Patents

Literature

266 results about "Tolylene Diisocyanate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Definition of tolylene diisocyanate. : any of six isomeric esters CH3C6H3(NCO)2 of isocyanic acid or a mixture of them; especially : a liquid isomer made by reaction of tolylenediamine (see tolylenediamine a) and phosgene and used by itself or in a mixture with another meta isomer in making polyurethanes; 4-methyl-meta-phenylene diisocyanate.

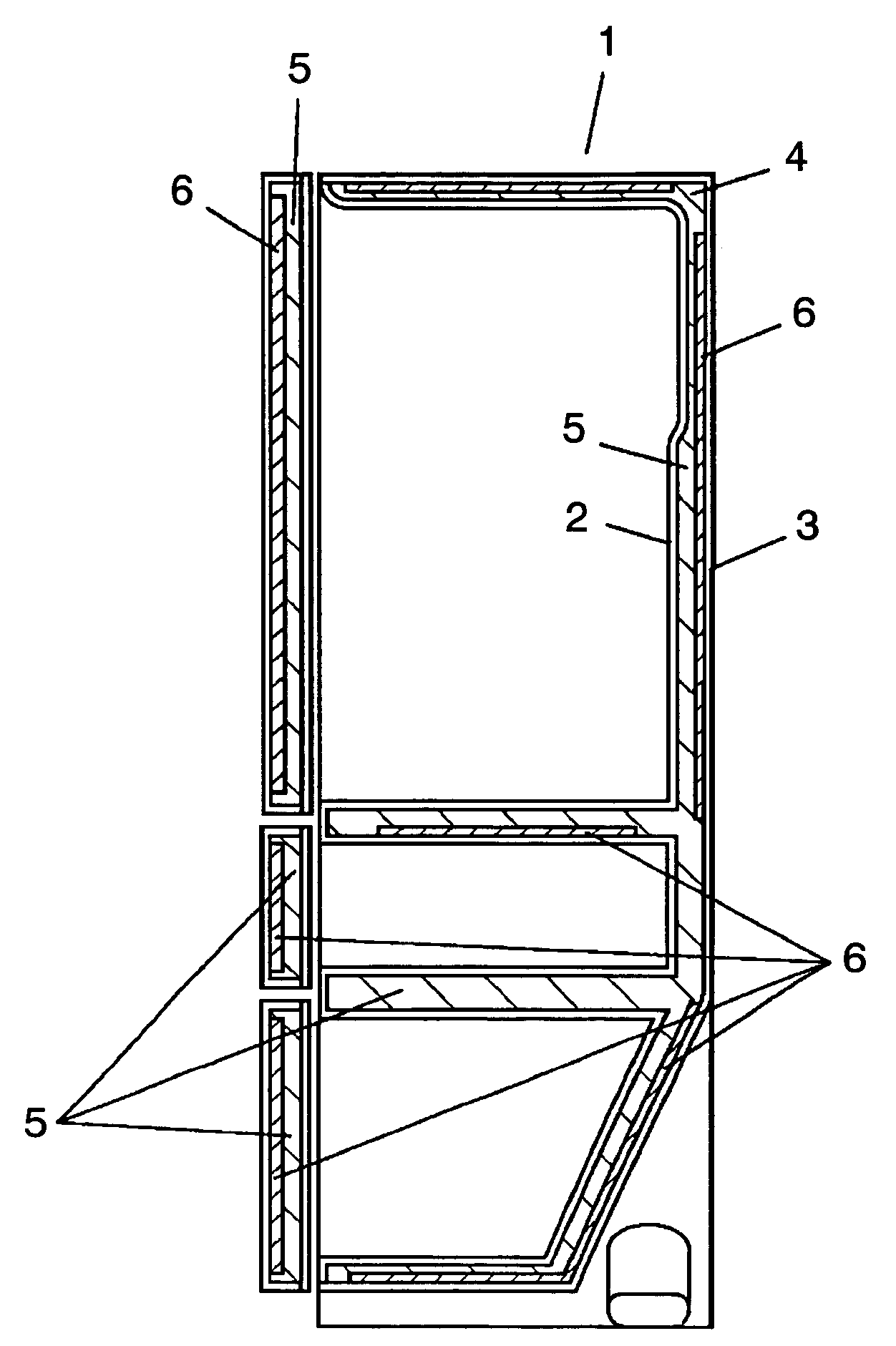

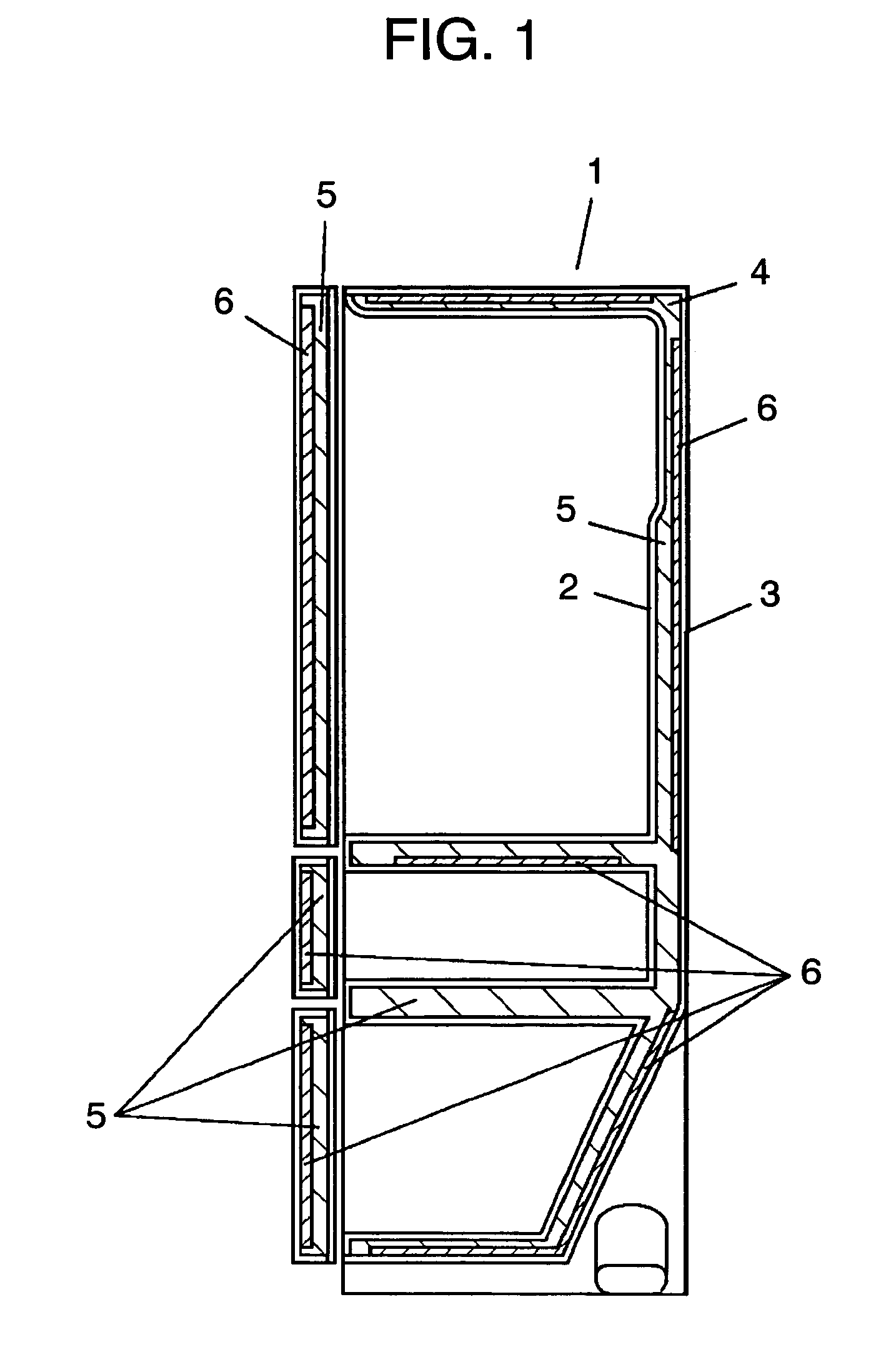

Insulated box body, refrigerator having the box body, and method of recycling materials for insulated box body

InactiveUS7316125B2Provide structural strengthImprove insulation efficiencyLighting and heating apparatusDomestic refrigeratorsVolumetric Mass DensityEngineering

An insulation box unit and a refrigerator of the present invention employs i) rigid urethane foam with a 8.0 MPa-or-greater bending modulus, and a 60 kg / m3-or-lower density, and ii) a vacuum insulation material. The proper bending modulus provides the insulation box unit with a substantial strength, even in the case that the coverage of the vacuum insulation material with respect to the surface of the outer box exceeds 40%. The proper density prevents the insulation box unit from poor insulation efficiency due to undesired solid thermal conductivity. Despite of an extended use of the vacuum insulation material, the insulation box unit offers an excellent insulation efficiency and therefore accelerates energy saving. According to the recycling method of the present invention, rigid urethane foam formed of tolylene di-isocyanate composition, which was separated from refrigerator wastes, is recycled as a material of rigid urethane foam.

