Patents

Literature

294results about How to "Won't explode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

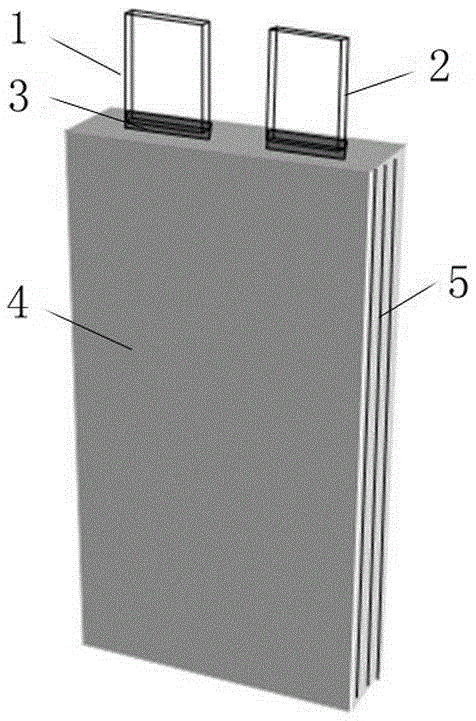

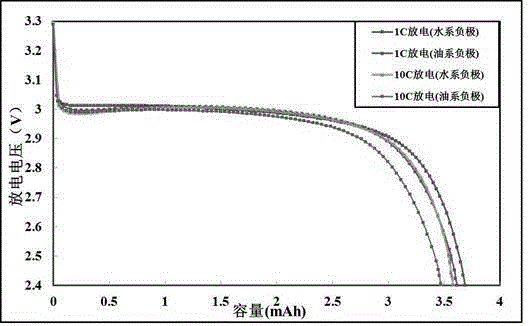

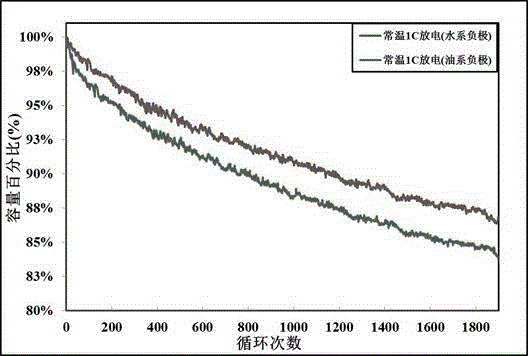

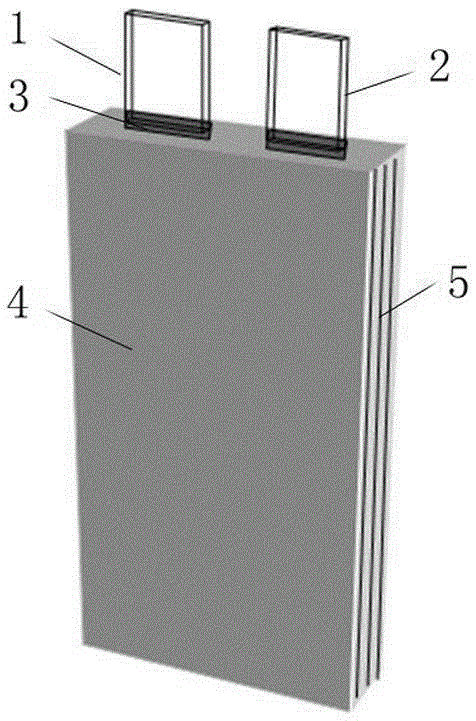

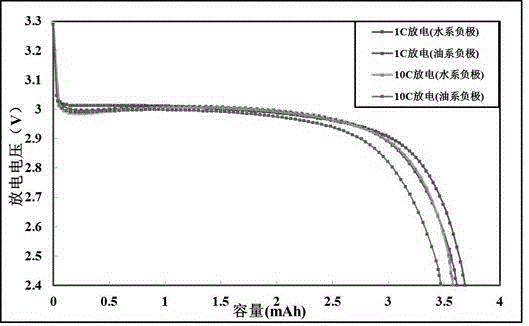

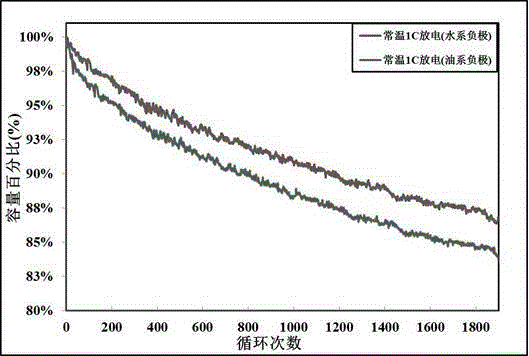

Lithium battery formed on basis of lithium nickel manganese oxide and lithium titanate and preparation method of lithium battery

InactiveCN105336943ALong cycle lifeFast cycle lifeFinal product manufactureCell electrodesElectrolytic agentElectrical battery

The invention discloses a lithium battery formed on the basis of lithium nickel manganese oxide and lithium titanate and a preparation method of the lithium battery. The lithium battery comprises an aluminum-plastic film casing, an anode lug, a cathode lug and a tab film, wherein the aluminum-plastic film casing contains a battery cell and electrolyte; the battery cell comprises an anode piece, a diaphragm and a cathode piece; materials of the anode piece comprise an anode slurry coating consisting of a positive active material, a binding agent, a conductive agent and a solvent and an anode current collector; the positive active material adopts an Al2O3 coating of lithium nickel manganese oxide; the binding agent adopts one or two of polyvinylidene fluoride and polytetrafluoroethylene; the conductive agent adopts one or more of conductive carbon black, conductive graphite and carbon nanotubes; the solvent adopts N-methyl-2-pyrrolidinone; the anode current collector adopts an aluminum foil; the cathode piece adopts an aqueous cathode or an oil-based cathode. According to the designed lithium battery, the purposes of improvement of the reversible specific capacity, the energy density and the rapid charge-discharge capability, the cycle performance and the safety performance of the battery are achieved while the production cost is reduced.

Owner:四川省有色冶金研究院有限公司

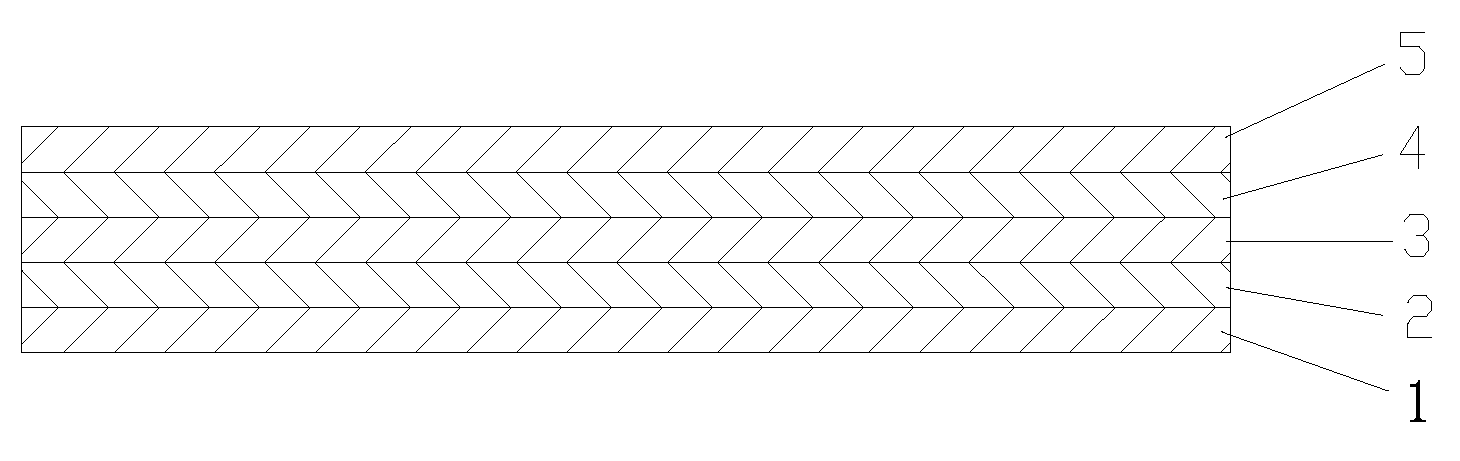

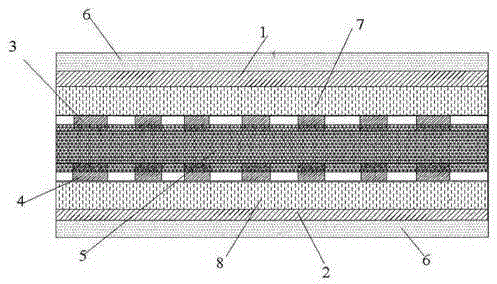

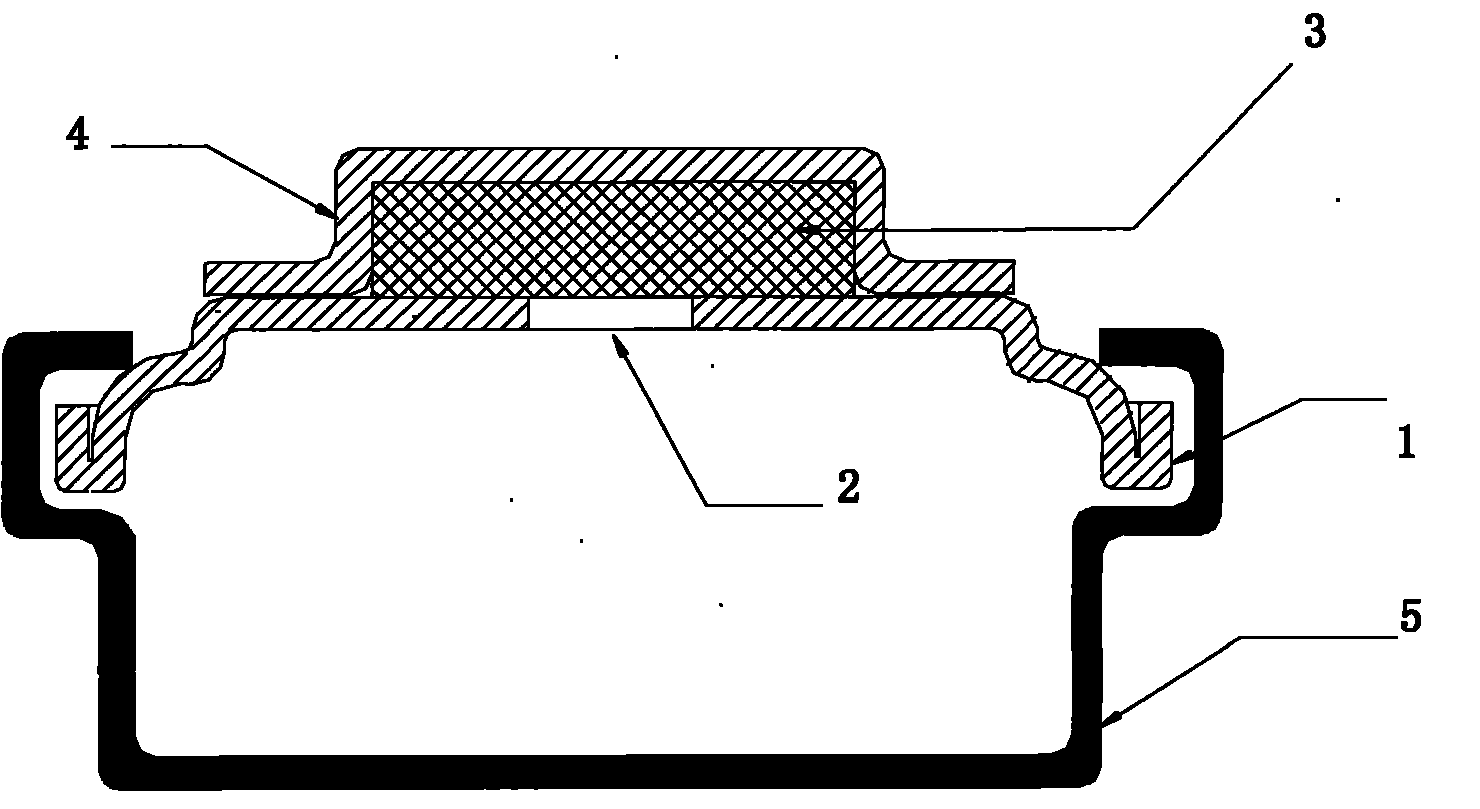

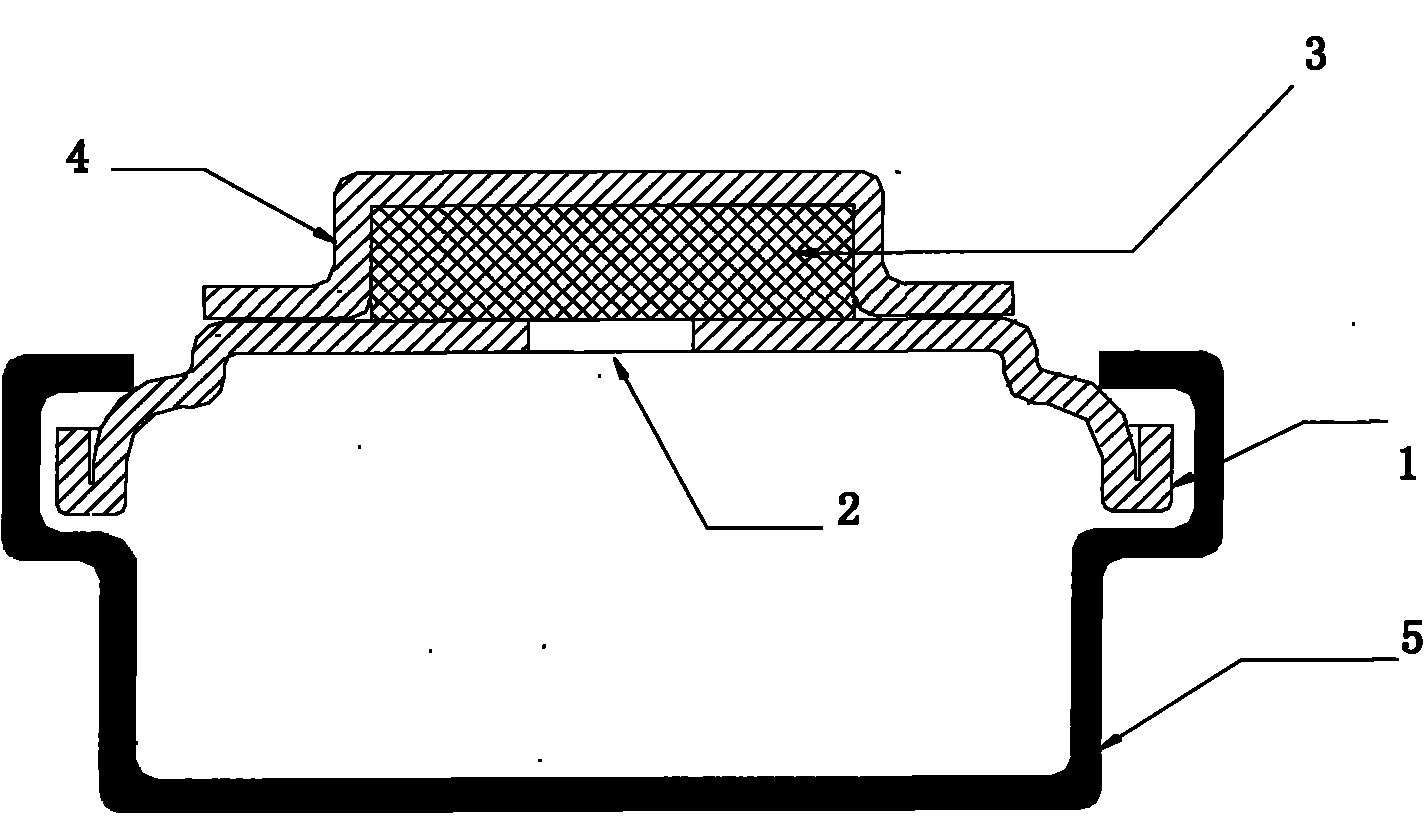

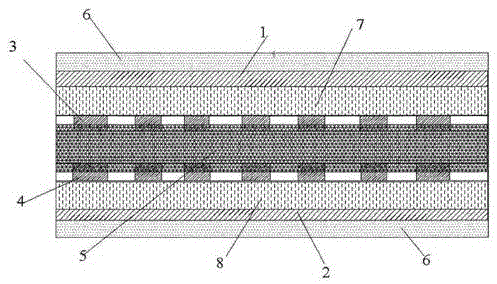

Stereoscopic thermal transfer membrane and preparation method and thermal transfer method thereof

InactiveCN102795014ASolve residual problemsSolve the manufacturing processLaminationLamination apparatusPolyethylene terephthalatePolyethylene terephthalate glycol

The invention discloses a stereoscopic thermal transfer membrane which comprises a substrate (1) of polyethylene terephthalate, an elastic coating (2) with release effect, a hardening coating (3), a printing layer (4), and a secondary curing type thermosol layer (5) which are layered orderly. The invention also discloses a preparation method of the transfer membrane, and a thermal transfer method of the transfer membrane. The invention improves the product structure, and simplifies the technical process. Therefore, the thermal transfer technology is provided with improved yield, increased productivity, and reduced cost.

Owner:深圳市鹰达行实业有限公司

Nickel lithium manganate-based positive electrode material of lithium ion battery and preparation method thereof

InactiveCN105355903AHigh reversible specific capacityFast charge and dischargeCell electrodesSecondary cellsSlurry coatingCarbon nanotube

The invention discloses a nickel lithium manganate-based positive electrode material of a lithium ion battery and a preparation method thereof. A material used for a positive plate comprises a positive electrode current collector and a positive electrode slurry coating which is composed of a positive electrode active substance, a binder, a conductive agent and a solvent, wherein the positive electrode active substance is an Al2O3 coating of nickel lithium manganate, the binder is one or more selected from the group consisting of polyvinylidene fluoride and polytetrafluoroethylene, the conductive agent is one or more selected from the group consisting of conductive carbon black, conductive graphite and a carbon nanotube, the solvent is N-methylpyrrolidone, and the positive electrode current collector employs an aluminum foil. The lithium ion battery designed in the invention has reduced cost, and the purposes of improving reversible specific capacity, energy density, rapid charging and discharging capability, cycle performance and safety performance are achieved.

