Patents

Literature

5575results about "Monocomponent synthetic polymer artificial filament" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fibers made from copolymers of propylene/alpha-olefins

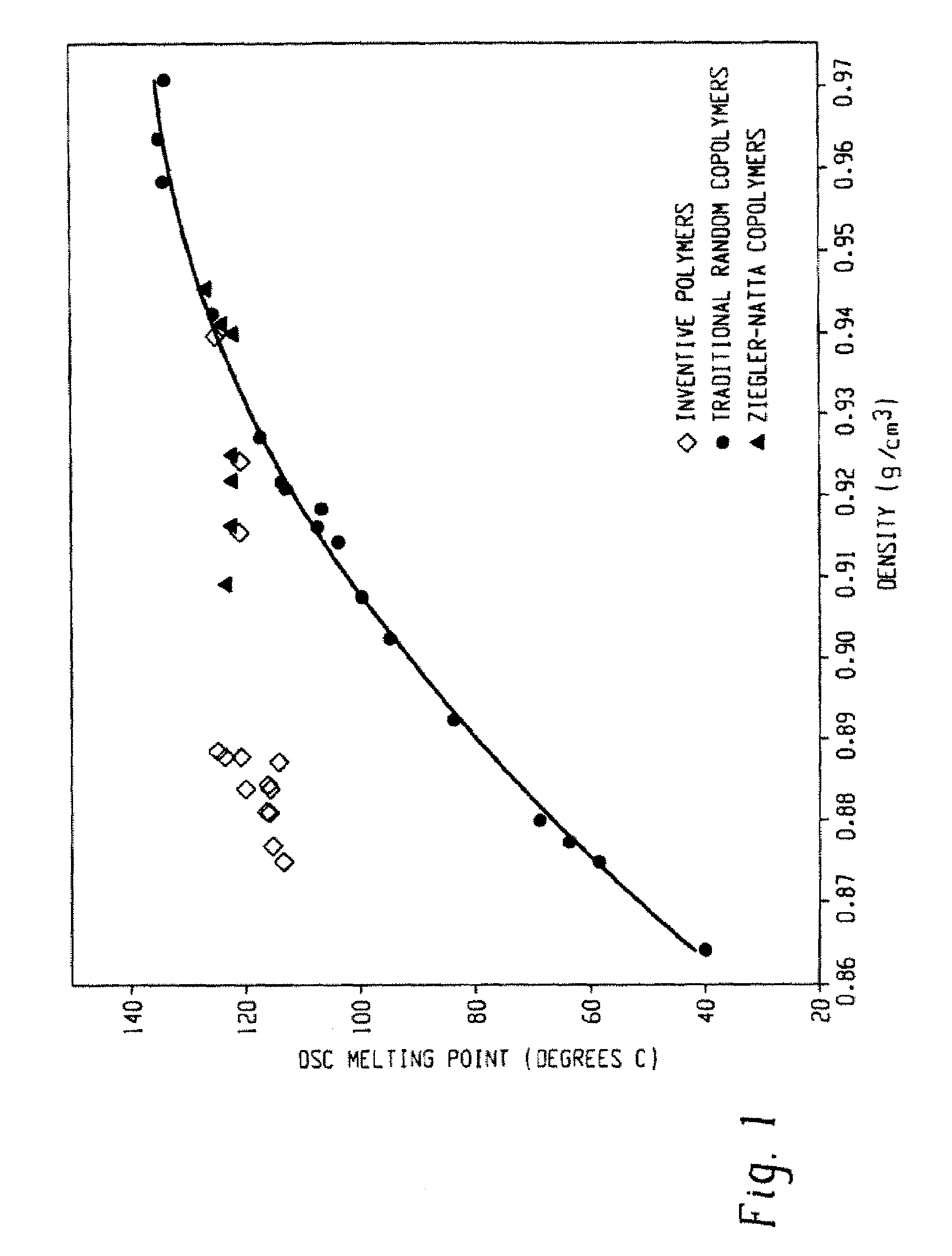

ActiveUS7504347B2Monocomponent synthetic polymer artificial filamentWoven fabricsFiberVolumetric Mass Density

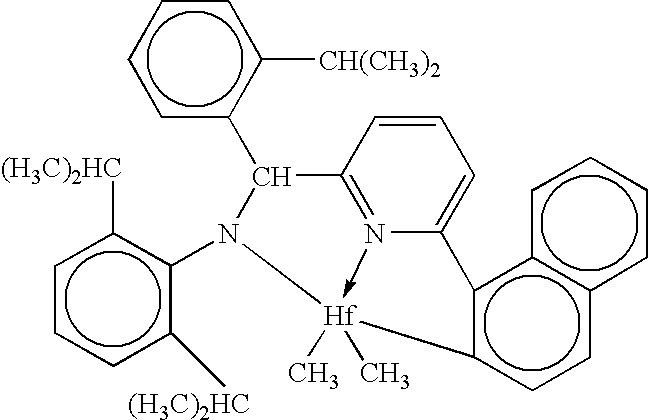

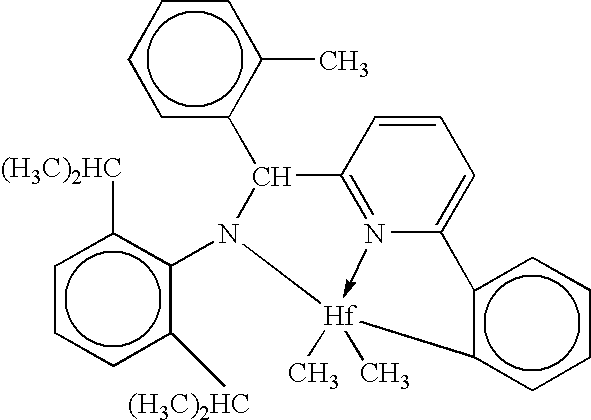

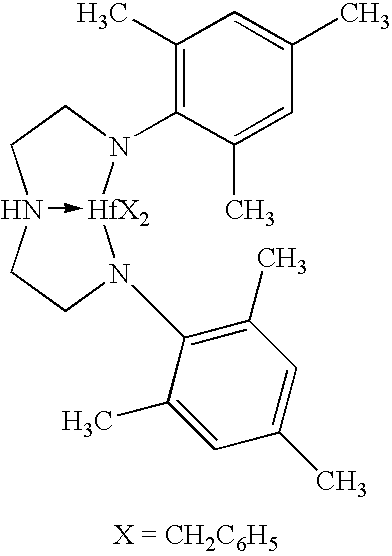

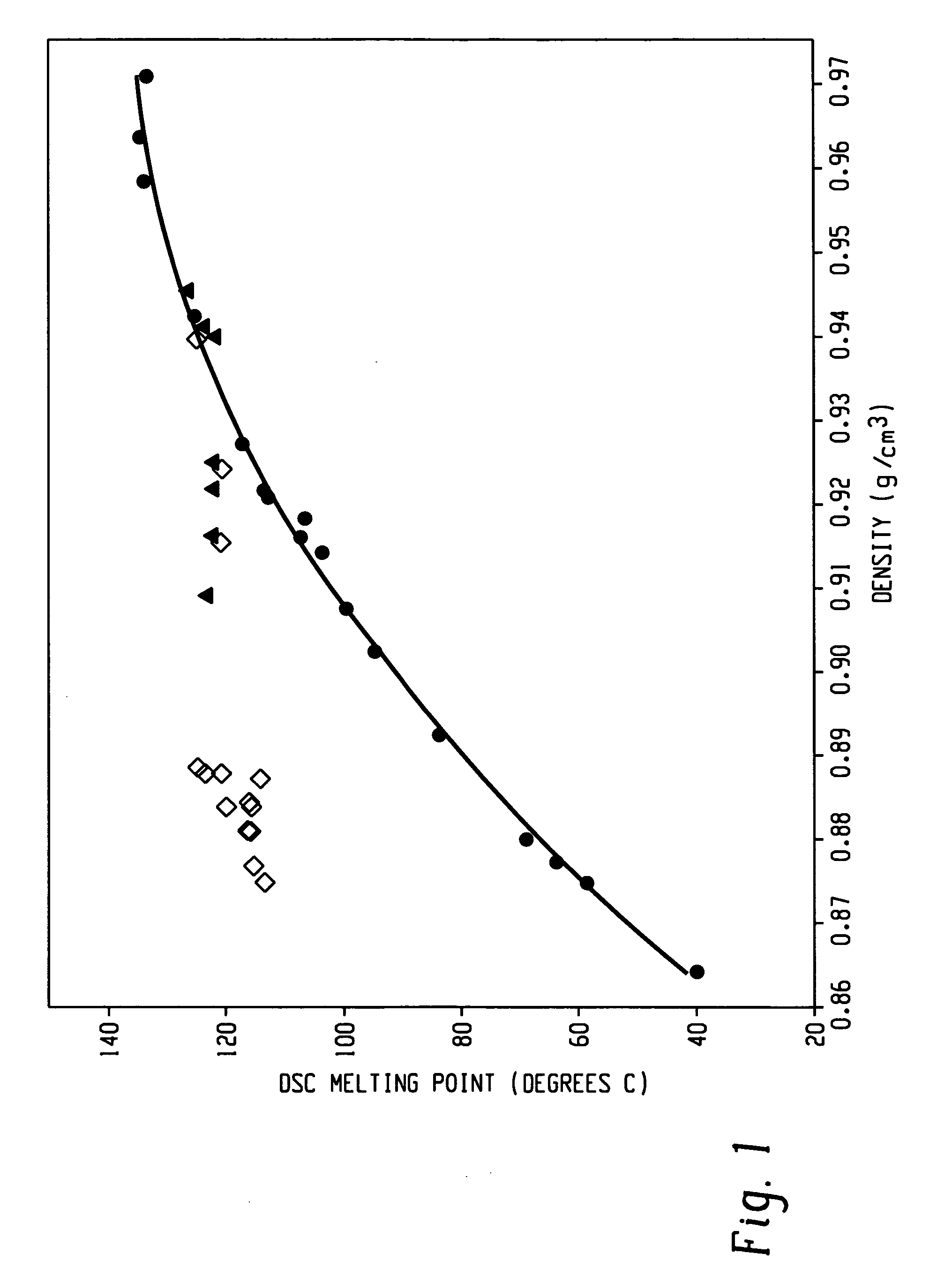

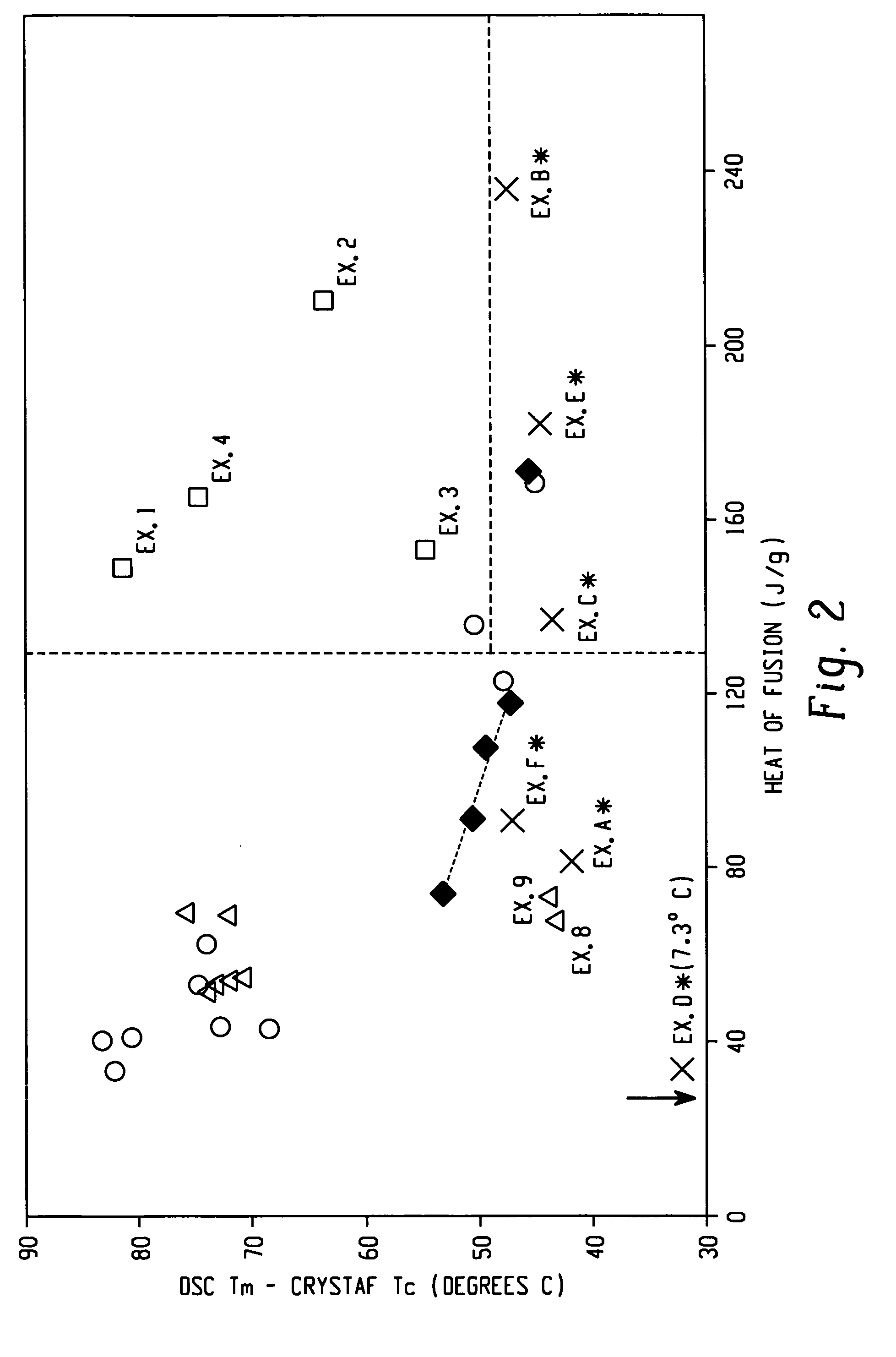

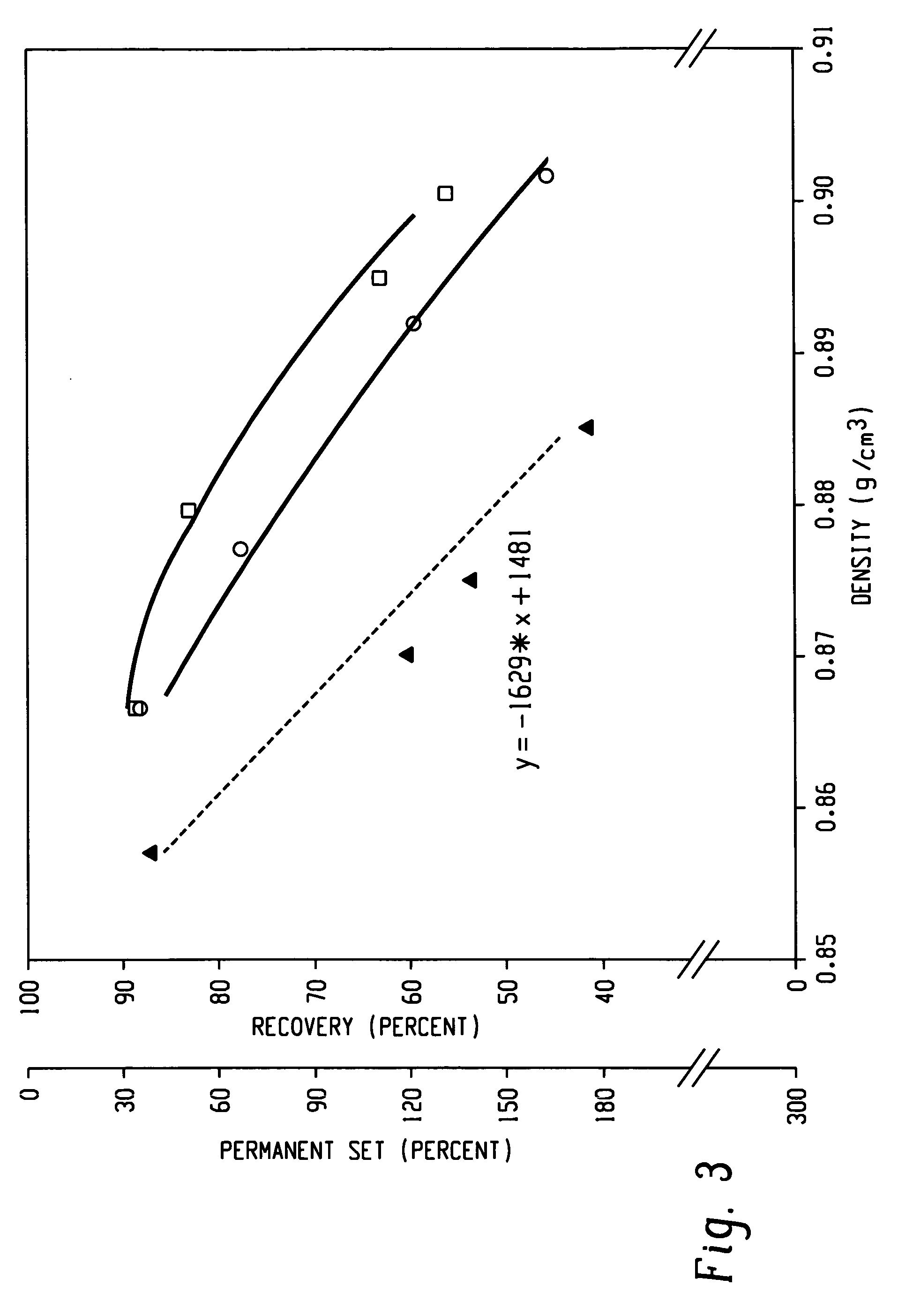

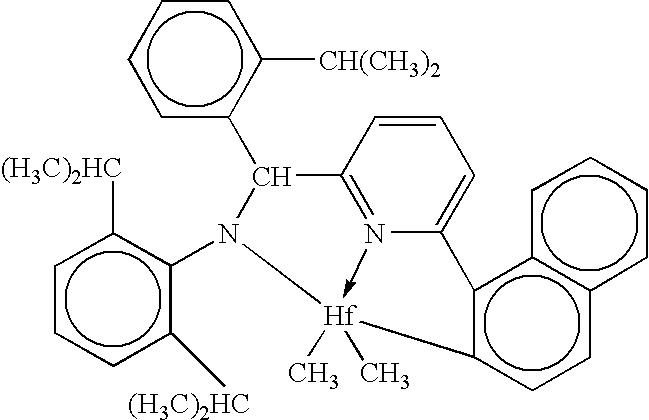

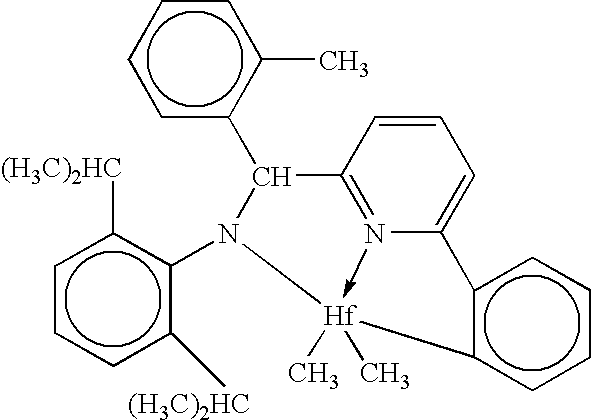

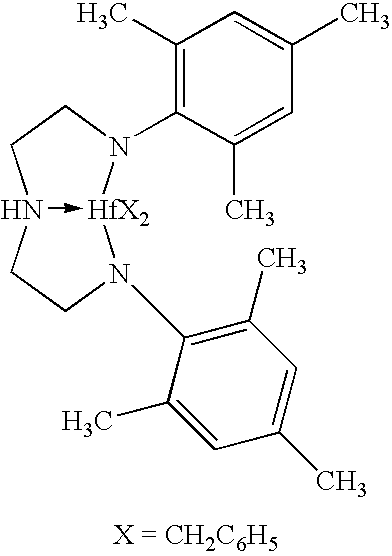

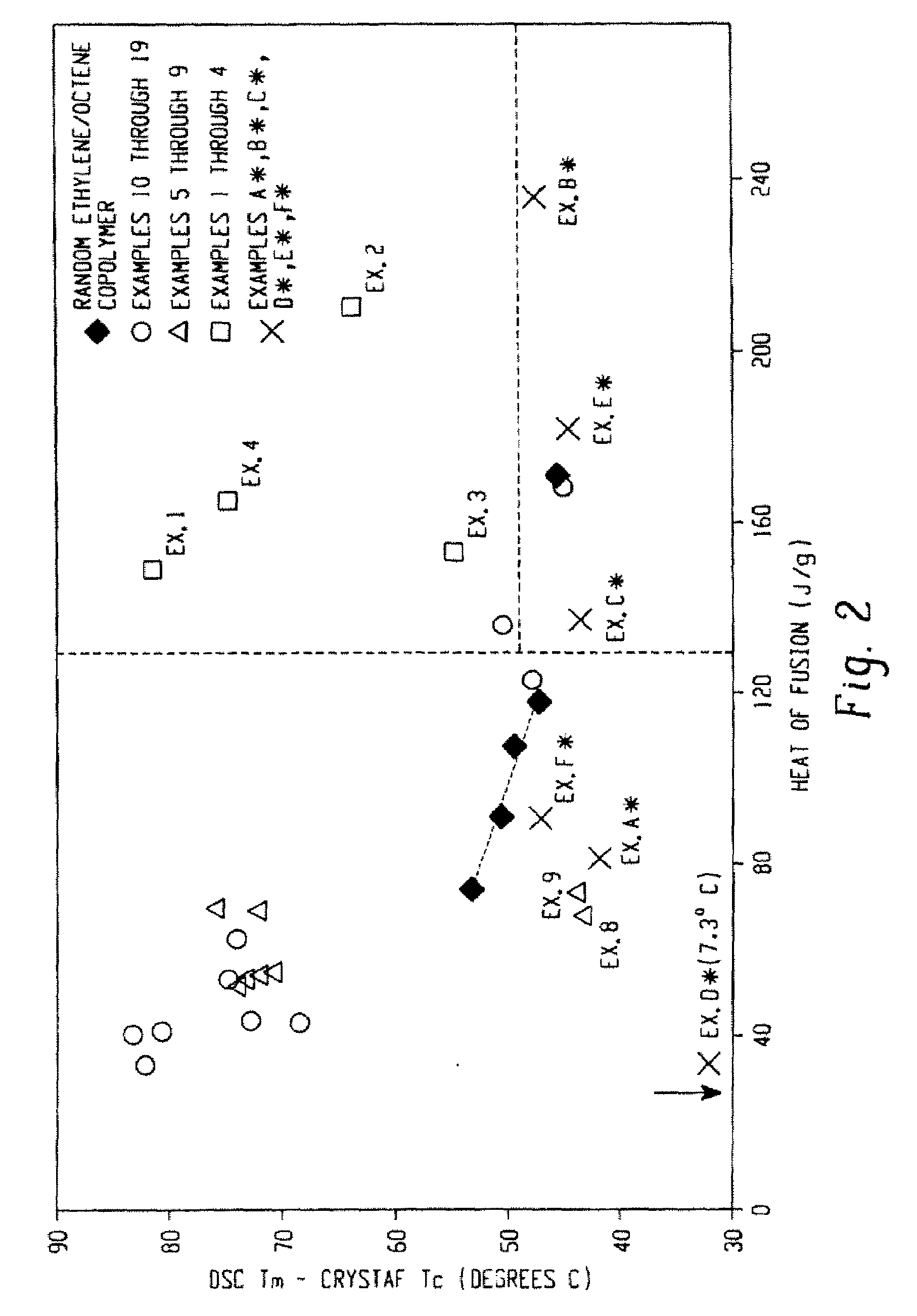

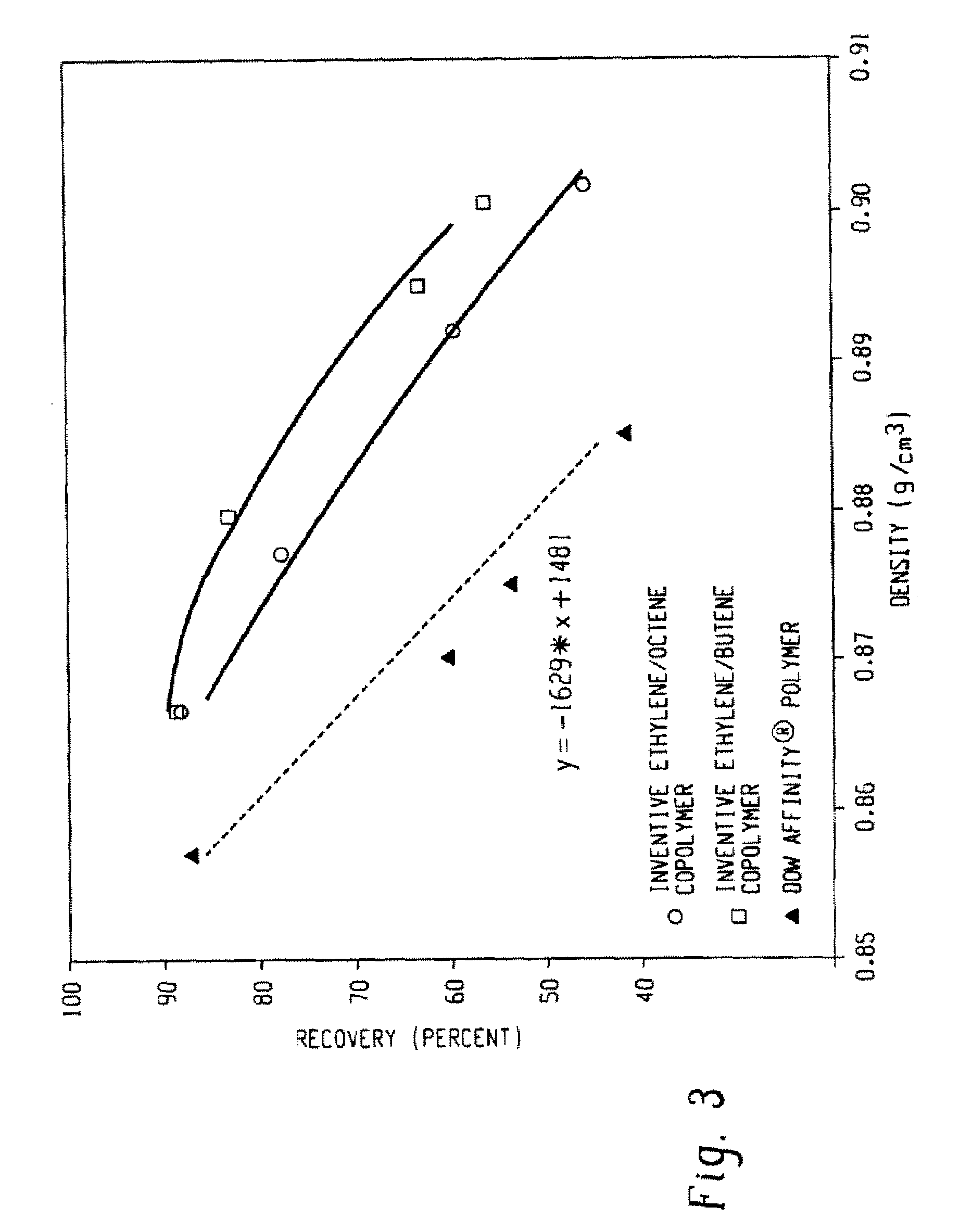

A fiber is obtainable from or comprises a propylene / α-olefin interpolymer characterized by an elastic recovery, Re, in percent at 300 percent strain and 1 cycle and a density, d, in grams / cubic centimeter, wherein the elastic recovery and the density satisfy the following relationship: Re>1481-1629 (d). Such interpolymer can also be characterized by other properties. The fibers made therefrom have a relatively high elastic recovery and a relatively low coefficient of friction. The fibers can be cross-linked, if desired. Woven or non-woven fabrics can be made from such fibers.

Owner:DOW GLOBAL TECH LLC

Fibers made from copolymers of ethylene/alpha-olefins

A fiber is obtainable from or comprises an ethylene / α-olefin interpolymer characterized by an elastic recovery, Re, in percent at 300 percent strain and 1 cycle and a density, d, in grams / cubic centimeter, wherein the elastic recovery and the density satisfy the following relationship: Re>1481−1629(d). Such interpolymer can also be characterized by other properties. The fibers made therefrom have a relatively high elastic recovery and a relatively low coefficient of friction. The fibers can be cross-linked, if desired. Woven or non-woven fabrics can be made from such fibers.

