Patents

Literature

132results about How to "Large flow cross-section" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

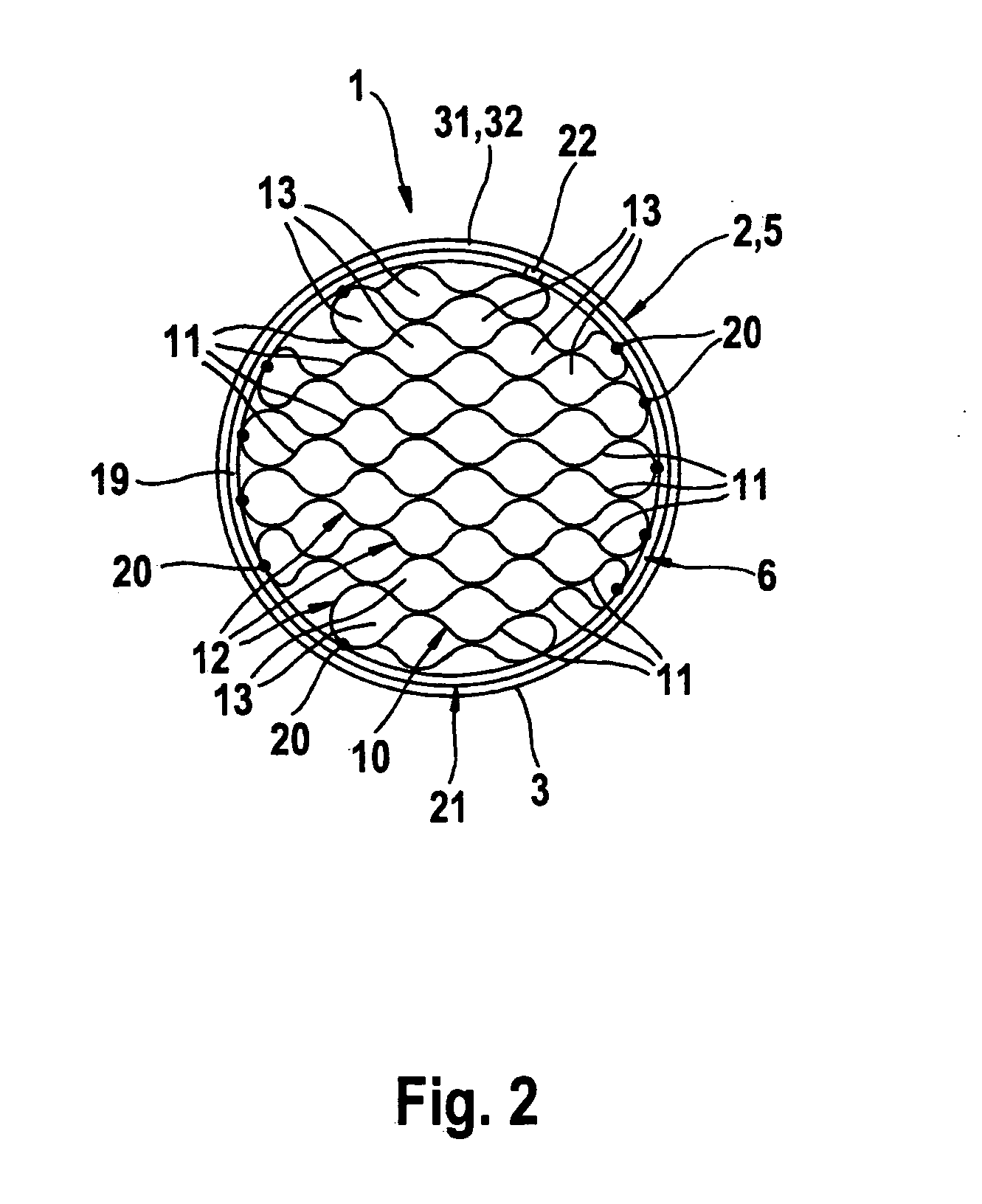

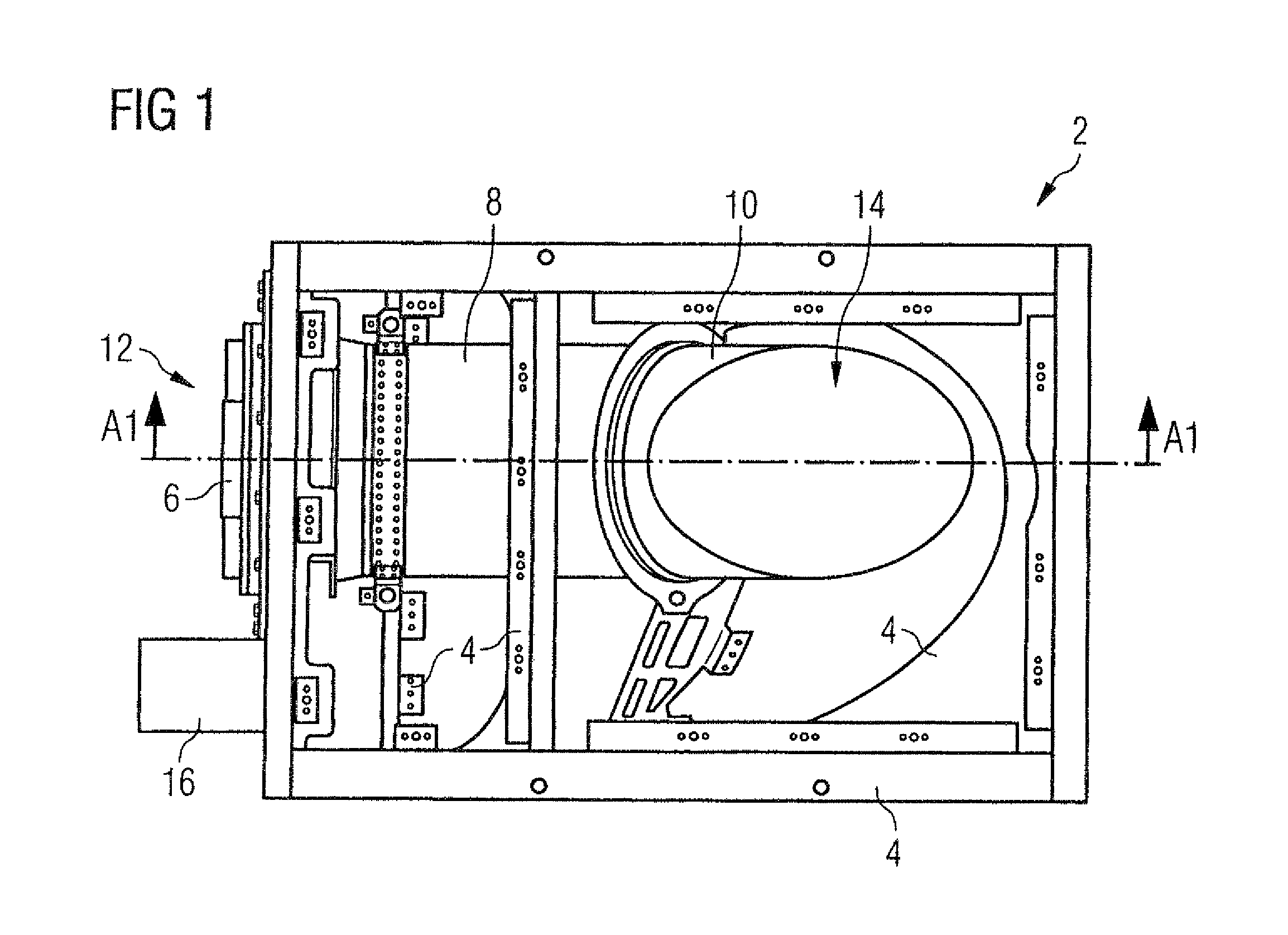

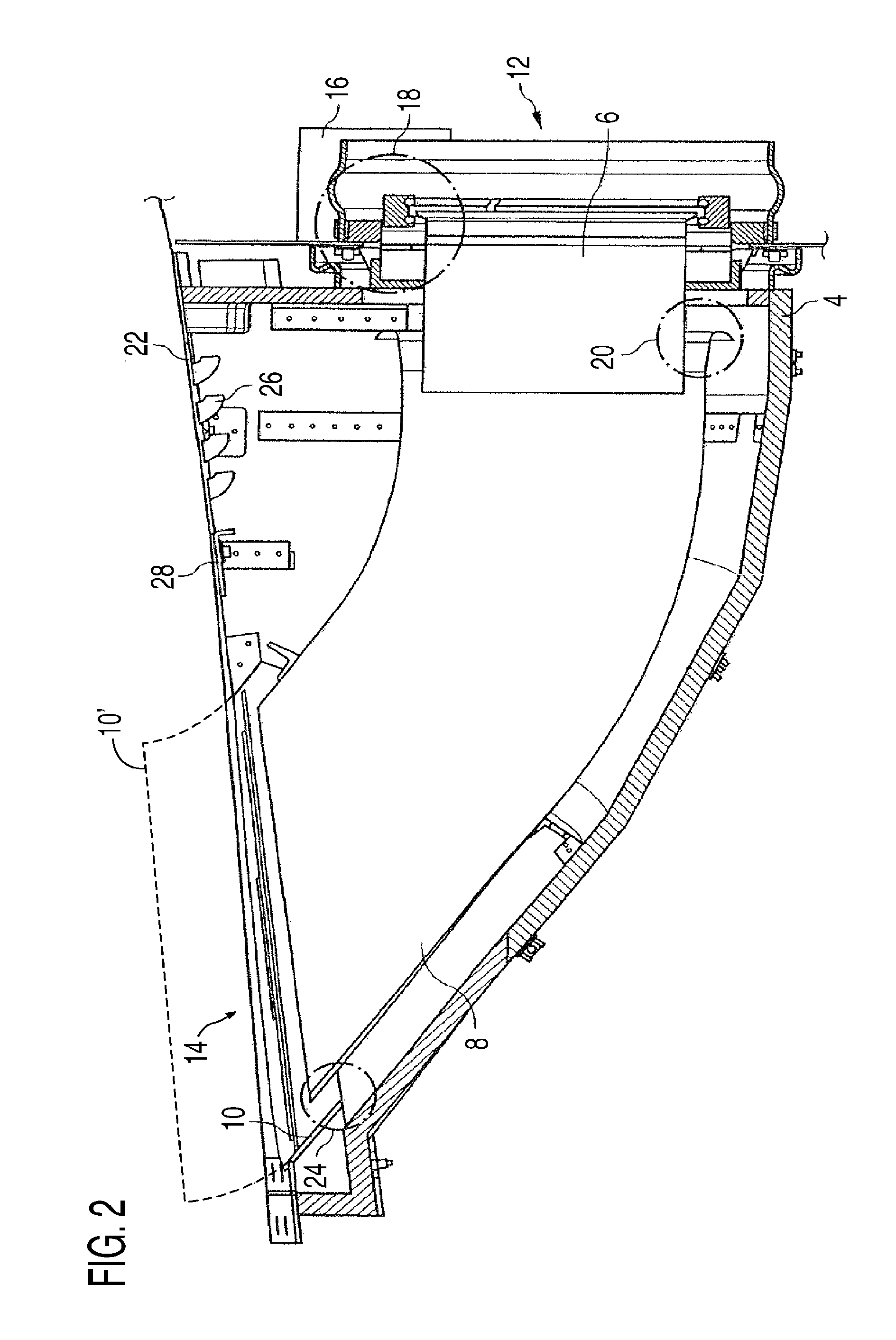

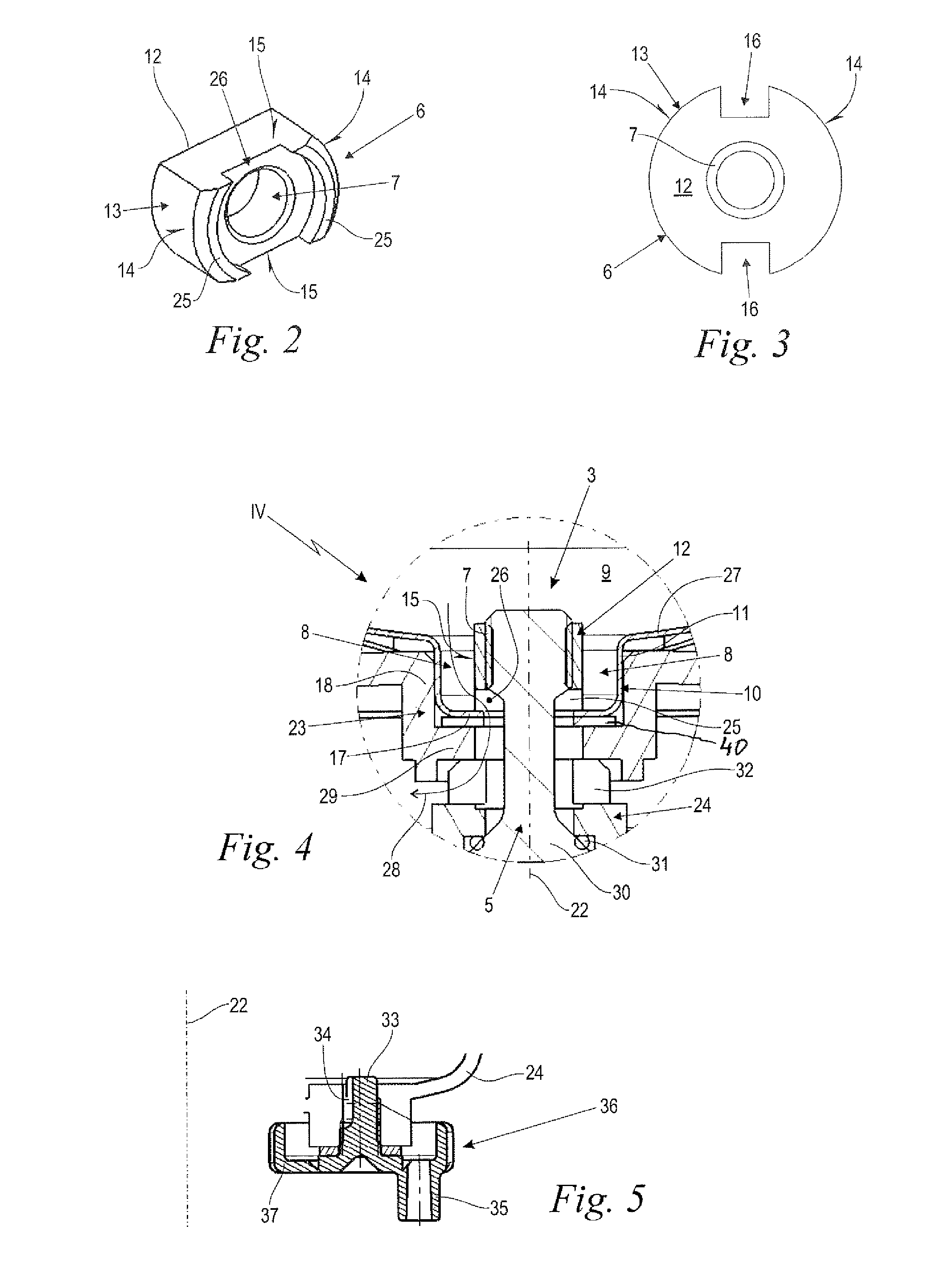

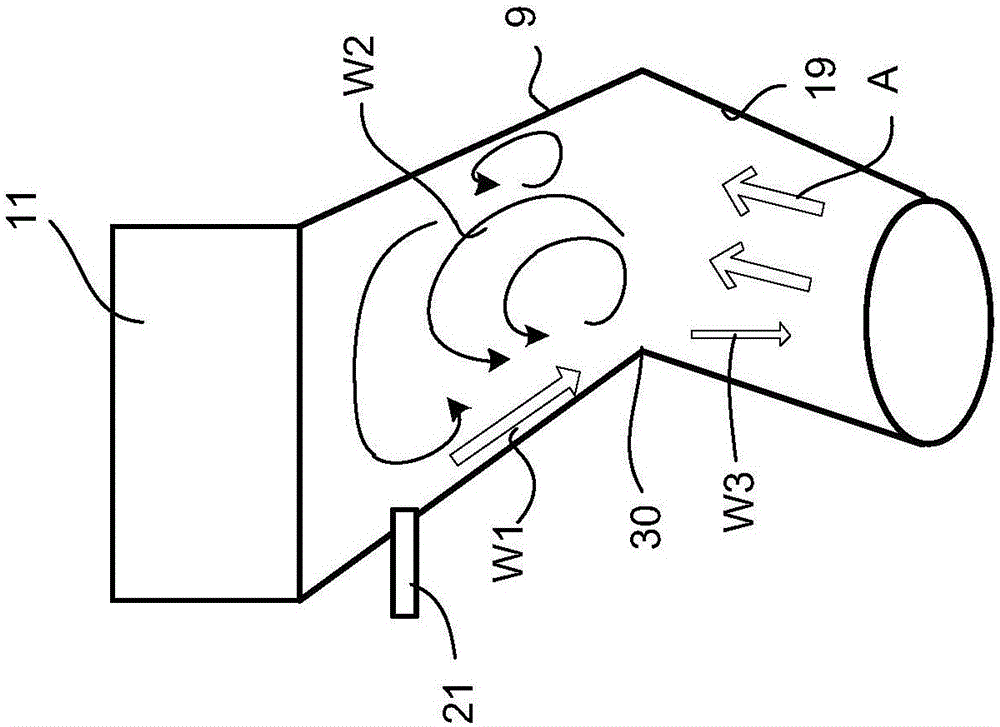

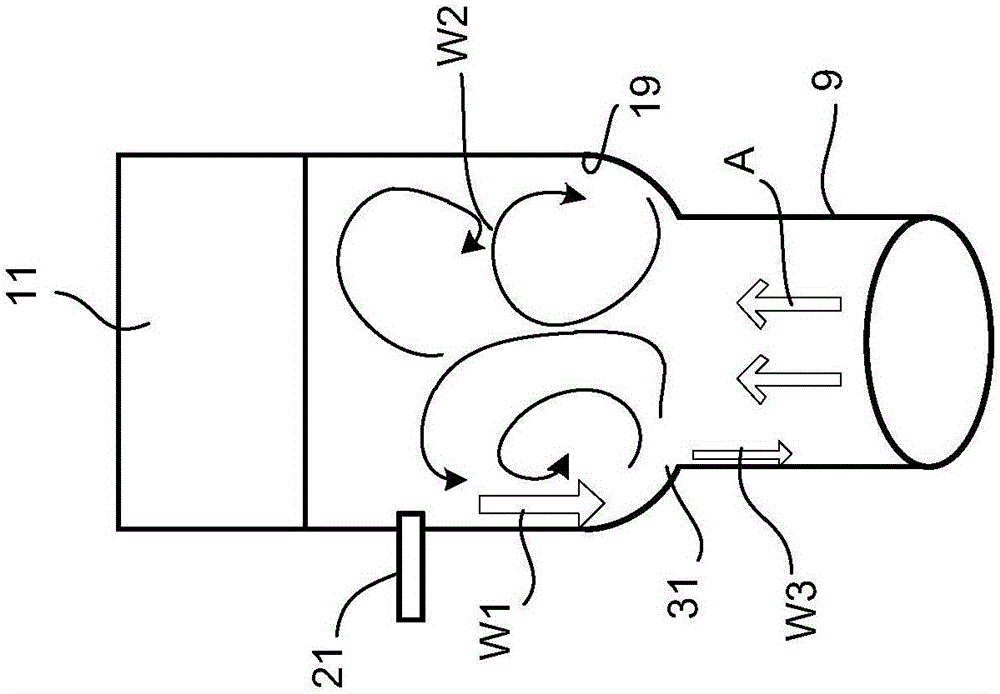

Static mixer and exhaust gas treatment device

InactiveUS7793494B2Design economyIntense mixing effect and vaporization effectInternal combustion piston enginesFlow mixersExhaust fumesEngineering

