Patents

Literature

46results about How to "Excellent surface scratch resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Special plastic/acrylonitrile butadiene styrene (PC/ABS) alloy for notebook computer shell

ActiveCN101974218AExcellent surface hardnessImprove scratch resistanceGlass fiberPolymethyl methacrylate

The invention discloses a special plastic / acrylonitrile butadiene styrene (PC / ABS) alloy for a notebook computer shell. The formula comprises the following materials in parts by weight: 30-80 parts of polycarbonate, 5-65 parts of acrylonitrile-butadiene-styrene copolymer, 5-15 parts of compatilizer, 1-15 parts of flame retardant agent, 3-20 parts of filler, 1-10 parts of hardness modifier, 0.5-5 parts of anti-falling agent and 0-1 part of auxiliary agent. By adopting specific high-molecular polymers of polymethyl methacrylate (PMMA), ultrahigh-molecular polysiloxane and the like, the special PC / ABS alloy selects mineral fillers of specific-size mica, glass fiber and the like to carry out rematching therewith and generates synergistic effect, thus obviously improving the surface hardness and scraping resistance of the material and simultaneously having no influence on the other performances of the material. The PC / ABS alloy material has excellent impact resistance, surface scraping resistance and flame retardance, can meet the requirements of plastic for the notebook computer shell and has considerable promotion and application values.

Owner:大河宝利材料科技(苏州)有限公司

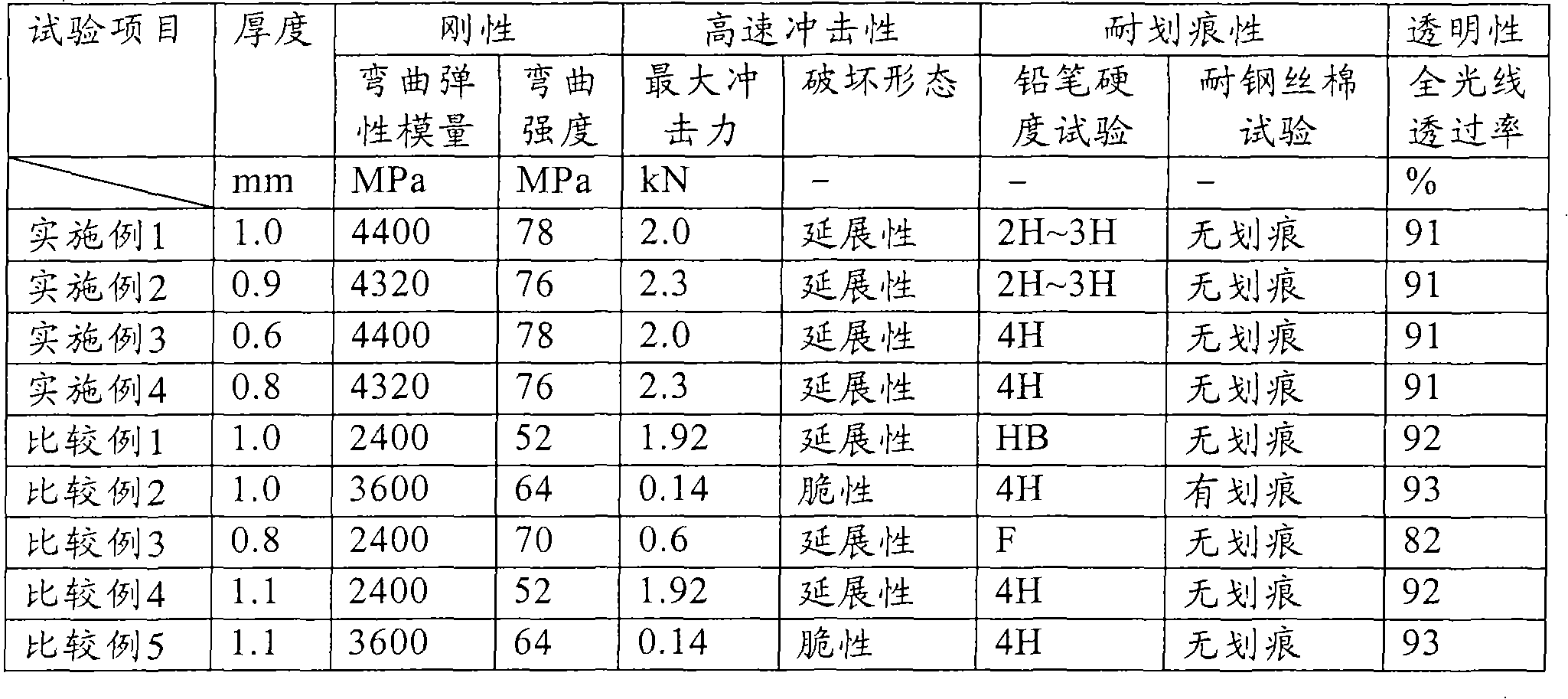

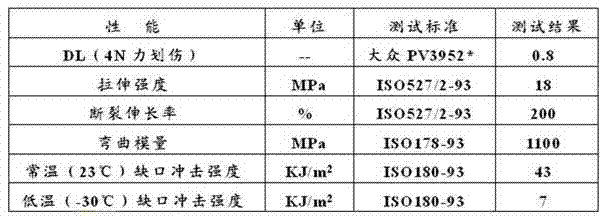

Scraping-resistant automobile inner fitting special-purpose material and preparation thereof

ActiveCN101255253AExcellent surface scratch resistanceLow costUltimate tensile strengthPolypropylene

The invention relates to a kind of scraping tolerance type special material for ornament in motor and preparation method, comprising(by weight parts): polypropylene 80-90 parts, superfine talcum powder 10-20 parts, lubricant 0.5-3.0 parts, antioxidant1010 1.0-2.0 parts. The method comprises: 1) stirring and mixing the polypropylene and lubricant, antioxidant at rotate speed of 300-500 rpm for 3-5 minutes; 2) adding superfine talcum powder and stirring and mixing at rotate speed of 300-500 rpm for 5-10 minutes; 3) stirring and mixing at rotate speed of 1500-2000 rpm for 10-15 minutes; 4) stirring and mixing at rotate speed of 300-500 rpm for 5-10 minutes to obtain premix material; 5) extruding the premix material by extruder to pelletizen finally the finished product being obtained. The invention has features: low odor emission, low cost, high surfaceness, better impact resistance, intension and toughness and good melt flowing, widely used in production of ornament in motor.

Owner:南京金杉合成材料有限公司

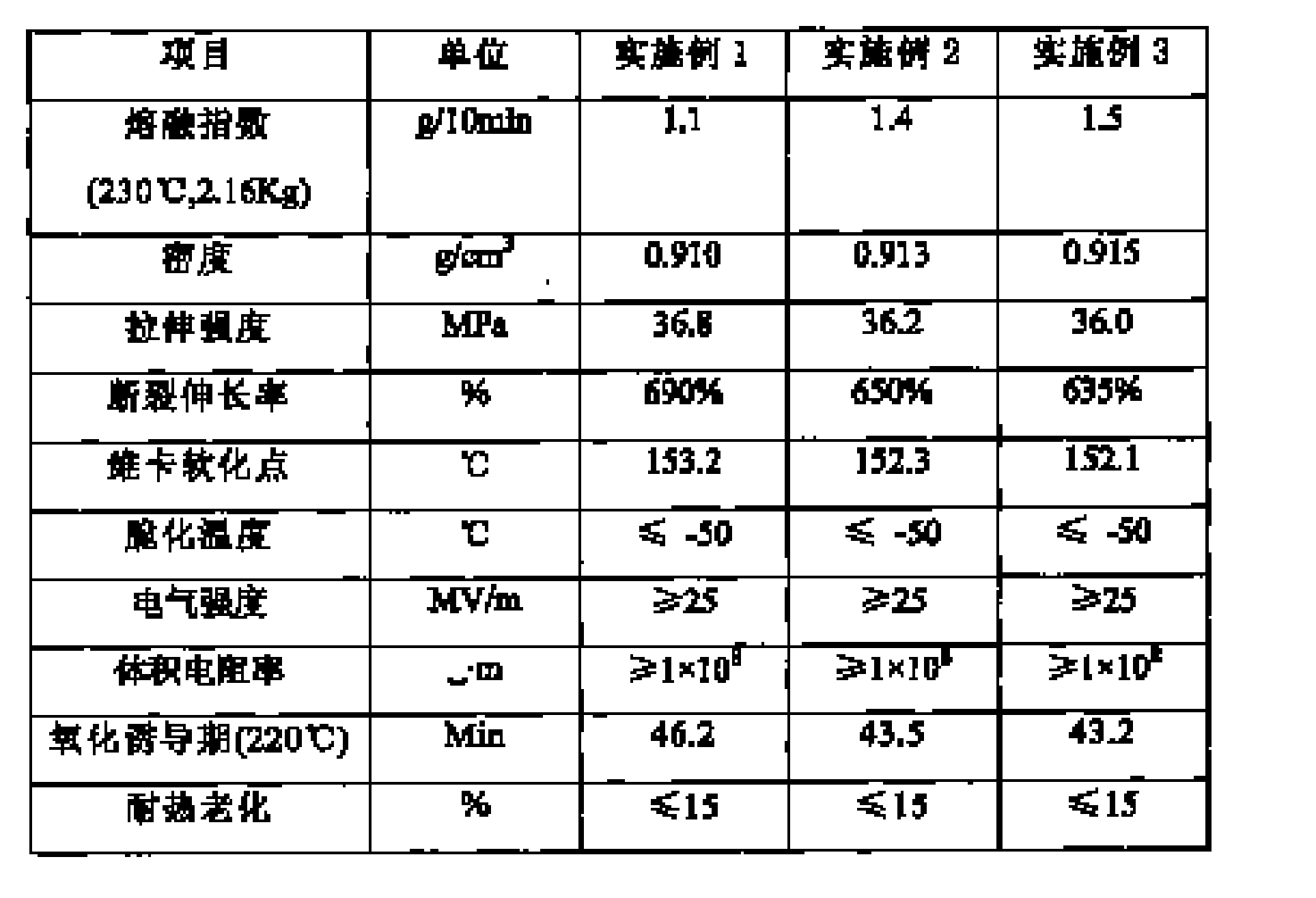

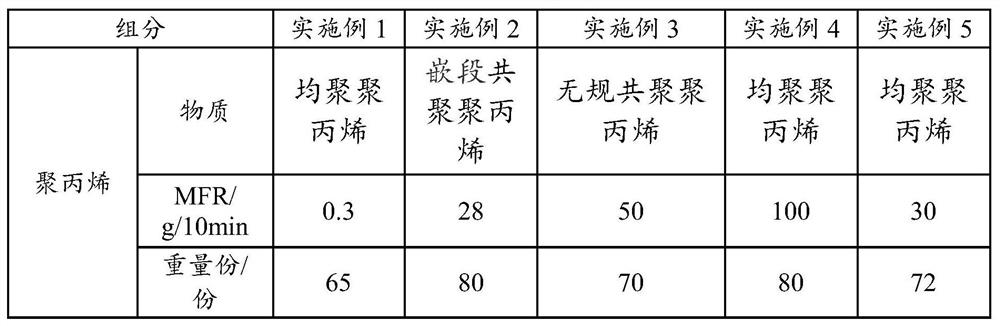

Metallocene polypropylene modified material for corrosion-inhibiting coating of steel pipe and preparation method and application thereof

ActiveCN101519513ACoating processing range is wideImproved environmental stress cracking resistanceAnti-corrosive paintsUltraviolet lightsWorking temperature

The invention discloses a metallocene polypropylene modified material for a corrosion-inhibiting coating of a steel pipe and a preparation method and application thereof. A formula of the material comprises 65 to 95 weight percent of metallocene polypropylene, 3 to 30 weight percent of co-polypropylene, 0.01 to 4 weight percent of thermal oxygen stabilizer, 0.03 to 3 weight percent of ultraviolet absorbent and light stabilizer, 0.02 to 5 weight percent of functional additive, 0.01 to 3 weight percent of inorganic nanometer reinforced material, and 0 to 5 weight percent of black color batch, and the material is prepared by adopting a double screw extruder to carry out plasticizing blending technology for extrusion and pelletization. The metallocene polypropylene modified material has wide casting and coating processing range, has strong adaptability to bottom glue of hot melt adhesives, has outstanding ultraviolet light aging resistance and thermal-oxidative aging resistance, and has excellent shock resistance and surface scratch resistance as well as extremely high environmental stress cracking resistance. The material can be suitable for terrestrial pipelines at continuous working temperature high up to 110 DEG C, and is also suitable for offshore pipelines atcertain special continuous working temperature high up to 140 DEG C at the same time.

