Patents

Literature

4735results about How to "Good orientation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

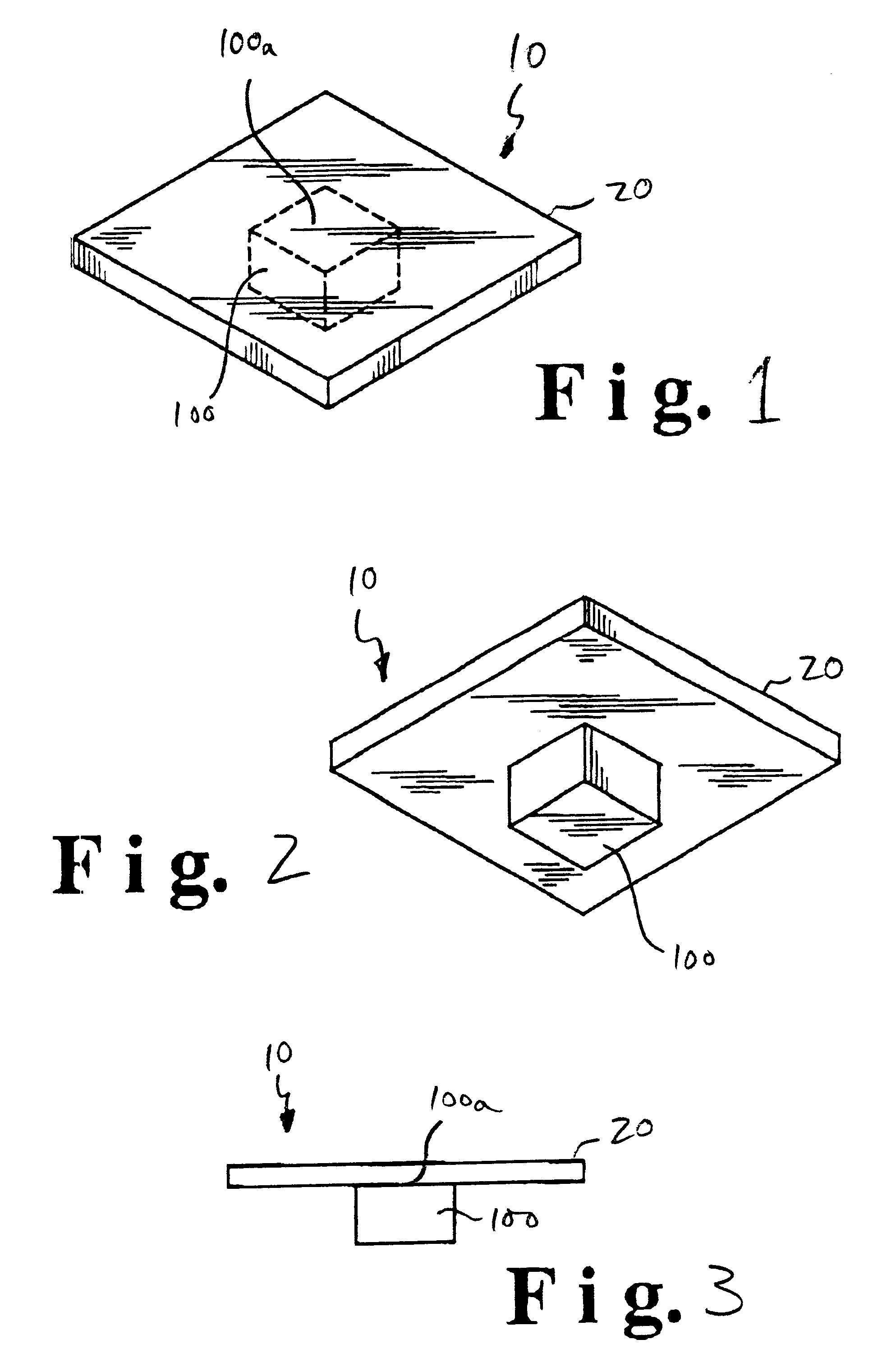

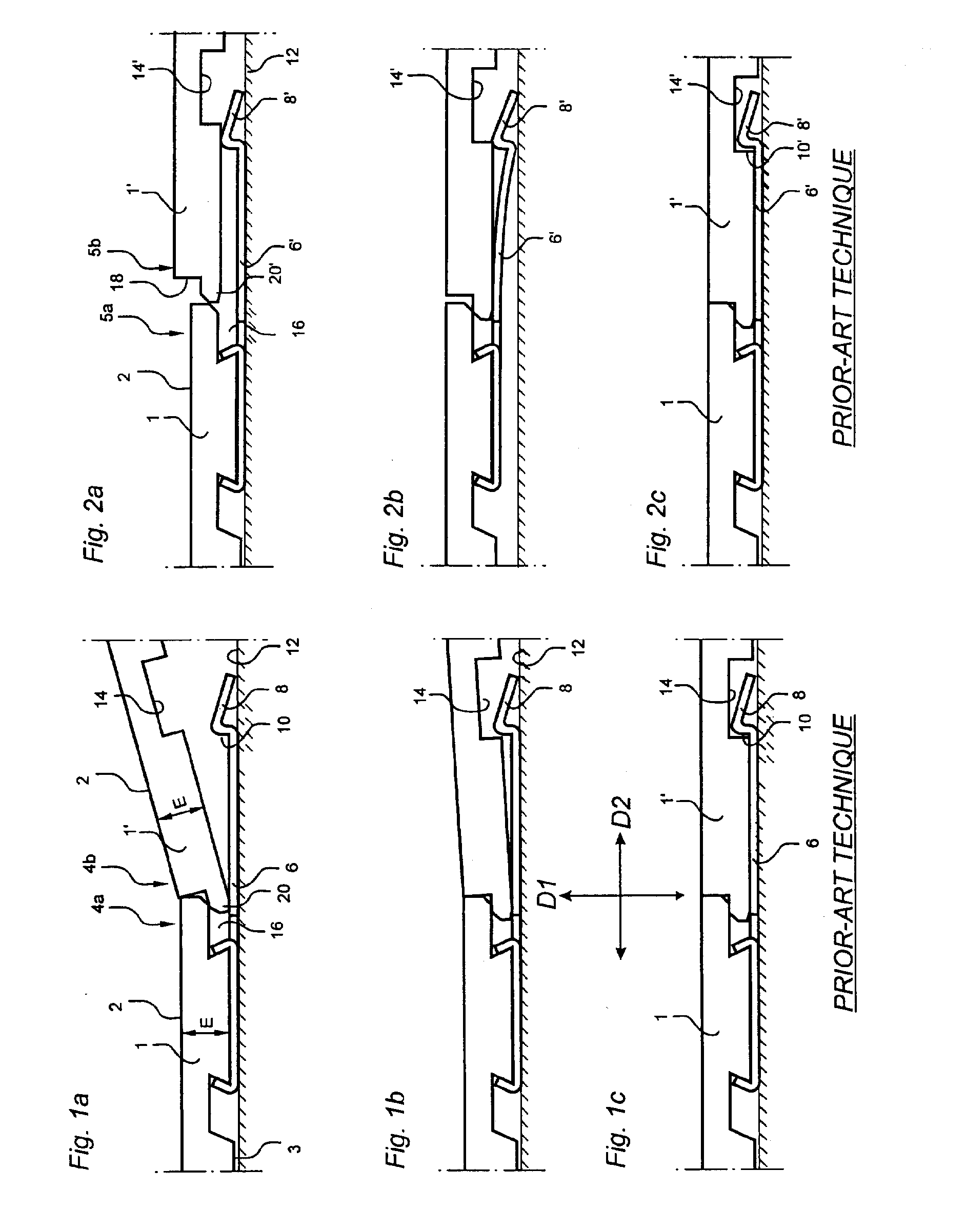

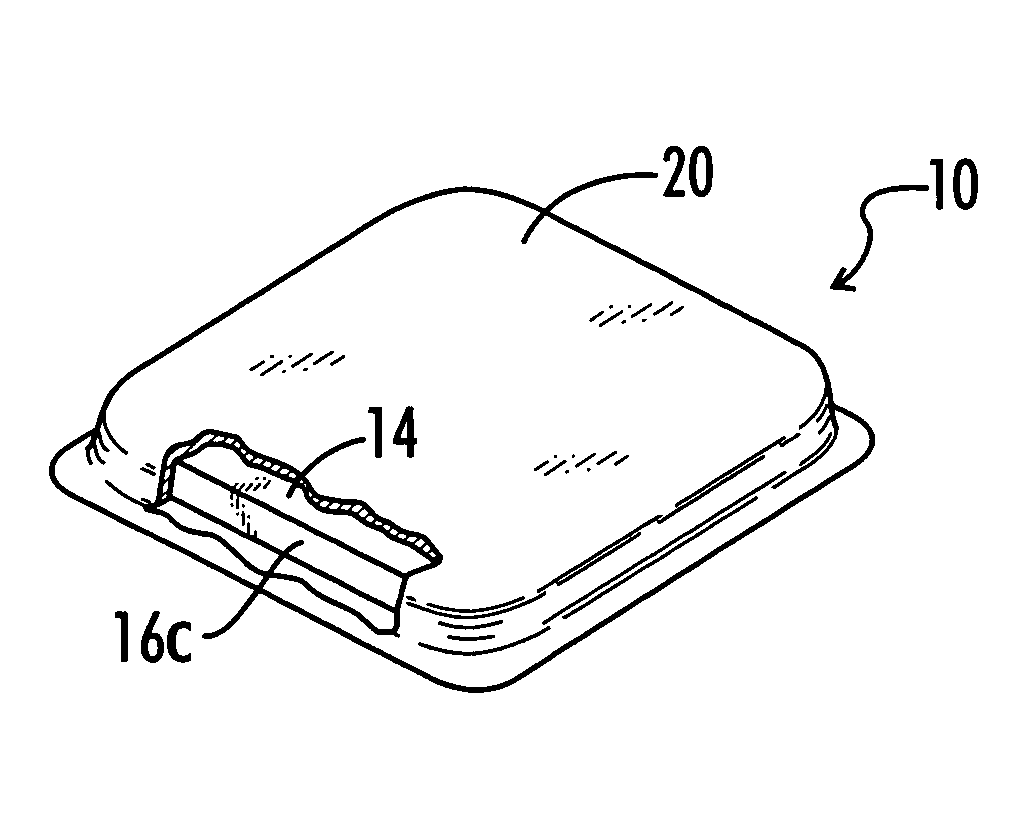

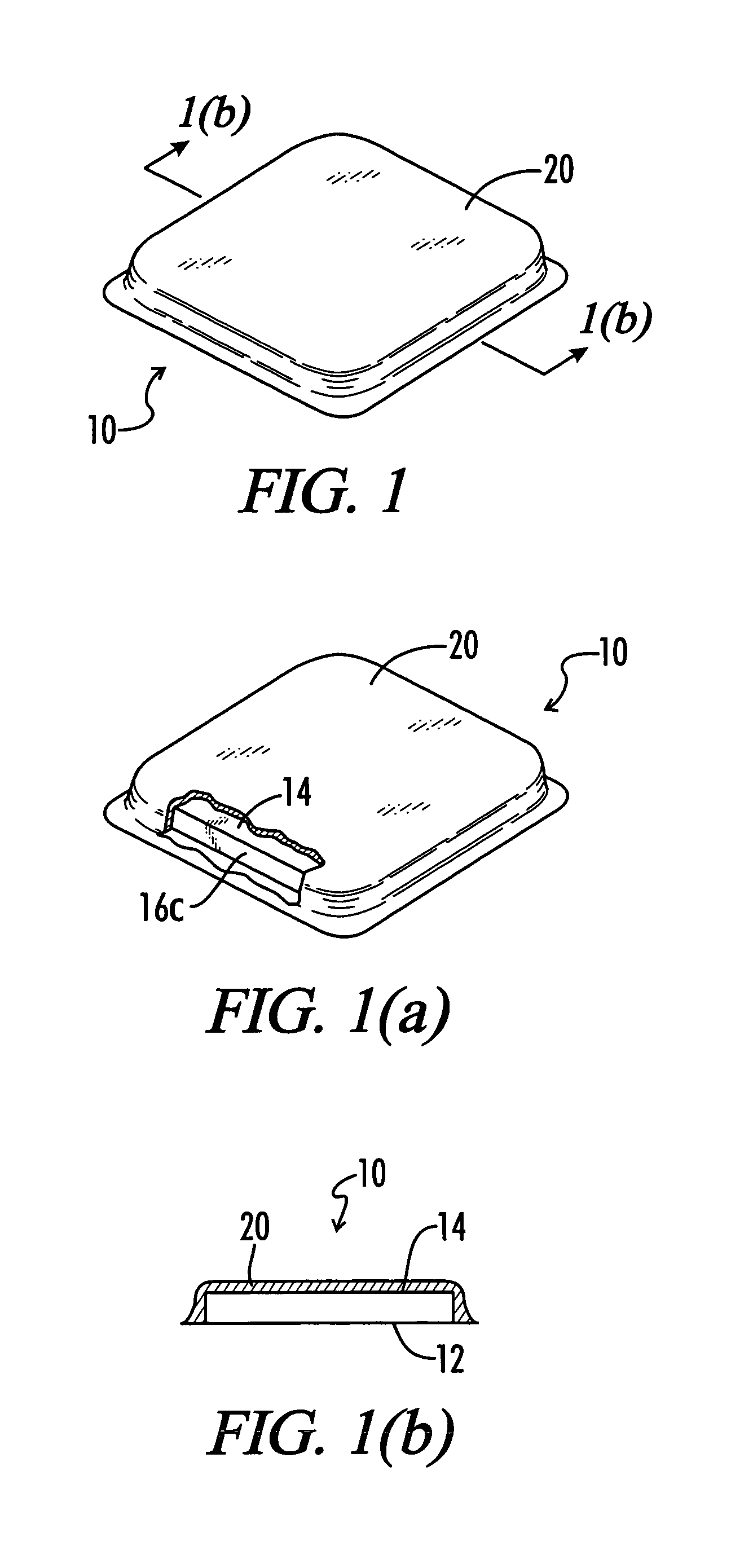

Locking System And Flooring Board

InactiveUS20080028707A1Good orientationCost of waste differsCeilingsStrutsEngineeringMechanical engineering

Owner:VÄLINGE INNOVATION AB

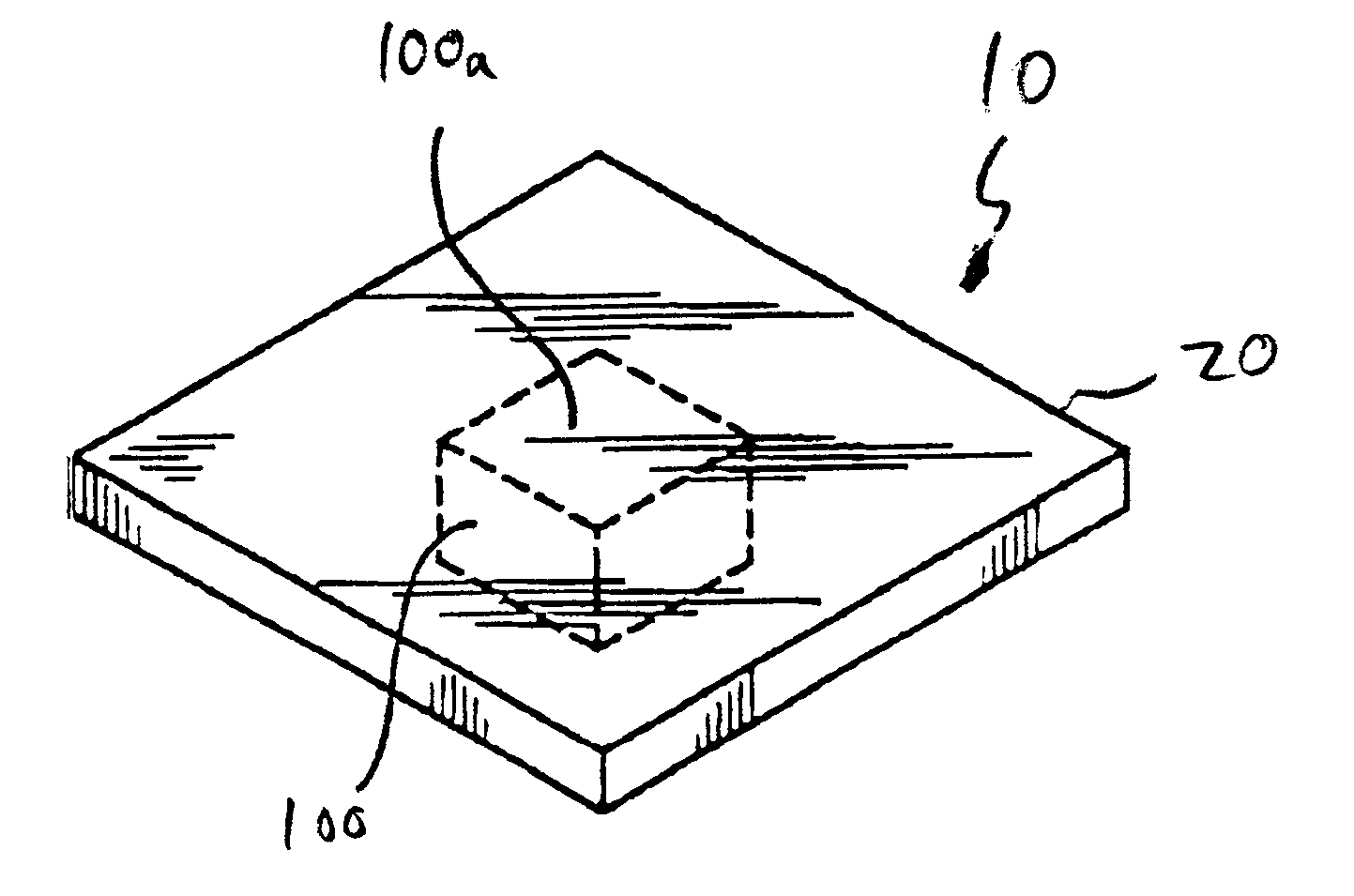

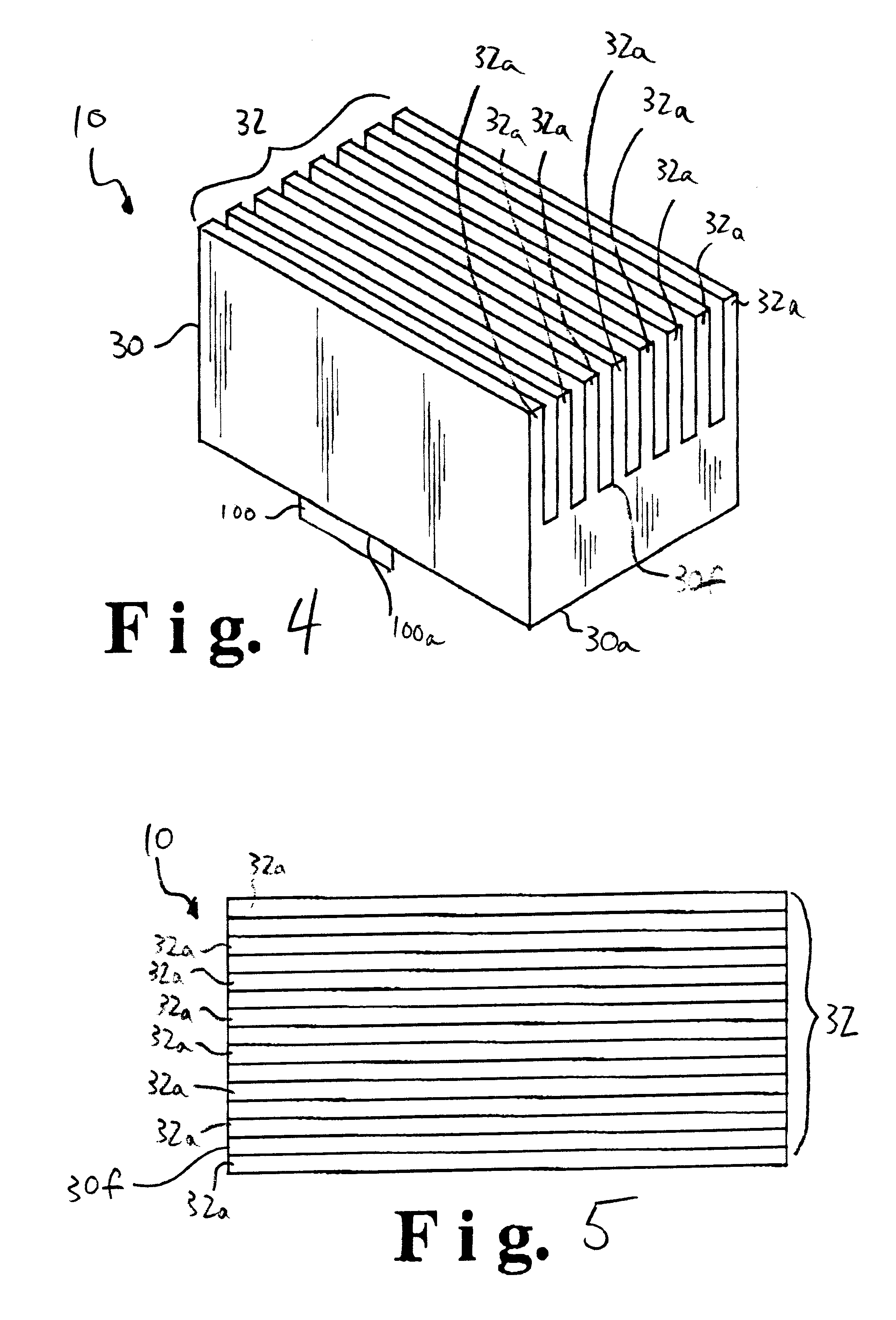

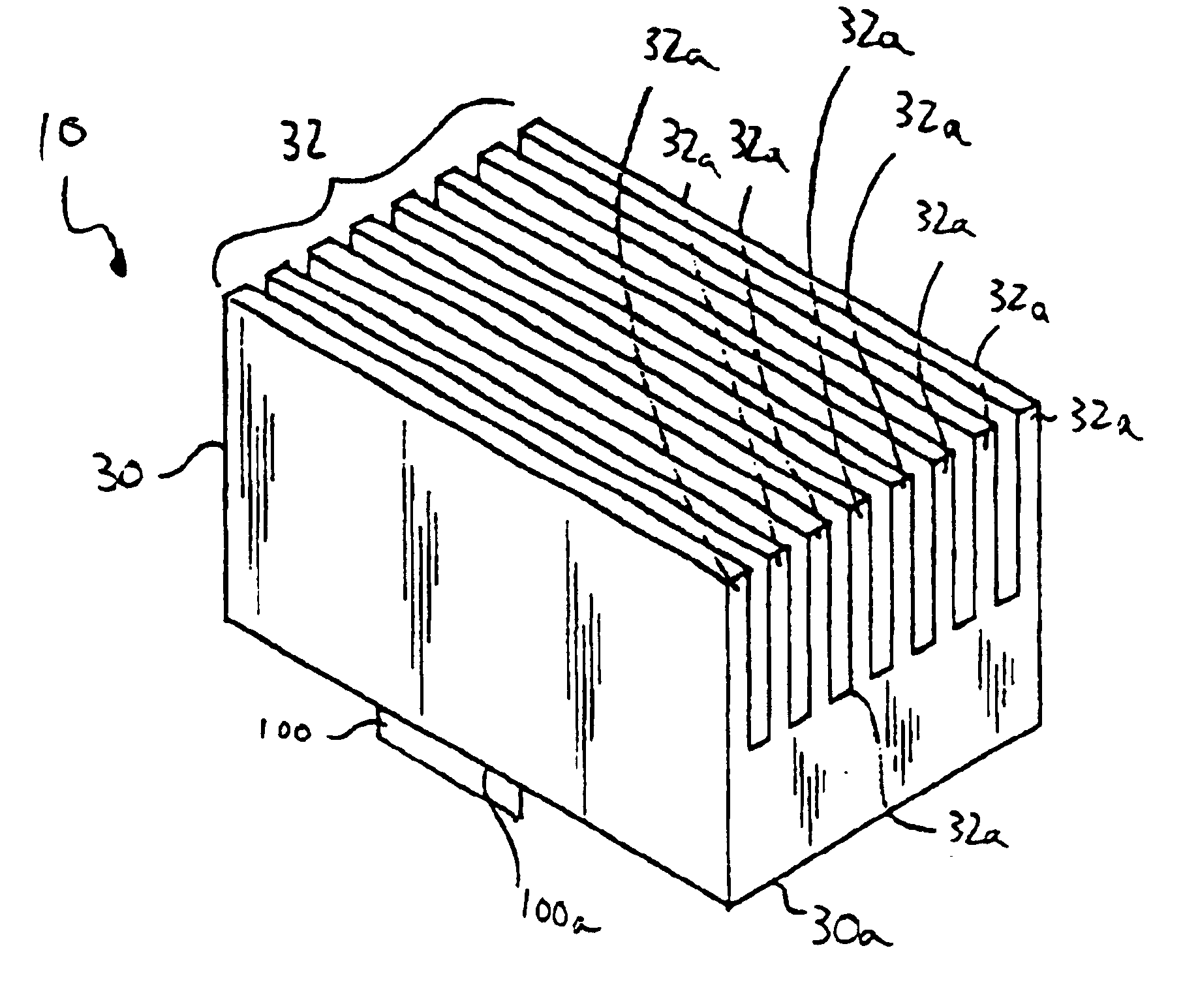

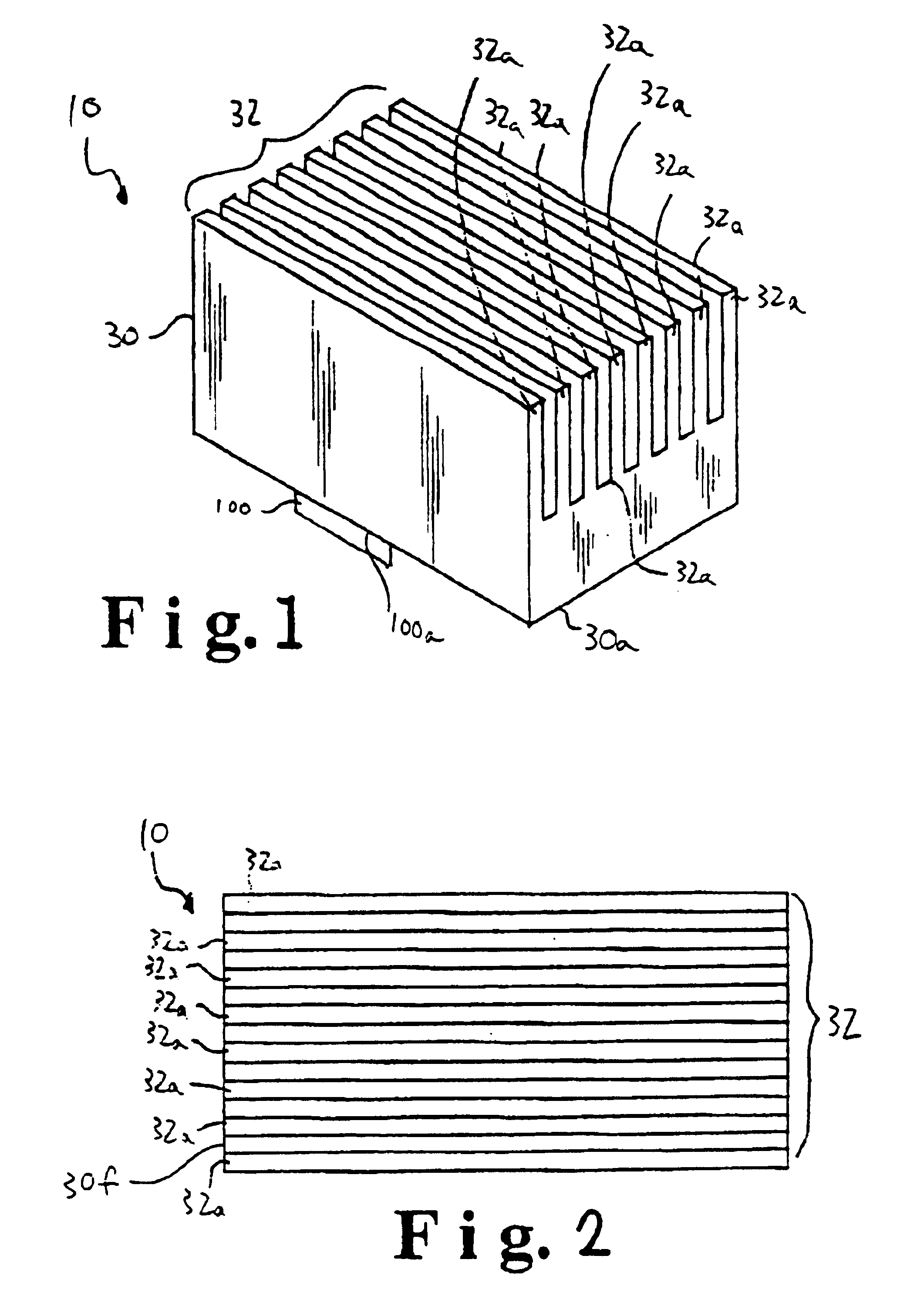

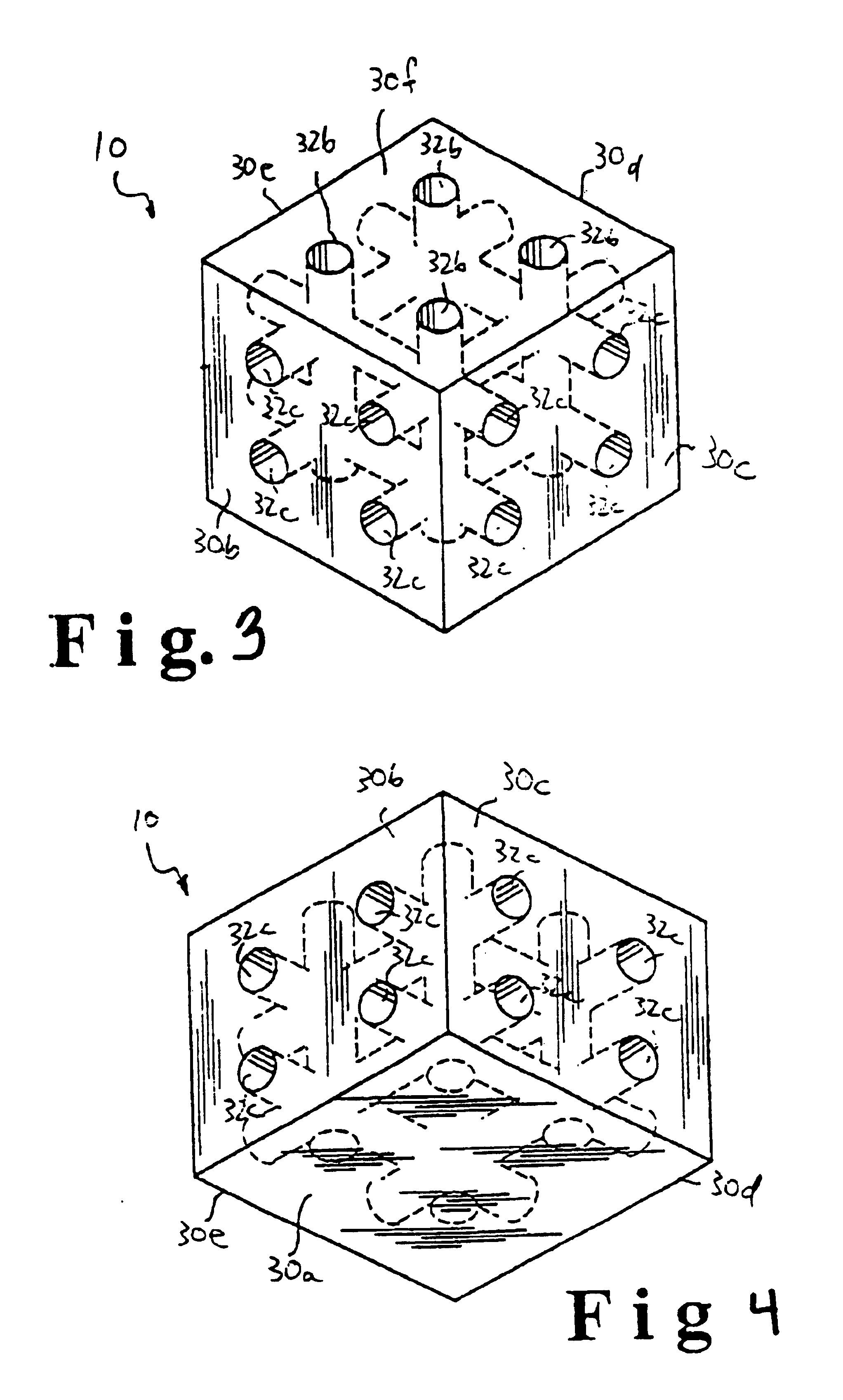

Thermal management system

InactiveUS6482520B1Improve cooling effectIncreased anisotropyLayered productsSemiconductor/solid-state device detailsEngineeringThermal management system

The present invention relates to a system for managing the heat from a heat source like an electronic component. More particularly, the present invention relates to a system effective for dissipating the heat generated by an electronic component using a thermal management system that includes a thermal interface formed from a flexible graphite sheet and / or a heat sink formed from a graphite article.

