Patents

Literature

2973results about "Pigment treatment with organosilicon compounds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

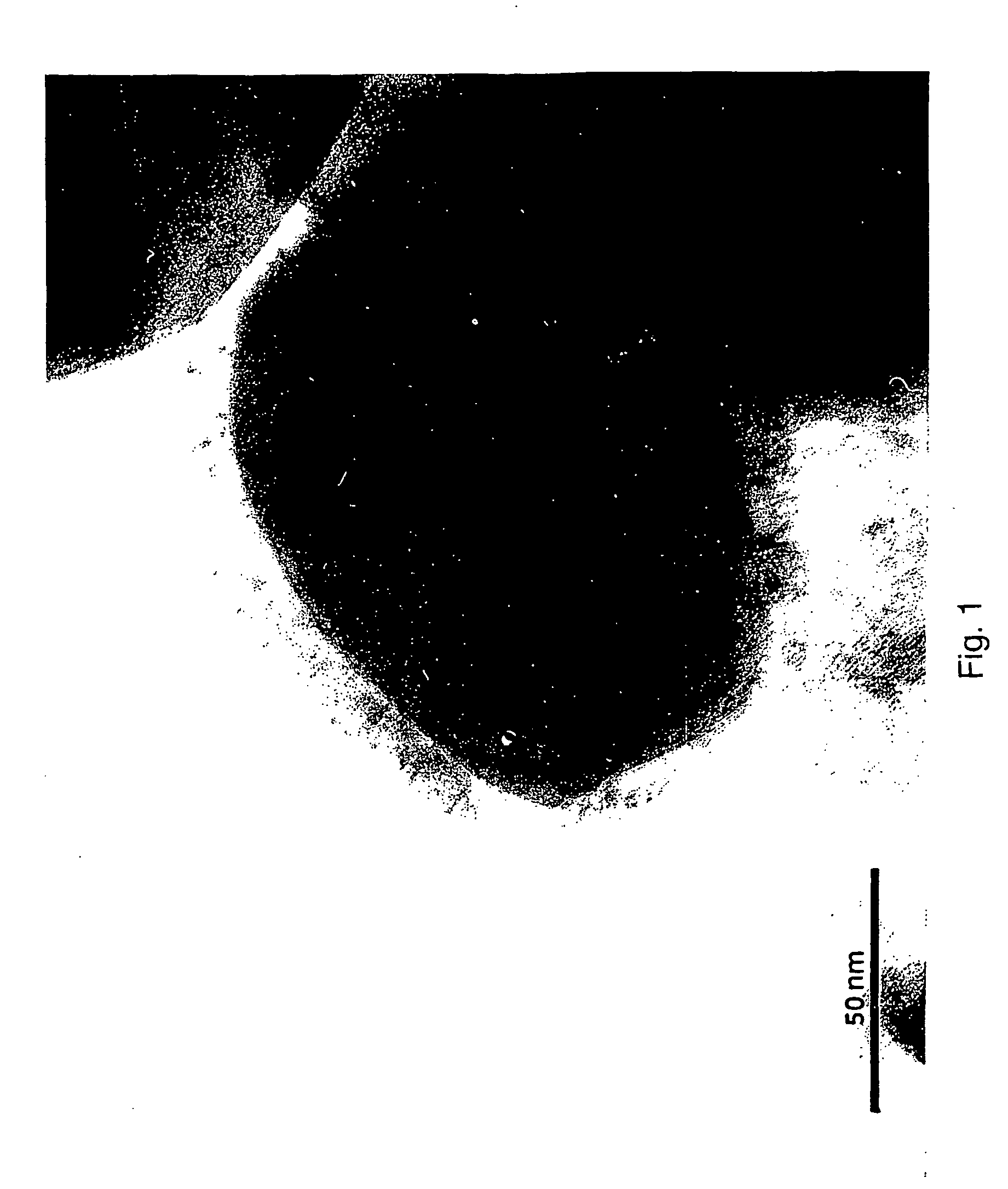

Post-deposition encapsulation of nanostructures: compositions, devices and systems incorporating same

ActiveUS20060040103A1Reduce and prevent other type of transmissionReduce probabilityMaterial nanotechnologyBoxes/cartons making machineryNanostructureNanometre