Owner:DOW GLOBAL TECH LLC

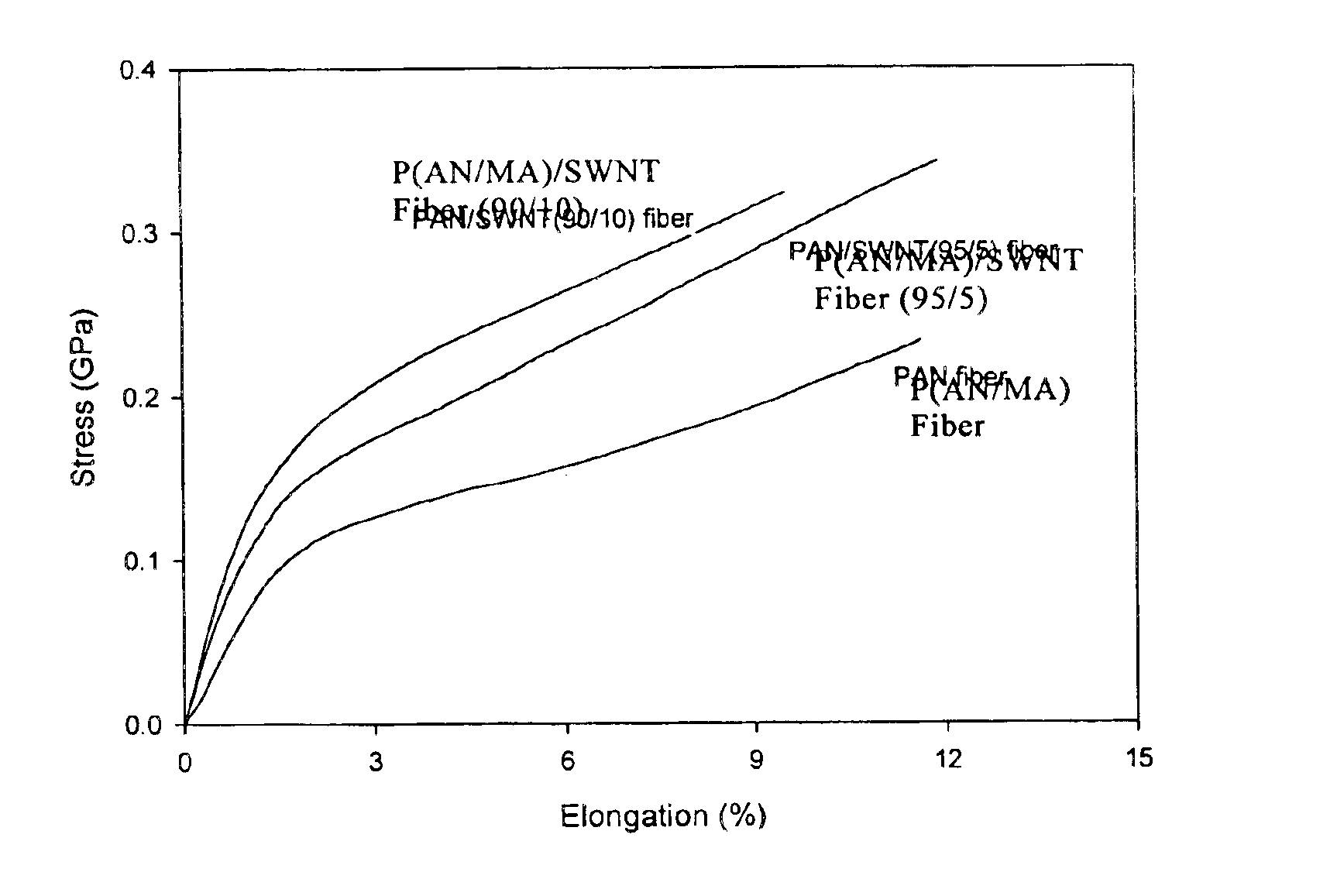

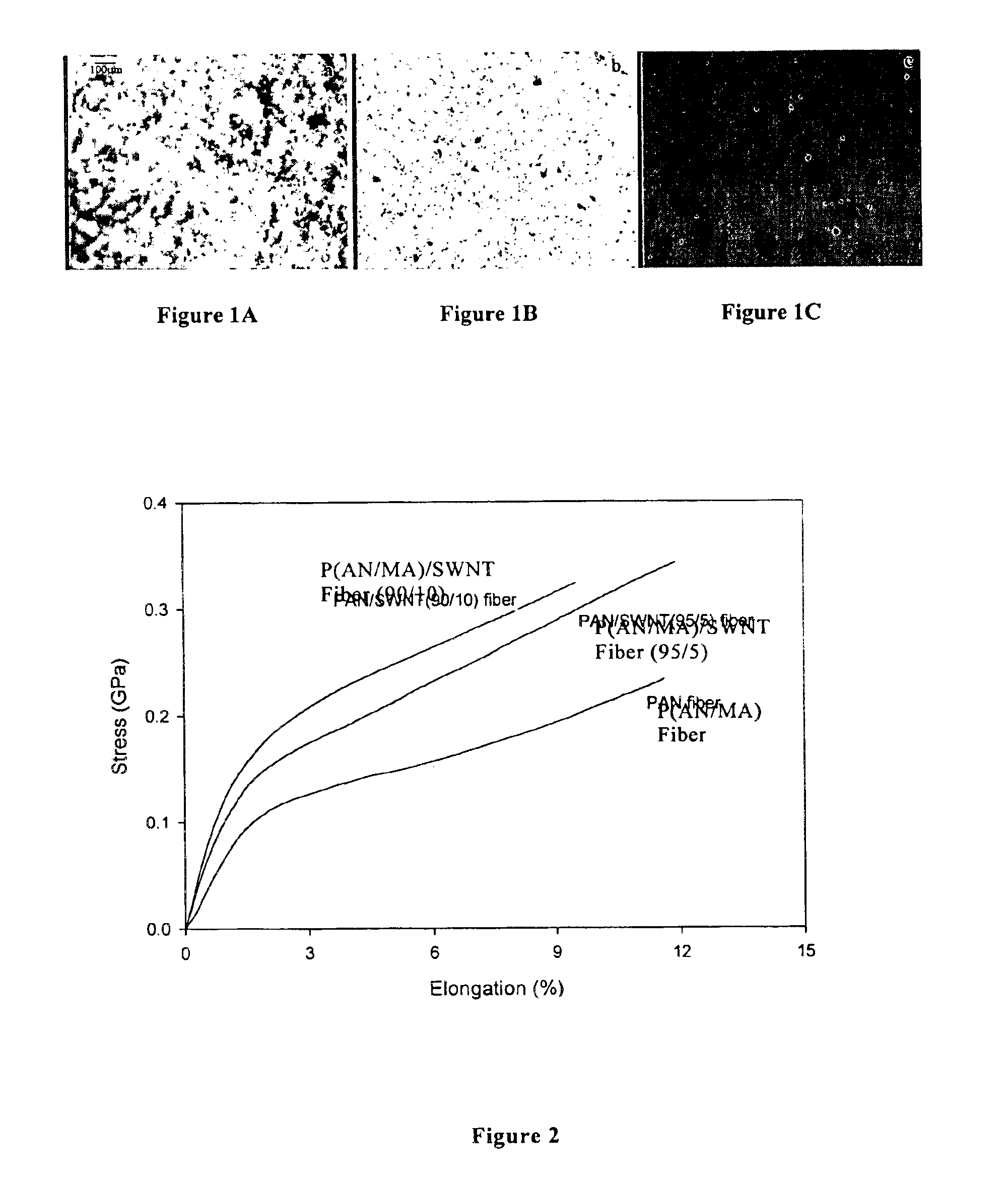

Macroscopic fiber comprising single-wall carbon nanotubes and acrylonitrile-based polymer and process for making the same

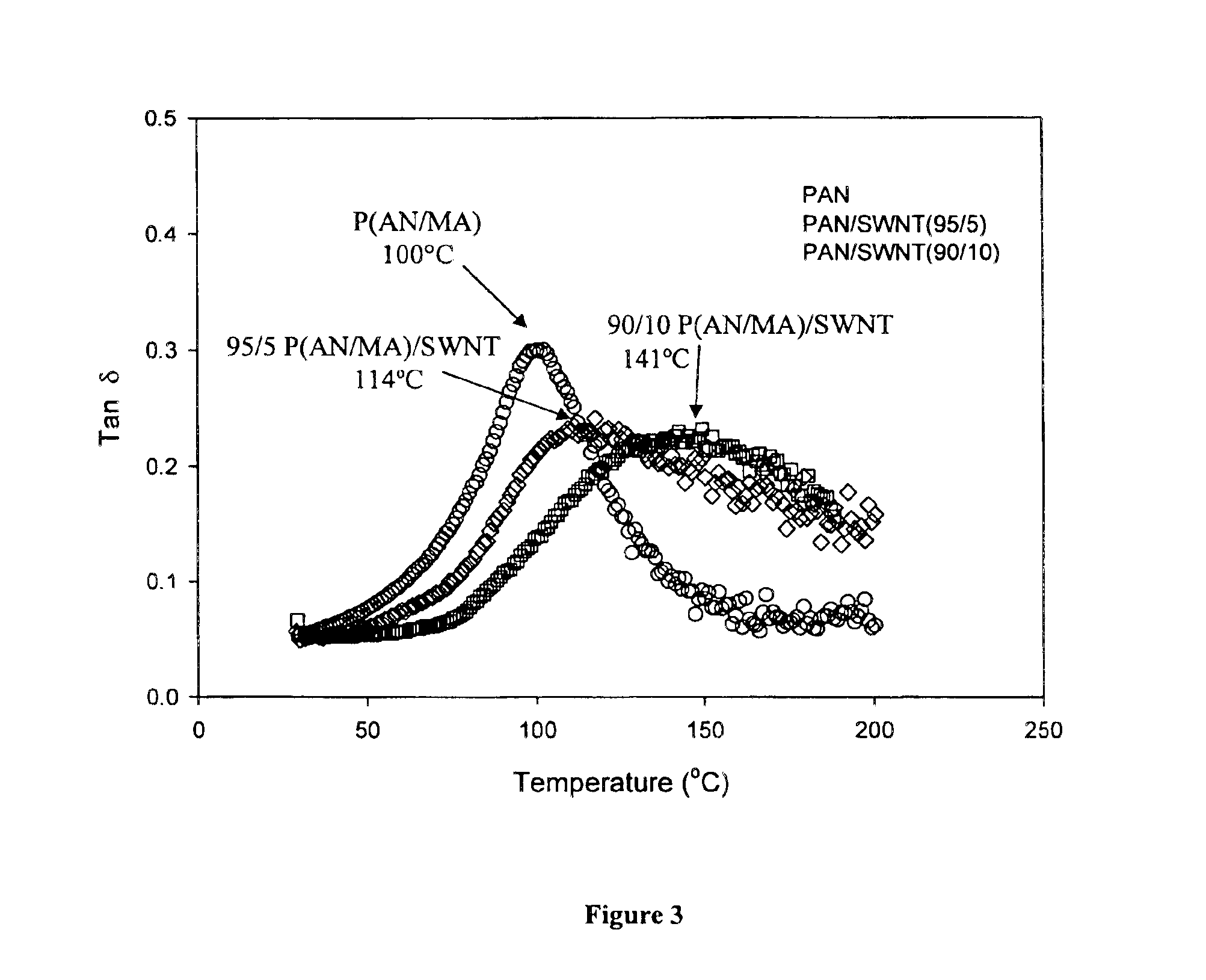

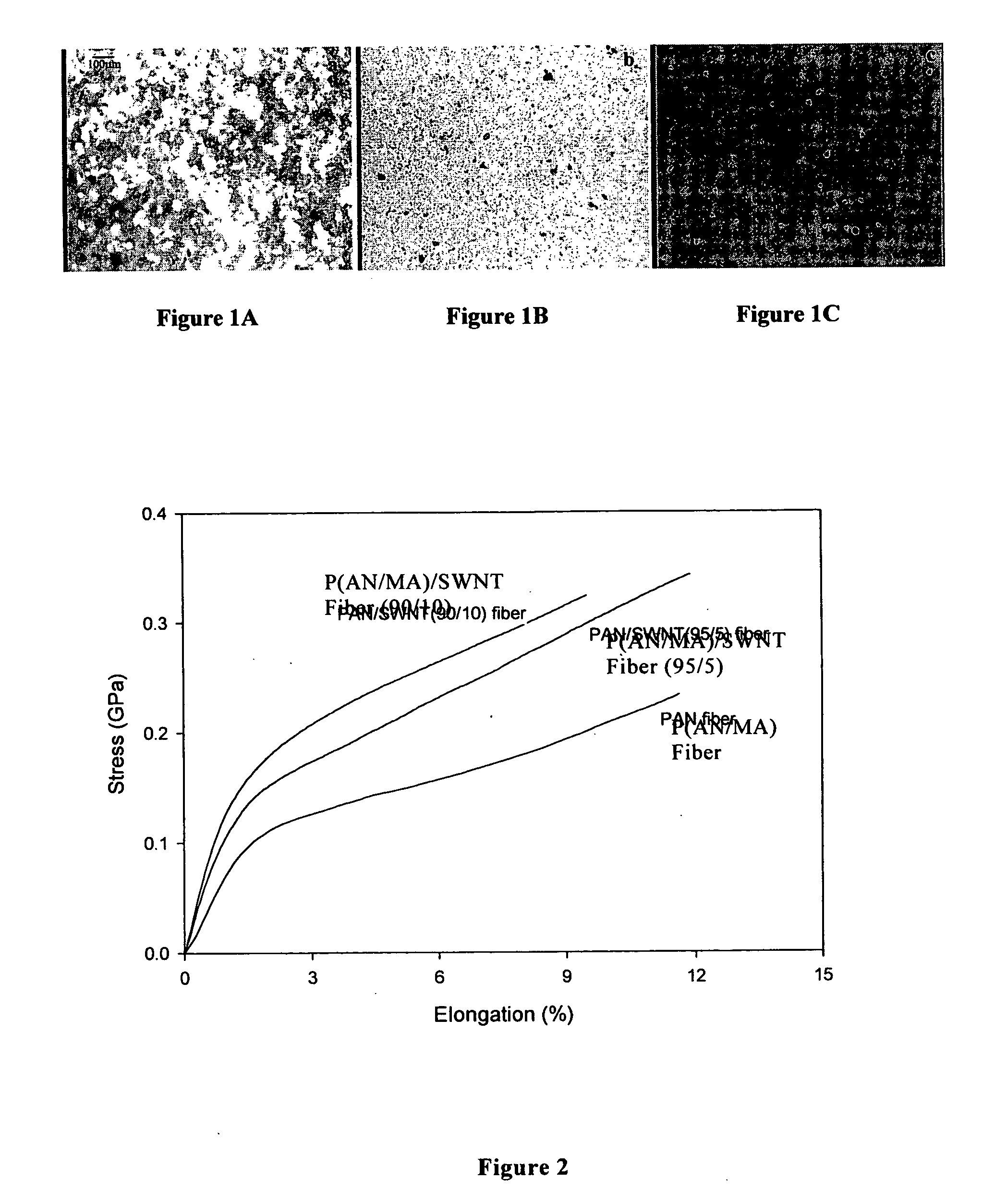

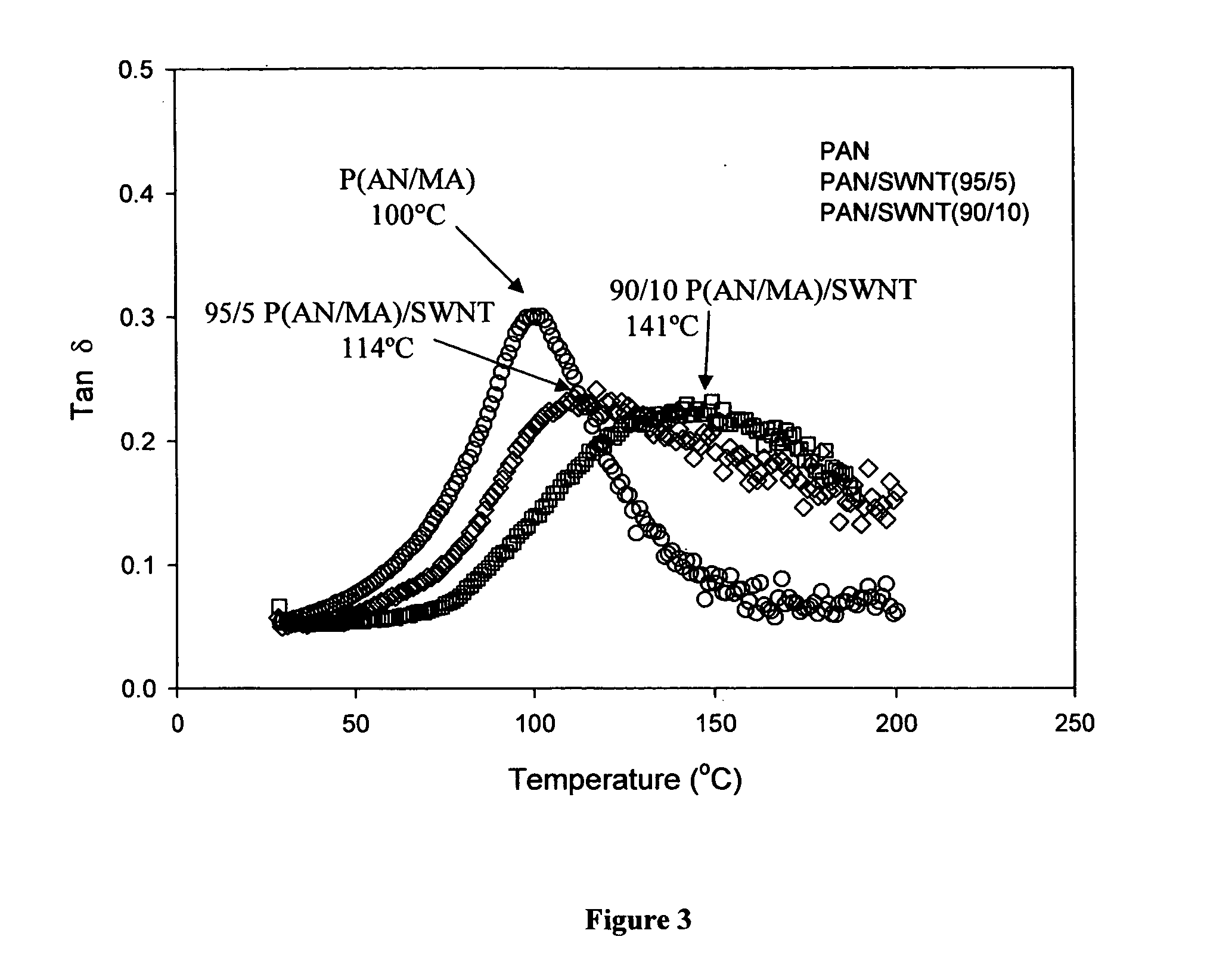

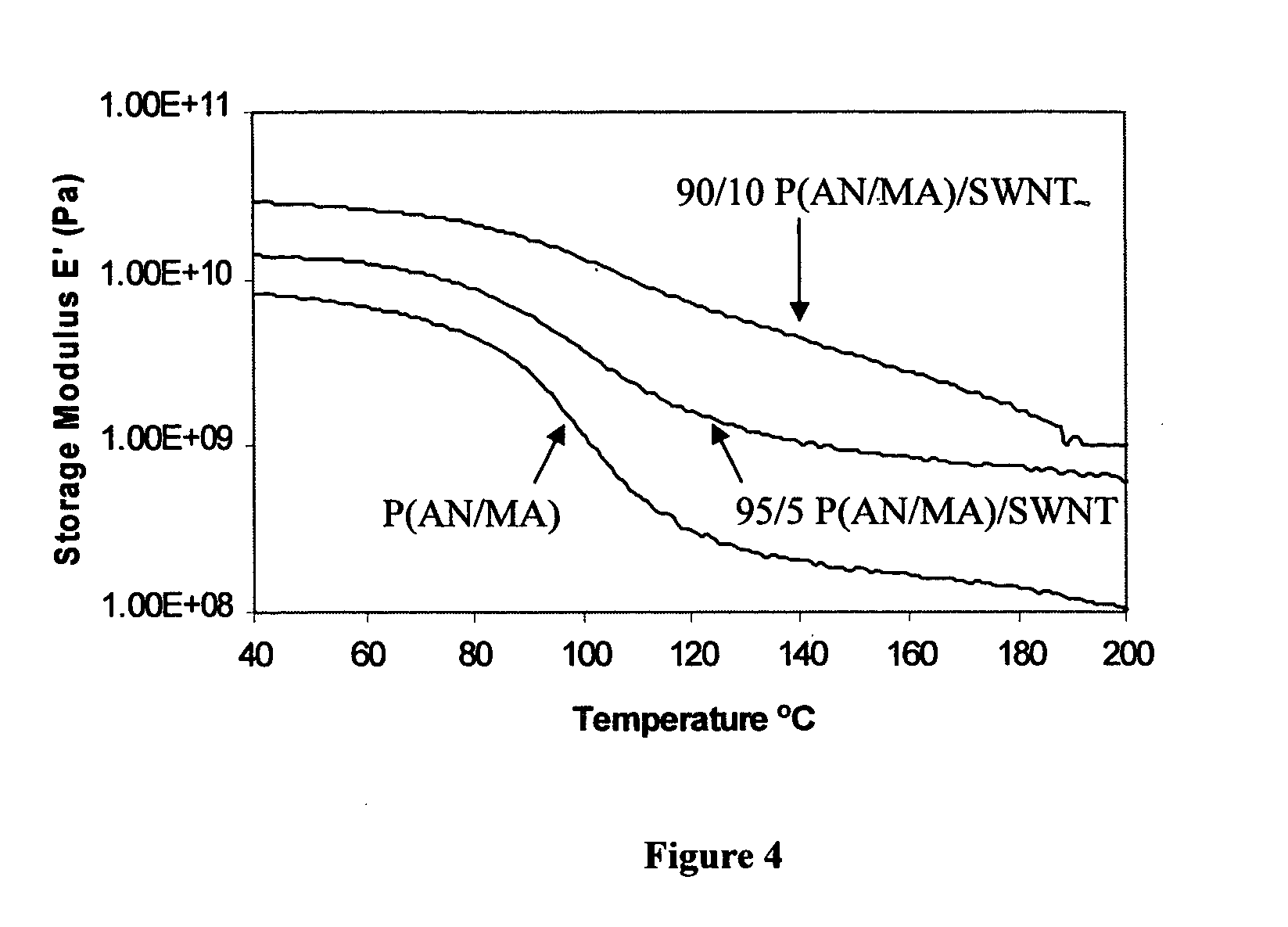

InactiveUS6852410B2Increased tensile modulusReduced thermal shrinkageMaterial nanotechnologyElectroconductive/antistatic filament manufactureVitrificationPolymer science

The present invention relates to a high modulus macroscopic fiber comprising single-wall carbon nanotubes (SWNT) and an acrylonitrile-containing polymer. In one embodiment, the macroscopic fiber is a drawn fiber having a cross-sectional dimension of at least 1 micron. In another embodiment, the acrylonitrile polymer-SWNT composite fiber is made by dispersing SWNT in a solvent, such as dimethyl formamide or dimethyl acetamide, admixing an acrylonitrile-based polymer to form a generally optically homogeneous polyacrylonitrile polymer-SWNT dope, spinning the dope into a fiber, drawing and drying the fiber. Polyacrylonitrile / SWNT composite macroscopic fibers have substantially higher modulus and reduced shrinkage versus a polymer fiber without SWNT. A polyacrylonitrile / SWNT fiber containing 10 wt % SWNT showed over 100% increase in tensile modulus and significantly reduced thermal shrinkage compared to a control fiber without SWNT. With 10 wt % SWNT, the glass transition temperature of the polymer increased by more than 40° C.

Owner:GEORGIA TECH RES CORP

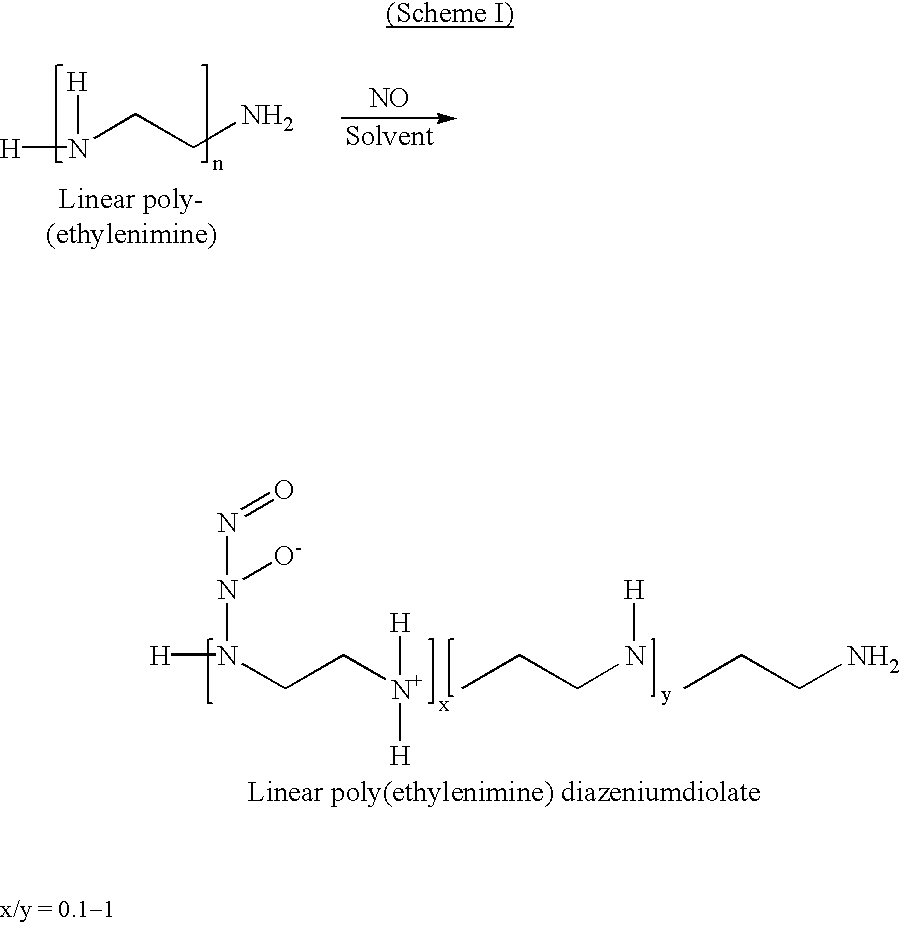

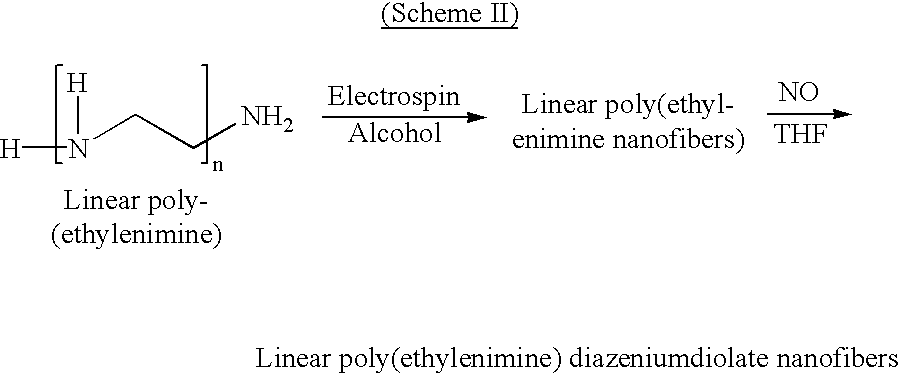

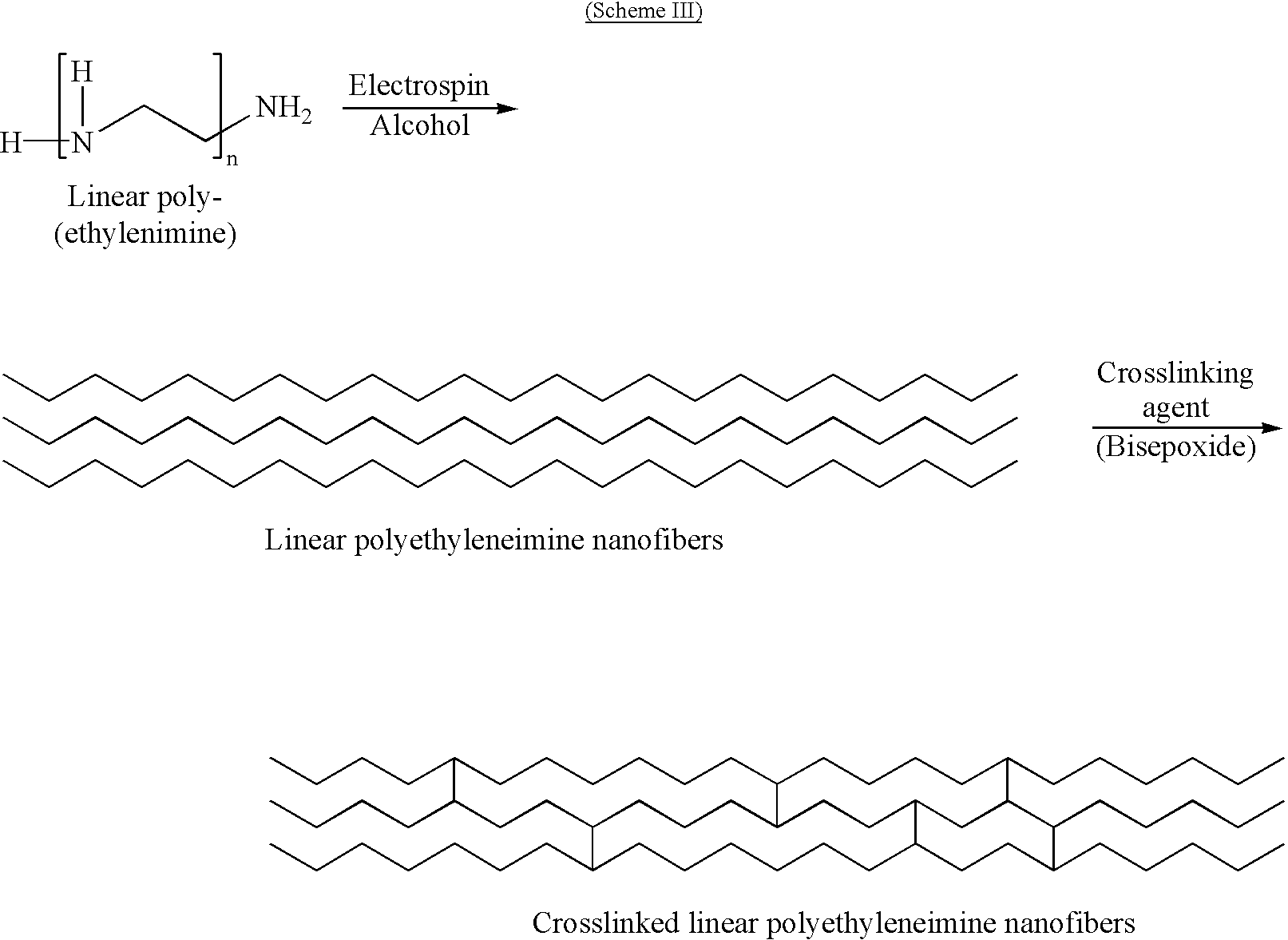

Nitric oxide-modified linear poly(ethylenimine) fibers and uses thereof

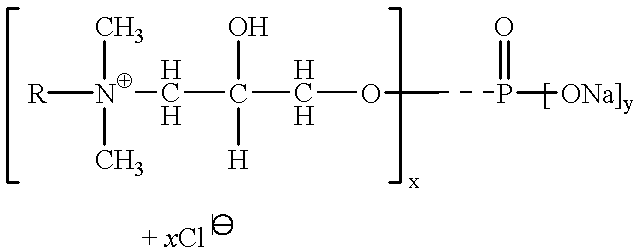

A novel coating for medical devices provides nitric oxide delivery using nanofibers of linear poly(ethylenimine)diazeniumdiolate. Linear poly(ethylenimine)diazeniumdiolate releases nitric oxide (NO) in a controlled manner to tissues and organs to aid the healing process and to prevent injury to tissues at risk of injury. Electrospun nano-fibers of linear poly(ethylenimine) diazeniumdiolate deliver therapeutic levels of NO to the tissues surrounding a medical device while minimizing the alteration of the properties of the device. A nanofiber coating, because of the small size and large surface area per unit mass of the nanofibers, provides a much larger surface area per unit mass while minimizing changes in other properties of the device.

