Patents

Literature

121 results about "Fluid shear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

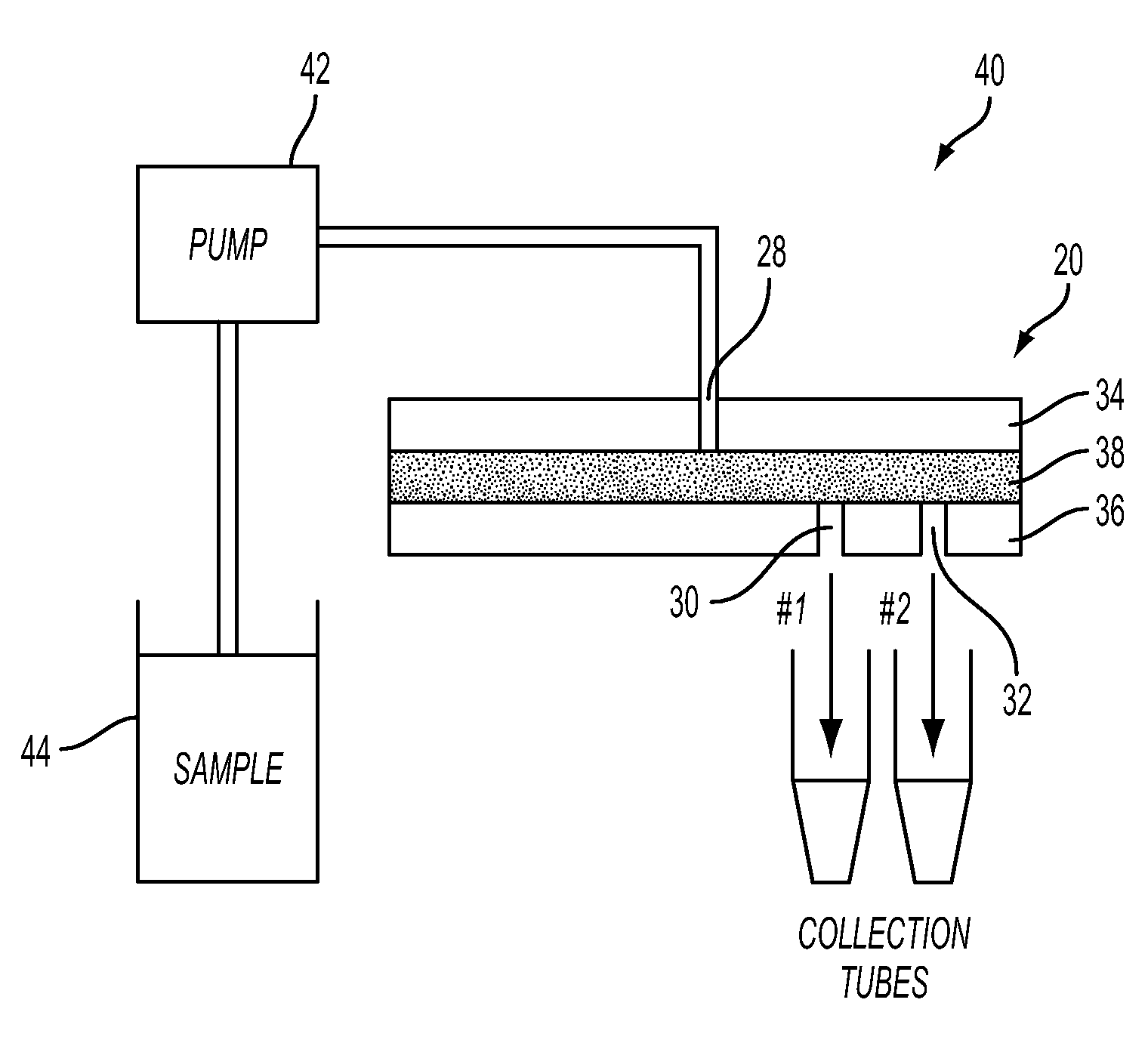

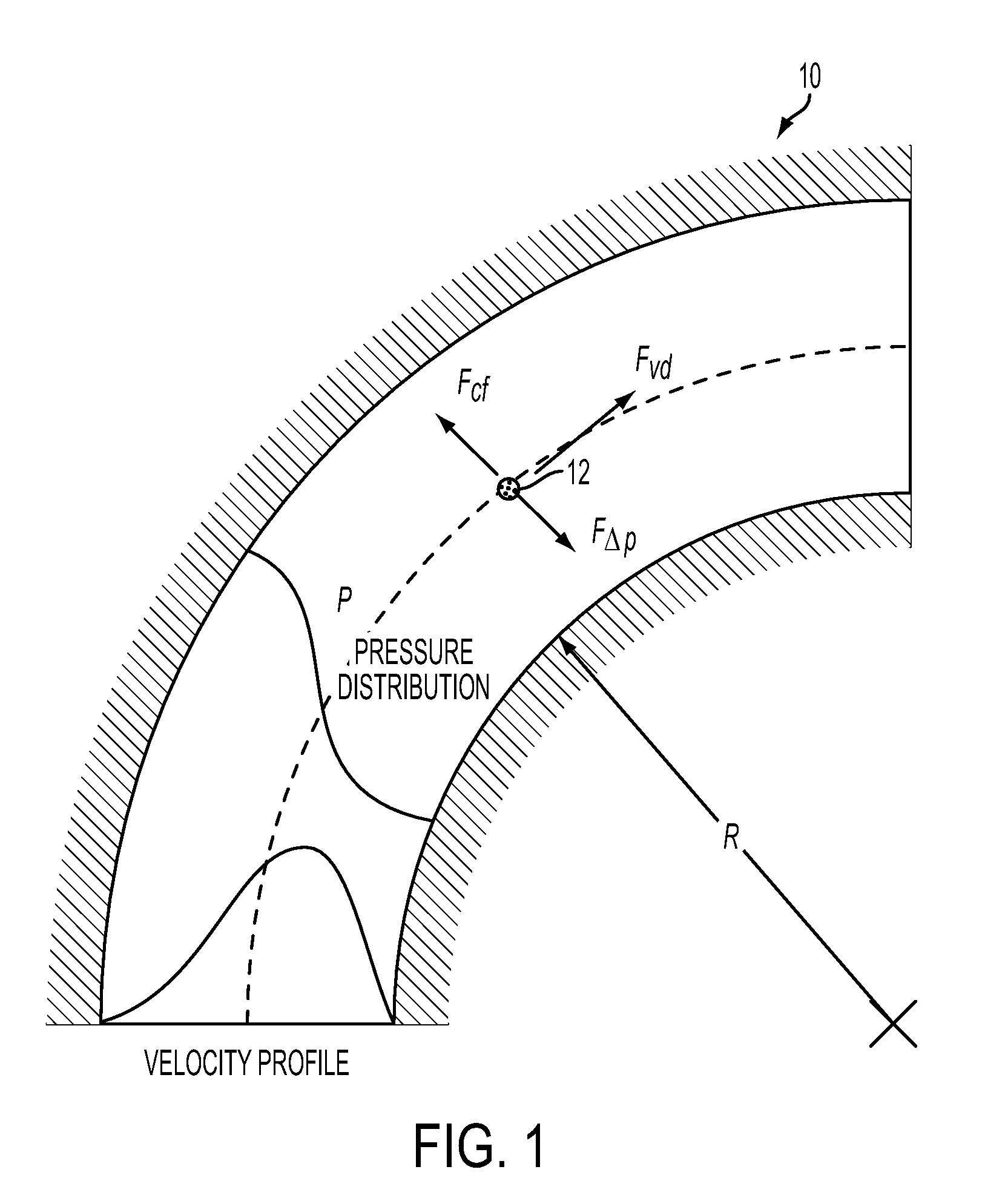

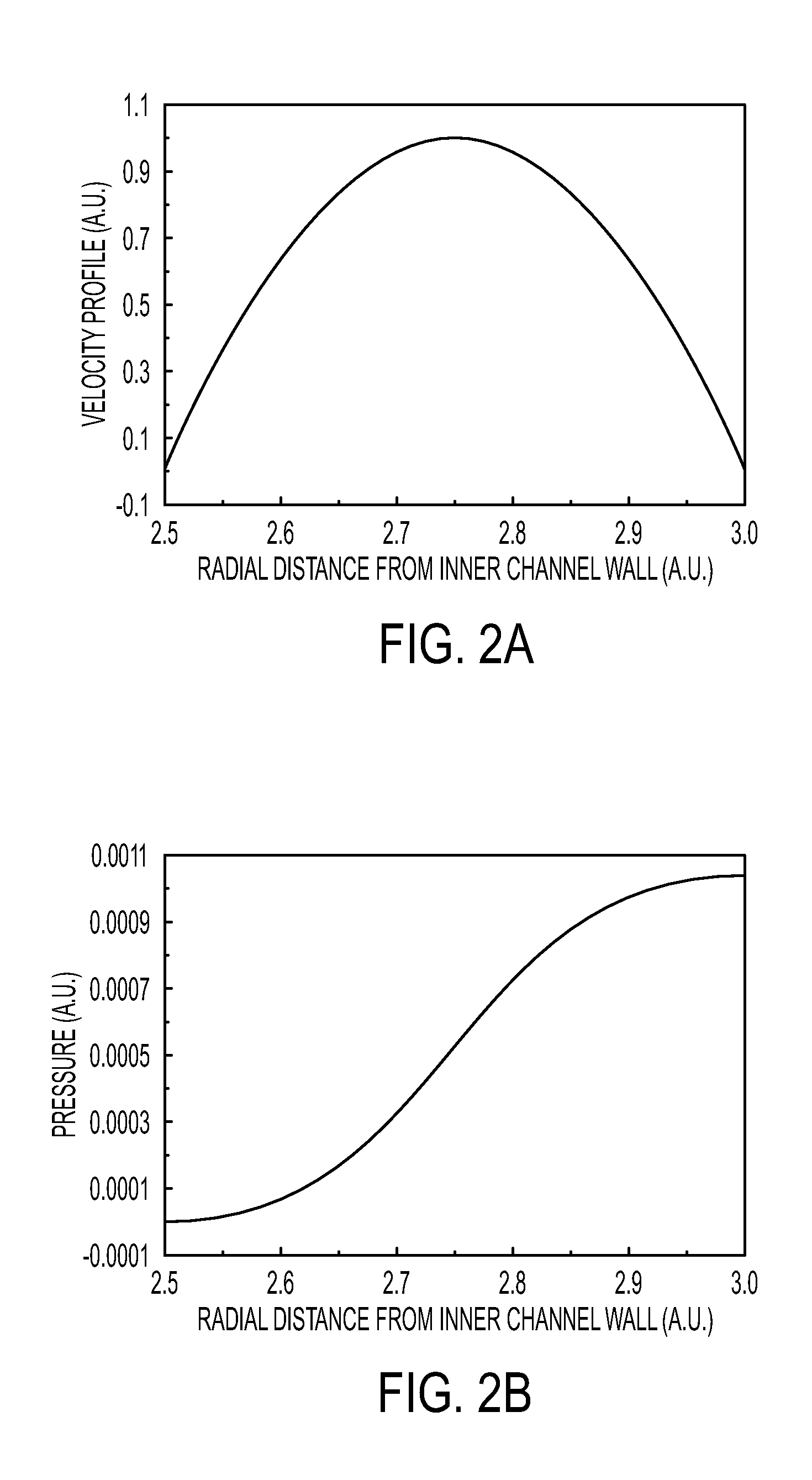

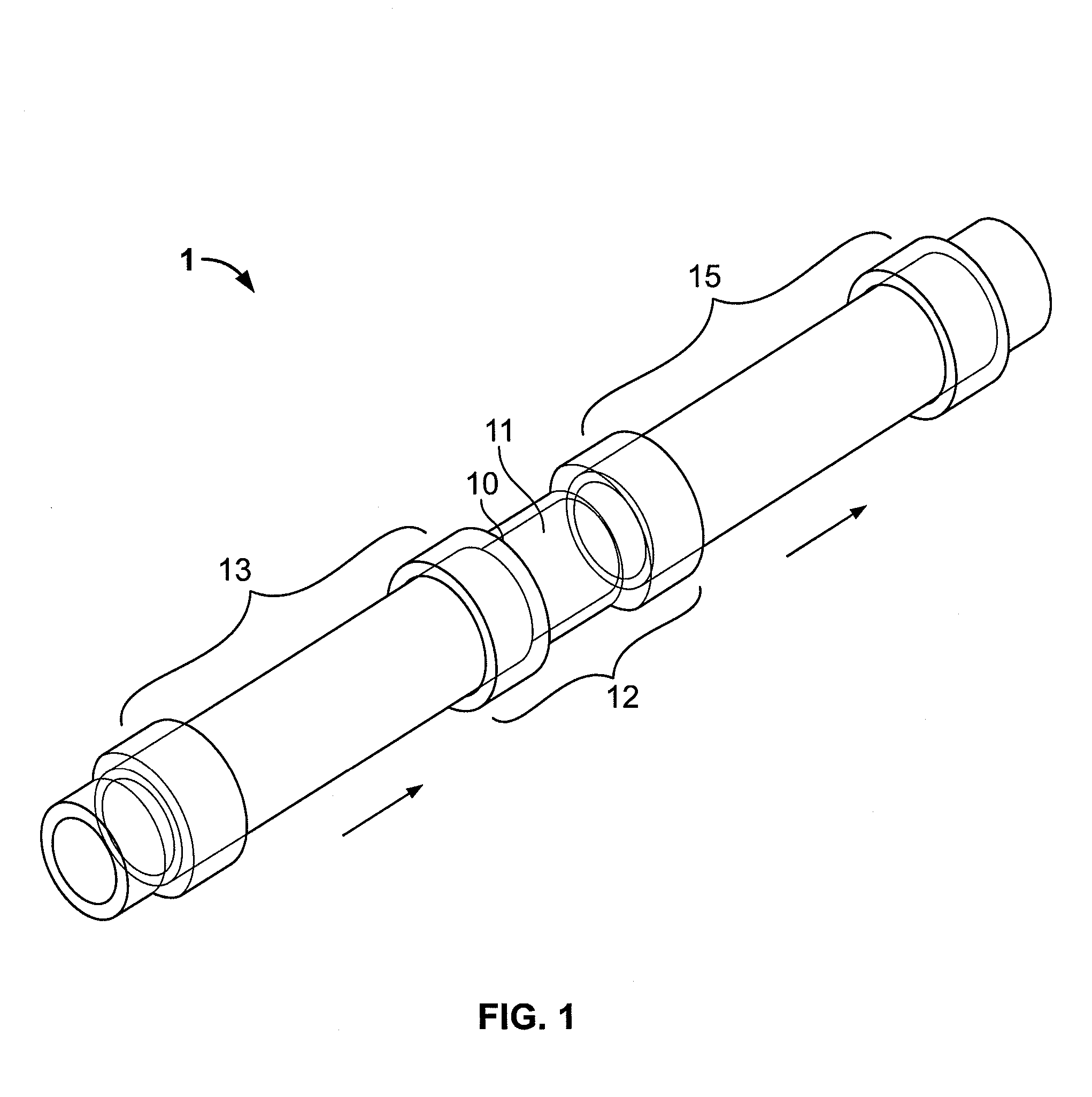

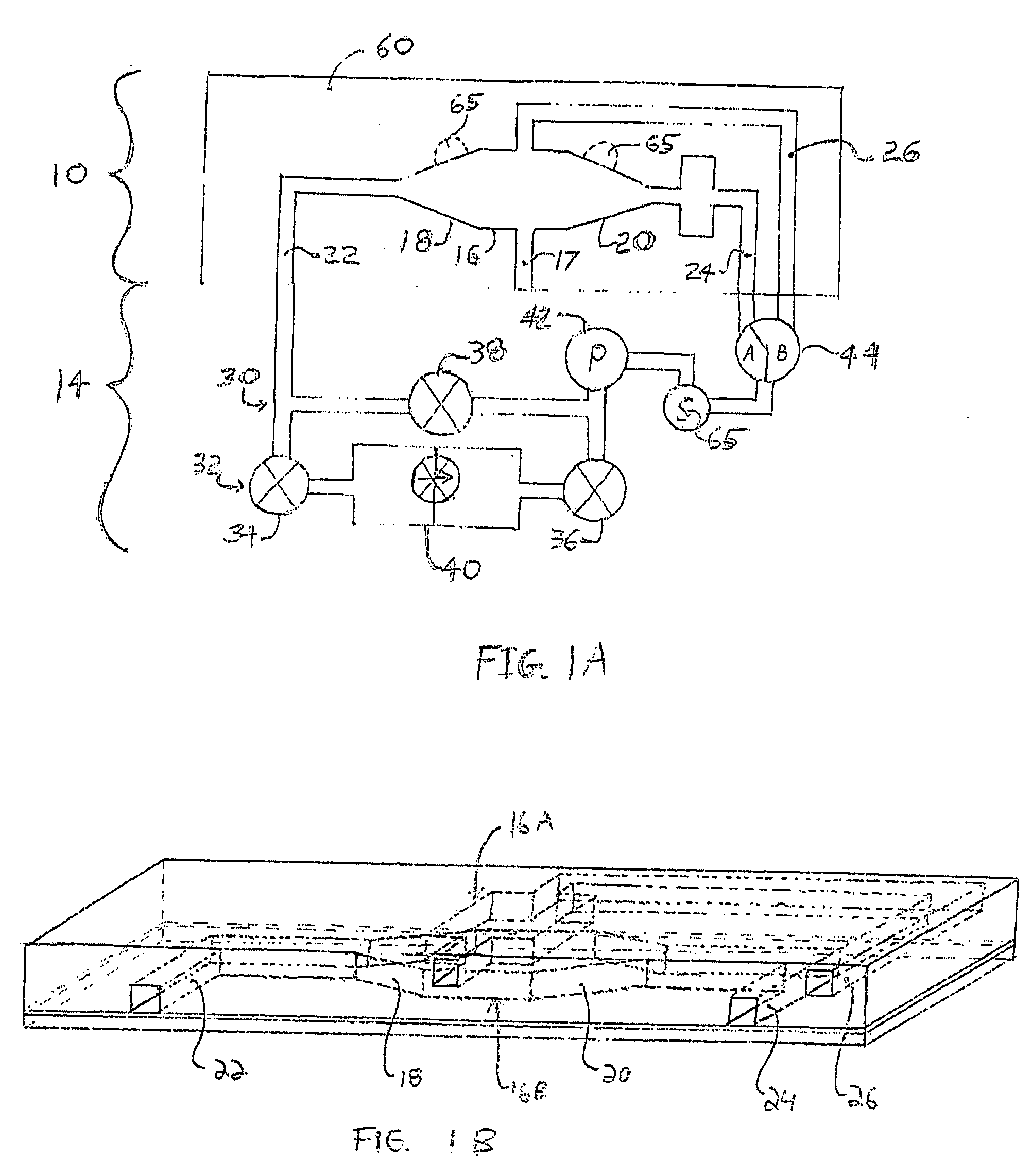

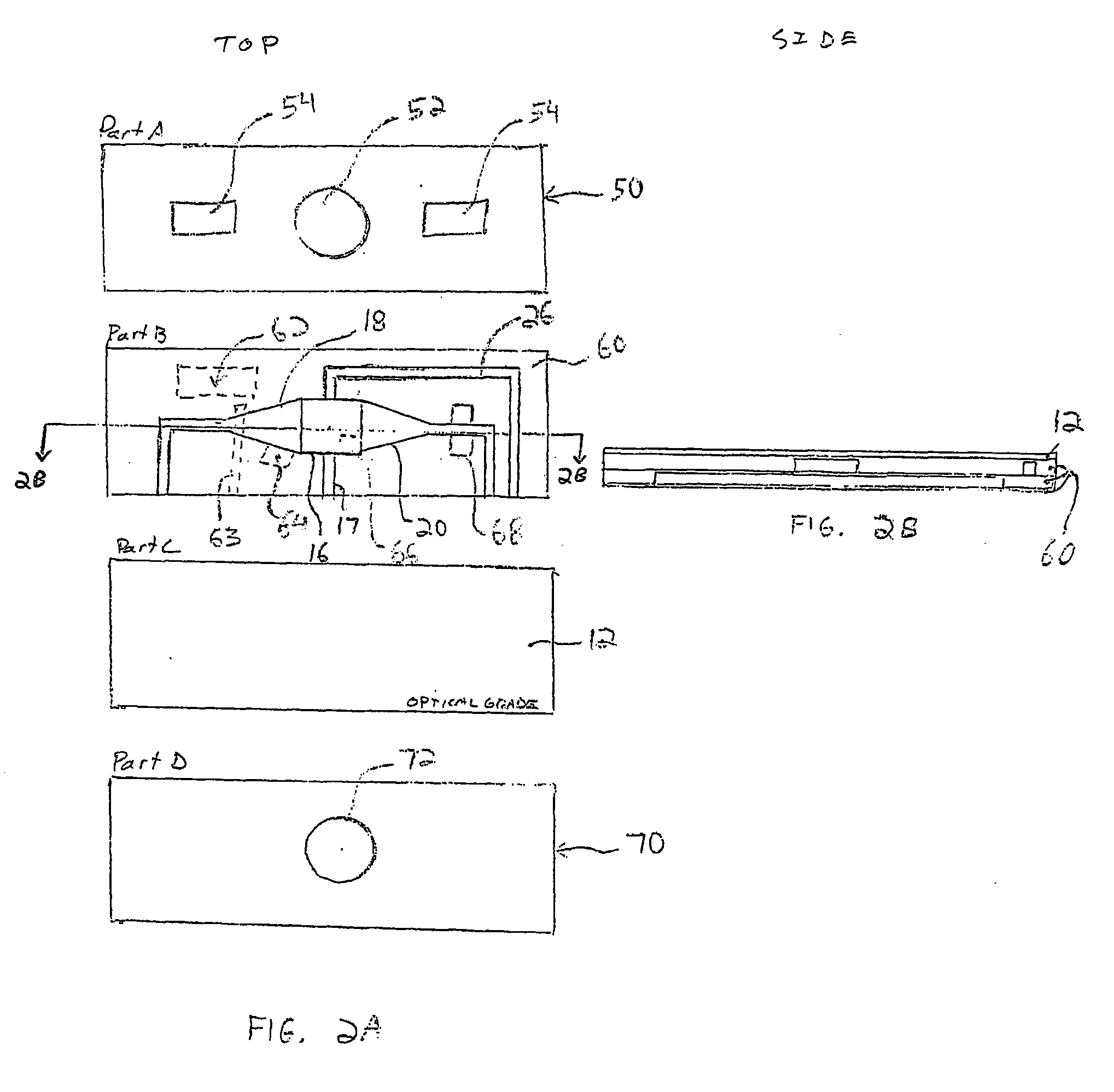

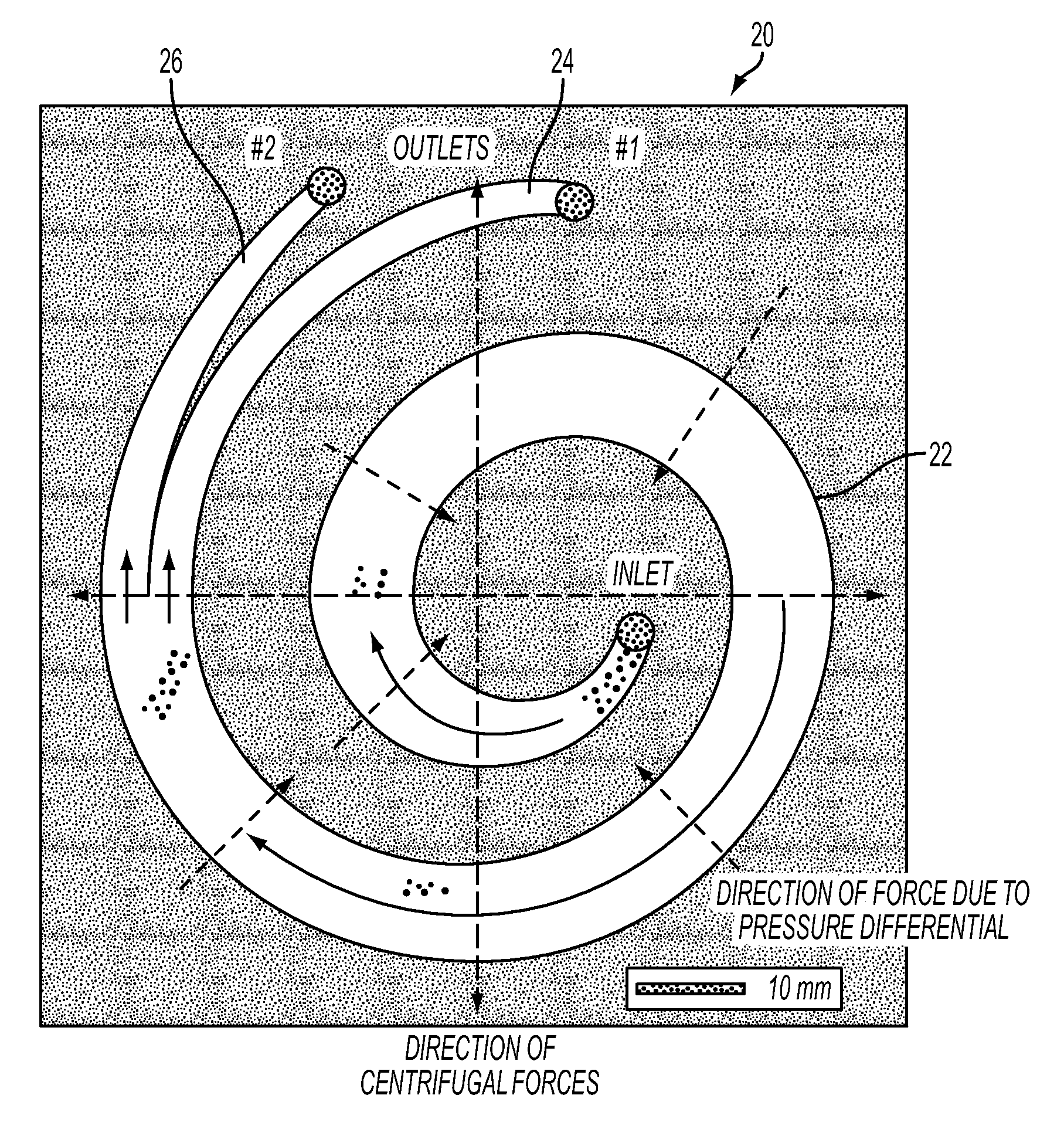

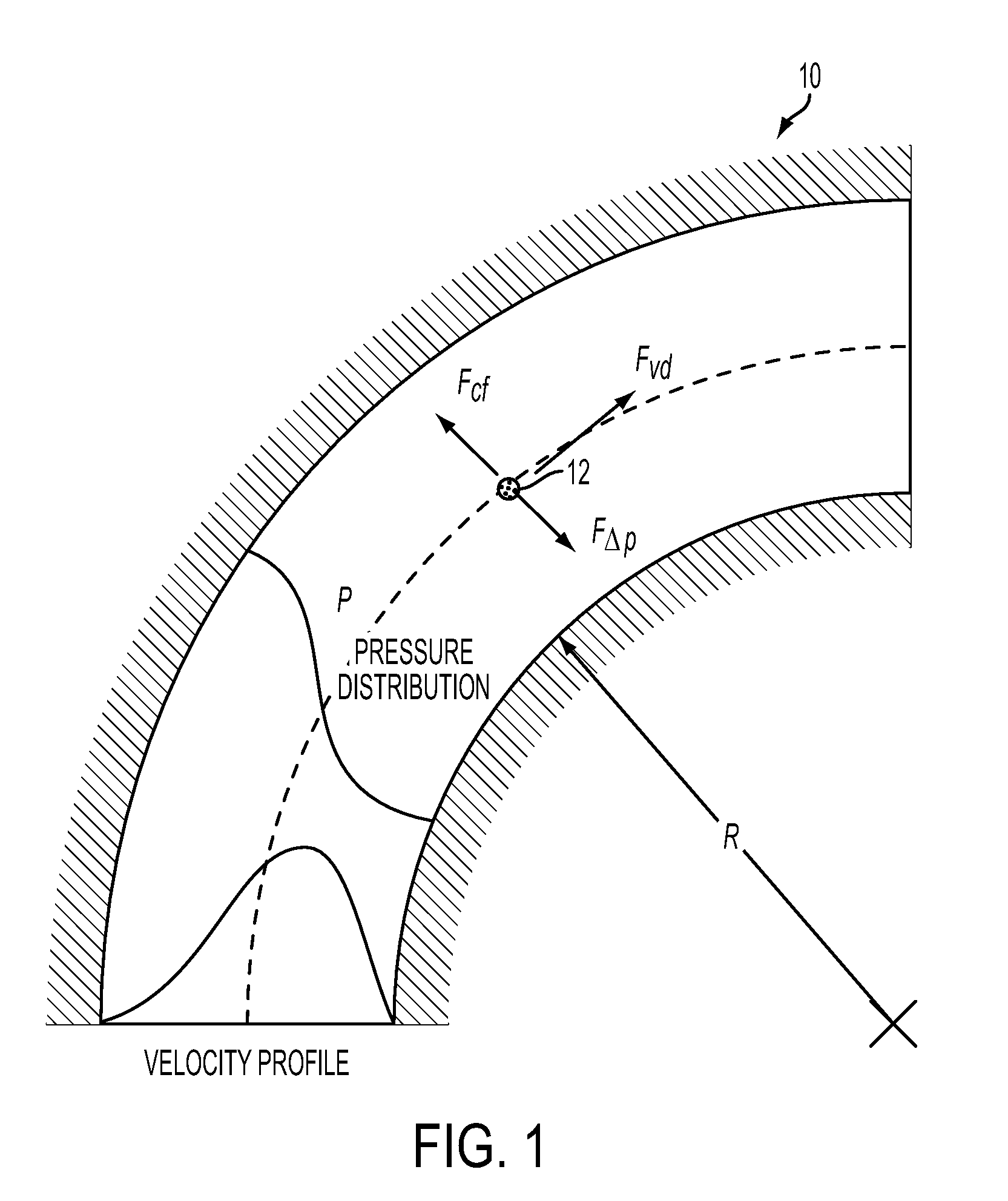

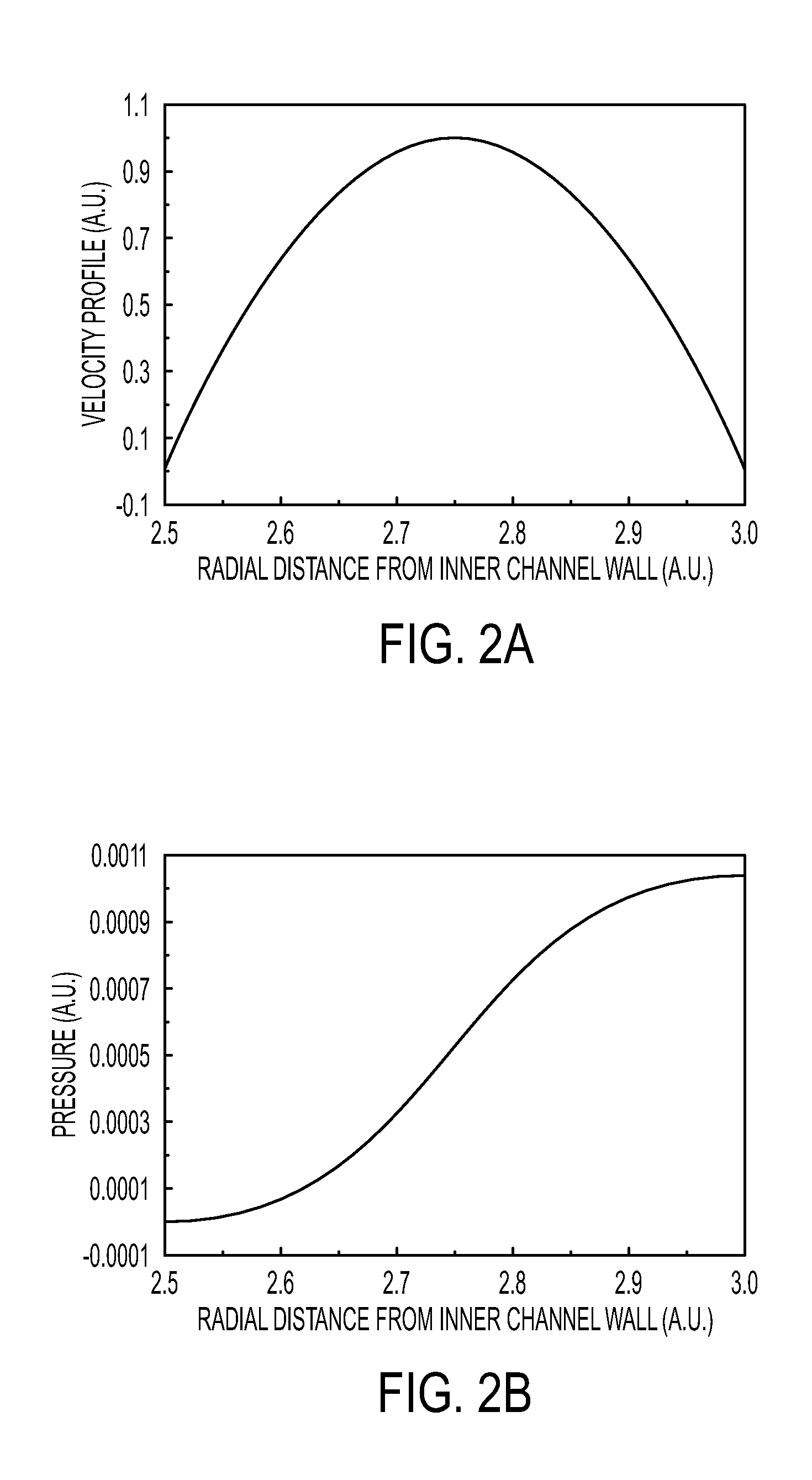

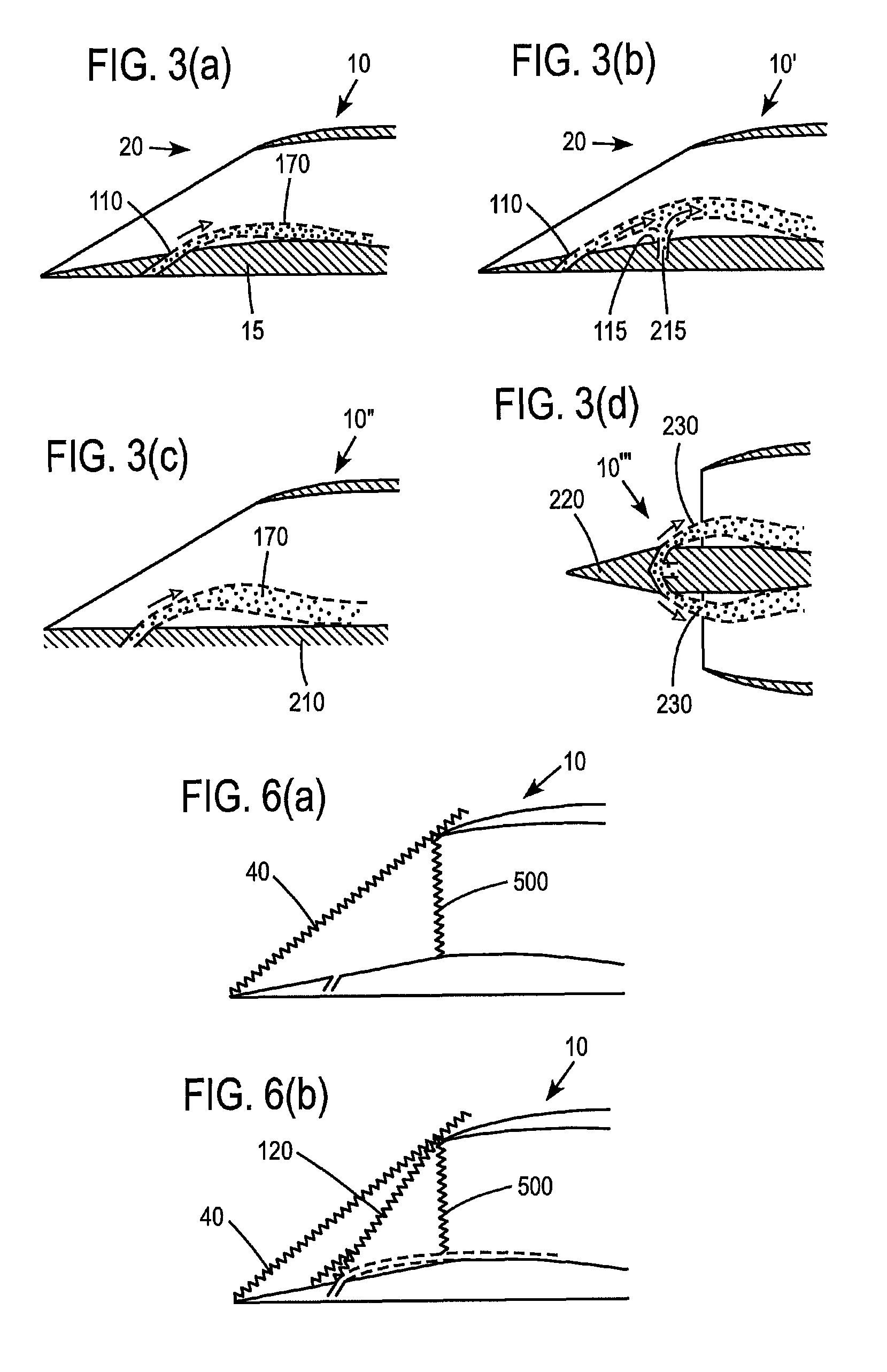

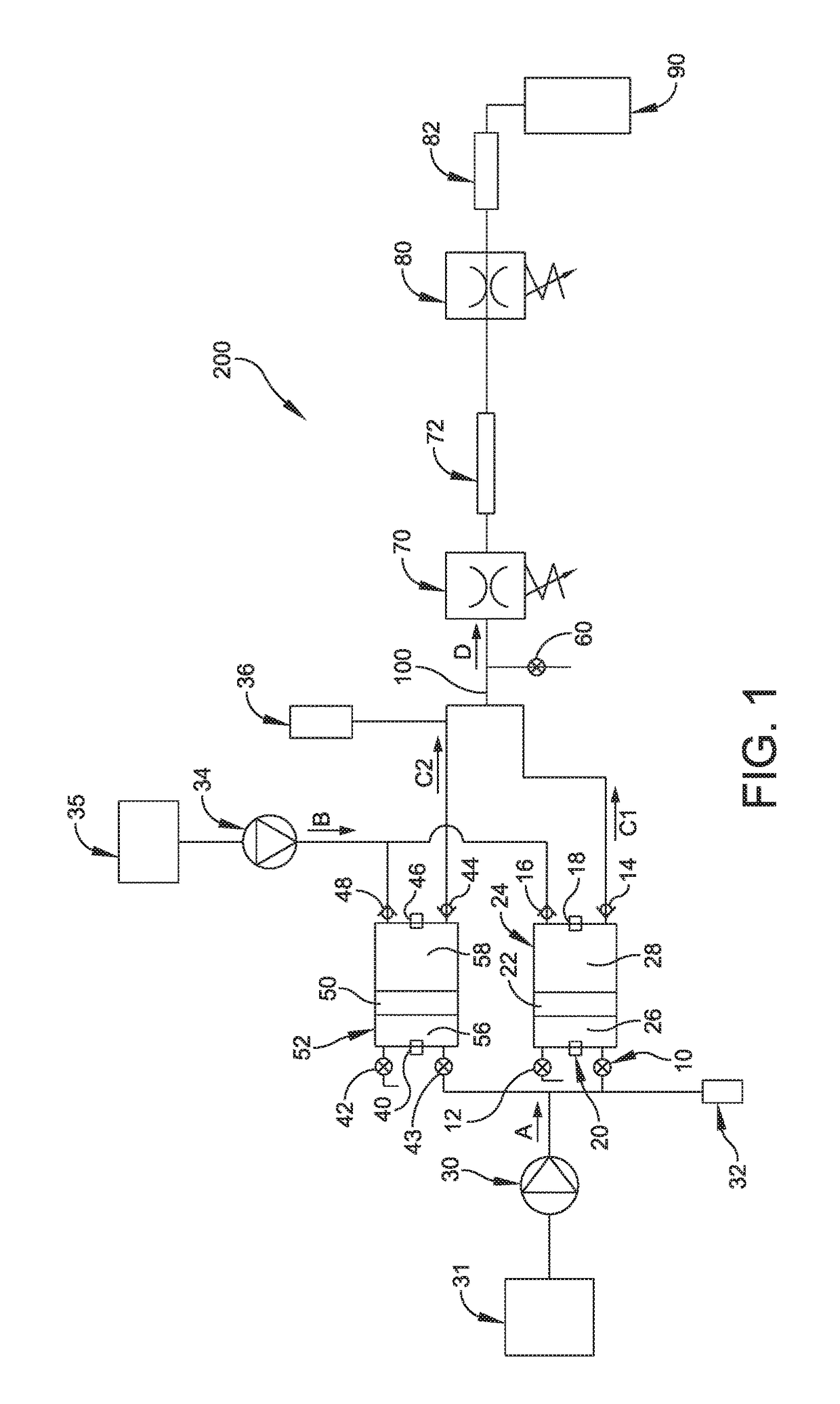

Particle separation and concentration system

This invention is based on size and mass separation of suspended particles, including biological matter, which are made to flow in a spiral channel. On the spiral sections, the inward directed transverse pressure field from fluid shear competes with the outward directed centrifugal force to allow for separation of particles. At high velocity, centrifugal force dominates and particles move outward. At low velocities, transverse pressure dominates and the particles move inward. The magnitudes of the two opposing forces depend on flow velocity, particle size, radius of curvature of the spiral section, channel dimensions, and viscosity of the fluid. At the end of the spiral channel, a parallel array of outlets collects separated particles. For any particle size, the required channel dimension is determined by estimating the transit time to reach the side-wall. This time is a function of flow velocity, channel width, viscosity, and radius of curvature. Larger particles may reach the channel wall earlier than the smaller particles which need more time to reach the side wall. Thus a spiral channel may be envisioned by placing multiple outlets along the channel. This technique is inherently scalable over a large size range from sub-millimeter down to 1 μm.

Owner:XEROX CORP

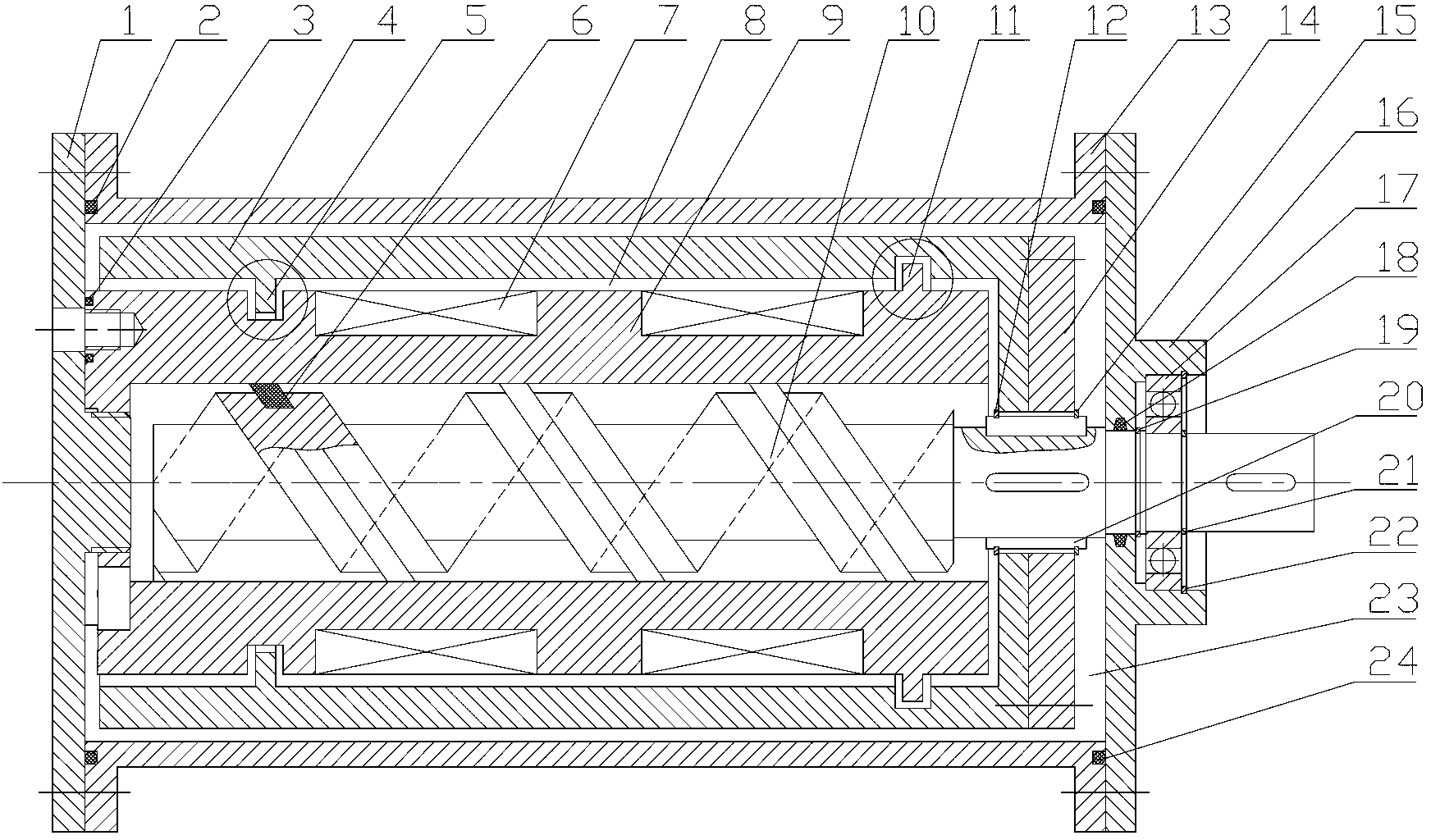

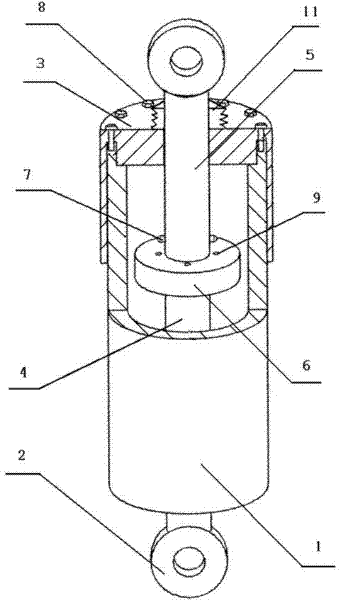

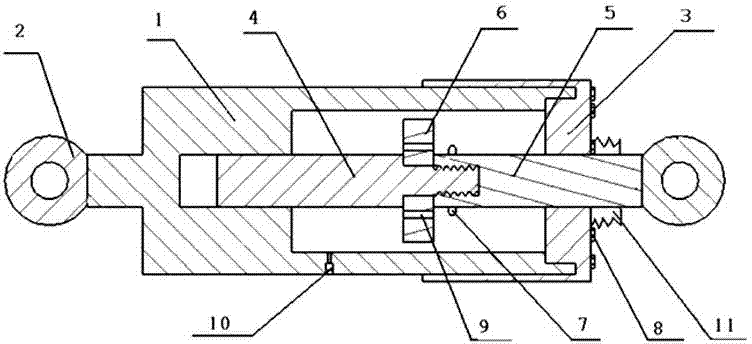

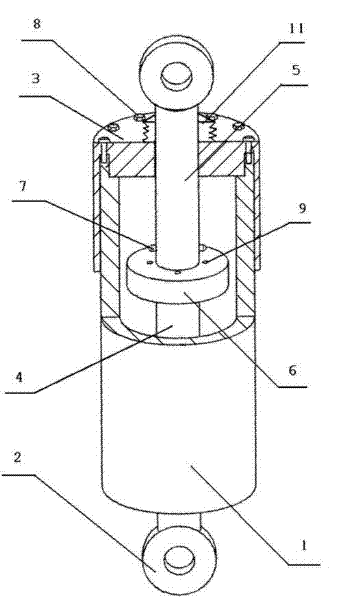

Magneto-rheological torsion damper

ActiveCN103016602ASimple structureLarge damping forceNon-rotating vibration suppressionFluid shearCoupling

The invention relates to a magneto-rheological torsion damper, which mainly comprises a stator, a rotor, a spiral propulsion rod and a shock absorber cylinder body, wherein the input end of the magneto-rheological torsion damper is connected with loading equipment via a coupler; the stator is wound with multiple stages of electromagnetic coils; a groove or a bulge matched with the rotor is processed on the outer wall of the stator; a certain gap is formed between the outer wall of the stator and