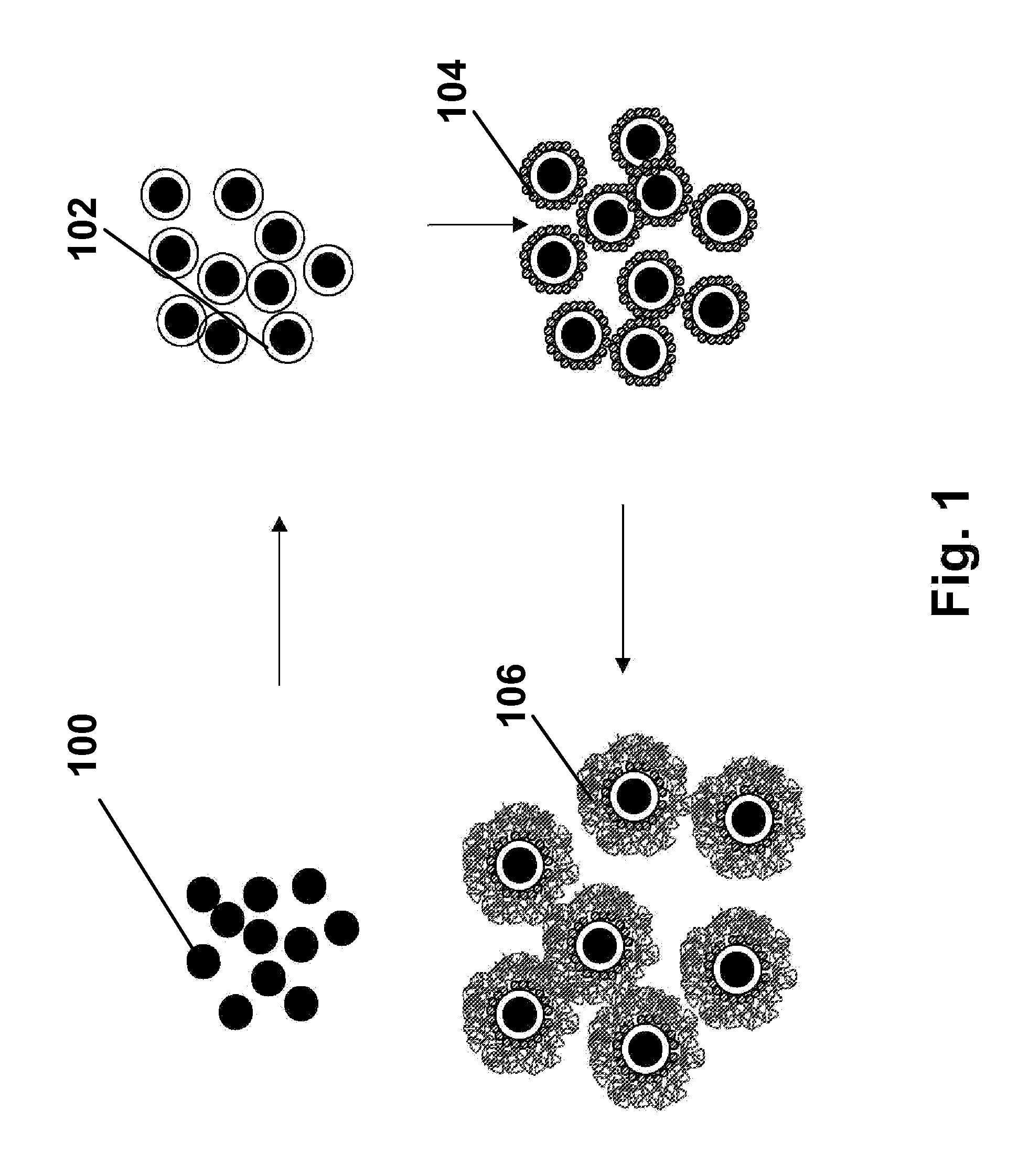

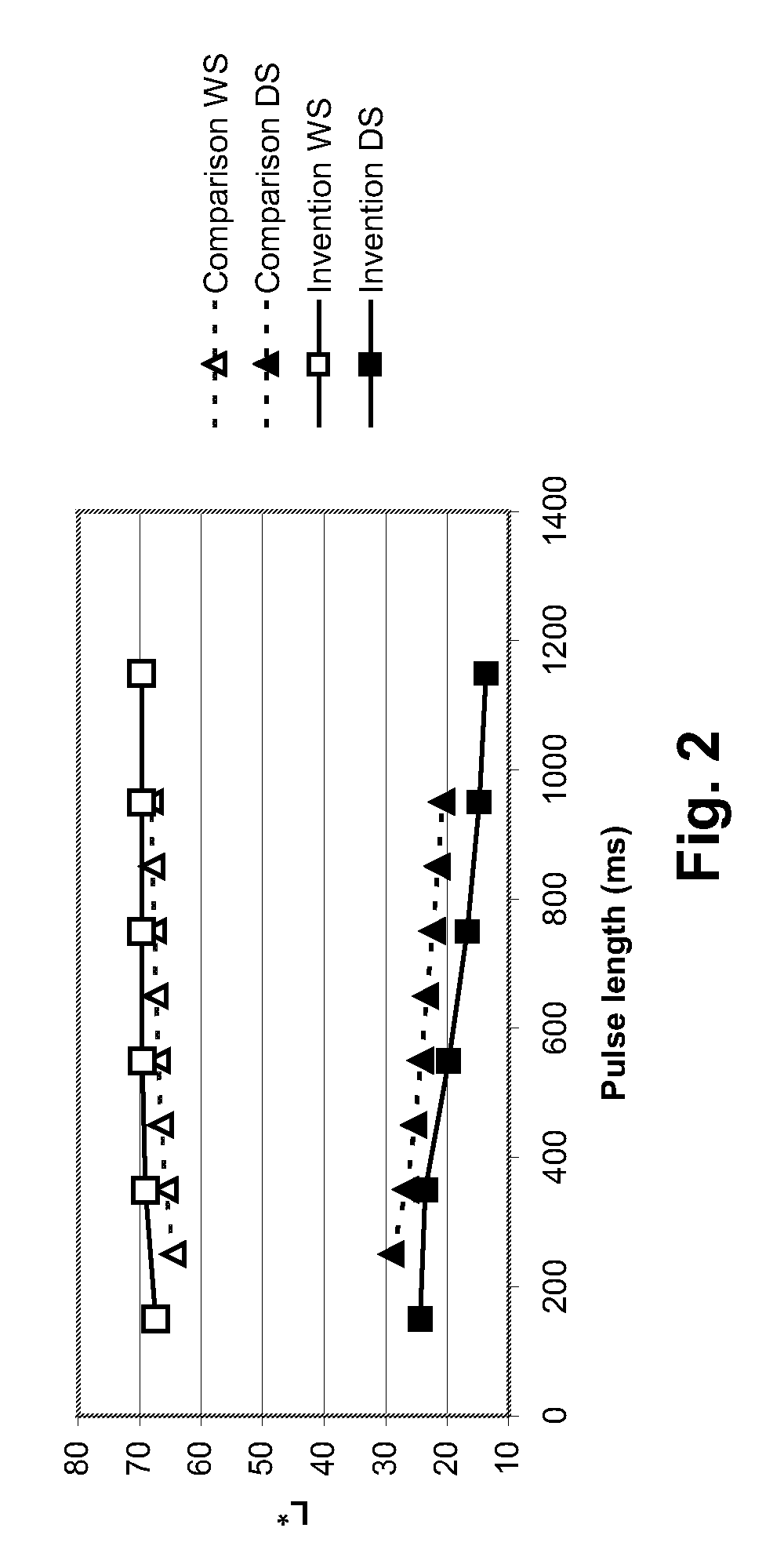

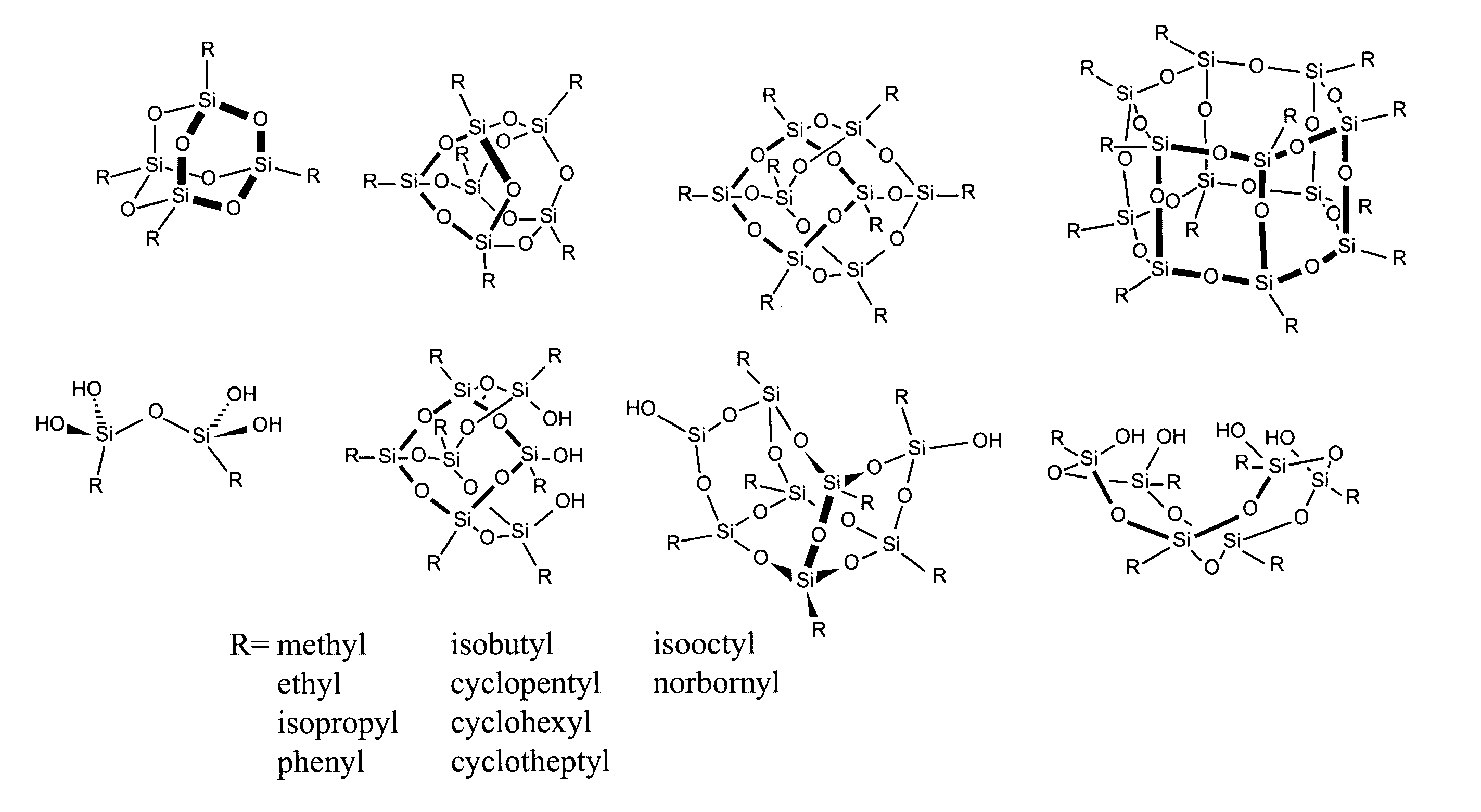

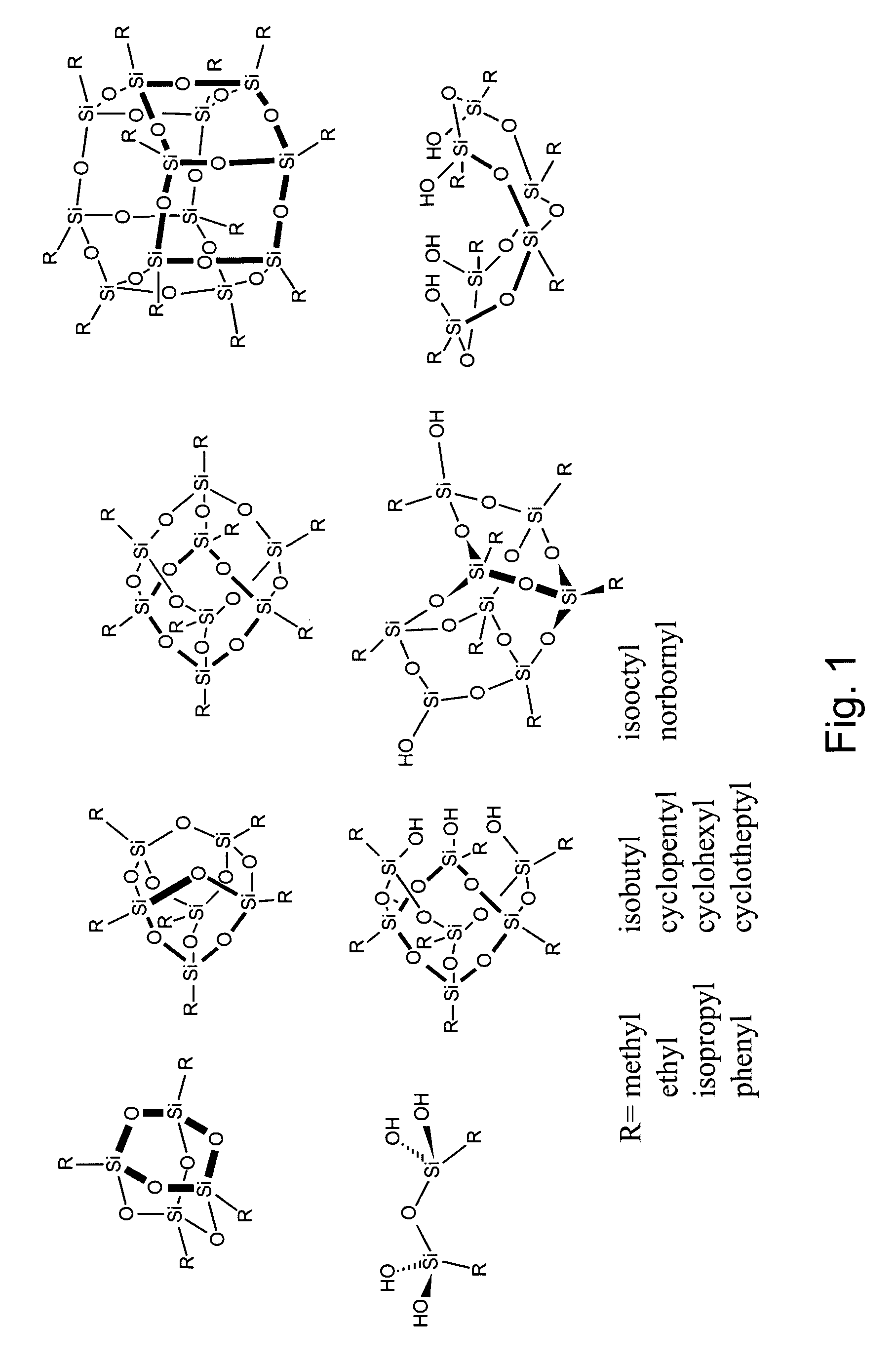

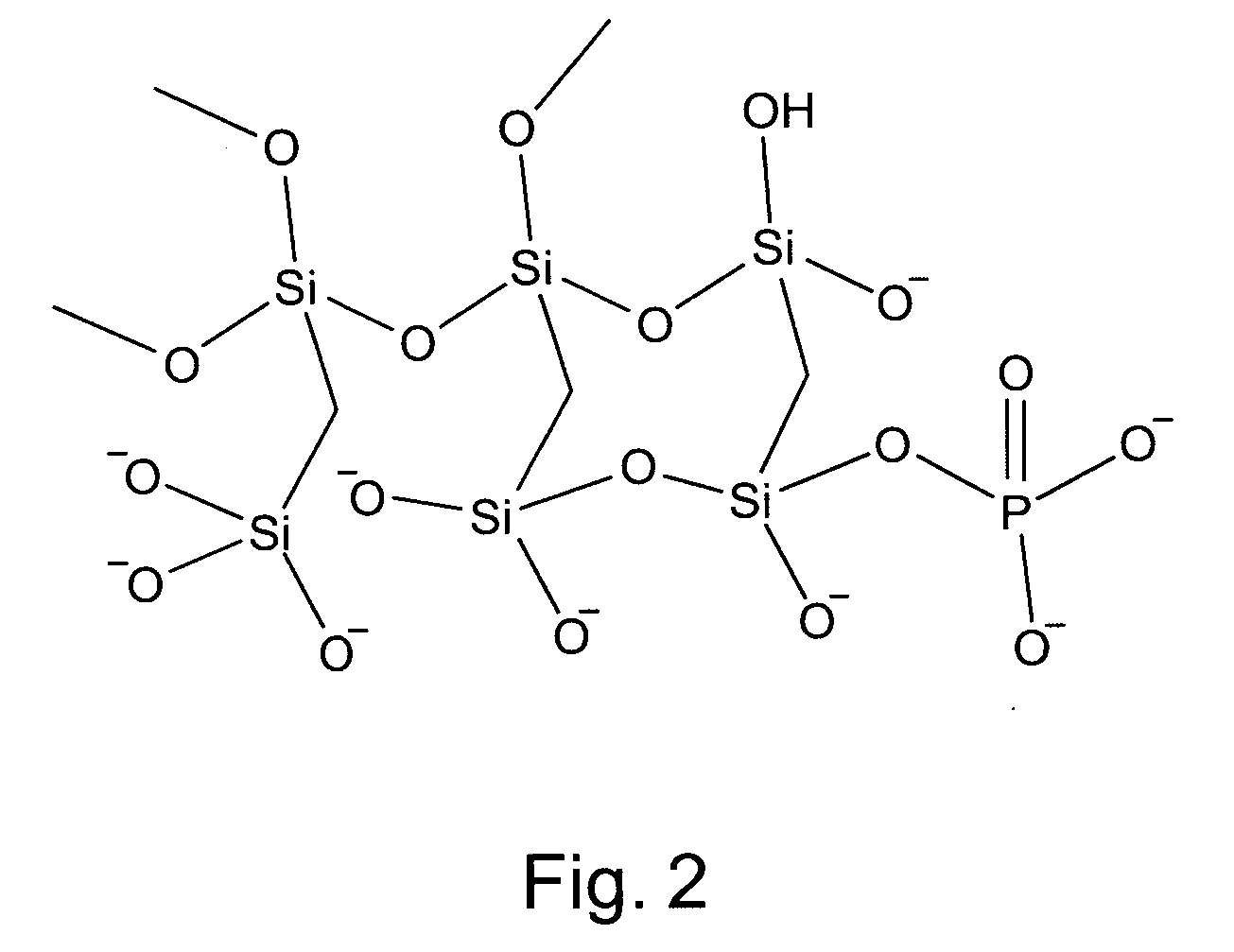

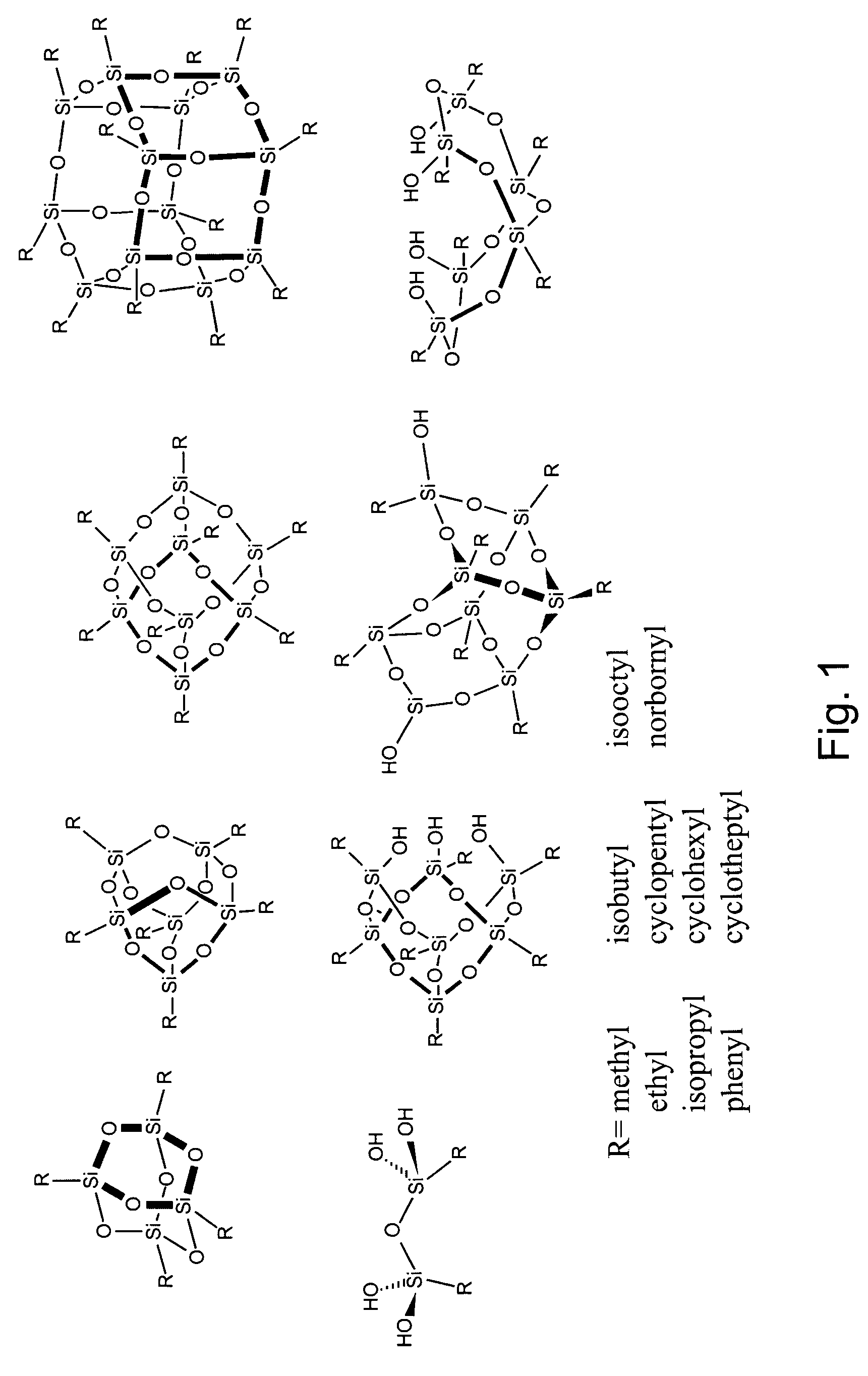

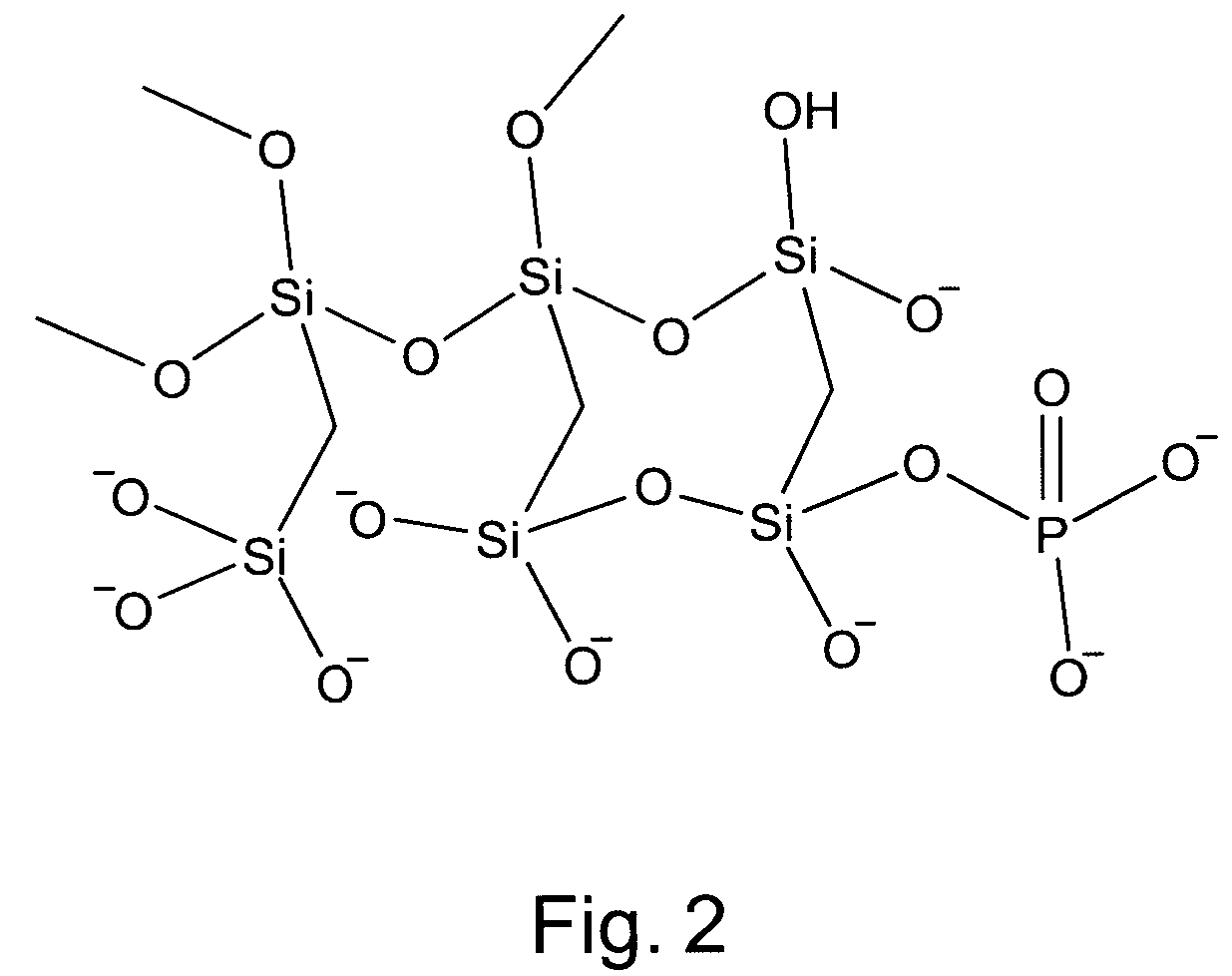

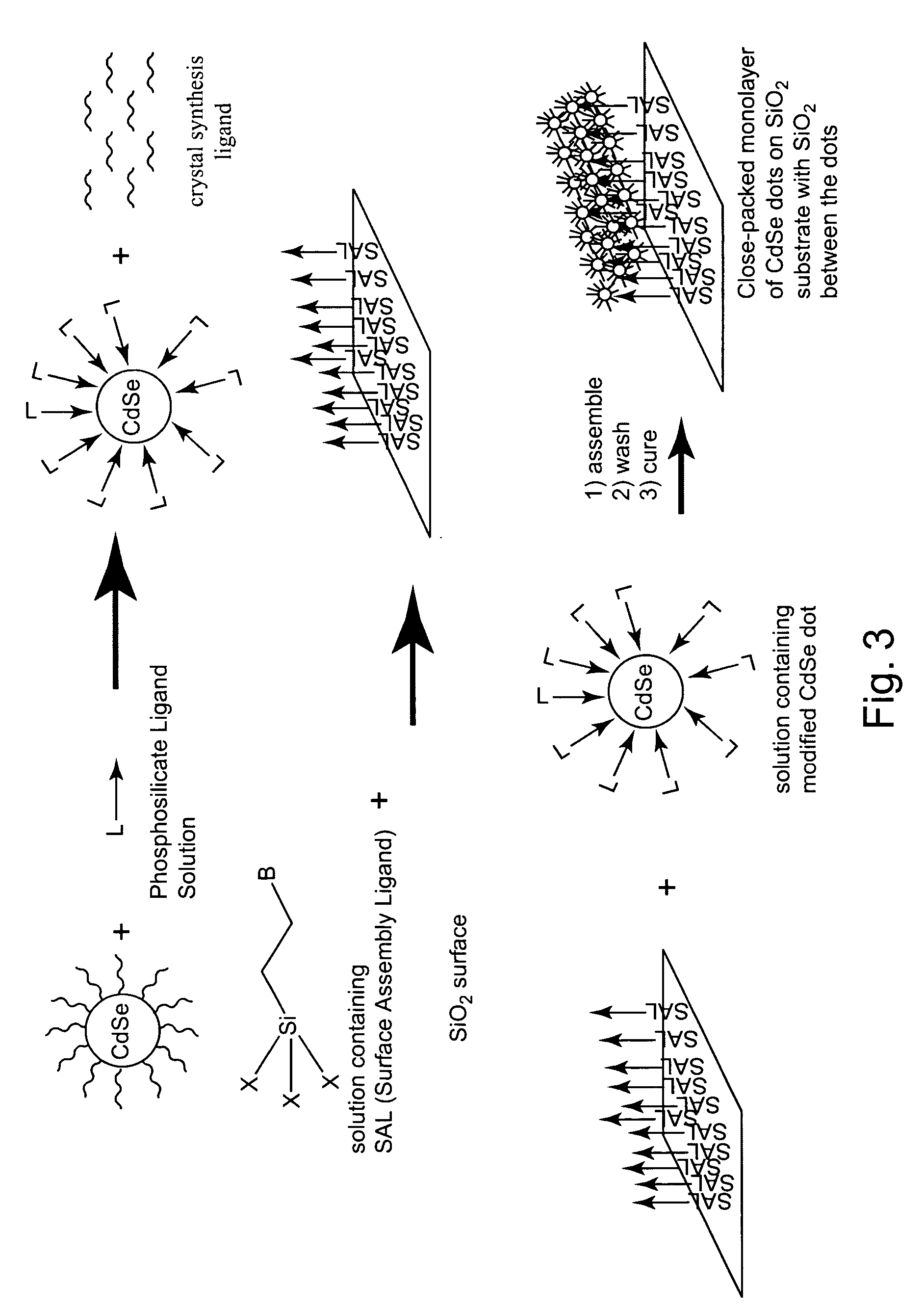

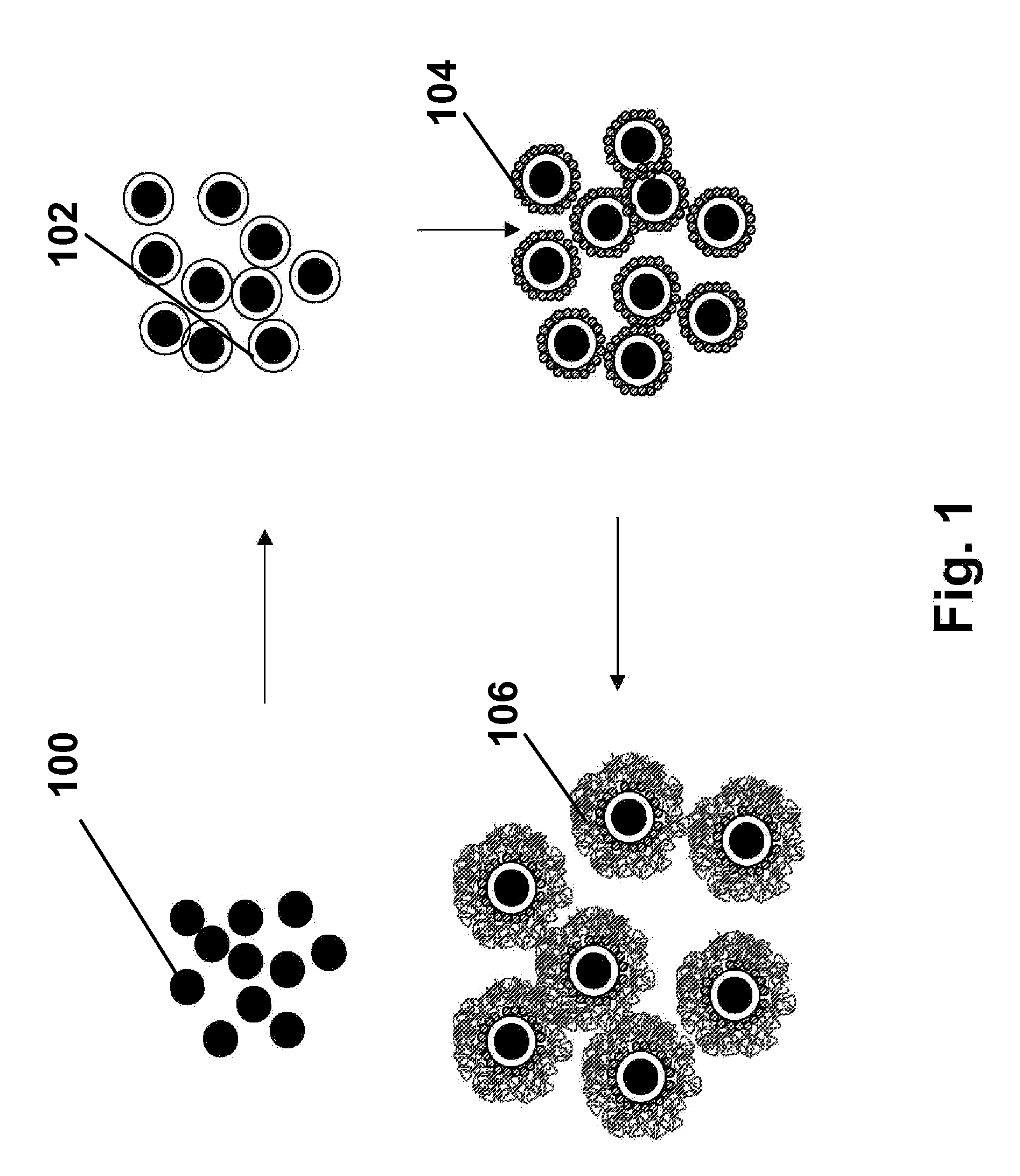

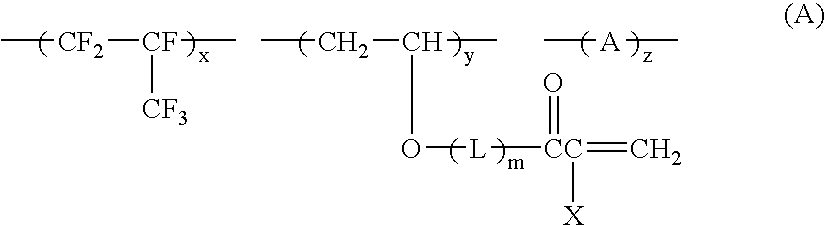

Ligand compositions for use in preparing discrete coated nanostructures are provided, as well as the coated nanostructures themselves and devices incorporating same. Methods for post-deposition shell formation on a nanostructure and for reversibly modifying nanostructures are also provided. The ligands and coated nanostructures of the present invention are particularly useful for close packed nanostructure compositions, which can have improved quantum confinement and / or reduced cross-talk between nanostructures.

Owner:WODEN TECH INC

Post-deposition encapsulation of nanostructures: compositions, devices and systems incorporating same

ActiveUS7267875B2Reduce and prevent other type of transmissionReduce probabilityMaterial nanotechnologyBoxes/cartons making machineryNanostructureNanometre

Ligand compositions for use in preparing discrete coated nanostructures are provided, as well as the coated nanostructures themselves and devices incorporating same. Methods for post-deposition shell formation on a