Patents

Literature

3831results about How to "High solid content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ceramic slurry preparation and 3D (three dimensional) printing light curing molding method

ActiveCN106810215ALow viscosityHigh solid contentAdditive manufacturing apparatusCeramic shaping apparatusFlexural strengthVolumetric Mass Density

The invention provides a ceramic slurry preparation and 3D (three dimensional) printing light curing molding method. 25-85vol% of ceramic powder and 15-75vol% of an optical resin premix solution are mainly involved, and the method includes: A), preparation of the optical resin premix : namely stirring a low polymer, a reactive diluent, a photoinitiator, a dispersing agent, a photosensitizer and a sensitizer according to a certain proportion under intermediate speed for 0.5-3 hours to enable the components to be mixed evenly; B), placing the premix solution and the ceramic powder in a ball mill according to certain volume for ball-milling for 5-15 hours to prepare the ceramic slurry high in solid content and low in viscosity; subjecting the ceramic slurry to curing molding layer by layer gradually on a 3D light curing molding machine to obtain a ceramic green body prior to aftertreatment of drying, degreasing, sintering and the like to obtain ceramic part. The method is high in preparation molding precision and free of molds to prepare complex structure parts, the ceramic product can reach more than 92% in density, 320-1750MPa in flexural strength and 1800-4500MPa in compression strength.