Owner:AKRON THE UNIV OF

Fibers made from copolymers of propylene/alpha-olefins

ActiveUS20060199006A1Monocomponent synthetic polymer artificial filamentWoven fabricsFiberAlpha-olefin

A fiber is obtainable from or comprises a propylene / α-olefin interpolymer characterized by an elastic recovery, Re, in percent at 300 percent strain and 1 cycle and a density, d, in grams / cubic centimeter, wherein the elastic recovery and the density satisfy the following relationship: Re>1481-1629(d). Such interpolymer can also be characterized by other properties. The fibers made therefrom have a relatively high elastic recovery and a relatively low coefficient of friction. The fibers can be cross-linked, if desired. Woven or non-woven fabrics can be made from such fibers.

Owner:DOW GLOBAL TECH LLC

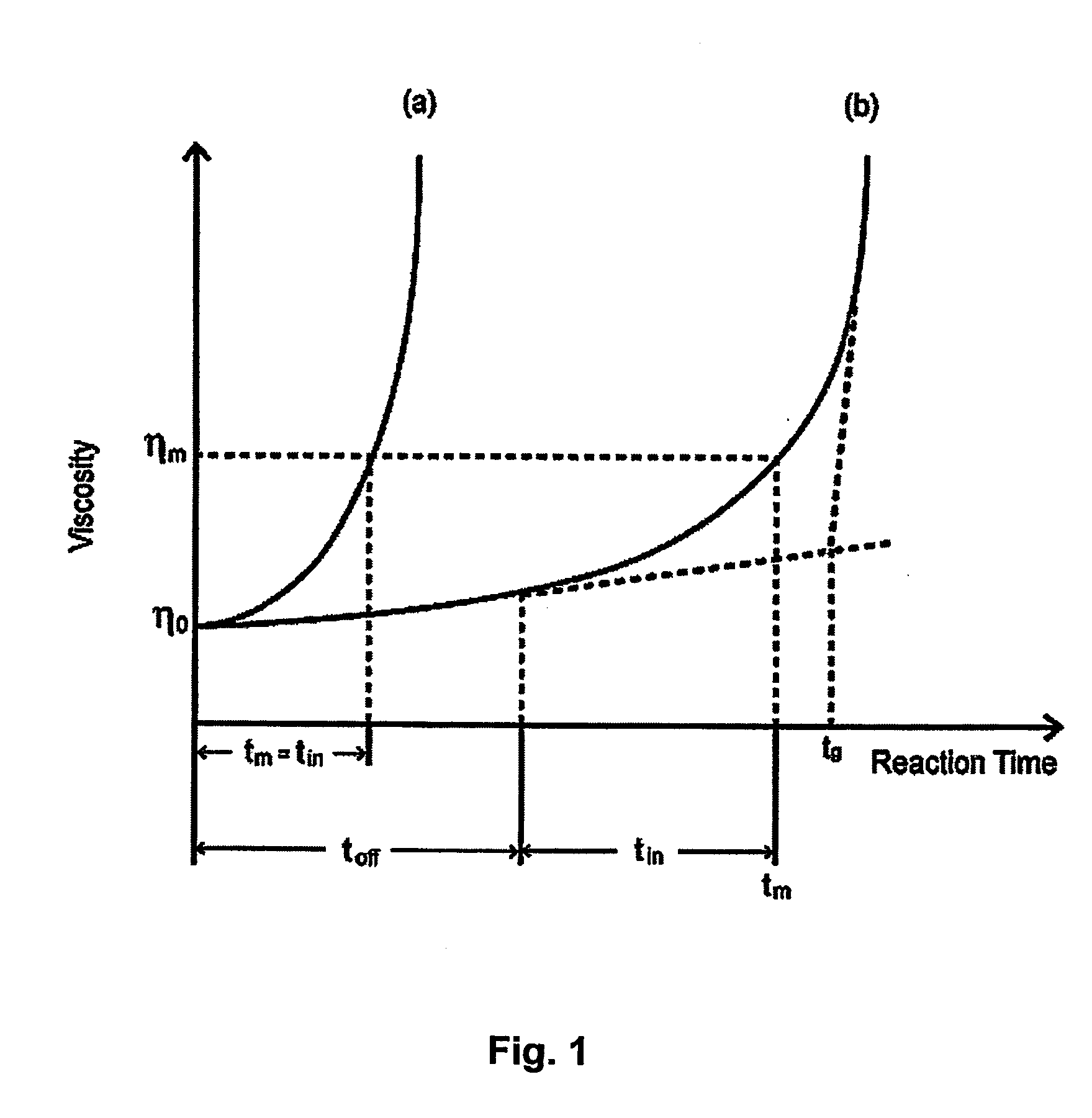

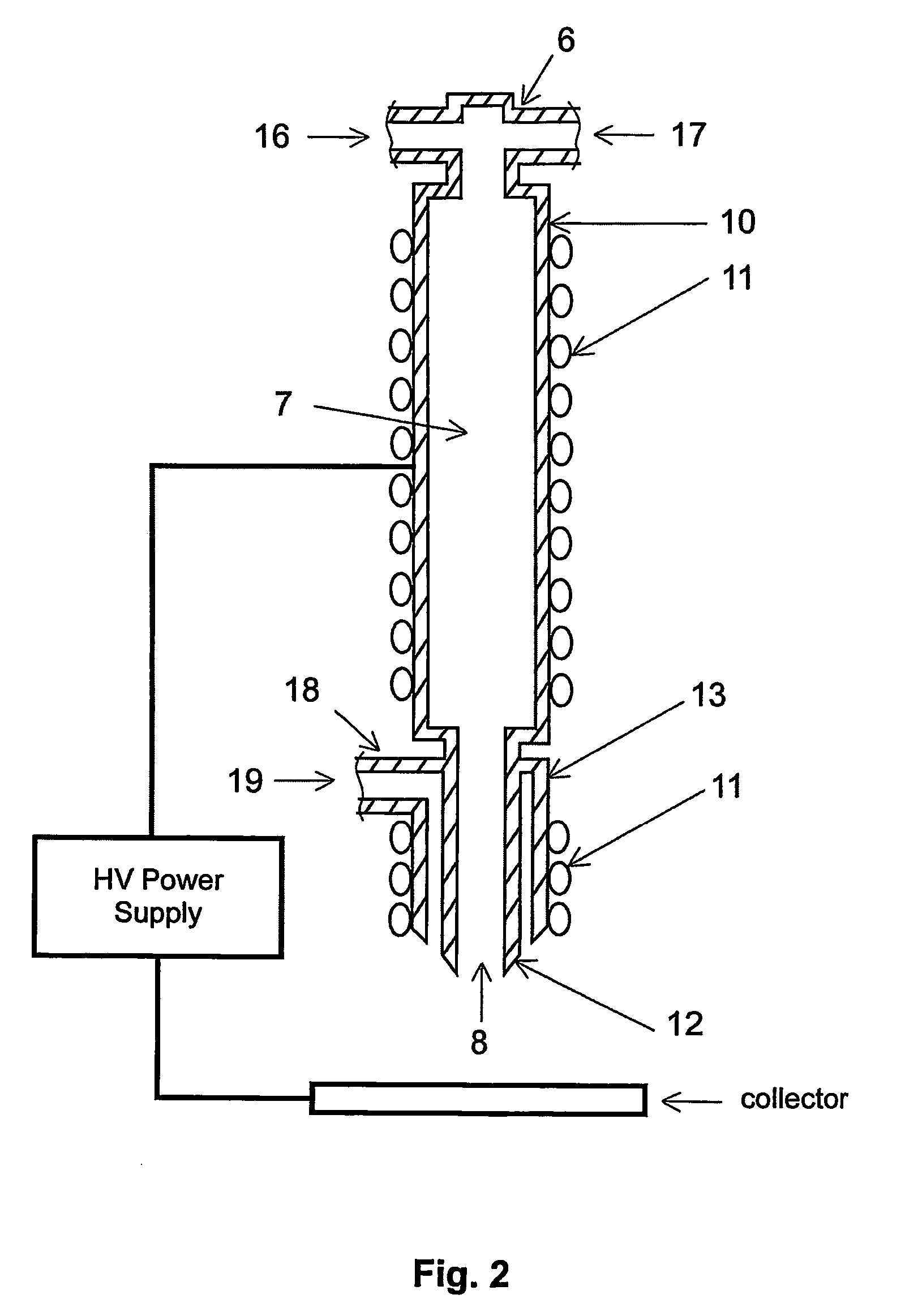

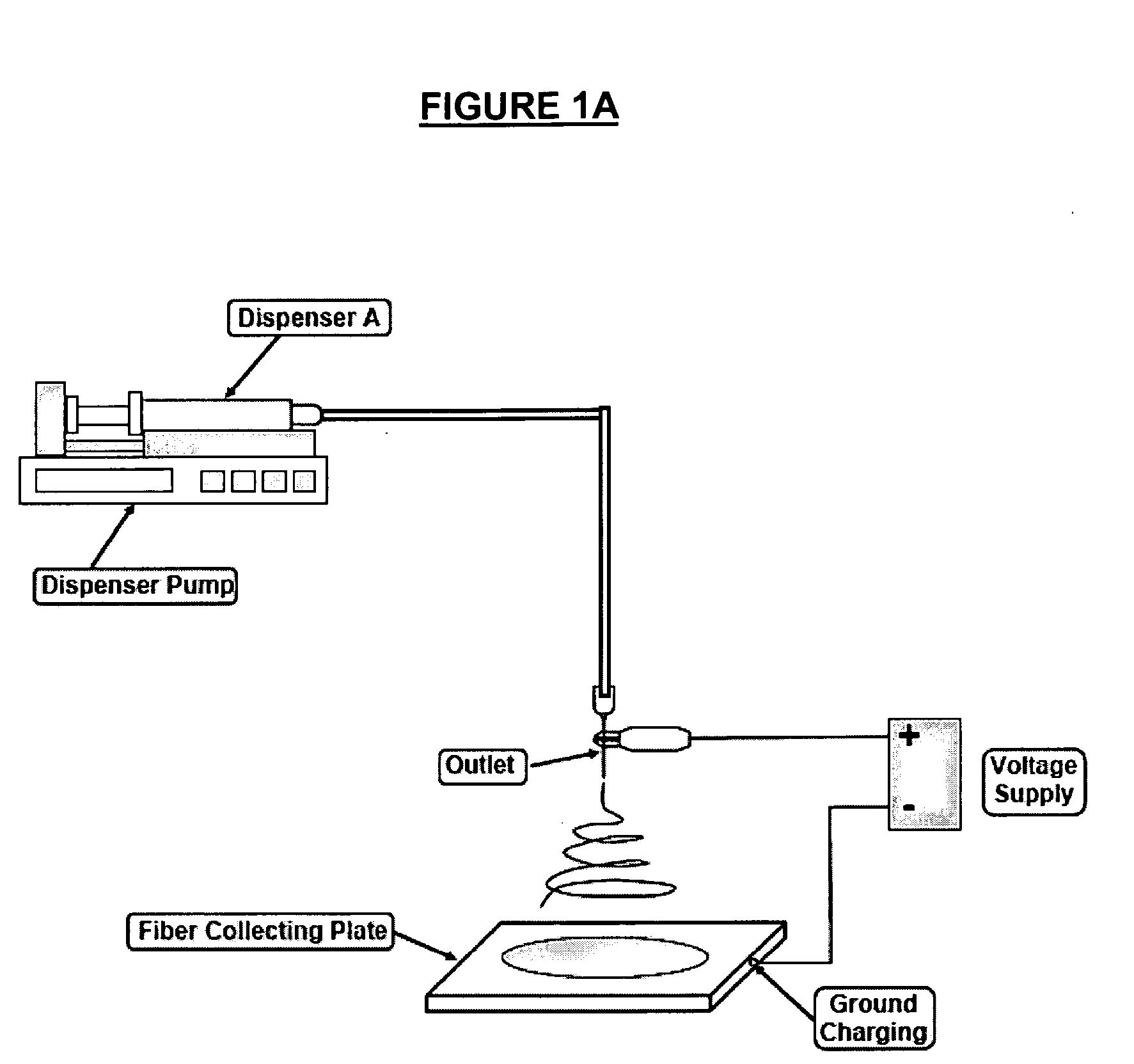

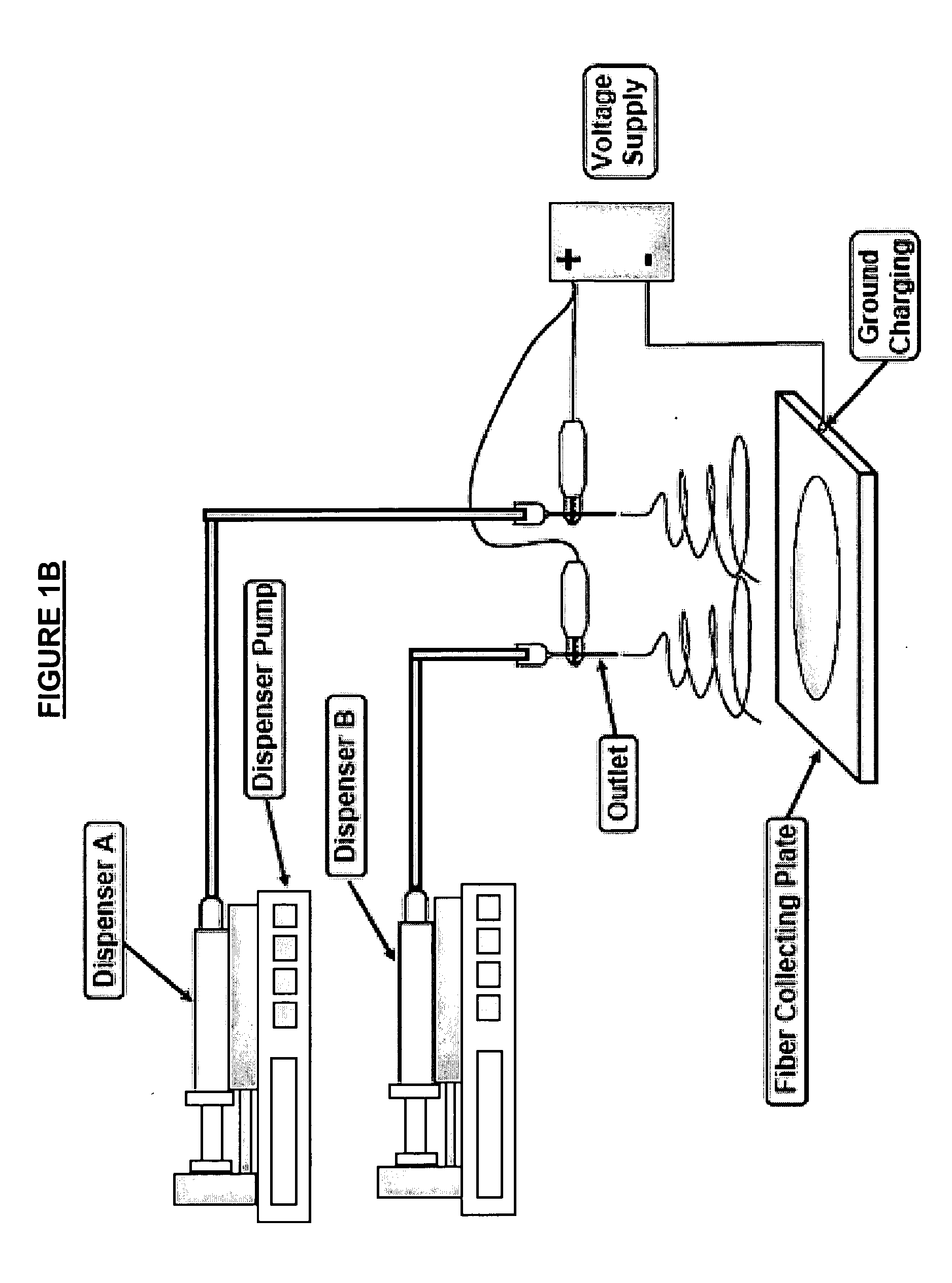

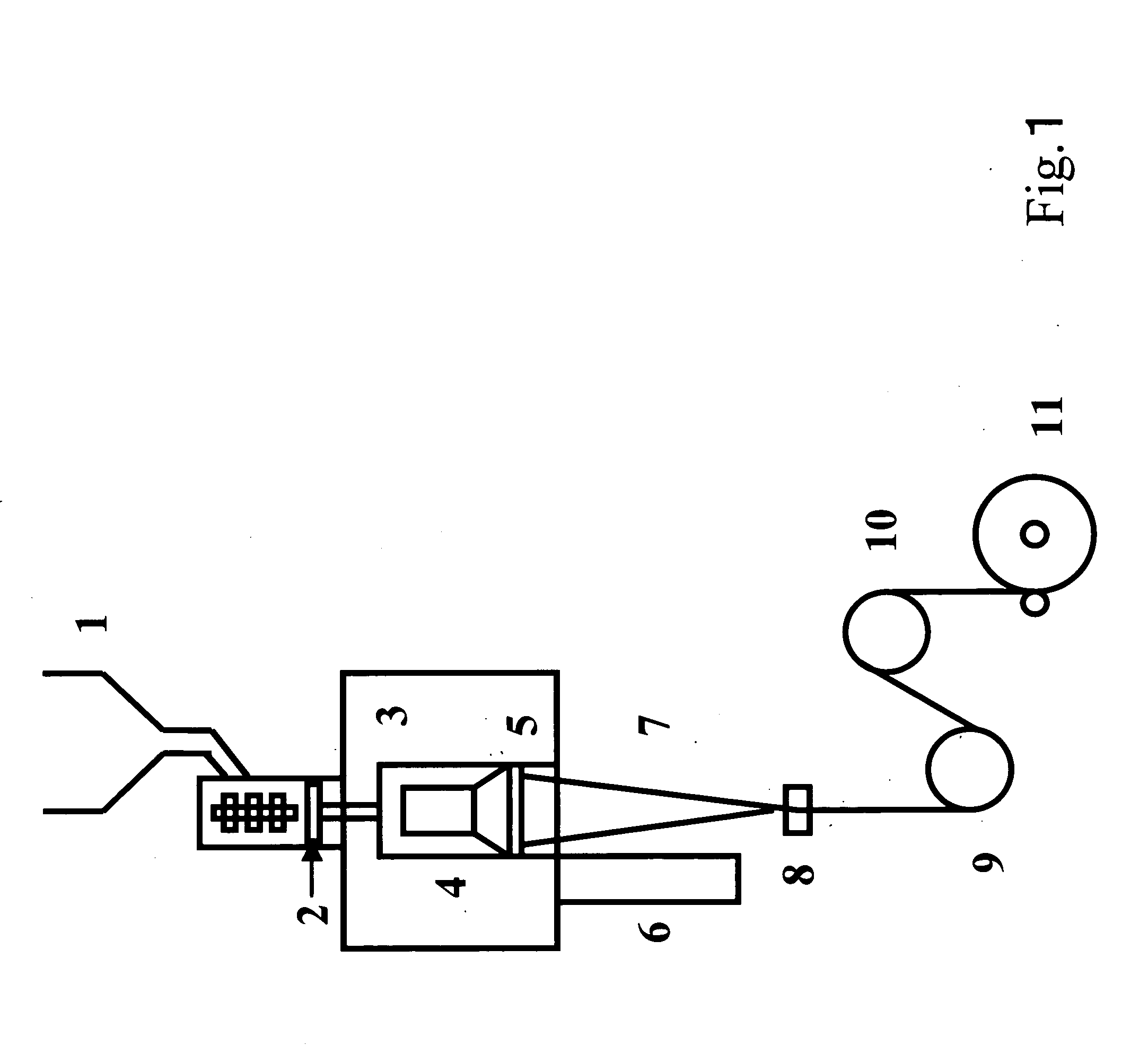

Nanofibers, and apparatus and methods for fabricating nanofibers by reactive electrospinning

ActiveUS20070018361A1Broaden applicationEasy to controlElectric discharge heatingInorganic material artificial filamentsFiberElectrospinning

Apparatus and methods for fabricating nanofibers by reactive electrospinning are described. An electrospinning process is coupled with an in-line reactor where chemical or photochemical reactions take place. This invention expands the application of the electrospinning and allows the production of nanofibers of crosslinked polymers and other new materials, such as gel nanofibers of ceramic precursors.

Owner:BOARD OF SUPERVISORS OF LOUISIANA STATE UNIV & AGRI & MECHANICAL COLLEGE

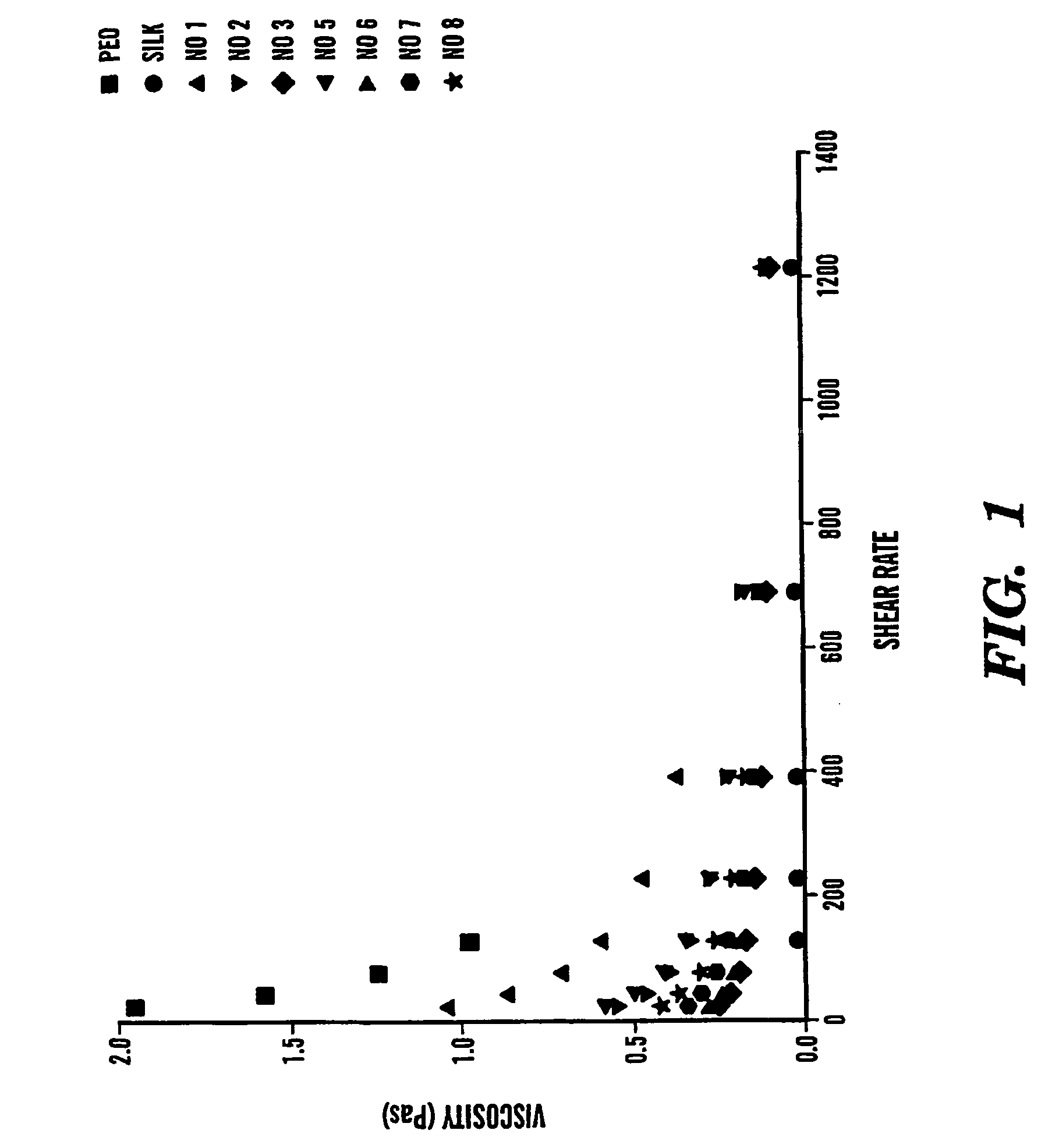

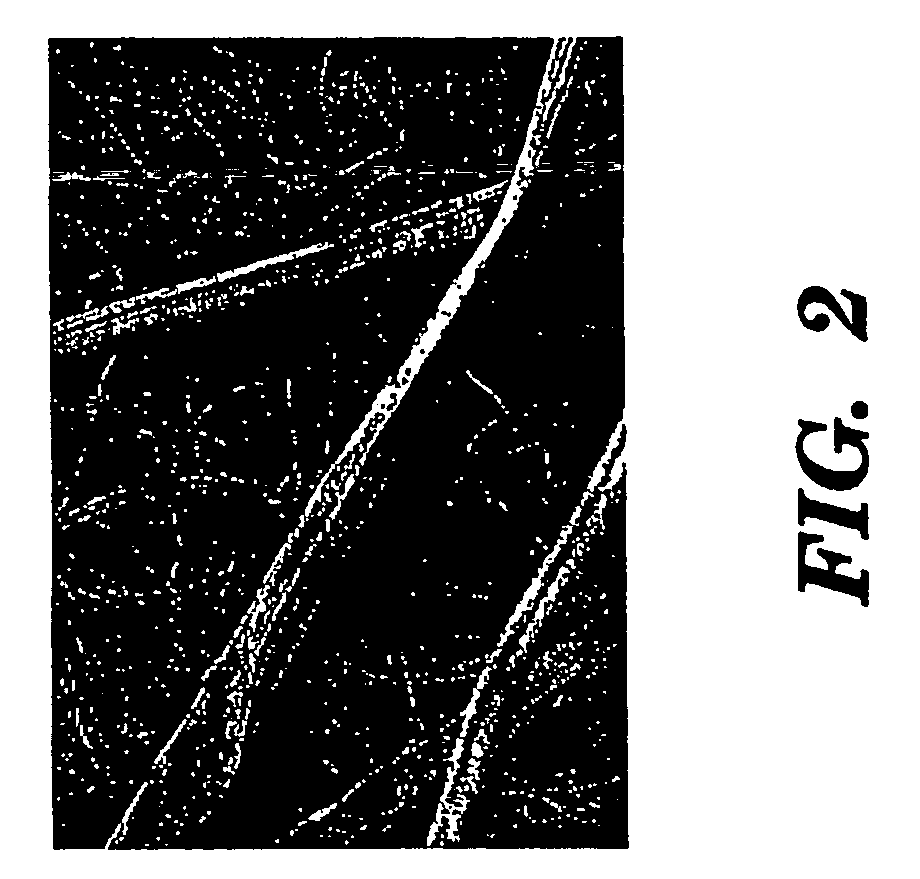

Silk biomaterials and methods of use thereof

ActiveUS7674882B2Avoid problemsReduce usagePeptide/protein ingredientsFilament/thread formingFiberIn vivo

The present invention provides an all-aqueous process and composition for production of silk biomaterials, e.g., fibers, films, foams and mats. In the process, at least one biocompatible polymer, such as poly(ethylene oxide) (PEO) (a well-documented biocompatible material), was blended with the silk protein prior to processing e.g., electrospinning. We discovered that this step avoids problems associated with conformational transitions of fibroin during solubilization and reprocessing from aqueous solution which lead to embrittled materials. Moreover, the process avoids the use of organic solvents that can pose problems when the processed biomaterials are exposed to cells in vitro or in vivo.