nanostructure and for reversibly modifying nanostructures are also provided. The ligands and coated nanostructures of the present invention are particularly useful for close packed nanostructure compositions, which can have improved quantum confinement and / or reduced cross-talk between nanostructures.

Owner:WODEN TECH INC

Electrophoretic particles, and processes for the production thereof

InactiveUS20050000813A1Volume/mass flow measurementFluid pressure measurement by electric/magnetic elementsElectrophoresisCopper chromite

Owner:E INK CORPORATION

Preparation method of silica aerogel aqueous heat-insulating coating

InactiveCN102719129ADoes not require surface hydrophobic modificationWon't collapseCoatingsSilicon compoundsMicrosphereAlkoxy group

The invention discloses a preparation method of a silica aerogel aqueous heat-insulating coating, and is characterized in that: prepared SiO2 microspheres are hydrophobic inside and hydrophilic outside; and the aerogel microspheres can be added into an aqueous coating carrier to prepare a good heat-insulating material. The main preparation method comprises the following steps of: before drying the prepared wet gel microspheres, performing surface modification by using an organic silane or an organic chlorosilane, so that the prepared wet gel microspheres are hydrophobic by grafting a large number of alkoxy groups or alkyl groups on the surfaces thereof, or directly preparing the hydrophobic wet gel microspheres; performing surface modification on the microspheres by using a hydrophilic silane coupling agent, and drying to obtain the SiO2 microspheres which are hydrophobic inside and hydrophilic outside; and adding the prepared microspheres into an aqueous coating for preparing the aqueous heat-insulating coating.

Owner:HENAN UNIVERSITY OF TECHNOLOGY +1

Radiation-curable metal particles and curable resin compositions comprising these particles

InactiveUS6521677B2High refractive indexHigh hardnessMaterial nanotechnologyConductive materialPolymer scienceMeth-

Provided is a liquid curable resin composition which can produce transparent cured products with a high refractive index, high hardness, and superior abrasion resistance, and which can be suitably used as a coating material. The liquid curable resin composition comprises: (A) a poly-functional (meth)acrylic compound having at least three (meth) acryloyl groups in the molecule; (B) a reaction product obtained by the reaction of a compound having a polymerizable unsaturated group and alkoxysilyl group in the molecule and particles metal oxide, the metals being preferably selected from the group consisting of zirconium, antimony, zinc, tin, cerium, and titanium; and (C) a radiation polymerization initiator.

Owner:JSR CORPORATIOON

Silica coated carbon blacks

InactiveUS6197274B1Alkali metal halidesPigment treatment with organosilicon compoundsElastomerOrganic group

