Patents

Literature

980results about How to "Excellent formability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

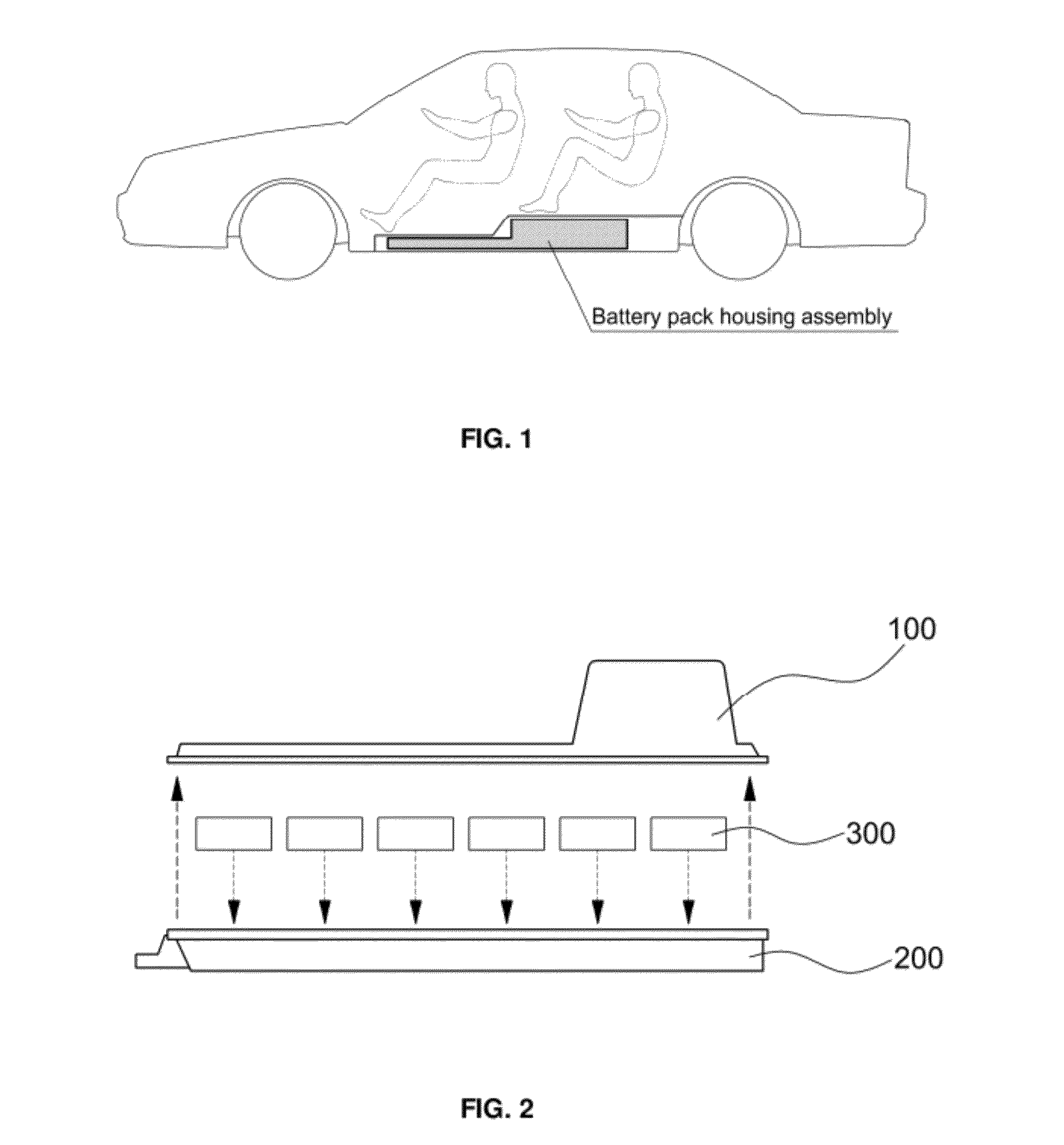

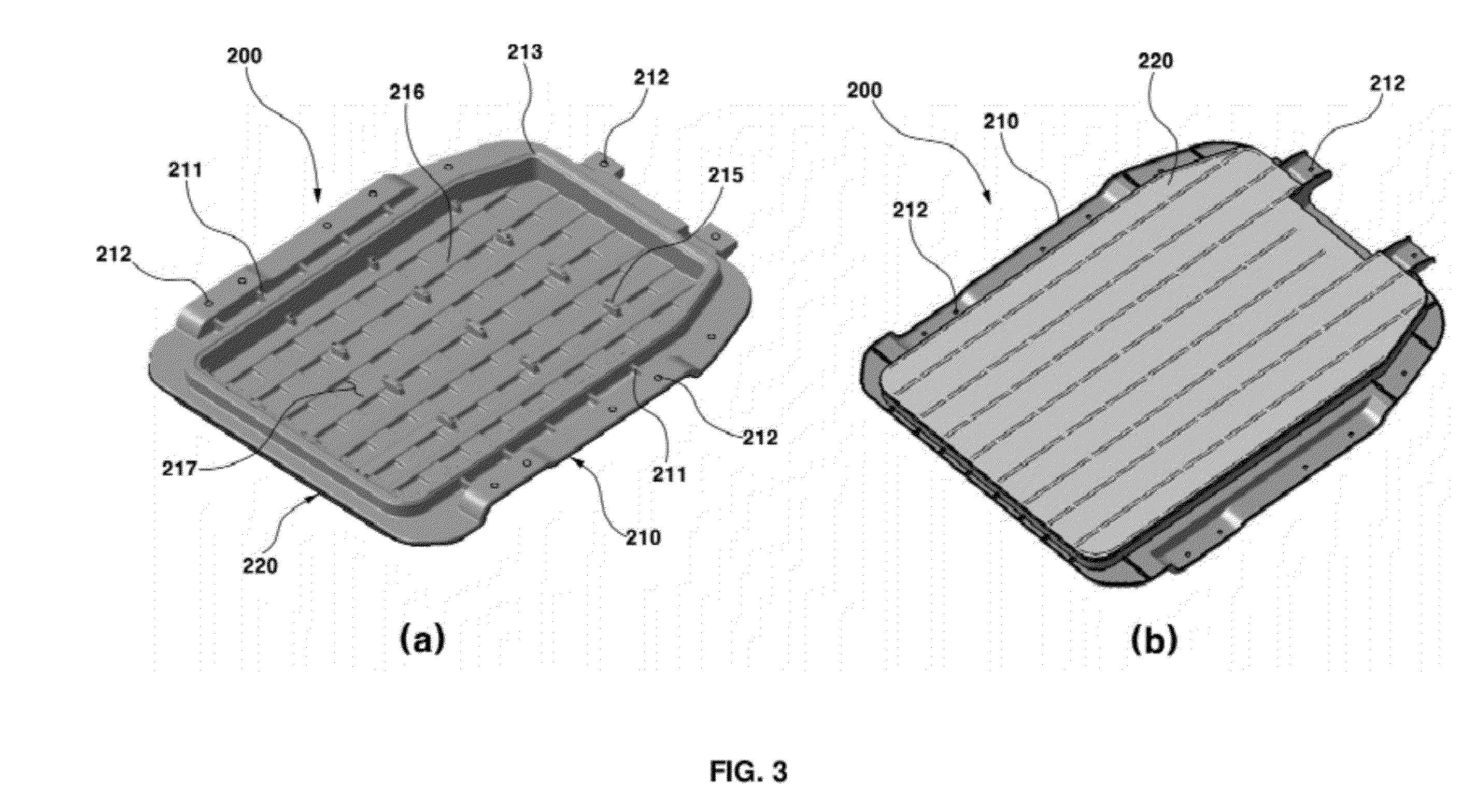

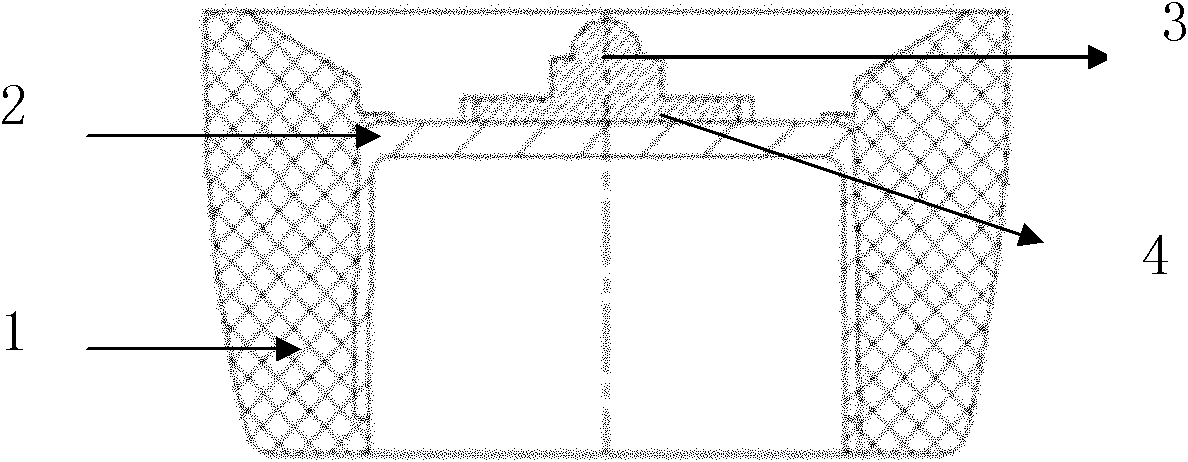

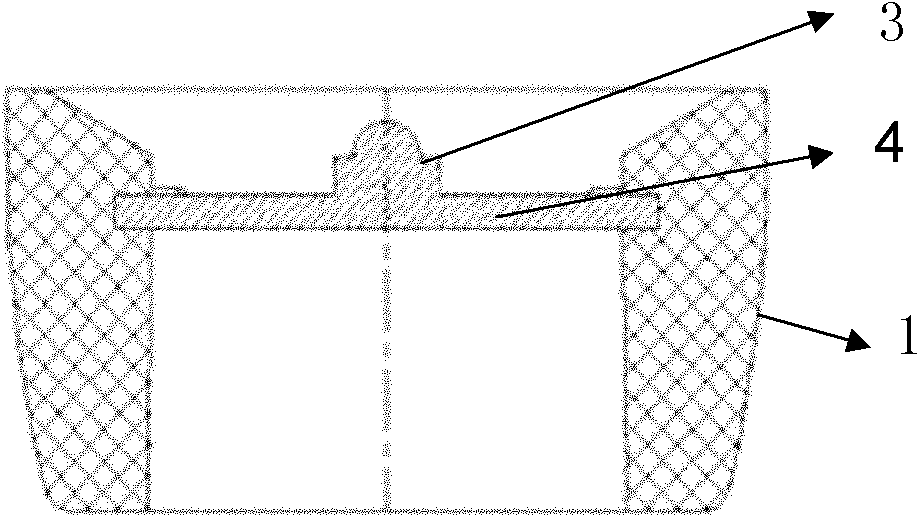

Battery pack housing assembly for electric vehicle using plastic composite material

InactiveUS20120103714A1Reduce vehicle weightImprove structural rigiditySuperstructure subunitsPropulsion by batteries/cellsFiberElectric vehicle

The present invention provides a battery pack housing assembly for an electric vehicle, which is formed of a lightweight composite material to reduce the weight and configured to have a dual laminated structure with a closed cross-sectional area formed by composite molding to absorb impact energy. For this purpose, the present invention provides battery pack housing assembly for an electric vehicle using a plastic composite material, the battery pack housing assembly having an upper cover mounted at the bottom of a vehicle body, a lower housing, and a battery pack received and mounted in the lower housing, wherein the lower housing has a dual laminated structure with a closed cross-sectional area formed by bonding an upper plate and a lower plate, each composed of a fiber reinforced plastic composite material, to absorb impact energy, thus increasing structural stiffness.

Owner:HYUNDAI MOTOR CO LTD +1

Composite material of poly lactic acid / natural faric, and production method

This invention discloses a poly (lactic acid) / natural fiber composite, which is mainly composed of poly (lactic acid) resin and natural fibers. The production method comprises: performing surface treatment on natural fibers with coupling agent, mixing with poly (lactic acid) resin, antioxidant, nucleating agent and lubricant, melt-extruding, and granulating to obtain the product. The method has such advantages as easy operation and high efficiency. The poly(lactic acid) / natural fiber composite has such advantages as high modulus, good heat resistance, good processability, and good biodegradability, and can be used in the fields of automobile industry, architecture and domestic decoration.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

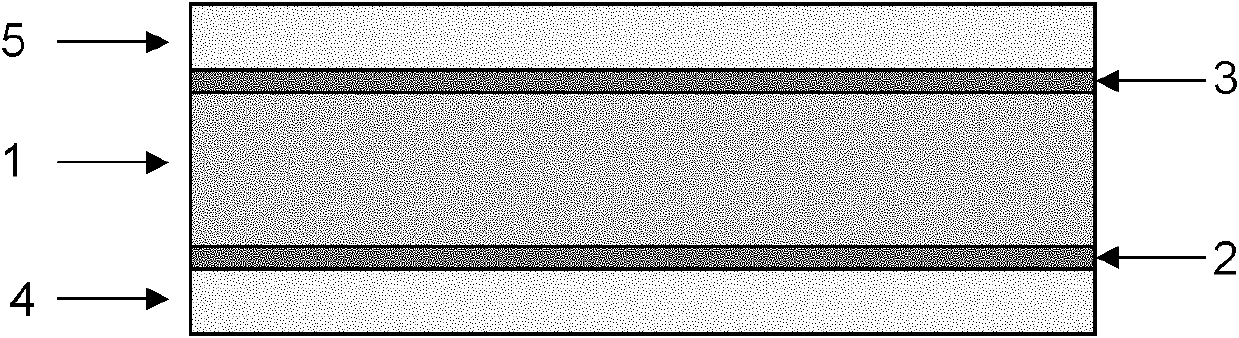

Solar cell assembly backplane and preparation method thereof

ActiveCN102738275AReduce usageExcellent formabilityFinal product manufactureSynthetic resin layered productsSolar technologyElectrical battery

The invention provides a solar cell assembly backplane, belonging to the technical field of solar energy. The solar cell assembly backplane comprises a base film layer as well as a second film layer and a third film layer arranged at two sides of the base film layer. The solar cell assembly backplane is characterized in that: the base film layer as well as the second film layer and the third film layer arranged at two sides of the base film layer are directly composited into one film through a melting co-extrusion process. At the same time, the invention also provides a preparation method of the solar cell assembly backplane. According to the invention, the use of an adhesive is avoided; and the preparation process of the solar cell assembly backplane can be completed by a single step with simple and efficient techniques; and the solar cell assembly backplane is advantaged in improved processing-shaping performance, mechanical properties, barrier properties and aging resistance performance.

Owner:DSM SUNSHINE SOLAR TECH (SUZHOU) CO LTD

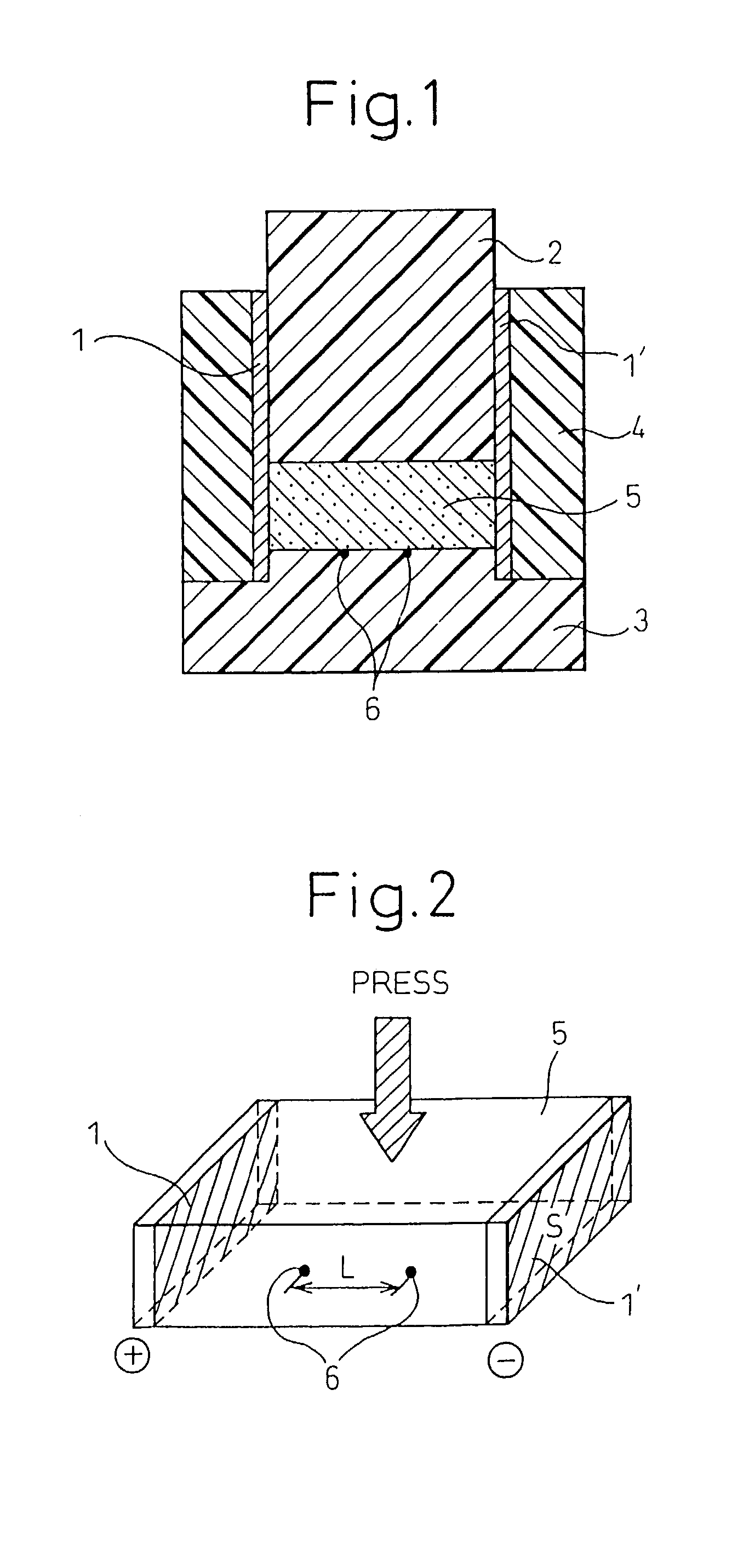

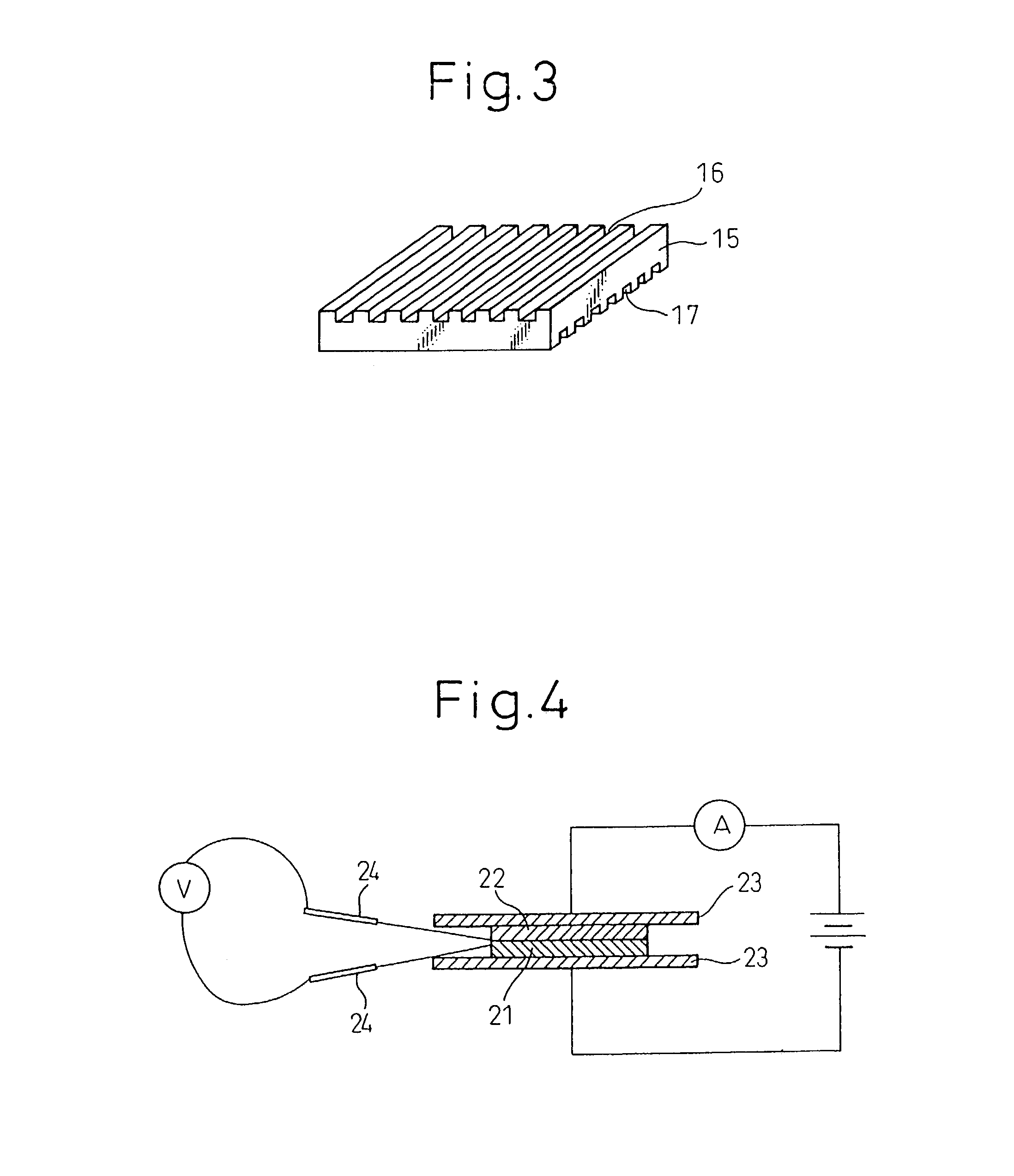

Conductive curable resin composition and separator for fuel cell

InactiveUS7329698B2Improve conductivityMaintain good propertiesMaterial nanotechnologyFinal product manufactureElastomerPolymer science

There is provided a conductive curable resin composition comprising (A) a curable resin composition comprising an elastomer with a Mooney viscosity (ML1+4 (100° C.)) of 25 or greater at 2-80 wt % and (B) a carbon material, with a weight ratio of component (A) to component (B) of 70-5:30-95. The curable resin composition of component (A) preferably comprises (A1) an elastomer at 80-2 wt %, (A2) a radical reactive resin at 20-98 wt % and (A3) an organic peroxide at 0.2-10 parts by weight to 100 parts by weight of (A1+A2). Also provided are a process for production of a conductive cured resin by shaping and curing of the conductive curable resin composition, and a fuel cell separator, an assembly for a cell, an electrode or a heat releasing plate, obtained thereby.

