Patents

Literature

3475results about How to "Small pressure loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

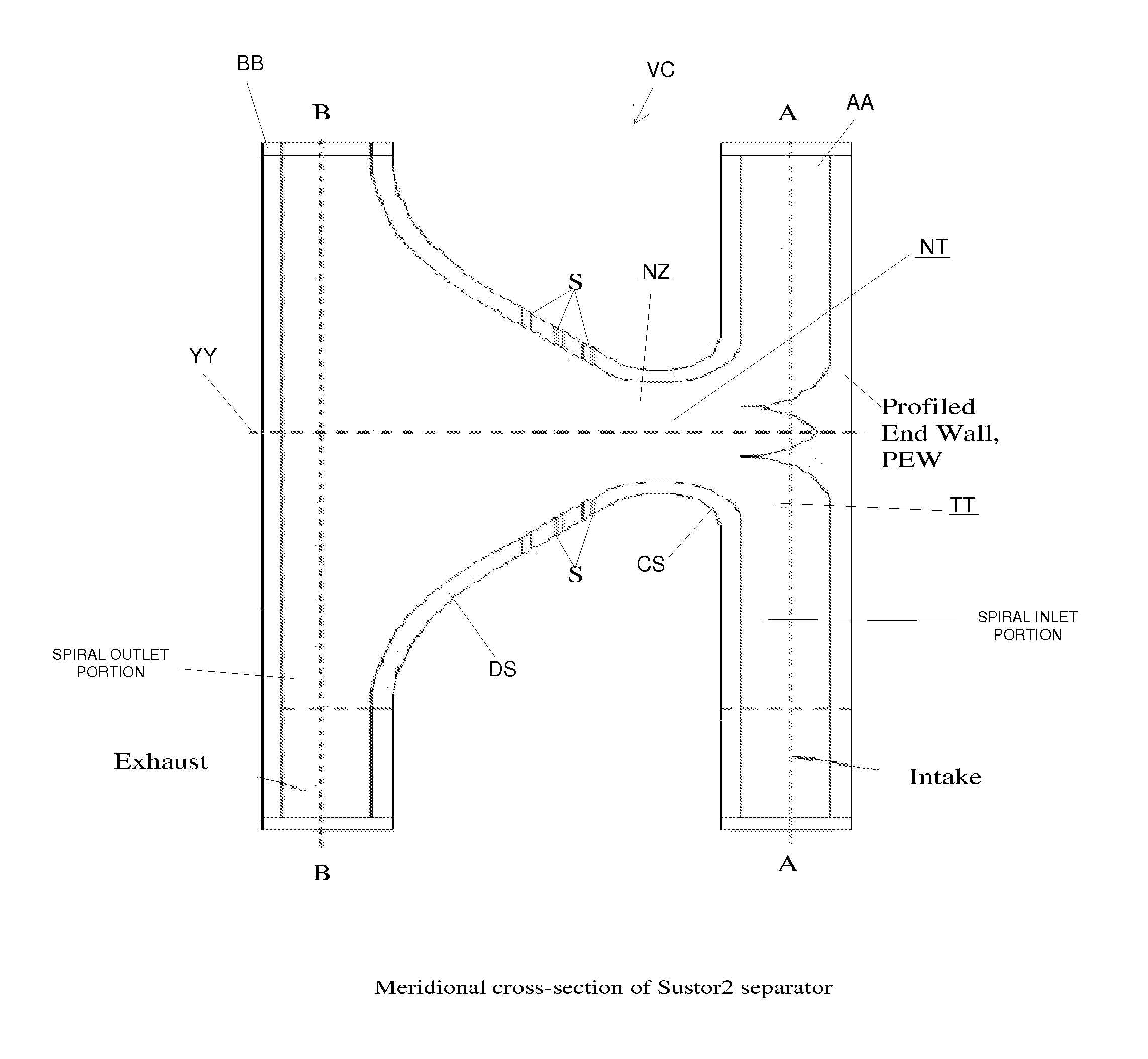

Supersonic swirling separator 2 (Sustor2)

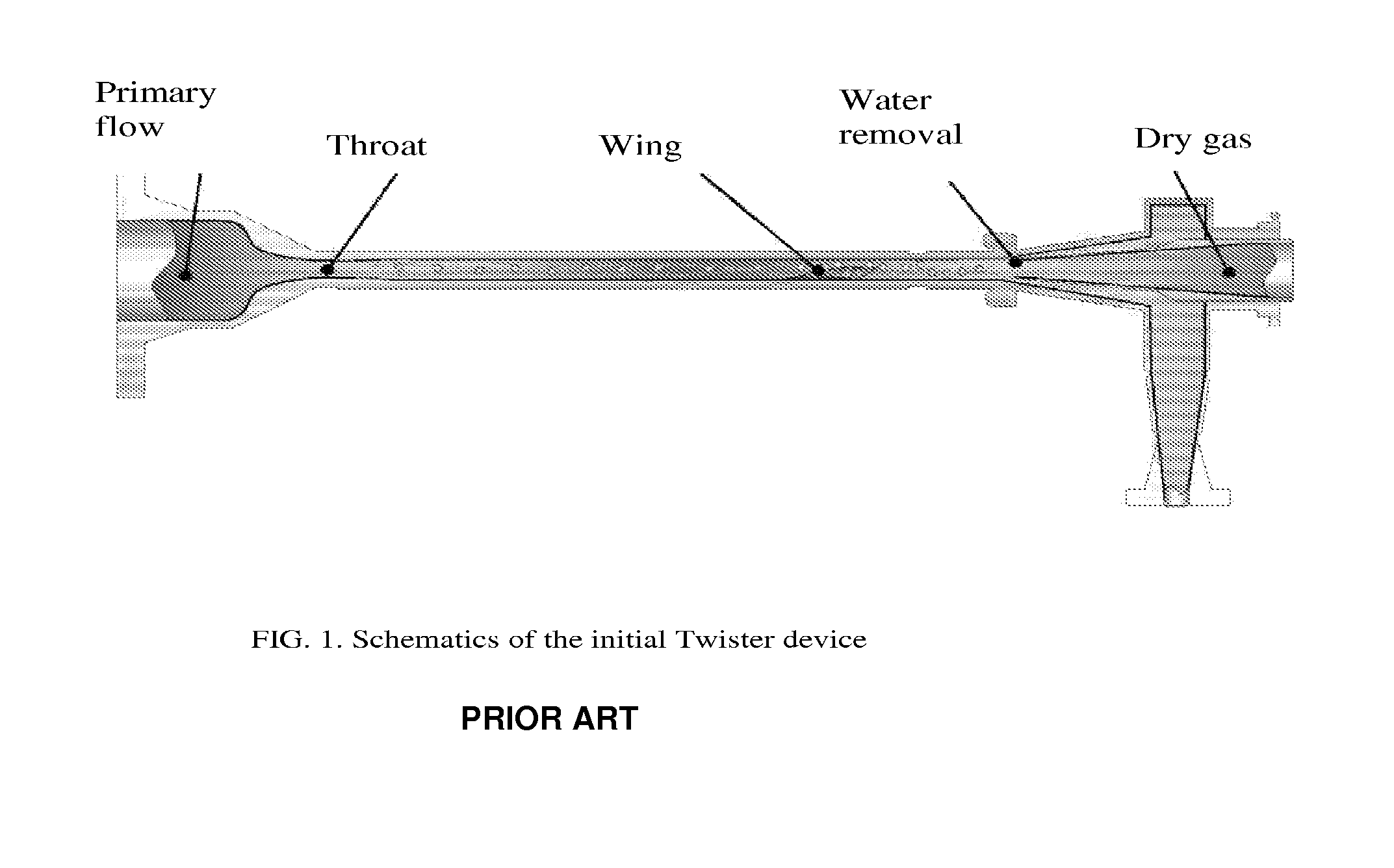

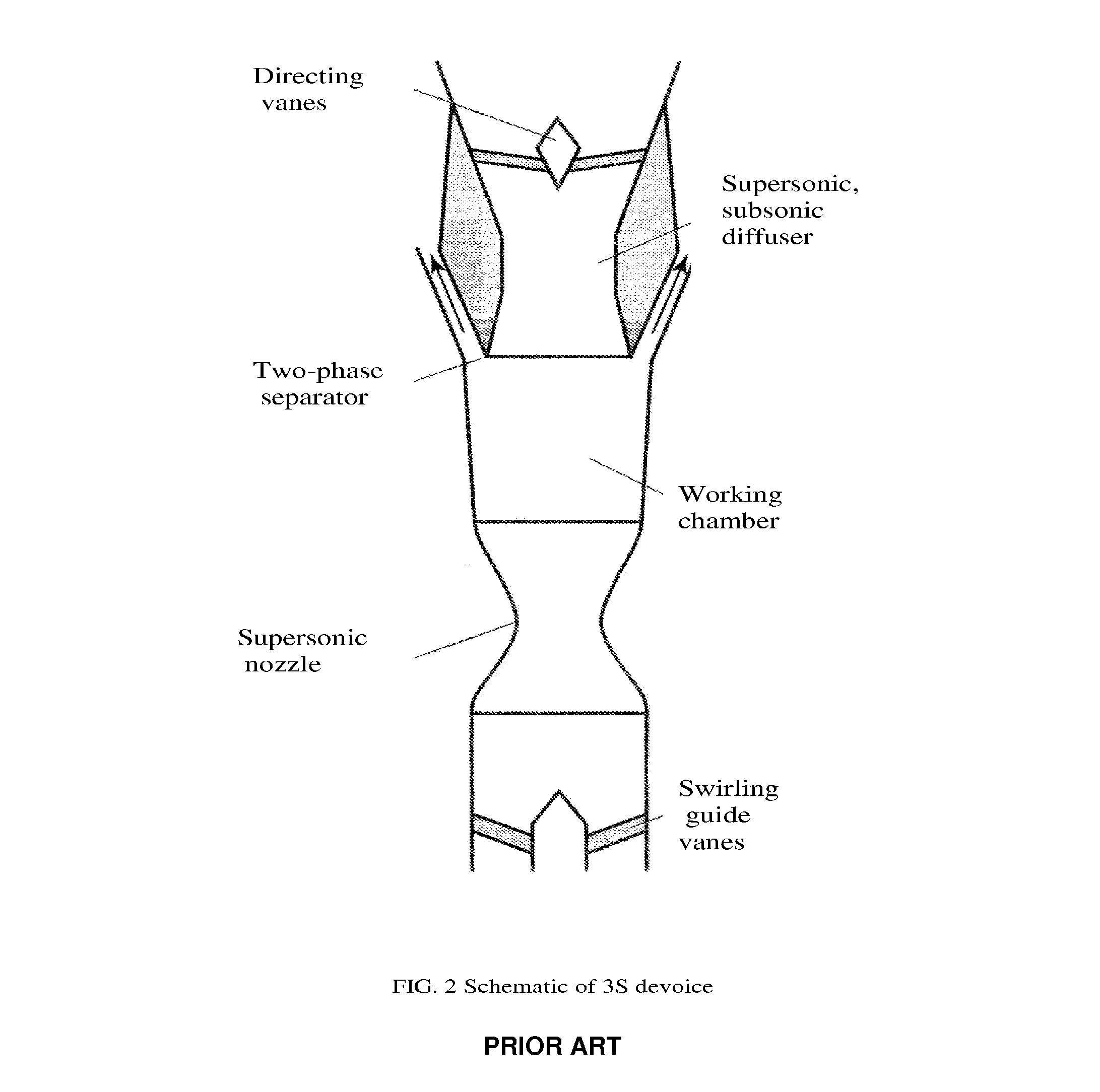

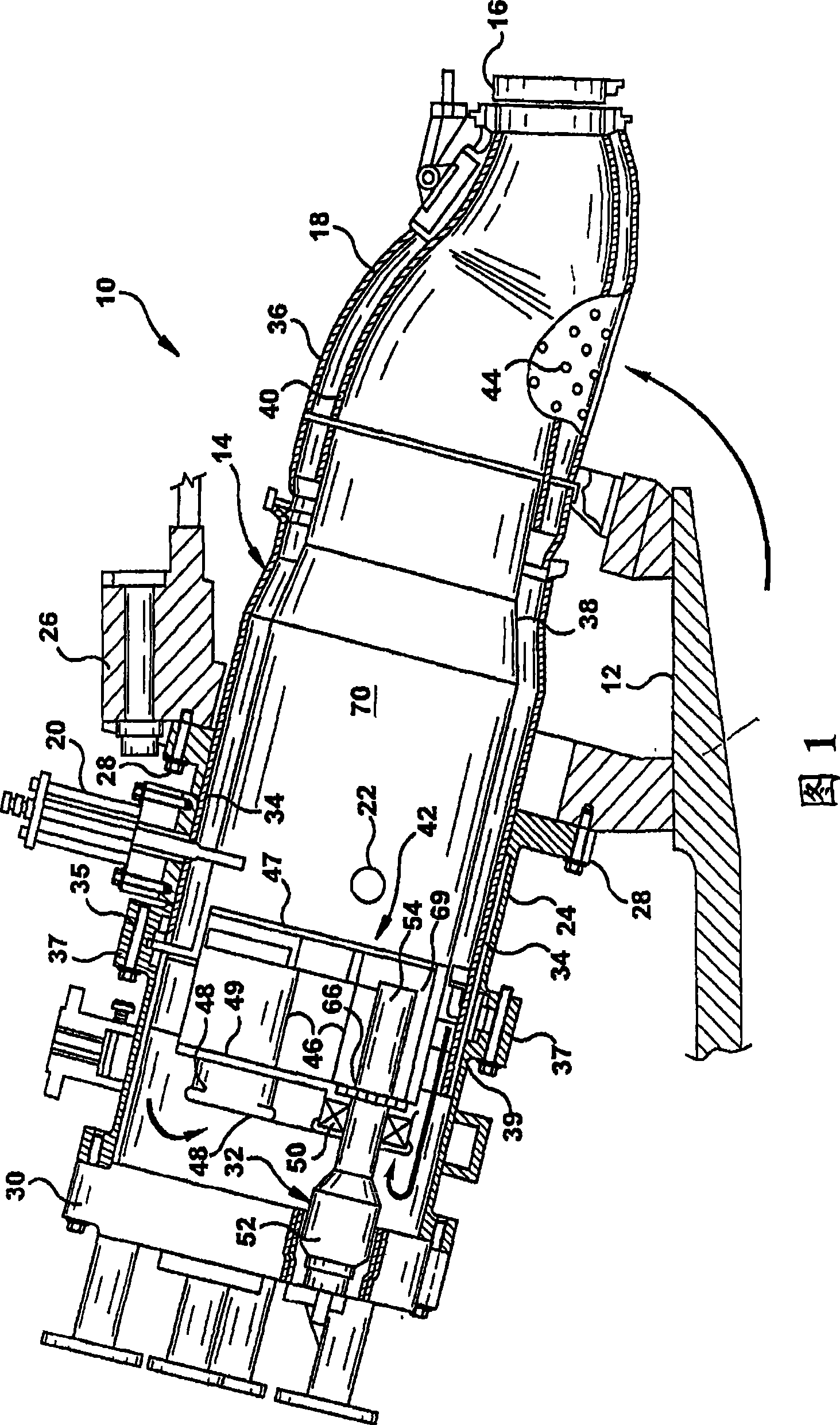

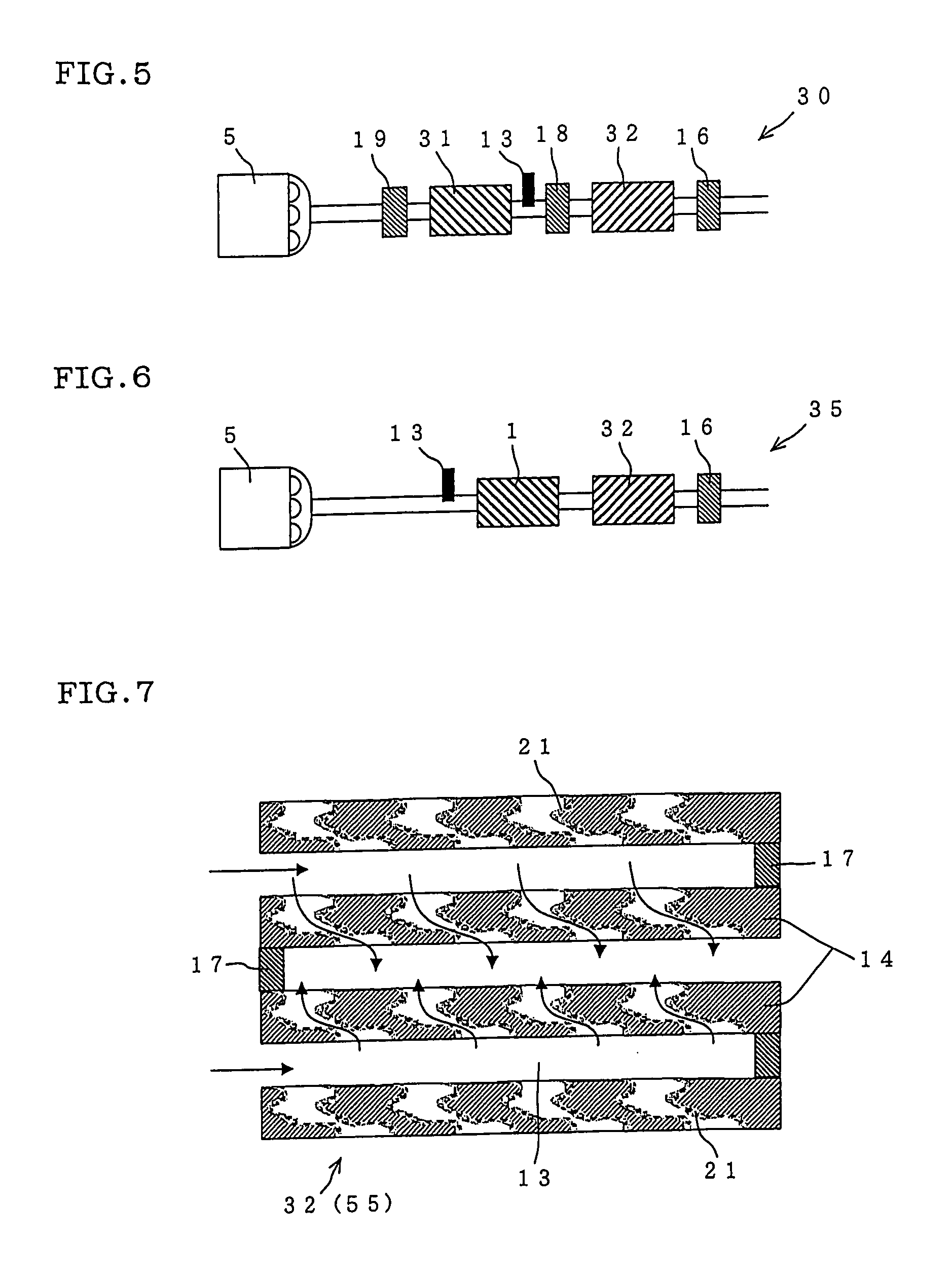

Sustor2 provides deep cooling of a gas flow, practically total condensation of a vapor, and fast and effective removal of the condensed liquid with a significantly reduced pressure losses compared with the prior art. Sustor2 performs the said operations by developing a strong swirling flow starting from its entrance, followed by spiral flow convergence in the inlet disc-like part, and then in a converging-diverging nozzle, by centrifugal removal of droplets, and removal of the liquid film through slits, then by spiral flow divergence and leaving the vortex chamber through tangential outlet.A gas enters from a pipeline (see the arrow in the A-A cross-section shown in FIG. 7) connected to Sustor2 by a flange and the inlet transition pipe ITP in FIG. 7, spirally converged in the disc-like part, marked by A-A in FIG. 6, enters the converging-diverging nozzle (FIG. 6). The flow is high-speed and swirling even at the near-entrance region of the vortex chamber. This swirl results in the centrifugal force that presses the through-flow to the sidewall. The flow accelerates near the nozzle throat up to a supersonic velocity with subsonic axial and supersonic swirl velocity components. This acceleration results in the gas temperature drop down to 200K and even less values. The reduced temperature causes rapid condensation of vapor into droplets. The centrifugal force pushes the droplets to the sidewall where they are removed through slits. Next the dried gas spirally diverges and leaves the vortex chamber through the tangential outlet. This results in the pressure recovery and transformation of the swirl kinetic energy into the longitudinal kinetic energy of the gas. Both the effects decrease pressure losses which is the Sustor2 advantage compared with the prior art.

Owner:BORISSOV ANATOLI +2

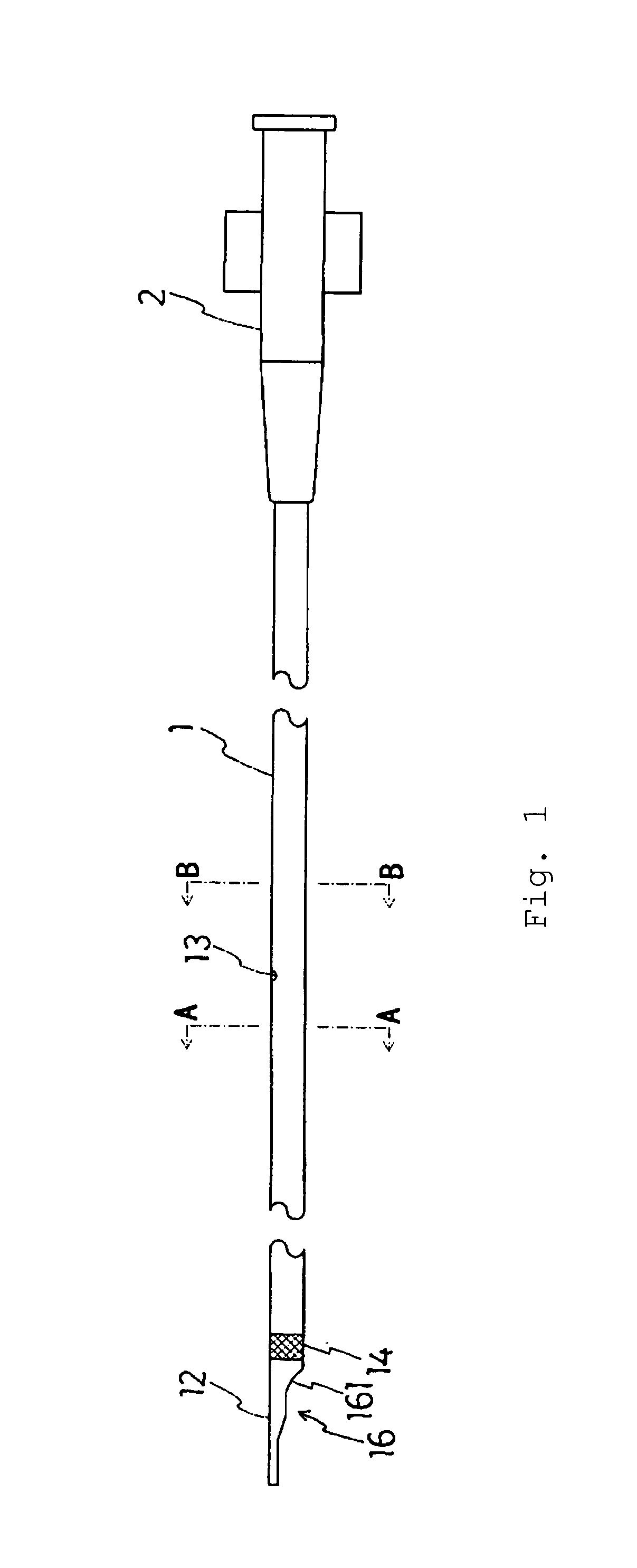

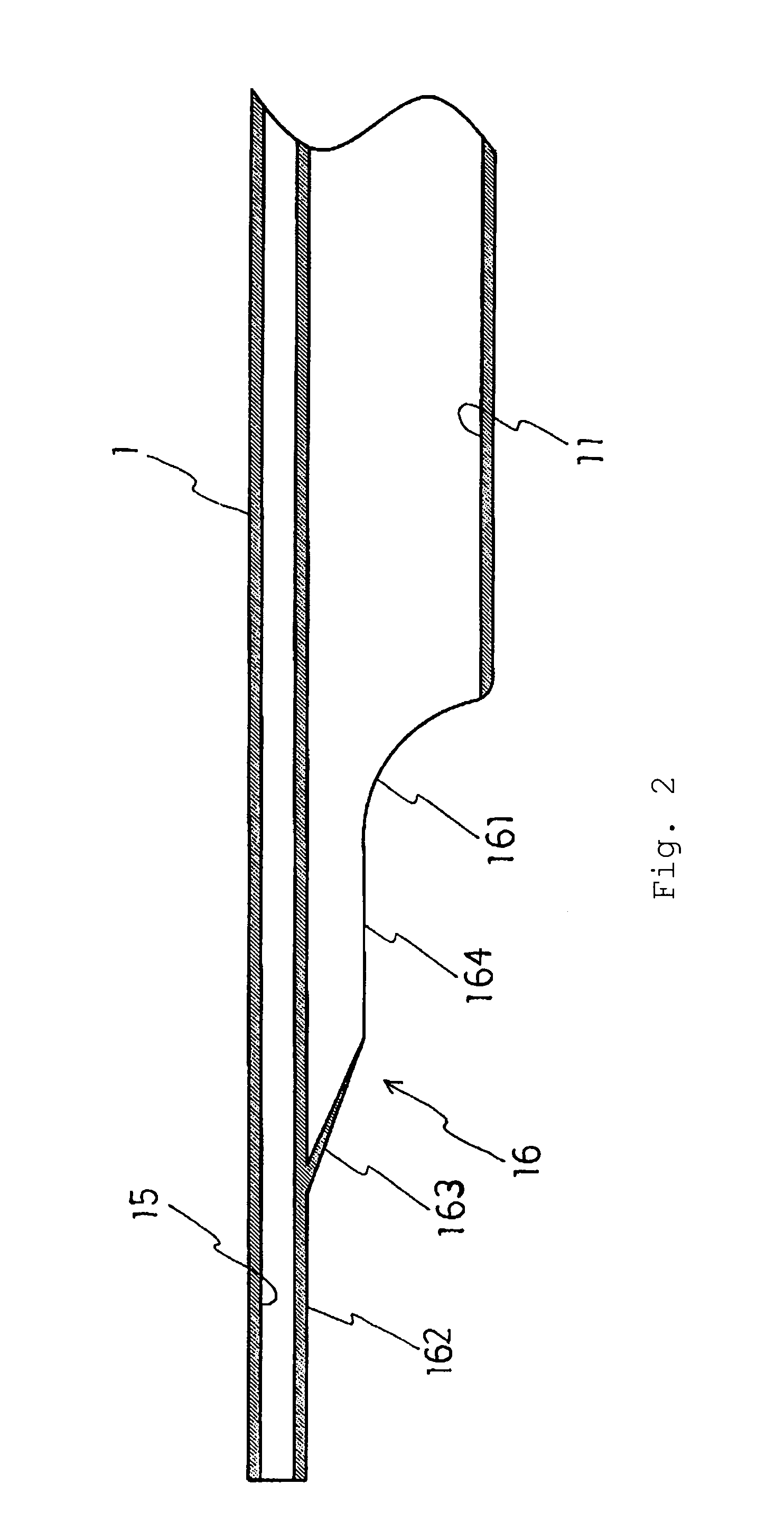

Thrombus suction catheter with improved suction and crossing

ActiveUS7250042B2Improved suction and crossingSmall pressure lossMulti-lumen catheterMedical devicesThrombusCatheter device

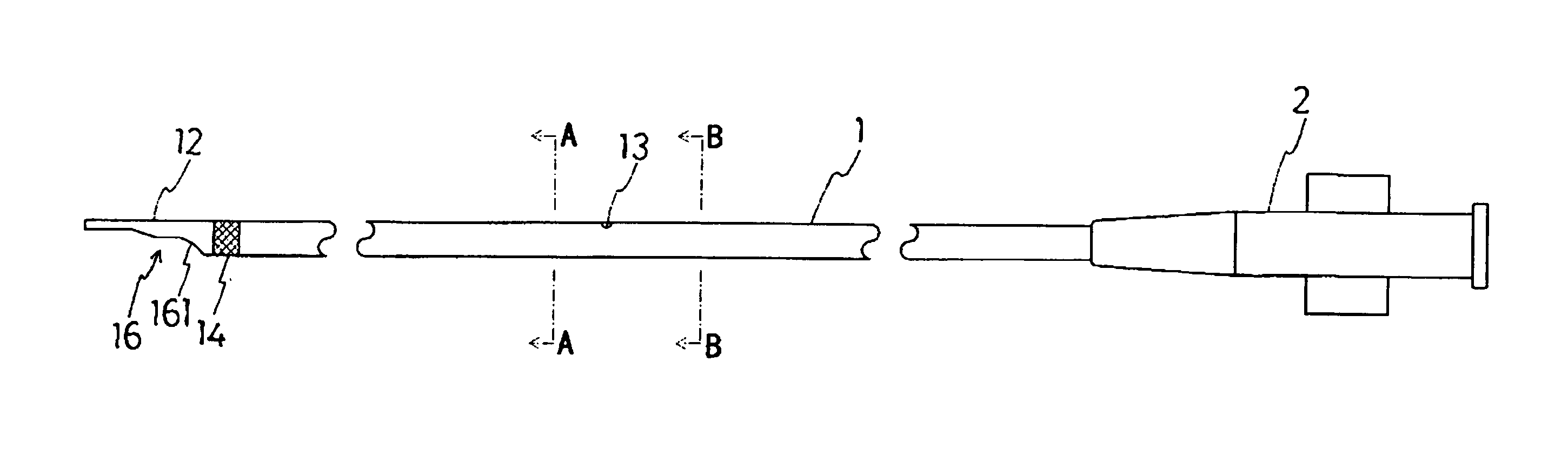

A thrombus suction catheter which is a tube having a distal end opening formed by an angled cut surface. In the distal end opening, at least a part on the proximal end side of the cut surface is formed in a concave shape in an angled direction, and the distal end side of the cut surface is formed to be flat and flexible. With the distal end configuration, suction and crossing are significantly improved.

Owner:NIPRO CORP

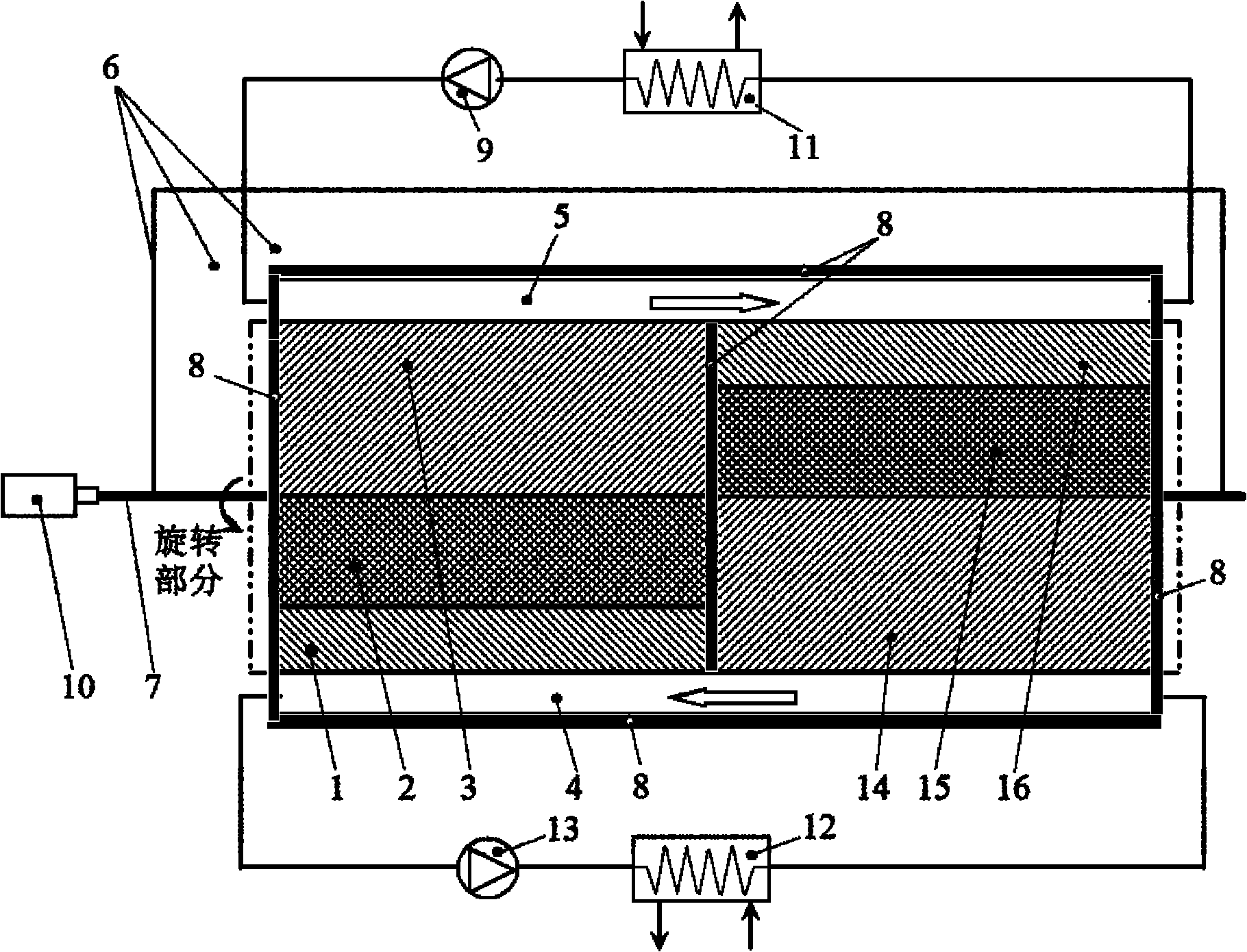

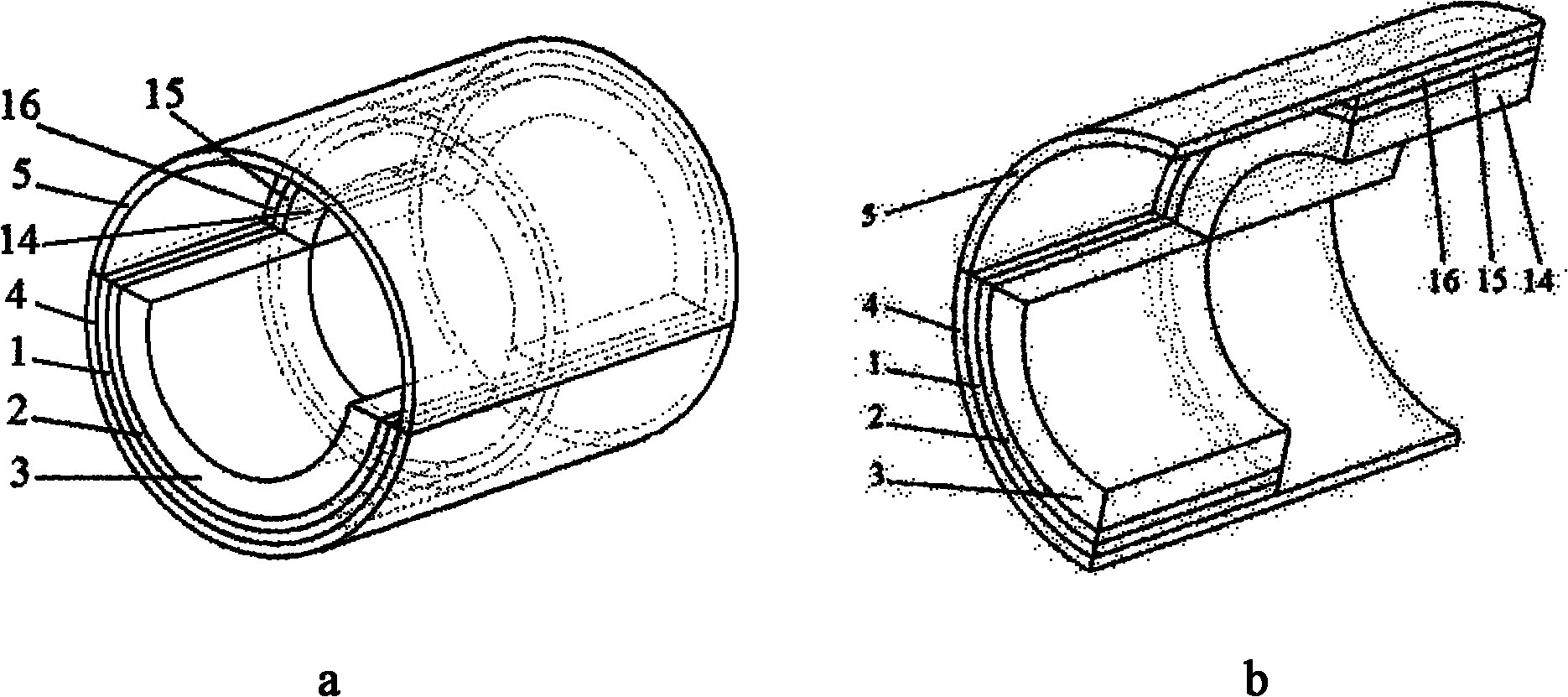

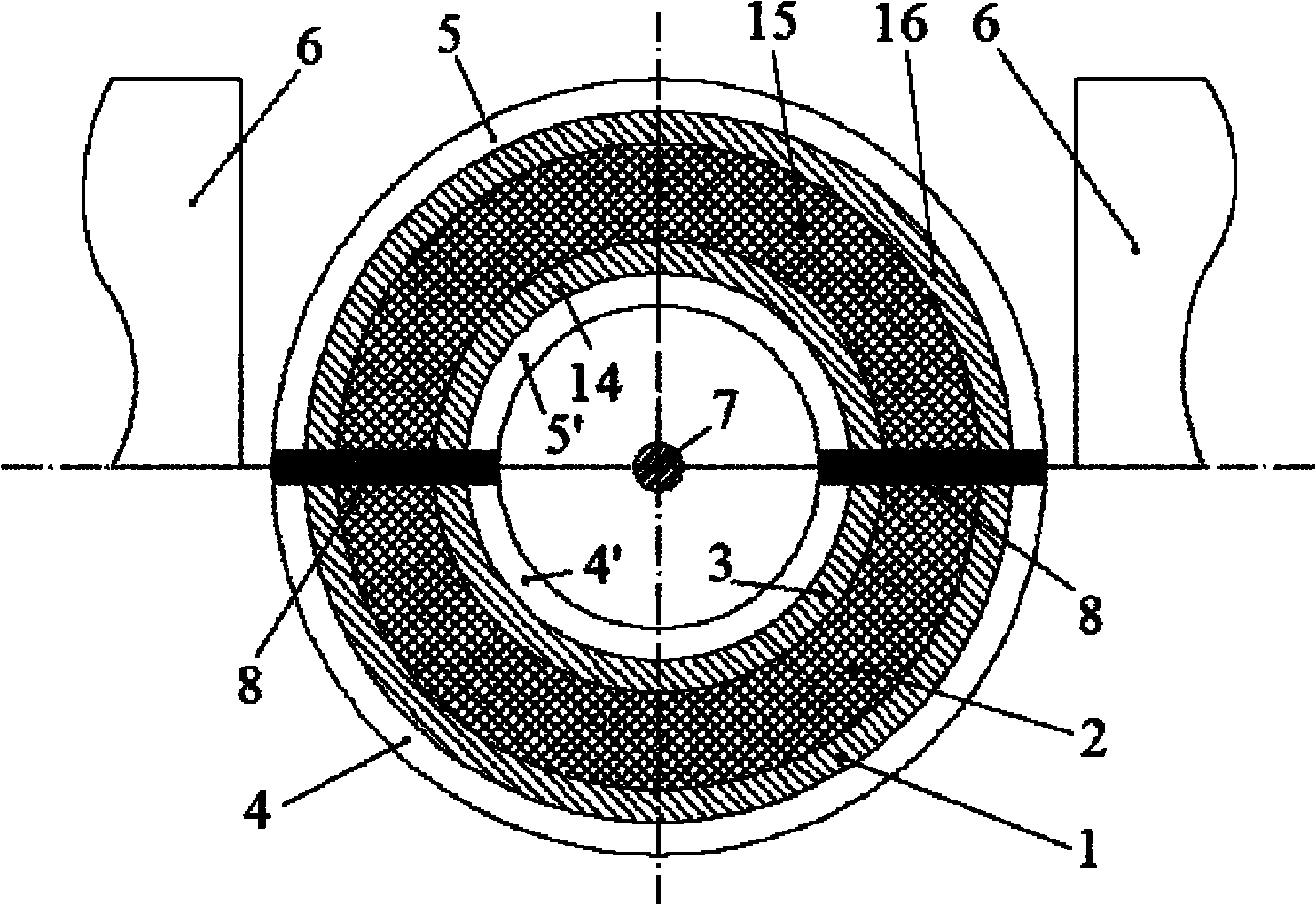

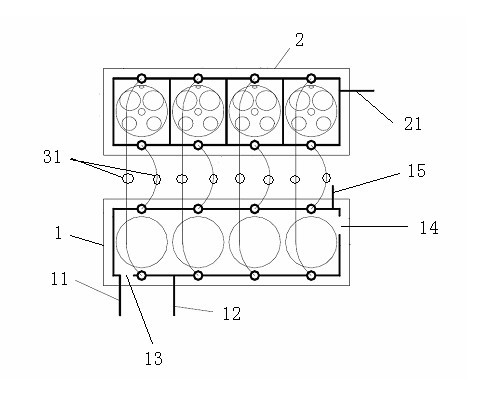

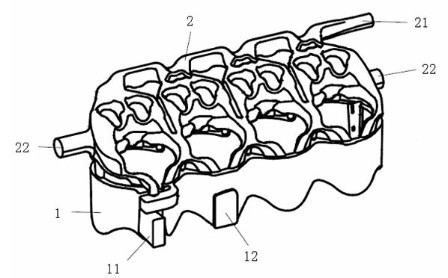

Rotary magnetic refrigeration device and application thereof

InactiveCN101979937AImprove cooling efficiencyImprove reliabilityEnergy efficient heating/coolingMachines using electric/magnetic effectsThermal insulationMagnetic media

