Patents

Literature

1964results about How to "Reaction conditions are easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

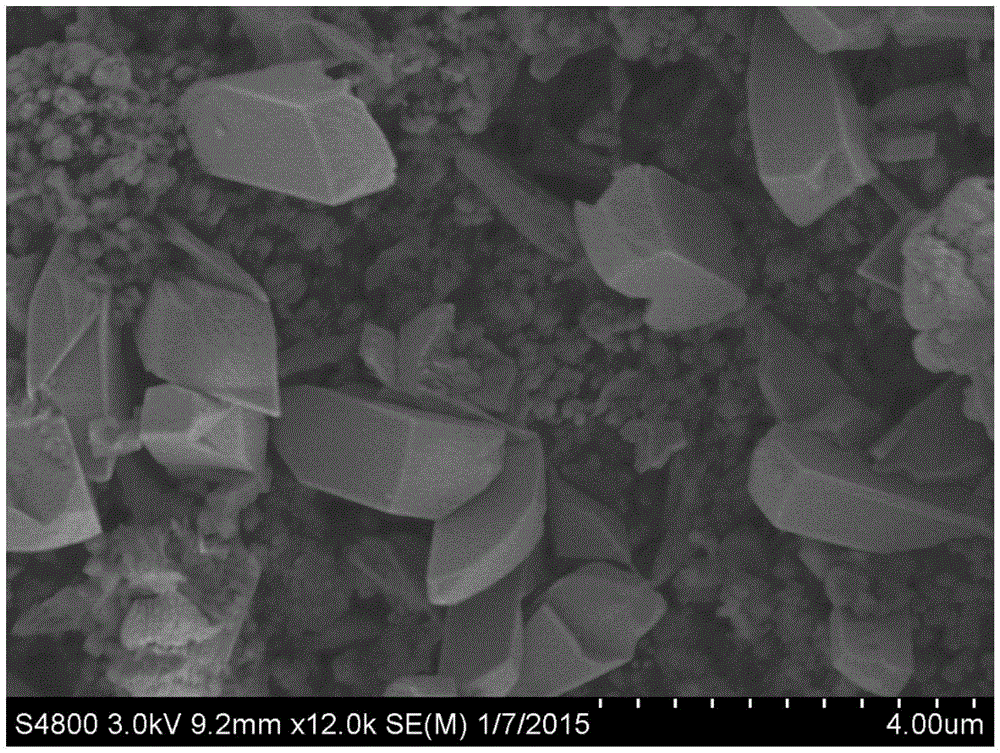

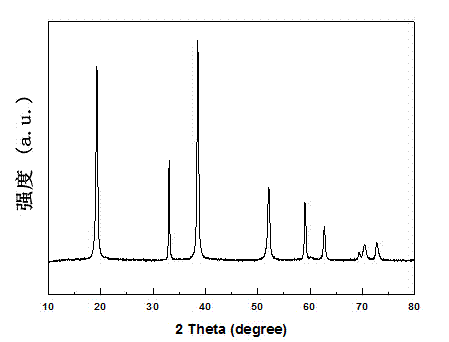

Doped and surface coating co-modified anode material for lithium ion battery and preparation method thereof

InactiveCN103779556APromote circulationEasy to operateSecondary cellsPositive electrodesEnvironmental resistancePhosphate

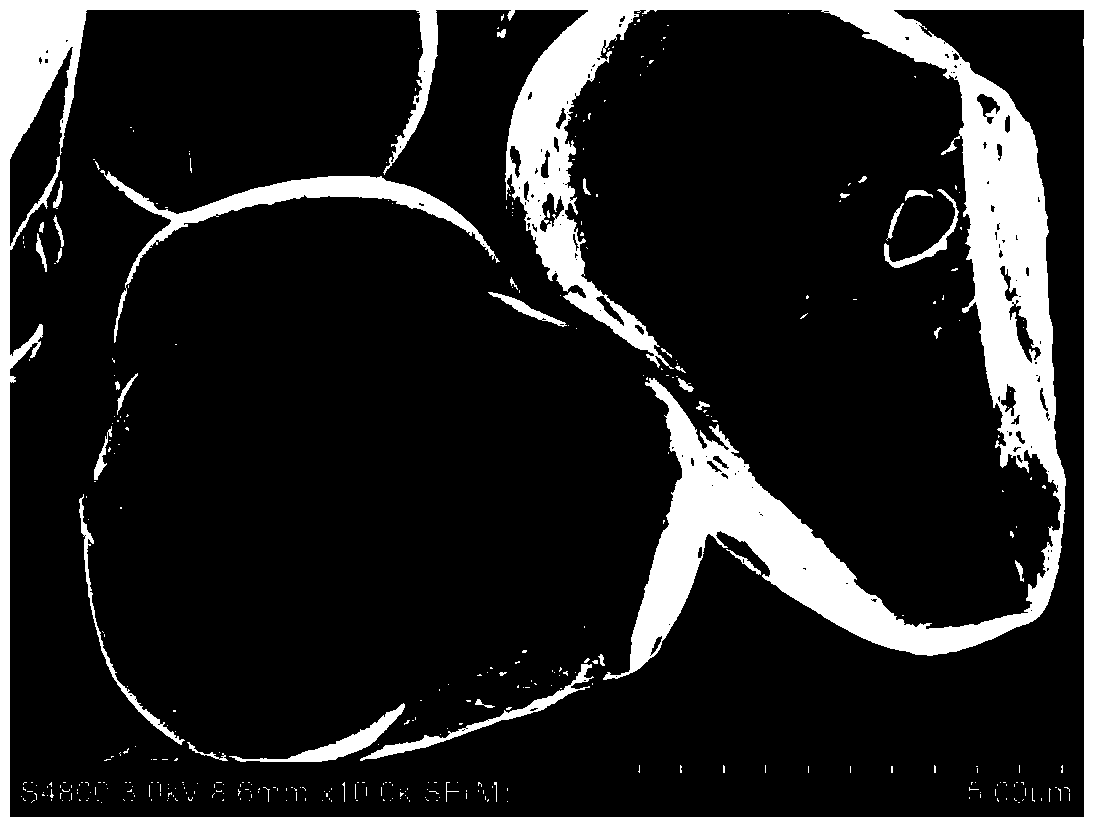

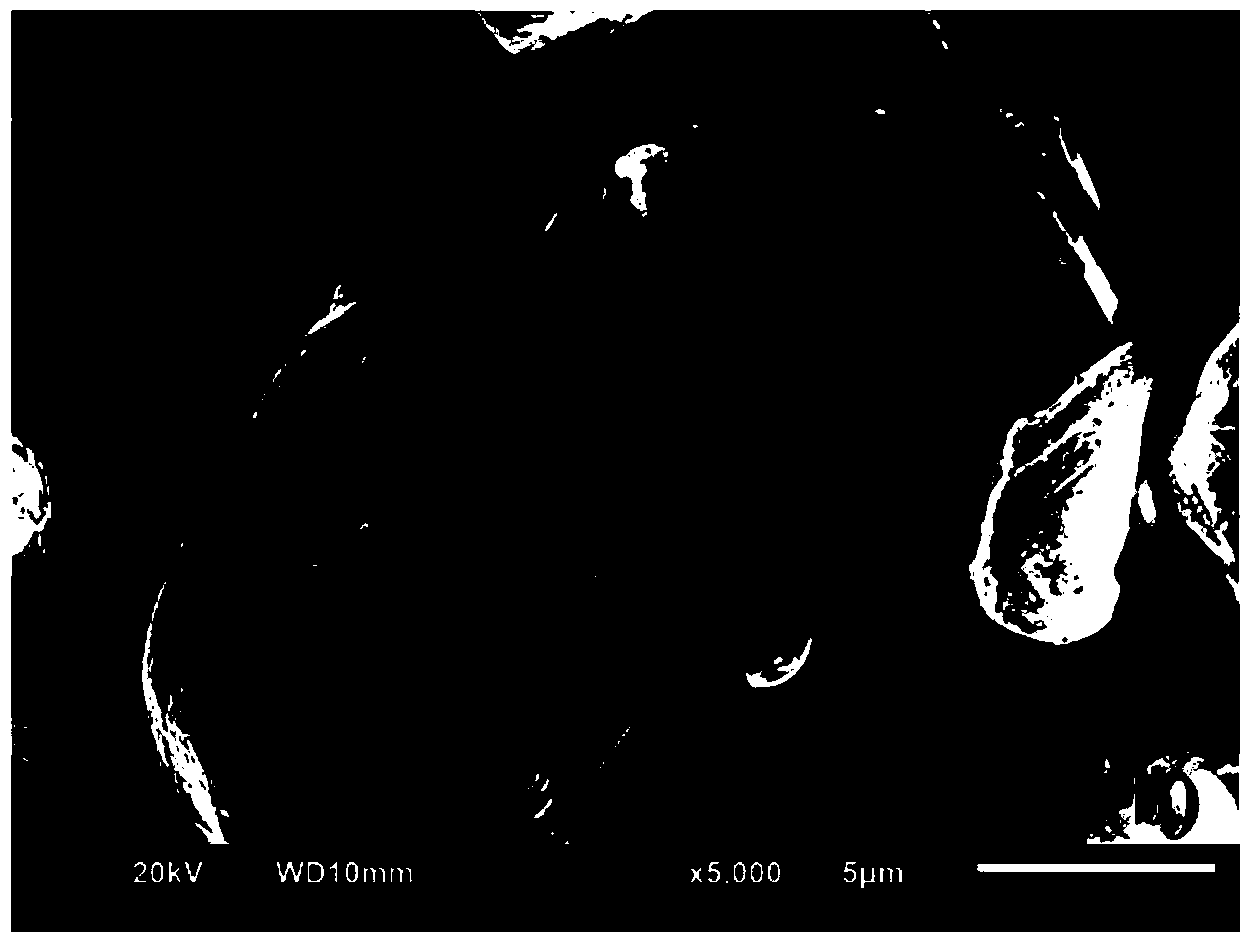

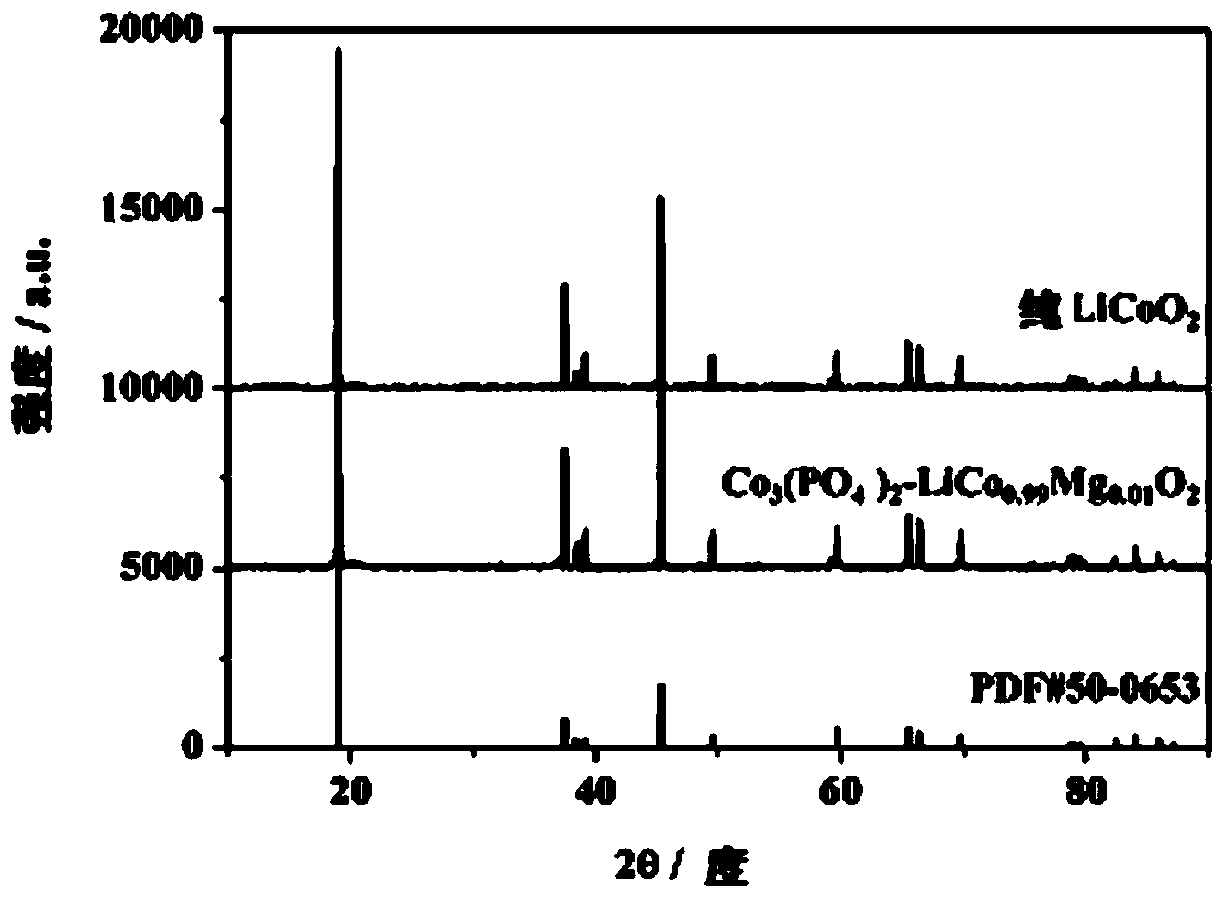

The invention discloses a doped and surface coating co-modified anode material for a lithium ion battery and a preparation method thereof. The anode material uses doped lithium cobalt oxide as a matrix, the surface of which is coated with Co3(PO4)2, AlPO4, Mn3(PO4)2, FePO4, Ni3(PO4)2, Mg3(PO4)2 and other phosphates, therefore, the electric conductivity, the circulating performance, the high temperature and high pressure resistance and other performances are improved. The preparation method has the advantages that the coating material is uniformly coated on the surface of the anode material to be beneficial to improving the electrochemical performance; the method is simple to operate, is green and environment-friendly and has industrial applicability.

Owner:北京盟固利新材料科技有限公司

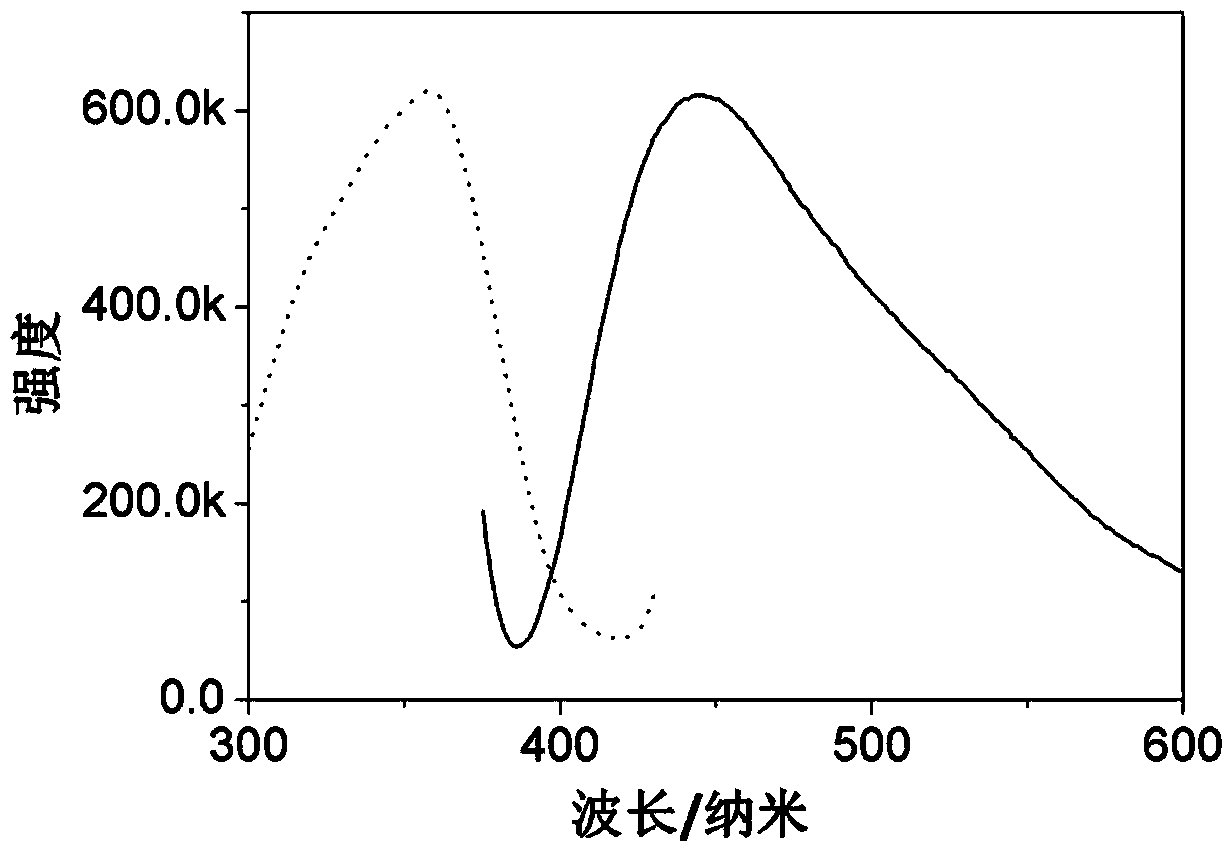

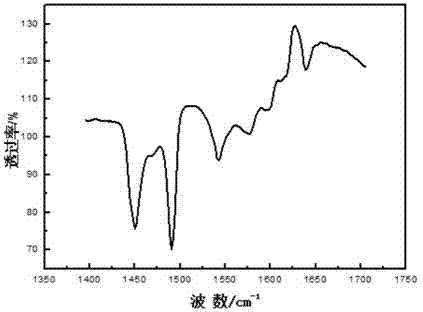

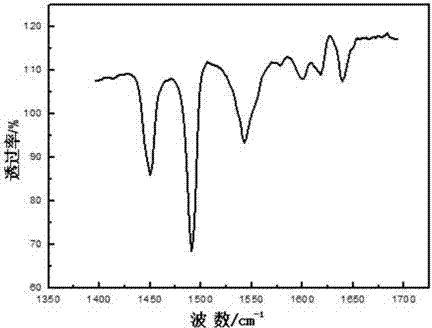

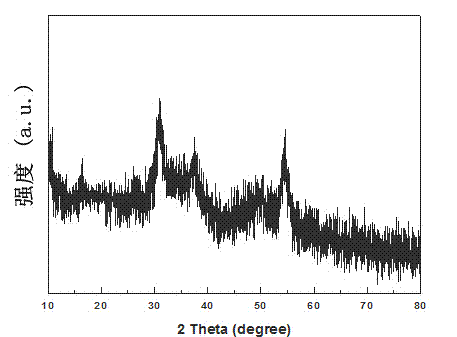

Preparation method of carbon quantum dots with adjustable fluorescence colors

InactiveCN103663412AHigh yieldImprove quantum efficiencyNano-carbonFluorescence/phosphorescenceUltraviolet lightsTumor cells

The present invention relates to a preparation method of carbon quantum dots with adjustable fluorescence colors, and belongs to the technical field of nanometer materials. According to method, citric acid or a citrate is adopted as a carbon source, a nitrogen-containing compound is adopted as a nitridation agent, hydrogen peroxide is adopted as an oxidant, a hydrothermal synthesis method is adopted to obtain an aqueous solution of carbon quantum dots emitting blue or green fluorescence under ultraviolet light excitation, reaction conditions are easily controlled, and the method is suitable for scale production. The prepared carbon quantum dots have advantages of adjustable fluorescence color, high yield, high quantum efficiency, good result reproducibility and the like, wherein the product can be directly used for tumor cell labeling and live cell imaging labeling. According to the present invention, only the one reactant is required, the raw materials are easily-available and non-toxic, the production process does not require special protection, the reaction condition is easily controlled, and the obtained carbon quantum dots have advantages of high yield, high quantum efficiency, good result reproducibility and the like; and the method has characteristics of high yield, simple preparation process, low cost, easy scale production and the like.