an inner sleeve; a bulge or groove matched with the stator is processed on the inner wall of a rotor cylinder; the propulsion rod with a spiral propulsion structure, the rotor and the spiral propulsion rod are mutually connected via a terminal pad; the shock absorber cylinder body consists of an outer sleeve, a sealing bearing, a left cover plate and a right cover plate; a certain gap is formed between the shock absorber cylinder body and the inner sleeve; and the gap between the stator and the shock absorber cylinder body as well as the gap between the shock absorber cylinder body and the rotor is full of magneto-rheological fluid. According to the magneto-rheological torsion damper disclosed by the invention, two working modes of magneto-rheological fluid shearing and flowing are fully utilized, and the magneto-rheological torsion damper has the advantages of compact structure, big adjustable damping force and wide dynamic range and can be widely applied to the occasion of torsional vibration control.

Owner:SUZHOU SHIHAO BUILDING MATERIAL NEW TECH ENG

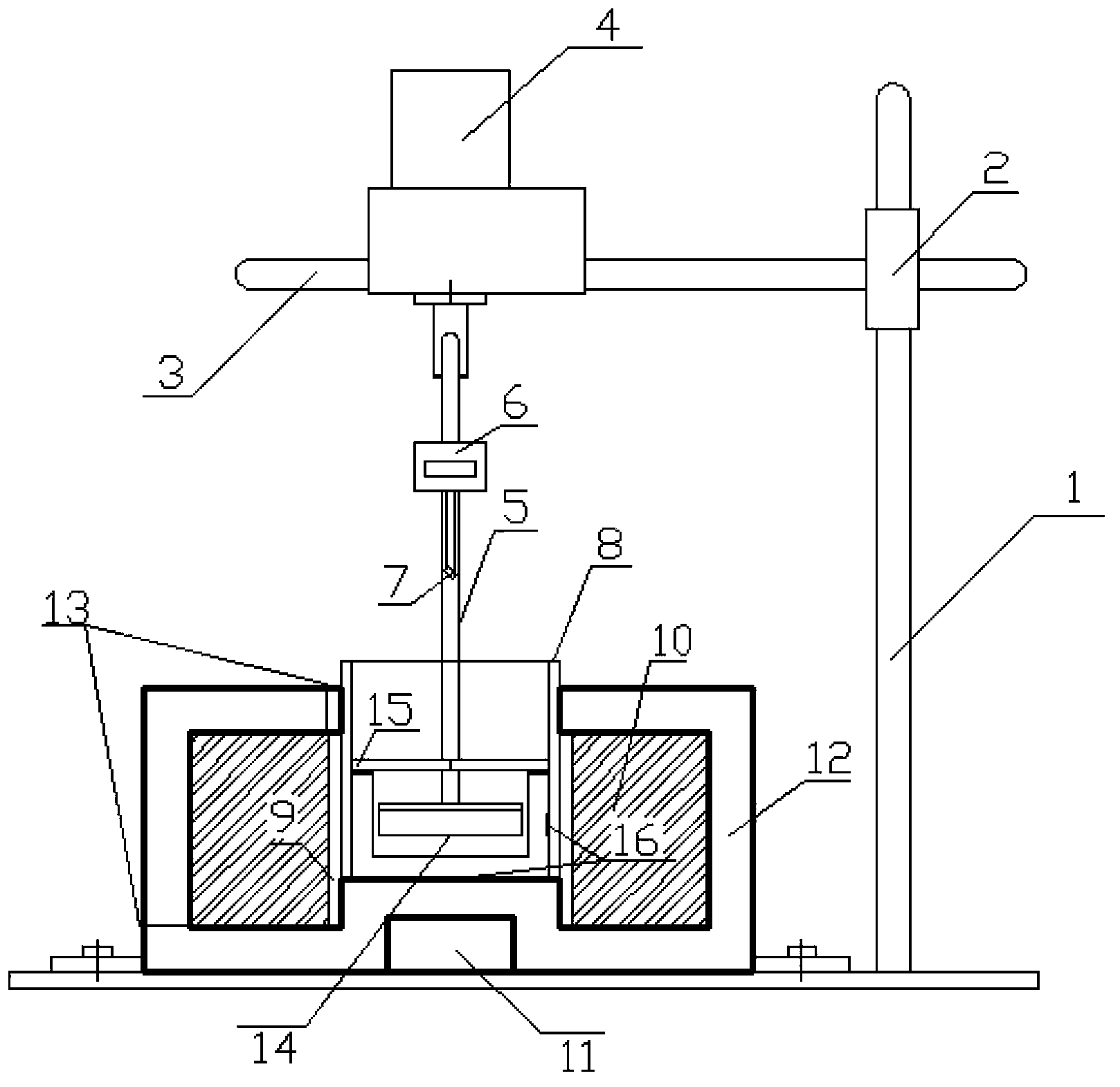

Testing device for magneto-rheological fluid shear yield stress

ActiveCN103512690AAvoid wall slipEasy to pass through verticallyFlow propertiesApparatus for force/torque/work measurementFluid shearClosing wound

The invention relates to a device used for testing magneto-rheological fluid shear yield stress. The testing device mainly comprises an adjustable uniform magnetic field generating device, a steel barrel, a rotary shaft, a seal ring cover plate, a support, a motor, a torque sensor, a Hall piece, a data demodulation single-chip microcomputer and a testing display instrument. The testing device has the advantages that the magnetic field generating device can generate a large adjustable uniform magnetic field; wall face sliding can be prevented from occurring to magneto-rheological fluid under the condition that the magnetic field exists; a testing and displaying device enables weak voltage difference signals to be output onto the testing display instrument accurately in real time through a torque sensor, the PWM theory, a signal amplifying circuit and A / D conversion; a low-reluctance closed loop is formed on the outer side of a close-wound coil through industrial pure iron, and a coil fixing frame on the inner side of the close-wound coil is made of nylon materials so that more magnetic lines can pass through the magneto-rheological fluid. The magneto-rheological fluid is arranged in the center of the magnetic field generating device, so that the magnetic induction strength generated by the detected magneto-rheological fluid is distributed evenly and perpendicularly.