Owner:重庆摩方科技有限公司

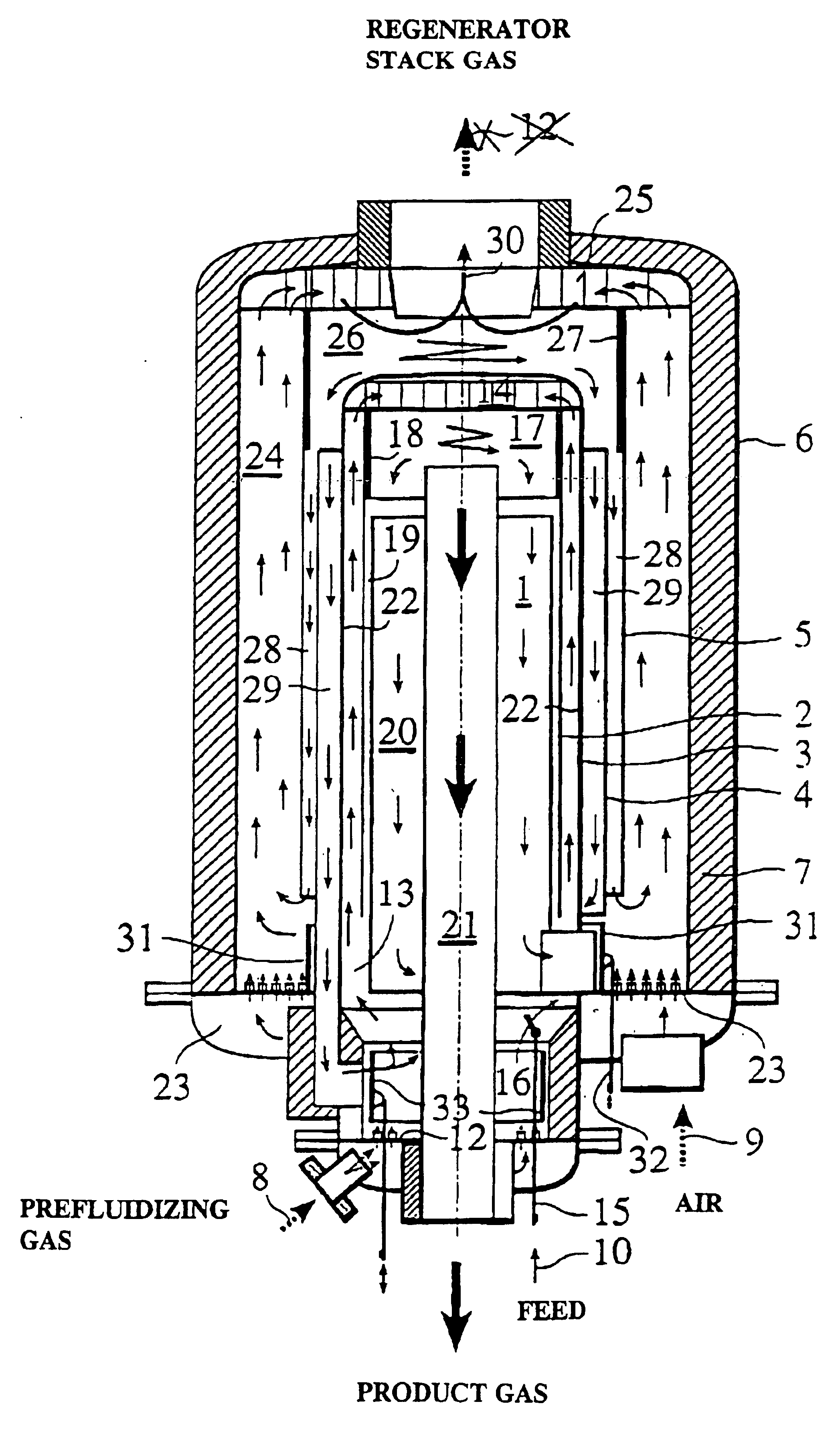

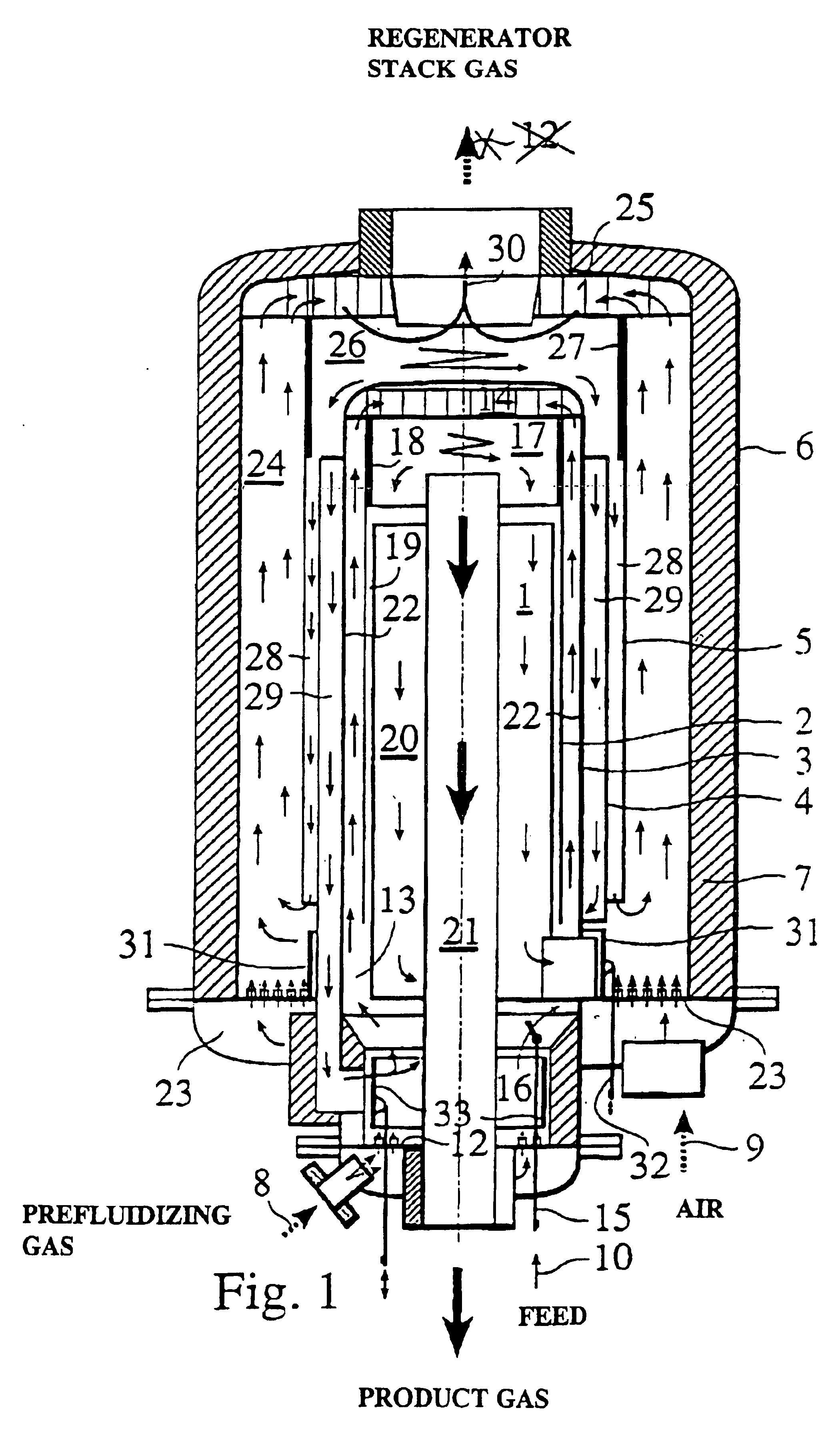

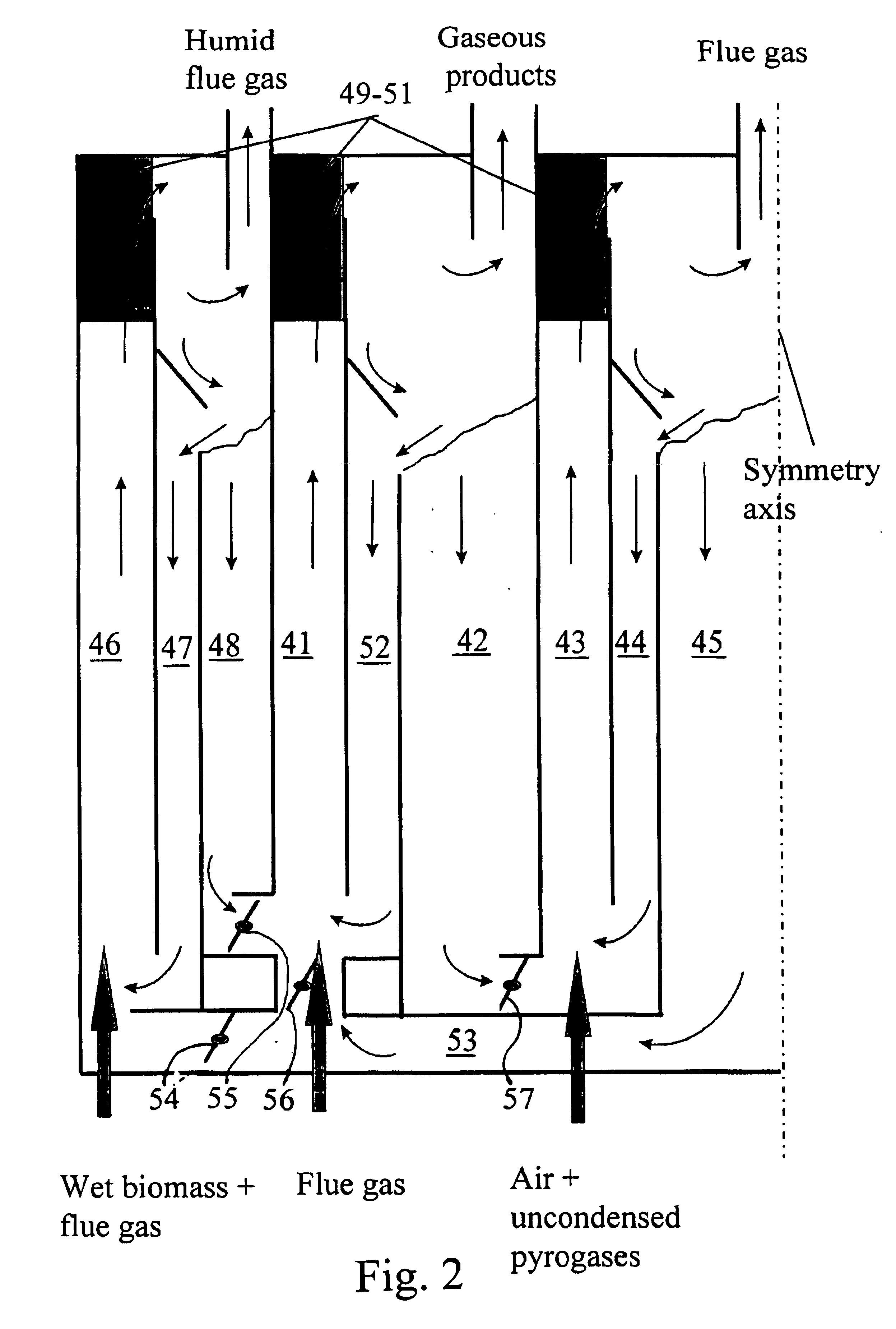

Process for pyrolyzing carbonaceous feedstocks

InactiveUS6814940B1Reduce gas velocityReduce dwell timeThermal non-catalytic crackingMuffle furnacesProcess engineeringProduct gas

The present invention concerns a process and an apparatus for thermal conversion of biomass and organic wastes. According to the invention, the feedstock is fed into a fluidized-bed reactor, wherein the feed is converted at an elevated temperature under the influence of particulate matter kept in a fluidized state by a fluidizing gas, the particulate matter is transferred from the reactor to a regenerator for regeneration and then recirculated to the reactor after the regeneration, and the converted hydrocarbon products are recovered from the reactor. Both the reactor and the regenerator comprise risers having an axially annular cross section and being equipped with multi-inlet cyclones for the separation of particulate matter. By means of the invention, it is possible to producer pyrolysis oil, the quality of which is higher than that of oil produced with the processes of the prior art. The incorporation of multi-inlet cyclones into the reactor configuration reduces gas velocities, reduces the physical size of the cyclone and shortens the residence time of gases in the cyclone.

Owner:FORTUM OY

Integration of alternative feedstreams for biomass treatment and utilization

InactiveUS20070037259A1High solid contentBiological substance pretreatmentsByproduct vaporizationHigh concentrationDry weight

The present invention provides a method for treating biomass composed of integrated feedstocks to produce fermentable sugars. One aspect of the methods described herein includes a pretreatment step wherein biomass is integrated with an alternative feedstream and the resulting integrated feedstock, at relatively high concentrations, is treated with a low concentration of ammonia relative to the dry weight of biomass. In another aspect, a high solids concentration of pretreated biomass is integrated with an alternative feedstream for saccharifiaction.

Owner:SUSTAINABLE TECH CORP +1

Intercalates formed by co-intercalation of monomer, oligomer or polymer intercalants and surface modifier intercalants and layered materials and nonocomposites prepared with the intercalates

The present invention discloses intercalates formed by contacting a layered material, e.g., a phyllosilicate, with an intercalant monomer surface modifier including an alkyl radical having at least 6 carbon atoms and a polymerizable monomer, oligomer or polymer. The intercalant monomer surface modifier converts the interlayer region of the layered materials from hydrophilic to hydrophobic, therefore, polymerizable monomers, oligomers or polymers can be easily intercalated into the interlayer spacing. The co-presence of the intercalant monomer surface modifier and polymerizable monomer, oligomer or polymer provide an environment for more polymerizable monomers, oligomers or polymers to be intercalated into the interlayer spacing and the intercalates are readily exfoliated into polymer matrices to form nanocomposites. The nanocomposites (e.g., epoxy-clay) prepared from the intercalates demonstrated enhanced mechanical, thermal and chemical resistance compared with pristine polymer matrices.

Owner:AMCOL INTERNATIONAL CORPORATION

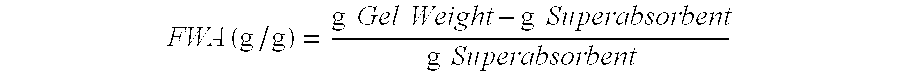

Superabsorbent polymers having delayed water absorption characteristics

InactiveUS6514615B1Shorten drying timeReduce removalNon-fibrous pulp additionPaper/cardboardMicrometerSuperabsorbent polymer

A superabsorbent polymer comprising a delayed absorption superabsorbent polymer having a free water absorbency property of absorbing less than about 3 grams of aqueous saline per gram of superabsorbent polymer in about 6 seconds, for a full particle size distribution of superabsorbent polymer ranging from about 40 micrometers to about 890 micrometers.

Owner:EVONIK OPERATIONS GMBH

Flexible ceramic wear-resistant heat-proof dual-anticorrosive coating

InactiveCN1528844AIncreasing the thicknessReduce the probability of water seepageAnti-corrosive paintsEpoxy resin coatingsCoated surfaceSaline water

The invention is a kind of flexible ceram wearing and heat resisting heavy corrosion preventing paint, which is made up of epoxy resin and several kinds of ceram powder, rust-protection paint and firming agent, the weights of each ingredient are: (1) epoxy resin: 100; (2) additive: 50-120; (3) rust protection paint: 8-25; (4) ceram powder: 100-200; (5) compound solvent: 40-70; paint: firming agent=(35-50):1. The paint needn't base coat, it can be painted directly or brushed on the surface of metal under normal temperature, it has excellent wearing and corrosion prevention performance, impact resisting performance and flexibility, it can insulate acid, alkali, salt, saline water. The surface is smooth; it can be applied to oil pipe, oil pot, and chemical device, ship, wheel vane, pump, dust catcher, etc.

Owner:REAR SERVICE TECH EQUIP INST NAVY PLA

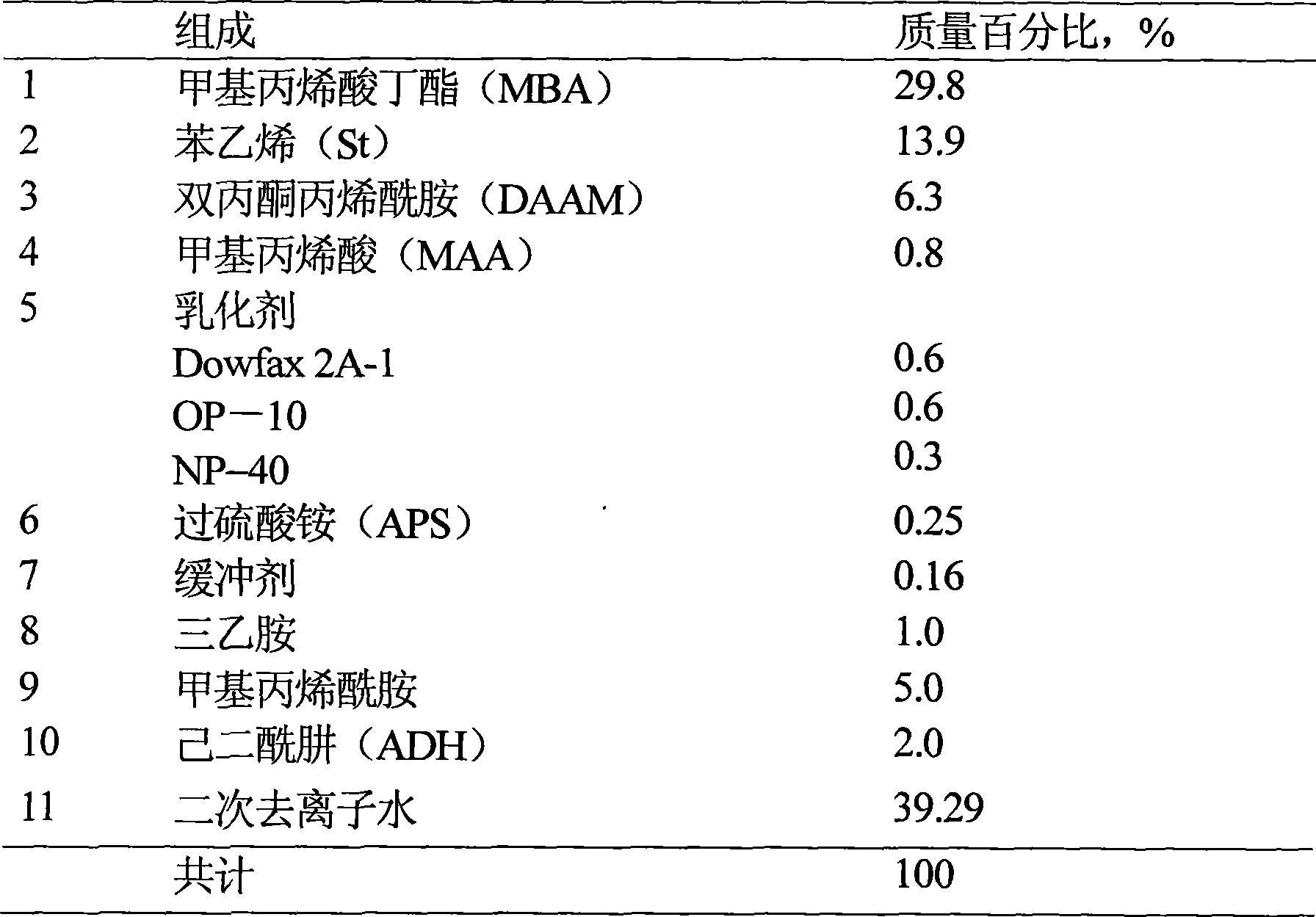

Preparation of high closeness polyacrylacid ester dispersion

The invention relates to a high-sealing polyacrylic ester dispersoid and a preparation method thereof; a multi-element emulsifier system which consists of an anionic emulsifier and a compound non-ionic emulsifier is adopted for controlling the charging process and components of the emulsifier in different polymerization periods, and the room-temperature self-crosslinking high-sealing polyacrylic ester dispersoid is prepared by a semi-continuous seeding emulsion polymerization process. The dispersoid has small particle size, good electrolyte-resistance (calcium ion) stability and high tolerance to various film forming accessory ingredients (various organic solvents with high boiling point). The dispersoid is used as seal coat of water-based wood coating and has good sealing performance to various woods; harmful volatile organic compounds (VOC) such as formaldehyde, and the like sealed against escaping from plates to pollute indoor environment, and the colored compounds such as turpentine, pine oil and tannin and the like are sealed against dissolving out of the plates to pollute pure top coating and white top coating of a water-based wooden ware; and in addition, the dispersoid can be used in water-based leather finishing agents.