Owner:UNIVERSITY OF CHINESE ACADEMY OF SCIENCES

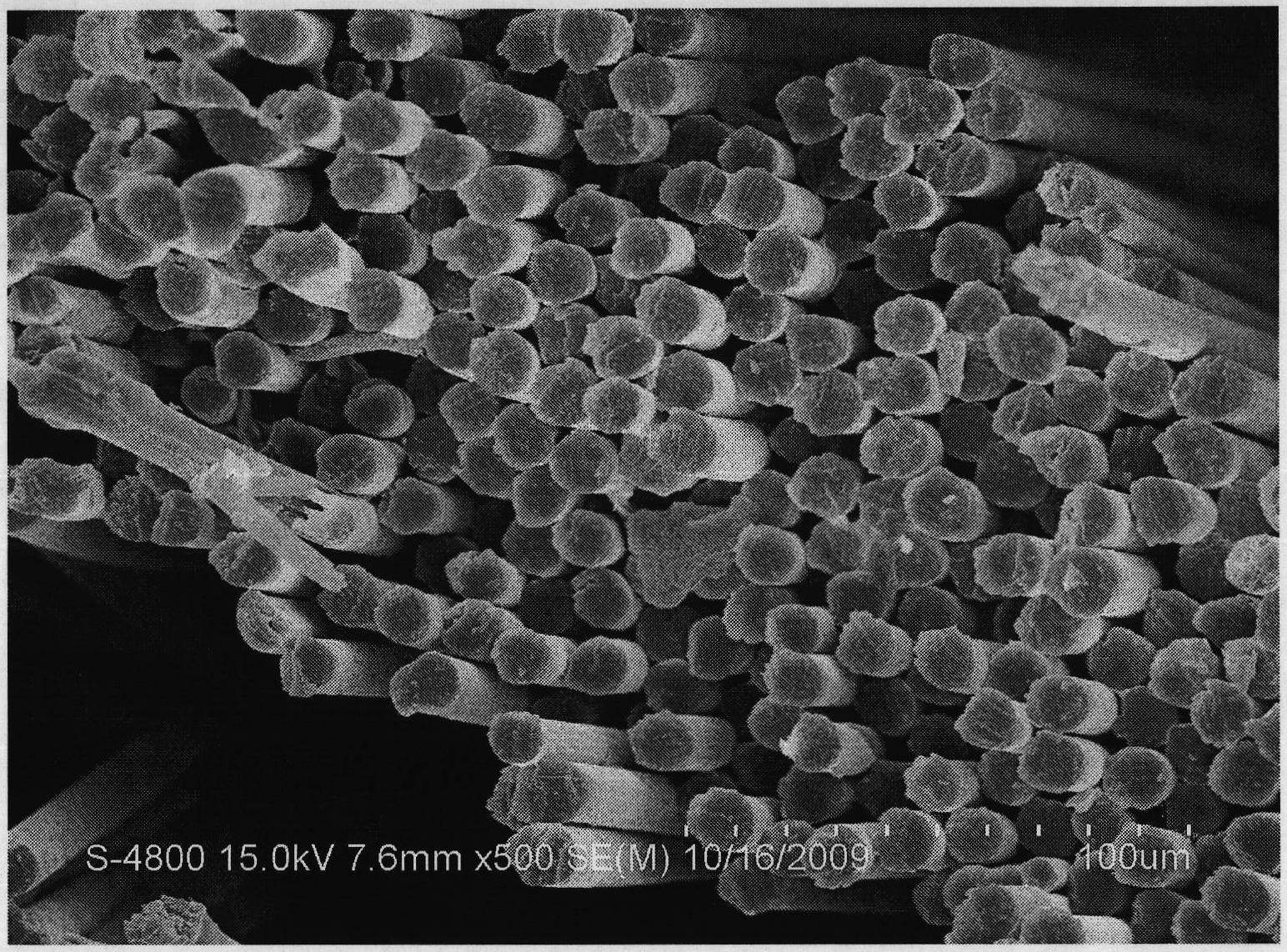

Method for reclaiming carbon fiber reinforced epoxy resin composite material

ActiveCN102181071ARelieve stressImprove degradation efficiencyPlastic recyclingBulk chemical productionEpoxyPhosphomolybdic acid

The invention relates to a method for reclaiming a carbon fiber reinforced epoxy resin composite material. The conventional method is high in equipment requirement and high in reclamation cost. The method comprises the following steps of: adding a catalyst into an organic reagent to prepare supercritical CO2 composite solution; putting the carbon fiber reinforced epoxy resin composite material tobe decomposed into a reaction kettle, and adding the supercritical CO2 composite solution; and reacting for 1 to 24 hours at the temperature of between 100 and 250 DEG C under the pressure of 7.5 to 25.0MPa, cooling the product to normal temperature, washing and drying the solid product in the product to obtain carbon fibers, and performing reduced pressure distillation on the liquid product in the product to obtain phenol and derivatives thereof. The catalyst is one or two of liquid super acid, solid super acid, phosphotungstic acid, phosphomolybdic acid, acetic acid, formic acid, hydrochloric acid, sulfuric acid and nitric acid. The method has the advantages of high degradation efficiency, environmental friendliness, low cost and the like, and is a green method for reclaiming the waste and old carbon fiber reinforced epoxy resin composite material.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

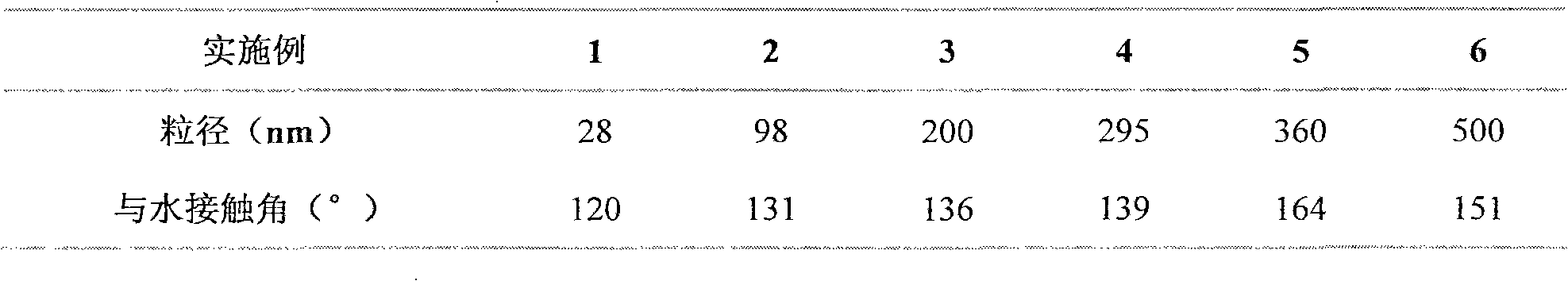

Method for preparing hydrophobic nano-silica with controllable grain diameter

InactiveCN101880478AGood dispersionHydrophobicPigment treatment with organosilicon compoundsSal ammoniacReaction temperature

The invention discloses a method for preparing hydrophobic nano-silica with a controllable grain diameter. The method comprises the following steps of: adding ammonia water and water into absolute ethanol and stirring the mixture for 0.5 to 1 hour at the temperature of between 20 and 70 DEG C; under an alkali condition, performing hydrolytic polycondensation to obtain nano-silica by using the absolute ethanol as solvent and tetraethoxysilane as a raw material; and preparing the hydrophobic nano-silica with the grain diameter in the range of between 20 and 500 nm by using a silane coupling agent as a hydrophobic modifier, wherein the using amount of ammonia water is 40 to 100 percent of the weight of the tetraethoxysilane; the using amount of the absolute ethanol is 12 to 25 times the weight of the tetraethoxysilane; and the using amount of the water is 30 to 150 percent of the weight of the tetraethoxysilane. The preparation method has the advantages of simpleness, easy operation and mild reaction condition. The hydrophobic nano-silica with the controllable grain diameter can be prepared by adjusting proportion and technological parameters of the materials.

Owner:SOUTH CHINA UNIV OF TECH

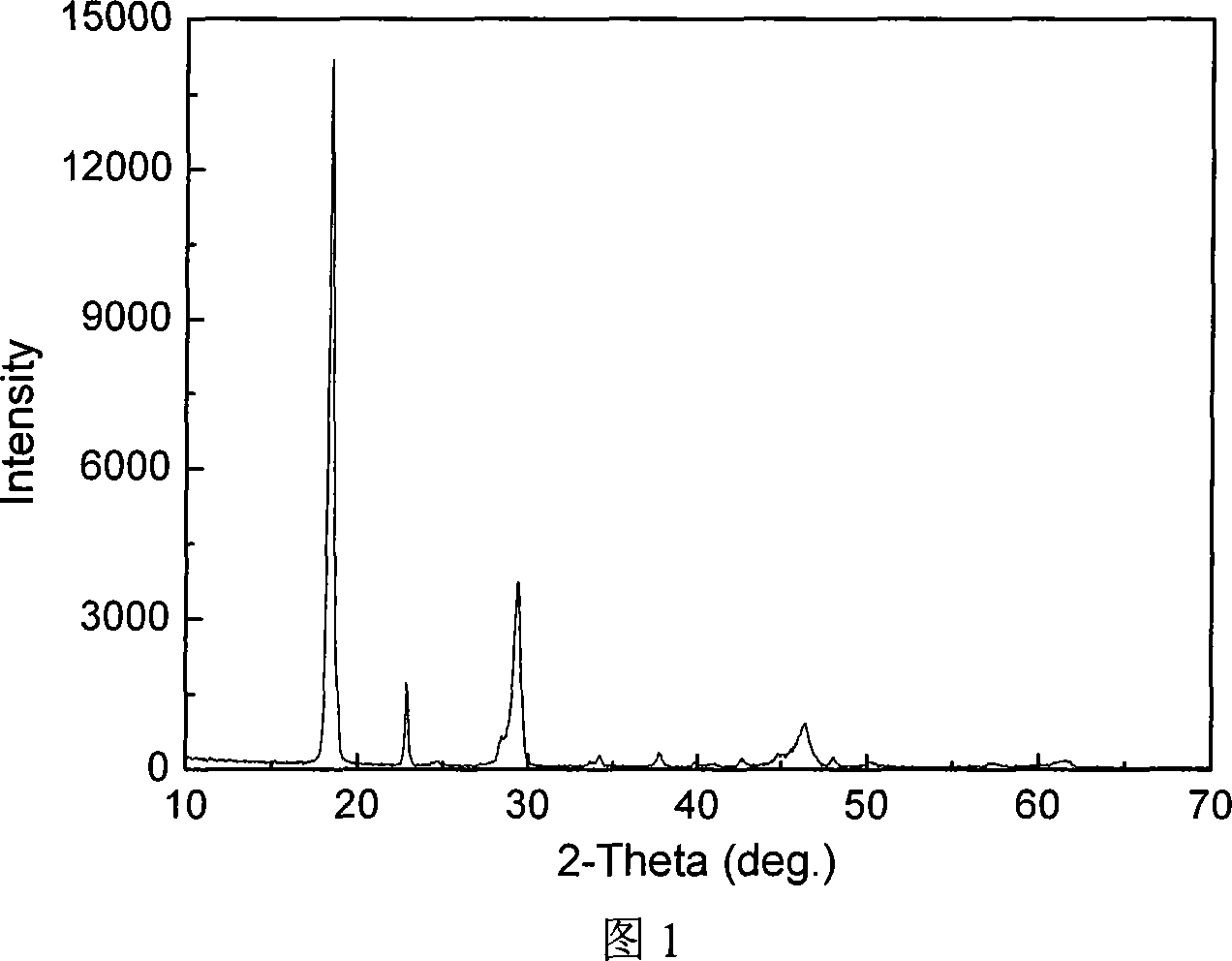

Method for preparing anode material of lithium ion battery in series of phosphate of olivine type

InactiveCN101049922AAchieve hybridEvenly distributedCell electrodesPhosphorus compoundsAluminium-ion batteryPhosphate

This invention relates to a method for preparing olivine-type phosphate-series lithium ion battery anode material. The method comprises: mixing one or more of ferrous salt solution, cobalt salt solution and manganese salt solution with oxalic acid or oxalate (precipitating agent) aqueous solution to obtain composite oxalate precursor, uniformly mixing with lithium source and phosphorus source by ball milling, and reacting in inert or weak-reductive atmosphere to obtain olivine-type phosphate-series lithium ion battery anode material. The method utilizes co-precipitation method for metal ion doping, and realizes molecular level uniform mixing among different ions. The obtained olivine-type phosphate-series lithium ion battery anode material has uniform chemical and physical compositions. The average particle size can be controlled within 0.3-10 mu.m. The first charge and discharge cycle specific capacity can reach 150 mAh / g at 0.1 C rate and room temperature. The livine-type phosphate-series lithium ion battery anode material has such advantages as high cycle performance and high charge / discharge performance.

Owner:CENT SOUTH UNIV

Fluorine-silicon modified self-crosslinking acrylic ester emulsion and preparation thereof

InactiveCN101348595ASimple preparation processReaction conditions are easy to controlCoatingsPolymeric surfacePolymer science

The invention provides a fluorine-silicon modified self-crosslinking acrylic ester emulsion and a preparation method thereof, belonging to the technical field of polymer synthesis. The emulsion is a product formed by organosilicon monomers, fluoride-containing acrylic monomers, (methyl) acrylic monomers and self-crosslinking monomers through core-shell emulsion polymerization. The preparation method adopts a core-shell emulsion polymerization method, thereby ensuring that the fluoride-containing acrylic monomers tend to surface polymerization, and fluorine atoms tend to polymer surface in emulsion film forming process; moreover, the monomers capable of self-crosslinking is added to a shell layer, so as to utilize the crosslinking of the monomers to fixedly limit the migration of the fluorine atoms towards the inside of latex particles, as well as the swing of chains, thereby ensuring that the performances of the fluoride-containing emulsion are completely embodied. The preparation method improves the water resistance, stain resistance, solvent resistance, weather resistance and other comprehensive performances of the emulsion. The fluorine-silicon modified self-crosslinking acrylic ester emulsion prepared through the preparation method can be widely applied to high-grade building paint, industrial paint and wooden ware varnish. Moreover, the preparation method has the characteristics of simple manufacturing process, easy reaction condition control, good emulsion stability and environment-friendly property.