Owner:四川省有色冶金研究院有限公司

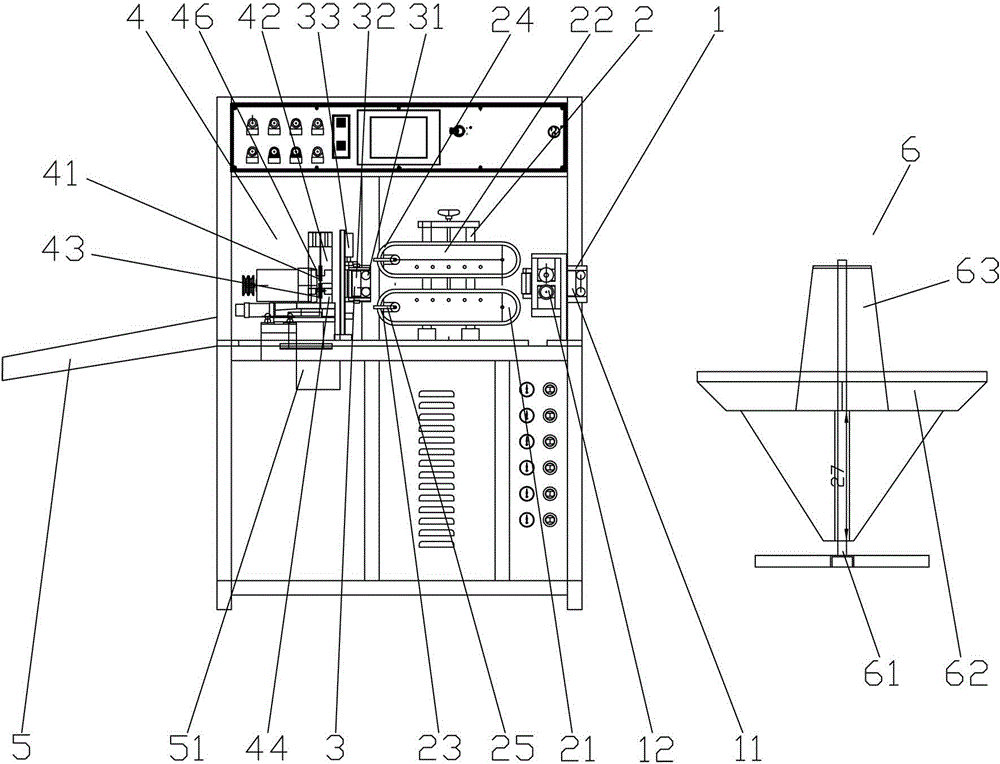

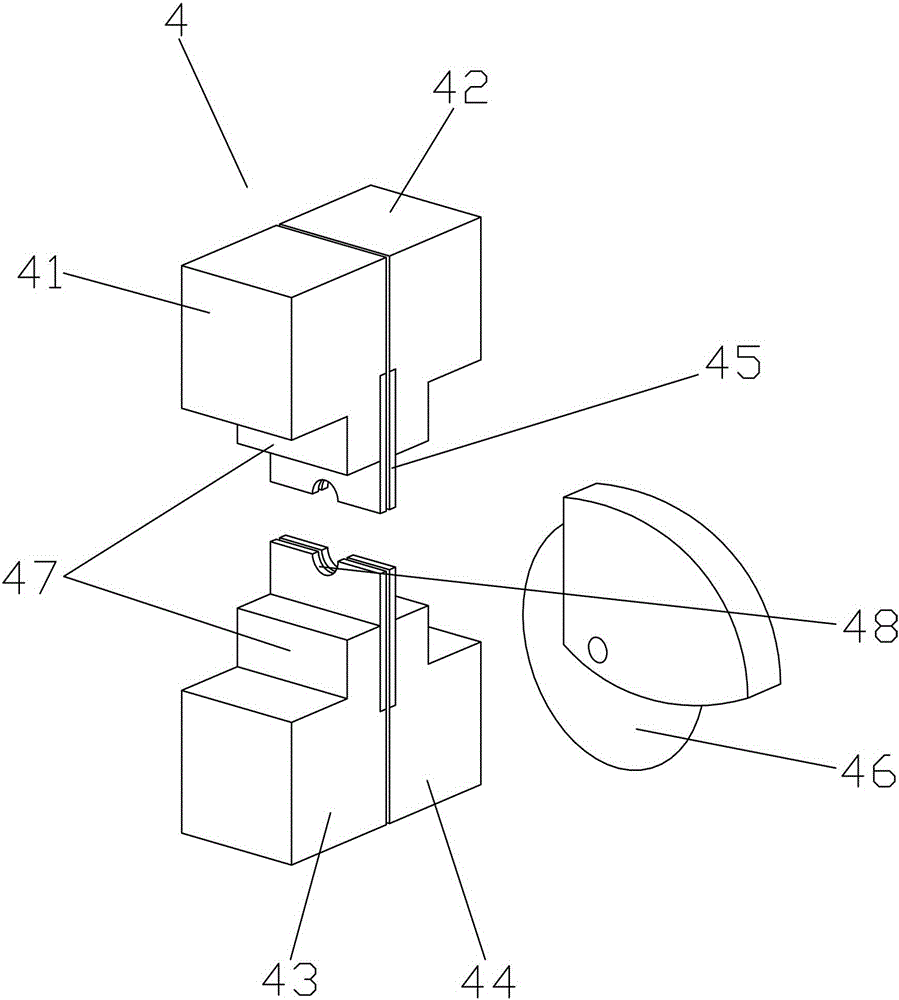

Automatic fusing cutting machine for stainless steel woven polytetrafluoroethylene tubes

The invention discloses an automatic fusing cutting machine for stainless steel woven polytetrafluoroethylene tubes. The machine comprises a wire feeding and pressing module, a belt wheel wire pressing module, a guiding wire pressing module and a fusing module in sequence from right to left. The fusing module comprises a left upper pressing block, a right upper pressing block, a left lower pressing block and a right lower pressing block, wherein the left upper pressing block and the right upper pressing block can slide vertically and move horizontally; the left lower pressing block and the right lower pressing block can move horizontally; the pipeline passing workstation positions among the left upper pressing block, the right upper pressing block, the left lower pressing block and the right lower pressing block are each provided with a dismountable fusing conductive copper knife installed vertically; a vertically installed saw blade is installed in front of the pipeline passing workstation position of the fusing module. For the characteristics of woven hoses, through the reasonable structural improvement, especially the design of combination of the pressing blocks and the saw blade, steel wire layers of the woven hoses are fused through the combination of the pressing blocks, then the saw blade cuts off tubes on the inner layers, the woven hoses are pulled broken when the combination of the pressing blocks is in a heating state, and therefore the steel wires do not explode without external force when fused, and it is ensured that the fracture surfaces after fusing are tidier and smoother.

Owner:FOSHAN HAOBANG MACHINERY CO LTD

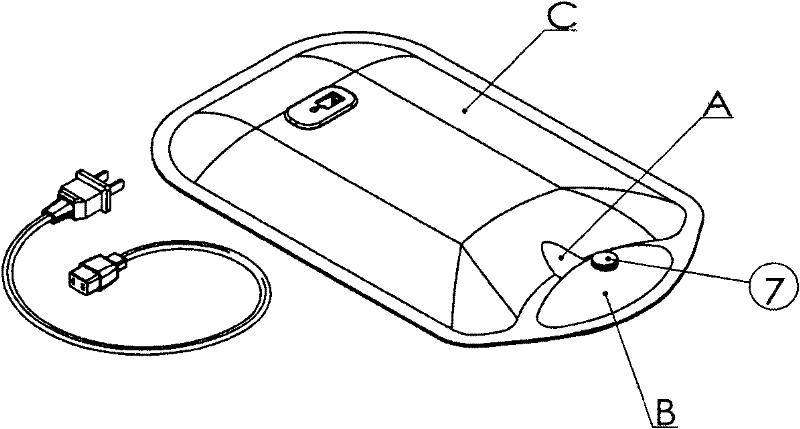

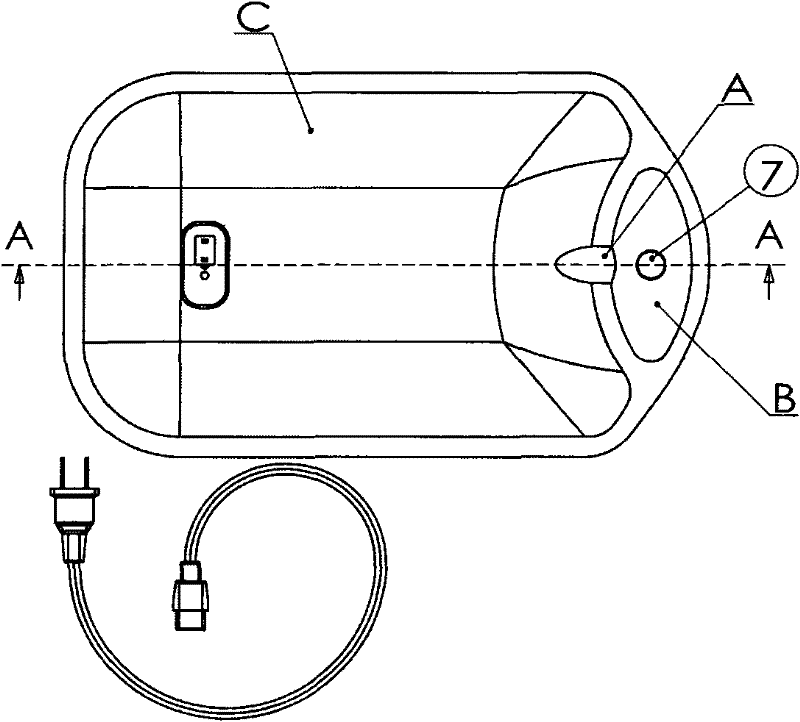

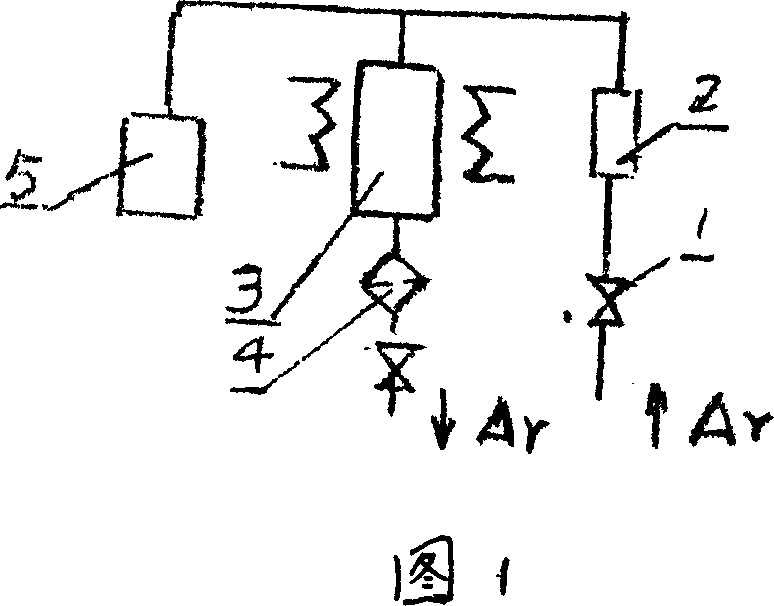

Automatic pressure control device capable of preventing explosion of hot water bottle constantly

InactiveCN102210619ARest assuredProtect when in useTherapeutic coolingTherapeutic heatingInternal pressureExhaust valve

The invention discloses an automatic pressure control device capable of preventing explosion of a hot water bottle constantly. The automatic pressure control device disclosed by the invention is characterized in that a pressure reduction cabin is arranged outside a bag body of a common hot water bottle, and the pressure reduction cabin and the bag body are connected through a pressure controller; the pressure controller comprises a tube-shaped shell, a ball baffle cover, and a sealing ball, a piston and a spring which are arranged in the shell; a vent hole and an air inlet are formed at the tail end of the shell and the ball baffle cover, respectively; an air bleeding valve is arranged on the pressure reduction cabin; under a normal state, the sealing ball baffles the air inlet on the ball baffle cover which is connected with the shell under action of the spring, and the pressure controller is in a closed state; when pressure intensity in the hot water bottle body is increased to a rated value due to heating or an external force, the sealing ball is pushed away from the air inlet, air or redundant liquid in the bottle enters the pressure controller from the air inlet, then enters the pressure reduction cabin via the vent hole, and is finally discharged at the air bleeding valve till internal pressure and external pressure are balanced, and the air inlet is sealed again by the sealing ball due to action of the spring. The automatic pressure control device disclosed by the invention has the greatest characteristics of being capable of controlling pressure intensity in the hot water bottle to be within a safe range constantly so as to ensure safety of a user.

Owner:焦纪平

Battery with membrane-coated electrodes

ActiveCN105406072AImprove affinityImprove ion conductivityElectrode carriers/collectorsSecondary cellsPerfluorosulfonic acidGraphene

The invention discloses a battery with membrane-coated electrodes, belonging to the field of batteries. The battery with the membrane-coated electrodes disclosed by the invention comprises a positive plate and a negative plate arranged in a battery shell; an isolation film is arranged between the positive plate and the negative plate; a positive membrane and a piece of positive catalytic gauze are arranged between the positive plate and the isolation film in sequence; the positive catalytic gauze coats the surface of the isolation film; a piece of negative catalytic gauze and a negative membrane are arranged between the isolation film and the negative plate in sequence; the negative catalytic gauze coats the surface of the isolation film; the positive plate is a nano Rh-graphene composite electrode; the negative plate is a nano Co2SnO4 naphthalene polysulfonic acid electrode; the positive membrane is a perfluorosulfonic acid proton film; the negative membrane is silicon dioxide; the thickness of the positive membrane is 300 nm; and the thickness of the negative membrane is 300 nm. The battery with the membrane-coated electrodes disclosed by the invention has the characteristics of being small in volume, light in weight, safe and steady in use process, large in battery capacity, difficult in electrode loss and excellent in discharging performance.

Owner:河北飞豹新能源科技有限公司

Medical equipment pipe disinfection method

A medical equipment pipe disinfection method comprises the following steps: ozone and atomized water are combined to form ozone-containing water spray and the water spray is used to disinfect the inside of a pipe; a push rod is driven by an electric device to pull up an air bag to suck the disinfected gas into the air bag; ozone in the air bag is reduced through negative ion or plasma; and after the gas reaches the emission standard, the electric device is started to drive the push rod so as to compress the air bag and discharge the gas in the air bag out to the outside air.