Owner:NEOGRAF SOLUTIONS LLC

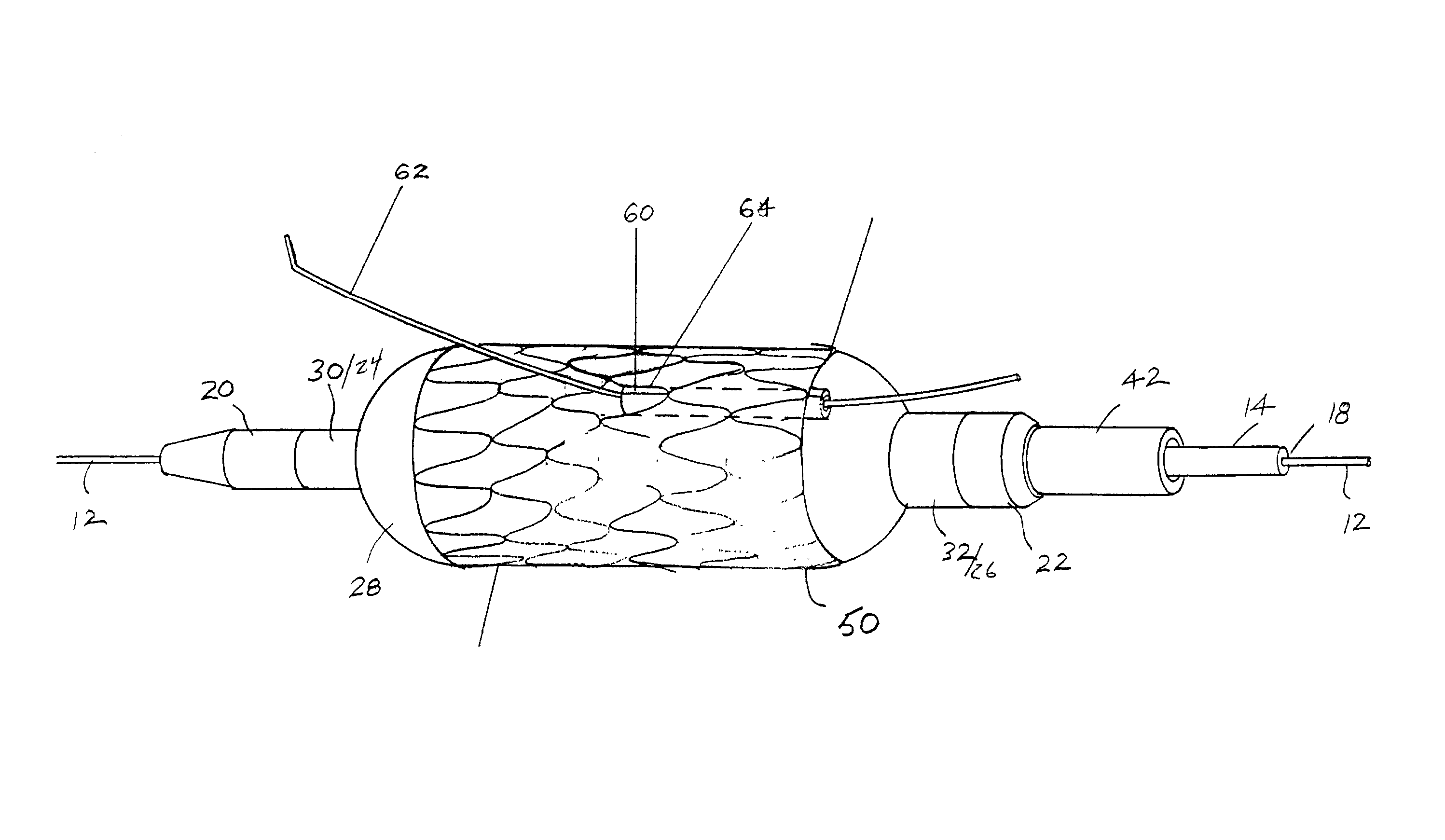

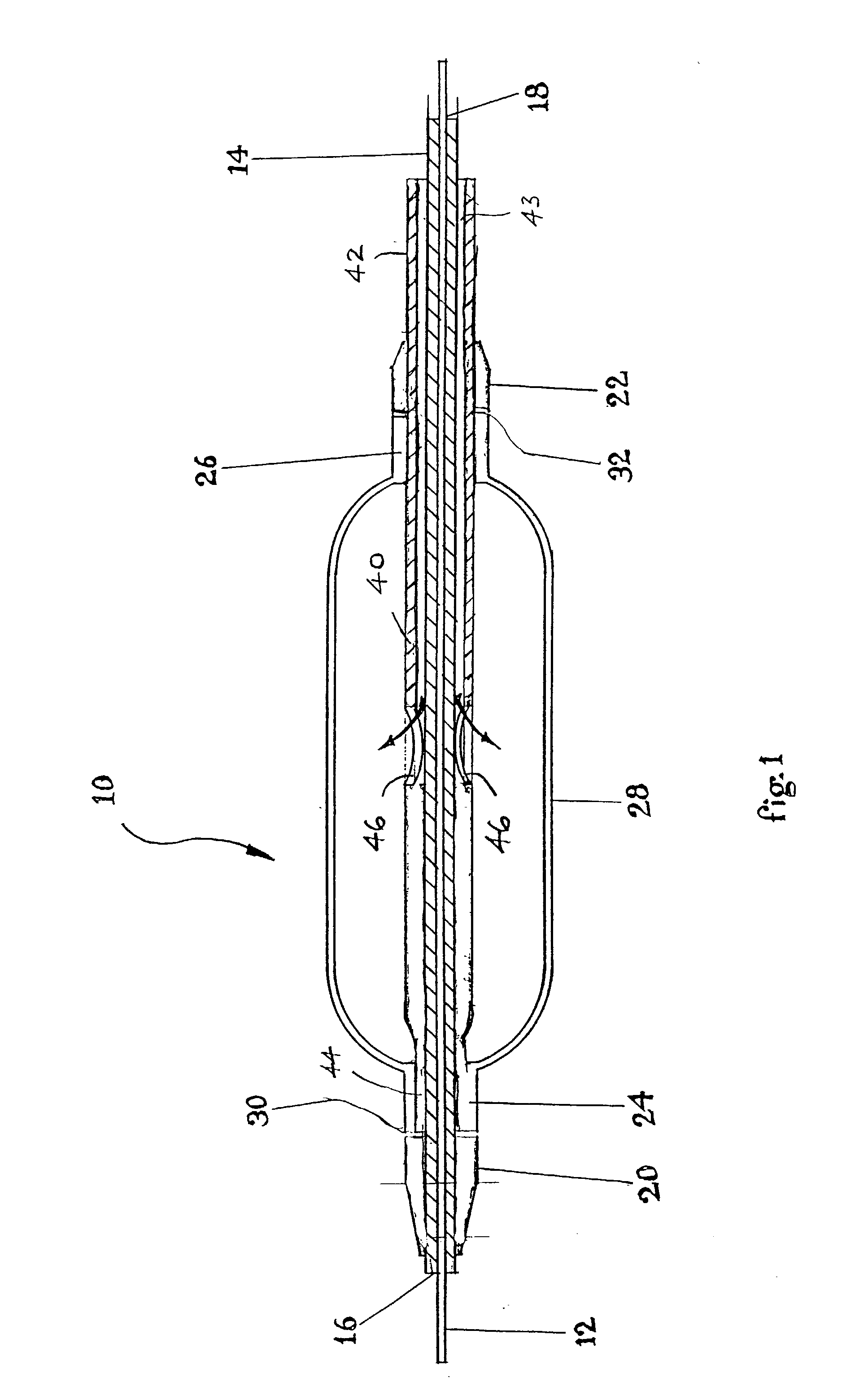

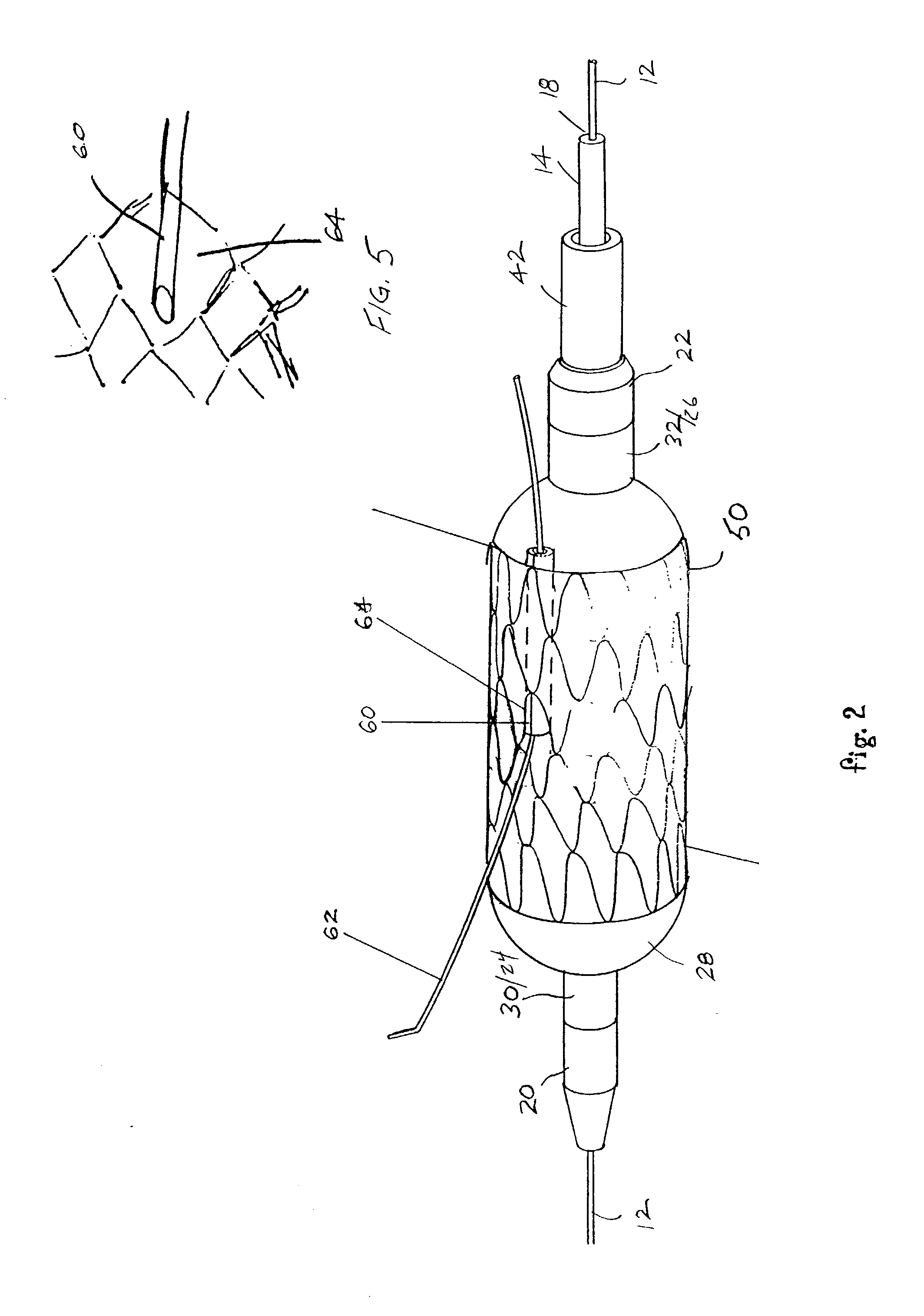

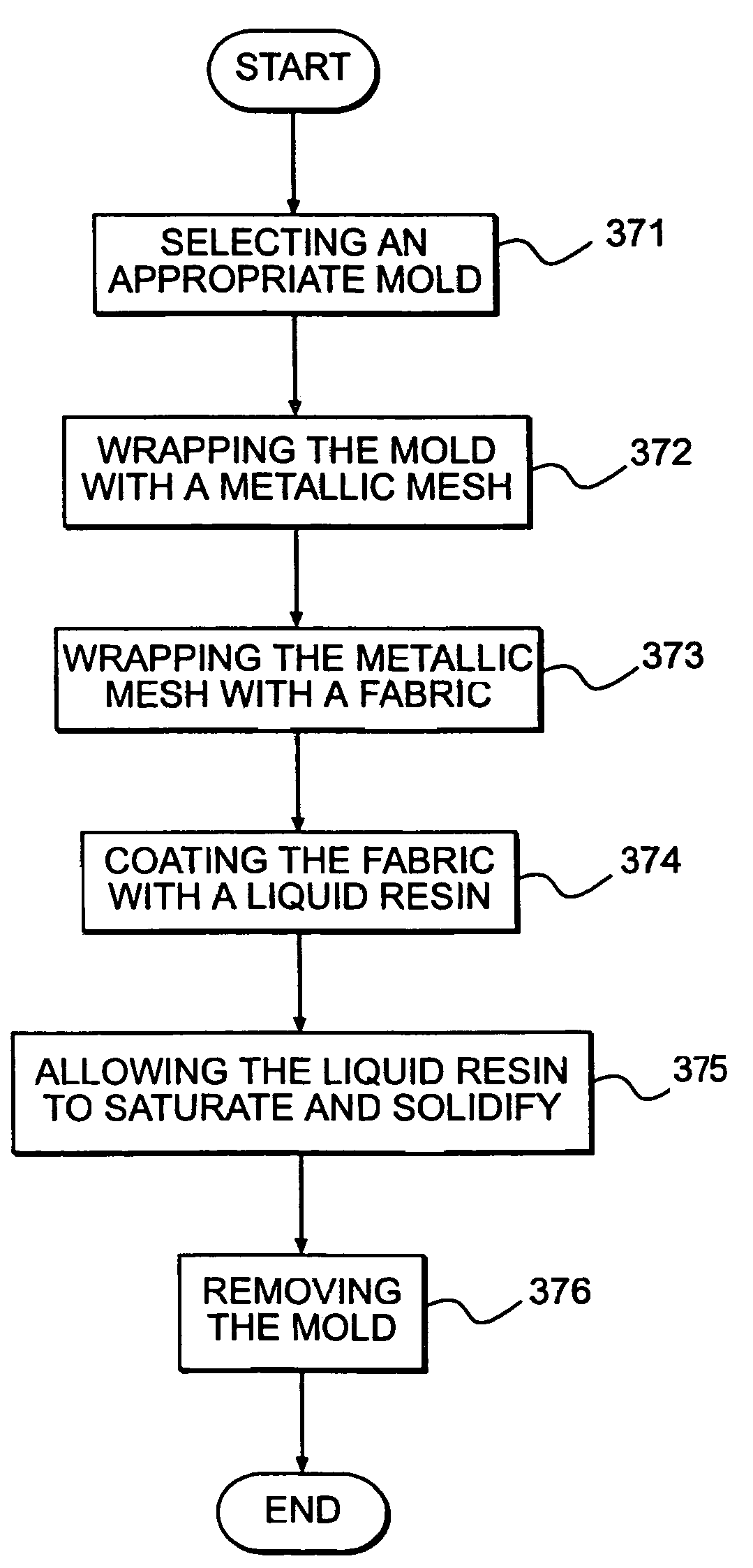

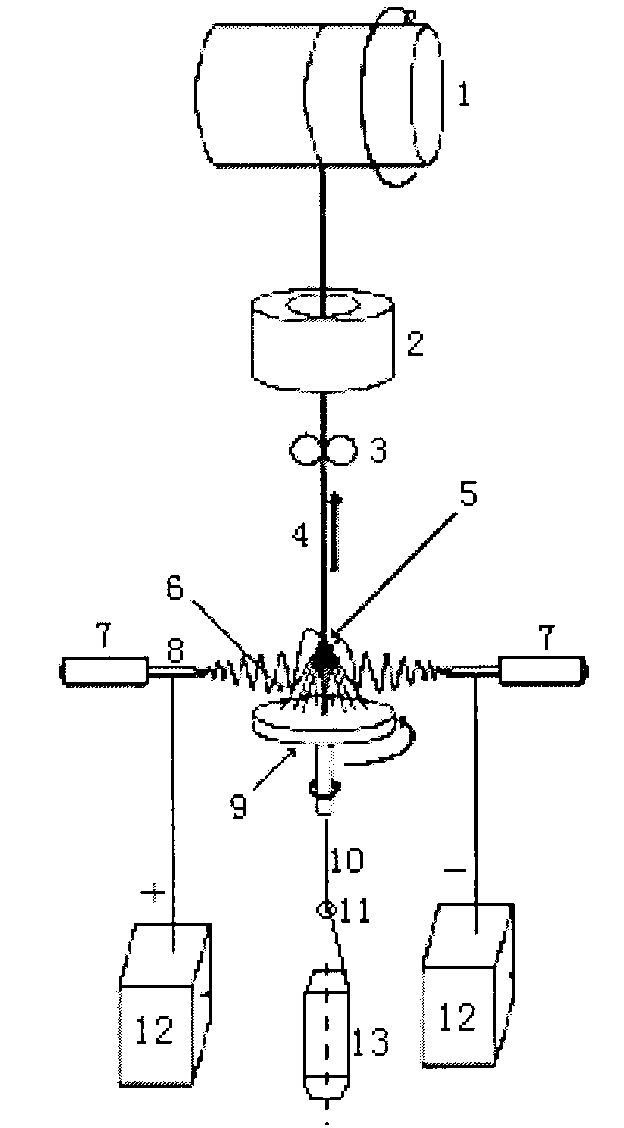

Rotating stent delivery system for side branch access and protection and method of using same

InactiveUS20030055483A1Improve directionImprove protectionStentsBalloon catheterGuide wiresCatheter device

A catheter assembly and method of use comprises advancing a catheter having a rotatably mounted balloon relative to the primary guide wire to a vessel bifurcation along first and second guide wires.

Owner:GUMM DARREL C

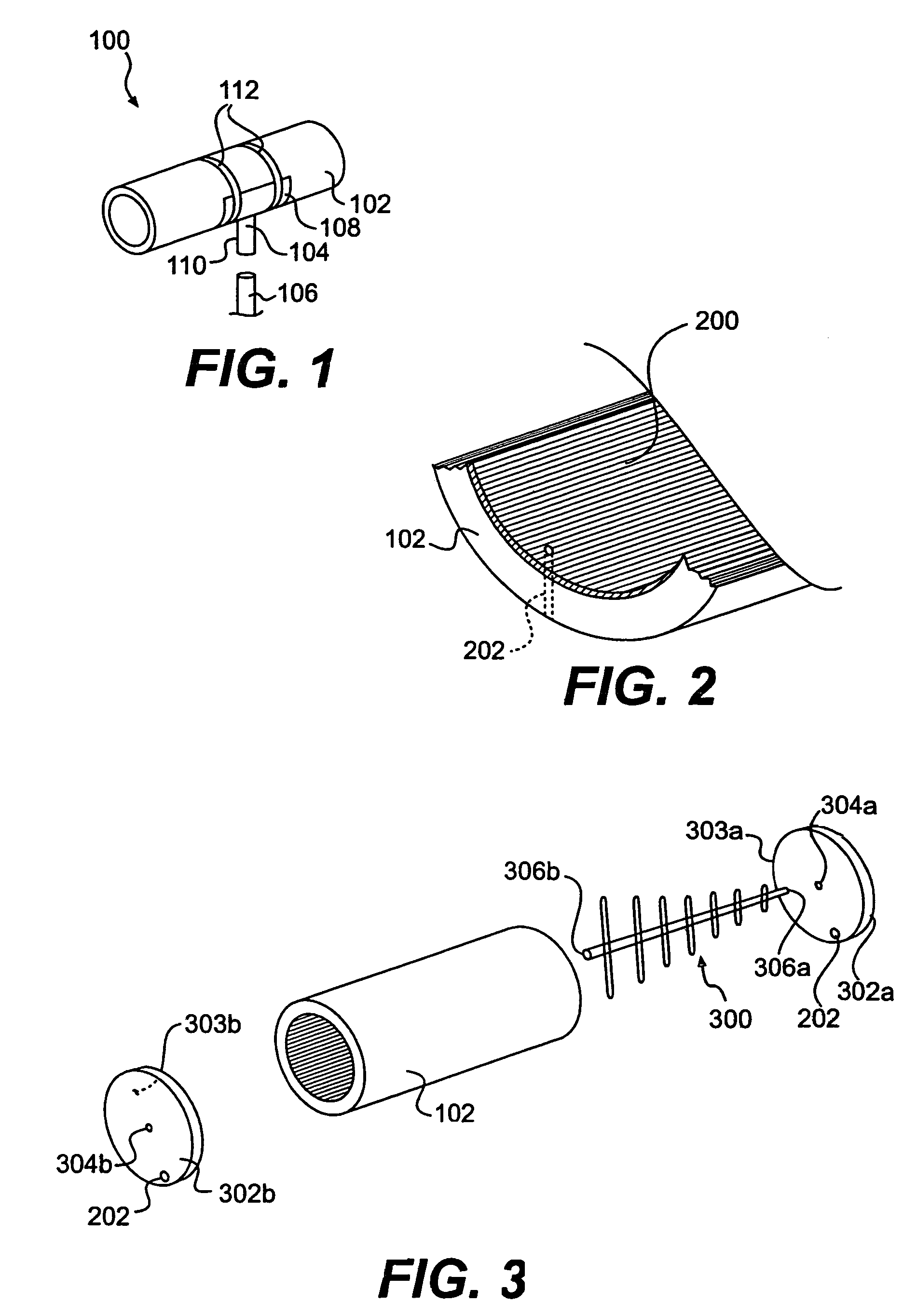

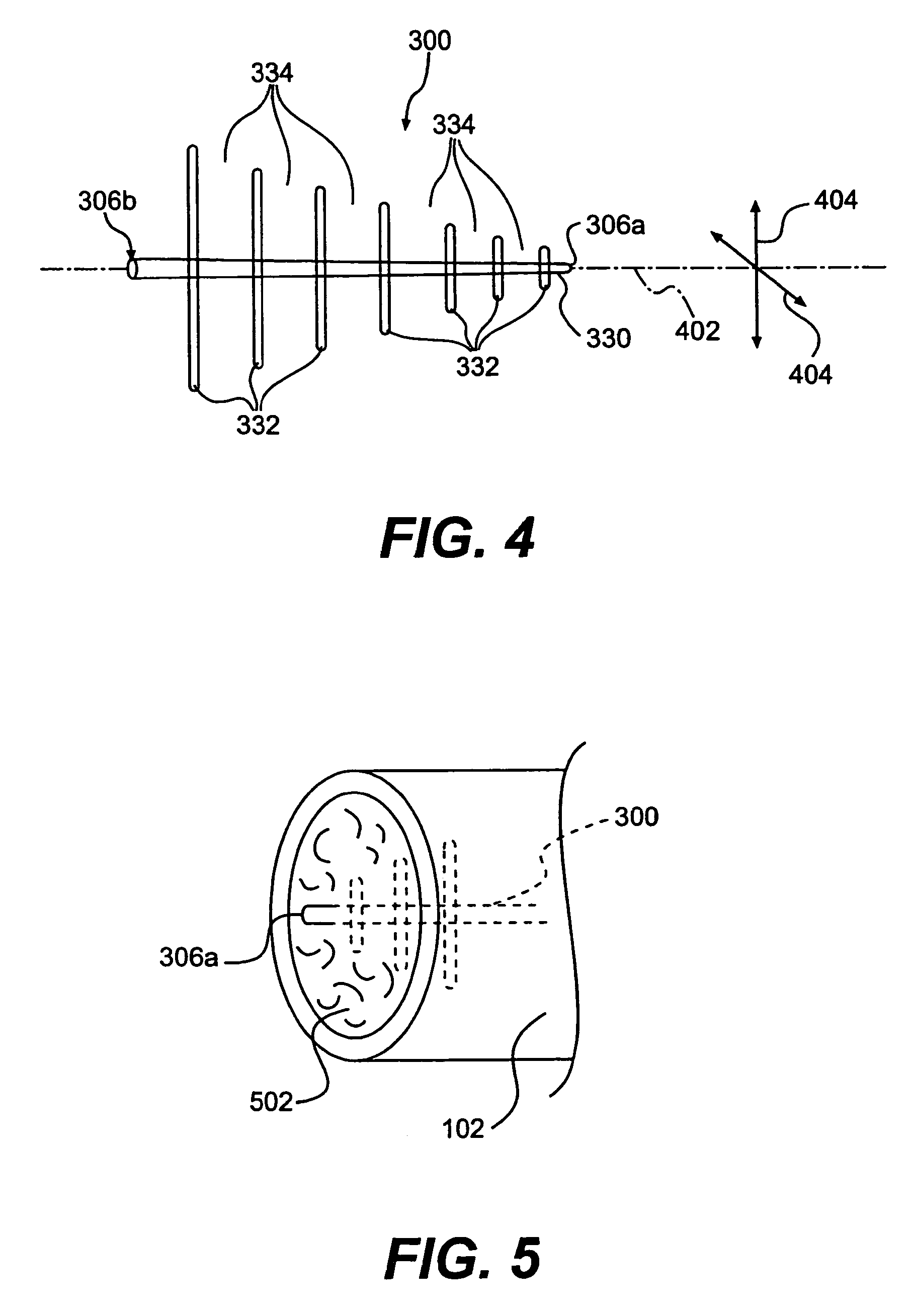

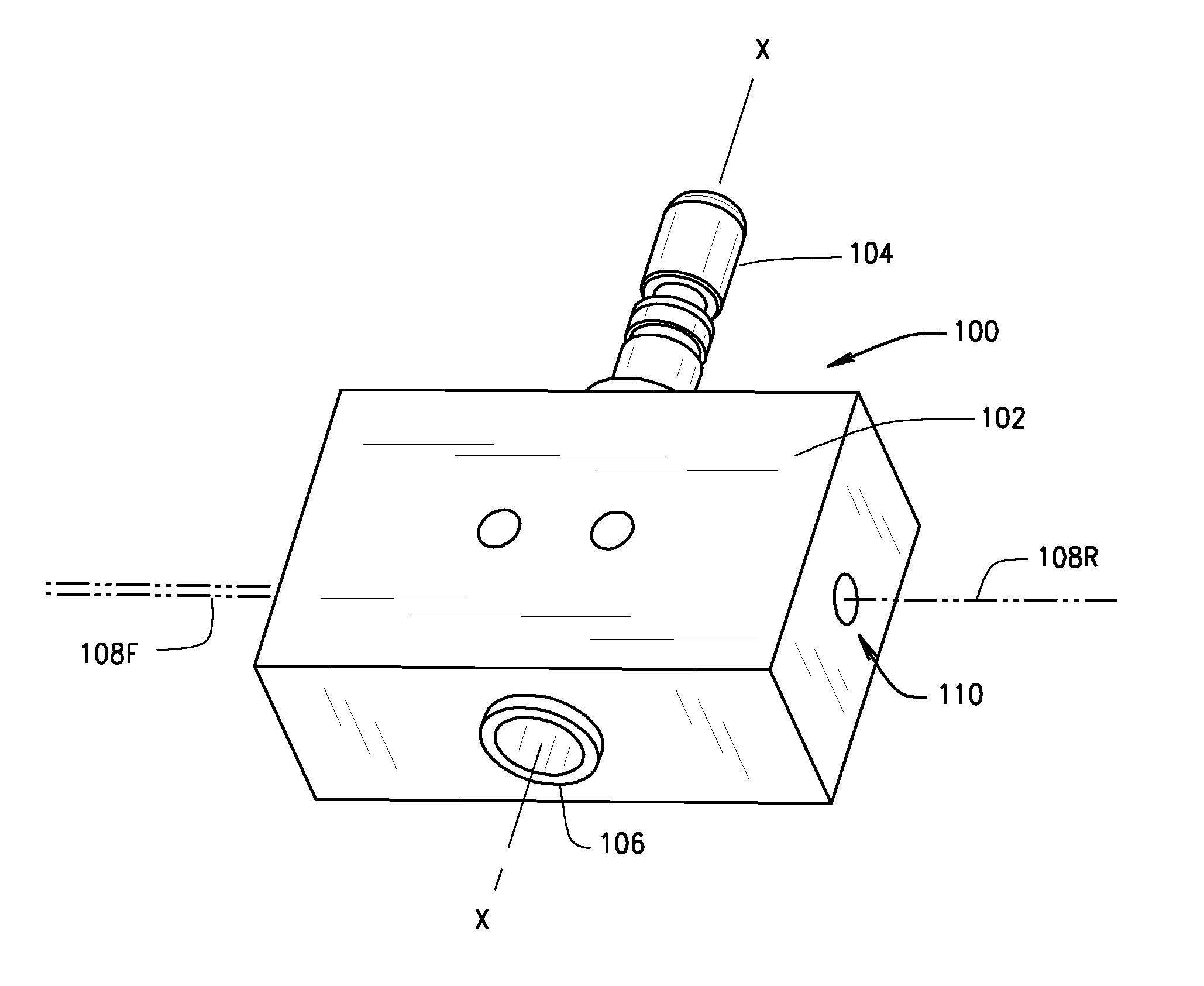

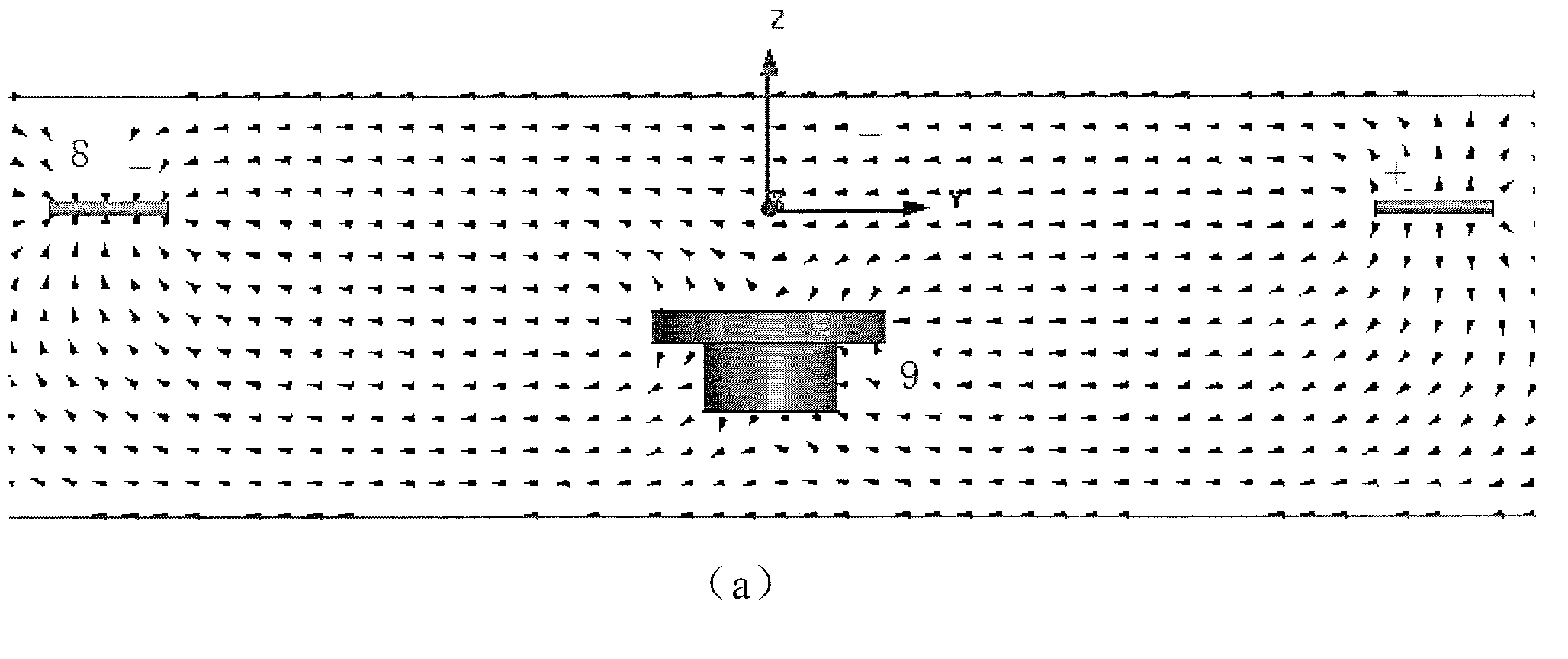

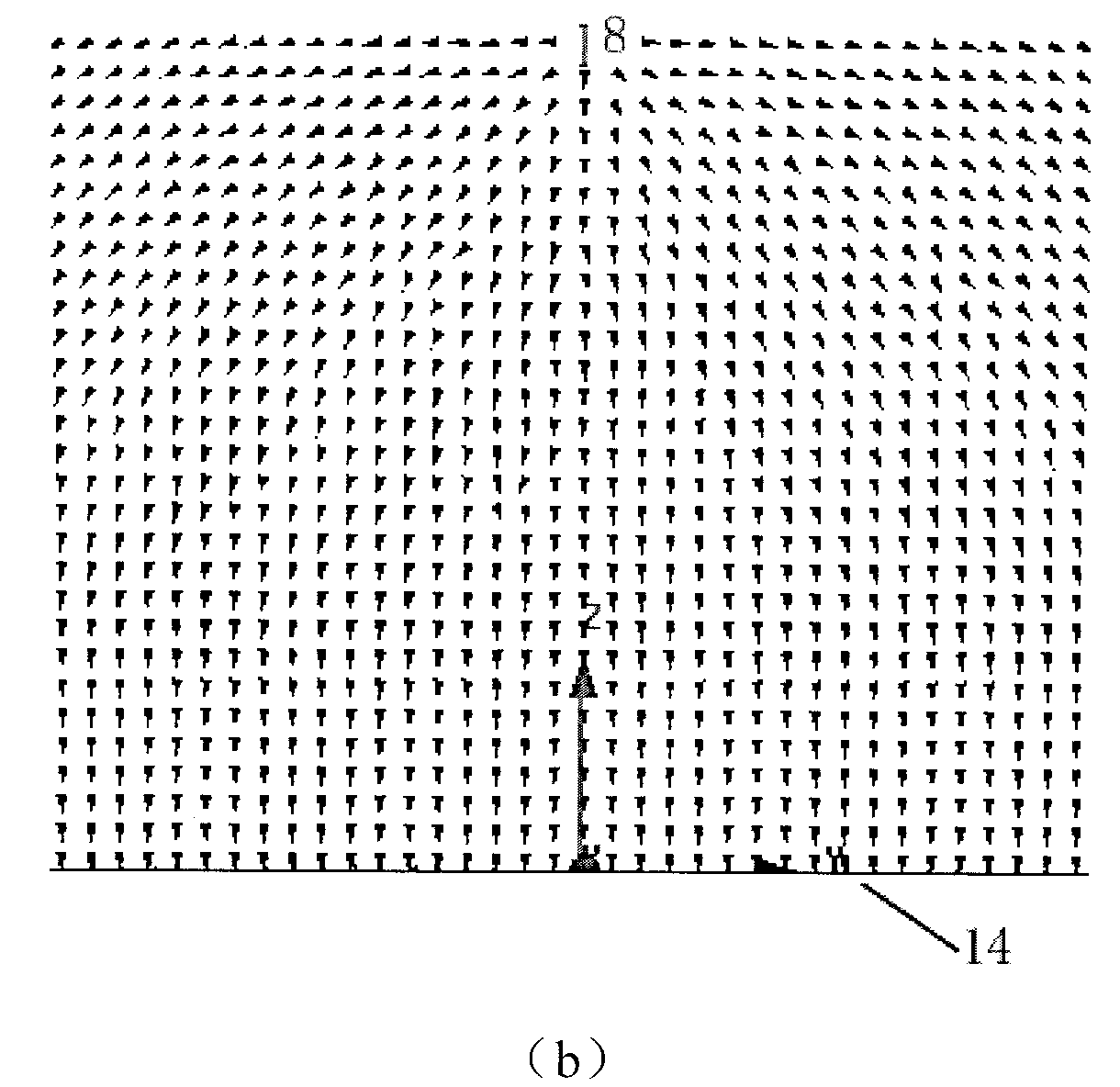

Antenna system

InactiveUS7023400B2Reduce decreaseMinimizing signal looping effectLogperiodic antennasAntenna supports/mountingsDirectional antennaSide lobe

An antenna system that includes a directional antenna designed to reduce the occurrence of side lobes, thus reducing the possibility of interference with other radio frequencies is disclosed. The directional antenna includes an antenna member and a reflecting tube. The reflective tube is sleeved over the antenna member. The reflective serves to block unwanted radial side lobes. The directional antenna can also include provisions that assist in suspending the antenna member within the reflective tube.