Owner:东南大学常州研究院

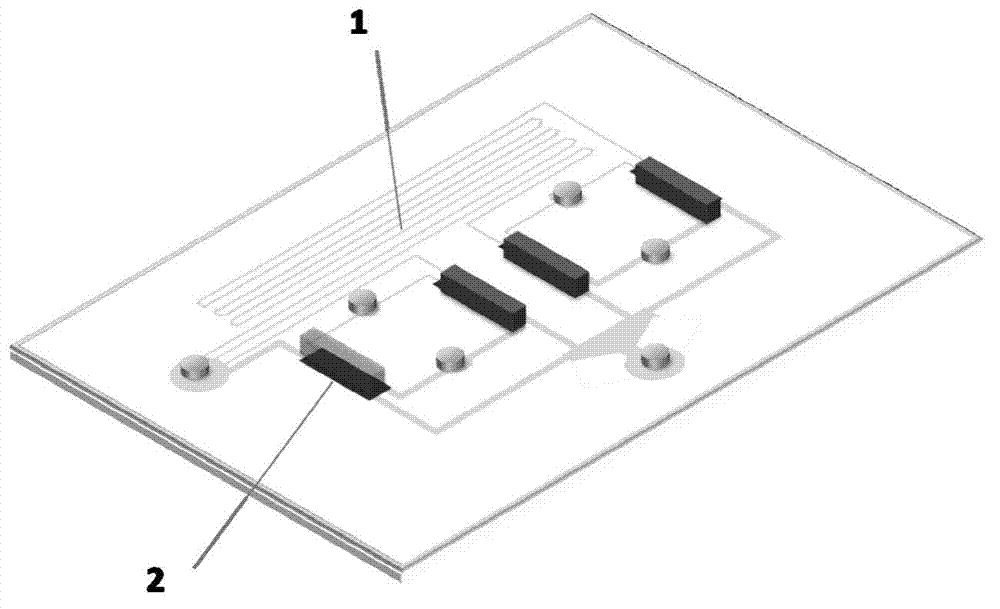

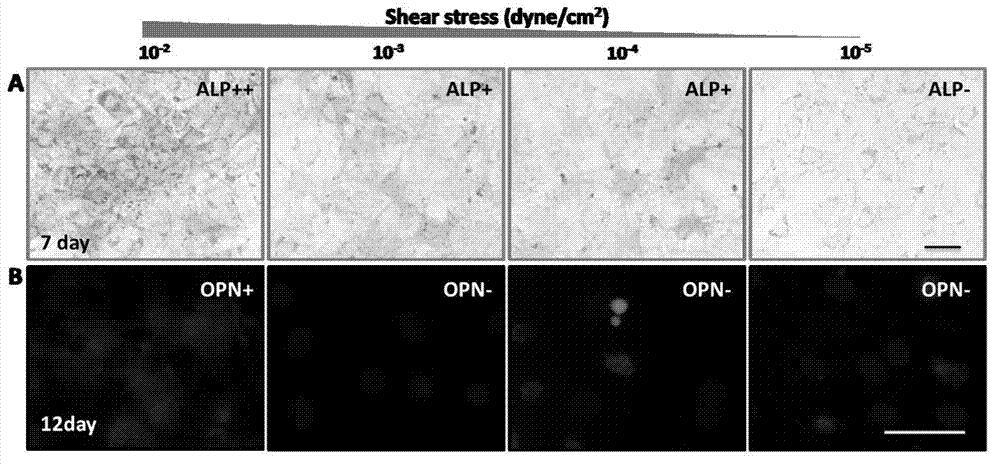

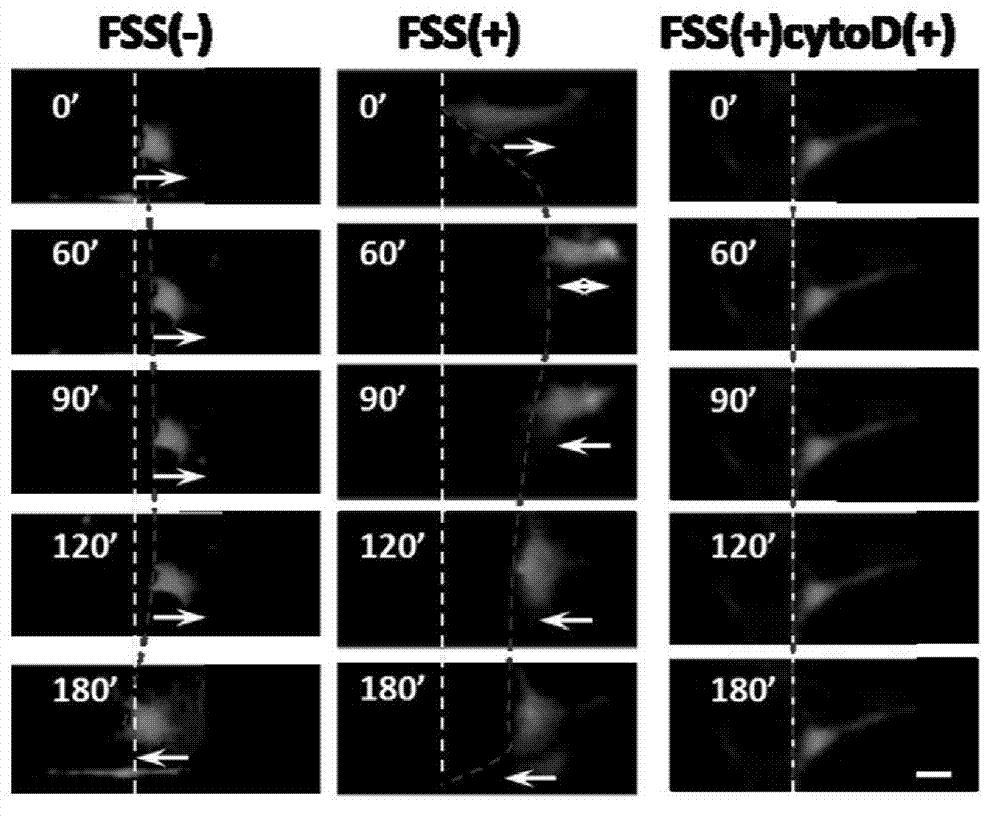

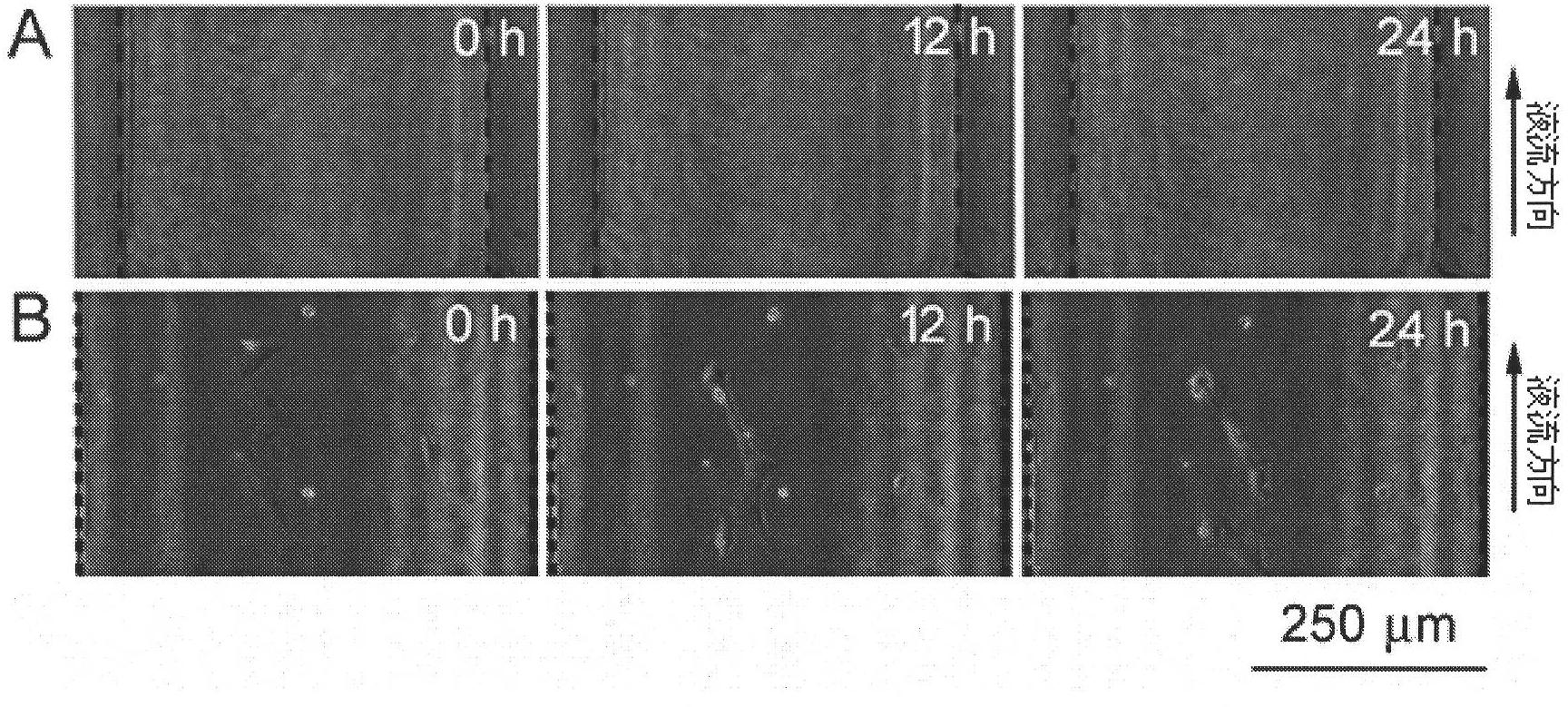

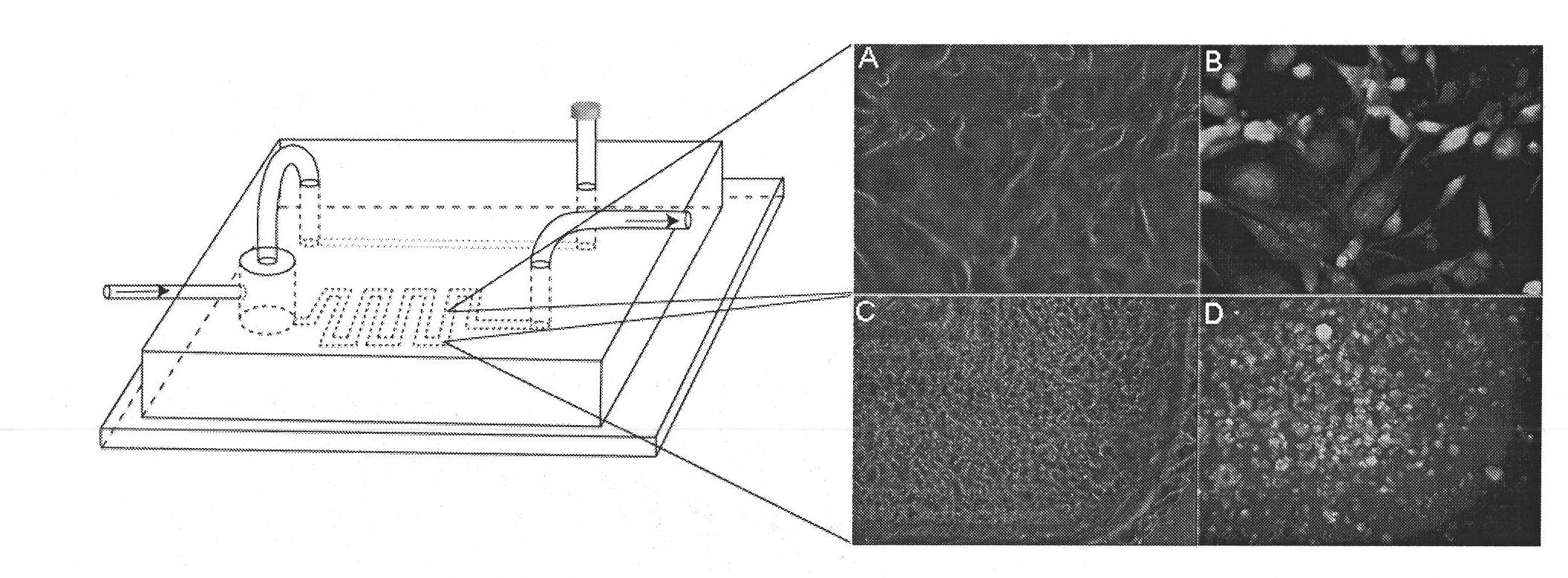

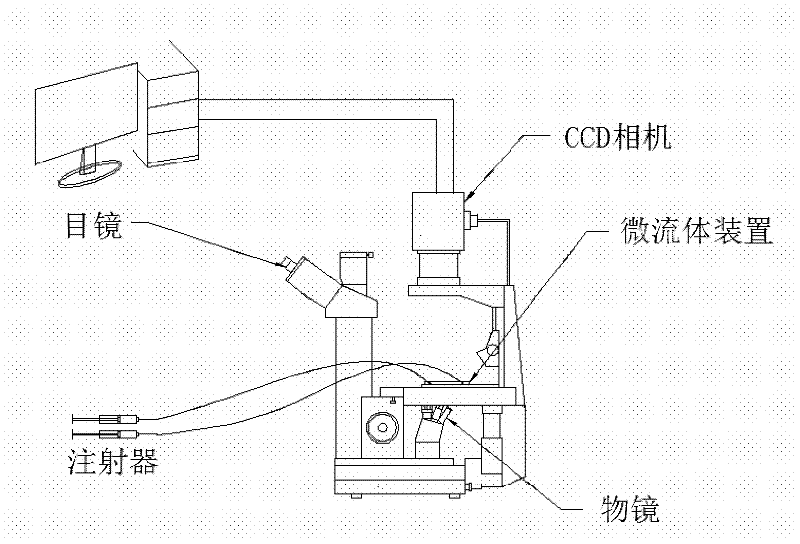

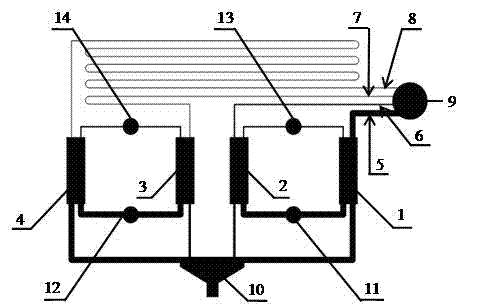

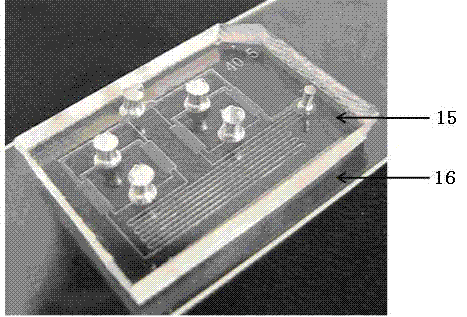

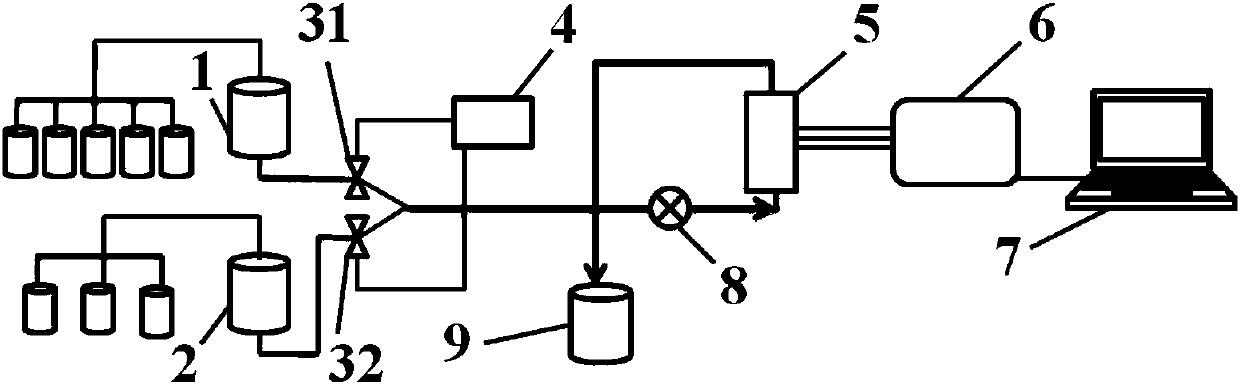

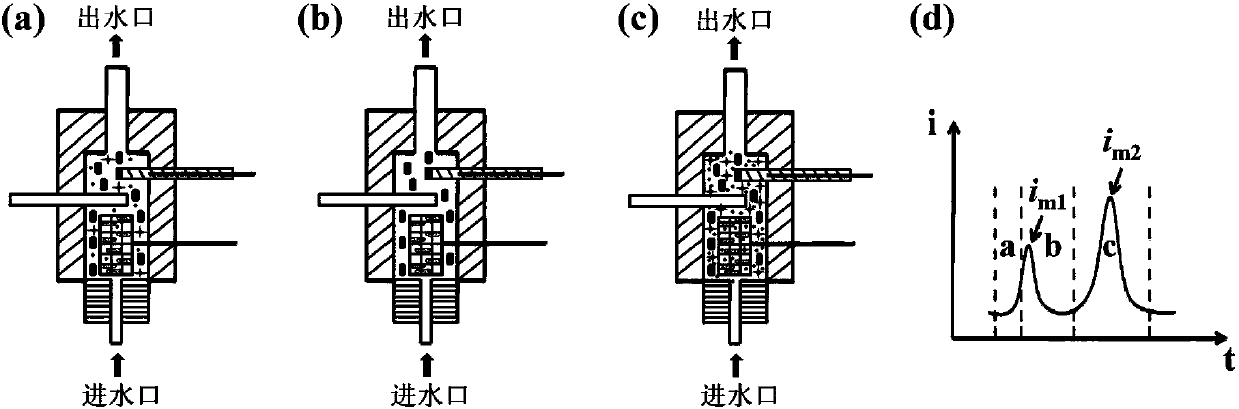

Study on in vivo fluid shearing force simulation cell behaviors on basis of microfluidic chip system

InactiveCN102787071AReduce consumptionSimple and fast operationBioreactor/fermenter combinationsBiological substance pretreatmentsFluid shearEngineering

The invention relates to a study on in vivo fluid shearing force simulation cell behaviors on the basis of a microfluidic chip system. An external precise fluid injection pump is used as a motive power source, a microfluidic chip soft etching technology is used as the basis, and the fluid resistance principle is utilized for designing and manufacturing a microfluidic passage resistance network, so cells in a microfluidic chip cell culture microchamber can feel fluid shearing force with different intensities, and further, the cell behavior change is studied. Through the microfluidic chip system, the process of the inoculation and long-term culture of cells, the fluid shearing force stimulation on the cells and the cell dyeing and analysis and detection are integrated on a functionalization chip to be completed, and the cell behavior analysis and the in vivo ultra-low fluid shearing force simulation on a microfluidic chip platform are realized.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

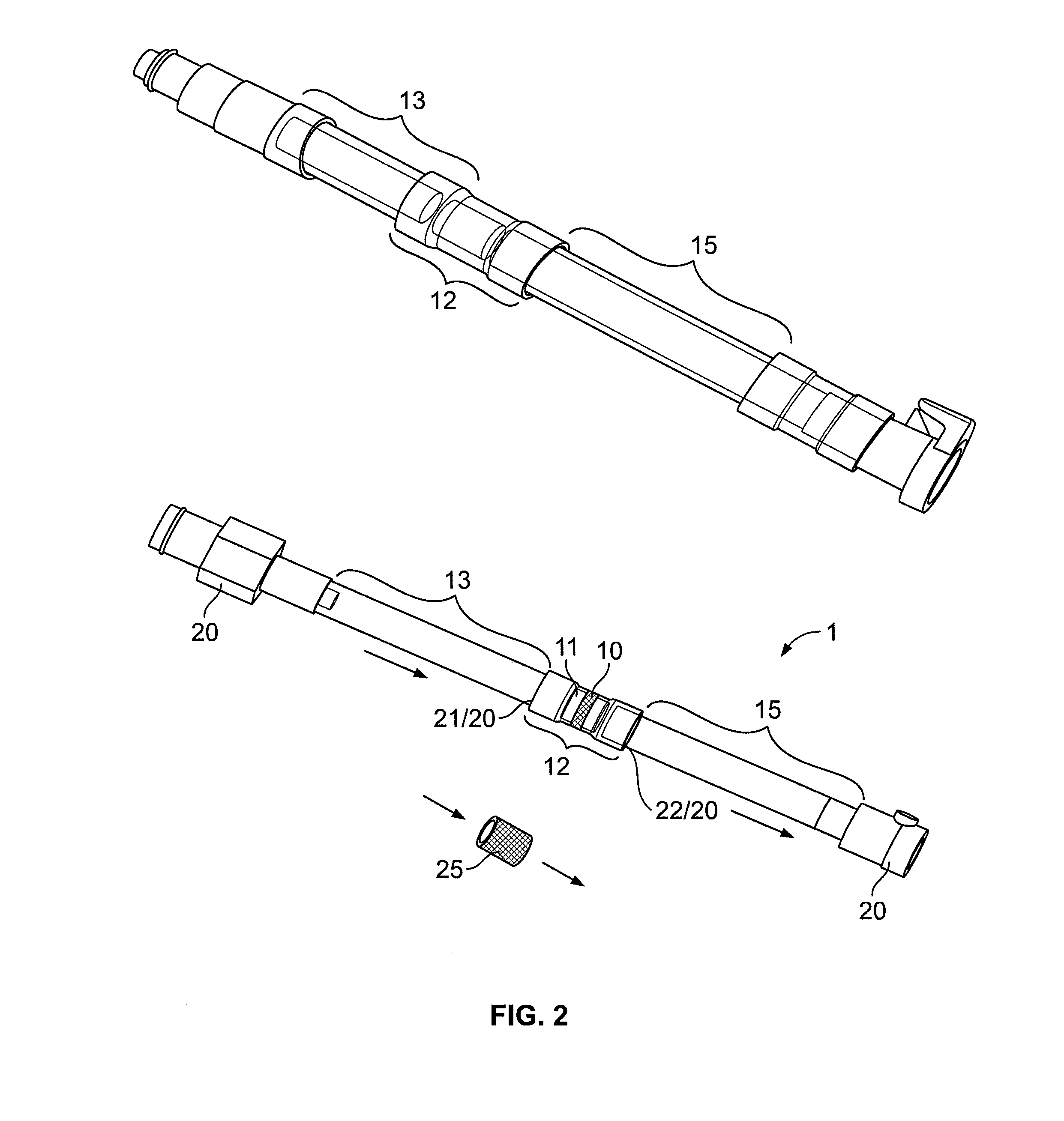

Bubble removing device used for microfluidic channel

ActiveCN102373153ASimple structureLightweightBioreactor/fermenter combinationsBiological substance pretreatmentsFluid shearEngineering

The invention provides a bubble removing device used for a microfluidic channel. The bubble removing device comprises: a cavity positioned at the liquid inlet of a microfluidic channel for buffering a liquid and capturing bubbles; a bubble drainage bypass connected with an upper opening of the cavity for removing bubbles captured by the cavity. And the bubble drainage bypass consists of two bypass pipes and a bypass channel, which is parallel to the microfluidic channel, with the two bypass pipes respectively positioned at two ends of the bypass channel. Specifically, one bypass pipe is used for connecting the bypass channel and the cavity, and the other bypass pipe is used for removing bubbles. The bubble removing device provided in the invention has the advantages of simple structure, high integration degree, no need for support of an external device, and no influence on a normal liquid flow inside the microfluidic channel, thus being suitable for all fluid shear force cell experiments and protein, nucleic acid biochemistry, and immune microfluidic chip detection experiments with a need for no bubble interference in immune microfluidic chips.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

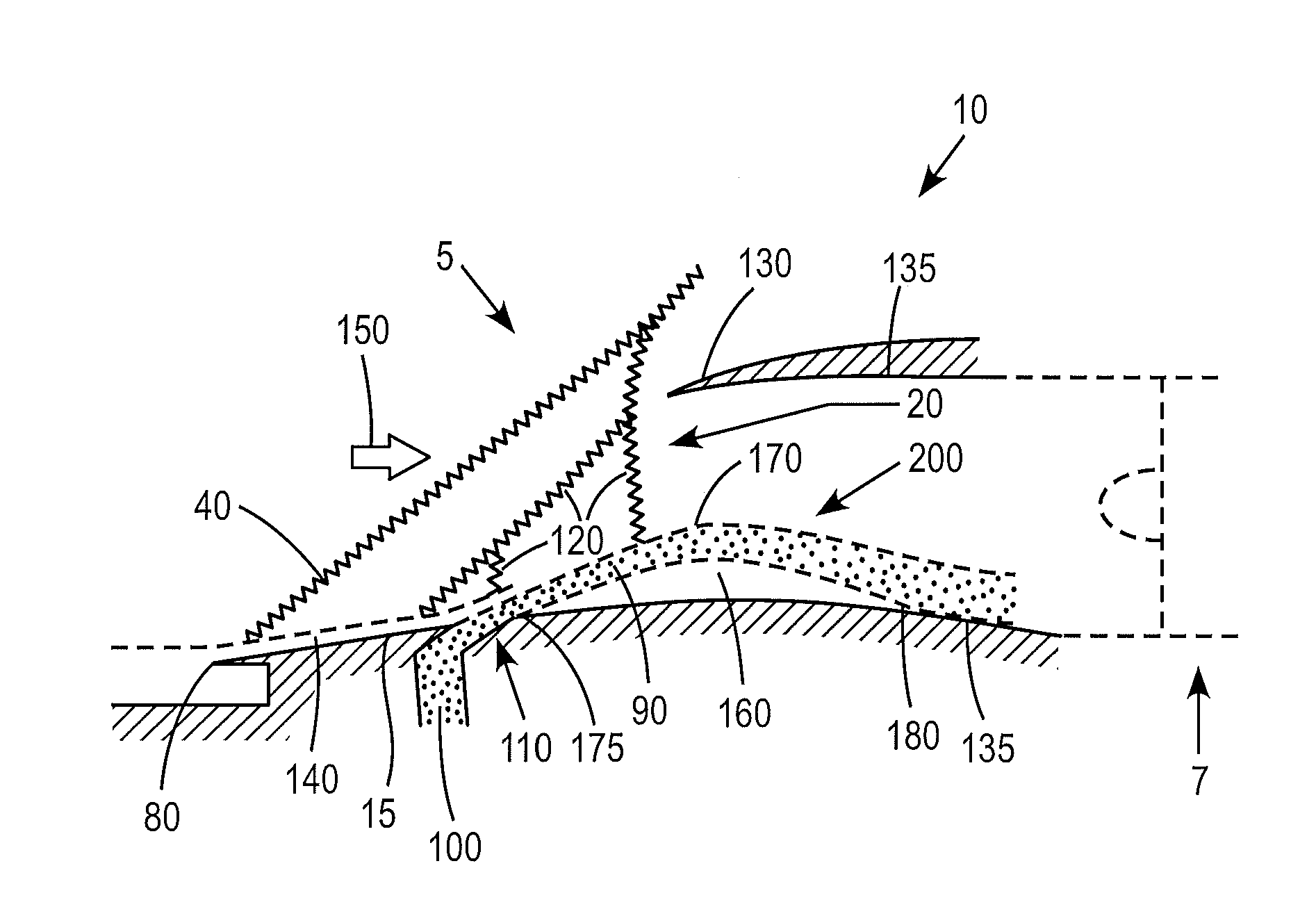

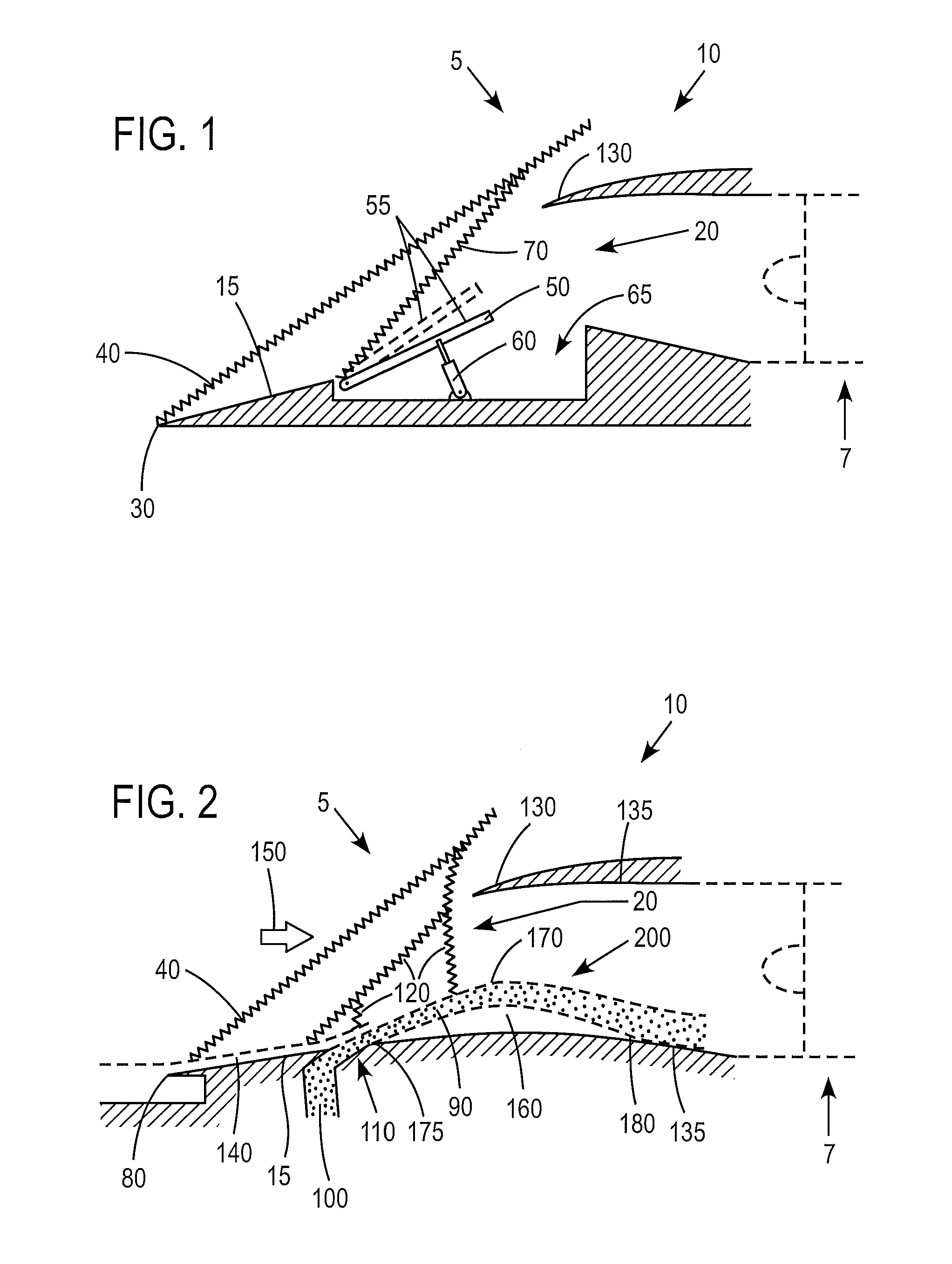

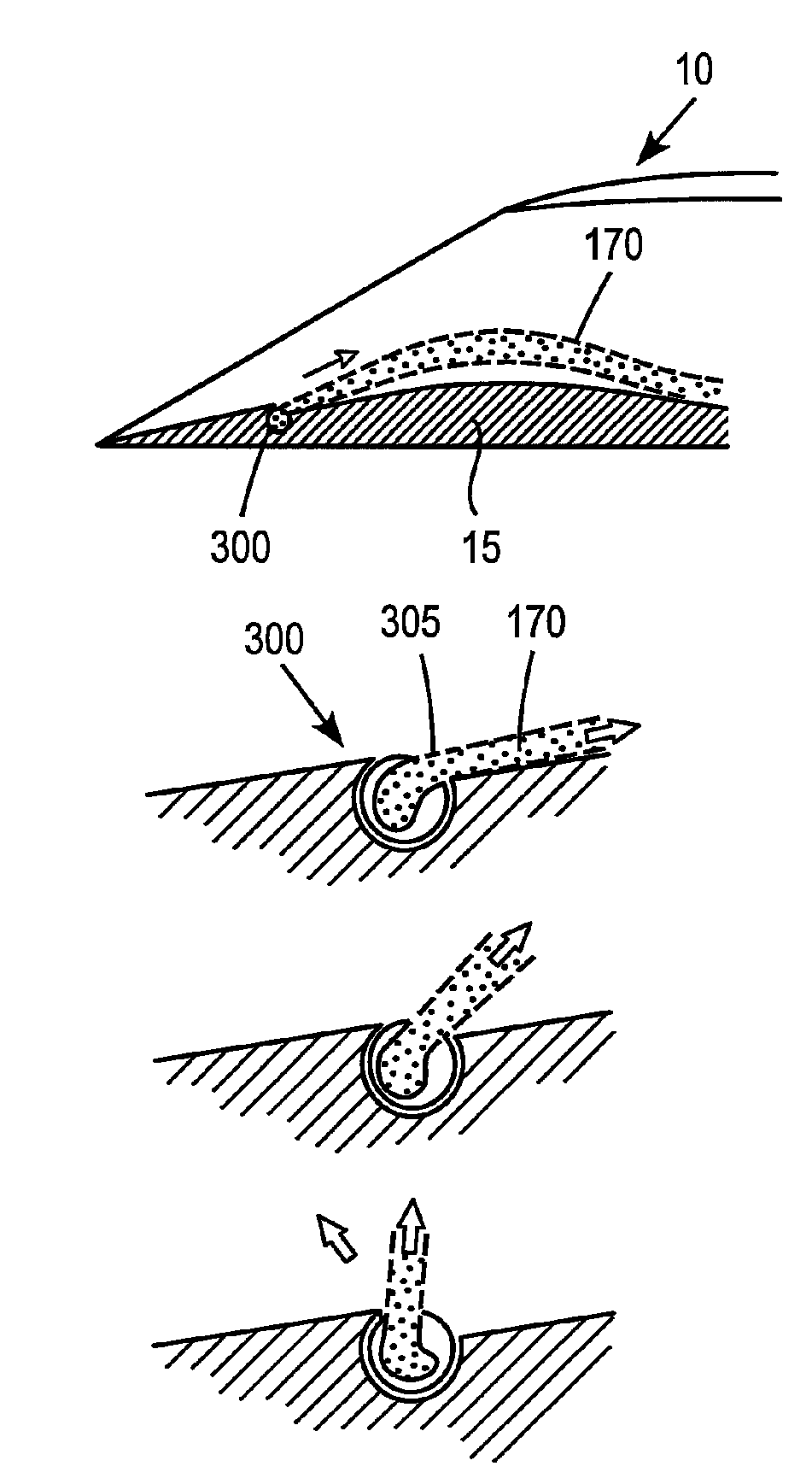

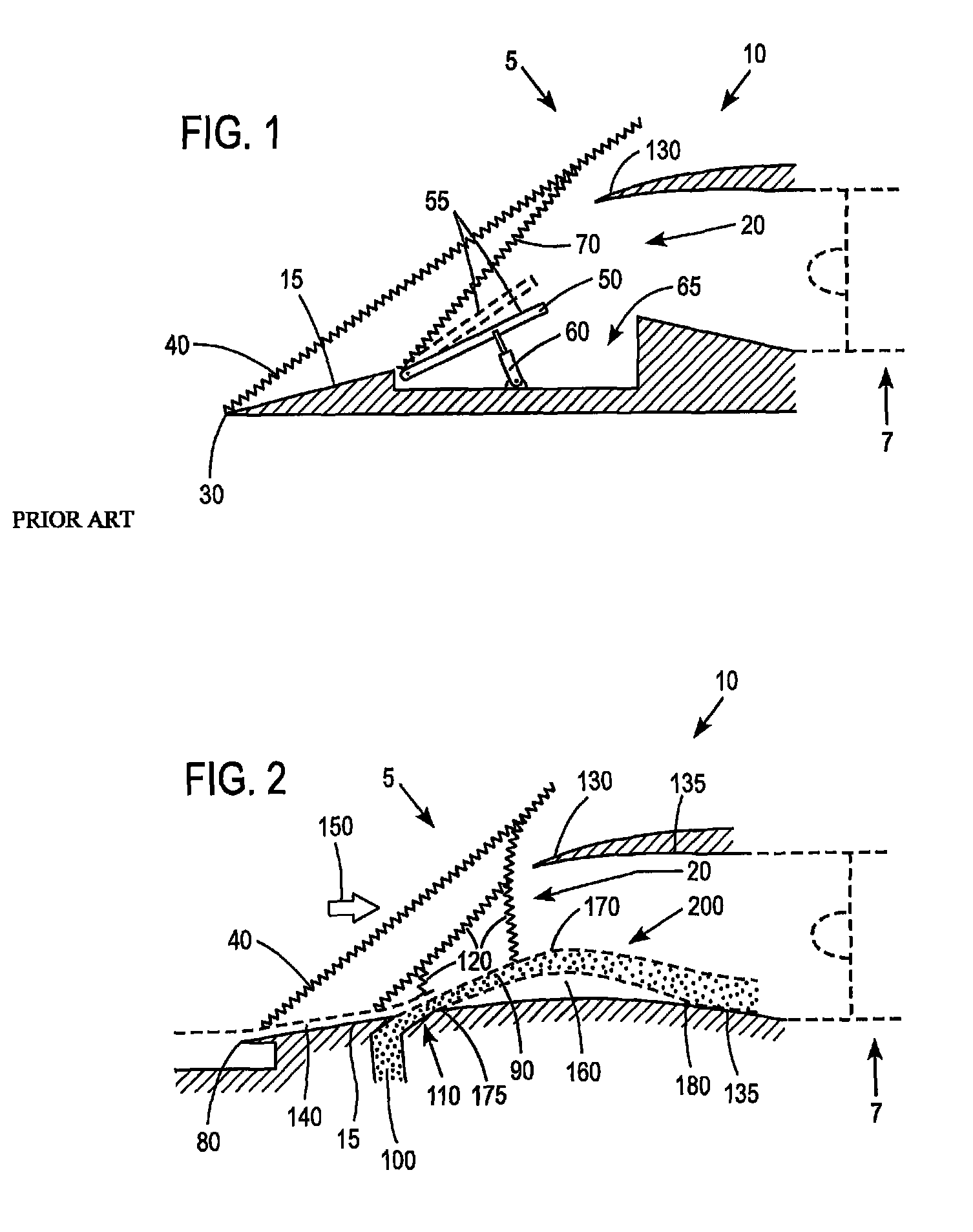

Relating to air-breathing flight vehicles

An air intake for a supersonic air-breathing flight vehicle introduces or injects fluid in order to create predetermined regions of separated flow and an attendant fluid shear layer. This shear layer forms an aerodynamic boundary for the capture flow with a profile determined and optimised by appropriate injection of fluid. The aerodynamic boundary so generated replaces mechanically moveable solid surfaces used to vary the geometry of prior-art intakes. Use of an introduced or injected fluid can provide an advantage of a variable geometry, but with reduced weight and reduced mechanical complexity. In some embodiments, the injection of fluid has the effect of re-energising any ingested boundary layer, thus obviating the conventional requirement for a bleed system to provide boundary layer control.