Owner:MASSACHUSETTS INST OF TECH +1

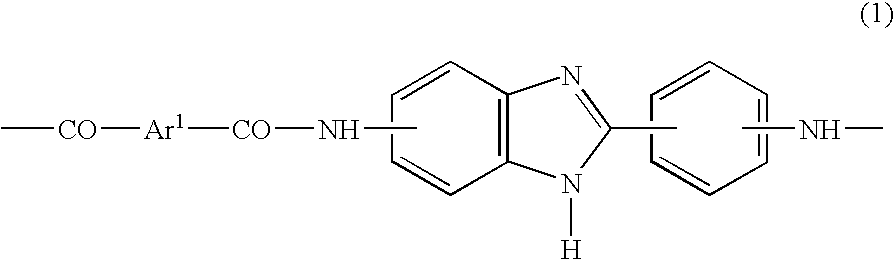

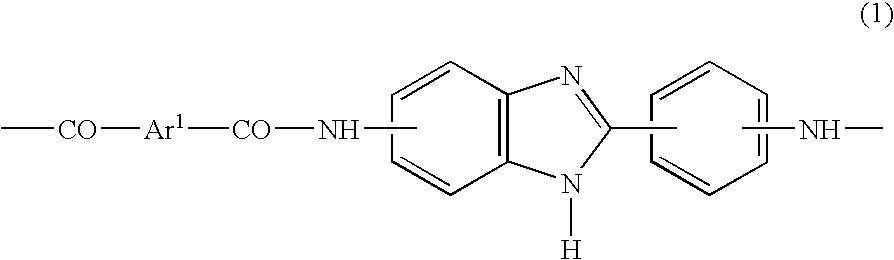

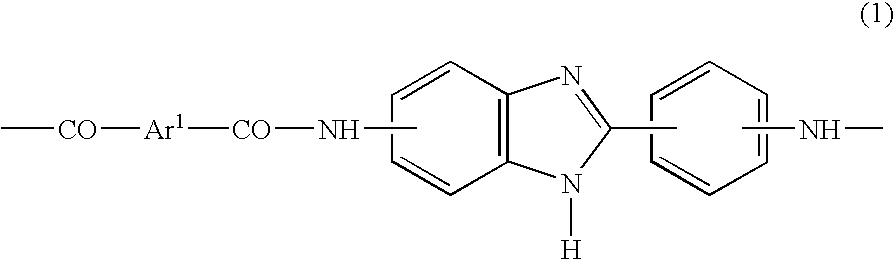

Heterocycle-containing aromatic polyamide fiber, method for producing the same, cloth constituted by the fiber, and fiber-reinforced composite material reinforced with the fiber

InactiveUS20100029159A1Improve balanceHigh strength holding ratioArtificial filament heat treatmentMonocomponent synthetic polymer artificial filamentAramidesFiber-reinforced composite

The heterocycle-containing aromatic polyamide fibers of the invention are excellent in balance among mechanical characteristics, particularly balance among tensile strength, initial modulus and strength in the direction perpendicular to the fiber axis, exhibit a high strength holding ratio under heat and humidity, and are excellent in flame retardancy, bulletproofness and cutting resistance, as compared to conventional aromatic polyamide fibers, and therefore can be favorably used in fields with severe mechanical characteristics and have stability to environmental variation. Accordingly, the heterocycle-containing aromatic polyamide fibers of the invention can be favorably used, for example, in fields including protective equipment, such as a helmet, a bulletproof vest and the like, a chassis for an automobile, a ship and the like, an electric insulating material, such as a printed circuit board and the like, and other various fields.

Owner:TEIJIN TECHNO PRODUCTS LTD

Dissolvable Fibrous Web Structure Article Comprising Active Agents

The personal care compositions of the present invention are in the form of an Article comprising a dissolvable fibrous web structure. The fibers of the dissolvable fibrous web structure comprise a surfactant; a water soluble polymeric structurant; and a plasticizer. Additionally the ratio of the water soluble water soluble polymeric structurant to the active agent in the fiber is 3.5 or less.

Owner:THE PROCTER & GAMBLE COMPANY

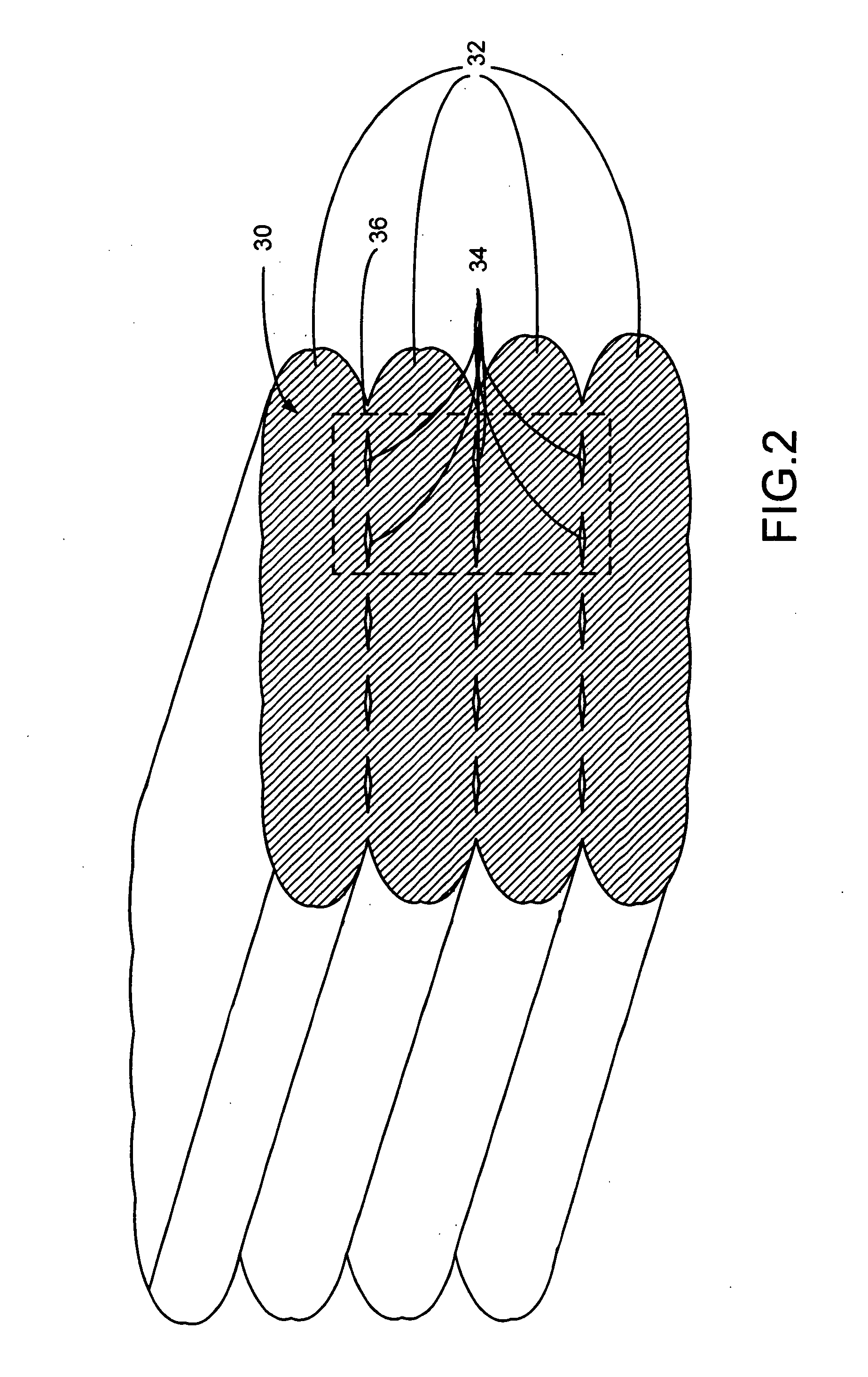

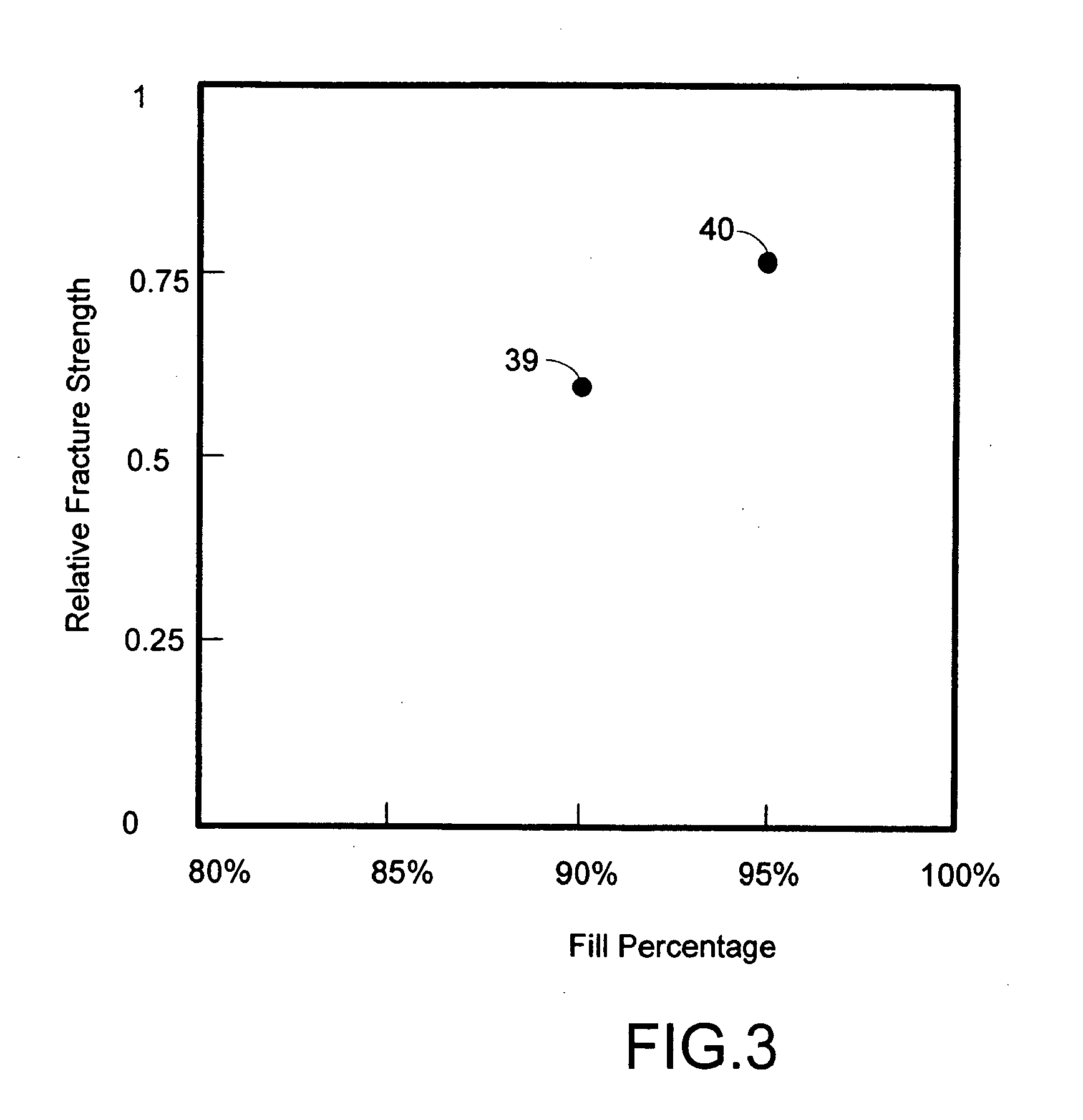

High-precision modeling filament

Disclosed is a modeling filament for use as feedstock in a fused deposition modeling liquifier, and a method for manufacturing the filament. The diameter and standard deviation of the filament are controlled to meet various tolerance requirements of jam resistance, slip resistance, model strength, liquifier overflow prevention and hysteresis-free transient response. Standard deviation of the filament diameter is matched to a filament target diameter. The resulting filament is used to form high-quality models.

Owner:STRATSYS INC

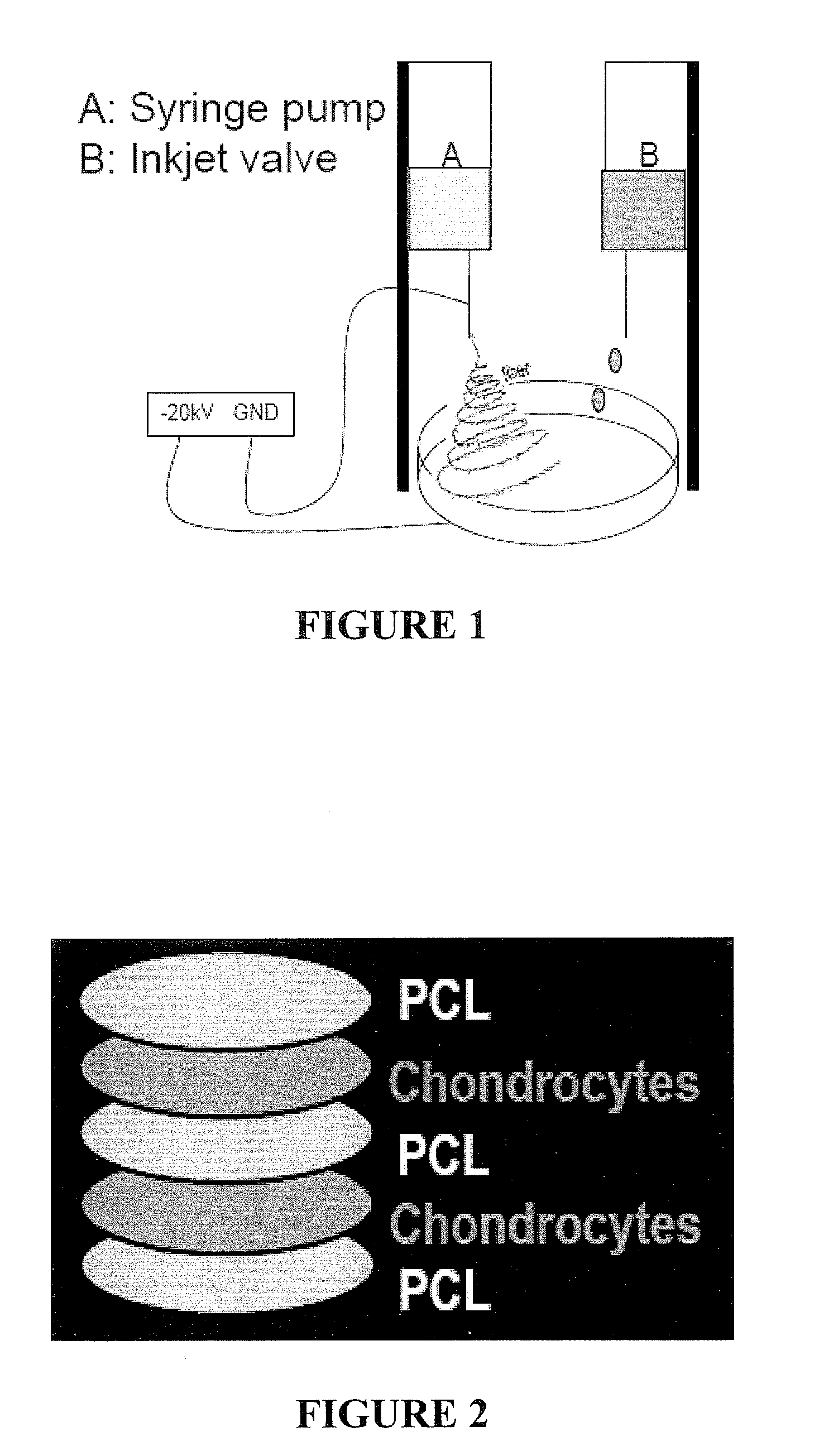

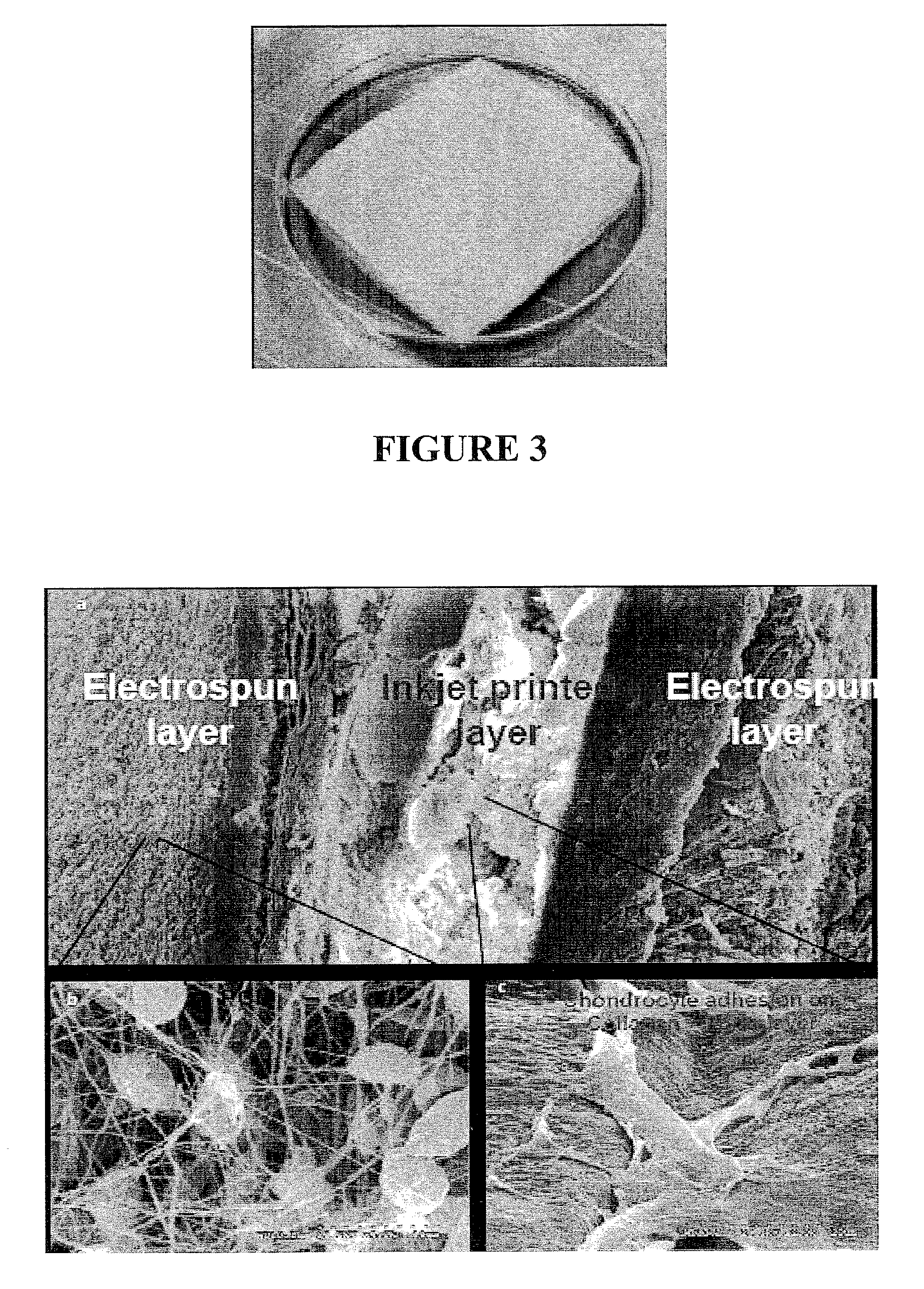

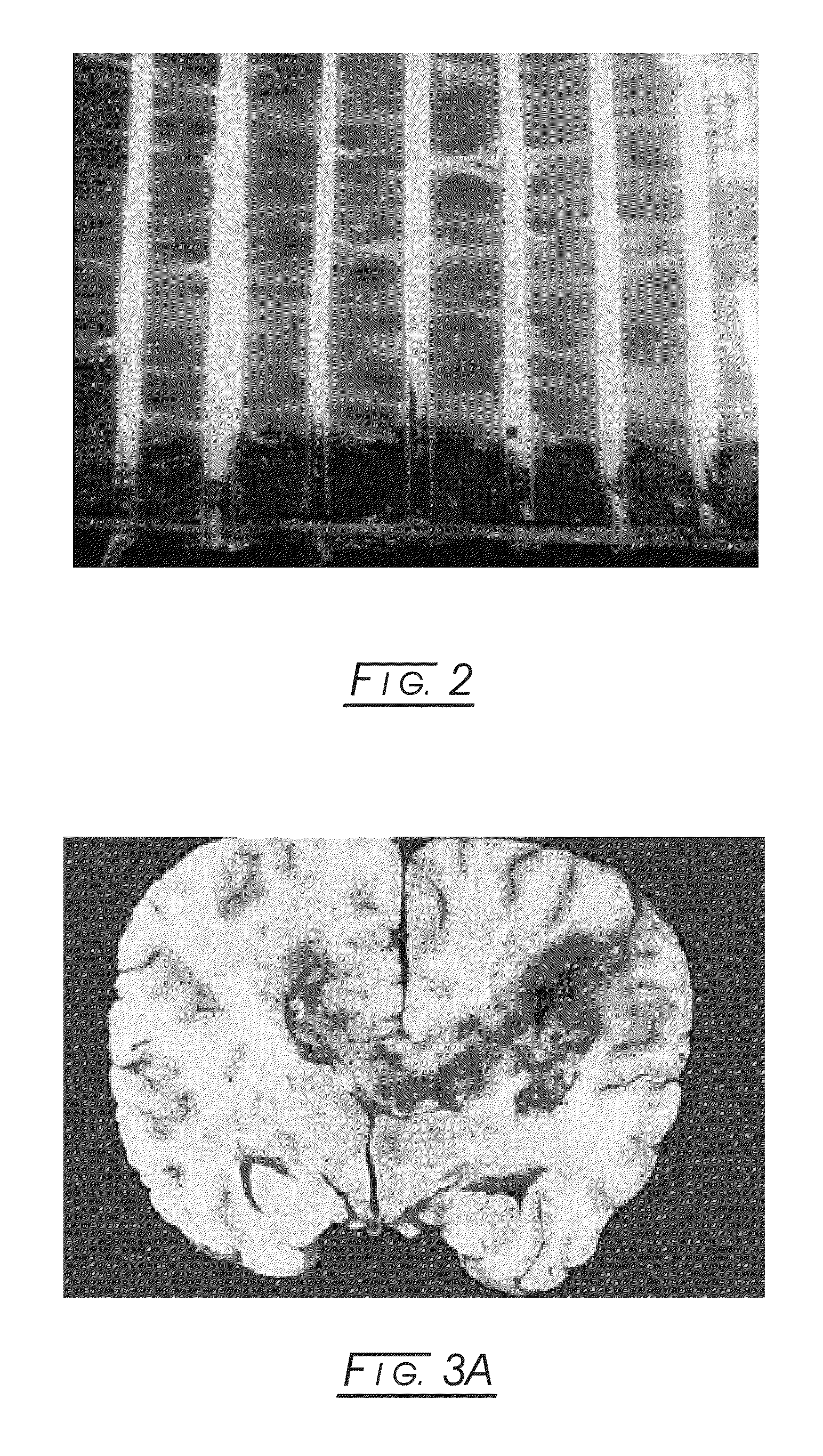

Inkjet Printing of Tissues and Cells

Provided herein is an apparatus for printing cells which includes an electrospinning device and an inkjet printing device operatively associated therewith. Methods of making a biodegradable scaffold having cells seeded therein are also provided. Methods of forming microparticles containing one or more cells encapsulated by a substrate are also provided, as are methods of forming an array of said microparticles.