Owner:BELLSOUTH INTPROP COR

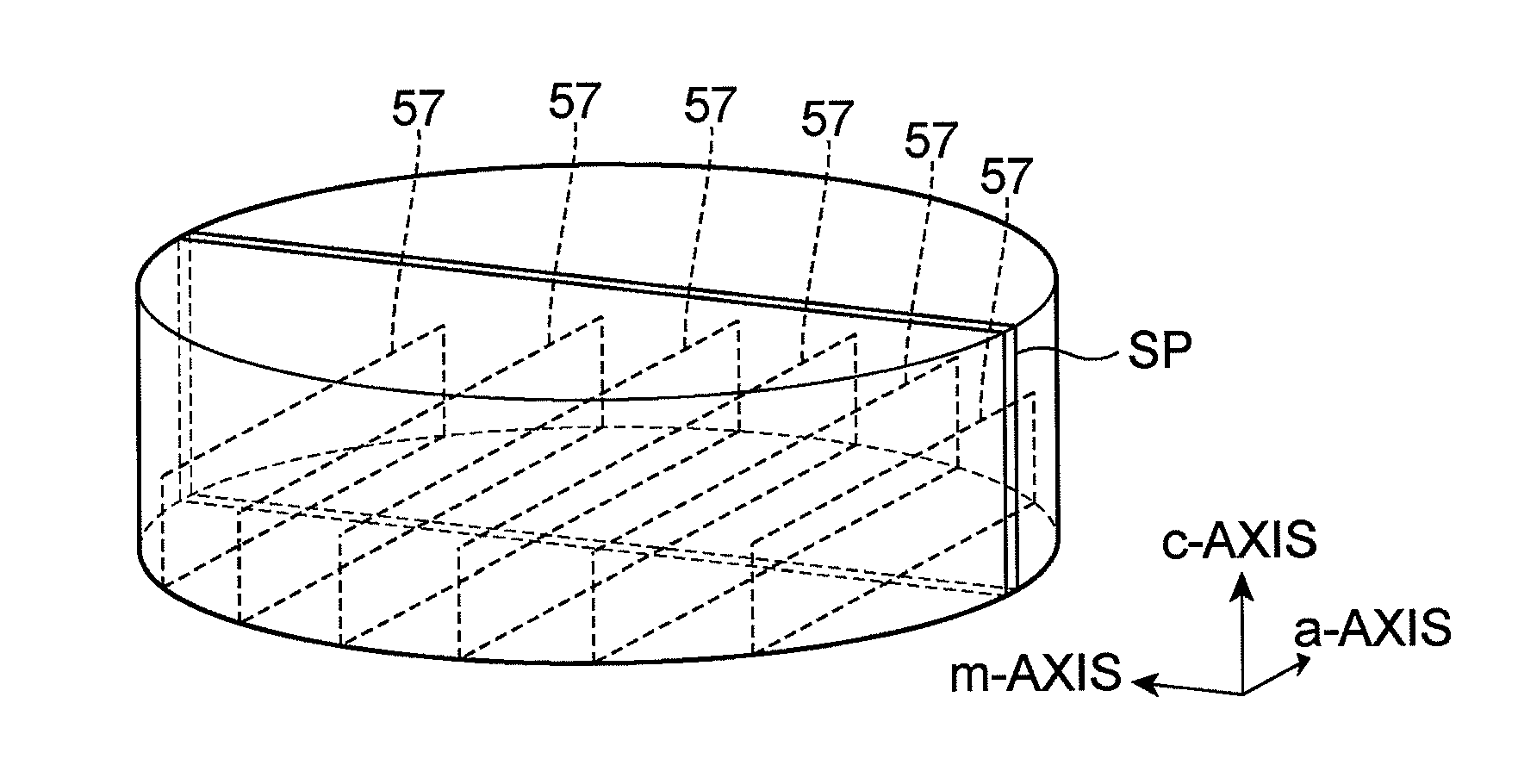

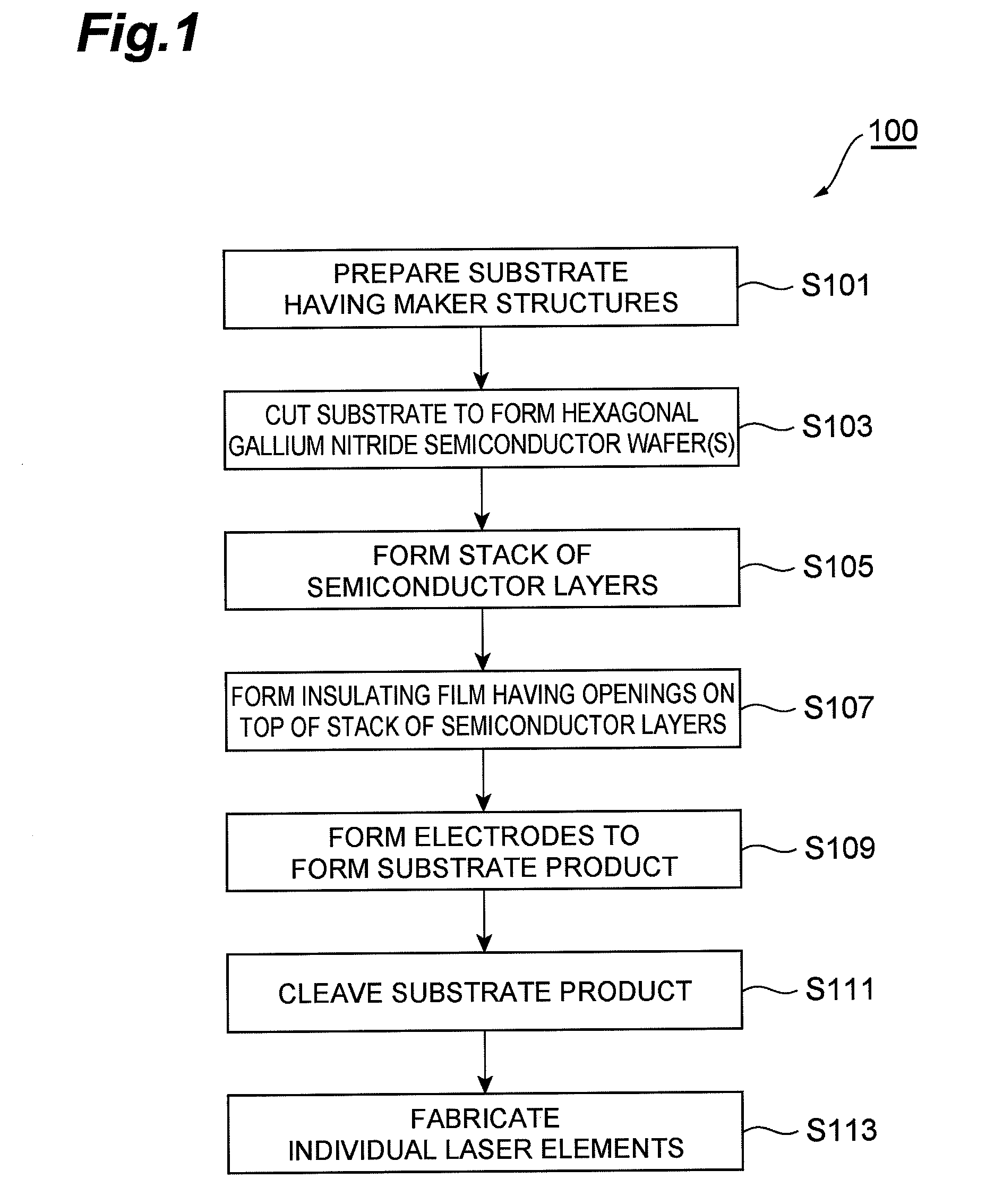

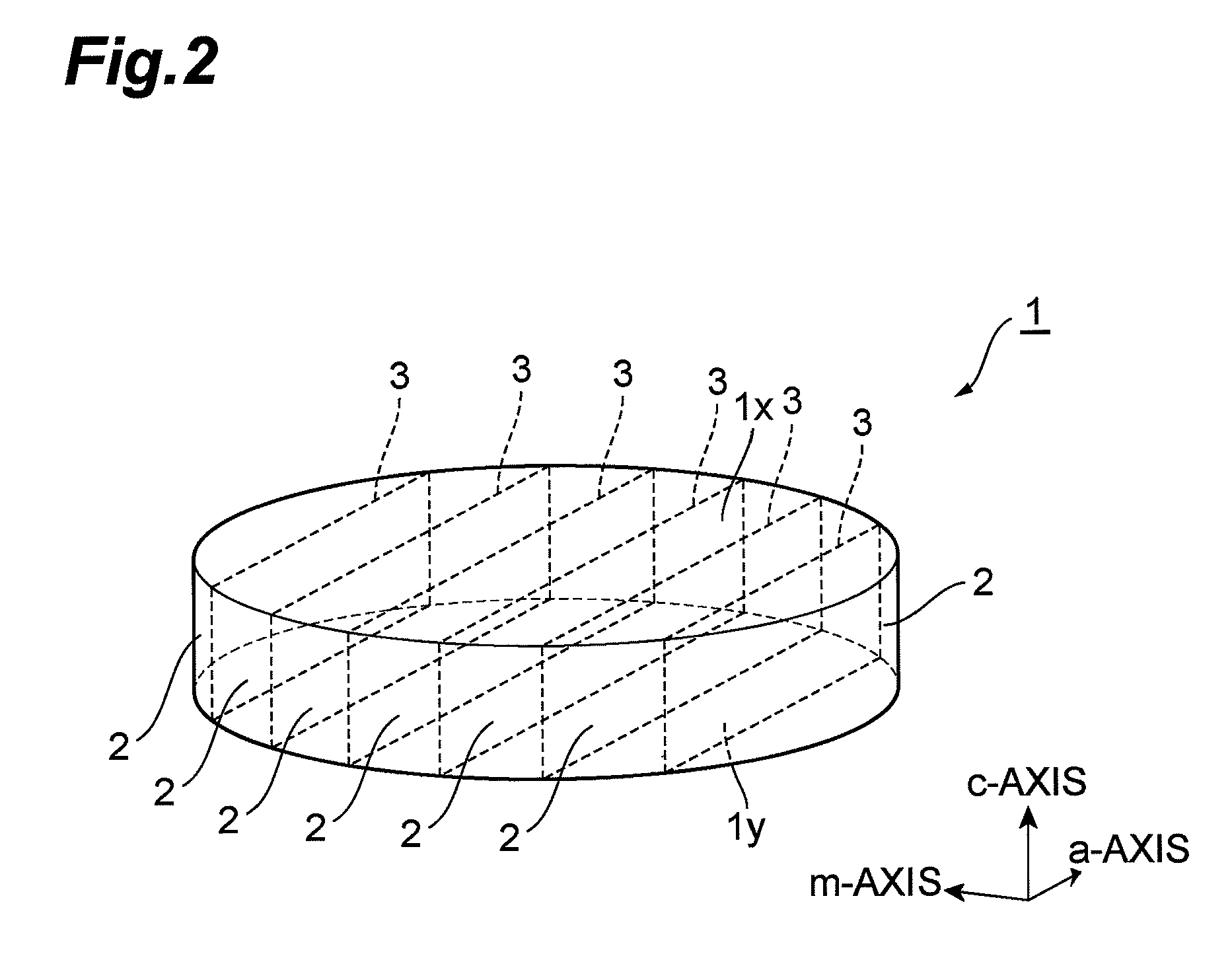

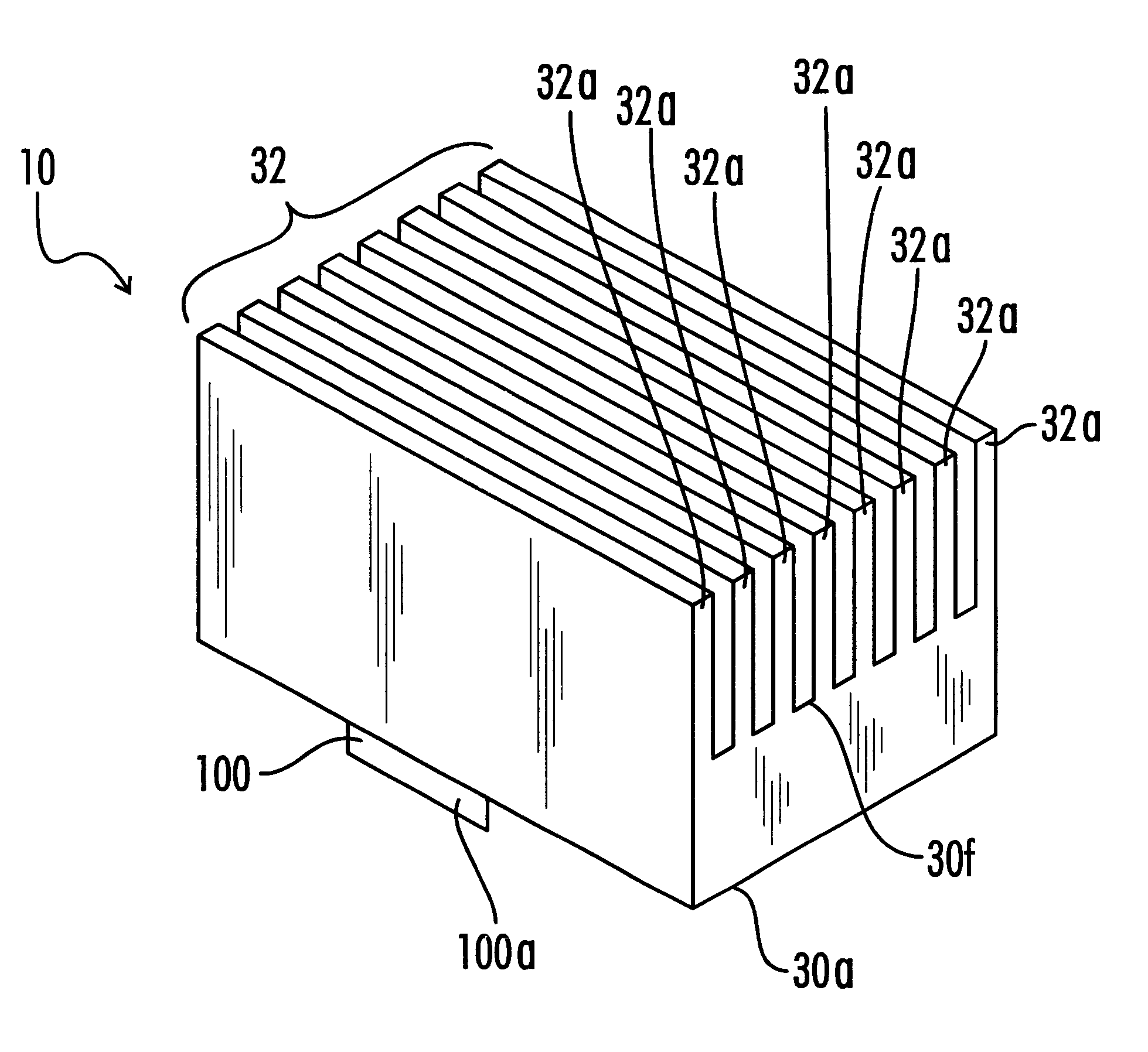

Method of fabricating nitride semiconductor laser

InactiveUS7939354B2Good orientationLarge caliberSemiconductor/solid-state device detailsSemiconductor laser structural detailsGallium nitrideNitride semiconductors

A method of fabricating a nitride semiconductor laser comprises preparing a substrate having a plurality of marker structures and a crystalline mass made of a hexagonal gallium nitride semiconductor. The primary and back surfaces of the substrate intersect with a predetermined axis extending in the direction of a c-axis of the hexagonal gallium nitride semiconductor. Each marker structure extends along a reference plane defined by the c-axis and an m-axis of the hexagonal gallium nitride semiconductor. The method comprises cutting the substrate along a cutting plane to form a wafer of hexagonal gallium nitride semiconductor, and the cutting plane intersects with the plurality of the marker structures. The wafer has a plurality of first markers, each of which extends from the primary surface to the back surface of the wafer, and each of the first markers comprises part of each of the marker structures. The primary surface of the wafer is semipolar or nonpolar. The method comprises growing a number of gallium nitride based semiconductor layers for a semiconductor laser. The method comprises cleaving the substrate product at a cleavage plane of the hexagonal gallium nitride semiconductor, after forming a substrate product in an electrode forming step.

Owner:SUMITOMO ELECTRIC IND LTD

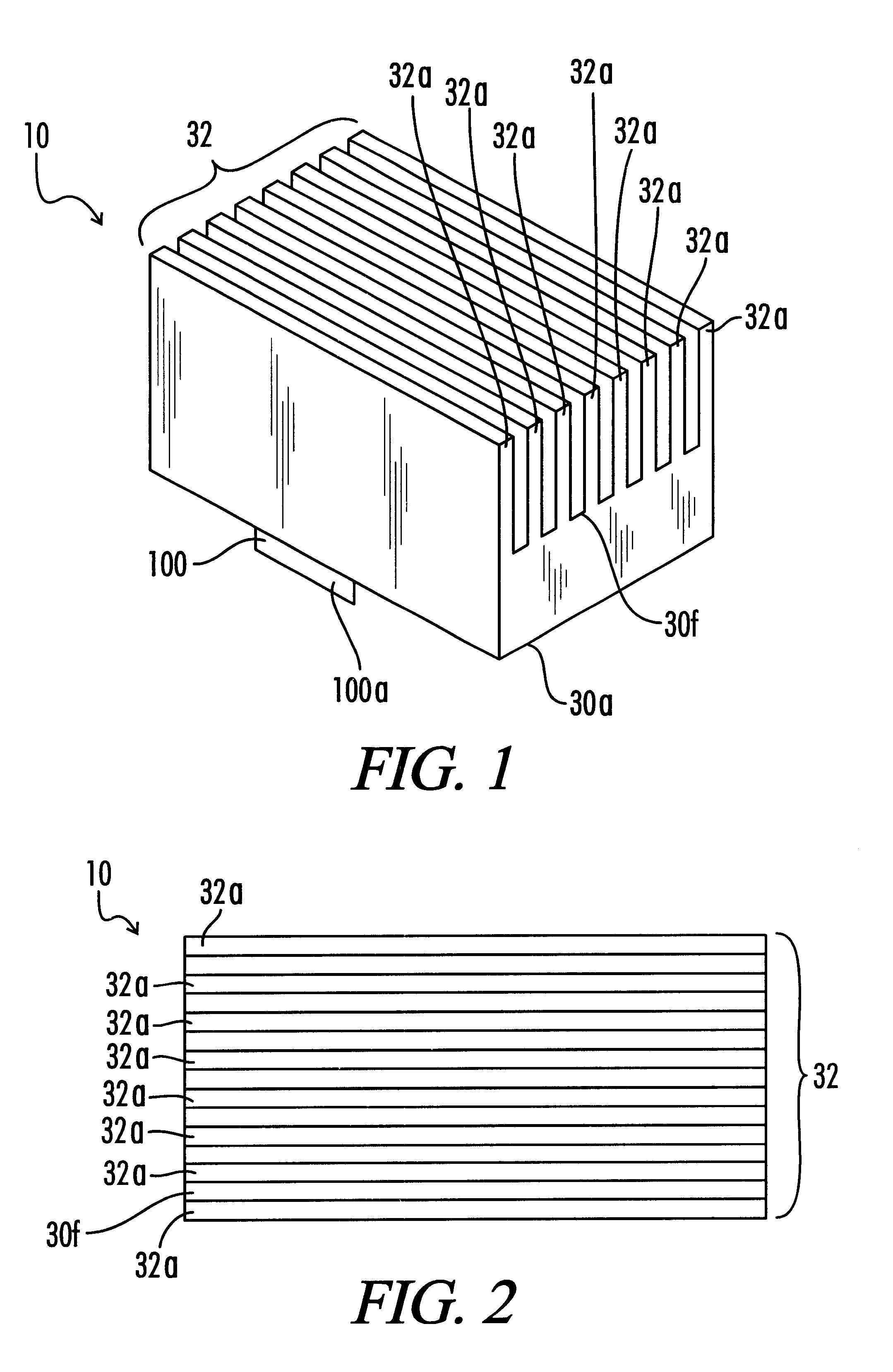

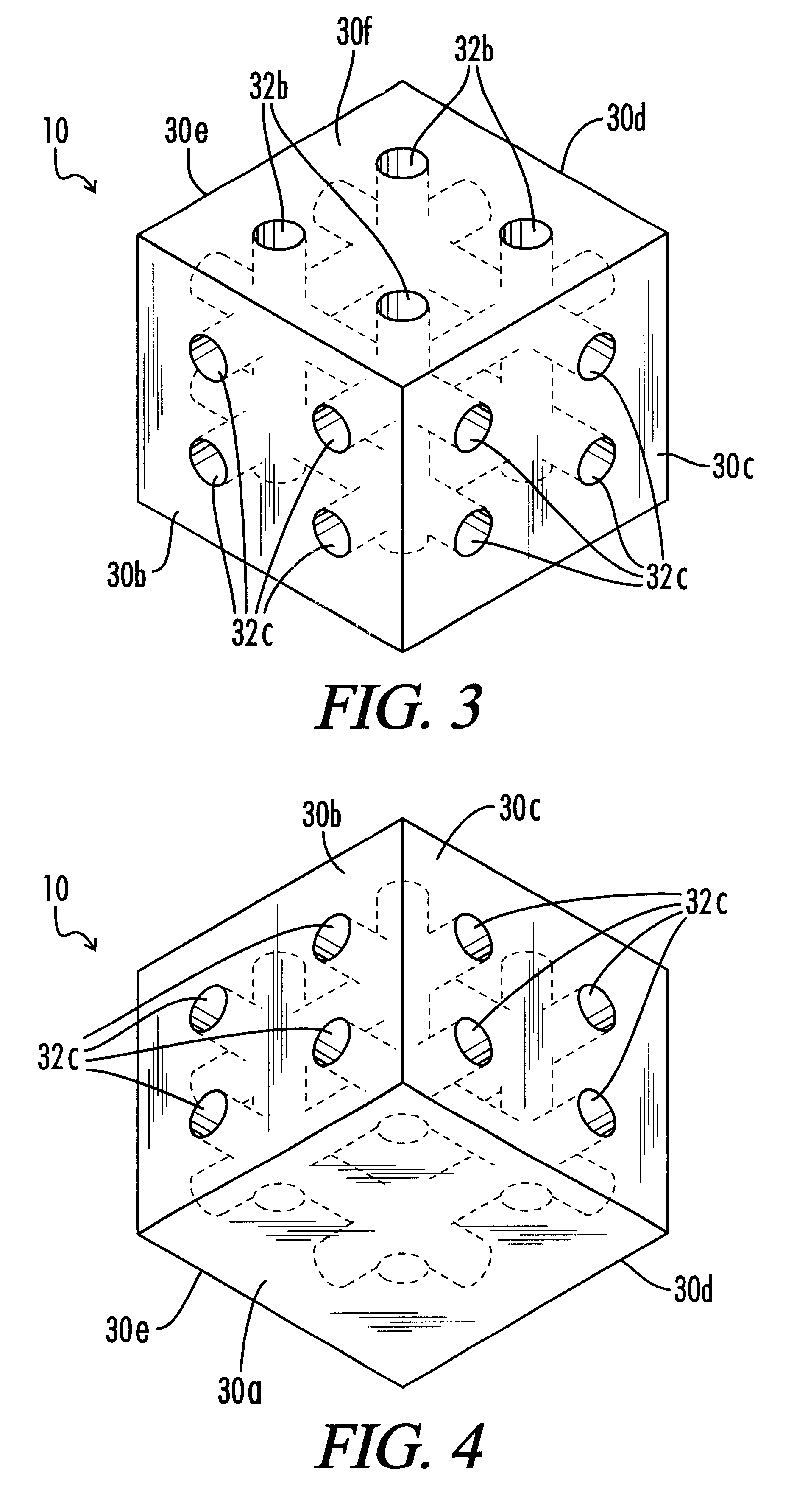

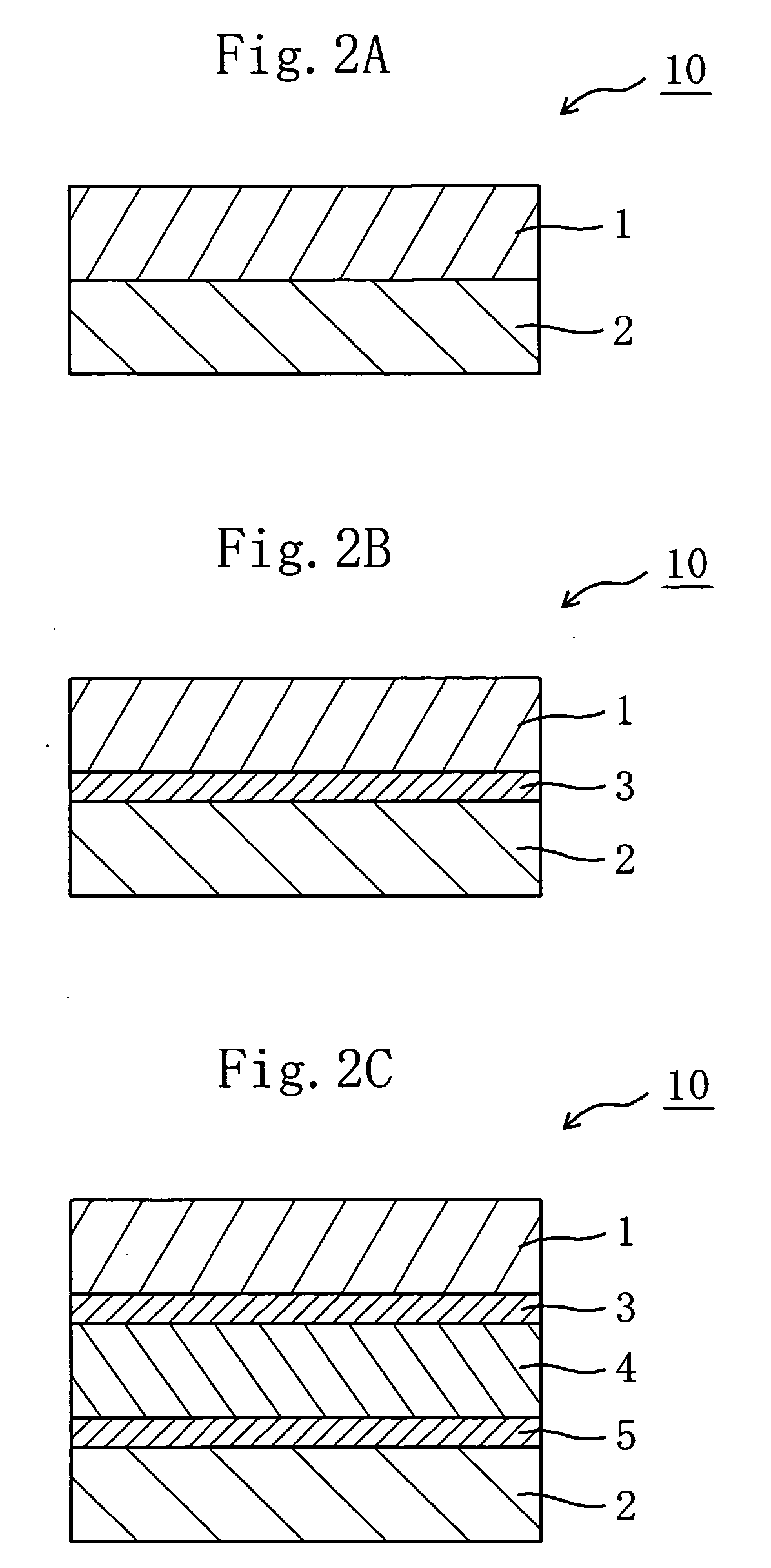

Graphite-based heat sink

InactiveUS6503626B1Improve cooling effectIncreased anisotropyLayered productsSemiconductor/solid-state device detailsNuclear engineeringGraphite

The present invention relates to a system for managing the heat from a heat source like an electronic component. More particularly, the present invention relates to a system effective for dissipating the heat generated by an electronic component using a heat sink formed from a compressed, comminuted particles of resin-impregnated flexible graphite mat or sheet.