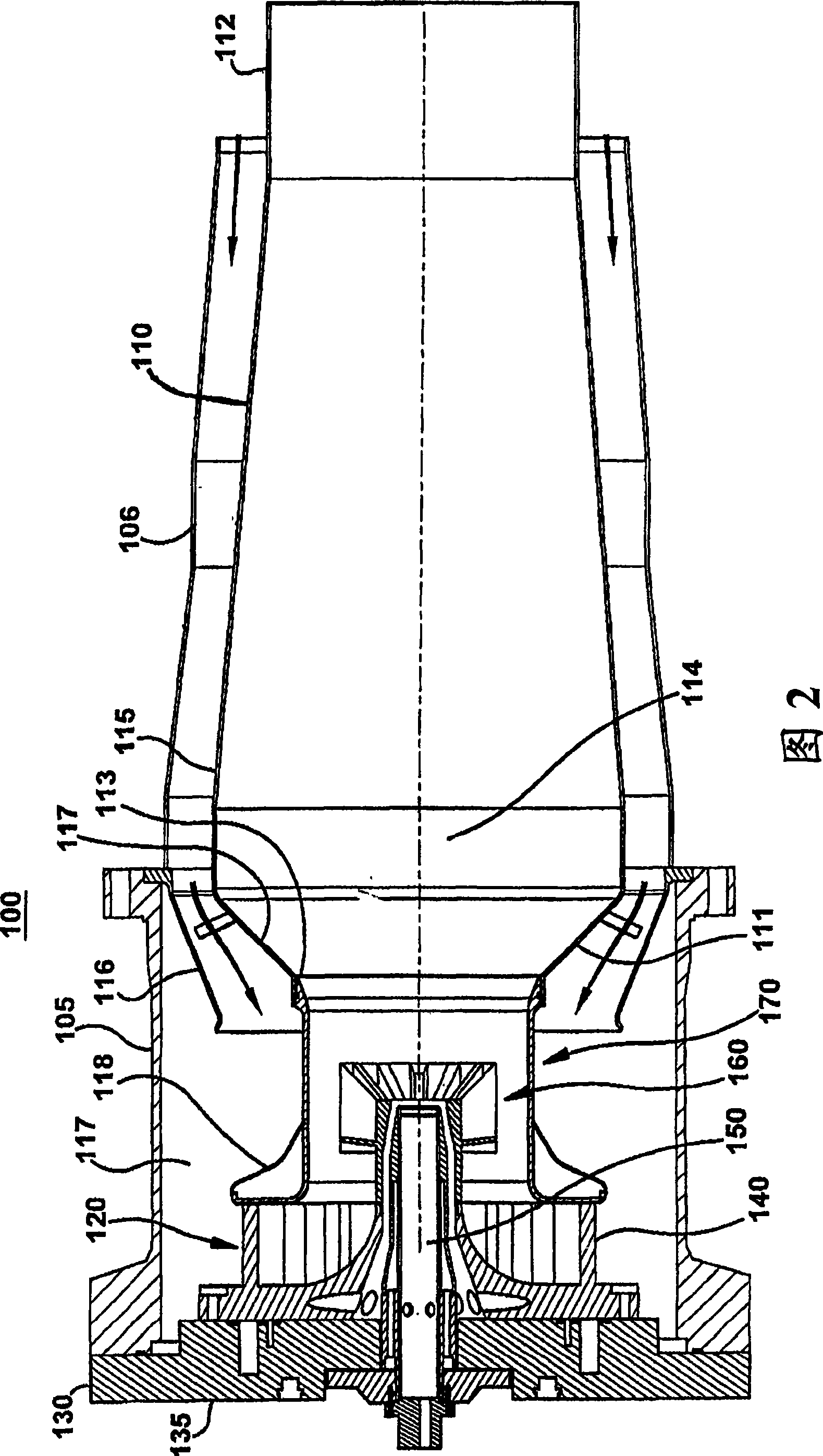

The invention discloses a rotary magnetic refrigeration device. The rotary magnetic refrigeration device comprises a magnetic field source, two active regenerator modules and cold and hot fluid heat exchange channels, and is characterized in that: two packing layers sandwich a magnetic medium in a radial direction so as to form one active regenerator module; the two active regenerator modules are staggered coaxially and axially and arranged at an interval of 180 DEG in the circumferential direction, and pass through an upper half magnetic field region covered with the magnetic field source and a lower half nonmagnetic region alternately when rotating synchronously; A hot fluid channel which is communicated with a high temperature end heat exchanger is statically arranged in the pace of the magnetic field region at the rotating periphery of the active regenerator module; and the cold fluid channel which is communicated with a low temperature end heat exchanger is statically arranged in the space of the nonmagnetic region at the rotating periphery of the active regenerator module, and thermal insulation layers are arranged between the two active regenerator modules in the axial direction, and at the periphery and left and right end faces of the cold and hot fluid channels.

Owner:XI AN JIAOTONG UNIV

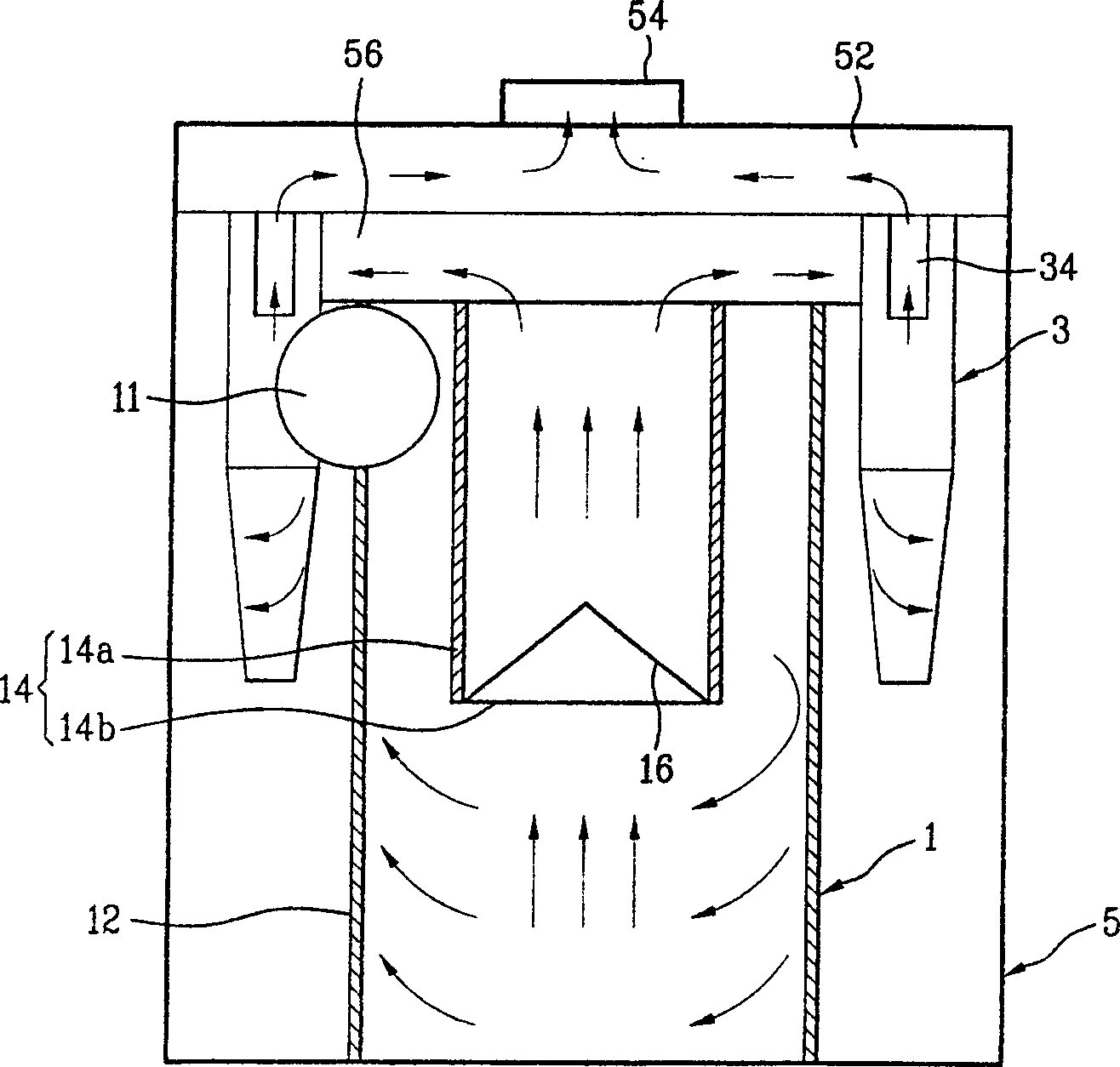

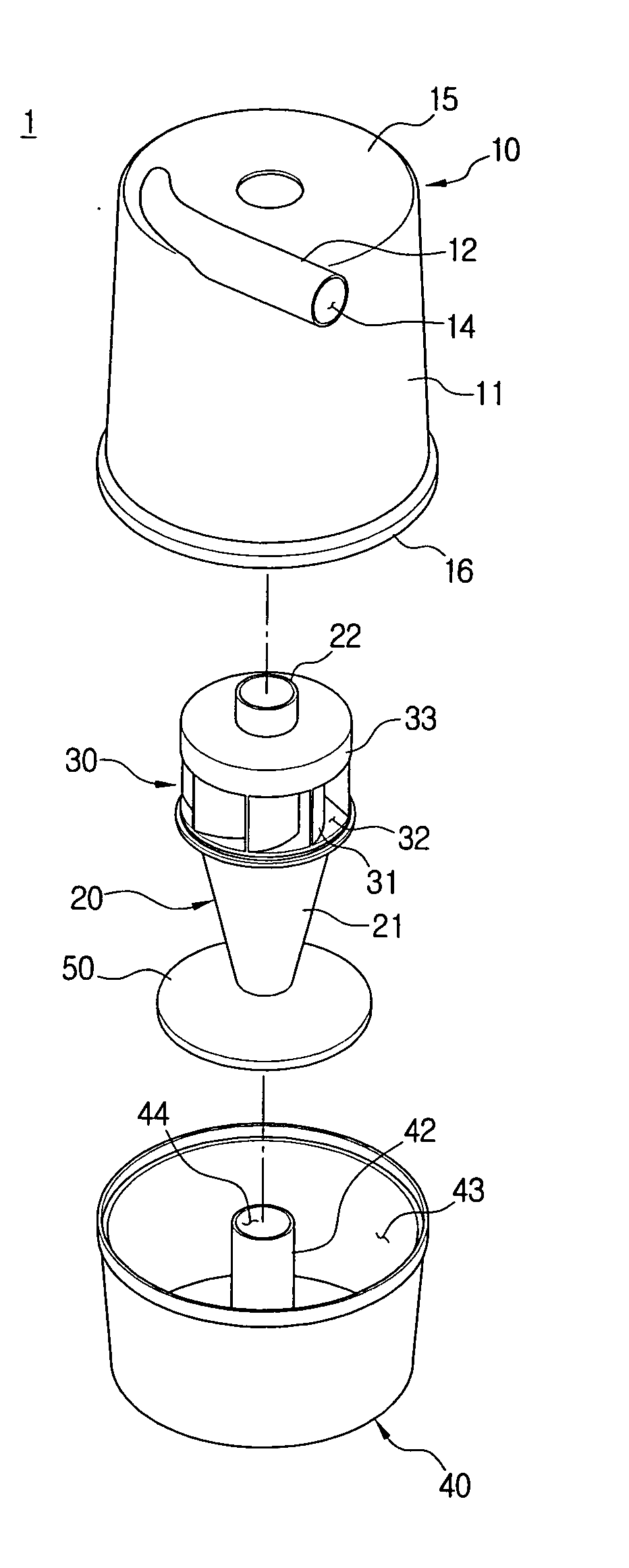

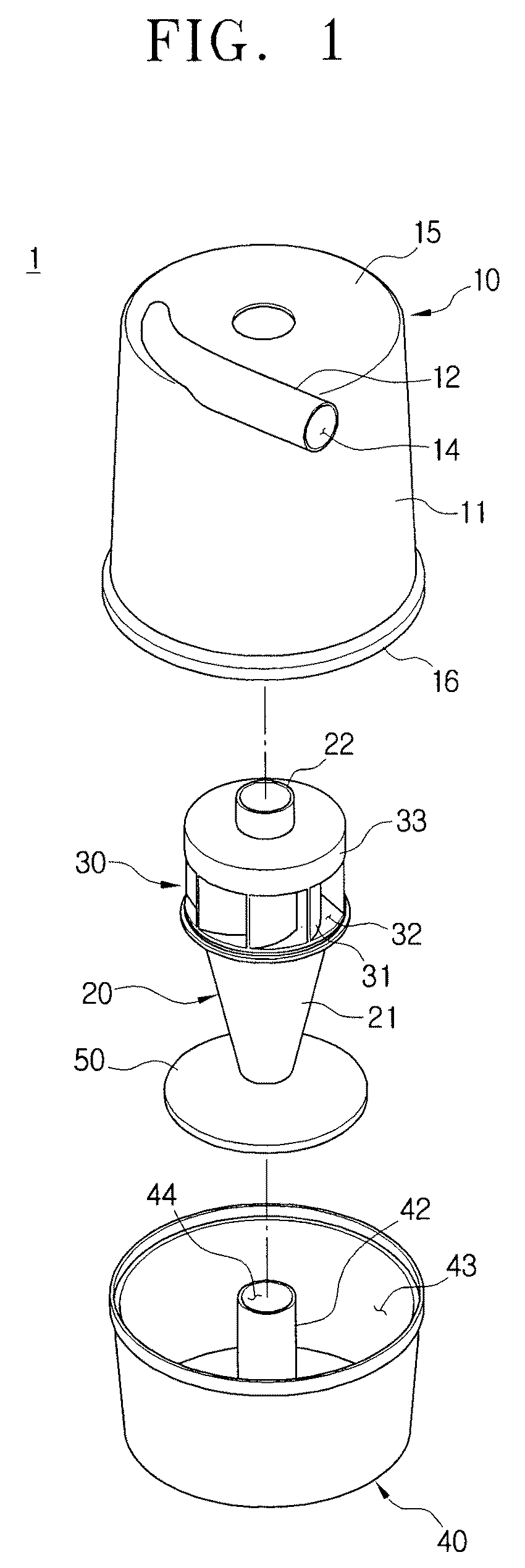

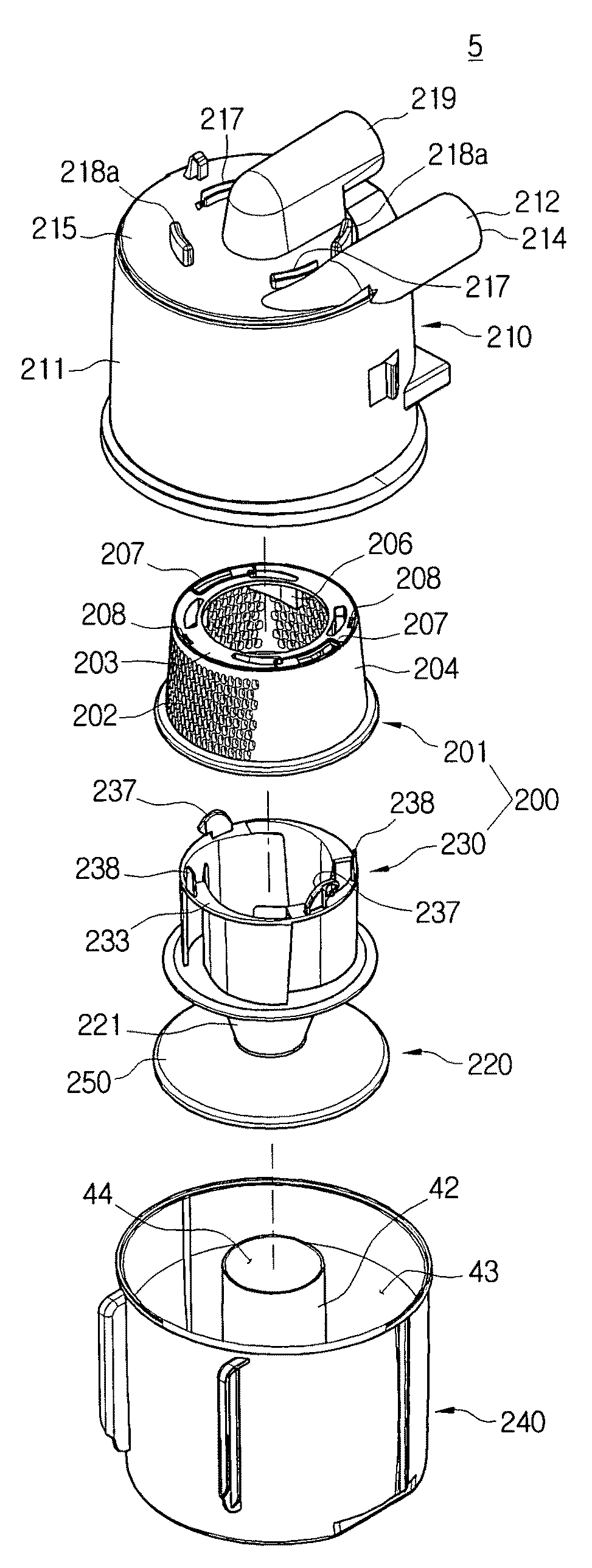

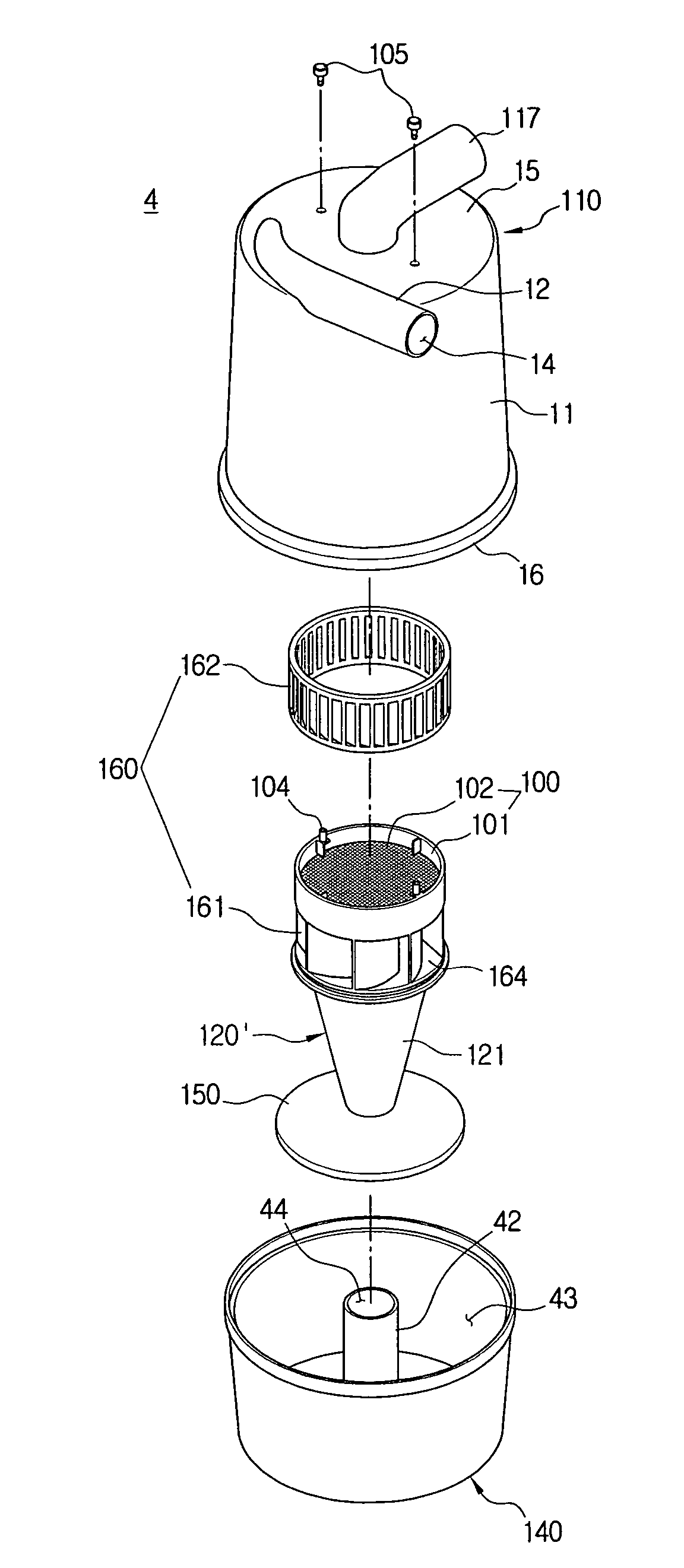

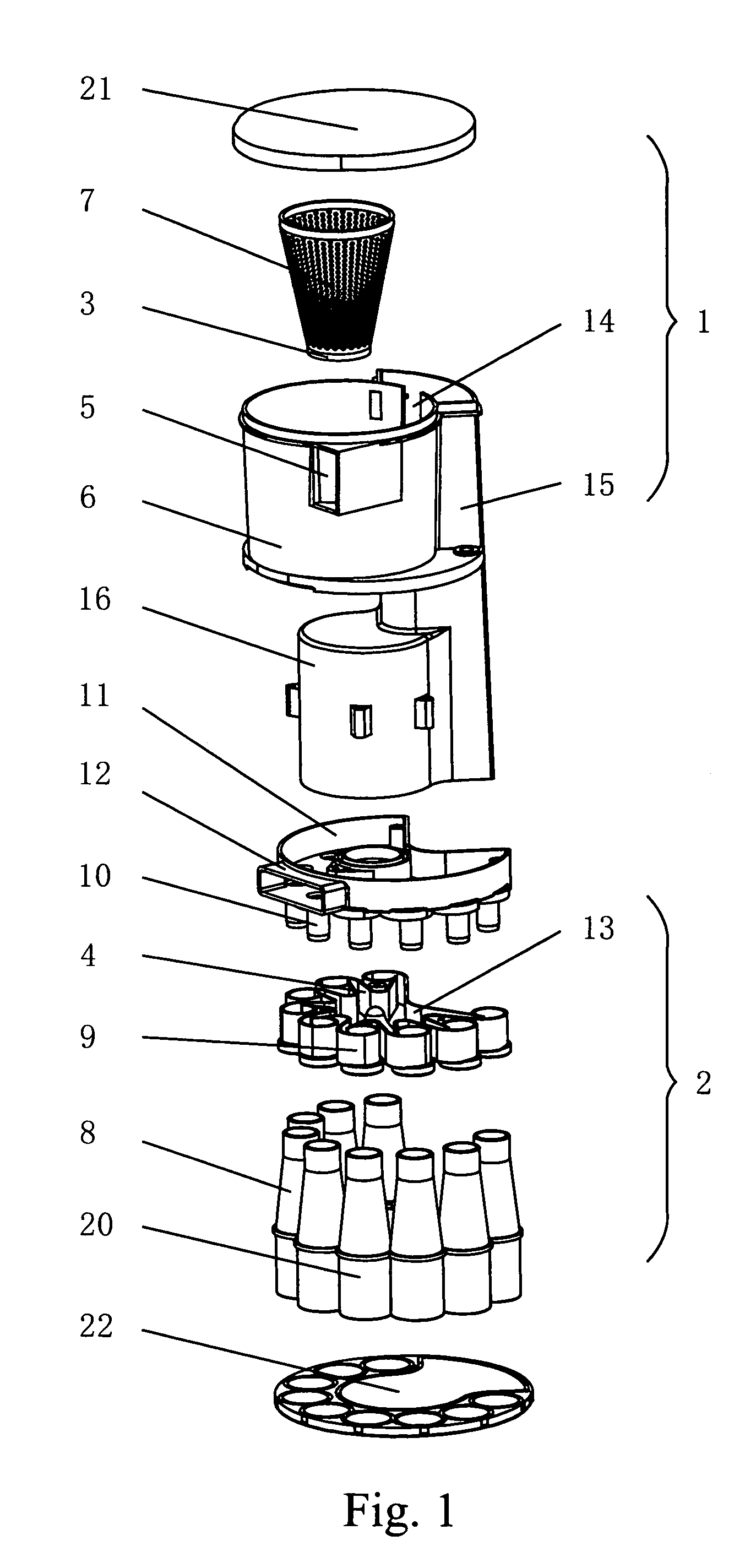

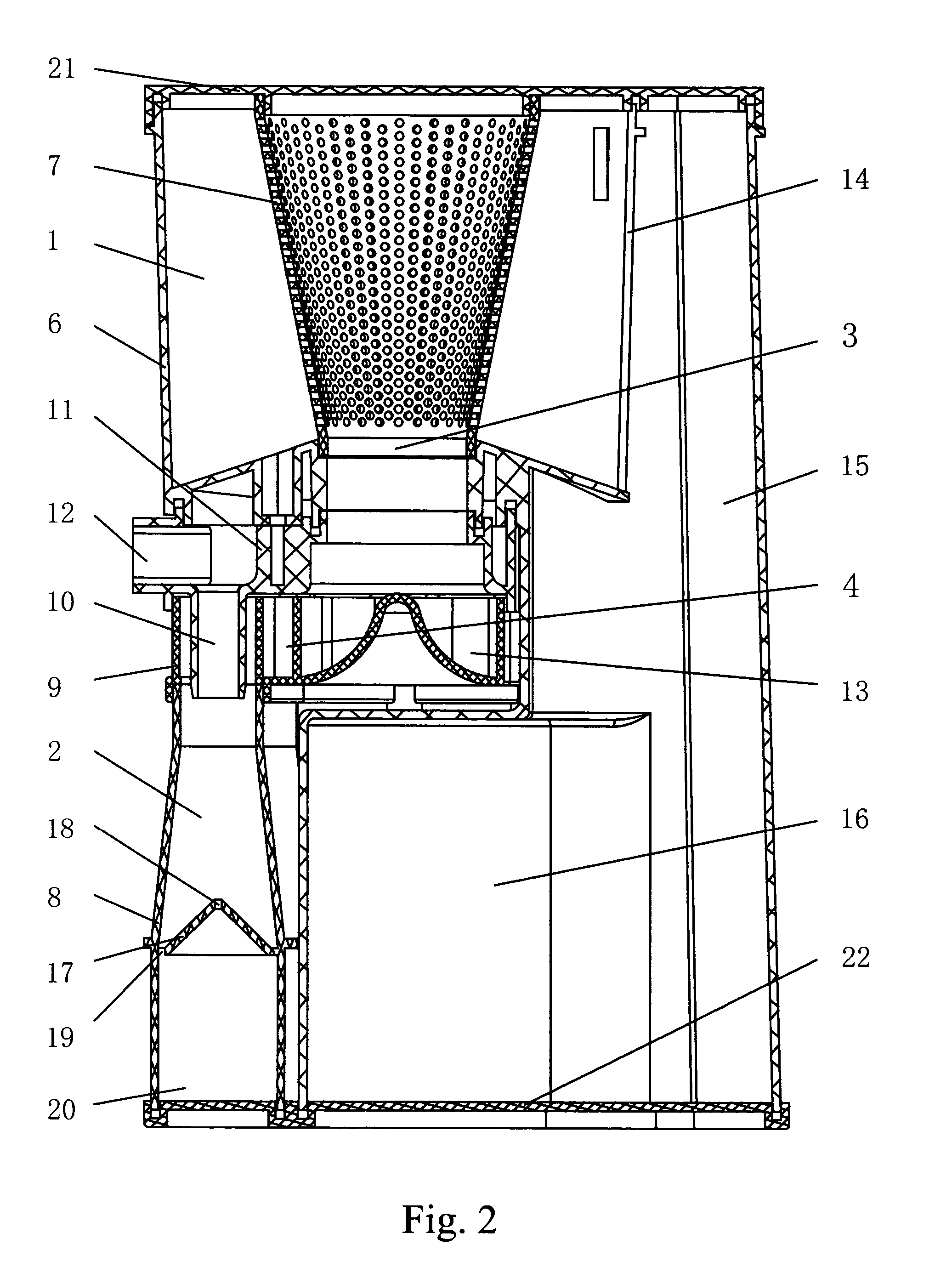

Multiple cyclonic dust collector

InactiveCN1887437AImprove dust collection effectImprove suction efficiencyReversed direction vortexInterior spaceForeign matter

The multiple cyclonic dust collector includes one primary cyclonic dust collecting device with first air inflow unit, the first main body to separate out foreign matters from the inflow air, one dust collecting tub set in the side bottom of the first main body to collect the foreign matters the first main body separates out, one extending unit extending from the bottom of the first main body and set inside the dust collecting tub, and the first air outflow unit for air to flow out of the first main body; and one secondary cyclonic dust collecting device installed outside the primary cyclonic dust collecting device to suck air from the primary cyclonic dust collecting device for secondary dust collection.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