Owner:PEKING UNIV +1

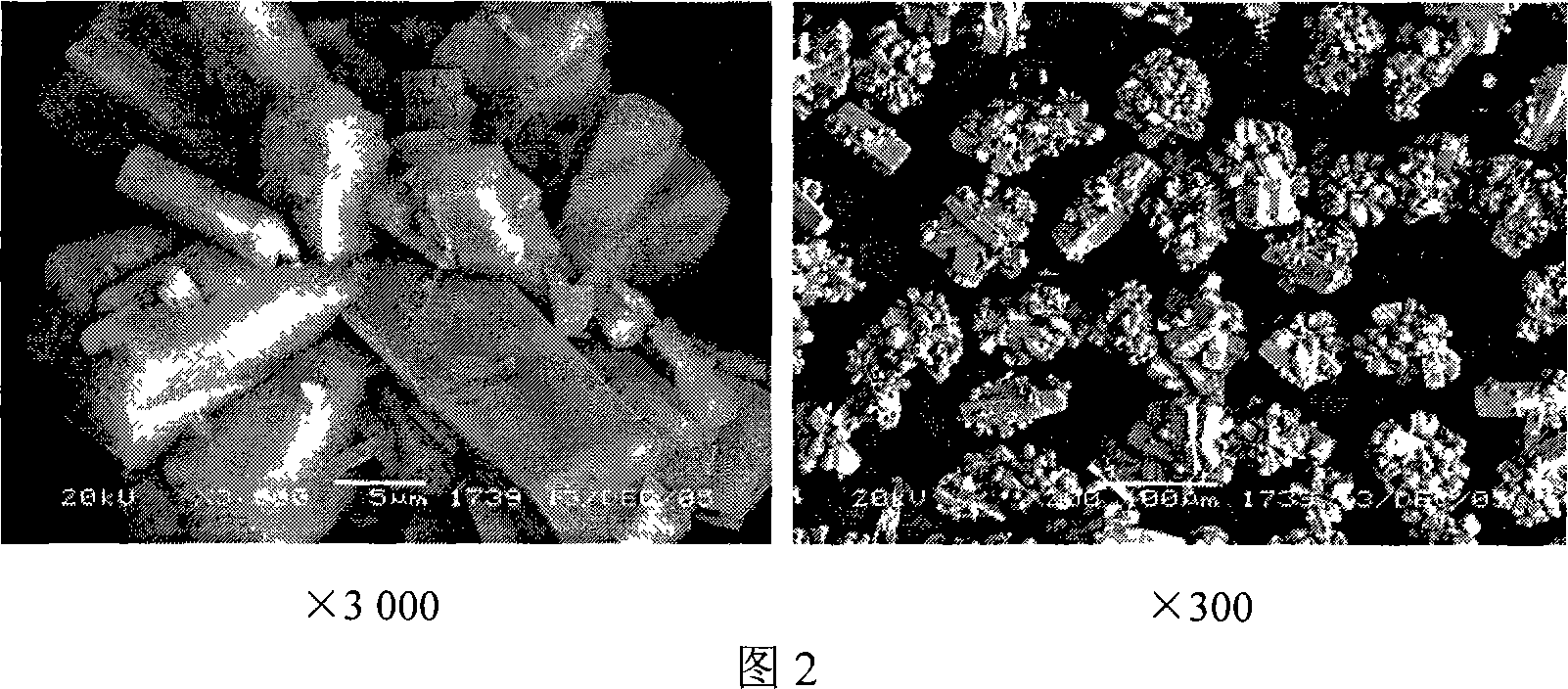

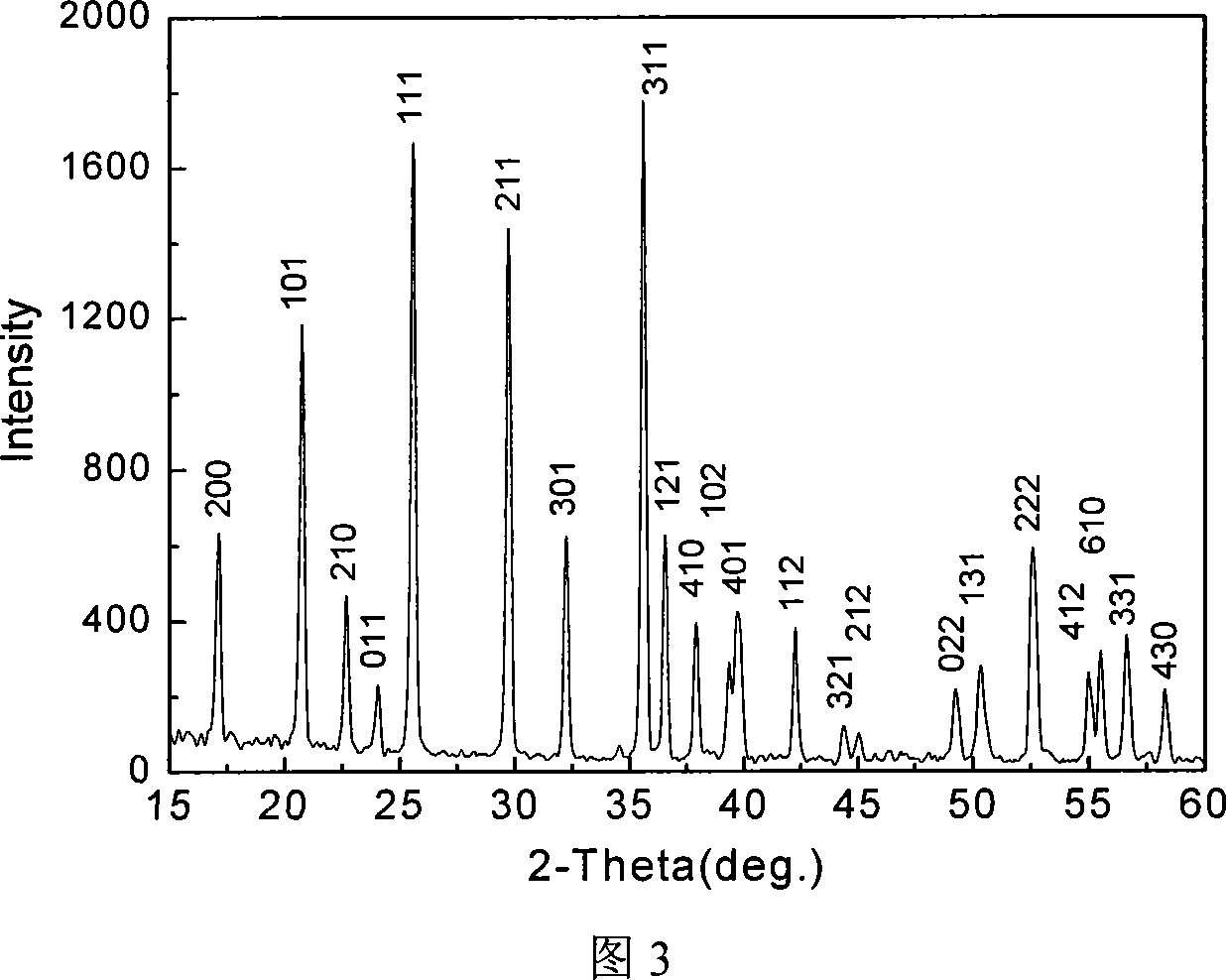

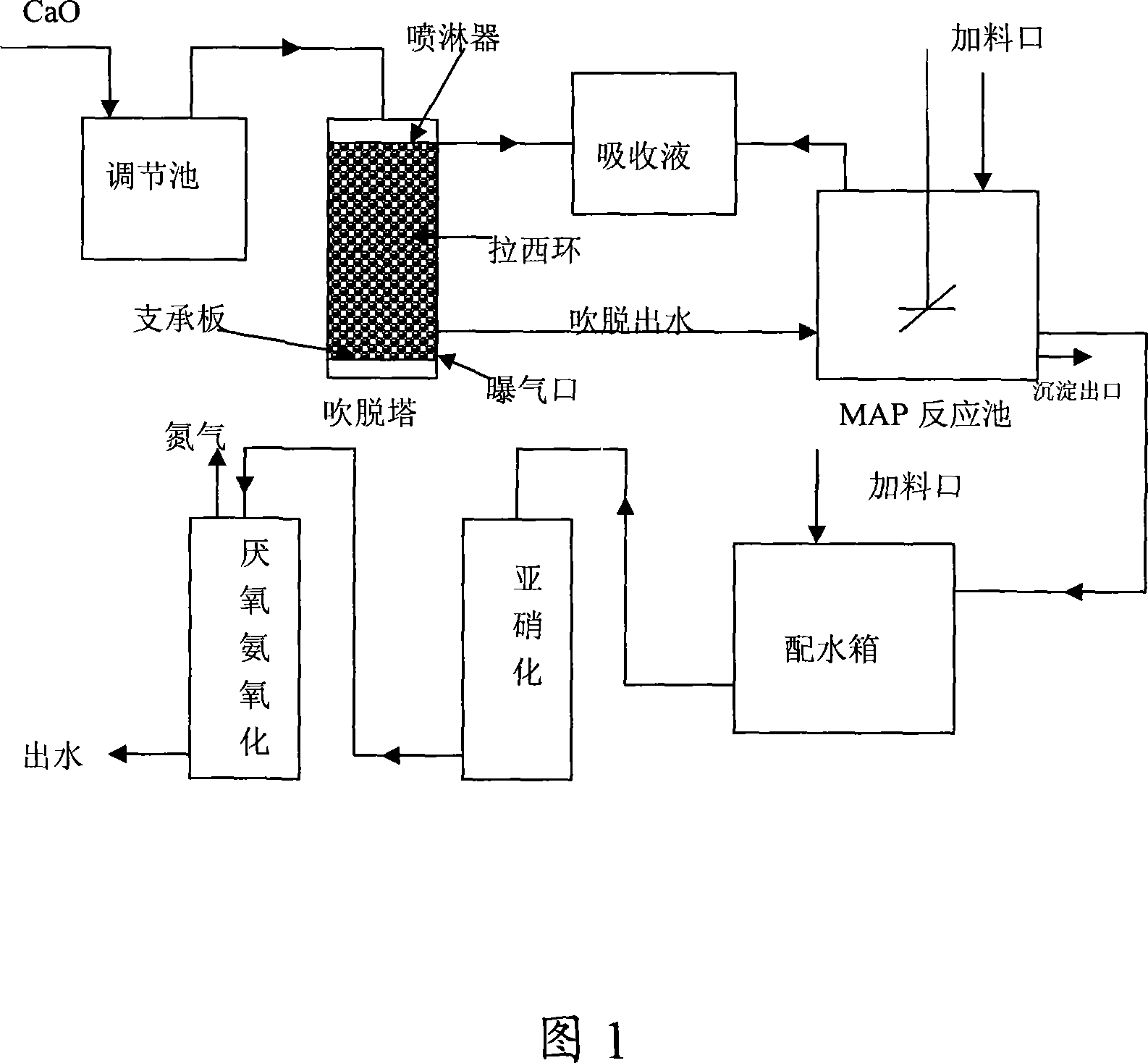

Combined treatment process for high-concentration ammonia nitrogen waste water

InactiveCN101066822AHigh total removal rateReduce energy consumptionTreatment with anaerobic digestion processesMultistage water/sewage treatmentHigh concentrationMagnesium ammonium phosphate

The combined treatment process of high concentration ammonia nitrogen waste water belongs to the field of waste water treating technology. The combined treatment process of high concentration ammonia nitrogen waste water features the combination of blow-off method, MAP method and nitrosation-anaerobic ammoxidation biological method. The treating process of the present invention includes the steps of: adding lime into the waste water in a regulating tank to reach pH of 11-12; blow-off and aerating in a blow-off tank, with the blow-off tail gas entering to an absorbing tank and the blow-off water entering to a MAP reaction tank; treating the blow-off effluent in the MAP reaction tank with thrown disodium hydrogen phosphate and magnesia to produce magnesium ammonium phosphate precipitate exhausted; and the final nitrosation-anaerobic ammoxidation biological treatment. The process has low power consumption and other advantages.

Owner:SHANGHAI UNIV

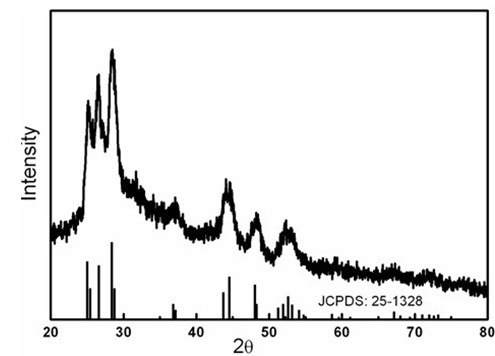

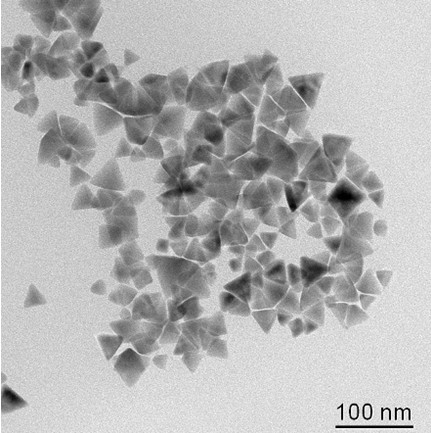

Preparation method of general-purpose multi-metal sulfide nano-material

InactiveCN102633297AHigh yieldAdjustable phaseTin compoundsGallium/indium/thallium compoundsPhenanthrolineDiethyldithiocarbamic Acid

The invention discloses a preparation method of a general-purpose multi-metal sulfide nano-material. The preparation method comprises the following steps of: taking two or more different metal diethyldithiocarbamates, or two or more different metal phenanthroline diethyldithiocarbamates, or the combination of the metal diethyldithiocarbamates and the metal phenanthroline diethyldithiocarbamates as reaction predecessors, performing co-thermal decomposition in a mixed solution of surfactants with different coordination properties, and performing nucleation and growth so as to prepare a high-quality multi-metal sulfide nano-material by one step. The multi-metal sulfide prepared by the preparation method disclosed by the invention has the advantages of pure phase state, adjustable composition, uniform and controllable appearance and size, high yield, low toxicity or no toxicity, better dispersivity in a non-polar organic solvent, easiness in control of reaction conditions, mild preparation conditions, simple operation, good repeatability and capability of realizing large-scale production.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

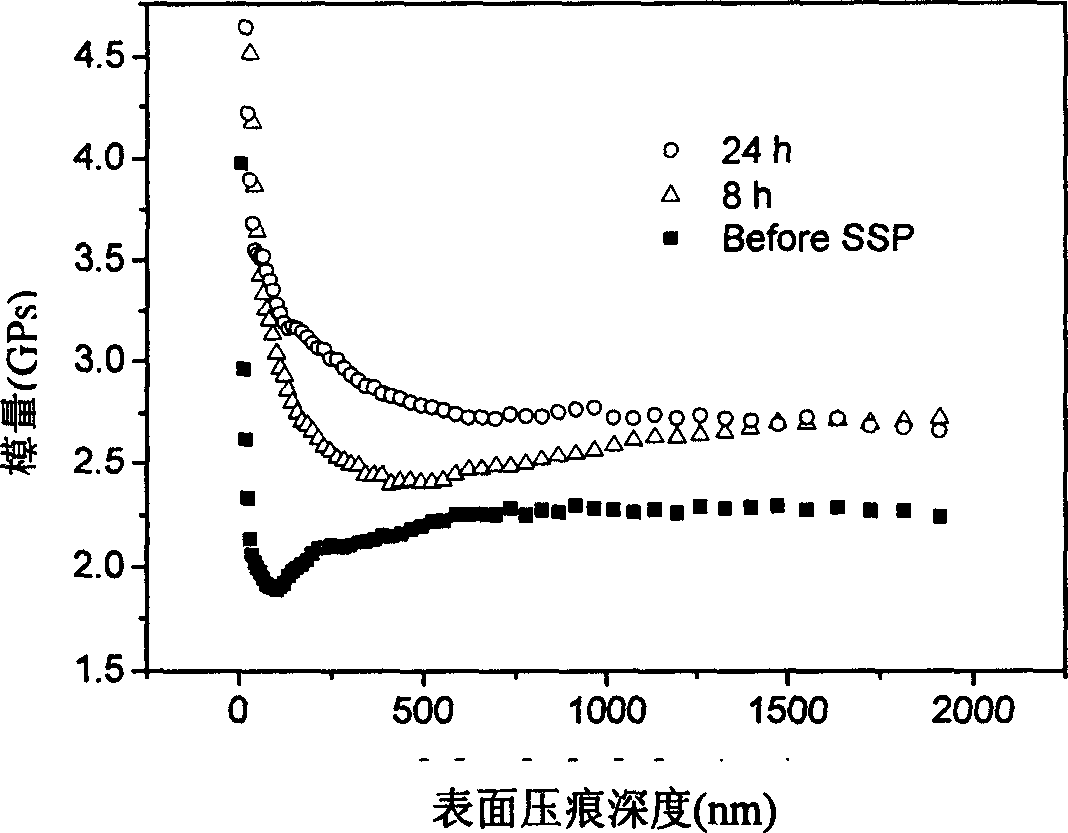

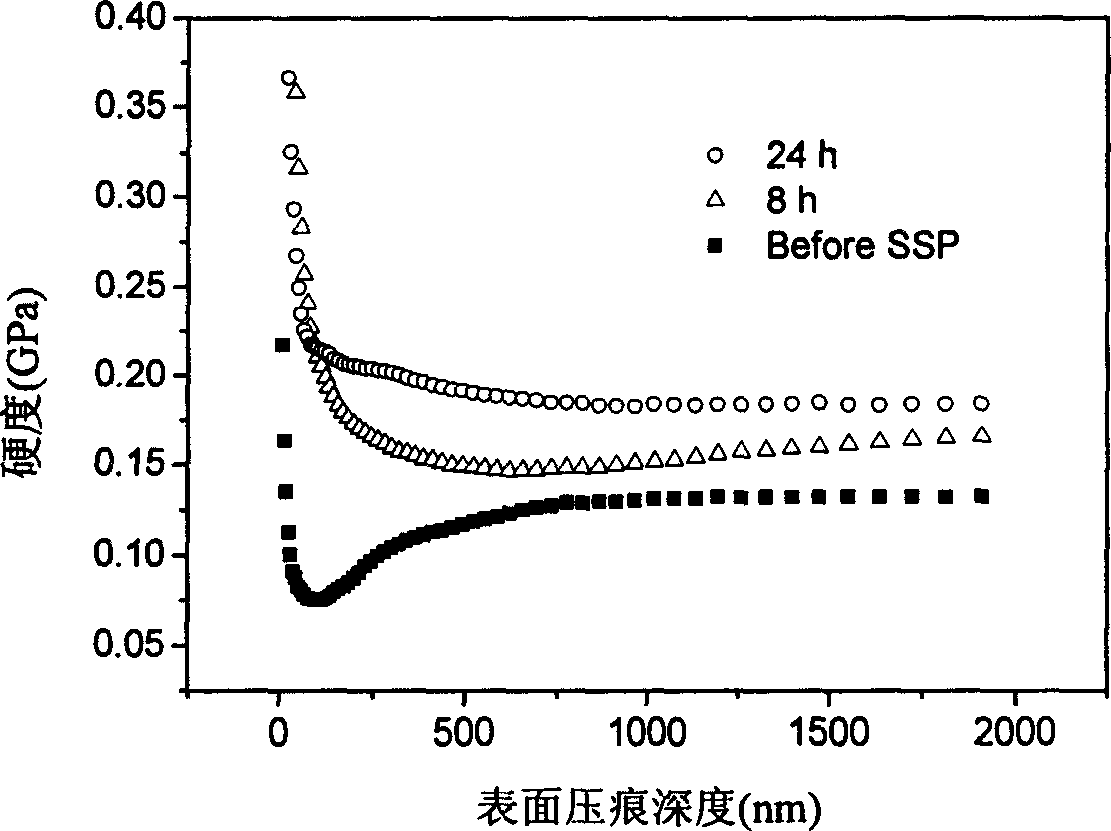

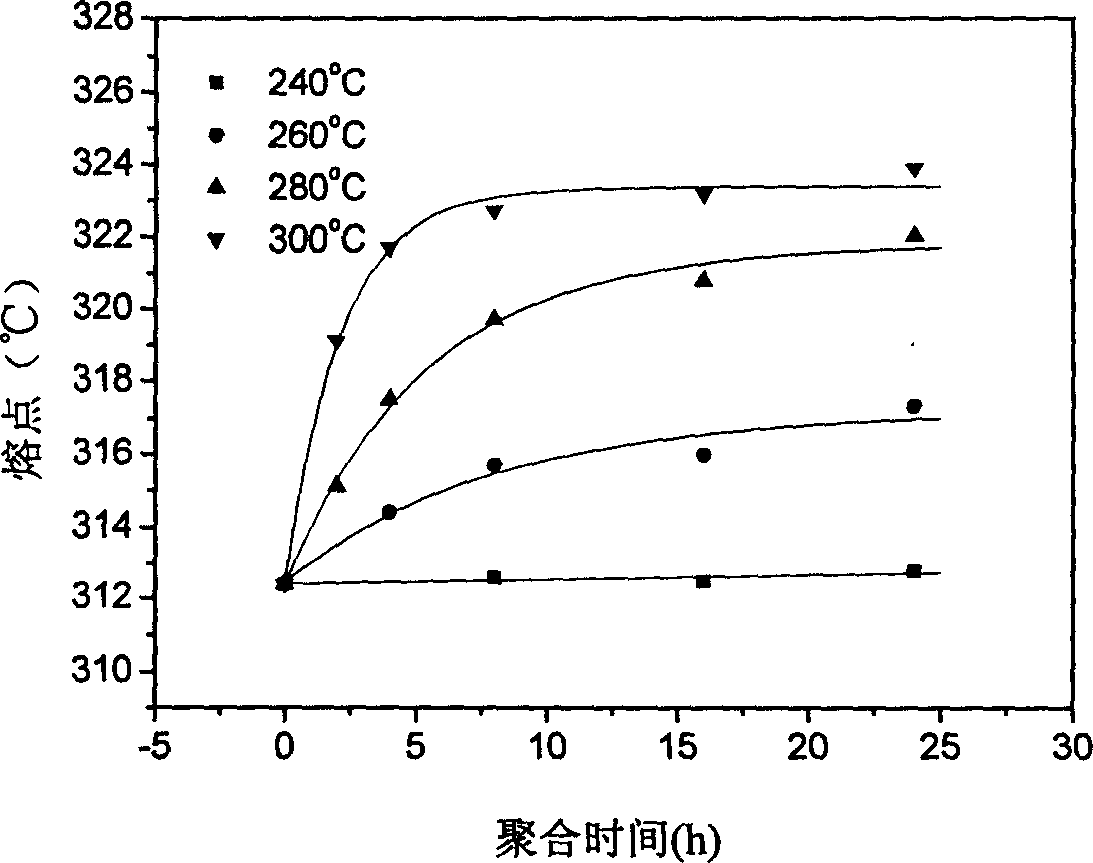

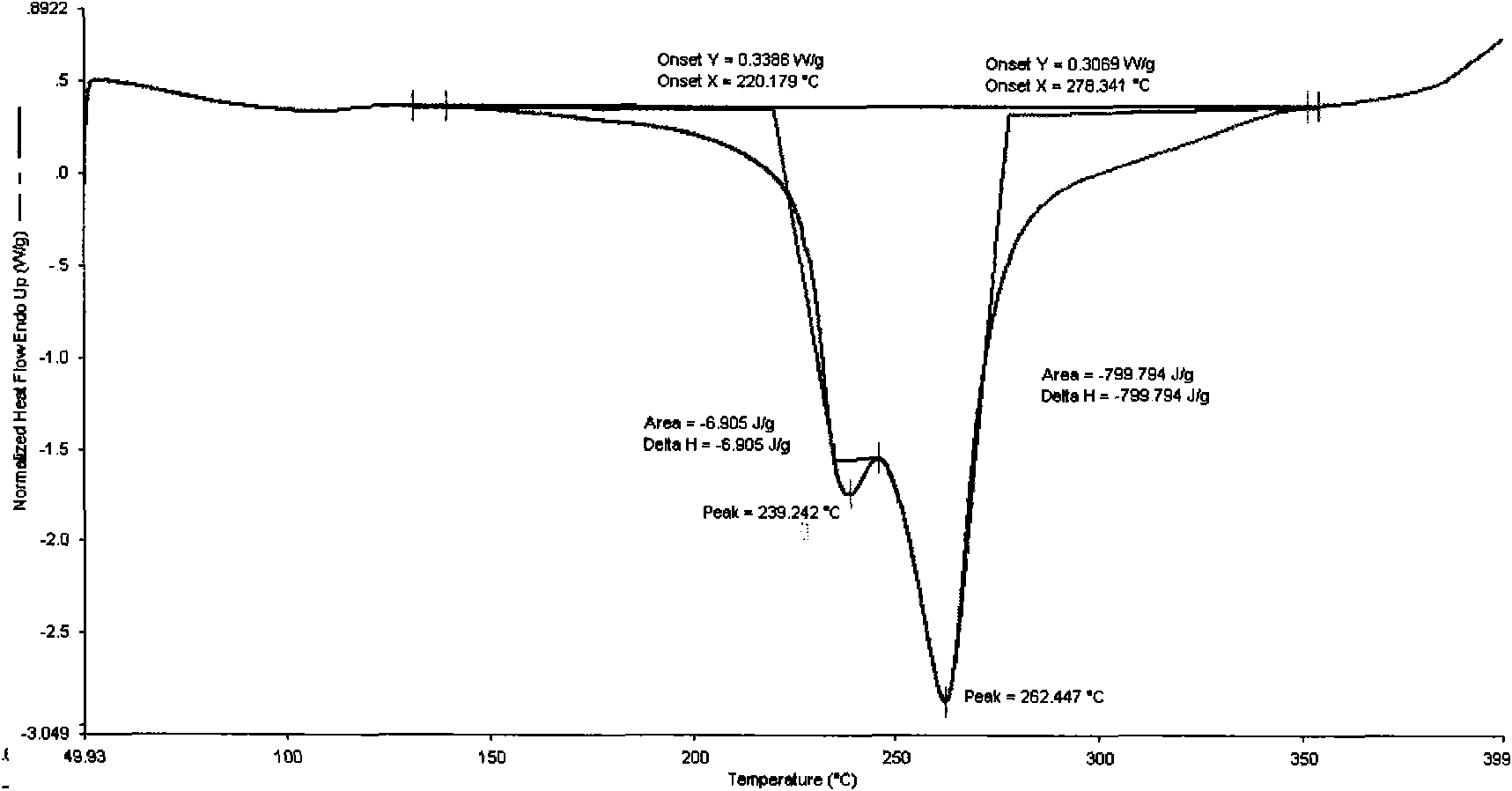

Solid state polymerization preparation method of liquid crystal copolyester

ActiveCN1597727ALower requirementLow costLiquid crystal compositionsBenzoic acidHydroquinone Compound

A process for preparing liquid crystal copolyester by solid polymerization includes such steps as heating the prepolymer poly(parahydroxy benzoic acid / 2,6-naphthalenediformic acid / terephthalic acid / hydroquinone) to a temp which is 10-60 deg.c lower than its fusion point, and solid polimerizing reaction under existance of inertial gas.