Owner:GUANGZHOU LUSHAN NEW MATERIALS +1

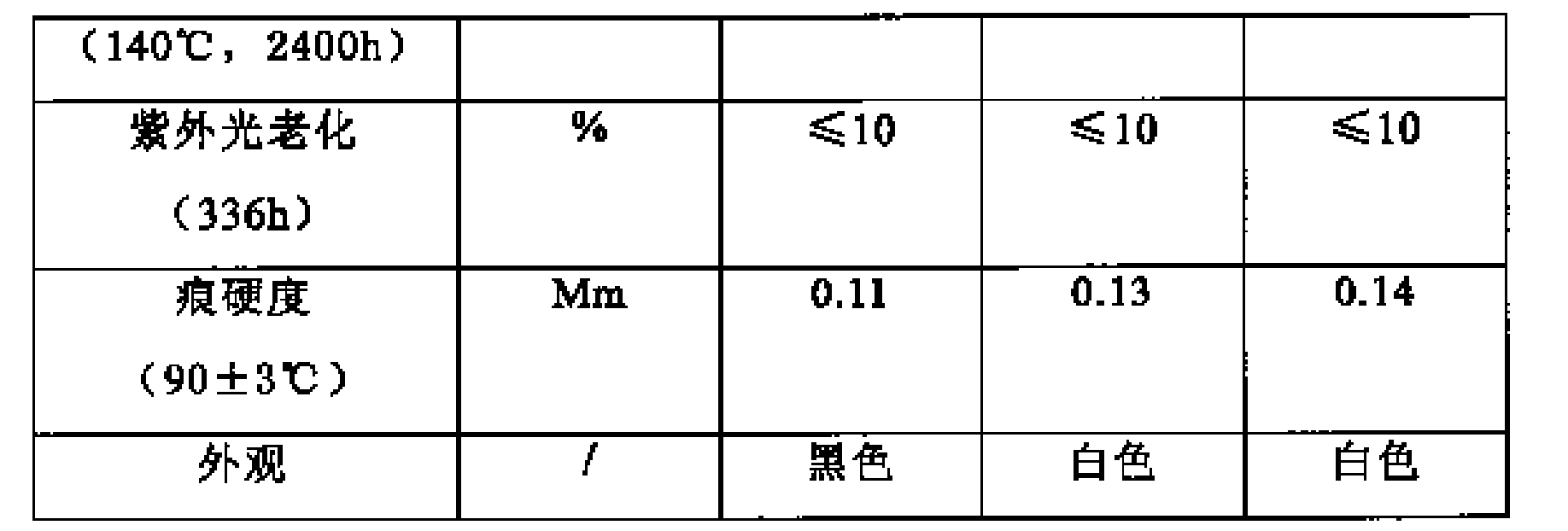

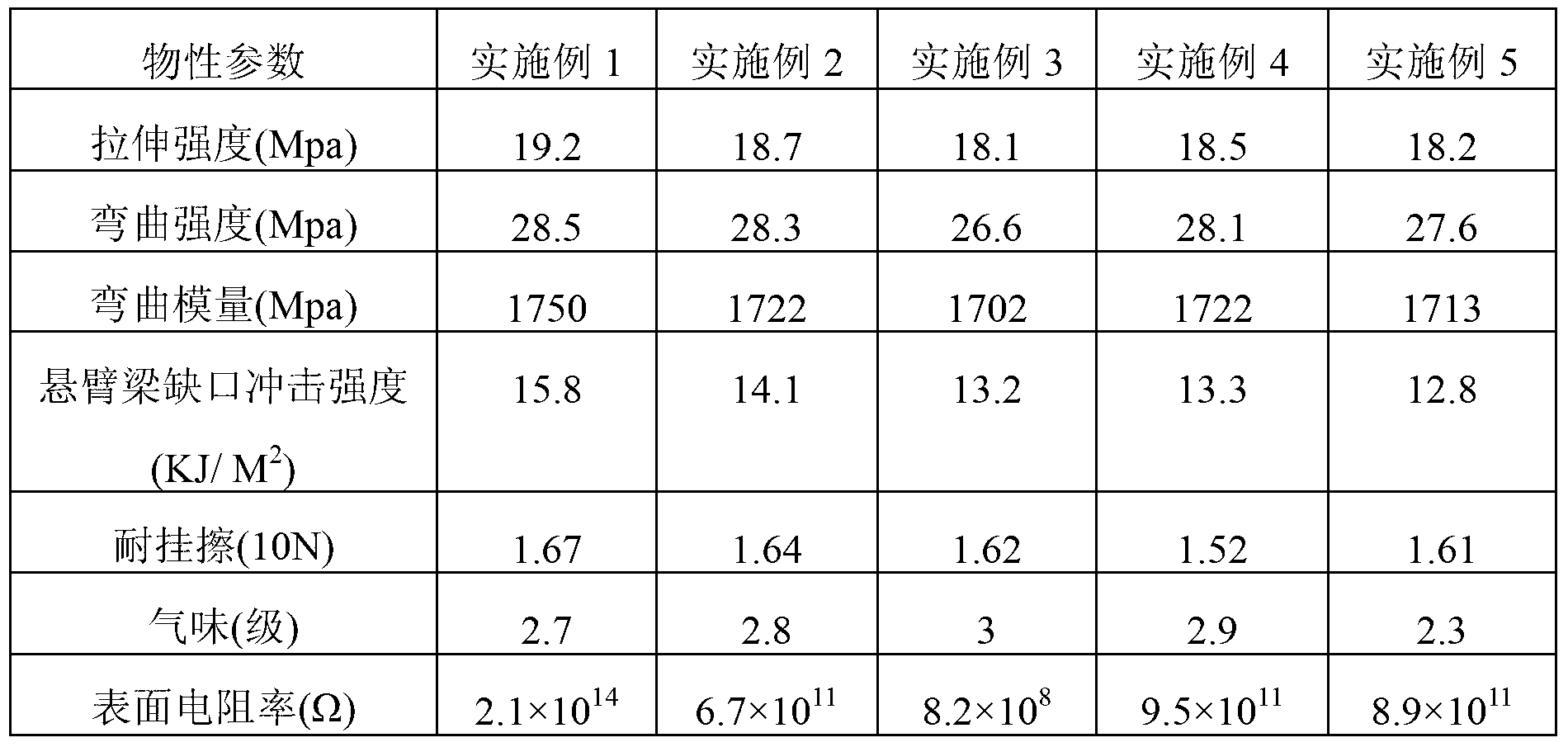

Polypropylene composite material for automobile internal ornament, preparation method thereof and internal ornament

ActiveCN103214740ASmall smellExcellent surface scratch resistanceSurface resistivityAntistatic agent

The invention provides a polypropylene composite material for an automobile internal ornament, a preparation method thereof and an automobile internal ornament. The polypropylene composite material for the automobile internal ornament comprises 40-60 parts by weight of polypropylene resin, 0-30 parts by weight of filler, 1-5 parts by weight of compatibilizer, 5-15 parts by weight of toughening agent, 1-5 parts by weight of scratch-resistant agent, 1-5 parts by weight of odor adsorption agent, 5-15 parts by weight of anti-static agent, 0.1-0.5 part by weight of antioxidant and 0.3-1 part by weight of lubricating agent. Therefore, the polypropylene composite material which has the characteristics of low odor, scratch-resistant surface, low surface resistivity and excellent mechanical properties and is used for the automobile internal ornament can be obtained.

Owner:GREAT WALL MOTOR CO LTD

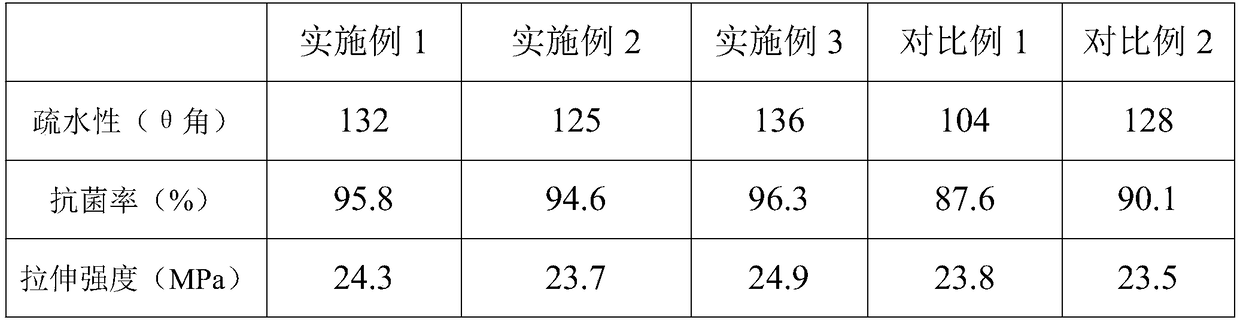

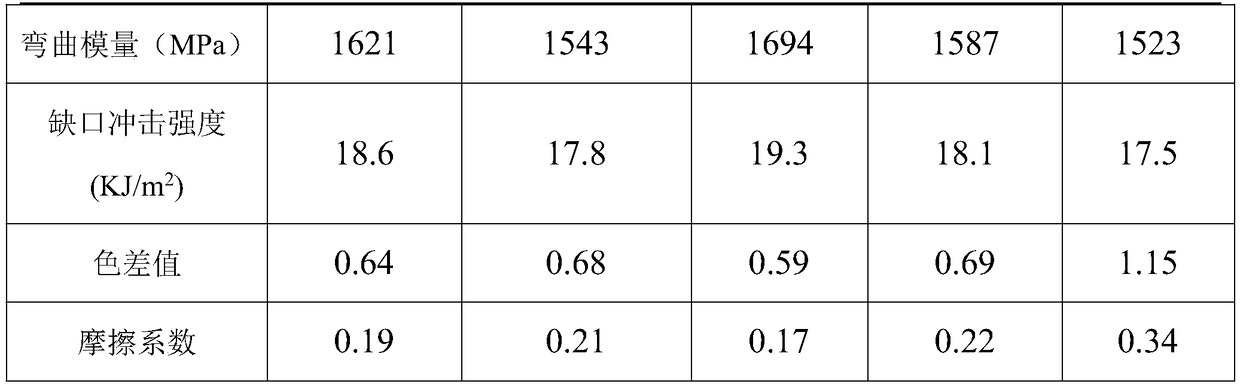

Antibacterial scratch-resistant thermoplastic elastomer composition and preparation method thereof

InactiveCN104045960AImprove antibacterial propertiesExcellent surface scratch resistancePolyolefinThermoplastic elastomer

The invention relates to an antibacterial scratch-resistant thermoplastic elastomer composition which is prepared from the following raw materials by weight percent: 15-25% of styrene thermoplastic elastomer, 25-40% of plasticizer, 6-10% of polypropylene, 0.5-2% of polyolefin thermoplastic elastomer, 30-40% of inorganic mineral, 0.6-0.9% of compatilizer, 0.06-0.2% of antibacterial agent, and 0.01-0.2% of additive. The invention also provides a preparation method for the antibacterial scratch-resistant thermoplastic elastomer composition. The thermoplastic elastomer composition has excellent antibacterial performance and surface scratch resistance as well as strong adhesive force, is kept attractive for long, and can be tightly bonded on the matrix in secondary forming, and the product made of the thermoplastic elastomer composition has a function of resisting bacteria and mould. The thermoplastic elastomer composition can be used for secondary forming (such as, rubber coating of tooth brushes, tool handles and the like), or can be used for forming alone (such as manufacturing bottle plugs).