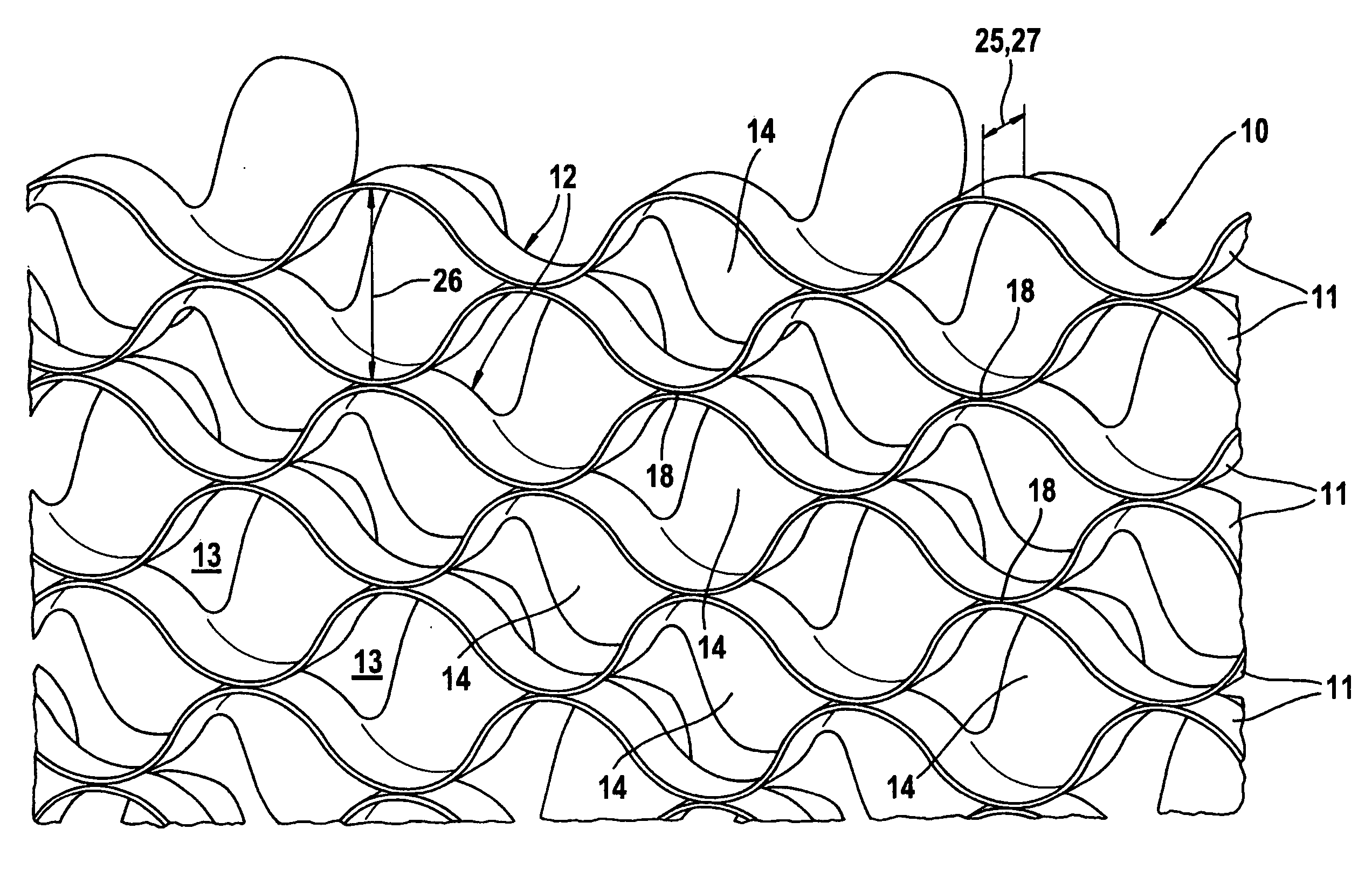

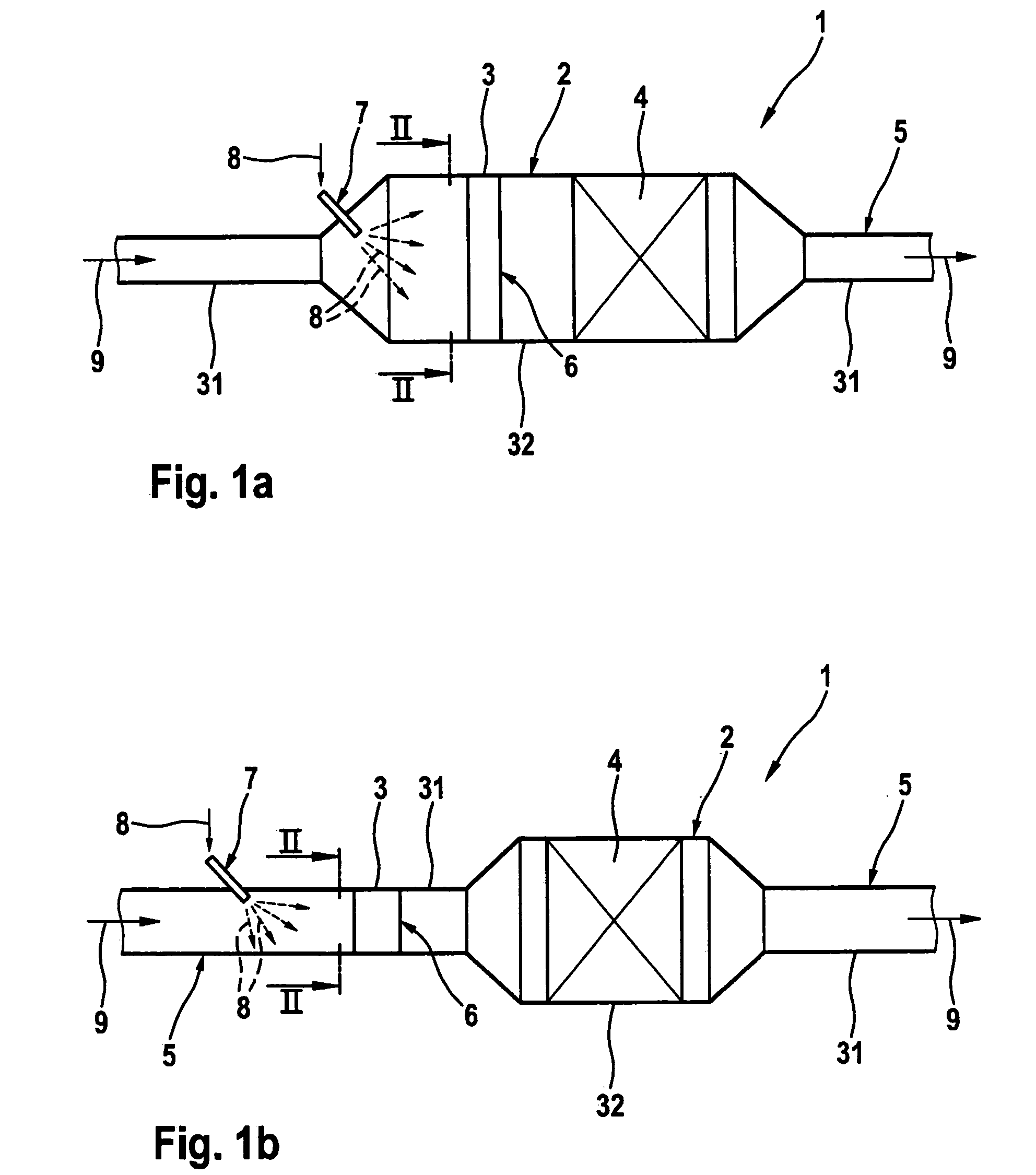

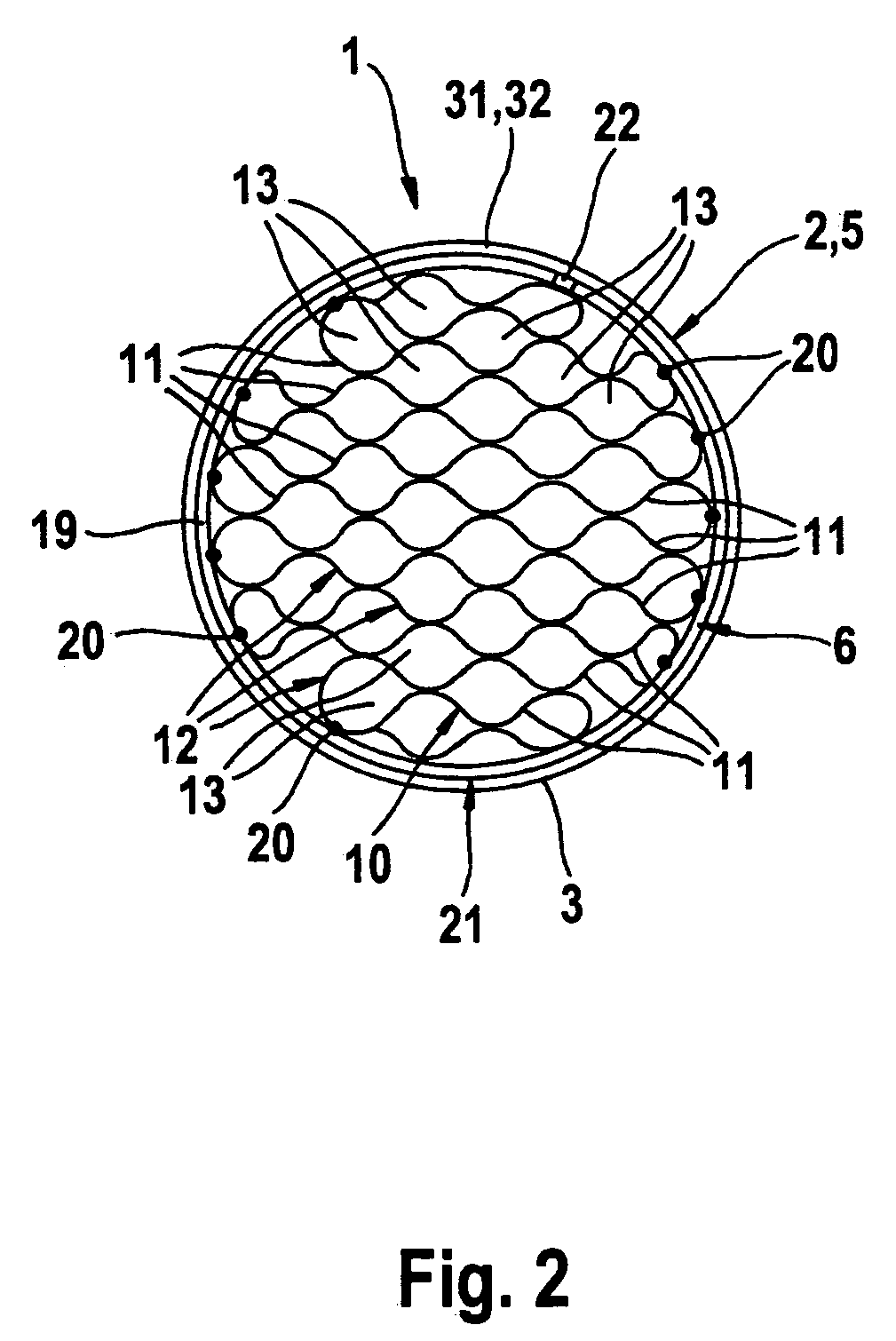

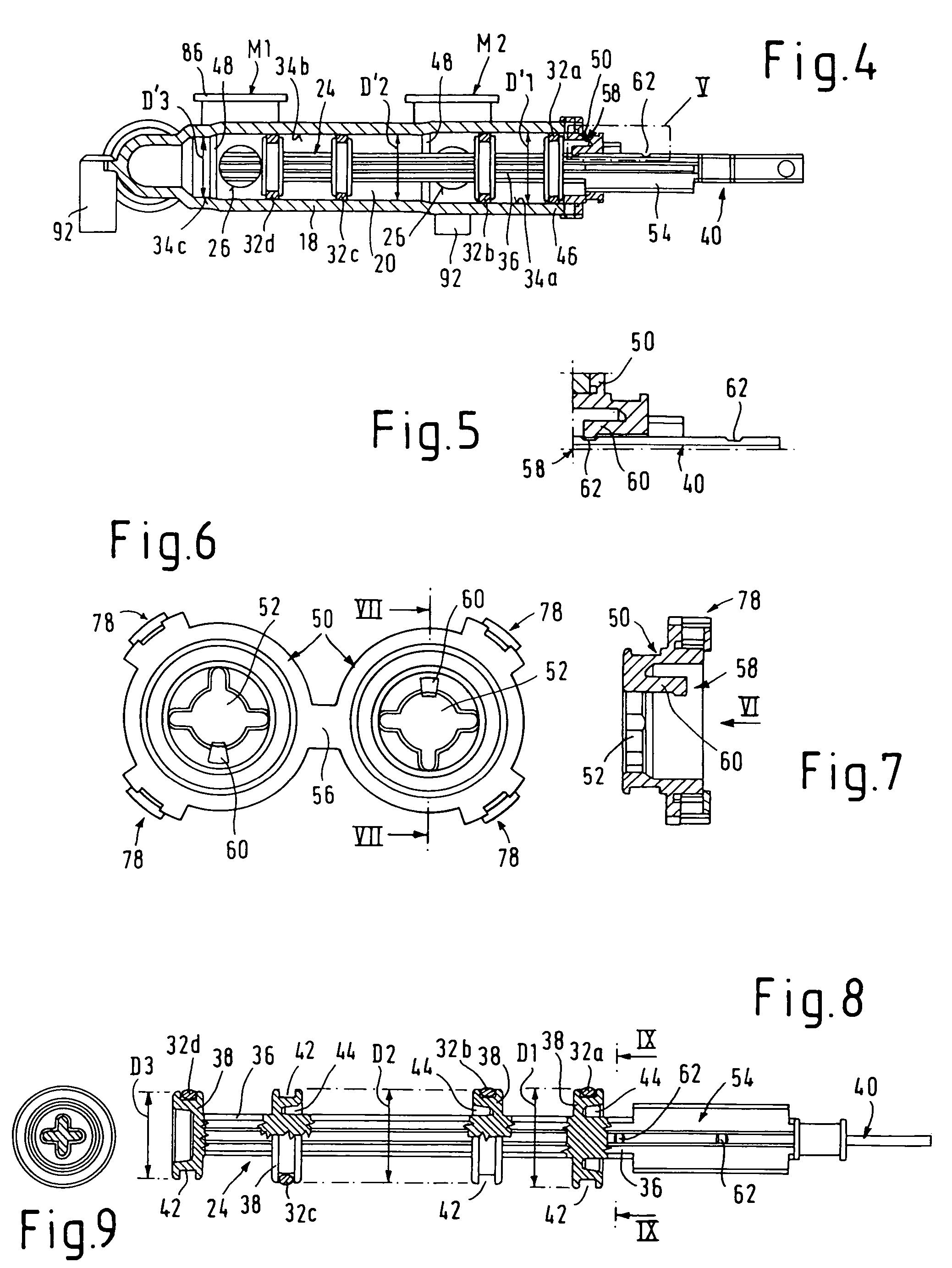

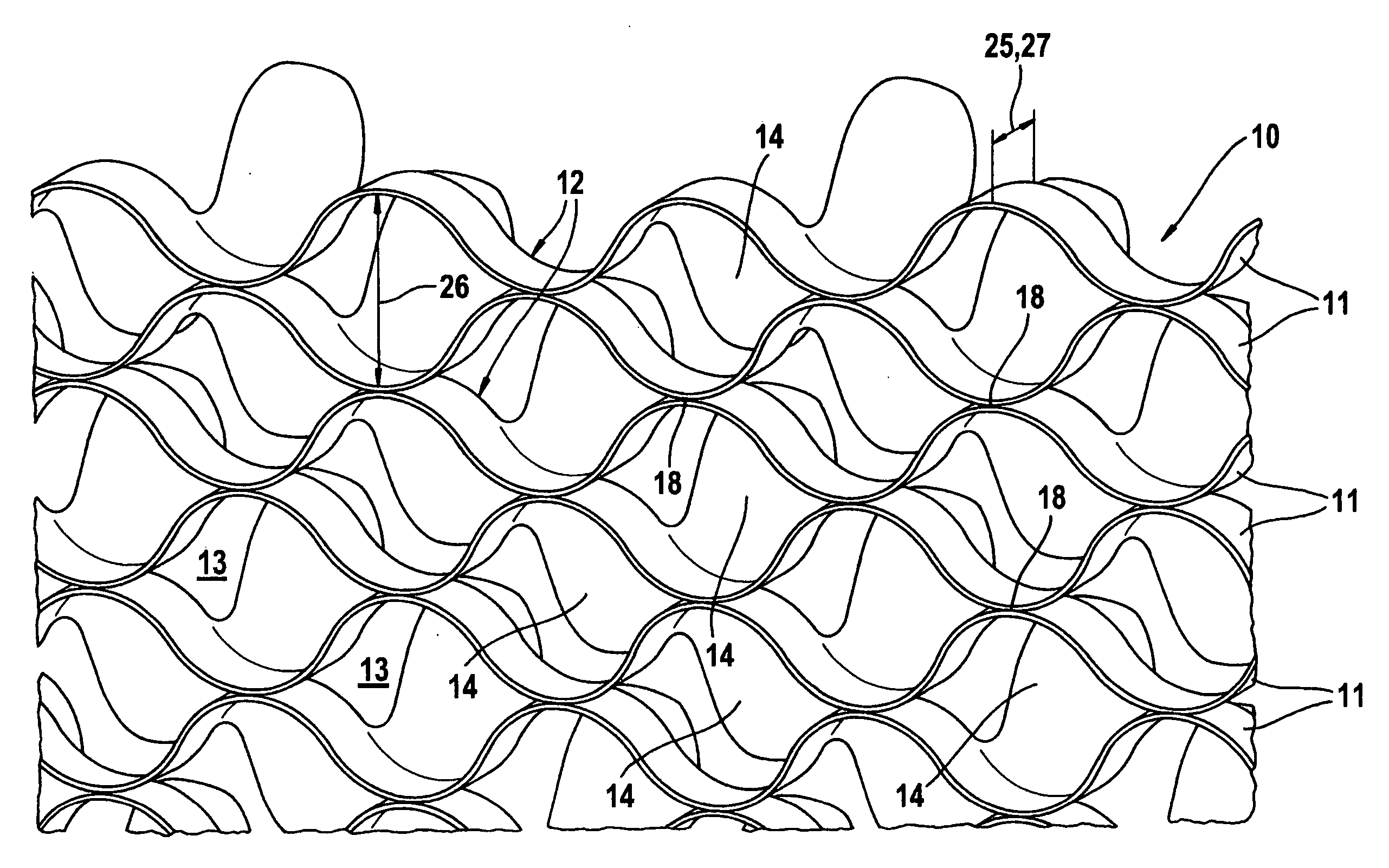

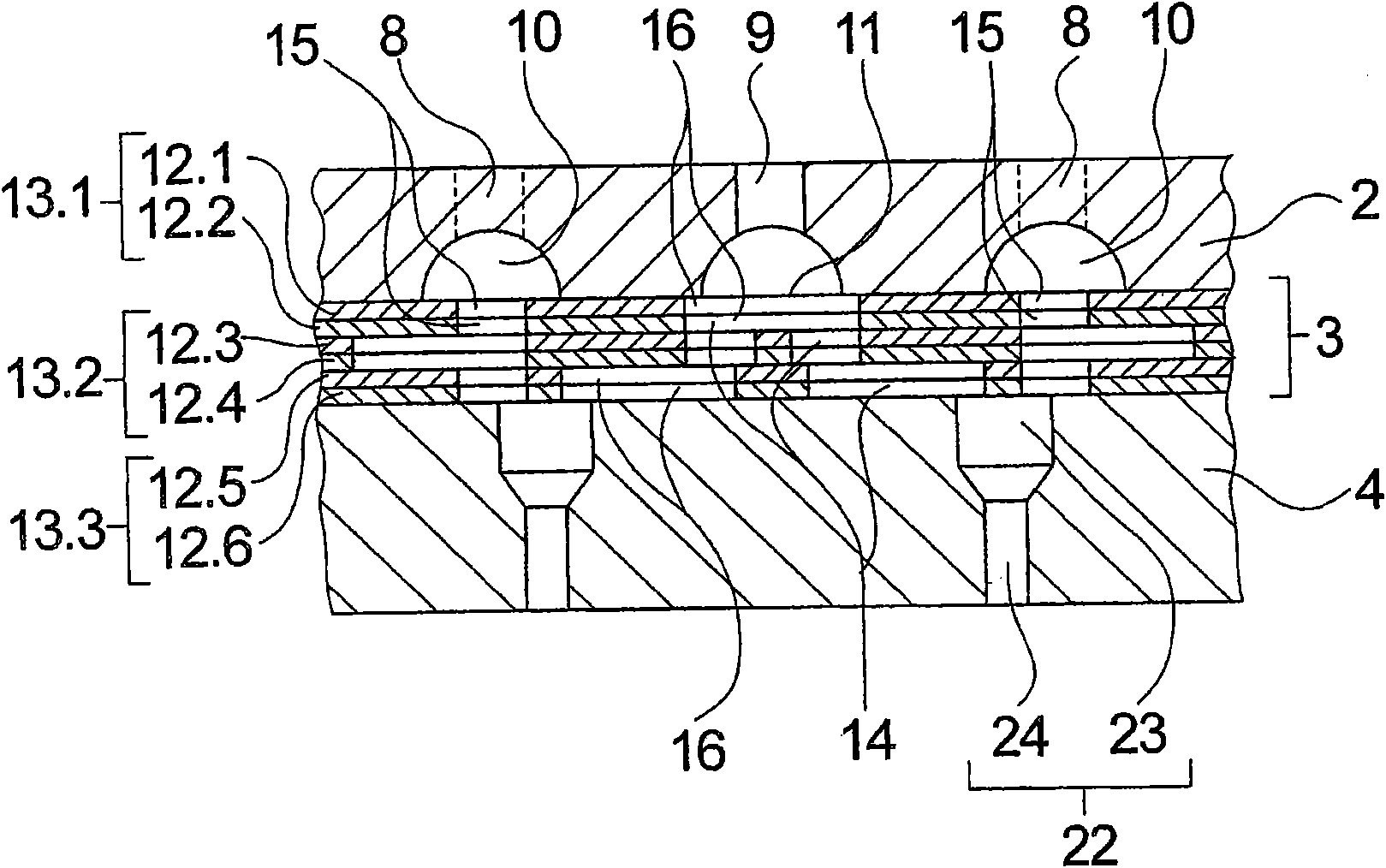

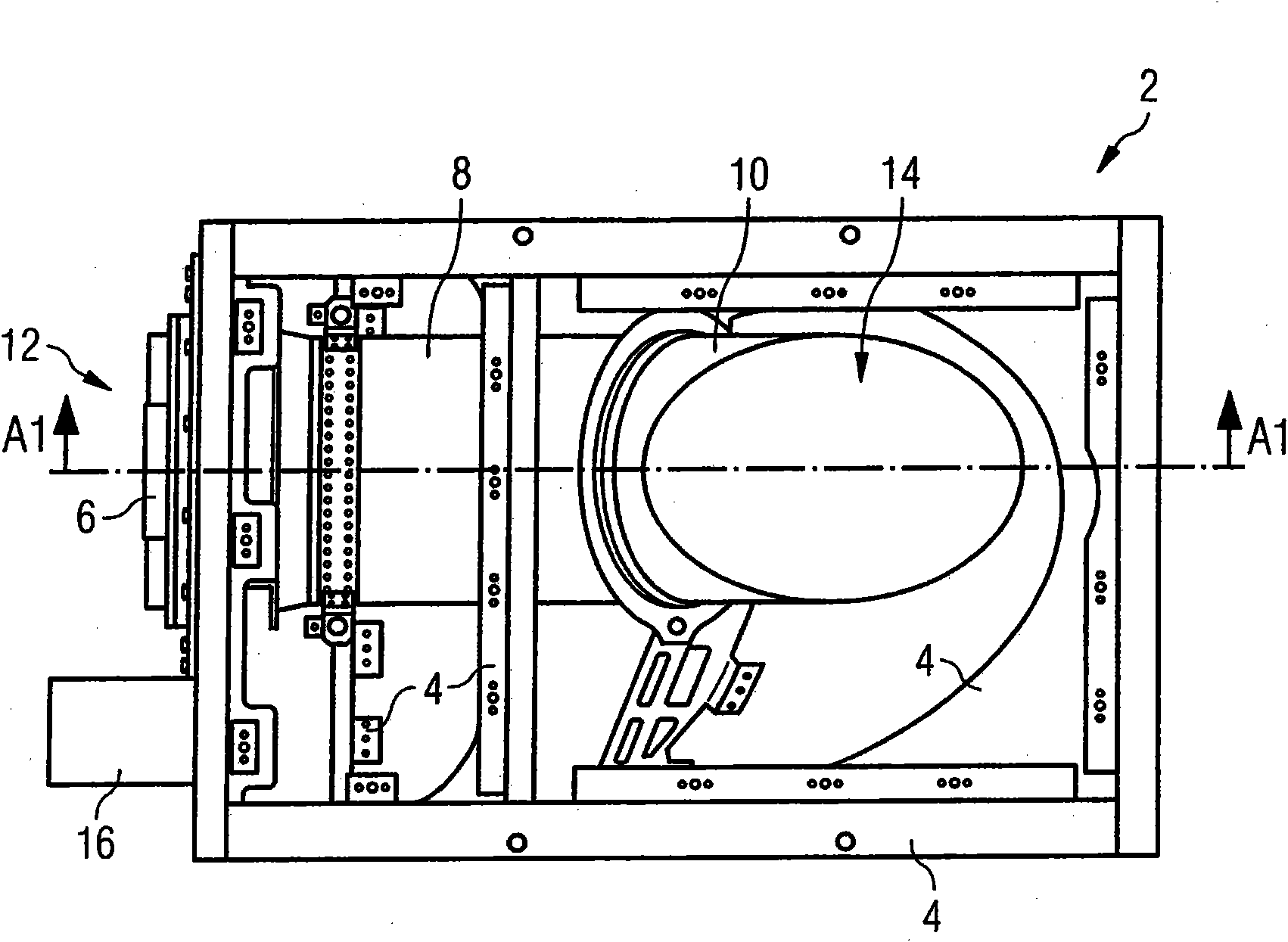

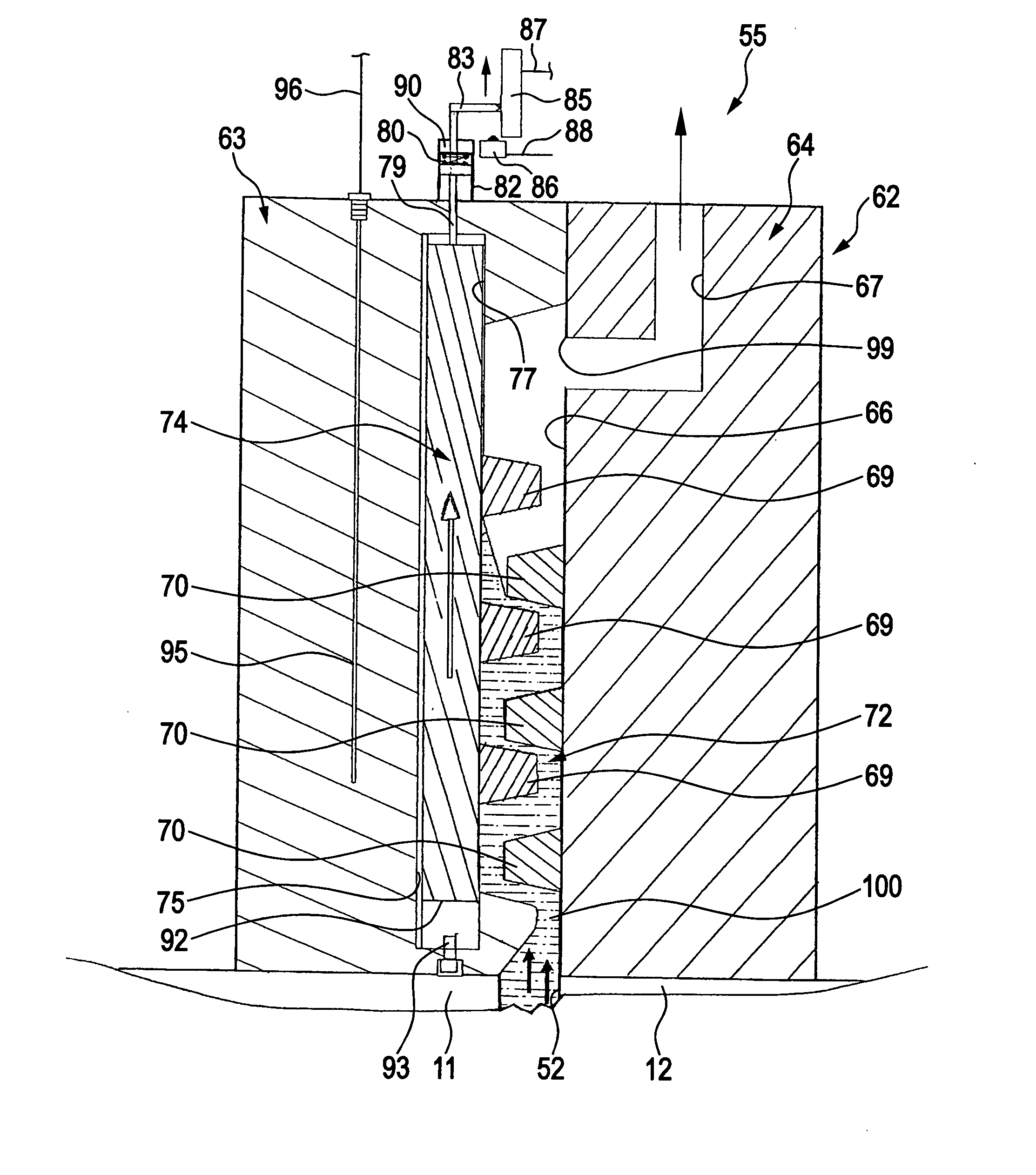

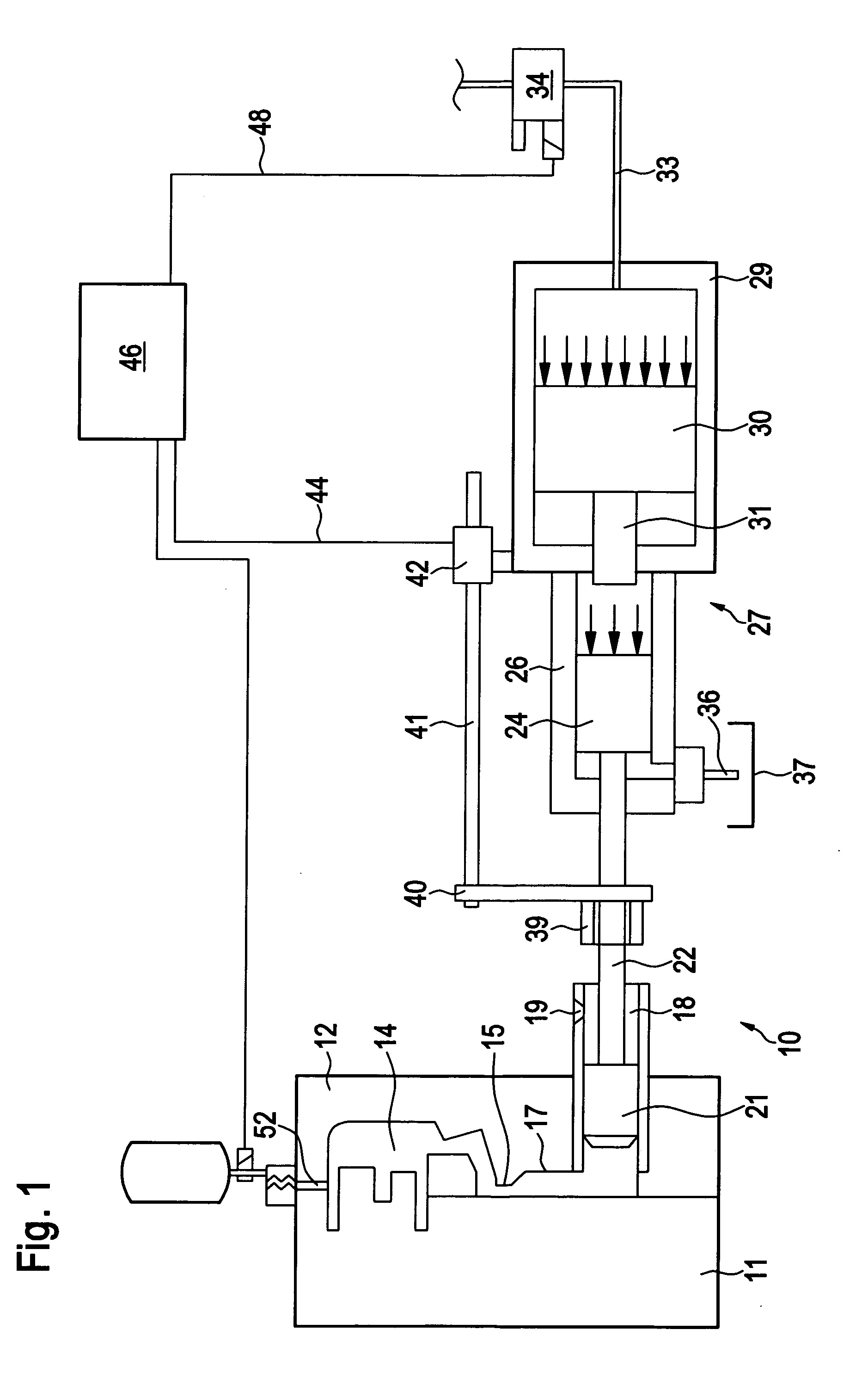

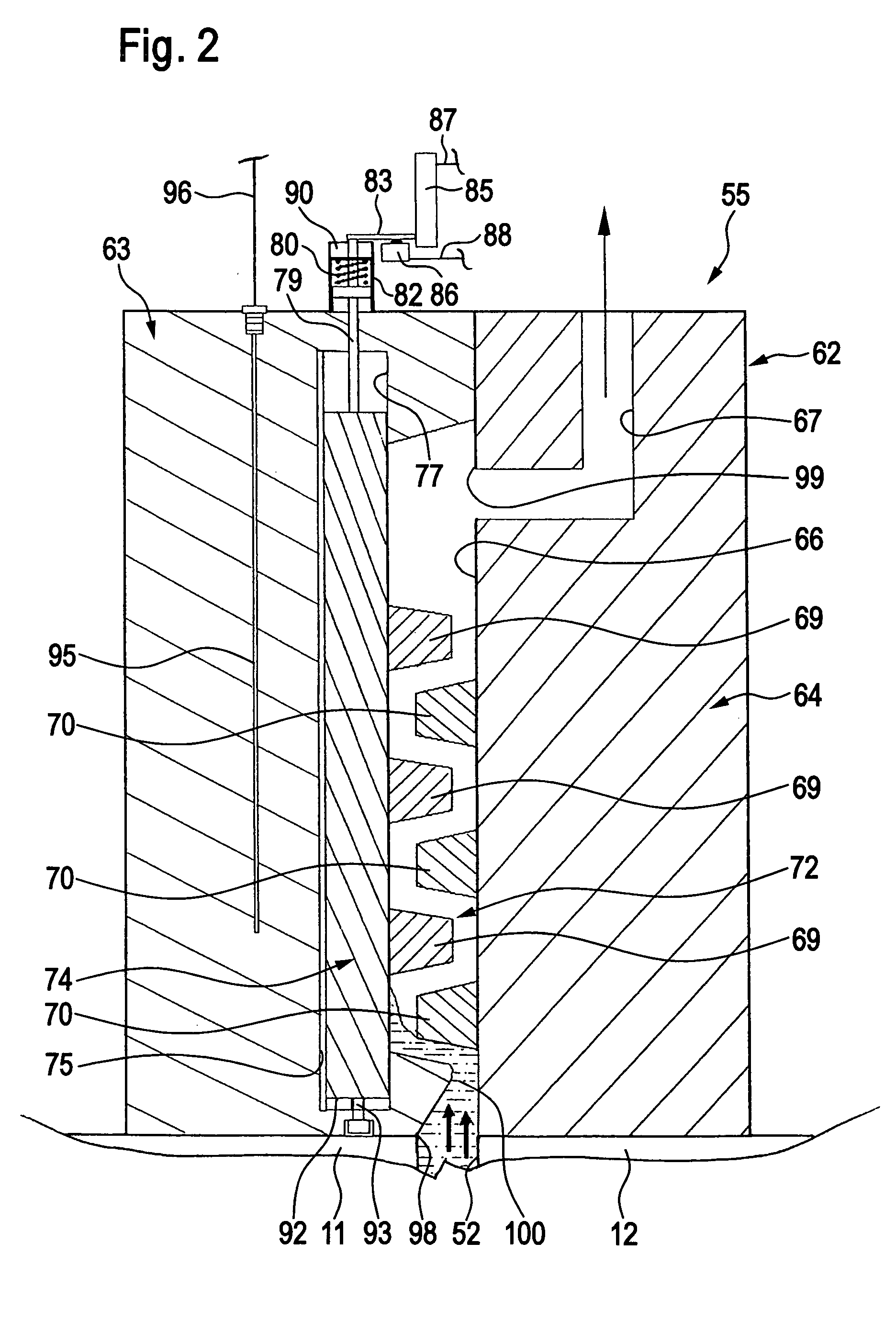

The invention relates to a static mixer for an exhaust system of an internal combustion engine. The mixer has a wall structure that is arranged across the directional of flow in a pipe and has several layers of a corrugated sheeting material laying across one another in the direction of flow. The cells through which the flow can pass in the direction of flow are provided between the sheeting material of neighboring layers. The sheeting material has baffles for all or several of the cells. The baffles are arranged on the sheeting material so that they are arranged on their outgoing flow side in the case of said cells and extend in the direction of flow and across it.