Owner:SOUTH CHINA UNIV OF TECH

Condensation products based on amino-s-triazines and the use thereof

In the proposed condensation product based on amino-s-triazines with at least two amino groups, formaldehyde and sulphite, the molar ratio of amino-s-triazine, formaldehyde and sulphite is 1:2.5-6.0:1.51-2.0 and the formiate content is less than 0.3 wt %. The condensation product is obtained by a) heating amino-s-triazine, formaldehyde and a sulphite in the molar ratio 1:2.5-6.0:1.51-2.0 in an aqueous solution at a temperature of 60-90° C. and a pH level of between 9.0 and 13.0 until the sulphite can no longer be detected; b) continuing the condensation at a pH level of between 3.0 and 6.5 and a temperature of 60-80° C. until the condensation product has a viscosity of 5-50 mm / s at 80° C.; and c) adjusting the pH level of the condensation product to 7.5-12.0 or carrying out thermal secondary treatment at a pH level of >10.0 and a temperature of 60-100° C. The product can be used as an additive for inorganic binders such as cement.

Owner:SKW POLYMERS GMBH

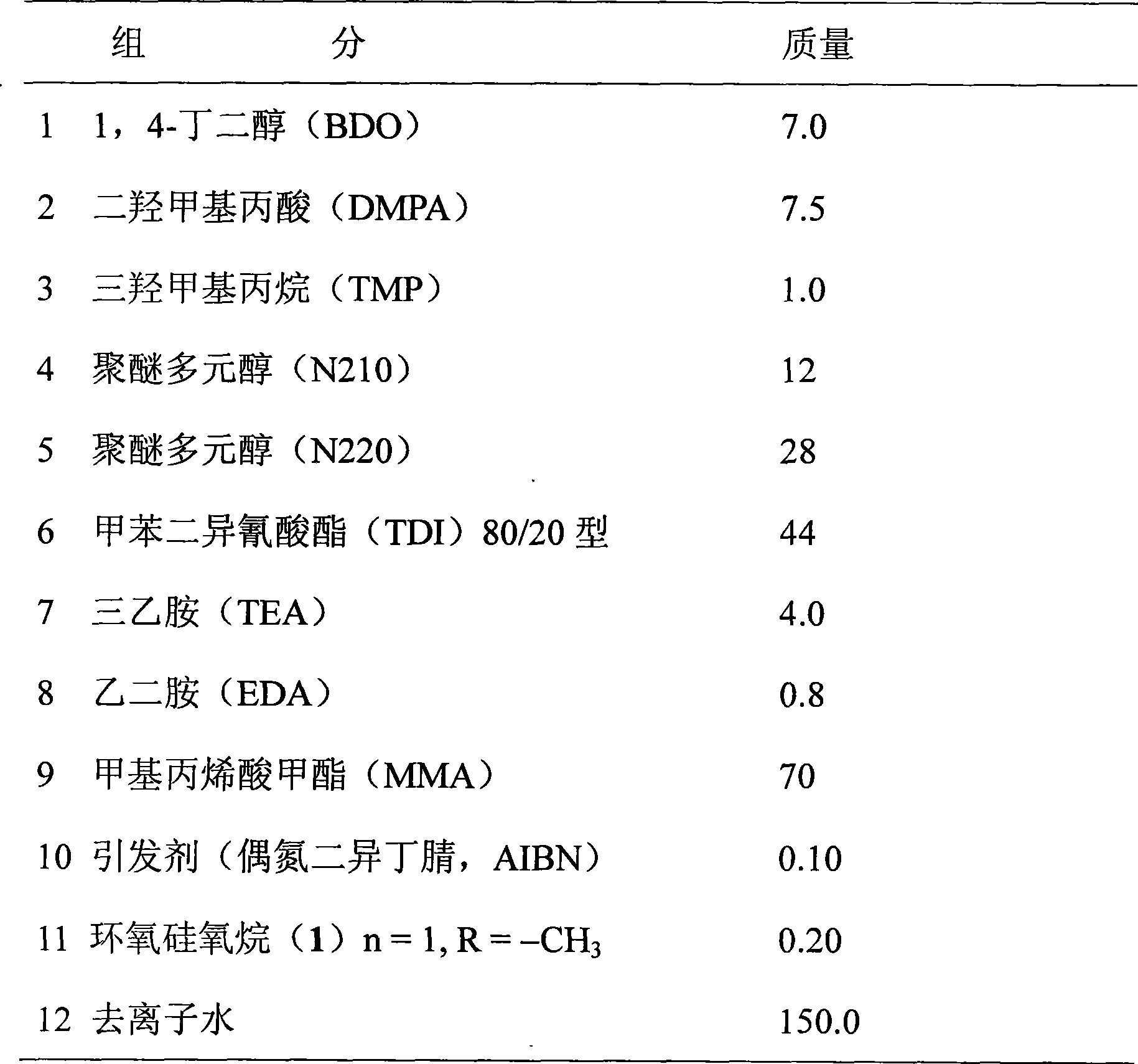

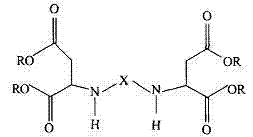

High solid content latent curing polyurethane acroleic acid hybrid emulsion

InactiveCN101481451AHigh solid contentHigh glossPolyurea/polyurethane coatingsPolyesterPolymer science

The invention relates to a method for preparing a high solid content latent cured polyurethane acrylic acid heterozygous latex and an application thereof. The preparation method comprises the following steps: pre-polymerizing polyester polyalcohol, hydrophilic chain extender and diisocyanate monomer to obtain the polyurethane prepolymer containing a hydrophilic group (carboxyl or sulfo group) and a terminal NCO group; then, neutralizing the polymer into salt and dispersing the salt in water to prepare the polyurethane water dispersoid; finally, using the dispersoid as macro molecular emulsifying agent and reactant to emulsify and disperse the acrylic ester monomer, initiating the polymerization by heating, dropping initiator to perform the latex polymerization, and regulating the pH of the latex by adding a latent curing agent to obtain the high solid content latent cured polyurethane acrylic acid heterozygous latex. The high solid content latent cured polyurethane acrylic acid heterozygous latex has a solid content of above 45%; the storage of the high solid content latent cured polyurethane acrylic acid heterozygous latex is stable; and high hardness film coating can be formed at the room temperature. Compared with acrylic acid latex and polyurethane latex, the high solid content latent cured polyurethane acrylic acid heterozygous latex has better film forming performance, water resistance, alcohol resistance, pollution resistance, dry / wet cleaning resistance and chemical solvent resistance, as well as high hardness.

Owner:SOUTH CHINA UNIV OF TECH

Soy composite materials comprising a reducing sugar and methods of making the same

InactiveUS20100129640A1Reduce slurry viscosityLow viscosityLayered productsPretreated surfacesEmulsionSoy flour

The present invention provides composite materials derived from formaldehyde-free aqueous binder compositions comprising defatted soy flour of no greater than 43 micron mesh particle size, polymer particles of at least one emulsion (co)polymer, and one or more reducing sugar. Also provided are methods of making and using composite materials containing the formaldehyde-free binder compositions.

Owner:ROHM & HAAS CO

Polyacrylamide reversed-phase microemulsion and preparation method thereof

The invention relates to polyacrylamide reversed-phase microemulsion and a preparation method thereof. The polyacrylamide reversed-phase microemulsion is mainly used for solving the problem that product solid content is low and emulsion is unstable in the prior art. A semicontinuous polymerization method is adopted to add an aqueous phase containing monomers such as acrylamide into an oil phase containing an emulsifier, so that polymerization process control of the microemulsion is relatively stable, the microemulsion stability is good, and the content of solids capable of being separated out is high. By adopting a technical scheme that the polyacrylamide reversed-phase microemulsion comprises the following components in parts by weight: 20-70 parts of an oil-soluble solvent, 5-20 parts of an emulsifier and a co-emulsifier and 20-70 parts of an aqueous phase containing acrylamide polymer, the problem is solved well; the prepared polyacrylamide reversed-phase microemulsion is directly used or compounded with other oil-field chemicals so as to use for field application such as deep profile control, water shutoff and displacement of reservoir oil, which can be used for increasing recovery efficiency, for oil-field tertiary oil recovery.

Owner:CHINA PETROLEUM & CHEM CORP +1

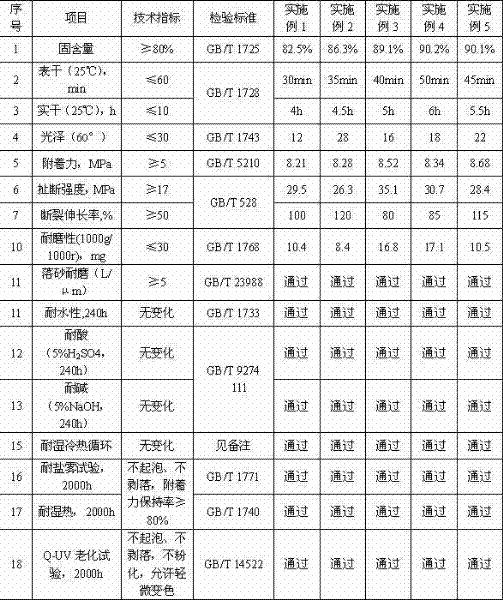

Thick paste quick-drying type weather-resistant and wear-resistant coating for wind turbine blades and preparation method thereof

ActiveCN102391771AFast dryingNot easy to foamAnti-corrosive paintsPolyurea/polyurethane coatingsWear resistantAgricultural engineering

The invention discloses a thick paste quick-drying type weather-resistant and wear-resistant coating for wind turbine blades and a preparation method thereof, the coating takes poly-asparaginic acid ester and elastic resin-modified aliphatic isocyanate as base materials, a nano-material is adopted for being effectively bonded with a resin matrix, and appropriate auxiliaries and additives for enhancing the performances of the coating. The thickness of a film which is formed by the coating for the wind turbine blades once can achieve 300 mu m; furthermore, the drying speed is fast and the coating is less prone to bubbling; the weather resistance is excellent, and the coating has higher tensile strength and elongation at break, and prominent wear resistance and impact resistance; the performances of water resistance, chemical product resistance, wet heat resistance, salt mist resistance and high and low temperature resistance are excellent; and the coating has certain anti-pollution and anti-icing properties. The construction efficiency of the coating is high, the performances of the coating are particularly suitable for wind field environments in China, the service life of a unit can be prolonged and the maintenance cost can be reduced.