Owner:MBDA UK

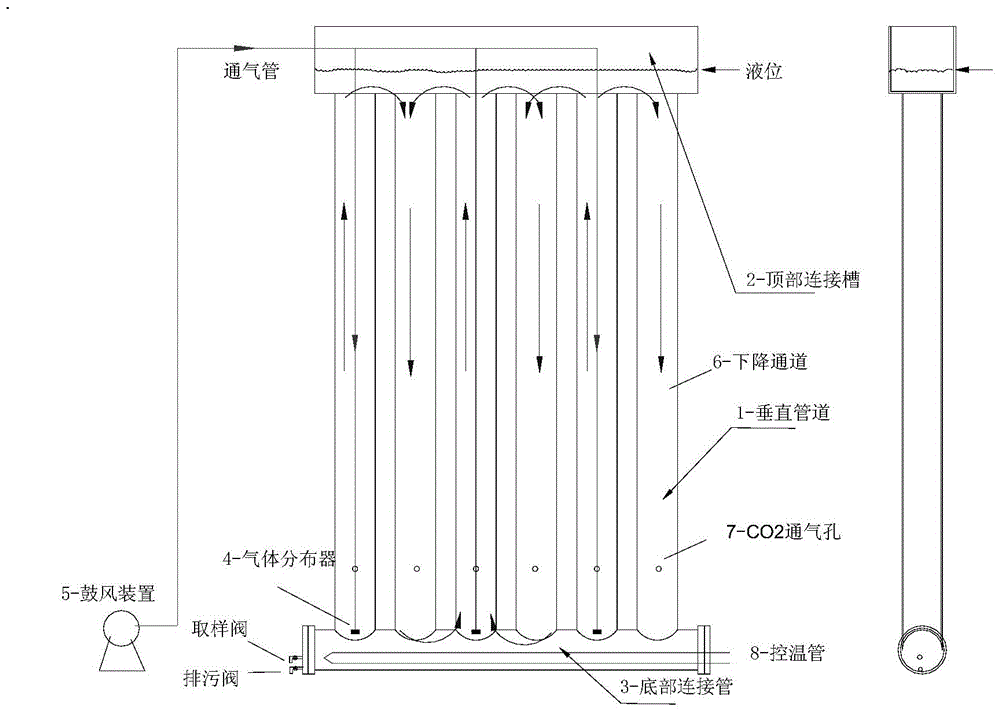

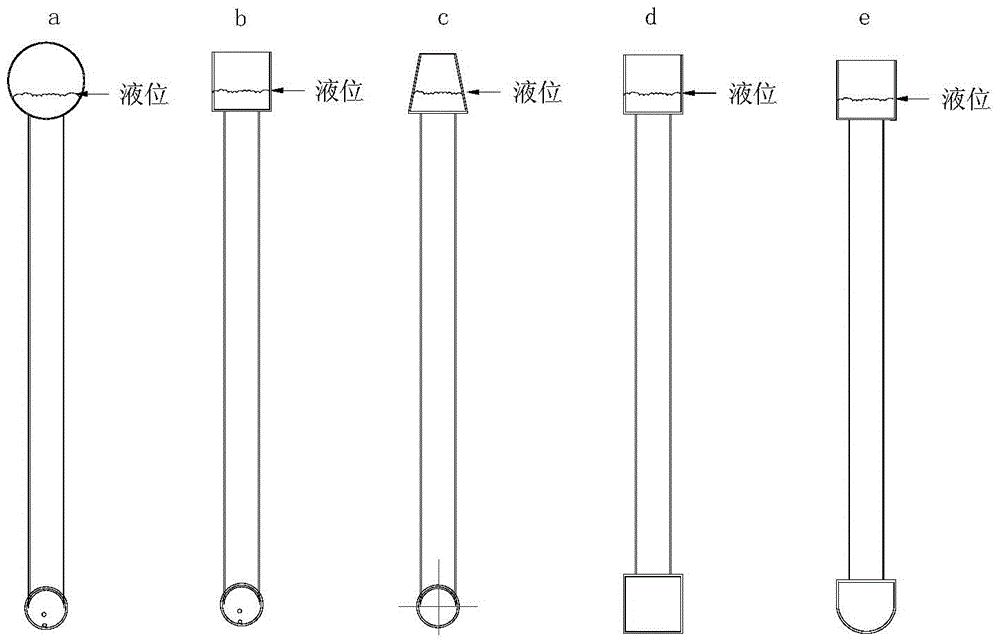

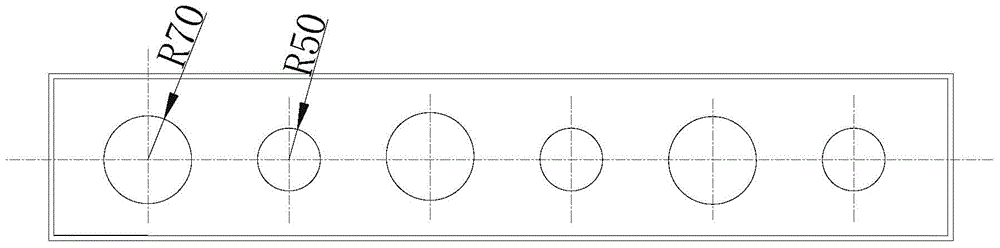

Novel multifunctional airlift tube photobioreactor

InactiveCN105462807ASolve the problem of difficult engineering enlargementAvoid elevationBioreactor/fermenter combinationsBiological substance pretreatmentsHigh densityControl system

The invention provides a reactor body and a multifunctional airlift tube photobioreactor. The reactor body, namely a reaction device, comprises two or more transparent perpendicular pipelines arranged side by side, and connecting tubes or connecting grooves communicated with the tops and the bottoms of the perpendicular pipelines respectively. The photobioreactor comprises the reactor body, a ventilation system and an optional parameter detection and control system. The invention further provides a microalgae culture method which comprises the step that the reactor body or the photobioreactor is used for carrying out photoautotrophic culture, photoinduction culture and mixotrophic nutrition culture of the microalgae. The multifunctional airlift tube photobioreactor has the advantages of being large in illumination specific surface area, high in gas-liquid mass transfer coefficient, small in fluid shear force and the like; engineering enlargement, cleaning and maintenance are easy, operation is convenient, high-density, high-efficiency and large-scale photoautotrophic culture, photoinduction culture and mixotrophic nutrition culture of the microalgae can be achieved, high-efficiency culture of photosynthetic bacteria can also be achieved, and meanwhile the multifunctional airlift tube photobioreactor can be used for microalgae carbon sequestration and wastewater treatment.

Owner:JIAXING ZEYUAN BIOLOGICAL PROD

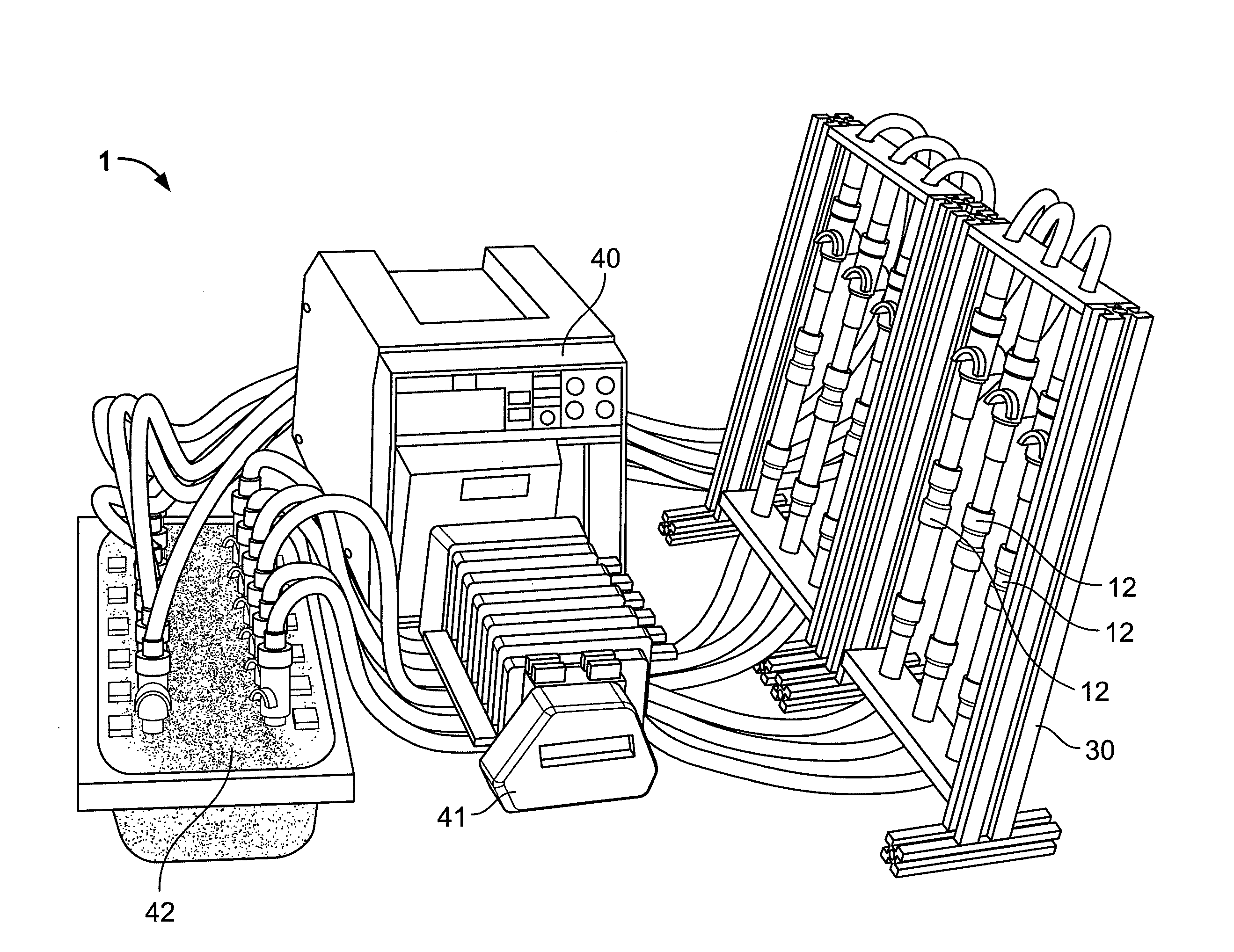

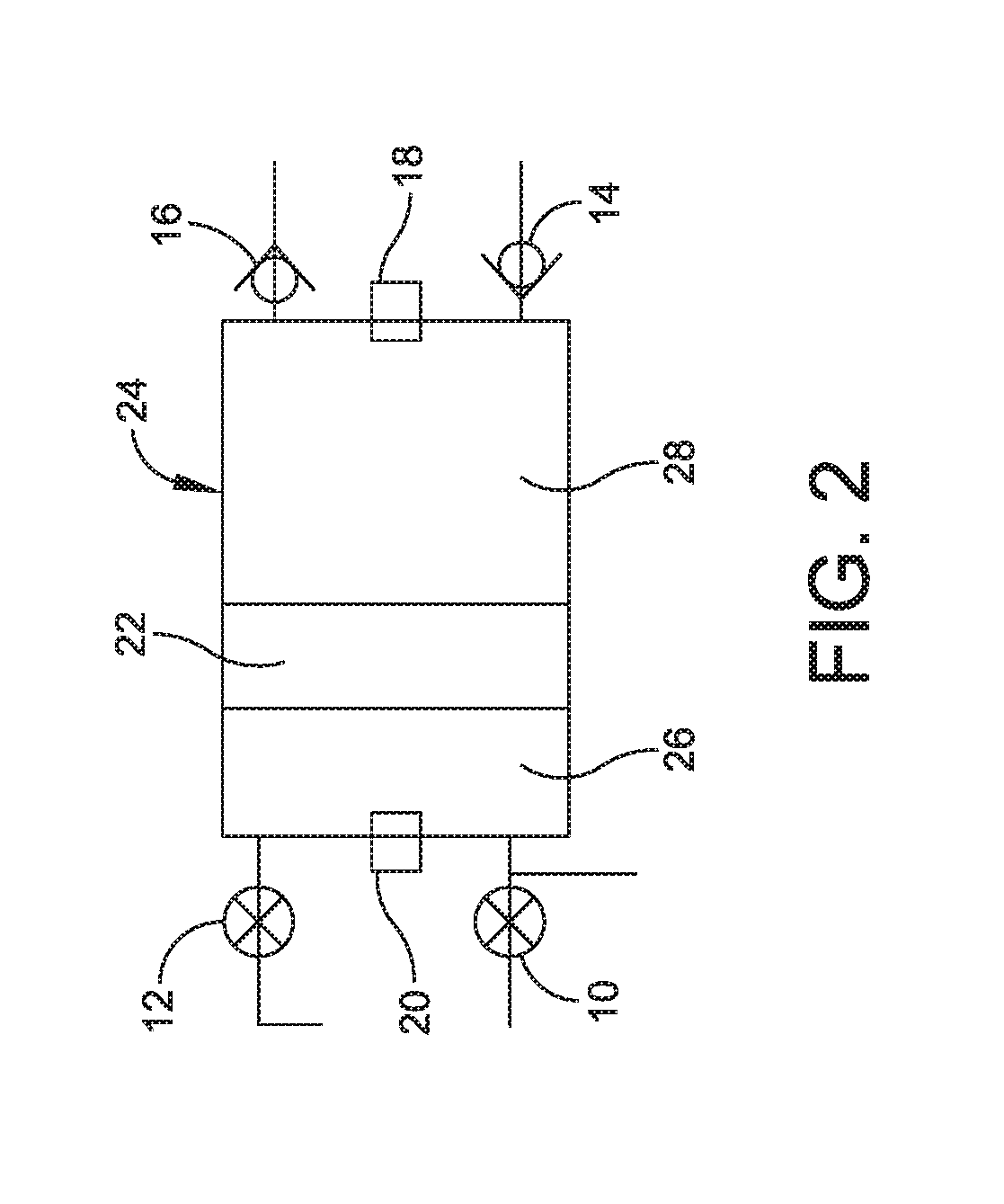

Bioreactor device for exposing a cell culture to a fluid shear force imparted by a fluid flow

InactiveUS20080057571A1Easy and non-destructive removalEasy to separateBioreactor/fermenter combinationsBiological substance pretreatmentsFluid shearEngineering

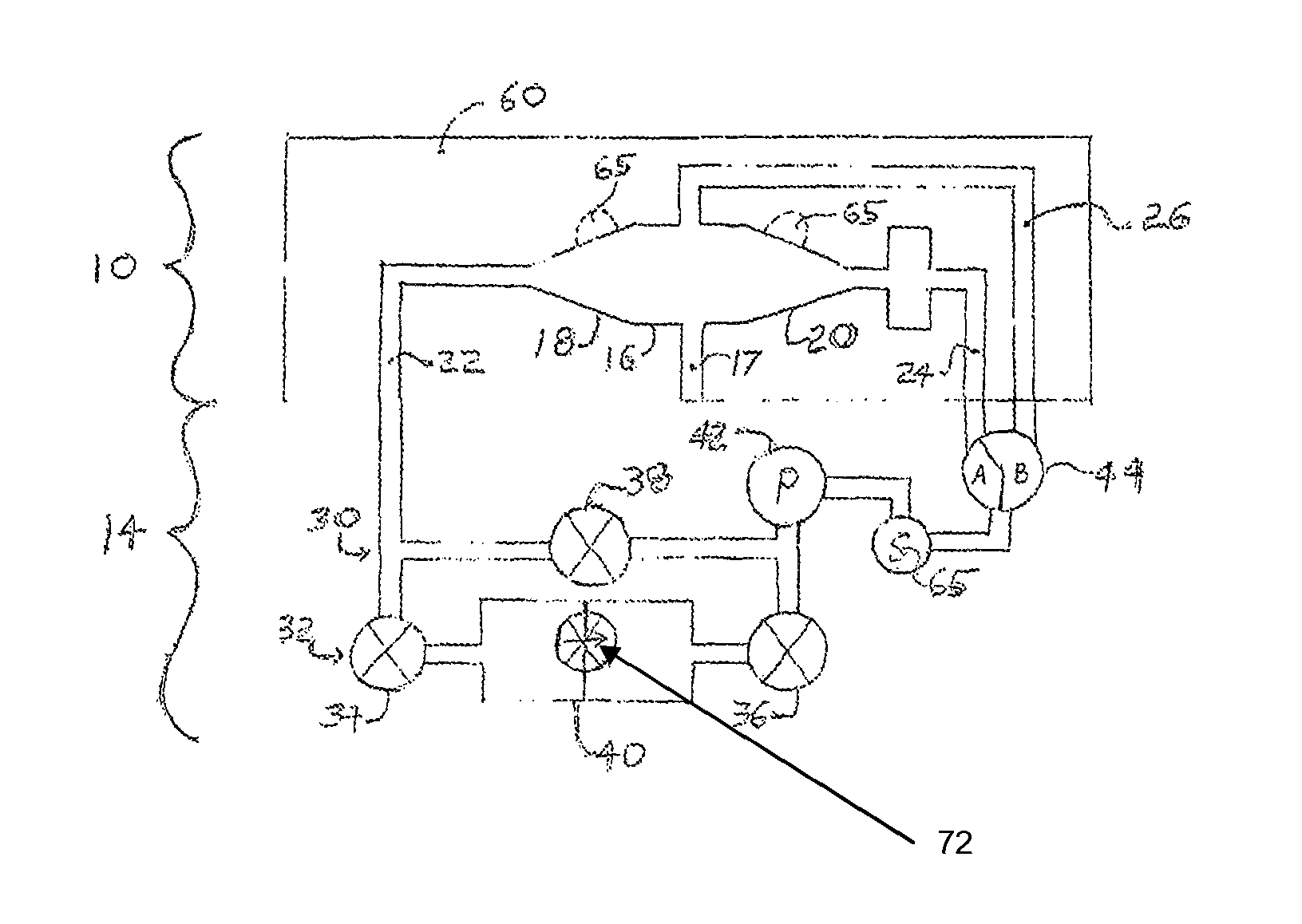

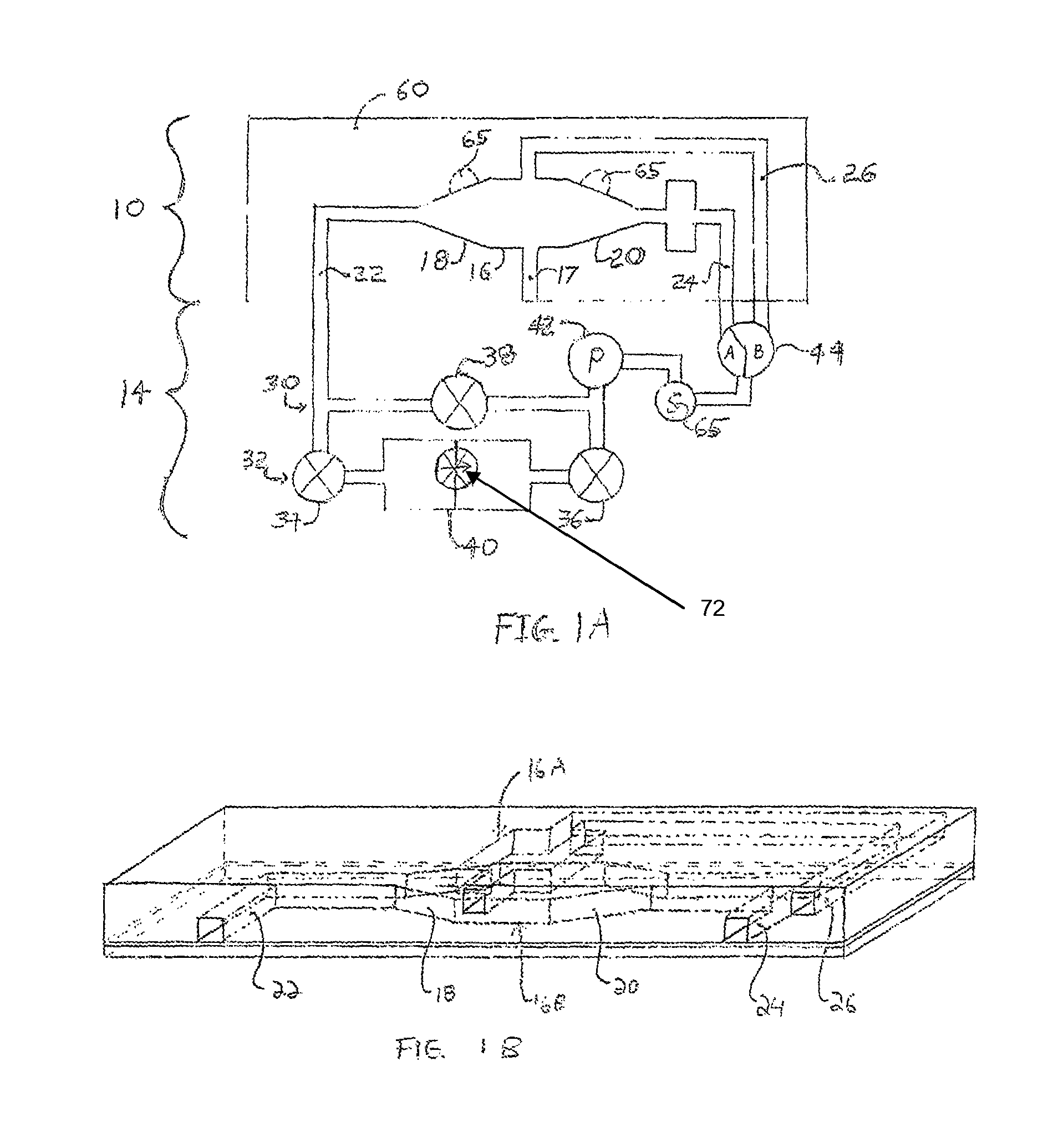

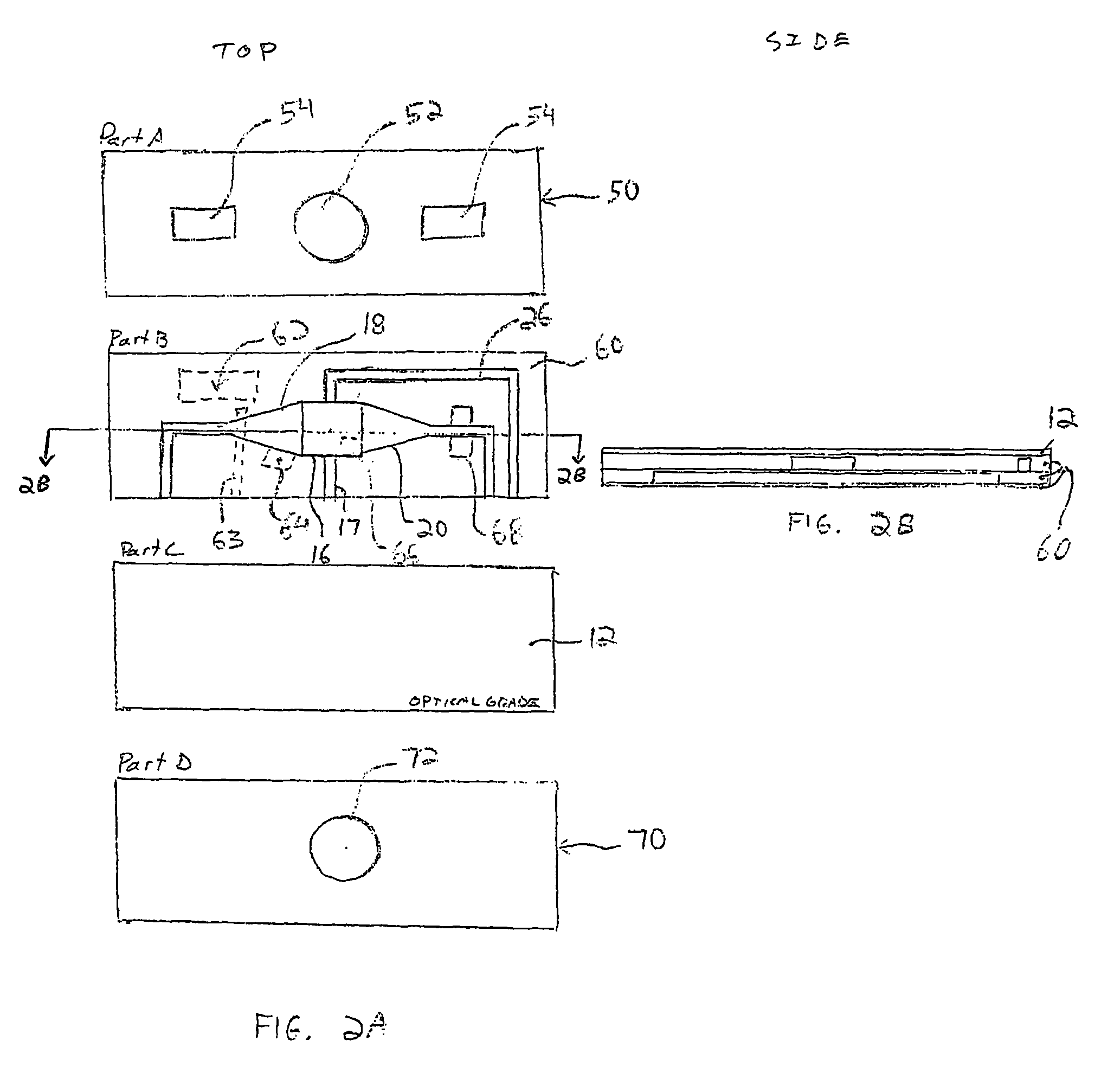

A system for exposing a cell culture to a fluid shear force imparted by a fluid flow is provided. Specifically, various embodiments of the present invention provide flow chambers defining channels for retaining a cell culture in the fluid flow wherein the flow chambers may be removably disposed within a bioreactor system such that the flow chambers may be removed and / or replaced without disturbing the cell cultures retained therein or disposed elsewhere within the bioreactor system. The flow chambers are composed of a transparent material such that a user of the system may observe the development of the cell culture retained within the chamber as the cell culture is imposed to a fluid shear stress imparted by the fluid flow.