Owner:SHANGHAI PRET COMPOSITES +1

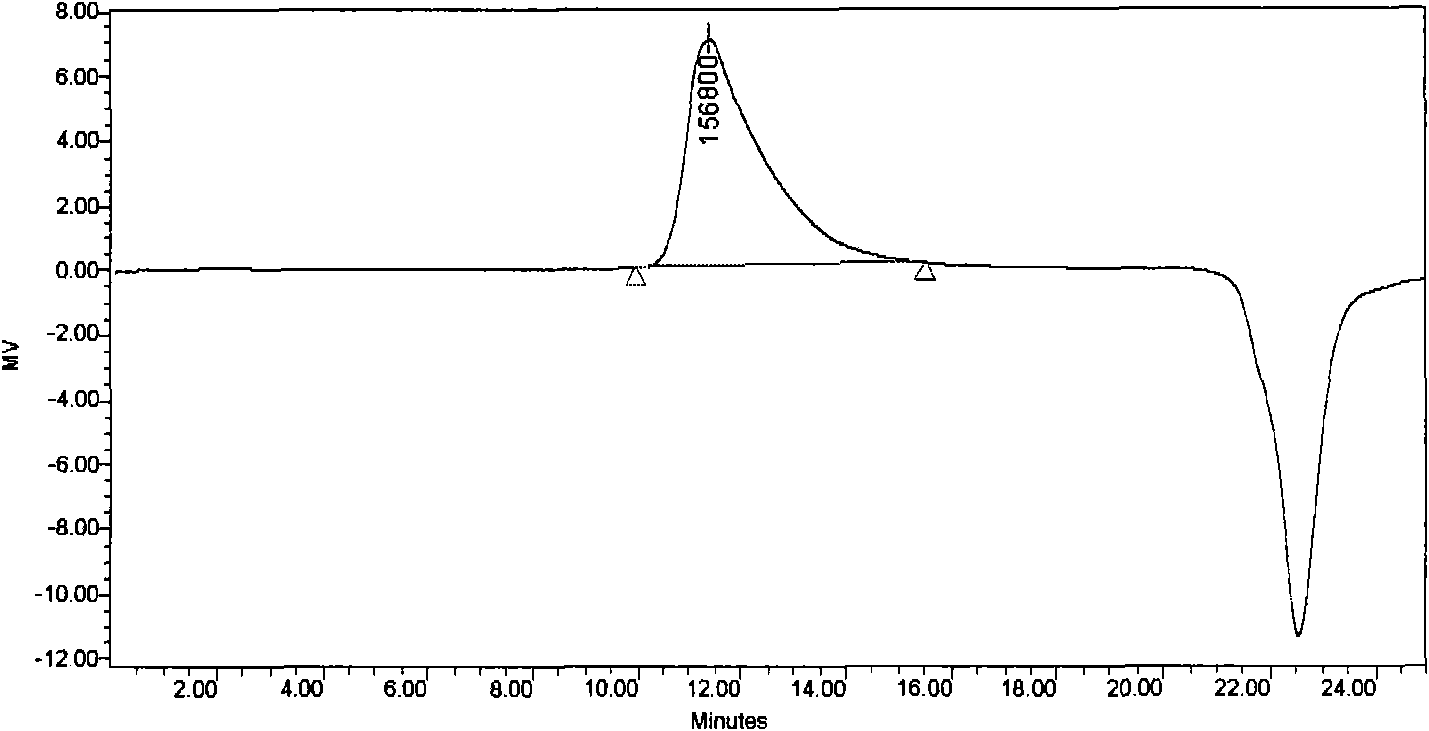

Acrylonitrile copolymer spinning solution with high molecular weight and narrow distribution and preparation method thereof

InactiveCN101805936AHigh molecular weightHigh solid contentMonocomponent synthetic polymer artificial filamentPolymer scienceAlcohol

The invention discloses an acrylonitrile copolymer spinning solution and a preparation method thereof. The spinning solution is a mixed solvent solution of an acrylonitrile copolymer; the acrylonitrile copolymer is formed by polymerization of a first acrylonitrile monomer and a comonomer, and the comonomer comprises unsaturated carboxylic acid monomers; the mass of the first acrylonitrile monomer is 90-99.5% of the total mass of monomers, and the mass of the comonomer is 0.5-10% of the total mass of monomers; the mixed solvent is a mixture comprising dimethyl sulfoxide and at least one of water, alcohol solvents and ketone solvents; and the mass percent concentration of the monomers in the spinning solution is 15-30%. In the invention, the mixed solvent of the dimethyl sulfoxide is adopted in the process of acrylonitrile copolymerization, and the proportion of each solvent is controlled to carry out copolymerization reaction in homogeneous phases; and meanwhile, the second comonomer is continuously replenished in a certain time of reaction to stabilize the instantaneous composition of the acrylonitrile copolymer to obtain the polyacrylonitrile copolymer spinning solution with high molecular weight, narrow molecular weight distribution and uniform chain structure.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Method for preparing polyacrylonitrile based carbon fibre spinning solution

InactiveCN1401675AEvenly distributedLow viscosityFibre chemical featuresDistilled waterFunction group

A polyacrylnitrile-base carbon fibre spinning liquid is prepared from acrylnitrile, dimethyl formamide, distilled water, azodiisobutylnitrile and chain transfer agent through homopolymerization, introducing ammonia gas to stop reaction, and regulating pH value by ammonia gas. Its advantages are uniform distribution of function groups on macro-molecular chain, simple process and easy control.

Owner:ZHONGJIAN TECH CO LTD

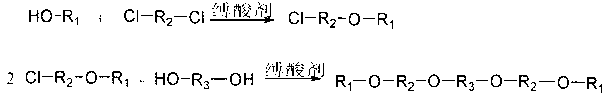

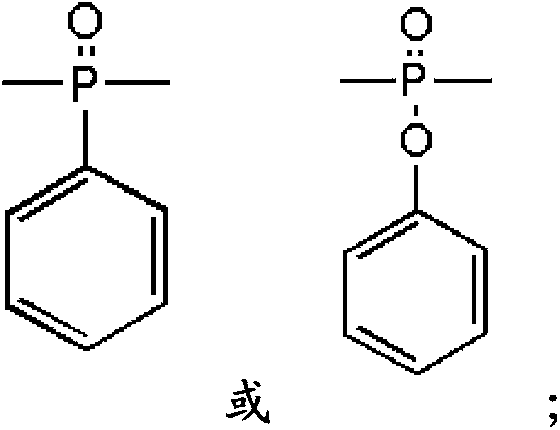

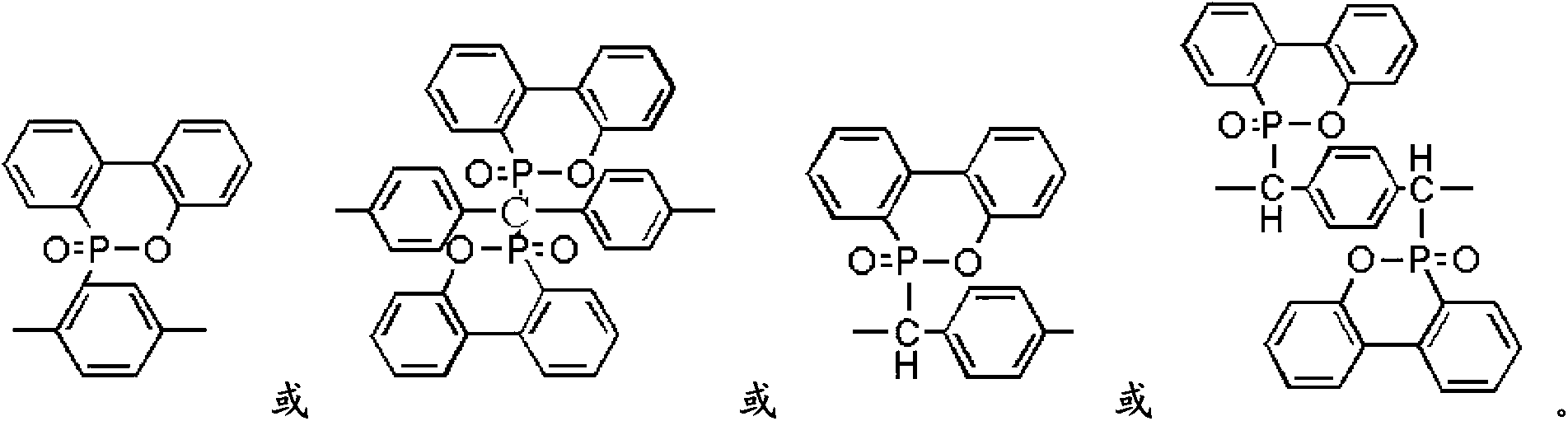

Reactive phosphorus flame retardant containing DOPO and active double bond and preparation method and application thereof

ActiveCN103073746ASimple manufacturing methodImprove reaction conditionsGroup 5/15 element organic compoundsDouble bondPhenol

The invention discloses a reactive phosphorus flame retardant containing DOPO and an active double bond and a preparation method and application thereof. Dichloro replaces phosphate to react with polyhydric alcohols or polyhydric phenol acidifying with propylene or partial methyl propene and then with DOPO modified aryl-dihydric phenol and DOPO modified aryl-dihydric alcohol, and a reactive flame retardant monomer molecule capable of being cured and provided with active double bonds and a DOPO flame retardant group are obtained and can be used in various flame retardants of epoxyacrylates and unsaturated polyester resins and the like containing unsaturated double bond polymer resins. The flame retardant overcomes defects that the compatibility between an additive flame retardant and a matrix is poor, the additive flame retardant and the matrix are easy to lose, the water resistance is poor, and the like, and the LOI (limit oxygen index) value of resins can be improved remarkably and the flame-resistant effect is good when the flame retardant is used for flame retarding in the epoxyacrylates and the unsaturated polyester resins.

Owner:苏州安鸿泰新材料有限公司

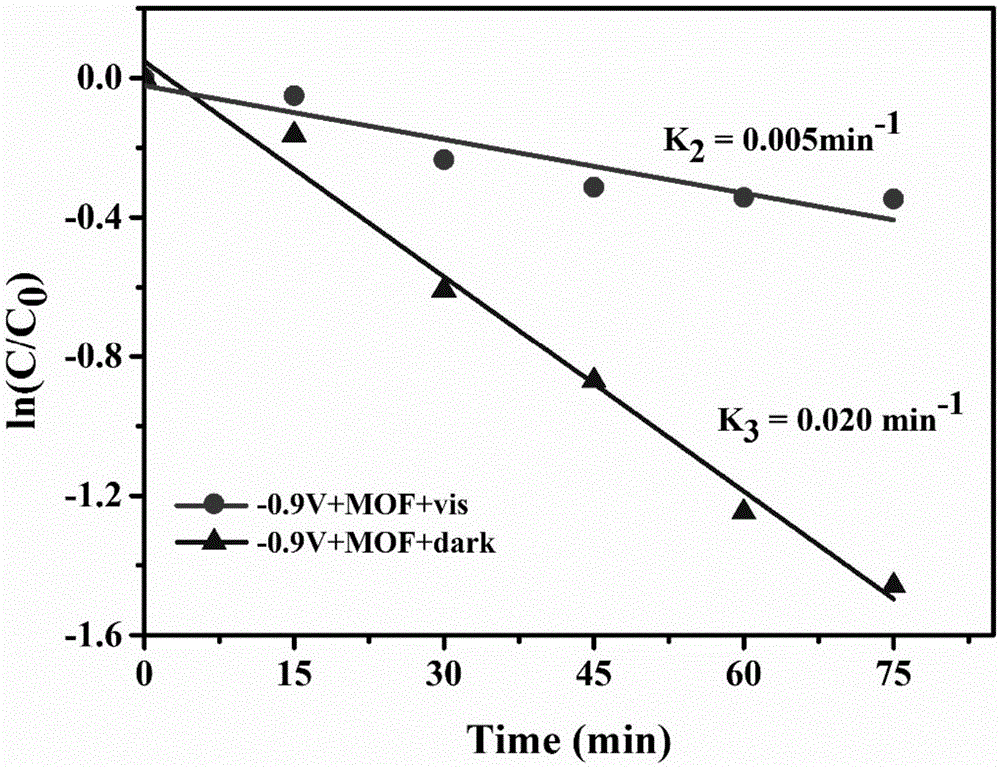

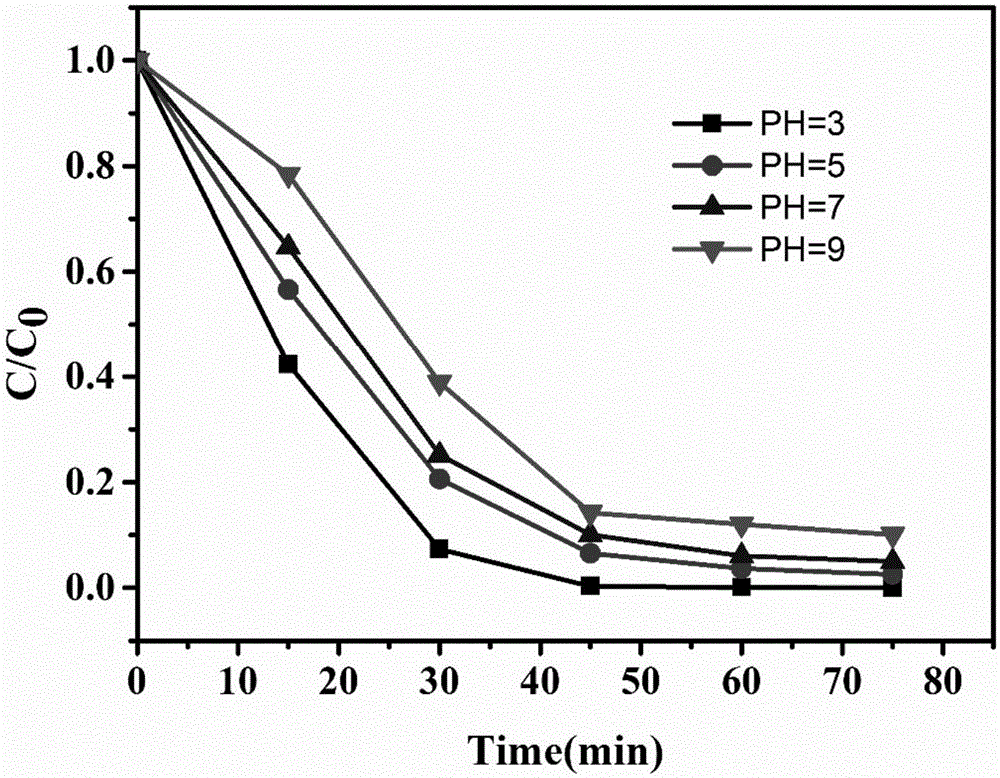

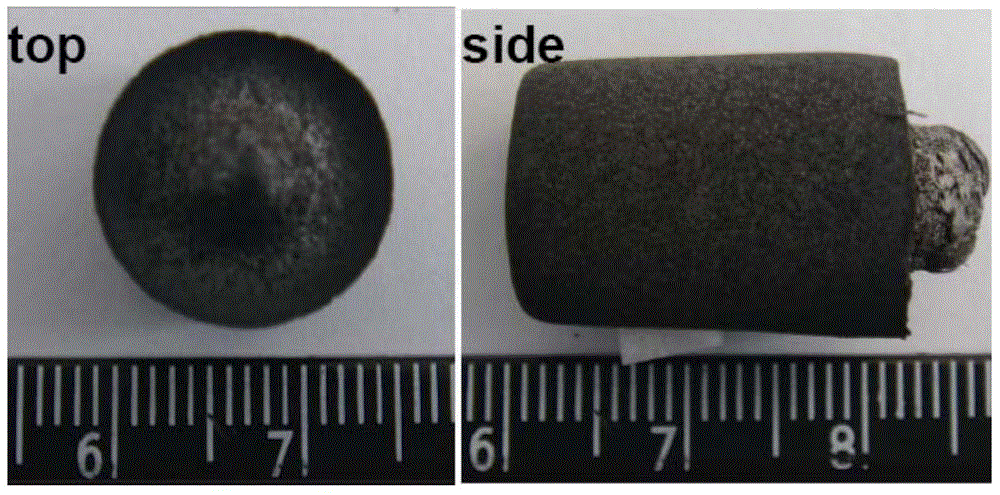

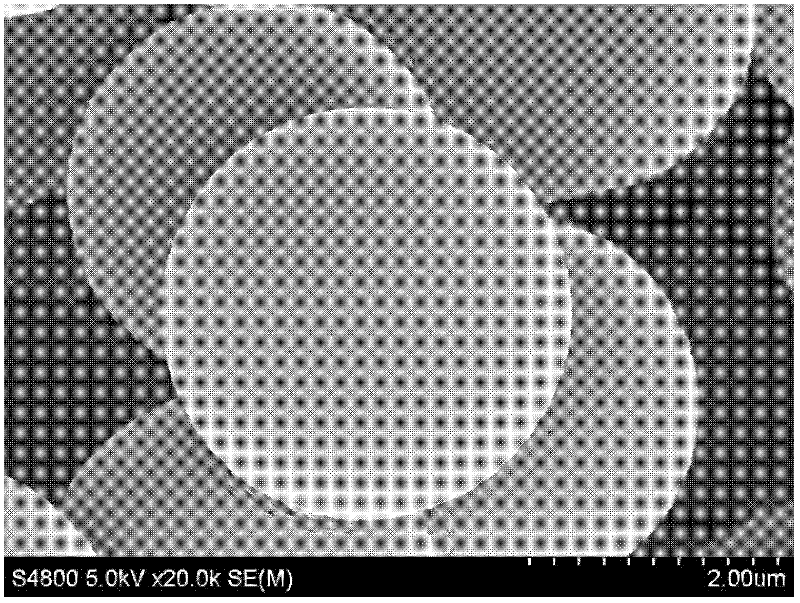

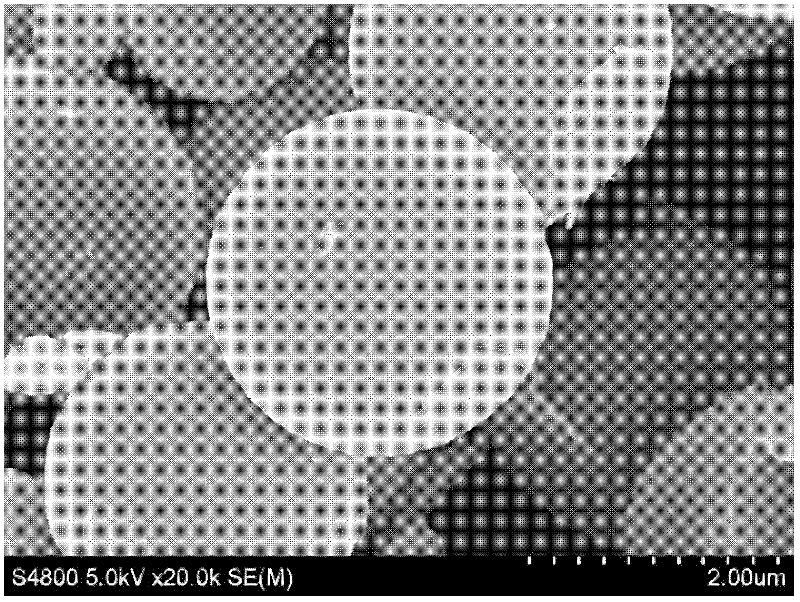

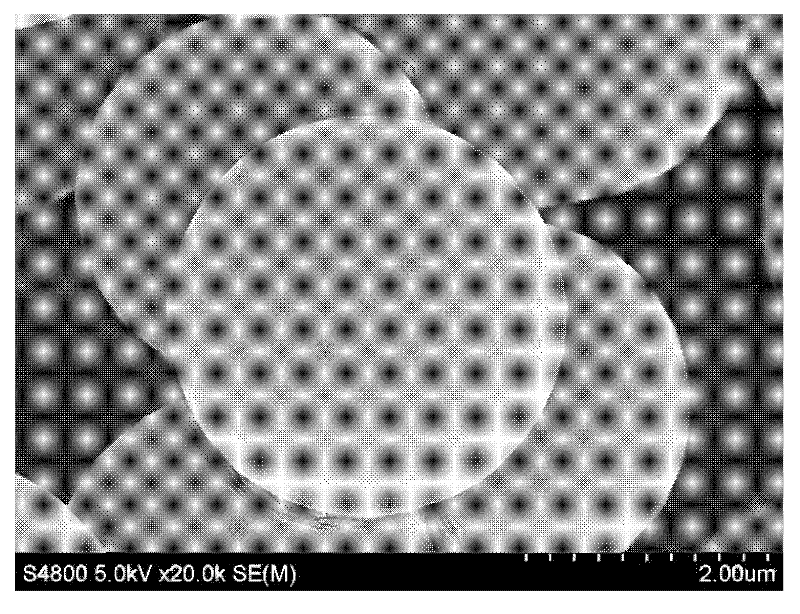

Carbon-aerogel-carried bimetal organic framework electro-Fenton cathode and preparation method thereof

ActiveCN105110423AEfficient degradationReduce energy consumptionWater/sewage treatment by irradiationWater contaminantsMetal-organic frameworkCombined technique

The invention relates to a carbon-aerogel-carried bimetal organic framework electro-Fenton cathode and a preparation method thereof. The preparation method comprises the following steps: by using a block carbon aerogel as a substrate electrode, carrying out hydrothermal reaction to load a bimetal organic framework onto the substrate electrode, filtering, washing, and carrying out vacuum drying to obtain the carbon-aerogel-carried bimetal organic framework electro-Fenton cathode, wherein the bimetal organic framework is a Fe / Co bimetal organic framework. Compared with the prior art, by combining the photocatalytic technique and electro-Fenton, the carbon-aerogel-carried bimetal organic framework electro-Fenton cathode can degrade organic pollutants by using the higher-efficiency low-energy-consumption advanced oxidation technique, thereby providing a new way for using the electro-Fenton cathode in the photocatalytic / electro-Fenton combined technique for treating nondegradable organic pollutants. The carbon-aerogel-carried bimetal organic framework electro-Fenton cathode has the advantages of simple technical operation, energy saving and high efficiency, and has very wide application range in the field of actual water treatment.