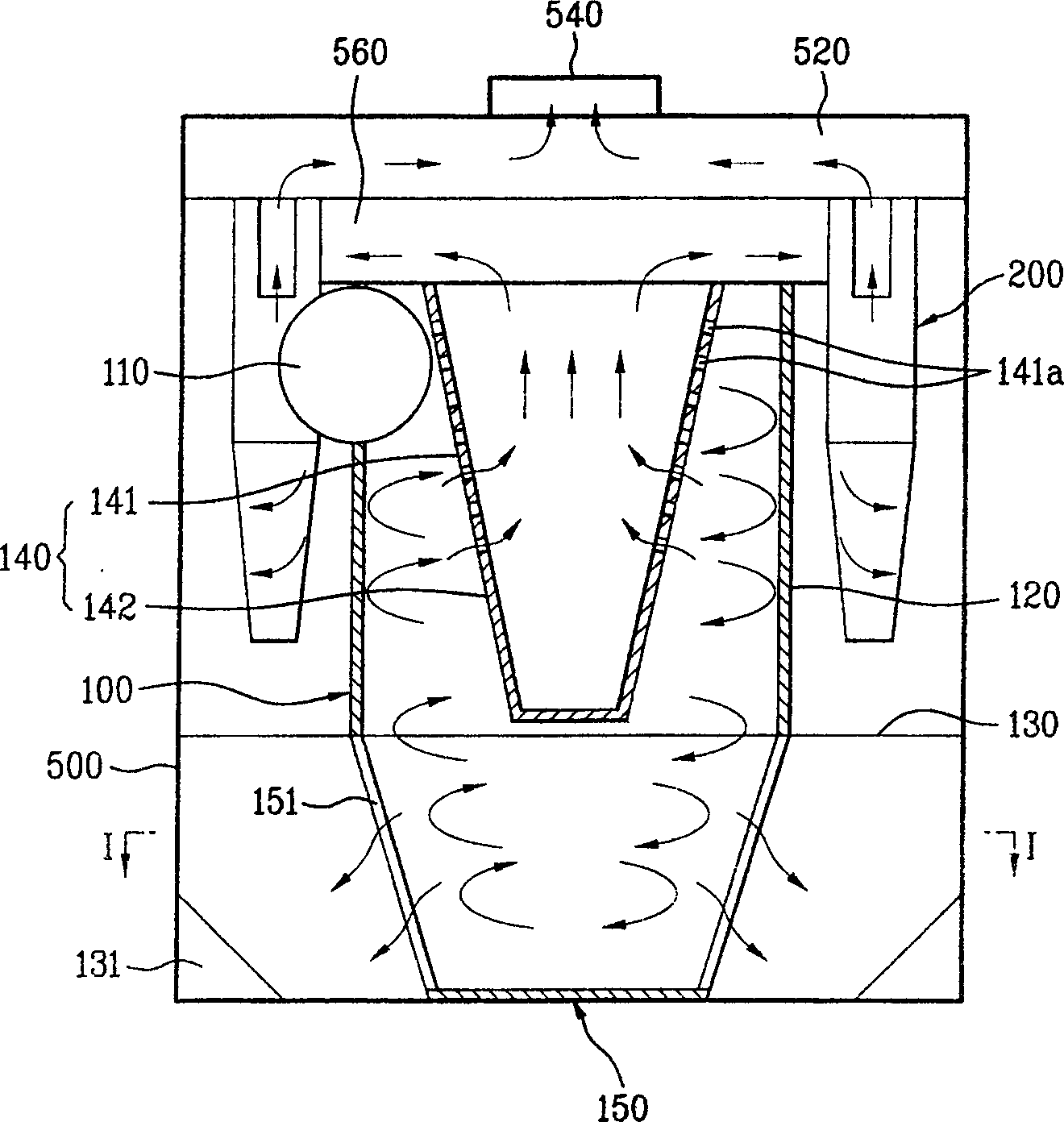

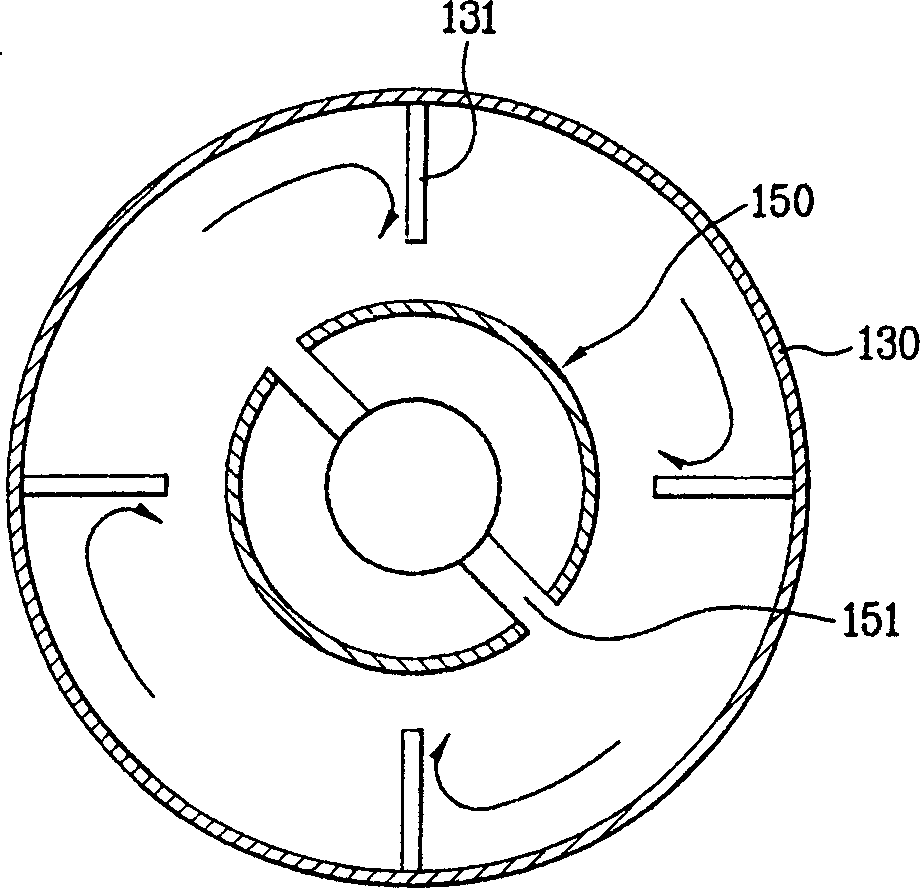

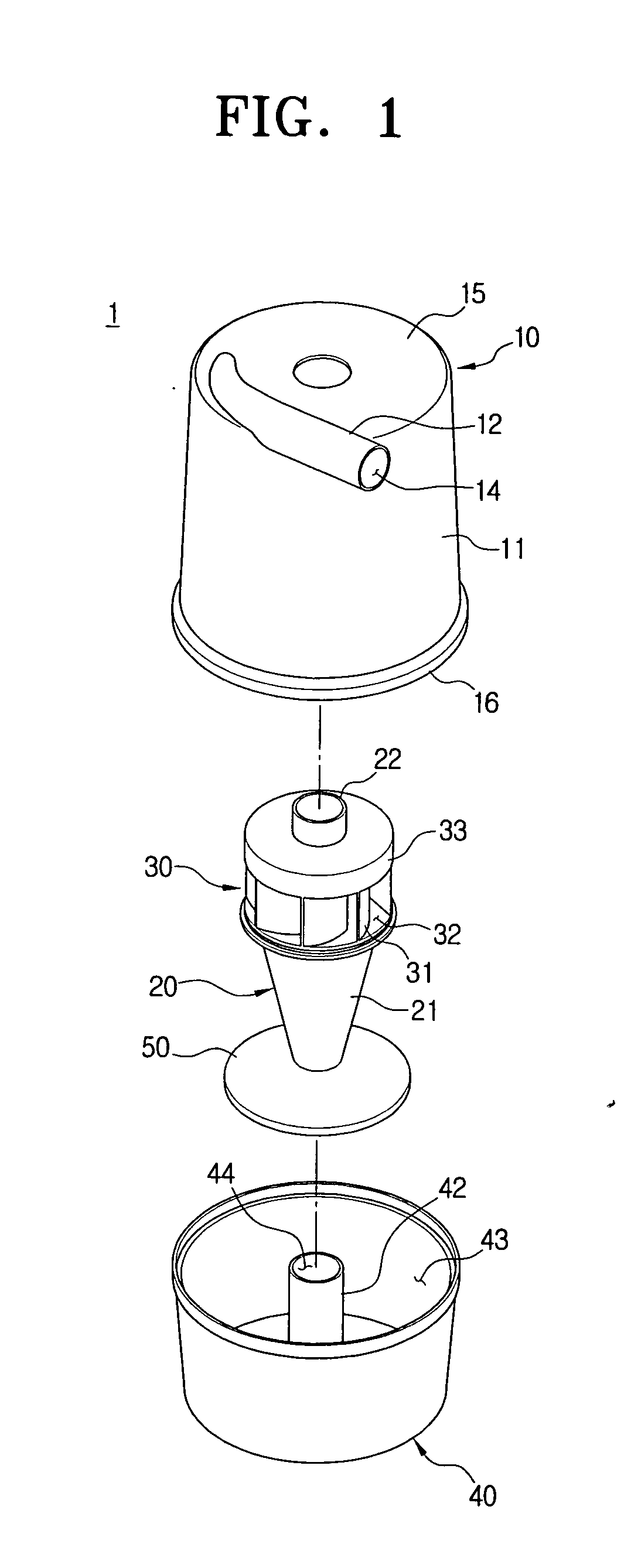

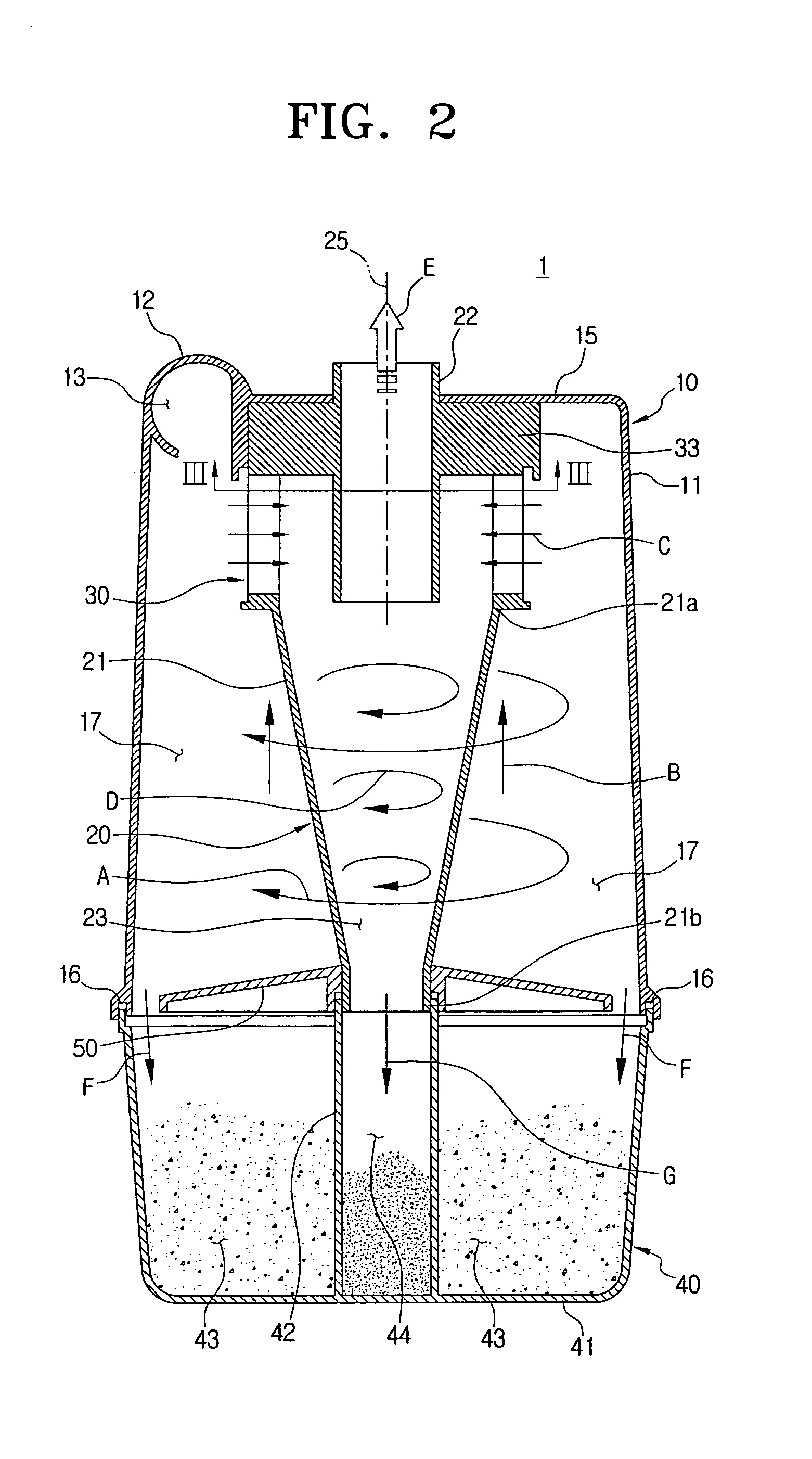

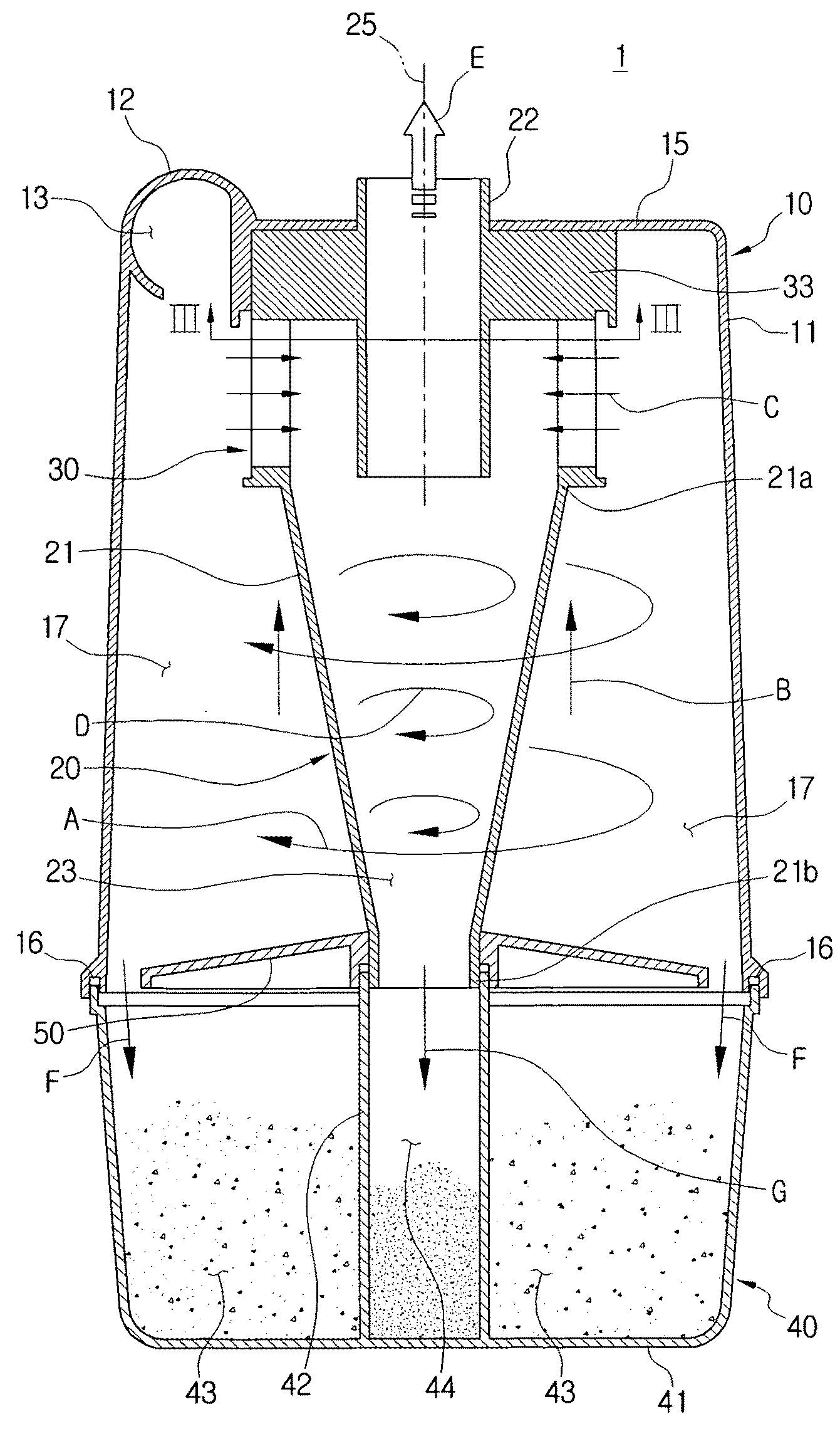

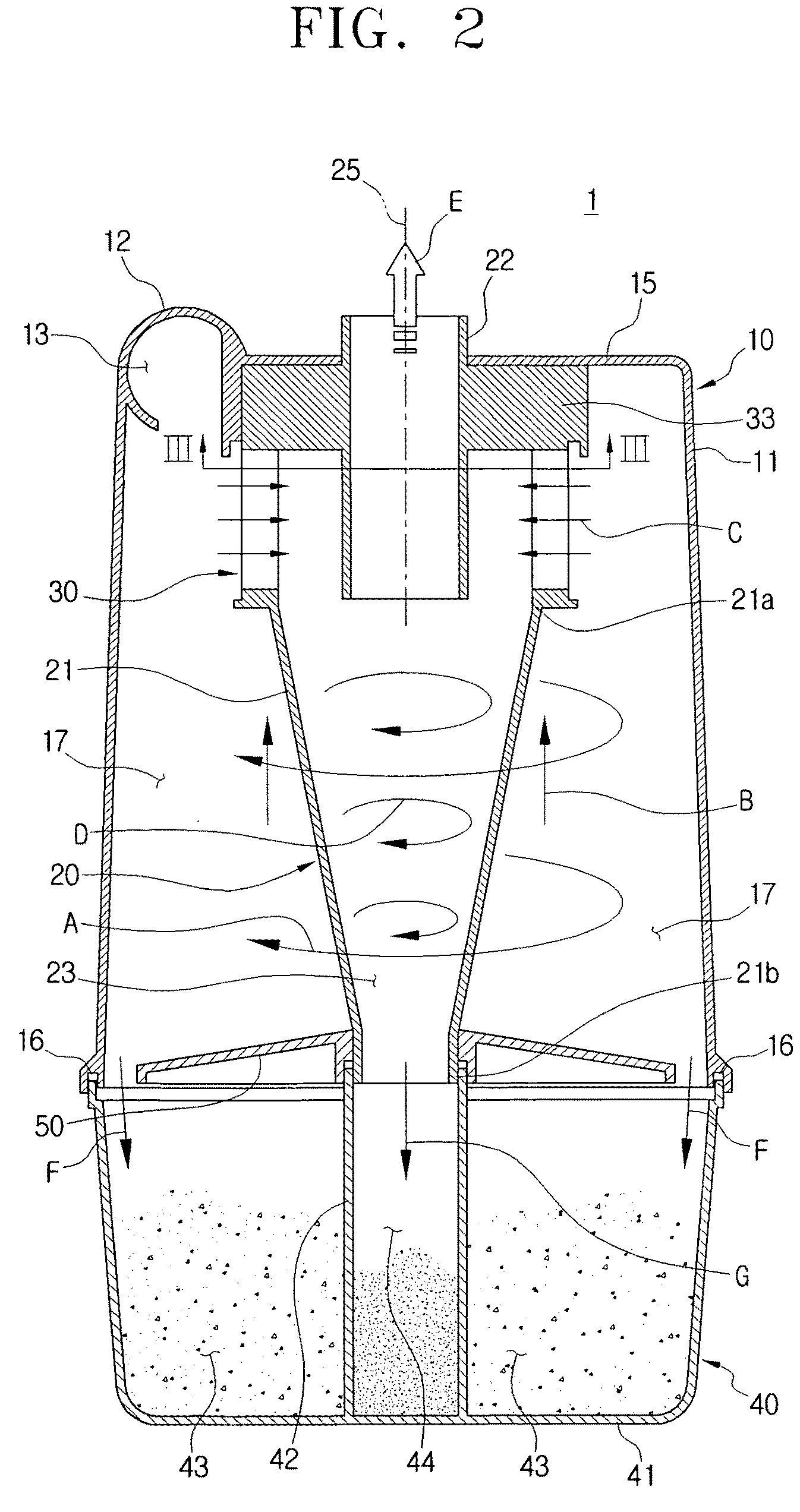

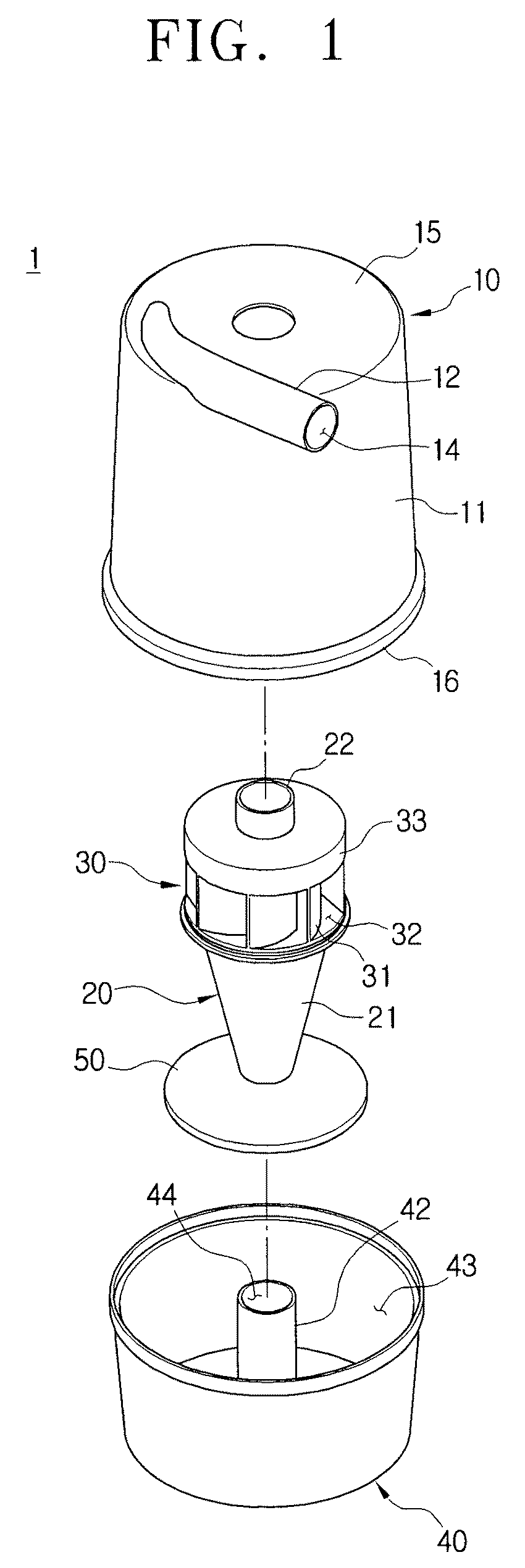

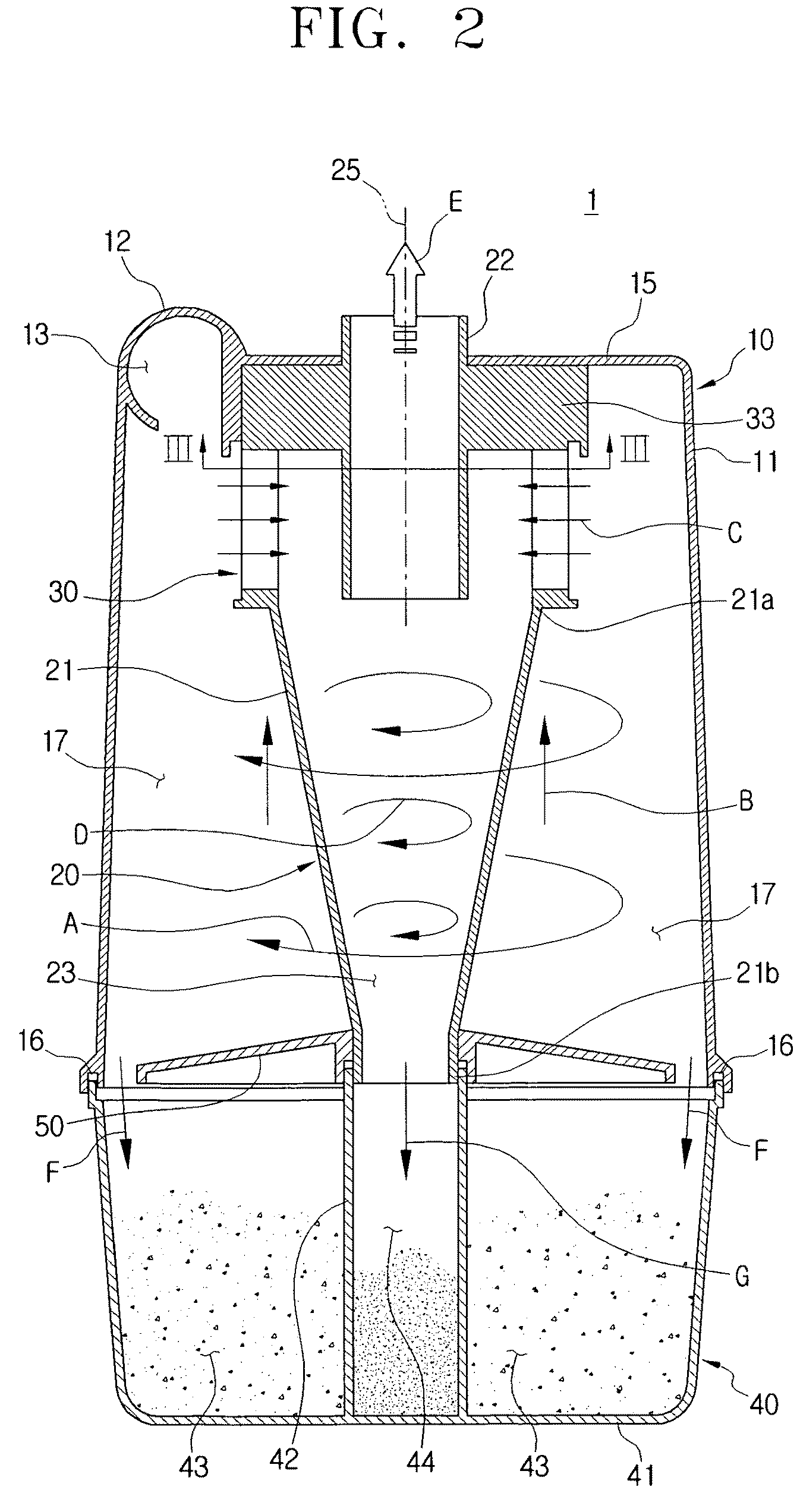

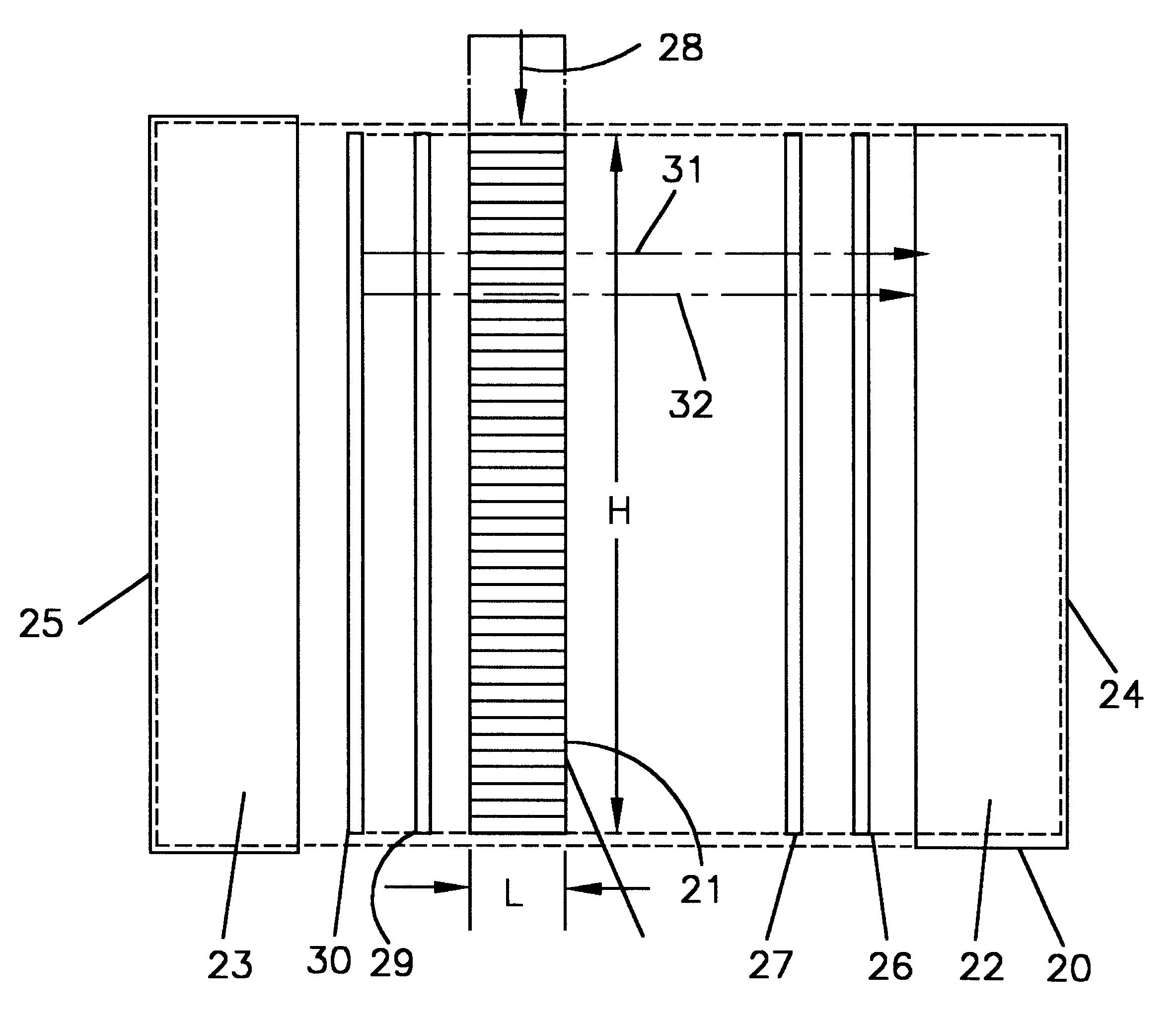

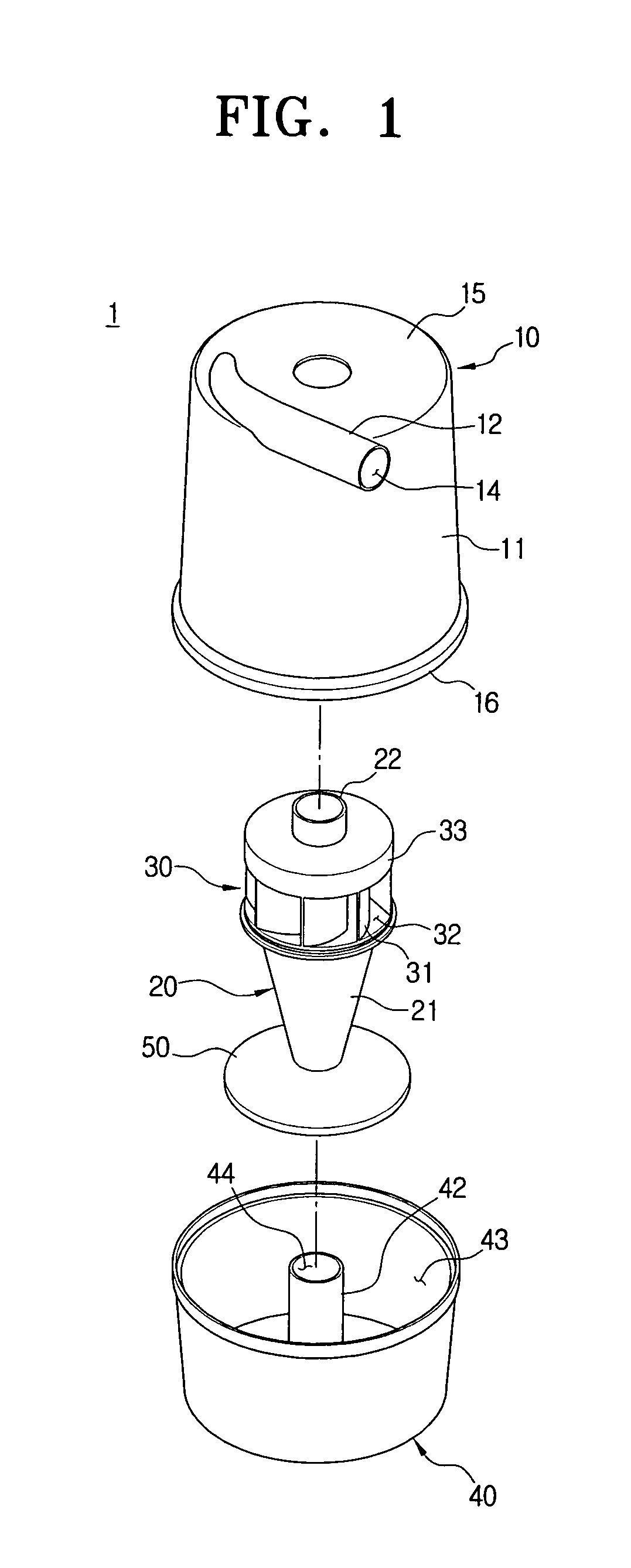

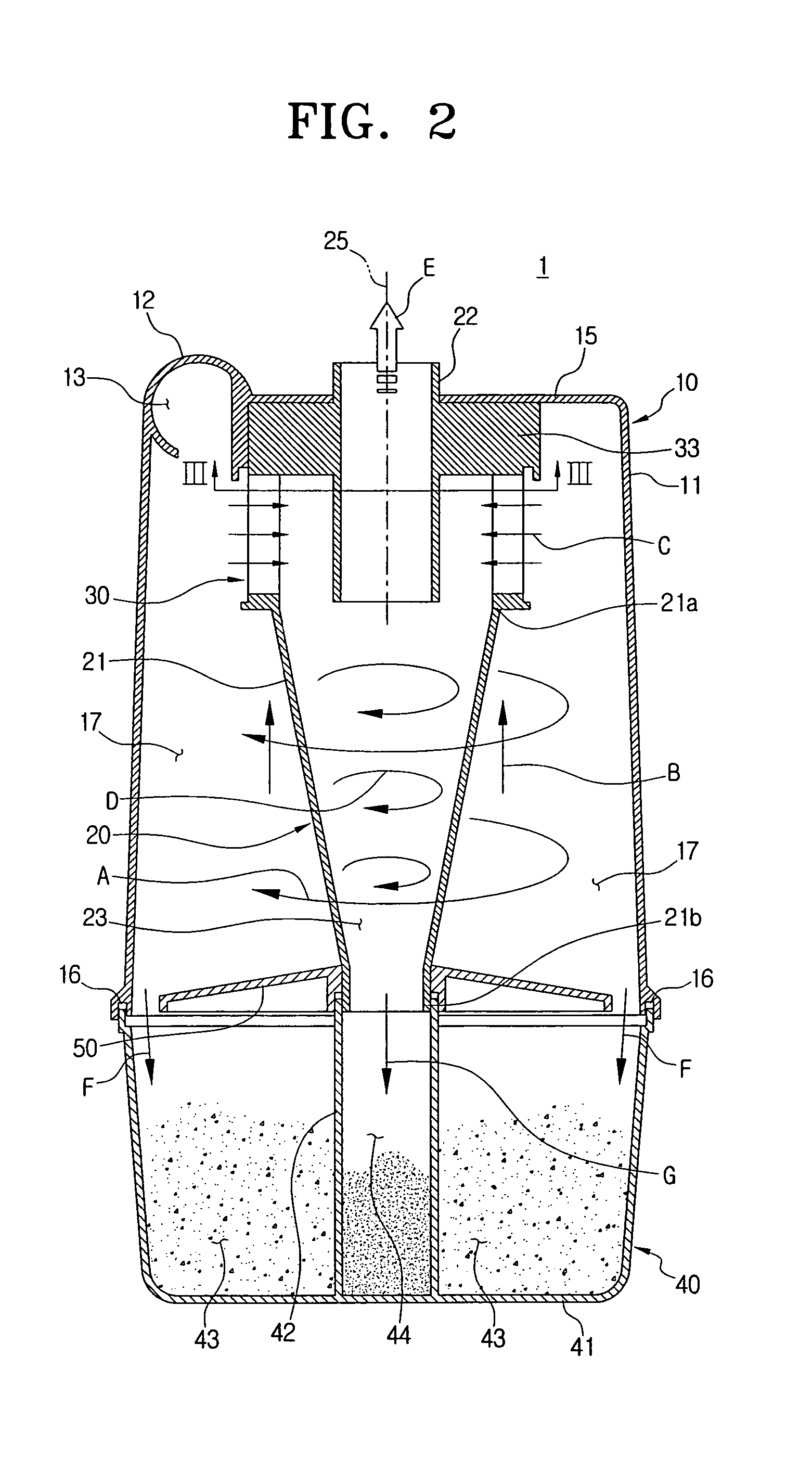

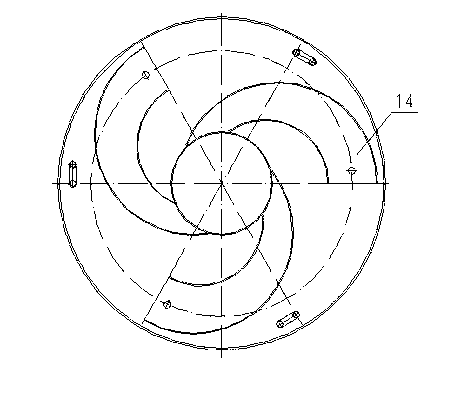

Cyclone dust collecting apparatus for vacuum cleaner

ActiveUS20070199284A1Small pressure lossHigh fine dust collecting efficiencyCleaning filter meansCombination devicesCycloneEngineering

The present disclosure relates to a cyclone dust collecting apparatus for a vacuum cleaner having a high fine dust collecting efficiency. The cyclone dust collecting apparatus includes a first cyclone having an air suction hole through which dust-laden air is drawn-in, the first cyclone forcing the dust-laden air to downwardly whirl in a space under the air suction hole so as to centrifugally separate dust from the dust-laden air; a second cyclone disposed inside the first cyclone, the second cyclone forcing semi-clean air entering from the first cyclone to downwardly whirl so as to centrifugally separate fine dust from the semi-clean air; and an air guiding member forcing the semi-clean air discharged from the first cyclone to directly enter the second cyclone and, the air guiding member having a plurality of guiding blades radially disposed in at least one circular shape based on a vertical axis of the second cyclone.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

Cyclone dust collecting apparatus for vacuum cleaner

ActiveUS20090133370A1Small pressure lossHigh fine dust collecting efficiencyCleaning filter meansCombination devicesEngineeringCyclone

A cyclone dust collecting apparatus for a vacuum cleaner includes a first cyclone, a second cyclone disposed inside the first cyclone, and an air guiding member to form an entrance of the second cyclone through which semi-clean air discharged from the first cyclone enters. The air guiding member includes a grill member to have a plurality of holes, and a plurality of guiding blades disposed inside the grill member.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

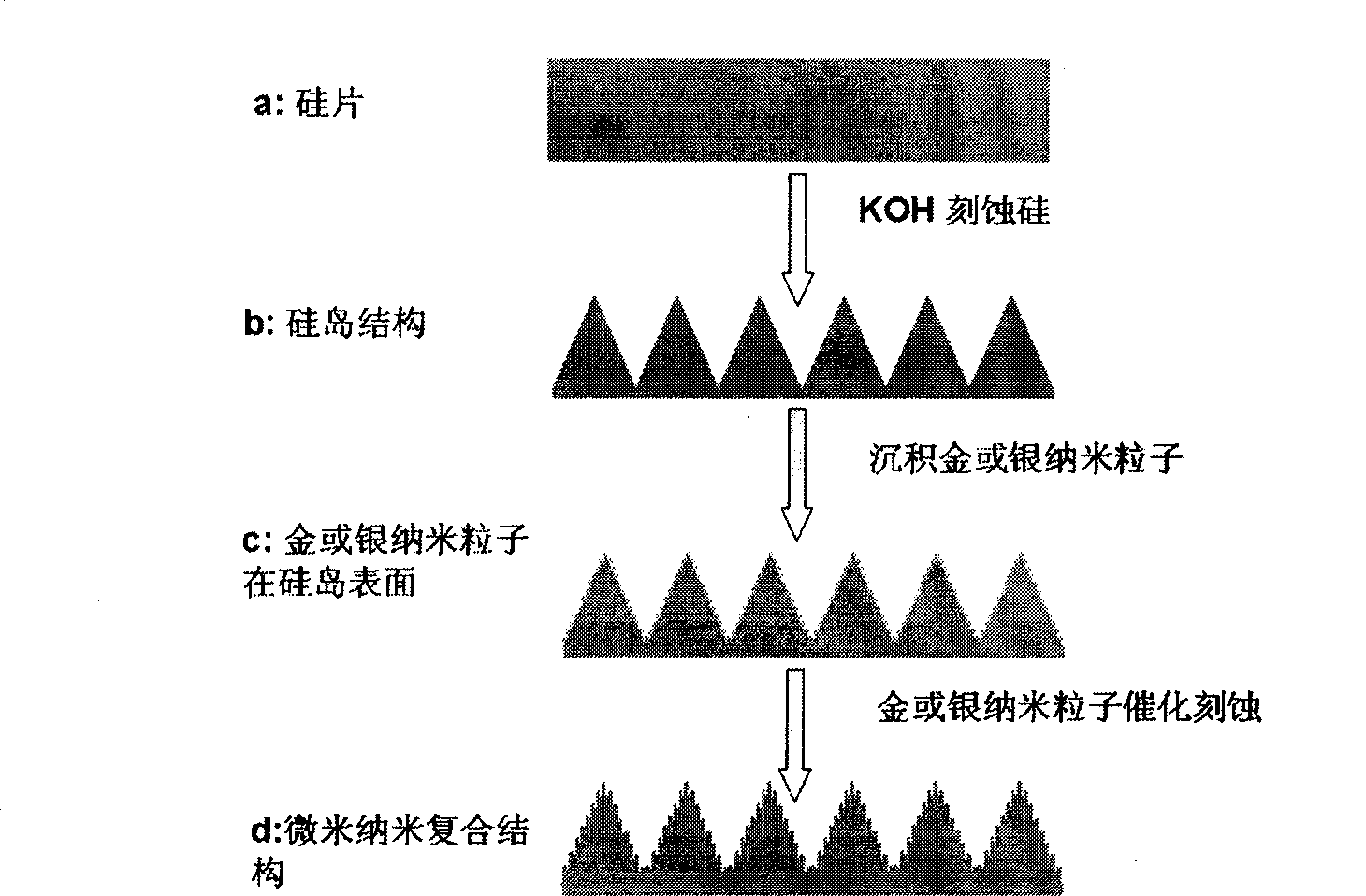

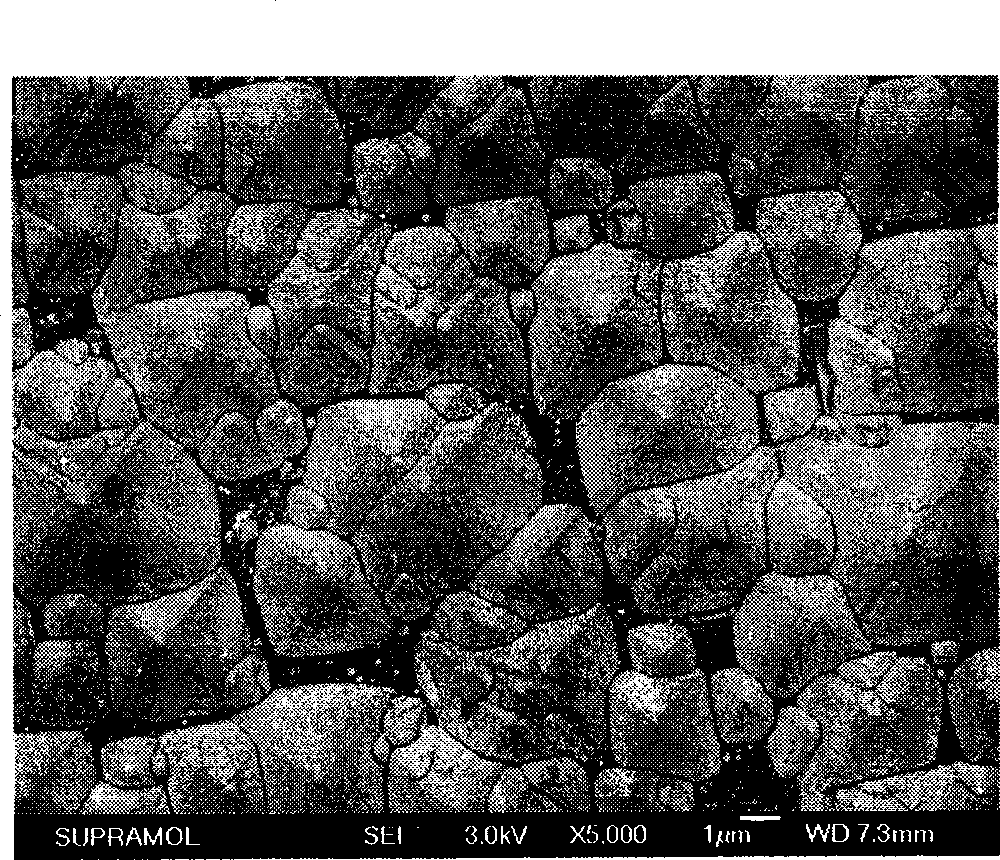

Method for preparing super-hydrophobic antireflex micron and nano composite structure surface

The invention belongs to the technical field of preparing the surface of a composite structure, and in particular relates to a method for preparing super-hydrophobic antireflective silicon surface with a micron and nanometer composite structure. The method comprises the following steps: cleaning a silicon chip; preparing a micron-level silicon island and a gridding structure on the surface of the silicon chip; carrying out catalytic etching taking silver or aurum nanoparticles as blockage; obtaining the surface of the micron and nanometer composite structure; and carrying out chemical modification of the surface of the composite structure. A static contact angle between the super-hydrophobic antireflective material surface prepared by the method and water is more than 150 degrees, and a static rolling angle of water is less than 3 degrees. The surface has superior antireflective performance, and in particular, the light reflectivity within the wavelength range between 800 and 1,100 nm is less than 3 percent. With application of the method, the super-hydrophobic antireflective silicon surface of the micron and nanometer composite structure can be produced on scale, can be widely applied to a solar cell, a microfluidic chip, a photoelectric device, and the like, and has good industrial application prospect.

