Patents

Literature

3421 results about "Acrylic monomers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acrylic Monomers. Acrylics are probably the most versatile family of monomers. They can be used to prepare polymers with rigid, flexible, ionic, nonionic, hydrophobic, or hydrophilic properties. The monomers are classified into 9 groups based on composition and functionality. They are polymerized primarily by a free radical process,...

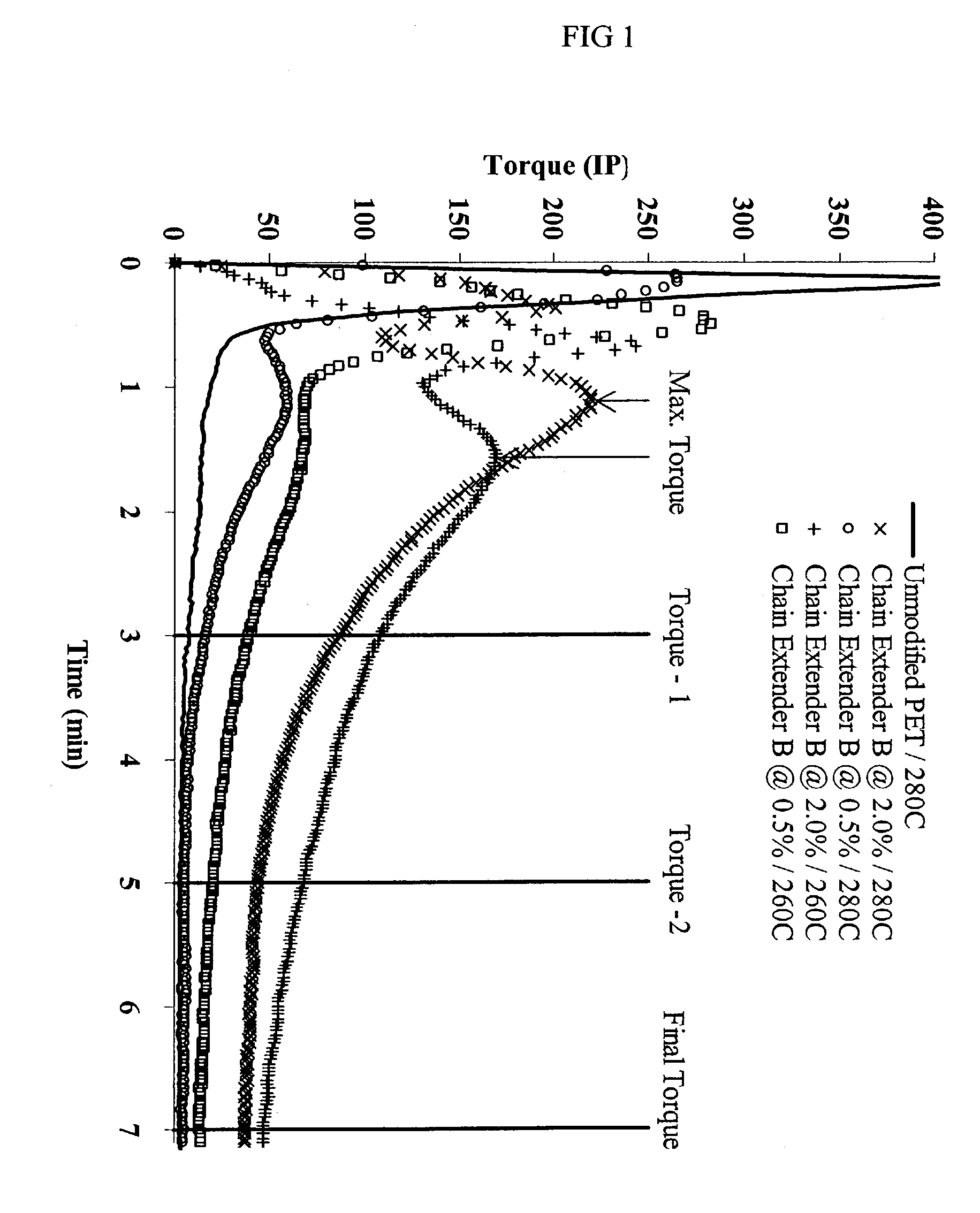

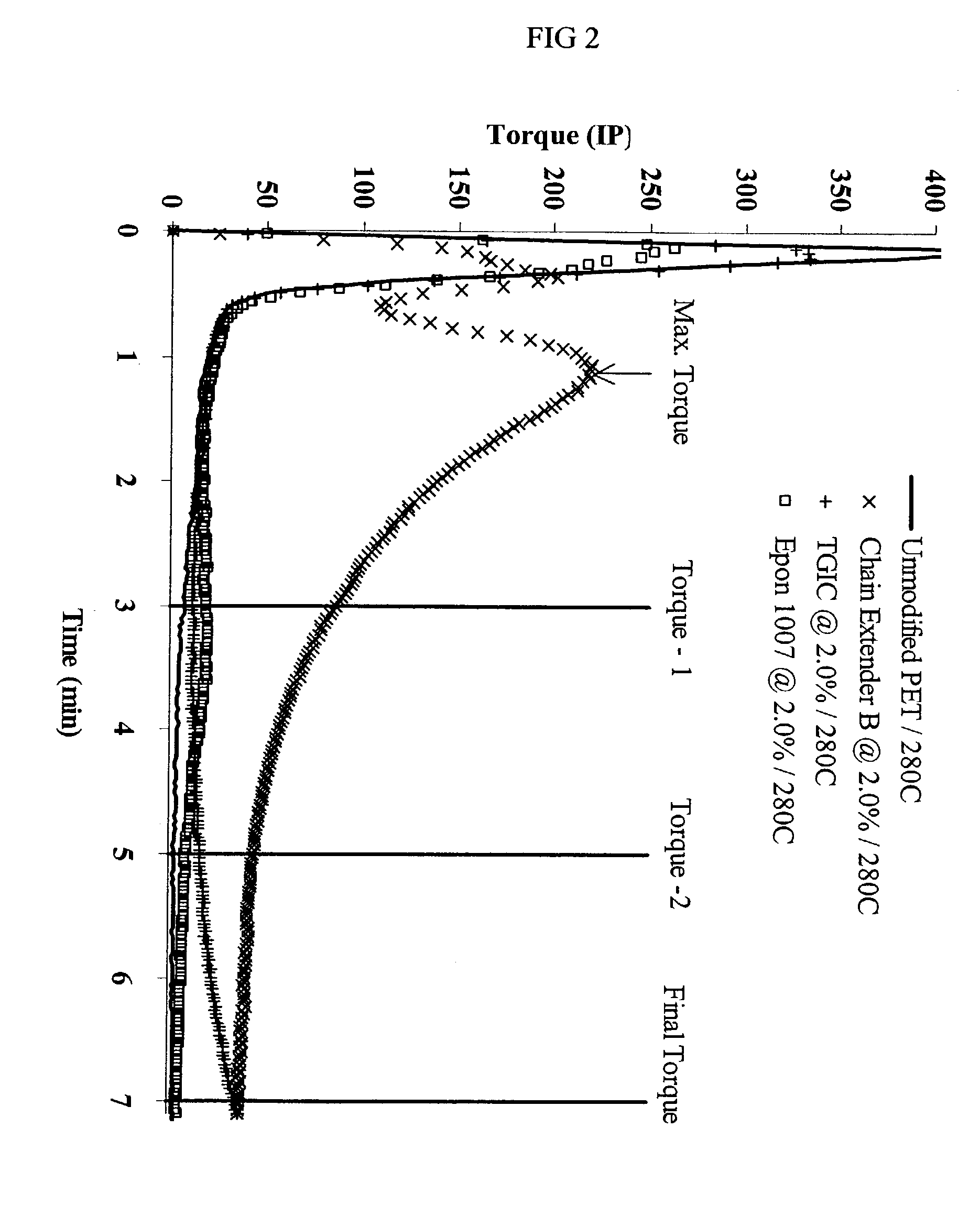

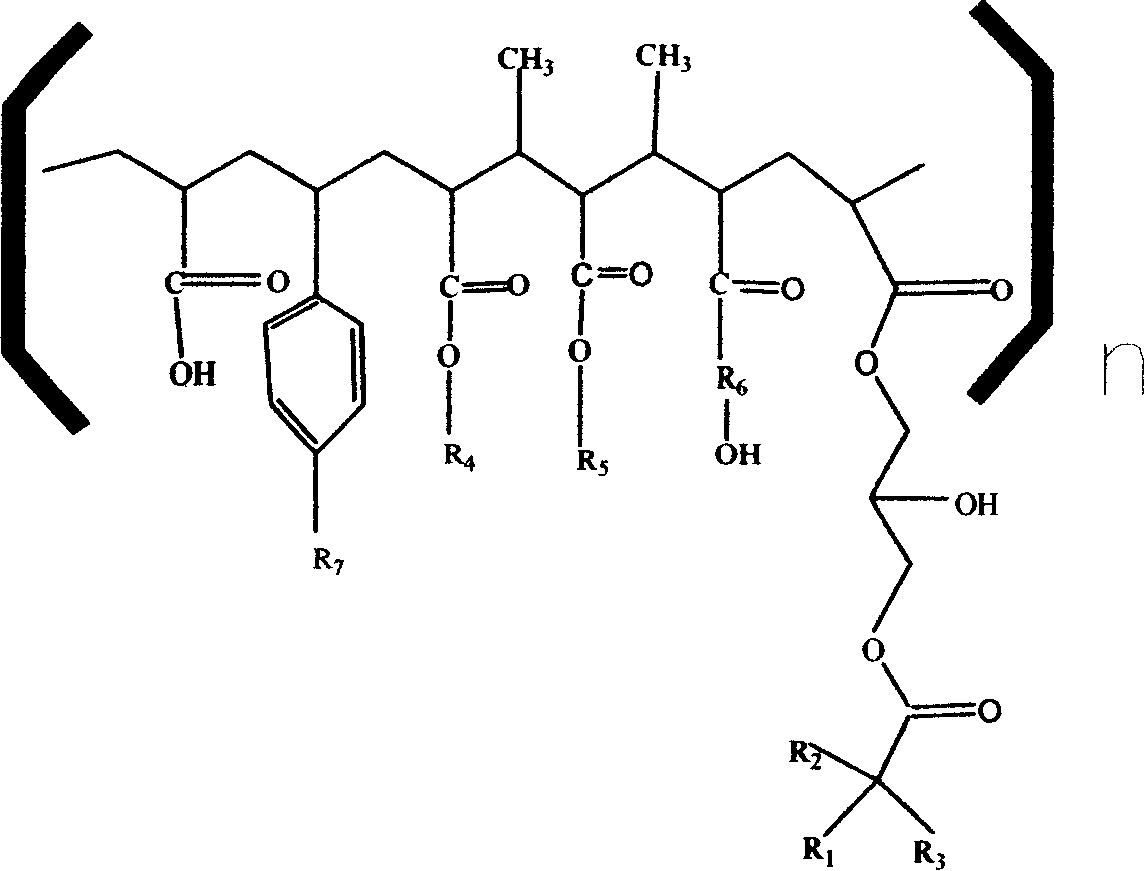

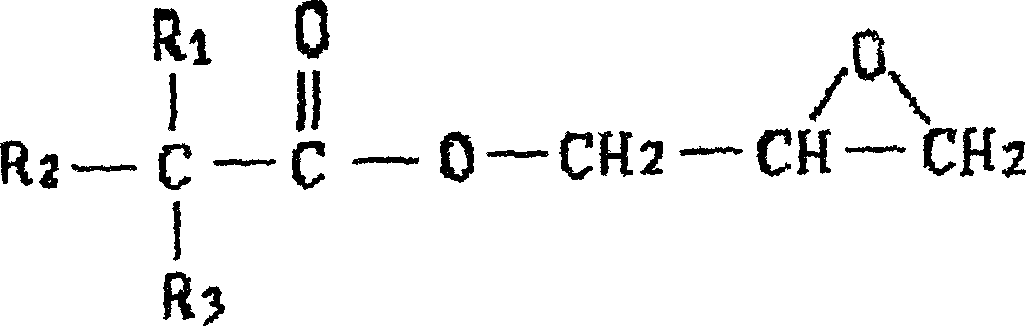

Oligomeric chain extenders for processing, post-processing and recycling of condensation polymers, synthesis, compositions and applications

The invention provides chain extenders made from epoxy-functional (meth)acrylic monomers and styrenic and / or (meth)acrylic monomers. The invention further provides polymeric compositions made from the chain extenders and plastic articles made from the compositions. Finally, the invention provides methods of using the chain extenders to improve the properties of virgin, recycled, and reprocessed condensation polymers.