Owner:GUANGDONG KINGREAT HITECH

Halogen-free flame retardant polypropylene composition

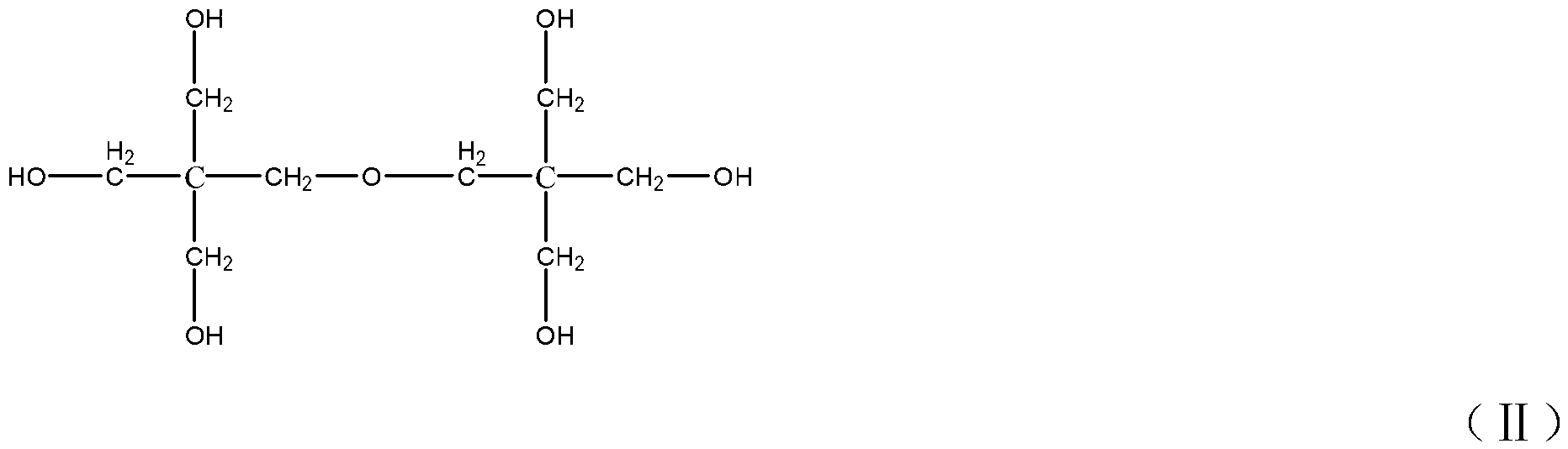

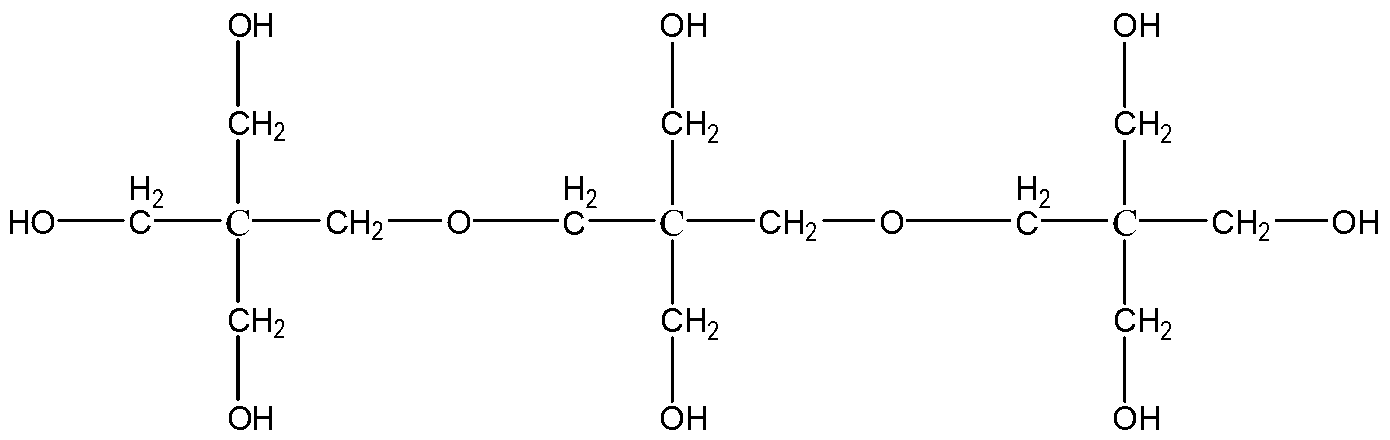

The invention provides a halogen-free flame retardant polypropylene composition. The composition comprises the following components: 20-80wt% of at least one polypropylene (A), 1-10wt% of at least one organic group modified polydimethylsiloxane (B), 1-10wt% of at least one compound (C) with a structure shown in formulas (I), (II) and / or (III), and 5-60wt% of ultrafine magnesium hydroxide with the particle size D50 being less than or equal to 2 micrometers. By utilizing the composition, the processing difficulty under high filling is reduced, and common silicone oil and pentaerythritol are prevented from migration; and moreover, the composition has excellent flame retardance, is easy to demould and has good surface scratch resistance and excellent combined multiple performances.

Owner:浙江通力新材料科技股份有限公司

Low-odor scratch-resistant high-rigidity polypropylene composition and preparation method thereof

The invention relates to a low-odor scratch-resistant high-rigidity polypropylene composition and a preparation method thereof. The low-odor scratch-resistant high-rigidity polypropylene composition comprises the following components in part by weight: 60 to 90 parts of polypropylene, 10 to 20 parts of talcpowder, 0.1 to 20 parts of nano scratch-resistant agent, 0.5 to 3.0 parts of lubricating agent, 1.0 to 3.0 parts of antioxidant and 0.5 to 3.0 parts of calcium stearate. The product prepared by the method is high in surface scratch resistance, low in cost, low in odor, high in rigidity, high in flowability and impact-resistant, and is typically applied to production of dashboard products.

Owner:HEFEI GENIUS NEW MATERIALS

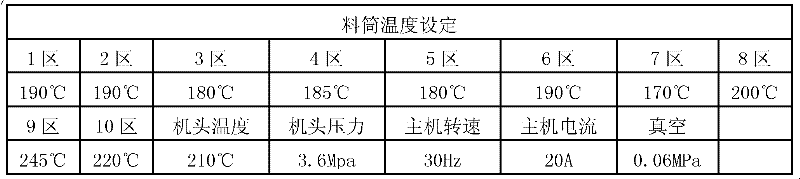

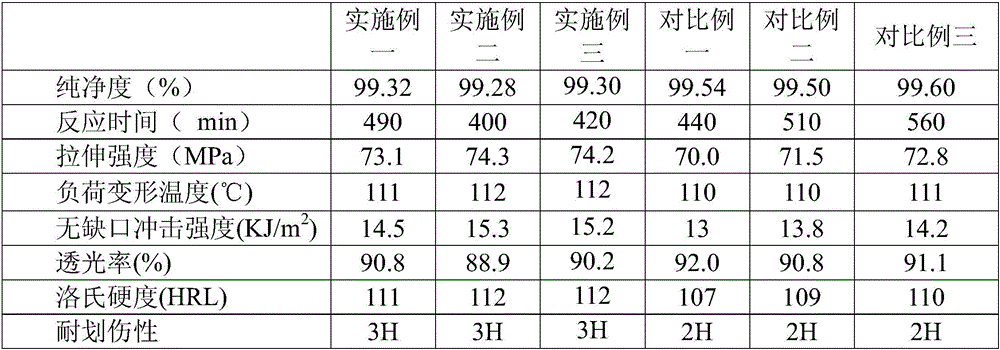

Preparation method of scratch-resistant high-impact-resistance PMMA (polymethyl methacrylate) material

The invention relates to a preparation method of a scratch-resistant high-impact-resistance PMMA (polymethyl methacrylate) material. The method comprises the following steps: taking 70-100 parts of main monomer methyl methacrylate, 5-10 parts of butyl acrylate, 5-15 parts of styrene, 15*10<-4>-35*10<-4> part of initiator and 0.1-0.3 part of chain-transfer agent, sufficiently stirring and uniformly mixing, adding the mixture into a three-neck flask provided with a reflux condensing unit, stirring at the speed of 300-500 r / min at 108-112 DEG C, and carrying out after-treatment to obtain the methyl methacrylate-butadiene copolymer. The preparation method is simple, and the steps are easy to operate. By adopting the mass polymerization process and adding the materials at one time, the whole reaction system is stable and controllable. The prepared methyl methacrylate-styrene-butyl acrylate copolymer has the advantages of high purity, favorable surface scratch resistance and favorable impact resistance.

Owner:SUZHOU DOUBLE ELEPHANT OPTICAL MATERIALS CO LTD

ABS alloy material for casing of notebook computer

The invention discloses an ABS alloy material for a casing of a notebook computer. The ABS alloy material consists of the following components in parts by weight: 30-45 parts of acrylonitrile butadiene styrene (ABS) resin, 20-25 parts of poly carbonate (PC) resin, 1-3 parts of zinc borate, 8-13 parts of acetylacetone salt, 1-2 parts of antimonous oxide, 2-5 parts of glass fiber, 3-7 parts of methyl vinyl silicone rubber, 1-3 parts of white carbon black, 2-5 parts of hydroxyl silicone oil, 1-3 parts of hydrogen containing silicone oil, 1-3 parts of a release agent, 8-16 parts of calcium stearate, 7-16 parts of stearic acid, 2-3 parts of N,N-ethylene bis stearamide and 1-3 parts of a flexibilizer. The ABS alloy material not only improves surface hardness and scratch resistance but also not affects other performances of the material; the alloy material is excellent in impact resistance, surface scratch resistance and flame resistance, and can meet demand of plastic for the casing of the notebook computer; the alloy material is worth popularizing and applying.

Owner:QINGDAO CHENGYANG HONGRUI PLASTIC PROD

Polypropylene composite material and preparation method thereof

InactiveCN109111644AImprove hydrophobicityGood antibacterial and antifungal effectPolymer scienceAntioxidant

The invention provides a polypropylene composite material and a preparation method thereof. The polypropylene composite material is prepared from the following components: 60 to 70 parts of polypropylene resin, 15 to 25 parts of talcum powder, 3 to 6 parts of modified nanometer zinc oxide, 5 to 10 parts of silicon rubber, 1 to 3 parts of titanate coupling agent, 5 to 10 parts of toughening agent,0.2 to 0.8 part of antioxidant and 0.5 to 1.5 parts of polyethylene wax. The preparation method comprises the following steps: 1) mixing the talcum powder, the silicon rubber, the titanate coupling agent, the polypropylene resin accounting for 30 to 40 percent of the total weight as well as the toughening agent accounting for 10 to 20 percent of the total weight, and preparing master batches by aninternal mixer; and 2) mixing the master batches obtained in the step 1), the modified nanometer zinc oxide, the antioxidant, the polyethylene wax, the remained toughening agent and the remained polypropylene resin, melting, mixing and dispersing at 210 to 240 DEG C by a double-screw extruding machine, and performing extrusion granulation. The composite material has high hydrophobicity and friction resistance.

Owner:安庆市泽烨新材料技术推广服务有限公司

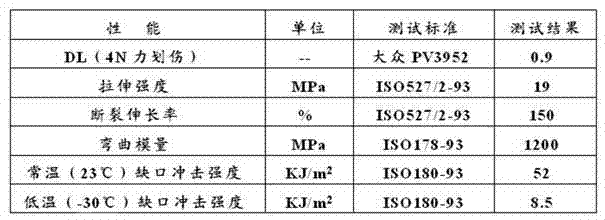

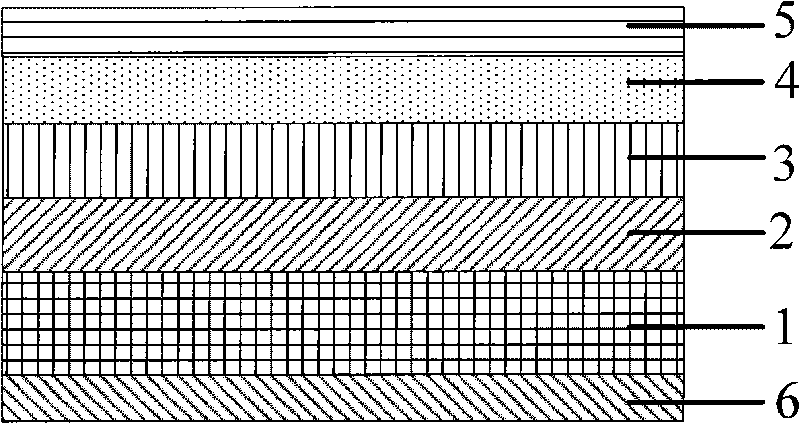

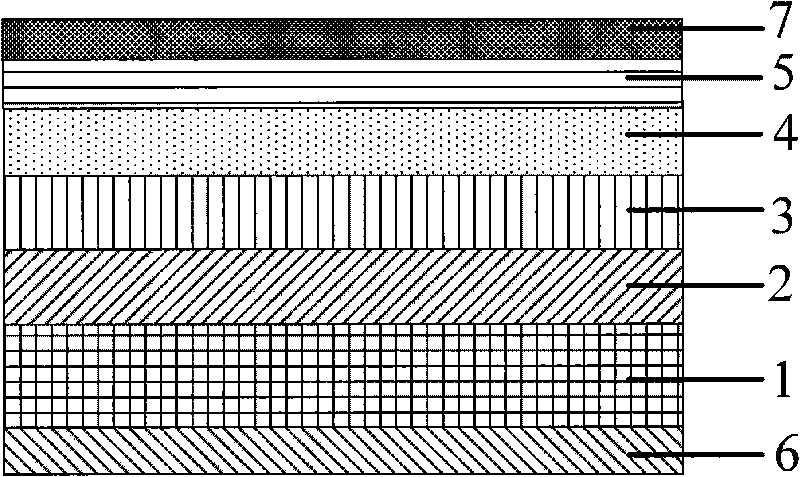

Continuous fiber ultrathin composite material sheet with different surface patterns and preparation method and application of sheet

ActiveCN103770390AImprove the finishExcellent surface scratch resistanceSynthetic resin layered productsEpoxy resin adhesivesResin bondingResin adhesive

The invention discloses a continuous fiber ultrathin composite material sheet with different surface patterns. The continuous fiber ultrathin composite material sheet comprises a continuous fiber composite material base material (I), wherein the upper surface of the continuous fiber composite material base material (I) is coated with a resin adhesive layer (II); the upper surface of the resin adhesive layer (II) is covered with a PET (polythylene terephthalate) material (III) with different patterns; the continuous fiber composite material base material (I) is 0.20-0.50mm thick; the PET material (III) with different patterns is 0.11-0.30mm thick. The continuous fiber ultrathin composite material sheet disclosed by the invention has different attractive surface patterns and is high in smoothness, high in surface scratch resistance, high in elastic modulus, high in impact resistance, high in heat resistance and high in corrosion resistance and can be widely applied to shells of various electronic products, electric appliances, aerospace equipment and the like; furthermore, a preparation method for the continuous fiber ultrathin composite material sheet is simple in technology, is suitable for large-scale continuous production and has the advantages of high yield, high efficiency, low cost and high product yield.