Owner:江苏奥普莱医疗用品有限公司

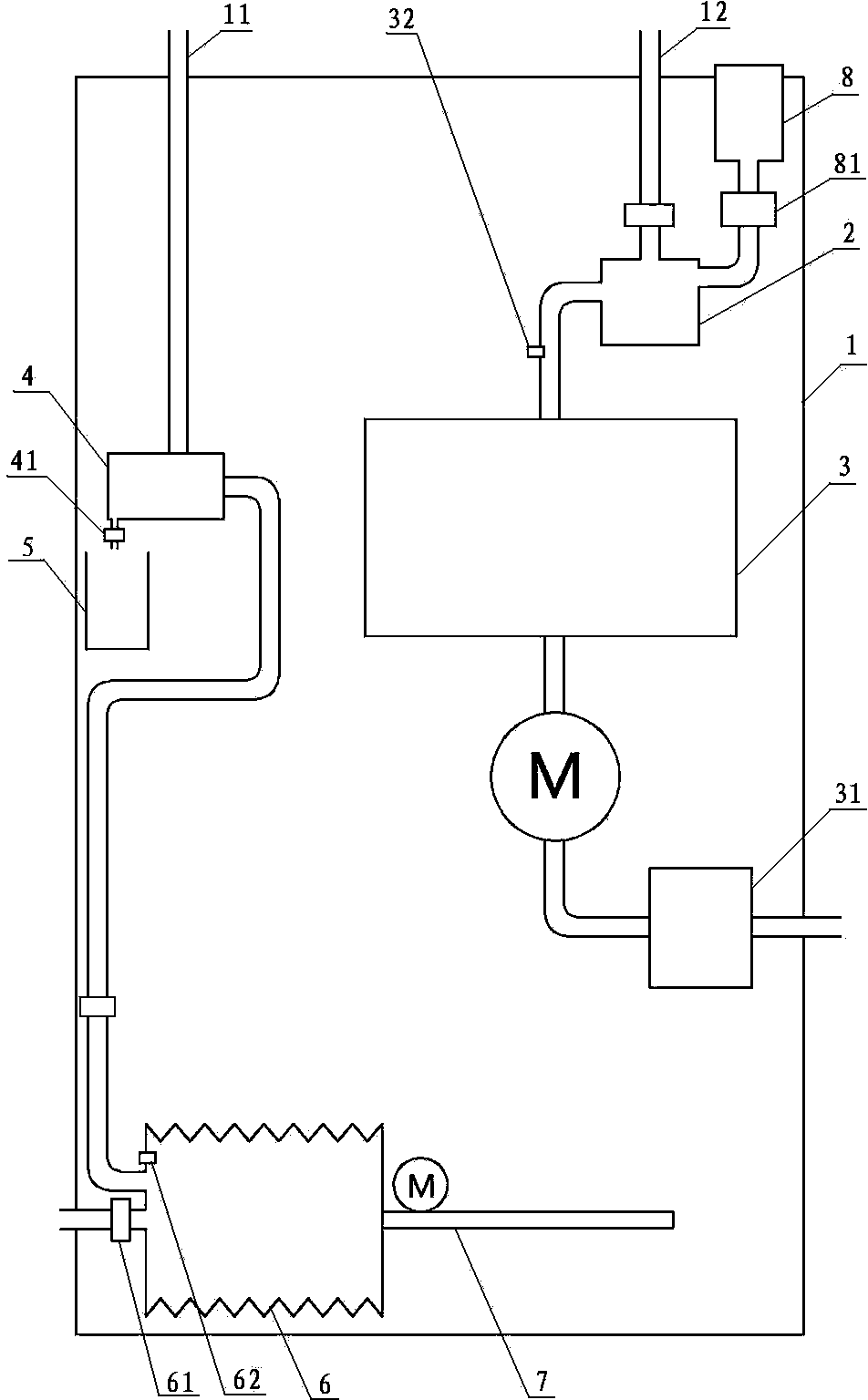

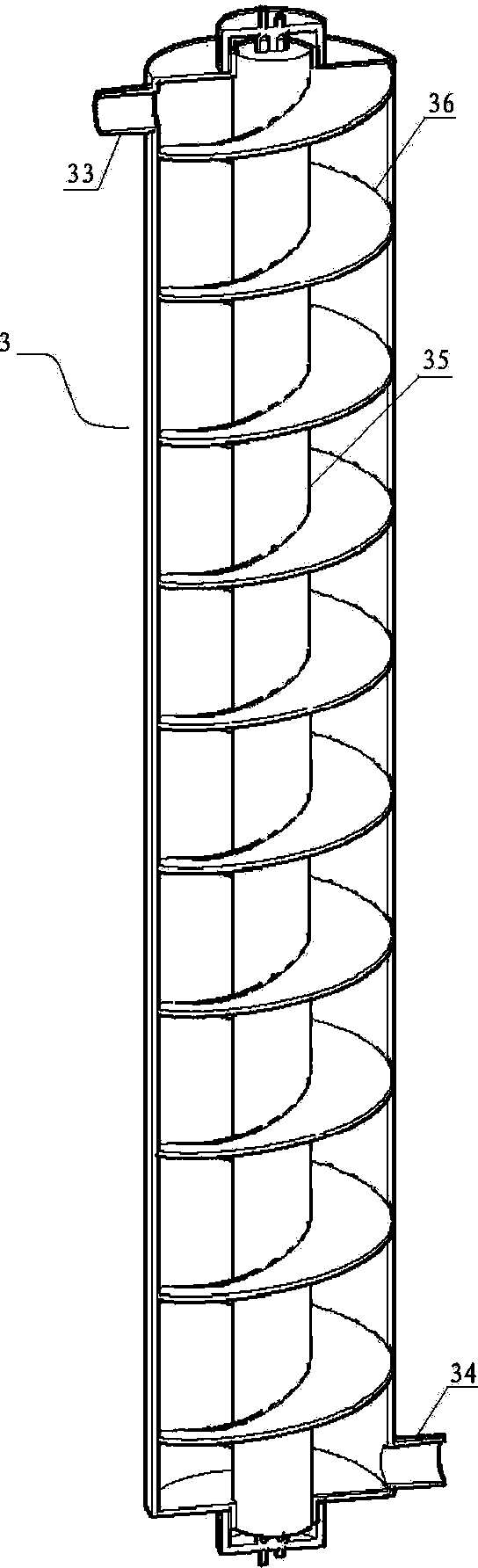

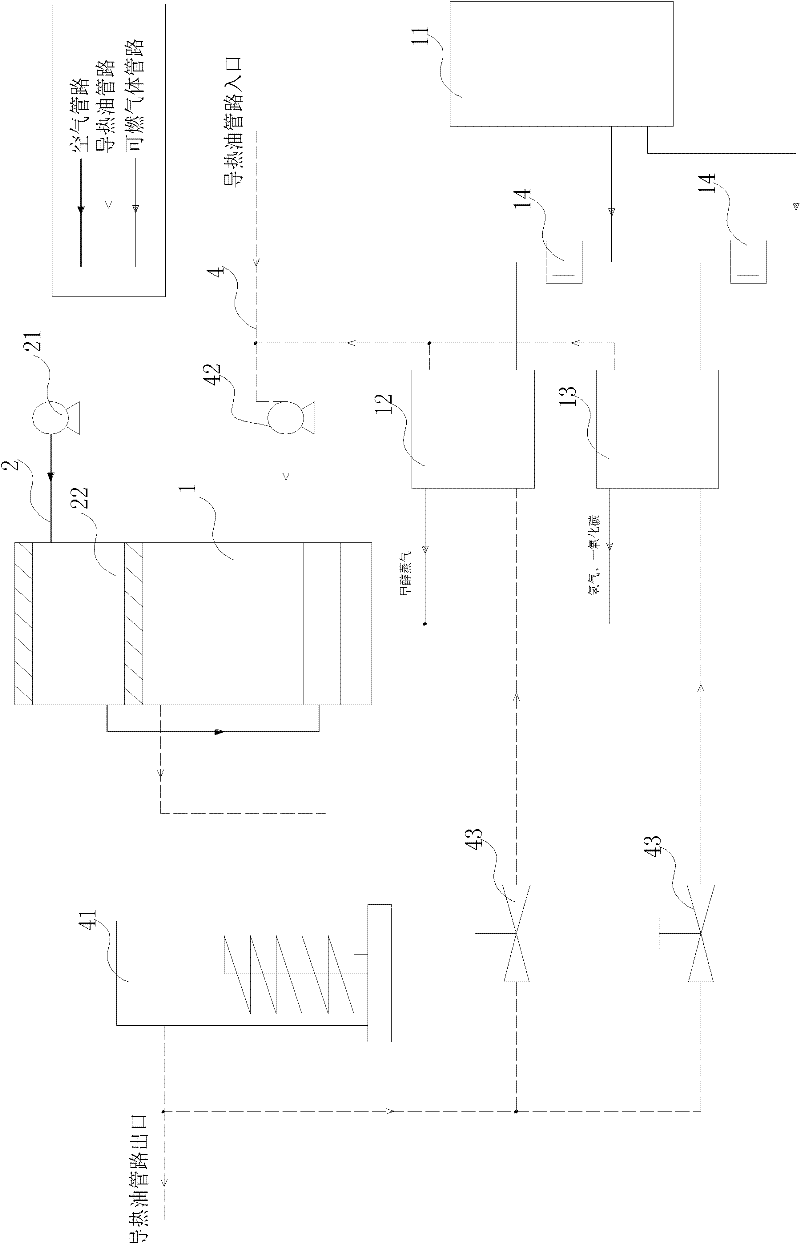

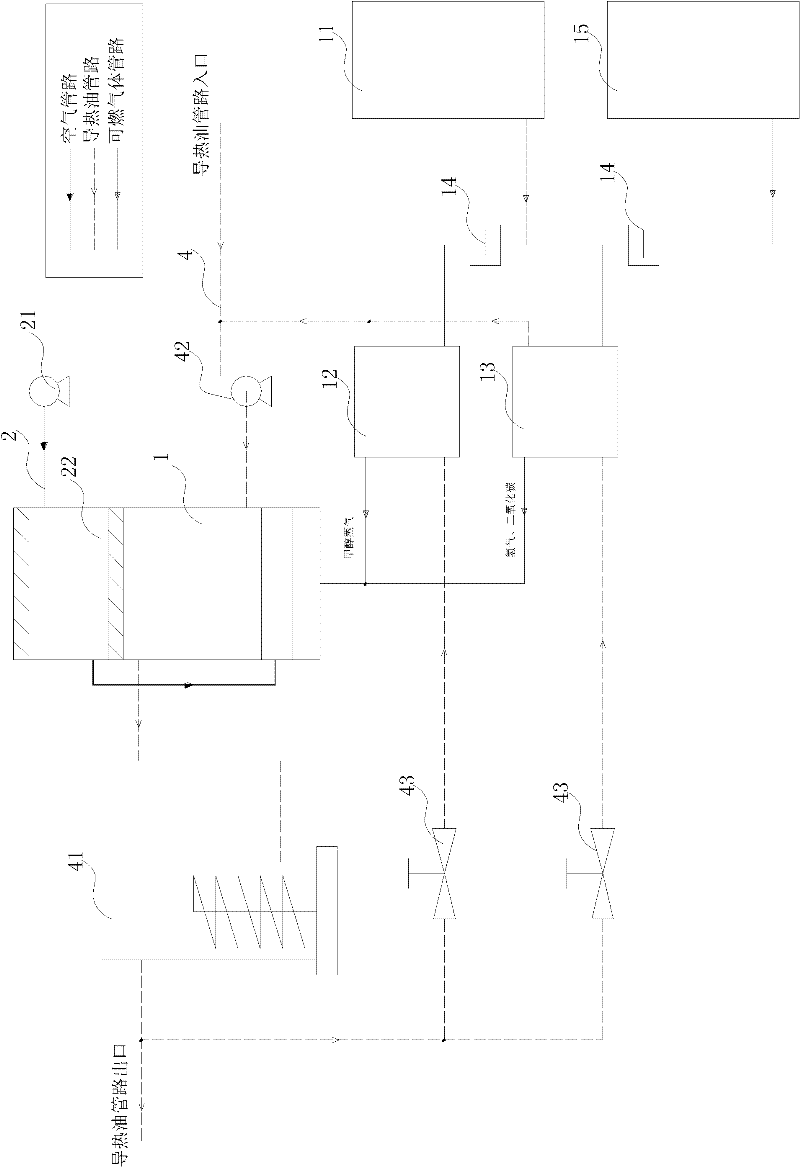

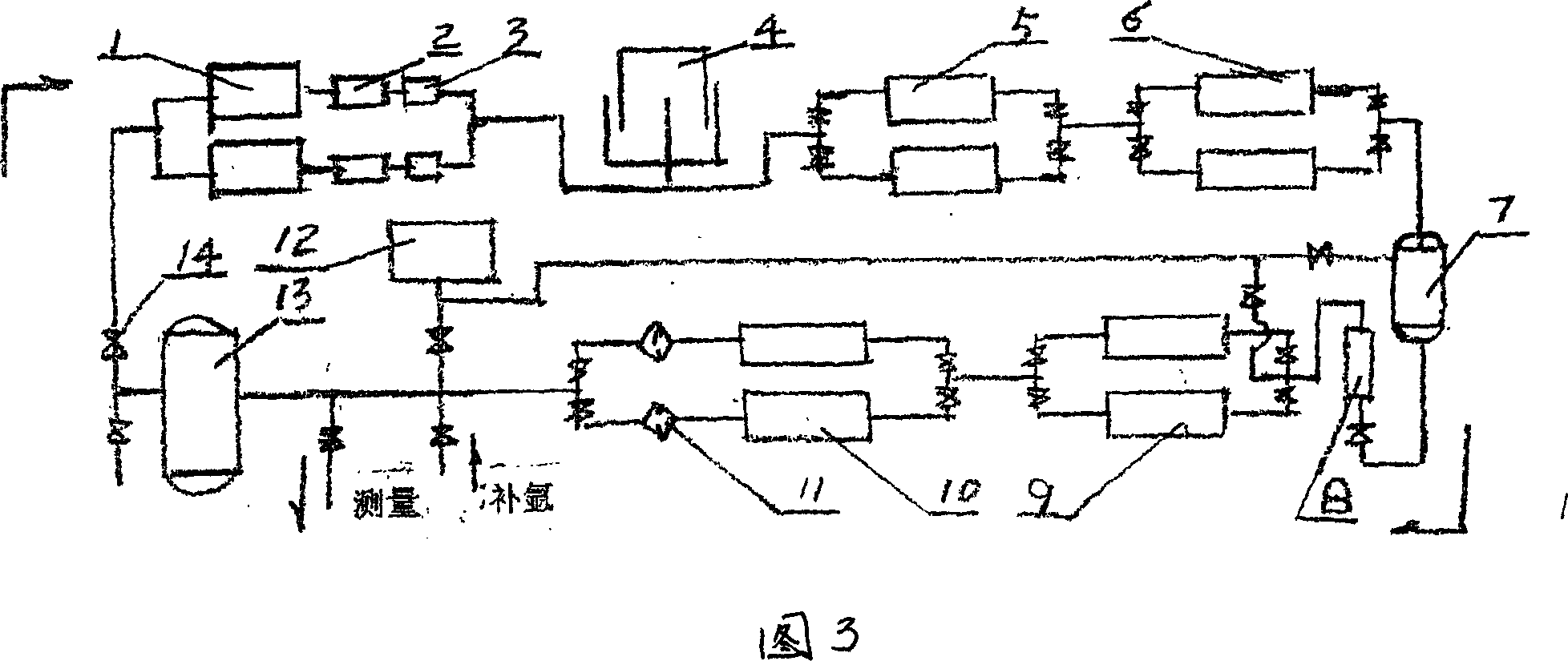

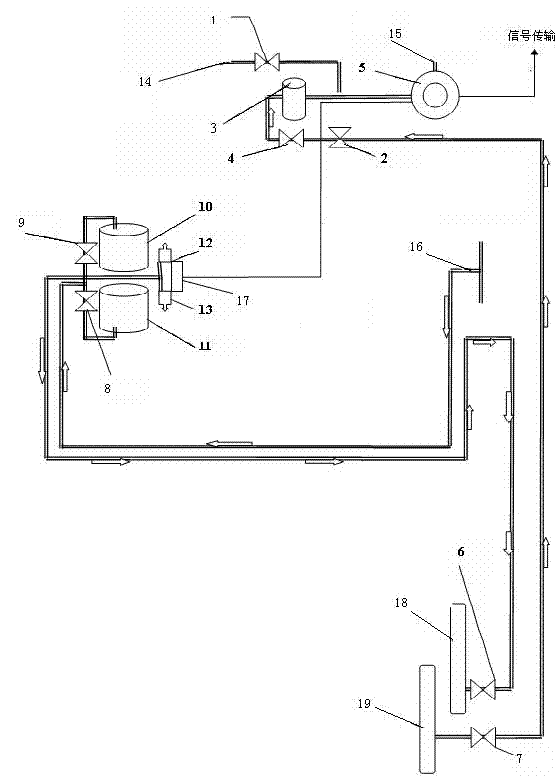

Methanol hydrogen oxidation heating system

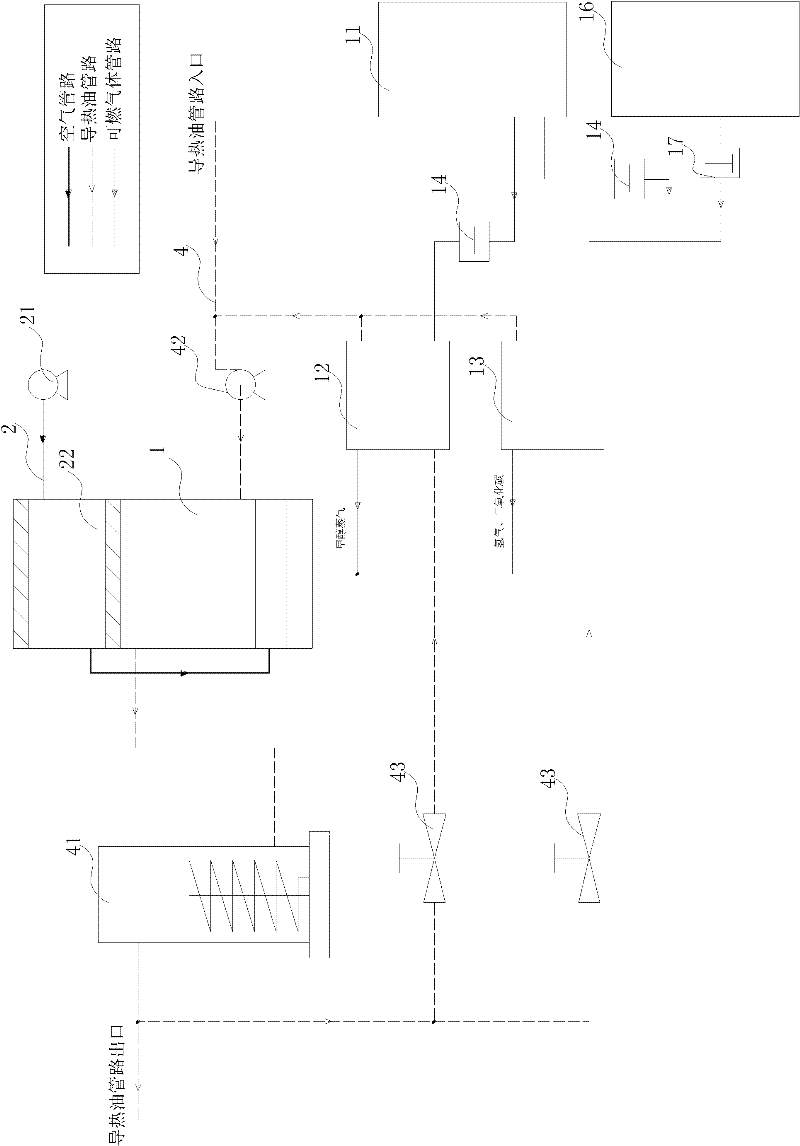

ActiveCN102287917AKeep aliveLong-lastingGaseous fuelsStorage heatersCatalytic oxidationHydrogen production

The invention discloses a heating system of methanol hydrogen-production oxidation. The heating system provided by the invention comprises a methanol oxygenation heat supply device (1) for carrying out a methanol catalytic oxidation reaction, a methanol evaporator (12), a methanol hydrogen production device (13), an air pipeline (2) for supplying ambient air to the methanol oxygenation heat supply device (1), and an inflammable gas pipeline (3) used for supplying mixed inflammable gas of methanol vapour generated by the methanol evaporator and hydrogen generated by the methanol hydrogen production device to the methanol oxygenation heat supply device (1); the heating system provided by the invention is characterized in that the outside of the methanol oxygenation heat supply device (1) isprovided with a heat-conduction oil pipeline (4), the heat-conduction oil pipeline (4) is provided with a heat-conduction oil heating device (41), and the heat-conduction oil is heated by virtue of the heat-conduction oil heating device (41) and then is introduced into the methanol oxygenation heat supply device (1) through the heat-conduction oil pipeline (4) so as to heat a methanol catalytic oxidation reaction system. The heating system disclosed by the invention has the advantages of environment friendliness, stability for control and in operation, safety and reliability.

Owner:SUZHOU XINENG ENVIRONMENTAL SCI & TECH CO LTD

Oil cooling system for high-temperature equipment

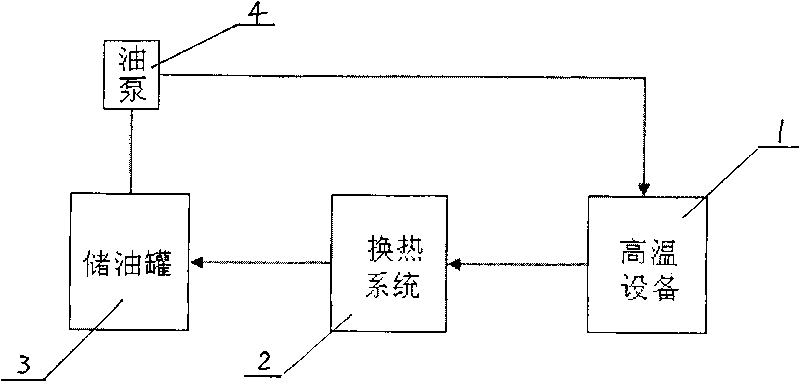

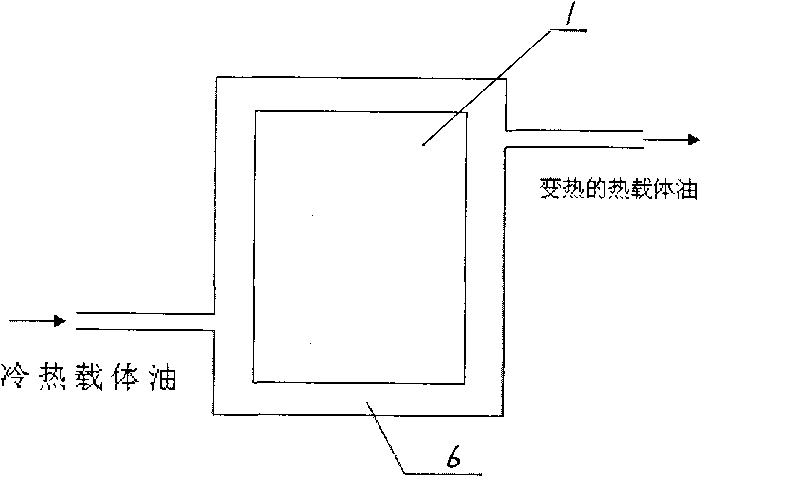

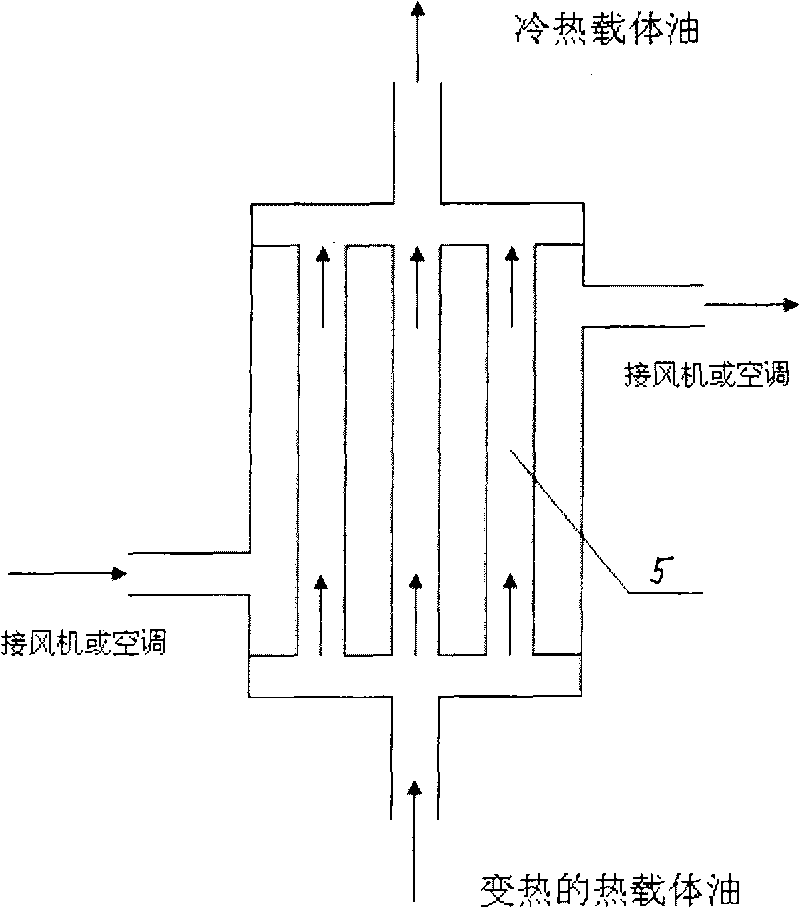

InactiveCN101738094AWon't explodeNo other spillsStationary tubular conduit assembliesFurnace coolingTemperature controlHeat carrier

The invention relates to an oil cooling system for high-temperature equipment, which comprises a storage tank, an oil pump, a heat exchange system, a connecting pipeline and a measurement control system, wherein a cooling medium is heat carrier oil; the heat carrier oil heat exchange system is a tubearray heat exchanger; one inlet of the tubearray heat exchanger is connected with a fan or an air conditioner; the other inlet of the tubearray heat exchanger is connected with the heat carrier oil getting hot; and low-temperature heat carrier oil flowing out from a tubearray enters the storage tank. The heat carrier oil (GB / T4016-83) used in the system is also named heat-transfer oil, heat-conduction oil or hot kerosene and the like, and is a heat transfer medium; the heat carrier oil has the advantages of uniform heating, accurate temperature regulation and temperature control, capability of absorbing heat and generating high temperature under low vapor pressure, good heat transfer effect, energy saving, convenient delivery and operation and the like; and the system saves a water treatment system and water treatment equipment, improves the cooling efficiency of the system, reduces the maintenance work load of the equipment and pipelines, and has higher safety and reliability.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Method for producing frosted glass

InactiveCN101618648AReduce cleaning processReduce cleaning costsPattern printingSurface treatment compositionsChemistryAqueous sodium hydroxide

The invention relates to a method for producing frosted glass, which comprises the following steps: firstly, selecting original white glass sheets, jointing the two sheets, and sealing four edges by tapes; putting the glass into a weak acid pool for soaking for 2 minutes; conveying the glass into a corrosion pool for frosting; clearing the frosting liquid after the glass is frosted, and drying the glass; removing the sealing tapes at the four edges of the glass; then, adopting a silk screen to print the preliminarily designed glass pattern on one surface, air-drying the glass for 2 hours, andthen, conveying the glass into a dryer for drying; pasting a protective film on the glass surface which is not printed with the pattern; scrubbing the surface which is printed with the glass pattern with weak acid liquid; soaking the glass into the corrosion liquid for 80-120 minutes; putting the glass into a sodium hydroxide solution for cleaning; and then, conveying the glass into a cleaning and drying machine for cleaning and drying to obtain a finished product. The patterned glass which is produced by the method of the invention has uniform and fine etched depth, strong aesthetic feeling of the pattern, better quality, simple processing method and environment protection, and can greatly reduce the production cost in the production process.