Owner:WAKE FOREST UNIV HEALTH SCI INC

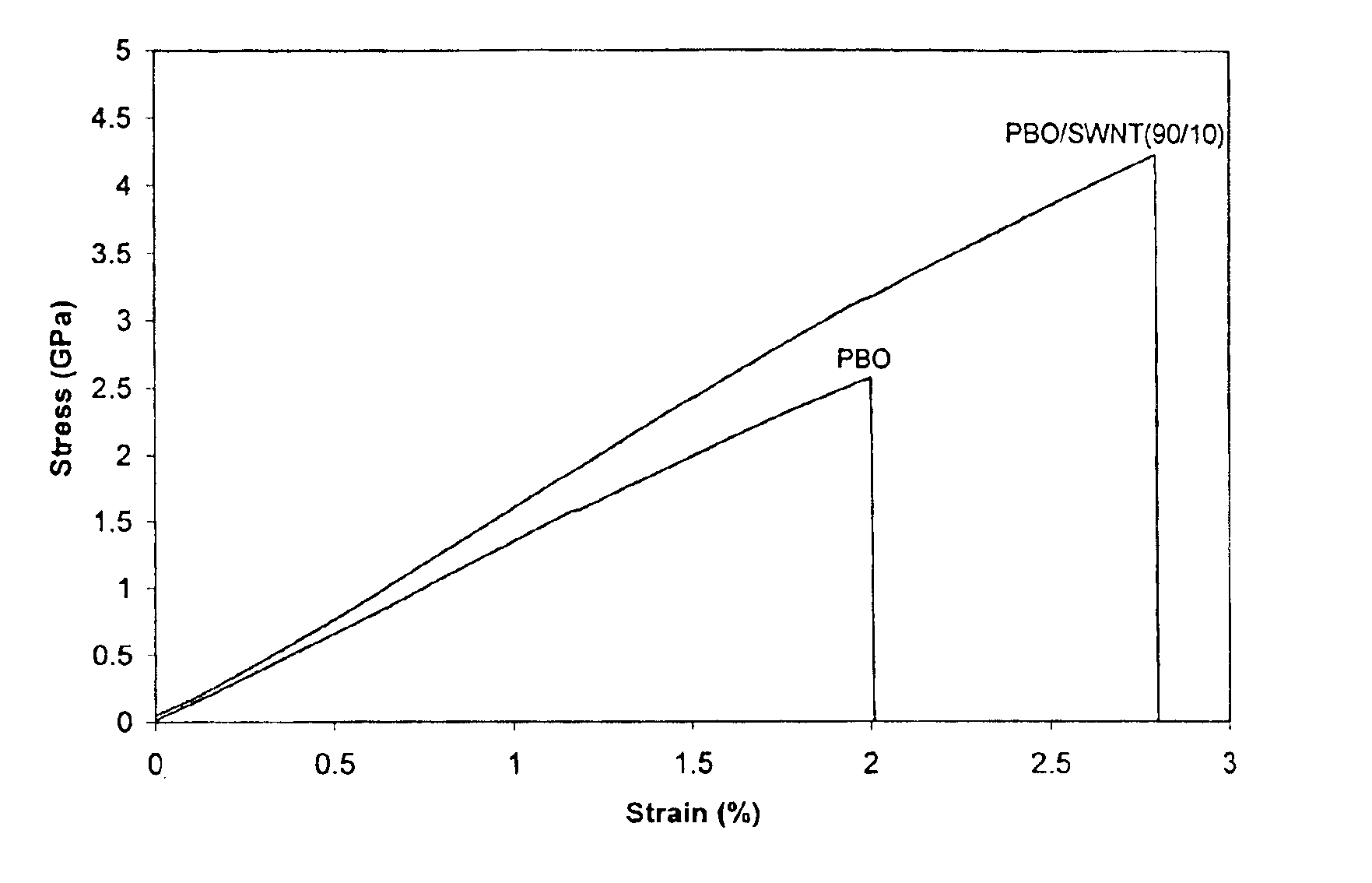

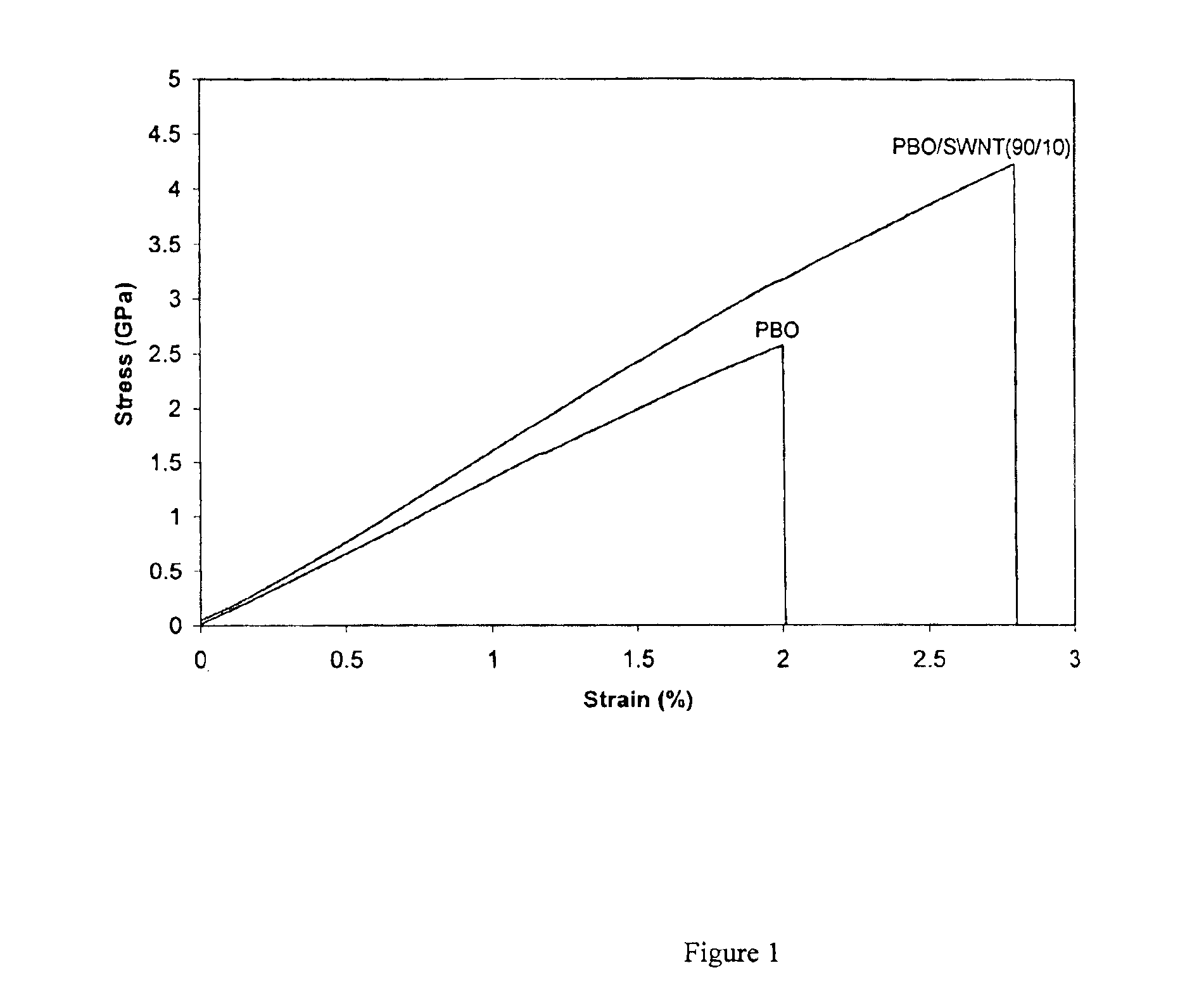

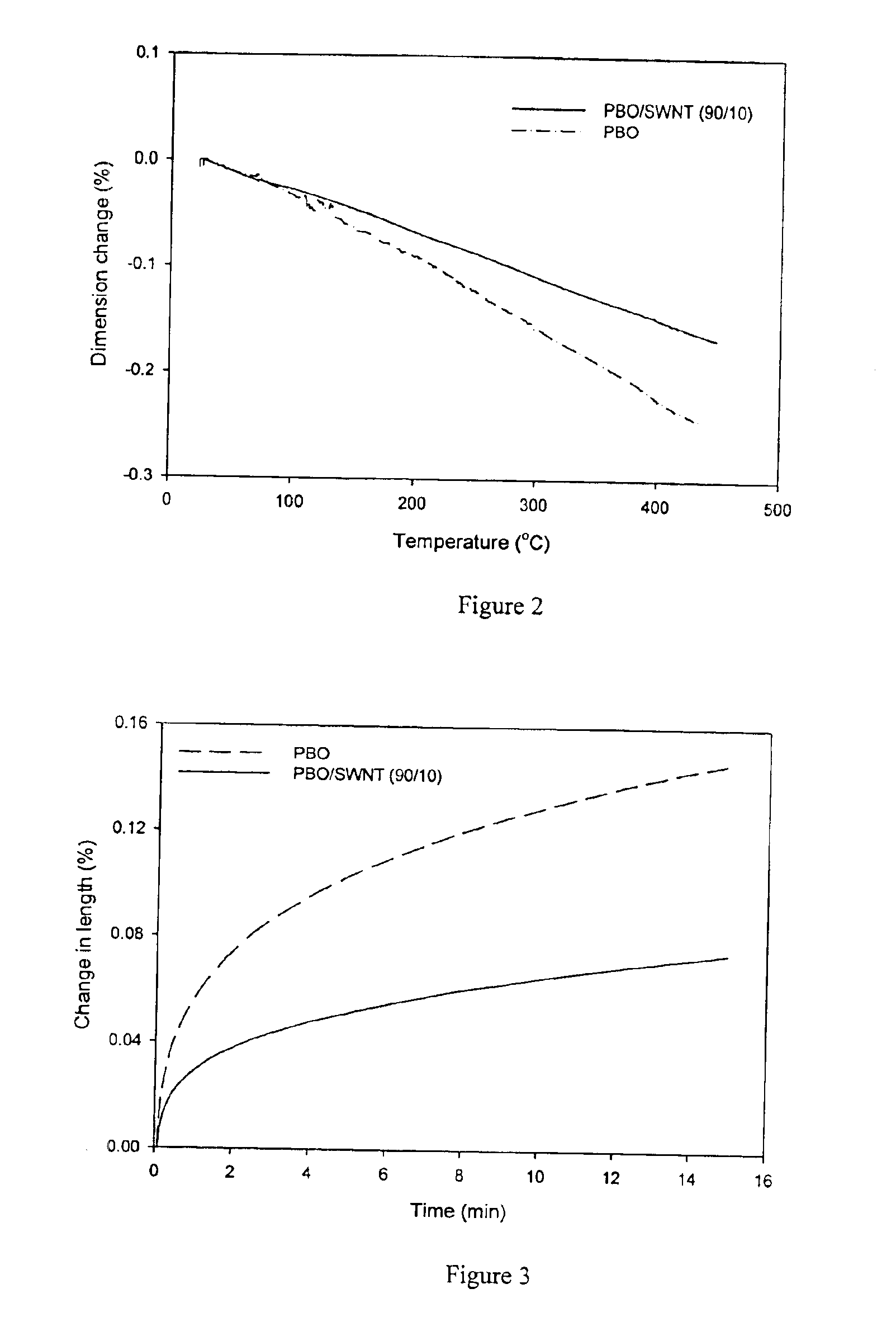

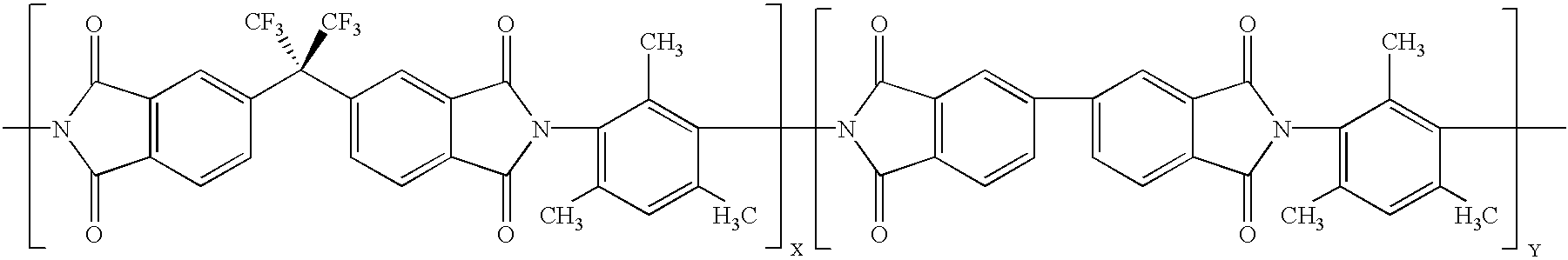

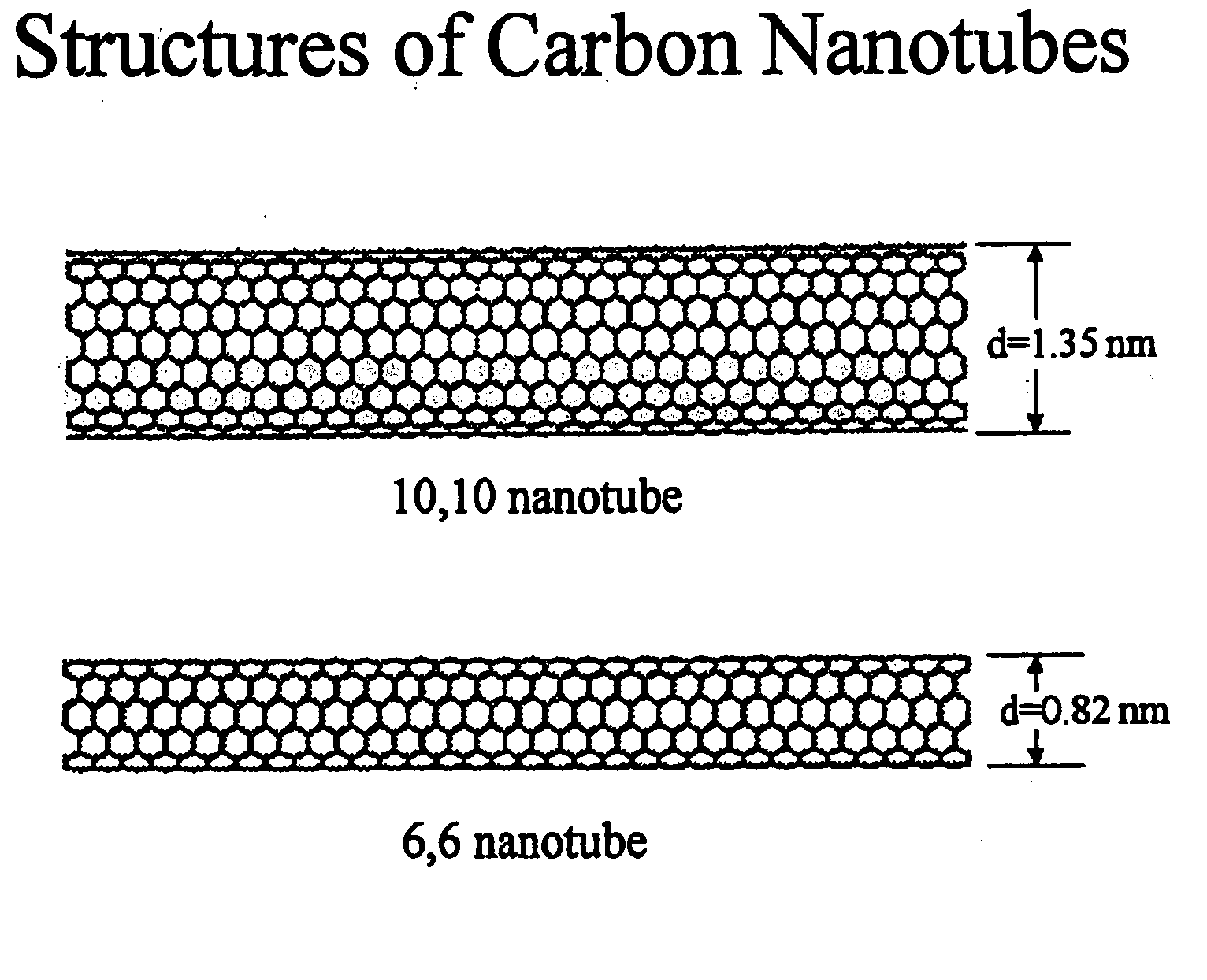

Compositions comprising rigid-rod polymers and carbon nanotubes and process for making the same

InactiveUS6900264B2High modulusHigh stiffnessMaterial nanotechnologySpecial tyresFiberLiquid crystalline

The present invention relates to compositions comprising rigid-rod polymers and carbon nanotubes. The compositions comprise dispersed carbon nanotubes aligned with rigid-rod polymers. The alignment of the nanotubes and polymers can be liquid crystalline. The rigid-rod polymers of this invention include, but are not limited to, polymers and copolymers comprising benzobisazole, pyridobisimidazole and benzamidazobenzo-phenanthroline repeat units. Dispersion of carbon nanotubes is achieved by in-situ polymerization in the presence of the carbon nanotubes, which may be either single-wall or multi-wall or a combination of both. The polymer compositions comprising carbon nanotubes may be spun into fibers or formed into films. The strength of the resulting fibers of the present invention is significantly greater than that of fibers without carbon nanotubes.

Owner:GEORGIA TECH RES CORP

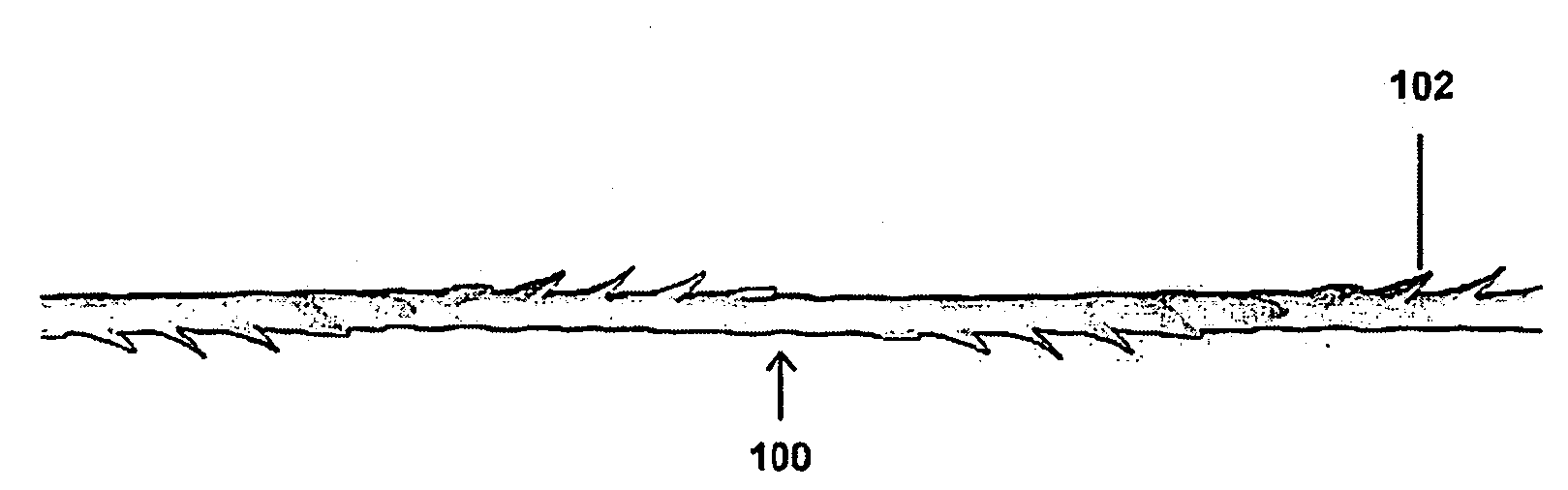

Recombinant expressed bioadsorbable polyhydroxyalkonate monofilament and multi-filaments self-retaining sutures

InactiveUS20090112259A1Suture equipmentsMonocomponent synthetic polymer artificial filamentMicroorganismBreaking strength

The present invention provides polymers made by genetically engineering microorganisms for making a self-retaining suture. In an embodiment of the present invention the genetically engineering microorganisms synthesize polyhydroxyalkanoate (PHA) polymers. In an alternate embodiment of the invention, the genetically engineering microorganisms synthesize polybetahydroxybutyrate (PHB) polymers. In an alternative embodiment of the invention, the self-retaining sutures can be made from a copolymer such as polyhydroxybutyratevalerate (PHBV), where the genetically engineering microorganisms produces PHA polymers as the monofilament base material and a different genetically engineering microorganisms produces polyhydroxybutyratevalerate (PHBV) polymers. In various embodiments of the invention, recombinant expressed self-retaining suture materials have a melting point in the range from between approximately 40° C. to approximately 180° C. In various embodiments of the invention, recombinant expressed self-retaining suture materials have extension-to-break strength of between approximately 8% and approximately 42%.

Owner:ETHICON INC

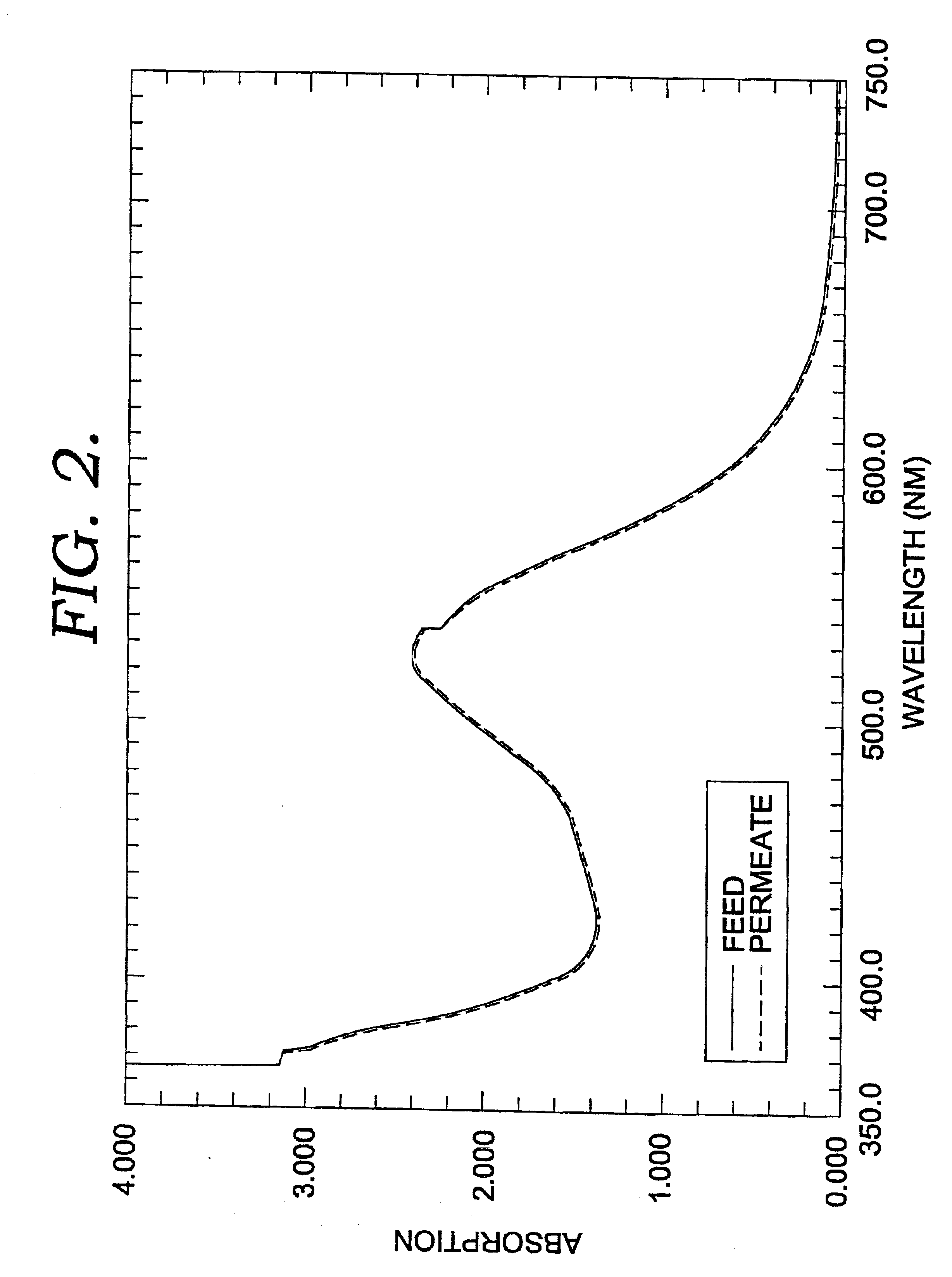

Dimensionally stable balloons

InactiveUS6977103B2Minimal longitudinalIncrease heightSurgeryMedical devicesUltimate tensile strengthMaterials science

An inflatable medical balloon comprises a polymer matrix material and a plurality of fibers distributed in the matrix material. The plurality of fibers operatively adhere to the matrix material and provide reinforcement thereof. The fibers may be parallel or angularly oriented relative to the longitudinal balloon axis, and may be helically disposed thereabout. The fibers may be composed of material which has a greater tensile strength than the matrix material. The fibers may be microfibers formed by phase separation of a melt blend material during extrusion or polymer cores coextruded with the matrix material and surrounded thereby. The balloon may be formed of alternating layers of fiber-free polymer and layers of fiber-containing polymer.