Owner:GUANGZHOU KINGFA CARBON FIBER NEW MATERIALS DEV +1

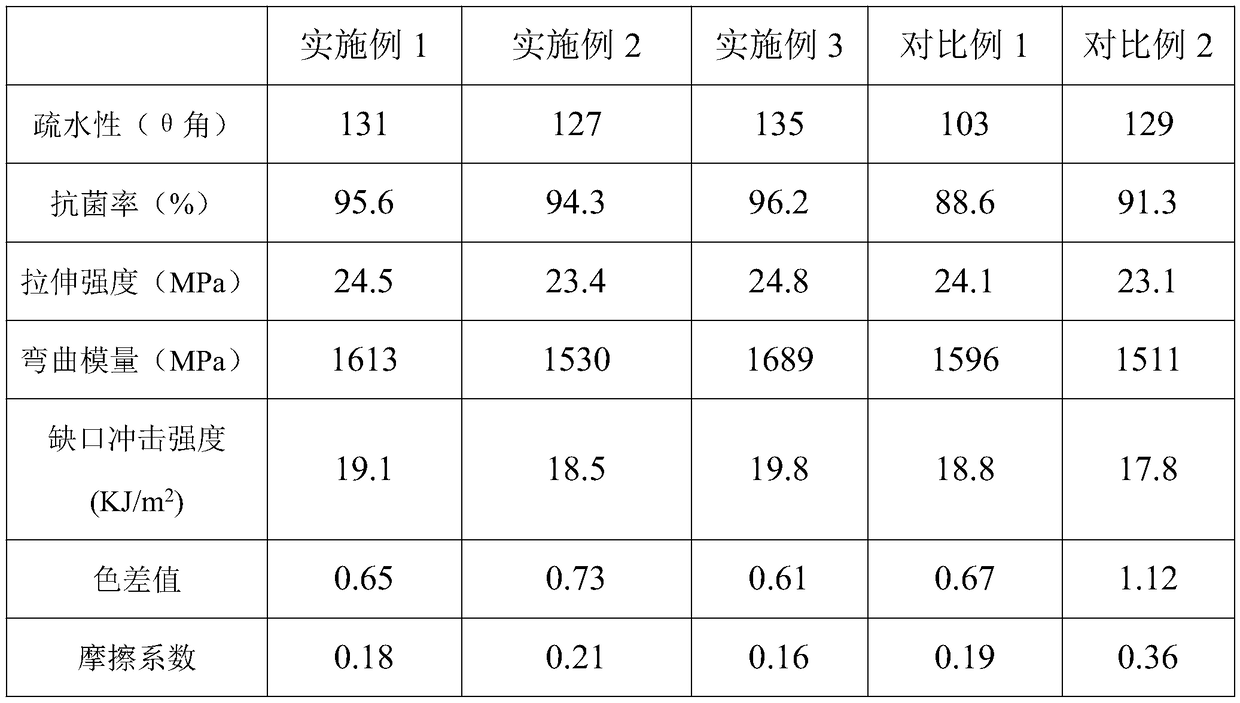

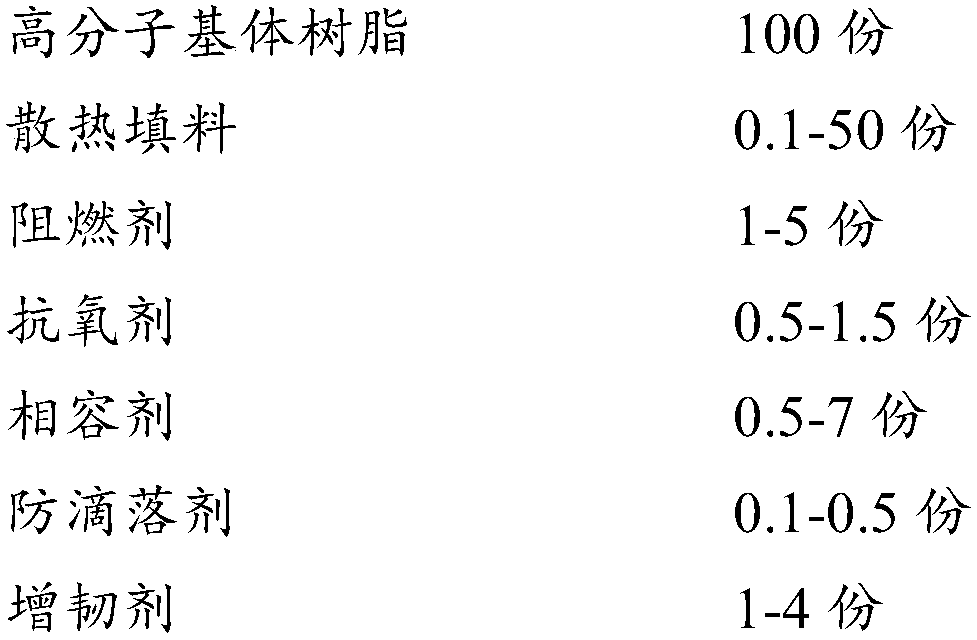

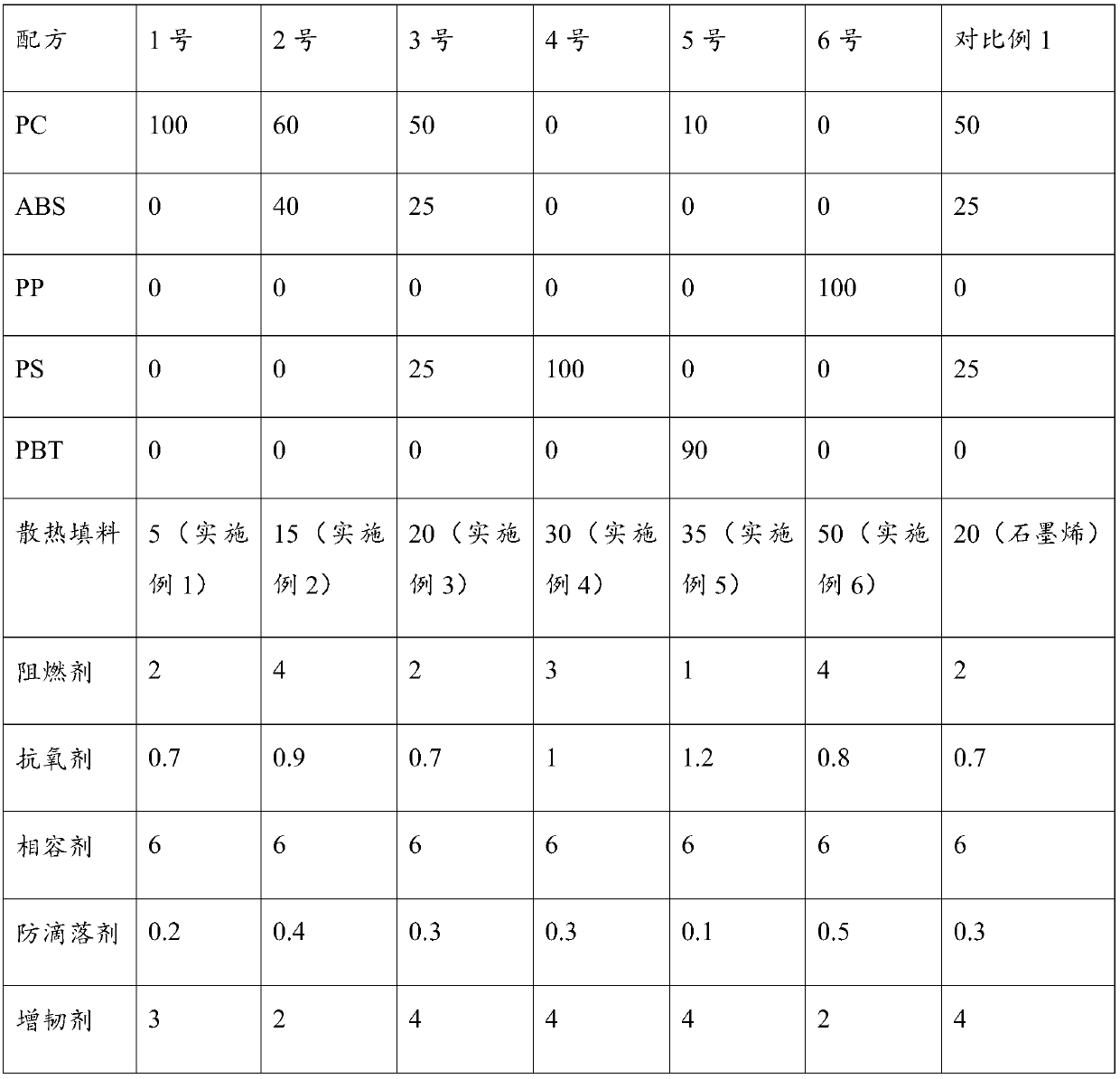

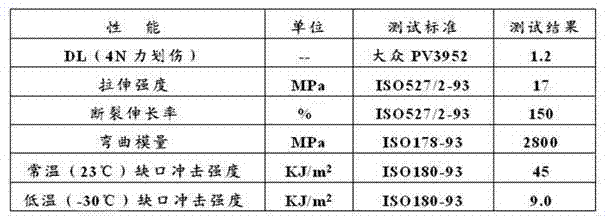

Polymer composite material for laptop computer outer shell and preparation method of polymer composite material

InactiveCN109575558AHigh hardnessImprove scratch resistanceHeat-exchange elementsAnoxomerMacromolecule

The invention belongs to the technical field of polymer composite materials and discloses a polymer composite material for a laptop computer outer shell and a preparation method of the polymer composite material. The composite material is prepared from, by weight, 100 parts of polymer matrix resin, 0.1-50 parts of heat dissipation filler, 1-5 parts of a flame retardant, 0.5-1.5 parts of an antioxidant, 0.5-7 parts of a compatilizer, 0.1-0.5 part of an anti-dripping agent and 1-4 parts of a toughening agent. The polymer composite material is excellent in impact resistance, surface scratch resistance and flame retardation, requirements on plastic for the laptop computer outer shell can be met, and a high popularization and application value is achieved.

Owner:山东利特纳米技术有限公司

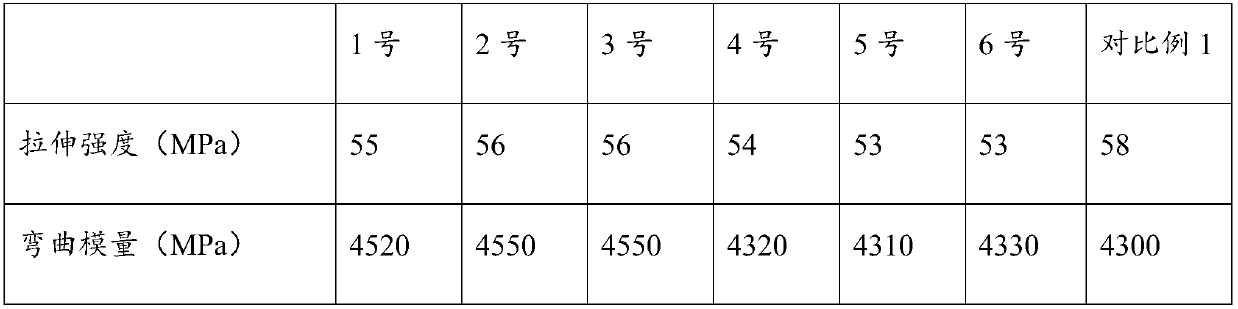

Window material for display

InactiveCN101088114AHigh transparencyHigh strengthSynthetic resin layered productsThin material handlingPolyesterFlexural strength

This invention provides a window material for a display that comprises a biaxially stretched sheet of a polyester having a multilayer structure of two or more layers, one of which is disposed on an outer layer in a display face in a display, and has a thickness of 0.3 to 5 mm and a light transmittance of 80 to 99.5%. Preferably, the window material for a display has a layer of other resin such as polycarbonate. Further, the window material for a display has a bending strength of 50 to 100 MPa, a bending modulus of elasticity of 3000 to 5500 MPa, and a maximum impact force in a high-speed impact test is not less than 1 kN. The window material for a display is usable as a window material for a display, for example, for liquid crystal display devices (LCDs), cathode-ray tube display devices (CRTs), EL display devices, plasma display devices (PDPs), and projection display devices.

Owner:MITSUI CHEM INC

Polypropylene material with paint spraying effect and preparation method for polypropylene material

The invention relates to polypropylene material with a paint spraying effect. The polypropylene material comprises the following components by weight percent: 38-99.9% of polypropylene, 0-1% heat stabilizer, 0-1% lubricant, 0-15% flexibilizer, 0-5% interfacial compatilizer, 0-30% inorganic mineral powder and 0.1-10% superfine aluminium powder, wherein the particle diameter of the superfine aluminium powder ranges from 1 to 100 Mum. The polypropylene material has excellent surface scratch resistance and superior comprehensive mechanical property, and the surface of the polypropylene material is smooth and glossy like paint. The polypropylene material can be obtained through extruding granulation with a screw rod, the preparation method is simple, and the technological conditions are easy to control. When the polypropylene material is used to manufacture exterior trimming parts of an automobile, the procedure of paint spraying can be omitted on the condition that the service performance and the attractiveness are not influenced, so as to simplify technological process, lower production cost, reduce volatilization of VOC (Volatile Organic Compound) gas and achieve the purposes of energy conservation and environmental friendliness.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD

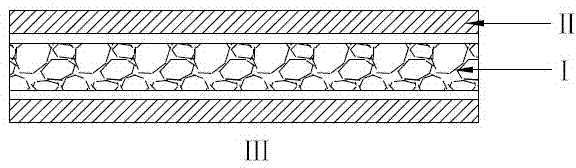

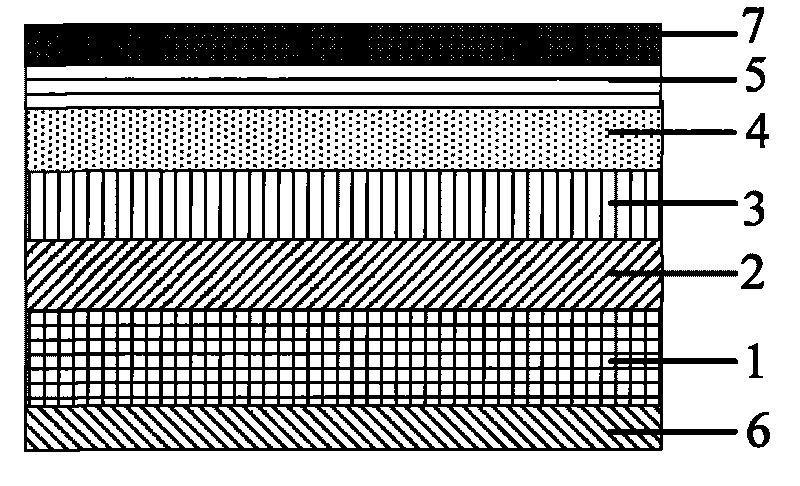

Ultrathin metal sheet sandwich structural body and preparation method thereof

InactiveCN103692723AThe overall thickness is thinLight in massLamination ancillary operationsSynthetic resin layered productsFiberThin metal

The invention relates to an ultrathin metal sheet sandwich structural body which is an ultrathin metal sheet sandwich structural body (III) consisting of a core material (I) and ultrathin metal sheets (II) arranged on the upper and lower surfaces of the core material (I), wherein the core material (I) has a gap; the specific gravity of the core material (I) is 0.01-1.0, and the core material (I) is 0.2-5.0mm thick. The gap is formed by bubbles of a foaming body, or the core material (I) is formed by discontinuous reinforced fibers and thermoplastic resin. The gap is formed by gaps formed at mutual intersections among the discontinuous reinforced fibers. The ultrathin metal sheet sandwich structural body prepared by the invention is small in thickness, light in weight, high in rigidity, good in surface scratch resistance, puncture resistance and easy to process. The middle core material is bended but not cracked, so that the structural body is good in weather ability and high in fireproof grade, and is mainly applied to surface structural panels of crates in the fields of 3C (computer, communication and consumer electronic) industry, household appliance industry and related industries.