Owner:BASF CORP +1

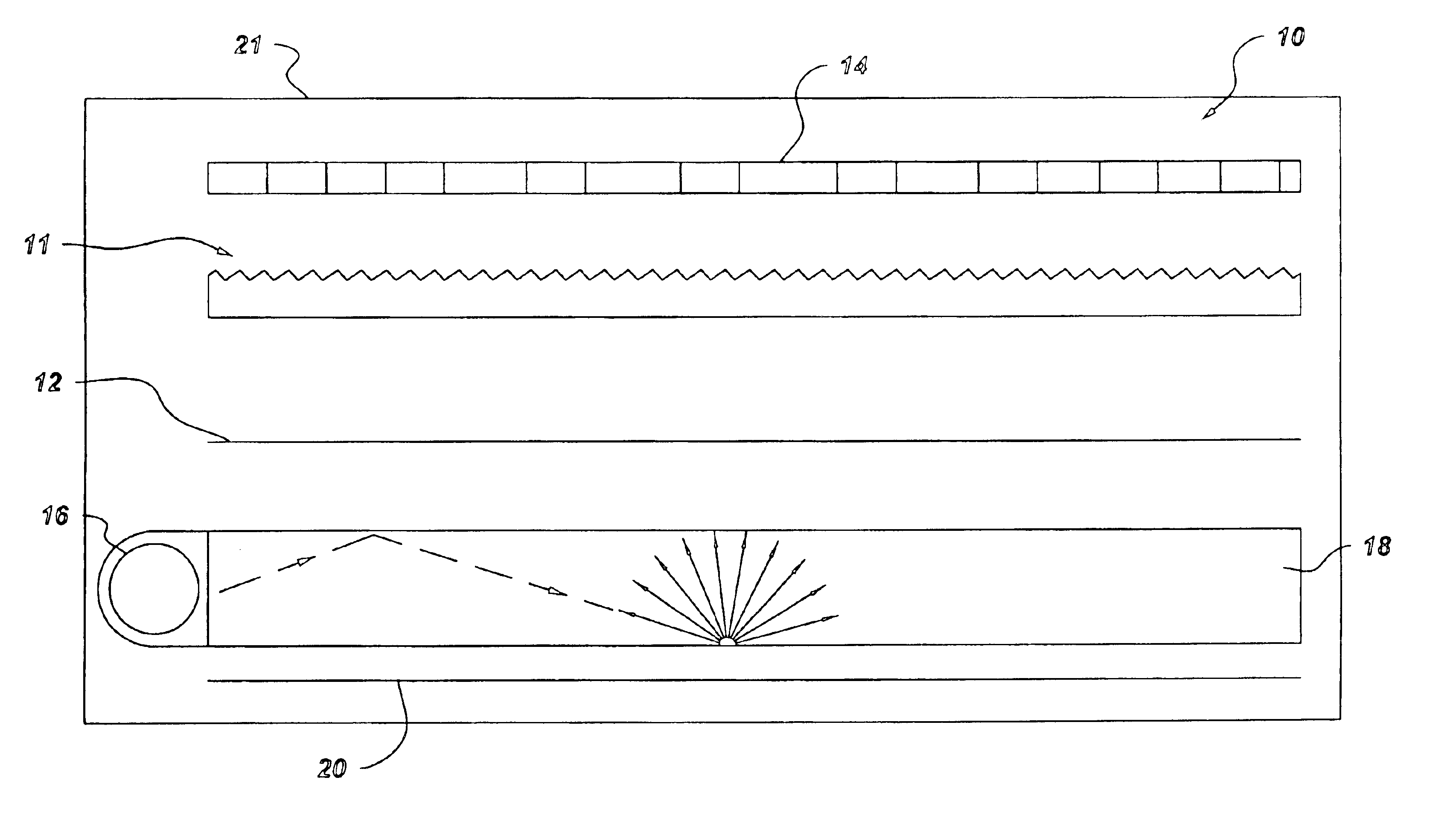

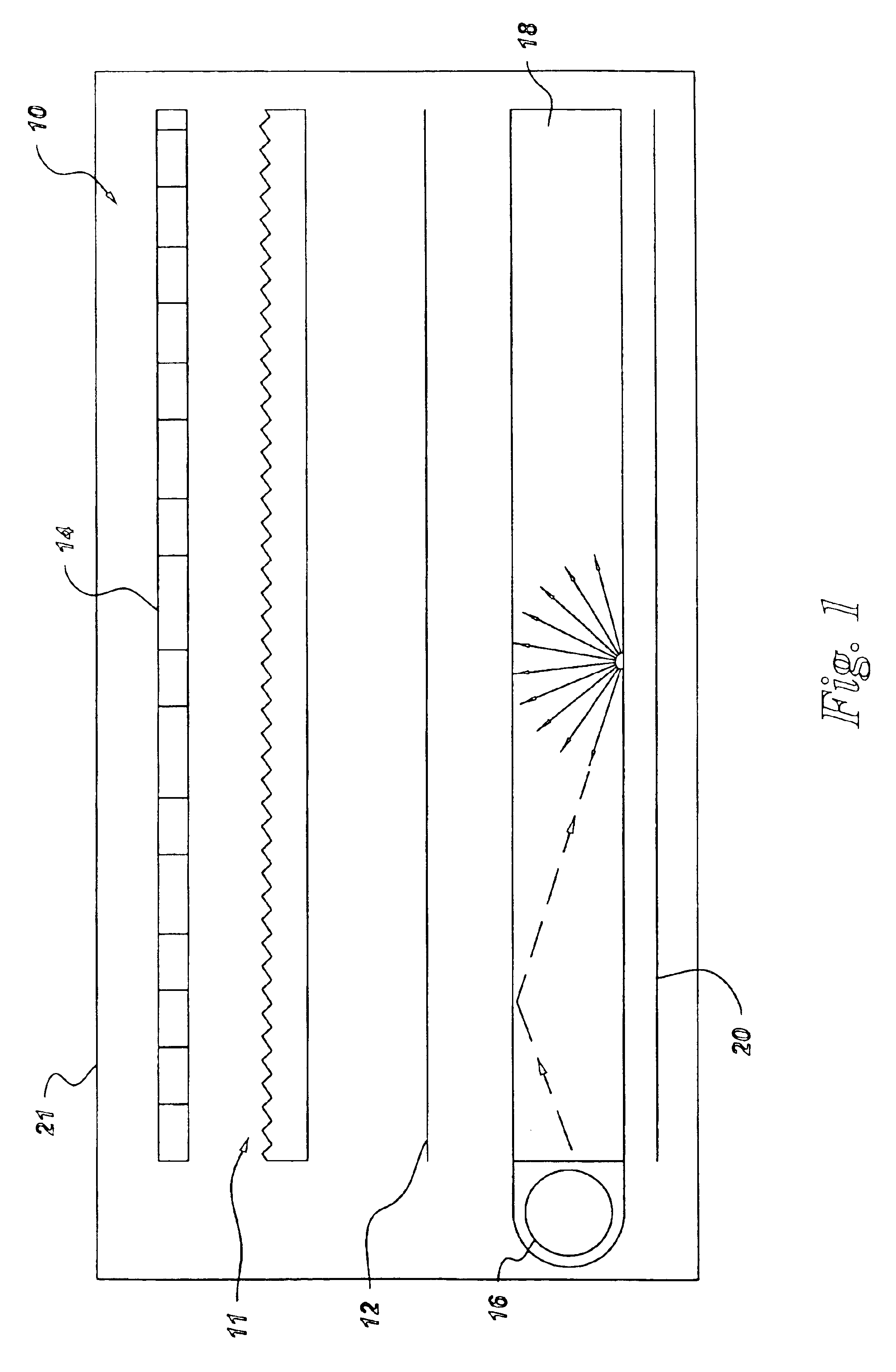

Microstructure-bearing articles of high refractive index

InactiveUS6844950B2High refractive indexLiquid crystal compositionsImpression capsPolymer scienceMeth-

Blends of oligomeric urethane multi(meth)acrylate; optionally at least one other monomer selected from the group consisting of acrylic monomers, styrenic monomers and ethylenically unsaturated nitrogen heterocycles, preferably a polyol multi(meth)acrylate; and nanoparticles of an ethylenically unsaturated, preferably (meth)acrylic-functionalized, titanium or zirconium compound can be cured by ultraviolet radiation in contact with a photoinitiator to produce optical resinous articles having high refractive indices, haze ratings of at most 5% and other properties which may be tailored according to the desired use.