Owner:PANASONIC CORP

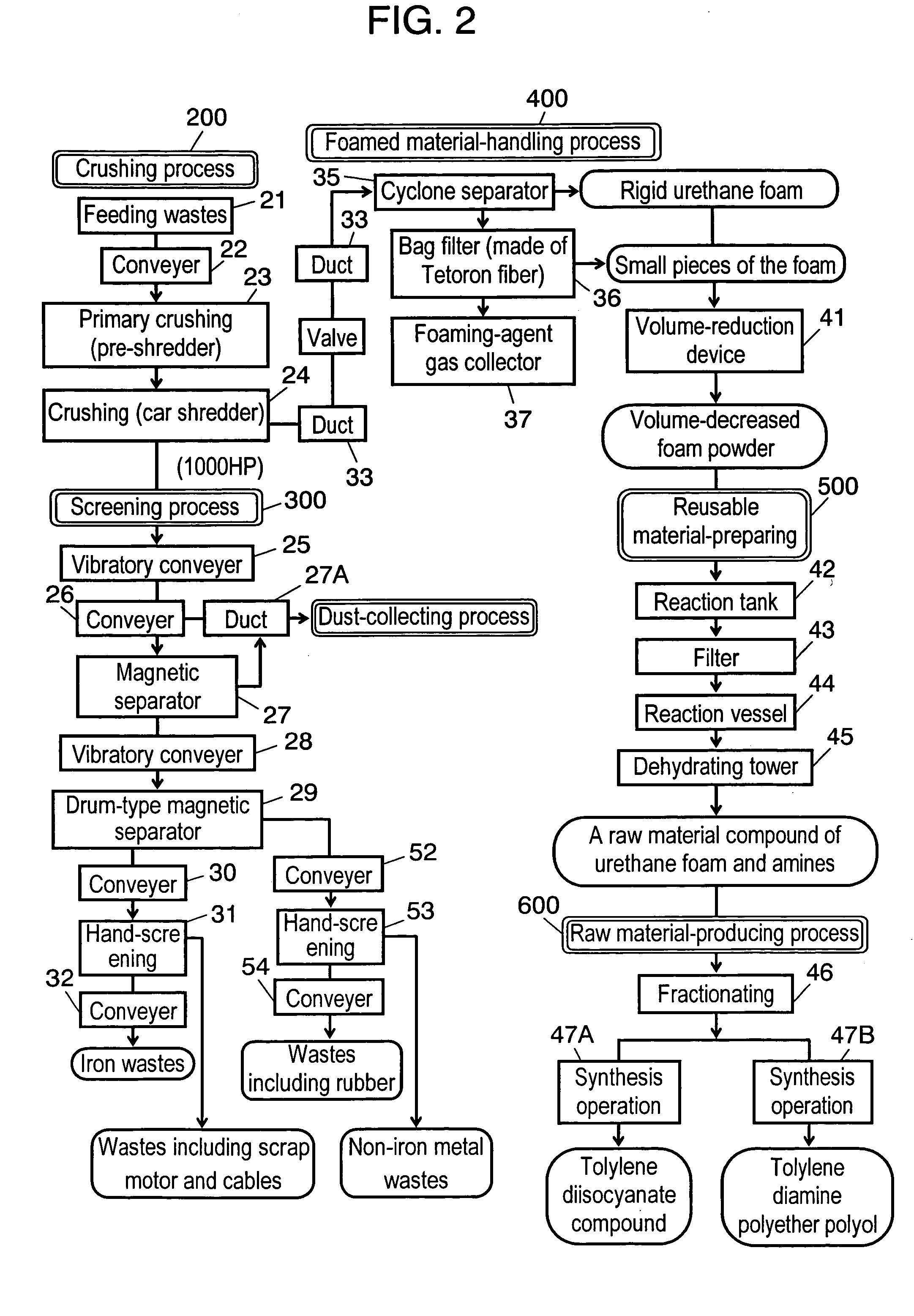

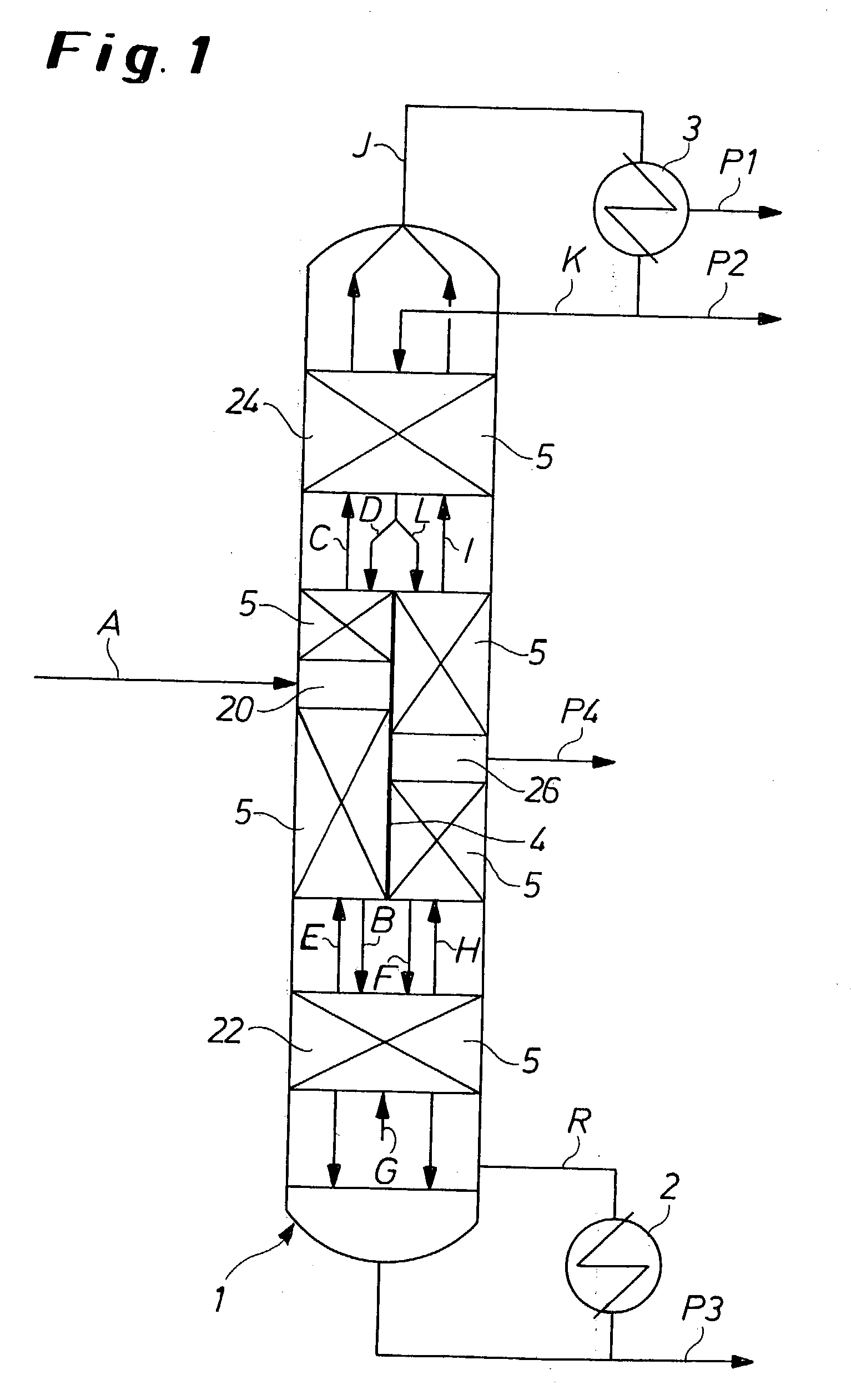

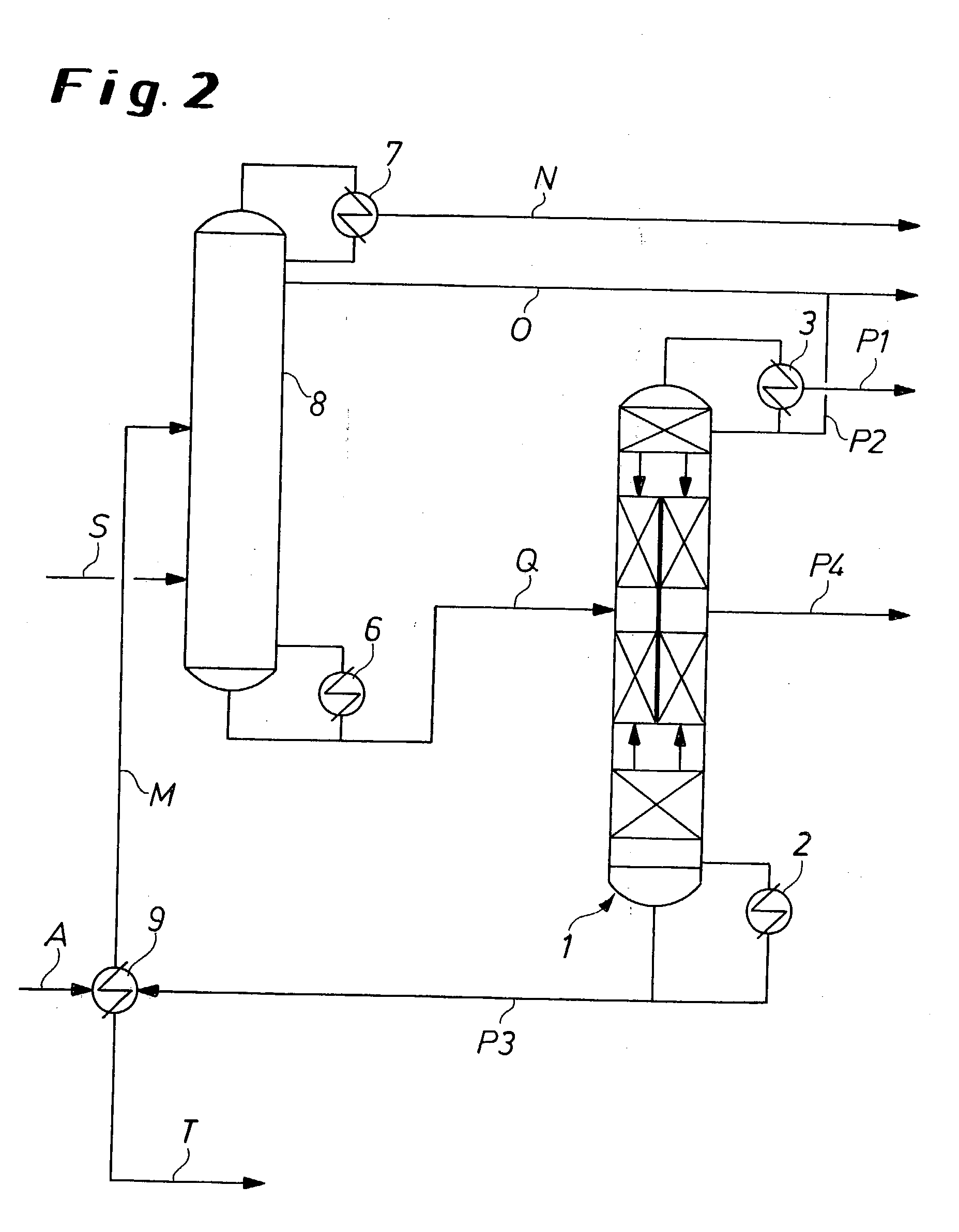

Process for the purification of mixtures of toluenediisocyanate incorporating a dividing-wall distillation column

InactiveUS20030230476A1Weaken energyLow investment costThermal non-catalytic crackingOrganic compound preparationPurification methodsOrganic solvent

Process for the purification of toluenediisocyanate from a crude distillation feed comprising toluenediisocyanate, an organic solvent and less than 2% by weight phosgene by separating the crude distillation feed in a dividing-wall distillation column into at least four product fractions P1-P4. P1 is a phosgene enriched low-boiler product, P2 is a solvent-enriched product, P3 is a high boiler enriched bottoms and P4 is a toluenediisocyanate product stream.

Owner:COVESTRO DEUTSCHLAND AG

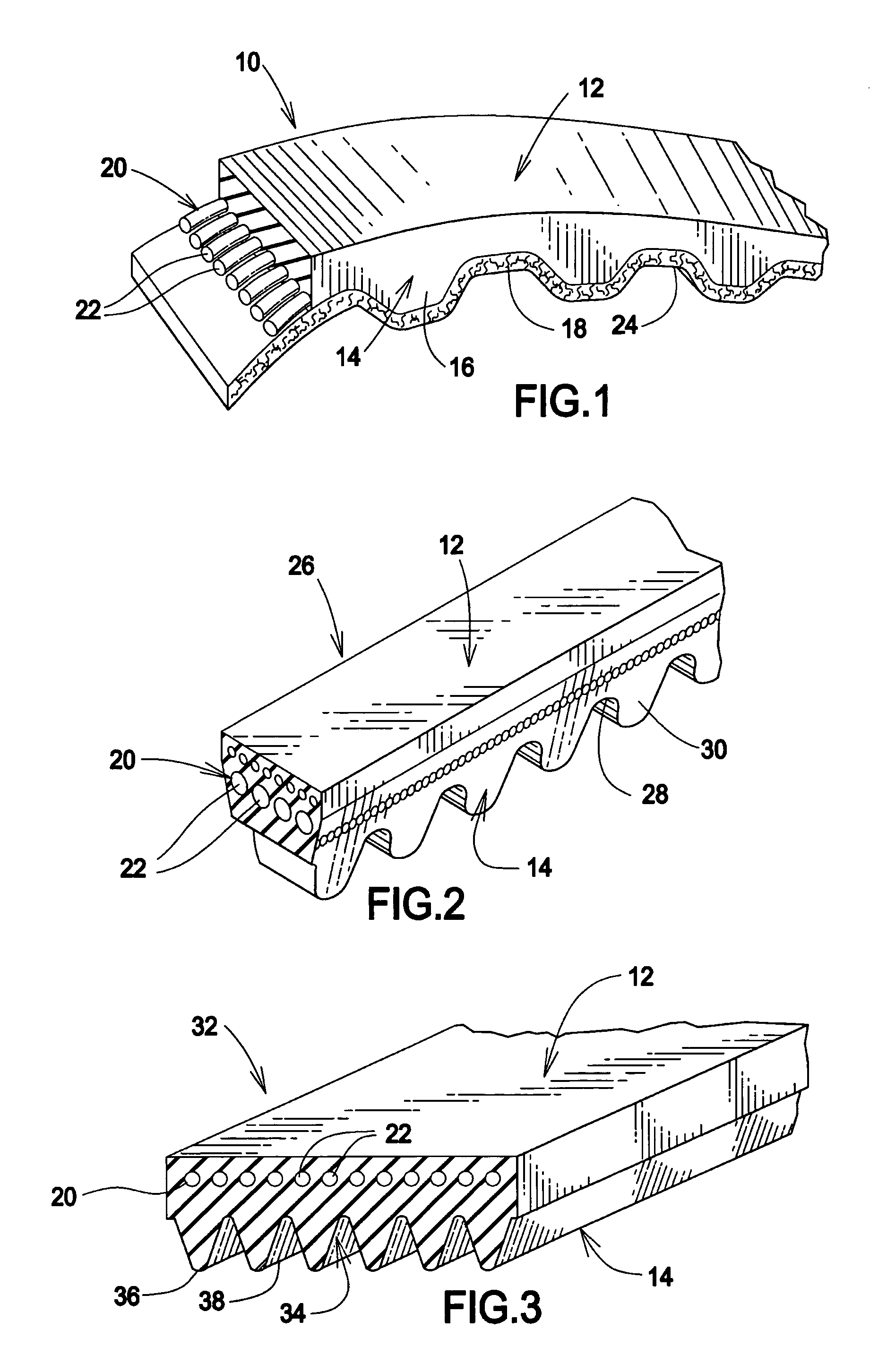

High temperature polyurethane/urea elastomers

InactiveUS6964626B1High and low temperature resistance propertiesHigh and low temperature resistance propertyV-beltsRopes and cables for vehicles/pulleyElastomerPolyester

The present invention relates to molded polyurethane / urea elastomers, and specifically to improved polyurethane / urea elastomers having high temperature stability to about 140–150° C. and low temperature flexibility at about −35–(−40)° C., for use in dynamic applications. These elastomers are particularly useful for application in belts, specifically in automotive timing or synchronous belts, V-belts, multi V-ribbed or micro-ribbed belts, flat belting and the like. The polyurethane / urea elastomers of the present invention are prepared by reacting polyisocyanate prepolymers with symmetric primary diamine chain extenders, mixtures of symmetric primary diamine chain extenders and secondary diamine chain extenders, or mixtures of symmetric primary diamine chain extenders and non-oxidative polyols, which are all chosen to eliminate the need for catalysts via standard molding processes, and to improve phase separation. The polyisocyanate prepolymers are reaction products of polyols which are nonoxidative at high temperatures, such as polycarbonate polyols, polyester polyols, or mixtures thereof, with organic polyisocyanates which are either compact, symmetric and aromatic, such as para-phenylene diisocyanate, 1,5-naphthalene diisocyanate, and 2,6-toluene diisocyanate, or are aliphatic and possess trans or trans,trans geometric structure, such as trans-1,4-cyclohexane diisocyanate and trans,trans-4,4′-dicyclohexylmethyl diisocyanate.

Owner:THE GATES CORP

High-fullness high-resolution environment protection polyureshane sublight uarnish

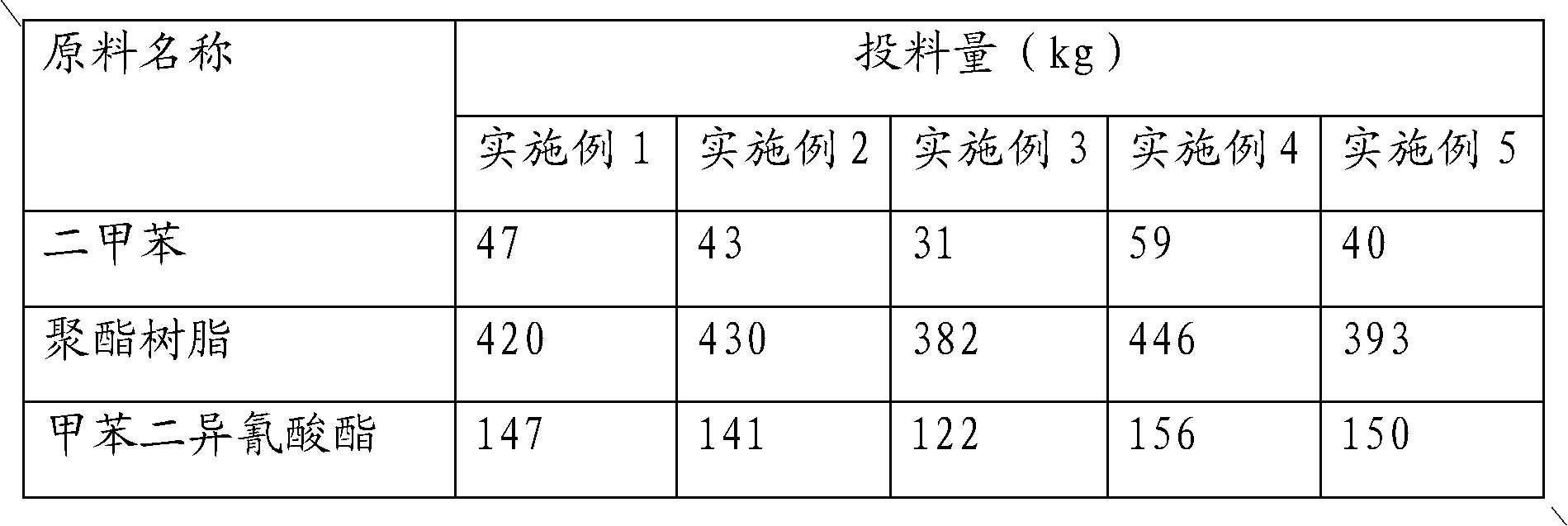

InactiveCN1483777AIncreased weight percentageReduce weightPolyurea/polyurethane coatingsKetoneSolvent

The present invention relates to a high-fullness high-distinctness environment-protecting type polyurethane matte varnish. Said varnish consists of the paint component, polyurethane solidifying agent component and diluting agent component according to the ratio of 1:0.5:0.6-0.8. The polyurethane solidifying agent component contains 50-70 wt% of tolylene diisocyanate trimer, and the rest is the affixture of 80% of tolylene diisocyanate and 20% of trimethylol propane, the paint component contains 15-25% of short oil soya alkyd resin whose solid content is 80%, 50-60% of modified saturated polyester resin, 0-5% of castor oil, 10-12% of aldehyde ketone resin whose solid content is 60%, 3-5% of flatting silica, 0.3-1.0% of teflon wax and 4%-10% of conventional adjuvant and solvent, and the diluting agent component contains 70-80% of butyl acetate, 10-20% of mixed diacid dimethyl ester and 10-15% of isophorone.