Owner:JILIN UNIV

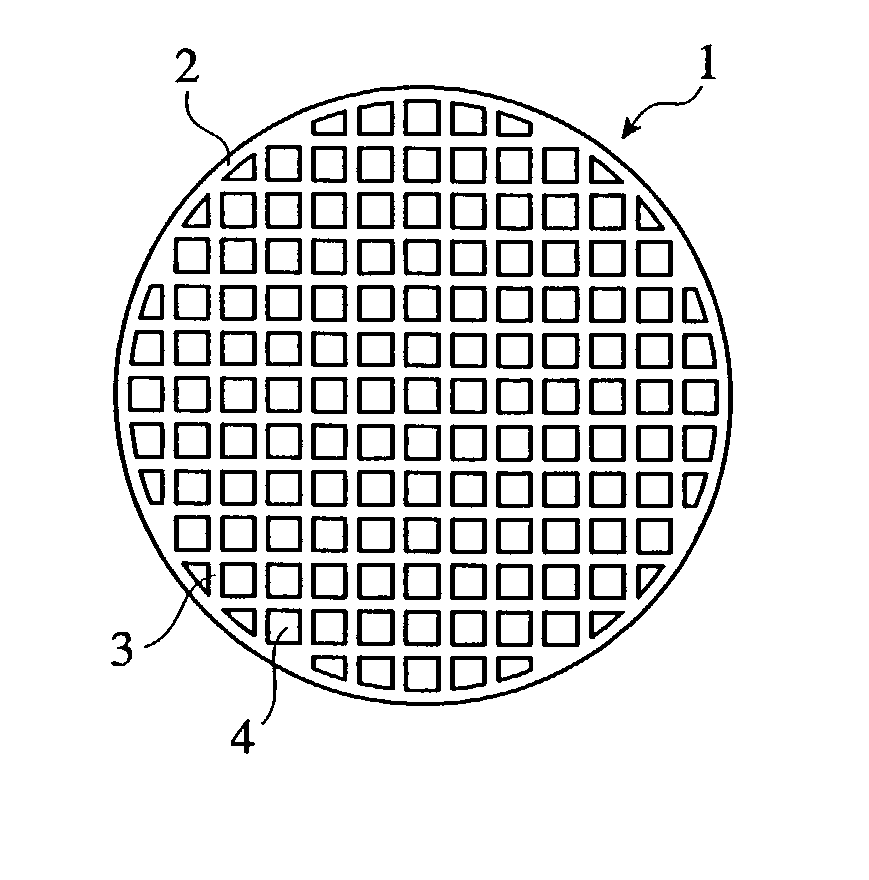

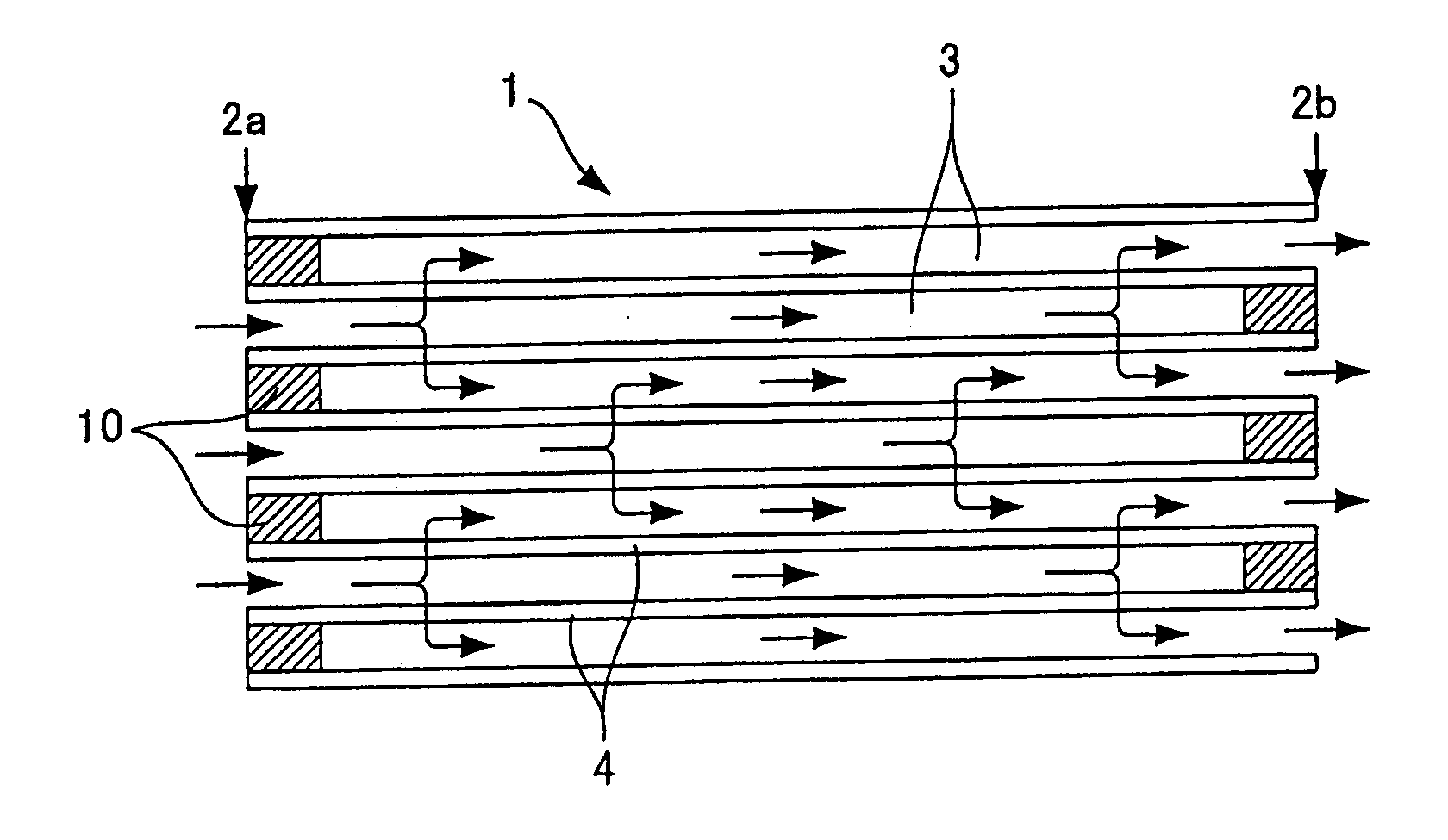

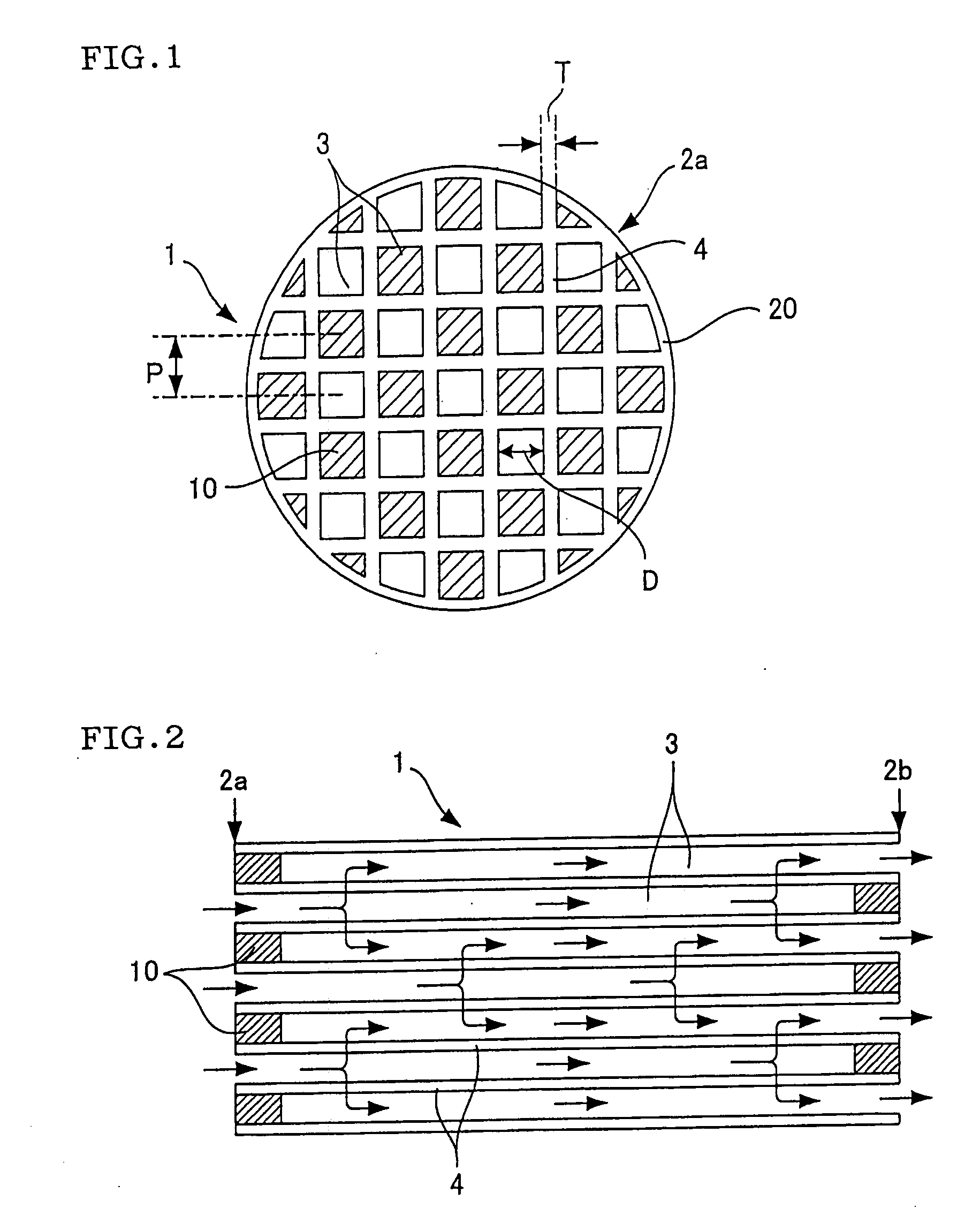

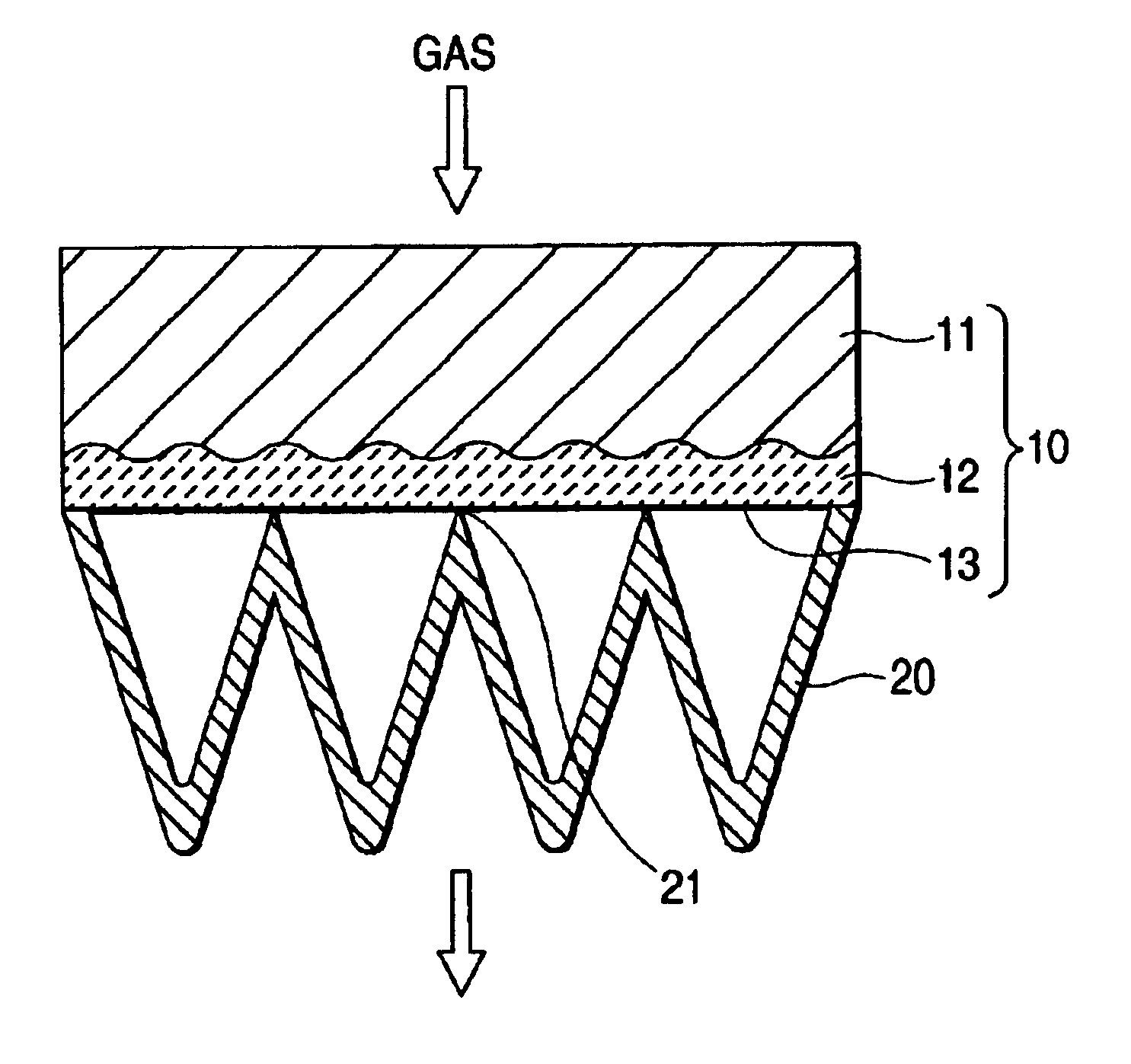

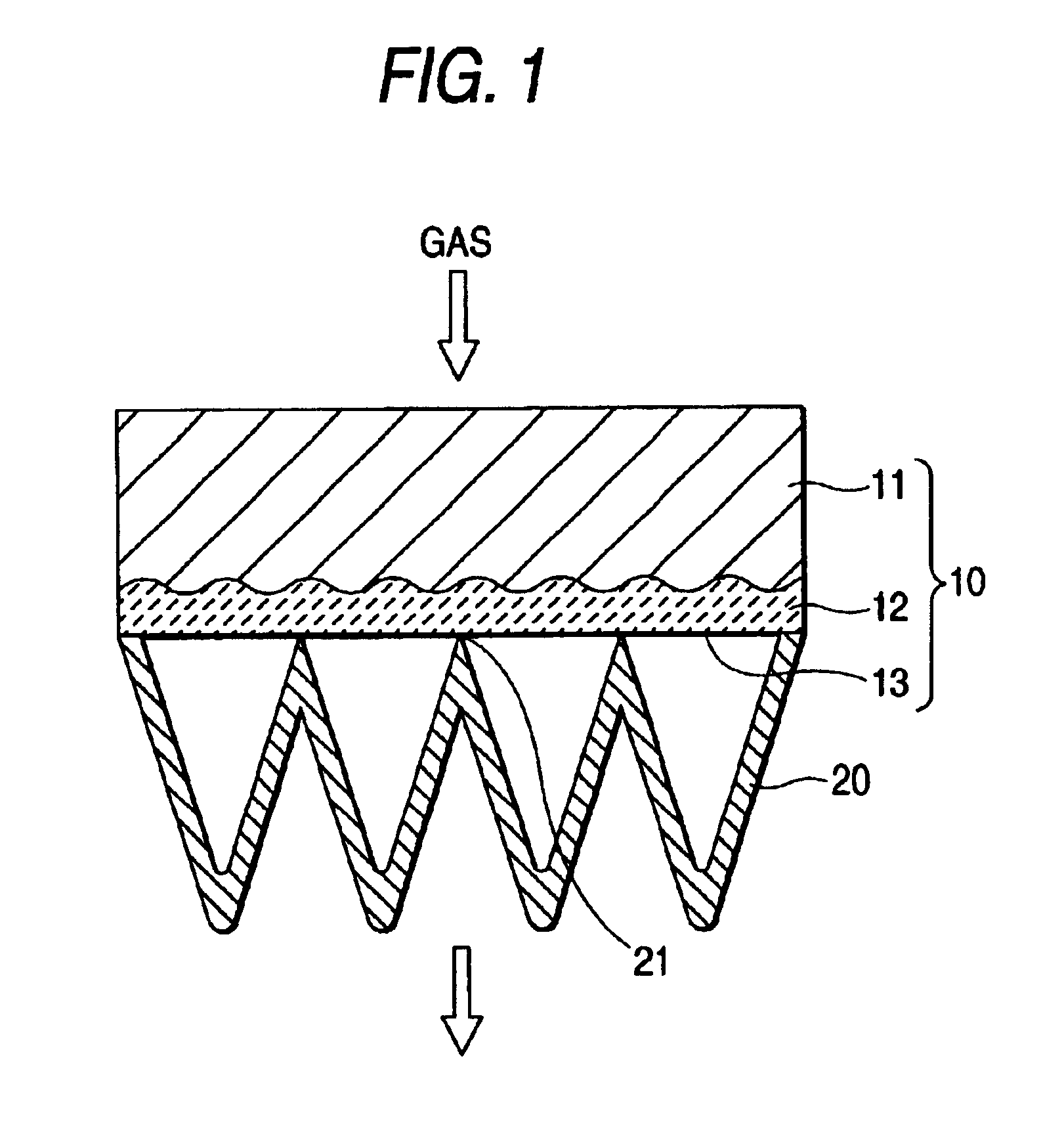

Ceramic honeycomb filter and its structure

InactiveUS20030165662A1Large cracking resistanceSmall cracking resistanceCombination devicesInternal combustion piston enginesExhaust gasMetallurgy

A ceramic honeycomb filter comprising a ceramic honeycomb structure having porous partition walls defining a plurality of flow paths for flowing an exhaust gas through the porous partition walls to remove particulates from the exhaust gas, wherein one end of each flow path is provided with a sealer, such that sealers of the flow paths in an inlet and an outlet of the ceramic honeycomb structure in a desired pattern; wherein the partition walls have thickness of 0.1-0.5 mm and a porosity of 50-80%; wherein the porosity of the sealers is larger than that of partition walls; and wherein the depth of the sealers is 3-15 mm.

Owner:HITACHI METALS LTD

Cyclone dust collecting apparatus for vacuum cleaner

ActiveUS7722693B2Small pressure lossHigh fine dust collecting efficiencyCleaning filter meansCombination devicesCycloneMechanical engineering

A cyclone dust collecting apparatus for a vacuum cleaner includes a first cyclone, a second cyclone disposed inside the first cyclone, and an air guiding member to form an entrance of the second cyclone through which semi-clean air discharged from the first cyclone enters. The air guiding member includes a grill member to have a plurality of holes, and a plurality of guiding blades disposed inside the grill member.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

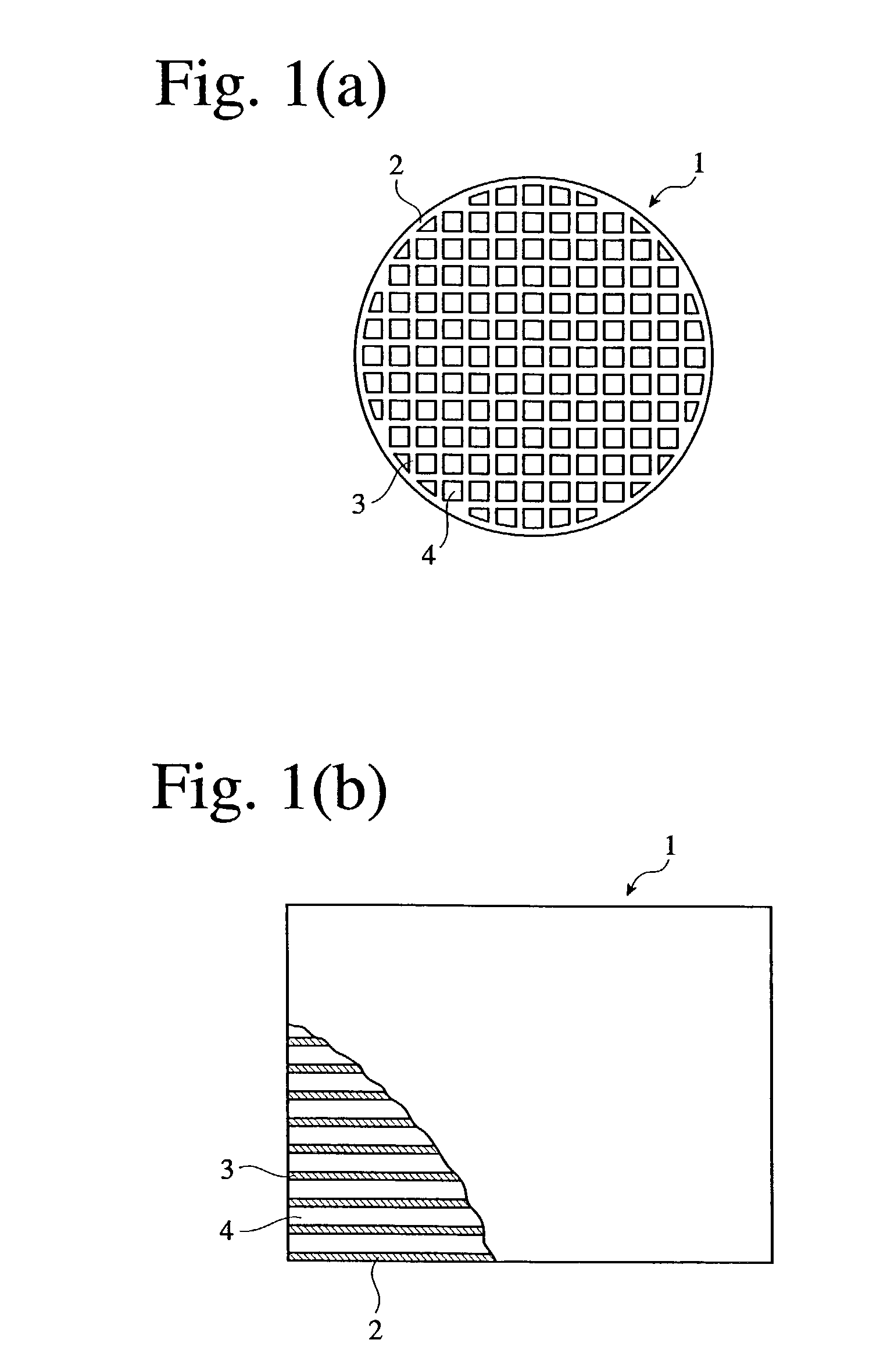

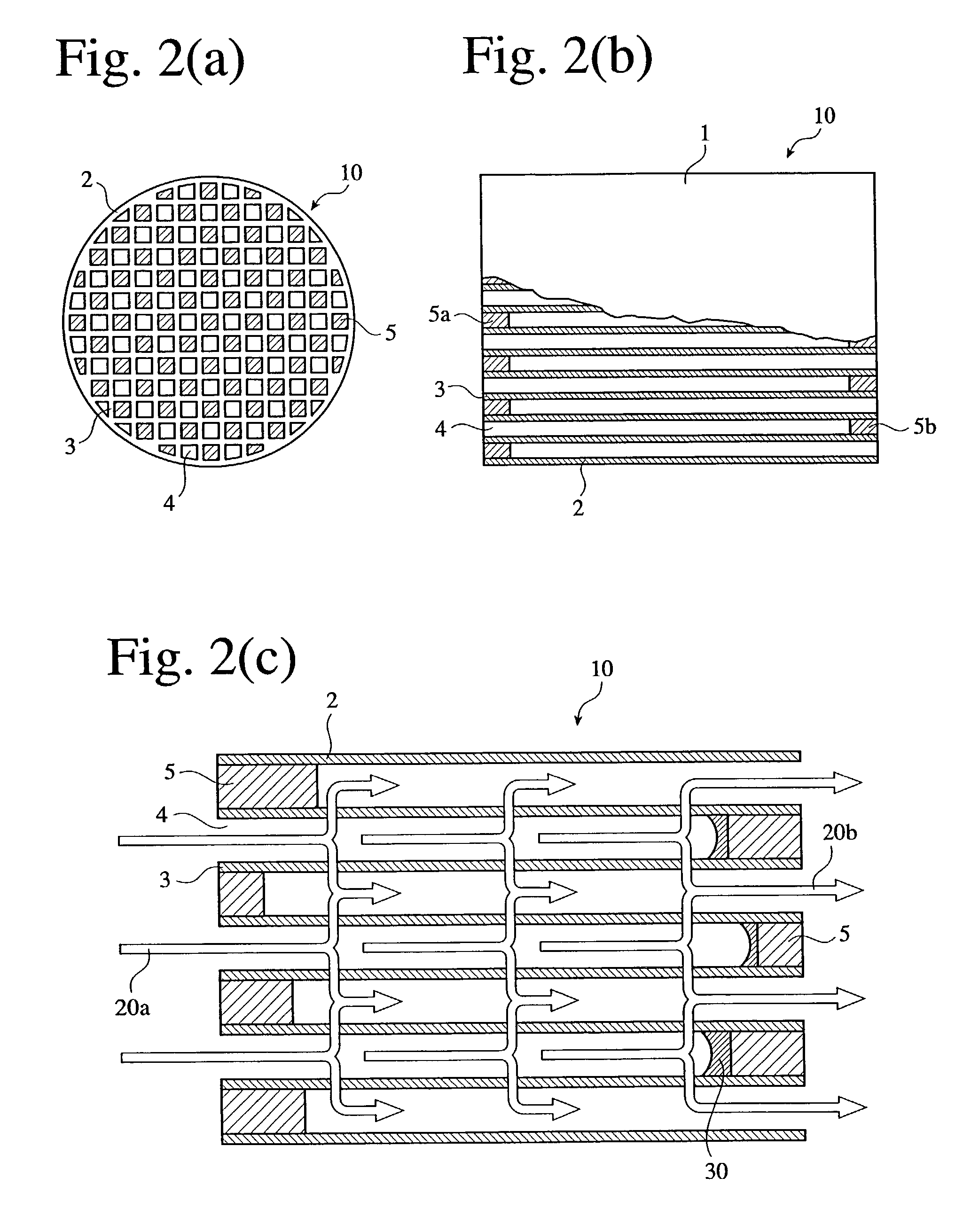

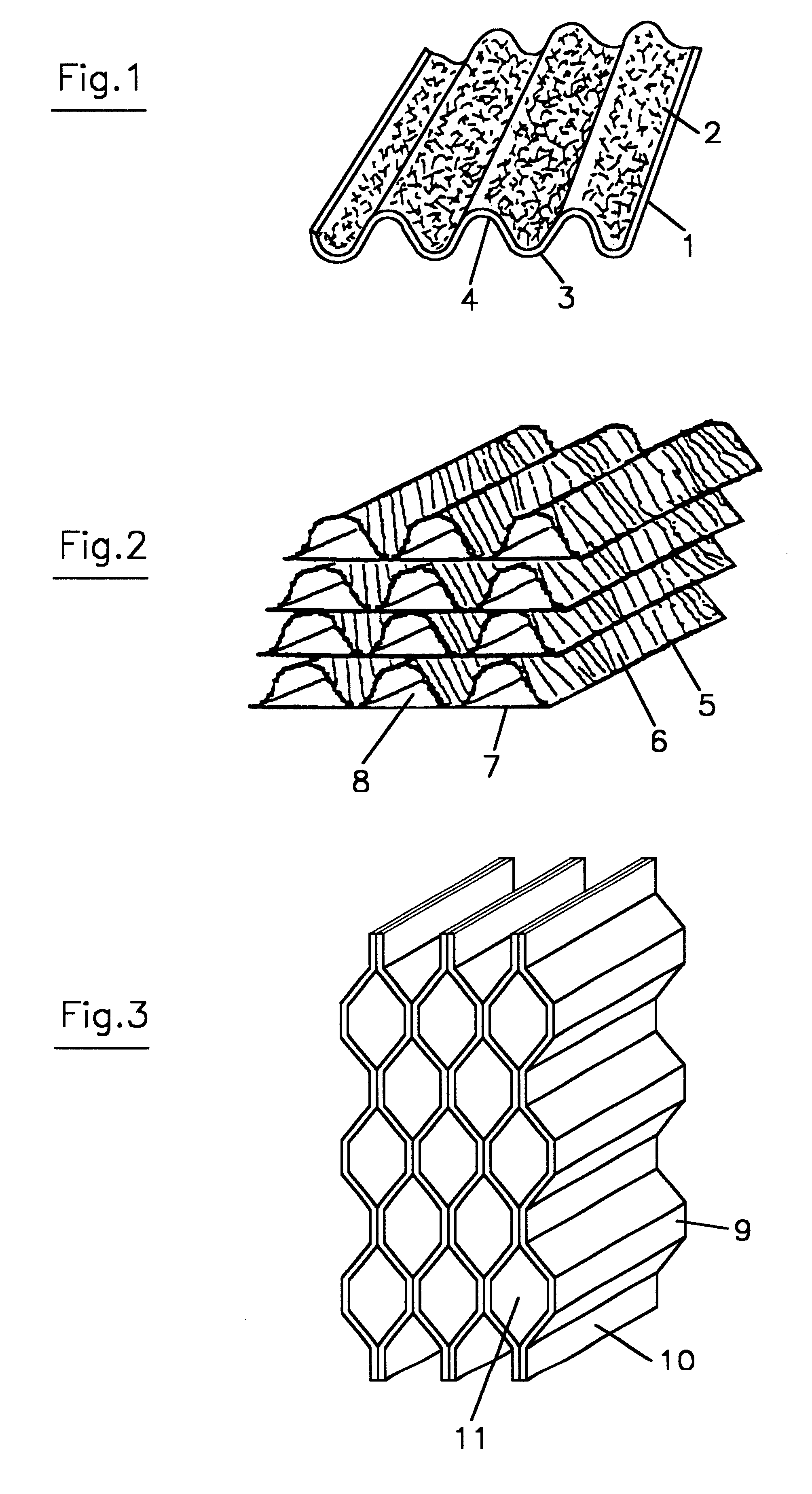

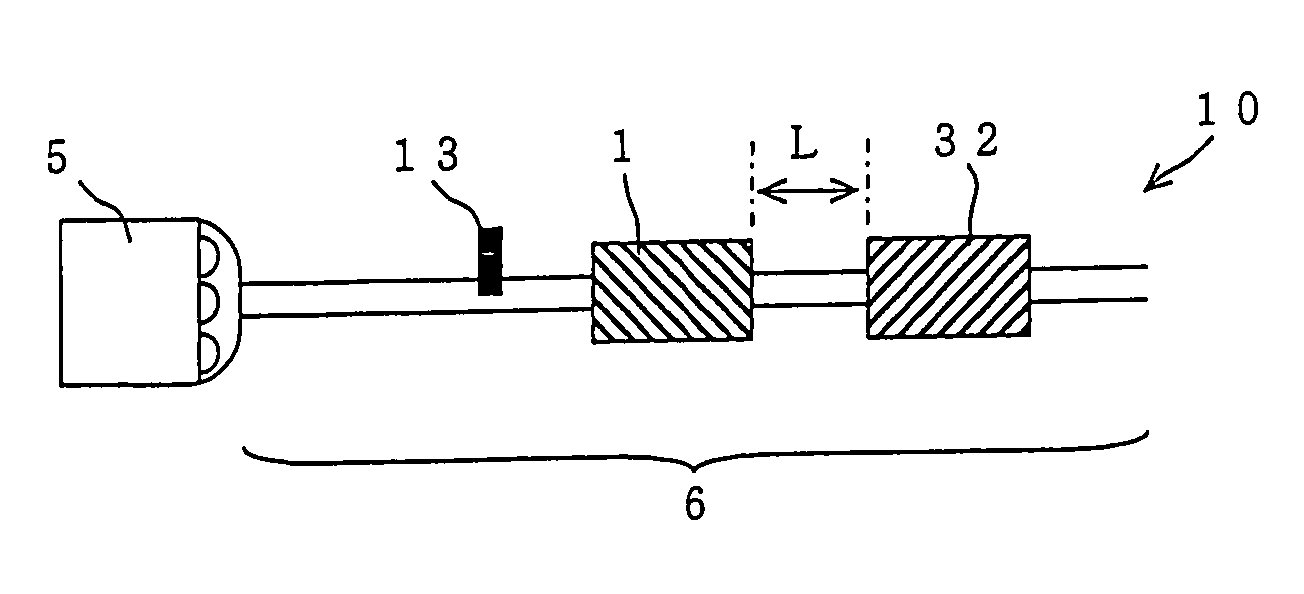

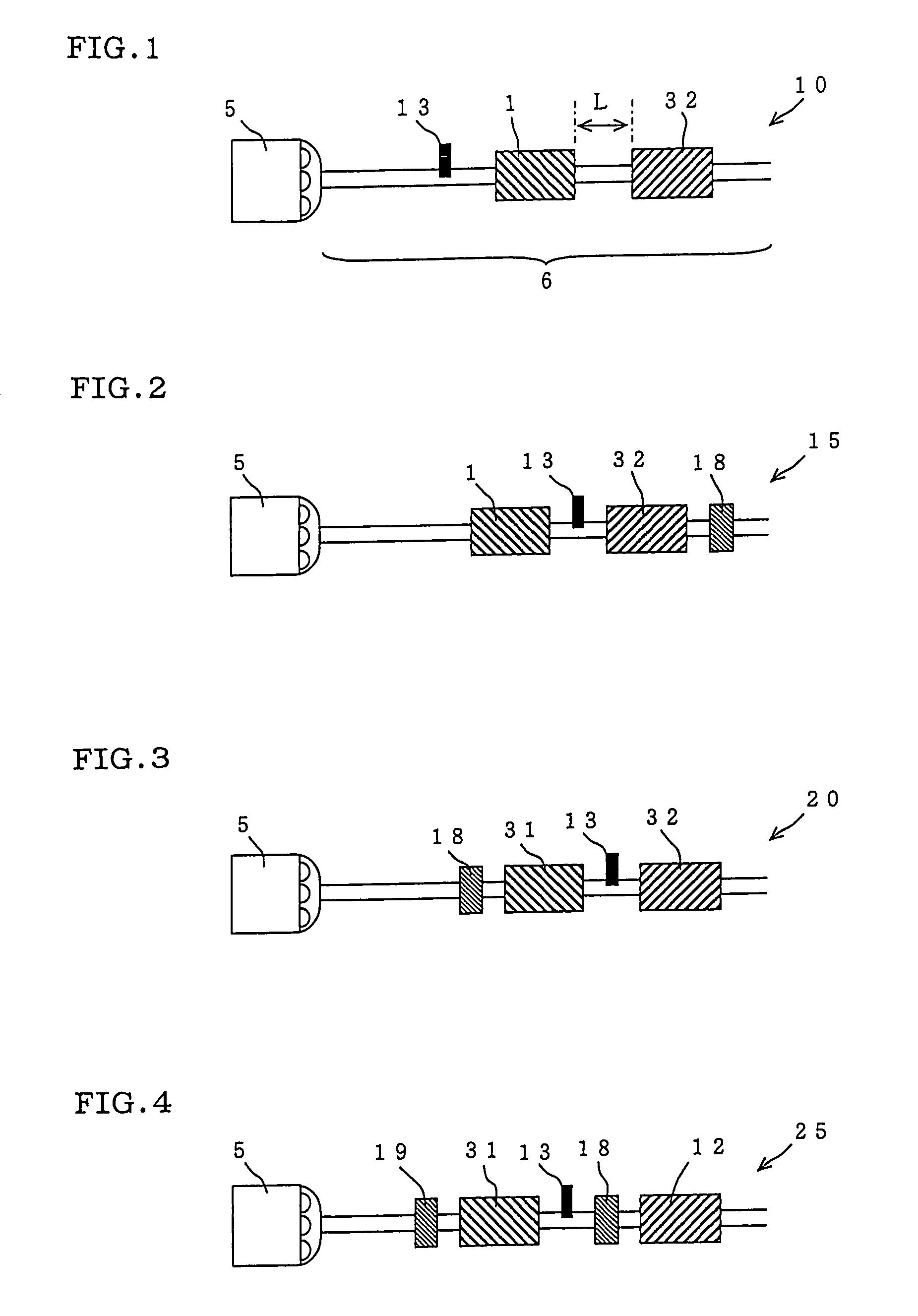

Chemical filter unit and gas purification system

InactiveUS6352579B1Large adsorption capacitySmall pressure lossCombination devicesGas treatmentIon exchangeProcess engineering

