Preparation method capable of realizing chemical blending of modified nano silicon dioxide particles in acrylate monomer

A nano-silica and acrylate technology, applied in the treatment of dyed organosilicon compounds, fibrous fillers, coatings, etc., can solve the problems of poor dispersion of nano-silica, cumbersome industrialization steps, and poor long-term storage stability. To achieve uniform distribution, improve wear resistance, increase the effect of uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

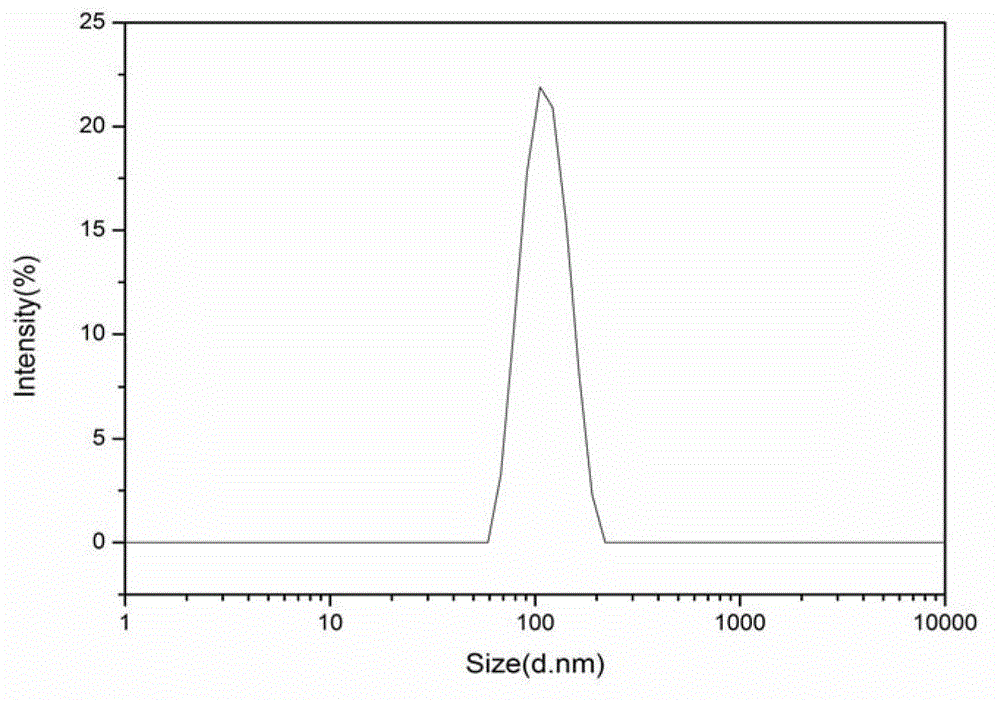

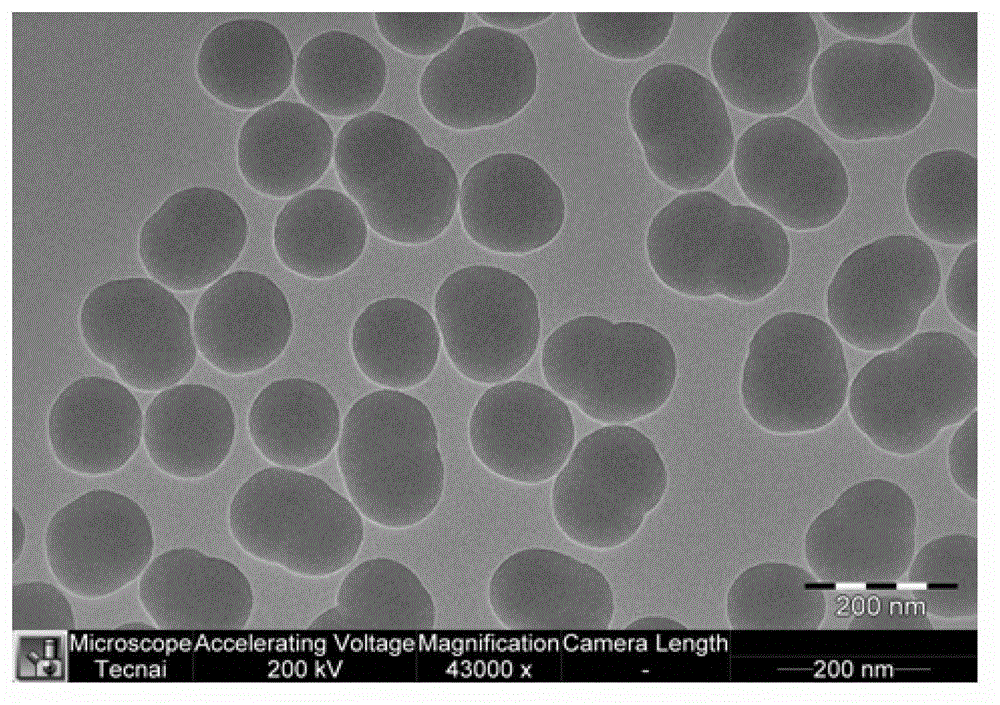

[0029] (1) Put 2g of deionized water, 10ml of ammonia water (analytical grade, mass fraction 25%), and 200ml of absolute ethanol (analytical grade) into a 1000ml four-necked flask and stir at room temperature. Using a constant pressure dropping funnel, drop 20g of tetraethyl orthosilicate (TEOS) into the flask and react at 40°C for 5h to prepare nano silicon dioxide. Among them, ammonia water and deionized water are catalysts.

[0030] (2) Lower the nano-silica prepared in step (1) to room temperature, pass N through the solution 2 After half an hour, use a constant pressure dropping funnel to drop 4g of γ-methacryloxypropyltrimethoxysilane into the flask, and after the addition, the solution is heated to 50°C and passed through N 2 After reacting for 12 hours, modified nano-silica was prepared.

[0031] (3) Mix the solution obtained in step (2) with 14.7g of 1,6-hexanediol diacrylate monomer, and use a constant pressure dropping funnel to mix the polymerization inhibitor (0...

Embodiment 2

[0037] (1) Put 4g of deionized water, 20ml of ammonia water (analytical grade, mass fraction 25%), and 300ml of absolute ethanol (analytical grade) into a 1000ml four-necked flask and stir at room temperature. Using a constant pressure dropping funnel, drop 30g of tetraethyl orthosilicate (TEOS) into the flask and react at 50°C for 8h to prepare nano silicon dioxide. Among them, ammonia water and deionized water are catalysts.