Owner:SHENZHEN FEIYANG JUNYAN TECH DEV

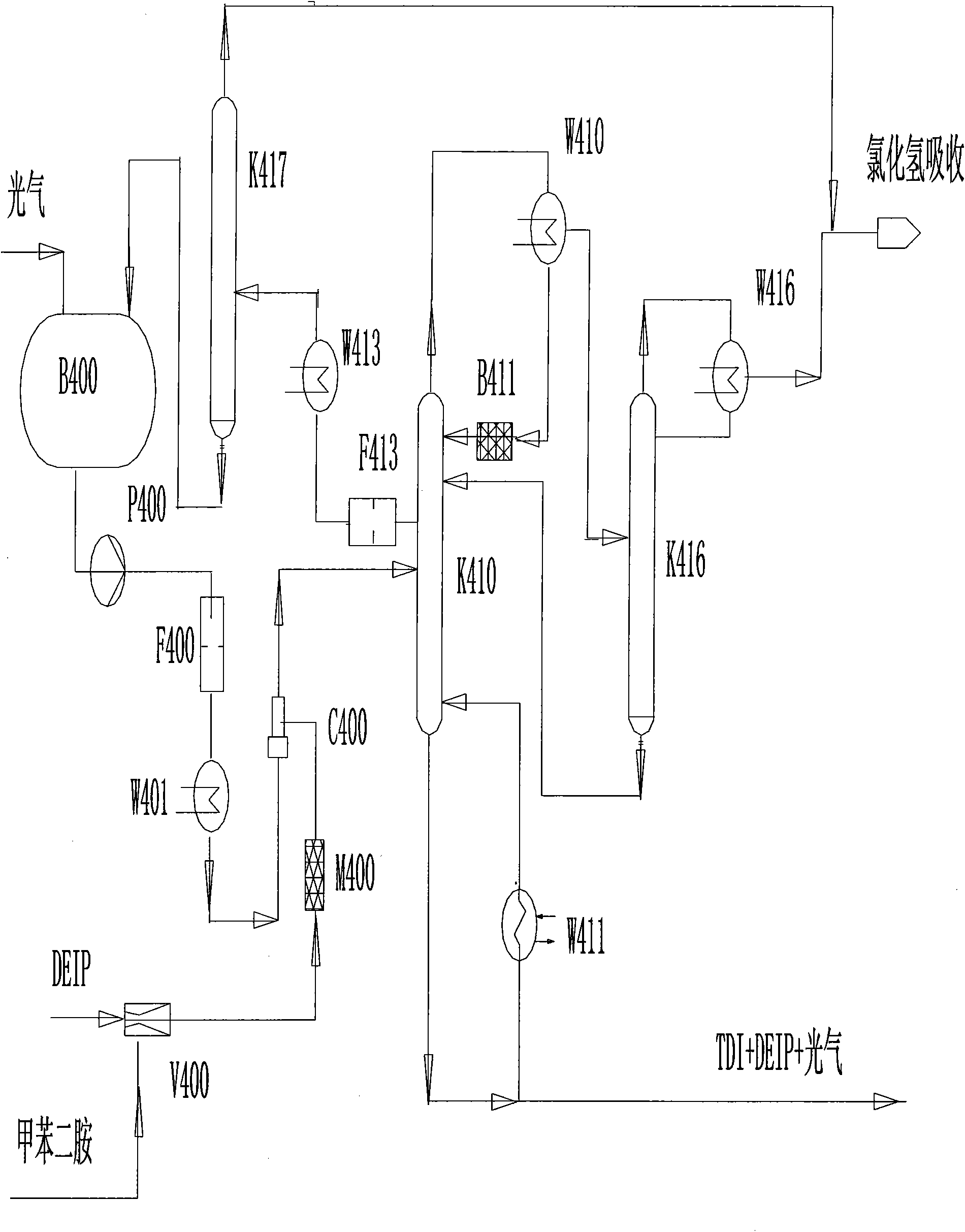

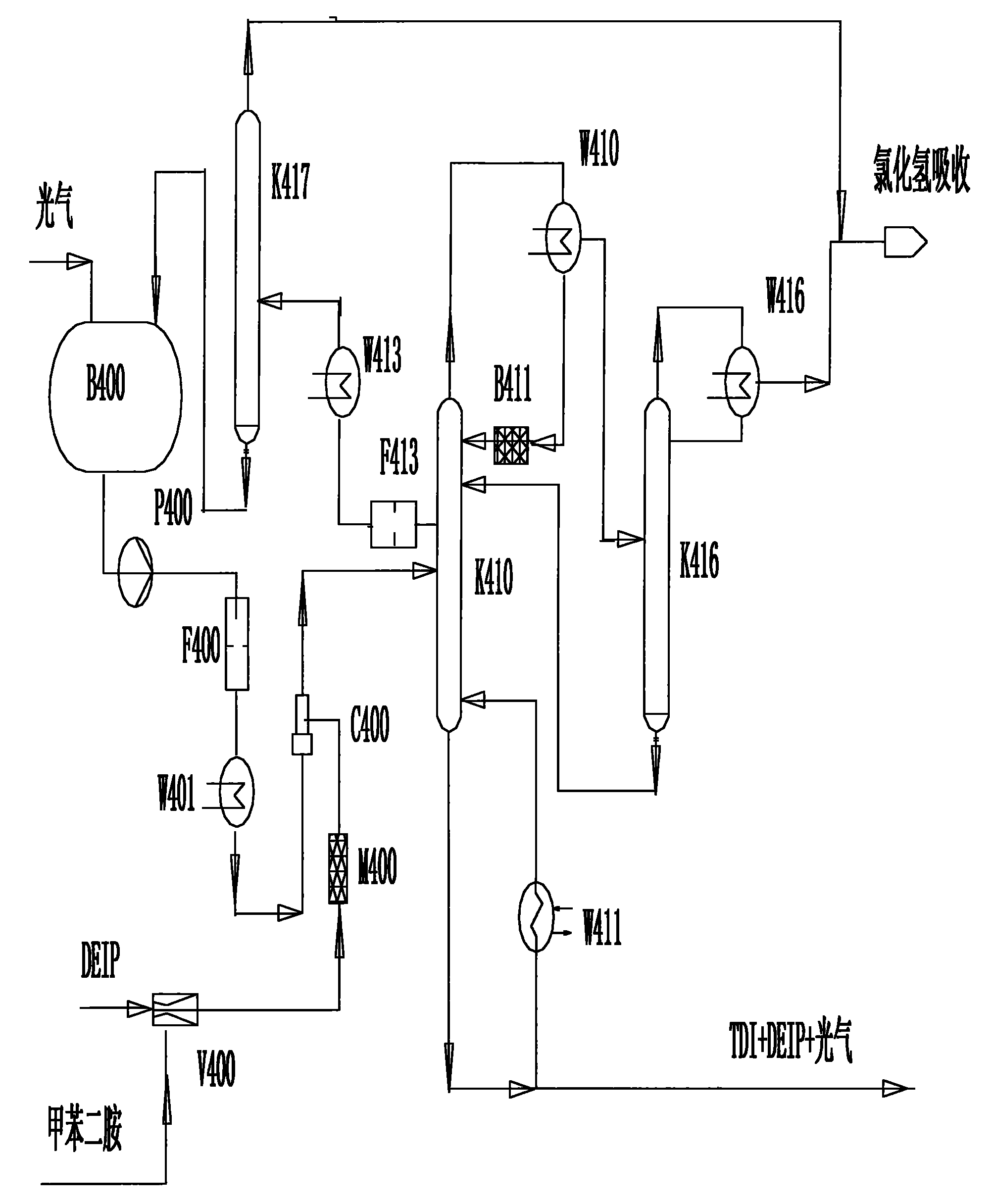

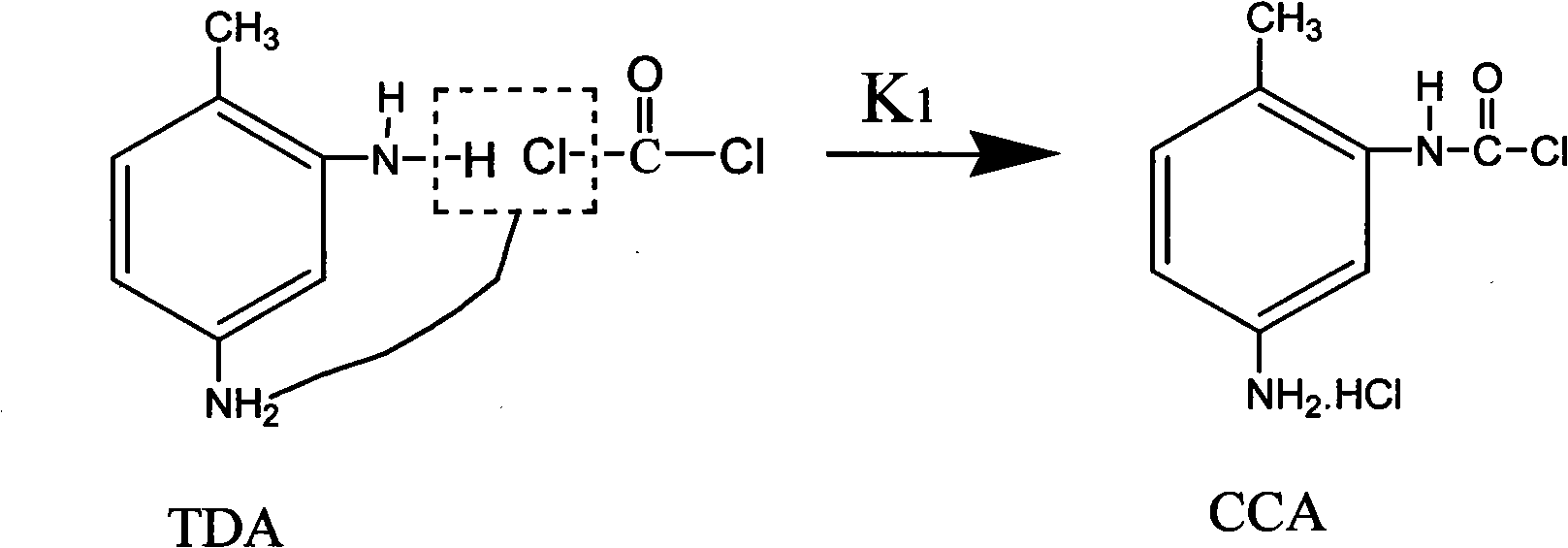

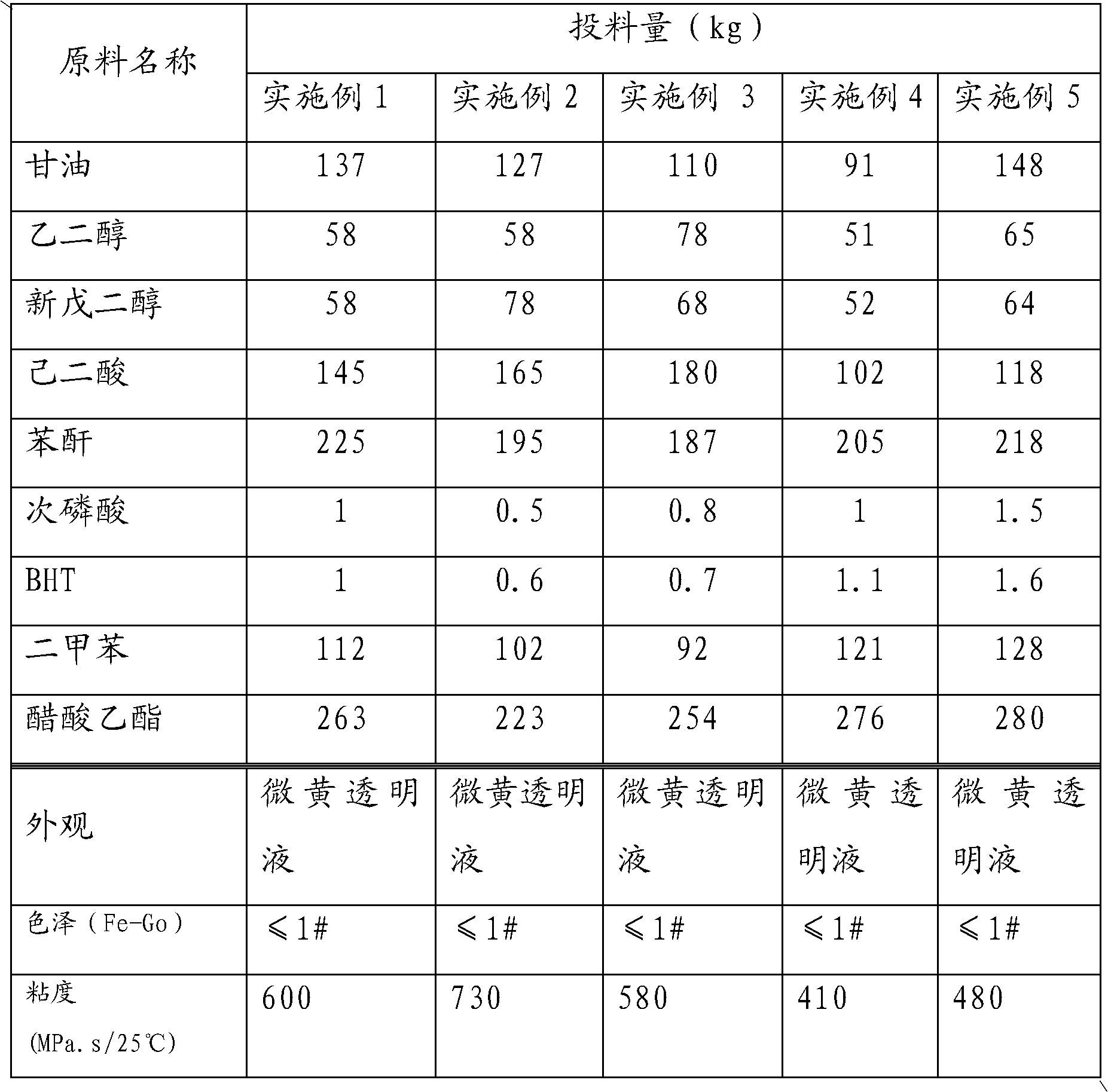

Method for continuously preparing toluene diisocynate

The invention relates to a method for continuously preparing toluene diisocynate, in particular to a method for preparing coarse toluene diisocynate by a phosgene method. The method comprises the following steps: mixing toluene diamine and DEIP solvent, performing low-temperature photochemical reaction on the mixture and excessive liquid phosgene in a jet reactor, heating and cracking a reaction product in a photochemical reaction tower to further decompose toluene dicarbamic chloride serving as an intermediate product to form the toluene diisocynate, recycling the reclaimed phosgene and the DEIP solvent, and delivering the hydrogen chloride gas serving as a side product to a hydrogen chloride absorption system.

Owner:甘肃银光聚银化工有限公司

Preparation method of ethidene diamine type polyether demulsifying agent

ActiveCN102060971AHigh molecular weightGood broad spectrumDewatering/demulsification with chemical meansEthylenediamineCarboxylic acid

The invention discloses a preparation method of ethidene diamine type polyether demulsifying agent. The ethidene diamine type polyethers demulsifying agent is prepared by that ethidene diamine serving as a raw material is subjected to crosslinking modification after reacting with ethylene oxide and epoxypropane. The preparation method comprises the following steps: in the presence of base catalyst, causing the ethidene diamine serving as an initiator to react with propylene oxide and ethylene oxide to prepare polyethers demulsifying agent A by two stages; then, in the presence of catalyst, carrying out selfcrosslinking reaction on the polyethers demulsifying agent A by utilizing polycarboxylic acid, thus preparing a product B; and finally, carrying out selfcrosslinking reaction on the polyethers demulsifying agent A and the product B by toluene diisocynate in the solvent, thus preparing the final product of the ethidene diamine type polyethers demulsifying agent. The demulsifying agent prepared by the preparation method has the advantages of higher relative molecular weight, ideal dehydration effect, good broad spectrum and small use amount, and is suitable for demulsifying and dehydrating crude oil in oil fields, and the removed water has good quality.

Owner:JURONG NINGWU CHEM

Production of low-free TDI polyurethane curing agent, curing agent therefrom and its products

A low-free radical TDI polyurethane curing agent, its production and product are disclosed. The process is carried out by putting tolylene-diisoester cyanate, solvent S and catalyst A into reactor, adding into antioxidant and long-chain alcohol, agitating in reactor, heating, keeping temperature, inspecting NCO value, adding into phase-transferring solvent X while reaching NCO value to 20-40%, adding into catalyst B till reaching NCO value to 10-15, adding into inhibitor to stop reaction, adding into solvent S, decreasing pressure, distilling and removing phase-transferring solvent X. It's cheap and convenient.

Owner:BEIJING ZHANCHEN CHEM +2

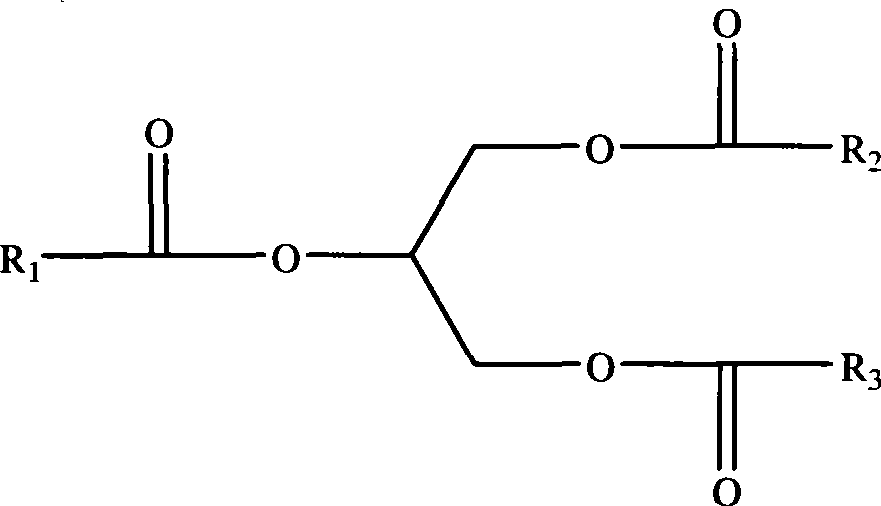

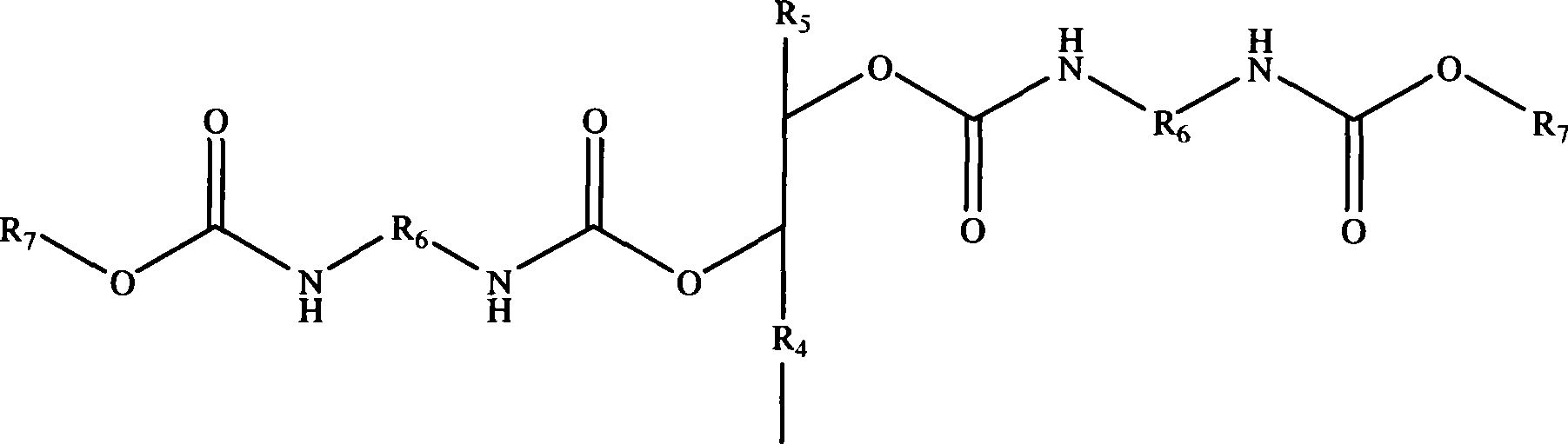

Vegetable oil based polyurethane acrylic ester, preparing process and use thereof

InactiveCN101497684AWide variety of sourcesEasy to makePolyurea/polyurethane coatingsSurface treatment compositionsAlkaneVegetable oil

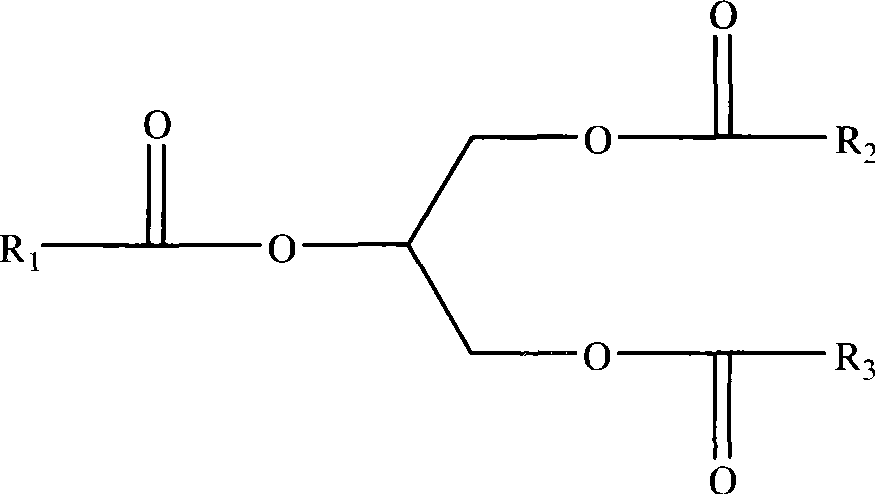

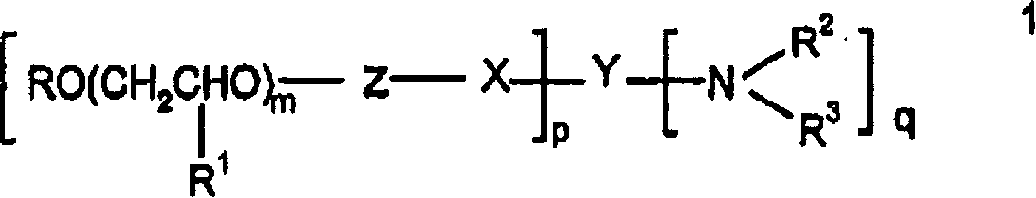

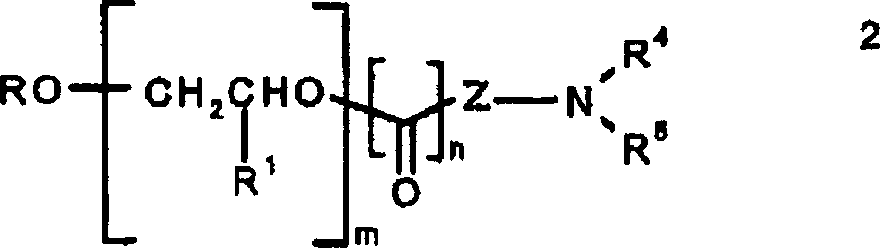

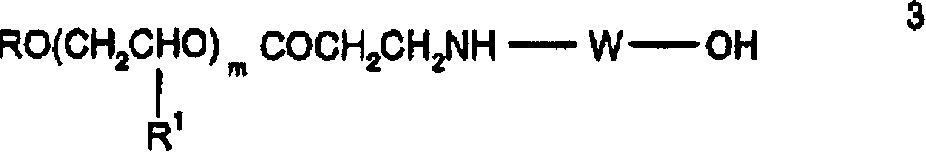

The invention relates to vegetable oil based polyurethane acrylic ester, belonging to the field of photosensitive polymer material. The vegetable oil based polyurethane acrylic ester is characterized in that the general chemical formula is Formula I, wherein R1, R2 and R3 are respectively chosen from alkane of C1-C18, at least one of the alkane is chosen from Formula II, R4 and R5 are respectively chosen from alkane of C1-C16, R6 is diphenyl methane-4,4'-diisocyanate, or hexamethylene diisocyanate, or isophorone diisocyanate or residue of 2,4-toluene diisocyanate with two isocyanate functional group removed, and R7 is 2-hydroxyethyl acrylate, or hydroxypropyl acrylate, or residue of pentaerythritol triacrylate with hydroxy functional group removed.