Owner:EBERSPACHER EXHAUST TECH GMBH & CO KG

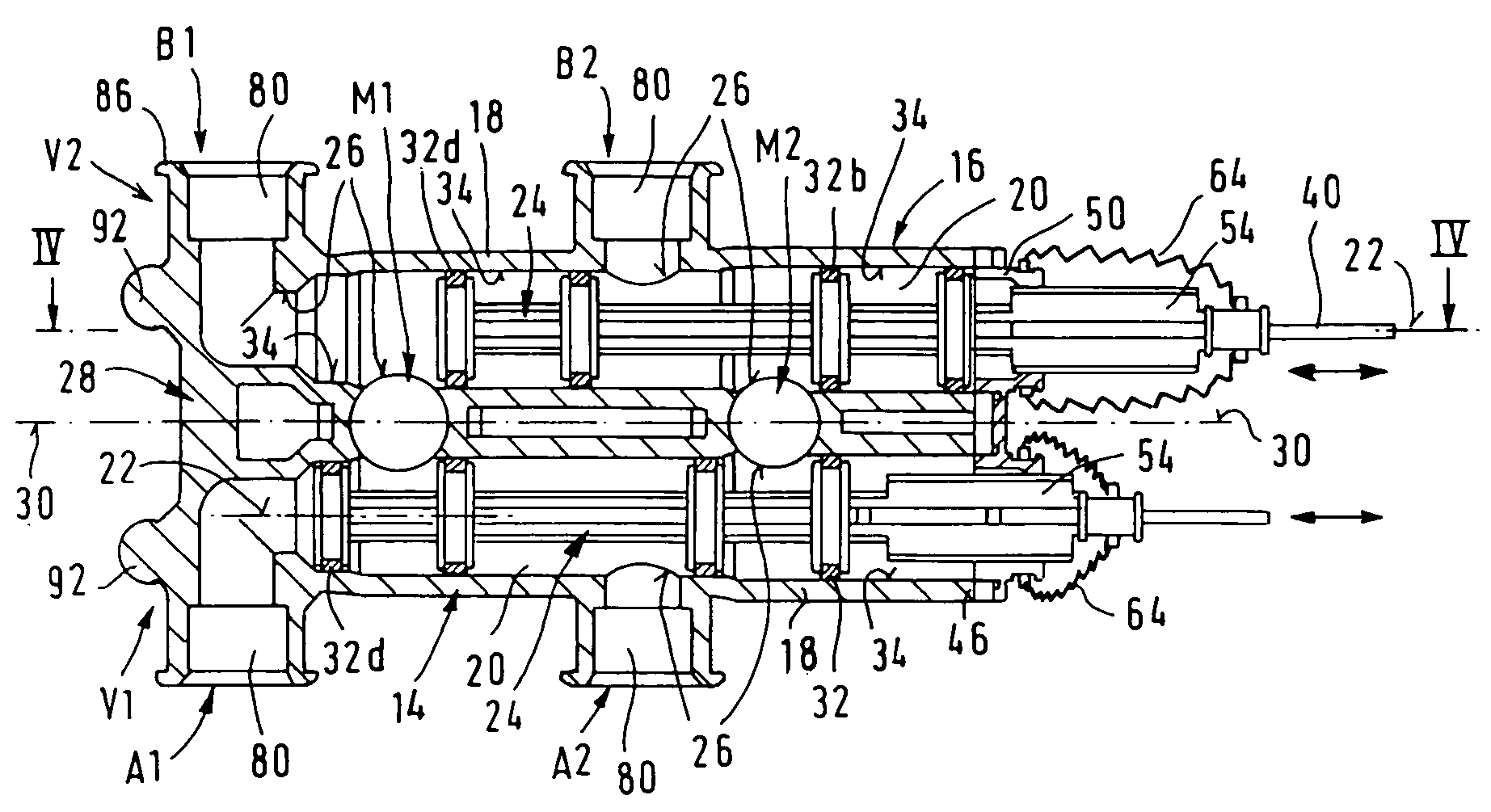

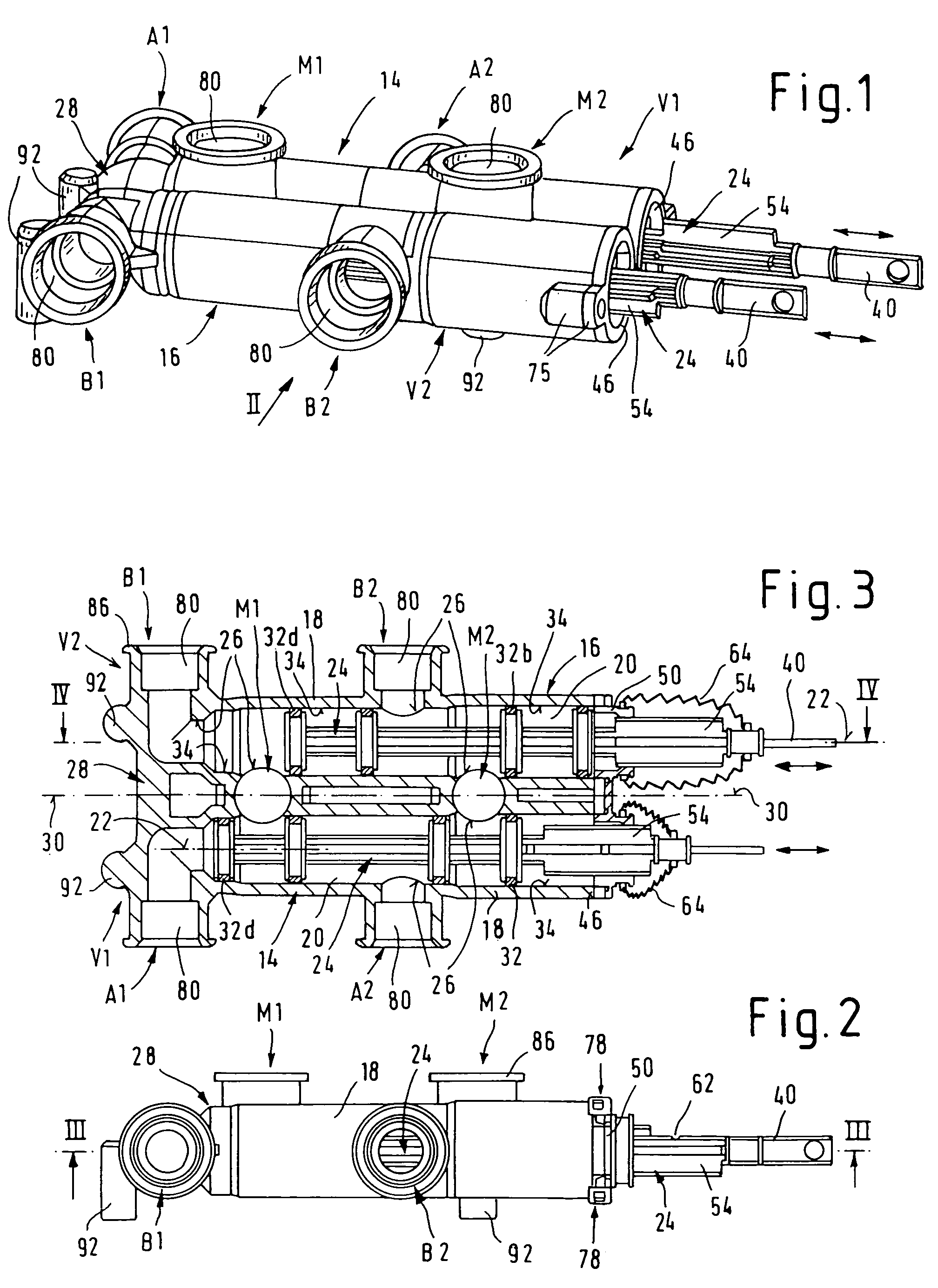

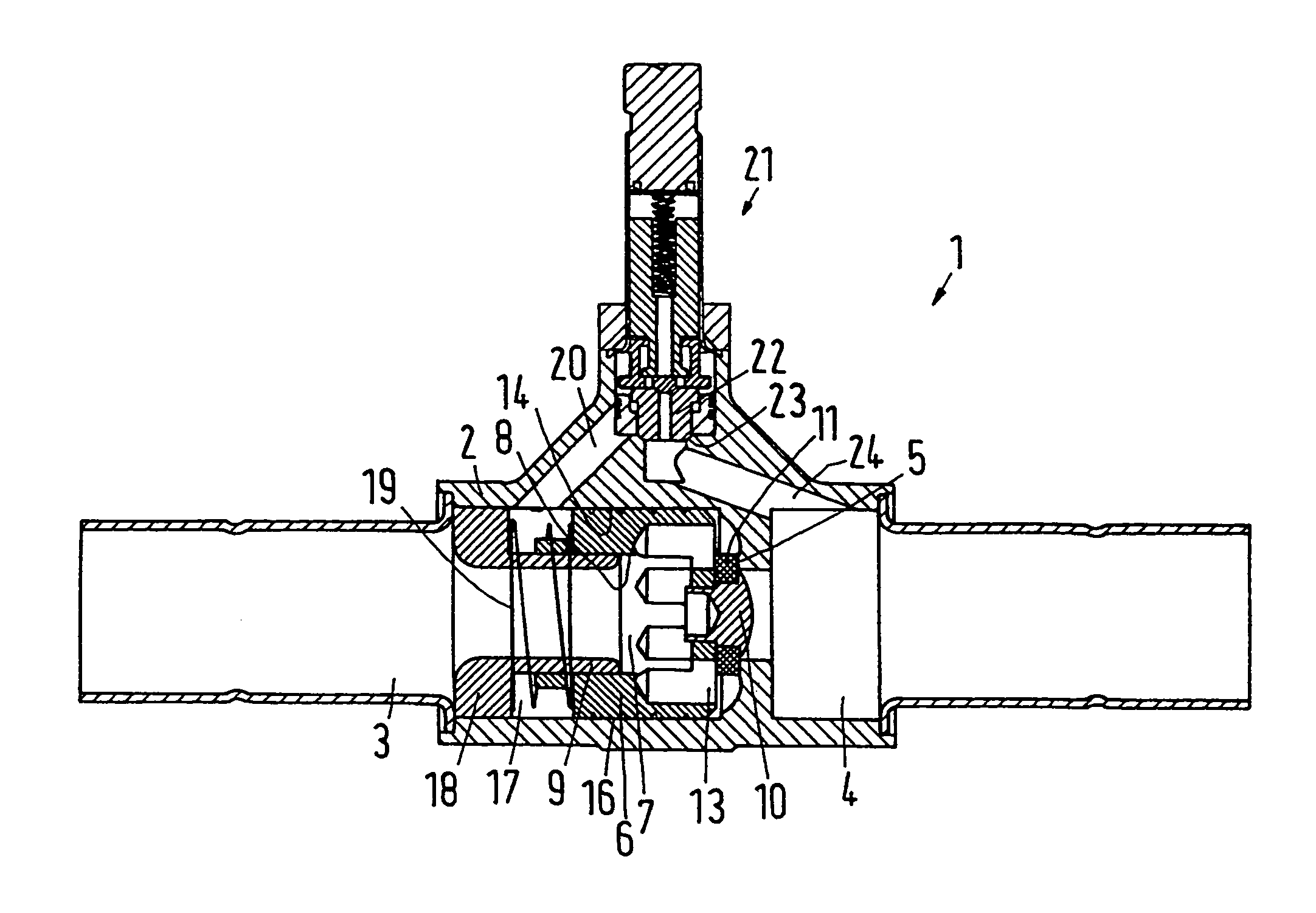

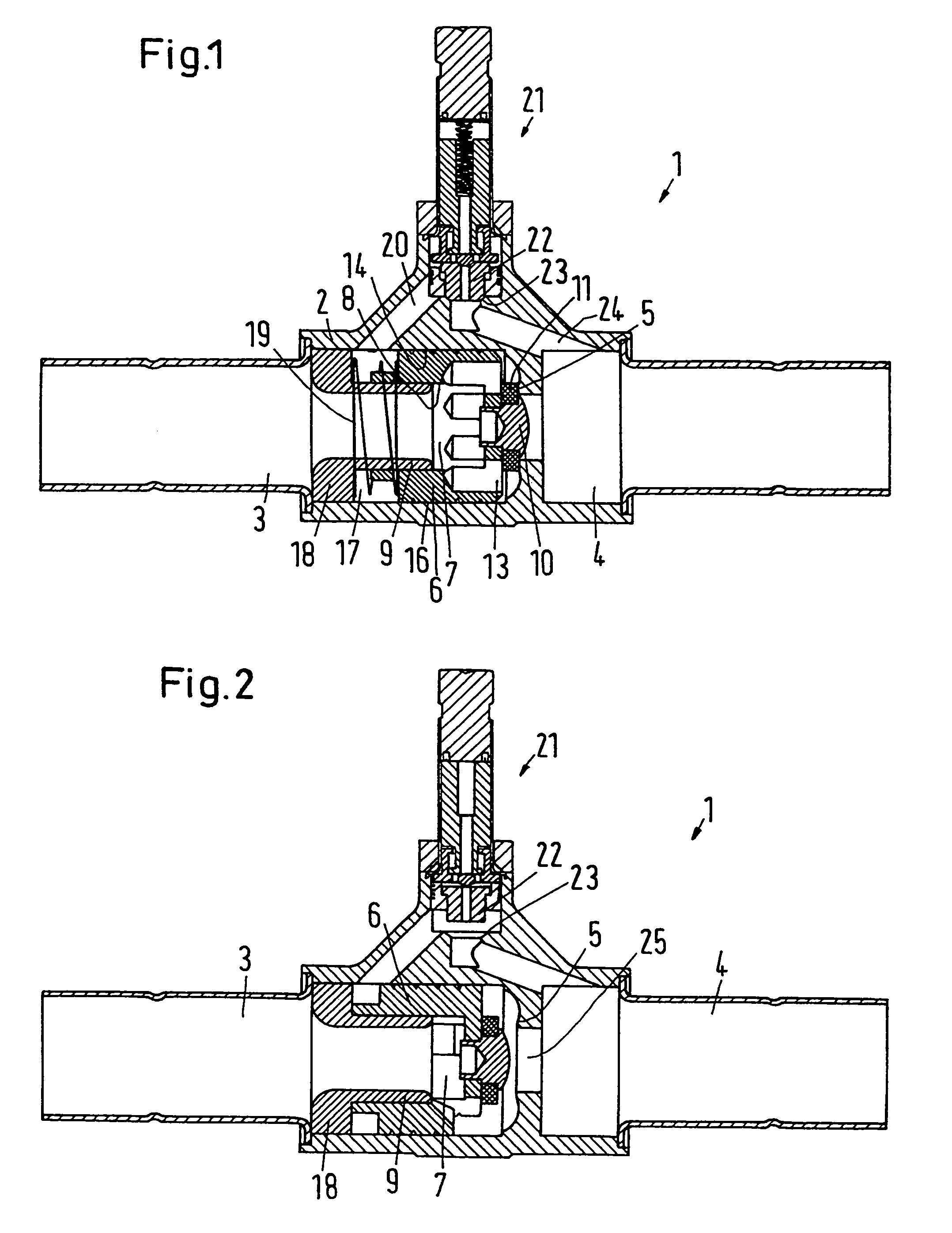

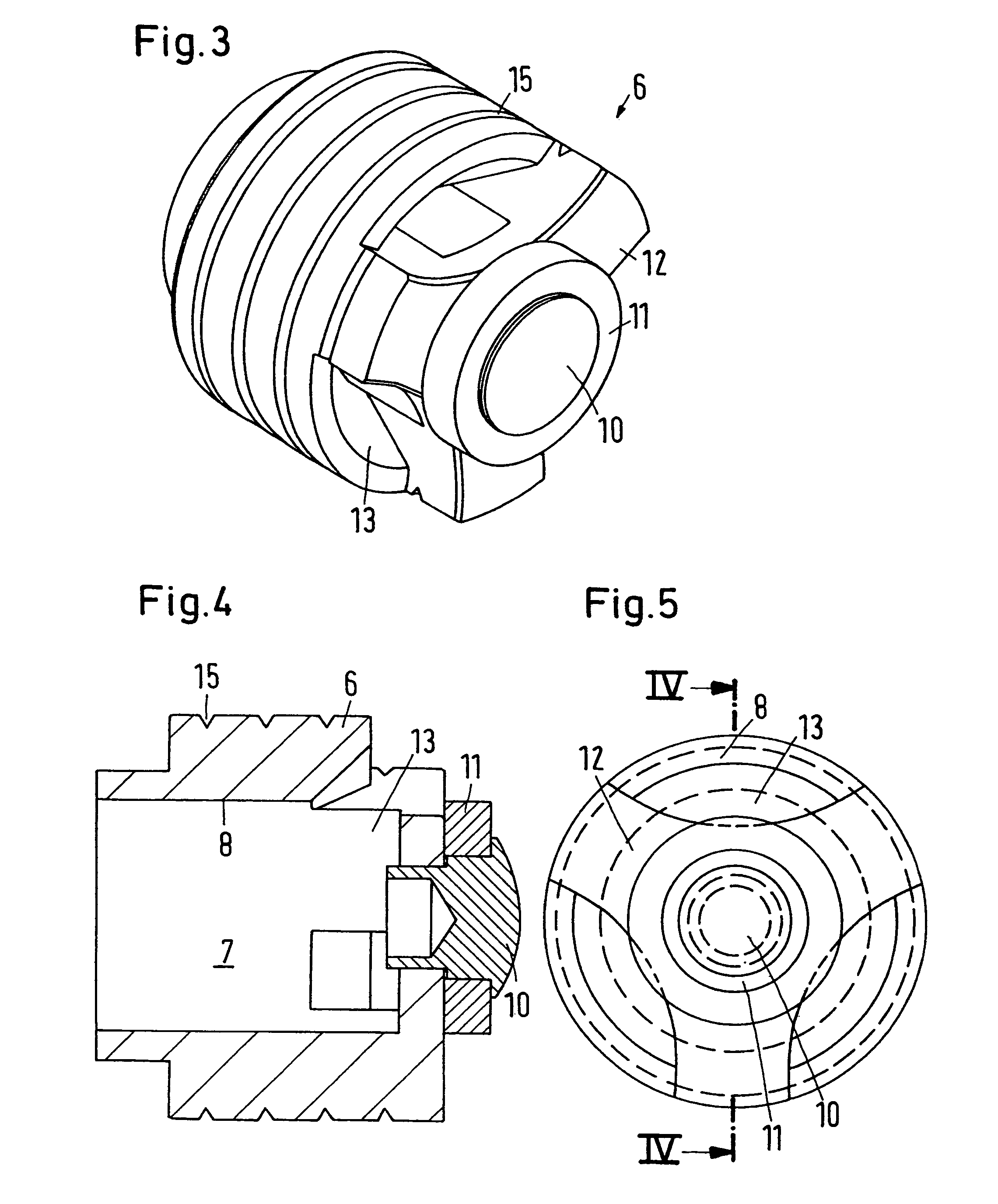

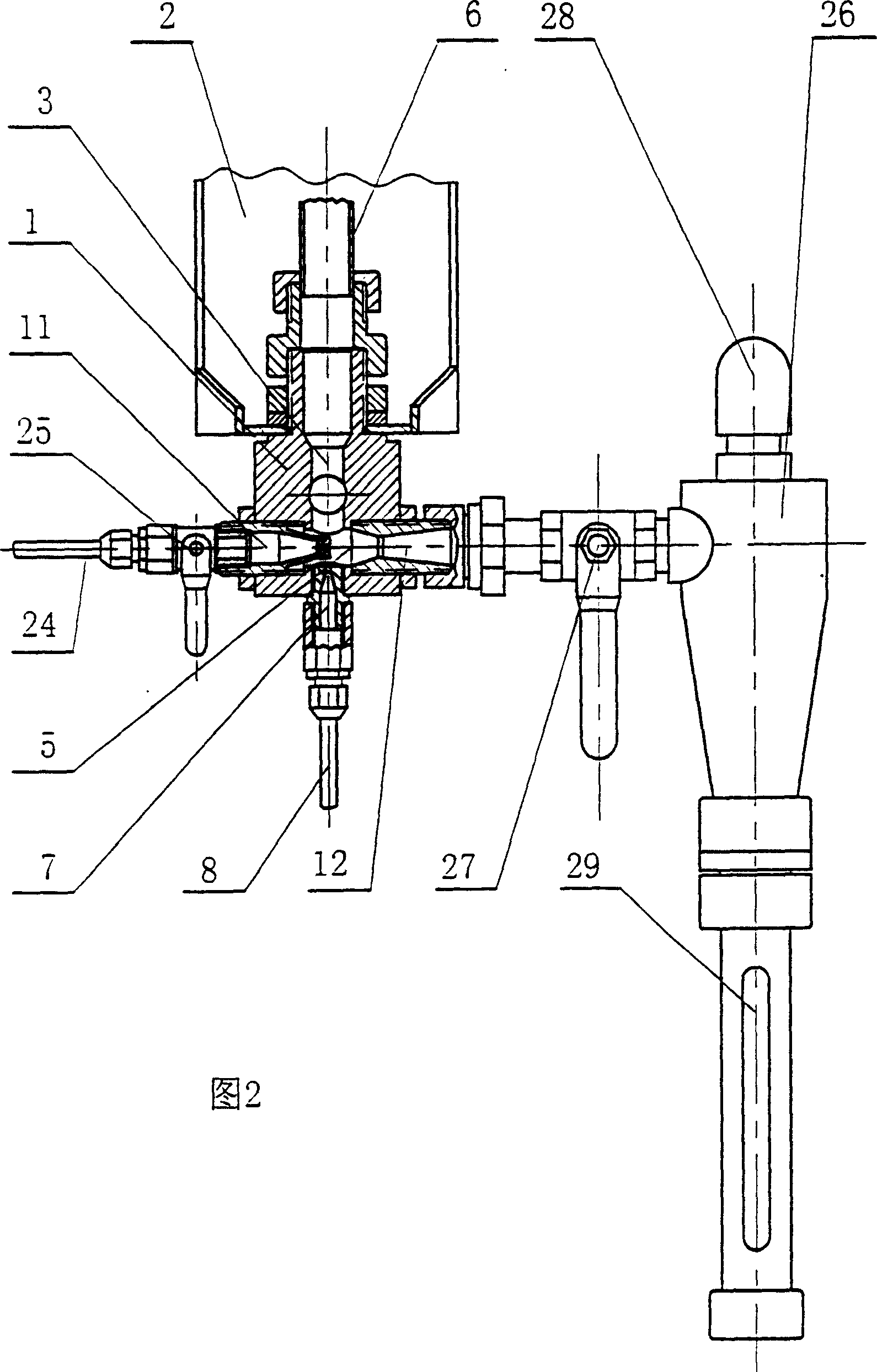

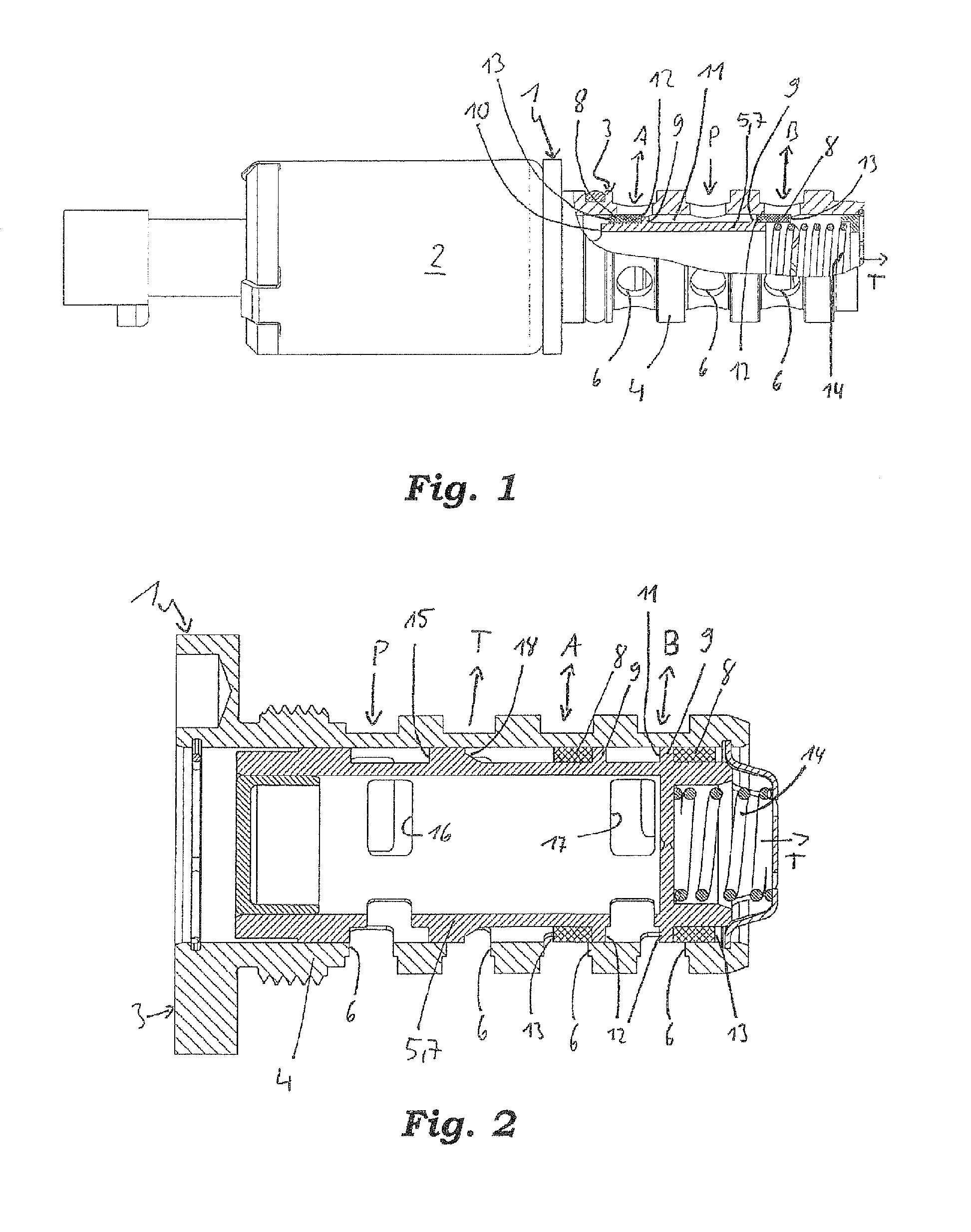

Multiway valve arrangement

InactiveUS7367352B2Cost-effectiveReduce spendingOperating means/releasing devices for valvesInternal combustion piston enginesCombustionFuel tank

The valve device consists, according to the invention, of (at least) two part valves which are symmetrical in circuit terms with respect to the existing connections and which are designed, in particular, as four-way, two position valves of any desired type of construction, but preferably are provided as slide valves. There is preferably a double slide valve with two cooperating slide valves. The valve device features internal seals and sealing surfaces which minimize wear and damage to the seals as they move across flow ports. The valve device is particularly adapted for use as a fuel control valve for an internal combustion powered motor vehicle having two separate fuel tanks. The valve device permits control over which tank supplies fuel to the engine, and allows controlled mixing of the fuels from each tank.

Owner:VOSS AUTOMOTIVE

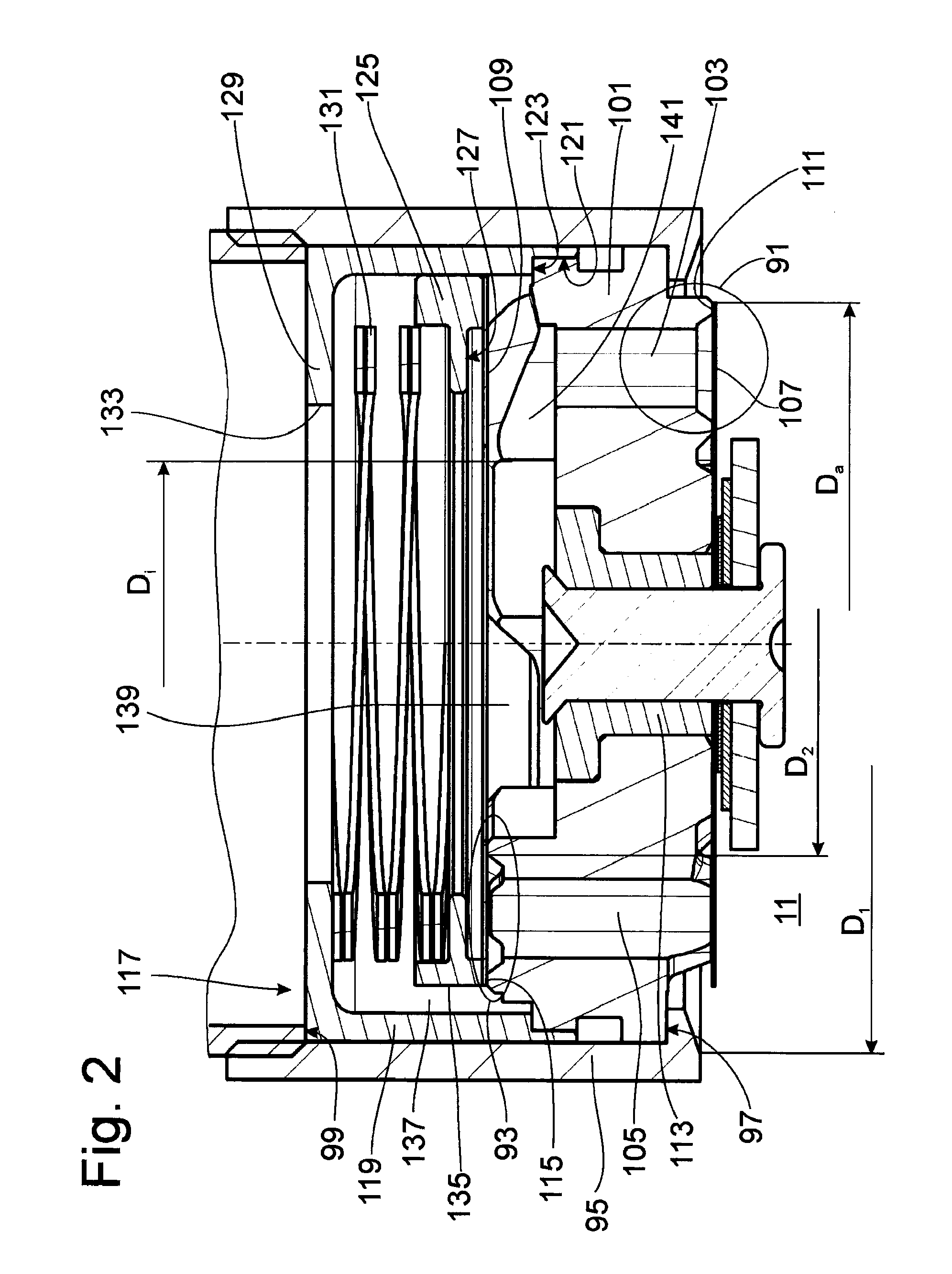

Static mixer and exhaust gas treatment device

InactiveUS20070204751A1Design economyIntense mixing effect and vaporization effectInternal combustion piston enginesFlow mixersExhaust fumesEngineering

The invention relates to a static mixer for an exhaust system of an internal combustion engine. The mixer has a wall structure that is arranged across the directional of flow in a pipe and has several layers of a corrugated sheeting material laying across one another in the direction of flow. The cells through which the flow can pass in the direction of flow are provided between the sheeting material of neighboring layers. The sheeting material has baffles for all or several of the cells. The baffles are arranged on the sheeting material so that they are arranged on their outgoing flow side in the case of said cells and extend in the direction of flow and across it.

Owner:EBERSPACHER EXHAUST TECH GMBH & CO KG

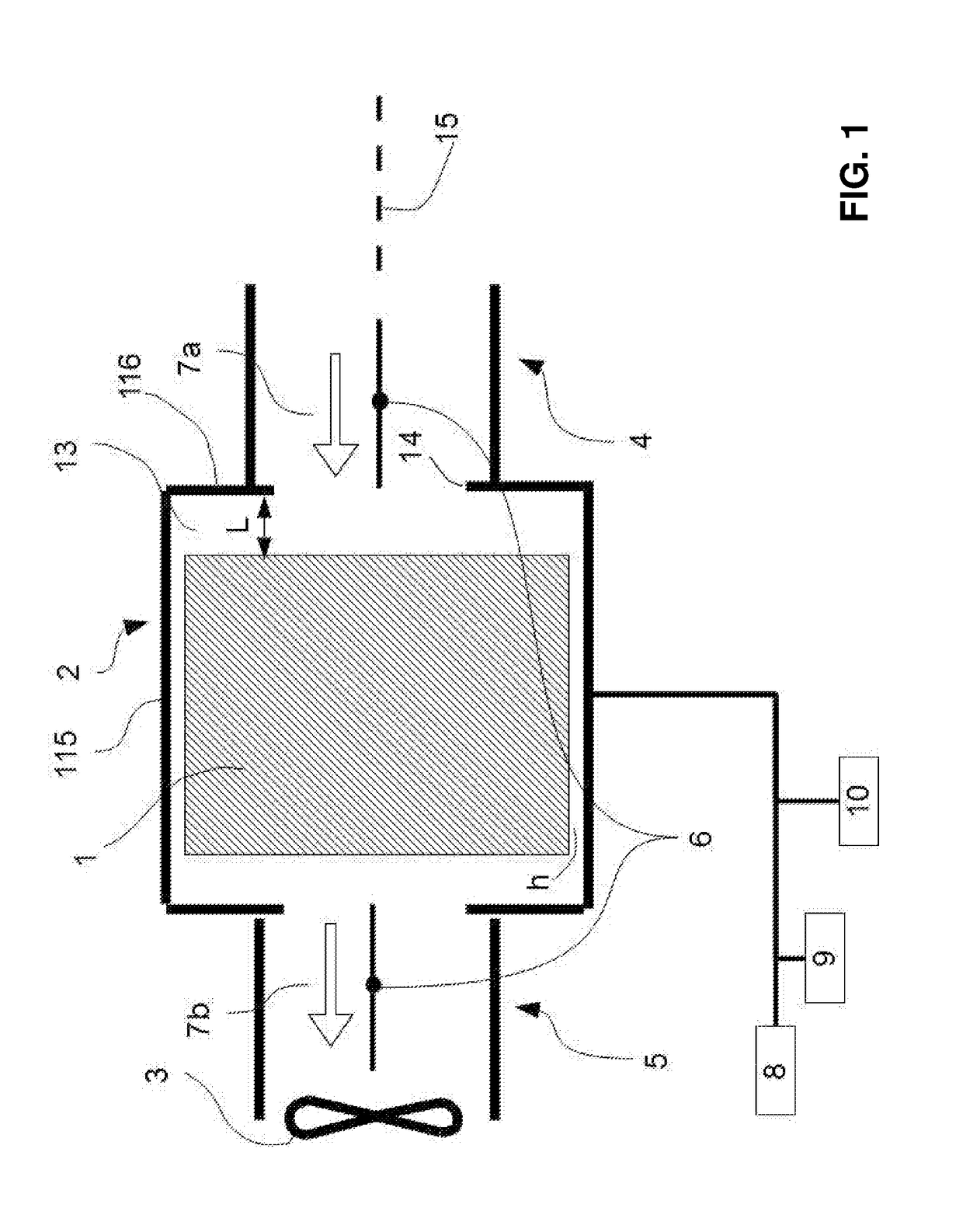

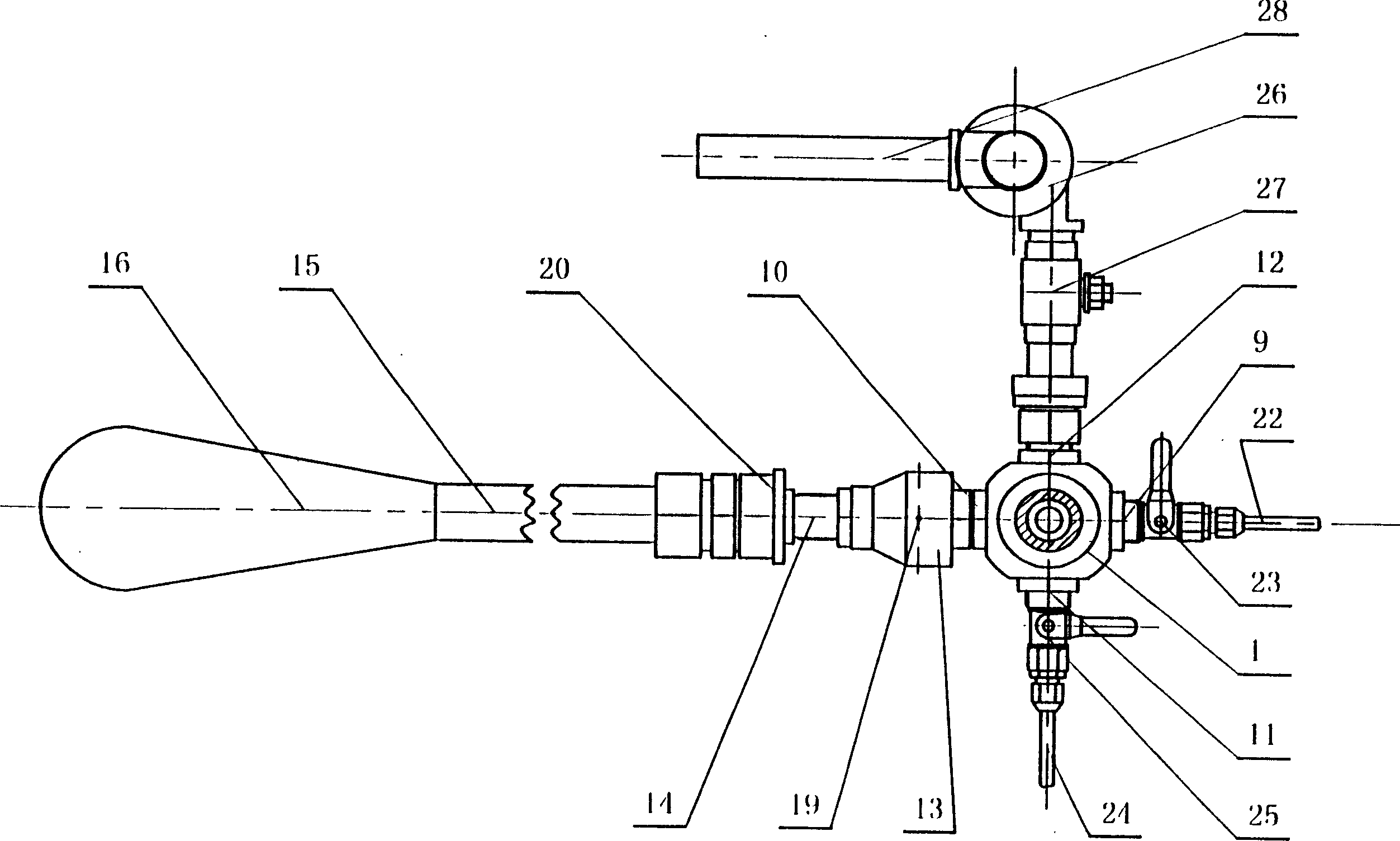

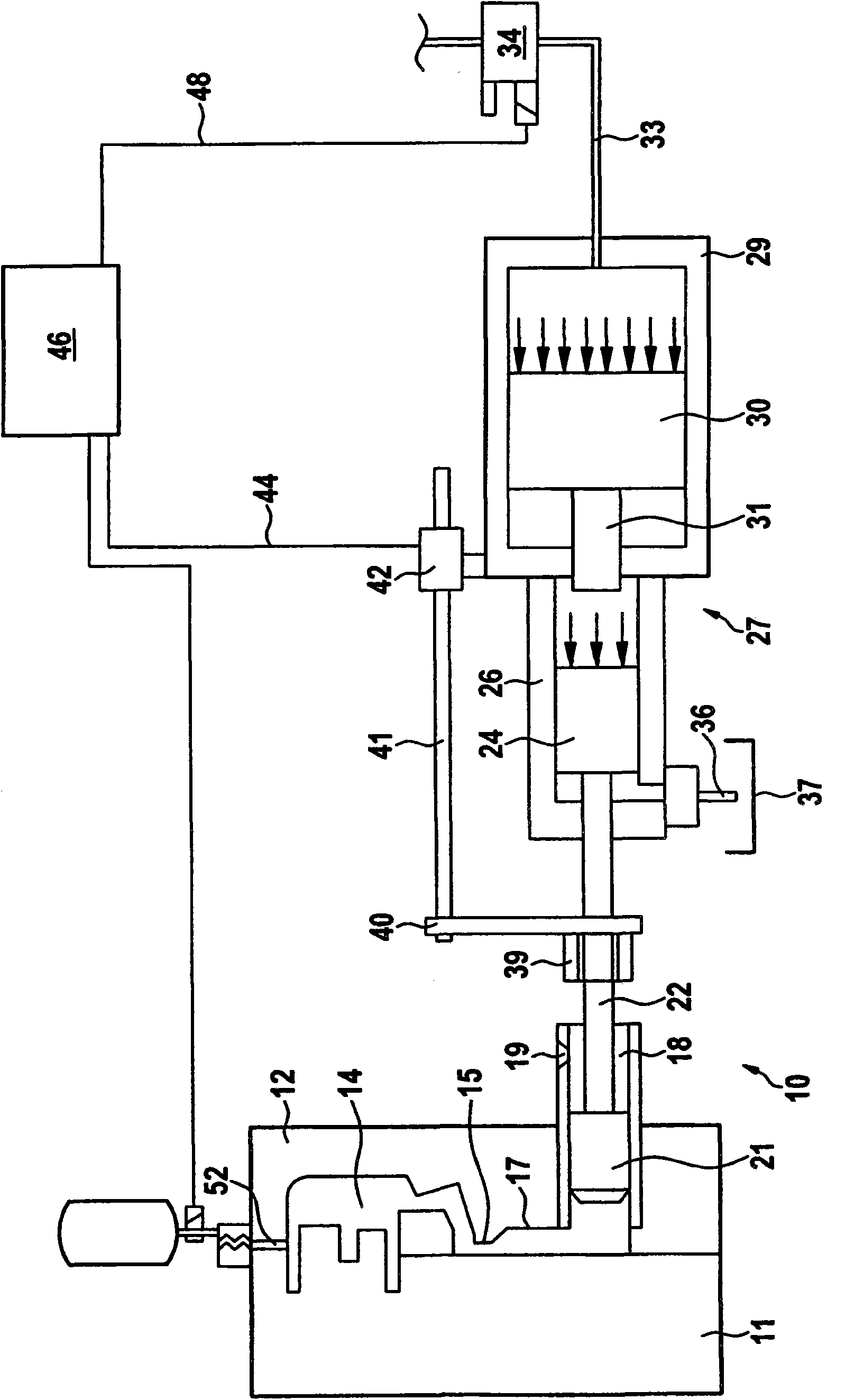

Fuel Cell System with Variable Coanda Amplifiers for Gas Recirculation and System Pressure Regulation

InactiveUS20070259226A1Easy to controlLarge flow cross sectionNon-fuel substance addition to fuelInternal combustion piston enginesFuel cellsAudio power amplifier

A Coanda flow amplifier has a suction intake, an outlet, a fluid channel extending between the suction intake and the outlet, and a drive-flow inlet, which is fluidly connected to the fluid channel via a drive-flow discharge slit, whereby the flow cross section of the drive-flow discharge slit is variably adjustable. In a method to operate the Coanda flow amplifier, the variably adjustable flow cross section of the drive-flow discharge slit is chosen such that a pressure ratio between an output pressure of the drive flow when it leaves the drive-flow discharge slit, and an intake pressure of the drive flow when it enters the drive-flow discharge slit, does not exceed a critical pressure ratio. A fuel cell system comprises at least one fuel cell, a fluid source, a fluid line, and a Coanda flow amplifier arranged in the fluid line, whereby the Coanda flow amplifier is equipped with a drive-flow discharge slit with a variably adjustable flow cross section.

Owner:NUCELLSYS GMBH

Gas-liquid separating device

ActiveCN102872655ALarge flow cross sectionSmall pressure lossDispersed particle separationTowerMechanics

The invention discloses a device for separating a gas phase and a liquid phase in an air conditioner, a compressor, a tower, or an evaporator. The device comprises a shell cover, a cylindrical structure, and a flow baffling cover, a flow guide conical surface, a flow distributing cylinder, centrifugal channels, a liquid discharge pipe and an exhaust port, wherein the cylindrical structure is arranged below the shell cover, the flow baffling cover and the flow guide conical surface are arranged in the device, the flow distributing cylinder is provided with a top cover, the exhaust port is arranged on the shell cover and is communicated with the external world; the lower bottom of the flow guide conical surface is fixed on the inner wall of the cylindrical structure; the bottom of the flow distributing cylinder is fixed on the top of the flow guide conical surface; the flow baffling cover is fixed on the lower part of the flow guide conical surface through a connecting rod; at least two rectangular holes are equidistantly formed in the side wall of the flow distributing cylinder; the centrifugal channels are arranged at each of the rectangular holes, wherein a section of each of the centrifugal channels is a rectangular expanded section, and the centrifugal channels are arranged along the tangential direction of the flow distributing cylinder; and a liquid channel communicating the upper part and the lower part of a flow guide cone is arranged at the bottom of the flow guide conical surface.

