Controllable drop coalescence prepared anisotropic particle material and microfluid device

An anisotropic, droplet technology, applied in chemical/physical/physical-chemical processes, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as small particle size range and inability to modify the surface of solid particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

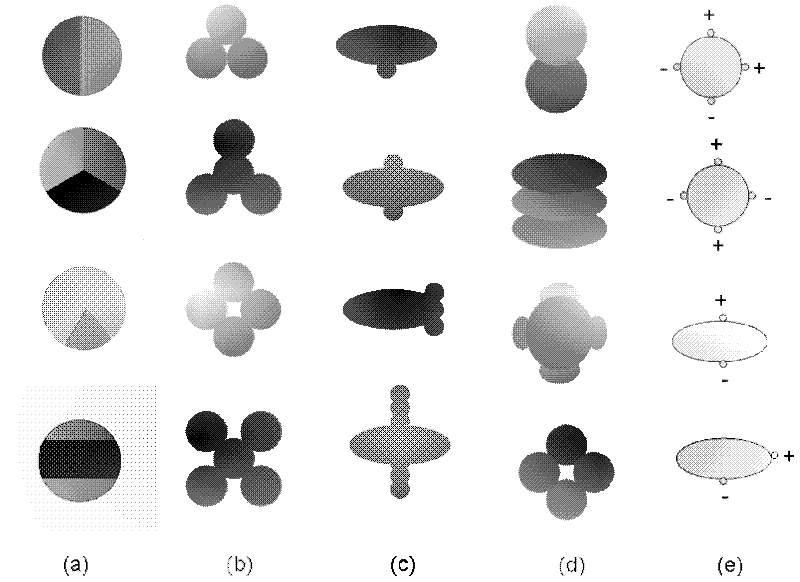

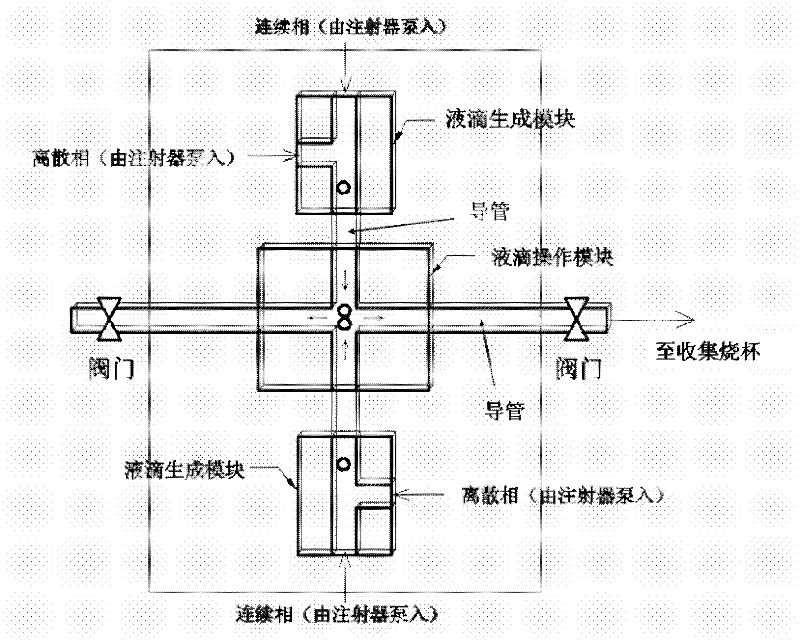

[0048] Spherical functional particle materials with partial properties ( figure 1 a). by figure 1 The three-color block particles in a are taken as an example: EGDMA is colored with inks of three colors, and then three T-shaped droplet generation modules are used to generate three EGDMA droplets with a diameter of 10 microns in light blue, black and red. Afterwards, these three droplets are respectively passed into the three inlets of the six-arm hydrodynamic well, allowing them to gather at the center of the hydrodynamic well ( Image 6 c), due to surface tension, these droplets will fuse into one large spherical droplet, but the colors will not mix very quickly, leaving a clear interface. Finally, the three-color EGDMA balls were cured with ultraviolet light to prepare three-color segmented spherical particles.

Embodiment 2

[0050] Colloidal cluster-like functional particle materials with a certain lattice structure ( figure 1 b). by figure 1 The three-spherical particle cluster in b is an example: after the EGDMA droplet (diameter 10 microns) is generated, it can be directly cured into spherical particles by ultraviolet light. Then three spherical particles are respectively passed into the three inlets of the six-arm hydrodynamic well, allowing them to gather and merge at the center of the hydrodynamic well ( Image 6 c). When the EGDMA droplets are fully solidified, they coalesce without deformation; while when the droplets are partially solidified before coalescence, they coalesce, they will partially deform under the action of the fluid, but will not fully fuse into a large sphere , and finally generate particle clusters.

Embodiment 3

[0052] Dendritic functional particle material with small branch structure ( figure 1 c). by figure 1 The first case in the c-column particles is an example: first, after the EGDMA droplet (40 microns in diameter) is generated, it is passed into the cross-shaped hydraulic well, placed on the stagnation point of the operation module, and it is transported by extensional flow. It is deformed into an ellipsoid, and then cured by ultraviolet light; secondly, a small droplet with a diameter of 10 microns is generated by the droplet generation module, and after being partially cured, it is passed into a cross-shaped hydraulic well to converge with the large ellipsoid already at the stagnation point. and( Image 6 b), thus generating small branches. If branch lengths are to be increased, multiple prepreg droplets can be coalesced sequentially at the same location.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com