Owner:NORTH CAROLINA STATE UNIV

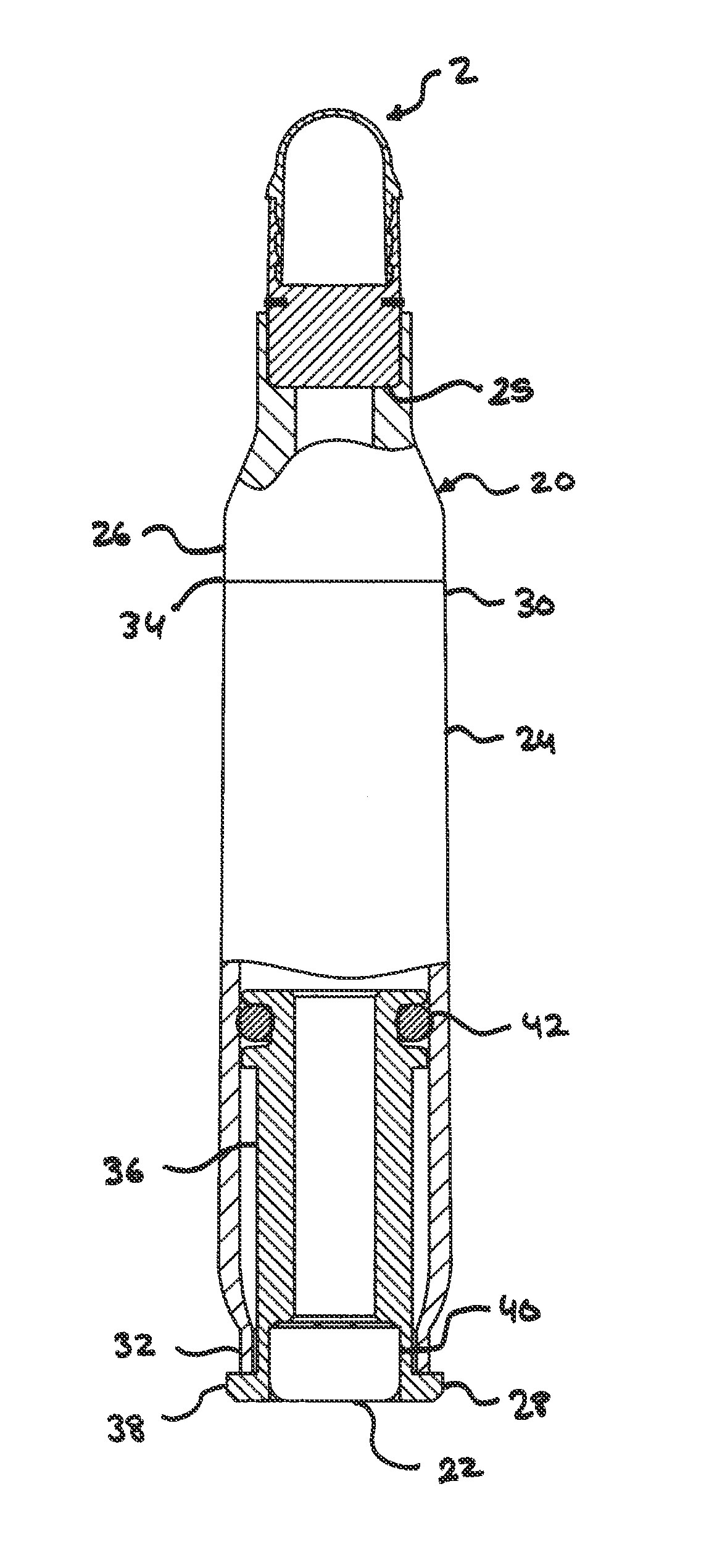

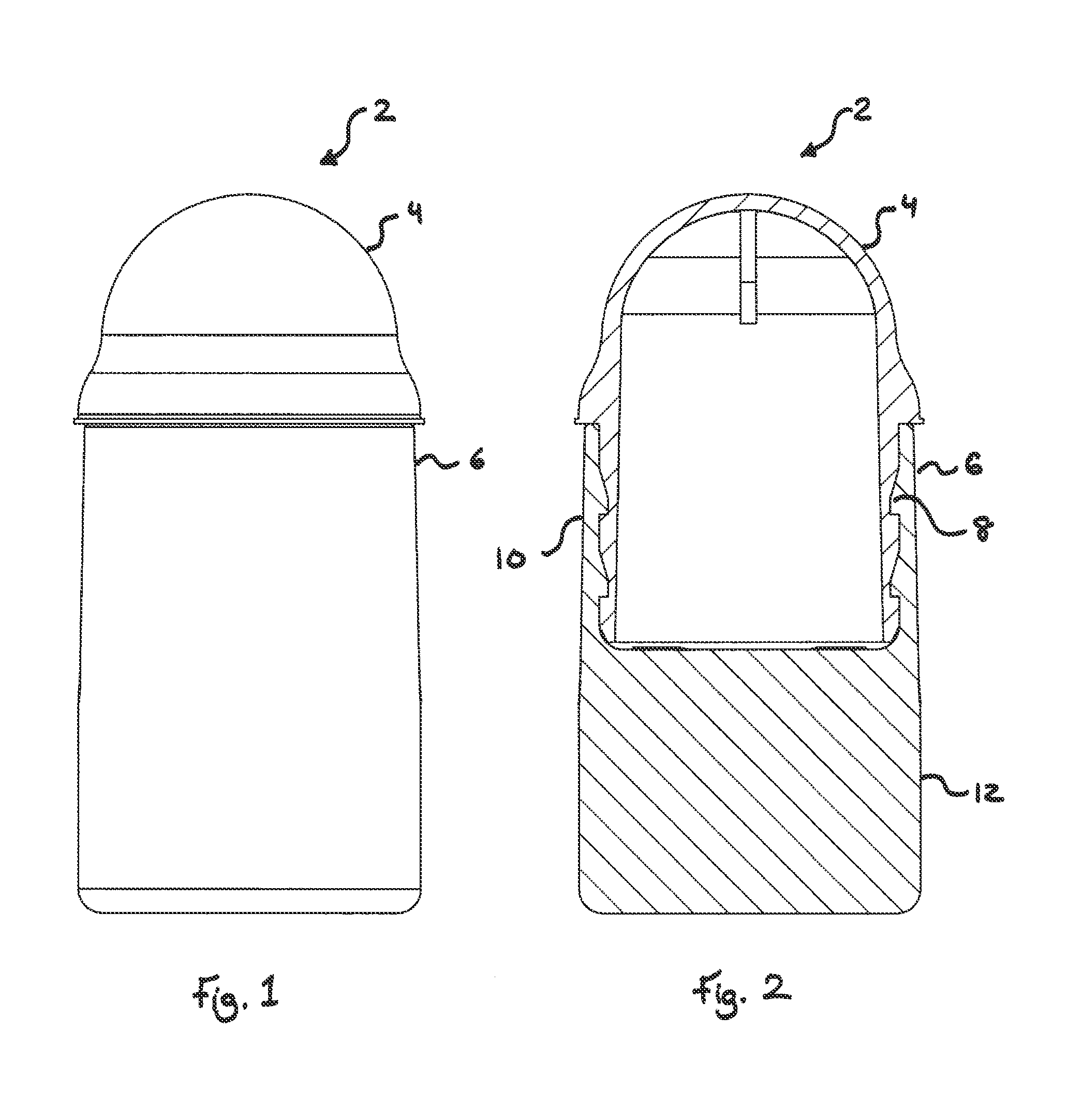

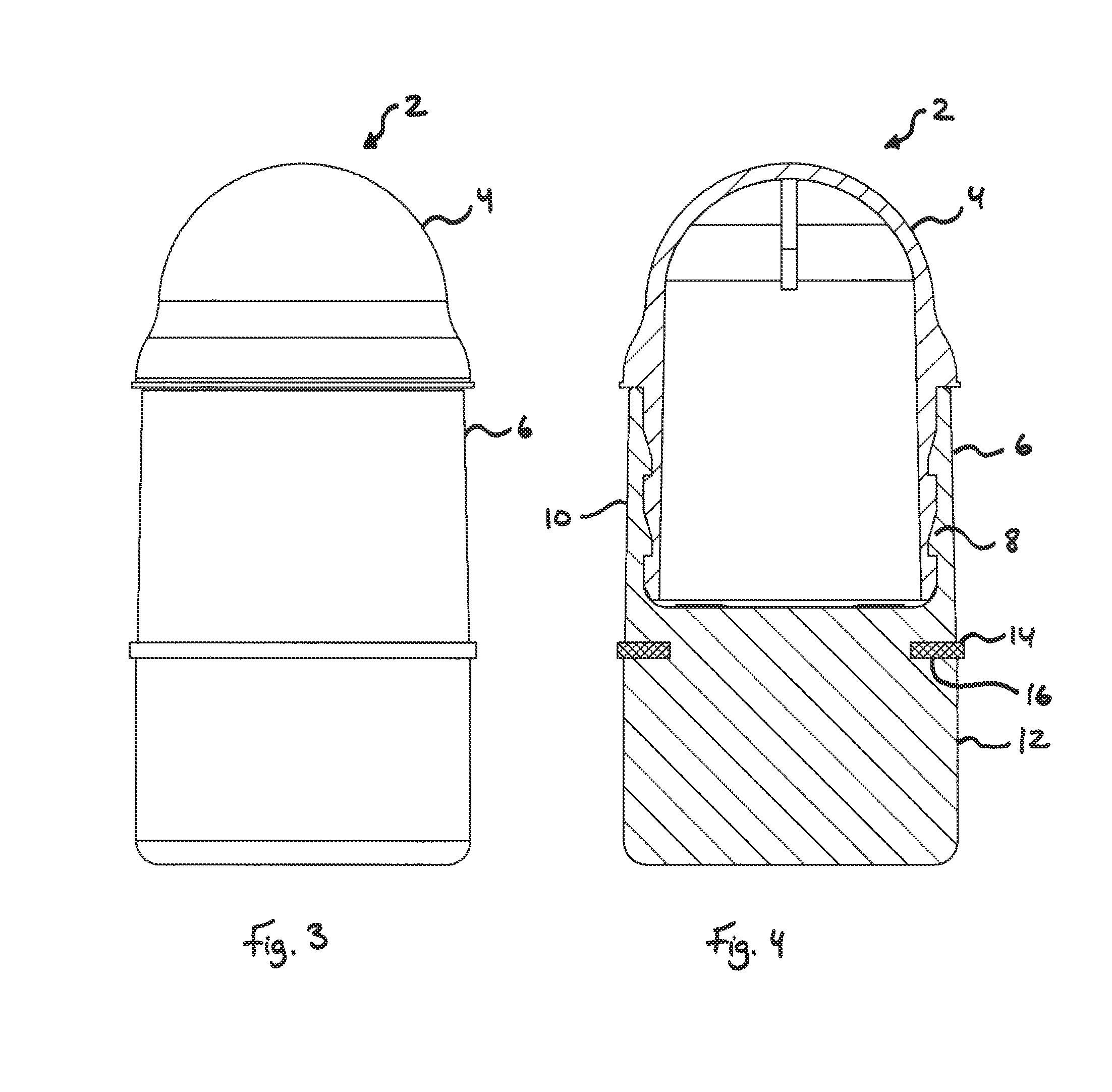

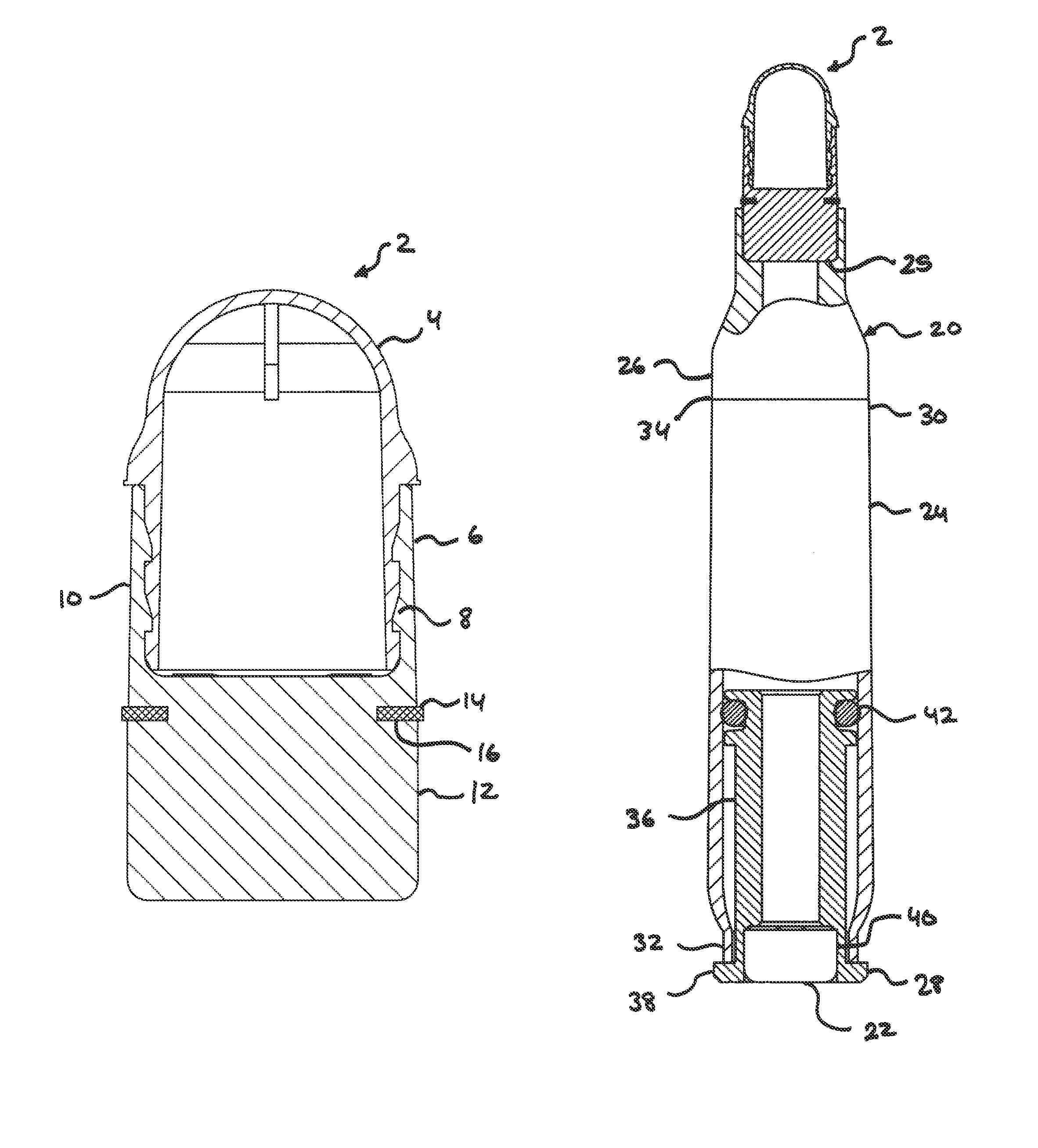

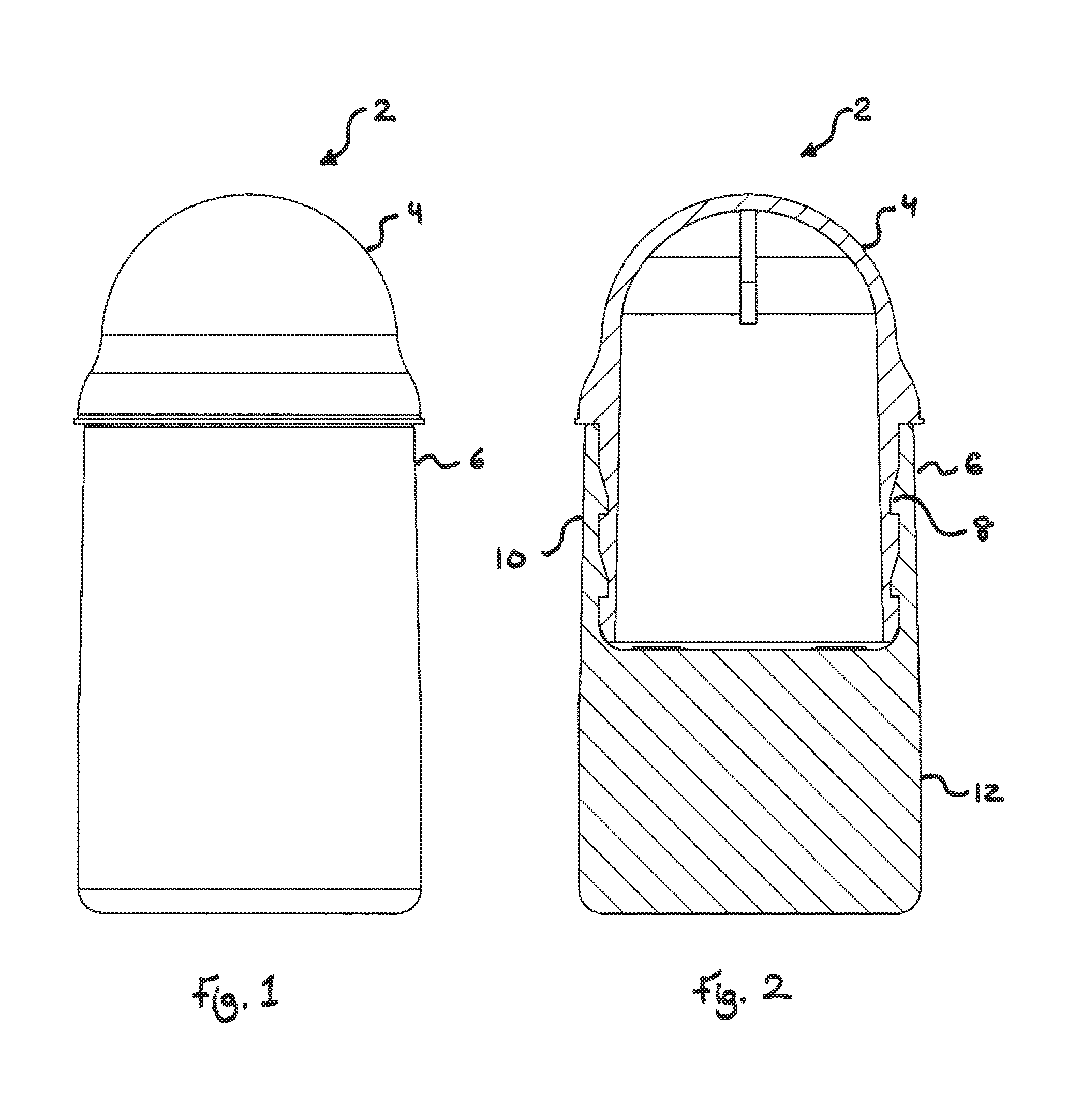

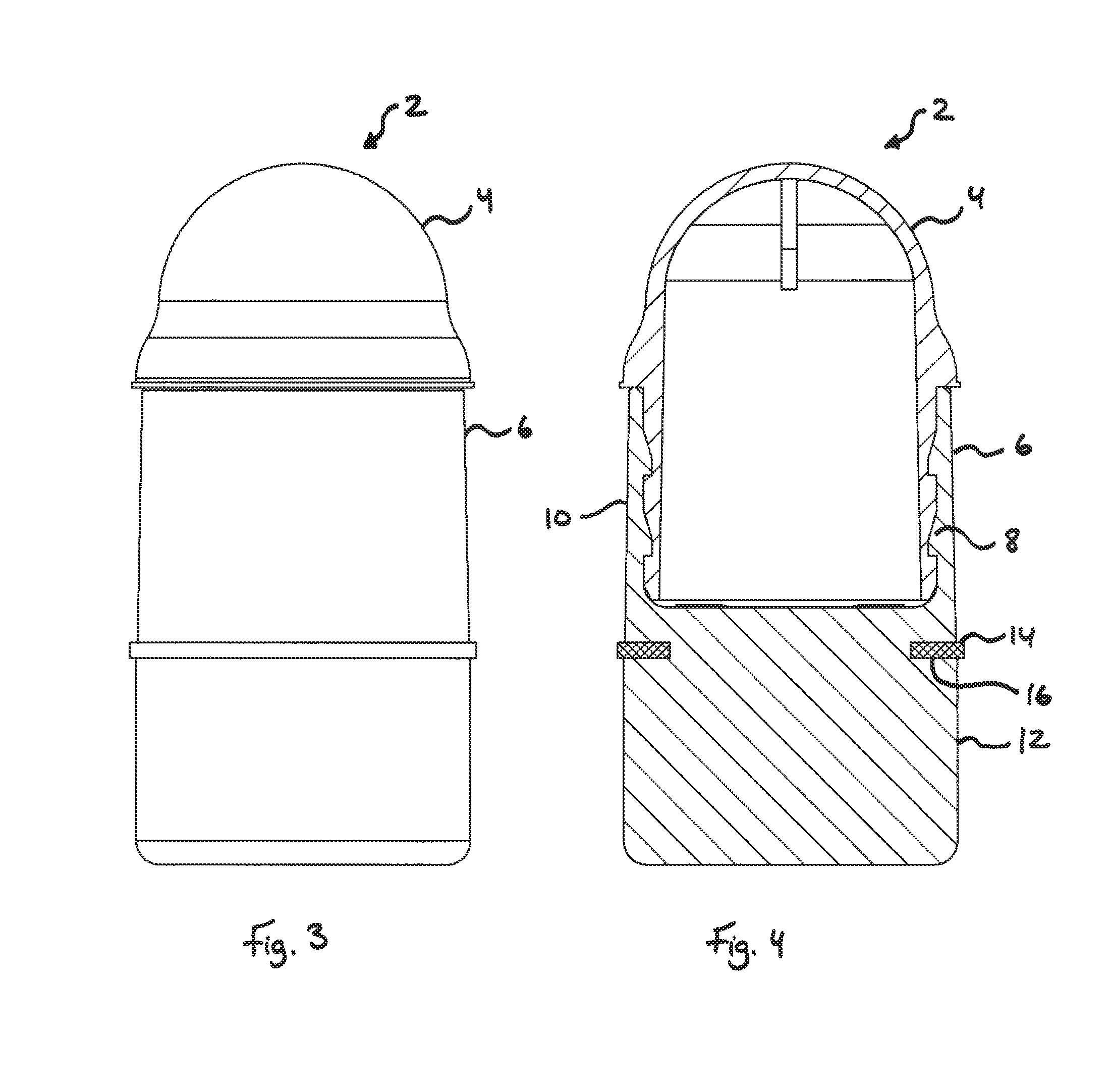

Spin-stabilized non-lethal projectile with a shear-thinning fluid

ActiveUS20140373745A1Reduce the amount requiredReduce momentumAmmunition projectilesTraining ammunitionEmulsionApparent viscosity

A non-lethal projectile having a shear-thinning fluid within an interior cavity. The shear-thinning fluid having a greater apparent viscosity at low shear rates to spin-stabilize the non-lethal projectile during flight and a lower apparent viscosity at a high shear rate corresponding with the shear-thinning fluid shearing against the frangible cap upon the non-lethal projectile striking the target, with the low viscosity of the shear-thinning fluid allowing proper dispersal upon impact with the target. The shear-thinning fluid can comprise a marking media and be in the form of an emulsion with less than about 50% liquid by volume to effectively disperse upon impact with the target.

Owner:GEN DYNAMICS ORDNANCE & TACTICAL SYST

High-precision speed locker for multi-span bridge anti-seismic

InactiveCN102296528AHigh sensitivityGood reversibilityBridge structural detailsShock proofingSeismic velocityThickened fluids

The invention relates to a high-precision speed locker for anti-seismic use of multi-span bridges. Including the cylinder part, the piston part and the working material; the piston part and the cylinder part are assembled to form a whole, and the working material is located in the cylinder; the working material is a shear thickening liquid or a shear thickening gel; the cylinder body The end cover is a cylindrical sealing cover, and the bottom of the sealing cover is provided with a boss matching the inner diameter of the cylinder; the outer side of the sealing cover is provided with a dust cover; the piston rod and the connecting rod are threaded ; A liquid injection hole is opened on the side wall of the cylinder body, and a plunger is arranged in the liquid injection hole. The shear thickening liquid and shear thickening gel used in the present invention are very soft at ordinary times and have easy flowability under normal conditions. Once the critical shear rate is reached, the viscosity increases rapidly and finally becomes a hard solid. Return to the soft state; make the speed locker have the characteristics of precision, high sensitivity, and good reversibility.

Owner:UNIV OF SCI & TECH OF CHINA

Method for planting esoderma/endothelial cell on inner surface of artificial blood vessel

InactiveCN1559360AImprove adhesionInhibit hyperproliferationMicroorganismsGenetic material ingredientsBlood vessel featureFluid shear

A method for implanting the endothelial cells on the inner surface of artificial blood vessel features that a biomechanical method is used, that is, an external pulsive fluid shearing force increased step by step acts on the planted endothelial cells to make them be attached well on the inner surface of artificial blood vessel in advance.

Owner:CHONGQING UNIV

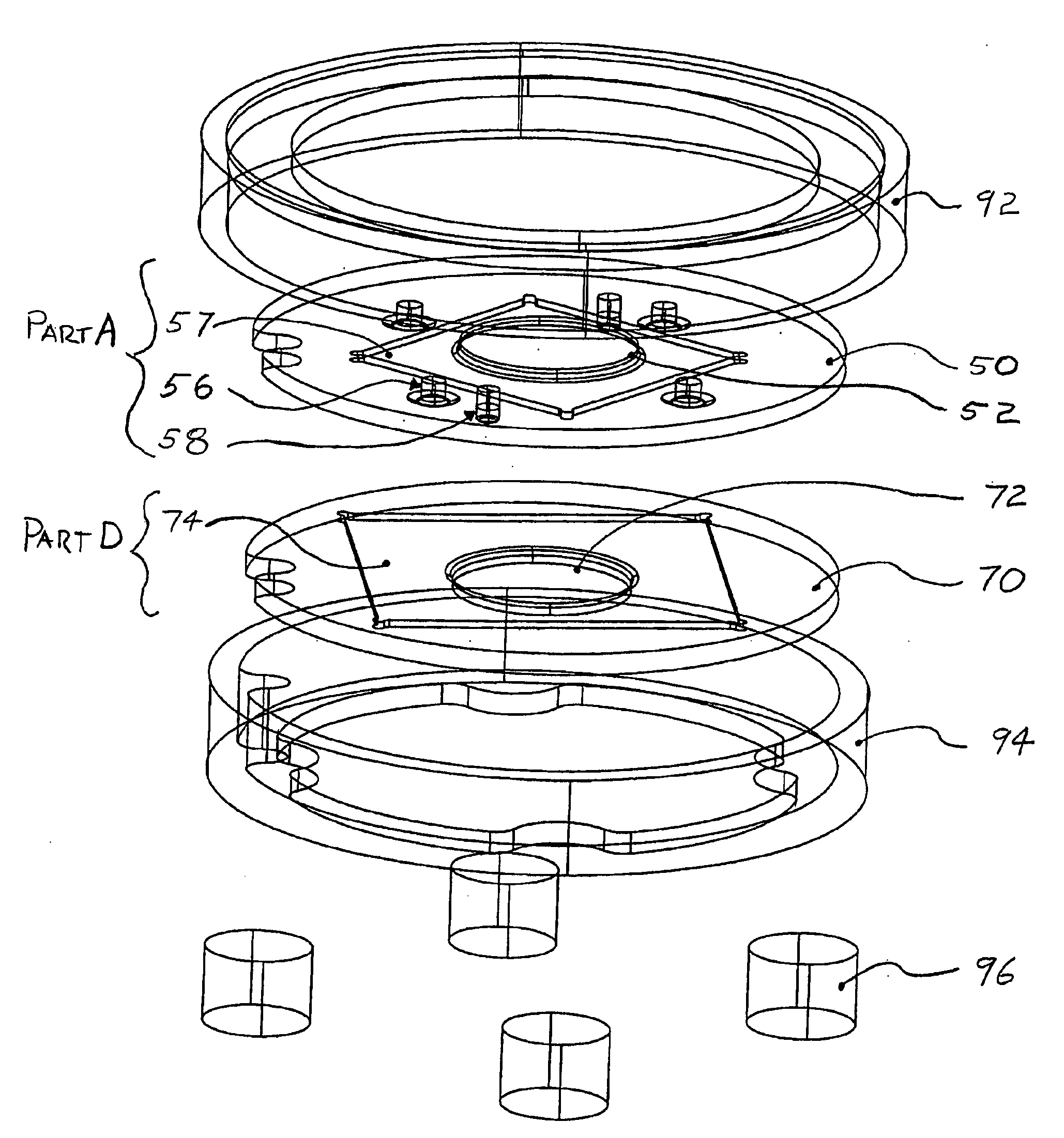

Bioreactor Device, and Method and System for Fabricating Tissues in the Bioreactor Device

InactiveUS20090215104A1Increase sample sizeBioreactor/fermenter combinationsBiological substance pretreatmentsFluid shearHydrostatic pressure

A bioreactor device, and a method and system for fabricating tissues and growing cells and tissues in the bioreactor device, accommodates less than about 1 mL (or less than about 200 μL) of local medium volume but sample sizes of about 100 μL or greater. The bioreactor device includes a bioreactor chamber for containing a sample, where sample growth in response to mechanical, electrical, and biofactor stimulation is monitored through one or more optical ports. Embedded sensors are provided for measuring fluid pressure, pH, temperature, and oxygen tension. The bioreactor device can receive different types of mechanical loadings, including fluid shear, hydrostatic pressure, matrix compression, and clinorotation.

Owner:UNITED STATES OF AMERICA

Particle separation and concentration system

This invention is based on size and mass separation of suspended particles, including biological matter, which are made to flow in a spiral channel. On the spiral sections, the inward directed transverse pressure field from fluid shear competes with the outward directed centrifugal force to allow for separation of particles. At high velocity, centrifugal force dominates and particles move outward. At low velocities, transverse pressure dominates and the particles move inward. The magnitudes of the two opposing forces depend on flow velocity, particle size, radius of curvature of the spiral section, channel dimensions, and viscosity of the fluid. At the end of the spiral channel, a parallel array of outlets collects separated particles. For any particle size, the required channel dimension is determined by estimating the transit time to reach the side-wall. This time is a function of flow velocity, channel width, viscosity, and radius of curvature. Larger particles may reach the channel wall earlier than the smaller particles which need more time to reach the side wall. Thus a spiral channel may be envisioned by placing multiple outlets along the channel. This technique is inherently scalable over a large size range from sub-millimeter down to 1 μm.