Owner:SHOWA DENKO KK

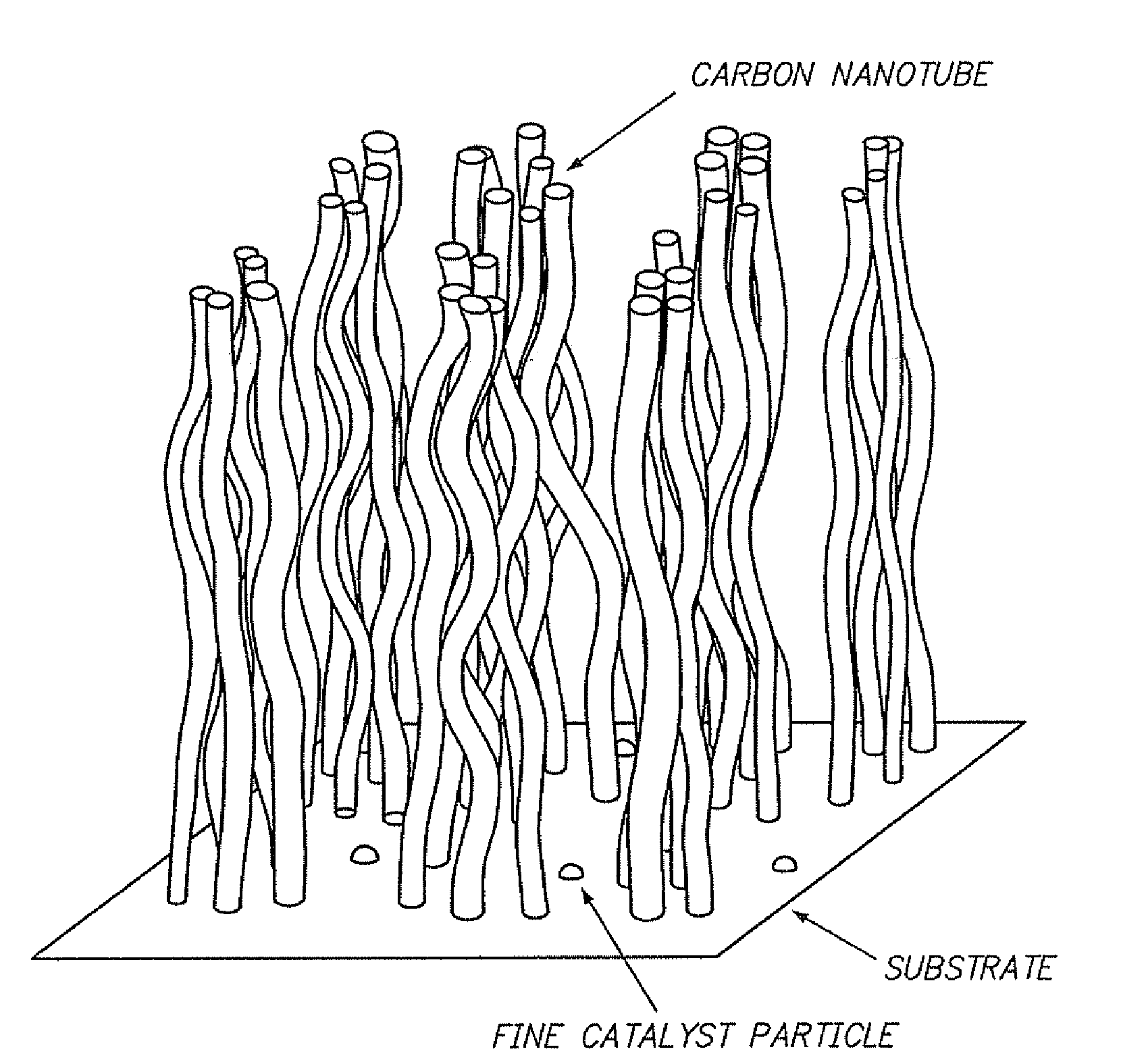

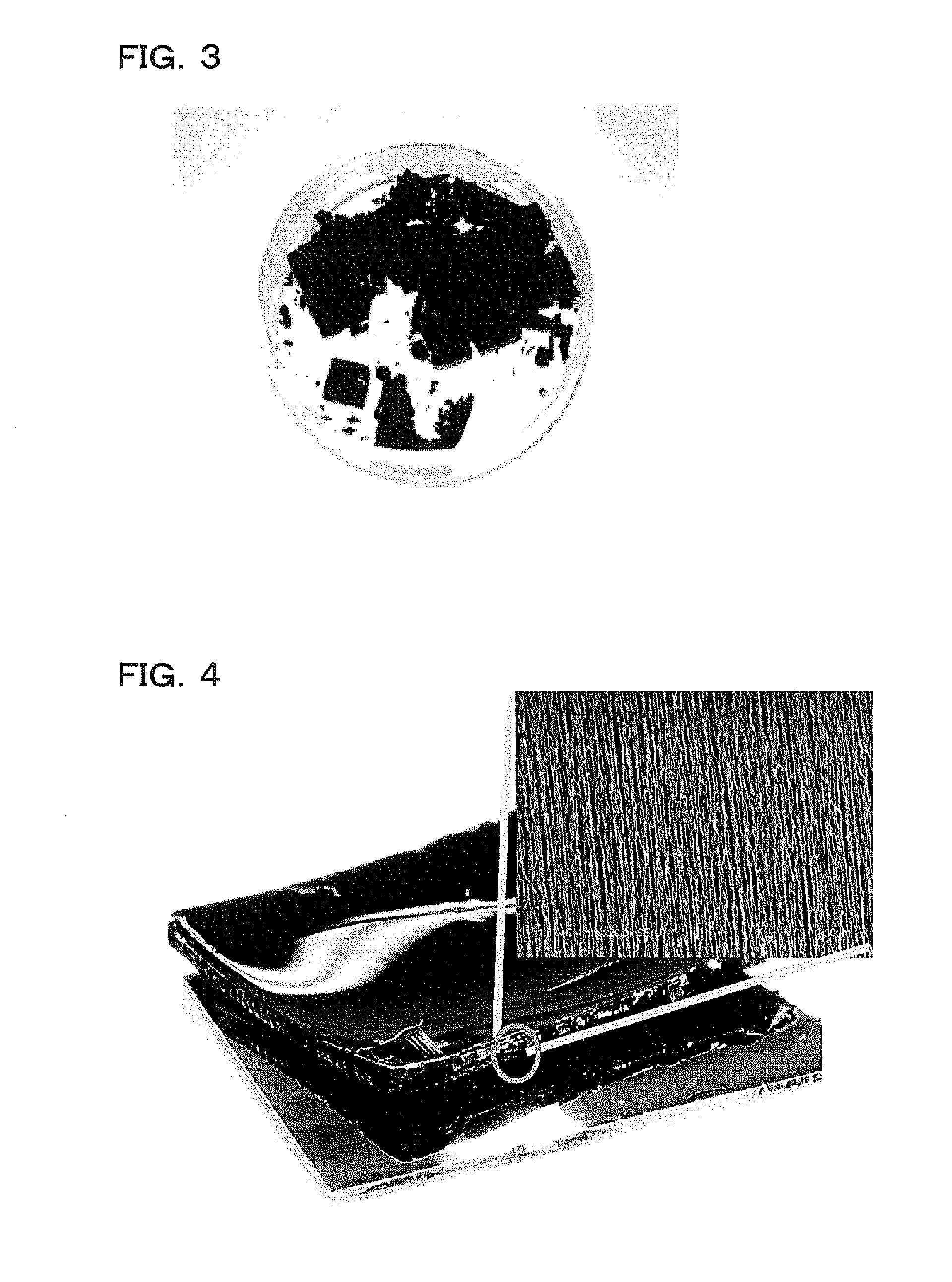

Aligned single-walled carbon nanotube aggregate, bulk aligned single-walled carbon nanotube aggregate, powdered aligned single-walled carbon nanotube aggregate, and production method thereof

InactiveUS20100062229A1Large specific surface areaExcellent formabilityMaterial nanotechnologyDecorative surface effectsCarbon nanotubeVolumetric Mass Density

This invention intends to provide an aligned single-walled CNT aggregate and the like which can be produced easily and has a high specific surface area, in which individual CNTs are aligned and which has excellent shape processability due to low bulk density. The aligned single-walled CNT aggregate of this invention comprises a base material, catalyst particles with a density of 1×1010 to 5×1013N / cm2 disposed on the base material, and a plurality of single-walled carbon nanotubes (CNTs) grown from the fine particles of the catalyst, in which the plurality of single-walled CNTs have a specific surface area of 600 m2 / g to 2600 m2 / g, and a weight density from 0.002 g / cm3 to 0.2 g / cm3, and the alignment degree is defined by a specific condition or conditions.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Polymer back panel of solar battery assembly and manufacture method of polymer back panel

ActiveCN102569452AExtend your lifeHigh bonding strengthSynthetic resin layered productsCoatingsPolymer alloyPolyethylene terephthalate glycol

The invention provides a polymer back panel of a solar battery assembly. The polymer back panel comprises a base film layer, binding layers on both sides of the base film layer, a fourth thin film layer and a fifth thin film layer on the other two sides of the binding layers, wherein the base film layers contain at least one of the following components: polyamide polymers, polypropylene and acrylic polymers, polyethylene and ethylene polymers, polyvinylidene chloride, styrene polymers, ABS (acrylonitrile butadiene styrene) resins, liquid crystal polymers, acrylic acid polymers, polyphenyl ether, polycarbonate and polymer alloy of polycarbonate and poly(C2-6 alkal terephthalate). In addition, the invention also provides a manufacture method of the back panel. By adopting a thin film structure made of one or more of the above polymers to substitute for the conventional PET (polyethylene terephthalate) layer, the polymer back panel has excellent processing formation performance, material mechanical performance, barrier performance and anti-aging performance; and a back panel laminated film can be prepared by molten co-extrusion or extrusion composite process, with the advantages of significantly improved bonding strength between the films and simplified production process.

Owner:DSM SUNSHINE SOLAR TECH (SUZHOU) CO LTD

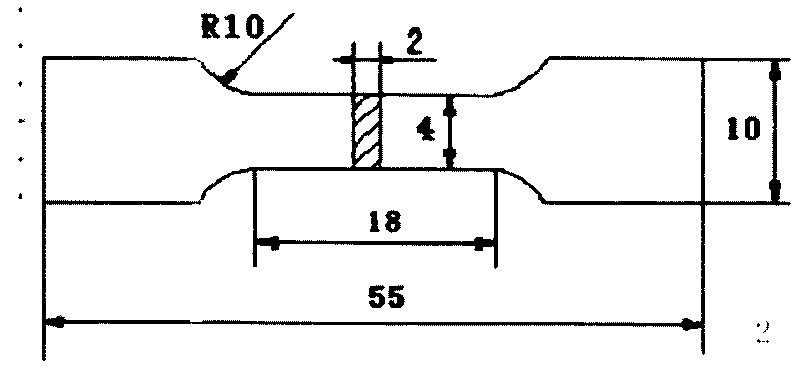

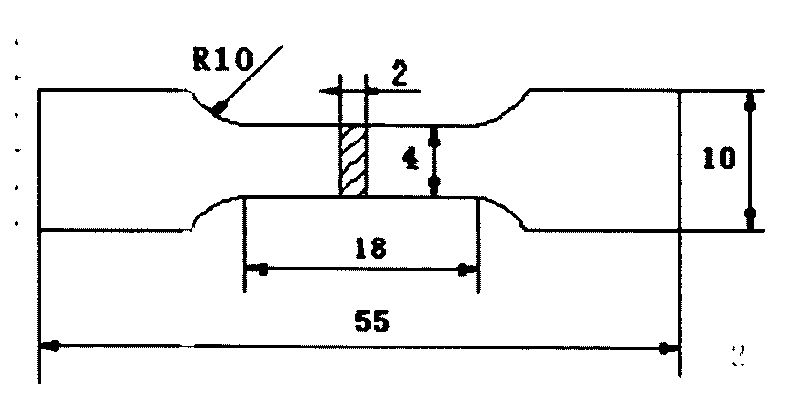

Process for preparing biomedical beta-titanium alloy

InactiveCN101724764AImprove performanceHigh strengthImpression capsFurnace typesMaterials processingQuenching

The invention discloses a process for preparing a biomedical beta-titanium alloy. The process comprises the following steps: A) alloy preparation; B) surface coating; C) hot forging and cogging; D) hot rolling; E) cold rolling and molding; and F) heat treatment. In the process, the material is manufactured to a 2mm plate after the beta-titanium alloy is subjected to high vacuum electric arc melting, repeated stirring, casting, phase transformation point measuring, homogenization under the protection of vacuum and argon, coating, hot forging, hot rolling, cold rolling, solid solution, water quenching, artificial aging and water cooling so as to prepare the biomedical beta-titanium alloy with excellent comprehensive performance. The process is a biomedical beta-titanium preparation process capable of improving the material strength, abrasion resistance and corrosion resistance, reducing the elasticity modulus of the material, and maintaining excellent manufacturing and molding performance of the material.

Owner:CENT SOUTH UNIV

Heat-conducting thermosetting molding composite material and application thereof

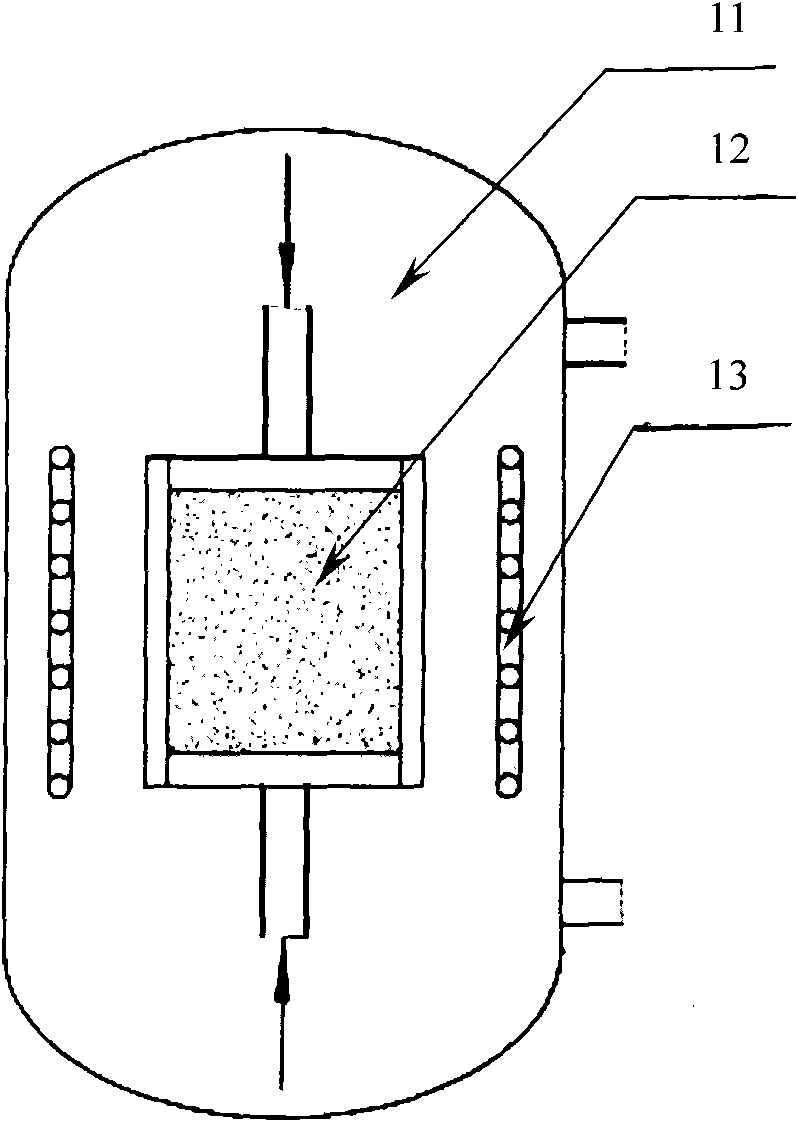

The invention discloses a heat-conducting thermosetting molding composite material and application thereof. The heat-conducting thermosetting molding composite material comprises the following basic components in percentage by weight: (1) 15-65% of thermosetting matrix resin; (2) 20-80% of heat-conducting filler with a thermal conductivity greater than 1 W / m.DEG C; and (3) other additives, such as a toughening agent, an enhancer, a stabilizer and the like. The invention also discloses application of the heat-conducting thermosetting molding composite material in manufacturing LED (light emitting diode) lighting heat-radiation components. The molding temperature of the composite material can be controlled to below 220 DEG C that is the general soldering operation temperature, so that the assembly process of an LED lamp and a heat radiator and the molding process of a thermosetting material heat radiator can be integrated, and the substrate surface or heat-conducting metal support of the LED lamp can be directly connected with the heat-conducting material; and the molding die of the composite material and auxiliary systems thereof have the characteristics of effective heat insulation and temperature control and easy cleaning, and can effectively lower the processing and manufacturing cost of the LED lamp and improve the heat radiation capability of the LED heat radiator, thereby reducing the operating temperature of LED devices.