[0038] (2) Lower the nano-silica prepared in step (1) to room temperature, pass N through the solution 2After half an hour, use a constant pressure dropping funnel to drop 3g of γ-(methacryloxy)propylmethyldimethoxysilane into the flask. 2 After reacting for 18 hours, modified nano-silica was prepared.

[0039] (3) Mix the solution obtained in step (2) with 9.45 g of trimethylolpropane triacrylate monomer, and use a constant pressure dropping funnel to mix the polymerization inhibitor (0.5% by mass fraction of p-hydroxyanisole) and three Methylolpro...

Embodiment 3

[0045] (1) Put 6g of deionized water, 30ml of ammonia water (analytical pure, mass fraction 25%), and 400ml of absolute ethanol (analytical pure) into a 1000ml four-necked flask and stir at room temperature. Using a constant pressure dropping funnel, drop 40g of tetraethyl orthosilicate (TEOS) into the flask and react at 60°C for 10h to prepare nano silicon dioxide. Among them, ammonia water and deionized water are catalysts.

[0046] (2) Lower the nano-silica prepared in step (1) to room temperature, pass N through the solution 2 After half an hour, use a constant pressure dropping funnel to drop 2g of γ-methacryloxypropyl triethoxysilane into the flask. 2 After reacting for 24 hours, modified nano-silica was prepared.

[0047] (3) Mix the solution obtained in step (2) with 6.3 g of trifluorooctyl methacrylate monomer, and use a constant pressure dropping funnel to mix the polymerization inhibitor (0.5% by mass fraction of p-hydroxyanisole) and formaldehyde Add trifluorooc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com