Owner:XEROX CORP

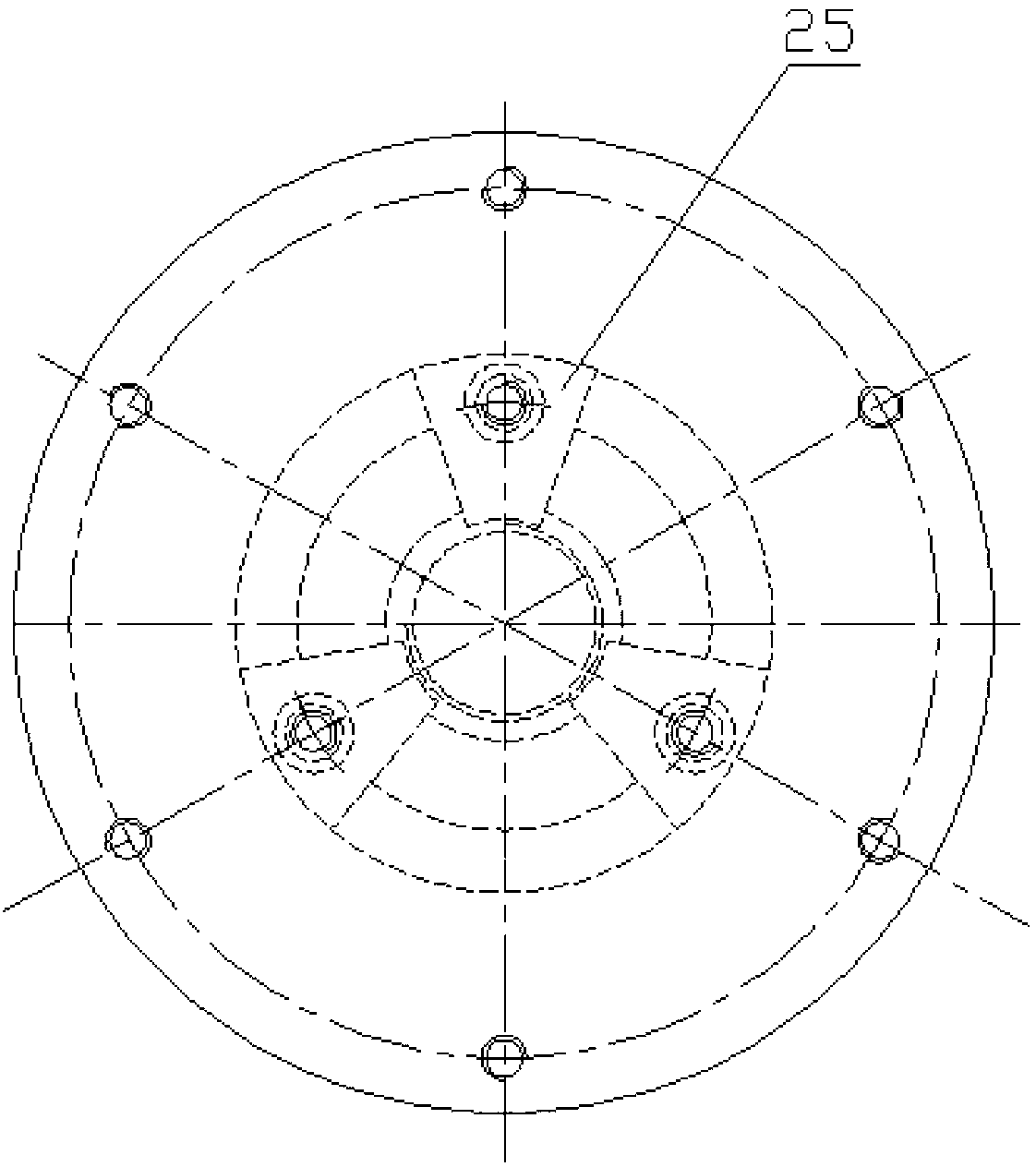

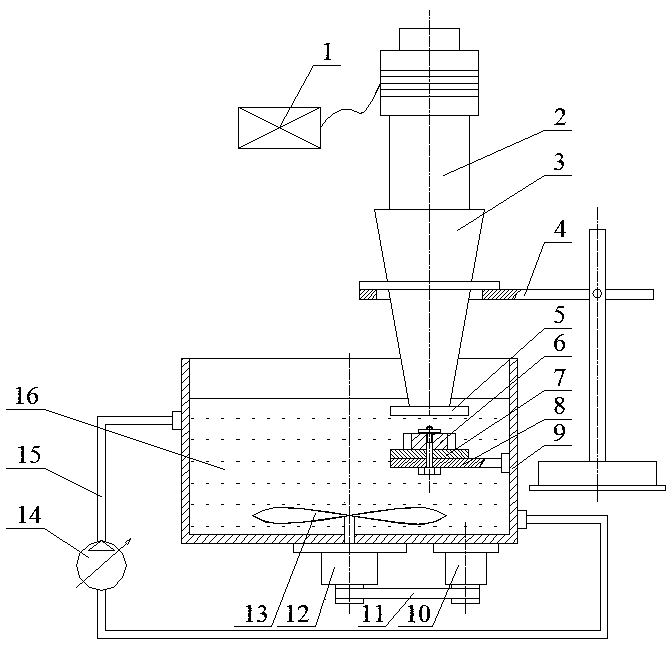

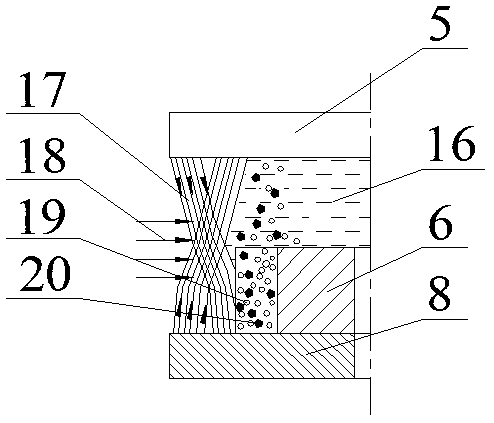

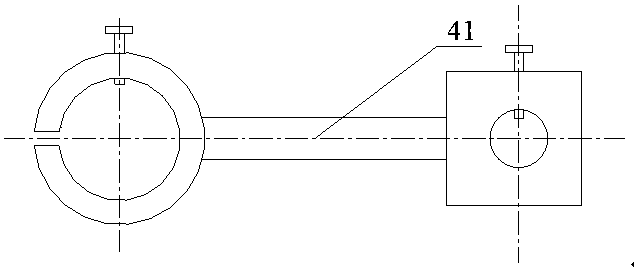

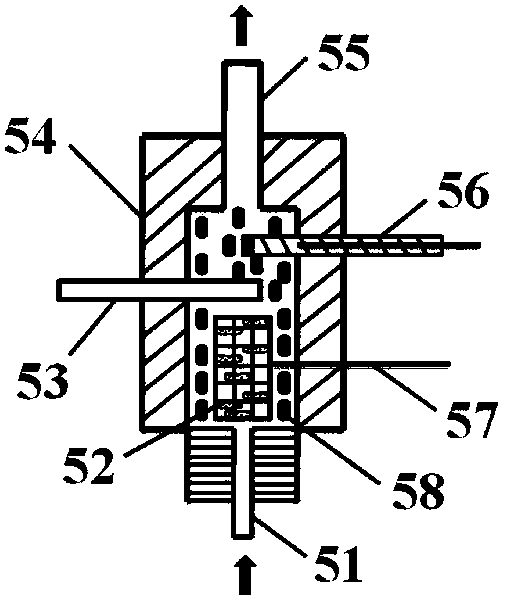

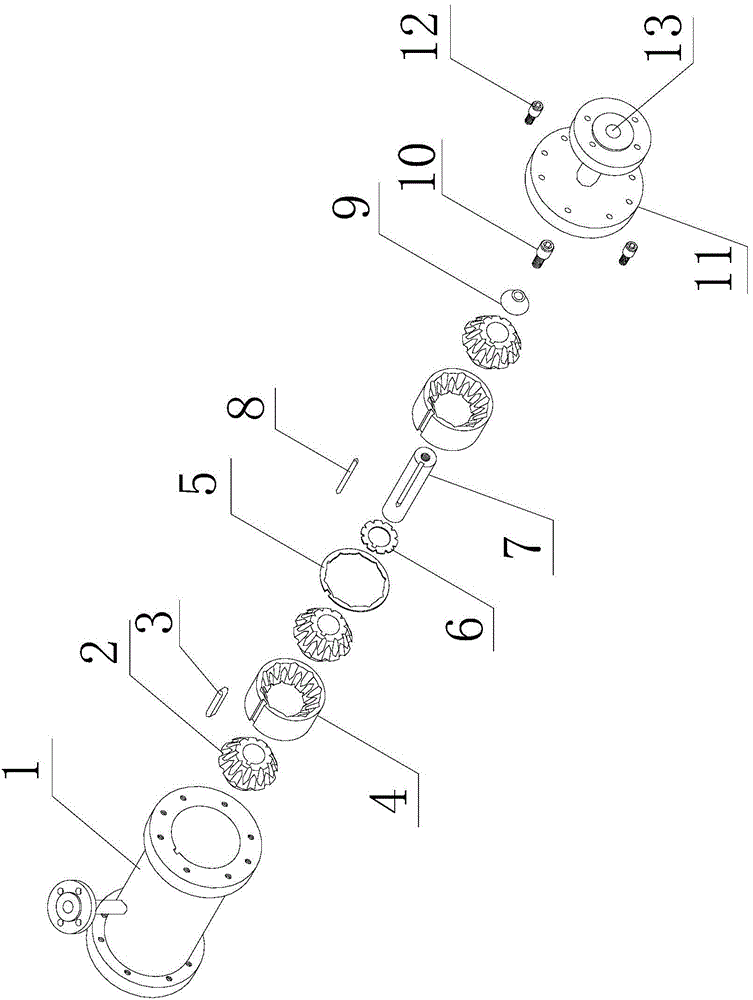

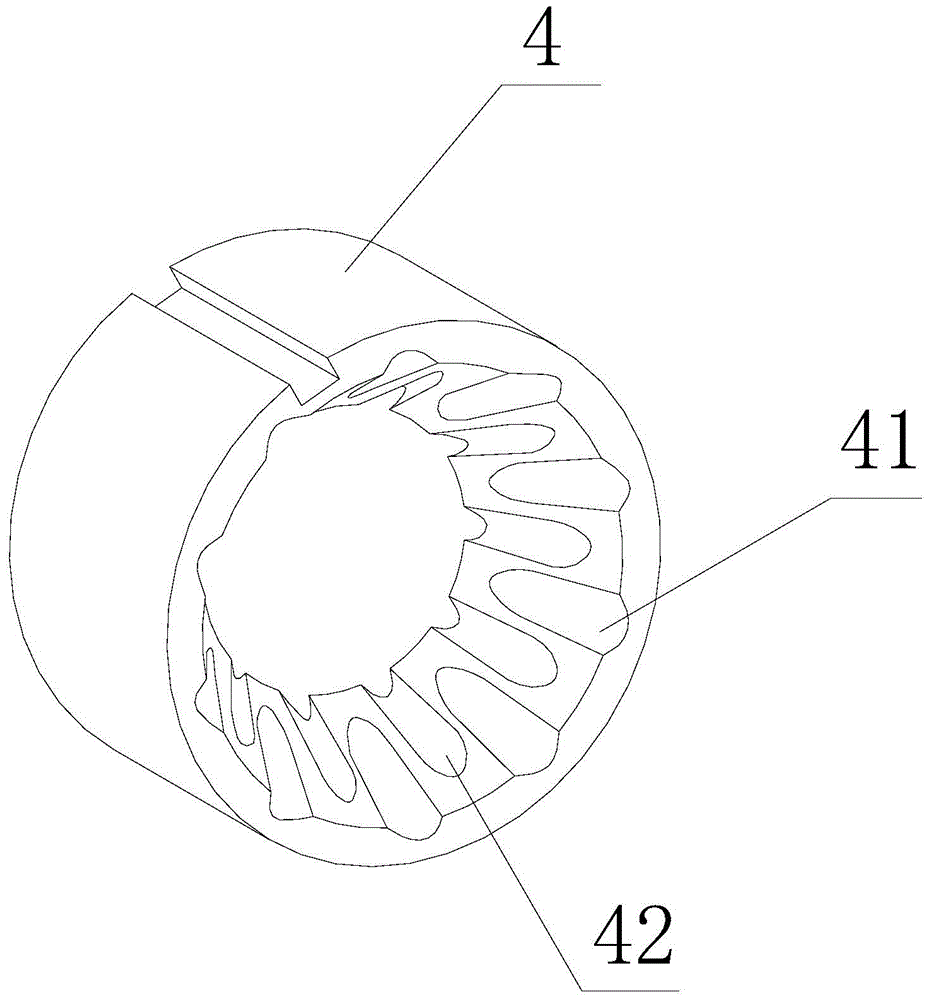

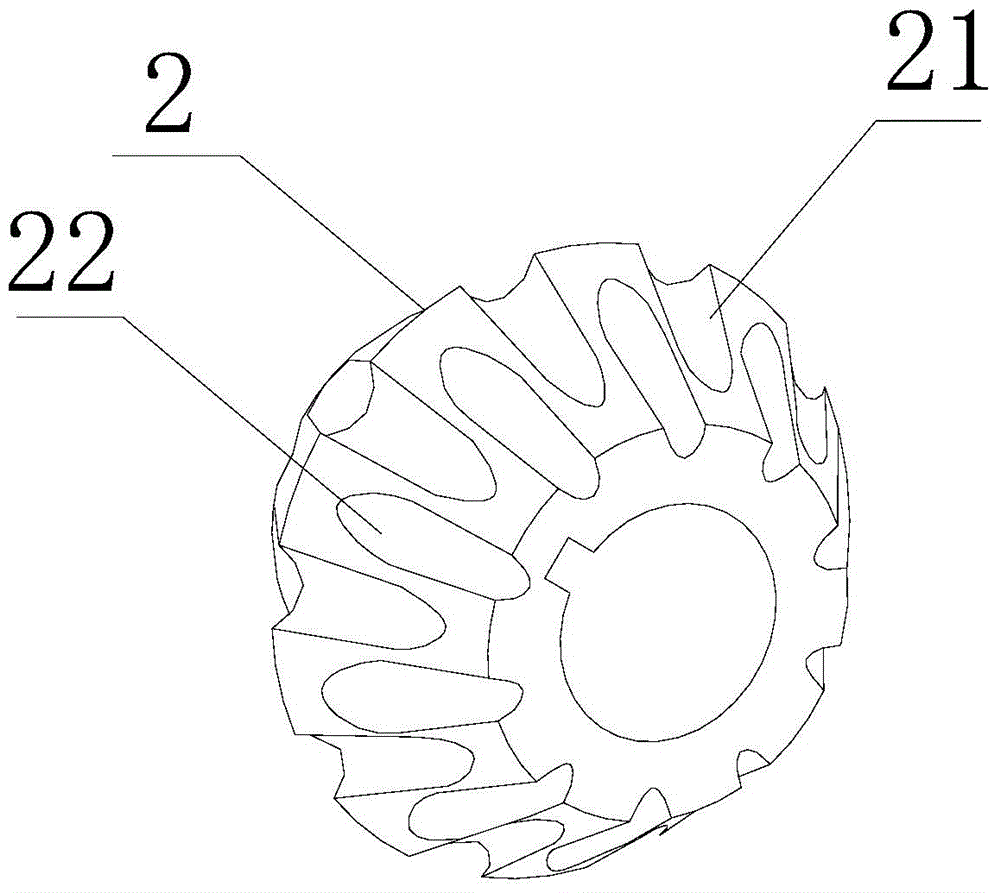

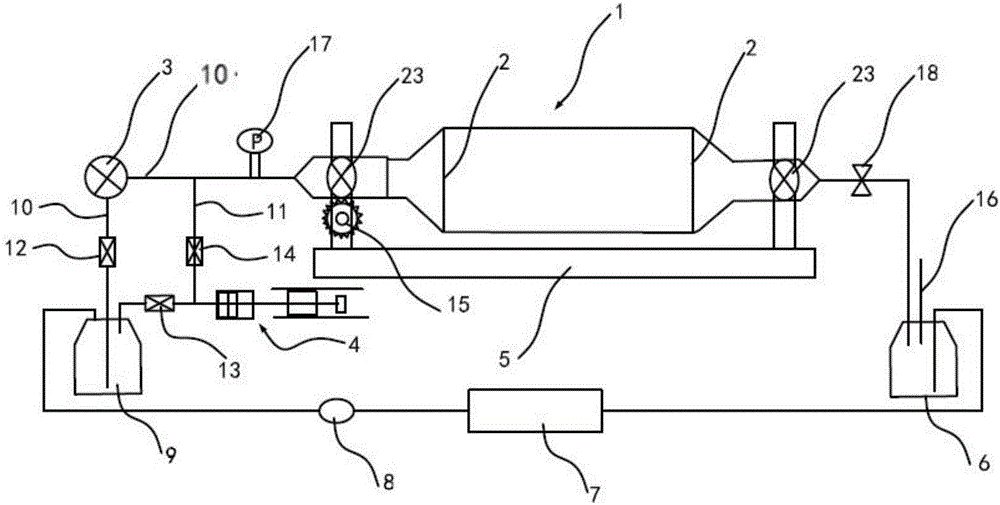

Near-field ultrasonic cavitation and fluid shearing combined type micro-gear finishing machining device and machining method

InactiveCN110315399ARealize finishingOvercome the problem of low utilization of cavitation effectEdge grinding machinesGrinding work supportsUltrasonic cavitationFluid shear

The invention belongs to the field of precision and ultra-precision machining, and particularly relates to a near-field ultrasonic cavitation and fluid shearing combined type micro-gear finishing machining device and a machining method. The near-field ultrasonic cavitation and fluid shearing combined type micro-gear finishing machining device comprises a near-field ultrasonic cavitation system, afluid shearing system and a polishing solution circulation system, wherein the near-field ultrasonic cavitation system comprises an ultrasonic generator, a piezoelectric transducer, an amplitude-change rod, an upper supporting disc, a lower supporting disc and a precise support, the ultrasonic generator is connected with the piezoelectric transducer through a wire, the piezoelectric transducer isconnected with the amplitude-change rod through a double-head stud, a flange plate used for being fixed to the precise support is arranged on the amplitude-change rod, the amplitude-change rod is connected with the upper supporting disc through a bolt, the lower supporting disc is arranged below the upper supporting disc, a micro-gear is arranged on the lower supporting disc, and the micro-gear isconnected with a clamp through a bolt. According to the near-field ultrasonic cavitation and fluid shearing combined type micro-gear finishing machining device and the machining method, cavitation bubbles and solid abrasive particles of a polishing solution can effectively clean a micro-groove structure interface, so that efficient, precise, green and flexible finishing machining of the micro-gear is realized.

Owner:TAIYUAN UNIV OF TECH

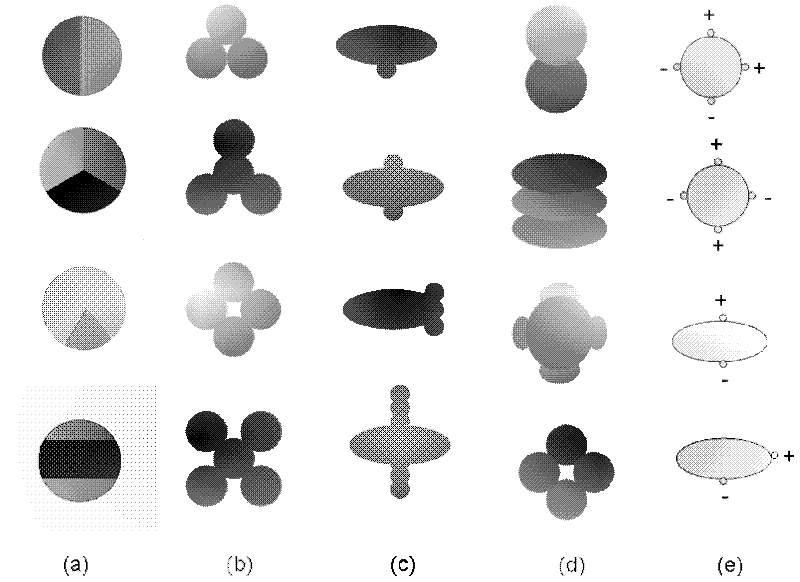

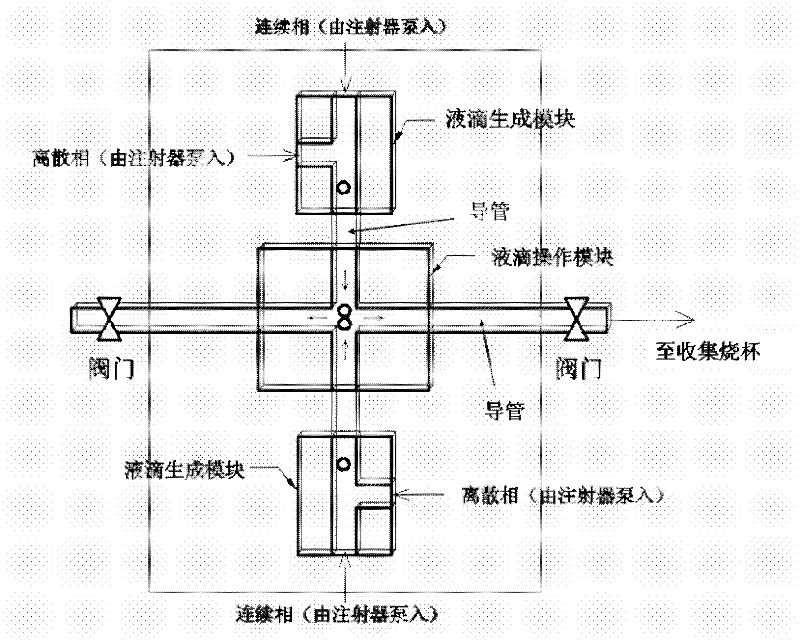

Controllable drop coalescence prepared anisotropic particle material and microfluid device

InactiveCN102351964ALow viscosityControl surface tensionChemical/physical/physico-chemical processesMultiple formsState of art

The invention relates to a controllable drop coalescence prepared anisotropic particle material and a microfluid device. The particle material provided by the invention is prepared by the following steps: preparing liquid drop of a polymer monomer by the use of fluid shear force of a continuous phase in a liquid drop generation module; simultaneously preparing various desired liquid drops by the use of a plurality of liquid drop generation modules; allowing the liquid drops to simultaneously or successively enter into a hydraulic trap of a liquid drop operation module according to the requirement of the liquid drops and according to the position and direction of coalescence controlling for coalescence and photo polymerization, so as to prepare the anisotropy functional particle material. The liquid drop generation modules are connected with the liquid drop operation module through conduits; the liquid drop generation modules are formed by commonly-used microfluidic liquid drop generation chips; the liquid drop operation module is composed of a four-arm, six-arm or eight-arm hydraulic trap, and the dimension of micro channels in each module varies from several micrometers to hundreds of micrometers; coalescence between liquid drops and curing operation are carried out. The device provided by the invention is used to realize the preparation of the anisotropic particle material which has a plurality of forms and can be prepared only by the combination of many present prior arts.

Owner:TIANJIN UNIV

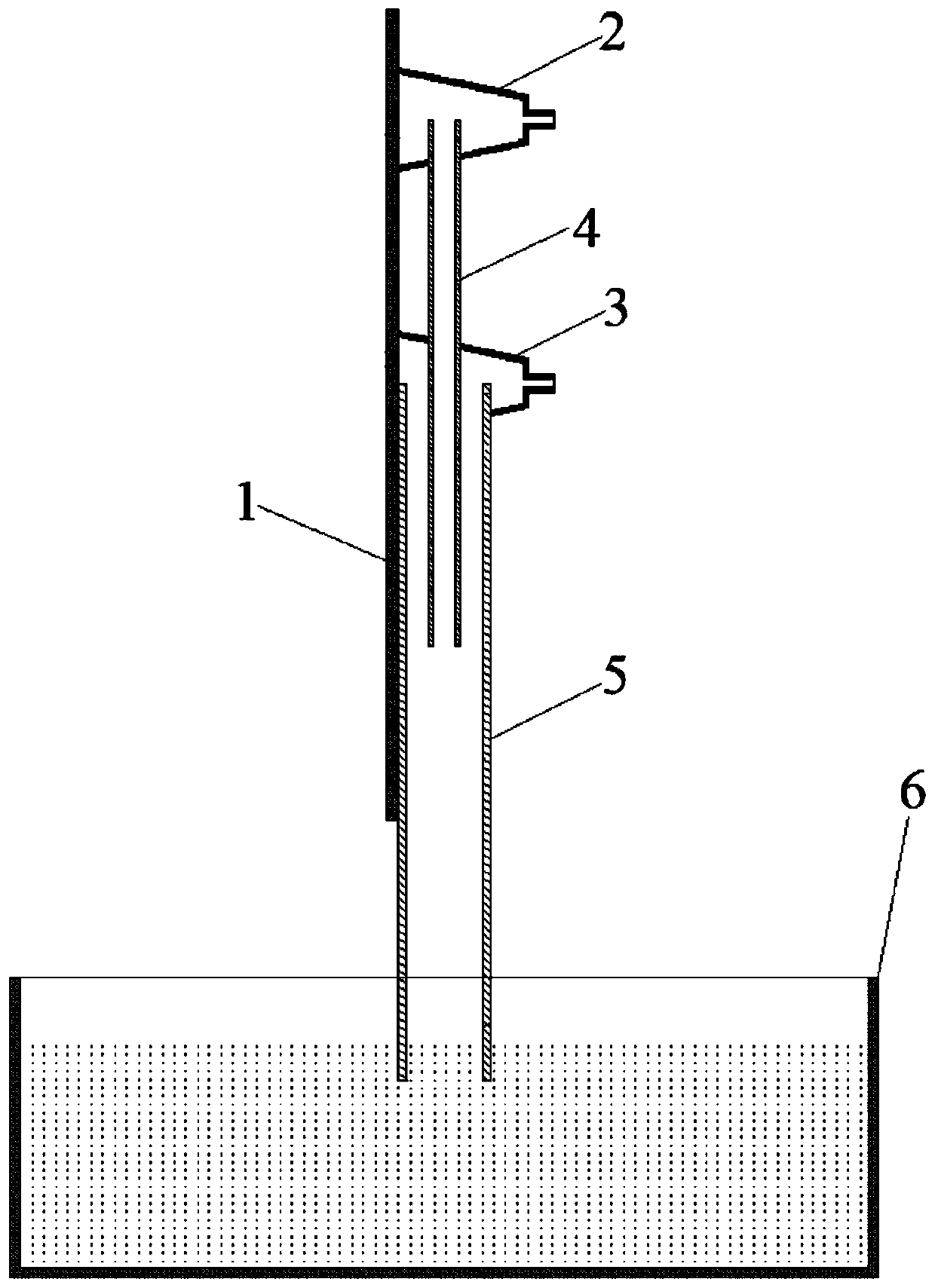

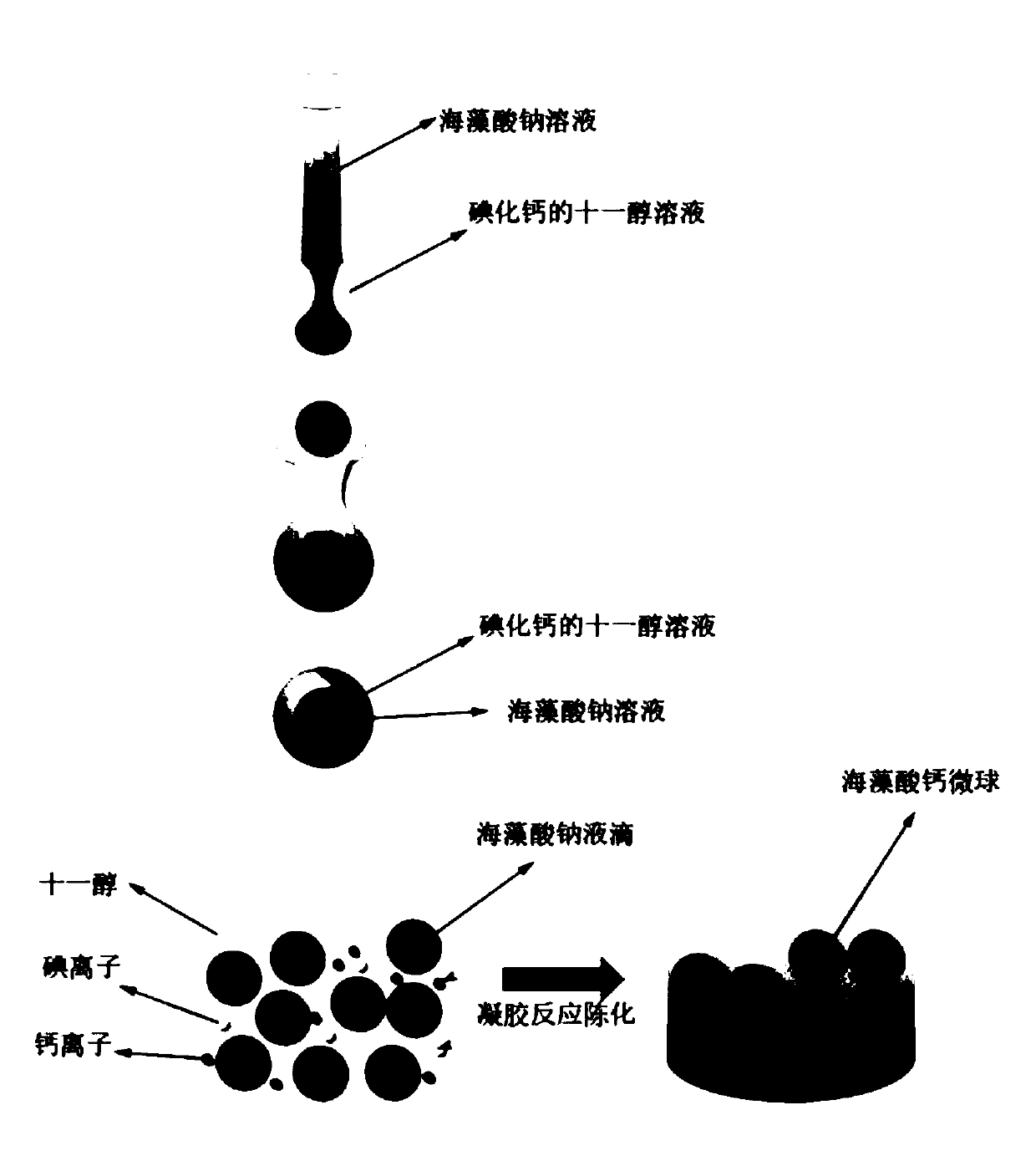

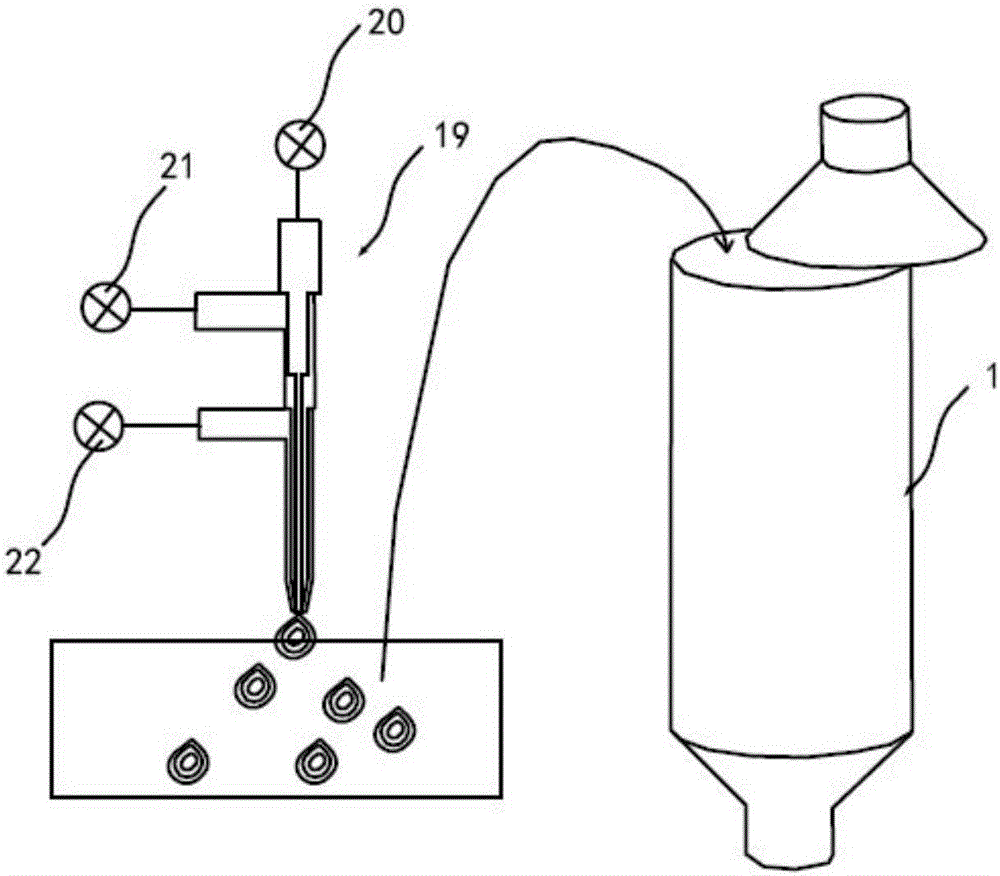

Device and method for preparing calcium alginate microspheres by using micro-reactor, and applications thereof

ActiveCN110639450AUniform particle sizeGood sphericityChemical/physical/physico-chemical microreactorsLaboratory glasswaresMicroreactorPetri dish

The invention relates to the technical field of calcium alginate microsphere preparation, and especially relates to a device and a method for preparing calcium alginate microspheres by using a micro-reactor, and applications thereof. The method comprises the following steps: (1) an outer-phase fluid is introduced into a second dispensing needle head, and then enters an outer-phase glass tube, andan inner-phase fluid is introduced through a first dispensing needle head and an inner-phase glass tube when the outer-phase fluid flows out of the outlet of the outer-phase glass tube; (2) the inner-phase fluid forms liquid drops coated with the outer-phase fluid at the outlet of the inner-phase glass tube under the action of shearing force of the outer-phase fluid, and the liquid drops flow intoa collecting culture dish along with the outer-phase fluid; and 3) the position of a chip is continuously moved during collection to separate the liquid drops collected in the culture dish from eachother, and the obtained liquid drops stands after the collection is completed in order to move the redundant outer-phase fluid and obtain the calcium alginate microspheres. The device and the method are realized by using the micro-reactor, and the calcium alginate microspheres prepared by utilizing an oil phase and a water phase have the characteristics of uniform particle size, good sphericity degree and controllable swelling ratio, and can well meet the applications in the fields of drug loading, catalysis and detection.