Owner:TORAY IND INC

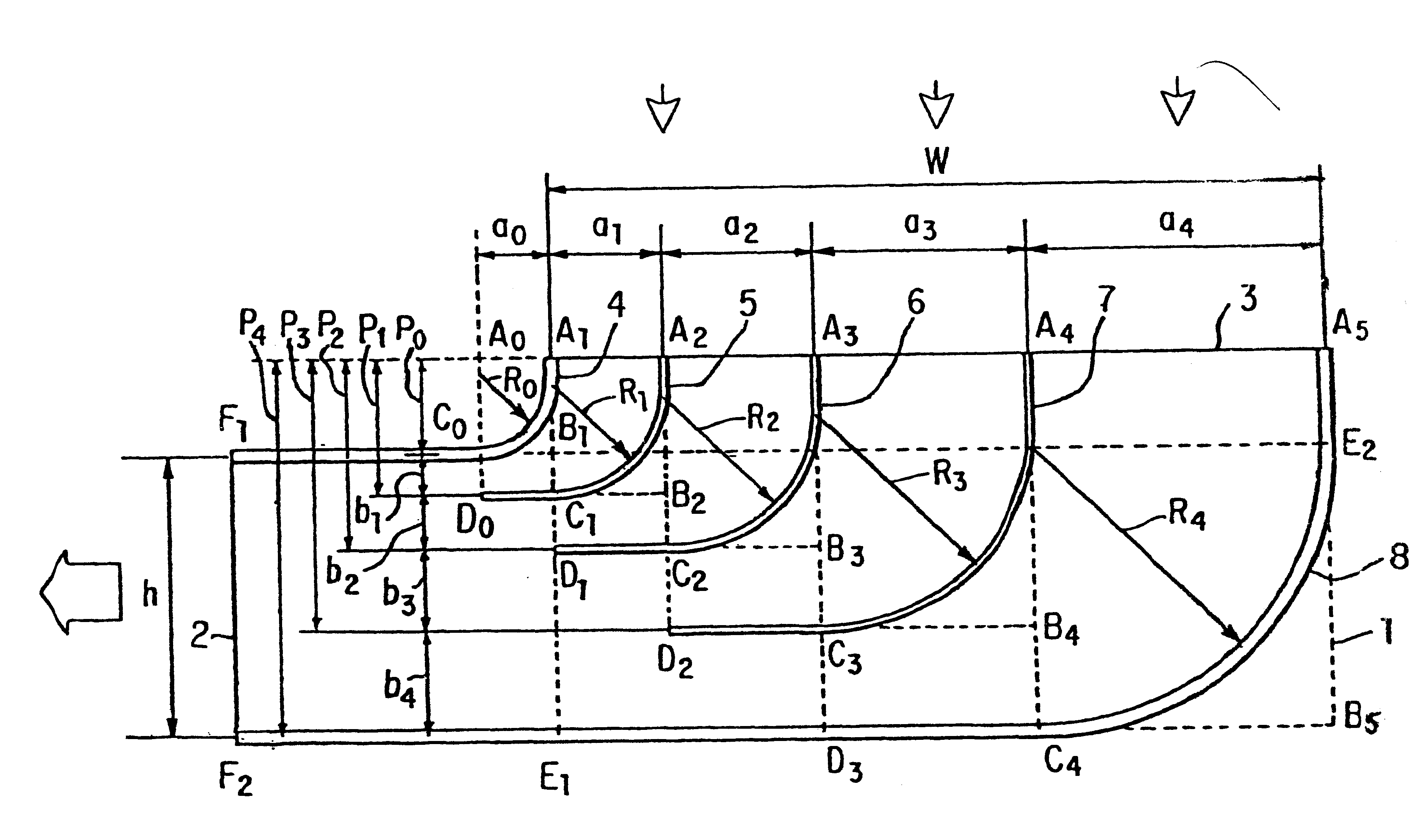

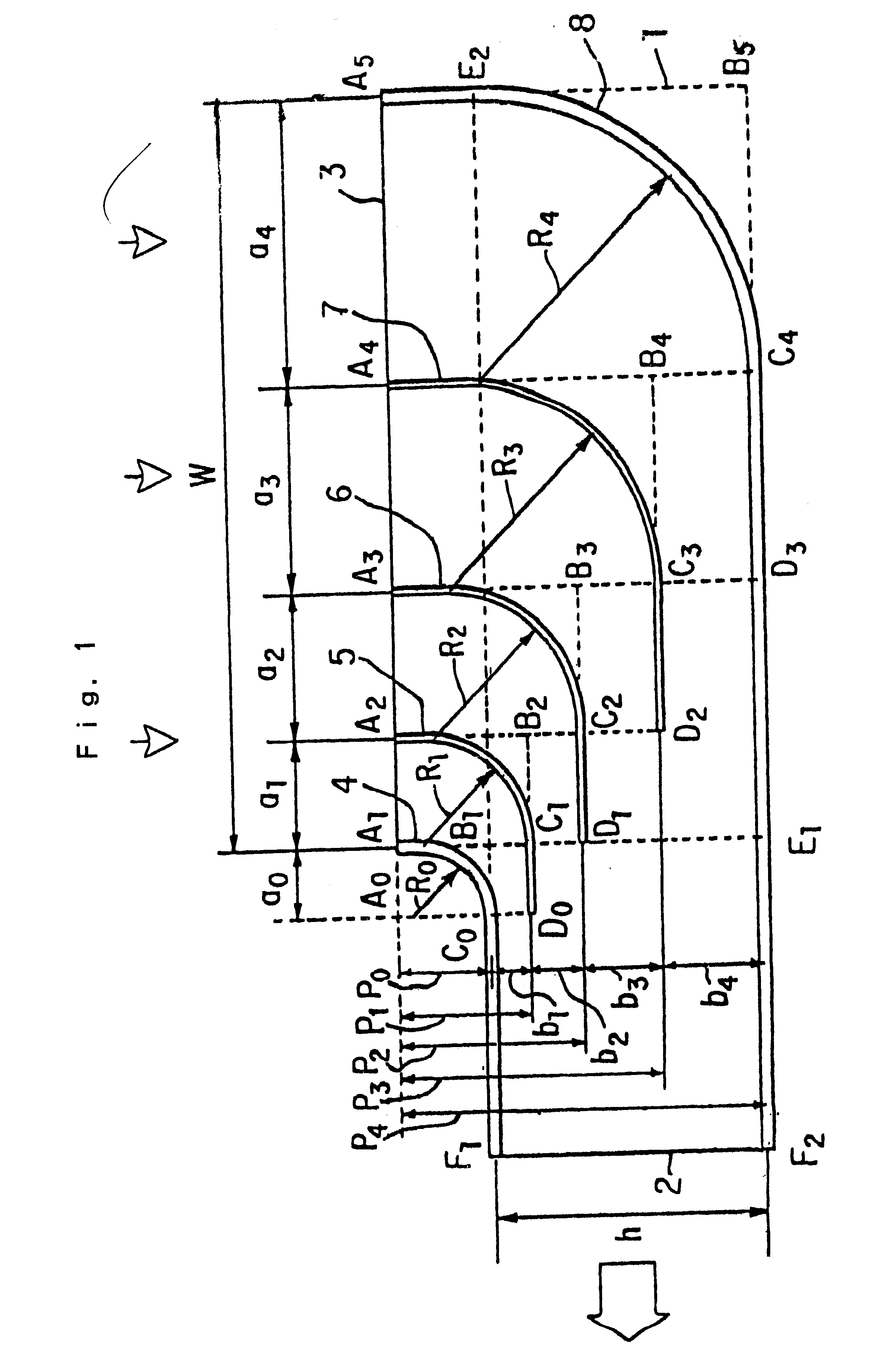

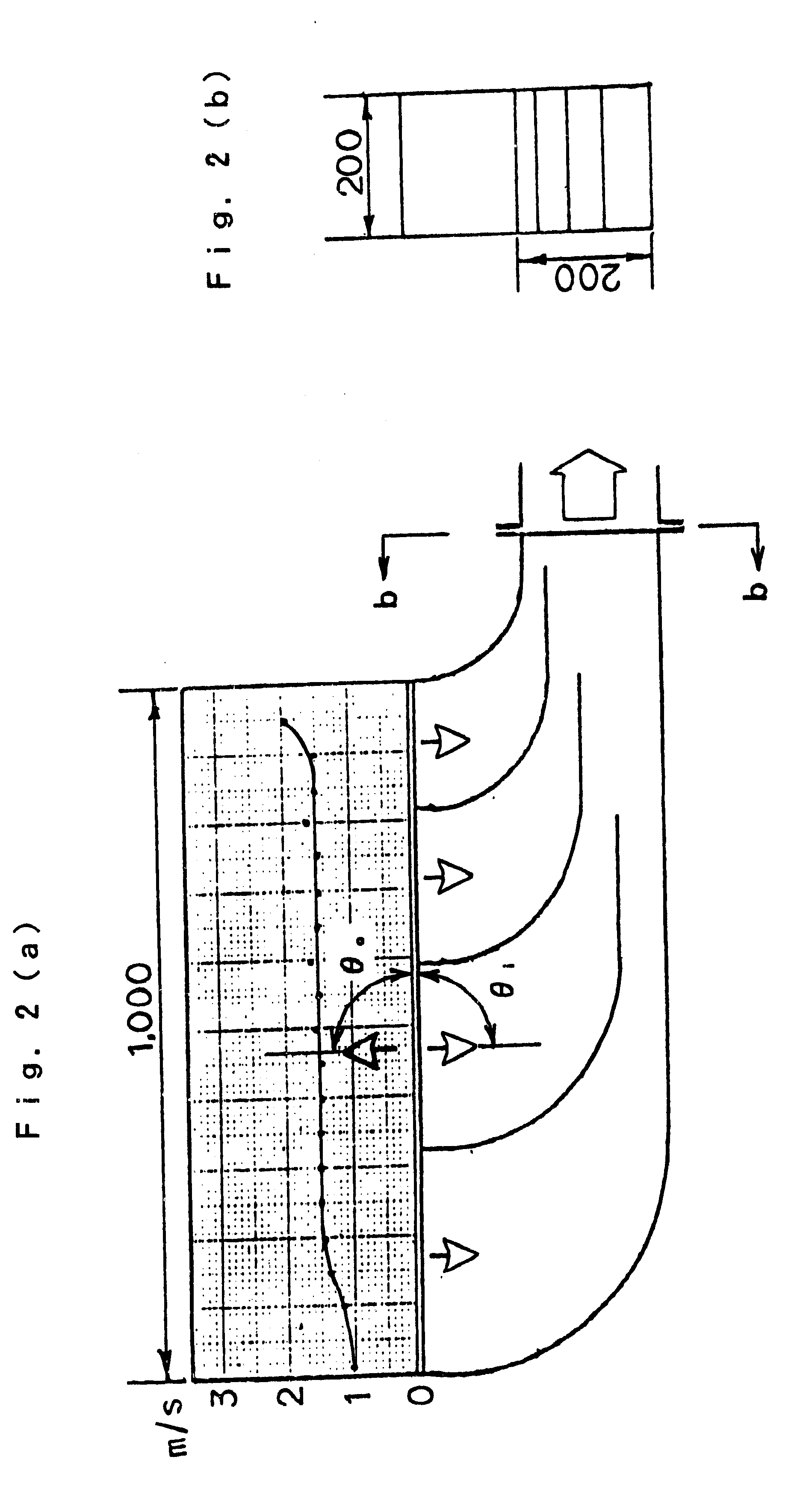

Suction elbow provided with built-in guide blades

InactiveUS6290266B1Evenly distributedSmall pressure lossPipeline expansion-compensationPump componentsEngineeringElbow

A suction elbow is divided in a plurality of sub-channels similar to each other by one or more guide vanes made of a curved plate and flat plates connected to the curved plate based on the following formulas.p0: overhang length at the inlet of the elbowh: outlet breadth of the elbowf: reduction ratio of the elbow (f=W / h)W: inlet breadth of the elbowm: number of sub-channels (m>=2)an: inlet breadth of n-th sub-channel (a0 indicates the radius of curvature of the inner side wall and am indicates the radius of curvature of the outer side wall)r: aspect ratio of the sub-channelsbn: outlet breadth of n-th sub-channel

Owner:KAWANO MICHIHIKO

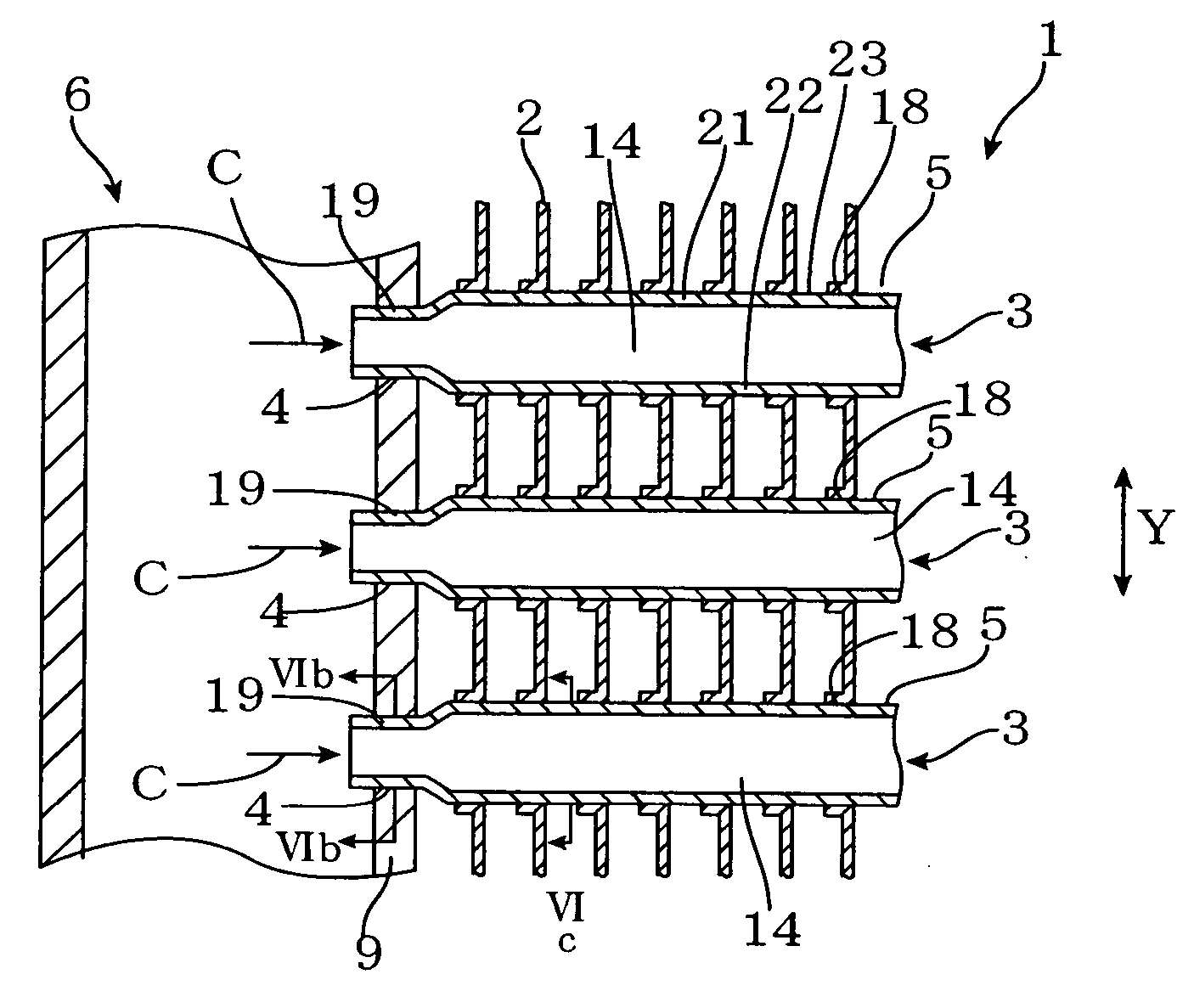

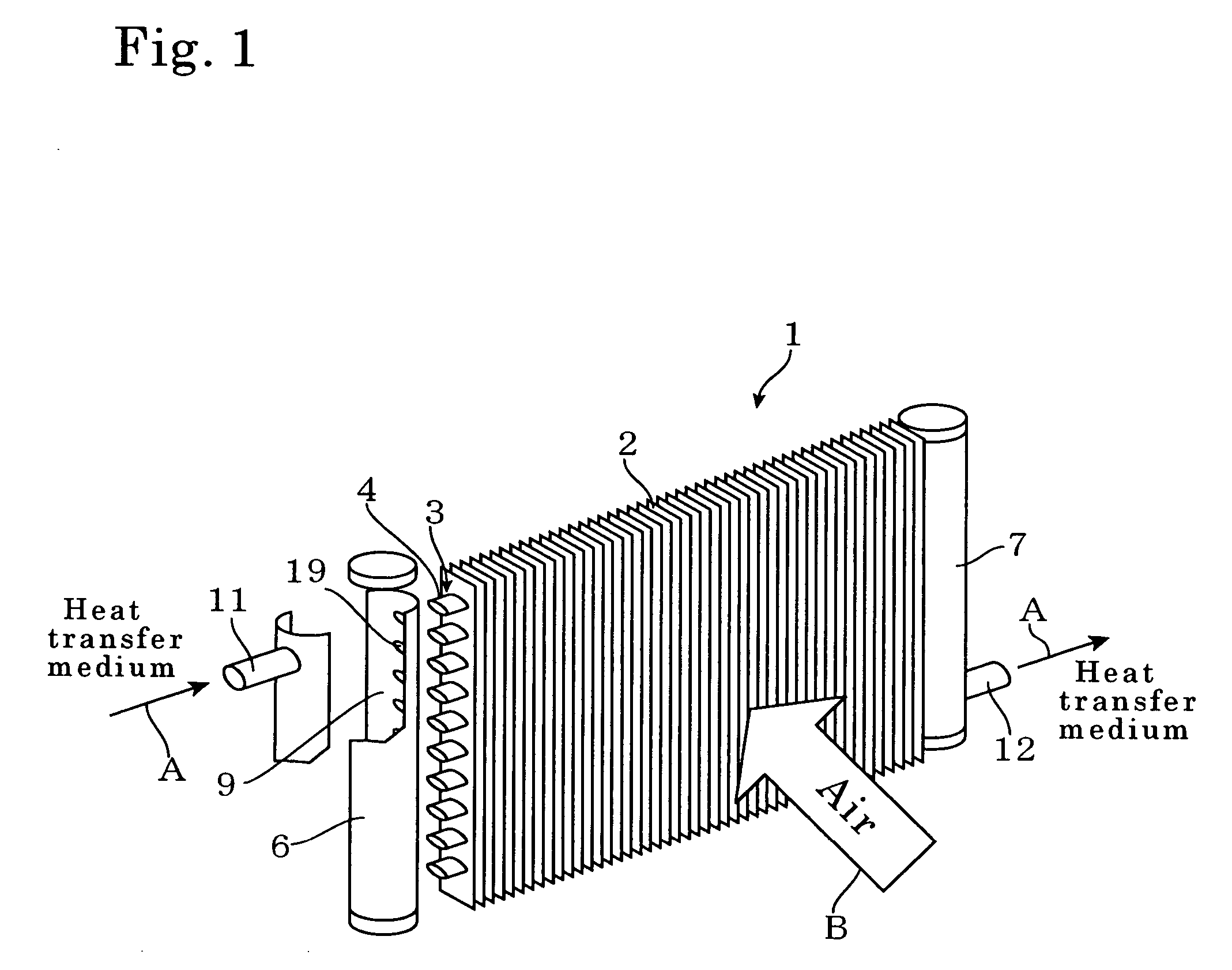

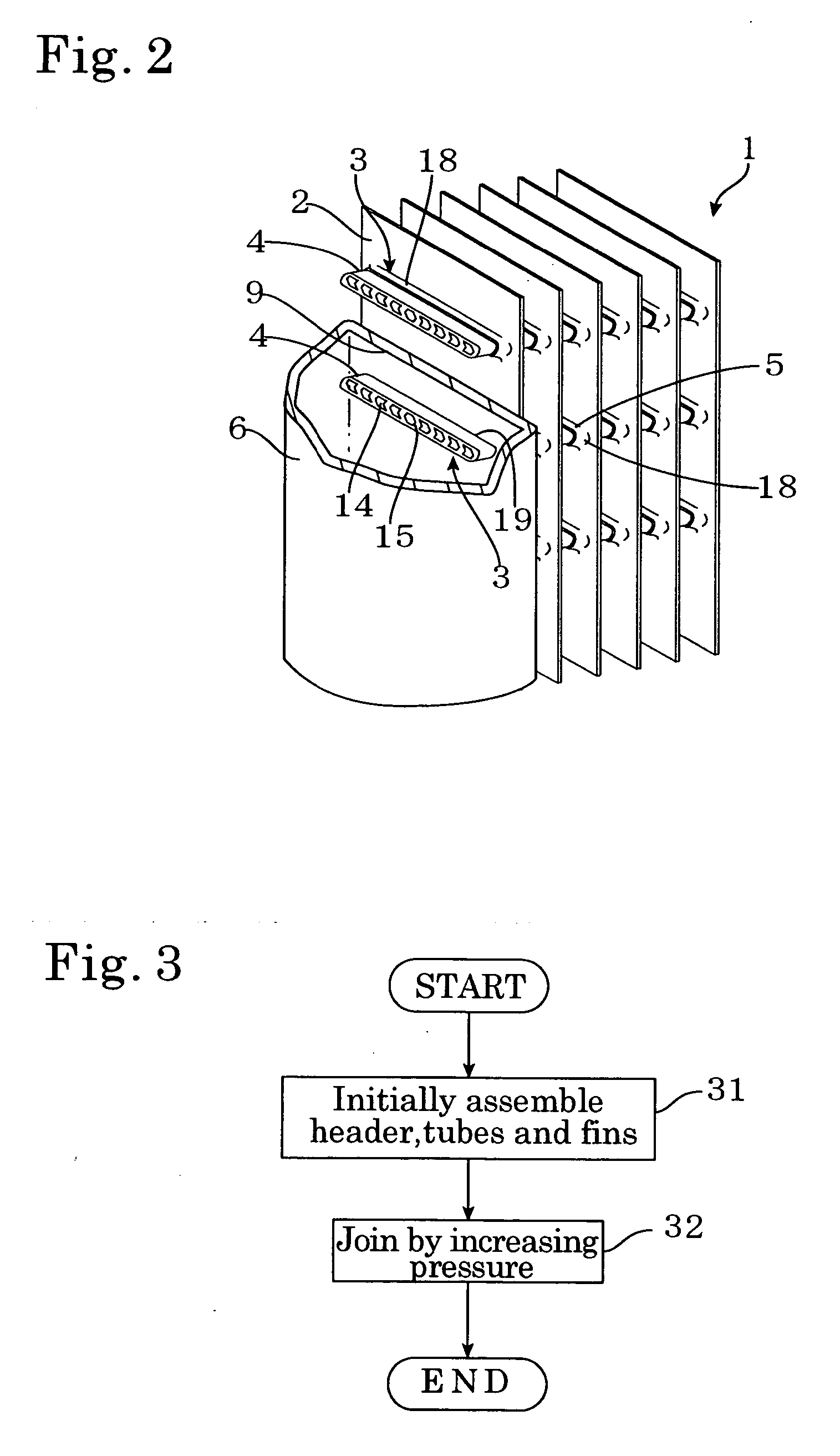

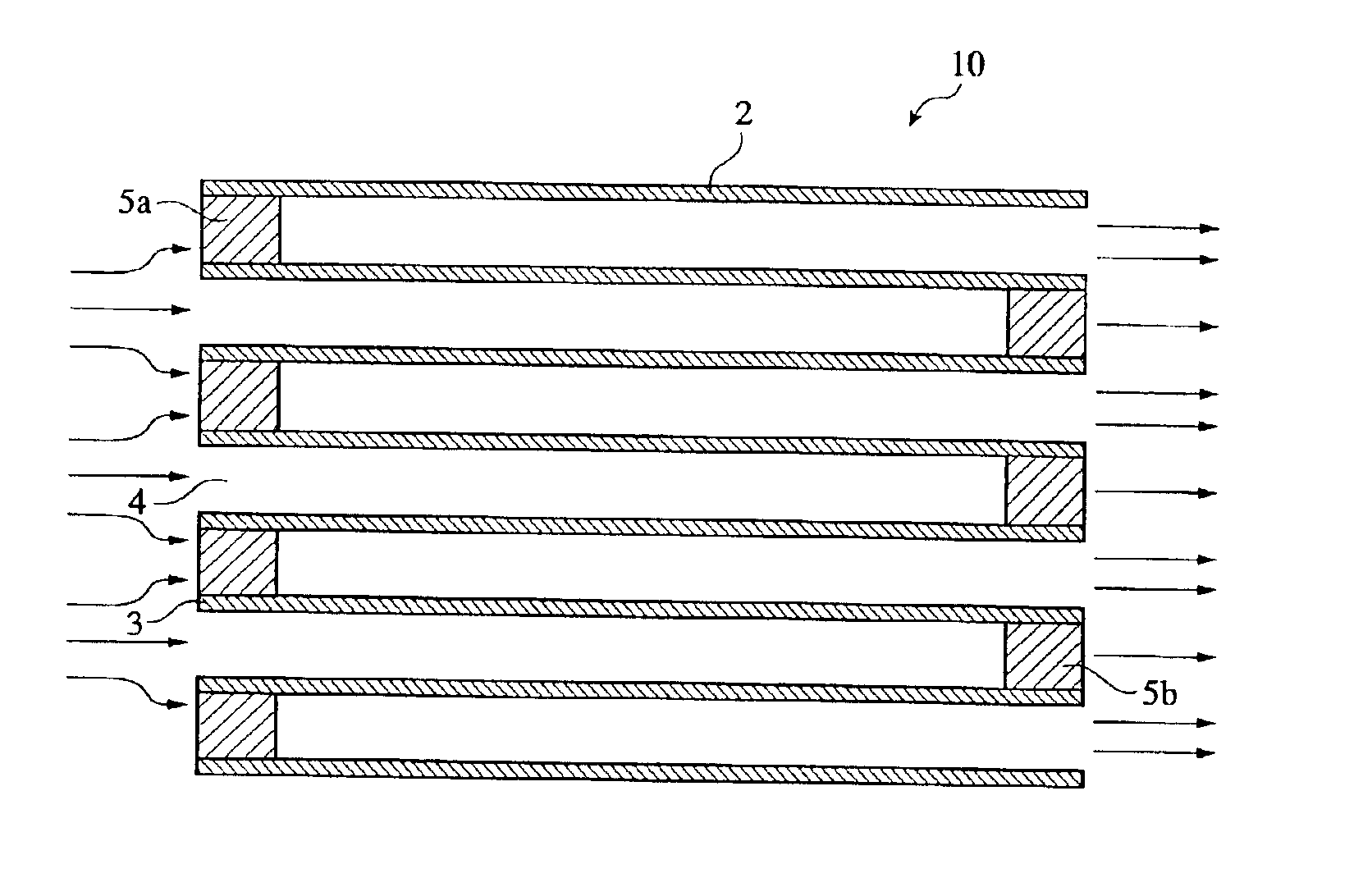

Heat exchanger and method of manufacturing the same

InactiveUS20050061494A1Increase internal pressureAdd partsStationary conduit assembliesHeat exchanger casingsInternal pressureEngineering

There is provided a method of manufacturing a heat exchanger, including a first step of mounting an end part of flat tube to a header, assembling the flat tube and fins, and sealing a part where the header and the end part is attached, and a second step of increasing an internal pressure of the flat tube to expand other part of flat tubes aside from the end parts with respect to the end part of the tube in order to make the fins and the other part of the flat tube in contact each other. According to this method of manufacturing, in the second step, the other part of the flat tube that passes through the fins is expanded, so that it is possible to mechanically join the flat tube and the fins, and a plate fin-type heat exchanger with high strength and heat exchange efficiency can be easily provided.