Owner:BOSTON SCI SCIMED INC

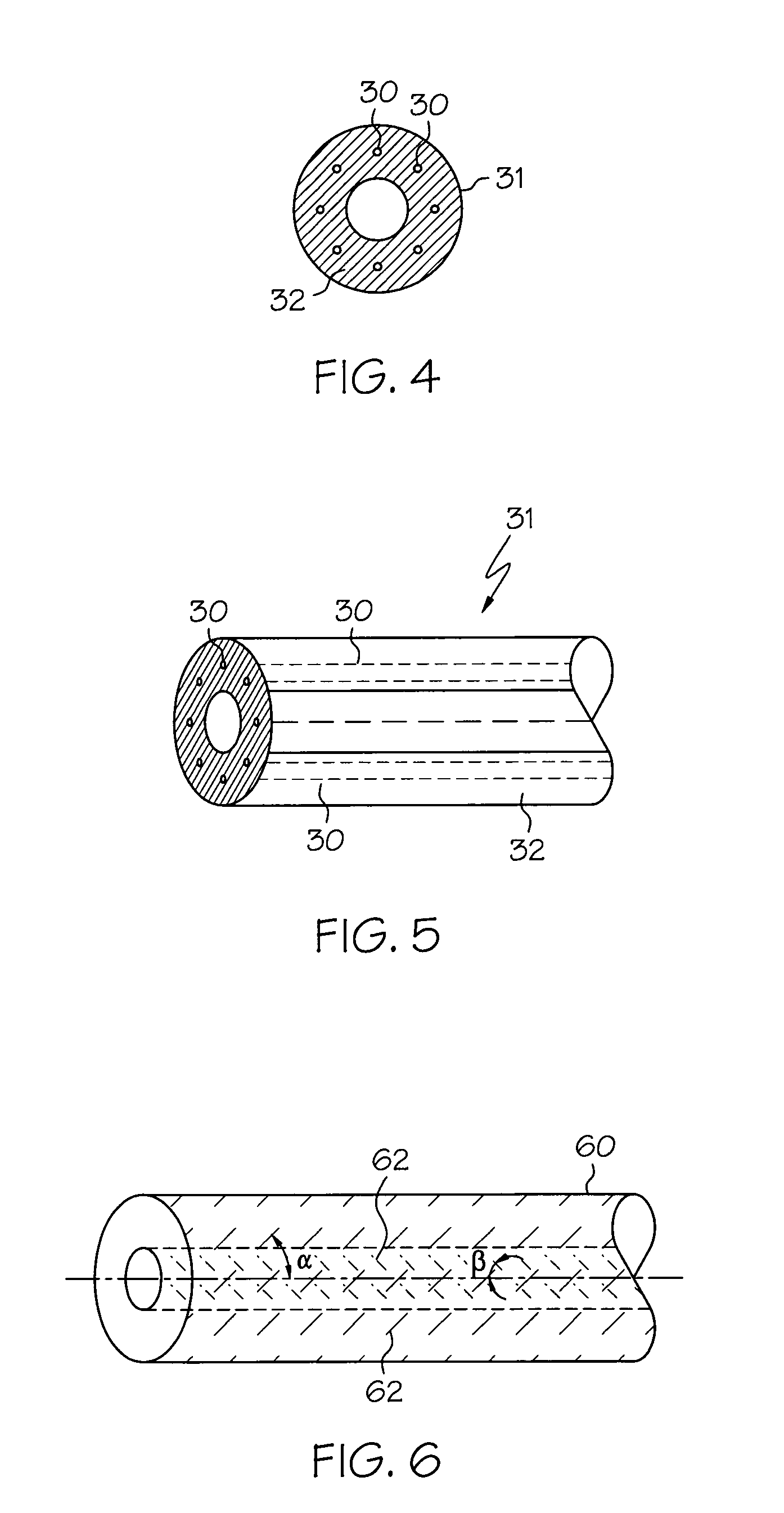

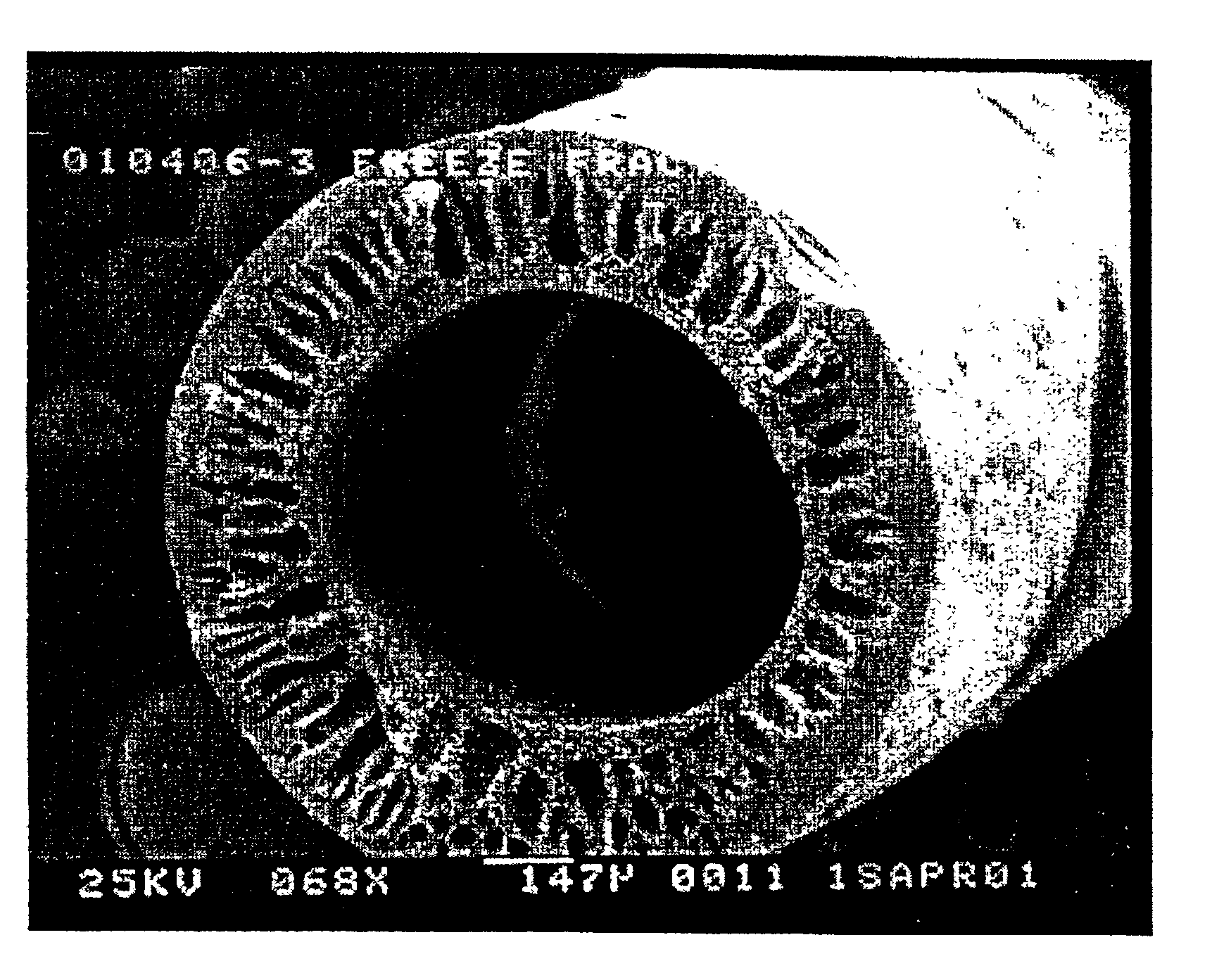

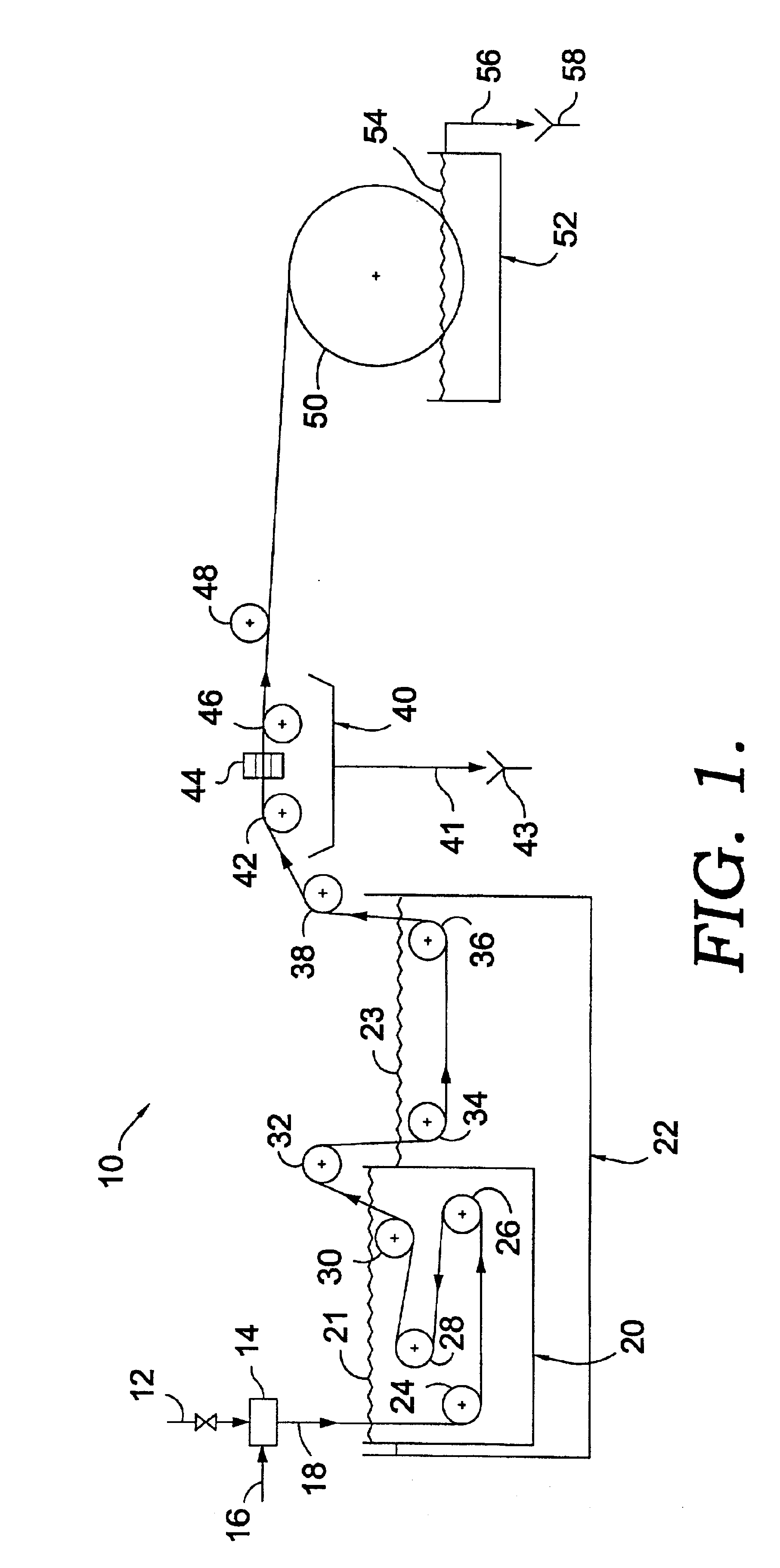

Hollow fiber microfiltration membranes and a method of making these membranes

InactiveUS6890435B2Narrow pore size distributionHigh mechanical strengthSemi-permeable membranesMembranesFiberHollow fibre membrane

A hollow fiber microfiltration (MF) membrane is provided. The casting solution used to make this membrane includes a fiber-forming polymer having a degree of polymerization greater than about 1000, a water-soluble polymer, an anhydride with about 2 to 12 carbon atoms, and a solvent. The membrane is formed by mixing and heating these components to form a viscous dope and then extruding the dope through an annular orifice to form a hollow fiber MF membrane. The hollow fiber membrane is then fed through a coagulation bath and two leaching baths. The membrane is especially useful for filtering liquids, such as wine and juice, so as to remove bacteria, gel, and solid particles from the liquids.

Owner:KOCH MEMBRANE SYST

High carbon content filamentary membrane and method of making the same

A high carbon content membrane and method for making the same are disclosed. The carbon membrane includes an asymmetric hollow filamentary carbon membrane, including a partial carbonization product of an asymmetric hollow filament including an aromatic imide polymer material. The carbon membrane is at least 95 weight percent carbon, and has a dense layer located in the outside surface portion of the hollow filamentary membrane and a porous base layer continued from the dense layer and located in the inside portion of the hollow filamentary membrane. A process for separating CO2 from natural gas is described including: contacting a mixture of CO2 and natural gas with a first side of a carbon membrane in a manner to cause a portion of the mixture to pass through the carbon membrane to a permeate side. The resulting mixture on the permeate side becomes enriched in CO2 over that of the mixture on the first side. The contacting step occurs at a pressure of at least about 200 psia.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

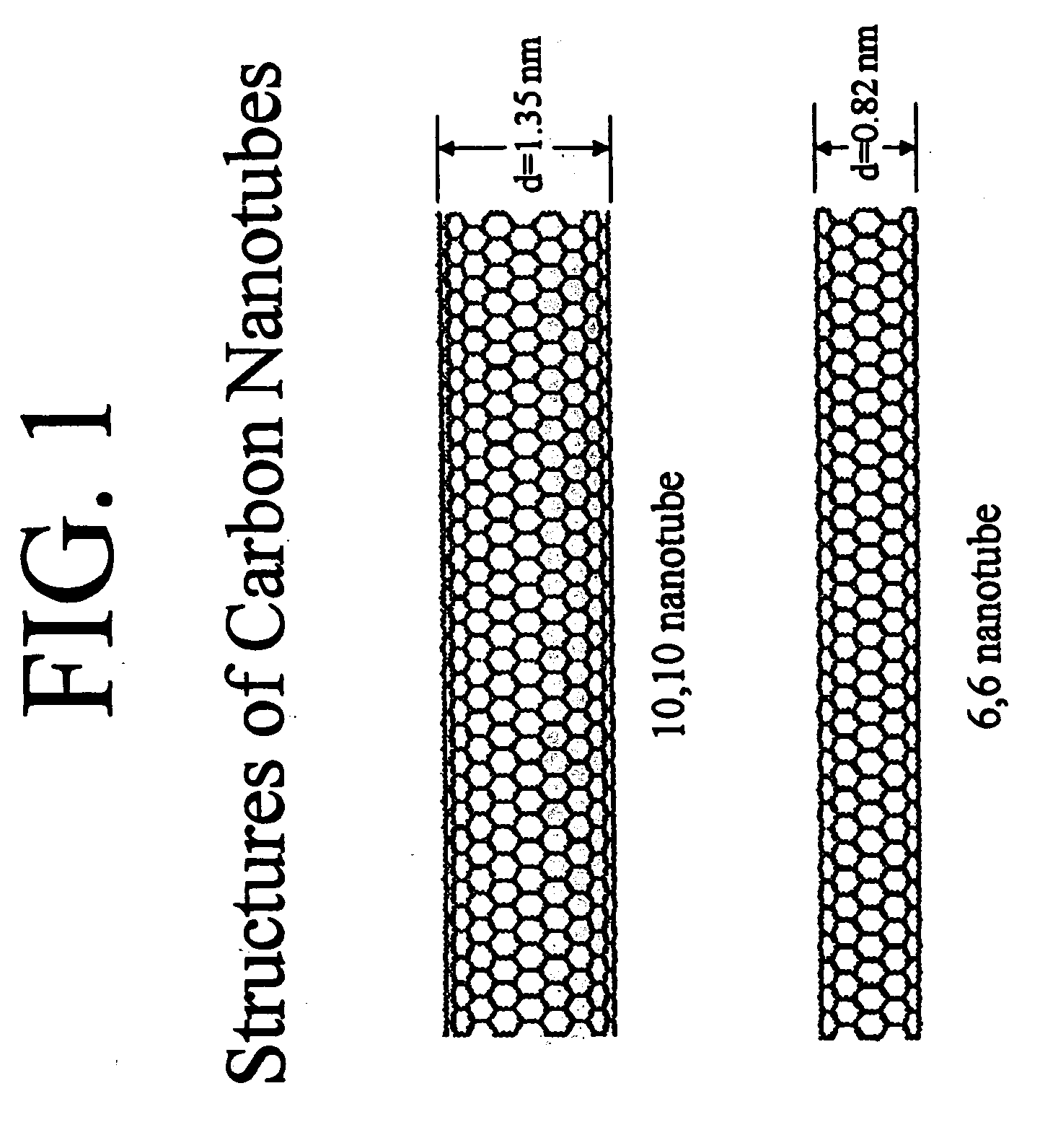

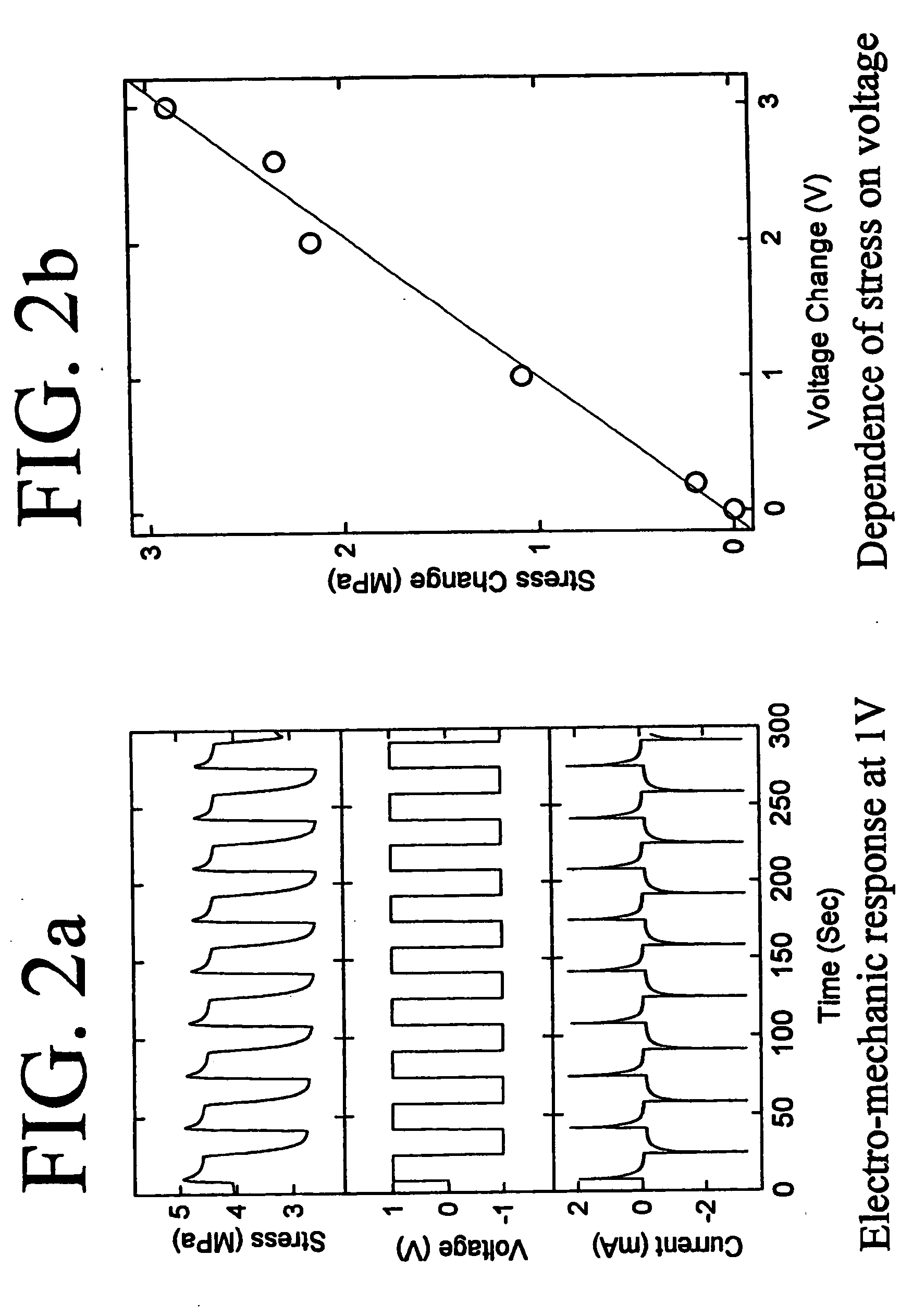

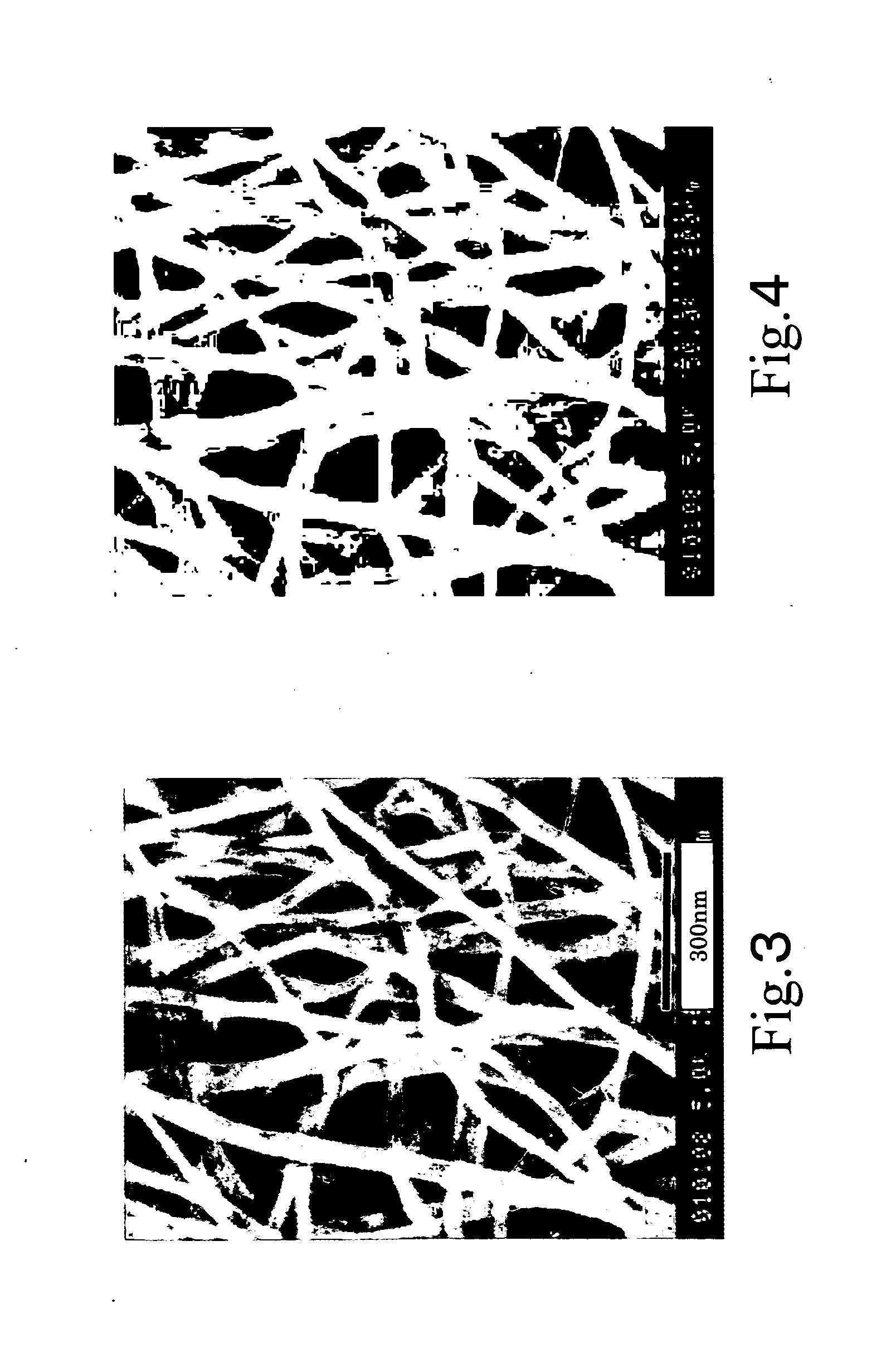

Spinning, processing, and applications of carbon nanotube filaments, ribbons, and yarns

InactiveUS20040096389A1Improve mechanical propertiesRaise the ratioMaterial nanotechnologyWet spinning methodsYarnFiber

Coagulation spinning produces structures such as fibers, ribbons, and yarns of carbon nanotubes. Stabilization, orientation, and shaping of spun materials are achieved by post-spinning processes. Advantages include the elimination of core-sheath effects due to carbonaceous contaminants, increasing mechanical properties, and eliminating dimensional instabilities in liquid electrolytes that previously prohibited the application of these spun materials in electrochemical devices. These advances enable the application of coagulation-spun carbon nanotube fibers, ribbons, and yarns in actuators, supercapacitors, and in devices for electrical energy harvesting.

Owner:HONEYWELL INT INC

Macroscopic fiber comprising single-wall carbon nanotubes and acrylonitrile-based polymer and process for making the same

InactiveUS20050100501A1Good orientationIncrease modulusMaterial nanotechnologyElectroconductive/antistatic filament manufactureVitrificationPolymer science

The present invention relates to a high modulus macroscopic fiber comprising single-wall carbon nanotubes (SWNT) and an acrylonitrile-containing polymer. In one embodiment, the macroscopic fiber is a drawn fiber having a cross-sectional dimension of at least 1 micron. In another embodiment, the acrylonitrile polymer-SWNT composite fiber is made by dispersing SWNT in a solvent, such as dimethyl formamide or dimethyl acetamide, admixing an acrylonitrile-based polymer to form a generally optically homogeneous polyacrylonitrile polymer-SWNT dope, spinning the dope into a fiber, drawing and drying the fiber. Polyacrylonitrile / SWNT composite macroscopic fibers have substantially higher modulus and reduced shrinkage versus a polymer fiber without SWNT. A polyacrylonitrile / SWNT fiber containing 10 wt % SWNT showed over 100% increase in tensile modulus and significantly reduced thermal shrinkage compared to a control fiber without SWNT. With 10 wt % SWNT, the glass transition temperature of the polymer increased by more than 40° C.

Owner:GEORGIA TECH RES CORP

Olefin block compositions for heavy weight stretch fabrics

InactiveUS20080299857A1Improved ratio of stretch to growthHigh temperature toleranceMonocomponent synthetic polymer artificial filamentWoven fabricsSquare yardHeavy weight

Heavy weight stretch fabrics comprising ethylene / α-olefin interpolymer are described. The fabric often has a weight of at least 10 ounces per square yard measured according to ASTM 3776 and has a stretch of at least 10 percent measured according to ASTM D3107. These fabrics exhibit excellent chemical, resistance (for example chlorine or caustic resistance) and durability, that is they retain their shape and feel over repeated exposure to processing conditions, such as stone-washing, dye-stripping, PET-dyeing and the like, and industrial laundry conditions.

Owner:DOW GLOBAL TECH LLC

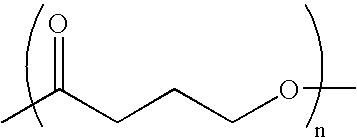

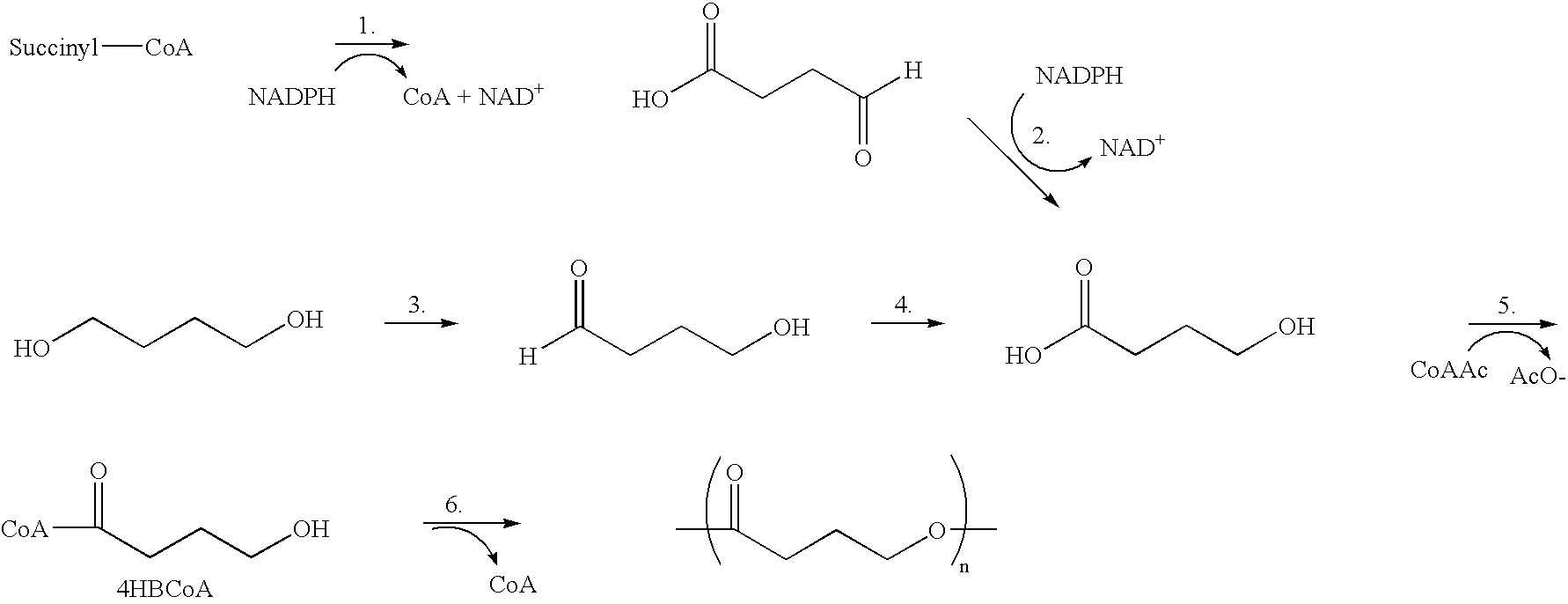

Biodegradable copolymers

The present invention relates to biodegradable PHA copolymers comprising at least two randomly repeating monomer units. The present invention further relates to a plastic article comprising a biodegradable copolymer, wherein the biodegradable copolymer comprises at least two randomly repeating monomer units (RRMU) wherein the first RRMU has the structure wherein R1 is H, or C1 or C2 alkyl, and n is 1 or 2; the second RRMU has the structure wherein R2 is a C4-C19 alkyl or alkenyl; and wherein at least 50% of the RRMUs have the structure of the first RRMU. The present invention further relates to an absorbent article comprising a liquid pervious topsheet, a liquid impervious backsheet comprising a film comprising a PHA of the present invention and an absorbent core positioned between the topsheet and the backsheet.