Owner:兰州节能环保工程有限责任公司 +1

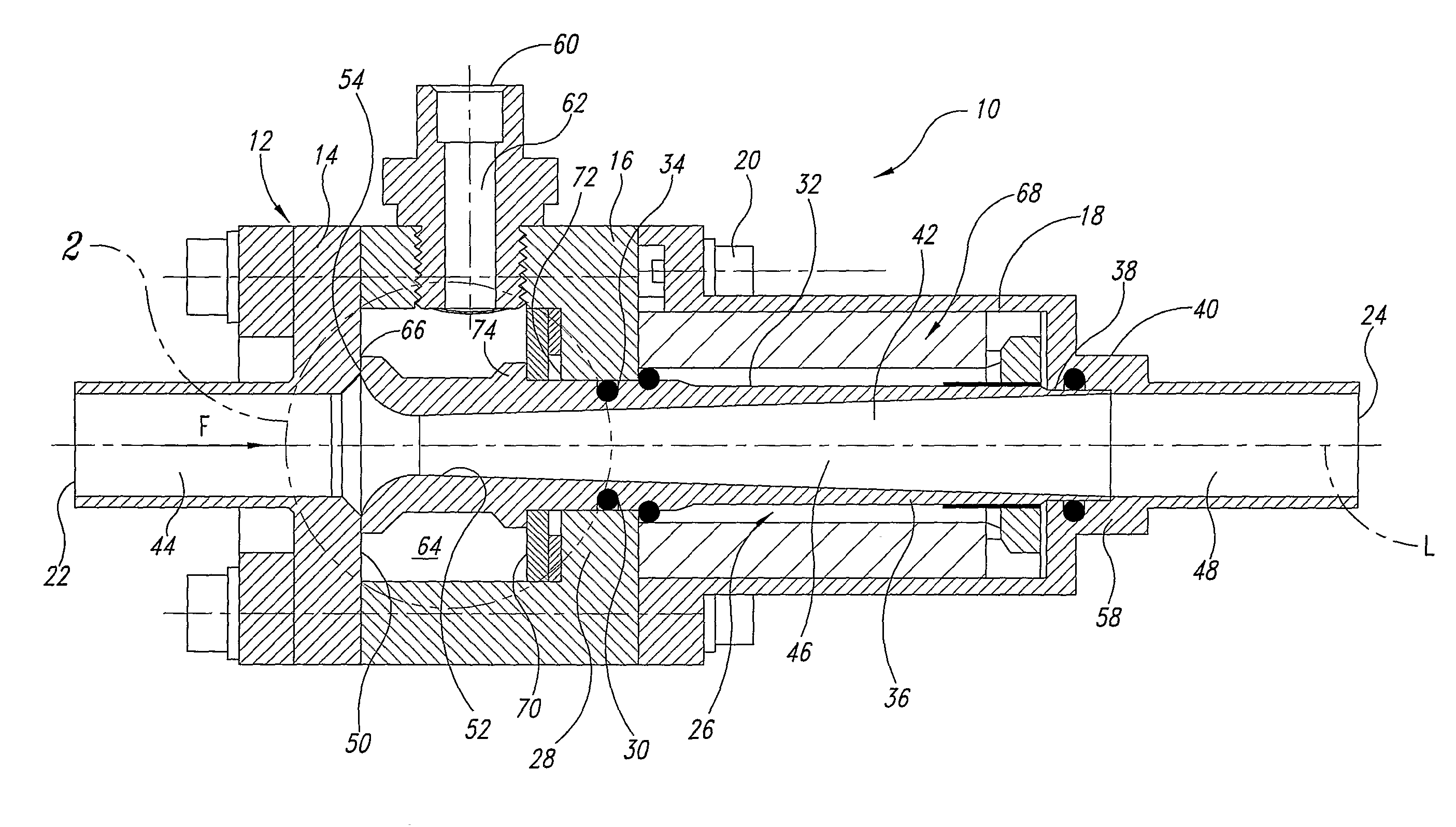

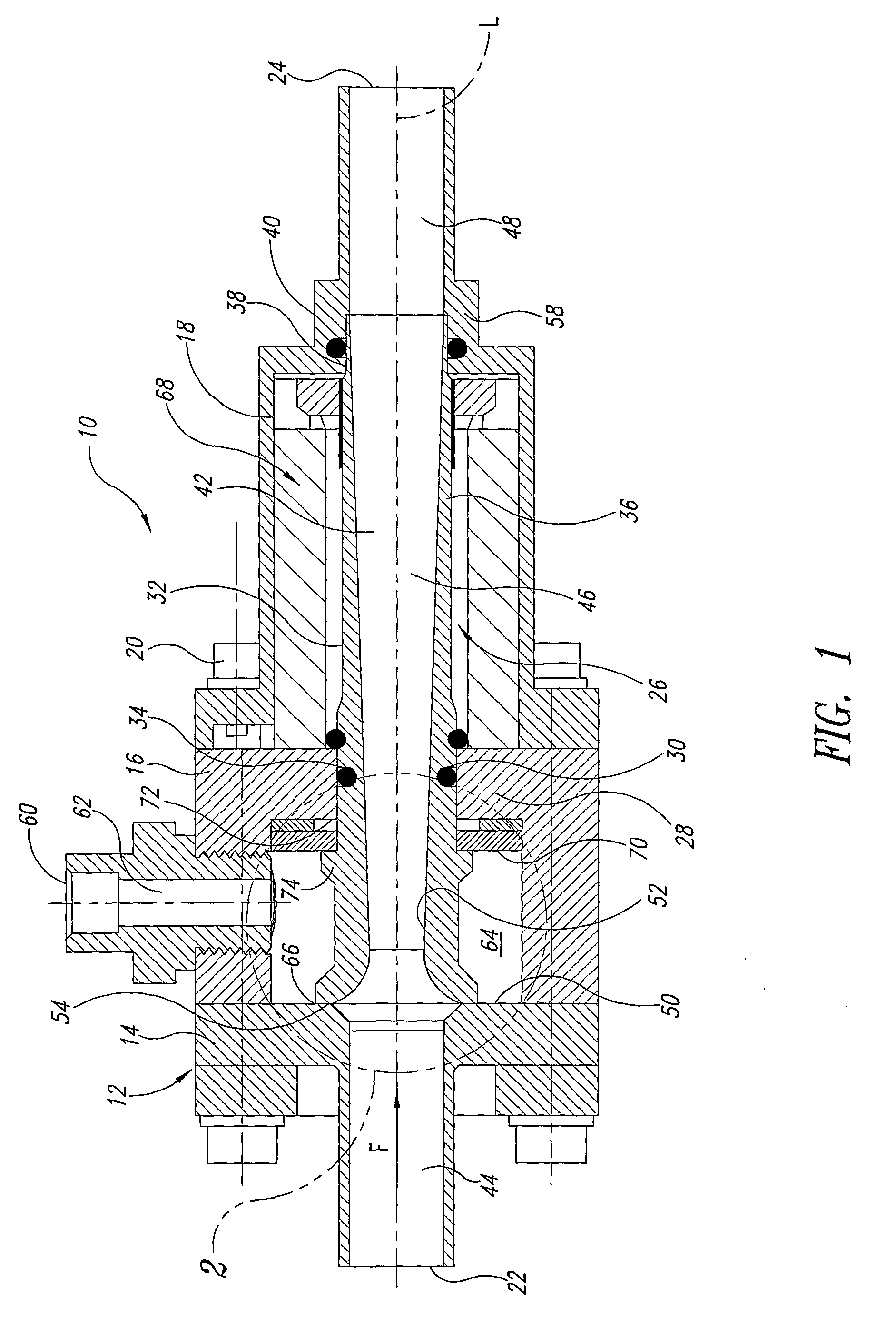

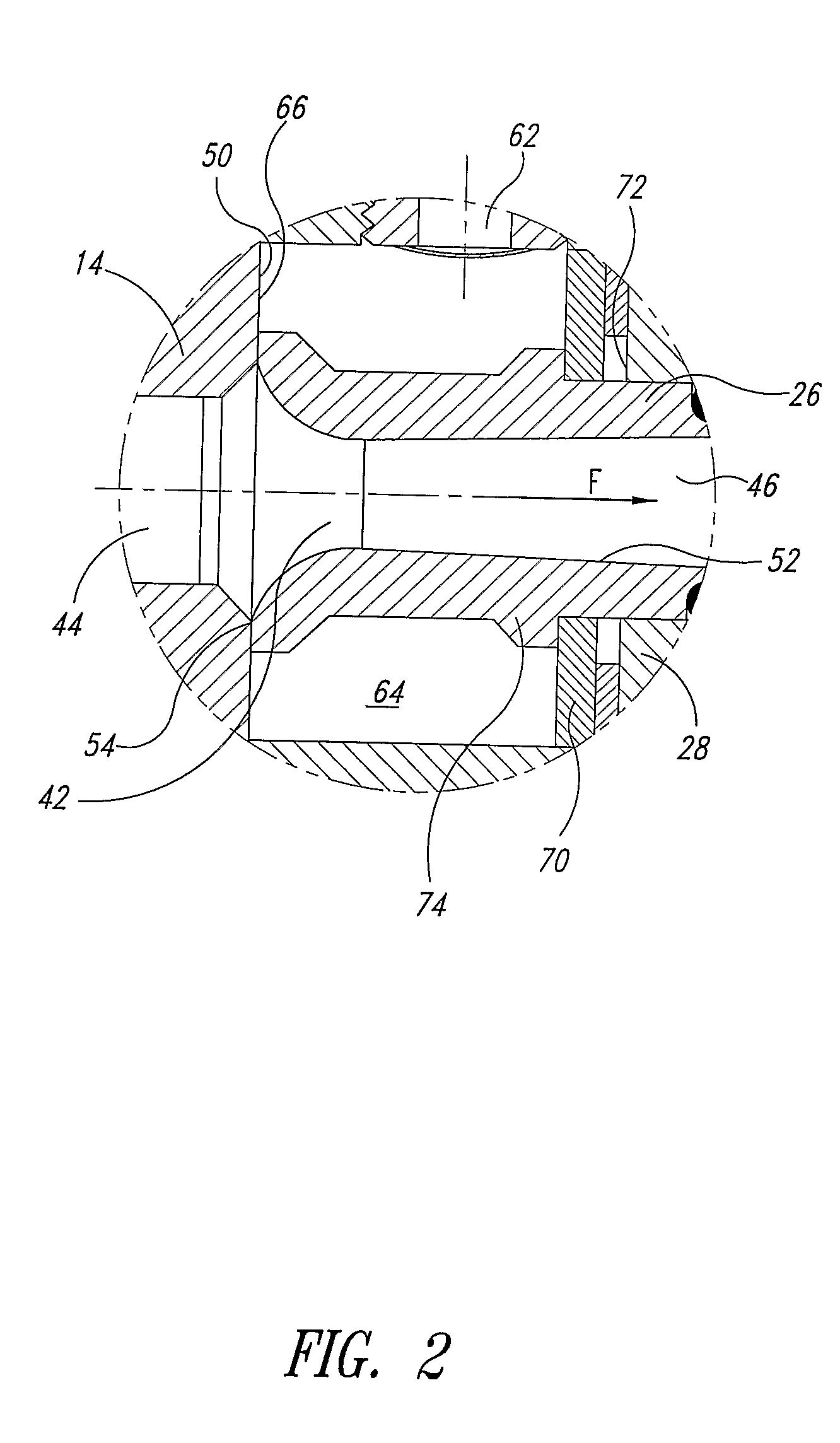

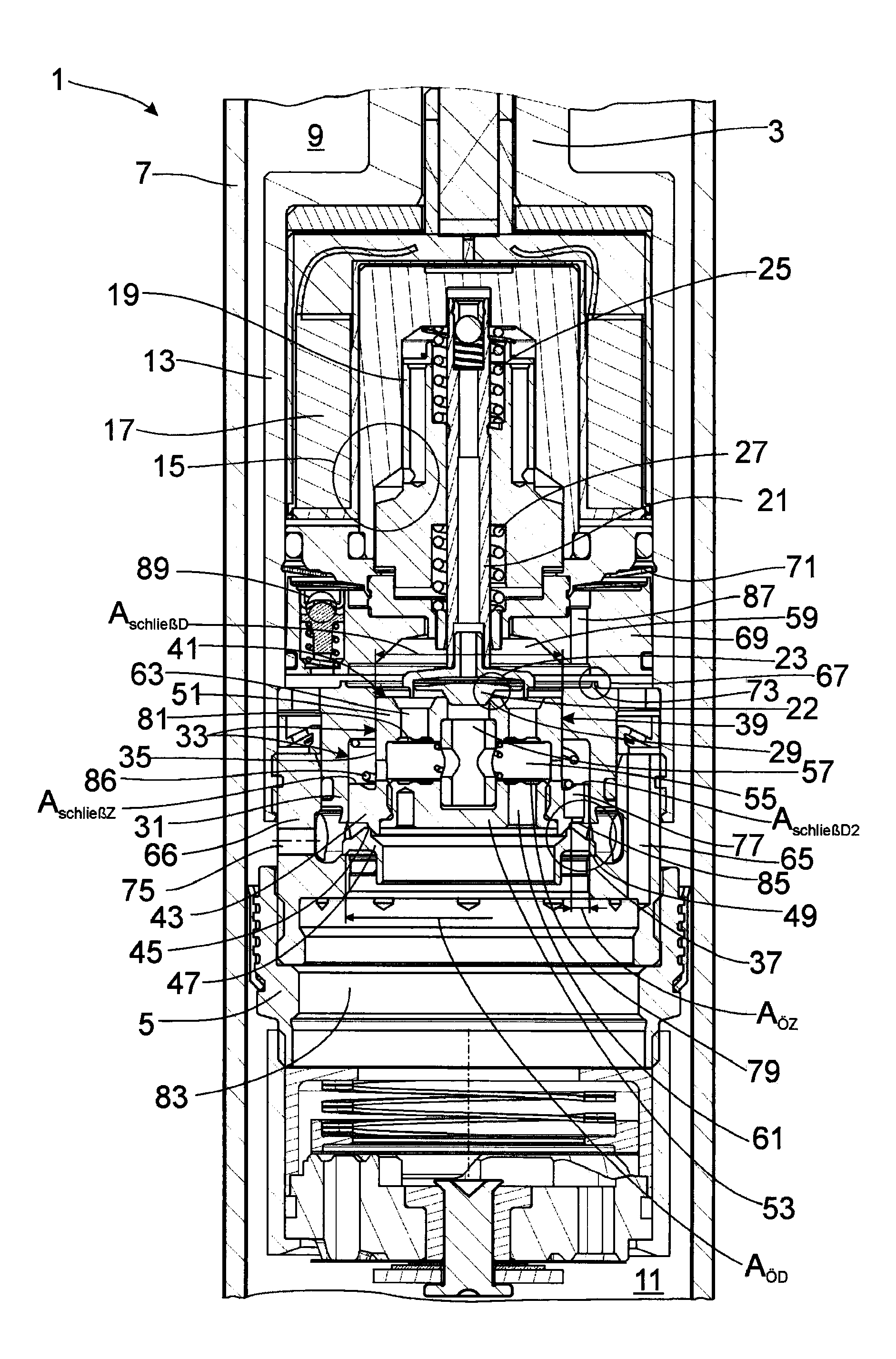

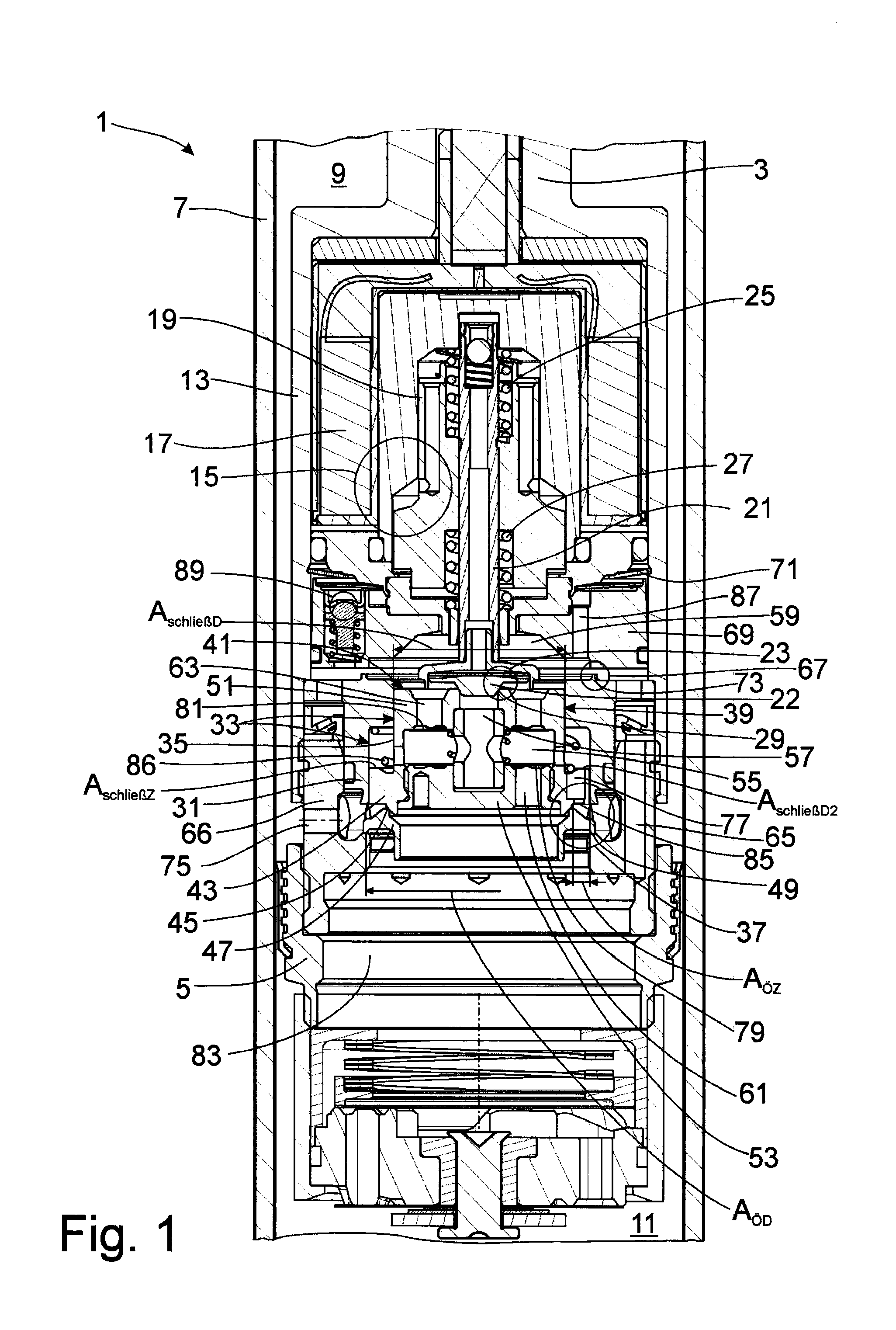

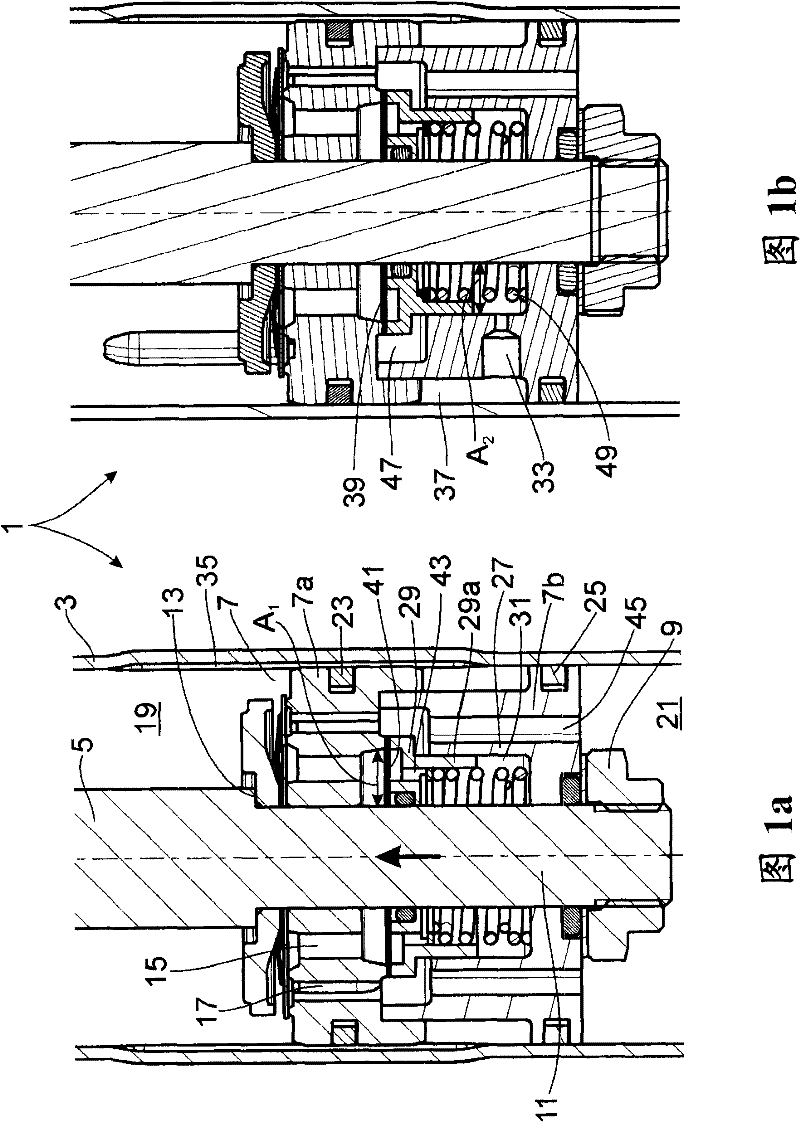

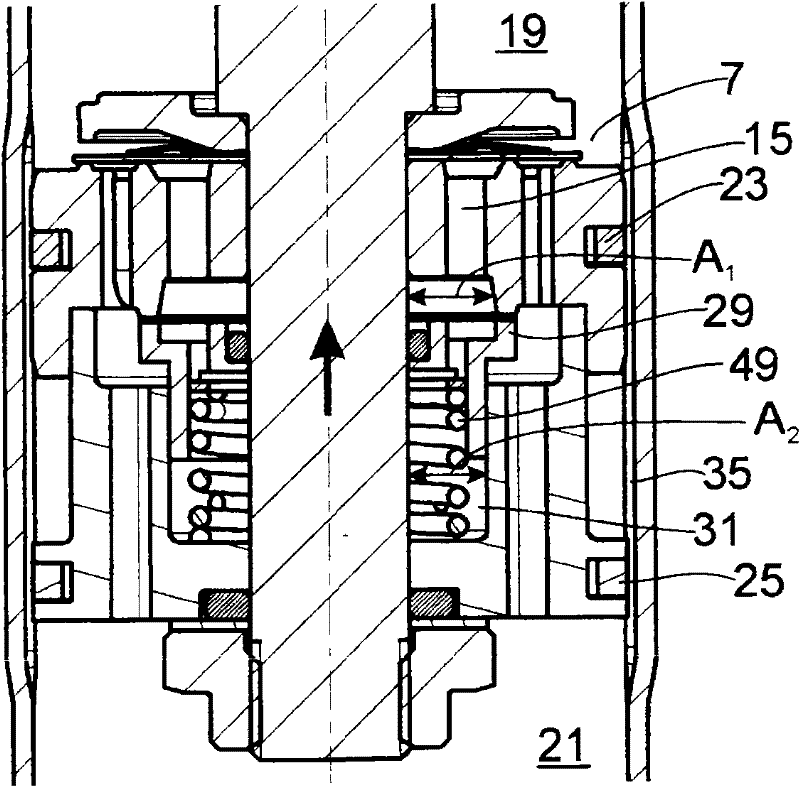

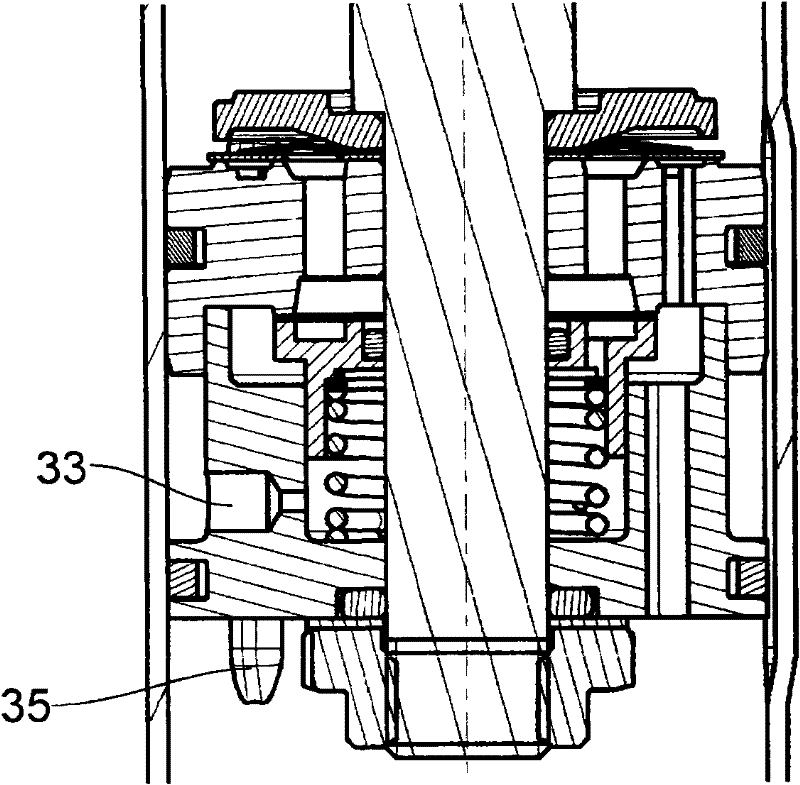

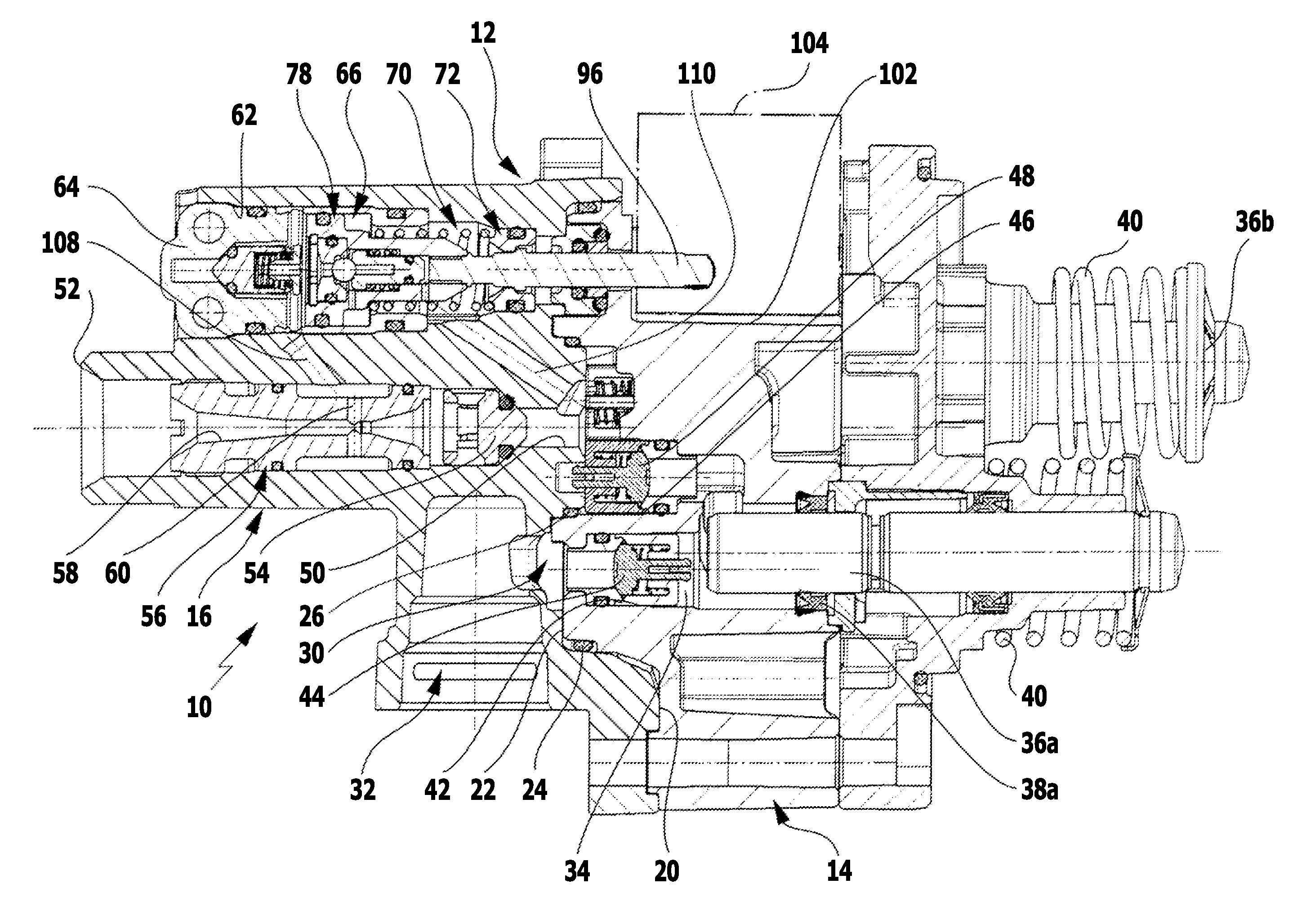

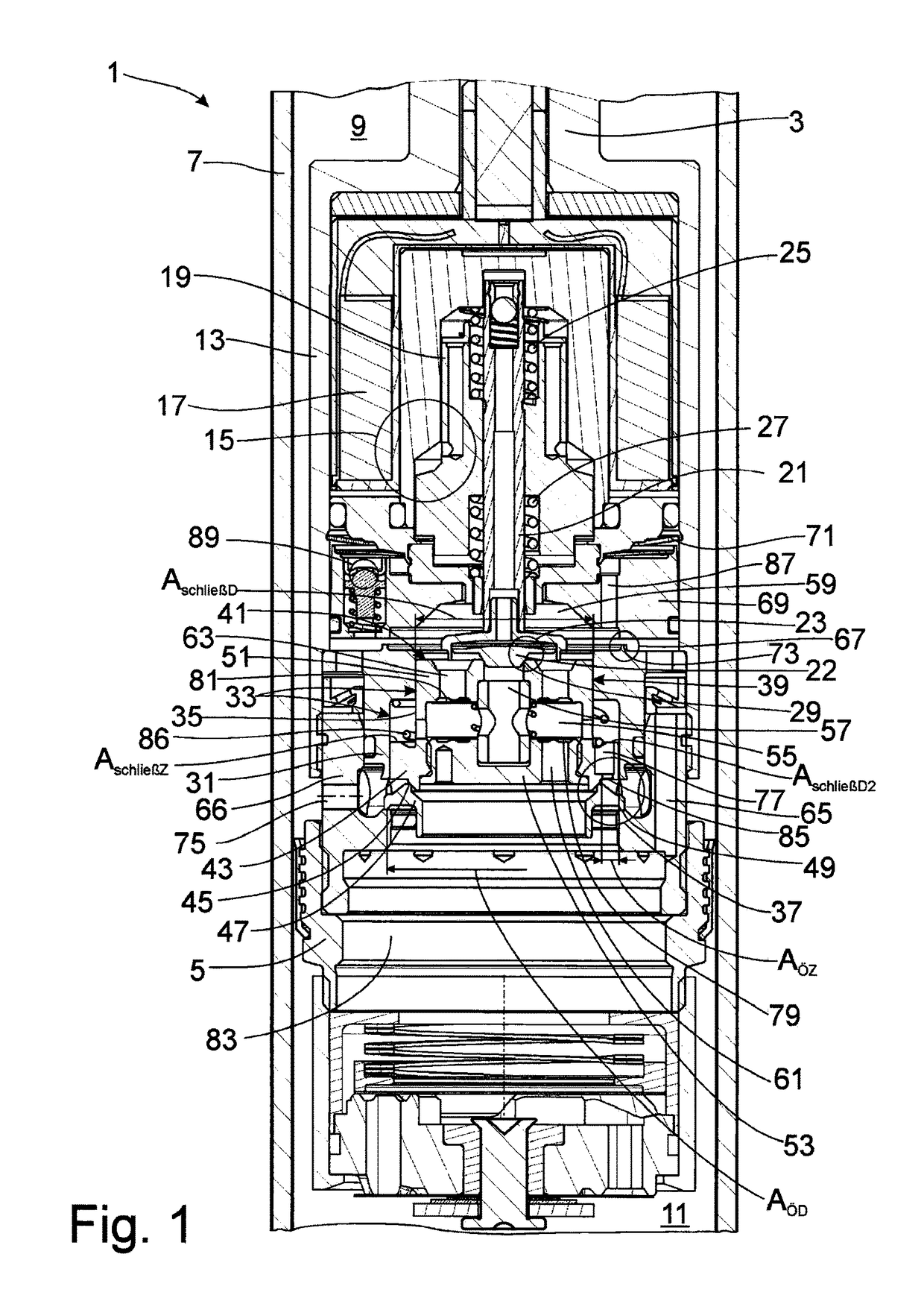

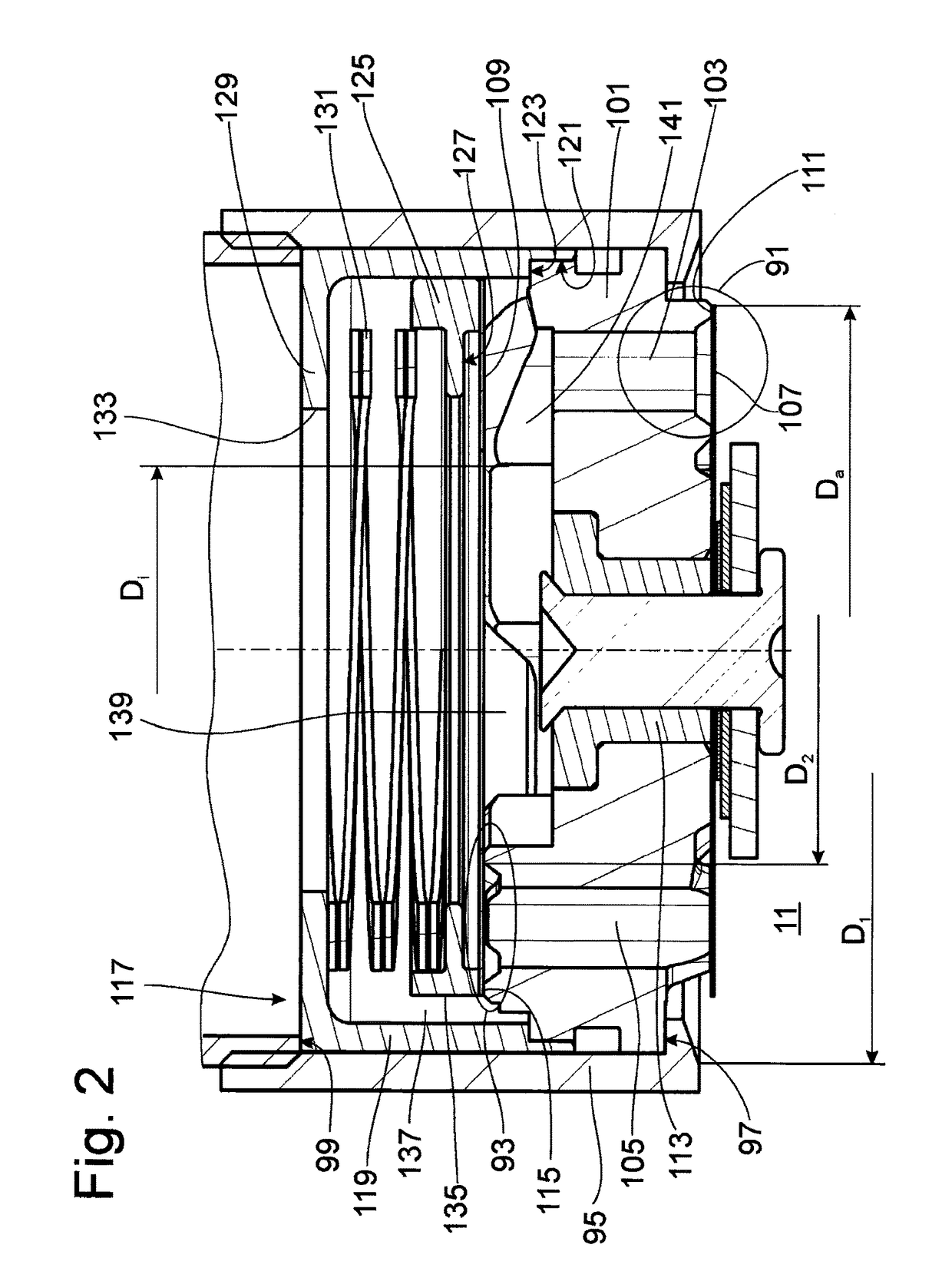

Adjustable damping valve arrangement

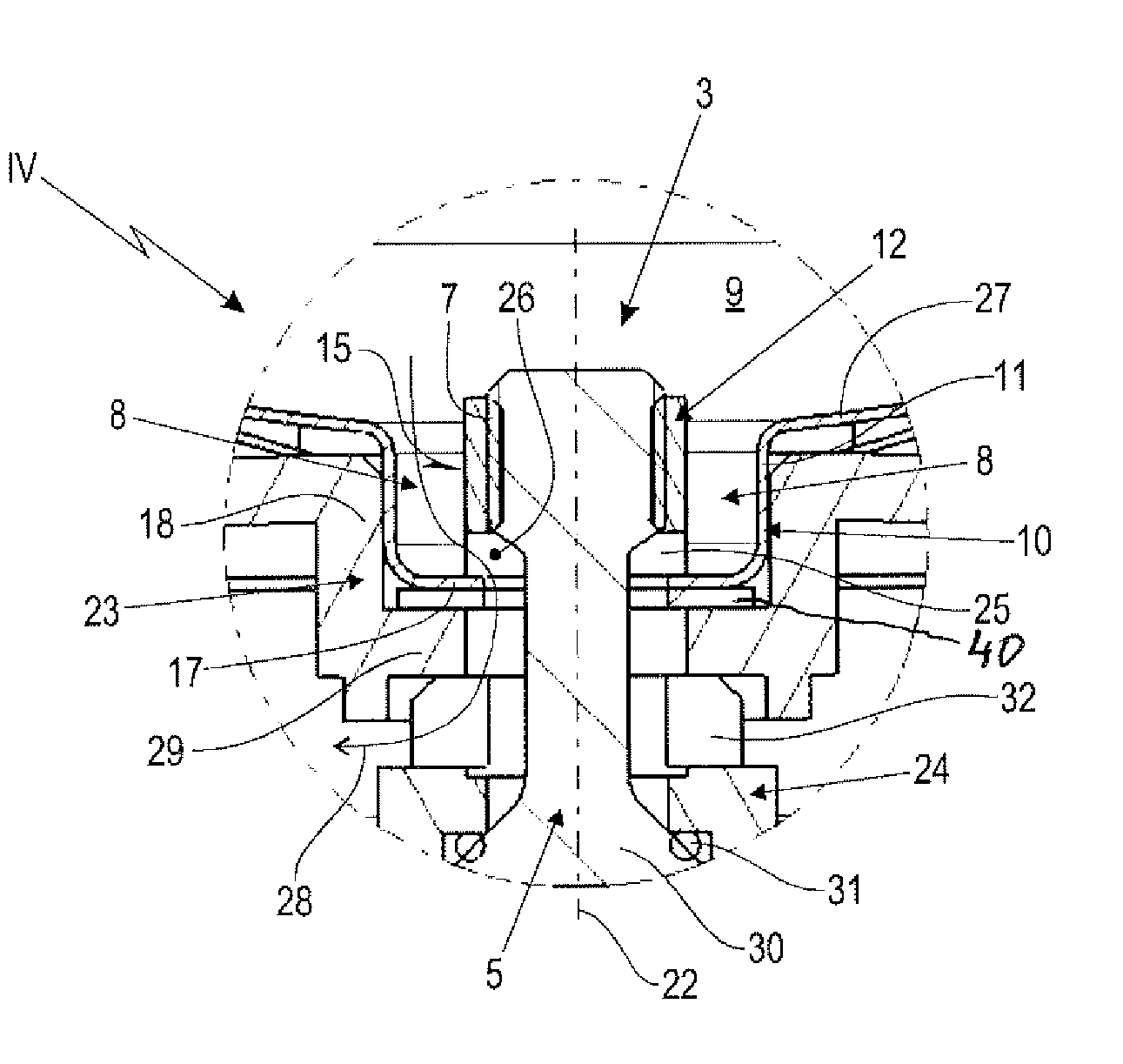

ActiveUS20130340865A1Increase installation spaceLarge flow cross sectionPipe supportsSpringsEngineeringVALVE PORT

An adjustable damping valve arrangement comprises an adjustable damping valve in which flow is bidirectional, wherein a pressure-dependent supplementary valve is associated with the adjustable damping valve in series therewith for each through-flow direction, wherein each supplementary valve has at least one separate through-channel, the outlet side thereof being at least partially covered by at least one valve disk, wherein the flow path proceeding from the adjustable damping valve in flow direction is carried out through the first supplementary valve from a smaller inlet diameter to a larger outlet diameter, and the at least one valve disk carries out a peripheral lift movement, wherein the flow path through the second supplementary valve in flow direction to the adjustable damping valve is implemented from a larger inlet diameter to a smaller outlet diameter.