Owner:TONGJI UNIV

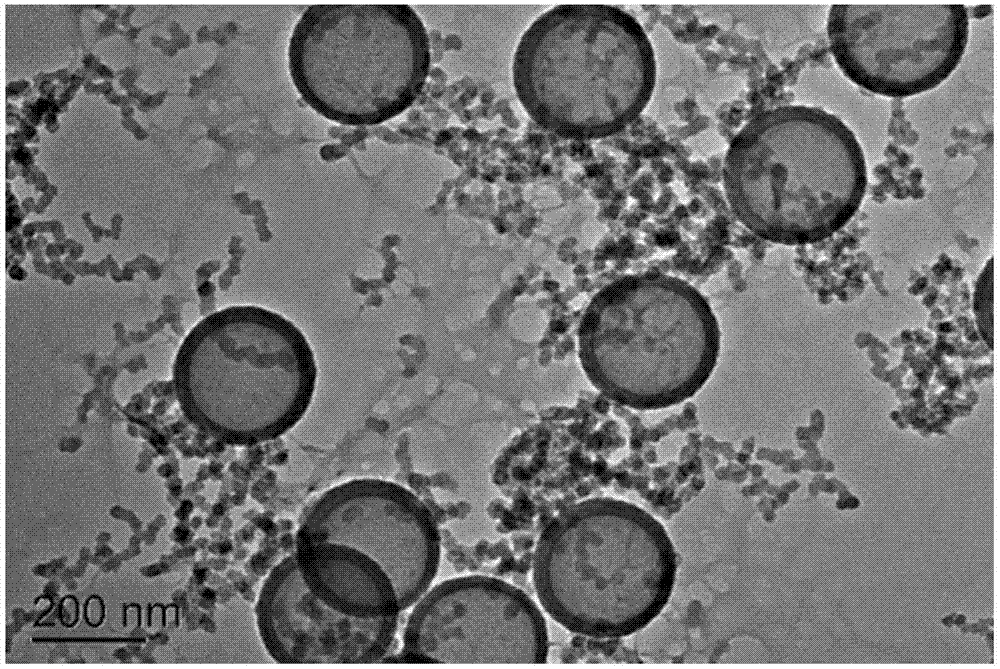

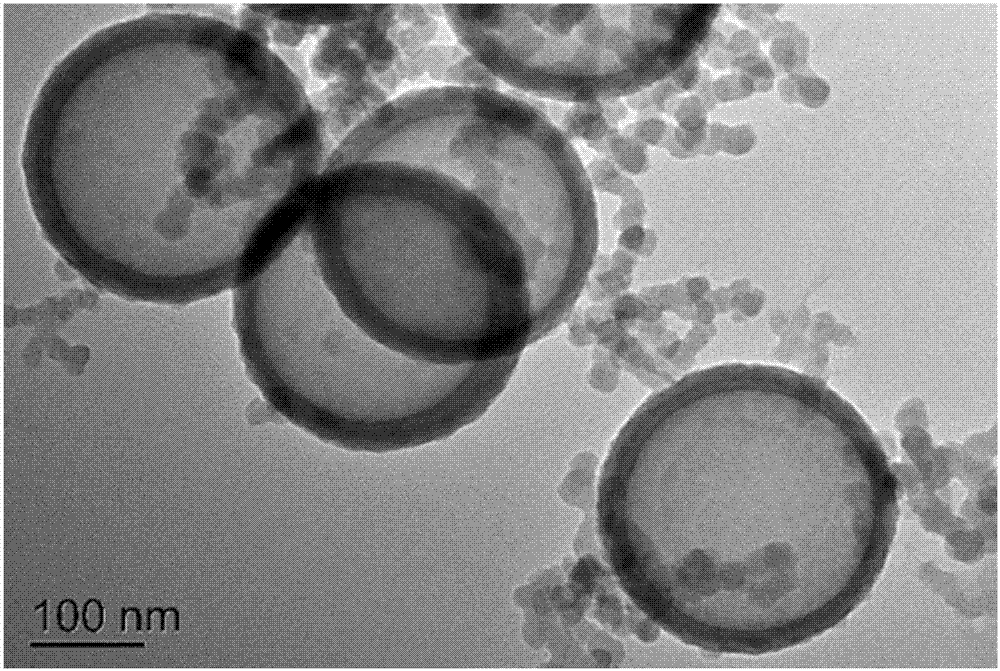

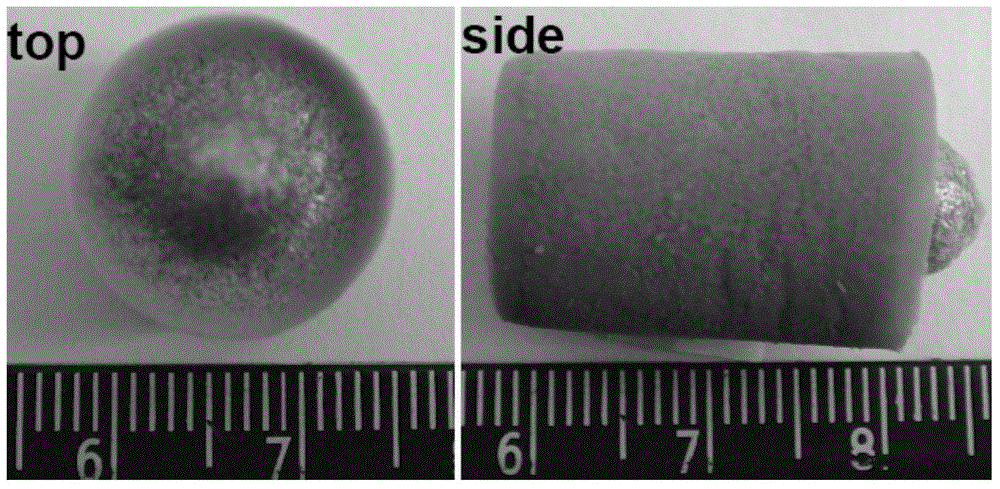

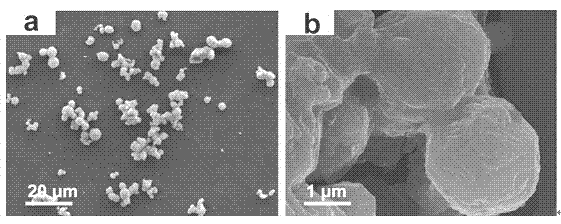

Silicon dioxide hollow microsphere, preparation method thereof, application thereof to thermal insulating coating

The invention discloses a silicon dioxide hollow microsphere, a preparation method thereof, application thereof to thermal insulating coating. The silicon dioxide hollow microsphere is prepared by taking polystyrene as the template and absolute ethyl alcohol as solvent, adding in tetraethoxysilane, hydrolyzing the mixture in alkaline conditions, controlling the reaction temperature at 28-32 DEG Cfor reaction for 22-26 h, performing centrifugal treatment, washing and drying to obtain solid powder and sintering the obtained solid powder at 540-560 DEG C for 7-8 h. The obtained silicon dioxide hollow microsphere is stable in structure, uniform in size and controllable in grain size; the thermal insulating coating obtained through the silicon dioxide hollow microsphere is good in film-formingproperty, easy to construct and good in thermal insulating effects and has a broad application prospect in development of the thermal insulating coating industry.

Owner:广东吉美帮新材料有限公司

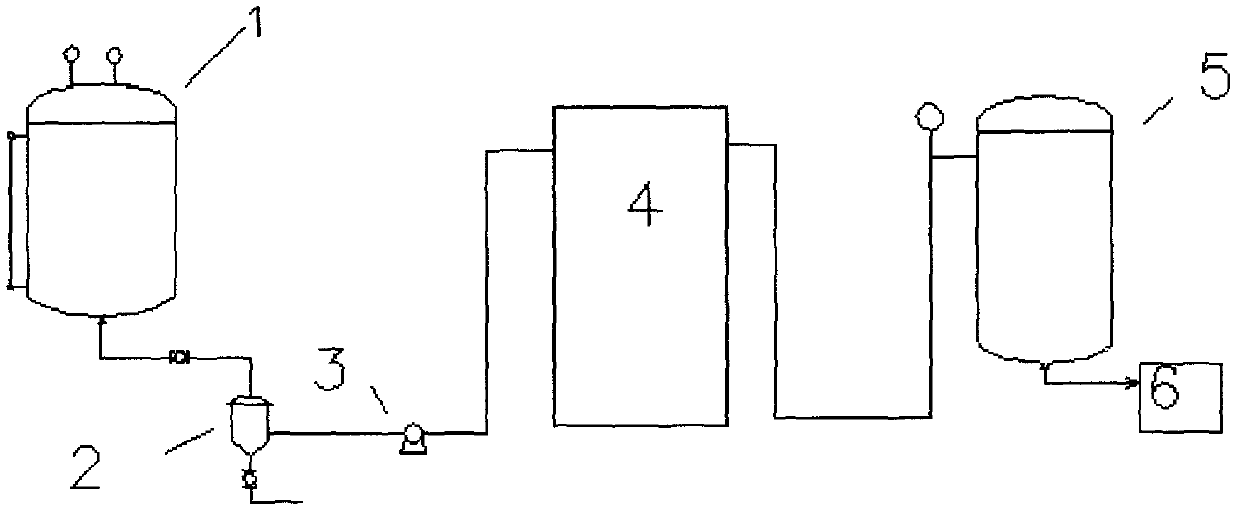

Device and method for continuously producing sodium methyl taurate in pipeline mode

InactiveCN102675160ALess energy consumptionStable concentrationSulfonic acids salts preparationHeat conductingDistillation

The invention relates to a device and a method for producing sodium methyl taurate, in particular to a device and a method for continuously producing sodium methyl taurate in a pipeline mode. The method comprises the following steps of: adding sodium hydroxyethyl sulfonate, water, methylamine and catalyst into a storage tank, pumping the materials into a continuous pipeline reactor through a boosting pipeline pump under the high pressure of 10 to 25MPa, heating to the temperature of between 150 and 300 DEG C through heat conducting oil, and reacting for 10 to 60 minutes in the pipeline reactor; and feeding the materials into an evaporator after reaction, performing multistage distillation, decolorizing, moisturizing, refining, and thus obtaining the qualified sodium methyl taurate. The device is simple and high in process safety, the reaction conditions are easy to control, continuous production is realized, the yield reaches over 90 percent, the sodium methyl taurate is stable in quality, and large-scale production can be realized with low investment in the industry.

Owner:HUANGGANG YONG AN PHARMA

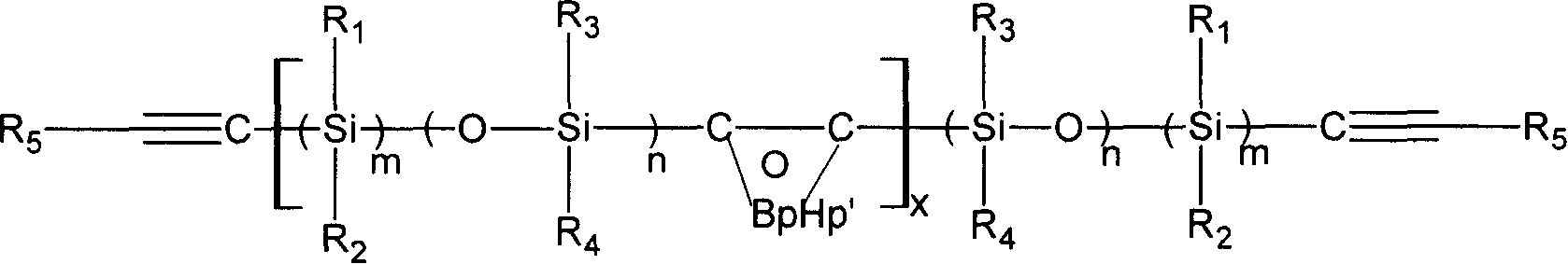

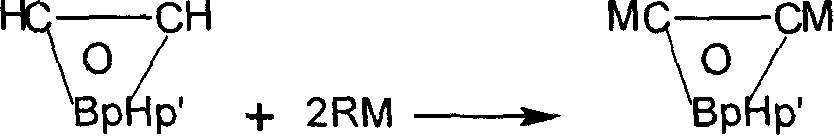

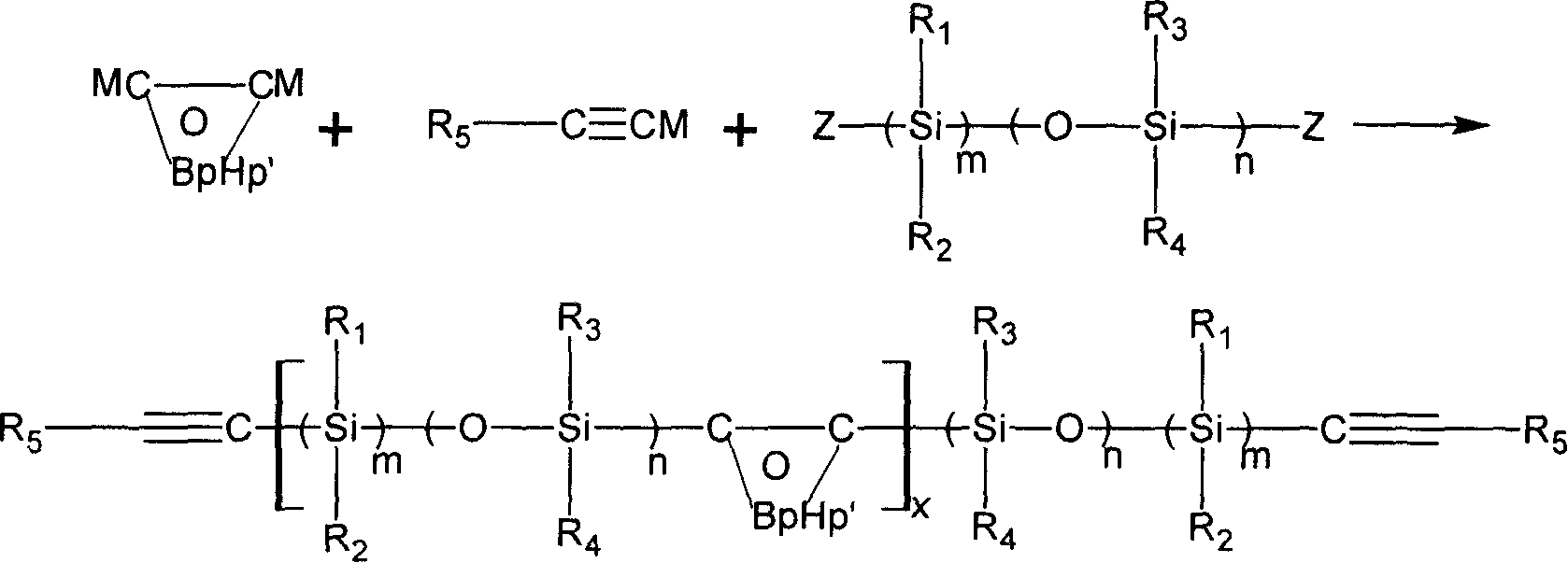

Novel carborane- (siloxane or silane)- ethinyl high temperature resistant polymer and its preparation method

InactiveCN1884343AThe synthesis process is simpleRaw materials are easy to getFireproof paintsSilanesFunction group

The invention discloses a new kind of carborane- silane- phenylacetylene polymer and the method for preparing the same. Said polymer employs methylchlorosilane, phenylacetylene, carborane and organic lithium agent as raw material, anhydrous tetrahydrofuran (THF) as dissolvent and preparing with protection of nitrogen. The invention moderates molar ratio between simple function group ethynyl compound and carborane to easily control molecular weight of polymer, crosslinking density and carborane content, and realizes purpose of adjustable polymer property. The invention is characterized by simple process and easy operation. The prepared polymer forms thermostable thermosetting material with excellent thermal oxidation performance by heat, light and chemical initiation. Said thermosetting material can be produced to ceramic structure by heating on air or inactive gas. The polymer can be used as base resin and thermo-stable coating for advanced complex material and for preparing ceramic pioneer body.

Owner:EAST CHINA UNIV OF SCI & TECH

Preparation method of biodegradable polyester with low carboxyl end group content

The invention relates to a preparation method of biodegradable polyester, and specifically relates to a preparation method of biodegradable polyester with a low carboxyl end group content. The method comprises esterification reactions and condensation and polymerization reactions: after the esterification reaction, polycyclic oxy-compounds are directly added into the reaction products to carry out reactions, and the reaction products are subjected to carry out condensation and polymerization reactions so as to obtain the biodegradable polyester with a low carboxyl end group content, wherein the carboxyl end group content is 5 to 20 mmol / kg. The invention aims to solve the problem of high carboxyl end group content in biodegradable polyesters, namely aliphatic polyester / copolymer and aliphatic-aromatic copolyester materials. The method provided by the invention reduces the carboxyl end group content in the materials, improves the flux strength, shortens the reaction time, obtains a polyester material with a good color (low b value), improves the anti-aging ability of the biodegradable polyester material, and prolongs the service life of the biodegradable polyester material. The preparation method has the advantages of controllable reaction conditions, low cost, and suitability for industrial production.

Owner:山东悦泰生物新材料有限公司

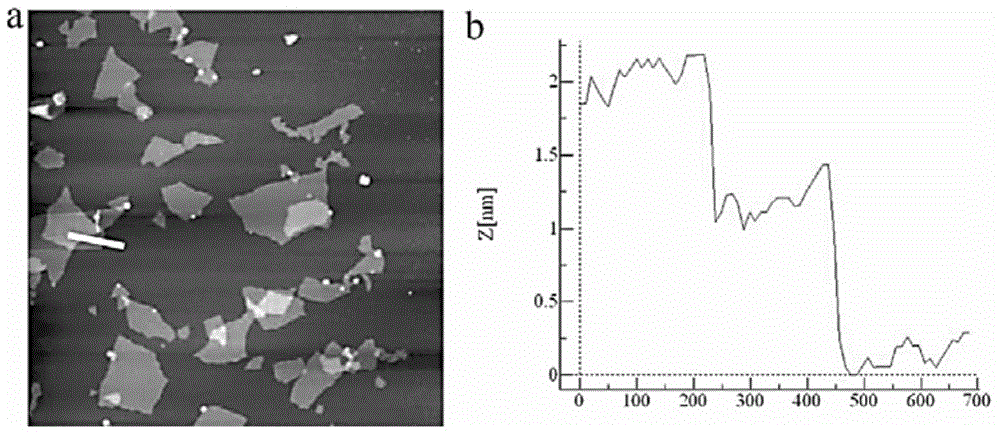

Preparation method of graphene aerogel and graphene-carbon nanotube aerogel

The invention relates to a preparation method of graphene aerogel and graphene-carbon nanotube aerogel. According to the method, graphene oxide or a mixture of graphene oxide and carbon nanotube is subjected to drying treatment; graphene oxide is reduced through a magnesium thermal reaction; the material is soaked in an acidic water solution; and impurities are removed, and the material is dried, such that graphene aerogel or graphene-carbon nanotube aerogel is obtained. Compared with prior arts, the method provided by the invention has the advantages of simple process, and is green and environment-friendly. Magnesium powder is adopted as a reducing agent. Compared to reducing agents such as hydrazine hydrate, sodium borohydride, formaldehyde, carbohydrate compounds, ascorbic acid and hydroiodic acid, magnesium powder has higher reducibility, such that the graphene aerogel or graphene-carbon nanotube aerogel with high carbon-oxygen ratio can be prepared. The electrical conductivity of the graphene aerogel or graphene-carbon nanotube aerogel can reach 10<4>s / cm. The graphene aerogel or graphene-carbon nanotube aerogel has large specific surface area, and is non-toxic and harmless. The graphene aerogel or graphene-carbon nanotube aerogel can be widely applied.

Owner:TONGJI UNIV

Preparation method of phenolic resin microballoons and method for preparing phenolic resin-based carbon spheres by use of preparation method

InactiveCN102352003ASimple processReaction conditions are easy to controlPhenolsPhenol formaldehyde resin

A preparation method of phenolic resin microballoons and a method for preparing phenolic resin-based carbon spheres by the use of the preparation method relate to resin microballoons and a preparation method of carbon spheres. The invention aims to solve the problem that present preparation method of phenolic resin microballoons and that of phenolic resin-based carbon spheres are complex and require high cost with the sphere diameter of microballoons being hard to control. The preparation method of the phenolic resinmicroballoons comprises the following steps of: 1, mixing resorcinol, phenol,formaldehyde, sodium carbonate, sodium bicarbonate and water with stirring; 2, placing into an oil bath and heating for 4-6 hours; 3, carrying out pumping filtration, washing by the use of water, anddrying to obtain the phenolic resin microballoons. The preparation method of the phenolic resin-based carbon spheres comprises the following steps of: putting the phenolic resinmicroballoons into a tubular furnace, heating to 700-1000 DEG C in shielding gas atmosphere and maintaining for 2-6 hours to obtain the phenolic resin-based carbon spheres. The dynamic suspension polymerization method is simple and the reaction condition is easy to control; phenol is introduced into the raw materials so as to reduce the reaction cost; the phenolic resin microballoons and the phenolic resin-based carbonspheres with random sphere diameter between 10nm to 10 microns can be prepared.