Owner:天津市天骄辐射固化材料有限公司

Waterborne polyurethane grouting material and preparation method thereof

InactiveCN102093537AConvenient sourceAvoid poisoningOther chemical processesIsophorone diisocyanatePolymer chemistry

The invention discloses a preparation method of a waterborne polyurethane grouting material. The method is as follows: isocyanate, retarding agent and hydrophilic polyether polyol are mixed to react and obtain the finished product, wherein isocyanate is selected from diphenylmethane diisocyanate, liquefied diphenylmethane diisocyanate, polymethylene polyphenyl isocyanate isophorone diisocyanate, dicyclohexylmethylmethane-4,4'-diisocyanate, hexamethylene diisocyanate and polymethylene polyphenyl isocyanate or the mixture of toluene diisocynate and the isocyanates; and the degree of functionality of hydrophilic polyether polyol is 2-6, the ratio of ethylene oxide to propylene oxide is 99 / 1-60 / 40 and the molecular weight is 1000-20000. The invention also relates to the hydrophilic polyurethane grouting material prepared by the method. The preparation method of the invention is simple and convenient and has wide raw material sources; the prepared hydrophilic polyurethane grouting material does not contain organic solvent, thus avoiding the damage on the health of the constructor and promoting environmental protection; and the grouting material can have lower viscosity and good permeability and waterproof and leaking stoppage effect.

Owner:SHANGHAI DONGDA CHEM

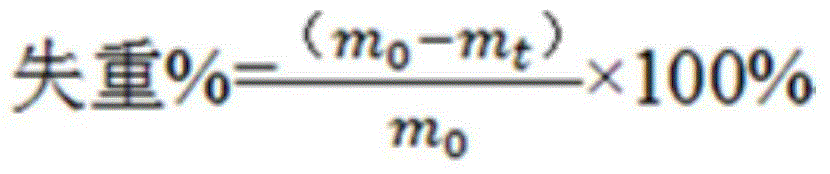

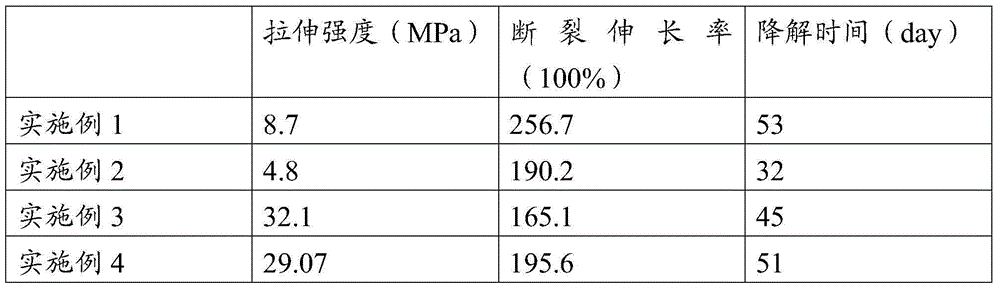

Polyurethane material and preparation method thereof

The invention provides a polyurethane material which is obtained through a reaction of a first polyurethane prepolymer, a second polyurethane prepolymer and a chain extender. The first polyurethane prepolymer is obtained through a reaction of a polyhydroxy compound and one or two kinds of toluene diisocynate and benzene diisocyanate. The second polyurethane prepolymer is obtained through a reaction of a polyhydroxy compound and one or two kinds of 4,4'-diphenylmethane diisocyanate and naphthalene diisocyanate. The polyurethane material can be decomposed through the effect of water or microorganisms, and pollution is avoided; meanwhile, on the basis of the combination of the specific aromatic diisocyanate and the chain extender, the finally-obtained polyurethane material has the good strength and toughness.

Owner:JILIN NORMAL UNIV

Preparation method and use of aqueous polymer/isocyanate adhesive

InactiveCN101948669AHigh bonding strengthLow costMacromolecular adhesive additivesWater basedPolymer science

The invention relates to a preparation method and use of an aqueous polymer / isocyanate adhesive, which belong to the technical field of chemical adhesives. In the invention, recycled polyethylene terephthalate (PET), diethanol amine, caprolactam and aqueous solution of glacial acetic acid are used to prepare a PET water-based polymer; toluene diisocynate and castor oil are used to prepare an isocyanate-terminated polyurethane prepolymer; and when used, PET aqueous polymer emulsion and the isocyanate-terminated polyurethane prepolymer are mixed at room temperature to obtain the aqueous polymer / isocyanate adhesive. The aqueous polymer / isocyanate adhesive is used for adhering wood.

Owner:UNIV OF JINAN

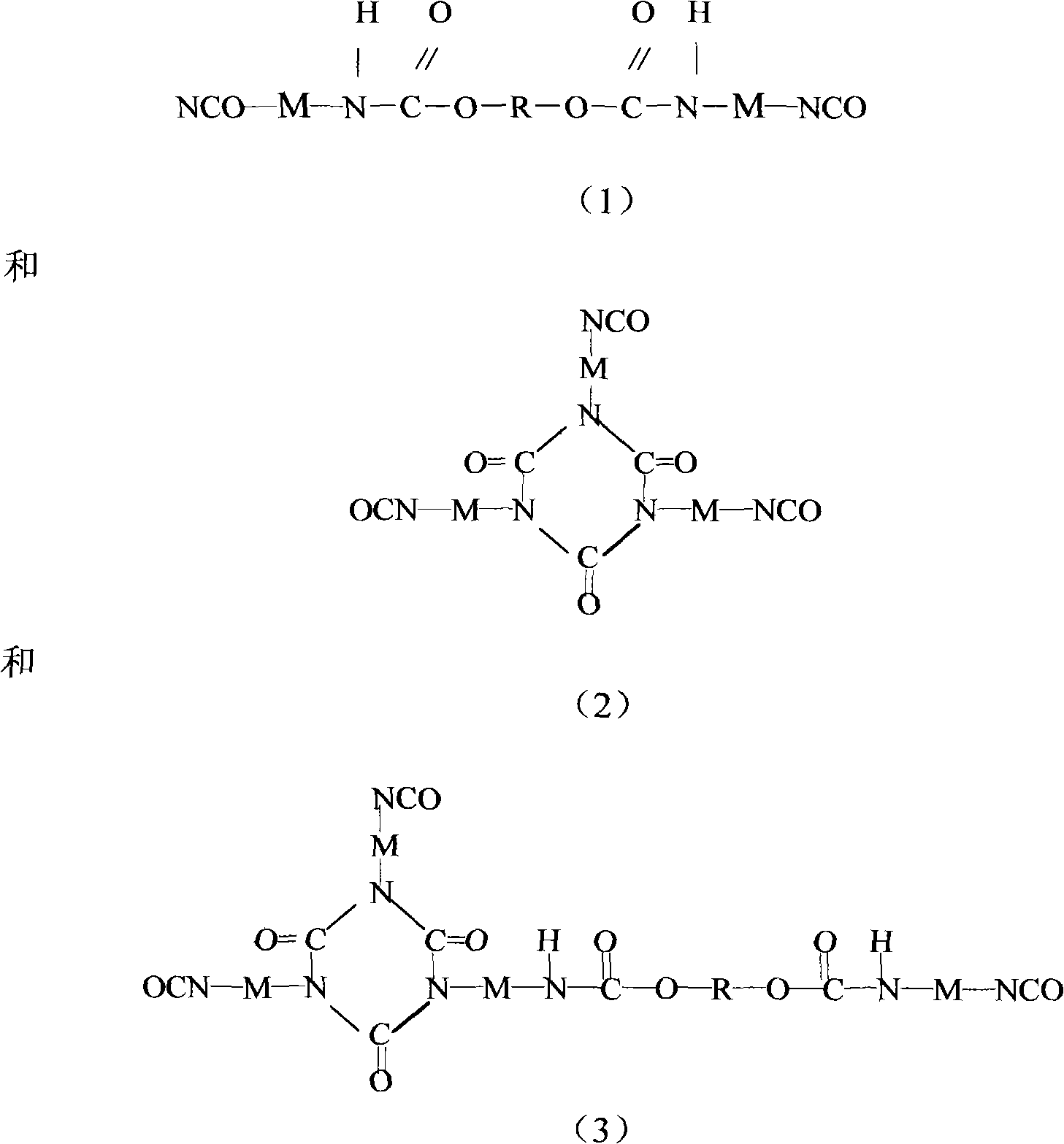

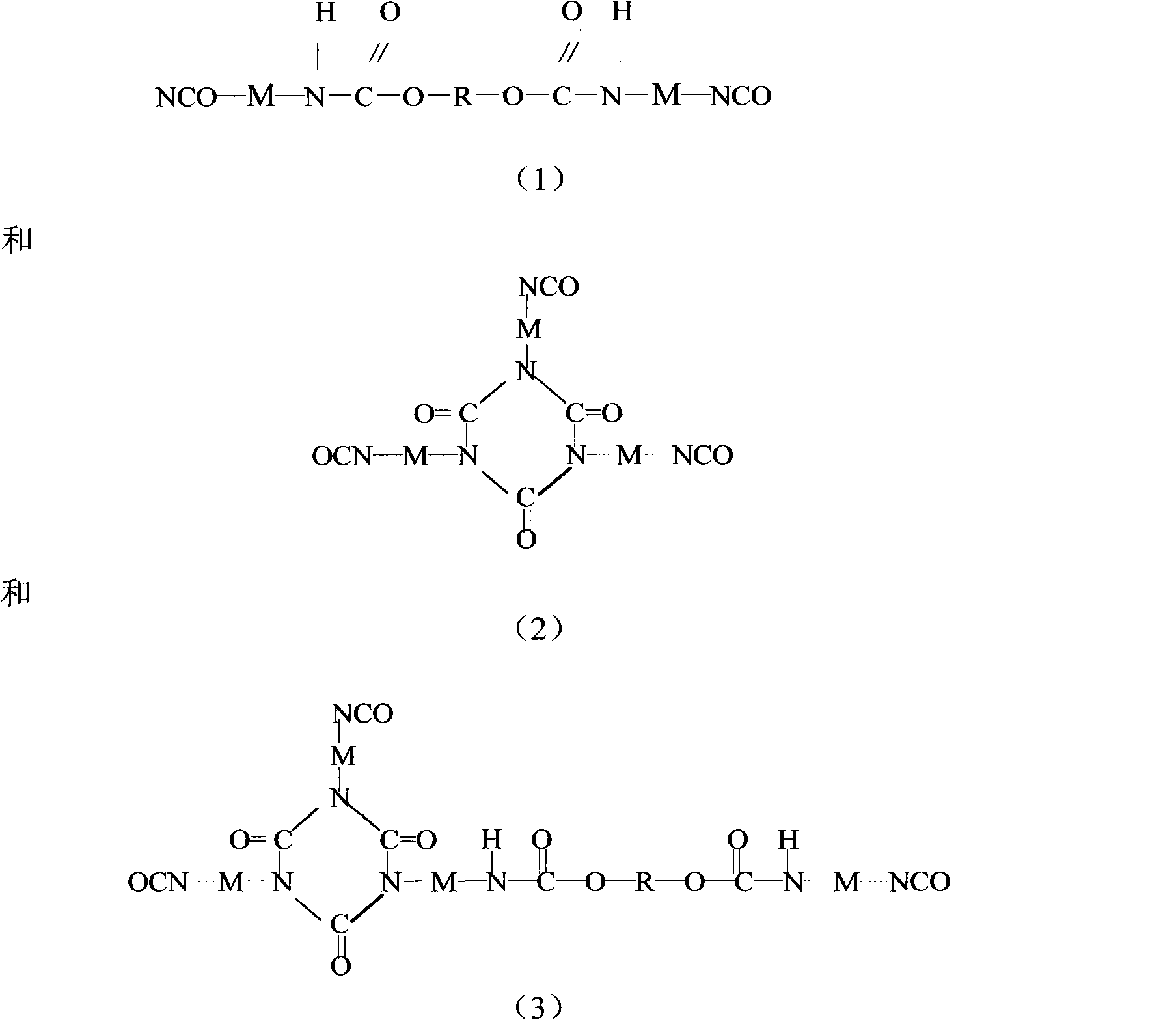

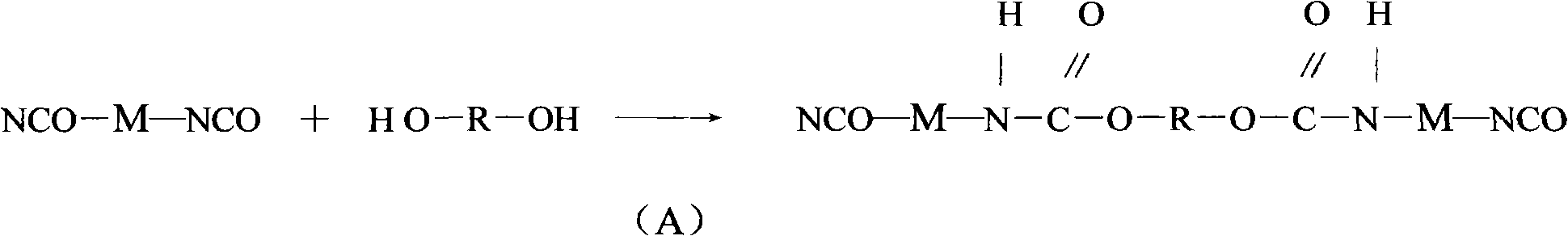

Liquid partially trimerized and allophanized polyisocyanates based on toluene diisocyanate and diphenylmethane diisocyanate

InactiveUS7553963B2Urea derivatives preparationIsocyanic acid derivatives preparationPrenylationToluene diisocyanate

This invention relates to storage-stable, liquid, partially trimerized and allophanized polyisocyanates having an NCO group content of 15 to 41% by weight, and comprising 5 to 85% by weight of toluene diisocyanate, 5 to 85% by weight of a polyisocyanate of the diphenyl-methane series and an organic compound or mixture thereof. The present invention also relates to a process for the preparation of the storage-stable, liquid, partially trimerized and allophanized polyisocyanates; to storage-stable, liquid urethane prepolymers of these partially trimerized and allophanized polyisocyanates; and to a process for the production of these storage-stable, liquid, urethane prepolymers.