Owner:ZF FRIEDRICHSHAFEN AG

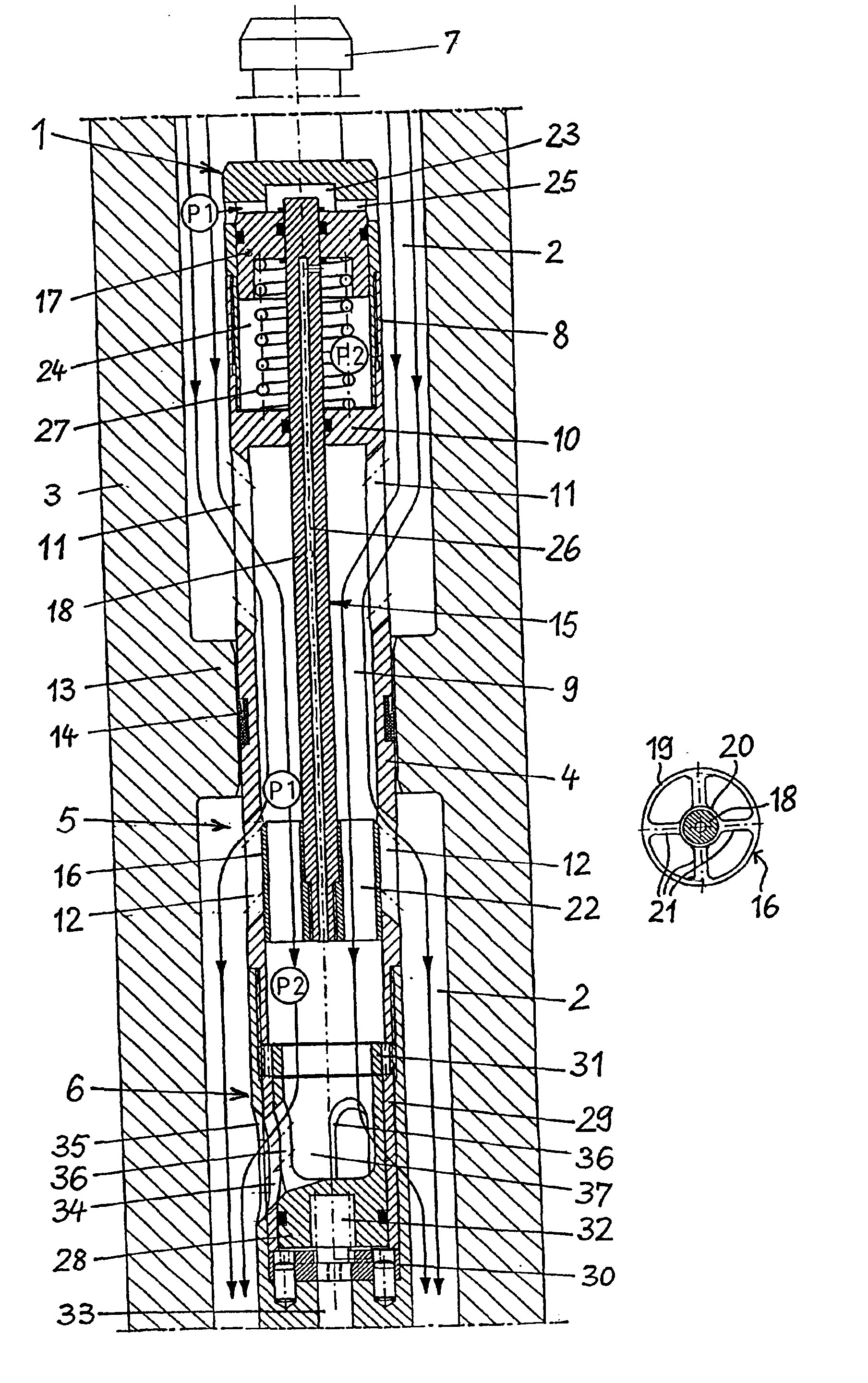

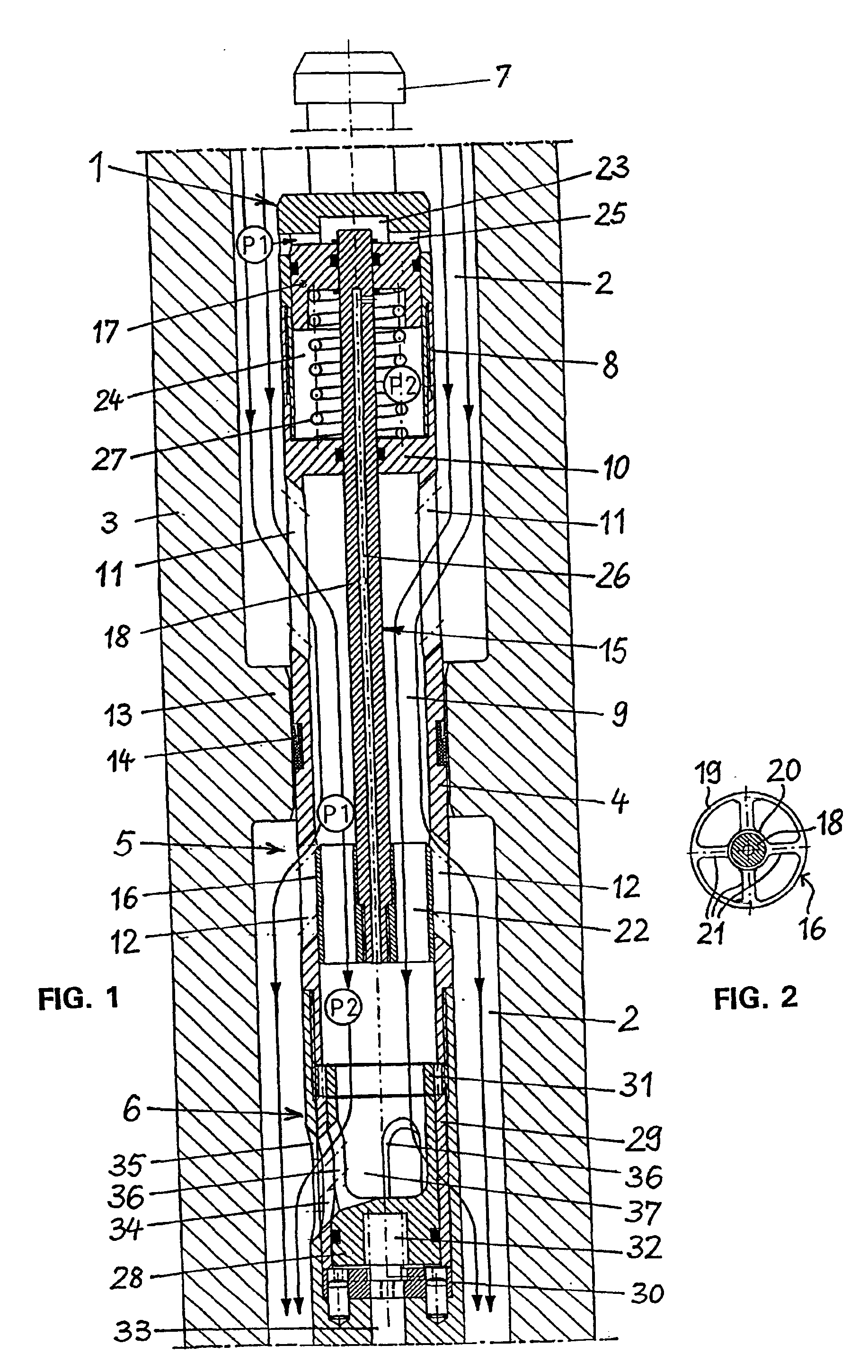

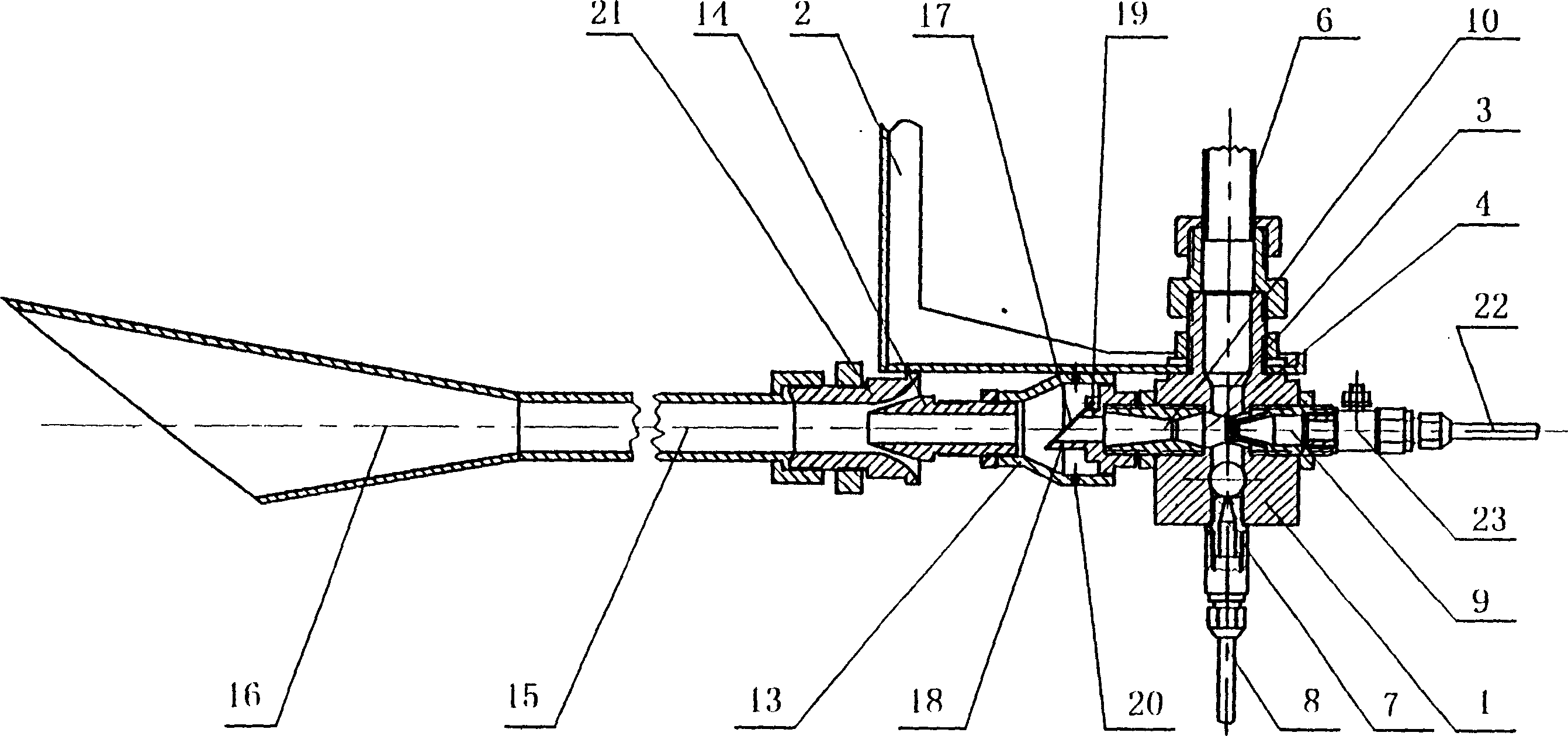

Borehole logging apparatus for deep well drilling

The invention is directed to a borehole logging apparatus for deep well drilling, with a signal transmitter for transmitting measured data obtained while drilling from a borehole through the drilling fluid to the earth's surface, and with an elongated housing which is adapted for insertion in the drilling fluid conduit of a drill string. Accommodated in the housing is a flow regulator with a control piston, which controls the cross-section of opening of a bypass opening in response to the pressure differential generated by a flow restrictor and in response to the force of a spring in such manner that the part of the drilling fluid current fed to the signal transmitter through the flow restrictor is maintained substantially constant, and the remaining excess drilling fluid current is routed to the drilling fluid conduit via the bypass opening.

Owner:PRECISION ENERGY SERVICES

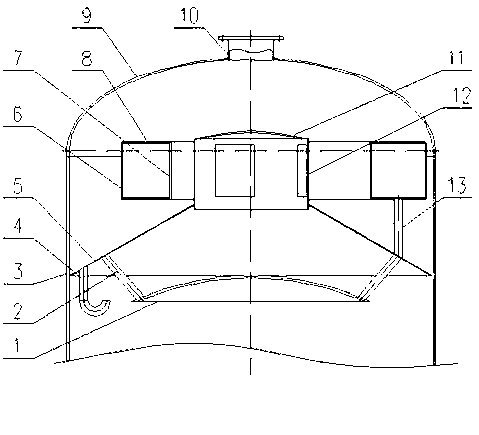

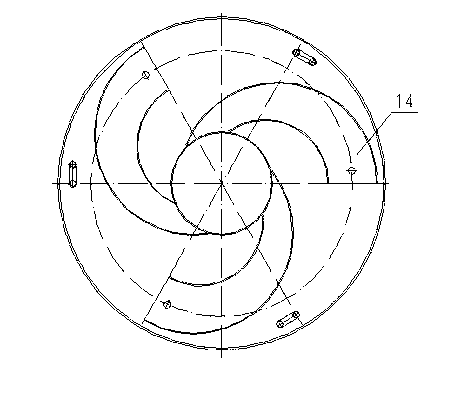

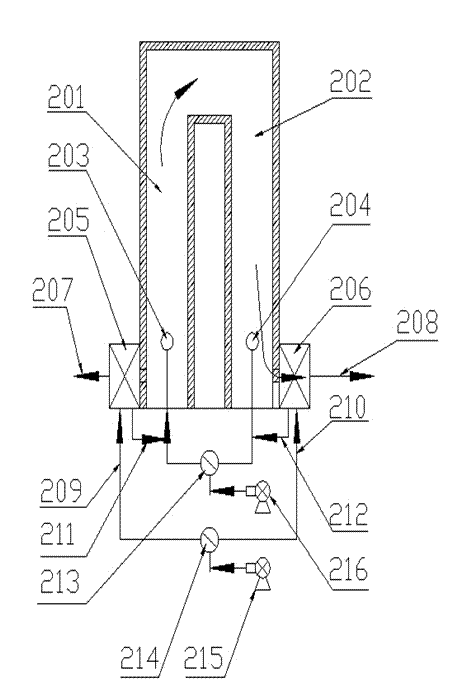

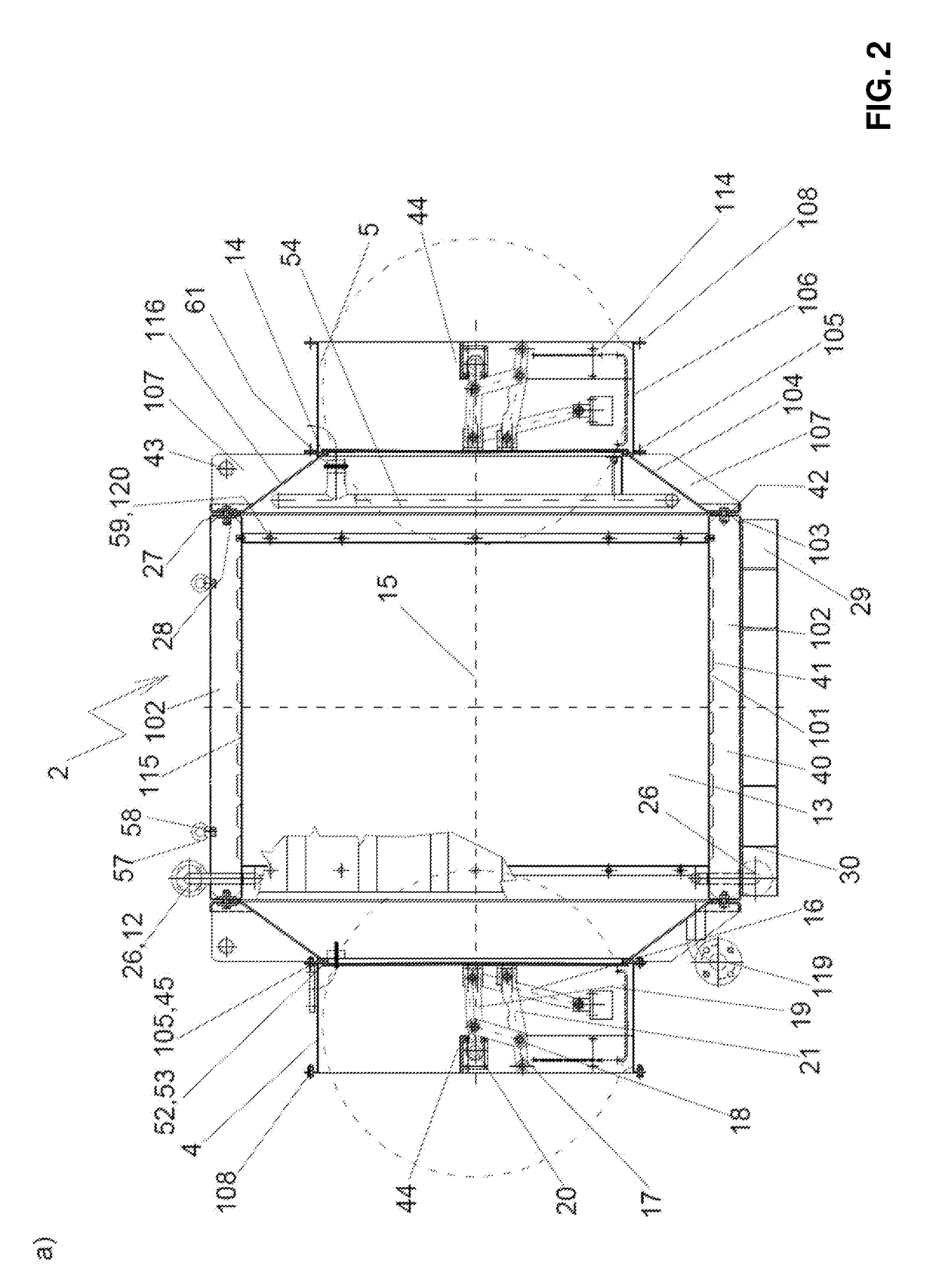

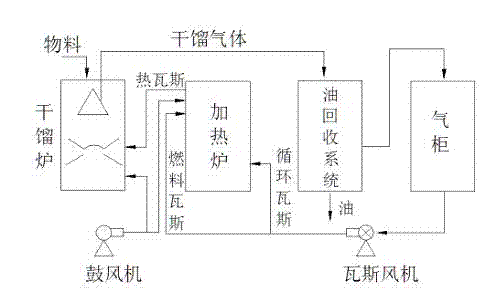

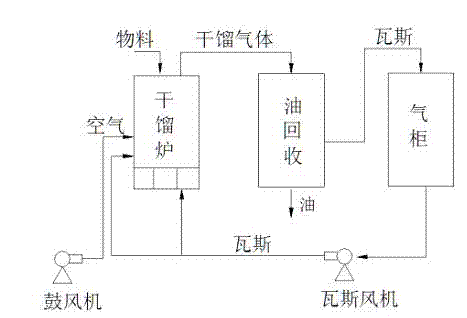

HY type dry distillation furnace

ActiveCN103923676ASolve the problem of low utilization efficiencyImprove utilization efficiencyIndirect and direct heating destructive distillationEnergy inputCombustion chamberHeat carrier

The invention discloses an HY type dry distillation furnace which is characterized by comprising a plurality of dry distillation subunits, wherein each dry distillation subunit comprises a charging device, an oil gas discharge device, a dry distillation device, a heating device and a coke discharge device; materials are subjected to dry distillation by using a combined radiation heat exchange and convection heat exchange mode in the furnace; gas generated in a dry distillation process is used as a dry distillation heat source, and the dry distillation heat can be self-balanced; the materials are directly heated by virtue of radiation of a furnace wall of a combustion chamber, and a heat carrier does not need to be subjected to secondary heating and long-distance conveying; a dry distillation gas outputting device is arranged in the furnace, so that the gas in the furnace flows smoothly; coke is discharged by a dry method. The dry distillation furnace is high in heat utilization efficiency, low in outlet gas quantity, low in water consumption, high in oil yield and large in daily treatment capacity capable of being more than 6,000 tons, and is suitable for low and medium-temperature dry distillation of the materials such as oil sand, oil shale, coal and the like, and suitable for oil refining and dry distillation of large particle materials and small particle materials of less than 15mm.

Owner:辽宁智越建设有限公司

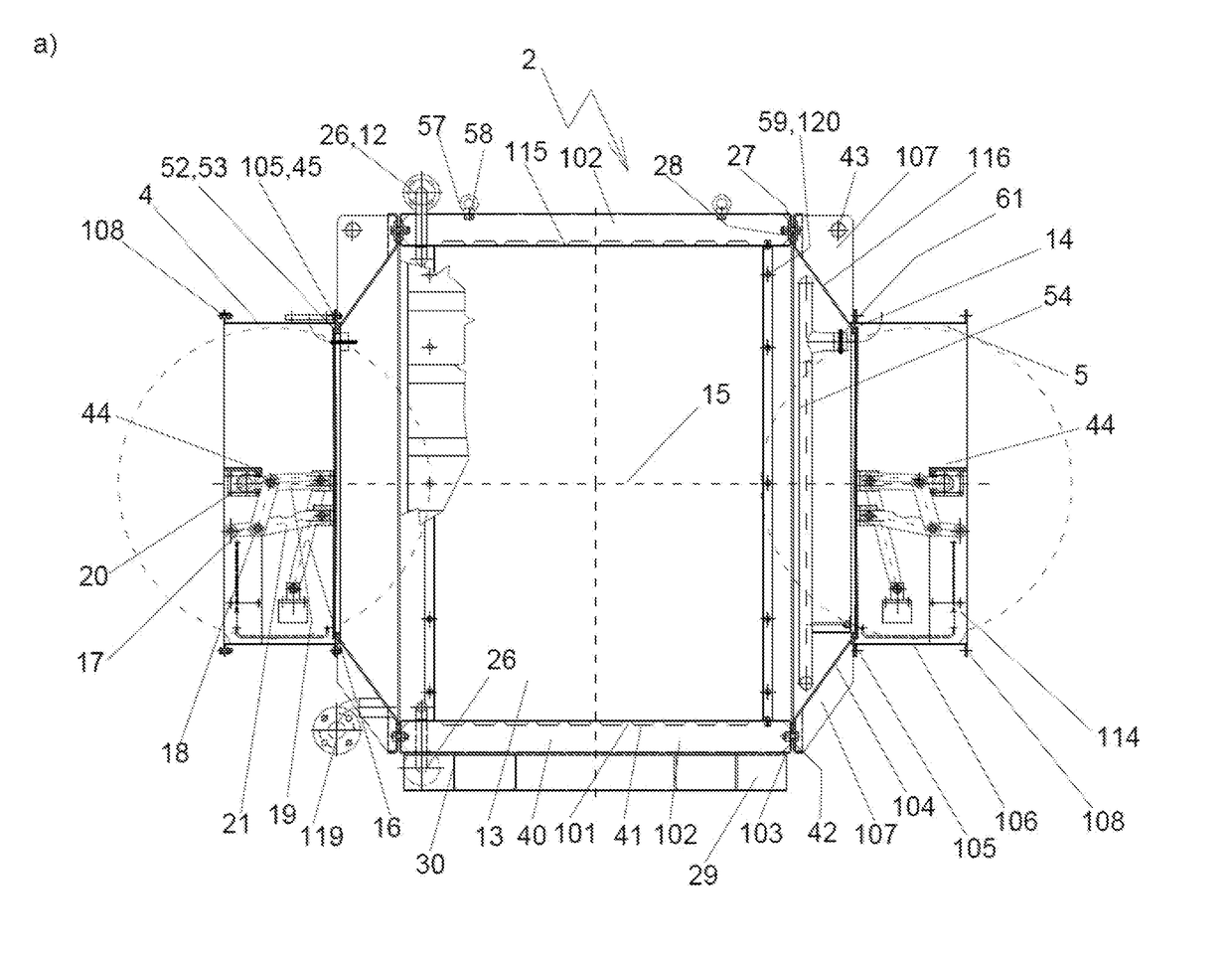

Direct air capture device

ActiveUS20170106330A1Improve mechanical stabilityLarge flow cross sectionGas treatmentDispersed particle separationInterior spaceEngineering

A vacuum chamber (2) for a direct air capture process and enclosing an interior space (13) for housing an adsorber structure (1) is given comprising a contiguous circumferential wall structure (115) along an axis (15), which circumferential wall structure (115) in an axial direction is closed by an inlet and an outlet axial wall (116), respectively, both axial walls (116) comprising at least one closing stainless steel lid (6) allowing for, in an open position, gas to be circulated through the vacuum chamber (2) for passing an adsorber structure (1), and, in a closed position, to close the interior space (13) and to allow evacuation of the interior space (13) down to pressure of 500 mbarabs or less.

Owner:CLIMEWORKS

Axial valve

InactiveUS6955331B2Precise positioningLarge forceOperating means/releasing devices for valvesInterior spaceEngineering

An axial valve has a housing, an inlet, an outlet, a valve seat between the inlet and the outlet, and a valve element cooperating with the valve seat, and is controlled by a pilot valve arranged between the inlet and the outlet, with the valve element being moveable parallel to a flow path from the inlet to the outlet and surrounding an interior space. Without changing the external measurements of the valve an increased through flow is achieved in that a first section of the flow path leads through the interior space and a pressure space is arranged between the housing and the valve element, in which pressure space in the closed condition of the pilot valve a closing pressure is formed and applied to the valve element.

Owner:DANFOSS AS

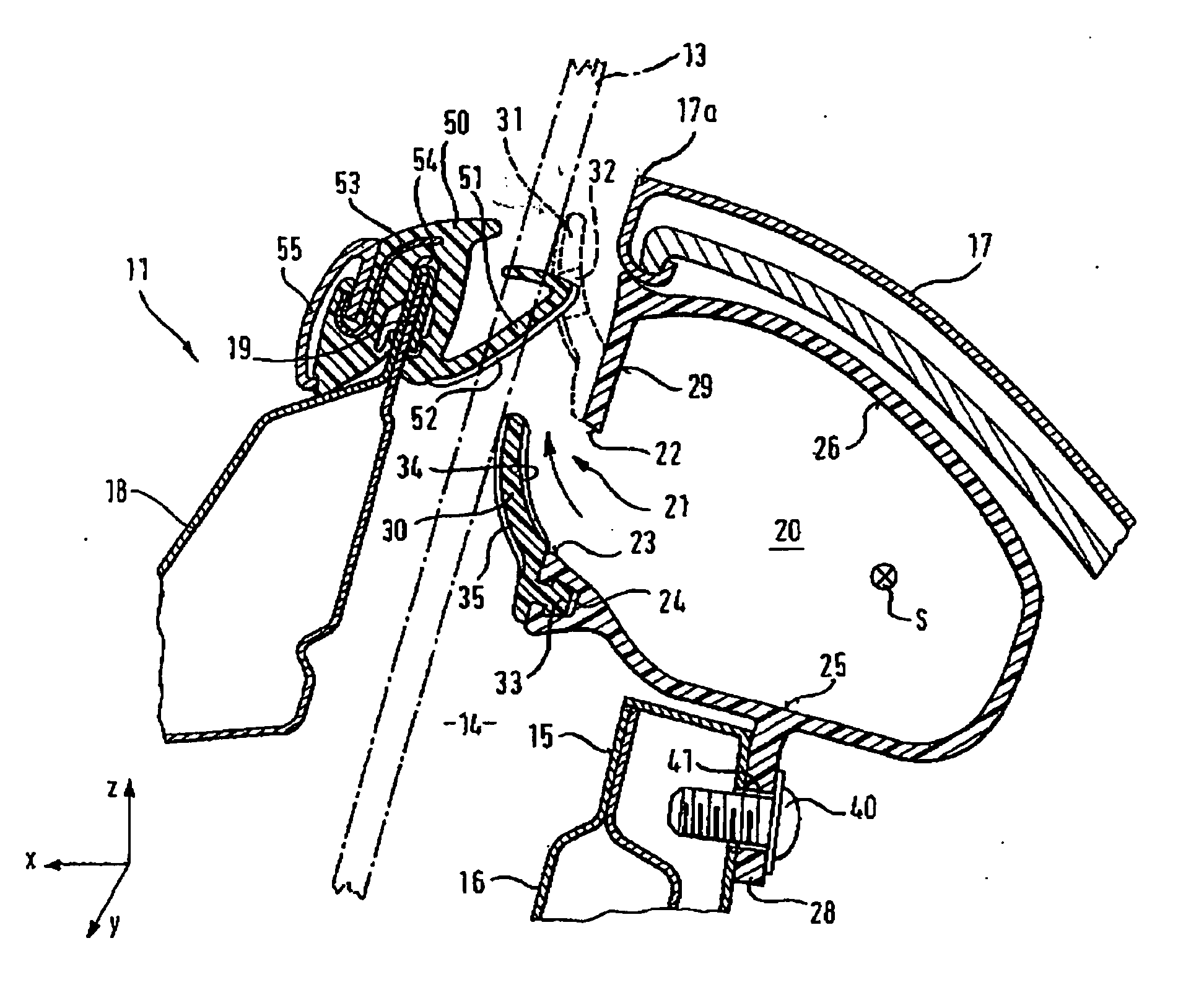

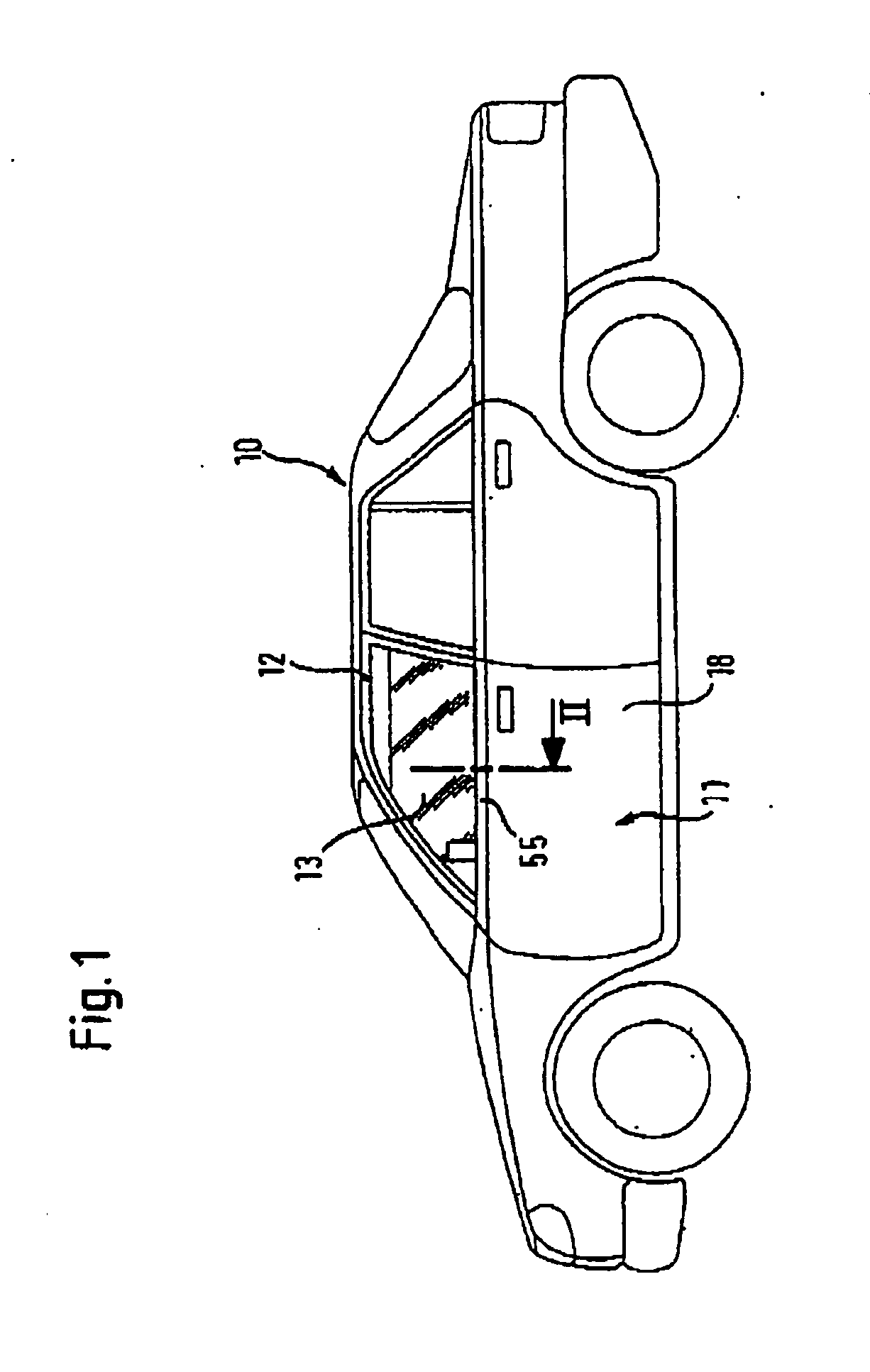

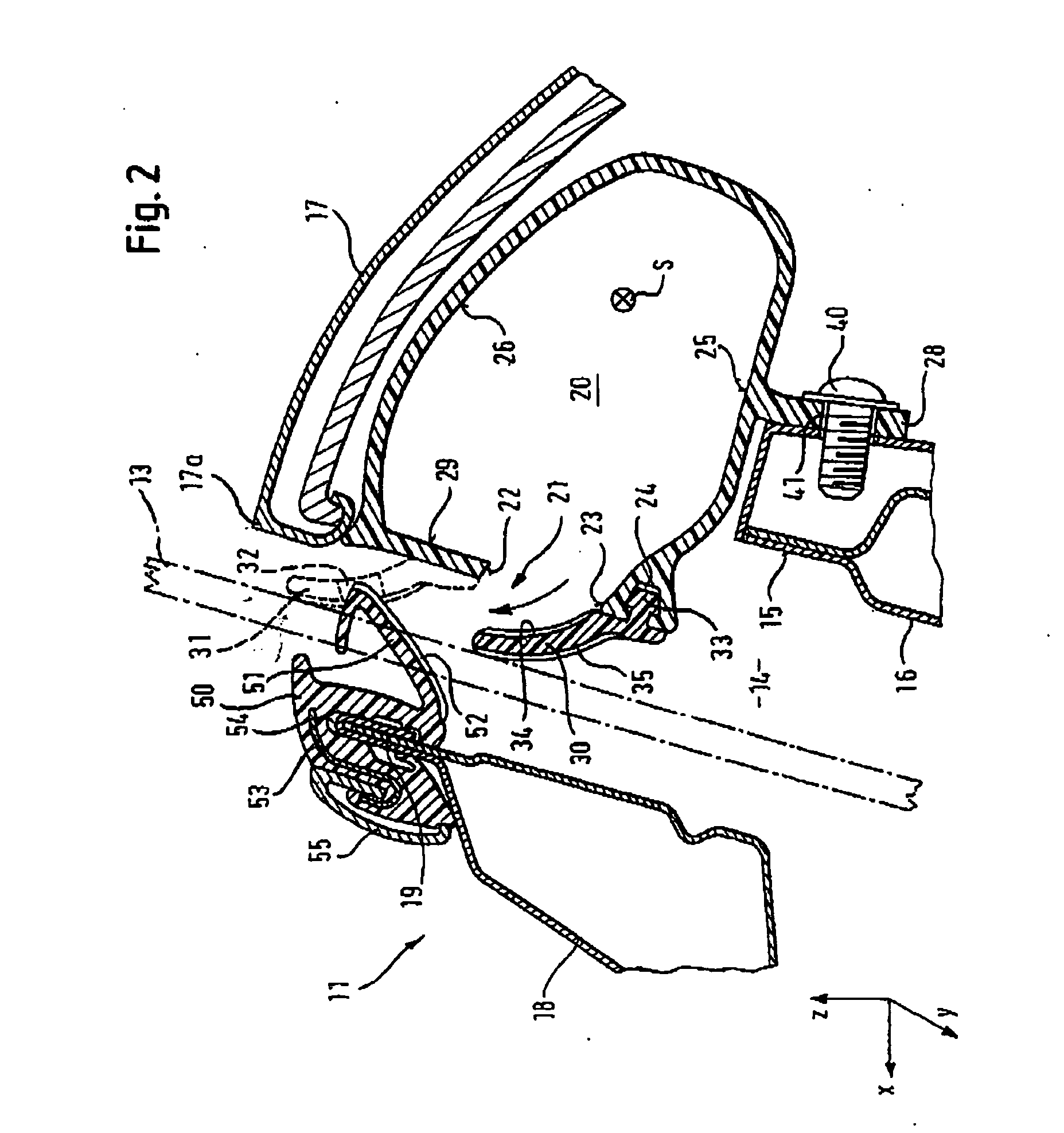

Ventilation component for window panes, especially window panes of a motor vehicle

InactiveUS20060079167A1Easy to sprayLarge flow cross sectionWindowsAir-treating devicesEngineeringMotorized vehicle