Owner:HEFU NEW MATERIAL TECH WUXI

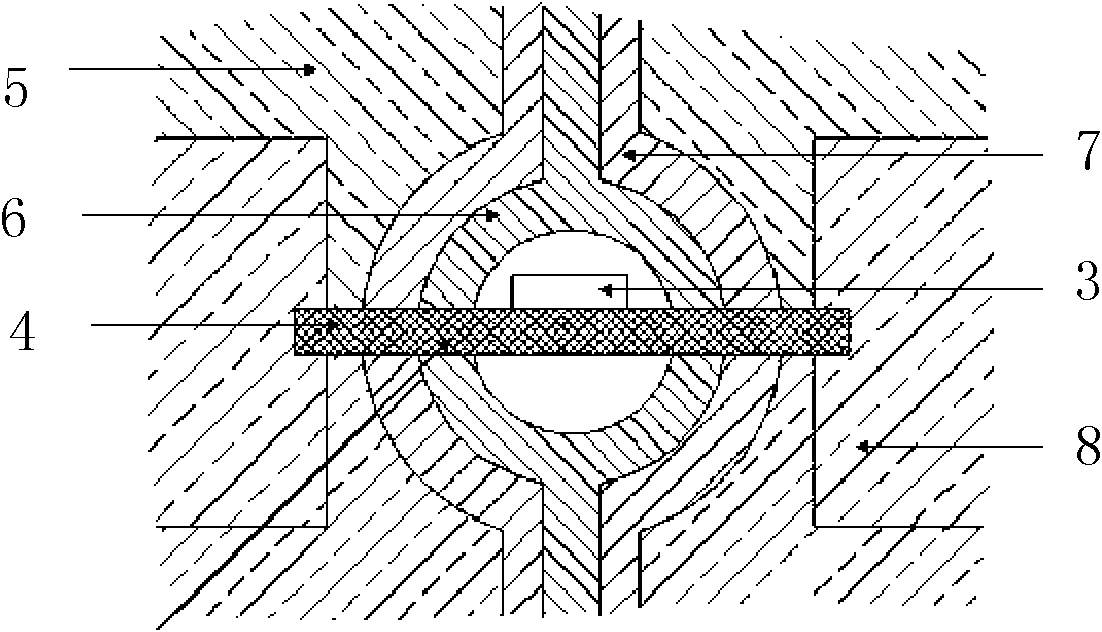

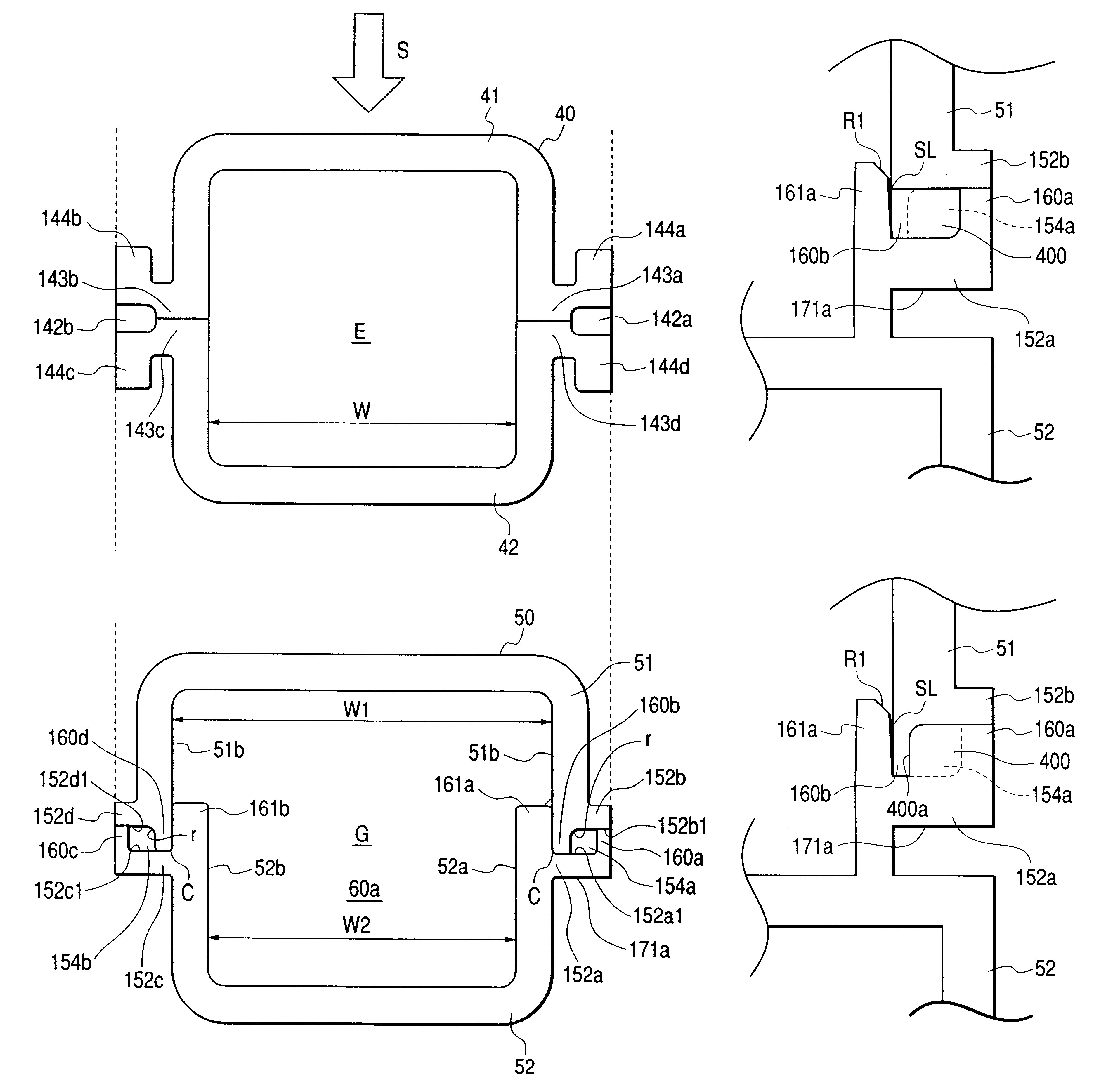

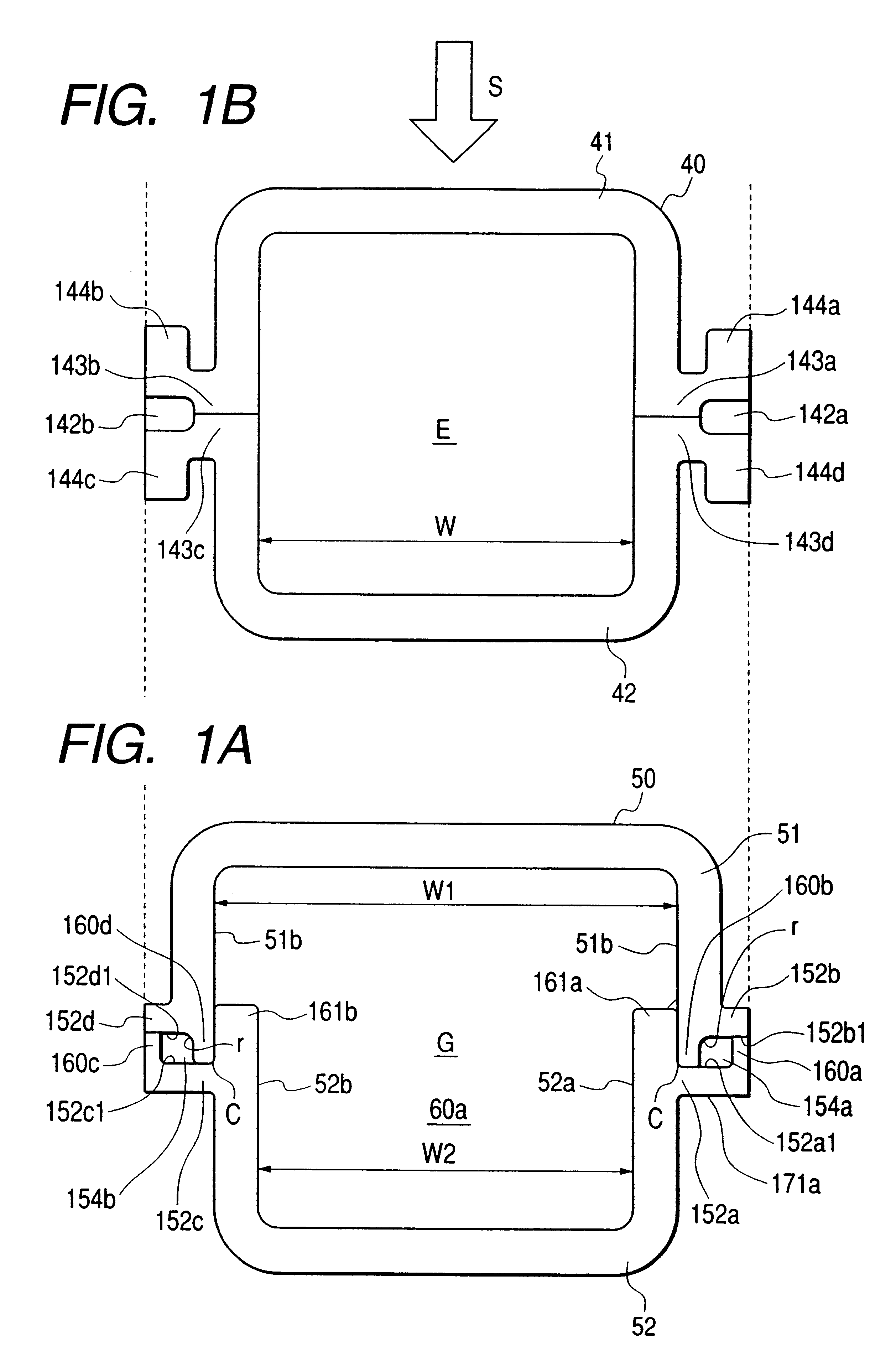

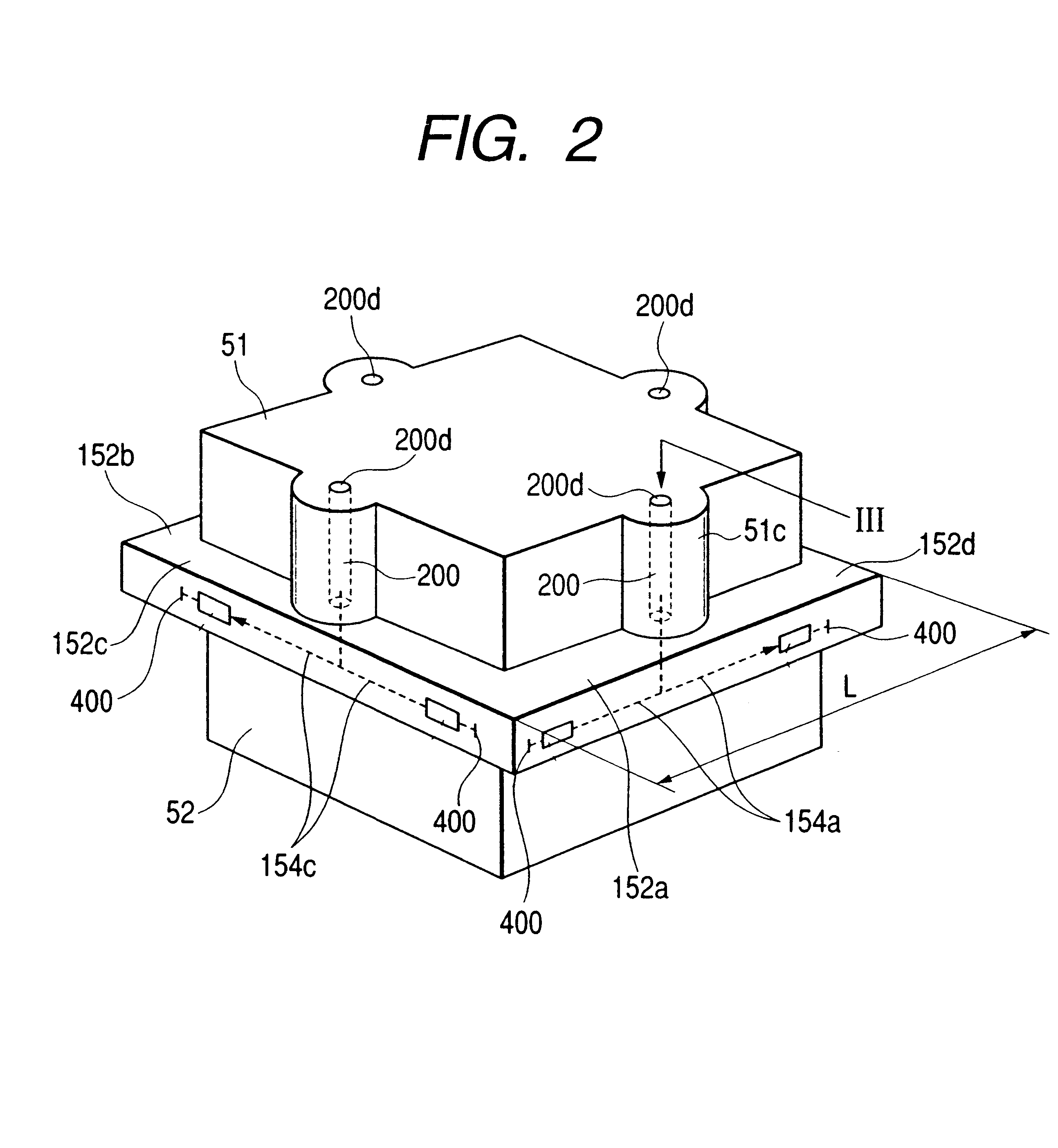

Image forming apparatus to which a process cartridge having a part connecting member is detachably mountable, process cartridge having a part connecting member, and part connecting member

InactiveUS6654578B2Excellent formabilityIncrease freedomLaminationLamination apparatusEngineeringSynthetic resin

A synthetic resin part connecting member connects at least two injection molded pieces that can be used as frames for a process cartridge detachably mountable on an image forming apparatus. The molded pieces are set in dies different from the dies used for forming the molded pieces, and a molten resin is injected into a gap formed between opposed surfaces of the molded pieces. An injection channel for the molten resin up to the gap is formed in one of the molded pieces. A rib for stopping resin is provided in the injection channel to stop the flow of the molten resin injected into the injection channel.

Owner:CANON KK

Moulding-grade wood-plastic composite and processing process

InactiveCN101024709AImprove high temperature fluidityExcellent formabilityCoatingsMoulding gradeStearic acid

The invention relates to an injection moulding wood plastic compound material and the process technology. It is made up from recycled P or HDPE or PVC 100 portions, wood flour 80-130 portions, chlorinated polyethylene 5-10 portions, polyethylene wax 0.5-5.0 portions, geoceric acid or stearate 1.0-5.0 portions, nanometer reinforcing agent 4.0-8.0 portions, organic esters flexibilizer 5.0-15.0 portions, and PE grafted by maleic anhydride 5.0-20 portions. Mixing the materials at low speed (300-600round / min), high speed (1500-2500 round / min), low speed (300-600 round / min) for 5-10min, 25-40min, and 5-10min, the premixed material would be gained. After being extruded from extruder, the moulding wood plastic compound material would be gained. It could be widely used in producing complex shaped products.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

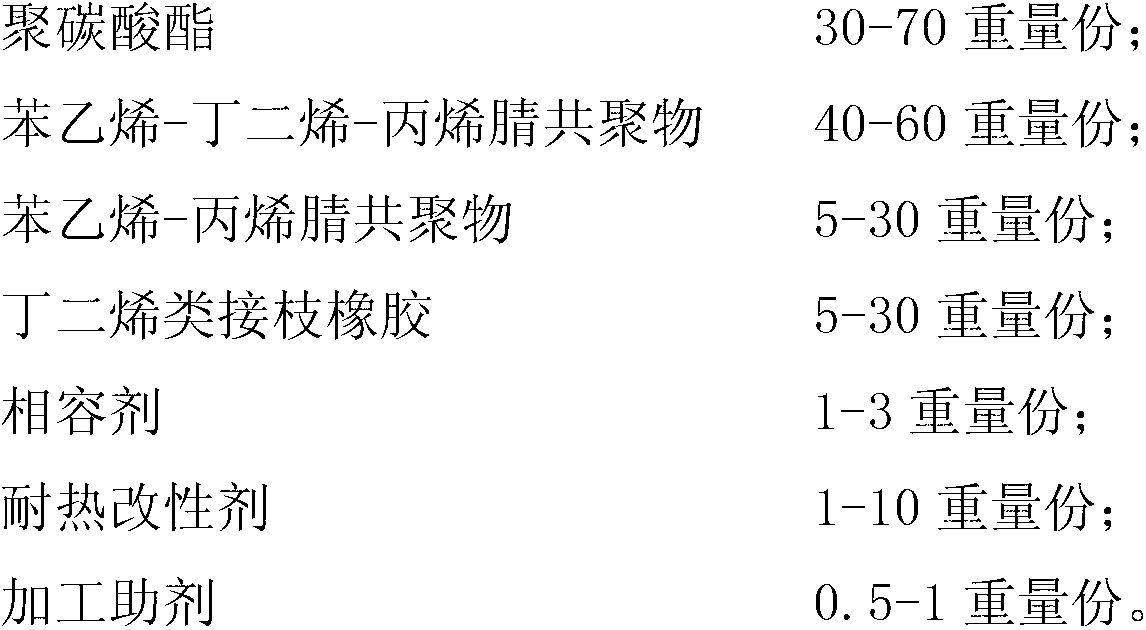

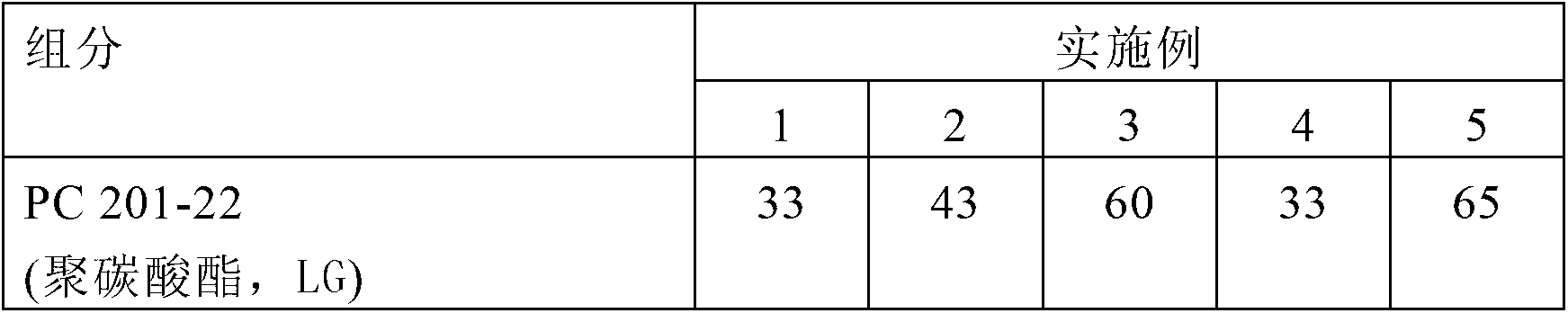

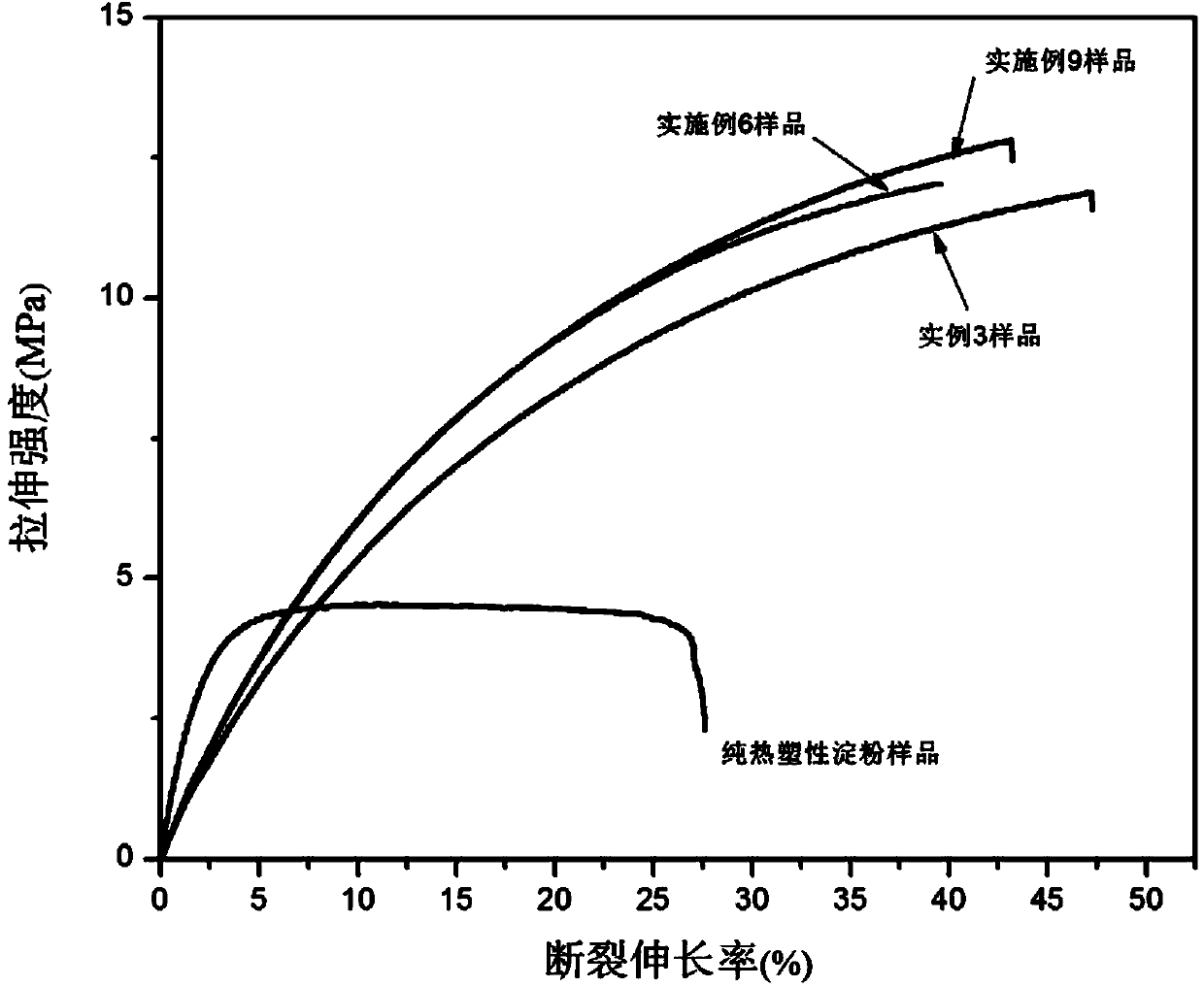

Electroplating PC/ABS (polycarbonate/acrylonitrile-butadiene-styrene) alloy material and preparation method thereof

The invention provides an electroplating PC / ABS (polycarbonate / acrylonitrile-butadiene-styrene) alloy material and a preparation method thereof. The electroplating PC / ABS alloy material comprises the following components in parts by weight: 30-70 parts of PC, 40-60 parts of ABS, 5-30 parts of styrene-acrylonitrile copolymer, 5-30 parts of butadiene graft rubber, 1-3 parts of compatilizer, 1-10 parts of heat-resistance modifier and 0.5-1 part of processing assistant. The alloy material provided by the invention has the advantages of favorable electroplating properties, excellent mechanical properties and favorable heat resistance, and can be used for designing automobile internal and external ornaments, including heat dissipation grids, door grips, vehicle logos, instrument panel decorating strips and the like.