Owner:BAYER MATERIALSCIENCE AG

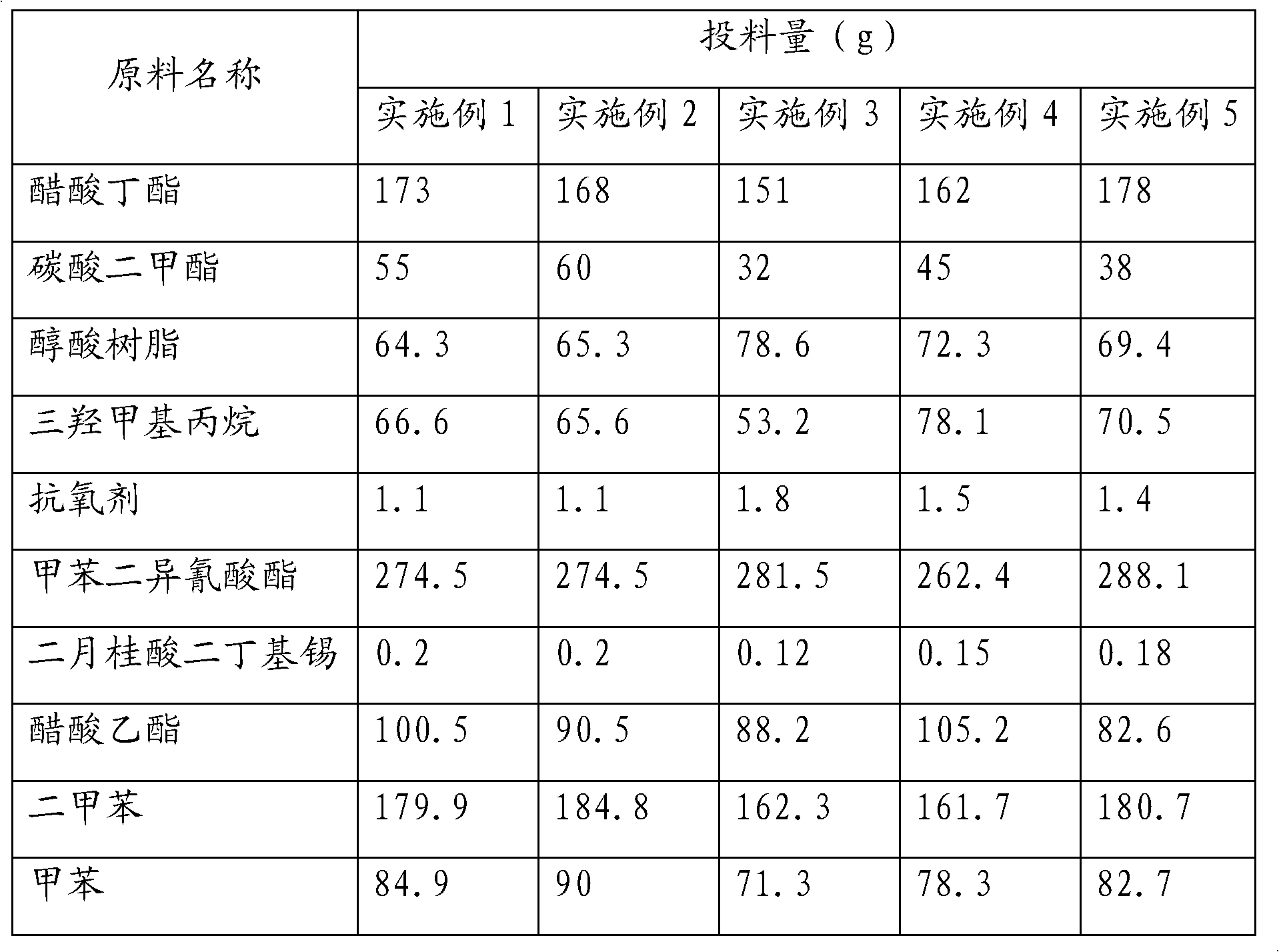

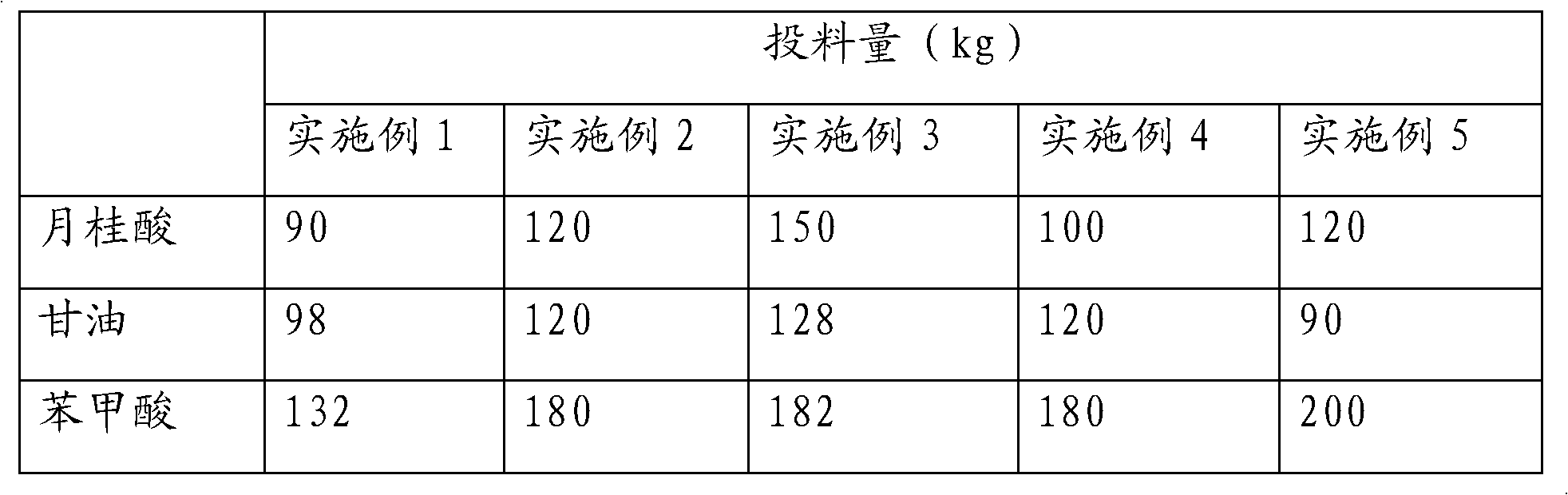

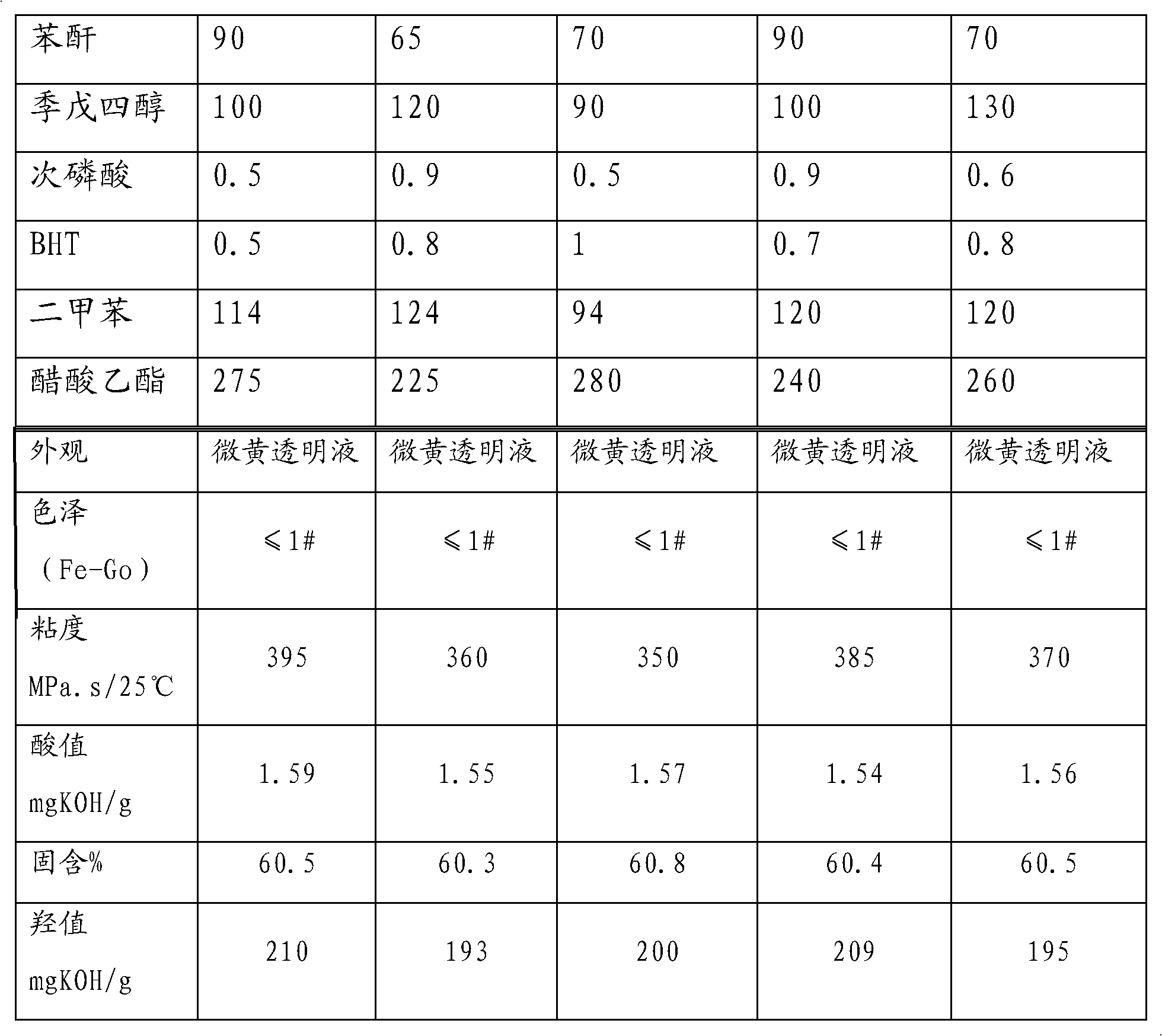

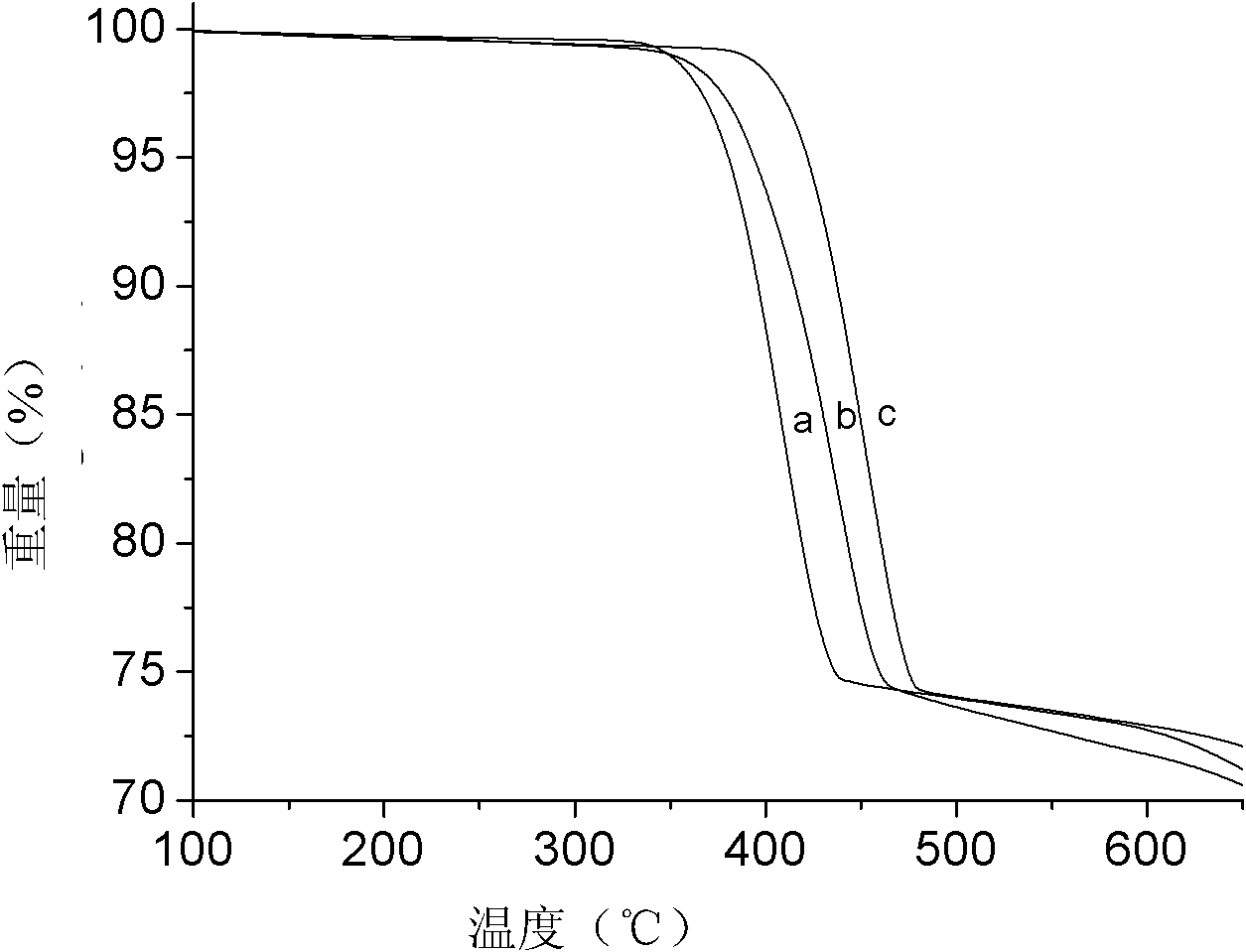

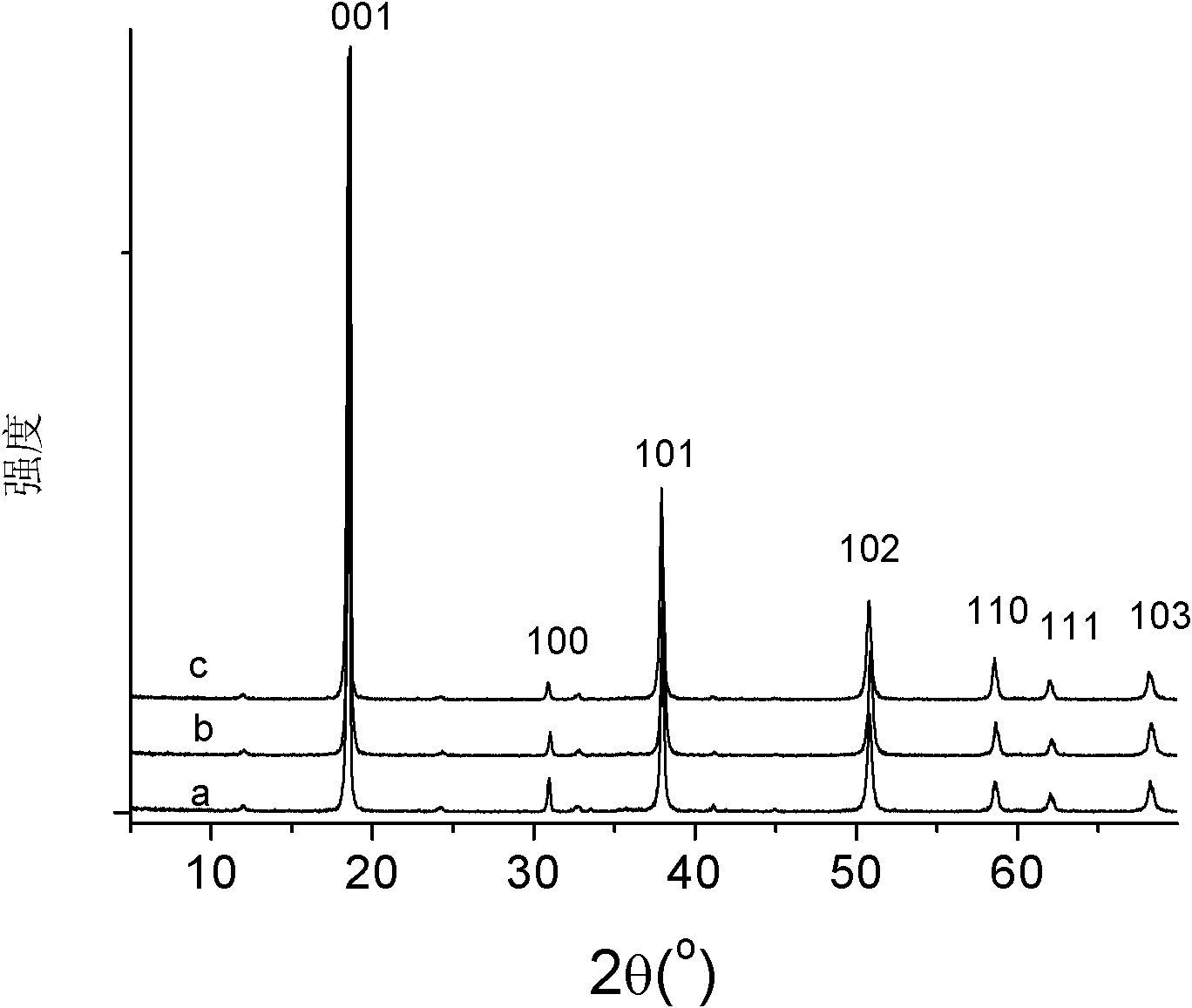

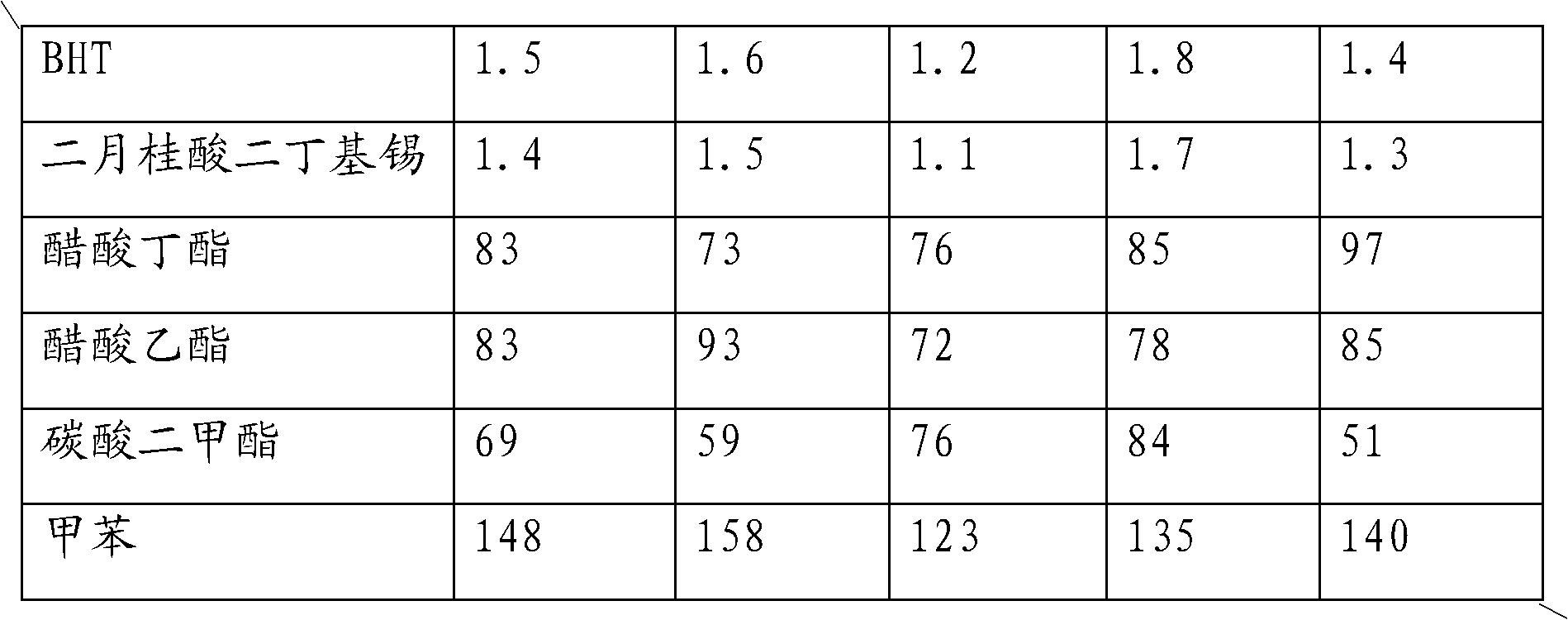

High-solid and averaged-molecular weight non-toxic polyurethane curing agent for sub-gloss varnish and preparation method thereof

The invention belongs to the technical field of curing agents and discloses a high-solid and averaged-molecular weight non-toxic polyurethane curing agent for a sub-gloss varnish and a preparation method thereof. The method comprises the steps of (1) in the nitrogen protection environment, adding a catalyst drop by drop in a reaction vessel filled with a solvent and toluene diisocynate during the stirring process, reacting at the temperature of 40-55 DEG C, cooling on the condition that the content of NCO is lowered to be 13%-23%, and adding an acidic polymerization inhibitor to obtain a toluene diisocyanate trimer; (2) mixing a polyhydroxy compound with a dehydrating agent, adding the obtained mixture in the toluene diisocyanate drop by drop, reacting and cooling to obtain a polyurethane addition product; (3) stirring and mixing the toluene diisocyanate trimer with the polyurethane addition product, separating in a film evaporator, adding a dilution solvent and stirring evenly to obtain the high-solid and averaged-molecular weight non-toxic polyurethane curing agent. The curing agent is centralized in the distribution of molecular weight, low in viscosity, and high in content of effective isocyanate groups. After a varnish is prepared by the curing agent, a paint film is fast in drying speed, good in levelability and high in fullness.

Owner:SOUTH CHINA UNIV OF TECH

High performance aqueous polyurethanes dispersion and methods of fabricating the same

InactiveUS20050020767A1Less overall consumptionHigh molecular weightPolyurea/polyurethane coatingsPolyurethane dispersionPolyol

Disclosed are high performance aqueous polyurethanes and methods of making the same. The aqueous polyurethane is prepared by prepolymerizing the following components (a), (b), and (c) in the absence of aliphatic or cycloaliphatic diisocyanates; and chain-extending the hydrophilic prepolymer with component (d): (a) 10-40 wt % of an aromatic diisocyanate consisting of toluene diisocyanate (TDI); (b) 1-15 wt % of a compound containing active hydrogen and a hydrophilic group or a group capable of forming hydrophilicity; (c) 30-80 wt % of a polyol; and (d) 0.1-5 wt % of a chain extender having active hydrogen. The aqueous dispersions of the polyurethane have good storage stability and the dried films produced therefrom possess superior mechanical properties.

Owner:IND TECH RES INST

Modified polyurethane curing agent for alkyd resin with high hydroxyl content and preparation method thereof