Owner:杜广武

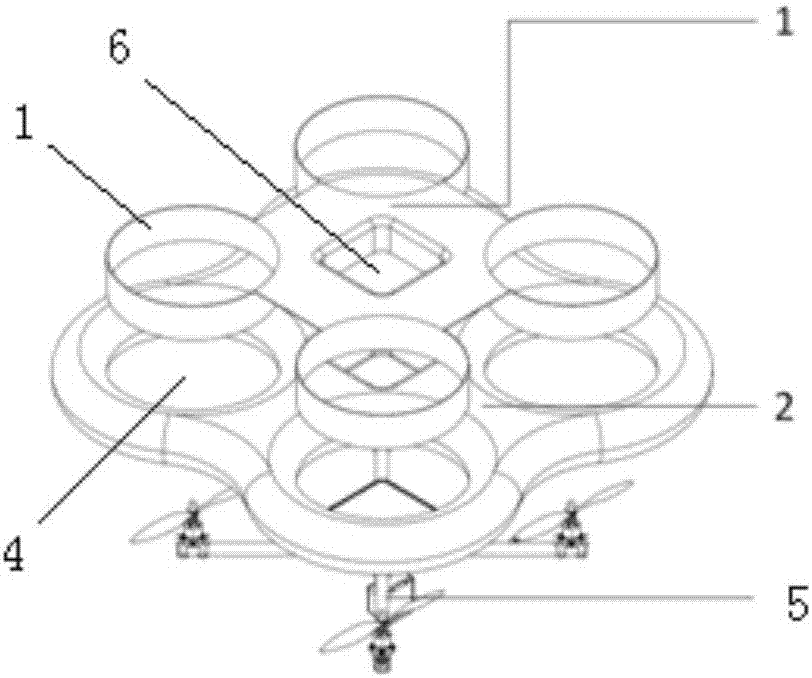

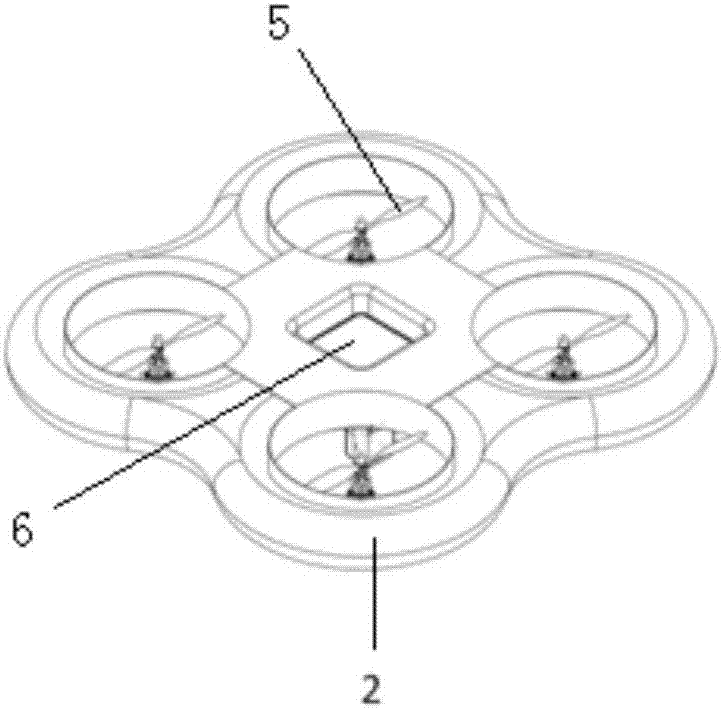

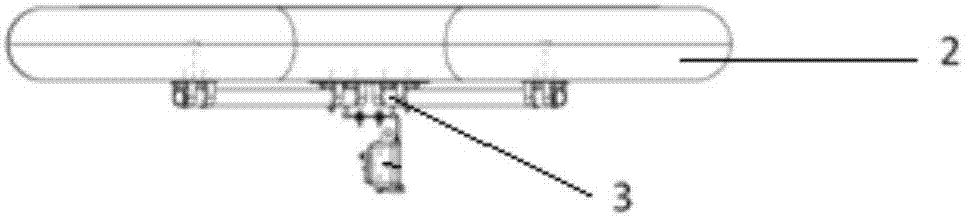

Small-sized anti-collision multi-rotor unmanned aerial vehicle

The invention relates to the technical field of unmanned aerial vehicles (UAVs) and provides a small-sized anti-collision multi-rotor UAV which comprises a UAV body and an aluminum film inflatable protective ring arranged on the UAV body, wherein the aluminum film inflatable protective ring is provided with a plurality of hollow areas which correspond to positions of UAV propellers; the UAV propellers are capable of rotating freely in the hollow areas; a connecting mechanism is arranged at the center of the aluminum film inflatable protective ring; the aluminum film inflatable protective ring is connected with the UAV body by the connecting mechanism; and a lightweight air-leak guard is also arranged around each UAV propeller and among the corresponding hollow area of the aluminum film inflatable protective ring. The small-sized anti-collision multi-rotor UAV has the advantages that the UAV propellers can be fully protected during the flight in an indoor or complex space environment and the failure of gyroscopes, accelerometers and other sensors caused by the impact of the collision can be avoided because the structure of an airbag of the UAV can absorb impact load during the collision, the weight of the UAV is not increased by virtue of the lightweight airbag so that the endurance ability is high, and the flight is stable and reliable by virtue of the tumbler structure.

Owner:北京华信智航科技有限公司

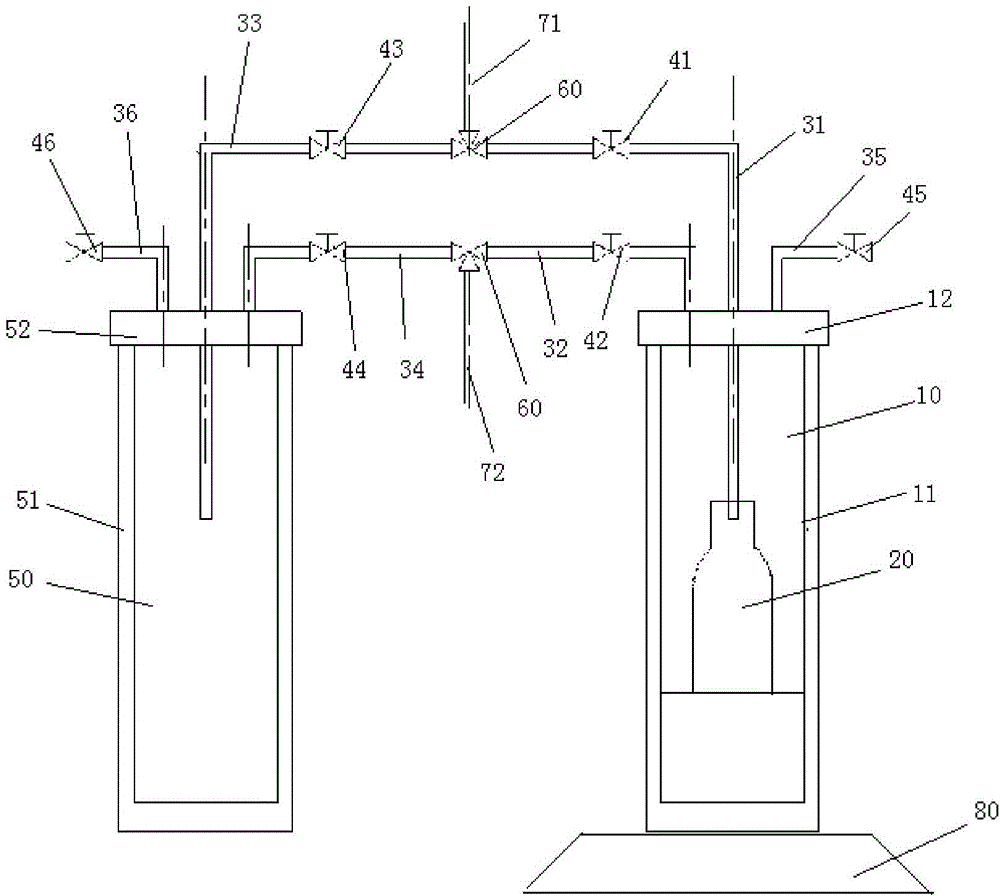

Pressure sampling device

ActiveCN105651550AGuaranteed to proceed normallySmall pressure lossWithdrawing sample devicesEngineeringBottle

The present invention provides a pressure sampling device comprising a first closed vessel; a sample bottle, a first conduit and a second conduit, the sample bottle is placed in the first closed vessel; one end of the first conduit passes through the first closed vessel, and then faces an opening of the sampling bottle, the other end of the first conduit is connected with a to-be-sampled test vessel, one end of the second conduit is connected with the first closed vessel, and a second end of the second conduit is an air outlet end. Since during an experiment, the first closed vessel maintains a certain pressure, pressure in the test vessel drops slowly, the pressure loss of the first closed vessel is slowed, the normal operation of the experiment is ensured, and then an experiment product in the test vessel is sampled in real time.

Owner:PETROCHINA CO LTD

Technique for purifying and recovering argon gas by rare earth lanthanide series radical alloy degasser in single-crystal silicon preparation

The invention discloses a rare earth lanthanide base alloy getter (CF01 agent), comprising 65% of rare earth lanthanide and 35% metal element. Said rare earth lanthanide includes lanthanum, cerium, praseodymium and Neodymium; and said metal element concludes ferric, titanium, magnesium, copper and zinc. The invention also discloses a method for purifying argon gas with CF01 agent during high-purity argon gas preparation, which comprises following steps: (1) preparing high-purity argon gas through purifying cheap and non-high purity argon gas by using CF01 agent, and applying it into single-crystal silicon preparing process; (2) purifying and cyclic recovering argon gas from mono-crystal single-crystal silicon with CF01 agent; (3) purifying and cyclic recovering argon gas from czochralski single-crystal silicon with CF01 agent; (4) purifying and recovering (not cyclic) argon gas from mono-crystal and czochralski single-crystal silicon and preparing regenerative high-purity argon gas. The CF01 agent is characterized in that the comprehensive gettering performance and ratio of performance to price are better than that of current ones, and it can also recover argon gas discharged in single-crystal silicon preparation process, which can not only increase economic benefit, but also save energy and protect environment.

Owner:天津环煜电子材料科技有限公司

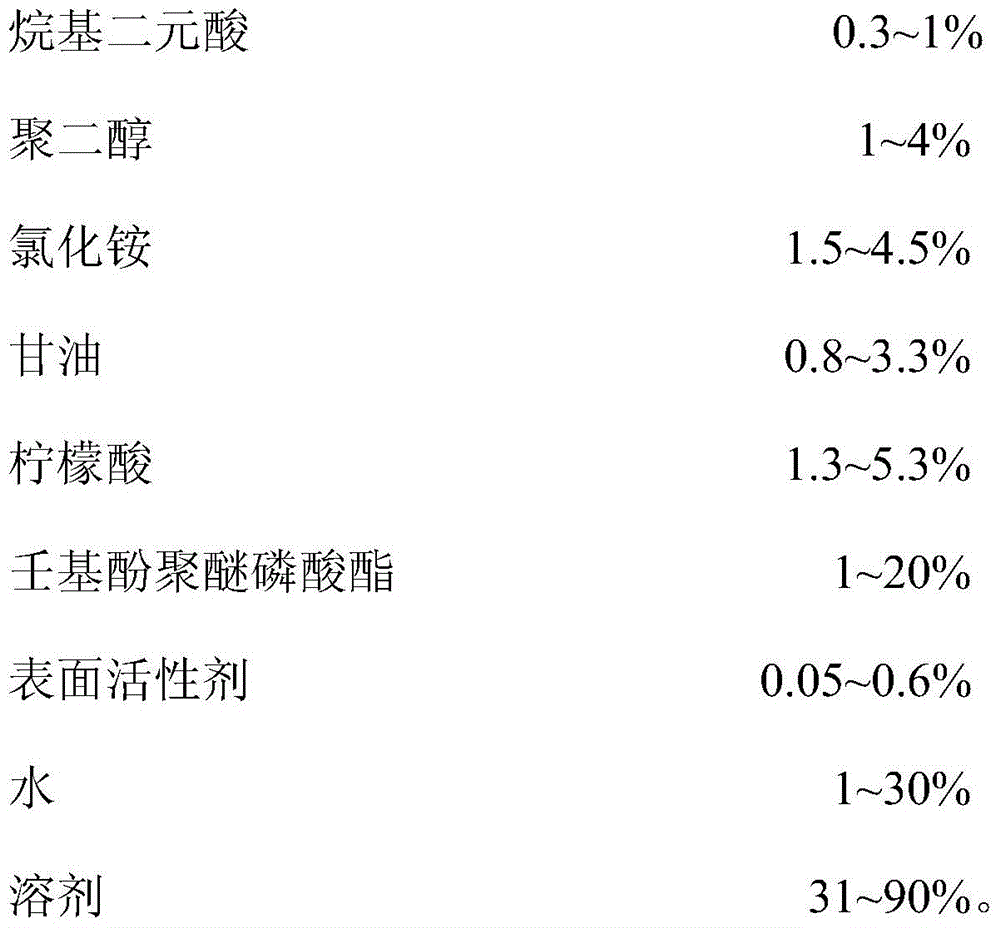

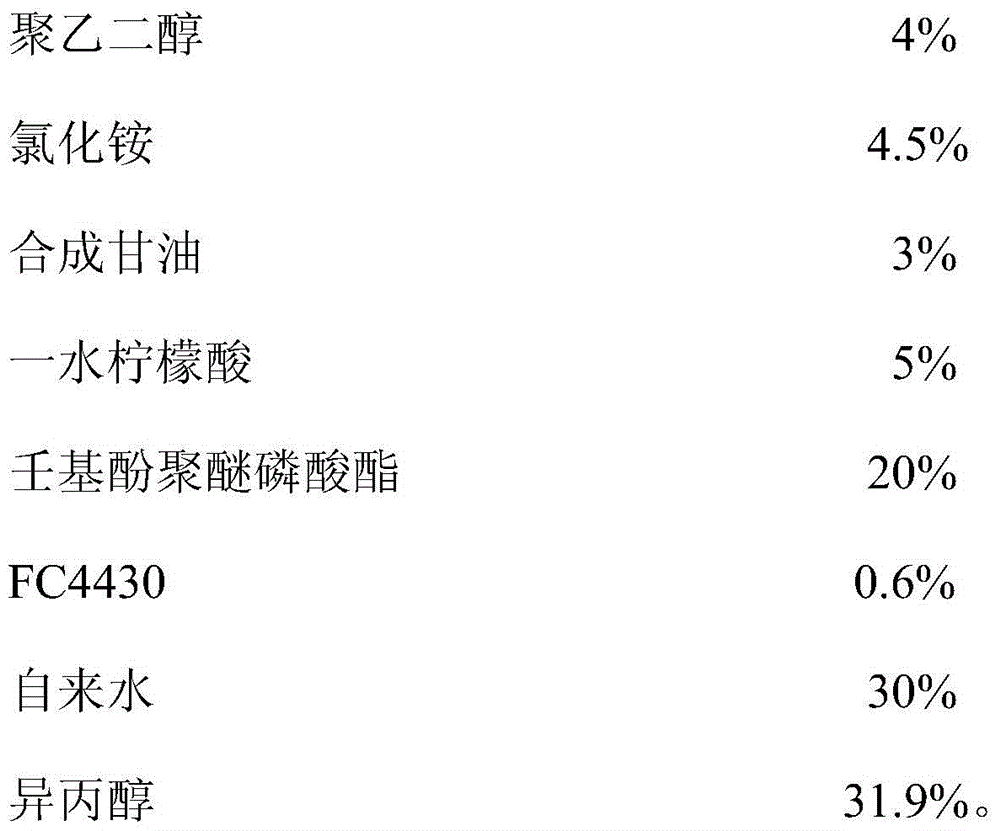

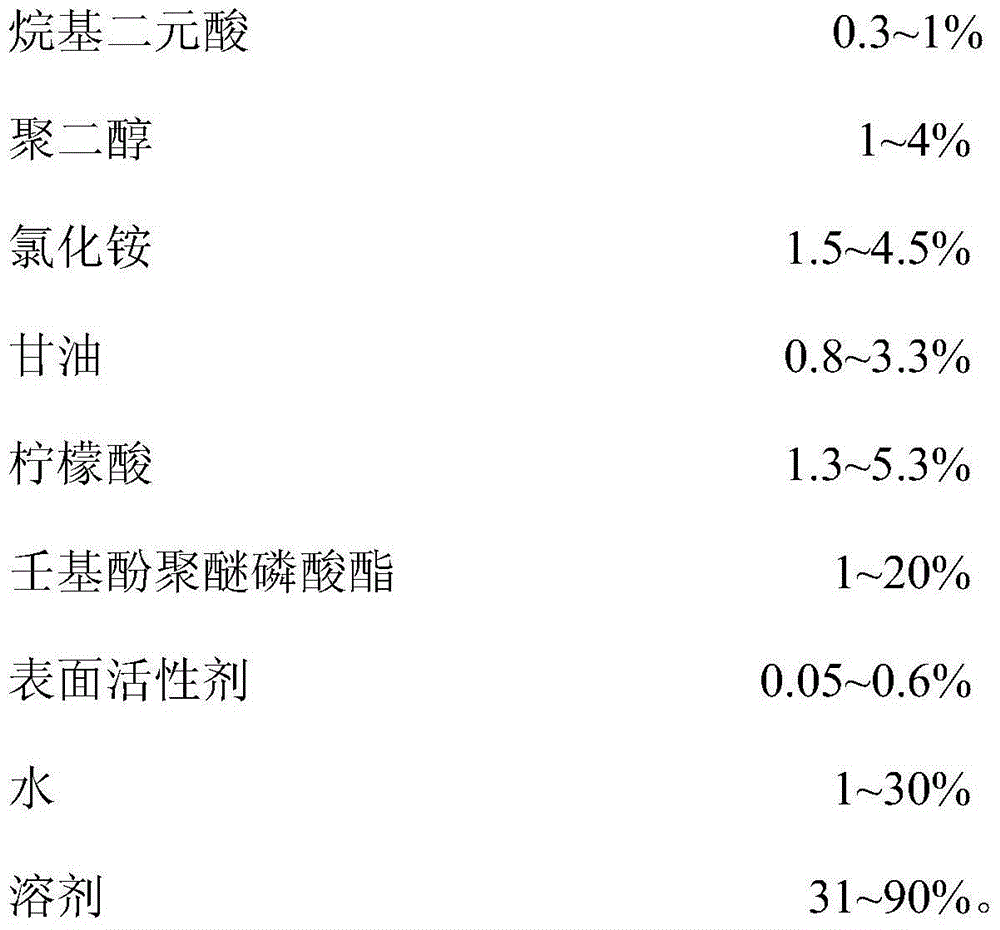

A kind of water-based flux and preparation method thereof

ActiveCN104551452BLow solid contentHigh boiling pointWelding/cutting media/materialsPrinted circuitsWater basedPhosphate

The invention relates to a water-based soldering flux, which comprises the following raw materials in parts by weight: 0.3-1% of alkyl dicarboxylic acid, 1-4% of polyglycol, 1.5-4.5% of ammonium chloride, 0.8-3.3% of glycerinum, 1.3-5.3 of citric acid, 1-20% of nonylphenol polyether phosphate, 0.05-0.6% of surfactant, 1-30% of water, and 31-90% of solvent. The water-based soldering flux has advantages of low solid content, high boiling point, slow volatilization, fire resistance, high safety and environment protection, without smell. The invention further discloses a preparation method of the water-based soldering flux, comprising the following steps of: weighing the material according to formula ratio; adding solvent in a first vessel and nonylphenol polyether phosphate to a first reacting kettle, and then completely stirring; adding the surfactant and solvent in a second vessel to a second reacting kettle, and then completely stirring; adding the alkyl dicarboxylic acid, the polyglycol, the ammonium chloride, the glycerinum, the citric acid, the water, a first dispersion, a second dispersion and solvent in a third vessel to a third reacting kettle, and then completely stirring; uniformly dispersing to obtain a finish product. The preparation method of the water-based soldering flux has advantages of simple process, easy operations and high production efficiency.