Owner:中广核俊尔(上海)新材料有限公司

Car body aluminum alloy plate and manufacturing method thereof

InactiveCN103173661ALower yield strengthExcellent formabilityUltimate tensile strengthBake hardening

The invention provides a high-strength brake hardening car body aluminum alloy plate and a manufacturing method thereof, and belongs to the technical field of aluminum alloy. The aluminum alloy has the component characteristic that a Zn element is added on the basis of the conventional AL-Mg-Si-Cu quaternary alloy, so that the alloy has higher brake hardening performance; and interaction, strengthening-phase separation process and the like among solute elements are reasonably adjusted through reasonable pre-ageing process optimization control, and therefore, a novel car material Al-Mg-Si-Cu-Zn quinary aluminum alloy with excellent comprehensive performances is successfully developed. By adding the element Zn, the aluminum alloy material disclosed by the invention has the performance characteristic of being low in yield strength, good in plasticity and conductive to stamping and forming a car covering piece before baking finish; and after baking finish is finished, the yield strength is greatly improved, the tensile strength is high and the bake hardening performances are high.

Owner:UNIV OF SCI & TECH BEIJING +1

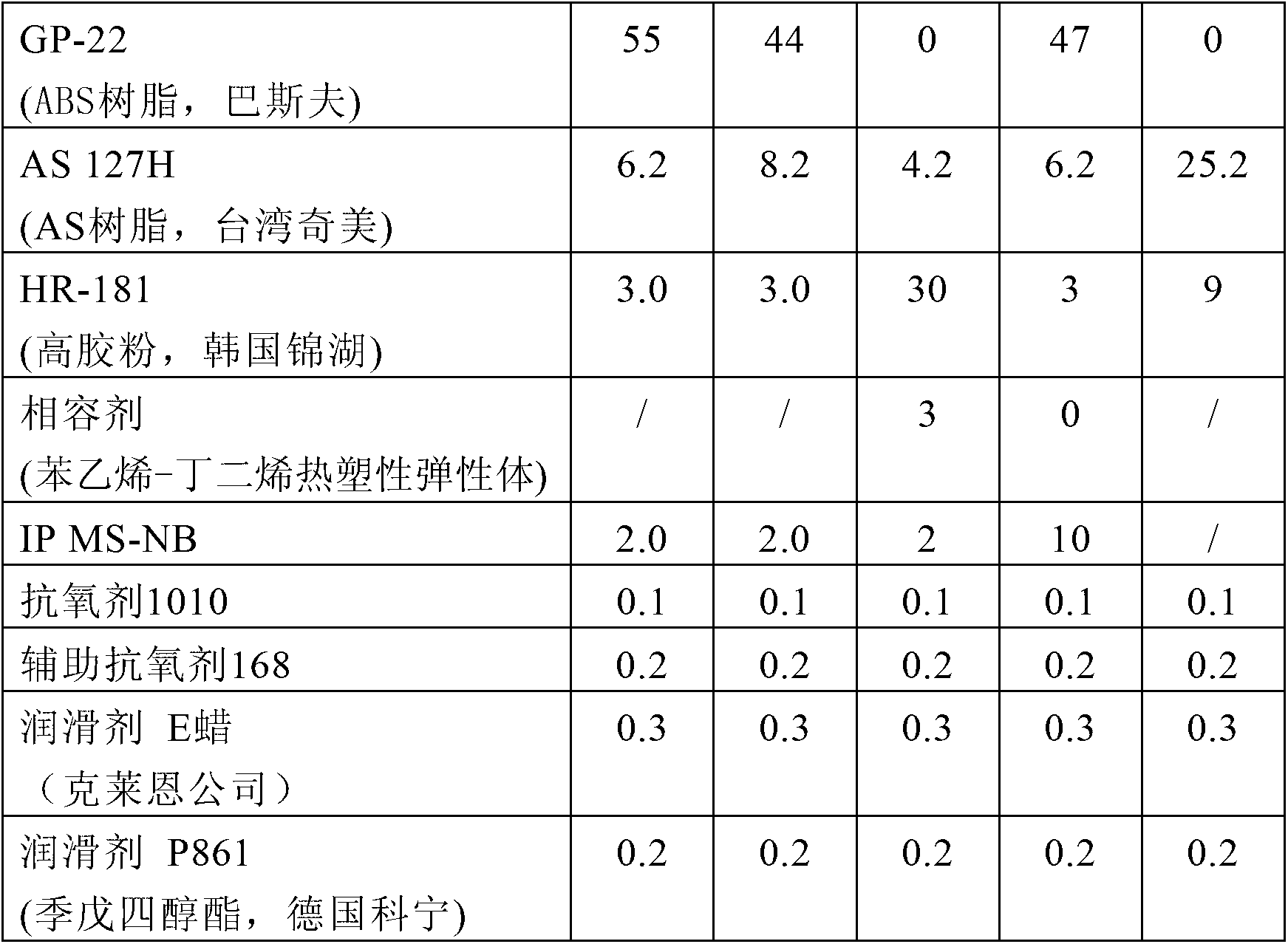

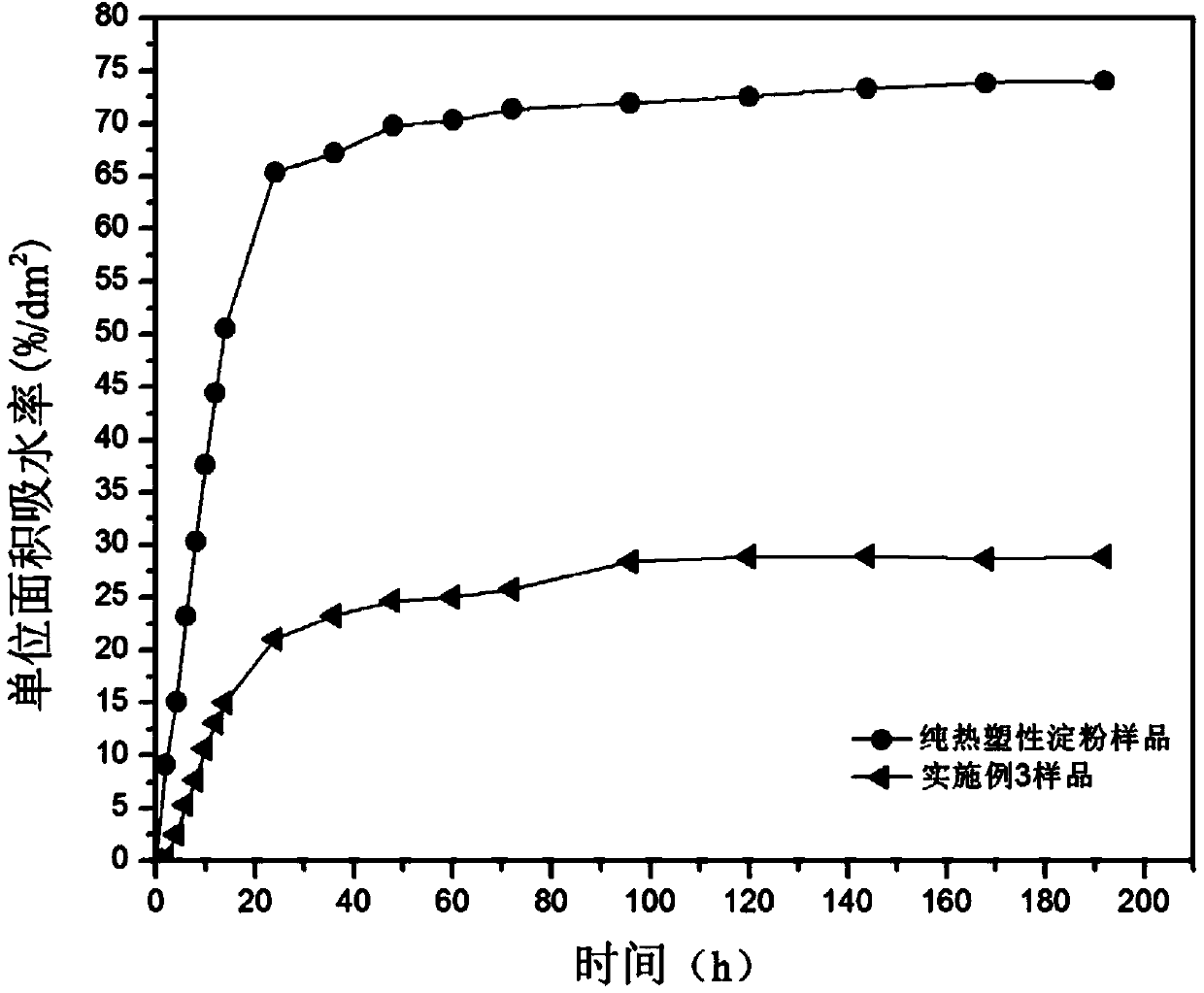

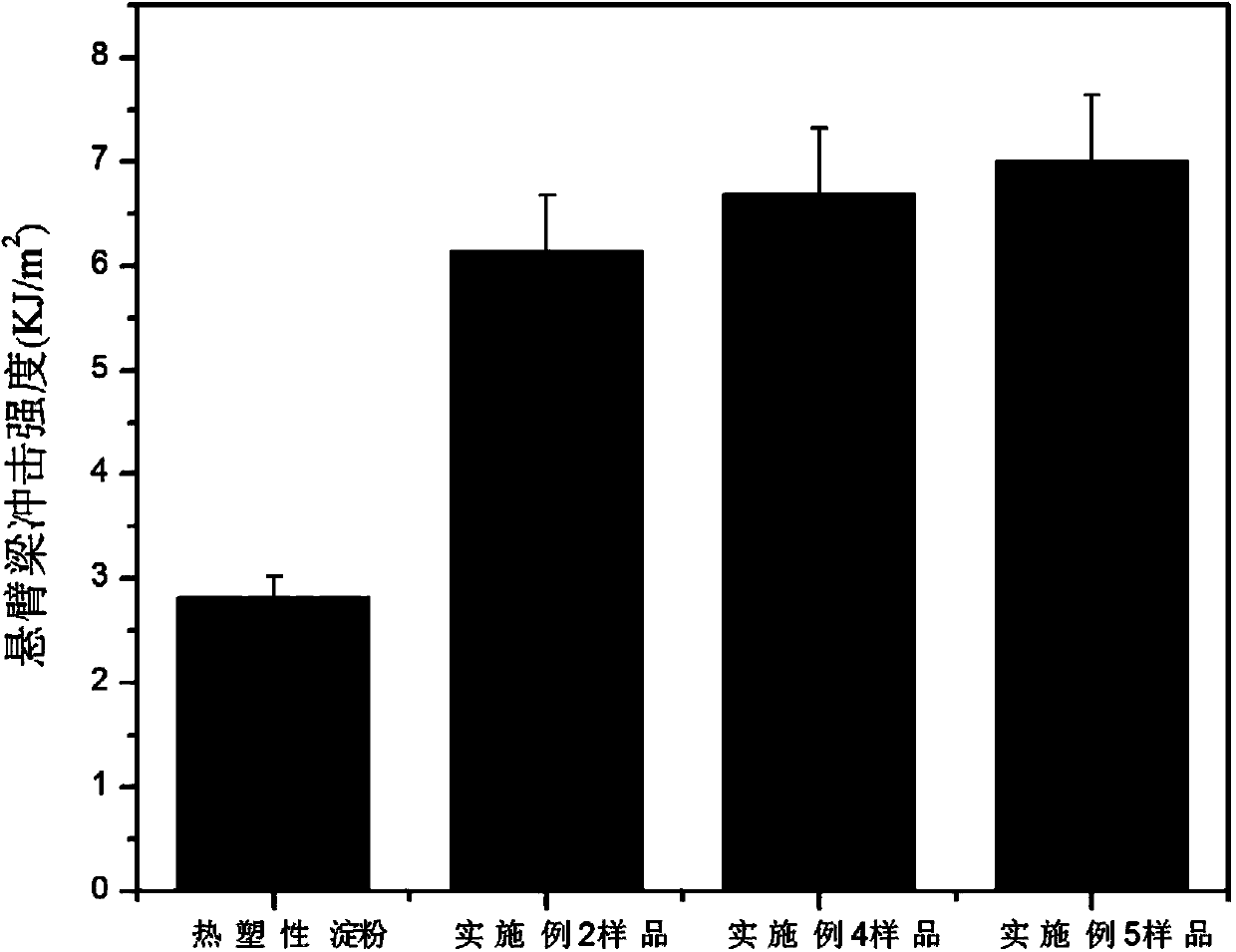

Continuously-produced full-degradable starch-based plastic alloy and preparation method thereof

The invention discloses a continuously-produced full-degradable starch-based plastic alloy and a preparation method thereof. The starch-based plastic alloy contains the following components in parts by weight: 40-90 parts of starch, 5-60 parts of poly(butylene succinate), 5-60 parts of polylactic acid, 10-40 parts of plasticizer, 0.1-10 parts of compatibilizer and 1-10 parts of processing acid. The preparation method comprises the steps of mixing starch, plasticizer and part of processing aid, and extruding to obtain thermoplastic starch particles; then, mixing the thermoplastic starch particles with poly(butylene succinate), polylactic acid, compatibilizer and the residual processing aid, and extruding to obtain the starch-based plastic alloy. The starch-based plastic alloy disclosed by the invention is favorable in hydrophobicity and strength, good in component compatibility, favorable in thermoplastic processability, capable of realizing continuous production and processing as well as simple and feasible in technical process.