Owner:SABIC INNOVATIVE PLASTICS IP BV

Pigment ink jet ink composition

An ink jet ink composition comprising an aqueous media and a pigment dispersion comprising a pigment and a polymeric dispersant wherein said polymeric dispersant is a copolymer comprising at least a hydrophobic methacrylate or acrylate monomer containing an aliphatic chain having greater than or equal to 12 carbons; and a hydrophilic methacrylic or acrylic acid monomer; wherein said copolymer comprises at least 10% by weight of the methacrylate or acrylate monomer and at least 5% by weight of the methacrylic or acrylic acid monomer; and wherein the copolymer comprises, in total, 20 to 95 weight % of hydrophobic monomer.

Owner:EASTMAN KODAK CO

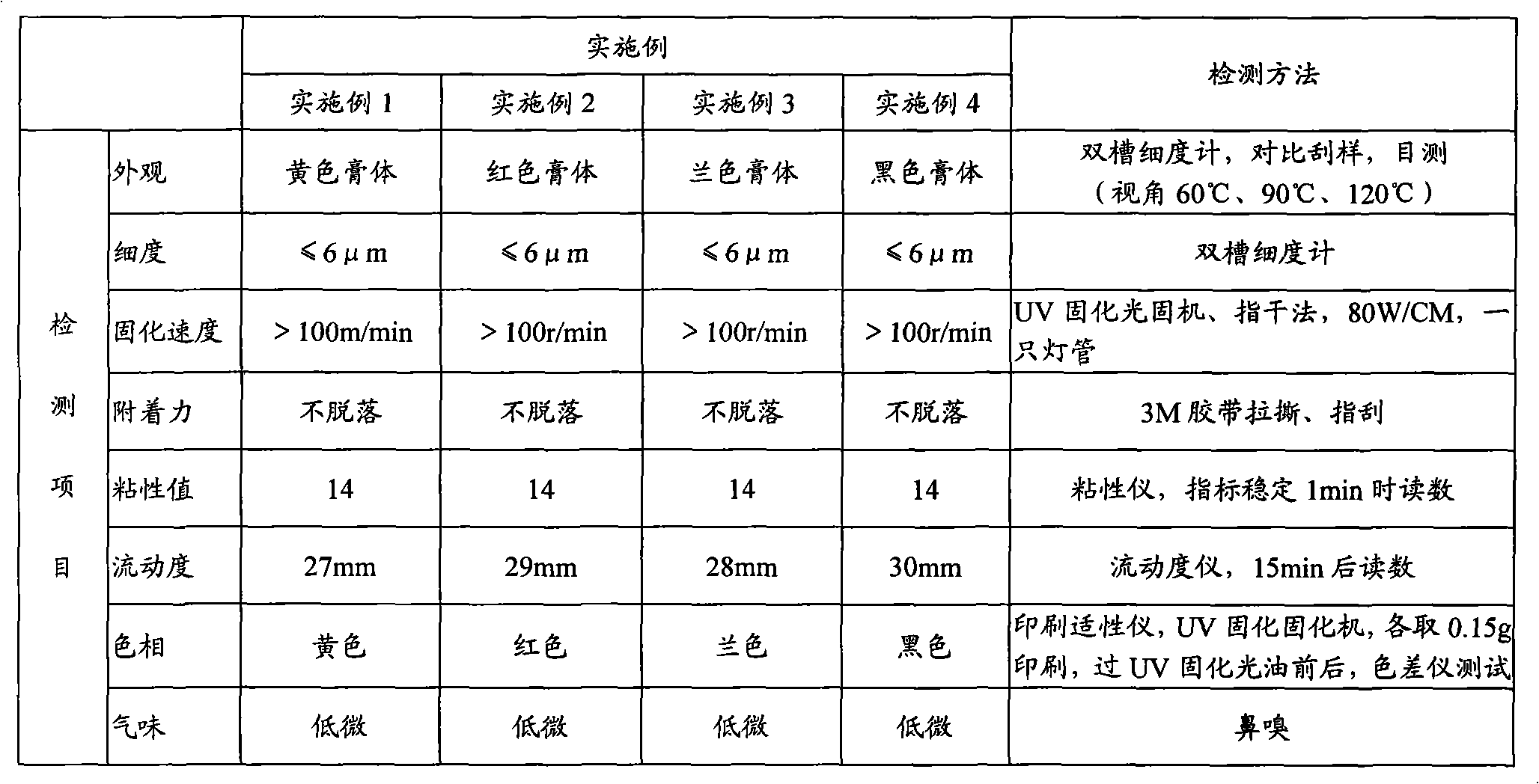

Ultraviolet light curing offset printing ink and preparation method thereof

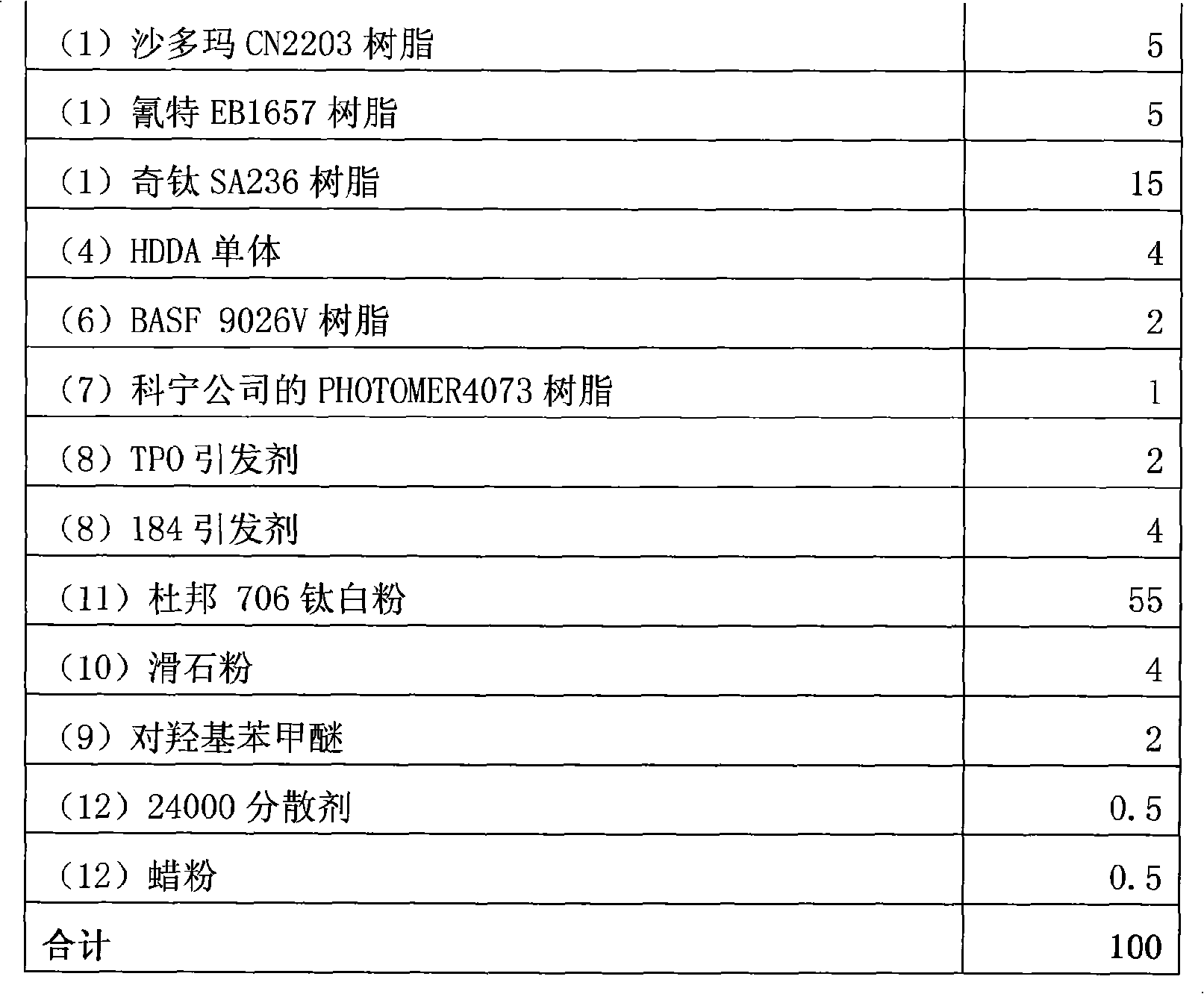

The invention relates to an ultraviolet light curing offset printing ink and a preparation method thereof. The ultraviolet light curing offset printing ink is made of 25.0-50.0% of polyfunctional polyester acrylic resin or polyfunctional chlorinated polyester acrylate, 0.0-15.0% of epoxy acrylate oligopolymer, 0.0-20.0% of polyfunctional urethane acrylate, 0.0-15.0% of difunctional or polyfunctional acrylic monomer, 0.0-20.0% of grinding-type resin, 2.0-10.0% of polyether acrylate modified by nano silicon dioxide, 0.0-5.0% of adhesion promoter, 3.0-5.0% of photoinitiator, 0.1-2.0% of polymerization inhibitor, 0.0-10.0% of filler, 16.0-55.0% of paint or dye and 0.2-5.0% of accessory ingredient. The prepared offset printing ink has high transparency as well as good adhesive attraction and flexility, and can be widely applied to packages printing industry and the printing of various transfer paper.

Owner:CHUZHOU JINQIAO TEXAS NEW MATERIALS CO LTD

Ultraviolet curable organic silicon-acrylic resin electronic adhesive and application thereof

InactiveCN101812278AFast curingIncrease elasticityOther chemical processesCoatingsNon toxicityAdhesive

The invention provides an ultraviolet curable organic silicon-acrylic resin electronic adhesive, which comprises the following components: (1) 100 parts of doublebond-containing acrylic monomers or prepolymer, (2) 5 to 500 parts of doublebond-containing organic silicon resin with a molecular weight of 1,000 to 10,000, (3) 1 to 100 parts of vinyl compound modified inorganic nano particle, (4) 1 to 50 parts of radical ultraviolet initiator, (5) 1 to 100 parts of organosilan, (6) 0 to 200 parts of inorganic reinforcing agent, and (7) 0 to 50 parts of auxiliary agent, wherein the ultraviolet curable organic silicon-acrylic resin is prepared by carrying out ultraviolet curing on the materials, and the solid content thereof is 100 weight percent. The product produced by the invention has the excellent characteristics of firm bonding with metal, glass and plastic materials and electronic devices, good optical property, good elasticity, good weather resistance, safety, non-toxicity, convenient construction and the like, can replace traditional solvent electronic adhesives, and is used for protective coatings, protective adhesives, packaging materials and the like of electronic devices, integrated circuits, printed circuits, LED chips and the like.