Owner:HUIZHOU QIANGDA ELECTRONICS

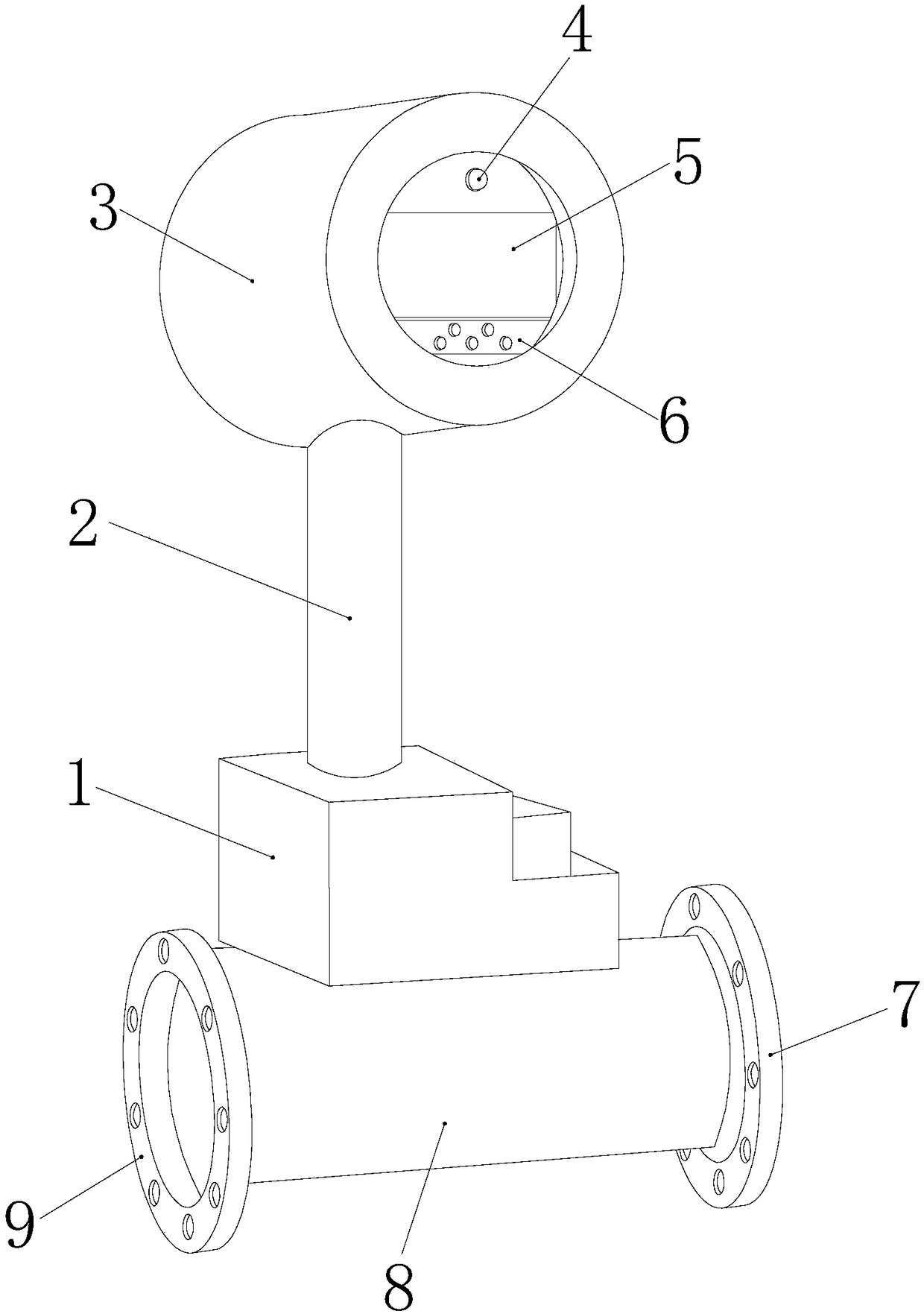

High-efficiency, environment-friendly and energy-saving natural gas pressure feeding equipment

The invention discloses high-efficiency environment-friendly and energy-saving natural gas pressure feeding equipment. The high-efficiency environment-friendly and energy-saving natural gas pressure feeding equipment structurally comprises a leakproof device, a transmission rod, a measuring machine host, an indicator light, a display screen, a control panel and a right connecting flange. The high-efficiency environment-friendly and energy-saving natural gas pressure feeding equipment implements metering of natural gas transportation data errors through rotation of a paddle blade disk; naturalgas data errors measured by a sensor is large due to natural gas diffusion are avoided; meanwhile, when a natural gas transportation pipeline leaks gas, the high-efficiency environment-friendly and energy-saving natural gas pressure feeding equipment can automatically shut down pipeline transportation and drive a buzzer to be electrified to give an alarm in time; the high-efficiency environment-friendly and energy-saving natural gas pressure feeding equipment has the function of reminding related personnel of pipeline gas leakage in time to prevent the situation that a great deal of natural gas escapes into the air and the future trouble of a fire is caused; moreover, the high-efficiency environment-friendly and energy-saving natural gas pressure feeding equipment can automatically guide nitrogen into the pipeline; the nitrogen belongs to inert gas and cannot explode when mixed with natural gas. The high-efficiency environment-friendly and energy-saving natural gas pressure feeding equipment has the functions of reducing the air concentration in the pipeline and prevent the phenomenon of natural gas explosion caused by excessive air concentration in the pipeline.

Owner:杨勇强

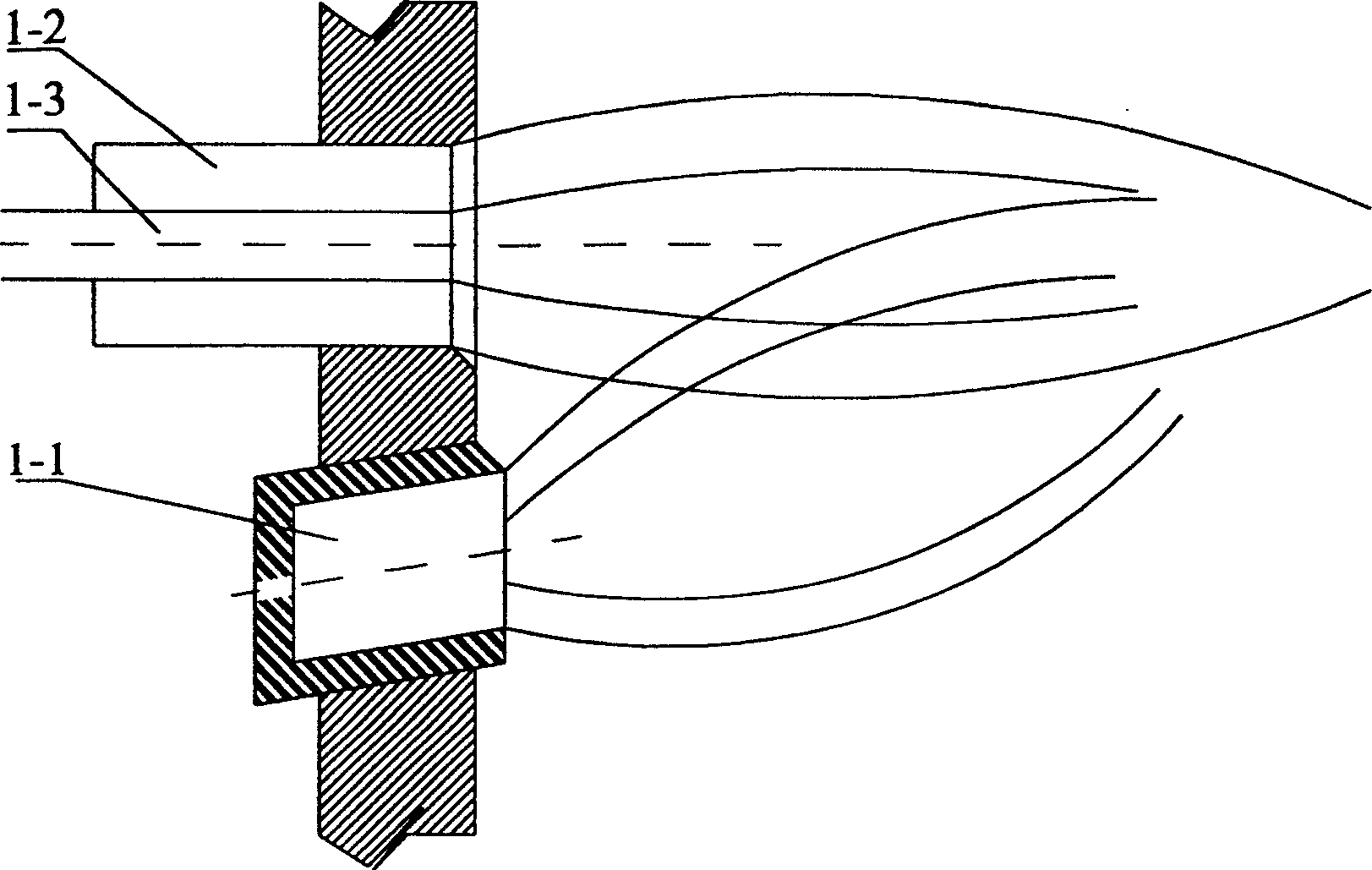

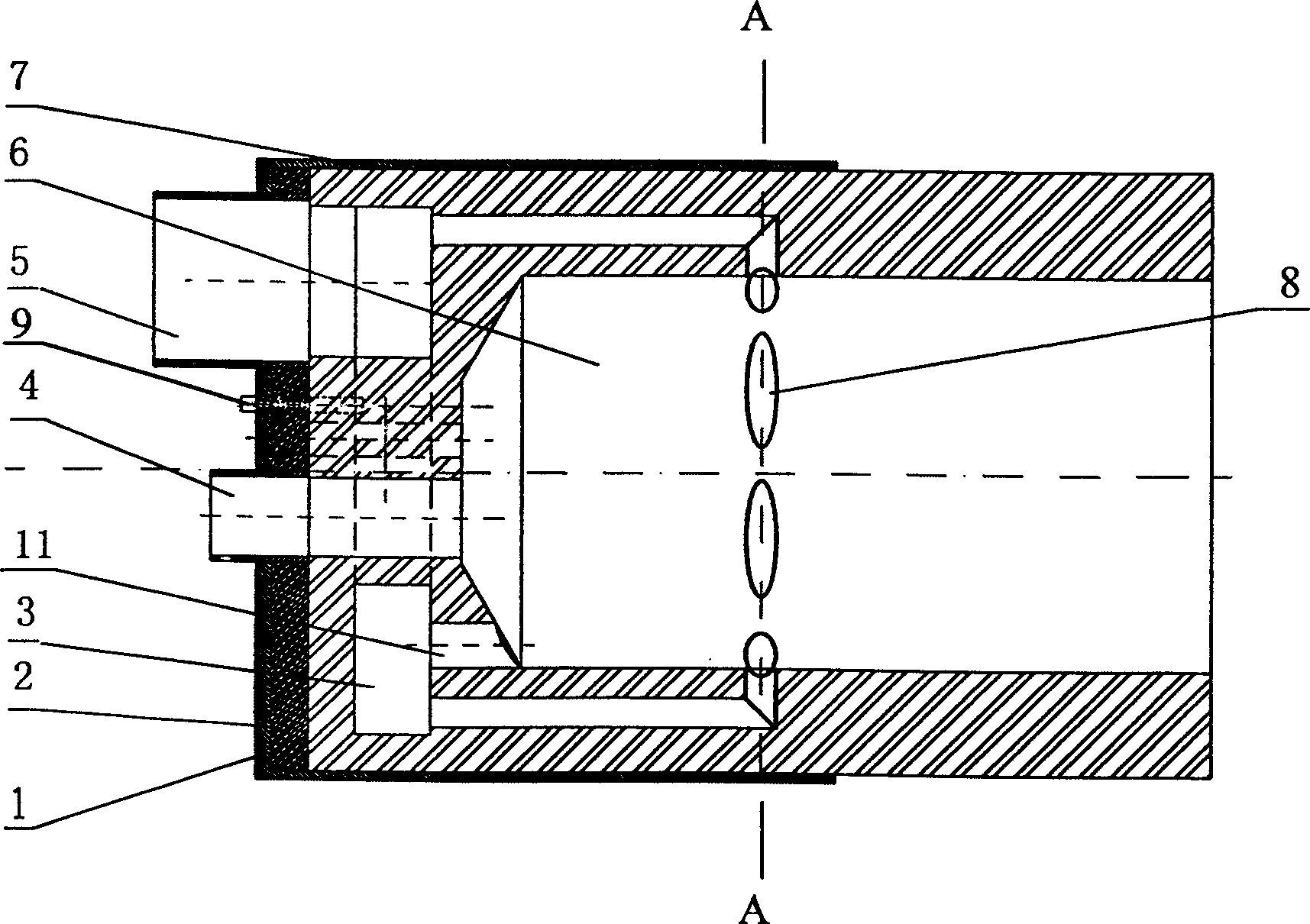

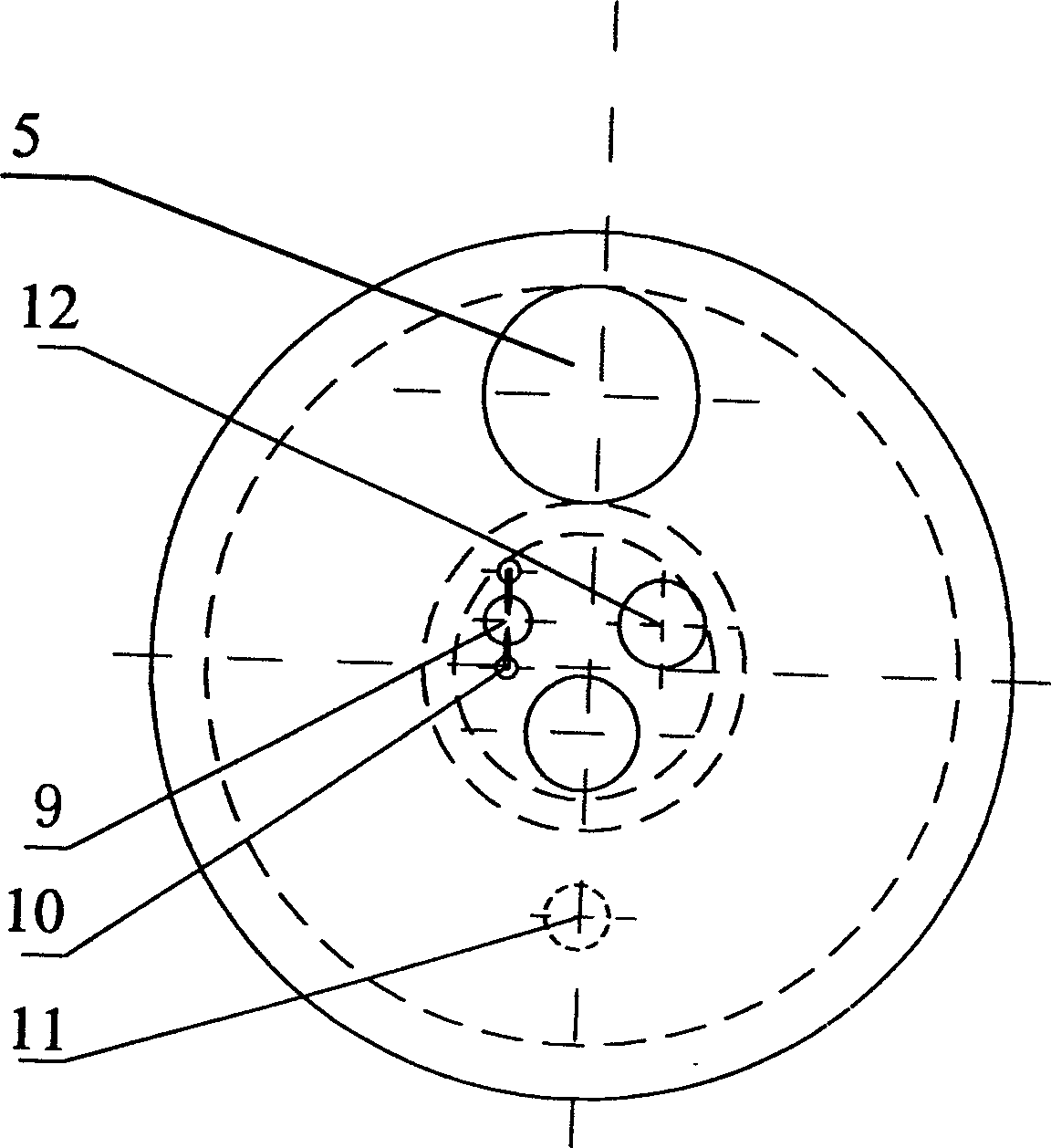

Large space burning method of water coal slurry and its special device

InactiveCN1782493AFront wall temperature is lowWill not cause burnsBurnersIndirect carbon-dioxide mitigationOxygen deficiencySlag

The present invention belongs to the field of fuel combustion technology, and aims at solving the problem that water coal slurry can not be burnt at low temperature with air as combustion improver unless some auxiliary heat source is adopted. Oxygen-rich air is used as combustion improver in realizing large space combustion and oxygen-deficiency combustion to produce certain amount of CO and H2 to inhibit thermal generation of nitrogen oxide and eliminate environmental pollution. CO and H2 in oxygen atmosphere produce secondary combustion, resulting in violent combustion. The present invention is used in burning water coal slurry to eliminate ash and slag effectively and has unique tangent air port for violent and complete combustion.