Owner:HEILONGJIANG UNIV

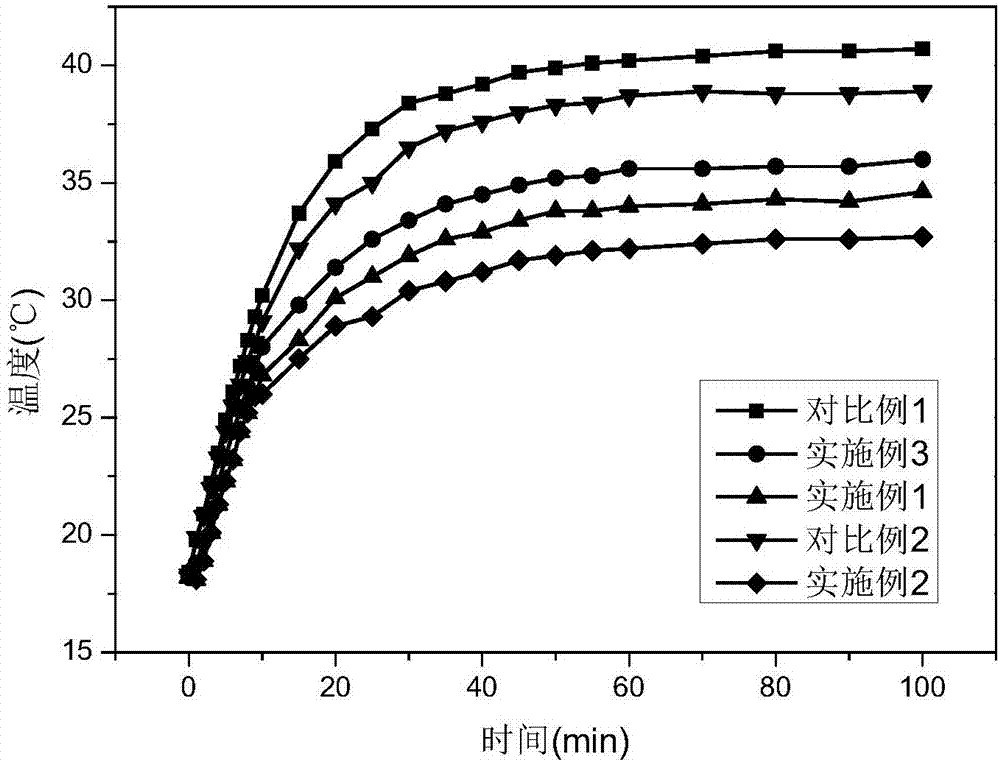

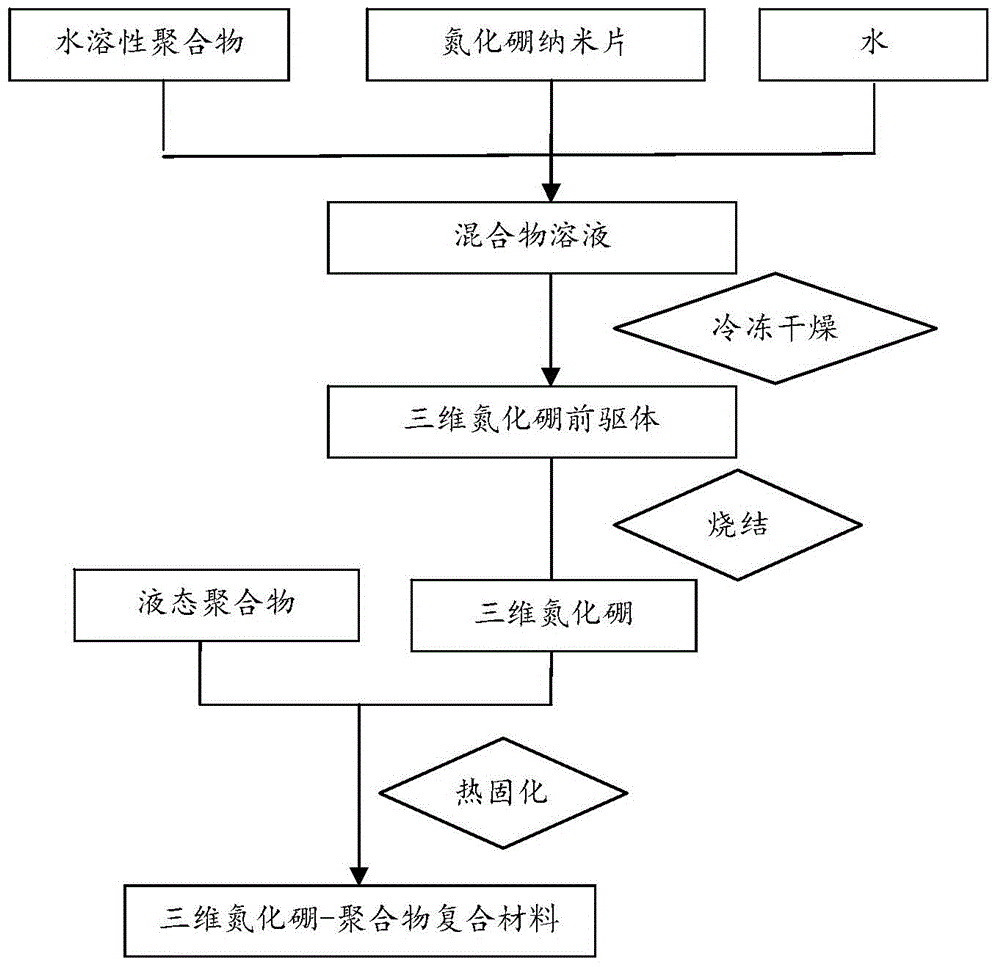

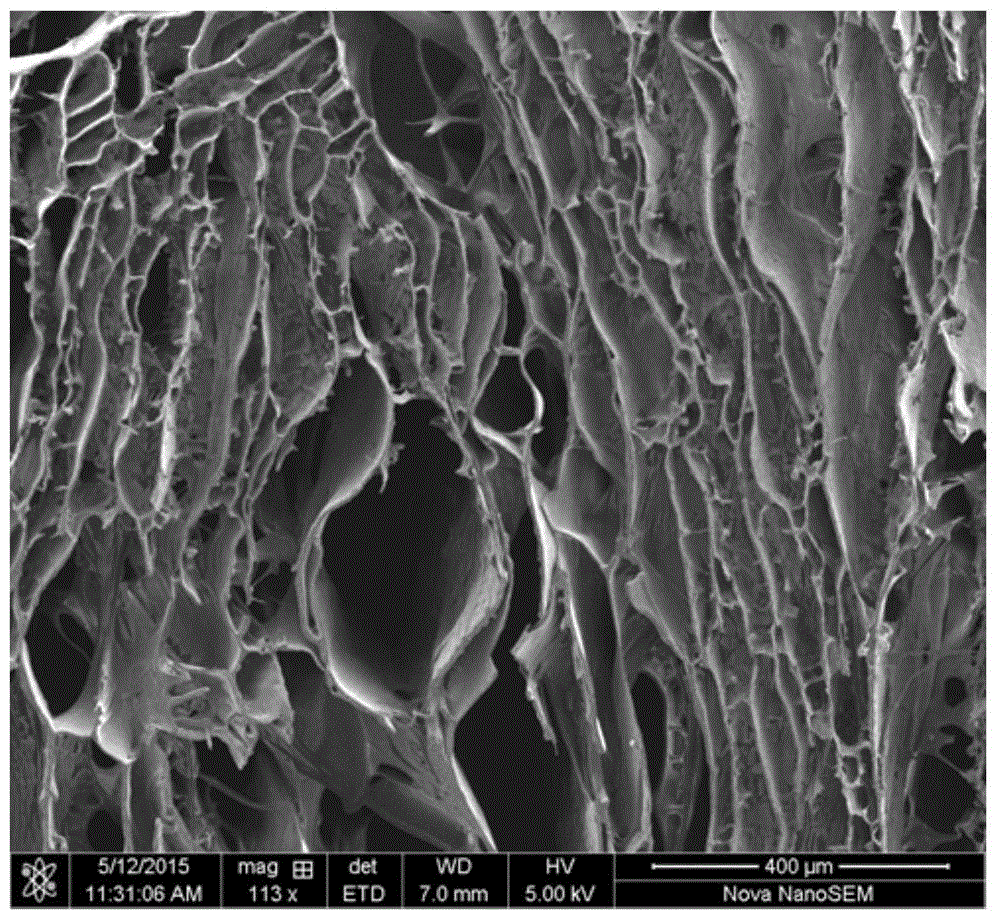

High-thermal-conductivity polymer composite material and preparation method and application thereof

ActiveCN105062007AImprove thermal conductivityReduce manufacturing costNitrogen compoundsNetwork structureBoron nitride

The invention discloses a high-thermal-conductivity polymer composite material and a preparation method and application thereof. The high-thermal-conductivity polymer composite material comprises a polymer base body and three-dimensional boron nitride arranged in the polymer base body in a filling mode. The volume fraction of the three-dimensional boron nitride in the high-thermal-conductivity polymer composite material is 5-50%. According to the high-thermal-conductivity polymer composite material, the three-dimensional boron nitride is adopted to build a three-dimensional network structure in the polymer base body. A heat conductive channel is built in the polymer base body. Thus, the high-thermal-conductivity polymer composite material has a high heat conductive coefficient, the condition of the preparation method of the material is moderate and easy to control, the technology is simple, and the method is safe and environmentally friendly.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

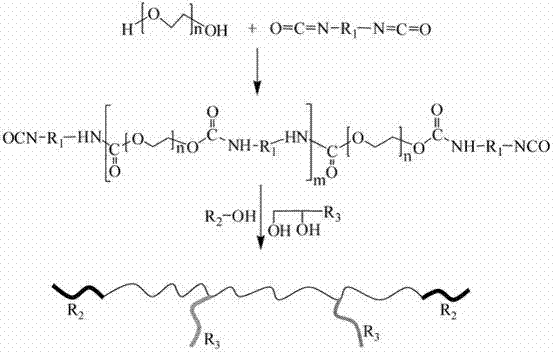

Preparation method of linear water-based polyurethane thickener containing hydrophobic side bases

InactiveCN102898612ASimple preparation stepsReaction conditions are easy to controlPolyurea/polyurethane coatingsEndcappingPolymer science

The invention relates to a linear water-based polyurethane thickener containing hydrophobic side bases and a preparation method of the linear water-based polyurethane thickener. The preparation method is characterized in that 40 weight percent to 60 weight percent of dibasic alcohol polymers, 10 weight percent to 30 weight percent of diisocyanate and 0 weight percent to 5 weight percent of catalysts are mixed, under the condition of N2 gas existence and the temperature being 50 DEG C to 100 DEG C, the stirring is carried out for 1 to 6 hours, then, 10 weight percent to 30 weight percent of end-capping agents are added, under the condition of the temperature being 50 DEG C to 100 DEG C, the stirring is carried out for 1 to 6 hours, polyurethane prepolymers are prepared, then, 5 weight percent to 20 weight percent of chain extenders are added into the prepared polyurethane prepolymers, the stirring is carried out for 1 to 6 hours under the condition of the temperature being 50 DEG C to 100 DEG C, and the linear water-based polyurethane thickener containing hydrophobic side bases is prepared. The linear water-based polyurethane thickener and the preparation method have the characteristics that no solvent exists, the toxicity is low, the environment is protected, the preparation process is simple, and the like. The prepared linear water-based polyurethane thickener containing hydrophobic side bases is applicable to the thickening of water-based paint, and the obvious thickening effect is realized.

Owner:LISHUI UNIV

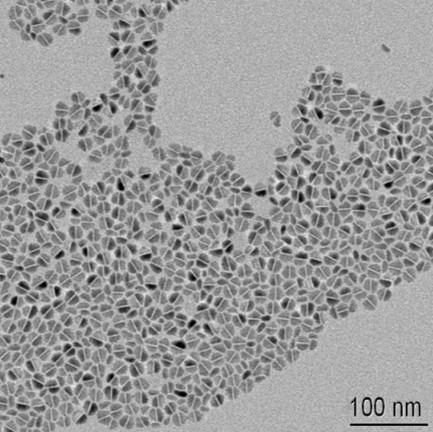

Method for synthesizing NANO hydroxyapatite

InactiveCN1760121ASmall particlesUniform size distribution of sedimentPhosphorus compoundsApatiteNano hydroxyapatite

A process for synthesizing nano-class hydroxy apatite includes such steps as dissolving the organic compound containing carboxy, hydroxy and sulfonyl in the aqueous solution of Ca(NO3)2*4H2O at 40-100 deg.C, proportionally dripping H3PO4, regulating pH=10 or more, reaction for at least 4 hr, reaction at 40-200 deg.C for at least 8 hr, filter, washing and drying.

Owner:JIANGSU UNIV

Normal-paraffin isomerization catalyst, preparation method and application thereof

ActiveCN104117369ALow reaction temperatureReaction conditions are easy to controlHydrocarbon by isomerisationPhysical/chemical process catalystsAlkaneLow activity

The invention provides a normal-paraffin isomerization catalyst, a preparation method and application of the normal-paraffin isomerization catalyst, and relates to the technical field of the paraffin-isomerization catalyst, and is used for solving the problems of low activity, poor stability and low conversion rate in the existing isomerization catalyst. The normal-paraffin isomerization catalyst comprises the following components in percentage by mass: 0.1-1.0% of metal component Pt and 2.0-5.0% of halogen Cl and the balance of carrier gamma-Al2O3. The normal-paraffin isomerization catalyst provided by the invention is prepared by dipping, reduction, inorganic chlorination and organic chlorination; the metal elementary substance Pt is loaded on the multi-porous carrier gamma-Al2O3, and after chlorination treatment, the Pt-Al2O3-Cl normal-paraffin low-temperature isomerization catalyst is formed; and the normal-paraffin isomerization catalyst has the advantages of high liquid absorption, high isomerization rate, high reaction activity and good stability.

Owner:JIANGSU YANGZI CATALYST CO LTD +1

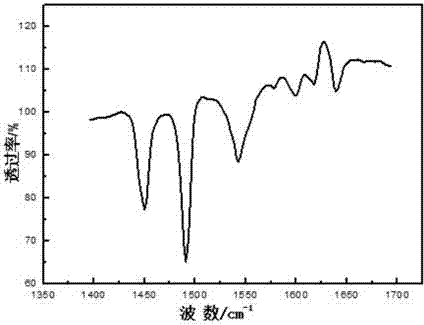

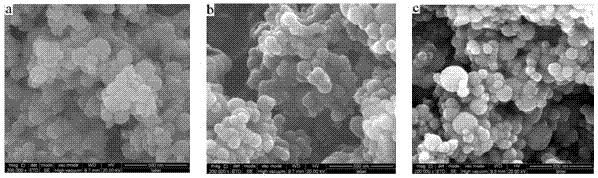

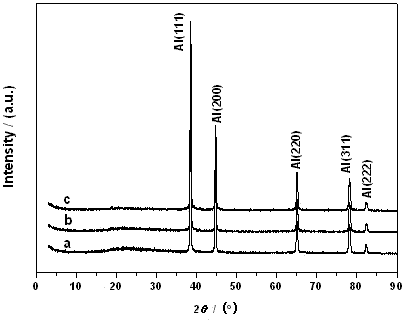

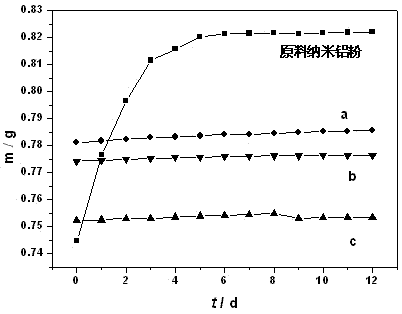

Method for preparing nanometer aluminum composite powder coated with nitro-cotton

InactiveCN102581272AGuaranteed reactivityKeep aliveMaterial nanotechnologyEthyl acetateEthyl fumarate

The invention discloses a method for preparing nanometer aluminum composite powder coated with nitro-cotton. The method includes the steps of: dispersing nanometer aluminum powder into absolute ethyl alcohol; adding silane coupling agent with the weight accounting for 5-10% of that of the nanometer aluminum powder to obtain nanometer aluminum powder treated by the silane coupling agent; dissolving the nitro-cotton and plasticizer into ethyl acetate or acetone; dispersing the nanometer aluminum powder treated by the silane coupling agent into cyclohexane to form cyclohexane dispersing agent; adding nitro-cotton liquor into the cyclohexane dispersing agent and evenly mixing the nitro-cotton liquor; and performing filtering and vacuum drying to obtain the nanometer aluminum composite powder coated with the nitro-cotton, wherein the weight of the nitro-cotton is 0.04-0.15 time that of the aluminum powder, and the weight of the plasticizer accounts for 3-10% of that of the nitro-cotton. The nanometer aluminum powder is firstly treated by the silane coupling agent and then coated with the nitro-cotton, the surface of the nanometer aluminum powder is effectively coated with the nitro-cotton, the activity of the nanometer aluminum powder can be kept, and the oxidation resistance of the nanometer aluminum powder is improved.

Owner:XIAN MODERN CHEM RES INST

Antibacterial composite TPU (Thermoplastic Polyurethane) film and preparation method thereof

ActiveCN104262946AStrong antibacterial functionReaction conditions are easy to controlBiocideDisinfectantsChemistryWork in process

The invention relates to an antibacterial composite TPU (Thermoplastic Polyurethane) film and a preparation method thereof. The TPU film comprises the following components in parts by weight: 60-80 parts of TPU particles, 20-30 parts of an antibacterial agent, 0.1-0.3 part of an antioxidant and 1-3 parts of an additive. The preparation method comprises the steps: (1) mixing the components to obtain a mixture according to the parts by weight; (2) plastifying the mixture by virtue of an extruder to form a semi-product; (3) filtering the semi-product by virtue of a filter and plastifying again; and (4) processing by virtue of a four-roller molding device so that the film is molded. The TPU film obtained by the preparation method disclosed by the invention has the advantage of good antibacterial effect.