Owner:洛阳双瑞防腐工程技术有限公司

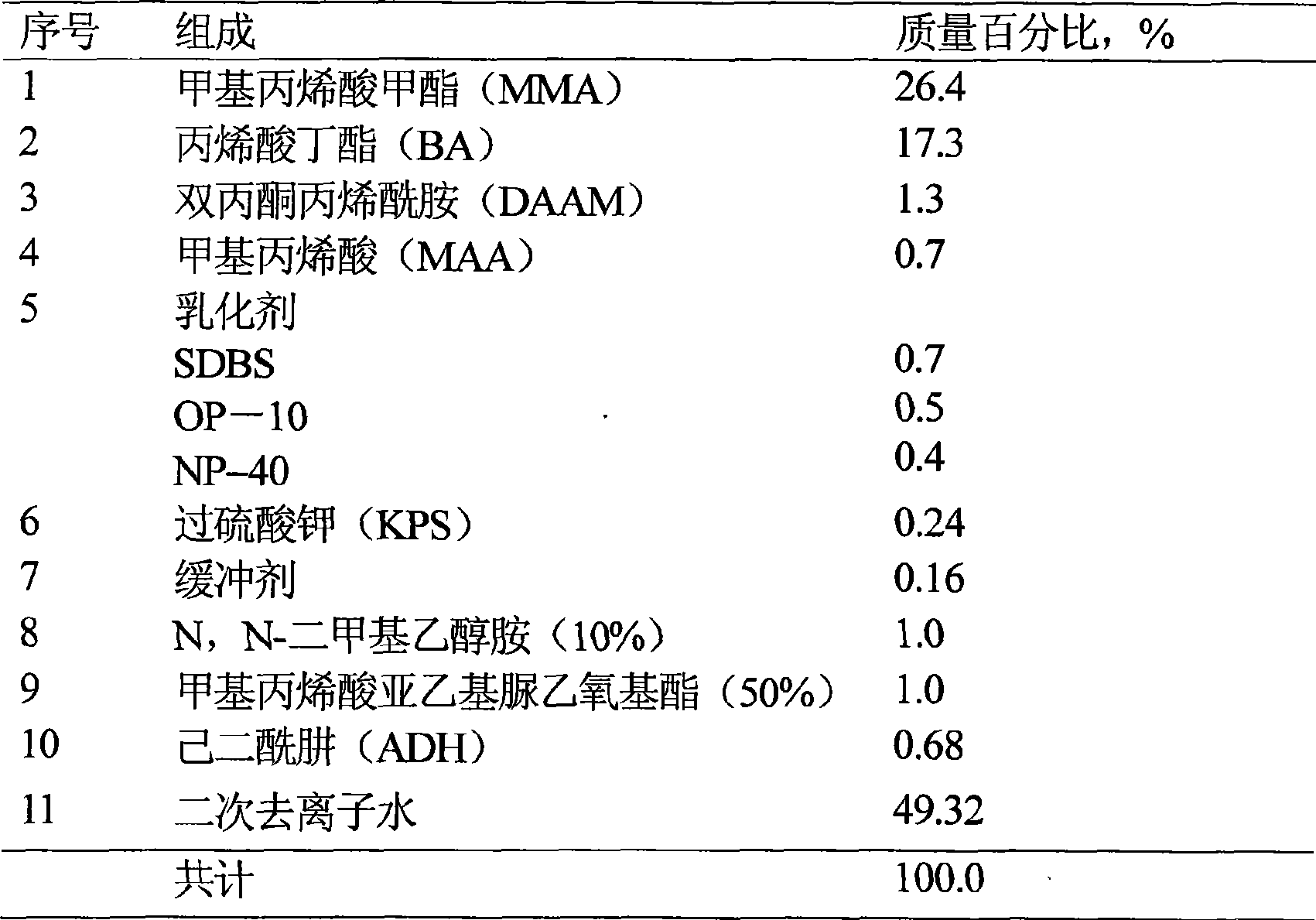

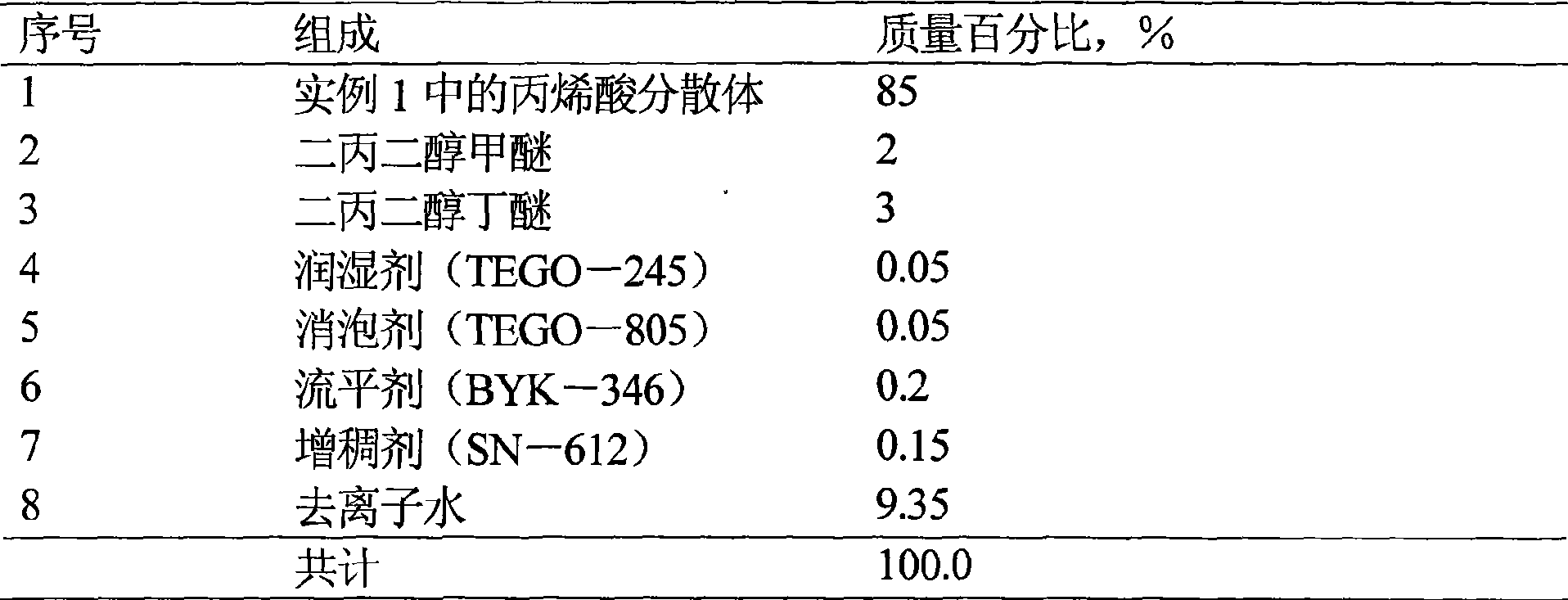

Acrylate micro-emulsion with high solid content, its preparation method and use

The invention refers to a high-solid content acrylate micro-latex, its making method and its application to carpentry dope. It adopts the technique of half-continuous starvation feeding, and is obtained by the polymerizing method of seed latex. It leads into cross-linking groups in the course of polymerization such as amidogen, acetoacetyl and amido, depends on the reaction of the groups of form film, gets painting film with cross-linking construction, and improves the water and solvent resistance of the painting film.

Owner:SOUTH CHINA UNIV OF TECH

Bicomponent high-strength sprayed polyurethane waterproof paint

InactiveCN101608094AHigh solid contentFast curingLiquid surface applicatorsAntifouling/underwater paintsAlcoholPolyol

The invention provides bicomponent high-strength sprayed polyurethane waterproof paint. The paint consists of a component A and a component B according to the volume ratio of 1 to 1, wherein the component A is a semi-prepolymer synthesized by polyisocyanate with low functionality and polyether glycol; according to weight portion, the component A comprises 50 to 80 portions of the polyisocyanate with functionality of between 2.0 and 2.4 and 20 to 50 portions of the polyether glycol with functionality of between 2 and 4; and the component B comprises 40 to 84 portions of the polyether polyol or amino-terminated polyether or mixture of the polyether polyol and the amino-terminated polyether, 10 to 40 portions of amine chain extender or alcohol chain extender or mixture of the amine chain extender or the alcohol chain extender and 0 to 20 portions of pigment filler and additive. The bicomponent high-strength sprayed polyurethane waterproof paint has mechanical performance close to or even higher than that of a waterproof coiled material, adopts a spraying construction method, is convenient and high-efficient and greatly prolongs the service life of the waterproof material; and a solvent-free system also greatly ensures the environment-friendly requirement of the material, so that the performance is more reliable, high efficient and environment-friendly. Compared with a conventional waterproof material, the bicomponent high-strength sprayed polyurethane waterproof paint has high strength and elongation rate.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

Preparation method of high-solid-content aqueous polyurethane for leather

The invention relates to the field of synthetic leather material polyurethane, in particular to a preparation method of high-solid-content aqueous polyurethane for leather. The method comprises the process steps of: prepolymerization reaction: reacting polyol, a hydrophilic chain extender and isocyanate monomer; monomer modification: adding polyhydroxy monomer to be modified together with polyurethane prepolymer; salt formation by neutralization: adding a neutralizing agent so that an emulsion forms salt ion groups; and chain extension subsequent to emulsification: dissolving an external emulsifying agent and a sulfonic acid chain extender in water to obtain a solution and adding the solution to the system for performing emulsification. In the invention, the emulsification property of theemulsion is improved by using carboxylic acid type and sulfonic acid type chain extenders, so that polyurethane and water are fully emulsified; simultaneously, due to the employment of the method in which self emulsification and external emulsification are combined, not only the stable emulsion can be synthesized, but also the solid content can be increased; in addition, the use of water as the solvent in emulsification is consistent with the requirement of clean production process; and the finally-synthesized emulsion has good film forming performance, high drying speed, no yellowing, excellent mechanical properties and short process flow, is suitable for the synthesis of leather substrates or surface materials, and can take the place of solvent-type products.