Owner:EAST CHINA UNIV OF SCI & TECH

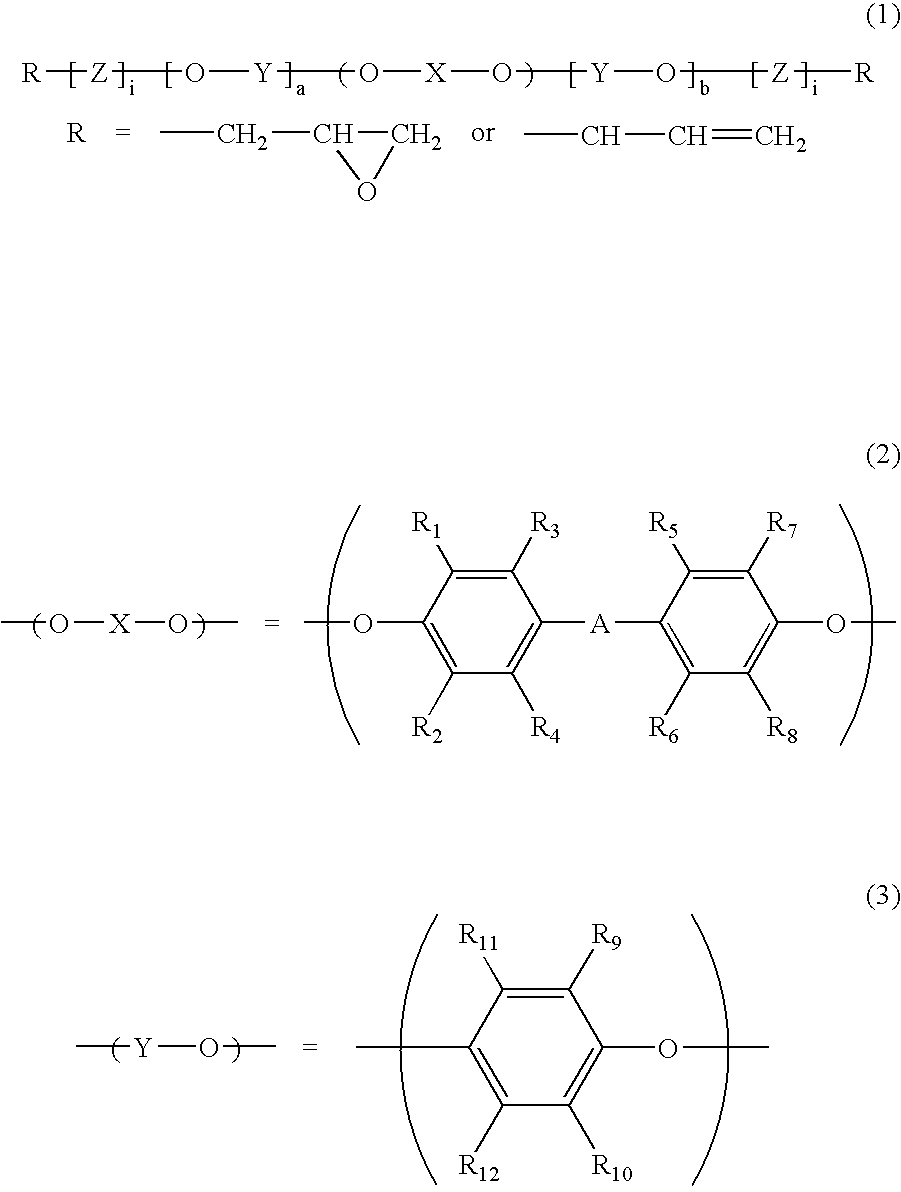

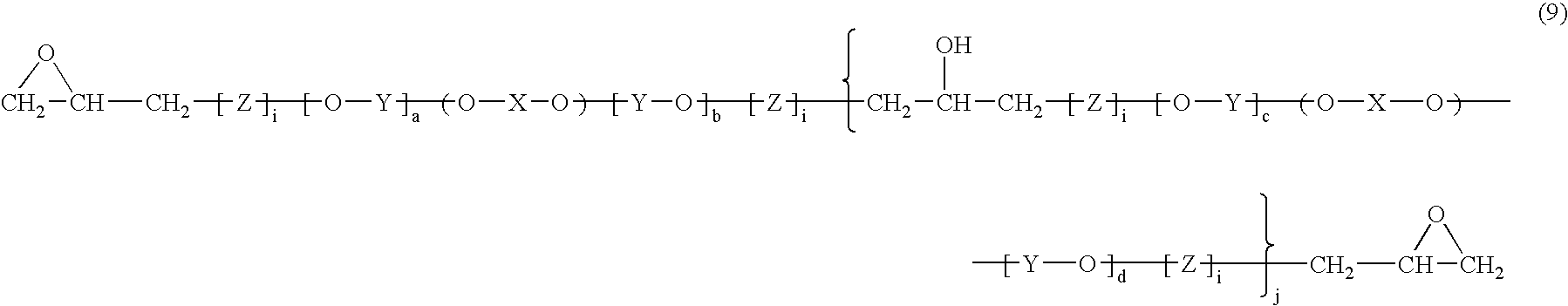

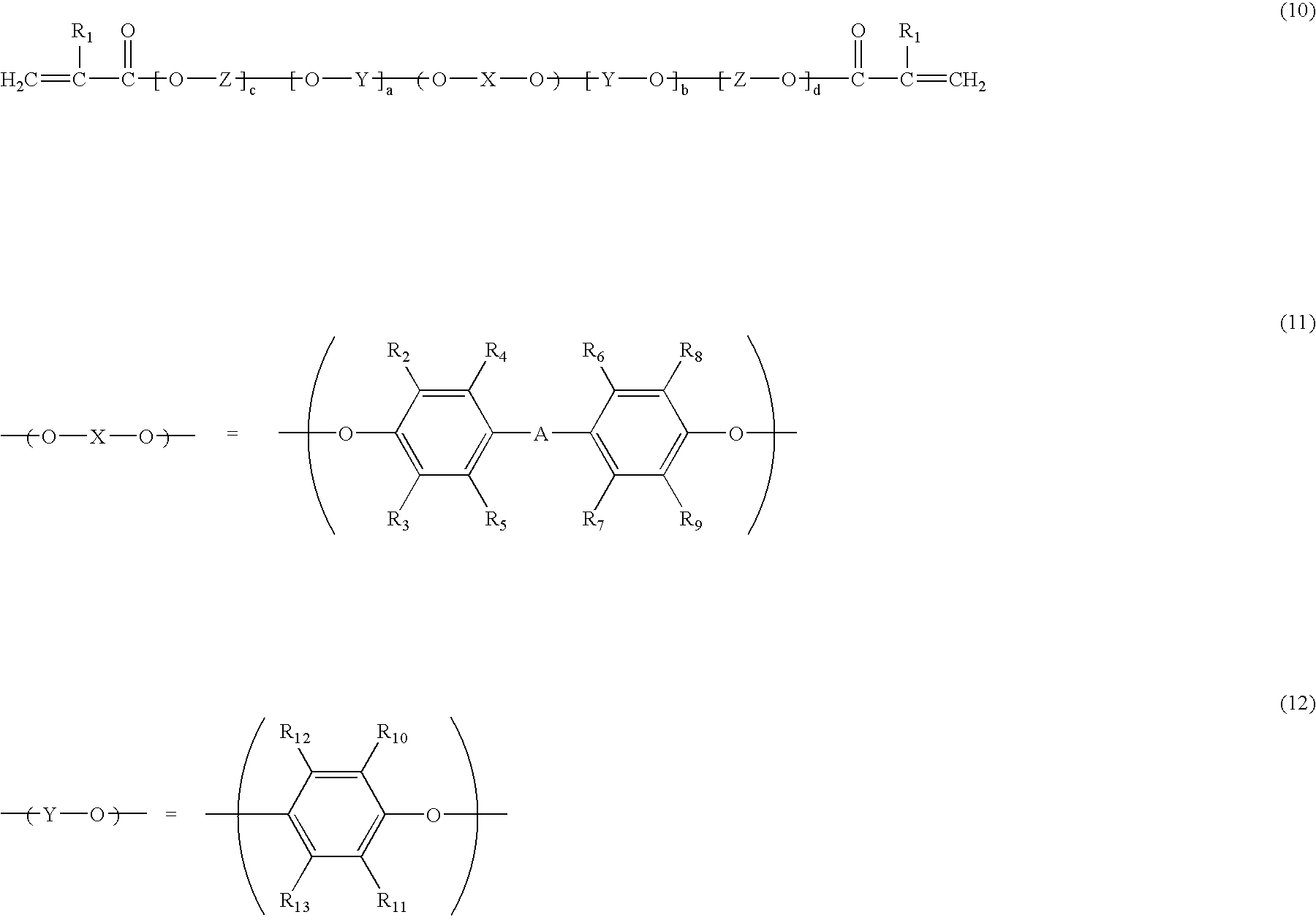

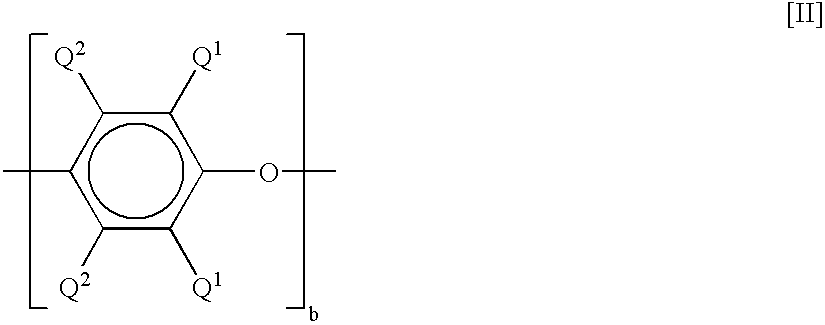

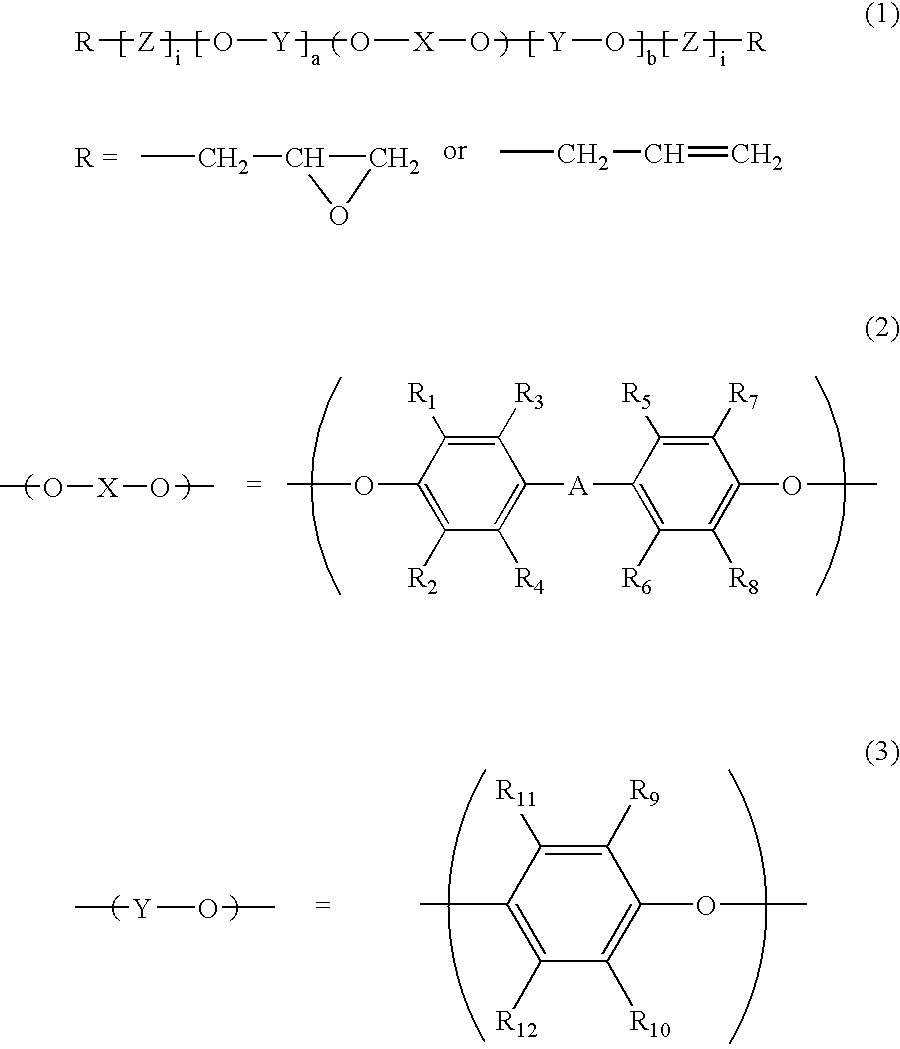

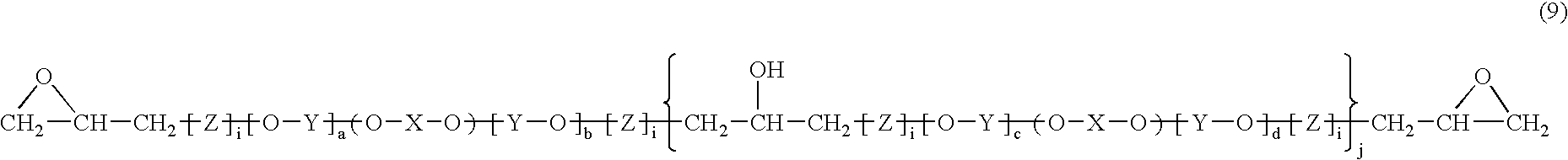

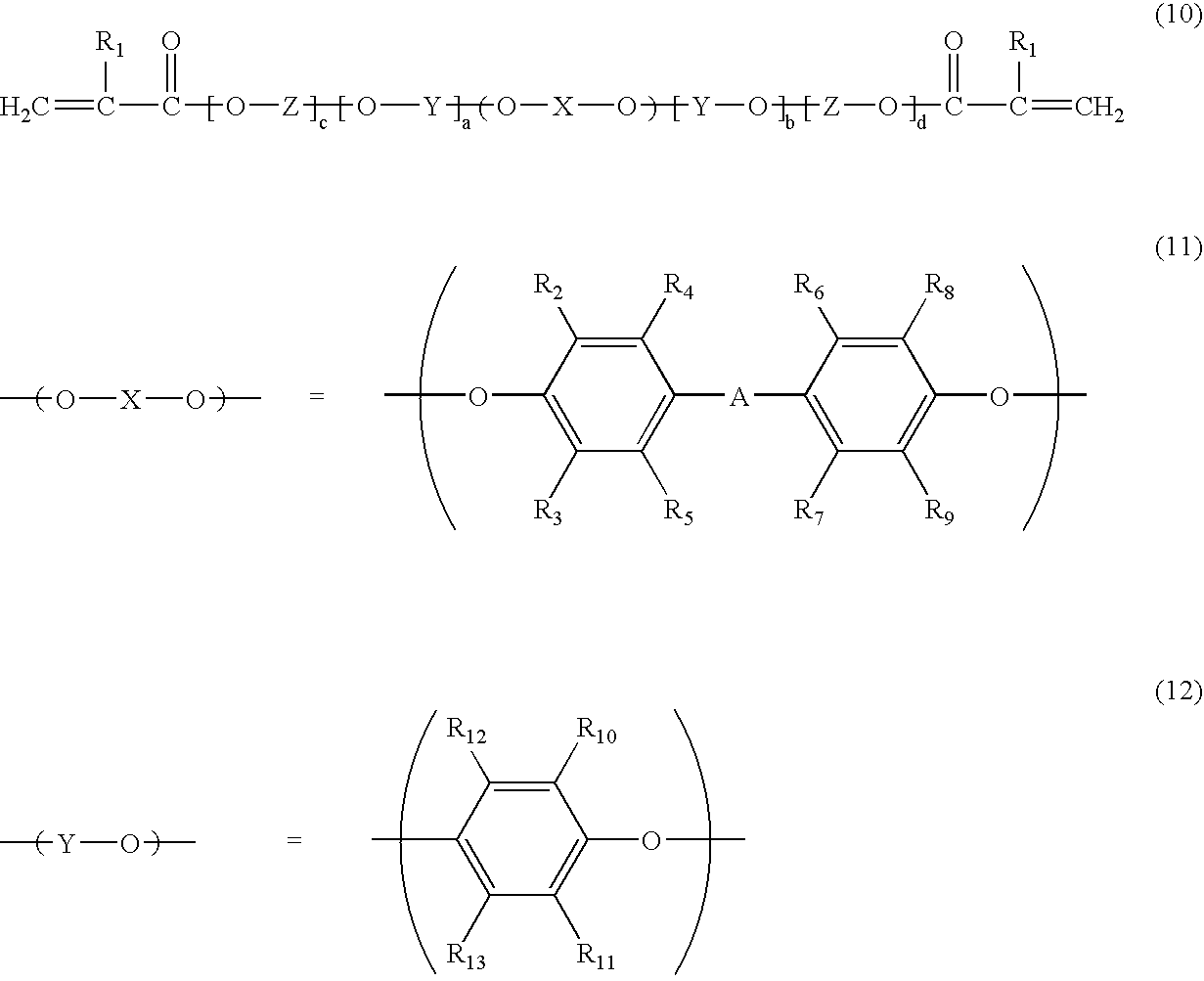

Polyphenylene ether oligomer compound, derivatives thereof and use thereof

InactiveUS20080033117A1Maintain good propertiesImprove compatibilityPrinted circuit aspectsPrinted circuit manufactureEpoxyOligomer

The present invention provides a bifunctional phenylene ether oligomer compound having a thermosetting functional group at each terminal, an epoxy resin containing the above oligomer compound and a use thereof. That is, it provides a sealing epoxy resin composition for sealing an electric part, an epoxy resin composition for laminates, a laminate, a printed wiring board, a curable resin composition and a photosensitive resin composition. The resins and resin compositions of the present invention are used in electronics fields in which a low dielectric constant, a low dielectric loss tangent and high toughness are required and also used for various uses such as coating, bonding and molding.

Owner:MITSUBISHI GAS CHEM CO INC

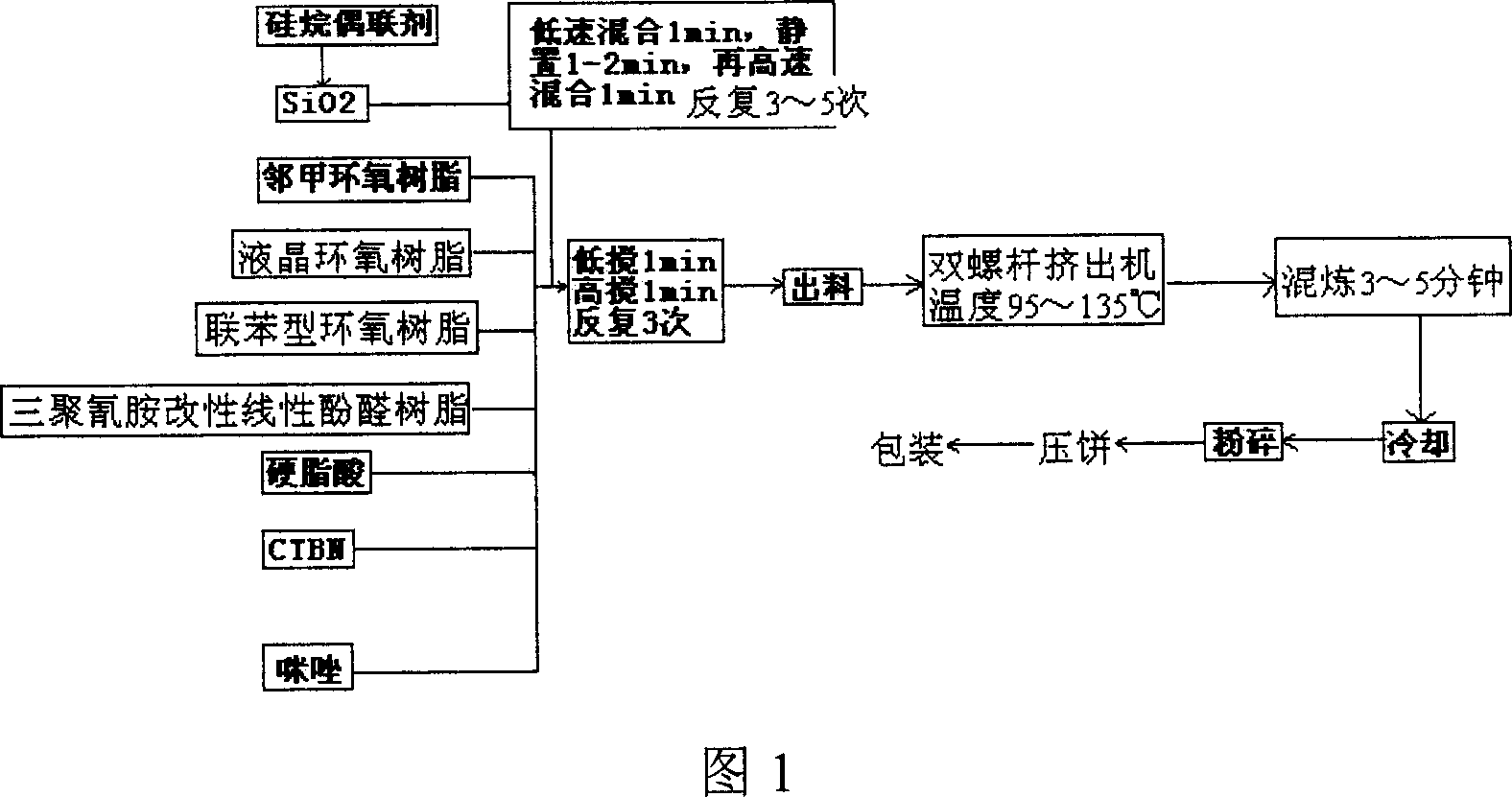

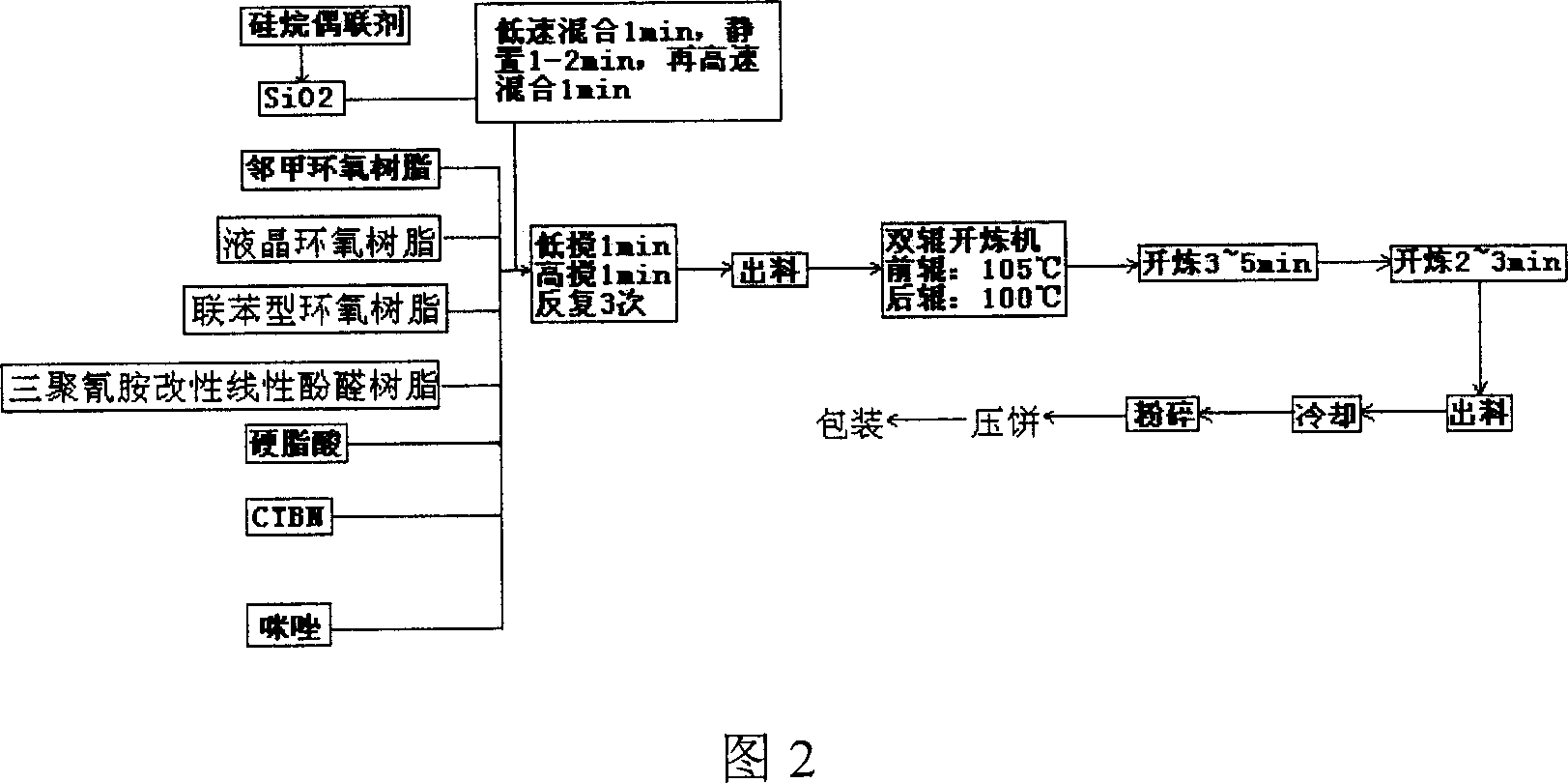

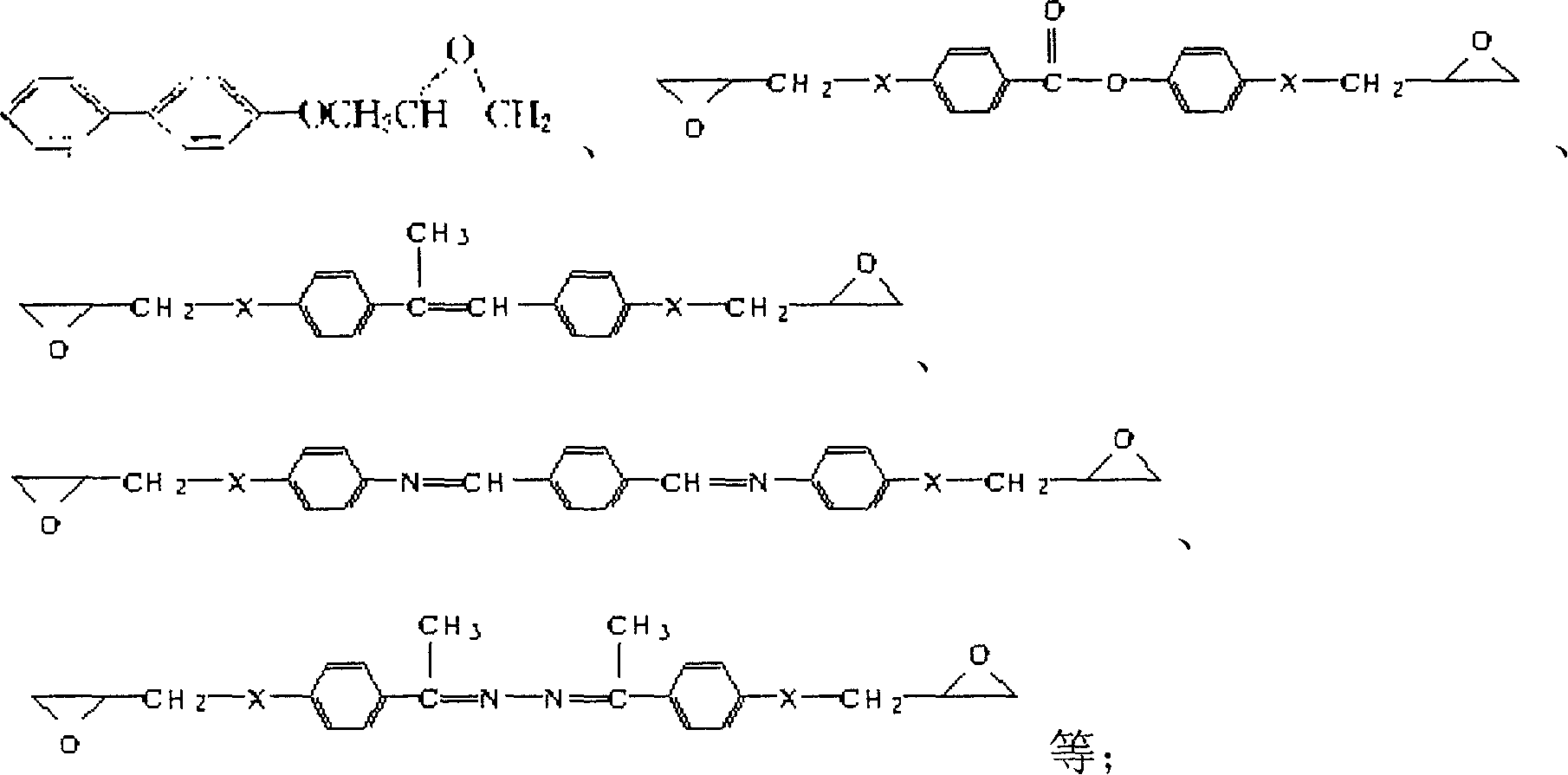

Epoxy-resin mould plastic for packing IC circuit and its production

InactiveCN101029165AHigh glass transition temperatureReduce melt viscositySemiconductor/solid-state device detailsSolid-state devicesEpoxyThermal expansion