Owner:GRAFTECH INT HLDG INC

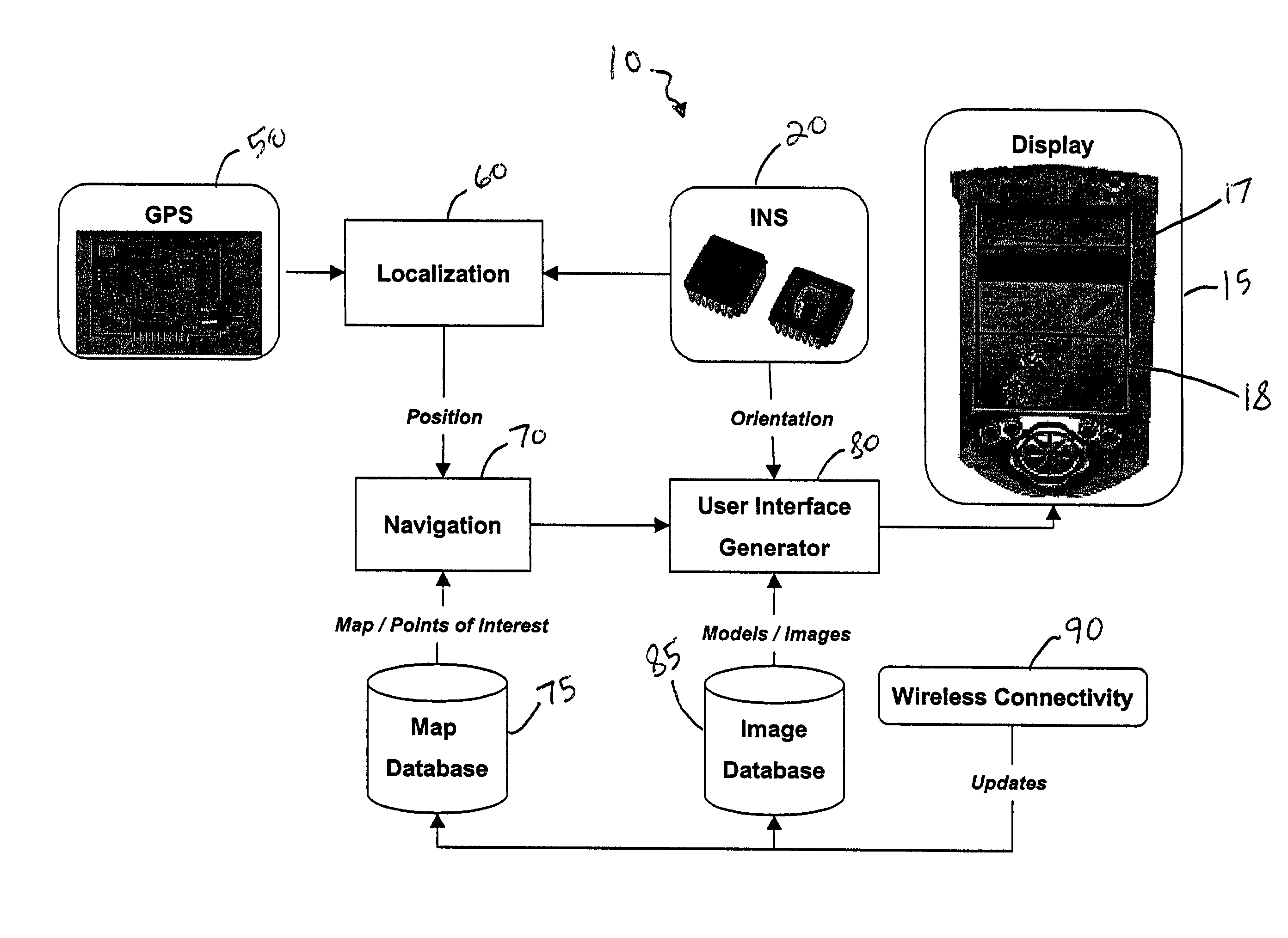

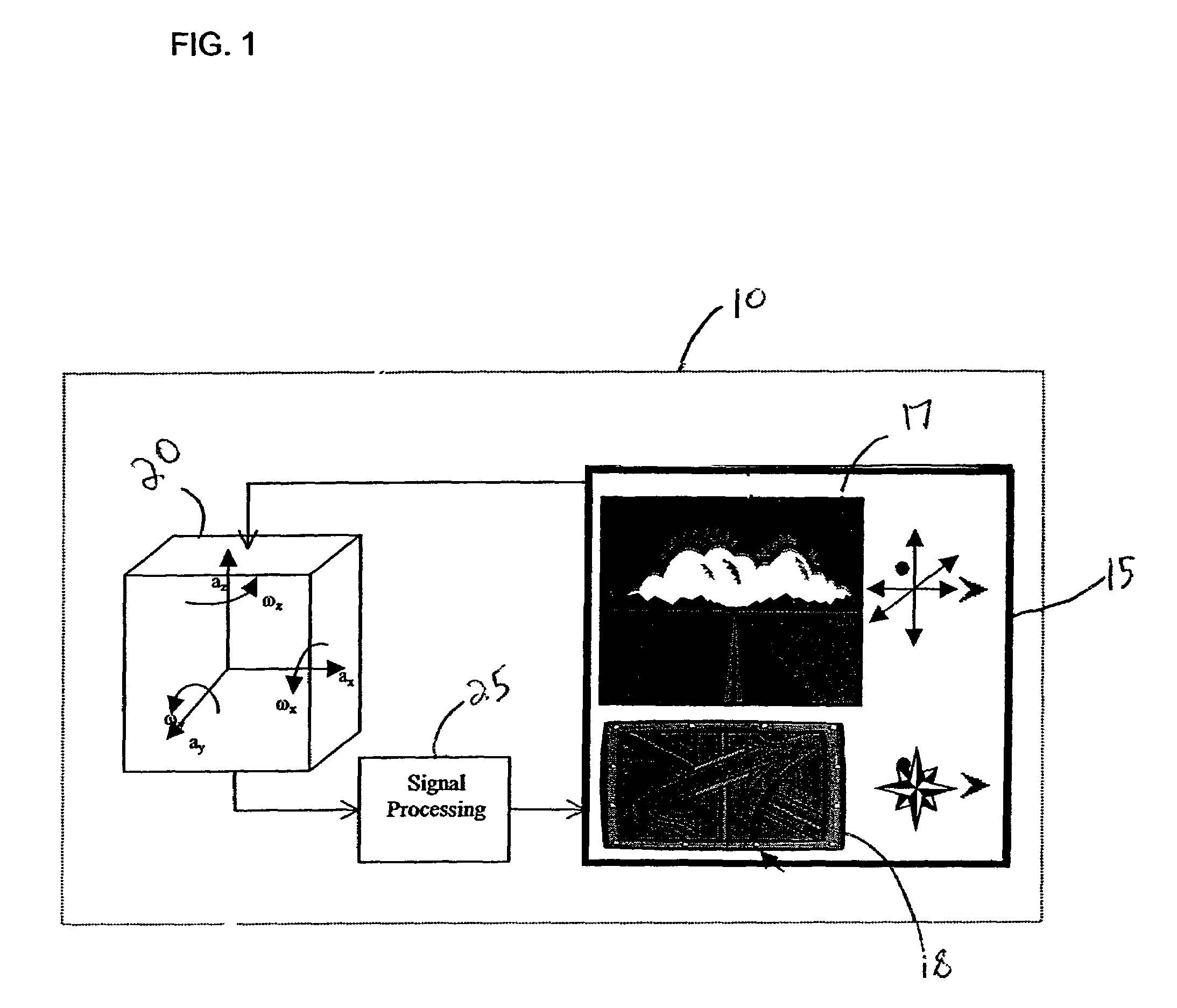

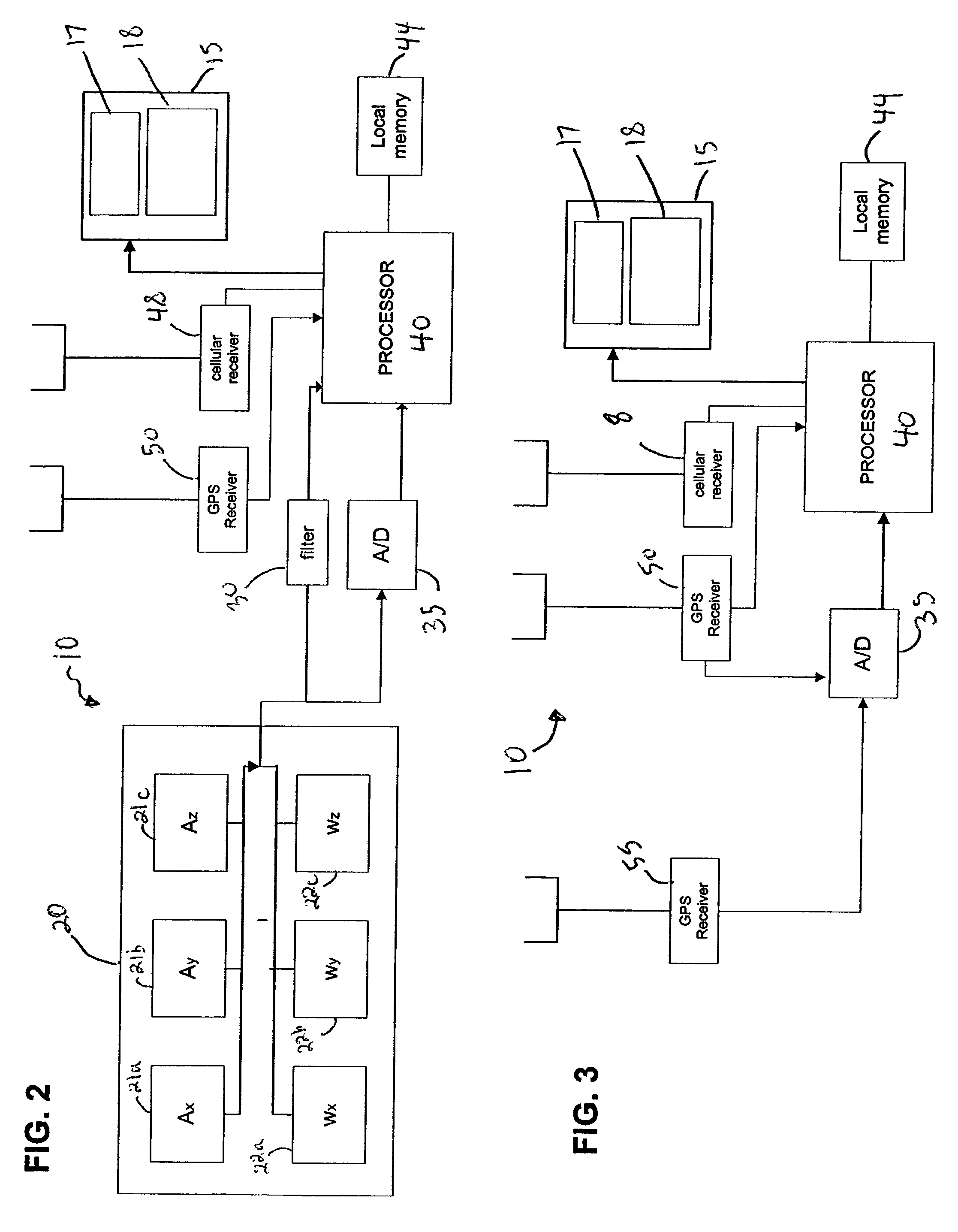

Orientation and navigation for a mobile device using inertial sensors

InactiveUS6975959B2Convenient manual controlEasy to navigateInstruments for road network navigationNavigational calculation instrumentsReal-time simulationGps receiver

A mobile device for enhanced navigation and orientation including a visualization interface, a first sensor for providing signals indicative of a movement of the mobile device, a second sensor for providing further signals indicative of a movement of the mobile device, and a processor receiving signals from the first and second sensors, calculating a position and an orientation of the mobile device from the received signals, and generating a real time simulation of an environment via the visualization interface based on the position and orientation of the mobile device. According to an embodiment, the first and second sensors are implemented as an inertial sensor and a GPS receiver, respectively.

Owner:ROBERT BOSCH GMBH

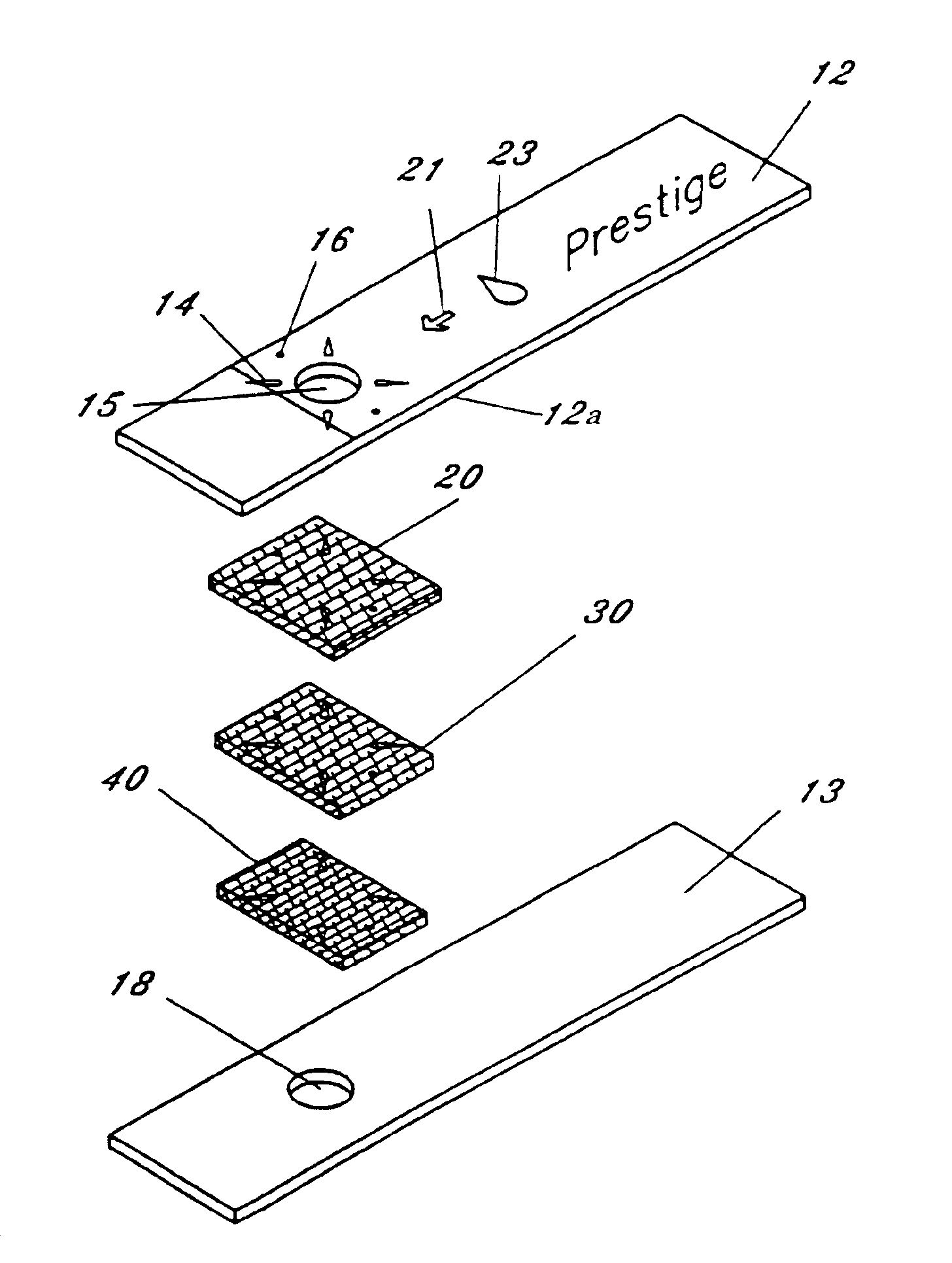

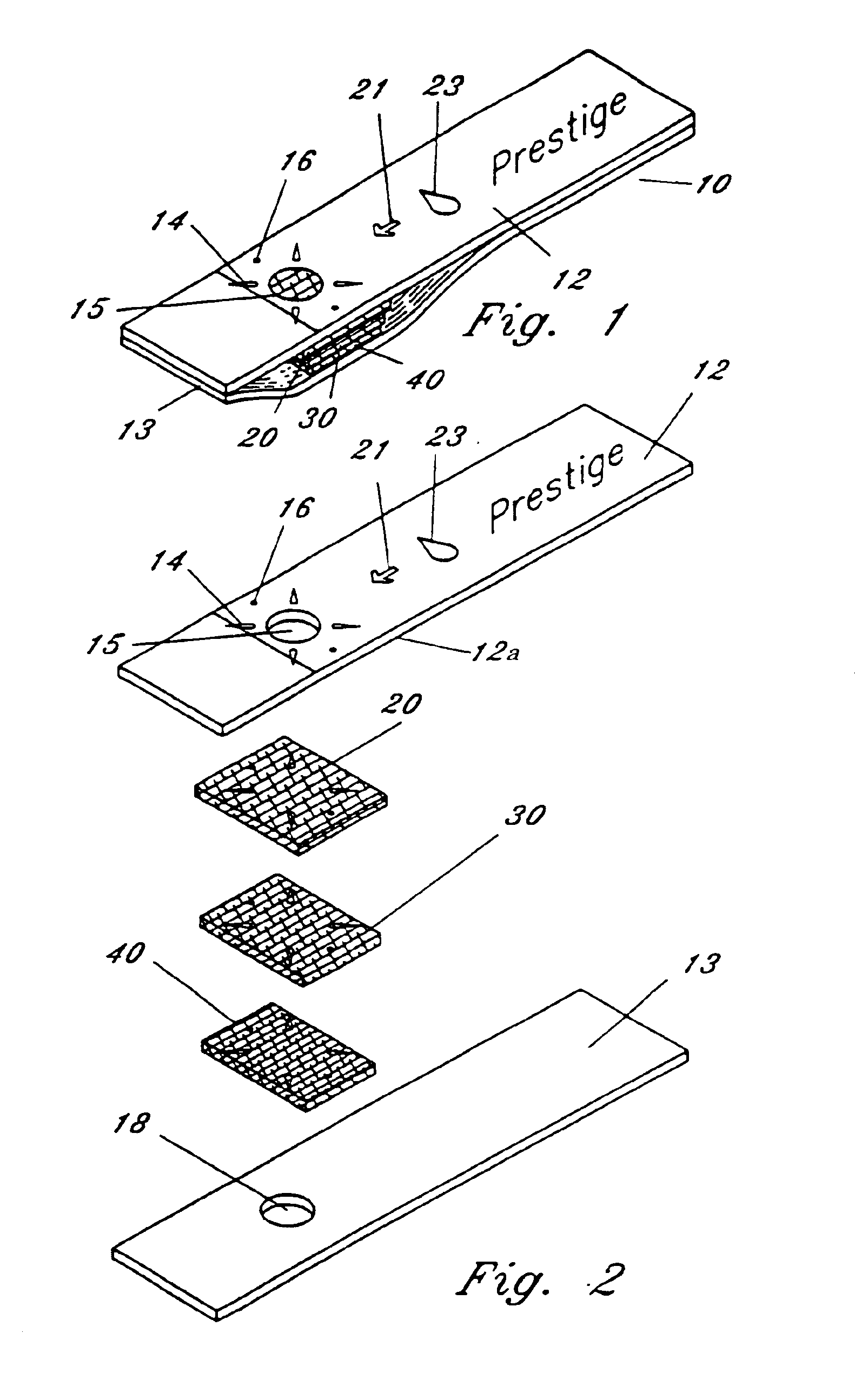

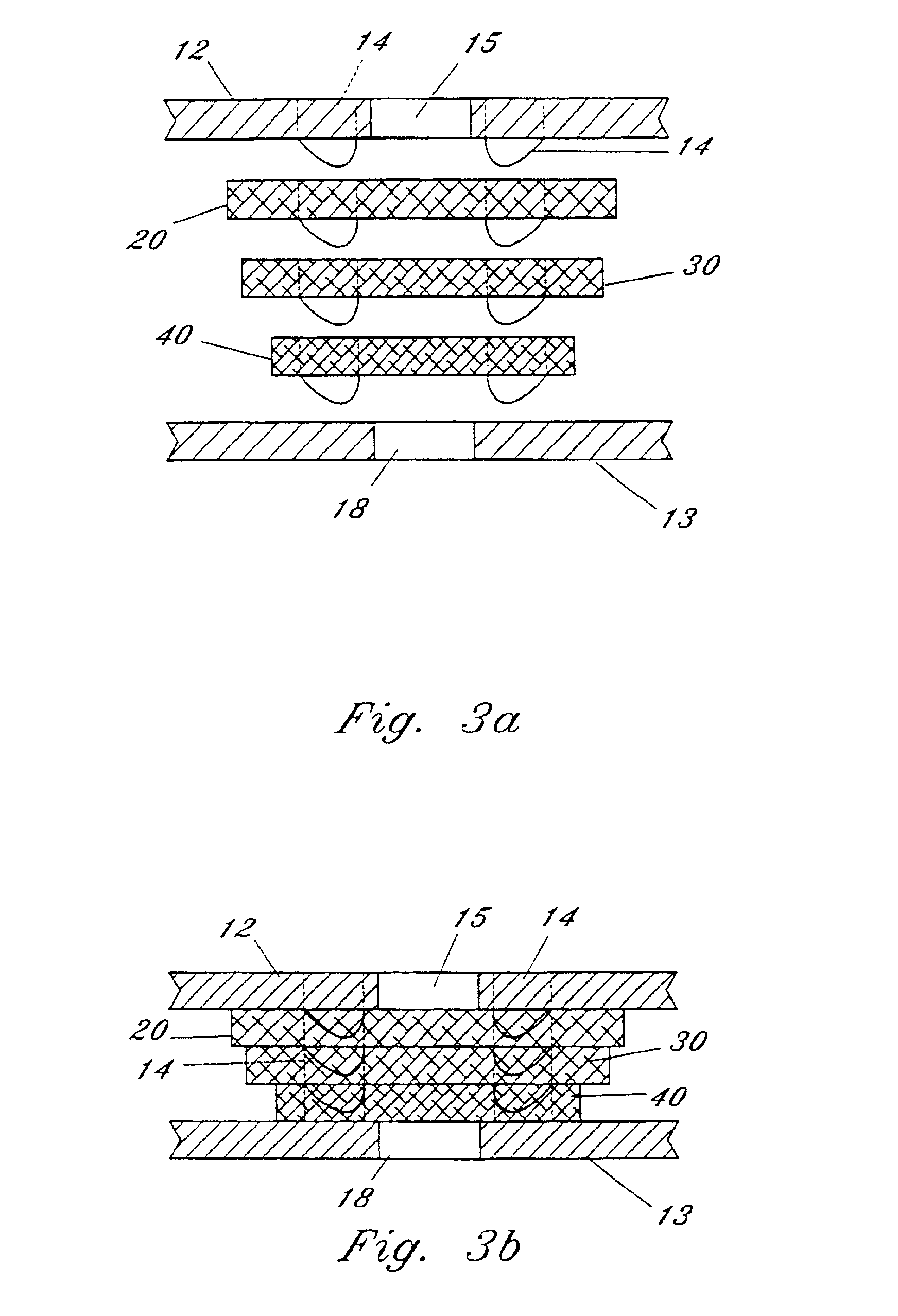

Diagnostic sanitary test strip

InactiveUS6991940B2Easy to useBroaden applicationBioreactor/fermenter combinationsBiological substance pretreatmentsColor changesFluid specimen

An improved multi-layered diagnostic sanitary test strip for receiving a heterogenous fluid, such as whole blood, to test for presence and / or amount of a suspected analyte in the fluid by facilitating a color change in the strip corresponding to the amount of the analyte in the fluid, wherein the test strip includes fluid volume control dams to prevent spillage of the fluid from the strip and a chemical reagent solution that facilitates end-point testing. The improved test strip comprises no more than two operative layers and: (a) a reaction membrane containing a reagent capable of reacting with the analyte of interest to produce a measurable change in said membrane; (b) an upper support layer defining a sample receiving port for receiving the fluid sample thereat; (c) one or more structures for directing the sample containing the analyte of interest through at least a portion of said reaction membrane; and (d) a lower support layer having a reaction viewing port in vertical alignment with said membrane for displaying said measurable change, said lower support being associated with said upper support to secure said reaction membrane in said test strip.