Owner:DENSO AIRCOOL CORP

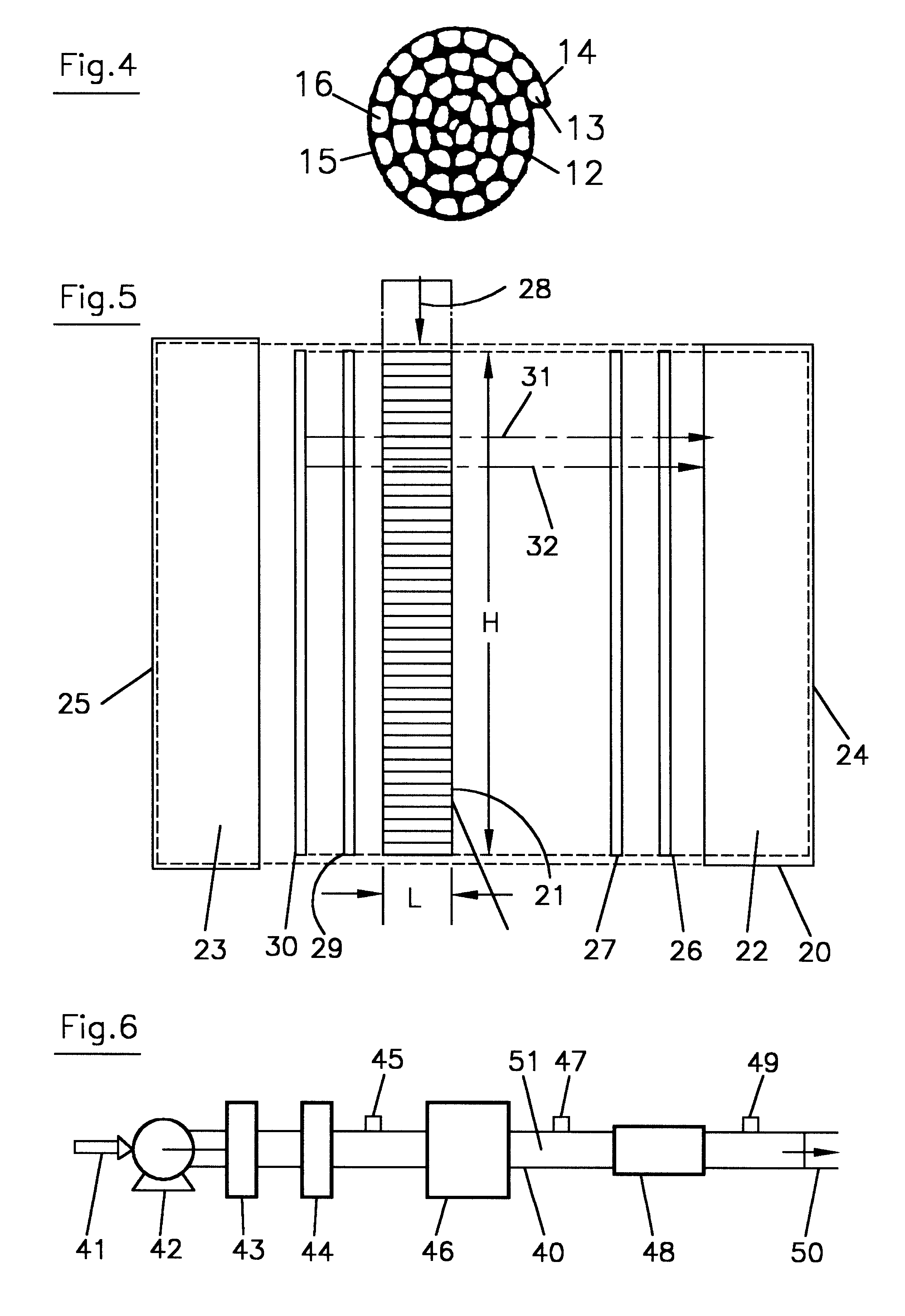

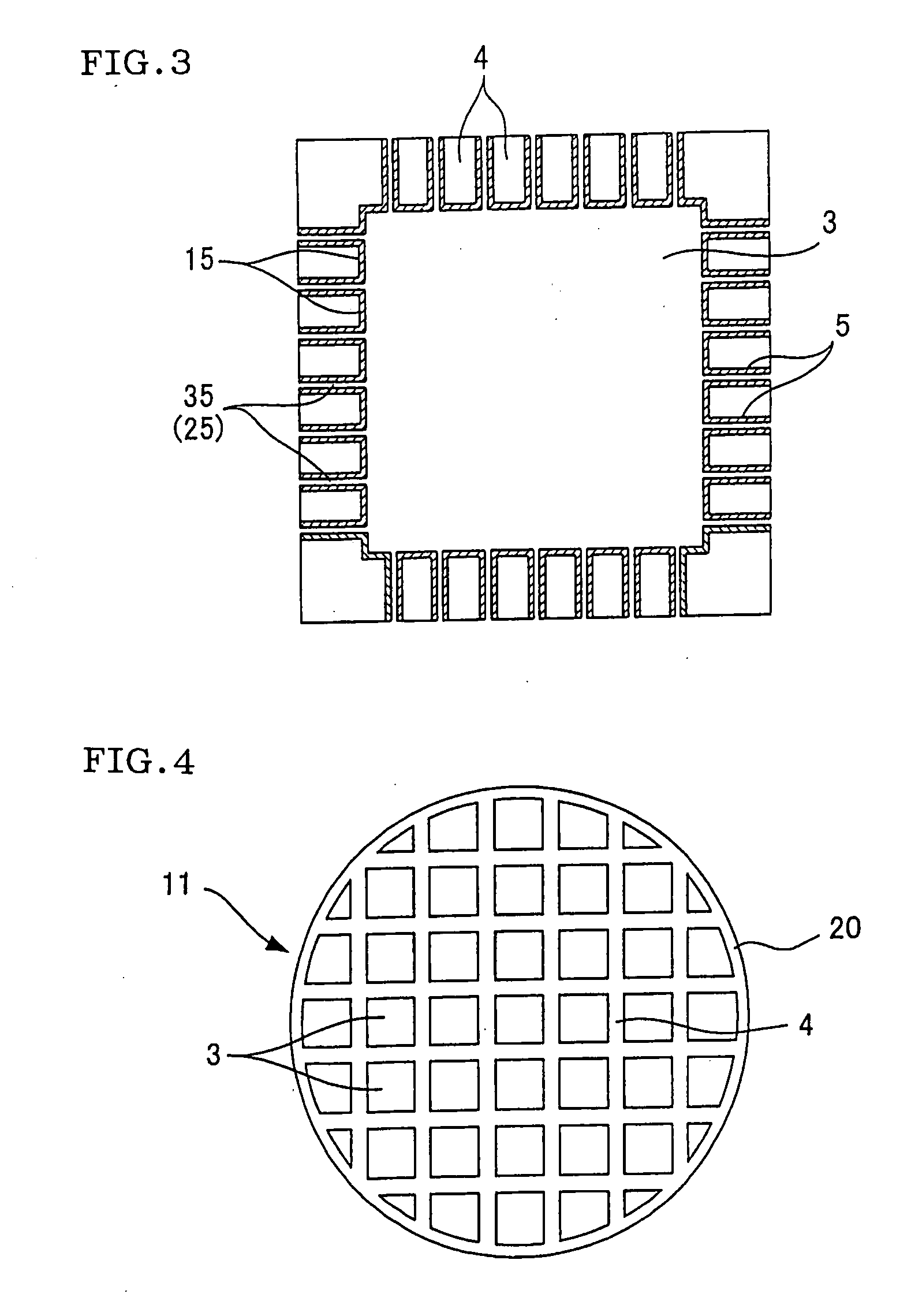

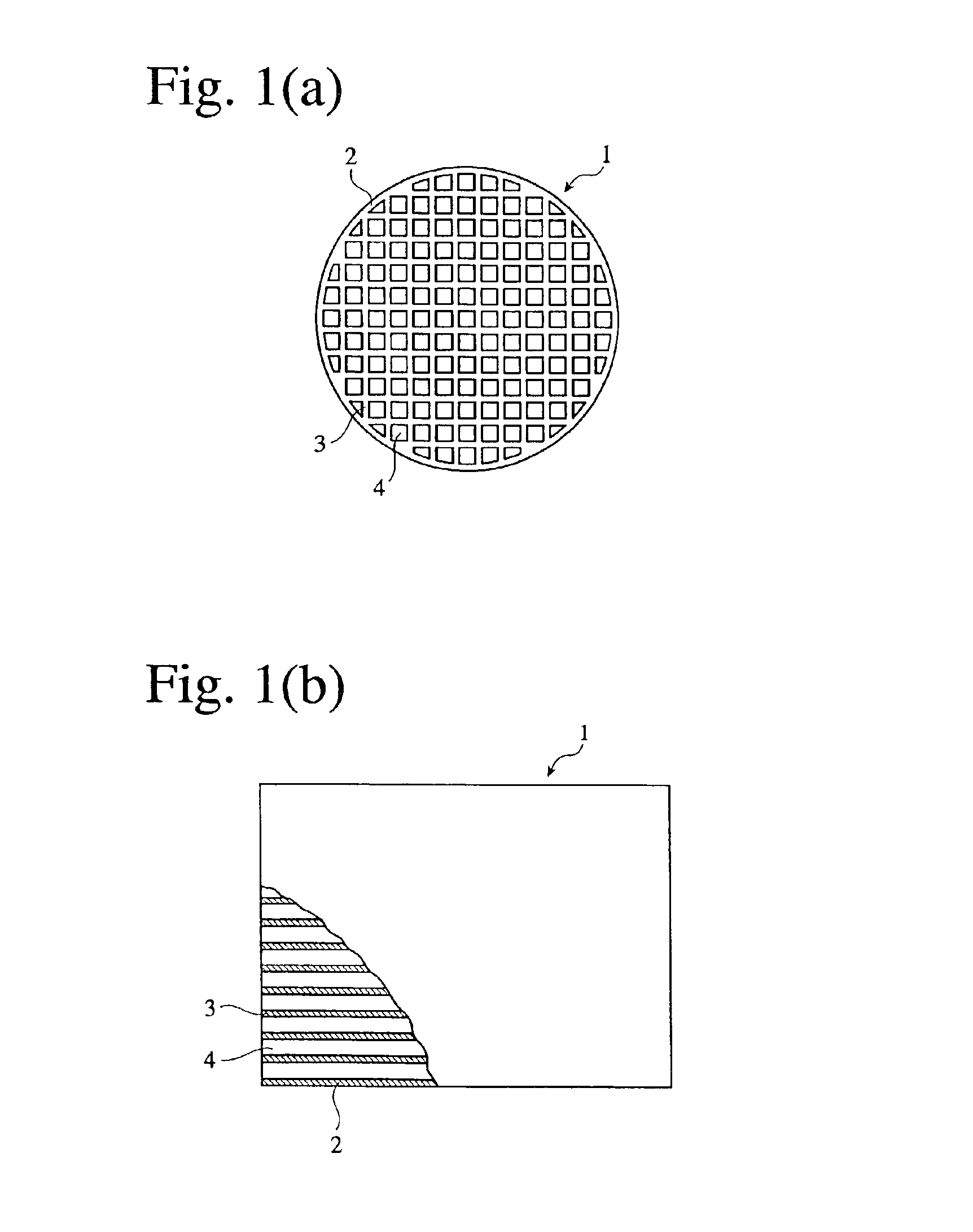

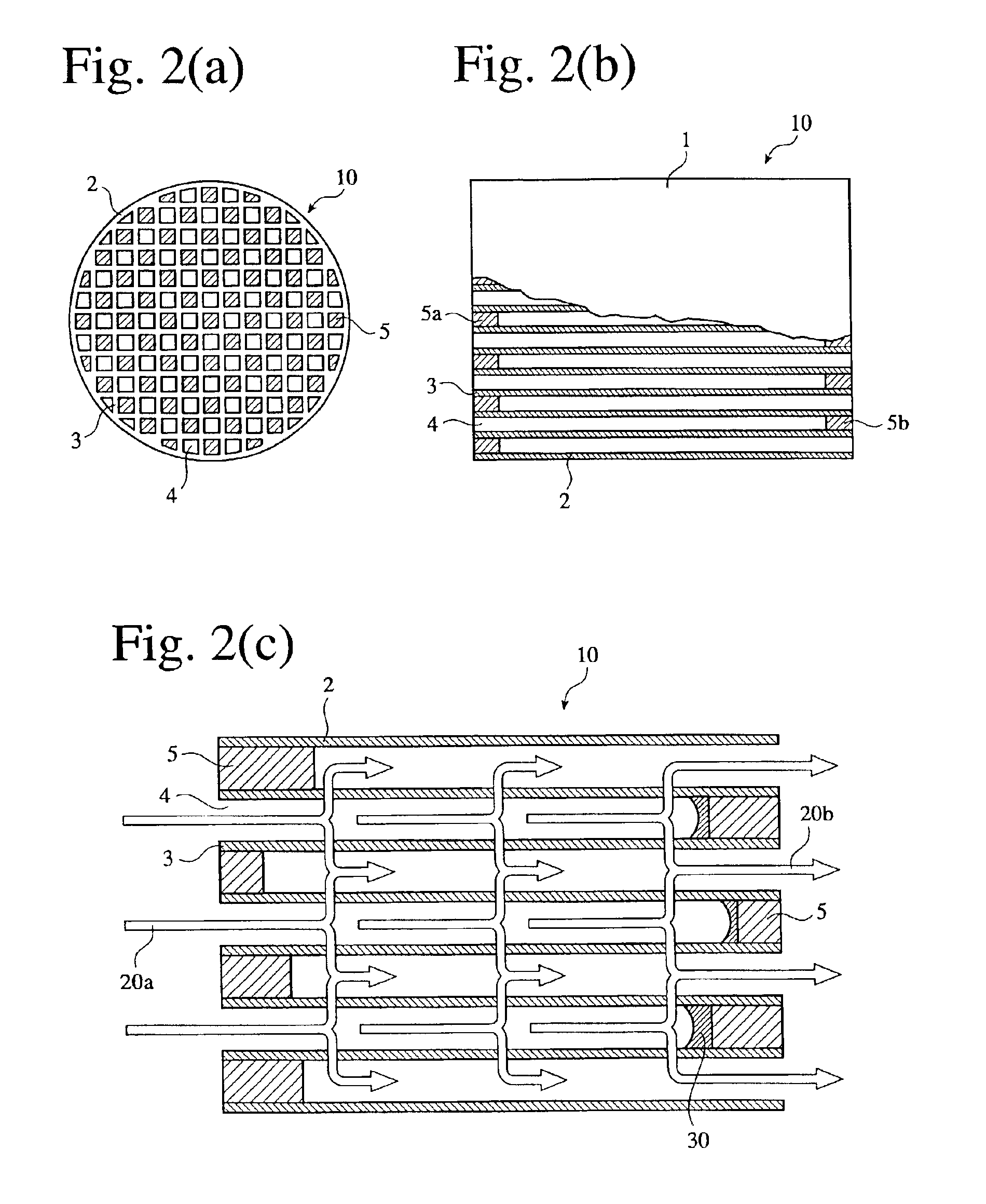

Honeycomb catalyst and manufacturing method thereof

ActiveUS20080044319A1Small pressure lossImprove purification efficiencyCombination devicesGas treatmentHoneycombEngineering

This invention provides a honeycomb catalyst having an excellent purification efficiency and a small pressure loss and can be mounted even in a limited space, the honeycomb catalyst comprising: porous partition walls 4 having plural pores 25, which are arranged to form plural cells 3 allowing communication between two end faces; plugging portions being arranged to plug the cells 3 in one of the end faces; and catalytically active components 5, 15 loaded on surfaces of partition walls 4 and inner surfaces of pores 25, wherein many catalytically active component-loading pores 35 through which a gas can pass are formed in partition walls 4, and a ratio of a mass (MW) of the catalytically active component loaded on the surfaces of partition walls 4 to a mass (MP) of the catalytically active component 5 loaded on the inner surfaces of the pores 25 is (MW):(MP)=1:3 to 3:1.

Owner:NGK INSULATORS LTD

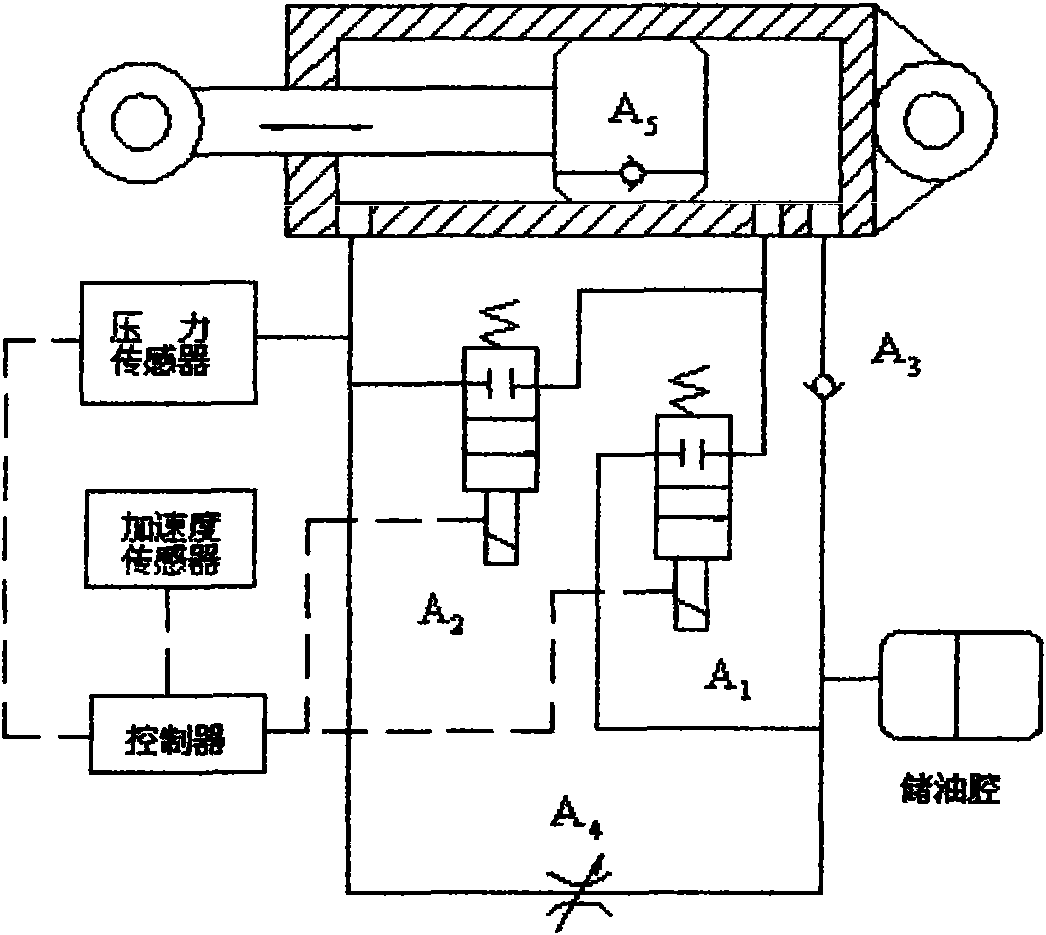

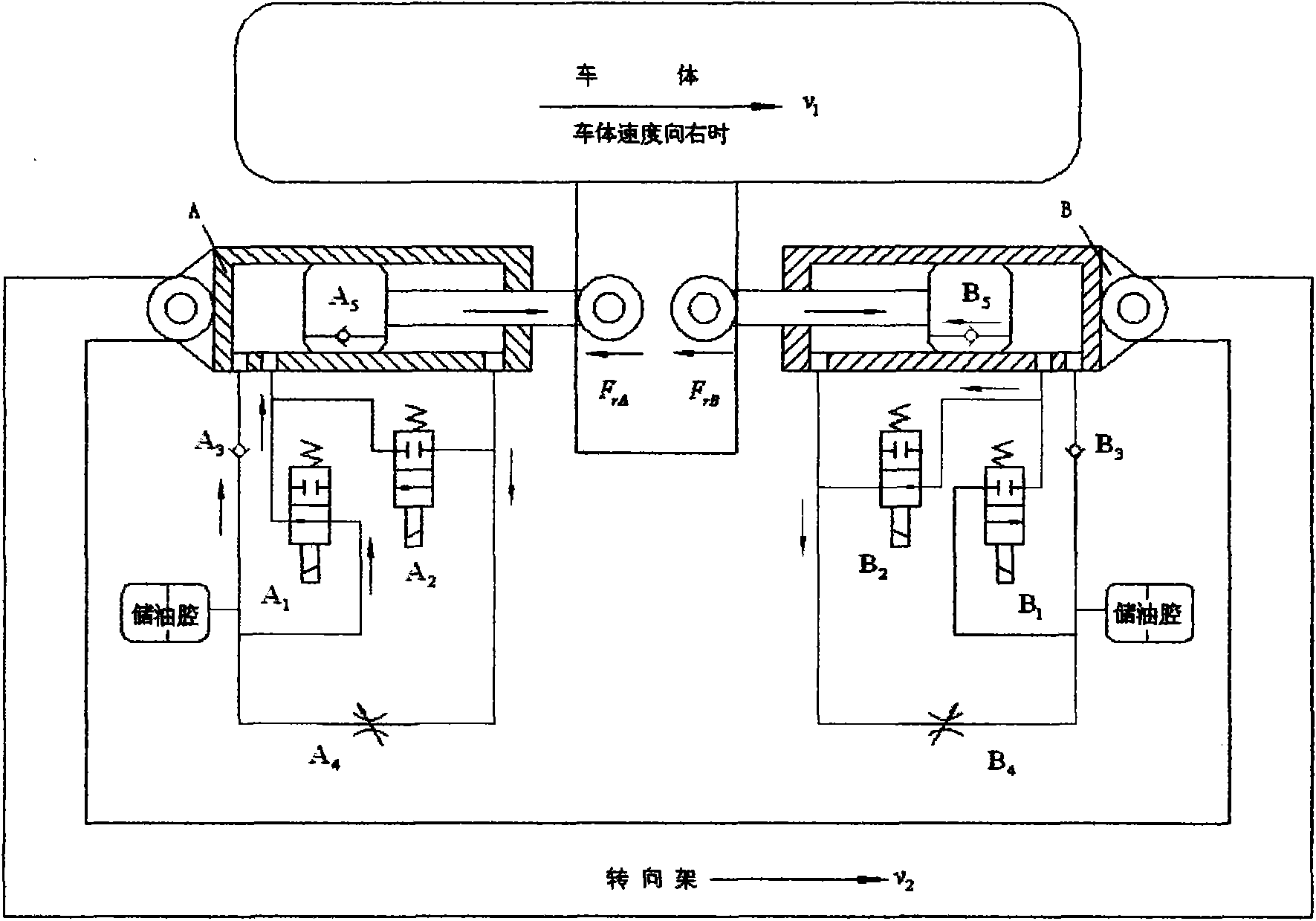

Switch type semi-active suspension system

ActiveCN102069813AReduce damping forceSmall pressure lossResilient suspensionsBogiesBogieSemi active

The invention relates to a switch type semi-active suspension system, which comprises four sets of switch type semi-active vibration absorbers, two acceleration sensors and a detection control system, wherein each two sets of the switch type semi-active vibration absorbers are arranged diagonally and act between a car body and a bogie; each set of switch type semi-active vibration absorbers respectively comprise a vibration absorber body A, high-speed switch valves A1 and A2, an adjustable damper valve A4 and a pressure sensor, wherein the high-speed switch valve A1 is used for communicating a rodless cavity with an oil storage cavity of the vibration absorber body; a check valve A3 is arranged between the oil storage cavity and the rodless cavity; the high-speed switch valve A2 is used for communicating the rodless cavity with a rod cavity; the adjustable damper valve A4 is arranged between the rod cavity and the oil storage cavity; and the pressure sensor is used for detecting the pressure of an oil way led out of the rod cavity of the vibration absorber body; and output signals of the acceleration sensor and the pressure sensor are transmitted to a controller after being processed, and the high-speed switch valves A1 and A2 are controlled by the controller to act.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

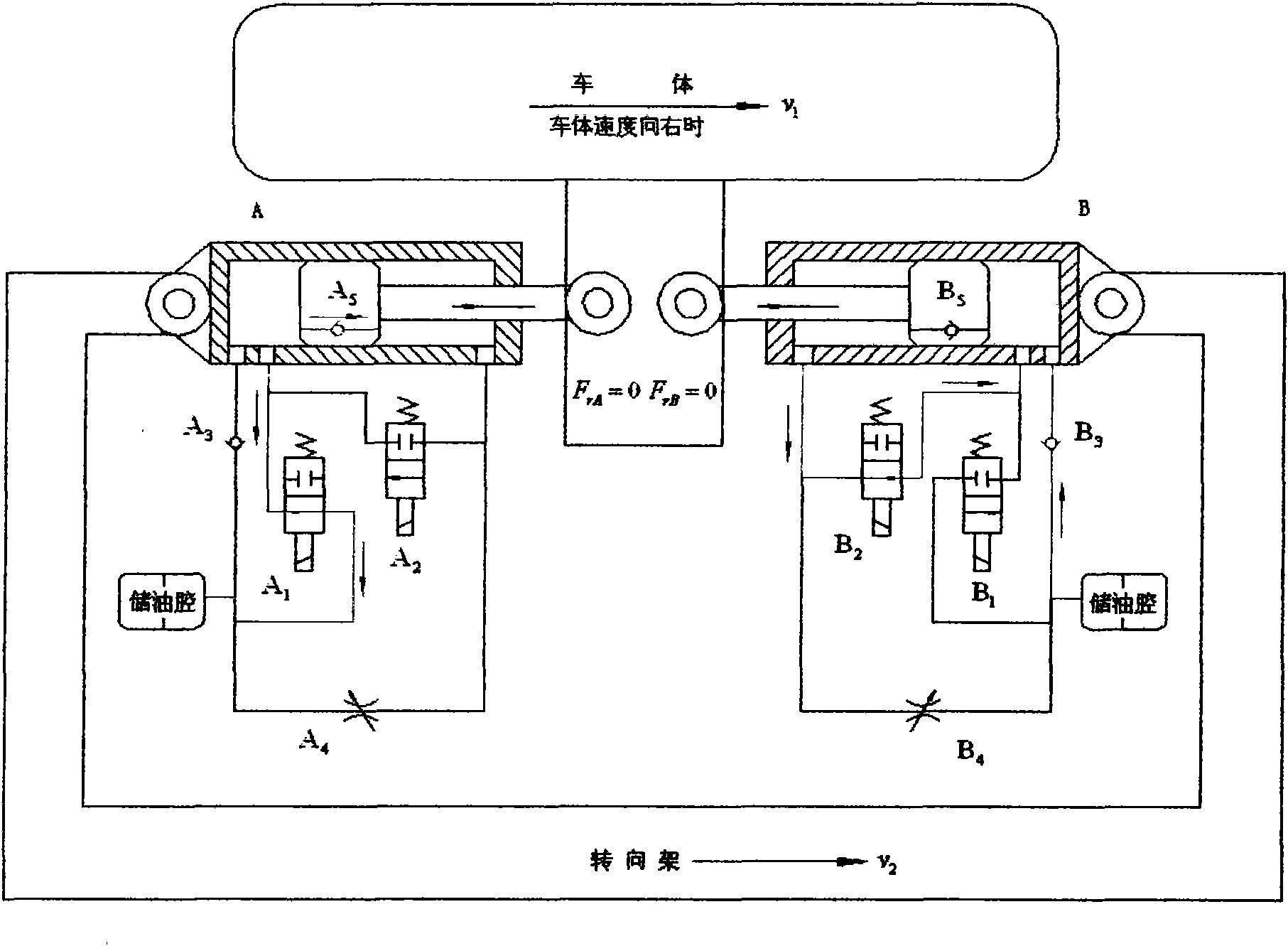

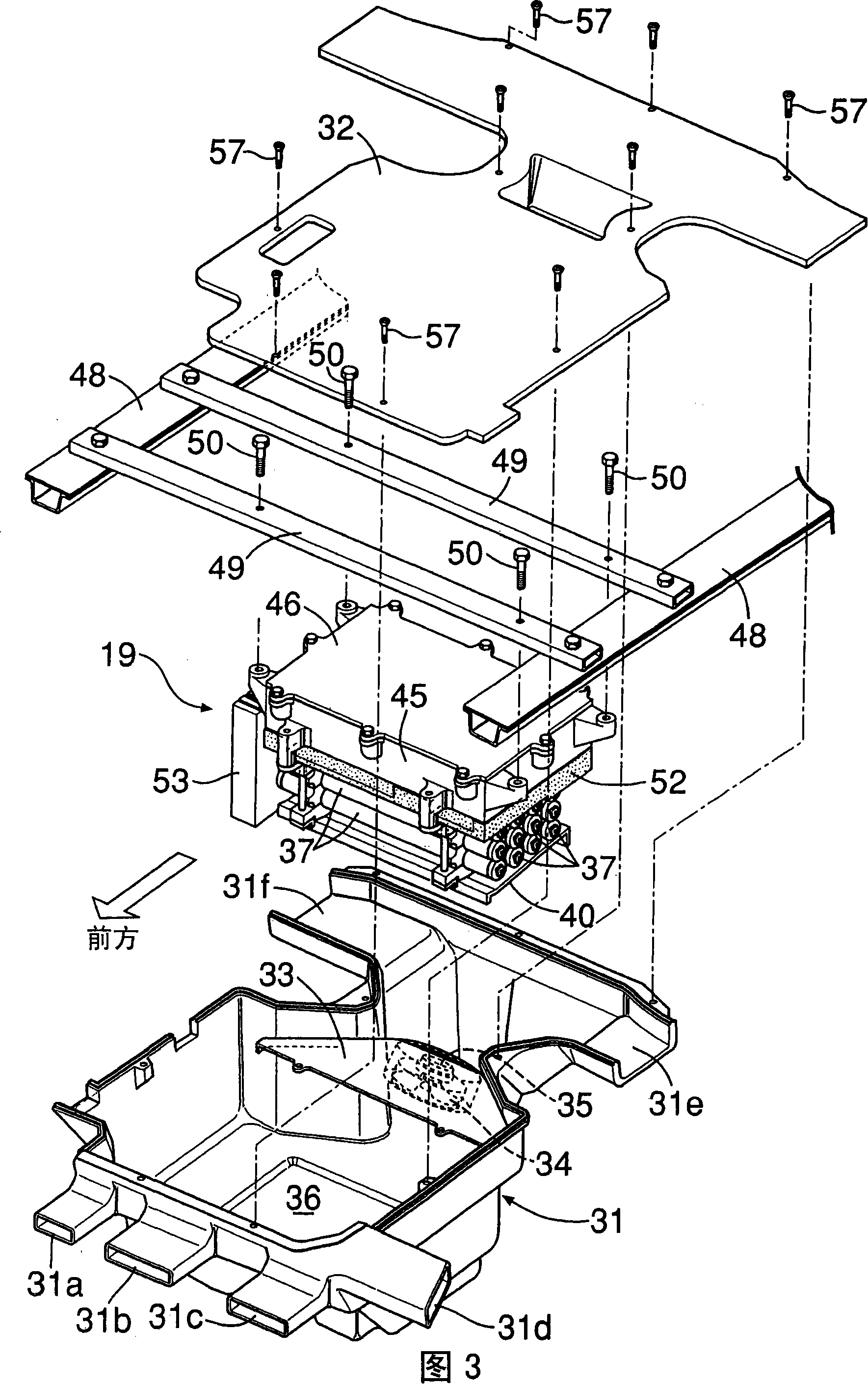

Electrical device cooling structure in vehicle

InactiveCN101138963ASmall pressure lossLow costSpeed controllerCell temperature controlMotor driveElectrical battery

In a power supply unit (19) disposed below a floor behind a seat, battery modules (37) are disposed in a lower position, and a DC / DC converter (41) and a motor driving inverter (42) are disposed side by side in a vehicle width direction above the battery modules (37). Thus, cooling air flowing from the front side to the rear side of a vehicle body is divided into upper and lower portions to cool in parallel the DC / DC (41) and the motor driving inverter (42) on the upper side and the battery modules (37) on the lower side. Thus, it is possible to simplify a passage of the cooling air to reducethe size of the entire power supply unit (19), and improve mountability of the power supply unit (19) on the vehicle body. Also, it is possible to apply cooling air at low temperature before heat exchange to all the battery module (37), the DC / DC converter (41), and the motor driving inverter (42), thereby enhancing cooling effect.

Owner:HONDA MOTOR CO LTD

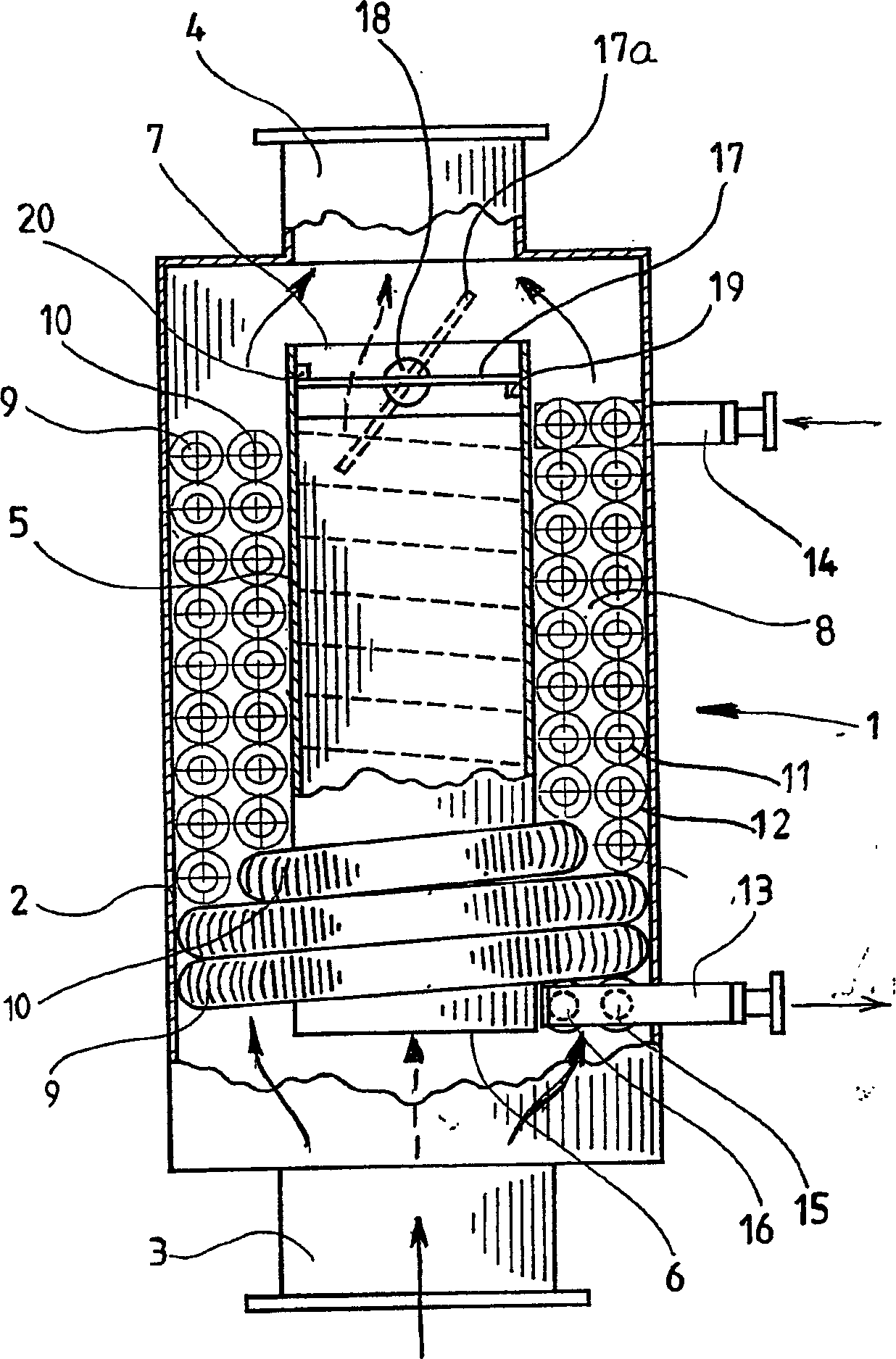

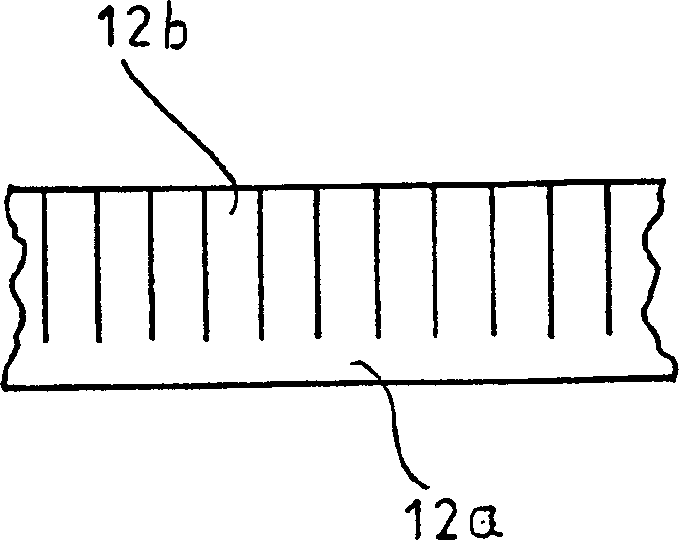

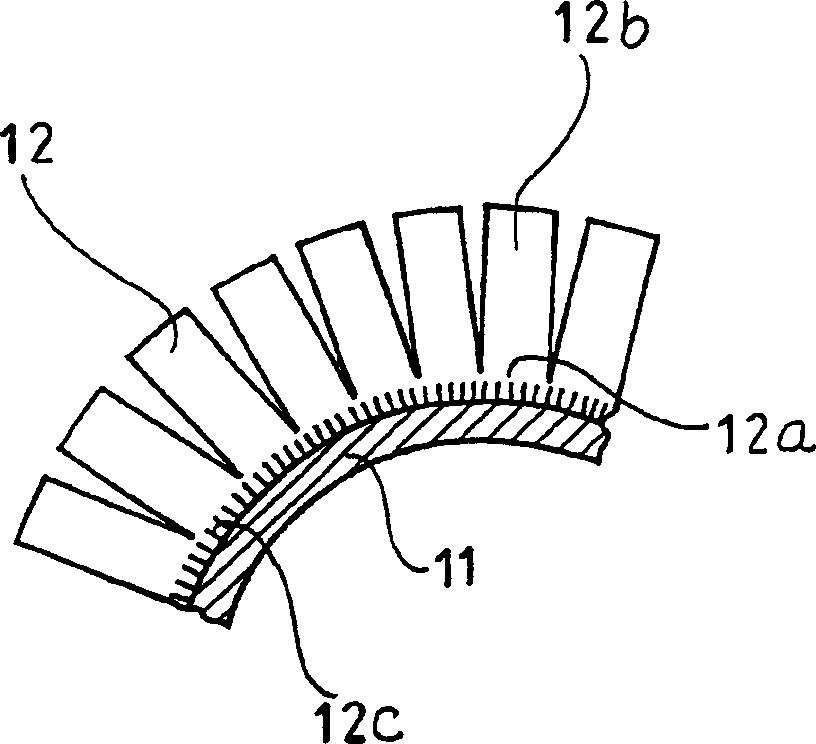

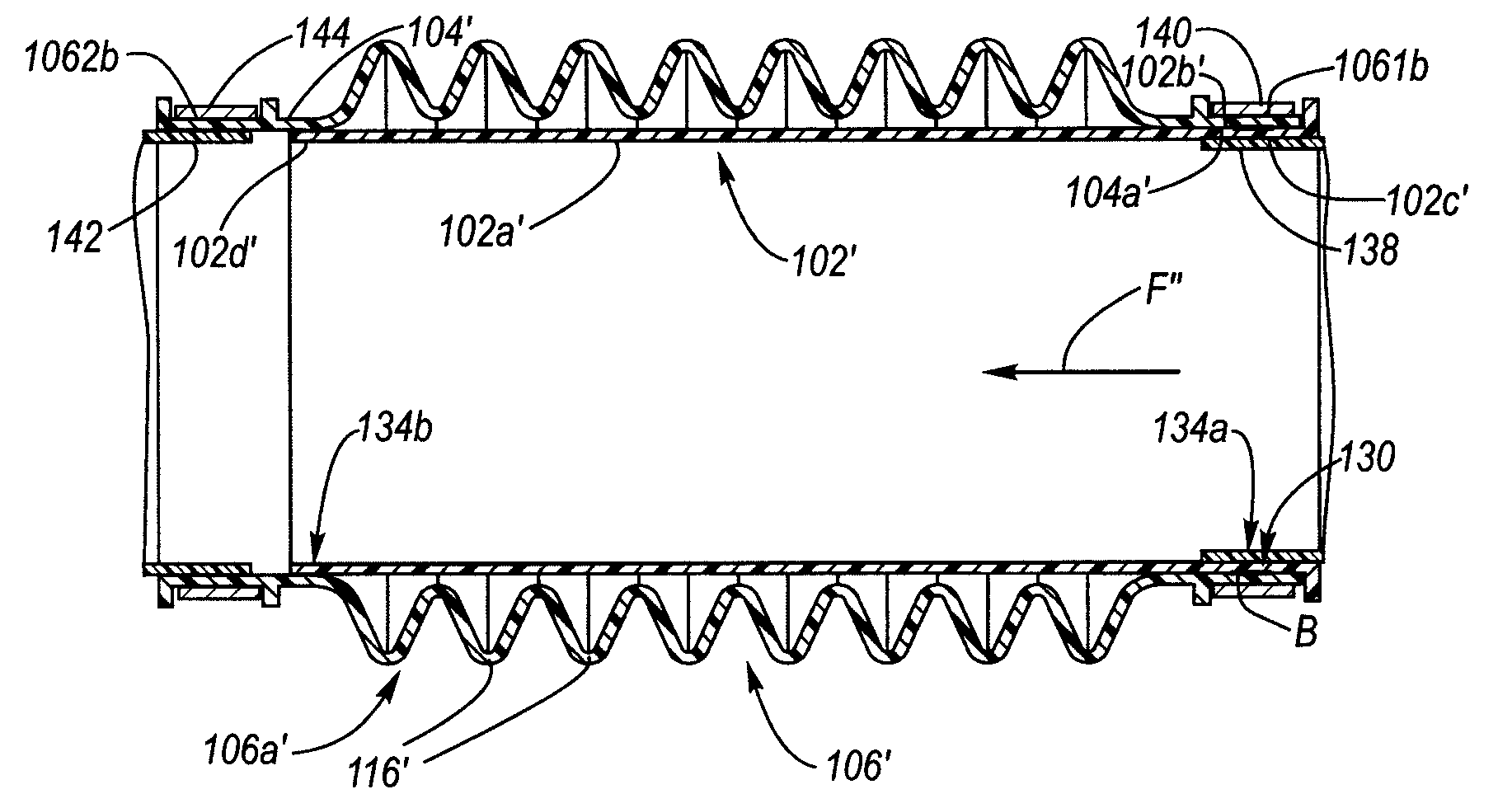

A heat exchanger, combination with heat exchanger and method of manufacturing the heat exchanger

InactiveCN1585884ANo loss of efficiencySmall pressure lossDistrict heating systemRecuperative heat exchangersPlate heat exchangerHelical coil

A heat exchanger for heat exchange between a first and a second fluid and comprising a cylindrical casing 2 , a cylindrical fluid conduit 5 arranged inside the casing such that an axially extending tubular space 8 is defined, at least one helical coil 9, 10 of a finned or corrugated tube being arranged inside the tubular space, and adjustable throttle means 17, 17 a , 18 adapted and arranged for adjustably throttling flow of the first fluid through the conduit 5 to adjust the flow of the first fluid through the conduit and the first tubular space for adjusting the heat exchange between the first fluid and the second fluid flowing through the helical coils 9, 10.