Owner:GUANGZHOU KINGFA CARBON FIBER NEW MATERIALS DEV +1

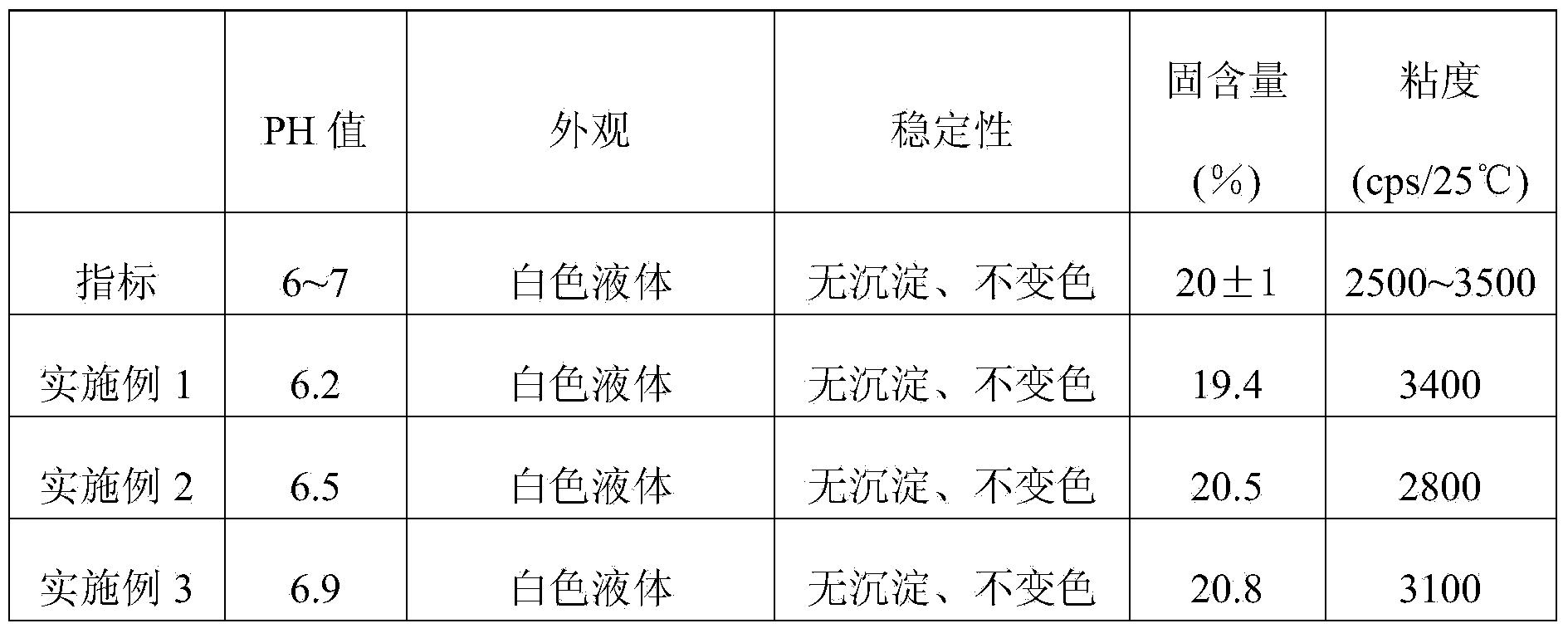

Waterborne oily leather treatment agent for synthetic leather and preparation method of leather treatment agent

InactiveCN104032578AComply with environmental standardsImprove mechanical propertiesFibre treatmentMedicineScratching

The invention relates to a waterborne oily leather treatment agent for synthetic leather and a preparation method of leather treatment agent. The treatment agent is prepared from the following components: modified waterborne polyurethane, water, a waterborne leveling agent and a waterborne thickening agent. The waterborne oily leather treatment agent is a novel material for later printing of the synthetic leather, and the treatment agent can enable the synthetic leather to have smooth hand feeling; the synthetic leather treated by the treatment agent has strong glossiness and crystalline effect, cannot be broken when baked at high temperature and has good surface scratching resistance.

Owner:JIANGSU BAOZE POLYMER MATERIAL

LED four-color printing ink for intaglio printing and preparation method of LED four-color printing ink