Owner:NIPRO DIAGNOSTICS INC

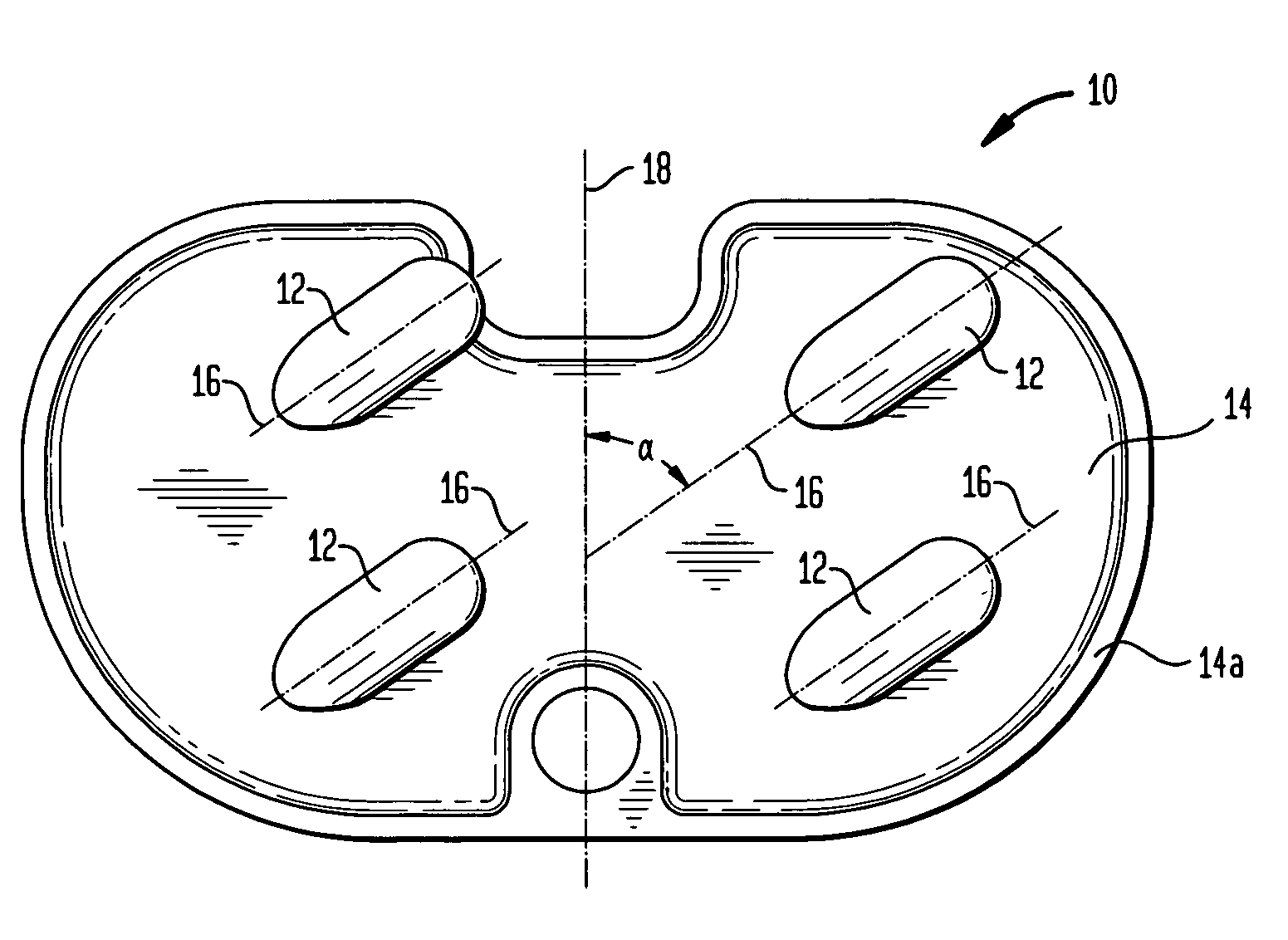

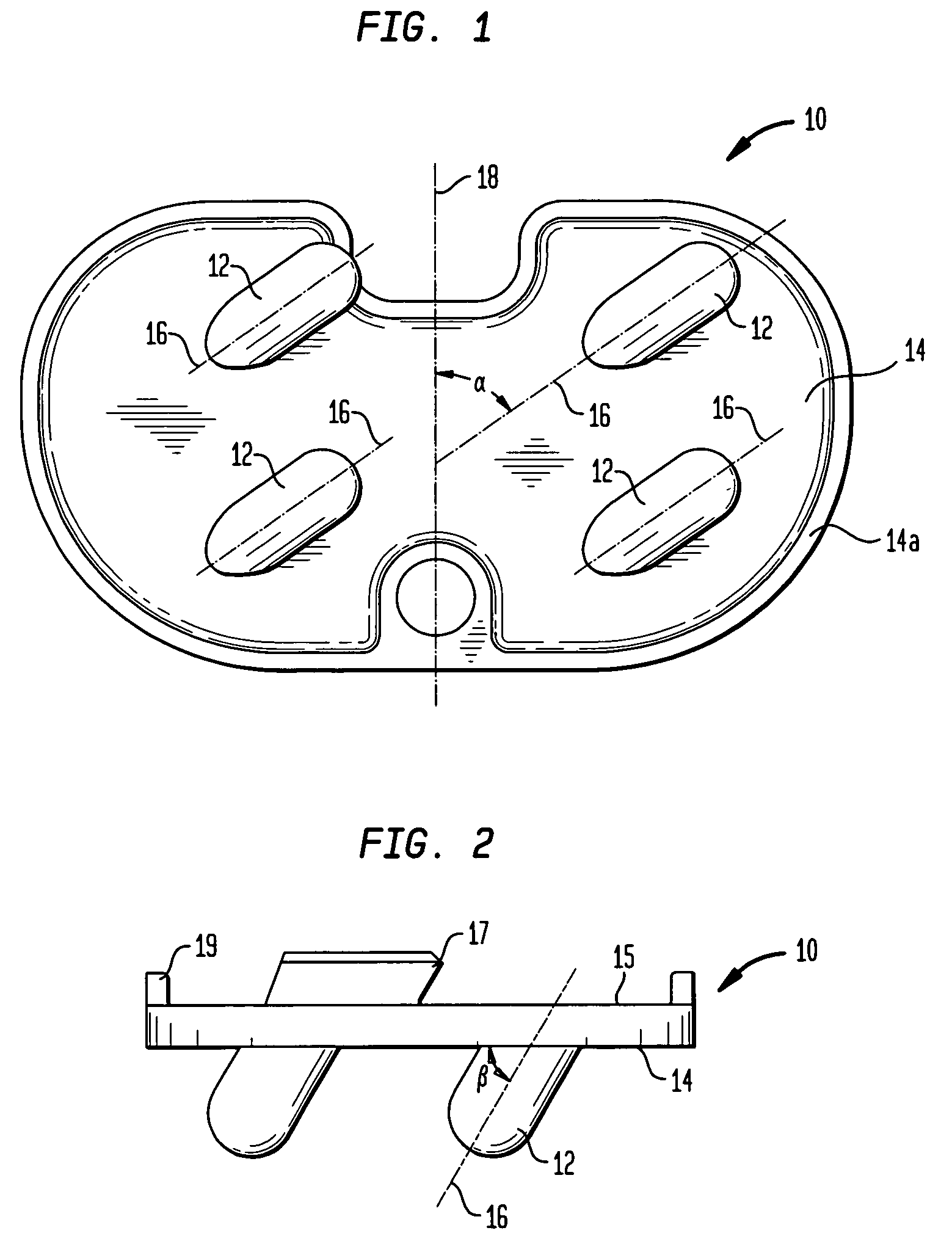

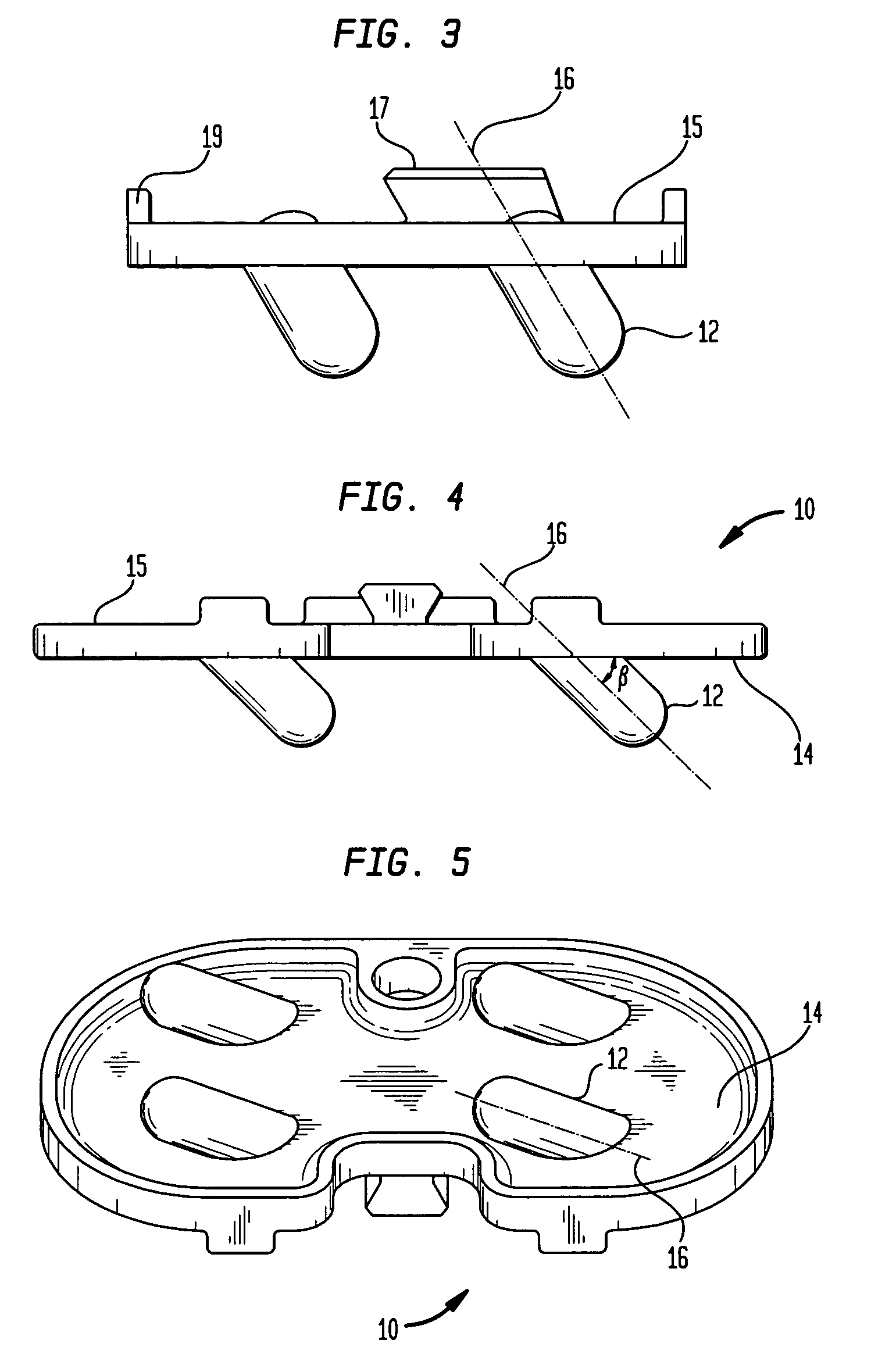

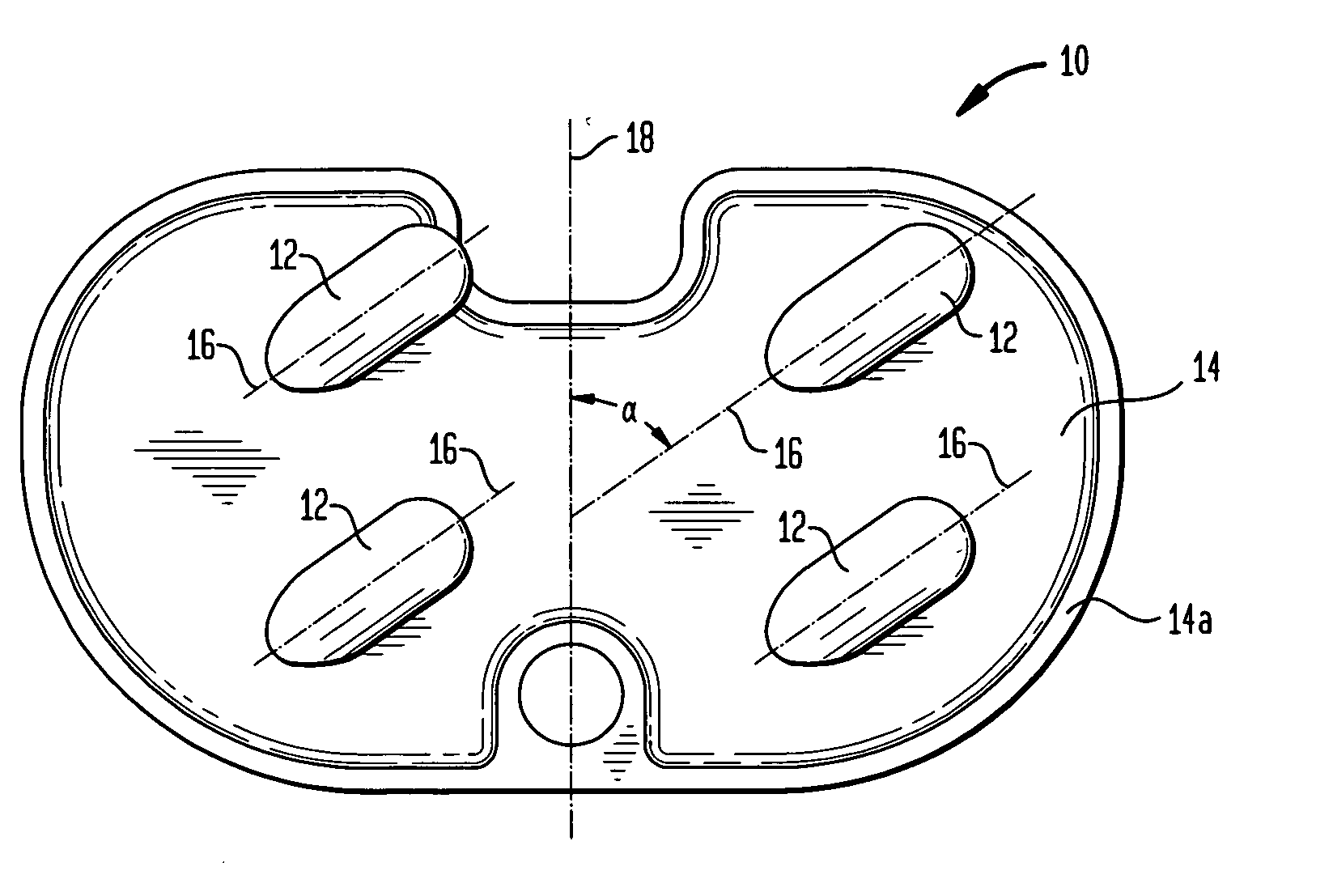

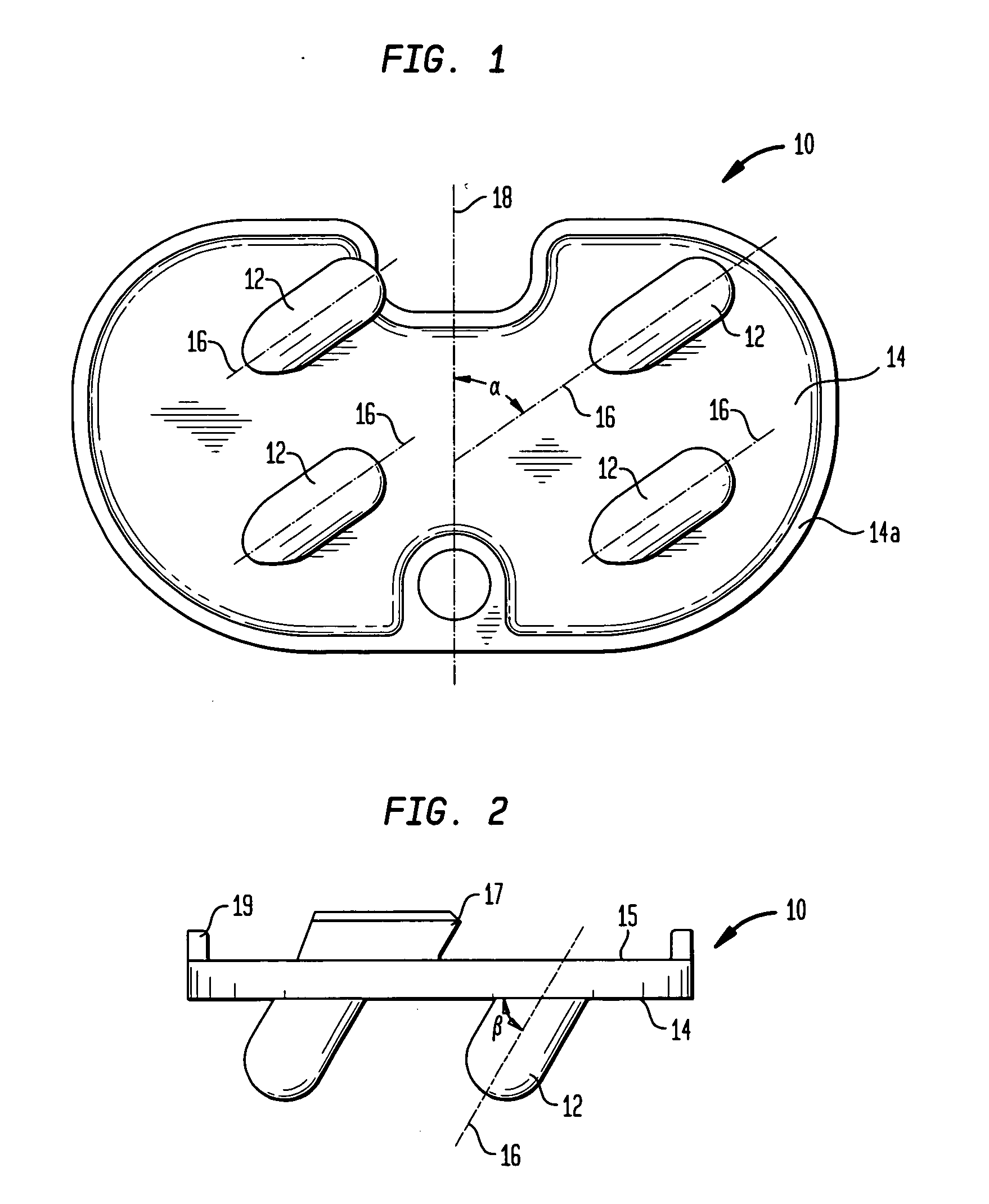

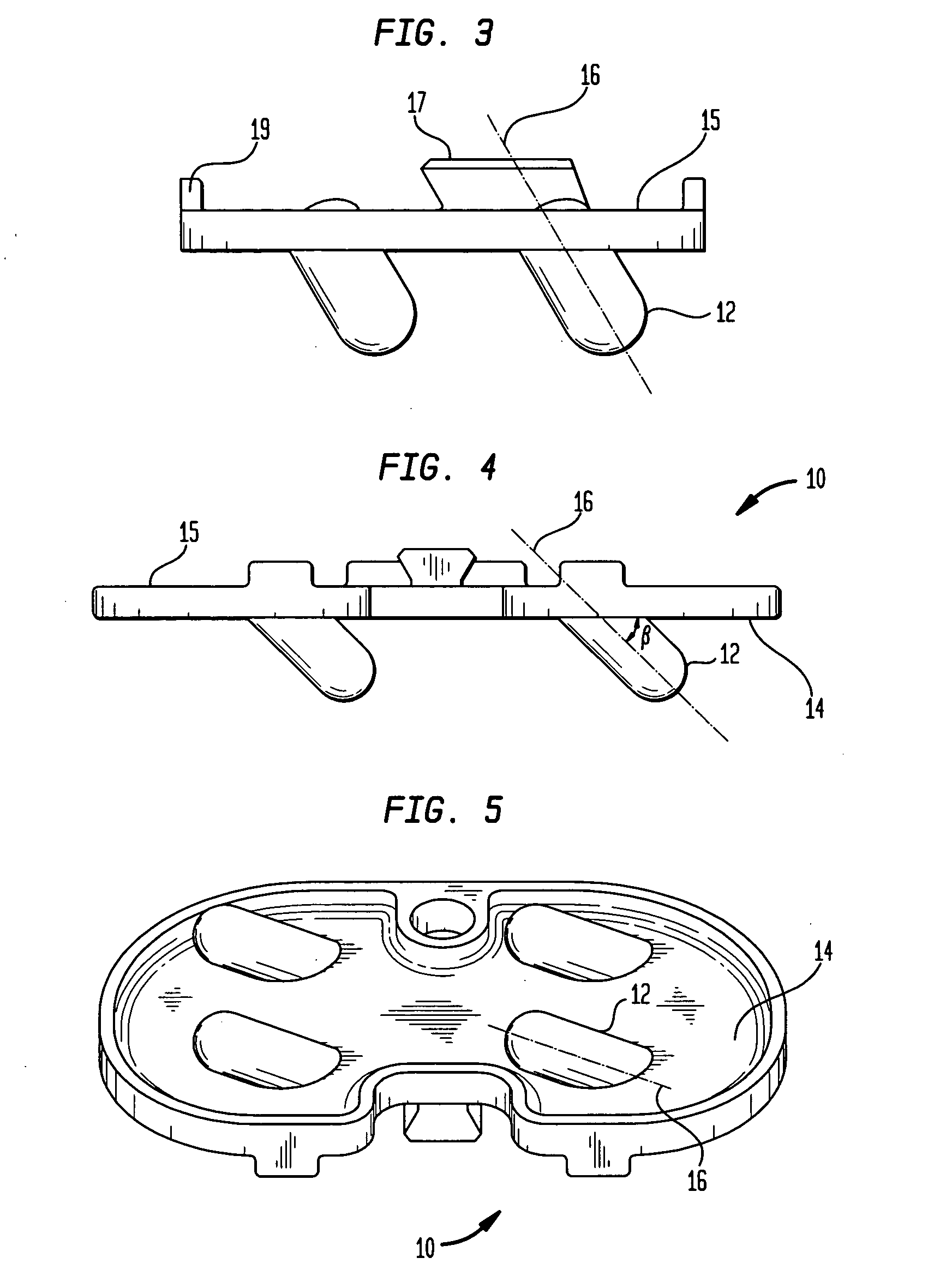

Orthopedic implant with angled pegs

An orthopedic implant, such as a tibial tray, includes a body having a bone contacting surface with at least one and preferably two pegs extending from the bone contacting surface. Each of the pegs has a longitudinal axis angled with respect to the bone contacting surface and also angled in at least one direction consisting of a medial-lateral direction, an anterior-posterior direction and an inferior-superior direction. In the case of the tibial tray, the pegs form a non-perpendicular angle with the bone contacting surface of the baseplate and are angled in both a posterior direction and a medial or lateral direction.

Owner:HOWMEDICA OSTEONICS CORP

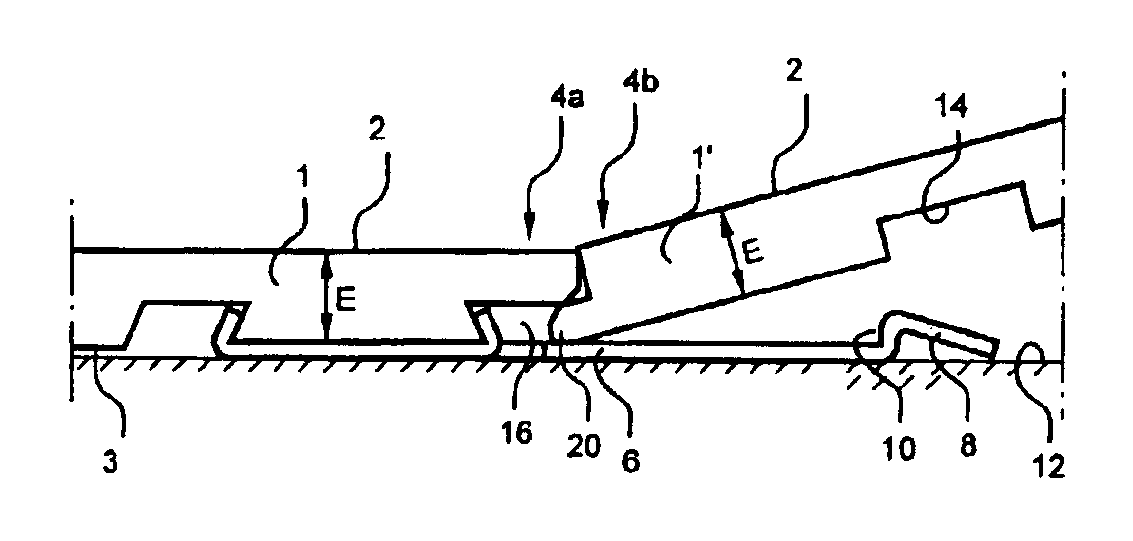

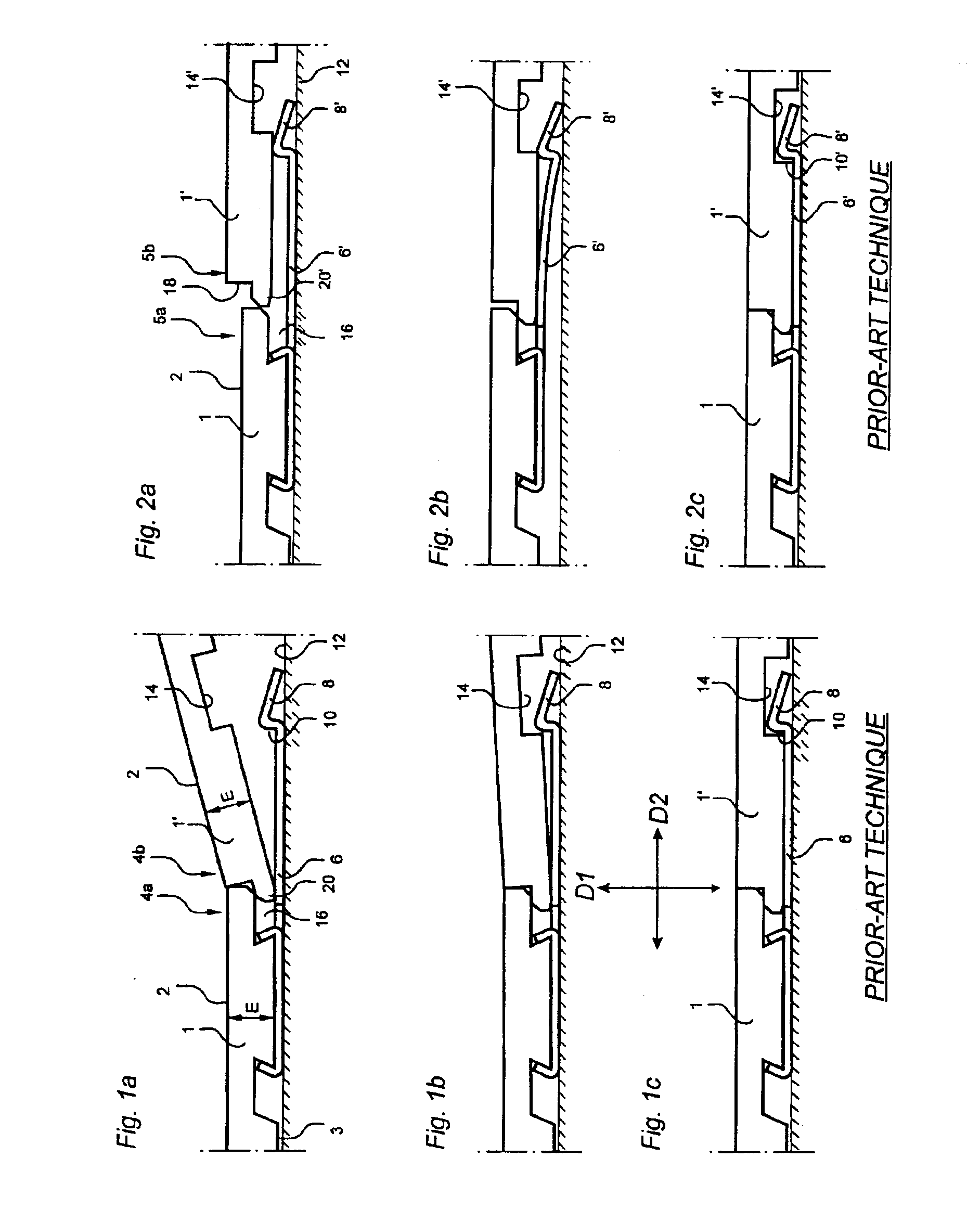

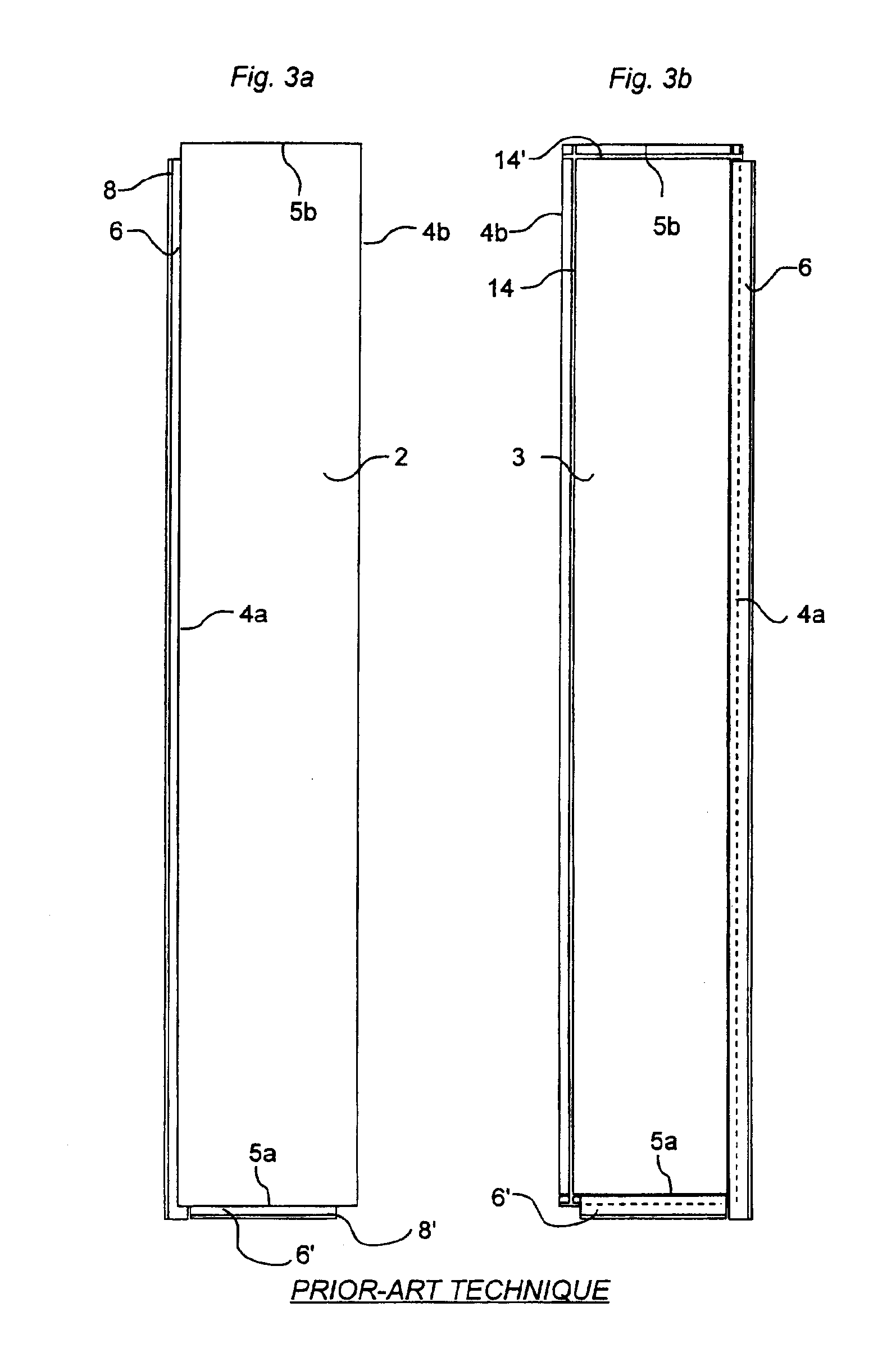

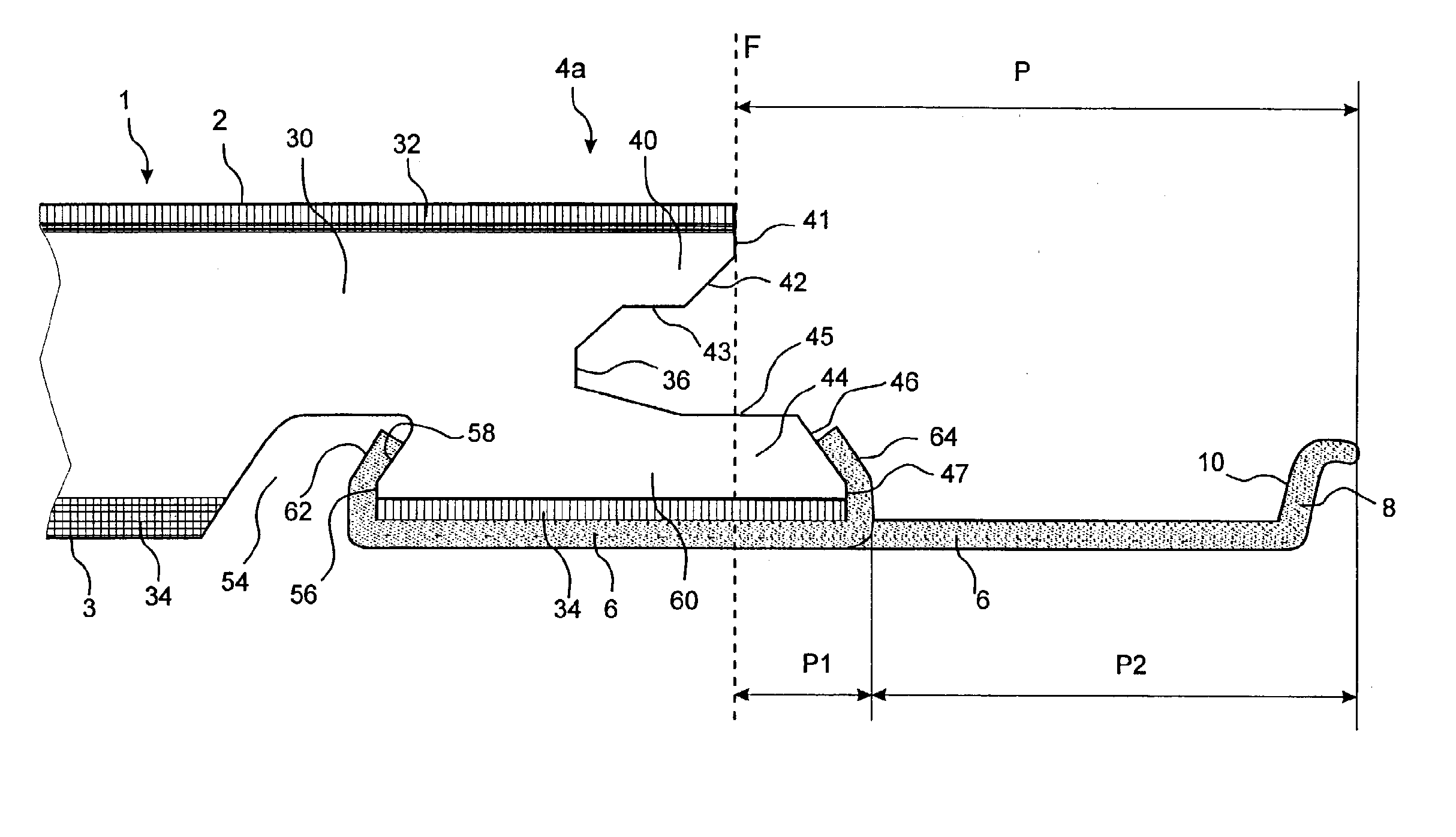

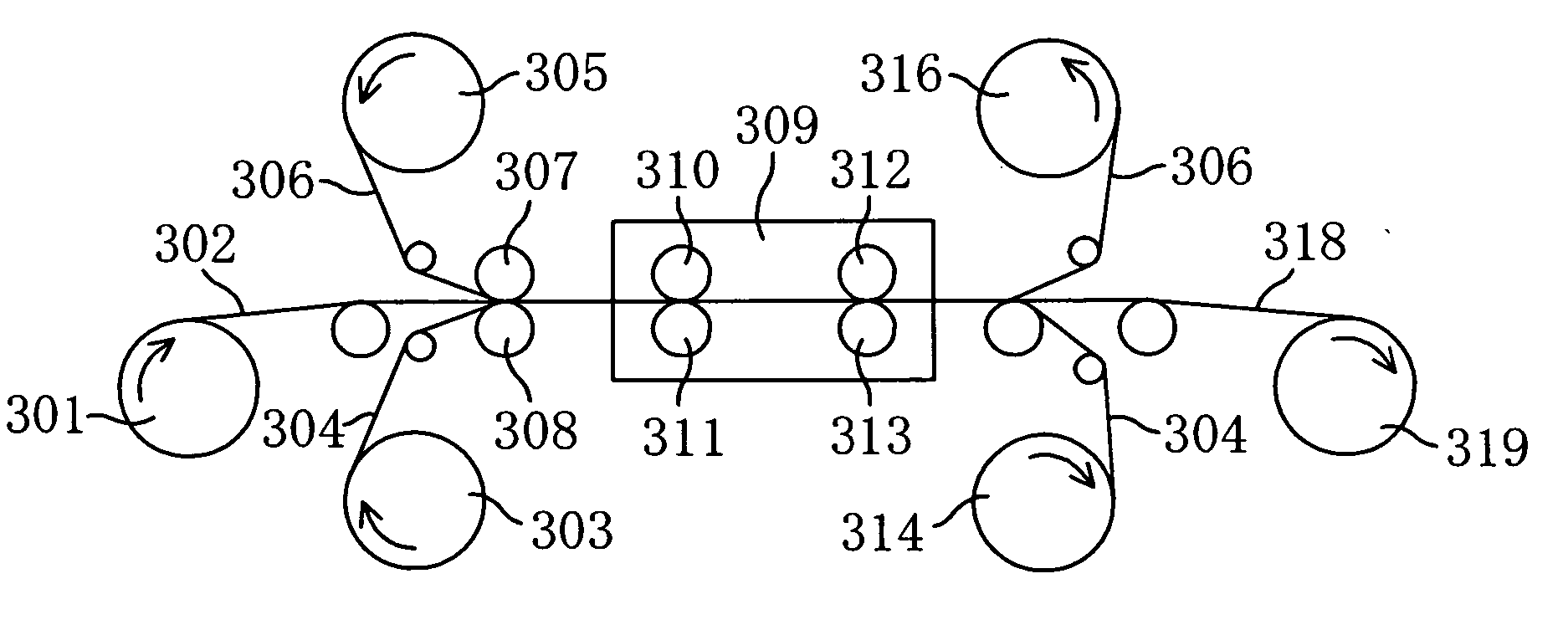

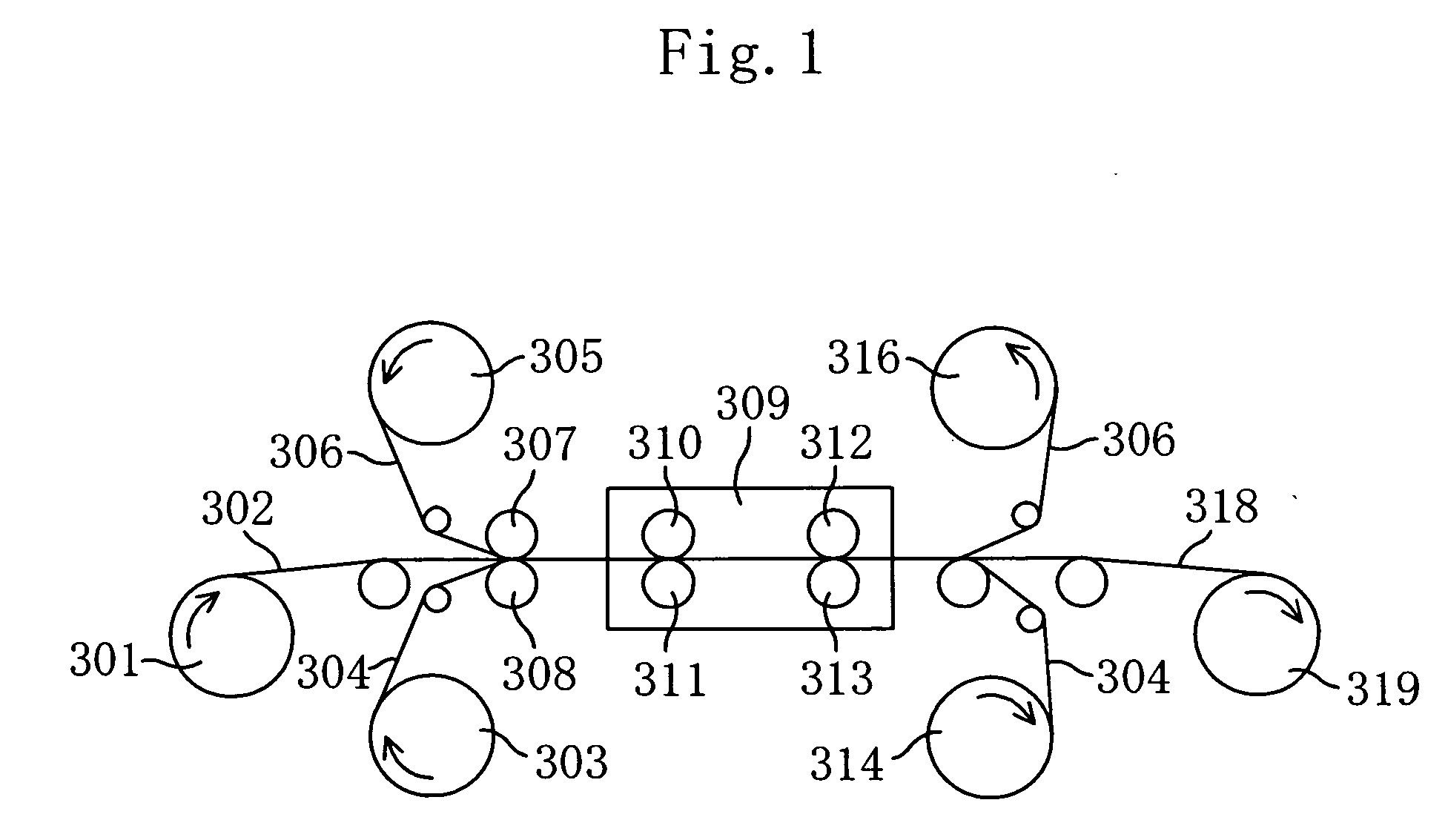

Locking System And Flooring Board

InactiveUS20050102937A1Good orientationReduce frictionBuilding roofsStrutsEngineeringMechanical engineering

A locking system for mechanical joining of floorboards has a locking groove which is formed in the underside of and extends in parallel with the first joint edge at a distance from the joint plane, and a portion projecting from the lower part of the second joint edge and below the first joint edge and integrated with a body of the board. The projecting portion supporting at a distance from the joint plane a locking element cooperating with the locking groove and thus positioned entirely outside the joint plane seen from the side of the second joint edge, the projecting portion having a different composition of materials compared with the body of the board. The projecting portion presents at least two horizontally juxtaposed parts, which differ from each other at least in respect of the parameters material composition and material properties.

Owner:VÄLINGE INNOVATION AB

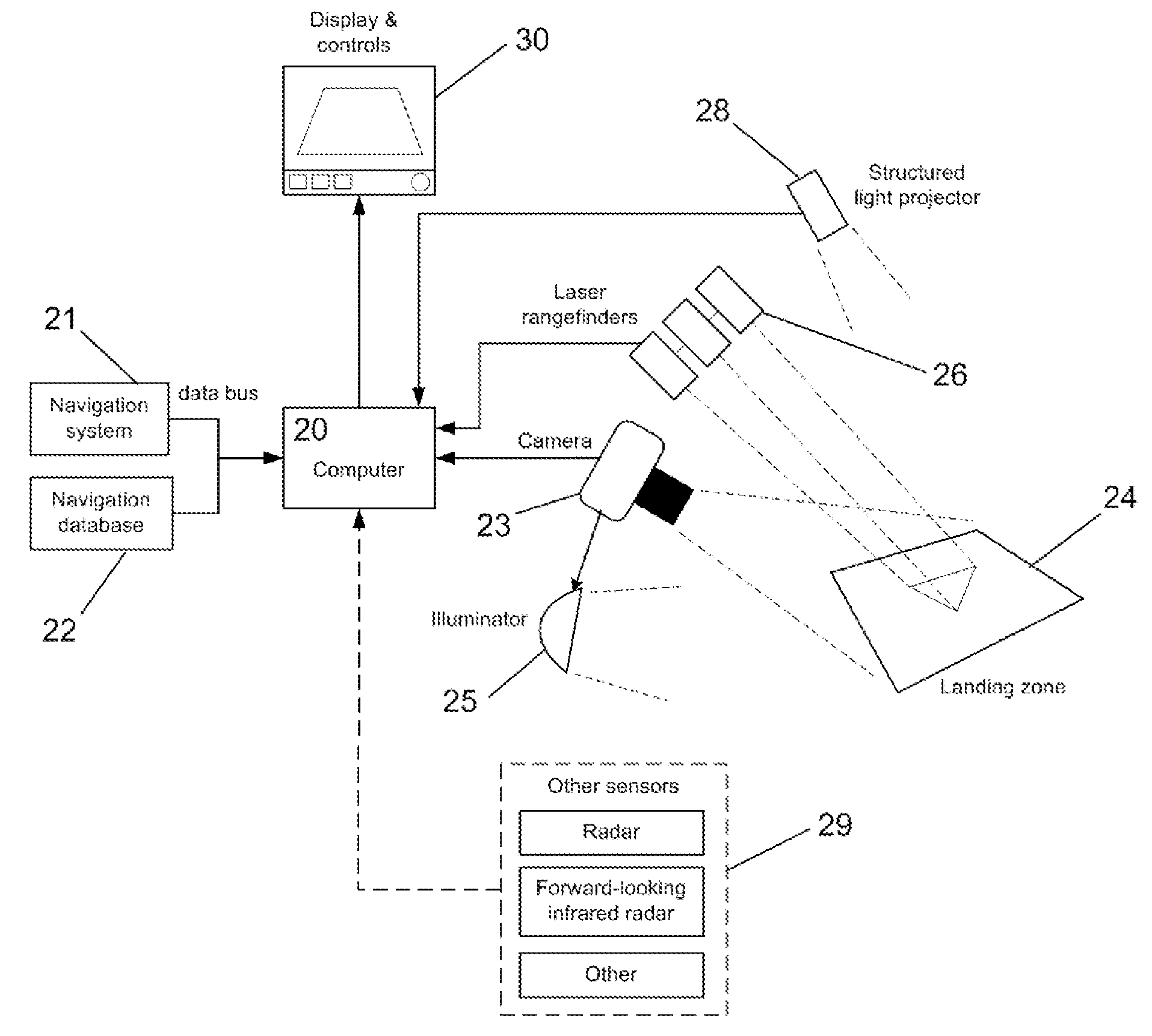

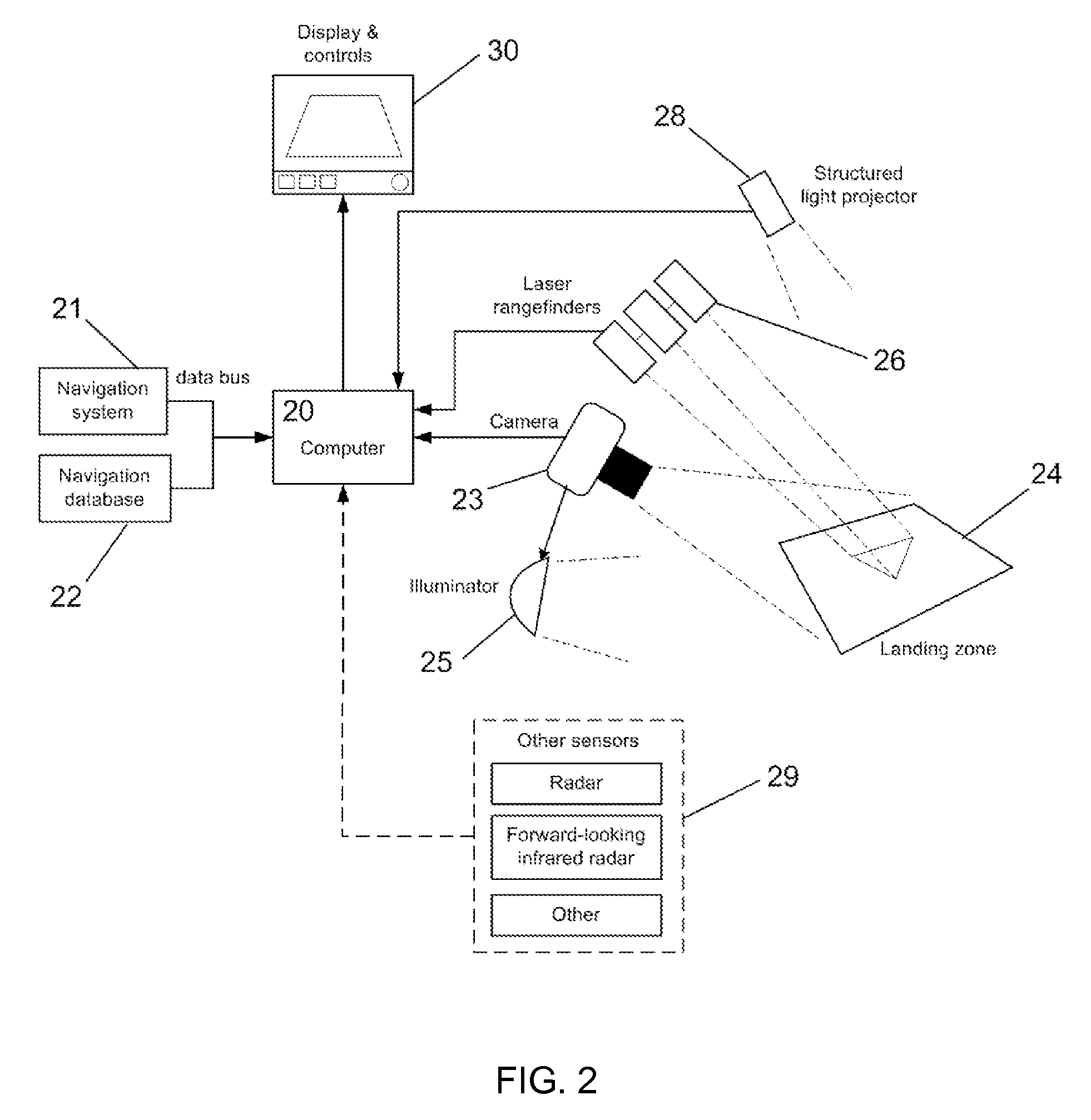

Imaging and display system to aid helicopter landings in brownout conditions

ActiveUS20090138138A1Good orientationImprove situational awarenessLaser detailsRoad vehicles traffic controlElectricityVisibility

An imaging and display system provides helicopter pilots with an unobstructed display of a landing area in a brownout or whiteout condition by capturing a high resolution image of the landing area prior to obscuration. Using inertial navigation information from the aircraft or an independent system, the system transforms the image to a desired viewpoint and overlays a representation of the helicopter's current position relative to the landing area. The system thus greatly improves orientation and situational awareness, permitting safe and effective operation under zero visibility brownout conditions.