Silica coated carbon blacks are disclosed and can be prepared by coating a fine dispersion of carbon black, such as a carbon black having an attached organic group(s). Compositions and articles of manufacture, including elastomeric compositions, containing such carbon black are also disclosed.

Owner:CABOT CORP

Preparing method of coated aluminium powder pigment

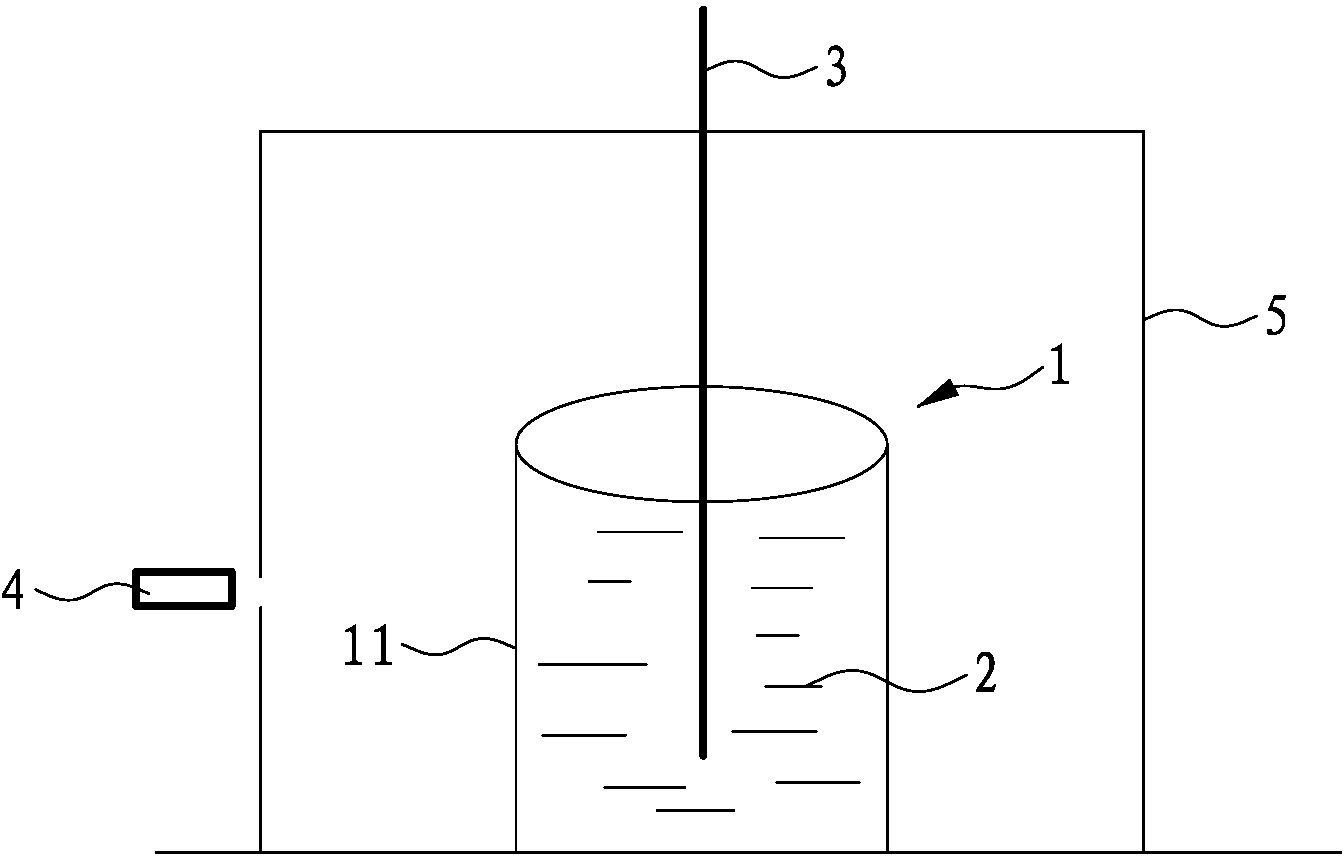

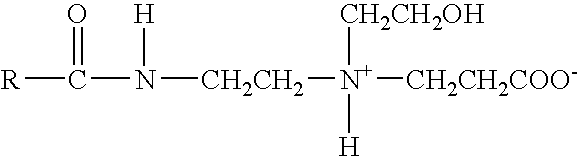

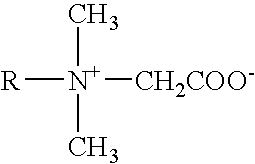

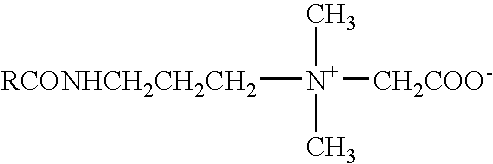

InactiveCN1986648AGood storage stabilityEasy to usePigment treatment with organosilicon compoundsWater bathsAlcohol

The present invention is coated aluminum powder pigment and its preparation process. The coated aluminum powder pigment is prepared through the following steps: mixing aluminum powder pigment with alcohol solvent; adding organosiloxane, water and acid catalyst, and heating in water bath to react to obtain organosiloxane coated aluminum powder pigment; heating the reaction system to 65-120 deg.c, adding polymer monomer and initiator to react to obtain organosiloxane and polymer coated aluminum powder pigment; and cooling, filtering, washing and drying to obtain the coated aluminum powder pigment product. The coated aluminum powder pigment with two coating layers has excellent metal luster and high acid and alkali resistance, and is suitable for water paint.