Owner:METZELER AUTOMOTIVE PROFILES GMBH

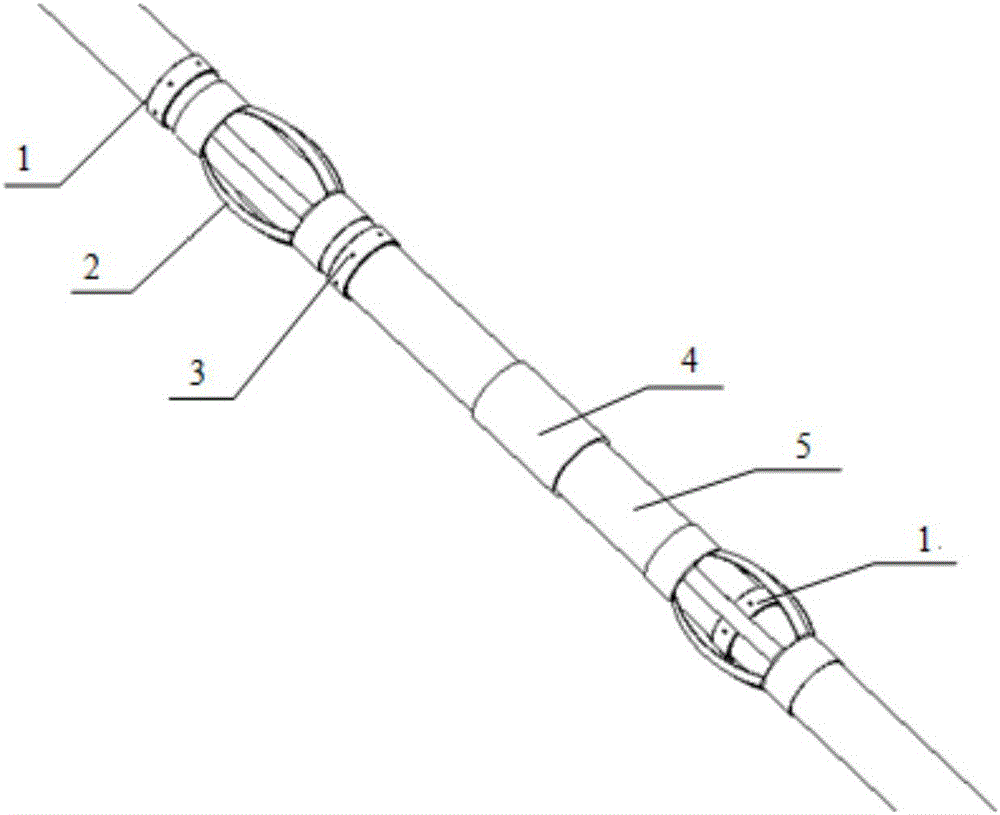

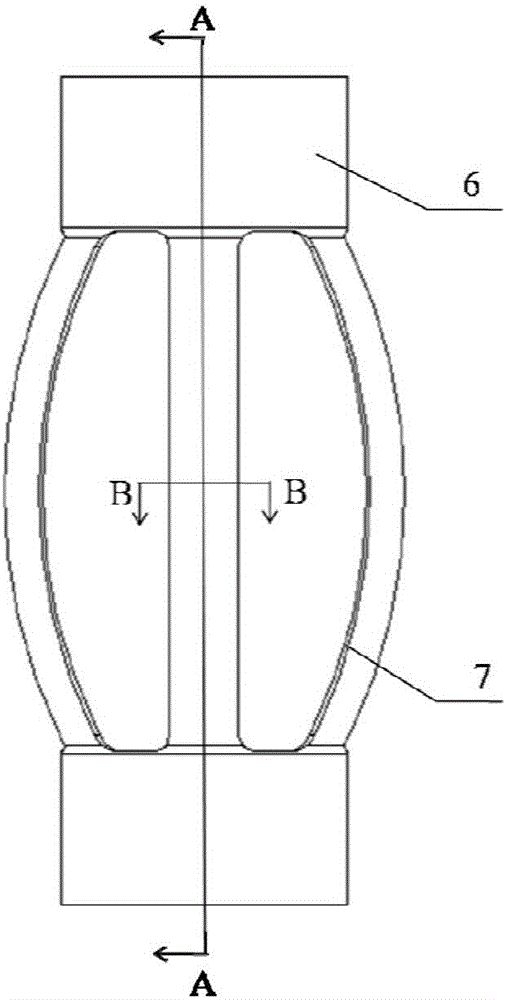

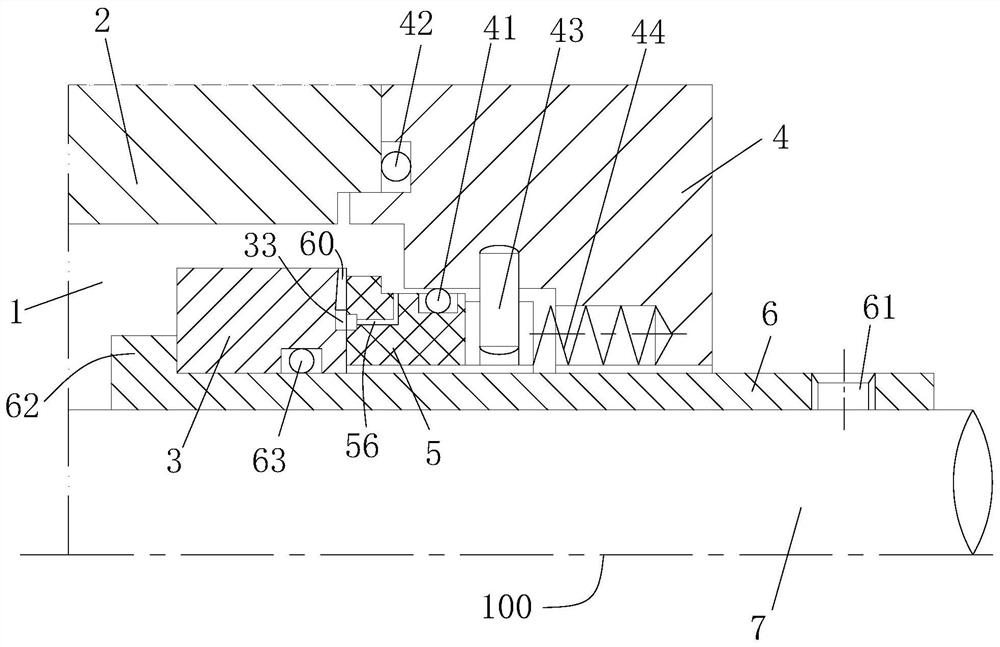

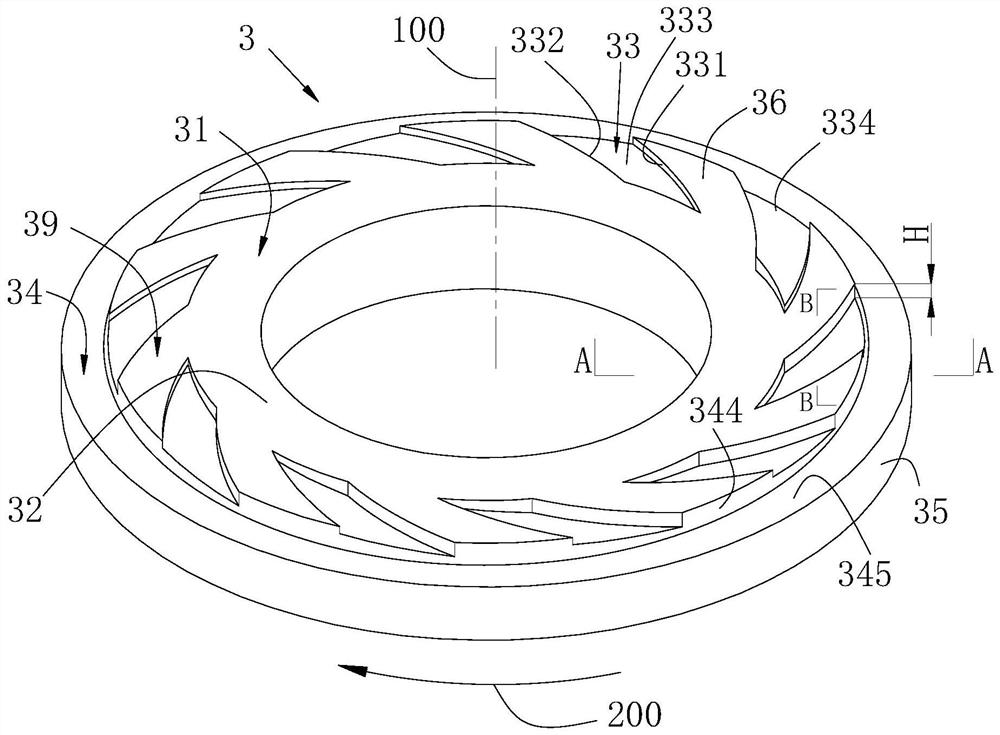

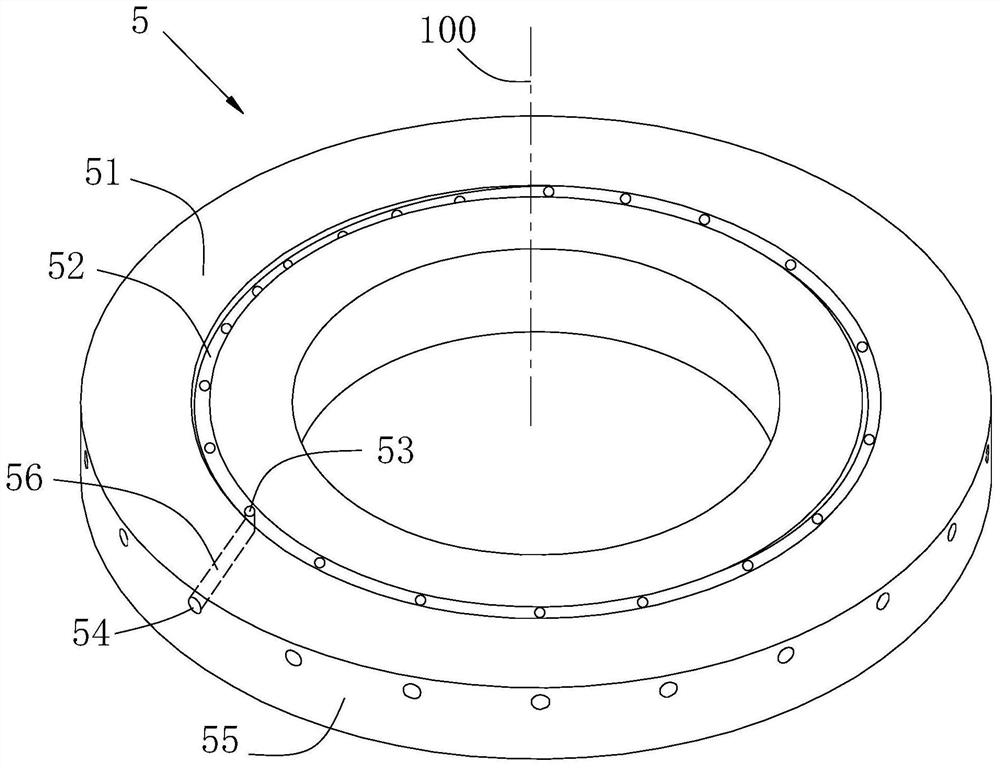

Integral type casing centralizer and manufacturing method thereof

The invention provides an integral casing centralizer and a manufacturing method thereof, belonging to the field of oil and gas well cementing. The integral casing centralizer is processed by uniform wall thickness material pipe or plate, including hoops at both ends, and limbs located between the hoops at both ends; the limbs are evenly distributed on the circumference, and each The two ends of each limb are respectively connected with the hoops at both ends; each limb is arched outward; the outer diameter of the centralizer formed by all the limbs is smaller than or equal to the inner diameter of the upper casing.

Owner:CHINA PETROLEUM & CHEM CORP +1

Vibration damper with stroke-dependent damping force

InactiveCN102207159ASmall structural space requirementsEasy to manufactureSpringsShock absorbersPosition dependentControl space

A vibration damper with stroke-dependent damping force includes a cylinder in which a piston rod with a piston is axially movable. The piston divides the cylinder into two work spaces filled with damping medium. A bypass between the work spaces is opened or closed depending on the piston position. The piston has a damping valve for at least one through-flow direction formed by a valve body that partially covers a through-flow channel in the damping valve. The valve body has first and second pressure-actuated surfaces on opposite sides of the valve body. The action of the second pressure-actuated surface depends on the position of the piston in relation to the bypass. The first pressure-actuated surface exerts a lifting force and the second pressure-actuated surface exerts a closing force on the valve disk. The second pressure-actuated surface is connected to a control space and a connection channel that overlaps with the bypass depending on the stroke position of the piston.

Owner:ZF FRIEDRICHSHAFEN AG

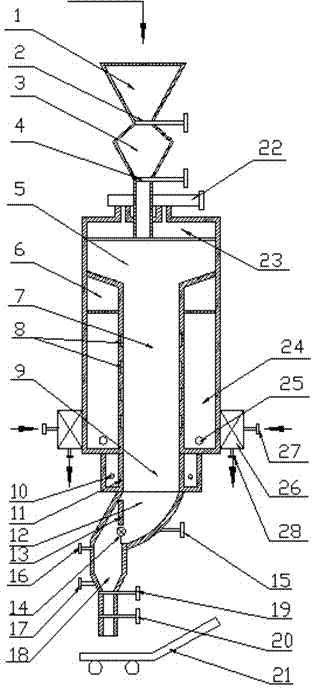

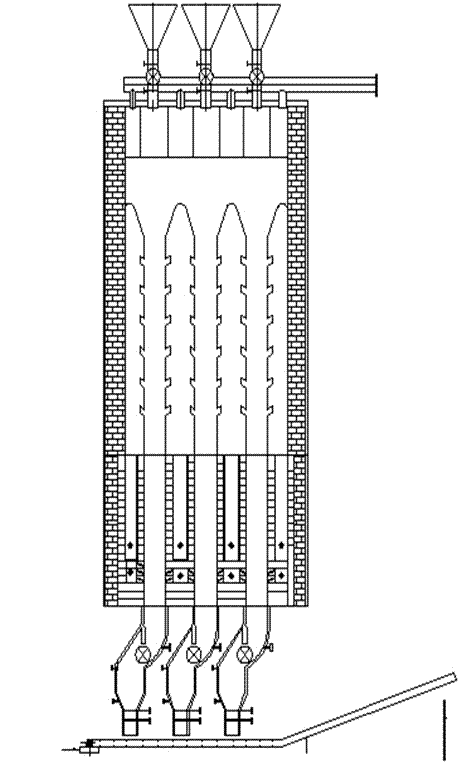

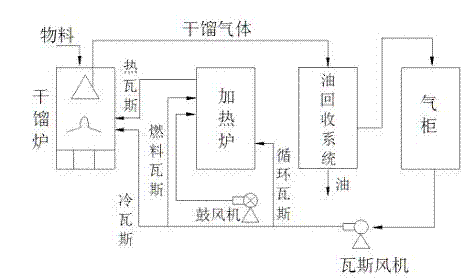

Integrated gas retort

ActiveCN102827619AReduce consumption costsLow running costEnergy inputIndirect heating destructive distillationCombustion chamberHeat carrier

The invention relates to an integrated gas retort integrating heating of a heat carrier and dry distillation of materials into the same one dry distillation unit. The integrated gas retort is characterized in that smoke gas is used as dry distillation heat carrier for indirectly heating materials; the gas retort is formed by combining a plurality of dry distillation sub units. Each dry distillation sub unit is independent, one combustion chamber corresponds to one dry distillation chamber to form one dry distillation sub unit, the upper parts of retorts comprising a plurality of dry distillation sub units are communicated, the two dry distillation sub units are separated by a smoke gas chamber, and the lower parts share one water seal tank and a tar exhaust device. The actual daily capacity of the gas retort can achieve more than 6000. The integrated gas retort is applicable to low-temperature dry distillation oil refining of materials oil sand, oil shale, coal and the like. The integrated gas retort is applicable to dry distillation and oil refining of small-particle materials, as well as various qualities of materials with low gas content, low fixed carbon content and high moisture content, and the oil recovery rate of the gas retort can achieve about 90%.

Owner:辽宁智越建设有限公司

Flying ash sampling ejector

InactiveCN1854708ALarge flow cross sectionThe flow cross section becomes larger and smallerWithdrawing sample devicesChimneysEngineeringFly ash

A sampling ash-ejector of fly ash is prepared as setting top and bottom, left and right and front and back through holes on ash ejecting seat; connecting top hole to quarts detection tube and bottom hole to inverse blowing nozzle and compressed air inlet; setting ash ejecting nozzle and according tube on top player left and right through holes as ash ejection according tube being connected to air locker, ash ejecting nozzle head, ash ejecting tube, etc; setting a sampling nozzle and sampling acceleration tube on bottom layer front and back through hole as sampling nozzle one end being connected to compressed air inlet and another end to sampling separator.

Owner:内蒙古自治区科学技术开发中心

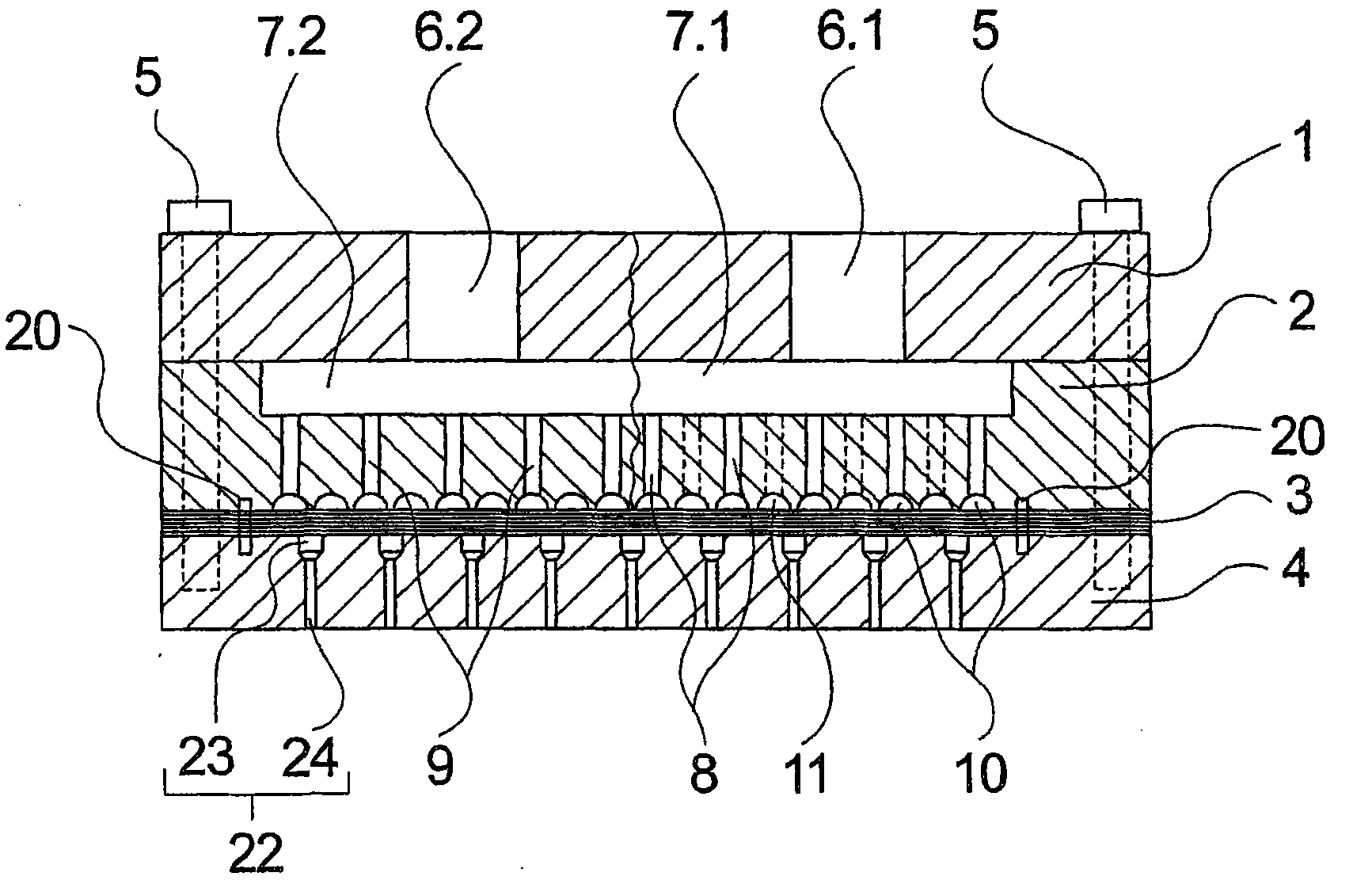

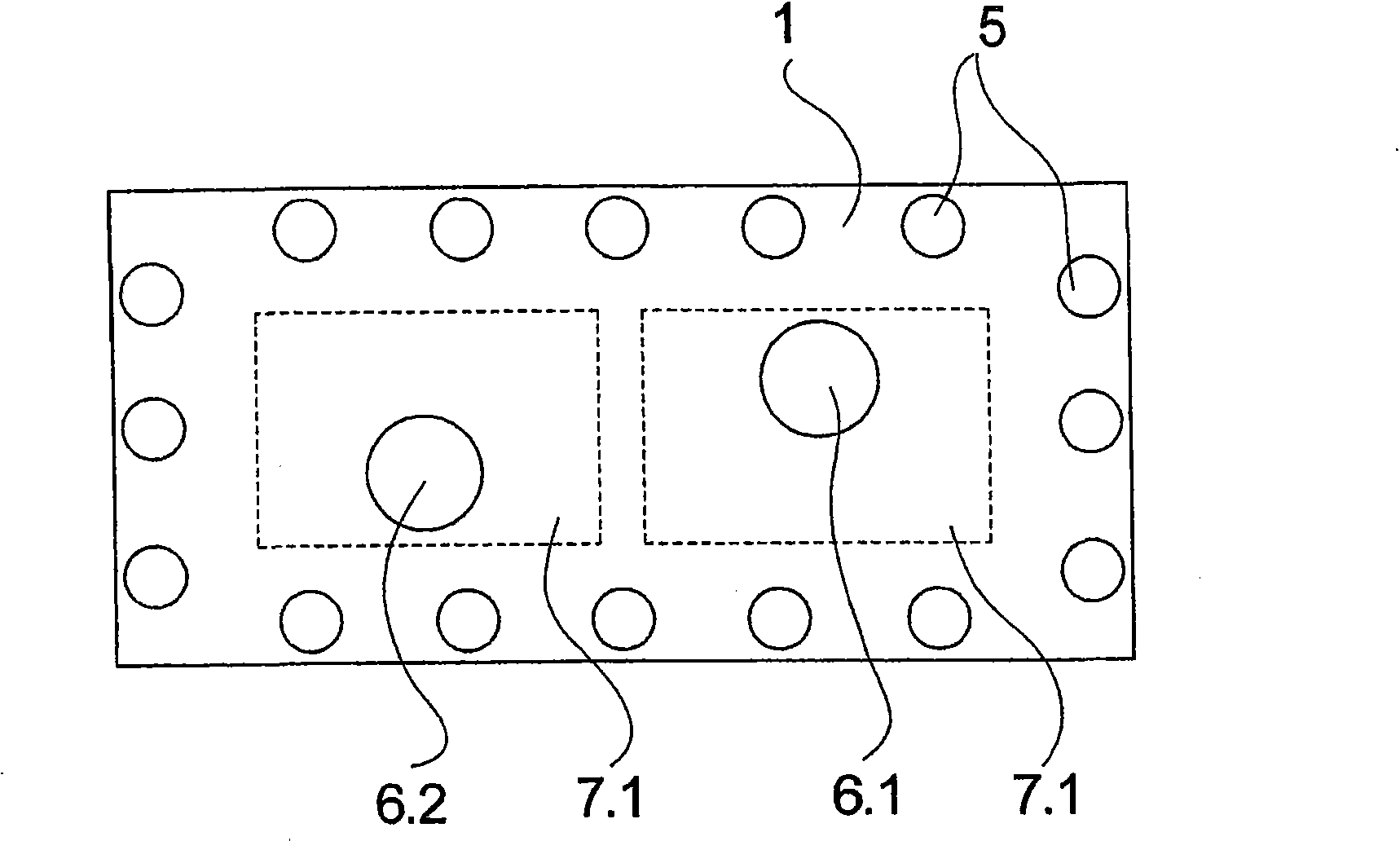

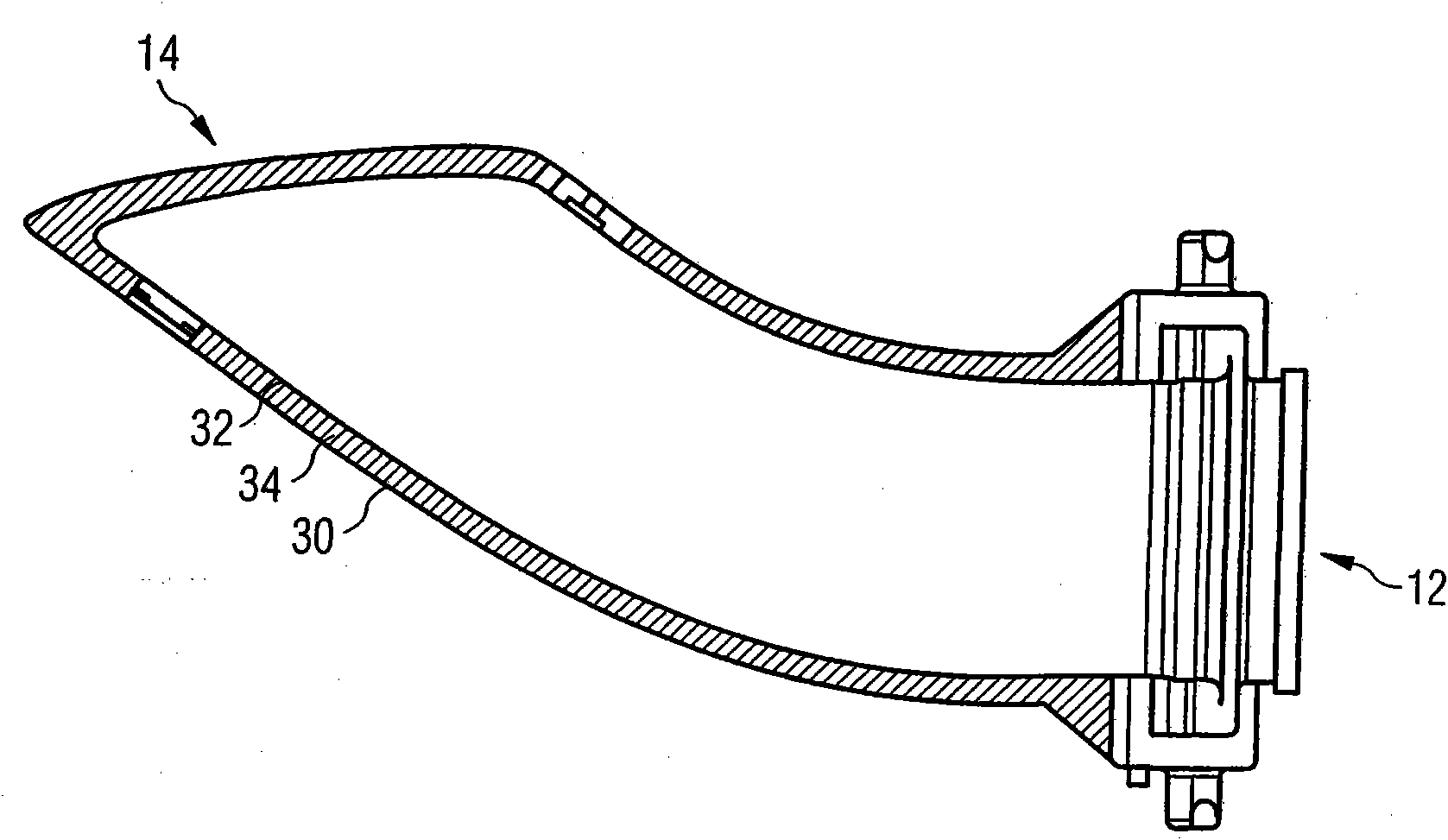

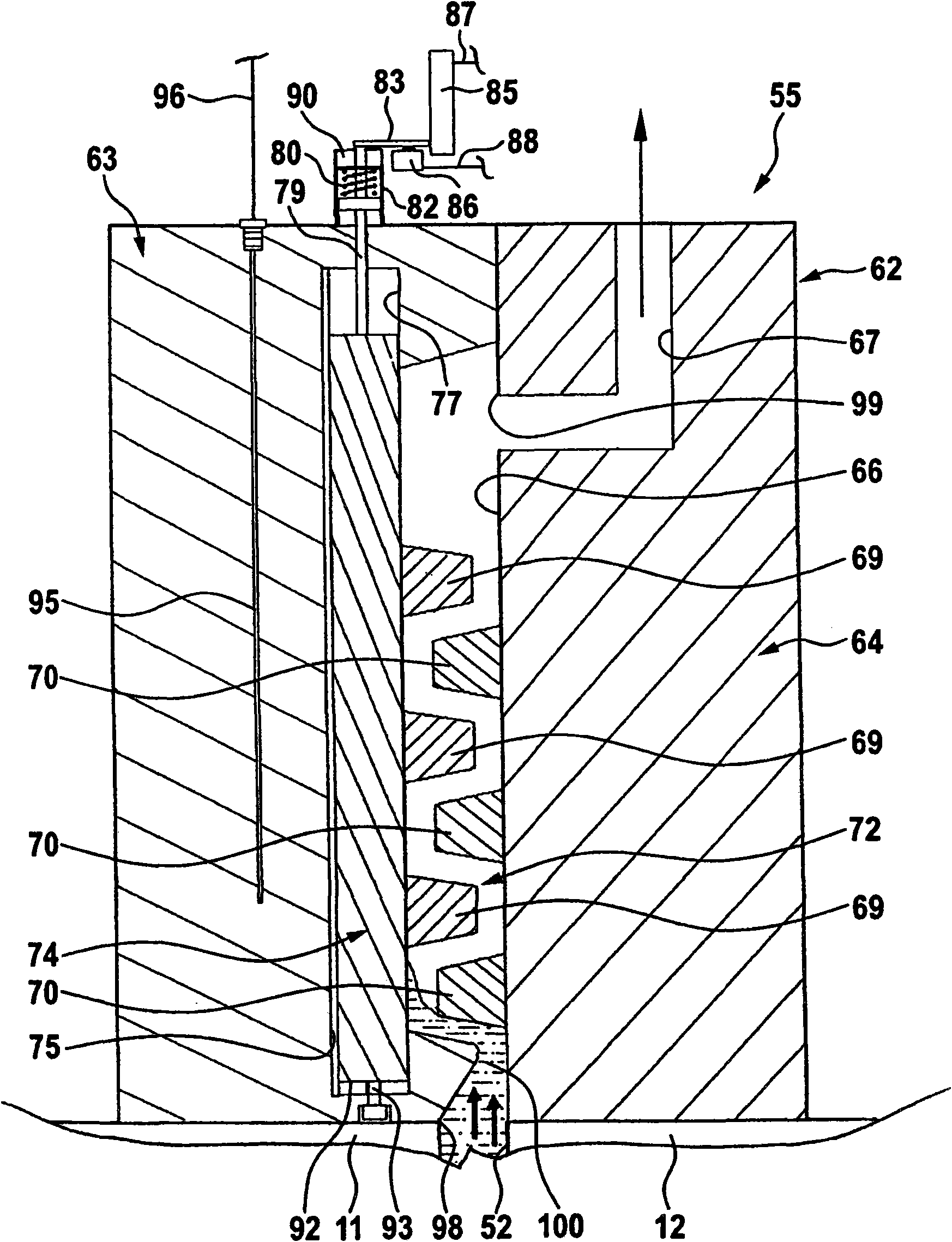

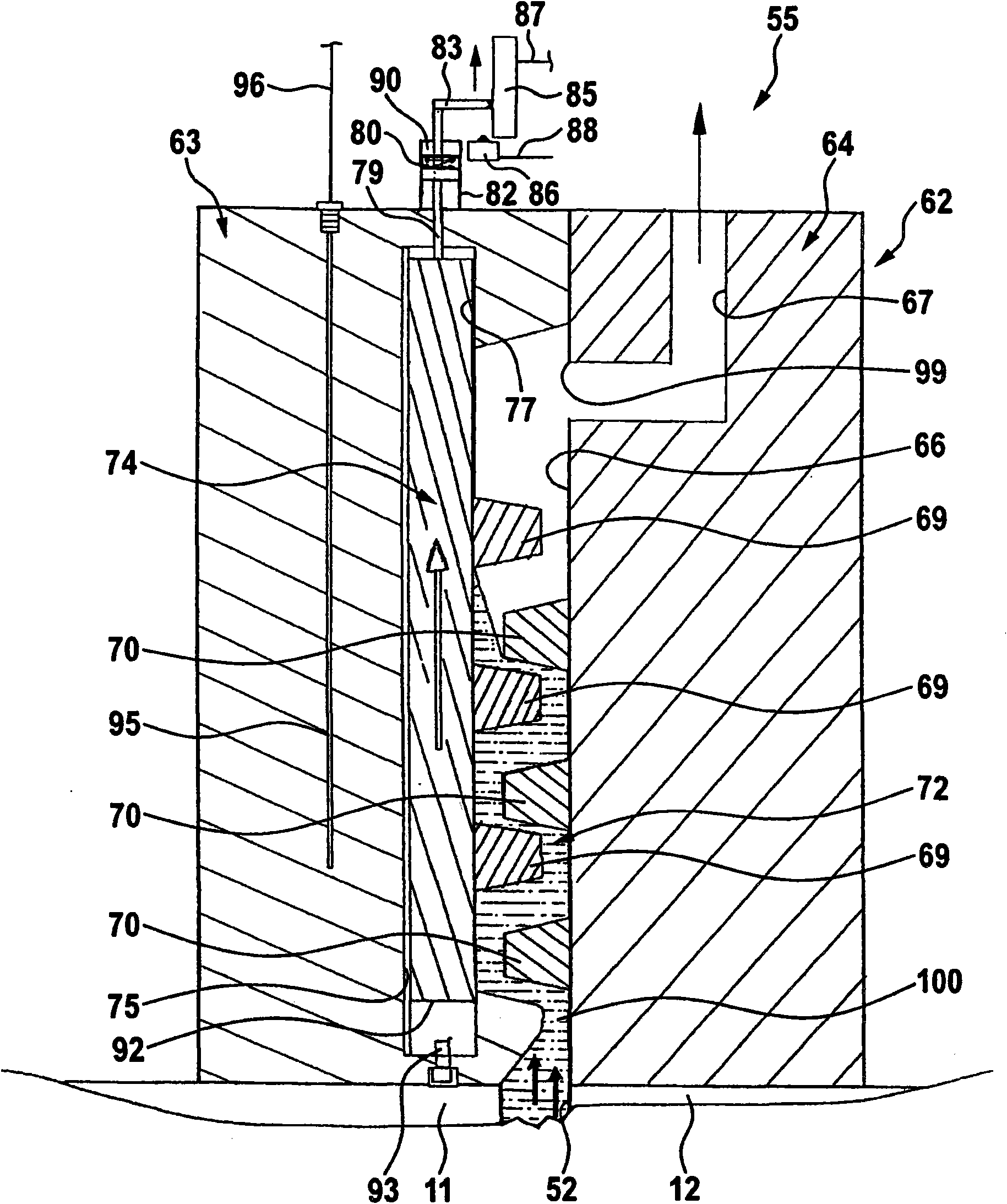

Device for melt spinning multi-component fibers

InactiveCN101970731ALarge flow cross sectionSimple preparation processSpinnerette packsFilament/thread formingDistributorMelt spinning

The invention relates to a device for melt spinning multi-component fibers, comprising at least two melt inlets for introducing separately guided melt components. For this purpose, the device comprises a feed plate having a plurality of feed channels for distributing the melt components, a distributor block associated with the feed plate, and a nozzle plate adjoining the distributor block and comprising a plurality of nozzle bores, wherein the distributor block has several thin distributor plates that are stacked on top of each other and each have a hole pattern with multiple distribution openings. The thin distributor plates are configured inside the distributor block such that a plurality of melt channels form, which connect the feed channels of the feed plate to the nozzle bores of the nozzle plate. In order to implement high flow volumes, particularly for flows of the melt components on one plate plane of the distributor plates, multiple distributor plates having identical hole patterns of the distribution openings are stacked in a tightly sealing manner inside the distributor block. In this way, larger flow cross-sections can be implemented while adhering to simple manufacturing techniques for the production of such distributor plates.