Owner:唐艳芬

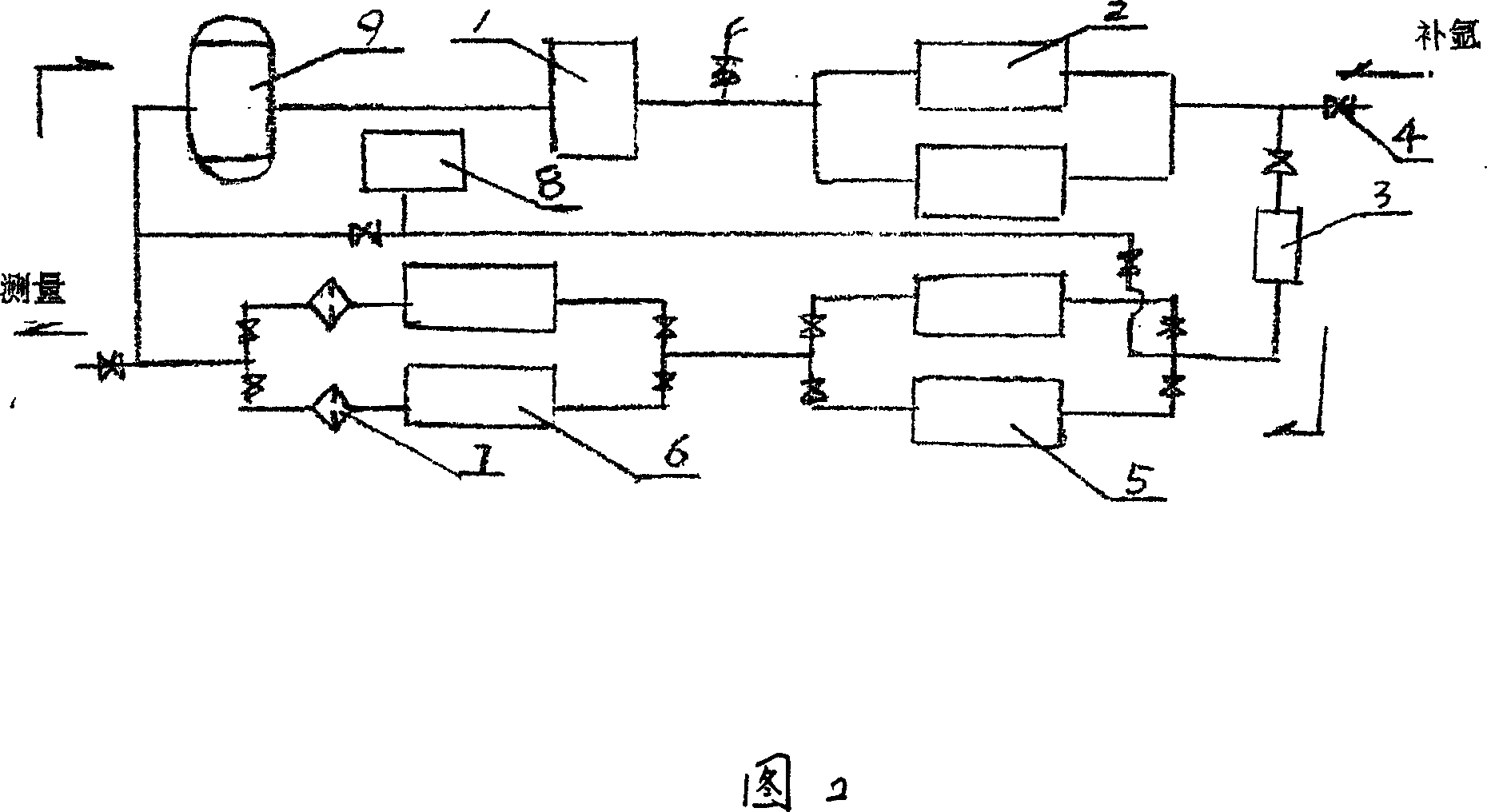

Dosing device for improving pH value of boiler supply water

InactiveCN102826644AControl dosing concentrationReduces pungent odorsWater/sewage treatment by neutralisationMetallic materialsControl room

The invention relates to a dosing device for improving the pH value of boiler supply water, which consists of a drug storage barrel I, a drug storage barrel II, a reducing valve, an on-line instrument, a cooler, a metering pump I, a metering pump II, a plurality of stop valves and a pipeline. An opening joint pipe, a valve, reduced pressure cooling and the on-line instrument of a boiler supply water pipeline are controlled, so that the dosage concentration can be conveniently controlled, the preset best PH value range can be reached, the PH values of boiler supply water, steam and drained water can be improved and stabilized, and metal materials of a boiler and a whole water supply and return pipeline are protected from being corroded. Meanwhile, automatic dosage control can be realized, and the detection result of the pH value of the boiler supply water can be transmitted to a control room to be monitored and managed in real time.

Owner:KUNMING CELLULOSE FIBERS CO LTD

Adhesive with anti-line-explosion function for corrugated paperboard production and preparation method of adhesive

InactiveCN104513636AHigh curing temperatureIncrease moisture contentNon-macromolecular adhesive additivesStarch adhesivesAdhesive cementPaperboard

The invention discloses an adhesive with an anti-line-explosion function for corrugated paperboard production and a preparation method of the adhesive. The adhesive comprises the following components in parts by weight: 1,000 parts of water, 300-400 parts of corn starch, 5-10 parts of sodium hydroxide, 2-4 parts of borax, 7-9 parts of a stabilizer, 2-3 parts of a reinforcing agent and 1-3 parts of sodium chloride. The preparation method adopts a two-step method. Due to the use of the adhesive, the problem of line explosion and breakage of paperboards in a dry climate is effectively solved without adding a spraying system, the production cost of the paperboards is scarcely increased, and the paperboard uniformity is improved.

Owner:XIAN CHANGMING PACKING

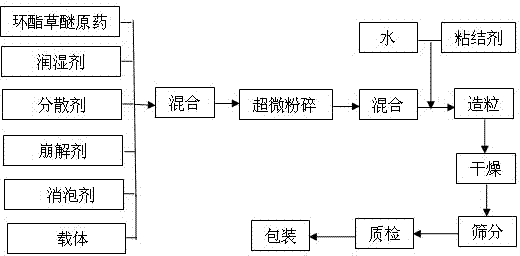

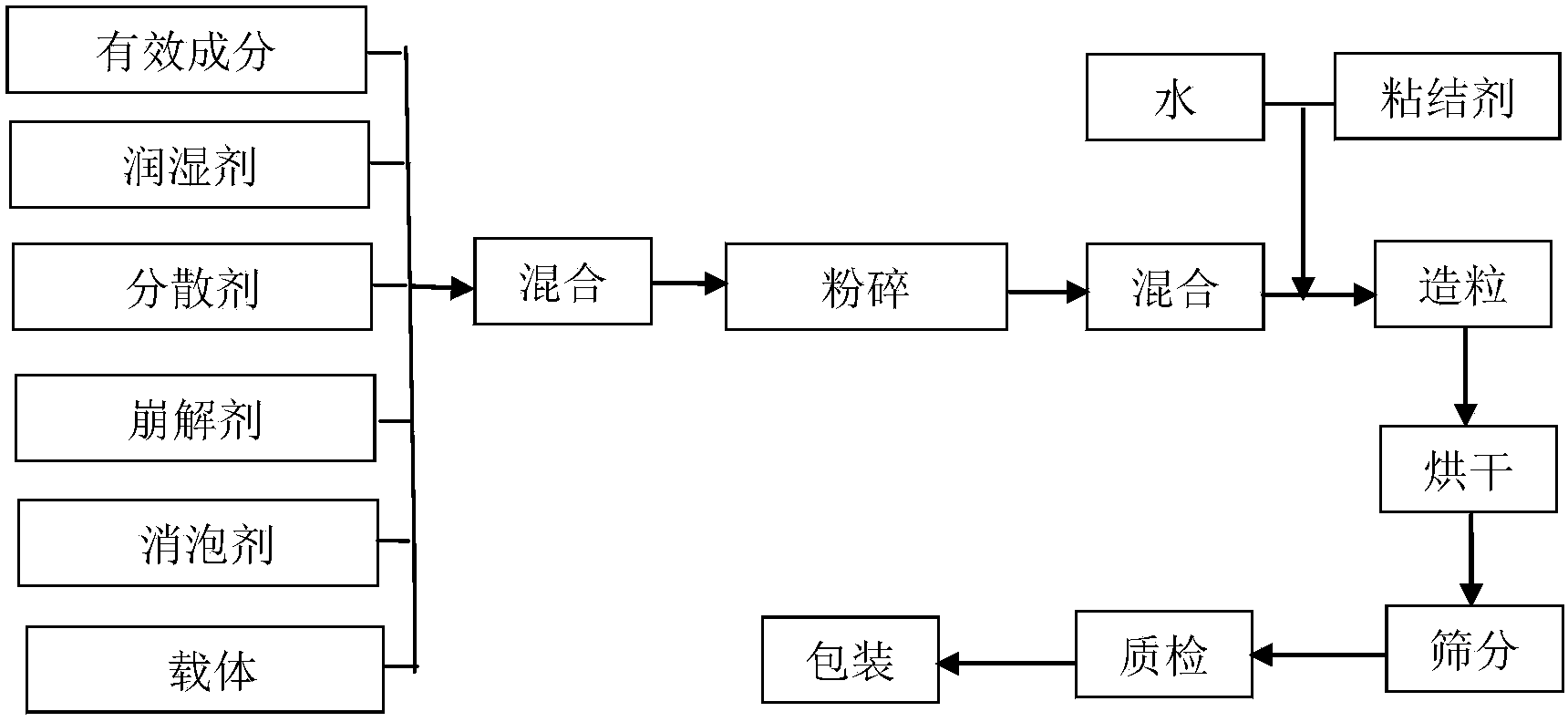

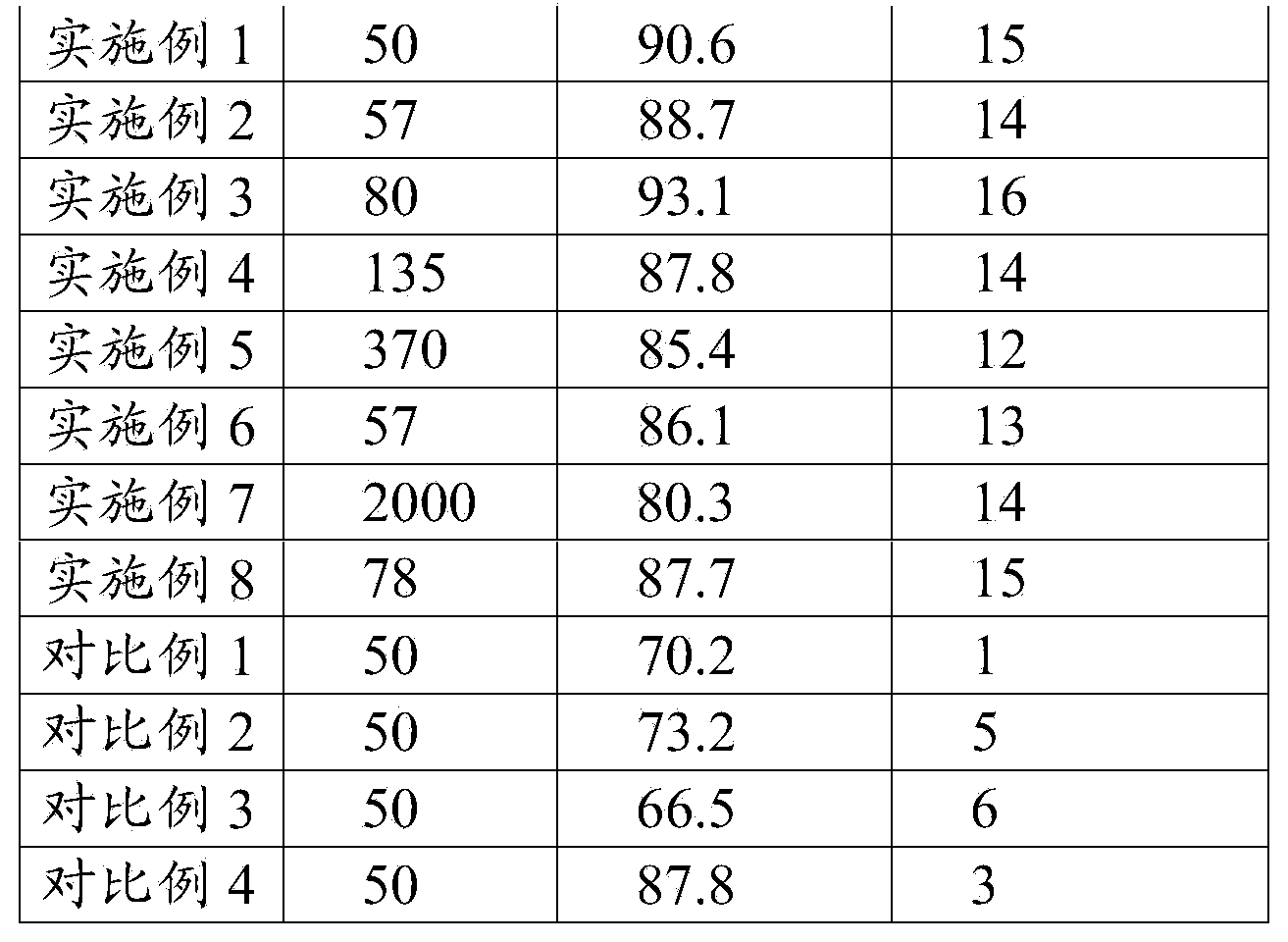

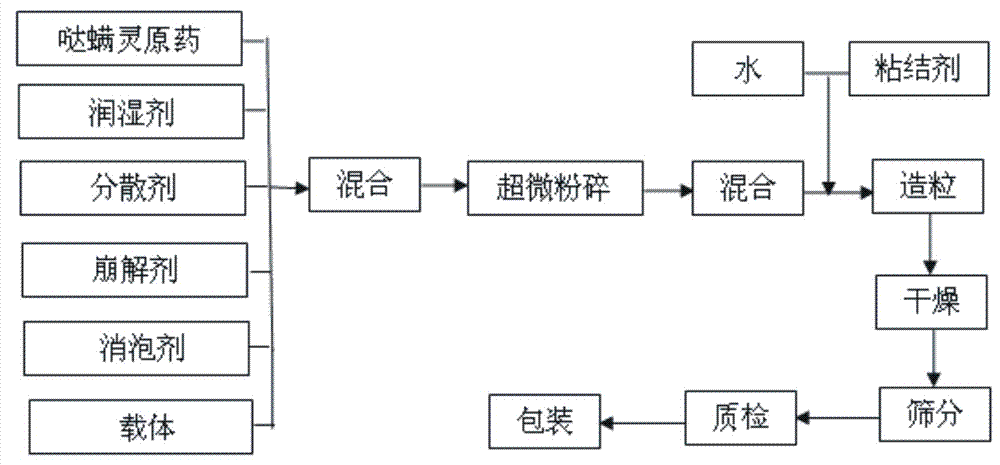

Pyriftalid water dispersible granule and preparation method thereof

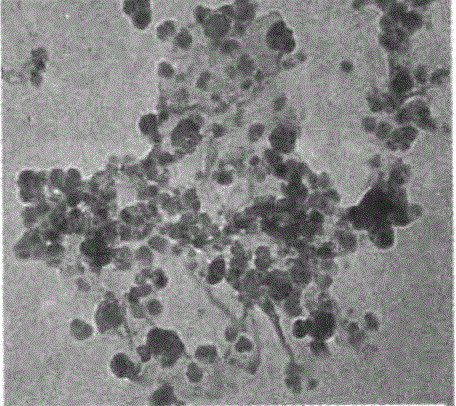

InactiveCN102405902AImprove performanceEasy to packBiocideAnimal repellantsSuspending AgentsAqueous solution

The invention relates to a pyriftalid water dispersible granule and a preparation method thereof. The pyriftalid water dispersible granule is prepared from the following components in percentage by weight: 10-80% of pyriftalid, 1-8% of a wetting agent, 1-10% of a dispersing agent, 1-40% of a disintegrating agent, 0.3-5% of a defoamer, 0.5-4% of an adhesion agent, and the balance is a carrier; the preparation method comprises the following steps: uniformly mixing the raw materials except the adhesion agent; adding the mixture after ultrafine grinding to a water solution of the adhesion agent so as to carry out granulation; and finally, drying, screening, analyzing, testing, and putting in a storage. The pyriftalid water dispersible granule provided by the invention has the advantages of overcoming defects of a suspending agent and wettable powder, and having environmental friendliness and low use cost; and in processing and use processes, environmental pollution use cost of farmers are reduced.

Owner:GUANGDONG ZHONGXUN AGRI TECH

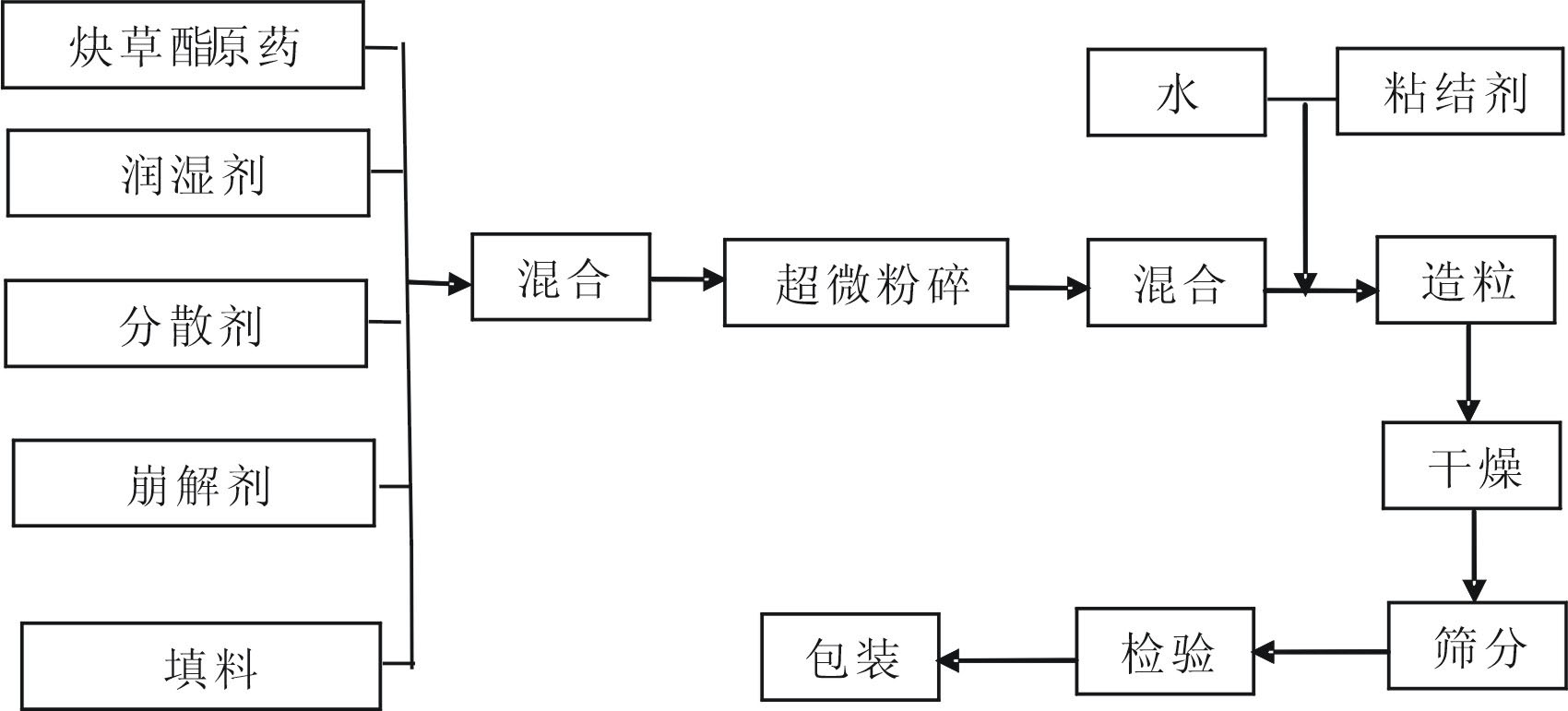

Clodinafop-propargyl water dispersible granule and preparation method thereof

InactiveCN102428921ASave resourcesReduce pollutionBiocideAnimal repellantsSuspending AgentsEnvironmental engineering

The invention relates to a clodinafop-propargyl water dispersible granule and a preparation method thereof. The clodinafop-propargyl water dispersible granule comprises the following components in percentage by weight: 5-85% of clodinafop-propargyl, 1-8% of wetting agent, 1-10% of dispersing agent, 1-10% of disintegrating agent, 0.5-4% of binding agent and the balance of packing material. The preparation method comprises the following steps of: uniformly mixing the above raw materials except for the binding agent; then, ultrafine grinding the mixture, and adding the powder into the water solution of binding agent to granulate; and finally drying, screening, analyzing, inspecting and warehousing the granule. The clodinafop-propargyl water dispersible granule overcomes the defects of suspension and wettable powder and combines the advantages of environmental protection and low use cost. The pollution to the environment is lowered during the processing and use process, and the use cost of peasants is lowered.