Owner:AALBORG IND

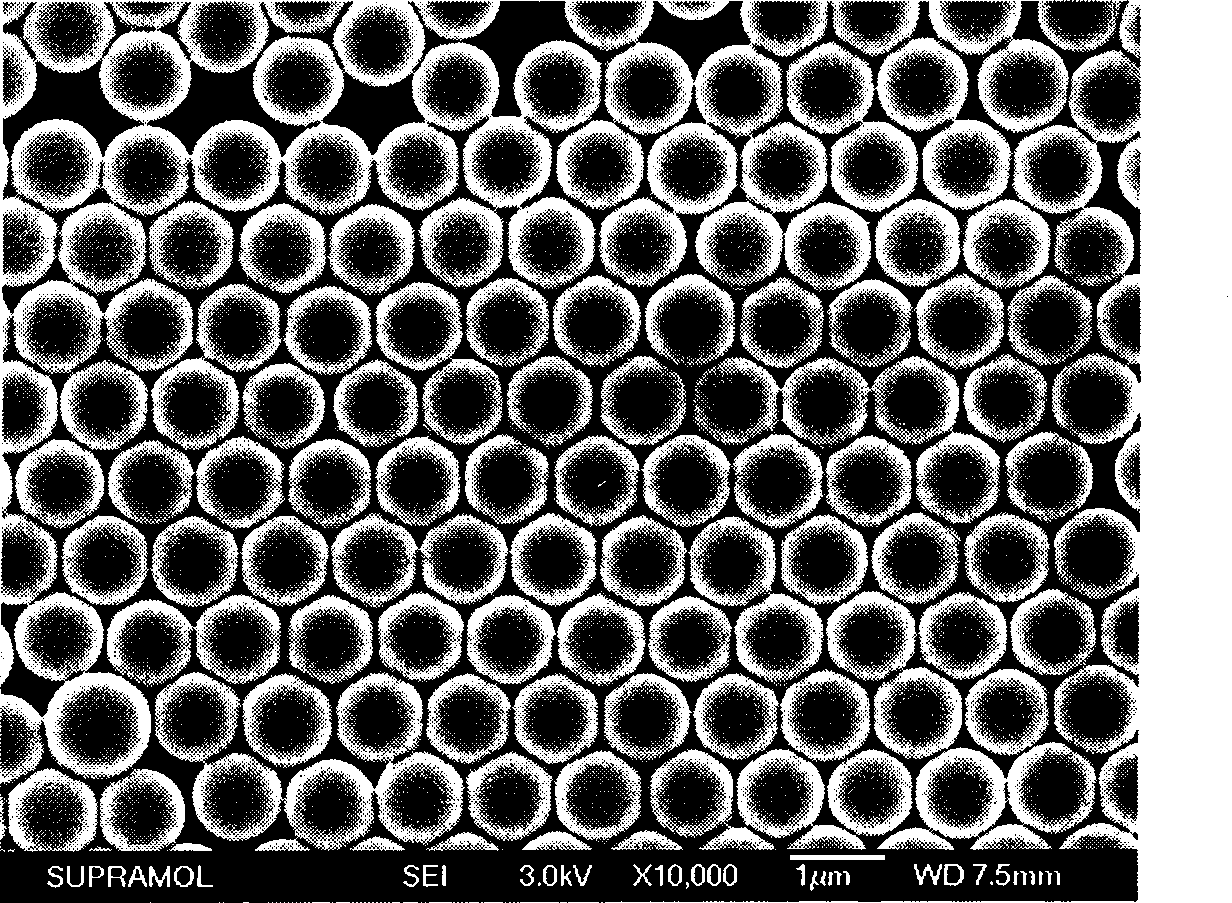

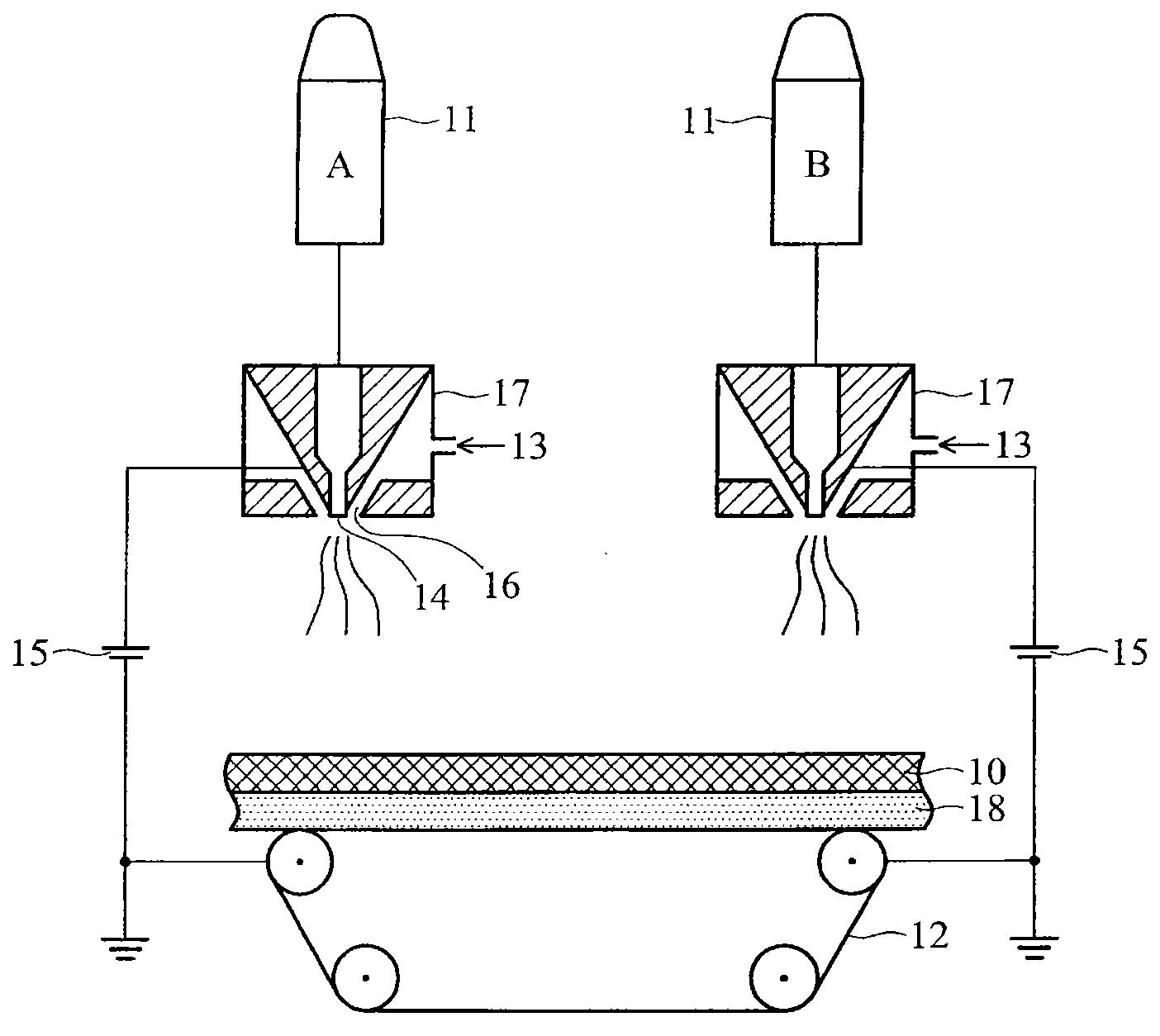

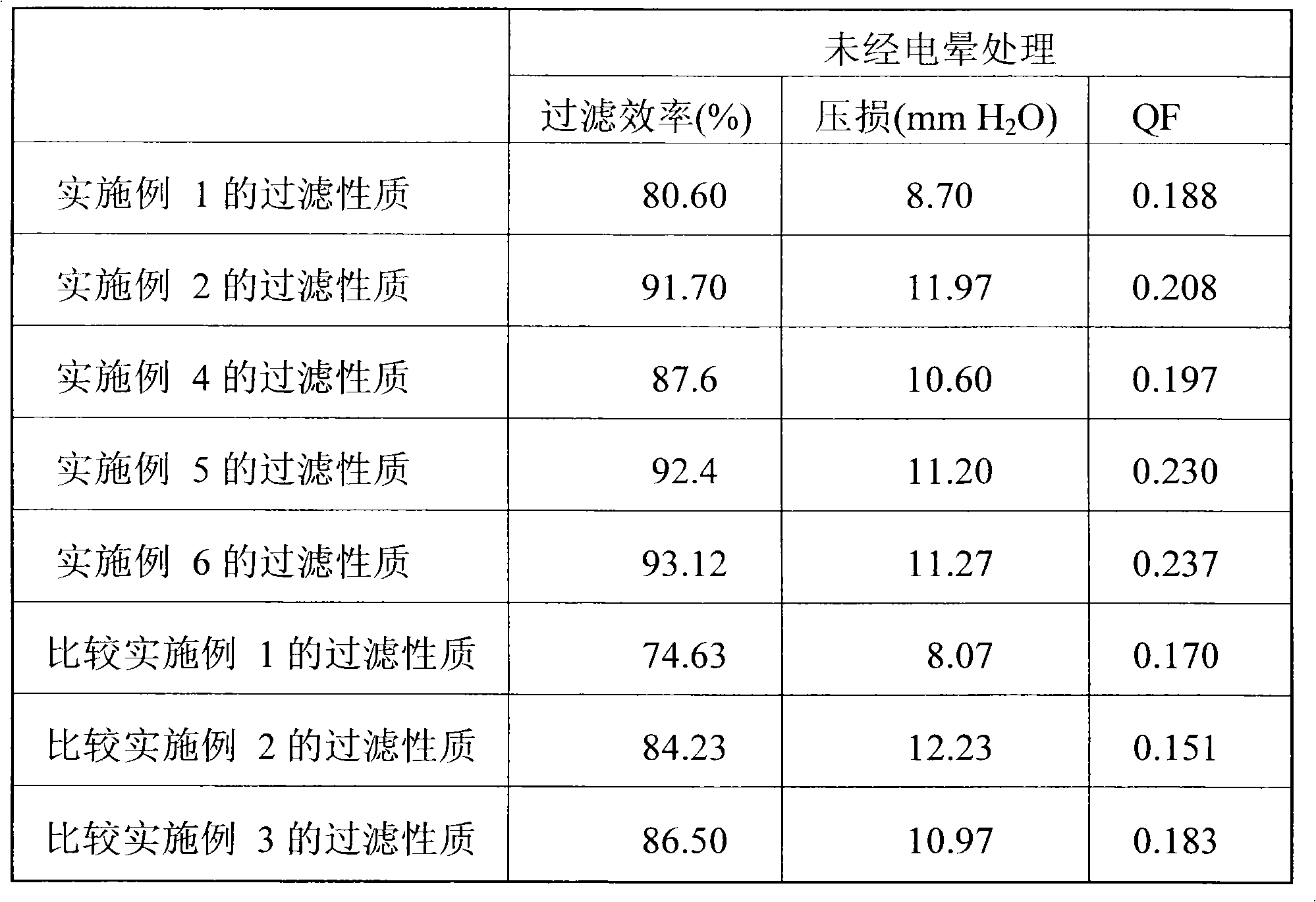

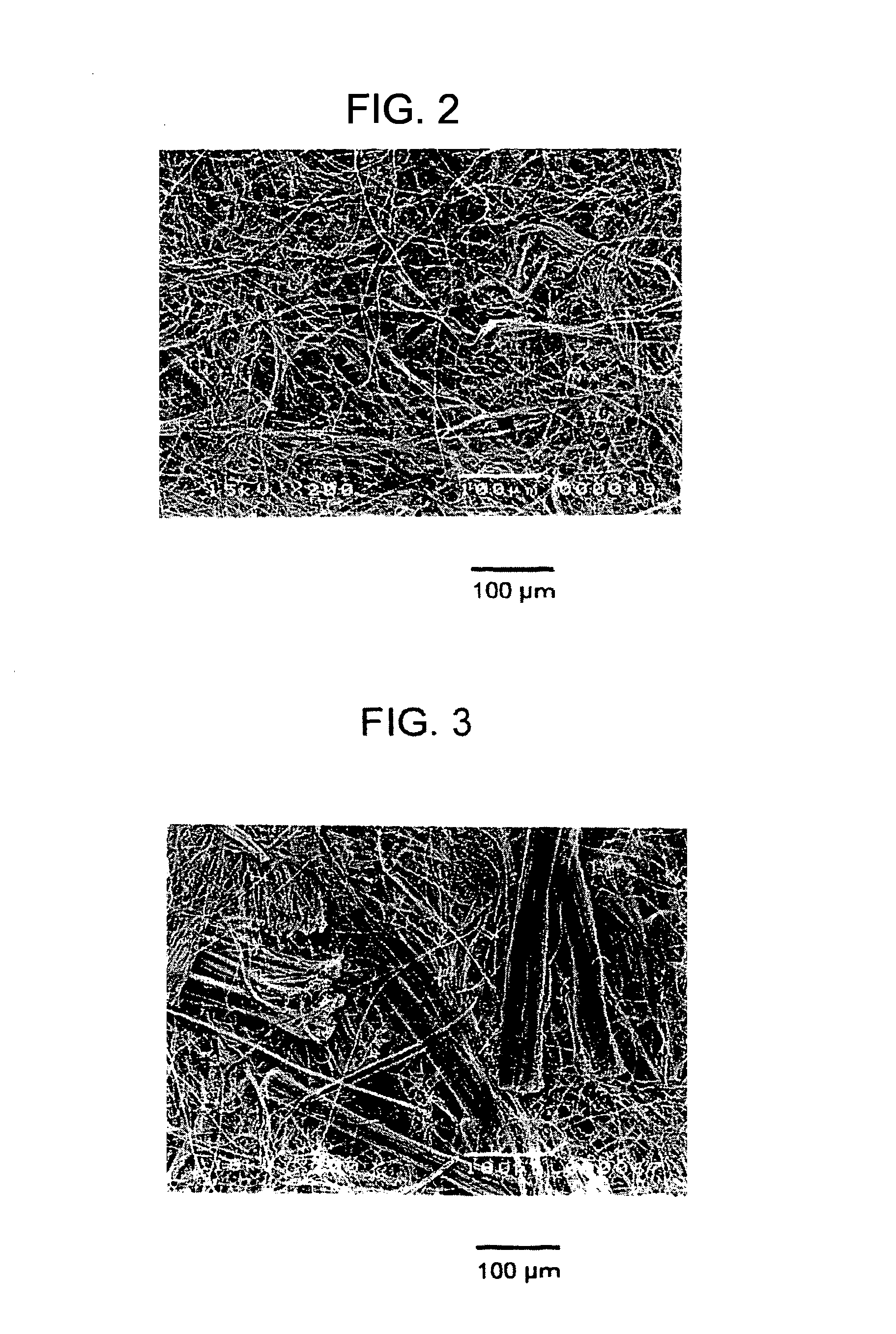

Nanofiber filtration material and forming method thereof

InactiveCN101653676AImprove efficiencySmall pressure lossFiltration separationNon-woven fabricsPolymer scienceFiltration

The invention relates to a nanofiber cotton net containing more than two different fiber diameter distributions, which is prepared from a polymer solution by an electrospinning method. More than two nanofibers with different fiber diameters are interlaced with each other in the process of electrospinning to form a nanofiber cotton net layer as a nanofiber filtration material of the invention. Thefiltration material has the characteristics of high efficiency and low pressure loss.

Owner:IND TECH RES INST

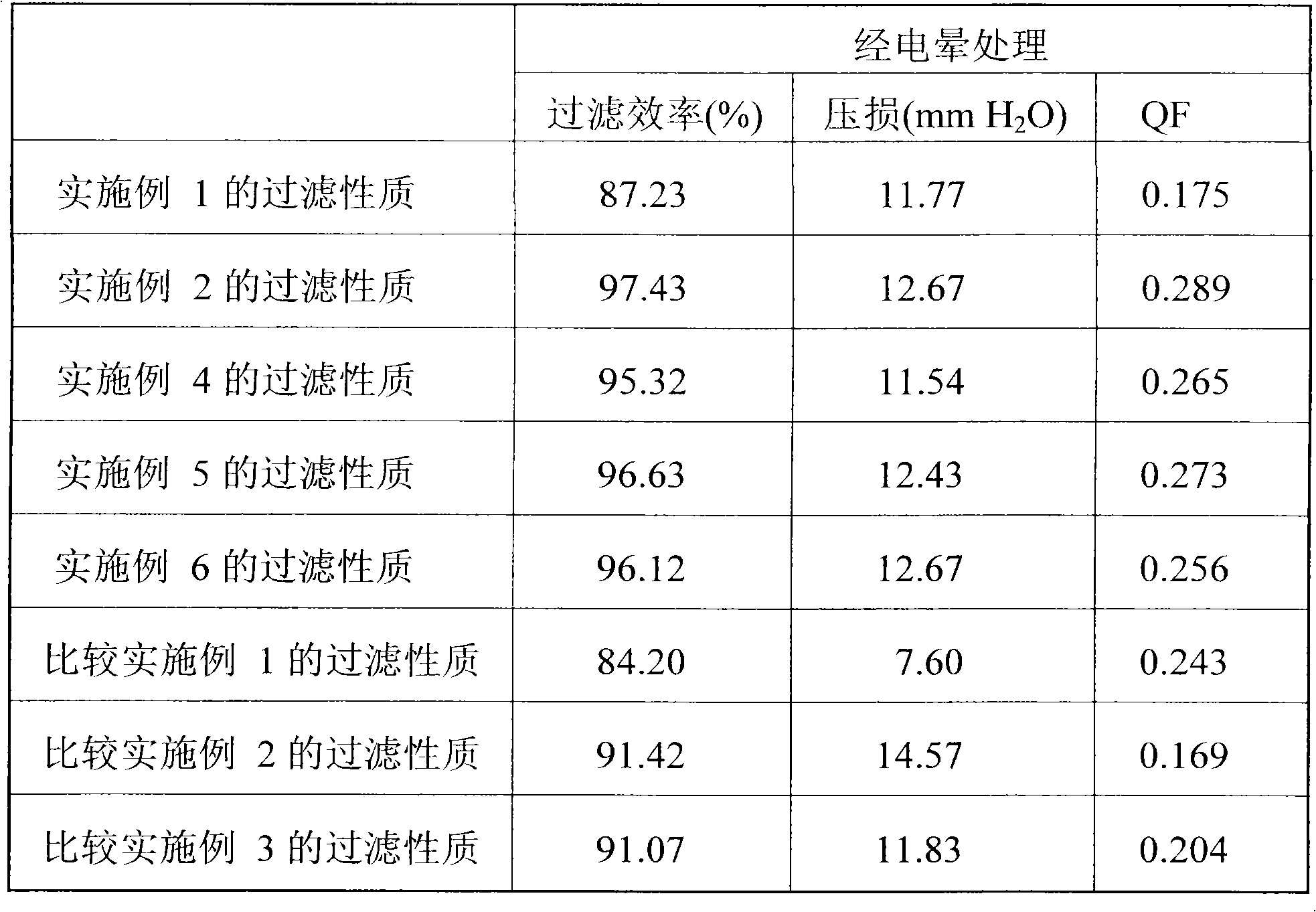

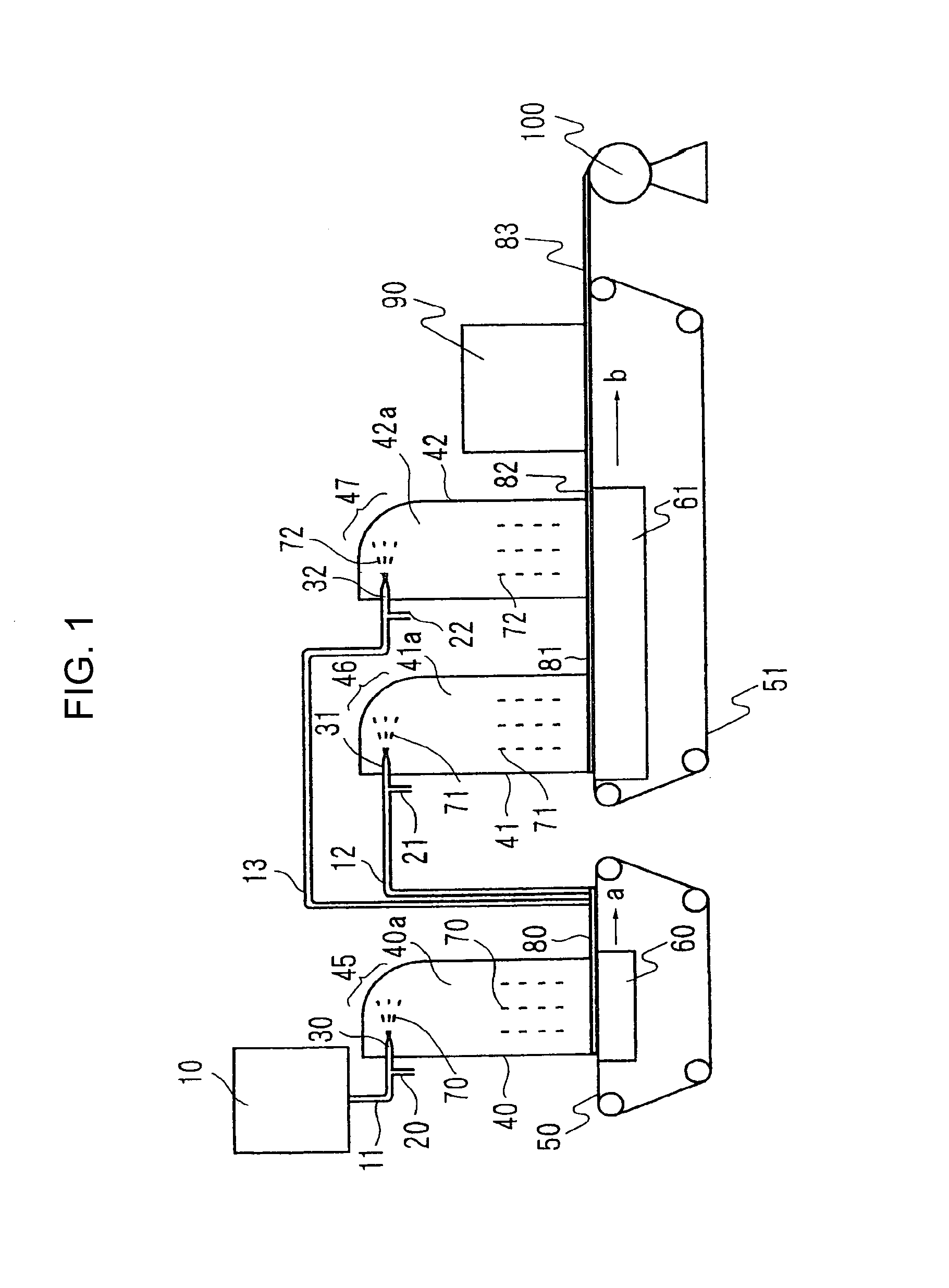

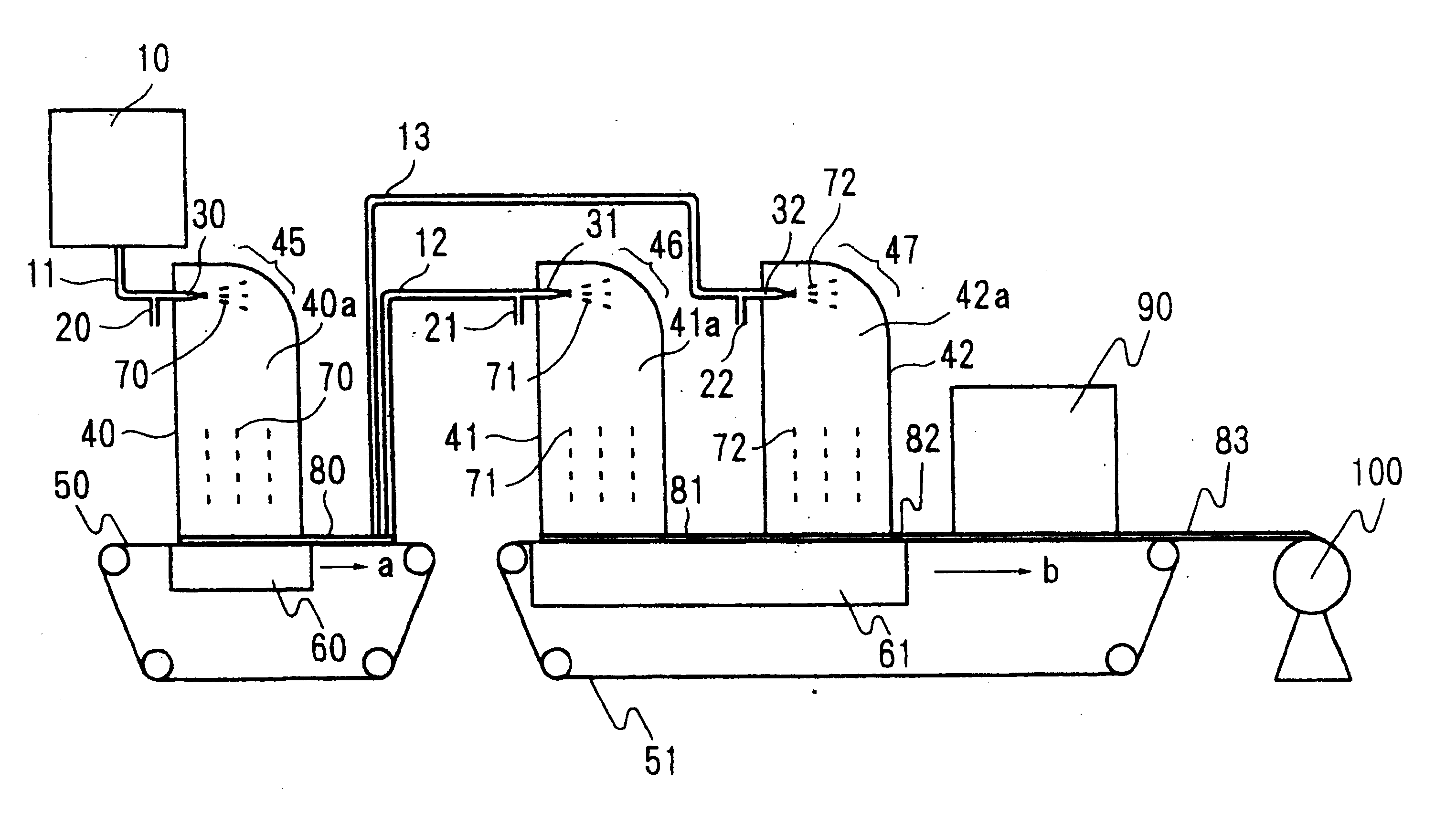

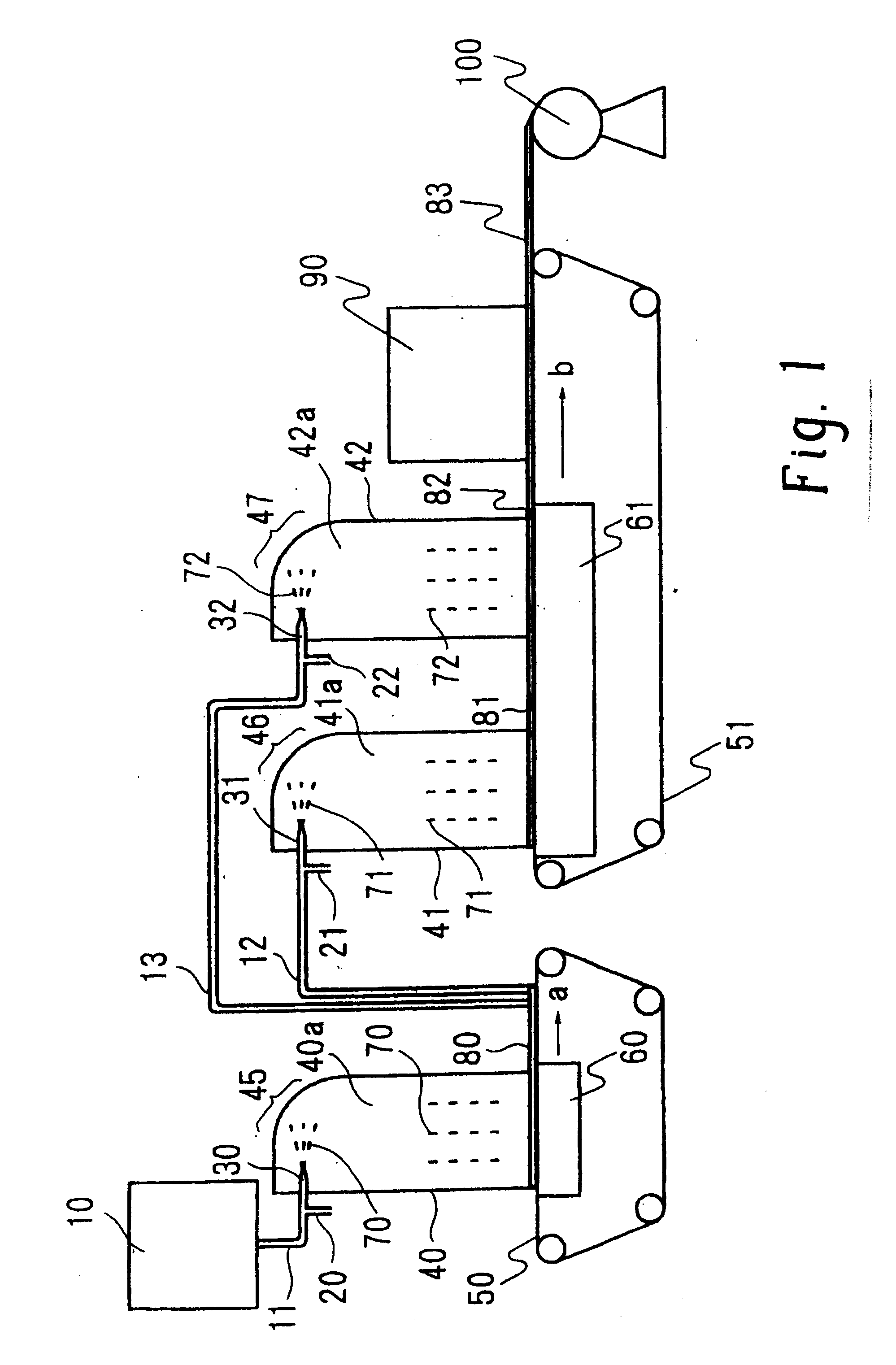

Fine-fibers-dispersed nonwoven fabric, process and apparatus for manufacturing same, and sheet material containing same

InactiveUS7837814B2High apparent densityGood adhesionSynthetic resin layered productsAbrasion apparatusPolymer scienceFiber diameter

Disclosed is a fine-fibers-dispersed nonwoven fabric comprising dispersed fine fibers having a fiber diameter of 4 μm or less and a fiber length of 3 mm or less, wherein an adhesion rate of substances adhered to the nonwoven fabric is 0.5 mass % or less. Further, a process and an apparatus for manufacturing the fine-fibers-dispersed nonwoven fabric, as well as a sheet material comprising the fine-fibers-dispersed nonwoven fabric are also disclosed.

Owner:JAPAN VILENE CO LTD

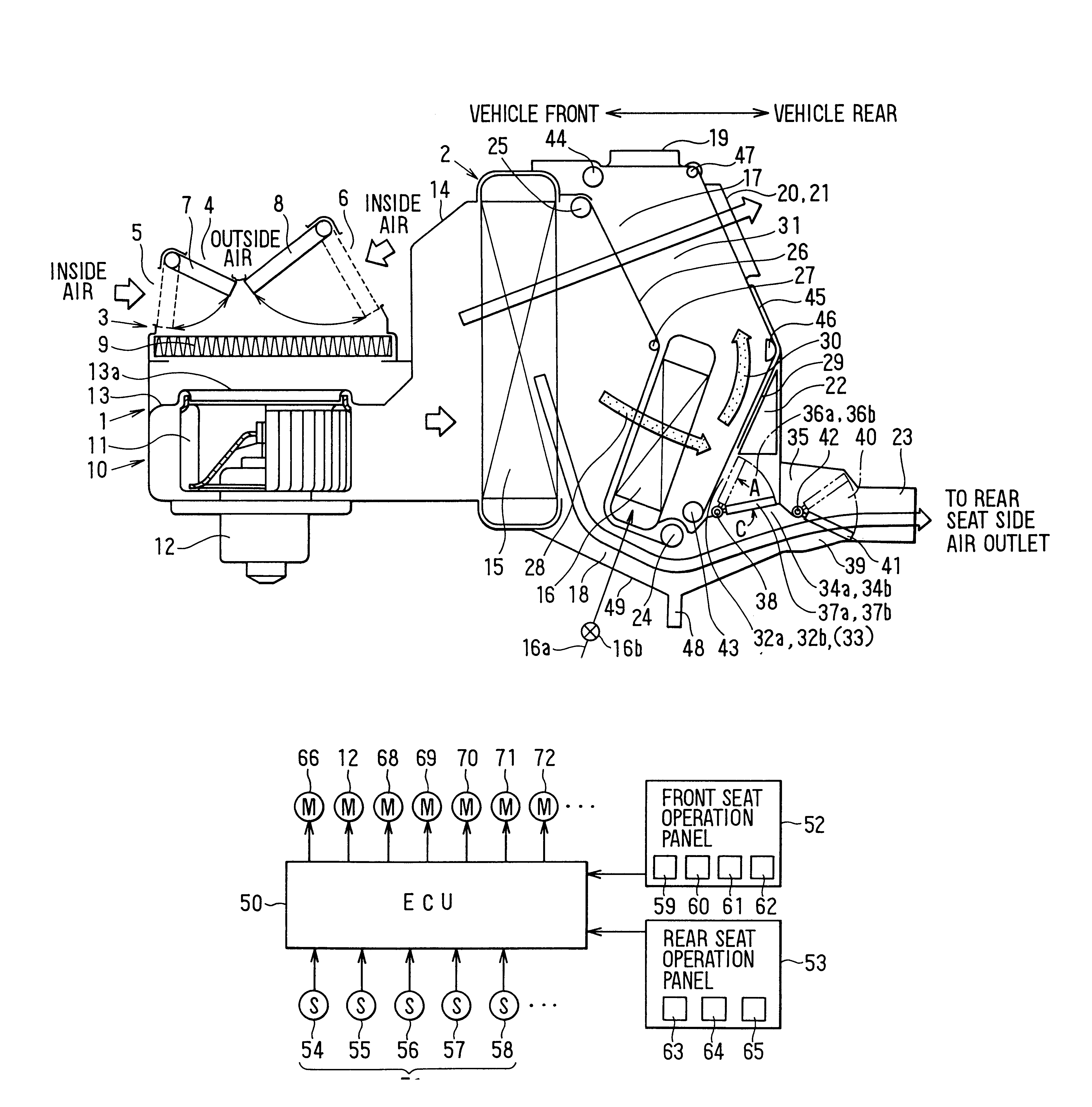

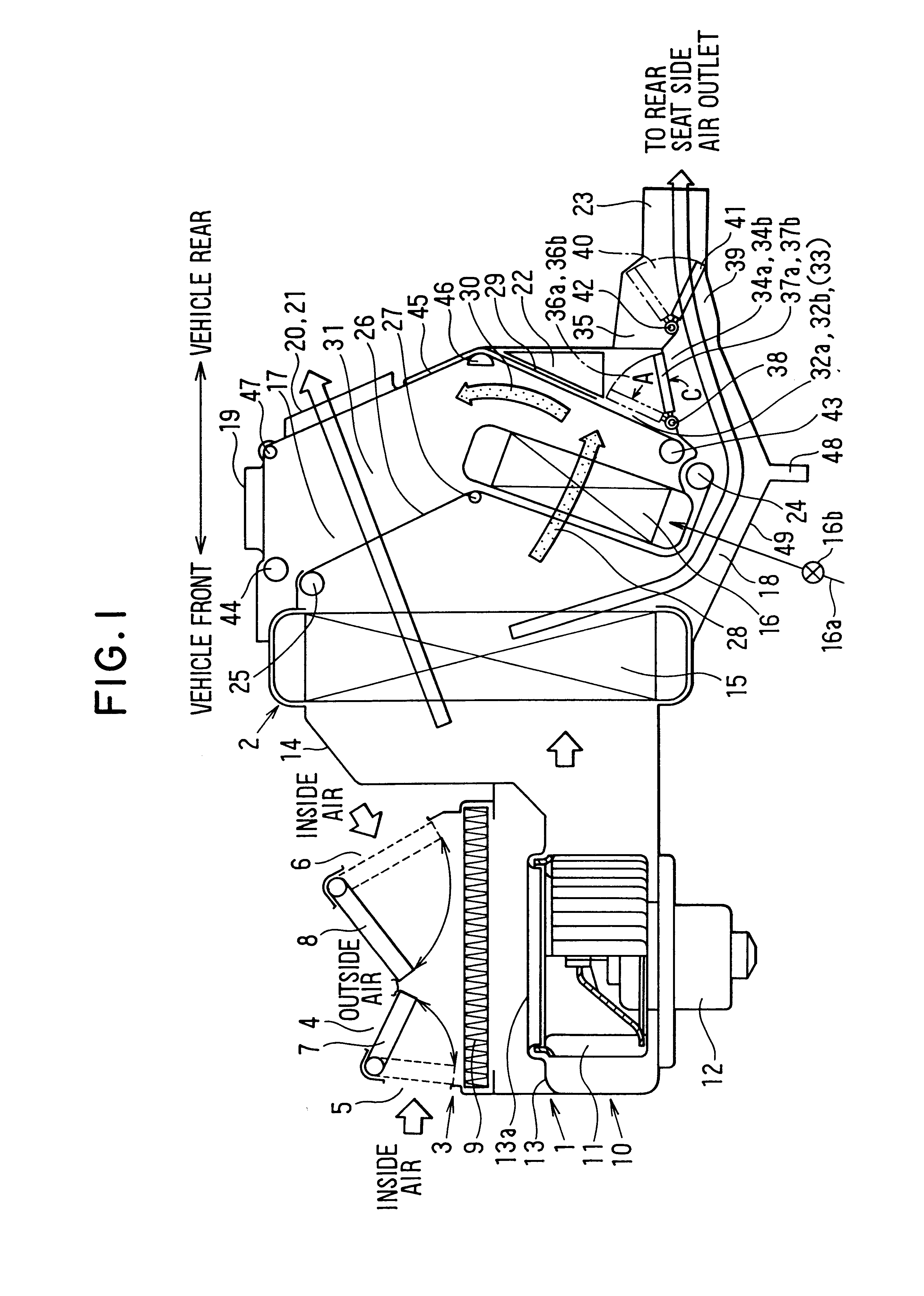

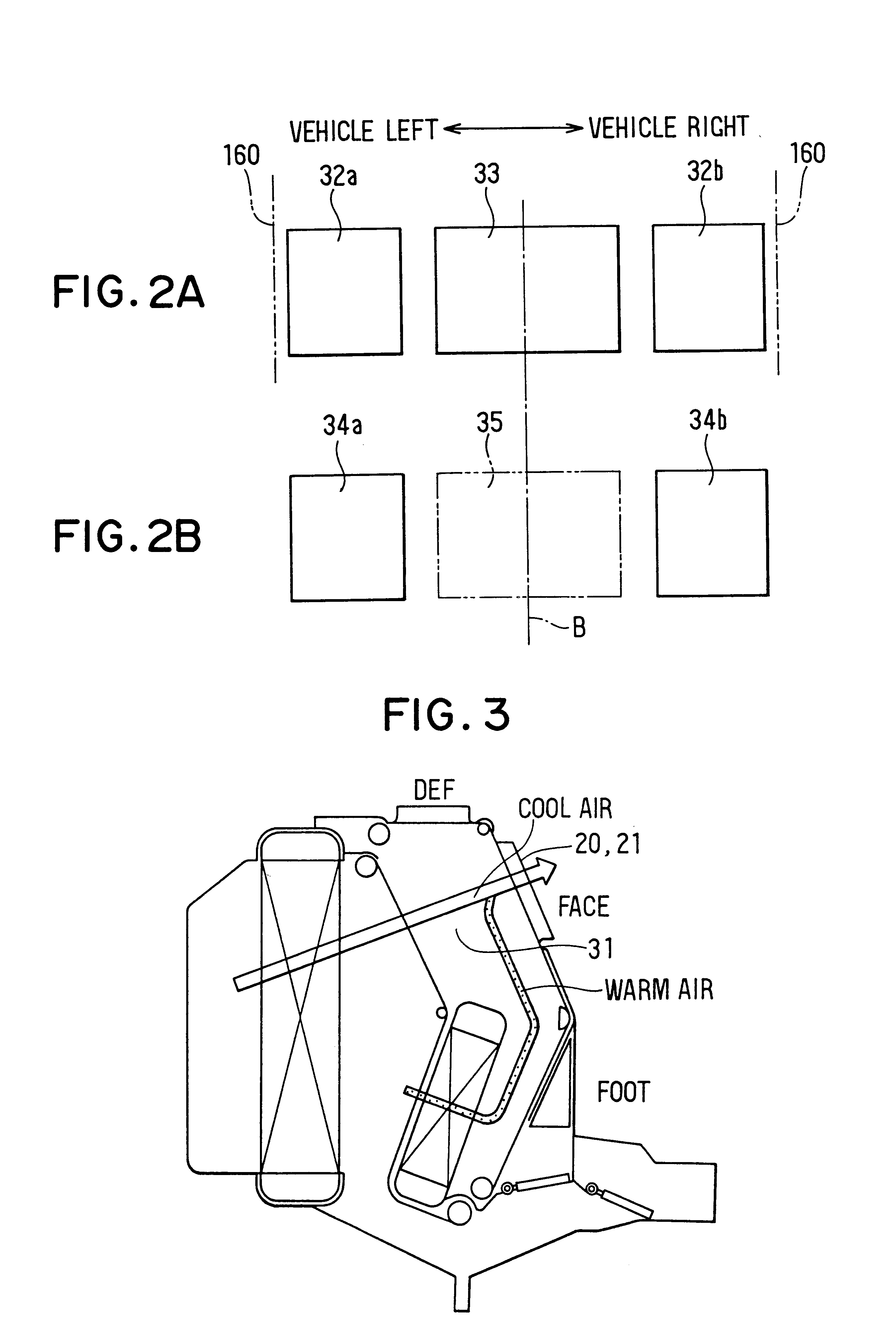

Air conditioning apparatus for vehicle

InactiveUS6568468B1Reduce device sizeReduce total pressure lossValve arrangementsAir-treating devicesCold airEngineering

In an air conditioning apparatus for a vehicle, a first cool air bypass passage is provided at an upper side of a heater core, and a second cool air bypass passage is provided at a lower side of the heater core. Cool air from the first cool air bypass passage and warm air having passed through the heater core are mixed in a first air mixing chamber, and a ratio between an amount of cool air and an amount of warm air is adjusted by an air mixing film member. Further, cool air from the second cool air bypass passage and warm air from the heater core are mixed in a second air mixing chamber, a ratio between an amount of cool air and an amount of warm air is adjusted by an air mixing door, and the second air mixing chamber is provided at an immediately downstream air side of the heater core. Thus, in the air conditioning apparatus, a pressure loss in a ventilation system can be reduced.