The invention discloses a modified polyurethane curing agent for an alkyd resin with high hydroxyl content. The modified polyurethane curing agent is prepared by the following raw materials by weight parts: 5-8 of alkyd resin, 5-8 of trimethylolpropane and 26-29 of toluene diisocynate, wherein the hydroxyl content of the alkyd resin is 5.5 to 6.4 percent. The invention also provides a preparation method for the modified polyurethane curing agent. The addition reaction is performed among the alkyd resin with hydroxyl content of 5.5 to 6.4 percent, trimethylolpropane and toluene diisocynate containing NCO groups, and the prepared modified bicomponent polyurethane curing agent has crosslinked NCO groups with high reactivity, so that modified polyurethane curing agent can be copolymerized with paint component containing hydroxyl groups at normal temperature to form paint films with different characteristics. Therefore, the modified polyurethane curing agent is excellent in operational performance and wide in application field.

Owner:四川嘉宝莉涂料有限公司

Polymerizable composition for optical material, optical material and method for producing optical material

Disclosed is a polymerizable composition for o an optical material containing tolylene diisocyanate, hexamethylene diisocyanate, and one or more polythiol compounds selected from the group consisting of 4-mercaptomethyl-1,8-dimercapto-3,6-dithiaoctane,4,8-, 4,7- or 5,7-dimercaptomethyl-1,11-dimercapto-3,6,9-trithiaundecane, pentaerythritol tetrakismercaptoacetate, pentaerythritol tetrakismercaptopropionate, 2,5-bis(mercaptomethyl)-1,4-dithiane, bis(mercaptoethyl)sulfide, 1,1,3,3-tetrakis(mercaptomethylthio)propane, 4,6-bis(mercaptomethylthio)-1,3-dithiane and 2-(2,2-bis(mercaptomethylthio)ethyl)-1,3-dithietane.

Owner:MITSUI CHEM INC

Modified magnesium hydroxide, preparation method thereof and application thereof in polymer

InactiveCN101787223ASimple processReduce manufacturing costPigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsToluene diisocyanateStearic acid

The invention discloses modified magnesium hydroxide, a preparation method thereof and application thereof in a polymer. The preparation method of the invention comprises the following steps: stirring magnesium hydroxide for 20-30min at the temperature of 30-120 DEG C while adding modifier slowly and evenly; and continuously stirring for 30-90min to obtain the modified magnesium hydroxide, wherein, the modifier is at least one of stearic acid, silicone oil, toluene diisocyanate or diphenyl methane diisocyanate. The preparation method improves the thermal stability of the magnesium hydroxide and the compatibility of the modified magnesium hydroxide with polymer; and when the obtained magnesium hydroxide is applied to preparing a fire retardant polymer, even the use amount of the modified magnesium hydroxide reaches 60% of the total weight of the polymer material, and the processability and mechanical property of the obtained fire retardant polymer are obviously improved and meet the requirement of fire resistance. The obtained modified magnesium hydroxide of the invention has simple used device and process, low production cost and capability of being widely applied to industrial production processes.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