Owner:溧阳常大技术转移中心有限公司

Adhesive composition comprising a particulate thermoplastic component

InactiveUS6548579B2Improve interface adhesionInhibition formationMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesWater basedParticulates

The invention is directed to an adhesive composition comprising a water based component including a film-forming polymer and a particulate thermoplastic component selected from the group consisting of thermoplastic polymers, thermoplastic resins, hot melt adhesive compositions, and mixtures thereof. The thermoplastic component has a mean particle size of from about 10 microns to about 1,500 microns. The adhesive composition is useful as a one-shot bookbinding adhesive, a primer composition as well as a second-shot adhesive for two-shot bookbinding method. The invention is also directed to the bookbinding methods using the adhesive composition.

Owner:HB FULLER CO

Method for preparing organosilicon and nano-silicon dioxide modified acrylic resin soap-free emulsion

InactiveCN101735412AIncreased stability and solids contentImproves water resistance and adhesionSolventEmulsion

The invention relates to a method for preparing an organosilicon and nano-silicon dioxide modified acrylic resin soap-free emulsion. According to the method, a reactive emulsifier is used to replace a conventional emulsifier, and the method comprises the steps of: performing soap-free emulsion polymerization on acrylic ester monomers, (methyl) acrylic acid, vinyl silicone oil and alkoxy silane containing double bonds; and then adding ethyl orthosilicate for a sol-gel reaction to obtain the organosilicon and nano-silicon dioxide modified acrylic resin soap-free emulsion. The organosilicon and nano-silicon dioxide modified acrylic resin soap-free emulsion is suitable to be taken as a leather finishing agent. The method can completely eliminate the adverse effect of a small molecular emulsifier on an acrylic resin emulsion finishing agent, introduce good characteristics of organosilicon and nano-silicon dioxide into an acrylic resin, overcome the disadvantages of hot sticking and cold shortness, poor waterproof performance and poor solvent resistance and the like of the acrylic resin, and improve the mechanical property, adhesive force and wear resistance of the acrylic resin.

Owner:山西佳宇丰化工科技有限公司

Method for producing atmosphere heat drying and vacuum oil frying combined dewatered fruit and vegetable crisp chip

InactiveCN1554274AAvoid severe deformationKeep shapeFood preservationFood preparationFood materialEdible mushroom

The present invention belongs to the field of fruit and vegetable food producing technology. The production process of crisp fruit and vegetable chip includes the steps of: selecting fruit, vegetable material, edible mushroom and other food material; pre-treatment including washing, peeling, slicing, scalding to kill enzyme, etc; heating to dry at normal pressure; oil frying to dewater, centrifuging to eliminate oil, seasoning and packing. Owing to the combined dewatering process of normal pressure hot drying and vacuum frying, the present invention has low oil content in crisp fruit and vegetable chip, short frying time and well maintained food shape.

Owner:JIANGNAN UNIV +1

High solid content vinyl acetate-ethylene copolymer emulsion and method for synthesizing the same

ActiveCN101200518AReduce consumptionIncrease the conversion rate of the polymerization reactionMonocarboxylic acid ester polymer adhesivesSodium bicarbonatePhenol

The present invention relates to high solid content vinyl acetate-ethylene copolymer latex for binder and the synthetic method, including 55 to 75 portion of vinyl acetate, 24 to 45 portion of ethylene, 3 to 5 portion of N-methylol acrylamide, 2 to 4 portion of PVA1788 and PVA0588, 0.4 to 1.0 portion of the compound of nonionic emulsifying agent nonyl phenol polyoxyethylene alkyl ether and anion emulsifying agent alkyl sulphate with 2:1 mixture ratio, 0.2 to 1.0 portion of 35 percents oxydol with 1:1 mixture ratio, 0.05 to 0.4 portion of formol zinc sulphate, 0.1 to 0.5 portion of ferrous sulphate, 0.5 to 1.0 portion of regular dodeca-carbon thiol-alcohol, 0.05 to 0.35 portion of potassium phosphate, 0.1 to 0.5 portion of sodium bicarbonate and 45 to 55 portion of de-ionized water. With the adoption of latex polymerization, low-residual monomer VAE latex with solid content more than 65 percents is synthesized, which is used as binder to be applied in timber processing industry and packaging industry.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

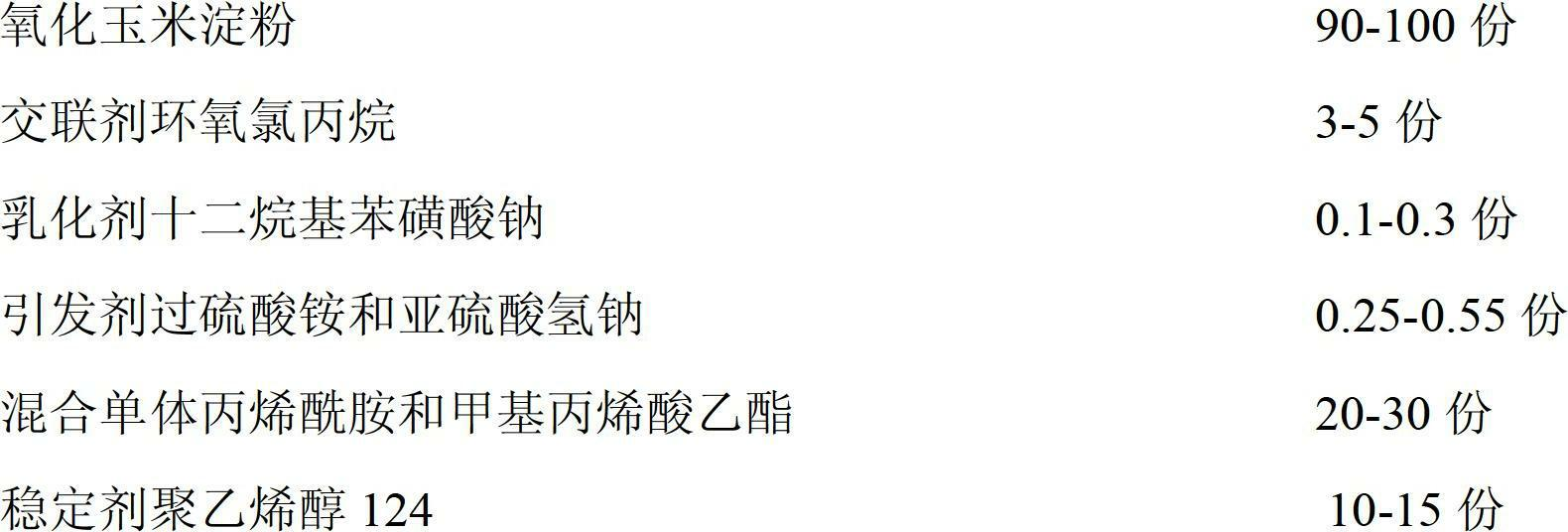

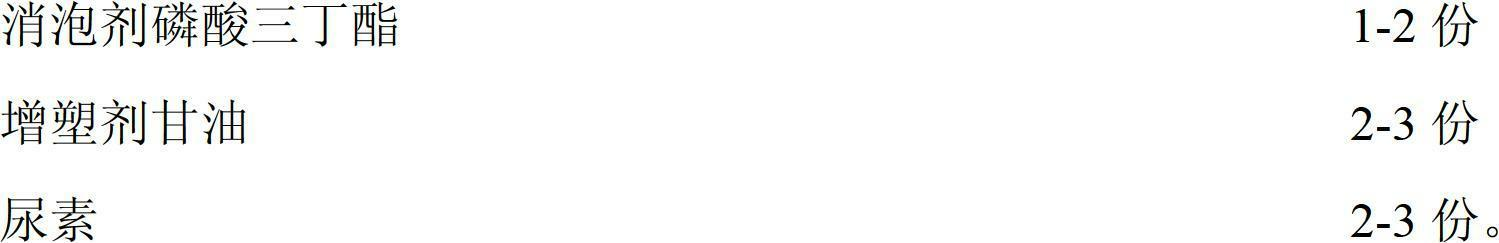

Modified-starch-based wood adhesive and preparation method thereof

InactiveCN102676098AReduce dependenceStrong water resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesCelluloseCross-link

The invention discloses a modified-starch-based wood adhesive and a preparation method thereof. The preparation method comprises the steps that oxidized corn starch is used as a main raw material, a cross-linking agent is added into the oxidized corn starch to conduct crosslinking modification, and then an initiating agent and a high molecular monomer are added to the oxidized corn starch to conduct graft modification, so as to obtain a modified starch emulsion in a complex net structure; and after the modified starch emulsion is warmed up and pasted, modifying agents comprising a stabilizing agent, a defoaming agent, a plasticizing agent and the like are added into the modified starch emulsion, and the high-performance green environment-friendly adhesive is manufactured. Each performance of the adhesive disclosed by the invention can reach or exceed requirements of a GB / T9846-2004 standard, the adhesive has the characteristics of high bonding strength, good water resistance, long storage time, high solid content, low cost, greenness, environment friendliness and wide use range, and can be widely applied to the bonding and the use of wood materials such as artificial boards, plywood and cellulose boards.