Owner:DENSO CORP

Ceramic honeycomb filter and its structure

InactiveUS6890616B2Small pressure lossLong-term useCombination devicesInternal combustion piston enginesPorosityParticulates

A ceramic honeycomb filter comprising a ceramic honeycomb structure having porous partition walls defining a plurality of flow paths for flowing an exhaust gas through the porous partition walls to remove particulates from the exhaust gas, wherein one end of each flow path is provided with a sealer, such that sealers of the flow paths in an inlet and an outlet of the ceramic honeycomb structure in a desired pattern; wherein the partition walls have thickness of 0.1-0.5 mm and a porosity of 50-80%; wherein the porosity of the sealers is larger than that of partition walls; and wherein the depth of the sealers is 3-15 mm.

Owner:HITACHI METALS LTD

Mager vorgemischte dual-fuel-ringrohrbrennkammer mit radial-mehrring-stufenduse

InactiveCN101424407AReduce in quantitySimplify the headendContinuous combustion chamberEfficient propulsion technologiesCombustorTurbine

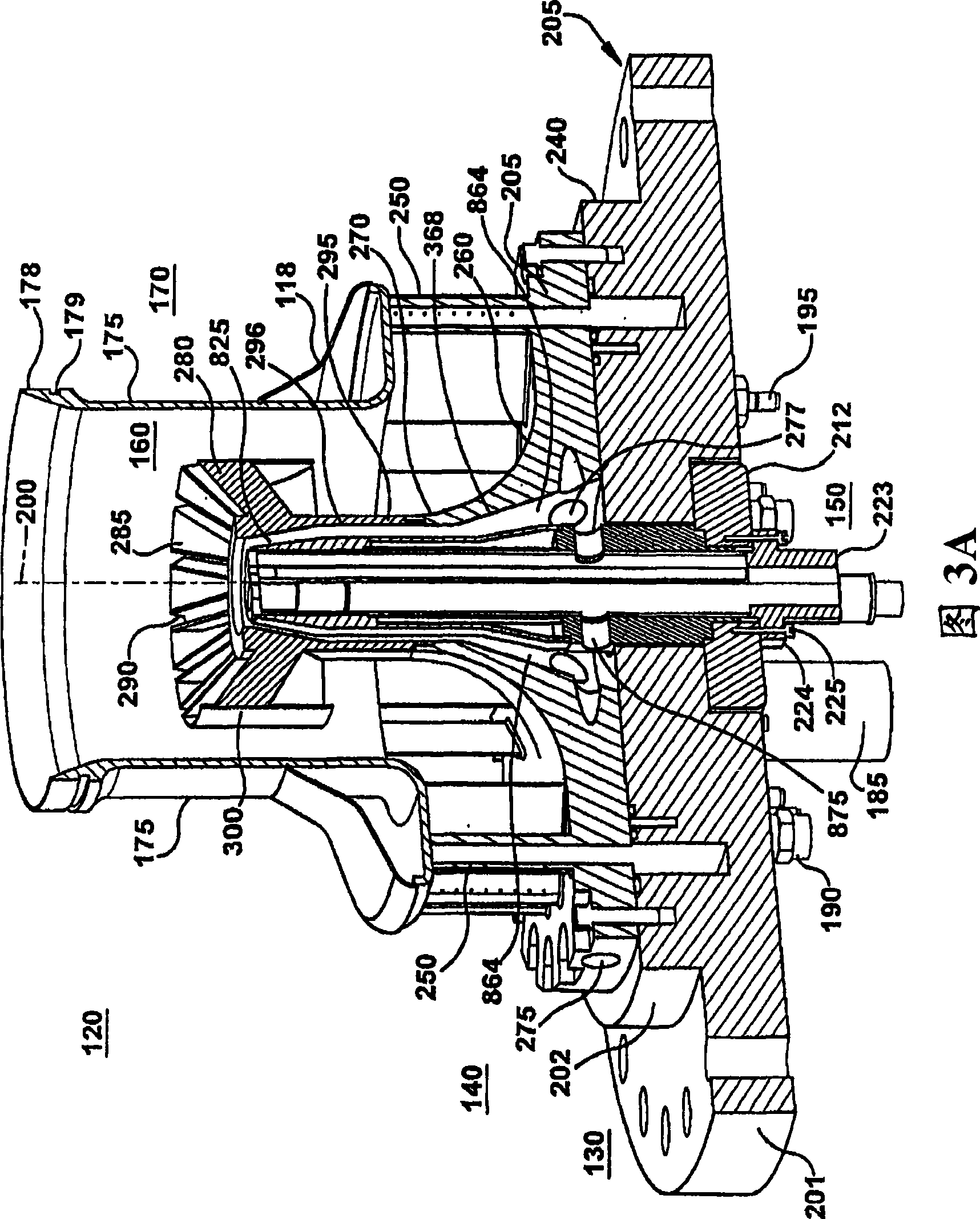

A lean premixed, radial inflow, multi-annular staged nozzle for creating three independent combustion zones within a can-annular, dual-fuel gas turbine combustor is provided. The nozzle includes a pilot zone fueled by a gas pilot nozzle and center cartridge; a flame holder zone fueled by an inner main gas fuel; a main flame zone fueled by an outer main gas fuel; a main radial swirler for mixing a portion of incoming air to the nozzle with the inner main gas fuel supply and the outer main gas fuel supply; an endcover; and means for controlling the ratio of an inner main gas fuel supplied and an outer main gas fuel supplied.

Owner:GENERAL ELECTRIC CO

Engine cooling water jacket

InactiveCN102042116AImprove powerImprove performanceLiquid coolingCylinder headsThermal stateEngineering

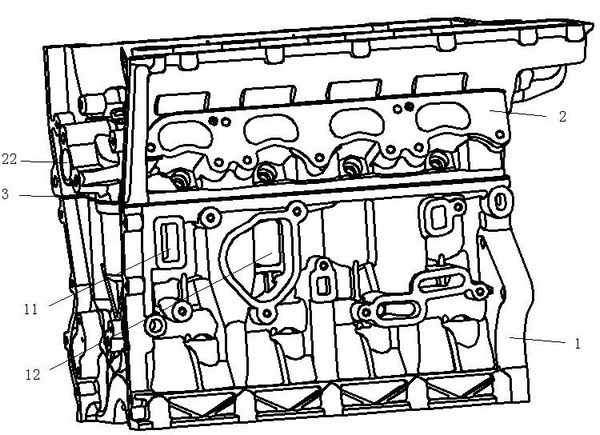

The invention provides an engine cooling water jacket which has the advantages of simple structure, small volume, uniform flow rate and low pressure loss. The engine cooling water jacket comprises a cylinder body water jacket and a cylinder cover water jacket, wherein the cylinder body water jacket is separated by two baffle plates to form a first flow channel and a second flow channel, and the first flow channel and the second flow channel are communicated with the cylinder cover water jacket through water holes in a cylinder gasket; and coolant mainly flows into the first flow channel from a water inlet and flows through an air exhaust side, then flows into the cylinder cover water jacket through the water holes at one side of the cylinder gasket, subsequently flows into the second flow channel through the water holes at the other side of the cylinder gasket and flows through an air admission side, and finally flows out from a water outlet. Thus, the invention enables the flow rate of the coolant in the whole engine cooling water jacket to be more uniform, reduces the thermal-state deformation of the cylinder holes and improves the dynamic performance of the engine; and the water holes in the cylinder gasket can be arranged as required without being influenced by the design of traditional water jacket cylinder holes, thereby integrally increasing the flow areas of the water holes in the cylinder gasket, reducing the pressure loss of the whole water jacket and lowering the performance requirements for water pumps.

Owner:CHERY AUTOMOBILE CO LTD

Fine-fibers-dispersed nonwoven fabric, process and apparatus for manufacturing same, and sheet material containing same

InactiveUS20060081330A1Maintain good propertiesSmall pressure lossSynthetic resin layered productsAbrasion apparatusPolymer scienceFiber diameter

Disclosed is a fine-fibers-dispersed nonwoven fabric comprising dispersed fine fibers having a fiber diameter of 4 μm or less and a fiber length of 3 mm or less, wherein an adhesion rate of substances adhered to the nonwoven fabric is 0.5 mass % or less. Further, a process and an apparatus for manufacturing the fine-fibers-dispersed nonwoven fabric, as well as a sheet material comprising the fine-fibers-dispersed nonwoven fabric are also disclosed.

Owner:NIPPON BAIRIIN

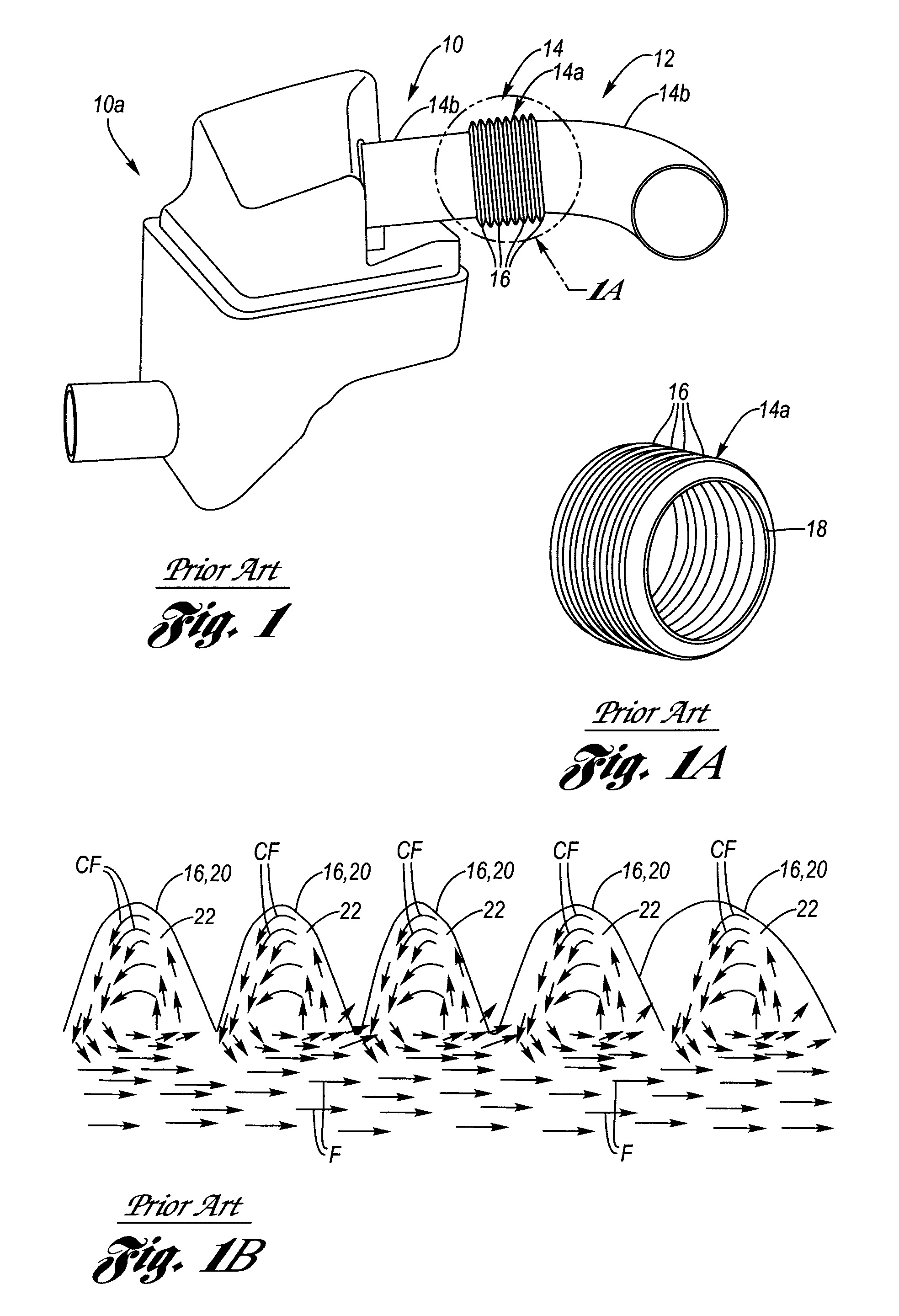

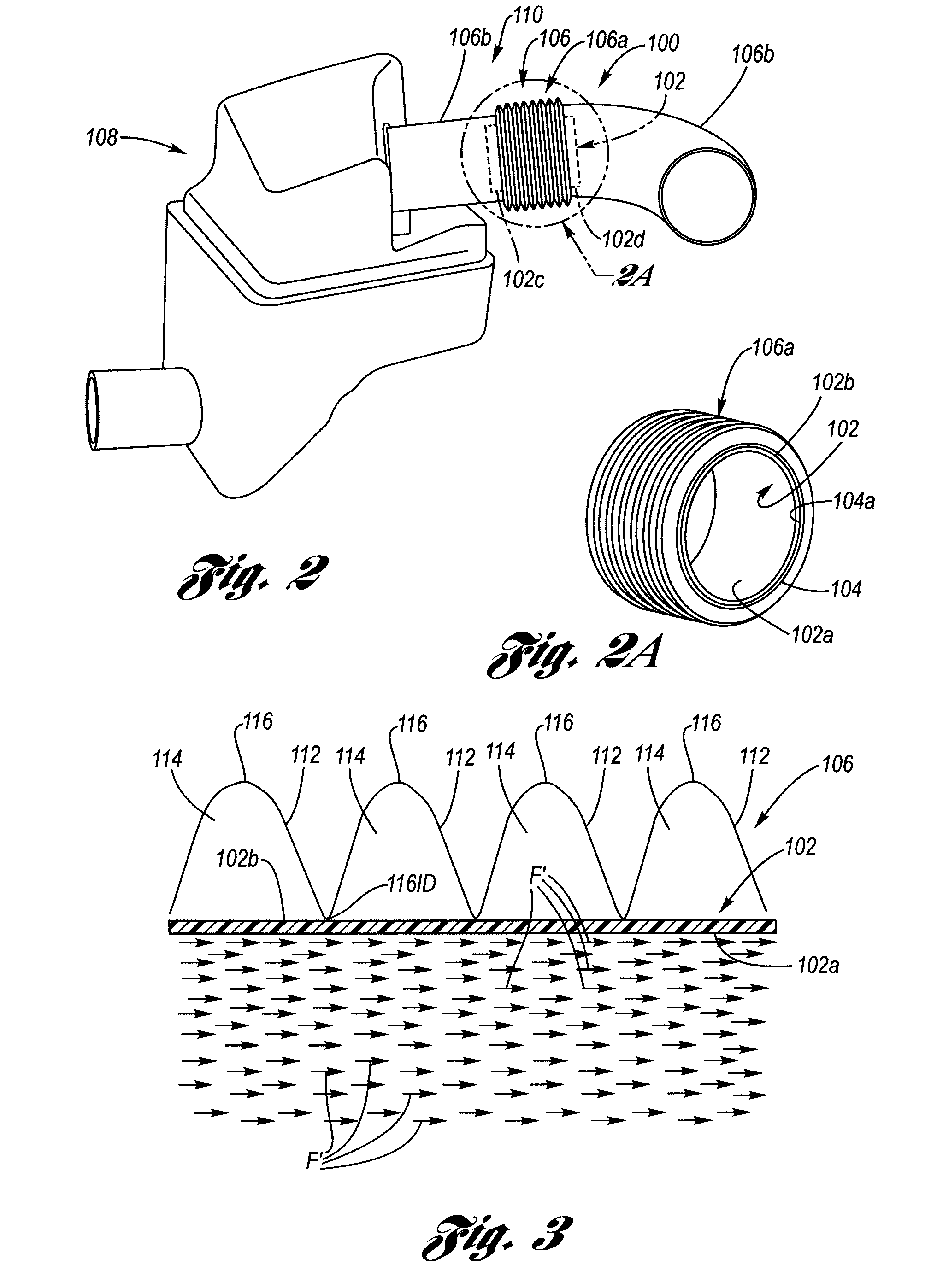

Flexible sleeve liner for a convolute duct

InactiveUS7398798B2Avoids inherent frictional pressure lossSmall pressure lossSleeve/socket jointsInternal combustion piston enginesEngineeringCuff

Owner:GM GLOBAL TECH OPERATIONS LLC

Filter element

InactiveUS6818037B2Easy to cleanSmall pressure lossCombination devicesDispersed particle filtrationVolumetric Mass DensityEngineering

A filter element is made of a first filtering member, and a second filtering member that is arranged on a downstream side of the first filtering member and is impregnated with an oil. The first filtering member consists of a downstream wet layer that is impregnated with the oil, which is transferred by contact to the second filtering member, and an upstream dry layer that is not impregnated with the oil. A density of the first filtering member may be set smaller than that of the second filtering member.

Owner:HONDA MOTOR CO LTD +1

Exhaust gas purifying system

ActiveUS7763222B2Improve efficiencyLow pressure lossCombination devicesNitrogen compoundsHoneycombDiesel engine

Owner:NGK INSULATORS LTD

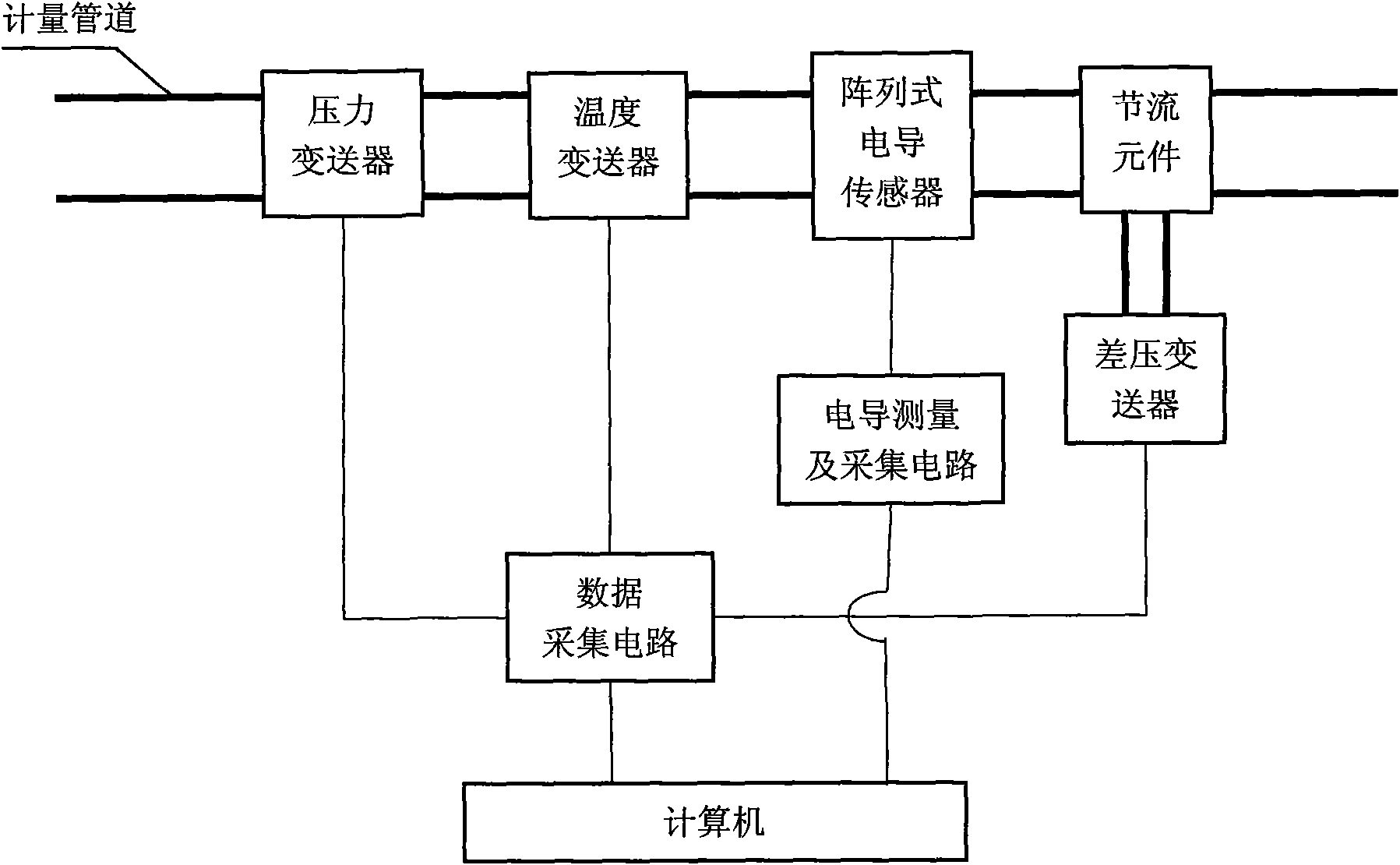

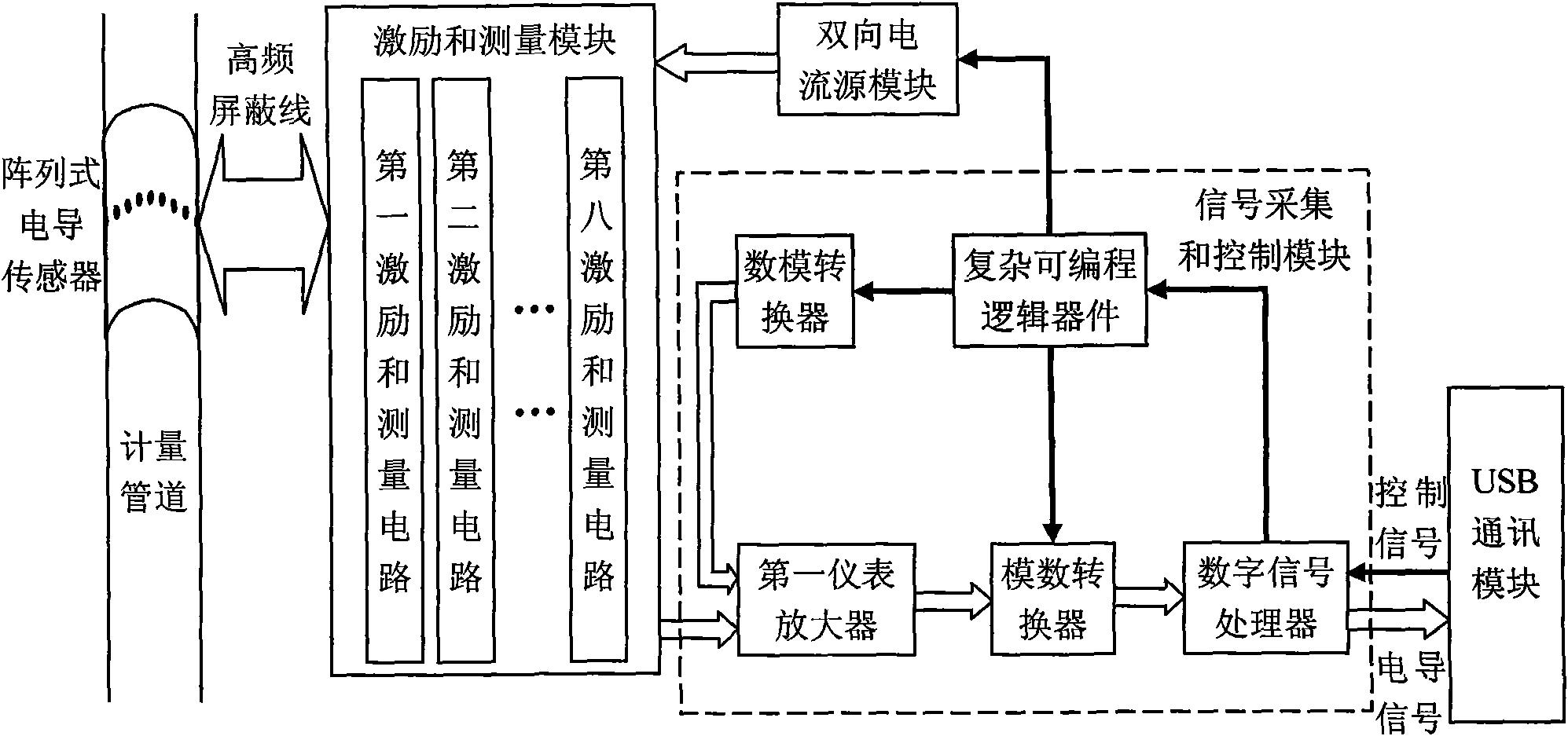

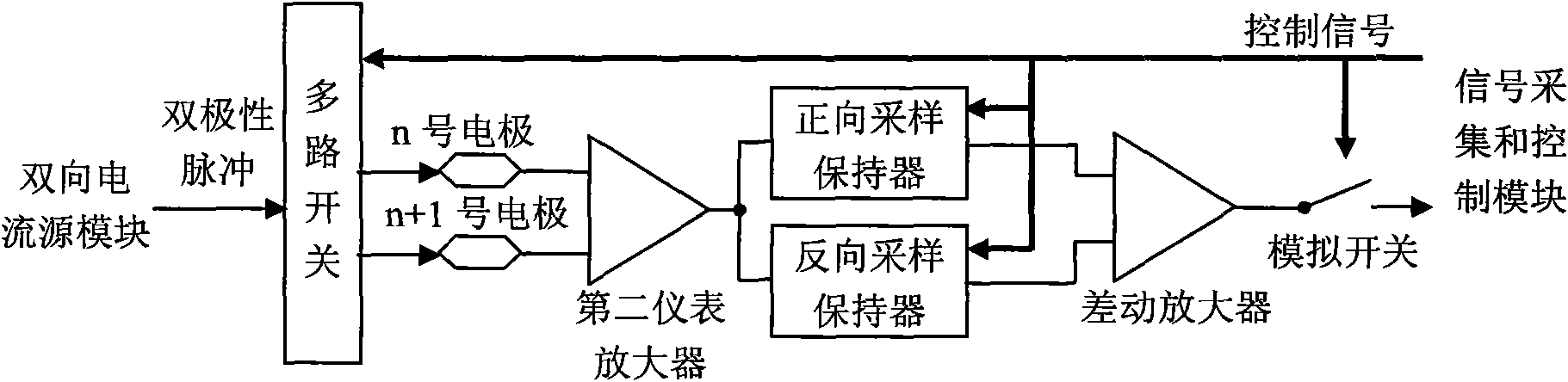

Gas-water two phase flow multiparameter measuring method and device

InactiveCN101556234ASolve online real-time measurement problemsSimple structureFlow propertiesVolume/mass flow by differential pressureVoid ratioDifferential pressure

The invention discloses a gas-water two phase flow multiparameter measuring method and a device thereof, wherein the device comprises a measuring pipe, a throttling element, a differential pressure transmitter, an array conductivity sensor, a pressure transmitter, a temperature transmitter, a conductivity measuring and collecting circuit, a data acquisition circuit and a computer; the array conductivity sensor is connected with the computer through the conductivity measuring and collecting circuit; and each transmitter is connected with the computer through the data acquisition circuit. According to the differential pressure obtained by the throttling element, the conductivity signal obtained by the array conductivity sensor, the pressure obtained by the pressure transmitter, and the temperature obtained by the temperature transmitter, a plurality of parameters such as flow pattern, void ratio, dryness, flow rate and the like of the gas-water two phase flow are obtained. In the measurement, according to the flow pattern judgement result, a corresponding measurement model or relational expression under the flow pattern is selected to calculate the void ratio, dryness and flow rate. The invention has simple structure, small loss of pressure, high reliability, low cost and wide range of application, and can be applied to the gas-water two phase flow measurement in the fields of energy, power, chemical engineering and the like.

Owner:ZHEJIANG UNIV

Cyclone dust collecting apparatus for vacuum cleaner

ActiveUS7678166B2Small pressure lossHigh fine dust collecting efficiencyCleaning filter meansCombination devicesCycloneEngineering

The present disclosure relates to a cyclone dust collecting apparatus for a vacuum cleaner having a high fine dust collecting efficiency. The cyclone dust collecting apparatus includes a first cyclone having an air suction hole through which dust-laden air is drawn-in, the first cyclone forcing the dust-laden air to downwardly whirl in a space under the air suction hole so as to centrifugally separate dust from the dust-laden air; a second cyclone disposed inside the first cyclone, the second cyclone forcing semi-clean air entering from the first cyclone to downwardly whirl so as to centrifugally separate fine dust from the semi-clean air; and an air guiding member forcing the semi-clean air discharged from the first cyclone to directly enter the second cyclone and, the air guiding member having a plurality of guiding blades radially disposed in at least one circular shape based on a vertical axis of the second cyclone.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

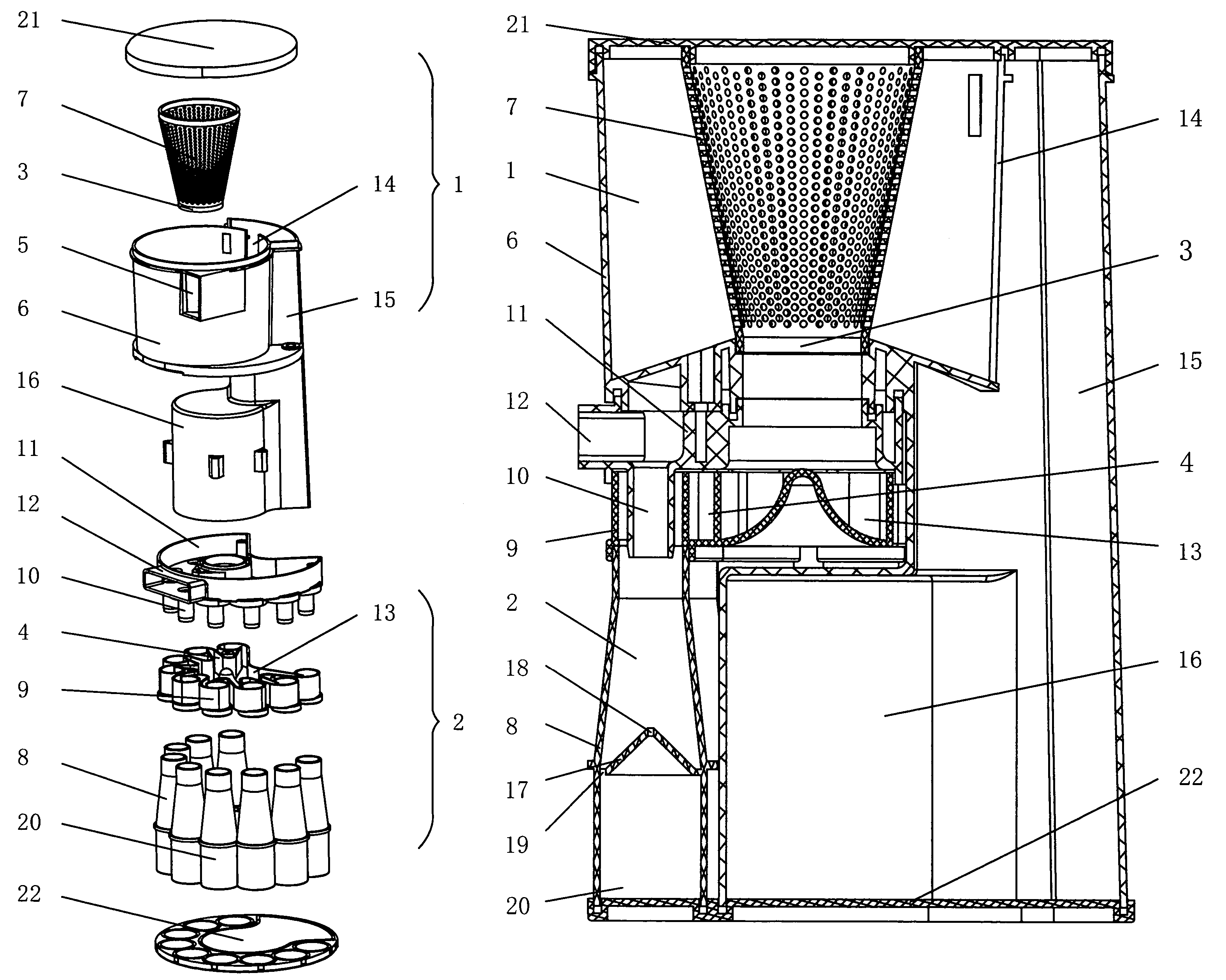

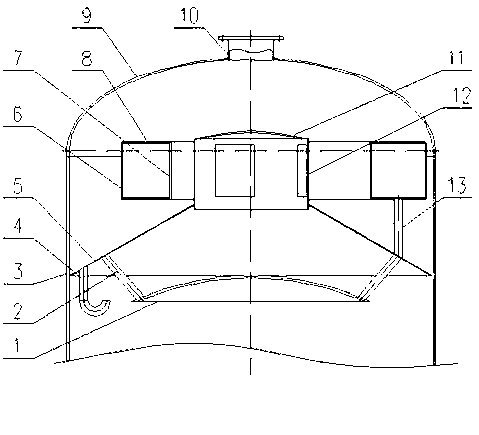

Subsection dedusting device for a vacuum cleaner

ActiveUS7540894B2Increase air volumeWithout increasing the whole bulk of the machineCleaning filter meansCombination devicesCycloneEngineering

This invention discloses a subsection dedusting device for a vacuum cleaner comprising an upper cyclone separator including a wind outlet and several lower cyclone separators located below said upper cyclone separator, wind inlets of said lower cyclone separators in fluid communication with said wind outlet of said upper cyclone separator, thereby increasing wind quantity while reducing the whole bulk of the machine, and keeping a relatively high dedusting efficiency, and besides the lower cyclone separator of the present invention adopts a pervasion construction, and air flow rotates in a decelerated and acentric state in the conical barrel, thereby the pressure loss of the air flow is little, and accordingly, obtain a good dust suction effect.

Owner:SUZHOU KINGCLEAN FLOORCARE

Gas-liquid separating device

ActiveCN102872655ALarge flow cross sectionSmall pressure lossDispersed particle separationTowerMechanics

The invention discloses a device for separating a gas phase and a liquid phase in an air conditioner, a compressor, a tower, or an evaporator. The device comprises a shell cover, a cylindrical structure, and a flow baffling cover, a flow guide conical surface, a flow distributing cylinder, centrifugal channels, a liquid discharge pipe and an exhaust port, wherein the cylindrical structure is arranged below the shell cover, the flow baffling cover and the flow guide conical surface are arranged in the device, the flow distributing cylinder is provided with a top cover, the exhaust port is arranged on the shell cover and is communicated with the external world; the lower bottom of the flow guide conical surface is fixed on the inner wall of the cylindrical structure; the bottom of the flow distributing cylinder is fixed on the top of the flow guide conical surface; the flow baffling cover is fixed on the lower part of the flow guide conical surface through a connecting rod; at least two rectangular holes are equidistantly formed in the side wall of the flow distributing cylinder; the centrifugal channels are arranged at each of the rectangular holes, wherein a section of each of the centrifugal channels is a rectangular expanded section, and the centrifugal channels are arranged along the tangential direction of the flow distributing cylinder; and a liquid channel communicating the upper part and the lower part of a flow guide cone is arranged at the bottom of the flow guide conical surface.

Owner:兰州节能环保工程有限责任公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com