Owner:GUANGDONG ZHONGXUN AGRI TECH

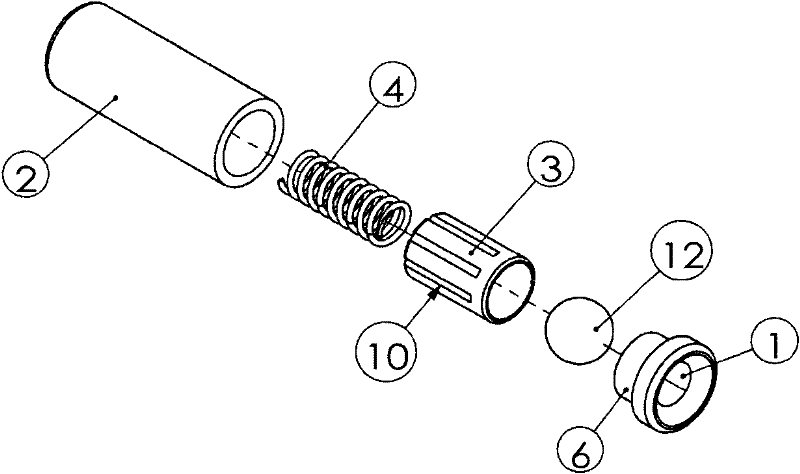

Charging button-type battery

InactiveCN101859910AWon't explodeAvoid harmFinal product manufactureSecondary cells manufactureSafety valveElectrical and Electronics engineering

The invention relates to a charging button-type battery with an explosion-proof device, which consists of a battery body and a cap, wherein the cap consists of a cap chassis, an explosion-proof ball and a nickel-plated steel cap, the cap chassis is provided with an explosion-proof safety valve air outlet hole, the explosion-proof ball and the nickel-plating steel cap are arranged on the explosion-proof safety valve air outlet hole, and the explosion-proof ball is arranged inside the nickel-plating steel cap. By adopting the nickel-plating steel cap to compress the explosion-proof ball towards the explosion-proof safety valve air outlet hole, when the pressure is more than the explosion-proof opening pressure of a battery explosion-proof valve, the pressure pushes the explosion-proof ball in the cap, so the cap is opened to discharge the air, and when the pressure is decreased to be lower than the critical value, the cap is re-closed through the elasticity of the explosion-proof ball, so the battery is free from explosion because of the large pressure. Therefore, the injure of the battery on the charging device and the personnel, caused by the explosion during the manufacturing and application process, can be prevented, and the safety of the charging button-type battery can be improved.

Owner:王立志

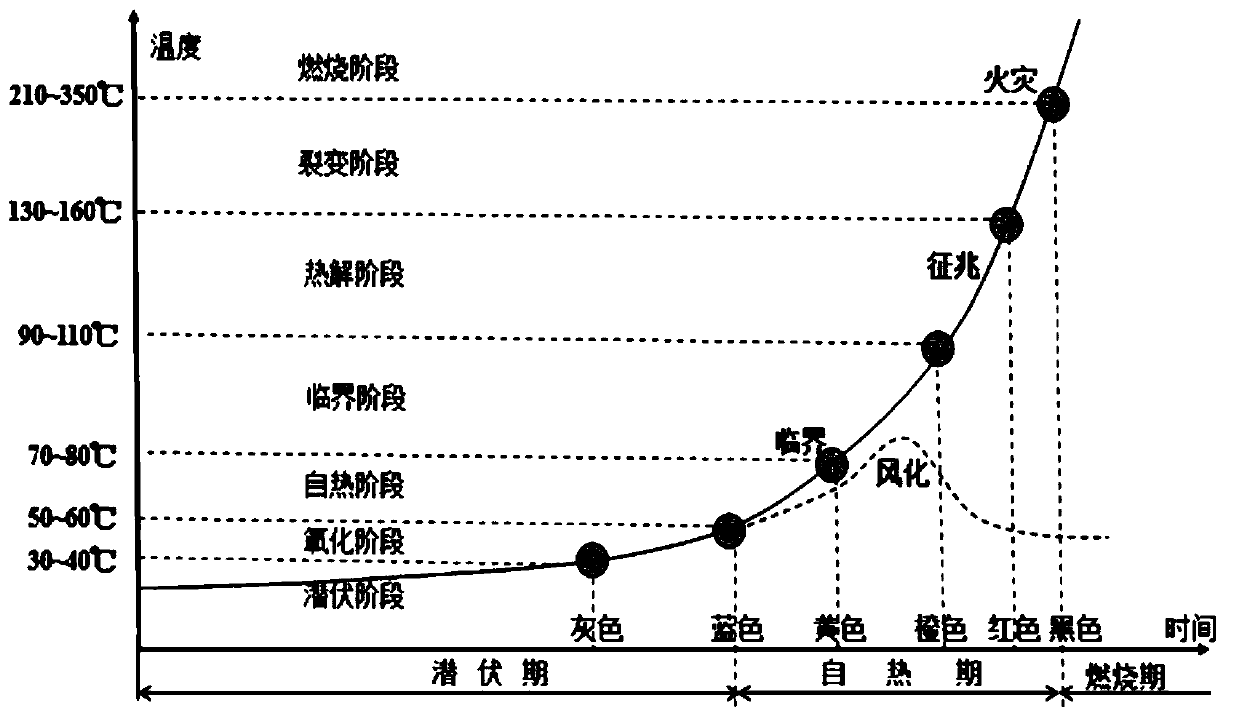

Low-temperature modified grouting reinforcement material

The invention discloses a low-temperature modified grouting reinforcement material. The low-temperature modified grouting reinforcement material is formed by mixing a material A with a material B in an isopyknic manner, wherein the material A is composed of water glass, a catalyst (ZR70) and polyol; and the material B is composed of polyisocyanate, polyether polyol, composite plant ester, a flameretardant and an antistatic agent. The temperature generated by a reaction of the material is controlled at 67-80 DEG C, so heat accumulation is reduced after grouting, and spontaneous combustion of coal is well prevented. No harmful gas is generated, so the health and safety of constructors are guaranteed. The material has good fluidity at the initial stage of the reaction, and can rapidly permeate into surrounding rocks and coal seam fracture spaces to fill and reinforce surrounding rocks and coal seams. The material has a high adhesion and a short solidification time, and the compressive strength after solidification can reach 40 MPa or above, so that surrounding rocks and coal seams are wholly stable, and are not prone to flaking.

Owner:淮南东华欧科矿山支护设备有限责任公司

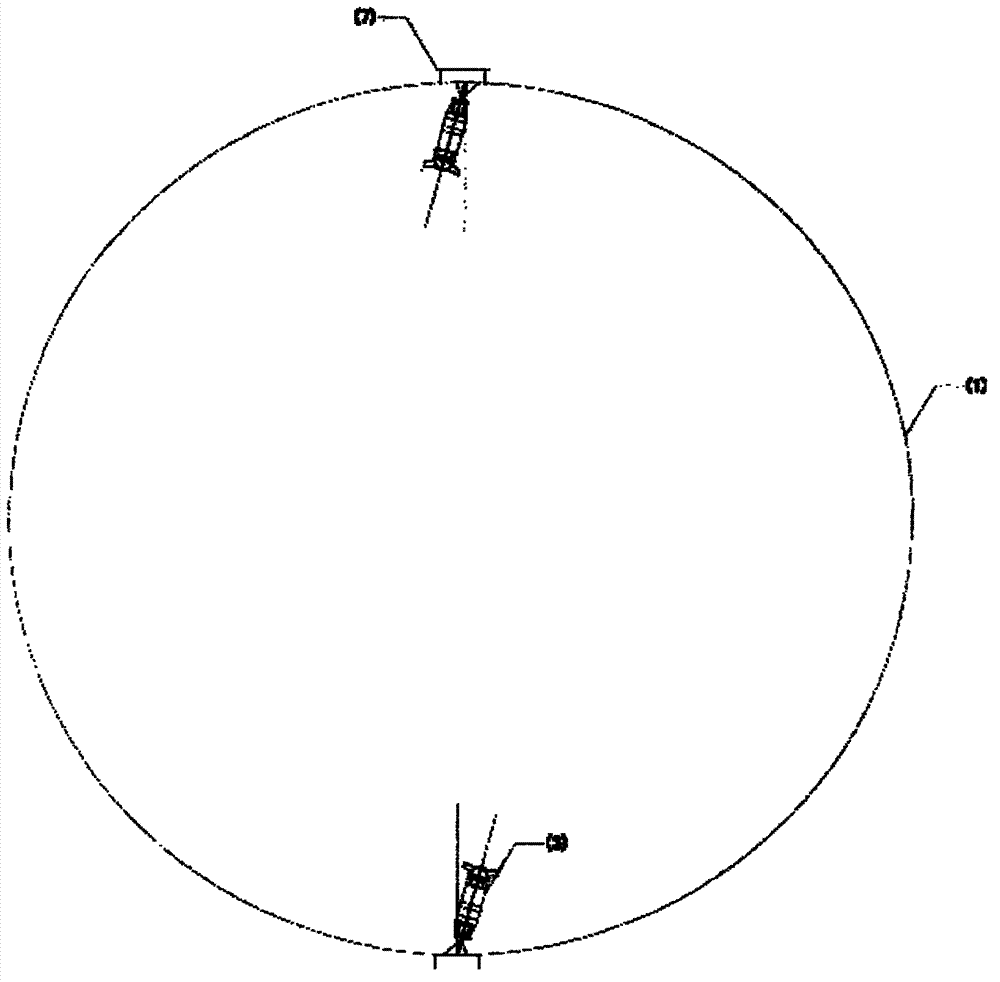

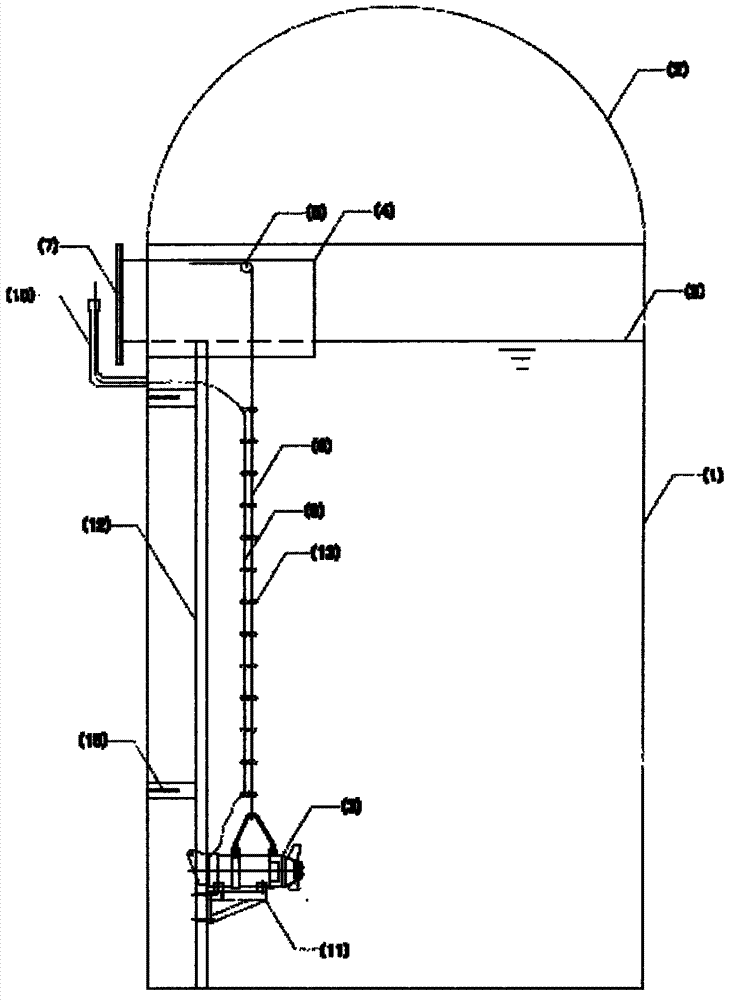

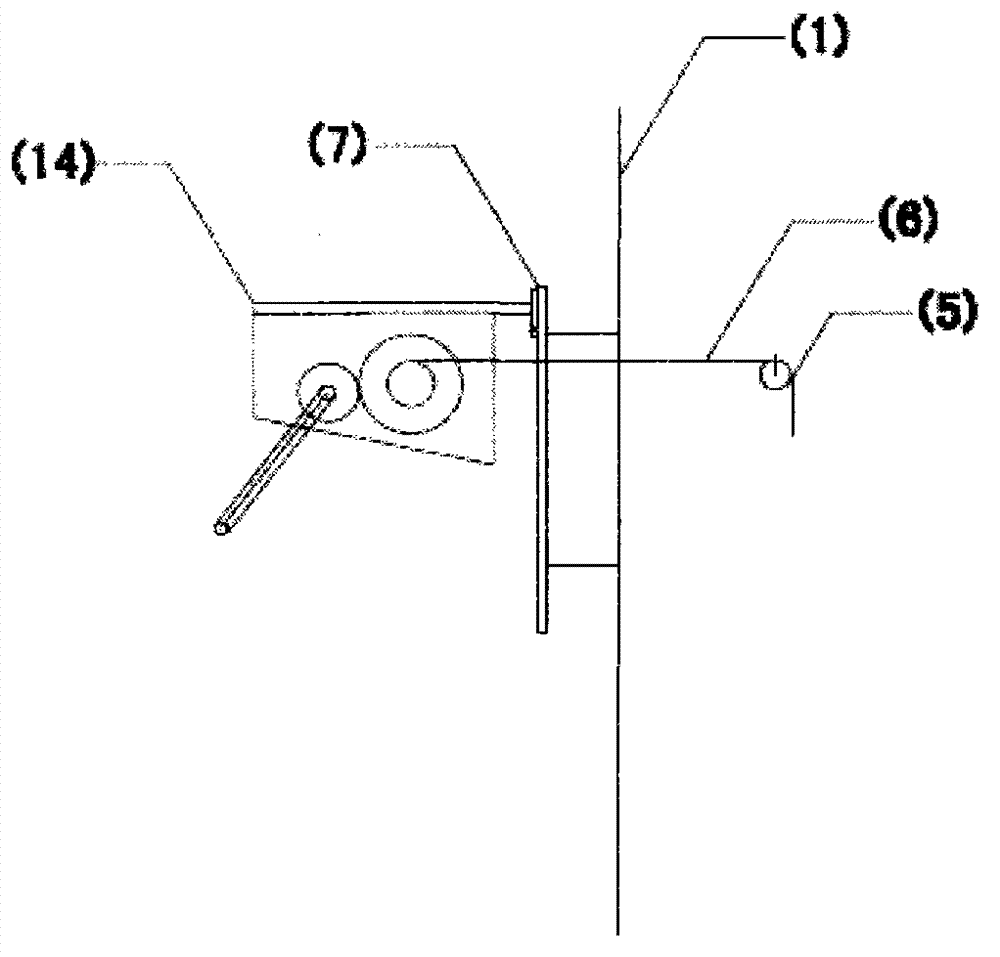

Installation method and device of submersible mixer for anaerobic reactor

ActiveCN102774960AEasy to installBiogas leakGas production bioreactorsWaste based fuelLower limitPulley

The invention relates to an installation device of a submersible mixer for an anaerobic reactor. The device comprises a tank wall, a manhole, guide rods, a connecting bracket, safety covers and the like, wherein a plurality of guide rods are installed at a position close to the tank wall inside the anaerobic reactor according to the amount of the submersible mixer, lower limiting positions of the submersible mixer are welded at certain heights on the guide rods, the safety covers for preventing methane from escaping out are arranged on the upper portions of the guide rods, fixed pulleys for lifting the submersible mixers are installed below the safety covers on the guide rods, a manual capstan for lifting the submersible mixers is arranged on the inspection manhole, and a cable discharging device provided with water seal is adopted for leading cables out of the anaerobic reactor so as to prevent the methane from escaping. According to the installation method, a submersible pump can be installed inside the anaerobic reactor conveniently, and the problem that the submersible mixer cannot be applied to the anaerobic reactor is solved.

Owner:欧仁(日照)环保装备有限公司

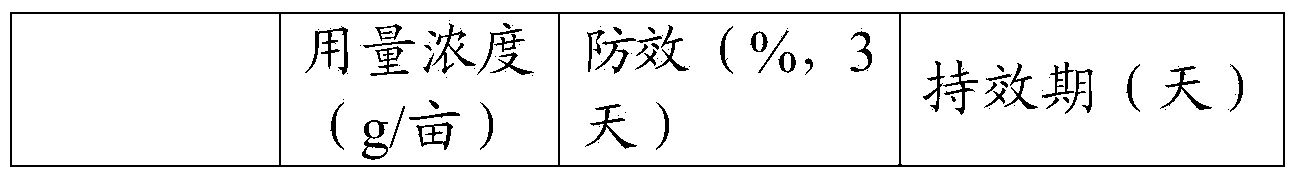

Insecticide composition as well as preparation method and application of insecticide composition

ActiveCN104222161AImprove stabilityImprove survival rateBiocideAnimal repellantsSporeActive component

The invention discloses an insecticide composition as well as a preparation method and application of the insecticide composition. The insecticide composition comprises active components, namely isaria fumosorosea and rotenone, wherein the mass percentage of isaria fumosorosea to rotenone in the insecticide composition is 2%-80%; and the mass ratio of isaria fumosorosea to rotenone is (0.1-70) to 1. The active components of the insecticide composition are compounded by adopting isaria fumosorosea and rotenone, so that the stability and validity period of the isaria fumosorosea are effectively increased, the spore survival rate is increased, the validity period is long, the insecticidal efficiency is high, the control efficiency reaches over 80%, and meanwhile, the insecticide composition is safe to environment, people and livestock, does not pollute the environment, and is beneficial to ecological balance.