An epoxy resin mold plastic and its production are disclosed. The mold plastic consists of liquid-crystal epoxy resin, methyl-phenolic epoxy resin, epoxy resin containing biphenyl unit structure, melamine modified linear phenolic resin, silicone micro-powder, imidazo curing improver, toughening agent and silane coupling agent. The process is carried out by treating silicone micro-powder in mixer by coupling agent for 2-5mins, adding into other components, mixing for 3-5mins, melt milling at 95-135 degree for 3-5mins, cooling, crushing, mesh screening, pressing into material cake and storing below 6degree. Its advantages include low thermal expansion coefficient, excellent heat and fire resistances, better toughness and fluidity, no phosphor, no antimony and environmental pollution. It can be used to pack large-scale circuit and electronic devices.

Owner:GUANGDONG RONGTAI IND

Thermoplastic Polymer Composition

InactiveUS20090011164A1Excellent formabilityMaintain good propertiesBottlesSynthetic resin layered productsPolymer scienceThermoplastic elastomer

An object of the present invention is to provide a thermoplastic polymer composition which is flexible and capable of melt-molding and has excellent heat resistance, chemical resistance and oil resistance. The thermoplastic polymer composition comprises 10 to 95% by weight of a fluororesin (A) and 90 to 5% by weight of a crosslinked fluororubber (B), in which the fluororubber (A) comprises a fluorine-containing ethylenic polymer (a) having a melting point of 120° to 330° C. and the crosslinked fluororubber (B) is obtained by cross-linking dynamically at least one kind of fluororubber (b-1) or a fluorine-containing thermoplastic elastomer (b-2) in the presence of the fluororubber (A) and a crosslinking agent (C) under melting condition.

Owner:DAIKIN IND LTD

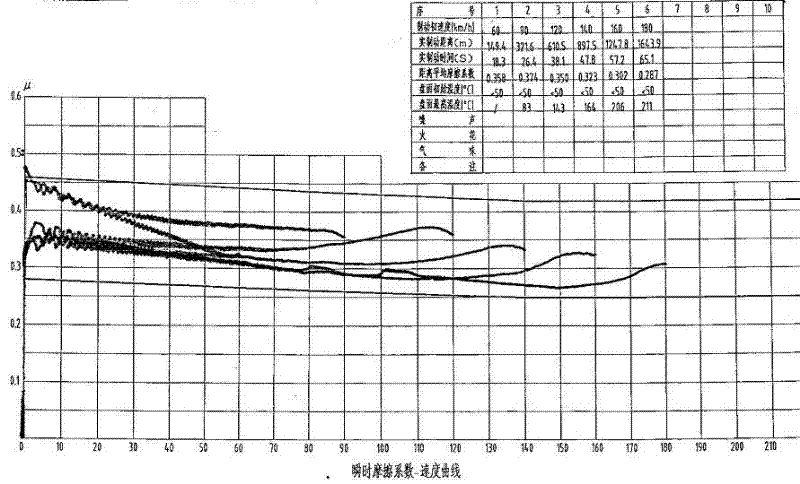

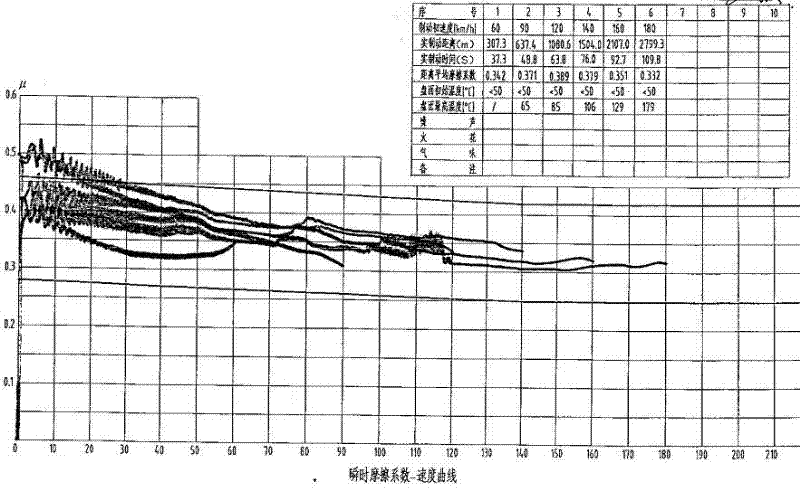

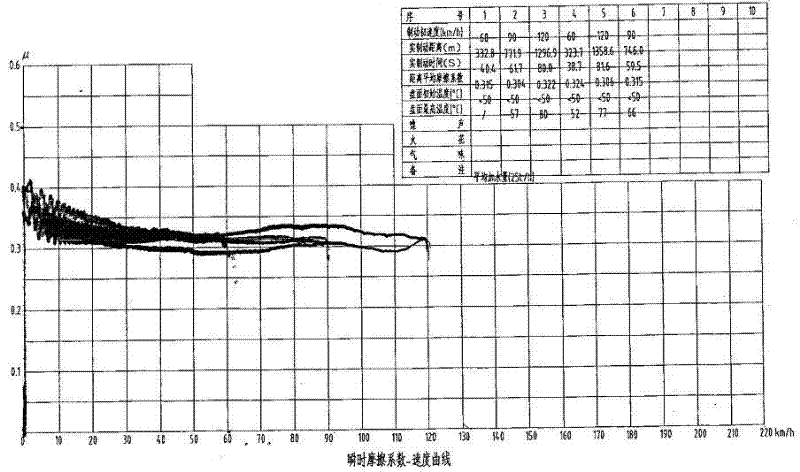

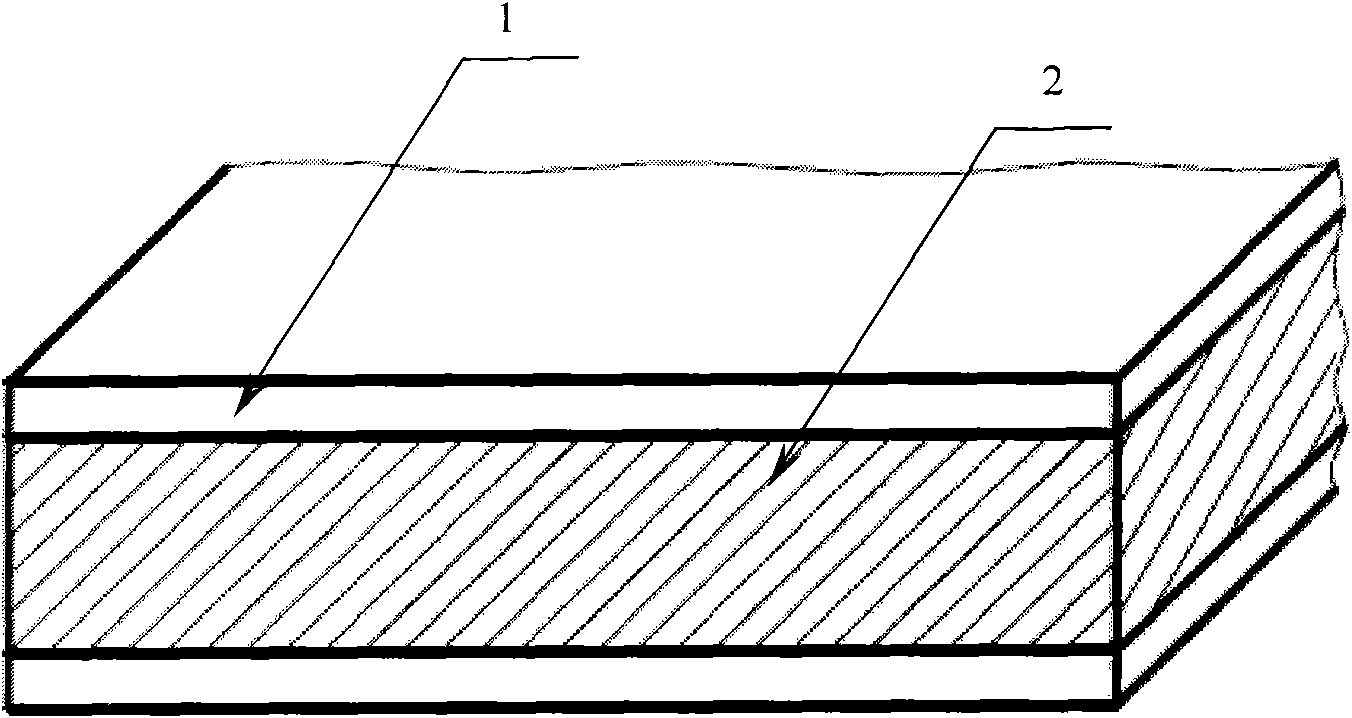

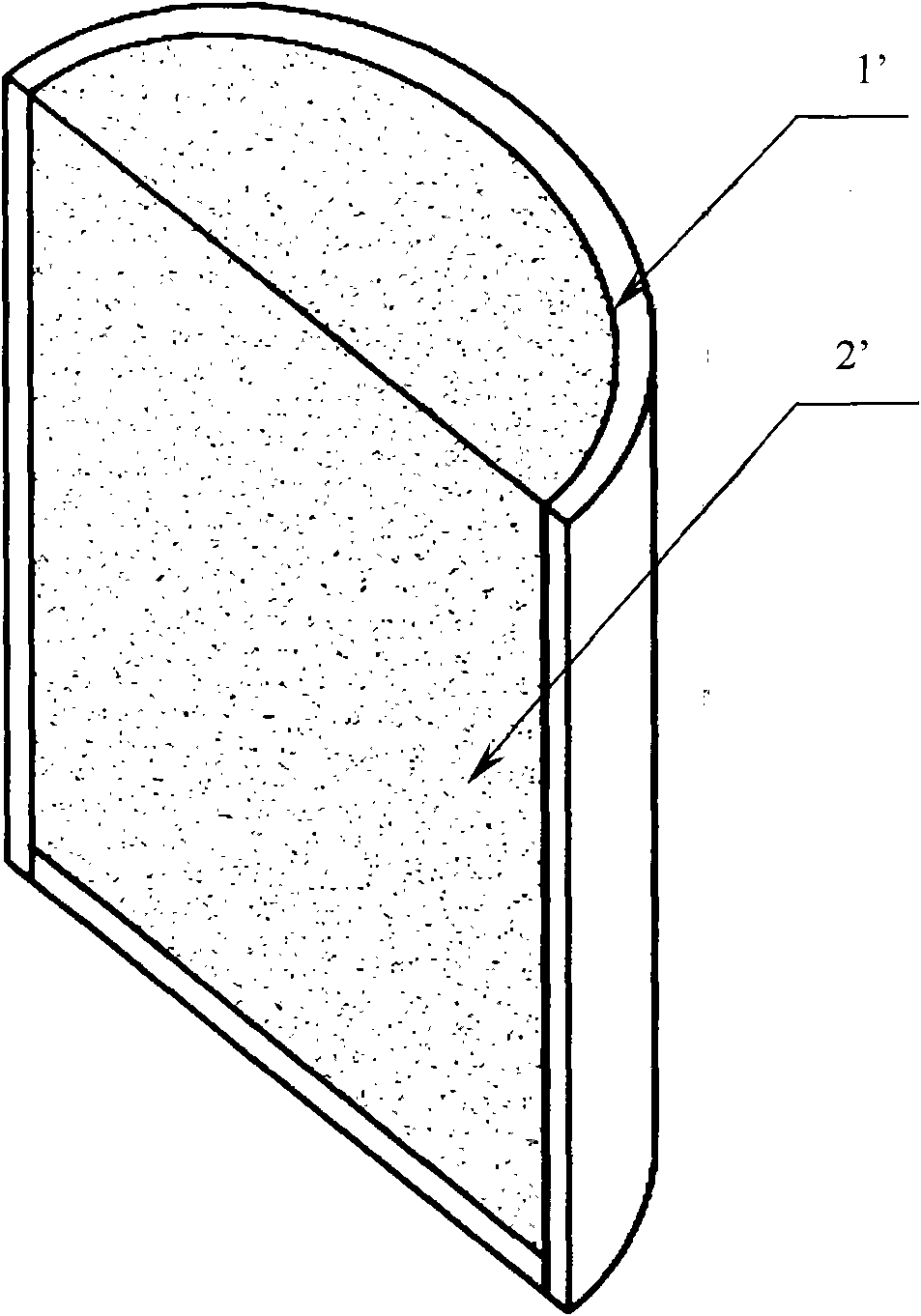

Hybrid fiber reinforced friction material for train braking and preparation method thereof

InactiveCN102191015AImprove toughnessImprove yieldOther chemical processesFriction liningFreight trainsAdhesive

The invention belongs to the technical field of materials, and particularly relates to a hybrid fiber reinforced friction material for train braking and a preparation method thereof. In the invention, a composite modified phenolic resin is used as an adhesive, and hybrid fibers, including carbon fiber, metal fiber, inorganic mineral fiber and the like, are used as the reinforcing fibers. Compared with the prior art, the invention improves the contour machining property of the organic synthetic brake, and the yield of the material is high; the brake has stable frictional property at different braking speeds, does not has obvious degradation of frictional property at high speed, and does not have the phenomena of shedding and cracking on the working surface after the braking test. The friction material provided by the invention can be widely used for manufacturing brake pads, brakes, brake shoes and the like in braking systems of passenger and freight trains, municipal rail transportation, subways and the like.

Owner:FUDAN UNIV

Aluminium-plated particle reinforced aluminum-matrix composite material and preparation method thereof

InactiveCN102114719AEnhanced powder densificationImprove mechanical propertiesMetal layered productsSurface layerElectromagnetic shielding

The invention belongs to the technical filed of particle reinforced aluminum-matrix composite materials and in particular relates to an aluminium-plated particle reinforced aluminum-matrix composite material and a preparation method thereof. The aluminium-plated particle reinforced aluminum-matrix composite material is characterized in that the surface layer of the aluminium-plated particle reinforced aluminum-matrix composite material is made of pure aluminium, and the core interlayer of the aluminium-plated particle reinforced aluminum-matrix composite material is composed of a particle reinforced aluminum-matrix composite material. The aluminium plating of the aluminium-plated particle reinforced aluminum-matrix composite material is realized in the process of carrying out vacuum hotpressing or hot isostatic pressing by using a powder metallurgic method. The method disclosed by the invention comprises the following steps: carrying out powder densification on particle reinforced aluminum-matrix composite materials through vacuum hotpressing or hot isostatic pressing, and simultaneously, carrying out metallurgical bonding on an aluminum die-sleeve and a composite material blank at high temperature and high pressure so as to obtained the aluminium-plated particle reinforced aluminum-matrix composite material. The aluminium-plated particle reinforced aluminum-matrix composite material can be subjected to one or more subsequent processing such as extrusion, forging, rolling and heat treatment so as to obtain various aluminium-plated particle reinforced aluminum-matrix composite materials with different specifications and properties. The aluminium-plated particle reinforced aluminum-matrix composite material can be applied to occasions with anticorrosion or electromagnetic shielding demands.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Reinforced toughened self-lubricating polyformaldehyde composite material and preparation method thereof

The invention discloses a reinforced toughened self-lubricating polyformaldehyde composite material and a preparation method thereof, belonging to the field of polymer materials and molding processing thereof. The polyformaldehyde composite material disclosed by the invention comprises the following components in percent by weight: 45-70 percent of POM (Polyoxymethylene), 10-30 percent of TPEE (Thermoplastic Polyether Ester Elastomer), 4-6 percent of polytetrafluoroethylene, 5-15 percent of glass fiber, 0.2-1 percent of antioxygen, 0.5-0.8 percent of formaldehyde absorbing agent, 0.3-0.5 percent of surface lubricating agent, 1-8 percent of zinc oxide whiskers, 0.1-0.2 percent of coupling agent and 1-2 percent of compatilizer. The polyformaldehyde composite material is prepared by adopting the method comprising the steps of: drying 10-30 percent of TPEE at a temperature of 100 DEG C for 2-4h; adding the dried TPEE in a high-speed mixing machine, adding the 45-70 percent of POM, the 4-6 percent of polytetrafluoroethylene, the 5-15 percent of glass fiber, the 0.2-1 percent of antioxygen, the 0.5-0.8 percent of formaldehyde absorbing agent, the 0.3-0.5 percent of surface lubricating agent, the 0.1-0.2 percent of coupling agent and the 1-2 percent of compatilizer for mixing for 15-20min at a room temperature; and adding a mixture obtained in the last step into an extruder, adding the 1-8 percent of zinc oxide whiskers from an exhaust hole on the dual-screw extruder, extruding and granulating, and injection-molding. The composite material provided by the invention has the advantages of dispersing uniformity, good mechanical property and better abrasion resistance.

Owner:HEFEI GENIUS NEW MATERIALS

Novel high-silicon aluminum alloy electronic packaging material and preparation method thereof

InactiveCN102978485AImprove thermal stabilityHigh strengthSemiconductor/solid-state device detailsSolid-state devicesIngotElectronic packaging

A novel high-silicon aluminum alloy electronic packaging material and a preparation method thereof. The alloy of the present invention consists of the following ingredients, in percentage by mass: 12-40% of Si, 0.3-0.6% of Fe, 0.3-0.45% of Mn, 0.3 to 0.5% of Mg, and the balance being industrial pure aluminum. Spray deposition is used to prepare ingots; and then a plurality times of small deformation thermal densification are carried out for the ingots after annealing for elimination of thermal stress, to prevent cracking of the alloy during processing, thereby enhancing the density of the material. The alloy of the present invention has the characteristics of high strength, low coefficient of expansion, high thermal conductivity and good air tightness.