Owner:SOUTH CHINA UNIV OF TECH

Silane-modified white carbon black-carbon black composite filling and preparation method thereof

ActiveCN101798473AImprove glue burn resistanceGood processing characteristicsPigment treatment with organosilicon compoundsRolling resistanceGas phase

The invention discloses a silane-modified white carbon black-carbon black composite filling and a preparation method thereof. The method is characterized in comprising the following steps of: (1) adding white carbon black which is prepared by means of precipitation and white carbon black which is prepared by means of gas phase into a high-speed mixer according to the weight ratio of 3:1-3:2, slowly and evenly adding silane polysulfide in a spraying way, and gradually heating up at 100-120 DEG C to promote the surface modification reaction to be thoroughly performed; and (2) adding carbon black and mixing for 60-180min according to the weight ratio of the carbon black to the white carbon black which is prepared by means of gas phase and the white carbon black which is prepared by means of precipitation of 1:5-1:10 under the condition of continuous stirring and temperature persevering, and cooling by means of temperature reducing to obtain the silane-modified white carbon black-carbon black composite filling. The silane-modified white carbon black-carbon black composite filling which is prepared by the method improves the dispersibility of the white carbon black which is prepared by means of gas phase in rubber, reduces the charging time of a production field, obviously improves the operation environment, is used for the prescription of a tread rubber of a tire, can obviously reduce the rolling resistance of the tire, and saves the gasoline.

Owner:HUBEI HUIFU NANOMATERIAL CO LTD

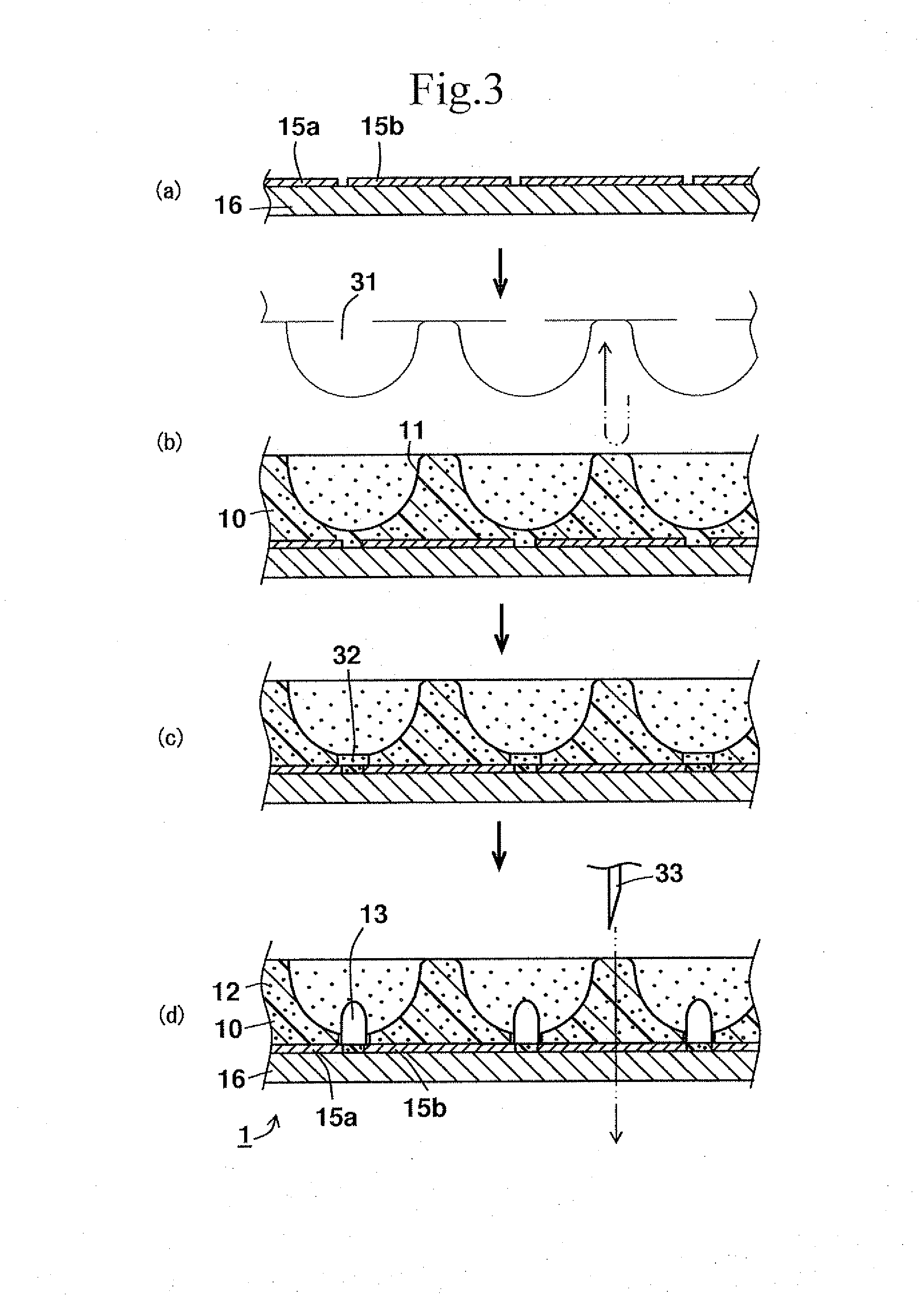

Silicone resin reflective substrate, manufacturing method for same, and base material composition used in reflective substrate

ActiveUS20130011617A1Low viscosityImprove adhesionDiffusing elementsSolid-state devicesCross-linkInfra-red color

A versatile silicone resin reflective substrate which exhibits high reflectance of high luminance light from an LED light source over a wide wavelength from short wavelengths of approximately 340-500 nm, which include wavelengths from 380-400 nm near lower limit of the visible region, to longer wavelength in the infra-red region. The silicone resin reflective substrate has a reflective layer which contains a white inorganic filler powder dispersed in a three-dimensional cross linked silicone resin, the inorganic filler powder having a high reflective index than the silicone resin. The reflective layer is formed on a support body as a film, a solid, or a sheet. The silicone resin reflective substrate can be easily formed as a wiring substrate, a packaging case or the like, and can be manufactured at low cost and a high rate of production.

Owner:ASAHI RUBBER

Process of making hydrophobic metal oxide nanoparticles

InactiveUS7081234B1Uniform coatingSulfur compoundsCopper oxides/halidesMetal oxide nanoparticlesTransport layer

A process of treating metal oxide nanoparticles that includes mixing metal oxide nanoparticles, a solvent, and a surface treatment agent that is preferably a silane or siloxane is described. The treated metal oxide nanoparticles are rendered hydrophobic by the surface treatment agent being surface attached thereto, and are preferably dispersed in a hydrophobic aromatic polymer binder of a charge transport layer of a photoreceptor, whereby π—π interactions can be formed between the organic moieties on the surface of the nanoparticles and the aromatic components of the binder polymer to achieve a stable dispersion of the nanoparticles in the polymer that is substantially free of large sized agglomerations.

Owner:XEROX CORP

Free flowing filler composition based on organofunctional silane

ActiveUS20070228322A1Improve performanceLong scorch timeSilicon organic compoundsOther chemical processesElastomerThiol

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

Method for preparing aminosilane coupling agent modifying ammonium polyphosphate

InactiveCN101235221AHigh flame retardant efficiencyReduce solubilityFireproof paintsFibre treatmentSolubilityPolyolefin

The invention discloses a preparation process of modifying ammonium polyphosphate with amino silane coupling agent, relating to the flame-retardant technology in chemical field. The invention provides a surface organic modified technology which can significantly reduce the water-solubility of ammonium polyphosphate, increases the compatibility of ammonium polyphosphate expansion flame-proof macromolecule material and the flame-proof efficiency, aiming to the problems existing the current ammonium polyphosphate flame-retardant that the current ammonium polyphosphate flame-retardant has higher dissolvability in water, and serious mechanical loss after applied on flame-proof plastic. The invention is conducted through two steps that firstly mixing amino silane coupling agent with deionized water according to weight ratio to hydrolyze, and secondly conducting surface organic modifying processing for ammonium polyphosphate (II type) with hydrolyzed amino silane coupling agent, which makes the dissolvability of II type ammonium polyphosphate in water be reduced to 0.43g / 100mL H2O from 1.101g / 100mL H2O, and respectively increases elongation at break and tension strength by 39.4% and 8.0% through applying modified ammonium polyphosphate on expansion flame-proof polypropylene. The modified ammonium polyphosphate can be extensively applied on the expansion flame-proof of polyolefins plastic, textile, lumber, paper and painting.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

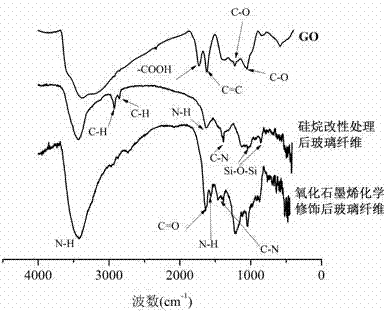

Method for chemically modifying inorganic filler with graphene oxide, product and application

InactiveCN103788413AImprove adhesionHigh mechanical strengthPigment treatment with organosilicon compoundsPigment physical treatmentEpoxySilanes

The invention discloses a method for chemically modifying inorganic filler with graphene oxide and a product. The method comprises the following steps: performing surface hydroxylation treatment and silane coupling agent treatment on the inorganic filler; maintaining the pH of a graphene oxide solution at 5.8-6.0 with an MES buffer solution; sequentially adding EDC and NHS, and performing ultrasonic treatment for 1-3 hours; adding the treated inorganic filler, and performing an amidation reaction at room temperature; and after the reaction, filtering, washing and drying to obtain the graphene oxide modified inorganic filler. The invention also discloses a method for preparing an inorganic filler / epoxy resin composite by use of the product. The process flow of the method disclosed by the invention is simple and environmentally friendly; the GO is connected to the surface of the inorganic filler by a chemical modification process, and the firm covalent bond combination between the GO and inorganic particles is generated, so that the interface adhesiveness and mechanical strength between the inorganic filler and the polymer are enhanced, and a new idea is provided to the modification of an inorganic filler surface and the preparation of a high-performance composite.