Owner:SHANDONG UNIV

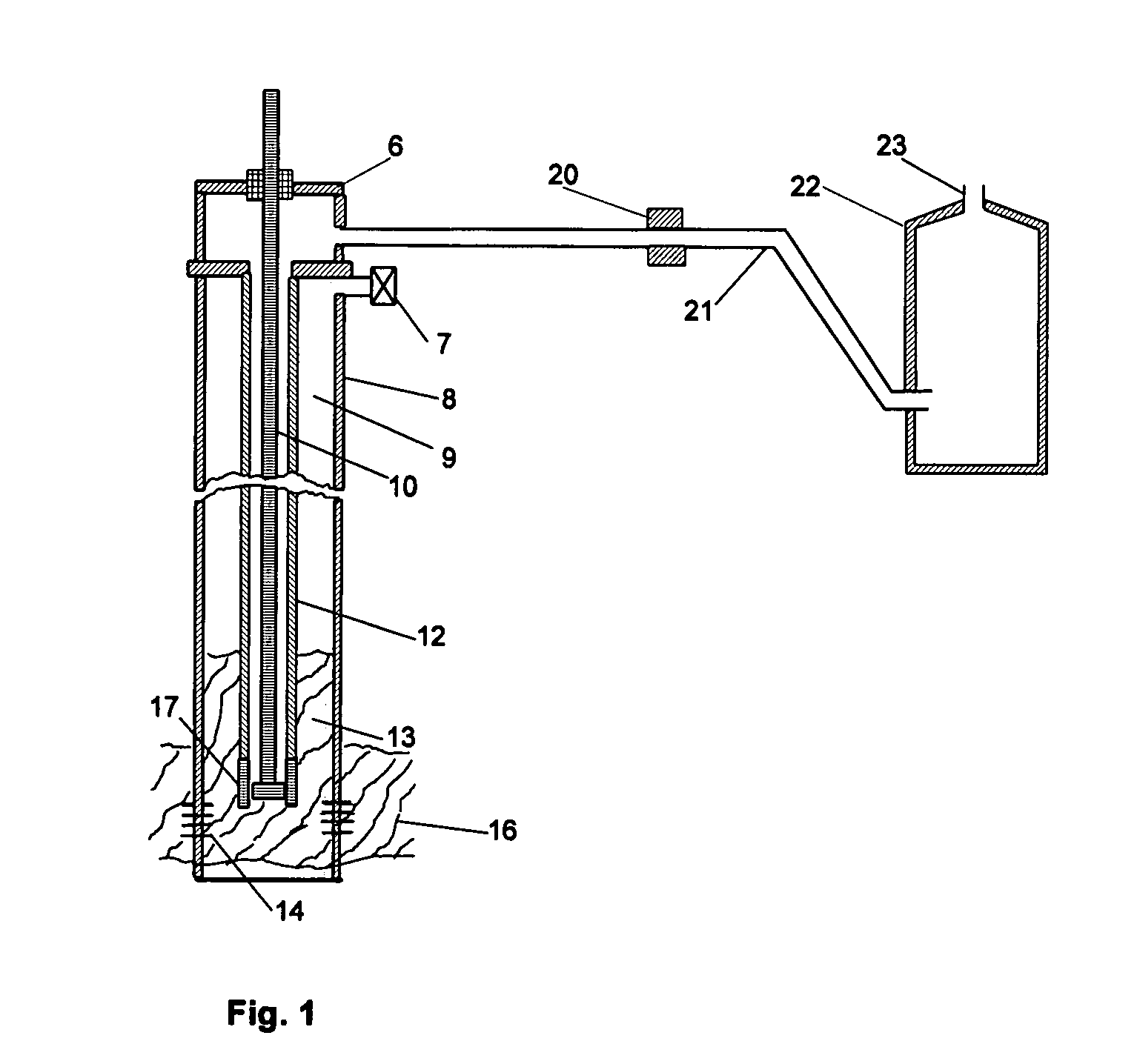

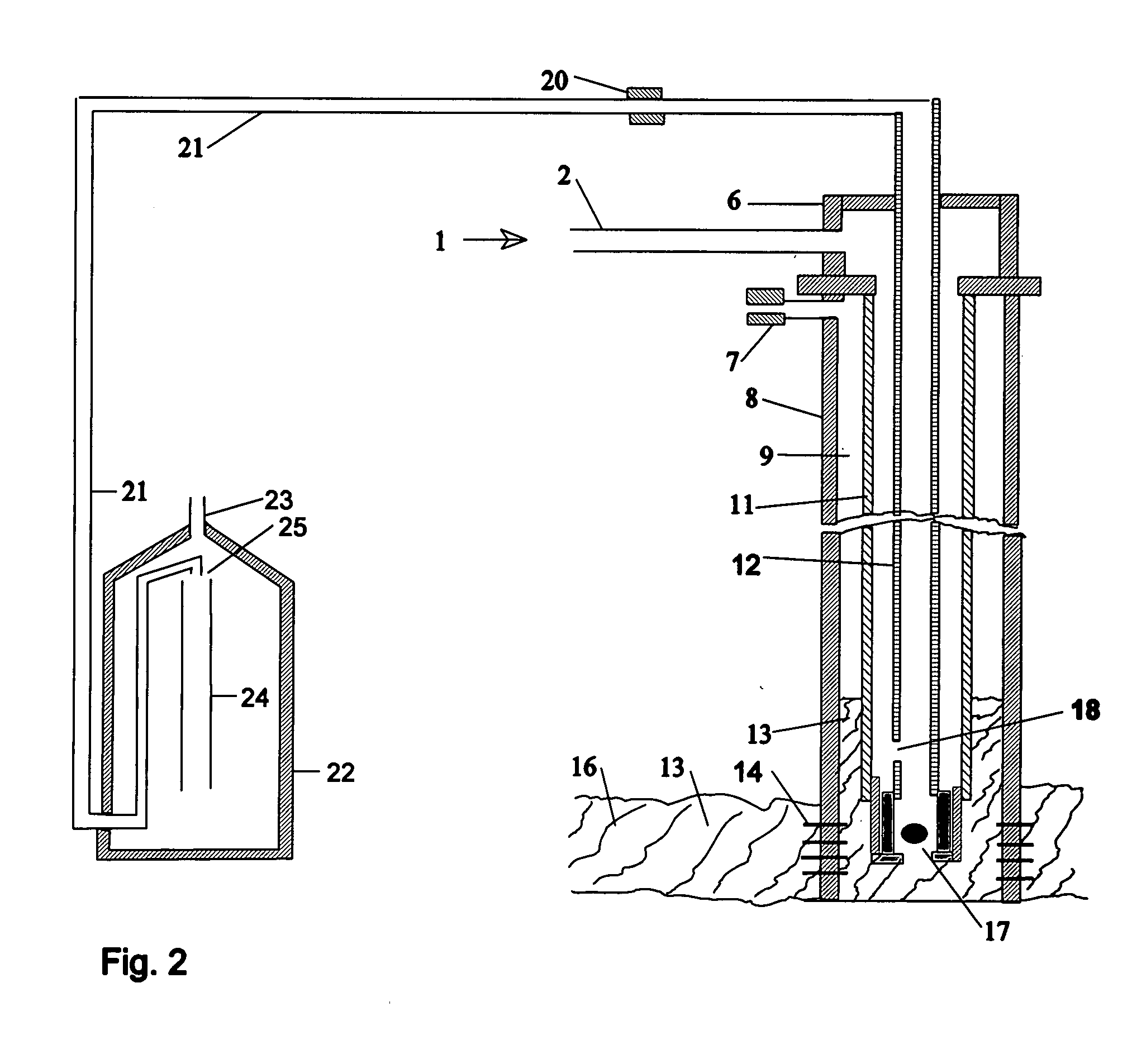

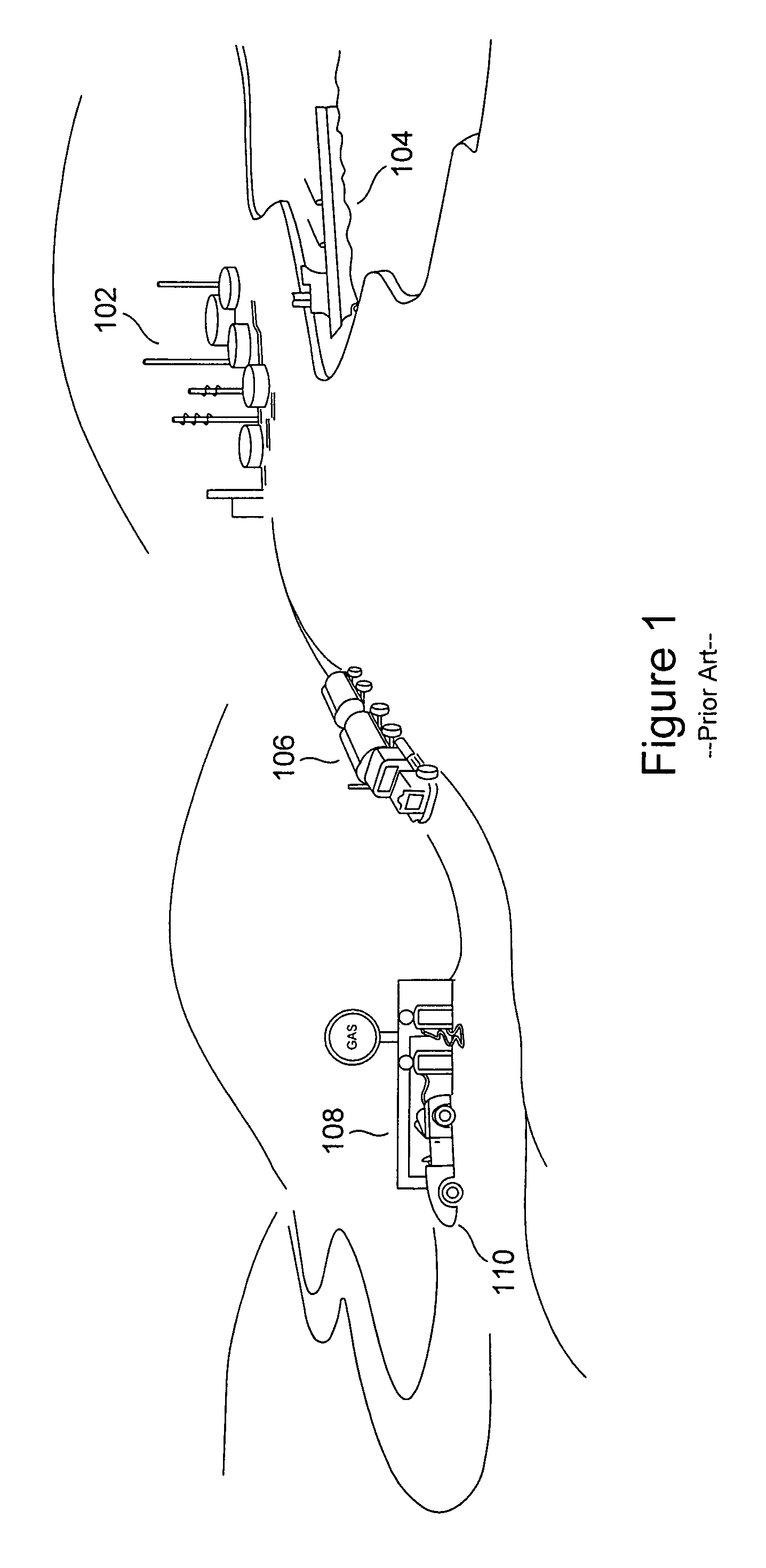

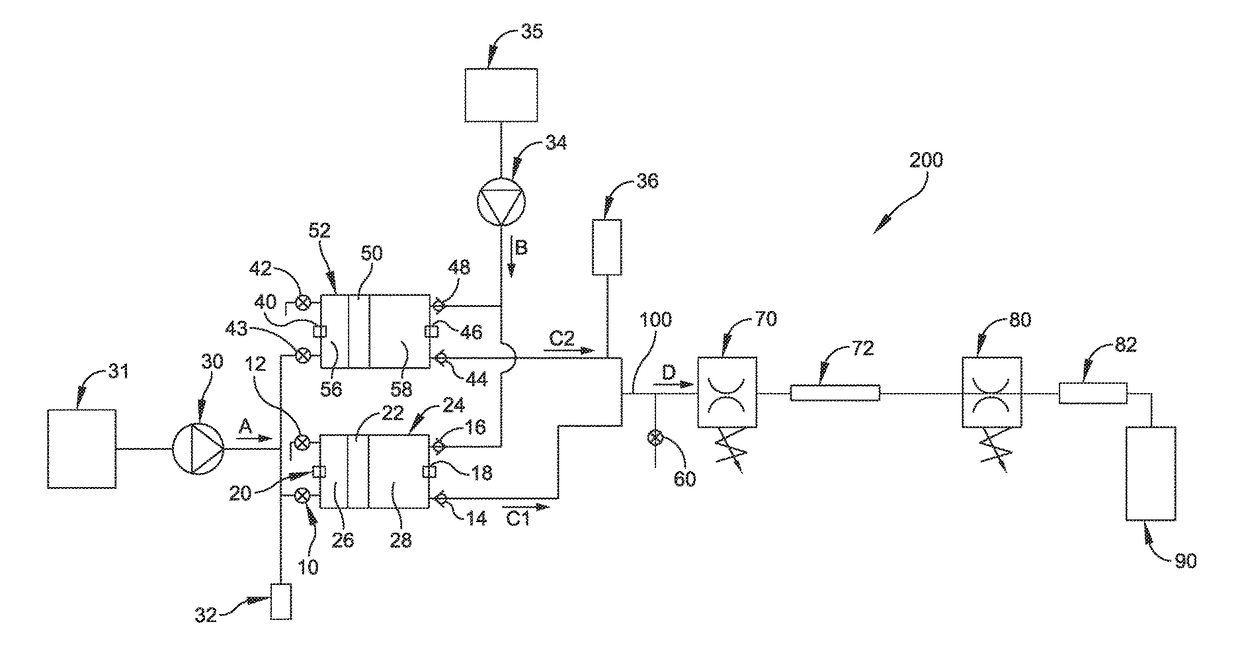

Hydrocarbon production system and method of use

InactiveUS20080164034A1Extended service lifeEasy to produceConstructionsFluid removalFluid shearCoal

The method of the present invention employs a subsurface production pump to displace hydrocarbon fluid, including any and all accompanying ground water and / or earthen contaminants, from the subterranean hydrocarbon reservoir depth of an oil well to surface storage and handling facilities via the subsurface production tubing, wellhead and surface flow line. As the subsurface production pump operates, compressed gas, or a mixture of compressed gases of sufficient volume and force is fed into the lower end of the subsurface production tubing in proximity to, or at a point above the subsurface production pump to mix into the hydrocarbon production fluid column. The resultant and considerably reduced density of the subsurface hydrocarbon production fluid column provides a reduction of subsurface production pump loading with all types of subsurface production pumps, and an improvement of sucker rod fall time when sucker rod activated subsurface plunger pumps are employed. Due to the additional cubic volume of the injected compressed gas, the increased hydrocarbon production fluid and gas velocity within the subsurface production tubing and the surface flow line improves hydrocarbon fluid shear from the conduit walls and sucker rod surfaces, and prevents earthen contaminants such as sand, clay, shale, coal or other rock fragments, from precipitating, accumulating and blocking the flow of hydrocarbon production fluid within the subsurface production tubing and the surface flow line.

Owner:UTTLEY DENNIS FRLIN

Bioreactor device, and method and system for fabricating tissues in the bioreactor device

InactiveUS8709793B2Bioreactor/fermenter combinationsBiological substance pretreatmentsFluid shearEngineering

Owner:UNITED STATES OF AMERICA

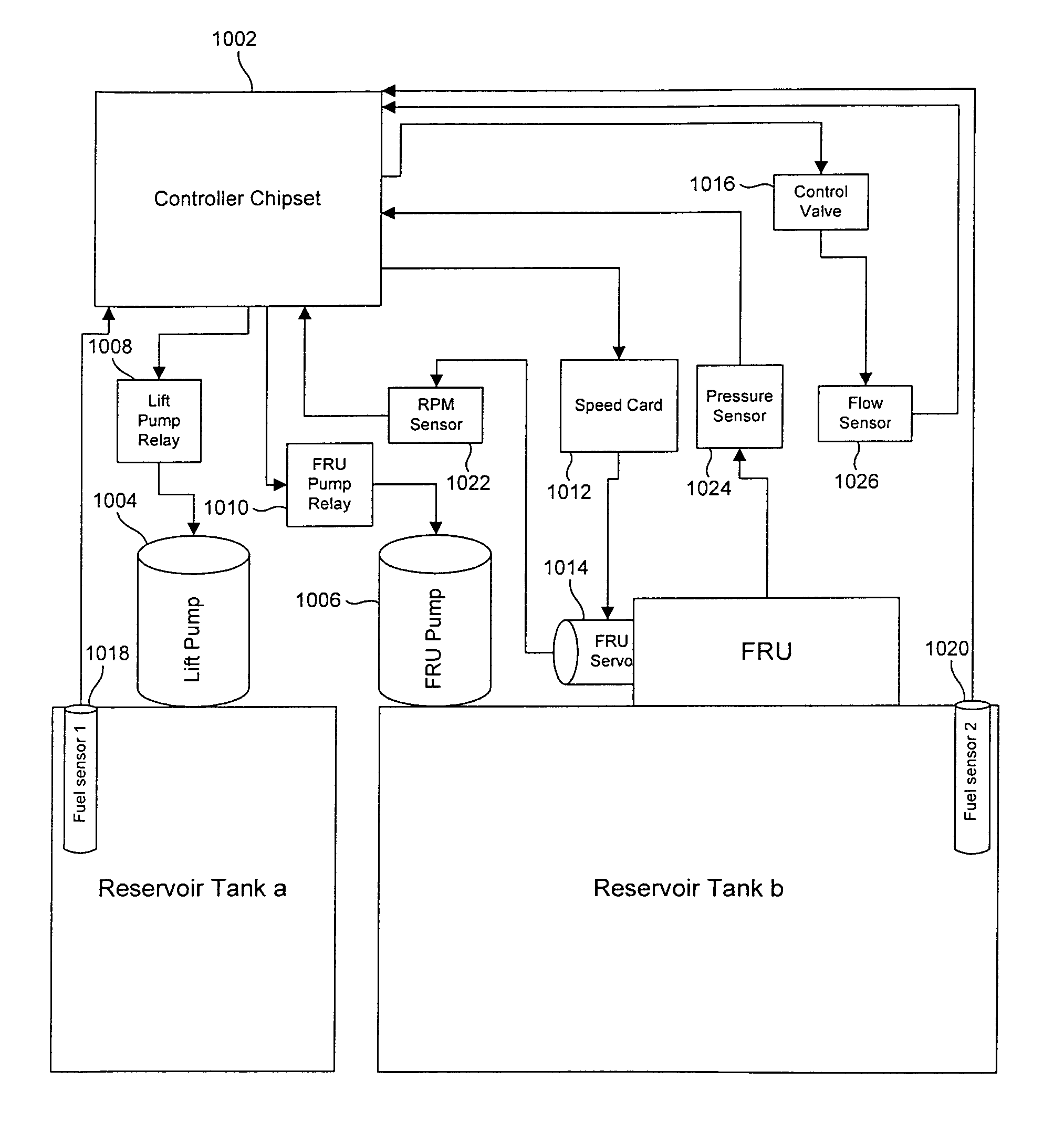

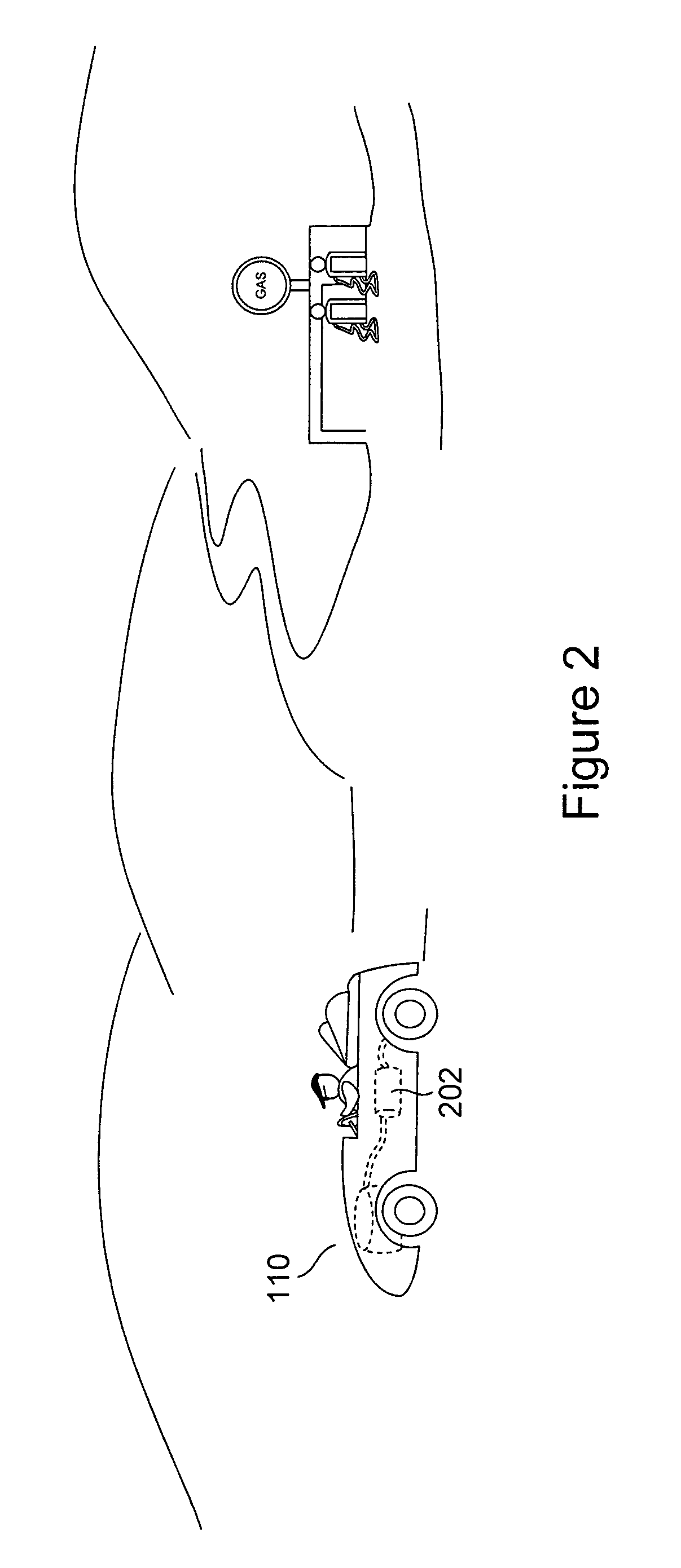

On-board fuel refining in motorized vehicles

Various embodiments of the present invention are directed to systems and methods for on-board refining of fuels within motorized vehicles. On board fuel refining is a finish-refining step that allows a fuel to be more precisely tailored to a particular vehicle and internal-combustion engine and to the current conditions under which the fuel is being used. In one embodiment, the fuel is subjected to fluid-shear forces and cavitation.

Owner:DONNELLY LABS

Relating to air-breathing flight vehicles

An air intake for a supersonic air-breathing flight vehicle introduces or injects fluid in order to create predetermined regions of separated flow and an attendant fluid shear layer. This shear layer forms an aerodynamic boundary for the capture flow with a profile determined and optimised by appropriate injection of fluid. The aerodynamic boundary so generated replaces mechanically moveable solid surfaces used to vary the geometry of prior-art intakes. Use of an introduced or injected fluid can provide an advantage of a variable geometry, but with reduced weight and reduced mechanical complexity. In some embodiments, the injection of fluid has the effect of re-energizing any ingested boundary layer, thus obviating the conventional requirement for a bleed system to provide boundary layer control.

Owner:MBDA UK

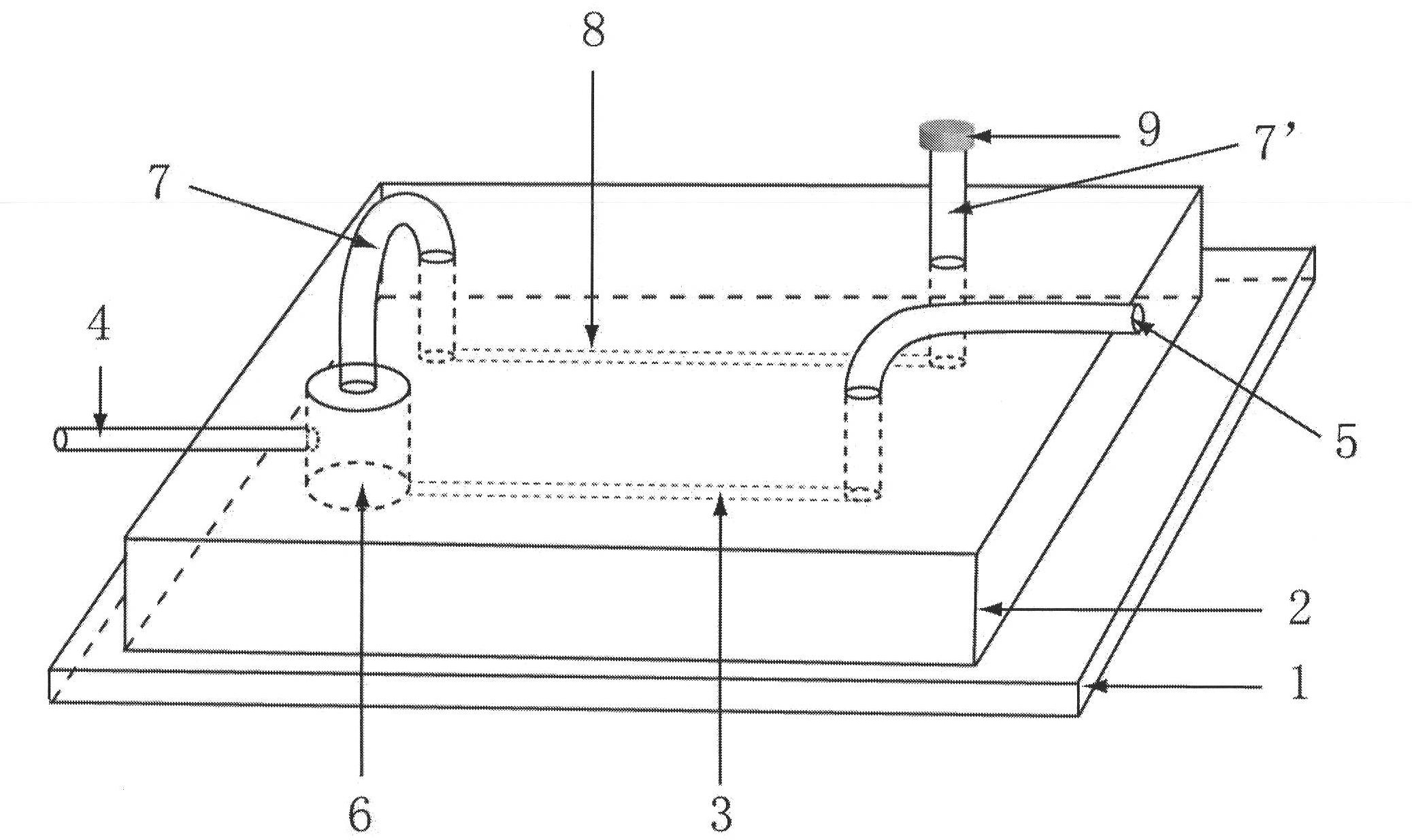

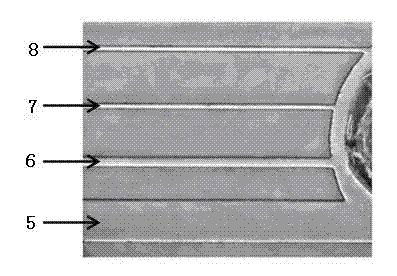

Micro-fluidic chip and method for studying effect of fluid shearing force on cell with the micro-fluidic chip

InactiveCN102816695AMicrobiological testing/measurementTissue/virus culture apparatusFluid shearEngineering

The invention provides a micro-fluidic chip and a method for studying an effect of fluid shearing force on a cell with the micro-fluidic chip. The micro-fluidic chip is composed of four cell culture inserts and four fluid passages, wherein the four cell culture inserts have the same size and are parallel mutually; a cell culture insert a and a cell culture insert b share one cell injection port and one cell waste reservoir; a cell culture insert c and a cell culture insert d share one cell injection port and one cell waste reservoir; the upper ends of the four cell culture inserts are separately connected with the four fluid passages; the lower ends of the four cell culture inserts are connected with the same waste reservoir; and the four fluid passages collectively start from a nutrient solution injection port, with the tail ends being connected with the four cell culture inserts respectively. The micro-fluidic chip can be used for studying the effect of the fluid shearing force on the cell.