Owner:OERLIKON TEXTILE GMBH & CO KG

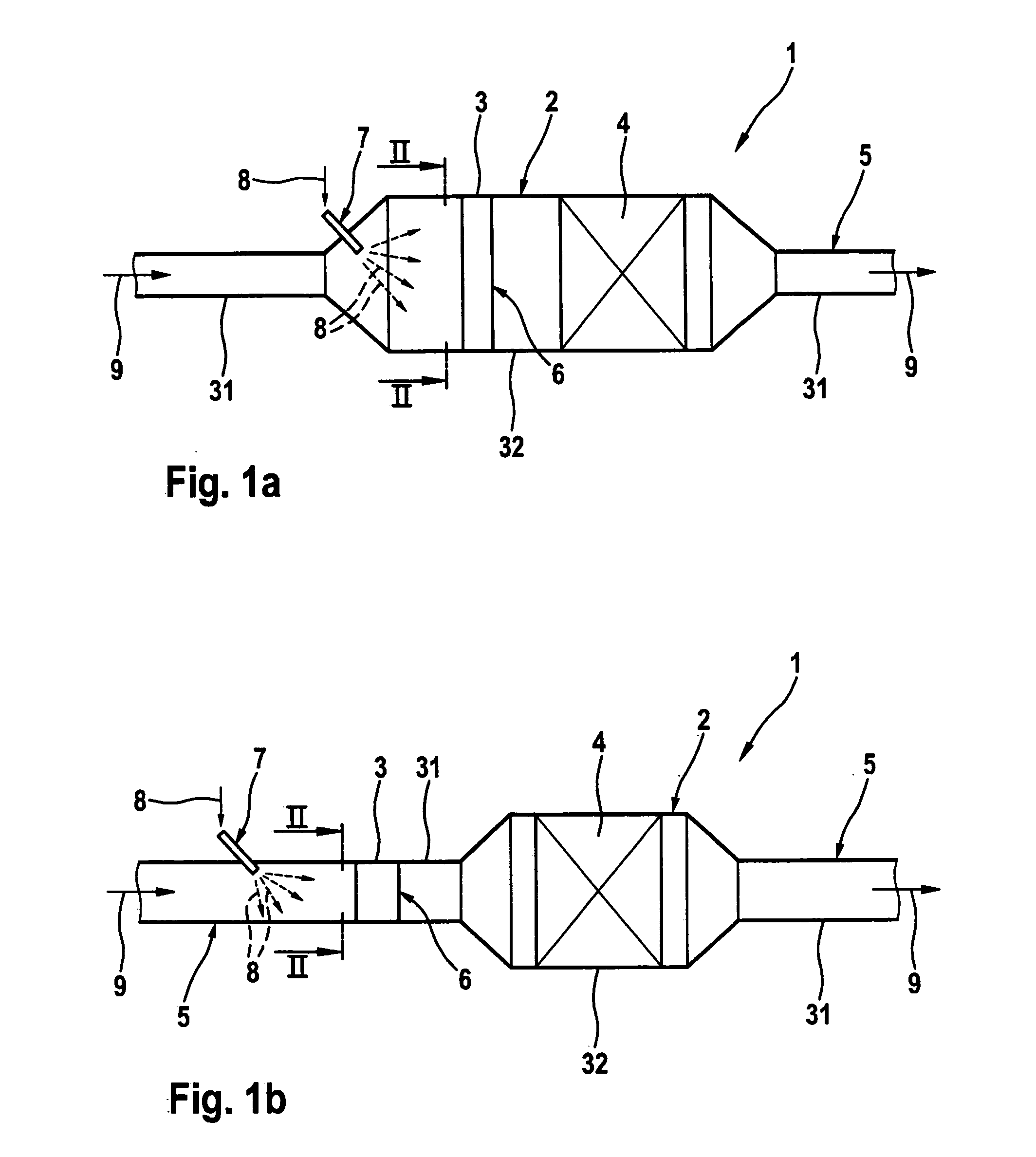

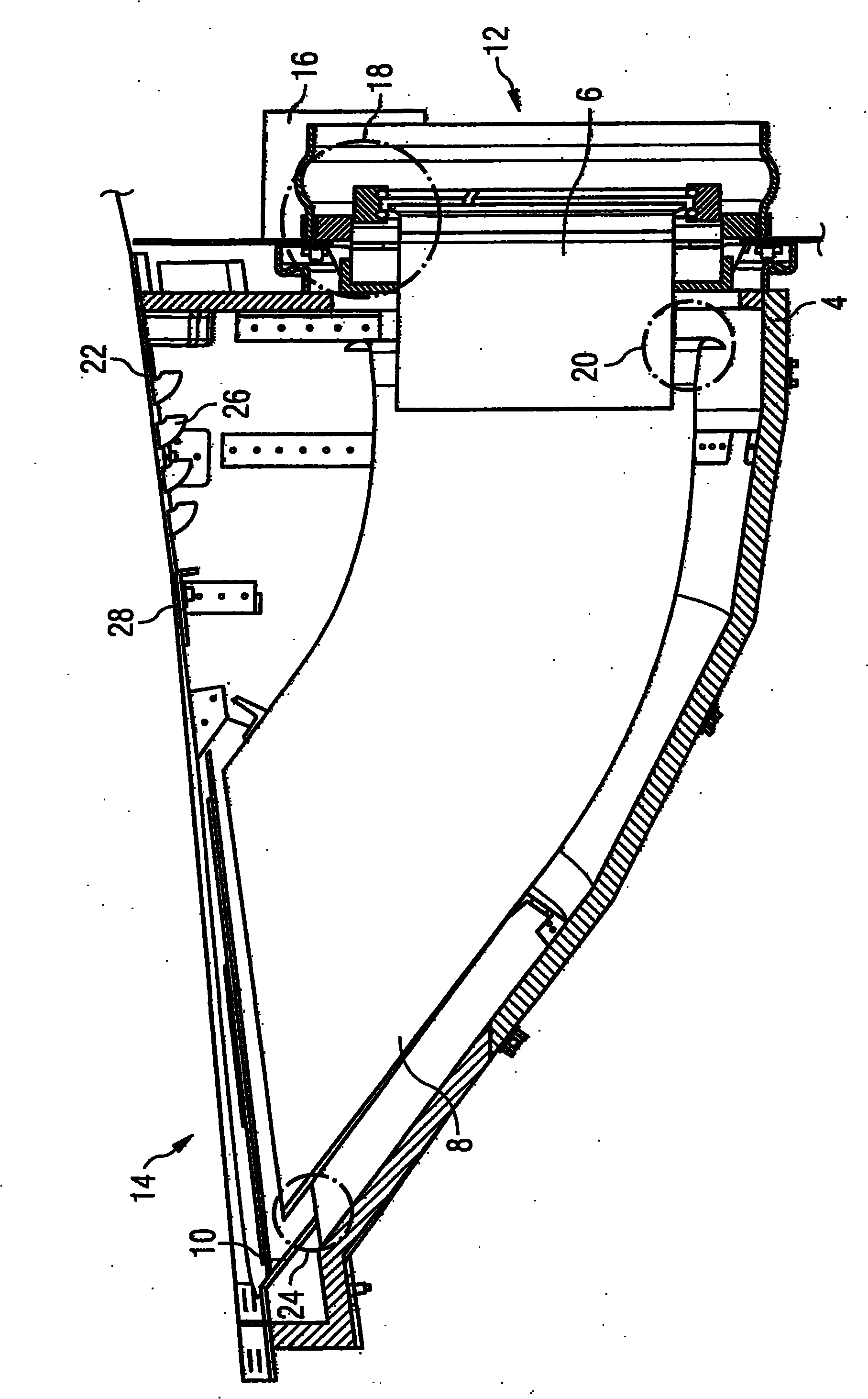

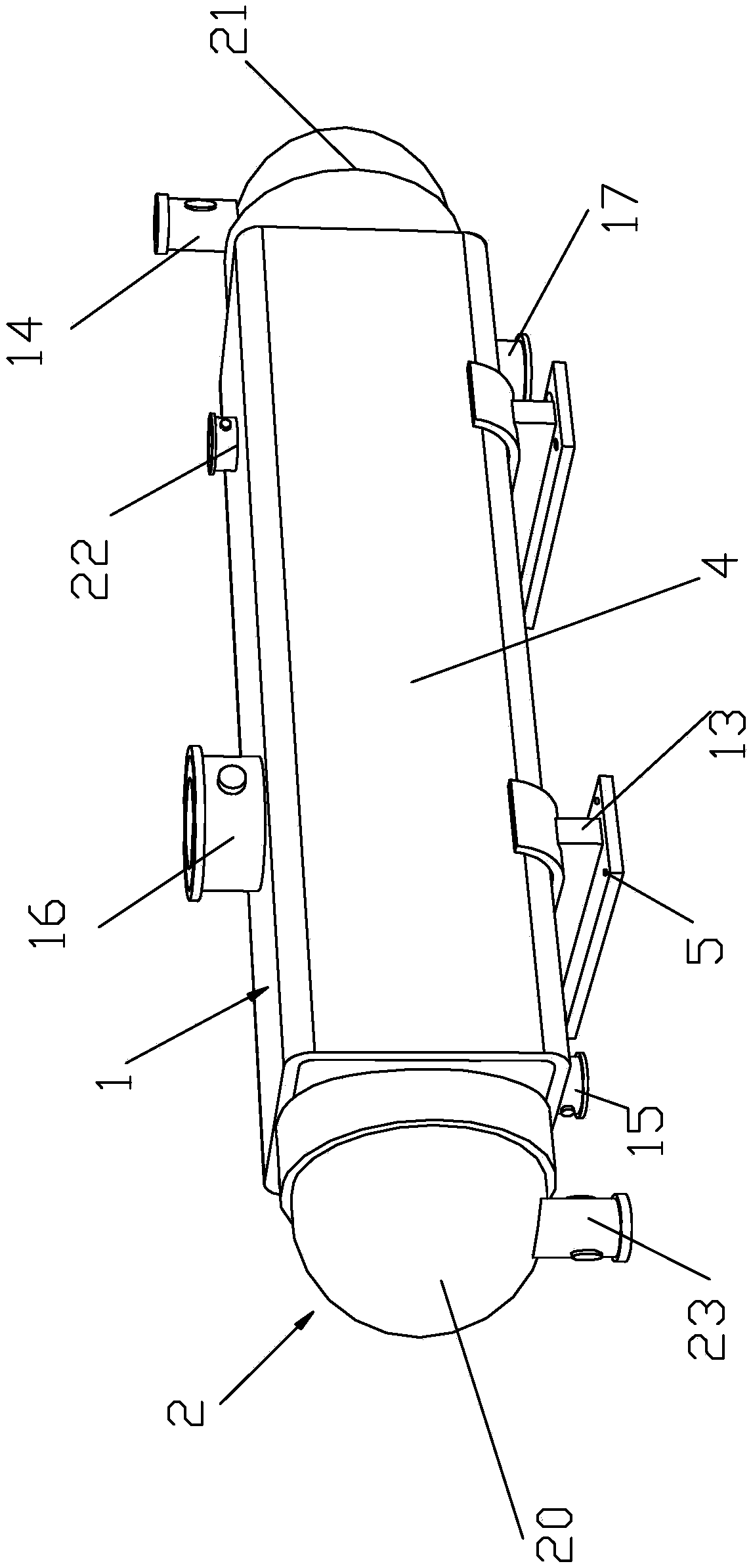

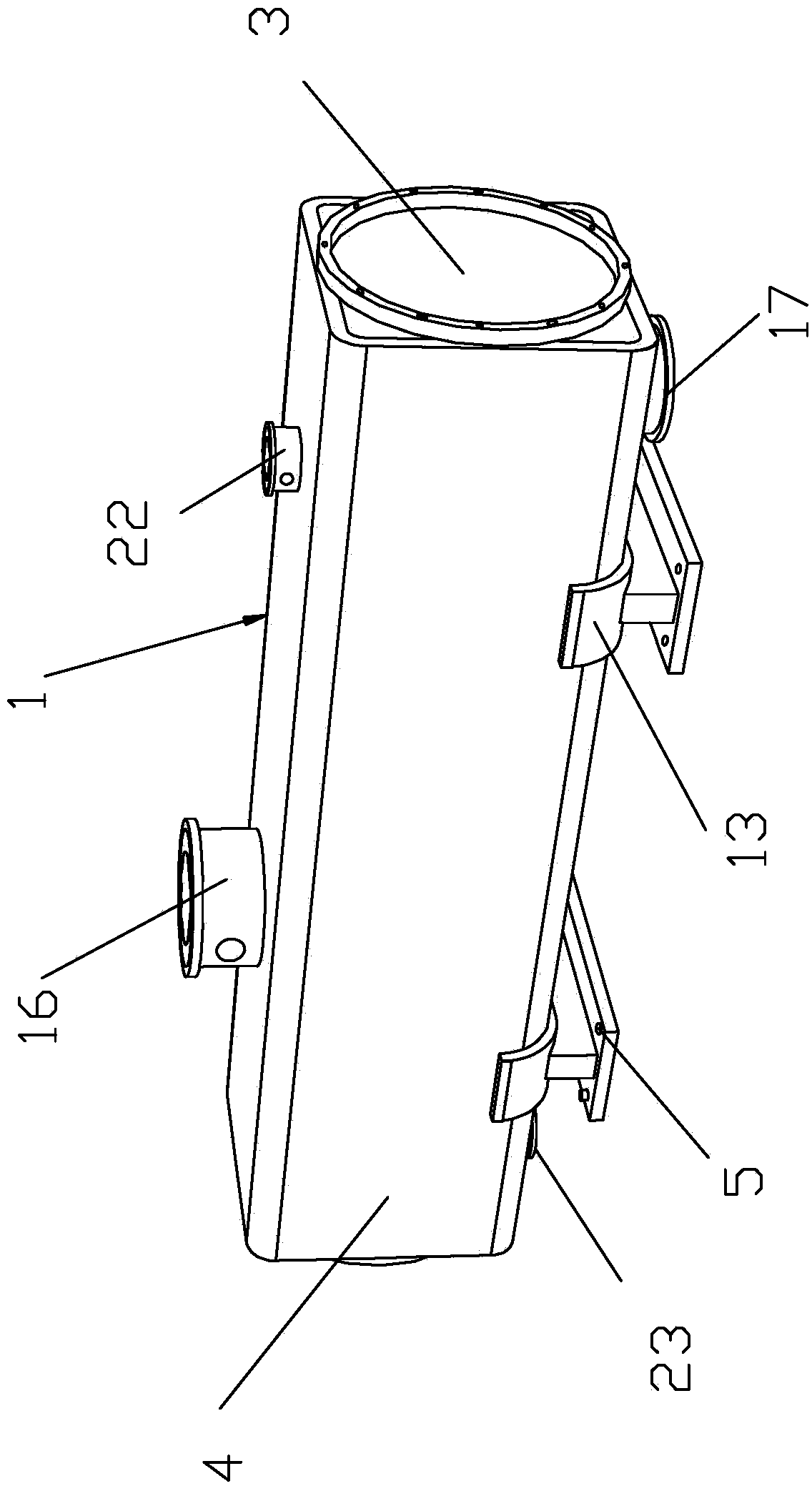

Device for cooling hot gas to be discharged from an aircraft

InactiveCN101903244ASlow down the flowReduce outgoing noisePower plant exhaust arrangementsPower installationsAerospace engineering

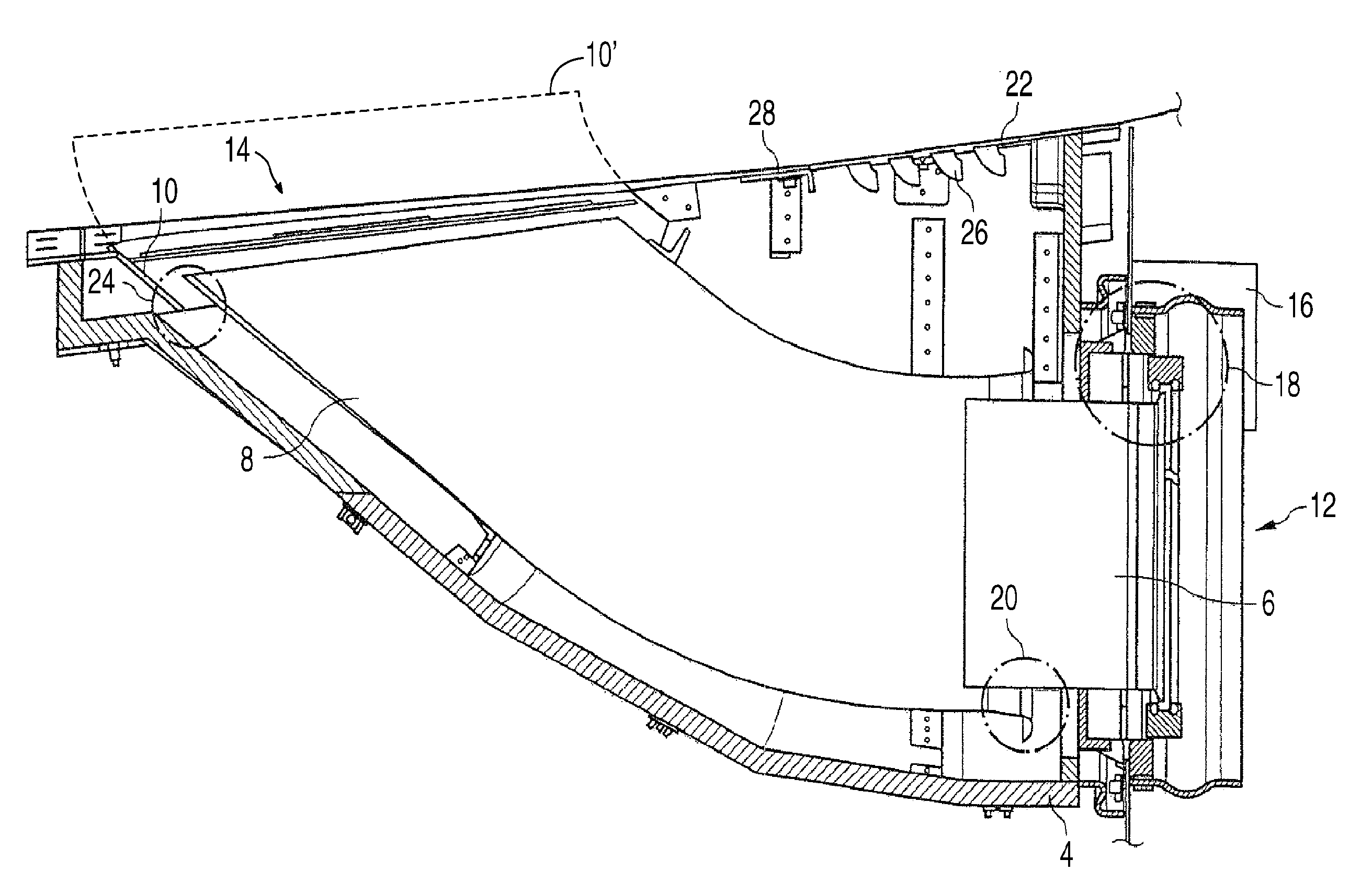

The invention relates to a device (2) for cooling hot gas that is to be discharged from an aircraft. Said device (2) comprises a duct (6, 8, 10) for conducting the hot gas from a hot gas source that can be connected to the device to a discharge point, and a frame (4) which surrounds the duct and is used for mounting the duct. The duct is formed from one or more pipe sections (6, 8, 10) and has one or more cooling air intake points (20, 24) which can be connected to one or more cooling air sources (16) in order to mix the hot gas with cooling air.

Owner:AIRBUS OPERATIONS GMBH

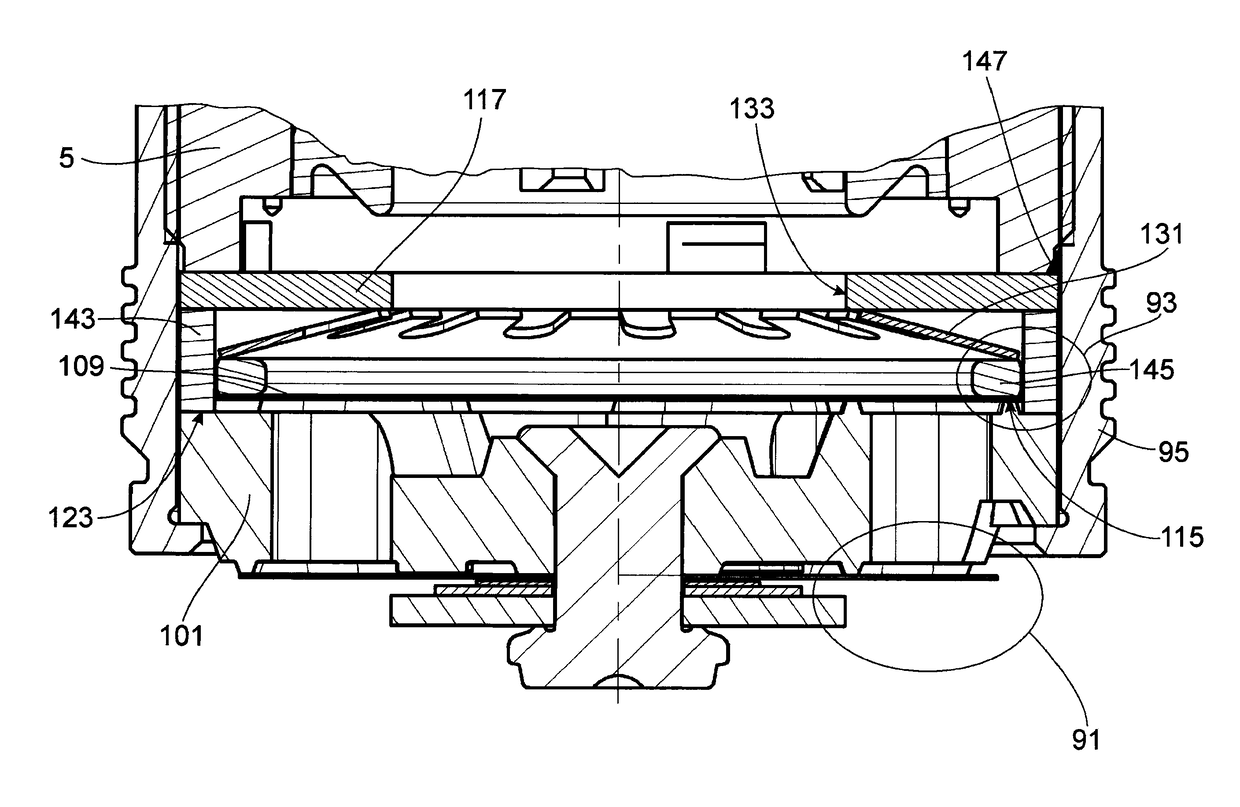

Venting unit for a Die Casting device

InactiveUS20100276107A1Reduce traffic lossLarge flow cross sectionFoundry mouldsMoulding machine componentsDie castingProduct gas

The invention relates to a venting unit for a die casting device which has a mold cavity that is adapted to be filled with liquid casting material and a gas suction device that is connected to the mold cavity for extracting gas from the mold cavity by suction, the venting unit comprising a flow labyrinth, the inlet of which is adapted to be connected to the mold cavity and the outlet of which is adapted to be connected to the gas suction device. In order to develop the venting unit in such a way that it makes improved evacuation of the mold cavity possible without the risk that liquid casting material can escape from the venting unit, it is proposed according to the invention that the flow cross-section of the flow labyrinth is variable. Furthermore, a die casting device with a venting unit of this kind is proposed.

Owner:ELECTRONICS GMBH VERTRIEB ELEKTRONISCHER GERATE

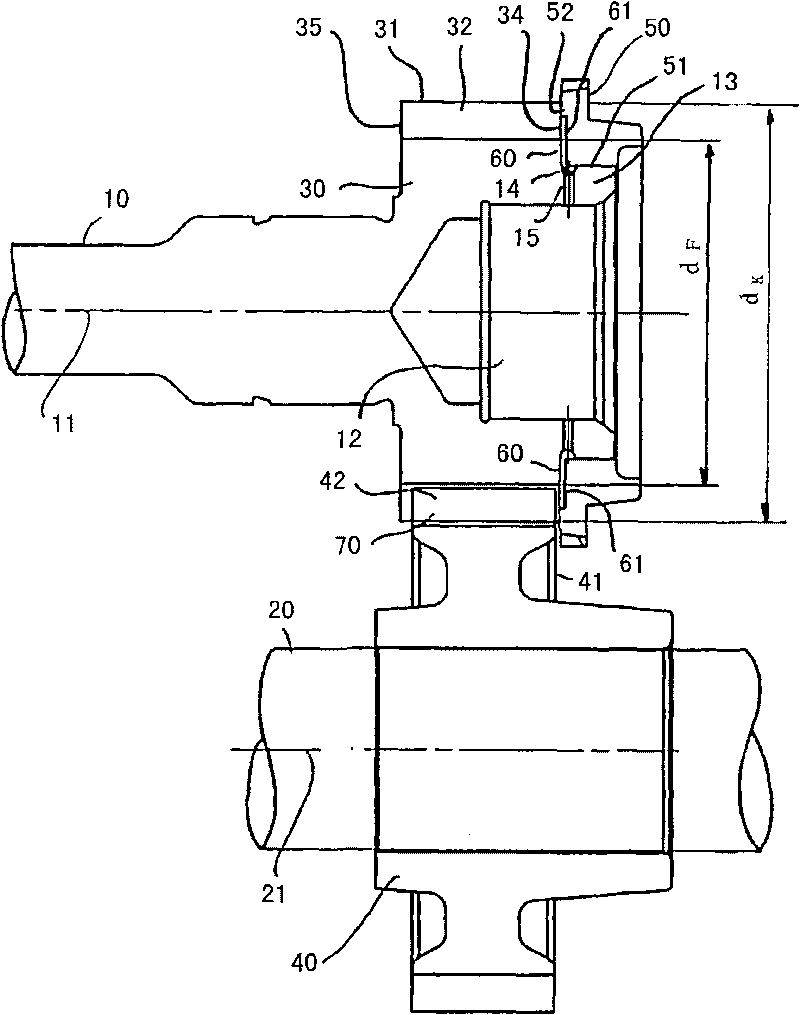

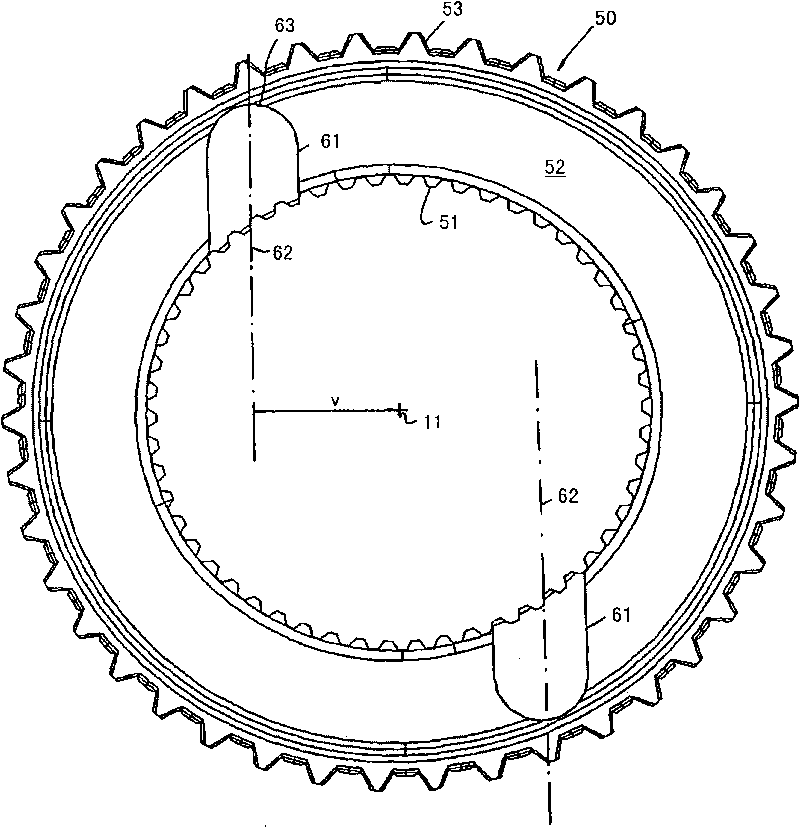

Device for cooling hot gas to be discharged from an aircraft

InactiveUS8371522B2Reduce flow soundReduce noisePower plant exhaust arrangementsPower installationsGas passingProduct gas

A device for cooling hot gas to be discharged from an aircraft includes a duct for leading the hot gas from a hot gas source which is connectable to the device to an outlet point, and a frame which surrounds the duct and serves for mounting the duct. The duct is formed from one or more pipe sections and has one or more cooling air inlet points which is connectable to one or more cooling air sources in order to mix the hot gas with cooling air. An outlet pipe section of the duct extends outwards beyond the aircraft outer skin to lead hot gas through and out of a flow boundary layer on the outer skin.

Owner:AIRBUS OPERATIONS GMBH

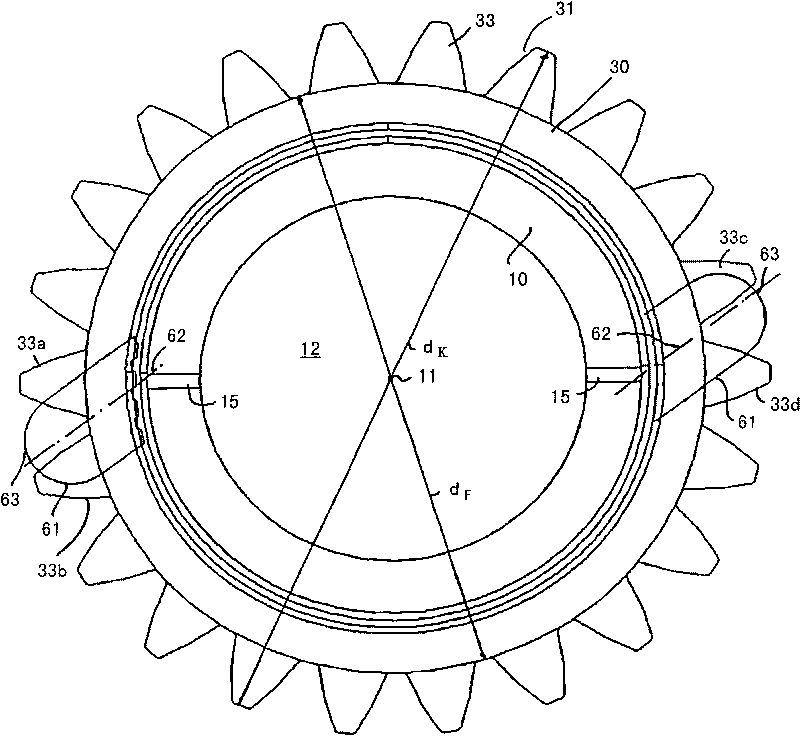

Transmission with gear and oil channel

The present invention relates to a transmission which is provided with a first gear (30) and at least one second gear (40). The first gear is provided on one shaft (10). The second gear is matched with the first gear (30) through engaging, wherein, oil or analog is used as lubricant between the engaged gears (30,40), wherein, an oil guiding-out device is provided. At least one part of the oil is guided out radially from the engaged gears (30,40) inwards to a central axis (11) of the shaft (10) through the oil guiding-out device. According to the invention, a sealing device is provided at one axial side surface (34) of the first gear (30). The oil guiding-out device comprises at least one oil channel (60) which is radially closed outwards. The oil channel is provided in the axial side surface (34) or at the axial side surface (34). The oil which is provided in front of the sealing device (5) or at the sealing device (52) can be guided out through the oil channel.

Owner:GETRAG FORD TRANSMISSIONS GMBH

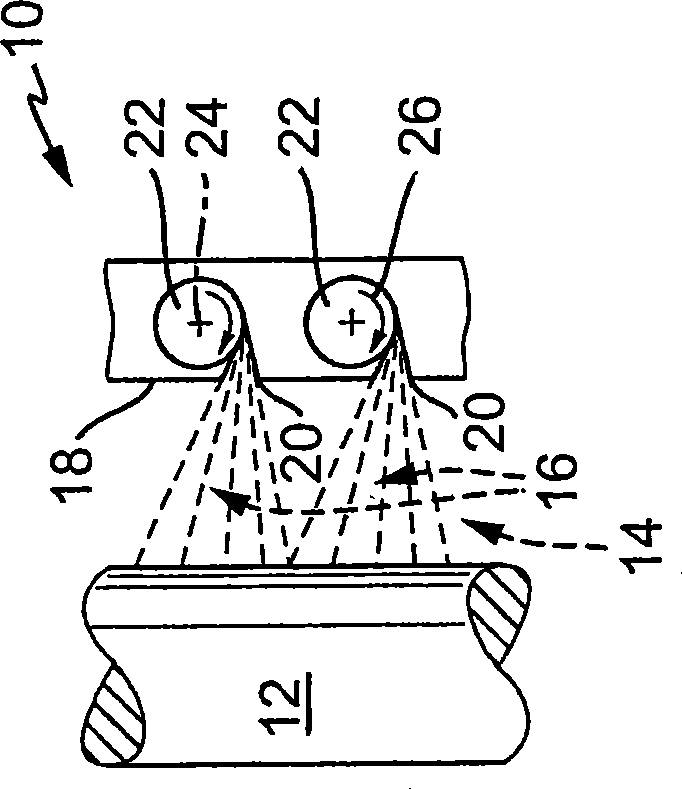

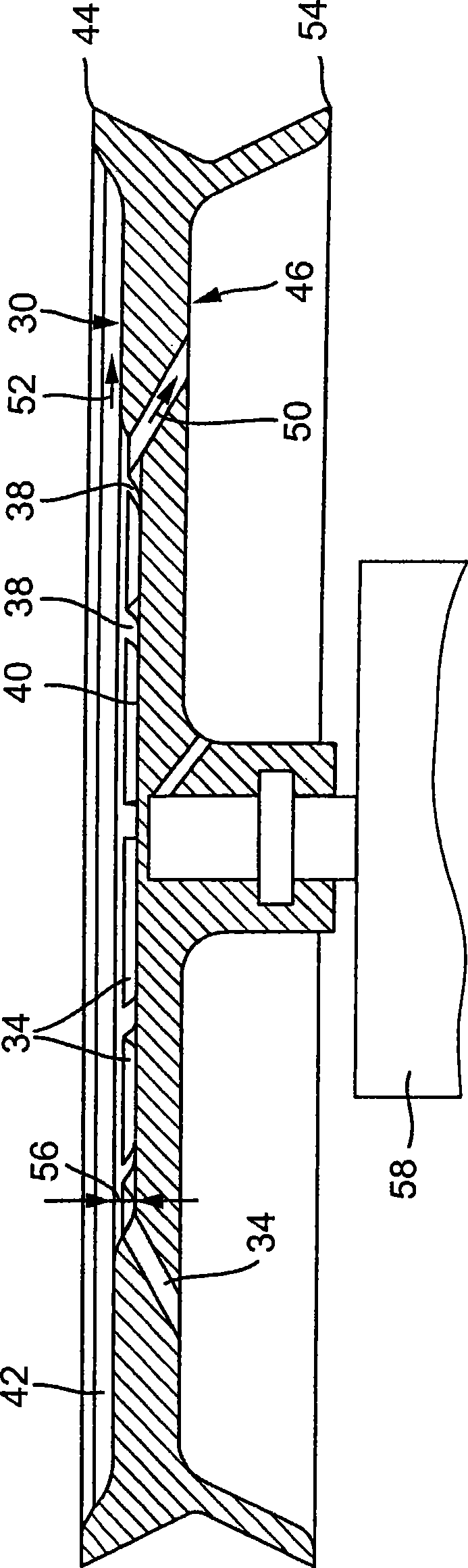

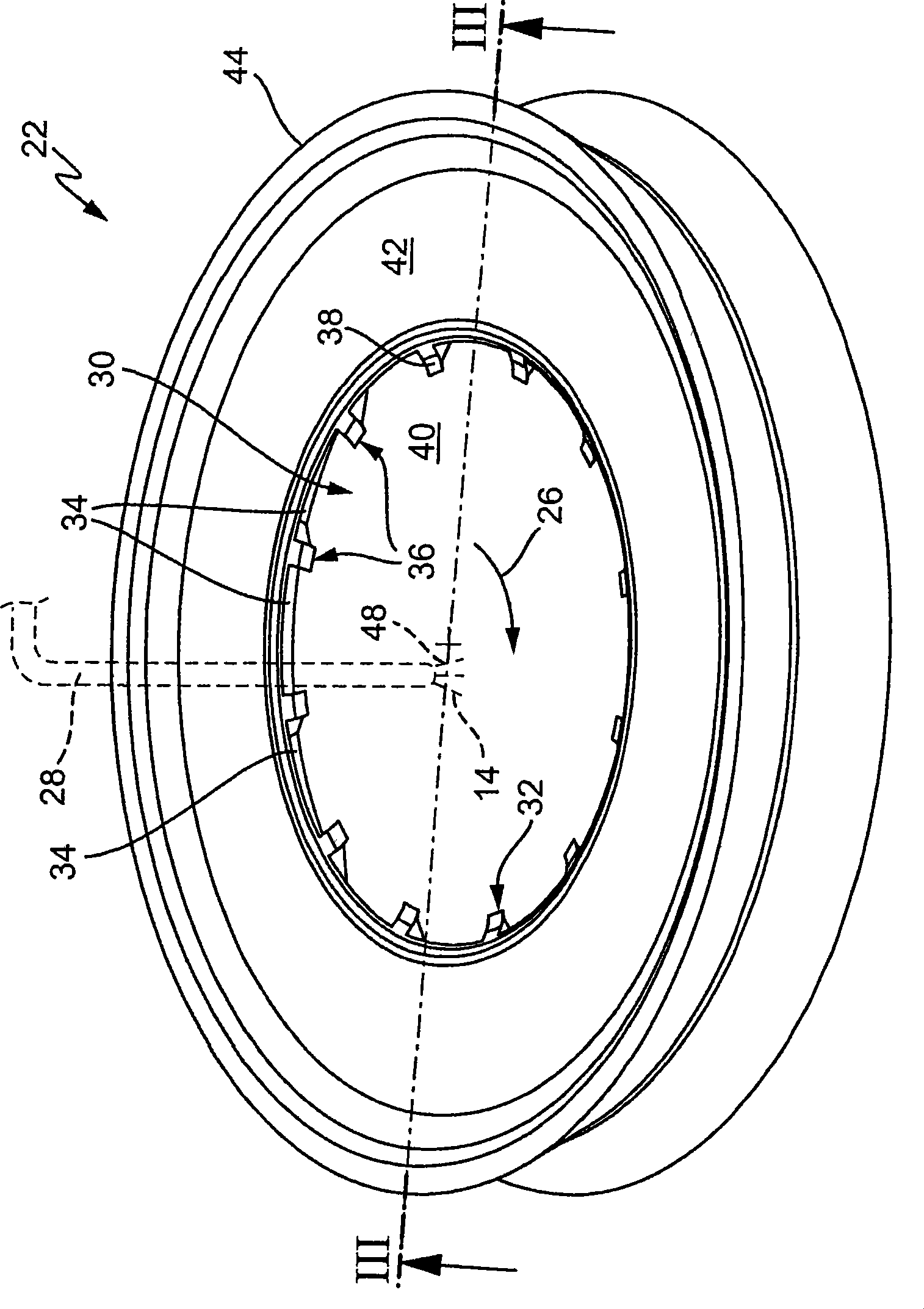

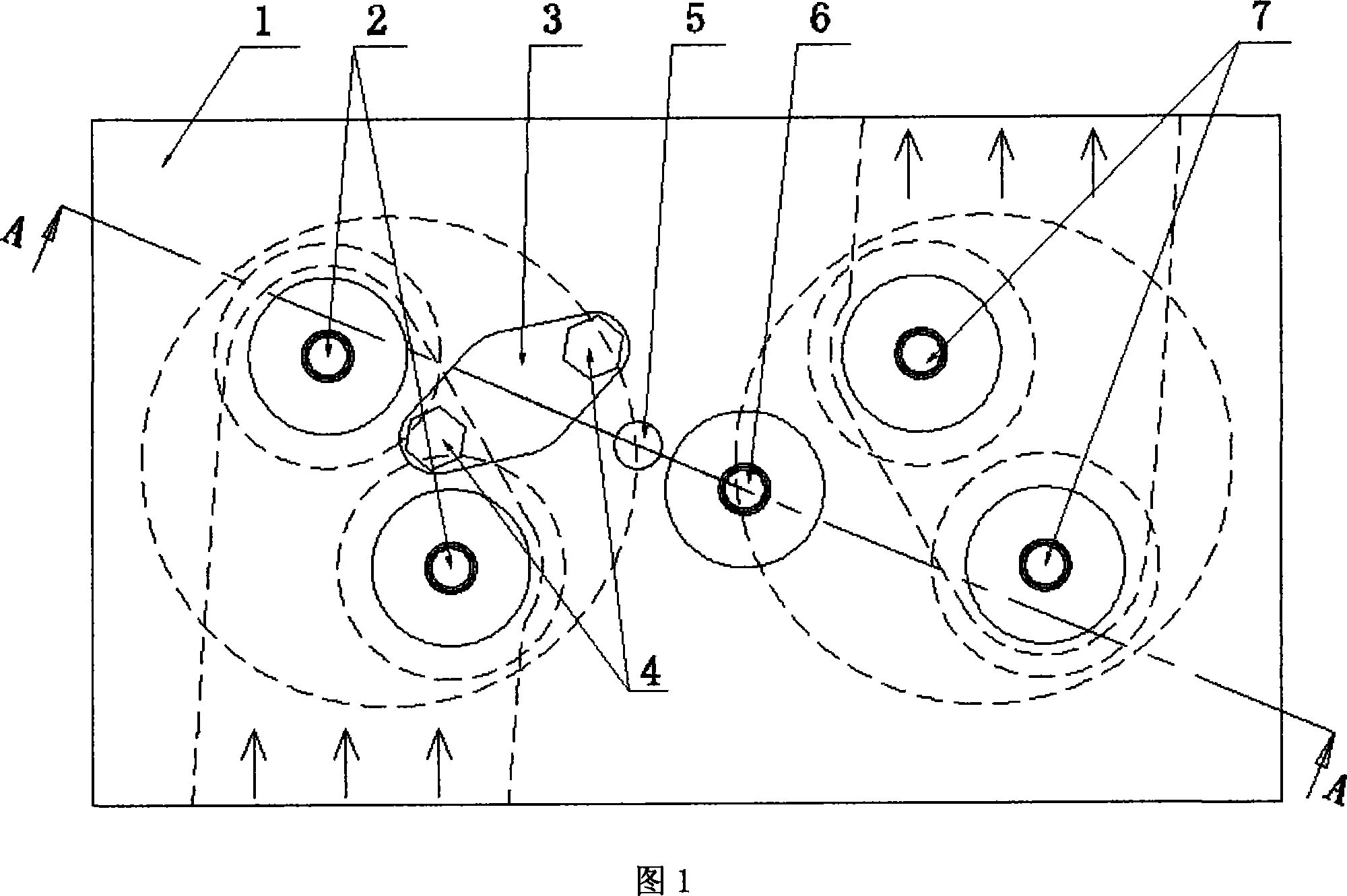

Rotary sprayer

ActiveCN101518763ALarge flow cross sectionLess quantityLiquid surface applicatorsMovable spraying apparatusSprayerEngineering

The invention relates to a rotary sprayer, especially a rotary sprayer (10) for fluids (14). The rotary sprayer has a rotating disc (22), a drive (58) for the disc (22), and a supply device (28) for the application of fluid (14) onto the disc (22). The disc (22) has a distribution plane (30) for the fluid (14), and at least one opening (34) is provided in the distribution plane (30), via which a secondary flow (50) of the fluid (14) is separated from the main flow (48) to another plane (46). The disc (22) has a first spray edge (44) for spraying the working flow (52) of the fluid (14) and a second spray edge (54) for spraying the secondary flow (50) of the fluid (14).