Owner:APPLIED MINDS

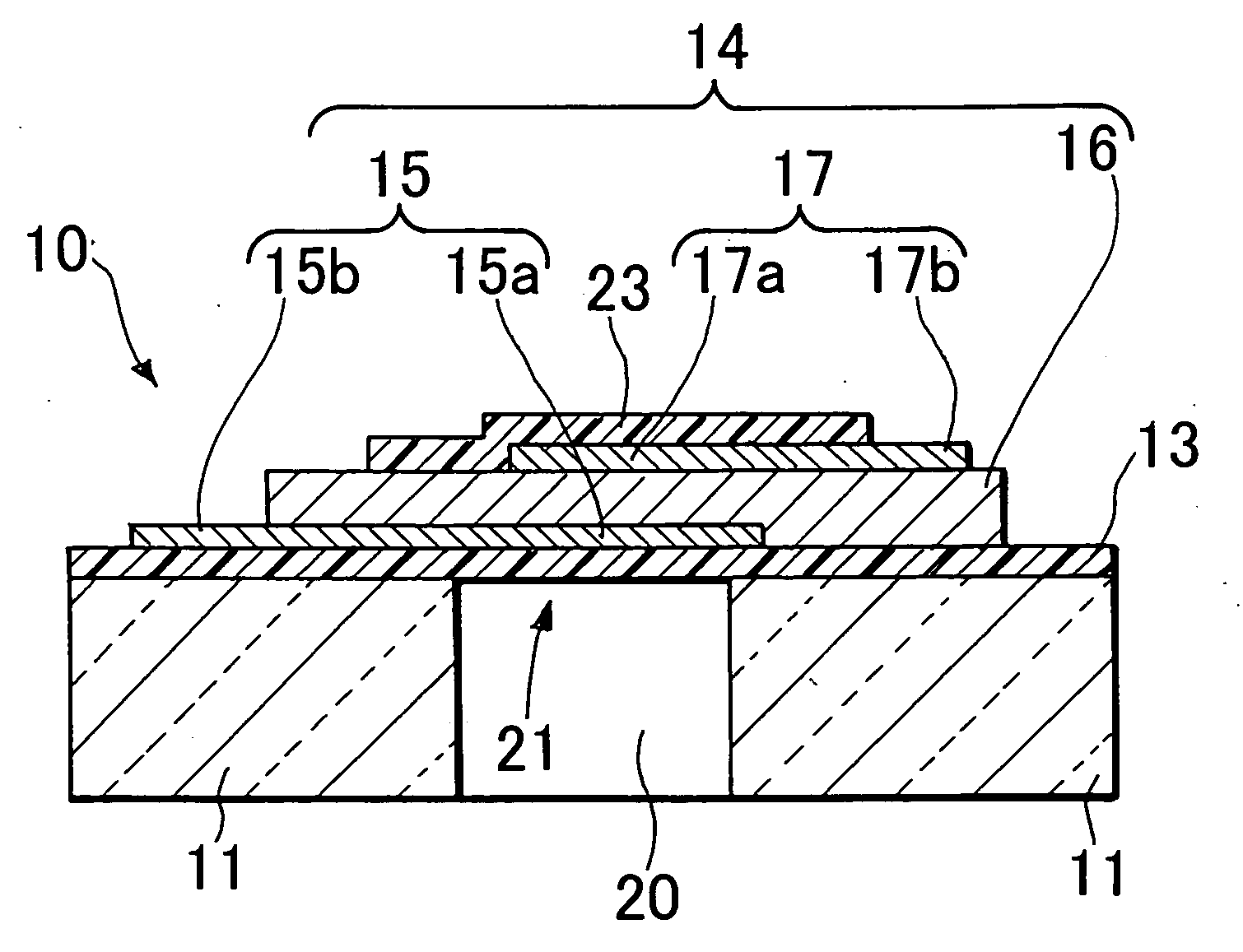

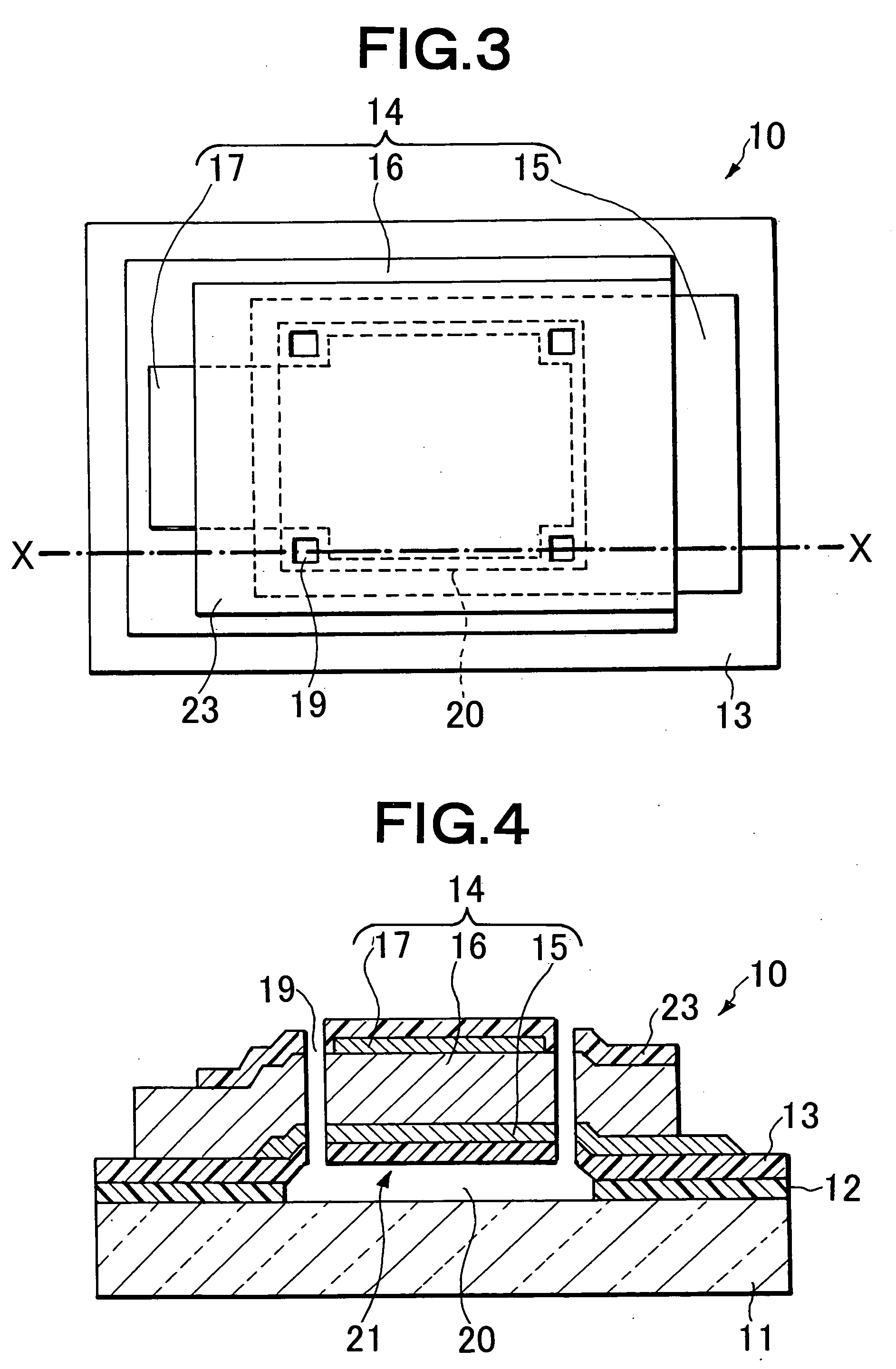

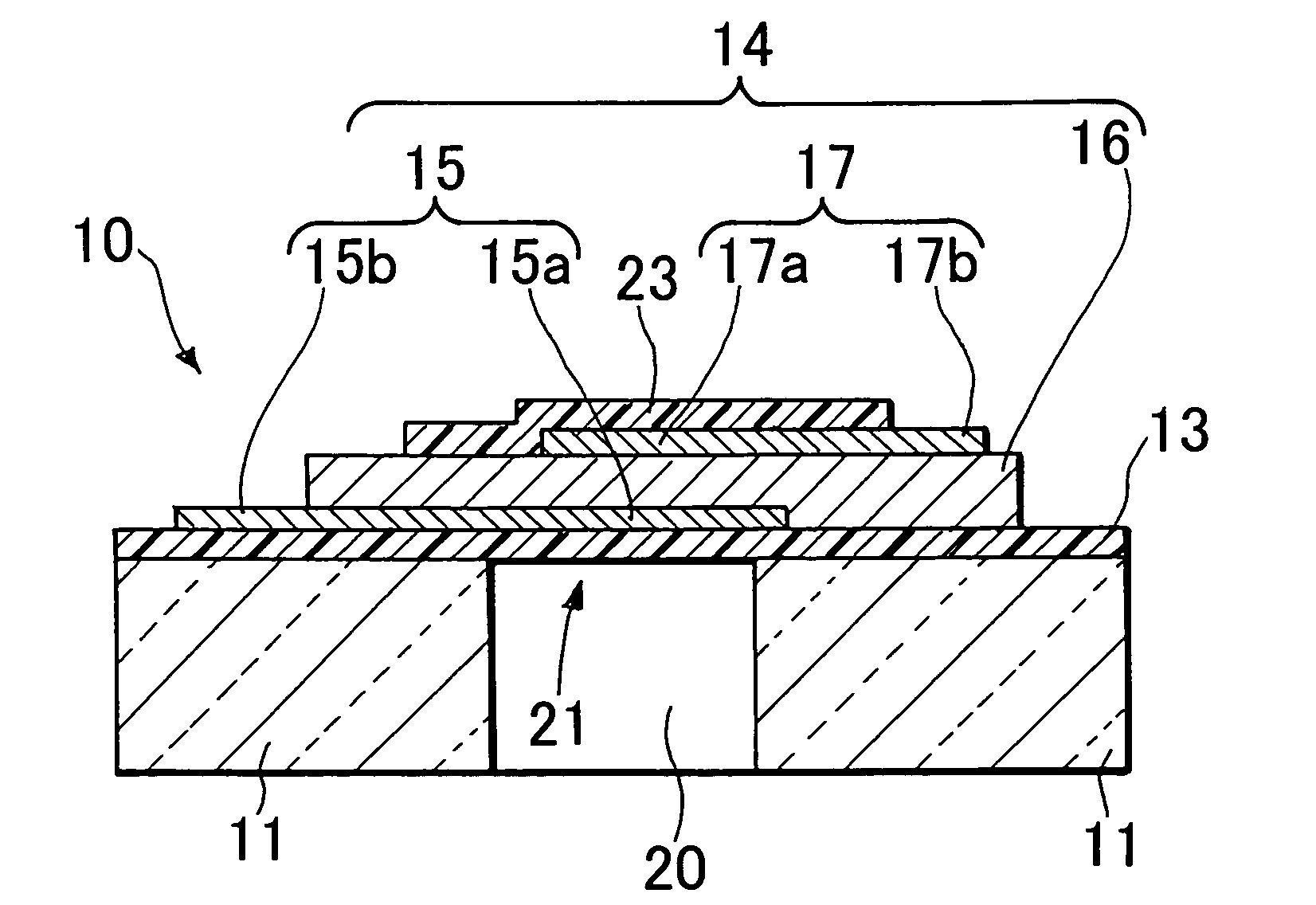

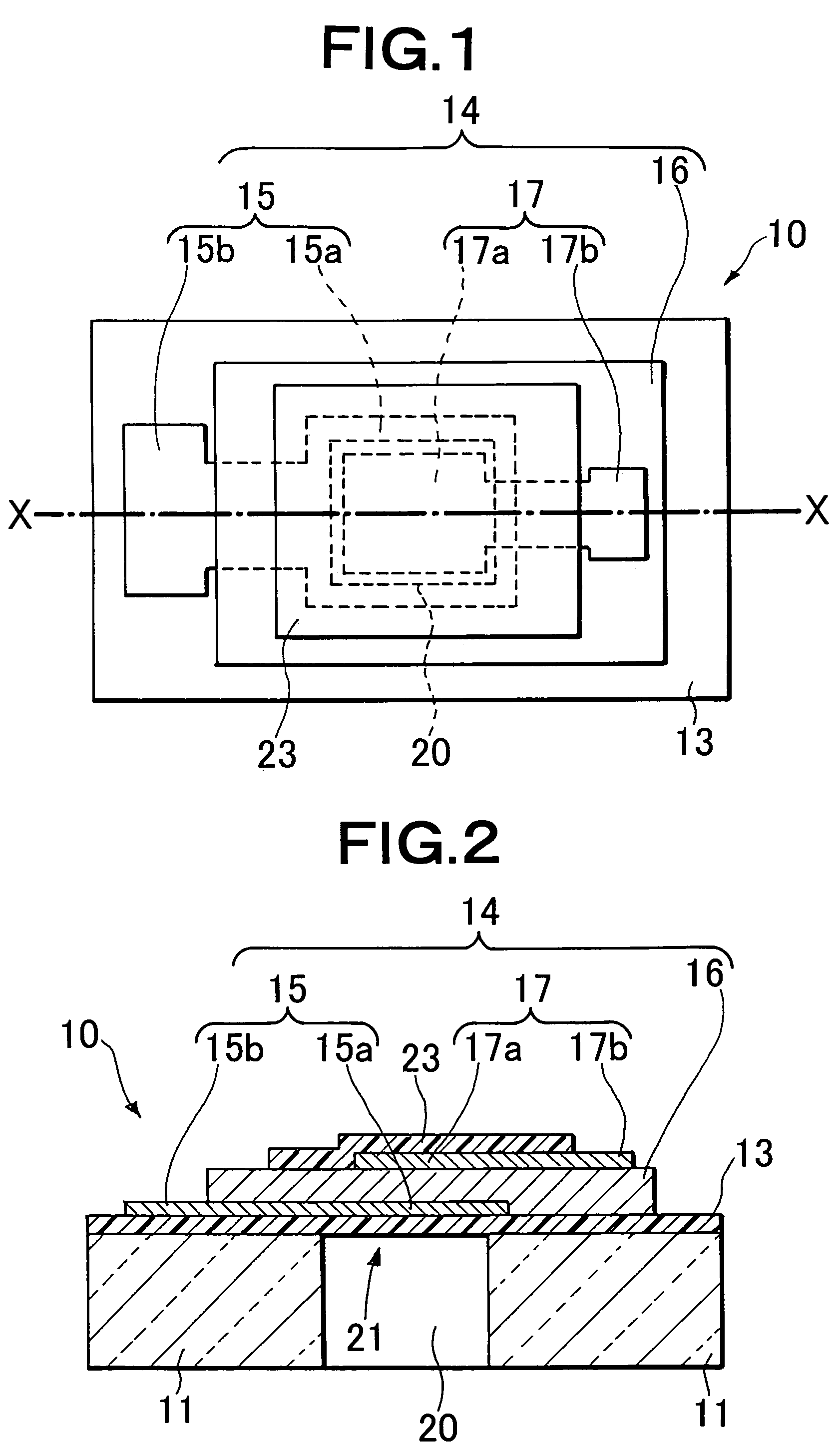

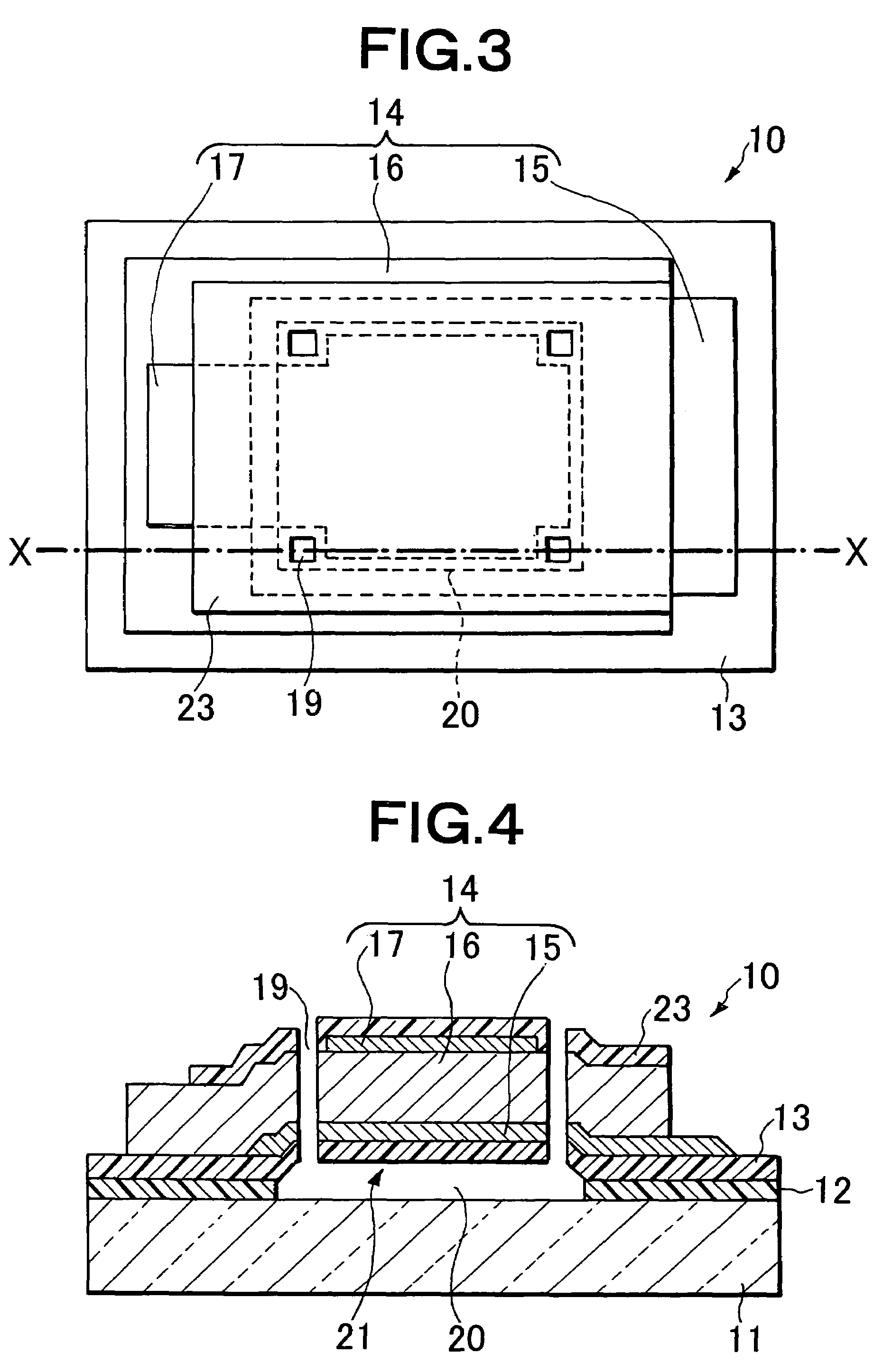

Aluminum nitride thin film, composite film containing the same and piezoelectric thin film resonator using the same

ActiveUS20070080611A1Improve featuresHigh crystallinityPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesRocking curveComposite film

A piezoelectric thin film resonator has a substrate and a piezoelectric layered structure including a lower electrode, piezoelectric aluminum nitride thin film with c-axis orientation and upper electrode formed on the substrate in this order. The lower electrode are made of a metal thin film including a layer containing ruthenium as a major component having a full-width half maximum (FWHM) of a rocking curve of a (0002) diffraction peak of ruthenium of 3.0° or less. The piezoelectric aluminum nitride thin film formed on the lower electrode has a full-width half maximum (FWHM) of a rocking curve of a (0002) diffraction peak of 2.0° or less.

Owner:MEMS SOLUTIONS INC

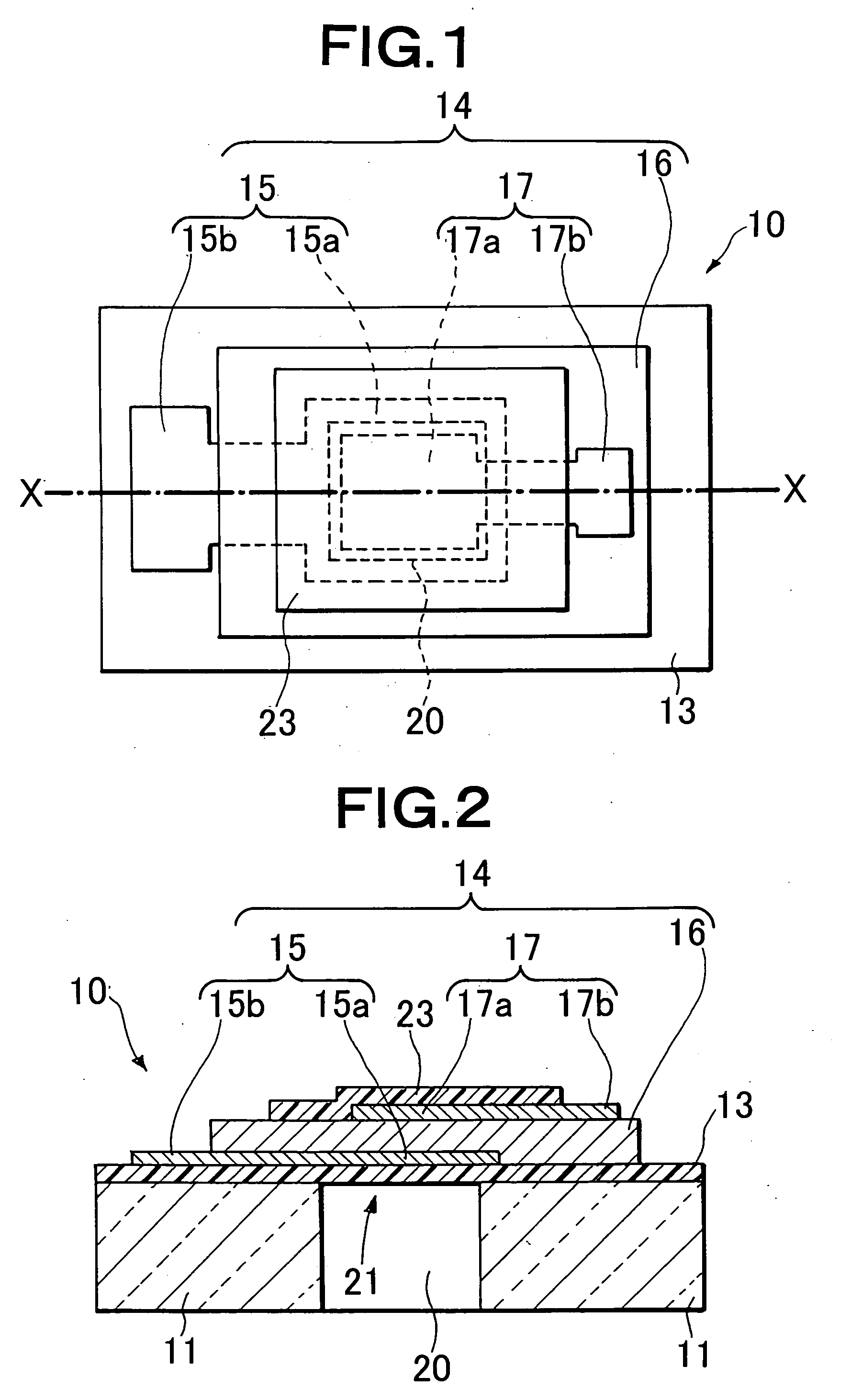

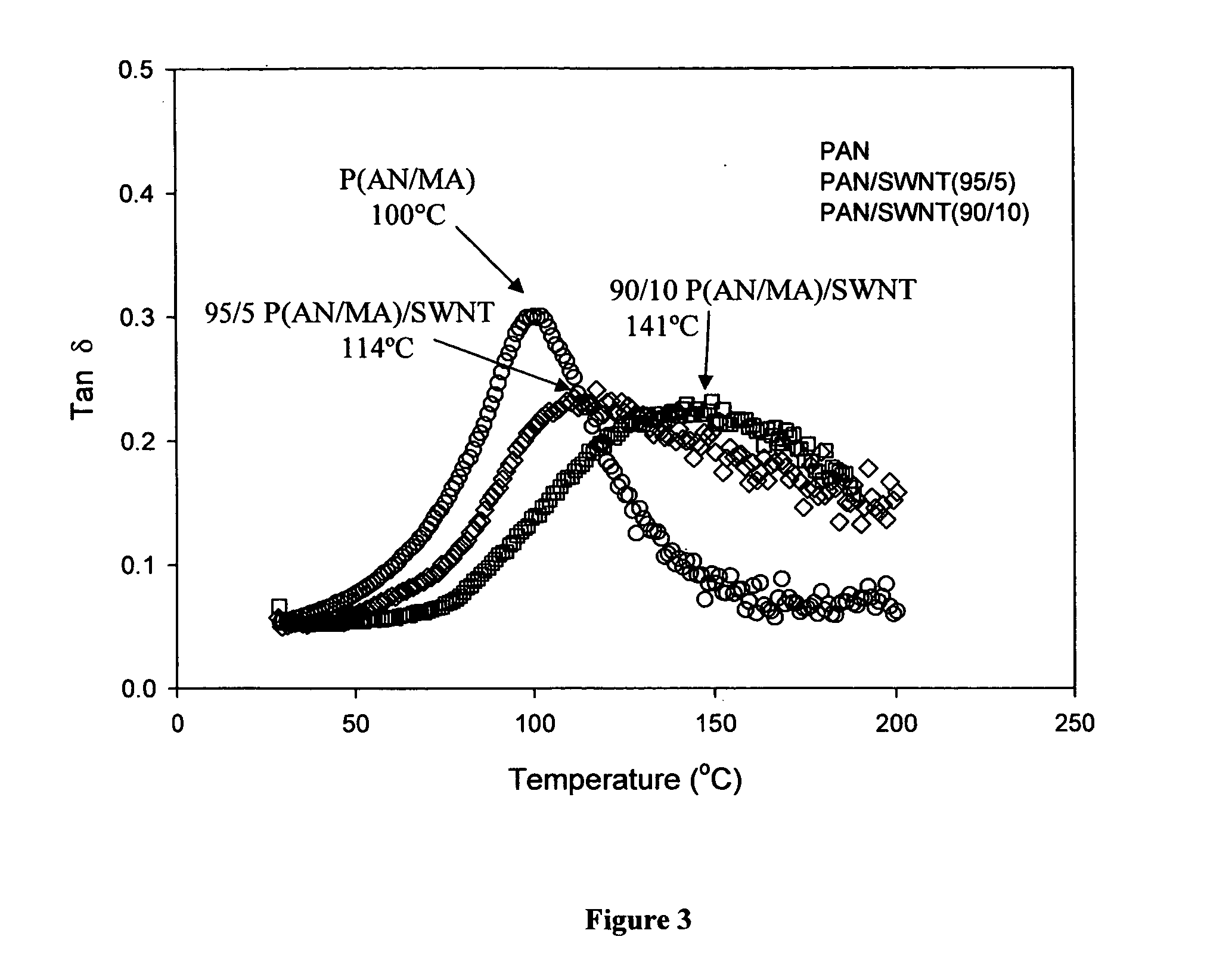

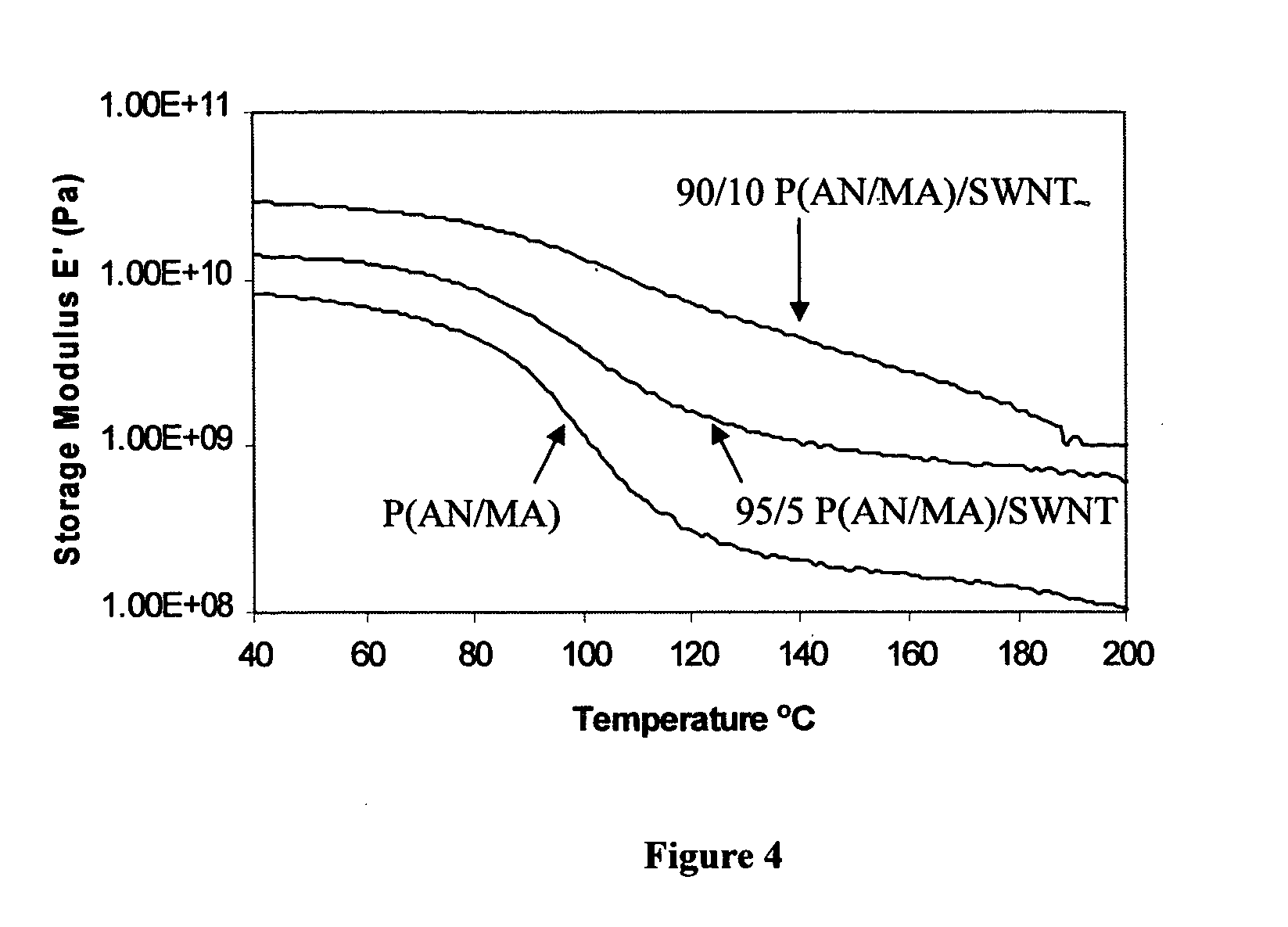

Macroscopic fiber comprising single-wall carbon nanotubes and acrylonitrile-based polymer and process for making the same

InactiveUS20050100501A1Good orientationIncrease modulusMaterial nanotechnologyElectroconductive/antistatic filament manufactureVitrificationPolymer science

The present invention relates to a high modulus macroscopic fiber comprising single-wall carbon nanotubes (SWNT) and an acrylonitrile-containing polymer. In one embodiment, the macroscopic fiber is a drawn fiber having a cross-sectional dimension of at least 1 micron. In another embodiment, the acrylonitrile polymer-SWNT composite fiber is made by dispersing SWNT in a solvent, such as dimethyl formamide or dimethyl acetamide, admixing an acrylonitrile-based polymer to form a generally optically homogeneous polyacrylonitrile polymer-SWNT dope, spinning the dope into a fiber, drawing and drying the fiber. Polyacrylonitrile / SWNT composite macroscopic fibers have substantially higher modulus and reduced shrinkage versus a polymer fiber without SWNT. A polyacrylonitrile / SWNT fiber containing 10 wt % SWNT showed over 100% increase in tensile modulus and significantly reduced thermal shrinkage compared to a control fiber without SWNT. With 10 wt % SWNT, the glass transition temperature of the polymer increased by more than 40° C.