Owner:DALIAN MEDICAL UNIVERSITY

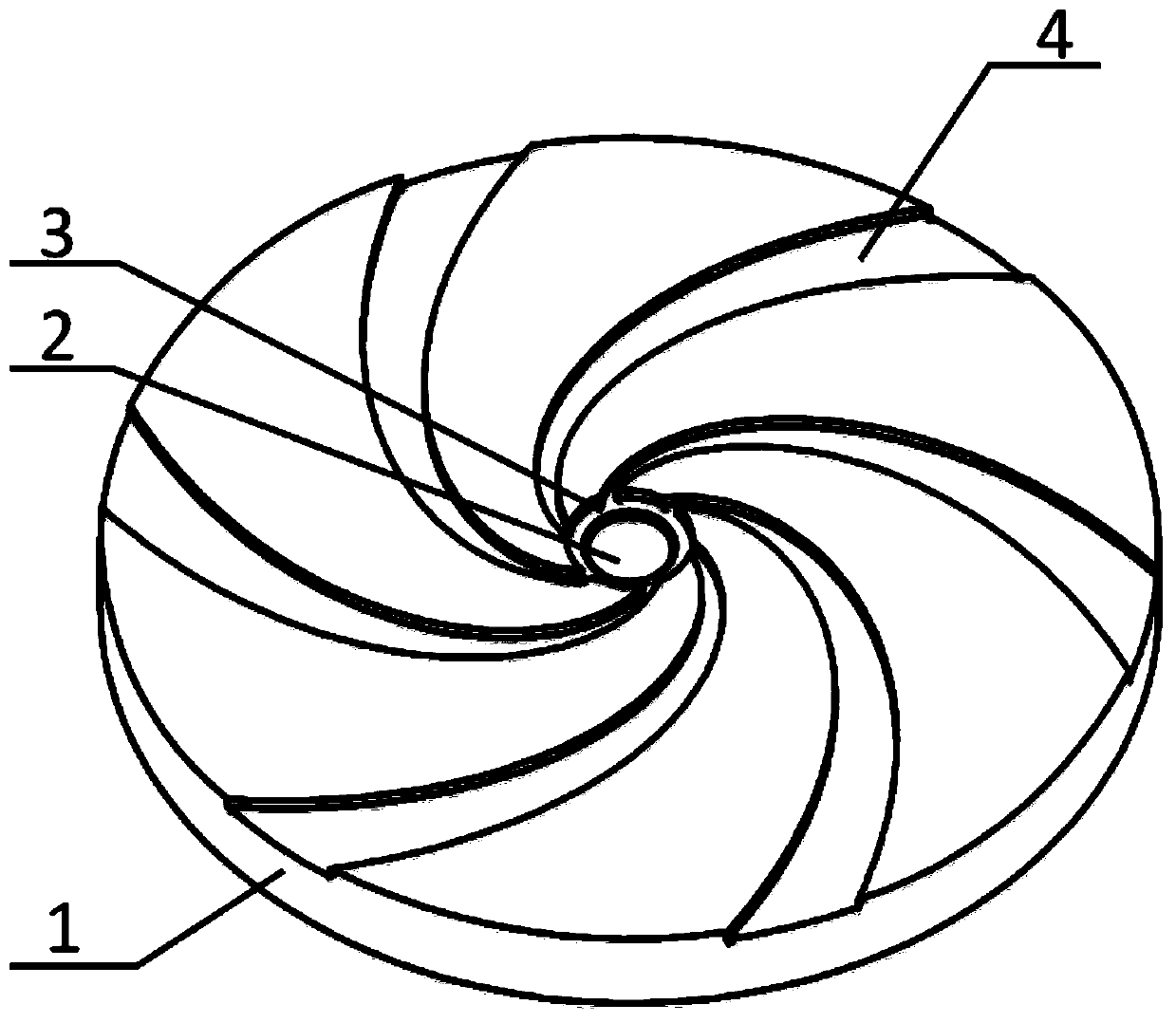

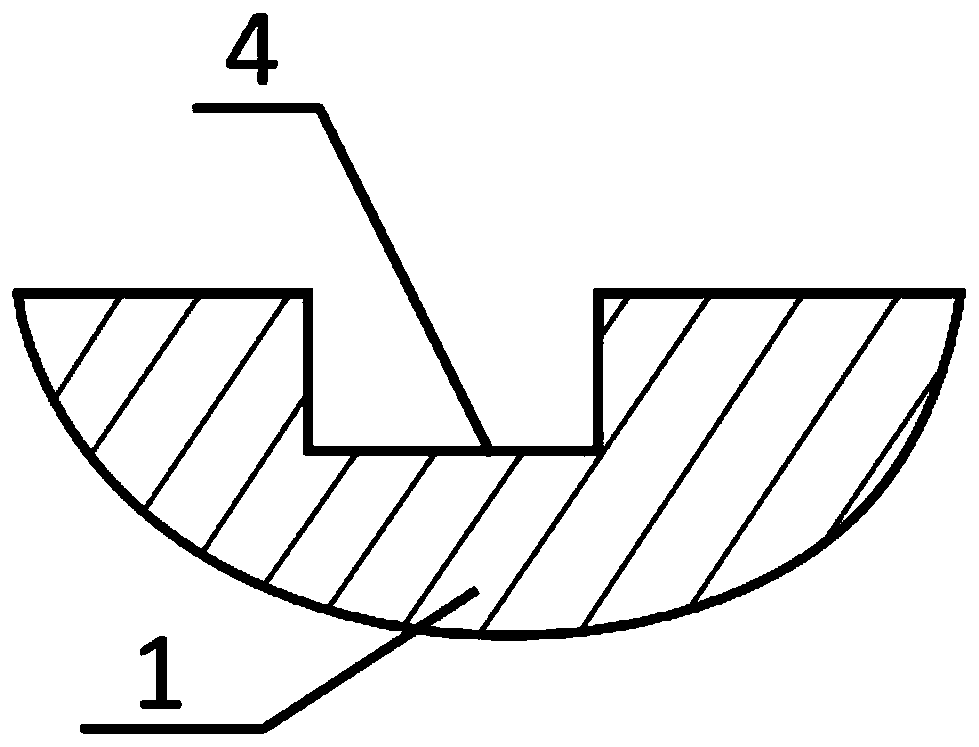

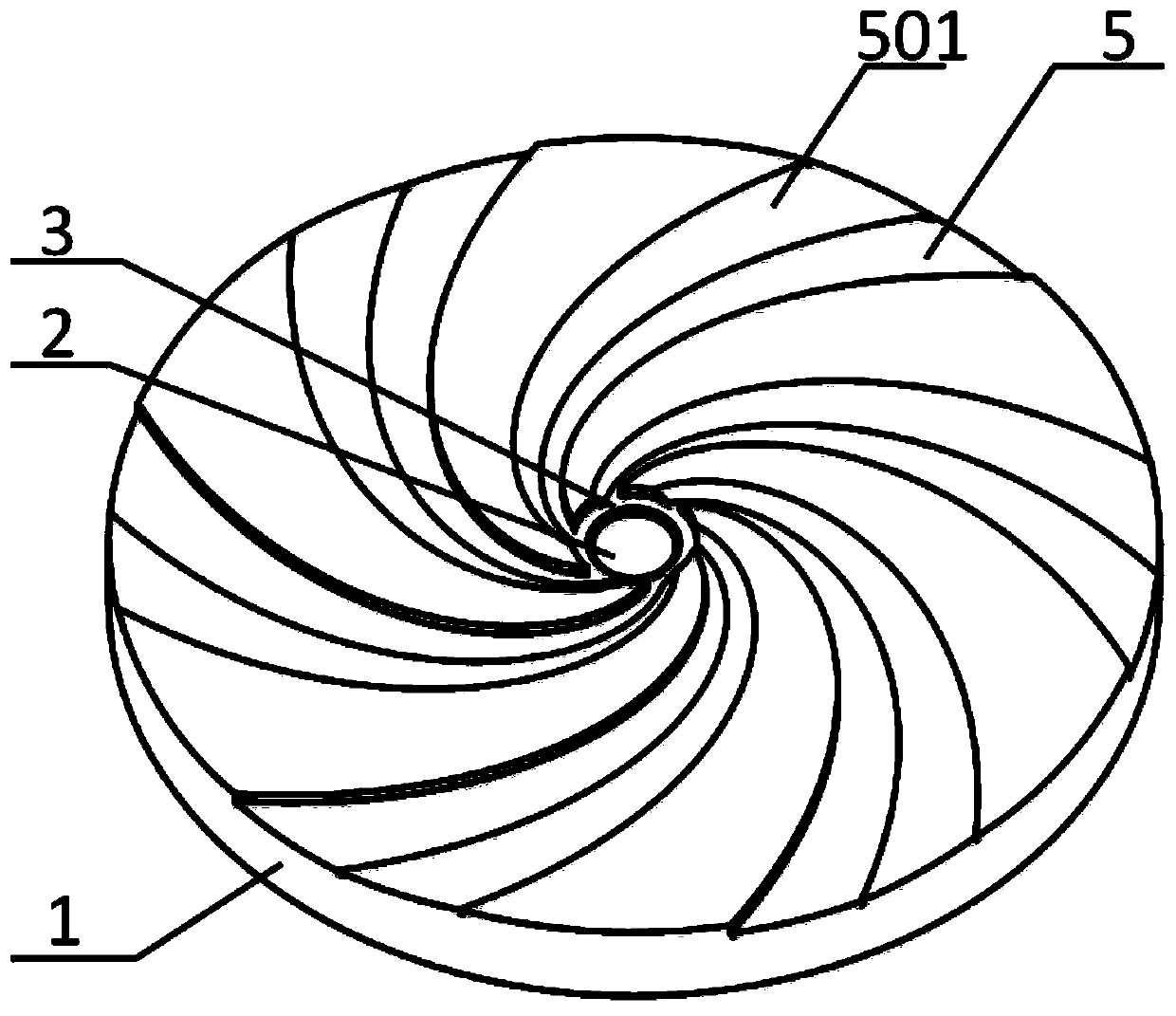

Spiral fluid dynamic pressure polishing pad and polishing method thereof

PendingCN110480497AReduce removalImprove removal efficiencyPolishing machinesAbrasion apparatusFluid shearContact mode

The invention discloses a spiral fluid dynamic pressure polishing pad and a polishing method thereof, and aims to change polishing action modes of a tangent point and a tangent line of a traditional spherical tool and a cylindrical tool and expand action area between the tool and a workpiece to a surface contact mode to improve the polishing efficiency. According to the polishing pad and the polishing method, a center liquid supply hole and a middle liquid storage area are formed in the center of a polishing pad base body, spiral dynamic pressure grooves are formed in the surface, and the spiral dynamic pressure grooves are uniformly distributed on the surface of the polishing pad base body; in the polishing process, a polishing solution mixed with polishing particles in advance is injected into a liquid film gap between the polishing pad and the surface of the workpiece from the central liquid supply hole under a pressure, and meanwhile, the polishing pad rotates at a high speed so asto enhance the dynamic pressure effect of the polishing solution in the liquid film gap; and according to a fluid dynamics theory, fluid dynamic pressure and fluid shearing force in the liquid film gap can obviously improve the effect of the particles in the polishing solution on eroding the surface of an optical element, remove material on the surface of the element and achieve the purpose of polishing.

Owner:TIANJIN UNIV

Bio-electrochemical system, as well as on-line monitoring device and monitoring method for biochemical oxygen demand (BOD) thereof

ActiveCN107505369AHigh fluid shear forceFully degraded substrateMaterial analysis by electric/magnetic meansFluid shearEngineering

A bio-electrochemical system, as well as an on-line monitoring device and an on-line monitoring method for biochemical oxygen demand (BOD) thereof. The invention belongs to the technical field of water body monitoring and solves a problem by providing a device and a method, which can achieve sensitive, quick, low-cost and accurate monitoring to BOD in a water body. The bio-electrochemical system can be a M3C sensor, a MFC sensor or a MEC sensor; the M3C sensor includes granular filler, a shell and a tri-electrode system, wherein the shell is in a sealed structure with a chamber therein and is provided with a sample inlet and a sample outlet that are communicated with the chamber; the granular filler is packed in the chamber in the shell and work electrodes are arranged in same; for the MFC sensor or the MEC sensor, granular filler is packed in a bio-anode chamber and / or a bio-cathode chamber. In the bio-electrochemical system, the reactor is filled with granules, so that fluid shear force is high and degradation of a substrate is more complete; therefore, detection sensitivity is higher.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

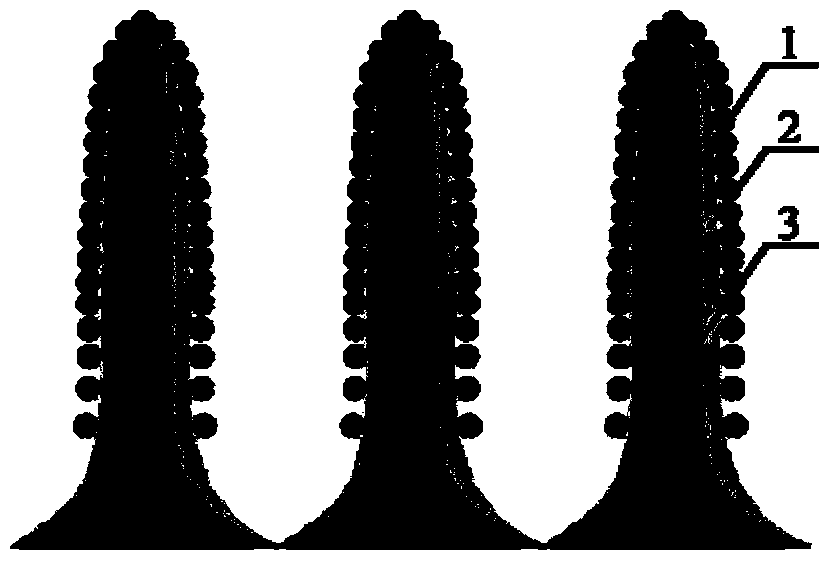

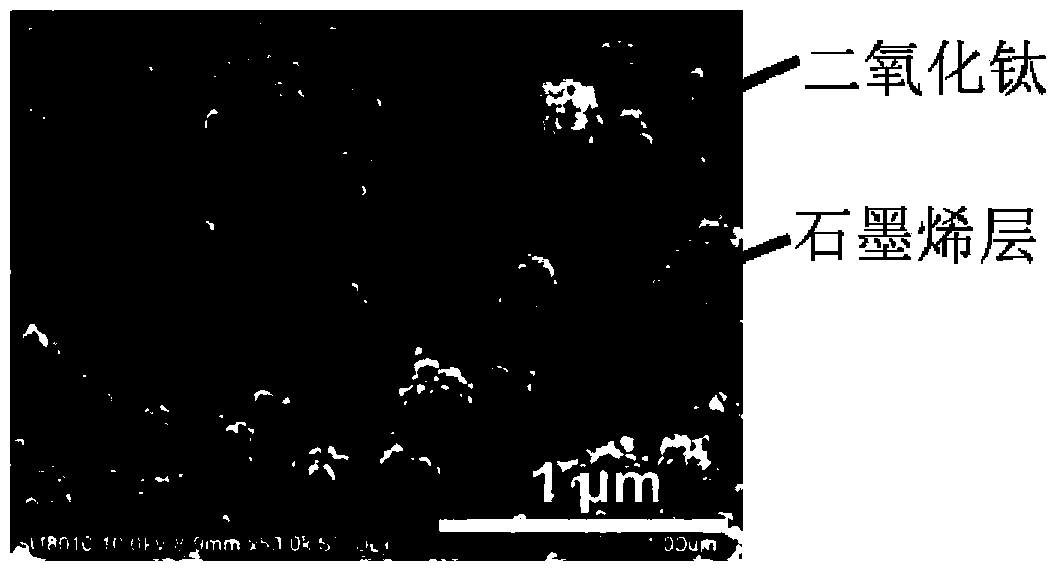

Magnetic-control dynamic ciliary bionic photocatalytic array and preparation method thereof

ActiveCN103551198AImprove photocatalytic activityHigh photocatalytic stabilityWater/sewage treatment by irradiationOrganic-compounds/hydrides/coordination-complexes catalystsBionicsFluid shear

The invention provides a magnetic-control dynamic ciliary bionic photocatalytic array and a preparation method thereof. The photocatalytic array can be flexibly bent and rotate under the action of a magnetic field. The preparation method comprises the steps: preparation of the ciliary bionic array, surface modification of the ciliary bionic array and further growth of photocatalytic substances. In a photocatalysis process, the magnetic field rotating at a high speed can drive the ciliary bionic photocatalytic array to carry out high-speed disturbance so as to realize effective and mixed mass transferring in a catalytic system, and due to a fluid shearing force generated by movement of the photocatalytic array, degradation products can be desorbed rapidly and the active positions of the catalytic substances can be exposed in time, so that the photocatalytic array can keep lasting photocatalytic activity. The magnetic-control dynamic ciliary bionic photocatalytic array provided by the invention can carry different photocatalytic substances and can play an important role in the fields of a micro-catalytic reactor and the like.

Owner:NANJING UNIV OF TECH

Spin-stabilized non-lethal projectile with a shear-thinning fluid

ActiveUS9470492B2Improve shelf-stability and performance characteristicImproves ballistic characteristicAmmunition projectilesTraining ammunitionEmulsionApparent viscosity

A non-lethal projectile having a shear-thinning fluid within an interior cavity. The shear-thinning fluid having a greater apparent viscosity at low shear rates to spin-stabilize the non-lethal projectile during flight and a lower apparent viscosity at a high shear rate corresponding with the shear-thinning fluid shearing against the frangible cap upon the non-lethal projectile striking the target, with the low viscosity of the shear-thinning fluid allowing proper dispersal upon impact with the target. The shear-thinning fluid can comprise a marking media and be in the form of an emulsion with less than about 50% liquid by volume to effectively disperse upon impact with the target.

Owner:GEN DYNAMICS ORDNANCE & TACTICAL SYST

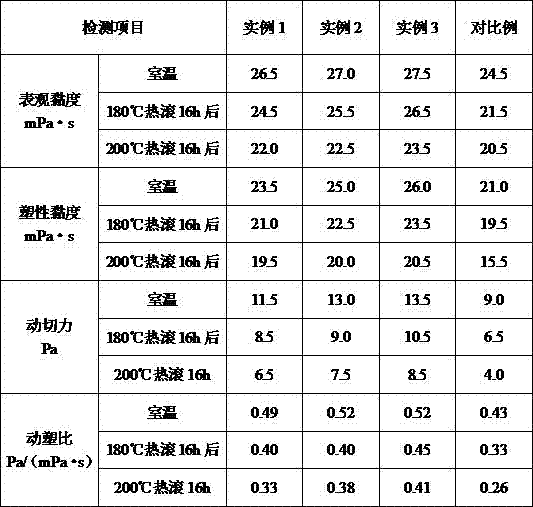

Preparation method of drilling fluid shearing enhancer

The invention discloses a preparation method of a drilling fluid shearing enhancer and belongs to the technical field of preparation of drilling fluid treatment agents. The preparation method comprises the following steps: putting methyl methacrylate, ethylene glycol, butyl acrylate and epoxy propane into a reactor; regulating the pH (Potential of Hydrogen) with a sodium hydroxide solution and then adding zinc stearate; reacting under the protection of nitrogen gas; then adding chitosan and vinyltrimethoxysilane and uniformly mixing and standing; then adding a catalyst and an initiator and carrying out modification reaction; after reacting, adding a cross-linking agent; reacting and discharging materials; filtering the discharged materials and collecting filtrate; after distilling, collecting distillation residues and uniformly mixing the distillation residues with sodium oxalate, an emulsifier and an auxiliary agent; collecting and stirring a mixture to obtain the drilling fluid shearing enhancer. The drilling fluid shearing enhancer prepared by the preparation method has relatively good high-temperature ageing resisting performance and still has a relatively good shearing enhancing effect under a high-temperature environment; the aim of suspending rock fragments on drilling fluid can be effectively realized; the drilling speed is improved and any damage to oil and gas reservoirs is not caused after the drilling fluid shearing enhancer is used.

Owner:常州西夏墅东方工具有限公司

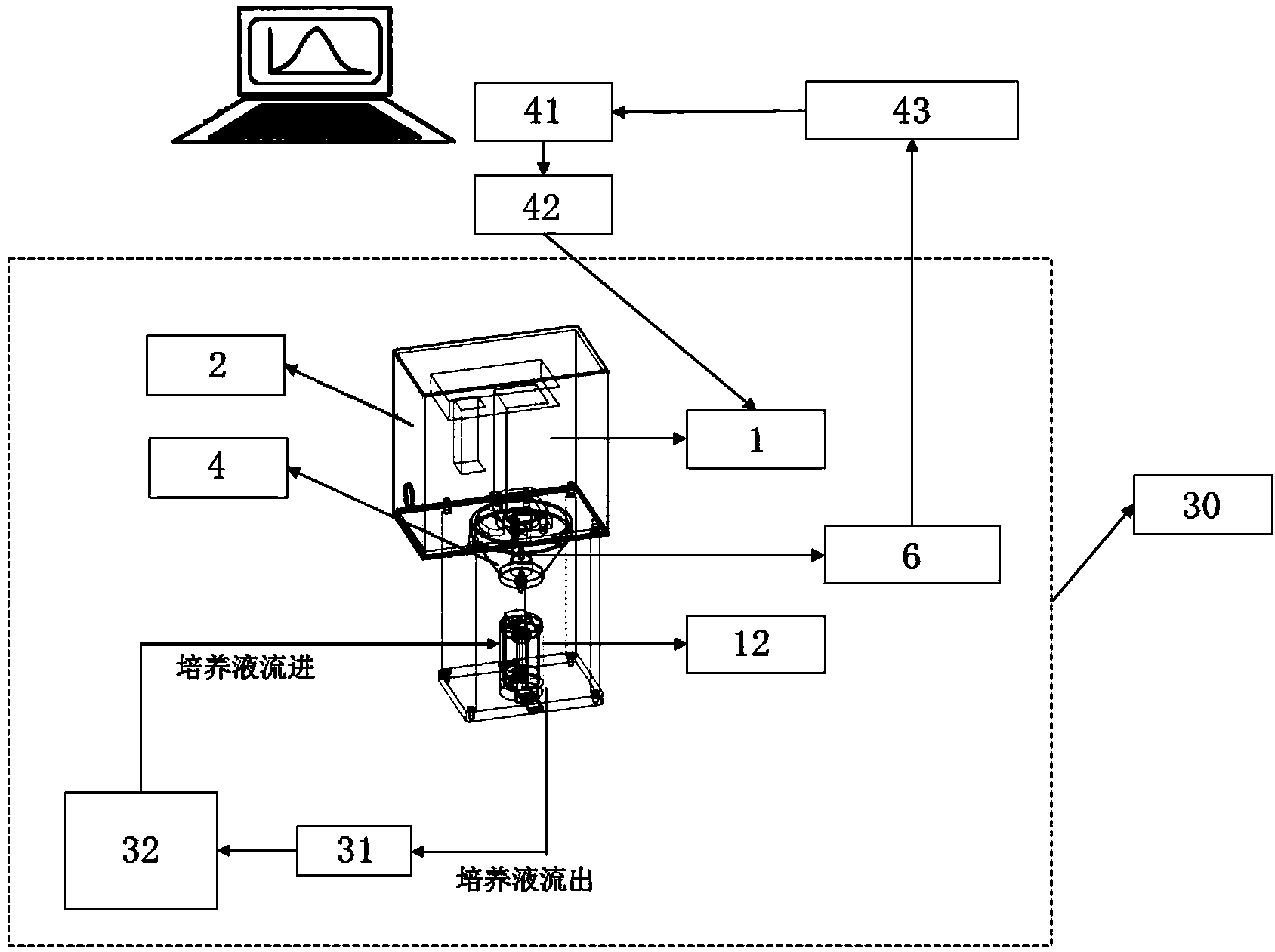

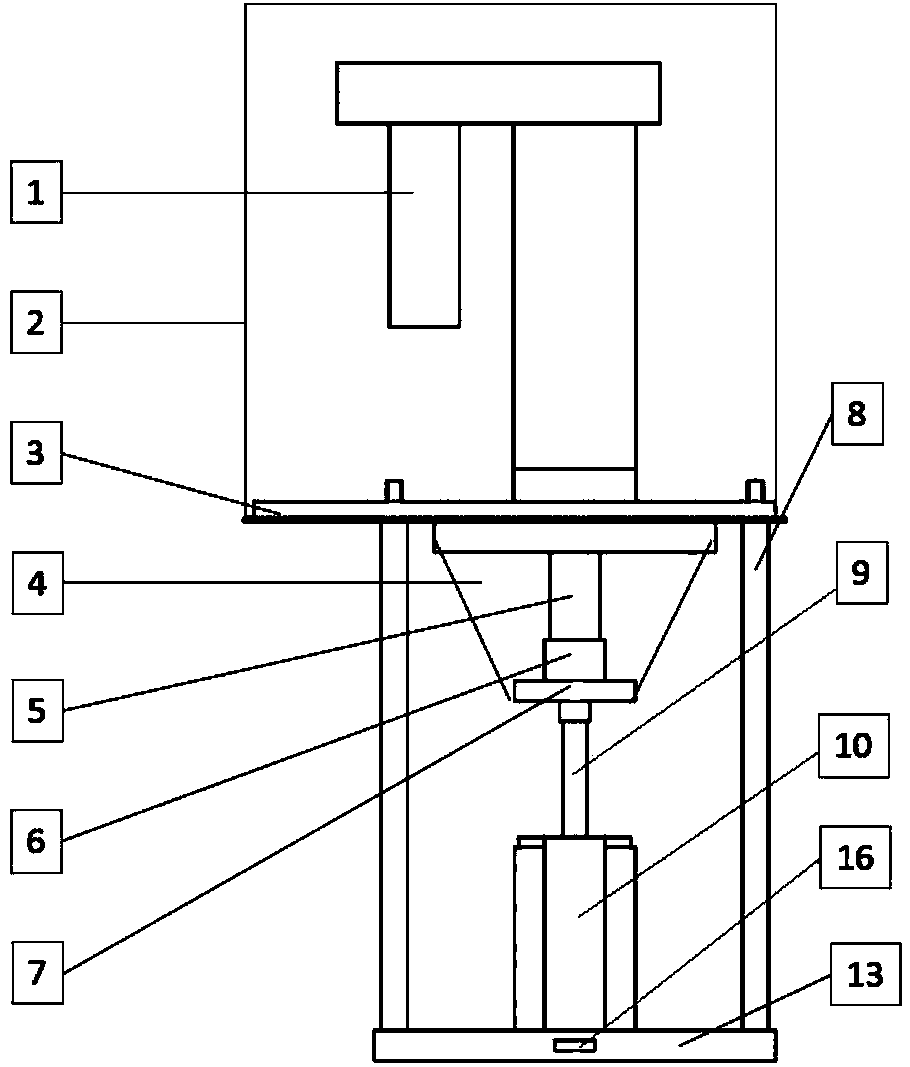

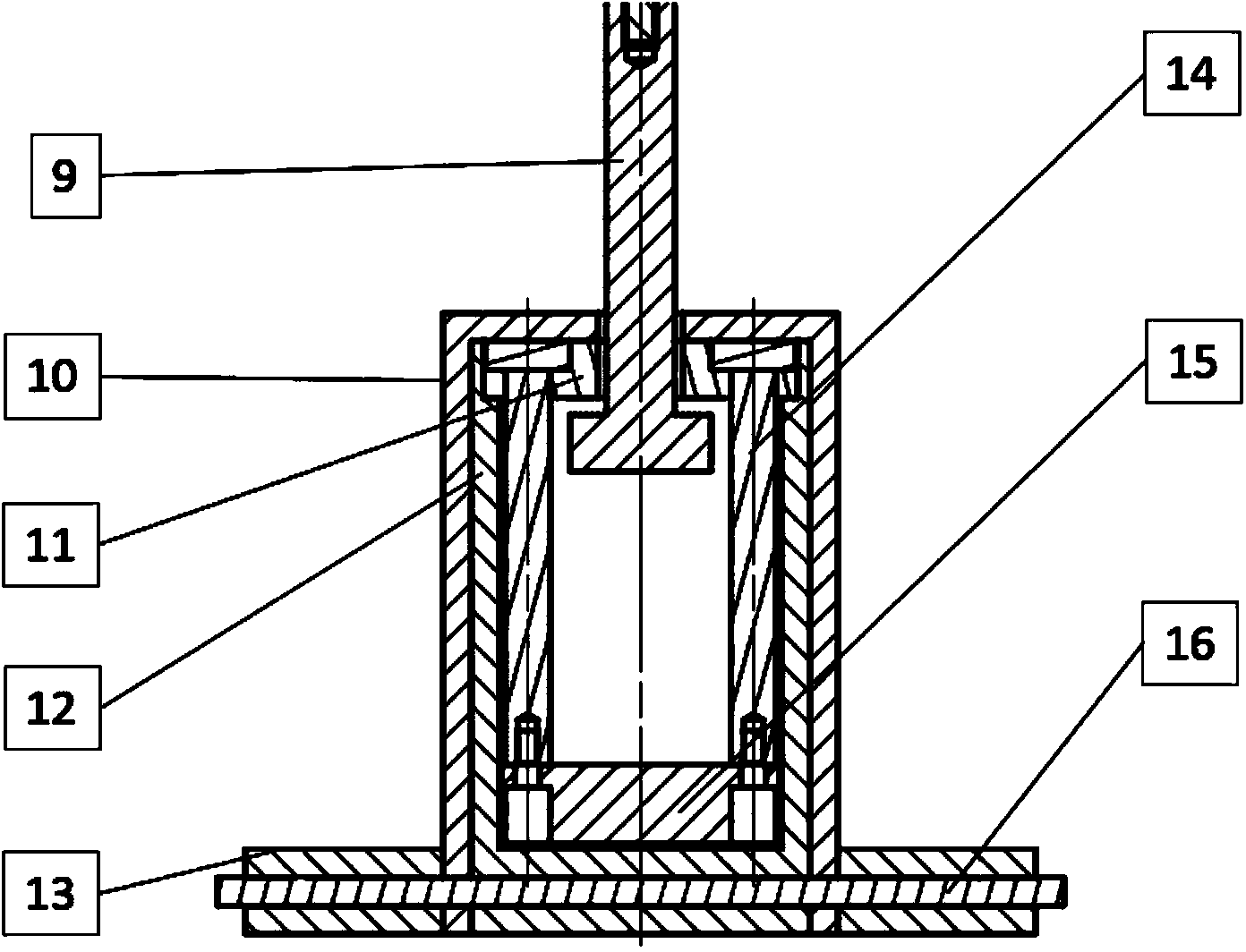

Physiological environment-imitating mechanical stimulation type biological reactor system

InactiveCN104046564AMultifunctionalMonitor real-time loadBioreactor/fermenter combinationsBiological substance pretreatmentsShear stressCulture fluid

The invention discloses a physiological environment-imitating mechanical stimulation type biological reactor system. The physiological environment-imitating mechanical stimulation type biological reactor system comprises a CO2 incubator, a main body part, a circulatory flowing part and a control part, wherein a working environment for the CO2 incubator is as follows: 100% humidity, CO2 concentration of 5% and a temperature of 37 DEG C; the main body part is placed in the CO2 incubator, comprises a culturing room used for placing engineered tissues and a loading component used for applying force to the engineered tissues; the loading component extends into the culturing room filled up with culture liquid; the control part is placed on the outer surface of the CO2 incubator and is connected with the main body part; the control part controls the loading component to apply the corresponding stretching force load or compressing force load to the engineered tissues according to preset change laws; the circulatory flowing part is connected with the culturing room; the culture liquid forms circulatory flow between the culturing room and the circulatory flowing part; the engineered tissues bear stimulation of fluid shearing force produced by the flow of the culture liquid. The physiological environment-imitating mechanical stimulation type biological reactor system disclosed by the invention has the multifunctional characteristic, so that the engineered tissues can bear shearing force of a more like human physiological environment and mechanical stimulation action of stretching or compressing in the system.

Owner:SHANGHAI JIAO TONG UNIV

Double-cone dynamic mixer

The invention discloses a double-cone dynamic mixer, which comprises a mixing chamber with a feed opening and a discharge opening, wherein fixed plates and moving plates matched in a rotating manner are coaxially arranged in the mixing chamber; butted working surfaces are arranged between the fixed plates and the moving plates; feed flow passages and discharge flow passages communicated with the discharge opening are formed in the working surfaces of the fixed plates; diversion flow passages communicated with the feed opening are formed in the working surfaces of the moving plates; in a relative rotating process of the fixed plates and the moving plates, the diversion flow passages are alternately communicated with the feed flow passages and the discharge flow passages. According to the double-cone dynamic mixer, the flow passages are conically distributed, so that the extension of length of the flow passages is facilitated, and more fixed and moving plate combinations can be distributed within a finite distance; the double-cone dynamic mixer has good diversion effects, and is complete in self mixing, strong in fluid shear force, wide in application range and free of flowing dead angles.

Owner:ZHEJIANG MODERN TEXTILE IND RES INST

System for high pressure, high shear processing of fluids

ActiveUS20180080444A1Temperature controlPositive displacement pump componentsFood preservationUltra high voltageFluid shear

A method for high fluid shear processing of a fluid uses an isolator that has a first sub-chamber for containing a first fluid and a second sub-chamber for containing a second fluid defined by a separator positioned in the chamber and movable between a first end of the chamber and a second end of the chamber. The two sub-chambers are in pressure communication with each other but are not in fluid communication with each other. A first fluid is pumped at an ultrahigh pressure into the first-sub chamber, and the pressure in the first sub-chamber causes a second fluid to be processed to be discharged from the second sub-chamber into a processing valve. A system is also provided for performing the steps of this method.

Owner:PRESSURE BIOSCI

Tumor microvessel self-assembly generation system

InactiveCN106264745AGuaranteed cycleTo achieve the purpose of ventilationDiagnosticsSurgeryPeristaltic pumpMicropore Filter

The invention discloses a tumor microvessel self-assembly generation system. The system comprises a tumor microsphere column and a pulsation system; the tumor microsphere column comprises a perfusion column and tumor microspheres located in the perfusion column, and the two ends of the perfusion column are each provided with a micropore filter membrane; the pulsation system comprises a peristaltic pump, a pulse piston pump, a rotating culture support, a liquid storage bottle, an oxygenator, a filter and a buffer bottle; the perfusion column, the liquid storage bottle, the oxygenator and the buffer bottle are sequentially communicated end to end to form a circulating channel. In the working process, the peristaltic pump is started to start to conduct perfusion, a fluid in the buffer bottle forms fluid circulating through a first pulse pipeline, when the pulse piston pump conducts extraction operation, more fluids can swarm into the perfusion column in a pulsed mode to form a pulsed fluid to pass through the perfusion column, then a pulsed fluid caused by cardiac impulse is simulated, and fluid flow and fluid shear force are applied to the tumor microspheres in the perfusion column; oxygen is supplied and carbon dioxide is removed by combining the oxygenator which simulates a lung air exchange device, and then occurrence of the tumor microvessels in a body is finally simulated.

Owner:THE SECOND HOSPITAL AFFILIATED TO SUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com