Owner:SHANGHAI XIYI NEW MATERIAL SCI & TECHCO

Dispersant for plaster

InactiveUS6264739B1PowerfulSolve the real problemTransportation and packagingMixingCarboxylic acidGypsum

An dispersant for plaster comprising a copolymer prepared by copolymerizing (a) a polyalkylene glycol monoester monomer having 2 to 300 mols of an oxyalkylene group(s) each having 2 to 3 carbon atoms, with (b) at least one monomer selected from among acrylic monomers, unsaturated dicarboxylic monomers and allylsulfonic monomers. When the dispersant of the present invention is used in preparing a plaster board, the foam stability is maintained so that the quality of the plaster board composition can be easily controlled.

Owner:KAO CORP

Polyacrylic water-absorbent resin powder and method for producing the same

ActiveUS20110313113A1Improve water absorptionEfficient productionPolymer scienceCrosslinked polymers

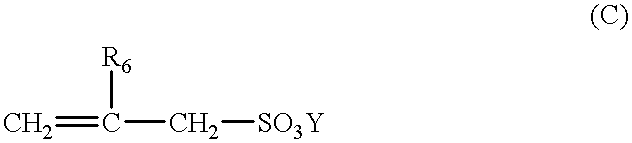

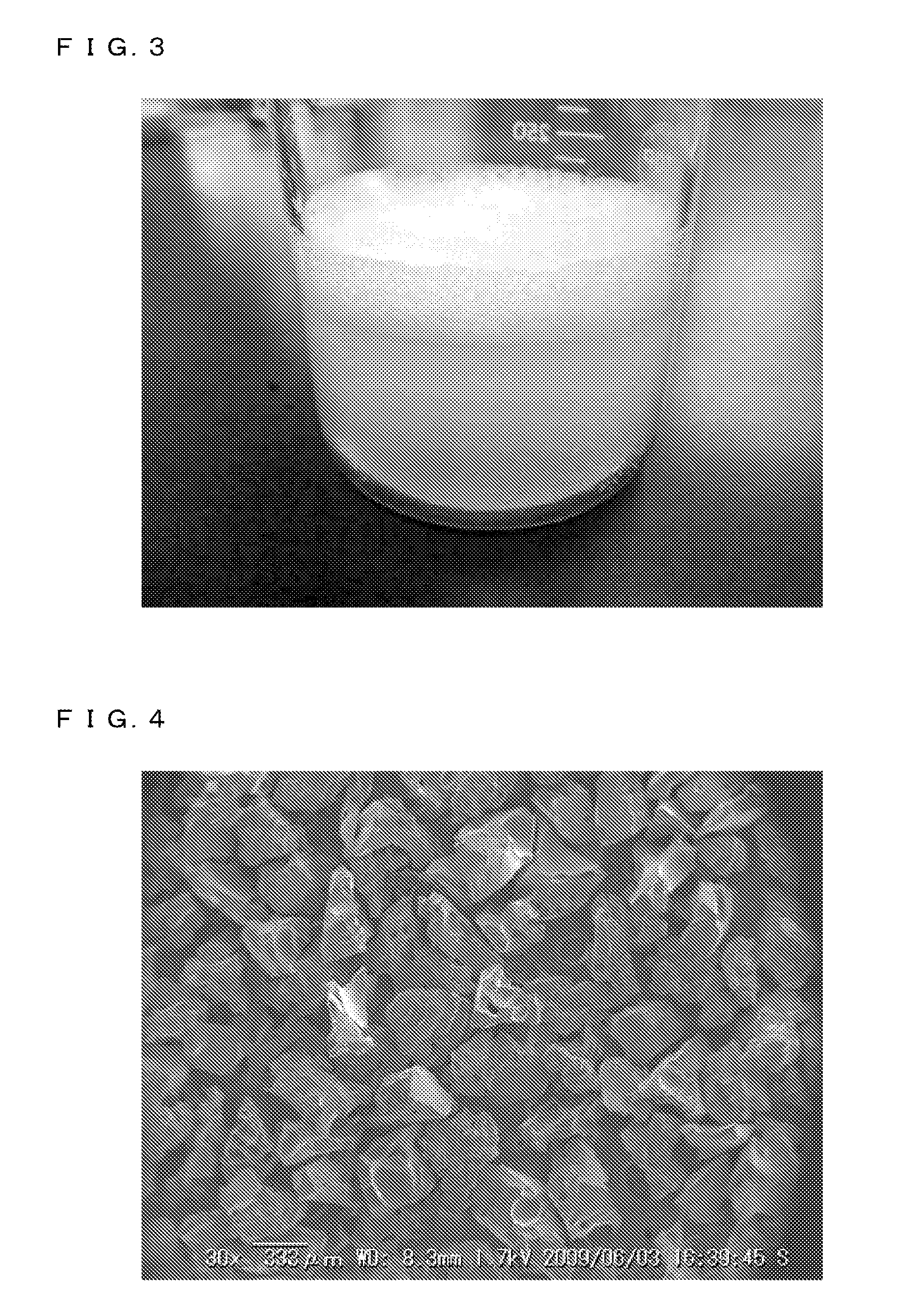

A production method of the present invention is a polyacrylic water-absorbent resin powder production method including the steps of: producing an acrylic monomer solution in which gas is dissolved and / or dispersed; polymerizing the acrylic monomer solution in the absence of a surface active agent or in the presence of not more than 300 ppm of a surface active agent; during or after the step of polymerizing, fragmenting a hydrated gel crosslinked polymer obtained by polymerizing the acrylic monomer solution; and drying by heat the hydrated gel crosslinked polymer thus fragmented, the gas being dissolved and / or dispersed in the acrylic monomer solution by at least one of the methods (a) to (c): (a) applying pressure to the acrylic monomer solution and the gas; (b) creating swirling flows of the acrylic monomer solution and the gas; and (c) introducing the gas with the acrylic monomer solution via fine holes. Accordingly, the production method of the present invention makes it possible to efficiently produce a water-absorbent resin having an excellent water-absorption rate without deteriorating a liquid-absorbent property of a sanitary product or the like.

Owner:NIPPON SHOKUBAI CO LTD

Tailoring material composition for optimization of application-specific switchable holograms

InactiveUS7175780B1Improve efficiencyOptical qualityLiquid crystal compositionsThin material handlingCrystallographyChemical composition

The process described herein offers the optimizing of performance parameters of holograms, such as reducing scattering effects in a polymer-dispersed liquid crystal optical element. In the process, an interfacial tension agent is added to a polymer-dispersed liquid crystal material. The polymer-dispersed liquid crystal material has at least one acrylic acid monomer, at least one type of liquid crystal material, a photoinitiator dye, and a co-initiator. The polymer-dispersed liquid crystal material is subjected to a polymerization. The interfacial tension agent reduces the size of liquid crystal droplets formed within the polymer-dispersed liquid crystal optical element during polymerization.

Owner:LEIDOS

Curable liquid resin composition

PCT No. PCT / JP97 / 01871 Sec. 371 Date Feb. 3, 1998 Sec. 102(e) Date Feb. 3, 1998 PCT Filed Jun. 2, 1997 PCT Pub. No. WO97 / 46601 PCT Pub. Date Dec. 11, 1997A curable liquid resin composition containing 100 parts by weight of the following (meth)acrylic liquid resin (A) and 1 to 1,000 parts by weight of a (meth)acrylic monomer (B) having an unsaturated double bond in its molecule and having a number average molecular weight of 1,000 or less, the (meth)acrylic liquid resin (A) being a liquid resin which is obtained by polymerizing monomers containing an alkyl (meth)acrylate monomer (a-1-1) of the formula (1),CH2 C(R1)COO-R2(1)wherein R1 is a hydrogen atom or CH3 and R2 is an alkyl group, and / or an alkylene glycol (meth)acrylate monomer (a-1-2) of the formula (2),CH2=C(R1)COO(CnH2nO)mR3(2)wherein R1 is a hydrogen atom or CH3, R3 is an alkyl group or a phenyl group, n is an integer of 1 to 3, and m is an integer of 3 to 25, and other polymerizable vinyl monomer (a-2), an average of molecular weights of all the monomers being 100 to 1,500, the liquid resin having a number average molecular weight of 10,000 to 200,000 and a viscosity of 1 to 10,000 poise (measured at 50 DEG C.), or a modified product of the above liquid resin, the curable liquid resin composition can form a film as a film-forming material or as a resin for an adhesive without using a solvent and give a cured film.