Owner:DONGGUAN XIONGLIN NEW MATERIAL TECH

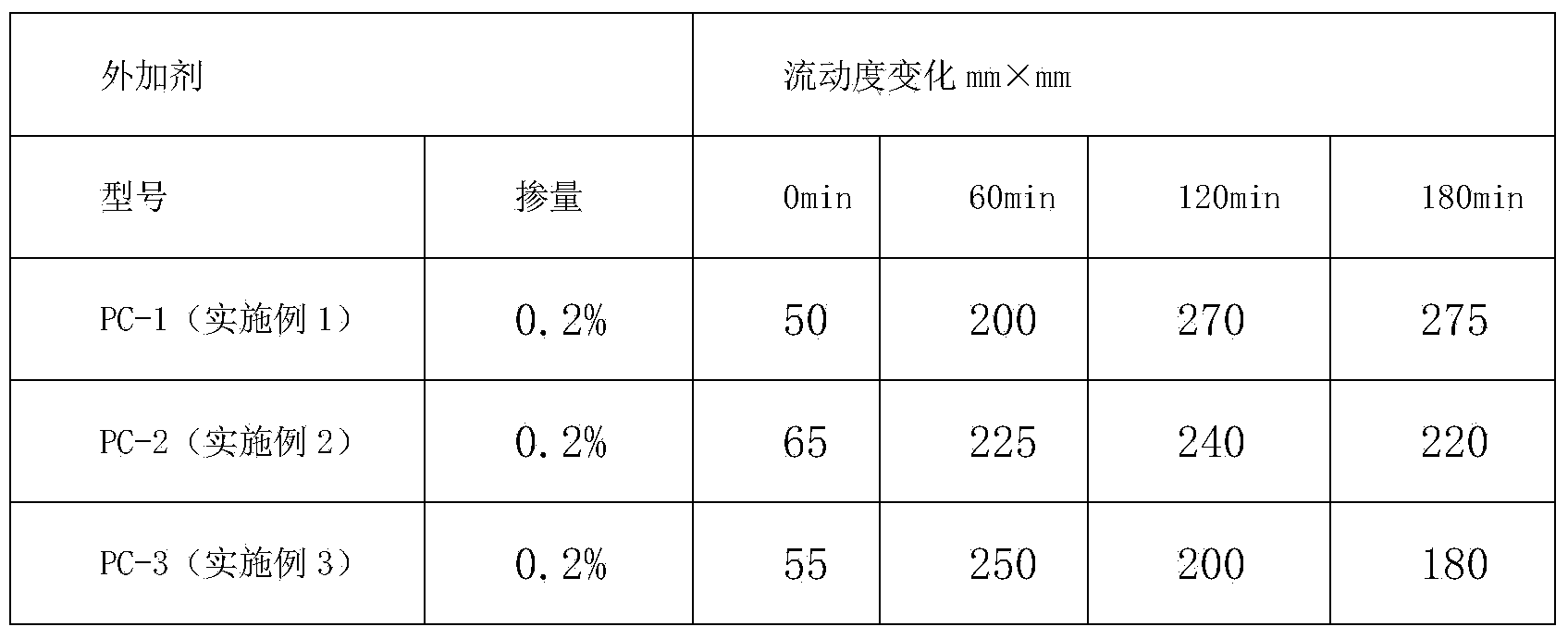

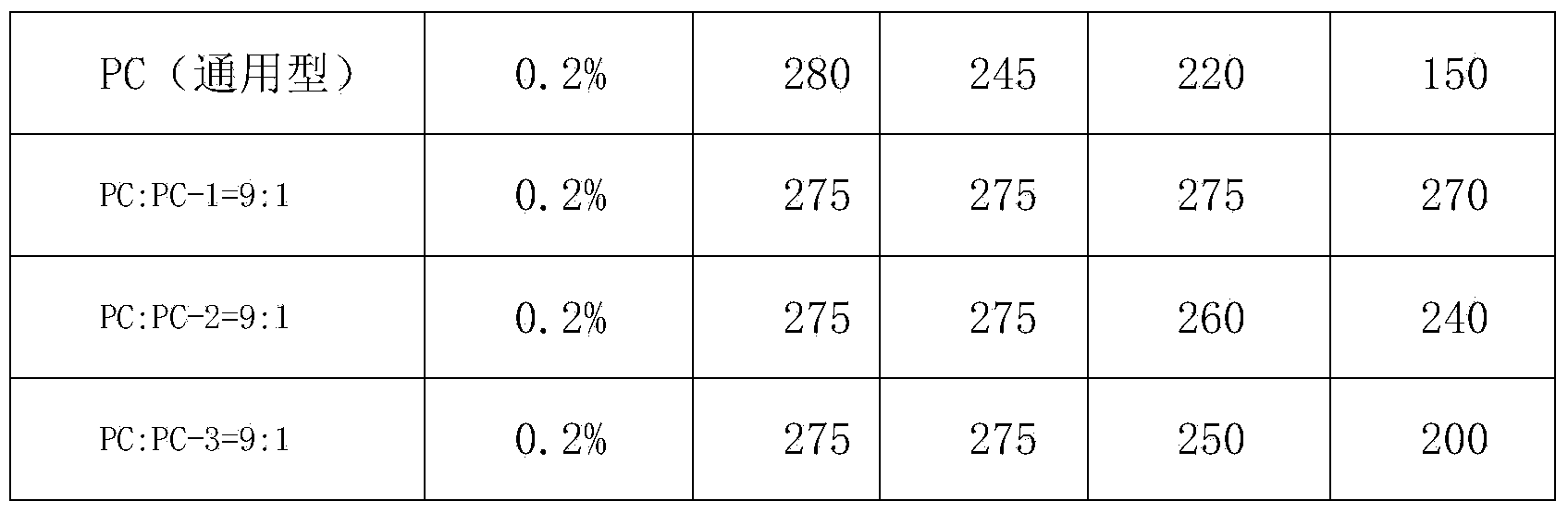

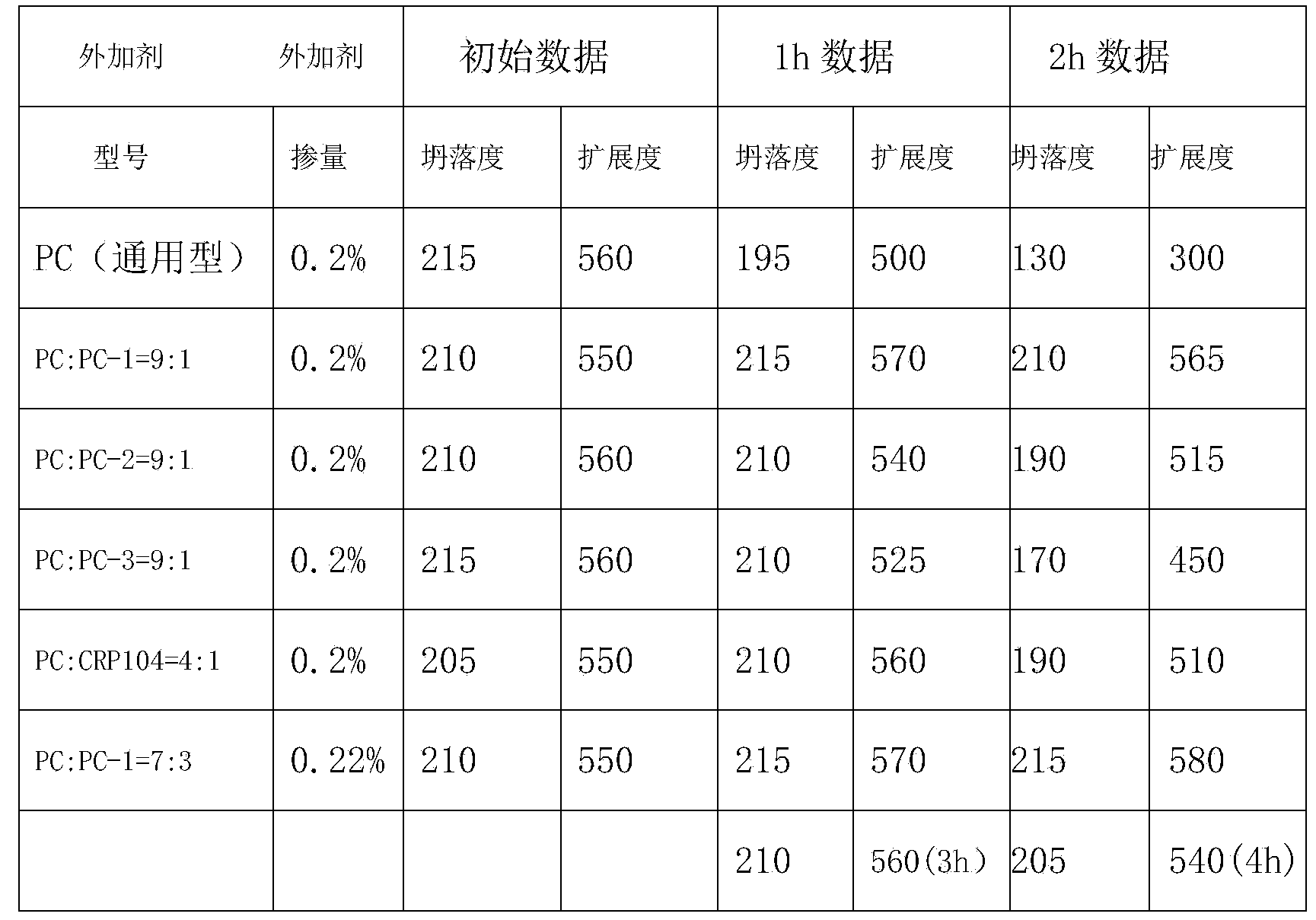

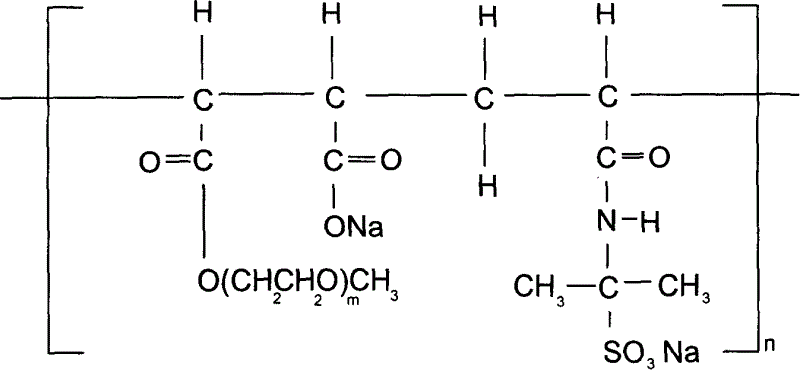

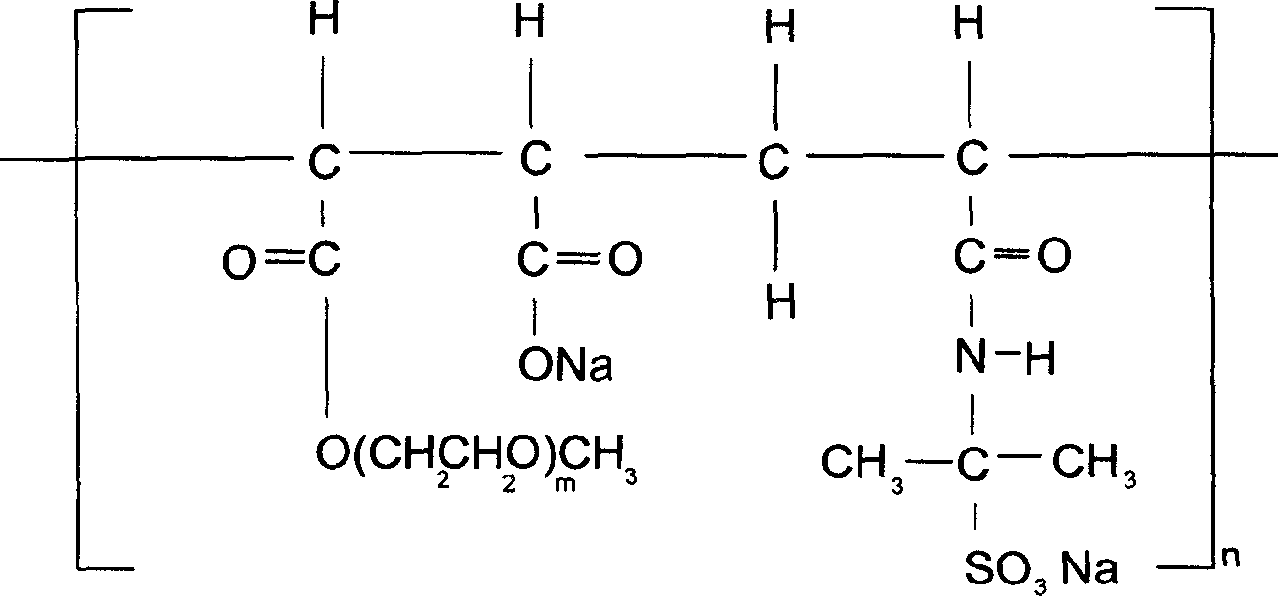

Super controlled release type polycarboxylate slump retention agent and preparation method thereof

The invention discloses a super controlled release type polycarboxylate slump retention agent and a preparation method thereof. The preparation method of the polycarboxylate slump retention agent comprises the following steps: carrying out free radical polymerization on a monomer A, namely polyoxyethylene ether (TPEG), a monomer B, namely maleic anhydride or polyethylene glycol maleic acid esters, a monomer C, namely acrylic acid, a monomer D, namely hydroxyalkyl acrylate or vinyl acetate, an initiator, a chain transfer agent and water, adding an alkaline liquor to neutralize the mixture, wherein a molar ratio of the monomer A to the monomer B to the monomer C to the monomer D is 1 to (1.0-2.5) to (1.0-2.5) to (2.0-4); the dosage of the initiator accounts for 1%-8% of the total mole number of the monomer A, the monomer B, the monomer C and the monomer D; the dosage of the chain transfer agent is 1%-3% of the total mole number of the monomer A, the monomer B, the monomer C and the monomer D. The super controlled release type polycarboxylate slump retention agent disclosed by the invention is in a liquid state, has solid content of 50%, and has performances of low alkaline content, a low water-reducing rate and excellent slump retention performance. Besides, the production process is simple, the reaction conditions are easy to control, and the environmental pollution is avoided.

Owner:YUEYANG ORIENTAL YUHONG WATERPROOF TECH +1

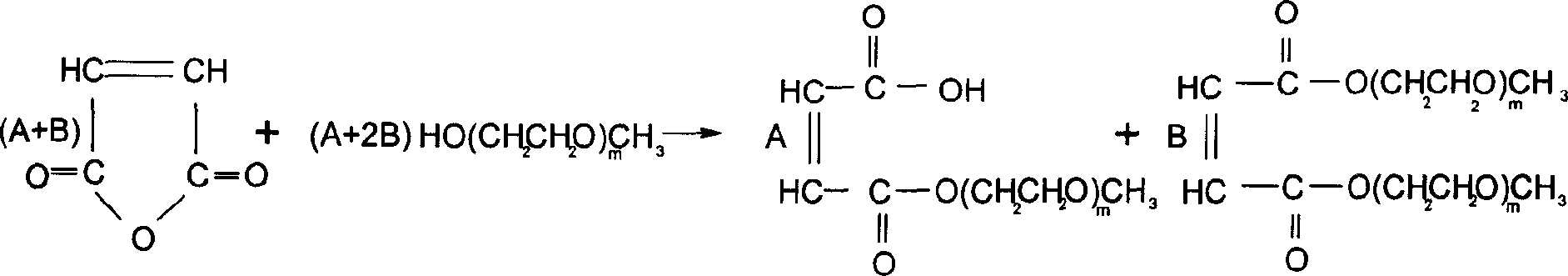

Maleic acid anhydride series concrete water-reducing agent and preparation process thereof

InactiveCN1792960AThe feeding procedure is simpleReaction conditions are easy to controlMaleic anhydrideMaterials science

A maleic anhydride series water-reducing agent for concrete is prepared through reaction between methoxy polyethanediol and maleic anhydride to generate monomethoxy polyethanediol maleate, and copolymerizing on 2-acrylamide-2-sodium methylpropyl sulfonate. Its advantages are high water-reducing effect, low content of alkali, and high flowability and low slump of concrete.