Owner:WEITMANN & KONRAD

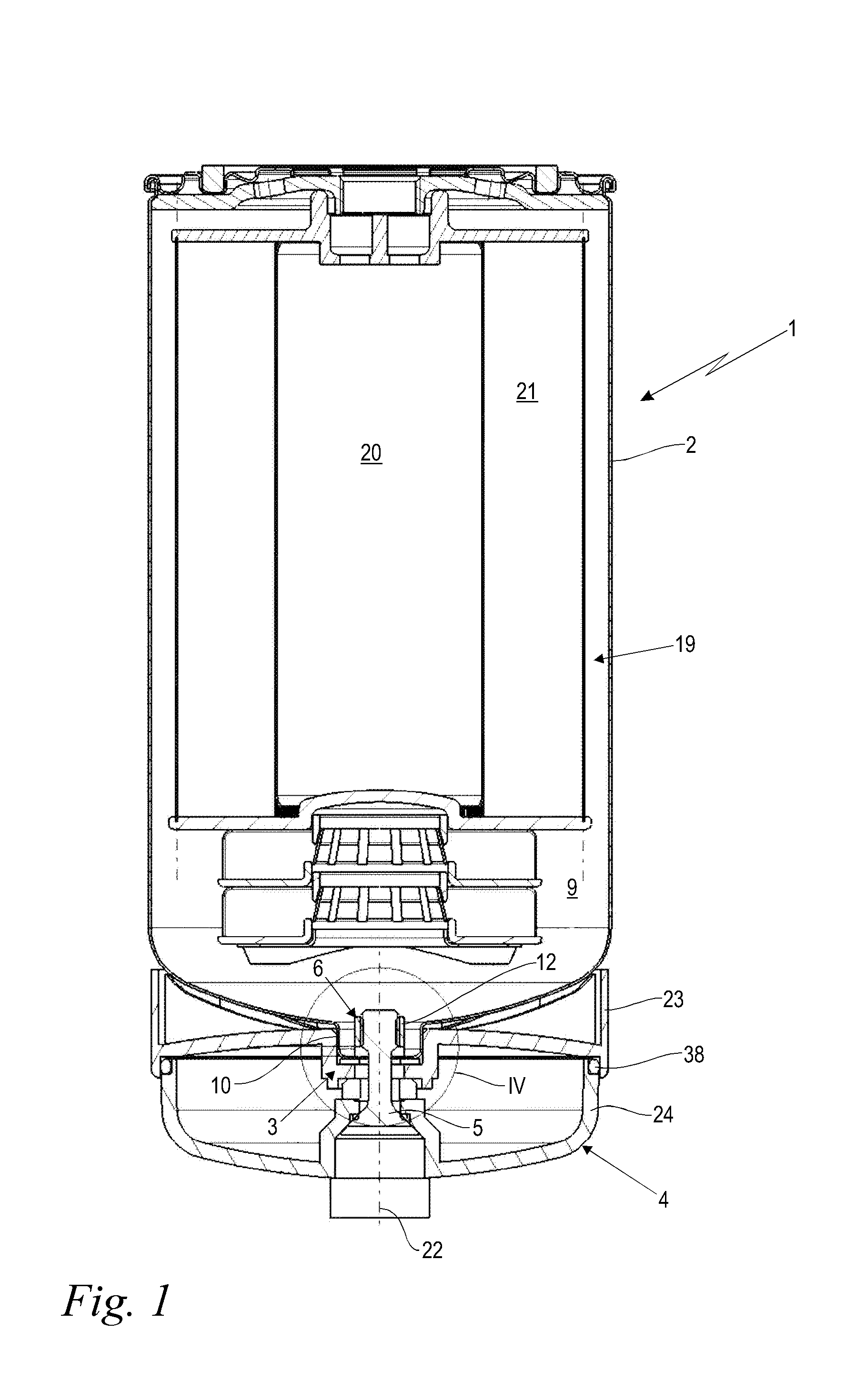

Filter

ActiveUS20100116729A1Improve anti-rotation effectReduce expenditureLiquid separation auxillary apparatusMachines/enginesScrew thread

A filter has a filter housing having an interior. A drainage device is provided that has a collecting cup, a fastening screw for the collecting cup, and a threaded part secured in the filter housing and provided with an inner thread for receiving the fastening screw. The threaded part has an outer surface with at least one drainage passage connecting the interior of the filter housing to the collecting cup. The filter housing has a cup-shaped receptacle for the threaded part and the cup-shaped receptacle has a securing wall that at least partially extends about a circumference of the cup-shaped receptacle. The threaded part is a press-fit bushing pressed into the receptacle. The press-fit bushing has a circumferential wall provided with a circumferential contact surface secured by the securing wall and extending at least partially about a circumference of the press-fit bushing.

Owner:MANN HUMMEL GMBH

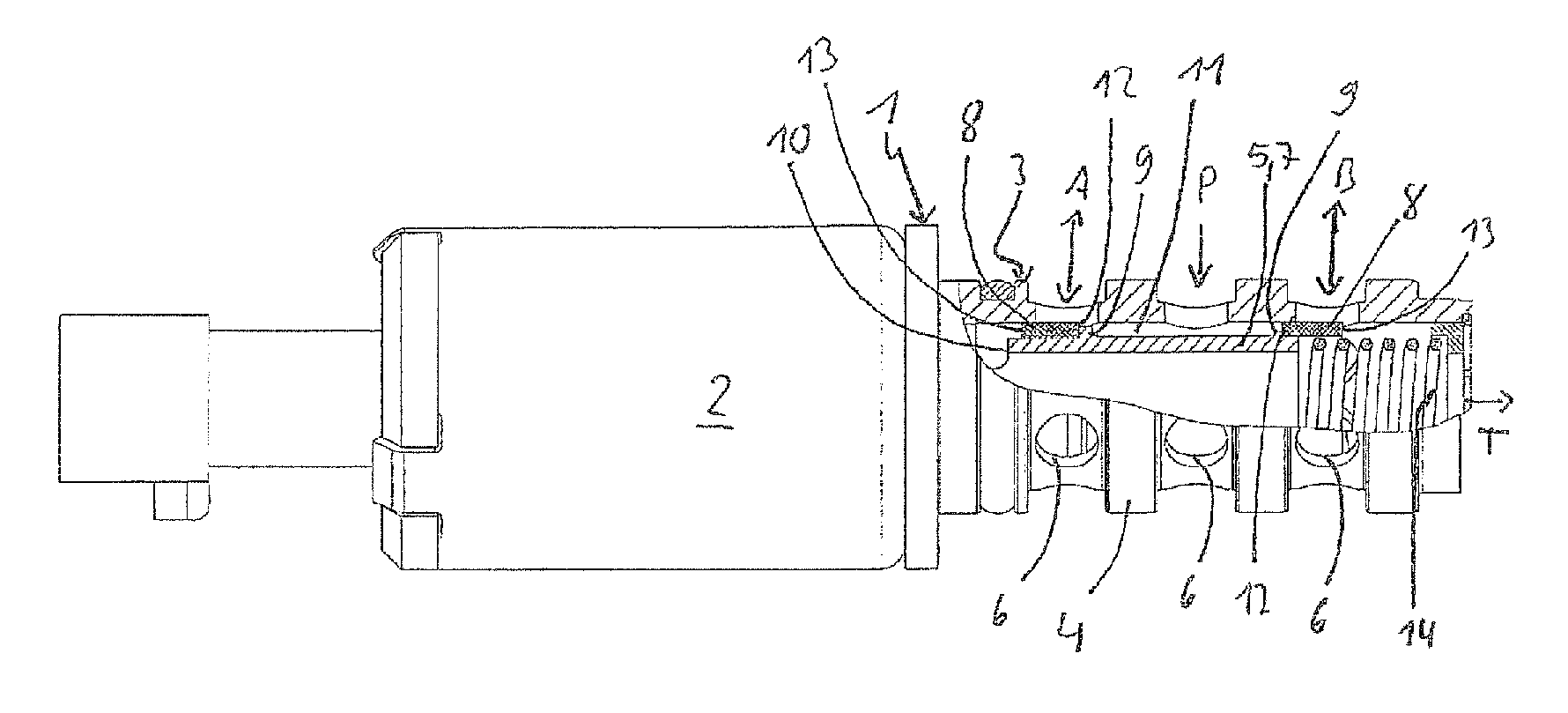

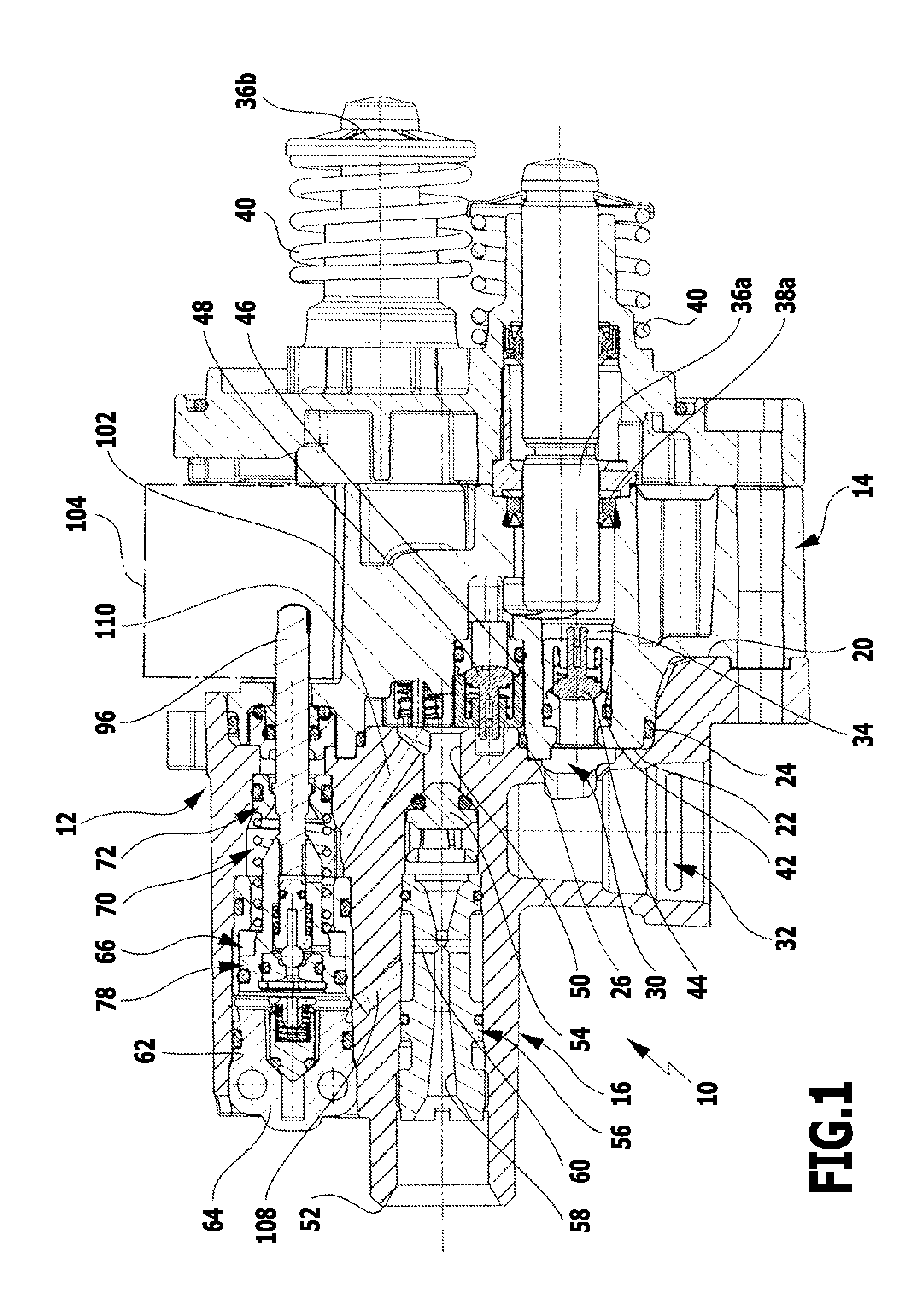

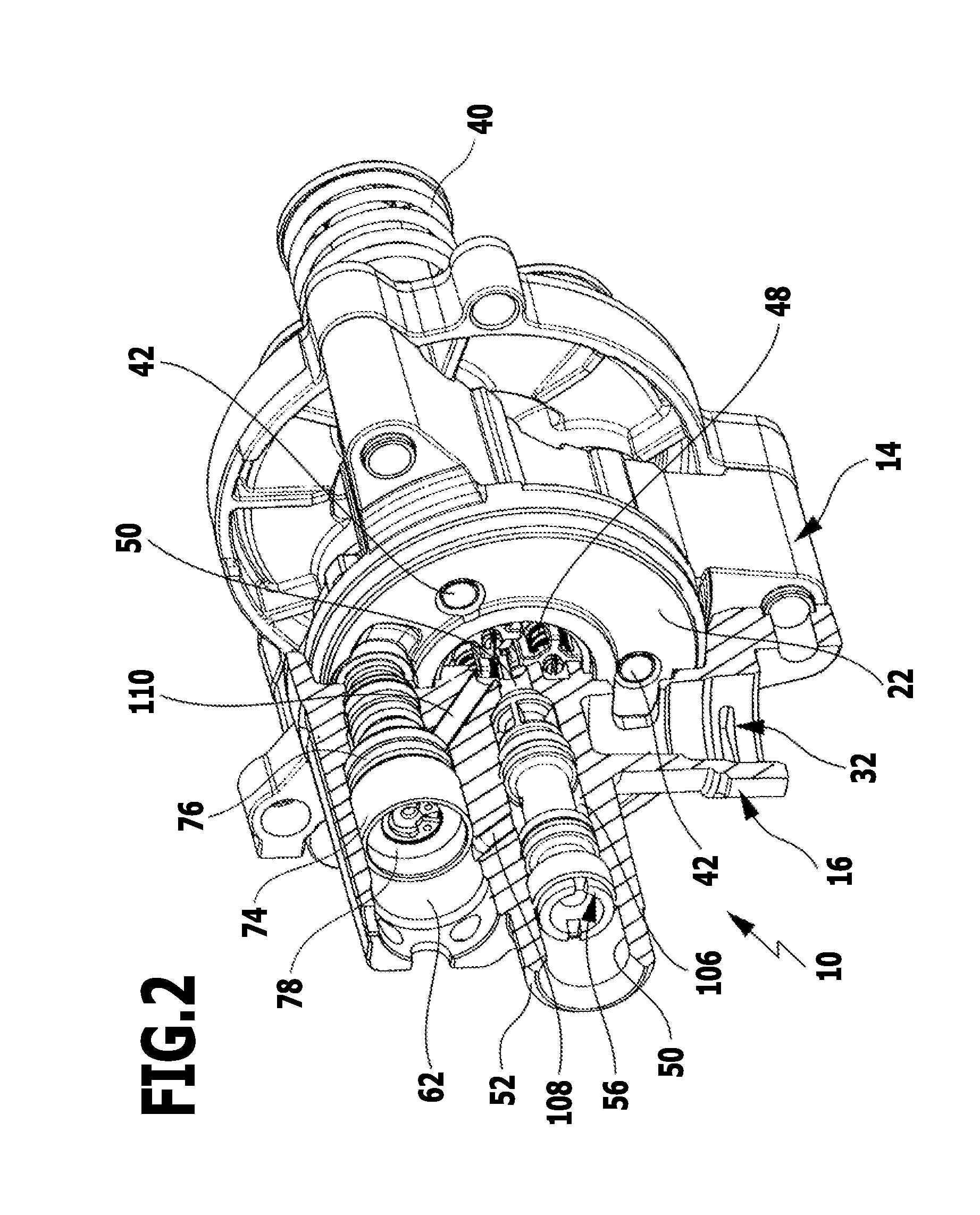

Electromagnetic actuating unit

ActiveUS8490654B2Low pressure lossImprove stabilityOperating means/releasing devices for valvesWatering devicesEngineeringMechanical engineering

A hydraulic directional control valve which has a valve housing and a control piston that is arranged therein in a displaceable manner. The valve housing has at least one outflow connection, at least one inflow connection and a working connection. The control piston has a main body and at least one control section. The control section controls a pressure medium flow from the inflow connection to the working connection and / or a pressure medium flow from the working connection to the outflow connection, and the control section is made separately from the main body and is fastened thereon.

Owner:SCHAEFFLER TECH AG & CO KG

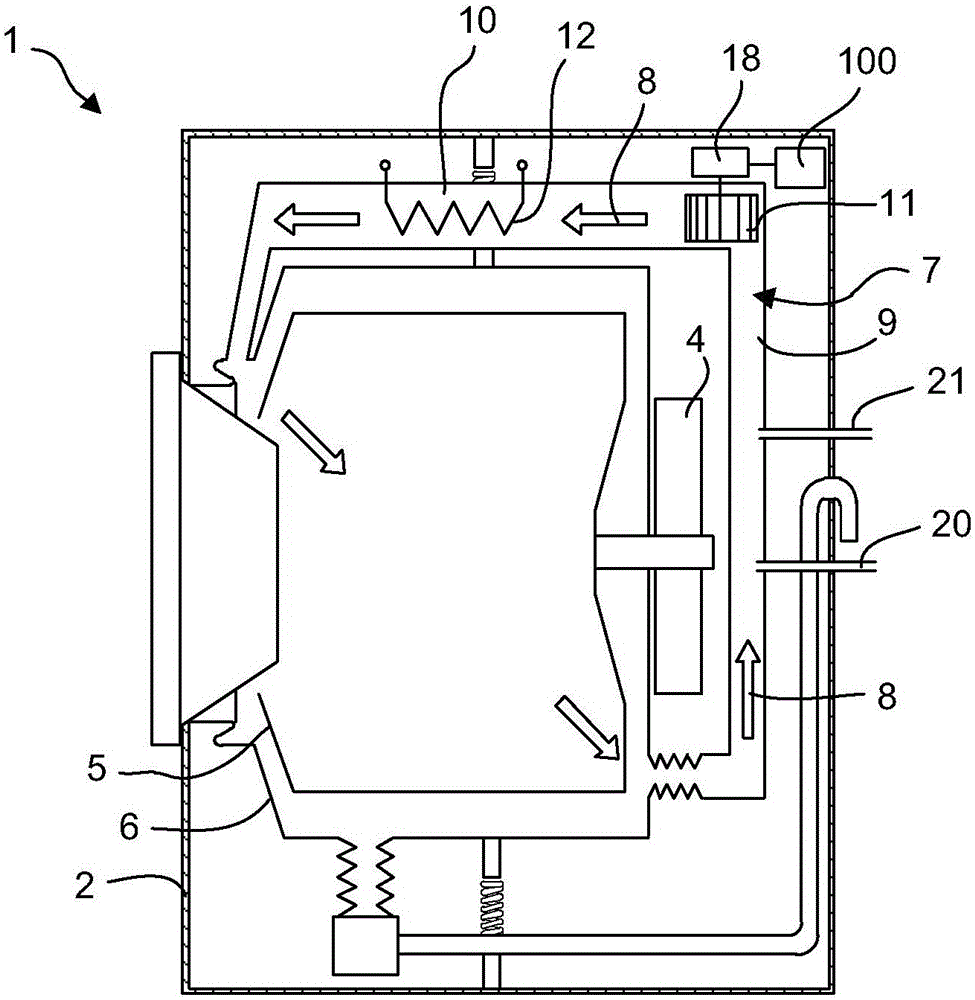

Clothes dryer with condensation device and cleaning method for condensation device thereof

ActiveCN106400433ABig liftIncrease airflow resistanceWashing machine with receptaclesTextiles and paperCleaning methodsWaste management

The invention discloses a cleaning method for a condensation device of a clothes dryer. The condensation device comprises an air channel, a water supply device connected with the air channel, and a fan enabling air from a drying bucket to flow through the air channel. The air channel is provided with a flow-distributing device enabling air flowing through the air channel to generate turbulent flows. The cleaning method comprises following the step of operating a cleaning process. The cleaning process comprises following steps: continuously supplying water to the air channel through the water supply device; controlling the device to operate the fan, controlling operating parameters of the fan such that the rotating speed of the fan gradually increases, at least to the extent at which a part of water can be lifted in the air at the flow-distributing device and gradually converge, and rolling and agitating water which converges in the air channel in the air channel such that the inner wall of the air channel can be washed. The invention further discloses the clothes dryer realizing the cleaning method.

Owner:BSH ELECTRICAL APPLIANCES JIANGSU +1

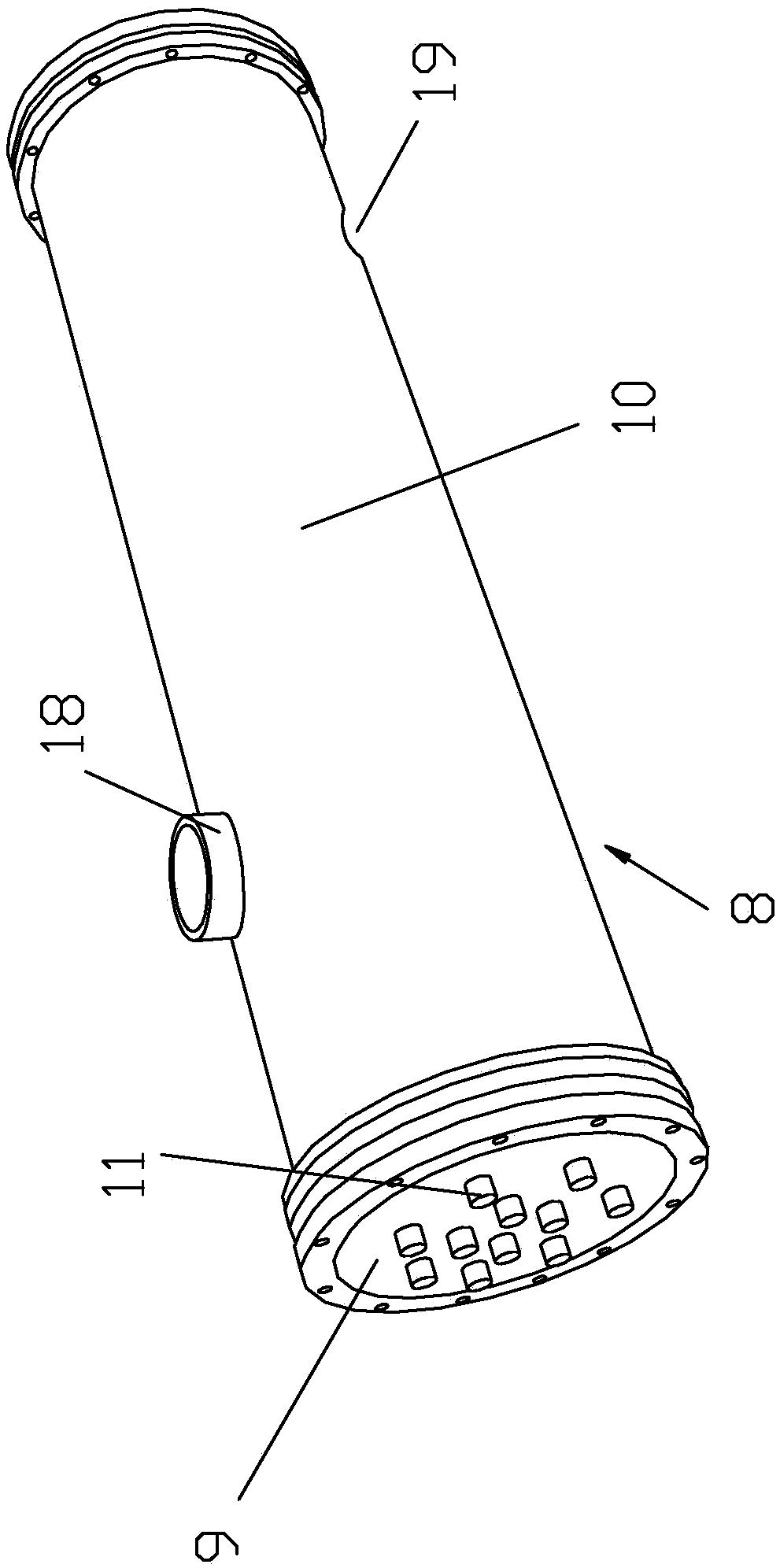

Tube-type heat exchanger for producing anhydrous hydrofluoric acid and manufatcuring method of tube-type heat exchanger

InactiveCN109253639AGuaranteed temperatureLittle influence of temperatureSafety devices for heat exchange apparatusHeat exchanger casingsHydrofluoric acidPlate heat exchanger

The invention discloses a tube-type heat exchanger for producing anhydrous hydrofluoric acid. The tube-type heat exchanger comprises a shell and a packing head, the outer sides of the two ends of an inner shell are fixedly connected with the packing head separately to form a tube box, a tube plate body is arranged inside the inner shell and comprises a cylinder, a tube bundle and a deflection baffle, the right side of the cylinder is fixedly connected with the inner shell, the two ends of the tube bundle are connected to the side face of the cylinder separately, and the tube bundle penetratesthrough the cylinder and extends into the tube box. A manufacturing method comprises the following steps of 1, manufacturing and assembly of the shell; 2, manufacturing and assembly of the tube platebody; 3, splicing of the tube plate body and the shell; 4, splicing of the shell and the packing head. The tube-type heat exchanger is simple in structure, low in cost and wide in flow cross section,limescale is easy to clean away, and the heat exchanger can be used under the high-temperature, high-pressure and strong-acid conditions, and simultaneously applied to three fluids; the fluid at the outermost layer is used for weakening the temperature influence of the fluid on the shell, the thermal stress is eliminated to the greatest extent, and the service life of the heat exchanger is prolonged.

Owner:浙江森田新材料有限公司

Pump for a high-pressure cleaning device

ActiveUS20120213652A1Large flow cross sectionSmall flow resistancePump controlLiquid spraying apparatusPump chamberEngineering

A pump for a high-pressure cleaning device for delivering cleaning fluid is provided. The pump has at least one pump chamber, into which at least one piston plunges, and which is connected to a suction line via at least one inlet valve and to a pressure line via at least one outlet valve. A bypass line leads from the pressure line to the suction line. An overflow valve is arranged in the bypass line. The valve body of the overflow valve is connected to a control piston which is displaceably held in a control chamber with the interposition of a sealing element and moves the valve body into a closed or an open position as a function of the flow rate of the cleaning fluid in the pressure line. A sliding element is arranged in the control chamber and abuts sealingly on the wall of the control chamber.

Owner:ALFRED KARCHER GMBH & CO KG

Adjustable damping valve arrangement

ActiveUS9618138B2Increase installation spaceLarge flow cross sectionSpringsValve members for absorbing fluid energyMechanical engineeringPressure dependent

Owner:ZF FRIEDRICHSHAFEN AG

Ventilation unit for a die casting device

InactiveCN101883650ALarge flow cross sectionSmall flow sectionFoundry mouldsFoundry coresDie castingEngineering

Owner:ELECTRONICS GMBH VERTRIEB ELEKTRONISCHER GERATE

Diffusion-type self-pumped fluid dynamic and static pressure mechanical seal

ActiveCN112963543ADoes not dilute quicklyLarge flow cross sectionEngine sealsMechanical engineeringMechanics

The invention discloses a diffusion-type self-pumped fluid dynamic and static pressure mechanical seal. The mechanical seal comprises a movable ring and a static ring which are coaxially arranged, wherein a first sealing face of the movable ring comprises a diffusion ring groove, a spiral groove area and a sealing dam from outside to inside, and a backwardly-bent spiral groove is formed in the spiral groove area; the orientation of a fluid outlet of the backwardly-bent spiral groove is opposite to the rotating direction of the movable ring; a current collecting ring groove is formed in a second sealing face of the static ring, a drainage hole channel communicating with a sealing cavity is formed in a ring body of the static ring, an inlet of the drainage hole channel is located in the peripheral face of the static ring, and an outlet of the drainage hole channel is located in the current collecting ring groove; a gap between the second sealing face and the diffusion ring groove forms an annular diffusion cavity with a radial opening; and a first bottom face of the diffusion ring groove is arranged to be a slope face or a curved face from outside to inside in the radial direction, and the slope face or the curved face is gradually close to the second sealing face from inside to outside in the radial direction. By means of the mechanical seal, large sealing end face opening force can be provided, and the requirement for zero-leakage long-period operation of a non-contact mechanical seal is met.

Owner:NANJING FORESTRY UNIV

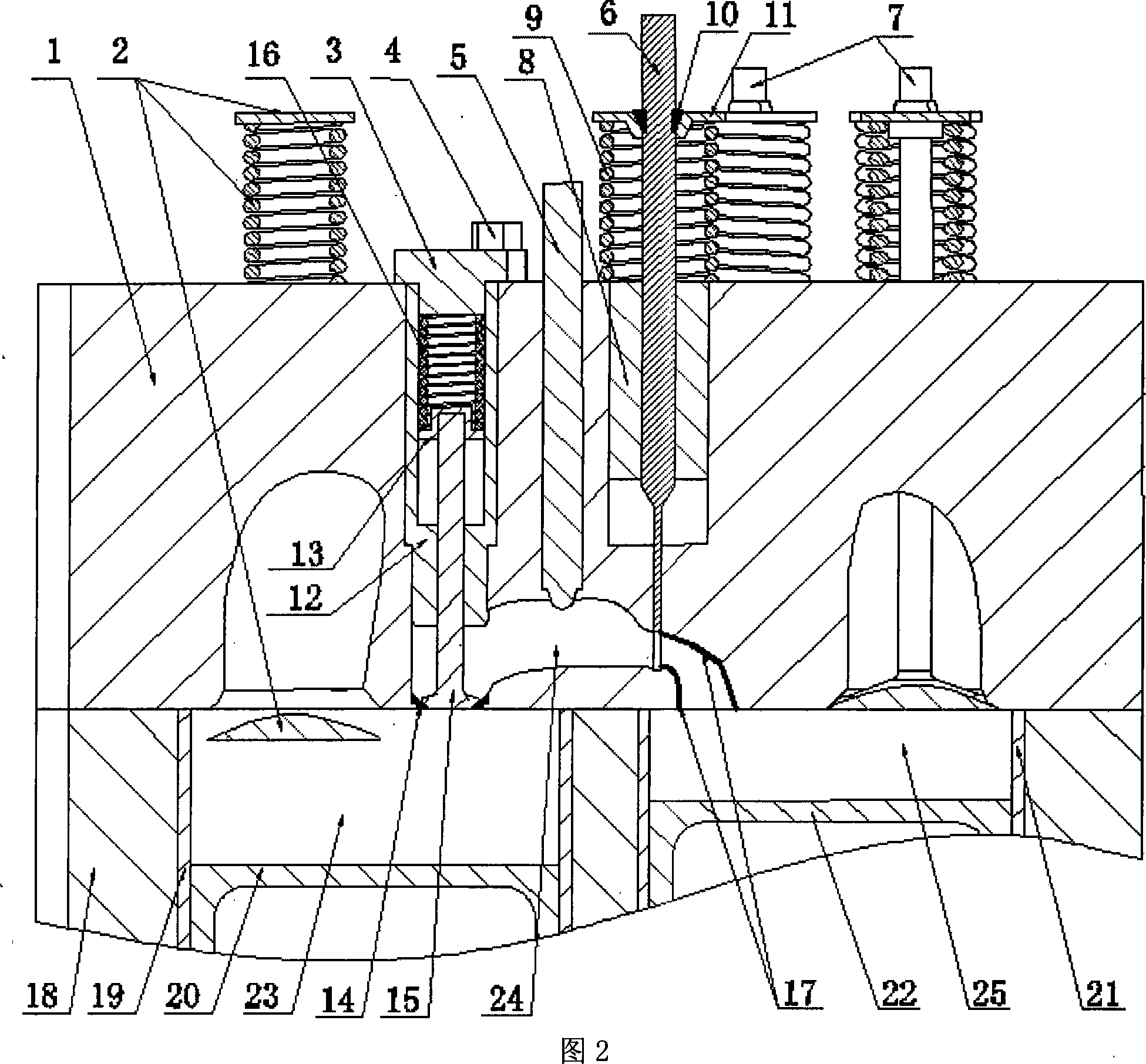

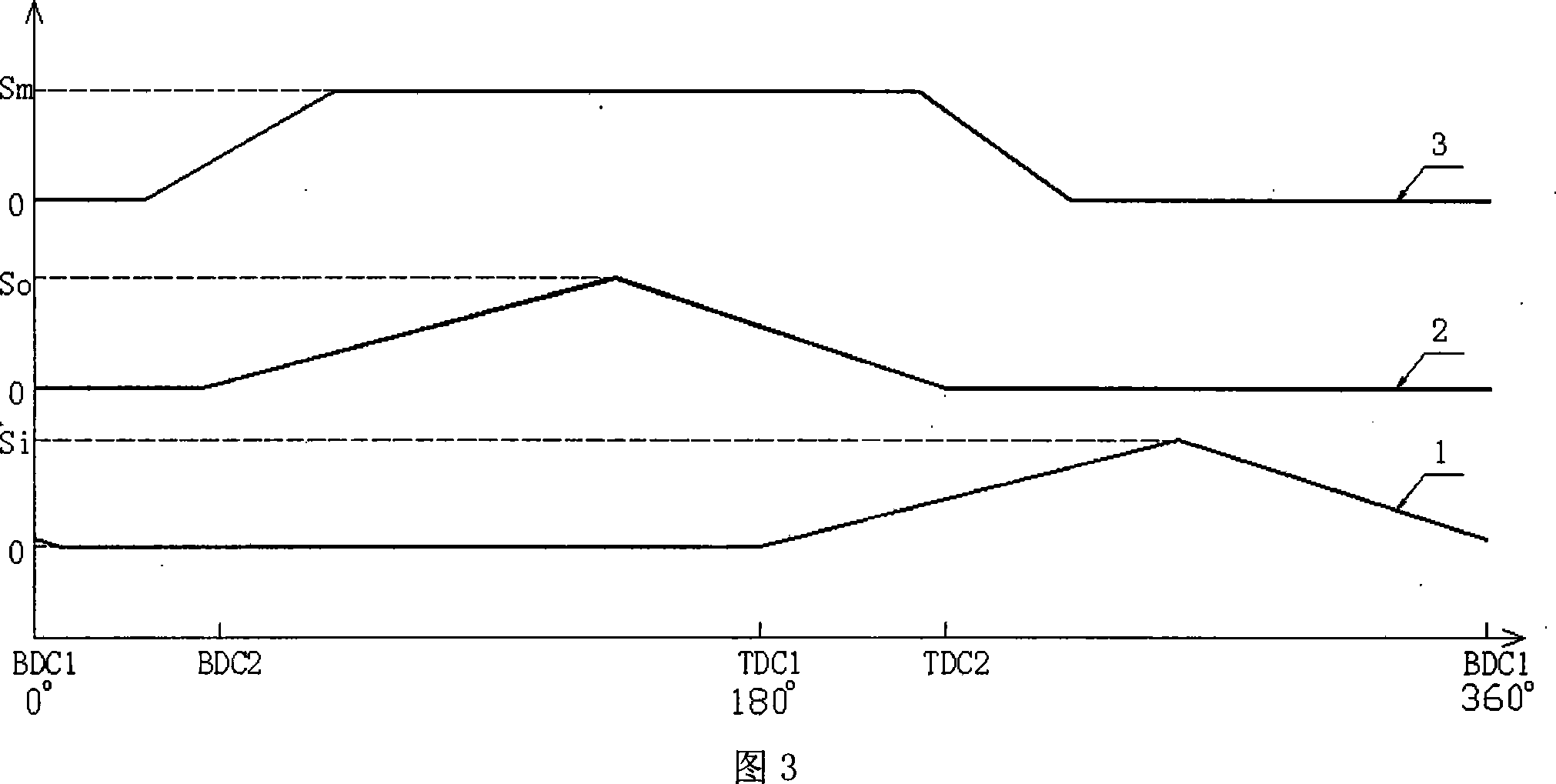

Compressed action independent-chamber reciprocating type four-stroke engine

InactiveCN101054920AReduce lossIncrease inflation coefficientInternal combustion piston enginesValve drivesFour-stroke engineEngineering

Two adjacent combustion chambers of existing four-stroke engine, one is only used for inspiration to compress, another is only used for expansion apply work to exhaust, the cylinder cover for compressing is not provided with an exhaust fungus valve and an exhaust passage for exhausting waste gas of the existing engine, the cylinder cover for apply work is not provided with an air intake fungus valve and an air intake channel for snifting of the existing engine, a channel is on the cylinder cover to communicate two cylinders, and is provided with a one way air valve for draining compressed gas into the channel on cylinder end for compressing, and is provided with an air valve with certain time obstruct channel closing to the cylinder end for apply work, catalysts are coated on the channel wall of the cylinder end for apply work or a heat accumulator is provided in the channel. The engine adopts catalysis or heat accumulation ignition, the combustion is completely exhausted, the structure is more simple than that of the existing reciprocating type four-stroke engine, the weight is lost and the efficiency is improved to realize that the expansion volume is larger than the compression volume.

Owner:陈崟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com