Owner:TOYO INK SC HOLD CO LTD

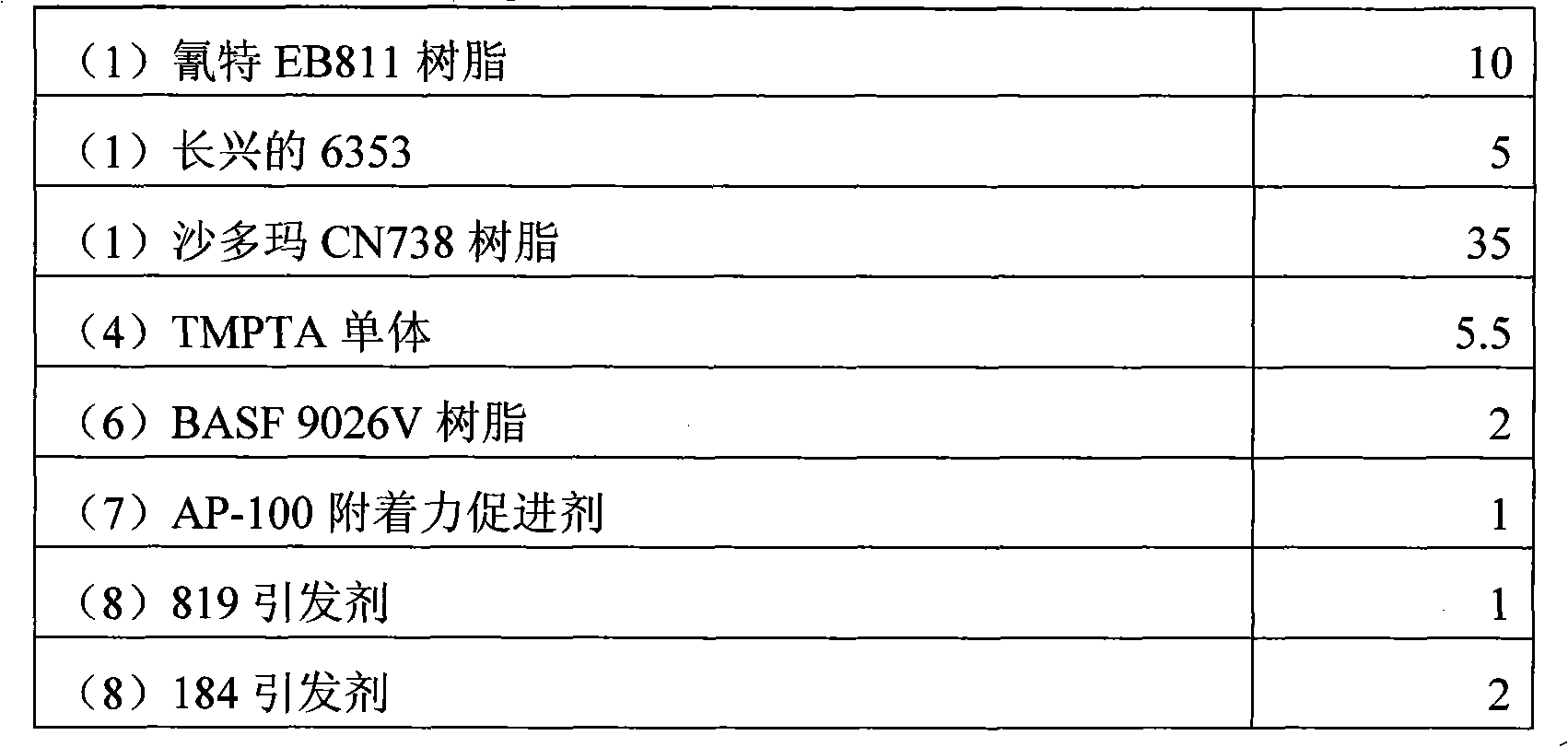

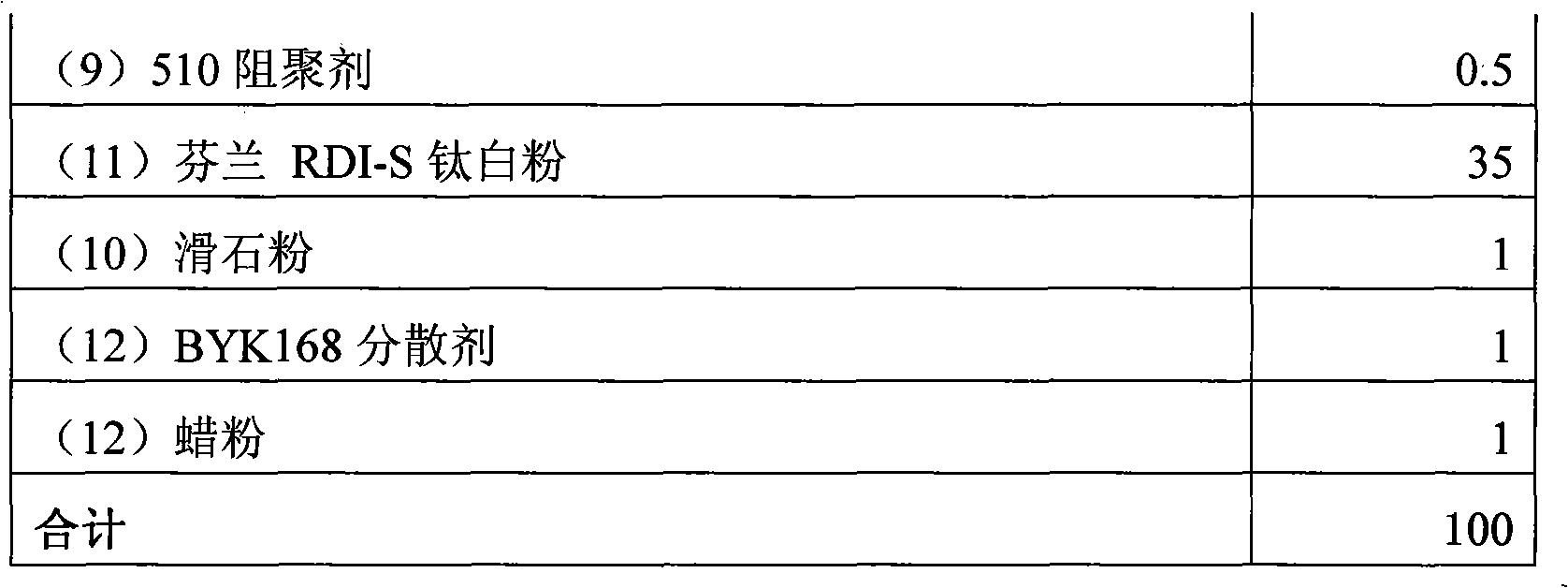

White composition capable of solidifying by ultraviolet light

InactiveCN101153127ASimple construction processImprove adhesionPolyurea/polyurethane coatingsEpoxy resin coatingsPolyesterUltraviolet lights

The present invention discloses a white composition for ultraviolet solidification. The composition comprises the components of the weight percentages: (1) 10 percent to 40 percent of epoxy acrylate containing carboxyl; (2) 5 percent to 20 percent of polyurethane acrylic ester containing carboxyl; (3) 10 percent to 30 percent of super branching polyester acrylate; (4) 15 percent to 40 percent of acrylic monomer of single- or multi-functional degree; (5) 8 percent to 20 percent of titanium dioxide; (6) 1 percent to 8 percent of light initiator; (7) 0.5 percent to 3 percent of auxiliary aid; and (8) 0.5 percent to 10 percent of adhesive assistant agent. The construction process of the coating of the present invention is simple; the coating can be widely used (not limited) for various density boards, and solid plate materials. After the coating is solidified by ultraviolet irradiation, the coating film has good adhesive capability, high hardness, good covering capability and leveling performances.

Owner:湖南阳光新材料有限公司

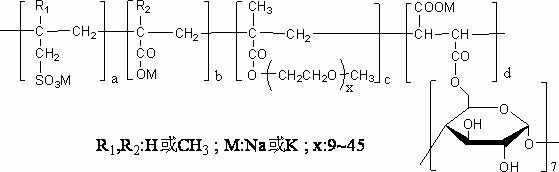

Preparation method of slow-setting polycarboxylic acid water reducing agent

The invention relates to a preparation method of a slow-setting polycarboxylic acid water reducing agent, which is implemented by carrying out free radical copolymerization reaction on allylsulfonate monomers, acrylic monomers, polyethylene glycol nono-methyl ether methacrylate macromonomers and maleic anhydride grafted beta-cyclodextrin macromonomers. The invention is characterized in that a beta-cyclodextrin side chain is introduced into a polycarboxylic acid main chain, so that the polycarboxylate water reducing agent has favorable slow setting property, micro air-entraining property and better fluidity. The obtained polycarboxylic acid water reducing agent has the advantages of stable product performance, strong adaptability to cement and favorable compatibility; and the cement paste fluidity is up to higher than 290mm (W / C=0.29), the water reducing rate of concrete is up to 30-40%, and the slump protection time is 3-5 hours. The preparation method provided by the invention has the characteristics of unique technique, excellent product performance and the like.

Owner:FUJIAN CONSTR ENG GRP BUILDING MATERIAL SCI & TECH DEV

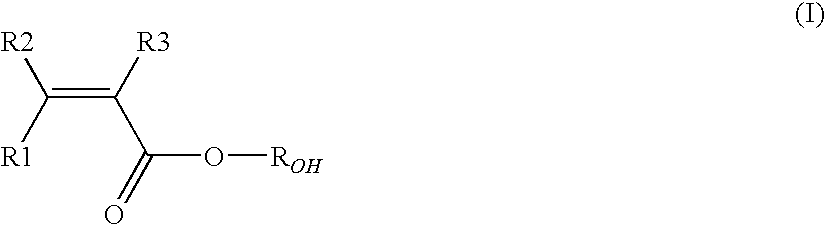

Vinylidene fluoride copolymers

ActiveUS20100133482A1Maximize the effectHigh viscosityMembranesSemi-permeable membranesPolymer scienceMeth-

The present invention pertains to a linear semi-crystalline copolymer [polymer (A)] comprising recurring units derived from vinylidene fluoride (VDF) monomer and at least one hydrophilic (meth)acrylic monomer (MA) of formula (I) wherein each of R1, R2, R3, equal or different from each other, is independently an hydrogen atom or a C1-C3 hydrocarbon group, and ROH is a hydrogen or a C1-C5 hydrocarbon moiety comprising at least one hydroxyl group, said polymer (A) comprising from 0.05 to 10% by moles of recurring units derived from said hydrophilic (meth)acrylic monomer (MA) and being characterized by a fraction of randomly distributed units (MA) of at least 40%, having improved thermal stability, to a process for its manufacture, to a composition comprising the same, and to its use as binder in batteries or for the manufacture of hydrophilic membranes.

Owner:SOLVAY SOLEXIS

Aqueous emulsion and use thereof

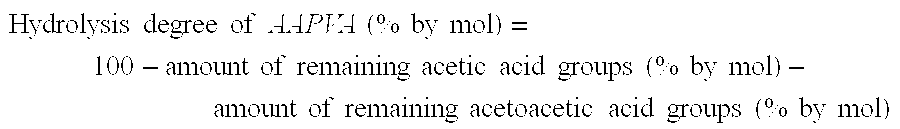

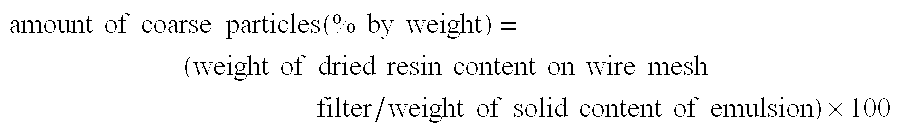

InactiveUS20050197441A1Improve polymerization stabilityNon-fibrous pulp additionGraft polymer adhesivesAcetic acidFiber

The present invention provides an aqueous emulsion having excellent polymerization stability and standing stability and a redispersible powder. Specifically, the present invention relates to an aqueous emulsion of a polymer obtained by polymerizing an acrylic monomer in the presence of a polyvinyl alcohol containing an acetoacetic ester group; wherein the polyvinyl alcohol containing an acetoacetic ester group has block character [η] of 0.3 to 0.6, hydrolysis degree of at least 97% by mol and acetoacetic esterification degree of 0.01 to 1.5% by mol, and the value obtained by dividing the maximum value by the minimum value of the respective average acetoacetic esterification degree for each of the polyvinyl alcohol containing an acetoacetic ester group separated by particle size of 44 to 74, 74 to 105, 105 to 177, 177 to 297, 297 to 500 and 500 to 1680 μm is 1.0 to 3.0. Also, the present invention relates to a redispersible fiber obtained by drying the aqueous emulsion.

