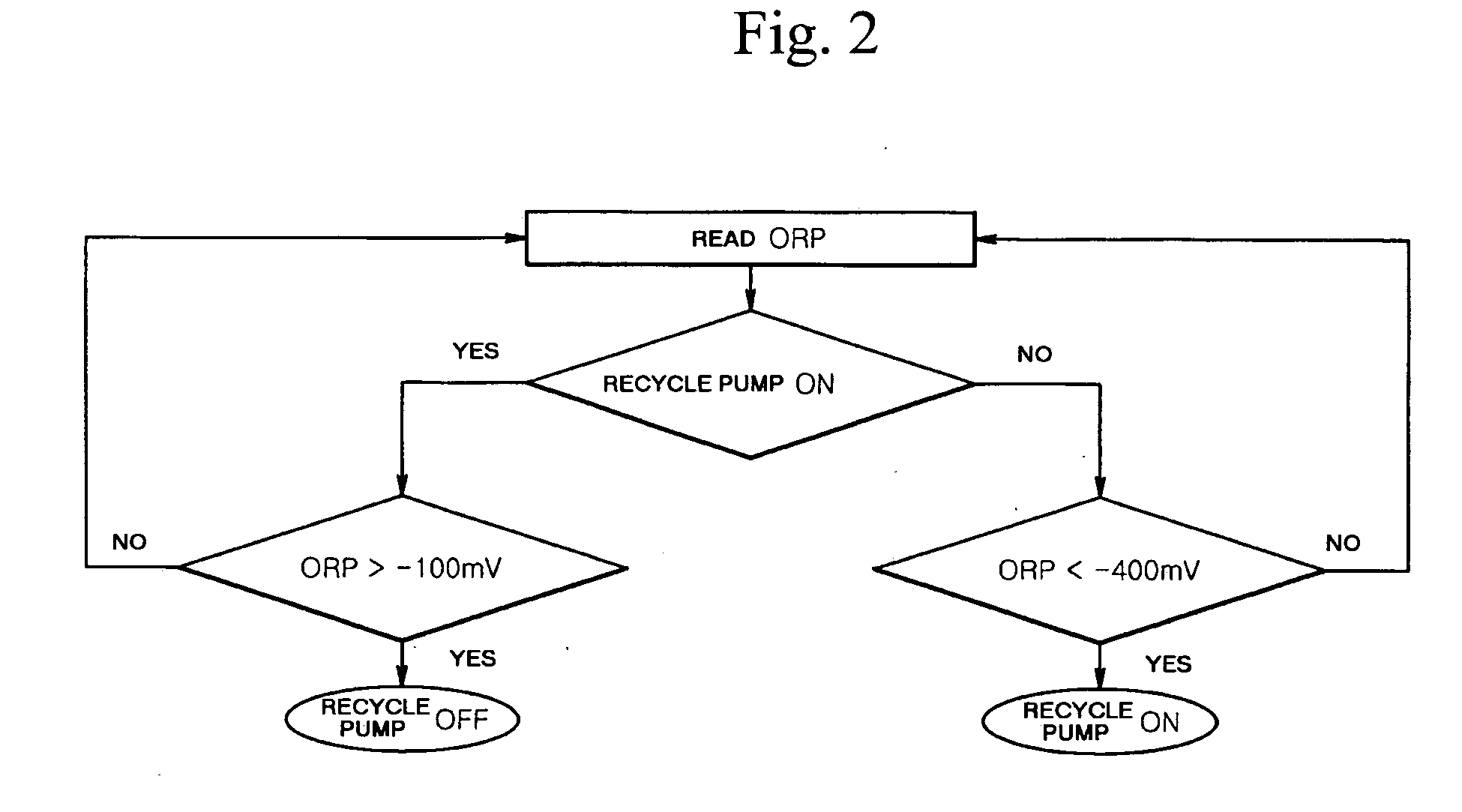

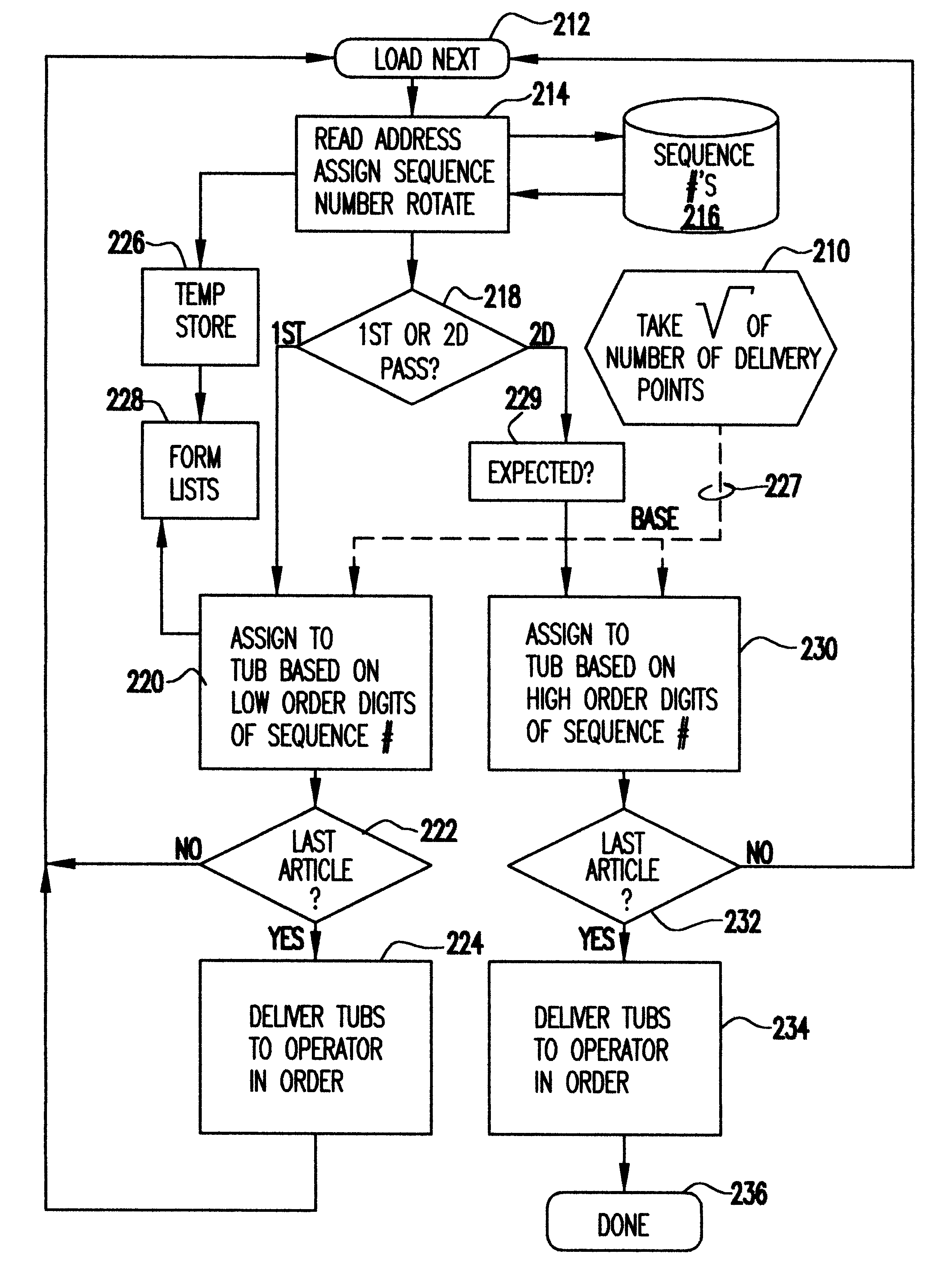

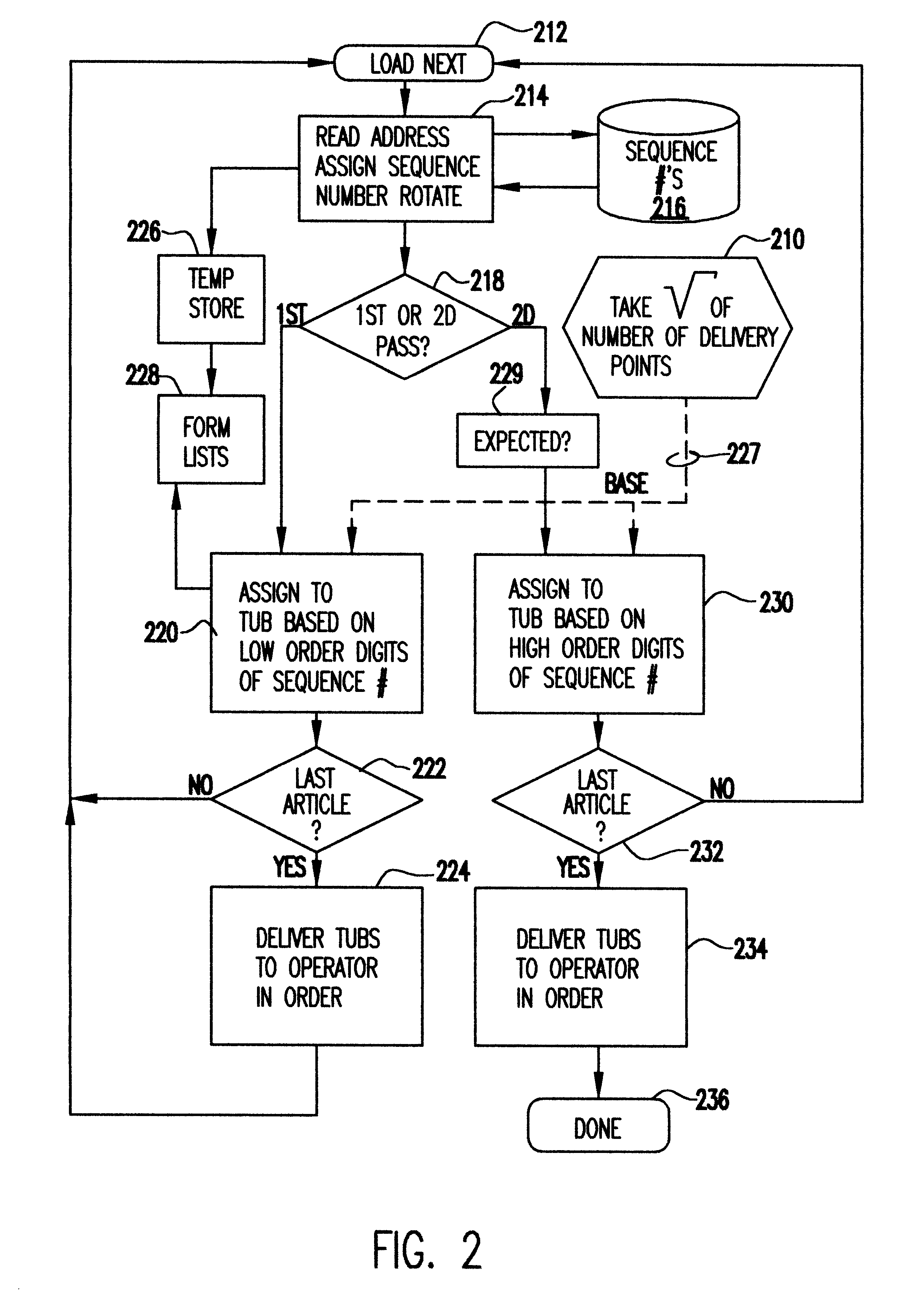

Object sortation for delivery sequencing

A sortation process provides high-speed sorting of randomly ordered articles into a desired order in a plurality of ordered bins or tubs such as standard USPS tubs in two passes, without additionally marking the articles in any way or requiring additional processes to do so. Optical character recognition or bar code reading performed on an image of the article provides a sequence number which is used to place the articles in respective bins or tubs during a first pass. The process then presents the content of the bins or tubs in order for a second pass during which they are placed in final desired order among a final ordered group of bins or tubs. During the first pass, sequence number information can be collected and used for error checking against the order of articles in each bin or tub during a second pass. The final output of the process provides the articles in standard (e.g. USPS) tubs face up and in delivery order.