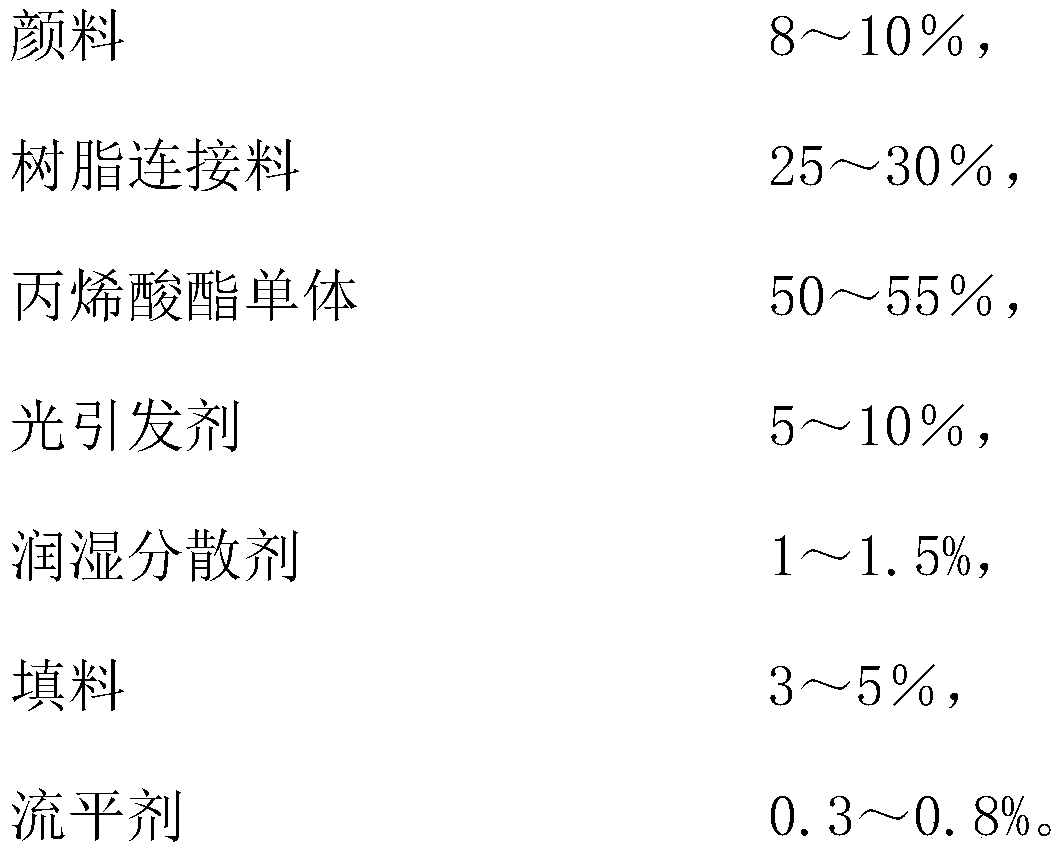

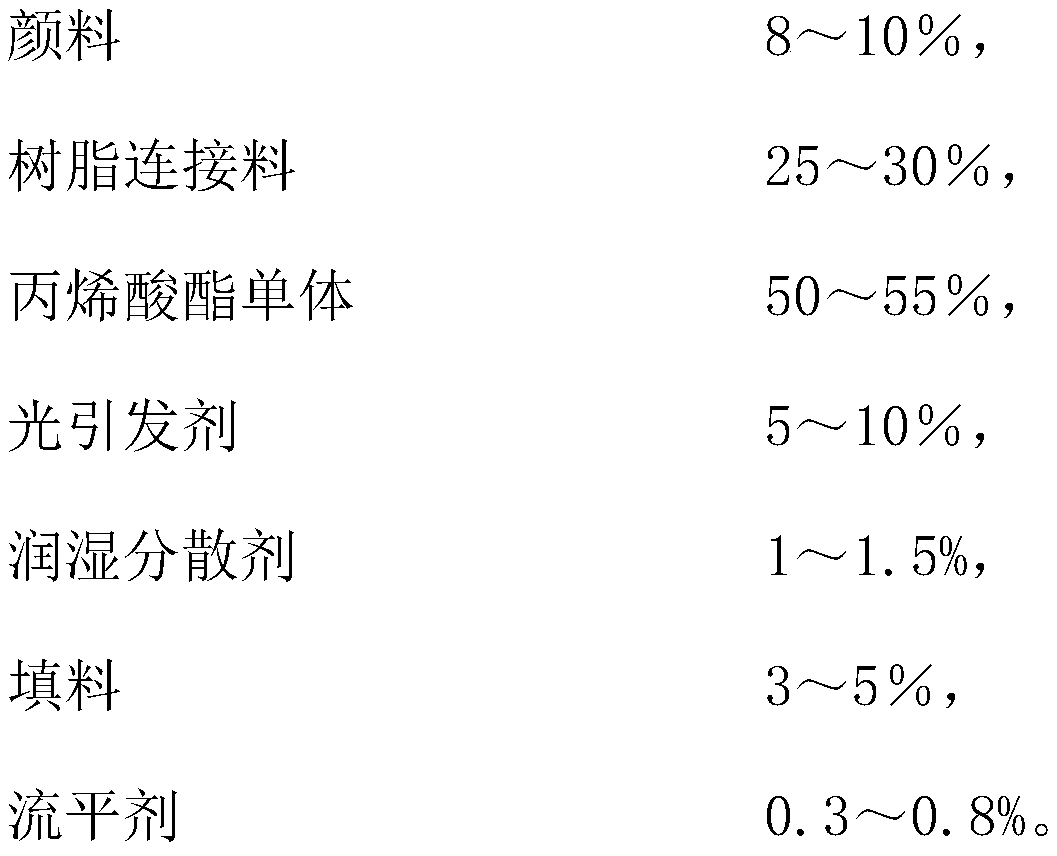

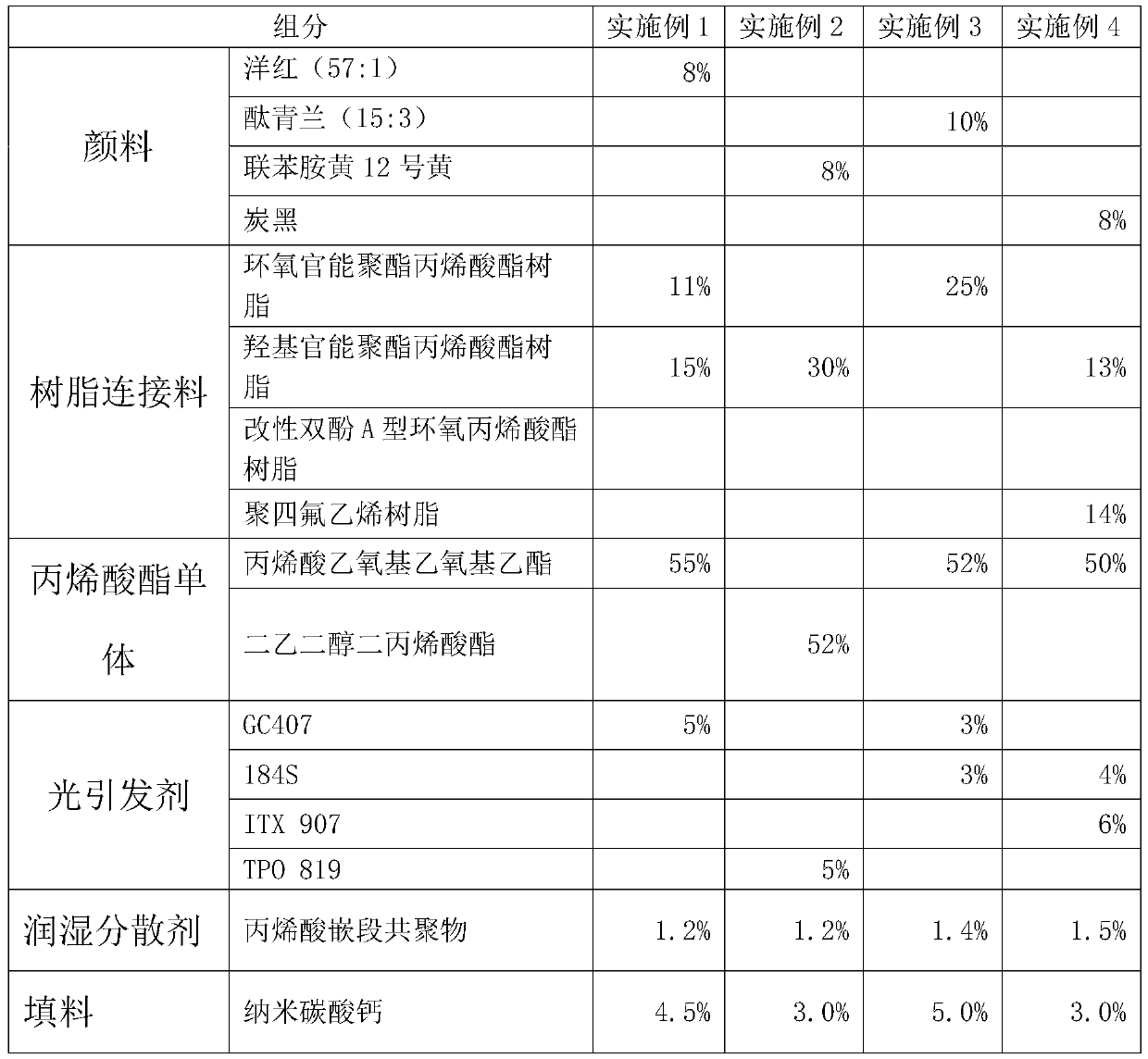

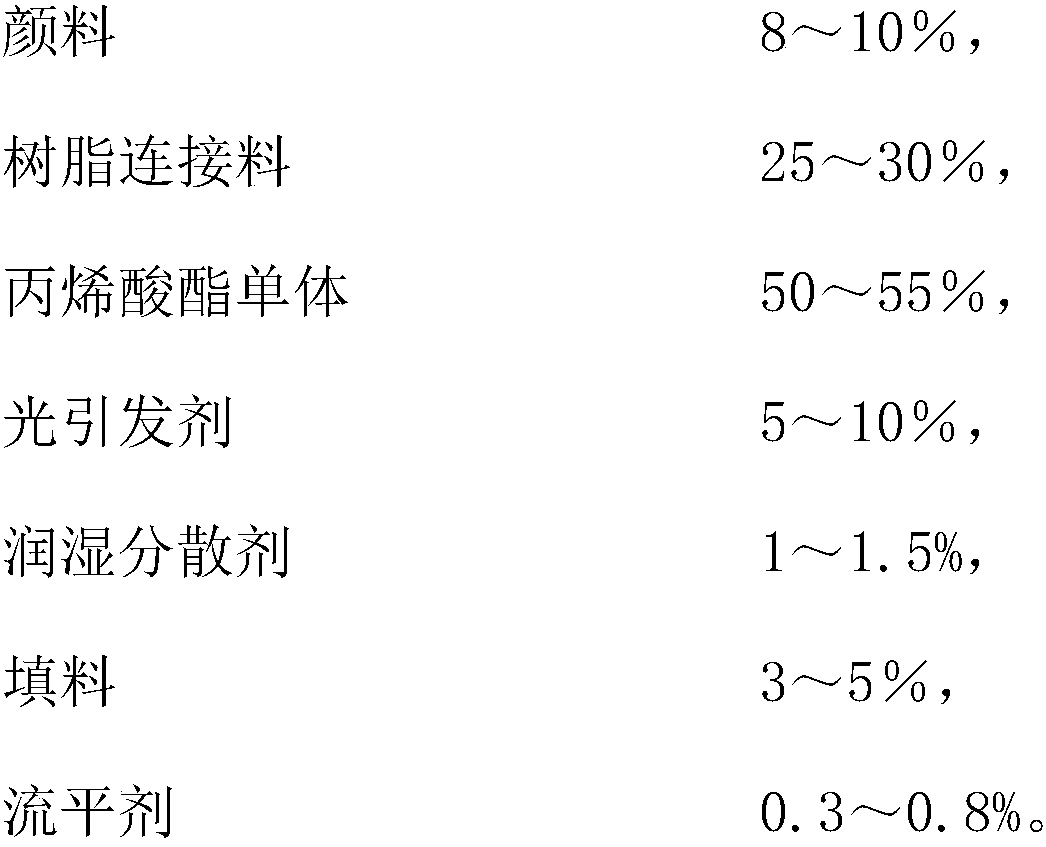

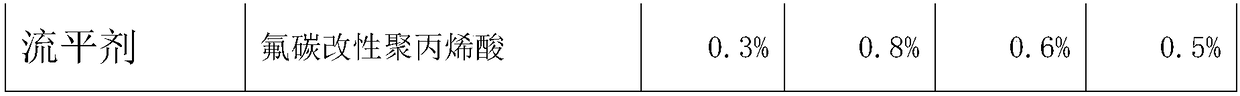

The invention discloses LED four-color printing ink for intaglio printing and a preparation method of the LED four-color printing ink. The technical scheme is characterized in that the LED four-colorprinting ink is prepared from components in percentage by weight as follows: 8%-10% of pigment, 25%-30% of a resin connecting material, 50%-55% of acrylate monomers, 5%-10% of a photoinitiator, 1%-1.5% of a wetting dispersant, 3%-5% of packing and 0.3%-0.8% of a leveling agent. According to the LED four-color printing ink for intaglio printing, a cured ink layer has bright luster, full color and clear lines, continuous printing is realized without stopping, and the ink layer is good in surface leveling property and high in lustrousness.

Owner:中山市中益油墨涂料有限公司

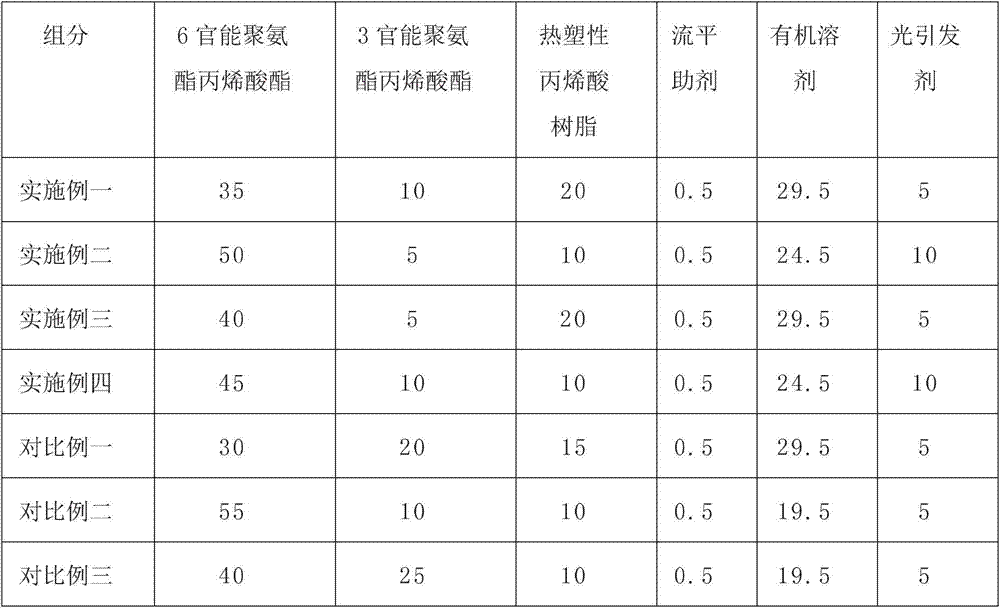

Heat-transfer-printing PET film ultraviolet-curing varnish and preparation method thereof

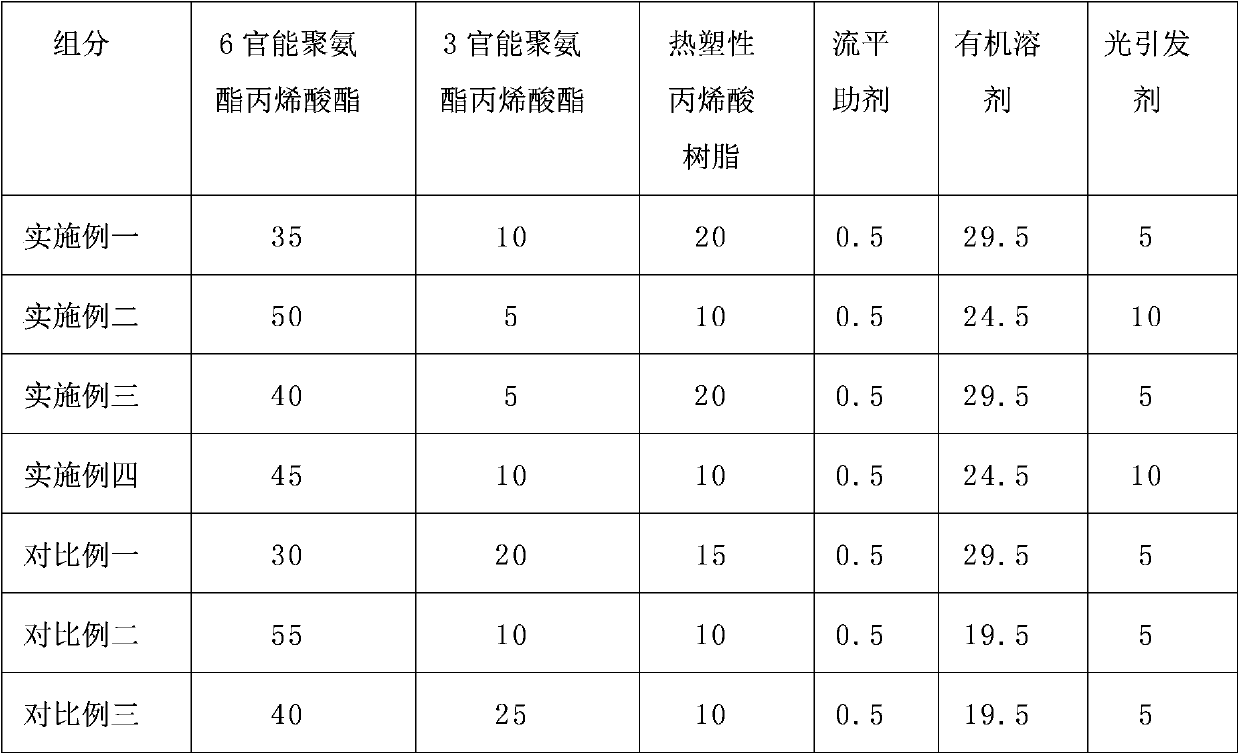

ActiveCN107365553AImprove adhesionStrong surface hardnessPolyurea/polyurethane coatingsAcrylic resinUltraviolet lights

The invention provides a heat-transfer-printing PET film ultraviolet-curing varnish and a preparation method thereof. The varnish comprises the following components in percentage by mass: 35-50% of hexafunctional polyurethane acrylate, 5-10% of trifunctional polyurethane acrylate, 10-20% of thermoplastic acrylic resin, 0.5-1% of leveling agent, 20-30% of organic solvent and 5-10% of photoinitiator. According to the heat-transfer-printing PET film ultraviolet-curing varnish, the paint film has the advantages of favorable adhesive force, high surface hardness, favorable scratch resistance of the surface, and favorable chemical resistance. The cured paint film has favorable flexibility, and can not crack even after being bent by 90 degrees. In the preparation method, the mild and nontoxic organic solvent is utilized, and has the advantages of small out-emission amount and no environment pollution; the heat-transfer-printing PET film ultraviolet-curing varnish is used instead of the traditional thermocuring transfer printing paint; when the heat-transfer-printing PET film ultraviolet-curing varnish is in use, the paint film can become dry and form a film after being irradiated by ultraviolet light for 10-20 seconds, and thus, the method has the advantages of higher production efficiency, simple film-forming technique, low requirements for film-forming equipment and energy saving, and further lowers the cost.