Owner:HEFEI UNIV OF TECH

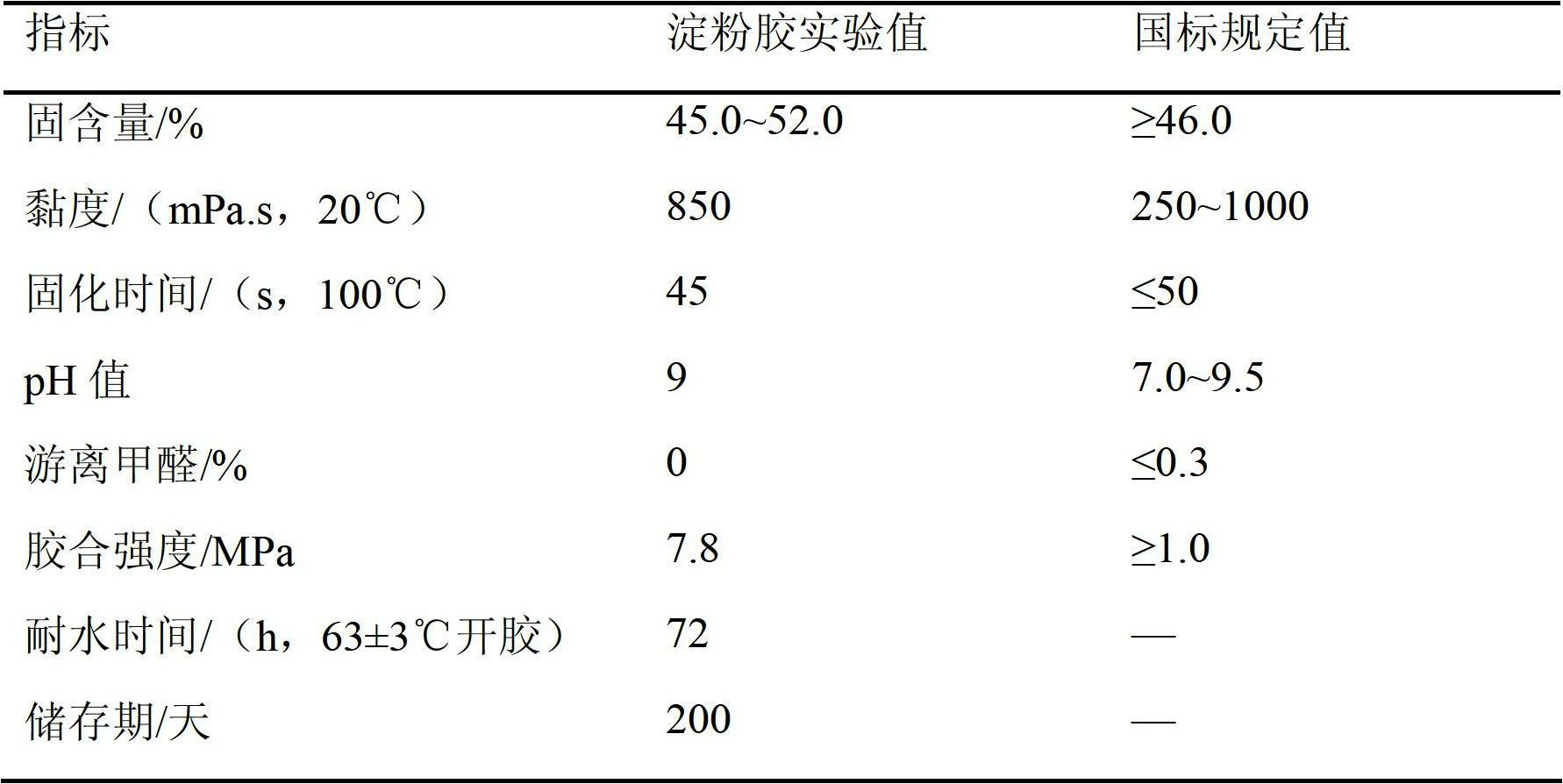

Preparation method of water-based polyurethane adhesive

ActiveCN102827571AHigh solid contentHigh bonding strengthPolyureas/polyurethane adhesivesDiamineDistillation

The invention discloses a preparation method of a water-based polyurethane adhesive, which is characterized by comprising the following steps: mixing adipic acid and dibasic alcohol according to a certain ratio, and performing esterification reaction and polycondensation reaction in the presence of catalyst and stabilizer to synthesize polyester diol; performing prepolymerization on the obtained polyester diol and diisocyanate, reacting for a certain time, and then adding carboxylic acid type hydrophilic monomer, chain extender, crosslinking agent trimethylolpropane and hydroxyl-terminated silicone oil to perform chain extension; adding acetone, cooling, and then adding aliphatic diamine sulfonate to perform chain extension; performing neutralization, dispersion, emulsification and chain extension, and performing reduced pressure distillation to remove the acetone so as to obtain water-based polyurethane emulsion having a high solid content; and adding leveling agent, thickener, defoaming agent and bactericide into the obtained emulsion to obtain the water-based polyurethane adhesive having a high solid content. According to the invention, the water resistance and the heat resistance of the water-based polyurethane adhesive are improved, and the bonding strength is high, thereby ensuring that the water-based polyurethane adhesive is suitable for bonding on shoe materials and leather.

Owner:广东多正树脂科技有限公司

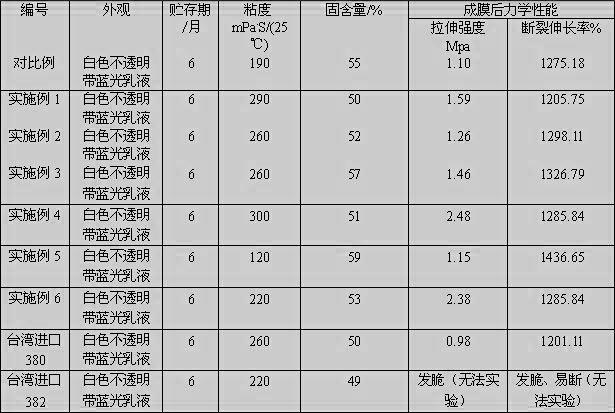

Bicompenent high solid content aqueous polyurethane, its preparation method and application

InactiveCN1786055ASimple processReduce dosageFibre treatmentPolyureas/polyurethane adhesivesWater basedWater dispersible

The present invention relates to double-component high solid content water-based polyurethane, its preparation method and application. Said method includes the following procedures: preparing water-dispersible polyurethane adhesive; preparing water-dispersivity polyisocynate cross-linking agent; and before application mixing the water-dispersible polyurethane adhesive and water-dispersivity polyisocynate cross-linking agent, in which the preparation of polyurethane adhesive includes the preparation of prepolymer, the prepolymer is neutralized and dispersed into the deioniced water to obtain dispersion, then the dispersion is chain-extended so as to form water-based polyurethane.