Owner:THE NIPPON SYNTHETIC CHEM IND CO LTD

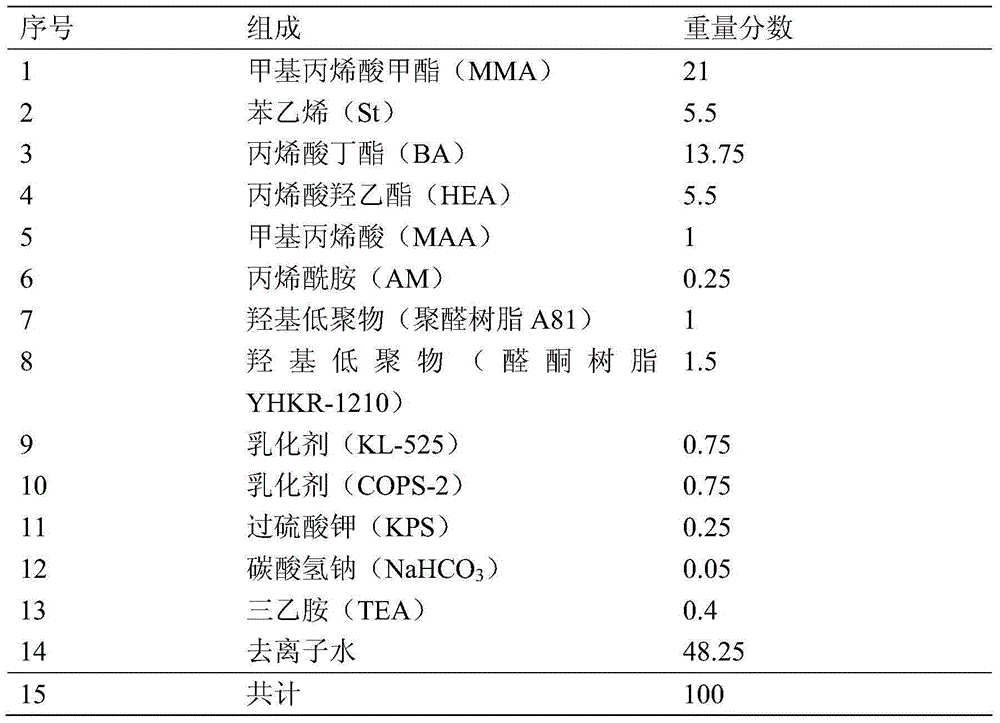

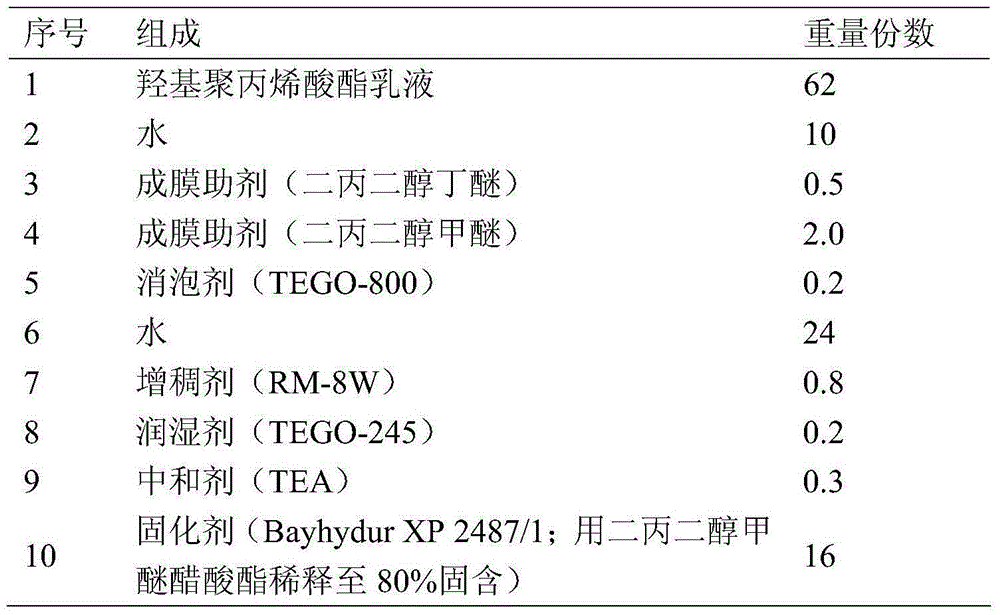

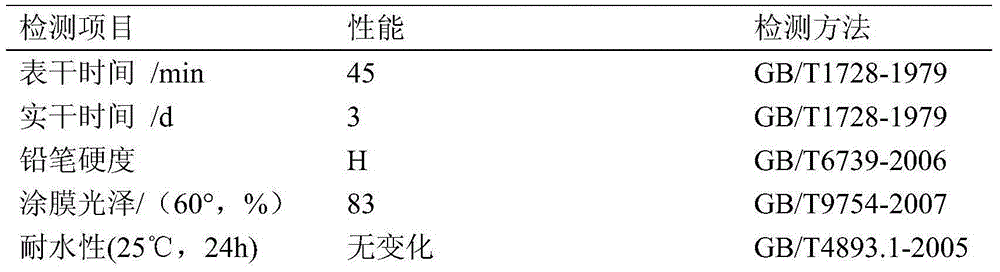

Hydroxypolyacrylate emulsion, and preparation method and application thereof

ActiveCN105061665AHydroxyl content is easy to adjustLarge adjustment rangePolyurea/polyurethane coatingsSodium bicarbonateMethacrylate

The invention discloses a hydroxypolyacrylate emulsion, and a preparation method and an application thereof. The preparation method comprises the following steps: weighing an acrylate monomer and / or a metacrylate monomer, a hydroxyacrylate monomer, an acrylic monomer, an acrylate function monomer and a hydroxy oligomer, uniformly mixing to prepare a monomer mixture, weighing 10-15% of the monomer mixture, and emulsifying by using an emulsifier to prepare a seed pre-emulsion for later use; and adding the emulsifier, sodium bicarbonate and deionized water into a reaction kettle, stirring, rising the temperature of a reaction system, adding an initiator, stabilizing, adding the seed pre-emulsion in a dropwise manner, stabilizing, adding the remaining monomer mixture and the remaining initiator in a dropwise manner, heating, slaking, cooling, neutralizing, carrying out heat insulation, cooling, and discharging to obtain the hydroxypolyacrylate emulsion. A film made by using an aqueous dual-component polyurethane coating prepared from the hydroxypolyacrylate emulsion and an aqueous polyisocyanate curing agent has the advantages of high hardness, high luster and excellent chemical resistance.

