Continuous preparation device and method for orientated electrostatic spinning nanofiber yarn

A nanofiber and preparation device technology, which is applied in spinning machines, fiber processing, open-end spinning machines, etc., can solve the problems that nanofibers cannot be oriented and twisted into yarns, and cannot be continuously produced, so as to achieve continuous and large-scale production. The effect of modernized production, simple structure and increased output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

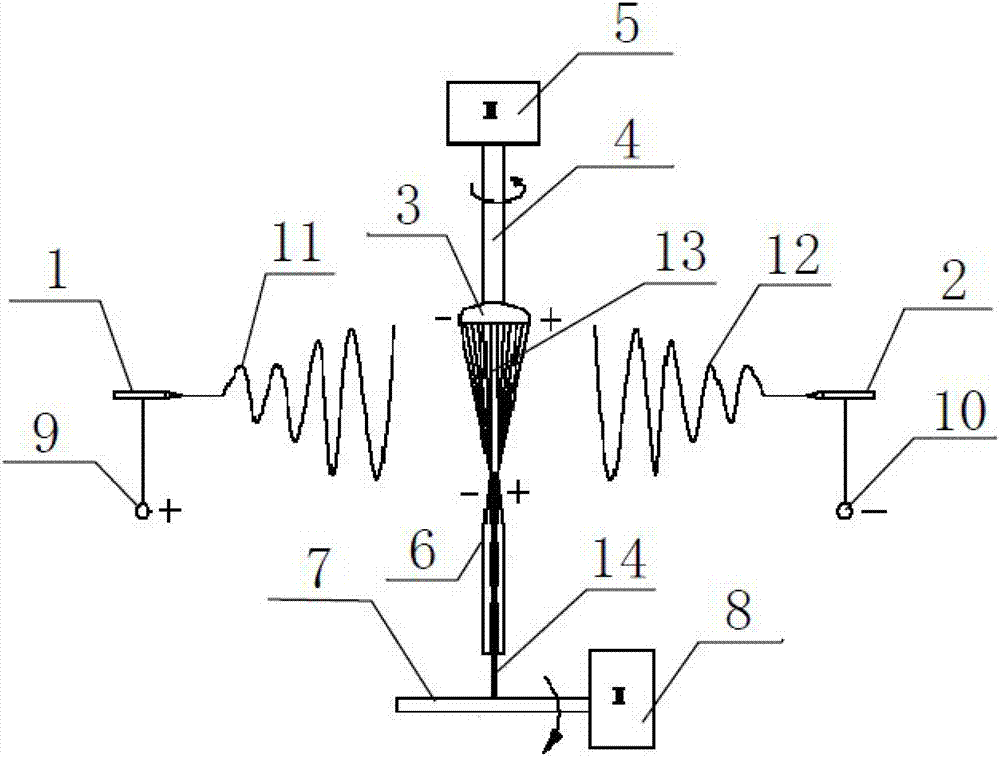

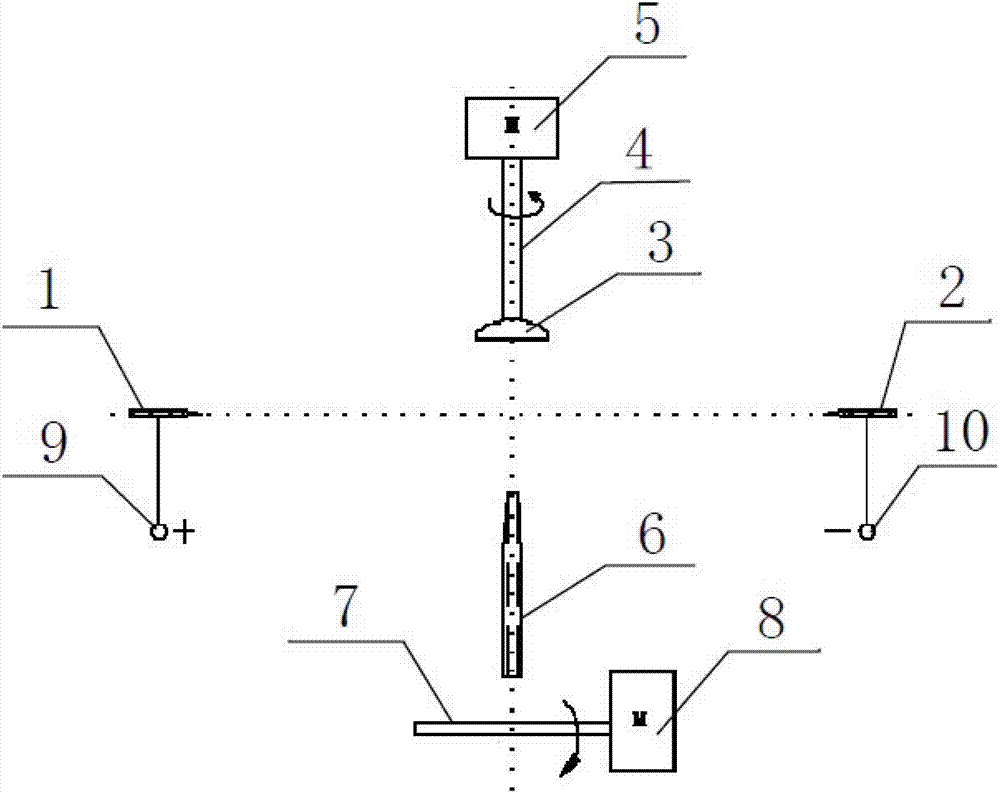

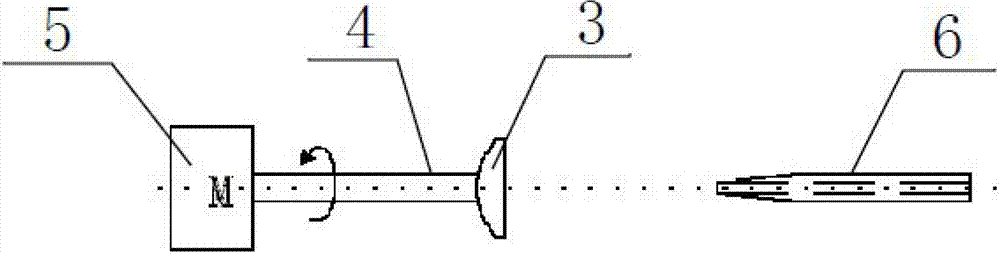

[0035]Spinning is performed with a solution prepared from polyacrylonitrile (PAN) and dimethylformamide (DMF). The 15% polyacrylonitrile (PAN) solution was injected into the spinneret I1 and the spinneret II2 through the automatic infusion device. The spinneret I1 was connected to the high-voltage electrostatic positive terminal 9, and the spinneret II2 was connected to the high-voltage electrostatic negative electrode. The terminal 10 is connected to each other, the relative distance between the spinneret I1 and the spinneret II2 is set to be 16cm, the distance between the metal circular target 3 and the tip of the yarn guide rod 6 is set to be 6cm, the high-voltage electrostatic generating device is turned on, and the positive and negative voltages are set. The values are +9kV and -9kV respectively. After the power is turned on, the spinneret I1 forms the jet I11, and the spinneret II2 forms the jet II12. The position between the tips and when the oriented nanofiber bundle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com