Owner:东周化学工业(昆山)有限公司

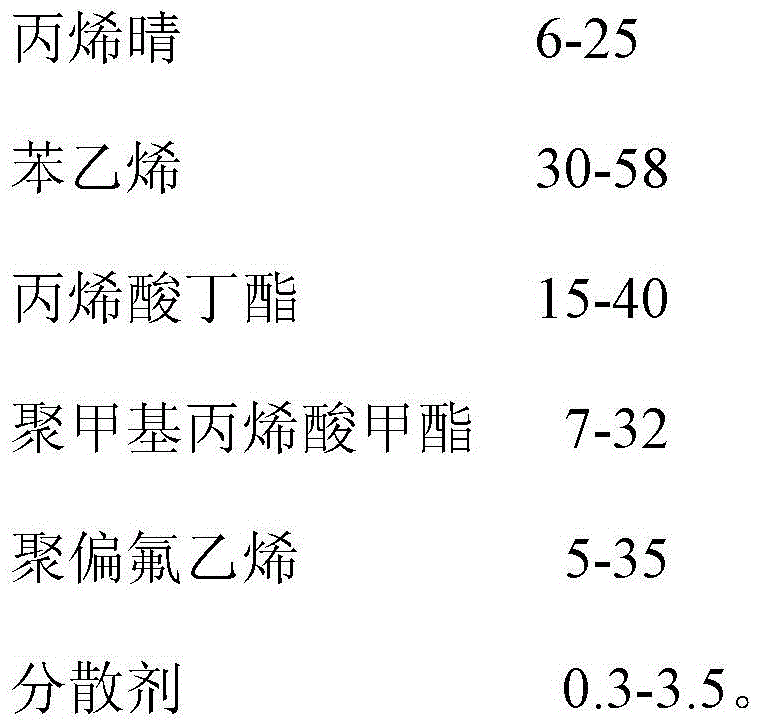

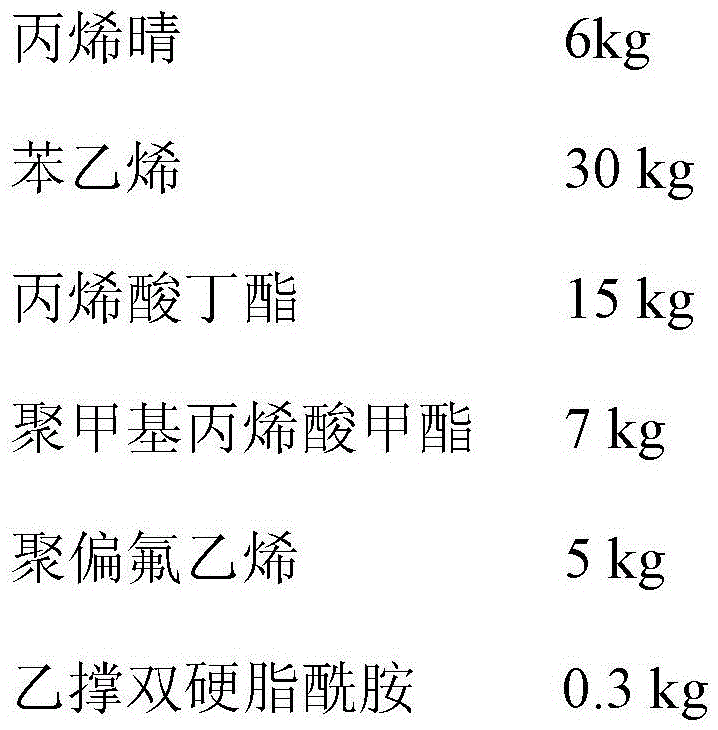

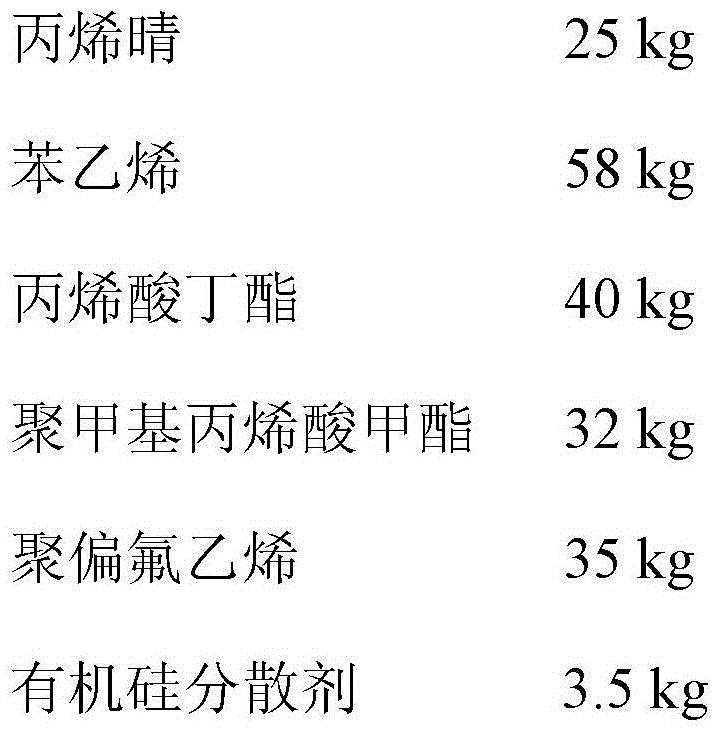

Outdoor decorative film composition for plastic door window and preparation method of outdoor decorative film

Provided are an outdoor decorative film composition for a plastic door window and a preparation method of the outdoor decorative film. The composition is prepared from 6-25 parts of acrylonitrile, 30-58 parts of styrene, 15-40 parts of butyl acrylate, 7-32 parts of polymethyl methacrylate, 5-35 parts of polyvinylidene fluoride and 1-8 parts of a dispersing agent. The outdoor decorative film composition for the plastic door window and the preparation method of the outdoor decorative film have the advantages that the outdoor decorative film is a single-layer film, the cost is far lower than that of an imported PVC multilayer composite film, and therefore application and promotion are facilitate; meanwhile, the stripping problem between two layers of the films can be avoided. The glass transition temperature of butyl acrylate is minus 55 degrees, and therefore the outdoor decorative film can still keep the good flexibility even in the cold winter. Polymethyl methacrylate is higher in weather resistance than that of ASA and high in hardness, and therefore the surface scratch resistance is good.

Owner:TIANJIN TRANSPARENT WALL TECH CO LTD

Printing color management (PCM) composite steel plate

InactiveCN101758736AAchieve visual effectsGood surface scratch resistanceSpecial ornamental structuresSheet steelLacquer

The invention provides a printing color management (PCM) composite steel plate. The front face of the steel plate is coated with a primer layer, an upper roller of the primer layer is coated with a finish layer, an upper roller of the finish layer is coated with a pattern printing layer, and the upper roller of the pattern printing layer is coated with a vanish layer. The surface of the composite steel plate has the advantages of good scoring-resistant strength and favorable glossiness and the pattern printing layer realizes the visual effect of various color and patterns so that the PCM composite steel plate has attractive appearance and can satisfy the demand of individual use.

Owner:SUZHOU HESHENG NEW MATERIALS

Flame-retardant PP (polypropylene) composite material and preparation method thereof

InactiveCN109337207AGood antibacterial and antifungal effectImprove self-cleaning abilityPhosphomolybdic acidPolypropylene

The invention provides a flame-retardant PP (polypropylene) composite material and a preparation method thereof. The flame-retardant PP composite material comprises components as follows: 55-65 partsof PP resin, 15-25 parts of wollastonite, 5-10 parts of magnesium-aluminum hydrotalcite, 1-3 parts of phosphomolybdic acid, 3-6 parts of modified nano-zinc oxide, 5-10 parts of silicon rubber, 1-3 parts of a titanate coupling agent, 5-10 parts of a flexibilizer, 0.2-0.8 parts of an antioxidant and 0.5-1.5 parts of polyethylene wax. The preparation method comprises steps as follows: 1), firstly, wollastonite, the silicon rubber, the titanate coupling agent, the PP resin accounting for 30%-40% of total mass and the flexibilizer accounting for 10%-20% of total mass are mixed uniformly, and masterbatches are prepared by an internal mixer; 2), the masterbatches obtained in step 1) are mixed with magnesium-aluminum hydrotalcite, phosphomolybdic acid, modified nano-zinc oxide, the antioxidant, polyethylene wax, the remaining flexibilizer and the remaining PP resin, and a mixture is subjected to melt mixing and dispersing at 210-240 DEG C in a twin-screw extruder and subjected to extruded granulation. The composite material has good hydrophobic property, friction resistance and flame retardant performance.

Owner:安庆市泽烨新材料技术推广服务有限公司

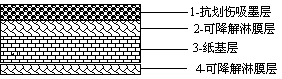

Degradable and anti-scratching microporous ink-jet printing photo paper and preparation method thereof

ActiveCN111016489AExcellent surface scratch resistanceExcellent degradabilityDuplicating/marking methodsCoatingsPolymer chemistryInkjet printing

The invention relates to the field of color spray printing media, and provides a preparation method of degradable and anti-scratching microporous ink-jet printing photo paper. The degradable and anti-scratching microporous ink-jet printing photo paper comprises an anti-scratching ink sucking layer, a degradable film spraying layer and a paper base layer, wherein the anti-scratching ink sucking layer contains nano-crystalline cellulose; and the nano-crystalline cellulose forms a three-dimensional network structure in a coating, so that the fastness and the hardness of the coating can be enhanced, and the friction resistance and the anti-scratching performance of the coating are further improved. The microporous ink-jet printing photo paper is safe and environmentally-friendly, high in degrading rate and high in anti-scratching performance, and a printed image is bright in color and high in precision.