Owner:MEREDIAN

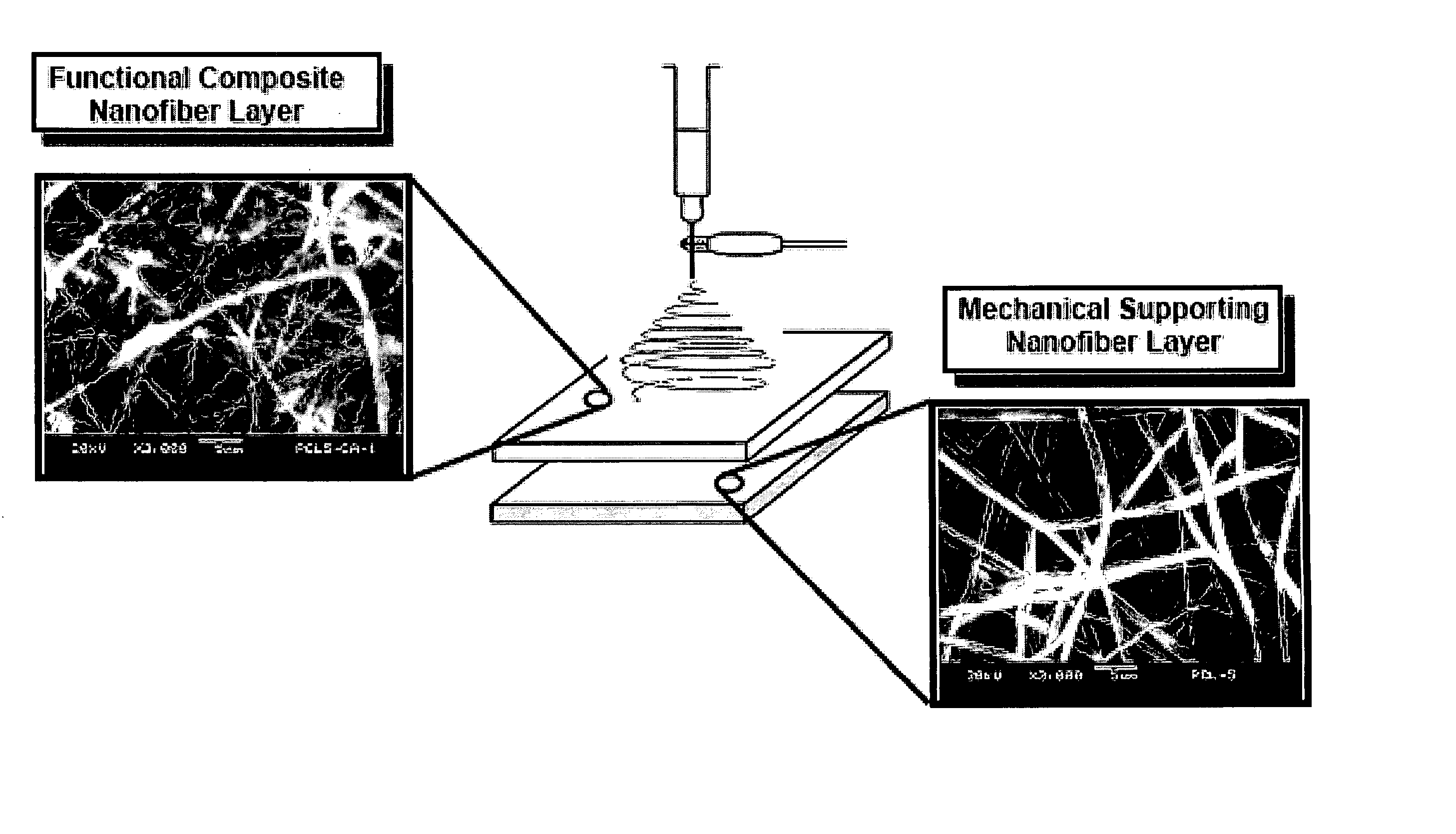

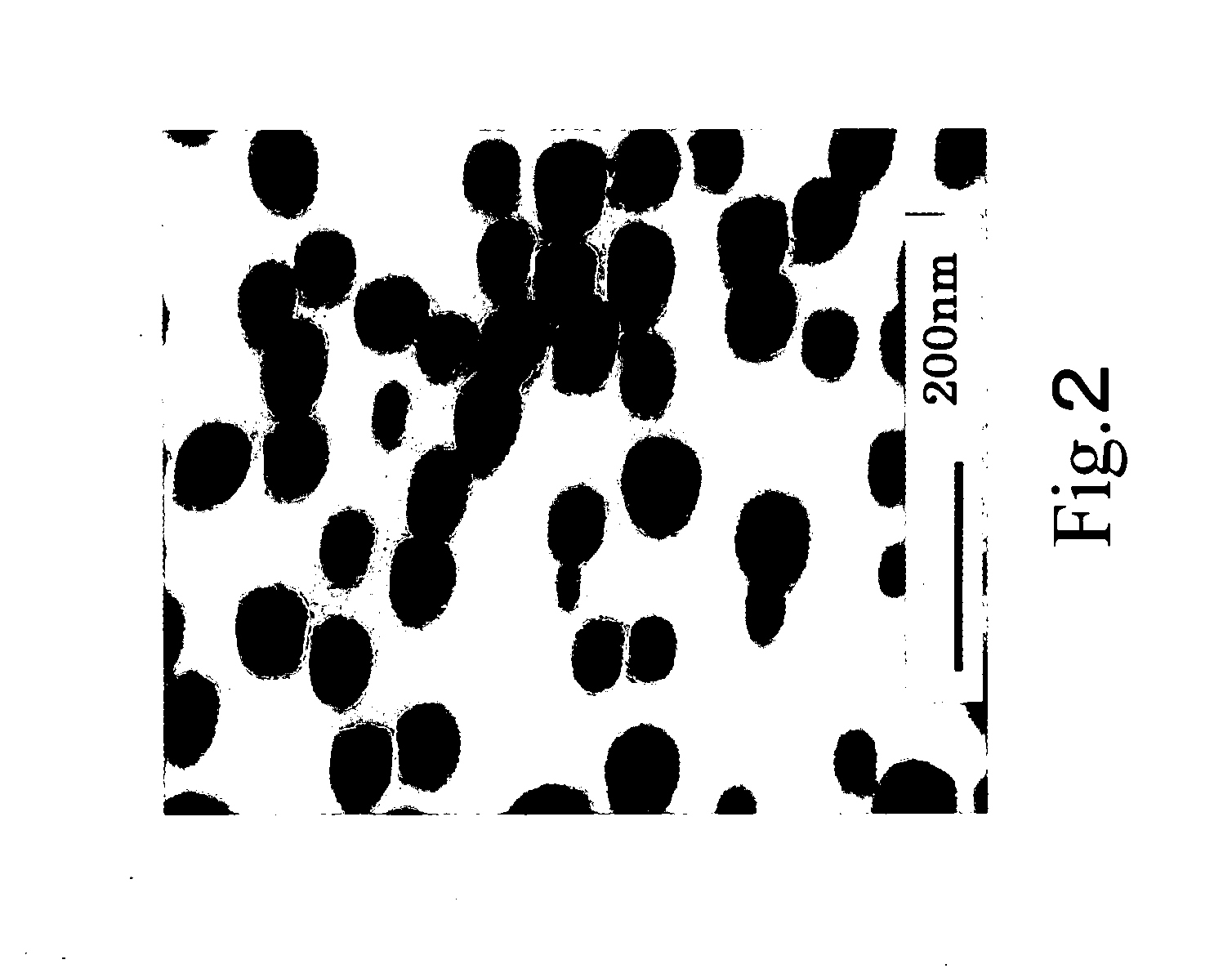

Nanofiber construct and method of preparing thereof

InactiveUS20060154063A1Improve hydrophilicityGood bone conductionPharmaceutical delivery mechanismElectro-spinningFiberComposite nanofibers

The present invention provides a composite nanofiber construct comprising: at least a first nanofiber comprising at least a polymer and at least a calcium salt nanoparticle, wherein the ratio of polymer to calcium salt nanoparticle is between the range of 99:1 and 10:90 weight percent; and at least a second nanofiber comprising at least a polymer and at least a calcium salt nanoparticle, wherein the ratio of polymer to calcium salt nanoparticle is between the range of 100:0 and 70:30 weight percent. The present invention also provides a method of preparing the composite nanofiber construct.

Owner:NAT UNIV OF SINGAPORE

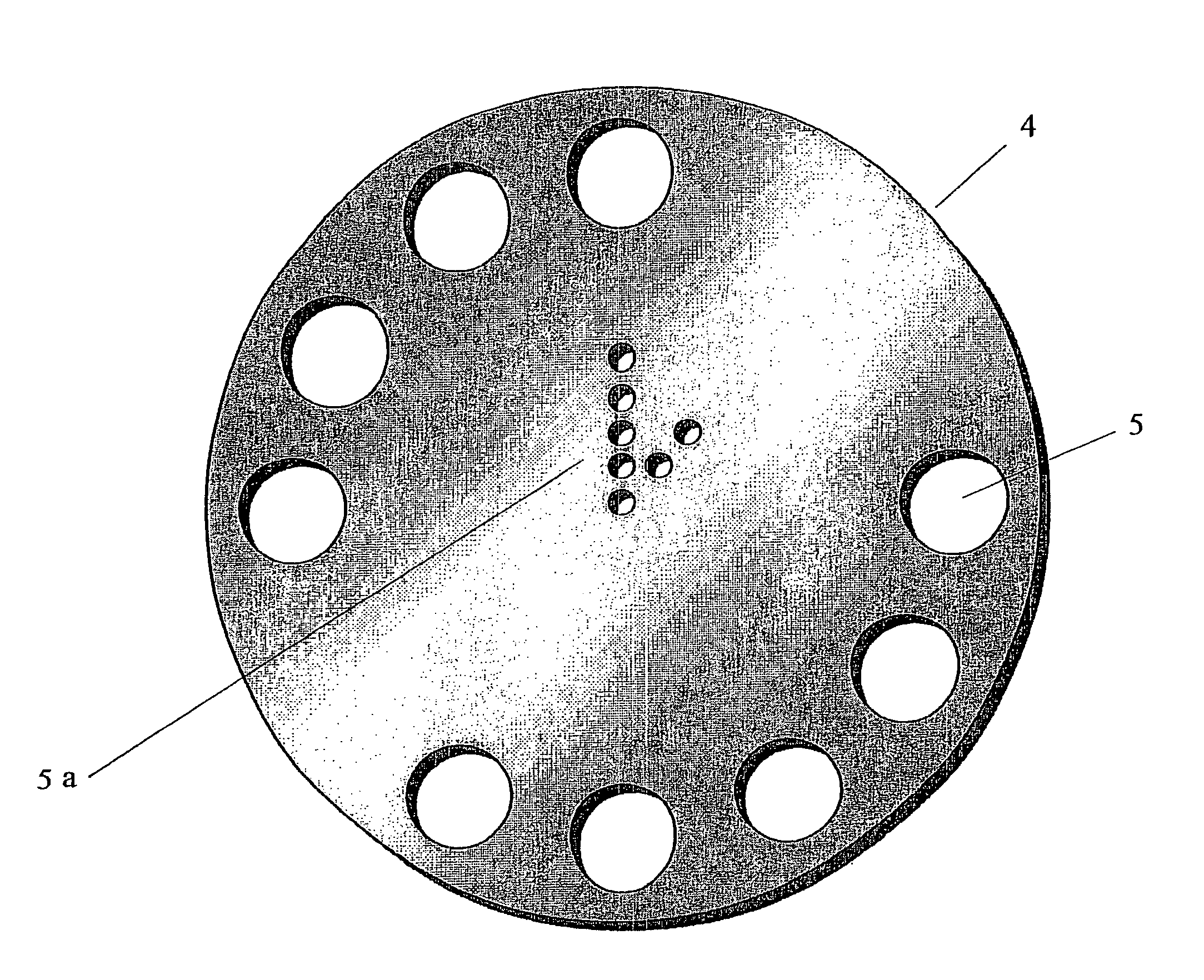

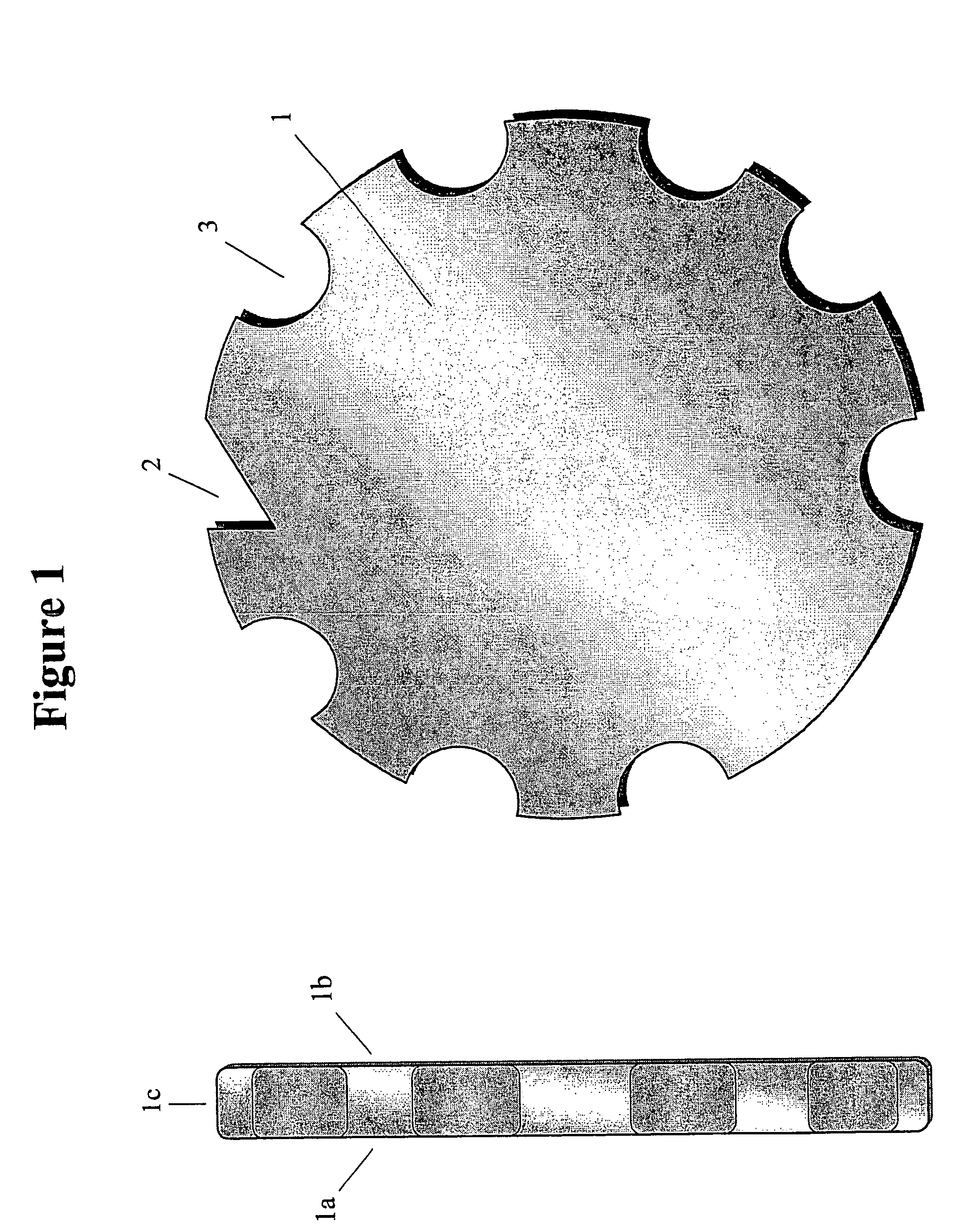

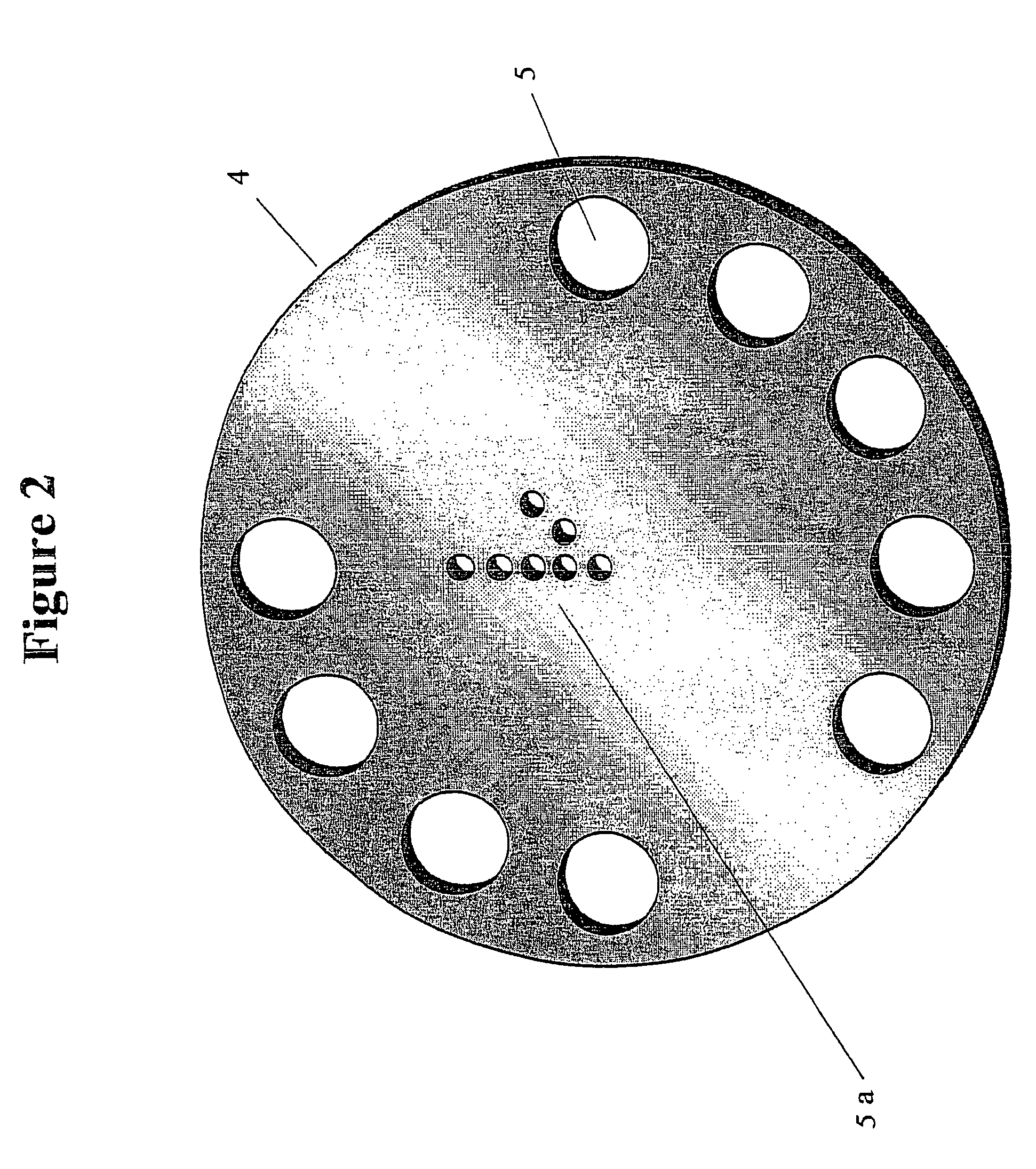

Multi-functional product markers and methods for making and using the same

InactiveUS7163744B2Increase information storage capacitySafe, reliable, easily read, and inexpensiveStampsFood coatingEngineeringMulti feature

Owner:BURNTSIDE PARTNERS

Nano-Fiber Compound Solutions, Emulsions And Gels, Production Method Thereof, Nano-Fiber Synthetic Papers, And Production Method Thereof

ActiveUS20070196401A1High affinitySoft skinCosmetic preparationsNon-fibrous pulp additionDispersion stabilityEmulsion

This invention provides compound solutions, emulsions and gels excellent in homogeneous dispersibility and long-term dispersion stability and also excellent in the properties as cosmetics, using disarranged nanofibers not limited in either form or polymer, widely applicable and small in the irregularity of single fiber diameter. This invention also provides a method for producing them. Furthermore, this invention provides synthetic papers composed of fibers, small in pore area and uniform in pore size, using disarranged nanofibers, and also provides a method for producing them. This invention provides compound solutions, emulsions, gels and synthetic papers containing disarranged nanofibers of 1 to 500 nm in number average diameter and 60% or more in the sum Pa of single fiber ratios.

Owner:TORAY IND INC

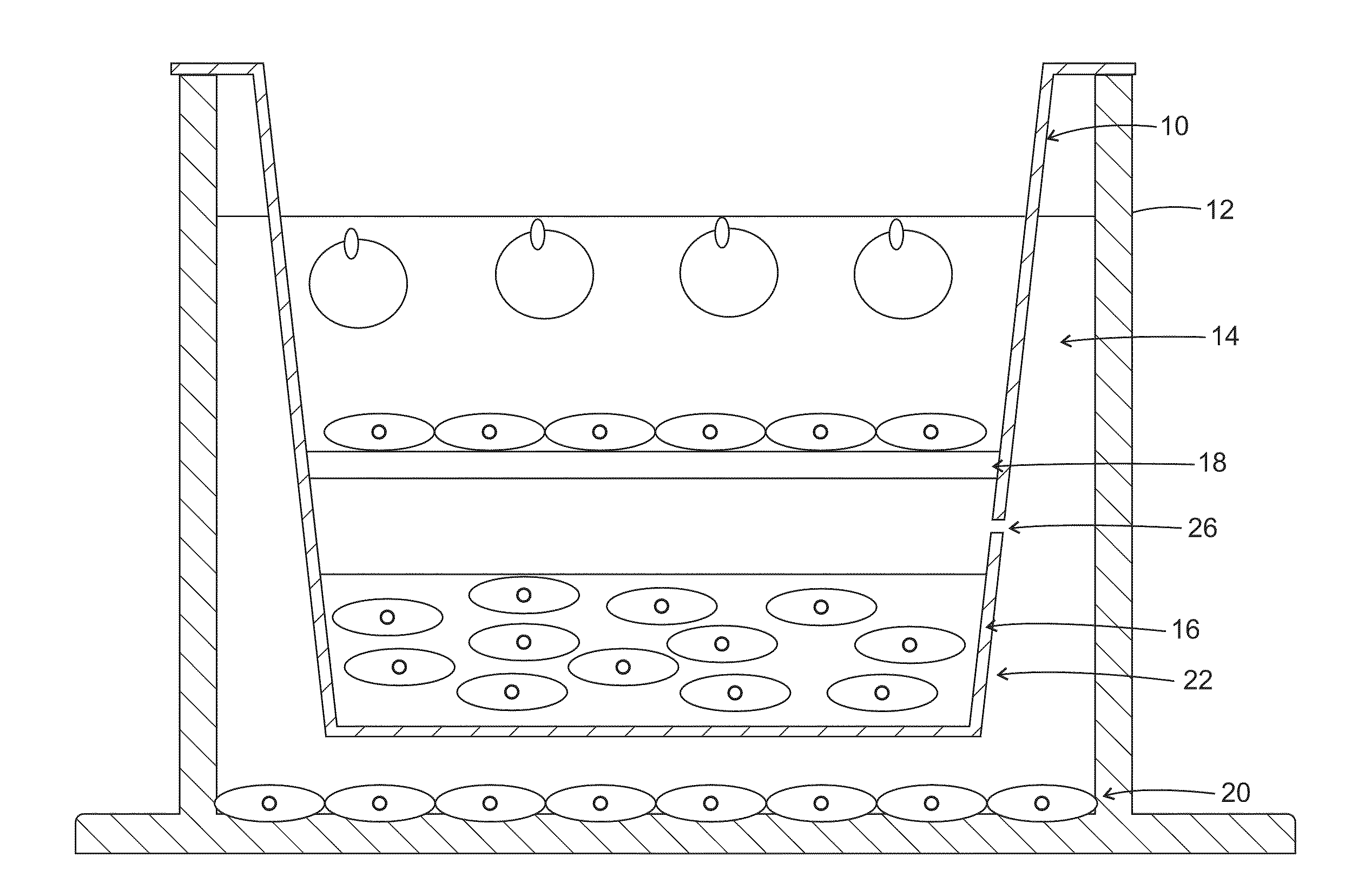

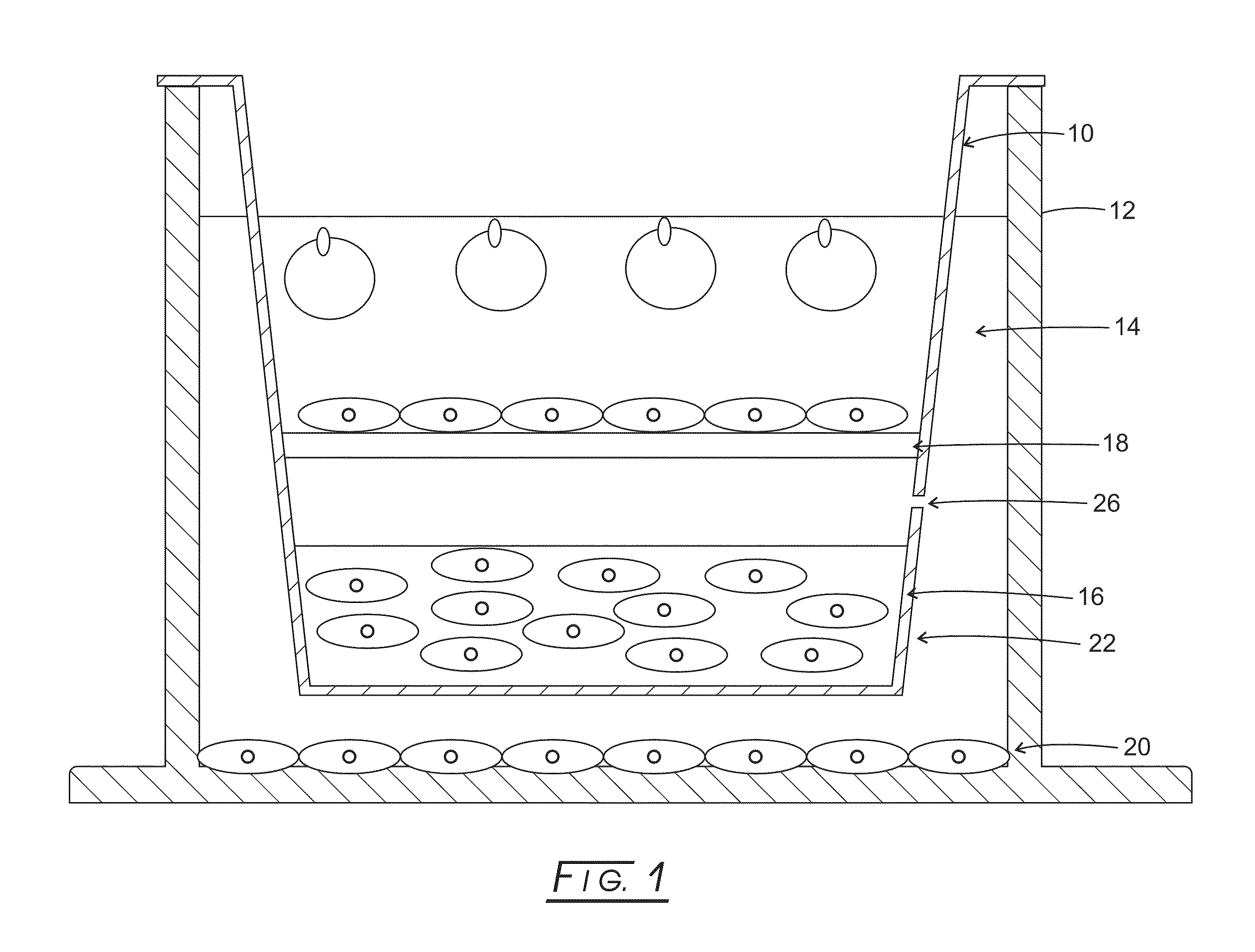

Interactive Microenvironment System

InactiveUS20100273258A1Targeted optimizationBioreactor/fermenter combinationsBiological substance pretreatmentsPorosityCulture cell

A culture cell for growing animal cells in vitro has sides and a bottom forming a volume. The volume contains a layer of nanofiber upon which animal cells can be cultured. The layer of nanofiber can be oriented or non-oriented. Multiple layers can be placed in the volume, where the layers have different composition and / or different porosity. The nanofiber can be, for example, surface treated or of a core-shell construction.

Owner:THE OHIO STATES UNIV

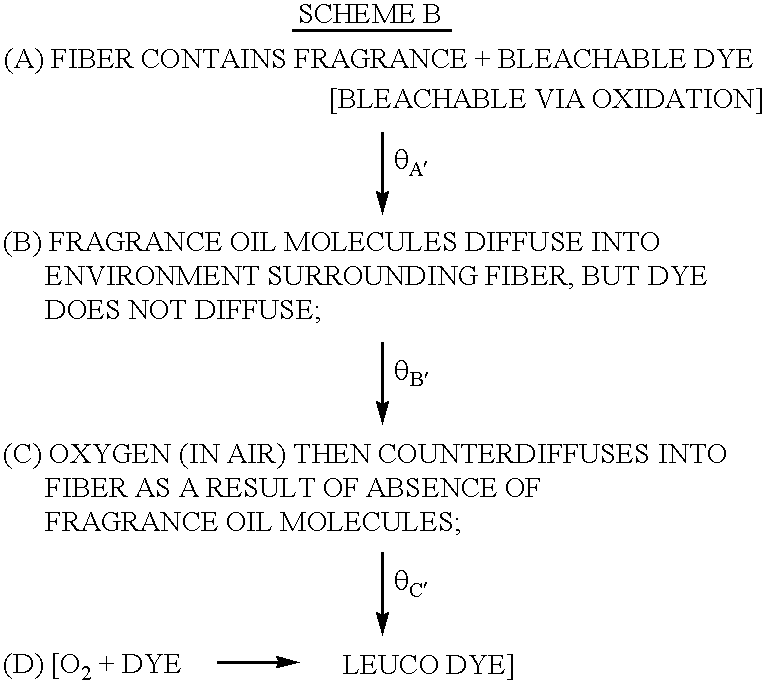

Fragrance containing fiber

InactiveUS6207274B1Easy to polishImprove sealingMonocomponent synthetic polymer artificial filamentYarnFiberPolymer chemistry

Described is a fragrance-containing and fragrance-emitting polymeric fiber which optionally contains (i) at least one antimicrobial agent; and (ii) at least one compatible coloring material or color-forming material which is useful in the ascertainment of the exhaustion or substantial reduction of fragrance, produced by either (i) a processing comprising the steps of:(a) co-extruding fragrance and optionally (i) antimicrobial agent and / or (ii) at least one compatible coloring material or color-forming material which is useful for ascertainment of the exhaustion or substantial reduction of fragrance with a thermoplastic polymer to form an extrudate;(b) forming fragrance and (optionally (i) antimicrobial agent and / or (ii) at least one compatible coloring material or color-forming material which is useful for ascertainment of the exhaustion or substantial reduction of fragrance agent)-emitting particles which may or may not be foamed from the extrudate; and(c) extruding a fiber of from about 3 denier up to about 60 denier from the thus-formed particles;or (ii) a process comprising the steps of:(a) forming fragrance-emitting particles, foamed or not foamed, from a mixture of fragrance and thermoplastic polymer; and then(b) extruding a fiber of from about 3 denier up to about 60 denier from the thus-formed particles.

