LED four-color printing ink used for intaglio printing, and preparation method thereof

A gravure printing and ink technology, used in the field of printing ink, can solve the problems of drying speed, adhesion, flexibility, chemical resistance, insufficient surface flexibility and hardness, and difficulty in increasing the crosslinking density of the ink layer. Eliminate environmental pollution and impact on workers' health, eliminate adverse effects, and have good surface scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

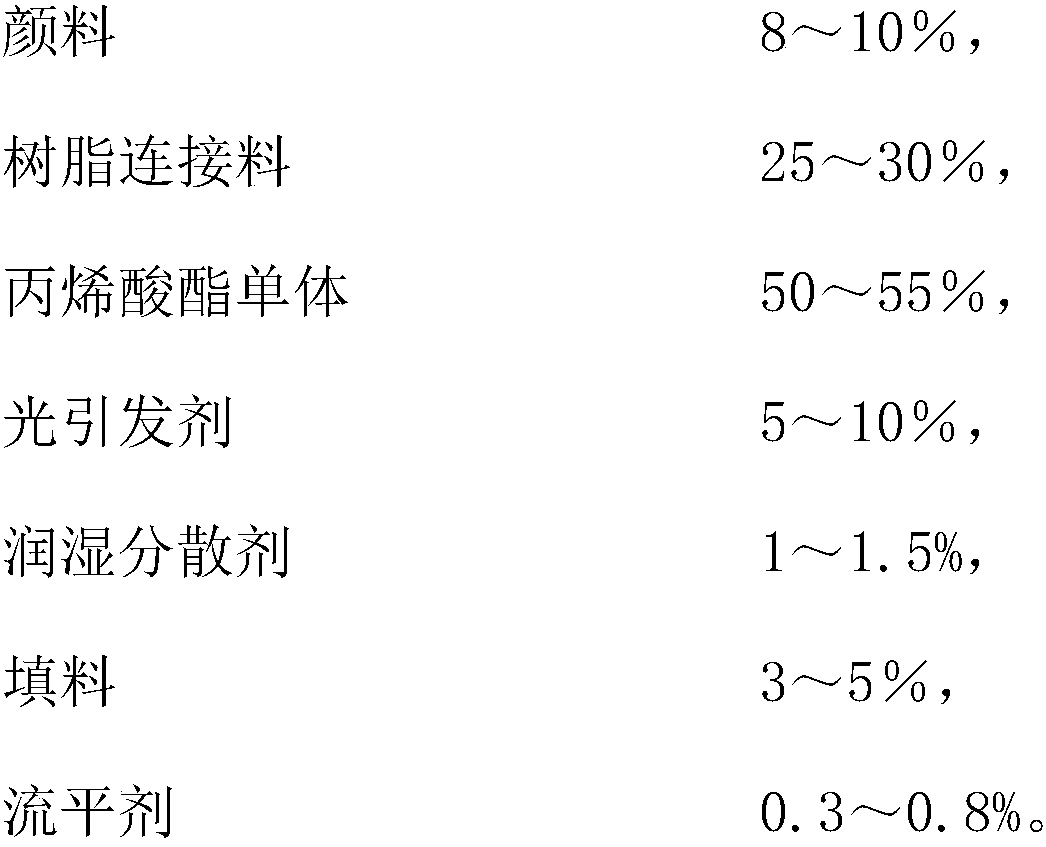

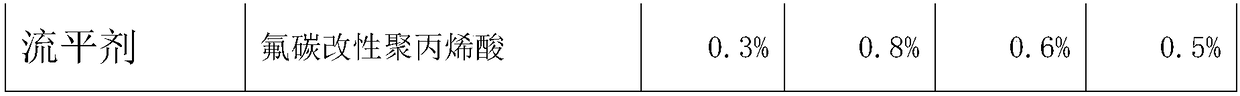

[0028] Further illustrate the LED four-color ink of gravure printing of the present invention in conjunction with specific embodiment 1~5:

[0029] A kind of preparation method of the LED four-color printing ink of gravure printing, comprises the steps:

[0030] 1) Weigh the resin binder, photoinitiator, and wetting and dispersing agent according to the weight percentage, and enter the high disperser to mix them fully to obtain the mixture A;

[0031] 2) Weigh the pigment according to the weight percentage and add it to the mixture A, and use a high-speed mixer to mix and stir it until the heat causes preliminary dispersion to obtain the mixture B;

[0032] 3) Add leveling agent and filler to mixture B, and continue stirring to obtain mixture C;

[0033] 4) Fully grind the mixture C on a three-roller machine to a specified fineness (less than 5 microns) to make a semi-finished product D, then add acrylate monomers, stir well, and filter with 200 mesh gauze. The product is se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com