Owner:GEORGIA TECH RES CORP

Orthopedic implant with angled pegs

An orthopedic implant, such as a tibial tray, includes a body having a bone contacting surface with at least one and preferably two pegs extending from the bone contacting surface. Each of the pegs has a longitudinal axis angled with respect to the bone contacting surface and also angled in at least one direction consisting of a medial-lateral direction, an anterior-posterior direction and an inferior-superior direction. In the case of the tibial tray, the pegs form a non-perpendicular angle with the bone contacting surface of the baseplate and are angled in both a posterior direction and a medial or lateral direction.

Owner:HOWMEDICA OSTEONICS CORP

Thermal management system

InactiveUS6841250B2Improve cooling effectIncreased anisotropyLayered productsSemiconductor/solid-state device detailsGraphiteThermal management system

The present invention relates to a system for managing the heat from a heat source like an electronic component. More particularly, the present invention relates to a system effective for dissipating the heat generated by an electronic component using a thermal management system that includes a heat sink formed from a graphite article.

Owner:NEOGRAF SOLUTIONS LLC

Retardation film, polarizing element, liquid crystal panel, and liquid crystal apparatus

InactiveUS20060177607A1Good molding effectImproved display property displayLiquid crystal compositionsThin material handlingIn planeLength wave

There is provided a retardation film including a stretched film of a polymer film having an absolute value of photoelastic coefficient (m2 / N) of 50×10−12 or less measured by using light of a wavelength of 550 nm at 23° C., which satisfies the following expressions (1) and (2):Re[450]<Re[550]<Re[650] (1)Rth[550]<Re[550] (2).In the expressions (1) and (2): Re[450], Re[550], and Re[650] respectively represent in-plane retardation values measured by using light of wavelengths of 450 nm, 550 nm, and 650 nm at 23° C.; and Rth[550] represents a thickness direction retardation value measured by using light of a wavelength of 550 nm at 23° C.

Owner:NITTO DENKO CORP

Method for preparing high-strength polyacrylonitrile-based precursor for carbon fiber

ActiveCN101724922ARegularity and compactnessImprove orientationArtificial filament washing/dryingArtificial filament heat treatmentSolventSolution polymerization

The invention discloses a method for preparing a high-strength polyacrylonitrile-based carbon fiber precursor. The method comprises the steps of: using azodiisobutyronitrile to trigger acrylonitrile and a comonomer to perform homogeneous solution polymerization in dimethyl sulfoxide to obtain spinning solution, and controlling the temperature of the spinning solution to be between 40 and 70 DEG C and the solid content to be between 18 and 24 percent; performing monomer removal on the spinning solution under the pressure of between -60 and -78kPa, and performing deaeration treatment under the pressure of between -78 and -97kPa; then extruding the spinning solution into a spin duct in a coagulation bath with a temperature of between 35 and 65 DEG C and a dimethyl sulfoxide concentration of between 50 and 70 percent for molding through a spinneret, and obtaining PAN-based as-spun fiber through 45 to 75 percent of minus stretch in the coagulation bath; then molding and stretching through a secondary coagulation bath, a third coagulation bath, a fourth coagulation bath and a fifth coagulation bath; and obtaining the high-strength polyacrylonitrile-based carbon fiber precursor through solvent removal by water scrubbing, hot water stretch, oiling, drying and densification, steam stretch, and hot air setting. The tensile strength of the high-strength polyacrylonitrile-based carbon fiber precursor reaches 10.2cN / dtex.

Owner:ZHONGFU SHENYING CARBON FIBER

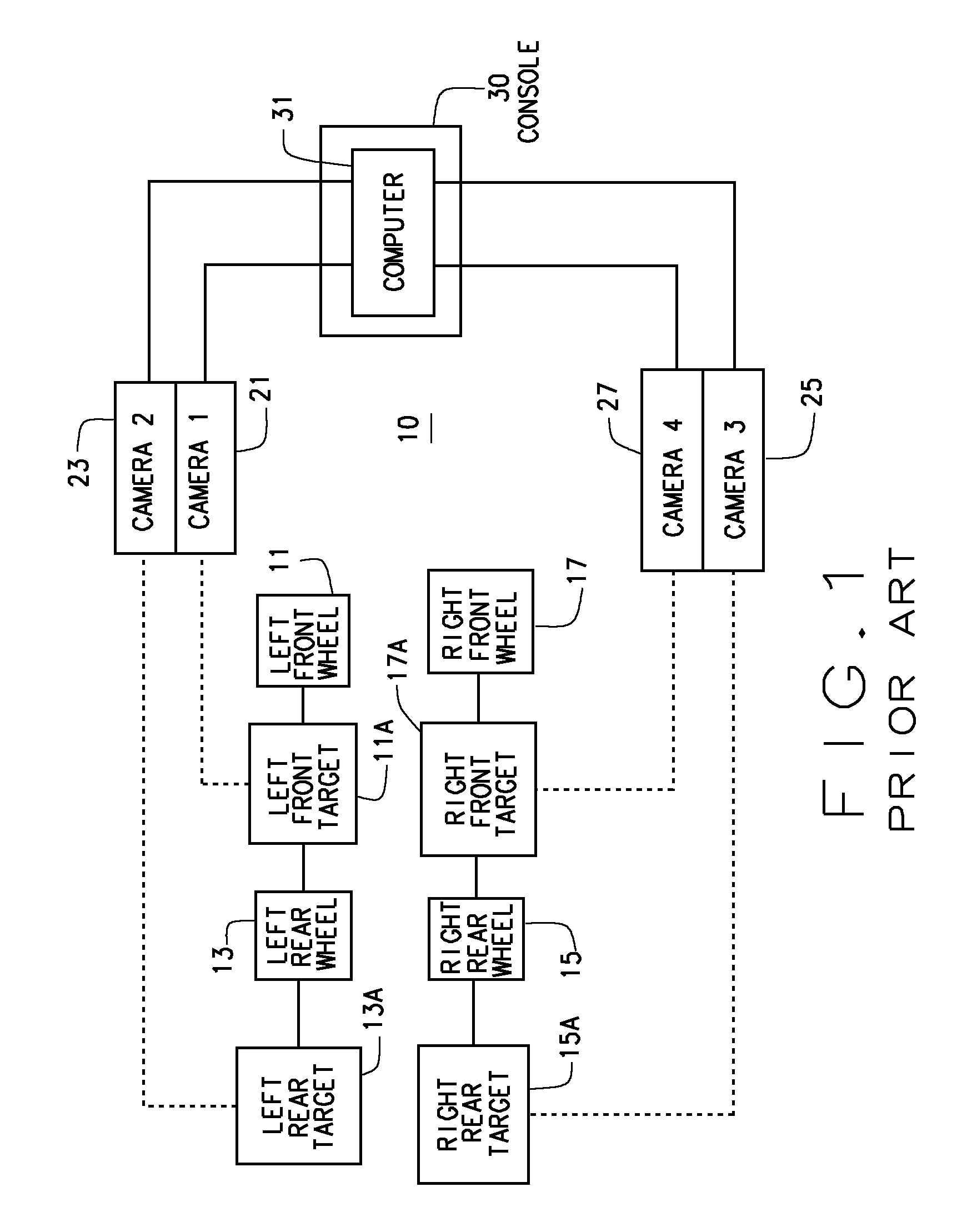

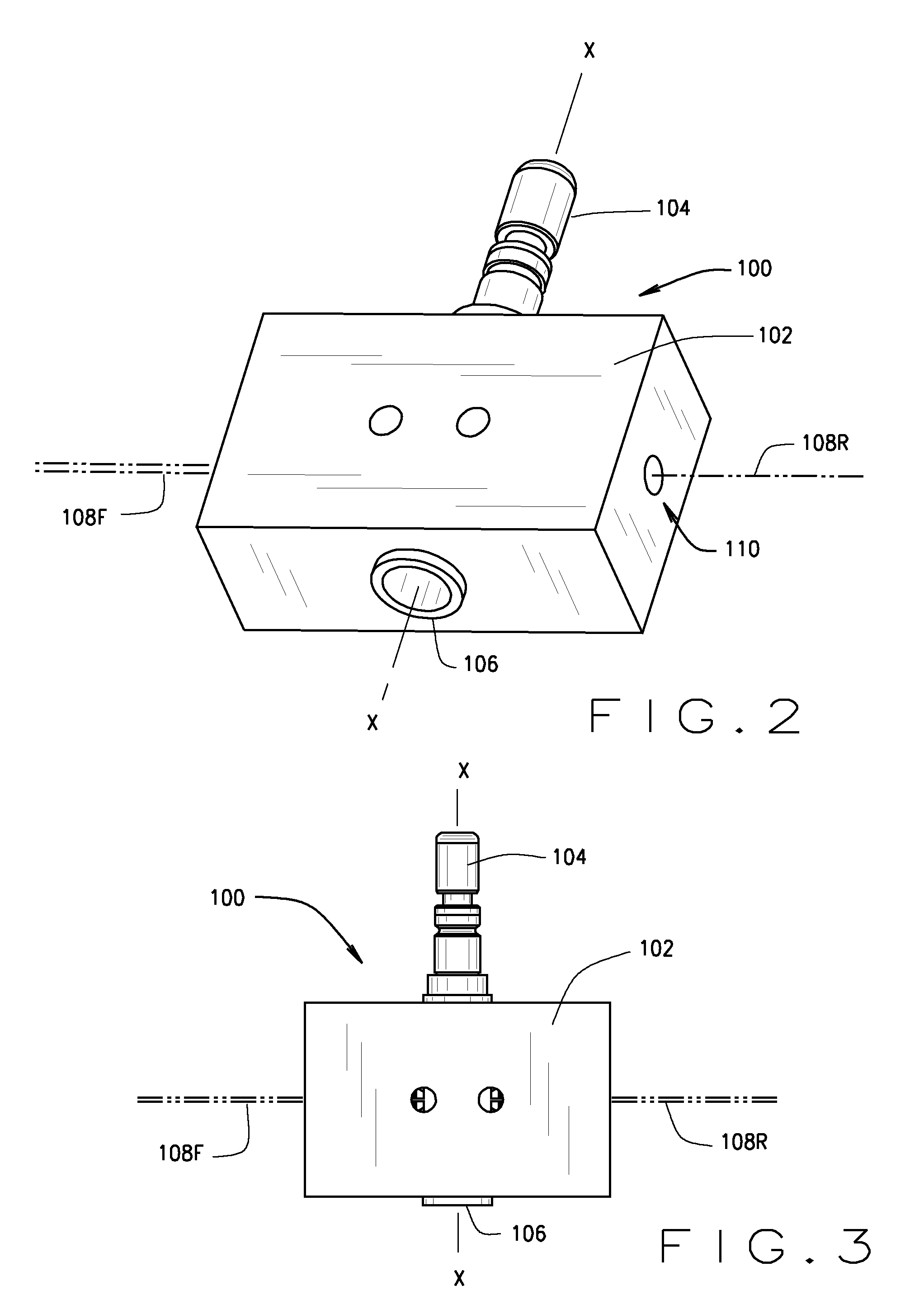

Method and Apparatus For Positioning A Vehicle Service Device Relative To A Vehicle Thrust Line

ActiveUS20130110314A1Good orientationEasy to placeDigital data processing detailsUsing optical meansLaser adaptorReference line

A method and apparatus for utilizing a vehicle wheel alignment system to guide the placement and orientation of a vehicle service apparatus or alignment fixture relative to the thrust line of a vehicle. A laser adapter for projecting a reference line is mounted to a steerable wheel of the vehicle, and is aligned relative to both a line of the vehicle and to the supporting surface on which the vehicle is disposed. The vehicle line is determined by the vehicle wheel alignment system, and the steerable wheel, together with the adapter, are steered relative to the determined vehicle line, such that a projected reference line defined by the position and orientation of the adapter is established parallel to both the supporting surface and the vehicle line. The placement and orientation of the vehicle service apparatus or alignment fixture is subsequently adjusted relative to the projected reference line.

Owner:HUNTER ENG

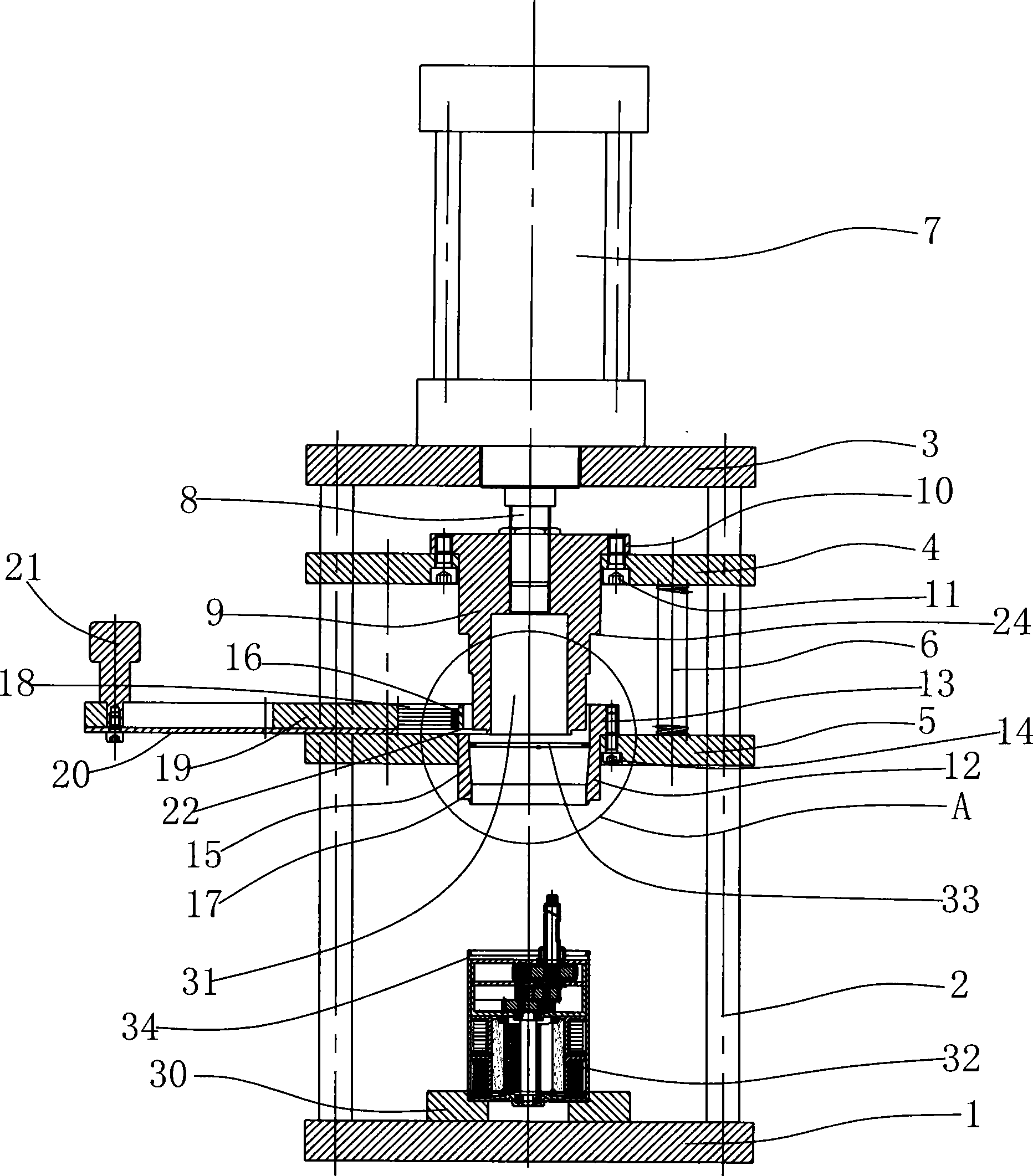

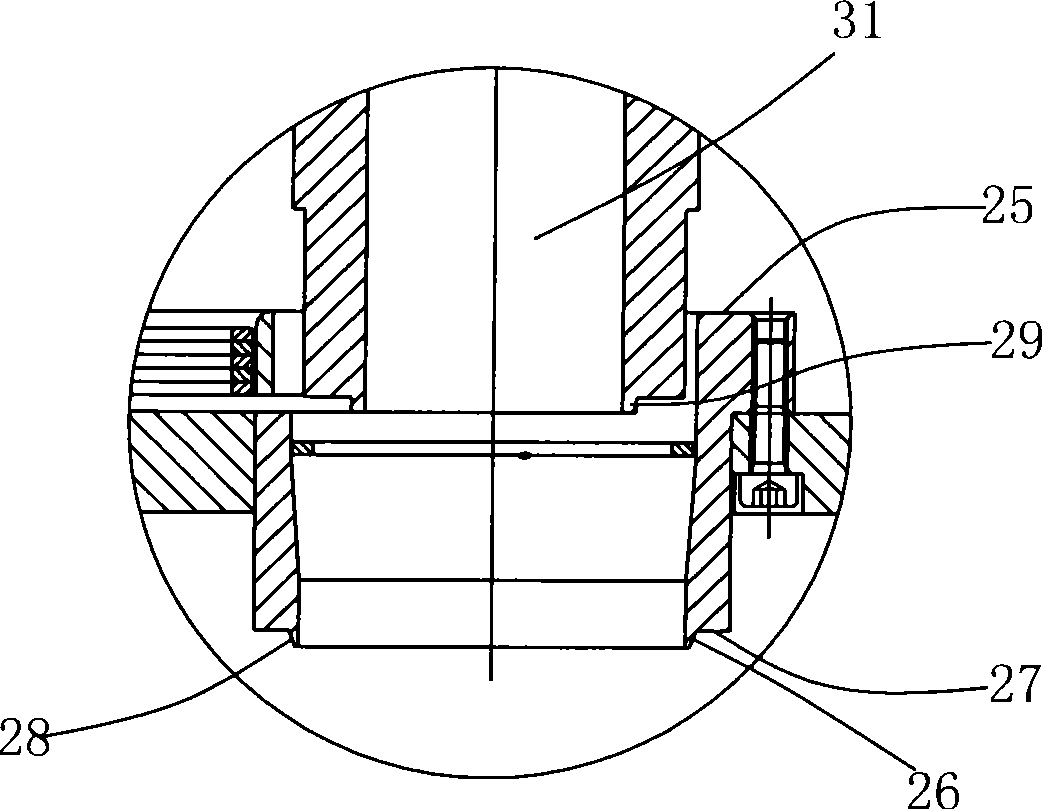

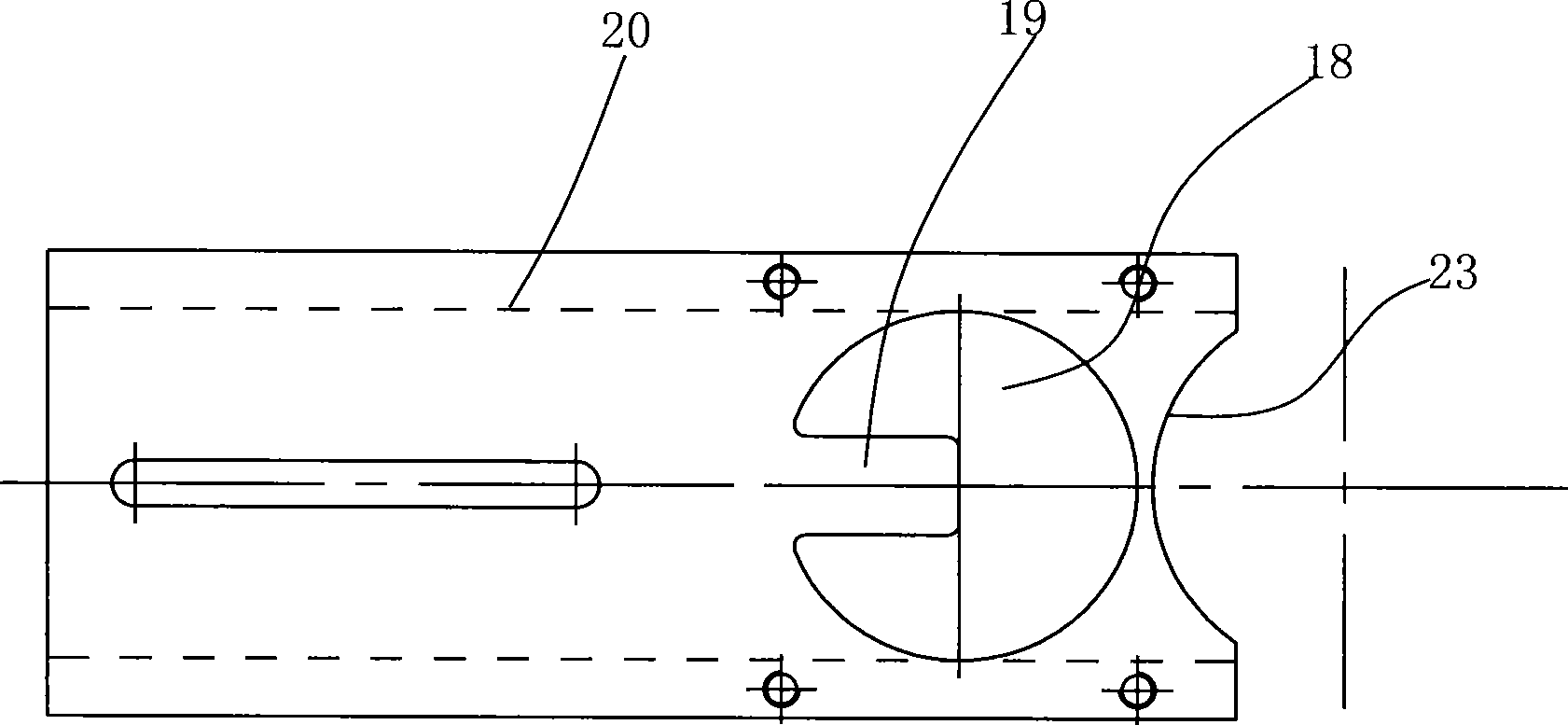

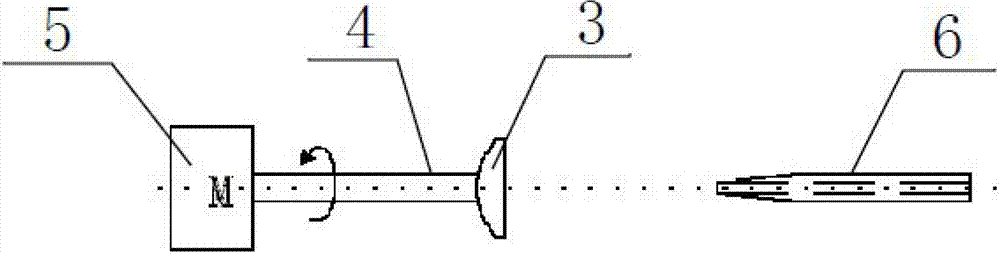

Internal circlip press-loading device

InactiveCN101386166AGuaranteed smooth assemblyGood orientationManufacturing dynamo-electric machinesMetal working apparatusEngineeringCirclip

The invention relates to an internal circlip compacting device, which belongs to the technical field of circlip mounting device. A guide pole is arranged on a bottom board; a cylinder retaining plate is arranged at the upper end of the guide pole; the guide pole between the bottom board and the cylinder retaining plate is connected with a core rod retaining plate and an outer sleeve retaining plate in a sliding way; the core rod retaining plate and the outer sleeve retaining plate are connected by a compression spring; a piston rod of the cylinder is fixed with the upper end of a core rod of a compact circlip after the piston rod of the cylinder downward passes through the cylinder retaining plate; the core rod of the compact circlip and the core rod retaining plate are fixed together; an outer sleeve is arranged on the outer sleeve retaining plate; a hollow structure of the outer sleeve is coaxial with the core rod of the compact circlip, and has a taper hole section with larger upper end and small lower end; the lower end of the core rod of the compact circlip can pass through the position with the smallest inner diameter of the taper hole section of the hollow structure of the outer sleeve; and the bottom board is provided with a workpiece positioning plate corresponding to the lower side of the outer sleeve. The internal circlip compacting device has good guidance quality, can ensure that the circlip is smoothly assembled with convenient operation.

Owner:ZHEJIANG LINIX MOTOR

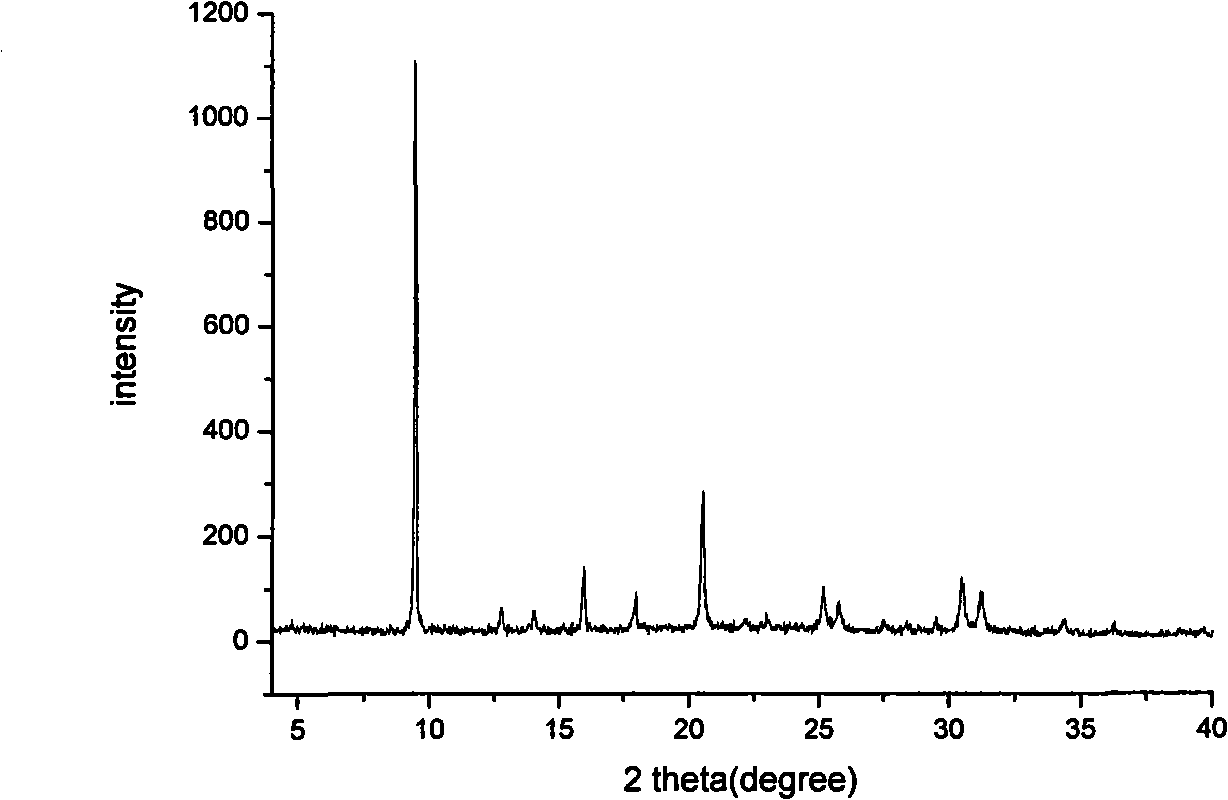

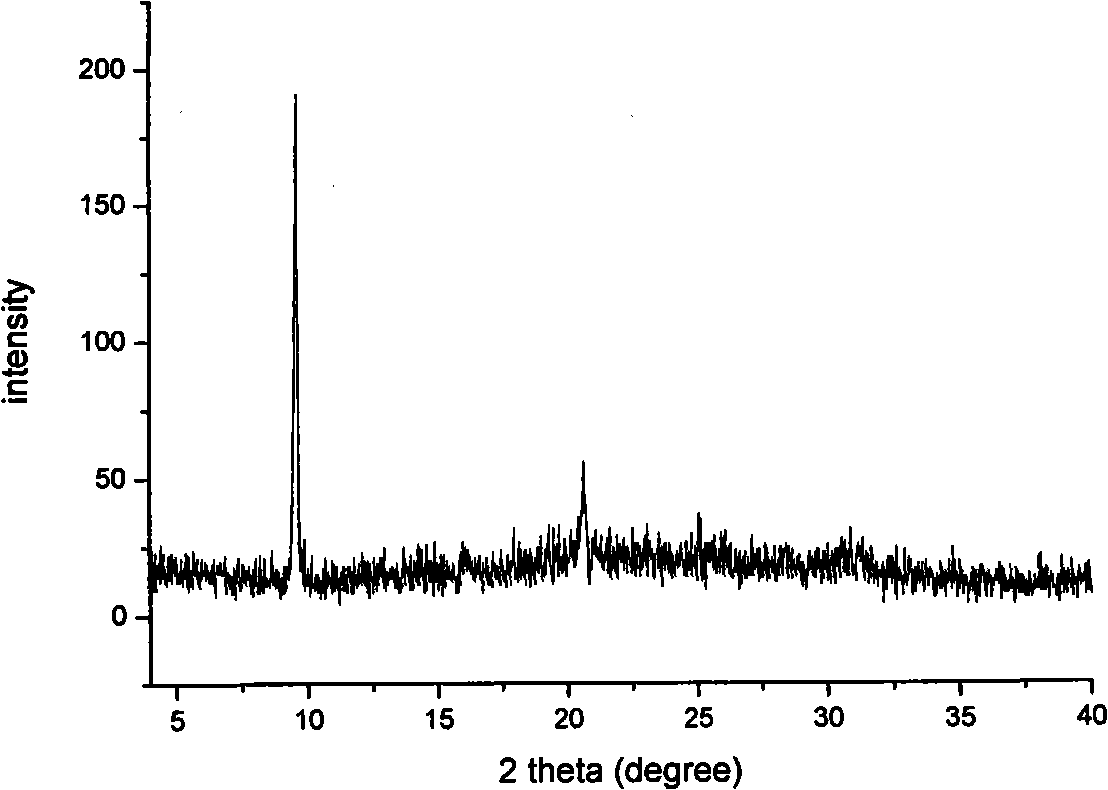

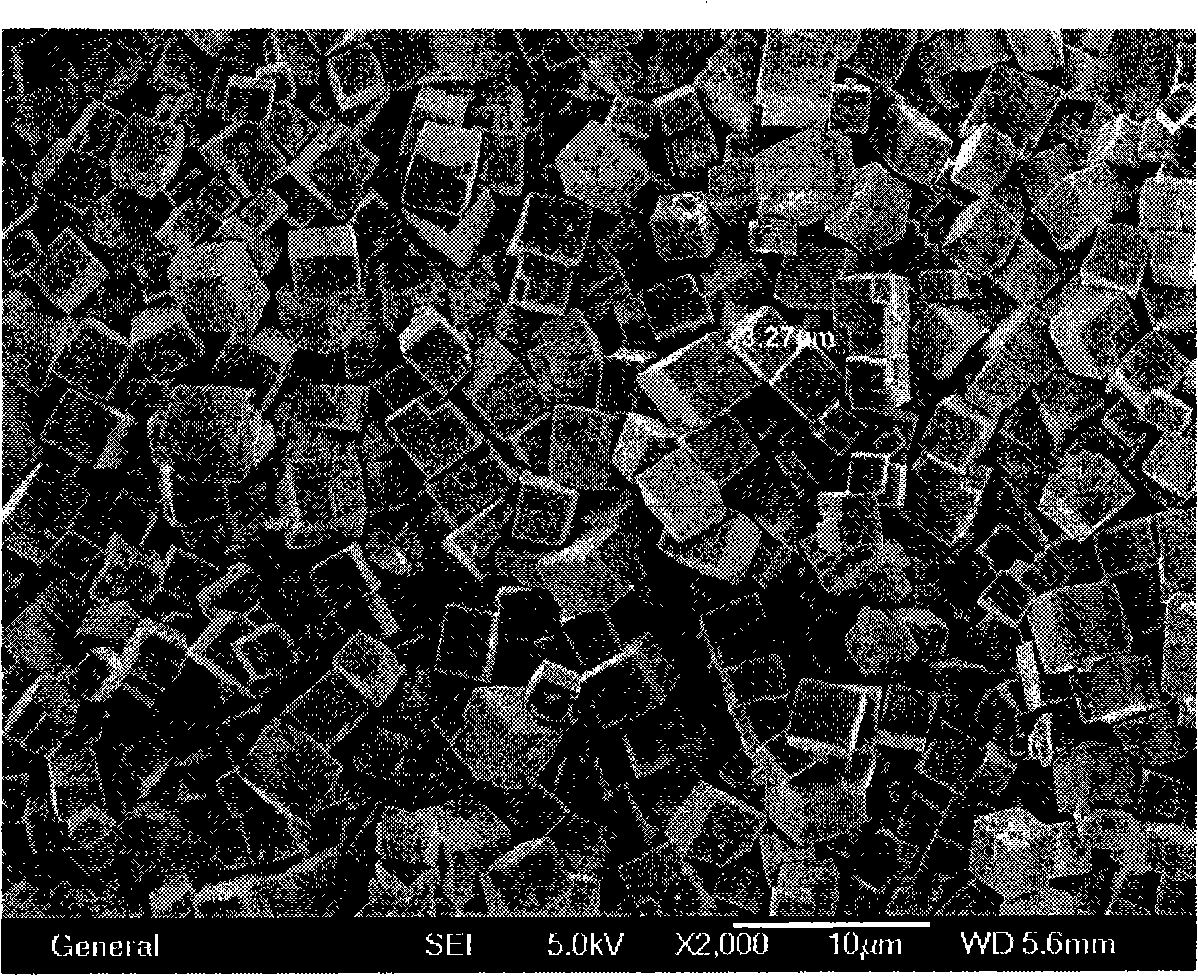

Preparation of SAPO-34 molecular sieve film for selectively separating methane gas

InactiveCN101279207AHigh repeatabilityGood orientationSemi-permeable membranesPhosphoric acidMolecular sieve

The invention relates to a novel method of SAPO-34 molecular sieve membrane for selectively separating methane gas by crystal guidance and secondary synthesis. The method includes three steps, namely synthesizing crystal seed, preparing basement membrane of crystal seed and synthesizing SAPO-34 molecular sieve membrane, in particular to the following steps: phosphoric acid, TEAOH and silica sol are added into adequately hydrolyzed aluminium isopropoxide to prepare a crystal seed solution of the molecular sieve and the molecular sieve composite mother solution; the crystal seed solution of the molecular sieve is prepared to be suspension after crystallization and rinsing for dripping onto a treated carrier; a basement membrane of crystal seed acquired is placed in a reaction kettle and is added with the molecular sieve composite mother solution for crystallization at a temperature ranging from 150 DEG C to 180 DEG C for 3 through 20 days, which is taken out for cleaning and drying and then is followed with actively removing a template agent at a temperature ranging from 400 DEG C to 600 DEG C. Synthesizing the molecular sieve membrane with the method of the invention is suitable for various porous supports with smooth surface, which is of high repetitiveness, good orientation, excellent separating property and ultrahigh gas permeability and is suitable for industrial application.