Owner:SOUTH CHINA UNIV OF TECH +1

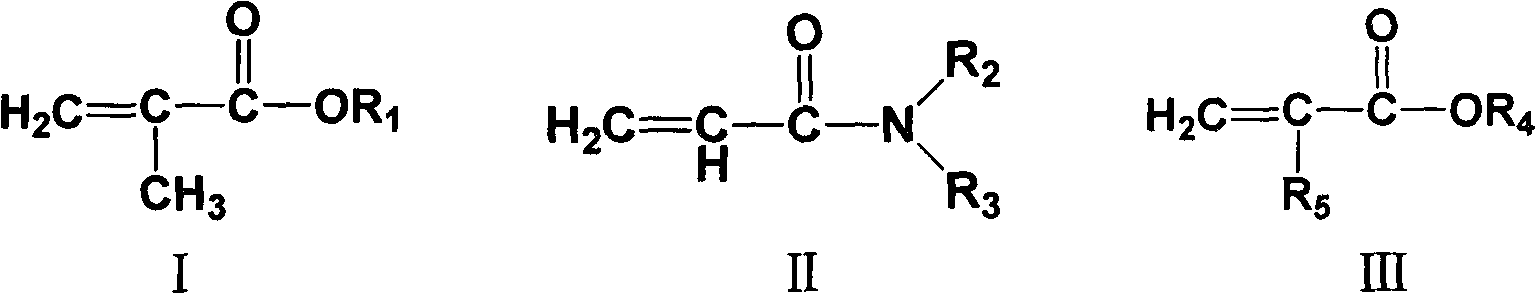

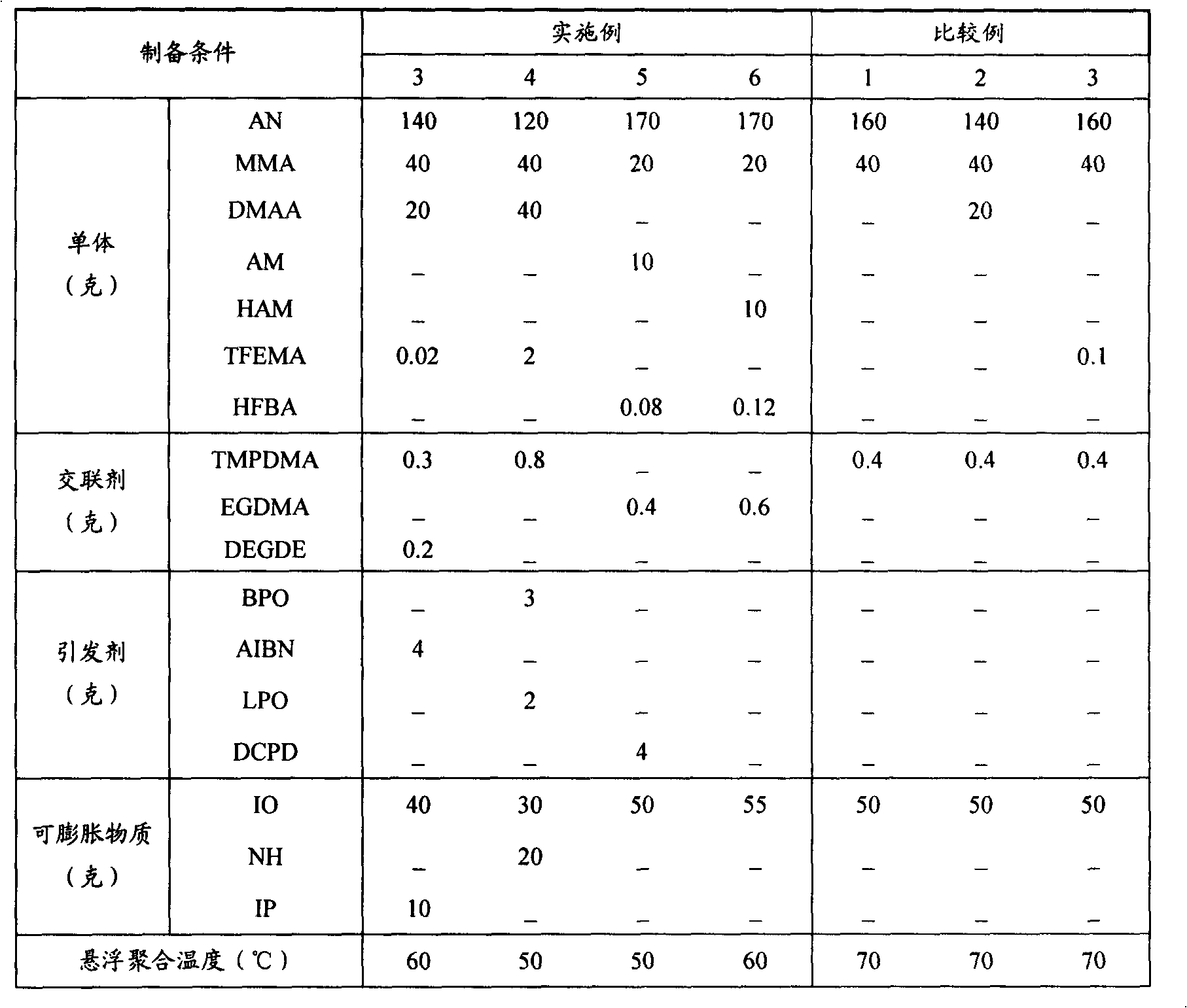

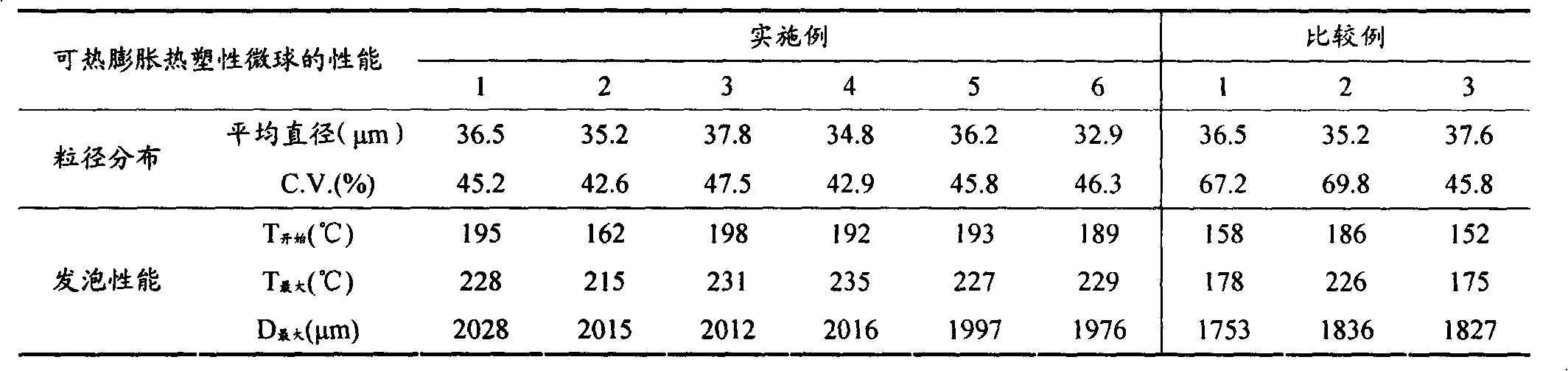

Thermoexpandable thermoplastic microspheres

The invention relates to thermoexpandable thermoplastic microspheres which are mainly prepared by carrying out suspension polymerization on olefine polymerizable monomers and expandable substances. The thermoexpandable thermoplastic microspheres have a core-shell structure which uses the thermoplastic polymers as the shell and the expandable substances as the cure. The invention is characterized in that on the basis of 100 wt% as the total weight of the olefine polymerizable monomers, the olefine polymerizable monomers are composed of 30-90 wt% of acrylonitrile, 5-50 wt% of methacrylate monomers, 1-20 wt% of acrylamide monomers, 0.01-1.0 wt% of fluorine-containing acrylate monomers and 0-40 wt% of acrylic monomers. The start T of the thermoexpandable thermoplastic microspheres is 160-200 DEG C.

Owner:NANOSPHERE SHANGHAI

High refractive index monomers, compositions and uses thereof

The invention relates to novel sulfur-containing (meth)acrylic monomers and compositions thereof characterized by a high refractive index, for optical and industrial applications. The invention also relates to a method for preparing high refractive index polymeric materials and more specifically to a method for formation of ultraviolet cast optical lenses and compositions thereof comprising the sulfur-containing (meth)acrylic monomers.

Owner:CIBA CORP

Glass protecting ink and preparation method thereof

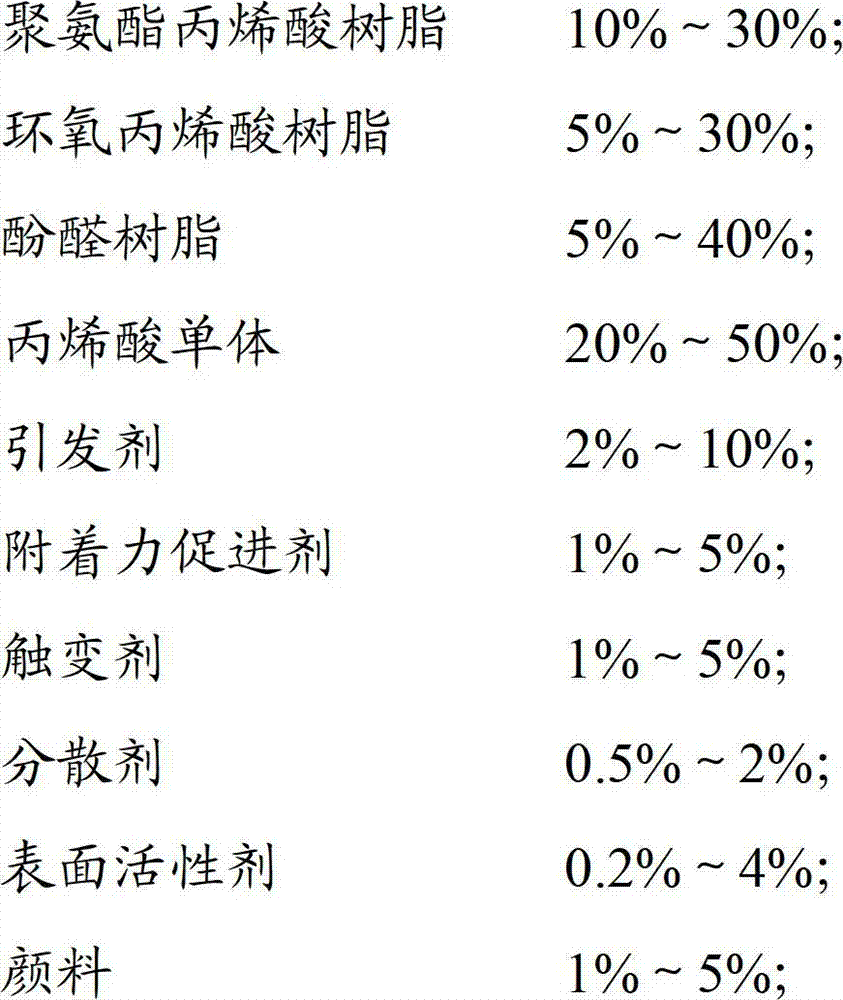

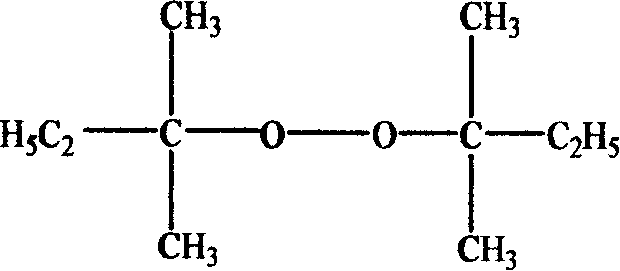

The invention discloses a glass protecting ink and a preparation method thereof. The glass protecting ink comprises the following components in percentage by weight: 10%-30% of polyurethane acrylate, 5%-30% of epoxy acrylic resin, 5%-40% of phenolic resin, 20%-50% of acrylic monomer, 2%-10% of initiator, 1%-5% of adhesion promoter, 1%-5% of thixotropic agent, 0.5%-2% of dispersing agent, 0.2%-4% of surface active agent, 1%-5% of pigment and 10%-30% of filler. The glass protecting ink disclosed by the invention has a good glass protecting performance, is easy to strip, and is convenient to operate.

Owner:FOSHAN 3Q ELECTRONICS MATERIALS

Polymerizable composition and method for producing (METH) acrylic thermally conductive sheet

InactiveUS20070261785A1Good flexibilityExcellent in bleed resistanceLamination ancillary operationsLaminationPolymer scienceMeth-

A polymerizable composition which contains a component (A): a (meth)acrylic monomer, a component (B): a (meth)acrylic polymer having at least one functional group capable of undergoing a cross-linking reaction in its molecule, a component (C): a (meth)acrylic oligomer having at one terminal of its molecule a functional group capable of undergoing a cross-linking reaction, a component (D): a cross-linking agent having a functional group capable of undergoing a cross-linking reaction, a compound (E): a photopolymerization initiator and / or a thermal polymerization initiator, and a component (F): a thermally conductive filler, is disclosed. Further, a (meth)acrylic thermally conductive sheet having a pressure-sensitive adhesive layer prepared by polymerizing and cross-linking the polymerizable composition on a support is disclosed. The thermally conductive sheet prepared by using the polymerizable composition according to the invention is excellent in flexibility, adhesiveness and bleed resistance and can dissipate heat generated from a heat-generating body such as an electronic device with good efficiency.

Owner:SOKEN CHEM & ENG CO LTD

Scale inhibitor for an aqueous system

InactiveUS20030091467A1Less-expensive to useInhibition formationOther chemical processesScale removal and water softeningSulfonateTricarboxylic acid

This invention relates to a composition and a method for inhibiting the formation of scale, particularly complex scale, in an aqueous system where more than one type of scale is present. The scale typically present in the aqueous system includes silica, silicates, and carbonates. The scale inhibiting composition comprises (1) 2-phosphonobutane-1,2,4-tricarboxylic acid and salts thereof, and (2) a copolymer of (1) one or more allyloxybenzenesulfonate monomers, and (2) one or more water-soluble acrylic monomers, substituted acrylic monomers, or mixtures thereof.

Owner:SOLENIS TECH CAYMAN

Initiator system and adhesive composition made therewith

InactiveUS6027813ALower Level RequirementsGood solvent resistanceSynthetic resin layered productsEster polymer adhesivesSolventAcid anhydride

Systems for initiating the polymerization of acrylic monomers comprising (1) organoborane amine complexes and (2) decomplexers comprising at least one anhydride group. Adhesive compositions prepared from the initiator systems advantageously exhibit low levels of mobile constituents, excellent solvent resistance, and good adhesion to low energy surfaces.