Owner:广东荣思达新材料有限公司

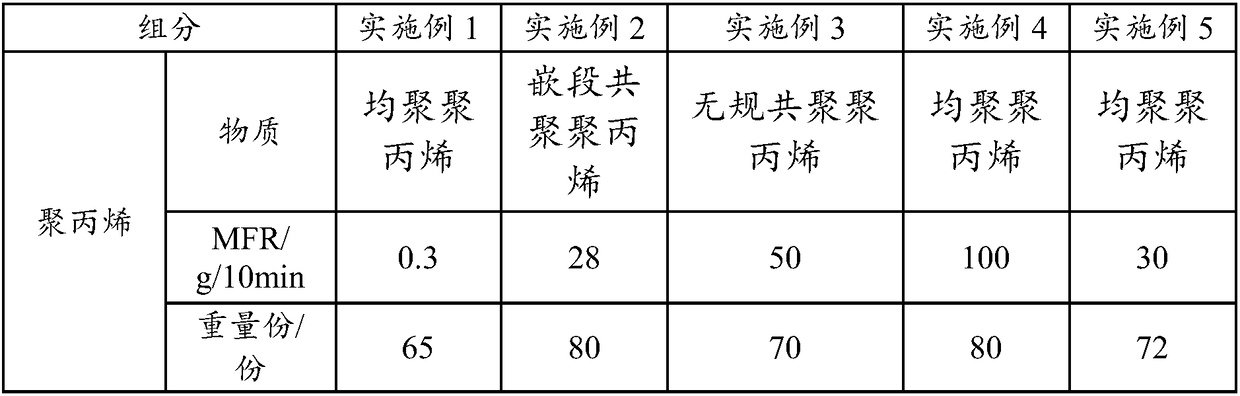

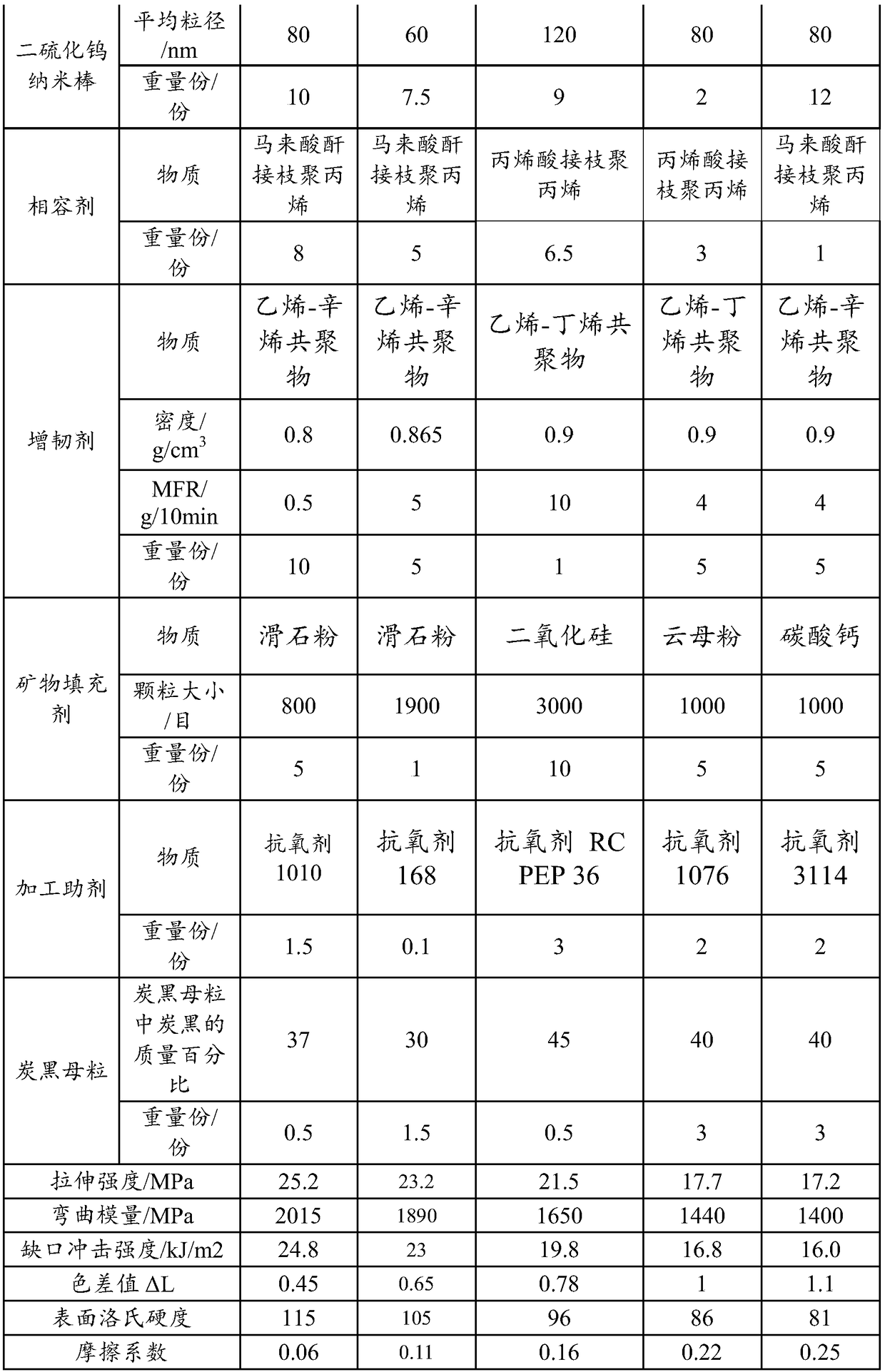

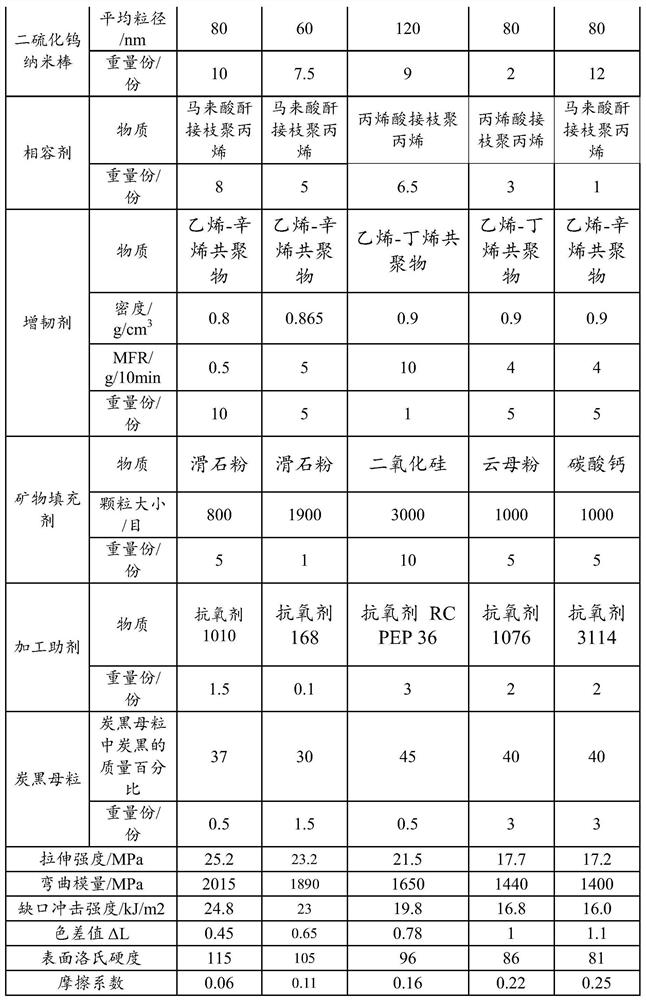

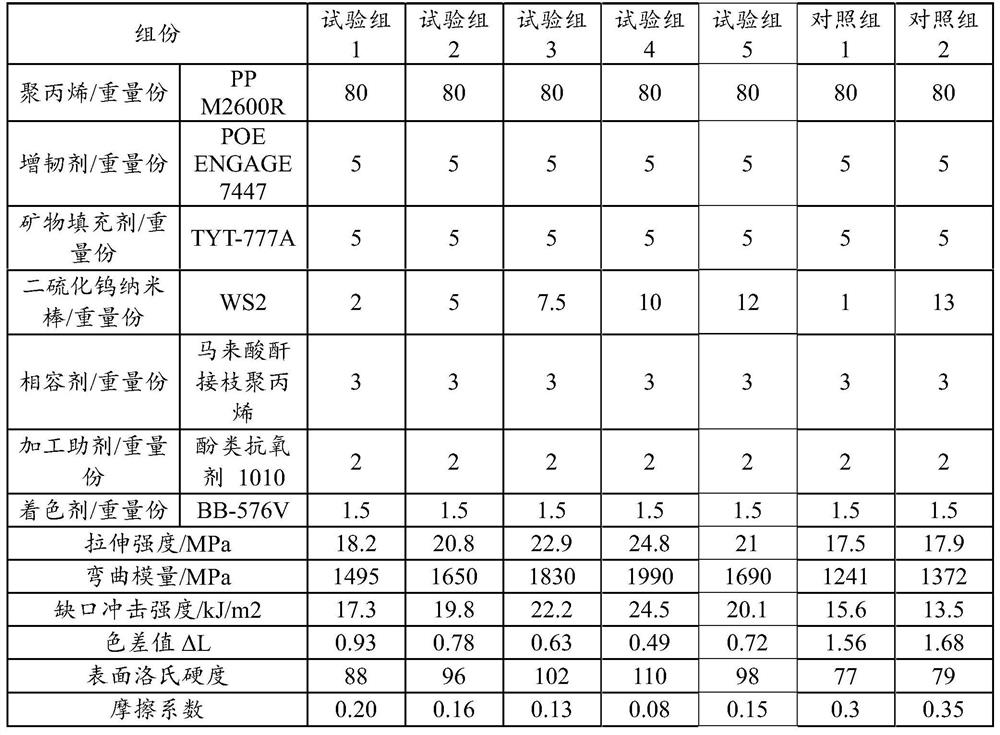

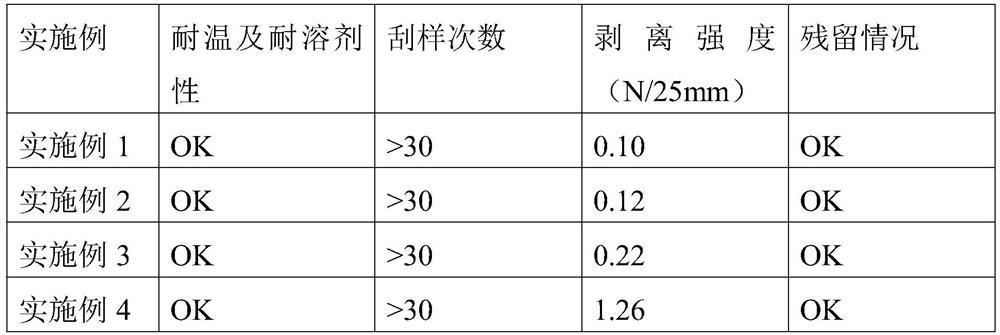

Polypropylene composite material and preparation method thereof

The invention relates to a polypropylene composite material and a preparation method thereof, and belongs to the technical field of a modified material. The polypropylene composite material is prepared from the following ingredients in parts by weight: 65 to 80 parts of polypropylene, 2 to 12 parts of tungsten disulfide nanometer rods and 1 to 8 parts of compatilizers. The specific content of tungsten disulfide nanometer rods are added into polypropylene substrates under the cooperated dispersion effect of the specific content of compatilizers, so that mutual friction is generated between WS2materials in the prepared polypropylene composite material; layered sliding is generated; the WS2 becomes thin and small through friction; small fragments fill the defects in the abrasion process, sothat the friction undulation is further reduced; the friction stability is enhanced. Therefore the anti-scratching performance and the intensity of the obtained polypropylene composite material are obviously improved.

Owner:WUHAN JINFA TECH CO LTD +1

Special plastic/acrylonitrile butadiene styrene (PC/ABS) alloy for notebook computer shell

ActiveCN101974218BExcellent surface hardnessImprove scratch resistanceAcrylonitrilePolymethyl methacrylate

The invention discloses a special plastic / acrylonitrile butadiene styrene (PC / ABS) alloy for a notebook computer shell. The formula comprises the following materials in parts by weight: 30-80 parts of polycarbonate, 5-65 parts of acrylonitrile-butadiene-styrene copolymer, 5-15 parts of compatilizer, 1-15 parts of flame retardant agent, 3-20 parts of filler, 1-10 parts of hardness modifier, 0.5-5 parts of anti-falling agent and 0-1 part of auxiliary agent. By adopting specific high-molecular polymers of polymethyl methacrylate (PMMA), ultrahigh-molecular polysiloxane and the like, the special PC / ABS alloy selects mineral fillers of specific-size mica, glass fiber and the like to carry out rematching therewith and generates synergistic effect, thus obviously improving the surface hardness and scraping resistance of the material and simultaneously having no influence on the other performances of the material. The PC / ABS alloy material has excellent impact resistance, surface scraping resistance and flame retardance, can meet the requirements of plastic for the notebook computer shell and has considerable promotion and application values.

Owner:大河宝利材料科技(苏州)有限公司

Modified ABS composite material for remote control shell

The invention discloses a modified ABS composite material for a remote control shell. The modified ABS composite material comprises raw materials in parts by weight as follows: 80-100 parts of modified ABS resin, 30-50 parts of polyphenylene sulfide, 2-4 parts of a compatilizer, 2-4 parts of diphenyl octyl phosphate, 1.5-2.5 parts of tricresyl phosphate, 50-60 parts of filler and 2-4 parts of coumarone indene resin and 2-4 parts of an antioxidant, wherein the compatilizer is prepared with the following process: ABS resin is subjected to irradiation treatment, polybutadiene is added, the mixture is heated and stirred, polyamide is added, the mixture is stirred continuously, and the modified ABS resin is obtained. The modified ABS composite material for the remote control shell is high in hardness, has excellent impact resistance, surface scratch resistance and flame retardance, is high in thermal decomposition temperature and glass transition temperature, can meet requirements of plastics for the remote control shell and has high popularization and application values.

Owner:天长市天利达电子厂

Thermal transfer PET film UV-curable varnish and preparation method thereof

ActiveCN107365553BImprove adhesionStrong surface hardnessPolyurea/polyurethane coatingsPolymer scienceAcrylic resin

Owner:东周化学工业(昆山)有限公司

LED four-color printing ink used for intaglio printing, and preparation method thereof

The invention discloses a LED four-color printing ink used for intaglio printing, and a preparation method thereof. The LED four-color printing ink used for intaglio printing comprises, by weight, 8 to 10% of a pigment, 25 to 30% of a resin binder, 50 to 55% of an acrylate monomer, 5 to 10% of a photoinitiator, 1 to 1.5% of a wetting dispersant, 3 to 5% of a filling material, and 0.3 to 0.8% of aleveling agent. The LED four-color printing ink used for intaglio printing is bright in curing ink layer color, rich in color, clear in lines, is excellent in ink layer surface levelability, and is high in glossiness, and is capable of realizing continuous printing without shutdown.

Owner:中山市中益油墨涂料有限公司

Wear-resistant polypropylene composite material and preparation method thereof

InactiveCN109467816AImprove hydrophobicityGood antibacterial and antifungal effectPolymer scienceWear resistant

The invention provides a wear-resistant polypropylene composite material and a preparation method thereof. The composite material comprises the following components: 55-65 parts of a polypropylene resin, 10-15 parts of a polyethylene resin, 15-25 parts of mica powder, 3-6 parts of modified nano zinc oxide, 5-10 parts of silicone rubber, 1-3 parts of a titanate coupling agent, 5-10 parts of a toughening agent, 0.2-0.8 part of an antioxidant and 0.5-1.5 parts of polyethylene wax. The preparation method comprises the steps of: 1) at first, uniformly mixing the mica powder, the silicone rubber, the titanate coupling agent, the polypropylene resin occupying 30-40% of the total mass and the toughening agent occupying 10-20% of the total mass, and preparing a masterbatch by using an internal mixer; and 2) mixing the masterbatch obtained in the step 1) with the polyethylene resin, the modified nano zinc oxide, the antioxidant, the polyethylene wax, the remaining toughening agent and the remaining polypropylene resin, carrying out fusion, mixing and dispersion at 210-240 DEG C in a twin-screw extruder, and carrying extrusion and granulation. The composite material has good hydrophobicity and friction resistance.

Owner:安庆市泽烨新材料技术推广服务有限公司

A kind of polypropylene composite material and preparation method thereof

ActiveCN108192213BIncrease surface polarityReduce surface friction coefficientPolypropylene compositesPolymer science

Owner:WUHAN JINFA TECH CO LTD +1

Release film for leather and preparation method thereof

PendingCN113527739ASolve the flatnessImprove flatnessPolyurea/polyurethane coatingsEpoxy resin coatingsPolymer sciencePropanoic acid

The invention discloses a preparation method of a release film for leather. The preparation method comprises the following steps: preparing a pre-coating coating; preparing a release layer coating; preparing a base material through corona treatment; coating the base material with a pre-coating layer paint, and curing to form a pre-coating layer to obtain a pre-coated base material; and embossing and curing the release layer coating on the pre-coated base material by adopting a slit coating mode assisted by electron beams to form a release layer, and obtaining the release film for leather. The invention further discloses the release film for leather. The release film for the leather comprises a three-layer structure, namely the release layer synthesized by aliphatic polyurethane propionic acid resin, the pre-coating layer of water-based acrylic emulsion and the base material subjected to corona treatment; embossing and curing are cured by adopting an electron beam assisted direct rolling mode, so that embossing and curing are carried out at the same time, and the problem that a traditional release film is poor in flatness and texture fidelity due to limitation of the physical strength of a base material is solved; and the obtained product has the advantages of being vivid in texture, high in repeated utilization rate and good in solvent resistance, surface scratch resistance and flatness.

Owner:瑞泰铸纸东莞有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com