Owner:CHANGSHA HUAXI METAL MATERIAL

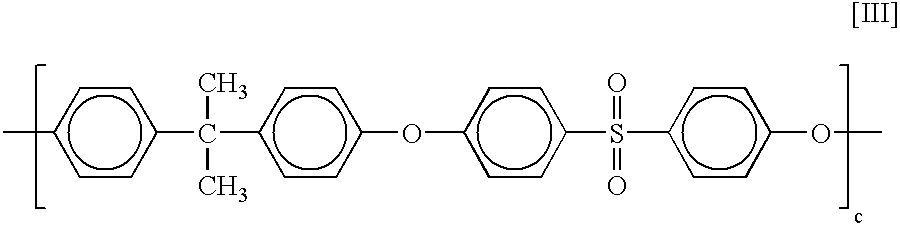

Thermoplastic resin composition

InactiveUS7008991B2Improve conductivityImprove antistatic performanceNon-metal conductorsConductive materialMicro structureFiber

The present invention relates to a thermoplastic resin composition comprising two different thermoplastic resins (component A and component B), conductive carbon black (component C), and conductive carbon black having a larger specific surface area than that of component C or hollow carbon fibril (component D),said thermoplastic resin composition having an island-and-sea micro structure constituted by component A and component B,component C existing mostly in the island phase, andcomponent D existing mostly in the sea phase.

Owner:MITSUBISHI ENG PLASTICS CORP

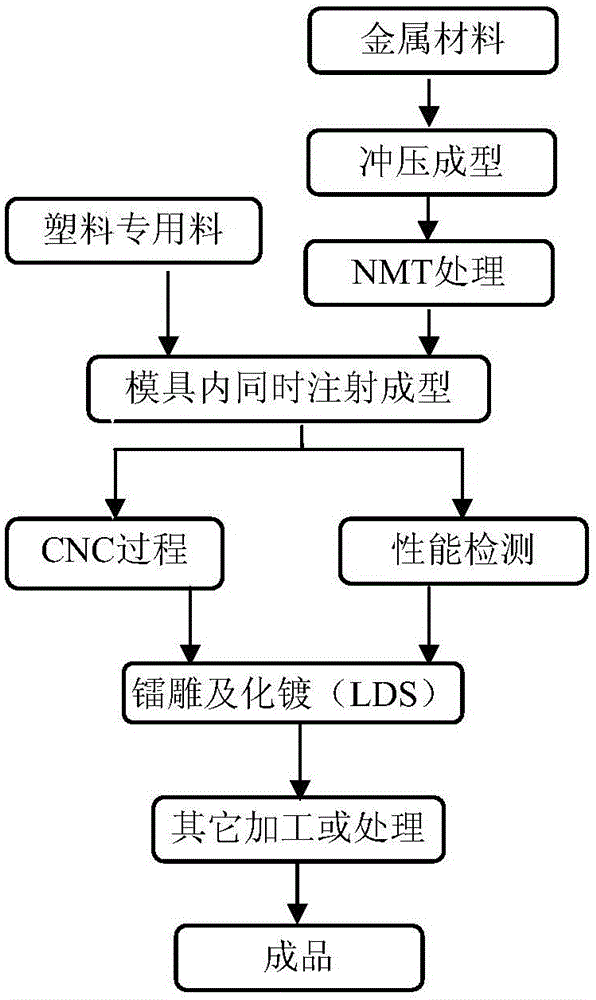

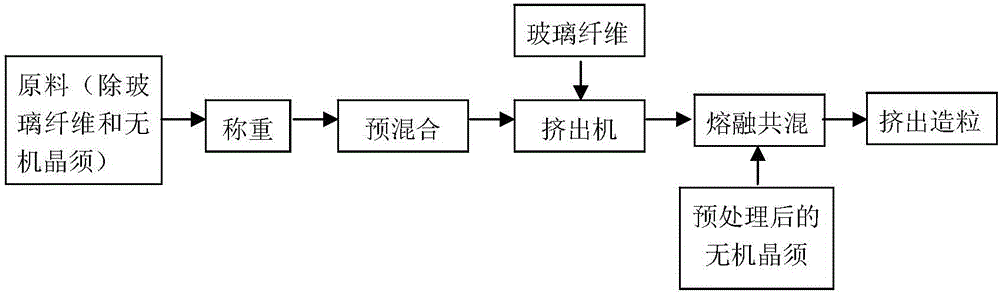

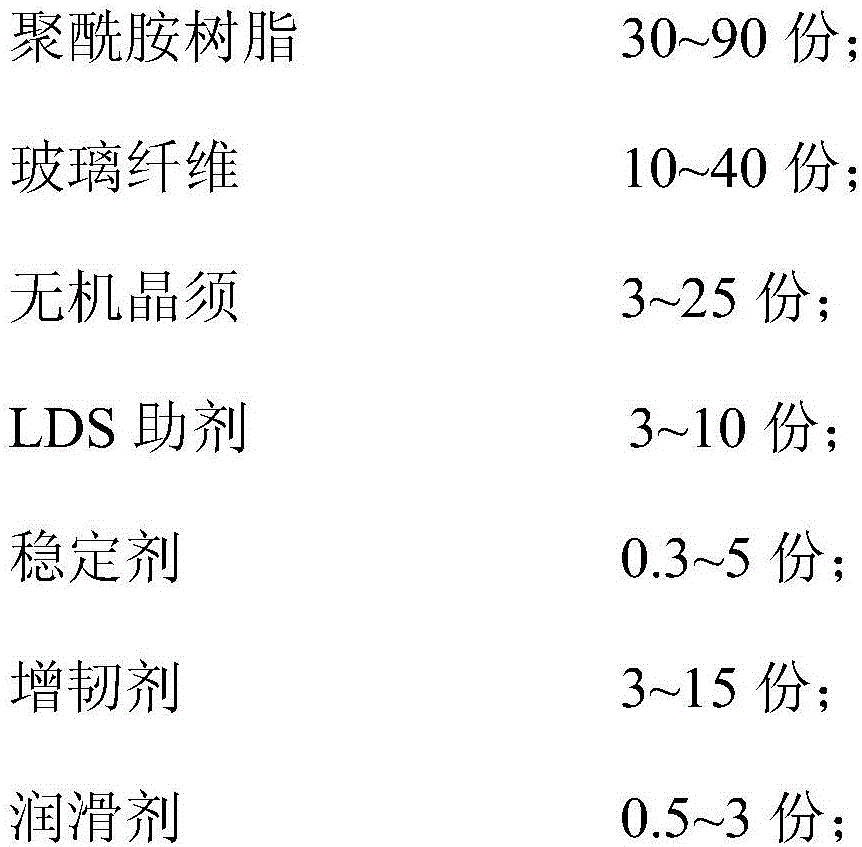

PA (polyamide) resin composition used for NMT (nano molding technology) and having LDS (laser direct structuring) function

The invention provides PA (polyamide) resin composition used for an NMT (nano molding technology) and having an LDS (laser direct structuring) function. The PA resin composition used for the NMT is mainly prepared from raw materials in parts by mass as follows: 30-90 parts of PA resin, 10-40 parts of glass fibers, 3-25 parts of inorganic whiskers, 3-10 parts of an LDS auxiliary, 0.3-5 parts of a stabilizer, 3-15 parts of a toughening agent and 0.5-3 parts of a lubricant, wherein PA resin is PA66 resin and / or PA6 resin. The glass fibers are partially replaced with inorganic whiskers, so that the sensitivity of an electromagnetic wave signal is improved, and the laser etching precision and accuracy of a material surface are improved; the defects that ordinary LDS special materials have poor binding force with metals, the molding shrinkage is large, the acid and alkali resistance is poor and LDS cannot be performed are overcome, the PA resin composition has strong binding force with metals, the binding strength is higher than 180 kgf / cm<2>, and the laser etching and chemical plating effects are good; besides, the requirements of LDS and NMT are met; material has excellent mechanical performance, good heat resistance and excellent molding machining performance.

Owner:SHENZHEN HALCYON NEW MATERIALS

Polyphenylene ether oligomer compound, derivatives thereof and use thereof

ActiveUS20050065241A1Improve compatibilityEasy to preparePrinted circuit aspectsSynthetic resin layered productsEpoxyOligomer

The present invention provides a bifunctional phenylene ether oligomer compound having a thermosetting functional group at each terminal, an epoxy resin containing the above oligomer compound and a use thereof. That is, it provides a sealing epoxy resin composition for sealing an electric part, an epoxy resin composition for laminates, a laminate, a printed wiring board, a curable resin composition and a photosensitive resin composition. The resins and resin compositions of the present invention are used in electronics fields in which a low dielectric constant, a low dielectric loss tangent and high toughness are required and also used for various uses such as coating, bonding and molding.

Owner:MITSUBISHI GAS CHEM CO INC

Scraping-resistant automobile inner fitting special-purpose material and preparation thereof

ActiveCN101255253AExcellent surface scratch resistanceLow costUltimate tensile strengthPolypropylene

The invention relates to a kind of scraping tolerance type special material for ornament in motor and preparation method, comprising(by weight parts): polypropylene 80-90 parts, superfine talcum powder 10-20 parts, lubricant 0.5-3.0 parts, antioxidant1010 1.0-2.0 parts. The method comprises: 1) stirring and mixing the polypropylene and lubricant, antioxidant at rotate speed of 300-500 rpm for 3-5 minutes; 2) adding superfine talcum powder and stirring and mixing at rotate speed of 300-500 rpm for 5-10 minutes; 3) stirring and mixing at rotate speed of 1500-2000 rpm for 10-15 minutes; 4) stirring and mixing at rotate speed of 300-500 rpm for 5-10 minutes to obtain premix material; 5) extruding the premix material by extruder to pelletizen finally the finished product being obtained. The invention has features: low odor emission, low cost, high surfaceness, better impact resistance, intension and toughness and good melt flowing, widely used in production of ornament in motor.

Owner:南京金杉合成材料有限公司

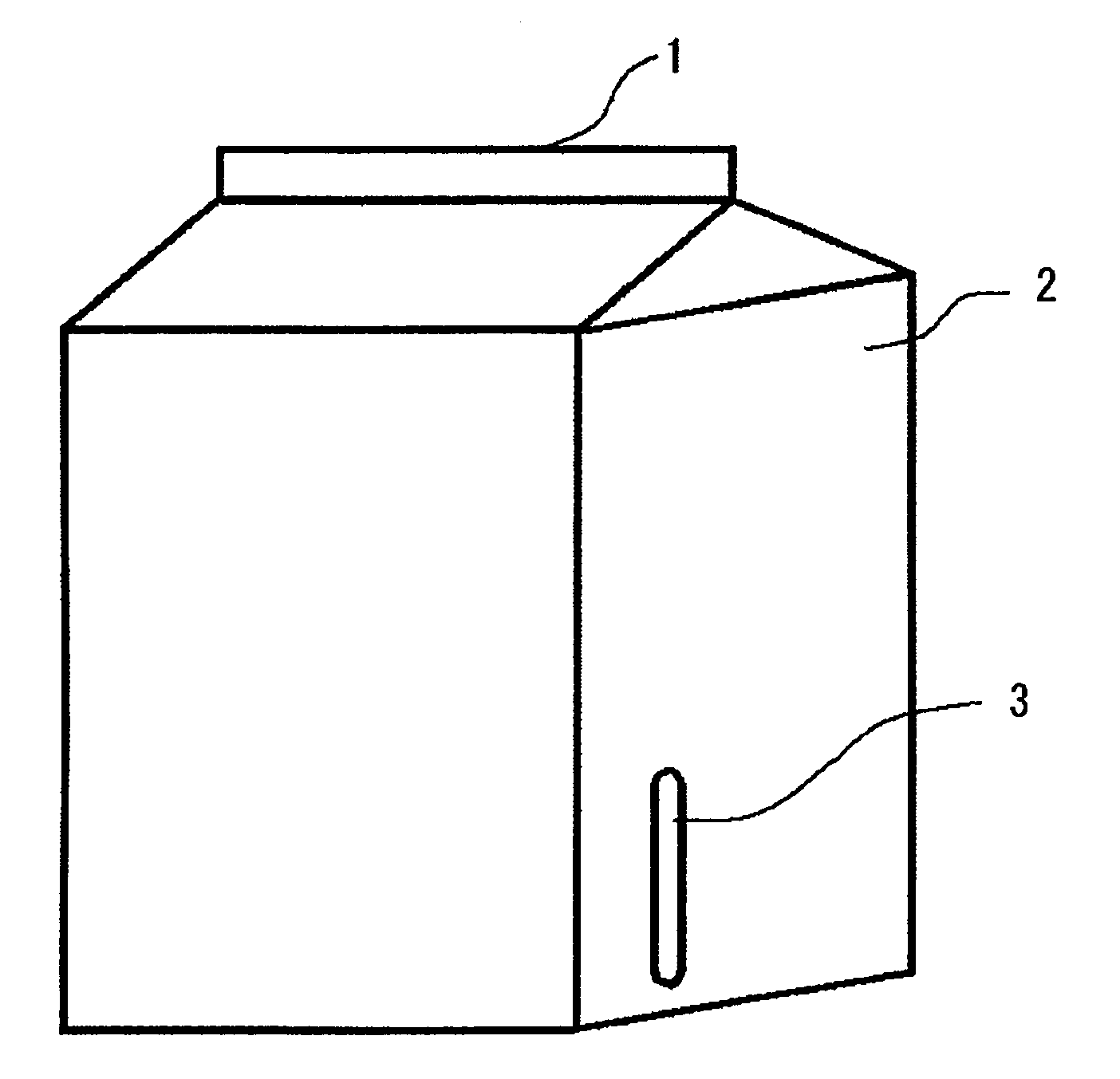

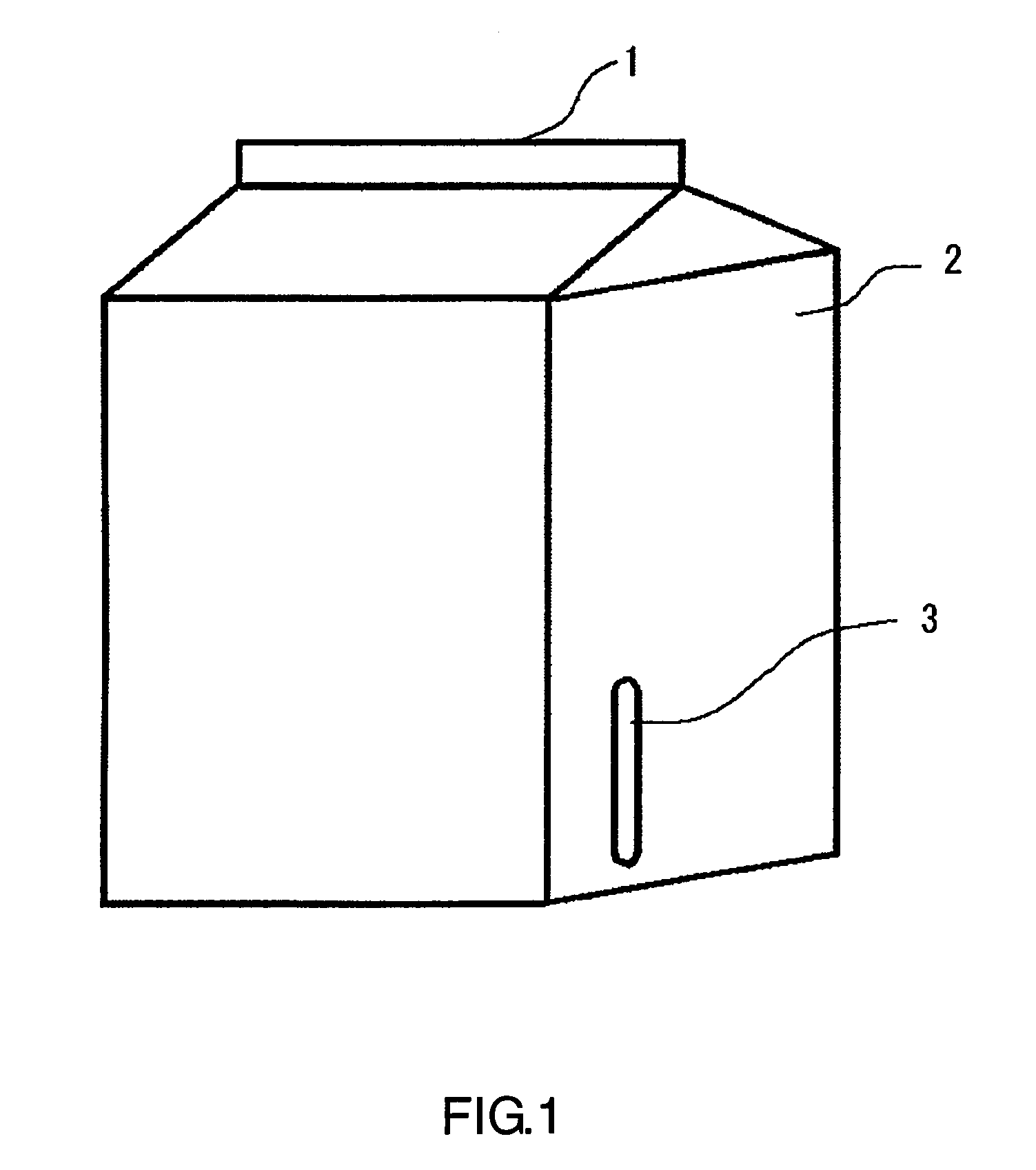

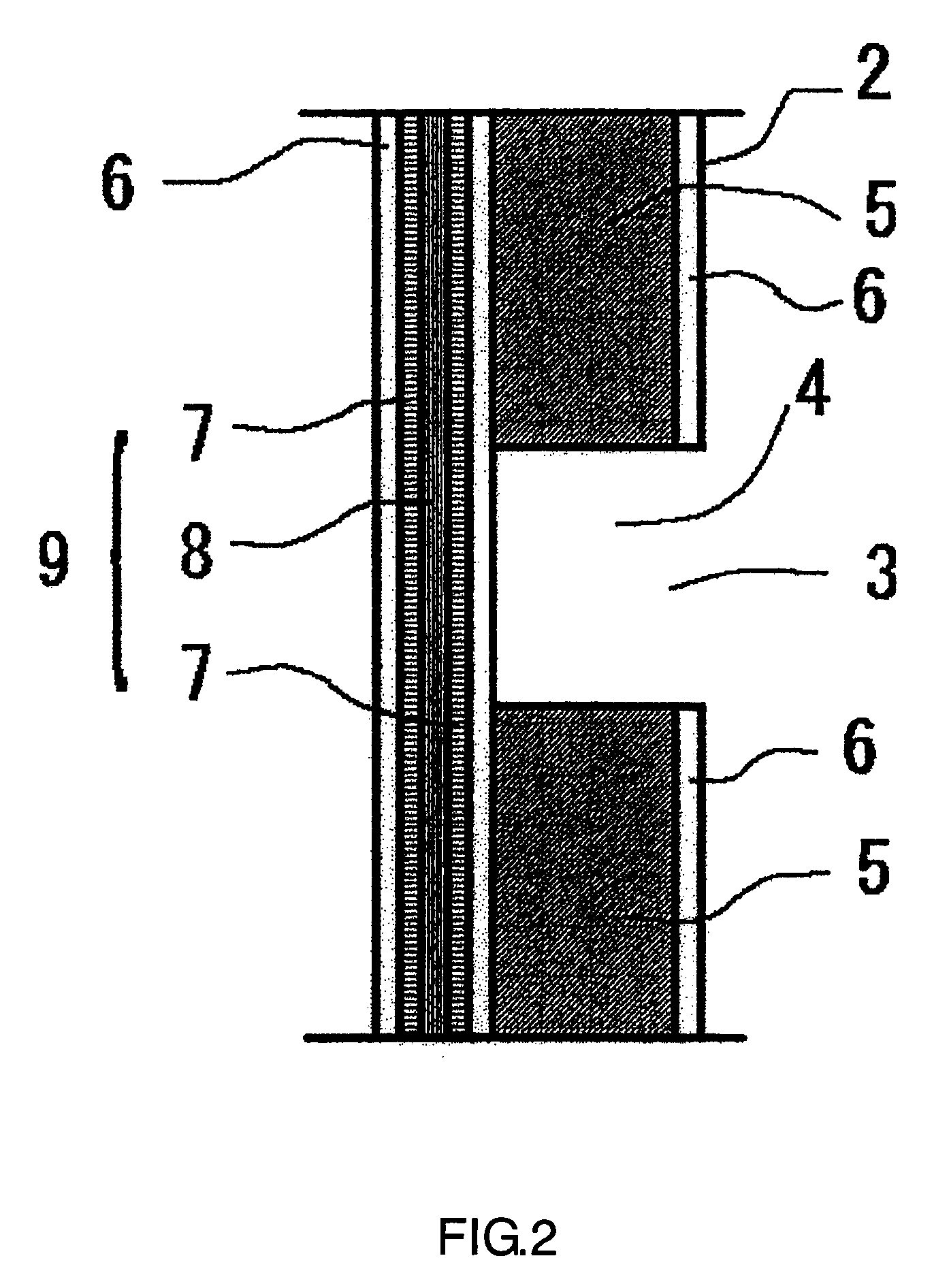

Paper container

ActiveUS20090297741A1Easy to produceExcellent gas barrier performancePretreated surfacesDomestic containersEngineeringHydrolysis

A paper container is provided that allows the content to be checked, prevents the content from deteriorating for a long period of time, and is excellent in, for example, storage and preservation properties. Furthermore, a paper container is provided that can be subjected to a retort sterilization process, prevents the content from deteriorating for a long period of time, and is excellent in, for example, storage and preservation properties. A paper container formed of a laminate including at least a paper layer is provided. The paper layer has a cutout part that is covered with a gas barrier laminate. The gas barrier layer of the gas barrier laminate is formed of a composition containing a neutralized product of a polymer containing at least one functional group selected from a carboxyl group and a carboxylic anhydride group, and a hydrolysis condensation product of at least one compound (L) containing a metal atom to which at least one characteristic group selected from a halogen atom and an alkoxy group has been bonded. The —COO— groups contained in the at least one functional group are neutralized at least partly with a metal ion having a valence of two or more.