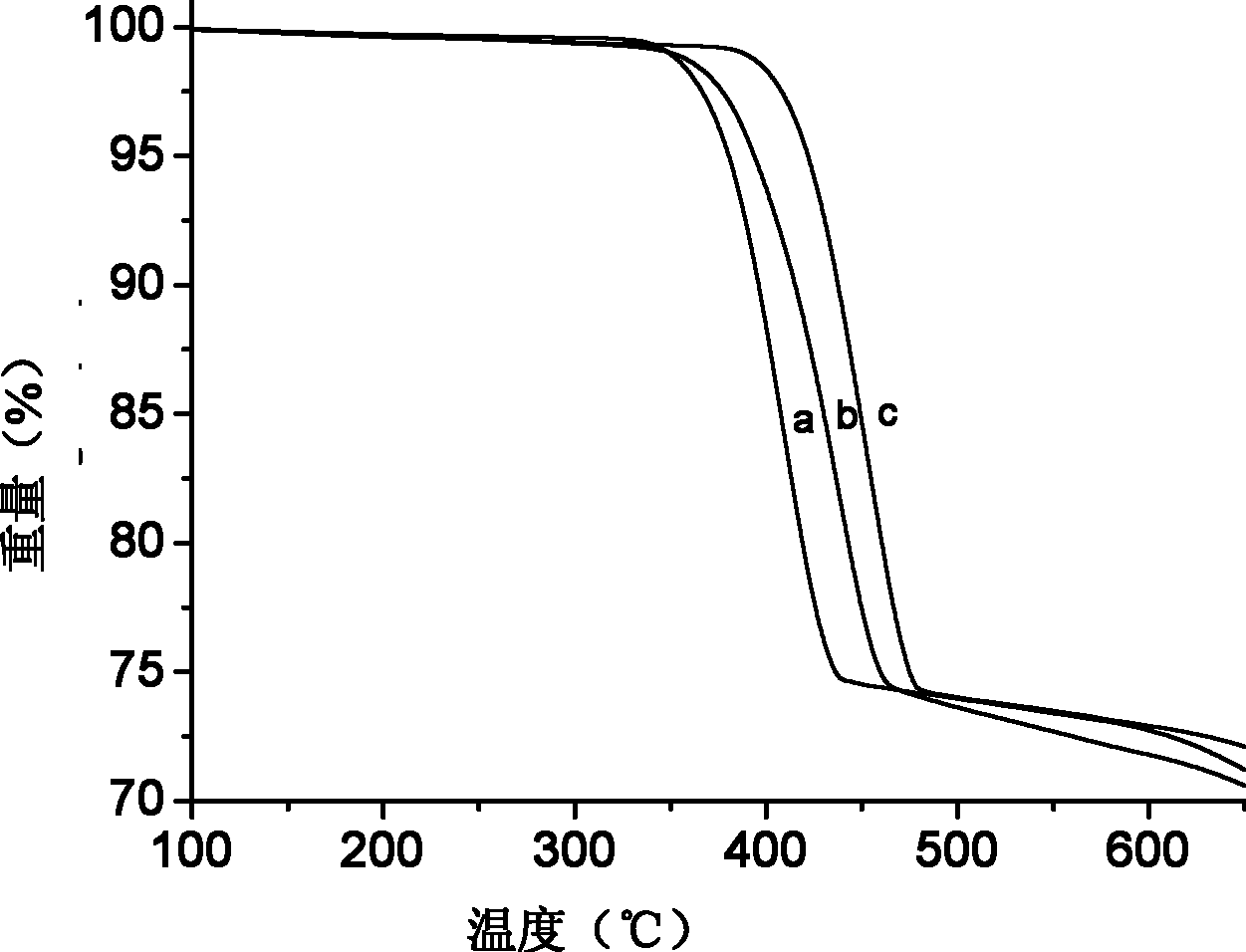

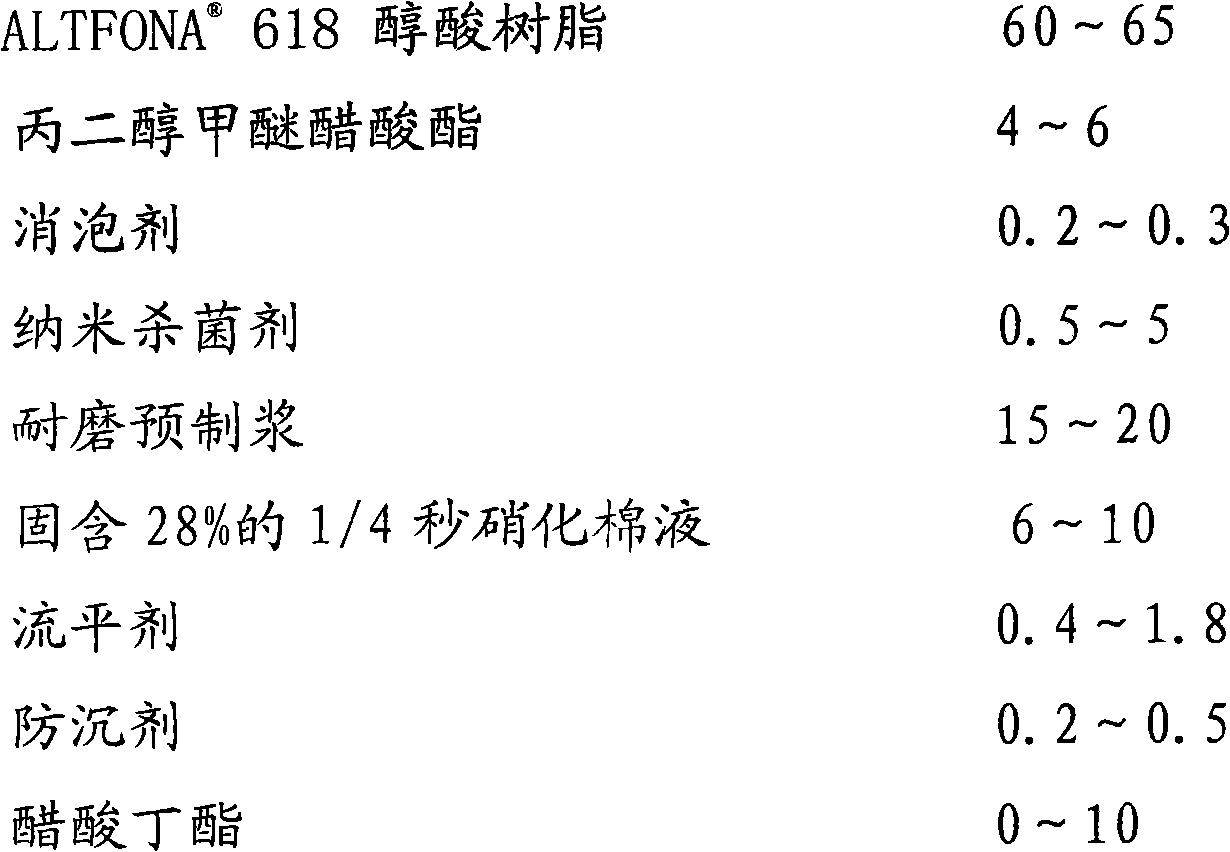

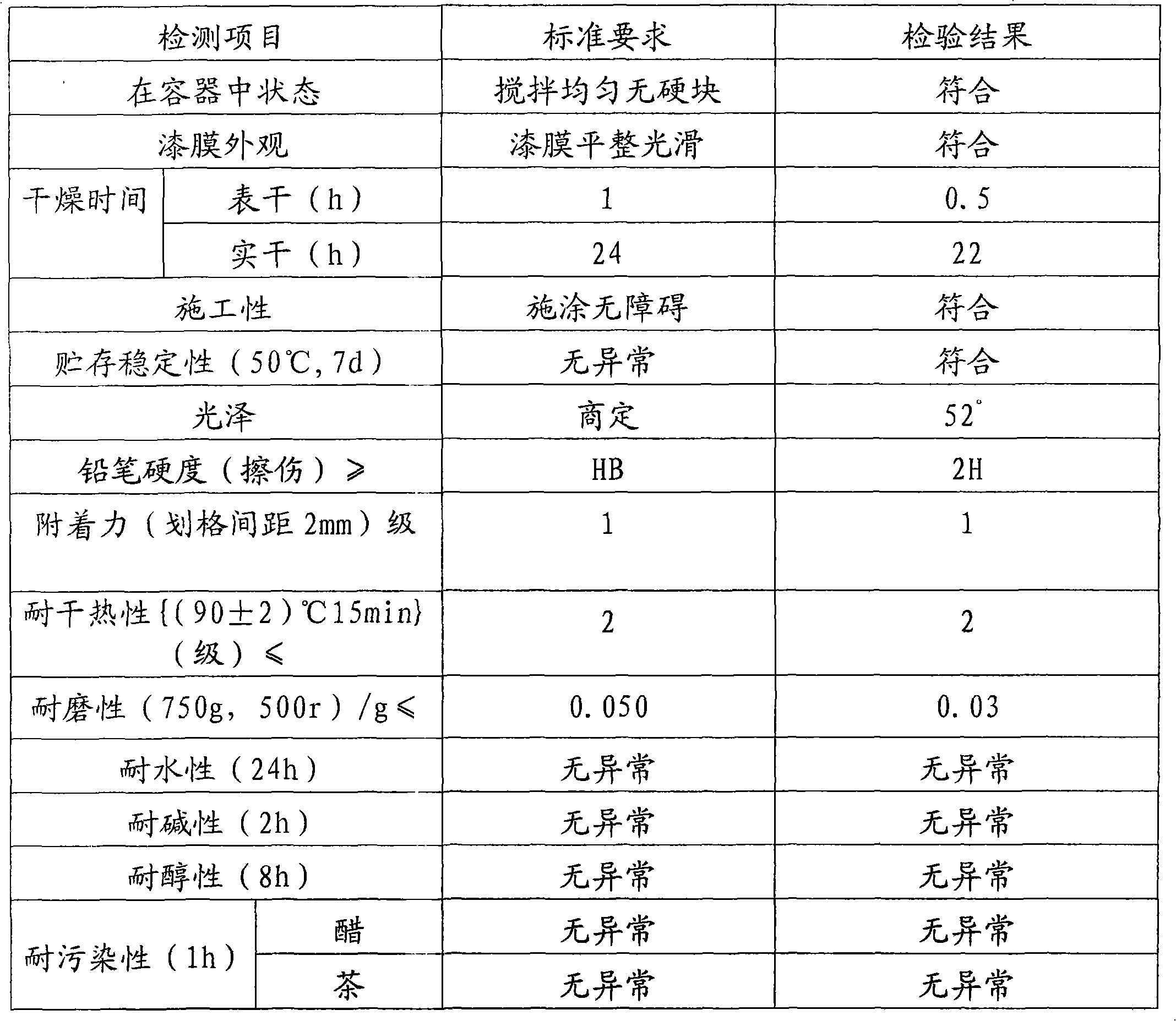

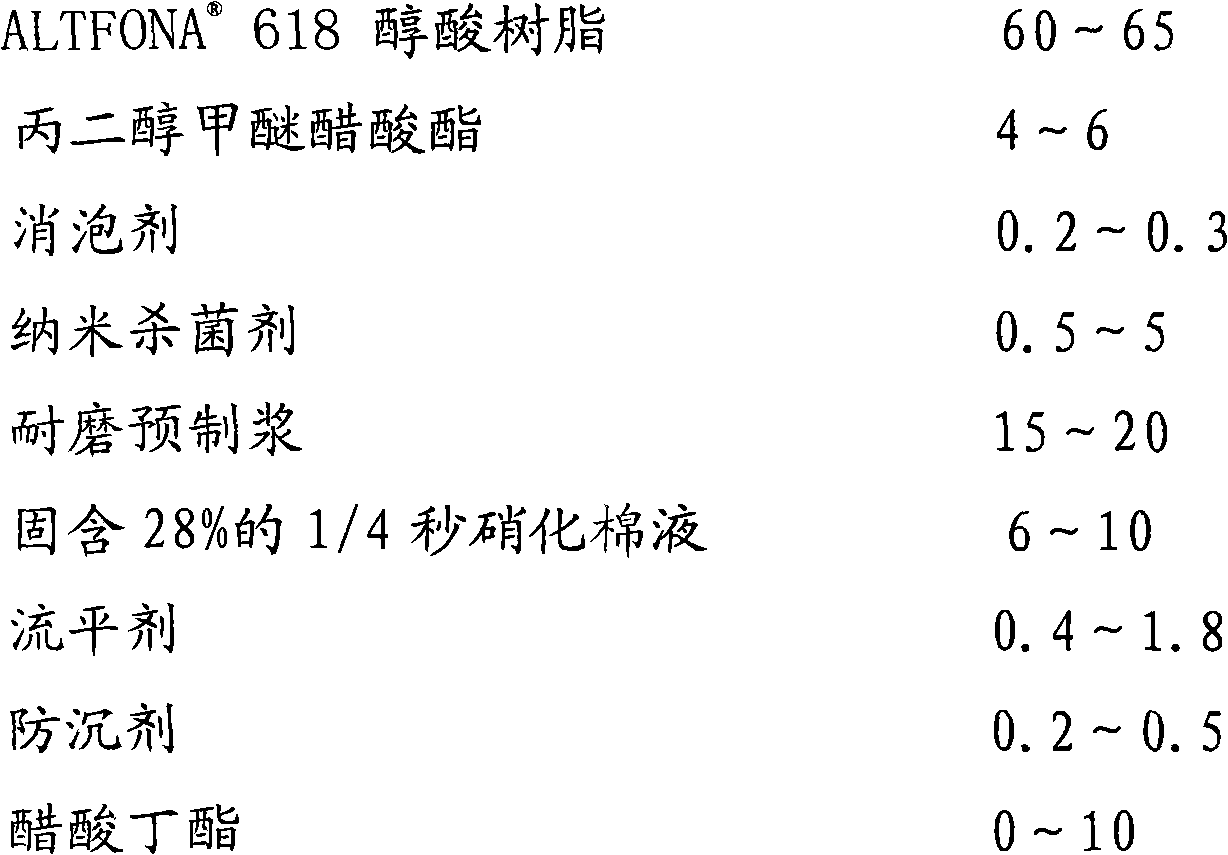

Sterilization and aldehyde-removal nanometer polyurethane paint

InactiveCN102634275AImprove the bactericidal effectImprove adhesionAntifouling/underwater paintsPaints with biocidesCyclohexanoneDecomposition

The invention discloses sterilization and aldehyde-removal nanometer polyurethane paint, which is composed of three components A, B and C. The component A is prepared by uniformly mixing alkyd resin 618, propylene glycol methyl ether acetate, a defoaming agent, a nanometer bactericide, wear-resisting prefabricated slurry, 1 / 4 second nitrocotton with a solid content being 28%, a leveling agent, an anti-settling agent and butyl acetate, the component B is prepared by uniformly mixing a tolylene diisocyanate (TDI) trimer, a TDI additive product and butyl acetate, and the component C is prepared by uniformly mixing propylene glycol methyl ether acetate, butyl acetate and cyclohexanone; and when the sterilization and aldehyde-removal nanometer polyurethane paint is used, the three components are uniformly mixed according to a weight ratio. Compared with similar products in the market, the sterilization and aldehyde-removal nanometer polyurethane paint disclosed by the invention has the function of removing formaldehyde in triple manners of absorption, decomposition and seal and has the advantages of favorable sterilization effect, good product adhesion force, scraping resistance, good application property and good tolerance.

Owner:GUANGDONG SANVO CHEM IND TECH

Preparation of wide compatible, stable and rheologic activating urethane solution

InactiveCN1338453AGood storage stabilityBroad compatibilityUrea derivatives preparationOrganic compound preparationLithiumSolvent

The invention relates to a process for preparing a solution which comprises urea urethanes and is effective as a thixotropic agent, which involves reacting at least two structurally different monohydroxy compounds with an excess of toluylene diisocyanate to form monoisocyanate adducts, removing the unreacted portion of the toluylene diisocyanate, and reacting the resultant monoisocyanate adducts with diamines in an aprotic solvent in the presence of a lithium salt to form urea urethanes. The invention also relates to the use of the solution to receive thixotropic coating compositions.

Owner:BYK CHEM GMBH

Aqueous urethane dispersants

InactiveCN1615322AIncrease the amount of participationLow viscosityPigmenting treatmentTransportation and packagingSide chainPolypropylene glycol

A polyurethane polymer containing 35 to 90 wt% of a poly(C2-4 alkylene oxide) based on the total weight of the polymer, wherein not less than 60% of the poly(C2-4 alkylene oxide) is poly(C2-4 alkylene oxide). Ethylene oxide, and wherein at least 5% of the poly(C2-4 alkylene oxide), based on the total weight of the polymer, is bound to the side chain, and when the polyurethane contains 35 to 45% by weight of poly(C2-4 alkylene oxide) Oxygen), for example, by using bis(hydroxymethyl)propionic acid, cyclohexanedimethanol, polypropylene glycol (1000), N-methylpyrrolidone, and a compound available from 2,4-toluene diisocyanate, methoxypolyethylene When a polymer is produced by reacting α,α-dihydroxypolyethylene glycol obtained by diol (750) and diethanolamine, it contains 10 to 180 milliequivalents (meq) of acid groups per 100g of polymer.

Owner:THE LUBRIZOL CORP

Waterproof coating material

InactiveCN102850890AAntisepticUnique water resistancePolyamide coatingsPolymer scienceDioxyethylene Ether

The invention relates to a waterproof coating material, which comprises the following components, by weight, 22-28 parts of a pure acrylate emulsion, 9-13 parts of an ethylene-vinyl acetate copolymerization emulsion, 2-5 parts of ethylene glycol monobutyl ether, 4-7 parts of xylene, 8-12 parts of ethyl acetate, 1-4 parts of polyacrylamide, 2-8 parts of toluene diisocyanate, 1-3 parts of fatty alcohol polyoxyethylene ether, 4-9 parts of silicone oil, 2-4 parts of titanium dioxide powder, 3-5 parts of talc powder, and the balance of water. The waterproof coating material of the present invention has characteristics of unique waterproof performance, stable chemical performance, safety, environmental protection, corrosion protection, direct brushing, and convenient operation.

Owner:JIANGSU ZHENGTAI PHARMA CHEM

Preparation method of polyurethane pervaporation phenol/water separating membrane compounded by inorganic particles

InactiveCN103084077AHigh temperature resistantHigh temperature resistanceDistillationFiberDiphenylmethane

The invention discloses a preparation method of a polyurethane pervaporation phenol / water separating membrane compounded by inorganic particles, and belongs to the field of pervaporation membrane separation. The polyurethane membrane basic material is obtained by polymerizing and mixing monomer hydroxyl-terminated polybutadiene, toluene diisocynate, 4,4'-diamine diphenylmethane solution, cyclodextrin and silica or carbon fiber powder. The preparation method comprises the following steps: reacting hydroxyl-terminated polybutadiene with toluene diisocynate to obtain blocked prepolymer, then adding 4,4'-diamine diphenylmethane solution and cyclodextrin as chain extenders to perform the chain extension, and adding inorganic modified particle silica or carbon fiber powder (using N,N-dimethylacetamide as solvent) to obtain prepolymer solution of polyurethane; casting the solution on a polyfluortetraethylene plate to form a membrane, solidifying for 1-1.5 hours at room temperature, and moving the membrane to an oven at 80 DEG C to thermally treat to obtain the polyurethane membrane compounded by inorganic particles. The preparation method disclosed by the invention is simple in process, and the prepared membrane has good heat and chemical stability and mechanical property.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Polyurethane composite material regenerated from waste polyurethane soles and preparation process thereof

InactiveCN104448775ASolving Recycling ProblemsRaw materials are easy to getAmmonium polyphosphateChemistry

The invention discloses a polyurethane composite material regenerated from waste polyurethane soles and a preparation process thereof. The polyurethane composite material is prepared from the following raw materials in parts by weight: 170-180 parts of waste polyurethane soles, 10-14 parts of a compatibilizer, 5-7 parts of toluene diisocynate, 2-4 parts of tri(2,4-di-tert-butylphenol) phosphite ester, 4-6 parts of medical stone powder, 6-8 parts of organic silicon, 2-3 parts of ammonium polyphosphate, 12-18 parts of polyisocyanate, 3-5 parts of hybrid polyester polyol, 5-7 parts of dibutyltin dilaurate, 6-8 parts of alkanolamide, 4-5 parts of nano-alumina powder, 2-3 parts of antioxidant TNP, 7-9 parts of aluminum stearate, 8-10 parts of isocyanate, 4-6 parts of zirconium oxide, 9-11 parts of nano montmorillonite and 10-12 parts of additives. According to the invention, on one hand, the recovery problem of the waste polyurethane soles is solved, on the other hand, the raw materials are easy to obtain, the cost is low, the operation is simple, and emission of three wastes is avoided in the production, so as to protect the environment and reduce the production cost, and ensure that the economic benefit and the social benefit are considerable.

Owner:JINJIANG MINGAO TEXTILE SCI & TECH

Curing agent methylene diphenyl diisocyanate tripolymer and method for preparing same

ActiveCN102212182ASolve the problem that can not be three polyEasy to manufacturePolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsOrganic solventAdhesive

The invention discloses a curing agent, namely a methylene diphenyl diisocyanate (MDI) tripolymer and a method for preparing the same. The method comprises the following steps of: adding the MDI and an organic solvent into a reaction kettle, raising the temperature, dissolving the MDI, stirring uniformly, adding dehydrated polyol, and reacting for 1 to 6 hours at the temperature of between 40 and 90 DEG C to obtain modified MDI; reducing the temperature to 40 DEG C, dripping mixed solution of a trimerization catalyst and an organic solvent, reacting at the temperature of between 30 and 80 DEG C, and adding a polymerization inhibitor when the percentage of isocyanate group (NCO) reaches a preset value; and reducing the temperature to obtain the MDI tripolymer curing agent. The invention provides the method for preparing the tripolymer curing agent by using the MDI. The process is simple, the requirements of equipment are low, the content of the tripolymer is high, and the curing agent is well soluble in resins and can substitute a tolylene diisocyanate (TDI) tripolymer with similar performance. The curing agent is mainly used for being matched with two-component polyurethane coatings and main agents of adhesives, and can also be used for other fields.