Owner:INTERNATIONAL FLAVORS & FRAGRANCES

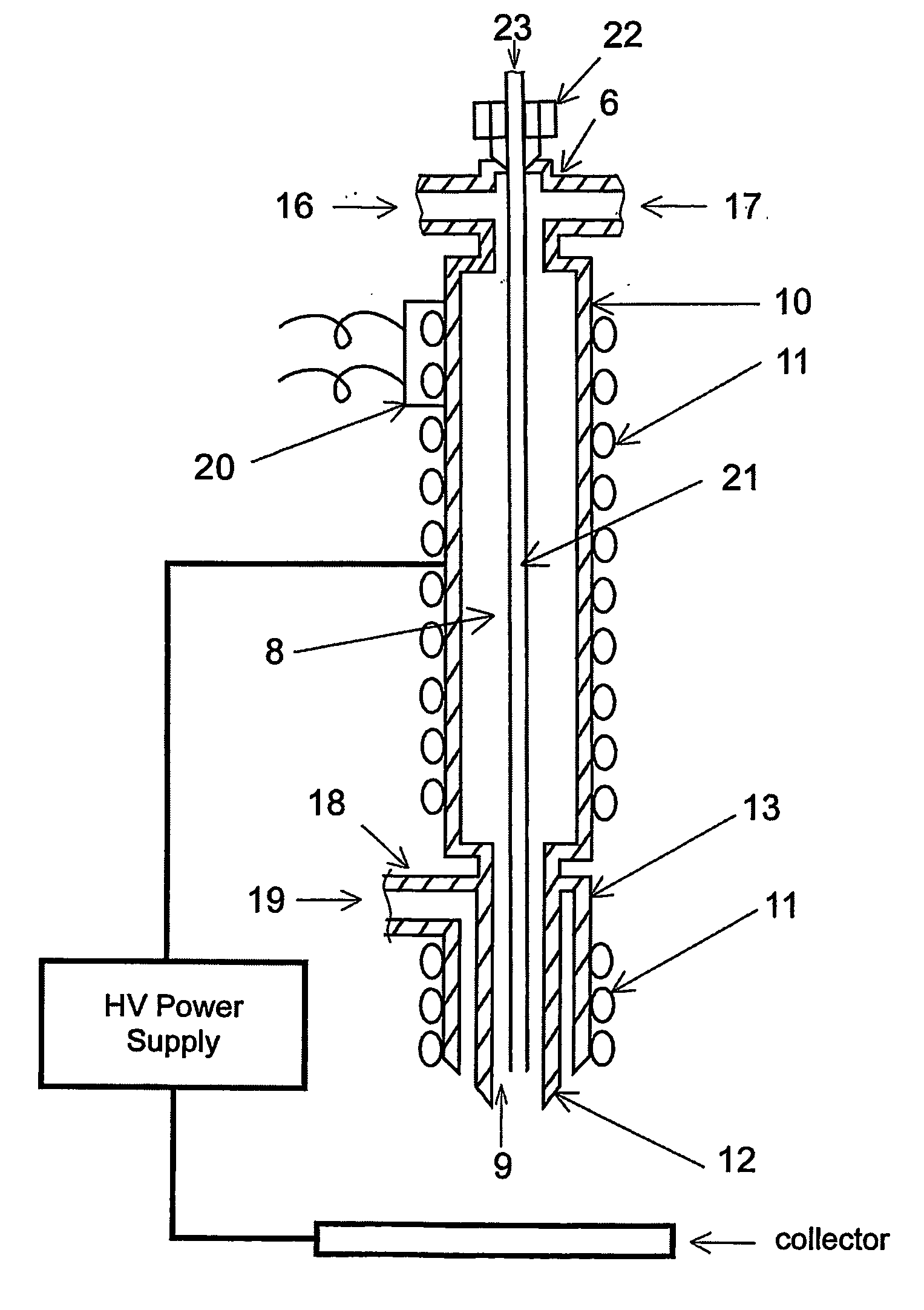

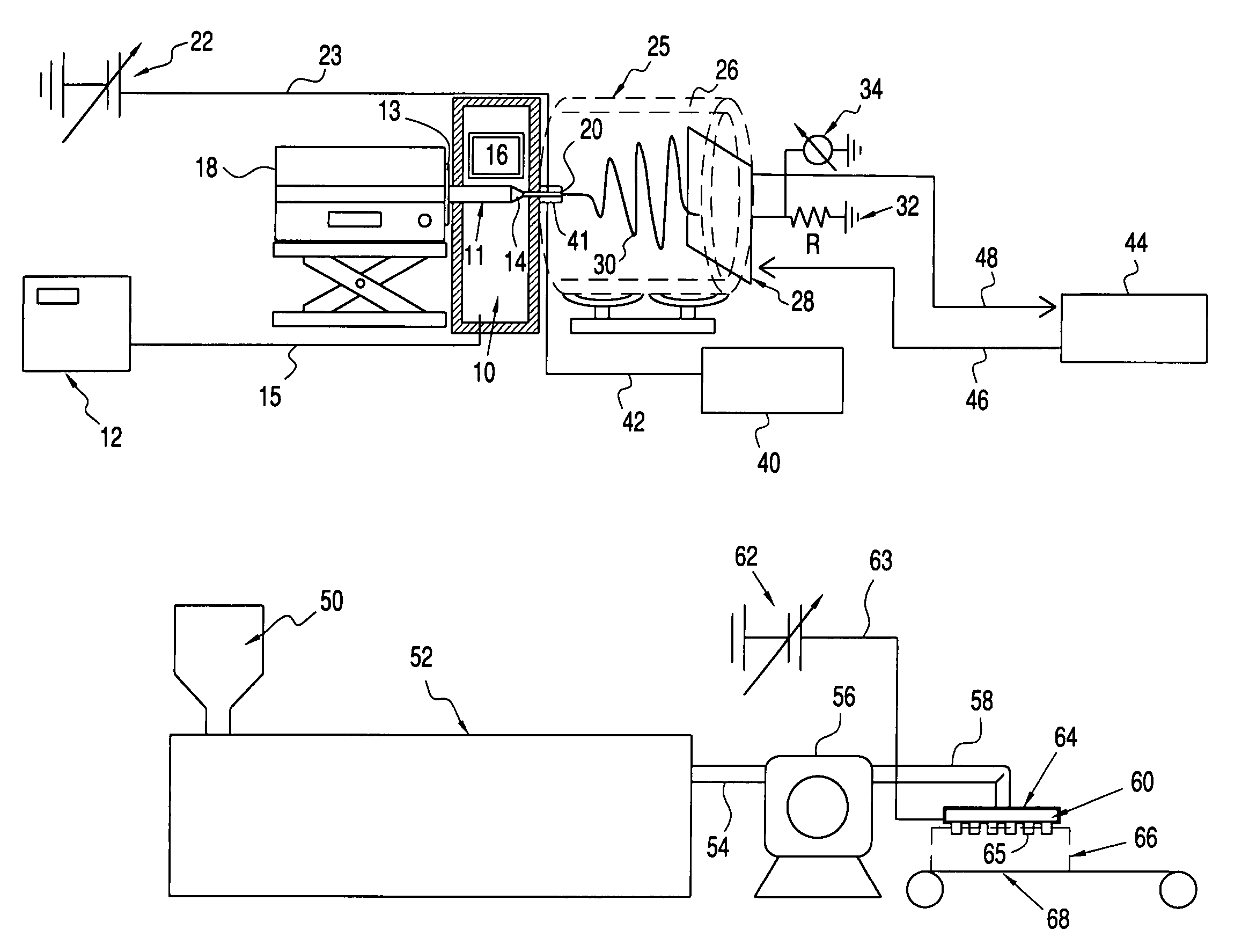

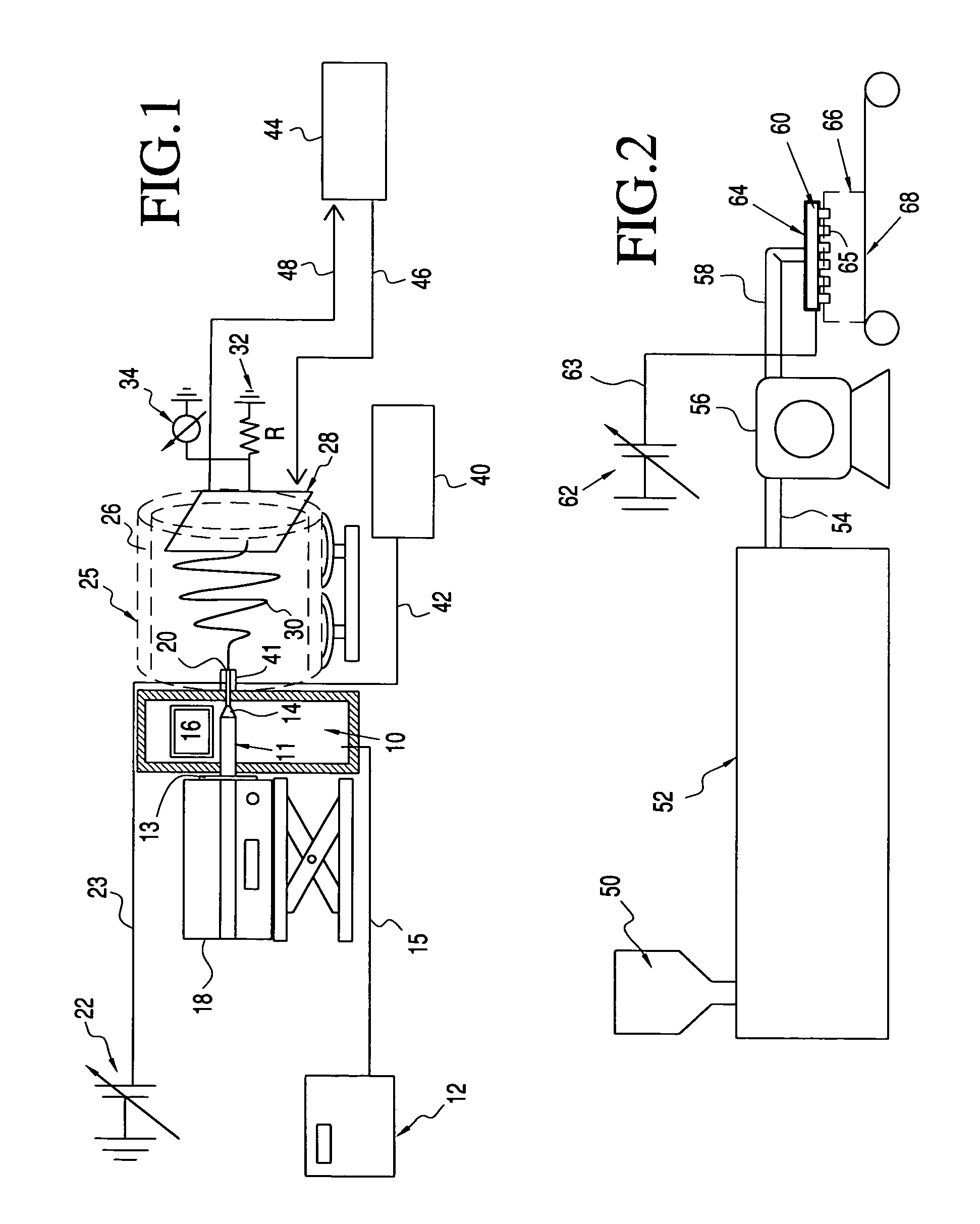

Apparatus and method for elevated temperature electrospinning

ActiveUS7326043B2Avoid disadvantagesConfectioneryWood working apparatusElectrical resistance and conductanceSpinning

Elevated temperature electrospinning apparatus comprises a pump upstream of or containing a resistance heater, means to shield applied electrostatic field from the resistance heater, and a temperature modulator for modulating temperature in the spinning region.

Owner:CORNELL RES FOUNDATION INC

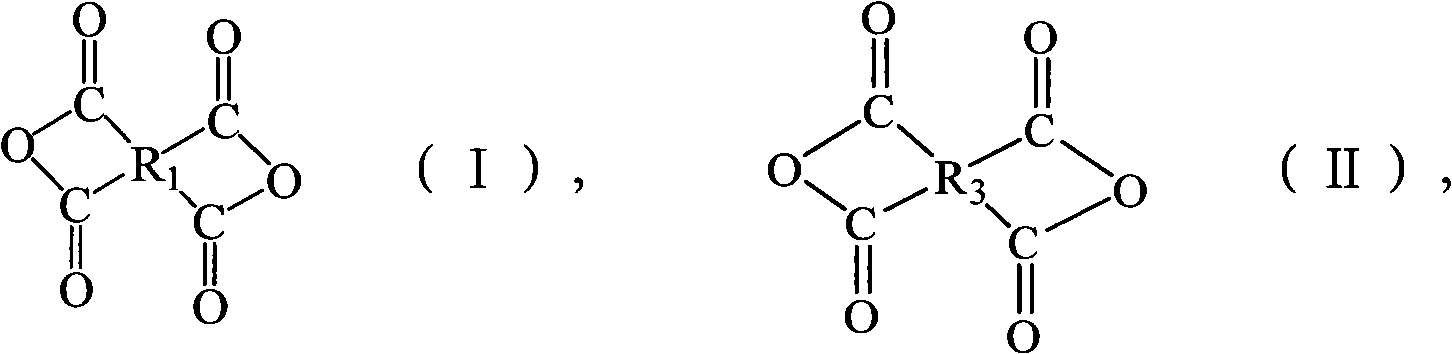

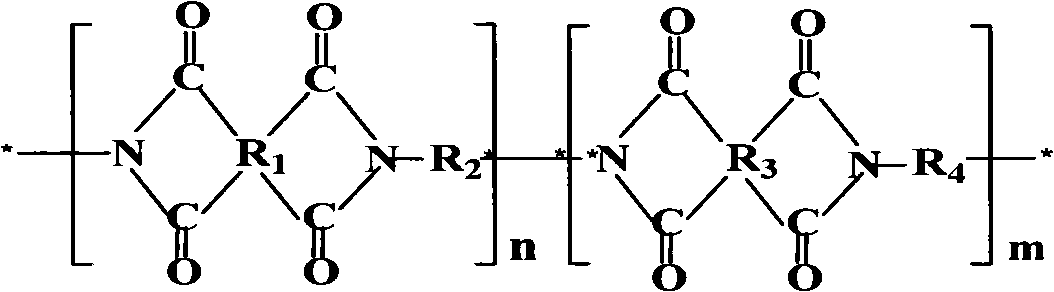

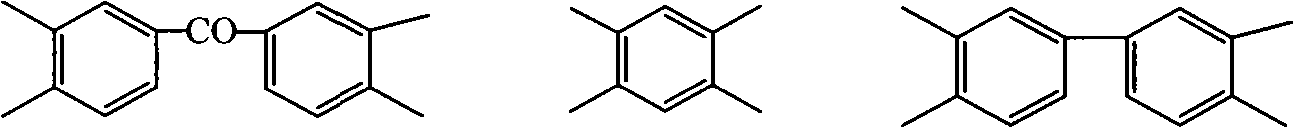

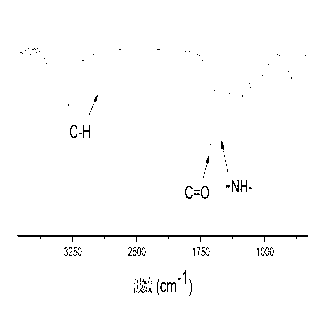

Copolymerized polyimide nanofiber nonwoven and preparation method and application thereof

ActiveCN101974828AHigh mechanical strengthElectrospun copolyimide nanofiber nonwovens with this property are tear-resistantMonocomponent synthetic polymer artificial filamentCell component detailsPorosityTear resistance

The invention relates to a copolymerized polyimide nanofiber nonwoven and a preparation method and application thereof. The preparation method comprises the following steps of: reacting a tetracid dianhydride monomer with a diamine monomer by taking a high-polar solvent as a reaction medium; performing condensation polymerization through mechanical agitation in a reaction kettle to form copolymerized polyimide acid solution; performing electrostatic spinning on the copolymerized polyimide acid solution in a high-voltage electric field so as to obtain the copolymerized polyimide nanofiber nonwoven; performing imidization on the nonwoven at a high temperature to prepare the copolymerized polyimide nanofiber nonwoven which has the characteristics of high tear resistance, high porosity, high temperature and low temperature resistance and high mechanical properties. The copolymerized polyimide nanofiber nonwoven is mainly used for battery diaphragms and capacitor diaphragms.

Owner:JIANGXI XIAN CAI NANOFIBERS TECH

Preparation method of graphene modified nylon 6 fiber

ActiveCN103215689AImprove performanceImprove interfacial bond strengthMonocomponent synthetic polymer artificial filamentArtifical filament manufactureFiberNylon 6

The invention relates to a preparation method of a graphene modified nylon 6 fiber and belongs to the technical field of a functional fiber material. The preparation method comprises the following steps of: carrying out carboxylation and acylating chlorination treatment on graphene; then carrying out diamine treatment to obtain graphene oxide with an active amino on the surface; carrying out polymerization reaction by utilizing the aminated graphene and caprolactam through an initiator 6-aminocaproic acid to prepare a modified nylon 6 melt of the graphene; and carrying out spinning and stretching through a fusion and spinning process to obtain the graphene modified nylon 6 fiber. The technical scheme of the invention utilizes aminated graphene enhanced 6 to improve the interface bonding strength with a base resin, so as to be good for improving the whole performance of the graphene modified nylon 6 fiber. A fiber material prepared by the preparation method provided by the invention can be widely applied to the technical fields of aerospace, cars and ships, communication and transportation, mechano-electronics and the like.

Owner:SUZHOU UNIV

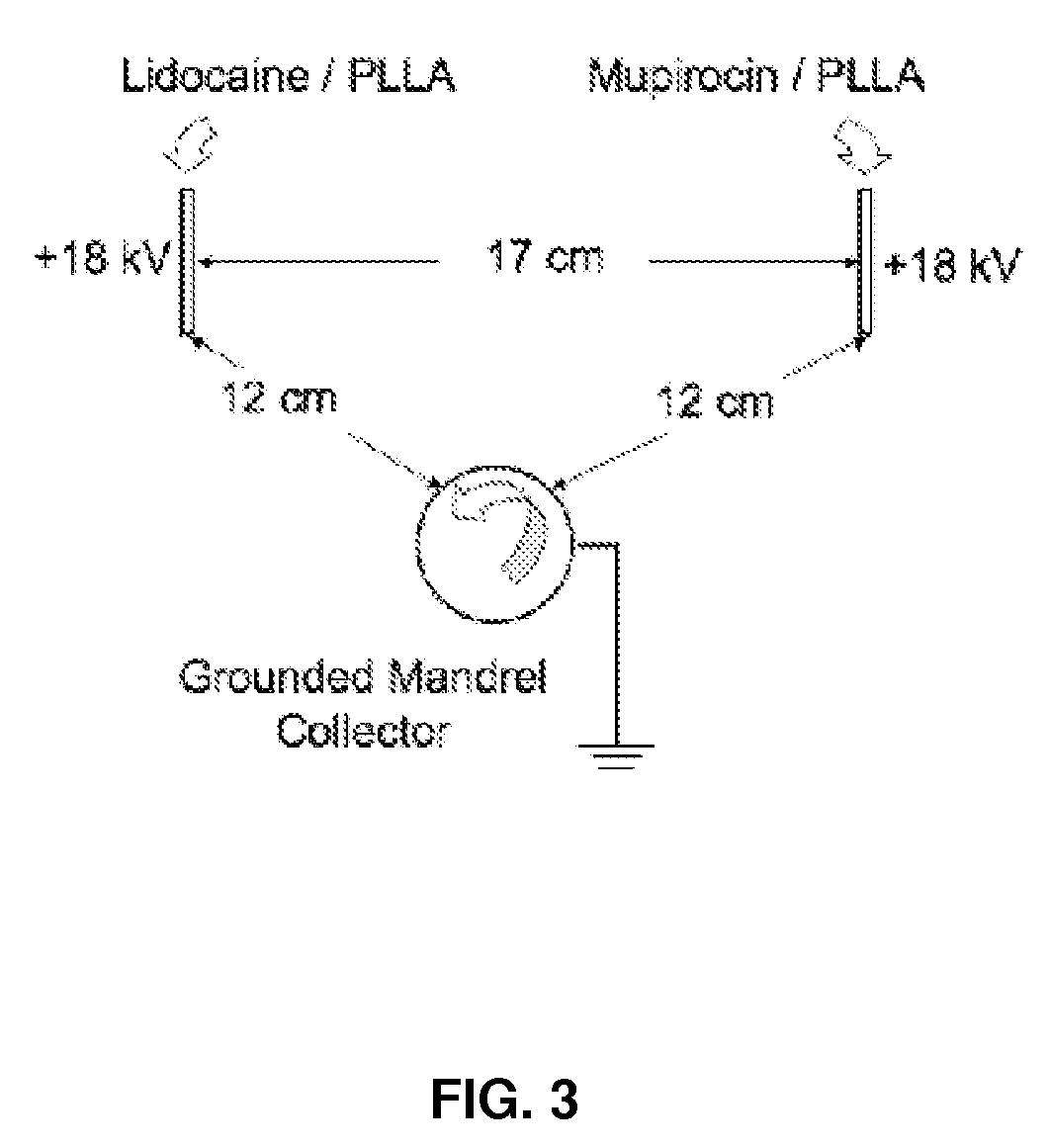

Electrospun matrices for delivery of hydrophilic and lipophilic compounds

InactiveUS20100166854A1Monocomponent protein artificial filamentElectric discharge heatingFiberCompound a

A method of forming electrospun fiber mats from a plurality of different biodegradable polymeric fibers is provided, in which a plurality of up to six different biodegradable polymer solutions are electrospun together by a method comprising the steps of providing a plurality of up to six different biodegradable polymer solutions each containing at least one biologically or pharmaceutically active material and each in communication with a needle for electrospinning a biodegradable polymer fiber from the solution, and pumping each solution through its respective needle into an electric field under conditions effective to produce uncontrolled charged jet streams of the polymer solutions directed at a grounded rotating mandrel, thereby forming fiber threads of the biologically or pharmaceutically active compounds and polymers in the solutions that are deposited on the mandrel to form an electrospun non-woven fiber mat, wherein the needles are positioned for co-deposition of the fiber threads from the polymer solution streams together on the mandrel to form a fiber mat.

Owner:RUTGERS THE STATE UNIV

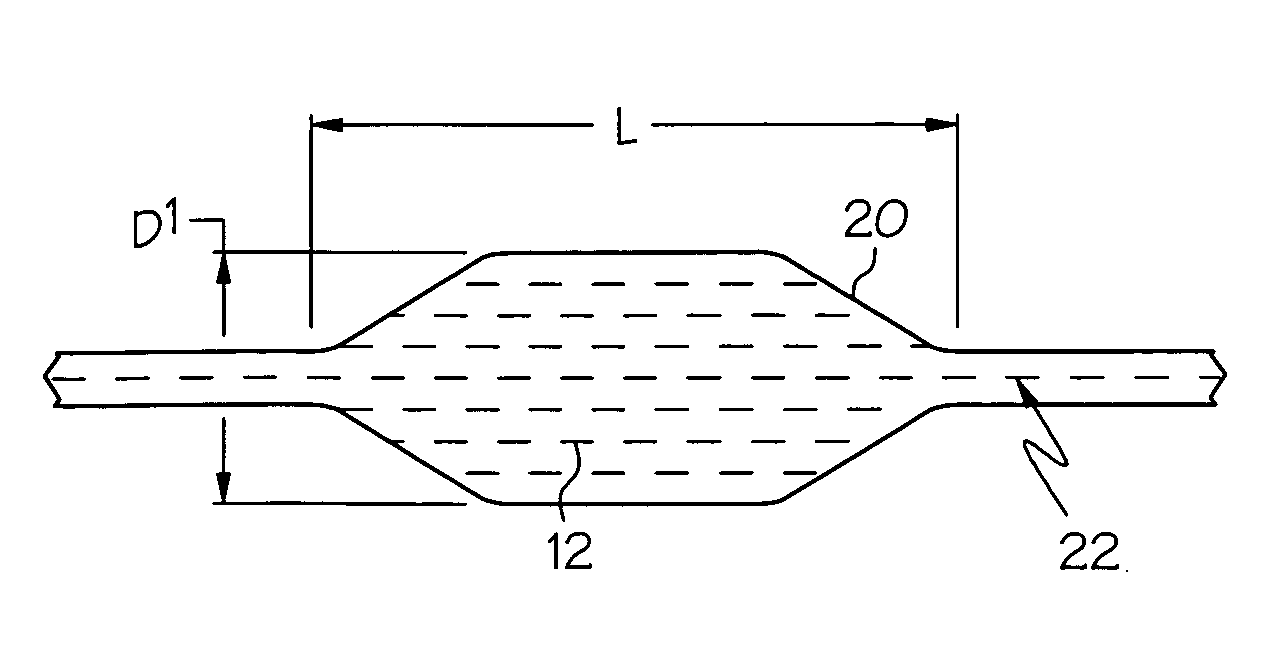

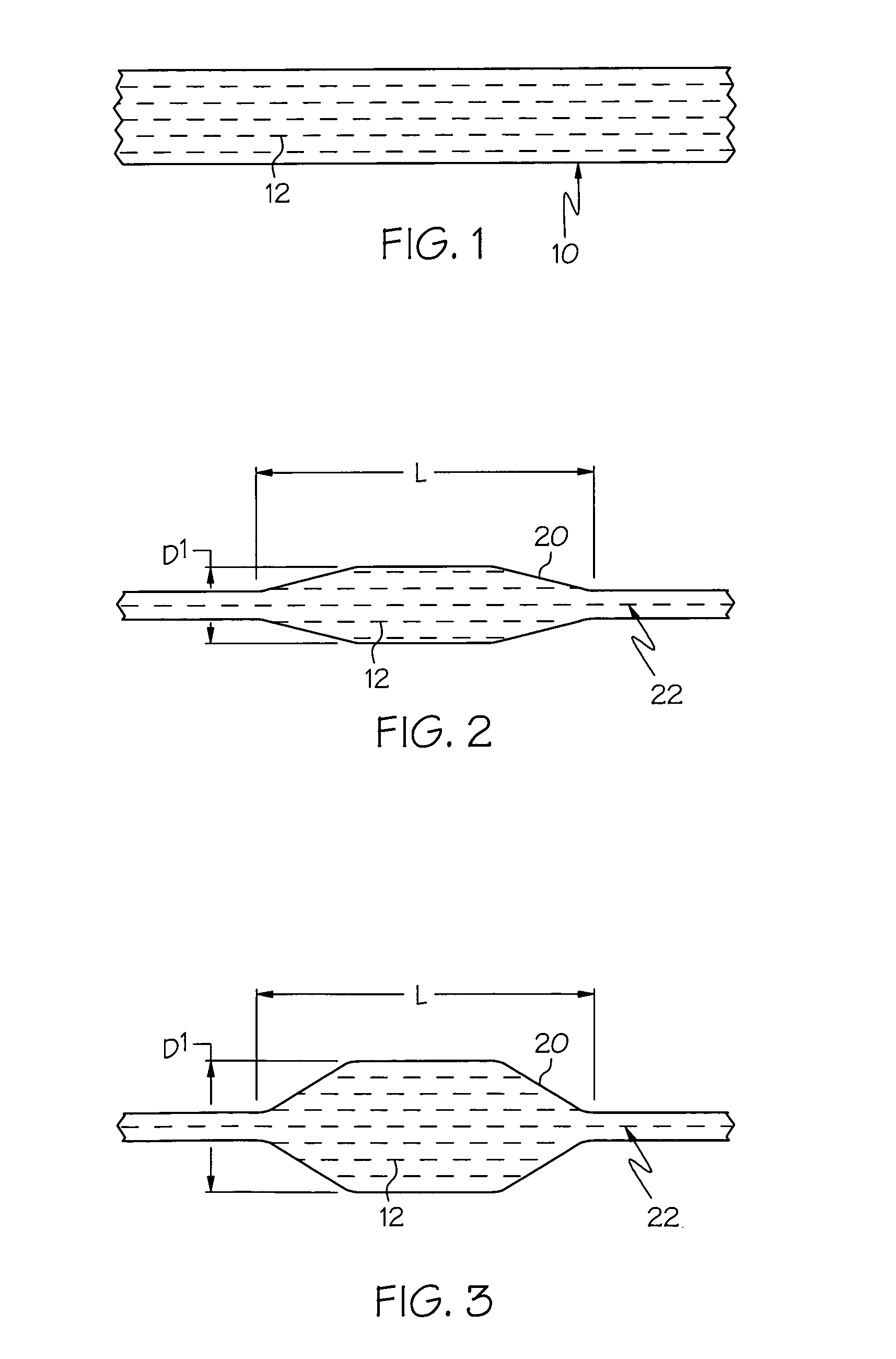

Non-curling polyhydroxyalkanoate sutures

ActiveUS20060058470A1Improve handlingSimple materialSuture equipmentsMovable spraying apparatusPolyesterFiber

Absorbable polyester fibers, braids, and surgical meshes with improved handling properties have been developed. These devices are preferably derived from biocompatible copolymers or homopolymers of 4-hydroxybutyrate. These devices provide a wider range of in vivo strength retention properties than are currently available and have a decreased tendency to curl, in the preferred embodiment, due to the inclusion of relaxation and annealing steps following extrusion and orientation of the fiber. Filaments prepared according to these methods are characterized by the following physical properties: (i) elongation to break from about 17% to about 85% (ii) Young's modulus of less than 350,000 psi, (iii) knot to straight ratio (knot strength / tensile strength) of 55-80% or (iv) load at break from 1100 to 4200 grams.

Owner:TEPHA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com