Owner:3M INNOVATIVE PROPERTIES CO

Pressure sensitive adhesive for protective film and preparation method thereof

InactiveCN101798491AHigh initial tackImprove cohesive strengthEster polymer adhesivesTectorial membraneFunctional monomer

The invention discloses a pressure sensitive adhesive for a protective film and a preparation method thereof. The pressure sensitive adhesive is formed by polymerizing acrylic monomers through radicals, wherein the acrylic monomers comprise the following components in percent by weight: 30-50 percent of acrylic soft monomer, 5-20 percent of acrylic hard monomer, 0.5-2.5 percent of acrylic functional monomer, 0.5-2.5 percent of acrylic crosslinking monomer, 40-60 percent of solvent, 0.2-2.0 percent of initiating agent and 0.01-0.2 percent of chain transfer agent. The adhesive has higher initial adhesion and permanent adhesion and excellent weather-proof and aging-resisting performances and can meet the requirement of a protective film adhesive with higher strength requirement.

Owner:BEIJING COMENS NEW MATERIALS

Preparation of gypsum compositions

ActiveUS7070648B1Delayed initial setting timeReduce the amount of waterCeilingsCovering/liningsSulfonateSlurry

A gypsum composition containing a sulfonate-containing comb-branched copolymer is disclosed. The sulfonate-containing comb-branched copolymer comprises recurring units of a polyether macromonomer, an acrylic monomer, and a sulfonate monomer. The sulfonate-containing comb-branched copolymer not only increases the fluidity of gypsum slurry but also has reduced retardation on the gypsum setting.

Owner:COATEX SA

Fluorine-silicon modified self-crosslinking acrylic ester emulsion and preparation thereof

InactiveCN101348595ASimple preparation processReaction conditions are easy to controlCoatingsPolymeric surfacePolymer science

The invention provides a fluorine-silicon modified self-crosslinking acrylic ester emulsion and a preparation method thereof, belonging to the technical field of polymer synthesis. The emulsion is a product formed by organosilicon monomers, fluoride-containing acrylic monomers, (methyl) acrylic monomers and self-crosslinking monomers through core-shell emulsion polymerization. The preparation method adopts a core-shell emulsion polymerization method, thereby ensuring that the fluoride-containing acrylic monomers tend to surface polymerization, and fluorine atoms tend to polymer surface in emulsion film forming process; moreover, the monomers capable of self-crosslinking is added to a shell layer, so as to utilize the crosslinking of the monomers to fixedly limit the migration of the fluorine atoms towards the inside of latex particles, as well as the swing of chains, thereby ensuring that the performances of the fluoride-containing emulsion are completely embodied. The preparation method improves the water resistance, stain resistance, solvent resistance, weather resistance and other comprehensive performances of the emulsion. The fluorine-silicon modified self-crosslinking acrylic ester emulsion prepared through the preparation method can be widely applied to high-grade building paint, industrial paint and wooden ware varnish. Moreover, the preparation method has the characteristics of simple manufacturing process, easy reaction condition control, good emulsion stability and environment-friendly property.

Owner:PEKING UNIV +1

Water acrylic resin and preparing method thereof

The utility model relates to a water-based acrylic resin paintand the manufacturing method. The basic ray materials comprise acrylic monomer, styrene monomer, initiator, cosolvent, and active solvent. The utility model is characterized in that the acrylic monomer comprises acrylic derivative with hydroxyl; the cosolvent is ether alcohol solvent; the active solvent is butyl carbonate ethylene derivative active solvent; the initiator is peroxide initiator; and the neutralizer is Amine neutralizer. The resin is manufactured through two-step process. In the first step, water-based acrylic resin prepolymer is manufactured and is then manufactured into resin latex through inner emulsification on the second step. The product is of long storage time and is of no added emulsifier. Under the room temperature, the product can cross-link with water-based isocyanate curing agent to form membrane. The utility model is of excellent membrane, good water resistance, anti-scrubbing property, chemical resistance and sullying resistance.

Owner:上海市涂料研究所有限公司

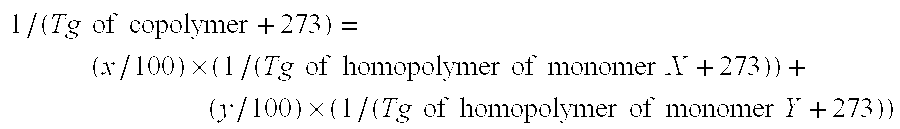

Fluoropolymer aqueous hybrid compositions with improved film formation

The invention relates to aqueous fluoropolymer hybrid compositions made by a seeded emulsion polymerization process, having improved film formation properties. The seed is a fluoropolymer dispersion. At least two different monomer compositions are added sequentially to the seeded dispersion. These monomer compositions preferably include acrylic monomers. The first monomer composition is selected for miscibility with the fluoropolymer dispersion. The second monomer composition is selected to have a glass transition temperature (Tg) of less than 30° C. The final composition can be formulated to make coatings with a minimum film forming temperature (MFFT) of less than 5° C., and a maximum VOC of 50 g / liter. The composition is especially useful for coatings and films.

Owner:ARKEMA INC

Fluorocopolymers blends

InactiveUS20080153977A1High glass transition temperatureImprove performanceChemical recyclingCoatingsMethacrylatePolymer science

A polymer blend including: (i) a fluoroolefin polymer prepared by a process, including contacting in a first reaction zone an initiator, 2,3,3,3-tetrafluoro-1-propene, and optionally, at least one first ethylenically unsaturated comonomer capable of copolymerizing therewith, wherein contacting is carried out at a first temperature, pressure and length of time sufficient to produce the fluoroolefin polymer; and (ii) an acrylic polymer prepared by a process, including contacting in a second reaction zone an initiator, at least one acrylic monomer selected from the group consisting of: acrylic acid, methacrylic acid, acrylate ester, methacrylate ester, and a mixture thereof, and optionally, at least one second ethylenically unsaturated comonomer capable of copolymerizing therewith, wherein contacting is carried out at a second temperature, pressure and length of time sufficient to produce the acrylic polymer. Processes for preparing the polymer blends are also provided.

Owner:HONEYWELL INT INC

Polylactic acid-containing resin composition and product molded therefrom

InactiveUS20090018237A1Satisfactory in durabilityMeet heat resistanceCoatingsHeat resistanceRefractive index

A polylactic acid-containing resin composition is provided which comprises 100 parts by mass of a resin containing 20 to 98 mass % of polymethyl methacrylate and 80 to 2 mass % of polylactic acid, and 1 to 100 parts by mass of an impact resistance improving material. The impact resistance improving material is a polymeric material comprising an acrylic monomer unit. The impact resistance improving material has a refractive index of 1.402 to 1.542. The resin composition is excellent in heat resistance, moldability, durability, transparency and impact resistance.

Owner:UNITIKA LTD

UV curing offset printing ink and use

The invention relates to UV cured lithographic ink and purposes thereof. The ink is a compound which comprises the following components by the weight percent: 30 to 50 of polyester acrylic ester, 0 to 15 of epoxy acrylic ester, 2 to 22 of high-viscosity monofunctional polyurethane acrylic ester, 0 to 10 of acrylic monomer, 10 to 15 of photoinitiator, 2 to 5 of filler and 16 to 22 of pigment. The UV curing glue printing ink of the invention can be cured at high speed, can meet the requirements of high-speed packaging, printing and environment protection, does not contain VOC, has little irritation to the human skin, and can be used as lithographic ink for the high-speed printing, and paper and plastic printing of packaging and printing.

Owner:深圳市美丽华科技股份有限公司

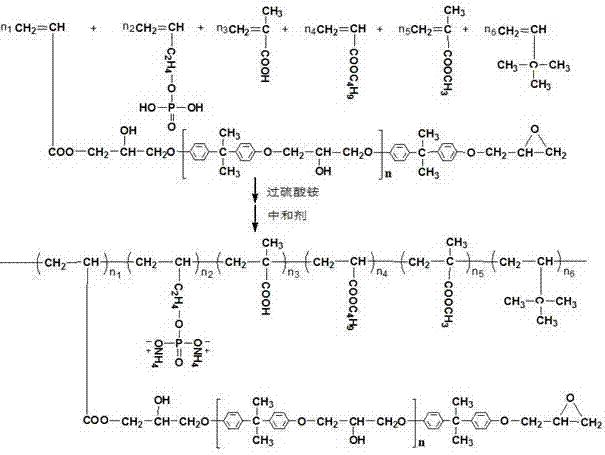

Single-component self-phosphatizing antirust acrylic emulsion, and preparation method and application thereof

InactiveCN102924667AImprove anti-corrosion performanceSolve the repeatabilityAnti-corrosive paintsWater basedEpoxy

The invention discloses a single-component self-phosphatizing antirust acrylic emulsion, and a preparation method and application thereof. Self-made epoxy monoacrylate and acrylic phosphate used as monomers are subjected to radical copolymerization with acrylic acid monomer; and a seed emulsion semicontinuous method is utilized to obtain the emulsion. The emulsion used as a film forming material is matched with related pigment, filler and assistants to obtain water-based paint. When being used on the automobile leaf spring surface, the water-based paint can be cured at 80 DEG C within 20 minutes to form a film, of which the adhesive force is Grade 0, the hardness is 3H and the salt-fog resistance is 1000 hours. The method solves the problems of poor water resistance, salt-fog resistance, weather resistance and storage stability of the coated film of the existing antirust emulsion; and the method also solves the problems of incapability of recycling ground waste, and poor antirust capacity of unit coating thickness in the existing automobile leaf spring application process, and omits the procedure of phosphatizing on the substrate surface before application due to the introduction of the phosphate monomer.

Owner:武汉海源九天新材料有限公司 +1

A kind of pressure-sensitive adhesive for PET protective film and preparation method thereof

ActiveCN102260478AAdaptableSlightly viscousFilm/foil adhesivesEster polymer adhesivesEthylene HomopolymersSolvent

The invention relates to a pressure-sensitive adhesive for a PET protective film and a preparation method thereof. The pressure-sensitive adhesive provided by the invention is made from the following raw materials of: by weight, 1-20 parts of a (methyl)acrylate monomer which is used for preparing homopolymers and whose glass transition temperature ranges from minus 45 DEG C to 10 DEG C, 60-90 parts of a (methyl)acrylate monomer which is used for preparing homopolymers and whose glass transition temperature ranges from minus 90 DEG C to minus 50 DEG C, 1-20 parts of a acrylic acid monomer containing functional groups, 0.01-15 parts of a cross-linking agent, 0.01-1 part of an initiator, 0.001-5 parts of a silane coupling agent, 0.001-5 parts of a plasticizer, 0.001-5 parts of an antistatic agent, and 70-100 parts of a solvent. The pressure-sensitive adhesive for the PET protective film in the invention has characteristics of strong adaptability to the PET basement film, microviscosity, repeelable performance, high temperature resistance and antistatic property, and can be widely applied in the production of the PET protective film. The invention also provides a preparation method ofthe above pressure-sensitive adhesive.

Owner:上海绘兰材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com