Owner:J&H XIANGYANG CHEM

Slowly-recoverable polyurethane foam material

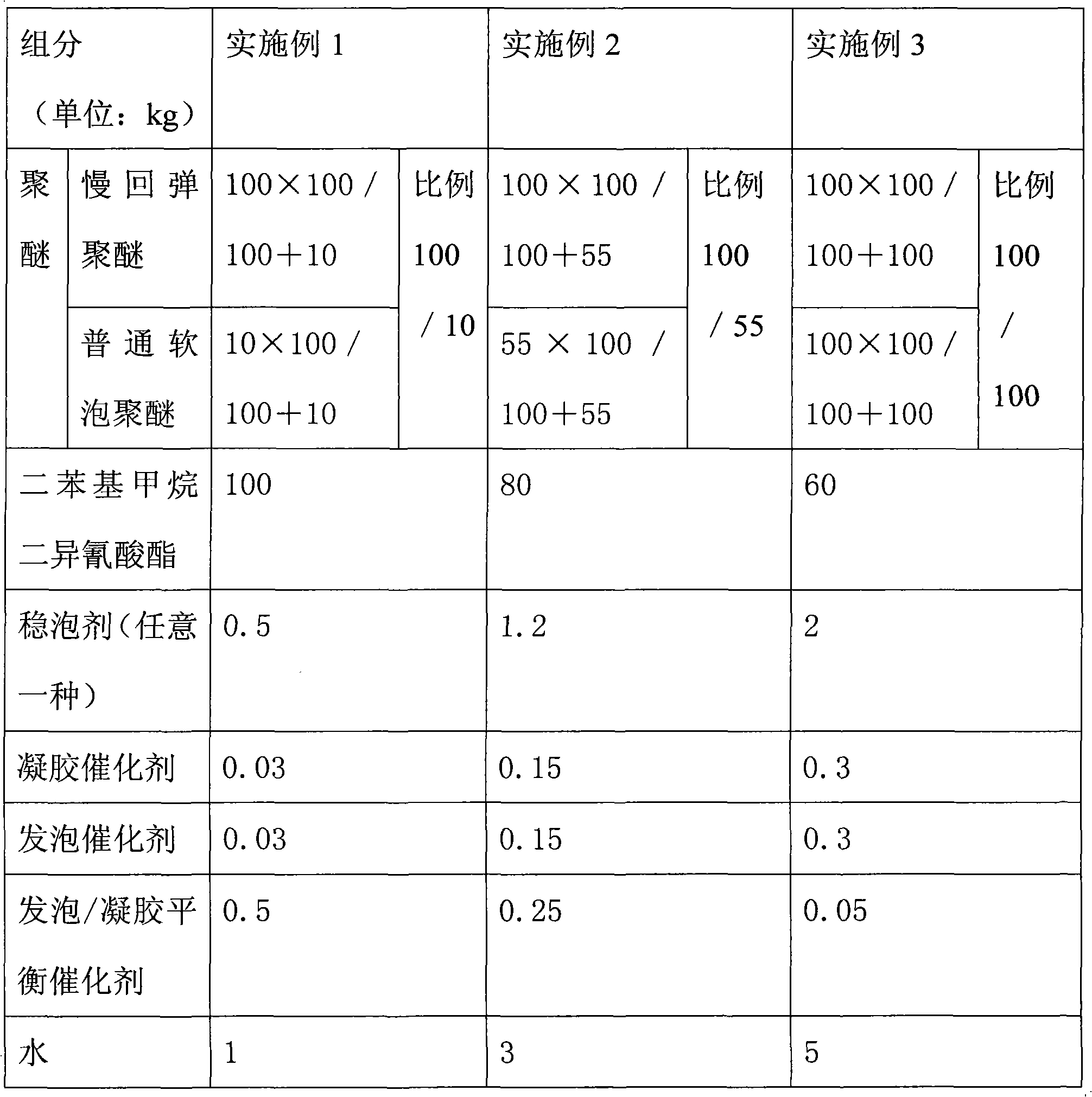

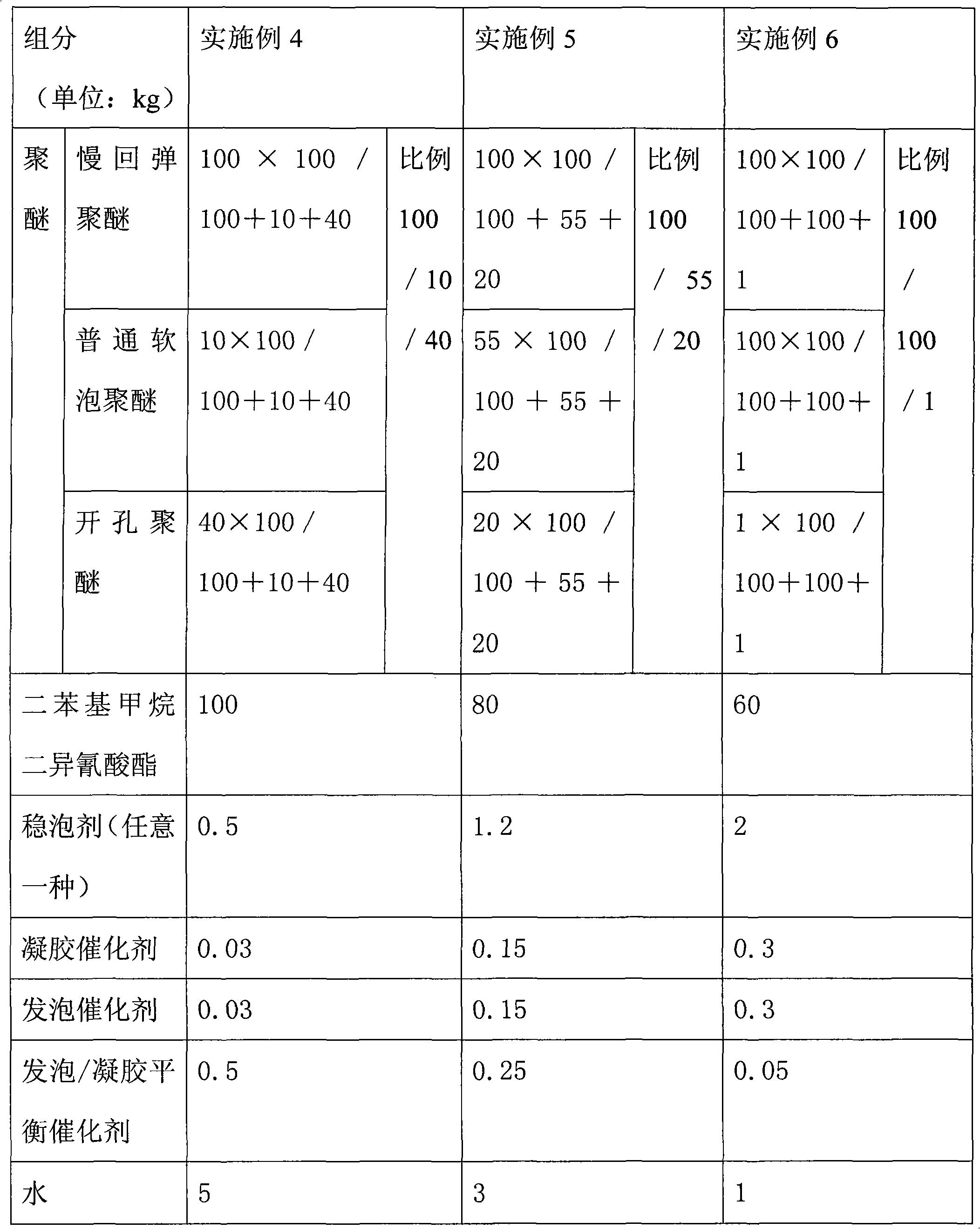

InactiveCN102115522AFeel goodWith decompression and anti-seismic functionHazardous substanceSynthetic materials

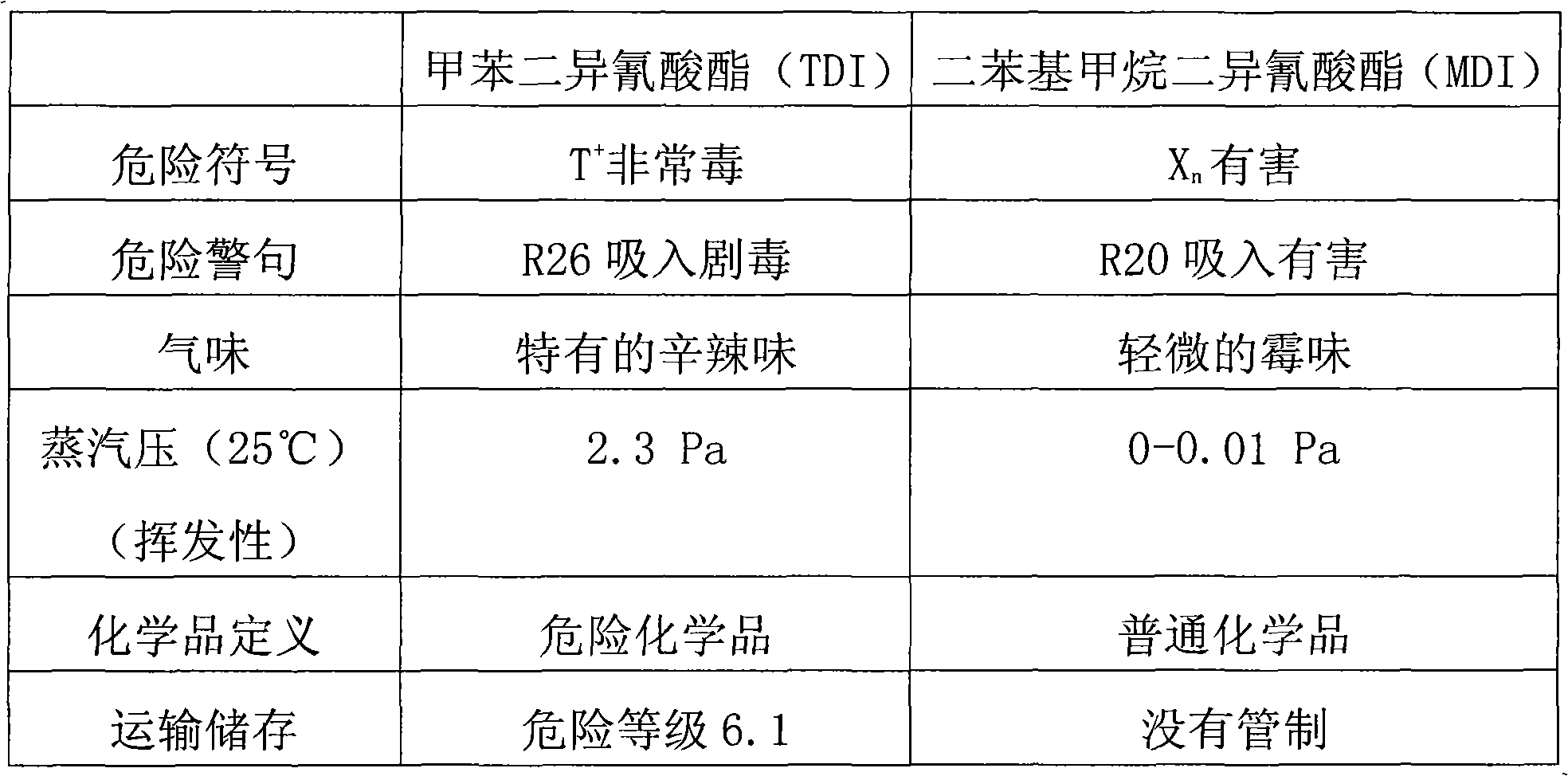

The invention relates to a high molecular synthetic material, in particular to a slowly-recoverable polyurethane foam material which is widely used as a filler. The slowly-recoverable polyurethane foam material comprises the following components in part by weight: 100 parts of polyether, 60 to 100 parts of diphenyl-methane-diisocyanate, 0.5 to 2 parts of foam stabilizer, 0.03 to 0.3 part of gel catalyst, 0.03 to 0.3 part of foam catalyst, 0.05 to 0.5 part of foam / gel equilibrium catalyst and 1 to 5 parts of water. The reaction activity of the diphenyl-methane-diisocyanate (MDI) is higher than that of toluene diisocynate (TDI), and the MDI can be fully reacted in the preparation process, so the final polyurethane product prepared from the MDI has a few residual harmful substances and nearly no toxicity, and also has properties of better handfeel, longer duration of slow recovery, better physical property, and higher flame retardancy.

Owner:上海人脊橡塑科技制品有限公司

Process for the production of polyurethane di(METH)acrylates

A process for the production of polyurethane di(meth)acrylates in which a diisocyanate component, a diol component and hydroxy-C2-C4-alkyl(meth)acrylate in the molar ratio x:(x-1):2 are reacted without solvent and without subsequent purification operations, wherein x means any desired value from 2 to 5, wherein 50 to 80 mol % of the diisocyanate component is formed by 1,6-hexane diisocyanate, and 20 to 50 mol % by one or two diisocyanates, each forming at least 10 mol % of the diisocyanate component and being selected from the group consisting of toluylene diisocyanate, diphenylmethane diisocyanate, dicyclohexylmethane diisocyanate, isophorone diisocyanate, trimethylhexane diisocyanate, cyclohexane diisocyanate, cyclohexanedimethylene diisocyanate and tetramethylenexylylene diisocyanate, wherein the mol % of the respective diisocyanates add up to 100 mol %, wherein the diol component comprises no more than four different diols, and 20 to 100 mol % of the diol component is formed by at least one linear aliphatic alpha,omega-C2-C12-diol, and 0 to 80 mol % by at least one (cyclo)aliphatic diol that is different from linear aliphatic alpha,omega-C2-C12-diols, wherein each diol of the diol component forms at least 10 mol % within the diol component, and wherein the mol % of the respective diols add up to 100 mol %.

Owner:EI DU PONT DE NEMOURS & CO

Modified polyurethane elastic curing agent and preparation method thereof

ActiveCN102153721AGood flexibilityHigh glass transition temperaturePolyurea/polyurethane coatingsDiolHardness

The invention discloses a modified polyurethane elastic curing agent. The modified polyurethane elastic curing agent is prepared from the following raw materials in part by weight: 38 to 45 parts of polyester resin, and 12 to 16 parts of toluene diisocynate, wherein the content of hydroxyl groups of the polyester resin is 7.2 to 7.8 percent. In the curing agent, the polyester resin which has highflexibility and contains 7.2 to 7.8 percent of hydroxyl groups is adopted; and long chain aliphatic diacids with high flexibility, aromatic diacids containing benzene ring structures and excessive long-chain diols are introduced into the structure of the polyester resin, so that the polyester resin also has the characteristics of high flexibility, high glass transition temperature, high hydroxyl content and high reaction activity. Therefore, the two-component polyurethane elastic curing agent synthesized by reacting the polyester resin and a toluene diisocynate monomer containing NCO groups has the advantages of high hardness, high flexibility, and high activity when reacting with the hydroxyl groups. The reaction activity and the hardness and flexibility of paint films can be synchronously met when a crosslinking reaction of the polyurethane curing agent and a paint component containing the hydroxyl groups are performed for film formation.

Owner:CARPOLY CHEM GRP

Environmental-protection type polyurethane paving material for sports ground

InactiveCN1470583AReduce pollutionGood for healthGround pavingsPolyurea/polyurethane coatingsBlack rubberTolylene Diisocyanate

The present invention discloses an environment-protecting type polyurethane paving material for sprorts ground. Said material is formed from component A, B and black rubber granules, which contains no high-toxicity tolylene diisocyanate and contains no heavy metal catalyst.

Owner:GUANGDONG PHARMA UNIV

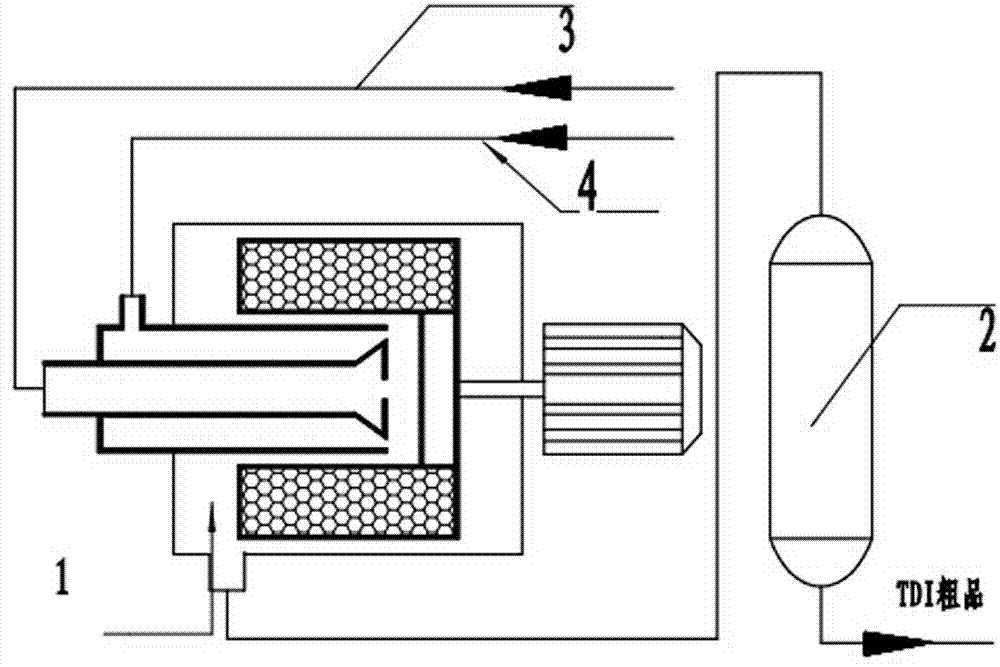

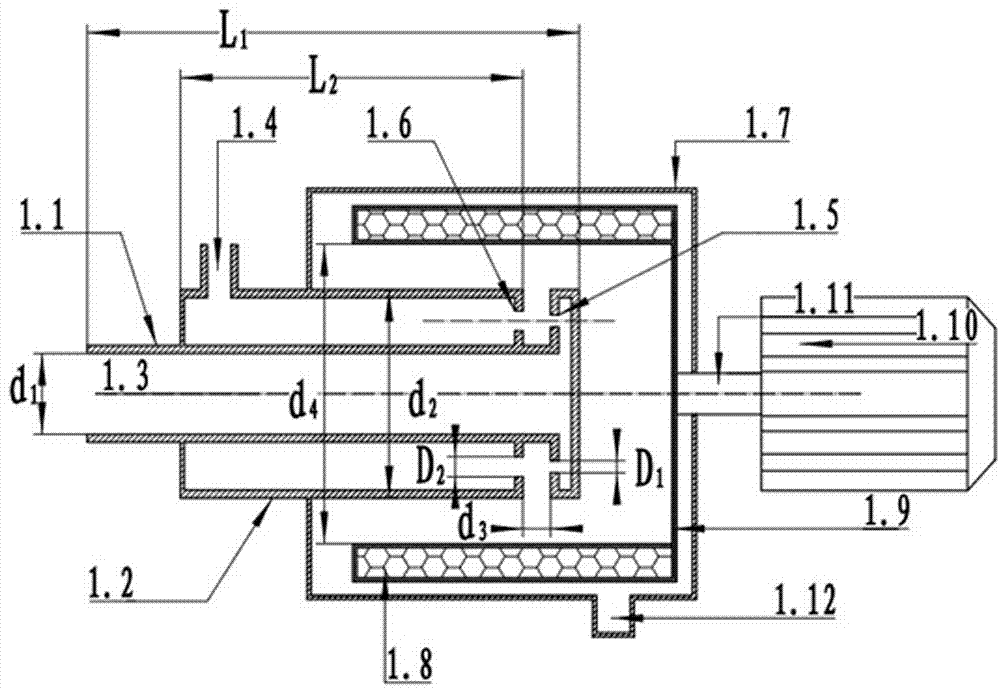

Device and technology for continuous preparation of toluene diisocyanate

ActiveCN104496851AThe result is obviousNo significant decrease in admixtureIsocyanic acid derivatives preparationOrganic compound preparationToluene diisocyanateToluenediamine

The invention belongs to the technical field of toluene diisocyanate production and discloses a device and technology for continuous preparation of toluene diisocyanate. The device and technology solves the problem that the existing toluene diisocyanate production technology has large difference of a material volume flow ratio, poor reaction selectivity, a low conversion rate and can cause reaction device fault. The device comprises a cold reactor and a heat reactor. The cold reactor comprises an unlimited impinging stream structure and a hypergravity structure. The unlimited impinging stream structure comprises a main material feeding pipe and a sleeve pipe, and the pipes have different diameters. The technology comprises that a phosgene inert solvent and a toluenediamine inert solvent solution are oppositely collided by the unlimited impinging stream structure so that macroscopic mixing and preliminary microscopic mixing are fast finished, and the mixture is fed into a rotating filler, stays for some time, then is fed into the heat reactor and undergoes a reaction to produce a toluene diisocyanate TDI crude product. The device and technology realize basically complete toluene diisocyanate reaction, prevent urea substance generation, effectively prevent pipe and reactor blocking and improve toluene diisocyanate production efficiency.

Owner:ZHONGBEI UNIV +2

Water solution treatment process of polyurethane elastomer to make plastic track

InactiveCN1673305ALow costPolyureas/polyurethane adhesivesGround pavingsPolyurethane elastomerSolution treatment

The making process of plastic track includes the following steps: reaction between dihydroxy polyether polyol and / or trihydroxy polyether polyol and toluene diisolcyanate to produce component A; preparing component B with 3, 3-dichloro-4, 4-amino diphenyl methane and / or 4, 4-methylene-bisdiethyl diphenyl, bis-6-methyl diphenylamine, tetrahydroxyamino polyether polyol, stuffing, plasticizer, nanometer base material, etc.; mixing component A, component B, catalyst and water solution to form the water solution processed polyurethane elastomer adhesive; and mixing the water solution processed polyurethane elastomer adhesive, waste tyre grain or other rubber grain and stuffing to form mixture for the plastic track. The plastic track has low cost.

Owner:广州大洋元亨化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com