Owner:UNIV OF JINAN

Fine inorganic oxide dispersion, coating composition, optical film, antireflection film, polarizing plate, and image display device

InactiveUS20050154086A1Improve dispersion stabilityImprove visibilityPigment treatment with organosilicon compoundsOrganic solventAlcohol

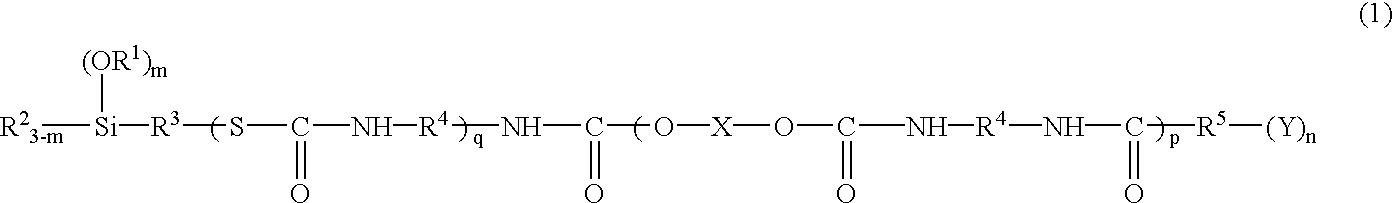

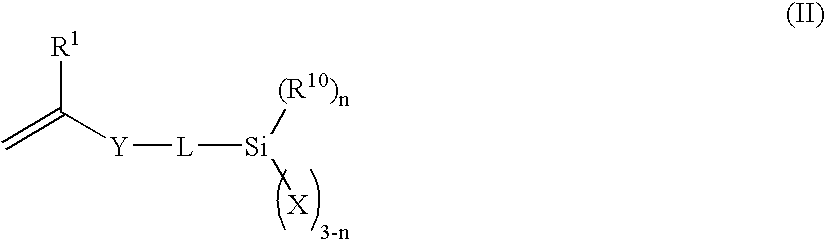

An inorganic oxide dispersion containing an organic solvent, and inorganic oxide particles surface-treated with at least one of a hydrolyzate and a partial condensate of an organosilane compound represented by formula (I), the inorganic oxide particles being dispersed in the organic solvent: (R10)m—Si(X)4−m (I) as defined herein, the surface treatment of the inorganic oxide particles being carried out in a presence of at least one of: (a) an acid catalyst; and (b) a metal chelate compound having Zr, Ti or Al as a center metal and at least one of an alcohol represented by formula: R3OH in which R3 represents an allyl group having 1 to 10 carbon atoms, and a compound represented by formula: R4COCH2COR5 as defined herein, as a ligand.

Owner:FUJIFILM CORP

Preparation method of double-layer coated water-based aluminum pigment

The invention discloses a preparation method of a double-layer coated water-based aluminum pigment, which comprises the following steps: coating ethyl orthosilicate on lamellar aluminum powder to form a single-layer coated aluminum pigment; and under the action of an azo initiator, coating a hydrophilic ester monomer on the single-layer coated aluminum pigment to form the double-layer coated water-based aluminum pigment. The double-layer coated water-based aluminum pigment prepared by the method provided by the invention has the advantages of high coating tightness and favorable water resistance, and the coating layer can not be easily damaged. The organic layer on the outer layer is easily compatible with high-molecular rein in the paint, has favorable dispersity in the paint, and is mainly used in various water-based paints and water-based inks.

Owner:HEFEI SUNRISE PIGMENTS

Enhanced retention capabilities through methods comprising surface treatment of functional particulate carrier materials, and functional particulate carrier materials made therefrom

InactiveUS20100239679A1Improve retentionIncreasing retention factorBiocideCosmetic preparationsParticulatesPreservative

Functional particulate carrier materials with enhanced retention capabilities are described. The materials comprise at least one functional particulate carrier material subjected to at least one surface treatment, and at least one active ingredient. The at least one surface treatment may be at least one physical surface treatment and / or at least one chemical surface treatment with at least one surface treating agent. The at least one active ingredient may be a biocide, a fungicide, a mildewcide, an antibiotic, an insecticide, a preservative, or an antimicrobial agent. Methods for enhancing the performance of plastics and liquid-based media, for example, coatings and paints, are also described by increasing the retention factors of active ingredients in those plastics and media through surface treatment of functional particulate carrier materials.

Owner:IMERYS FILTRATION MINERALS

Graphene-containing insulated radiating composition and preparation and application thereof

ActiveCN103804942AHigh thermal conductivityImprove mechanical propertiesCoatingsPigment treatment with organosilicon compoundsHeat conductingGraphene

The invention discloses a graphene-containing insulated radiating composition and preparation and application thereof. The composition comprises the components of silica-coating graphene, insulated heat-conducting filler, a surface treating agent, and a function additive. The preparation method comprises the following steps of: hydrolyzing ethyl silicate on the graphene surface by the sol-gel method to obtain graphene coated with a silica film on the surface; adding the surface treating agent to a mixture of the insulated heat-conducting filler and modified graphene; uniformly agitating; then adding the function additive; and uniformly dispersing to obtain the insulated radiating composition. The composition has the advantages that the graphene is processed by insulating and coating, and the insulated heat-conducting filler and additive of other forms are coordinately added, thus the composition shows high radiating improvement effect in the plastic cement and coating fields; and the composition can be widely applied to a heating element and a radiating facility of various electronic products and electrical equipment, and can greatly improve the radiating effect as well as prolong the service life of devices.

Owner:XIAMEN KNANO GRAPHENE TECH CORP

Treated filler and process for producing

The present invention is related to treated filler and processes for producing said treated filler. Untreated filler slurry can be treated with a treating material and, optionally, a coupling material and then subjected to conventional drying method(s), to produce the treated filler of the invention. Treated filler has a wide variety of applications including but not limited to battery separators and rubber compositions such as tires.

Owner:PPG IND OHIO INC

Methods of modifying particulate surfaces to affect acidic sites thereon

ActiveUS20070114030A1Reduce probabilityCreate and enhance fractureFluid removalFlushingParticulatesSurface modification

Methods comprising: providing a treatment fluid that comprises a base fluid and a least a plurality of coated particulates, the coated particulates having been treated with a surface modification agent and coated with a hydrolysable coating; placing the treatment fluid into a subterranean formation via a well bore. Also provided are methods comprising: treating a particulate with a surface modification agent; coating the particulate with a hydrolysable coating that has an initial degradation rate to produce a coated particulate; placing the particulate in a subterranean formation; and allowing the hydrolysable coating to degrade at a second degradation rate that is slower than its initial degradation rate.

Owner:HALLIBURTON ENERGY SERVICES INC

Inorganic powder organic surface modifying method

ActiveCN101134852AImprove performanceAchieve chemical modification of organic surfacesPigment treatment with organosilicon compoundsOrganic solventOil water

The present invention provides process of organizing the surface to modify inorganic powder, and during the process, inorganic superfine particles are dispersed homogeneously in non-polar organic solvent and have the surfaces well organization modified. The process includes preparing water solution for dispersing inorganic powder, dissolving organic surface modifier, organic surface modifying, solid-liquid separating and washing, and post-treatment. The process features that oil-water interface and phase transfer are utilized for organic surface modification of inorganic superfine powder in non-polar organic solvent.

Owner:江苏河海纳米科技股份有限公司 +1

Silane-modified oxidic or siliceous filler, process for its production and its use

InactiveUS20030200900A1Avoid problemsCosmetic preparationsSilicon organic compoundsPolymer scienceSilanes

Silane-modified oxidic or siliceous filler with a bead fraction below 75 mum of less than 15 wt. % and a median particle size distribution between of 150 to 500 mum, which is produced by the reaction of at least one microbeaded or microgranular, oxidic or siliceous filler in a compressed gas with at least one silane. The silane-modified oxidic or siliceous fillers are used in rubber compounds.