Owner:SOUTH CHINA UNIV OF TECH

Liquid removal apparatus

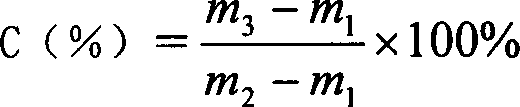

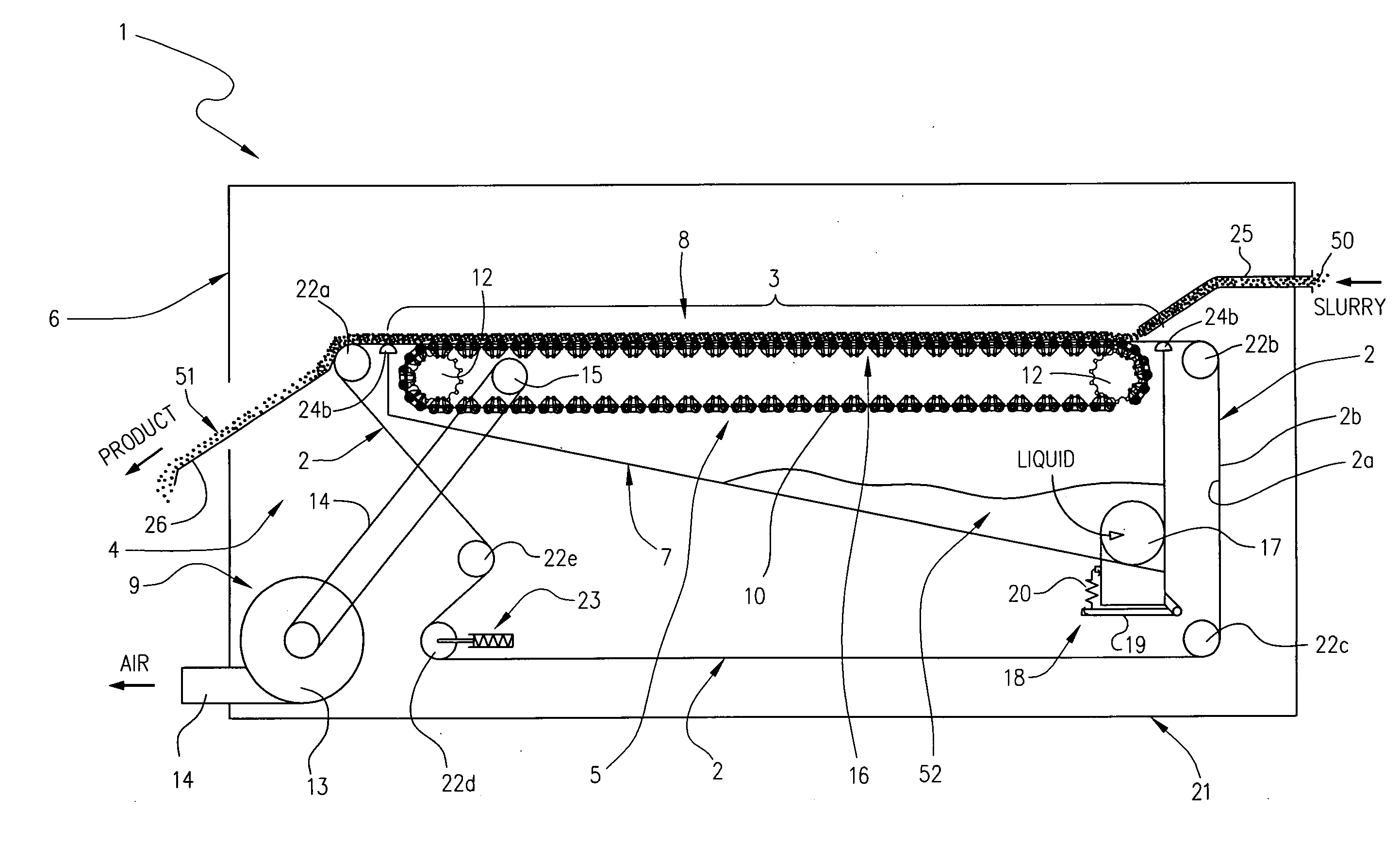

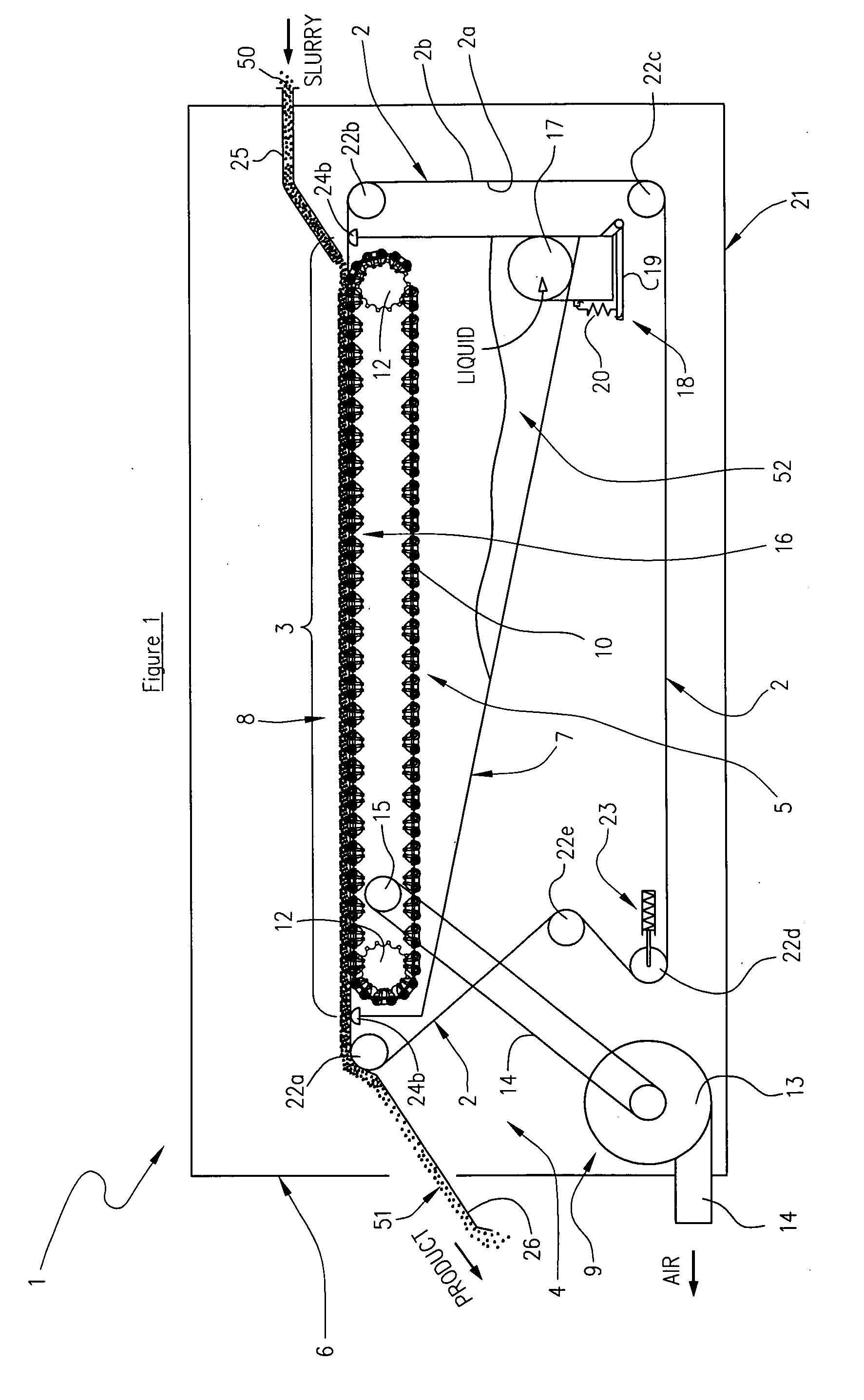

ActiveUS20110089122A1Prevent lodgingHigh solid contentWater/sewage treatmentSedimentation separationSupporting systemDifferential pressure

A liquid removal apparatus adapted to separate liquid from a composite slurry of liquid and solids. The apparatus includes a movable, permeable membrane having opposing first and second sides. A ‘loaded belt portion’ of the second side is configured to receive the slurry. A permeable membrane support system is configured to provide movable support for the loaded belt portion and includes a transport deck located in contact with the first side of the permeable membrane below the loaded belt portion. The liquid removal apparatus has a housing with a low-pressure chamber in sealing contact with the first side of the permeable membrane. A pressure conditioning system applies a differential pressure via the housing to generate a lower pressure on the first filter belt side than on the second side. The transport deck is located within the low pressure chamber.

Owner:CT CIVIL LTD

Method for improving solid content of catalytic cracking catalyst slurry

ActiveCN101134906ASimple structureHigh solid contentCatalytic crackingCatalyst activation/preparationMolecular sieveColloid

The present invention is method of raising solid content in catalytic cracking catalyst slurry. The method includes mixing clay, molecular sieve slurry, aluminum-containing binder, pseudo boehmite and inorganic acid to form catalyst slurry and the subsequent spray drying. It features that the addition of inorganic acid before adding pseudo boehmite and the molecular sieve, and the addition of inorganic acid after adding kaolin and aluminum-containing binder or into the aluminum-containing binder. The present invention can raise the solid content in catalyst slurry to over 40 % to short the colloid forming time greatly, raise the catalyst producing efficiency and lower catalyst producing cost while ensuring the wear strength of catalyst. At the same time, the catalyst has great pore volume, high micro reaction activity and improved comprehensive reaction performance.

Owner:PETROCHINA CO LTD

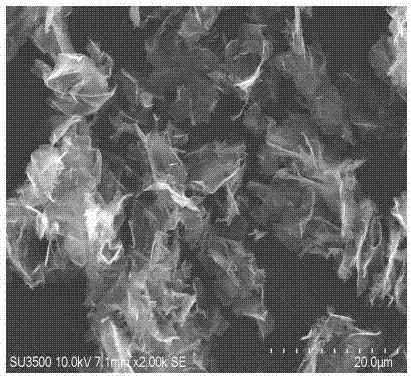

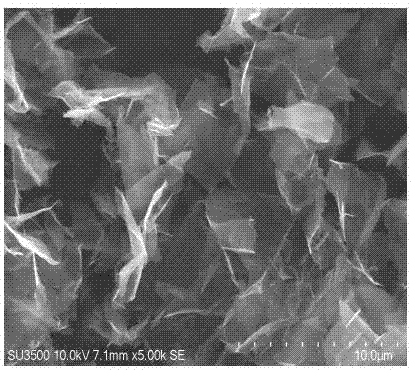

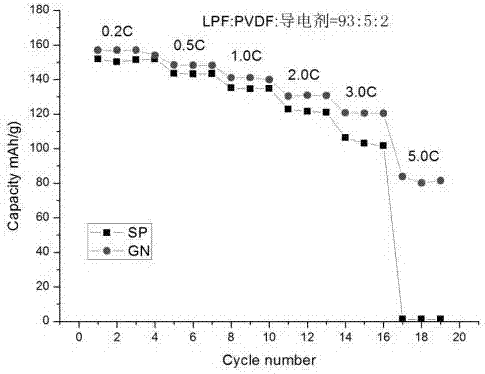

Graphene conductive slurry as well as preparation method and application method of graphene conductive slurry

InactiveCN107298924AGood stabilityImprove stabilityNon-conductive material with dispersed conductive materialCarbon-silicon compound conductorsSolventCvd graphene

The invention belongs to the technical field of graphene materials. Graphene conductive slurry is prepared from the following raw materials in parts by weight: 0.5 to 15.0 weight percent of oligegraphene, 0.1 to 0.5 weight percent of a dispersant, 80 to 99.4 weight percent of a diluent and 10 to 40 weight percent of organic resin. According to the graphene conductive slurry disclosed by the invention, by screening the dispersant in the early stage, the graphene can be more easily dispersed in the diluent during a mixing process of graphene powder and the diluent, and an obtained dispersion solution is good in stability; by adding the selected dispersant and using a technology adopted by the invention, stripping of the graphene in the diluent can be promoted; in the graphene conductive slurry, a part of solvent is replaced with a part of resin, so that the solid content of the graphene conductive slurry is increased, the stability of the graphene conductive slurry is increased, re-overlaying of the graphene is prevented, and very good compatibility is also provided for application in the late. The graphene conductive slurry which is good in performance and high in stability can be prepared, the cost is low, the technology is feasible, and the graphene conductive slurry is suitable for industrial production.

Owner:SHENZHEN GUOCHUANG JIAWEI GRAPHENE TECH CO LTD

High-fullness high-resolution environment protection polyureshane sublight uarnish

InactiveCN1483777AIncreased weight percentageReduce weightPolyurea/polyurethane coatingsKetoneSolvent

The present invention relates to a high-fullness high-distinctness environment-protecting type polyurethane matte varnish. Said varnish consists of the paint component, polyurethane solidifying agent component and diluting agent component according to the ratio of 1:0.5:0.6-0.8. The polyurethane solidifying agent component contains 50-70 wt% of tolylene diisocyanate trimer, and the rest is the affixture of 80% of tolylene diisocyanate and 20% of trimethylol propane, the paint component contains 15-25% of short oil soya alkyd resin whose solid content is 80%, 50-60% of modified saturated polyester resin, 0-5% of castor oil, 10-12% of aldehyde ketone resin whose solid content is 60%, 3-5% of flatting silica, 0.3-1.0% of teflon wax and 4%-10% of conventional adjuvant and solvent, and the diluting agent component contains 70-80% of butyl acetate, 10-20% of mixed diacid dimethyl ester and 10-15% of isophorone.

Owner:SHENZHEN FEIYANG JUNYAN TECH DEV

Frozen confectionery product

InactiveUS20050129810A1Trend downHigh storage temperatureFrozen sweetsConfectioneryWater iceChemistry

A frozen confectionery product is provided comprising a plurality of discrete water ice confections, each discrete water ice confection being able to contact directly other discrete water ice confections in the product, which water ice confections comprise an ice structuring protein (ISP), at least 6 wt % solids and have an average volume of less than 1 ml

Owner:GOOD HUMOR BREYERS ICE CREAM DIV OF CONOPCO

Waterborne metallic paint and preparation thereof

The invention provides a water metallic paint and a preparation method thereof. The paint mainly comprises the components of 30-60wt% of acrylic resin, 4-15wt% of amine resin used for paints, 10-40wt% of pigment, 3-10wt% of stuffing, 0.5-5wt% of lacquer solvent, 0.5-3wt% of addition agent and 20-50wt% of water. The components are weighted according to mixture ratio, mixed according to certain charging sequence, and then subjected to the working procedures of dispersing, grinding and the like, thus obtaining the water metallic paint. The paint takes water as a solvent, is added with a small amount of lacquer solvent, is environment-friendly, and has the main advantages of simple production technology, low cost, good levelability, high adhesive attraction, high luster, resistance to yellowing, high solid content, low viscosity, good heat resistance and capability of being used for a long time at the temperature of 180 DEG C.