Owner:LOCKHEED MARTIN CORP

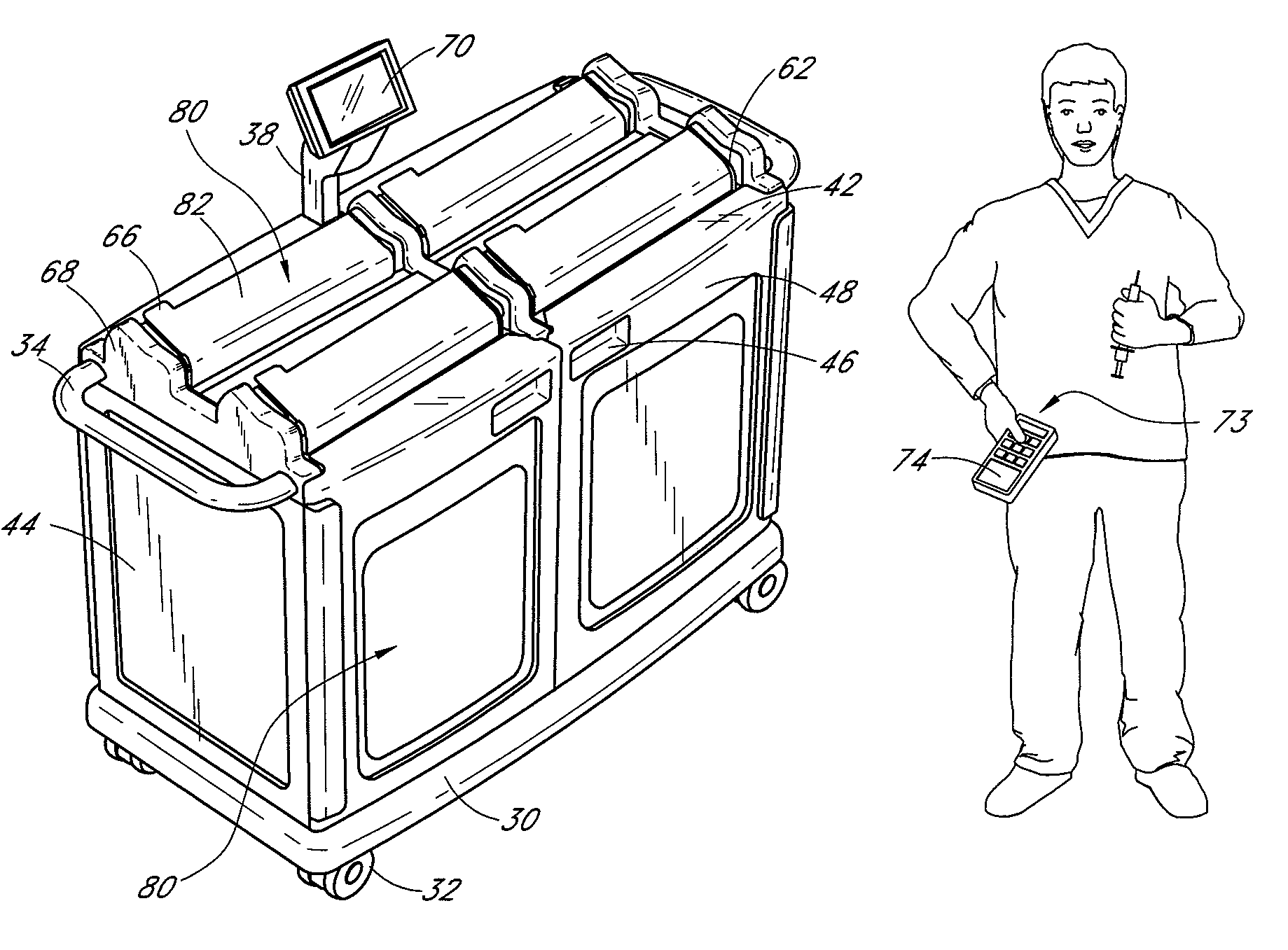

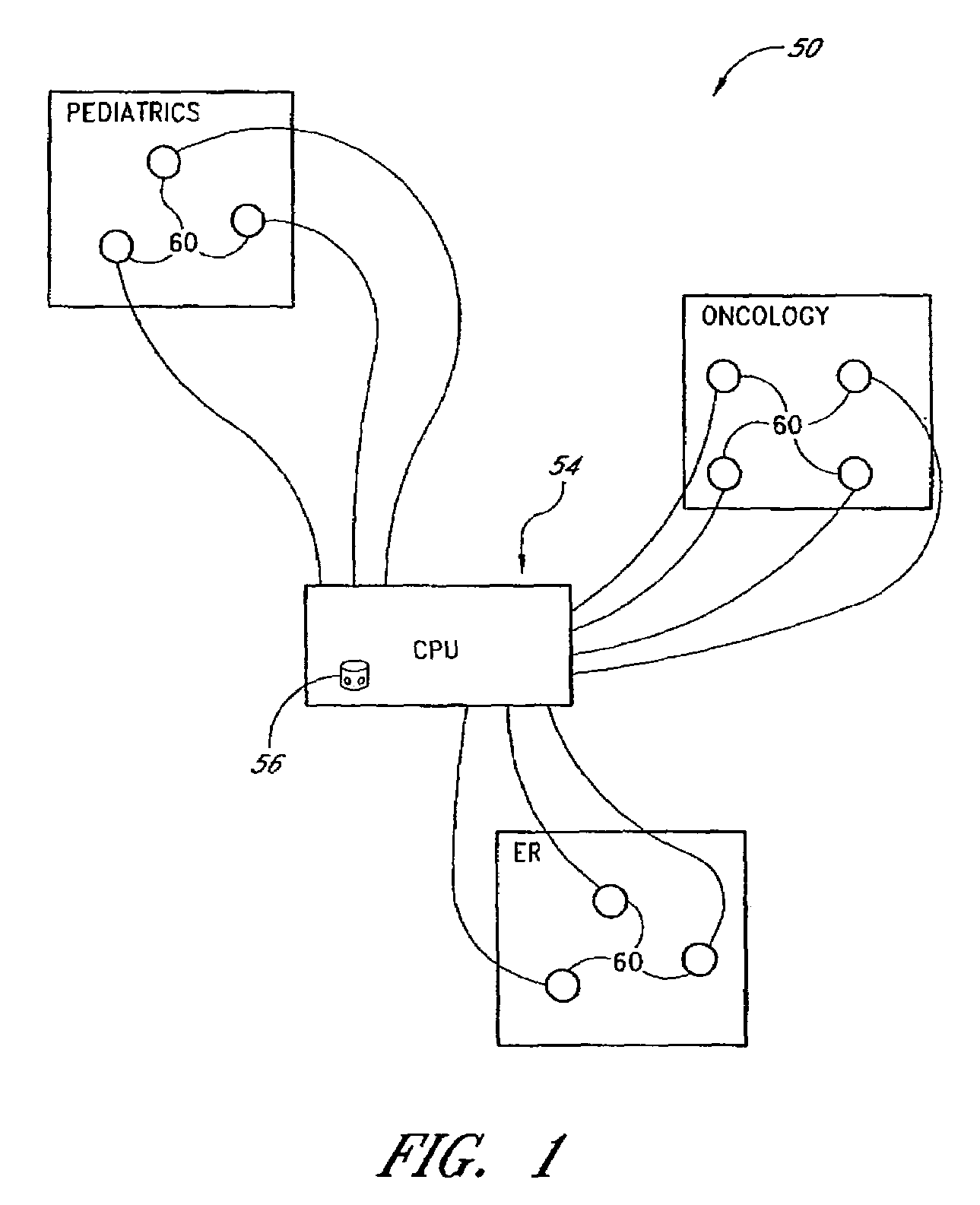

Method for sorting discarded and spent pharmaceutical items

ActiveUS7318529B2Easy to classifyEncourages and facilitates complianceSustainable waste treatmentDispensing apparatusMedical wasteWorkstation

Owner:CAREFUSION 303 INC

Integrated closed loop system for industrial water purification

InactiveUS20050061737A1Small surface areaIncreasing biofilm thicknessTreatment using aerobic processesWater/sewage treatment by irradiationOrganic matterIndustrial water

The present invention relates to an integrated closed loop system for aquaculture in at least one culturing tank and using continuous bioreactor technology for the biological treatment and removal of organic material, nitrogen and phosphorous, comprising: an integrated, partially or wholly closed loop system for waste water treatment, where the water contains nitrogen containing compounds and / or substances, comprising at least one production unit of such nitrogen containing compounds and / or substances and using continuous bioreactor technology for the biological treatment and removal of organic matter, nitrogen and phosphorous from the said water at continuous flow, comprising: a) at least one suspended carrier bioreactor for bacterial growth under anoxic conditions to cause anaerobic denitrification, with one or several compartments, preceding b) at least one suspended-carrier bioreactor for bacterial growth under oxic conditions to cause aerobic nitrification, c) the denitrification taking place after the production unit, and d) the nitrification taking place prior to the production unit in a by-pass mode as part of the continuous flow.

Owner:GREENFISH

Method and apparatus for sorting particles

InactiveUS20050183995A1Low costImprove sorting rateValve arrangementsCircuit elementsParticle sortingEngineering

A method and apparatus for sorting particles moving through a closed channel system of capillary size comprises a bubble valve for selectively generating a pressure pulse to separate a particle having a predetermined characteristic from a stream of particles. The particle sorting system may further include a buffer for absorbing the pressure pulse. The particle sorting system may include a plurality of closely coupled sorting modules which are combined to further increase the sorting rate. The particle sorting system may comprise a multi-stage sorting device for serially sorting streams of particles, in order to decrease the error rate.

Owner:CYTONOMEST

Popular searches

Macromolecular libraries Particle size analysis Selective adsorption Ion-exchange process apparatus Withdrawing sample devices Surface/boundary effect Chemical/physical/physico-chemical nozzle-type rreactors Material testing goods Chemical methods analysis Treatment with anaerobic digestion processes

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com