Owner:KURARAY CO LTD

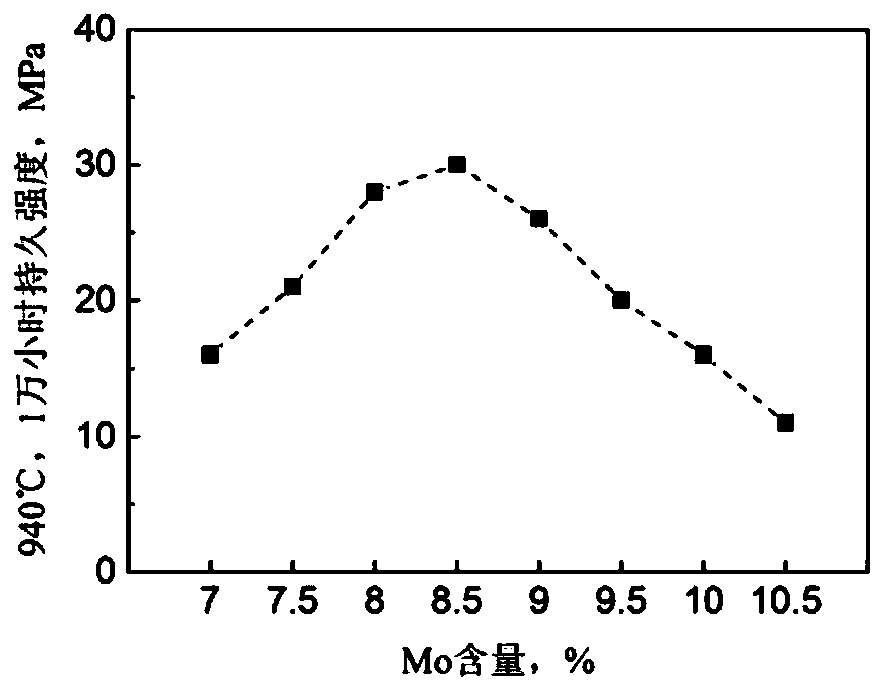

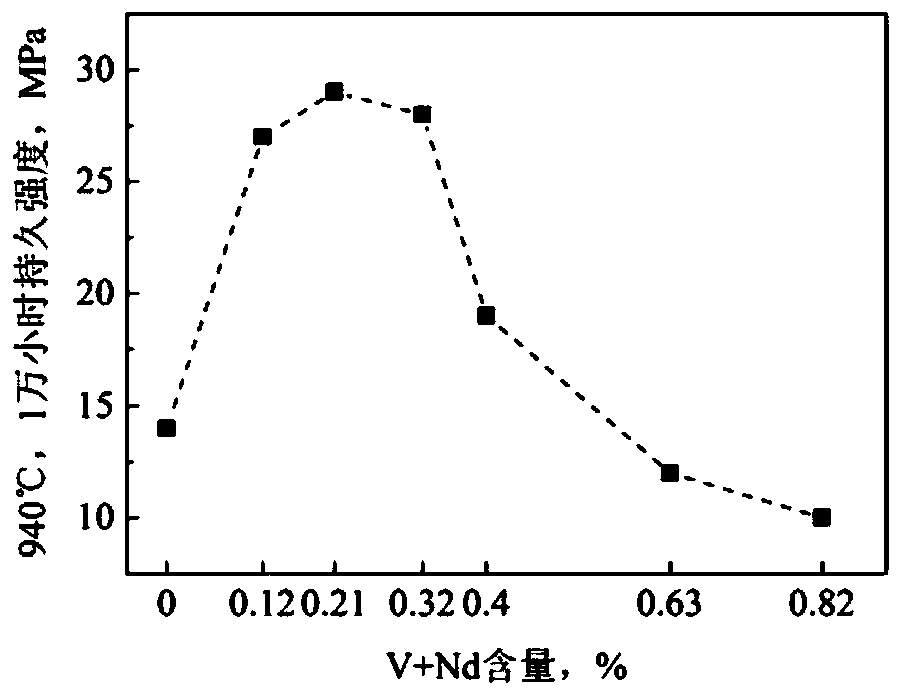

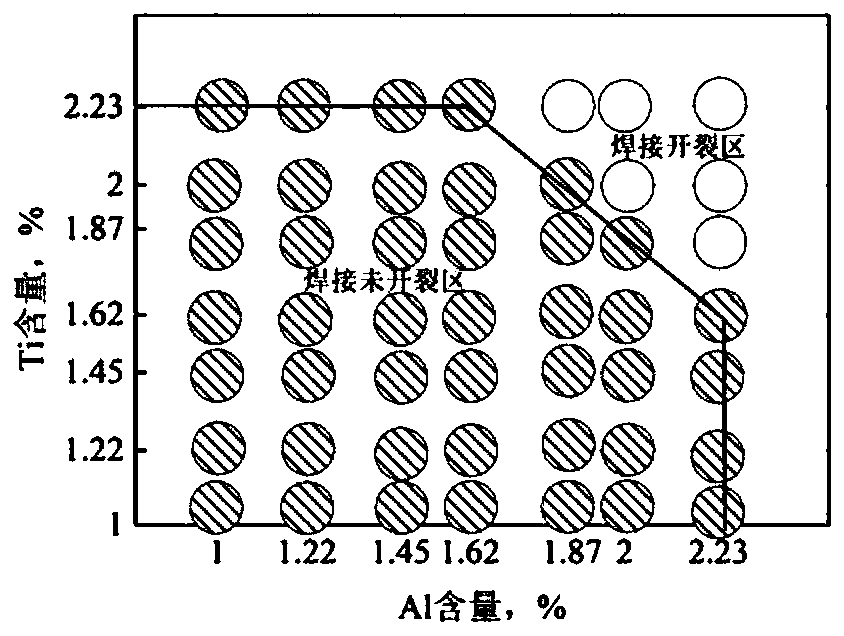

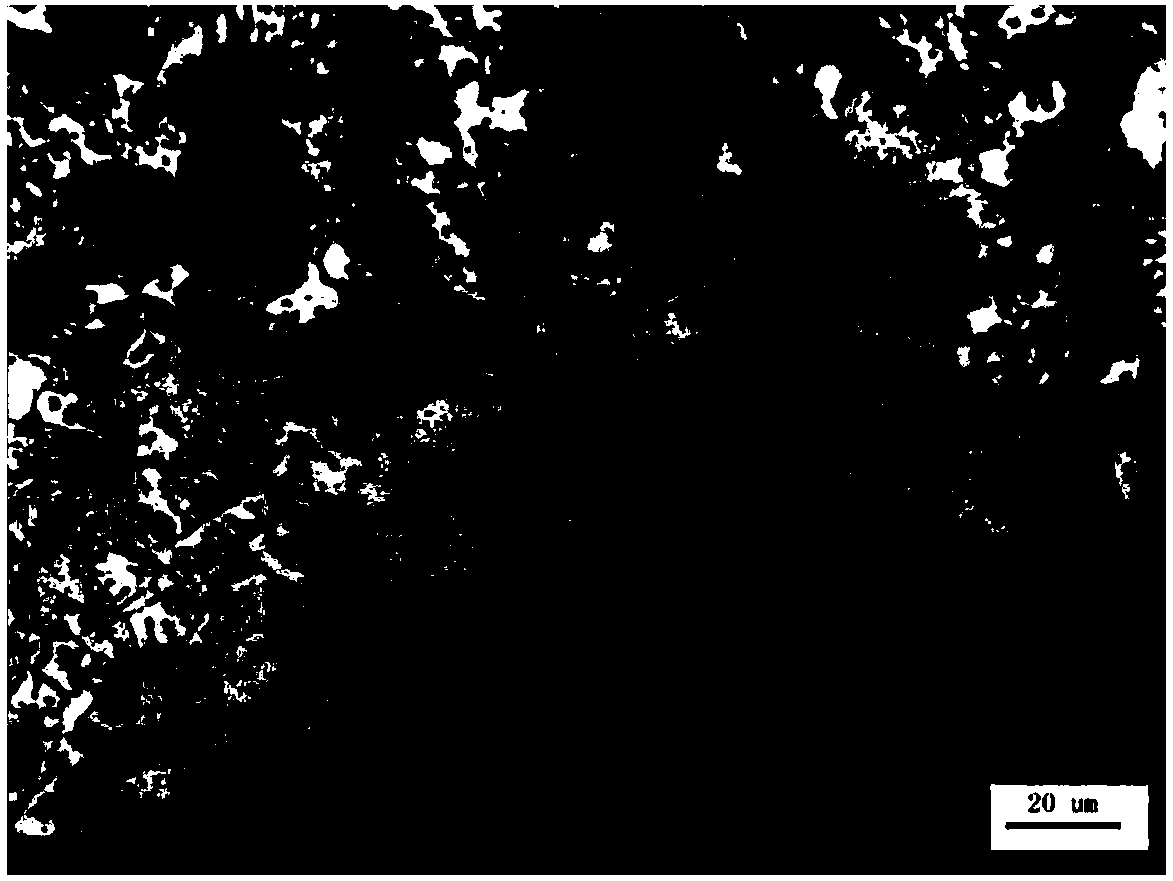

High-performance easy-to-process nickel-based deformation high-temperature alloy and preparation method thereof

ActiveCN110551920ALong high temperature durable lifeImprove creep resistanceChemical elementTemperature resistance

The invention discloses a high-performance easy-to-process nickel-based deformation high-temperature alloy and a preparation method thereof and belongs to the technical field of nickel-based deformation high-temperature alloy materials. The chemical elements of the deformation high-temperature alloy comprise, by mass, 0.02-0.08% of C, 18-20% of Cr, 9.1-12% of Co, 8.1-9.1% of Mo, 1.4-1.7% of Al, 1.8-2.25% of Ti, 0.002-0.012% of B, Nb with the mass percent less than or equal to 0.7%, Fe with the mass percent less than or equal to 2%, Zr with the mass percent less than or equal to 0.03%, 0.02-0.5% of V, 0.002-0.1% of Nd and the balance nickel and unavoidable impurities. The high-performance easy-to-process nickel-based deformation high-temperature alloy has the advantages that the demand foroperation at 940 DEG C or below is met, the alloy has four kinds of performance including long high-temperature-resistance service life, creep deformation resistance, good formation processing performance and excellent welding performance, through optimized matching of conventional alloy elements, novel alloy elements Nd and V are introduced, and the aim is achieved.

Owner:BEIJING BEIYE FUNCTIONAL MATERIALS CORP

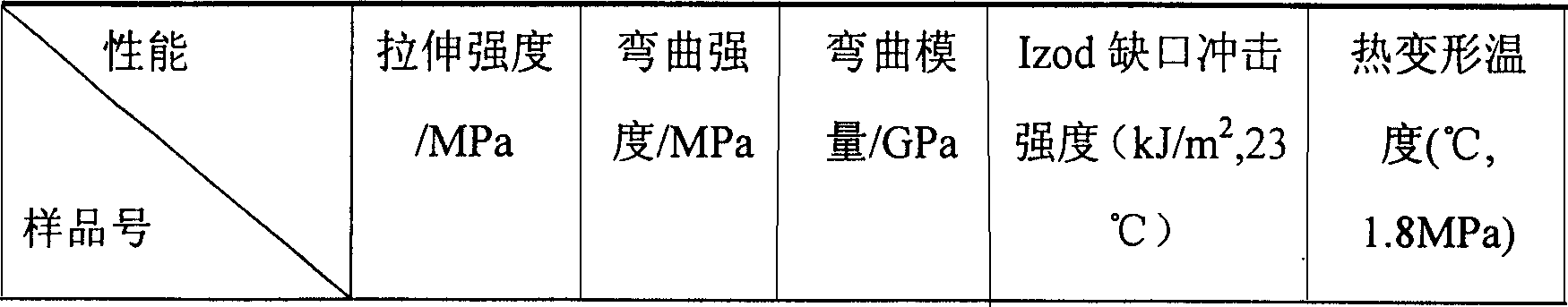

Flame-retardant reinforced polybutylene terephthalate compound and production method thereof

InactiveCN101225220AImprove mechanical propertiesHigh tensile strengthPolytetramethylene terephthalateHeat deflection temperature

The invention discloses a flame retardant reinforced polybutylene terephthalate (PBT) composite and a production method of the composite. The flame retardant reinforced PBT composite is prepared by PBT, other polyesters, fiberglass, bromide, antimony trioxide, toughening, a compatibilizer, an antioxidant, an anti-dripping agent and a nucleating agent. The flame retardant reinforced polybutylene terephthalate (PBT) composite has the advantages that: other polyester materials (PTT) are added into the flame retardant reinforced PBT composite, the comprehensive mechanical property of the composite is enhanced, such as the tensile strength and the bending strength, and a plurality of new characters are given to the composite, meanwhile, compared with the pure PBT resin as reinforced flame retardant material, the composite has higher heat distortion temperature; furthermore, the preparation technique has simple process and low cost.

Owner:南通市旺茂实业有限公司

Beta-titanium alloy material in biology medical application

InactiveCN101081311AHigh strengthImprove wear resistanceSurgeryProsthesisBreaking strengthThick plate

The present invention discloses one kind of biomedicine beta-titanium alloy material comprising Ti-Nb 25-30 wt%, Zr 1-5 wt%, Fe 0.2-1 wt%, and Ta 10-15 wt%. The beta-titanium alloy material is produced through vacuum arc melting, casting, vacuum homogenizing under the protection of argon, cold rolling, forming solid solution, water quenching, artificial ageing, water cooling and other steps. It is produced into 2 mm thick plate, and has excellent comprehensive performances, including elastic modulus 40-60 GPa, breaking strength 600-910 MPa, yield strength 480-650 MPa, elongation 14-18 % and reduction of area 40-52 %. It has simple and reliable production process.

Owner:CENT SOUTH UNIV

Process for preparing silumin electronic package materials

InactiveCN1877821AImprove featuresImprove performanceSemiconductor/solid-state device detailsSolid-state devicesSiluminMaterials processing

The invention discloses a making technology of high-silafont electronic packing material, which comprises the following steps: A) preparing powder: blending industrial pure aluminum and high-pure silicon at 6-8.8:4-1.2 percentage to prepare Al-Si alloy powder; B) proceeding ball grinding disposal for Al-Si alloy powder at 5-15:1 percentage for 8-32 h; C) loading oxide alloy powder in the pure aluminum; proceeding squeezing disposal on the 300-500 ton hydrostatic machine through forward squeezing pattern; keeping temperature at 400-520 deg.c for 0.5-2 h for Al-Si alloy powder before squeezing; placing each squeezing mould in the heat stove at 10-21 squeezing rate to preheat at 200-400 deg.c; squeezing to produce the product. The invention can improve heat conductivity, airtightness and tensile strength obviously, which keeps low expansion coefficient.

Owner:CENT SOUTH UNIV

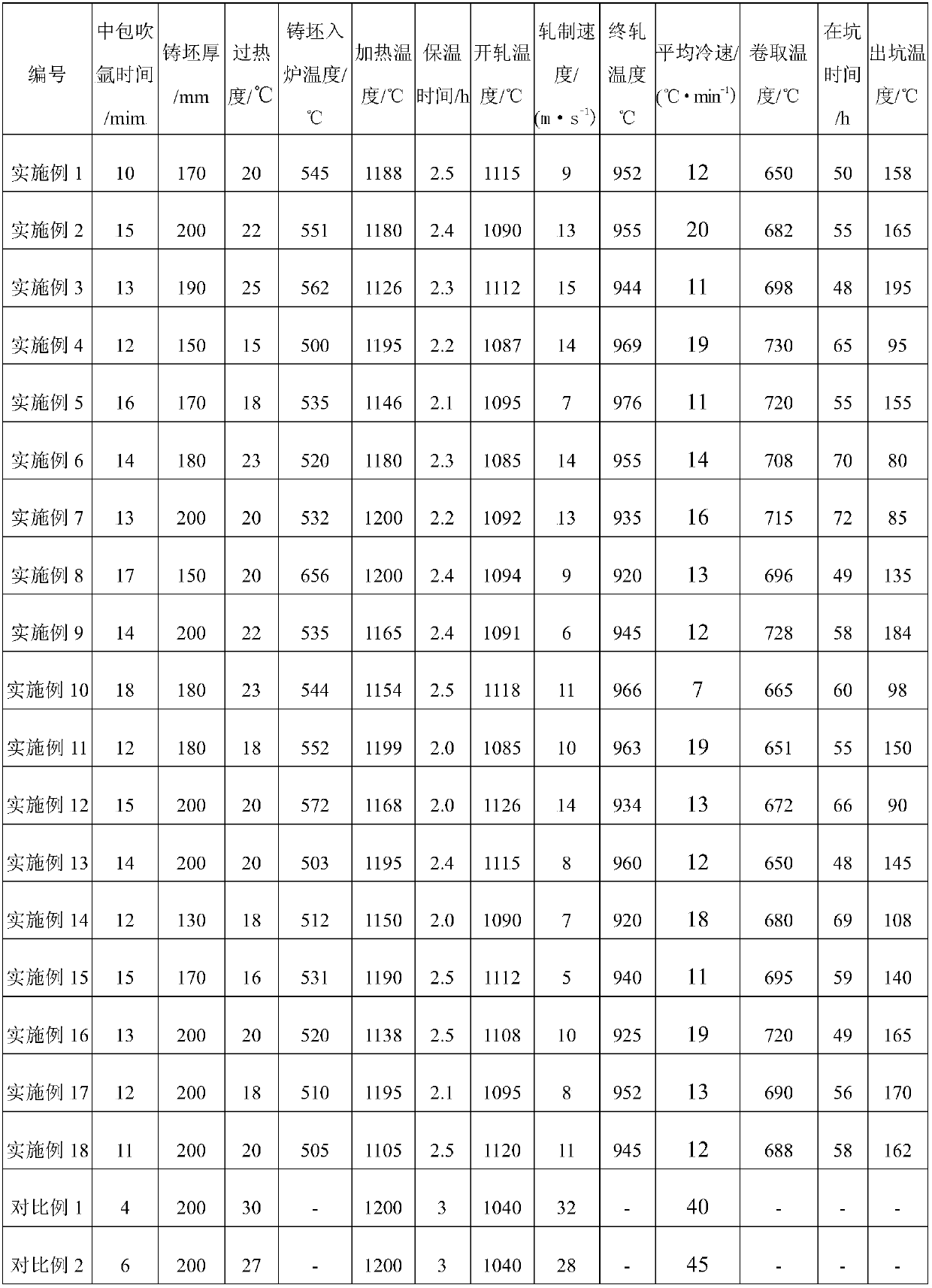

Steel with excellent processing performance for gardening tool and production method thereof

The invention discloses steel with excellent processing performances for a gardening tool and a production method thereof. The steel comprises the following components of, by weight, 0.45%-0.65% of C,0.1%-0.40% of Si, 0.5%-1.5% of Mn, 0.1%-0.5% of Cr, 0.02%-0.05% of Al, less than or equal to 0.4% of Ni, less than or equal to 0.5% of Cu, less than or equal to 0.020% of P, less than or equal to 0.010% of S and the balance Fe and inevitable impurities. The production method comprises the following steps that deoxidation is carried out by adopting Al, and time of argon blowing in tundish is larger than or equal to 10 minutes, the casting superheat degree is less than or equal to 25 DEG C, the thickness of a casting blank is 130-200 mm; charing temperature of the casting blank is larger than or equal to 500 DEG C; heating temperature is 1100-1200 DEG C, the temperature is kept for 2-5 hours, the rolling speed is 5-15 m per second, rolling start temperature is larger than or equal to 1080 DEG C, and rolling finish temperature is larger than or equal to 920 DEG C; and the cold speed is less than or equal to 20 DEG C per second, the casting blank is coiled at the temperature of 650-730 DEG C, then is put into a slow cooling pit for heat preservation and slow cooling for more than or equal to 48 hours, is cooled to below 200 DEG C, and then is air-cooled to the room temperature. According to steel with the excellent processing performances for the gardening tool and the production method thereof, the steel plate has excellent formability and wear resistance.

Owner:ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com