Owner:WUHAN UNIV OF TECH

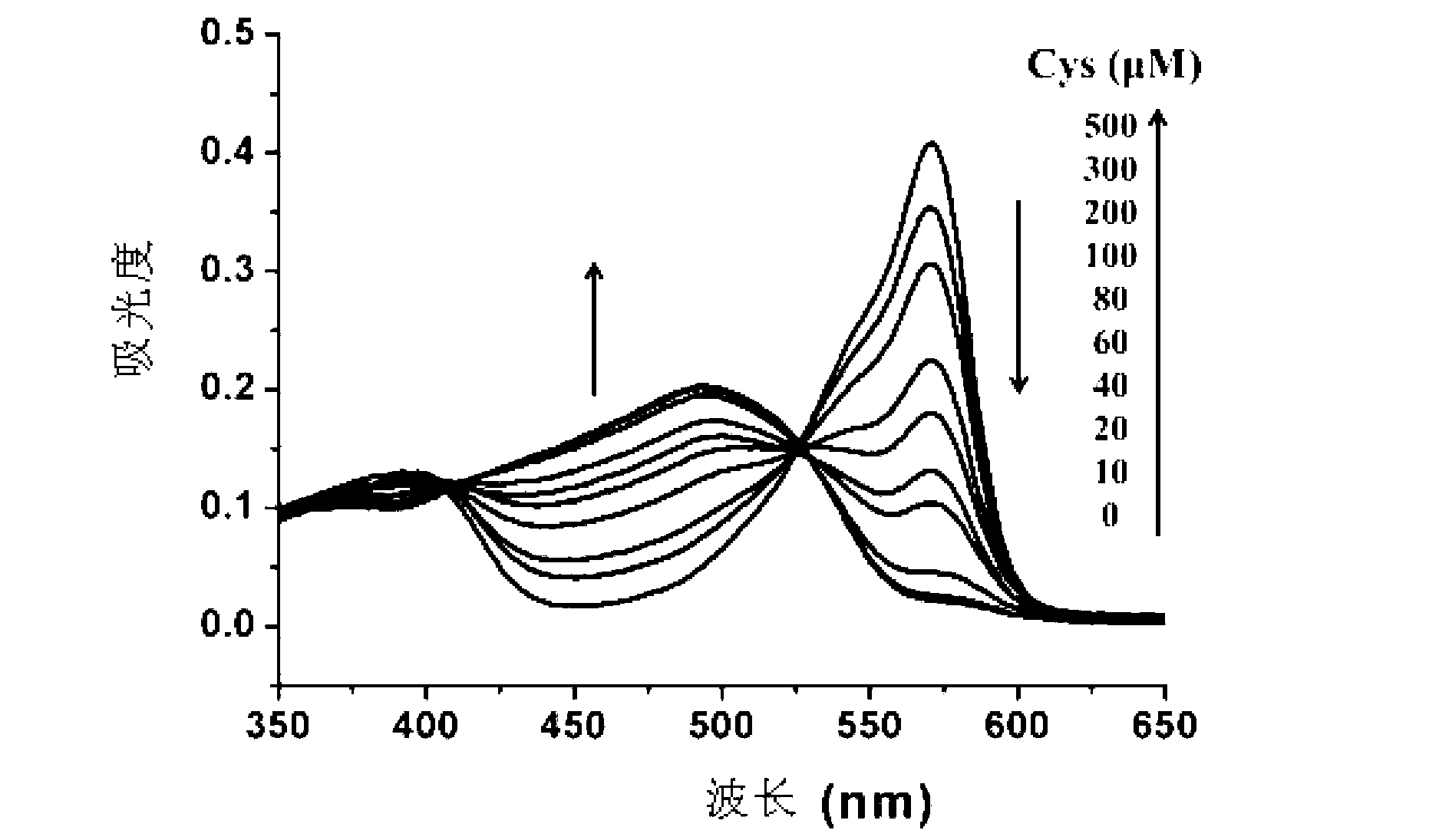

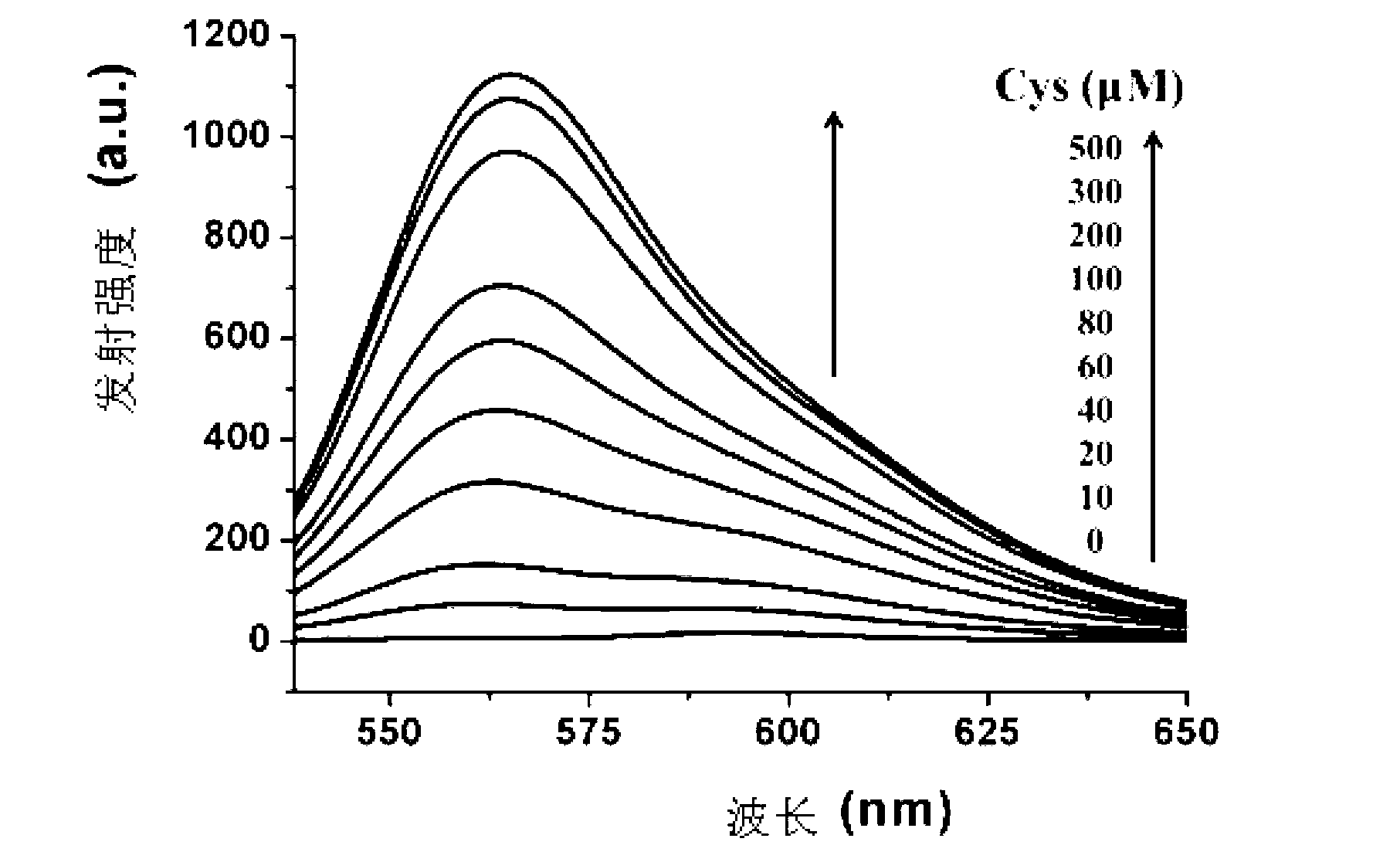

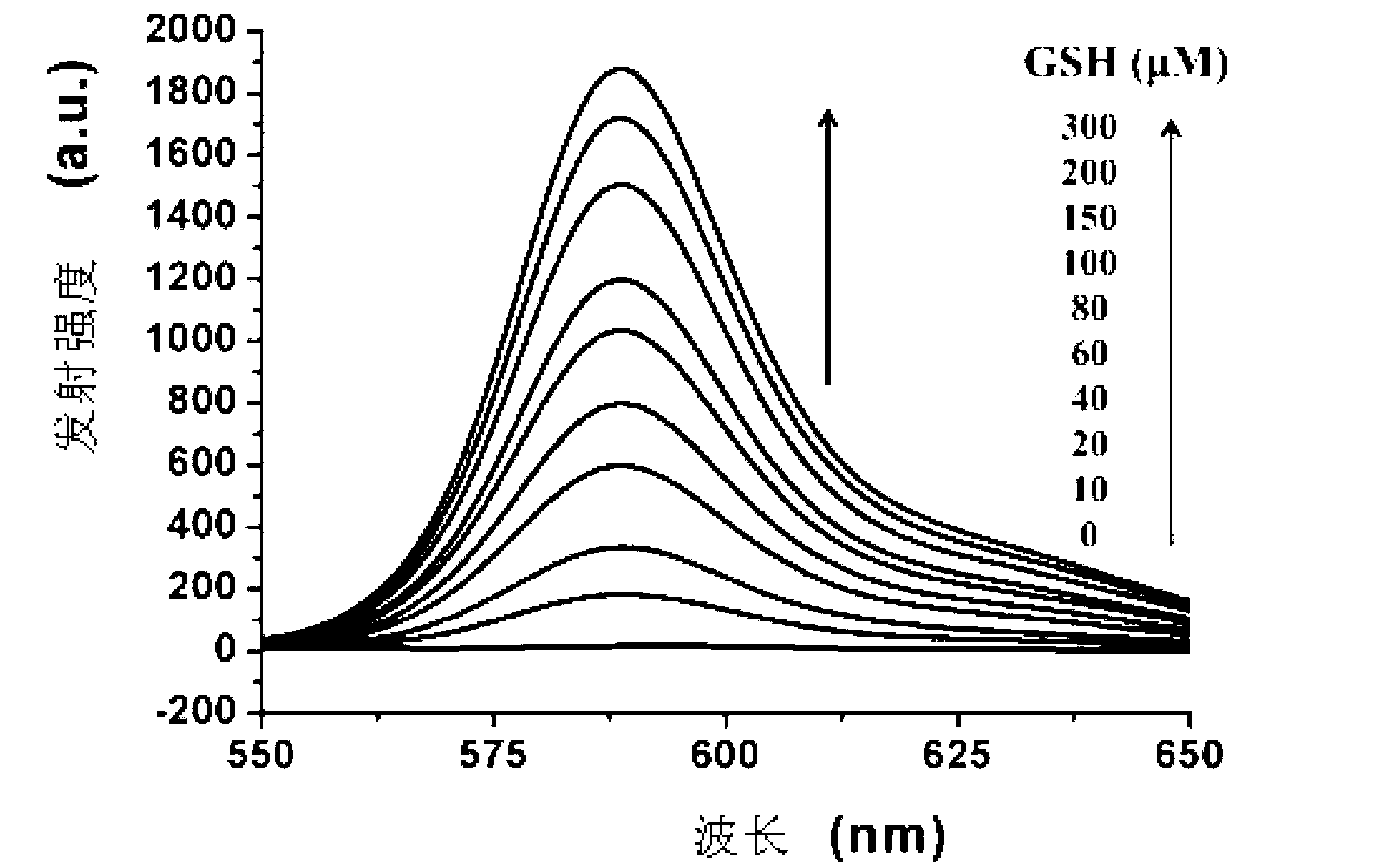

Fluorescence chemical sensor capable of selectively detecting biological sulfhydryl compound, preparation method and application of fluorescence chemical sensor

InactiveCN103013493ARaw materials are easy to getThe synthesis method is simpleChemiluminescene/bioluminescenceGroup 3/13 element organic compoundsFluorescenceSynthesis methods

The invention relates to a fluorescence chemical sensor capable of selectively detecting a biological sulfhydryl compound, which is characterized by comprising the structural formula shown in the description, wherein, in the formula, R is one of the following structures shown in the description. The fluorescence chemical sensor, provided by the invention, has the advantages that the used raw materials are easily obtained, a synthetic method is simple, reaction conditions are easy to control, the sensitivity is high, the sub yield of the molecular weight of a product is high, a sulfhydryl-containing compound can be selectively recognized, and cysteine, glutathione and homocysteine can be separated from each other.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

New method for two-step process preparation of nickel sulfide

InactiveCN104261490ASimple production processReaction conditions are easy to controlNickel sulfidesSODIUM SULFIDE NONAHYDRATEHigh pressure

The invention relates to a new method for two-step process preparation of nickel sulfide. The new method comprises the following steps: transferring a water and urea mixed solution of nickel chloride or a water, ammonia water and ethylene glycol mixed solution of nickel chloride into a high-pressure kettle, performing heating reaction at the temperature of 120-160 DEG C for 8-16h, filtering and washing a generated nickel hydroxide precipitate, and drying to prepare a nickel hydroxide precursor; and then dispersing into ethylene glycol, performing ultrasonic dispersion, adding sodium sulfide nonahydrate, transferring into a reactor, performing reflux reaction at the temperature of 160 DEG C for 12-24h, filtering, washing, and performing vacuum drying for 10-12h to prepare nickel sulfide. The new method provided by the invention has the advantages of simple production process, easiness in control of reaction conditions, no need of using a template agent and a surfactant, environmental friendliness and good consistency of the obtained product, is conductive to production of nickel sulfide, and has important practical significance.

Owner:XUZHOU NORMAL UNIVERSITY

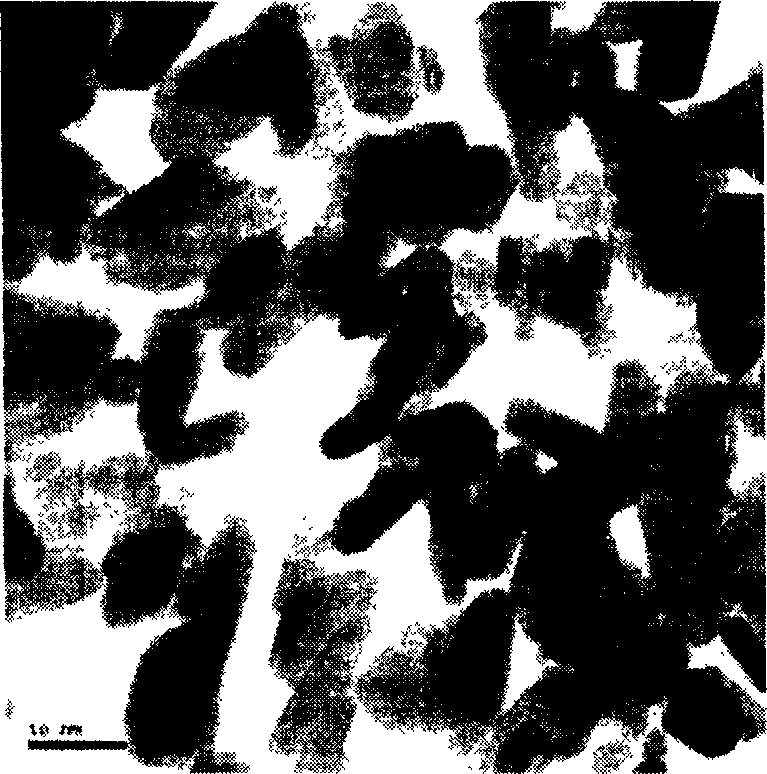

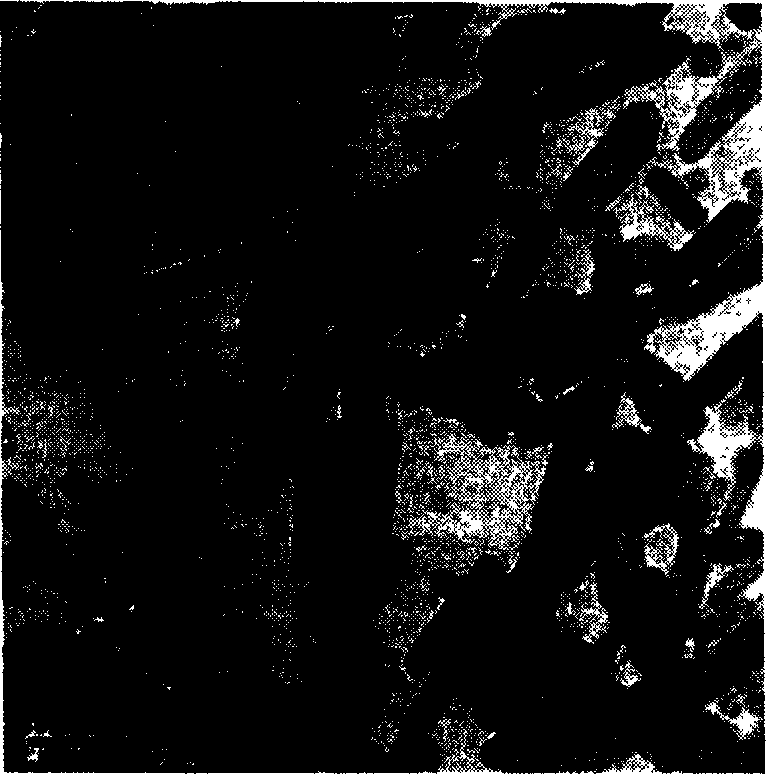

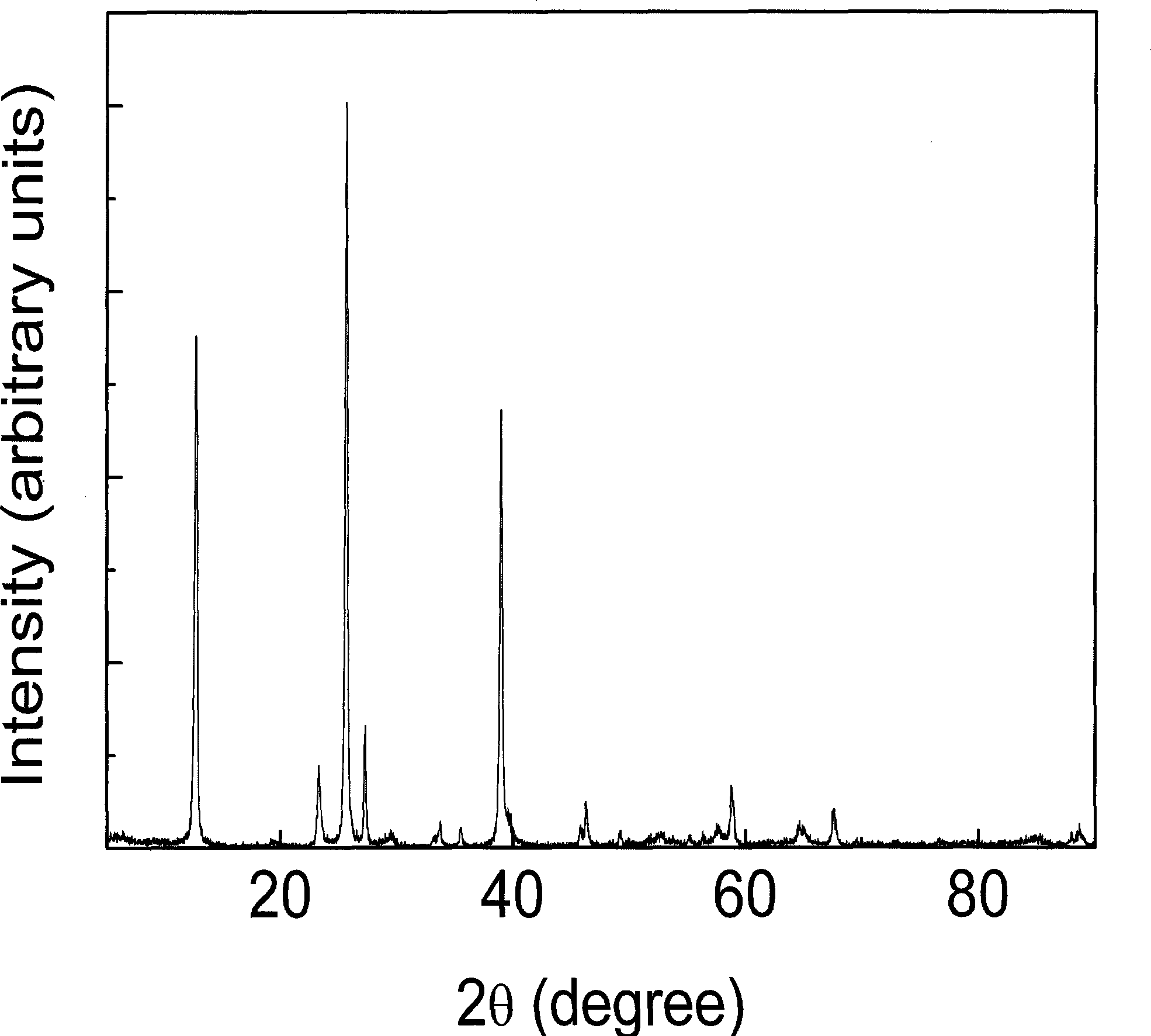

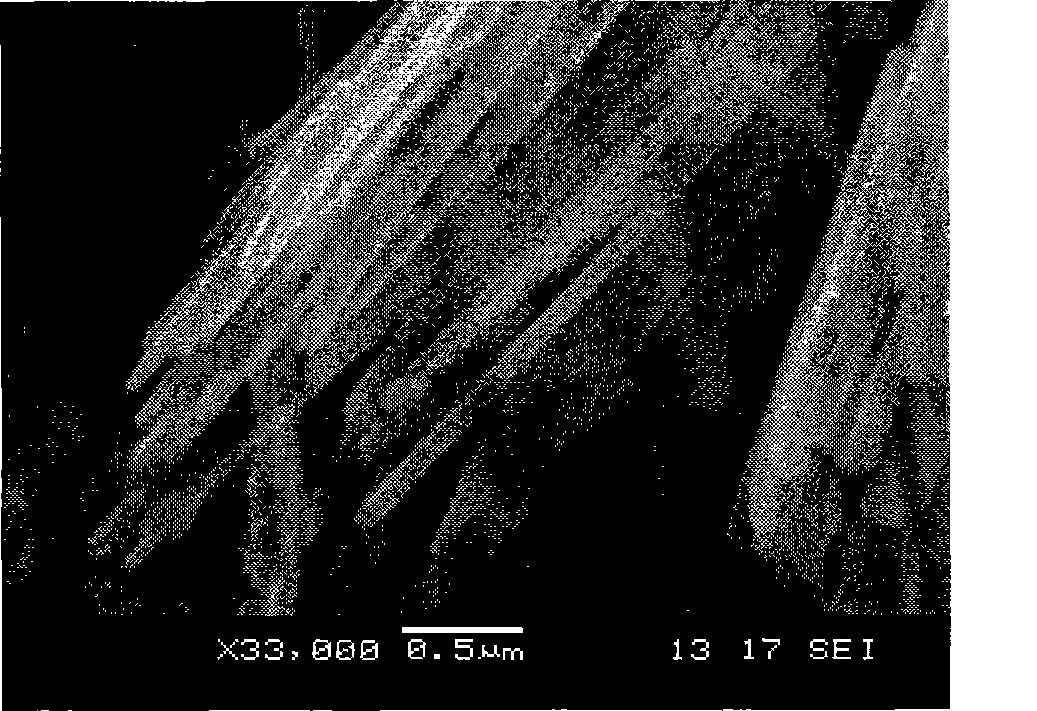

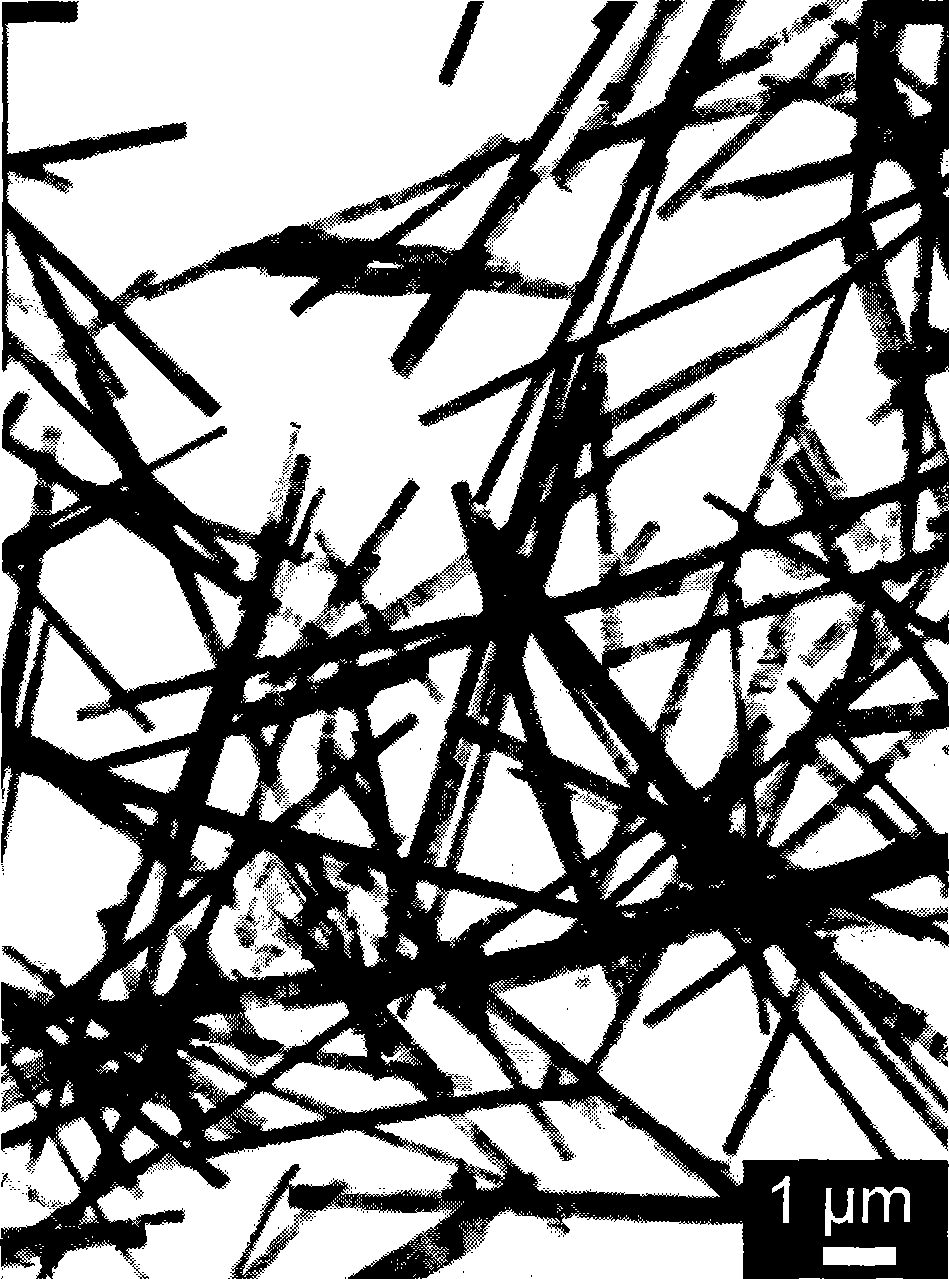

Method for synthesizing rod-like and echinoid molybdena-based nano-material

InactiveCN101412541ALow costUniform scaleNanostructure manufactureMolybdenum oxides/hydroxidesMolybdenum trioxidePeroxide

The invention relates to a quick and efficient non-template agent hydro-thermal synthesizing method. The system can synthesize an alpha-molybdenum trioxide nanometer rod and a high-density echinoid molybdenum oxide based nanometer materials. Molybdenum peroxide acid prepared from molybdenum trioxide and aqueous hydrogen peroxide solution is used as a precursor, is produced into scattered alpha-molybdenum trioxide nanometer rod by hydro-thermal synthesis at a temperature of between 80 and 180 DEG C, and is produced into the peroxide modified molybdenum oxide hydrate by hydro-thermal synthesis at a temperature of between 65 and 75 DEG C. The hydrate is a multiscale structure; a nanometer thin slice, a micron prism and a nanometer rod-shaped structure unit are divergently assembled into a micron-size high-density echinoid structure. The hydrate is roasted to obtain high-density echinoid alpha-molybdenum trioxide. Modulation of the synthesizing condition can realize fine adjustment for appearance of the nanometer rod, the micron-size echinoid structure and the structure unit thereof. The method uses raw materials with low cost, has the advantages of simple technical process, controllable conditions and the like, and can promote research and application of the molybdenum oxide in the fields of sensors, field transmission, electrode materials and so on.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com