Owner:中山创美涂料有限公司

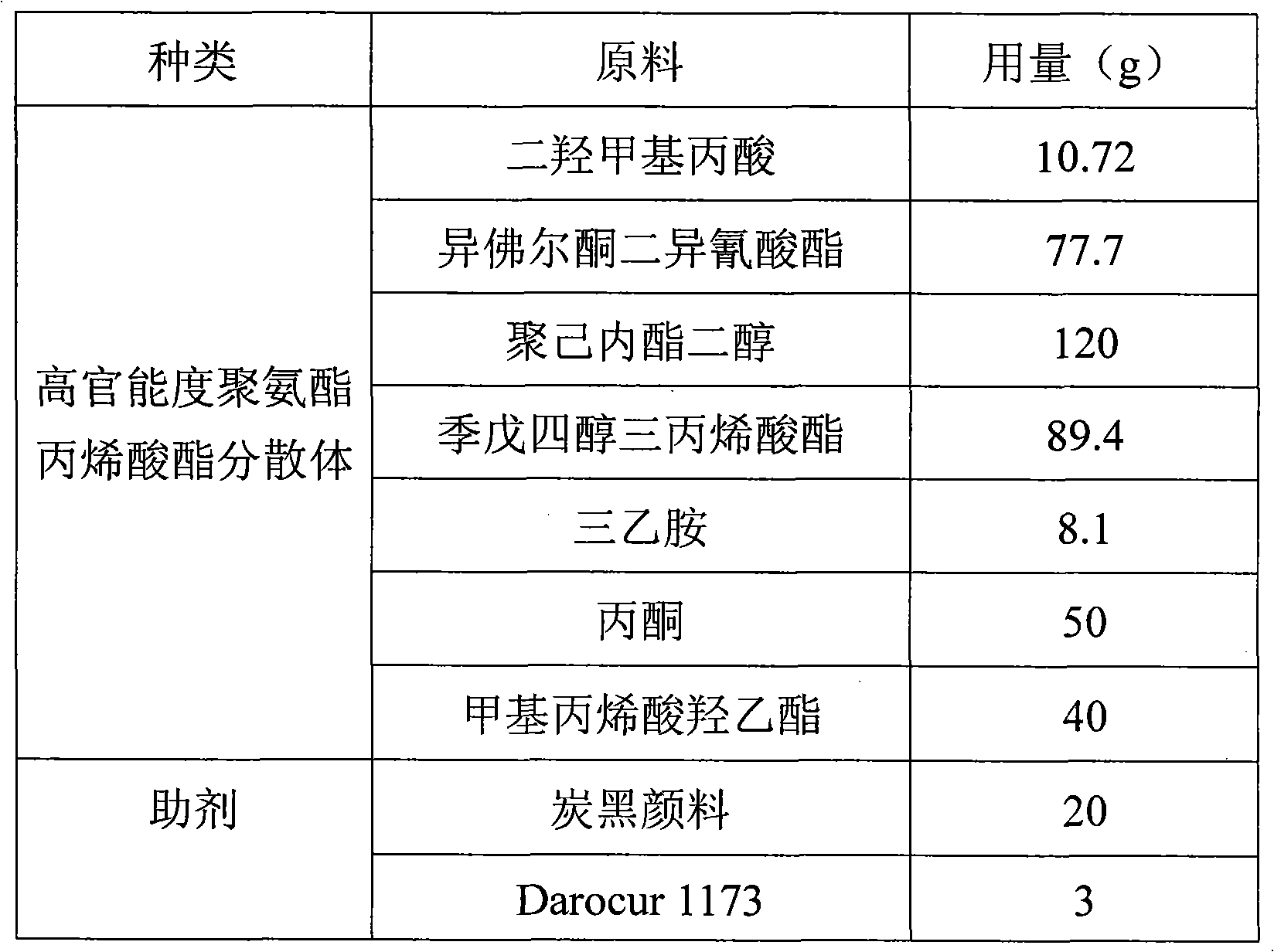

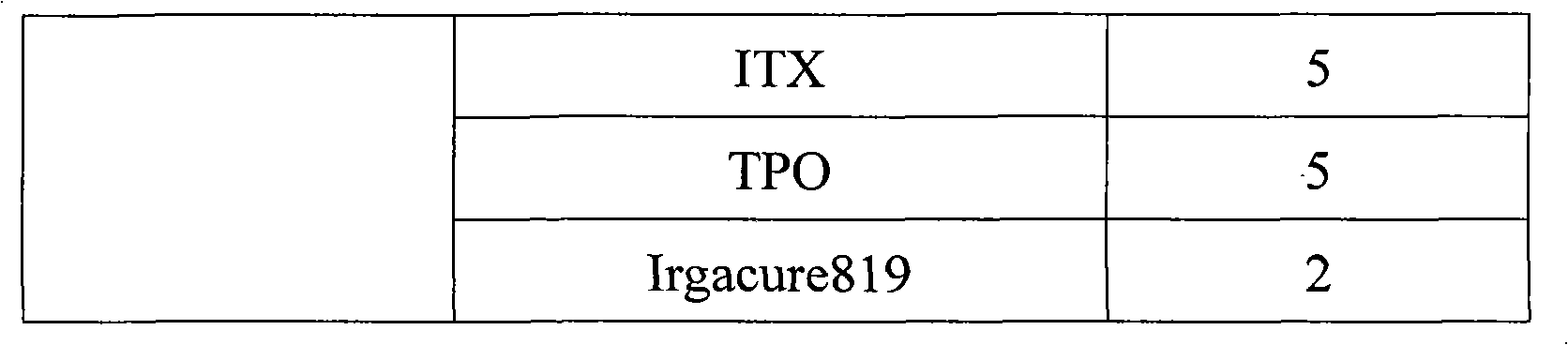

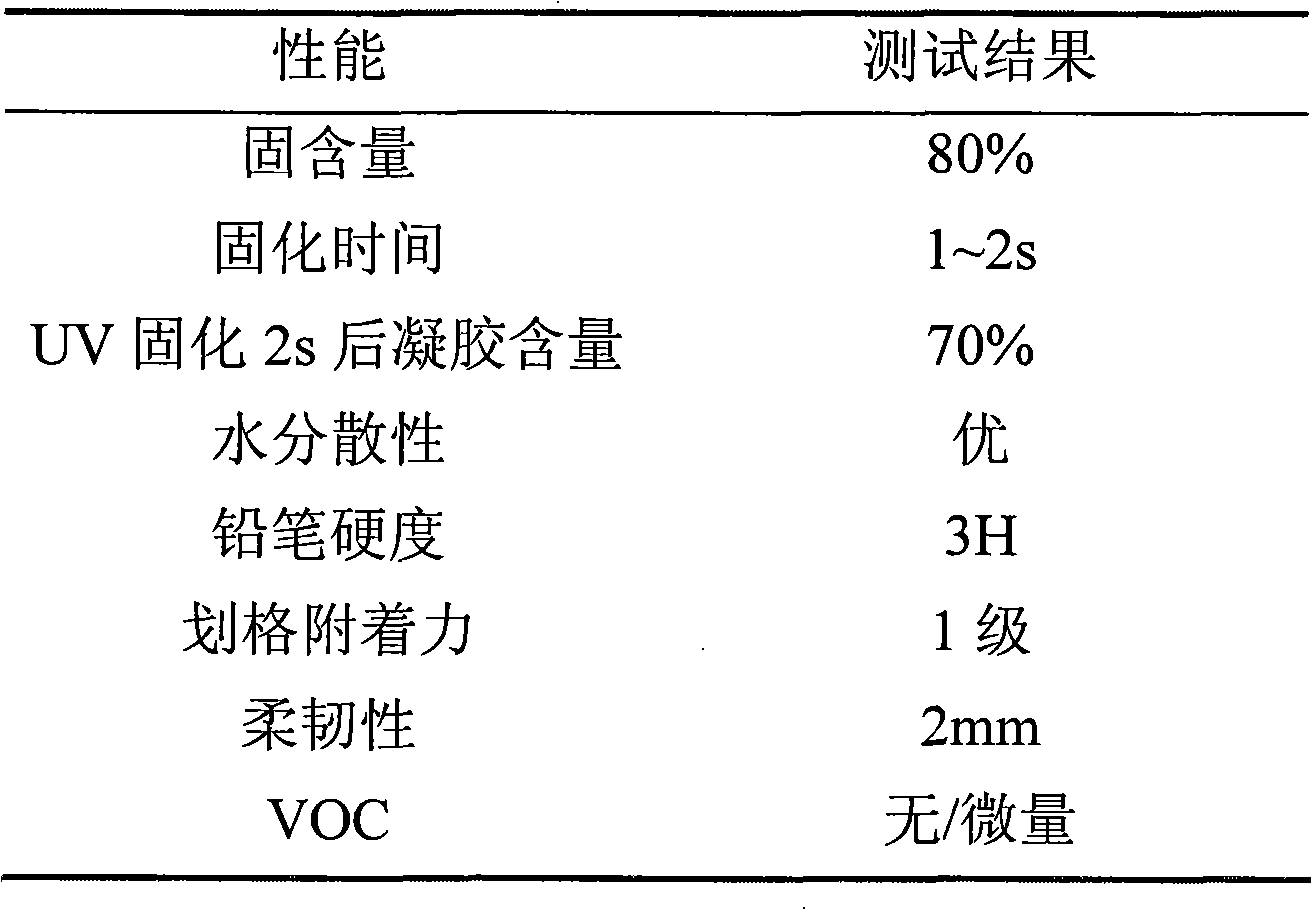

Water-based UV black ink with super-high solid content and preparation method thereof

InactiveCN101659809AEmissions are environmentally friendly and non-toxicHealthy littleInksWater basedPliability

The invention discloses water-based UV black ink with super-high solid content and a preparation method thereof. The black ink comprises the following components in percentage by weight: 20%-60% of high-functionality water-based polyurethane acrylate, 5%-8% of compound photoinitiator, 15%-35% of hydrophilic acrylate diluted body or prepolymer, 10%-25% of solvent and 5%-15% of nano-carbon black pigment. The light curing time of the water-based UV black colored paint of the invention is shorter than 5 seconds, the bottom layer can be completely cured, the comprehensive properties of adhesive force, hardness, toughness and the like are excellent, and the water-based UV black colored paint can be widely applied to the fields of ink, wood paint and the like; the solid content is as high as 80%;and the water-based UV black ink has short drying and curing time, simple construction technology and high production efficiency, can be diluted by water or ethanol or other nontoxic solvents for regulating the viscosity, is suitable for various production modes and production requirements, and is environment-friendly and nontoxic.

Owner:FOSHAN CITY SHUNDE DISTRICT DEMEI CHEM

Preparation method of aqueous polyurethane emulsion with high solid content

The invention relates to a preparation method of an aqueous polyurethane emulsion with a high solid content. The method comprises the following steps: first, adding polymer polyol, polyisocyanates, catalyst and chain extender into a reactor according to certain steps, and controlling hydrophilic groups to distribute on molecular chain ends; then adding polyisocyanates to form a performed polymer terminated with an NCO group; then reducing system temperature, adding a neutralizer for neutralization, adding deionized water, and stirring with high speed to carry out water dispersion; at last, adding a post chain extender to carry out chain extension in water; removing the solvents under a reduced pressure after reaction to obtain the aqueous polyurethane emulsion. According to the invention, hydrophilic efficiency of the hydrophilic groups is raised to lower intake amount of hydrophilic groups, and a small amount of solvents are added in the reaction to lower a system viscosity. The aqueous polyurethane emulsion prepared by the invention has characteristics of high solid content, low viscosity, good water resistance and stabile storage, and can be used in industries of paint, adhesive, leather finishing and fabric arrangement, etc.

Owner:FUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com