Owner:EVONIK DEGUSSA GMBH

Surface modification of silica in an aqueous environment

The present invention is drawn to a method of treating silica in an aqueous environment. The method can comprise steps of dispersing silica particulates in an aqueous environment to form an aqueous dispersion; reversing the net charge of a surface of the silica particulates from negative to positive using a surface activating agent, thereby forming surface-activated silica particulates dispersed in the water; and contacting the surface-activated silica particulates with organosilane reagents to form reagent-modified and surface-activated silica particulates.

Owner:HEWLETT PACKARD DEV CO LP

Silane-modified oxidic or siliceous filler, process for its production and its use

Silane-modified oxidic or siliceous filler with a bead fraction below 75 μm of less than 15 wt. % and a median particle size distribution between of 150 to 500 μm, which is produced by the reaction of at least one microbeaded or microgranular, oxidic or siliceous filler in a compressed gas with at least one silane. The silane-modified oxidic or siliceous fillers are used in rubber compounds.

Owner:EVONIK DEGUSSA GMBH

Method for producing special rutile type titanium white powder for power coating

ActiveCN101880479ALattice stabilizationGood dispersionPigment treatment with organosilicon compoundsPigment physical treatmentSlurryZircon

The invention discloses a method for producing special rutile type titanium white powder for power coating, which comprises the following steps of: preparing slurry of which titanium dioxide concentration is 300 to 400g / l by using bleached metatitanic acid, and adding a calcining auxiliary agent into the slurry; filtering the obtained metatitanic acid, then calcining solid, and grinding the solidto obtain a primary product; preparing titanium dioxide slurry of which titanium dioxide concentration is 650 to 850g / l by using the obtained primary product, adding a wetting agent into the titaniumdioxide slurry, and performing dispersion and grinding; heating the obtained titanium dioxide slurry to between 40 and 90 DEG C, adding dispersant, zircon salt or titanium salt, silicon salt and aluminum salt into the slurry in turn, adjusting the pH value to between 5 and 9, ageing the mixture, and adjusting the pH value to between 7 and 8; and then filtering, washing and drying the mixture, treating the dried product by an organic surface treatment agent, and vaporizing the product to obtain the rutile type titanium white powder. Compared with the prior art, the rutile type titanium white powder obtained by the method has the properties of stable crystal lattice, good dispersion, heat and yellowing resistance, and good oily whiteness, reducing power, covering power and weather resistance and the like; the appearance and properties of the rutile type titanium white powder are close to that of the rutile type titanium white powder prepared by a chlorination process; and the productionmethod has the advantages of easily obtained process raw materials and stable process control.

Owner:NINGBO XINFU TITANIUM DIOXIDE

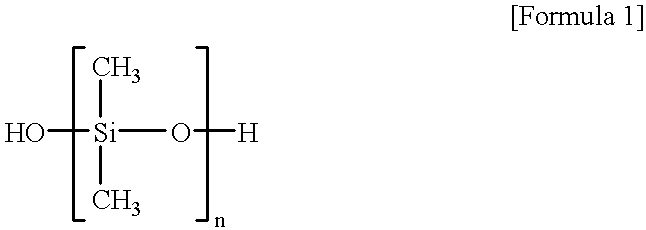

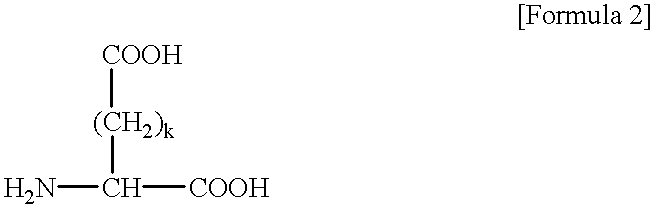

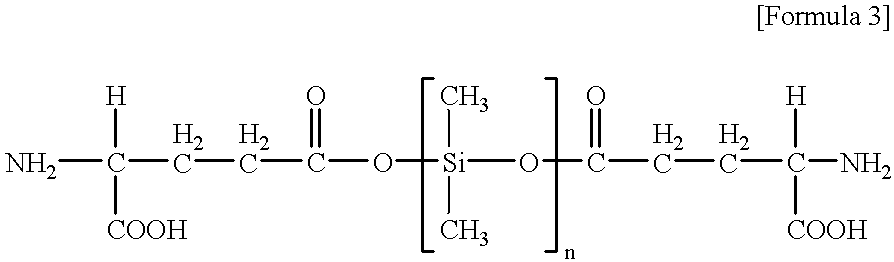

Amino acid silicon polymer, method for preparing the same, cosmetic particles surface-treated with the same, and cosmetic composition containing the particles

The invention relates to a novel amino acid silicon polymer with good adhesion to the keratin layer of the skin, a method of preparing the amino acid silicon polymer, a cosmetic particles surface-treated with the amino acid silicon polymer, and a color cosmetic composition including the cosmetic particles. According to the present invention, the particles surface-treated up to 3% to the maximum with the amino acid silicon polymer prepared by reacting an amino acid and a functional silicon polymer in the manner of organic synthesis have water resistance and usability peculiar to silicon-treated pigments and take positive surface charges, thereby offering good adhesion to the skin and durability. Due to these characteristics, the cosmetic containing the surface-treated particles of the present invention is superior in the cosmetic effect to that containing the conventional surface-treated particles.

Owner:PACIFIC

Microparticles and methods for their production

InactiveUS20050106098A1Improve image qualityThe process is simple and convenientPowder deliveryMaterial nanotechnologyLiquid mediumSource material

Microparticles having a metal-containing core encapsulated in a graphitic shell containing hetero atoms are made by forming, in a liquid medium, colloidal particles containing a metal-oxo species of Fe, Co, Ni and Pd, colloidally stabilized by a surfactant and containing source material of carbon and the hetero atoms. These particles are pyrolyzed in inert gas to yield the microparticles. In an alternative method, silica gel coated particles are formed by colloidally stabilizing particles containing metal species and forming silica at the boundary of the stabilized particle.

Owner:THE UNIV OF READING

Preparation method capable of realizing chemical blending of modified nano silicon dioxide particles in acrylate monomer

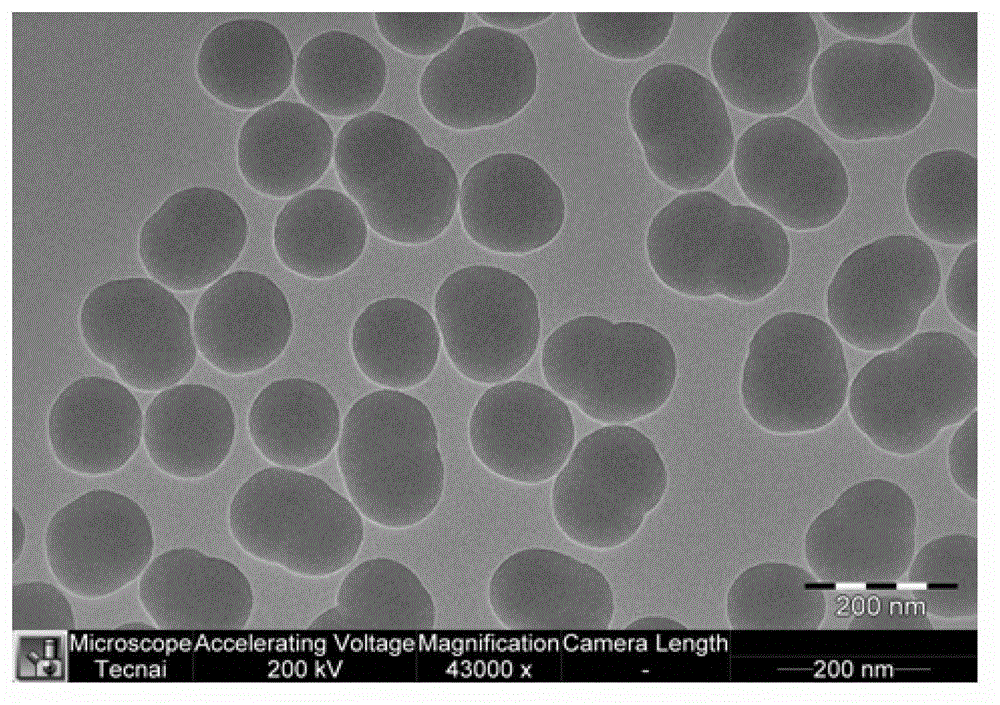

A preparation method capable of realizing chemical blending of modified nano silicon dioxide particles in an acrylate monomer relates to the field of the application of uniform dispersity of acryloyl oxygen radical contained silane couplint agent modified nano silicon dioxide particles in the acrylate monomer and the application of photocuring products in coating material. According to the method, the modified silicon dioxide is formed in a way that alkoxy on silane couplint agent and hydroxy on the surfaces of the nano silicon dioxide particles are reacted to form firm silicon-oxygen-silicon bonds; the double-bond silane couplint agent modified nano silicon dioxide is mixed in the monomer; during the photopolymerization process of the product, the acryloyl oxygen radical contained silane couplint agent modified nano silicon dioxide and the monomer are polymerized through the chemical bonds, so as to allow the nano silicon dioxide to be more uniformly distributed in the polymer; and the acryloyl oxygen radical contained silane couplint agent modified nano silicon dioxide particles are subjected to laser size analysis and transmission electron microscopy. The purpose of improving the application of the nano silicon dioxide composite acrylate monomer in the coating material field is achieved.

Owner:BEIJING UNIV OF CHEM TECH

Popular searches

Time-pieces with integrated devices Pigment treatment with macromolecular organic compounds Semiconductor devices Electrophoretic coatings Liquid/solution decomposition chemical coating Electrographic process Record carriers used with machines Non-linear optics Input/output processes for data processing Developers

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com