Owner:JILIN UNIV

Aluminum nitride thin film, composite film containing the same and piezoelectric thin film resonator using the same

ActiveUS7482737B2Improvement factorImprove sound qualityPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksRocking curveComposite film

A piezoelectric thin film resonator has a substrate and a piezoelectric layered structure including a lower electrode, piezoelectric aluminum nitride thin film with c-axis orientation and upper electrode formed on the substrate in this order. The lower electrode are made of a metal thin film including a layer containing ruthenium as a major component having a full-width half maximum (FWHM) of a rocking curve of a (0002) diffraction peak of ruthenium of 3.0° or less. The piezoelectric aluminum nitride thin film formed on the lower electrode has a full-width half maximum (FWHM) of a rocking curve of a (0002) diffraction peak of 2.0° or less.

Owner:MEMS SOLUTIONS INC

Preparation method of zinc oxide nano-rod film on fibre product

InactiveCN101012621ASmall granularityHigh purityFibre treatmentLiquid/gas/vapor textile treatmentFiberChemical solution

The invention relates to a manufacturing method for nanometer rod film of zinc oxide on fiber product, comprising (1) by sol-gel method ZnO nano-crystal grain is prepared and a great deal of ZnO seed crystal is deposited on the surface of fiber product, molar concentrations of zinc salt and alkaline agent are all 0.001M-0.75M; (2) by hydrothermal method or precipitation of chemical solution pool, nanometer rod film of zinc oxide grows on fiber product, molar concentrations of zinc salt solution and complexing agent solution are all 0.001M-0.05M; ZnO nanometer rod film with equal surface and good directivity is obtained. The manufacturing method is provided with simple method and low cost. It is suitable for industrial production.

Owner:DONGHUA UNIV

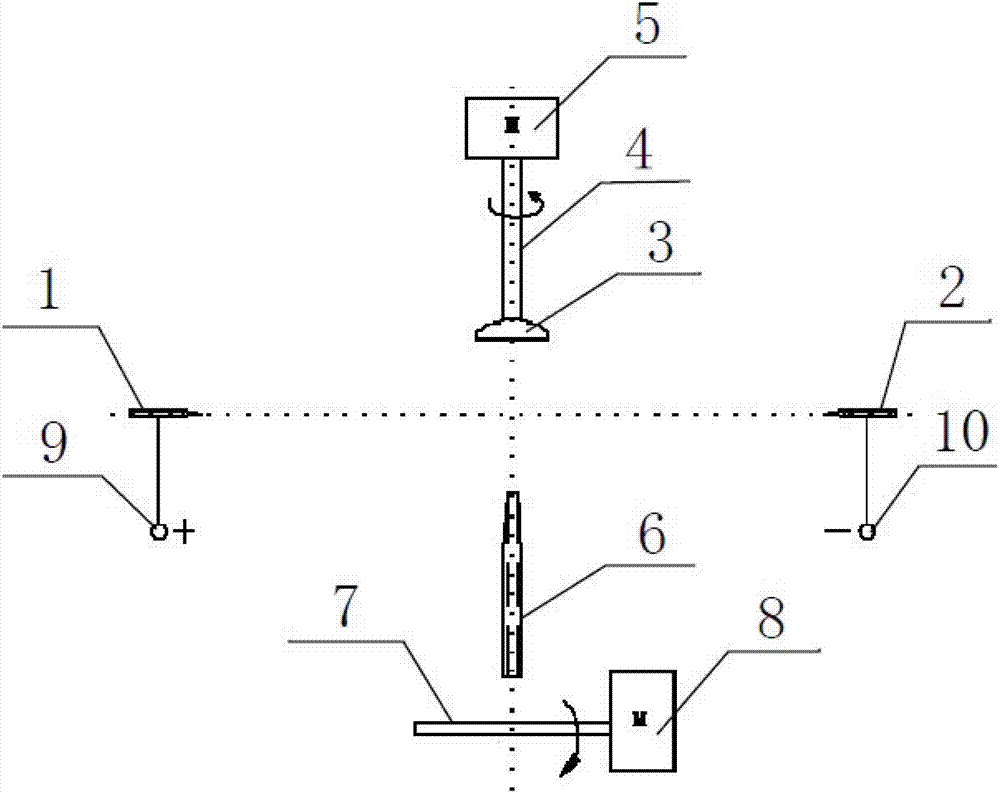

Orientation electro-spinning nanometer fiber spinning method and device thereof

InactiveCN103132194AHigh degree of axial orientationSuppress spinning instabilityDrafting machinesFilament/thread formingBobbinEngineering

The invention discloses an orientation electro-spinning nanometer fiber spinning method and a device thereof. A metal shower nozzle which exerts positive and negative high pressure is adopted to spin two strands of nanometer fibers with opposite charges, an electric field line of a spinning electric field, relative to a common spinning electric field, is straight, stability of spinning is effectively restrained, and the spinning nanometer fibers are straight. Two strands of the fibers surround the yarn tail and form a cone-shaped twisting trigonum on the upper portion of a metal twisting machine, and enable the nanometer fibers to be further oriented and twisted to form yarn through electric field force, tractive force of the yarn and acting force of the metal twisting force. The spinning nanometer fiber yarn is conducted heat shaping through a heat processing device under certain tensile force, degree of orientation of the nanometer fibers along the axial direction of the yarn, breaking force and yarn levelness are further improved, and the yarn after shaped is collected by a winding bobbin. The device can achieve the aim that orientation nanometer fiber yarn can be continuously prepared, is simple in device, convenient to operate, and good in resultant yarn continuity, yarn breaking strength and yarn levelness, and not only can spin pure nanometer fiber yarn, but also can spin nanometer fibers / filament core composite yarn. The orientation nanometer fiber spinning method and the device thereof have important application value in the fields, such as a biomedical field and a sensor field.

Owner:杨恩龙 +1

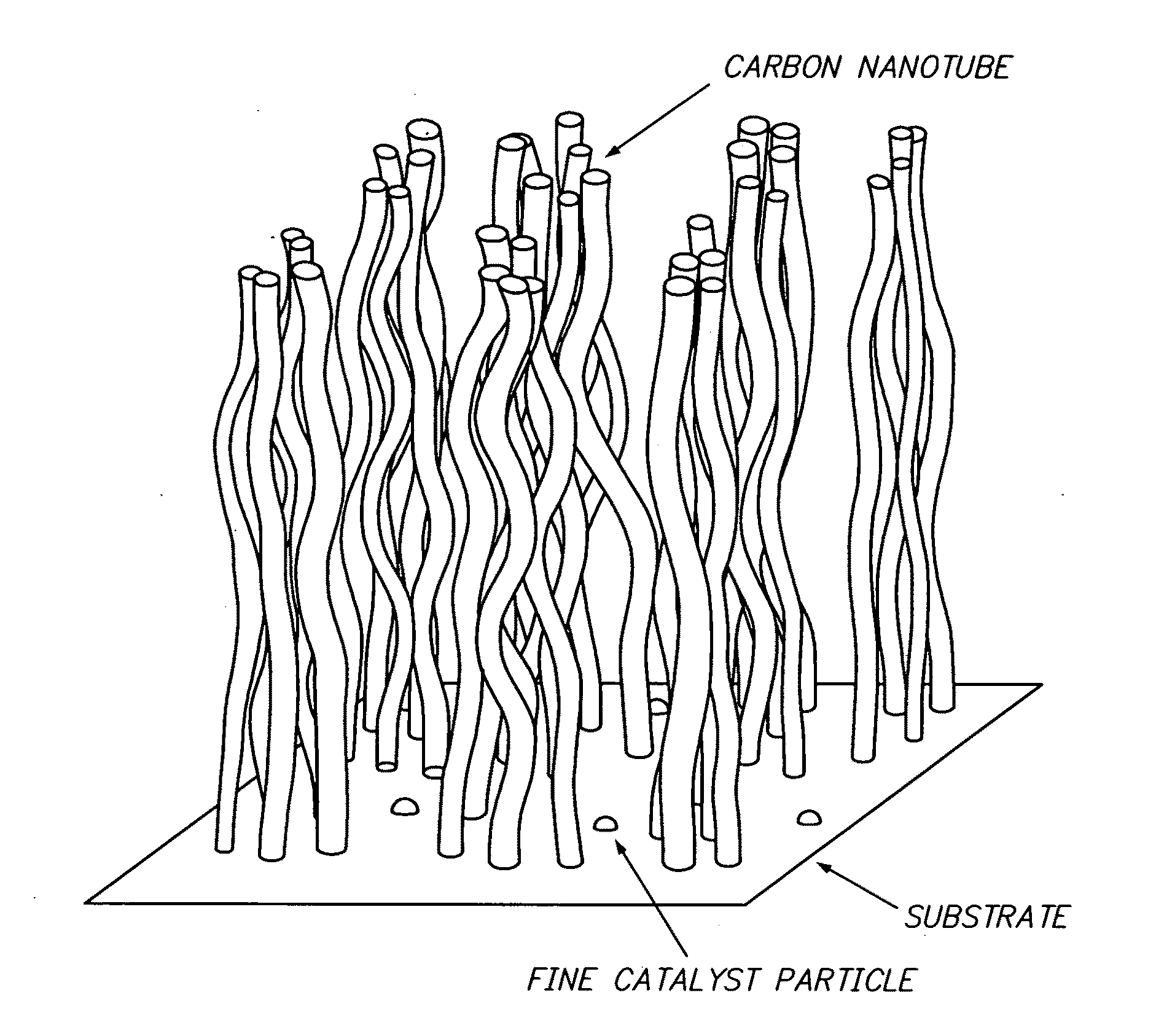

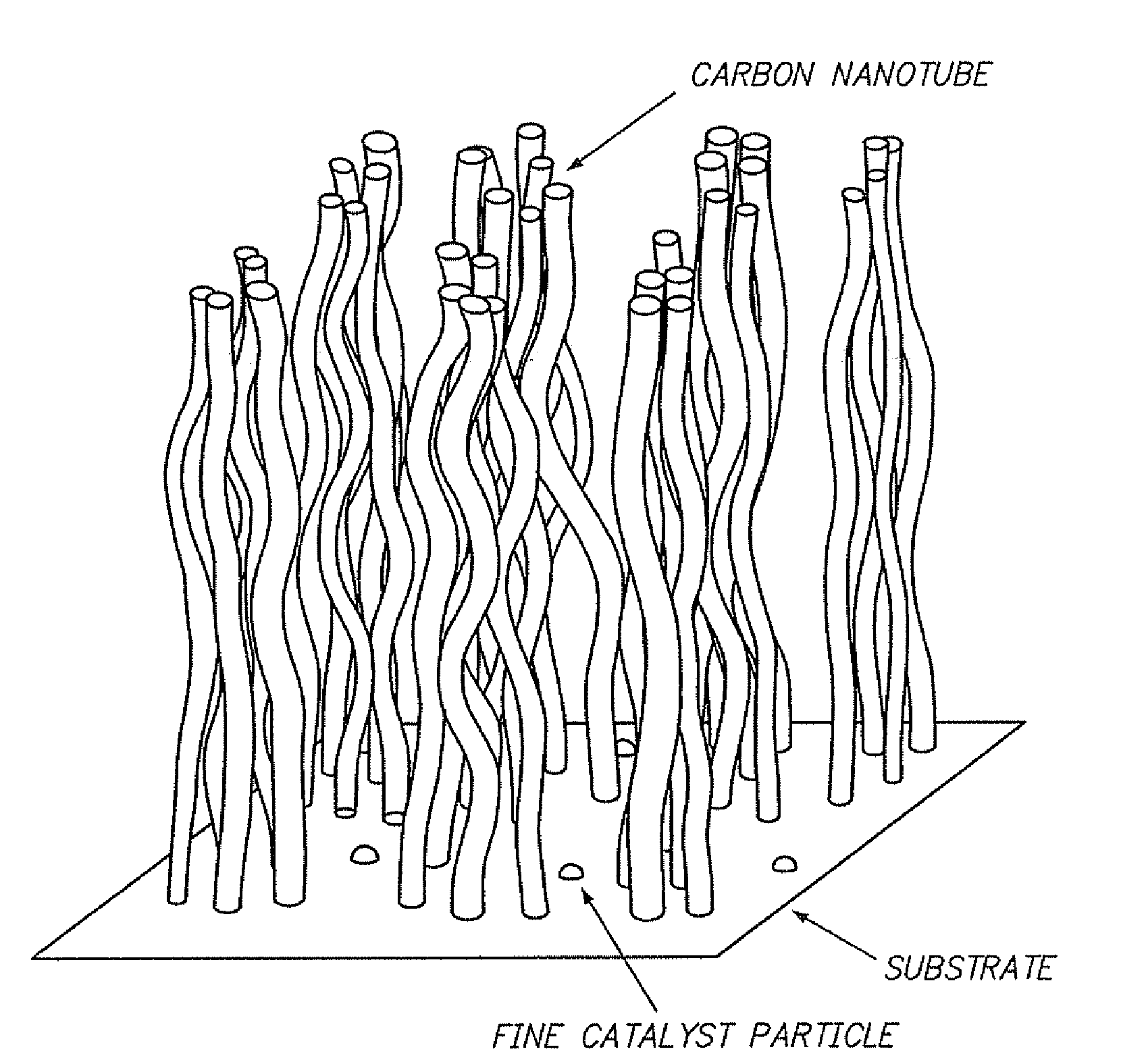

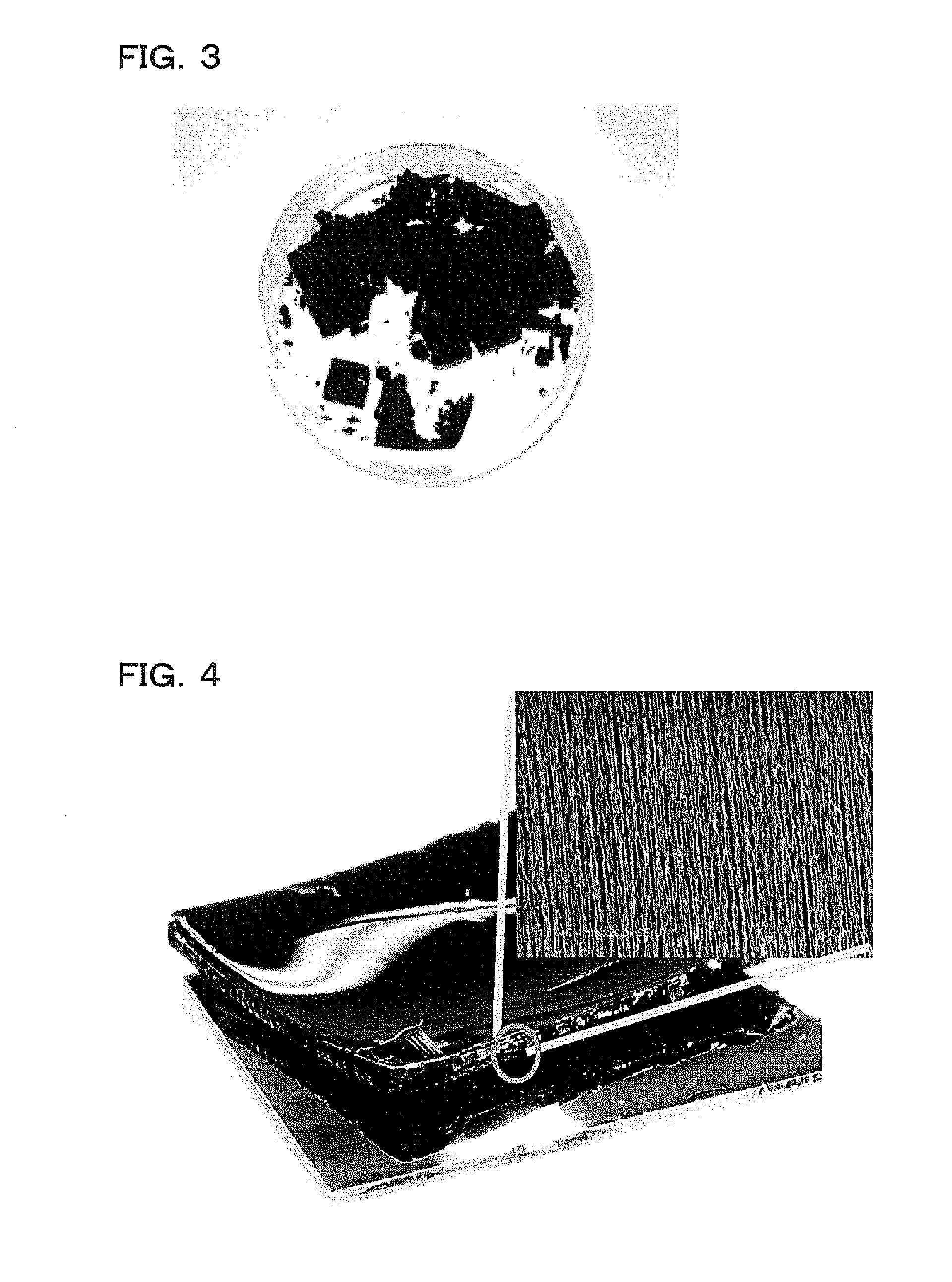

Aligned single-walled carbon nanotube aggregate, bulk aligned single-walled carbon nanotube aggregate, and powdered aligned single-walled carbon nanotube aggregate

ActiveUS20110008617A1Easy for density controlLow densityMaterial nanotechnologyLayered productsCarbon nanotubeAluminium oxide

This invention provides an aligned single-walled CNT aggregate comprising a substrate, fine particles of iron catalyst with a density of 1×1011 to 1×1014 / cm2 disposed on an alumina co-catalyst above the substrate, and a plurality of single-walled CNTs grown from the fine particles of the iron catalyst, in which the plurality of single-walled CNTs have a specific surface area of 600 m2 / g to 2600 m2 / g, and a weight density from 0.002 g / cm3 to 0.2 g / cm3, and the alignment degree which satisfies a few of specific conditions. This invention also provides a bulk aligned single-walled carbon nanotube aggregate and a powdered aligned single-walled carbon nanotube aggregate.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Soft Single-Ply Tissue

ActiveUS20100051218A1Low breaking lengthIncreased durabilityCellulosic pulp after-treatmentNon-fibrous pulp additionBiomedical engineeringPaper sheet

A soft single-ply tissue sheet is produced by making a textured, high bulk, through dried tissue sheet and calendering the sheet with a high level of compression energy to substantially reduce the bulk and impart improved properties to the sheet.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Aligned single-walled carbon nanotube aggregate, bulk aligned single-walled carbon nanotube aggregate, powdered aligned single-walled carbon nanotube aggregate, and production method thereof

InactiveUS20100062229A1Large specific surface areaExcellent formabilityMaterial nanotechnologyDecorative surface effectsCarbon nanotubeVolumetric Mass Density

This invention intends to provide an aligned single-walled CNT aggregate and the like which can be produced easily and has a high specific surface area, in which individual CNTs are aligned and which has excellent shape processability due to low bulk density. The aligned single-walled CNT aggregate of this invention comprises a base material, catalyst particles with a density of 1×1010 to 5×1013N / cm2 disposed on the base material, and a plurality of single-walled carbon nanotubes (CNTs) grown from the fine particles of the catalyst, in which the plurality of single-walled CNTs have a specific surface area of 600 m2 / g to 2600 m2 / g, and a weight density from 0.002 g / cm3 to 0.2 g / cm3, and the alignment degree is defined by a specific condition or conditions.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Total-biodegradation plastic film and preparation method thereof

InactiveCN101240086AQuality improvementImprove performanceFlat articlesPlastic filmMechanical property

A full-biodegradable plastic membrane, which uses thermoplastic starch with diameter of 1-9 mu m, biodegradable polymer and auxiliary component as raw material, processed by screw extruding apparatus and membrane producing apparatus. The raw material comprises 30-70 parts by weight of thermoplastic starch with diameter of 1-9 mu m, 10-40 parts by weight of biodegradable polymer, 5-10 parts by weight of compatible modified component, 3-5 parts by weight of complex plasticized component, 10-30 parts by weight of lubricant. These materials are mixed and processed by screw extruding apparatus and membrane producing apparatus, wherein the lubricant is at least adding into other materials for mixture before process by screw extruding apparatus and during melt blending, and the adding amount of lubricant before process by screw extruding apparatus is not more than 1 / 3 of the total amount thereof. By highly increasing dosage of lubricant and changing mixing way, thermoplastic degree of starch is increased, rheological property of the system and processing quality of product are dramatically improved, mechanical property of the product is enhanced.

Owner:上海悦仕生物材料有限公司 +1

Continuous preparation device and method for orientated electrostatic spinning nanofiber yarn

ActiveCN103088478AGood orientationIncrease productionFilament/thread formingContinuous wound-up machinesFiberYarn

The invention relates to a continuous preparation device and a method for orientated electrostatic spinning nanofiber yarn. The device comprises a metal round target and a yarn guide rod. The center of the metal round target is connected with one end of an insulating rod, the insulating rod is driven by a motor I to rotate, a metal top end of the front portion of the yarn guide rod is aligned with the center of the metal round target, the yarn guide rod is perpendicular to a bobbin, the bobbin is driven by a motor II to rotate, the metal round target, the insulating rod, the motor I and the yarn guide rod are arranged on the same center straight line, a spinning jet I and a spinning jet II which are symmetrical with each other are arranged on the left side and the right side of the metal round target and the yarn guide rod, the spinning jet I is connected with a high voltage static positive terminal, and the spinning jet II is connected with a high voltage static negative terminal. By means of the continuous preparation device and the method for the orientated electrostatic spinning nanofiber yarn, continuous production of the nanofiber yarn is achieved, the yield of electrostatic spinning is increased, and both the degree of orientation and the yield of the nanofiber yarn are high.

Owner:DONGHUA UNIV

Isolated thermal interface

InactiveUS7166912B2Avoid interferenceDissipate heat from an electronic componentSemiconductor/solid-state device detailsSynthetic resin layered productsGraphiteEngineering

Owner:NEOGRAF SOLUTIONS LLC

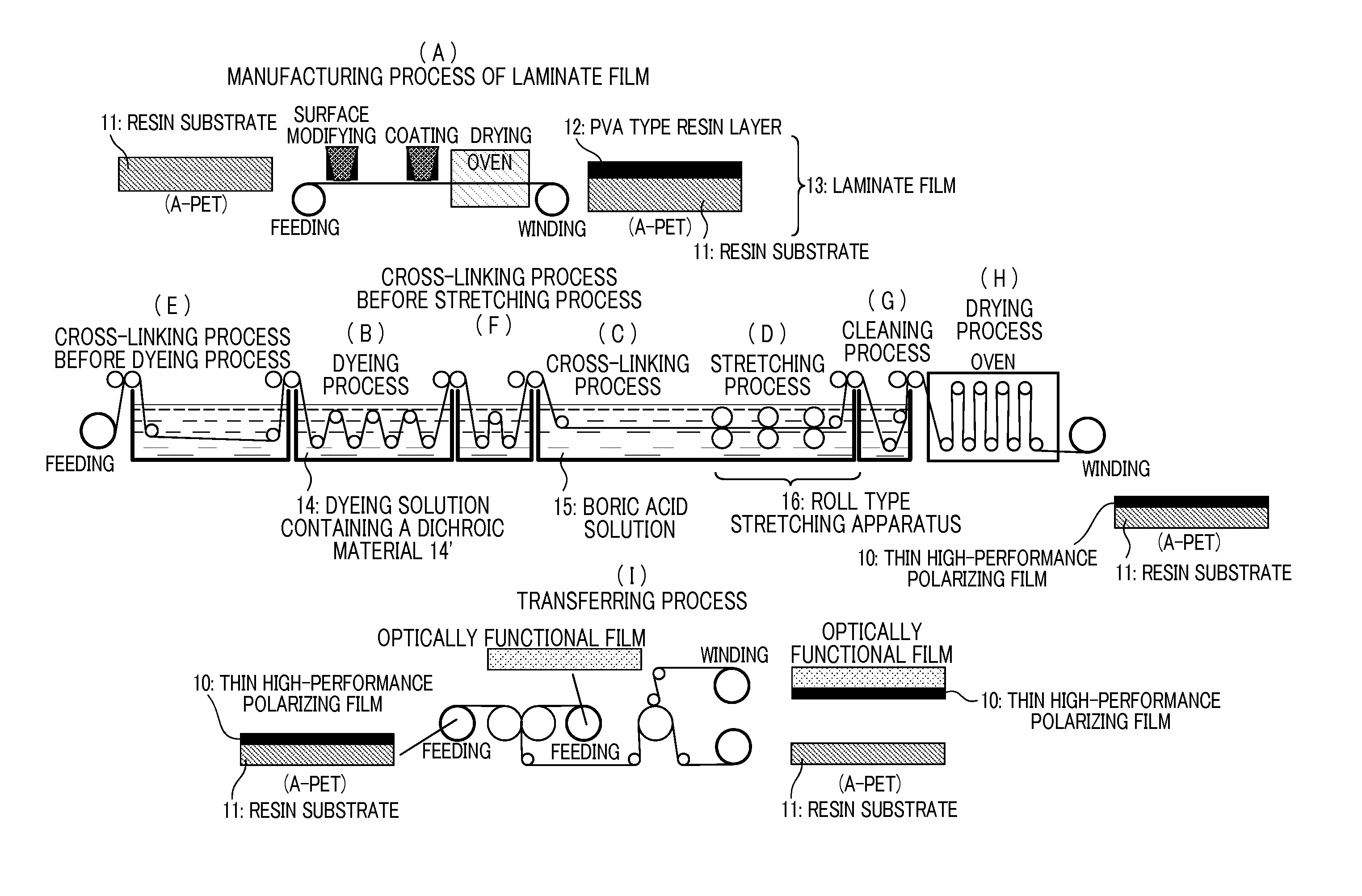

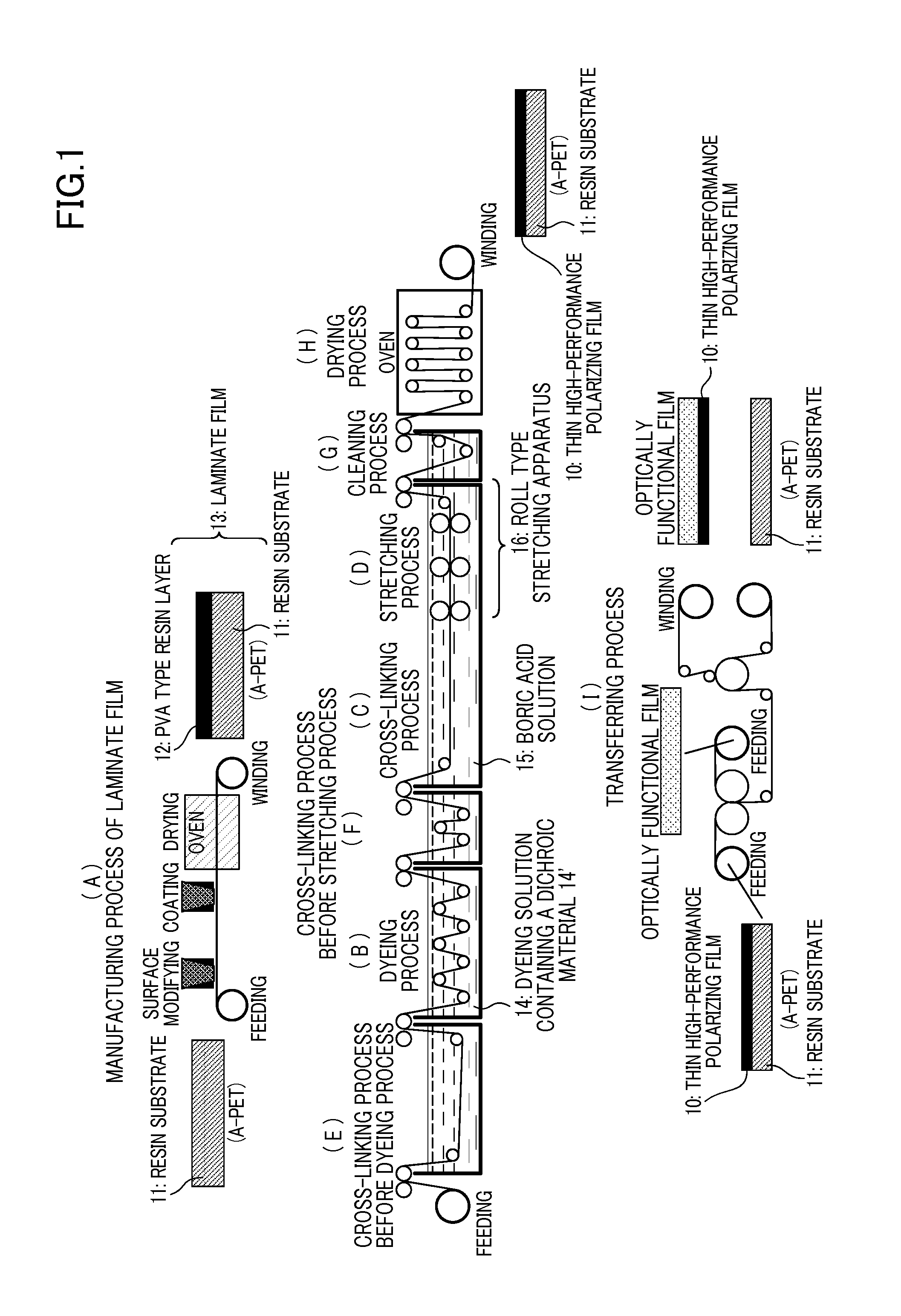

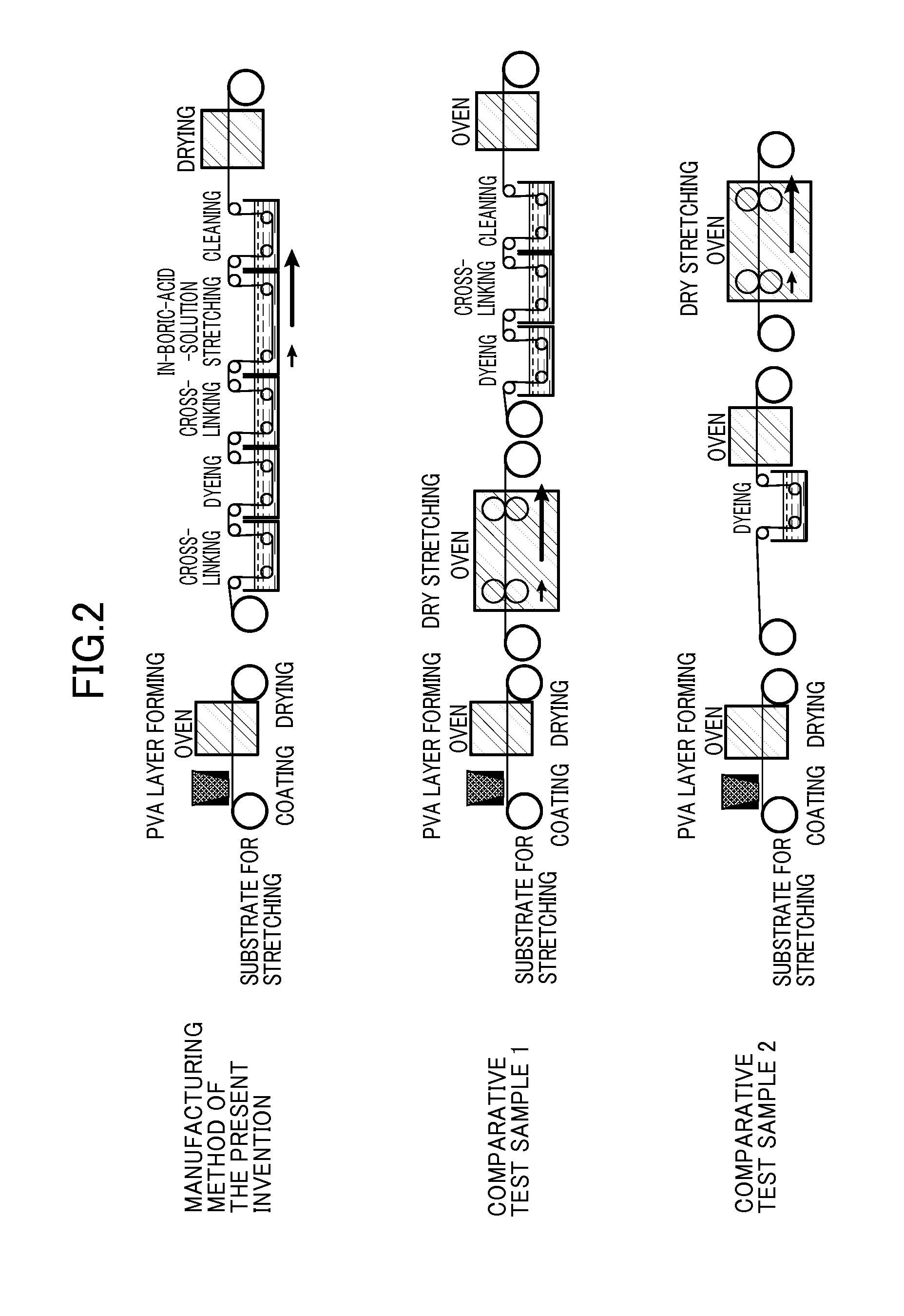

Thin high-performance polarizing film and method for manufacturing the same

InactiveUS20110315306A1High magnificationReduced optical performanceMonocomponent cellulose artificial filamentPolarising elementsStretch ratioBoric acid

A method for manufacturing a thin high-performance polarizing film includes coating a polyvinyl alcohol type resin on a resin substrate having a thickness of at least 20 μm and then drying the resin to thereby form a polyvinyl alcohol type resin layer, immersing thus produced polyvinyl alcohol type resin layer in a dyeing solution including a dichroic material to thereby have the dichroic material impregnated in the polyvinyl alcohol type resin layer, stretching the polyvinyl alcohol type resin layer having the dichroic material impregnated therein together with the resin substrate in a boric acid solution such that a total stretching ratio of 5.0 or more of the original length is achieved.

Owner:NITTO DENKO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com