Owner:PLANT PROTECTION RES INST OF GUANGDONG ACADEMY OF AGRI SCI +1

Pyridaben water dispersible granule and preparation method thereof

ActiveCN102726412ASave resourcesReduce pollutionBiocideAnimal repellantsSuspending AgentsDefoaming Agents

The invention discloses a pyridaben water dispersible granule and a preparation method thereof. The pyridaben water dispersible granulethe comprises components of, by weight, 10-80% of pyridaben, 1-8% of wetting agent, 1-10% of dispersing agent, 1-40% of disintegrating agent, 0.3-5% of defoaming agent, 0.5-4% of binder and the balance of carrier. The invention also discloses the preparation method of the water dispersible granule. The invention overcomes shortcomings of suspension and wettable powder, has both advantages of environmental protection and low cost, reduces environmental pollution during processing and usage, and also reduces usage cost for farmers. Therefore, the pyridaben water dispersible granule is a main trend in the development of pesticide formulations.

Owner:中高(天津)知识产权管理有限公司

Graphene catalyst

InactiveCN105552318AIncrease capacityWork lessMaterial nanotechnologyCell electrodesPolymer scienceRotary evaporator

The invention discloses a graphene catalyst, and belongs to the field of a catalyst. The graphene catalyst is prepared through three steps, and the step 1 includes: weighing a part of gamma-mercaptopropyltrimethoxy silane, taking a proper amount of absolute ethanol as a solvent, performing uniform mixing, adding phenyltriethoxysilane to the obtained solution according to a mole ratio of gamma-mercaptopropyltrimethoxy silane to phenyltriethoxysilane being 1:1, performing uniform mixing, adding tetraethylammonium hydroxide to the obtained solution according to a mole ratio of gamma-mercaptopropyltrimethoxy silane to tetraethylammonium hydroxide being 1:1.2, performing heating and a reflux reaction for 48h, naturally cooling the reaction to room temperature, evaporating the solvent out through a rotary evaporator to obtain a lime-milk-shaped product, washing the product with a mixed solvent of tetrahydrofuran and methanol, and performing freeze-drying to obtain diamino-POSS. The graphene catalyst can be applied to a lithium polymer battery, and can effectively improve capacity and a working platform of the battery.

Owner:宋宏婷

Water-based soldering flux and preparation method thereof

ActiveCN104551452AGood water solubilityGood lubricityWelding/cutting media/materialsPrinted circuitsSolventChemistry

The invention relates to a water-based soldering flux, which comprises the following raw materials in parts by weight: 0.3-1% of alkyl dicarboxylic acid, 1-4% of polyglycol, 1.5-4.5% of ammonium chloride, 0.8-3.3% of glycerinum, 1.3-5.3 of citric acid, 1-20% of nonylphenol polyether phosphate, 0.05-0.6% of surfactant, 1-30% of water, and 31-90% of solvent. The water-based soldering flux has advantages of low solid content, high boiling point, slow volatilization, fire resistance, high safety and environment protection, without smell. The invention further discloses a preparation method of the water-based soldering flux, comprising the following steps of: weighing the material according to formula ratio; adding solvent in a first vessel and nonylphenol polyether phosphate to a first reacting kettle, and then completely stirring; adding the surfactant and solvent in a second vessel to a second reacting kettle, and then completely stirring; adding the alkyl dicarboxylic acid, the polyglycol, the ammonium chloride, the glycerinum, the citric acid, the water, a first dispersion, a second dispersion and solvent in a third vessel to a third reacting kettle, and then completely stirring; uniformly dispersing to obtain a finish product. The preparation method of the water-based soldering flux has advantages of simple process, easy operations and high production efficiency.

Owner:HUIZHOU QIANGDA ELECTRONICS

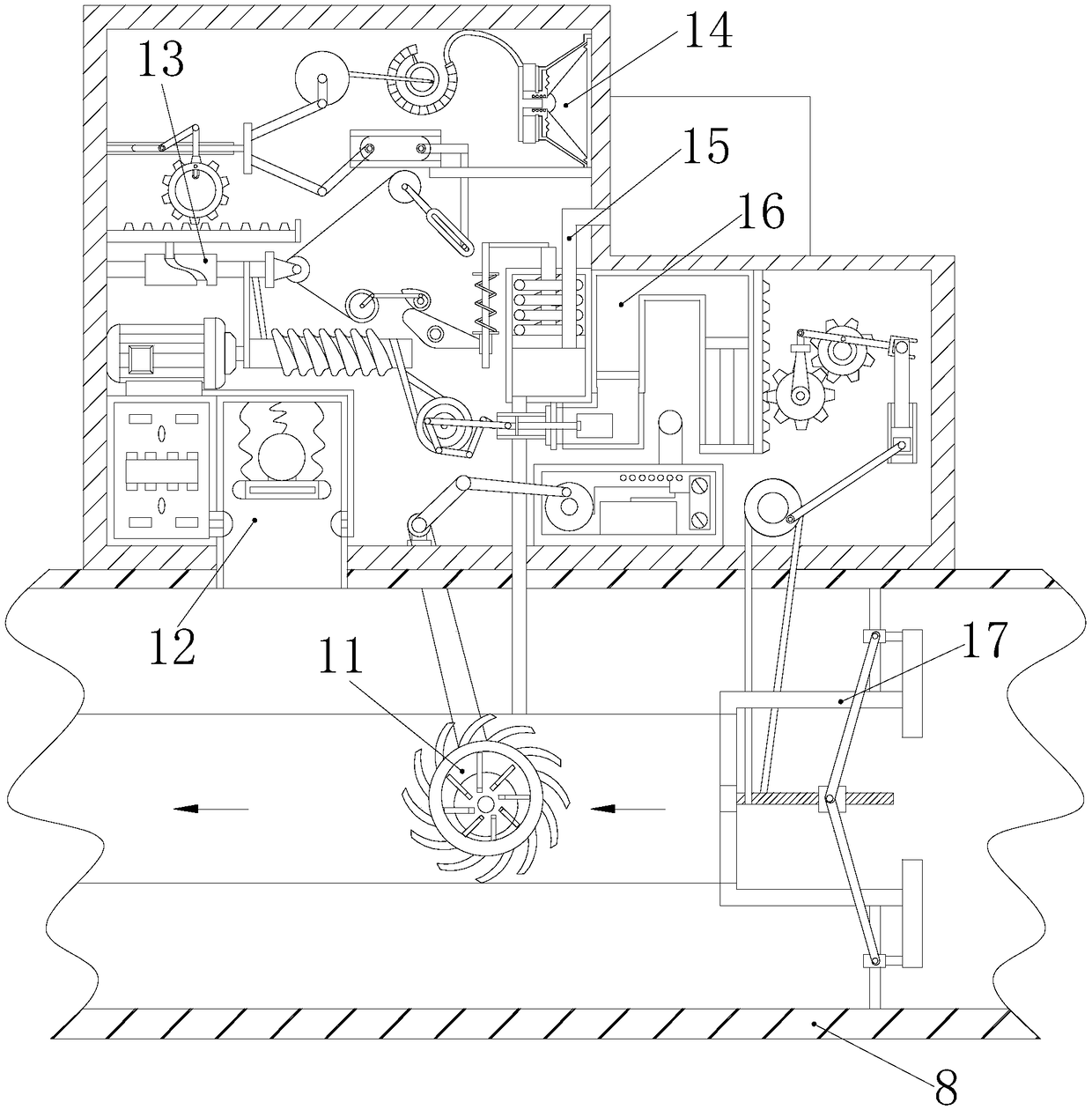

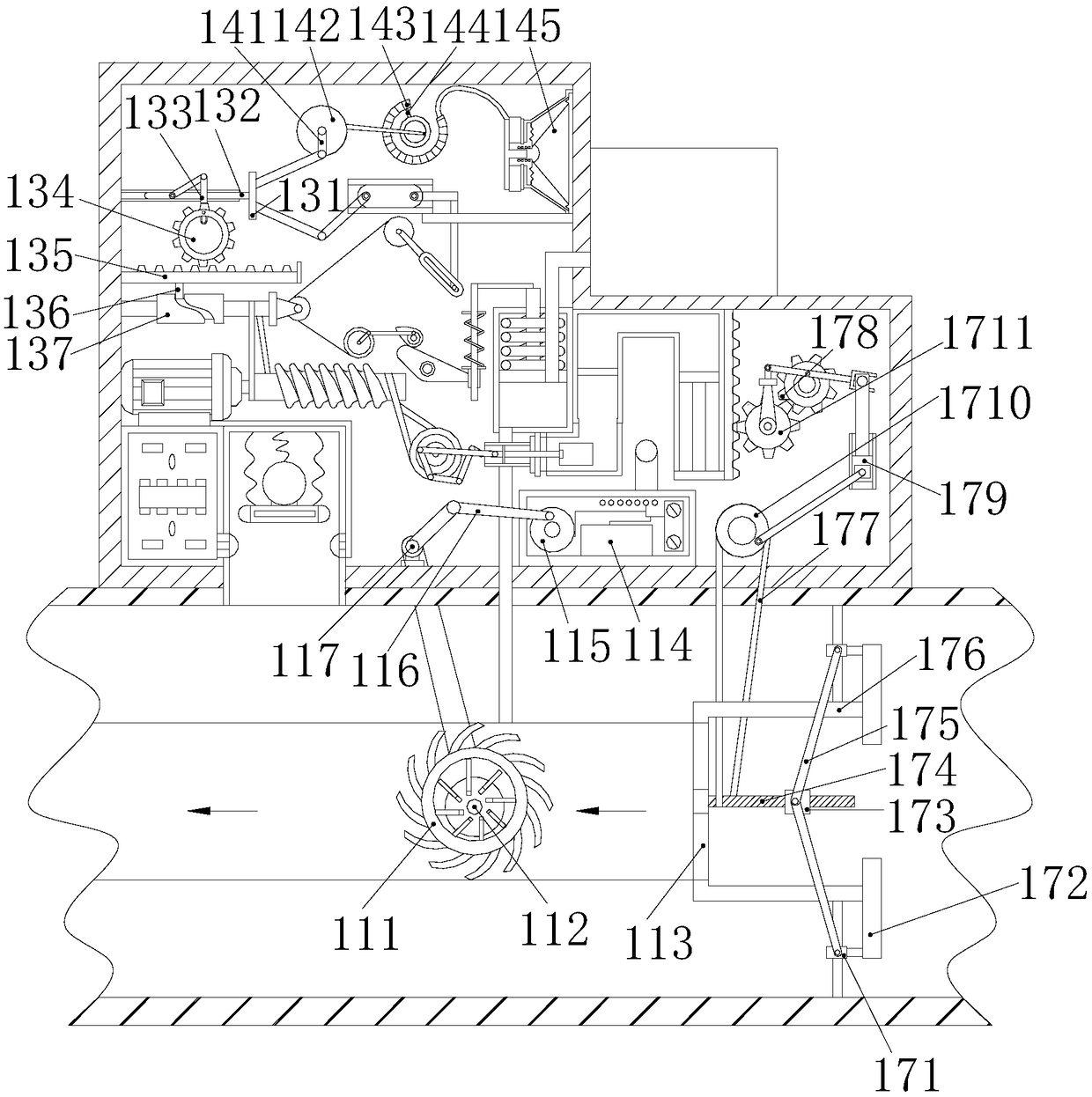

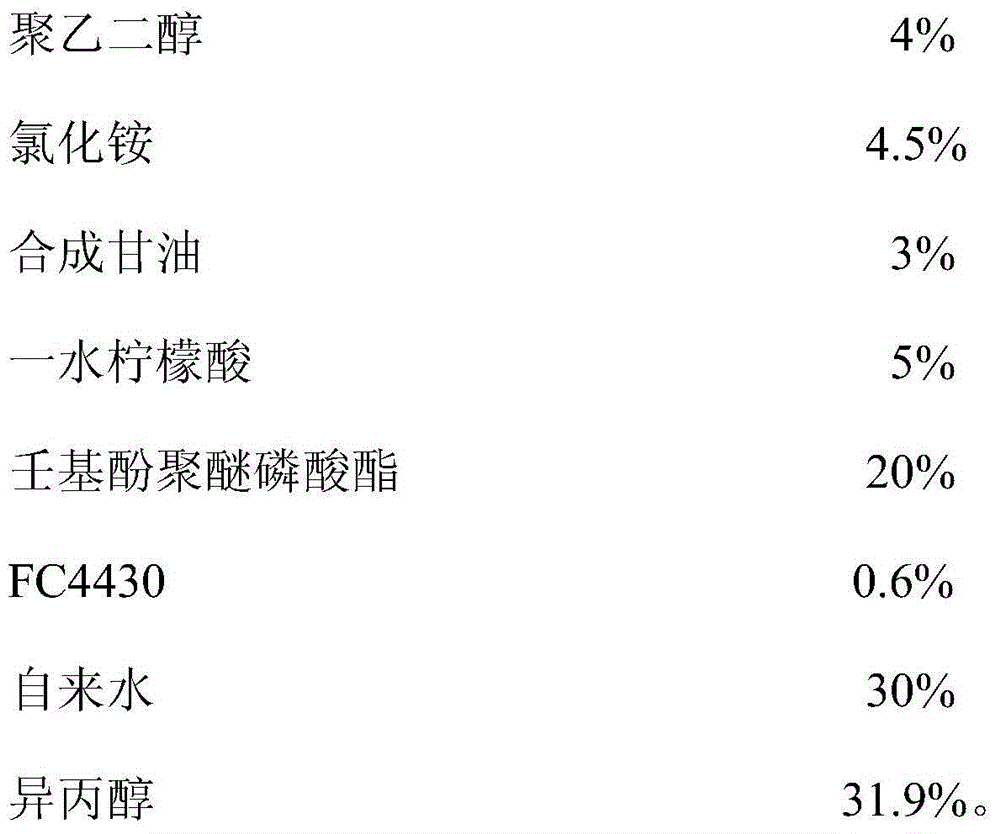

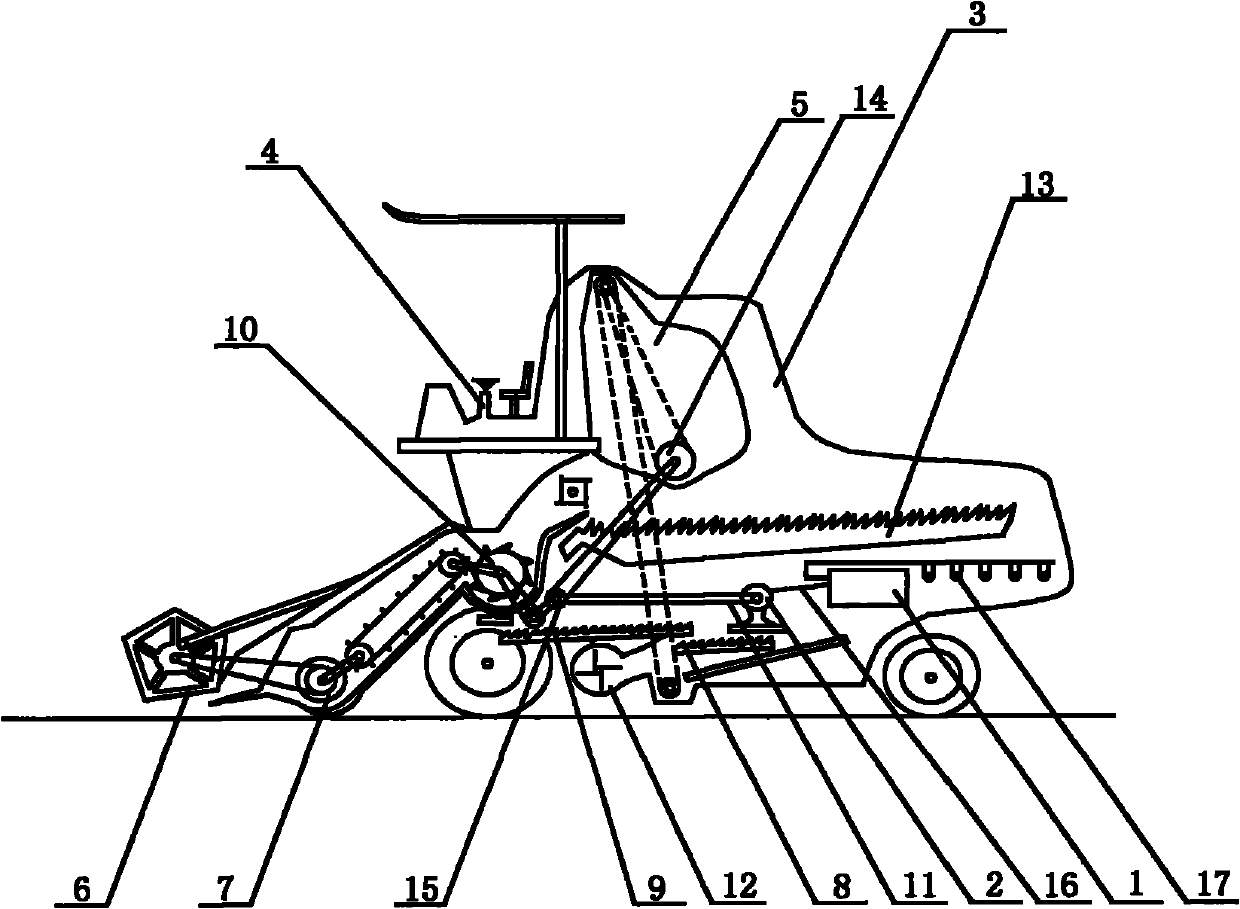

Harvester using lithium ion battery new energy as power unit

InactiveCN101904249AExtended service lifeEasy to useBatteries circuit arrangementsMowersElectrical batteryNew energy

The invention relates to a harvester using lithium ion battery new energy as a power unit, and belongs to the technical field of new energy application. An electric harvester mainly comprises a harvester device and a lithium ion battery power unit, wherein the lithium ion battery power unit charges lithium ion batteries through a power grid and storages the current; after a circuit switch is switched on, the lithium ion batteries supply power to a matched motor so as to convert the electric energy into mechanical energy; and the mechanical energy is respectively transmitted to various working parts of the harvester through a conveyor belt and a transmission wheel so as to complete the harvesting operation such as reeling, stripper header push and convey, threshing, grain convey, grain unloading, straw raking and the like of grain crops according to the operation order. The rear of the harvester is provided with a light-emitting diode for lighting, which is powered by the lithium ion batteries, so as to facilitate checking the threshing quality of the harvester at any time and making timely adjustment.

Owner:WUXI TONGCHUN NEW ENERGY TECH

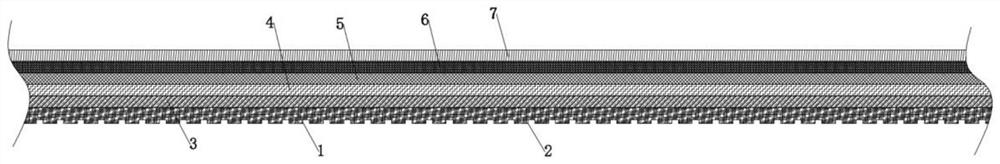

Rock plate applied to kitchen range, range hood, water heater and refrigerator door

PendingCN113290954ASimple structureVariety of colorsLamination ancillary operationsLaminationToughened glassInsulation layer

The invention discloses a rock plate applied to a kitchen range, a range hood, a water heater and a refrigerator door. The rock plate is suitable for panels of a gas stove, the water heater, the range hood, a disinfection cabinet and the refrigerator door and sequentially comprises an environment-friendly base layer, a flame-retardant heat insulation layer, a waterproof layer, a grid reinforcing layer, an environment-friendly heat dissipation layer and a smooth heat dissipation decoration panel layer from bottom to top, wherein the bottom face of the environment-friendly base layer is of a V-shaped concave-convex grain arrangement structure. The rock plate is simple in structure, is applied to panels of gas stoves, water heaters, range hoods, disinfection cabinets and refrigerator doors, has more colors and patterns than toughened glass, is resistant to high temperature, and cannot burst to hurt people.

Owner:万旭东

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com